Patents

Literature

8851 results about "Specific gravity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Specific gravity, also called relative density, is the ratio of the density of a substance to the density of a reference substance; equivalently, it is the ratio of the mass of a substance to the mass of a reference substance for the same given volume. Apparent specific gravity is the ratio of the weight of a volume of the substance to the weight of an equal volume of the reference substance. The reference substance for liquids is nearly always water at its densest (at 4 °C or 39.2 °F); for gases it is air at room temperature (20 °C or 68 °F). Nonetheless, the temperature and pressure must be specified for both the sample and the reference. Pressure is nearly always 1 atm (101.325 kPa).

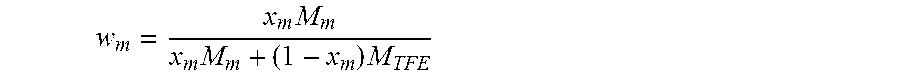

Copolymers of tetrafluoroethylene

ActiveUS7531611B2Synthetic resin layered productsThin material handlingBreaking strengthTetrafluoroethylene

A polymerization process for producing a tetrafluoroethylene copolymer, and the copolymer produced thereby, are provided. The copolymer is of the dispersion / fine powder type and contains polymerized tetrafluoroethylene monomer units and co-polymerized higher homologous comonomer units having the formula (CnF(2n+1))CH═CH2, wherein 6≦n<10, in which the primary particles are believed to have a core and shell structure and the polymerized comonomer units are present in an amount from 0.01 mol % to 0.3 mol %, based upon total copolymer composition. The copolymer has a raw dispersion primary particle size (RDPS) of less than 0.210 microns coupled with a standard specific gravity (SSG) of less than 2.143. Preferably the copolymer has comonomer units present in an amount from 0.05 mol % and 0.25 mol % and the RDPS is within the range between 0.178 microns and 0.200 microns, coupled with a SSG of less than 2.140. Copolymers produced according to the invention, (perfluorohexyl)ethylene (PFHE) and (perfluorooctyl)ethylene (PFOE), may be shaped into the form of 0.1 inch diameter expanded beading, which expanded beading can have a break strength of at least 10.0 lbs, and which may exceed 13.0 lbs.

Owner:WL GORE & ASSOC INC

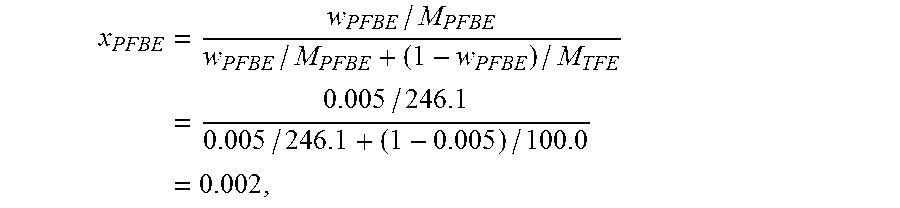

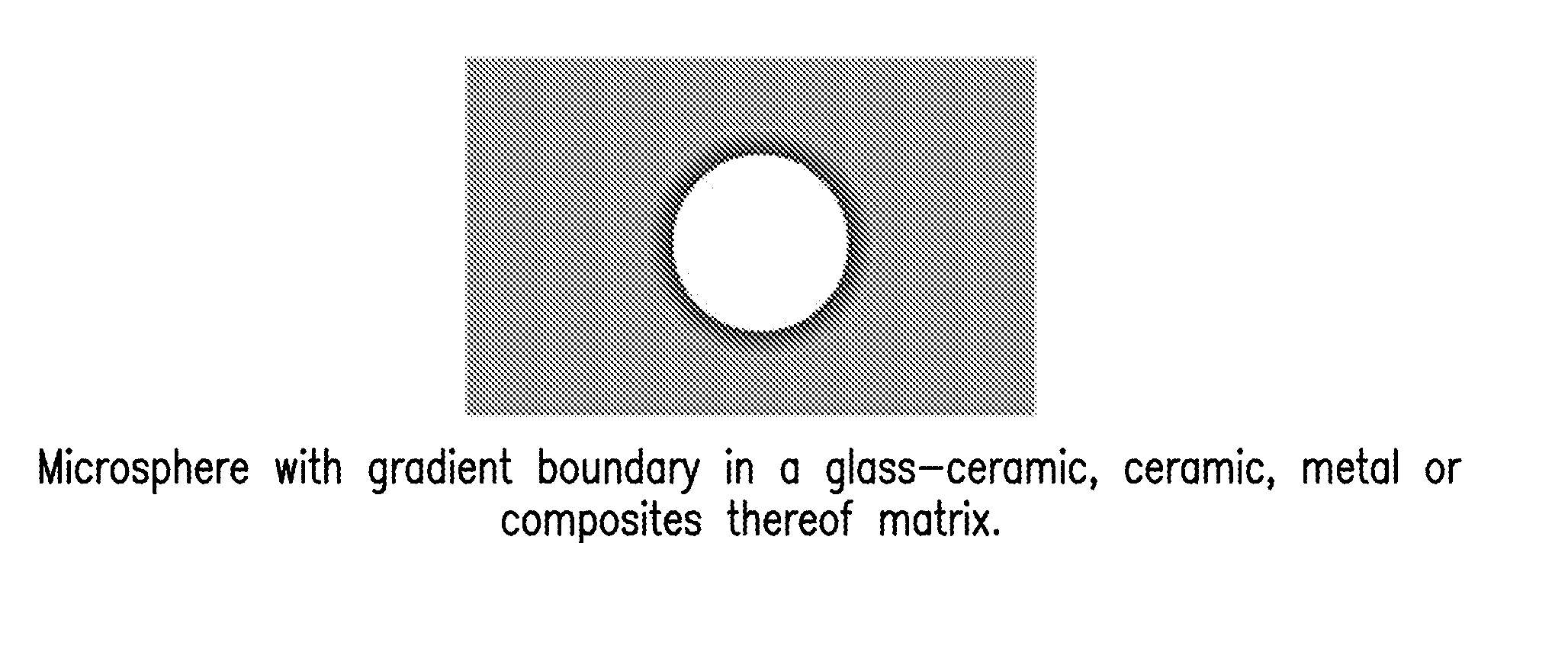

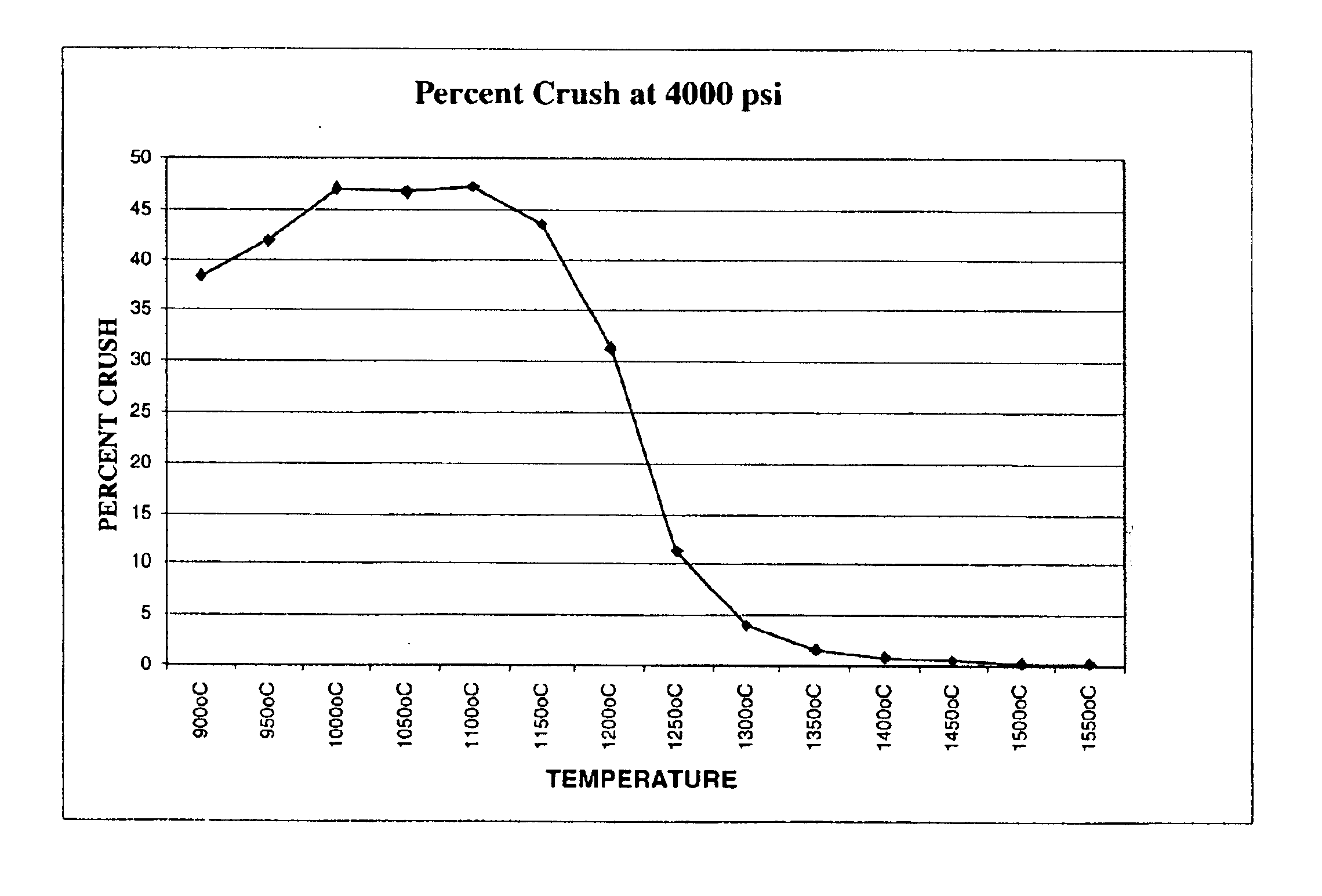

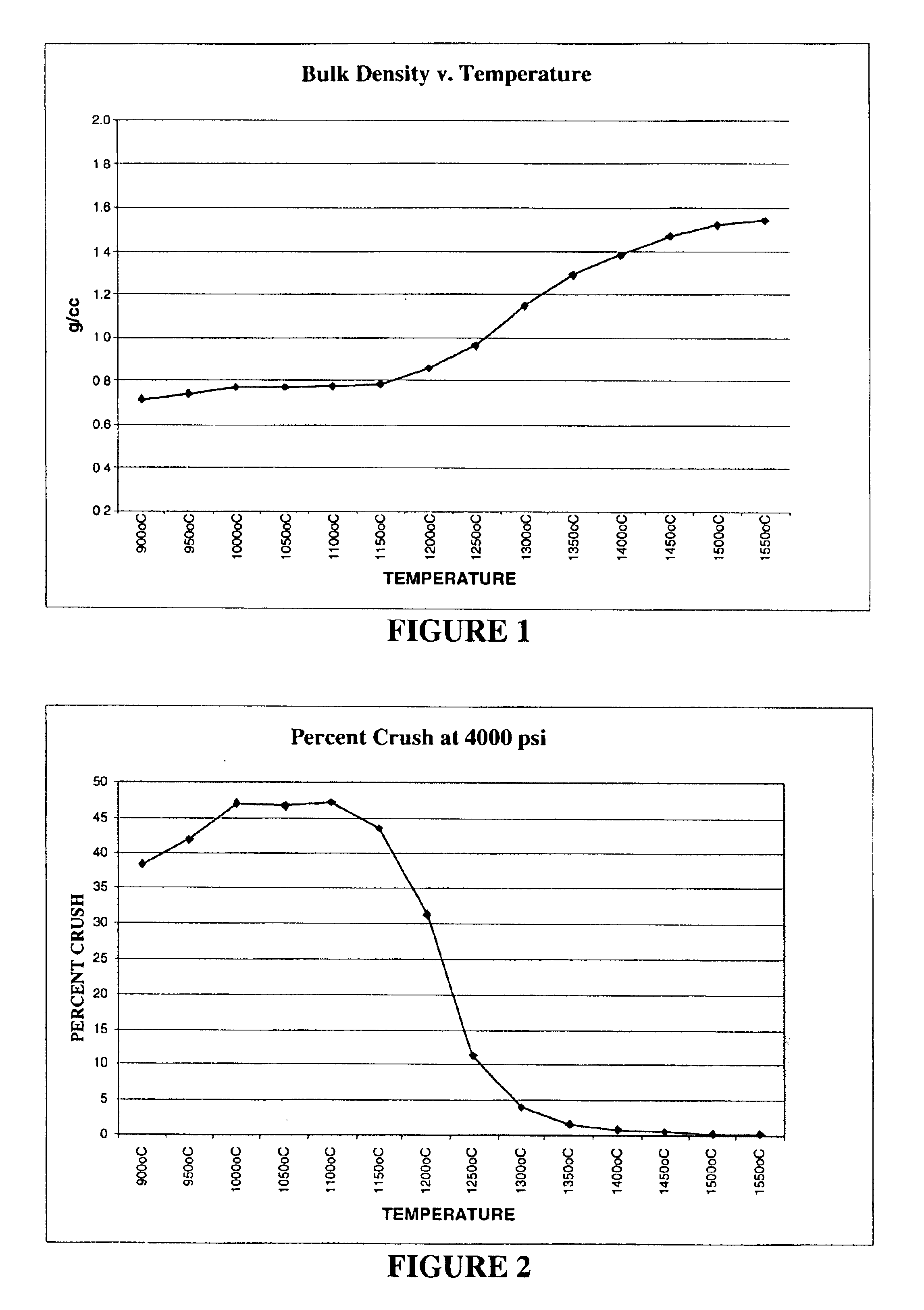

Ceramic Particles With Controlled Pore and/or Microsphere Placement and/or Size and Method Of Making Same

InactiveUS20110160104A1Improve balanceFluid removalCeramic shaping apparatusMicrosphereHigh intensity

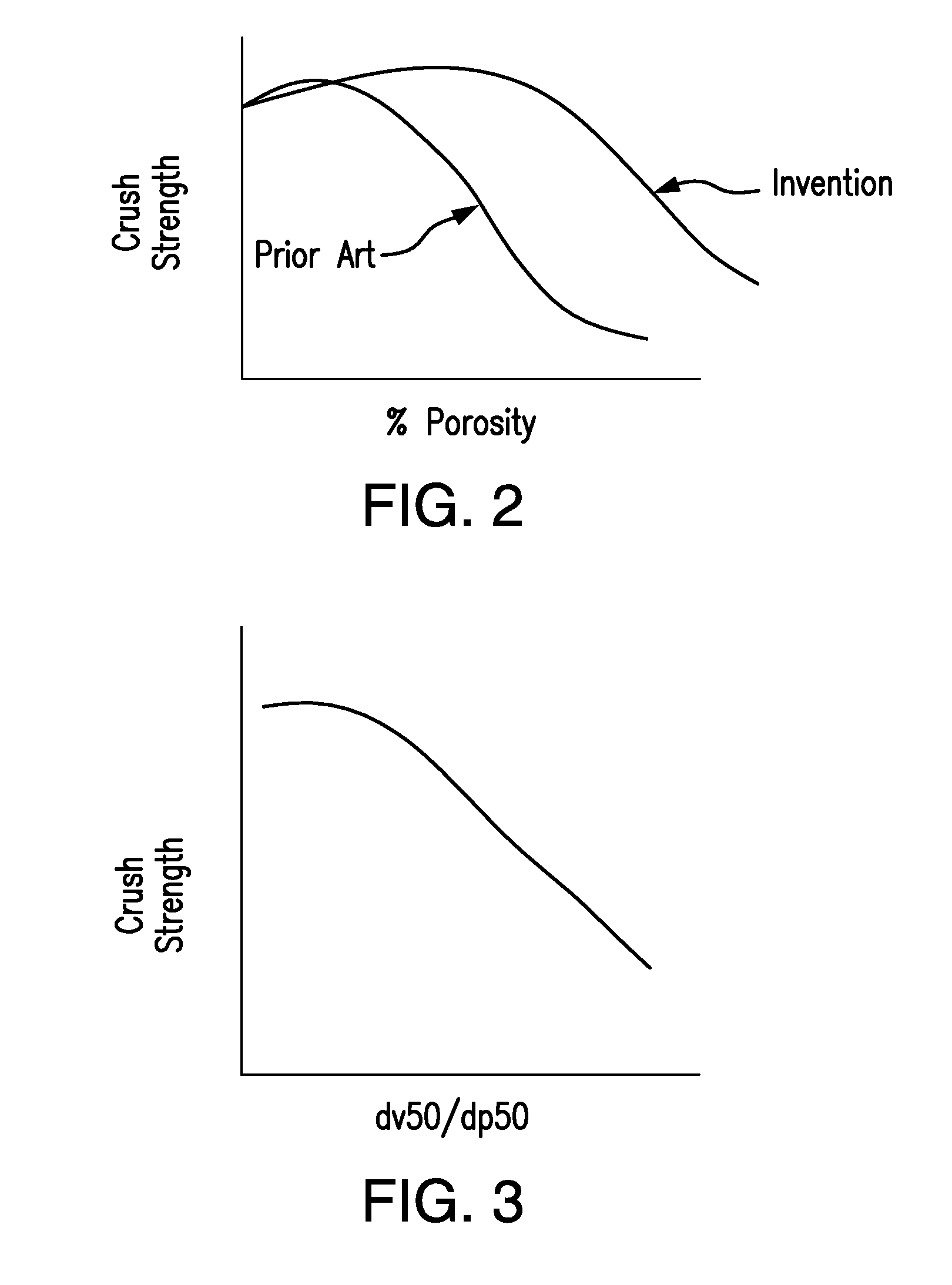

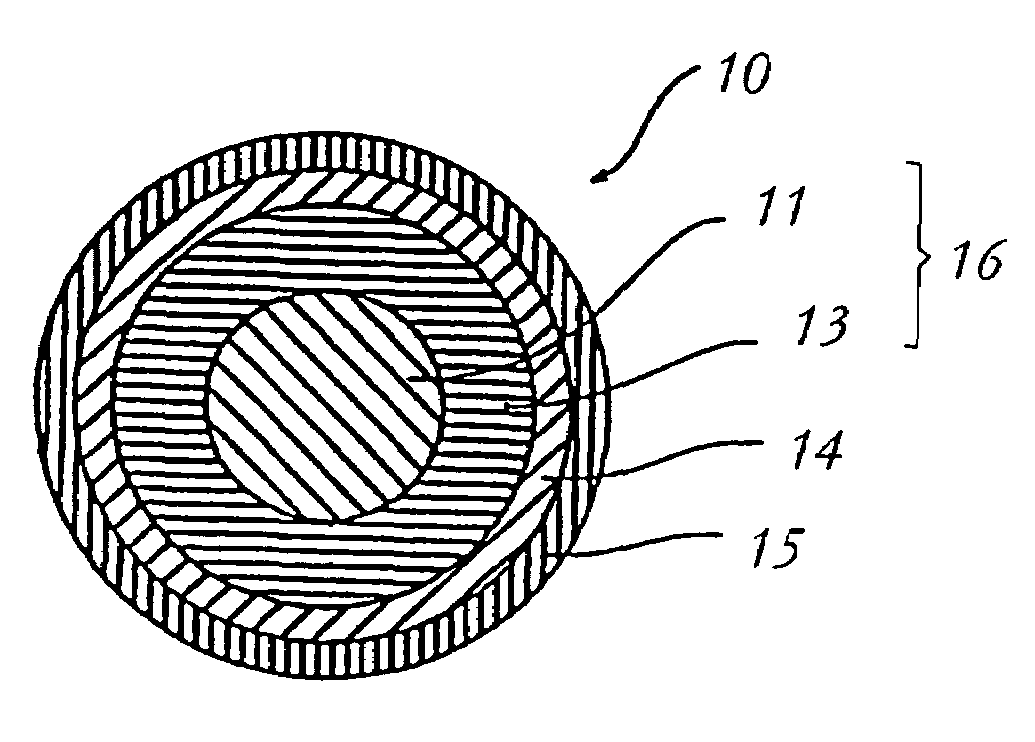

The present invention relates to lightweight high strength microsphere containing ceramic particles having controlled microsphere placement and / or size and microsphere morphology, which produces an improved balance of specific gravity and crush strength such that they can be used in applications such as proppants to prop open subterranean formation fractions. Proppant formulations are further disclosed which use one or more microsphere containing ceramic particles of the present invention. Methods to prop open subterranean formation fractions are further disclosed. In addition, other uses for the microsphere containing ceramic particles of the present invention are further disclosed, as well as methods of making the microsphere containing ceramic particles.

Owner:HALLIBURTON ENERGY SERVICES INC

Lead free reduced ricochet limited penetration projectile

A frangible projectile with a specific gravity similar to a lead projectile. The projectile comprises 34-94%, by weight, binder. The binder comprises poly ether block amide resin. The projectile further comprises 6-66%, by weight, ballast. The ballast comprises at least one member selected from a group consisting of tungsten, tungsten carbide, molybdenum, tantalum, ferro-tungsten, copper, bismuth, iron, steel, brass, aluminum bronze, beryllium copper, tin, aluminum, titanium, zinc, nickel silver alloy, cupronickel and nickel. The projectile can be prepared with a particularly preferred specific gravity of 5-14 and more preferably 11-11.5.

Owner:ACCUTEC USA

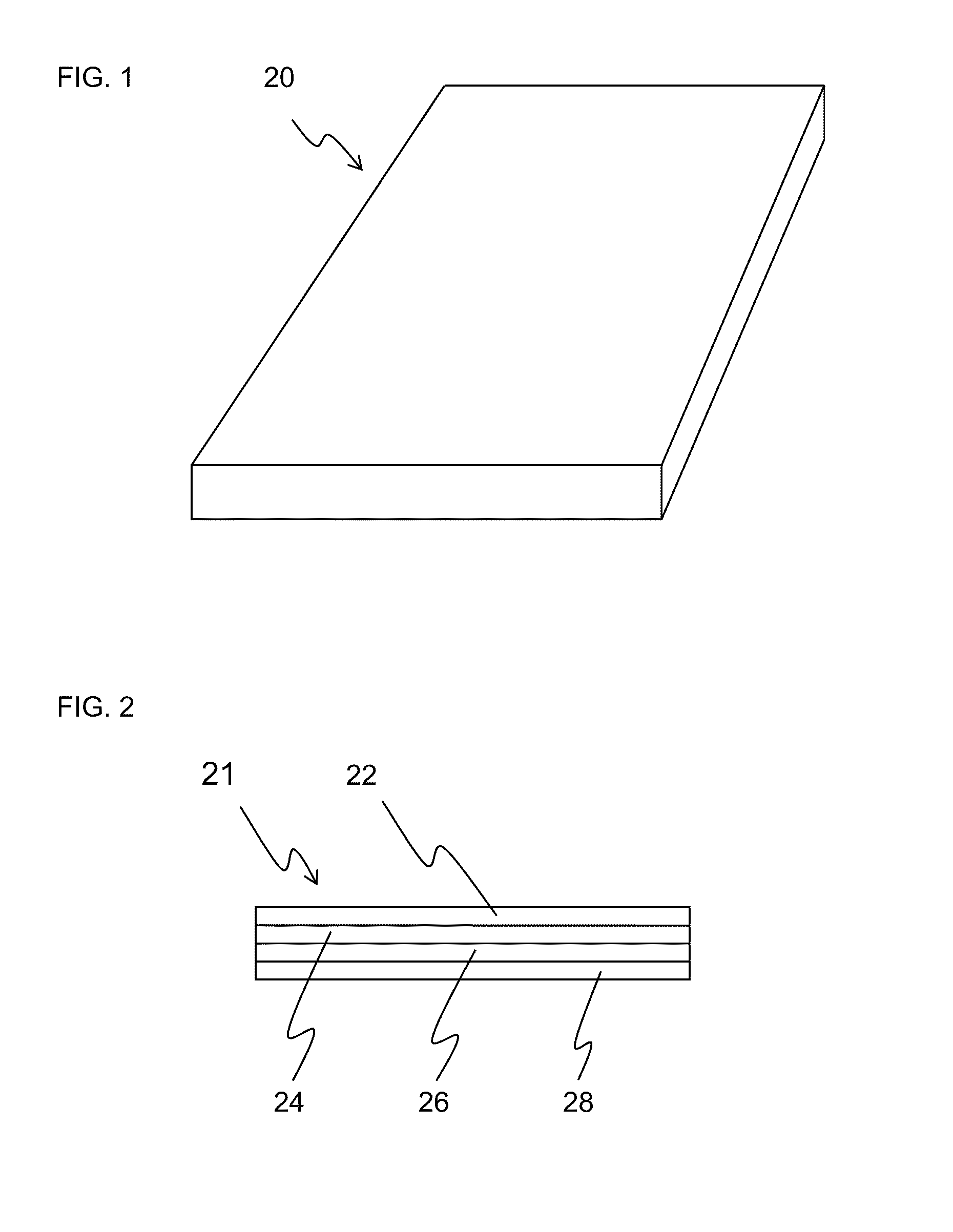

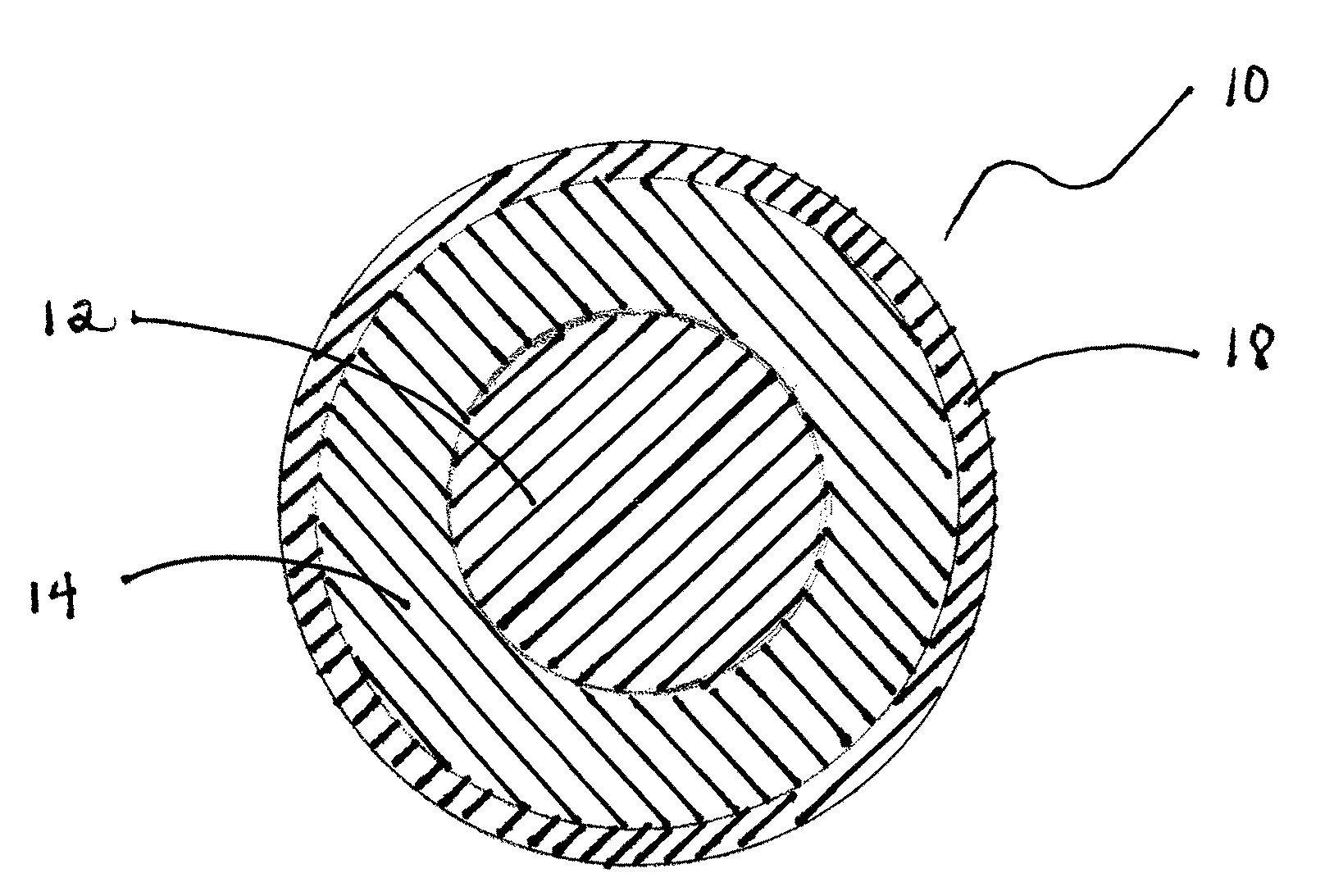

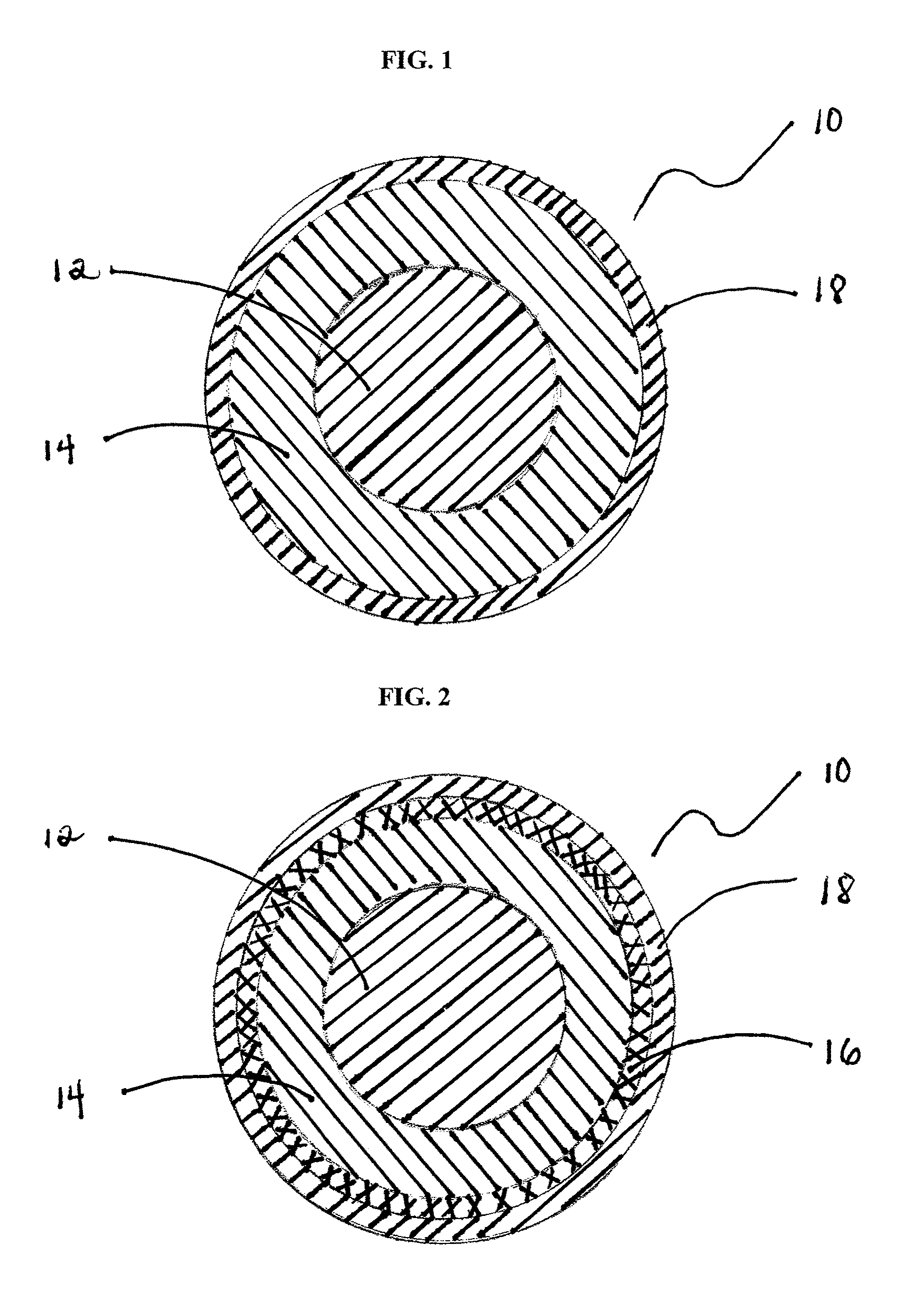

Multi-layer core golf ball

InactiveUS7255656B2Extended service lifeGolf ballsDomestic articlesMoisture vapor transmission rateEngineering

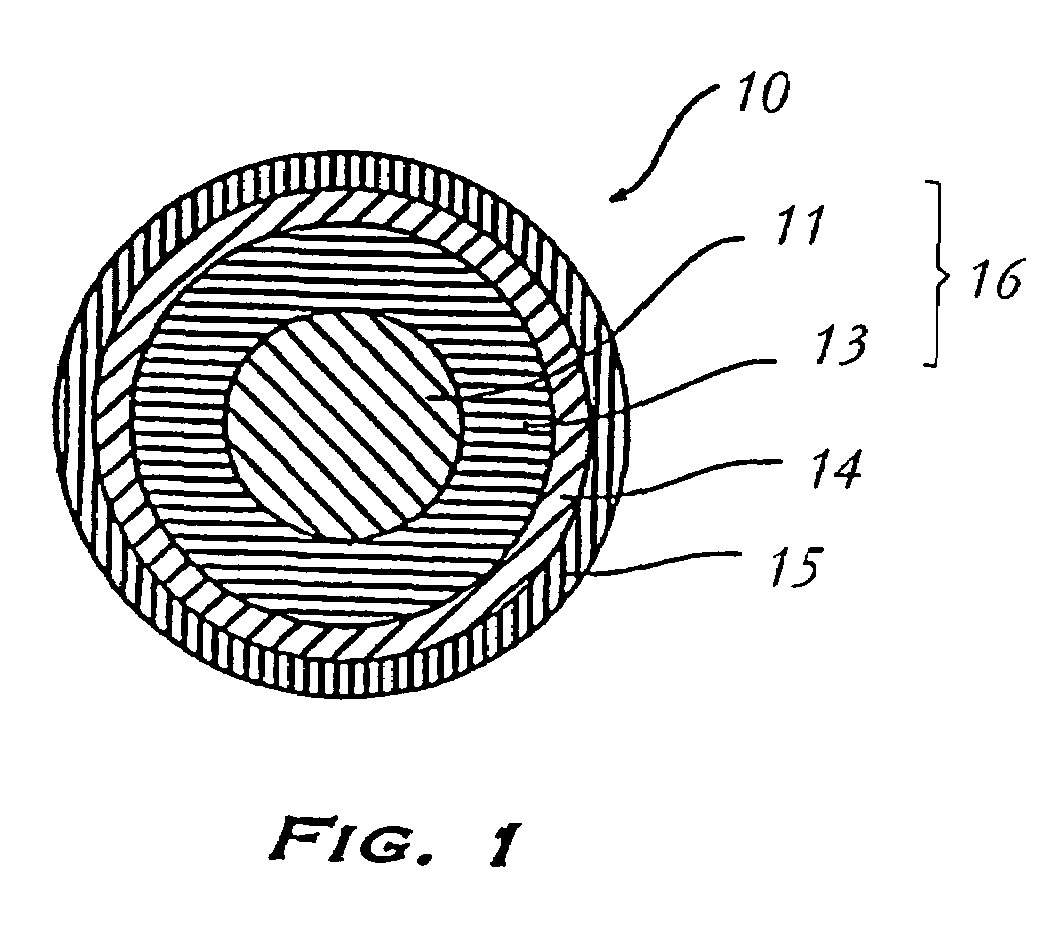

The present invention is directed to an improved golf ball displaying the desired spin profile and having a generally rigid, thermoset polybutadiene outer core surrounding a relatively soft, low compression inner core. In general, this golf ball has an inner core and at least one outer core layer surrounding the inner core. The inner core has a hardness less than a hardness of the outer core and a specific gravity less than or equal to the outer core specific gravity. Overall the inner core compression and outer core are formulated to provide a combined overall core compression of greater than about 50, preferably greater than about 70. A cover layer is provided to surround and to cover the outer core layer. A moisture barrier layer is provided between the outer core layer and the cover layer to protect the inner and outer cores from degradation due to exposure to water. The moisture vapor transmission rate of the moisture barrier layer is selected to be less than the moisture vapor transmission rate of the cover layer.

