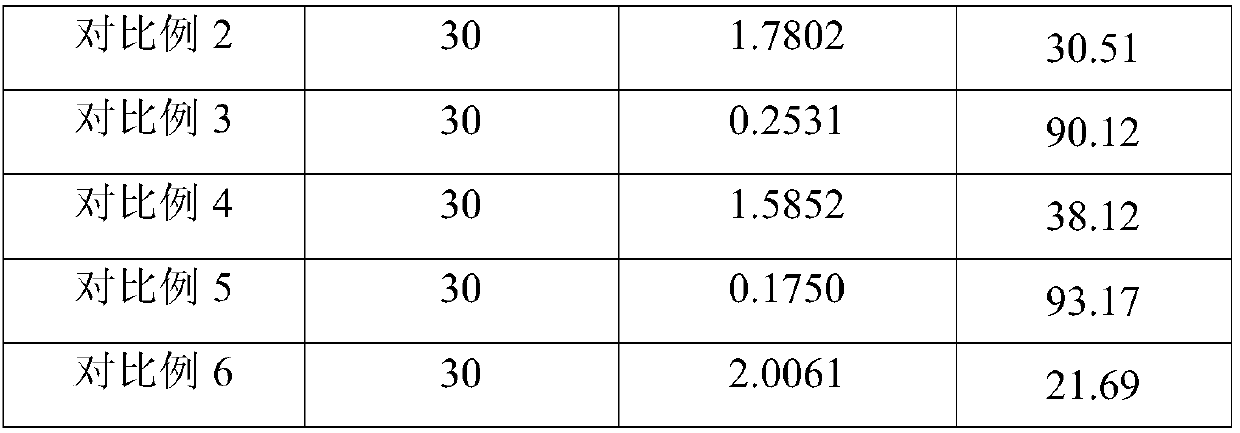

Patents

Literature

273 results about "Thiourea dioxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thiourea dioxide or thiox is an organosulfur compound that is used in the textile industry. It functions as a reducing agent. It is a white solid. The compound exhibits tautomerism.

