Patents

Literature

85results about How to "Improve crystal state" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

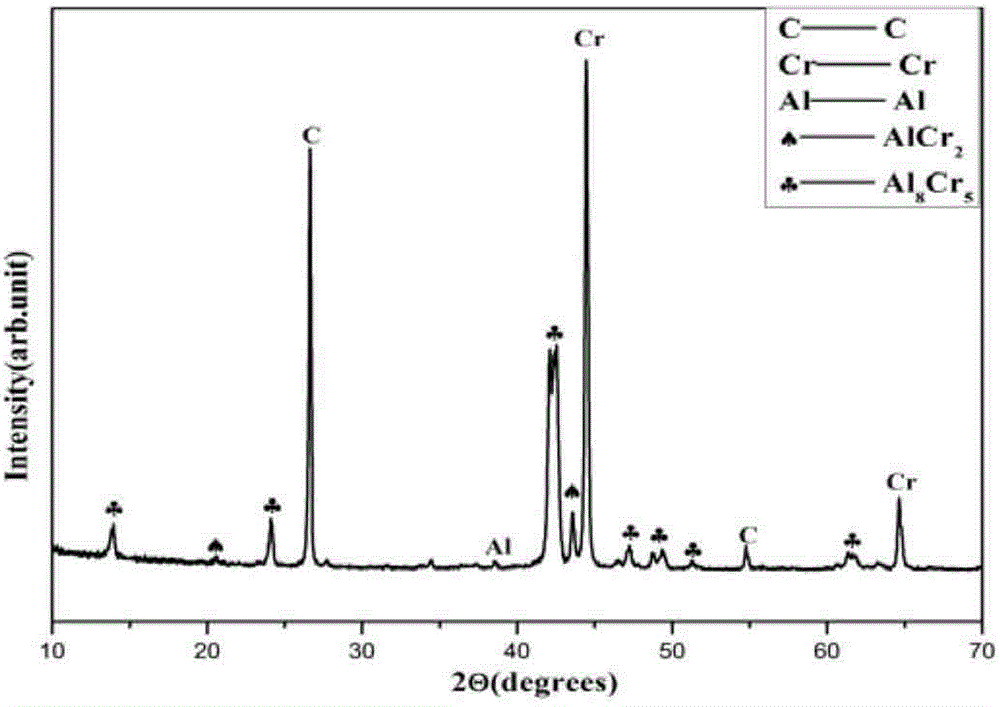

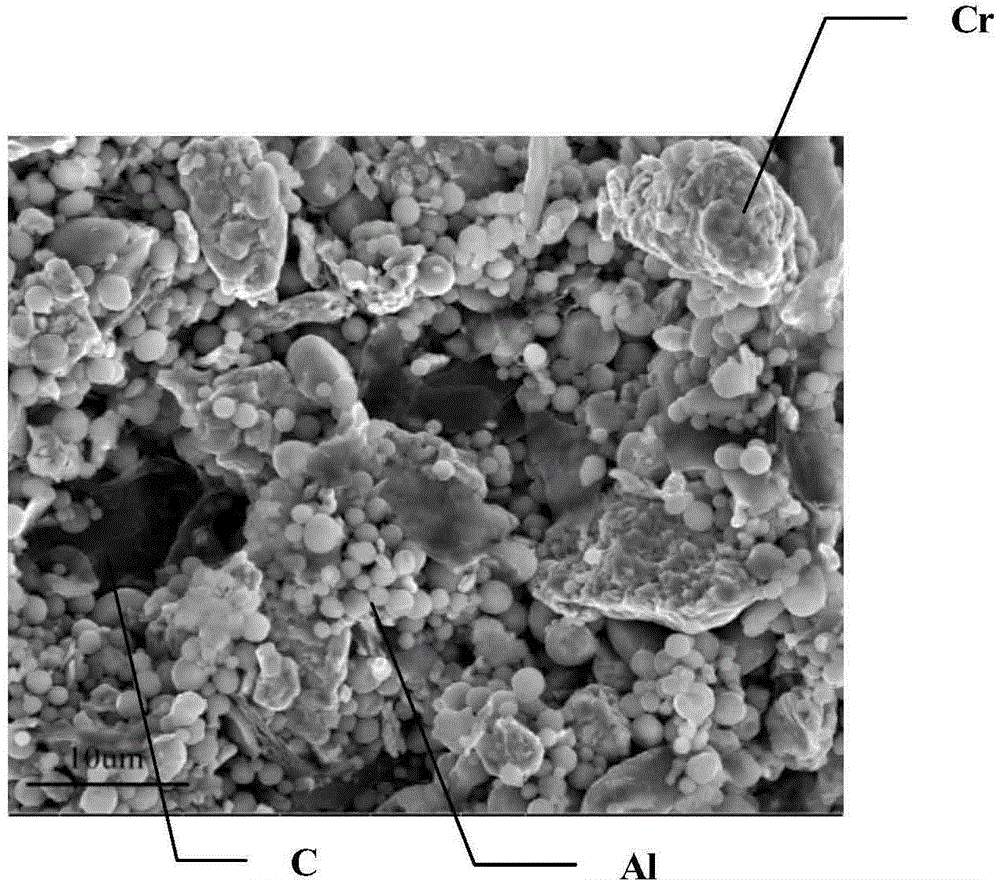

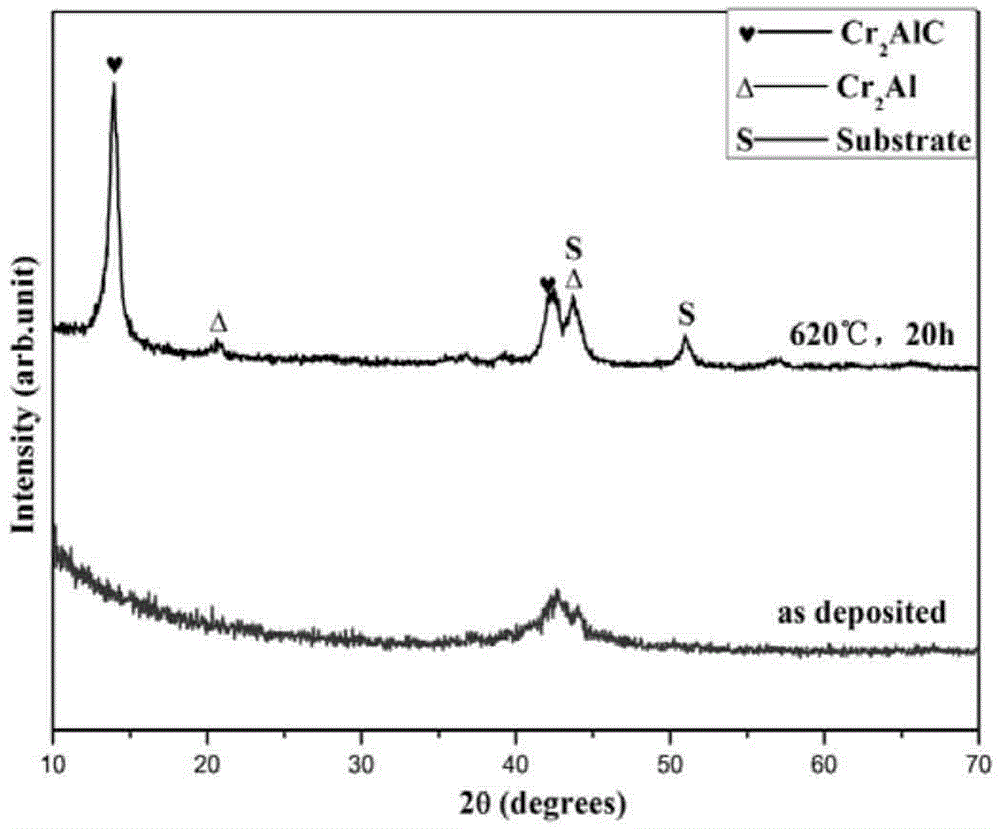

Method for efficiently preparing ternary laminar MAX phase ceramic coating layer at low temperature

InactiveCN104894516AReduce manufacturing costSimple processVacuum evaporation coatingSputtering coatingGas phaseCeramic coating

The invention relates to a preparation technology of a ternary laminar MAX phase ceramic coating layer, and in particular, provides a method for efficiently preparing a ceramic coating layer with a ternary laminar MAX phase as a main phase at low temperature by a physical vapor deposition technology. M, A and X element powders with a certain mol ratio or electrically conducted binary and ternary compound powders are uniformly mixed and pressed to produce a cathode target at a certain temperature; the physical vapor deposition (multi-arc ion plating or magnetron sputtering) is adopted under optimized process conditions; and then, the crystallization heat treatment is adopted, thereby realizing the preparation of the ceramic coating layer with the MAX phase as the main phase by a two-step method. The method has the characteristics of deposition at room temperature, easy adjustment of target components, simple process, high deposition efficiency and low cost, has obvious advantages in the aspect of preparing the MAX phase coating layer, can solve the problems of high cost and complicated process in traditional preparation of the MAX phase coating layer, and promotes the large-scale industrial production of the MAX phase coating layer.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

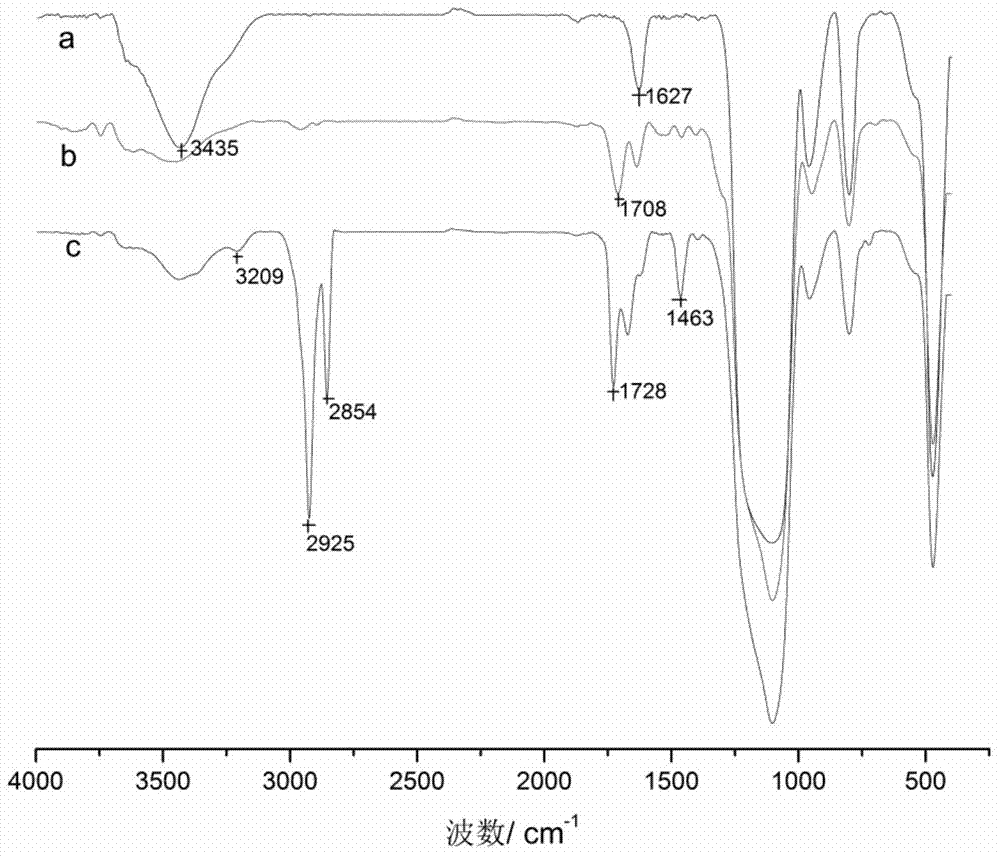

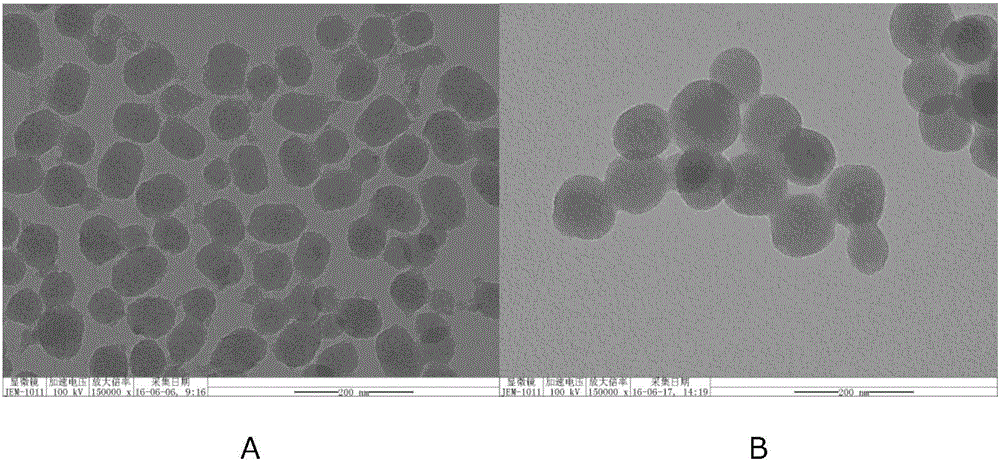

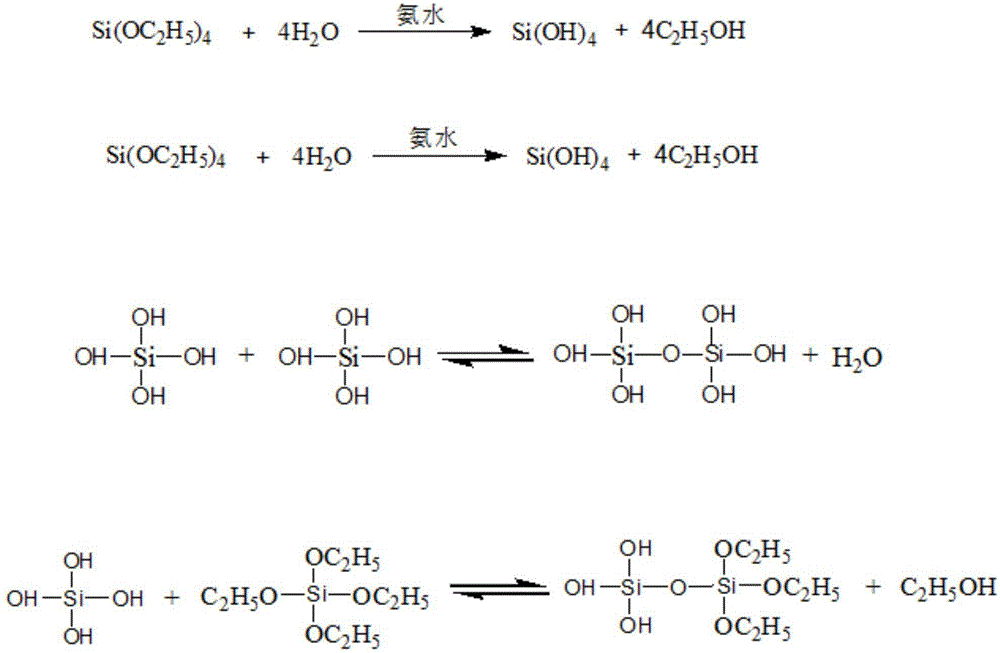

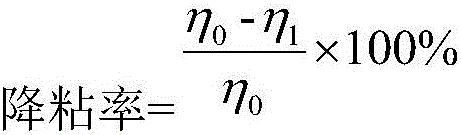

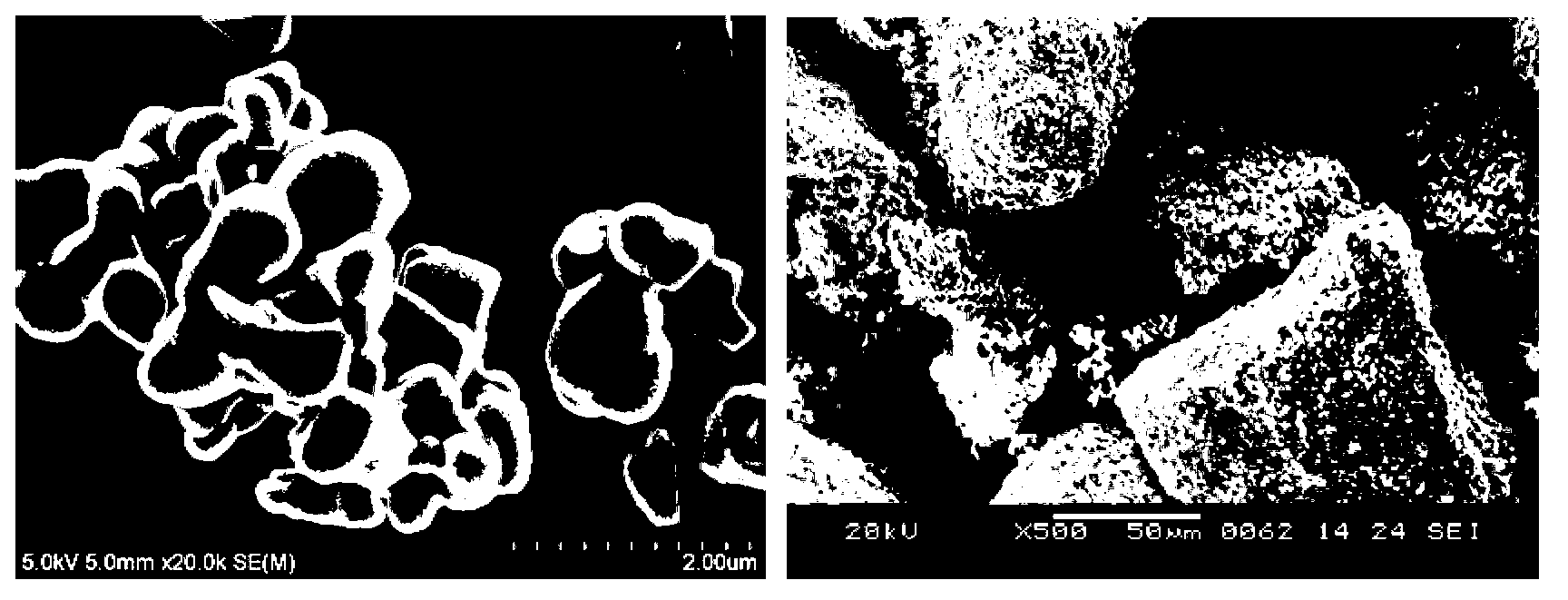

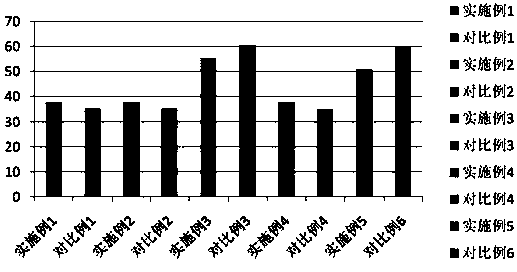

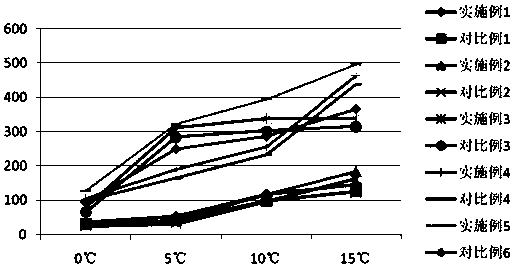

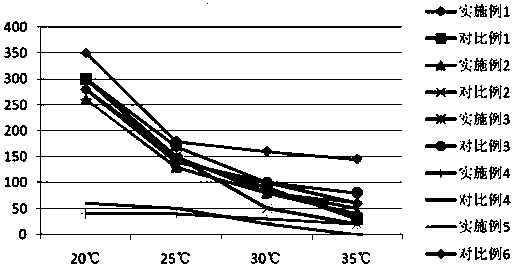

Nano SiO2 composite material thickened oil viscosity reducer and preparation method thereof