Owner:ACUSHNET CO

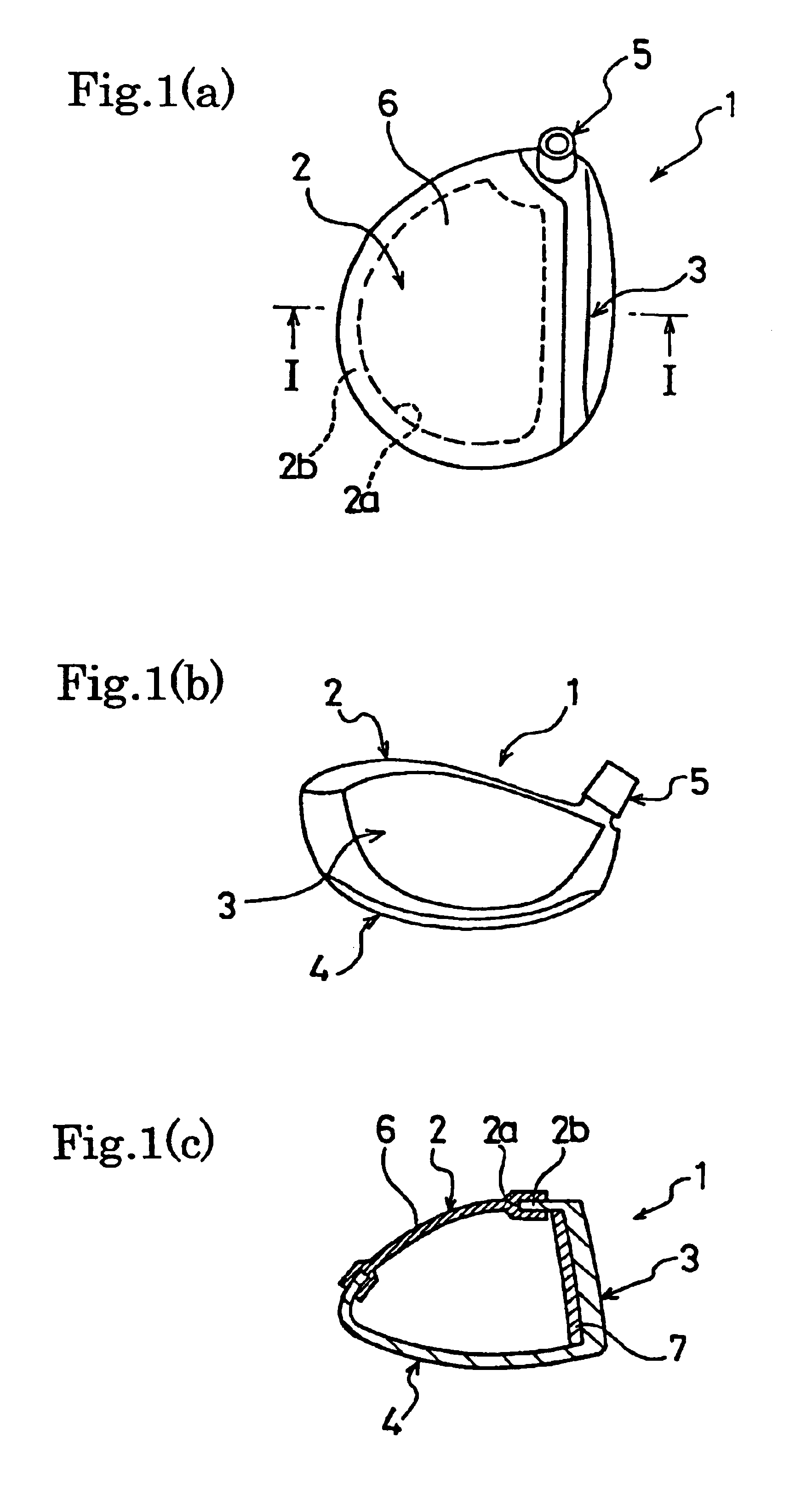

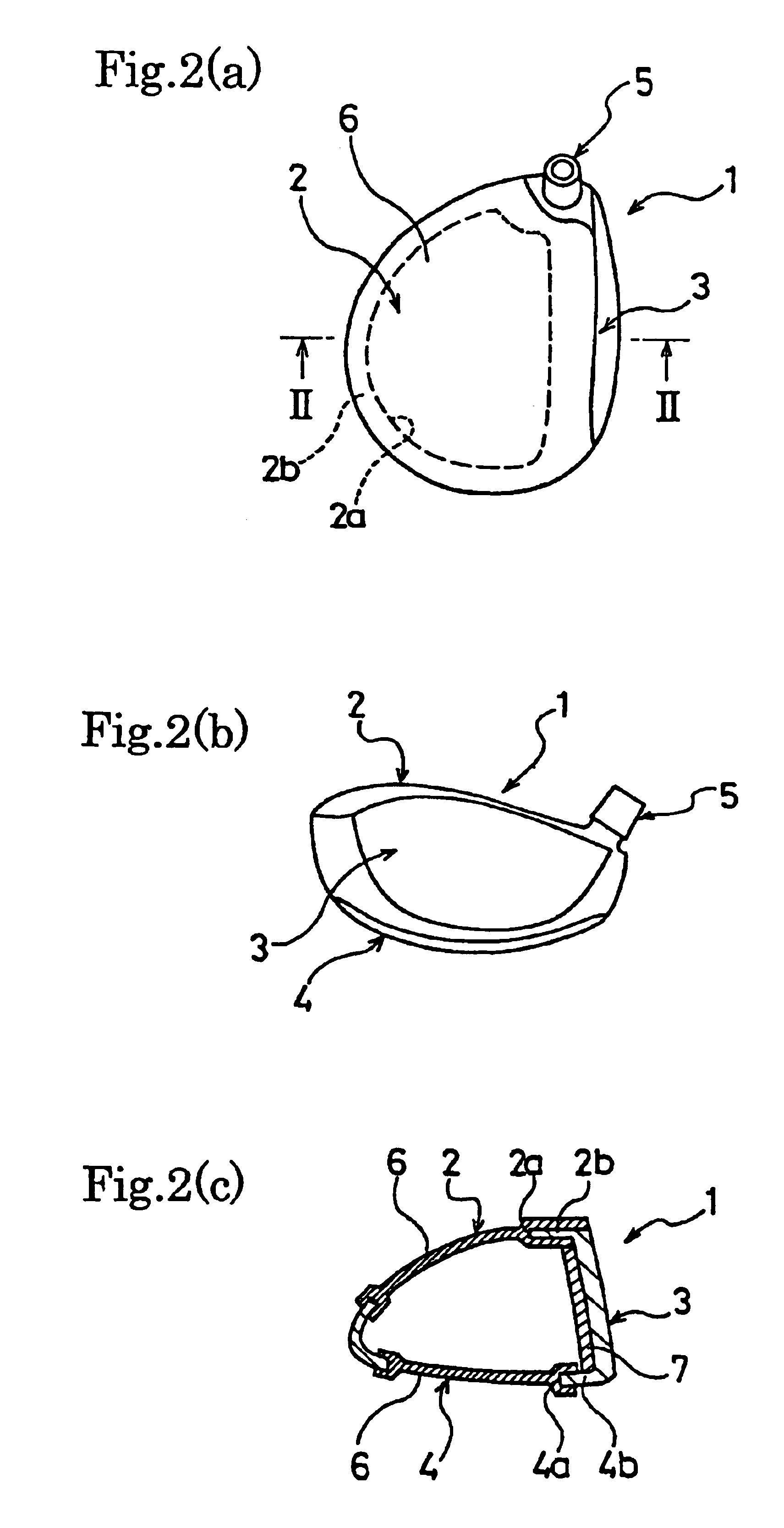

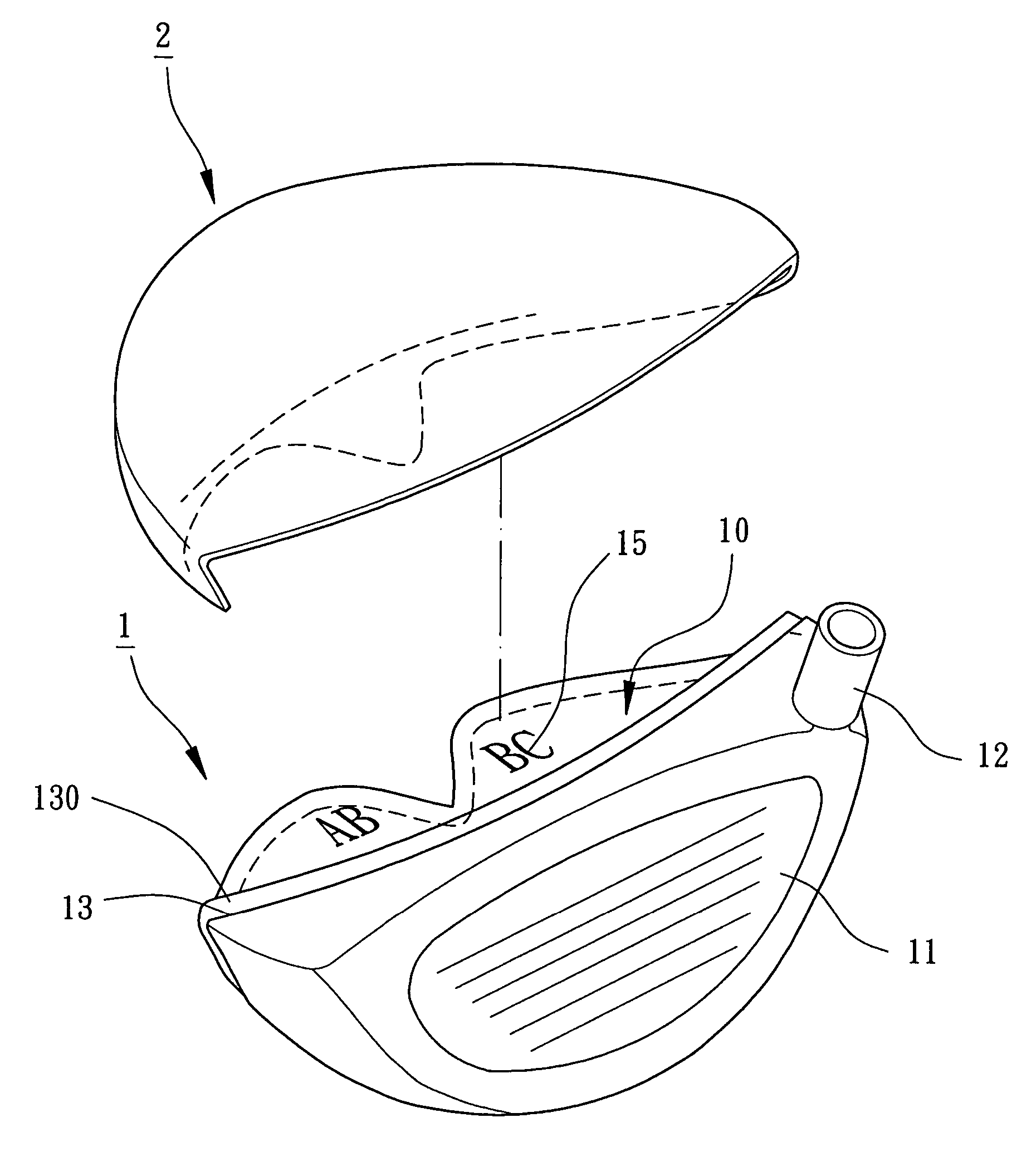

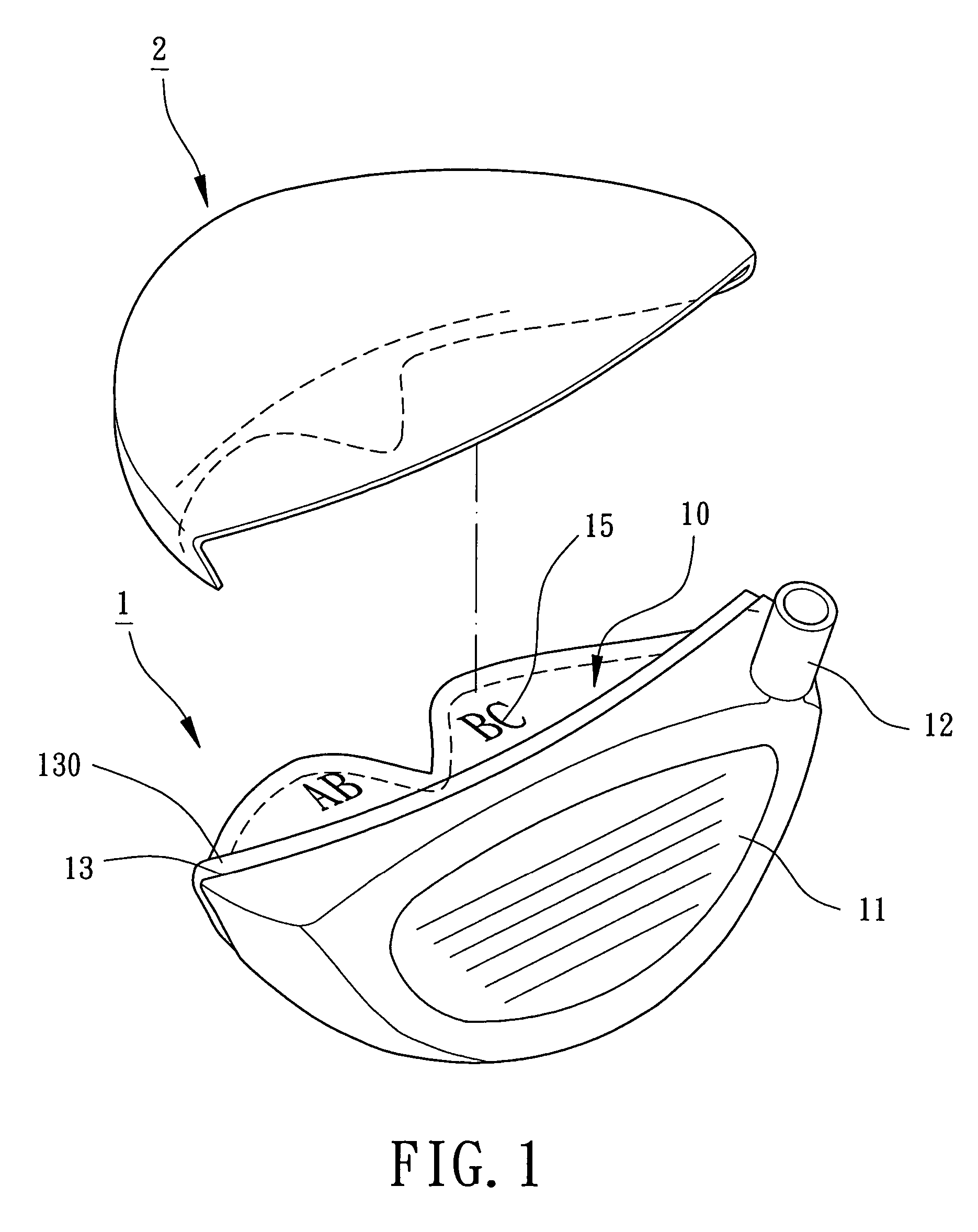

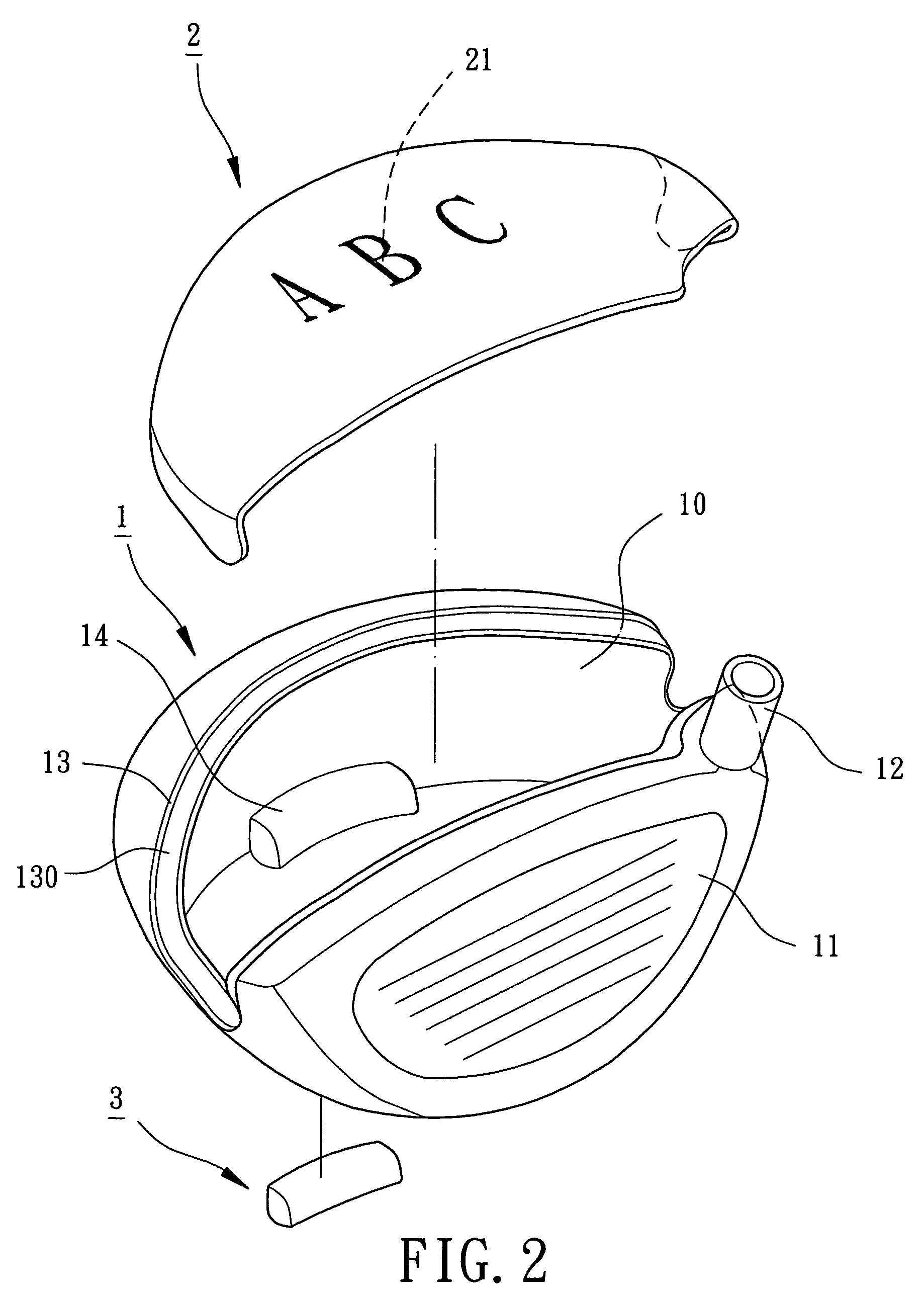

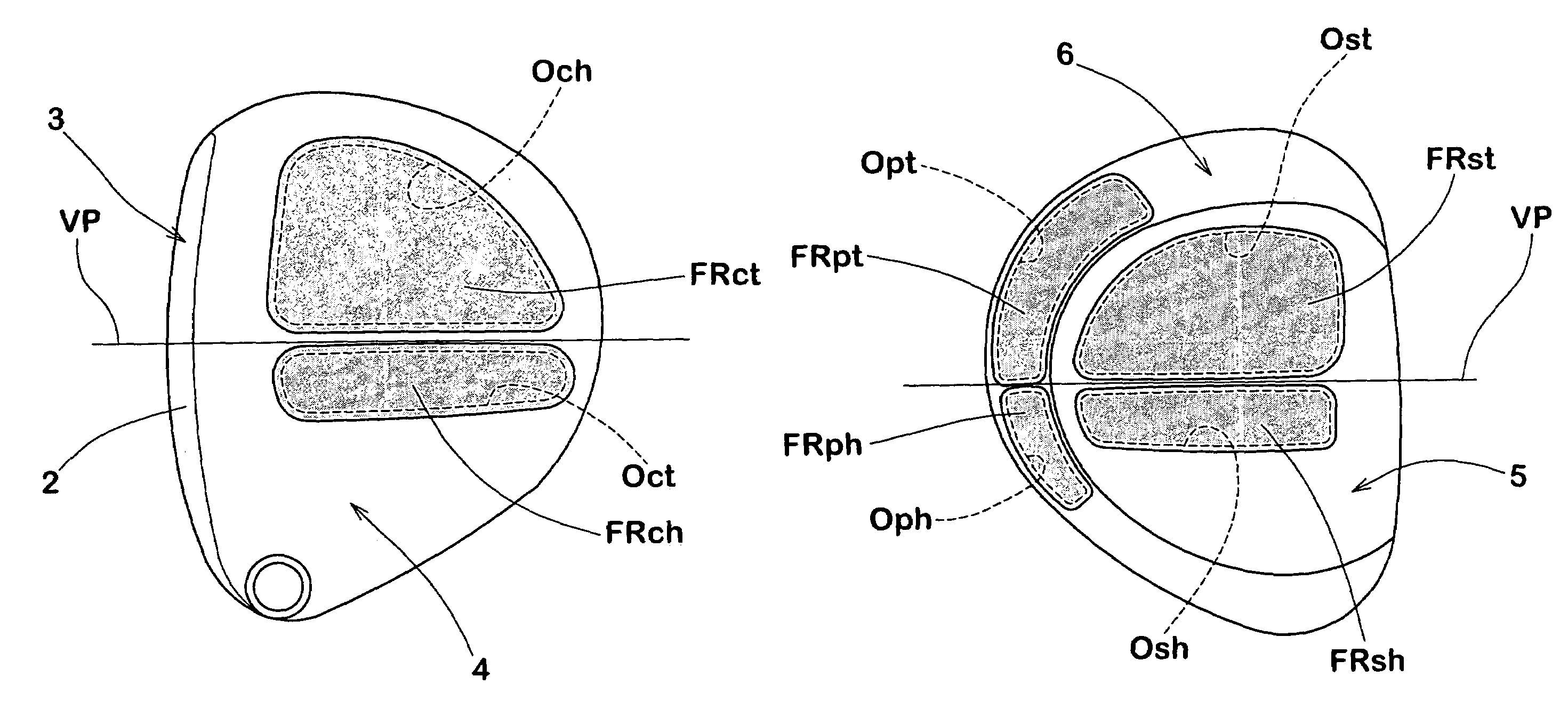

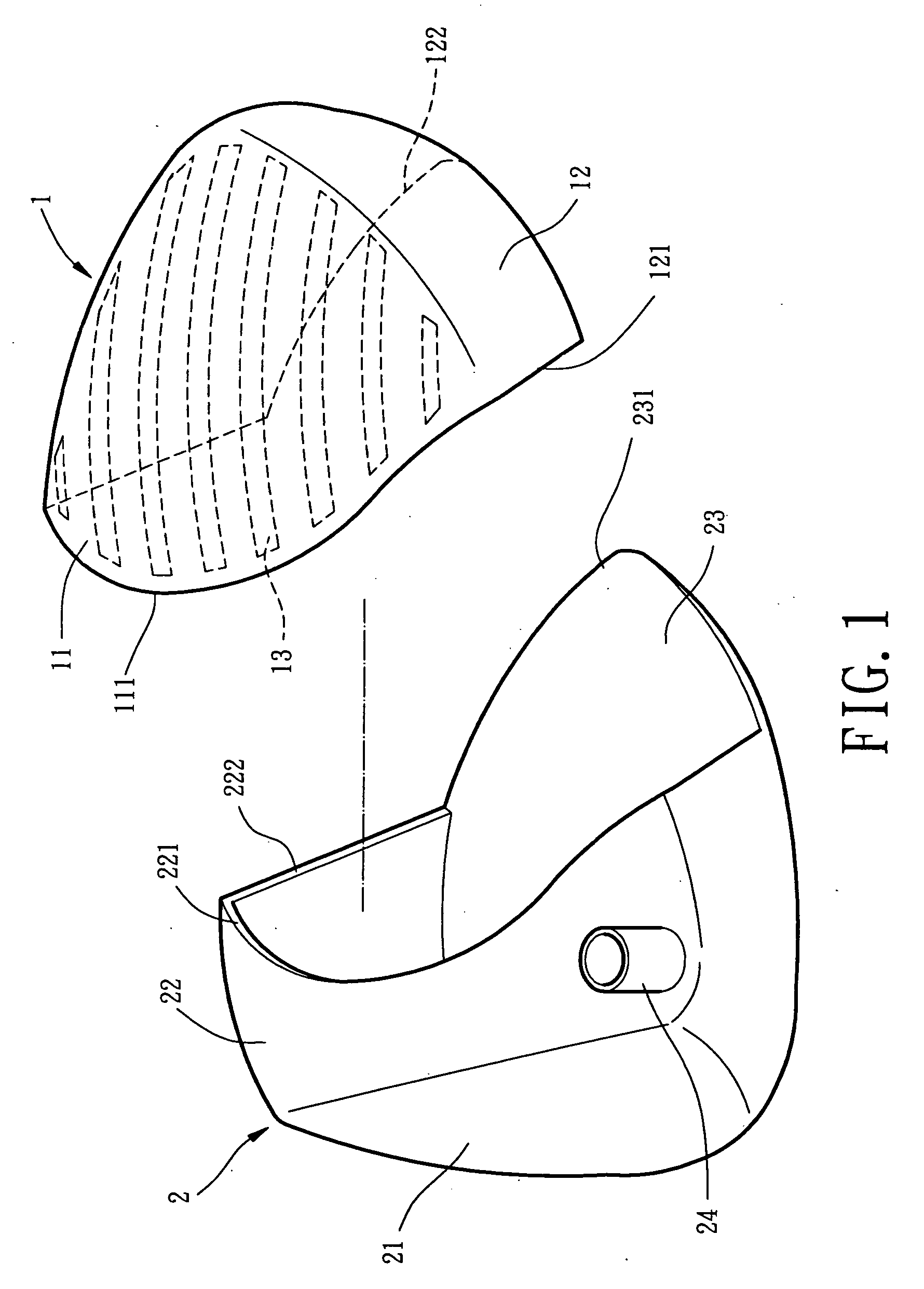

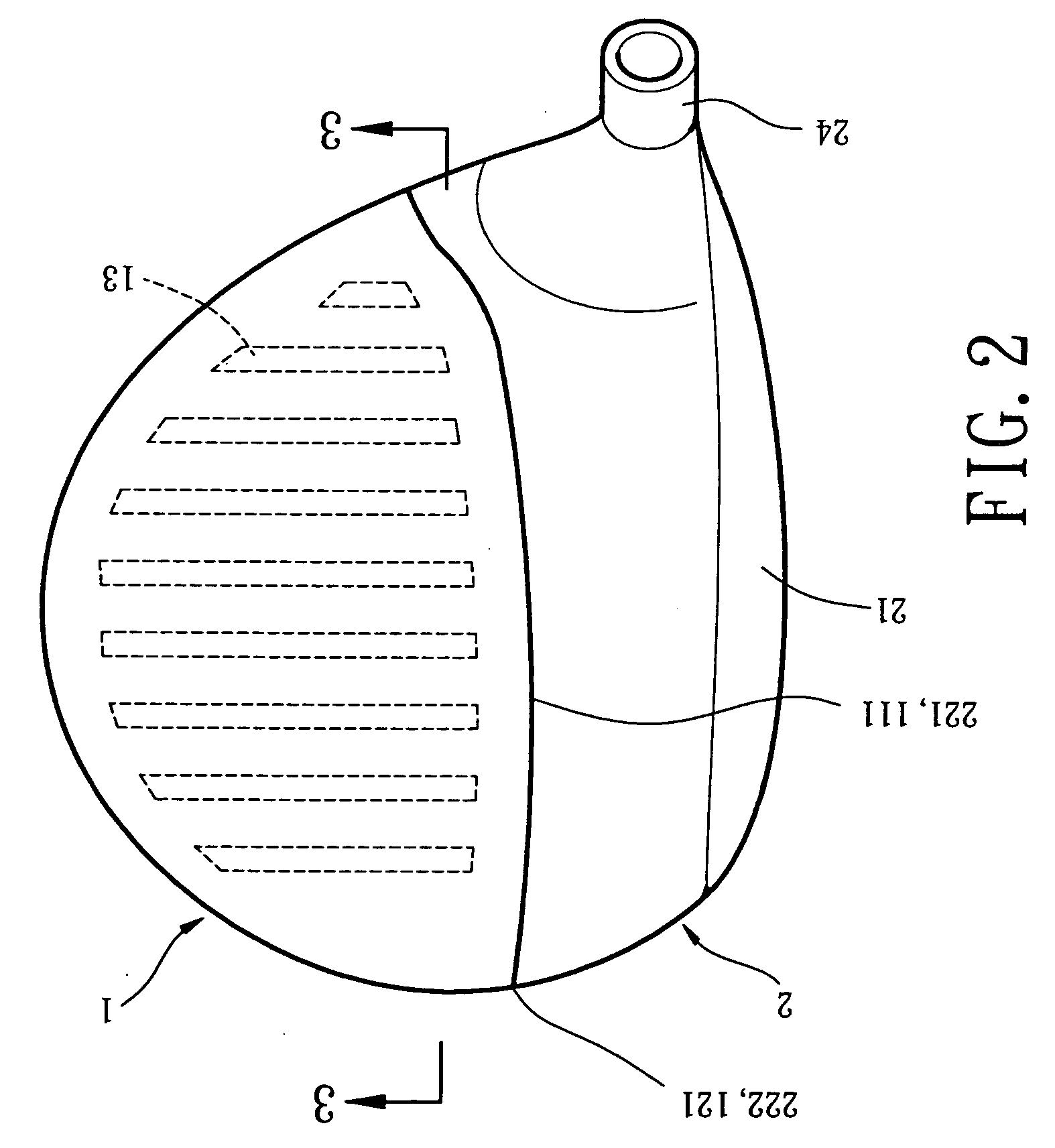

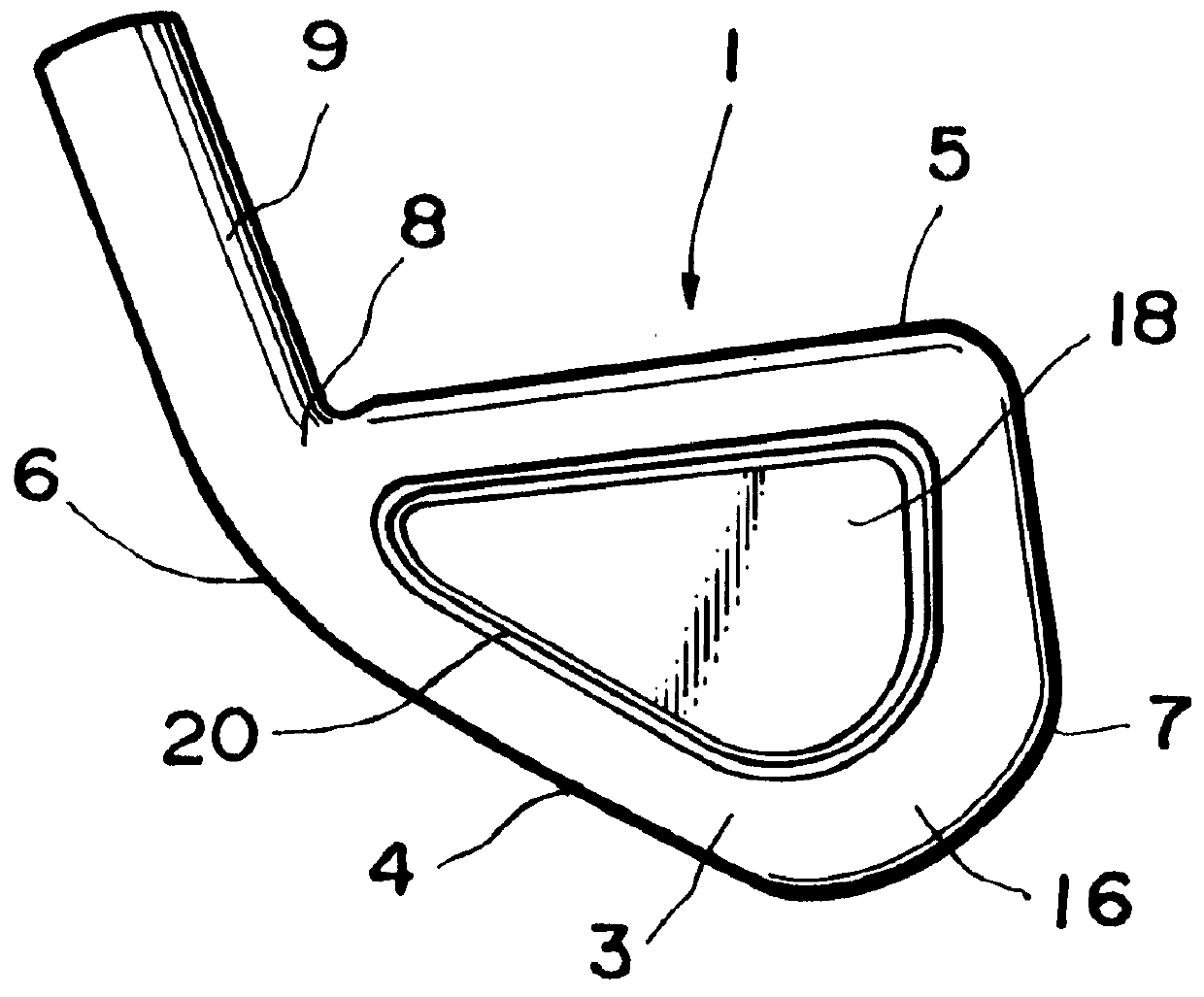

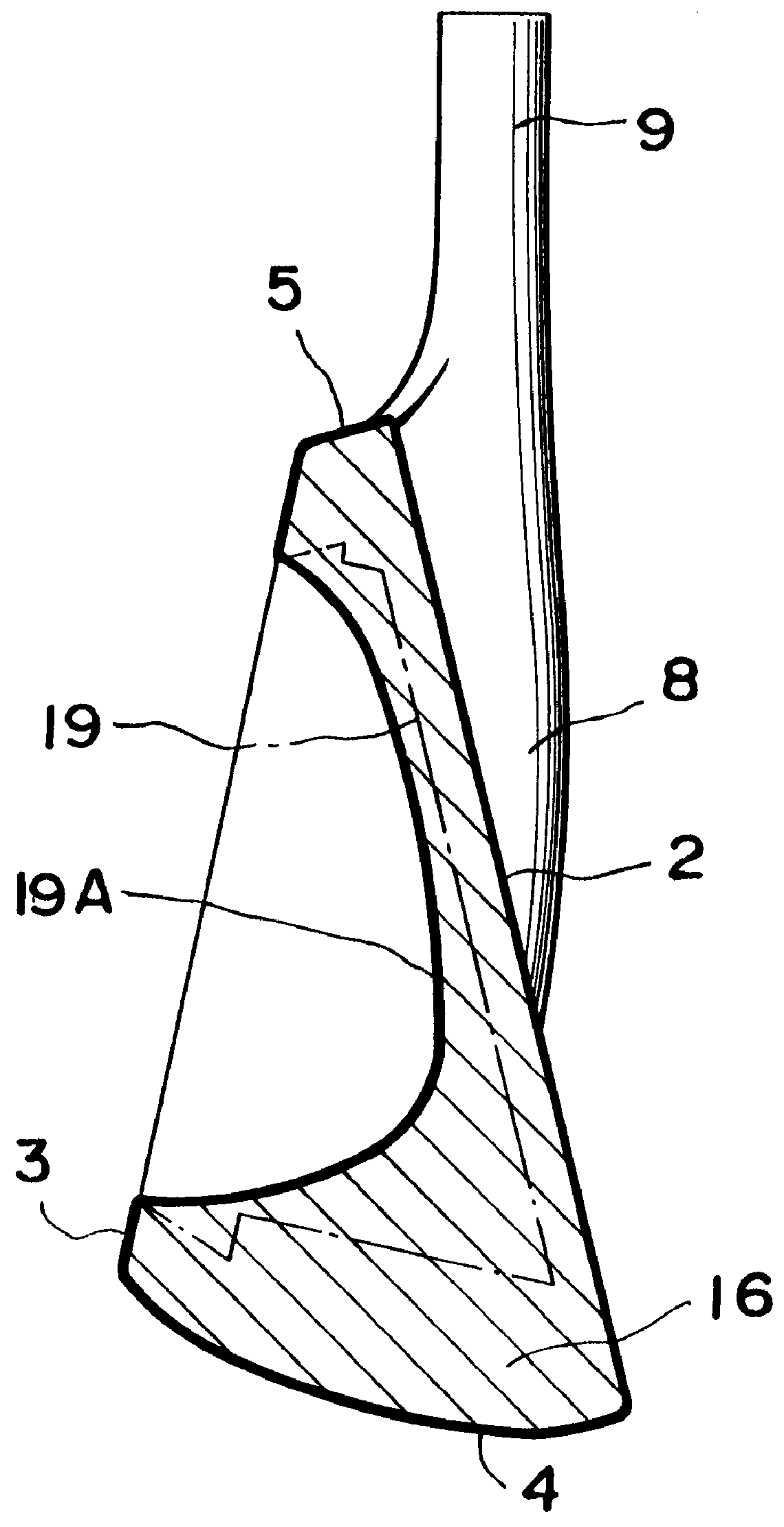

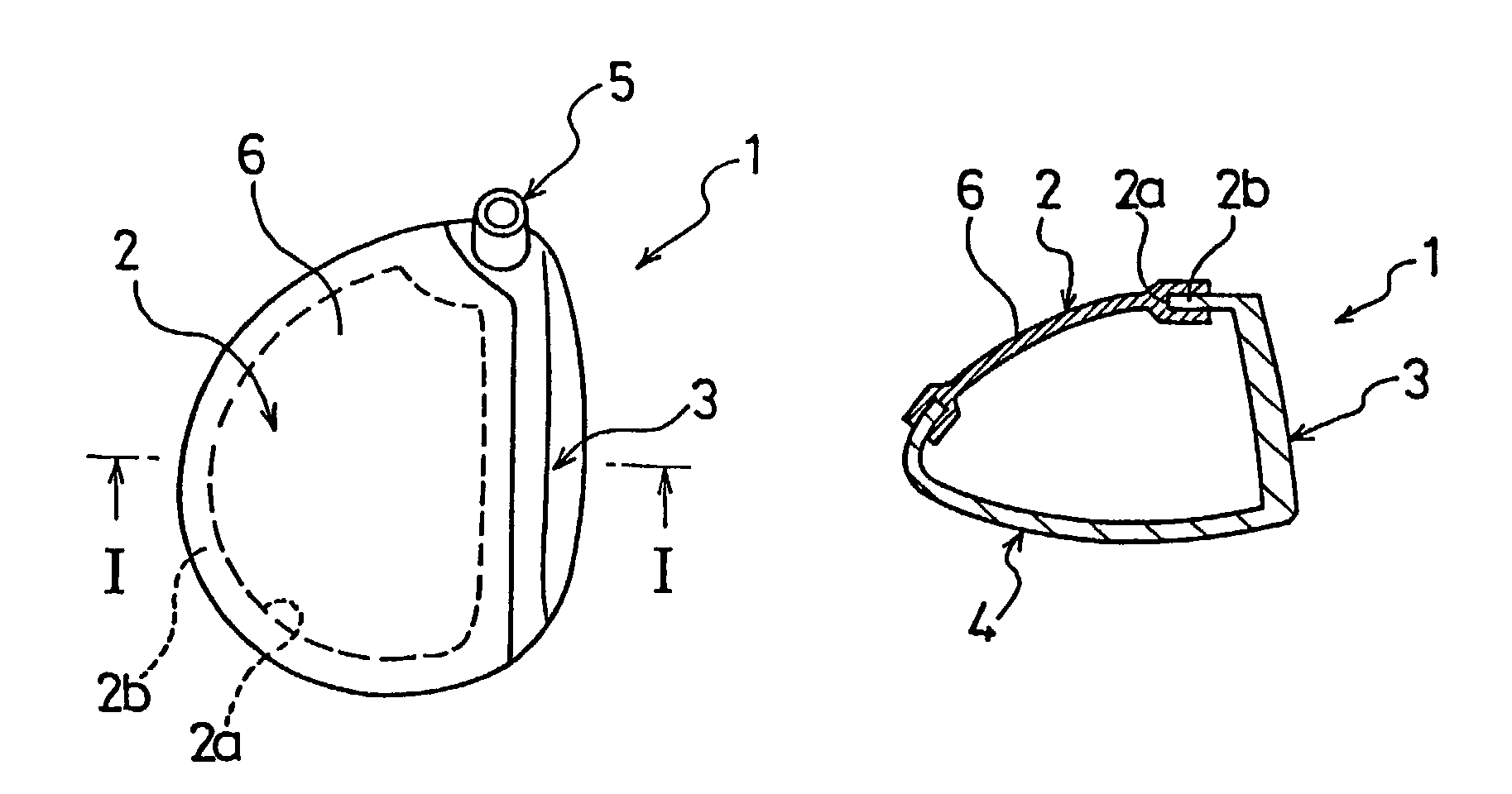

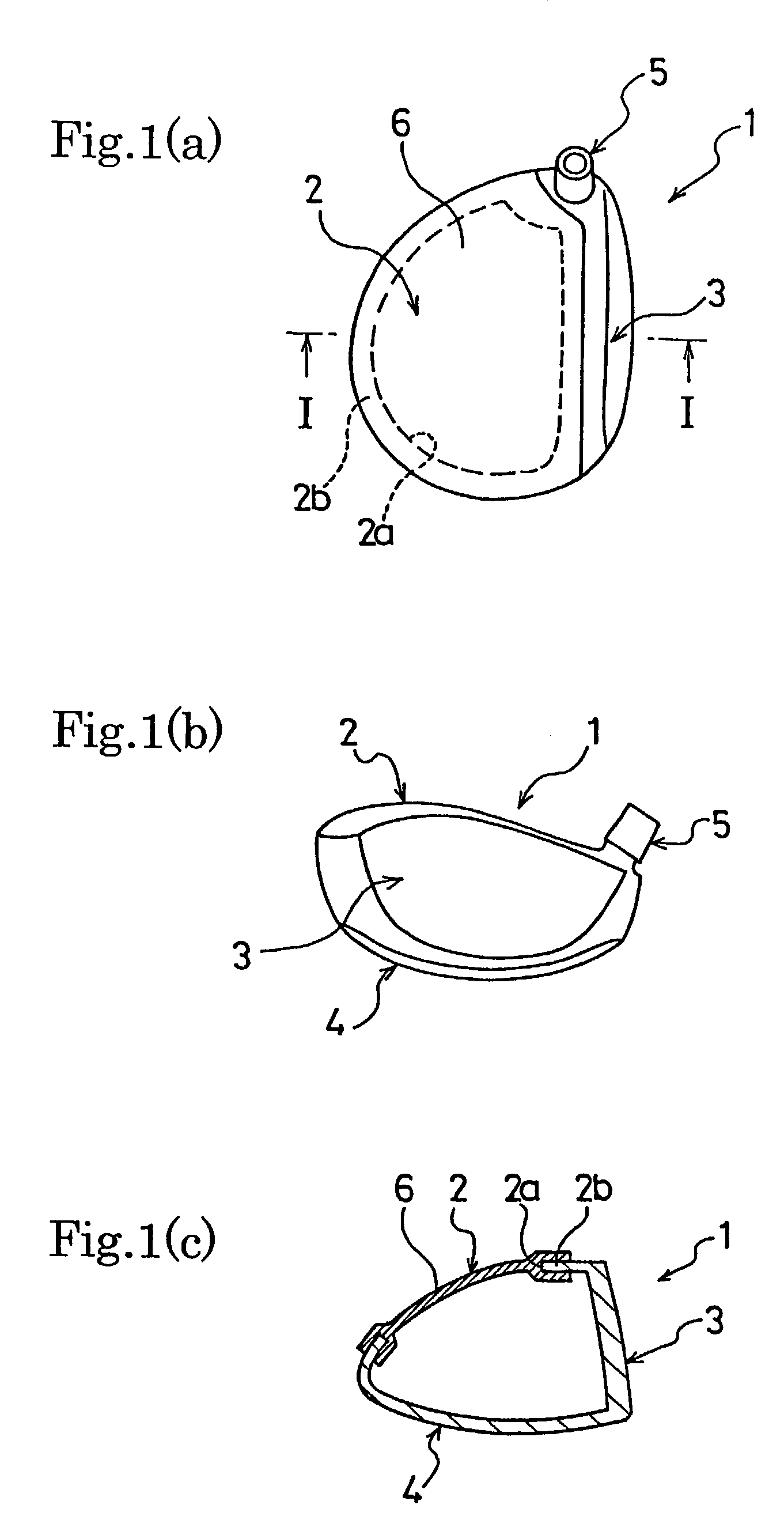

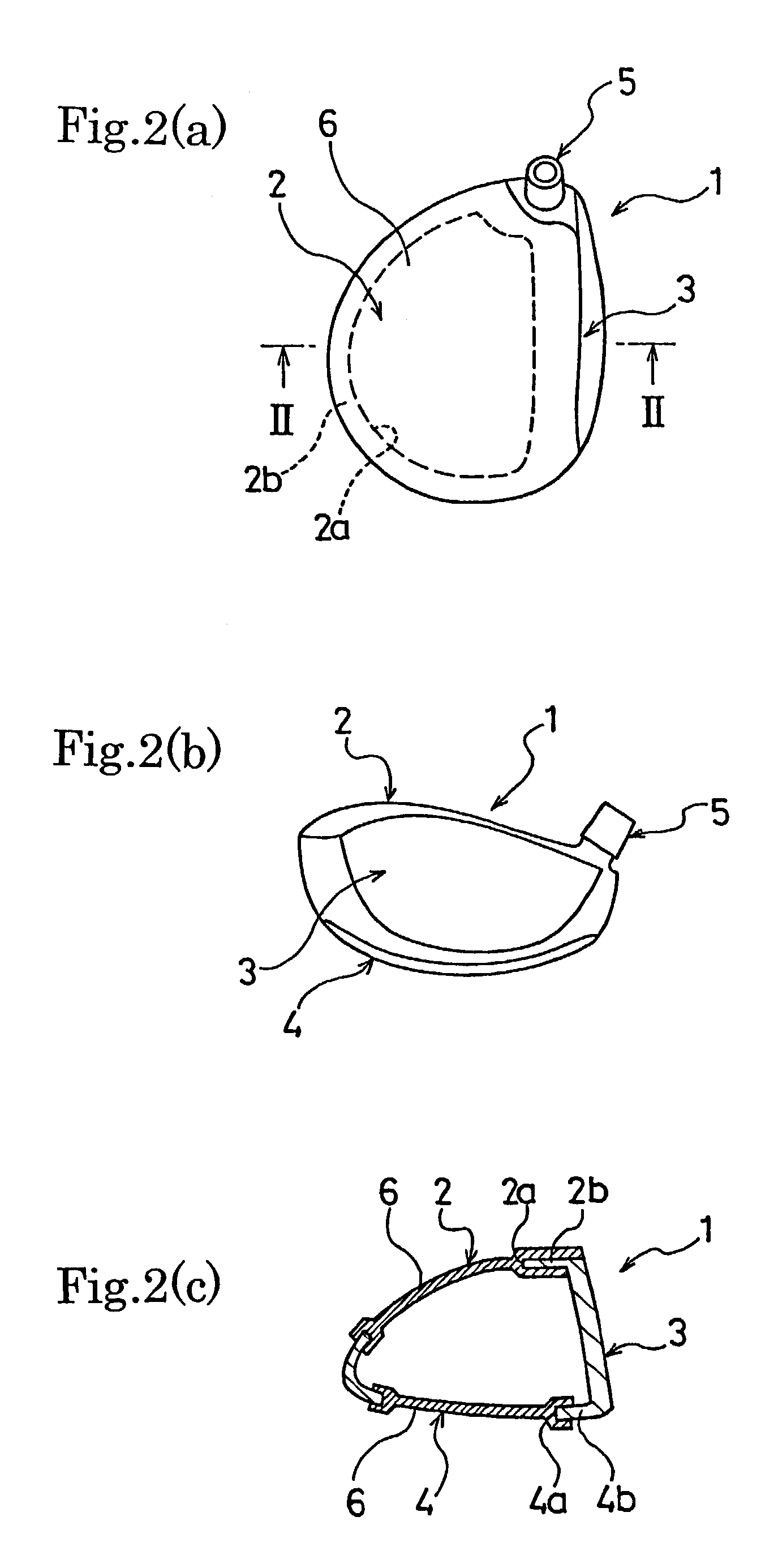

Hollow golf club head

InactiveUS6945876B2Great weight marginDegree of design is increasedGolf clubsRacket sportsEngineeringGolf Ball

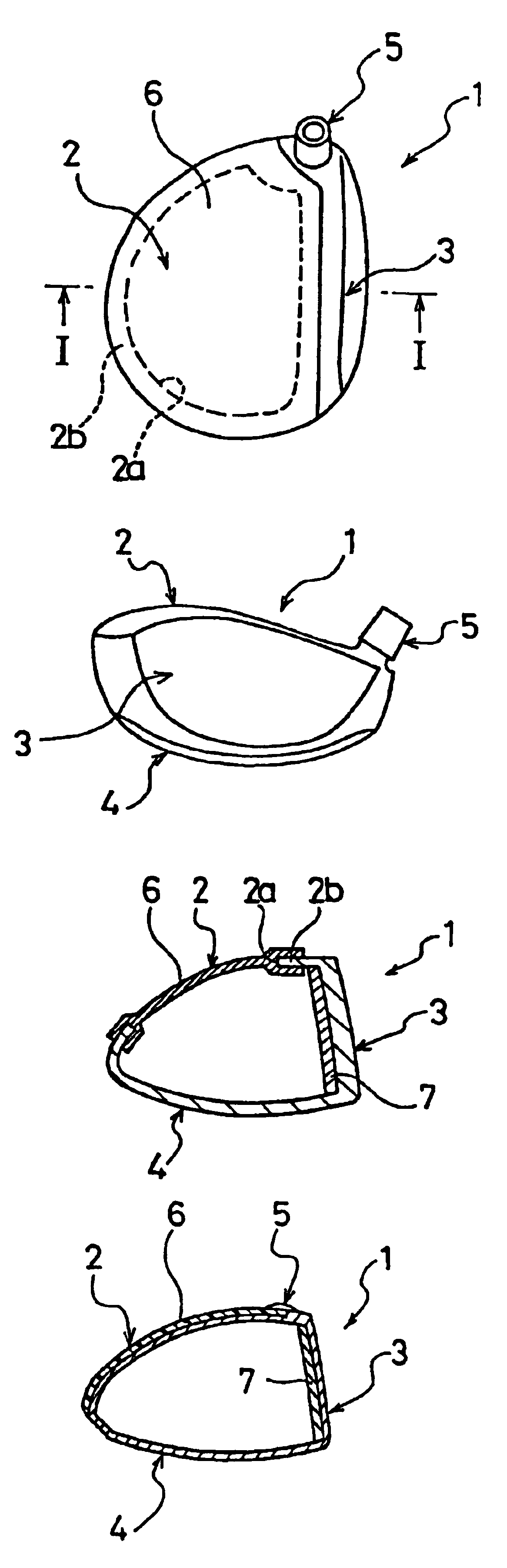

A hollow golf club head allowing to increase the repulsion and the degree of design freedom, while maintaining the durability. A hollow golf club head having a head body formed from a metal, wherein a hole is formed in the vicinity of the middle of a crown portion in the head body, the hole is closed with a cover member made of a material different from the head body, the ratio (ρm / ρf) of the specific gravity ρm of the head body and the specific gravity ρf of the cover member is set equal or superior to 1.3, and the ratio of the face area of a portion where the reinforcement and the head body are combined to the face area of the head body is set equal or superior to 20%.

Owner:YOKOHAMA RUBBER CO LTD

Low density proppant

Owner:CARBO CERAMICS

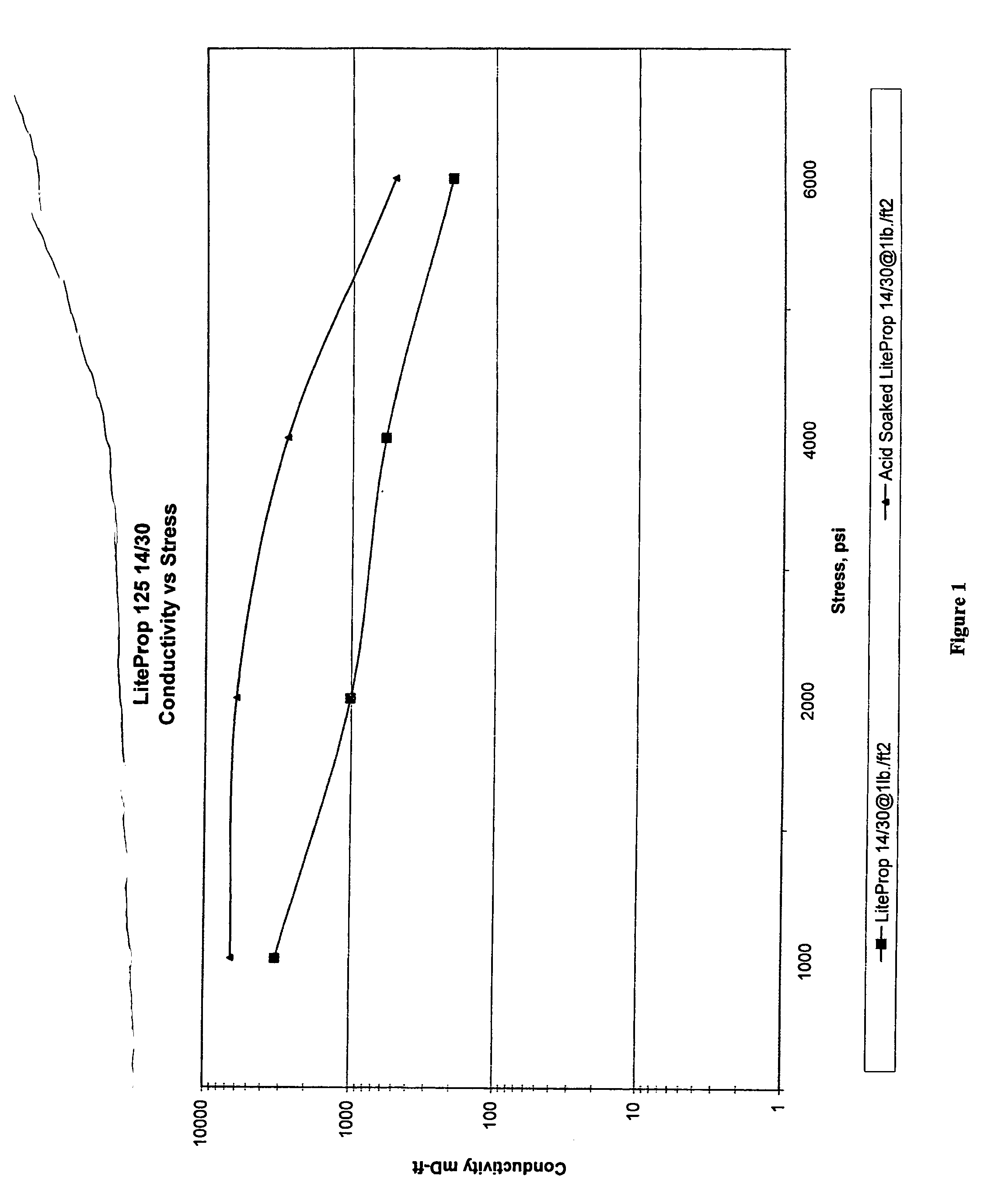

Well treating composition containing relatively lightweight proppant and acid

InactiveUS20060073980A1Satisfied with placementImprove productivityFluid removalFlushingParticulatesAcid fracturing

A well treating composition contains an aqueous acid and at least one relatively lightweight proppant, preferably having an apparent specific gravity (ASG) less than or equal to 2.45. The acid fracturing composition may used to acid fracture a hydrocarbon reservoir within a subterranean formation of an oil or gas well. The composition may further be used to stimulate the production of hydrocarbons. The proportion of relatively lightweight proppant to acid in the composition is such that the dimensional fracture conductivity (CfD) is in excess of 1.0. The aqueous acid typically has an ASG substantially equal to the ASG of the relatively lightweight particulate. As such, the relatively lightweight particulate is suspended in the aqueous acid.

