Patents

Literature

1463 results about "Specific density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

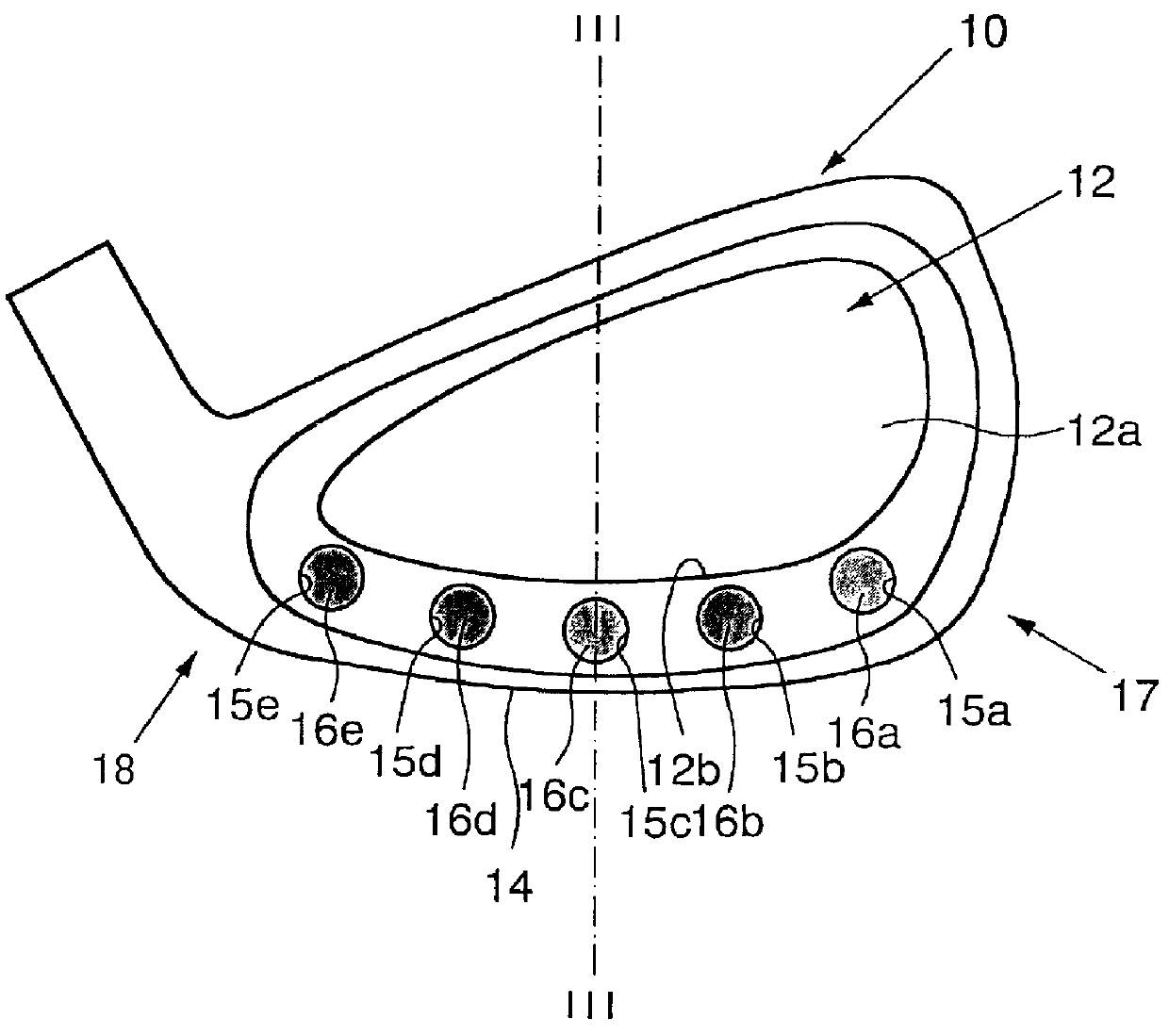

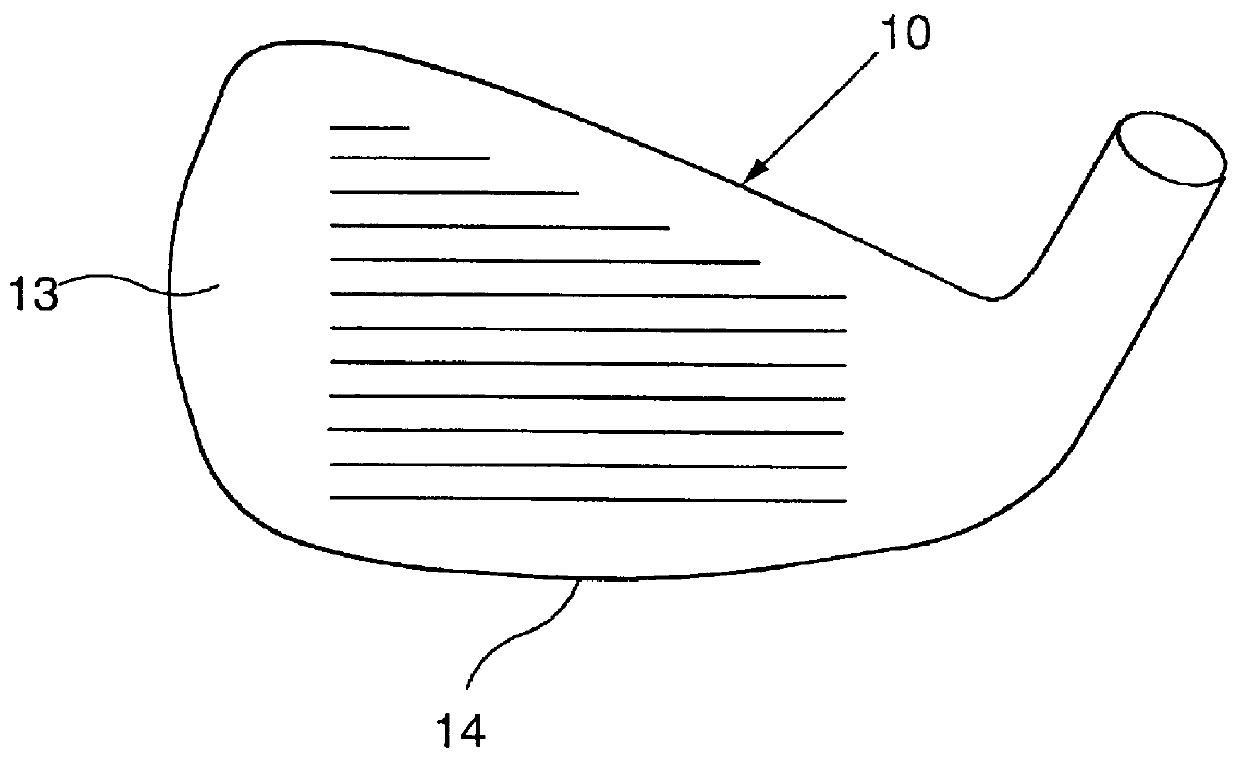

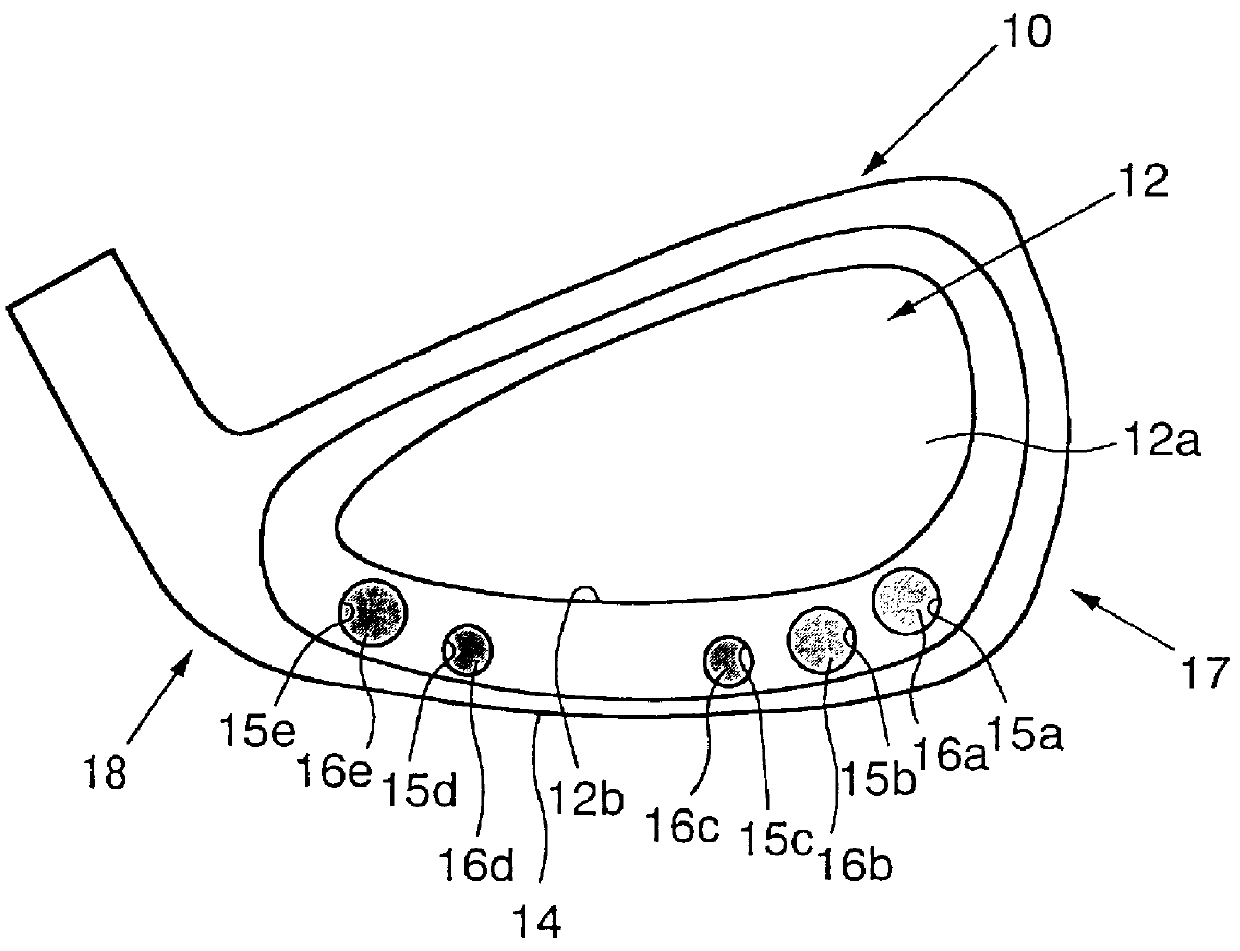

Iron golf club head including weight members for adjusting center of gravity thereof

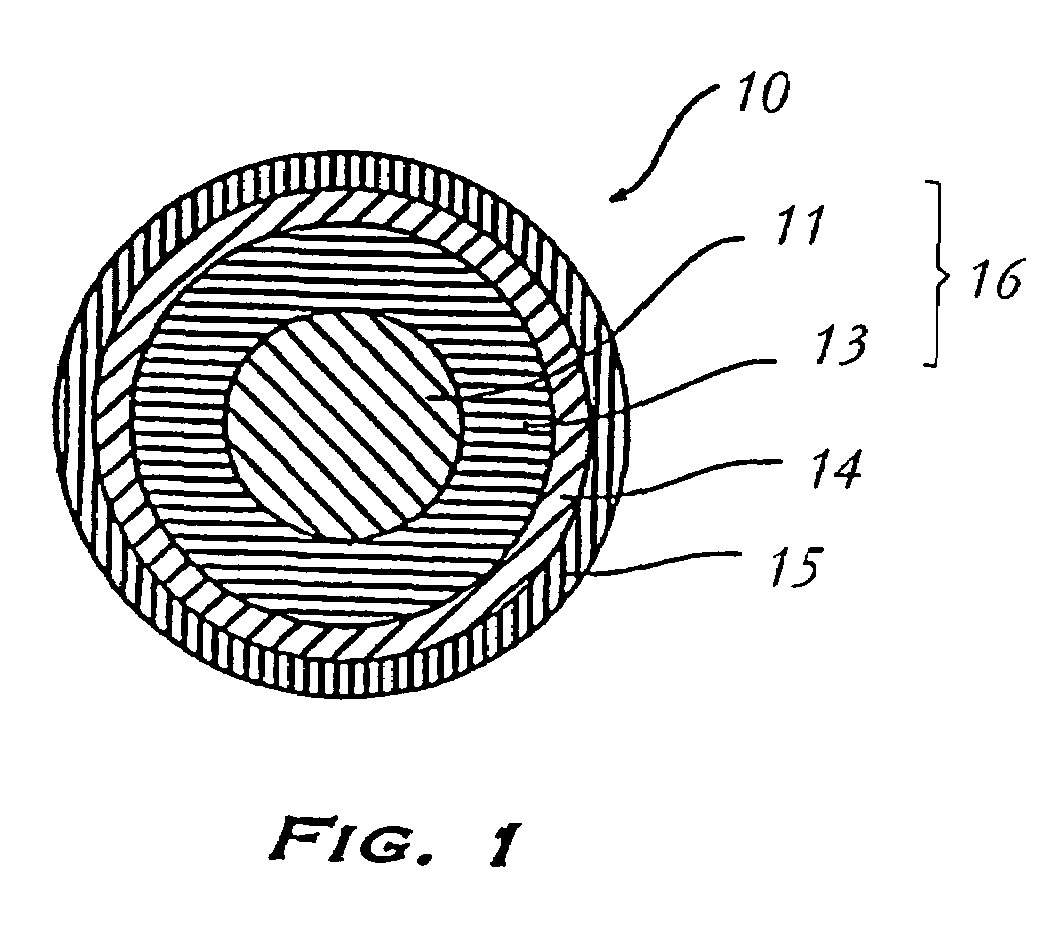

An iron golf club head comprised of a head body 10 made of light metal such as titanium and containing a plurality of weight members 16. The head body 10 includes a front surface 13, a rear surface 13a, a cavity 12 disposed at the rear surface 13a, and a plurality of holes 15 disposed in the head body 10 at the rear surface 13a between a lower side wall 12b of the cavity 12 and a sole 14 of the head body 10 at predetermined intervals between a toe part 17 and a heel part 18. The center axis of each hole 15 is oriented substantially parallel to the sole 14 of the head body 10. The weight members 16 are press-inserted into the holes 15 in a direction going toward the front surface 13 of the head body 10 to a predetermined depth. Each weight member 16 is made of a material having a heavier specific weight than the light metal used for the aforesaid head body 10. Tungsten or tungsten alloy can be used as the material for the weight members 16. The combined weight of the weight members 16 does not exceed forty percent of the weight of the entire head.

Owner:YONEX CO LTD

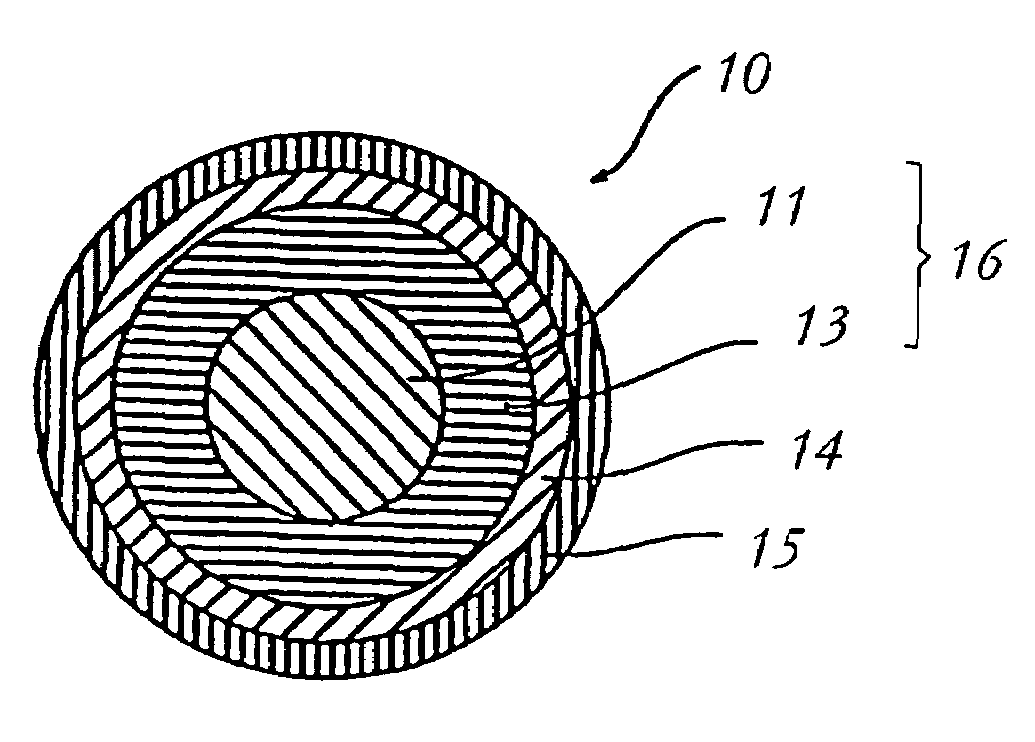

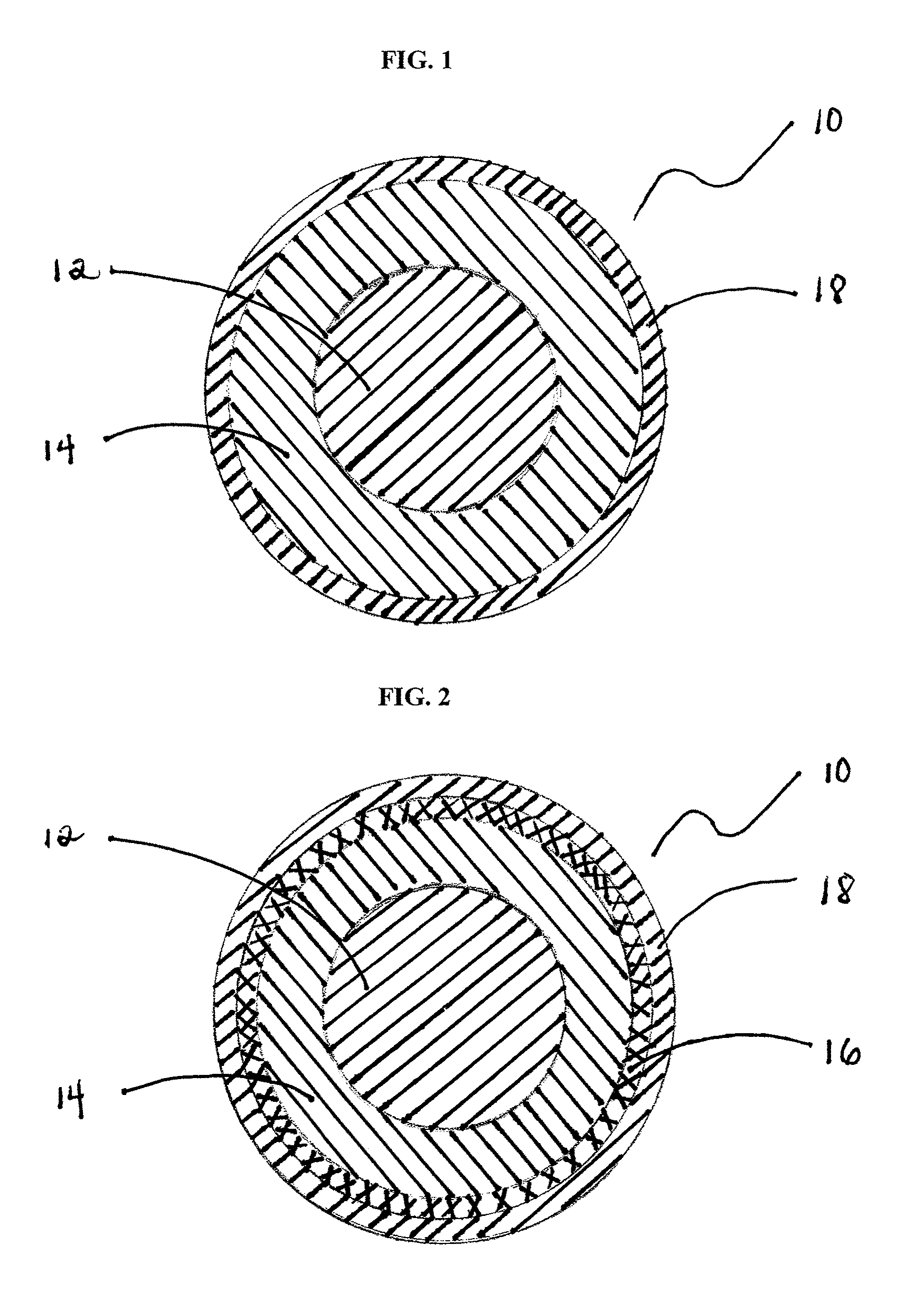

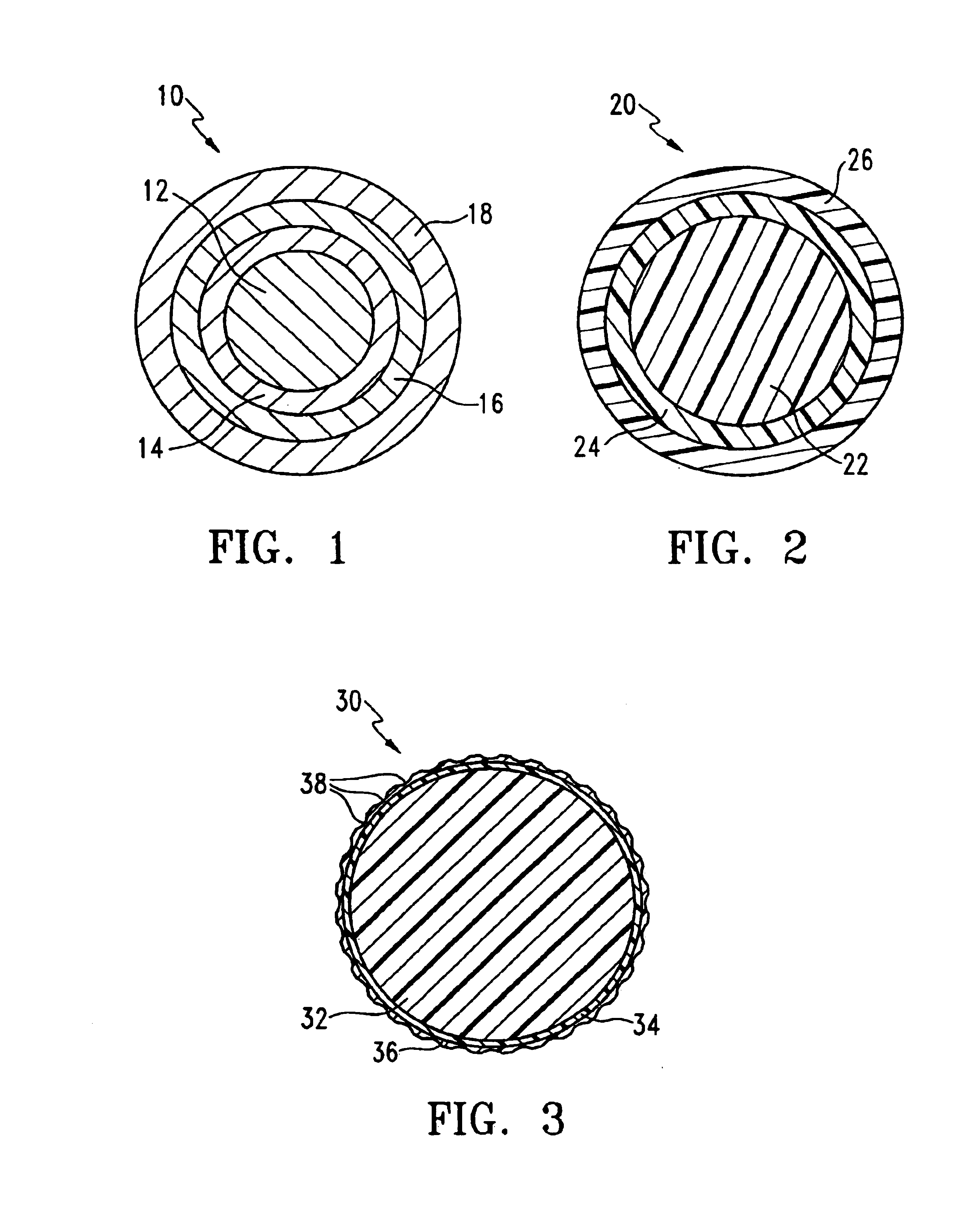

Multi-layer core golf ball

InactiveUS7255656B2Extended service lifeGolf ballsDomestic articlesMoisture vapor transmission rateEngineering

The present invention is directed to an improved golf ball displaying the desired spin profile and having a generally rigid, thermoset polybutadiene outer core surrounding a relatively soft, low compression inner core. In general, this golf ball has an inner core and at least one outer core layer surrounding the inner core. The inner core has a hardness less than a hardness of the outer core and a specific gravity less than or equal to the outer core specific gravity. Overall the inner core compression and outer core are formulated to provide a combined overall core compression of greater than about 50, preferably greater than about 70. A cover layer is provided to surround and to cover the outer core layer. A moisture barrier layer is provided between the outer core layer and the cover layer to protect the inner and outer cores from degradation due to exposure to water. The moisture vapor transmission rate of the moisture barrier layer is selected to be less than the moisture vapor transmission rate of the cover layer.

