Patents

Literature

354results about "Organic reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of hydrogenation catalyst

ActiveCN101491766AImprove stabilityGood dispersionOrganic reductionMetal/metal-oxides/metal-hydroxide catalystsVulcanizationActive component

The invention provides a method for preparing a hydrogenation catalyst. Active components are introduced by a two-stage method; previously introduced metal components have strong action with a carrier through a roasting step, and subsequently introduced active components have no roasting step and have weak action with the carrier; and during vulcanization and usage of the catalyst, the active metal components having strong action with the carrier can inhibit migration and concentration of the active metals having weak action with the carrier, so the catalyst keeps ideal activity and stability. The catalyst prepared by the method can be used in a hydrotreating process of various distillate oils.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation of hydrogenation catalyst

ActiveCN101439289AOrganic reductionMetal/metal-oxides/metal-hydroxide catalystsMolybdateActive component

The invention discloses a preparation method for a hydrogenation catalyst. The metal components of the catalyst comprise one or two metals from Co and Ni as well as one or two metals from Mo and W; carbamide or ammonia is used as a reaction addition agent; a method of reaction in-situ in the hole of a carrier is adopted to lead the metal active components to generate nickel molybdate (cobalt) or nickel tungstate (cobalt) compounds, thereby being capable of avoiding the reaction between the metals and the carrier, simultaneously leading the metal active components to be easier to be sulfurized and being capable of improving the activity of the hydrogenation catalyst.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Conversion reactions for organic compounds

InactiveUS6482997B2High activityReduce interactionOrganic reductionHydrocarbon by hydrogenationOrganic compoundAverage size

Owner:INST FR DU PETROLE

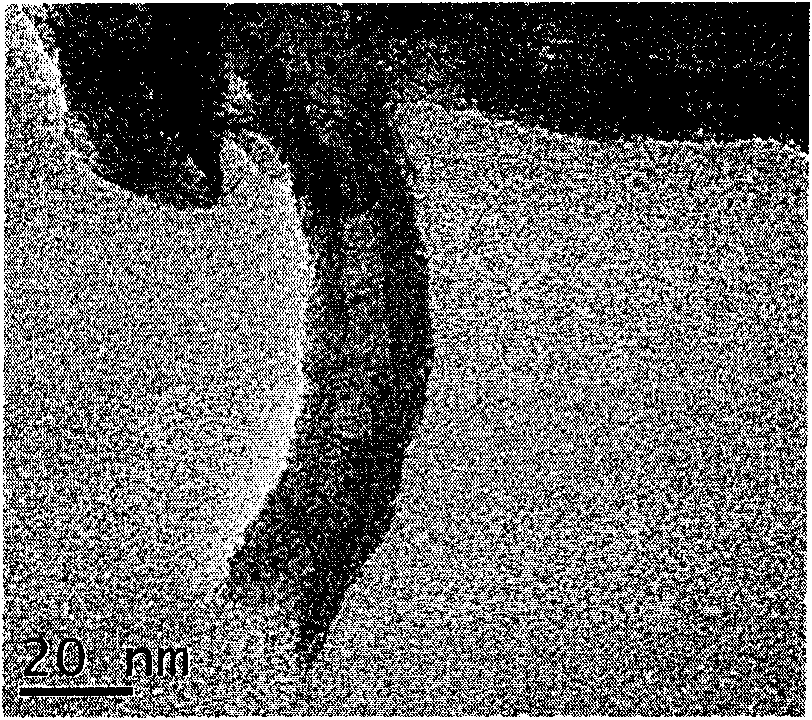

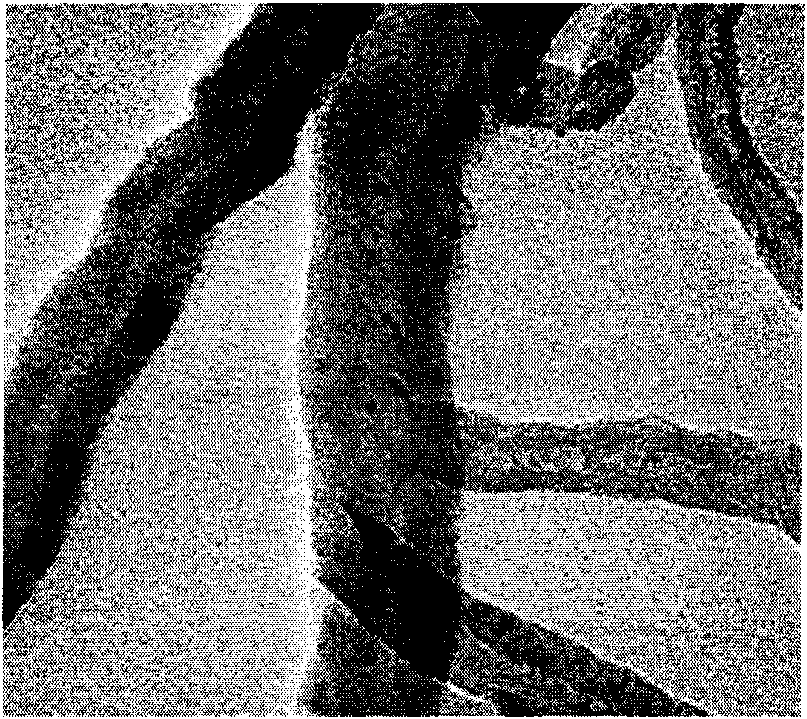

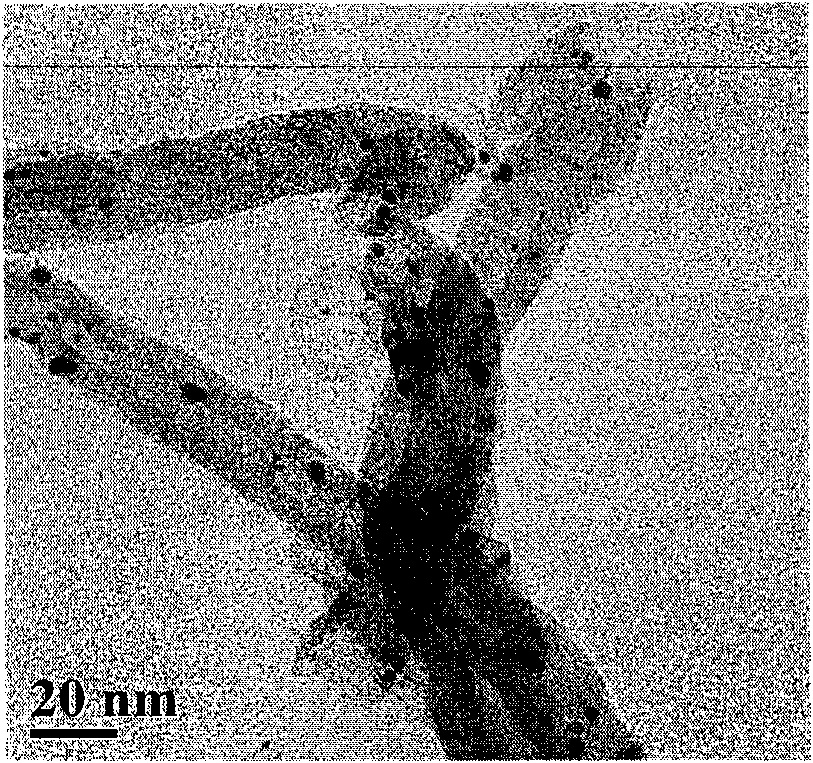

Platinum/carbon nanotube catalyst and preparation method and application thereof

InactiveCN102039121AMild conditionsEasy to manufactureOrganic reductionMaterial nanotechnologyCarbon nanotubeRoom temperature

The invention relates to a platinum / carbon nanotube catalyst suitable for multiphase asymmetric hydrogenation reaction. Platinum is loaded on a carbon nanotube carrier. A preparation method comprises the following steps of: heating a purified carbon nanotube in nitric acid, washing, filtering, washing by using water until the pH value of filtrate is neutral, drying to obtain the carbon nanotube carrier, soaking in aqueous solution of chloroplatinic acid, and performing ultrasonic treatment at room temperature; and stirring and impregnating a mixture of the carbon nanotube and the aqueous solution of chloroplatinic acid, raising the temperature to 110 DEG C from room temperature, drying at the temperature of 110 DEG C, grinding into fine powder, reducing by using aqueous solution of sodiumformate with heating, filtering, washing by using deionized water and drying. The invention also provides the preparation method of the catalyst and application of the catalyst to the multiphase asymmetric hydrogenation reaction.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Process for preparing Cu-Zn-Al vapor hydroformylation catalyst and products therefrom

ActiveCN1883795AImprove crystal stateHigh selectivityOrganic reductionMetal/metal-oxides/metal-hydroxide catalystsGas phaseSide reaction

The invention belongs to catalyst technique field, concretely relates to a preparation method of catalyst for copper-zinc-aluminum gas phase aldehyde hydrogenation and product thereof, which solves the problems in existing technique that the preparation process of aldehyde hydrogenation catalyst is complex, repeatability is bad, catalyst crystal-size is heterogeneous, dispersion degree of active copper is not high, mechanical strength is small, selectivity to product is bad, especially when rising reactive temperature to enhancing reactive speed and heat energy efficiency, activity, selectivity and stability are bad. The method modifies the intermittent feeding mode to continuous feeding mode by step continuous coprecipitation method, specific surface and pore volume of catalyst is large, dispersion degree of active metal is high, catalytic activity is good, selective and stability have more improvement, and side reaction of esterification and etherification is reduced.

Owner:PETROCHINA CO LTD

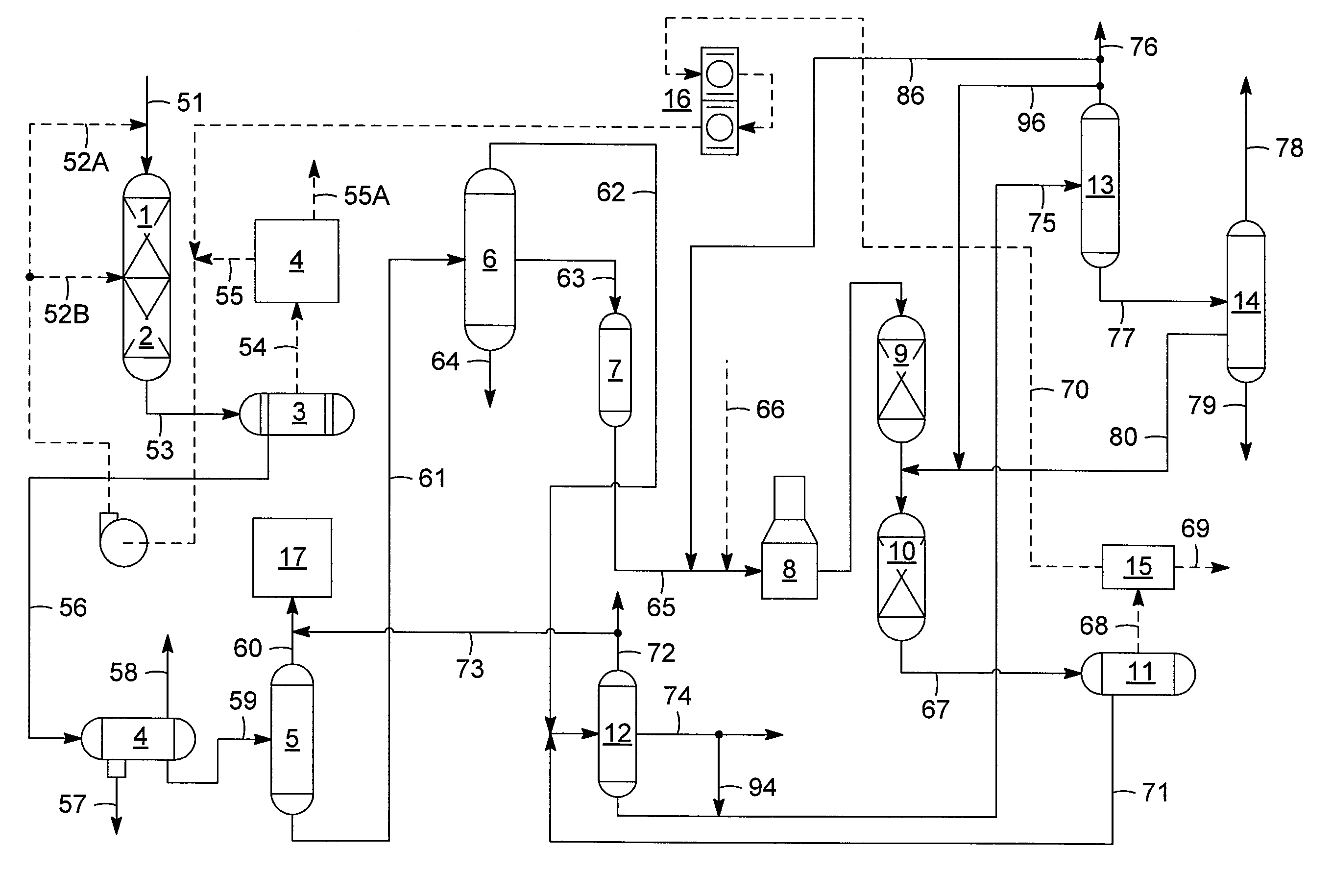

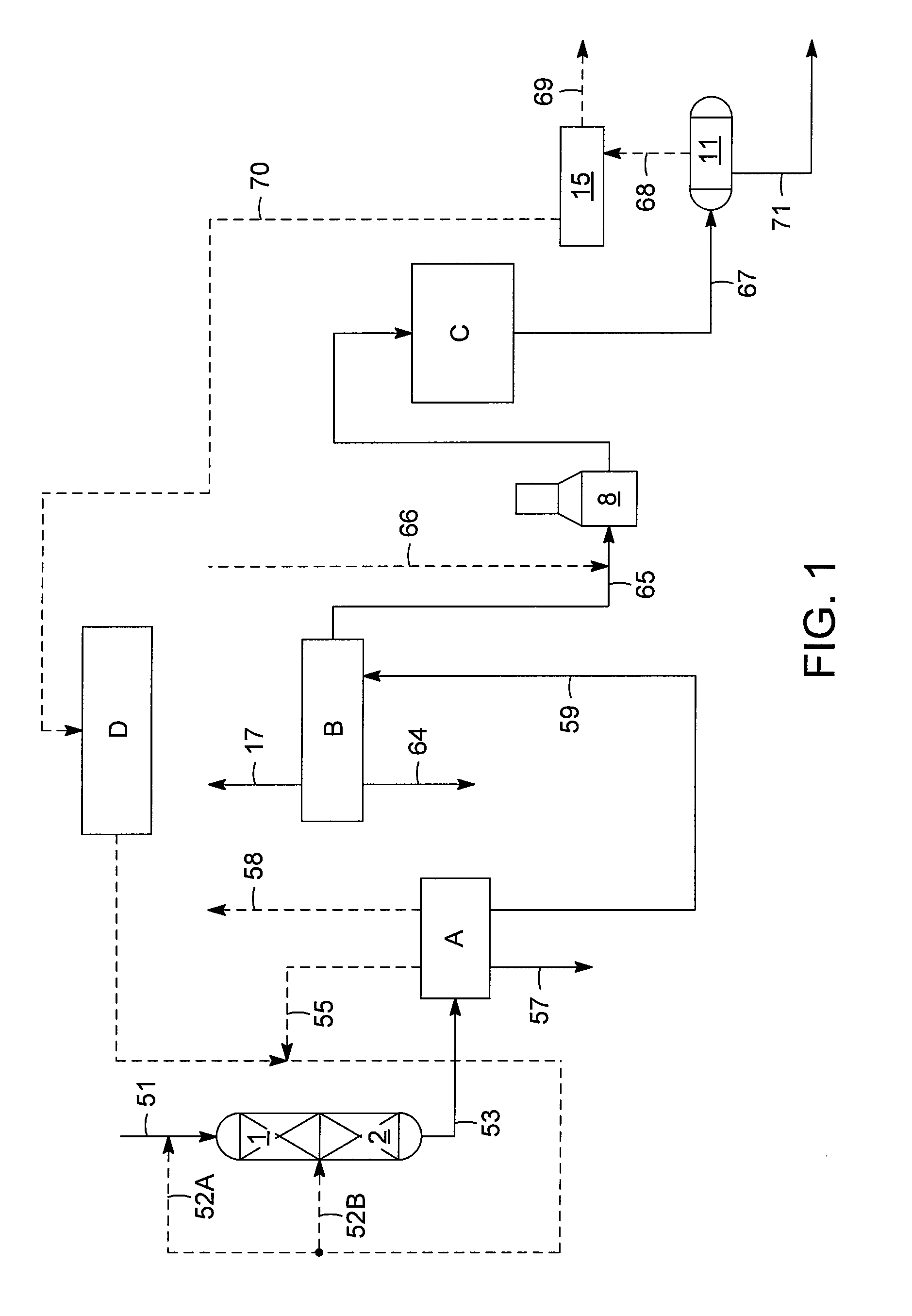

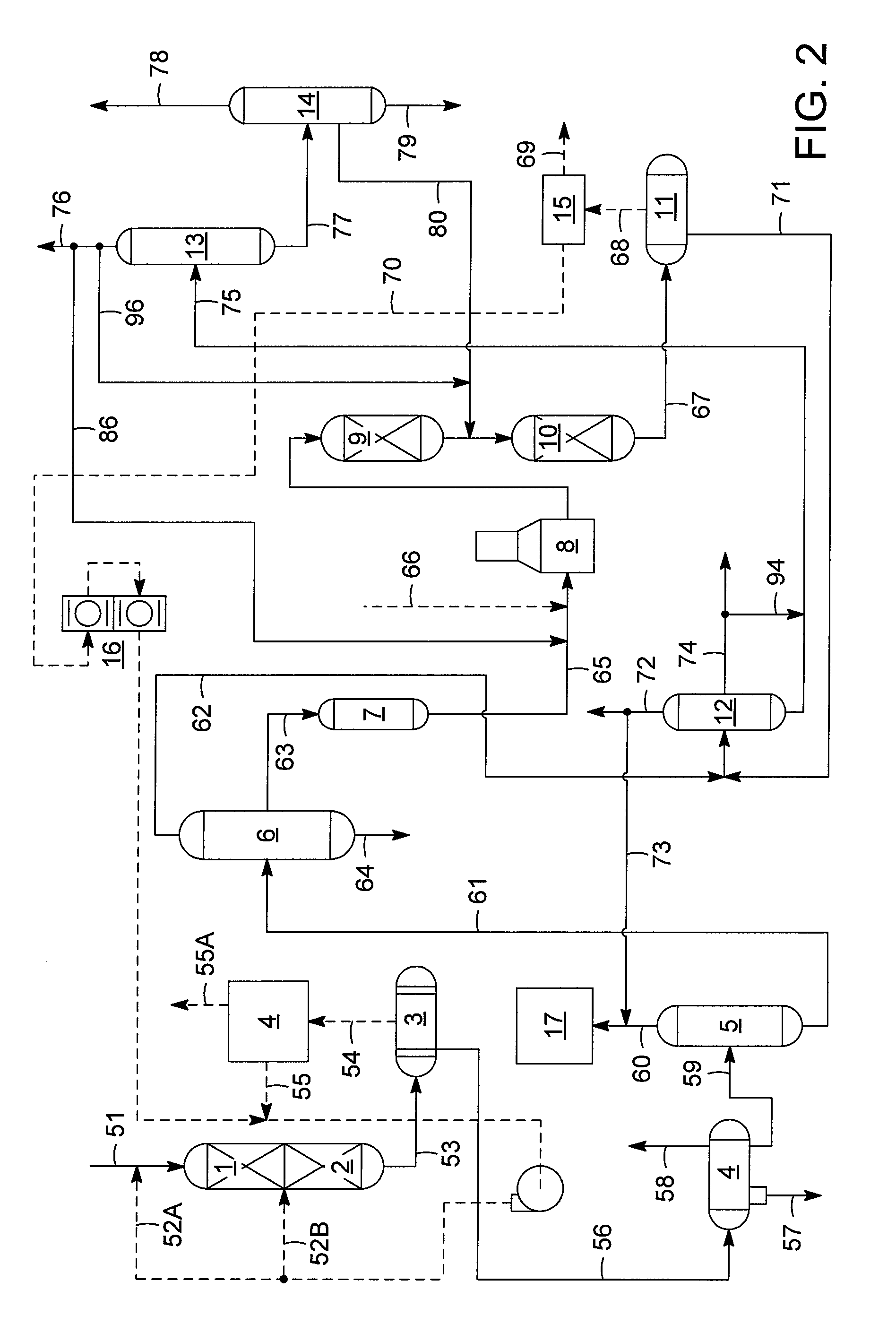

Method for efficient use of hydrogen in aromatics production from heavy aromatics

InactiveUS20100160699A1Reduce needEasy to useOrganic reductionHydrocarbon by hydrogenationLiquid productBoiling point

A method for efficient use of hydrogen in aromatics production from heavy aromatic oil. A hydrocarbonaceous stream comprising C9+ hydrocarbons and an essentially pure hydrogen stream are hydrotreated and hydrocracked to produce a hydrocracking zone effluent comprising aromatics. The hydrocracking zone effluent is fractionated to separately recover C4 and lighter hydrocarbons, hydrocarbons boiling between about 180° F. and about 380° F., and diesel. The heavier hydrocarbons are combined with a low purity hydrogen-containing stream and heated, then dehydrogenated or transalkylated to form hydrogen, volatile compounds, and aromatics. The hydrogen and volatile components are separated from the aromatics and treated by pressure swing adsorption to provide an essentially pure hydrogen-containing stream, which is compressed and provided to the hydrotreating and hydrocracking steps. Liquid products are recovered from the aromatics-containing stream.

