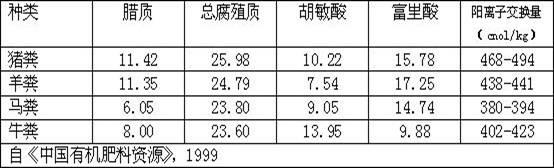

Patents

Literature

19621results about How to "Promote degradation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

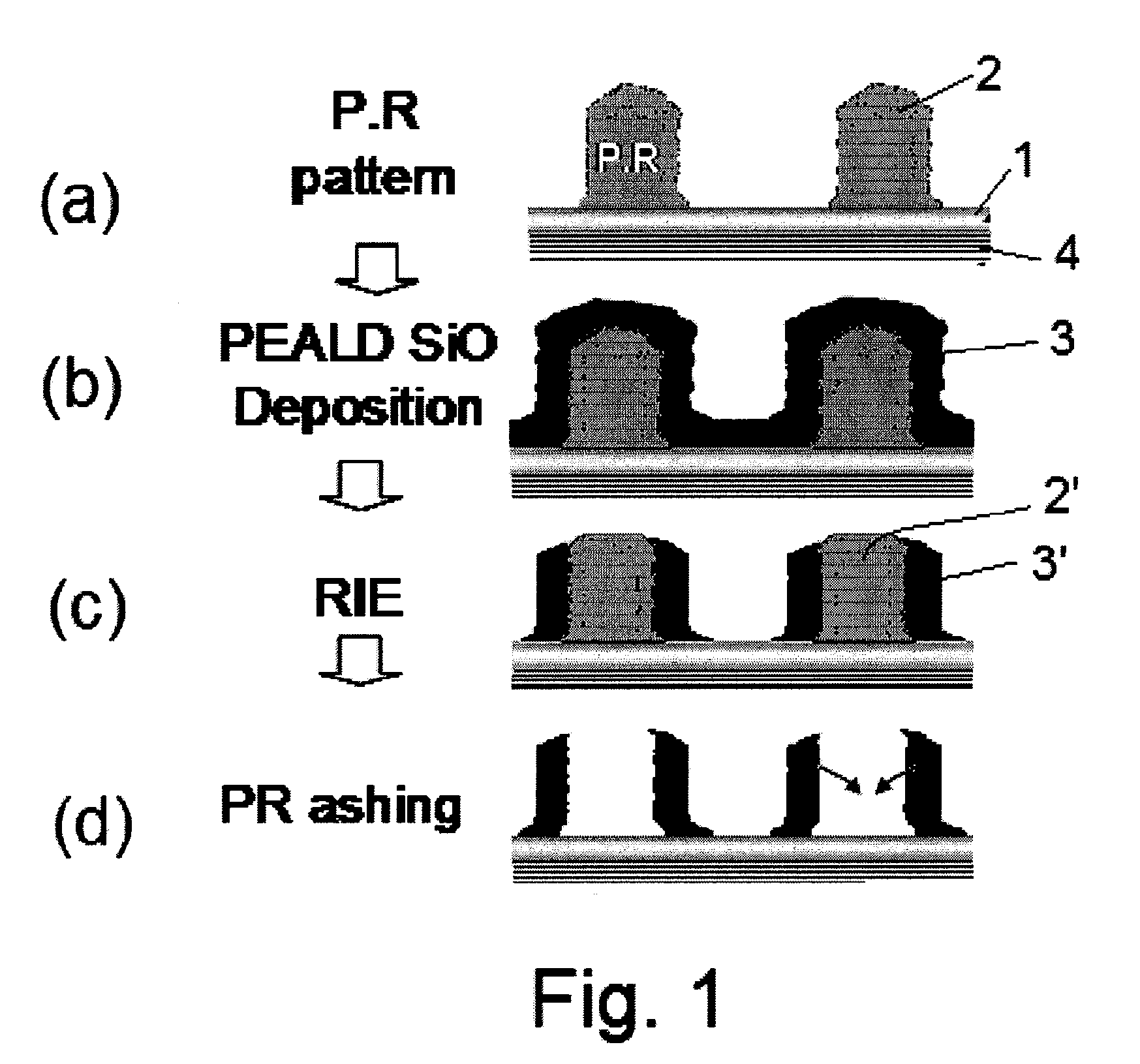

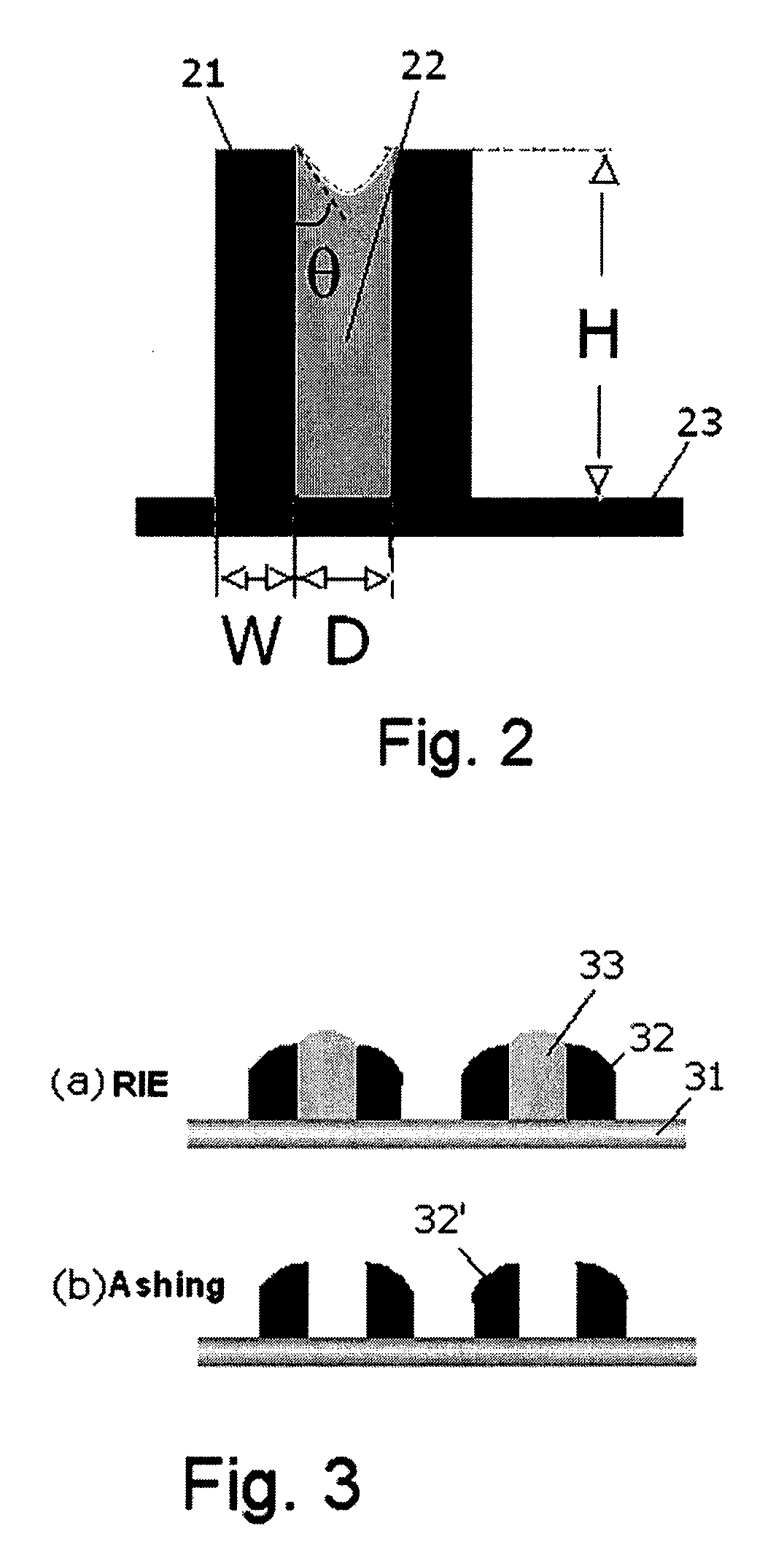

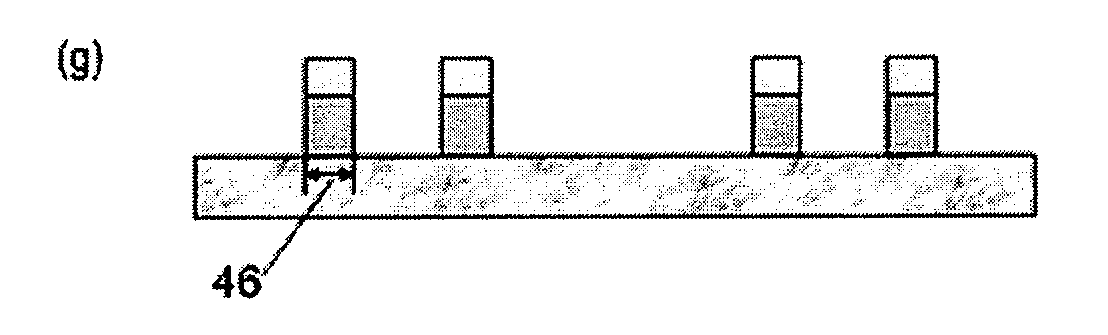

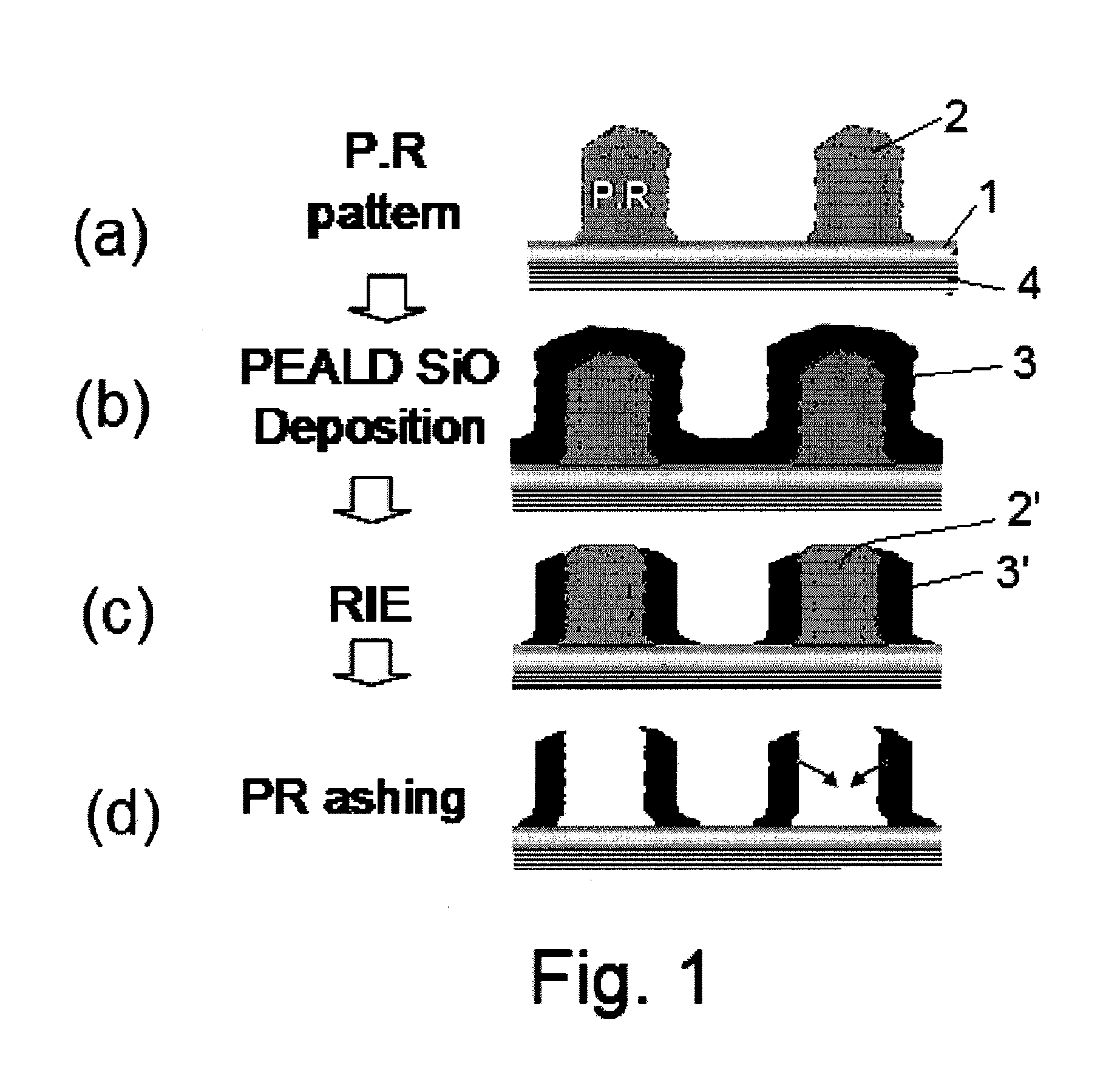

Method of forming metal oxide hardmask

ActiveUS8901016B2Promote degradationSemiconductor/solid-state device manufacturingOriginals for photomechanical treatmentAtomic layer depositionMetal

Owner:ASM JAPAN

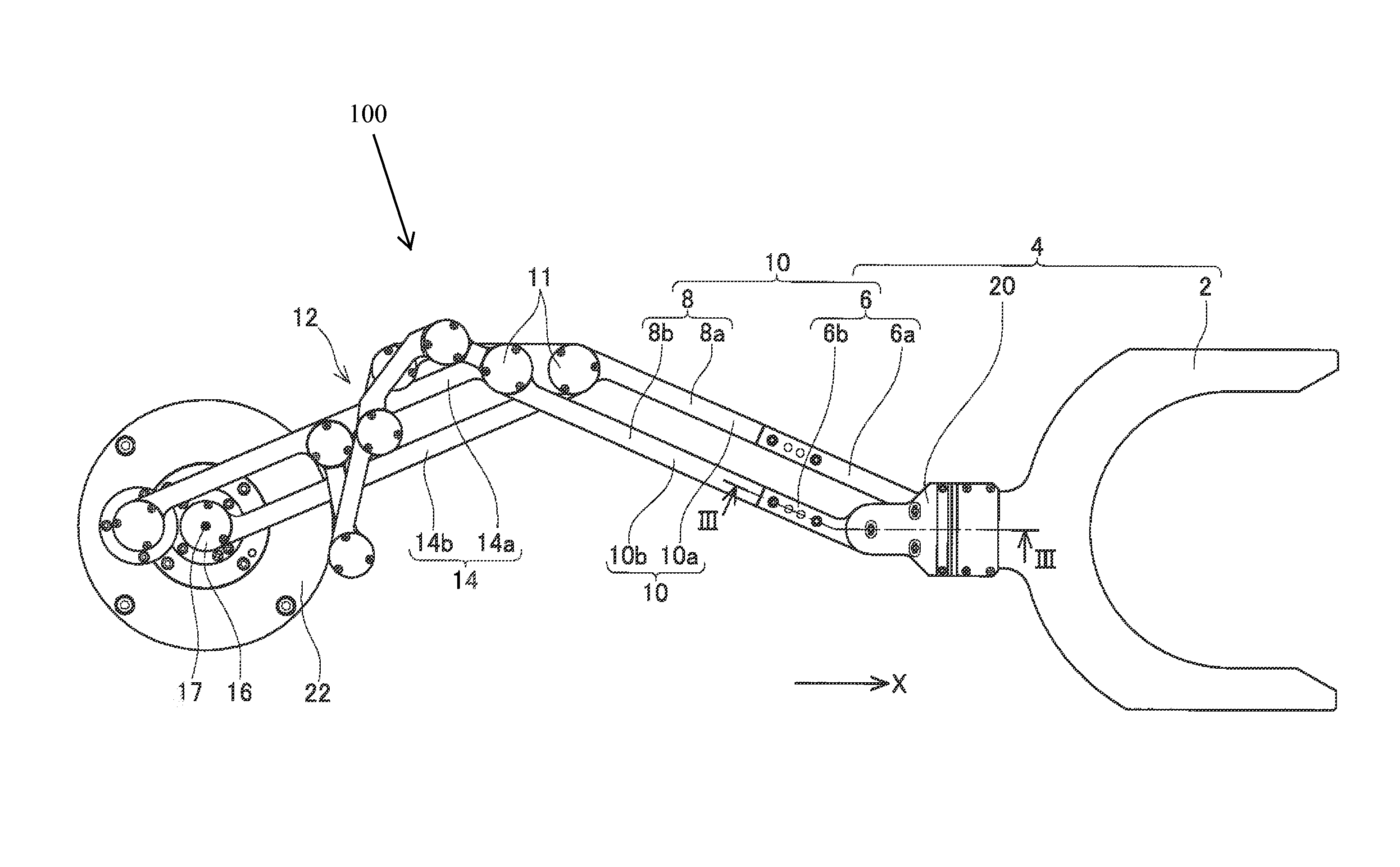

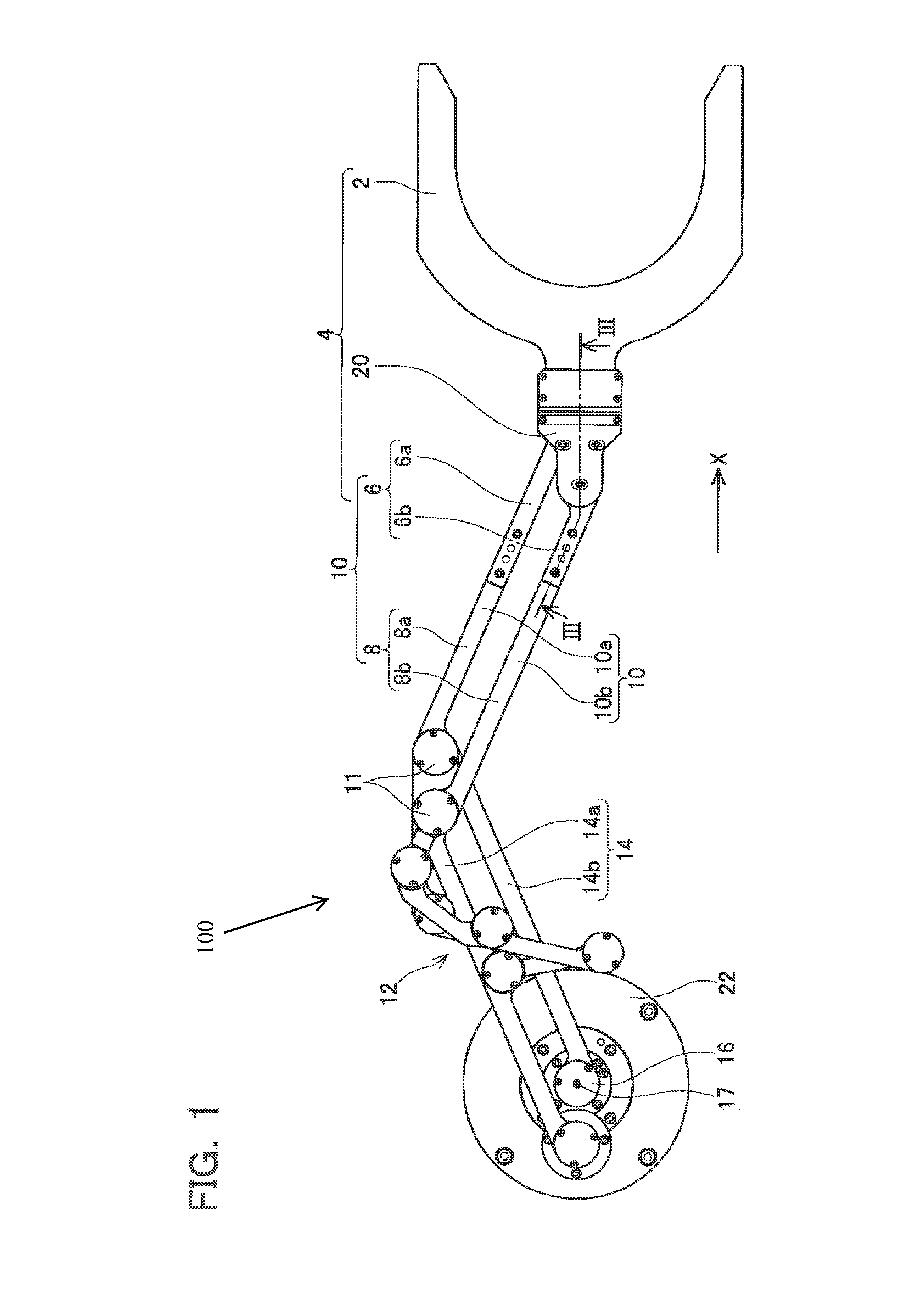

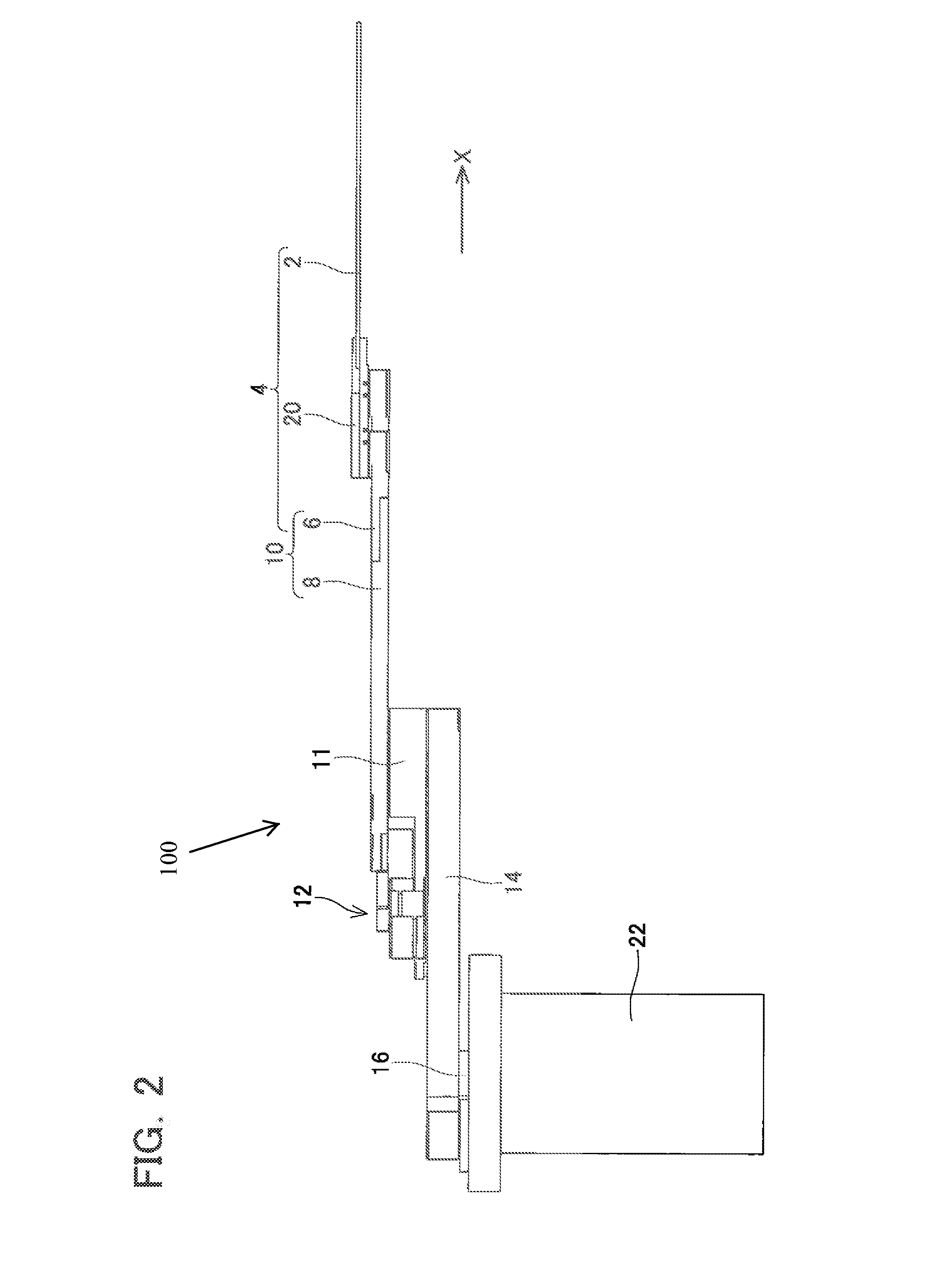

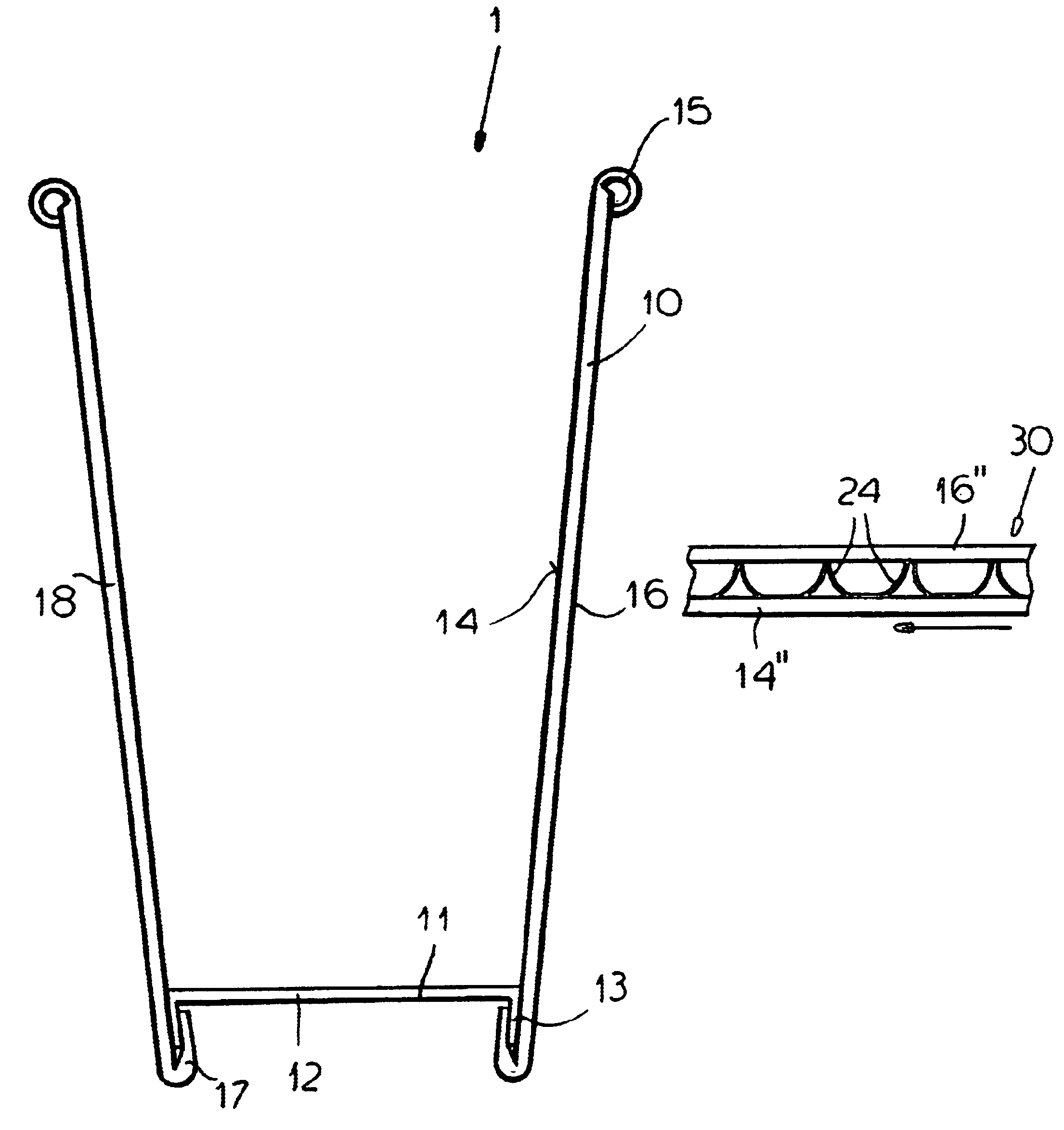

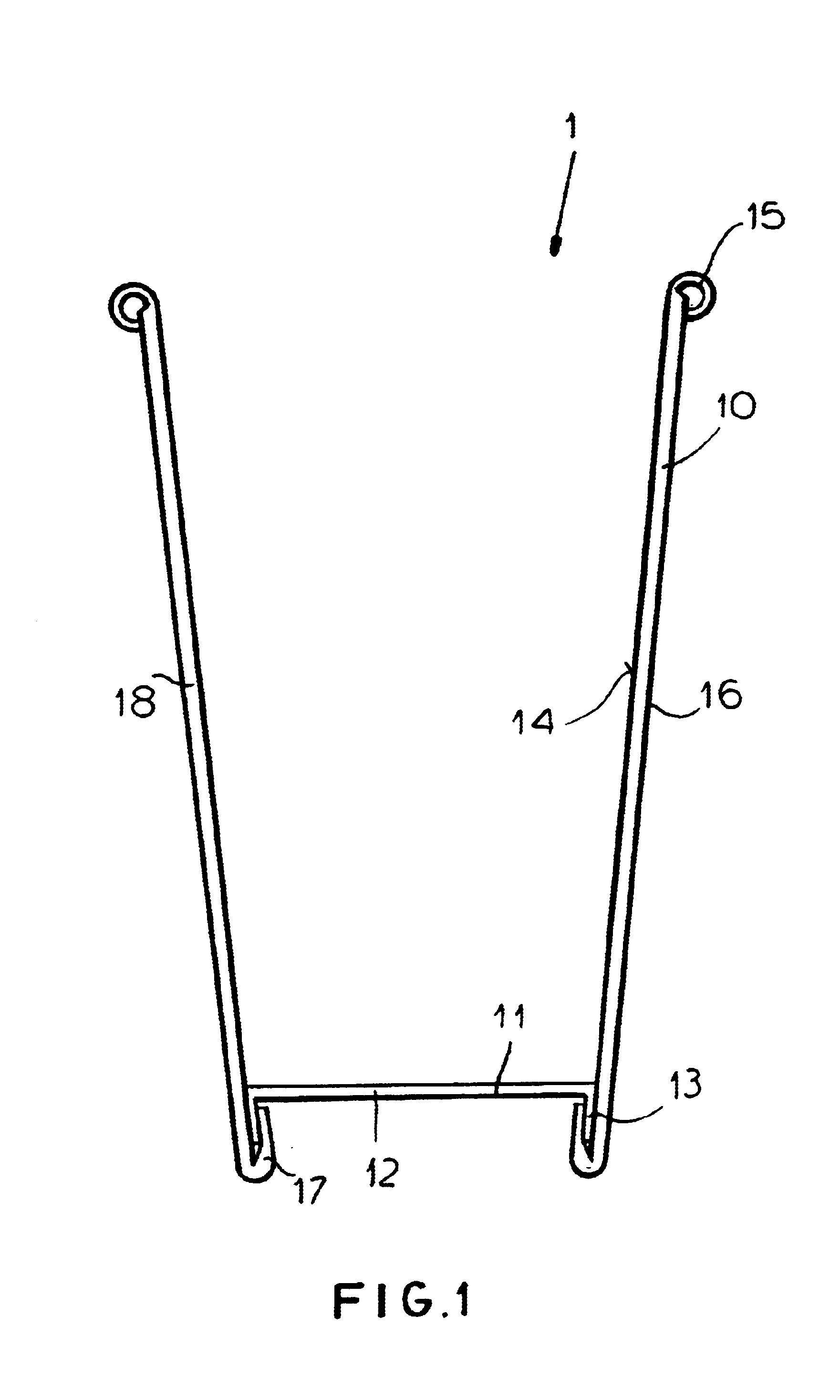

Robot arm

ActiveUS20130084156A1Precise positioningPollution suppressionProgramme-controlled manipulatorSemiconductor/solid-state device manufacturingPhysical medicine and rehabilitationWafering

The robot arm of the present application is a robot arm that transports semiconductor wafers. The robot arm includes a hand, a lower arm link, and an upper arm link. The hand is connected to the lower arm link via a first joint. The upper arm link is connected to the lower arm link via a second joint. In the robot arm of the present application, the lower arm link is capable of being separated at a location between the first joint and the second joint.