Owner:ACUSHNET CO

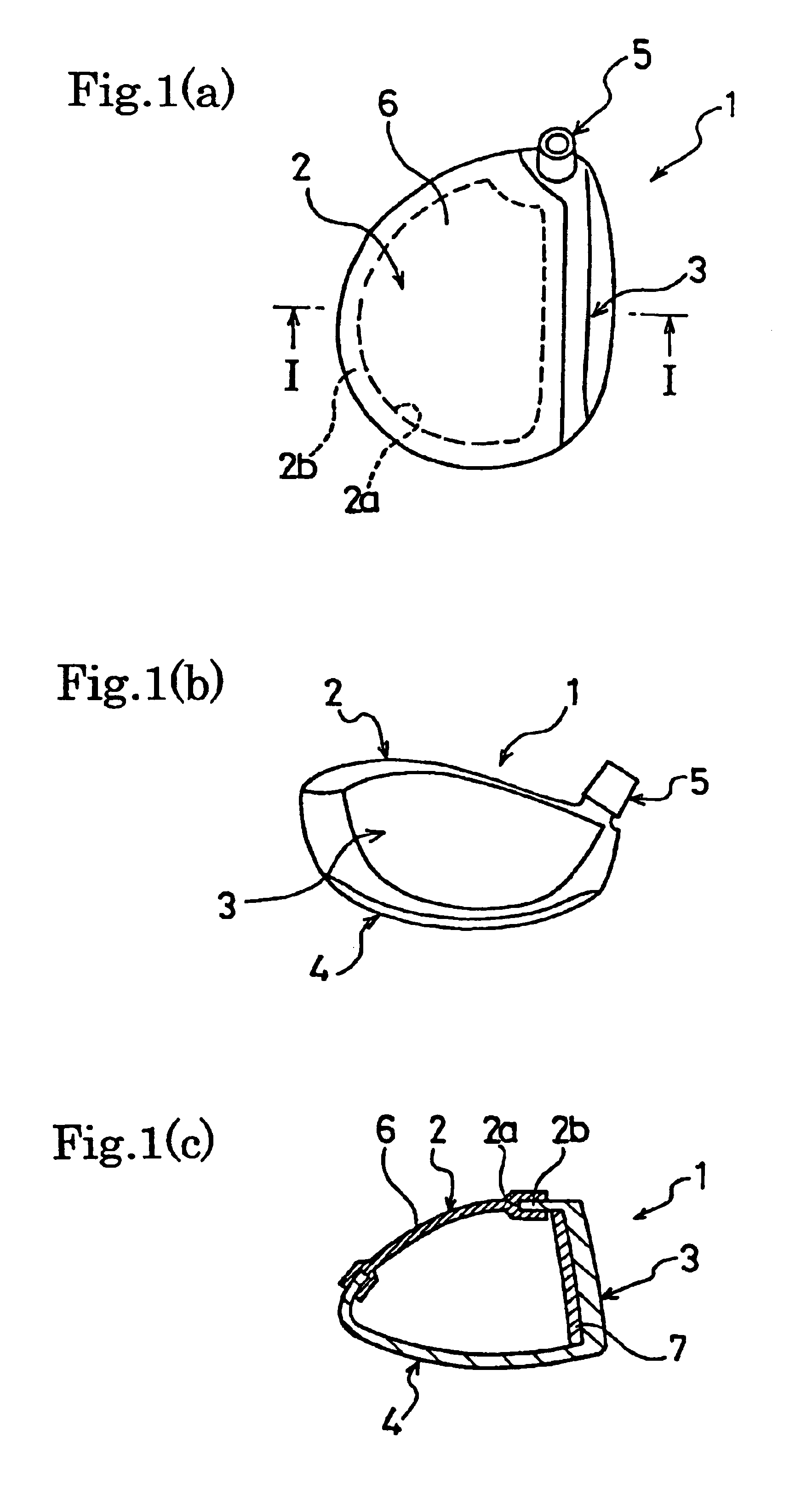

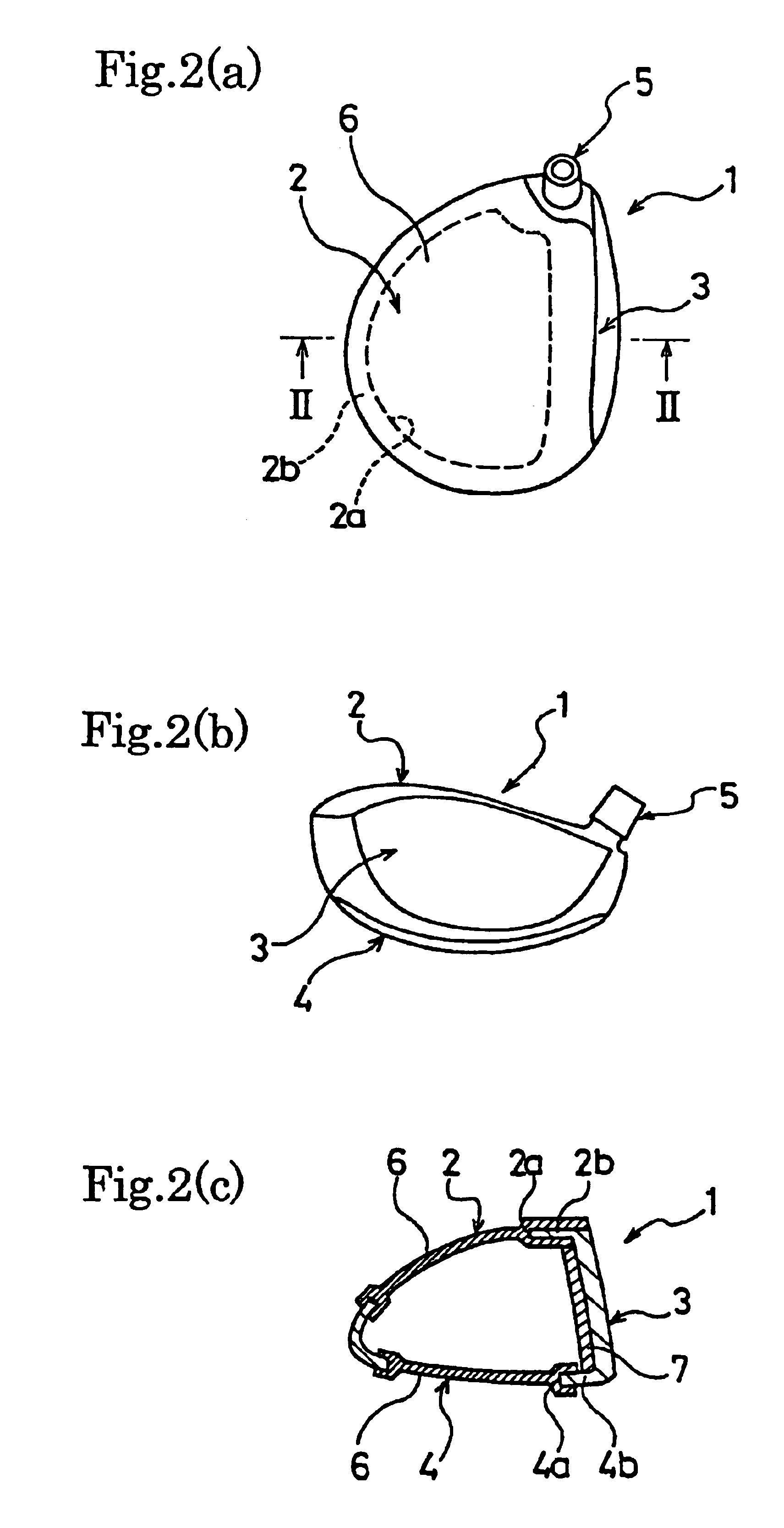

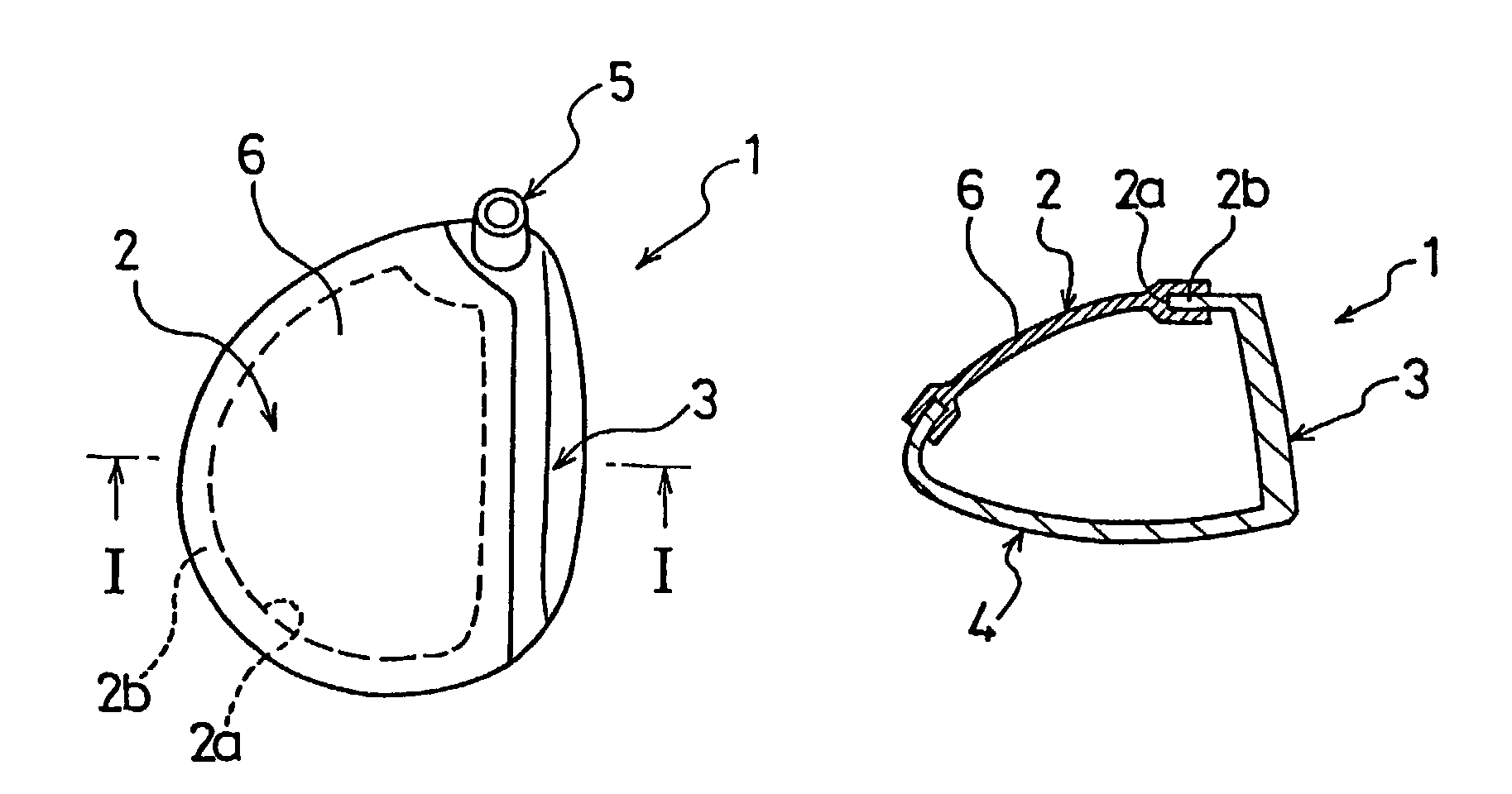

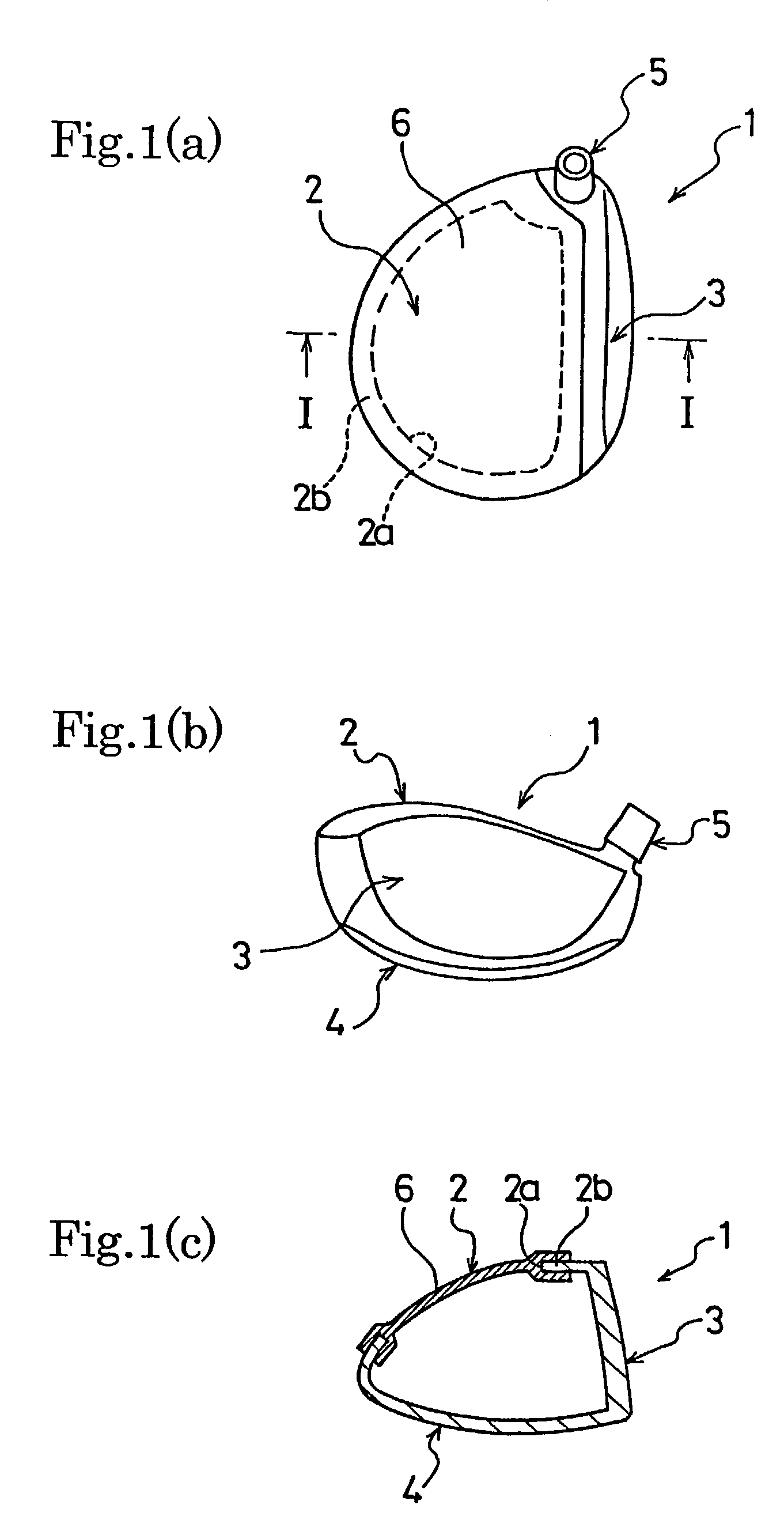

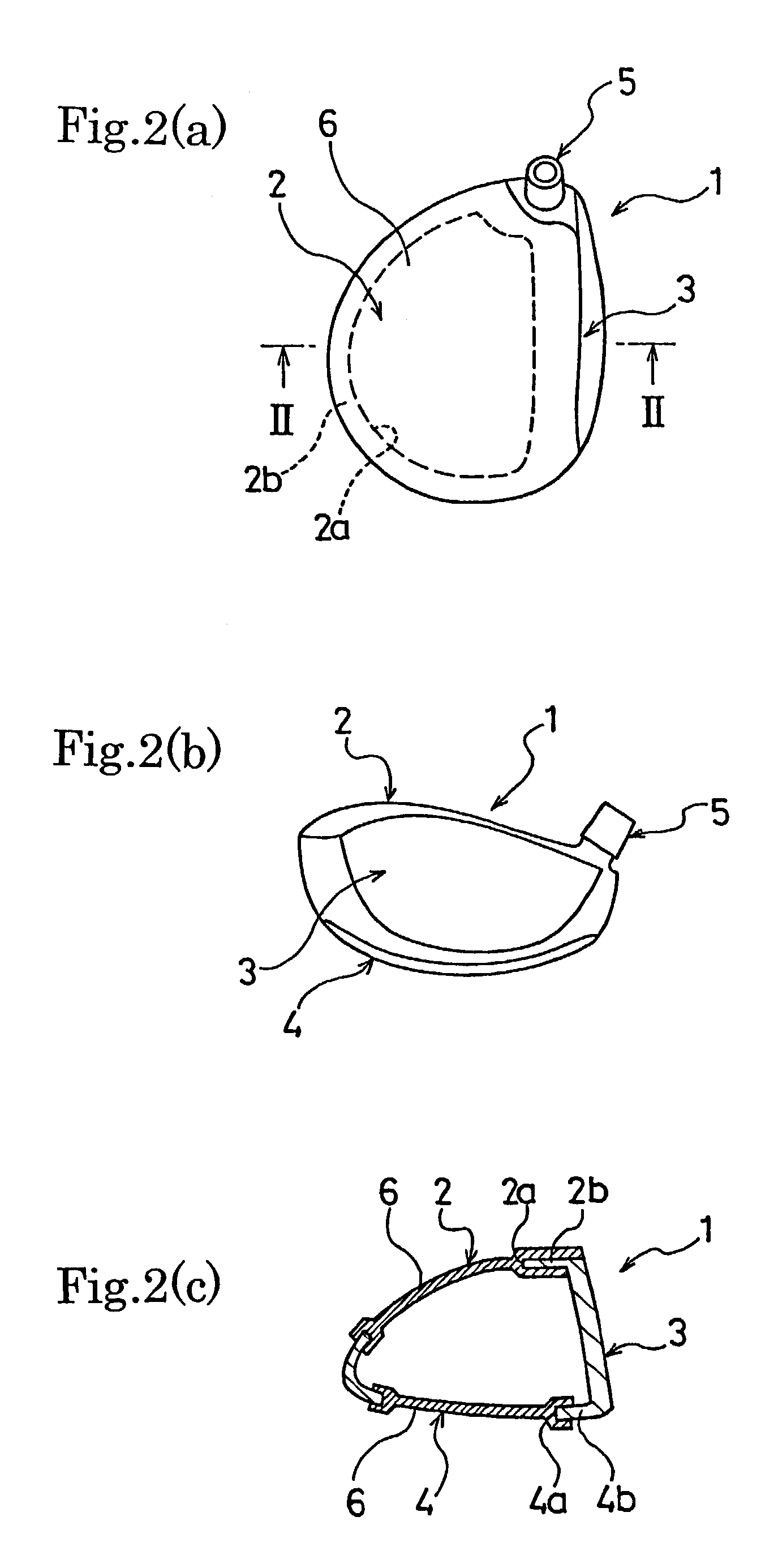

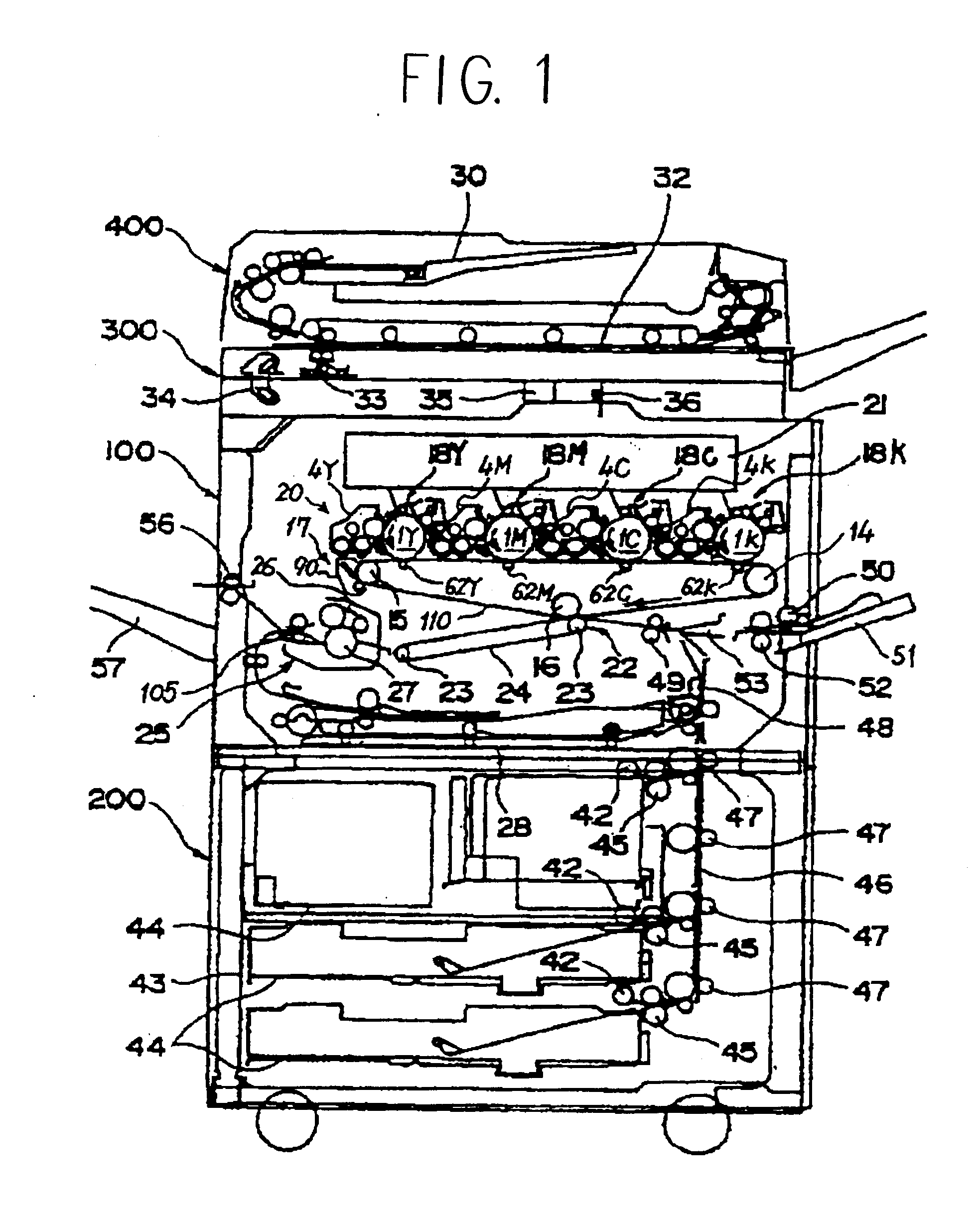

Hollow golf club head

InactiveUS6945876B2Great weight marginDegree of design is increasedGolf clubsRacket sportsEngineeringGolf Ball

A hollow golf club head allowing to increase the repulsion and the degree of design freedom, while maintaining the durability. A hollow golf club head having a head body formed from a metal, wherein a hole is formed in the vicinity of the middle of a crown portion in the head body, the hole is closed with a cover member made of a material different from the head body, the ratio (ρm / ρf) of the specific gravity ρm of the head body and the specific gravity ρf of the cover member is set equal or superior to 1.3, and the ratio of the face area of a portion where the reinforcement and the head body are combined to the face area of the head body is set equal or superior to 20%.

Owner:YOKOHAMA RUBBER CO LTD

Low density proppant

Owner:CARBO CERAMICS

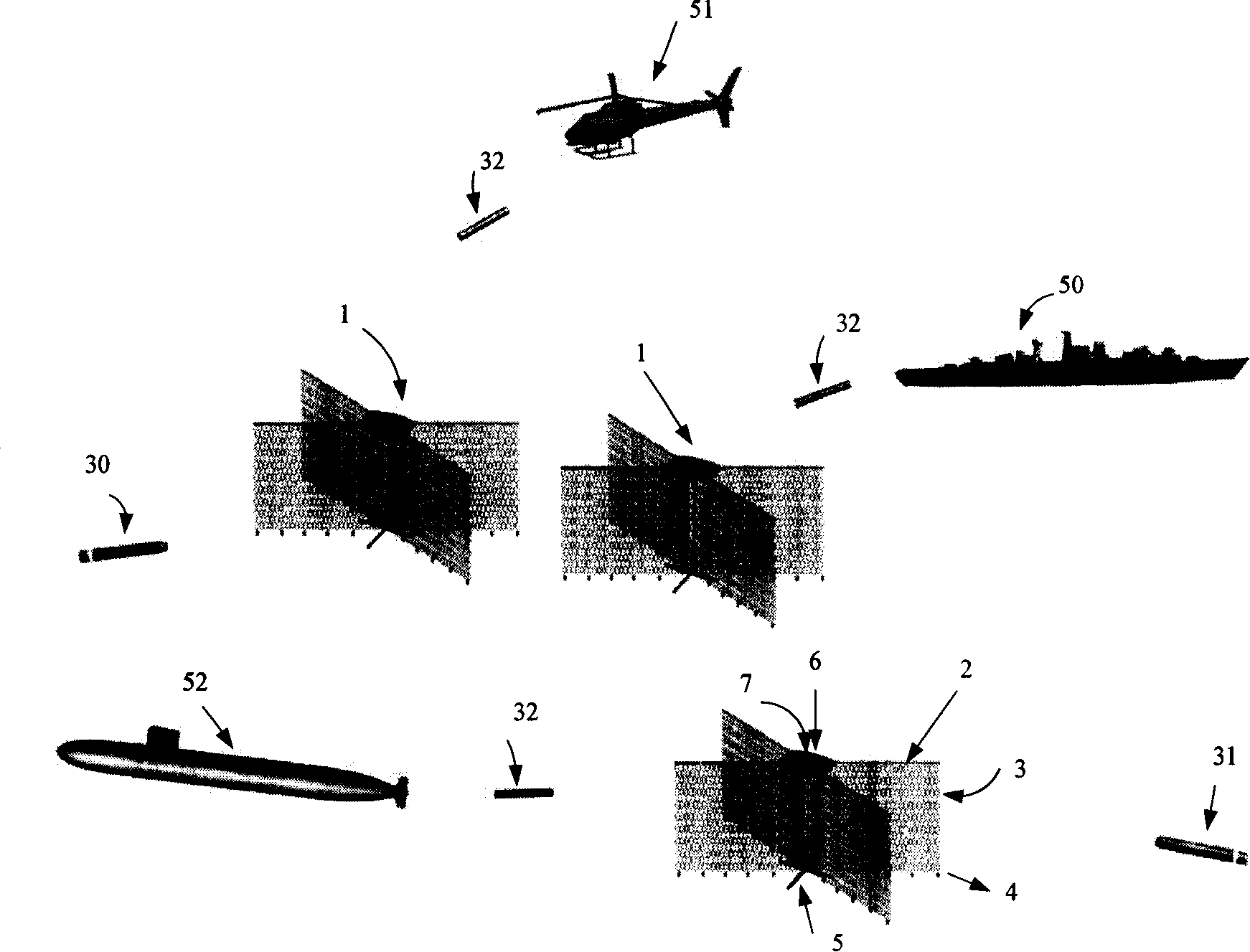

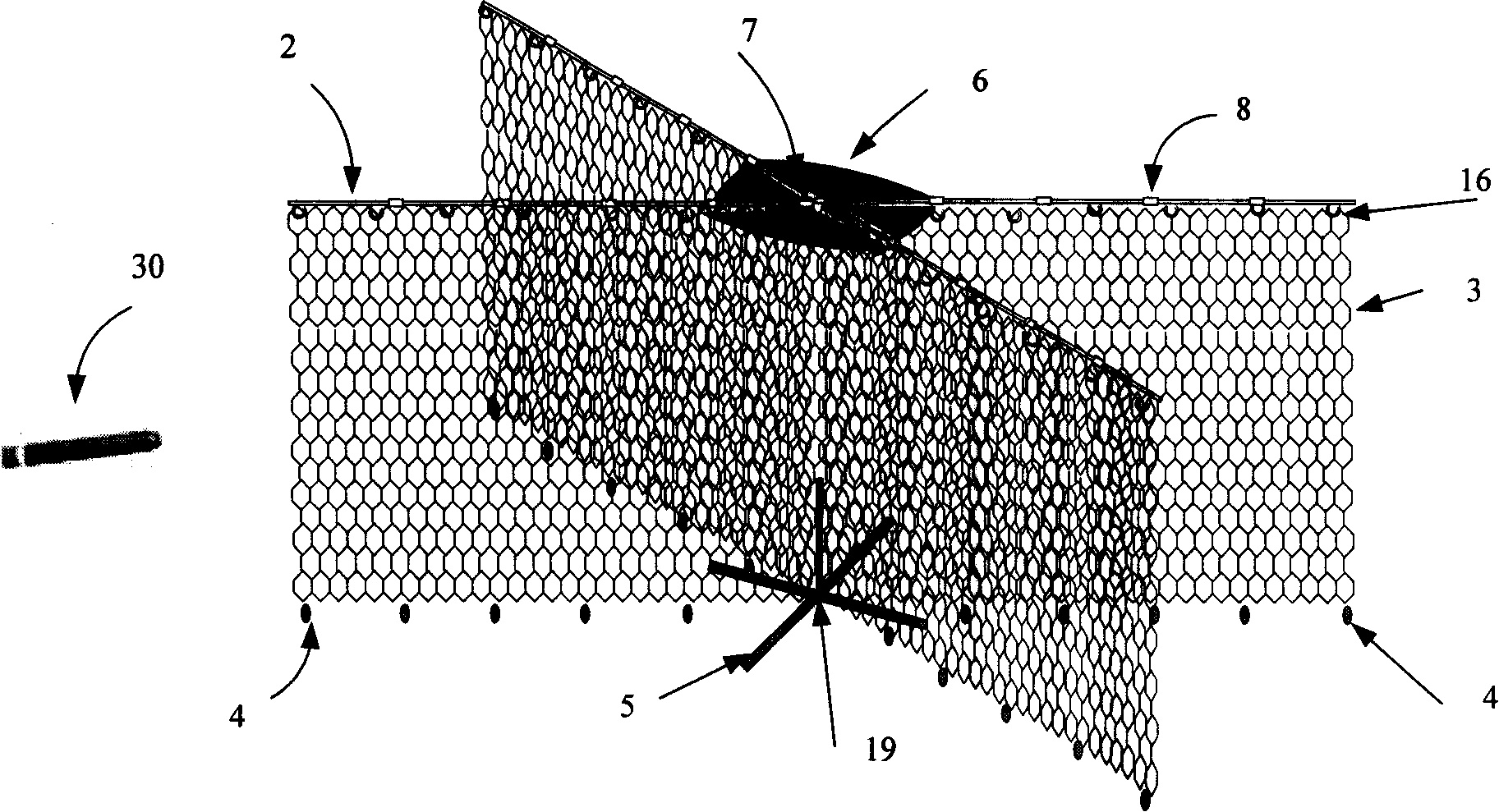

Decussation stereo torpedo catching net

InactiveCN101226043ADoes not affect mobilityLarge effective interception areaDefence devicesPull forceDecussation

The invention relates to a crossed three-dimensional torpedo interception net capable of intercepting torpedoes, especially a torpedo interception net which can be projected or cast and can outspread automatically when entering into the water to form a decussate three-dimensional torpedo interception net. The appearance is column-shaped, a top cover is arranged at the top part and is fixed and sleeved by bayonet locks on the casing which is divided into four sections, the specific density of the top part is lighter than the seawater and the specific density of the bottom part is heavier than the seawater. A decussate bracket is arranged inside, a telescopic link is connected on the lateral side, and a suspended net is connected with the telescopic link via a hanger. When the torpedo interception net is projected or cast into sea via a surface ship, a submarine or a helicopter, the top cover is ejected via a spring, the casing is opened, a going barren dives the telescopic link to expand and the suspended net is dragged to outspread in horizontally. Under the upward pulling force of the telescopic link and the downward pulling force of the weight of the connector of the suspended net, the suspended net is outspreaded along vertical direction; a stabilization membrane connected with the inner side of the suspended net control the stability of the torpedo interception net along the vertical direction.