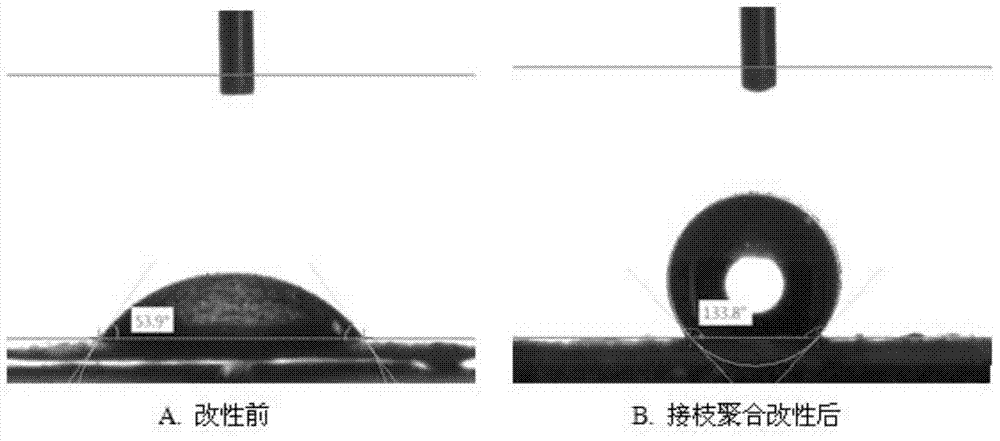

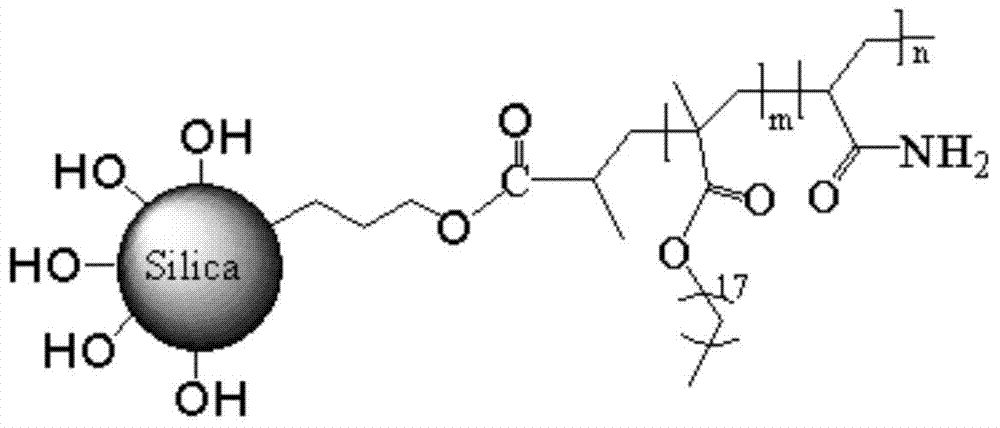

InactiveCN104327225AImprove hydrophobicityGood viscosity reduction effectDrilling compositionMaterials preparationNano sio2

The invention discloses a nano SiO2 composite material thickened oil viscosity reducer and a preparation method thereof, which belongs to the technical field of nano SiO2 composite material preparation and application thereof. The viscosity reducer is nano (polymethacrylate higher alcohol-acrylamide) / SiO2 composite material. The preparation method comprises the following steps: 1)pre-modifying the surface of the nano SiO2 by a silane coupling agent; and 2)performing graft copolymerization of (methyl)acrylate higher alcohol and acrylamide on the surface of nano SiO2 to obtain the (polymethacrylate higher alcohol-acrylamide) / SiO2 composite material powder. The nano viscosity reducer has the advantages of good viscosity reducing effect, low cost, simple production and no pollution during a cleaning process. Through the experiment, the viscosity reducing rate of the nano viscosity reducer to the high wax thickened oil at Daqing dandong station is 72.10% at 40 DEG C.

Owner:SHANDONG UNIV

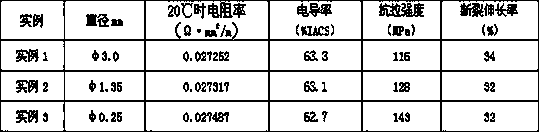

Method for manufacturing high-conductive heat-resistance aluminium alloy wire

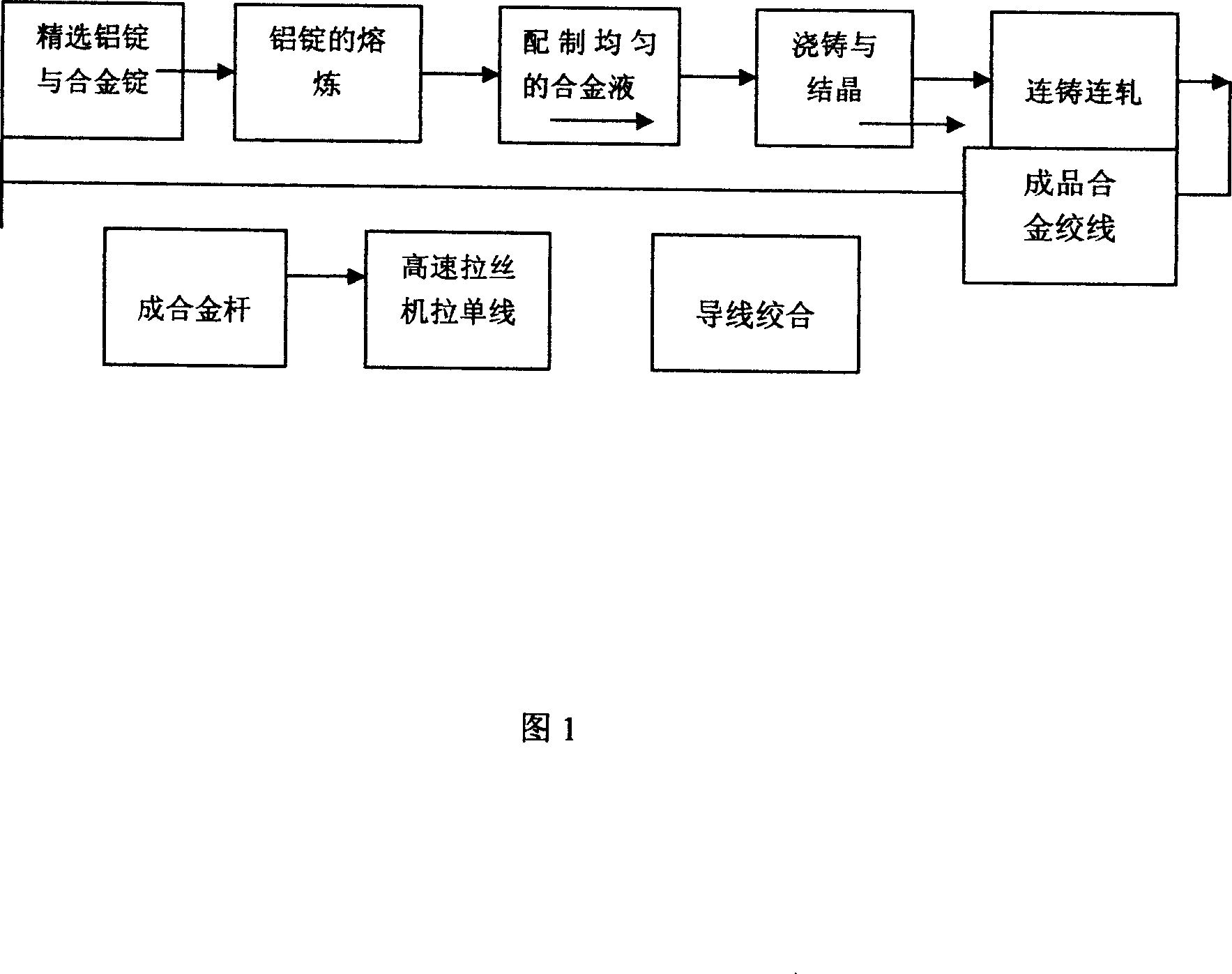

InactiveCN1978686AControl UniformityControlled dumpingMetal rolling arrangementsSpectrum analyzerShaft furnace

The invention relates high conduction heat-resistant aluminum alloy wire manufacturing method. It includes the following steps: adding aluminum ingot with 0.06% silicon, not more than 0.16% iron and 0.01% copper, 0.015% four elements Ti, V, Cr, Mn, and 0.03% other impurity into shaft furnace to melt; adding 0.03-0.5% zirconium as additional element; stirring; refining; degassing; deslagging; using solid covering agent to cover aluminum pad surface; standing for 445-60 minutes; using high speed spectrum analyzer to test, monitor, adjust each element, control element content; filtering; continuous casting to form aluminum casting ingot; tandem rolling; drawing to form aluminum alloy wire with need diameter.

Owner:SHANGHAI ZHONGTIAN ALUMINUM WIRE

Energy-saving high-elongation soft aluminum alloy wire and preparation method thereof

InactiveCN104032191AUniform compositionGuaranteed mass productionMetal/alloy conductorsImpurityEnergy analysis

The invention relates to an energy-saving high-elongation soft aluminum alloy wire and a preparation method thereof. The aluminum alloy wire is mainly composed of the following components in percentage by weight: 0.05-0.40% of Cu, 0.10-0.40% of Zr, 0.25-1.00% of Fe, 0.01-0.22% of Mg, 0.001-0.15% of Si, 0.05-0.15% of Y, 0.05-0.10% of Sc, and the balance of Al and other inevitable impurity elements. The amount of each element in the other inevitable impurity elements does not exceed 0.03%, and the total amount of all the other inevitable impurity elements does not exceed 0.15%. The aluminum alloy wire has the advantages of favorable creep resistance, high elongation percentage, favorable bending property and the like, is easy for machine-shaping, and can ensure the stability of the electrical connection.

Owner:JIANGSU CHANGFENG CABLE

Preparation of nano composite material high-wax-content heavy oil viscosity reducer and performance testing

ActiveCN106190084AImprove hydrophobicityGood viscosity reduction effectDrilling compositionHigh carbonOil viscosity

The invention discloses a nano composite material high-wax-content heavy oil viscosity reducer and a preparation method thereof and belongs to the technical field of nano composite material preparation and application. The viscosity reducer is a nano polymethylacrylic acid high carbon alcohol-acrylamide composite material. The preparation method of the viscosity reducer comprises the steps that surface pre-modification is conducted on synthesized MSN by using a silane coupling agent, and polymethylacrylic acid high carbon alcohol-acrylamide composite material powder is obtained through graft copolymerization of methylacrylic acid high carbon alcohol-acrylamide on the surface and pore channels of the MSN. The nano viscosity reducer has a good viscosity reduction effect, is low in cost, simple in production and clean and free of pollution in the process. An experiment proves that the viscosity reduction rate of the nano composite material high-wax-content heavy oil viscosity reducer is 70.30% Daqing Linyuan Sanku high-wax-content heavy oil at the temperature of 40 DEG C and is 79.37% for Daqing Dandong station high-wax-content heavy oil at the temperature of 40 DEG C. The steps are simple, the operation is convenient, and the practicability is strong.

Owner:SHANDONG UNIV

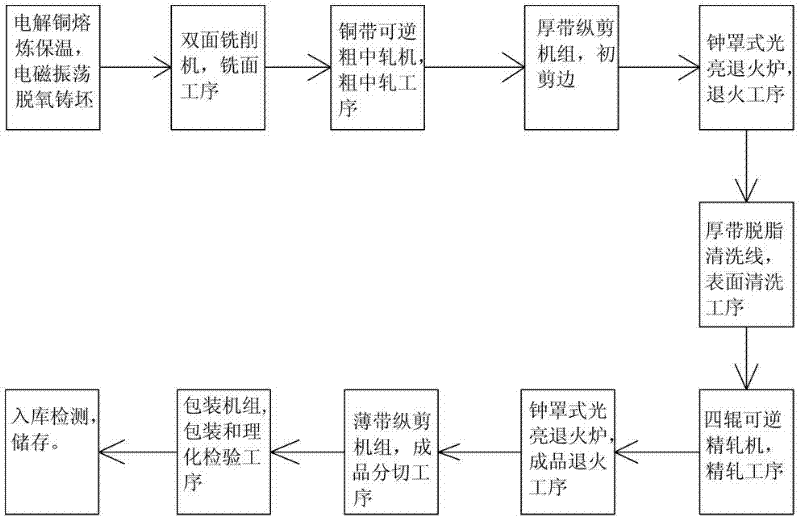

Production method of high-precision ultralong oxygen-free copper strip

ActiveCN102199711ACompact structureGuaranteed oxygen contentRoll mill control devicesBell type furnacesElectrolysisIngot

The invention relates to a production method of a high-precision ultralong oxygen-free copper strip and belongs to the technical field of oxygen-free copper strip production, processing and manufacturing. The production method of the high-precision ultralong oxygen-free copper strip comprises: (1) selecting electrolytic copper as a raw material, adding the electrolytic copper into a melting furnace, smelting the melting furnace, allowing molten copper to flow into a crystallizer added with an electromagnetic oscillation coil, performing electromagnetic deoxidization of the molten copper and horizontally casting a blank by electromagnetic continuous casting in the electromagnetic continuous casting crystallizer added with the electromagnetic oscillation coil, cooling in the electromagnetic continuous casting crystallizer, crystallizing to form strip copper blanks, and stretching by an ingot leading machine; (2) milling a strip blank by a double-sided miller; (3) performing reversible coarse medium rolling of the copper strip; (4) performing primary trimming by a thick strip longitudinal shearing machine; (5) annealing in a bell type bright annealing furnace; (6) cleaning surface on a thick strip degreasing cleaning line; (7) finely rolling in a four-roller reversible fine rolling machine; (8) annealing a finished product in the bell type bright annealing furnace; (9) cutting the finished product by a thin-strip longitudinal shearing machine; (10) packing in a packaging machine and performing physical and chemical examination; and (11) performing incoming inspection and storing.

Owner:ZHONGTIAN ALLOY TECH

Process for producing thiourea dioxide

The present invention belongs to the field of peroxide preparing technology in organic chemistry. Into reactor, water is added in advance, thiourea is thrown in batches and hydrogen peroxide solution containing stabilizer is dripped to produce thiourea dioxide. After finishing the reaction, thiourea dioxide is filtered and stoved to obtain crystallized thiourea dioxide powder. The added amountof the stabilizer is 0.1-5 wt% of thiourea and crystal habit modifier in 0..005-2 wt% of thiourea may be also added into water. The improved thiourea dioxide producing process has improved crystal state of thiourea dioxide and raised product purity and is suitable for industrial production in large scale.

Owner:陶华西

Aluminium-alloy conductor and manufacture method thereof

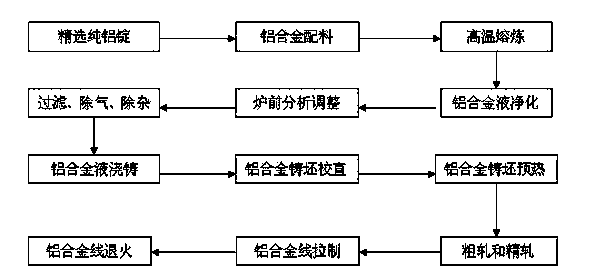

InactiveCN101740157AImprove conductivityImprove heat resistanceSingle bars/rods/wires/strips conductorsMetal/alloy conductorsTemperature controlHeat resistance

The invention provides an aluminium-alloy conductor and a manufacture method thereof. The aluminium-alloy conductor contains the components in percent by weight: 99.2-99.6 percent of aluminium, 0.03-0.5 percent of zirconium, 0.01-0.1 percent of yttrium and 0.2-0.3 percent of the rest. The aluminium-alloy conductor is manufactured by the following steps of: adding trace amount of zirconium and yttrium to a molten aluminium ingot, melting into aluminium-alloy liquid and then casting, crystallizing, rolling, drawing and the like. In the invention, the crystalline state is ensured to be good by strictly controlling the impurity content of the aluminium ingot and the content of the alloying adding element and adding boron alloy refined crystal particles, and aluminium liquid can be ensured to be completely poured out by adopting an automatic temperature-control kettle furnace, which enables the manufactured aluminium-alloy conductor to have high electrical conductivity and heat resistance, thereby meeting the requirements of industry for the performance of the aluminium-alloy conductor. The aluminium-alloy conductor is especially suitable for being manufactured into the high-electrical conductivity heat-resistant cables.