Owner:NABLESCO CORP

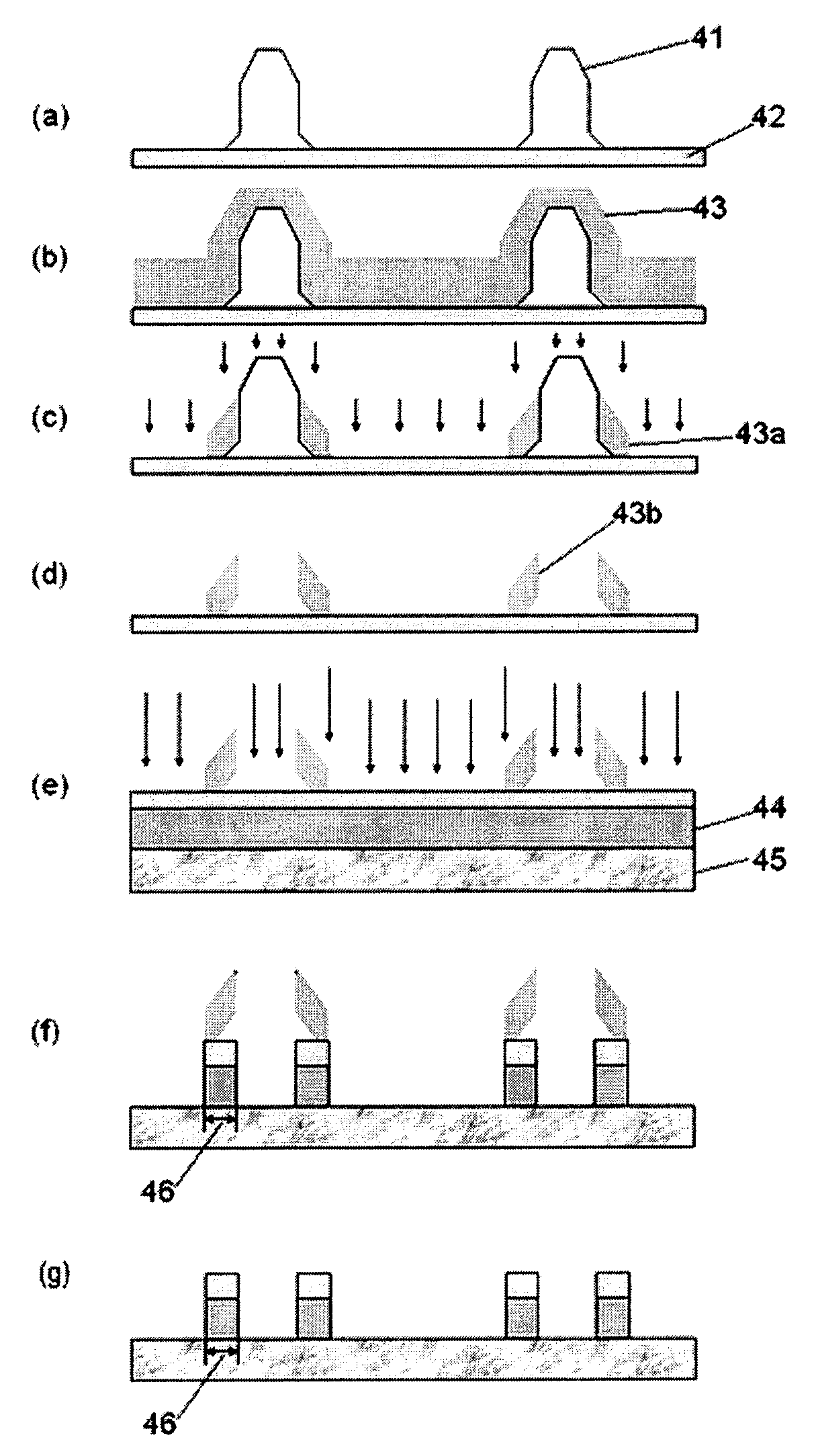

Method of Forming Metal Oxide Hardmask

ActiveUS20120164846A1Promote degradationSemiconductor/solid-state device manufacturingOriginals for photomechanical treatmentAtomic layer depositionMetal

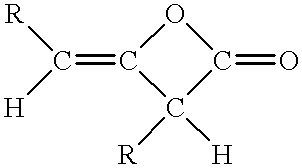

A method of forming a metal oxide hardmask on a template includes: providing a template constituted by a photoresist or amorphous carbon formed on a substrate; and depositing by atomic layer deposition (ALD) a metal oxide hardmask on the template constituted by a material having a formula SixM(1-x)Oy wherein M represents at least one metal element, x is less than one including zero, and y is approximately two or a stoichiometrically-determined number.

Owner:ASM JAPAN

Compositions and methods for manufacturing thermoplastic starch blends

InactiveUS6235816B1Improved chemical and physical propertyPromote degradationFireproof paintsPaper coatingPolyesterPolymer science

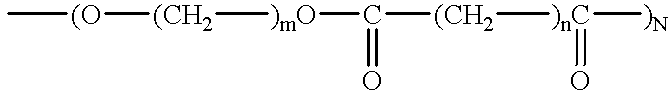

A biologically degradable polymer mixture containing at least one biopolymer made from renewable raw materials and a polymer selected from the following materials: an aromatic polyester; a polyester-copolymer with both aliphatic and aromatic blocks; a polyesteramide; a polyglycol; a polyester urethane; and / or mixtures of these components. The preferred renewable raw material is starch, more preferably native starch, most preferably native starch that has been predried.

Owner:BIO TEC BIOLOGISCHE NATURVERPACKUNGEN

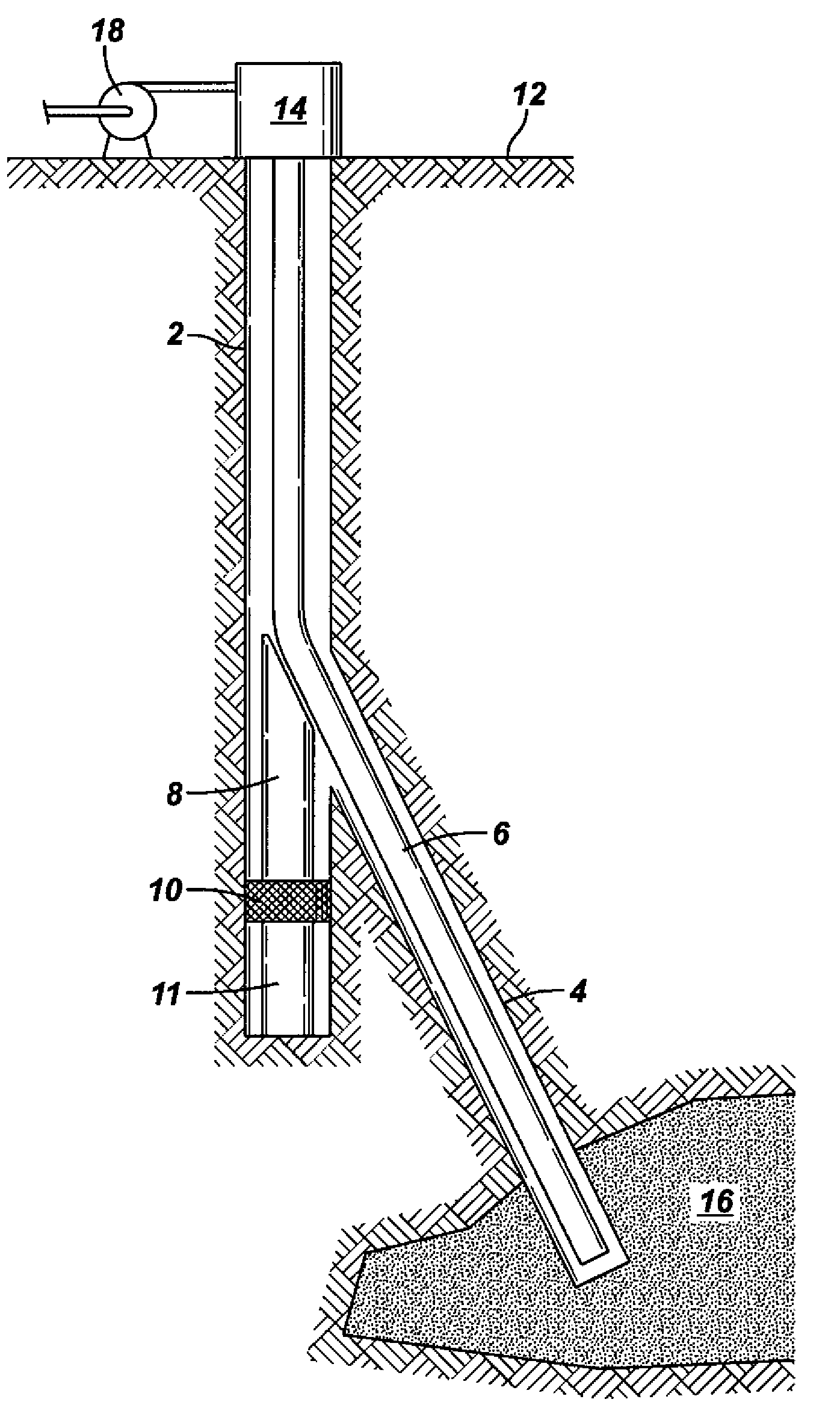

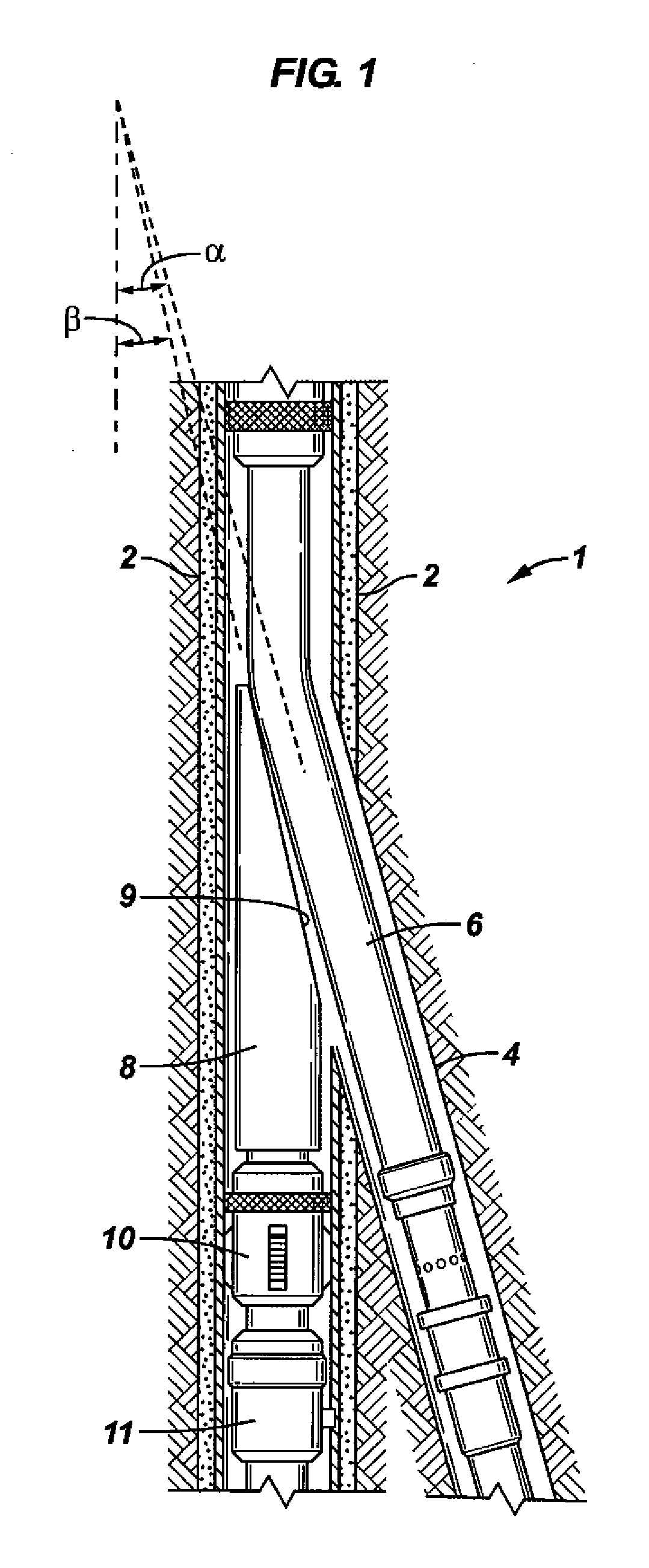

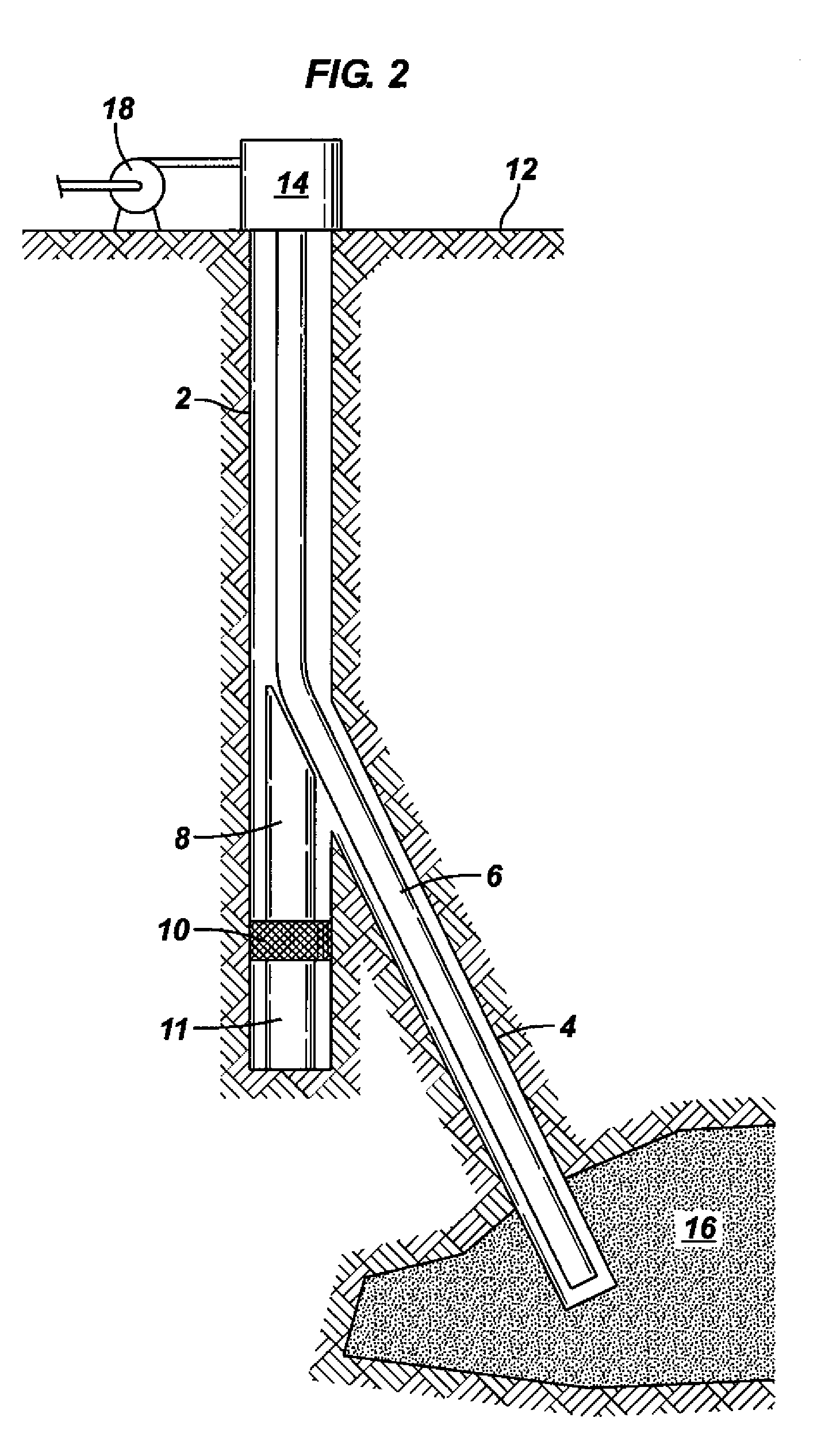

Degradable whipstock apparatus and method of use

InactiveUS20080105438A1Improve responseSafe handlingFluid removalDirectional drillingSubject matterHigh intensity

Whipstocks and deflectors comprising a degradable composition, and methods of using same are described. In one embodiment the degradable composition consists essentially of one or more reactive metals in major proportion, and one or more alloying elements in minor proportion, with the provisos that the composition is high-strength, controllably reactive, and degradable under defined conditions. Methods of using degradable whipstocks in oilfield operations are also described. This abstract allows a searcher or other reader to quickly ascertain the subject matter of the disclosure. It will not be used to interpret or limit the scope or meaning of the claims. 37 C.F.R. 1.72(b).

Owner:SCHLUMBERGER TECH CORP

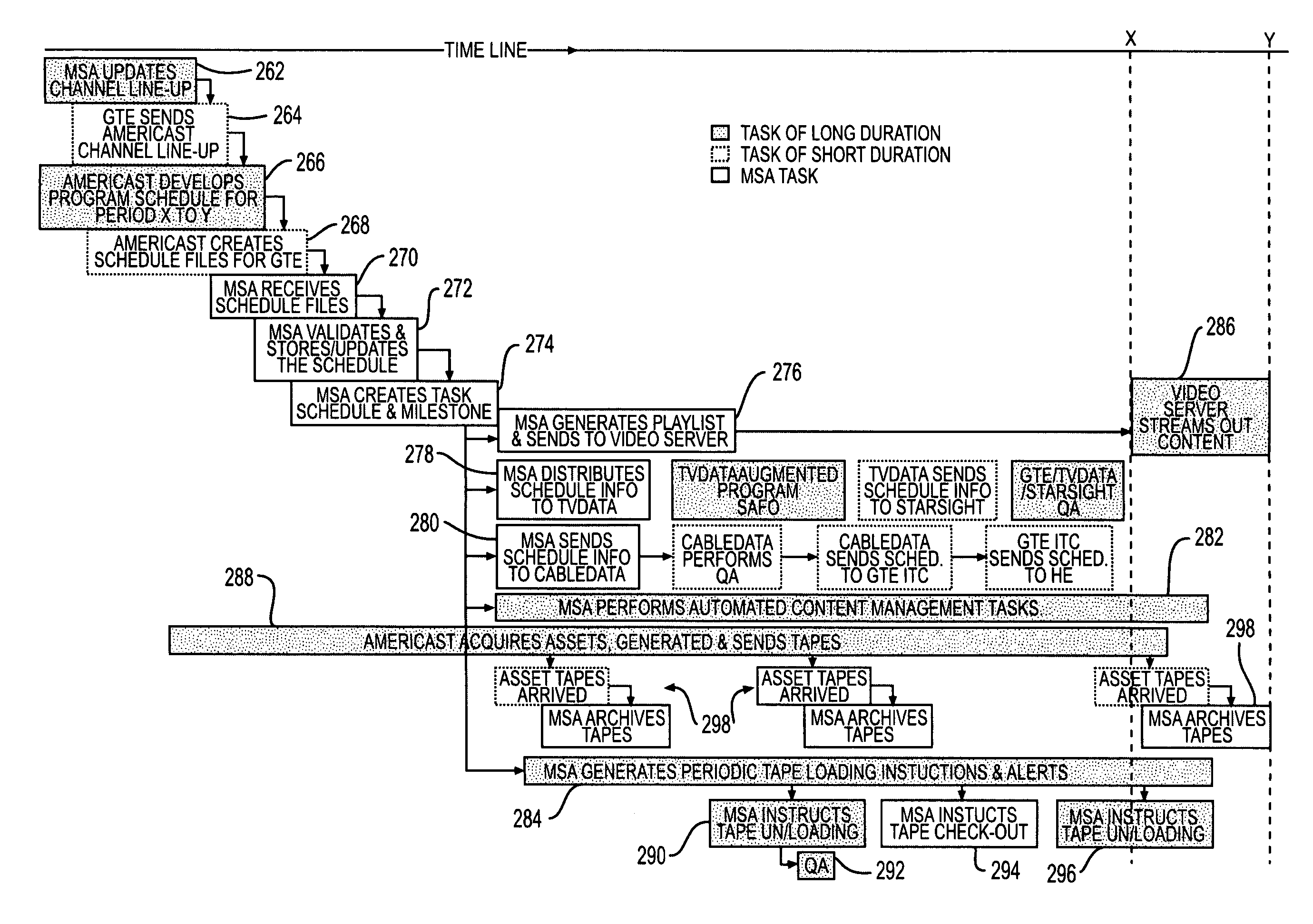

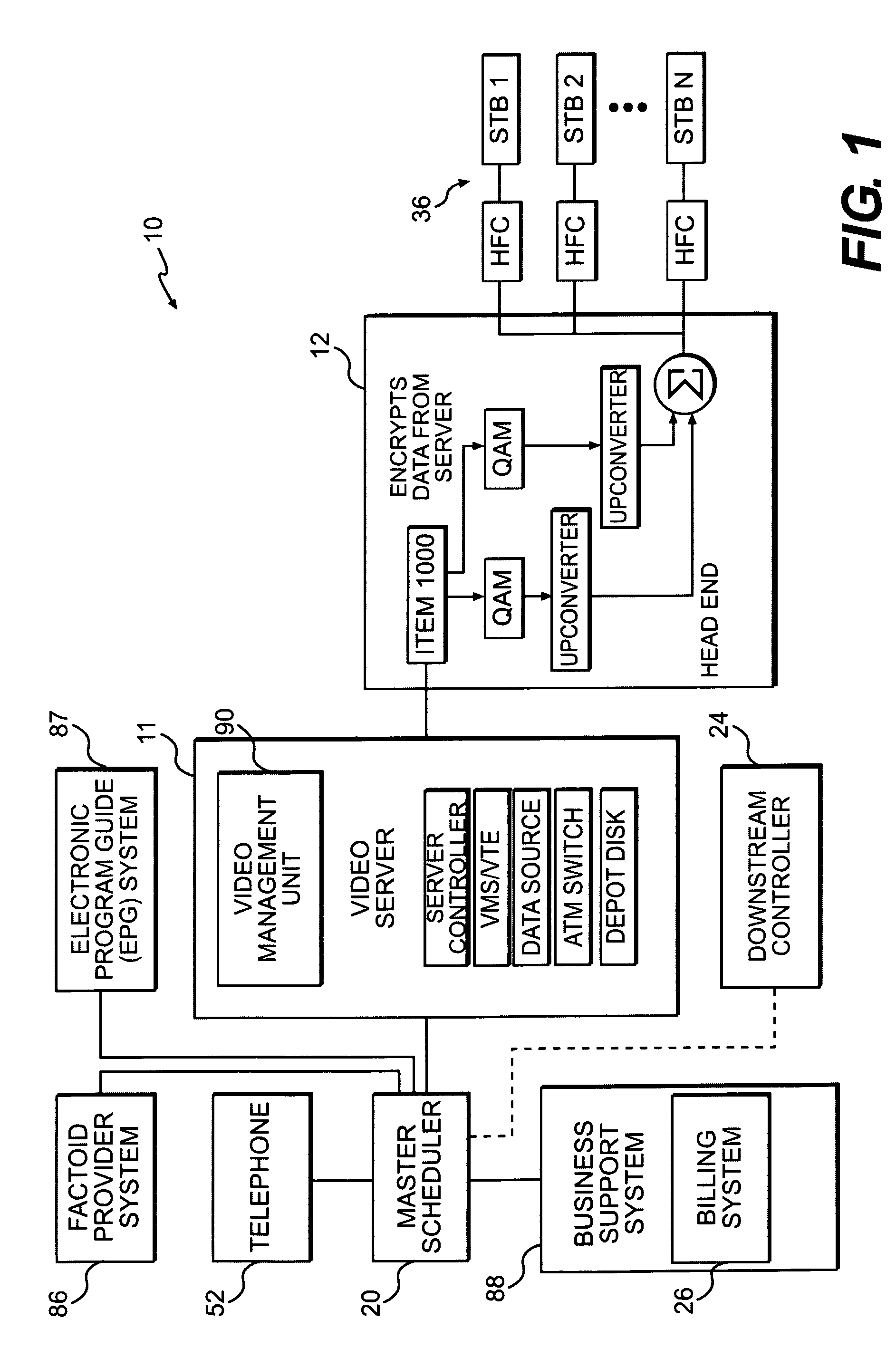

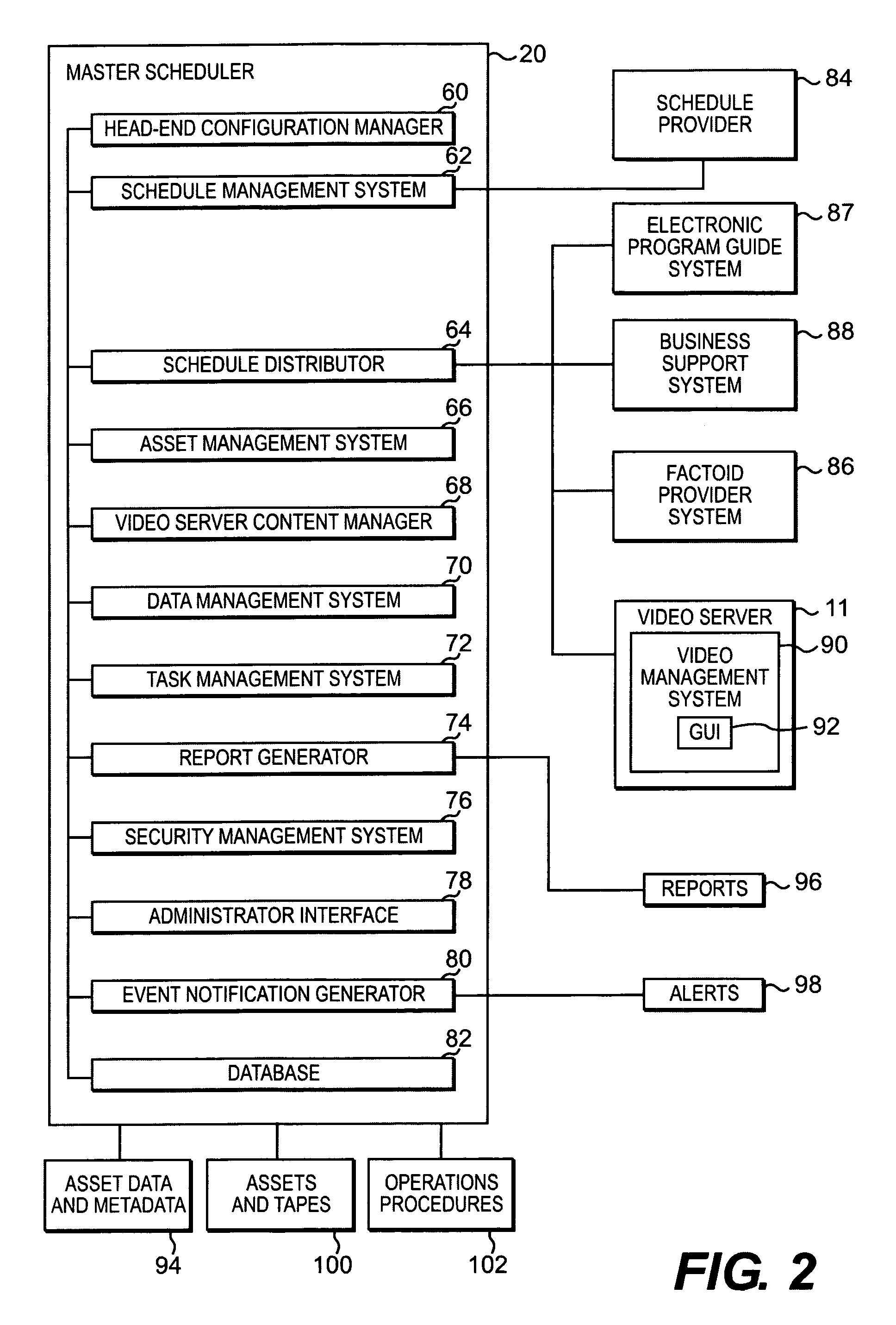

Method and apparatus for near video on demand

InactiveUS7024681B1Easy to implementEnsure consistencyAnalogue secracy/subscription systemsRecord information storageNear video on demandRelevant information

A master scheduler system and method automatically operate and / or coordinate operation of a plurality of relatively independent systems, including manual systems, to function as an NVOD system to provide automating diverse operations for supporting and maintaining an NVOD system. The master scheduler system and method may also be applied to automate manual processes of analog-based and digital broadcast based service. The master scheduler receives, processes, and disseminates NVOD schedule-related information for end-to-end NVOD service; that is, sending video from a back-end which stores video data to a head-end for viewing by a user. The master scheduler also provides operations support for the NVOD system, such as maintaining the head-end configuration, allocating channels, performing asset management, performing content management, etc. The master scheduler provides validation of scheduling information by comparing information such as programmed schedules, asset metadata, and data obtained by measuring asset parameters, for example duration.