Owner:孙珠峰

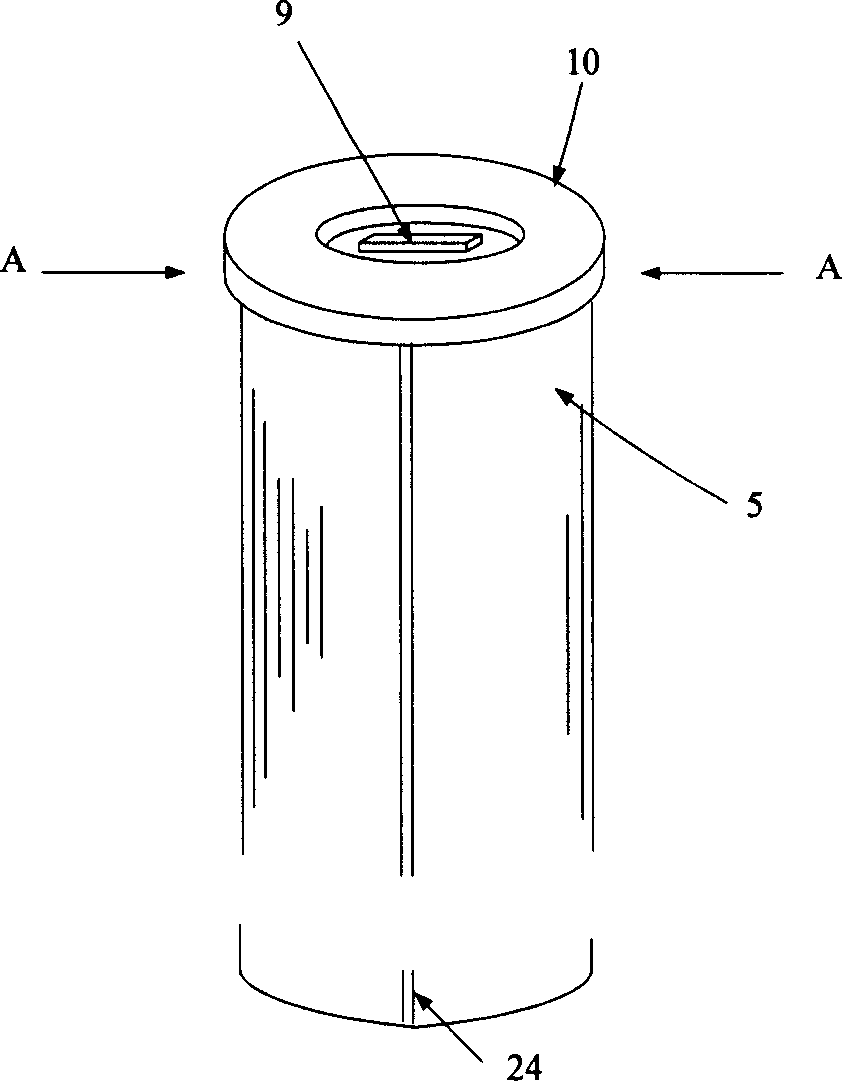

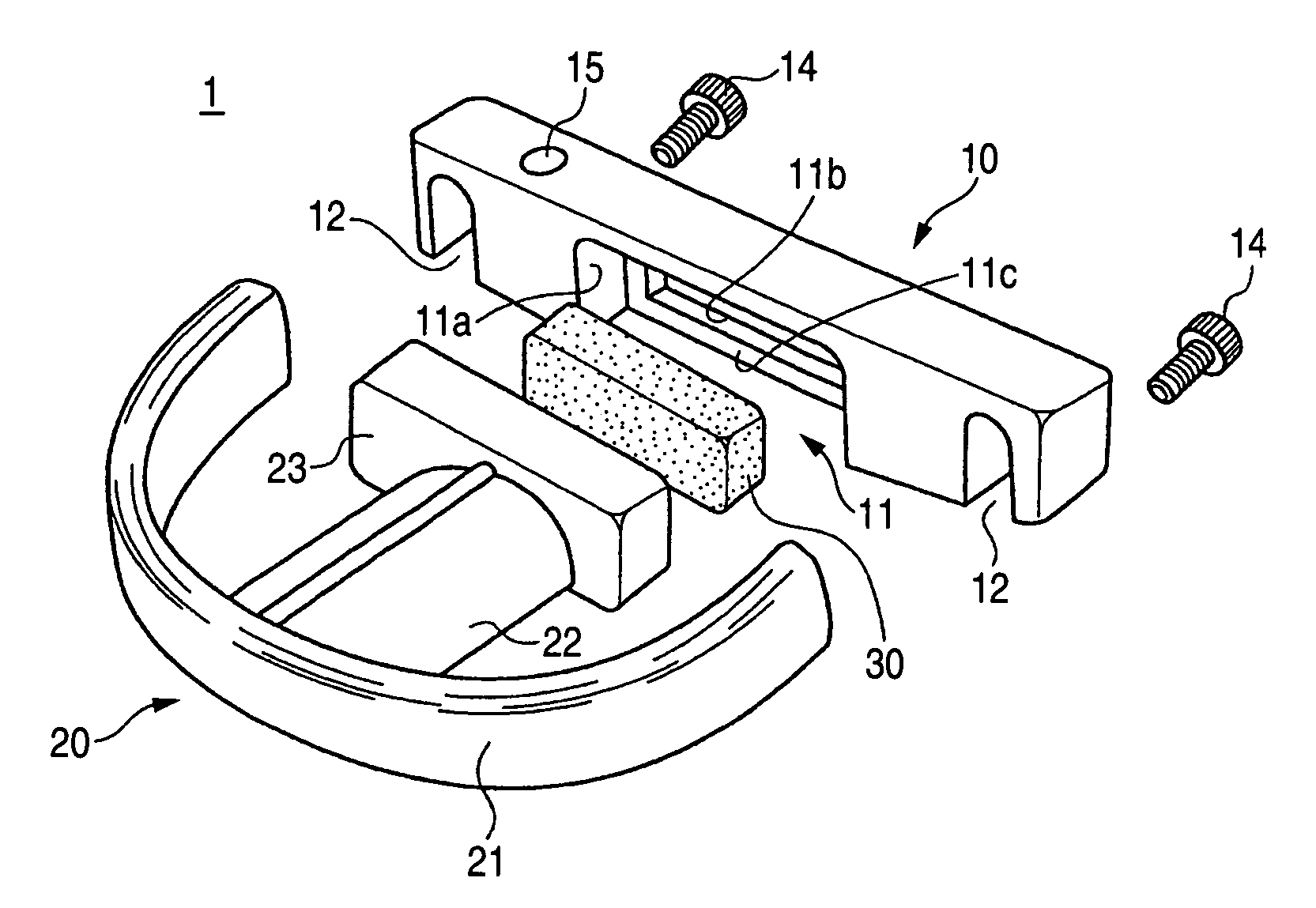

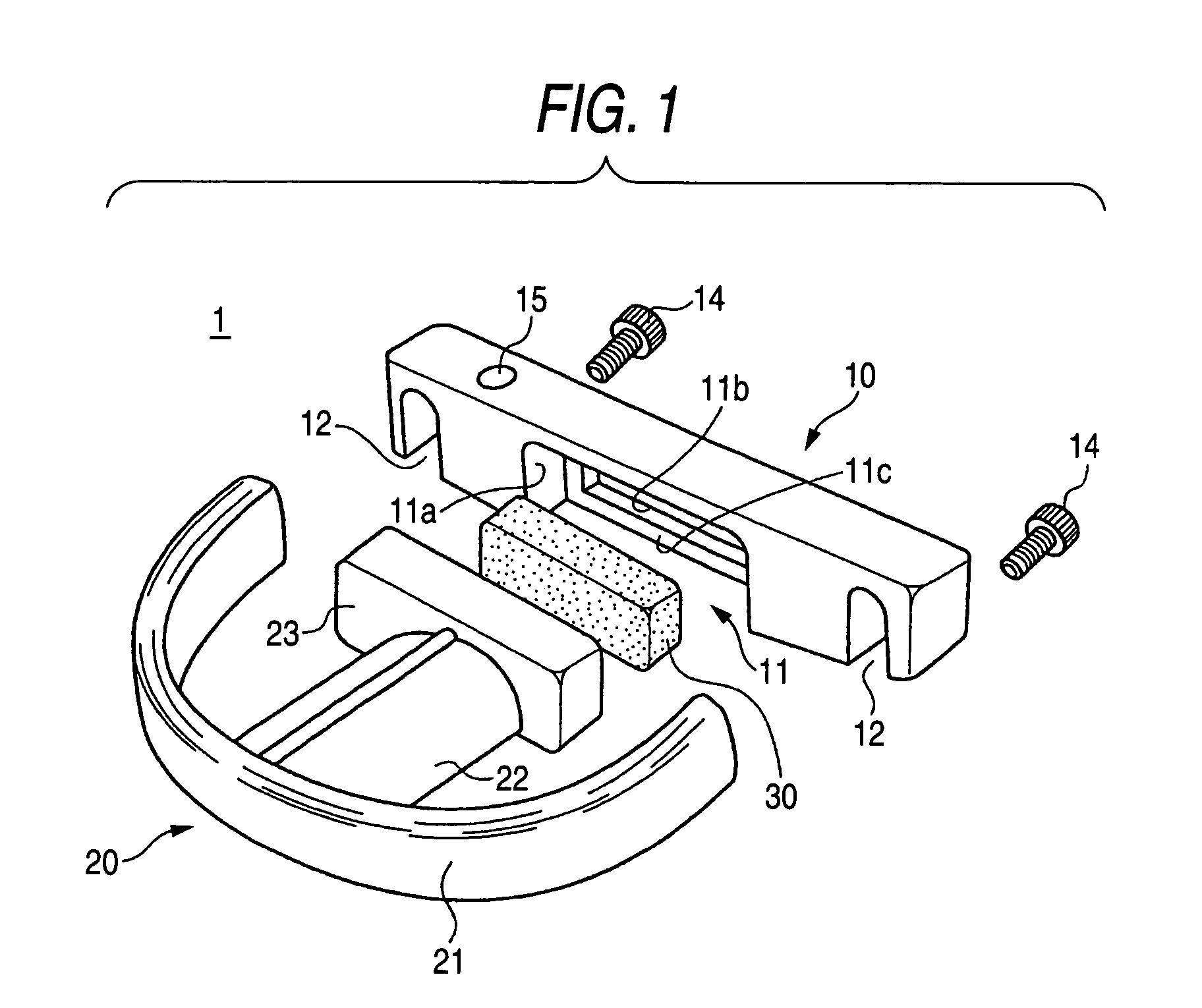

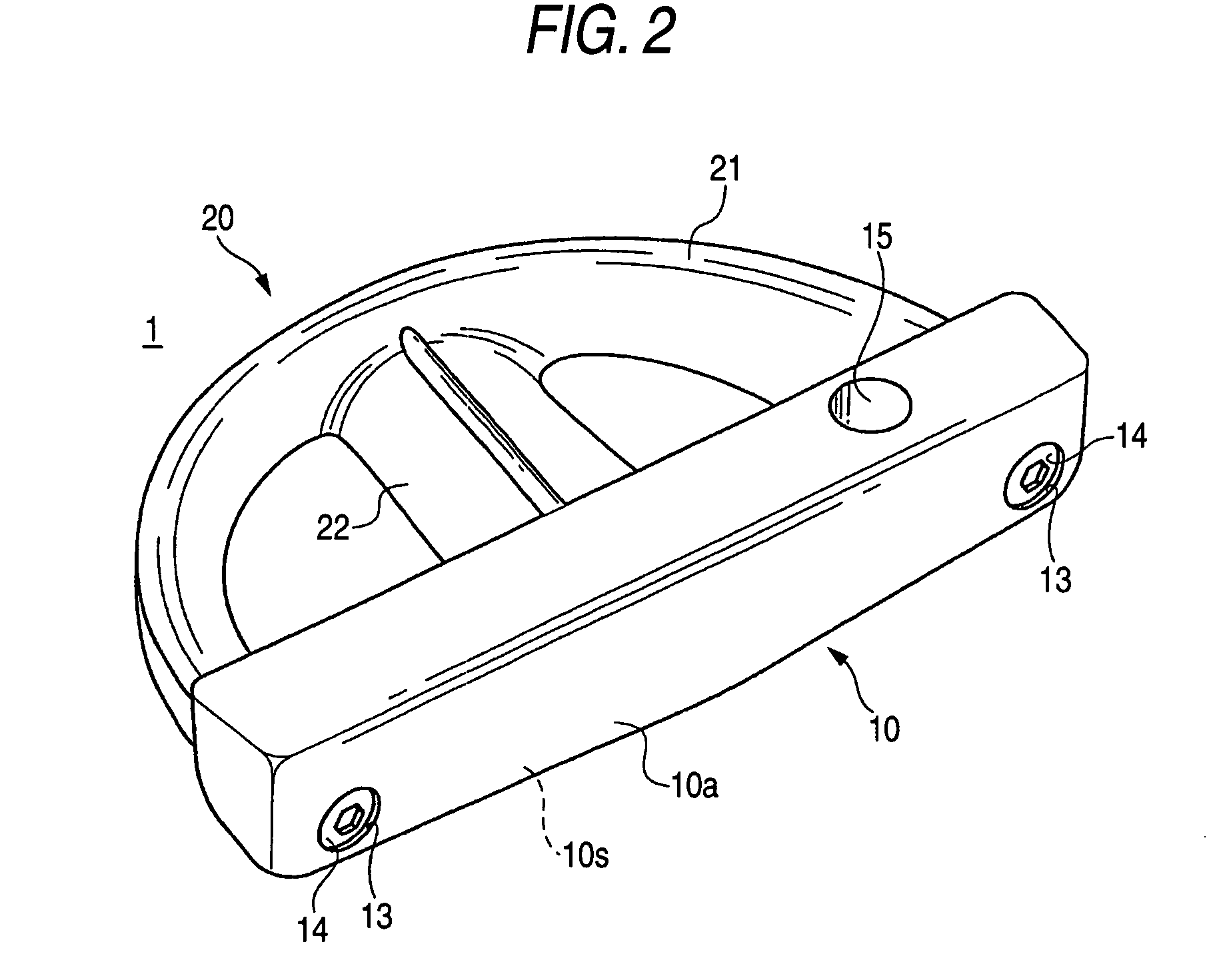

Putter head

Owner:BRIDGESTONE SPORTS

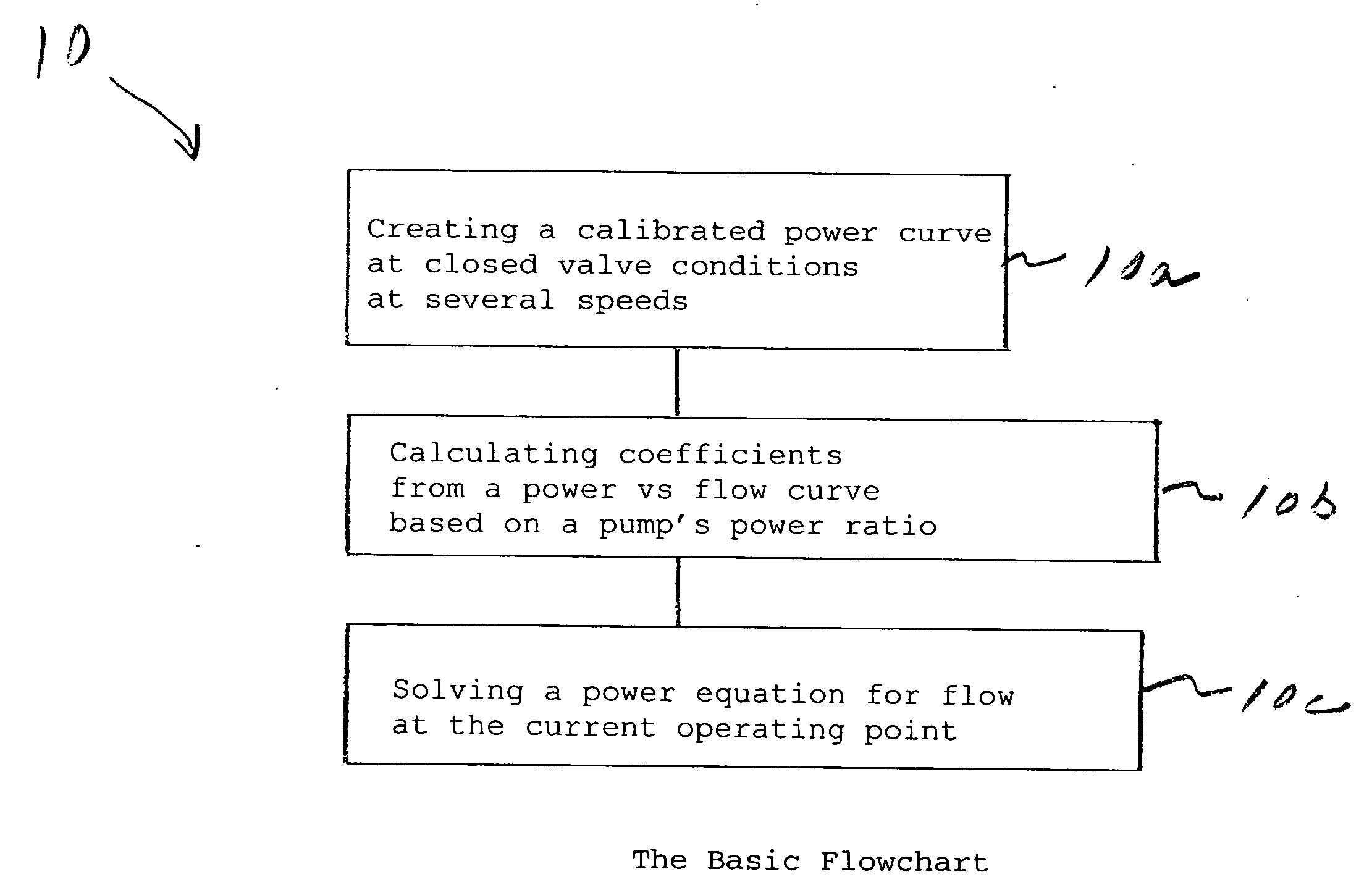

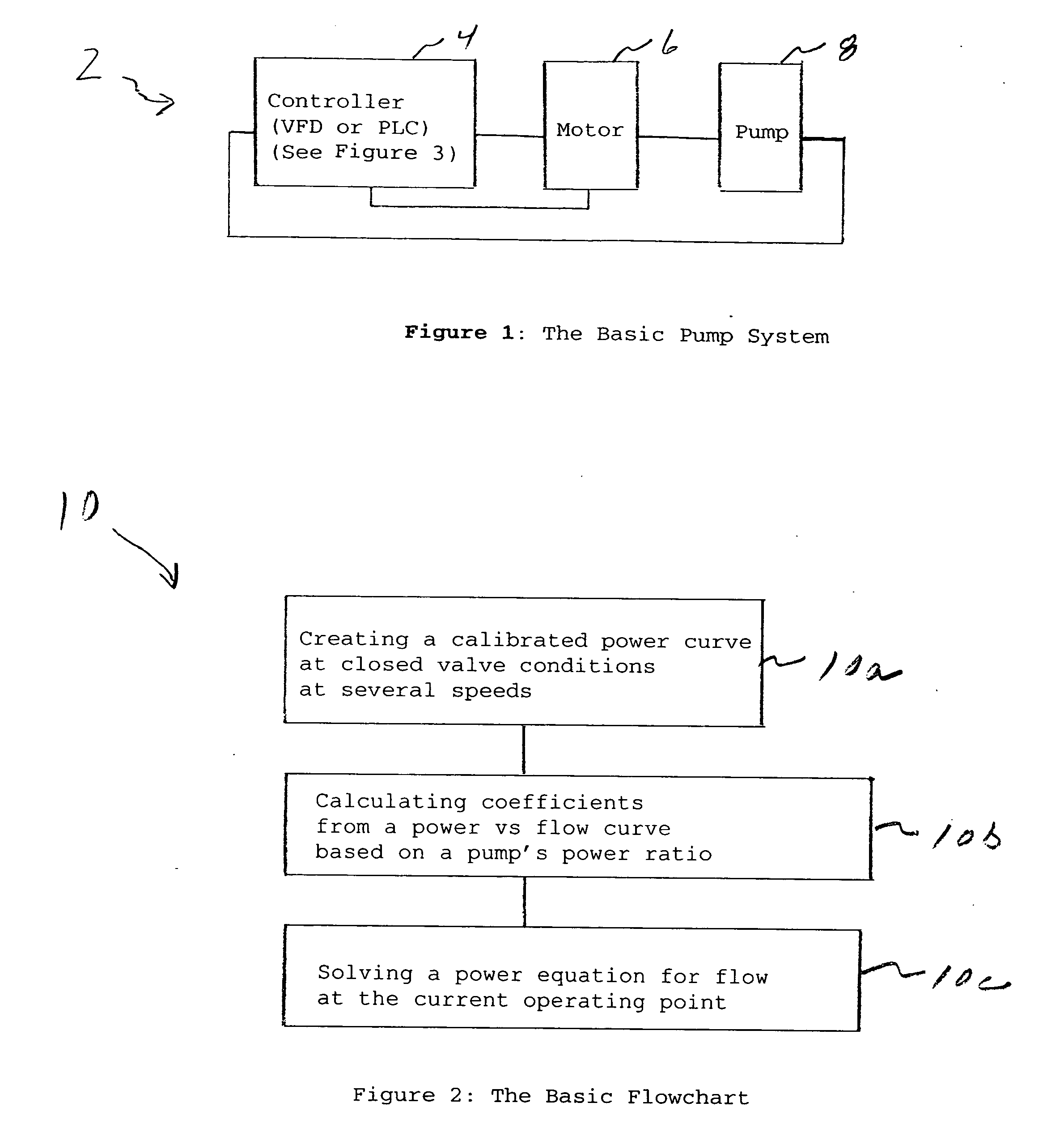

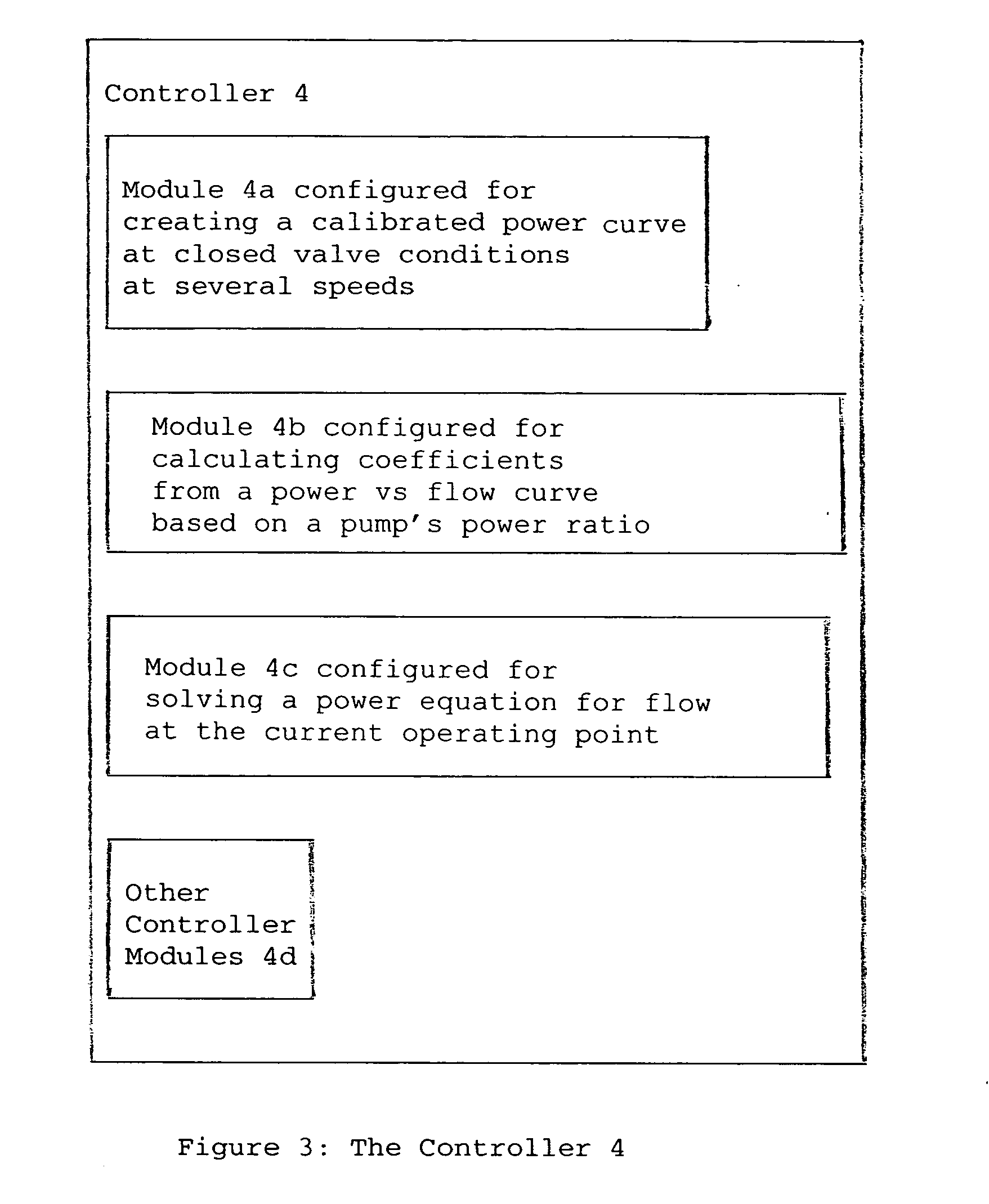

Method for determining pump flow without the use of traditional sensors

ActiveUS20070212210A1Testing/calibration apparatusAmplifier modifications to reduce noise influenceOperating pointMuller's method

A technique for determining pump flow without using traditional sensors features steps and modules for creating a calibrated power curve at closed valve conditions at several speeds; calculating coefficients from a normalized power curve based on a pump's power ratio; and solving a polynomial power equation for flow at the current operating point. The calibrated power curve may be created by increasing the speed of the pump from a minimum speed to a maximum speed and operating the pump with a closed discharge valve. This data is used to correct published performance for shutoff power and best efficiency point power at rated speed in order to determine the pump's power ratio. It is also used to accurately determine closed valve power at the current operating speed. The pump's power ratio is determined by the equation: Pratio=Pshutoff @100% / PBEP<sub2>—< / sub2>corr. The polynomial power equation may, for example, include a 3rd order polynomial equation developed using coefficients from the normalized power versus flow curve, and corrections may be made for speed, hydraulic efficiency and specific gravity in the polynomial power equation. Complex roots may be determined to solve the 3rd order polynomial equation using either Muller's method or some other suitable method, and the calculated actual flow may be determined for a specific operating point.