Owner:SHANGHAI ZHONGTIAN ALUMINUM WIRE

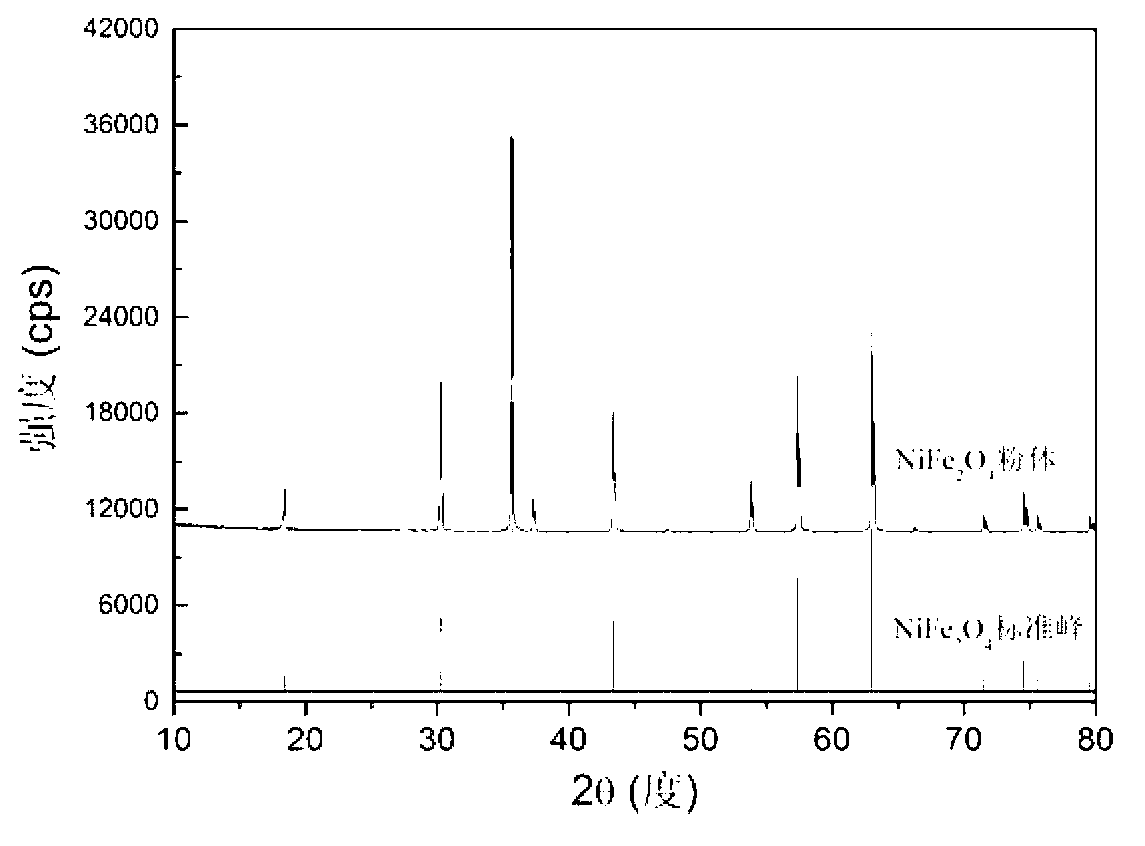

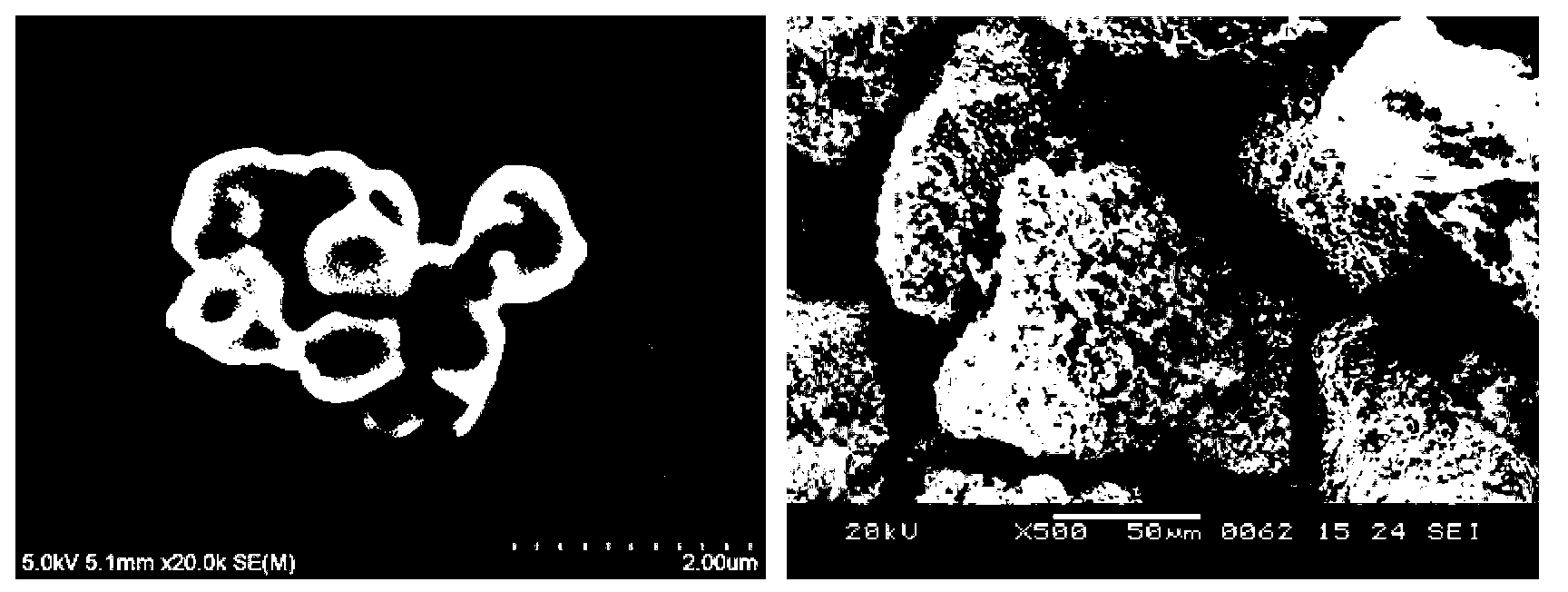

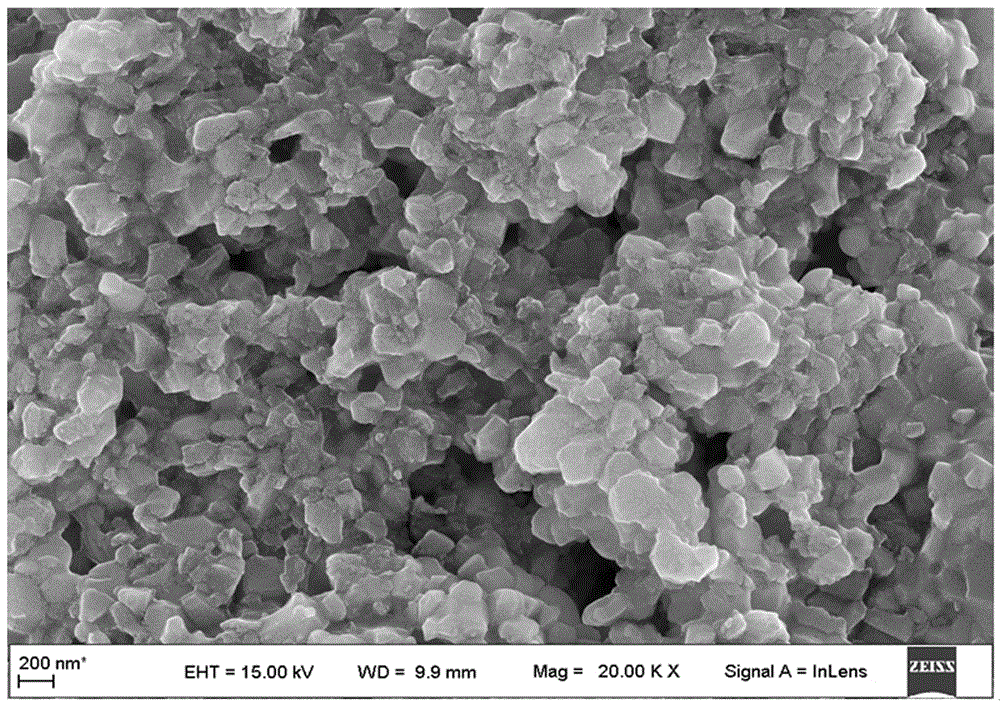

Preparation method of thermal spraying powder for ferrite corrosion-resistant coating

The invention relates to the technical field of thermal spraying powder and provides a preparation method of thermal spraying powder for a ferrite corrosion-resistant coating. The thermal spraying powder is NiFe2O4 powder for thermal spraying. The preparation method comprises the following steps of ball milling, evaporation, drying, grinding, sieving, calcination, agglomeration and granulation. The preparation method is simple and controllable, has low equipment requirements and a low cost, is convenient for operation, has a high powder yield, and is suitable for mass production of NiFe2O4 thermal spraying powder. The NiFe2O4 powder has high purity, a regular shape, a good crystal grain crystallization state, and uniform crystal grain size distribution. The coating prepared by a plasma spraying technology has good compactness and combinability, and is used as a protection coating of an AC grounding material. Compared with a carbon steel grounding material, the AC grounding material with the protection coating has greatly improved corrosion resistance.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +1

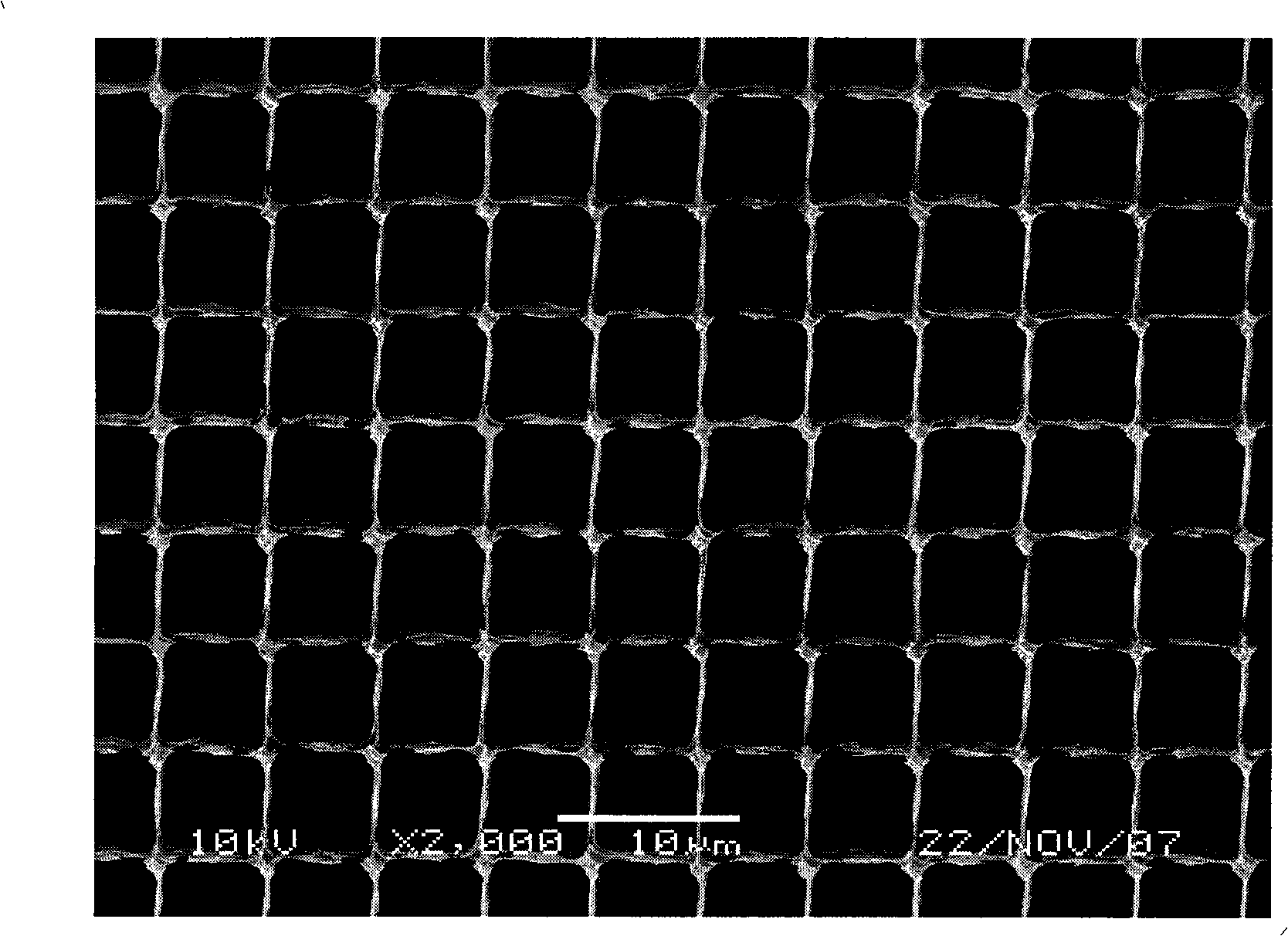

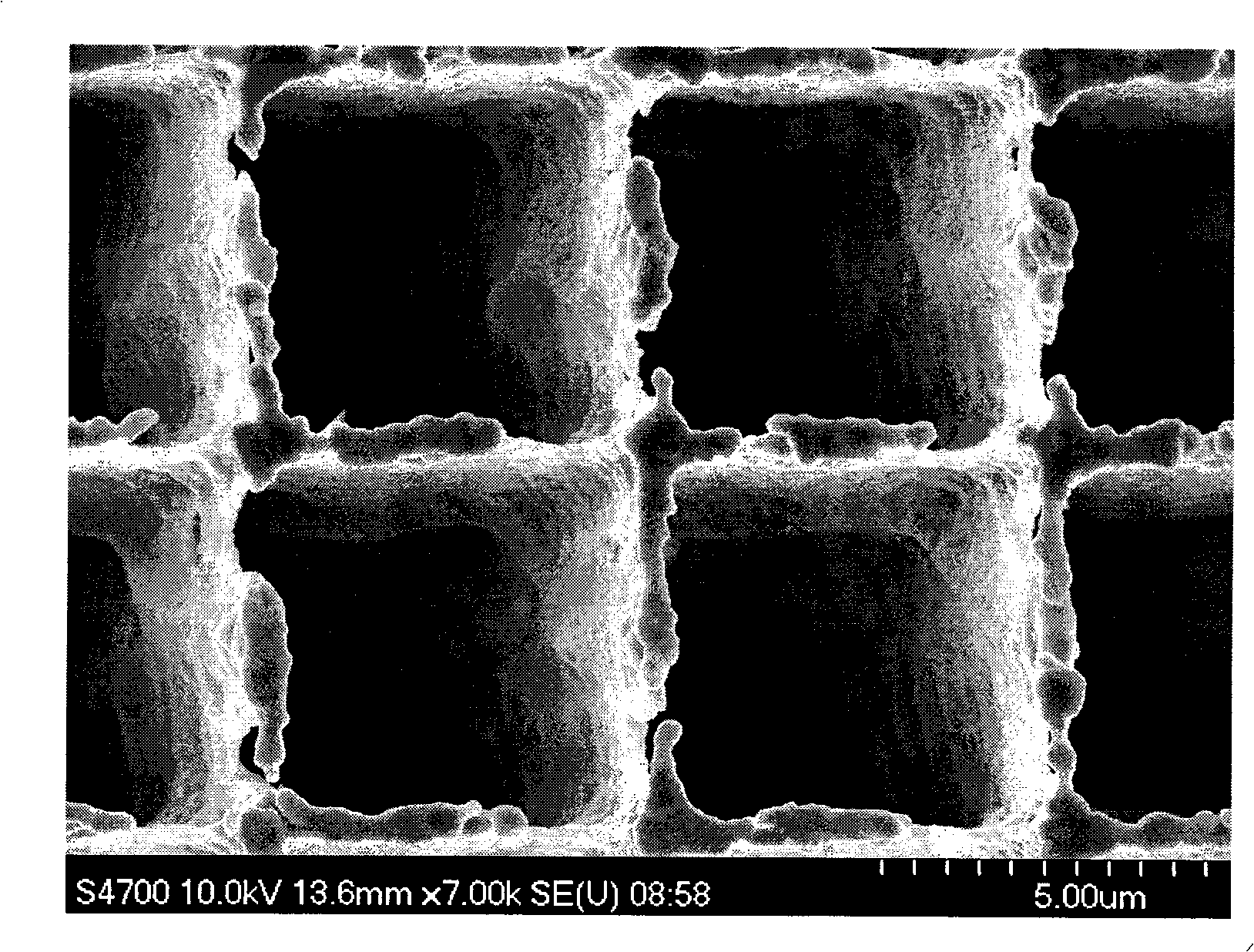

Method of electroless nickel plating on silicon substrate microchannel

InactiveCN101538704AEasy to prepareLow priceDecorative surface effectsAlkaline accumulator electrodesElectroless nickelPorosity

The invention discloses a method of electroless nickel plating on silicon substrate microchannel, comprising the following steps: prepared microchannel is put into aqueous solution containing 1% of polyoxyethylene octyl phenyl ether to be soaked for 10-30 seconds; hexahydrated nickel, sodium dodecyl sulfate, fluorinated ammonia, sodium citrate, ammonia water and ammonium sulfate are prepared into solution; the microchannel in step 1 is washed by deionized water and put into the solution, alkaline condition of the solution is preserved at a pH value of 7.5-8.5, the temperature is controlled at 80-85 DEG C, and the solution is deposited for 5-10 minutes; the microchannel is taken out after the deposition and is washed by deionized water, thus obtaining 3D current collecting layer with high specific surface area. The electroless nickel deposition technology of the silicon substrate microchannel has the advantages of low cost, simple operation and easy realization; the microchannel has uniform porosity and comparatively large specific surface area and aspect ratio.

Owner:EAST CHINA NORMAL UNIV

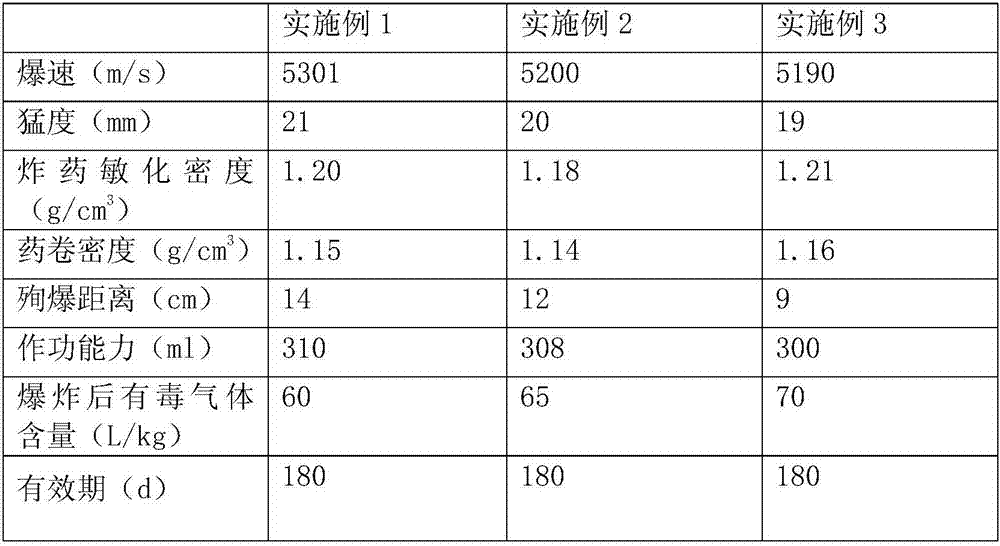

Colloidal emulsion explosive for high-detonation-velocity deepwater blasting and preparation method of colloidal emulsion explosive

InactiveCN107353173AImprove stabilityGood explosive performanceExplosive working-up apparatusNon-explosive/non-thermic compositionsExplosive AgentsFoaming agent

The invention discloses a colloidal emulsion explosive for high detonation velocity deep water blasting, which comprises the following components: main oxidant, auxiliary oxidant, reducing agent, water, additive, emulsifier, sensitizer, density regulator, crystal shape modifier, Stabilizer, foaming agent, sensitization aid, flame suppressant, adhesive, the explosive has high detonation velocity, good detonation performance, high safety, low production cost, no poison and no pollution.

Owner:宜兴市阳生化工有限公司

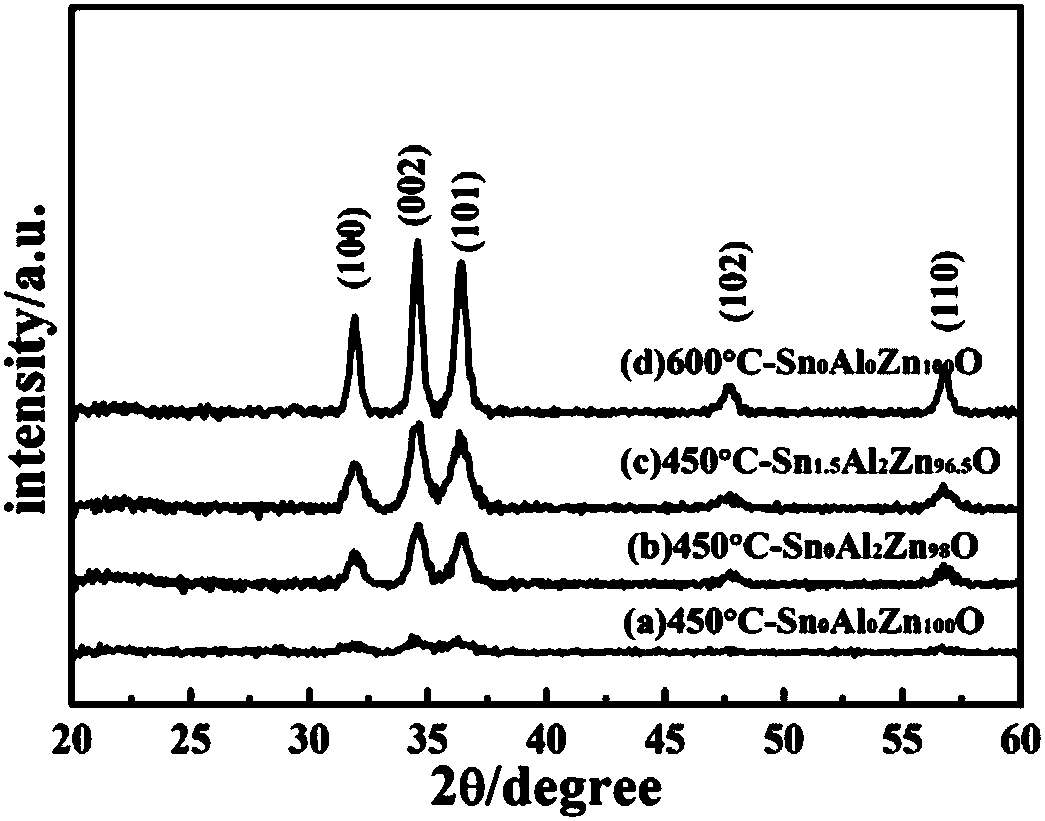

Method for preparing high-performance ZnO-based transparent conductive oxide thin film at low temperature

ActiveCN108546936ALower lattice energyHigh crystallinityLiquid/solution decomposition chemical coatingAir atmosphereNitrogen gas

The invention relates to a method for preparing a high-performance ZnO-based transparent conductive oxide thin film at a low temperature. The method comprises the following steps of 1), zinc acetate dihydrate and Al source and Sn source are combined according to requirements and are dissolved in ethylene glycol monomethyl ether, and then stabilizer is added dropwise into zinc-containing solution,after heating, stirring and filtering, and fully aging at room temperature, clear and transparent sol is obtained for later use; 2) substrate is cleaned up, the sol is uniformly spin-coated on the surface of the substrate by a glue homogenizing machine, the substrate is carried out pre-heat treatment, the spin coating process and the pre-heat treatment process are repeated until a gel film is obtained; and 3), first-step annealing treatment on the gel film in an air atmosphere is carried out, second-step annealing treatment in the atmosphere of nitrogen or argon is carried out, and the high-performance ZnO-based transparent conductive oxide thin film is obtained when cooling to room temperature. According to the method for preparing the high-performance ZnO-based transparent conductive oxide thin film at the low temperature, the preparation method is simple in process, the lattice energy of the reaction system can be effectively reduced, and the thin film can be crystallized in advanceat the temperature of about 450 DEG C.