Dye compound reducing agent and method of using the same

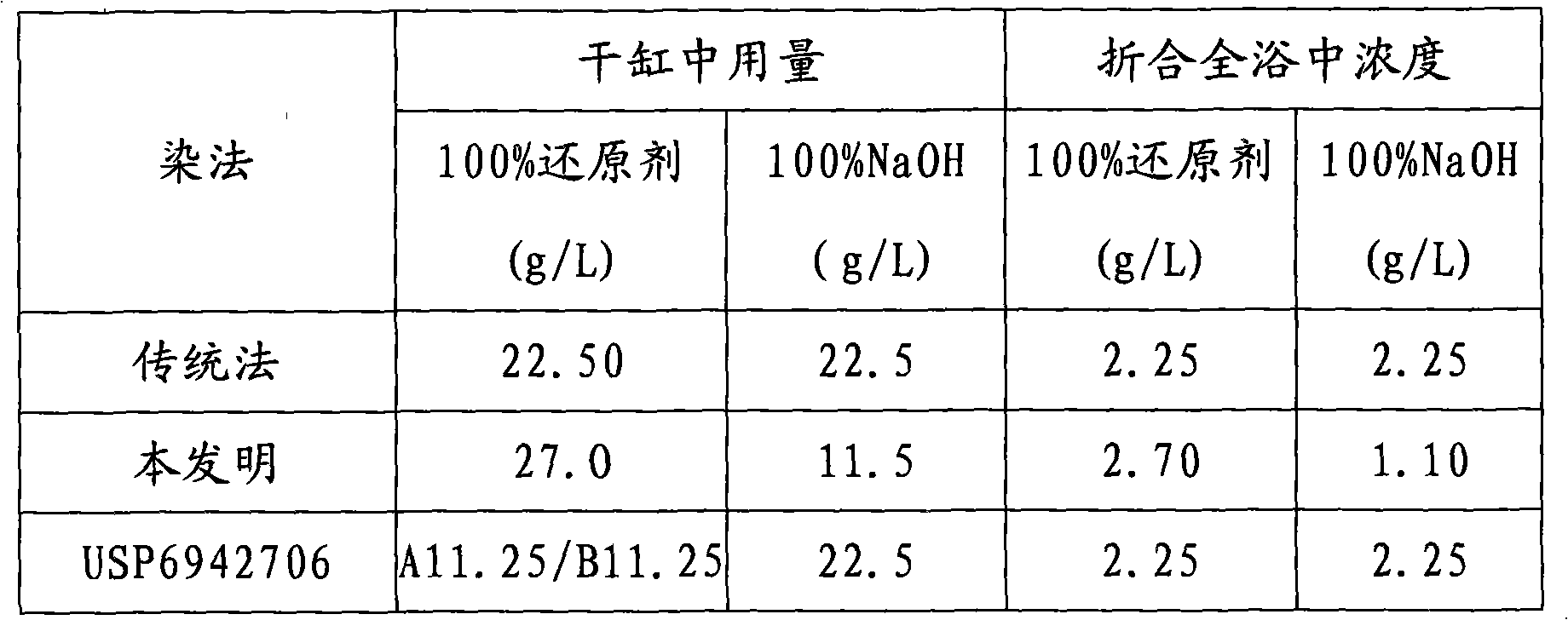

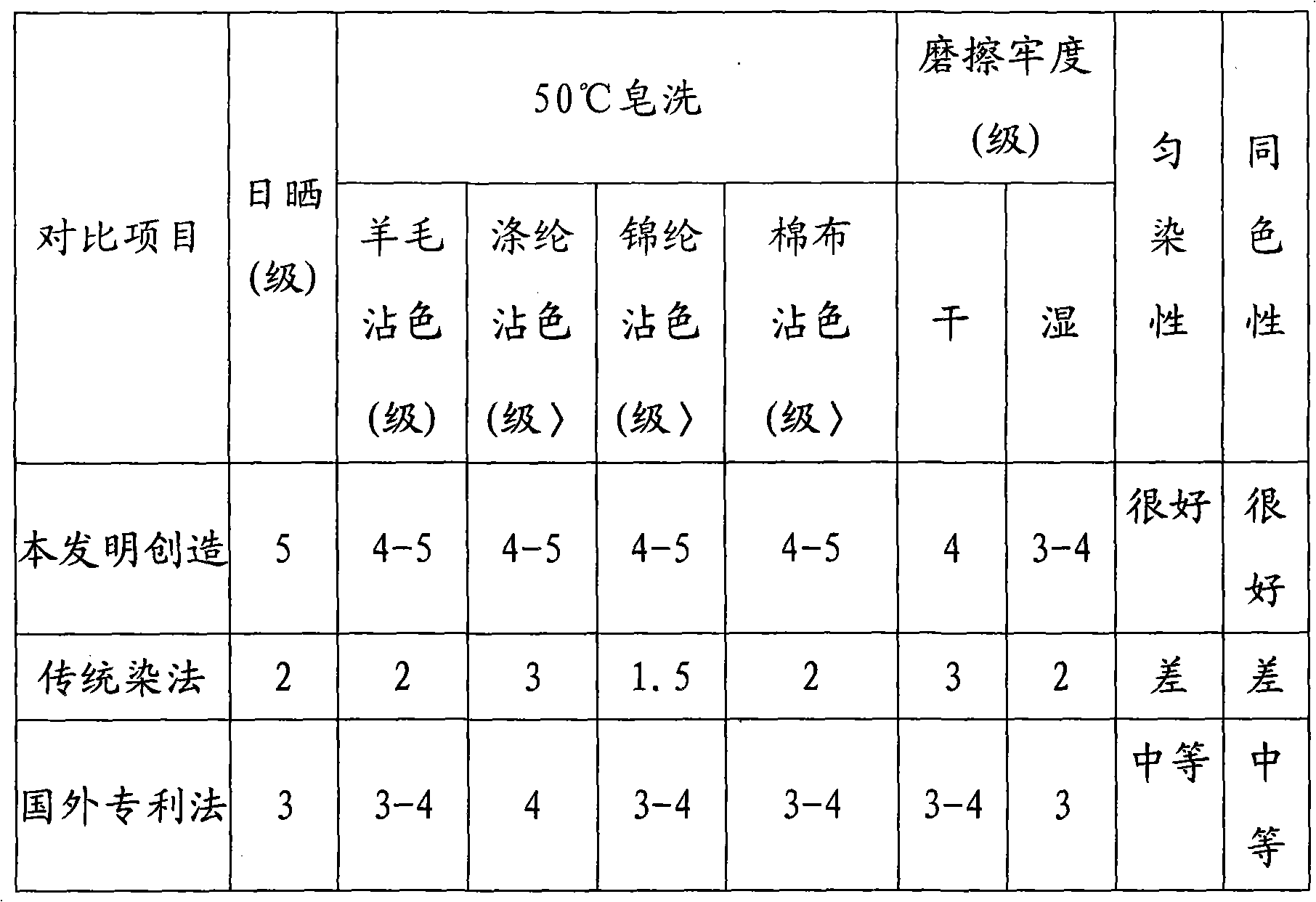

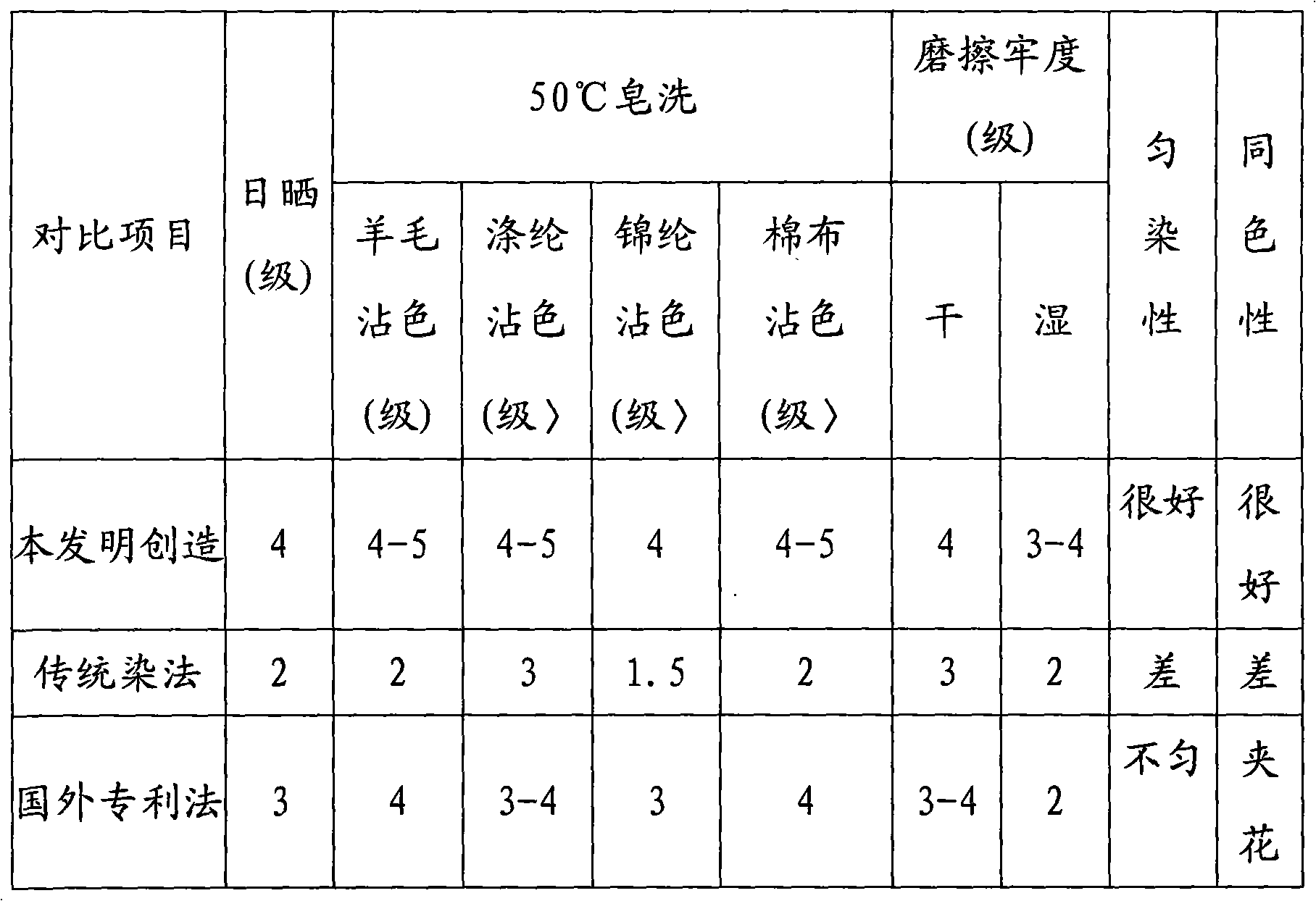

The invention discloses a composite reducing agent for dye, comprising the following compositions in weight portion: 8 to 20 portions of vat powder, 5 to 40 portions of thiourea dioxide, and 5 to 15 portions of sodium sulfite. The invention also discloses a method for dyeing by the reducing agent, comprising the following steps that: a reducing agent and sodium hydrate are used for reducing the dye by a vatting method; the weight ratio of a reducing solution to the dye is 37.5: 0.8 to 2.0 and the mixture is for later use; a leveling agent and the fiber penetrating swelling agent are added to dye or a buffering agent is added to adjust the pH value and is dyed by vat acid, the temperature is reduced and the mixture is washed; the mixture is subjected to oxidization to develop color, fixing, reducing temperature and washing; the fresh water bath is performed, the dye composite reducing agent is reduced and washed, and the temperature is reduced and the fiber penetrating swelling agent is produced. The composite reducing agent for the dye is a special reducing agent used for reducing the dye, a sulfur dye, a perylene dye and a leuco body, and improves the stability of the leuco body, color yield percentage, the color reproducibility, the color fixation and the color evenness degree, meanwhile, the dye composite reducing agent avoids the harm of formaldehyde on the environment and the human body.

Owner:SHANGHAI TEXTILE GRP DETECTION STANDARD CO LTD

Reducing agent for dyeing reduced dyes

The invention discloses a reducing agent for dyeing reduced dyes, belonging to the technical field of printing and dyeing technologies for textiles. The reducing agent consists of the following raw materials in percentage by mass: 5-10 percent of thiourea dioxide, 5-30 percent of sodium hydrosulfite 10-40 percent of reducing sugar type substances and 20-50 percent of salt. The reducing agent disclosed by the invention can effectively replace the sodium hydrosulfite to be used for dyeing of the reducer dyes and indigo dyes, the reduced dye leuco is long in existence time and slight in environment pollution, and the price of the dye leuco is superior to that of the sodium hydrosulfite. Moreover, the thiourea dioxide contained in the reducing agent for dyeing reduced dyes disclosed by the invention can be completely biodegraded, is high in reducing capacity, can effectively reduce the dyes into leuco, does not have a pungent smell and belongs to an environment-friendly substance; the reducing sugars refers to substances existing in the nature and have a certain reducing property, and the overall reducing capacity can be maintained and last for a long time; and moreover, according to salt substances, the stability of the components of the whole reducing agent can be enhanced.

Owner:濮阳圣恺环保新材料科技股份有限公司

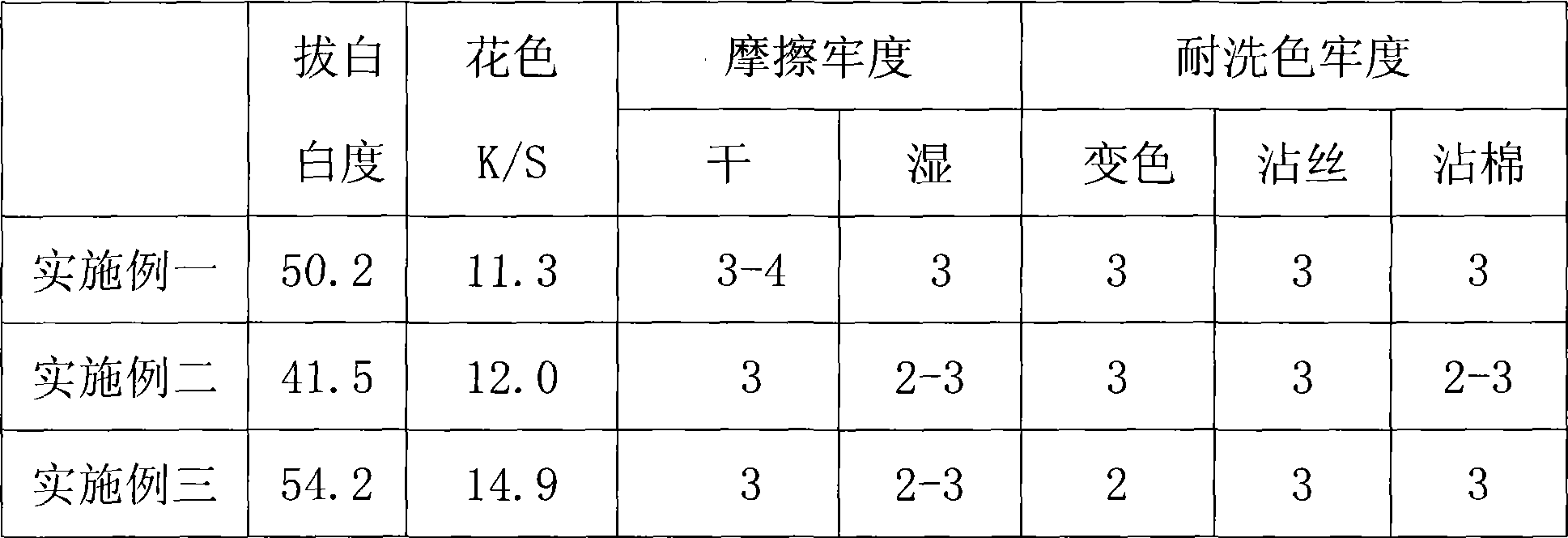

Silk broadcloth non-methanal discharge printing discharge paste and its discharge printing technique

InactiveCN101429730AReduce dosageSolve health and environmental protectionDyeing processPlanting seedEnvironmental engineering

The invention discloses formaldehyde-free discharge printing discharge paste, a preparation method and application to pure silk discharge printing thereof. The pure silk discharge printing discharge paste comprises the following components in weight percentage: 60 to 75 percent of thickener, 4 to 6 percent of hygroscopic latent solvent, 0 to 5 percent of discharge-resistant dye, 3 to 7 percent of formaldehyde-free discharging agent, and 10 to 30 percent of water, wherein the formaldehyde-free discharging agent is thiourea dioxide, the thickener is modified plant seed plasmagel or compound discharge-resistant thickening paste the solid content of which is 8 to 13 percent, the hygroscopic latent solvent is urea, and the discharge-resistant dye is acid or neutral dye resistant to reduction of the thiourea dioxide. By applying the discharge paste to the pure silk discharge printing, the discharge paste can avoid the problem of release of formaldehyde by using the prior discharge agent, and is favorable for human health and ecological environmental protection.

Owner:ZHEJIANG SCI-TECH UNIV

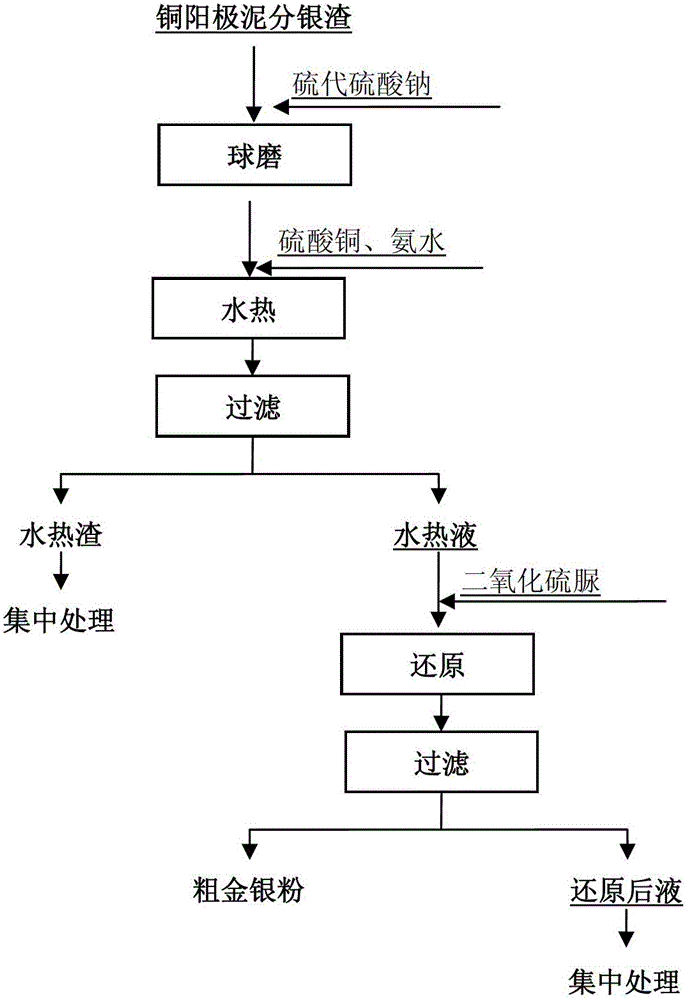

Method for recycling gold and silver from silver separating residues of copper anode slime

ActiveCN102943180AImprove leaching rateSimple processProcess efficiency improvementPhysical chemistryCopper

The invention relates to a method for recycling gold and silver from waste residues and particularly relates to a method for recycling gold and silver from silver separating residues of copper anode slime. The method specifically includes that the silver separating residues of the copper anode slime and sodium thiosulfate are subjected to mixing and ball-milling to obtain a ball-milling material; the ball-milling material and a reaction solvent are filled in a hydrothermal reaction still for hydrothermal reaction; and thiourea dioxide is added into a hydrothermal solution obtained by filtering a hydrothermal product for reduction reaction to obtain coarse gold and silver powders. Compared with methods in prior art, the method has the advantages that by means of the ball-milling and the hydrothermal reaction, leaching rates of the gold and the silver are greatly improved, the process is simple and easy to achieve, and raw materials are common, cheap and pollution-free.