Owner:ITT MFG ENTERPRISES LLC

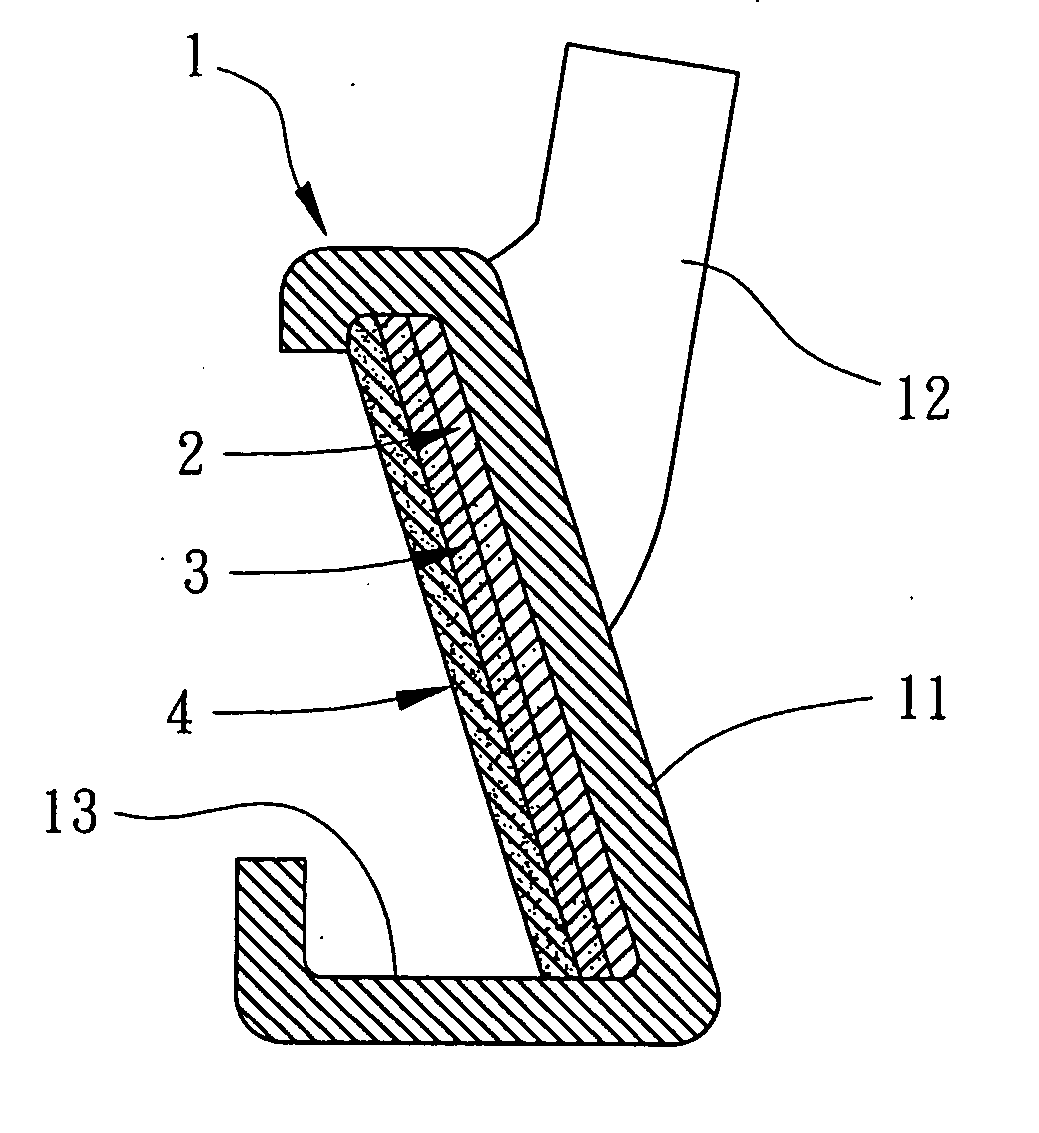

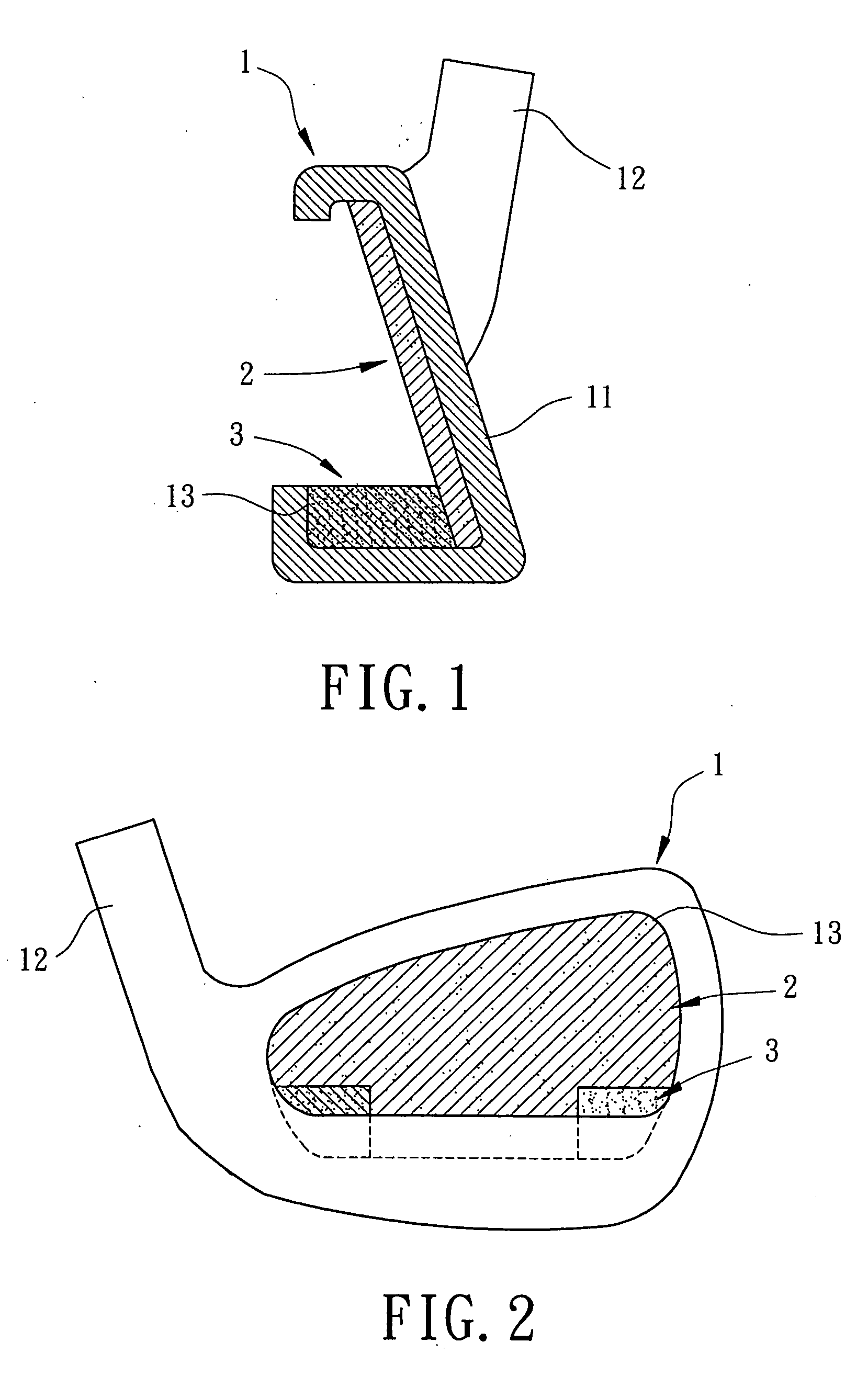

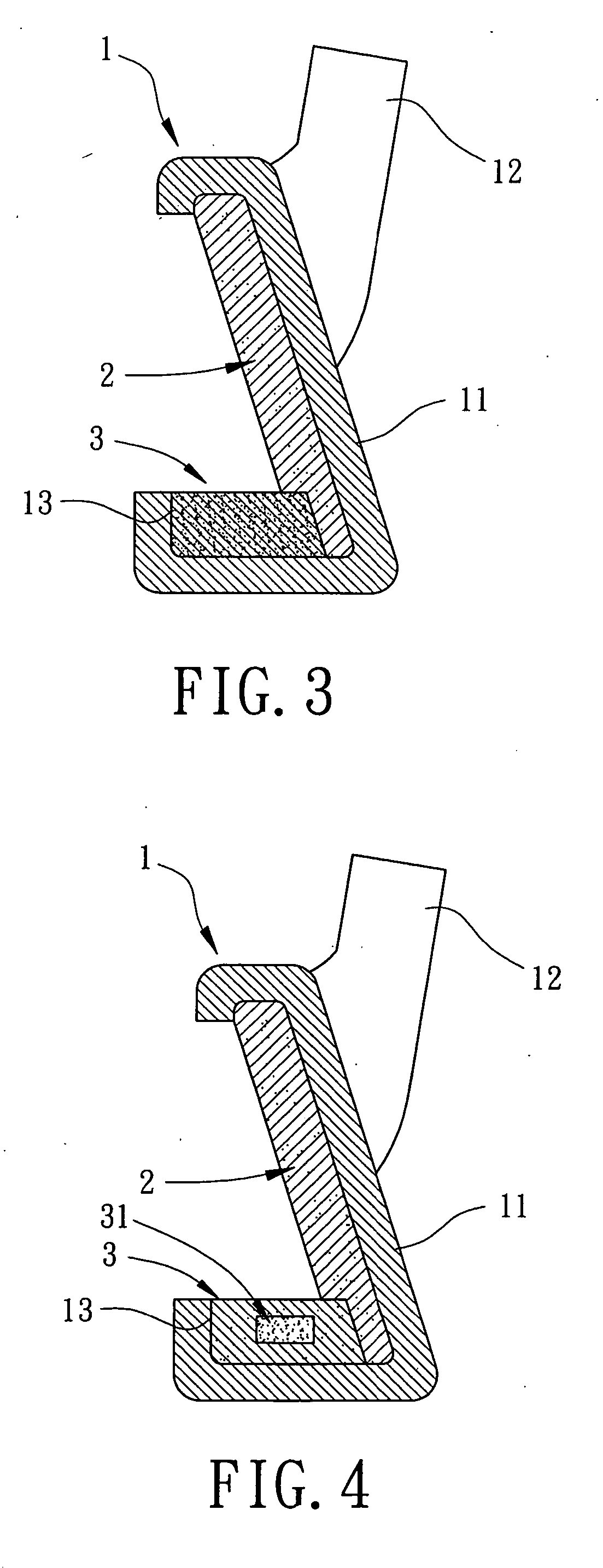

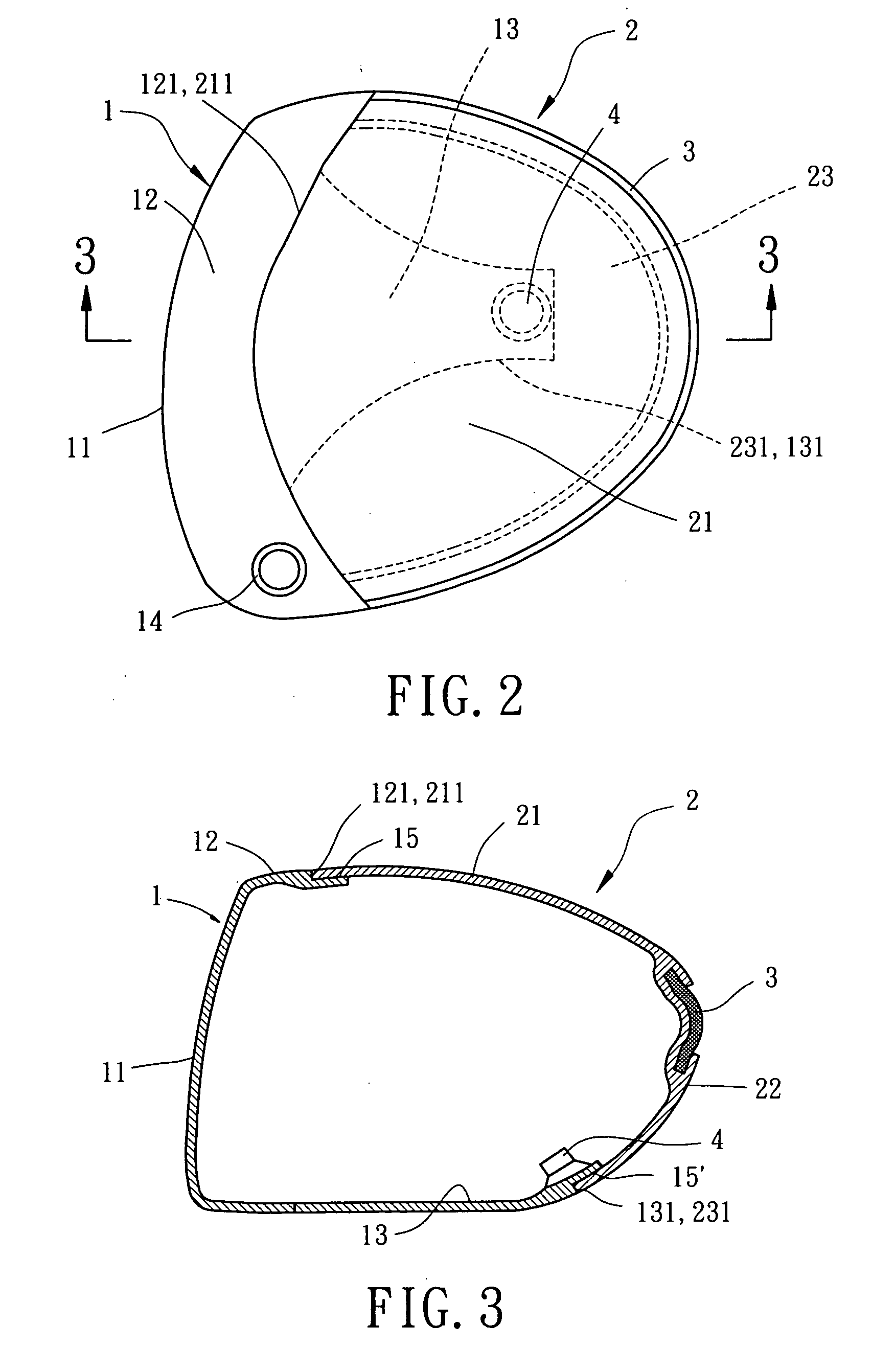

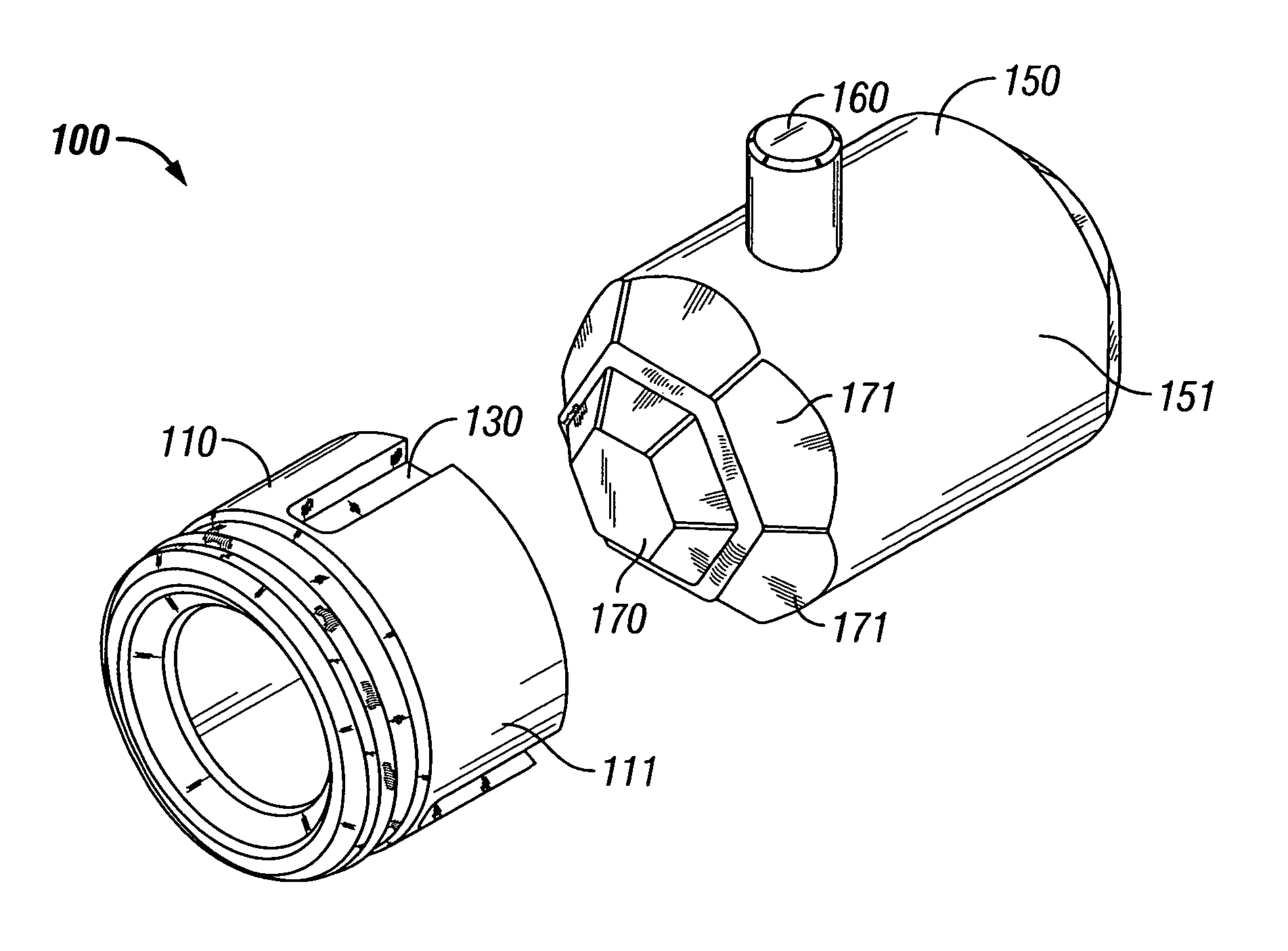

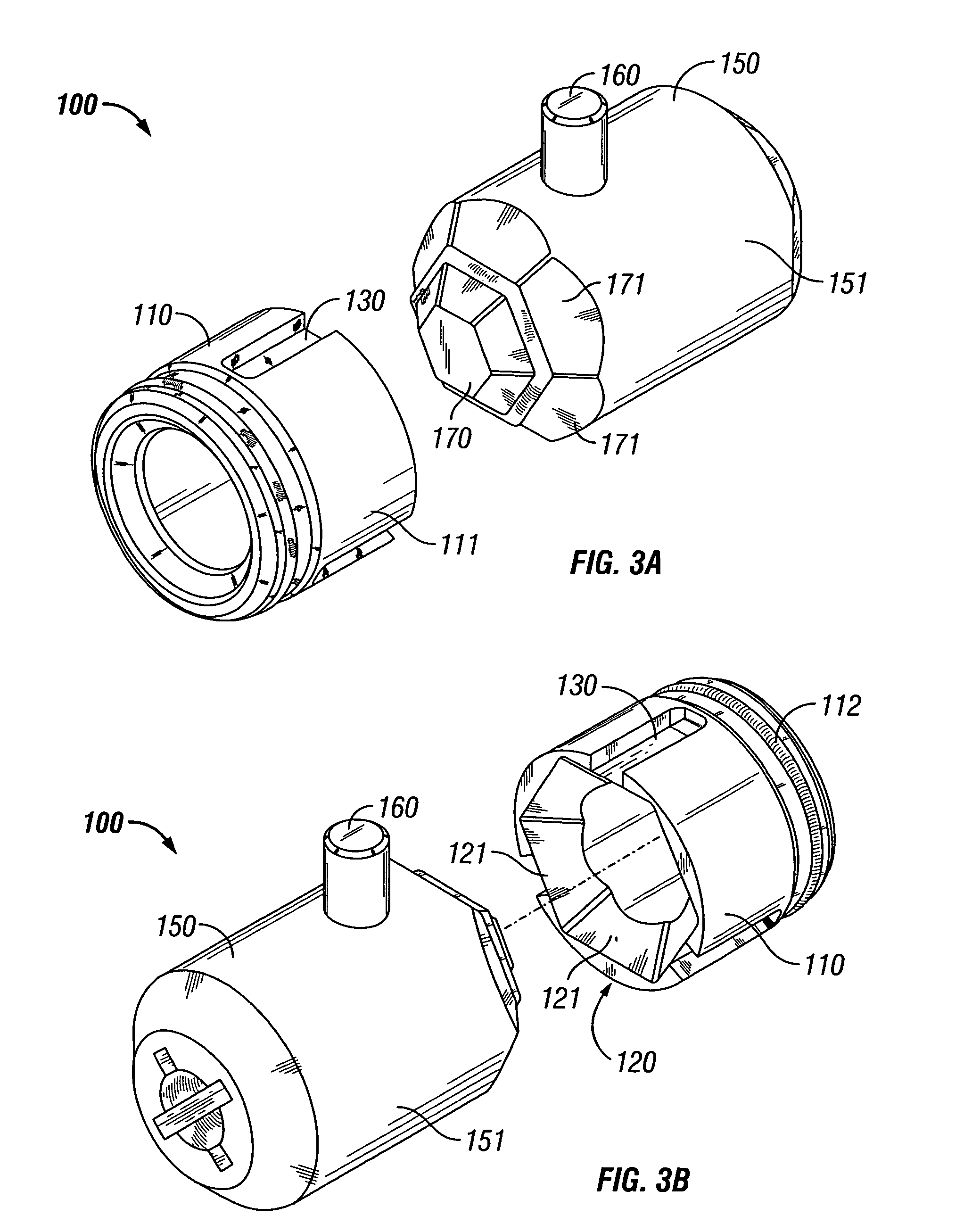

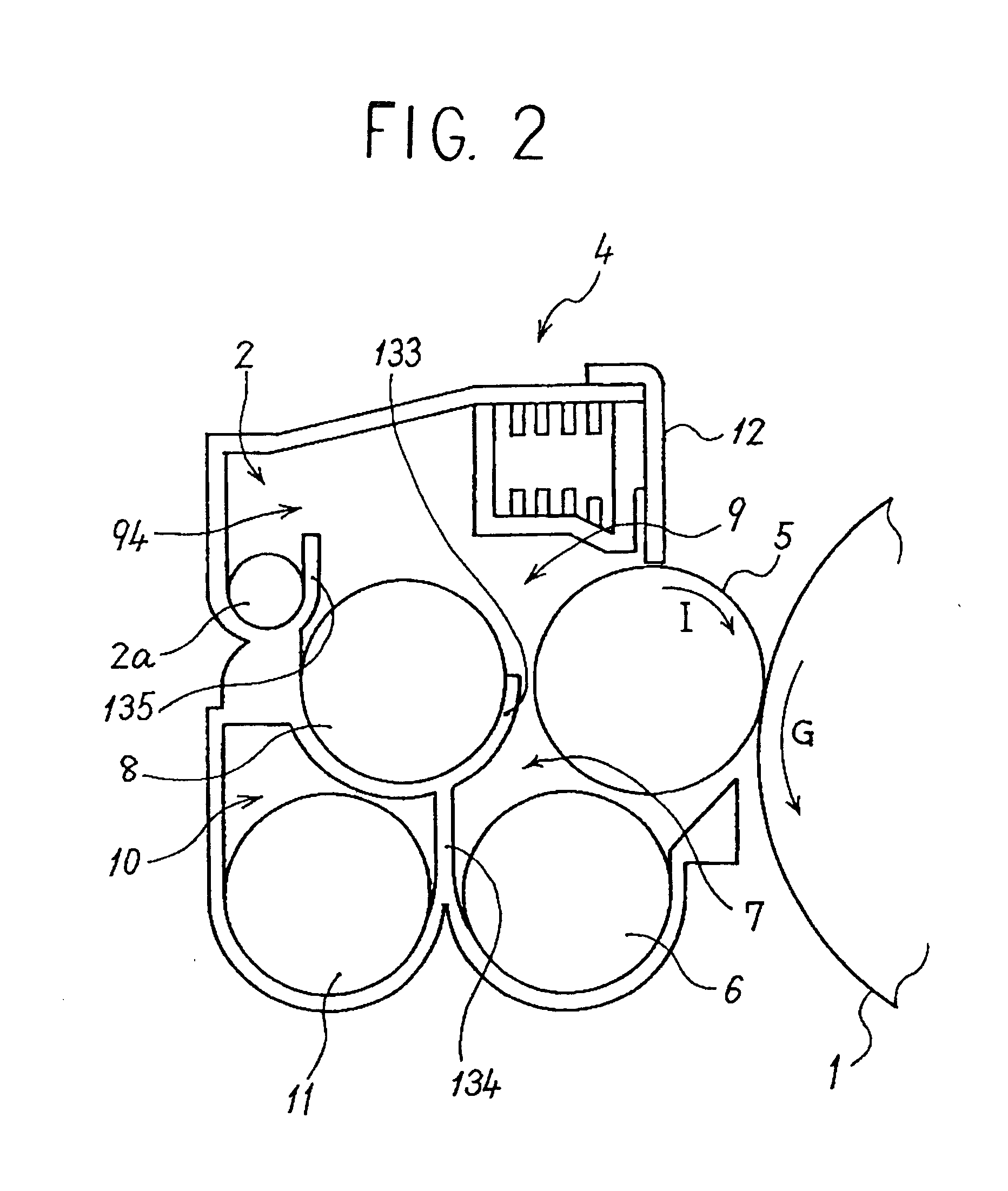

Golf club head with elastic weight members

InactiveUS20060258480A1Improve shock absorptionAdjustable center of gravityGolf clubsRacket sportsElastic matrixElastic vibration

A golf club head includes a body having a striking plate and an assembling portion, a first elastic weight member including an elastic matrix and a metal powder mixed in the elastic matrix, and a second elastic weight member including an elastic matrix and a metal powder mixed in the elastic matrix of the second elastic weight member. The second elastic weight member includes a specific density and an elastic coefficient different from those of the first elastic weight member. The first elastic weight member and the second elastic weight member are mounted in the assembling portion of the body to form a golf club head. The first elastic weight member and the second elastic weight member adjust a center of gravity of the golf club head and provide an elastic vibration-absorbing effect.