Owner:WUHAN UNIV OF TECH

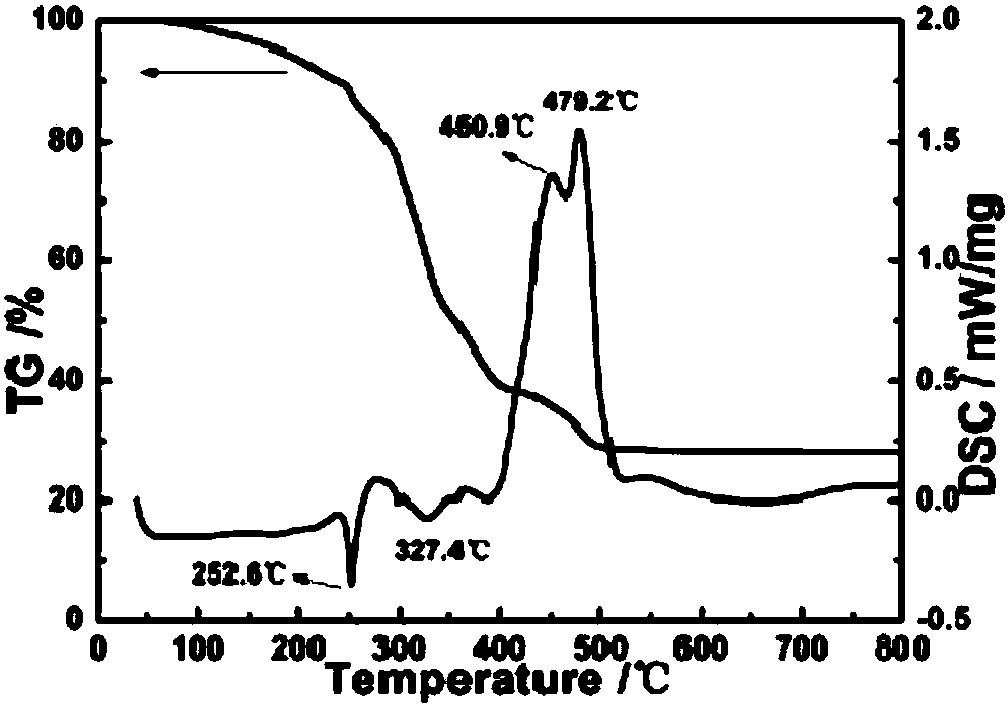

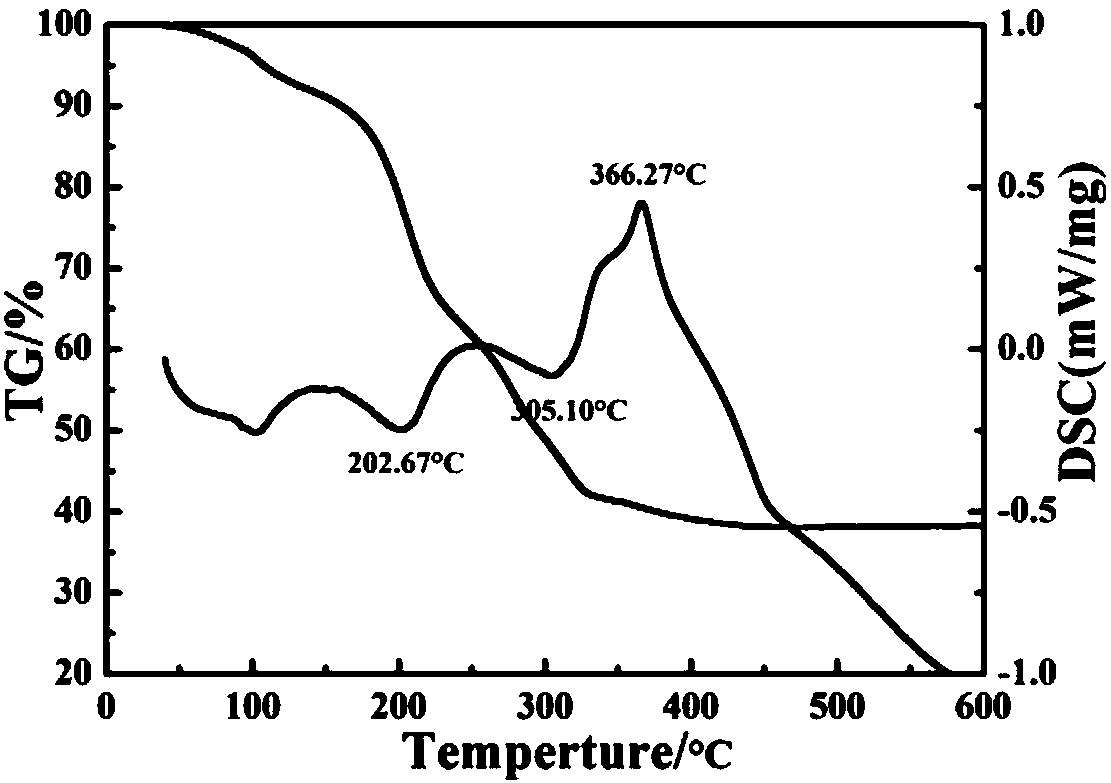

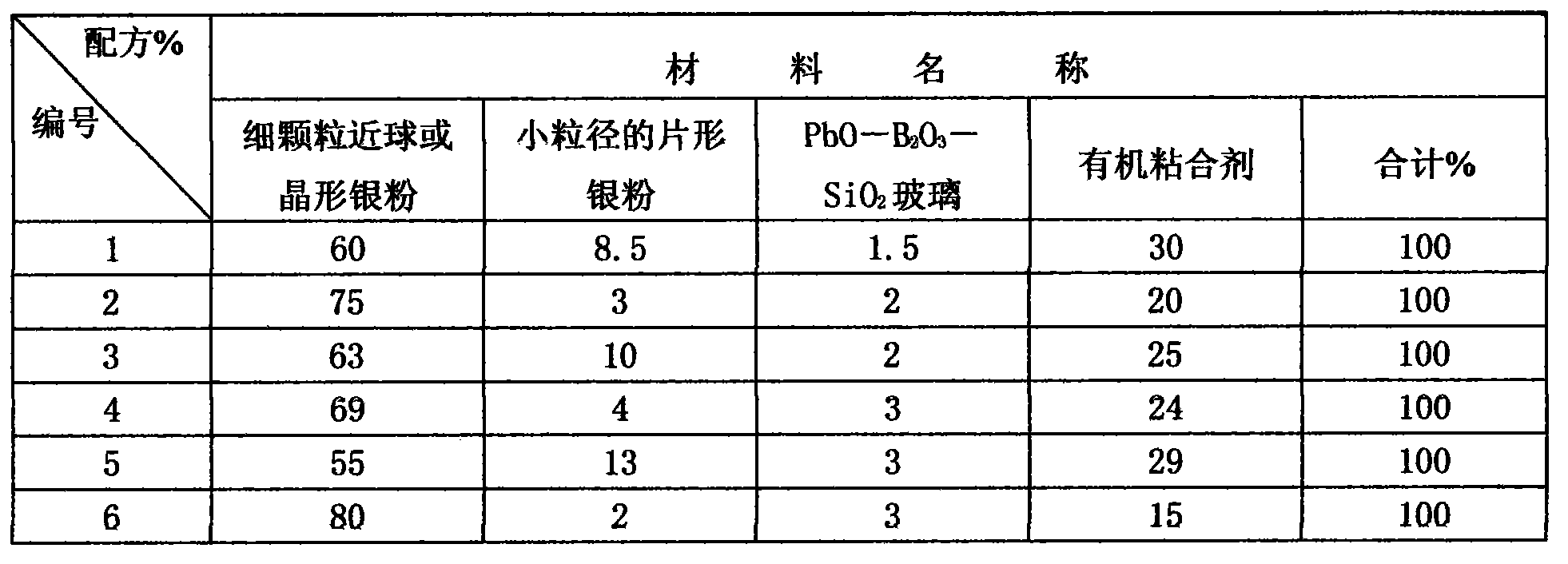

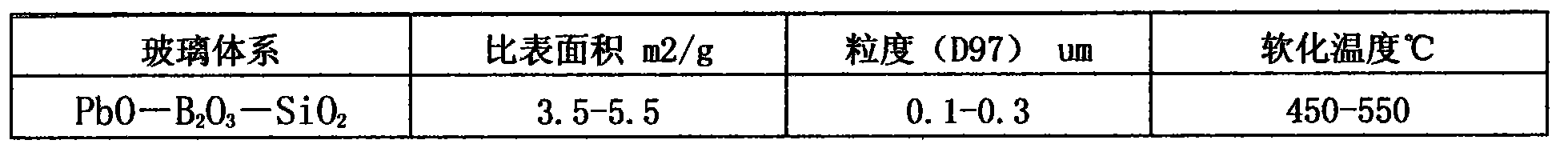

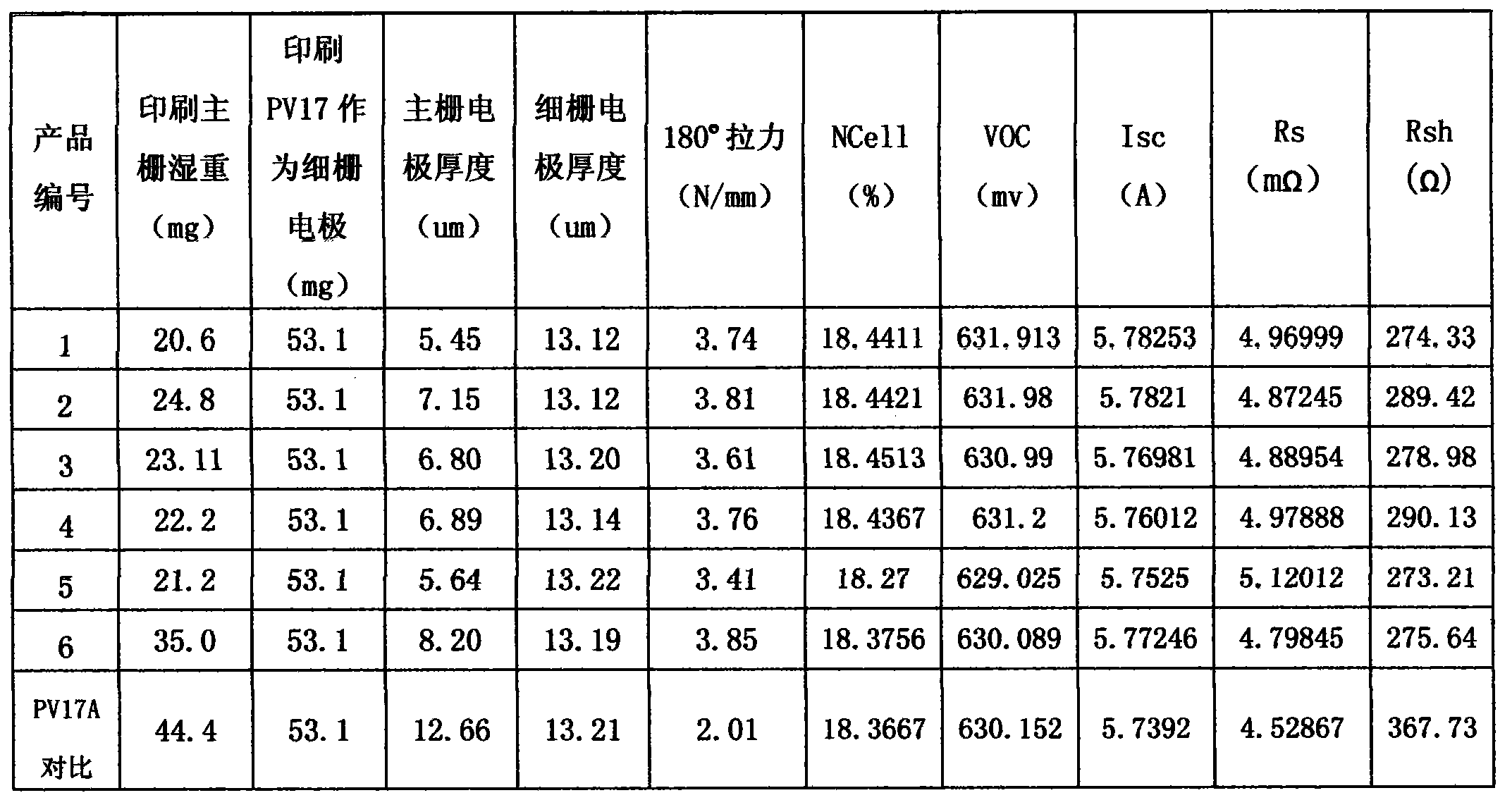

Method for preparing silicon solar cell positive electrode and main grid paste thereof

InactiveCN103441183AReduce usageImprove crystal stateFinal product manufactureNon-conductive material with dispersed conductive materialSilver pasteScreen printing

The invention discloses a method for preparing a silicon solar cell positive electrode and the main grid paste of the silicon solar cell positive electrode, and relates to the technical field of the manufacturing processes and the materials of electronic devices. The method for preparing the silicon solar cell positive electrode comprises the steps that 1) the electrode of a main grid and the electrode of a thin grid are respectively printed through two times of silk-screen printing; 2) different paste with silver or silver paste is adopted when the electrode of the main grid and the electrode of the thin grid are printed; 3) after sintering, the thickness of the electrode of the main grid is smaller than that of the electrode of the thin grid. The method can ensure the good dispersion of all components, even and soft silver electrode paste is obtained after rolling, and a silicon solar cell product is made to have good, stable and even electrical performance after the sintering.

Owner:ZHEJIANG GUANGDA ELECTRONICS TECH

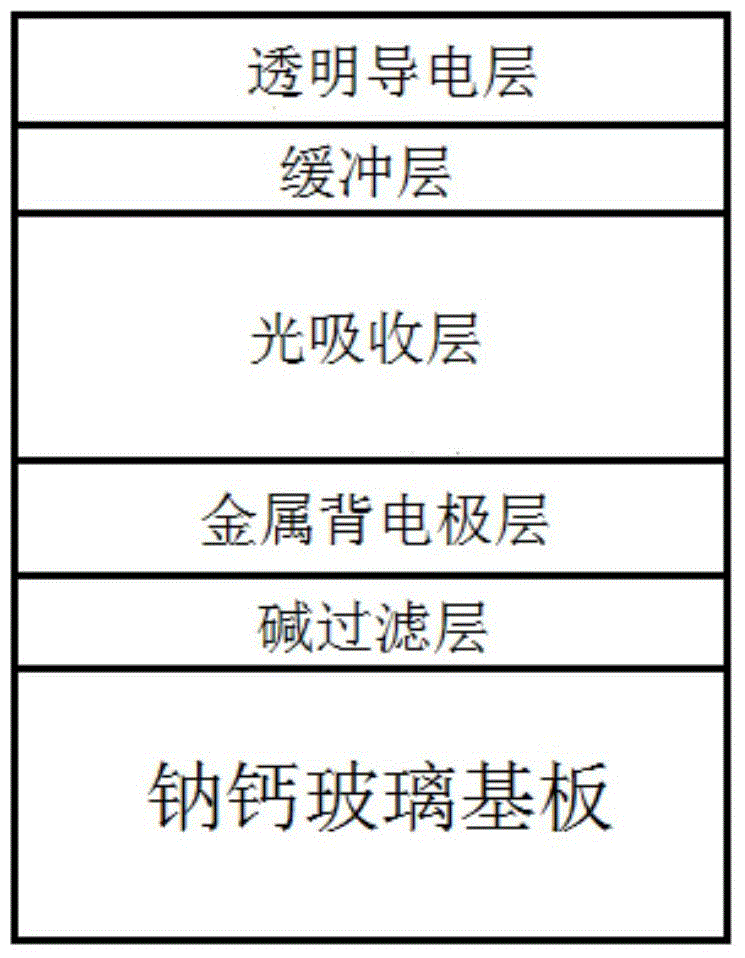

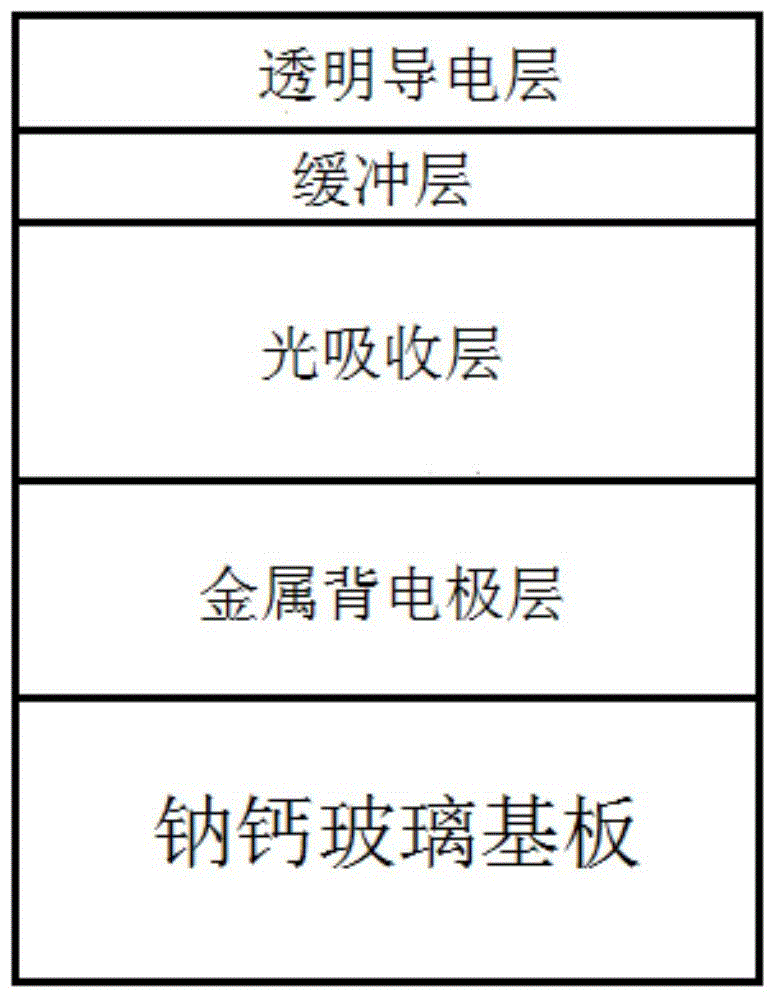

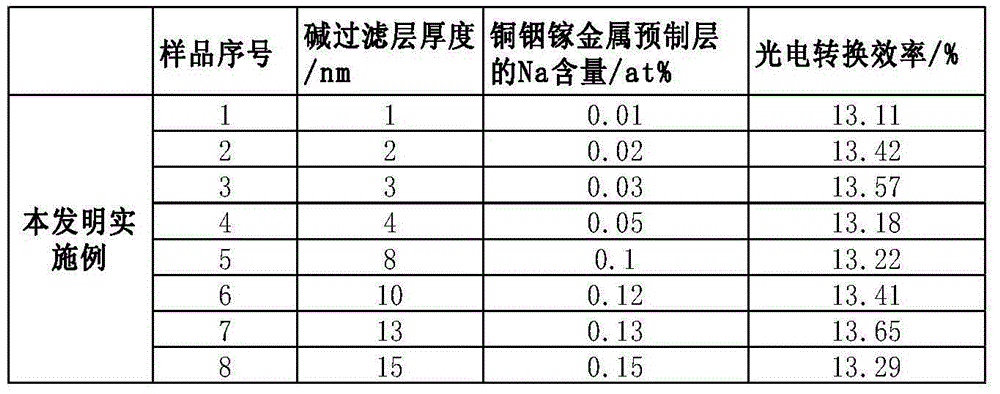

CIGS (Copper Indium Gallium Selenide)-based thin film solar cell and preparation method thereof

ActiveCN104617183AImprove photoelectric conversion efficiencyInhibited DiffusionFinal product manufacturePhotovoltaic energy generationIonCopper indium diselenide

The invention discloses a CIGS (Copper Indium Gallium Selenide)-based thin film solar cell and a preparation method thereof. The preparation method comprises the following steps: forming an alkali filter layer containing at least one element of Li and K on a glass substrate; forming a back electrode layer on the alkali filter layer; forming a light absorption layer on the back electrode; forming a buffer layer on the light absorption layer; forming an n-type transparent conductive layer on the buffer layer, and is characterized by being provided with the alkali filter layer with certain thickness to allow a part of alkali metal ions to be diffused into the CIGS-based light absorption layer from the glass substrate, wherein a certain amount of alkali metal is further added on the outer side of the CIGS-based light absorption layer.