Owner:VERIZON LAB

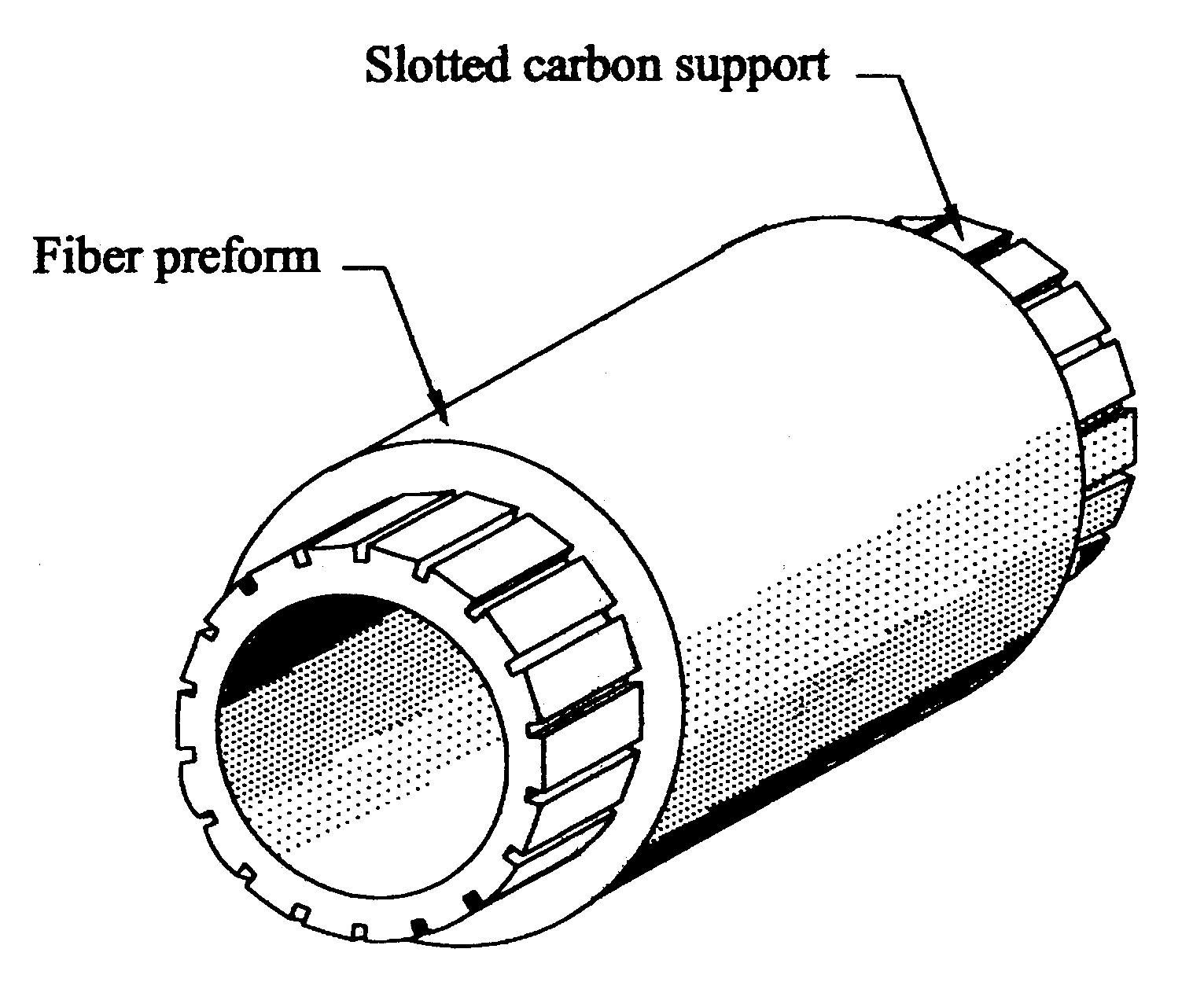

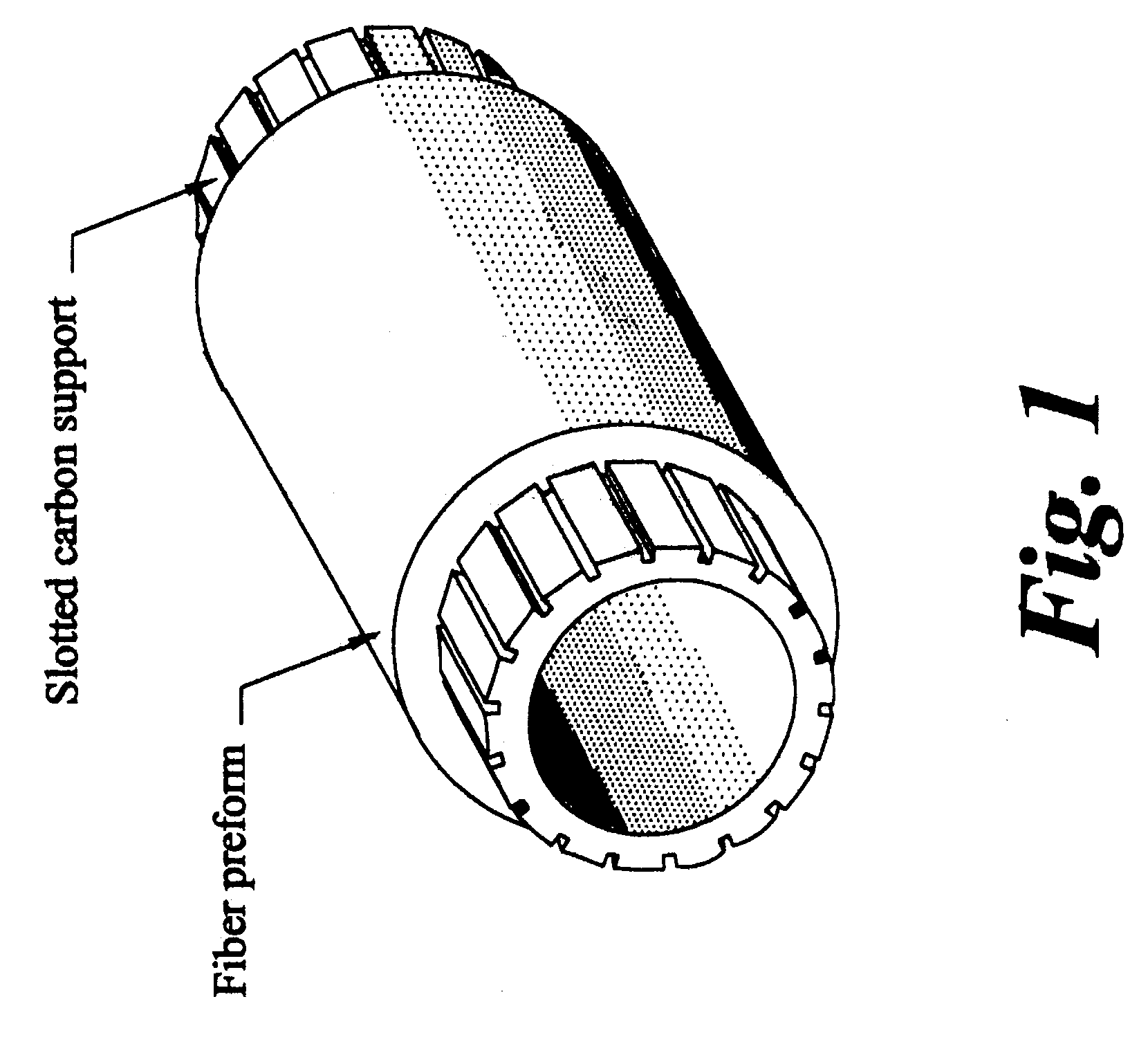

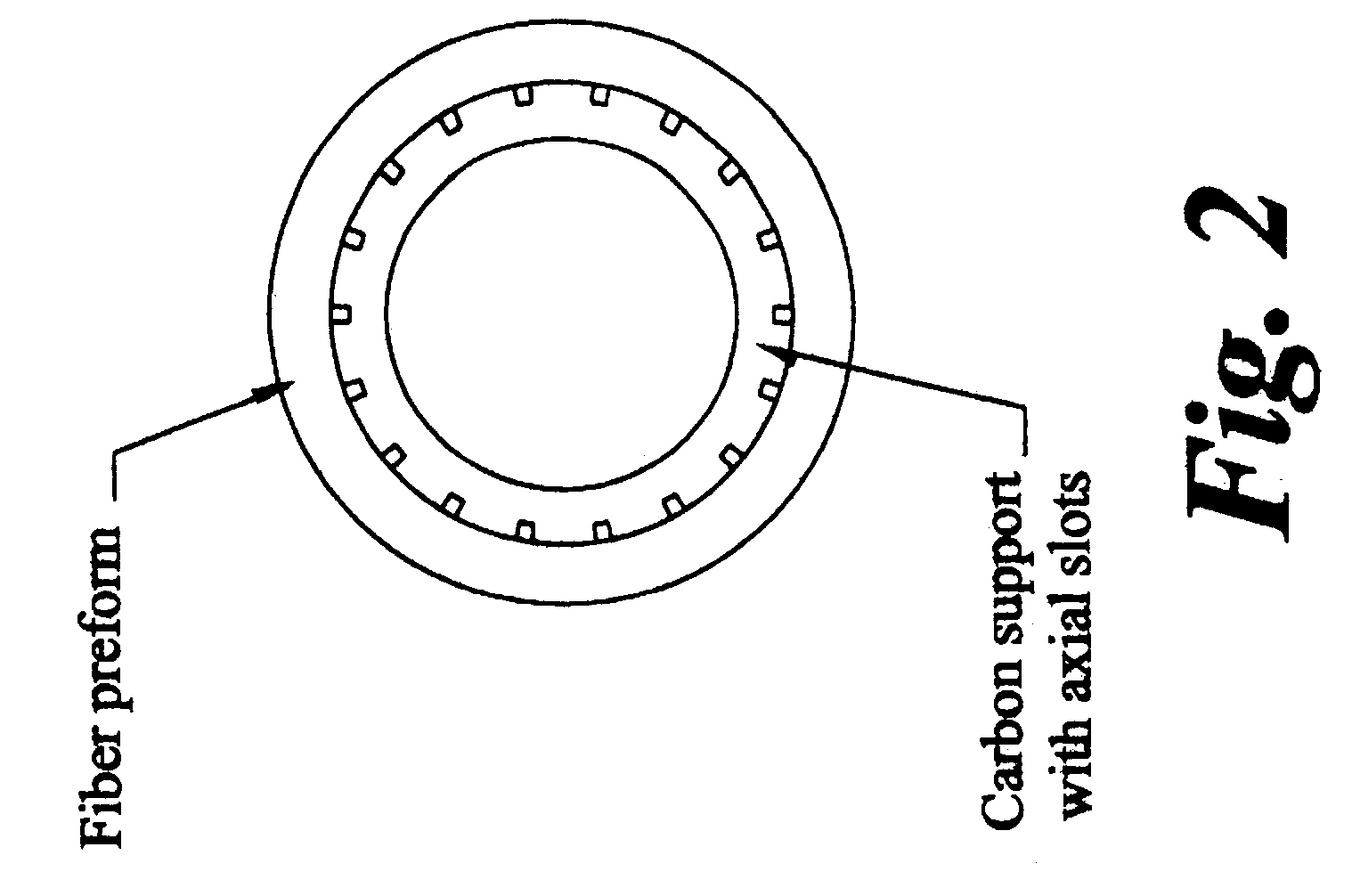

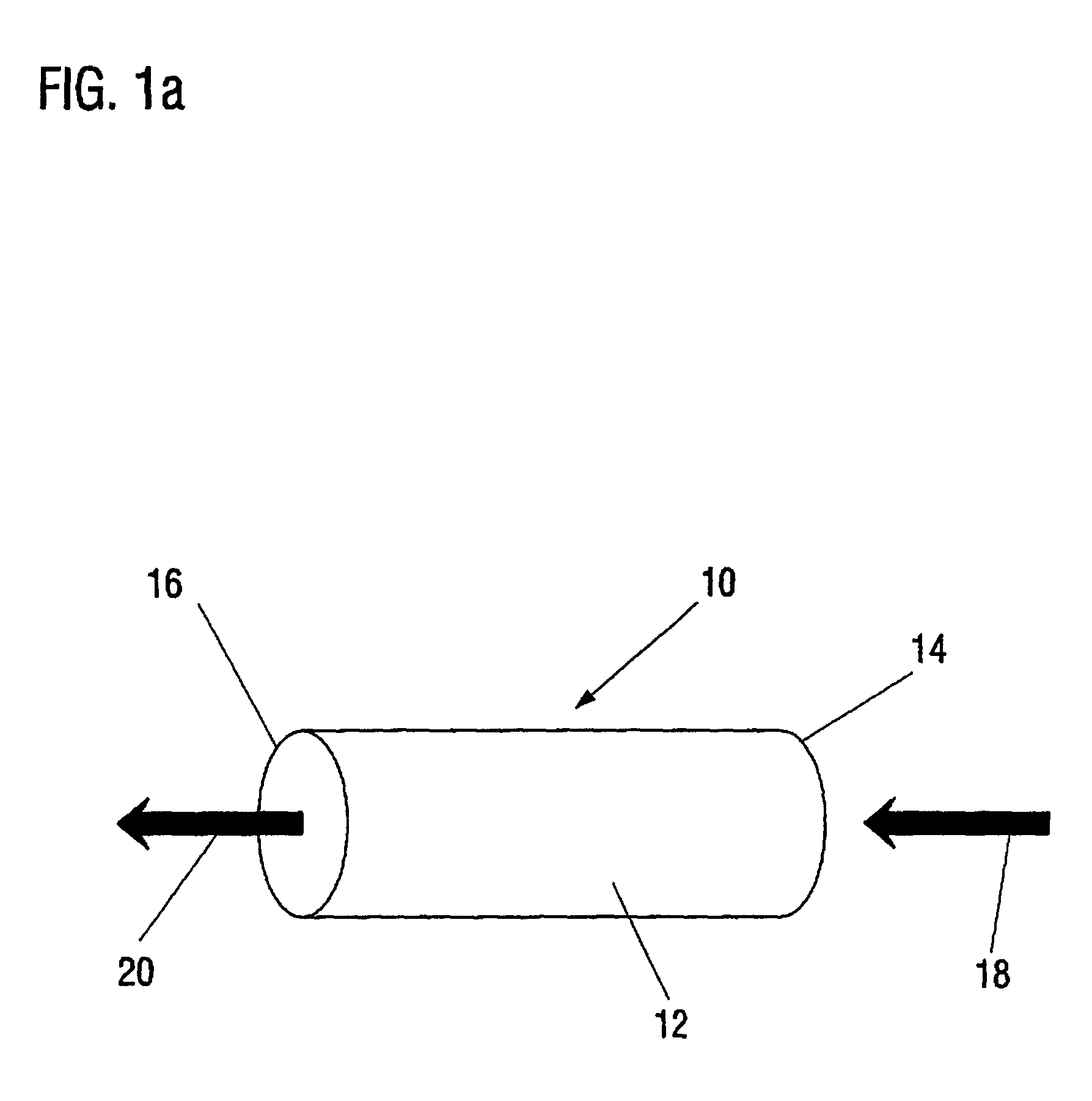

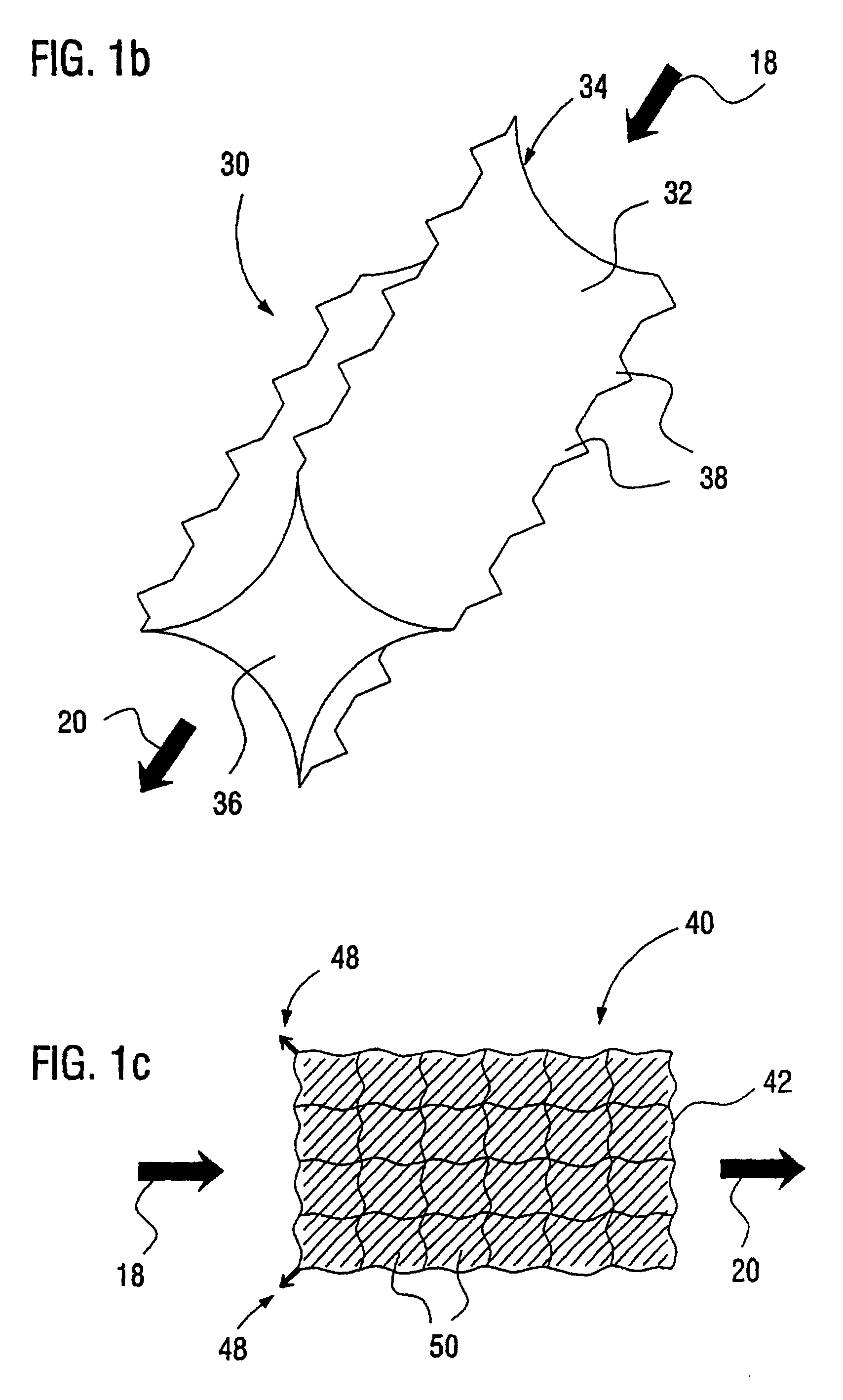

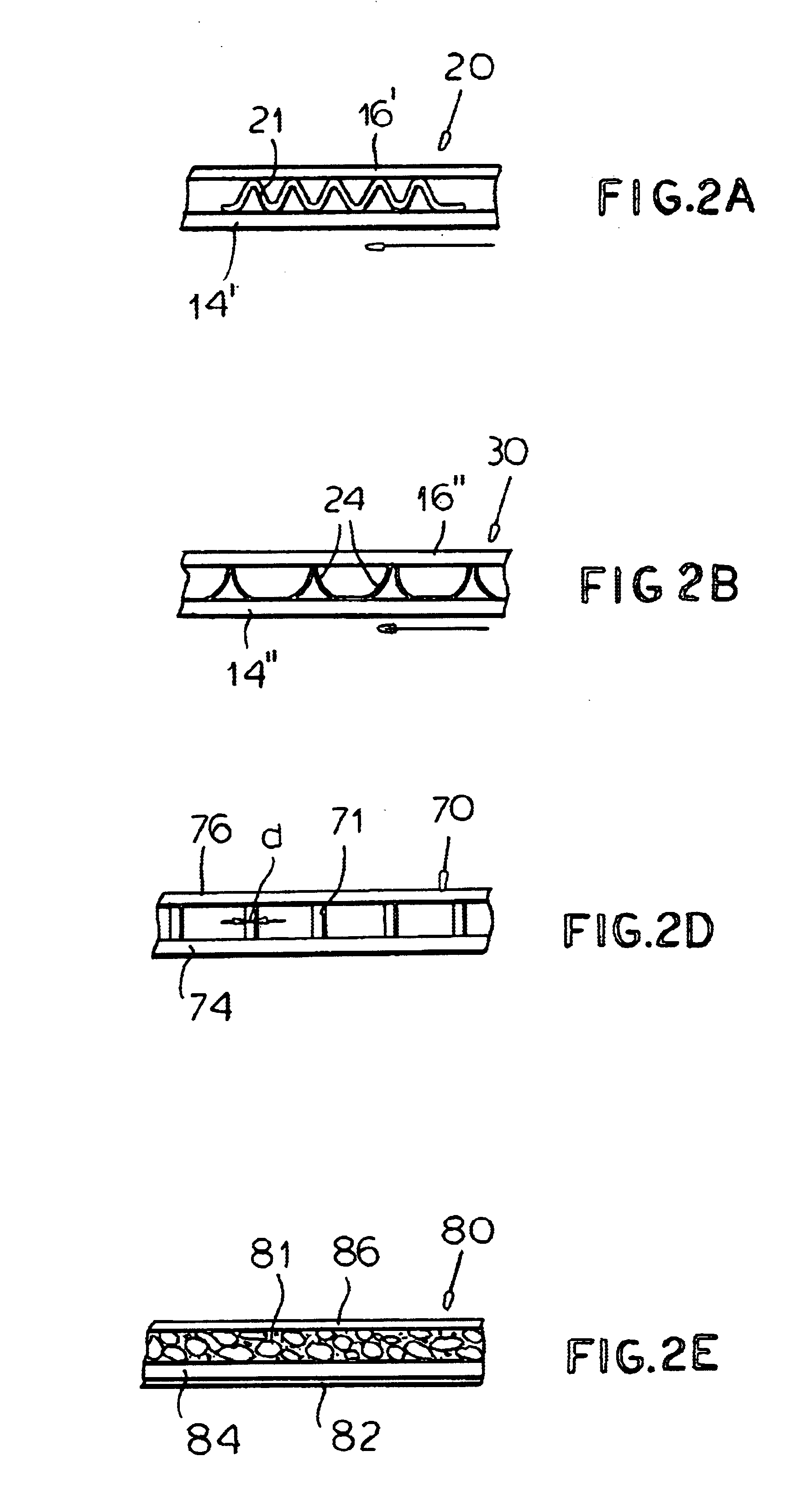

Method for producing melt-infiltrated ceramic composites using formed supports

InactiveUS6503441B2Avoid distortionEvenly distributedPretreated surfacesCeramic shaping apparatusCeramic compositeMetallurgy

A method for producing shaped articles of ceramic composites provides a high degree of dimensional tolerance to these articles. A fiber preform is disposed on a surface of a stable formed support, a surface of which is formed with a plurality of indentations, such as grooves, slots, or channels. Precursors of ceramic matrix materials are provided to the fiber preform to infiltrate from both sides of the fiber preform. The infiltration is conducted under vacuum at a temperature not much greater than a melting point of the precursors. The melt-infiltrated composite article substantially retains its dimension and shape throughout the fabrication process.

Owner:GENERAL ELECTRIC CO

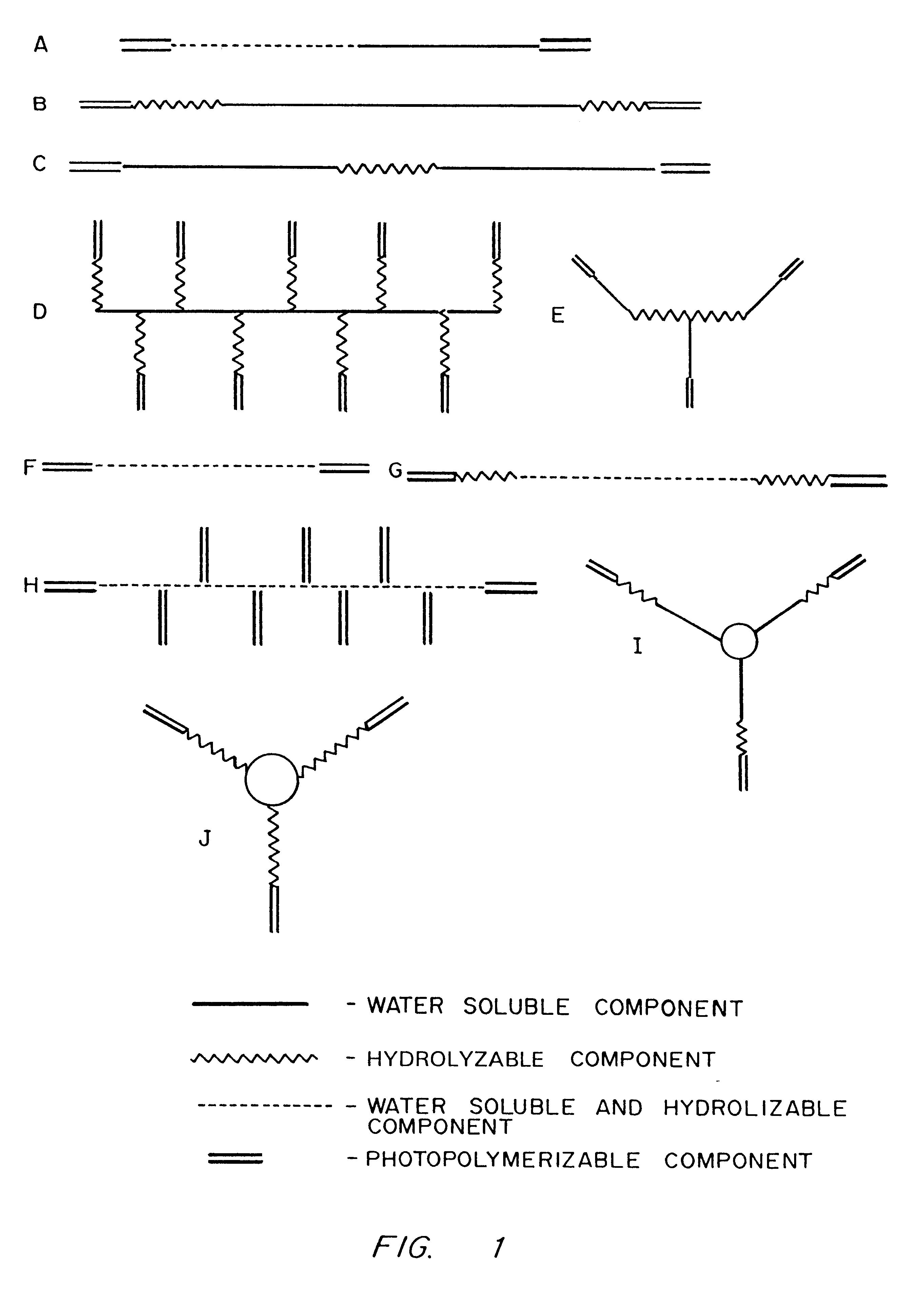

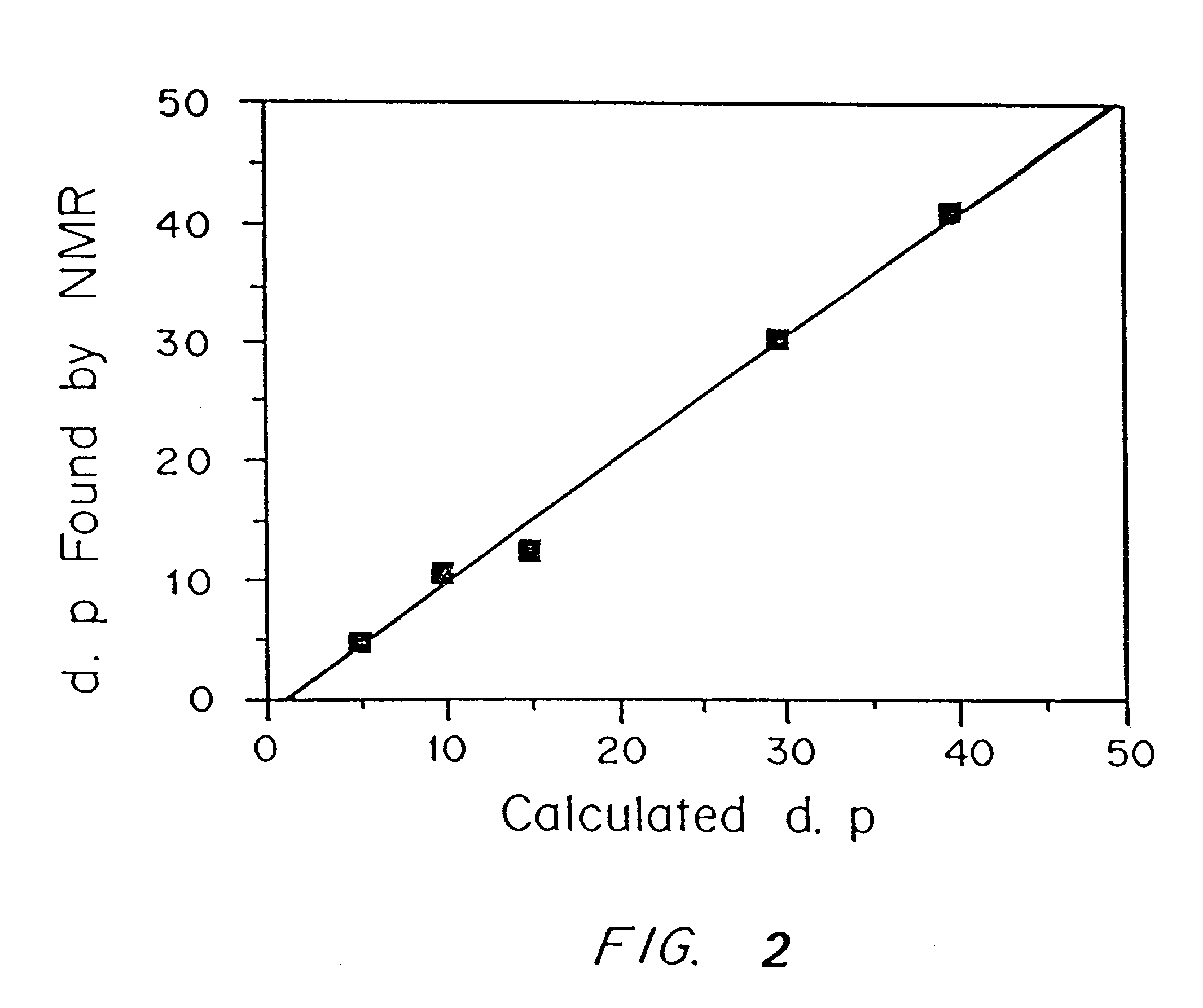

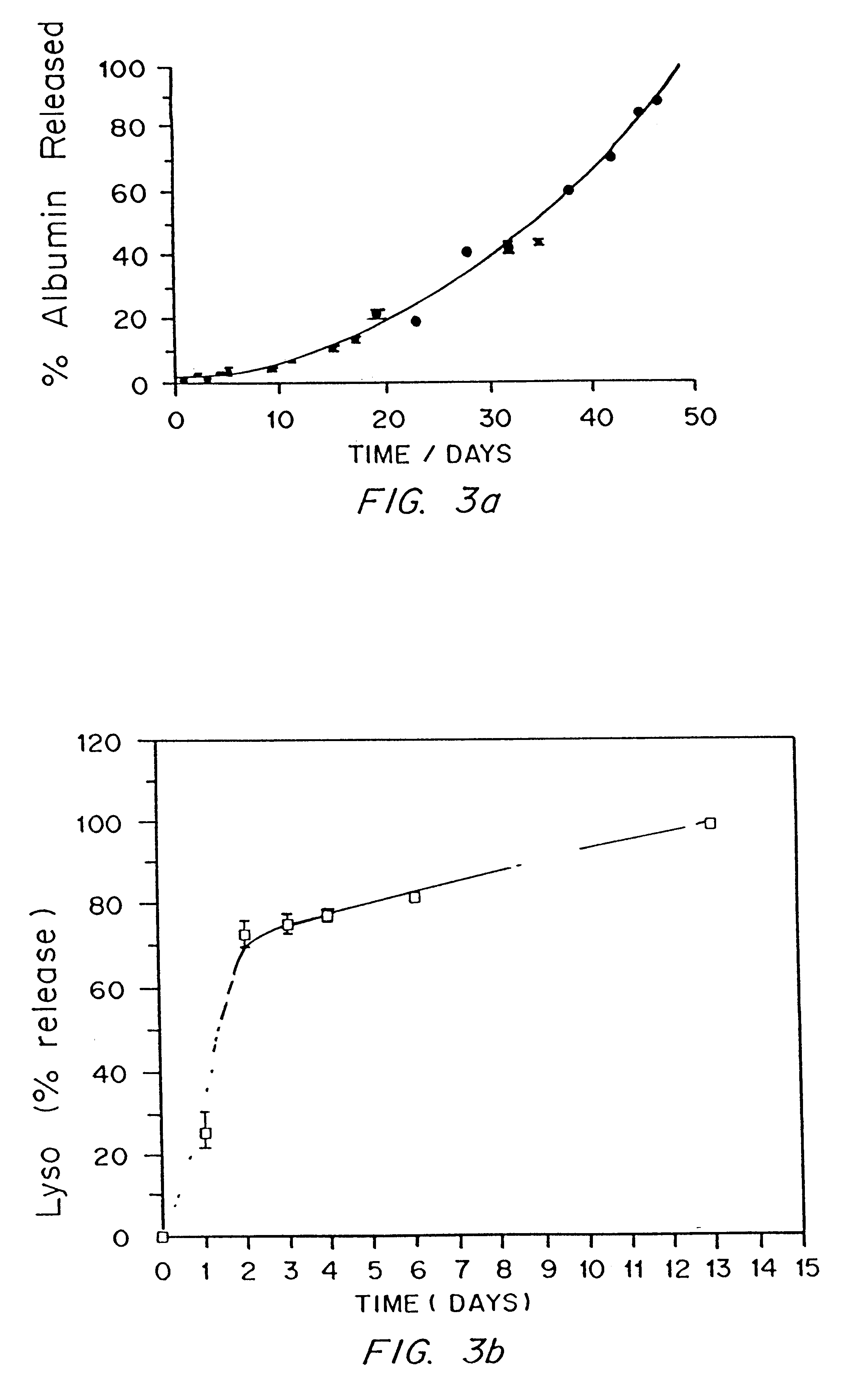

Photopolymerizable biodegradable hydrogels as tissue contacting materials and controlled-release carriers

InactiveUS6306922B1Fast gelationRapid polymerizationImmobilised enzymesPowder deliveryThermal energyUltraviolet lights

Hydrogels of polymerized and crosslinked macromers comprising hydrophilic oligomers having biodegradable monomeric or oligomeric extensions, which biodegradable extensions are terminated on free ends with end cap monomers or oligomers capable of polymerization and cross linking are described. The hydrophilic core itself may be degradable, thus combining the core and extension functions. Macromers are polymerized using free radical initiators under the influence of long wavelength ultraviolet light, visible light excitation or thermal energy. Biodegradation occurs at the linkages within the extension oligomers and results in fragments which are non-toxic and easily removed from the body. Preferred applications for the hydrogels include prevention of adhesion formation after surgical procedures, controlled release of drugs and other bioactive species, temporary protection or separation of tissue surfaces, adhering of sealing tissues together, and preventing the attachment of cells to tissue surfaces.

Owner:BOARD OF REGENTS

Implant for releasing an active substance into a vessel through which a body medium flows

InactiveUS9095642B2Well processed technicallyIdeal mechanical material propertyStentsSurgeryBiomedical engineering

An implant for releasing an active substance into a vessel through which a body medium flows. The implant release an active substance into a vessel through which a body medium flows downstream from the location of the implant. A base of a biodegradable material is a carrier of the active substance to be released. The body medium flows past the implant and the active substance is release. The implant is configured so that the active substance does not contact a vessel wall at the location of implant.