Owner:BAKER HUGHES INC

High performance non-combustible gypsum-cement compositions with enhanced water durability and thermal stability for reinforced cementitious lightweight structural cement panels

ActiveUS8038790B1Reduce weightPerformance requirementConstruction materialSolid waste managementOperating energyAir entrainment

Structural cement panel for resisting transverse and shear loads equal to transverse and shear loads provided by plywood and oriented strain board, when fastened to framing for use in shear walls, flooring and roofing systems. The panels provide reduced thermal transmission compared to other structural cement panels. The panels employ one or more layers of a continuous phase resulting from curing an aqueous mixture of calcium sulfate alpha hemihydrate, hydraulic cement, coated expanded perlite particles filler, optional additional fillers, active pozzolan and lime. The coated perlite has a particle size of 1-500 microns, a median diameter of 20-150 microns, and an effective particle density (specific gravity) of less than 0.50 g / cc. The panels are reinforced with fibers, for example alkali-resistant glass fibers. The preferred panel contains no intentionally added entrained air. A method of improving fire resistance in a building is also disclosed.

Owner:UNITED STATES GYPSUM CO

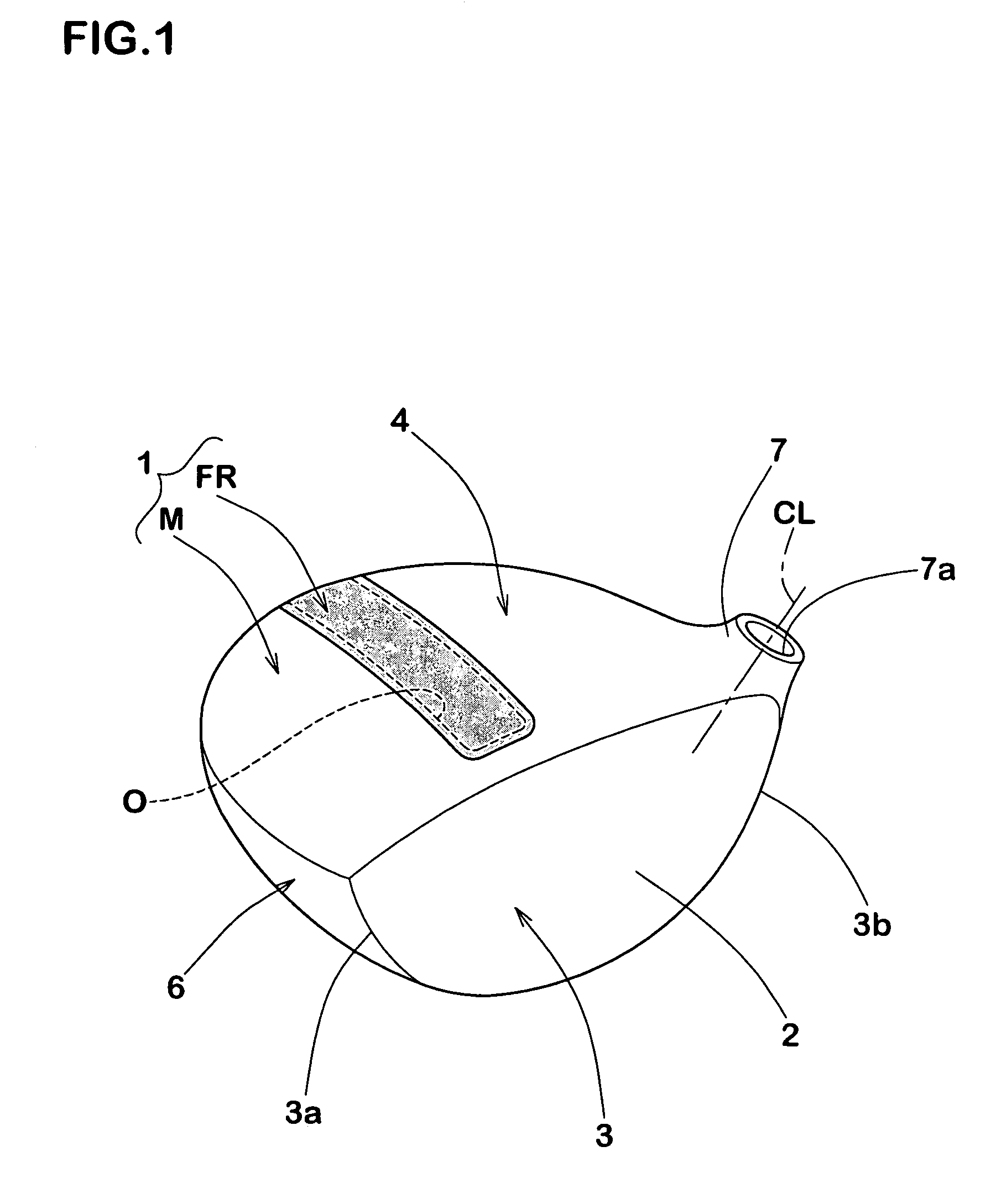

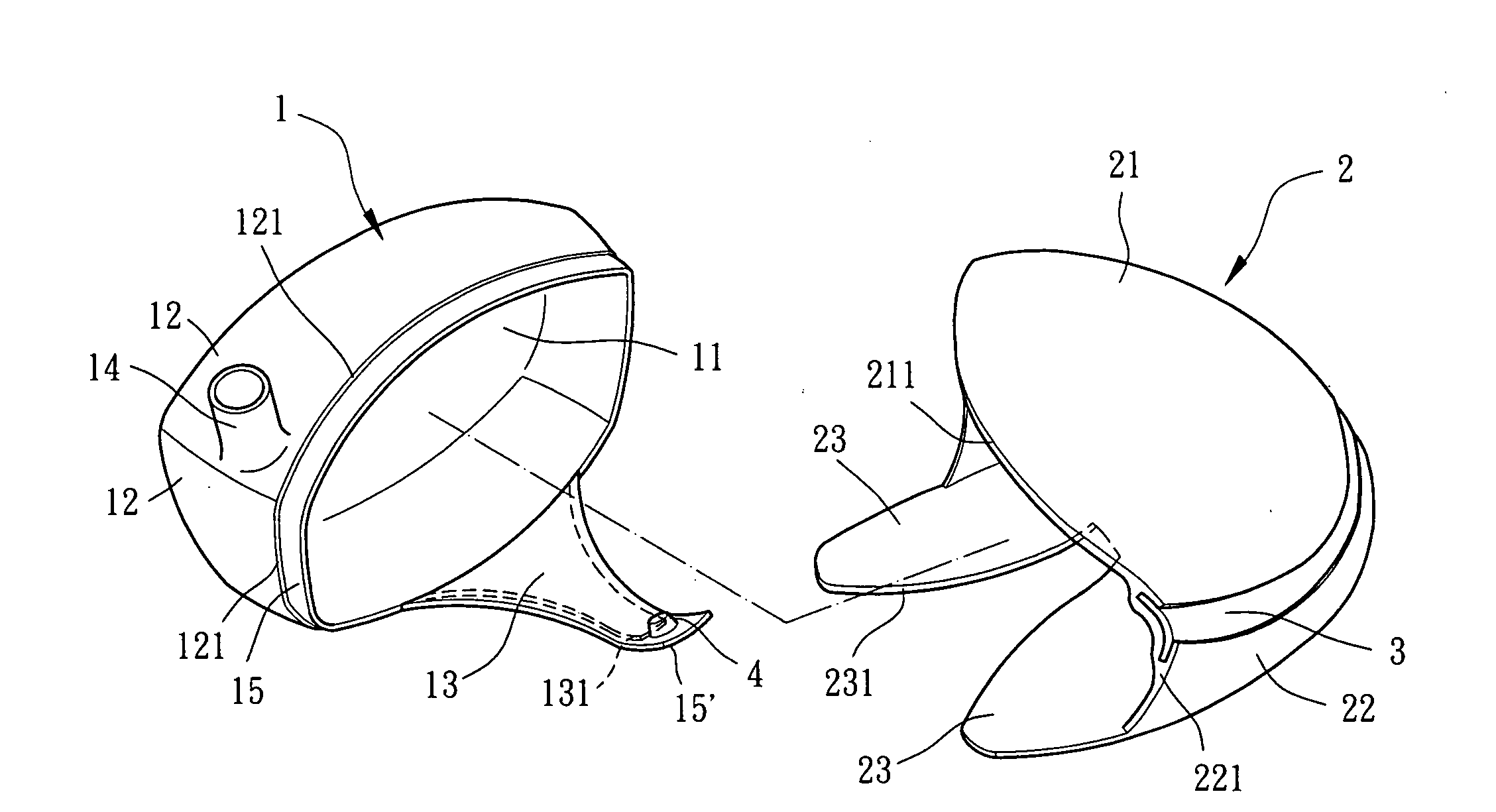

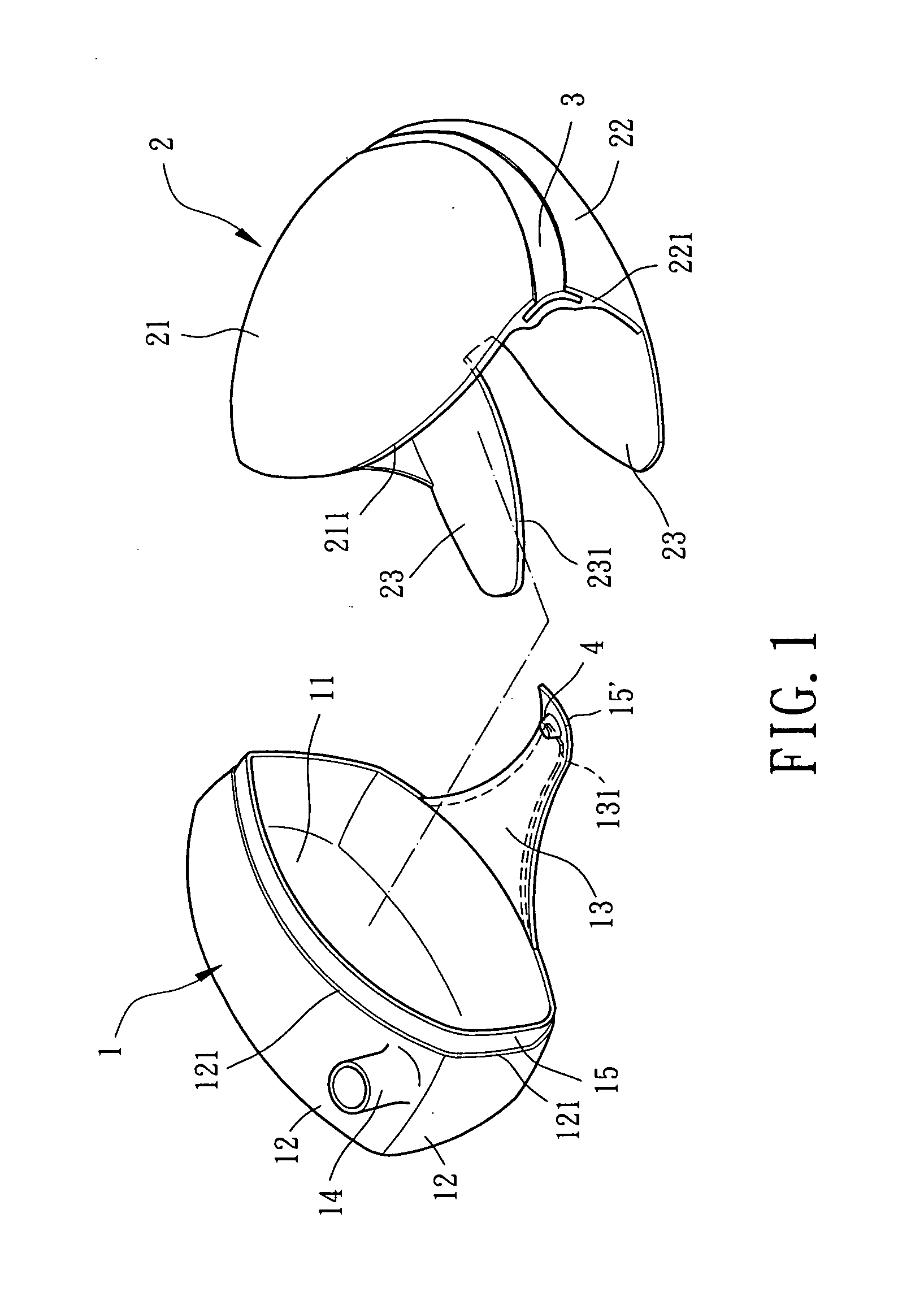

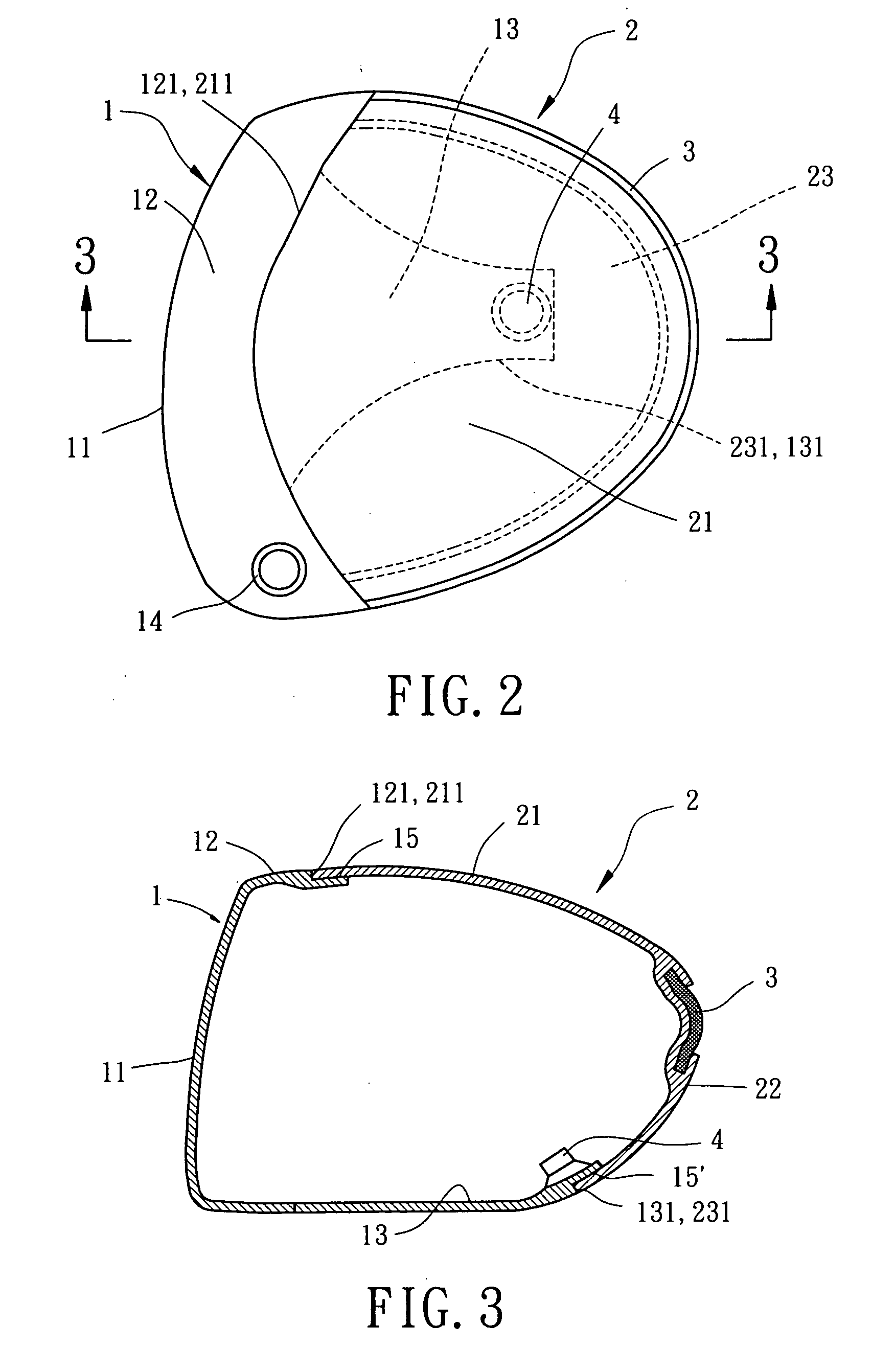

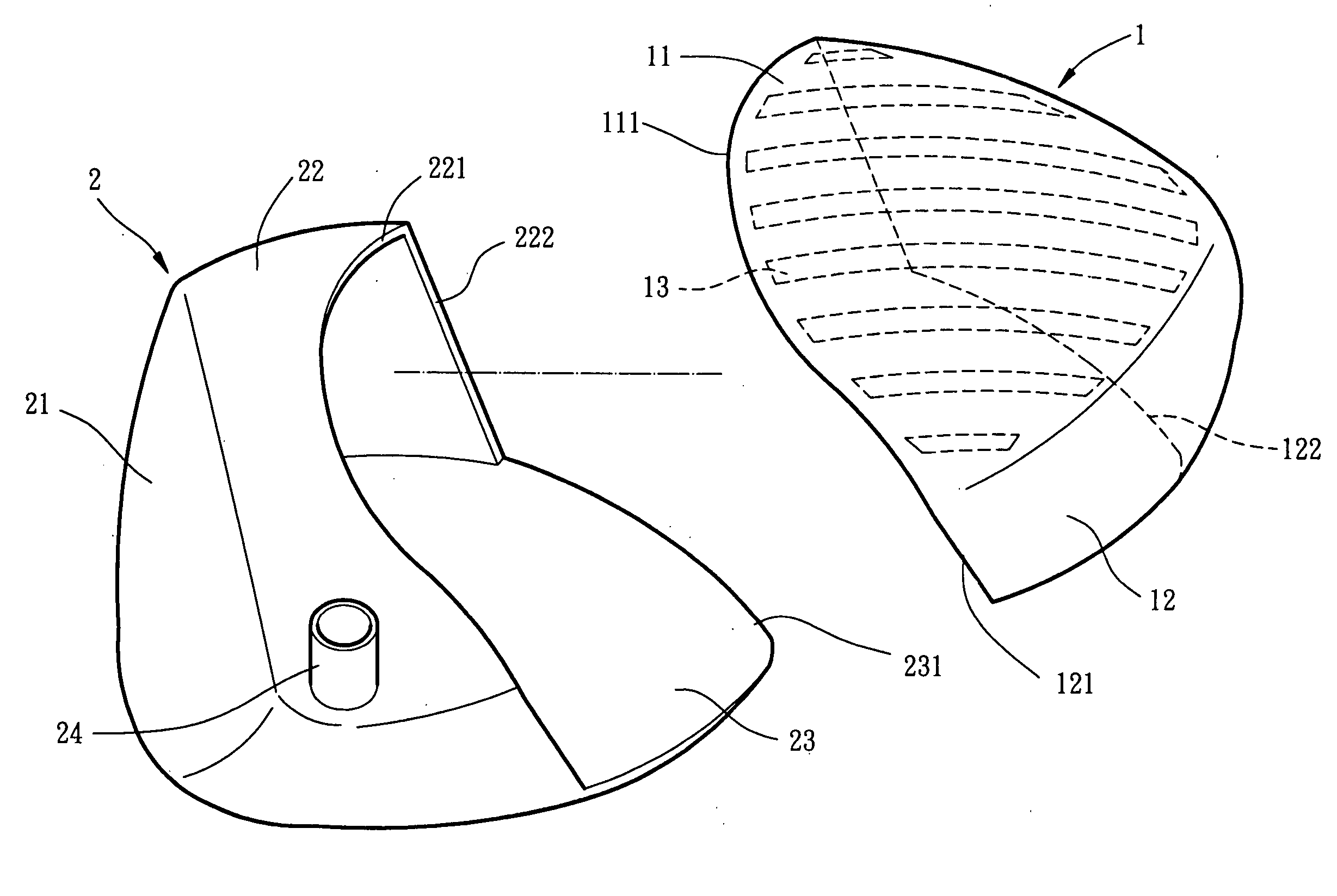

Golf club head

A golf club head includes a body and at least one transparent cover. The body includes a striking face for striking golf balls and a hosel for coupling with a shaft. The body includes a crown in which at least one opening is defined. A perimeter delimiting the opening includes a stepped portion. The transparent cover is securely mounted to the opening of the crown. The transparent cover is made of a transparent material having a specific gravity smaller than 1.5 g / cm3 for reducing a weight of the crown of the golf club head and for shifting a center of gravity of the golf club head downward and rearward.