Owner:厦门神科太阳能有限公司

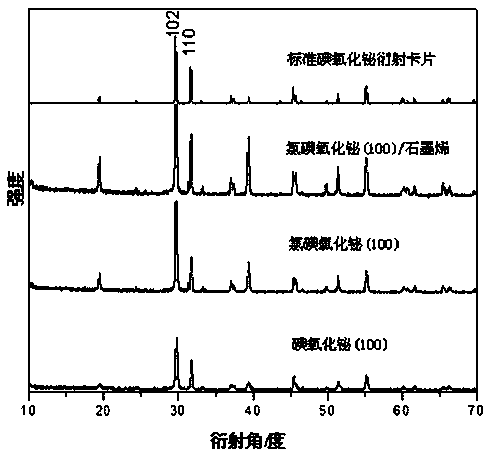

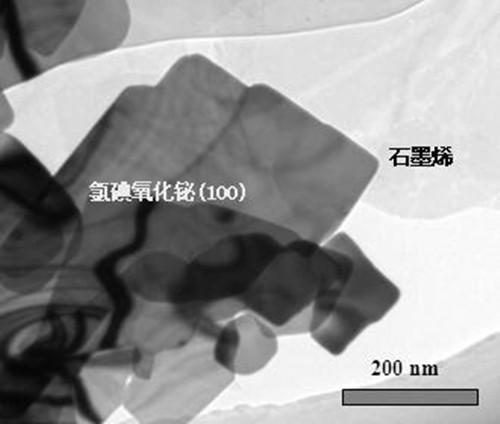

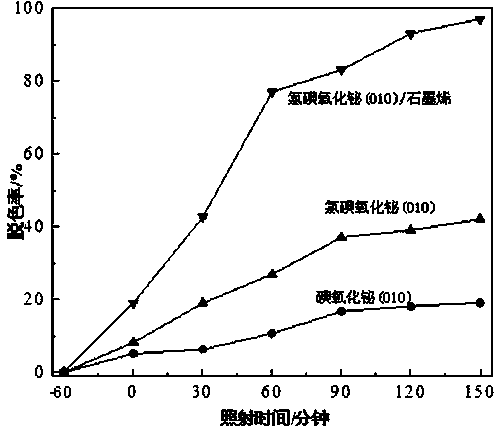

Chlorine bismuth oxyiodide (010)/graphene heterostructure and preparation method and application thereof

InactiveCN109261171AImprove photocatalytic performanceImprove separation rateWater/sewage treatment by irradiationWater treatment compoundsElectron holeGraphene

The invention discloses a chlorine bismuth oxyiodide (010) / graphene heterostructure and a preparation method and application thereof. The problem that existing bismuth oxyiodide (001) is likely to bedissociated, weak in optical absorption property and low in photocatalytic efficiency is solved. Firstly, dispersion liquid of graphene is prepared, then the dispersion liquid of graphene is mixed with a precursor solution of chlorine bismuth oxyiodide (010), and chlorine bismuth oxyiodide (010) / graphene powder with chlorine bismuth oxyiodide and graphene compounded is generated through a hydrothermal method. Effective separation of light-generated electrons and holes of chlorine bismuth oxyiodide (010) is promoted through the conductive capacity of graphene, the recombination probability of the light-generated electrons and the holes is reduced, and therefore the photocatalysis capacity of bismuth oxyiodide (010) is improved.

Owner:HARBIN UNIV OF SCI & TECH

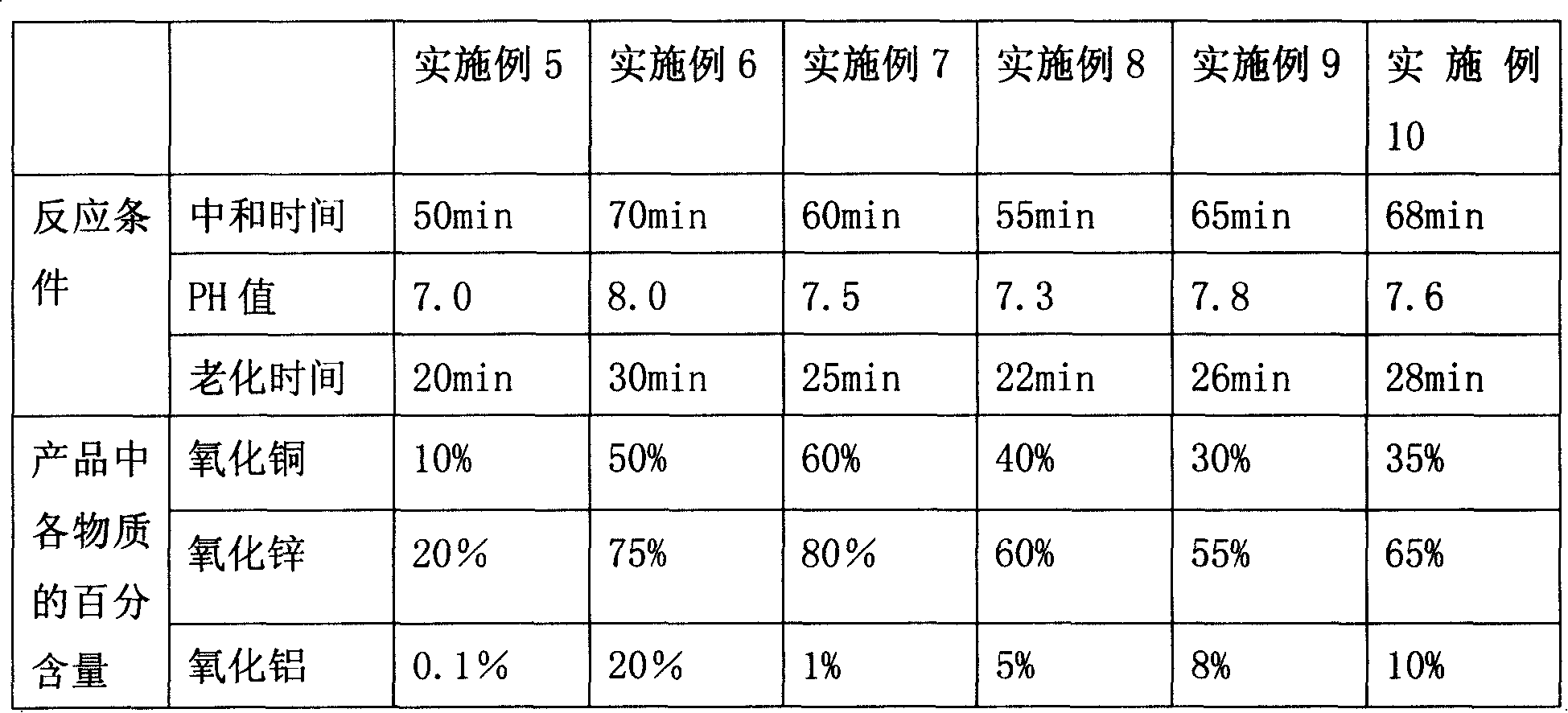

Process for preparing Cu-Zn-Al vapor hydroformylation catalyst and products therefrom

ActiveCN100398202CImprove crystal stateGood dispersionOrganic reductionMetal/metal-oxides/metal-hydroxide catalystsGas phaseSide reaction

The invention belongs to catalyst technique field, concretely relates to a preparation method of catalyst for copper-zinc-aluminum gas phase aldehyde hydrogenation and product thereof, which solves the problems in existing technique that the preparation process of aldehyde hydrogenation catalyst is complex, repeatability is bad, catalyst crystal-size is heterogeneous, dispersion degree of active copper is not high, mechanical strength is small, selectivity to product is bad, especially when rising reactive temperature to enhancing reactive speed and heat energy efficiency, activity, selectivity and stability are bad. The method modifies the intermittent feeding mode to continuous feeding mode by step continuous coprecipitation method, specific surface and pore volume of catalyst is large, dispersion degree of active metal is high, catalytic activity is good, selective and stability have more improvement, and side reaction of esterification and etherification is reduced.

Owner:PETROCHINA CO LTD

Preparation method of tris(tri-bromophenoxy) triazine

The invention discloses a preparation method of tris(tri-bromophenoxy) triazine. The method comprises steps of: adding anhydrous chlorobenzene and tribromophenol in a mass ratio of 2.0-2.25:1; adding a catalyst DMF with a weight of 8-10% of the tribromophenol; adding cyanuric chloride for three times with stirring at 25-35 DEG C, wherein a molar ratio of the cyanuric chloride to the tribromophenol is 1:3.03-3.05, and insulating at 40-45 DEG C for 2.5 h after addition; after reaction, adding deionized water with a weight of 1 / 6-1 / 8 of the organic solvent at 30-35 DEG C, adjusting a pH to 9-10 with 5% NaOH, stirring, washing and removing a water layer to obtain an organic feed liquid; transferring the washed organic feed liquid to a water azeotropic crystallization apparatus to carry out water azeotropic crystallization, centrifuging to obtain a wet product, drying the wet product at 110-120 DEG C for 4 h, controlling a water content lower than 0.2% to obtain the tris(tri-bromophenoxy) triazine product. The preparation method can reduce energy consumption and material consumption, increase product quality; and the product has good crystallization state and no dust, and is safe and environment friendly.

Owner:RUDONG JINKANGTAI CHEM CO LTD

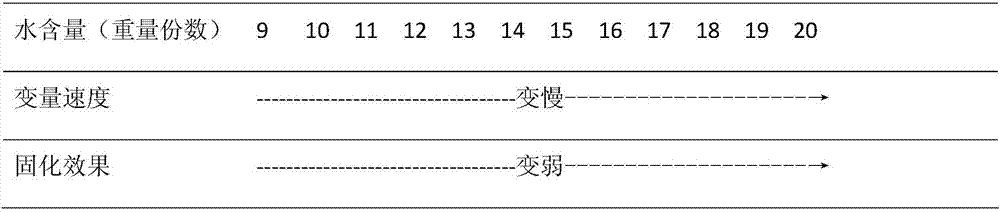

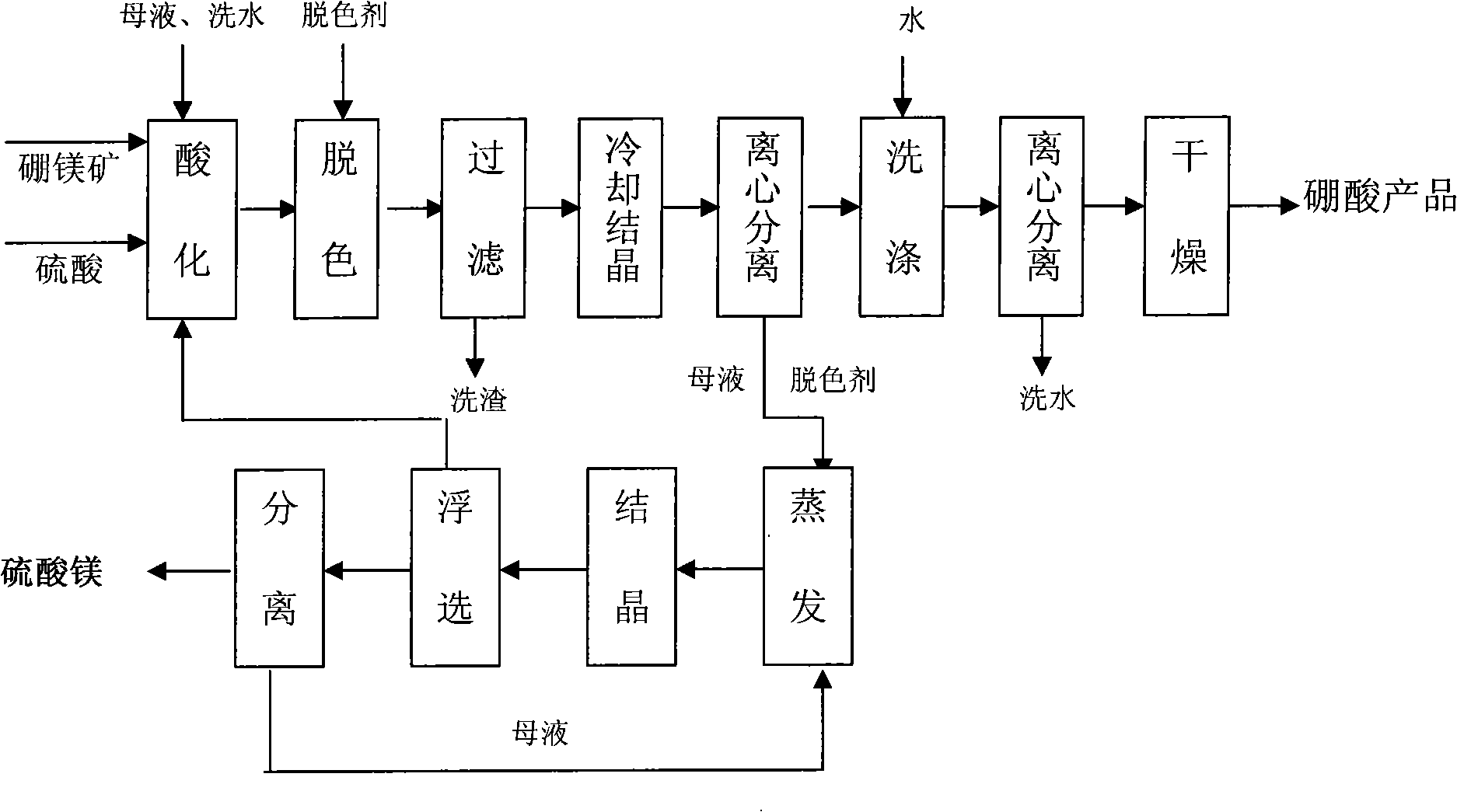

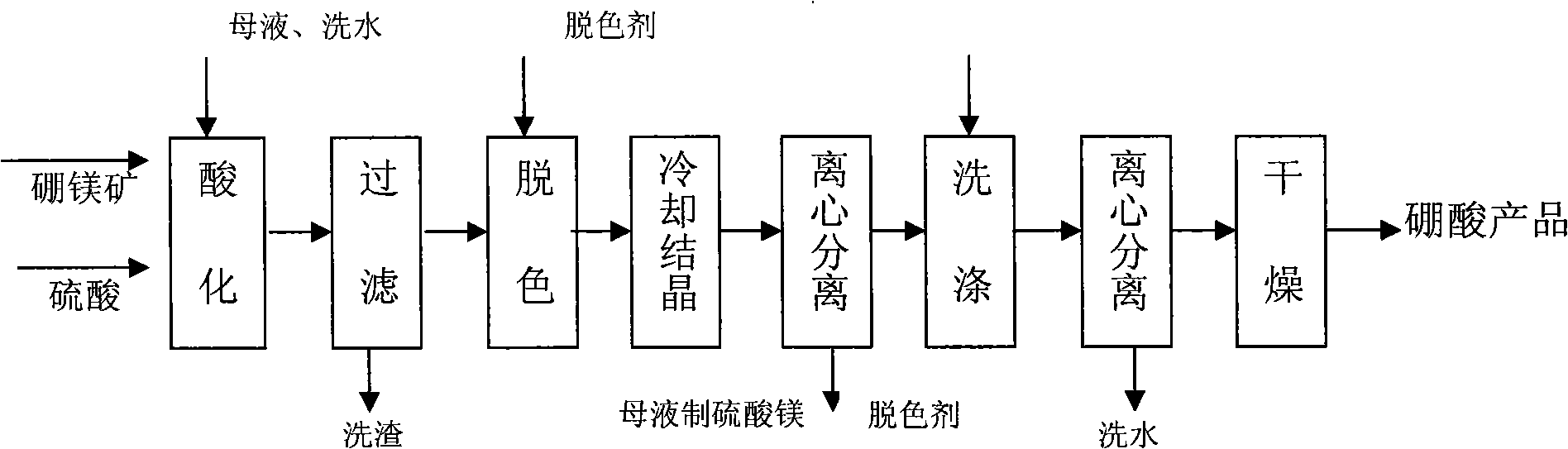

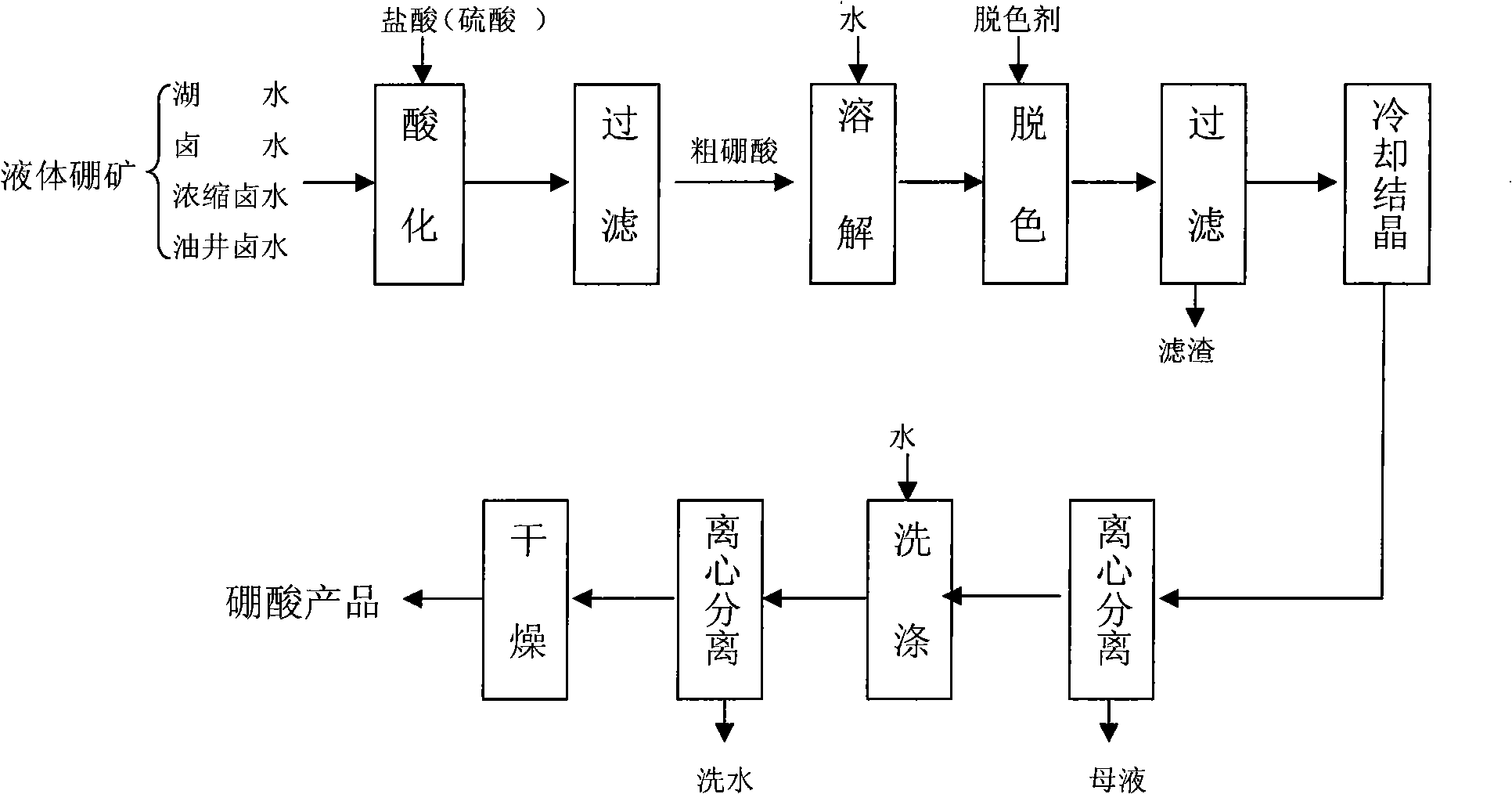

Crystallization control and whitening control method for producing boric acid and magnesium sulfate by salt lake type solid boron ore liquid boron ore

ActiveCN101254926AImprove crystal stateImprove filtering effectMagnesium sulfatesBoron-oxygen compoundsChemical industryFiltration

The invention belongs to the technology field of chemical industry and relates particularly to a crystallization and whitening control method of preparing boric acid and magnesium sulfate based on the salt lake type solid boron ore and liquid boron ore. The original technological process for preparing the boric acid from the salt lake type solid boric acid includes using acidifying szaibelyite, water, boron-containing mother liquor and boron-containing wash water as the material, acidificating with sulfuric acid, filtering, cooling and crystallizing, centrifugalizating, washing, further centrifugalizating, drying and obtaining the boric acid. Based on the process, the method adds the operational process of repeatedly adjusting the acidity to strictly control the pH value range to the process of chemical decolorization and cooling and crystallizing, heat preservation chemical decolorization of the acidified slurry or the acidified and filtered filtrate and repeatedly adjusting the acidity to strictly control the pH value range of the cooled and crystallized solution. The chemical decolorizer is employed to remove the colored ferric iron, algae, and organic matter in solution and improve the crystalline state, and the pH value of the cooled and crystallized solution is controlled by repeatedly adjusting acid to obtain the white boric acid granular crystals. The white boric acid granular crystals have good filtering property, washing property and high yield. The method can be widely used in the production of boric acid from the salt lake type boron ore.