Owner:UOP LLC

Supported ruthenium catalyst and preparation method thereof

InactiveCN102476052ALow costEasy to prepareOrganic reductionMolecular sieve catalystsAlkaline earth metalSecondary component

The invention discloses a supported ruthenium catalyst and a preparation method thereof. The preparation method is characterized in that the preparation method comprises the following steps: 1, preprocessing a carrier with a soluble alkaline earth metal salt, wherein the mass of the soluble alkaline earth metal salt accounts for 0.1-20% of the mass of the carrier; and 2, dipping the alkaline earth metal salt processed carrier with a material which comprises a primary active component metallic ruthenium and an assisted catalytic component comprising one or several of Ni, Co, Pd and Pt, wherein the mass of the primary component metallic ruthenium accounts for 0.1-5% of the carrier, and the mass of the secondary component comprising one or several of Ni, Co, Pd and Pt accounts for 0.01-5% of the mass of the carrier. The catalyst of the invention is mainly applied to the selective hydrogenation process of an aromatic ring of an aromatic compound, wherein the aromatic ring of the aromatic compound has at least one alkyl group, one ester group, one hydroxyl group or an amino group and also has at least one C1-8 alkyl group. Compared with catalysts prepared with the prior art, the catalyst of the invention has the advantages of low cost, simple preparation method, high activity, good selectivity, high safety in the operation of the aromatic ring hydrogenation, realization of the operation of the aromatic ring hydrogenation under a low pressure, and good economy.

Owner:CHINA PETROLEUM & CHEM CORP +1

Shaped metal fixed-bed catalyst, a process for its preparation and its use

A shaped metal fixed-bed catalyst is disclosed which contains at least one catalyst alloy formed of a catalyst metal and an extractable alloying component. The catalyst is activated in an outer layer with a thickness of 0.1 to 2.0 mm starting from the surface by complete or partial extraction of the extractable alloying component. The catalyst may also contain promoters. The catalyst is distinguished from known catalyst in that it is formed exclusively of the catalyst alloy and has a total pore volume of 0.1 to 0.6 ml / g. The catalyst is used for hydrogenation, dehydrogenation and hydrogenolysis reactions.

Owner:DEGUSSA AG

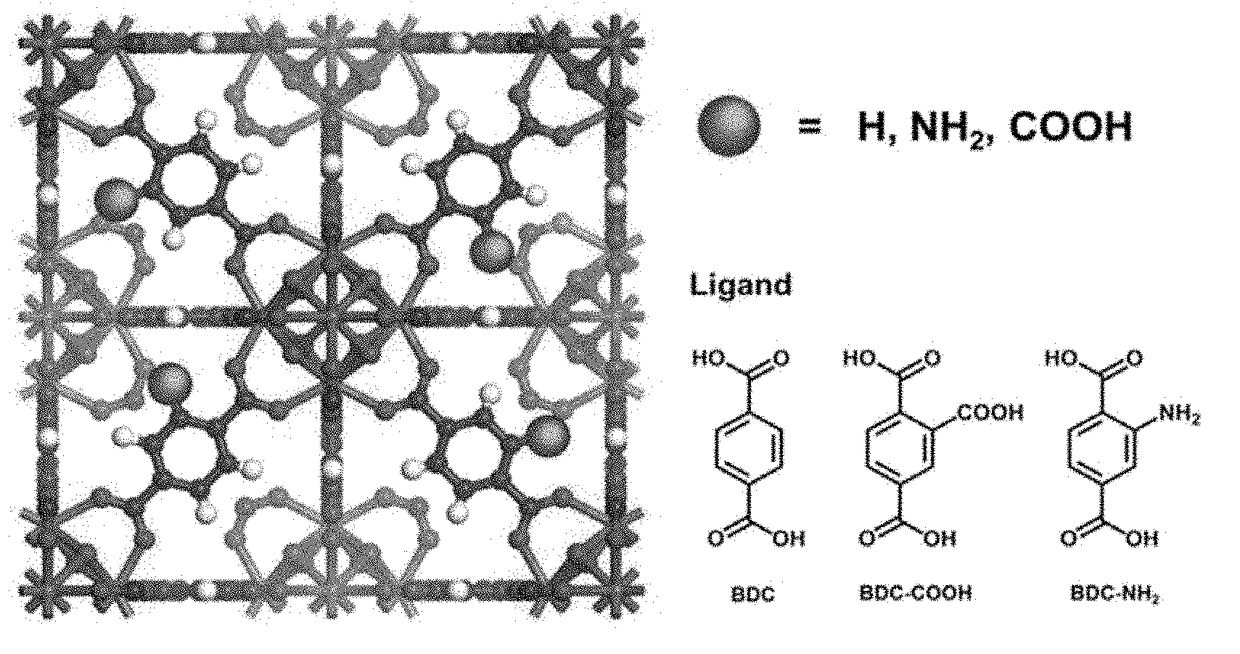

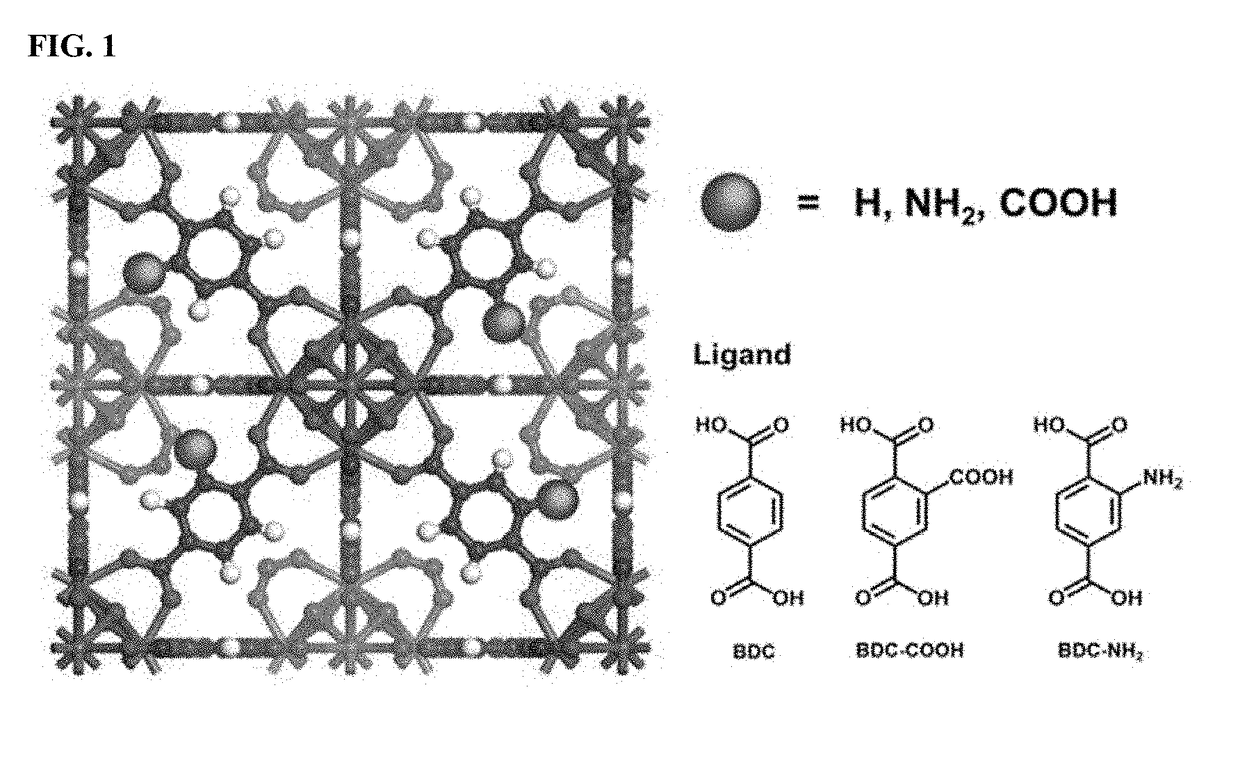

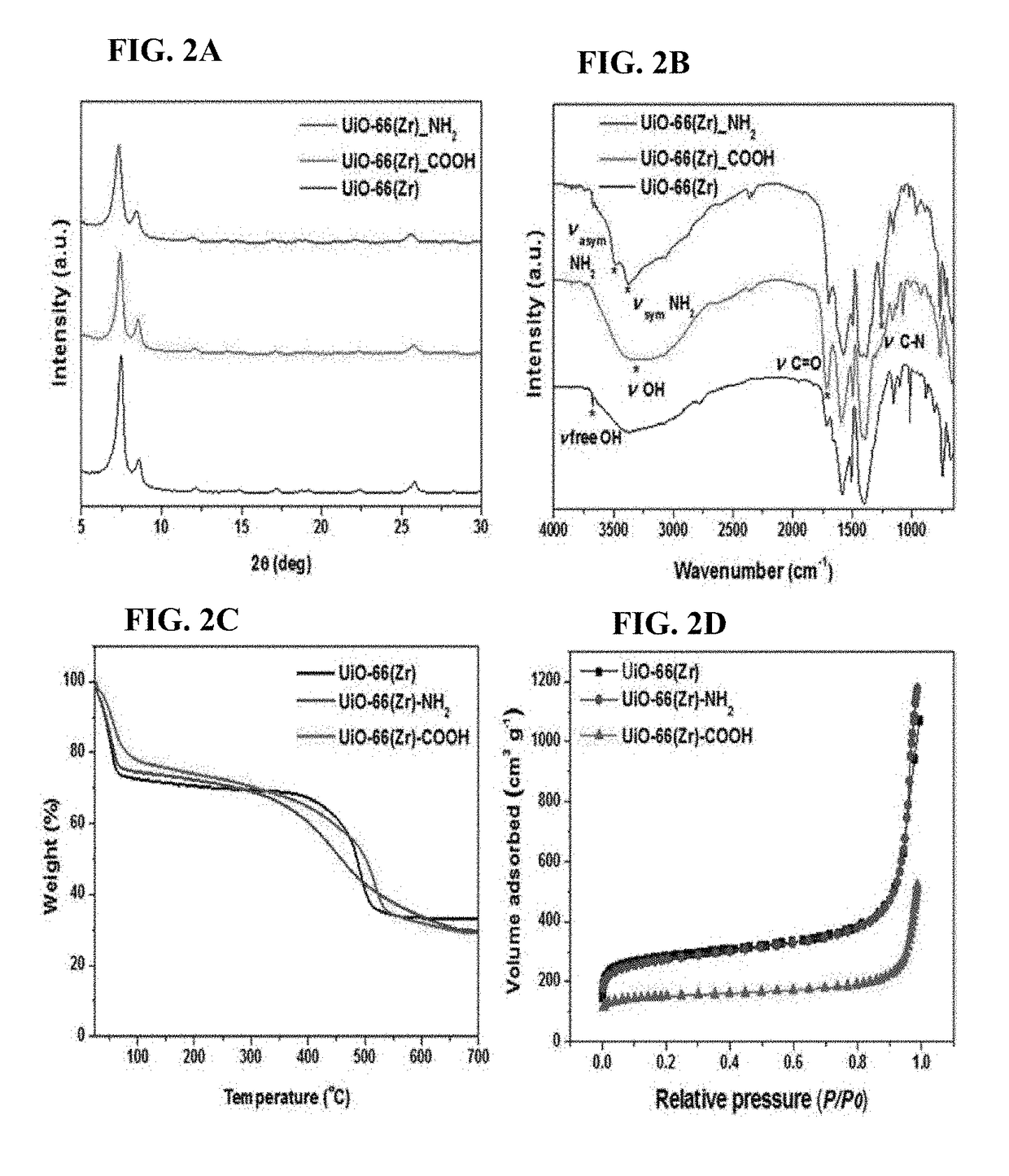

Zirconium-based metal-organic frameworks as catalyst for transfer hydrogenation

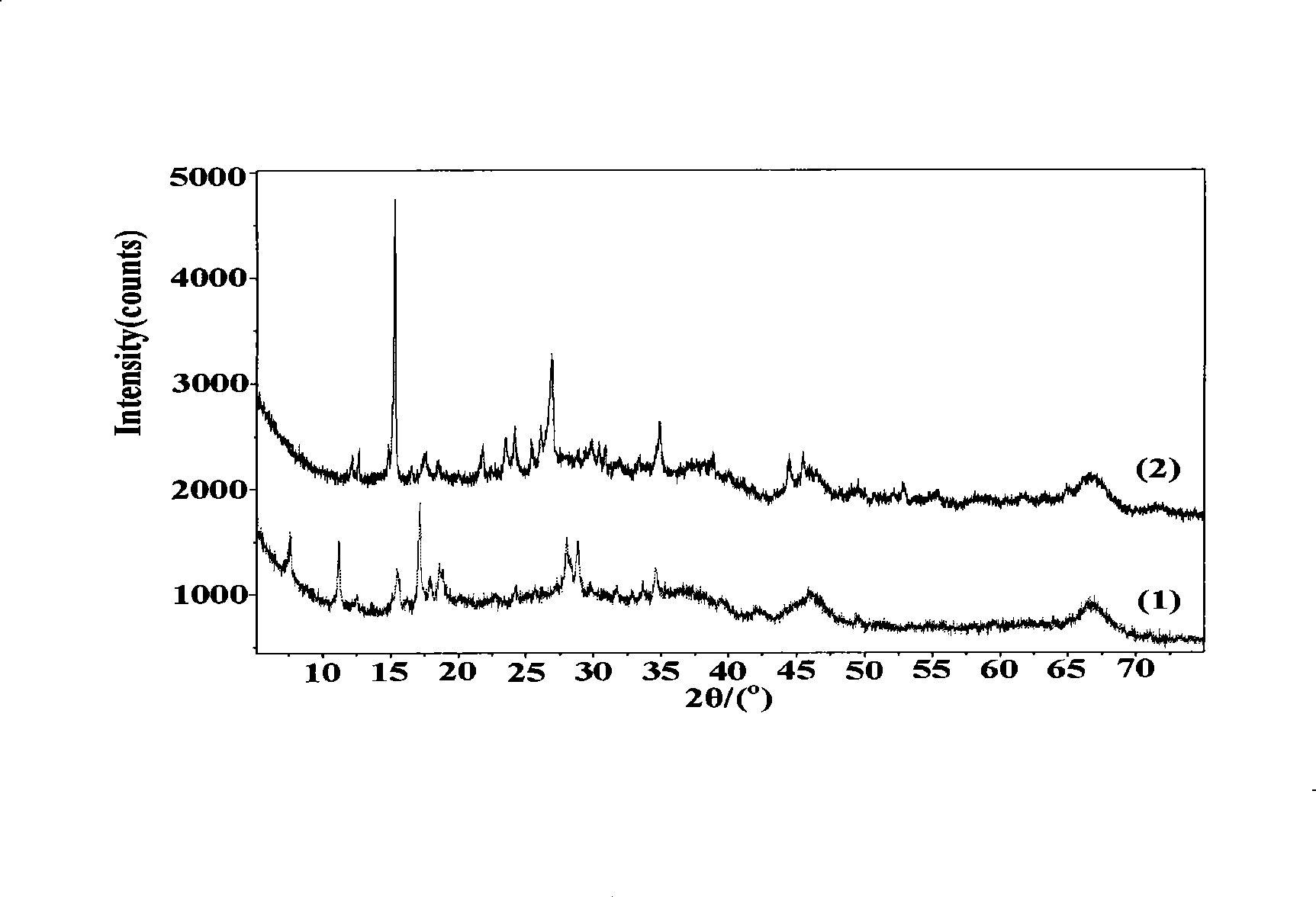

ActiveUS20170320790A1Improve performanceOrganic reductionOrganic-compounds/hydrides/coordination-complexes catalystsX-rayMetal-organic framework

The present invention relates to a catalyst for transfer hydrogenation, which is formed of a metal-organic framework having an MOF-808 based X-ray diffraction pattern.A high crystalline porous MOF-808 based metal-organic framework exhibits excellent performance in the transfer hydrogenation of ethyl levulinate (EL) at high and low temperature.