Owner:FUSHENG IND CO LTD

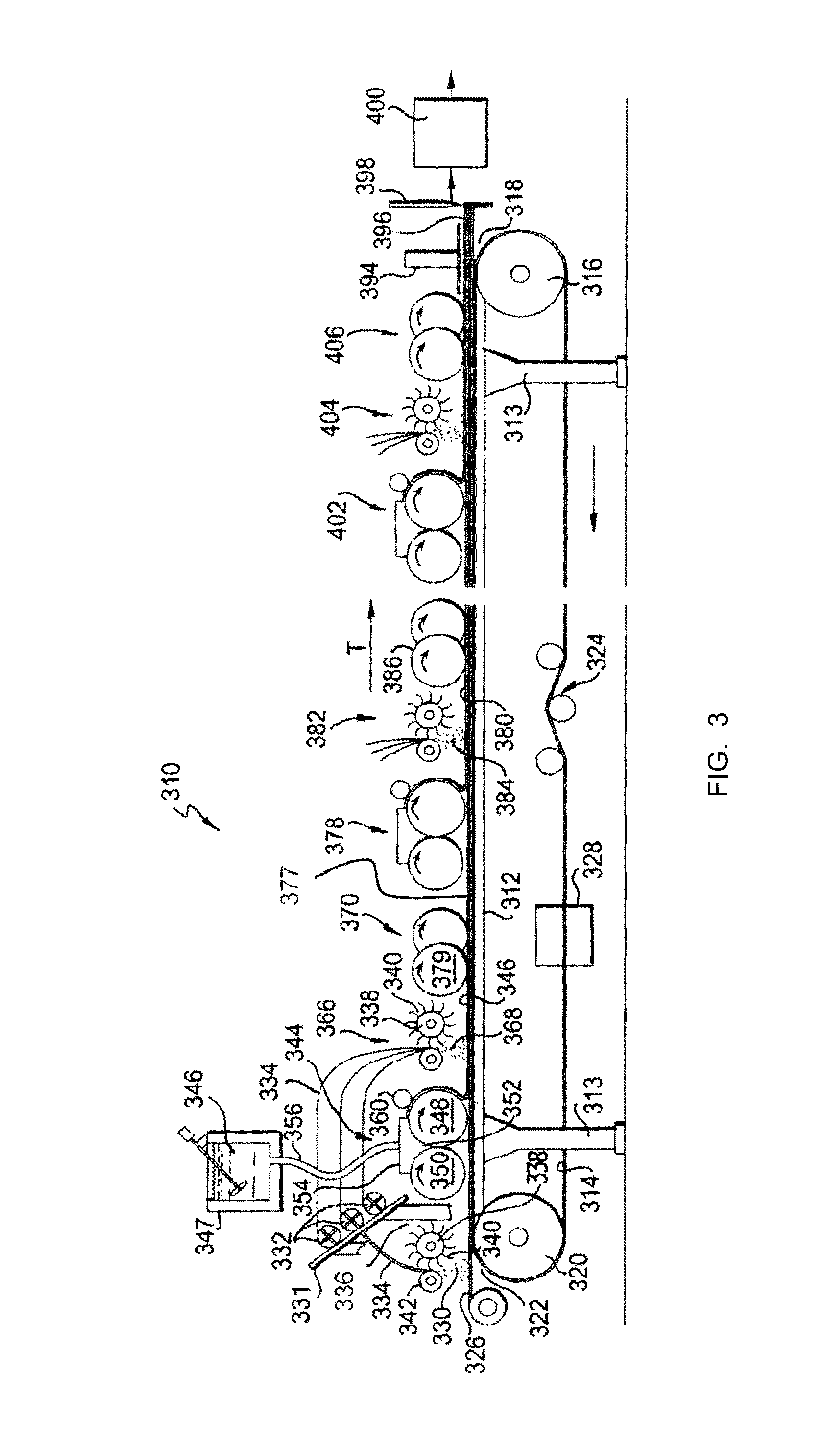

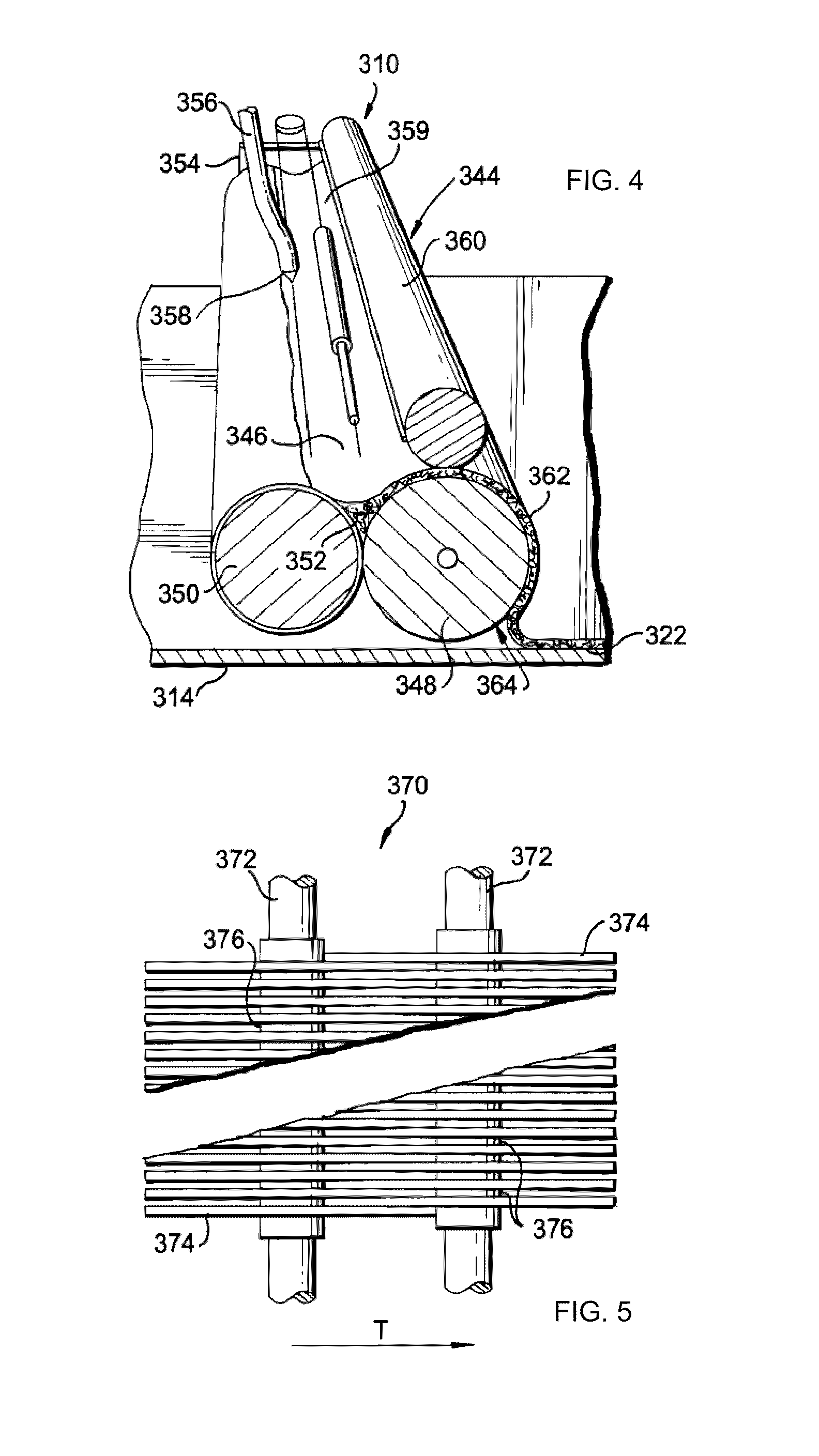

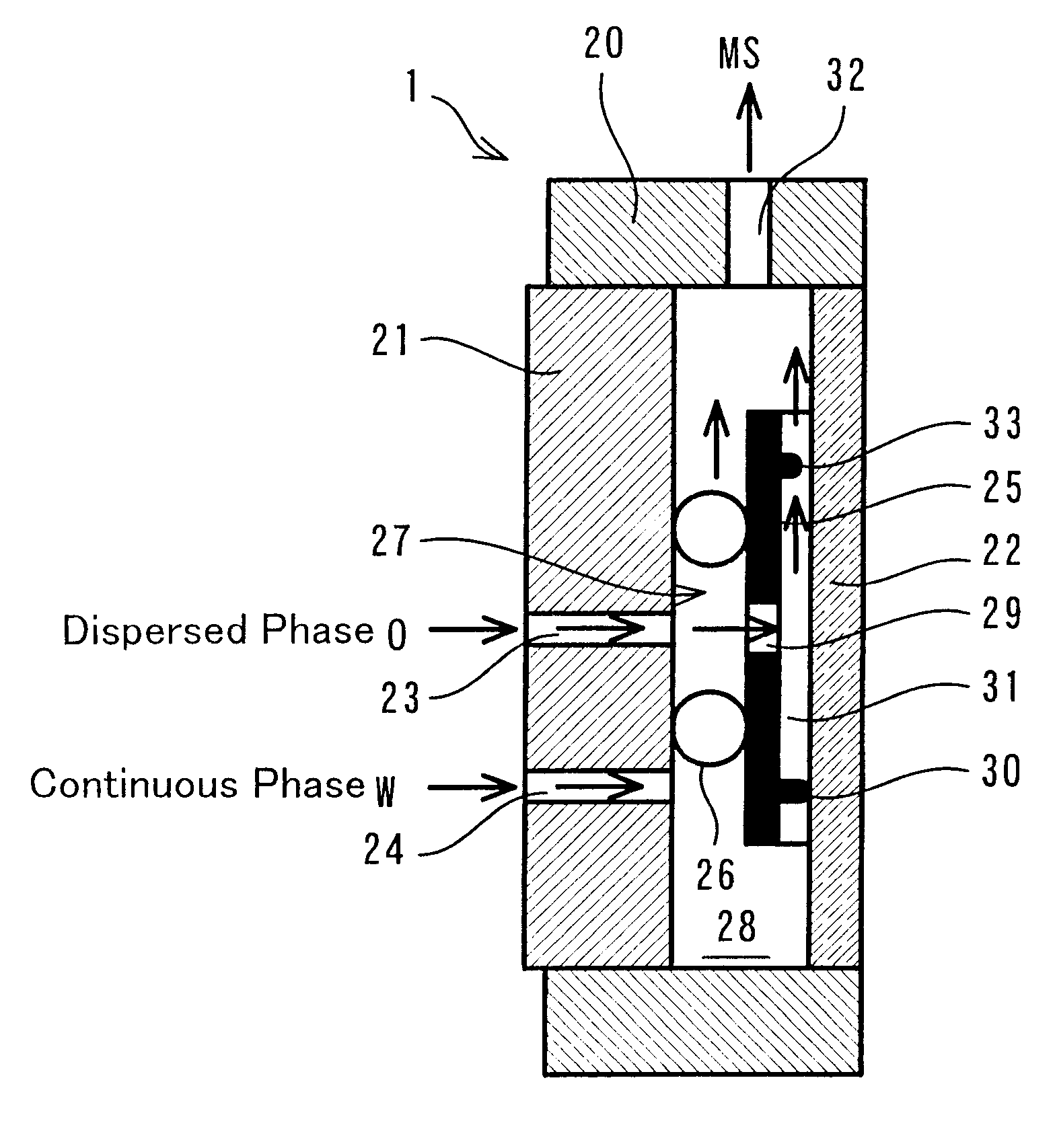

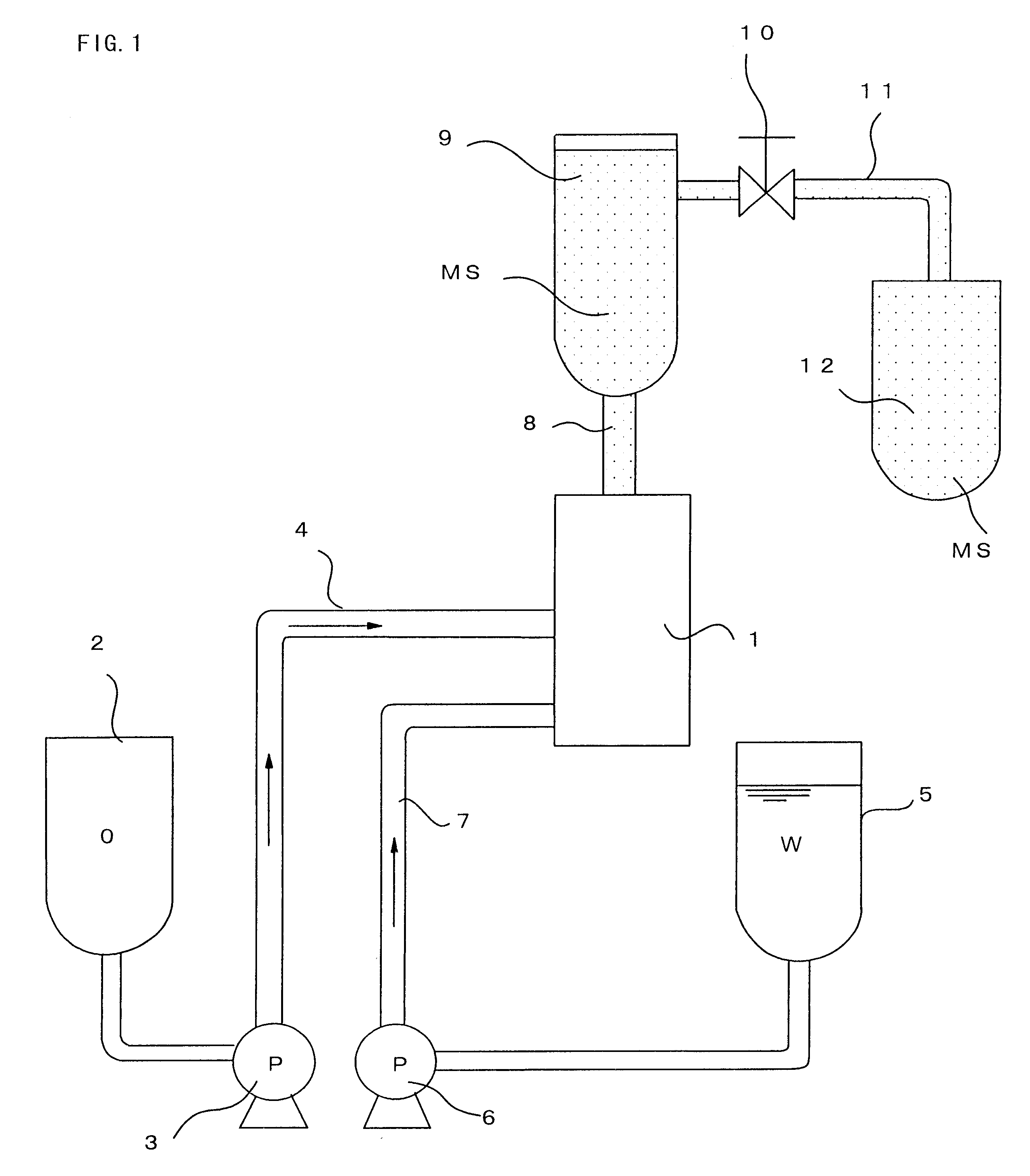

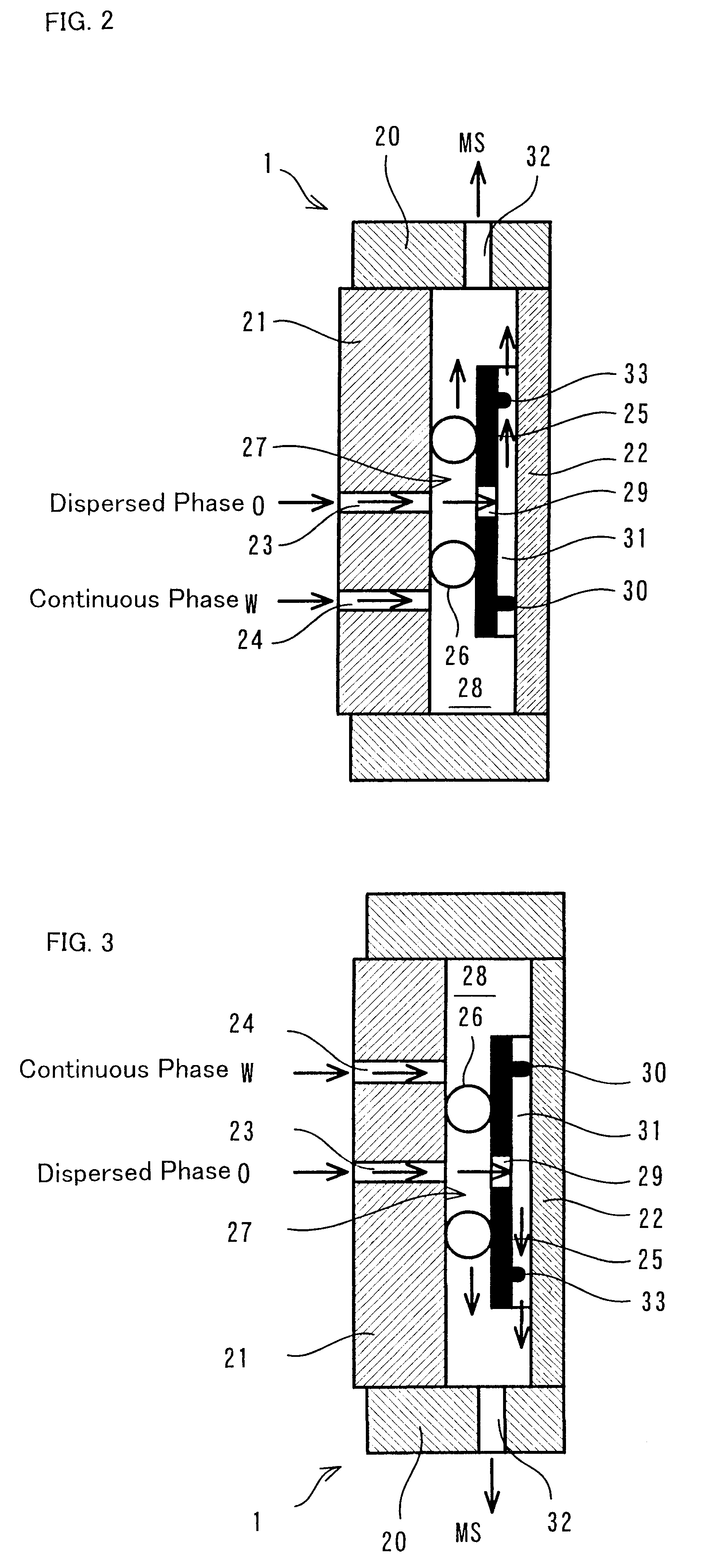

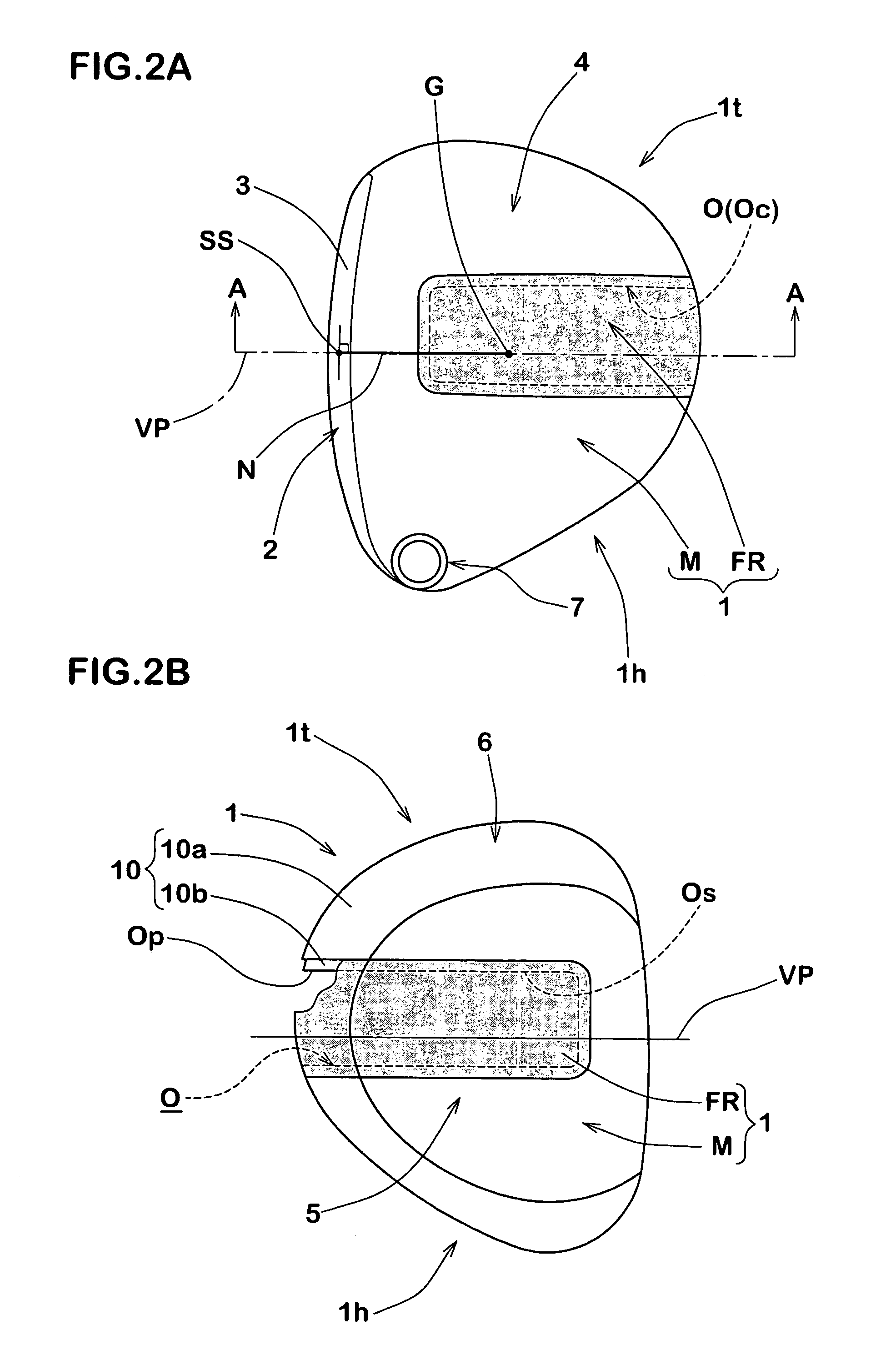

Continuous manufacturing method for microspheres and apparatus therefor

In an apparatus for continuously manufacturing microspheres, a dispersed phase (O) is supplied to a chamber 27 for the dispersed phase inside of a bulkhead member 26 via a supply port 23. Thereafter, the dispersed phase enters into a gap 31 between a plate 22 via a supply port 29 in a base 25. The dispersed phase which enters into the gap 31 grows microspheres (particles) having a certain diameter while passing through a microchannel 33 by pressure applied by, for example, a pump, and is mixed with a continuous phase (W), so that microspheres are produced. The thus-produced microspheres float or are suspended in the continuous phase without needing any particular external force in response to their specific gravity, allowing the microspheres to be generated and withdrawn from a withdrawal port 32 at a significantly reduced pressure in comparison to conventional methods and apparatus.

Owner:NAT FOOD RES INST +1

Decussation stereo torpedo catching net

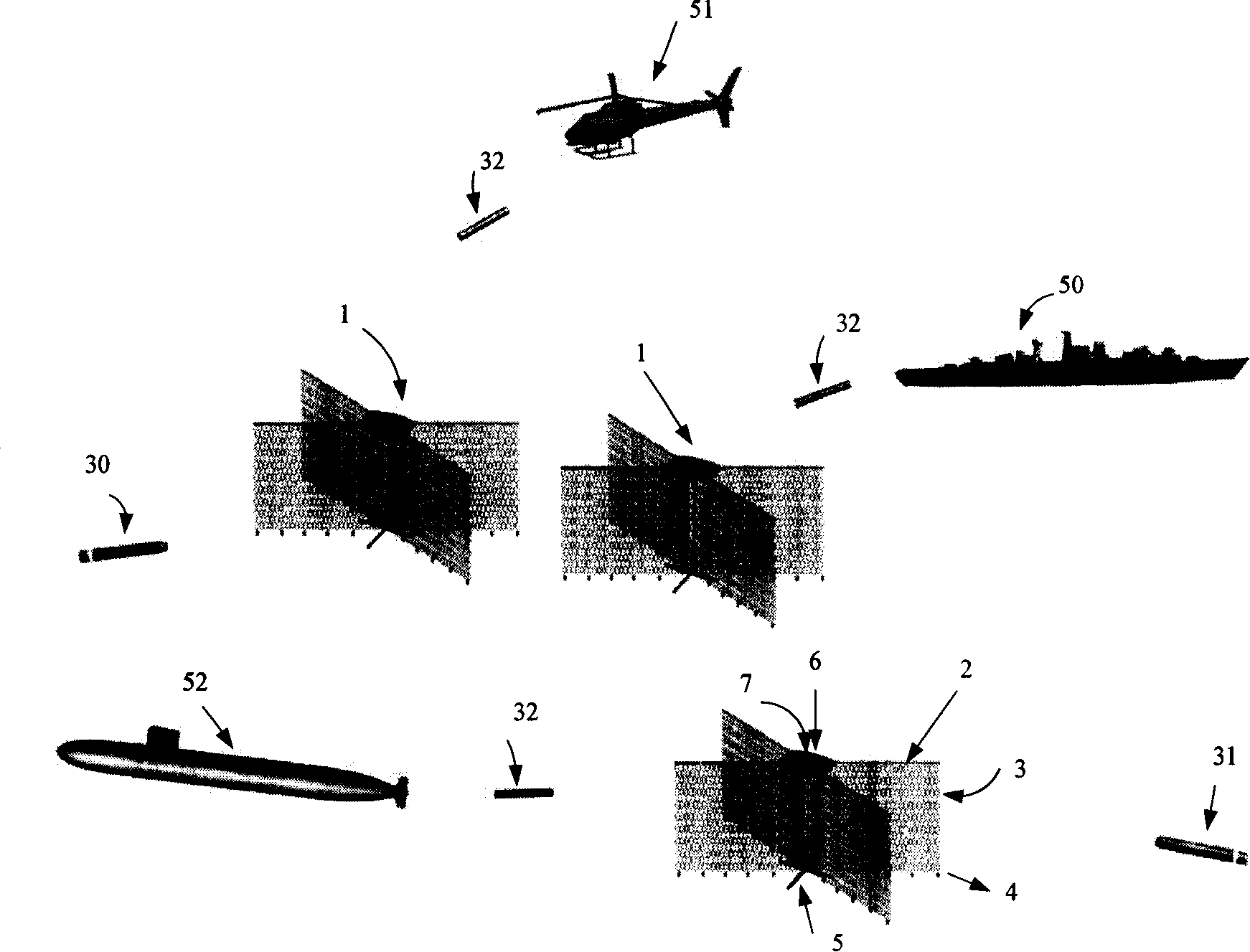

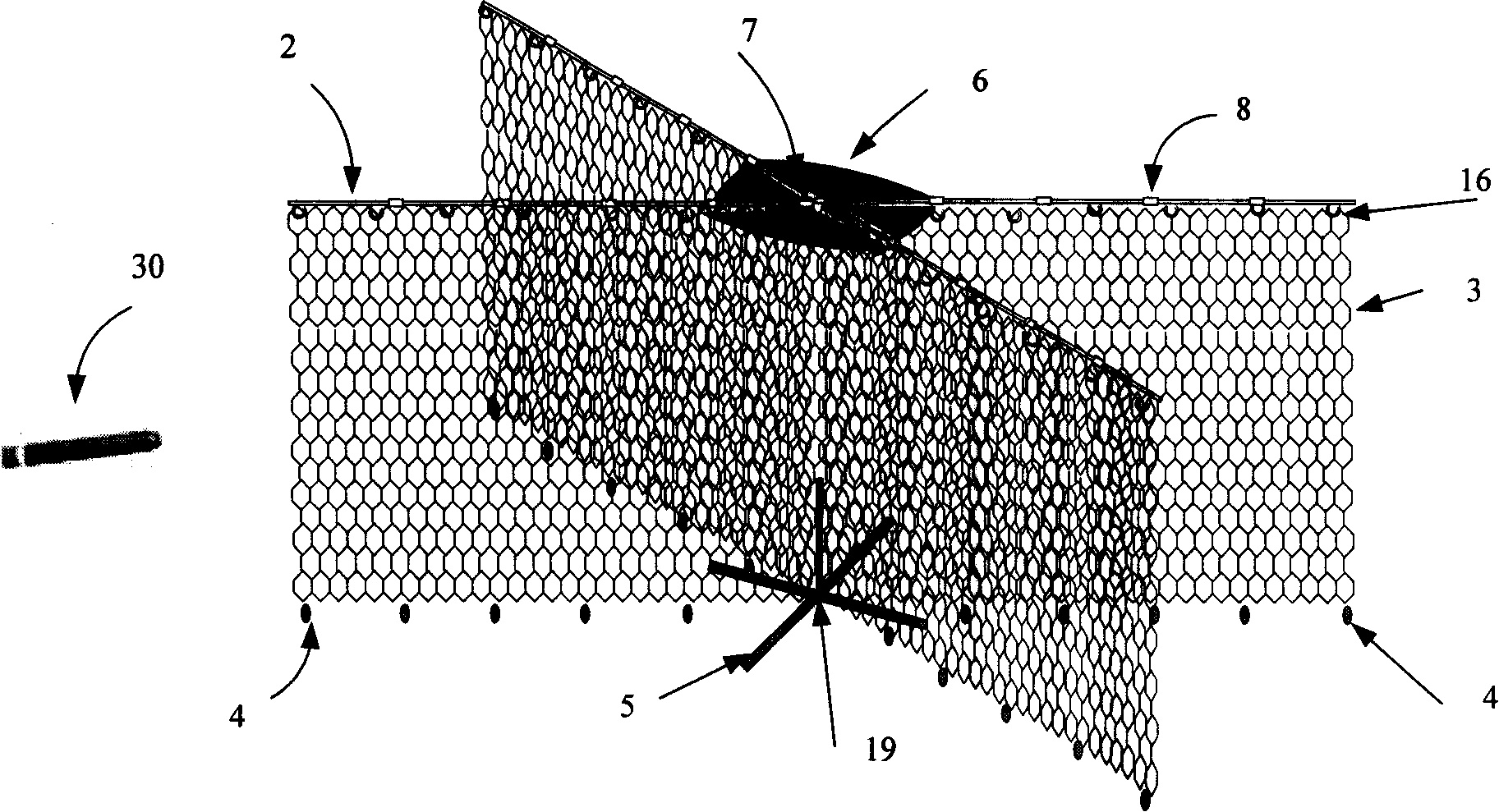

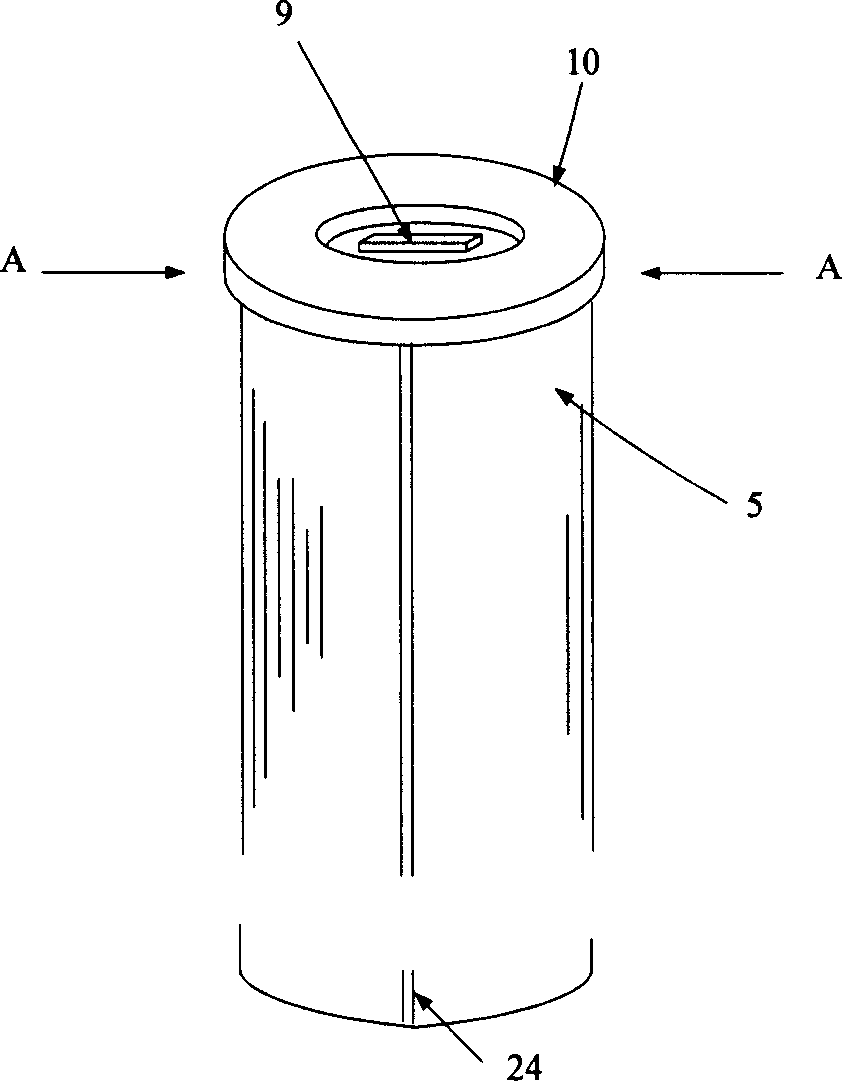

InactiveCN101226043ADoes not affect mobilityLarge effective interception areaDefence devicesPull forceDecussation

The invention relates to a crossed three-dimensional torpedo interception net capable of intercepting torpedoes, especially a torpedo interception net which can be projected or cast and can outspread automatically when entering into the water to form a decussate three-dimensional torpedo interception net. The appearance is column-shaped, a top cover is arranged at the top part and is fixed and sleeved by bayonet locks on the casing which is divided into four sections, the specific density of the top part is lighter than the seawater and the specific density of the bottom part is heavier than the seawater. A decussate bracket is arranged inside, a telescopic link is connected on the lateral side, and a suspended net is connected with the telescopic link via a hanger. When the torpedo interception net is projected or cast into sea via a surface ship, a submarine or a helicopter, the top cover is ejected via a spring, the casing is opened, a going barren dives the telescopic link to expand and the suspended net is dragged to outspread in horizontally. Under the upward pulling force of the telescopic link and the downward pulling force of the weight of the connector of the suspended net, the suspended net is outspreaded along vertical direction; a stabilization membrane connected with the inner side of the suspended net control the stability of the torpedo interception net along the vertical direction.