Owner:BIOTRONIK AG

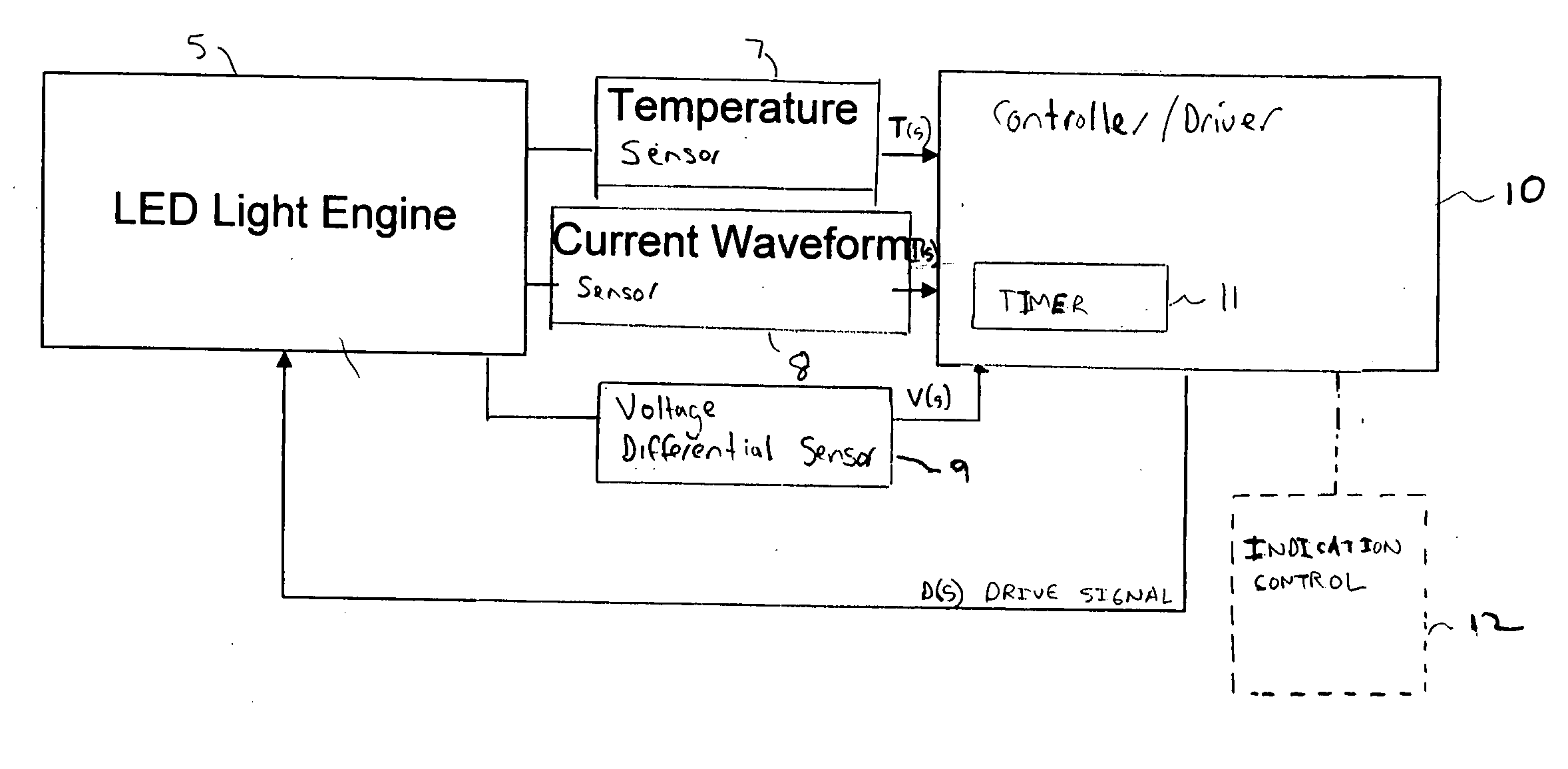

Intelligent drive circuit for a light emitting diode (LED) light engine

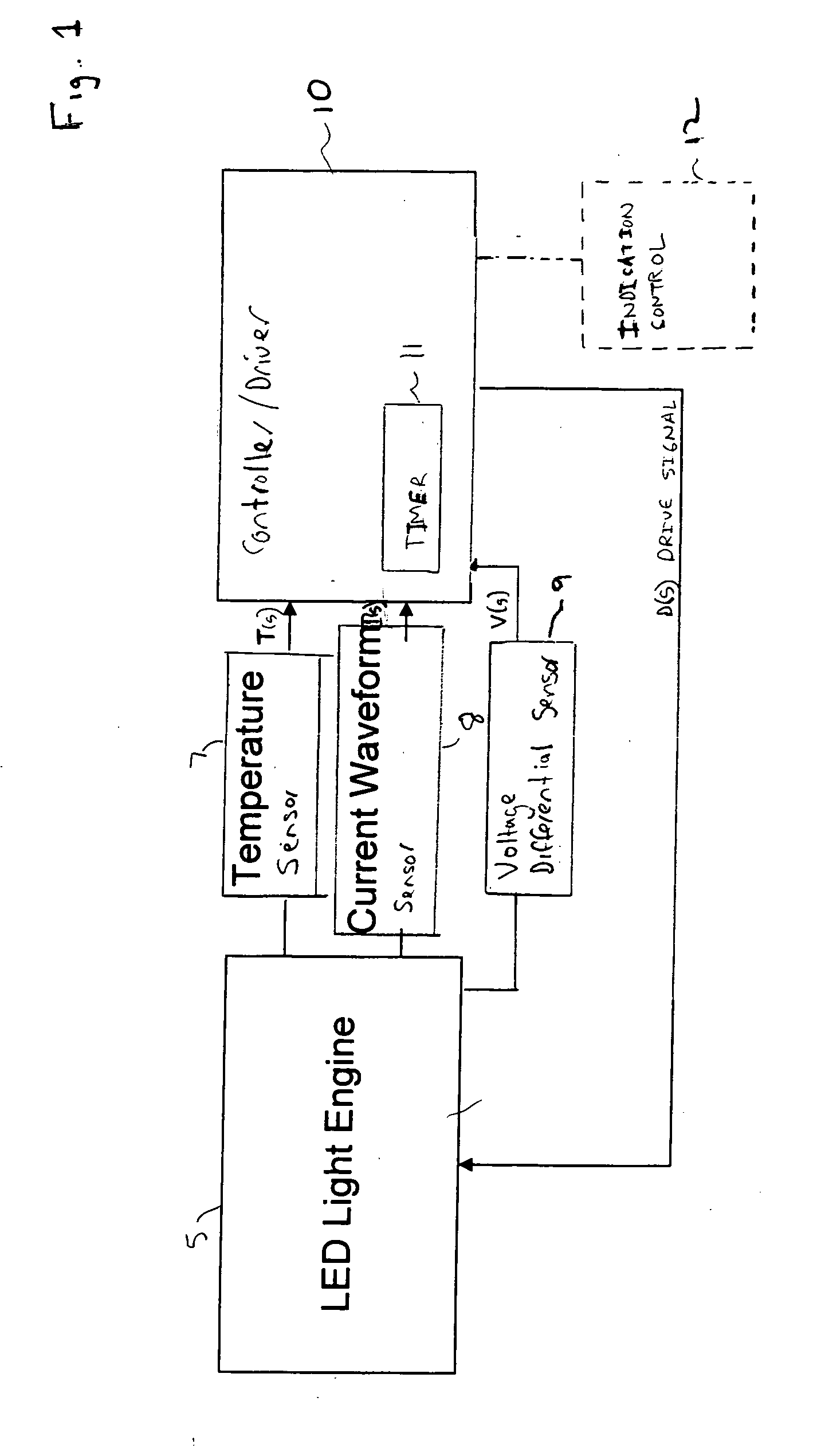

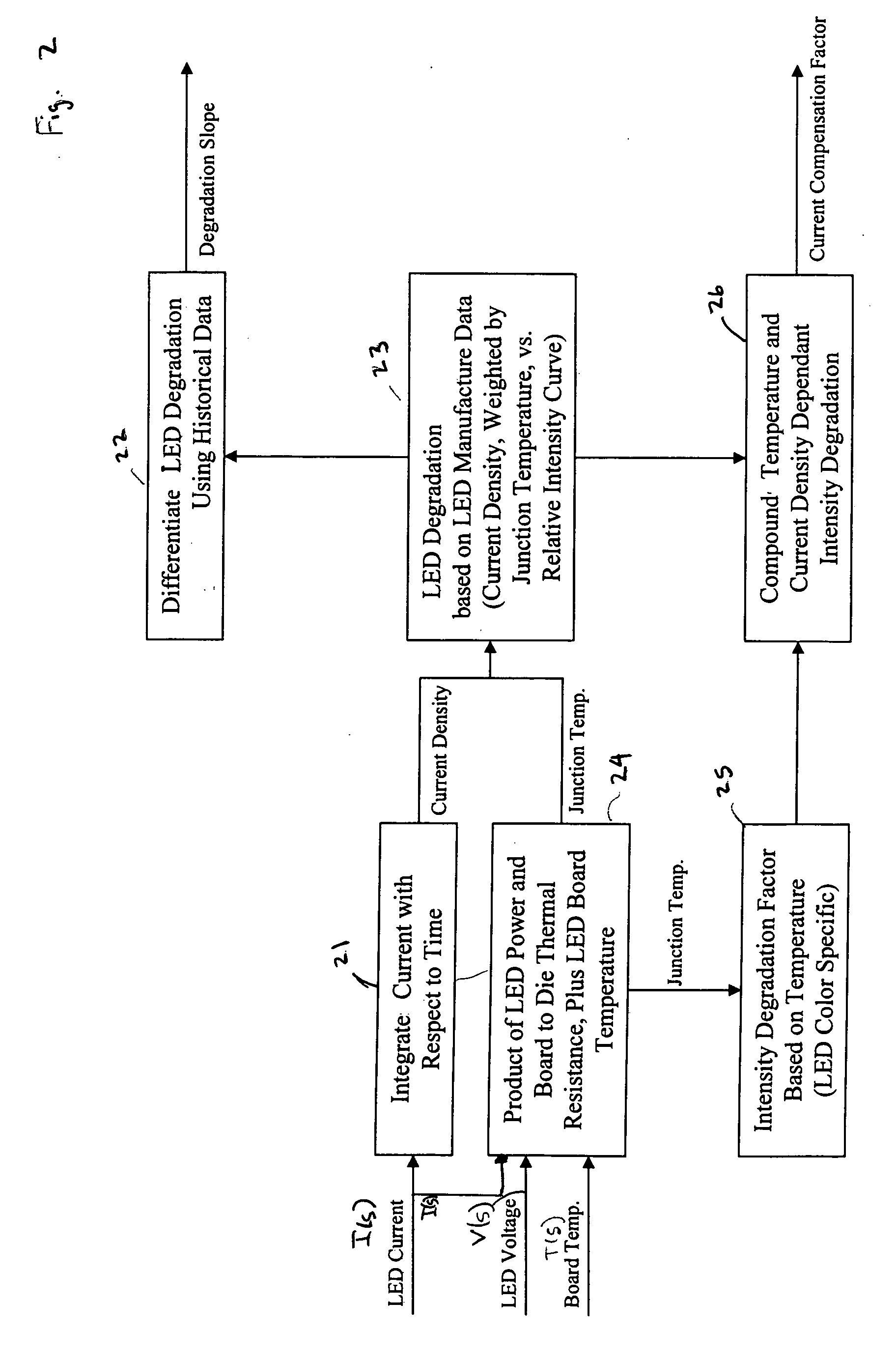

ActiveUS20060028155A1Increased operating lifeMore energy efficientElectroluminescent light sourcesElectric light circuit arrangementDriving currentDriver circuit

A controller for controlling a light emitting diode (LED) light engine. The controller includes a temperature sensor configured to sensor temperature at the LED light engine. A current sensor senses a drive current of the LED light engine. A voltage differential sensor senses a voltage differential across LEDs of the LED light engine. A timer monitors a time of operation of the LED light engine. Further, a control device controls the drive current to the LED light engine based on the sensed temperature, the sensed drive current, the sensed voltage differential, and the monitored time of operation. Further, the control device outputs an indication of intensity degradation of an LED, and if the intensity degradation exceeds a predetermined threshold the control can output an indication of such to a user, so that the user can be apprised that the LED needs to be changed.

Owner:DIALIGHT CORP

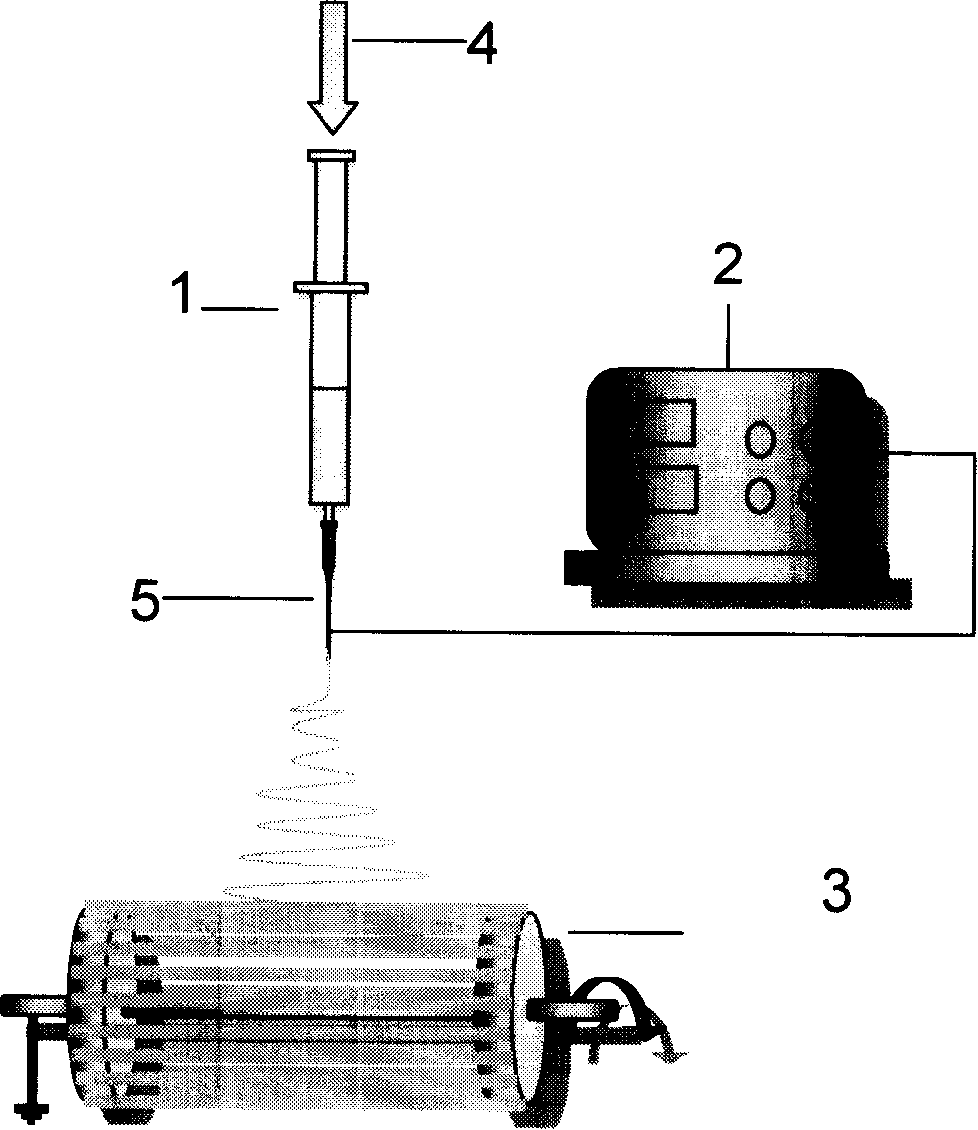

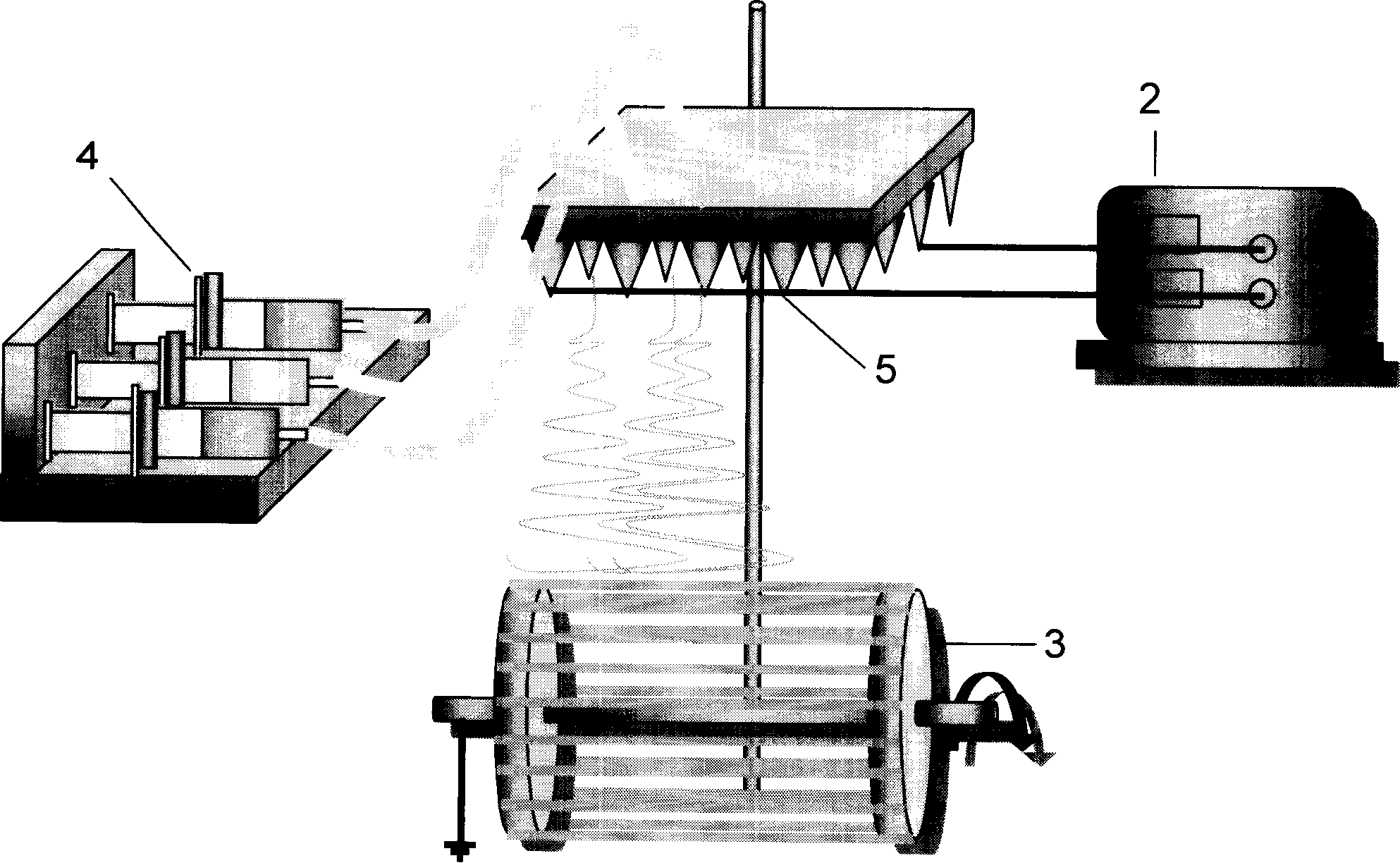

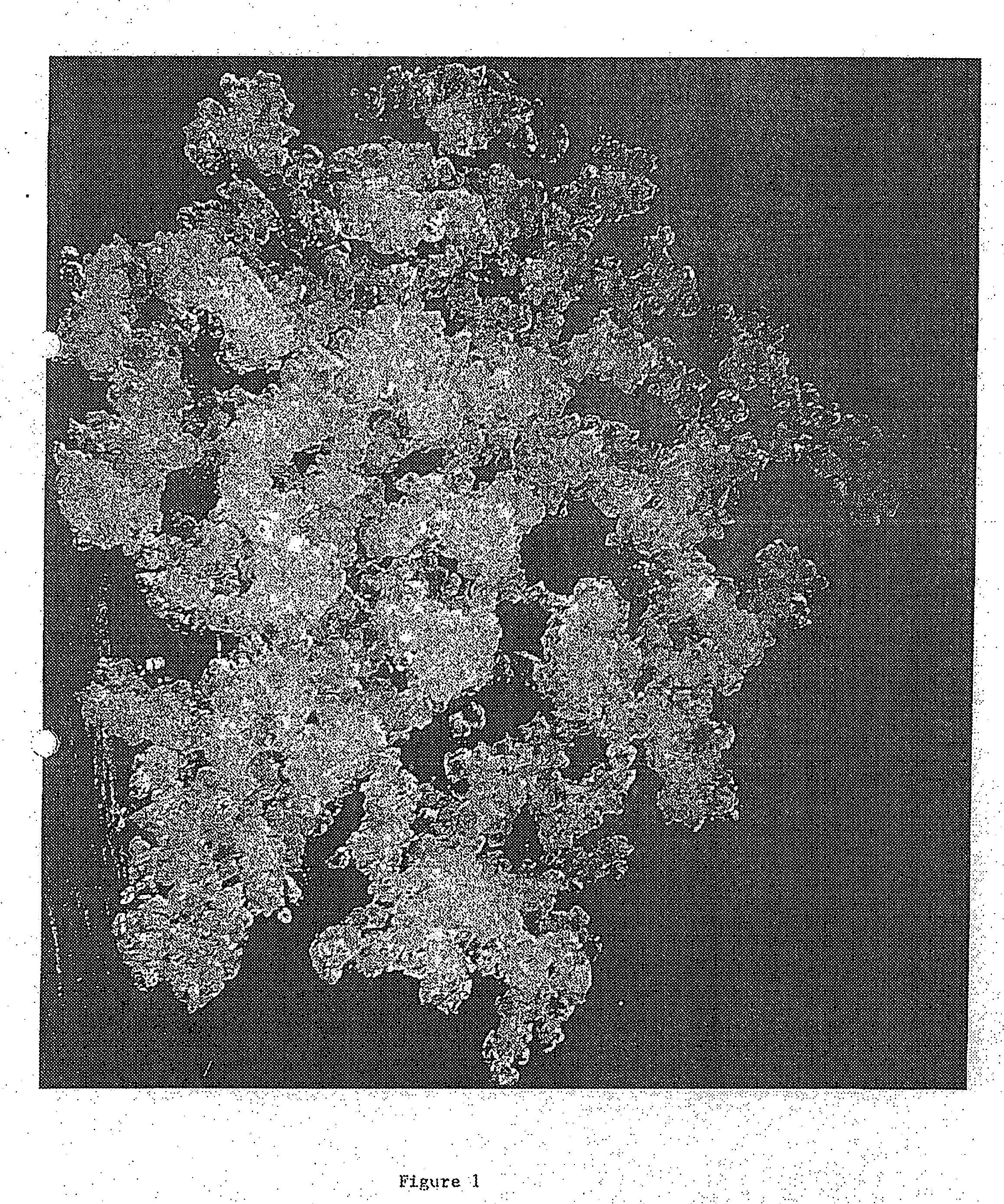

Biopolymer nano tunica fibrosa material capable of being biological degraded and absorbed, preparing method and uses of the same

InactiveCN101172164AGood biocompatibilityPromote degradationSurgeryFilament/thread formingFiberCellulose

The invention relates to compound millimicron fibrous membrane material of cellulose and cellulose matrix which can perform the biological degradation and the biological absorption and a preparation method thereof and an industry and medical purpose, and belongs to the biological macro-molecule non woven fabric material field which can perform the biological degradation and the biological absorption. Electrostatic spinning equipment is used to obtain the fibrous membrane material which can perform the biological degradation and the biological absorption, the weight of the cellulose is taken as basic reference, the component of the material comprises cellulose more than 0 and less than or equal to 100 weight parts, other biomacromolecule more than and equal to 0 and less than 100 weight parts, 0 to 10 weight parts of curative drug or 0 to 50 weight parts of inorganic catalyzer and / or 0 to 50 weight parts of inorganic strengthening agent. The material of the invention has good biological compatibility, biological degradation property and degradation absorptivity, and can be used for haemostasia material, wound cladding material, organization engineering supporting rack material, the transportation and release of medicine, artificial skin and blood vessel, and postoperation anti blocking material, beauty material and catalyzer carrier, filtering membrane and radiation protection material and so on.

Owner:INST OF CHEM CHINESE ACAD OF SCI

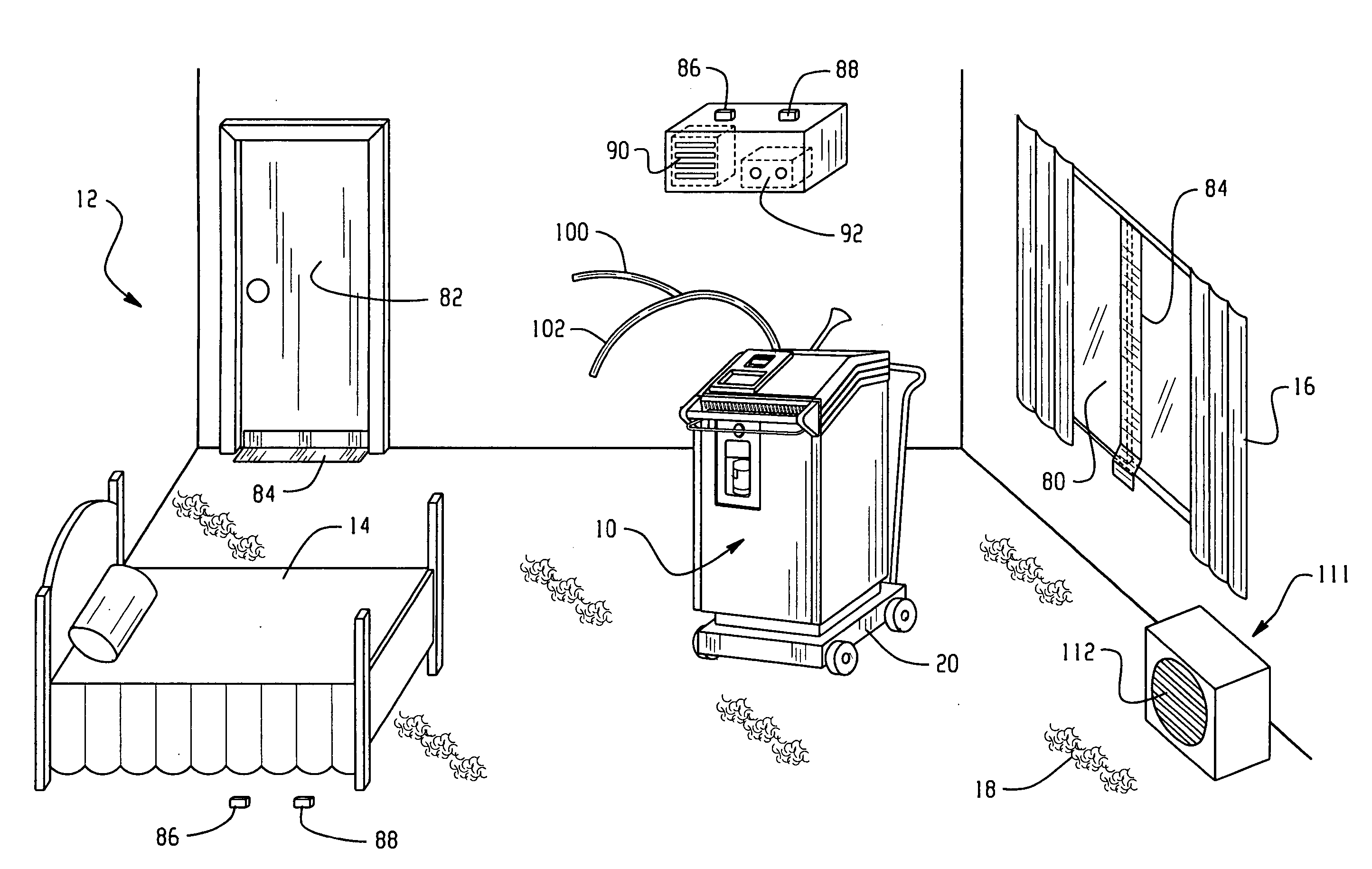

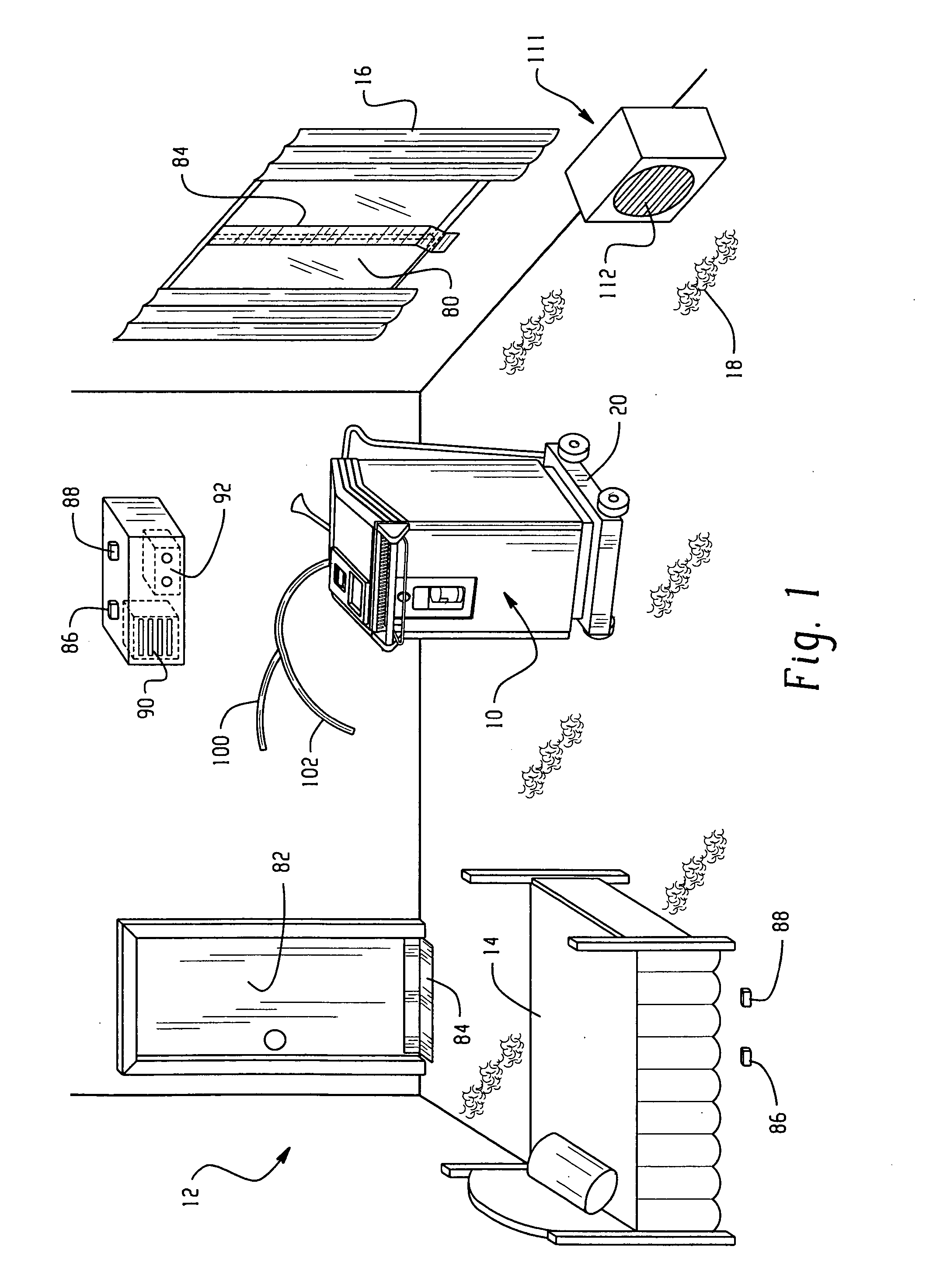

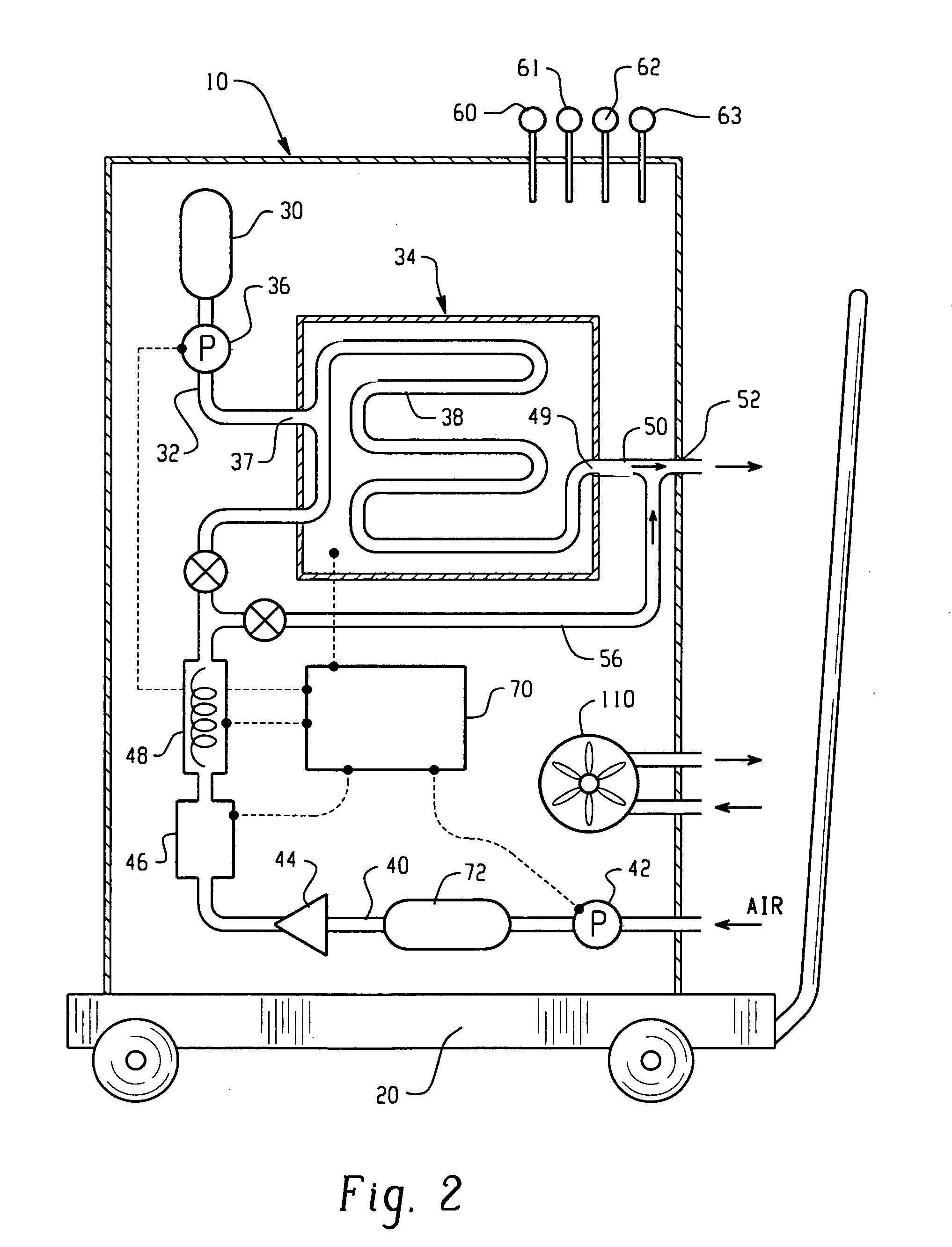

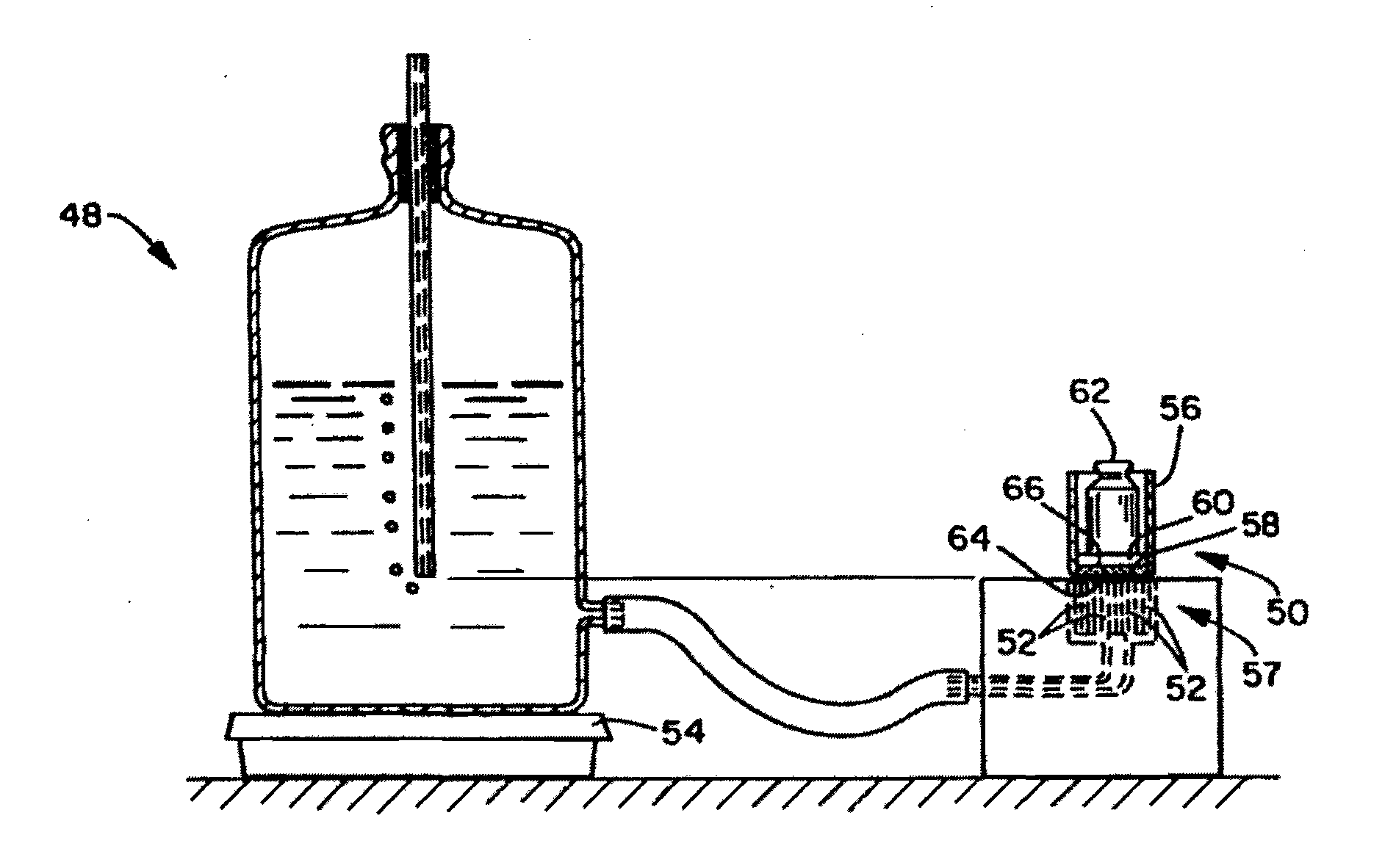

Room decontamination with hydrogen peroxide vapor

ActiveUS20060008379A1Reduce or even removeMinimize residual amountGaseous substancesDeodrantsHotel roomVapor generator