Owner:KOREA RES INST OF CHEM TECH

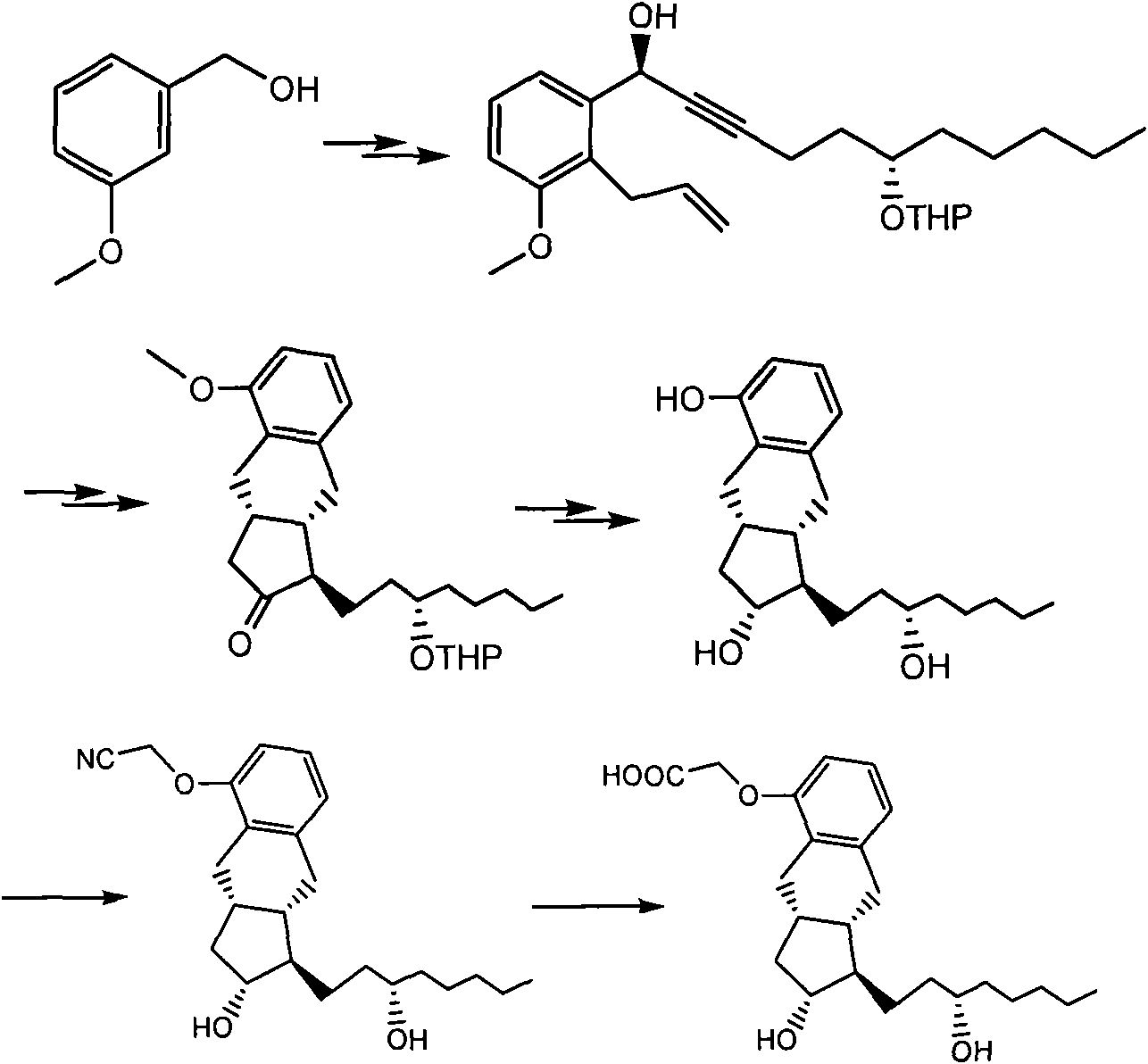

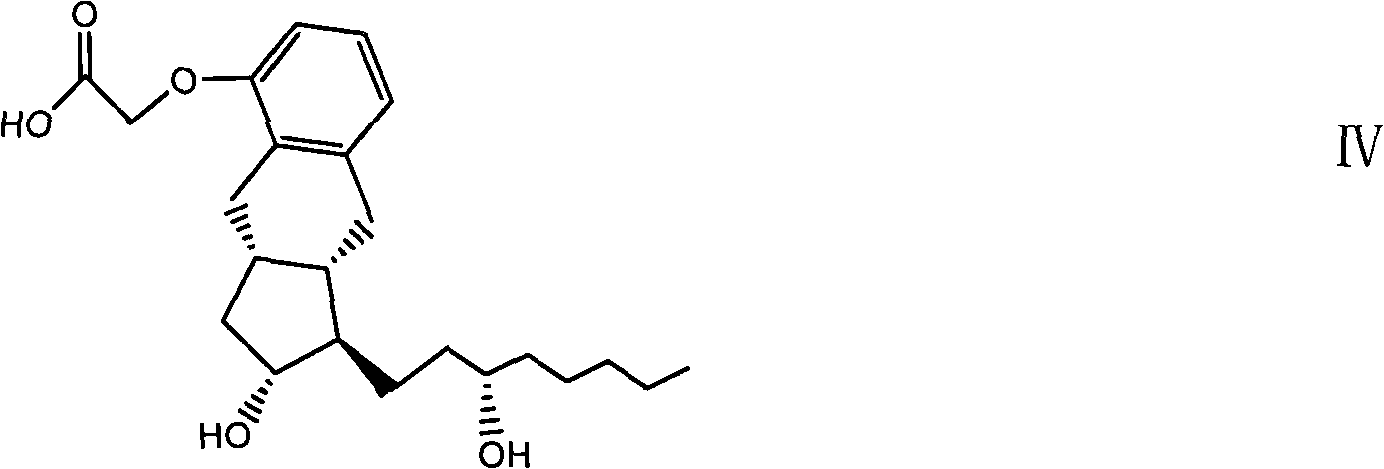

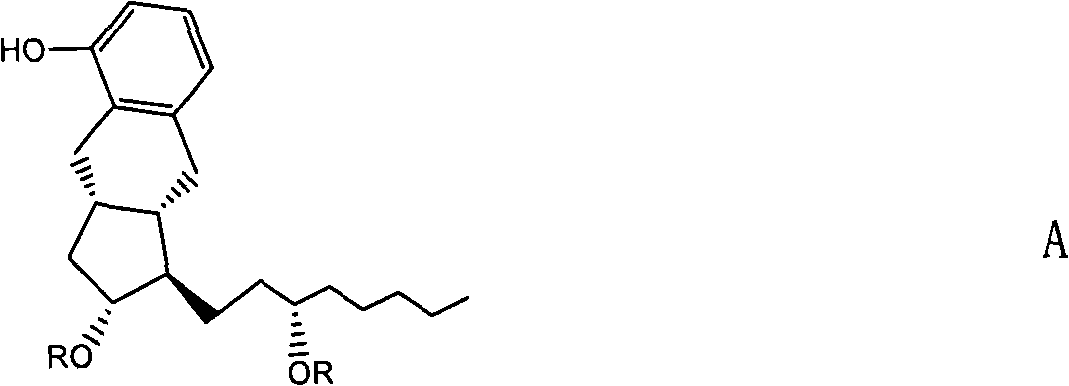

Novel compound and preparation method and use thereof

InactiveCN101891715AEasy to operateMild responseGroup 4/14 element organic compoundsOrganic reductionMedicinal chemistrySilicon based

Owner:SHANGHAI TECHWELL BIOPHARMACEUTICALS CO LTD

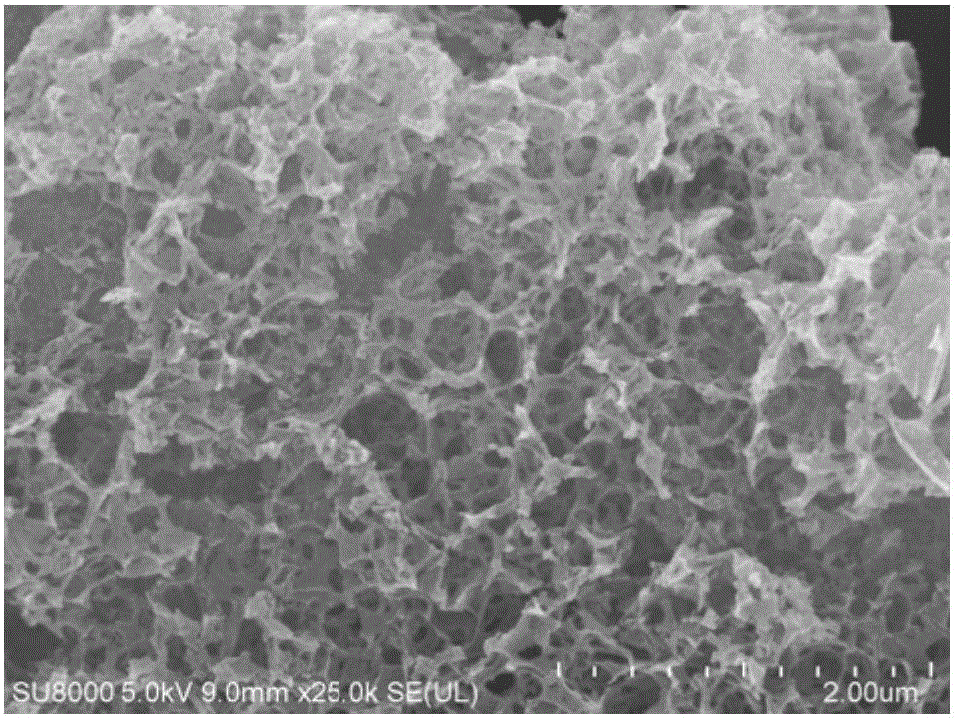

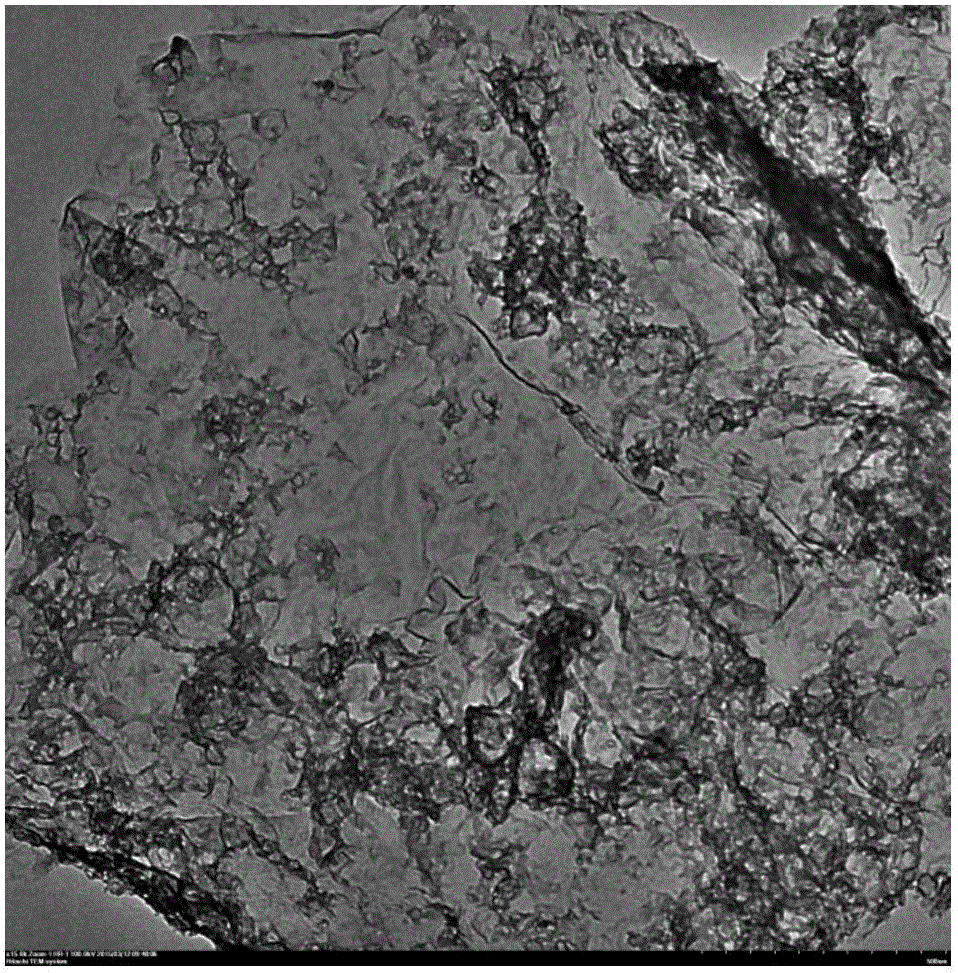

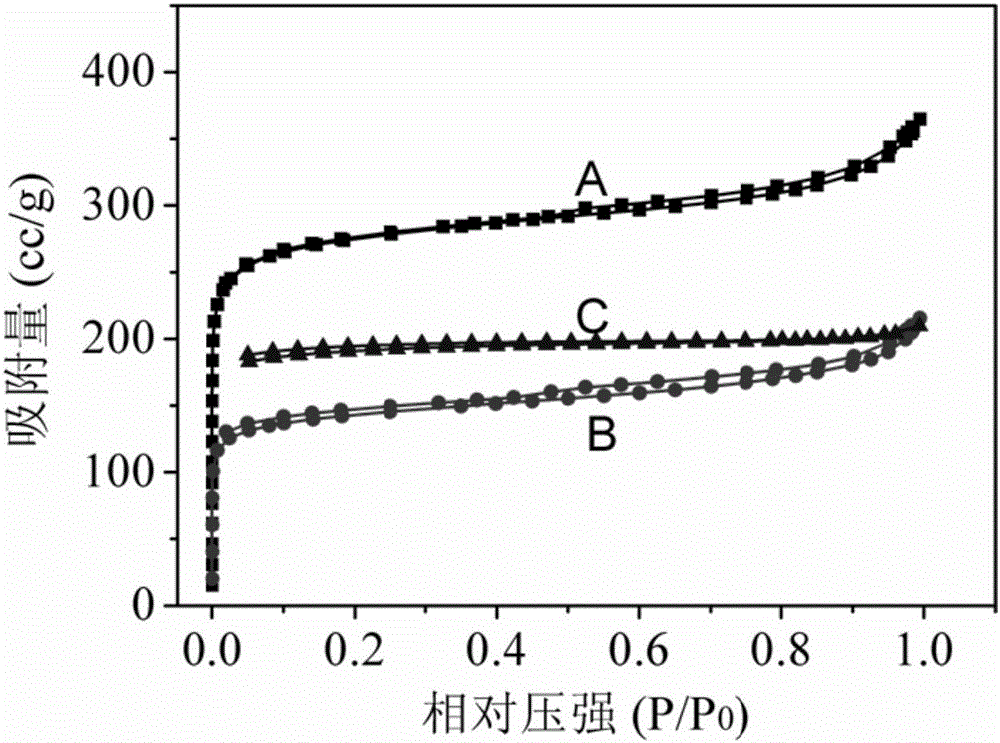

Nitrogen-doped hierarchical pore carbon and preparation method and application thereof

ActiveCN106179440AImprove usabilityLarge specific surface areaOrganic reductionPreparation by hydroxy compound hydrogenationNano catalystSodium bicarbonate

The invention discloses a preparation method of nitrogen-doped hierarchical pore carbon. The preparation method includes: using biomass as a raw material, and mixing the biomass with a composite activator; heating for calcining, mixing a calcining product with deionized water, standing for precipitation, and filtering to obtain precipitate; performing after-treatment to obtain the nitrogen-doped hierarchical pore carbon, wherein the composite activator is sodium hydrogen carbonate / nitrogen-containing compound, a mass ratio of sodium hydrogen carbonate to the nitrogen-containing compound is 0.25-4:1, the nitrogen-containing compound comprises at least one of ammonium oxalate, ammonium hydrogen carbonate, ammonium chloride and ammonium nitrate, and a mass ratio of the biomass to the composite activator is 1:2-16. The composite activator is utilized to activate the biomass to obtain a functionalized nitrogen-doped hierarchical pore carbon material, the preparation method is simple and easy to operate, the biomass existing in nature can be utilized directly, the obtained carbon material has rich hierarchical pore structure and can be used as a catalyst carrier to prepare high-performance nano catalysts, and utilization value of the biomass is increased greatly.

Owner:ZHEJIANG UNIV

Shaped, activated metal, fixed-bed catalyst

InactiveUS6262307B1Small volumeOrganic reductionOxygen-containing compound preparationFixed bedVolumetric Mass Density

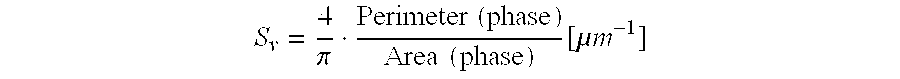

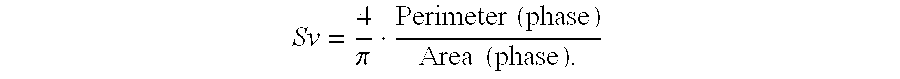

A shaped, activated metal, fixed-bed catalyst with a pore volume of 0.05 to 1 ml / g and an outer activated layer consisting of a sintered, finely-divided, catalyst alloy and optionally promoters. The catalyst alloy has metallurgical phase domains, resulting from the method of preparation of the alloy, in which the largest phase by volume has a specific interface density of more than 0.5 mum-1.

Owner:EVONIK DEGUSSA GMBH

Preparation method of supported nickel catalyst

InactiveCN101733106AOrganic reductionHydrocarbon by hydrogenationSupercritical dryingNickel catalyst

The invention discloses a preparation method of a supported nickel catalyst, which comprises the following steps of: reacting soluble nickel salt solution and a precipitator to obtain a green precipitate, wherein the precipitator is mixed solution of sodium silicate and sodium carbonate, the Na<+> concentration is 0.1-1 mol / L, the amount of the sodium silicate is calculated according to the content of SiO2 in a carrier, and the amount of the sodium carbonate is 10-30 percent more than that of nickel nitrate based on a stoichiometric ratio; washing the precipitate by distilled water and carrying out supercritical drying or azeotropic distillation drying to obtain a supported nickel catalyst precursor; roasting the supported nickel catalyst precursor for 2-5 hours under N2 atmosphere at 200-600 DEG C, changing the N2 atmosphere into H2 atmosphere, and reducing the supported nickel catalyst precursor for 2-4 hours under H2 atmosphere at 300-550 DEG C to obtain the supported nickel catalyst with the surface area of high active metal nickel. The surface area of the obtained catalyst is 250-450m<2> / g, the average aperture is 4-16nm, and the pore volume is 1.0 -1.9cm<3> / g. The surface area of the active metal nickel of the obtained catalyst is 40-70m<2> / g. The catalyst prepared by using the method can be used for catalyzing hydrogenation of a benzene ring.

Owner:NANJING UNIV

Process for preparing modified amorphous nickel alloy catalyst

ActiveCN101199934AAvoid dissolution lossPrevent embeddingOrganic reductionMetal/metal-oxides/metal-hydroxide catalystsAlloy catalystRare earth

Disclosed is a preparation method for modified noncrystalline nickel alloy catalyst, comprising processes of heating up the metallic nickel and the metallic aluminium into a melting state, preparing the nickel aluminium alloy by rapid quenching, and extraction and dealuminizing; the utility model is characterized in that the alloy got from the extraction and dealuminizing is washed to a PH value of 7 to 13 by the deionized water; and then the alloy is contacted with the salt solution of one or a plurality of metal promoters selected from the rare earth metal or the IIB,VIB,VIIB,VIII group metal; and calculated based on the weight of the metal nickel, the weight of the promoter metal used in the contact is less than 10 percent by weight. The metallic modified noncrystalline alloy prepared by the method has the advantages of high retention rate of the metal promoters, high hydrogenation activity and stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