Owner:孙珠峰

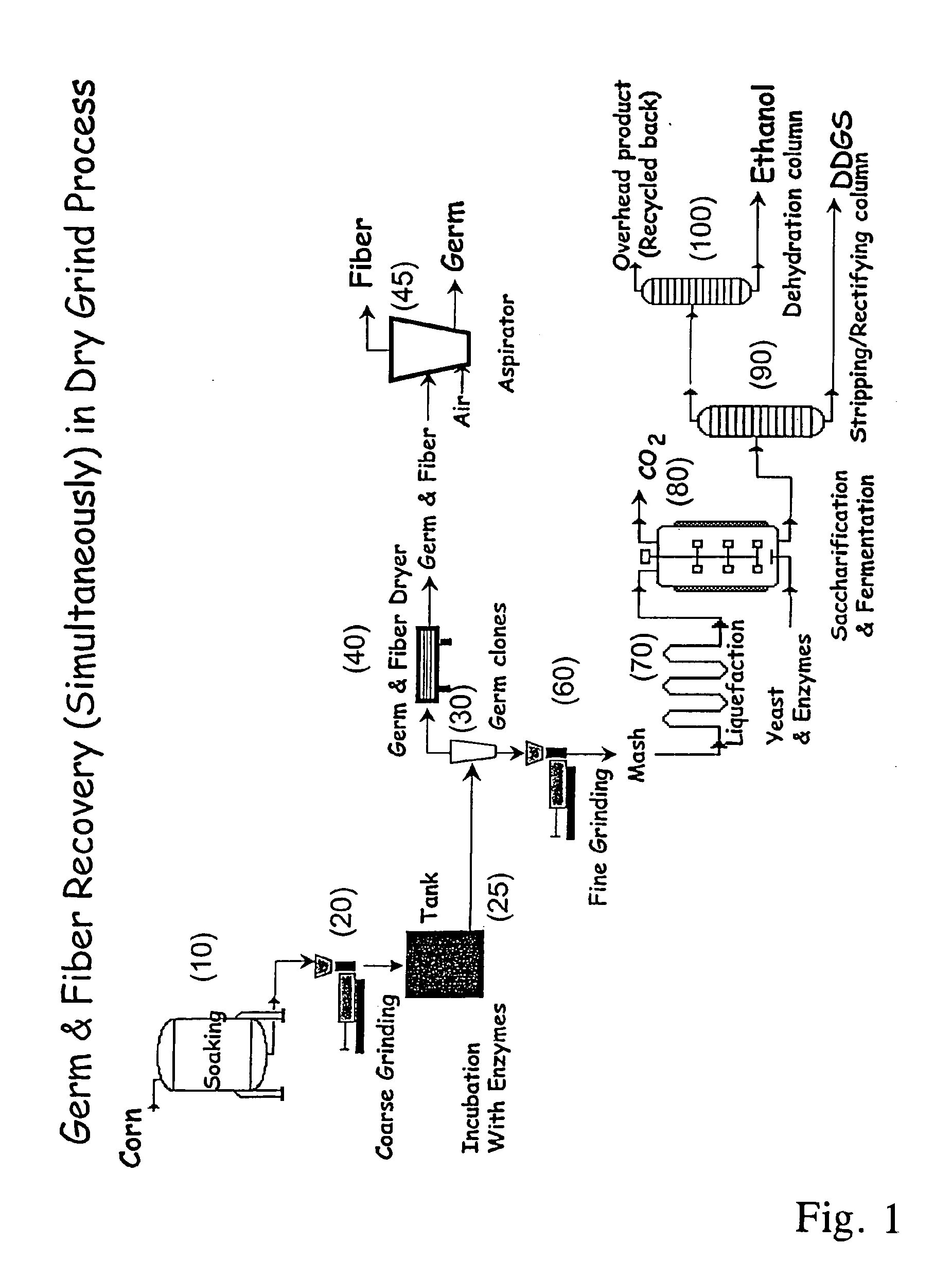

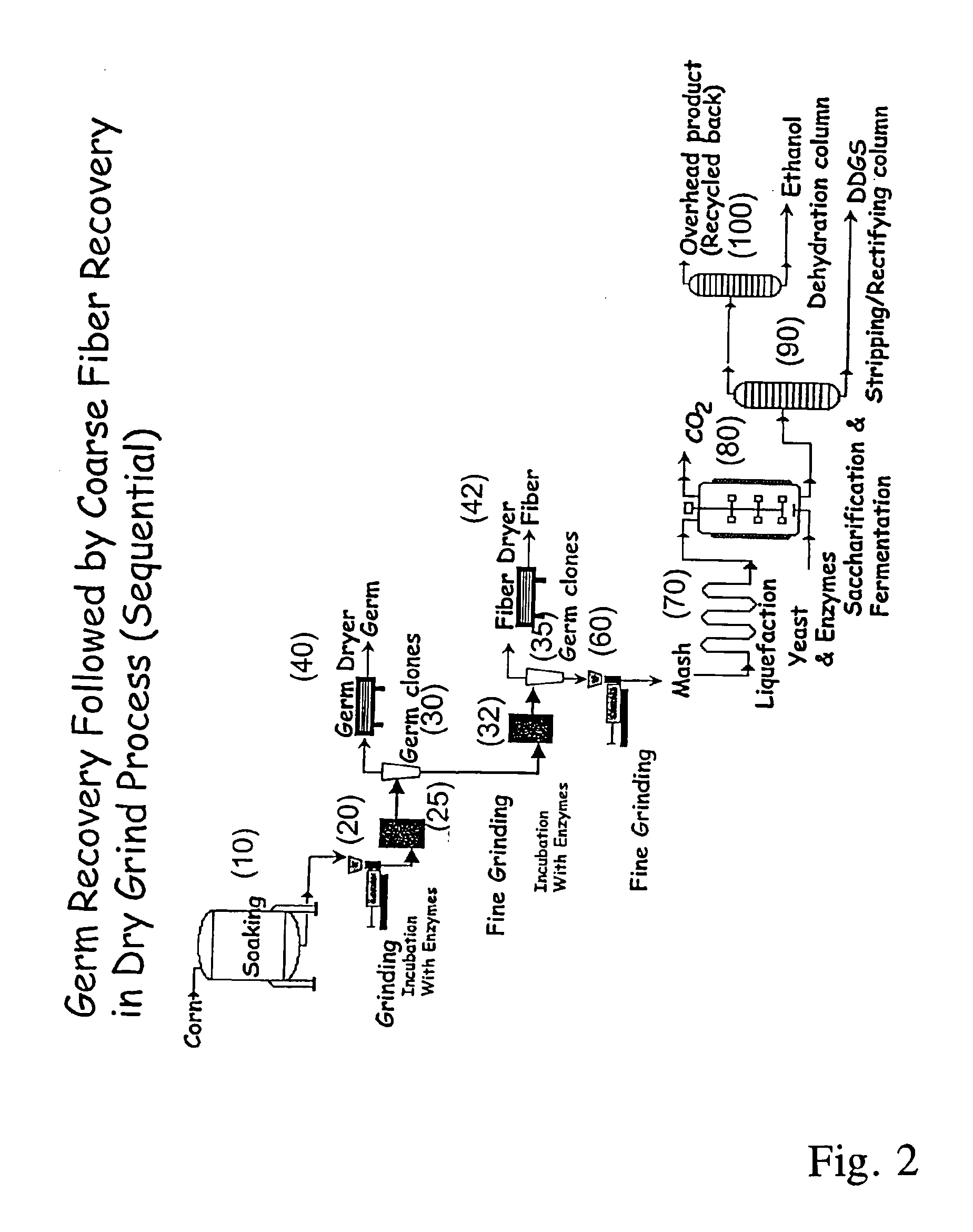

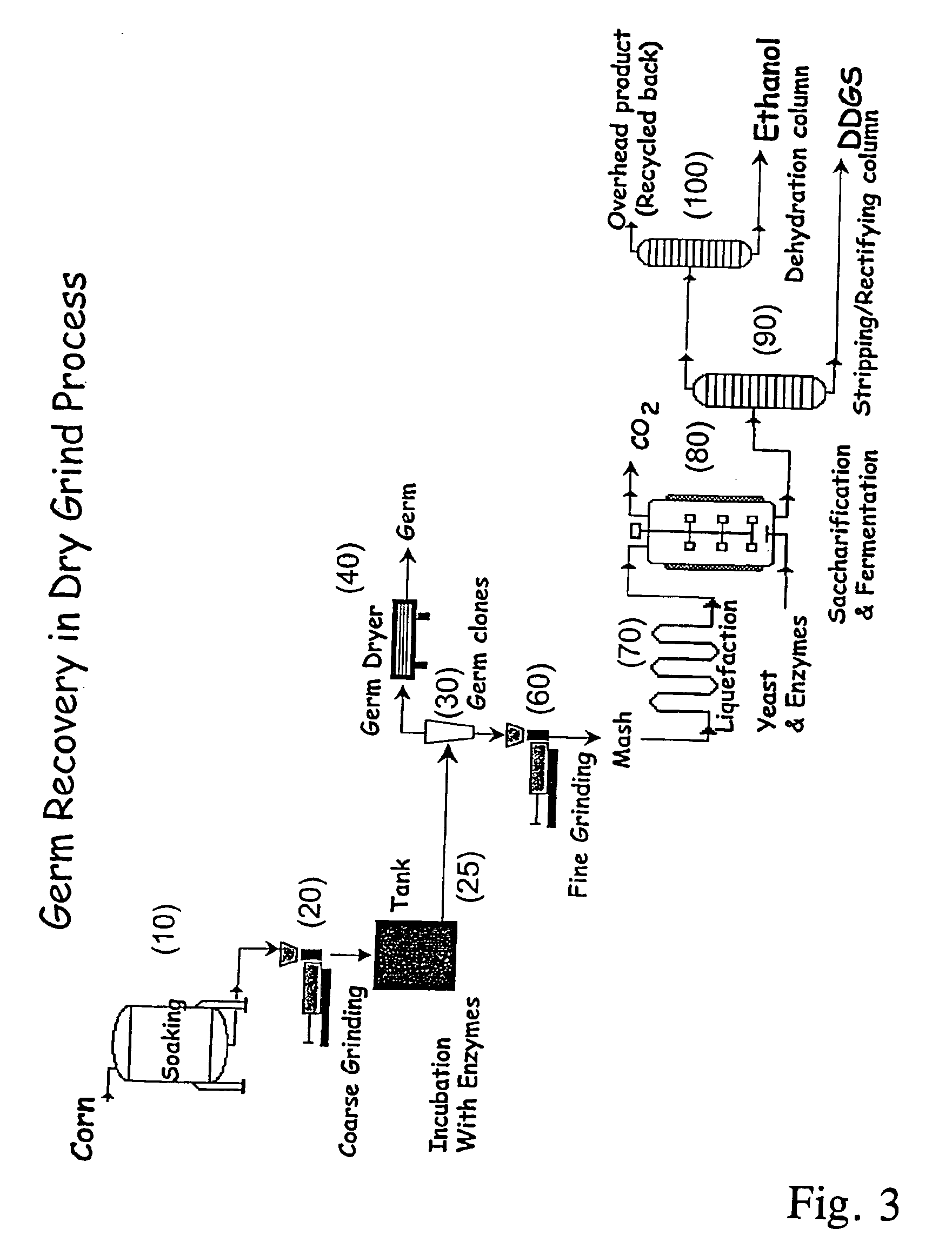

Processes for recovery of corn germ and optionally corn coarse fiber (pericarp)

A process for recovering corn germ and corn coarse fiber from corn in a dry grind process, involving soaking corn kernels in water to produce soaked corn kernels, grinding the soaked corn kernels to produce a ground corn slurry, and incubating the ground corn slurry with at least one enzyme (amylase(s), protease(s), cell wall degrading enzyme(s), or mixtures thereof, and optionally other enzyme(s)) to increase the specific gravity of the slurry to about 10-about 16 Baume so that the corn germ and corn coarse fiber floats to the top of the slurry, recovering the corn germ and the corn coarse fiber, and optionally producing ethanol from the slurry no longer containing the corn germ and corn coarse fiber. The process does not involve the addition of starch, a salt, a sugar syrup, or mixtures thereof to the slurry.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS +1

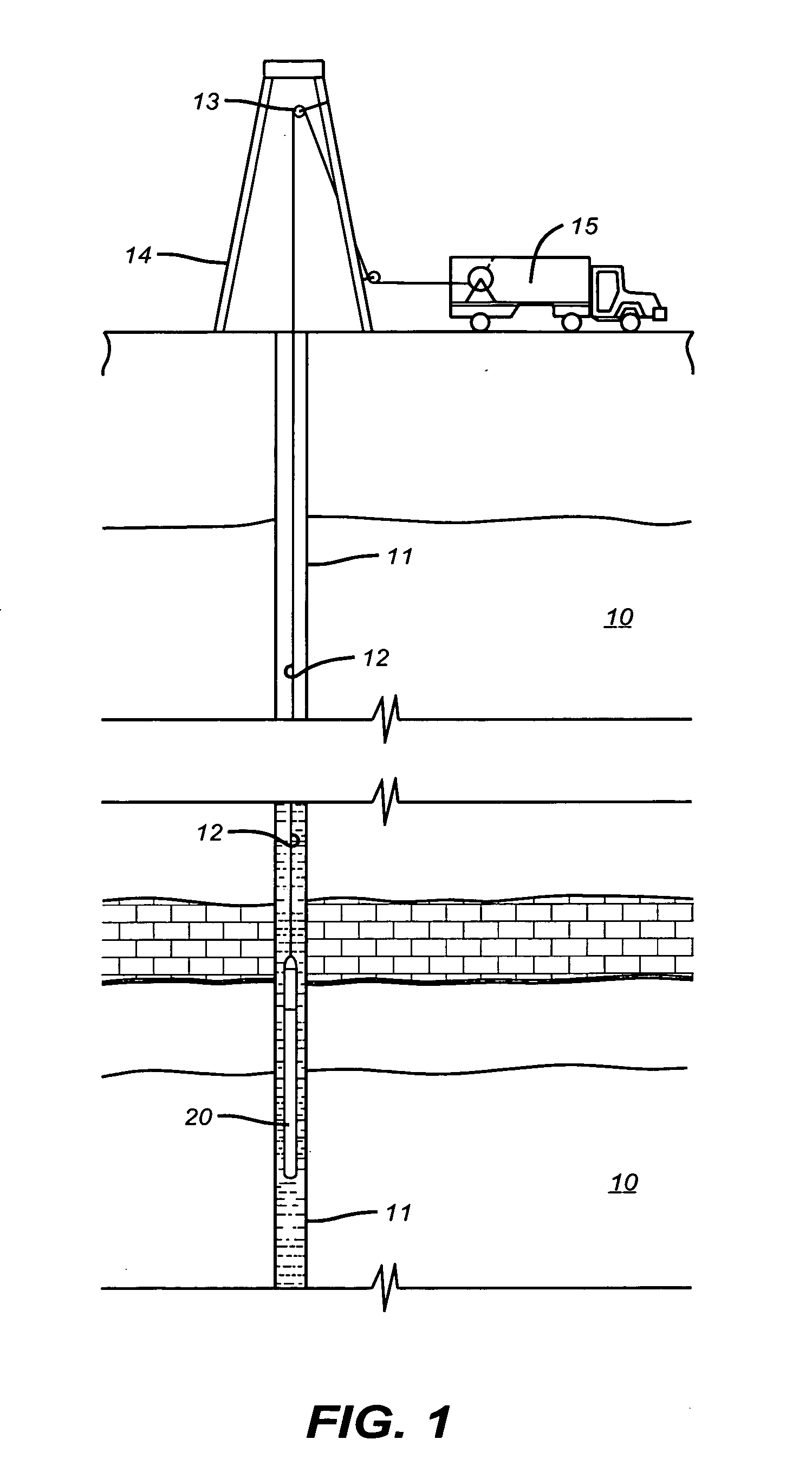

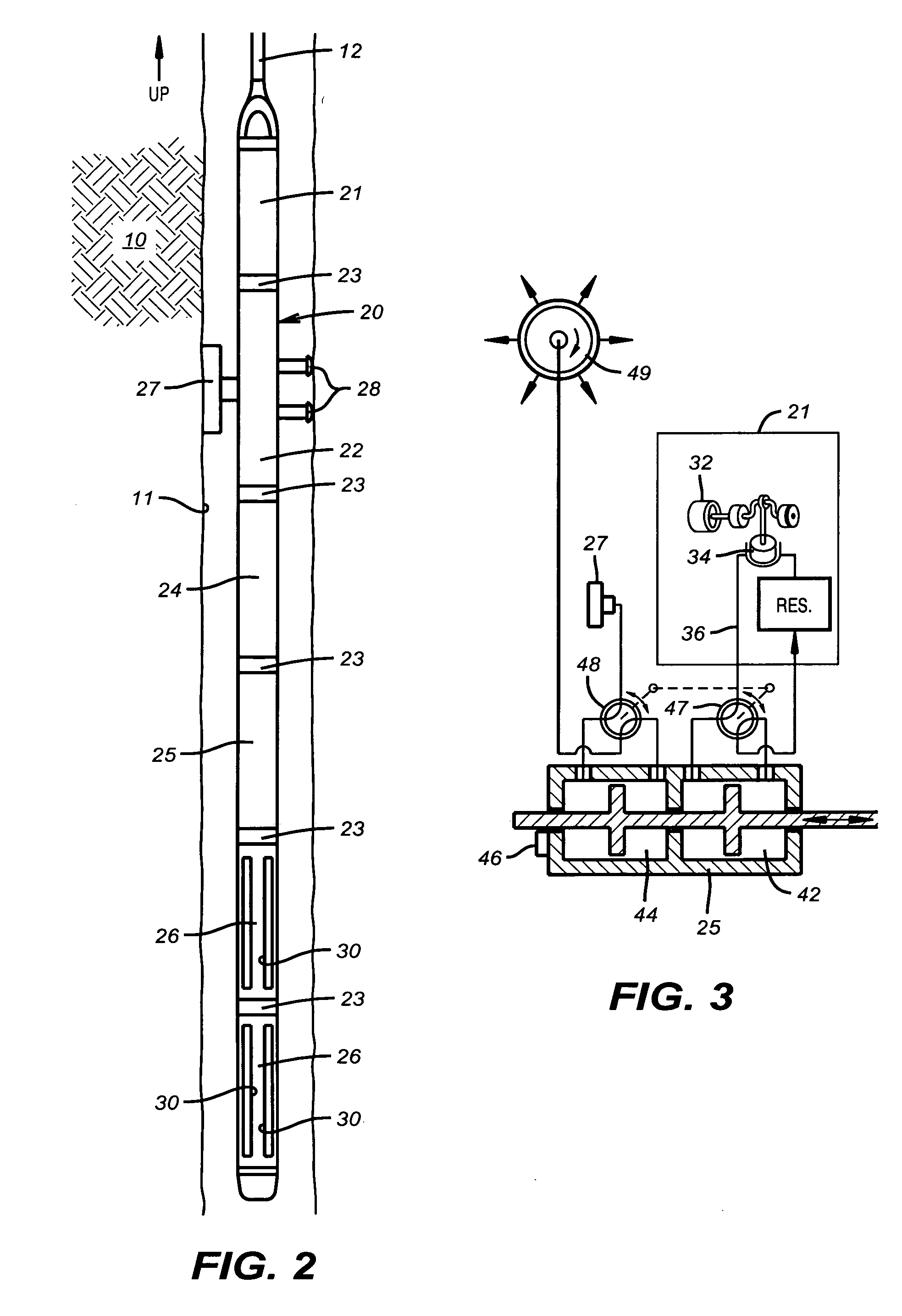

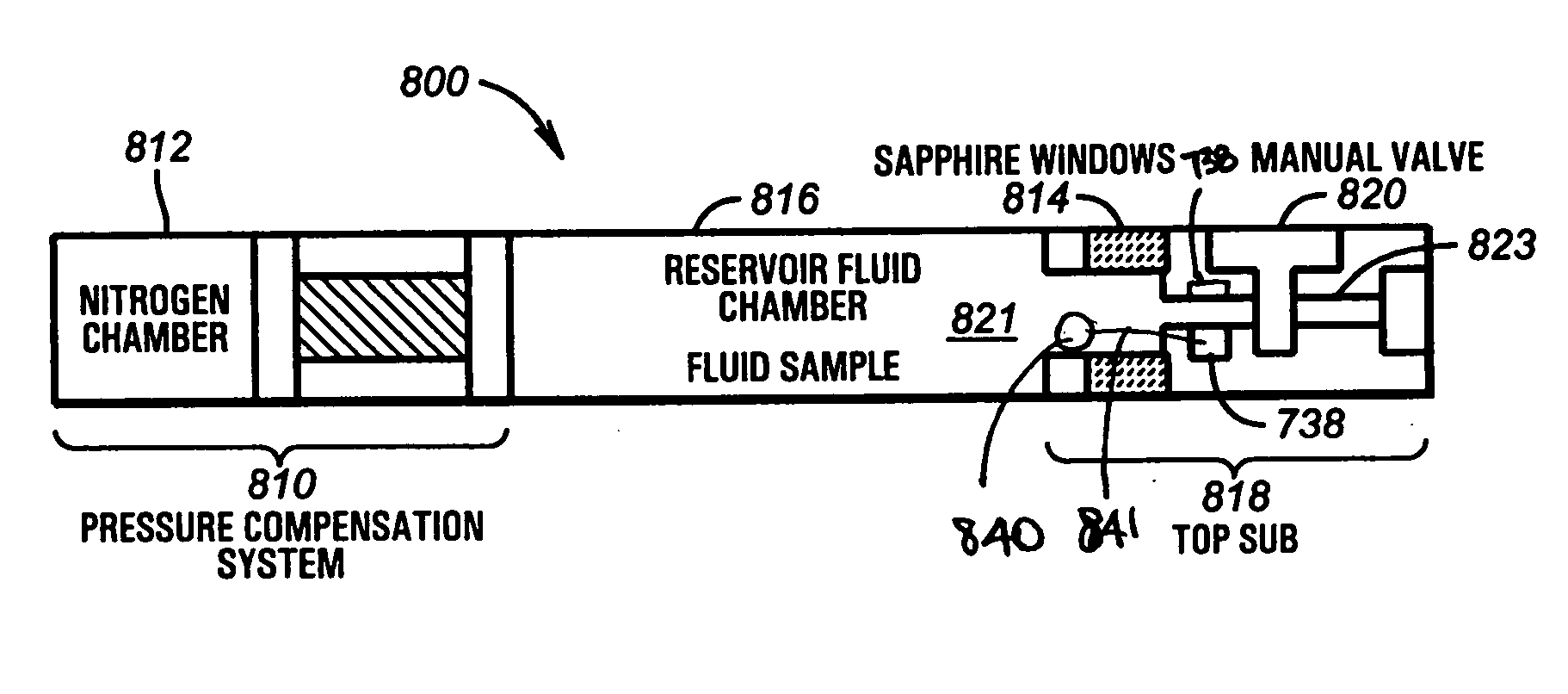

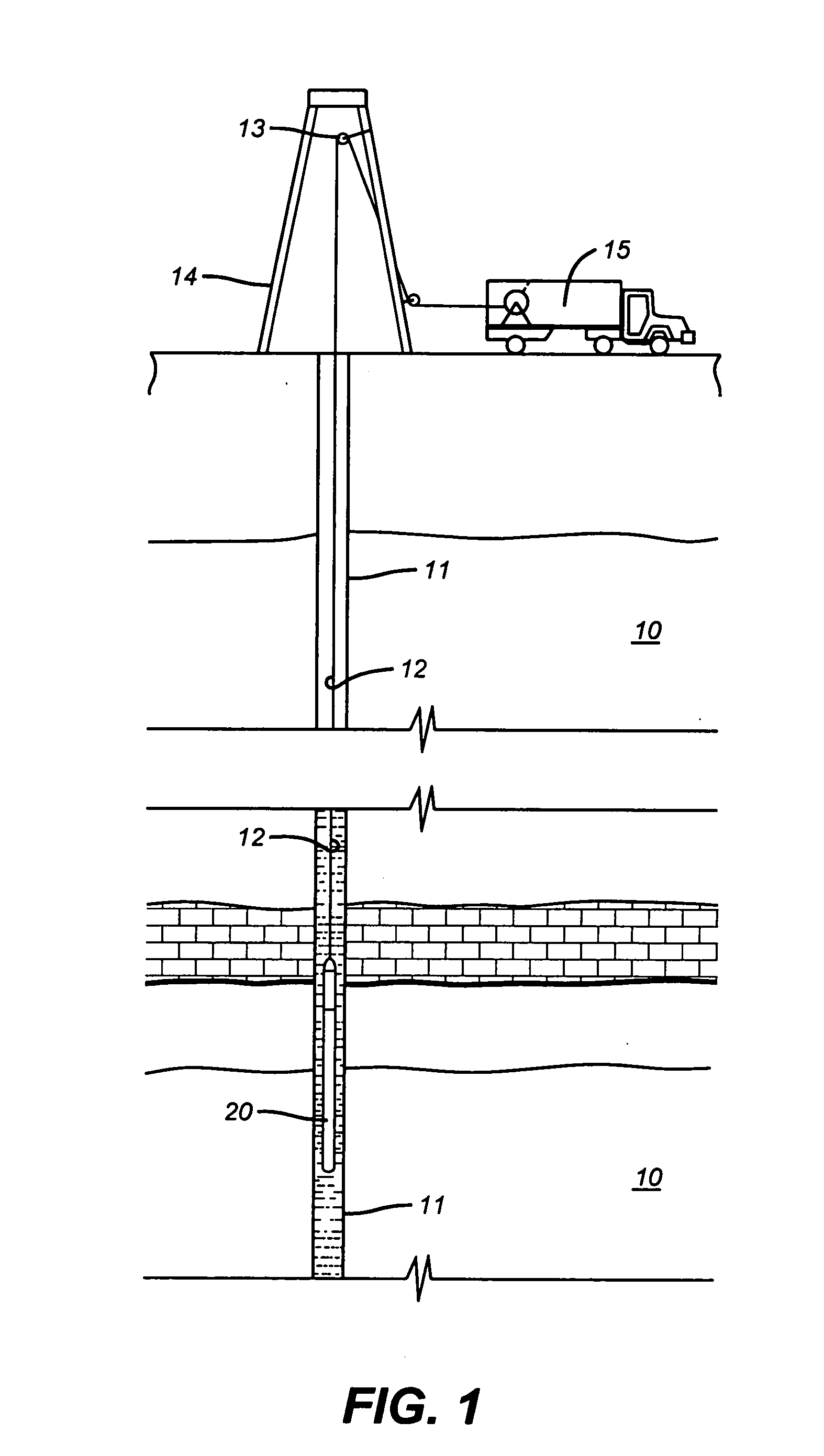

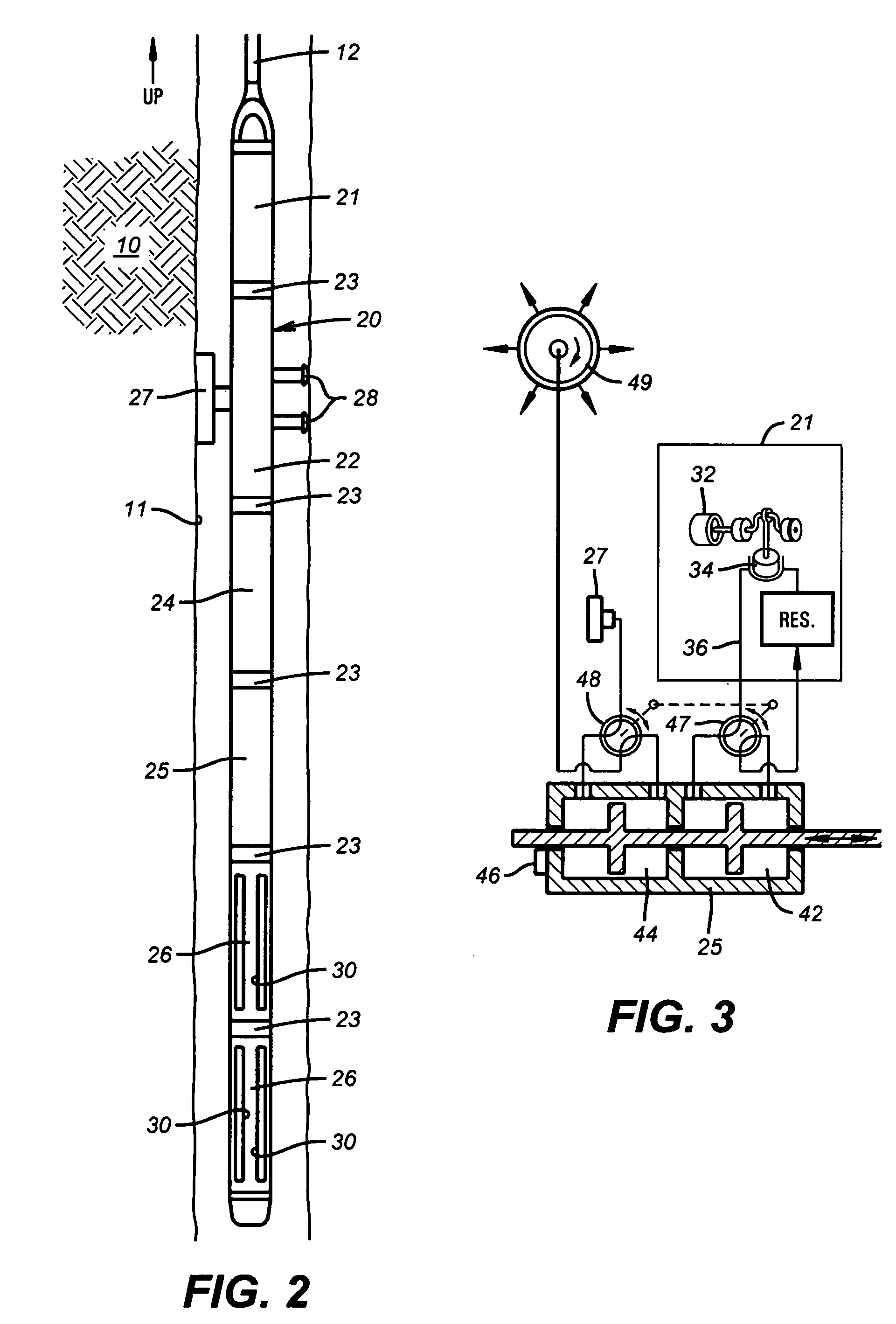

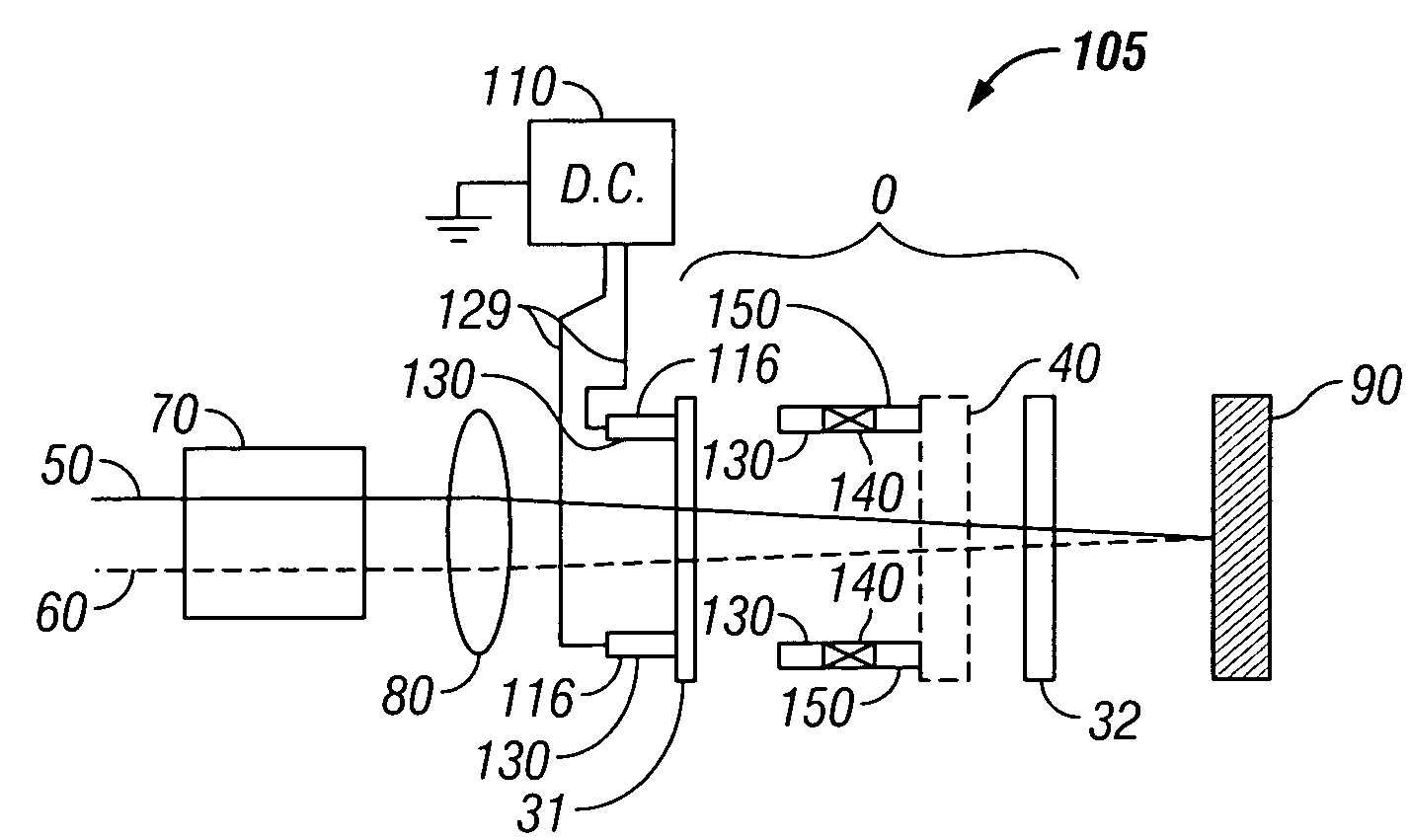

Method and apparatus for a tunable diode laser spectrometer for analysis of hydrocarbon samples

The present invention provides an down hole apparatus and method for ultrahigh resolution spectroscopy using a tunable diode laser (TDL) for analyzing a formation fluid sample downhole or at the surface to determine formation fluid parameters. In addition to absorption spectroscopy, the present invention can perform Raman spectroscopy on the fluid, by sweeping the wavelength of the TDL and detecting the Raman-scattered light using a narrow-band detector at a fixed wavelength. The spectrometer analyzes a pressurized well bore fluid sample that is collected downhole. The analysis is performed either downhole or at the surface onsite. Near infrared, mid-infrared and visible light analysis is also performed on the sample to provide an onsite surface or downhole analysis of sample properties and contamination level. The onsite and downhole analysis comprises determination of aromatics, olefins, saturates, gas oil ratio, API gravity and various other parameters which can be estimated by correlation, a trained neural network or a chemometric equation.