A system for microbially and / or chemically decontaminating a room such as a hotel room includes a vapor generator which supplies a decontaminant vapor, such as hydrogen peroxide vapor to the room. The room is then aerated to a level at which it is safe for normal occupants to enter. By using a two step aeration, with a second step at lower humidity than the first, the concentration of residual hydrogen peroxide is reduced rapidly to safe levels of 1 ppm or less, typically about 0.5 ppm, in under four hours. The room is rendered substantially free of contaminants, such as those responsible for Severe Acute Respiratory Syndrome (SARS), Norwalk virus, and unpleasant odors.

Owner:STERIS CORP

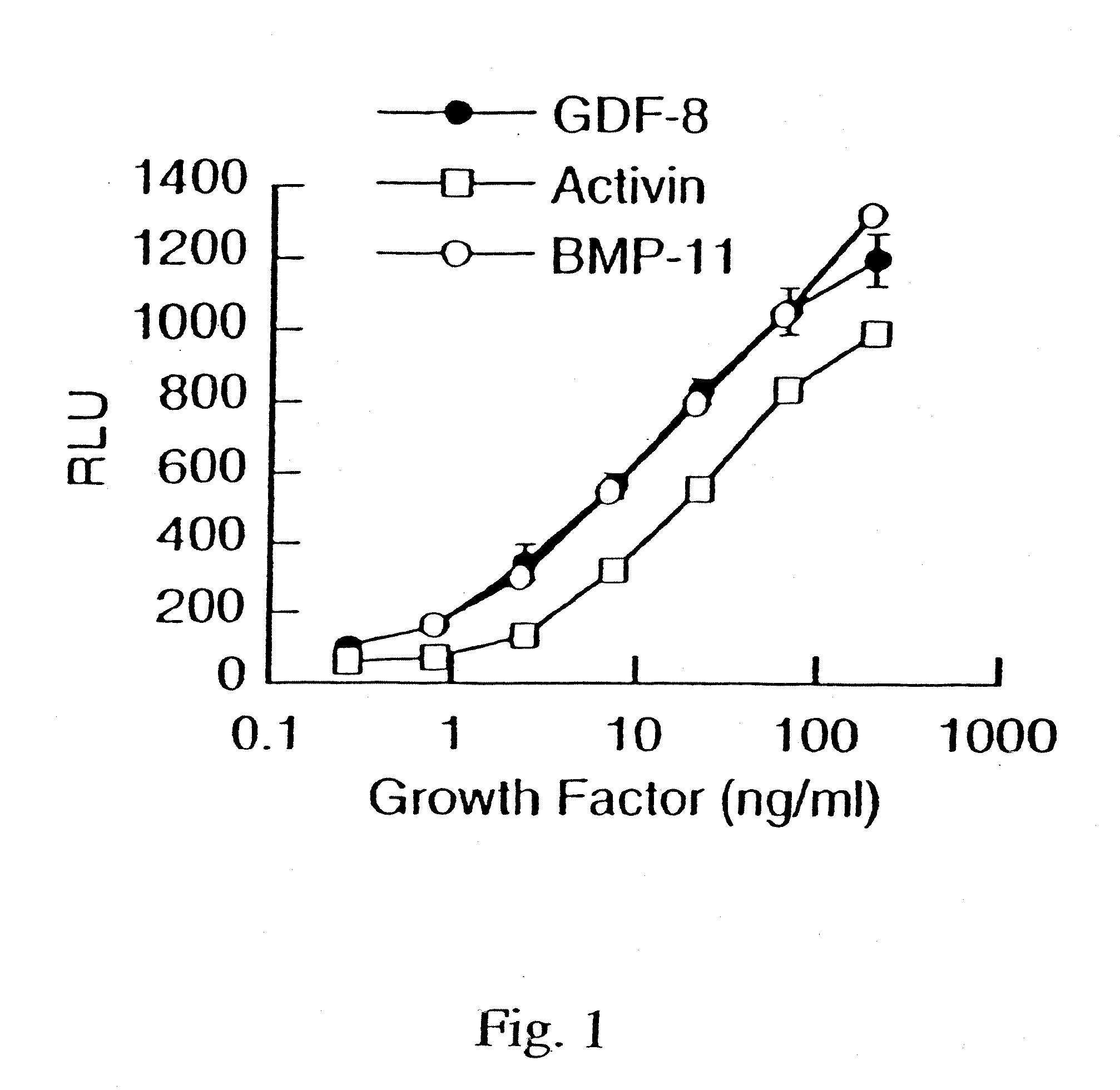

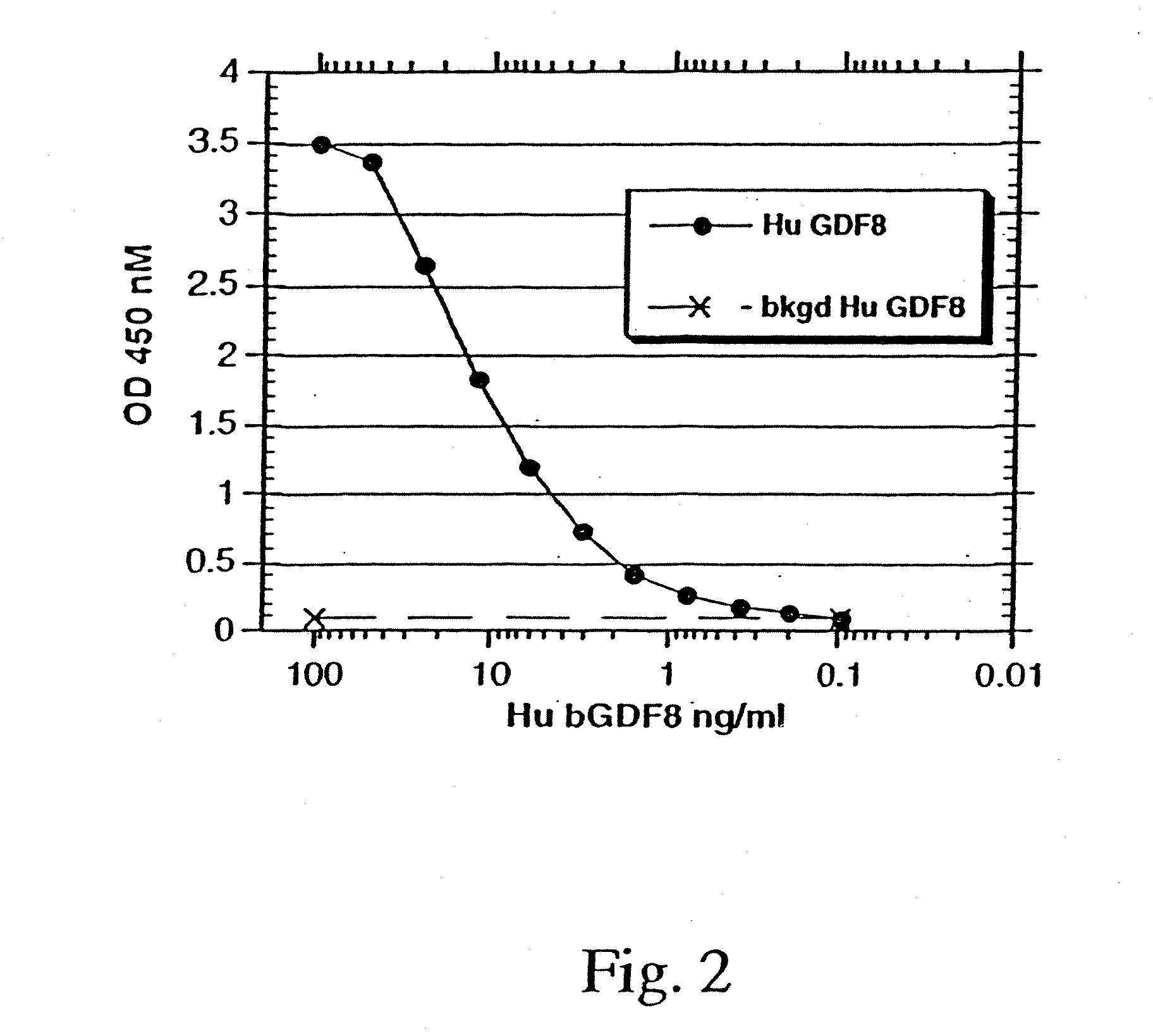

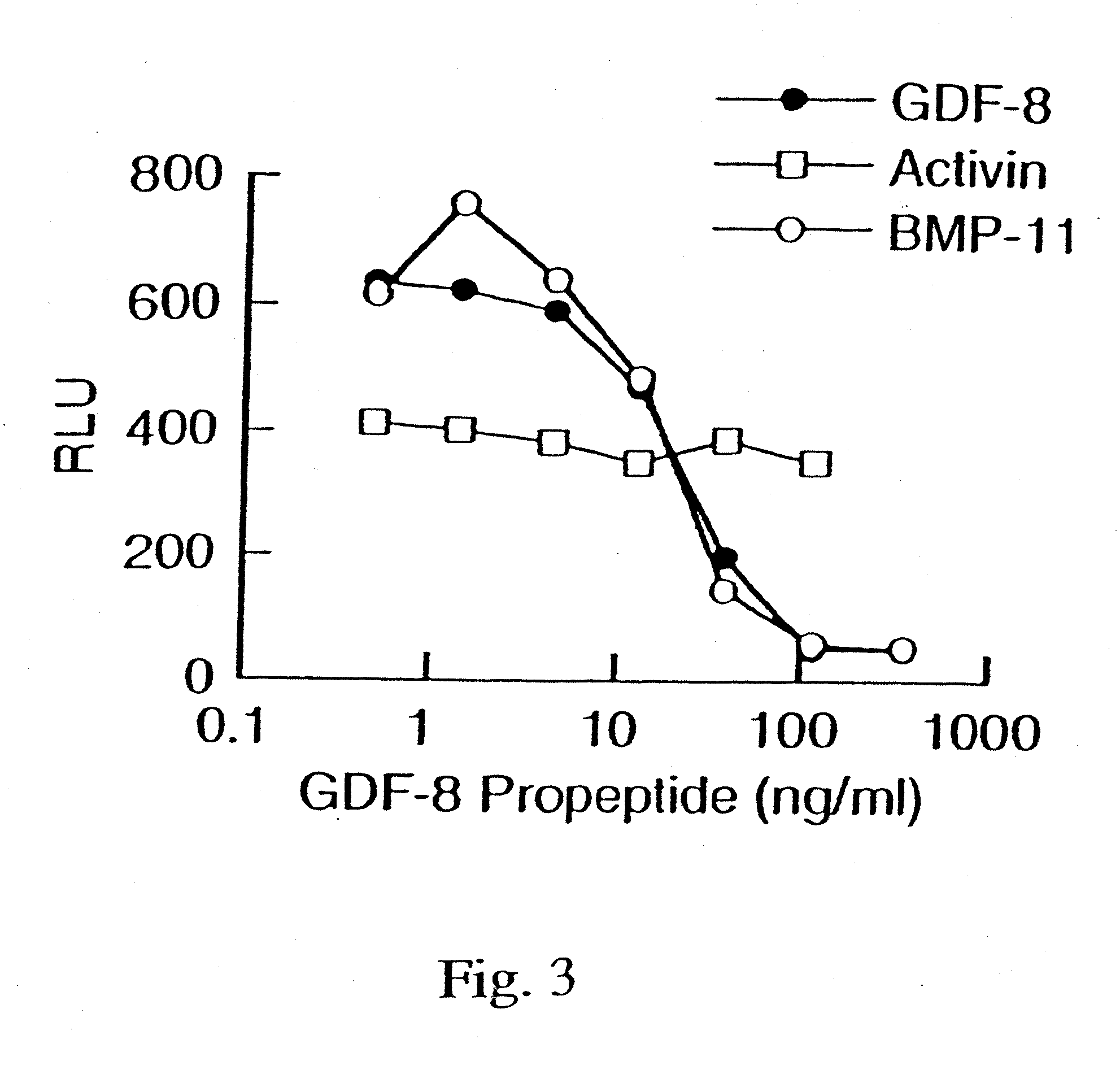

Modified and stabilized GDF propeptides and uses thereof

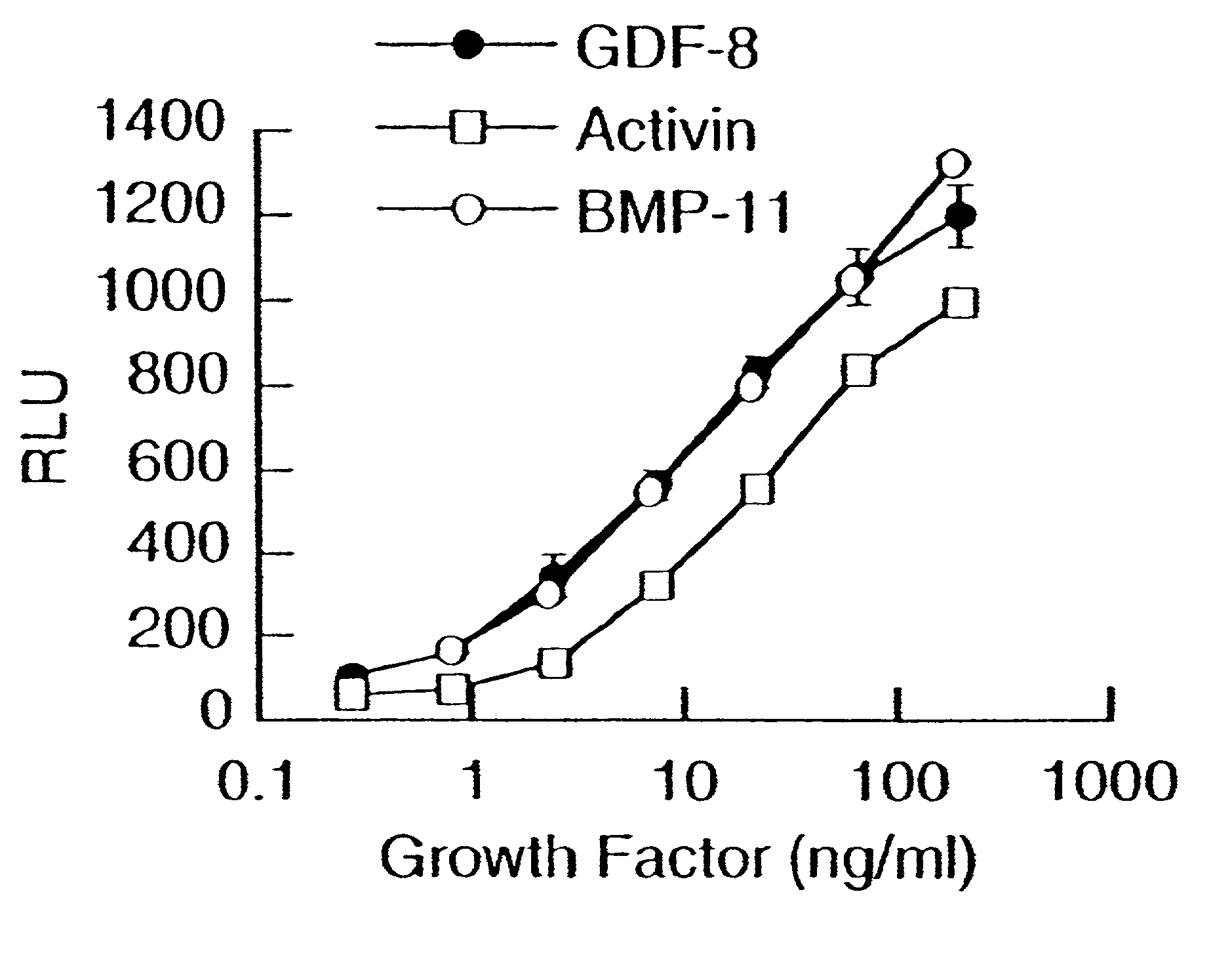

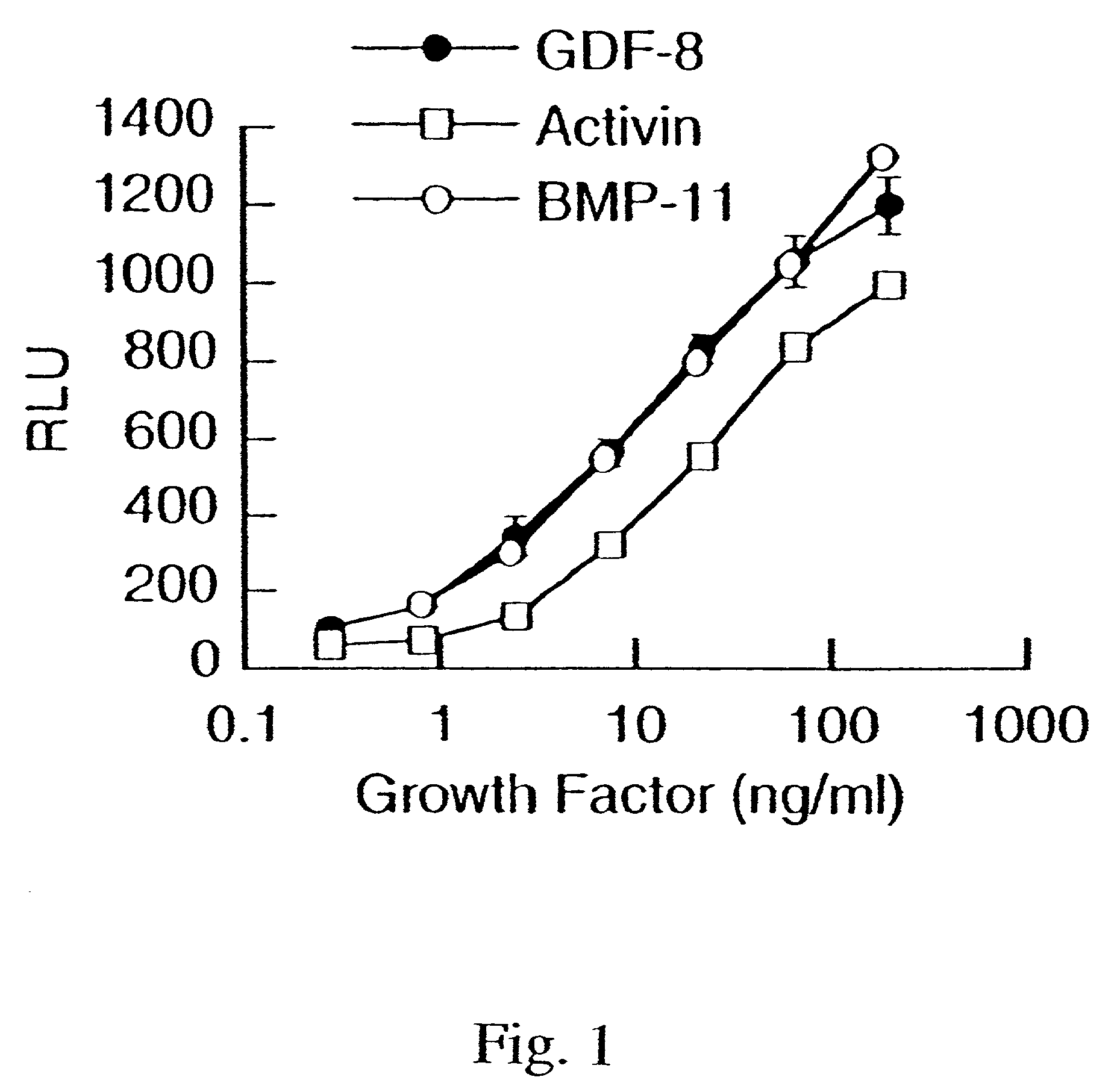

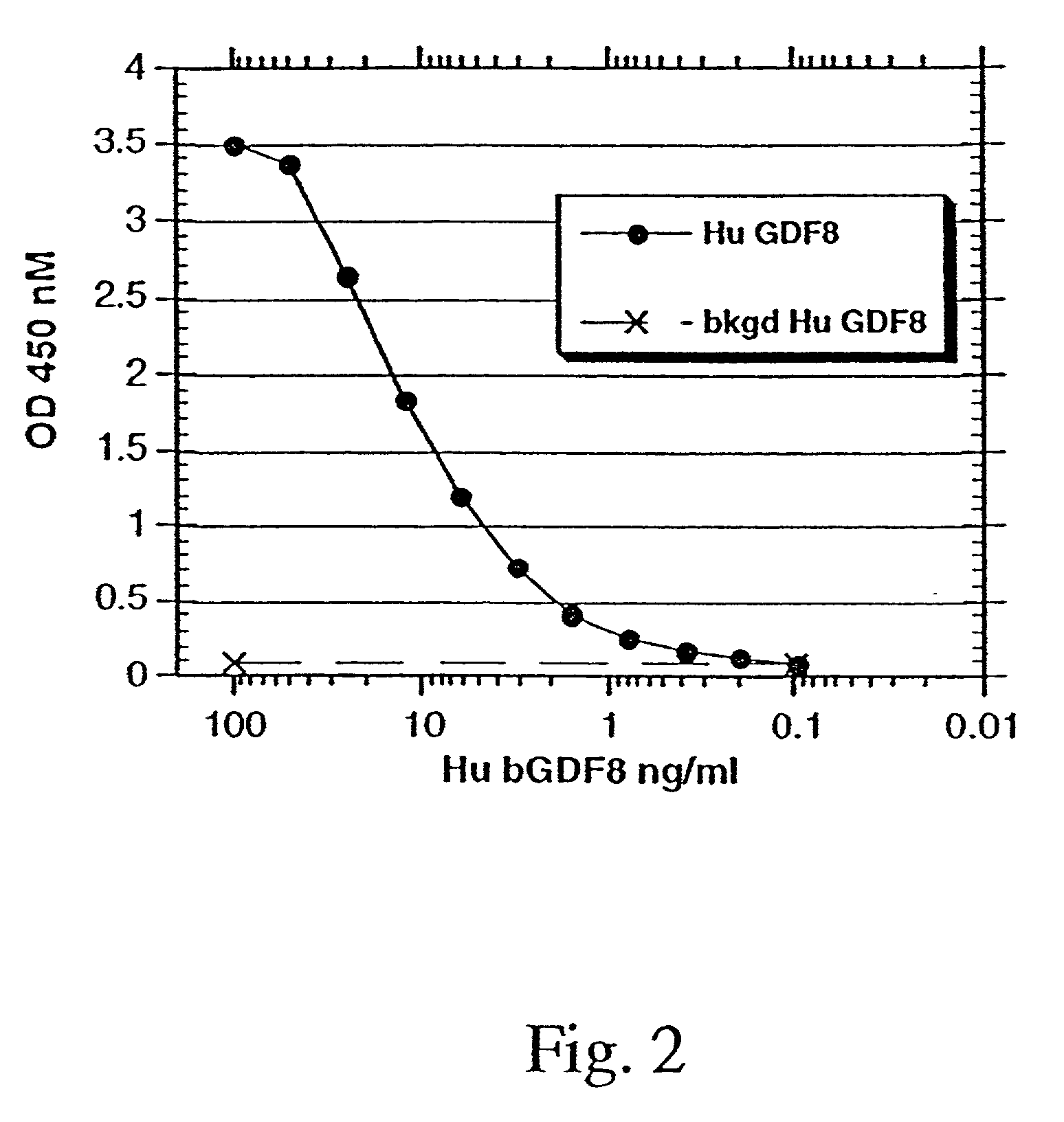

InactiveUS7202210B2Prevent practical therapeuticPrevent prophylactic utilityFungiBacteriaAcute hyperglycaemiaMuscle tissue

Modified and stabilized propeptides of Growth Differentiation Factor proteins, such as GDF-8 and Bone Morphogenetic Protein-11, are disclosed. Also disclosed are methods for making and using the modified propeptides to prevent or treat human or animal disorders in which an increase in muscle tissue would be therapeutically beneficial. Such disorders include muscle or neuromuscular disorders (such as amyotrophic lateral sclerosis, muscular dystrophy, muscle atrophy, congestive obstructive pulmonary disease, muscle wasting syndrome, sarcopenia, or cachexia), metabolic diseases or disorders (such as such as type 2 diabetes, noninsulin-dependent diabetes mellitus, hyperglycemia, or obesity), adipose tissue disorders (such as obesity), and bone degenerative diseases (such as osteoporosis).