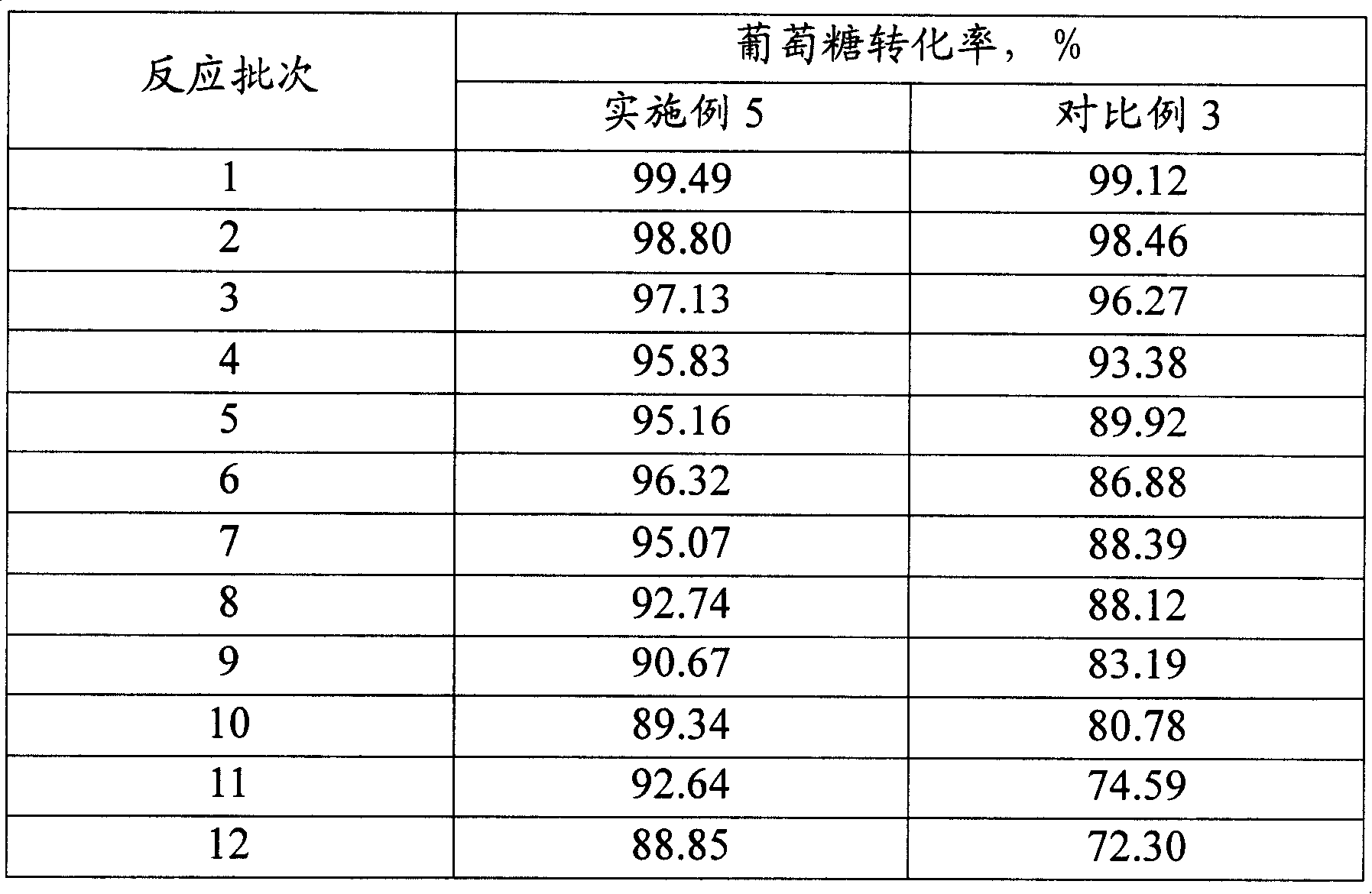

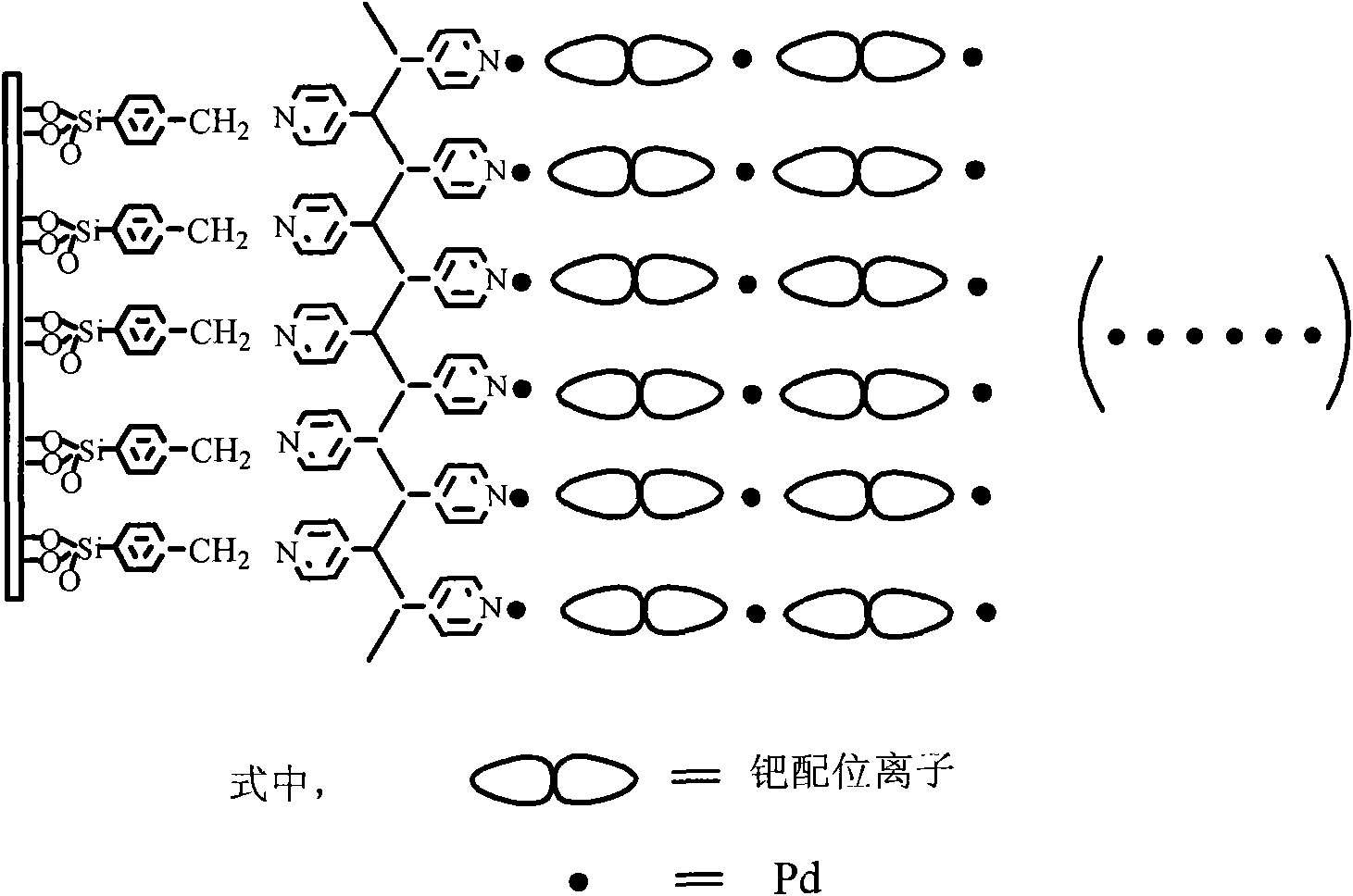

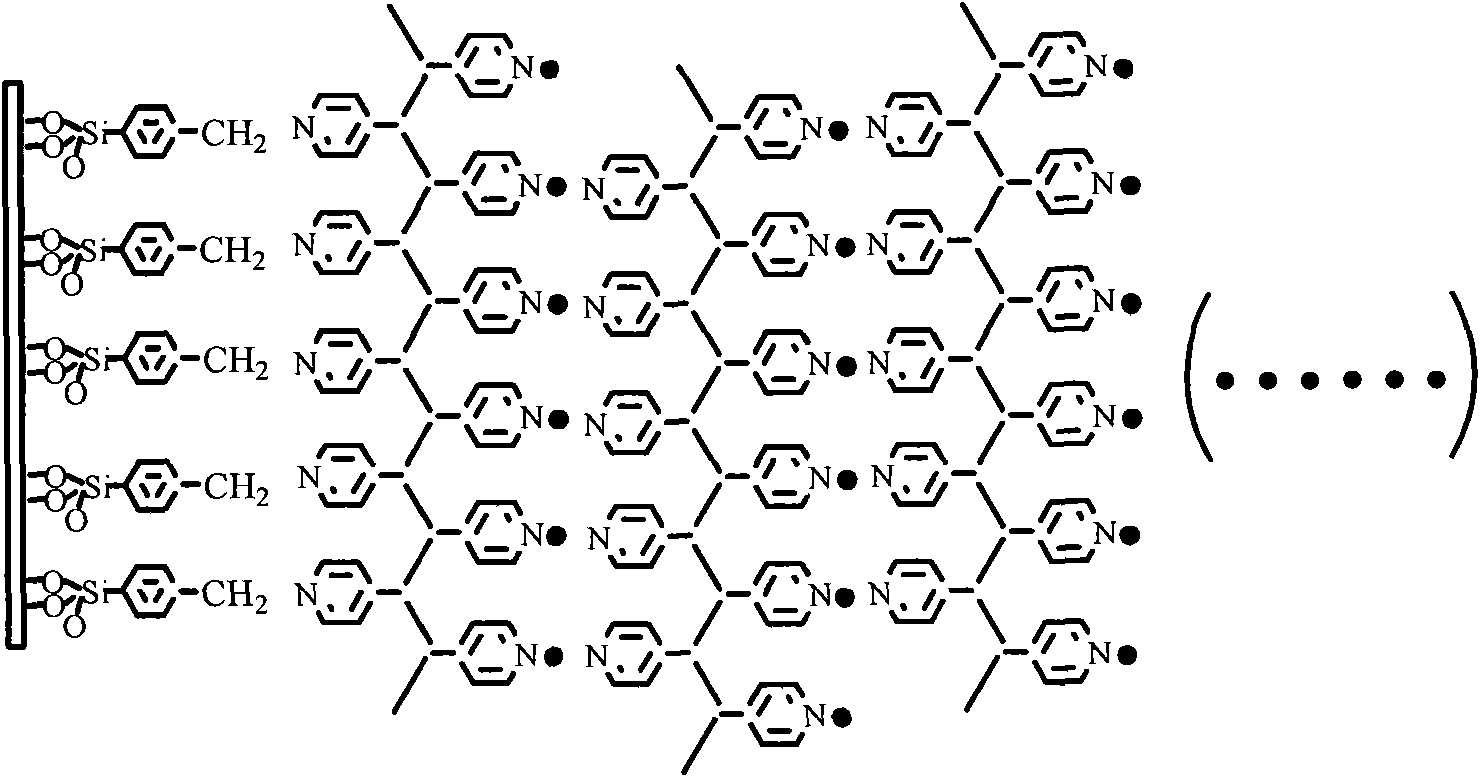

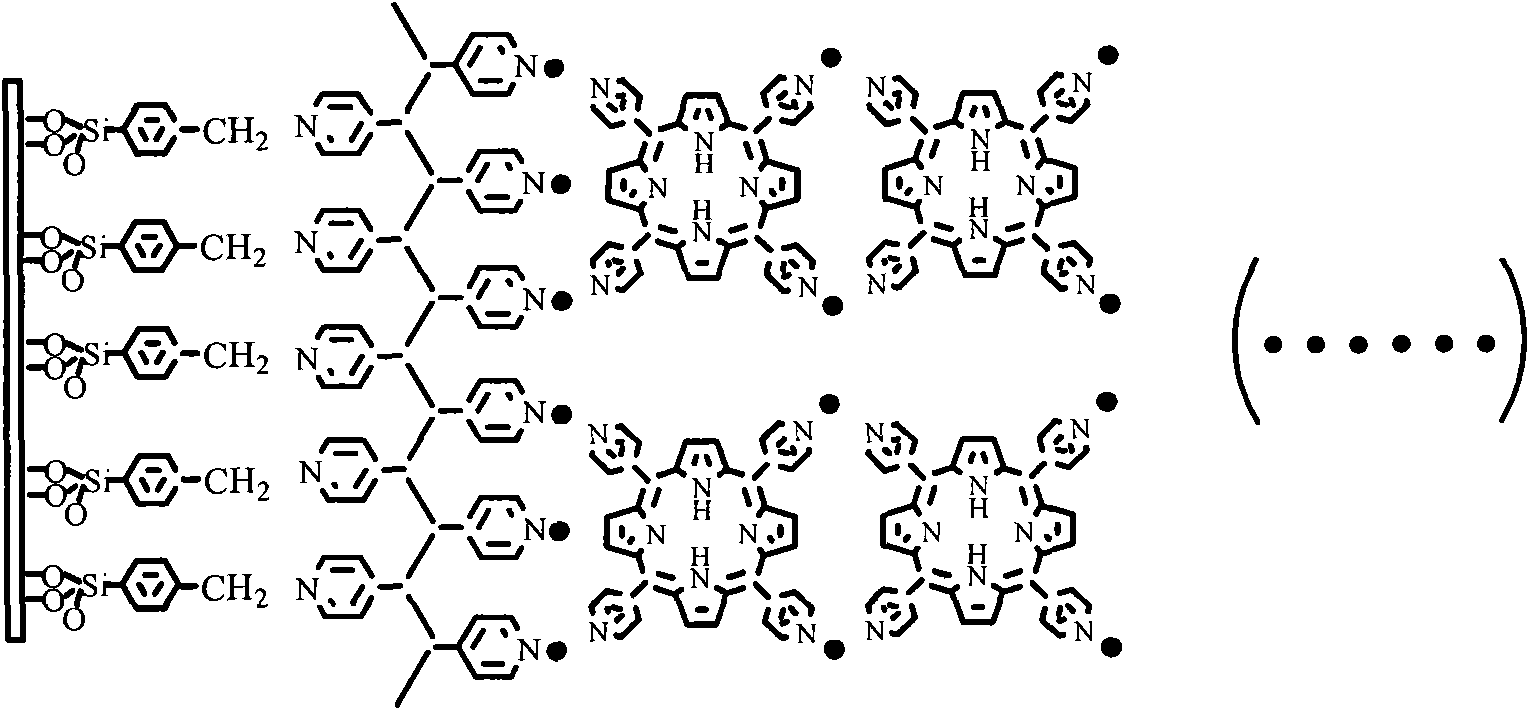

Palladium coordination polymer molecule aggregate catalysis material as well as preparation method and application thereof

InactiveCN101607213AEasy to makeEasy to separateOrganic reductionOrganic compound preparationPorphyrinSolid substrate

The invention relates to a palladium coordination polymer molecule aggregate catalysis material as well as a preparation method and an application thereof. The catalysis material is a coordination polymer molecule aggregate catalysis material formed by self-assembling on the surface of a solid substrate, the precursor of the catalysis material comprises palladium coordination ion as well as pyridine containing multidentate ligand or high molecular ligand, wherein the palladium coordination ion is selected from one of tetrachloro combined palladium acid radical, dichloro-2, 2'-dipyridine palladous, and dichloroacetamide palladous, and the pyridine containing multidentate ligand or high molecular ligand is selected from one of 4, 4'-combined pyridine, 2, 4, 6- collidine triazine, metal or hollow tetra pyridyl porphyrin, trans-1, 2- collidine ethylene, combined dipyridylzinc thiocyanate and polyethylene pyridine. LB film preparation technology or layered assembly method is adopted for organism selective ethylenic bond organic hydrogenation reaction, thus having high catalysis efficiency, easy realization in separation of catalyst and reactant and product, convenient operation and low cost.

Owner:FUDAN UNIV

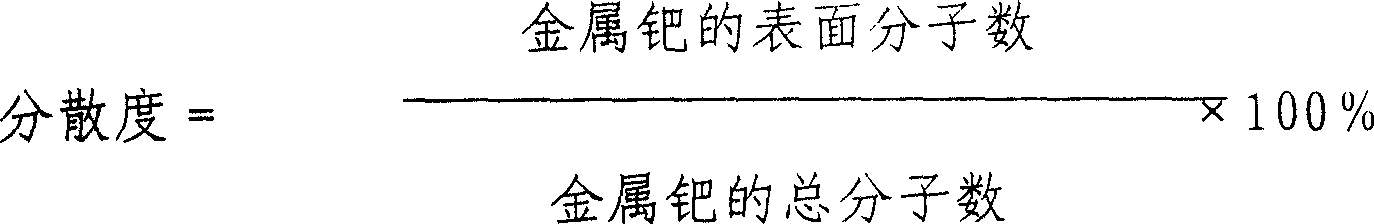

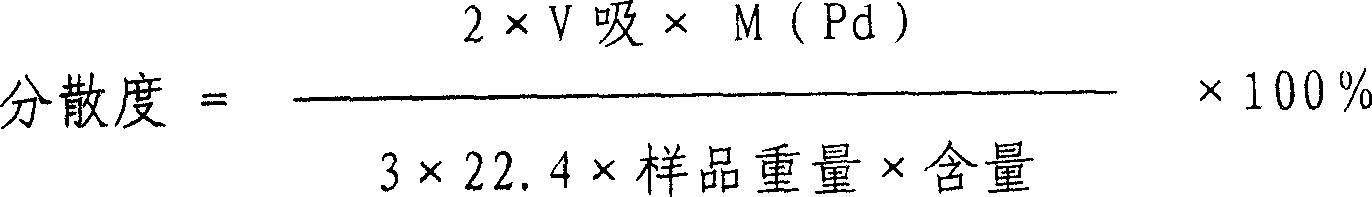

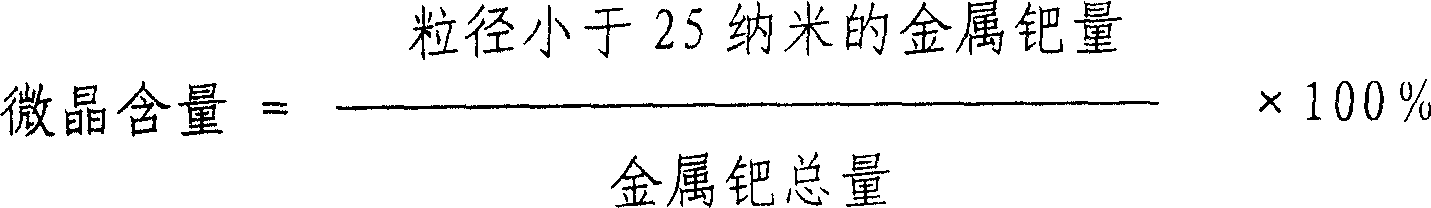

Method for preparing hydrogenising selectively palladium/carbon catalyzer

InactiveCN1565725AGood dispersionHigh microcrystalline contentOrganic reductionOrganic compound preparationAcid washingPhosphoric acid

A method for preparing Pd / C catalyst for selective hydrogenation is provided. The content of Pd in catalyst is 0.2 to 5% by weight. The preparing process includes the following steps: active carbon carrier is washed by 0.1 to 5N concentration of acid washing liquid selected from hydrochloric acid, nitric acid or phosphoric acid; active carbon carrier is washed to neutrality by water and dried; the active carbon carrier is soaked in halide ion containing solution for 2 to 24 hours and dried; the Pd compound is sprayed on the active carbon carrier to form catalyst precursor, after aging and reduction process, the catalyst product is obtained. Metal Pd in catalyst has higher dispersion degree and the content of crystallite is very high.

Owner:CHINA PETROLEUM & CHEM CORP

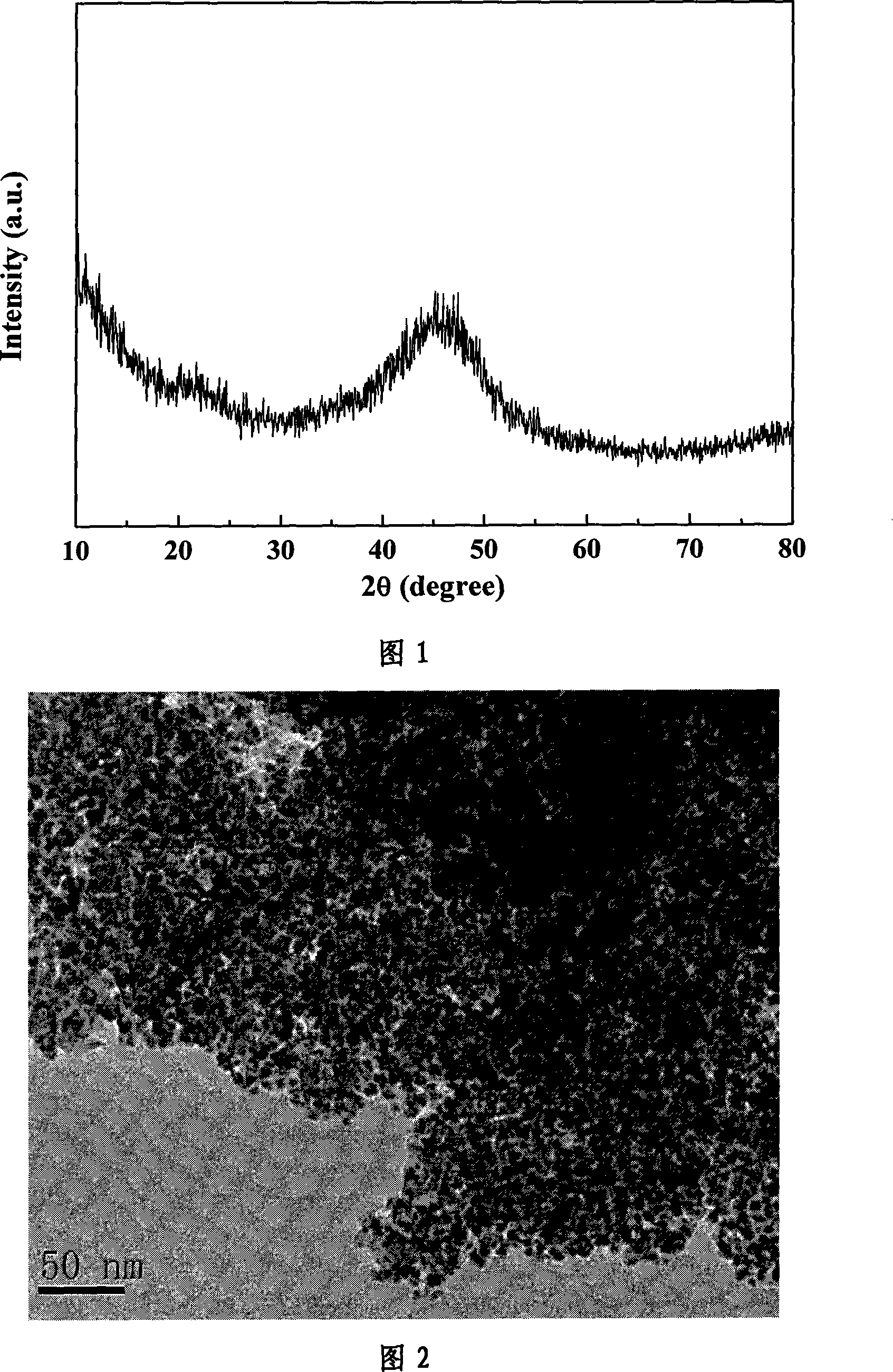

A non-crystal alloy catalyst as well as its preparing method and purpose

InactiveCN101157034AGood catalyticParticle size controllableOrganic reductionMetal/metal-oxides/metal-hydroxide catalystsNitro compoundReaction rate

The invention discloses amorphous alloy catalyst with controllable grain size being smaller than 50 nm and uniform grain size distribution, and adds a new variety for the prior amorphous alloy catalyst field. The activity ratio surface area of the amorphous alloy catalyst is 10 to 50 m<2> / g, the particle diameter can be controlled in the range of 2 to 50 nm, and the grain size distribution is uniform. The invention realizes the amorphous alloy catalyst with the grain size being smaller than 50 nm and achieves the controllable grain size and the uniform grain size distribution through the preparation method for controlling the reduction reaction rate by oil in water microemulsion. The amorphous alloy catalyst of the invention can be taken as hydrogenation catalyst containing unsaturated functional group compounds such as alkene, alkyne, arene, nitrile, nitro compound, carbonyl compound, etc., not only the catalytic performance is superior to the catalytic performance of the ordinary amorphous alloy catalyst, but also the catalytic performance can be controlled; the life of the catalyst is longer than the life of the ordinary amorphous alloy catalyst, and the catalyst can be recovered and reused time after time.