Owner:BAKER HUGHES INC

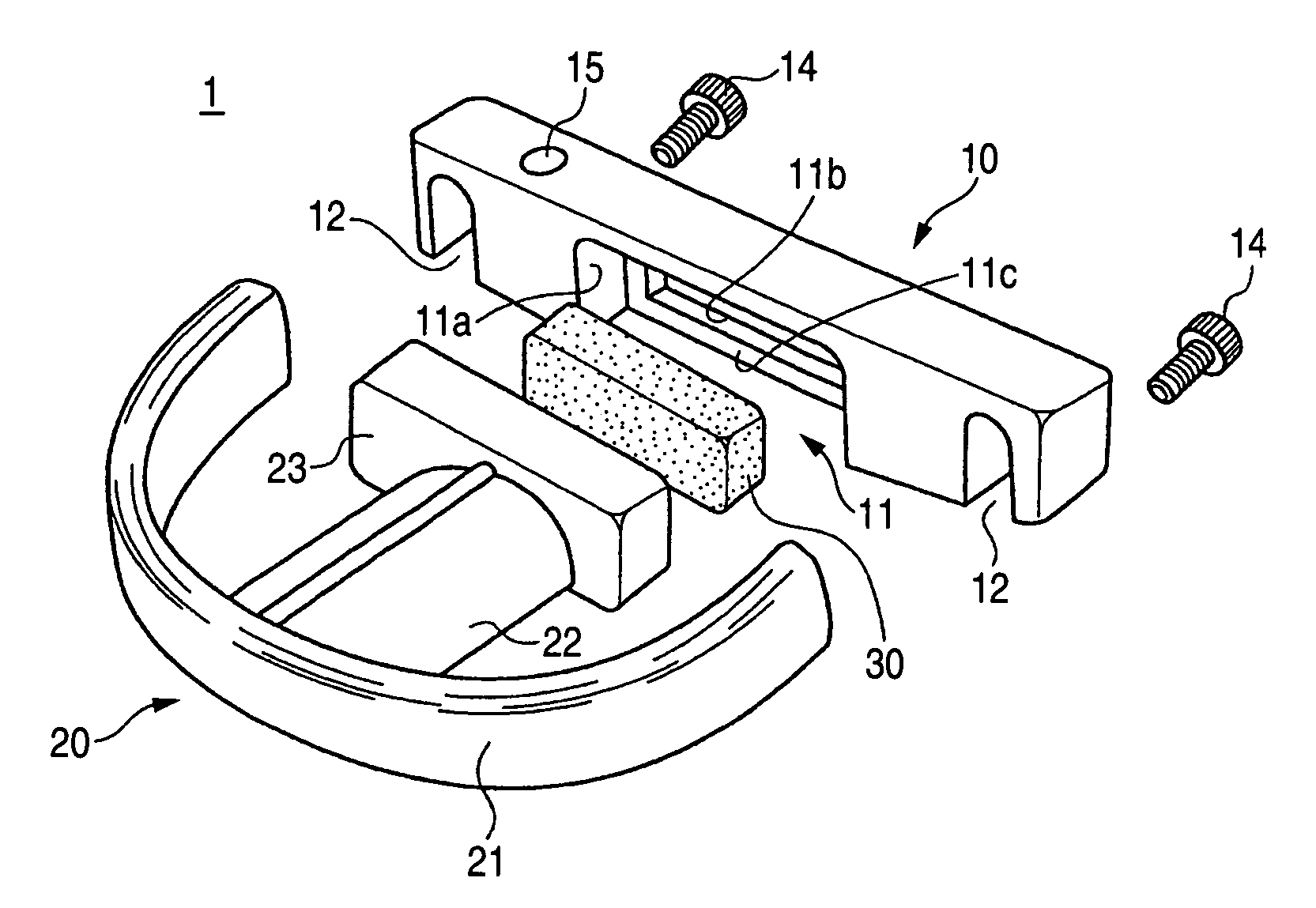

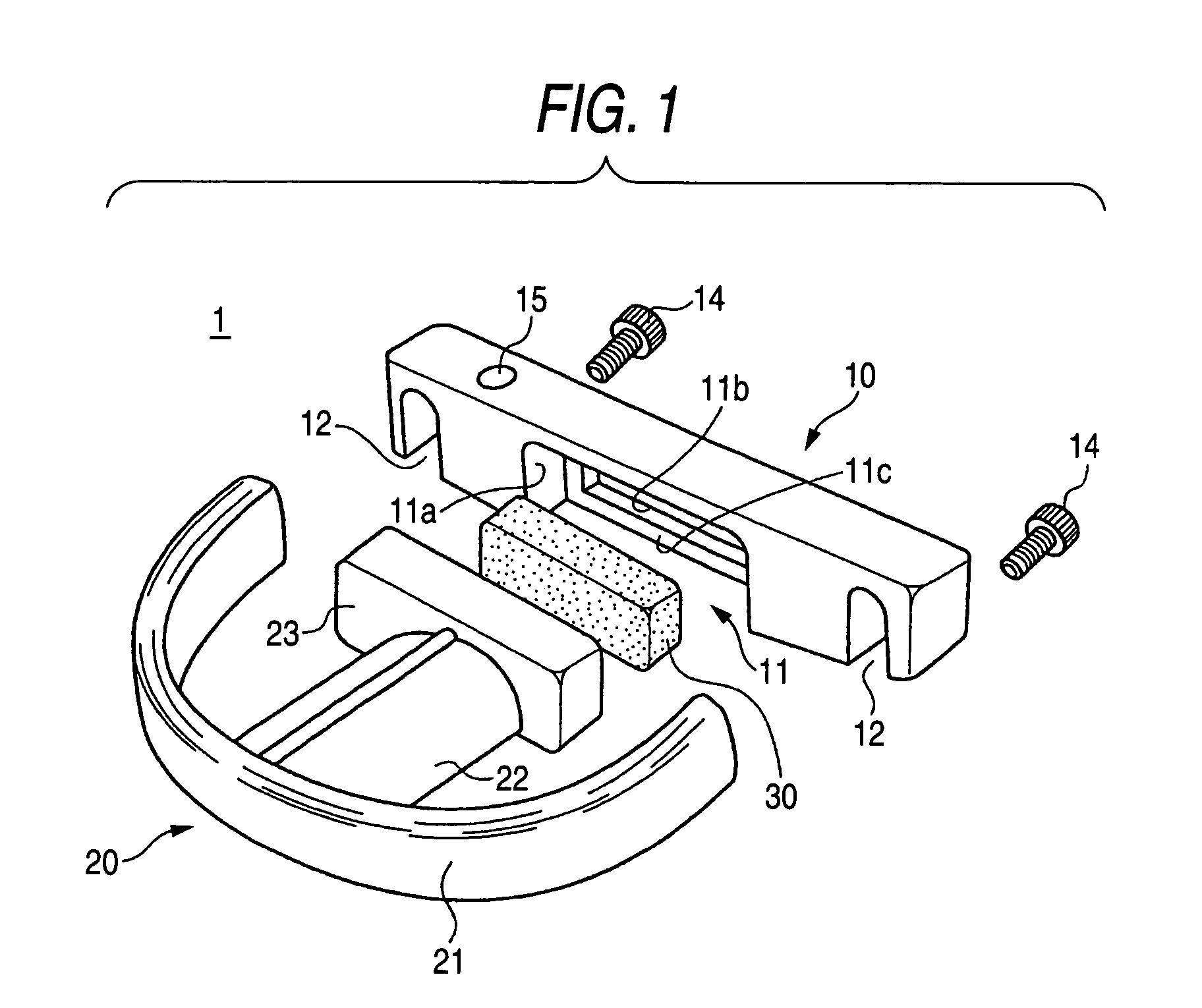

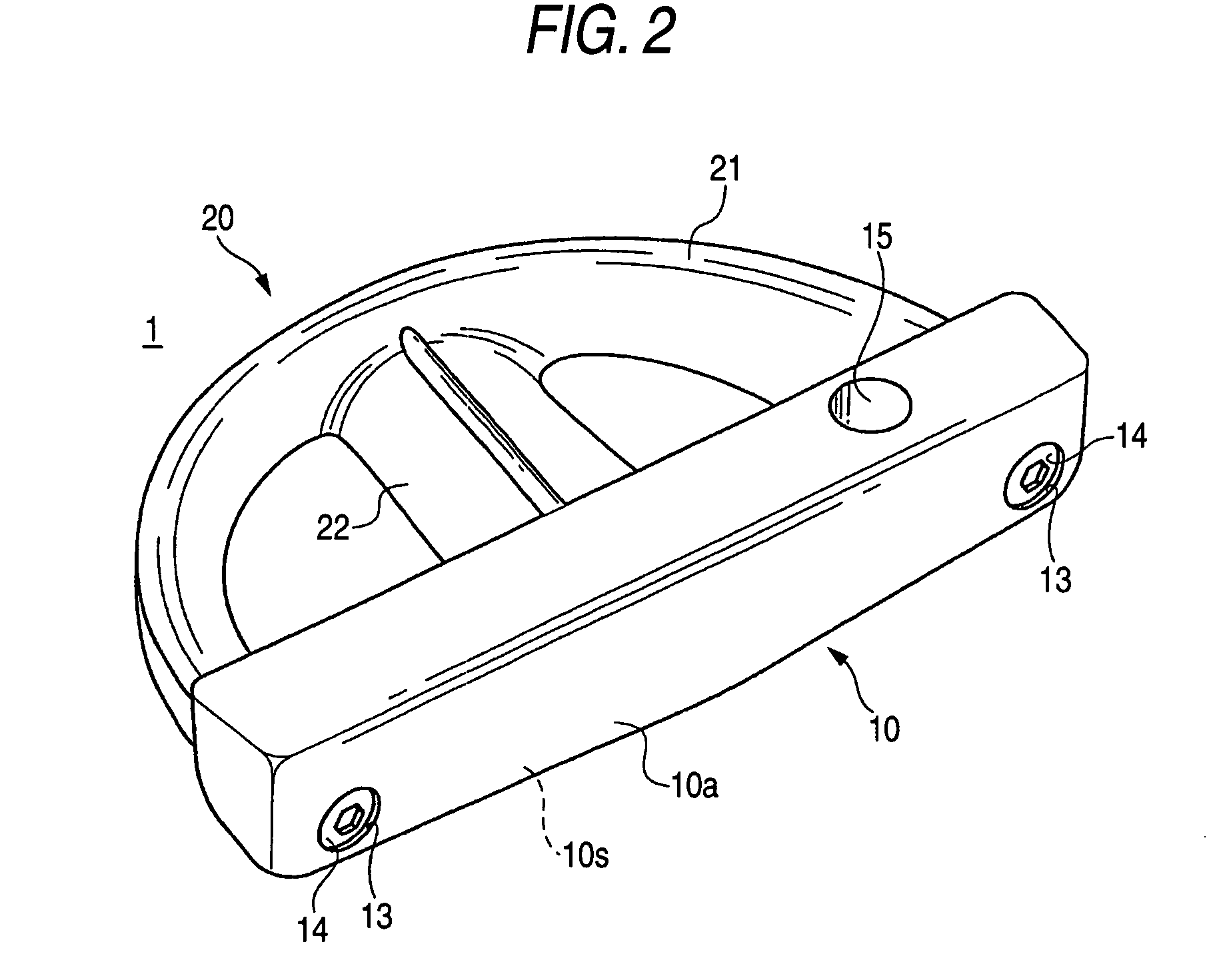

Putter head

Owner:BRIDGESTONE SPORTS

Golf club head

Owner:SUMITOMO RUBBER IND LTD

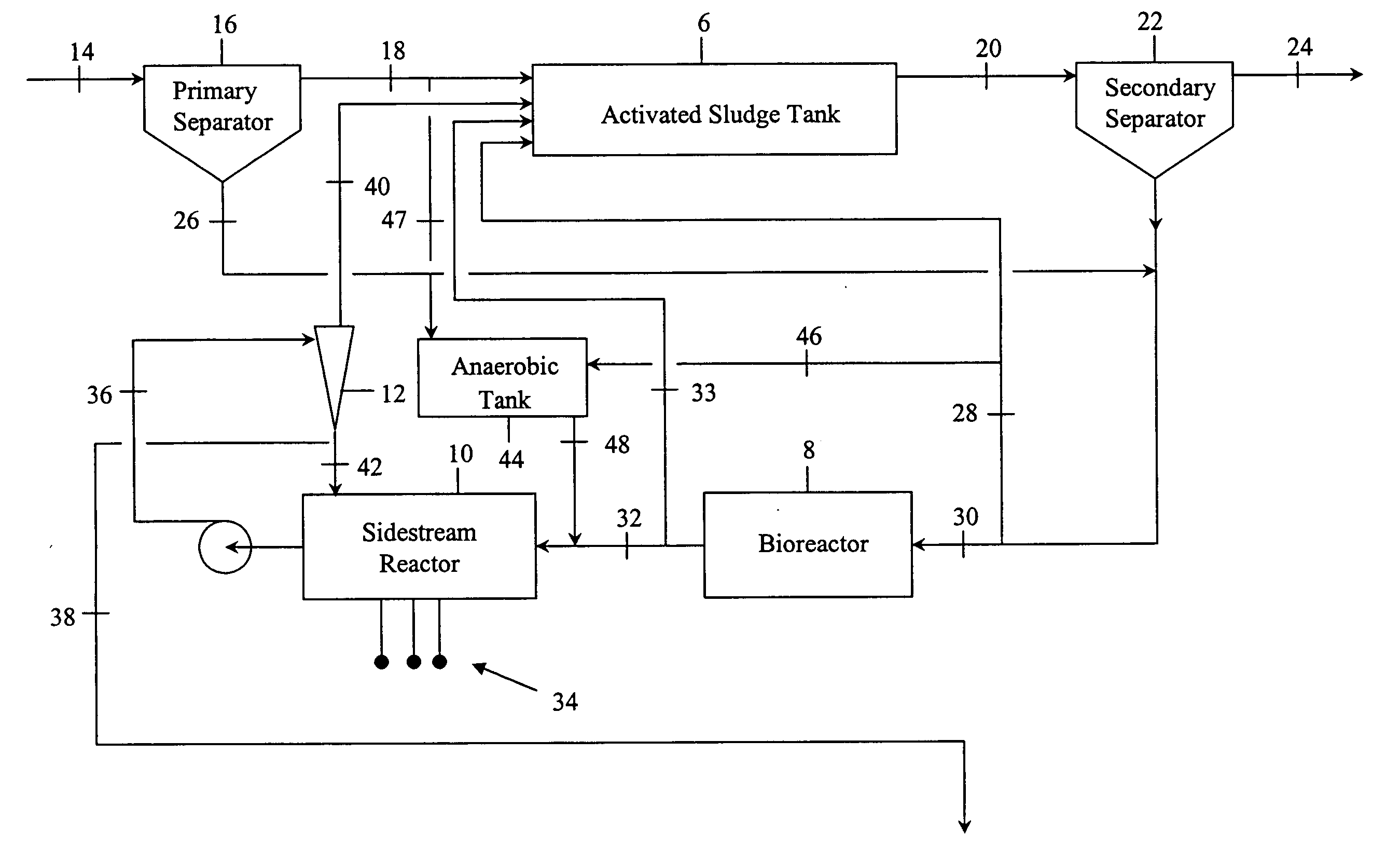

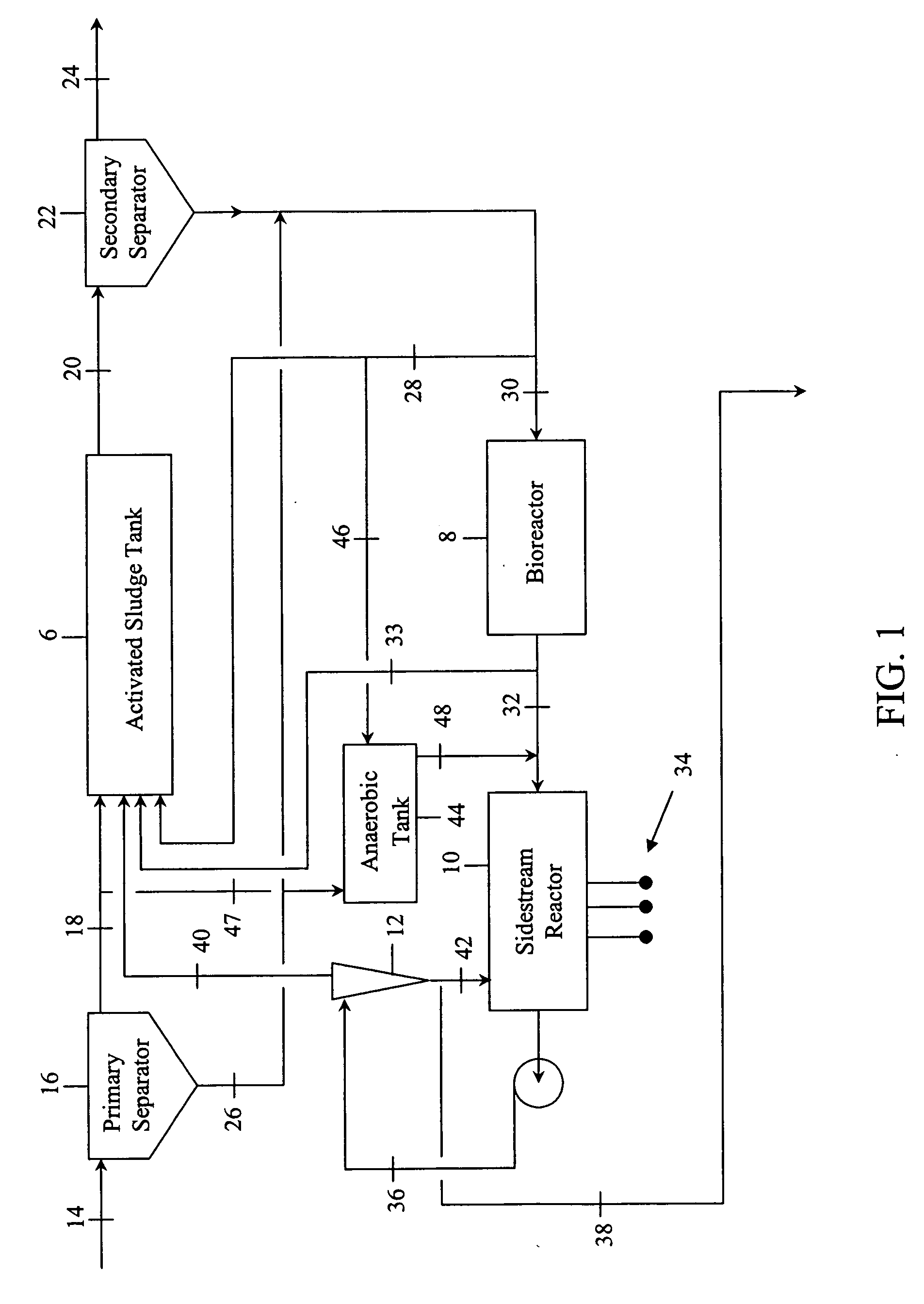

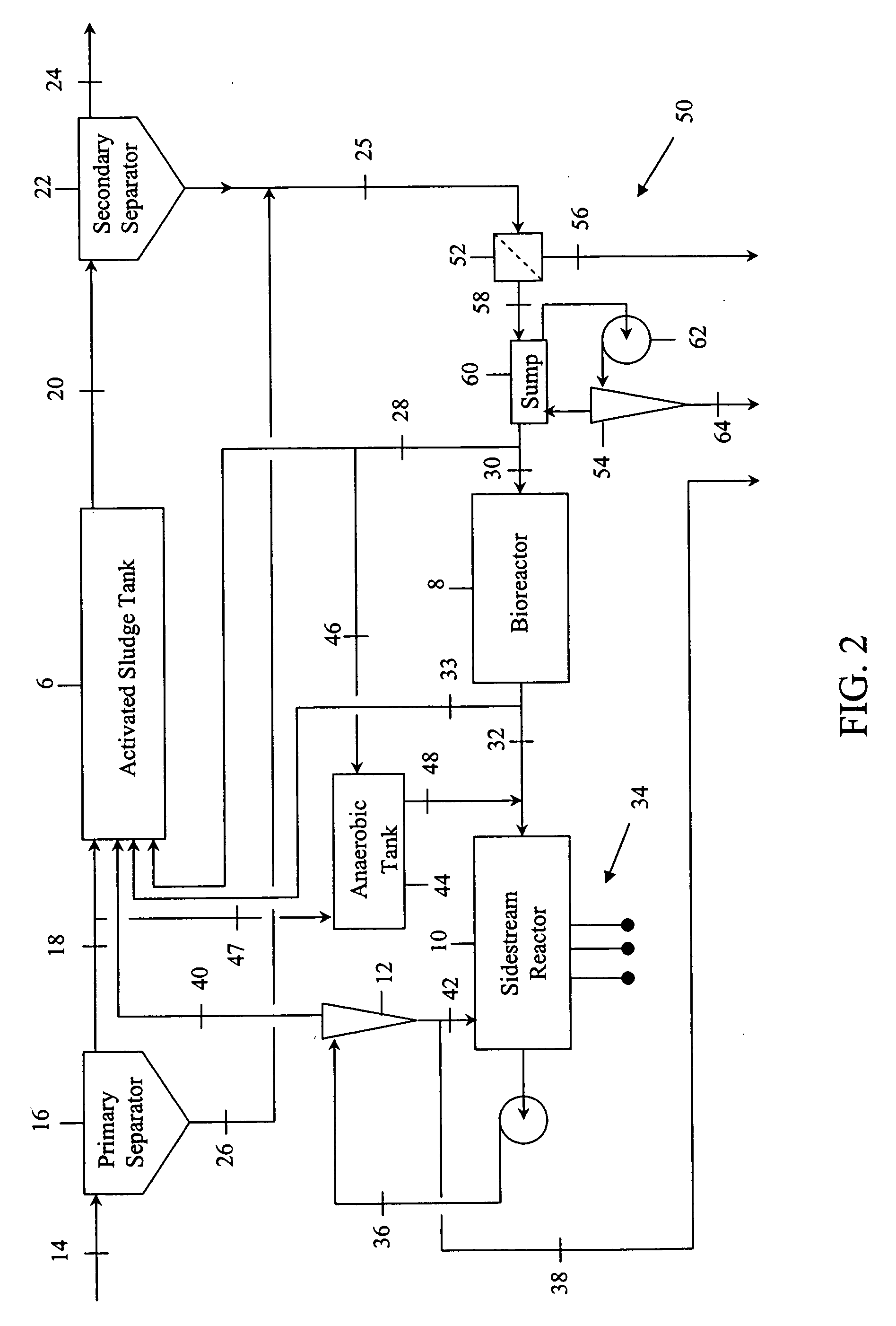

Process to enhance phosphorus removal for activated sludge wastewater treatment systems

InactiveUS20070000836A1Water/sewage treatment by centrifugal separationWater treatment parameter controlActivated sludgePhosphate

Contaminated wastewaters comprising biochemical oxygen demand (BOD), nitrogen and phosphorus are treated by an activated sludge process. The process utilizes an activated sludge tank, a solid-liquid separator, and a bioreactor to significantly reduce, or eliminate, waste activated sludge (WAS) within a sludge stream. A sidestream reactor is employed downstream from the bioreactor to remove soluble phosphates left in the sludge stream by the low WAS process. Within the sidestream reactor, a source of multivalent metal ions is added to a slightly alkaline sludge stream to precipitate the phosphates. The solid phosphates have a specific gravity higher than that of the organic matter in the sludge stream and may be separated from the sludge stream based upon differential settling velocity.

Owner:EVOQUA WATER TECH LLC

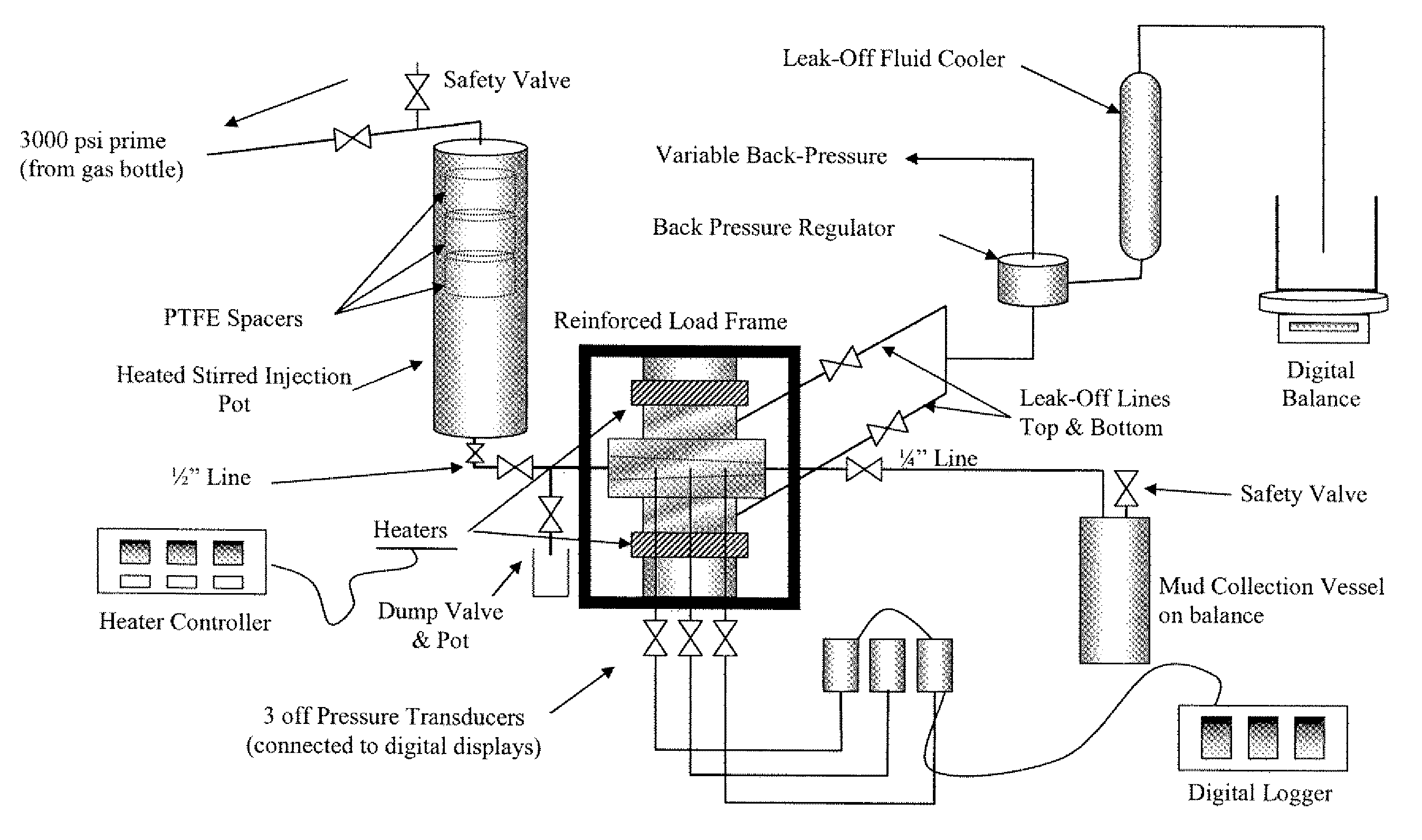

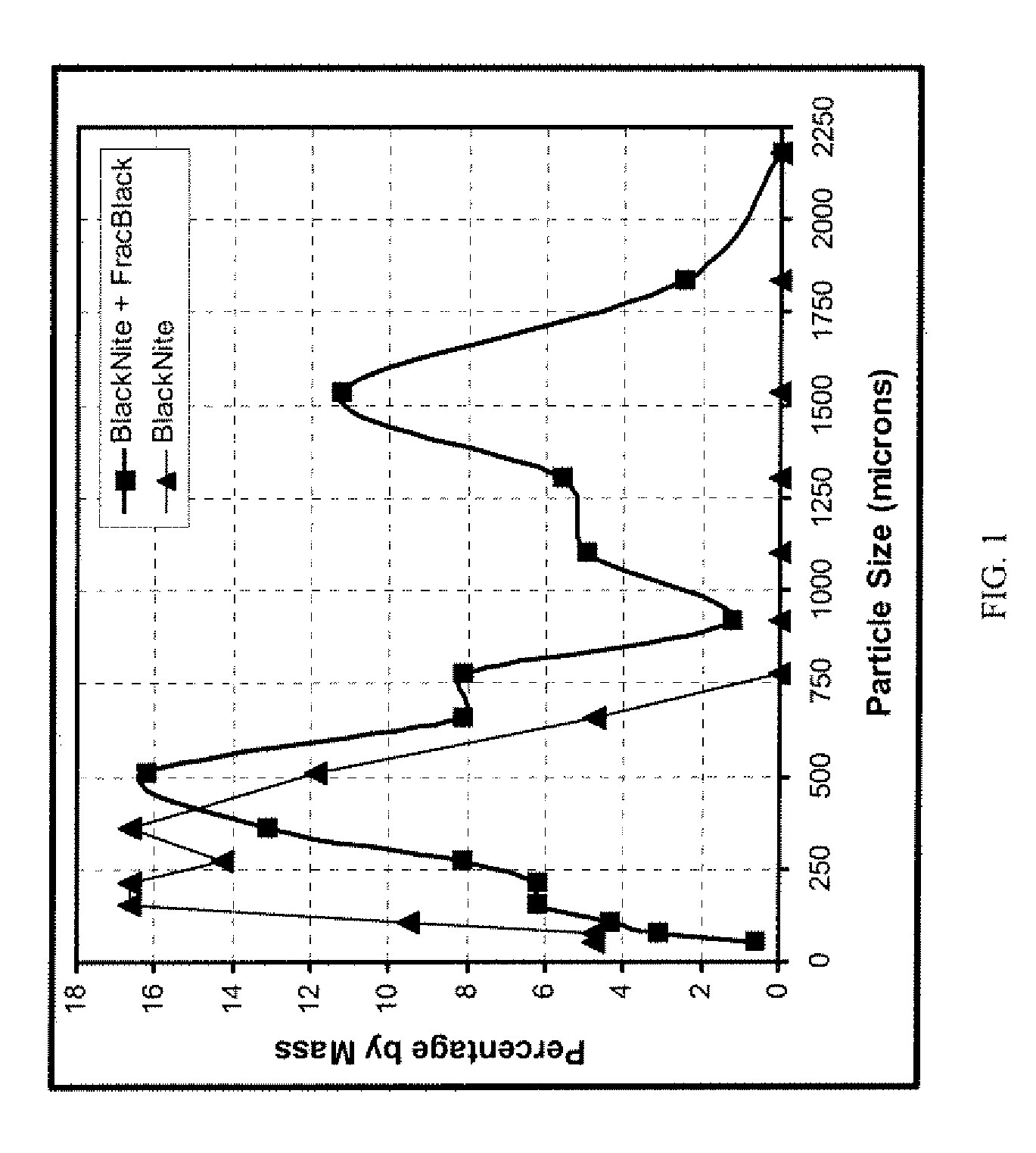

Drilling fluid, drill-in fluid, completition fluid, and workover fluid additive compositions containing thermoset nanocomposite particles; and applications for fluid loss control and wellbore strengthening

InactiveUS20090029878A1Loss in formationHigh strengthFlushingDrilling compositionWater basedDivinylbenzene

In one aspect, this invention relates to the use of thermoset nanocomposite particles as components of drilling fluid, drill-in fluid, completion fluid, and workover fluid additive packages to reduce fluid losses to a formation and / or to enhance a wellbore strength. In another aspect, this invention relates to the use particles of specific gravity ranging from about 0.75 to about 1.75 as components of drilling fluid, drill-in fluid, completion fluid, and workover fluid additive packages to reduce fluid losses to a formation and / or to enhance a wellbore strength. Using embodiments of the invention, reduction of fluid loss and / or enhancement of wellbore strength may be achieved while working with water-based, oil-based, invert emulsion, or synthetic drilling muds. The currently most preferred embodiments of the invention use substantially spherical thermoset nanocomposite particles, possessing a specific gravity from approximately 1.02 to approximately 1.15 wherein the matrix is a terpolymer of styrene, ethylvinylbenzene and divinylbenzene, and wherein carbon black particles possessing a length that is less than about 0.5 microns in at least one principal axis direction are incorporated as a nanofiller.