Owner:UNIV OF SCI & TECH BEIJING +1

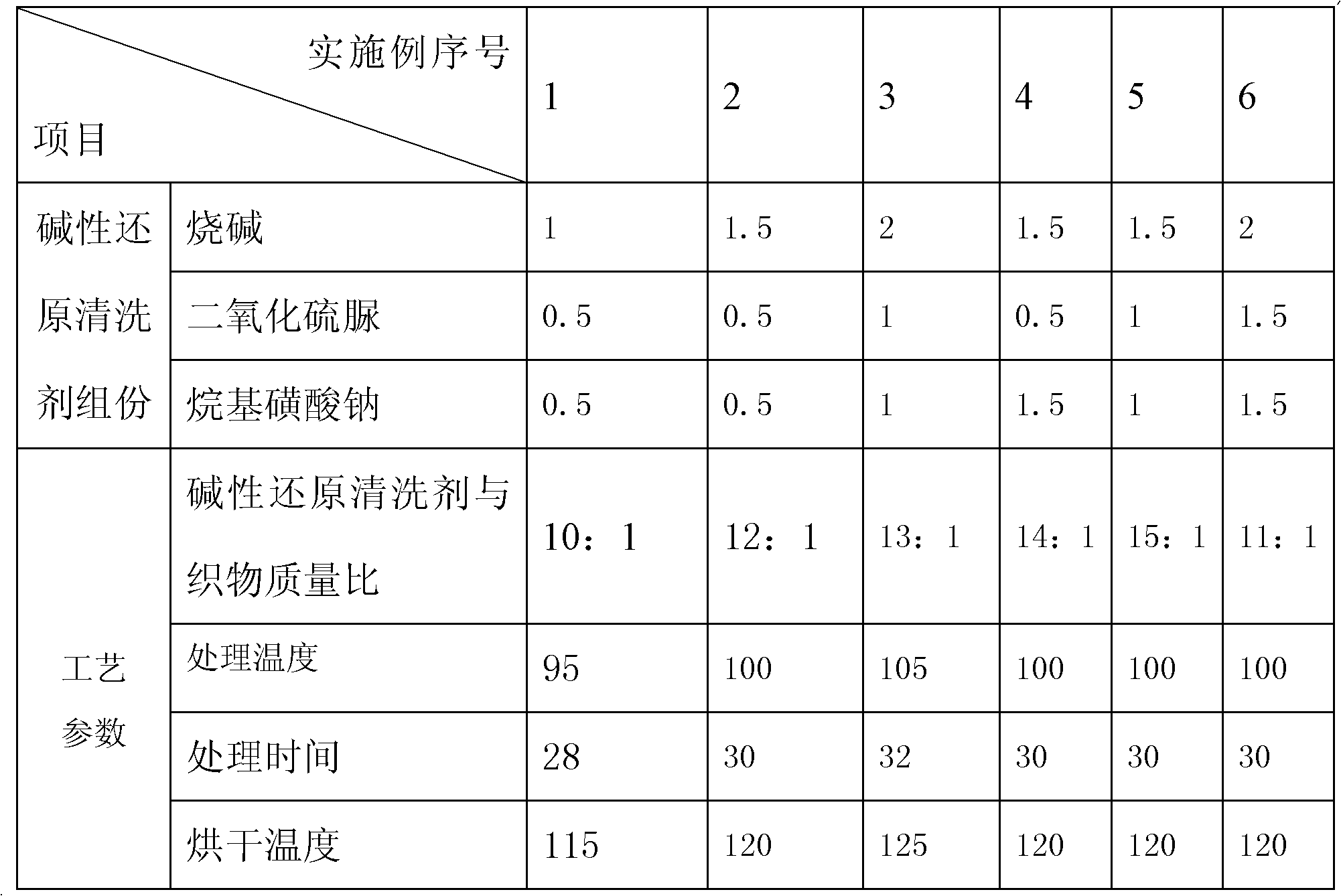

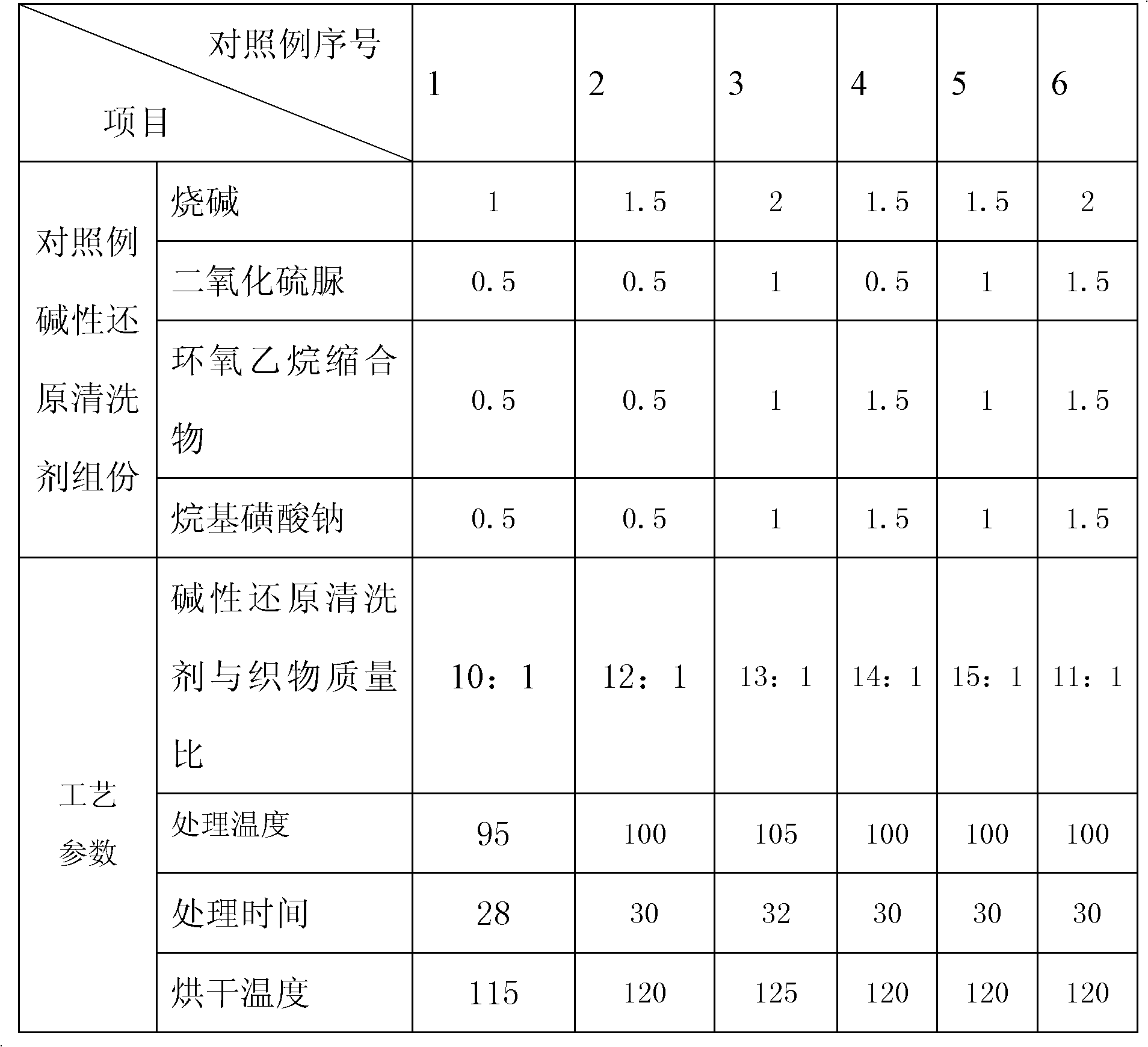

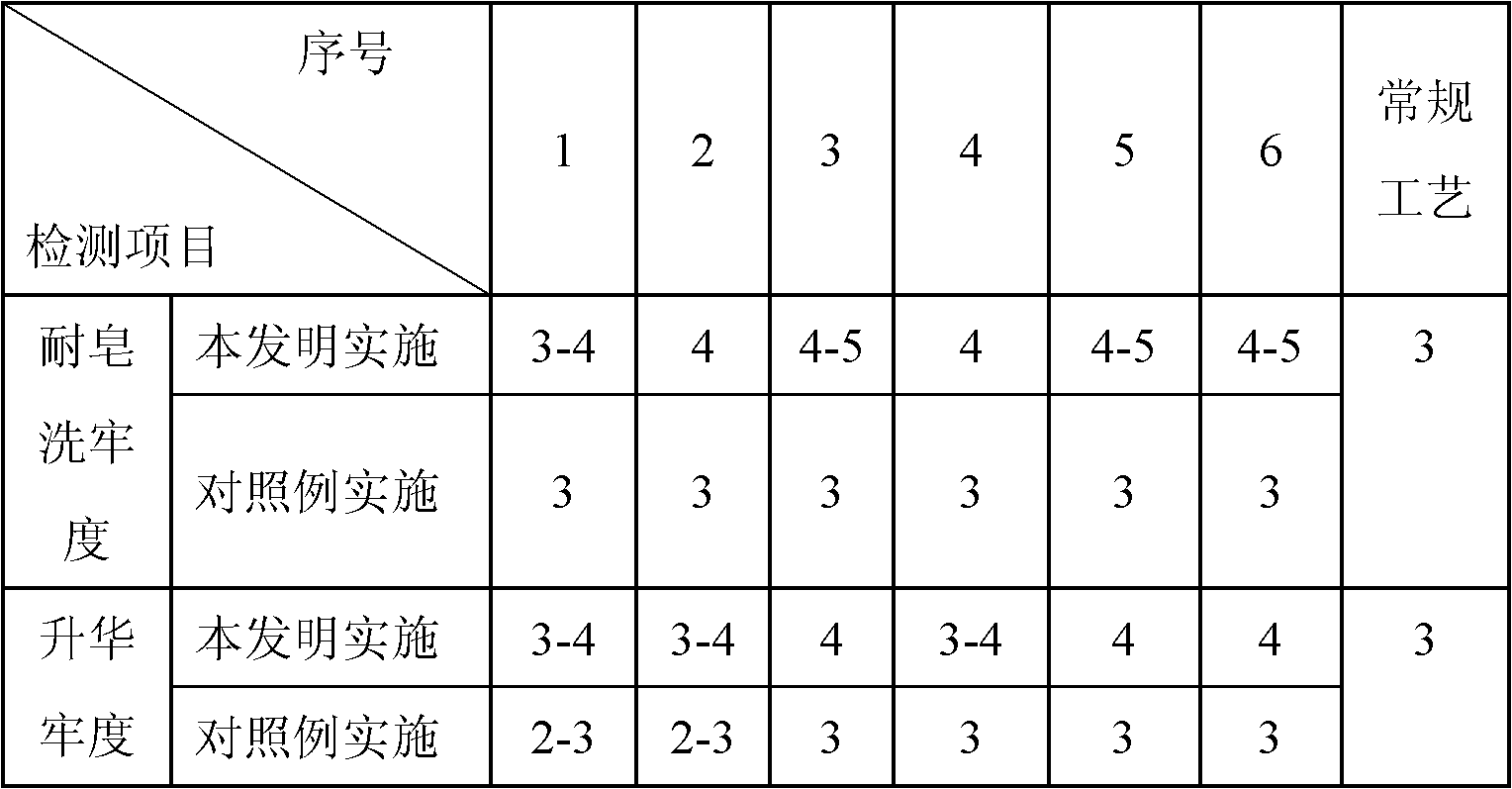

Fabric reductive cleaning agent with high soaping-resistant color fastness and high sublimation fastness, preparation method thereof and polyester fabric treatment method

ActiveCN102586038AHigh color fastnessConducive to three anti-heat setting finishingInorganic/elemental detergent compounding agentsSurface-active detergent compositionsPolyesterFiber

The invention provides a fabric reductive cleaning agent with high soaping-resistant color fastness and high sublimation fastness, a preparation method thereof and a polyester fabric treatment method specific to the defects of poor or instable soaping-resistant color fastness and sublimation fastness of a polyester fabric caused by unclean surface flooding of the cleaned fabric and instable three-proofing functional water resistance caused by the use of a reductive cleaning agent in the prior art. An alkaline reductive cleaning agent is an aqueous solution consisting of caustic soda, thioureadioxide, a soaping agent and a dispersant. The polyester fabric treatment method comprises the following steps of: dyeing a fabric, and adding the alkaline reductive cleaning agent into the fabric inthe weight ratio of (10-15):1 on a dyeing machine; performing reductive washing at the temperature of 100+ / -5 DEG C for 30+ / 2 minutes; washing with water; and drying at the temperature of 120+ / -5 DEGC. After a polyester fiber dyeing fabric is treated with the cleaning agent, flooding and low polymers are removed completely, and high color fastness of the fabric is realized.