Owner:SHANGHAI NORMAL UNIVERSITY

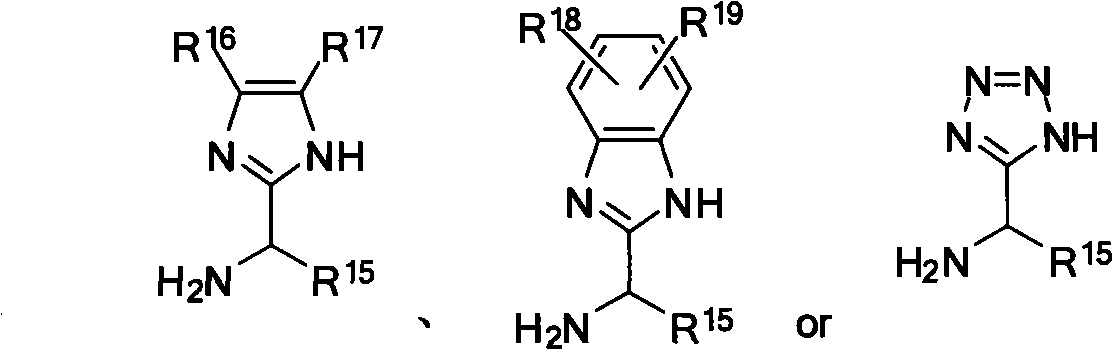

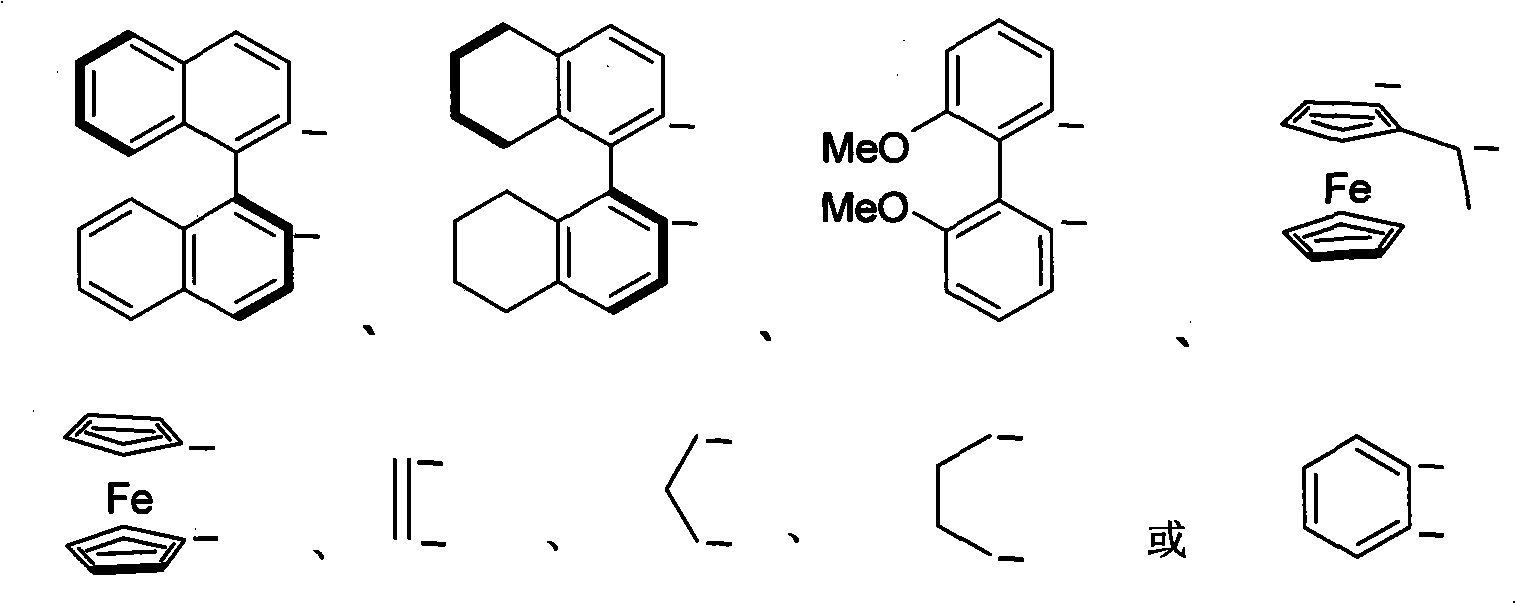

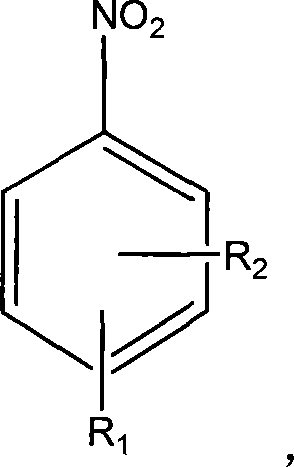

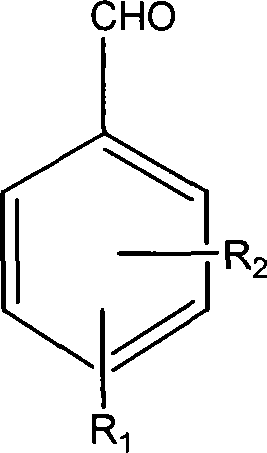

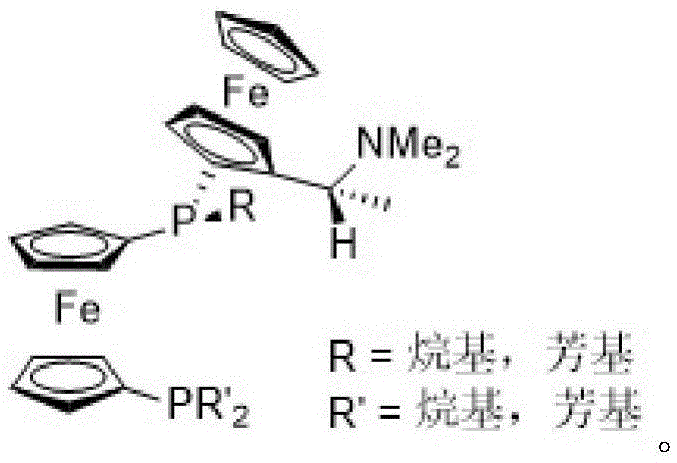

Nitrogen-containing ligand transient metal complex compound , synthetic method and use thereof

The invention relates to a nitrogenous ligand transition metal complex, a method for synthesizing the same and application of the same, in particular to a metal ruthenium complex with a structural formula shown on the right, other transition metal complexes, a method for synthesizing the same and an application of the same. A diphosphine and dinitrogen transition metal complex which is formed by coordination between a dinitrogen ligand with structural characteristics of NH2-N(sp<2>) and a transition metal can be used for catalytic asymmetrical transfer hydrogenation reaction and also can be used for catalytic hydrogenation reaction, and particularly used for asymmetric catalytic hydrogenation reaction of ketone with large steric hindrance alkyl on the alpha position, hypnone, hypnone derivatives, benzophenone, benzophenone derivatives, beta-N, N-dimethyl amino-alpha hypnone, derivatives of the beta-N, N-dimethyl amino-alpha hypnone, and other ketone compounds.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI +1

Noble metal carrier catalyst, preparing method and applications thereof

InactiveCN101229511AImprove adsorption capacityWide variety of sourcesOrganic reductionMetal/metal-oxides/metal-hydroxide catalystsRoom temperatureAtmospheric pressure

The invention discloses a noble metal supported catalyst and a preparation method and application thereof. The preparation method of the noble metal supported catalyst of the invention comprises the following steps: (a) titanium dioxide precursor dispersed solution with rich hydroxyl group and stannous salt solution are mixed, stirred, washed and dispersed into the water; (b) when stirring, soluble noble metal salt solution is added into the titanium dioxide precursor dispersed solution after being processed by the stannous salt solution, which is stirred, washed and dried, thus obtaining the noble metal supported catalyst. The method of the invention has no high requirements for preparation conditions which can be carried out under room temperature and atmospheric pressure and does not need heat and pressure; meanwhile, the raw materials adopted in the reaction have wide source and lower toxicity with the advantages of simplicity, economy, low energy consumption, convenient operation and convenience on realizing scale production.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Method for preparing aromatic amine, alcohol and alkane by heterogeneous catalytic hydrogen transfer

InactiveCN101182274AWide variety of sourcesHigh activityOrganic reductionOrganic compound preparationChemical industryNitro compound

The invention belongs to the chemical industry technical field and concretely provides a method of preparing for aromatic amine, alcohol or alkane by multi-phase catalytic hydrogenation transfer. The invention considers aromatic nitryl compound, aldehyde ketone and alkene compound as a substrate, hydrogenous polyatomic molecule as a hydrogen donor and loading type nano-gold as catalyst for reflux and stirring for the multi-phase catalytic hydrogenation transfer reaction under 80 DEG C to 200 DEG C and 0.4 to 0.6MPa to prepare for the aromatic amine, alcohol or alkane. The reaction condition of the method of the invention is gentle; the environment is friendly; the applied catalyst has high reaction activity and good selectivity.

Owner:FUDAN UNIV

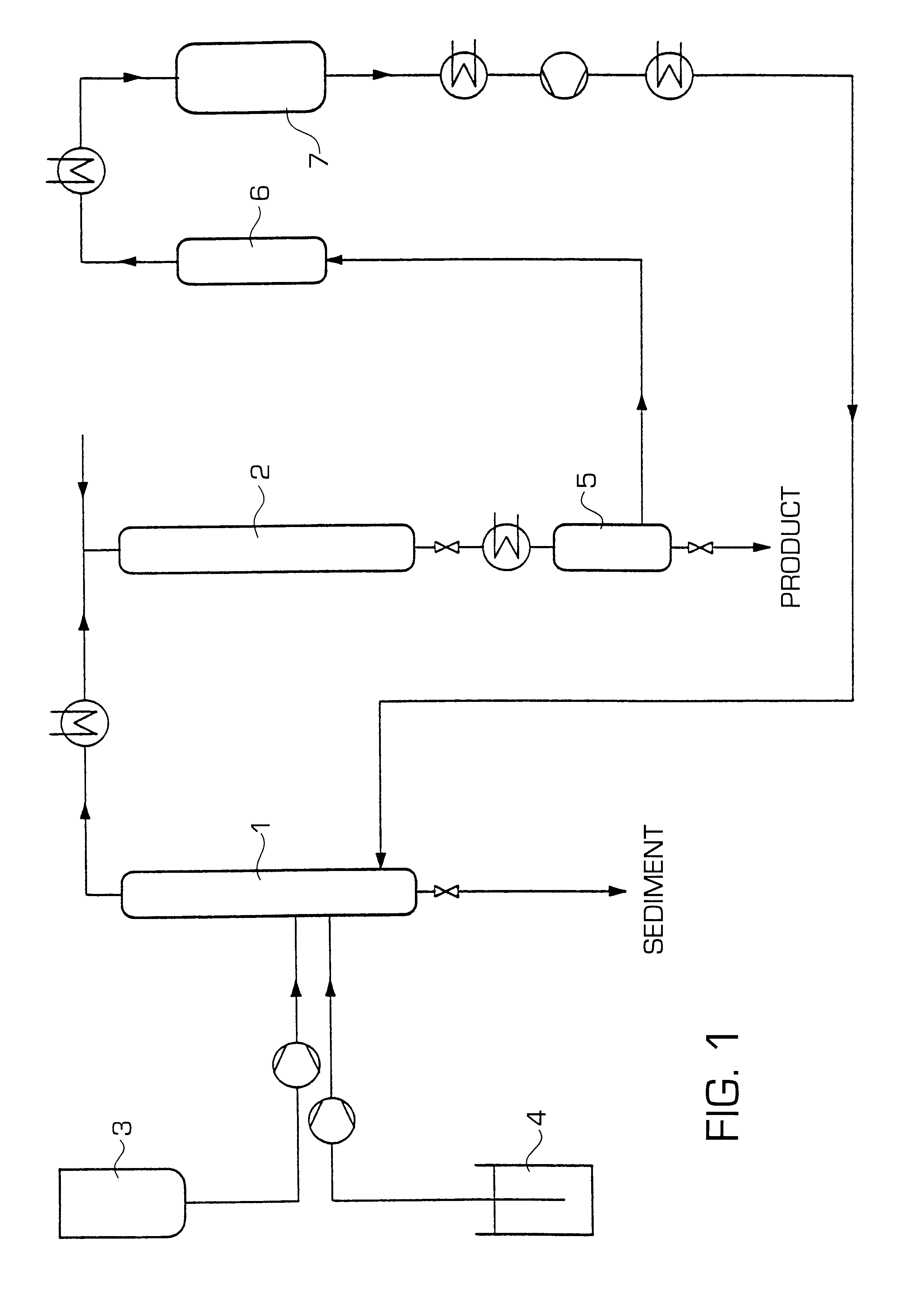

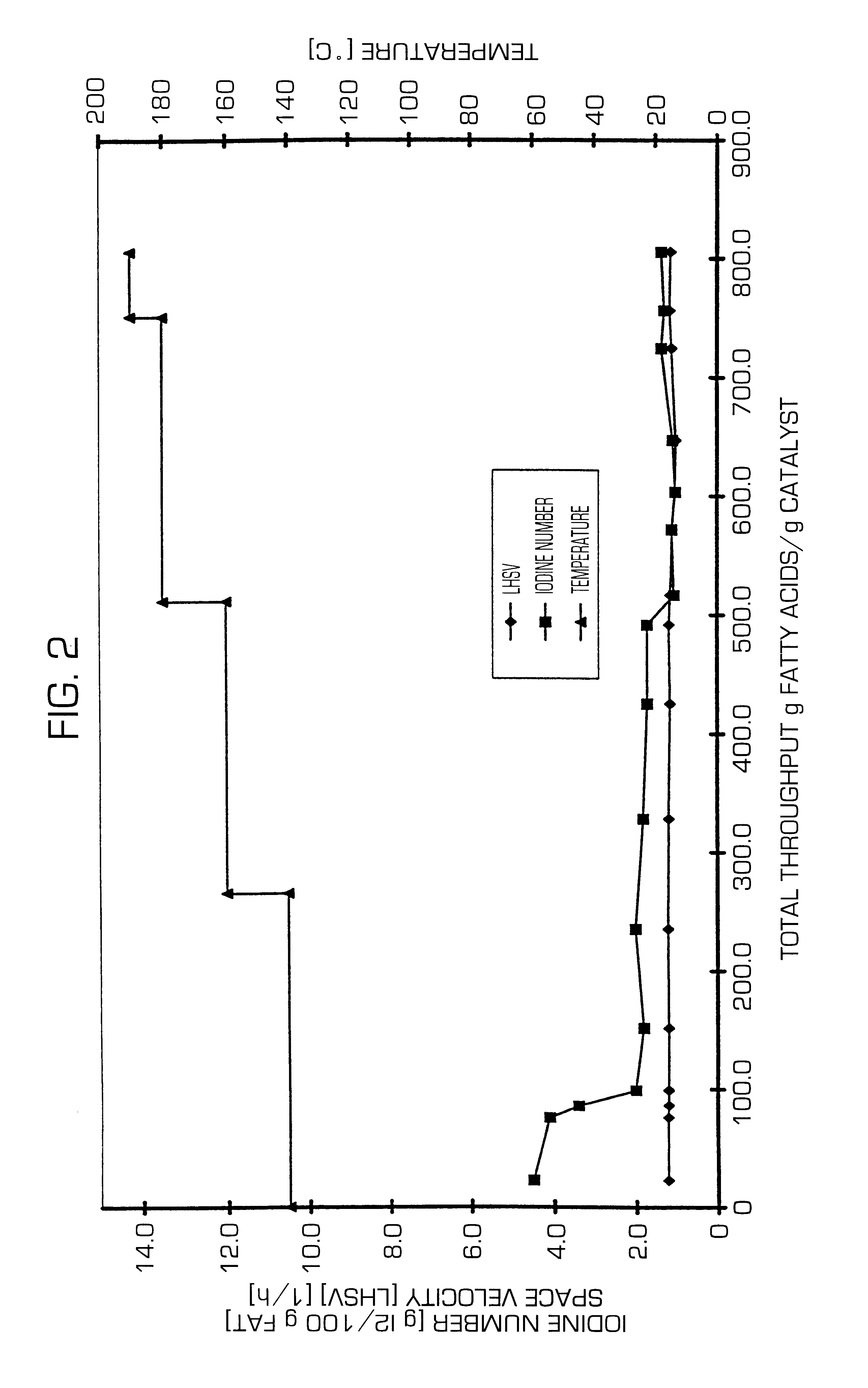

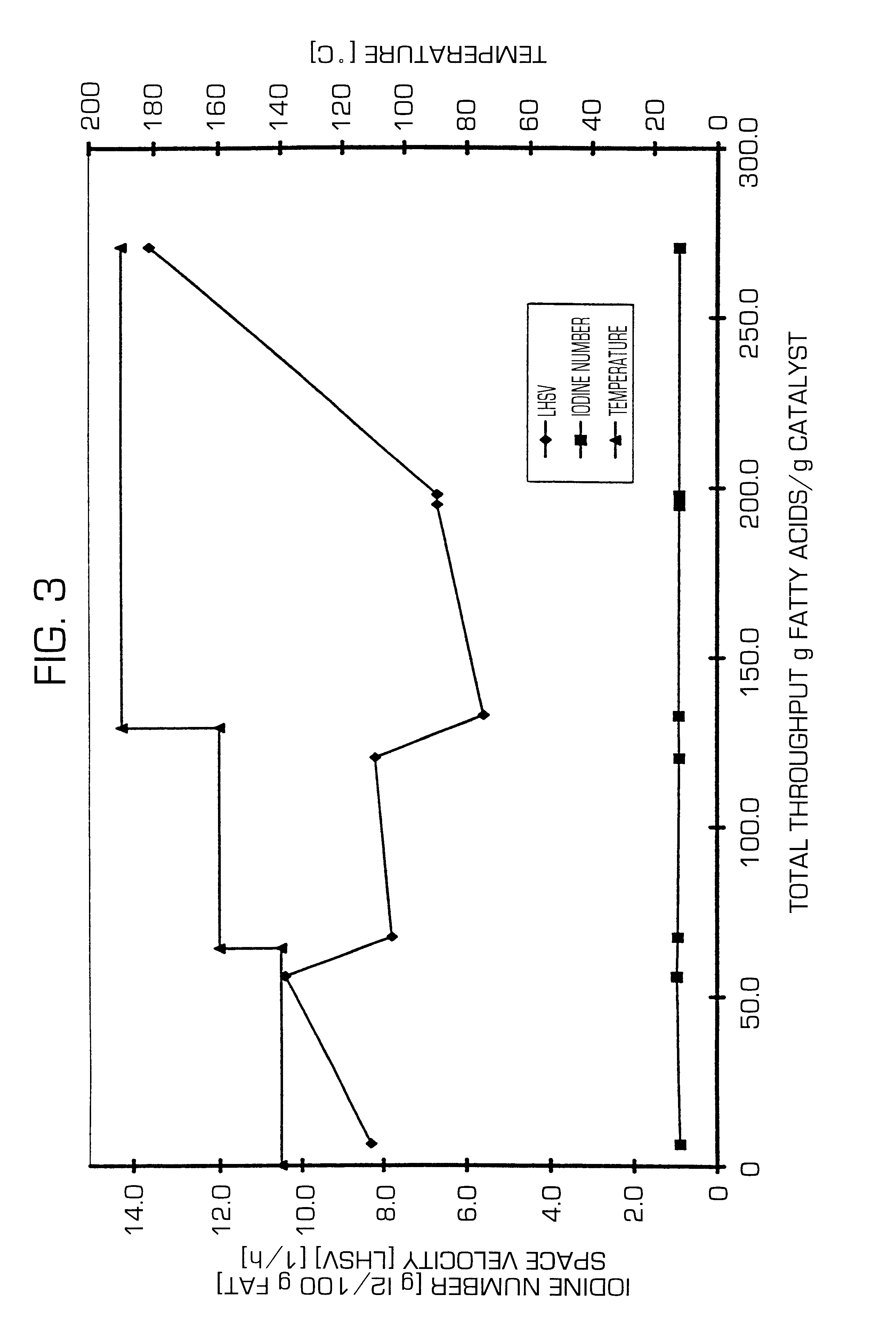

Process for the continuous catalytic transformation of organic compounds

InactiveUS6316646B1Organic reductionFatty acid hydrogenationCatalytic transformationOrganic compound