Owner:SUN DRILLING PRODS

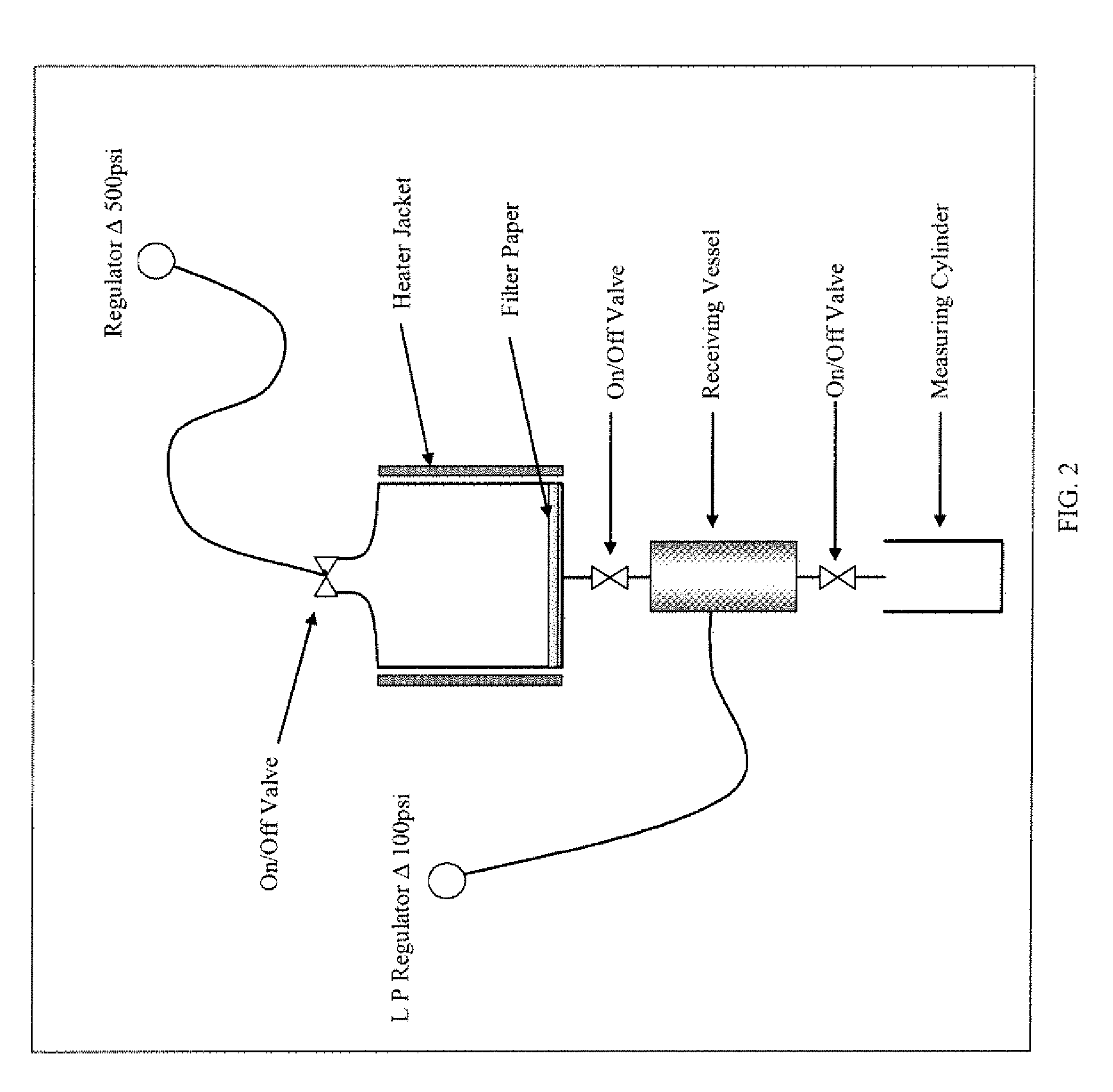

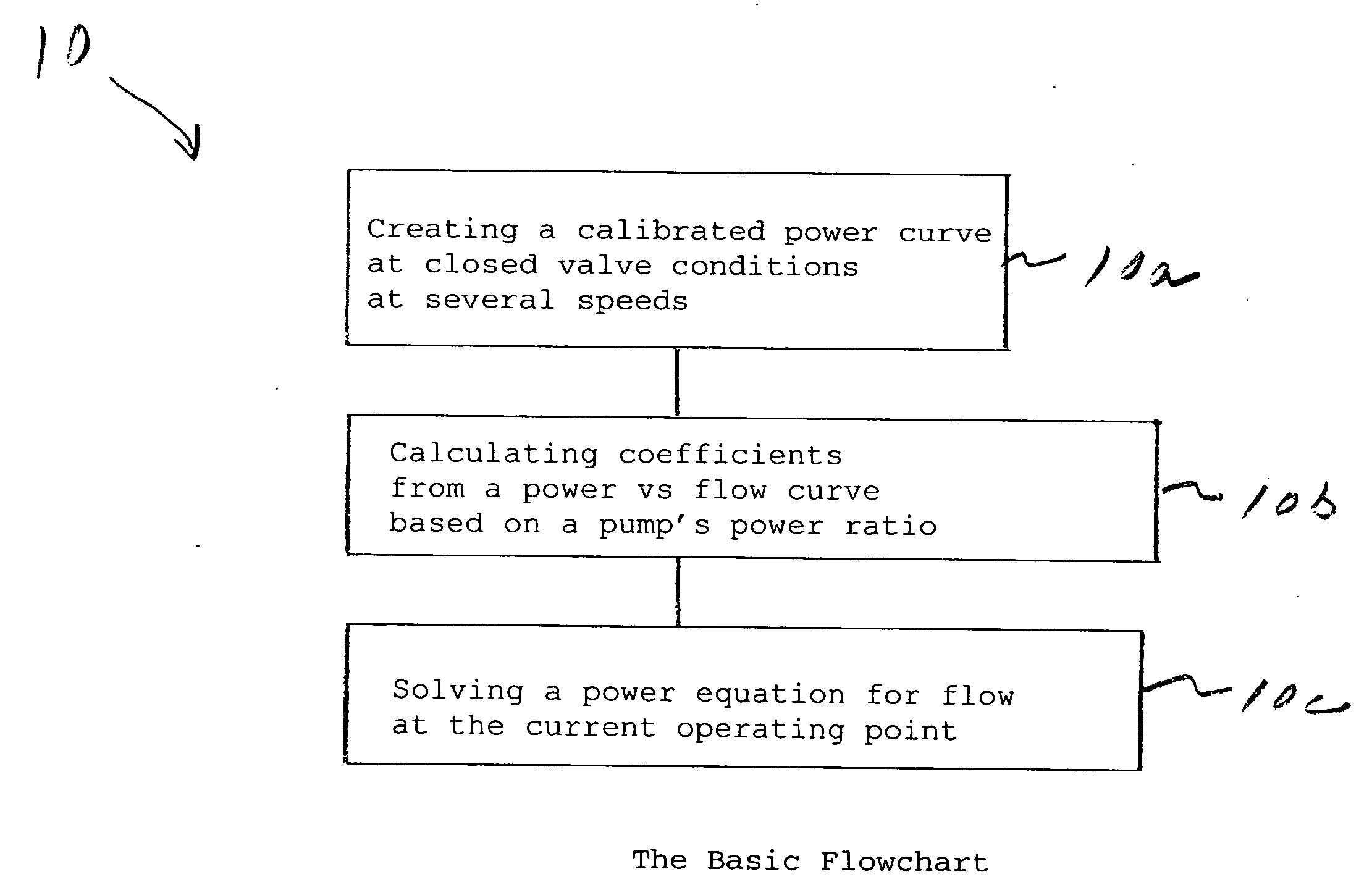

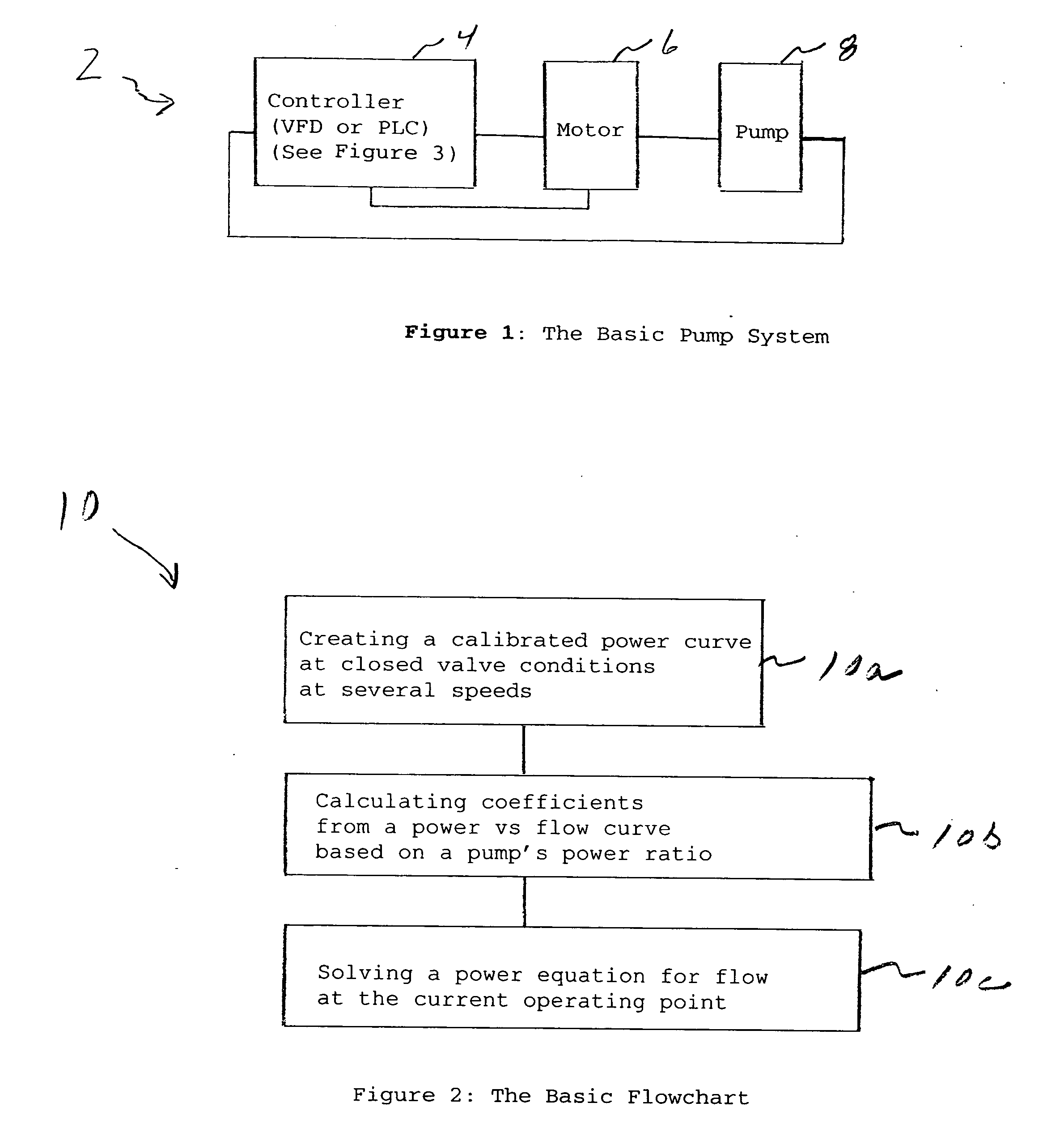

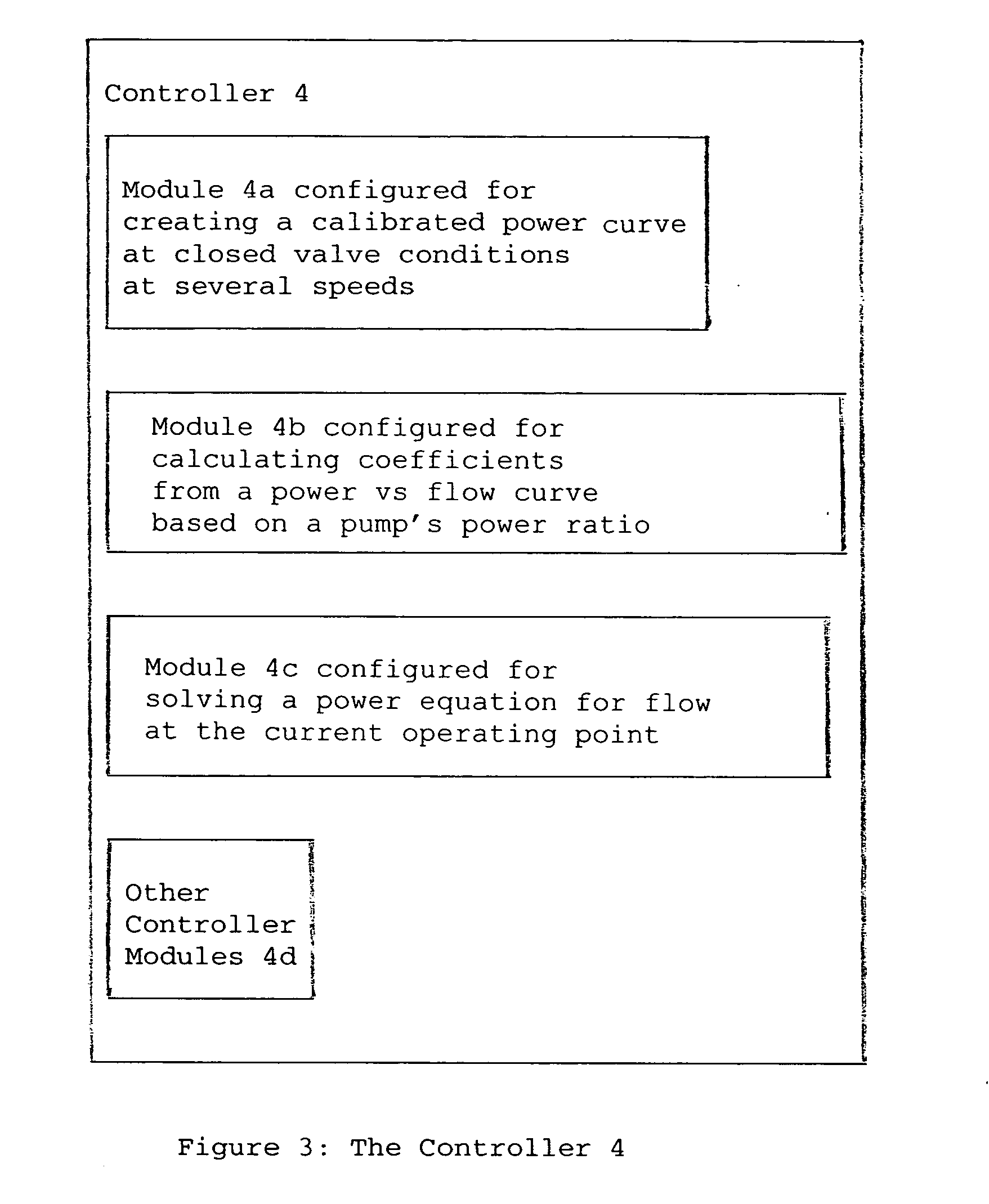

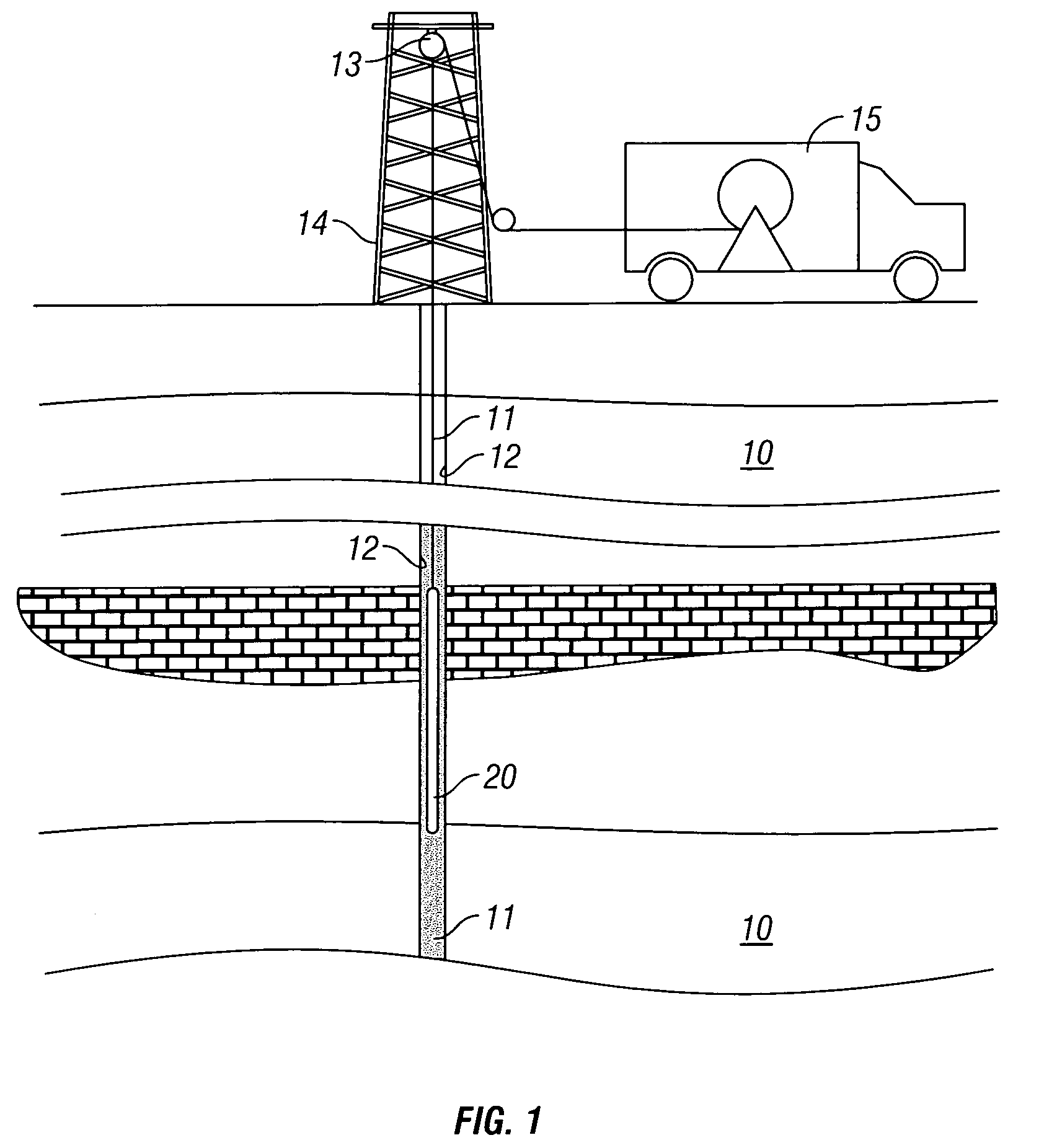

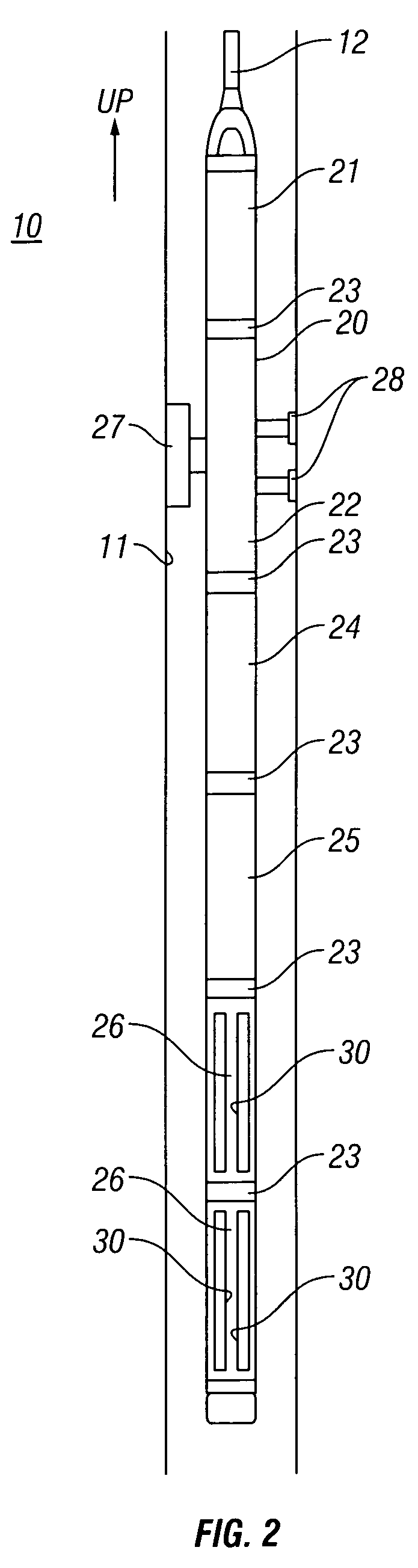

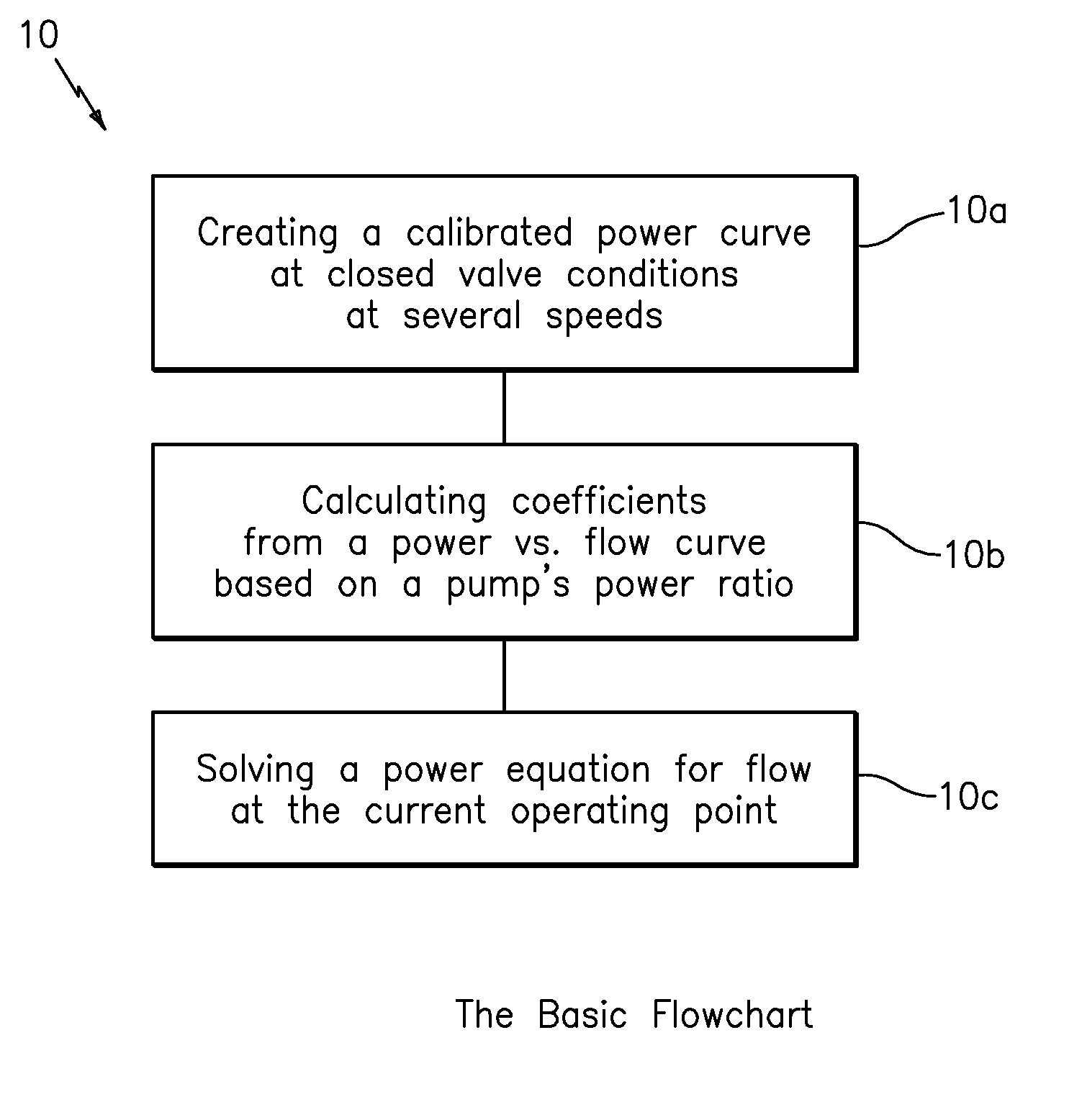

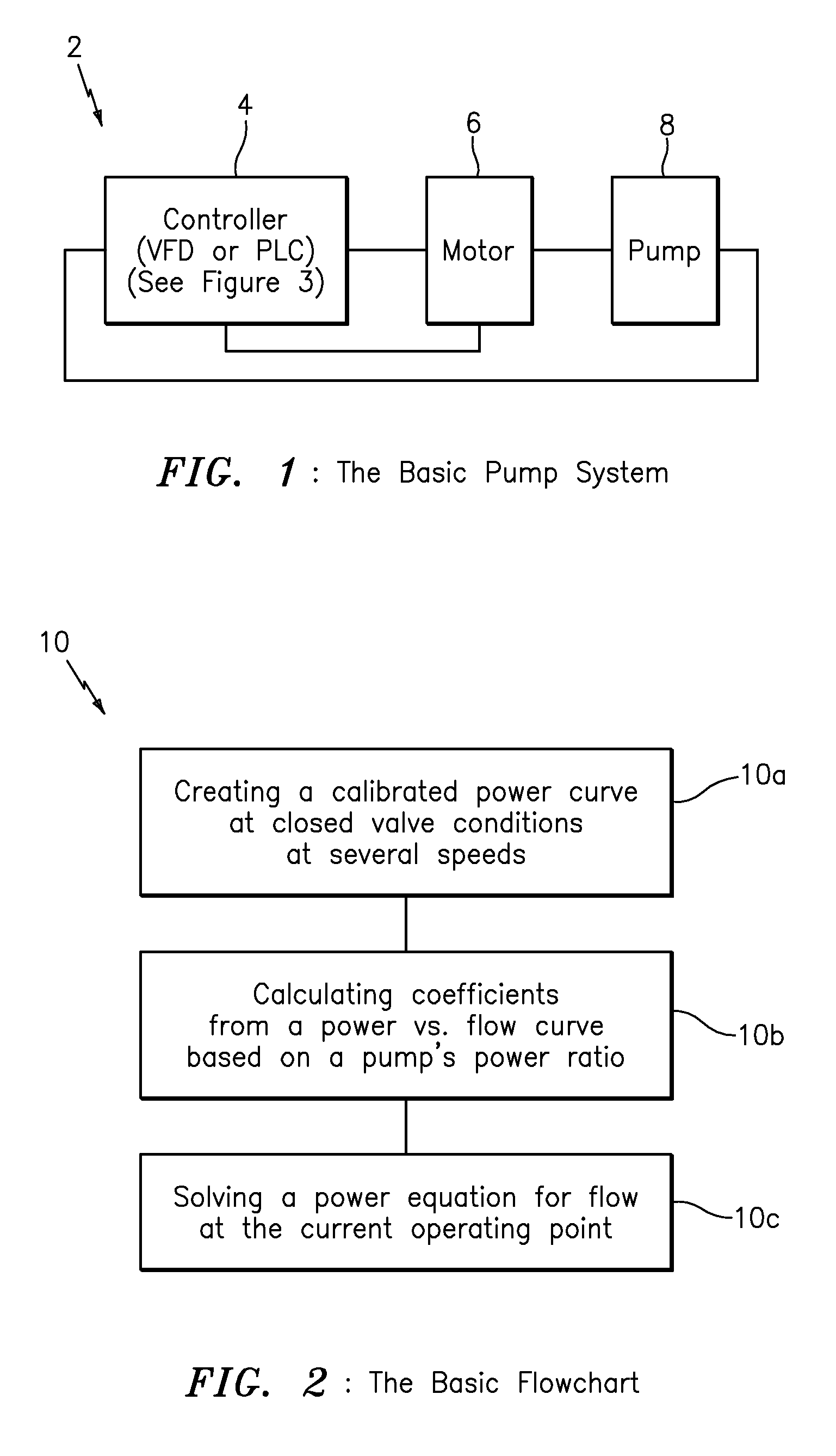

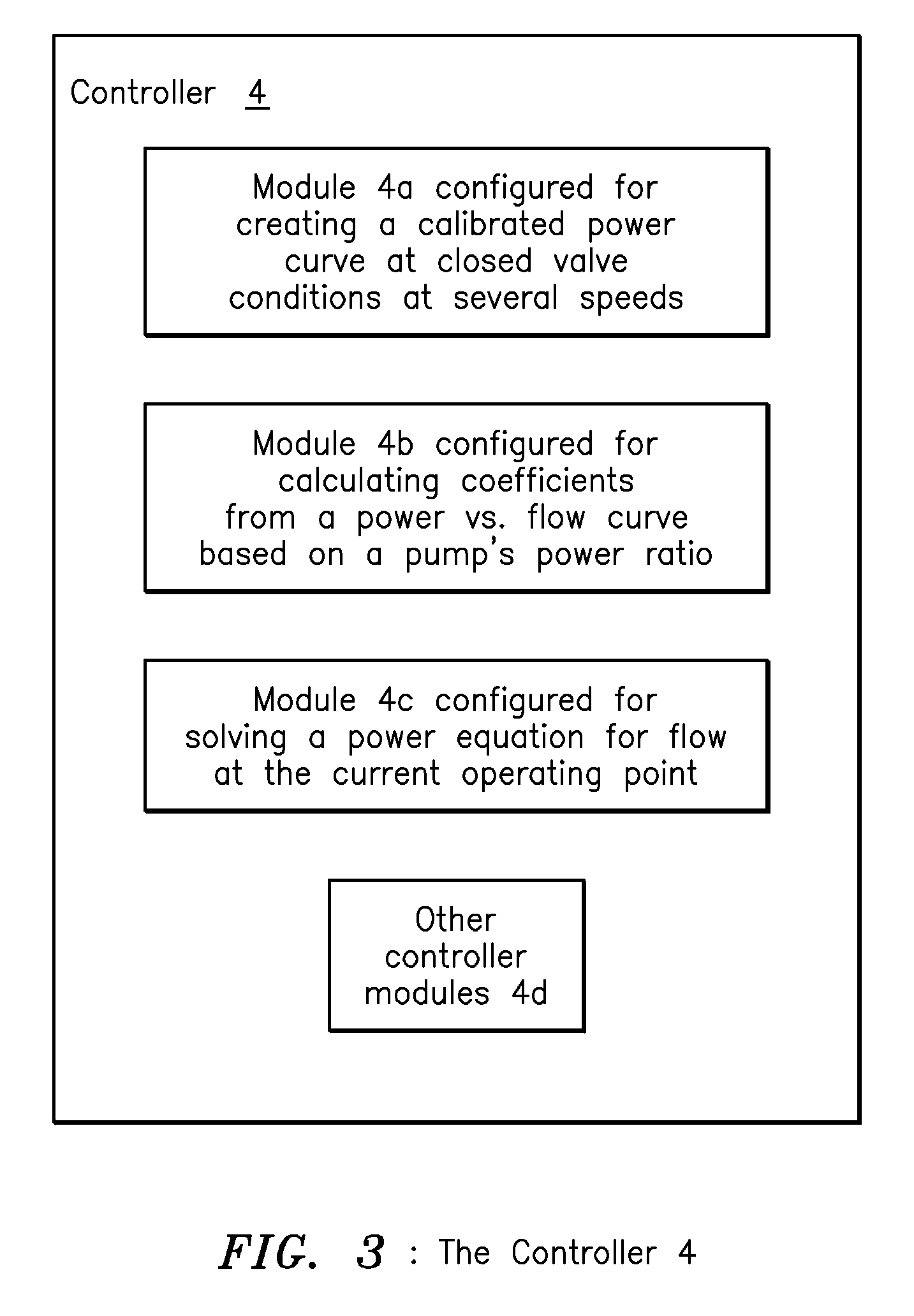

Method for determining pump flow without the use of traditional sensors

ActiveUS20070212210A1Testing/calibration apparatusAmplifier modifications to reduce noise influenceOperating pointMuller's method

A technique for determining pump flow without using traditional sensors features steps and modules for creating a calibrated power curve at closed valve conditions at several speeds; calculating coefficients from a normalized power curve based on a pump's power ratio; and solving a polynomial power equation for flow at the current operating point. The calibrated power curve may be created by increasing the speed of the pump from a minimum speed to a maximum speed and operating the pump with a closed discharge valve. This data is used to correct published performance for shutoff power and best efficiency point power at rated speed in order to determine the pump's power ratio. It is also used to accurately determine closed valve power at the current operating speed. The pump's power ratio is determined by the equation: Pratio=Pshutoff @100% / PBEP<sub2>—< / sub2>corr. The polynomial power equation may, for example, include a 3rd order polynomial equation developed using coefficients from the normalized power versus flow curve, and corrections may be made for speed, hydraulic efficiency and specific gravity in the polynomial power equation. Complex roots may be determined to solve the 3rd order polynomial equation using either Muller's method or some other suitable method, and the calculated actual flow may be determined for a specific operating point.

Owner:ITT MFG ENTERPRISES LLC

Compositions and methods for weighting a breaker coating for uniform distribution in a particulate pack

The present invention involves methods and compositions for treating subterranean formations, and more specifically, relates to improved methods and compositions for degrading filter cake deposited in a subterranean formation by effecting a uniform distribution of a filter cake breaker. One embodiment of the present invention provides a weighted encapsulated breaker comprising a breaker material; and, a coating material comprising a polymer material and a filler material having a specific gravity of at least about 6.5.

Owner:HALLIBURTON ENERGY SERVICES INC

Golf club head with strength-enhanced rear body

InactiveUS20080139339A1High strengthImprove structural strengthGolf clubsGolf club bagsMetallic materialsAlloy

A golf club head with strength-enhanced rear body comprises a front body, a rear body and at least one supporting member. The front body comprises a face and a plurality of abutting edges. The rear body comprises a crown, a ribbon and a plurality of abutting edges, with the rear body being made of a nonmetal material having a specific gravity lower than that of the front body, and the abutting edges of the rear body being corresponding to and connecting with those of the front body. The at least one supporting member being made of a light alloy is disposed along a border between the crown and the ribbon of the rear body.

Owner:FUSHENG IND CO LTD

Weight-adjustable golf club head provided with rear lightweight covering

InactiveUS20080070721A1Thin thicknessLower center of gravityGolf clubsRacket sportsEngineeringGolf Ball

A weight-adjustable golf club head includes a rear lightweight covering and a golf club head body combined therewith. The rear lightweight covering has a rear crown portion and a rear wall portion extended therefrom. The golf club head body is combined with the rear lightweight covering which is designed to have a striking face, a front crown portion and a sole portion. The rear lightweight covering is made from a low specific gravity metal, and is designed to have a thickness less than 0.6 mm. The rear lightweight covering has an inner surface formed with a plurality of reinforcing ribs.

Owner:FUSHENG IND CO LTD

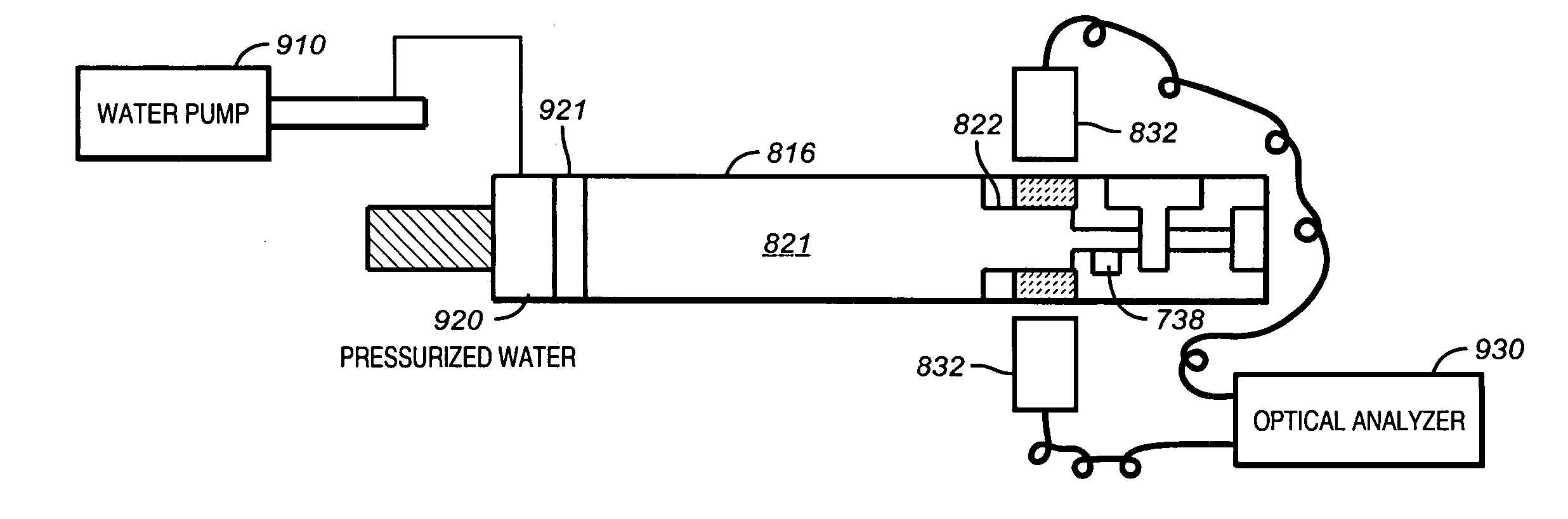

Method and apparatus for an advanced optical analyzer

ActiveUS20040218176A1Eliminate riskThe result is accurateRadiation pyrometrySpectrum investigationSmall sampleAPI gravity

The present invention provides a sample tank having a window for introduction of electromagnetic energy into the sample tank for analyzing a formation fluid sample down hole or at the surface without disturbing the sample. Near infrared, mid infrared and visible light analysis is performed on the sample to provide a downhole in situ or surface on site analysis of sample properties and contamination level. The onsite analysis comprises determination of gas oil ratio, API gravity and various other parameters which can be estimated by a trained neural network or chemometric equation. A flexural mechanical resonator is also provided to measure fluid density and viscosity from which additional parameters can be estimated by a trained neural network or chemometric equation. The sample tank is pressurized to obviate adverse pressure drop or other effects of diverting a small sample.

Owner:BAKER HUGHES INC

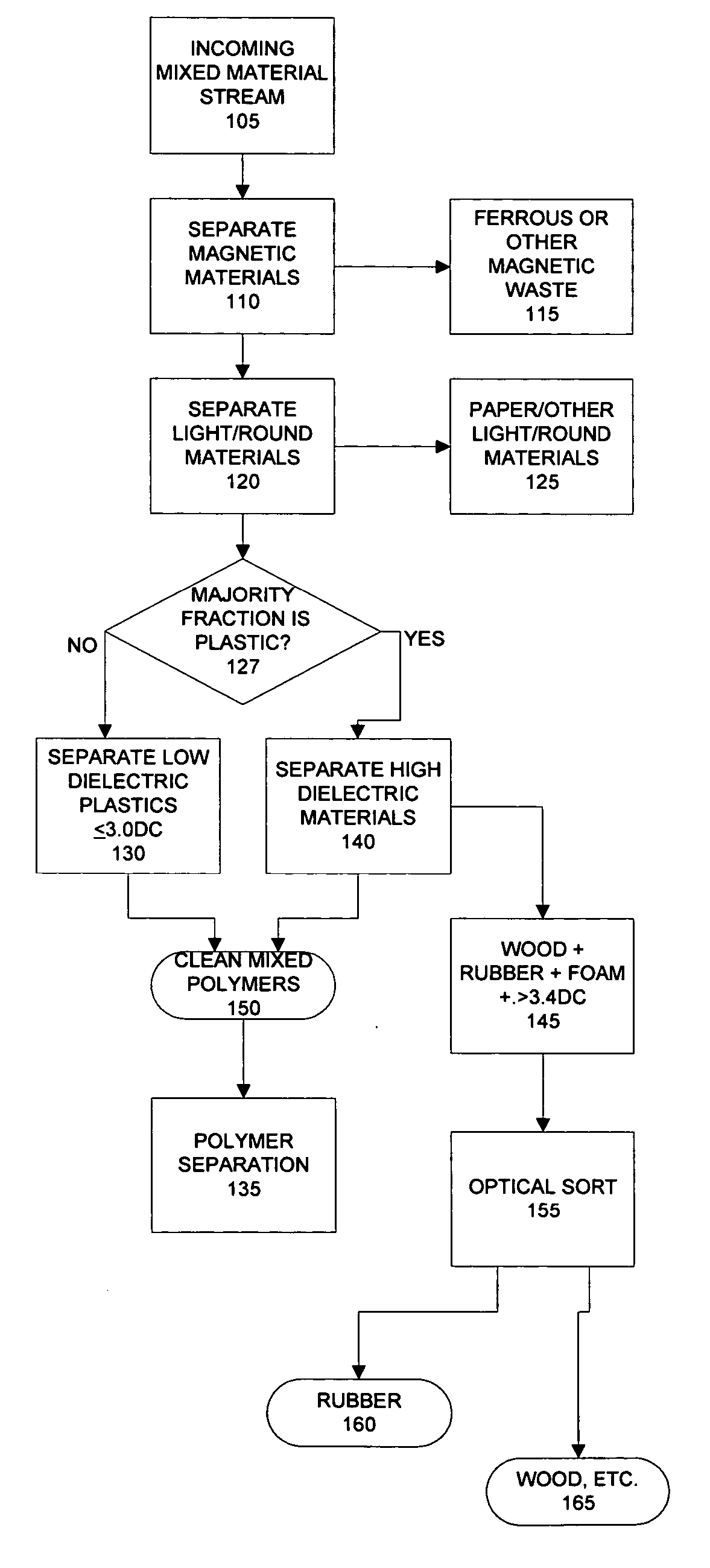

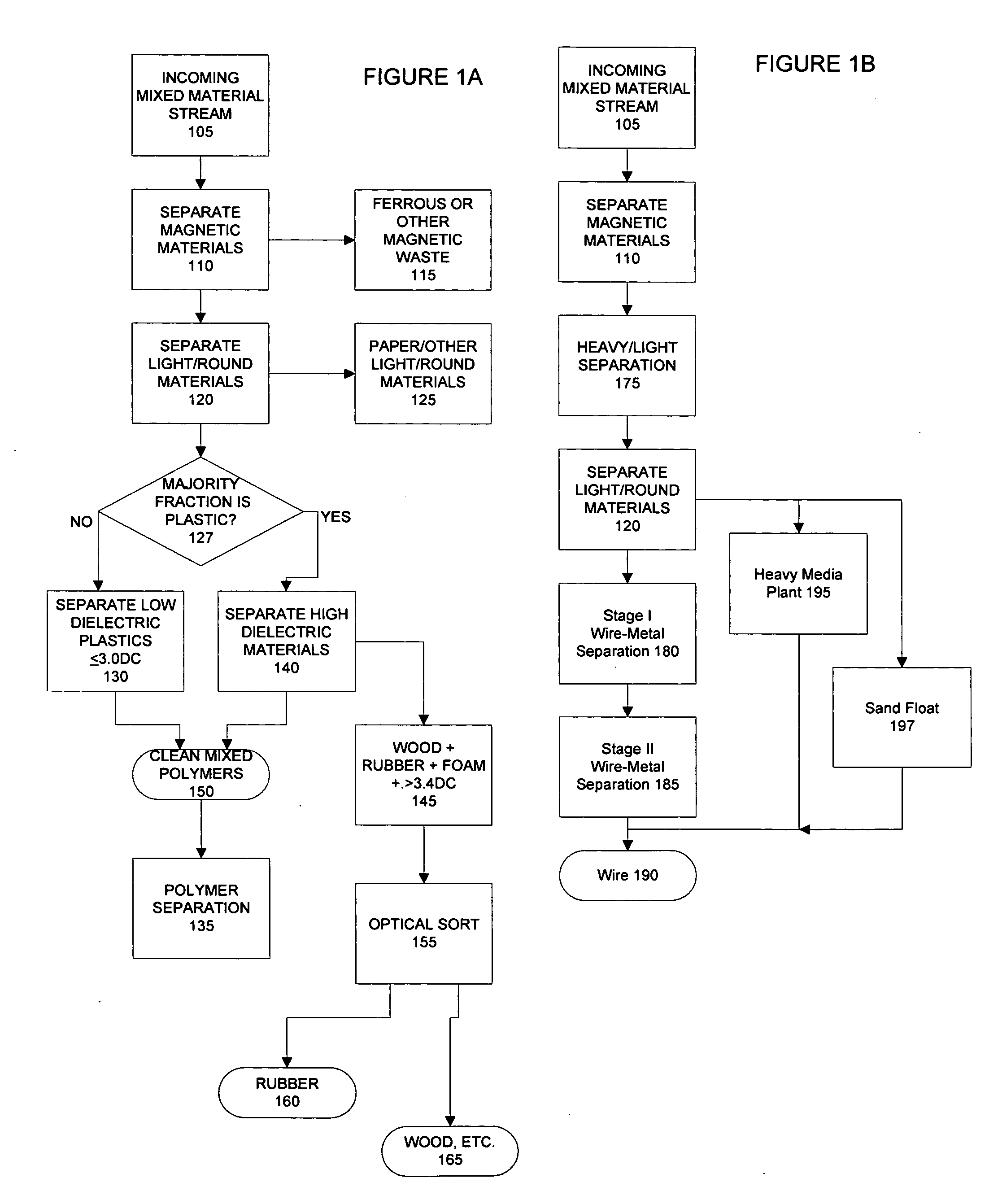

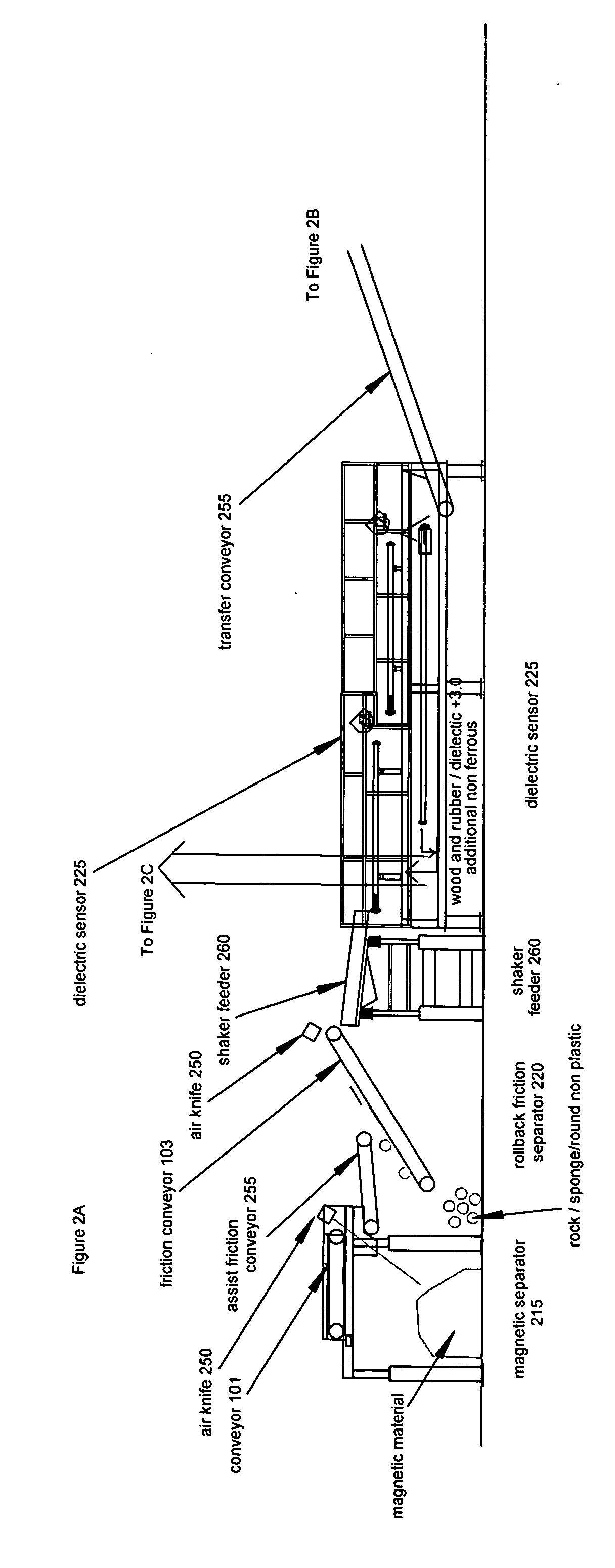

Dissimilar materials sorting process, system and apparata

InactiveUS20070187299A1Improve uniformityUnified operationGas current separationSolid waste disposalElectricityMagnetic separator

An automated system for sorting dissimilar materials, and in particular for sorting plastics from other materials and for sorting different types of plastics from one another comprises, depending upon the embodiment, combinations of a sizing mechanism, a friction separation, an air separator, a magnetic separator, a dielectric sensor sortation bed, shaker screening, a ballistic separator, an inductive sensor sortation system and a float / sink tank. The dielectric sensor sortation system may be either analog or digital, depending upon the particular implementation. One or more float / sink tanks can be used, depending upon the embodiment, each with a media of a different specific gravity. The media may be water, or water plus a compound such as calcium chloride. In addition, multiples of the same general type of module can be used for particular configurations. A heavy media system or a sand float process can be used either alternatively or additionally.