Owner:ZHEJIANG TAIHUA NEW MATERIAL

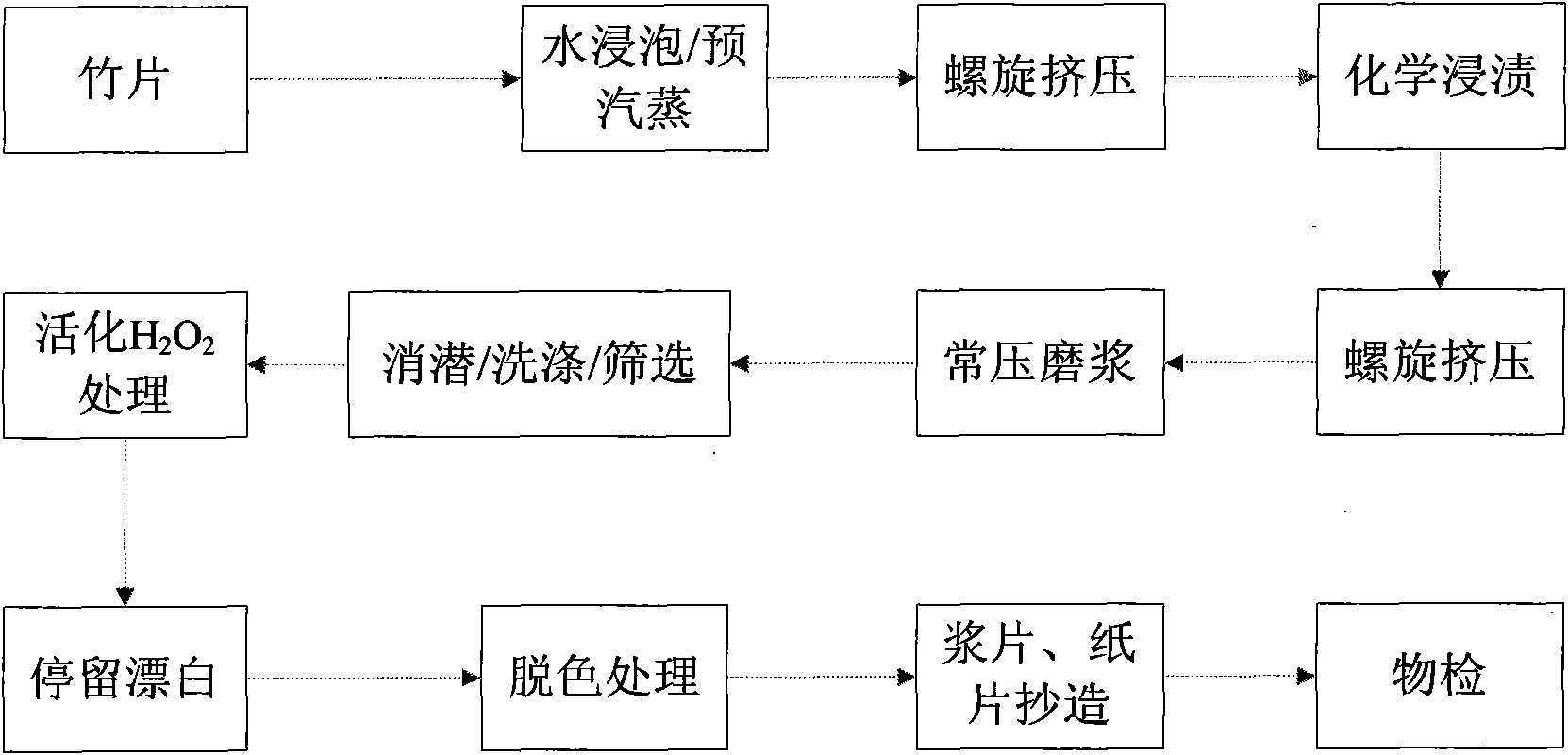

High-whiteness bleaching method for high-yield bamboo wood pulp

ActiveCN101638859AReduce dosageImprove bleaching efficiencyNon-macromolecular organic additionPulp bleachingHigh concentrationPre treatment

The invention discloses a high-whiteness bleaching method for high-yield bamboo wood pulp. The high-whiteness bleaching method comprises the following steps: firstly, using an extruder to carry out enhanced mechanical treatment on pretreated bamboo sheets; using a transition metal ion remover and the like to carrying out chemical impregnating treatment on extruded cizu materials; then, carrying out secondary spiral extrusion before pulping, straightening and screening; secondarily, using a peroxide activating agent and peroxide to carry out the activating treatment of 20 percent by weight of bamboo pulp at a treatment temperature of 60-90 DEG C for 30-60 minutes; thirdly, using a chlorine-free bleaching medicine H2O2 to carry out high-concentration rested bleaching of 10-30 percent by weight of bamboo pulp at a treatment temperature of 60-90 DEG C for 60-180 minutes; and using a decoloring agent of thiourea dioxide to decolour the bamboo pulp, remove a ground color, adjust a color phase and improve the bleaching white content. The invention forcefully and mechanically treats the bamboo sheets, synchronously realizes pulping, the removal of transition metal ions and deep extractionsand the break of complex cells, reduces the consumption of the bleaching medicine and improves the bleaching efficiency.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

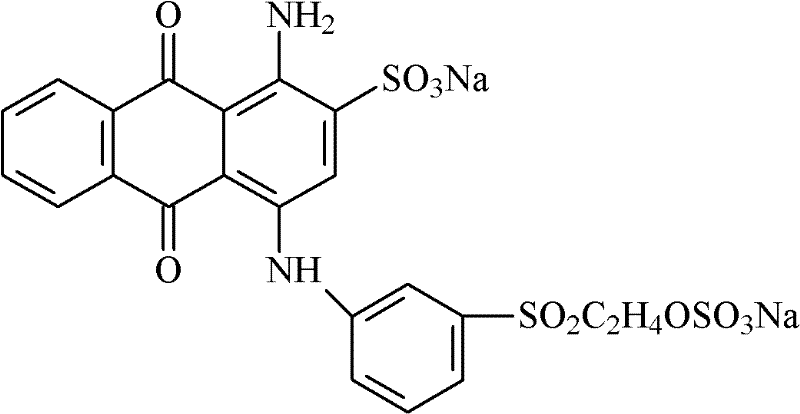

Blue alkali resistant active dye

The invention relates to a blue alkali resistant active dye, which comprises brilliant blue KN-R and a printing and dyeing auxiliary in a weight part ratio of 100:(25-40), wherein the printing and dyeing auxiliary comprises one or a mixture of two of a first auxiliary, a second auxiliary and a third auxiliary; the first auxiliary is one or a mixture of two of sodium sulfide, thiourea dioxide, sodium hydrosulfite and sodium sulfite; the second auxiliary is one or a mixture of two of a dispersing agent MF, a dispersing agent NNO, sodium lignin sulfonate and urea; and the third auxiliary is one or a mixture of two of an emulsifier OS-15, an emulsifier A-20, an emulsifier C-125 and triethanolamine. The alkali resistance of the brilliant blue KN-R under the conventional dyeing conditions is improved, and the application range of the brilliant blue KN-R is widened, namely the brilliant blue KN-R can be used in cold pad batch dyeing.

Owner:TIANJIN DEK CHEM

Pure cotton fabric reduced dye dyeing method

InactiveCN104047186AImprove reducibilityMaintain resilienceBleaching apparatusDyeing processPolymer scienceDioxyethylene Ether

The invention relates to a pure cotton fabric reduced dye dyeing method which comprises the following steps: (1) textile preparation; (2) textile pretreatment; (3) preparation of reduced dye leuco body solution; (4) dip dyeing of reduced dye; (5) soap boiling and (6) after-finishing. The reduced dye leuco body solution is prepared by the following raw materials: 1-10g / L thiourea dioxide, 2-5g / L of iso-tridecanol polyoxyethylene ether, 1-2g / L of glucose, 2-5g / L of sodium silicate, and 1-2g / L of sodium sulfide. The K / S value of the dyed textile is obviously improved.

Owner:福建金苑服饰有限公司

Process for producing thiourea dioxide

The present invention belongs to the field of peroxide preparing technology in organic chemistry. Into reactor, water is added in advance, thiourea is thrown in batches and hydrogen peroxide solution containing stabilizer is dripped to produce thiourea dioxide. After finishing the reaction, thiourea dioxide is filtered and stoved to obtain crystallized thiourea dioxide powder. The added amountof the stabilizer is 0.1-5 wt% of thiourea and crystal habit modifier in 0..005-2 wt% of thiourea may be also added into water. The improved thiourea dioxide producing process has improved crystal state of thiourea dioxide and raised product purity and is suitable for industrial production in large scale.