Owner:NELSON PRECISION CATING

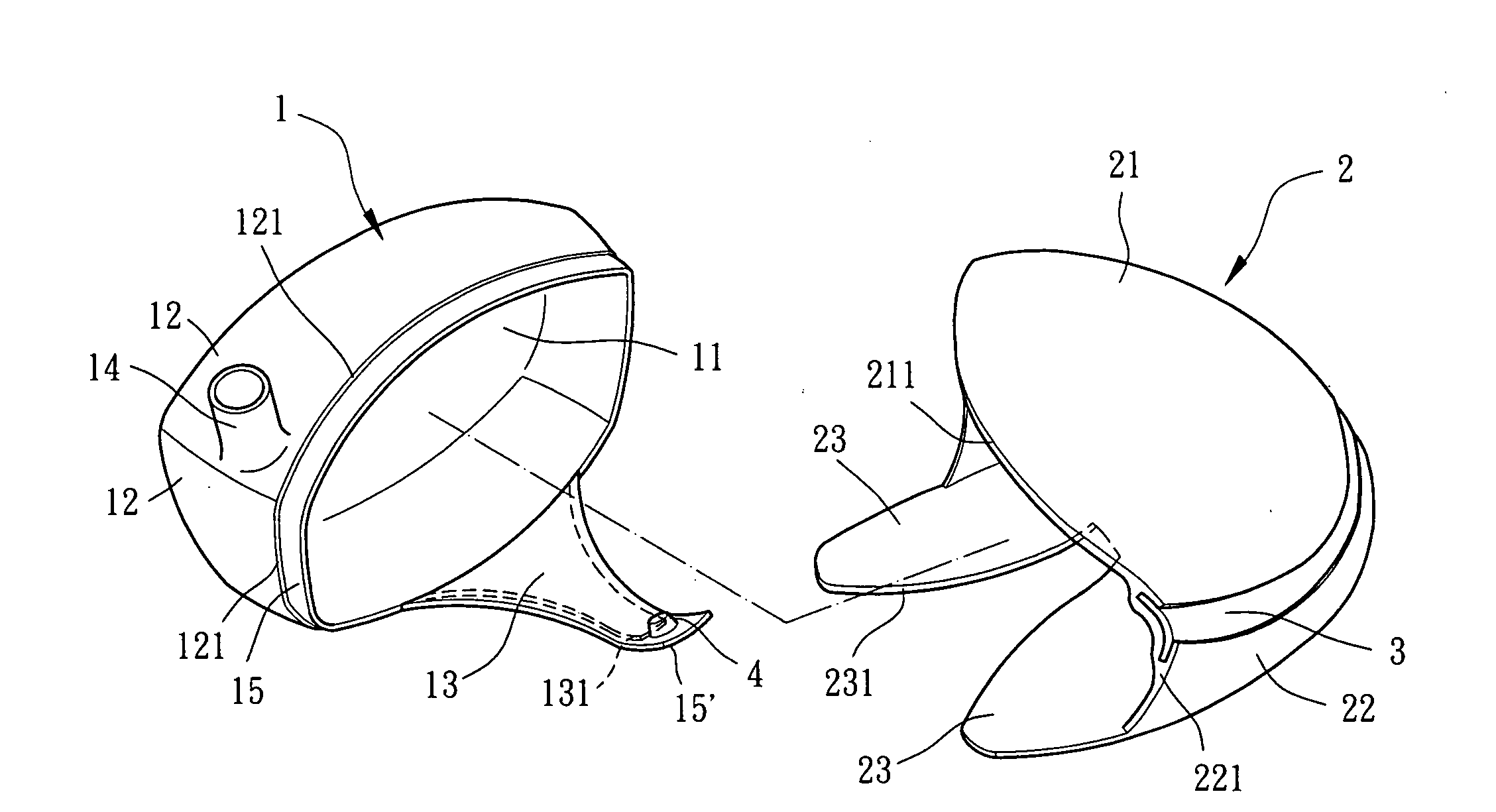

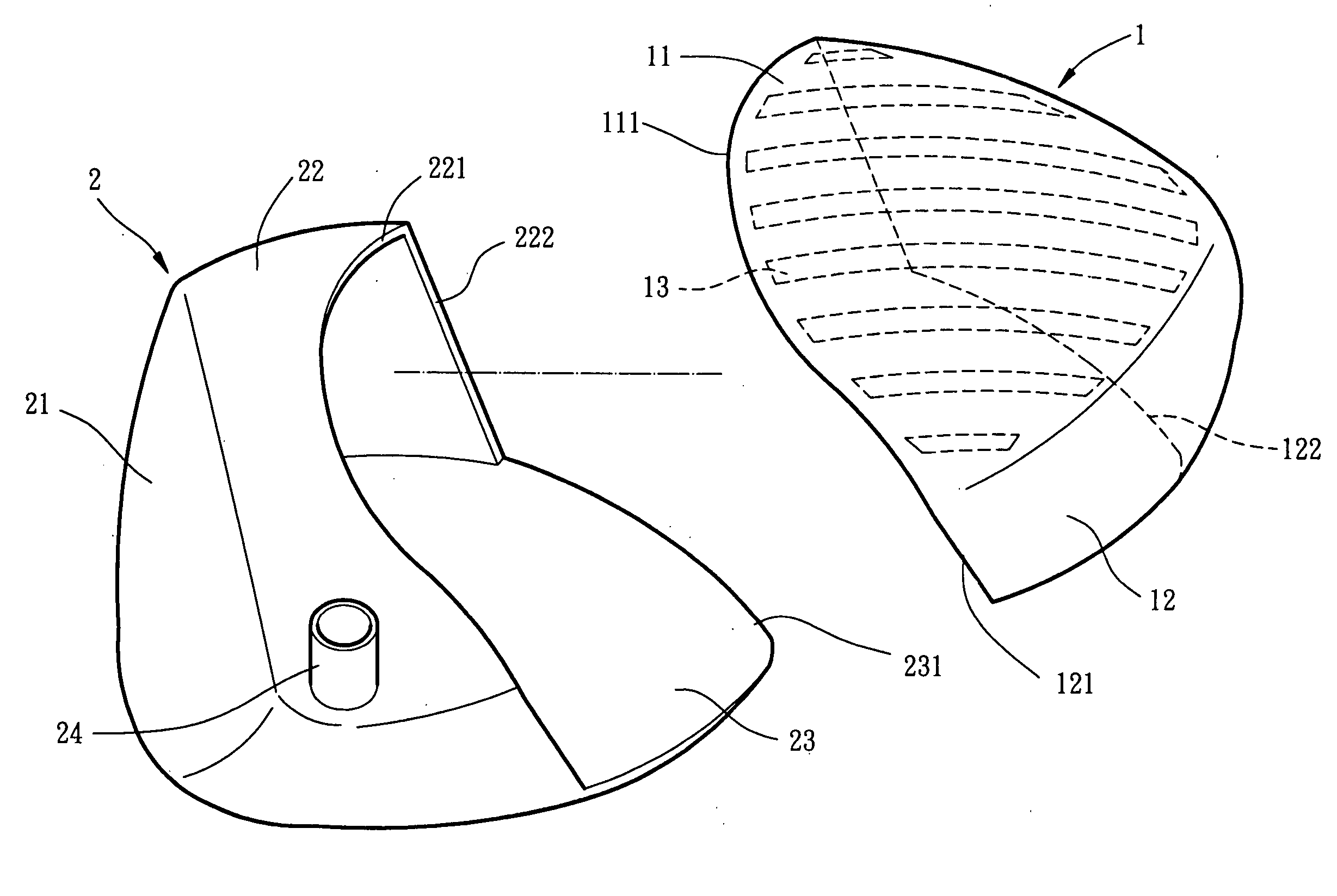

Golf club head with strength-enhanced rear body

InactiveUS20080139339A1High strengthImprove structural strengthGolf clubsGolf club bagsMetallic materialsAlloy

A golf club head with strength-enhanced rear body comprises a front body, a rear body and at least one supporting member. The front body comprises a face and a plurality of abutting edges. The rear body comprises a crown, a ribbon and a plurality of abutting edges, with the rear body being made of a nonmetal material having a specific gravity lower than that of the front body, and the abutting edges of the rear body being corresponding to and connecting with those of the front body. The at least one supporting member being made of a light alloy is disposed along a border between the crown and the ribbon of the rear body.

Owner:FUSHENG IND CO LTD

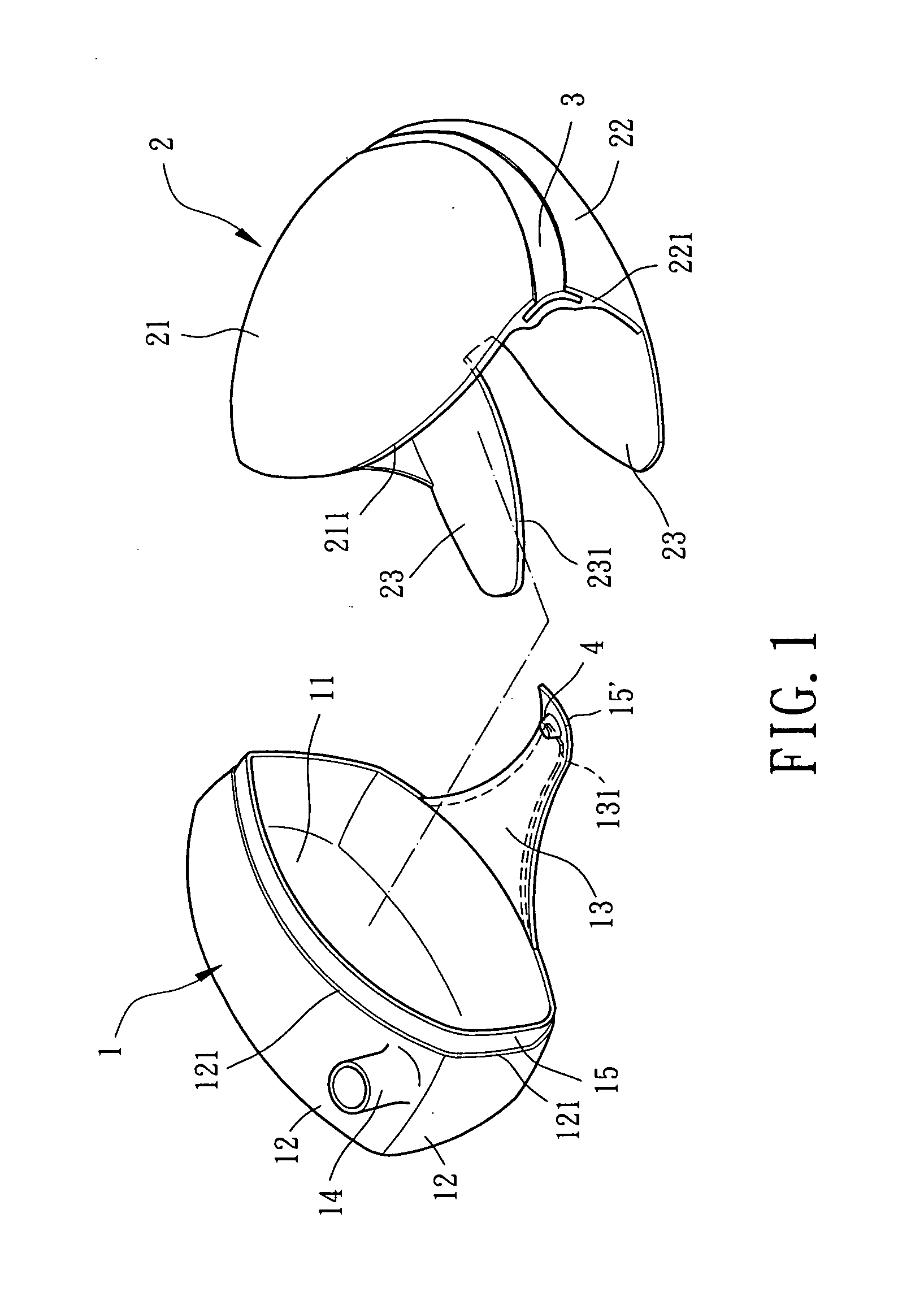

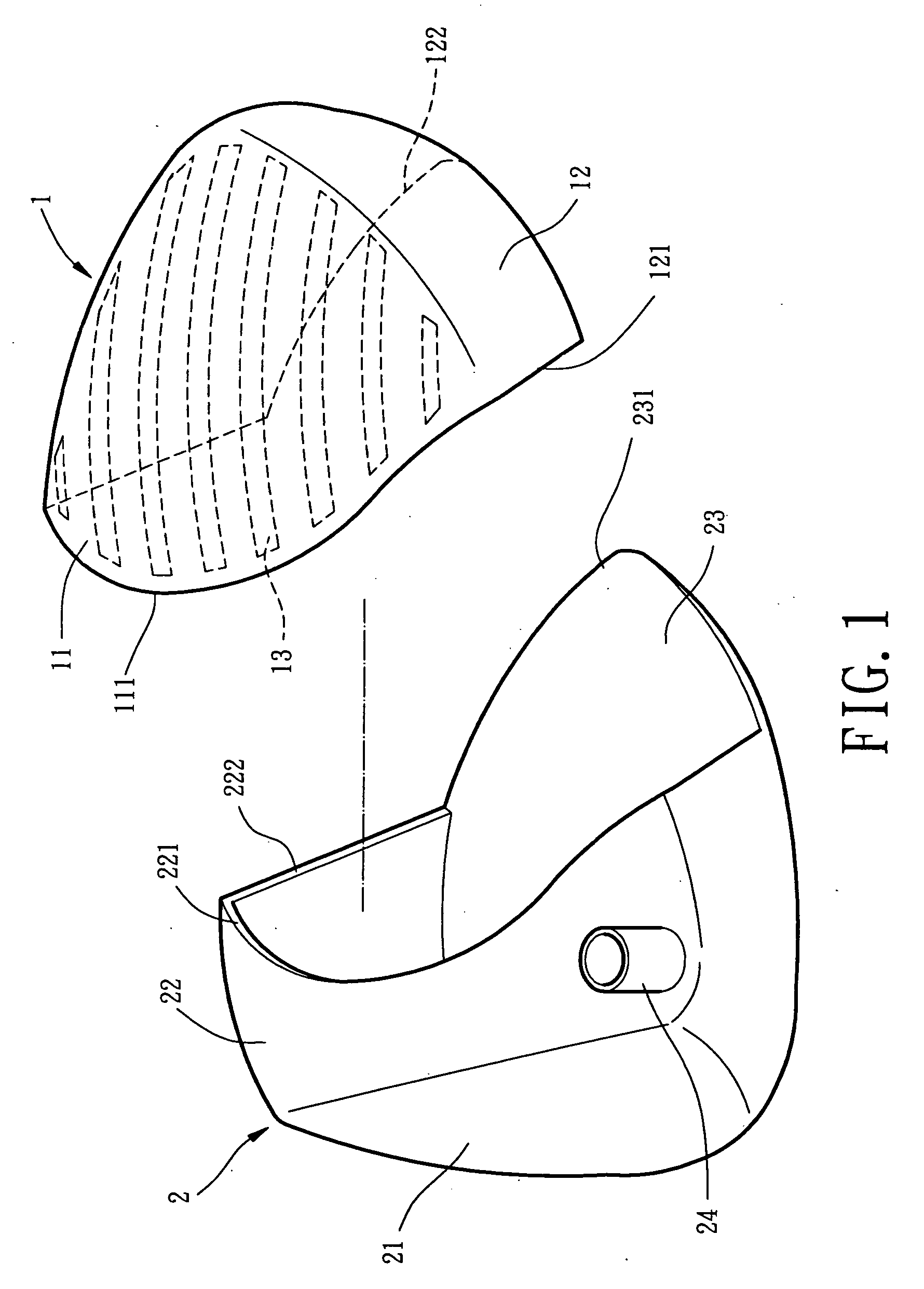

Weight-adjustable golf club head provided with rear lightweight covering

InactiveUS20080070721A1Thin thicknessLower center of gravityGolf clubsRacket sportsEngineeringGolf Ball

A weight-adjustable golf club head includes a rear lightweight covering and a golf club head body combined therewith. The rear lightweight covering has a rear crown portion and a rear wall portion extended therefrom. The golf club head body is combined with the rear lightweight covering which is designed to have a striking face, a front crown portion and a sole portion. The rear lightweight covering is made from a low specific gravity metal, and is designed to have a thickness less than 0.6 mm. The rear lightweight covering has an inner surface formed with a plurality of reinforcing ribs.

Owner:FUSHENG IND CO LTD

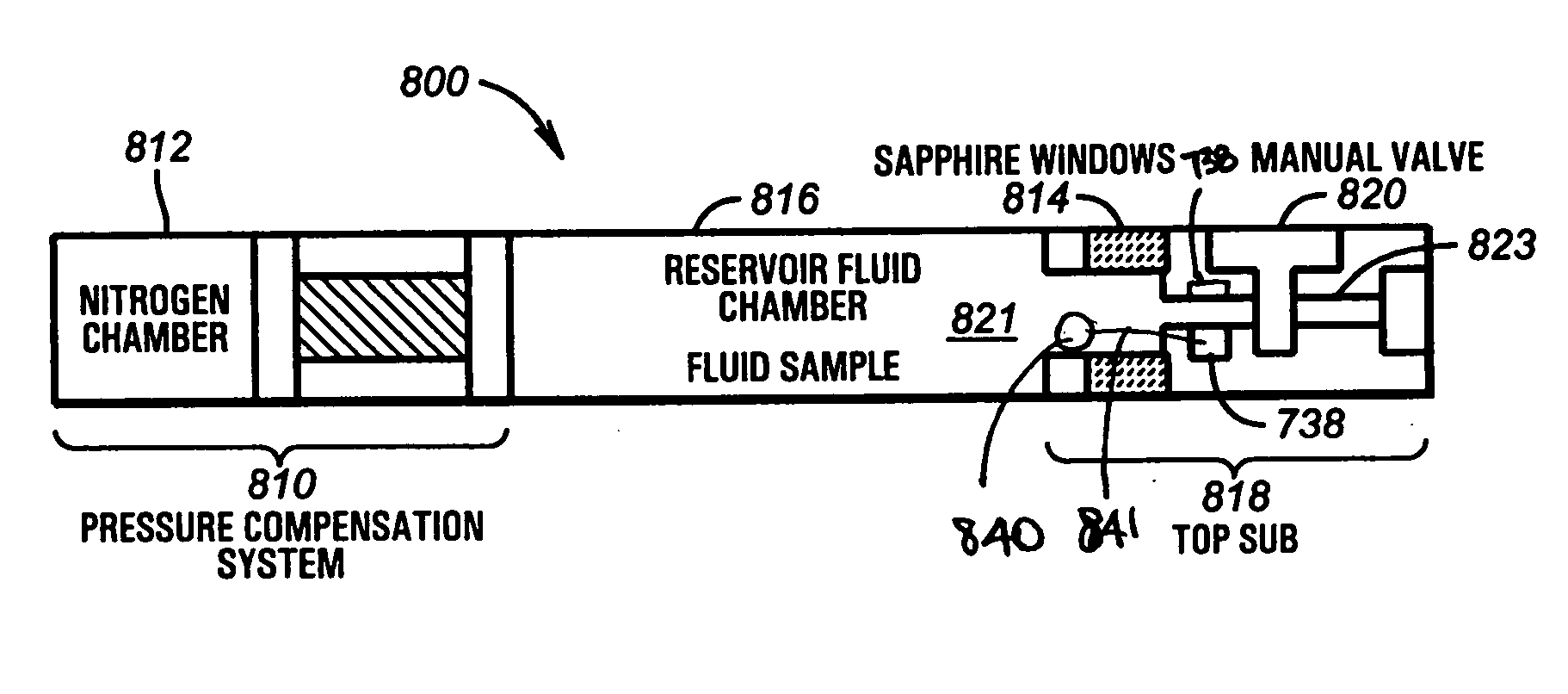

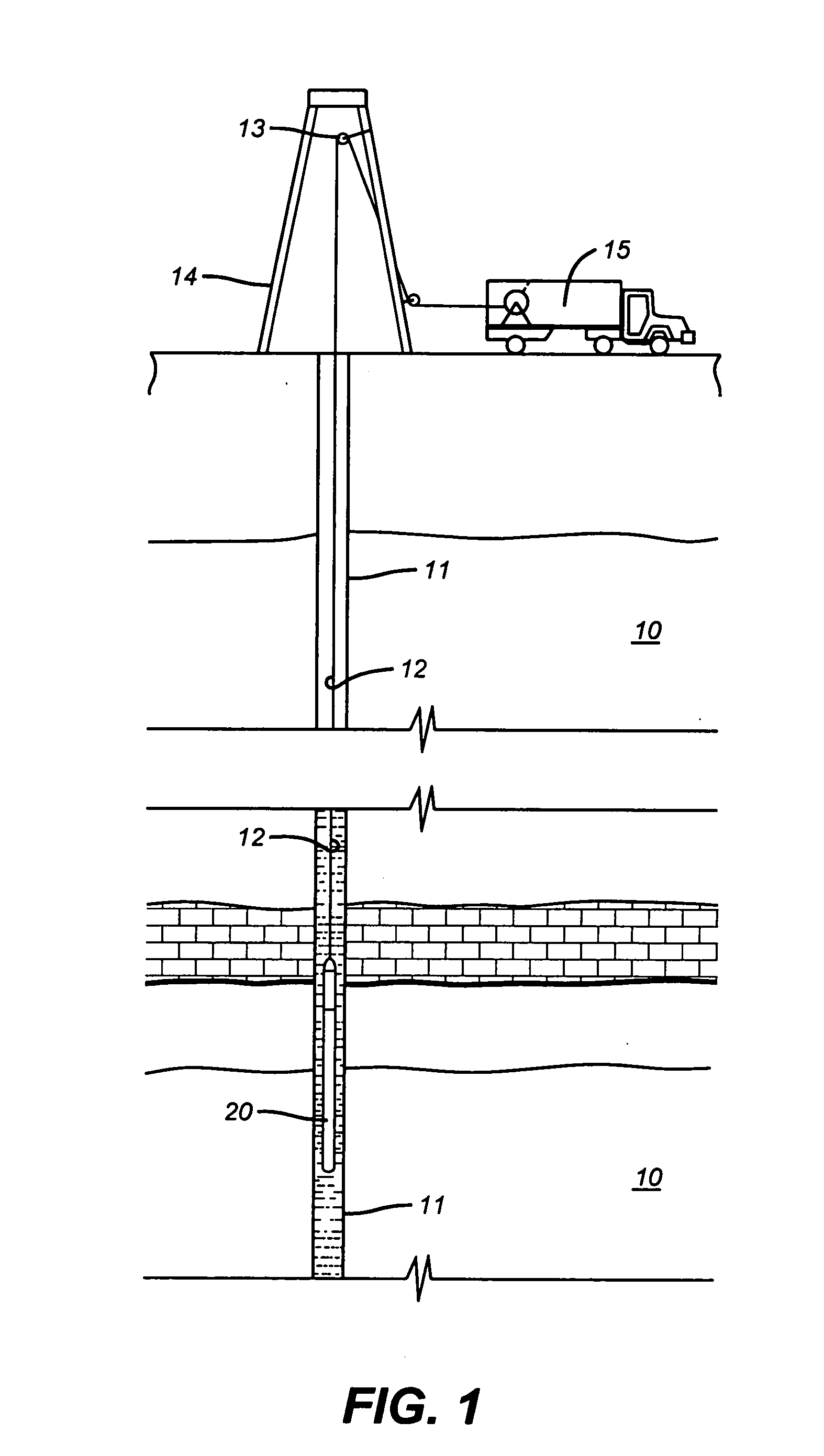

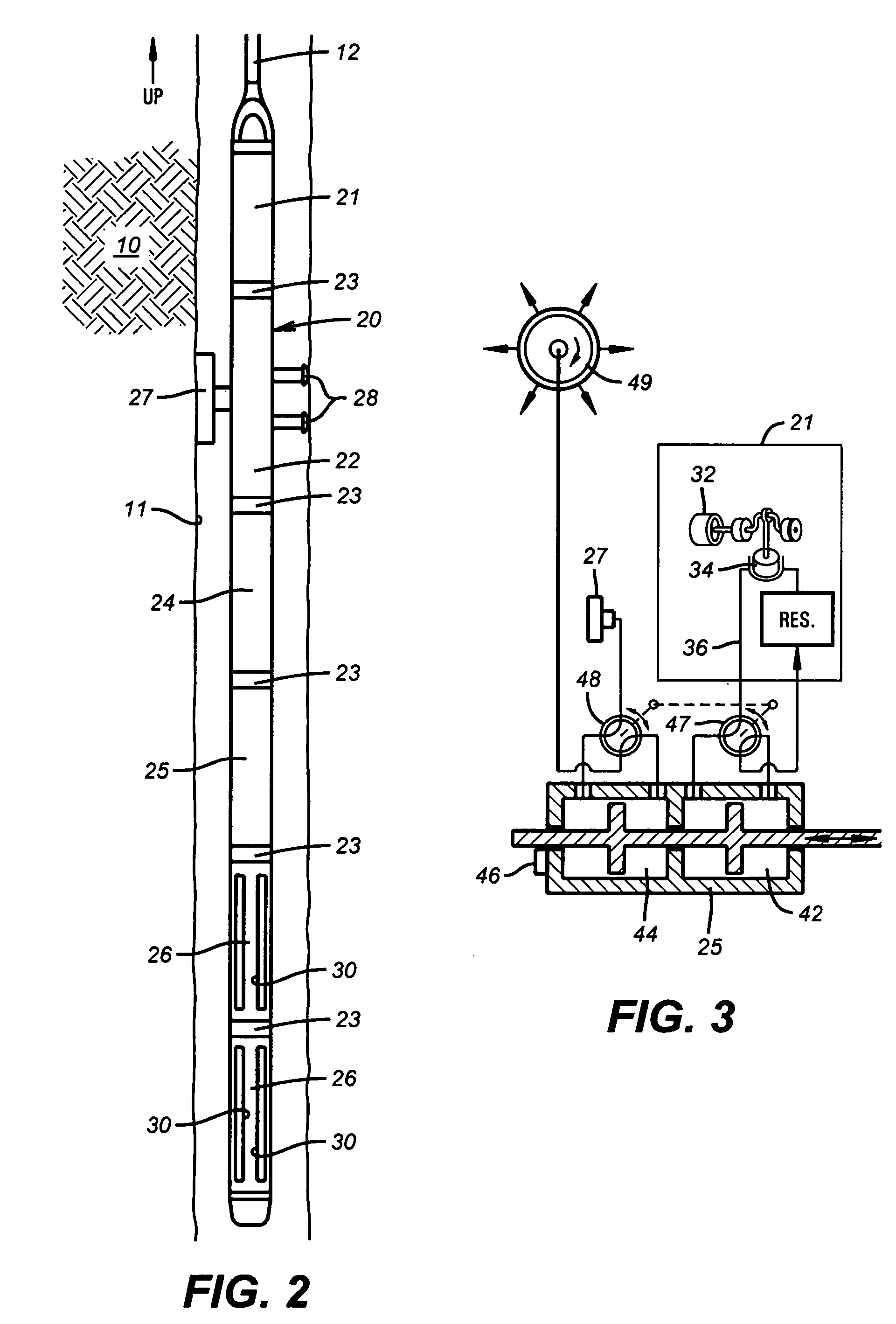

Method and apparatus for an advanced optical analyzer

ActiveUS20040218176A1Eliminate riskThe result is accurateRadiation pyrometrySpectrum investigationSmall sampleAPI gravity

The present invention provides a sample tank having a window for introduction of electromagnetic energy into the sample tank for analyzing a formation fluid sample down hole or at the surface without disturbing the sample. Near infrared, mid infrared and visible light analysis is performed on the sample to provide a downhole in situ or surface on site analysis of sample properties and contamination level. The onsite analysis comprises determination of gas oil ratio, API gravity and various other parameters which can be estimated by a trained neural network or chemometric equation. A flexural mechanical resonator is also provided to measure fluid density and viscosity from which additional parameters can be estimated by a trained neural network or chemometric equation. The sample tank is pressurized to obviate adverse pressure drop or other effects of diverting a small sample.

Owner:BAKER HUGHES INC

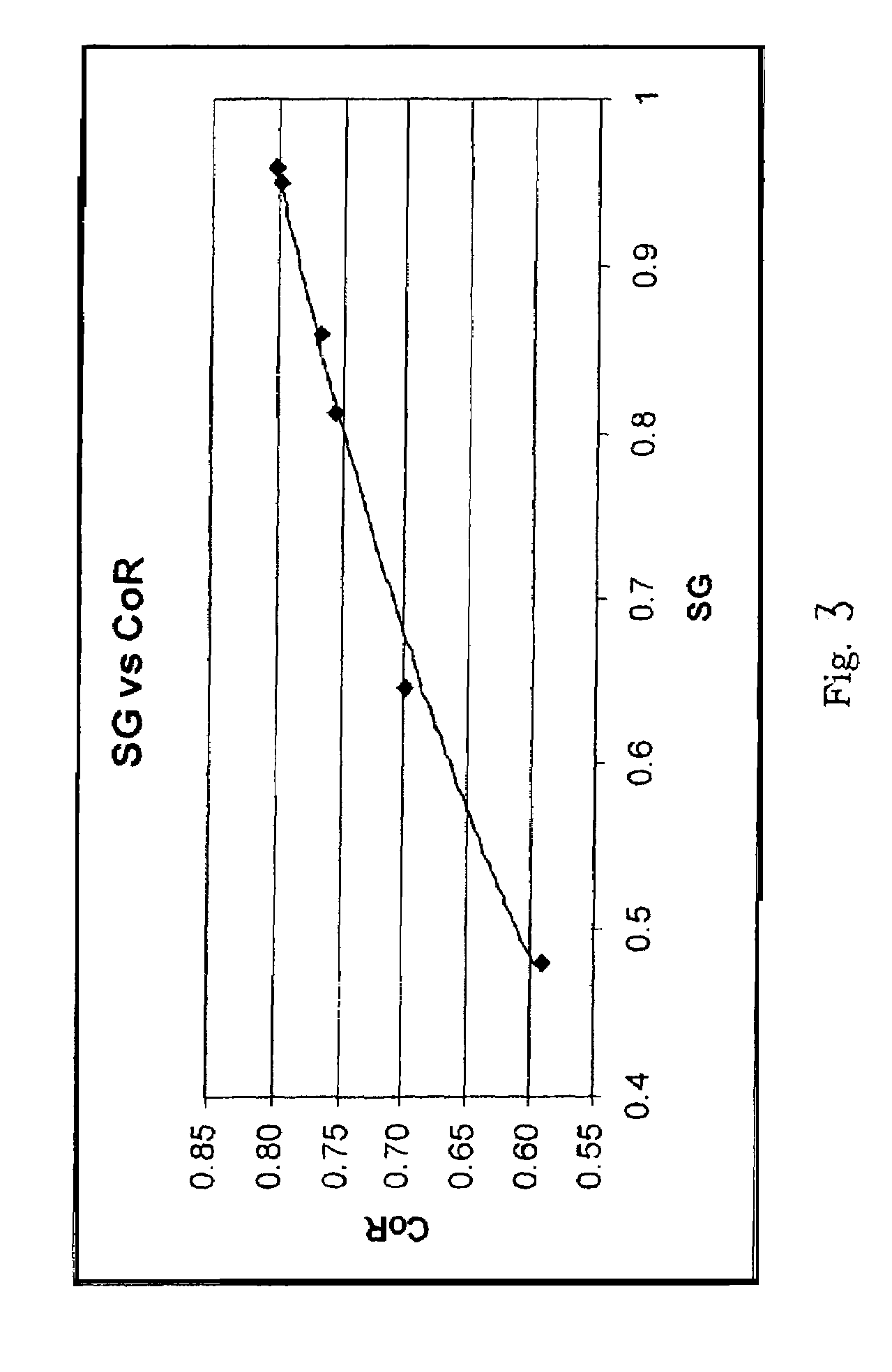

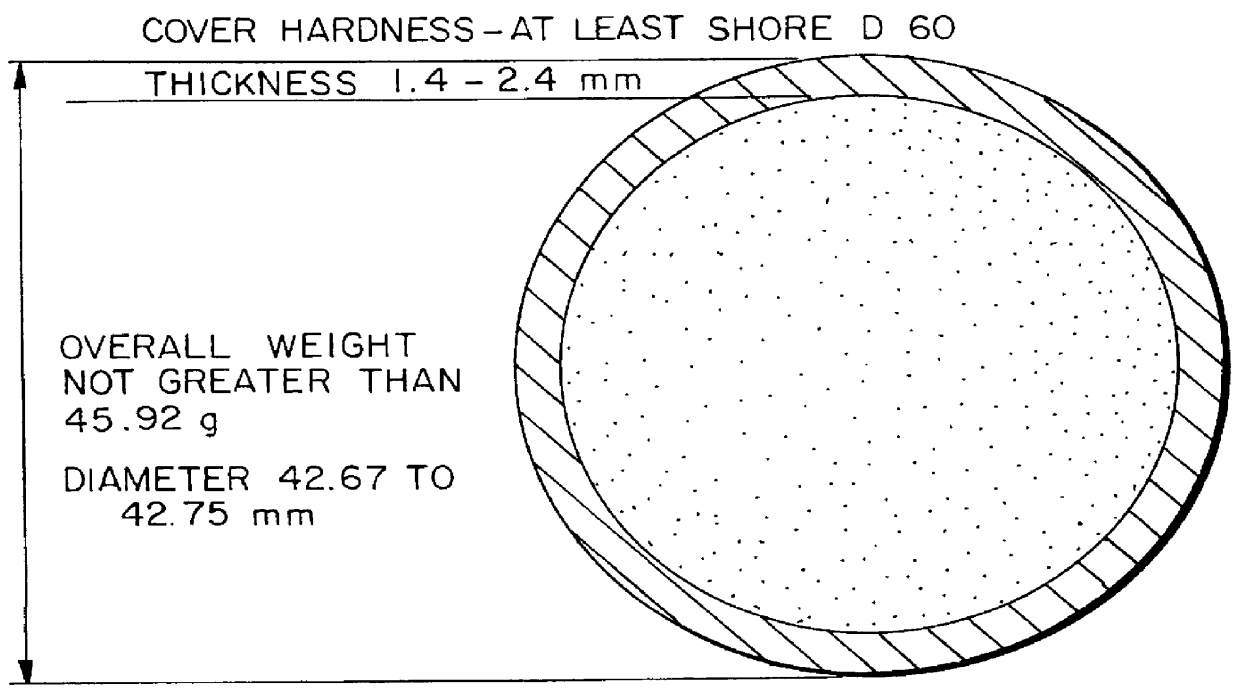

Foam-core golf balls

A golf ball with a controlled moment of inertia and controlled spin rate is disclosed. The ball has an intermediate layer positioned between the core and the cover and the intermediate layer has a reduced specific gravity. Preferably, this reduction is less than about 30% in specific gravity and the reduction in the coefficient of restitution is less than about 2%.