Owner:DEGUSSA HULS AG

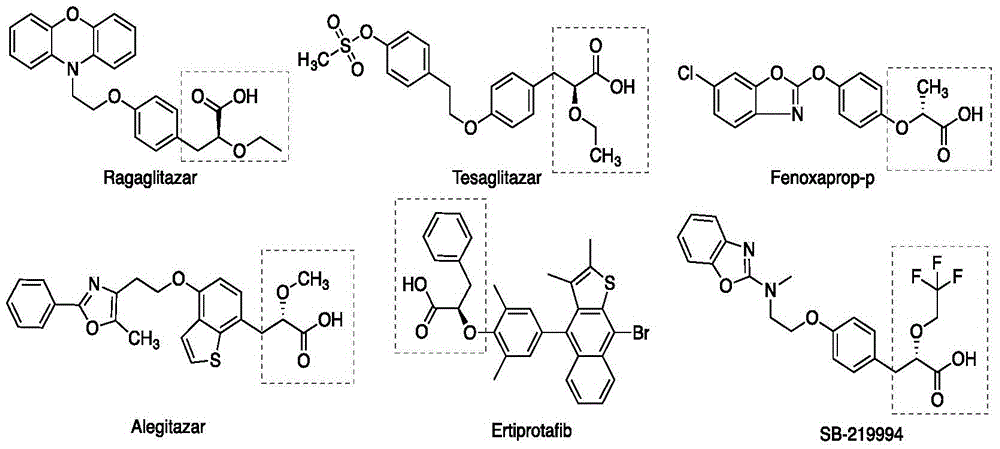

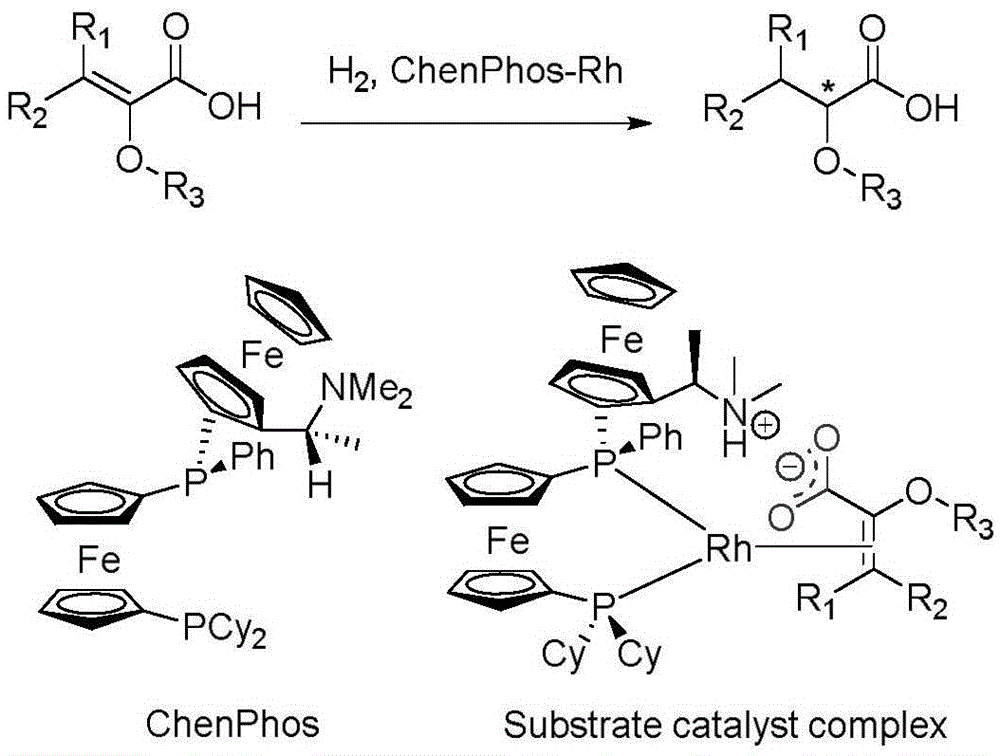

Asymmetric hydrogenation method of alpha-oxo-alpha, beta-unsaturated carboxylic acid

InactiveCN105481622AHigh catalytic activityHigh enantioselectivityOrganic reductionOrganic compound preparationEnkephalinase inhibitorAsymmetric hydrogenation

The invention relates to an asymmetric hydrogenation method of alpha-oxo-alpha, beta-unsaturated carboxylic acid. A metal complex containing ChenPhos chiral ligand is a catalyst high in conversion efficiency, and particularly, the catalyst can be used for synthesizing a core framework in enkephalinase inhibitor Sacubitril through asymmetric hydrogenation. The inhibitor is one of components of medicine LCZ 696 approved by American Food and Drug Administration. The asymmetric hydrogenation method of the alpha-oxo-alpha, beta-unsaturated carboxylic acid is efficient, and the application range of substrate is wide.

Owner:WUHAN CATALYS TECH CO LTD

Method for preparing high-selectivity Pd/TiO2-C hydrogenation catalyst

ActiveCN102125838AEvenly dispersedIncrease loadOrganic reductionMetal/metal-oxides/metal-hydroxide catalystsInorganic acidsHigh selectivity

The invention provides a method for preparing a high-selectivity Pd / TiO2-C hydrogenation catalyst, which comprises the following steps of: preparing an inorganic acid solution of a Pd-containing compound, and preparing an inorganic base solution of the Pd-containing compound; preparing a suspension solution of TiO2-C powder; adding the inorganic acid solution of the Pd-containing compound into the suspension solution of TiO2-C powder, regulating the pH value of the suspension to be 2-4, and standing for 0.01-1 hour; adding the inorganic base solution until the pH value reaches 8-12, and standing for 0.01-1 hour; adding the inorganic acid solution of the Pd-containing compound, regulating the pH value of the suspension to be 2-4, and standing for 0.01-1 hour, thereby finishing one PH swing; repeating the processes for 1-10 times; and then, reducing the suspension by a reducer to obtain the Pd / TiO2-C hydrogenation catalyst in which the Pd content is 1.1-20%. The Pd / TiO2-C hydrogenation catalyst prepared by the method provided by the invention has high hydrogenation conversion rate and high selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

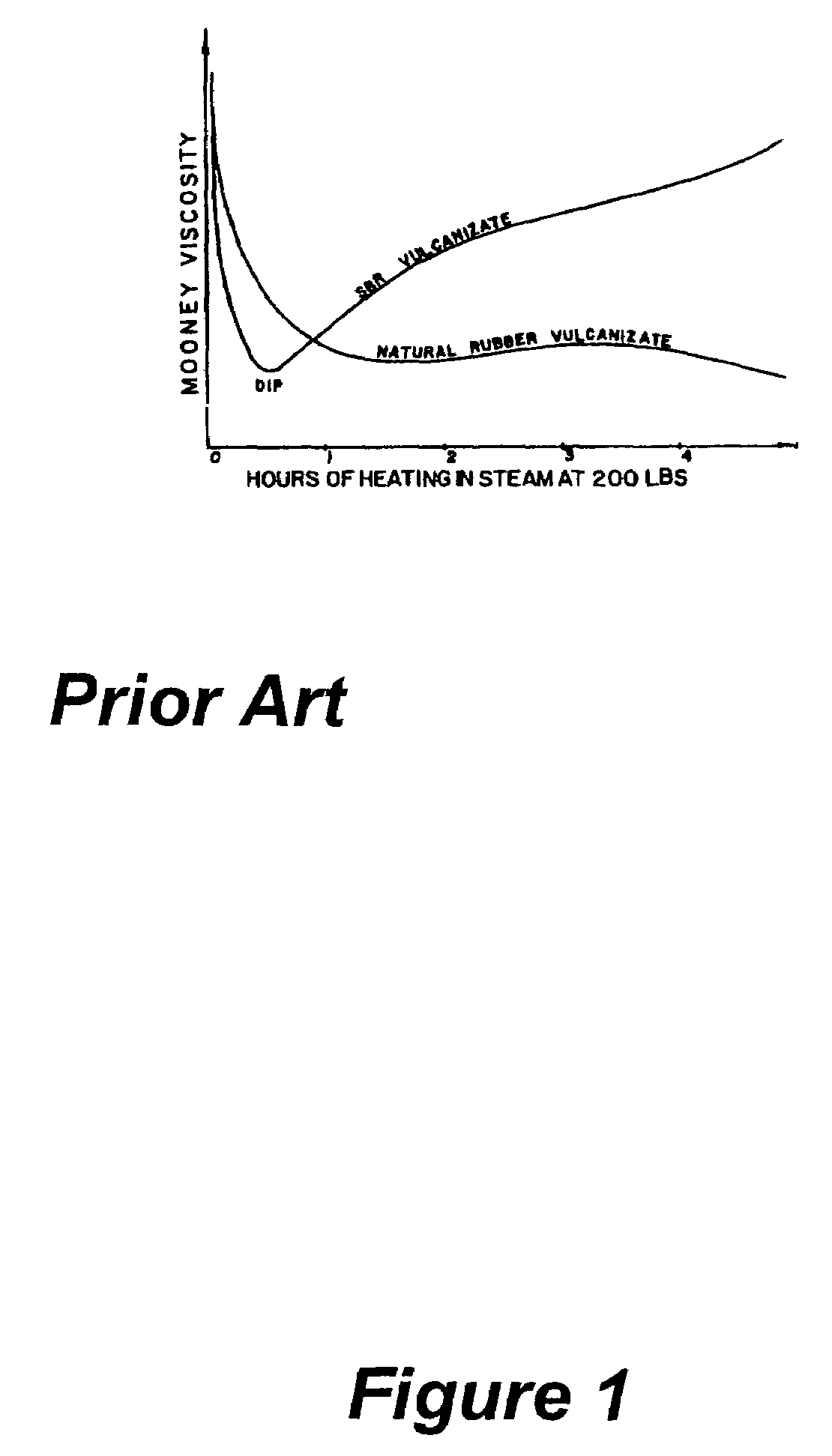

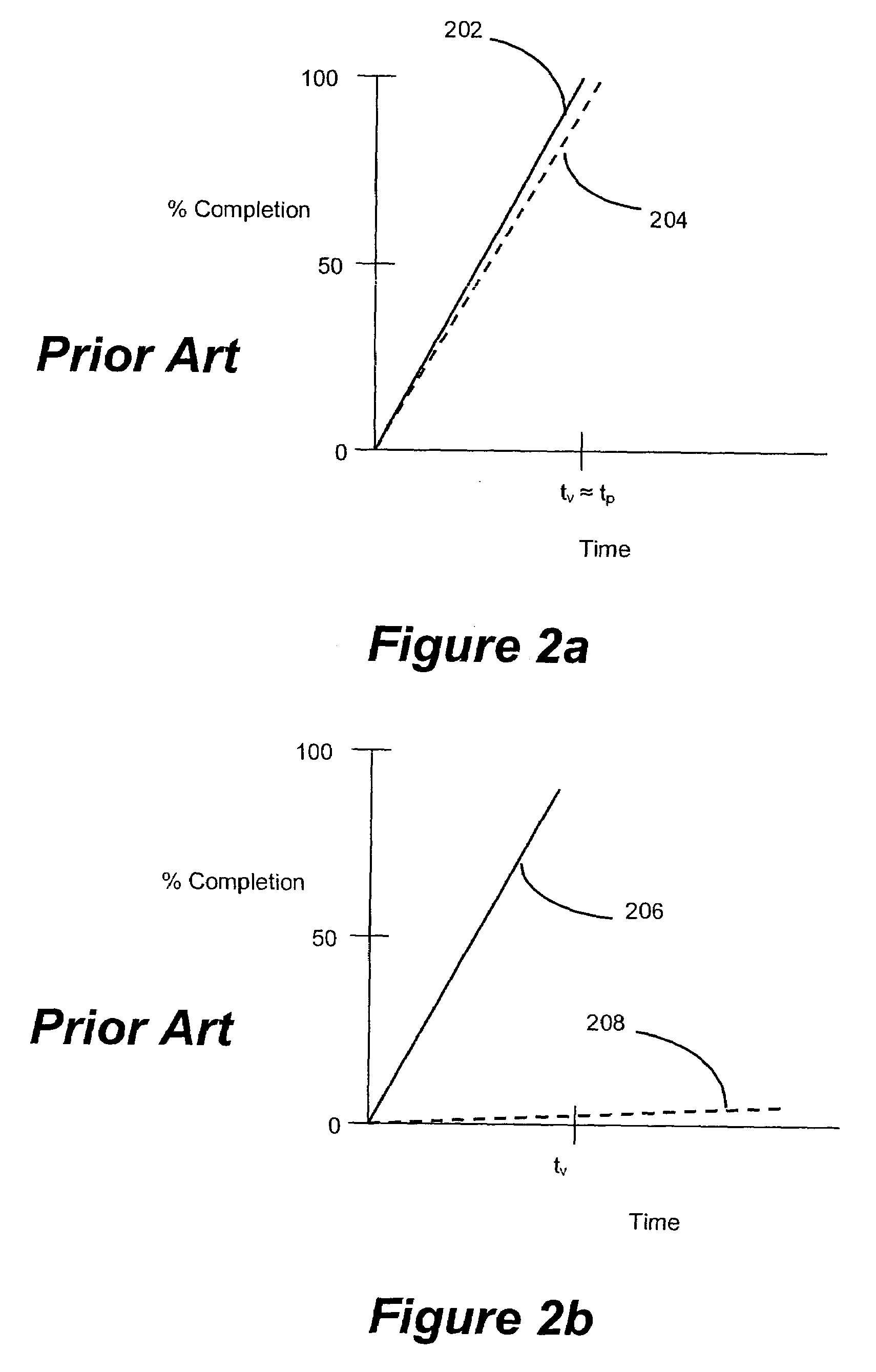

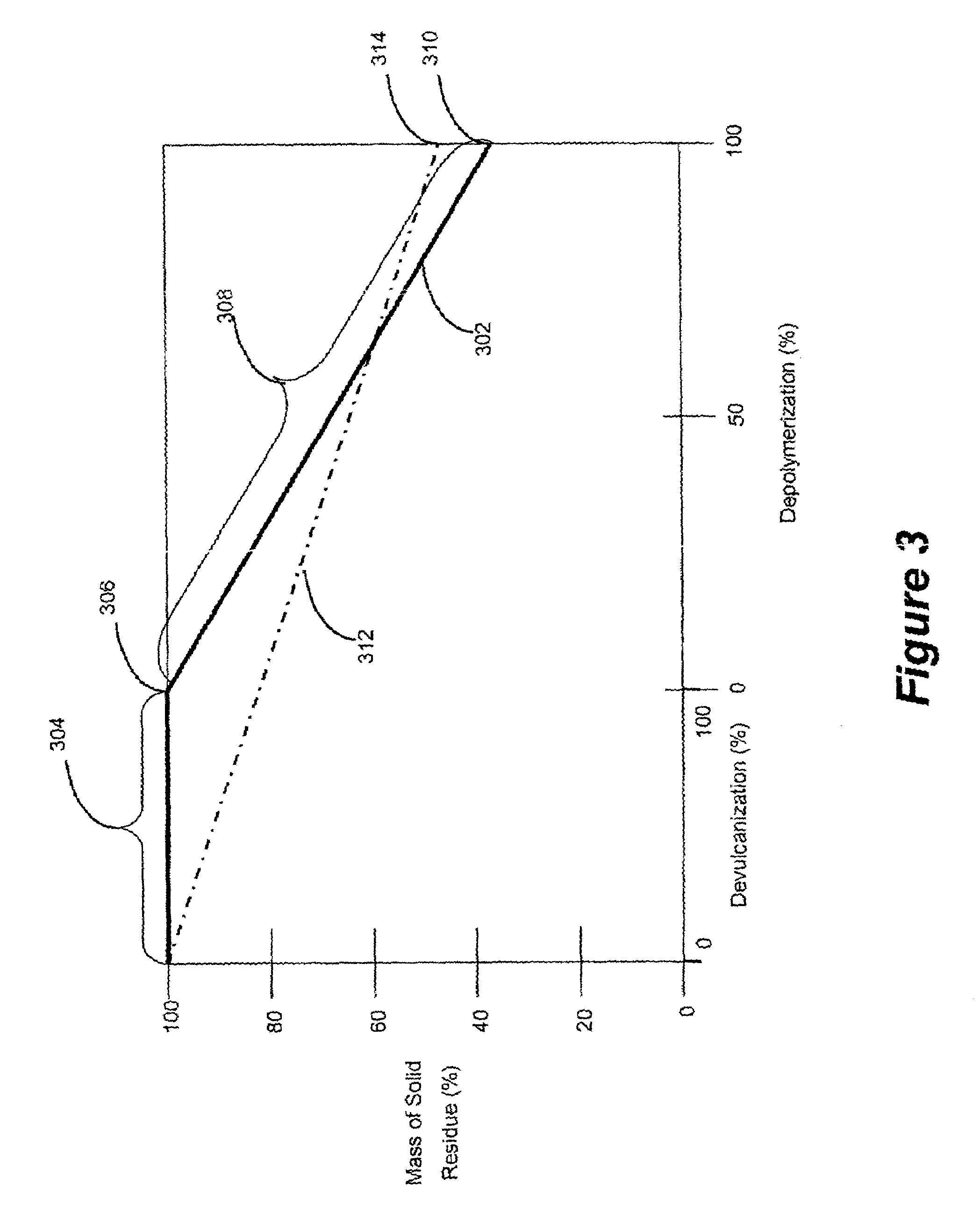

Rubber reduction

A method of reducing vulcanized rubber is provided. The method comprises the steps of heating the rubber, wherein the rubber includes synthetic rubber, in the presence of a solvent, wherein the solvent includes water to a temperature below a critical temperature of the solvent, providing a pressure that is at least equal to a saturated vapour pressure of the solvent at the temperature and maintaining the temperature and the pressure for a time sufficient to devulcanize the rubber and produce a reaction product that is primarily a solid phase and includes rubber hydrocarbon.

Owner:OPW ENTERPRISES +1

Highly active spherical metal support catalysts

InactiveUS20070117714A1Uniform shapeUniform sizeOrganic reductionCatalyst protectionCompound (substance)Polysaccharide

The invention relates to highly active spherical metal support catalysts with a metal content of 10 to 70% by mass, and a process for their production with the use of a mixture of polysaccharides and at least one metal compound which is dropped into a metal salt solution.