Owner:陶华西

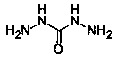

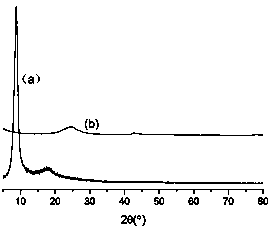

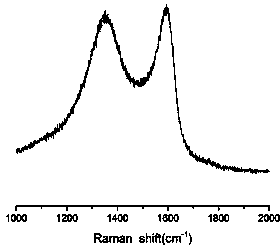

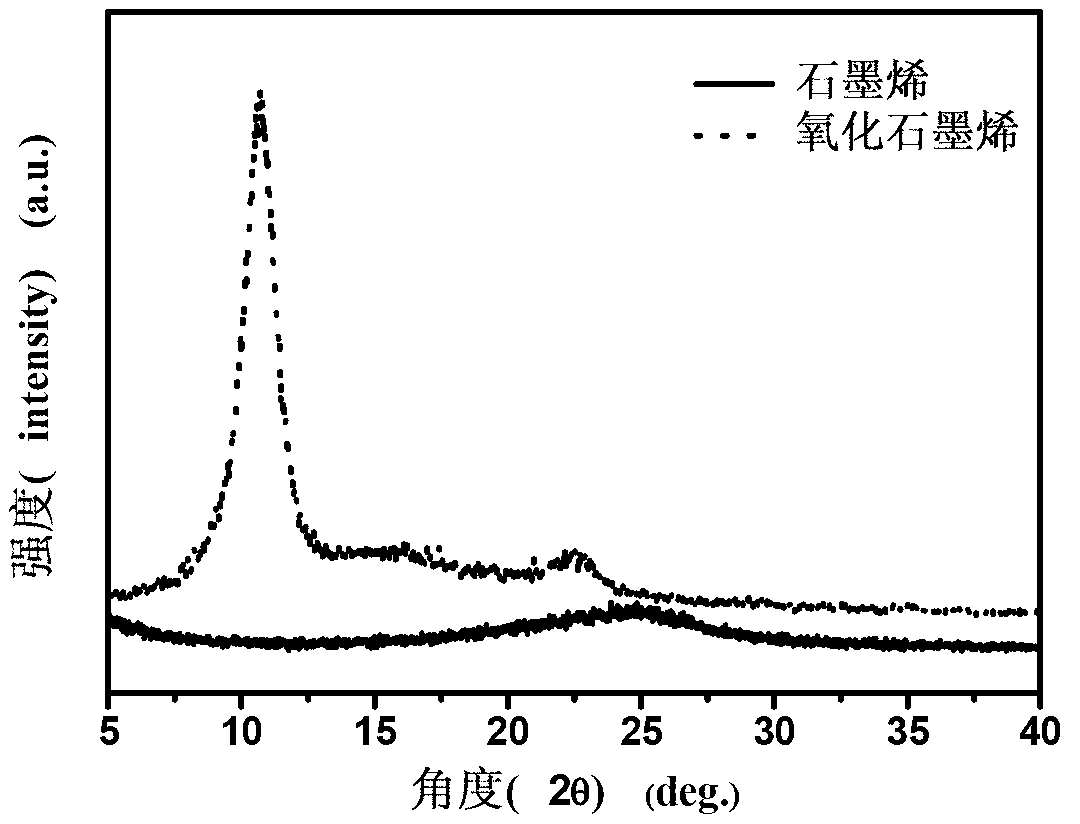

Graphene preparation method

The invention discloses a graphene preparation method. The mixed solution of thiourea dioxide and soluable alkali or carbohydrazide and the soluable alkali is taken as a reducing agent to perform reduction-oxidation on the graphene aqueous solution, and evenly dispersed graphene powder is obtained after washing and drying. The graphene preparation method, disclosed by the invention, solves the problems that hydrazine hydrate and other existing reducing agents are high-toxic and not thorough in reduction, and the graphene is liable to gathering in the graphene preparation process. The preparation method is simple and feasible, is rapid in reaction process and moderate in reaction condition and has no special requirements to equipment, and the prepared graphene is of high quality.

Owner:吴江市华诚电子有限公司

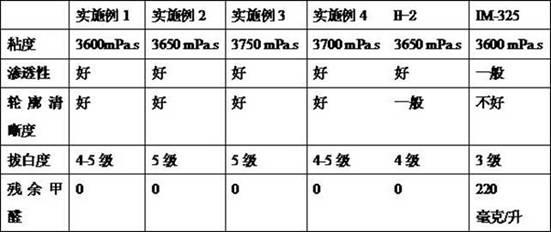

Non-formaldehyde dischargeable protoplasm and preparation method and usage thereof

The invention discloses a non-formaldehyde discharging plasmogen and a preparing method and application of the plasmogen. Modified plant seeds adhesive paste by quality portion and thiourea dioxide are put into a mixer with a proportion of 1-3:1, 10-40 water is added and stirred for 1-2 hours; then the non-formaldehyde discharging plasmogen can be made. Then the non-formaldehyde discharging plasmogen is made into discharge printing white discharge pulp used for discharging white printing or into discharge printing colored discharge pulp used for discharging colored printing. The invention solves the problems of free formaldehyde releasing, bad stability, large consumption and high cost caused by the existing discharge agent, provides the non-formaldehyde discharging plasmogen and the preparing method and application of the plasmogen, assures a high white discharge degree when discharging white printing and assures bright color when discharging colored printing and outstandingly displays the unique style and character of the fine pattern of discharge printing.

Owner:ZHEJIANG SCI-TECH UNIV

Method for synthesizing high-stability thiourea dioxide

A manufacture method for synthesizing thiourea dioxide with high stability is the manufacturing method of a chemical product, which overcomes the disadvantages in other technologies and is confected by adopting the following raw materials: the molar ratio between thiourea and oxydol of 27.5 percent is 1:1.9 to 1:2.1; the mass ratio between polyethyleneglycol that is a stabilizing agent and hydroxyl ethidene diphosphonate tetrasodium is 1:1, and the quantity of polyethyleneglycol and hydroxyl ethidene diphosphonate tetrasodium can be 0.5 to 2.0 percent of the total quantity of thiourea; the mass ratio between postassium acetate that is an accelerant and ammonia bicarbonate is 2:3, and the quantity of postassium acetate and ammonia bicarbonate is 4.0 to 6.0 percent of the total auantity of thiourea. A method for preparing thiourea dioxide comprises the steps of confecting an accessory ingredient, catalysis synthesis, crystallization, dehydration, drying, and completing through packing. The main performance index of the product includes the aspects as follows: the main content of thiourea dioxide is more than or equals to 99.0 percent; residual thiourea is less than or equals to 0.1 percent, and sulphate is less than or equals to 0.17 percent; the iron content is less than or equals to 10ppm; the moisture content is less than or equals to 0.05 percent; the thermal stability is more than or equals to 55 minutes in water bath when the temperature is 95 DEG C. The manufacture method has the high yield of product and high thermal stability, effectively changes the product quality, and increases the safety performance of product transport and storage.

Owner:濮阳圣恺环保新材料科技股份有限公司

Low-temperature cashmere bleaching agent and bleaching method thereof

InactiveCN104047156AHigh activityReduce effectivenessBleaching apparatusAnimal fibresDioxyethylene EtherGlycol synthesis

The invention relates to a method for bleaching through a low-temperature cashmere bleaching agent. A metal salt solution contains 1% fatty acid methyl ester ethoxylate sulfonate, and an oxidation bleaching solution comprises 15g / L of 30% hydrogen peroxide, 8g / L of tetraacetylenediamine, 3g / L of glucose, 2.5 / L of trisodium phosphate, and 0.5g / L of ethylene glycol monobutyl ether; a reduction bleaching solution comprises 3g / L of thiourea dioxide, 1g / L of iso-tridecanol polyoxyethylene ether, 1g / L of glucose, 2g / L of sodium silicate, and 1g / L of sodium sulfide. By adopting the low-temperature cashmere bleaching agent and the bleaching method thereof, the whiteness of cashmere can be effectively improved, the damage on the cashmere can be alleviated, and the yellowing index of the bleached cashmere is low.