Owner:ACUSHNET CO

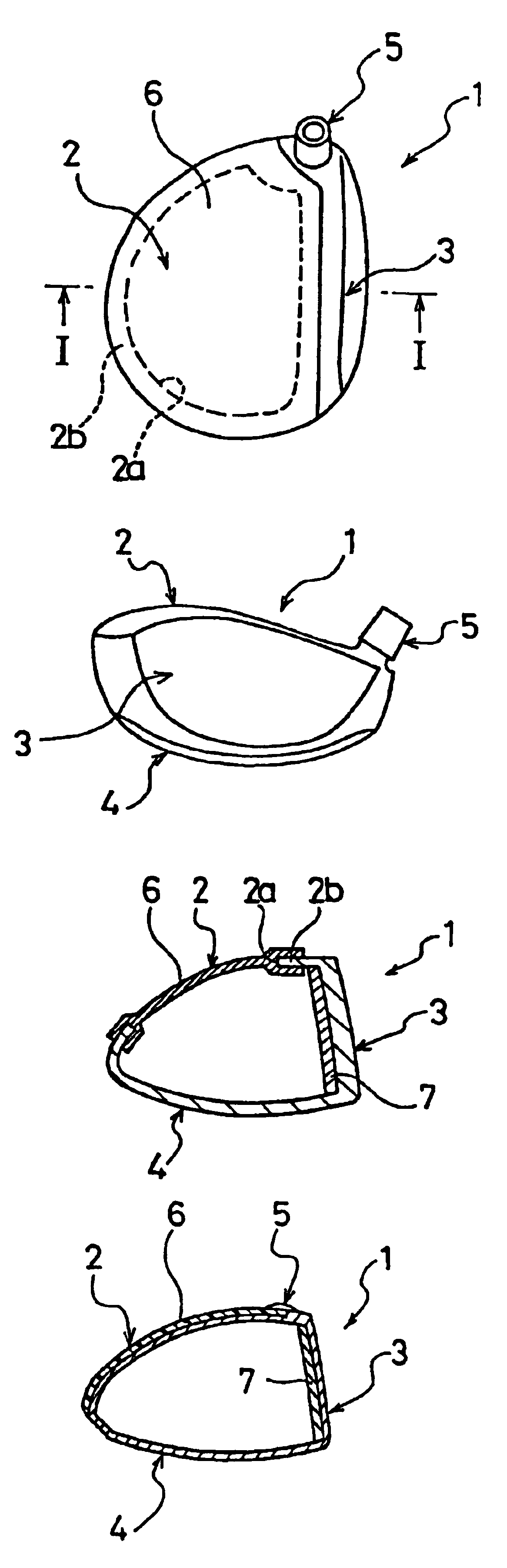

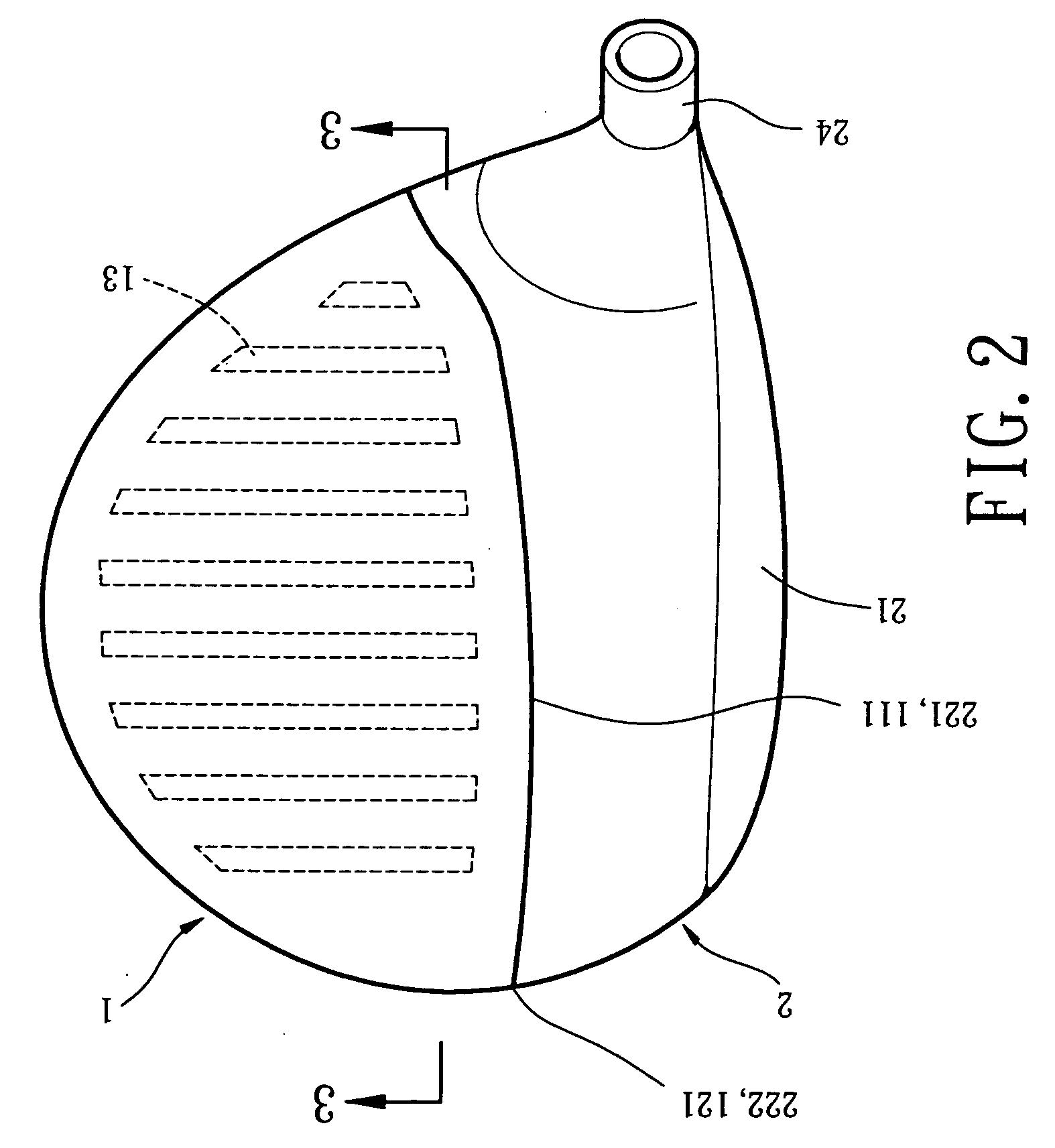

Hollow golf club head

InactiveUS7037214B2Sufficiently weight marginDegree of design is increasedGolf clubsRacket sportsEngineeringGolf Ball

A hollow golf club head allowing to increase the repulsion and the degree of design freedom, while maintaining the durability. A hollow golf club head having a head body formed from a metal, wherein a hole is formed in the vicinity of the middle of a crown portion in the head body, the hole is closed with a cover member made of a material different from the head body, and the ratio (ρm / ρf) of the specific gravity ρm of the head body and the specific gravity ρf of the cover member is set equal or superior to 1.3.

Owner:YOKOHAMA RUBBER CO LTD

Two-piece solid golf ball

Owner:BRIDGESTONE SPORTS

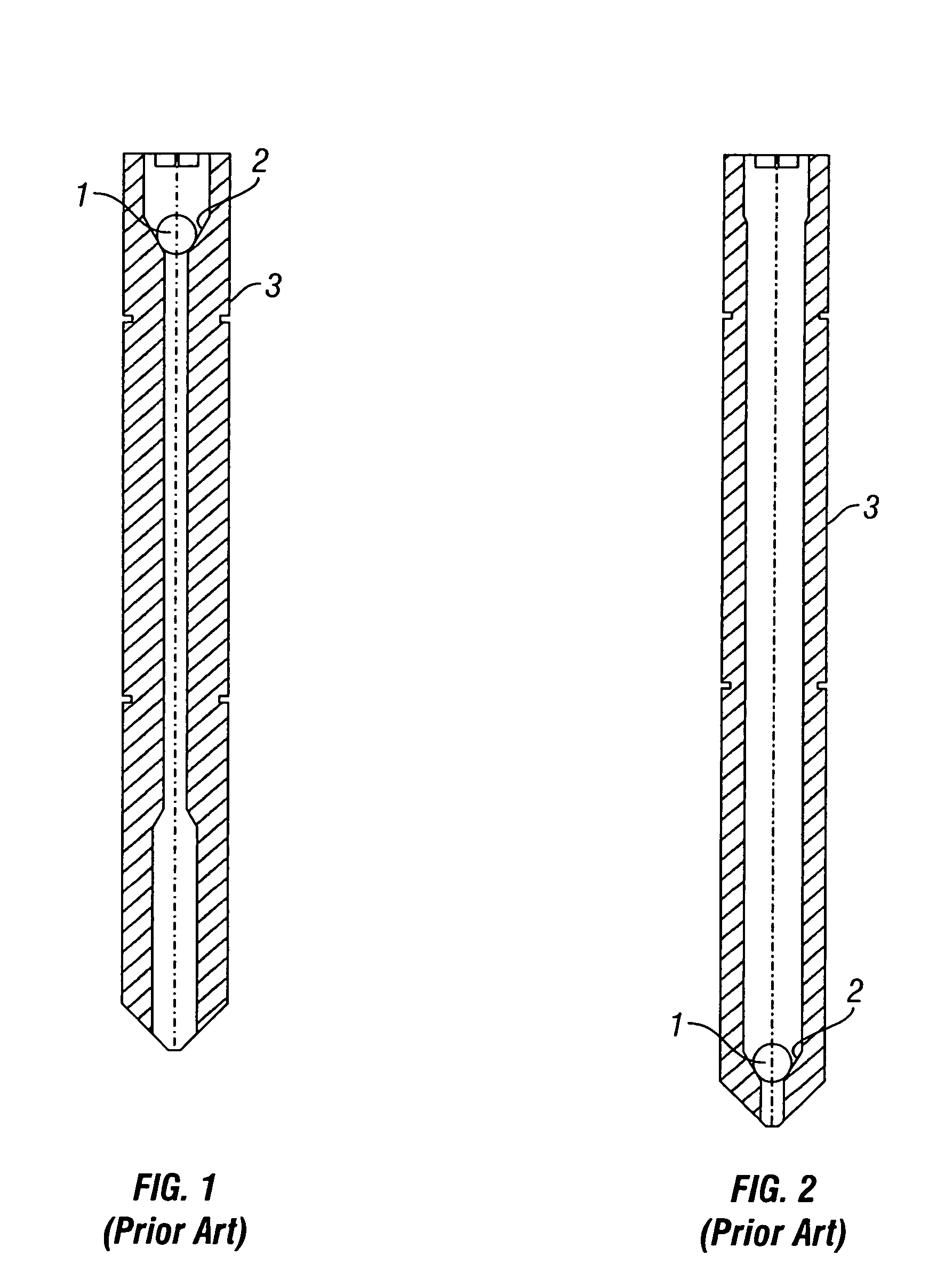

Gravity valve for a downhole tool

InactiveUS7163066B2Good removal effectEasy to disassembleOperating means/releasing devices for valvesConstructionsEngineeringMechanical engineering

A gravity valve for a downhole tool for use in a subterranean well and a method of use thereof. The gravity valve is adapted to control the flow of a dowuhole fluid through the downhole tool. The gravity valve typically includes a plunger and a seat. The plunger may embody a substantially non-spherical end that is adapted to mate with a complementary receiving end on the seat. The increase surface area of contact between the plunger and the seat acts to improve the seal therebetween, reduce the stresses thereon, and improve the performance of the gravity valve in general. The components of the gravity valve may be constructed of materials, which are selected based on the specific gravity of the materials in comparison with the specific gravity of the downhole fluid for a given application. A method of constructing and utilizing a gravity valve for a downhole tool.

Owner:BJ SERVICES CO

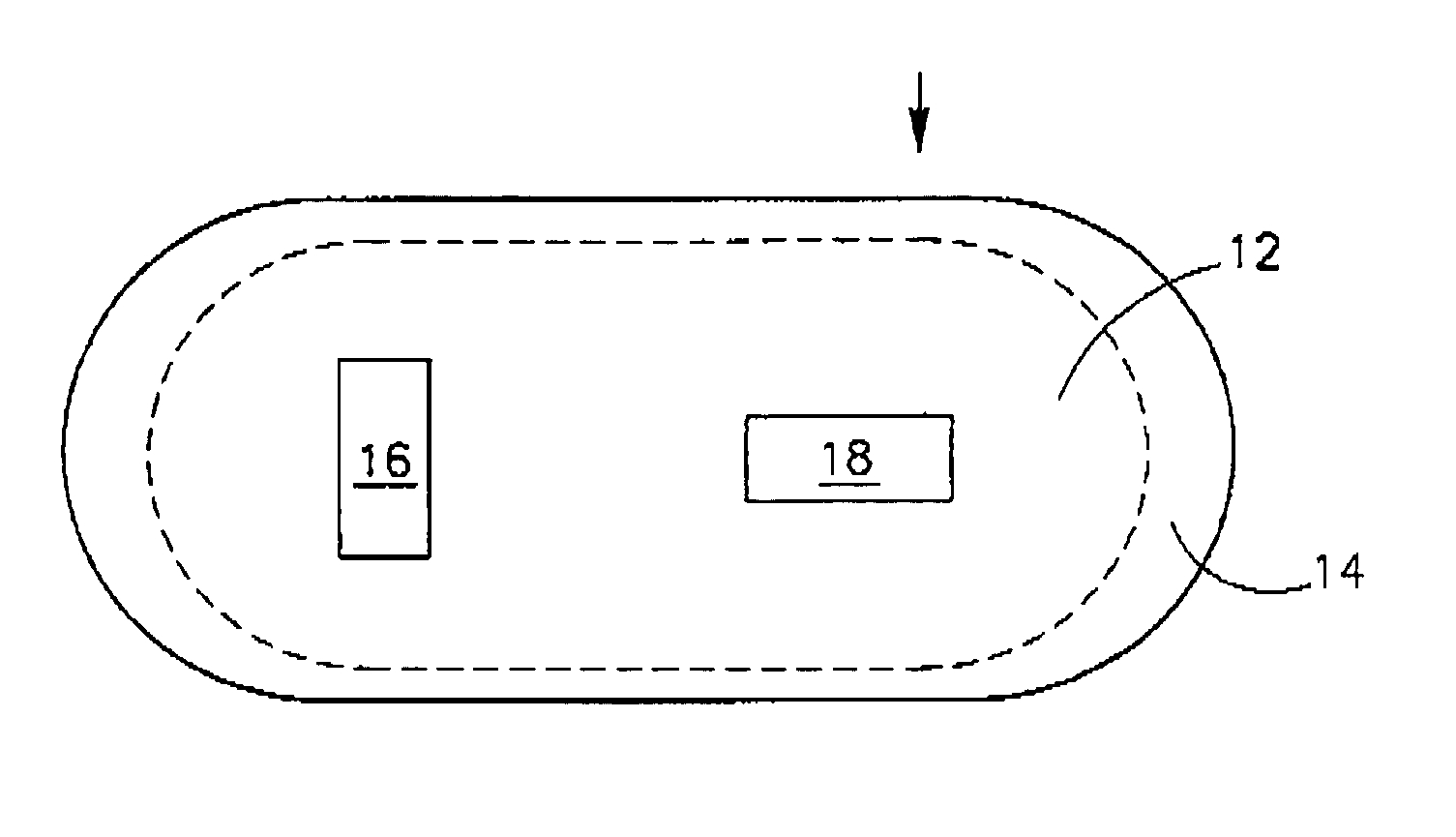

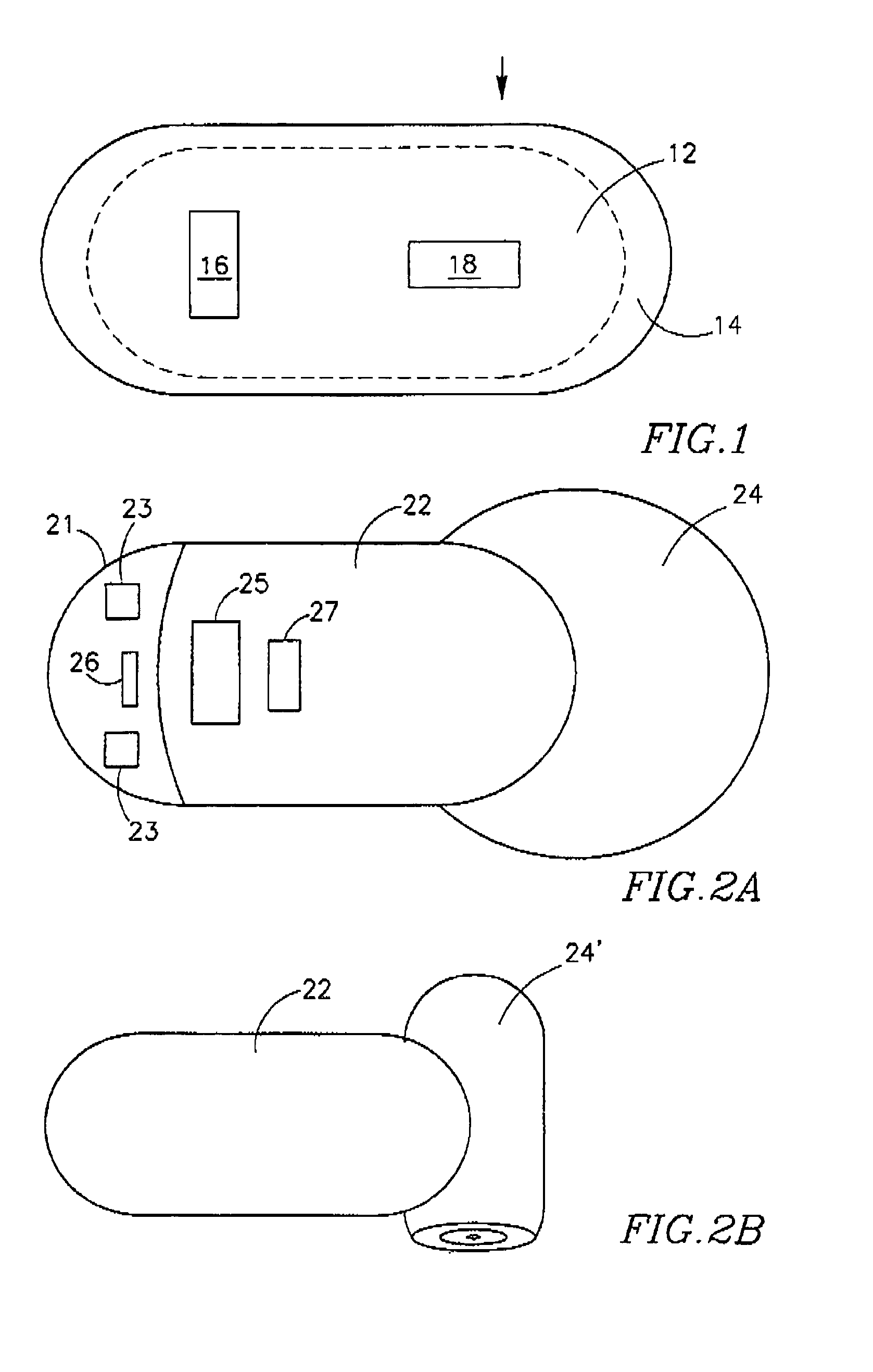

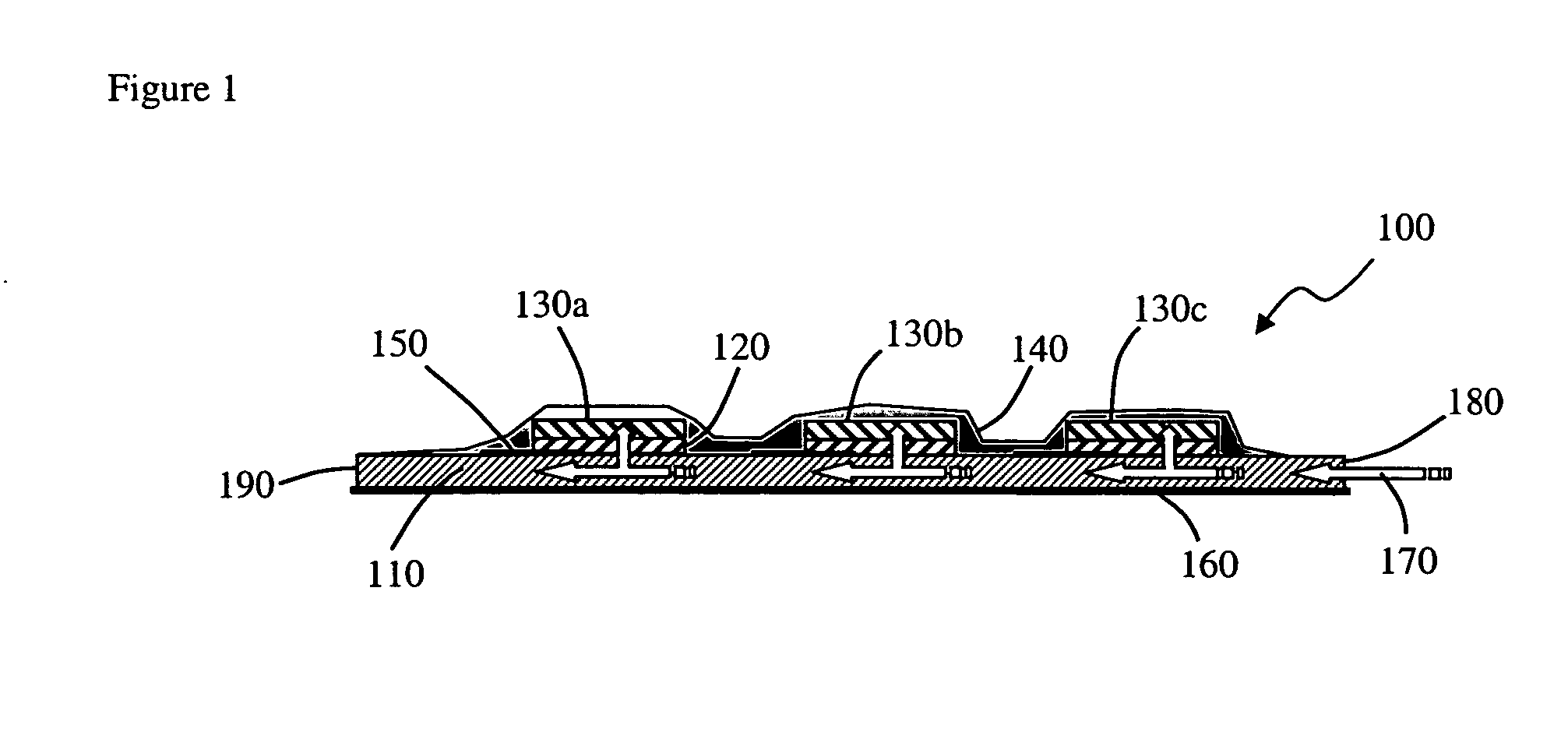

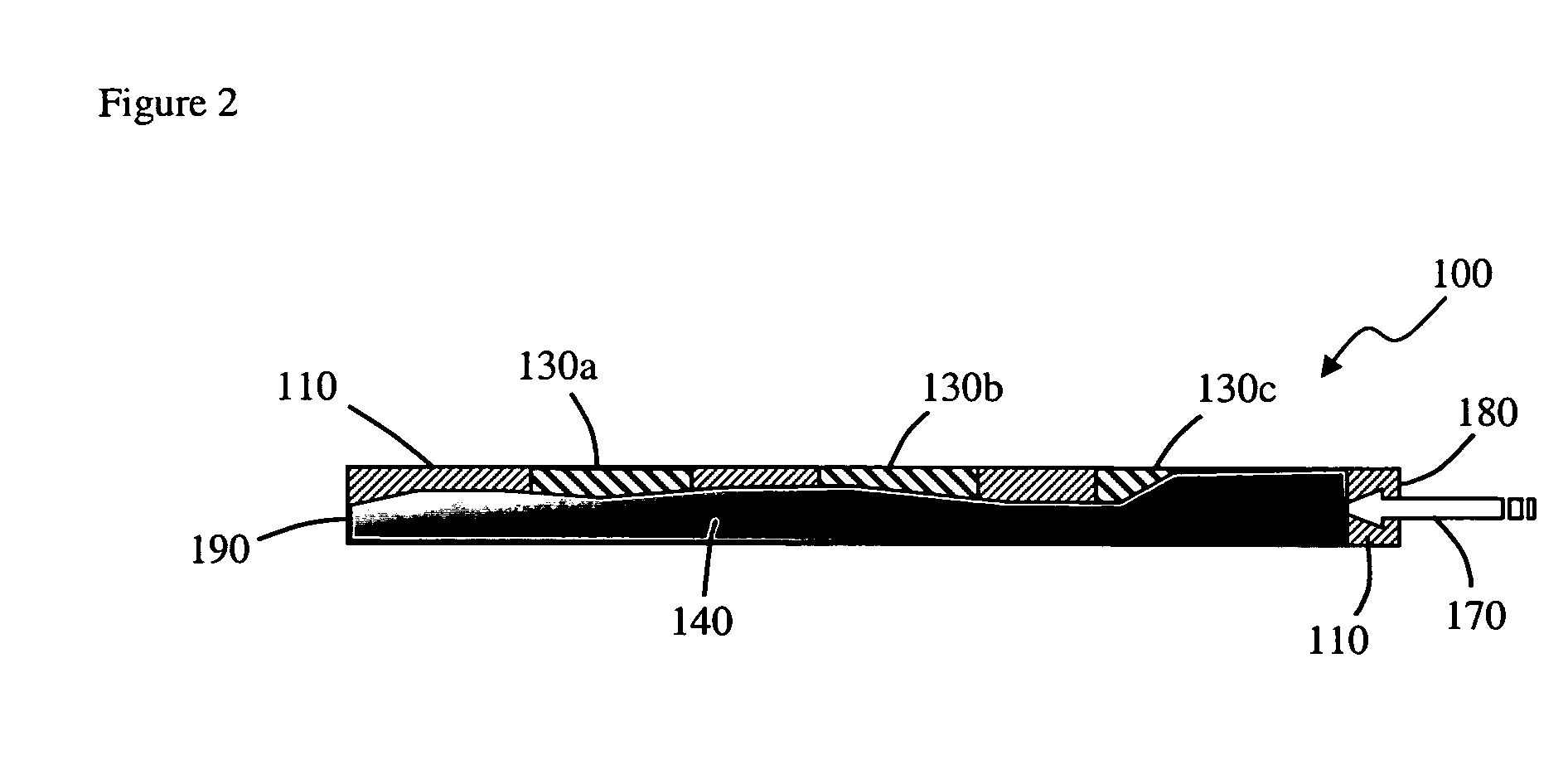

Floatable in vivo sensing device and method for use

The invention relates to an in vivo sensing device having a specific gravity of about 1 or a volume to weight ratio that enables it essentially to float. In one embodiment the in vivo sensing device consists of an image sensor system and a buoyant body. The buoyant body, which is attached to the sensor system or which can optionally house one or more elements of the sensor system, keeps the sensor system essentially floating in a body lumen liquid.