Owner:WYETH LLC

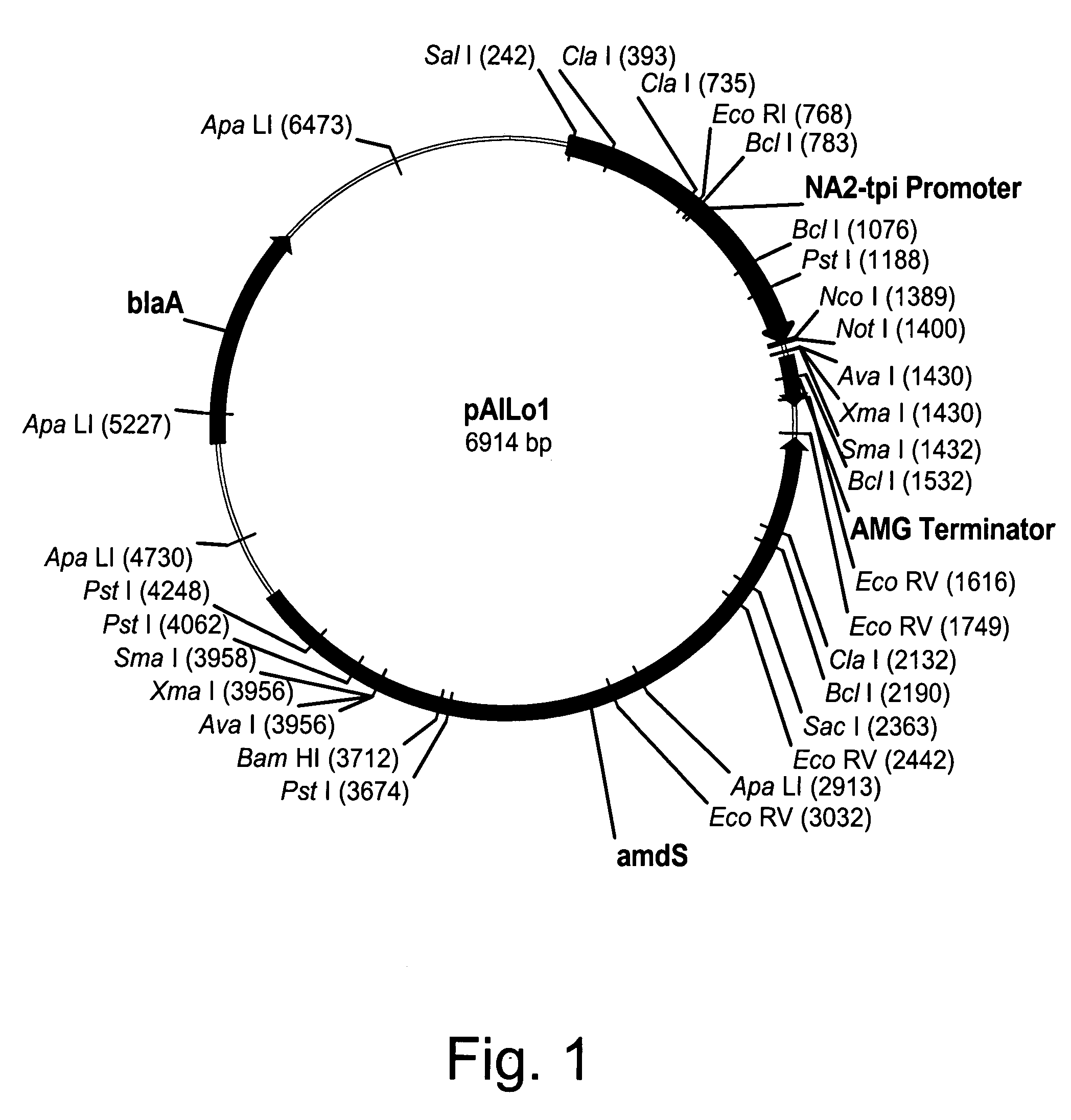

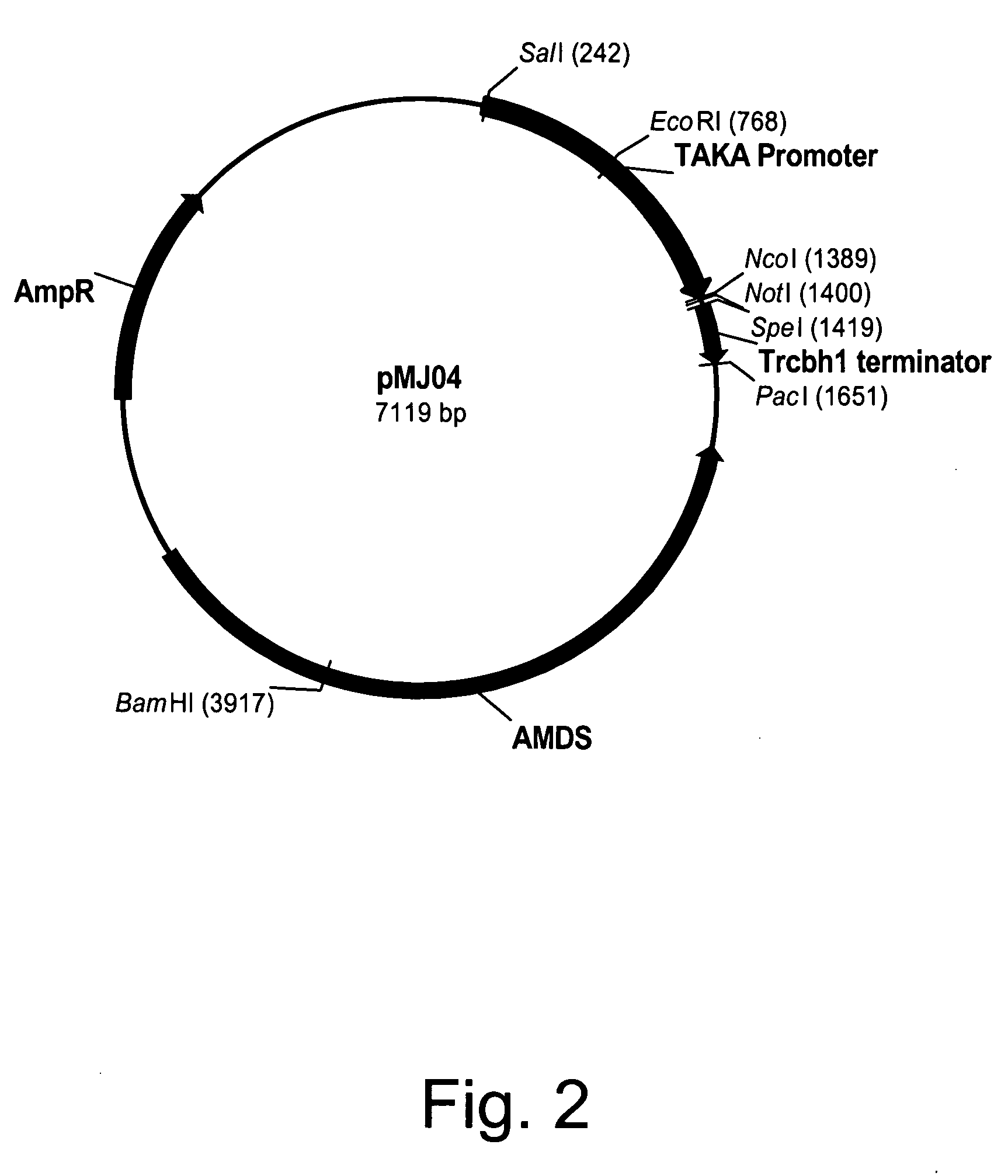

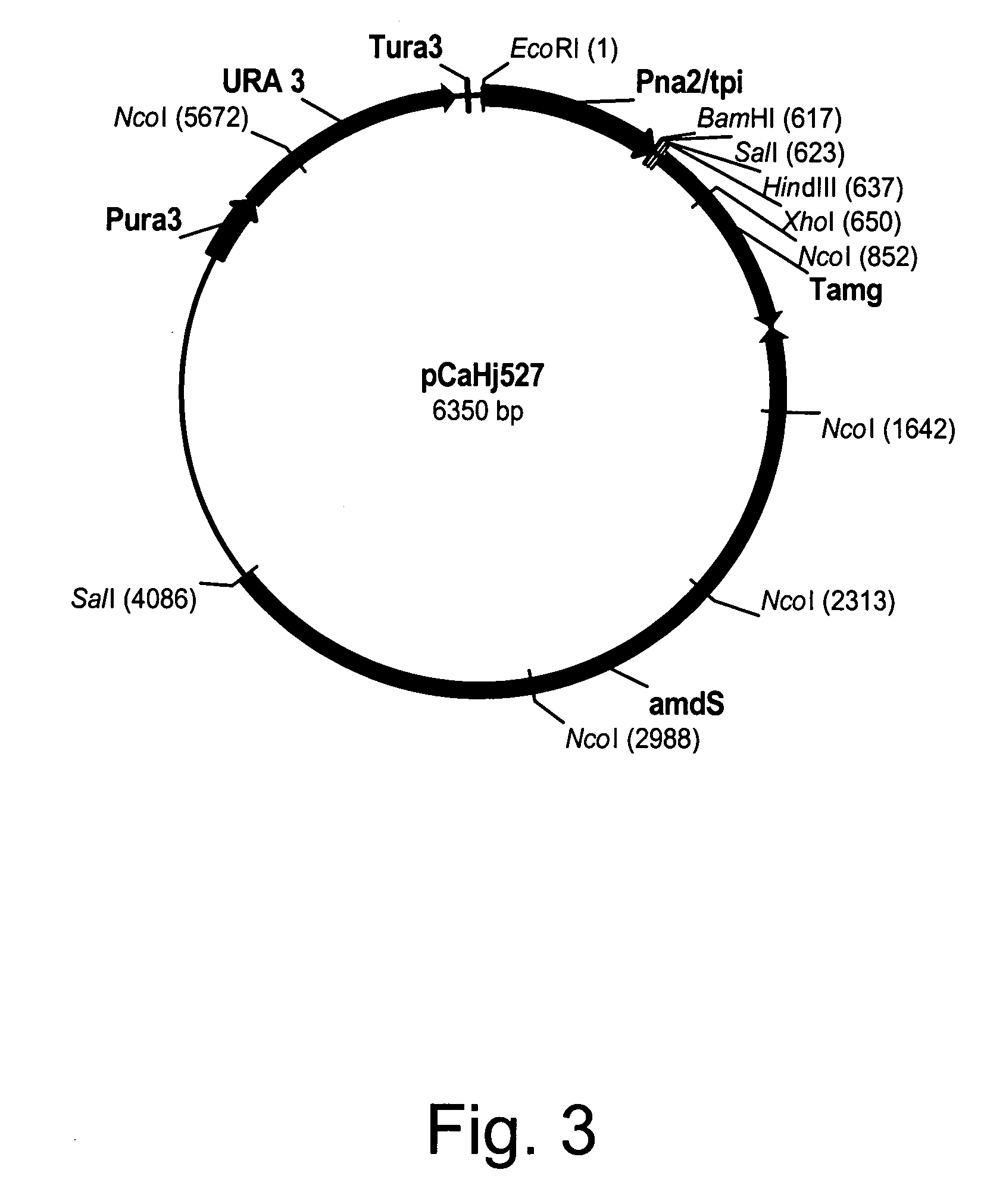

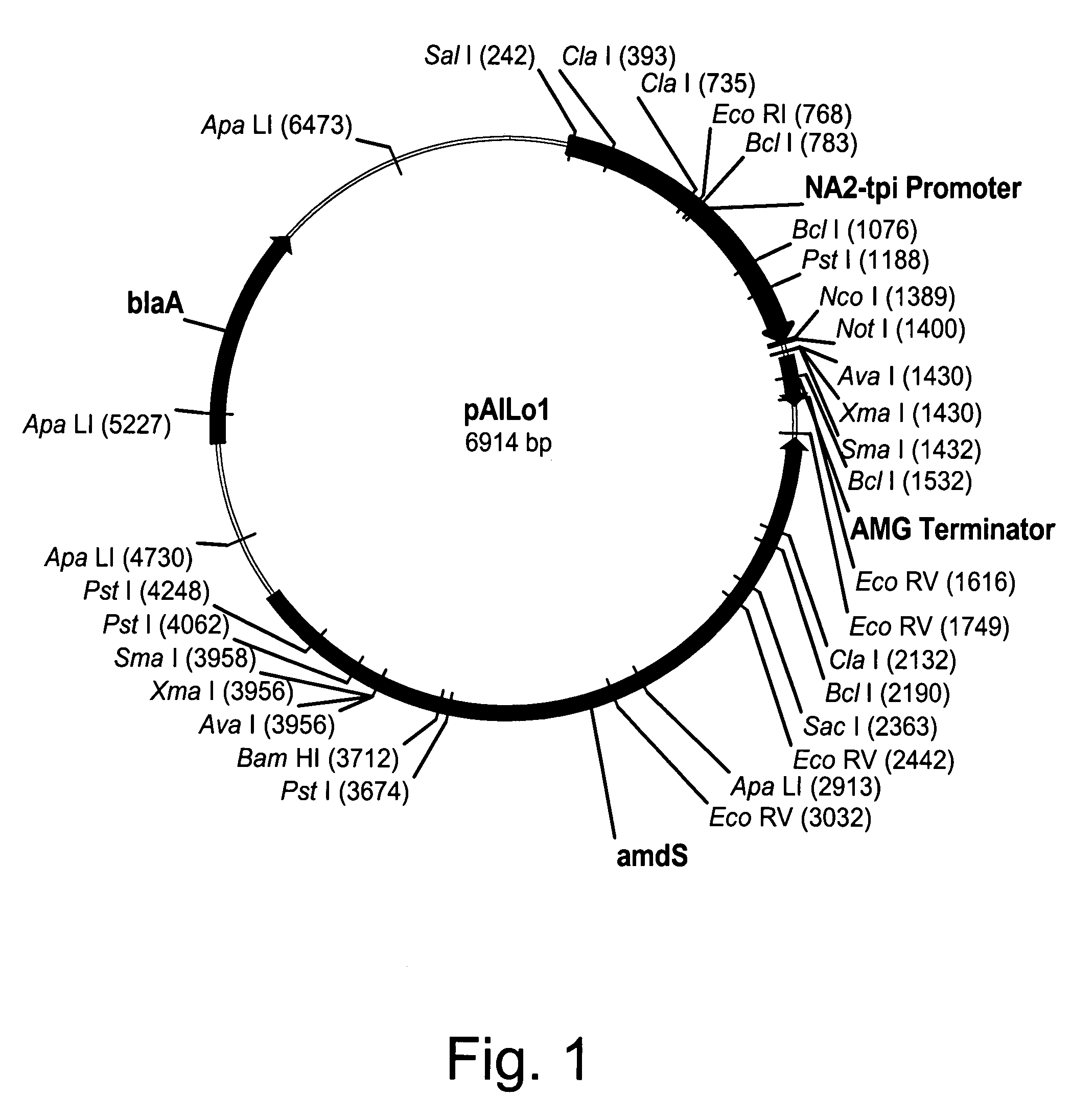

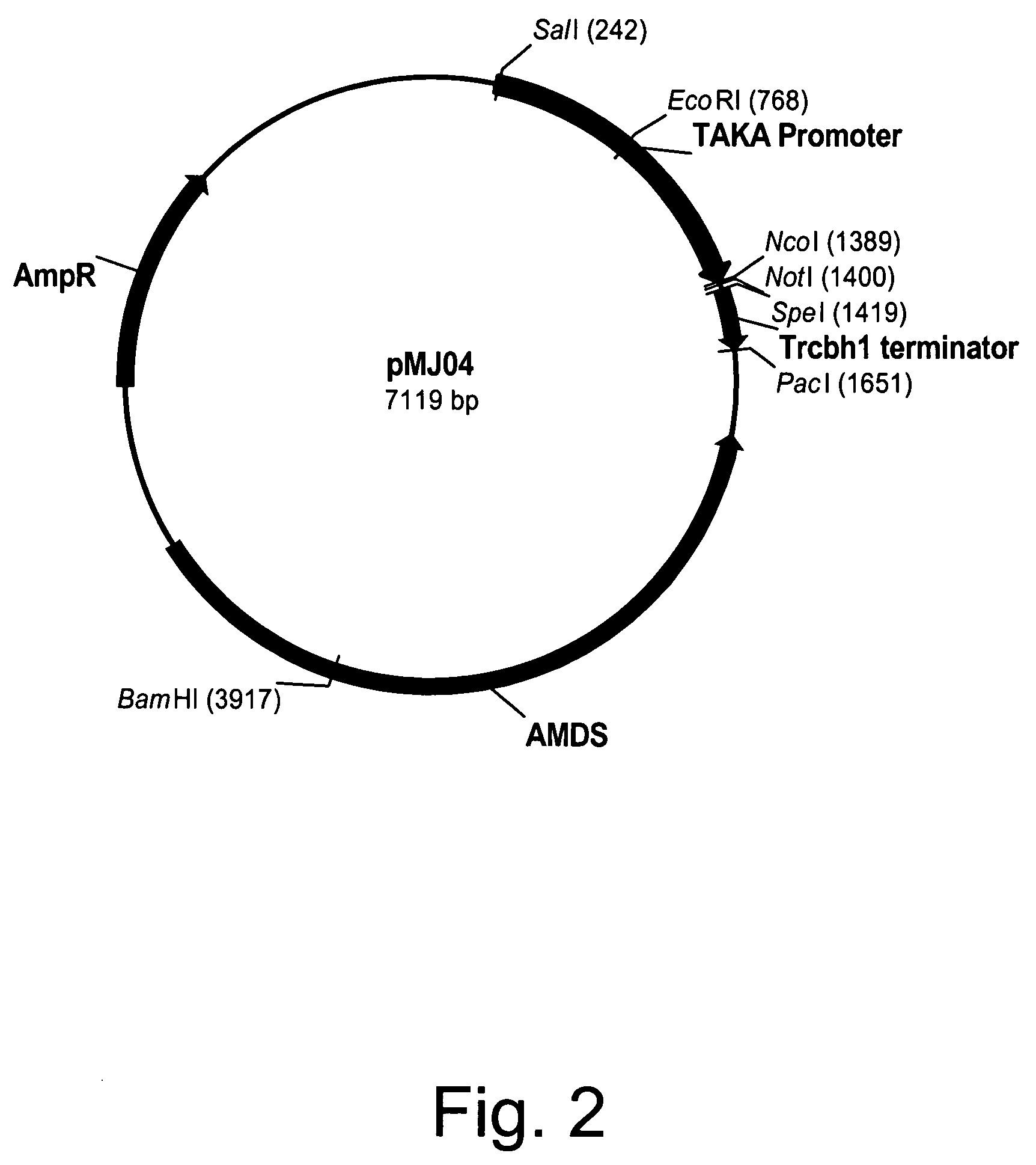

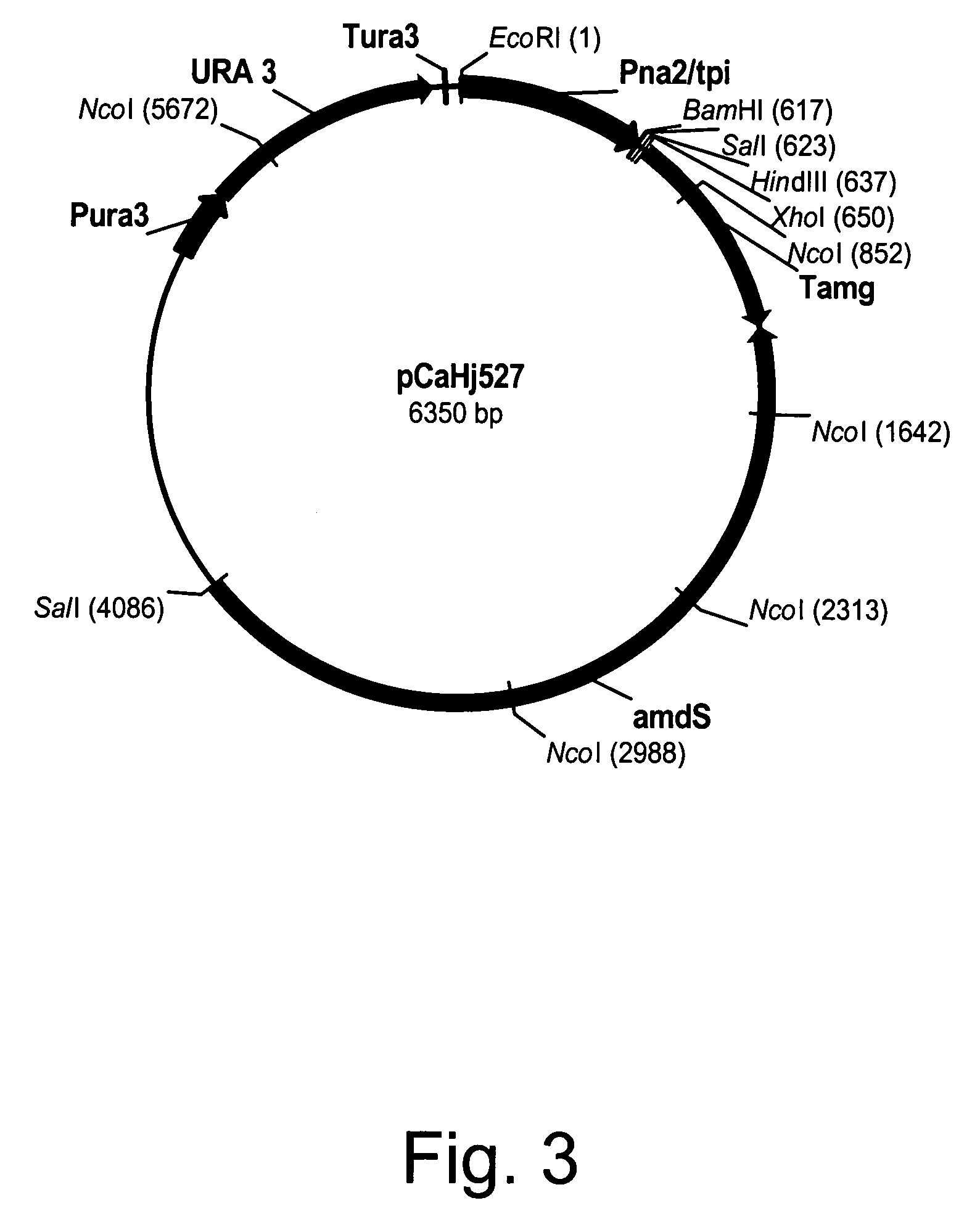

Enzymes for starch processing

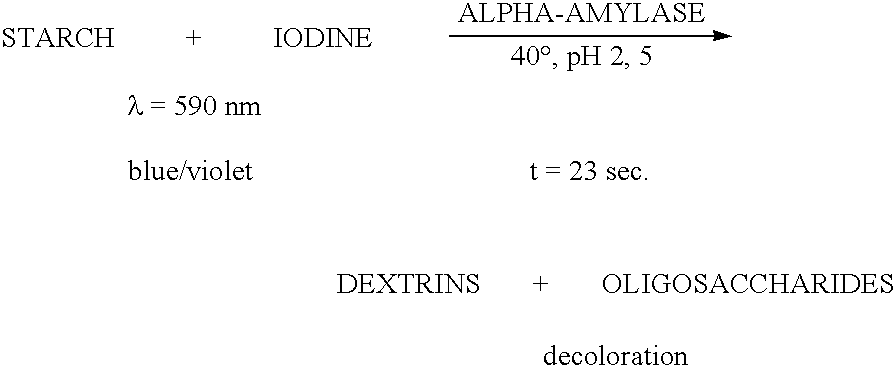

InactiveUS20060148054A1Good curative effectActivity be alteredFungiSugar derivativesCarbohydrate-binding proteinAlpha-amylase

The present invention relates to polypeptides comprising a carbohydrate-binding module amino acid sequence and,an alpha-amylase amino acid sequence as well as to the application of such polypeptides.

Owner:NOVOZYMES AS +1

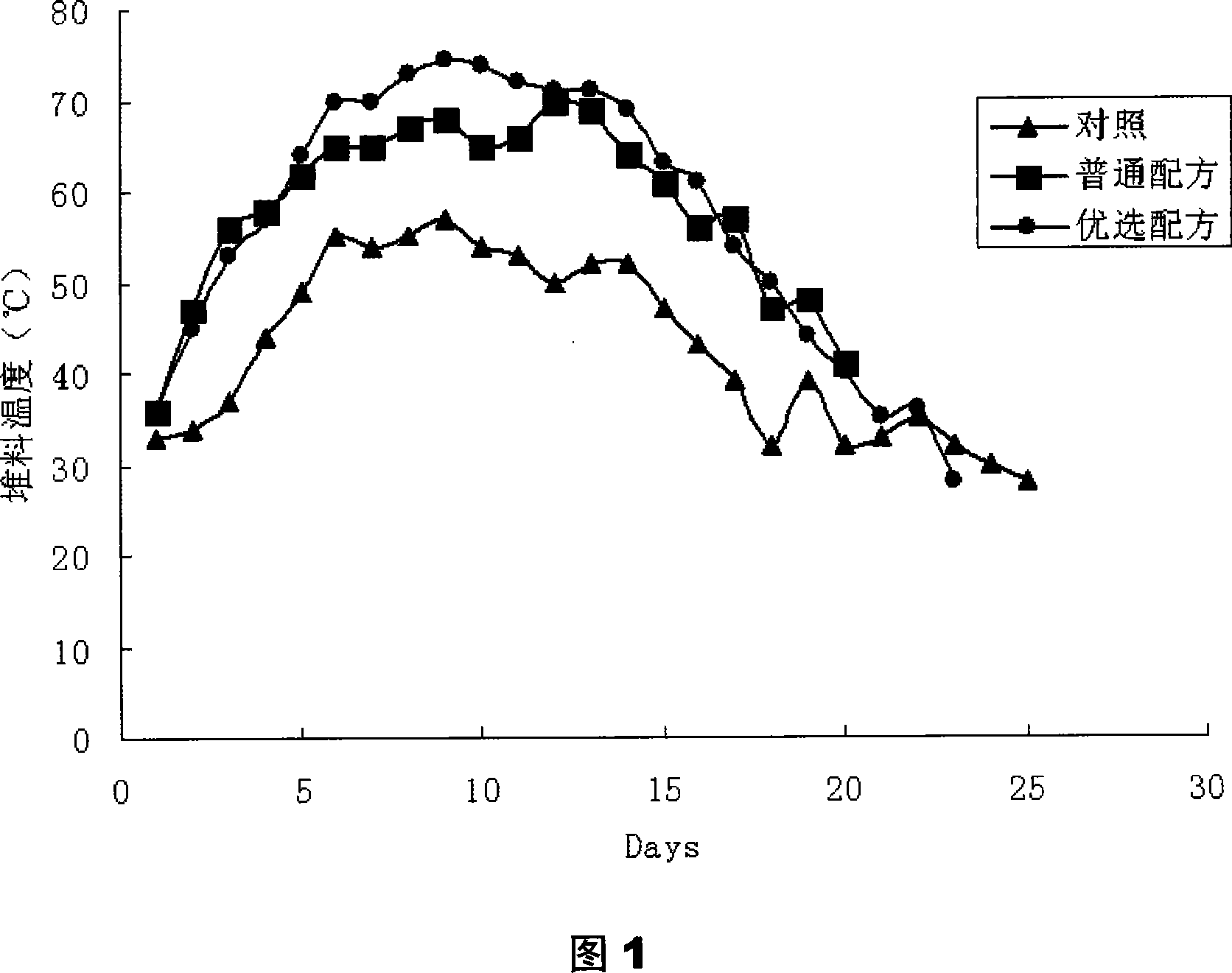

Agriculture castoff compost ternary microorganism composite microbial inoculum

ActiveCN101186879APromote degradationQuick conversionBio-organic fraction processingMicroorganismsMicroorganism resourceCompost

A composite biological agent with ternary microorganism for composting process of agricultural waste is composed of a composite biological agent I, a composite biological agent II, and a composite biological agent III, which is characterized in that the composite biological agent I is composed of bacillus, actinomycetes, microzyme and lactobacillus, the composite biological agent II is composed of trichoderma, ergillus, penicillium and trametes versicolor, and the composite biological agent III is composed of photosynthetic bacterium, azotobacter, phosphorus bacteria, and silicate bacterium. 30-60% composite biological agent I, 30-60% composite biological agent II, 10-20% composite biological agent III are mixed or applied to the process of composting process of agricultural waste in phases. Each component ratio and recruitment of biological agents can be both properly adjusted with different dung materials and dung purpose, thereby achieving purpose of using microorganism resources efficiently and raising fermentation efficiency.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

Water-Absorbing Polysaccharide and Method for Producing the Same

InactiveUS20080009616A1Drying processImprove retentionSugar derivativesBaby linensPolyphosphatePhosphoric acid

The present invention relates to a process for producing a water-absorbent polysaccharide including the process steps of bringing into contact an uncrosslinked polysaccharide with a polyphosphate or a polyphosphoric acid as crosslinking agent in the presence of water to form a polysaccharide gel and crosslinking the polysaccharide gel. The invention further relates to a water-absorbent polysaccharide obtainable by this process, a water-absorbent polysaccharide, a composite, a process for producing a composite, a composite produced by this process, the use of the water-absorbent polysaccharides or of the composites as well as the use of polyphosphates.

Owner:EVONIK DEGUSSA GMBH

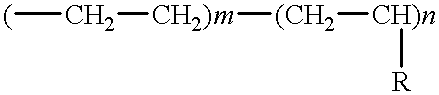

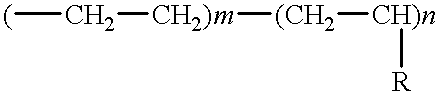

Methods for degrading lignocellulosic materials

The present invention relates to methods for degrading a lignocellulosic material, comprising: treating the lignocellulosic material with an effective amount of one or more cellulolytic enzymes in the presence of at least one surfactant selected from the group consisting of a secondary alcohol ethoxylate, fatty alcohol ethoxylate, nonylphenol ethoxylate, tridecyl ethoxylate, and polyoxyethylene ether, wherein the presence of the surfactant increases the degradation of lignocellulosic material compared to the absence of the surfactant. The present invention also relates to methods for producing an organic substance, comprising: (a) saccharifying a lignocellulosic material with an effective amount of one or more cellulolytic enzymes in the presence of at least one surfactant selected from the group consisting of a secondary alcohol ethoxylate, fatty alcohol ethoxylate, nonylphenol ethoxylate, tridecyl ethoxylate, and polyoxyethylene ether, wherein the presence of the surfactant increases the degradation of lignocellulosic material compared to the absence of the surfactant; (b) fermenting the saccharified lignocellulosic material of step (a) with one or more fermentating microoganisms; and (c) recovering the organic substance from the fermentation.

Owner:NOVO NORDISKBIOTECH INC

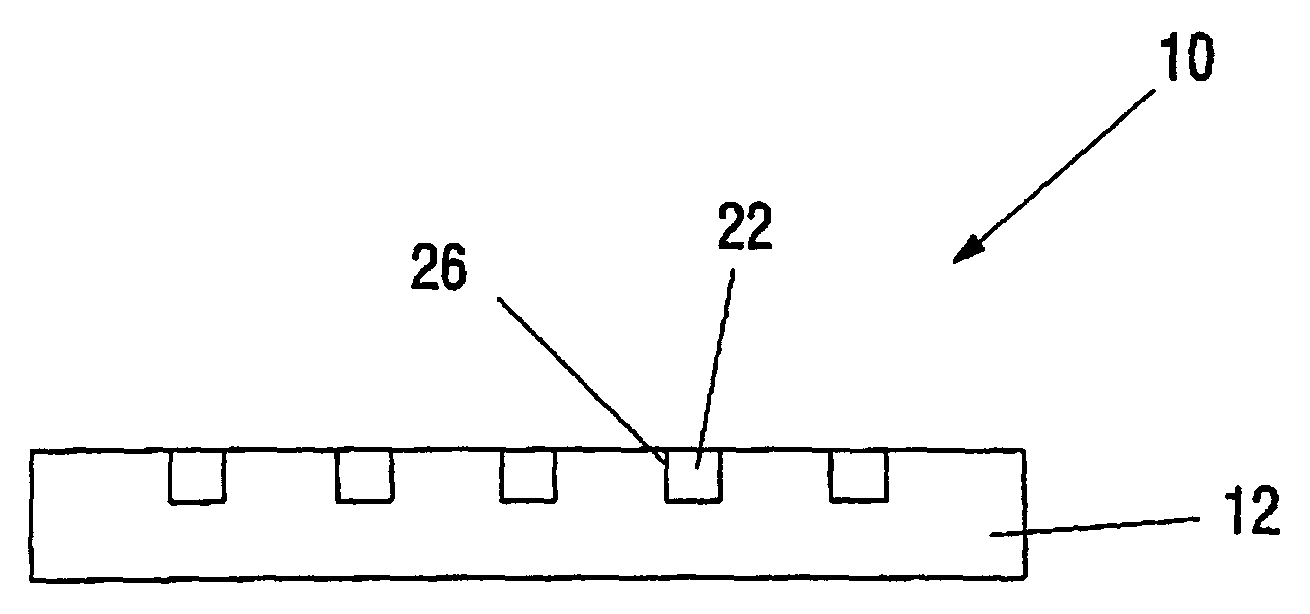

Use Of Heat-Activated Adhesive For Manufacture And A Device So Manufactured

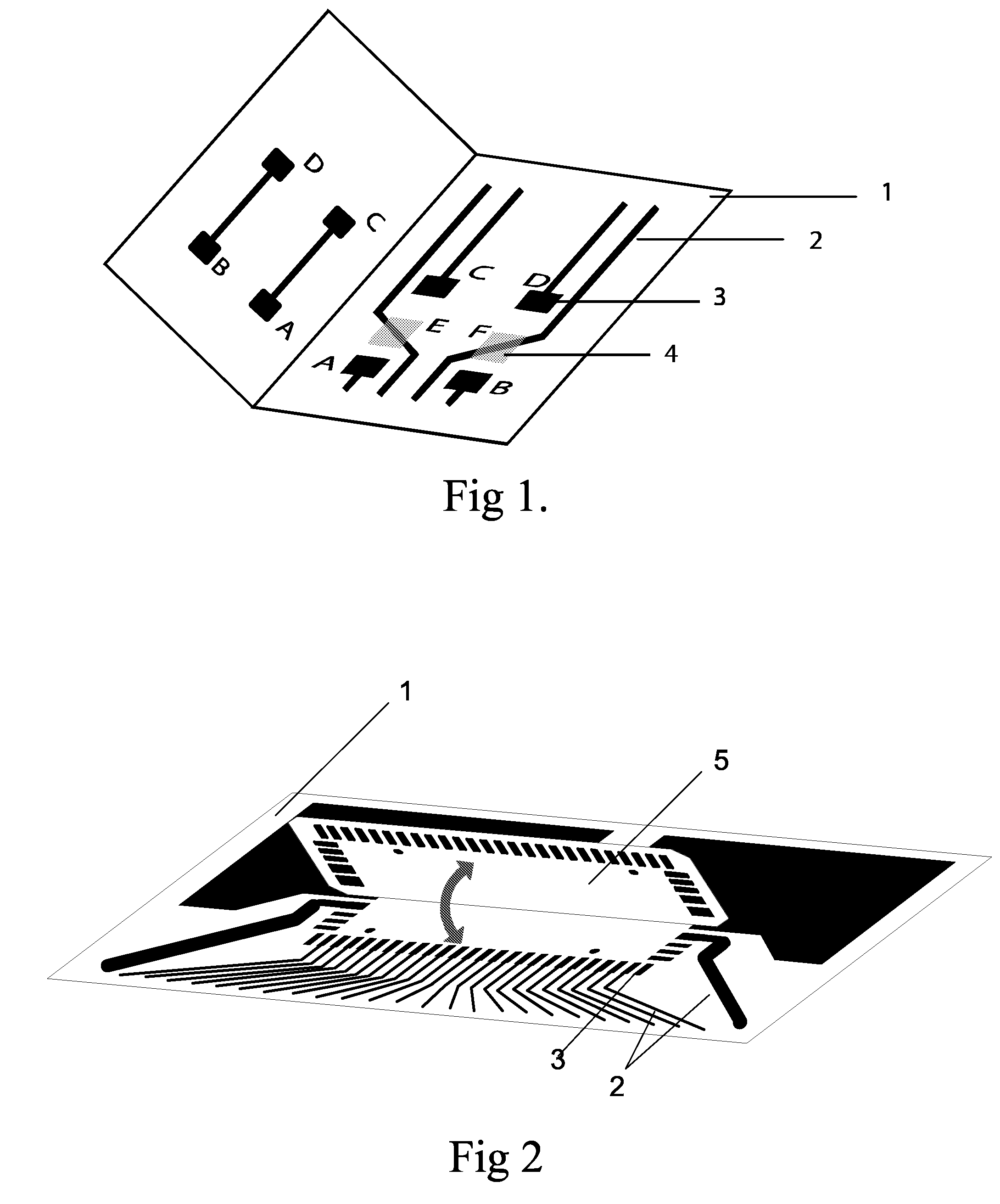

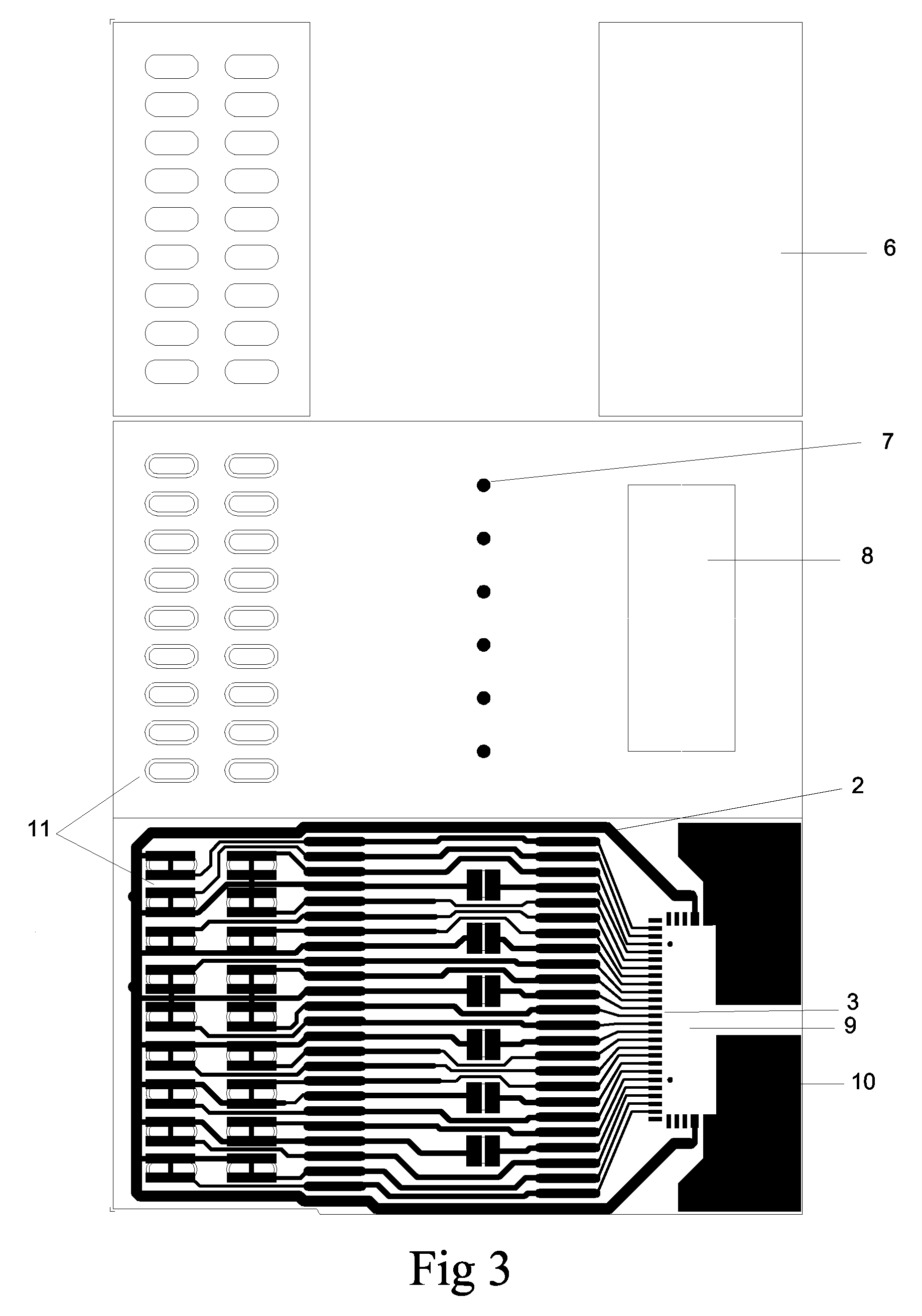

InactiveUS20080191174A1Promote degradationIncrease resistanceCircuit security detailsConductive materialElectrical connectionMechanical stability

The invention is based on use of a heat-activated adhesive for manufacturing of intelligent devices comprising printed conductive electronics on a flexible substrate, where the adhesive is an anisotropic electrically conductive adhesive and is applied to the substrate as a thin film which can be used for electrical connections and for providing mechanical stability to the printed conductive electronics.

