Method of preparing graphene through chemical reduction method

A graphene, reduction technology, applied in graphene, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problems of high toxicity of reagents, harsh reaction conditions, difficult to remove oxidation products, etc. Simple, low reaction temperature, low toxicity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

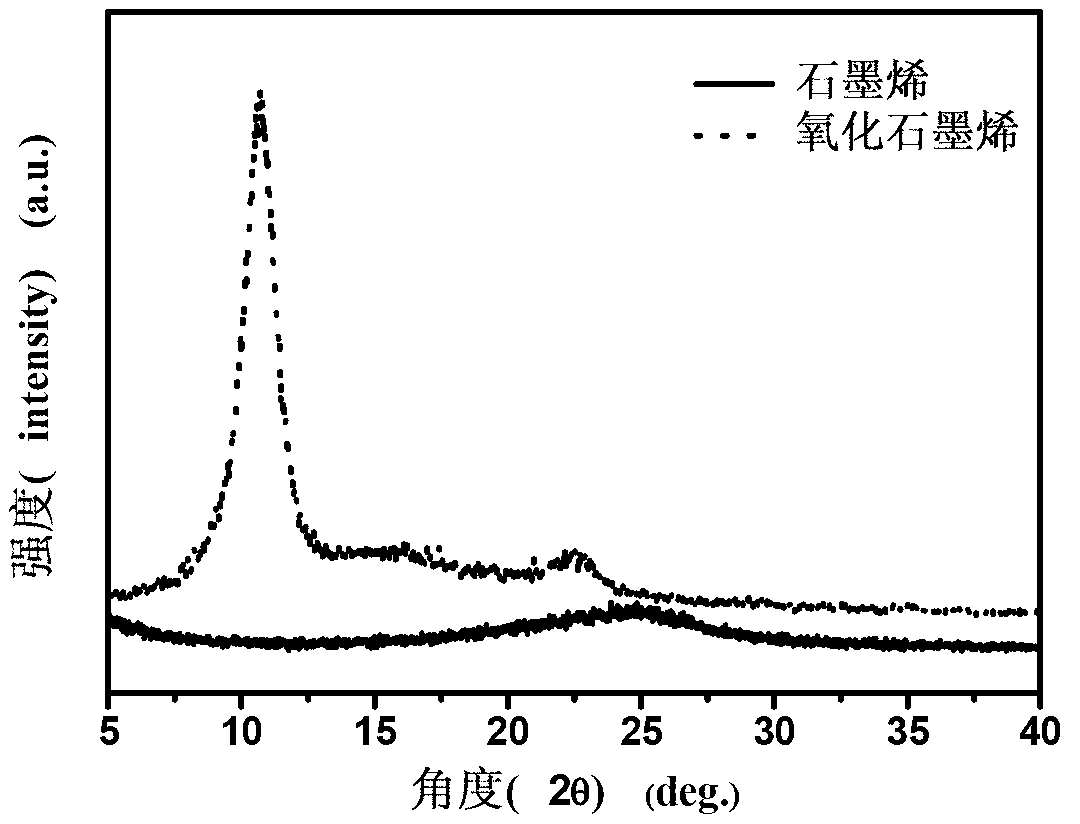

[0022] (1) Preparation of graphene oxide

[0023] Heat 16 mL of 98% concentrated sulfuric acid to 80 °C, add 3.5 g of potassium peroxodisulfate and 3.5 g of phosphorus pentoxide, and then slowly add 4 g of flake graphite, and the mixture reacts at 80 °C for 6 h, and the reaction ends Cool to room temperature, then add 600 mL of deionized water, filter and wash with deionized water to obtain expanded graphite.

[0024] Add expanded graphite to 160 mL of concentrated sulfuric acid, then add 20 g of potassium permanganate under mechanical stirring, react at 40 °C for 6 h after the addition, and then react for another 2 h at room temperature. After the reaction is completed, add 160 mL of deionized water; react at room temperature for 2 h after adding water, then add 500 mL of water and 10 mL ~20 mL of 30 wt% hydrogen peroxide solution until the solution turns bright yellow. The solution was allowed to stand, the supernatant was poured off, and the remaining suspension was centri...

Embodiment 2

[0030] (1) The preparation of graphene oxide is the same as in Example 1.

[0031] (2) Reduction of graphene oxide

[0032] Take 10 mL of the graphene oxide solution obtained in step (1), add it to a 50 mL round bottom flask, then add 100 mg sodium hydroxide, 150 mg thiourea dioxide, dilute to 25 mL with deionized water, stir at room temperature, the color of the solution Gradually from brown to black, after 1 h the reaction was completed, washed with deionized water three times, and dried at room temperature to obtain graphene.

Embodiment 3

[0034] (1) The preparation of graphene oxide is the same as in Example 1.

[0035] (2) Reduction of graphene oxide

[0036] Take 10 mL of the graphene oxide solution obtained in step (1), put it into a 50 mL round bottom flask, then add 600 mg of sodium carbonate, 160 mg of thiourea dioxide, dilute to 25 mL with deionized water, stir at room temperature, the color of the solution gradually From brownish yellow to black, the reaction was completed after 2 h, washed with deionized water three times, and dried at room temperature to obtain graphene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com