Owner:GIVEN IMAGING LTD

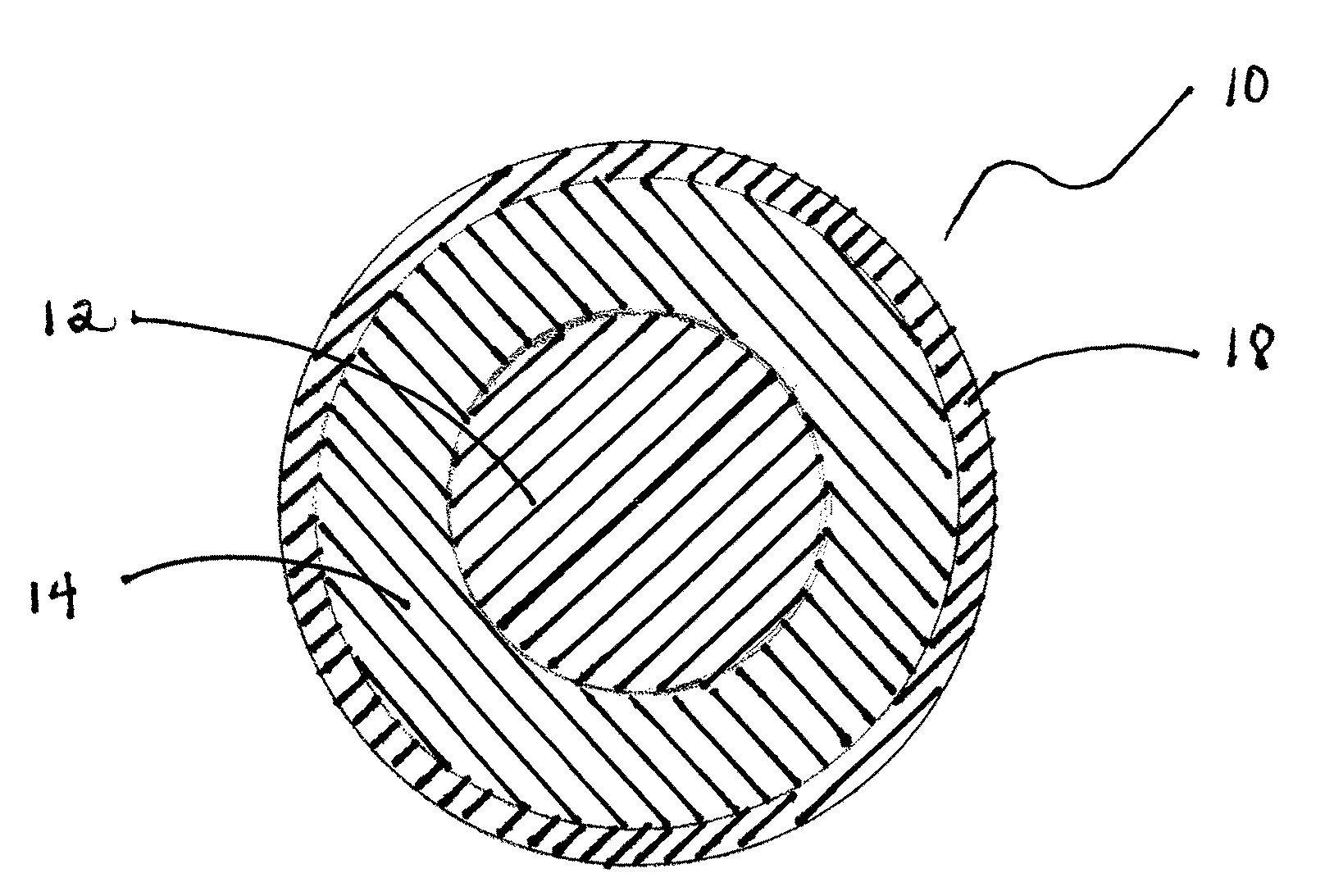

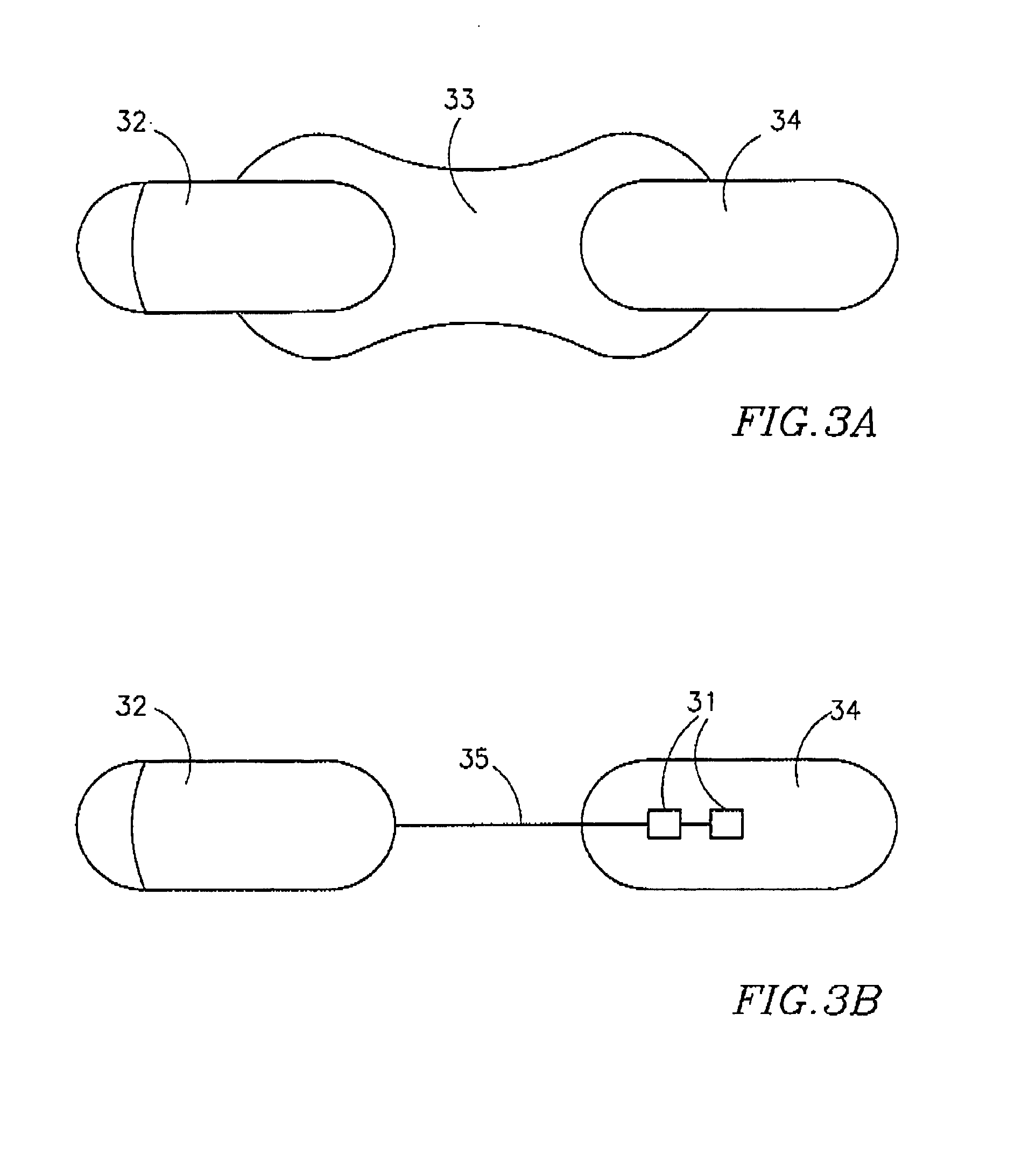

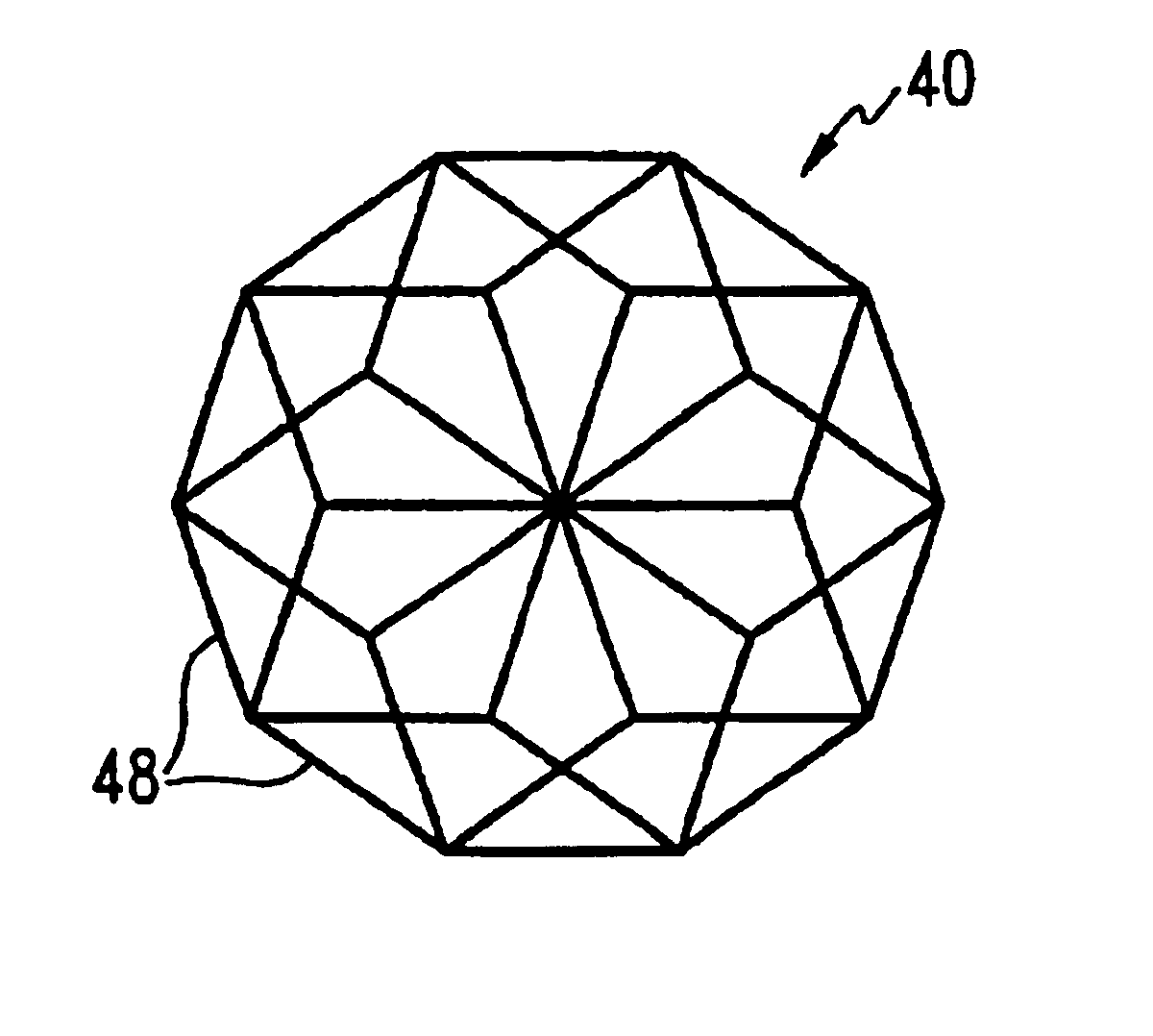

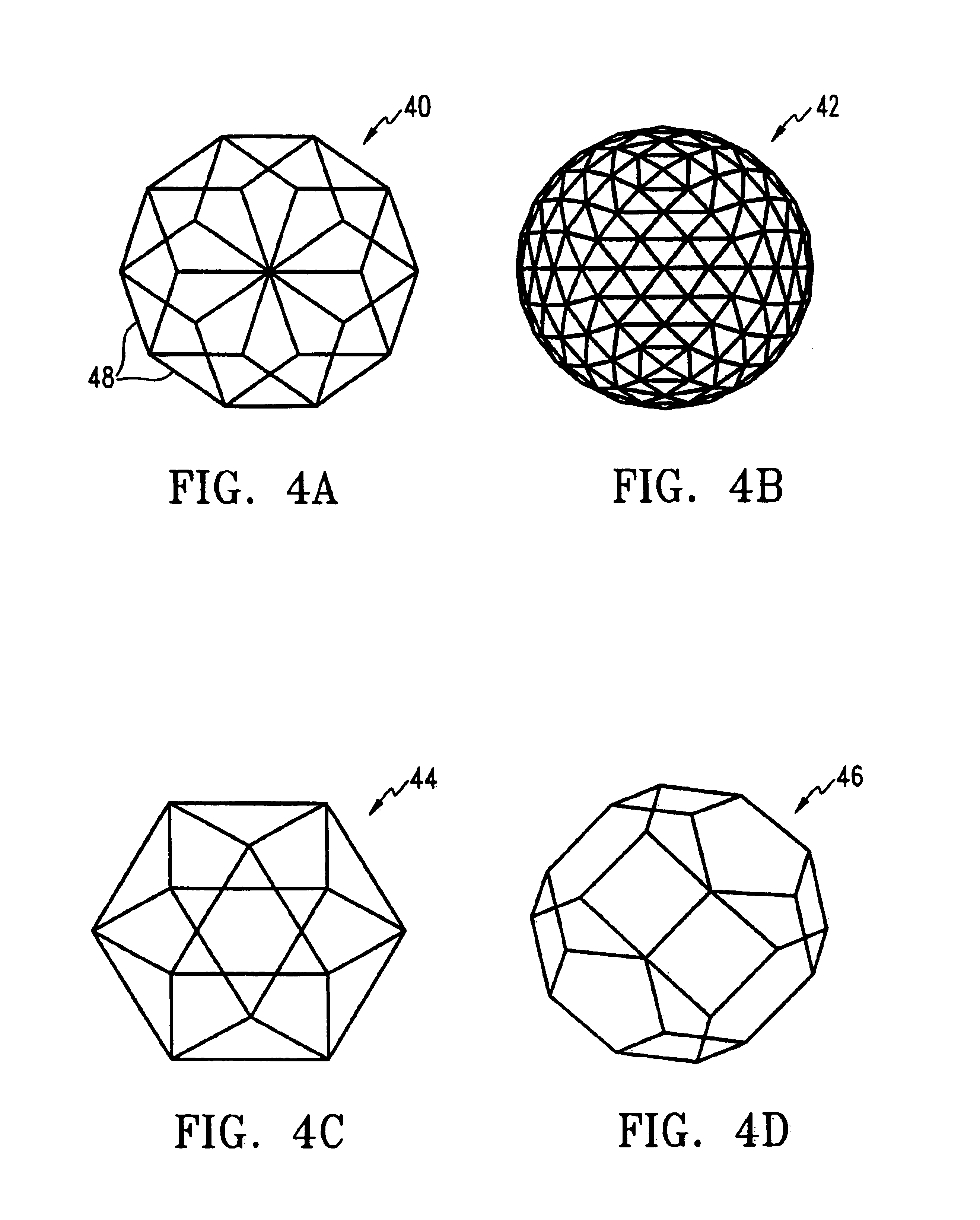

Golf ball having a high moment of inertia

InactiveUS6939249B2Reduced specific gravityLow specific gravityGolf ballsSolid ballsEngineeringMoment of inertia

A golf ball formed to have a low spin, high moment of inertia core assembly, which comprises a low specific gravity core and non-continuous high specific gravity intermediate layer. This core assembly is encased within a soft cover with Shore D hardness less than 65. The low specific gravity core is preferably made from a foamed polymer, and the non-continuous high specific gravity core is preferably a geodesic or polyhedron screen or a perforated shell.

Owner:ACUSHNET CO

Production of liquid center filled confections

InactiveUS20050260329A1Reduce the amount requiredLow viscosityMeat/fish preservationConfectioneryEngineeringSignificant difference

Liquid center filled confections, such as gummy or jelly candies or fruit snacks are continuously produced by co-deposition into a mold without candy tailing to obtain products with substantially uniform top and bottom walls and little, if any, shell breakage and liquid filling leakage or bleed-out problems. Excessive vertical decentering of the filling caused by substantial differences in specific gravity between the liquid filling component and the shell component and its accompanying production of thin or weak shell walls is substantially reduced or eliminated. A non-gellable liquid filling is deposited vertically off-center within a gellable shell, and the amount of sinking or floating is controlled so as to achieve an at least substantially centered product. The filling migration is limited by rapidly cooling the shell component below its gelling or setting temperature by use of a much colder filling component which itself does not gel or set at low temperatures.

Owner:WM WRIGLEY JR CO

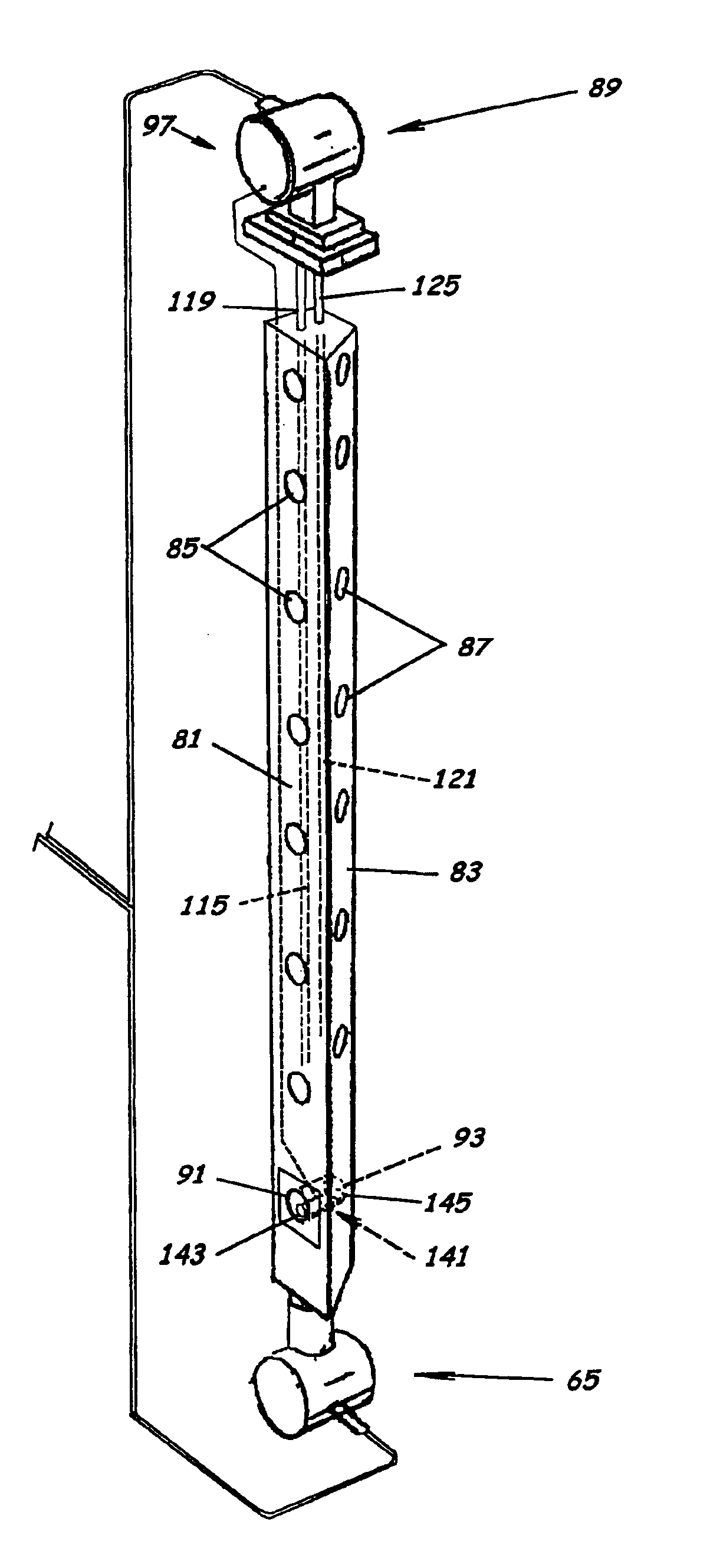

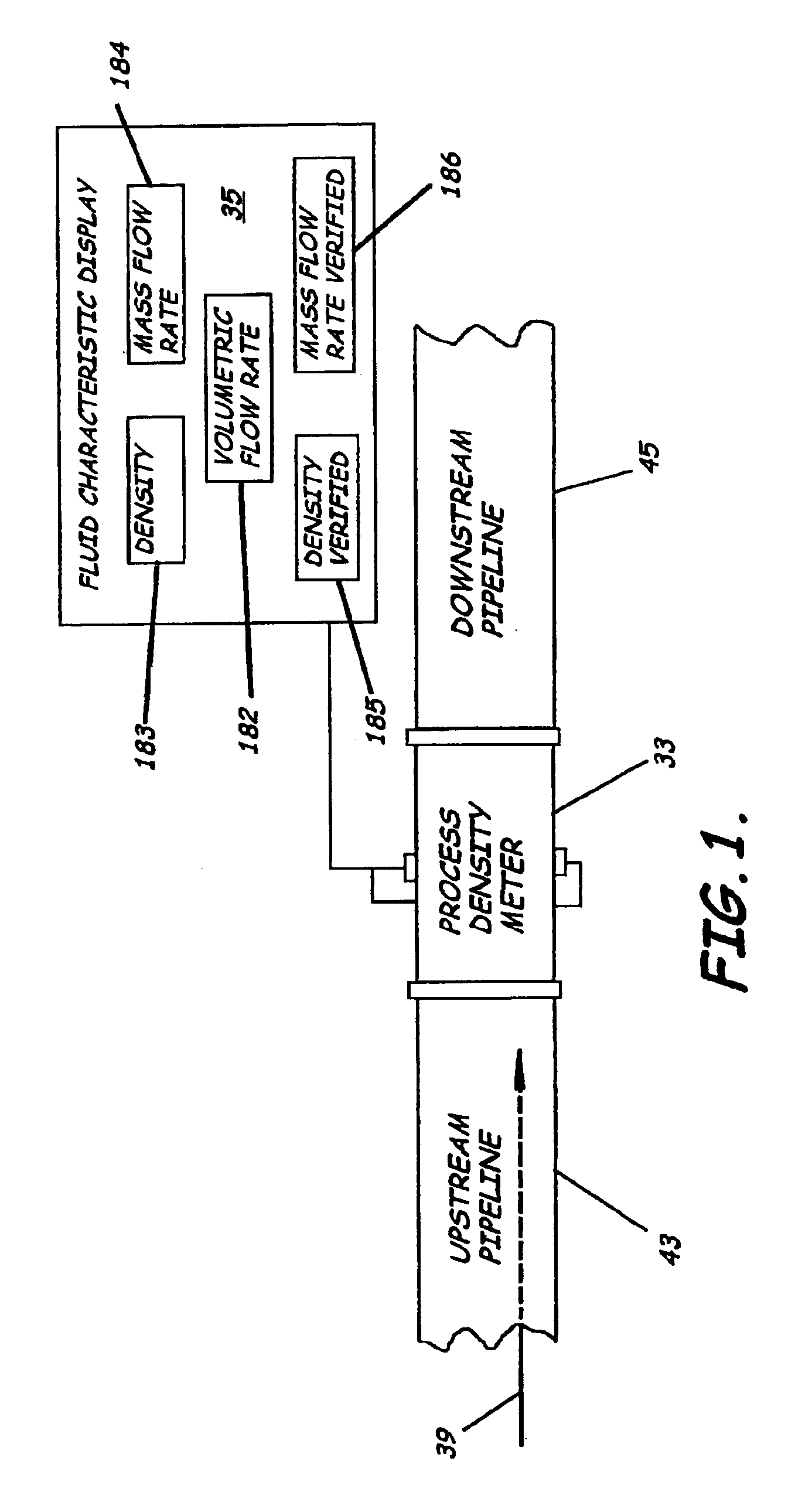

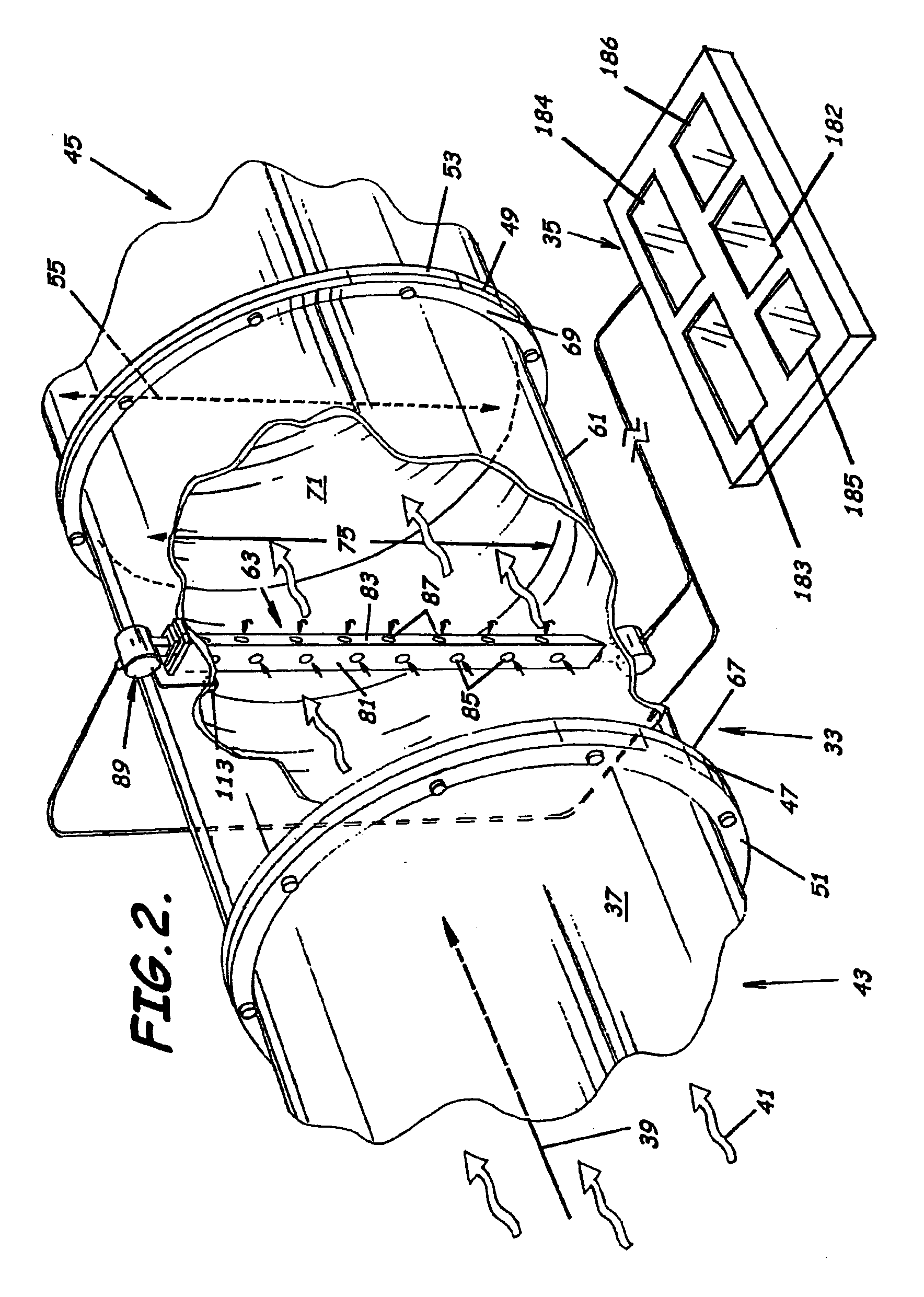

System to measure density, specific gravity, and flow rate of fluids, meter, and related methods

ActiveUS6957586B2Little maintenanceMinimization needsVolume/mass flow by thermal effectsSpecific gravity using flow propertiesDifferential pressureDisplay device

A system to measure fluid flow characteristics in a pipeline, meter, and methods includes a pipeline having a passageway to transport flowing fluid therethrough, a process density meter including at least portions thereof positioned within the pipeline to provide flowing fluid characteristics including volumetric flow rate, fluid density, and mass flow rate of the flowing fluid, and a fluid characteristic display to display the fluid characteristics. The process density meter includes a vortex-shedding body positioned within the pipeline to form vortices and a vortex meter having a vortex frequency sensor to measure the frequency of the vortices and to determine the volumetric flow rate. The process density meter further includes a differential pressure meter positioned adjacent the vortex-shedding body to produce a differential pressure meter flow rate signal indicative of the density of fluid when flowing through the pipeline. The process density meter also includes a thermal flow meter positioned adjacent the vortex-shedding body to produce a mass flow rate signal indicative of the mass flow rate of fluid when flowing through the pipeline. The process density meter produces an output of a volumetric flow rate, a flowing fluid density, and a mass flow rate to be displayed by the fluid characteristic display.