Owner:严海黄

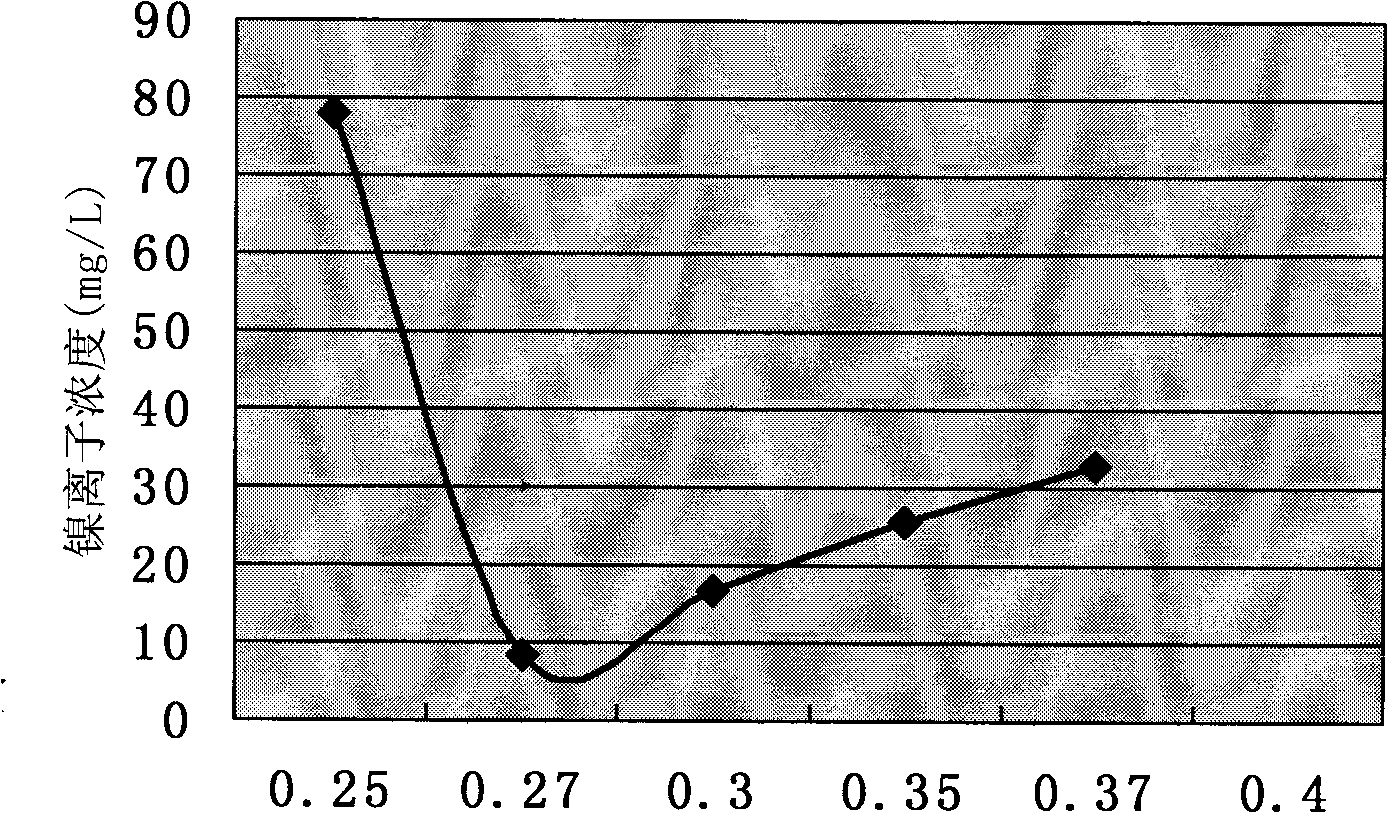

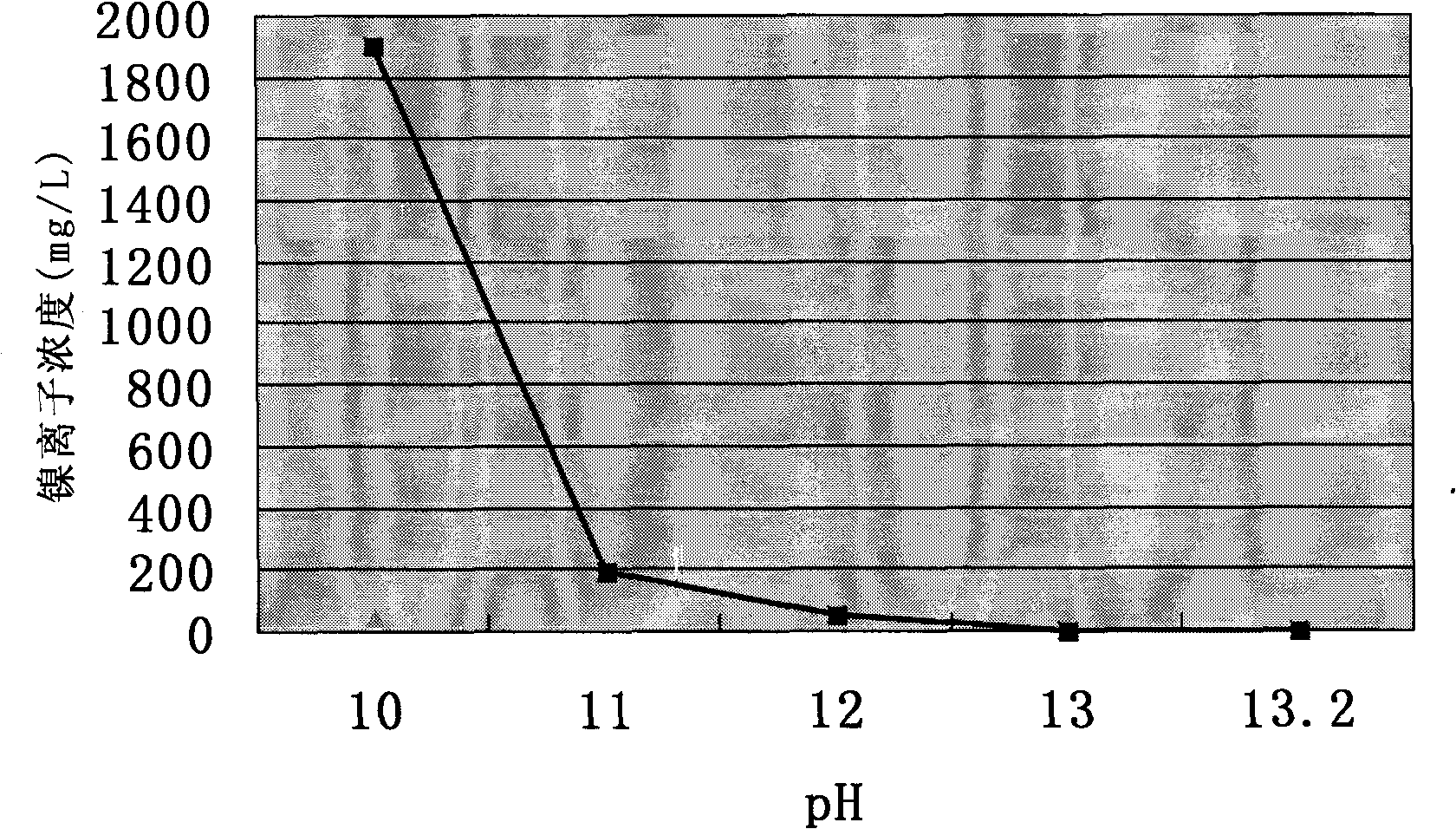

Method for preparing nano metallic nickel in spent electroless nickel plating solution

InactiveCN101892389ALower reaction conditionsLess investmentProcess efficiency improvementElectroless nickelLiquid waste

The invention discloses a method for preparing nano metallic nickel in spent electroless nickel plating solution. The method comprises the following steps: adding 0.20 to 0.33 grams of reducer thiourea dioxide into every 100ml of the spent electroless nickel plating solution; then, adjusting the spent electroless nickel plating solution to be alkalic with 3 to 7 grams of sodium hydroxide, and heating the spent electroless nickel plating solution to the temperature of between 70 and 100 DEG C; reacting at constant temperature for 5 to 20 minutes, and cooling the solution to the temperature of between 10 and 30 DEG C; filtering the spent electroless nickel plating solution; and washing the filtered substances with deionized water and absolute ethanol respectively; and drying the substances in a vacuum drier to prepare the nano metallic nickel. The method effectively solves the problem of spent electroless nickel plating solution pollution, simultaneously recycles noble metal nickel, and realizes double assurance of social benefit and economic benefit for enterprises. Furthermore, the reducer thiourea dioxide has lower requirement to the reaction condition, less investment, no toxic or side effect and environmental protection.

Owner:王昊杨

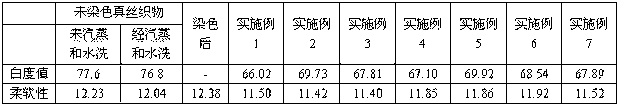

Reduction system for protein fiber stripping or bleaching and stripping or bleaching method

The invention discloses a reduction system for protein fiber stripping or bleaching and a stripping and bleaching method. The reduction system is aqueous solution of thiourea dioxide and weak base, that is, the thiourea dioxide and weak base serve as solute, water serves as solvent, and the weak base is a mixture of trisodium phosphate, sodium silicate and sodium carbonate; the concentration of the thiourea dioxide is 0.05 mol / L-0.2 mol / L, and the concentration of the weak base is 0.01 mol / L-0.10 mol / L. The bleaching method comprises the step of adopting the reduction system as bleaching liquid to treat protein fiber; the stripping method comprises the step of adopting the reduction system as stripping liquid to treat dyed protein fiber. According to the invention, the synergistic effect of three types of weak bases is utilized, so that the alkalinity of the system is reduced, the stripping, bleaching and impurity removing capacities are enhanced, and the strength loss of a textile is reduced.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

Heliotropin decolorizer and preparation method of heliotropin

The invention relates to the field of chemical synthesis. Concretely, a heliotropin decolorizer consists of water-soluble reducing agent and alkaline pH adjusting agent, wherein the water-soluble reducing agent is thiourea dioxide or sodium hydrosulfite, and the weight ratio of the water-soluble reducing agent to the alkaline pH adjusting agent is 1:0.3-1.3. The invention also includes a preparation method of heliotropin. The preparation method includes the steps as follows: adding water with weight equivalent to 0.5-5 times that of heliotropin in the heliotropin which is oxidized by nitrate oxidant; adding heliotropin decolorizer with mass concentration of 1-15%; stirring to uniform; heating to full reaction; standing for layering; removing supernatant and water-soluble reducing agent at the bottom layer; and fractionating residua to obtain heliotropin. With the method of the invention, the yield achieves above 85%; while the yield of white heliotropin crystals prepared with other methods is only 65%; and in the invention, the impurities are few, the appearance of the product is good (white crystal instead of faint yellow crystal), odour is intense, and no peculiar smell is generated.

Owner:重庆德馨香料植物开发有限公司

Method for bleaching hair

The invention relates to a method for bleaching hair. The method is characterized by comprising the following steps of: treating colored hair at a low-temperature area for certain time by using alkali solution containing thiourea dioxide to obtain the hair with off-white ground color; adjusting the pH value of the thiourea dioxide solution by using sodium bicarbonate and sodium carbonate; and adjusting the pH value of a bleaching solution to 8-10; wherein the concentration of the thiourea dioxide contained in the bleaching solution is 2-3 g / L, the temperature of the bleaching method is 40-60 DEG C and the heat preservation time lasts for 1-2 hours. By adopting the bleaching method, the bleached hair has lighter residual ground color, higher breaking tenacity, low injury tolerance, excellent handfeel and luster.

Owner:TIANJIN DEK CHEM

Digital printing process of wool fabric

The invention relates to a digital printing process of a wool fabric. The digital printing process comprises the following steps of (1) carrying out low-pressure plasma pretreatment at the power of 250-350W and the pressure of 20-40Pa for at least 5 minutes; (2) adding alkaline slurry, wherein the alkaline slurry comprises 1-4% of sodium alginate, 5-10% of urea, 0.5-3% of anhydrous sodium sulfate, 0.1-1% of thiourea dioxide, 0.1-0.6% of sodium bicarbonate and 0.5-2% of penetrating agent; (3) carrying out spray printing, and drying at the temperature of 45-70 DEG C for at least 2 minutes; (4) steaming for 50-70 minutes, washing and spraying by using cold water with the temperature of lower than 35 DEG C, and washing by using warm water with the temperature of 40-55 DEG C; (5) soaping at the temperature of 70-90 DEG C, wherein a soaping solution comprises 1-4g / L sodium hydrogen phosphate and 1-6g / L soap flakes, and regulating the pH value of the soaping solution to 8.5-9.5 by using ammonia water; and (6) washing by using warm water with the temperature of 40-55 DEG C, washing by using cold water with the temperature of lower than 35 DEG C, and drying. The printed wool fabric prepared by using the process disclosed by the invention is high in color fastness and uniform in pattern color.

Owner:WUXI DONGXIN WEAVING

Reactive dye-white discharge printing paste and preparation method thereof

The invention relates to a reactive dye--white discharge printing paste and a preparation method thereof. The white discharge printing paste comprises the following raw materials by weight: 75 to 80 parts of acrylic acid, 9 to 11 parts of acrylamide, 57 to 62 parts of methacrylic acid, 78 to 82 parts of 2-acrylamide-2-methylacrylsulfonate, 360 to 380 parts of 20 % ammonia, 3.5 to 4.0 parts of ammonium persulfate, 1.9 to 2.6 parts of sodium bisulfite, and 490 to 520 parts of water. The method comprises the following steps: polymerizing all the liquors, adding 114 to 118 parts of starch to the copolymer, pasting, and filtering. As thiourea dioxide is taken as a white discharge agent, a fabric is easy to wash with water after print discharging; and no methanal is left on the fabric, so as tobe more environment-friendly.