Owner:青海利亚达化工有限公司

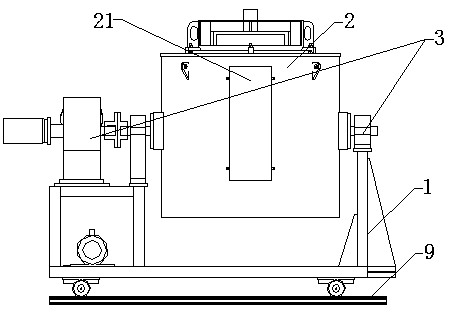

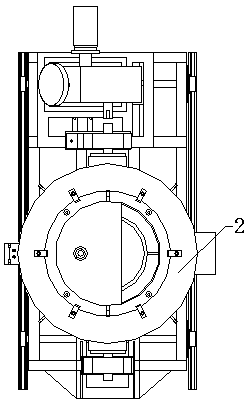

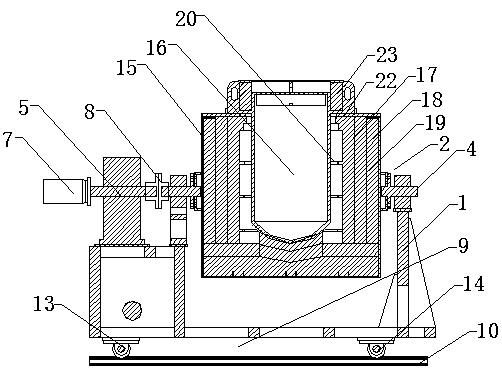

Tilting type magnesium alloy melting and heat preservation equipment

InactiveCN108145126AUniform tipping speedUniform discharge speedMelt-holding vesselsMelting heatCrucible

The invention discloses tilting type magnesium alloy melting and heat preservation equipment. The equipment comprises a machine frame, a melting and heat preservation device is arranged on the machineframe, and the melting heat preservation device can be overturned relative to the machine frame, the melting and heat preservation device is driven by a tilting device to be overturned, and a tiltingspeed of the melting and heat preservation device is uniform, the tilting speed of the melting and heat preservation device is adjustable, so that liquid outlet speed is uniform, a crystallization state is facilitated. According to the invention, a walking mechanism drives the machine frame to move, the melting and heat preservation device is used for pouring the molten liquid into a casting moldfor casting, the melting and heat preservation device of the walking mechanism can meet the requirements of a plurality of casting stations, and a sealing cover is arranged at the top of the meltingand heat preservation device, the top of a crucible is provided with a heat preservation cover, and the heat preservation cover is of a hollow structure with two layers, a raw material feeding hole isformed in one side of the heat preservation cover, and the raw material feeding opening is an open type opening, a liquid outlet is formed in the other side of the heat preservation cover; and the sealing cover at the top of the melting and heat preservation device and the heat preservation cover at the top of the crucible are arranged, so that the arrangement of a alloy liquid is facilitated, and oxidation is reduced.

Owner:山东奥琅能源科技有限公司

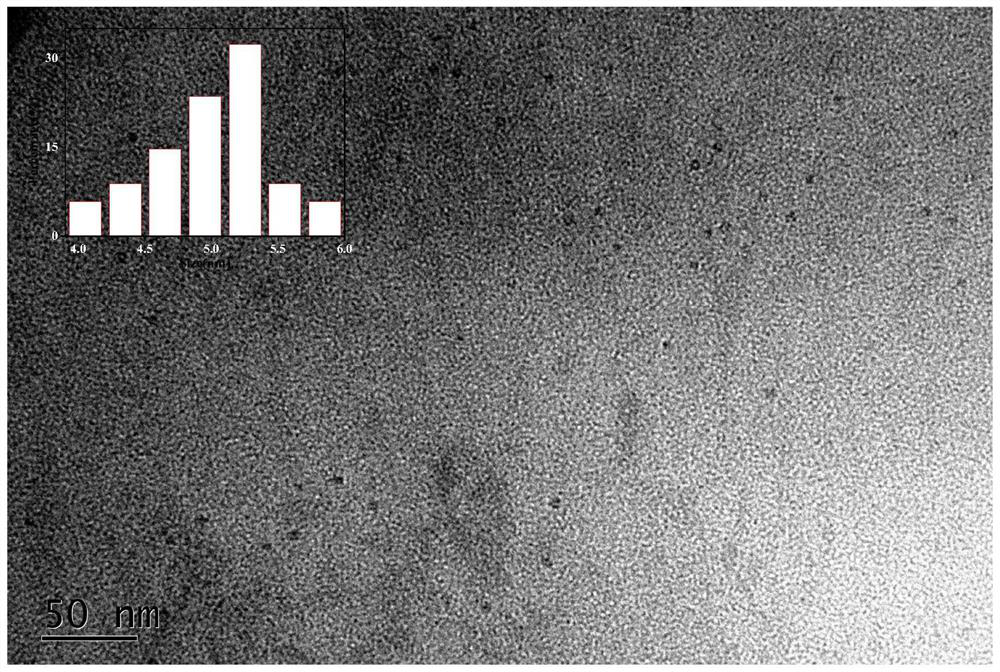

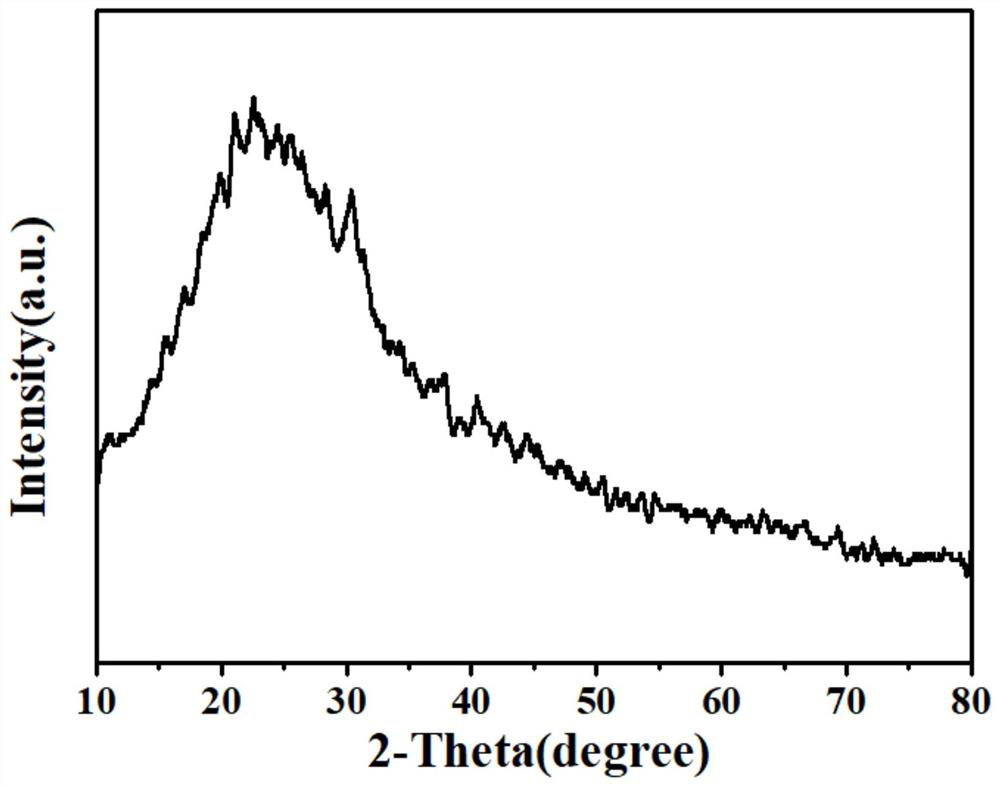

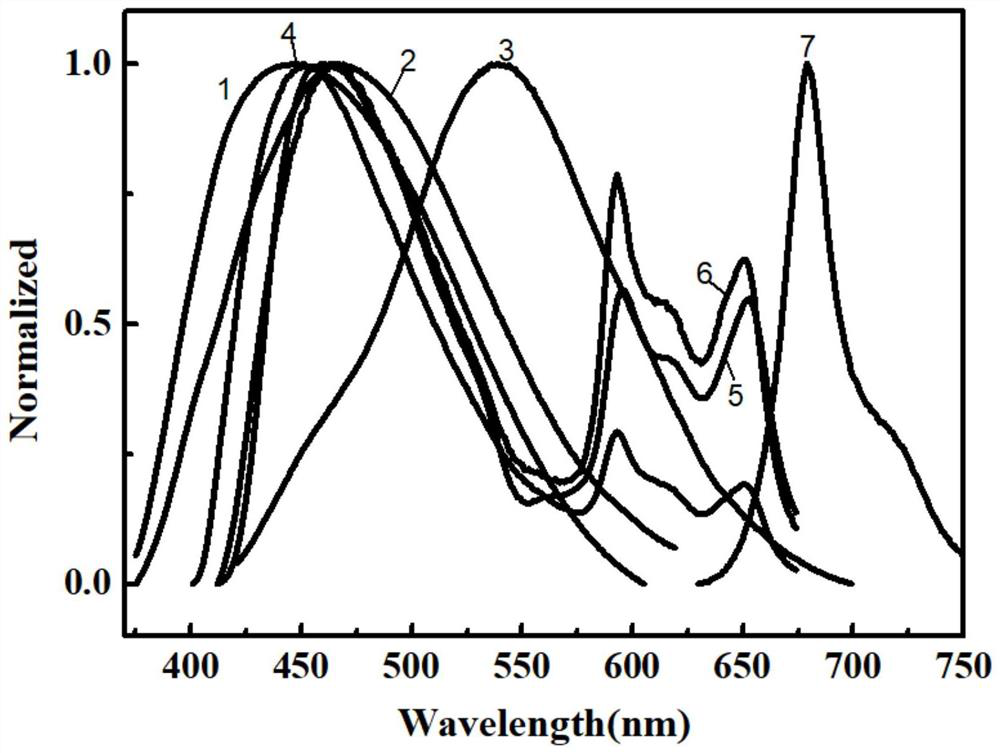

Green preparation method of spinach-based multicolor luminescent carbon quantum dots

InactiveCN111977632AImprove crystal stateGood water solubilityNanotechnologyNano-carbonOrganic solventFreeze-drying

The invention relates to a preparation method of spinach-based multicolor luminescent carbon quantum dots. The steps of the preparation method are as follows: washing and chopping fresh spinach, dispersing the chopped spinach in an organic solvent, adding reagents for modification, and ultrasonically treating the mixture for a certain period of time; filtering the obtained solid-liquid mixture toobtain a liquid A, transferring a supernatant B obtained by centrifugation to a reactor for hydrothermal carbonization, and conducting natural cooling to room temperature; then taking out the solutionin the reactor to perform centrifugation and dialysis purification, so as to obtain a solution of multicolor fluorescent carbon quantum dots; and conducting rotary evaporation on the obtained solution, then and performing freeze-drying, so as to obtain the prepared carbon quantum dot powder. According to the present invention, the multicolor luminescent carbon quantum dots have the characteristics of wide source of raw materials, simple preparation method, low cost, easiness for realizing large-scale and industrial production, etc., and the carbon quantum dots prepared by the method have theadvantages of adjustable color, good optical stability, good biocompatibility, etc., so the carbon quantum dots have broad application prospects in LED lighting, biological imaging, ion detection, anti-counterfeiting, etc.

Owner:NORTHEAST FORESTRY UNIVERSITY

Preparation method of spinel-mullite ceramic sagger

ActiveCN111056834AGood resistance to rapid cold and rapid heatImprove crystal stateAmmonium sulfateAluminium

The invention discloses a preparation method of a spinel-mullite ceramic sagger, and relates to the spinel-mullite ceramic sagger. A ceramic sagger matrix is prepared from the following raw materialsand a colloidal solution, and the raw materials comprise the components in percentage by weight: 40-50% of fused magnesia-alumina spinel, 15-25% of fused mullite, 15-20% of aluminum oxide micro powder, 4-8% of aluminum titanate fine powder, 5-10% of zirconium oxide, 3-5% of magnesite micro powder and 3-5% of clay fine powder; the colloidal solution is a gel, and the gel comprises the components inpercentage by weight: 10-14% of acrylamide, 0.2-0.4% of methylene bisacrylamide, 0.4-0.6% of ammonium persulfate, 0.2-0.4% of tetramethylethylenediamine and the balance being water, wherein the weight of the gel accounts for 8%-12% of the total weight of the raw materials. The preparation method comprises the steps of slurry preparation, injection molding, demolding, drying and firing. A productsintered by the method is high in volume density, high in strength, high in thermal shock stability and excellent in use performance.

Owner:洛阳索莱特材料科技有限公司

Efficient and energy-saving copper-clad aluminum magnesium alloy wire and producing method thereof

InactiveCN104332212AImprove conductivityImprove heat resistanceNon-insulated conductorsMetal/alloy conductorsRare-earth elementCerium

The invention discloses an efficient and energy-saving copper-clad aluminum magnesium alloy wire and a producing method thereof. The energy-saving copper-clad aluminum magnesium alloy wire is composed of a rare-earth aluminum magnesium alloy core wire and a copper layer coated on the core wire; the copper layer and the rare-earth aluminum magnesium alloy core wire are in metallurgical bonding; the copper-clad rare-earth aluminum magnesium alloy wire is composed of the components in proportion as follows: 0.5-1% of magnesium, 0.45-0.65% of silicon, 0.2%-0.5% of RE, and aluminum and unavoidable impurities of the balance. The RE is a mixed rare-earth element, and generally one or mixture of cerium, lanthanum and yttrium. The diameter of the copper-clad rare-earth aluminum magnesium alloy wire is 2-5 mm; the volume of the copper layer is 10-20% of that of the copper-clad rare-earth aluminum magnesium alloy wire; the weight of the copper layer is 25-35% of that of the copper-clad rare-earth aluminum magnesium alloy wire. The method of the invention comprises the specific steps of: smelting alloy liquid, casting and crystallizing, rolling, cladding and welding, and wire-drawing.

Owner:印培东

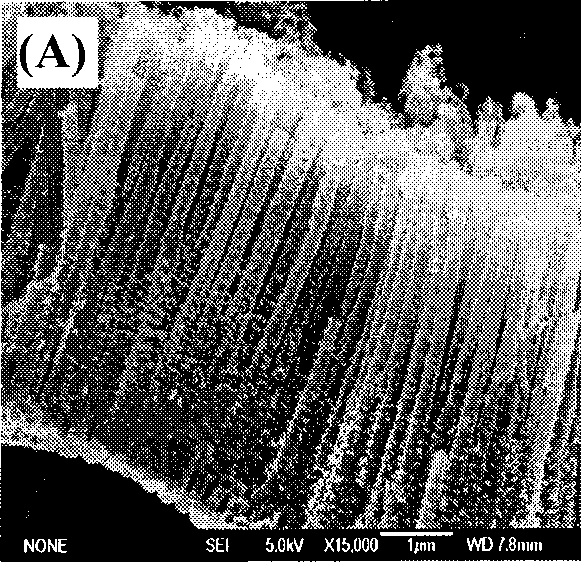

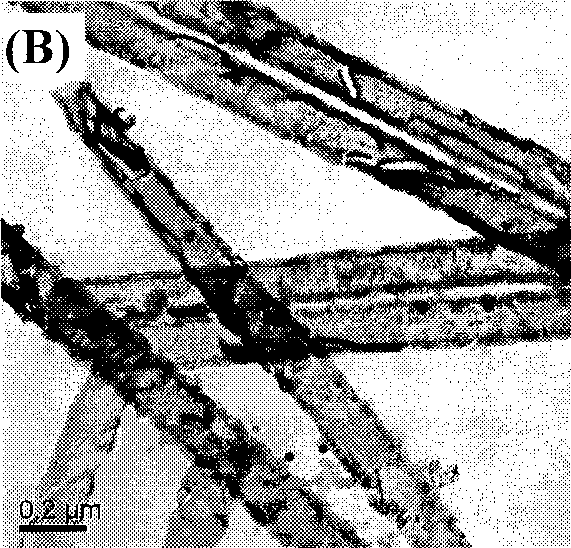

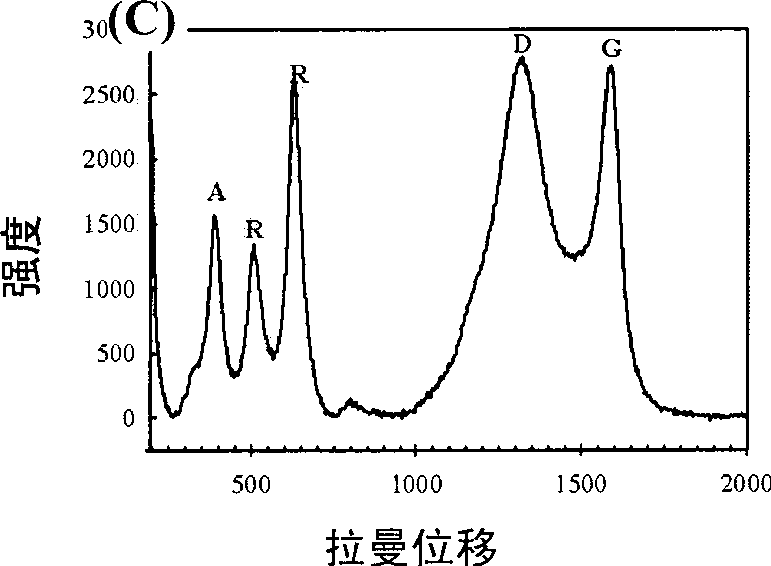

Preparation method of Fe-C-TiO2 nano tube array

InactiveCN101450328AIncrease the areaAperture adjustablePolycrystalline material growthSurface reaction electrolytic coatingElectrolysisTio2 nanotube

The invention relates to a method for preparing an Fe-C-TiO2 nanotube array, which comprises: firstly, preparing a titanium oxide nanotube array on a Ti substrate material by electrolysis in a mixed solution of hydrofluoric acid and dimethyl sulfoxide, and roasting the obtained titanium oxide nanotube array for crystallization molding; secondly, calcinating the TiO2 nanotube array in an oxygen-free vacuum system, and taking polyethylene glycol as a carbon source to prepare a C-TiO2 composite nanotube array; and thirdly, electroplating the C-TiO2 composite nanotube array in an FeSO4 electroplate liquid, and preparing the Fe-C-TiO2 nanotube array. The method has the advantages that the method has simple and mature technology and convenient operation, can effectively strengthen the absorption capacity and the electronic conduction capacity of the final product, namely the titanium oxide nanotube array, widen the absorption range of the titanium oxide nanotube array in a visible light region, improve the photoelectric conversion efficiency of the titanium oxide nanotube array and realize industrialized mass production, and has wide potential application prospect in the fields of degradation and nontoxic treatment of toxic and harmful pollutant, sewage purification and so on.