Owner:SHELL INT RES MAATSCHAPPIJ BV

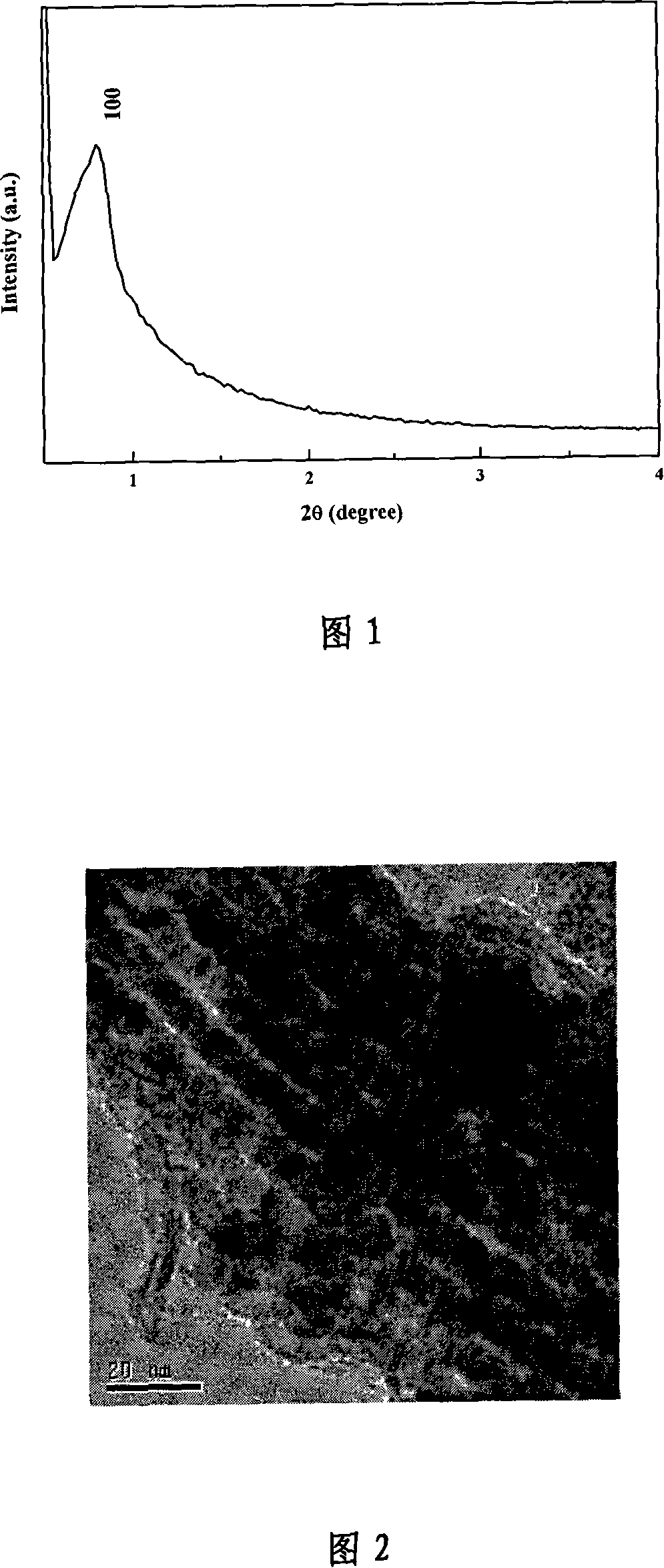

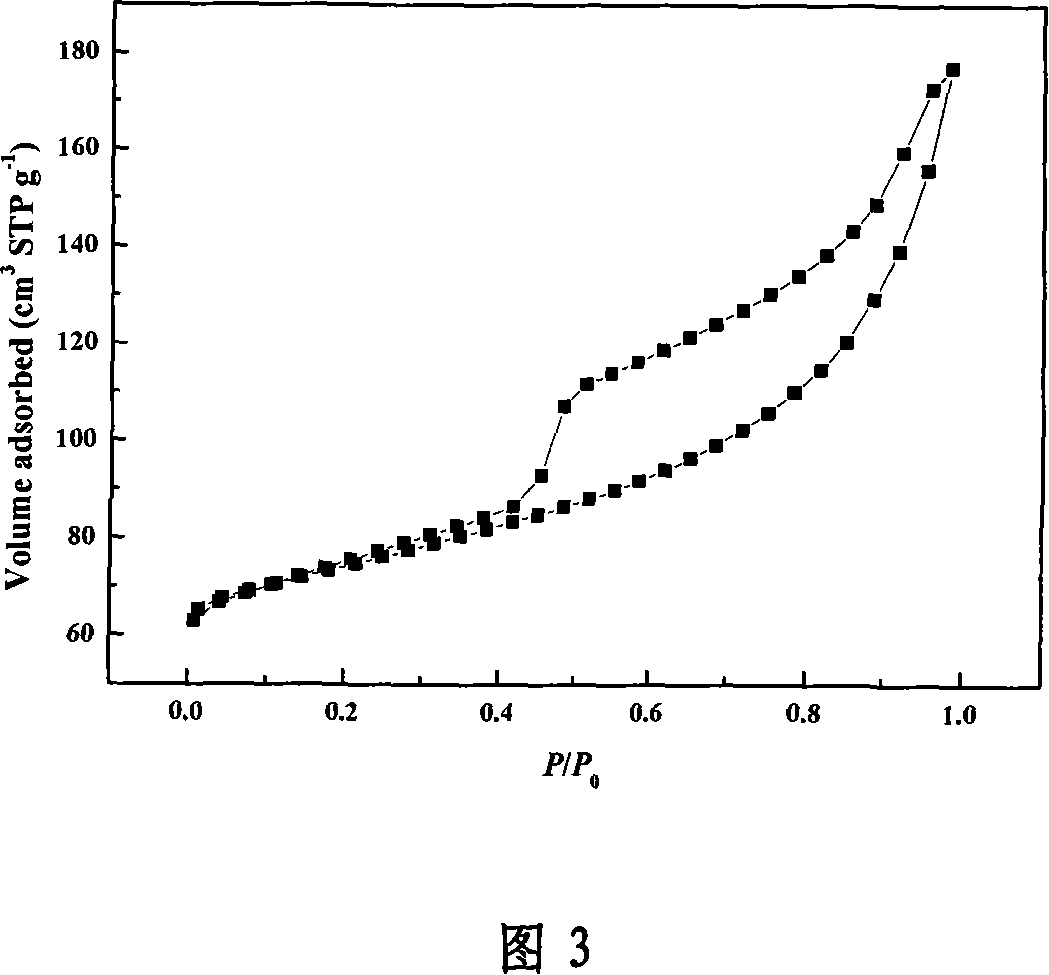

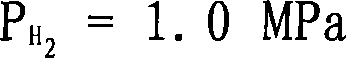

Mesoporous-structure metal nickel catalyst and its preparing method and use

InactiveCN101069847AGood effectOrganic reductionOrganic compound preparationNitro compoundChemical plating

The present invention discloses a metal nickel catalyst with mesohole structure. It is characterized by that its surface area is 50-250 sq.m / g, pore size is 2-5nm and pore volume is 0.2-0.8 cu.cm / g. Its preparation method includes the following steps: (1), preparing SBA-15 template; (2), preparing chemical plating solution; (3), implanting palladium crystal seed into the pore of template; (4), adopting chemical nickel-plating process to inject metal nickel into the pore of template; (5), using hot alkali liquor to remove template; and (6), filtering, washing and vacuum drying. The invented catalyst can be used for making hydrogenation reaction of the compounds containing unsaturated functional group, such as olefin, alkine, aromatic hydrocarbon, nitrile, nitro compound and carbonyl compound, etc.

Owner:SHANGHAI NORMAL UNIVERSITY

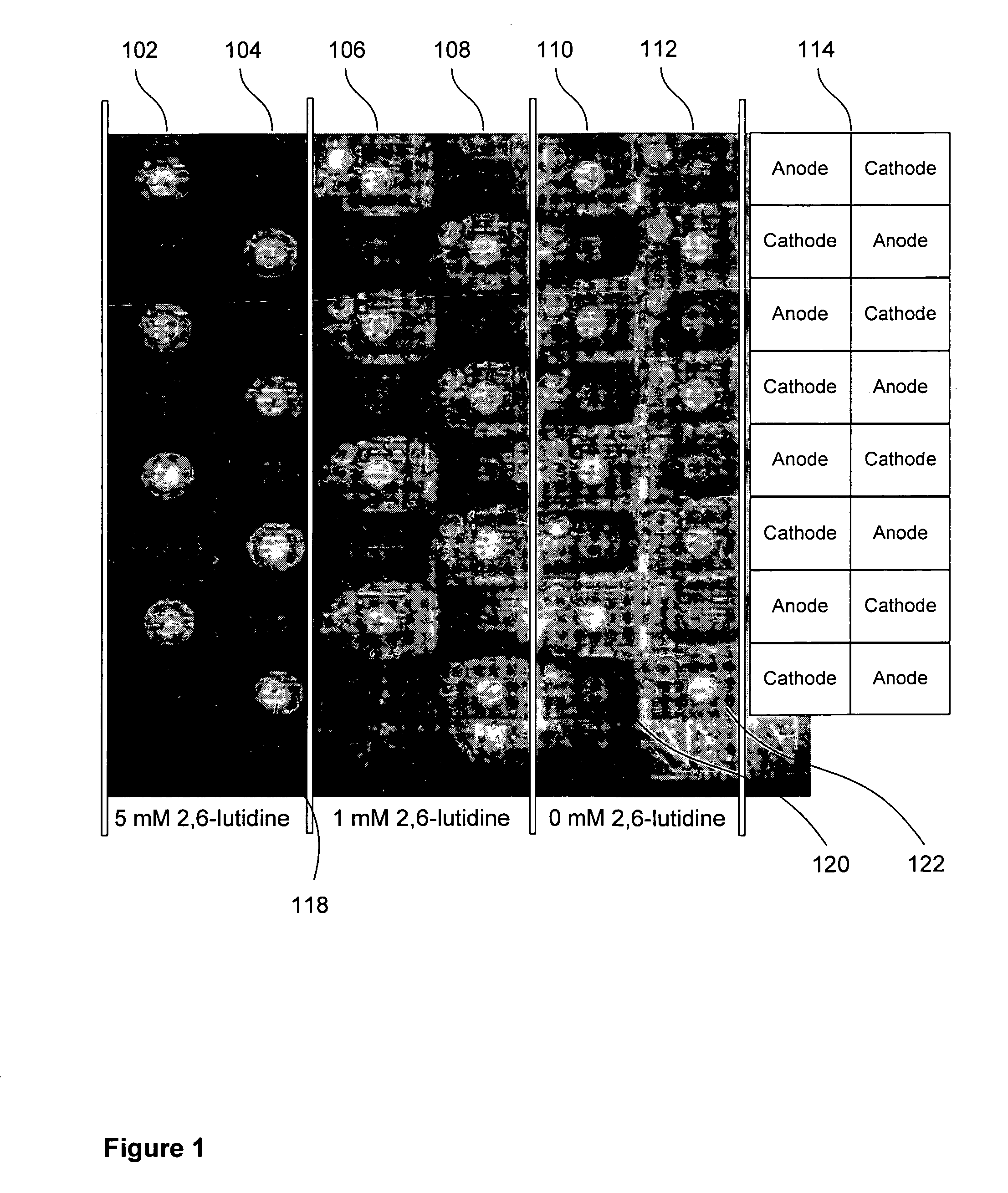

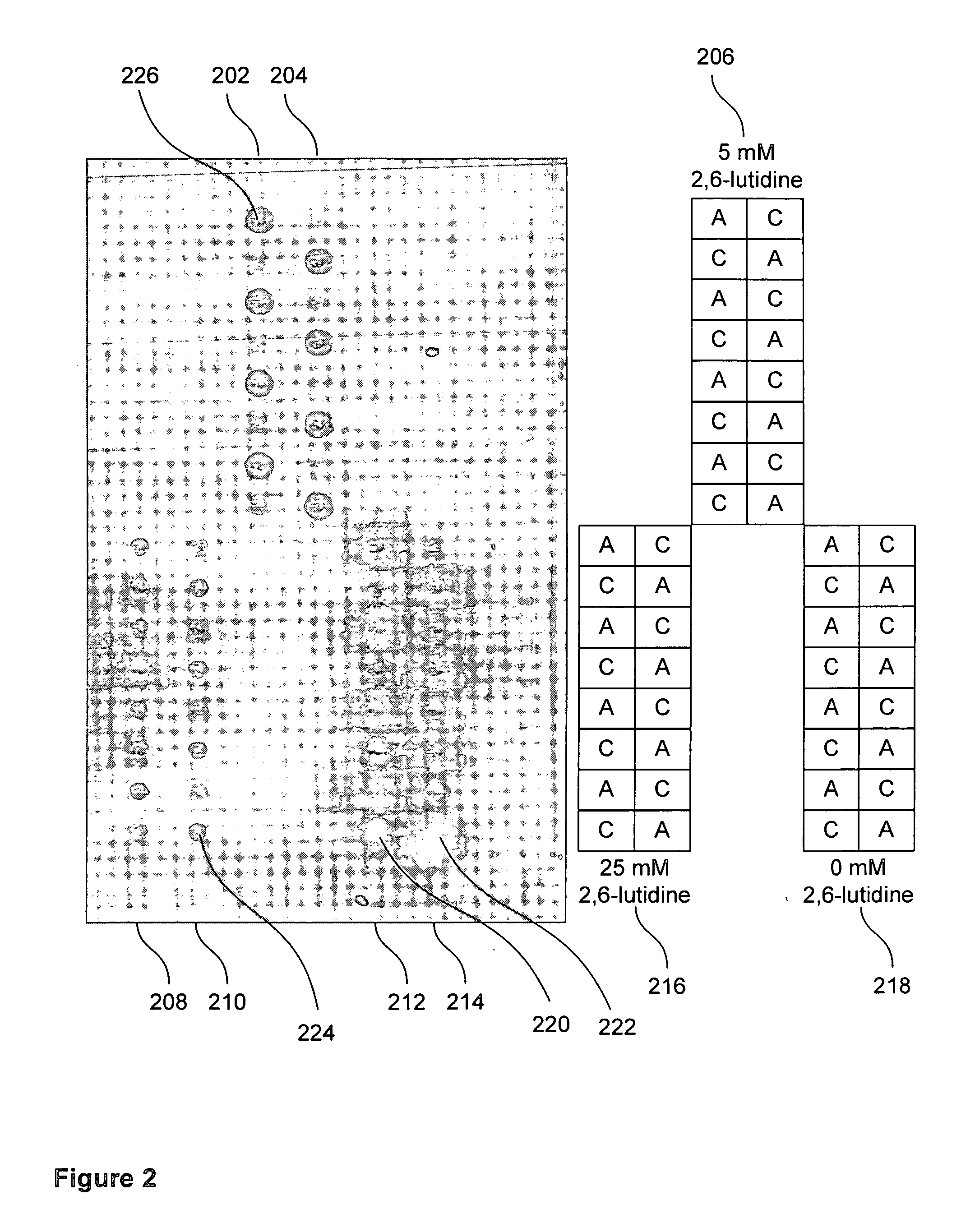

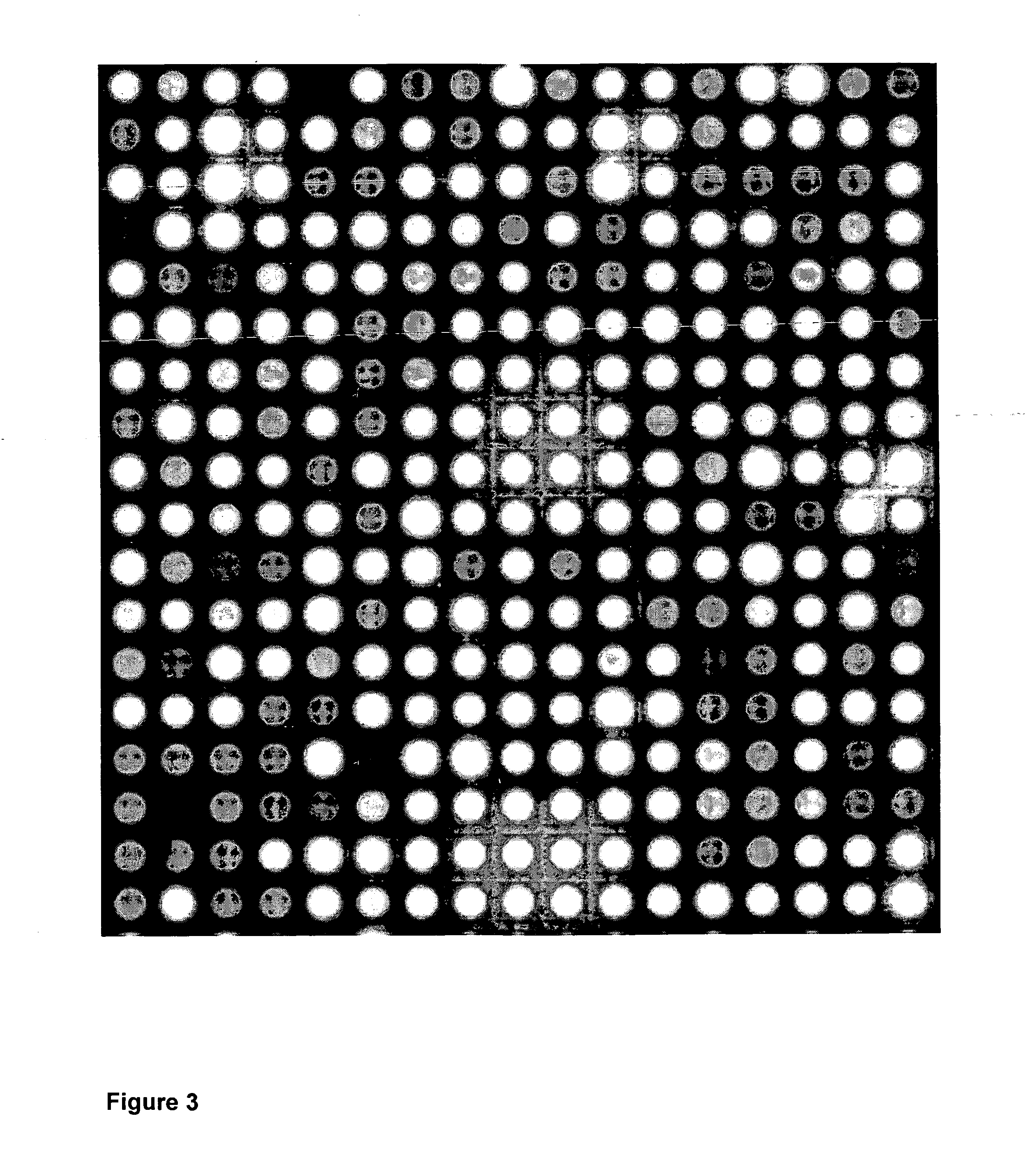

Electrochemical deblocking solution for electrochemical oligomer synthesis on an electrode array

InactiveUS20070034513A1Sequential/parallel process reactionsElectrolysis componentsOligomerElectrochemistry

There is disclosed an electrochemical deblocking solution for use on an electrode microarray. There is further disclosed a method for electrochemical synthesis on an electrode array using the electrochemical deblocking solution. The solution and method are for removing acid-labile protecting groups for synthesis of oligonucleotides, peptides, small molecules, or polymers on a microarray of electrodes while substantially improving isolation of deblocking to active electrodes. The method comprises applying a voltage or a current to at least one electrode of an array of electrodes. The array of electrodes is covered by the electrochemical deblocking solution.

