Preparation of hydrogenation catalyst

A hydrogenation catalyst and catalyst technology, applied in the direction of organic chemical methods, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of difficult sulfidation of active components, loss of activity, and reduction of catalyst activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

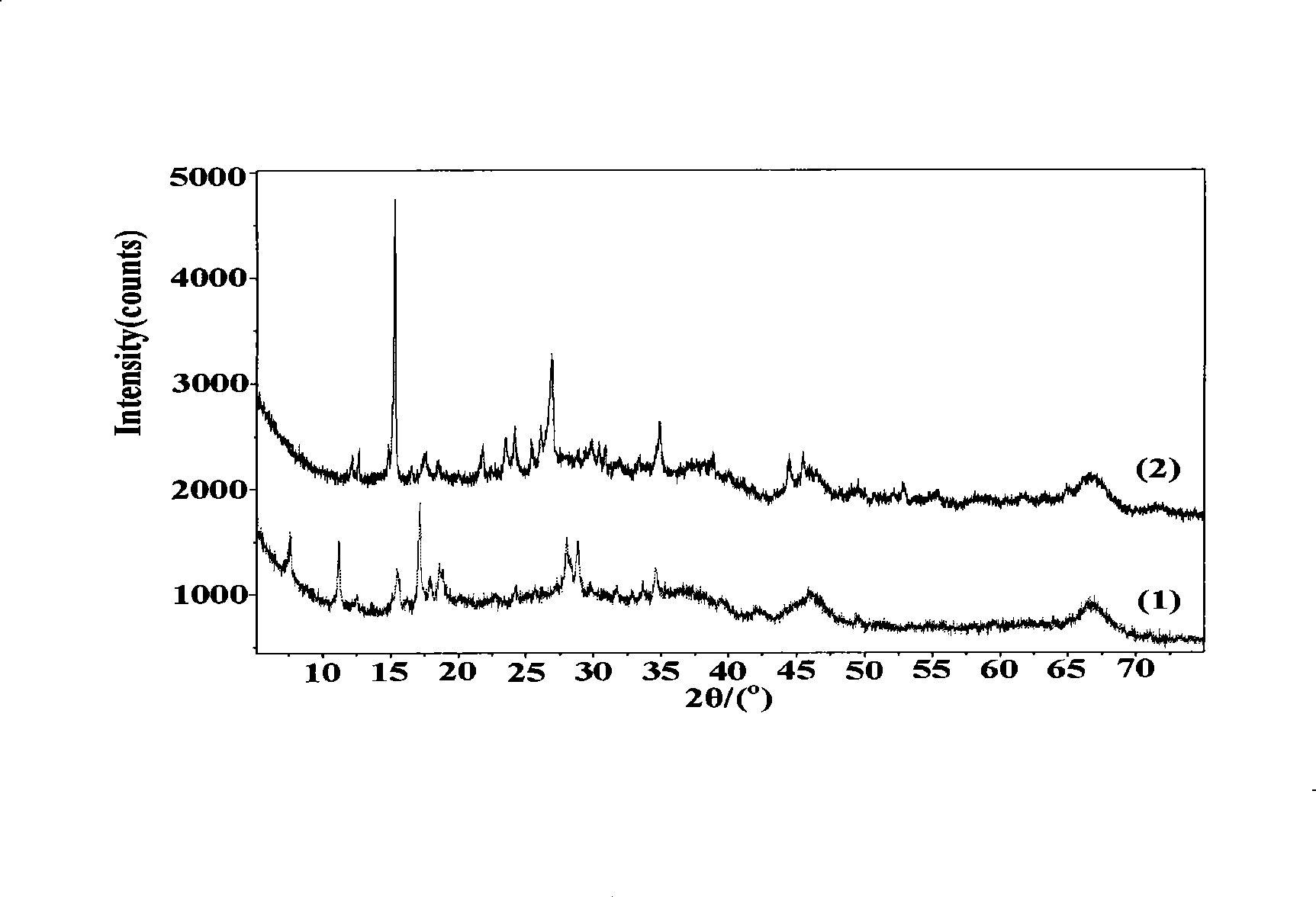

Image

Examples

Embodiment 1

[0015] Embodiment one (comparison catalyst 1): take by weighing 6.9g ammonium paramolybdate and be dissolved in 10mL water, add 11.4g nickel nitrate again, make it dissolve, be made into impregnating solution for subsequent use; Prepare 20g alumina carrier (about 30ml of volume), Impregnation is carried out according to the method of equal volume impregnation. Dry the impregnated catalyst under an infrared lamp, dry it in an oven at 120 degrees for 24 hours, and then bake it at 500 degrees for 4 hours to obtain the comparative catalyst I, NiO and MoO 3 The loading amount is about 30wt%.

Embodiment 2

[0016] Example 2 (comparative catalyst II): Weigh 2.9g ammonium paramolybdate and 4.4g ammonium metatungstate and dissolve them in 10mL water, then add 9.5g nickel nitrate to dissolve them, and make an impregnation solution for subsequent use; prepare 20g alumina The carrier (about 30ml in volume) is impregnated according to the method of equal volume impregnation. Dry the impregnated catalyst under an infrared lamp, dry it in an oven at 120 degrees for 24 hours, and then bake it at 500 degrees for 4 hours to obtain the comparative catalyst II, NiO, MoO 3 and WO 3 The loading amount is about 30wt%.

Embodiment 3

[0017] Embodiment three: take by weighing 6.9g ammonium paramolybdate and dissolve in 10mL water, add 11.4g nickel nitrate again, make it dissolve, then add 2.0g urea, be made into impregnating solution standby; Prepare 20g alumina carrier (volume about 30ml) , impregnated according to the method of equal volume impregnation. Dry the impregnated catalyst under an infrared lamp, put it into a closed crystallization kettle, put it into an oven to react at 120 degrees for 24 hours, then open the lid of the crystallization kettle, and continue drying in the oven at 120 degrees for 20 hours. The catalyst that has reacted is calcined at 400 degrees under air atmosphere for 4 hours to obtain the catalyst of the present invention, NiO and MoO 3 The loading amount is about 30wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com