Owner:LIAONING FIXED STAR FINE CHEM

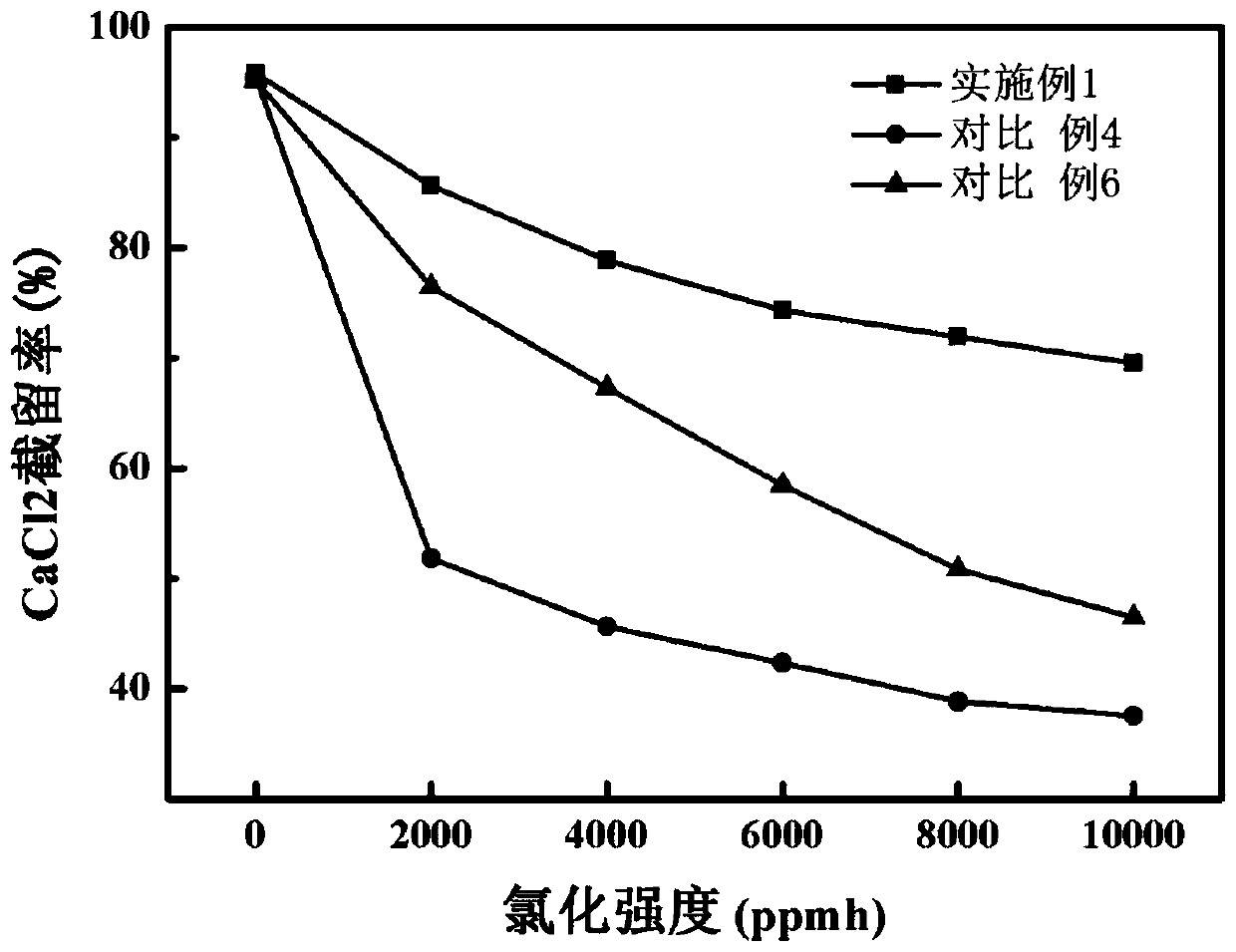

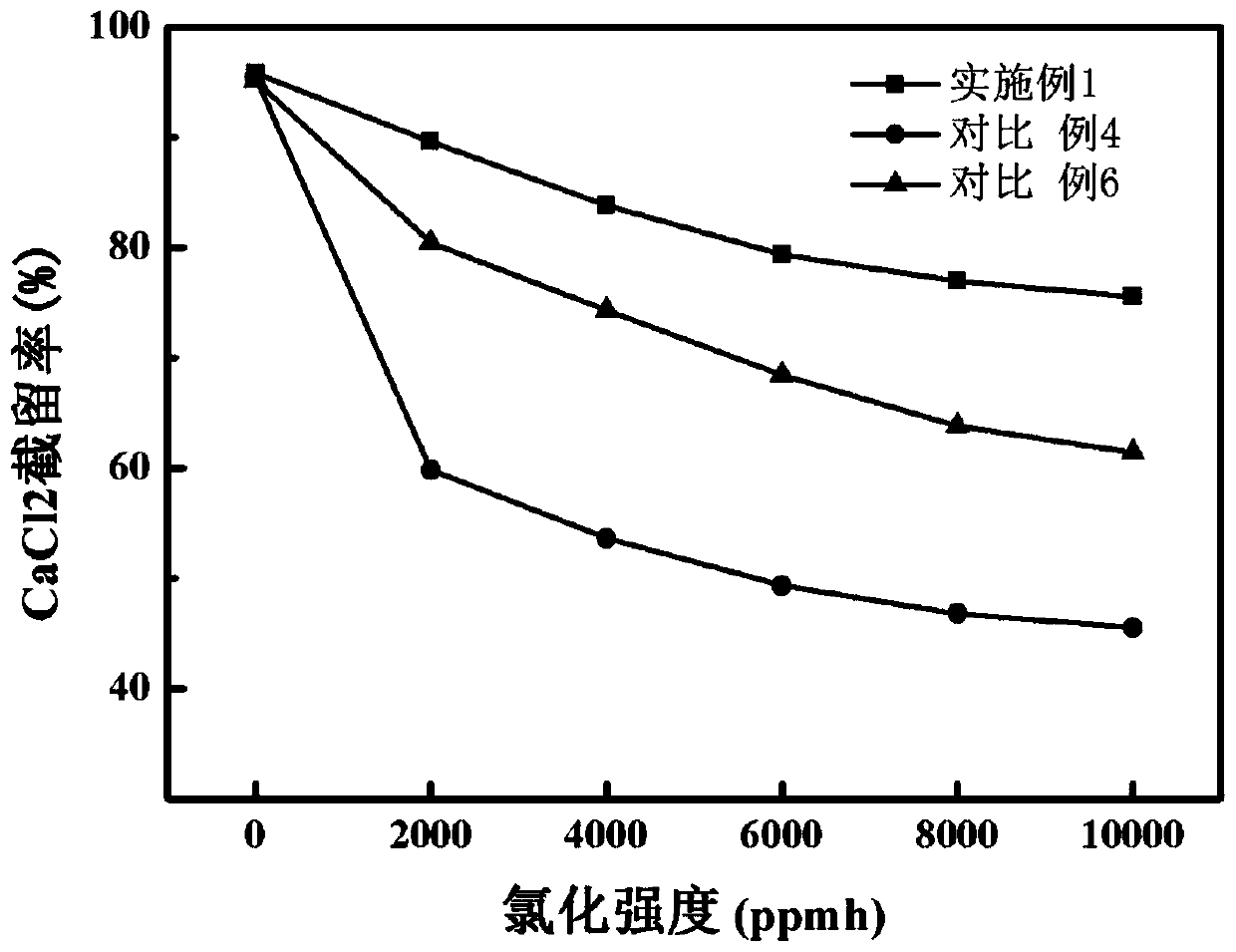

Chlorine-resistant anti-pollution nanofiltration membrane for soft water and preparation method thereof

ActiveCN111514769AImprove chlorine resistanceImprove pollutionMembranesWater/sewage treatment bu osmosis/dialysisPolyvinyl alcoholWater source

The invention provides a chlorine-resistant anti-pollution nanofiltration membrane for soft water and a preparation method of the nanofiltration membrane. The nanofiltration membrane comprises a polysulfone base membrane, and the polysulfone base membrane is sequentially covered with a polypiperazine amide layer and a surface modification layer; wherein the surface modification layer is formed byreacting thiourea dioxide and polyvinyl alcohol on the surface of the polypiperazine amide layer. The nanofiltration membrane has the advantages of a traditional salt separation nanofiltration membrane and has excellent hardness removal capacity and chlorine resistance and anti-pollution performance, the chlorine resistance and anti-pollution performance of the modified nanofiltration membrane areremarkably improved, and the high calcium chloride rejection rate of the nanofiltration membrane can be maintained. The nanofiltration membrane prepared by the invention has a wide application prospect in the field of advanced treatment of municipal drinking water with hard water quality in a water source area or with underground water as a water source.

Owner:WANHUA CHEM GRP CO LTD

Environment-friendly paste discharge agent for textile printing and preparation method thereof

ActiveCN102704292ANon-oxidizingNon-reducibleTransportation and packagingMixingSolubilityTextile printer

The invention discloses an environment-friendly paste discharge agent for textile printing and a preparation method thereof. The environment-friendly paste discharge agent comprises the following components in parts by weight: 30-60 parts of decamethyl cyclopentasiloxane, 40-70 parts of thiourea dioxide, 1-3 parts of surfactant and 3-6 parts of glycerin. The preparation method comprises the steps: putting the decamethyl cyclopentasiloxane into a ball grinder container; adding the surfactant to be uniformly dispersed or dissolved and uniformly agitated; and then adding the thiourea dioxide into the ball grinder container to blend and grind for 1-3 hours. Specific liquid compound decamethyl cyclopentasiloxane as a disperse medium and the thiourea dioxide are not subjected to chemical reaction; With the environment-friendly paste discharge agent provided by the invention, contact of the thiourea dioxide with the external water and air is isolated; the stability of the thiourea dioxide is improved; the discharge effect is excellent; and the problems of low solubility, poor dispersible uniformity in discharge pulp, poor net permeability and insufficient development of the discharge action caused by common thiourea dioxide used as the discharge agent are overcome.

Owner:HAINING GREEN SHIELD TEXTILE TECH CO LTD

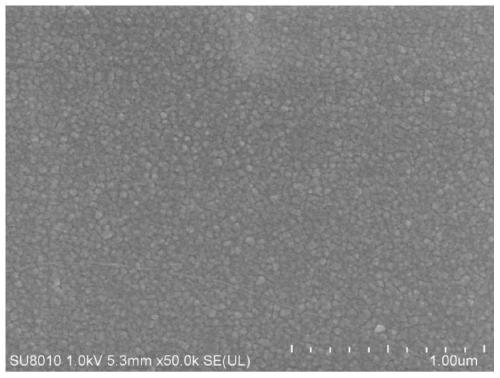

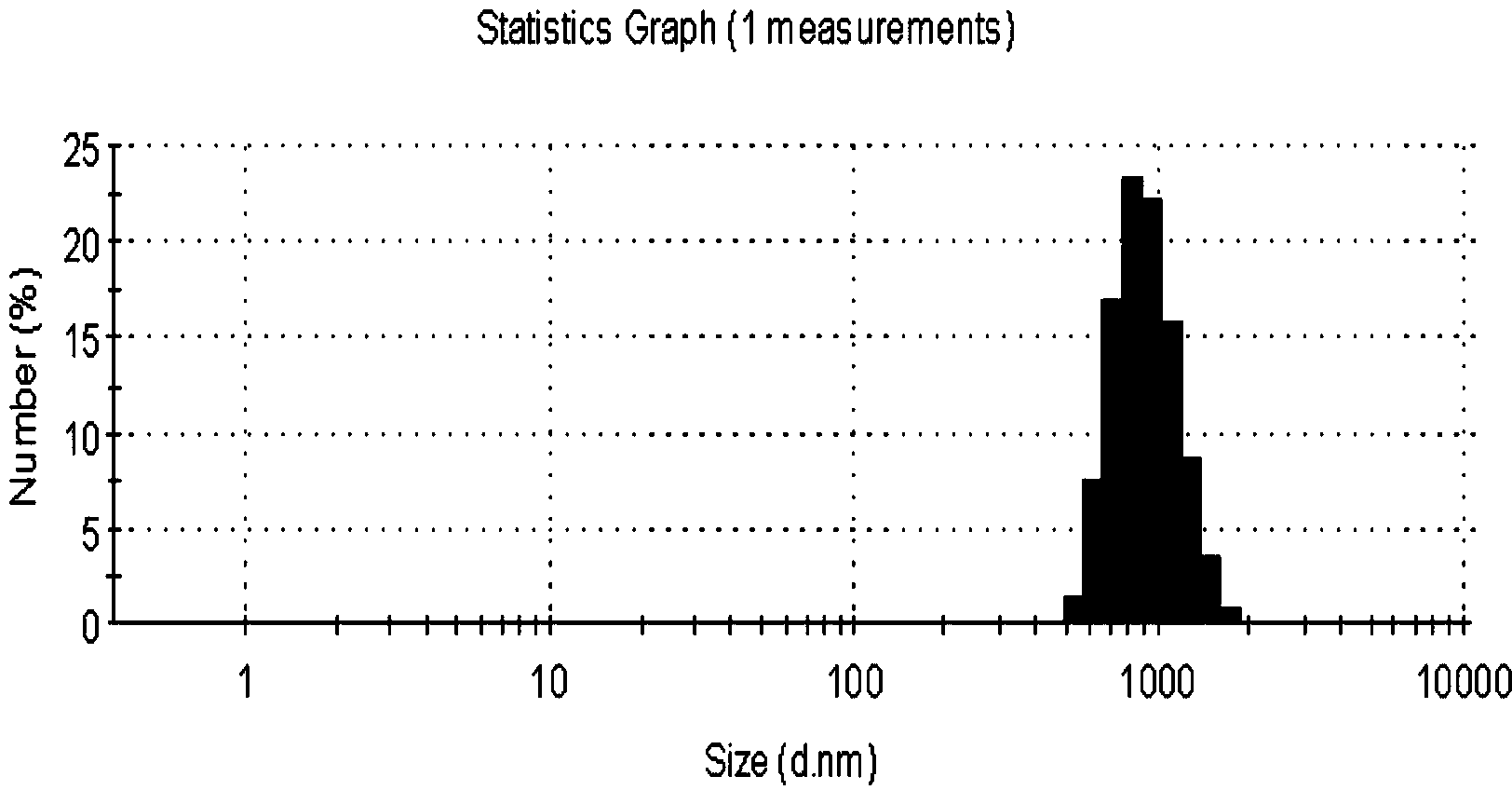

Method for producing ultrafine spherical silver powder for conductive silver paste