Owner:HUNAN UNIV

Grease composition for foods soft sandwich and preparation method thereof

ActiveCN104137917AImprove crystal stateSolve the problem of too hard and brittleEdible oils/fatsVegetable oilIodine

The invention provides a grease composition for foods soft sandwich and a preparation method thereof, and specifically provides a grease composition which uses specific content of fully hydrogenated vegetable oil as a seed crystal and can be simultaneously suitable to be used in winter and summer, the grease composition not only can solve the problem that grease is too hard and brittle in winter, and solve the problem of too much fluidity of the grease in summer caused by melting of the grease. The grease composition is characterized by comprising at least one grease selected from the group consisting of A, B and C and grease D, wherein the A is palm oil with the iodine value greater than or equal to 50, the proportion of A is 0-80%; the B is palm oil with the iodine value greater than or equal to 30 and less than 50, the proportion of B is 0-80%; the C is a non palm oil edible oil with the proportion of 0-80%; the D is the fully hydrogenated vegetable oil with the proportion of 0.1 to 20%.

Owner:COFCO NUTRITION & HEALTH RES INST +1

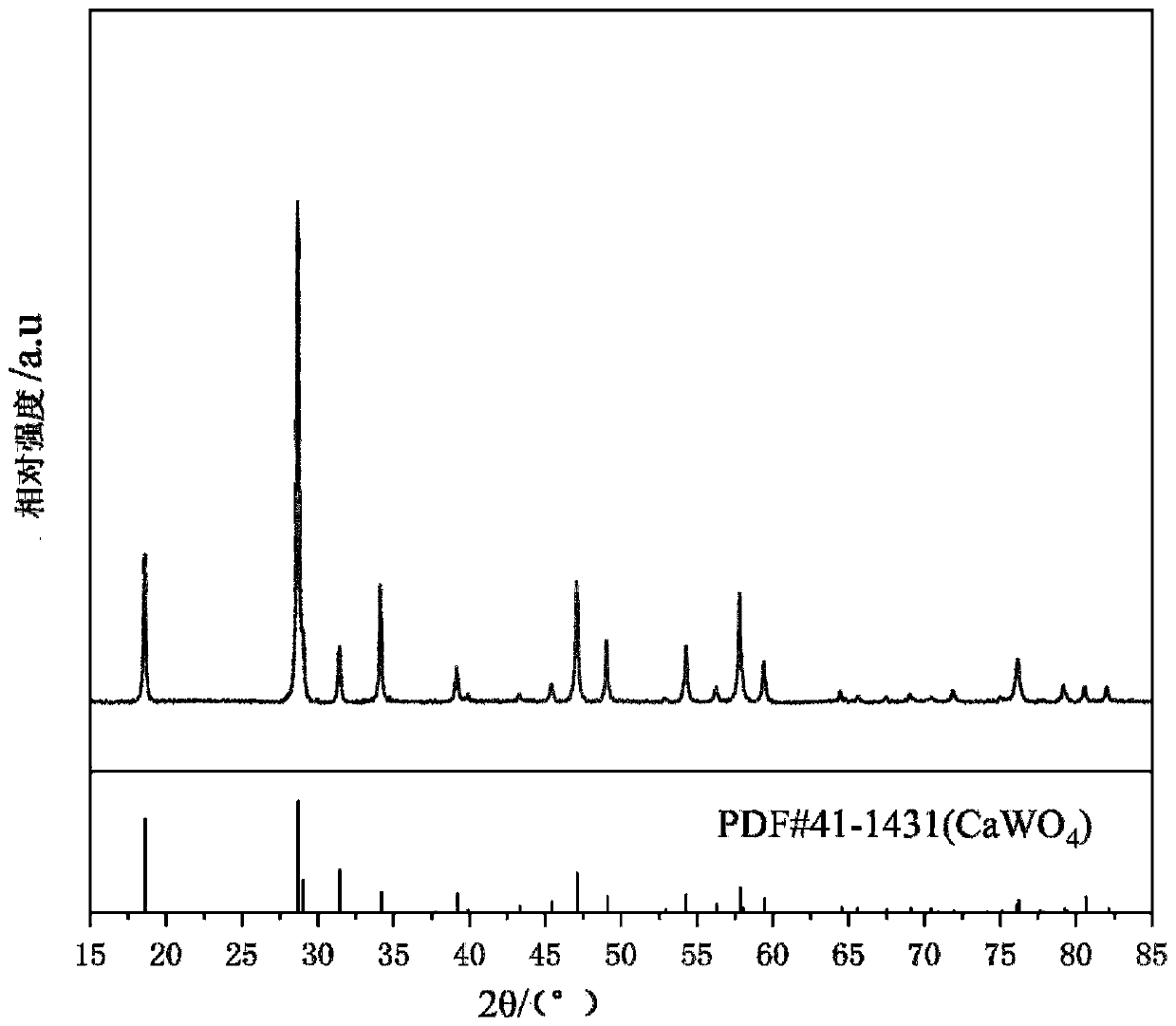

Preparation method of tungstate red phosphor

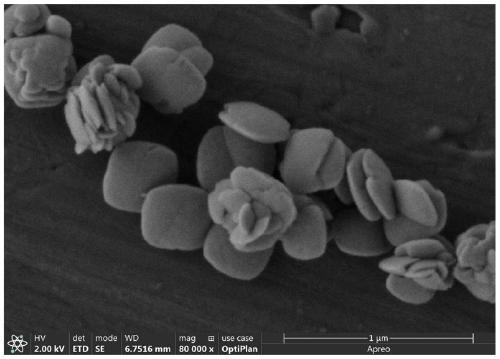

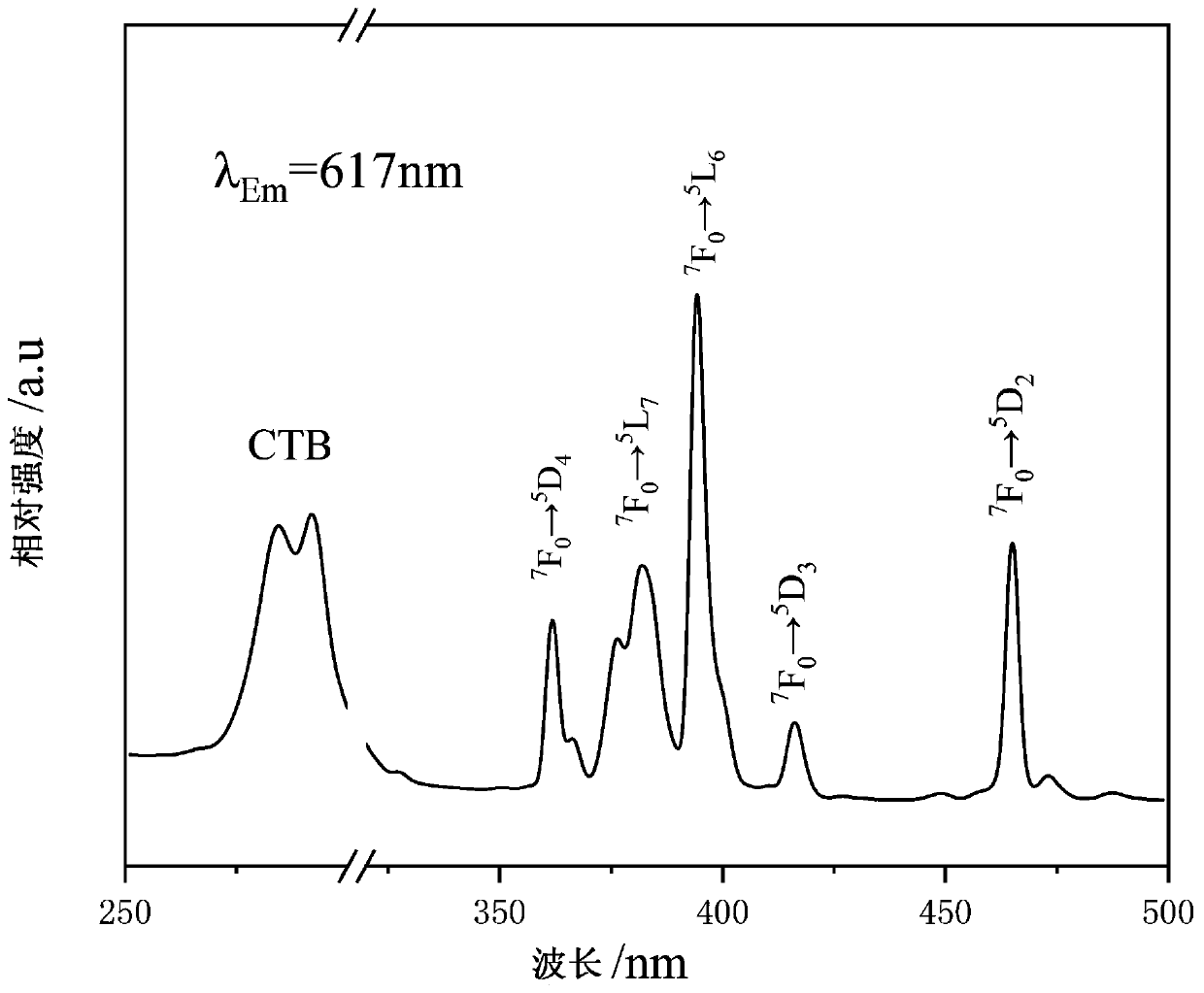

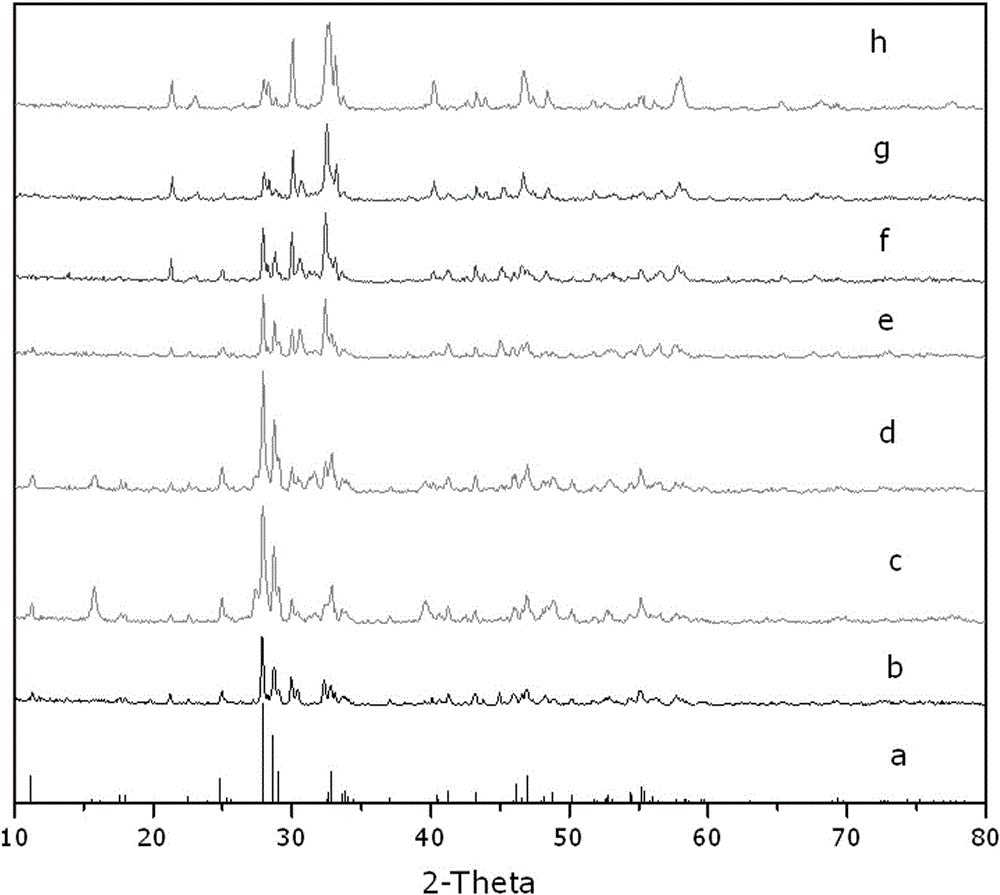

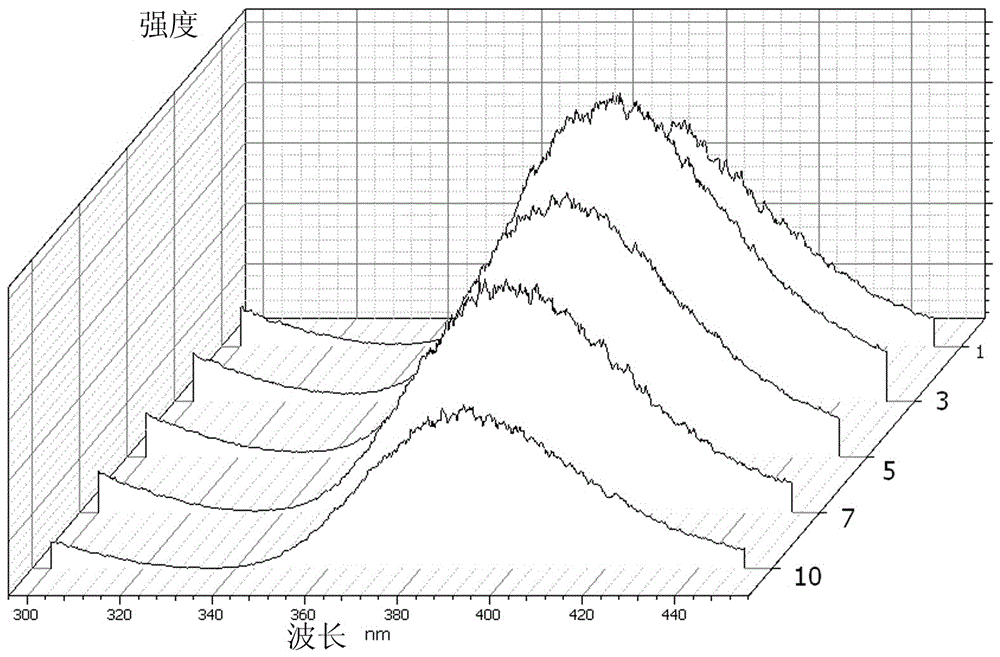

InactiveCN110172347ANo crystal regrowthRegular microscopic morphologyLuminescent compositionsSemiconductor devicesTungstateFiltration

The invention discloses a preparation method of a tungstate red phosphor. The preparation method mainly comprises the following steps: respectively preparing a salt solution of each component by massratio, stirring and mixing the salt solutions of calcium, gadolinium and europium to form a mixed solution A; then, dropwise adding a sodium tungstate solution into the mixed solution A, and then adjusting the pH value of the mixed solution to obtain a suspension C; performing hydrothermal reaction, centrifugal washing, filtration and drying on the suspension C to obtain the Eu<3+> ion doped tungstate CaGd2-xEux(WO4)4 red phosphor. The product obtained by the preparation method has the advantages of nanometer grade, good dispersibility and high color purity, and solves the problems that a traditional red phosphor has low luminous efficiency and poor thermal stability. The preparation method has low synthesis temperature and mild conditions, so that the product is high in granularity controllability.

Owner:XIDIAN UNIV

Preparation method of Mn doped lanthanum titanate photocatalyst fluorescent powder and application

InactiveCN106492787APollution Control Process ImprovementExpand the range of catalysisWater/sewage treatment by irradiationWater treatment compoundsFluorescenceRare earth

The invention belongs to the technical field of photocatalyst materials, particularly relates to a preparation method of Mn doped lanthanum titanate photocatalyst fluorescent powder and an application. The chemical formula of the photocatalyst fluorescent powder is MnxLa (2-x) TiO5-0.5x, wherein 0.01<=x<=0.4. The preparation method includes the steps: firstly preparing lanthanum titanate gel, doping manganese ions, and synthesizing corresponding powder at the lower temperature by the aid of a self-propagating combustion method; determining that the power has optimal photocatalytic performance when Mn doping amount is 10%, and the power has highest luminescence property when Mn doping amount is 3% according to photocatalytic effect and luminescent intensity. The preparation method is simple in process, easy to operate and low in calcination temperature, conditions are mild and easy to control, prepared samples are high in purity and yield, and the fluorescent powder is a novel rare earth composite material with photocatalysis and fluorescence performances.

Owner:SHENYANG POLYTECHNIC UNIV

Preparation method of high-conductivity polyaniline by using hydrochloric acid doped cellulose as template

The invention discloses a preparation method of high-conductivity polyaniline by using hydrochloric acid doped cellulose as a template. In the method, based on the conventional preparation method of the hydrochloric acid doped polyaniline, the cellulose is introduced as the template, so that the prepared polyaniline is relatively high in conductivity, and the probability of using the polyaniline as a conducting medium is increased. The method provided by the invention is simple and easy to control in the technical process, and is relatively lower in cost.

Owner:KUNMING UNIV OF SCI & TECH

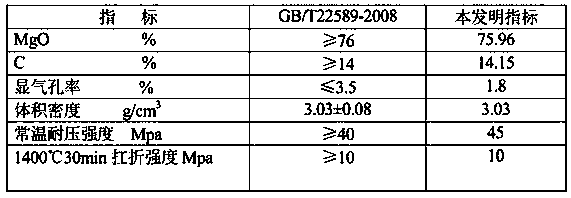

Method for producing magnesia carbon bricks for refining ladle lining by using waste magnesia carbon bricks

PendingCN109400192AReduce wasteAvoid harmCeramic materials productionClaywaresEnvironmental resistanceSteelmaking

The invention discloses a method for producing magnesia carbon bricks for a refining ladle lining by using waste magnesia carbon bricks. Ingredients include 62 parts of waste magnesia carbon bricks, 8parts of graphite, 2 parts of high temperature asphalt powder, 30 parts of fused magnesium and 3.0-3.2% of binder. The method includes immersing the waste bricks in water for 30 days, drying, crushing and sieving; mixing granules into a mixing mill for uniform mixing, adding the binder and powder for mixing for 30-40 minutes and rolling out; pressing the rolled material into blanks and calciningat low temperature for 10 hours. The waste magnesia carbon bricks are used as the main material and utilized to reduce resource waste, the manufacturing cost of products is also greatly reduced, the problem of disposal of waste materials is solved, the harm to the environment caused by the waste refractory materials is reduced, and the method is more environmentally friendly. Compared with the existing magnesia carbon bricks, the manufactured magnesia carbon bricks have comparable or improved performance indexes. When the manufactured magnesia carbon bricks are used in steelmaking furnaces orrefining ladles, the service life is not reduced, but the service life of the equipment is prolonged.