Owner:CYPAK

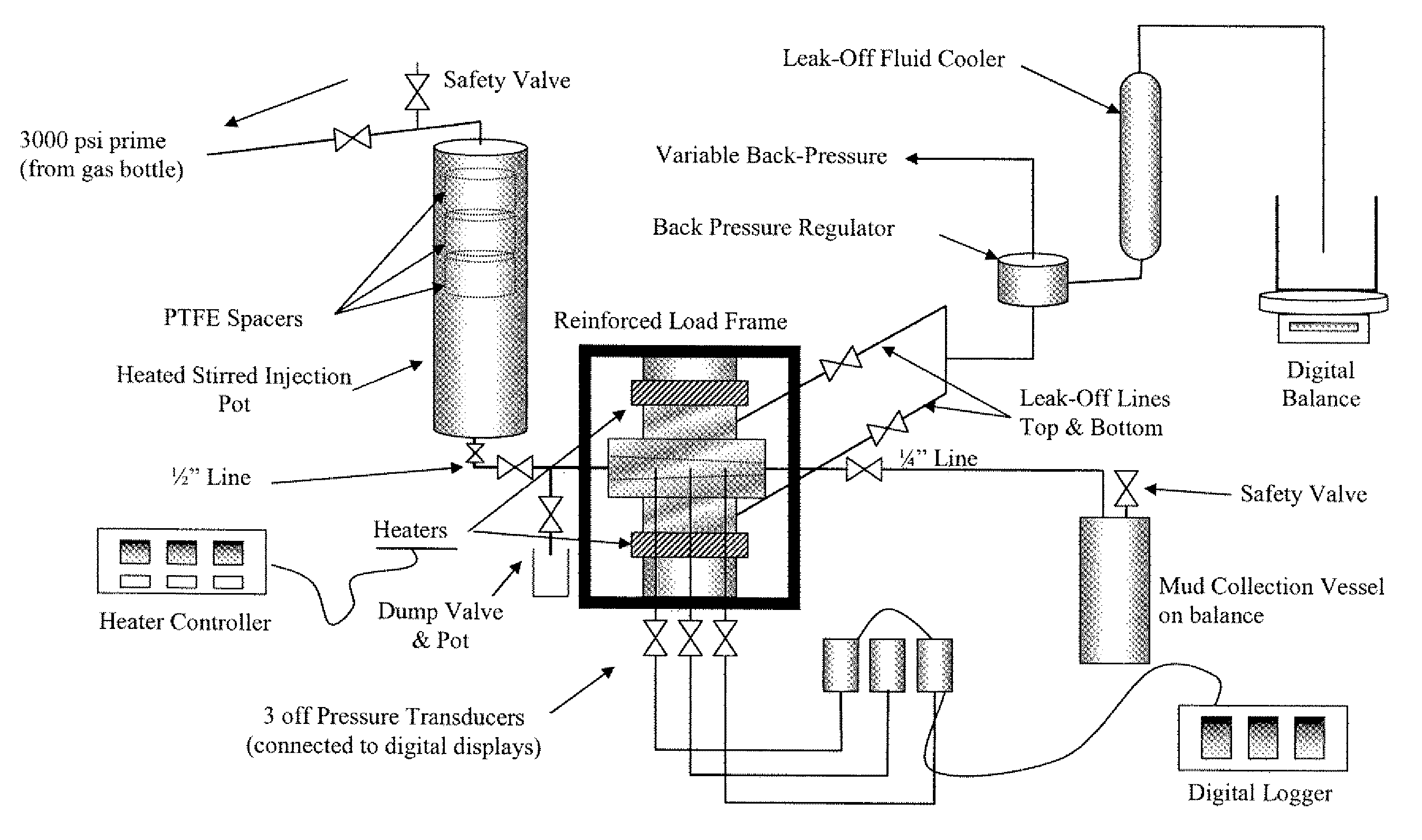

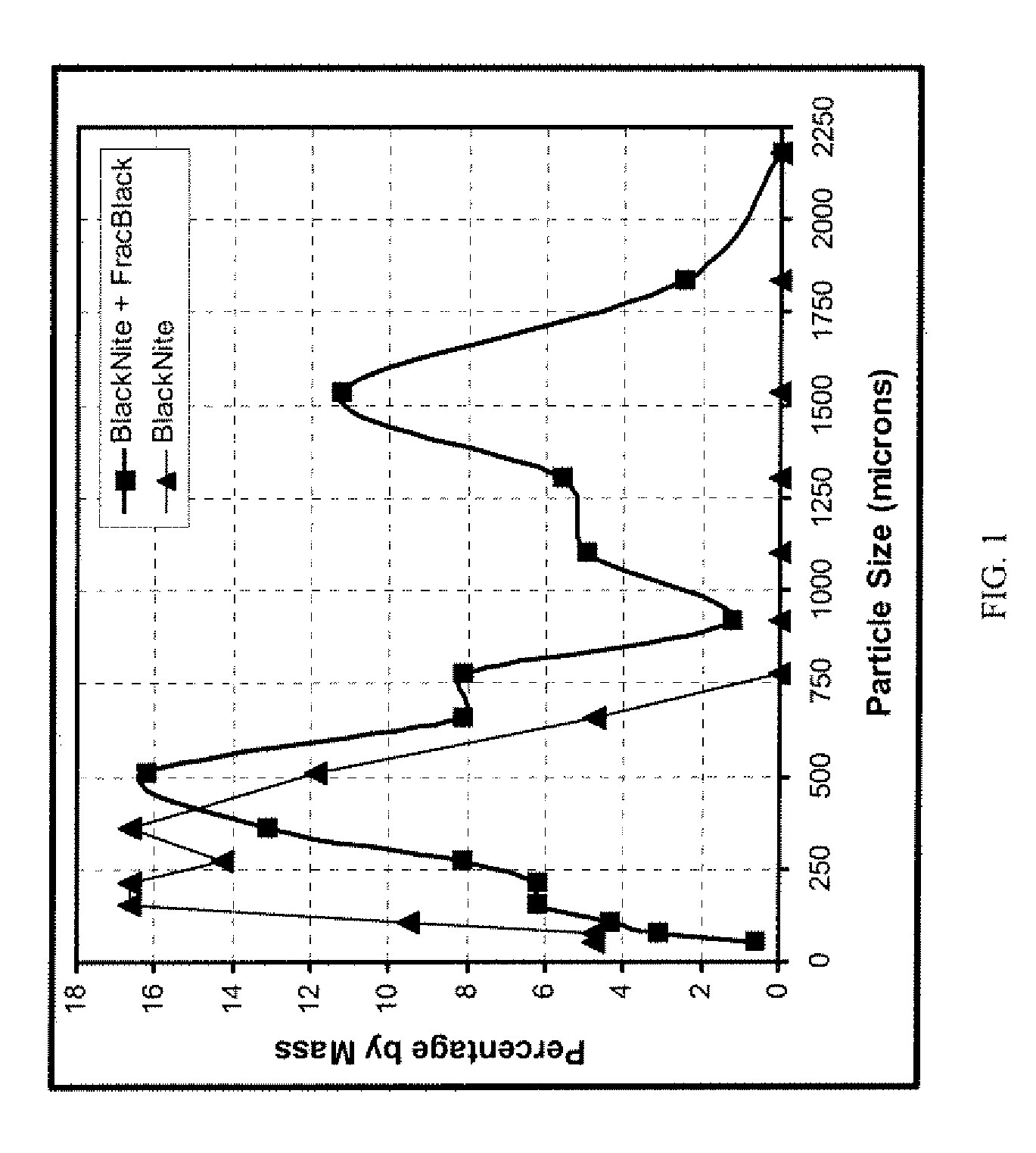

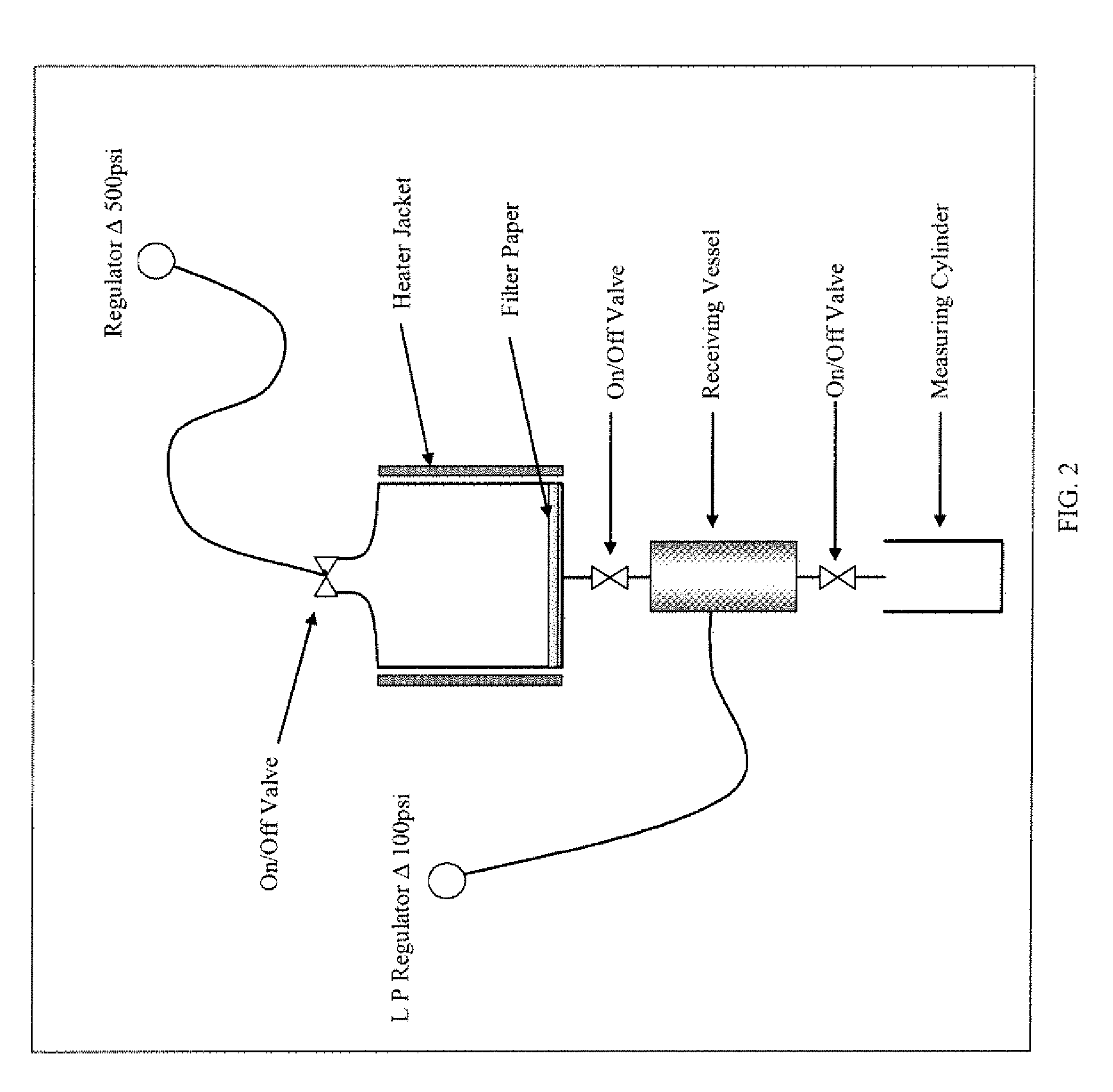

Drilling fluid, drill-in fluid, completition fluid, and workover fluid additive compositions containing thermoset nanocomposite particles; and applications for fluid loss control and wellbore strengthening

InactiveUS20090029878A1Loss in formationHigh strengthFlushingDrilling compositionWater basedDivinylbenzene

In one aspect, this invention relates to the use of thermoset nanocomposite particles as components of drilling fluid, drill-in fluid, completion fluid, and workover fluid additive packages to reduce fluid losses to a formation and / or to enhance a wellbore strength. In another aspect, this invention relates to the use particles of specific gravity ranging from about 0.75 to about 1.75 as components of drilling fluid, drill-in fluid, completion fluid, and workover fluid additive packages to reduce fluid losses to a formation and / or to enhance a wellbore strength. Using embodiments of the invention, reduction of fluid loss and / or enhancement of wellbore strength may be achieved while working with water-based, oil-based, invert emulsion, or synthetic drilling muds. The currently most preferred embodiments of the invention use substantially spherical thermoset nanocomposite particles, possessing a specific gravity from approximately 1.02 to approximately 1.15 wherein the matrix is a terpolymer of styrene, ethylvinylbenzene and divinylbenzene, and wherein carbon black particles possessing a length that is less than about 0.5 microns in at least one principal axis direction are incorporated as a nanofiller.

Owner:SUN DRILLING PRODS

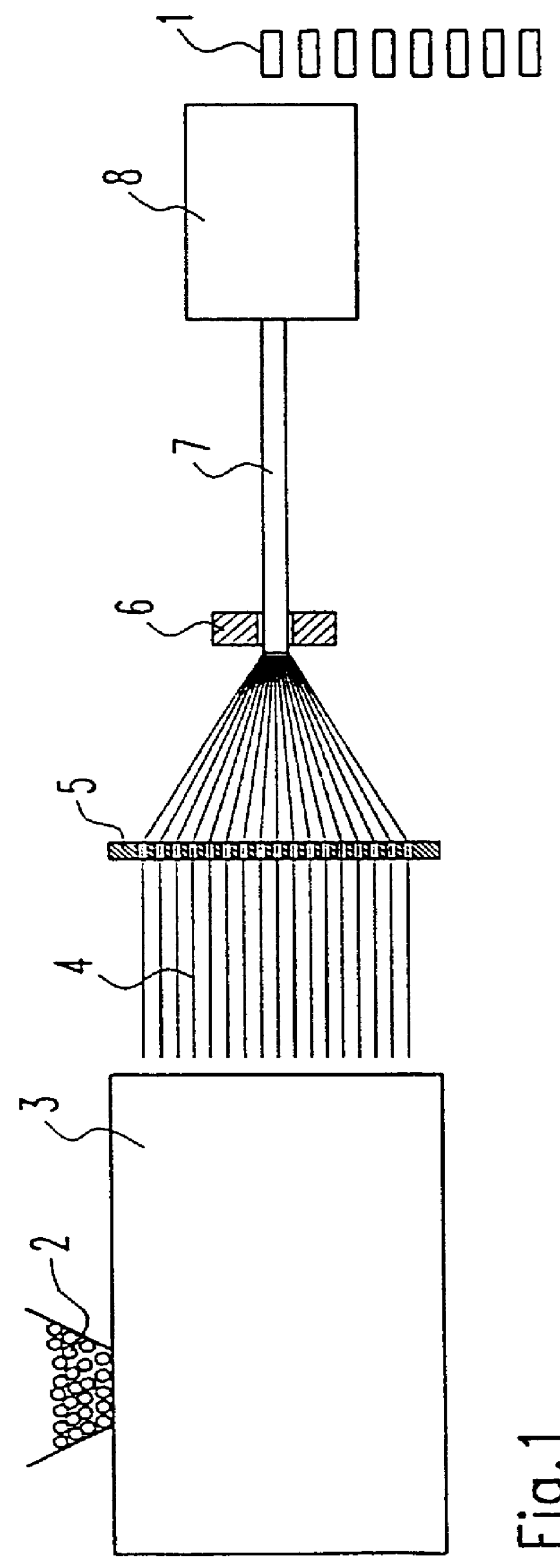

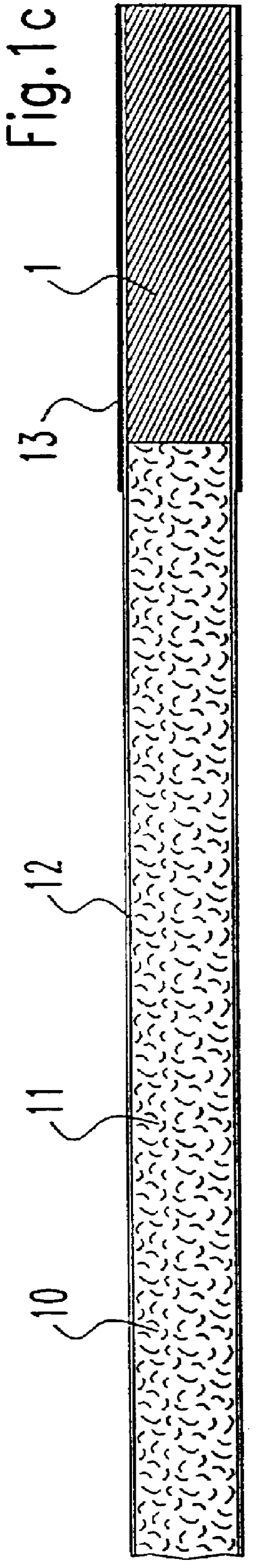

Biodegradable filter material and method for its manufacture

InactiveUS6062228AGood filtering propertyImprove biodegradabilityMechanical working/deformationTobacco treatmentFlavorFilter material

PCT No. PCT / EP96 / 04234 Sec. 371 Date Mar. 30, 1998 Sec. 102(e) Date Mar. 30, 1998 PCT Filed Sep. 27, 1996 PCT Pub. No. WO97 / 12528 PCT Pub. Date Apr. 10, 1997There is provided a biodegradable filter tow or filter material from renewable raw materials for the use as a tobacco smoke filter element of cigarettes, cigars or pipes as well as a method for preparing it, wherein fibers, films or foams prepared in an extrusion method from biopolymers based on thermoplastic starch or its polymer compositions are processed to the filter tow or filter material according to the present invention. The advantages of this invention reside in the use of mainly renewable raw materials, a fast and complete biodegradability of the natural biopolymer filter material, a pollutant-reducing flavor-increasing filtering effect and an economically favorable preparation method.

Owner:BIO TEC BIOLOGISCHE NATURVERPACKUNGEN

High nutrient compound selenium fertilizer and preparation method thereof

InactiveCN102320879AGood compatibilityPromote degradationFertilizer mixturesTrace element compositionInorganic materials

The invention discloses a high nutrient compound selenium fertilizer comprising selenium, nuisanceless organic material-inorganic material and medium and trace elements, and a preparation method thereof. The high nutrient compound selenium fertilizer comprises 45-60 wt% of organic material, 55-35 wt% of inorganic material, 1-6 wt% of medium and trace elements, and 0.011-0.025 wt% of purified selenium. The fertilizer disclosed in the invention can increase yield efficiently, and allow the applied plant to contain selenium element which has health care effect to human body. The fertilizer adopts a plurality of internal adsorptions to protect selenium to let the selenium in the selenium fertilizer be effective, has good intermiscibility and degradability, keeps selenium from fix, and obviously improves the biological absorption utilization rate of selenium of plants (including tea).

Owner:李子先 +1

Products useful as roof shingles and a process for making such products

InactiveUS6194519B1ExpensePromote degradationRoof covering using tiles/slatesOther chemical processesElastomerRubber material

The present invention relates to low-cost, efficiently-manufactured, polymer-based products useful as roofing shingles and similar products. The inventive shingles are weatherproof, inexpensive to manufacture and durable, particularly as contrasted with conventional shingles in areas of the country subject to hail damage. The invention also includes a method of making such shingle products. In a preferred embodiment, products of this invention use rubber material as the polymer base in combination with specific types of polyolefins. The rubber material can be most efficiently provided by the use of crumb rubber particles from spent automobile tires and other recycled rubber debris which are readily available and of very low cost. The products will have an average life far greater than that of current commercial roofing shingles, which are made using fiberglass or asphalt.The products of the instant invention are produced by extrusion as a mixture of materials, which product and its materials can be summarized as follows as a roofing shingle product which comprises:a. one or more side-branched polyolefins as an elastomer;b. optionally a blend of additional synthetic polymers, such as ethylene and propylene, as a second elastomer; andc. a rubber fraction, preferably obtained in part from recycled spent automotive or truck tires, and similar sources of waste rubber (sometimes known as "crumb rubber"), ground or recycled into particles having a mesh size of from 10 to 30 (i.e., approximately from about 500 to about 1000 microns).

Owner:MONTY MCWILLIAMS +3

Disposable and biodegradable paper cup

InactiveUS6926197B2Improve thermal performanceHigh biodegradabilityFlexible coversWrappersPaper sheetPhase transition

Owner:HED AHARON ZEEV +1

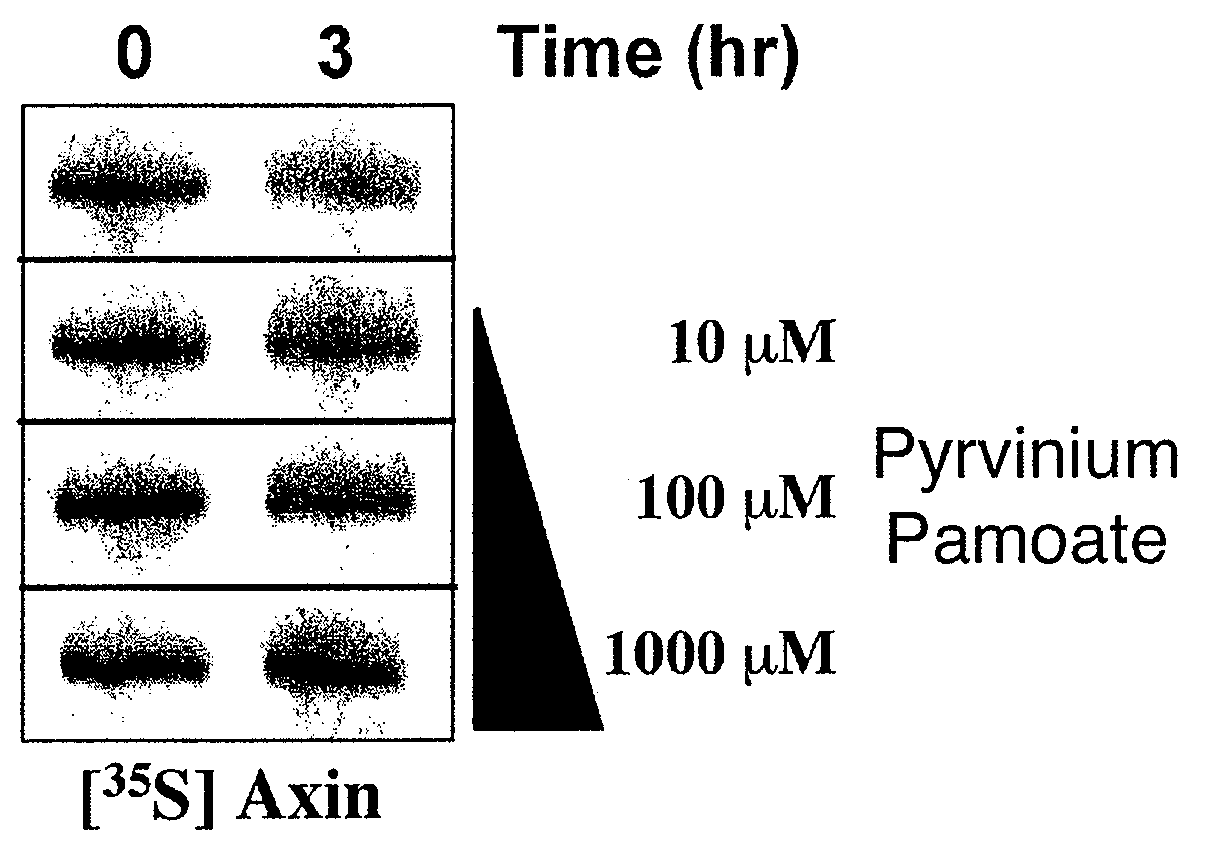

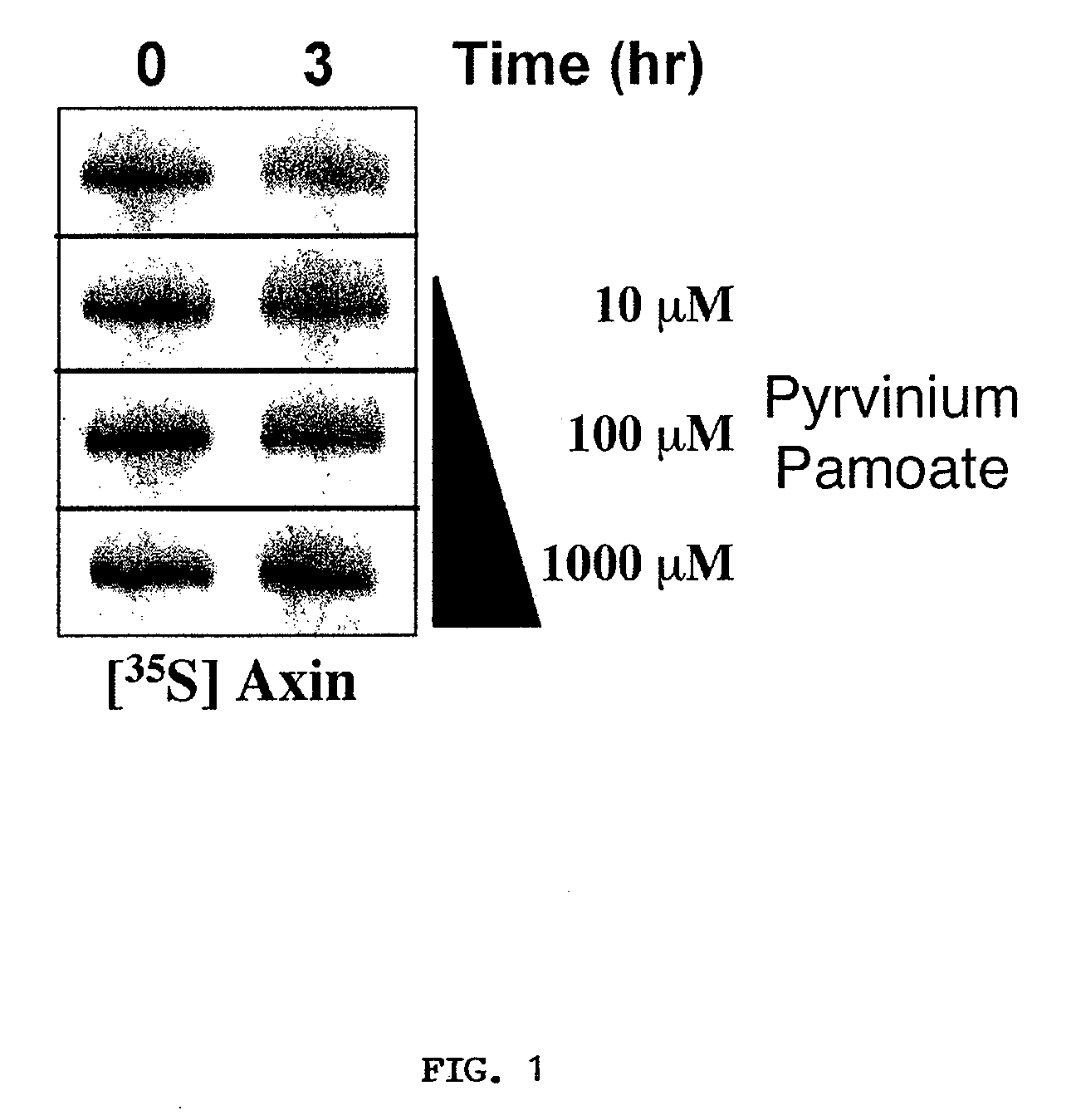

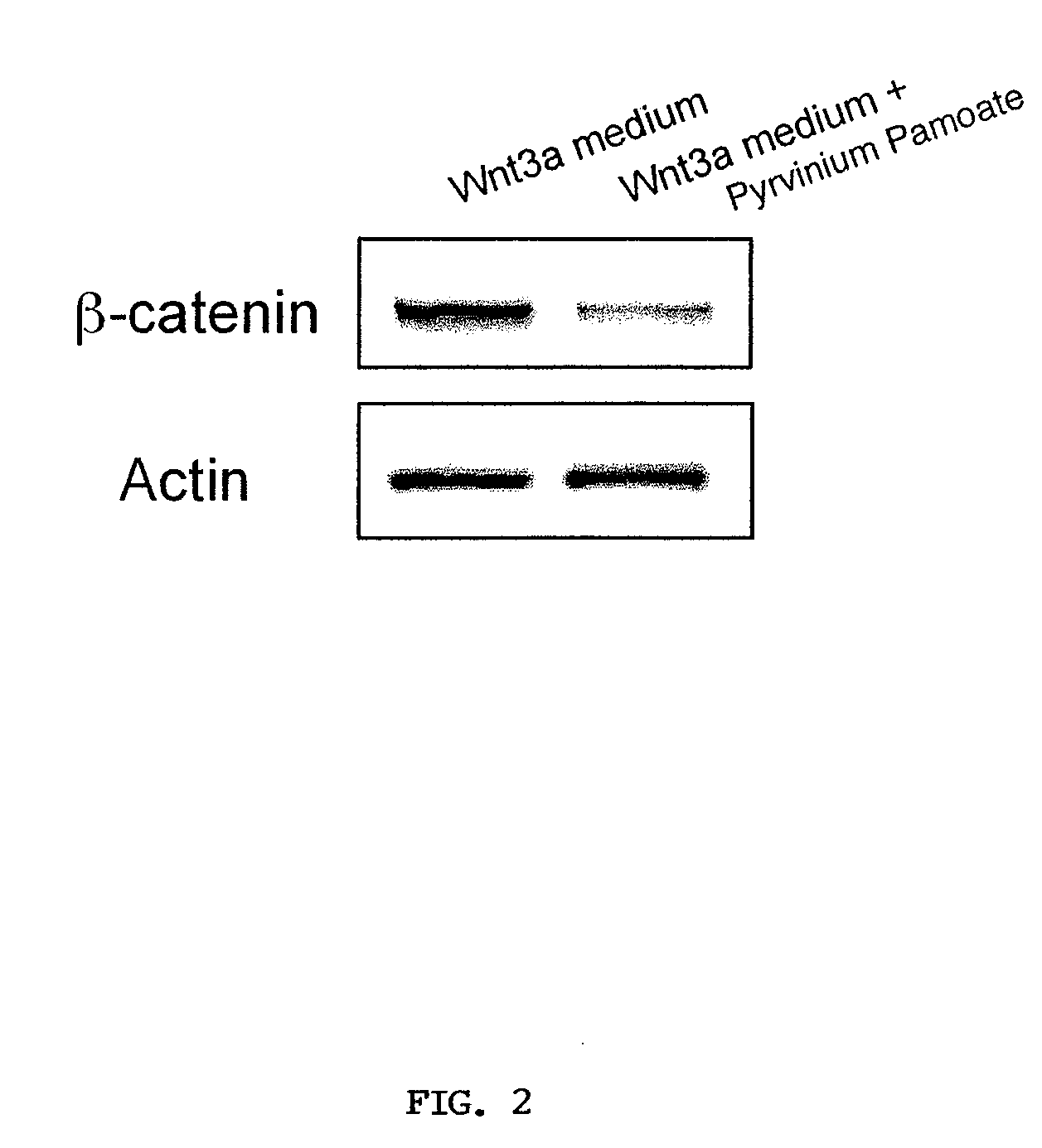

Pyrvinium For The Treatment of Cancer

InactiveUS20090099062A1Promote degradationImprove stabilityBiocideOrganic active ingredientsDiseaseNon cancer

The present invention concerns a pyrvinium compound or an analog thereof for the treatment of cancers. This compound inhibits Wnt activity in the cells of cancers such as adrenocortical, hepatocellular, hepatoblastoma, malignant melanoma, ovarian, Wilm's tumor, Barrett's esophageal, glioma, bladder, breast, gastric, head & neck, lung cell, mesothelioma, and cervical cancers. The present invention also provides a method for assaying for compounds that alter Wnt pathway activity. Also provided are methods for treating Wnt-related non-cancer disease states.