Owner:CUSTOMARRAY

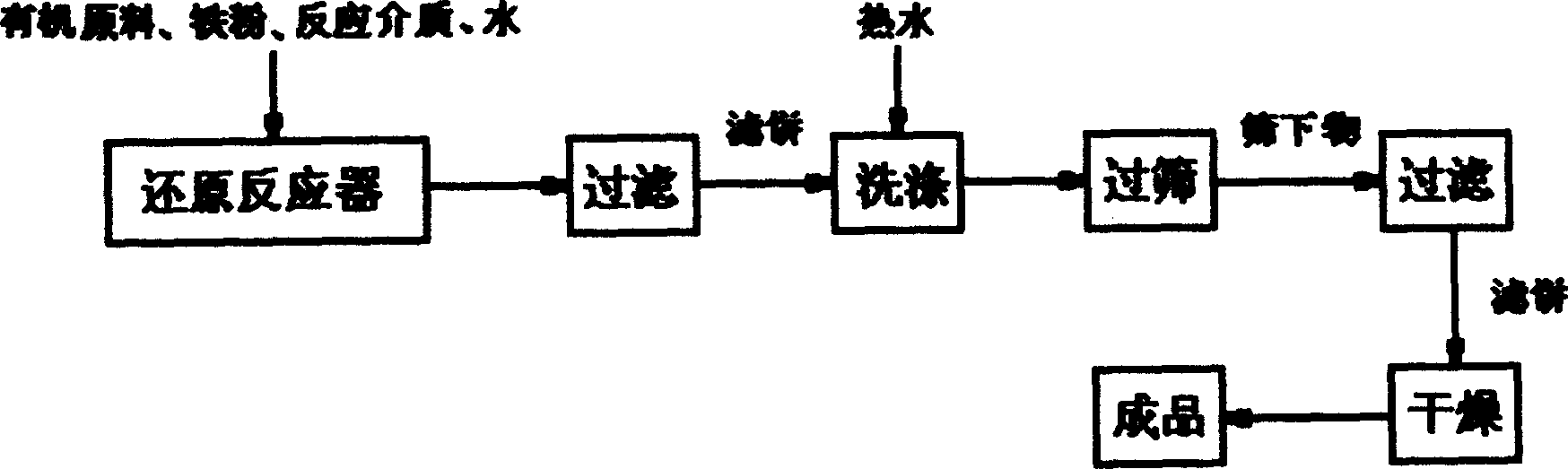

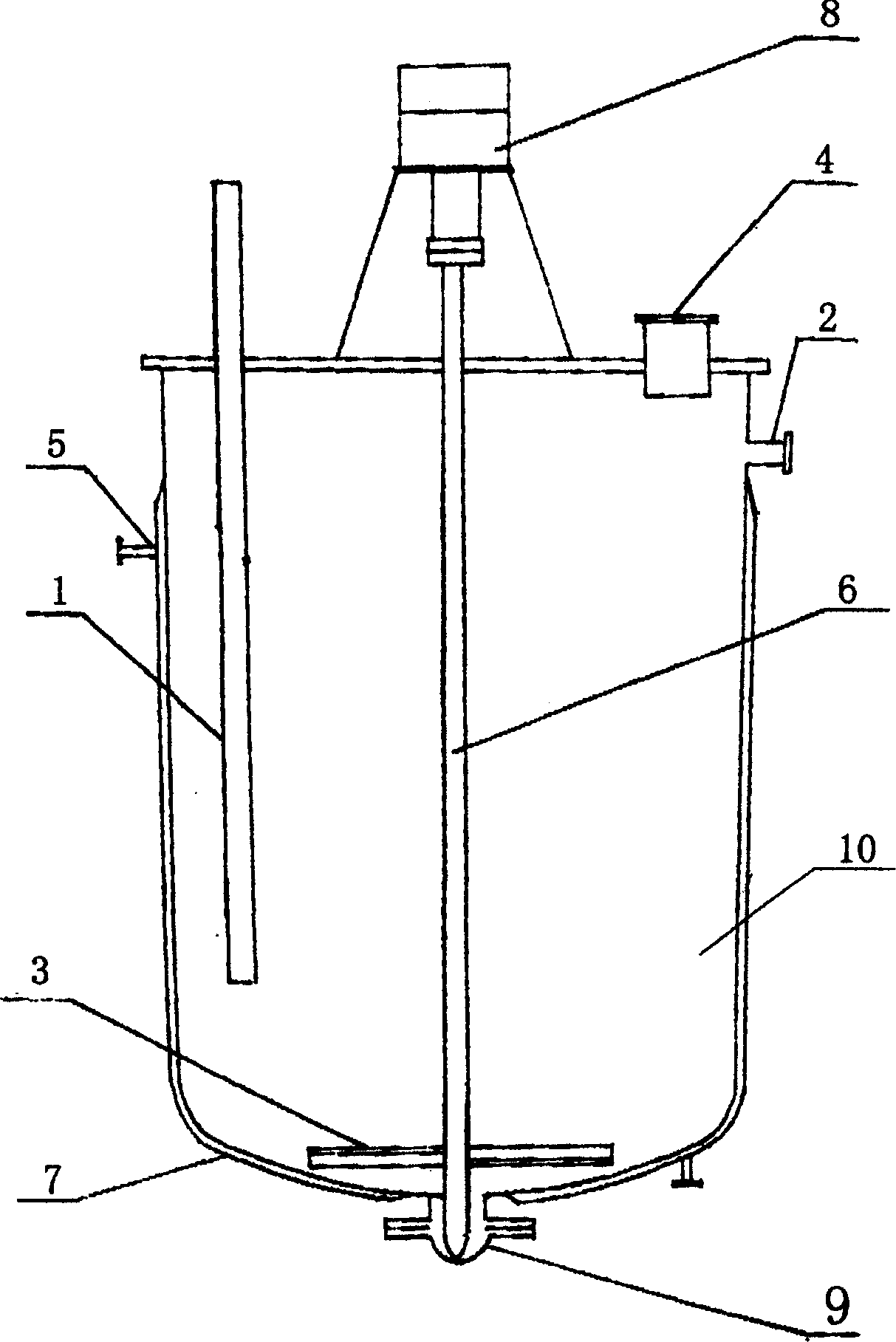

Iron powder reducing method for simultaneously producing organic product and ferric oxide black

InactiveCN1458134AReduce pollutionRealize continuous productionOrganic reductionIron oxides/hydroxidesIron powderResource utilization

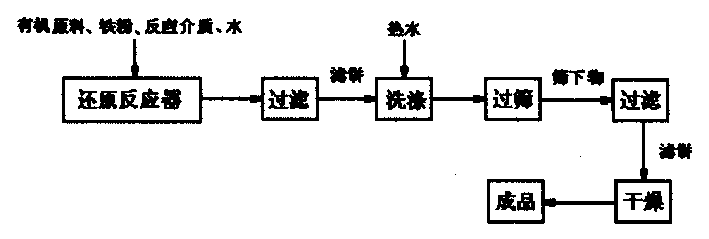

The production process includes reduction, filtering, washing, sieving, filtering and drying steps. In the reduction inside the reduction reactor with paddle stirrer, iron powder, water and reacted medium are heated with steam for 0.5-1 hr to activate, organic material is dropped continuously, iron powder, water and reacted medium are replenished intermittently to maintain the proper material ratio, and the suspension of organic product and iron mud is discharged continuously from the discharge port. The present invention is one continuous production process with low material consumption and high resource utilization.

Owner:湖北开元化工科技股份有限公司

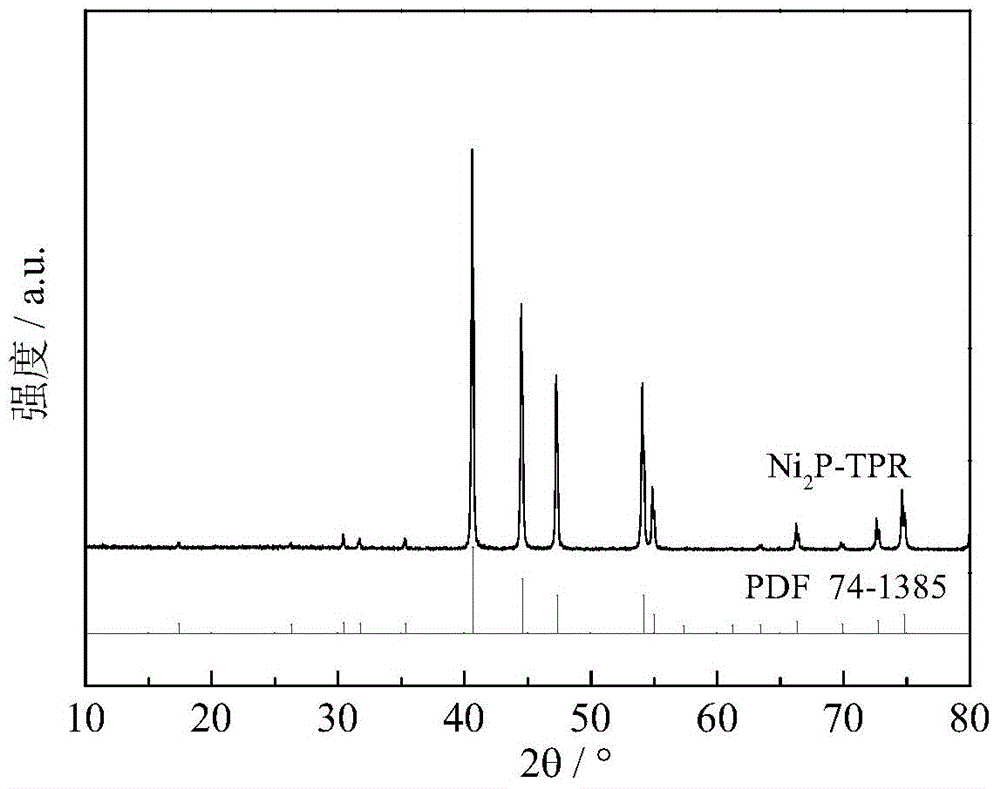

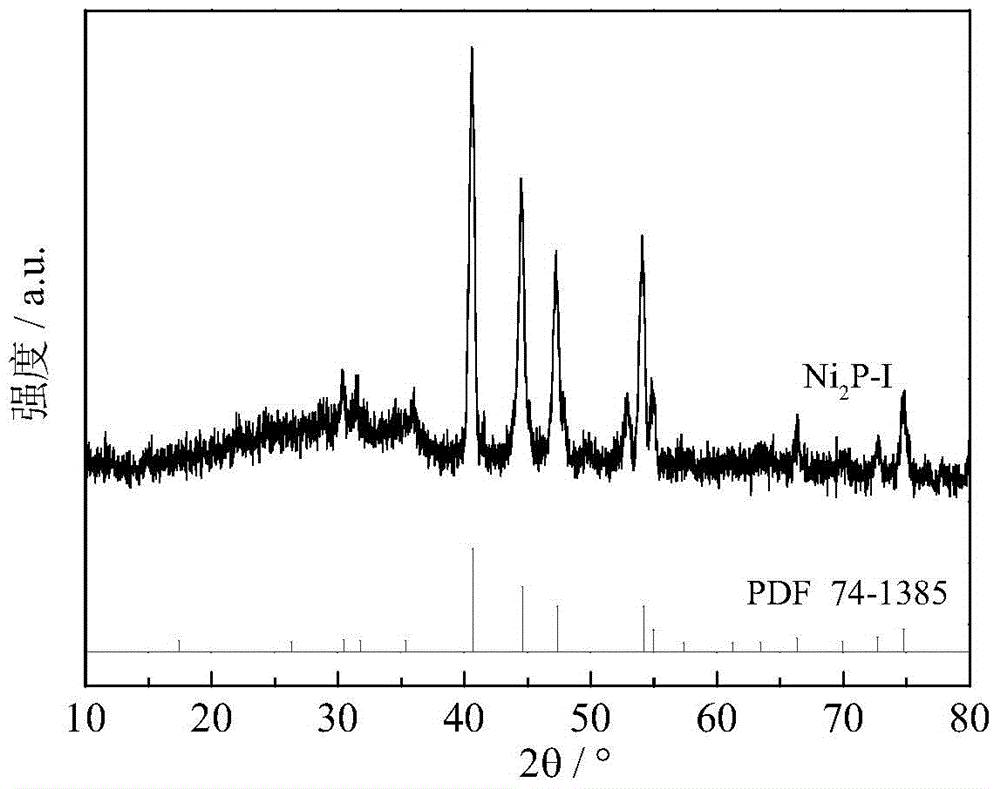

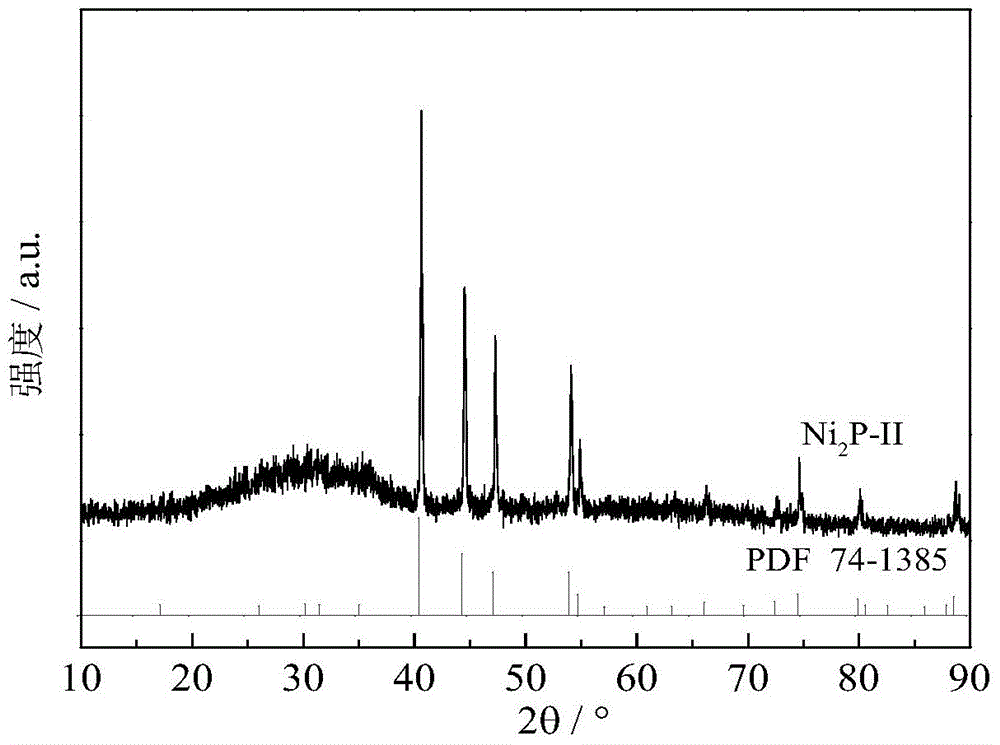

Nickel phosphide catalyst containing sulphur and application of nickel phosphide catalyst

InactiveCN104941673AHigh selectivityImprove hydrogenation activityOrganic reductionPhysical/chemical process catalystsToxicantSulfur

The invention relates to a nickel phosphide catalyst containing sulphur and application of the nickel phosphide catalyst. For the nickel phosphide catalyst, the molar ratio of nickel to phosphorus is 0.1-5, the content of phosphorus is 25% or below by atomic percentage. The nickel phosphide catalyst containing sulphur disclosed by the invention has high selectivity in selective hydrogenation reaction of unsatured unsaturated hydrocarbon compounds and nitrobenzene compounds, has selectivity equivalent to that of Ni2P prepared by adopting the traditional temperature programmed reduction method of phosphate, but has activity obviously improved. Compared with the viewpoint generally known in the prior art that sulphur has side effects for metal hydrogenation catalysts or metalloid hydrogenation catalysts, i.e., sulphur is a toxicant and can be used for greatly reducing the activity of the catalyst, the nickel phosphide catalyst containing sulphur provided by the invention has the advantage that by introducing an appropriate amount of sulphur into the Ni2P catalyst, the hydrogenation activity of the Ni2P catalyst can be significantly improved under the condition that the selectivity of the Ni2P catalyst is not affected.

Owner:DALIAN UNIV OF TECH

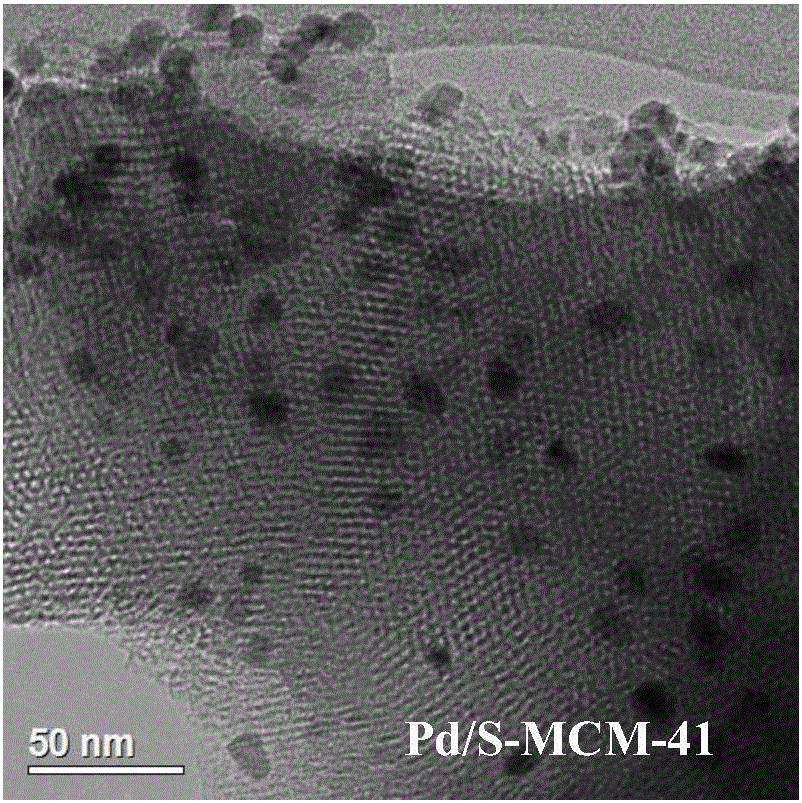

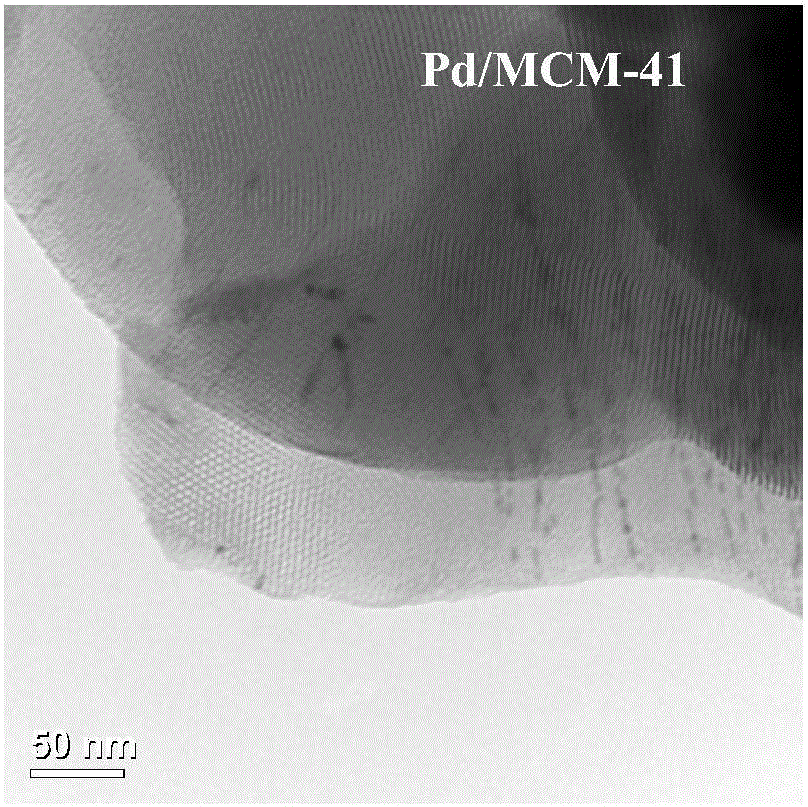

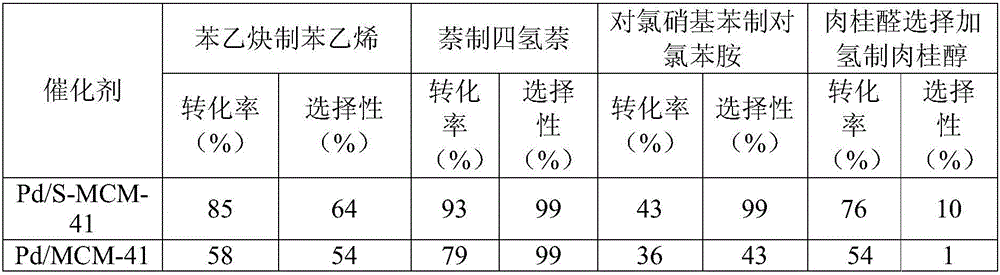

Application of supported palladium catalyst in selective hydrogenation reaction

The invention relates to application of a supported palladium catalyst in selective hydrogenation reaction. The supported palladium catalyst takes Pd as an active ingredient and takes a mesoporous molecular sieve MCM-41 as a carrier, and the nano-particles of the active ingredient Pd are dispersed on the surface and / or porthole of the carrier. A research finds that in the supported catalyst which takes Pd as the active ingredient and takes the mesoporous molecular sieve MCM-41 as the carrier, the catalyst activity and / or selectivity is obviously superior to that of Pd / MCM-41 catalyst which does not have the characteristic when the nano-particles of the active ingredient Pd are dispersed on the surface and / or porthole of the carrier, and the application especially aims at the selective hydrogenation reaction of unsaturated hydrocarbons, alpha, beta-unsaturated aldehydes and halogenated nitrobenzene compounds.

Owner:PETROCHINA CO LTD +1

Popular searches

Refining to eliminate hetero atoms Hydrocarbon purification/separation Catalyst activation/preparation Hydrocarbons Carboxylic acid esters preparation Hydroxy compound preparation Asymmetric syntheses Treatment with hydrotreatment processes Refining by aromatic hydrocarbon hydrogenation Hydrocarbon oils treatment products

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com