Owner:郑州顺通新型耐火材料有限公司

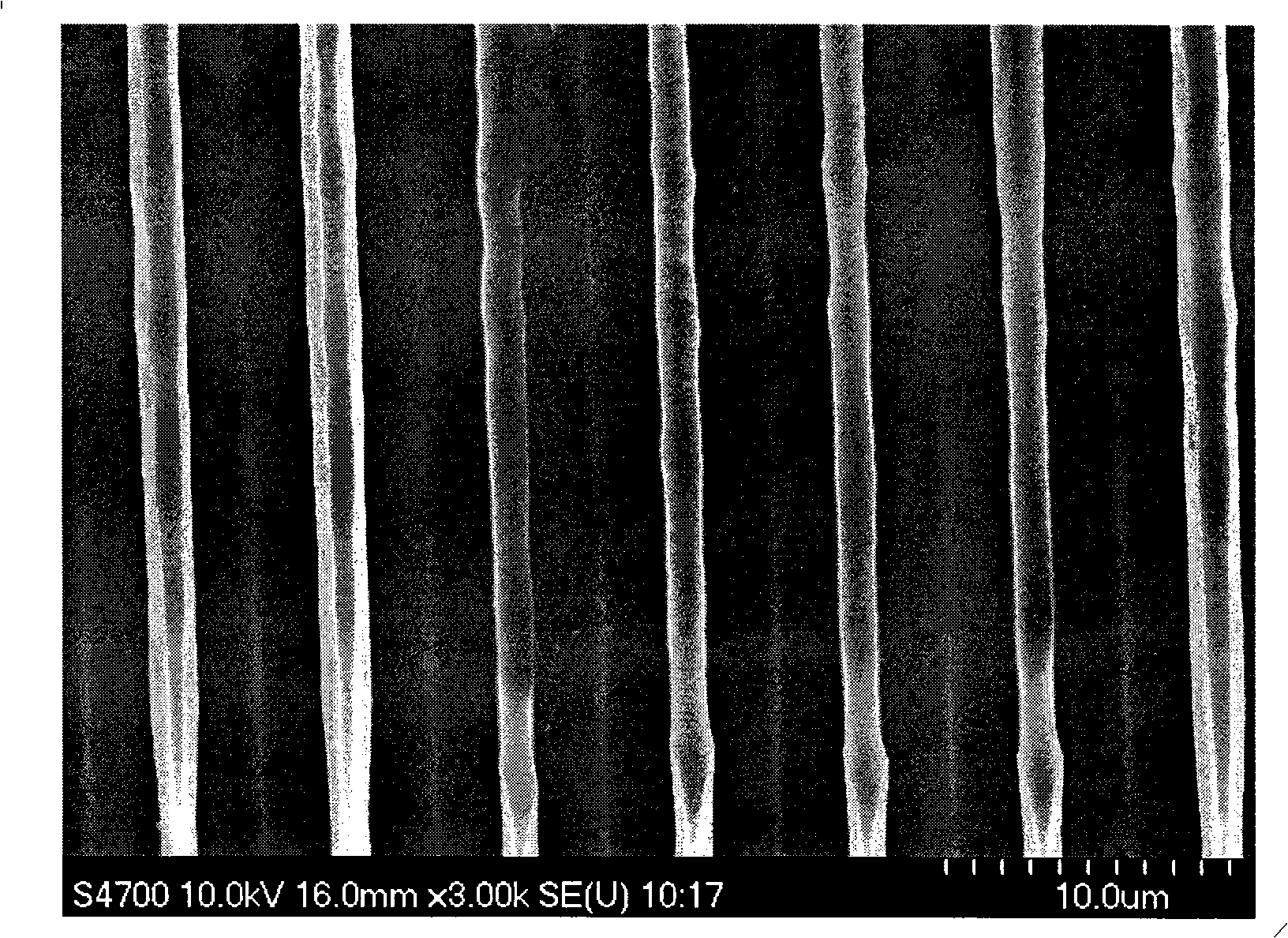

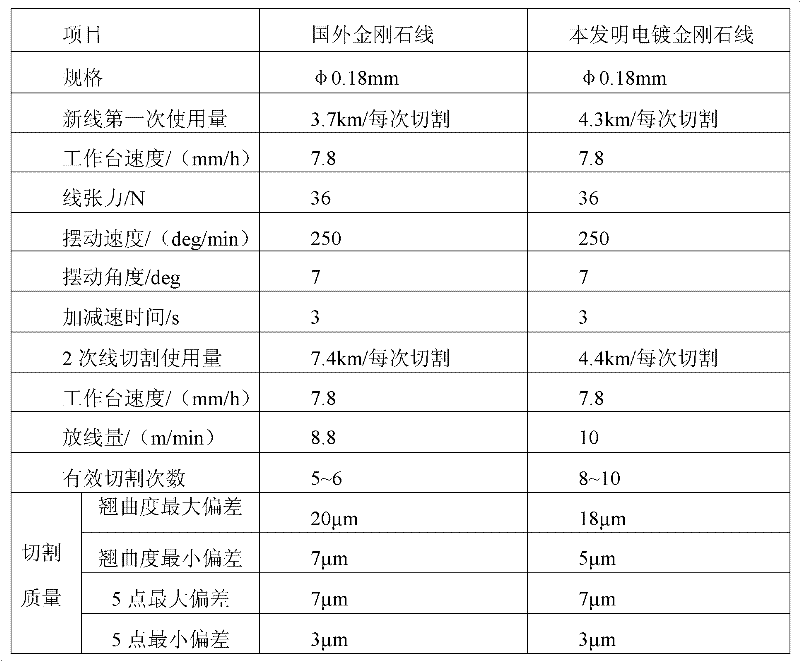

Preparation method of composite diamond fretsaw

InactiveCN101838838BImprove control abilityImprove sharpnessElectrolytic coatingsFine working devicesDiamond wire sawAlloy

Owner:CHANGSHA DIAT NEW MATERIAL SCI & TECH

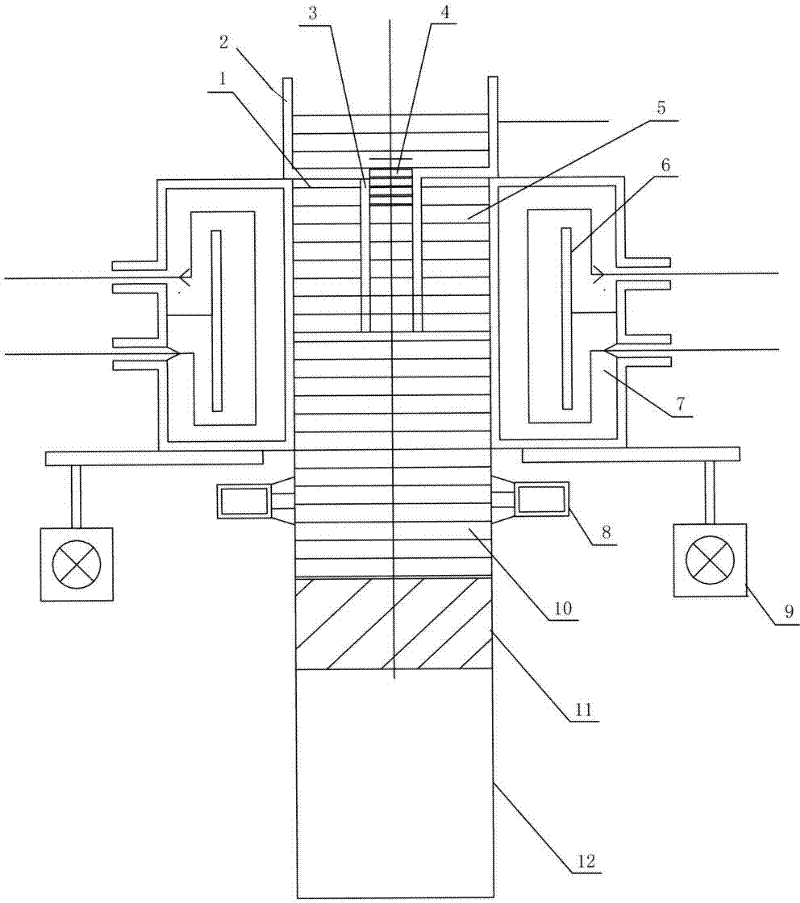

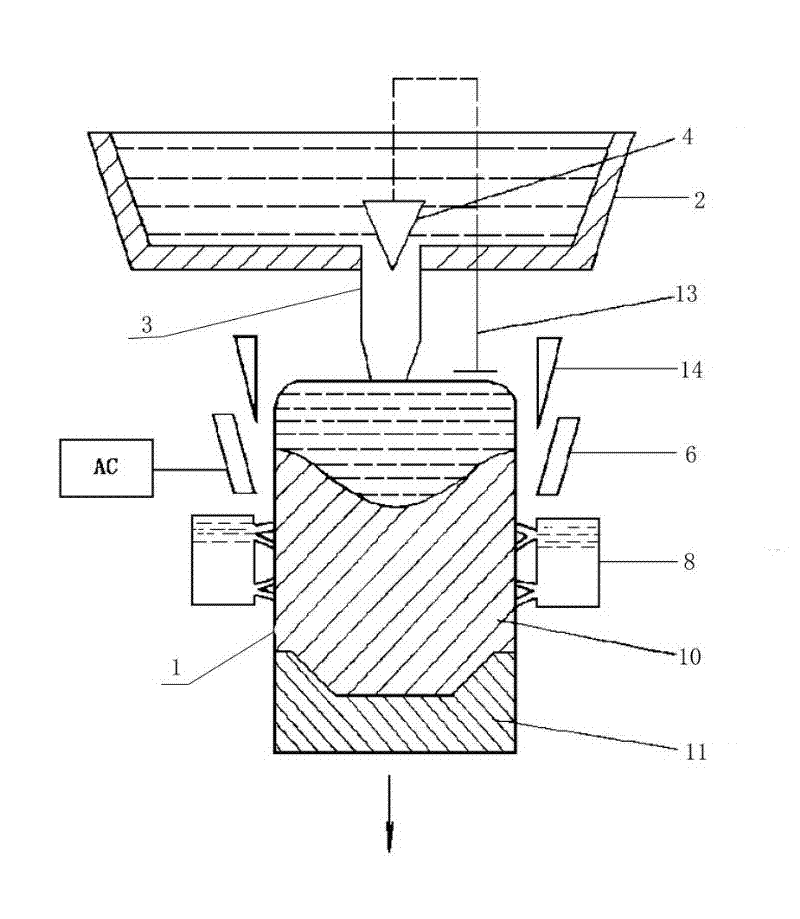

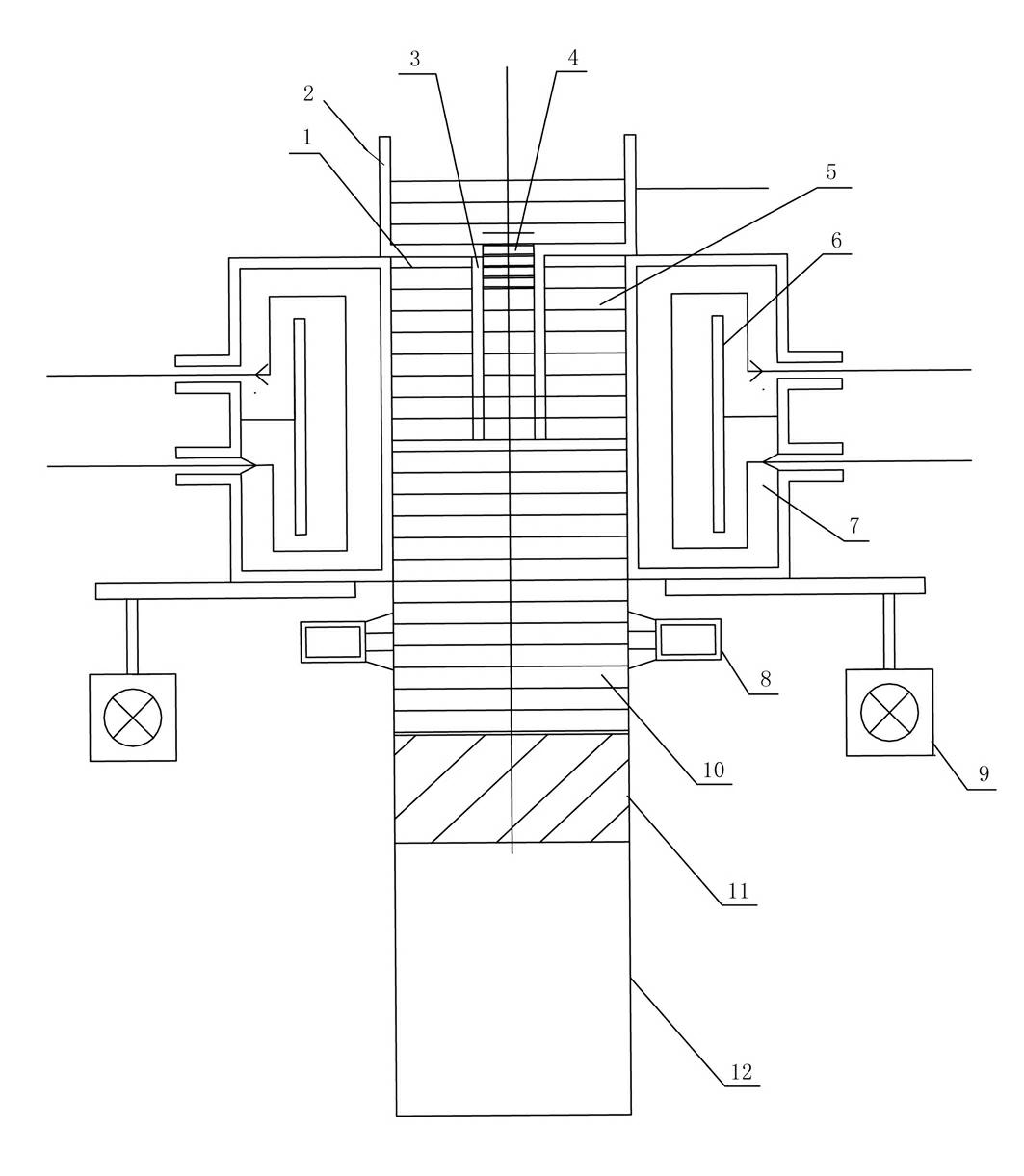

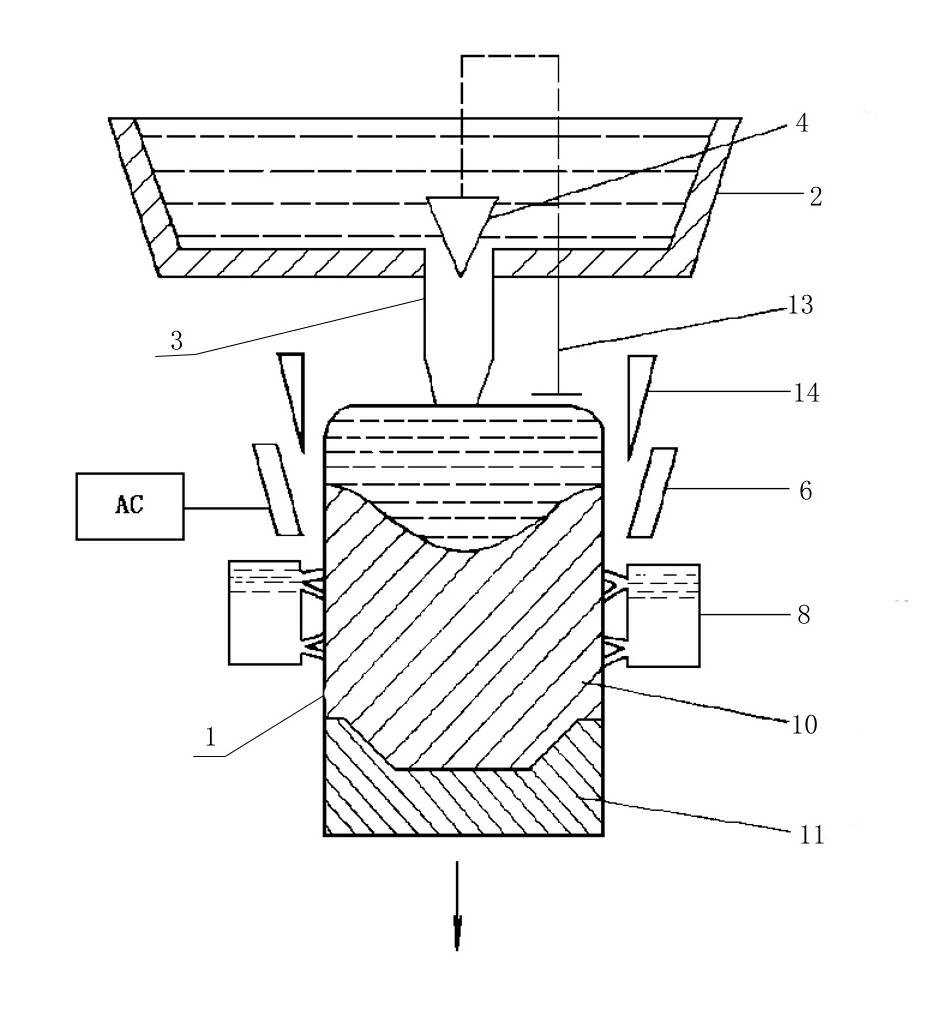

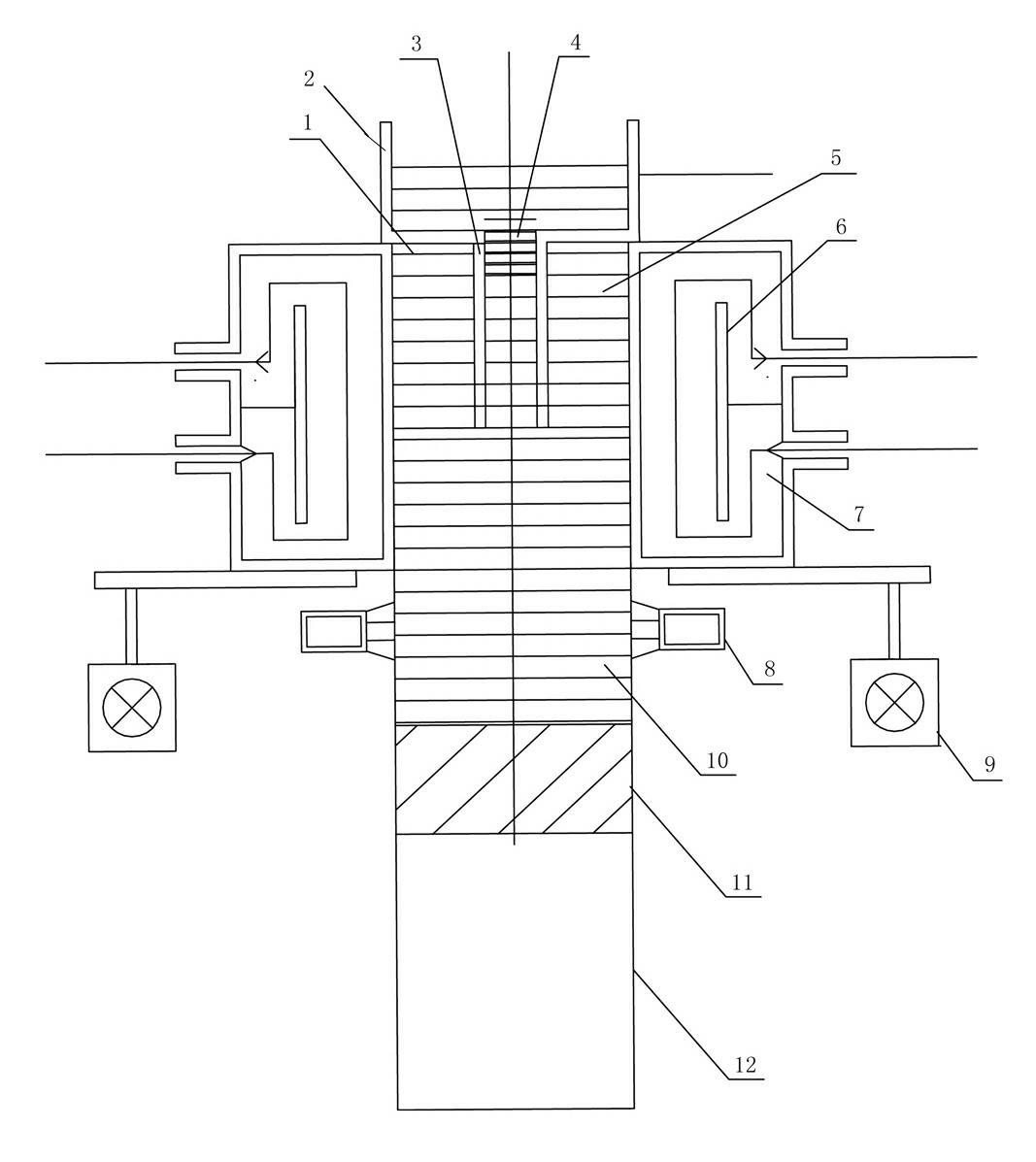

Oxygen-free copper strip horizontal electromagnetic casting device

InactiveCN102179490AImprove material performanceReduce broken belt rateElectromagnetic castingMedium frequency

The invention relates to an oxygen-free copper strip horizontal electromagnetic casting device and belongs to oxygen-free copper strip production and processing matched equipment. The oxygen-free copper strip horizontal electromagnetic casting device comprises a crystallizer shell, a medium-frequency power supply, an induction coil, an electromagnetic oscillator, a shielding cover, a cooling water tank, a bottom die and a pouring mechanism; the pouring mechanism consists of a tundish and a pouring gate plug; the tundish is arranged on the upper part of the crystallizer shell; the bottom of the crystallizer shell is provided with a pouring gate; the pouring gate plug is arranged in the pouring gate; the tundish is communicated with the upper part of the crystallizer shell through the pouring gate; the upper part of the crystallizer shell is provided with the induction coil; the electromagnetic oscillator is connected with the induction coil; the induction coil is connected with the medium-frequency power supply; the induction coil is formed by winding pure copper of which the section is rectangular; the circulating cooling water is filled in the hollow part of the induction coil for the primary cooling; a cooling water box and a shower pipe are arranged on the lower part of the crystallizer shell, and spray water to cool the crystallized stripped copper blank for the secondary cooling; and the bottom of the crystallizer shell is provided with the bottom die.

Owner:ZHONGTIAN ALLOY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com