Owner:VALERIO THOMAS A

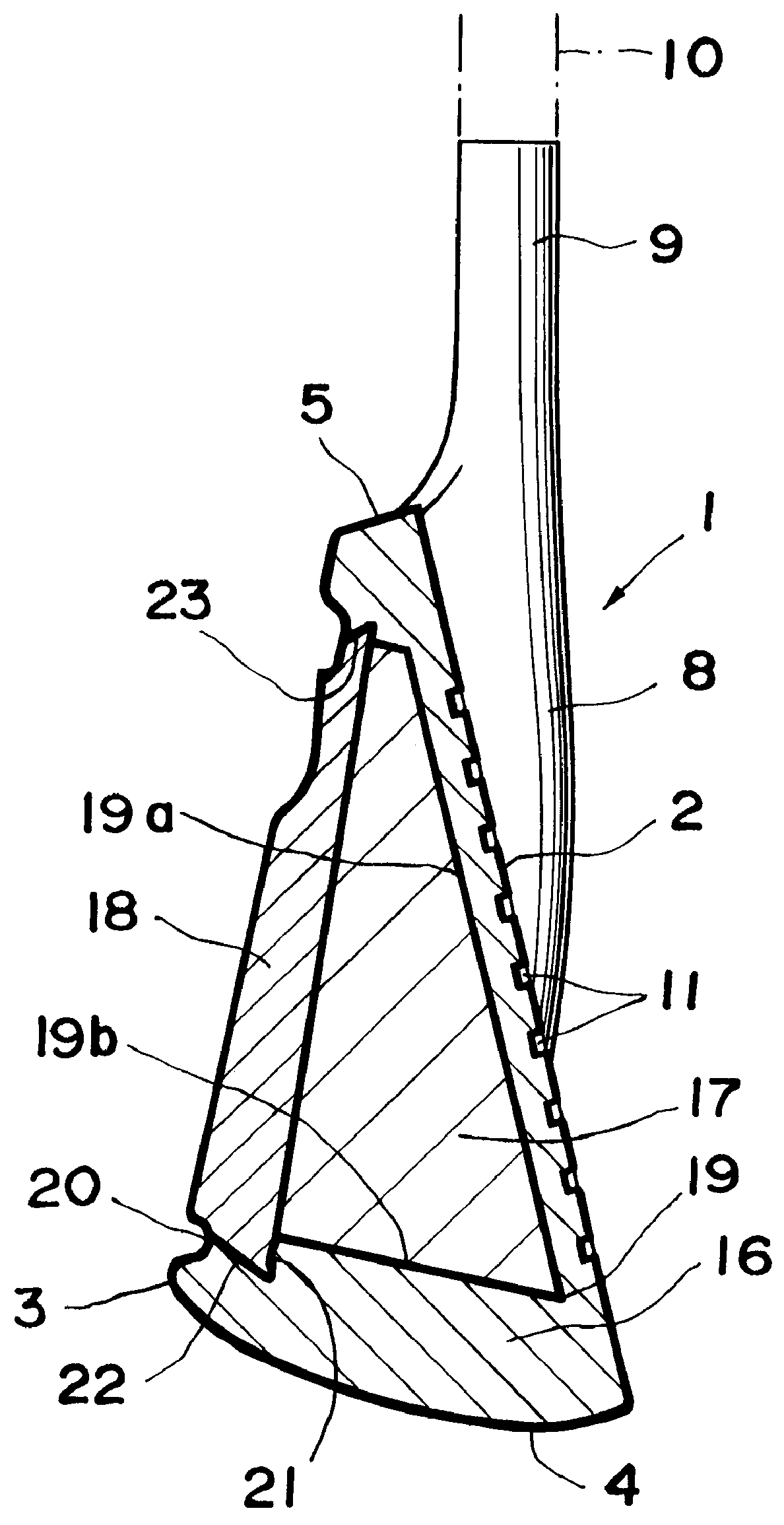

Golf club

A golf club with which you can strike a strong ball with a sharp feeling in striking as well as an enlarged sweet area. A concave portion 19 is formed at a rear side of a head body 16. A metallic balance weight 17 is fitted into the concave portion 19. A cover 18 for covering the balance weight 17 is fixed to the rear side of the head body 16. The specific gravity of a material for the balance weight 17 is smaller than that of the head body 16. Accordingly, a more sharp feeling in striking can be obtained as compared to a conventional head whose concave portion is hollow. Additionally, a sweet area can be enlarged owing to the weight distribution biased toward the periphery. The specific gravity of a material for the cover 18 is at least equal to that of the material for the head body 16. As a result, the depth of the center of gravity is made greater, thereby further widening a sweet area.

Owner:ENDO MFG COMPANY

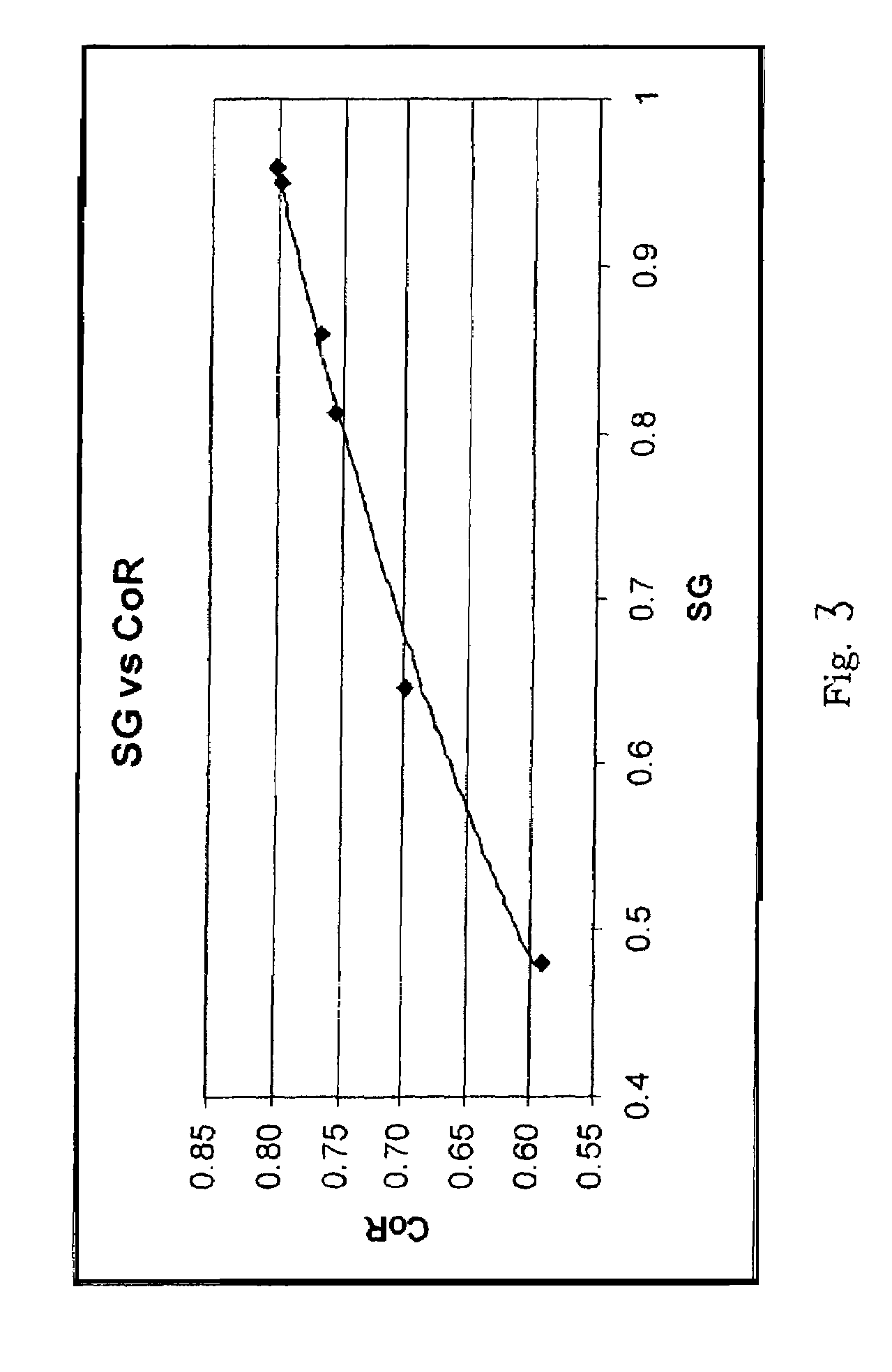

Foam-core golf balls

A golf ball with a controlled moment of inertia and controlled spin rate is disclosed. The ball has an intermediate layer positioned between the core and the cover and the intermediate layer has a reduced specific gravity. Preferably, this reduction is less than about 30% in specific gravity and the reduction in the coefficient of restitution is less than about 2%.

Owner:ACUSHNET CO

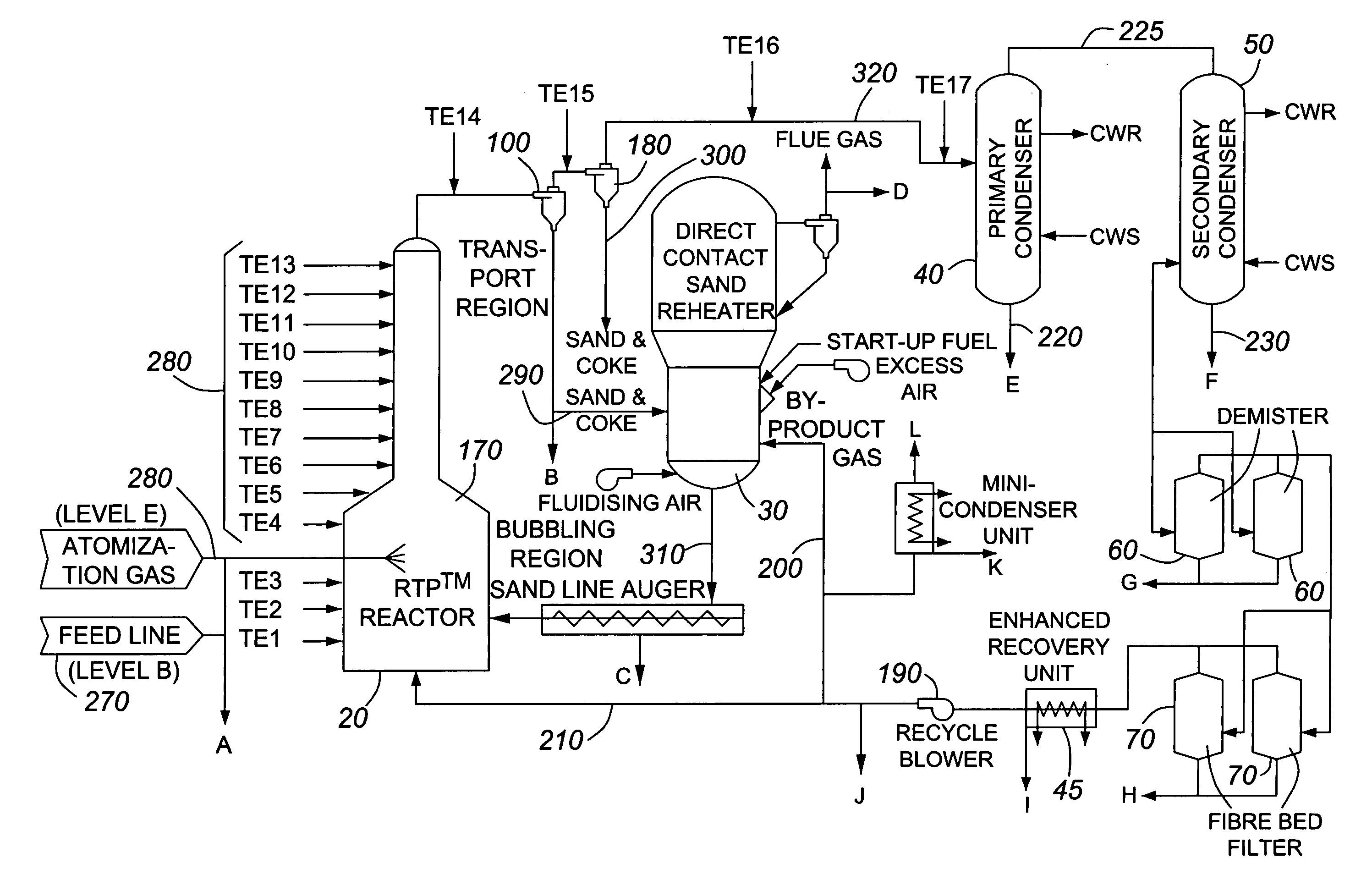

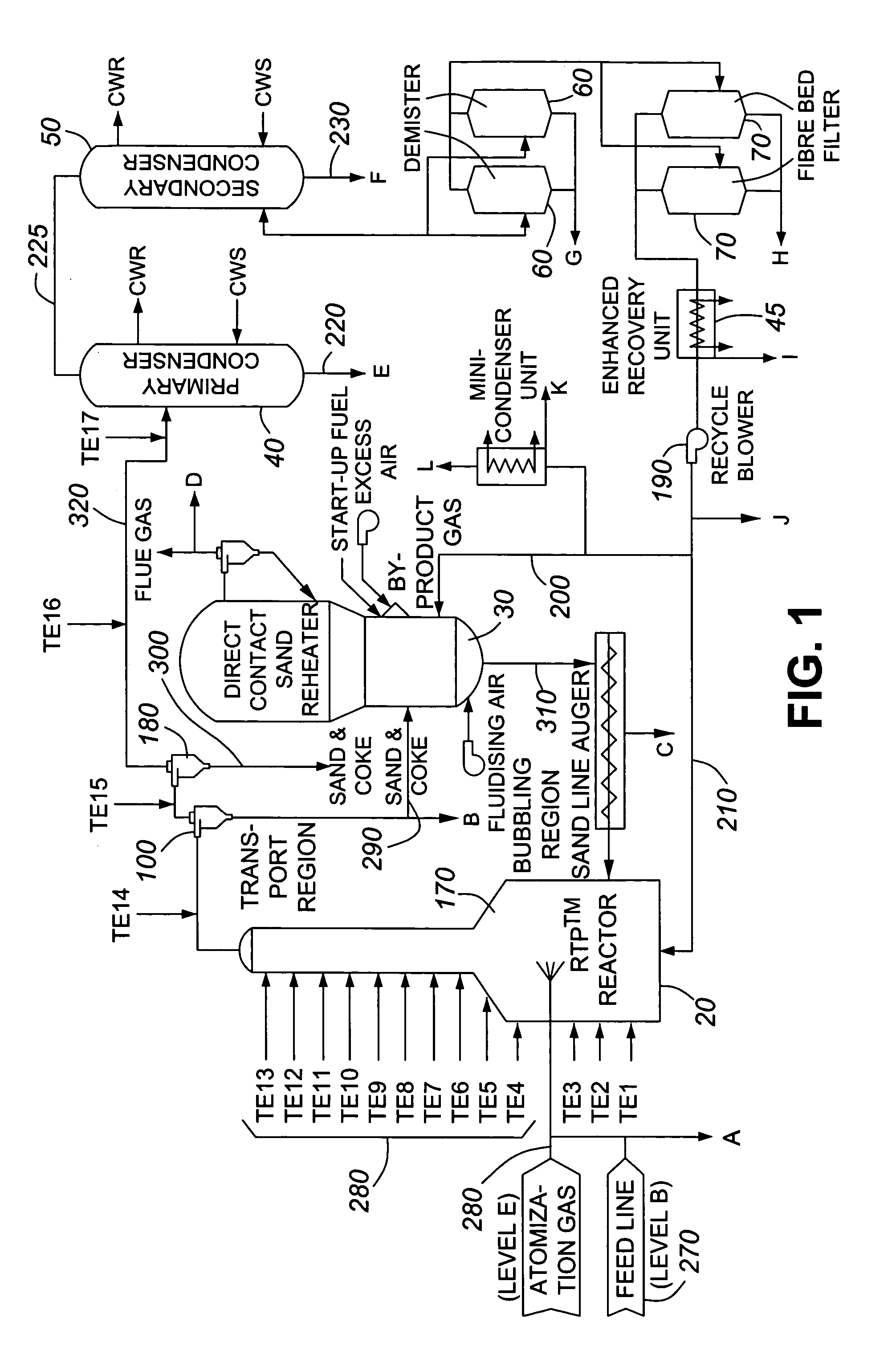

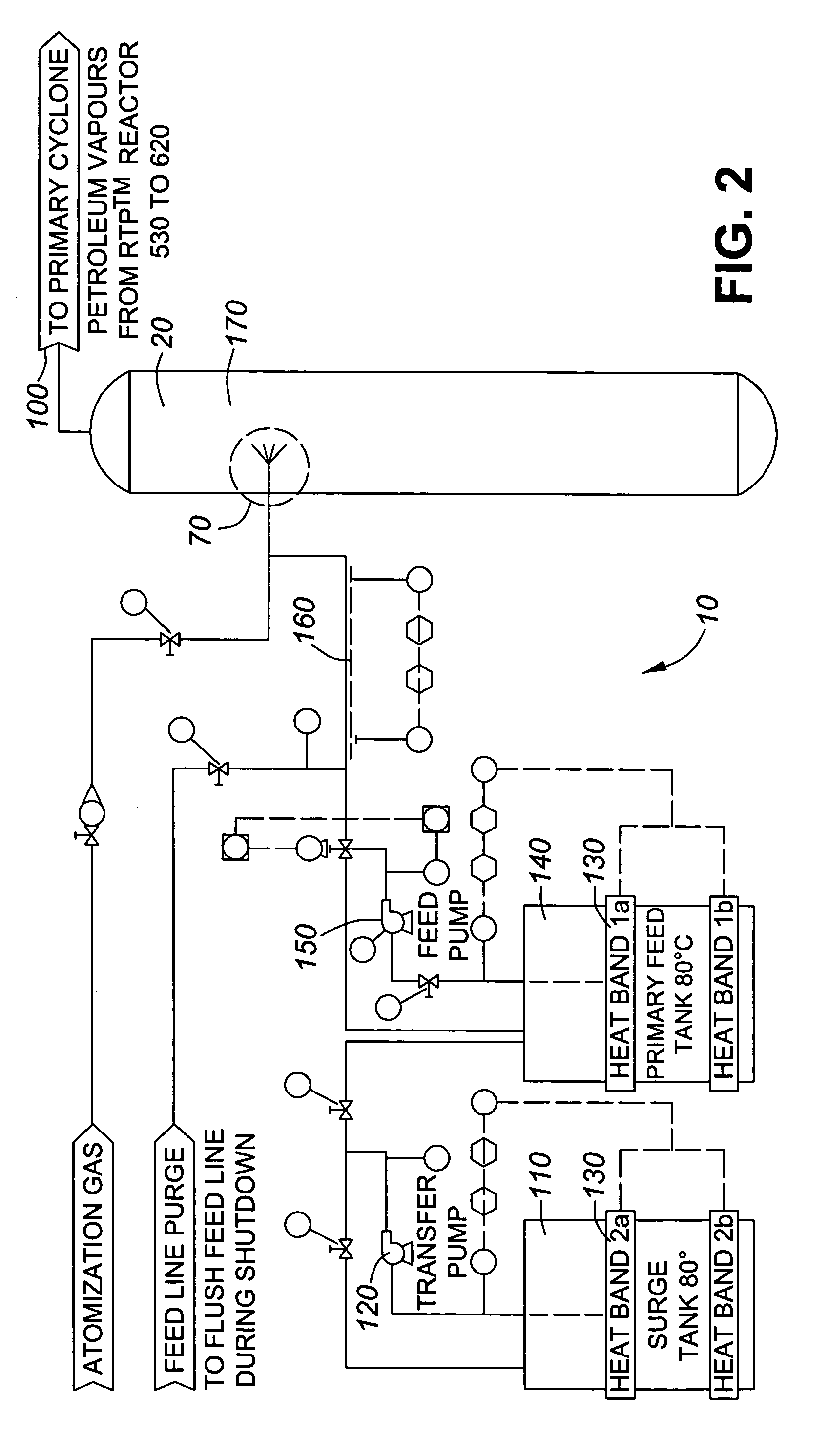

Modified thermal processing of heavy hydrocarbon feedstocks

InactiveUS7572362B2Quick upgradeReducing H2S contentThermal non-catalytic crackingTreatment with plural serial cracking stages onlyLiquid productParticulates

The present invention is directed to the upgrading of heavy petroleum oils of high viscosity and low API gravity that are typically not suitable for pipelining without the use of diluents. It utilizes a short residence-time pyrolytic reactor operating under conditions that result in a rapid pyrolytic distillation with coke formation. Both physical and chemical changes taking place lead to an overall molecular weight reduction in the liquid product and rejection of certain components with the byproduct coke. The liquid product is upgraded primarily because of its substantially reduced viscosity, increased API gravity, and the content of middle and light distillate fractions. While maximizing the overall liquid yield, the improvements in viscosity and API gravity can render the liquid product suitable for pipelining without the use of diluents. This invention particularly relates to reducing sulfur emissions during the combustion of byproduct coke (or coke and gas), to reducing the total acid number (TAN) of the liquid product, and to reducing the hydrogen sulfide content of one, or more than one component of the product stream. The method comprises introducing a particulate heat carrier into an up-flow reactor, introducing the feedstock at a location above the entry of the particulate heat carrier, allowing the heavy hydrocarbon feedstock to interact with the heat carrier for a short time, separating the vapors of the product stream from the particulate heat carrier and liquid and byproduct solid matter, regenerating the particulate heat carrier in the presence of the calcium compound, and collecting a gaseous and liquid product from the product stream.

Owner:IVANHOE HTL GASOLINEEUM

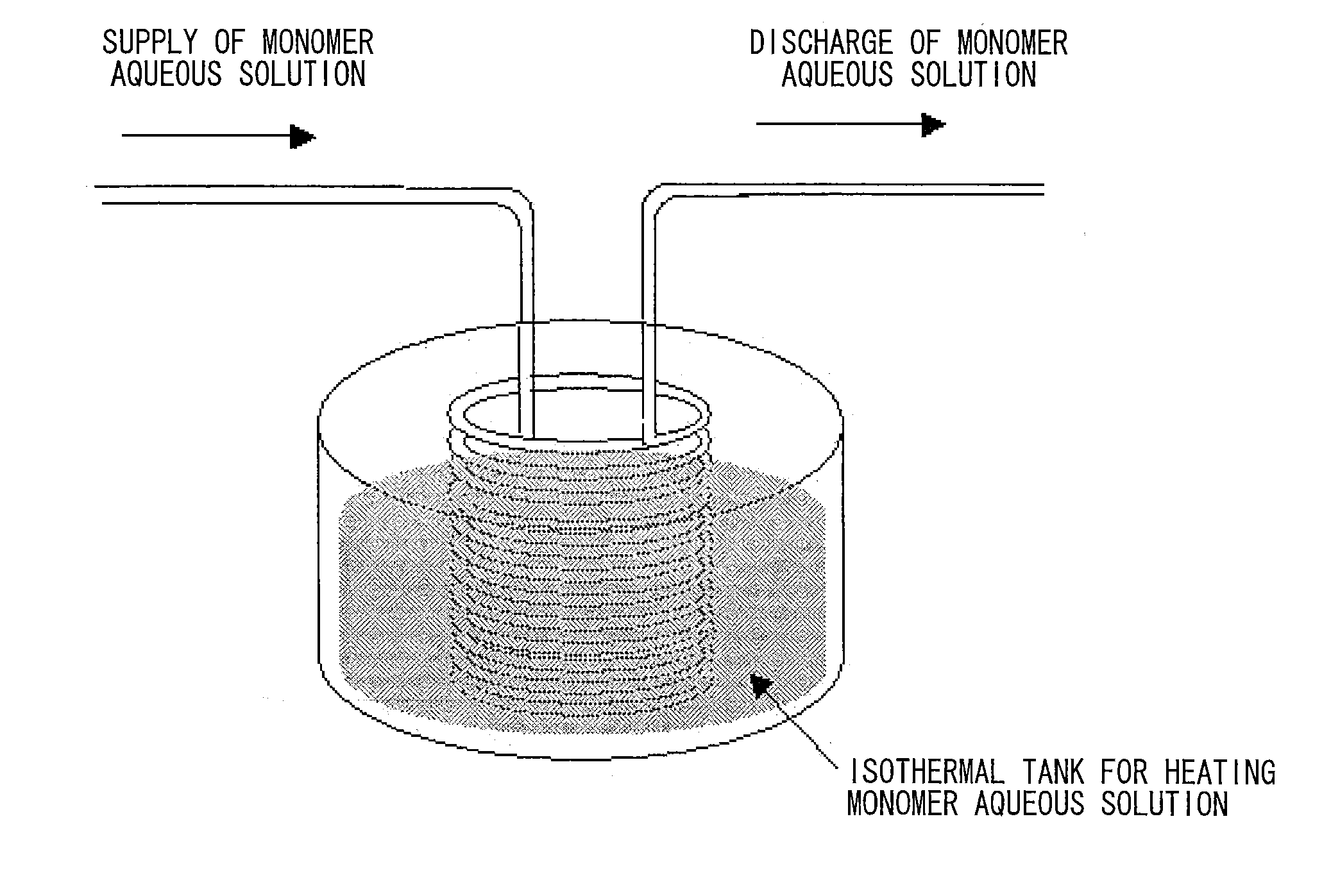

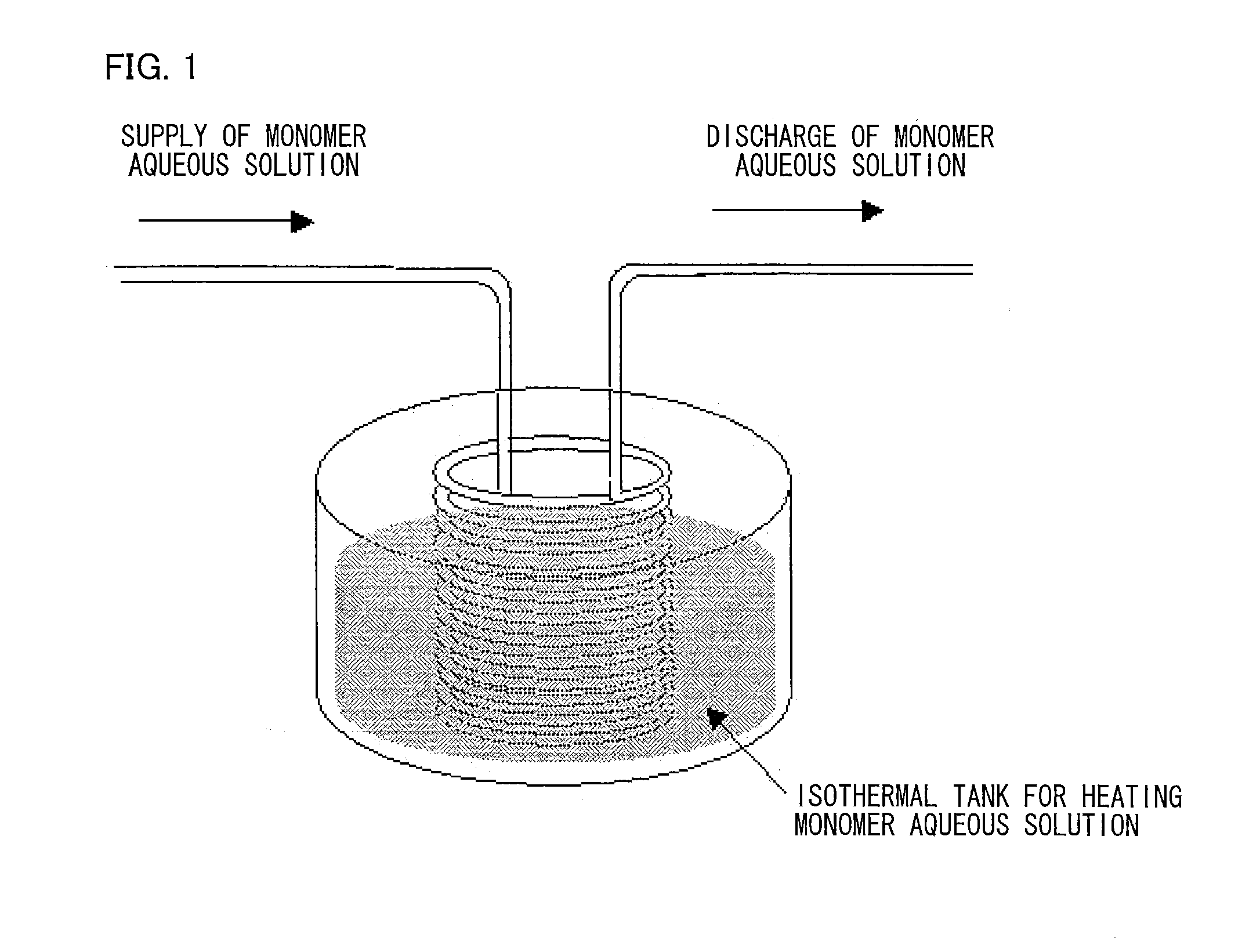

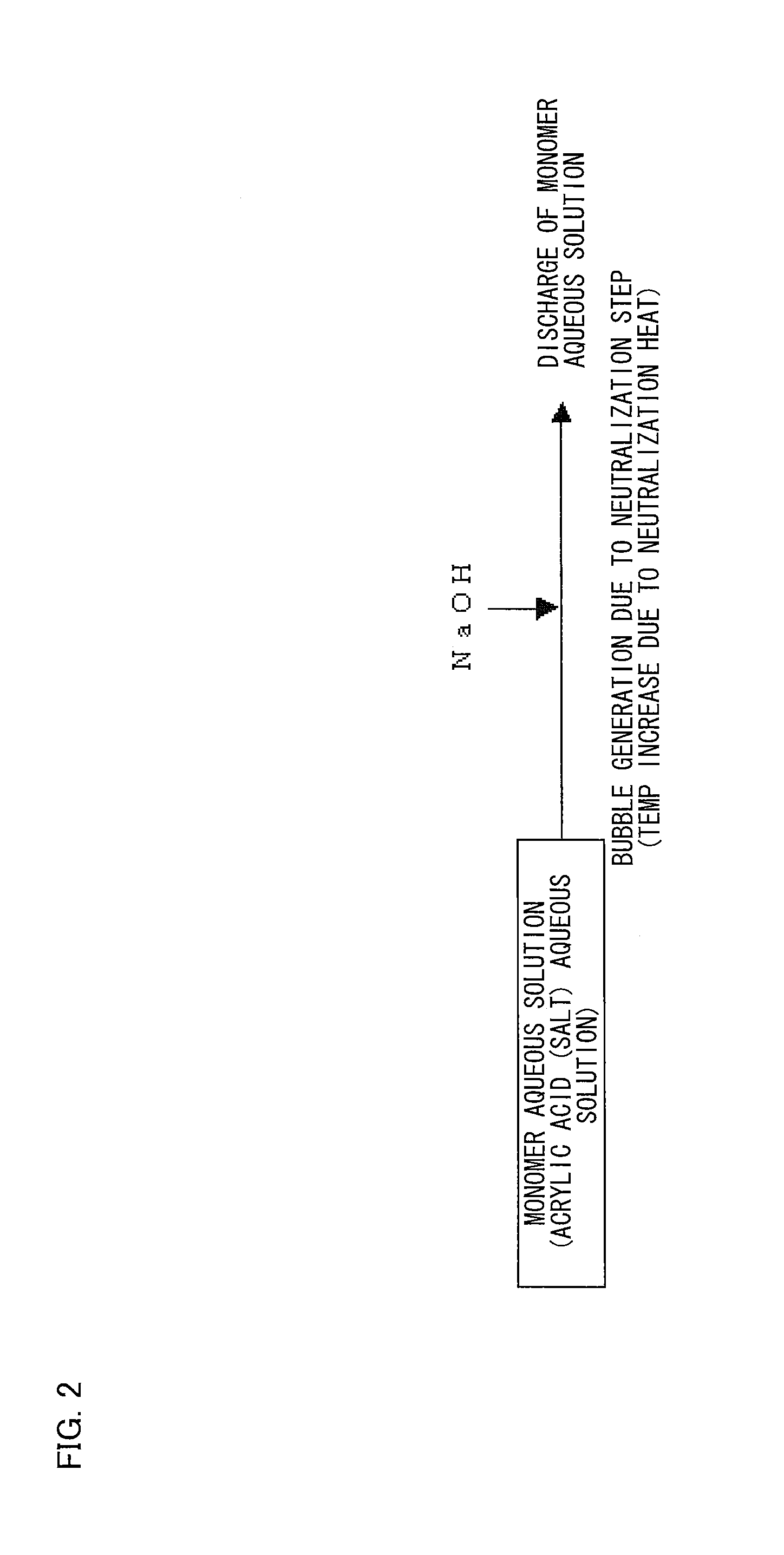

Water-absorbable polyacrylic acid resin powder, and process for production thereof

ActiveUS20120258851A1Improve water absorptionImprove impact resistanceOther chemical processesCatalyst activation/preparationSolubilityCrosslinked polymers

A process according to the present invention for production of water-absorbable polyacrylic acid resin powder, including: (a) polymerizing an acrylic acid-based monomer aqueous solution containing bubbles, and (b) drying a hydrogel crosslinked polymer thus obtained in the step of polymerizing, further includes (c) lowering solubility of dissolved gas in a monomer aqueous solution in the presence of a surfactant and / or a dispersing agent, so as to generate the bubbles in the acrylic acid-based monomer aqueous solution. With this arrangement, it is possible to provide white water-absorbable resin with better water absorbing rate, keeping or without significantly losing the other properties (permeability potential, bulk specific gravity, surface tension, absorbency against pressure, impact resistance, etc.)

Owner:NIPPON SHOKUBAI CO LTD

Hollow golf club head

InactiveUS7037214B2Sufficiently weight marginDegree of design is increasedGolf clubsRacket sportsEngineeringGolf Ball

A hollow golf club head allowing to increase the repulsion and the degree of design freedom, while maintaining the durability. A hollow golf club head having a head body formed from a metal, wherein a hole is formed in the vicinity of the middle of a crown portion in the head body, the hole is closed with a cover member made of a material different from the head body, and the ratio (ρm / ρf) of the specific gravity ρm of the head body and the specific gravity ρf of the cover member is set equal or superior to 1.3.

Owner:YOKOHAMA RUBBER CO LTD

Method and apparatus for a downhole spectrometer based on electronically tunable optical filters

The present invention provides an apparatus and method for high resolution spectroscopy (approximately 10 picometer wavelength resolution) using a tunable optical filter (TOF) for analyzing a formation fluid sample downhole and at the surface to determine formation fluid parameters. The analysis comprises determination of gas oil ratio, API gravity and various other fluid parameters which can be estimated after developing correlations to a training set of samples using a neural network or a chemometric equation.

Owner:BAKER HUGHES HLDG LLC

Method for determining pump flow without the use of traditional sensors

ActiveUS7945411B2Testing/calibration apparatusProcess and machine controlOperating pointMuller's method

A technique for determining pump flow without using traditional sensors features steps and modules for creating a calibrated power curve at closed valve conditions at several speeds; calculating coefficients from a normalized power curve based on a pump's power ratio; and solving a polynomial power equation for flow at the current operating point. The calibrated power curve may be created by increasing the speed of the pump from a minimum speed to a maximum speed and operating the pump with a closed discharge valve. This data is used to correct published performance for shutoff power and best efficiency point power at rated speed in order to determine the pump's power ratio. It is also used to accurately determine closed valve power at the current operating speed. The pump's power ratio is determined by the equation: Pratio=Pshutoff @100% / PBEP<sub2>—< / sub2>corr. The polynomial power equation may, for example, include a 3rd order polynomial equation developed using coefficients from the normalized power versus flow curve, and corrections may be made for speed, hydraulic efficiency and specific gravity in the polynomial power equation. Complex roots may be determined to solve the 3rd order polynomial equation using either Muller's method or some other suitable method, and the calculated actual flow may be determined for a specific operating point.

Owner:ITT MFG ENTERPRISES LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com