The invention relates to a method for producing ultrafine spherical silver powder for conductive silver paste. According to the method, thiourea dioxide is used as reducing agents to reduce silver nitrate, oxidation reaction products of the thiourea dioxide and ampholytic surface active agents are used as scattered protectants, thiourea dioxide solutions with the surface active agents, sodium hydroxide solutions and silver nitrate solutions are added into a reactor at the same time in a parallel flow mode, the molar ratio of raw materials of silver nitrate: thiourea dioxide: sodium hydroxide is controlled to be equal to 1:(0.5-0.7):(2-2.8), the pH of the reaction liquid is maintained to range from 11 to 12, the reaction temperature is maintained to range from 30 DEG C to 60 DEG C, after batch charging is completed, stirring continues, reaction is performed for 0.5 to 1 hour, then the reduction reaction is completed, and the excessive thiourea dioxide is decomposed. The silver powder particles are smooth in surface and spherical, the grain size is uniform, the average grain size is 1.2 micrometers to 2.0 micrometers, the tap density is 4.2-5.0 g / cm<3>, the specific surface area is 0.5-1.2 m<2> / g, and the molar yield is 98 percent to 99.5 percent. According to the method, the technology condition is easy to control, the production process is safe and environmentally friendly, few reducing agents are consumed, and the product quality is stable.

Owner:TIANJIN VOCATIONAL INST

Reductive cleaner used for polyester fabrics

InactiveCN102816656ASurface-active non-soap compounds and soap mixture detergentsDyeing processDisperse dyeAcetic acid

The invention provides a reductive cleaner used for polyester fabrics. The reductive cleaner comprises the following components in mass percentage: 30%-50% of sodium hydroxide; 10%-15% of sodium laurylsulfate; 20%-30% of thiourea dioxide; 15%-20% of sodium alkylsulfonate; 1.5%-4% of tetrasodium ethylenediamine tetraacetate and 1%-3% of polyvinyl pyrrolidine PVP-K. The reductive cleaner used for polyester fabrics can be used in the dyeing process of disperse dyes for polyester fabrics and can clean the flooding and oligomers on the surface of the polyester fabrics more cleanly, so that the fabrics have a more ideal color fastness.

Owner:太仓市璜泾飞达制衣厂

Denim discharge printing color paste and preparation method thereof

InactiveCN102418295AExcellent fastness performanceImprove discharge effectDyeing processTextile printerHazardous substance

The invention which provides a denim discharge printing color paste and a preparation method thereof relates to the technical field of textile printing and dyeing, and especially relates to a denim printing color paste and a preparation method thereof. The printing color paste comprises, by weight, 5-11% of a dye, 10-20% of a color fixing agent, 4-9% of a discharging agent, 30-45% of a thickener, and the balance water, wherein the color fixing agent is obtained by blending chitin, a high performance penetrant OP-6, fatty alcohol polyoxyethylene ether and water; the discharging agent is thiourea dioxide or stannous chloride; and the thickener is a protoplasm containing 7-10% of sodium alginate or a protoplasm containing 7-10% of guar. The printing color paste of the invention has the advantages of simple process flow, multiple printing pattern kind, washing resistance, difficult fading, and no containment of harmful substances in the environment friendly raw materials selected by the printing color paste, so the printing color paste has positive meanings to the environment protection.

Owner:DAFENG HAILONG CHEM

Compound reducing agent and reduction dyeing method

ActiveCN110453510AThe reduction potential value is stableSlow decomposition rateDyeing processTrichloroacetic acidSodium nitrite

The invention discloses a compound reducing agent with a stable chemical potential and not containing sodium hydrosulfite. The compound reducing agent is prepared from, by weight, 30-75% of thiourea dioxide, 60-20% of reducing sugar and 10-5% of one of sodium nitrite, acrylamide, furfural, cyclohexanone and trichloroacetic acid in a chemical potential control agent. By using the compound reducingagent, the dyeing process combining the pretreatment with the dyeing procedure is achieved, the treatment time is reduced, the production efficiency is improved, the dyed finished product is dyed uniformly, and the strength and hand feeling are improved.

Owner:李瑞卿 +2

Process for preparing still release agent

The present invention relates to the preparation of chemical product, and especially the preparation process of chemical assistant for polyvinyl chloride resin production. The still release agent is prepared with thiourea dioxide as reducing decolorant and through the condensation of 1-naphthol and formaldehyde under alkali environment. The preparation process is simple and low in cost, and the prepared still release agent has high still releasing capacity and no coloring.

Owner:JIANGSU JIAHUA ADVANCED MATERIALS TECH

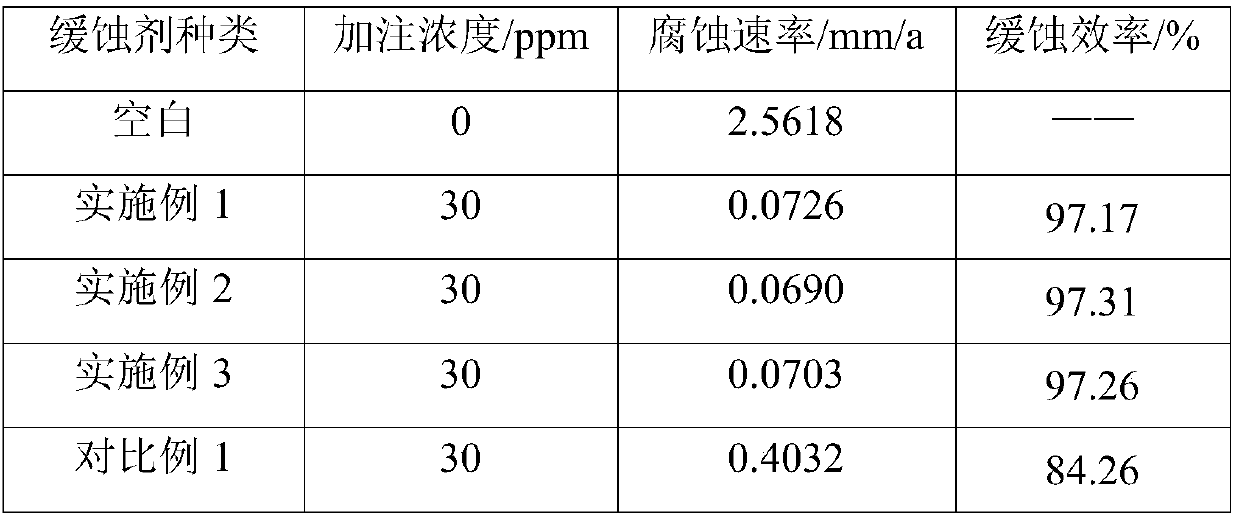

Compound corrosion inhibitor with corrosion inhibiting effect as well as preparation method and application of compound corrosion inhibitor

ActiveCN107629777AAvoid corrosionHarm reductionOrganic chemistryBorehole/well accessoriesSolubilityOrganic solvent

The invention provides a compound corrosion inhibitor with a corrosion inhibiting effect as well as a preparation method and an application of the compound corrosion inhibitor. In terms of total amount of 100%, the compound corrosion inhibitor is prepared from components as follows: 10wt.%-50wt.% of tall oil acid imidazoline quaternary ammonium salt, 10wt.%-30wt.% of a surfactant, 2wt.%-5wt.% of thiourea dioxide, 2wt.%-6wt.% of pyrophosphate, 10wt.%-70wt.% of an organic solvent and 0-30wt.% of water. The corrosion inhibitor is prepared from organic components and inorganic components by compounding, the organic components and the inorganic components achieve a synergistic corrosion inhibition effect, and corrosion of CO2 and H2S can be effectively inhibited; the compound corrosion inhibitor is good in water solubility, free of emulsification tendency and non-toxic, and can be used for preventing and treating corrosion of CO2 and H2S in an oil field system; the corrosion inhibitor has the advantages of small addition amount, low cost and small environmental harm.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method for recycling ultrafine copper powder from waste liquid containing complexing copper

ActiveCN103506632AImprove thermal conductivityImprove self-healing abilityRecovery methodLiquid waste

The invention discloses a method for recycling ultrafine copper powder from waste liquid containing complexing copper, and belongs to the technical field of chemical engineering recycling. According to the technical scheme, the method for recycling the ultrafine copper powder from waste liquid containing the complexing copper comprises the steps of adding a pvp dispersing agent in the waste liquid containing the copper, then adding glucose and NaOH, conducting heating and stirring to conduct a prereduction reaction, after the reaction, adding thiourea dioxide, conducting heating and stirring to conduct a reduction reaction, after the reaction is finished, conducting filtering, conducting washing for two times, conducting ethyl alcohol washing for two times, conducting vacuum drying, and obtaining the ultrafine copper powder. According to the method for recycling the ultrafine copper powder, the copper removal rate is 99%, the granularity of the recycled and obtained ultrafine copper powder can be 700nm-1500nm, the purity of the produced copper powder can be more than 99.95%, and the prepared ultrafine copper powder is applied to a plurality of fields of conducting resin, conductive coatings, conductive composite material raw materials, high-performance catalysts, lubricant additives, nanocrystalline copper, medicines and the like.

Owner:JINAN UNIVERSITY

Method of preparing graphene through chemical reduction method

The invention relates to a method of preparing graphene through a chemical reduction method, belongs to the field of preparation of nano carbon materials and aims to provide a chemical method of preparing the graphene, wherein the method is simple and efficient and free from pollution to environment. A raw material is oxidized graphene synthesized through a Hummers oxidation method. Under catalysis of alkali, reducing agent thiourea dioxide is added and is stirred for 0.5-4 hours, and then the graphene is obtained. After a reaction is completed, graphene products are obtained through suction filtration, washing and drying. The thiourea dioxide and the alkali used in the method of preparing the graphene through the chemical reduction method is low in cost and low in toxicity, organic solvent is not used, the reaction condition is moderate, simple and easy to operate, and the method of preparing the graphene through the chemical reduction method is prone to industrialized application.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Compostion for rust removal and method of removing rust with the same

InactiveUS20040102344A1Inorganic/elemental detergent compounding agentsOrganic detergent compounding agentsWater solubleAqueous medium

A composition for rust removal which is highly effective in removing rust. The composition is a water-soluble composition which comprises a basic compound, a water-soluble metal chelating agent, and thiourea dioxide and which, when dissolved in an aqueous medium, gives an alkaline solution.

Owner:AMTEC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com