Owner:VANDERBILT UNIV

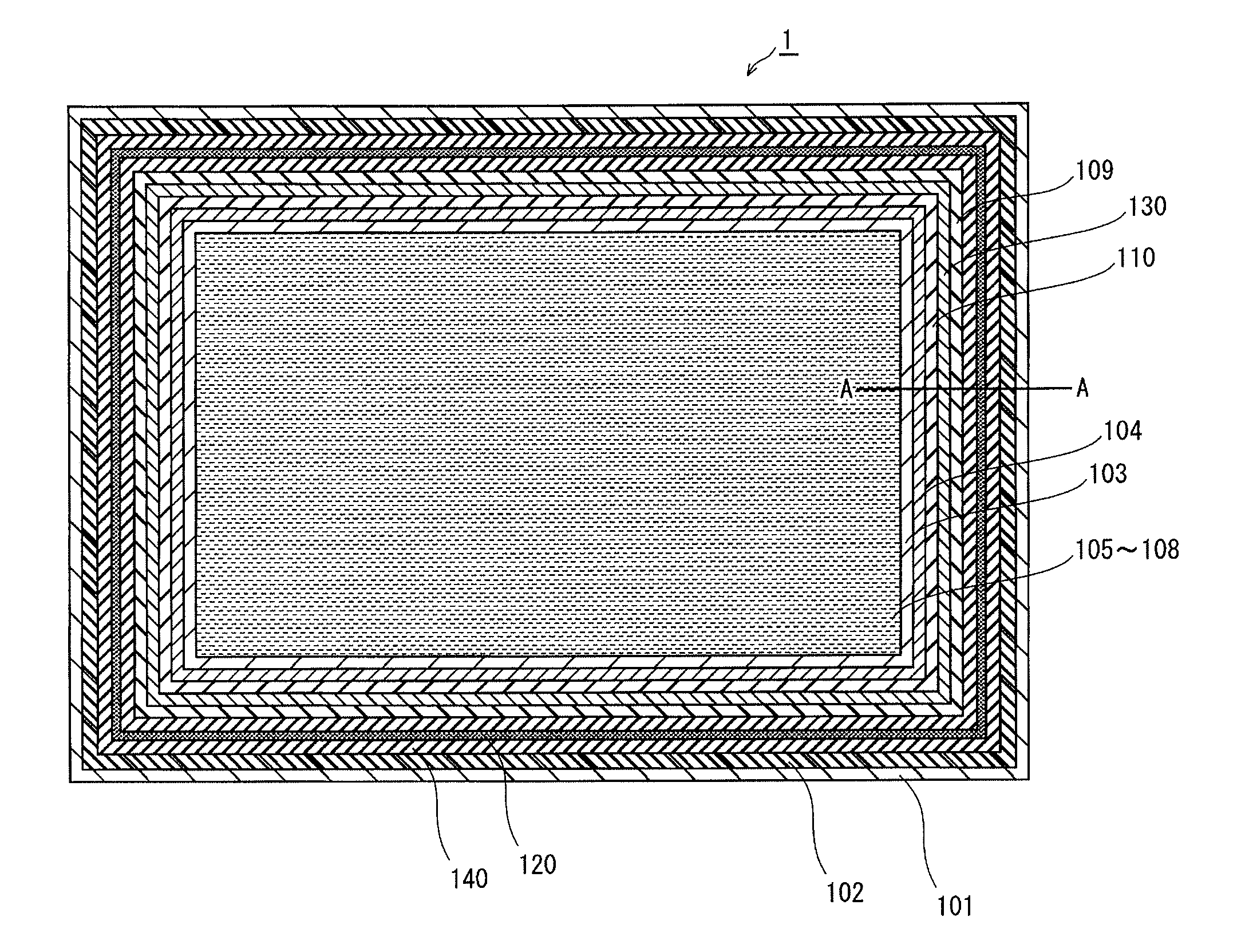

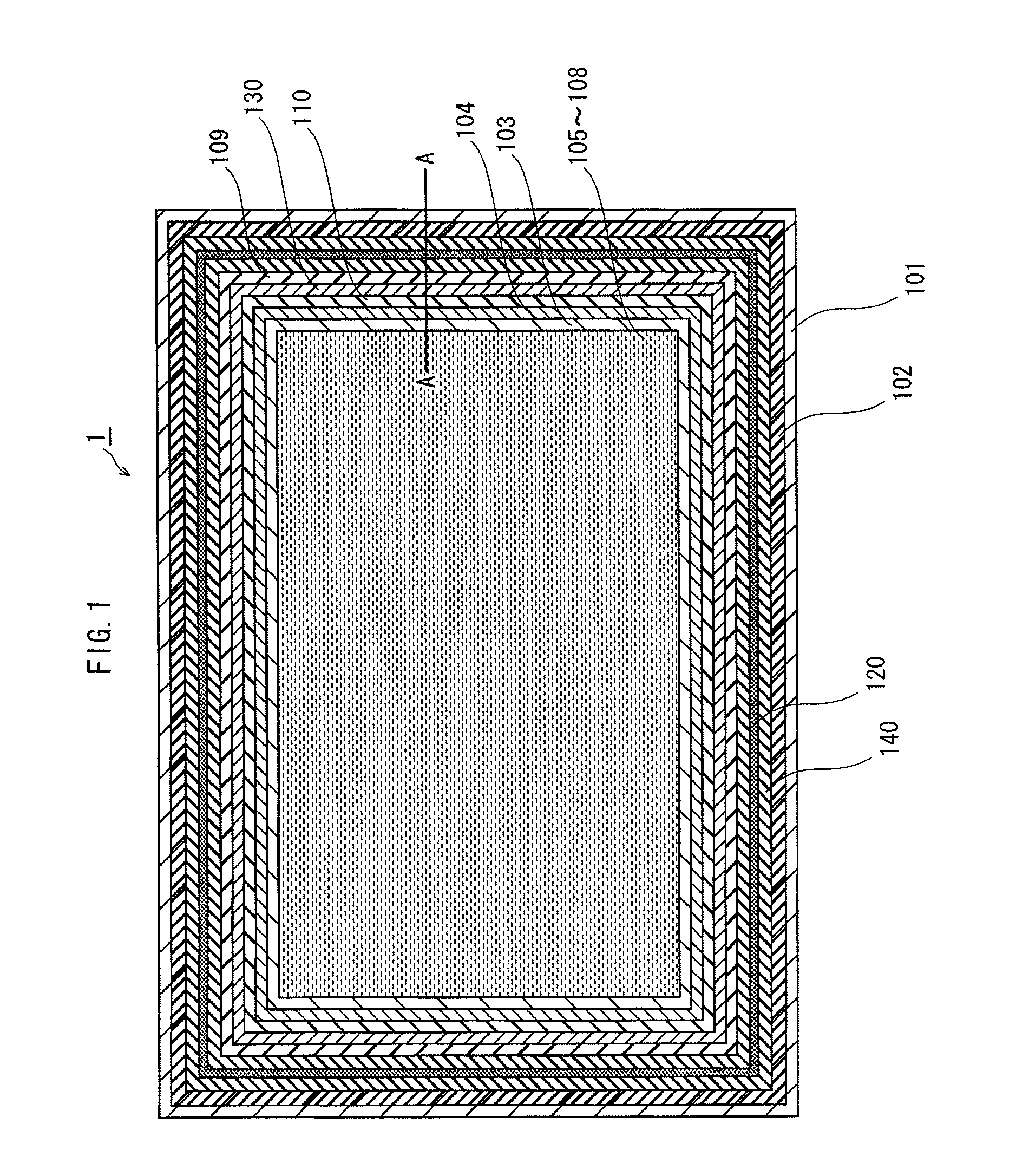

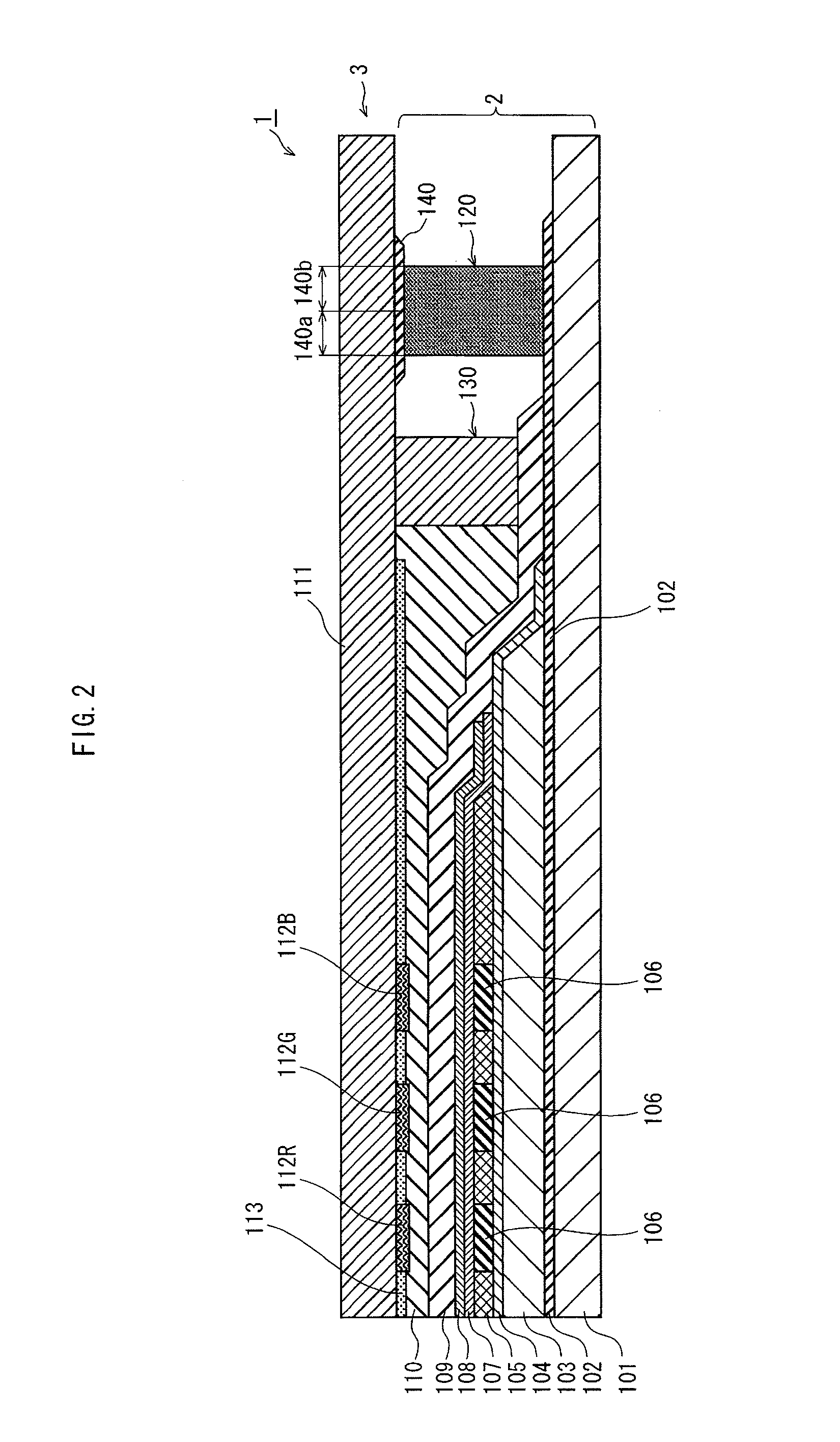

Display panel and production method thereof

ActiveUS20120287026A1Improve deteriorationReduced Surface Flatness RequirementsLamination ancillary operationsStatic indicating devicesPhoto irradiationHermetic seal

A display panel includes: a first substrate; light-emitting elements on a region of the first substrate; a second substrate facing the first substrate with the light-emitting elements therebetween; a glass frit between the first substrate and the second substrate so as to surround the region of the first substrate in which the light-emitting elements are disposed, the glass frit providing a hermetic seal between the first substrate and the second substrate; and a light-shielding part formed on one of the first substrate and the second substrate so as to extend along the glass frit, the light-shielding part shielding light. The light-shielding part has a lower light-shielding property in a region corresponding to the outer region of the glass frit than in a region corresponding to the inner region of the glass frit. The glass frit has been irradiated with light through the light-shielding part.

Owner:JOLED INC

Black-odor river pollution treatment method

InactiveCN101417840AEfficient removalControl and reduce the total amount receivedTreatment using aerobic processesWater aerationMicrobial agentSelf purification

The invention discloses a method for managing town black and olid river pollution in situ by utilizing biological repair technology, which takes the steps and measures of aerating and oxygenizing in riverway, adding a complex microbial agent, biologically repairing bottom sediment, arranging a bio-nest system and the like, so as to control and eliminate the exogenous and endogenous pollution of the river, purify the water quality of the river, improve the self-purification ability of the water body and achieve the purpose of eliminating black and olid. The method does not need to build structures in the riverway or lead the river water out of the riverway to be treated, or dredge the bottom sediment in the river, therefore the method is generally applicable to incomplete sewage interception and dredging or the rivers which can not be intercepted sewage or dredged temporarily, and the in situ treatment to the riverway which is affected by tide and has complicated fluid variation. Therefore, the method which can lead the water body to recover normal ecological function provides the practical, economic and convenient treatment method for various town black and olid rivers.

Owner:黎赓桓 +1

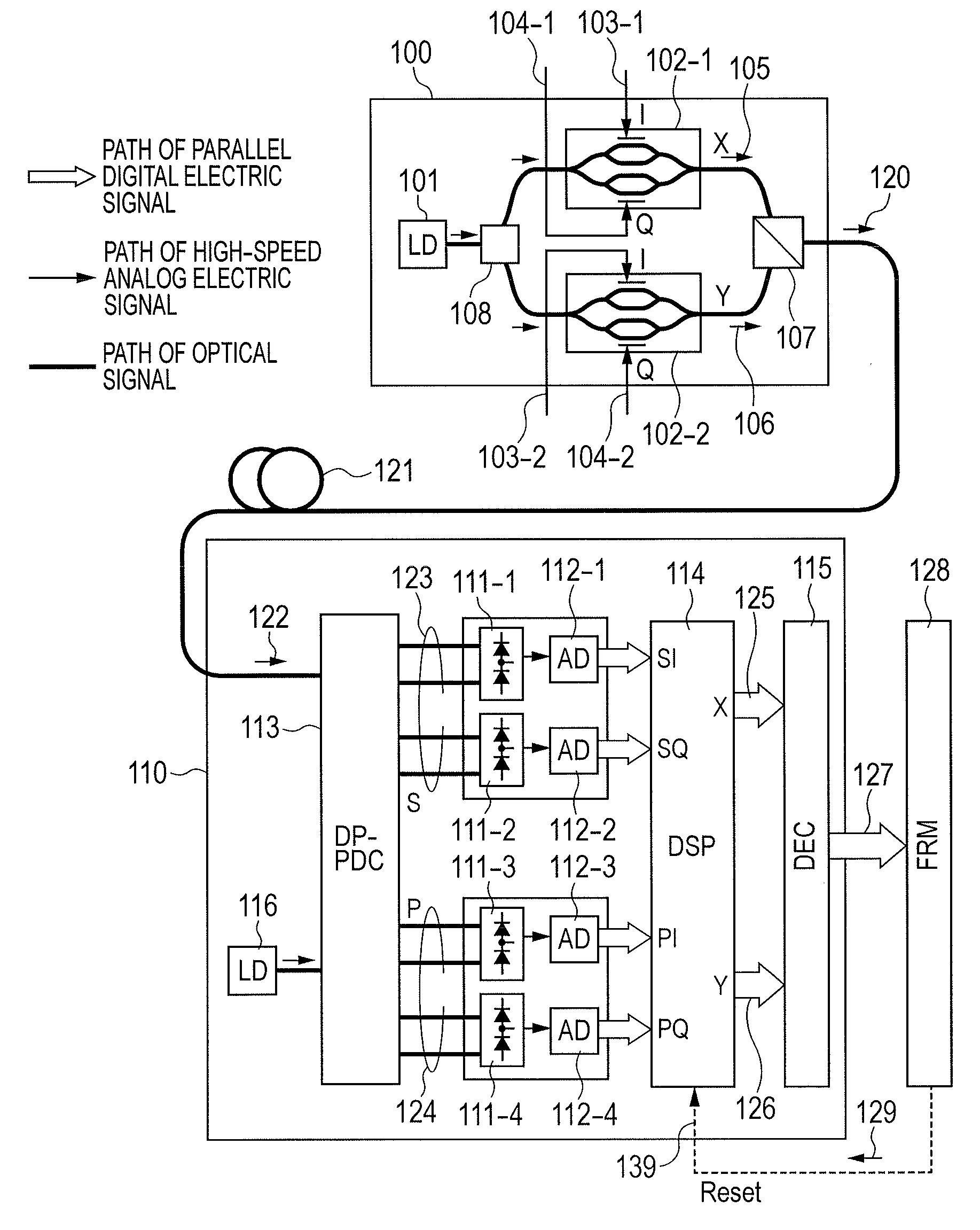

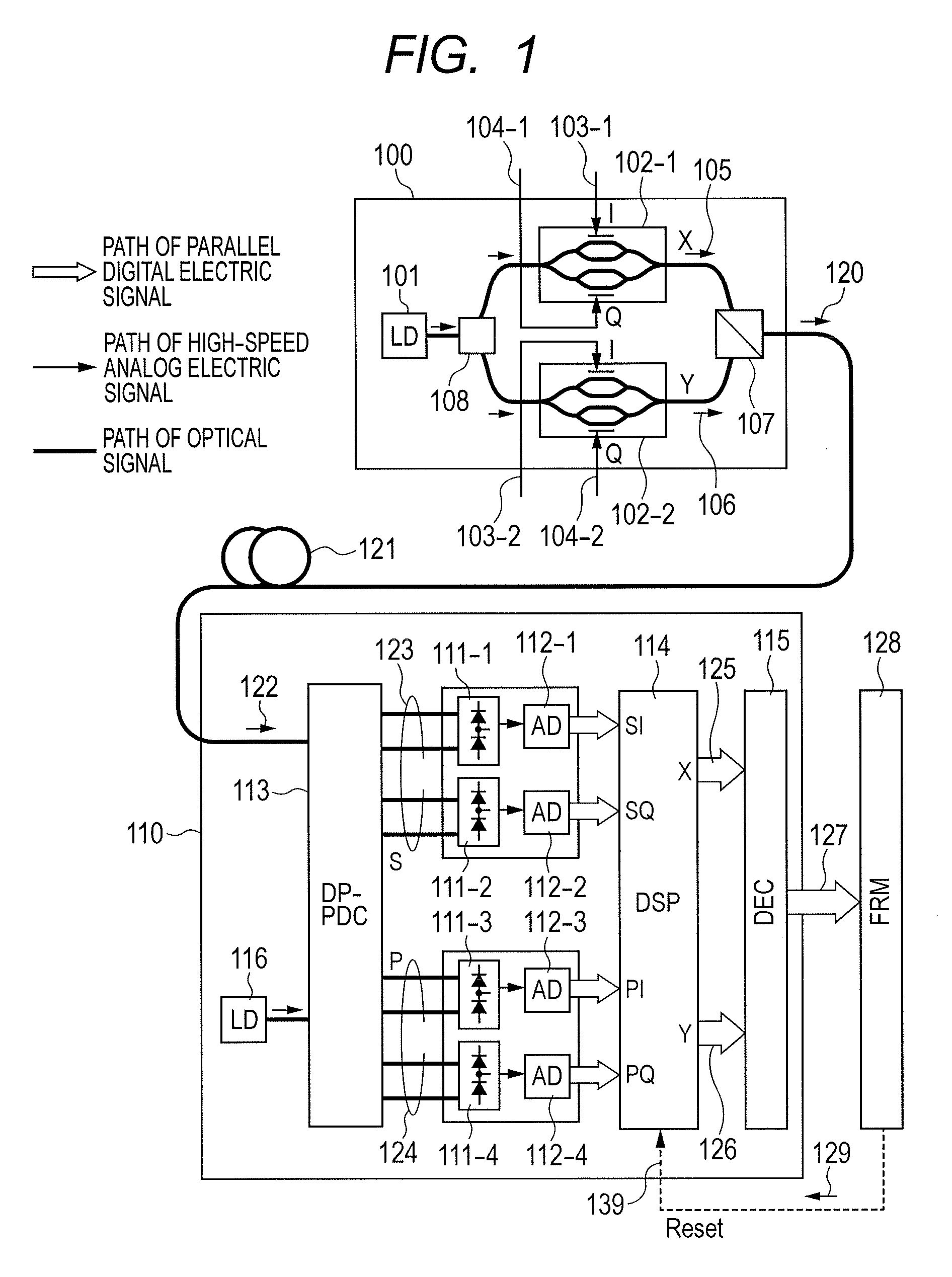

Polarization-Multiplexed Optical Transmission System, Polarization-Multiplexed Optical Transmitter, and Polarization-Multiplexed Optical Receiver

InactiveUS20120134676A1Preventing signal quality degradationReliable polarizationPolarisation multiplex systemsOptical mode multiplex systemsDigital signal processingPolarization diversity

There is a need to prevent two receivers from converging on a state of receiving the same polarization state, fast start receivers, and ensure highly reliable operations. A polarization-multiplexed transmitter previously applies frequency shifts of frequencies +Δf and −Δf to X-polarization and Y-polarization digital information signals to be transmitted. Optical field modulators modulate and polarization-multiplex the signals. As a result, a frequency difference of 2Δf is supplied to X-polarization and Y-polarization components. A polarization diversity coherent optical receiver 215 receives the signal. A frequency estimation portion in a digital signal processing circuit detects a frequency difference signal in both polarization components. This signal is used to a polarization splitting circuit in the digital signal processing circuit.

Owner:HITACHI LTD

Methods for degrading lignocellulosic materials

Owner:NOVO NORDISKBIOTECH INC

Modified and stabilized gdf propeptides and uses thereof

InactiveUS20070149455A1Avoid utilizationImproved pharmacokinetic propertiesFungiBacteriaMuscle tissueAmytrophic lateral sclerosis

Modified and stabilized propeptides of Growth Differentiation Factor proteins, such as GDF-8 and Bone Morphogenetic Protein-11, are disclosed. Also disclosed are methods for making and using the modified propeptides to prevent or treat human or animal disorders in which an increase in muscle tissue would be therapeutically beneficial. Such disorders include muscle or neuromuscular disorders (such as amyotrophic lateral sclerosis, muscular dystrophy, muscle atrophy, congestive obstructive pulmonary disease, muscle wasting syndrome, sarcopenia, or cachexia), metabolic diseases or disorders (such as such as type 2 diabetes, noninsulin-dependent diabetes mellitus, hyperglycemia, or obesity), adipose tissue disorders (such as obesity), and bone degenerative diseases (such as osteoporosis).

Owner:WYETH LLC

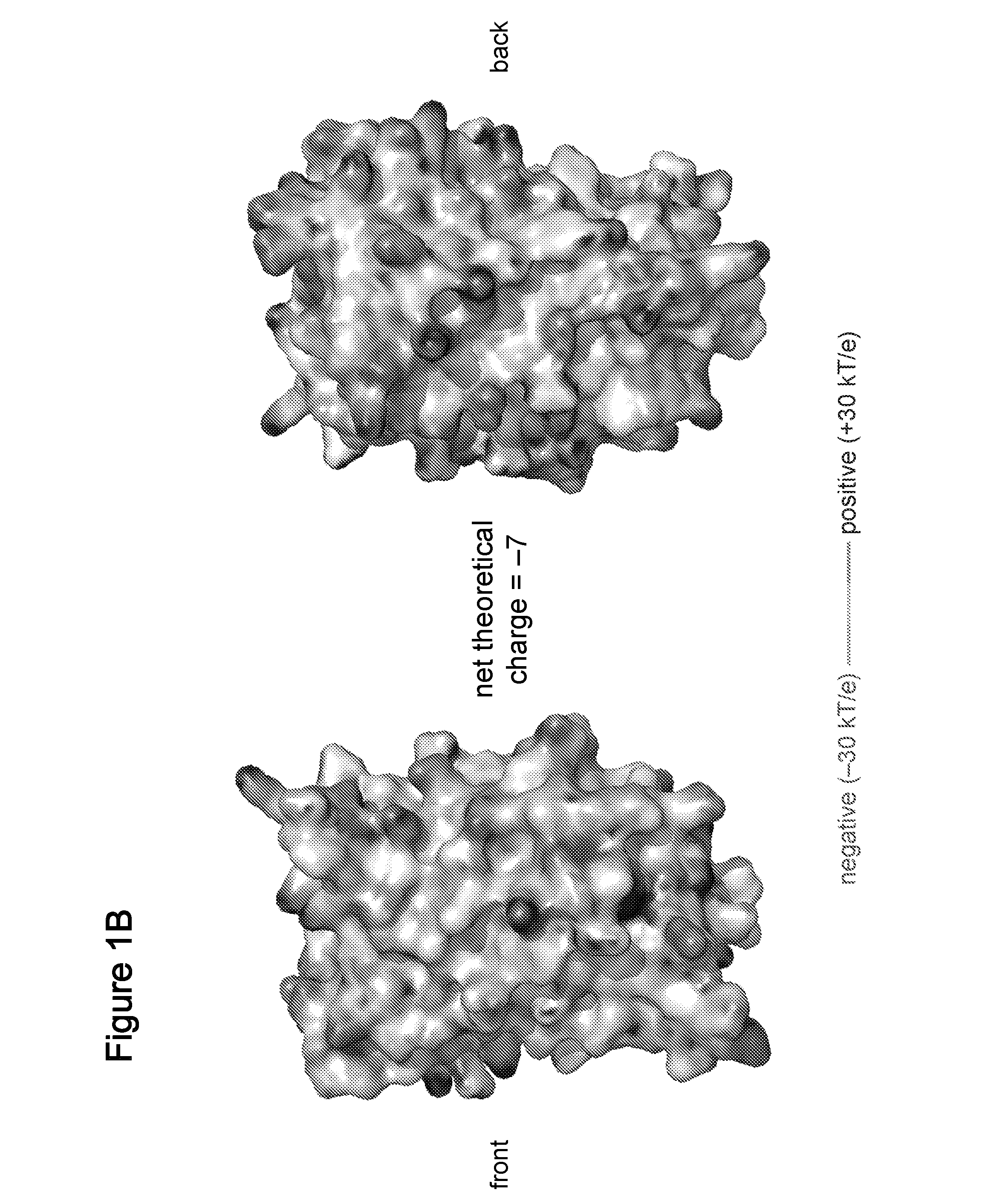

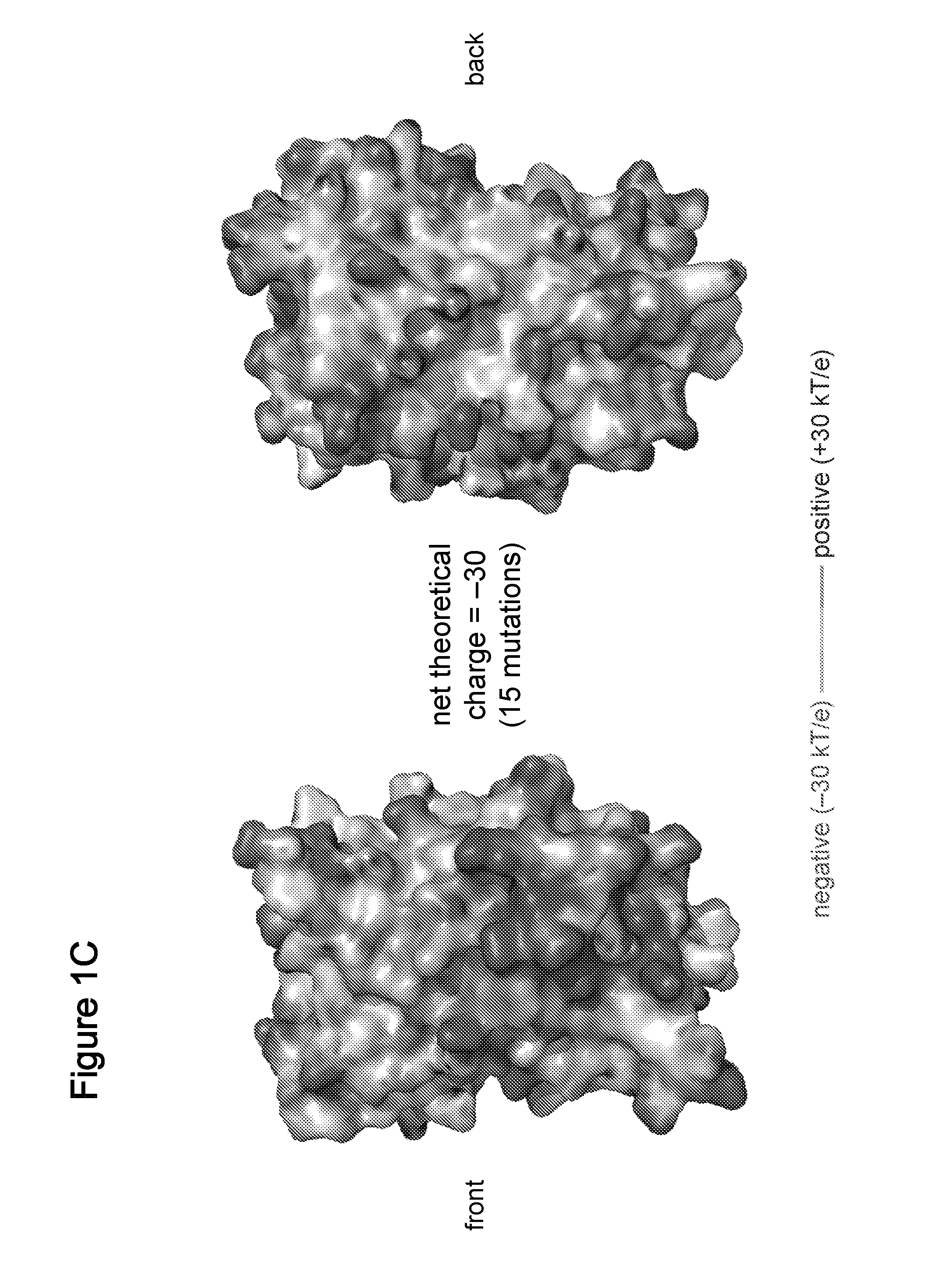

Supercharged proteins for cell penetration

InactiveUS20110112040A1Improved cell penetrationReduce biological activityMicrobiological testing/measurementSaccharide peptide ingredientsInfective disorderDisease cause

Compositions, systems and related methods for delivering a supercharged protein or a complex of a supercharged protein and therapeutic agent (e g, nucleic acid, peptide, small molecule) to cells are disclosed. Superpositively charged proteins may be associated with nucleic acids (which typically have a net negative charge) via electrostatic interactions. The systems and methods may involve altering the primary sequence of a protein in order to “supercharge” the protein (e g, to generate a superpositively-charged protein). The compositions may be used to treat proliferative diseases, infectious diseases, cardiovascular diseases, inborn errors in metabolism, genetic diseases, etc.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com