Owner:SAUDI ARABIAN OIL CO

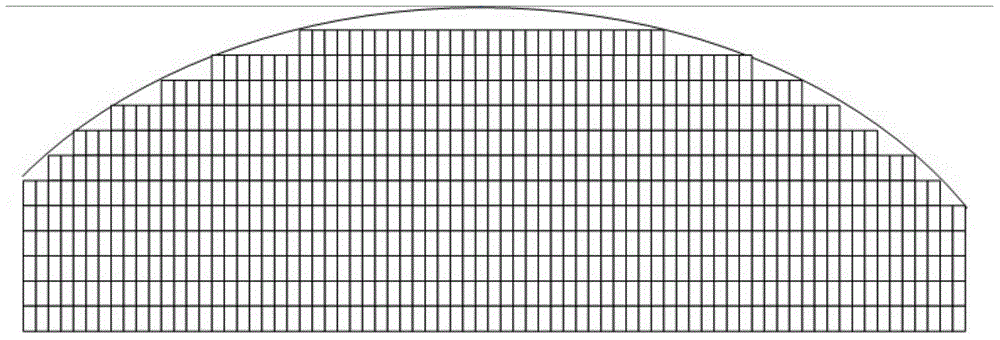

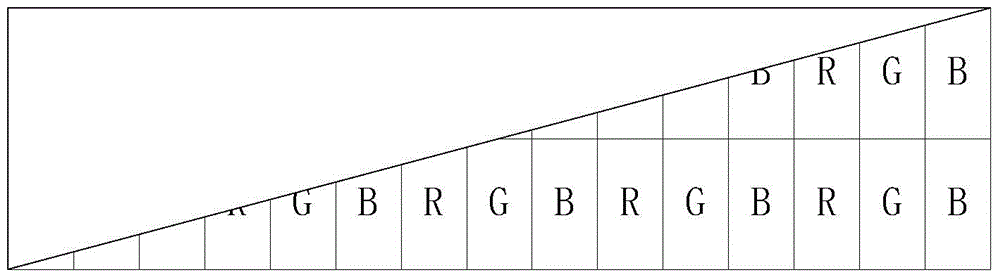

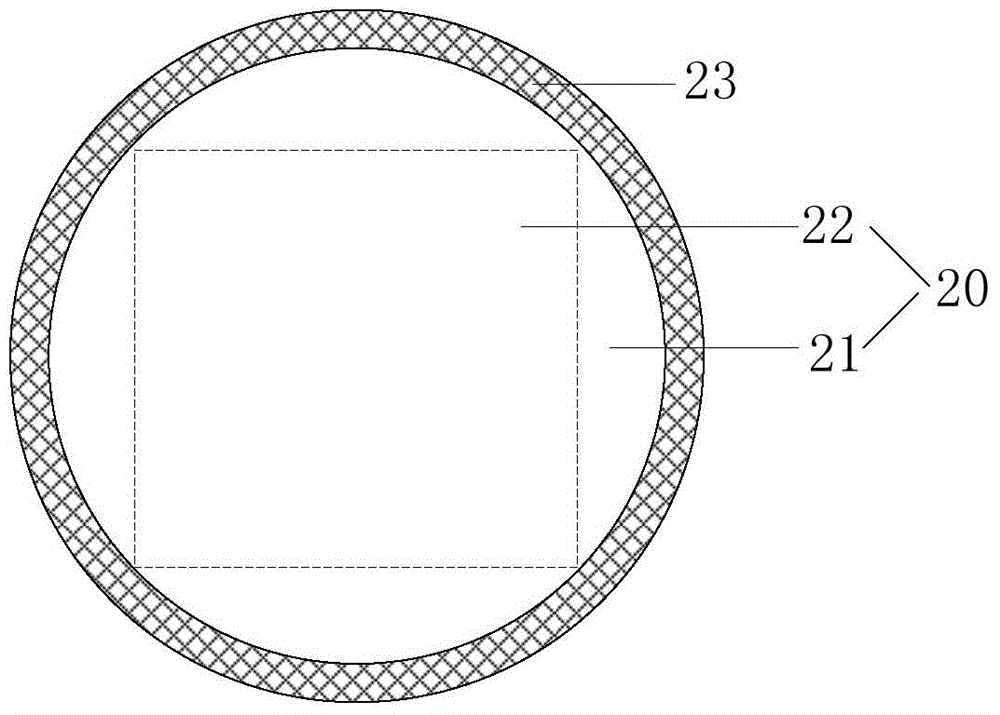

Color filter substrate and display device

The invention relates to the technical field of display, in particular to a color filter substrate and a display device. The color filter substrate comprises a non-rectangular display area and a non-display area surrounding the display area; the display area comprises an edge display area near the non-display area; the edge display area comprises a black matrix and a plurality of first sub-pixels, a plurality of second sub-pixels and a plurality of third sub-pixels, wherein the first sub-pixels, the second sub-pixels and the third sub-pixels are defined by the black matrix; the total that light transmission area corresponding to the first sub-pixels accounts for the area proportion value of the sub-pixels is P1; the total that light transmission area corresponding to the second sub-pixels accounts for the area proportion value of the sub-pixels is P2; the total that light transmission area corresponding to the third sub-pixels accounts for the area proportion value of the sub-pixels is P3; the difference value between the maximum value and the minimum value of P1, P2 and P3 is 0.3 time less than the average value of P1, P2 and P3; P1, P2 and P3 are all positive numbers greater than 0. According to the color filter substrate, the continuity of display information is increased; moreover, the proportions of the various sub-pixels blocked are approximately equal, and the visual effect of the display device is enhanced.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

Compositions containing oils having a specific gravity higher than the specific gravity of water

InactiveUS20050037087A1Increase the proportionAntibacterial agentsCosmetic preparationsMicroparticleBULK ACTIVE INGREDIENT

The invention relates to pharmaceutical or cosmetic compositions preferably in the form of microcapsules or microparticles which include at least one active ingredient and an oil or a mixture of oils wherein the oil or mixture of oils alone or in combination with the active ingredient have a specific gravity higher than the specific gravity of water. The invention further relates to a process for preparing said compositions.

Owner:SOL GEL TECH

Quick disintegrating tablet in buccal cavity and manufacturing method thereof

InactiveUS6656492B2Good effectDisintegrates quicklyPowder deliveryLiquid surface applicatorsHigh concentrationLow speed

The present invention pertains to a quick disintegrating tablet in buccal cavity, characterized in that drug-containing particles with a mean particle diameter of approximately 50~approximately 250 mum and an apparent specific gravity of approximately 0.5~approximately 1.2 consisting of a bitter tasting drug and / or drug of inferior fluidity and a pharmaceutical preparation carrier and obtained by spray drying are added to a quick disintegrating tablet in buccal cavity comprising a drug and saccharide. Moreover, the present invention pertains to a method for manufacturing drug-containing particles having a specific mean particle diameter and specific apparent gravity by dissolving and suspending a bitter tasting drug and / or drug of inferior fluidity and a pharmaceutical preparation carrier (preferably containing water-insoluble polymer, particularly at least aqueous ethyl cellulose suspension (preferably containing plasticizer)) to a high concentration in terms of solid concentration in a solvent that is pharmaceutically acceptable and then spray drying this liquid using a rotating disk-type spray dryer, with the disk operating at low speed, and a method for manufacturing a quick disintegrating tablet in buccal cavity comprising said particles.

Owner:ASTELLAS PHARMA INC

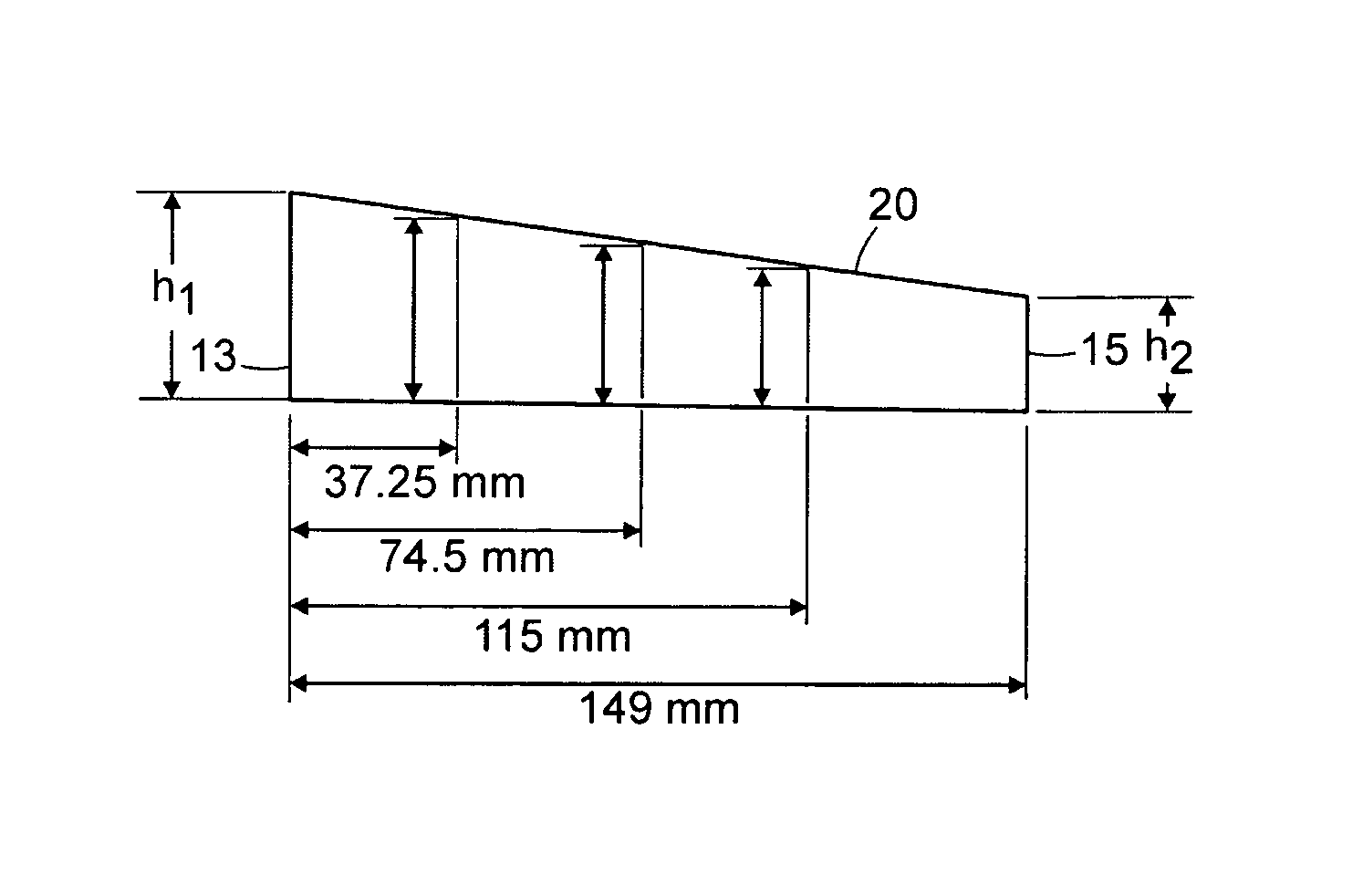

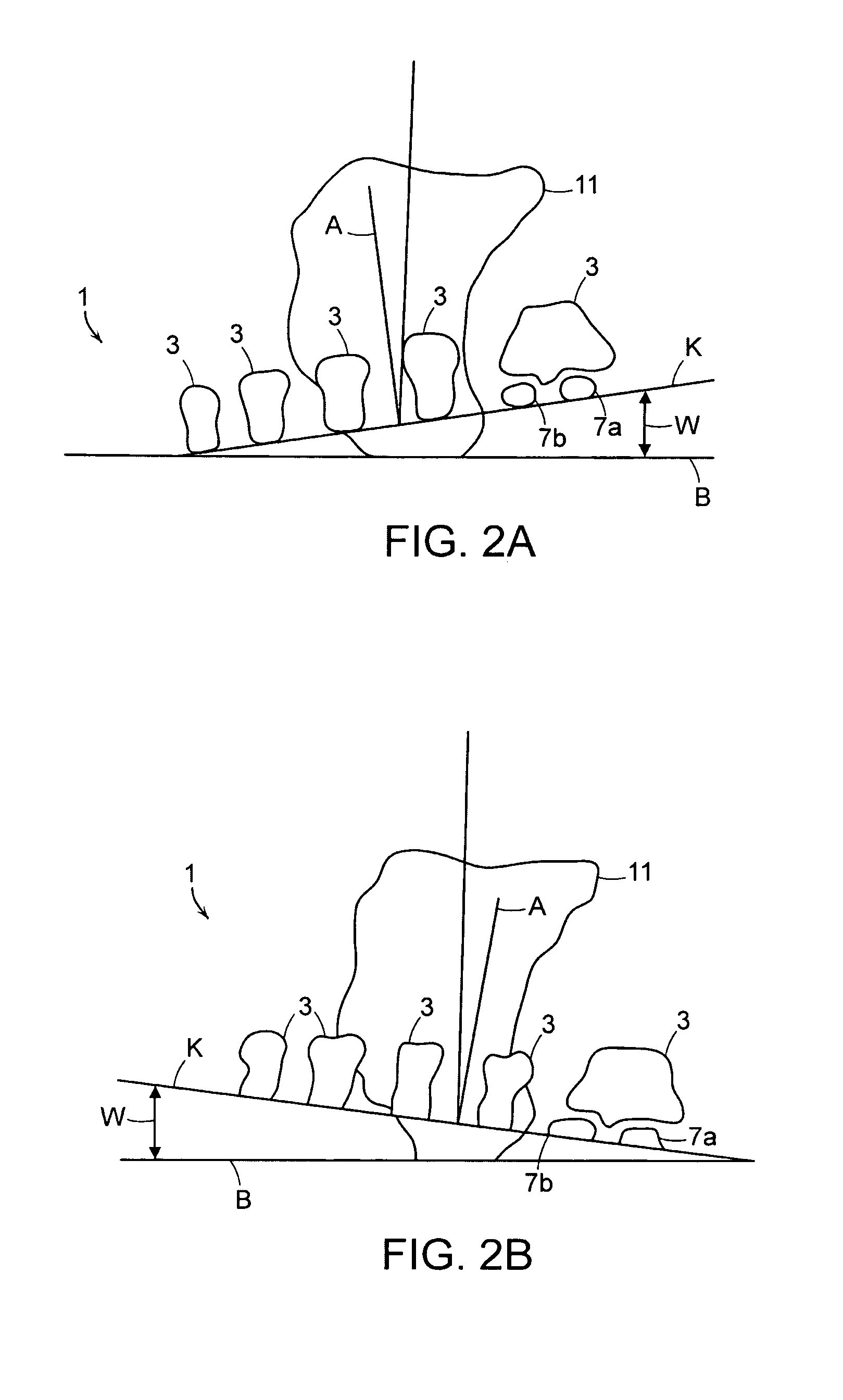

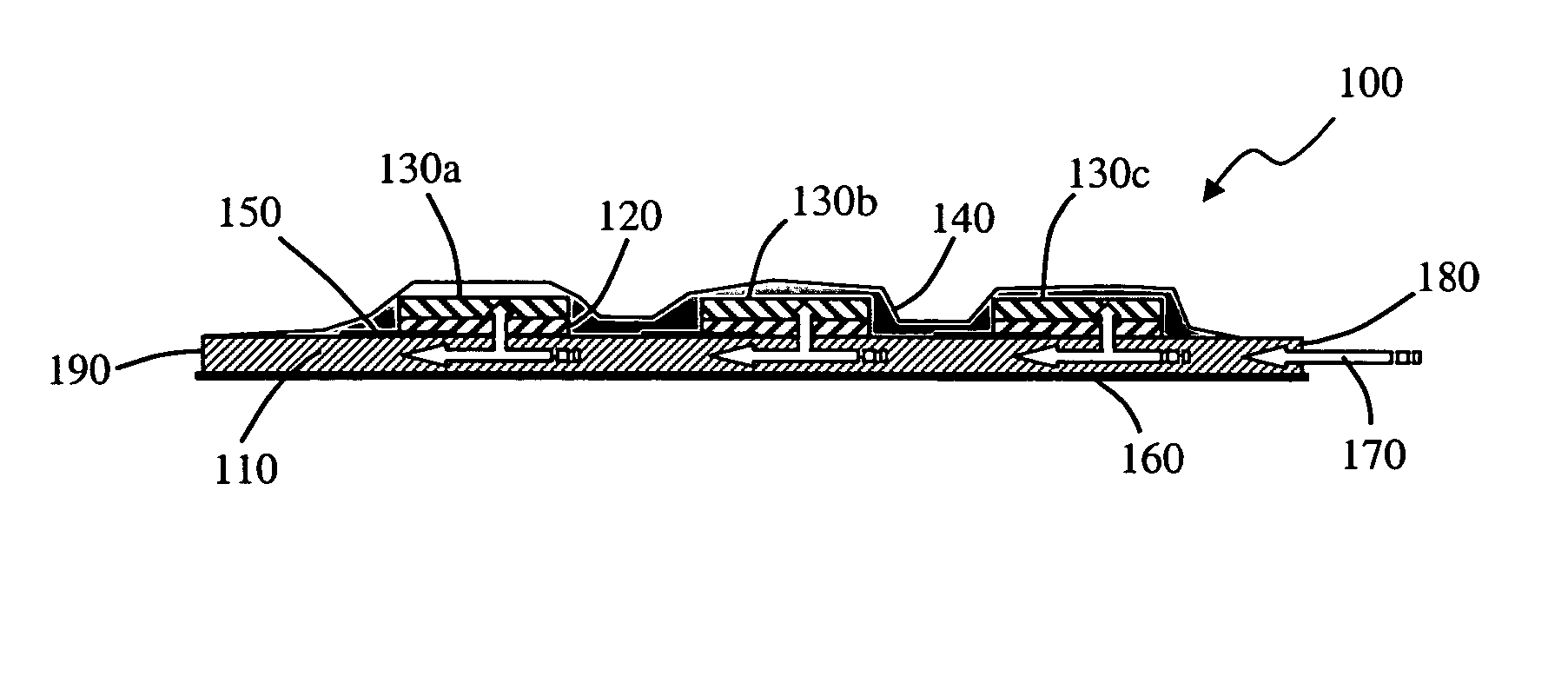

Sole elements of varying density and methods of manufacture

The invention relates to sole elements and methods for manufacturing sole elements for shoes, in particular for sport shoes, with a specific density distribution in a transverse and / or longitudinal direction. The methods include the steps of manufacturing a sole element preform from a polymer material with a thickness varying in the transverse and / or longitudinal direction depending on the desired density distribution and the press-forming of the sole element preform in a forming tool to form the finished sole element from the sole element preform.

Owner:ADIDAS

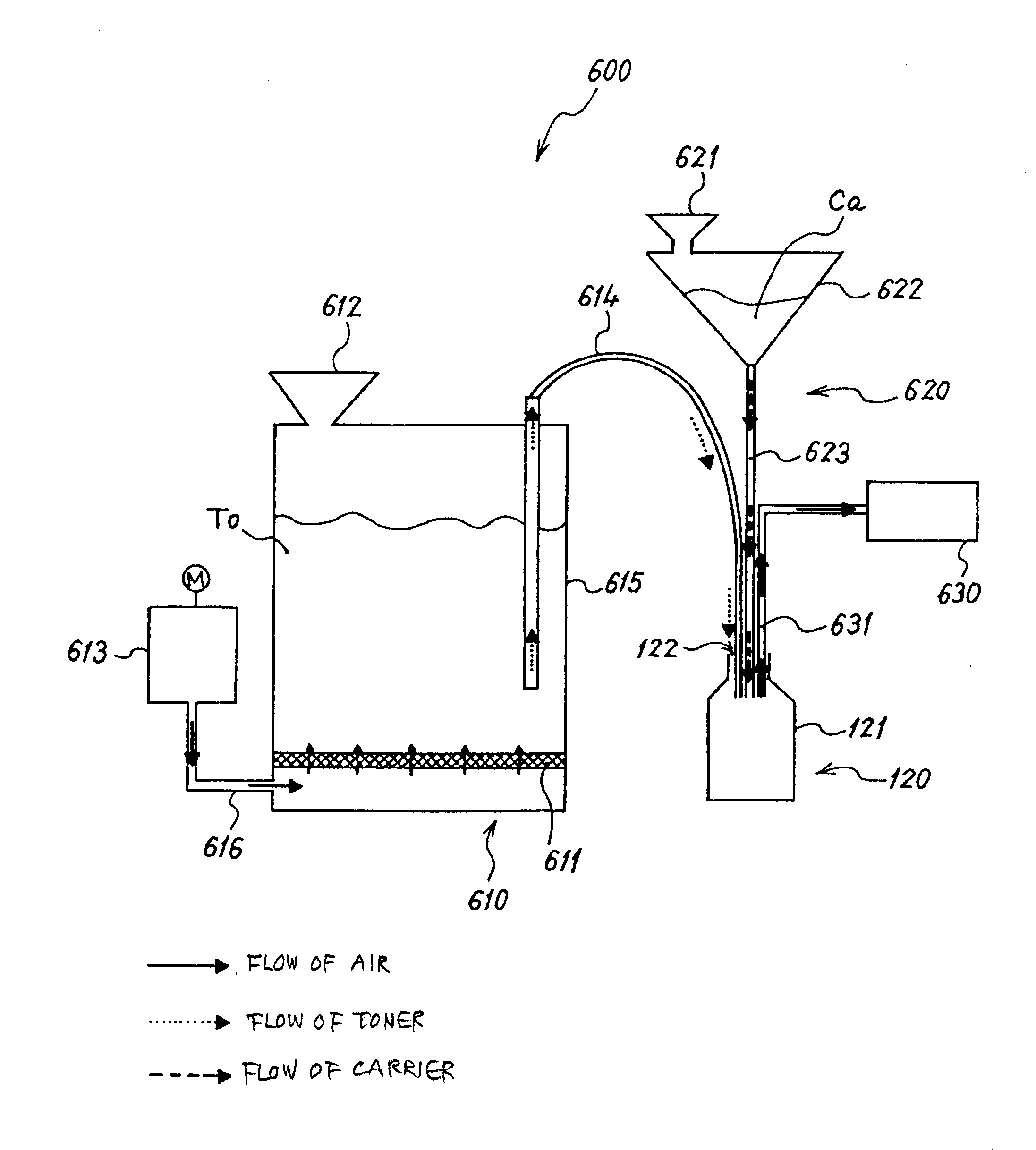

Powder filling method, powder container, developer replenishing device, developer replenishing method, and image forming apparatus

A powder filling method, which fills at least two kinds of powders with different specific gravities into a powder container, and by which a region having only a powder with the highest specific gravity out of the at least two kinds of powders is prevented from being generated in the filled powder container. A toner, which is a first powder that does not include a carrier having the highest specific gravity, is mixed with air in a toner storage portion. The air is introduced into the toner particles to increase the bulk of the toner, and then a toner filling device fills a toner bottle serving as the powder container with the toner having the air. Upon completion of such filling, a carrier filling device starts filling the carrier, which is a second powder, into the toner bottle. Filling of the carrier is completed before the air is released from the toner particles contained in the toner bottle and thereby the bulk of the toner is reduced and then stabilized.

Owner:RICOH KK

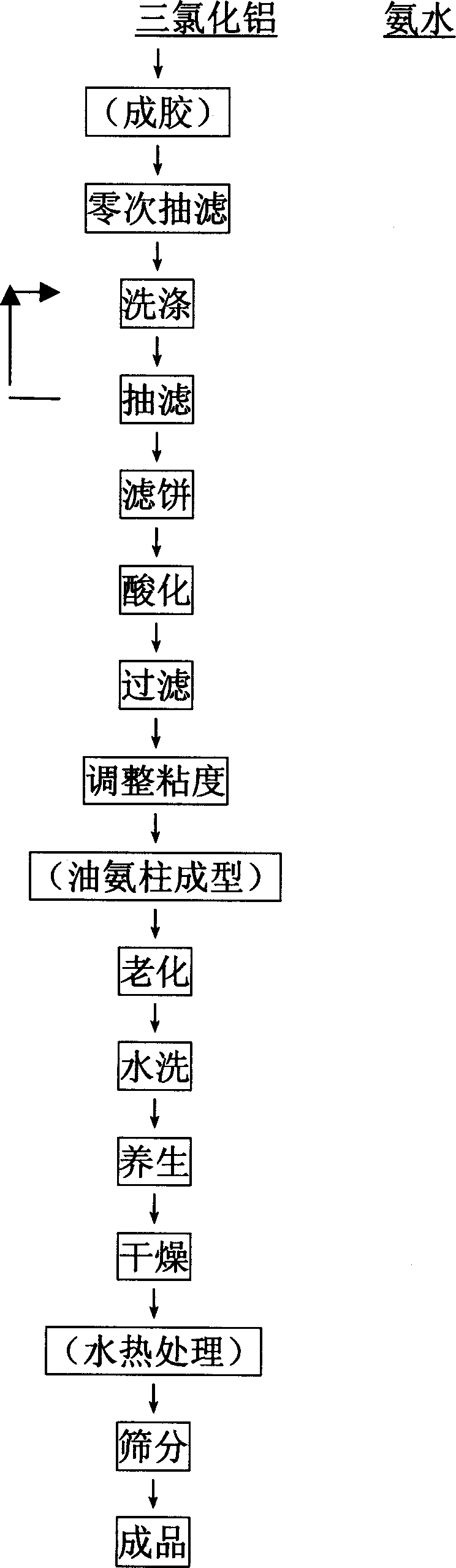

Straight chain paraffin dehydrogenation catalyst carrier production process

InactiveCN1579616AAdapt to the needs of dehydrogenation catalytic reactionImprove stabilityCatalyst carriersAluminium oxides/hydroxidesAlkaneDehydrogenation

The invention relates to linear alkanes dehydrogenation catalyst carrier technics used in petrochemical industry. Its aperture distribution can be adjusted through producing macroporous alumina globule. Then add surface active agent in globule dropping process. Finally conduct hydrothermal treatment in supporter producing process. On base of self-research, globule dropping technics is designed by self to make product cost reduce remarkably. Using self produced macroporous alumina dropping globule, side pressure intensity of alumina globule can reach more than 20N per grain. Using self-researched macroporous gamma-Al2O3 with binocular construction, reaction performance of linear alkanes dehydrogenation catalyst can reach conversion>12-13 percent and selectivity>90 percent. Compared with international like products, its stability is better.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Lateral flow assay devices and methods of use

ActiveUS20050079629A1Prevent backflowGuarantee smooth developmentAnalysis using chemical indicatorsSamplingChemical testBody fluid

The present invention is directed novel lateral flow devices for analyzing liquid samples. The devices contain chemical test strips and are useful for testing liquids for physical properties, such as pH, specific gravity, contamination or adulteration, the presence of proteins or blood, and the like. The test strips contain a bibulous material, a filter element, a reagent pad, and in some embodiments also contain a hydrophobic member and a cover. Any fluid can be tested, for example, urine or other body fluids, environmental samples, biological samples, clinical samples, or food and beverage samples.

Owner:ABBOTT RAPID DIAGNOSTICS INT UNLTD

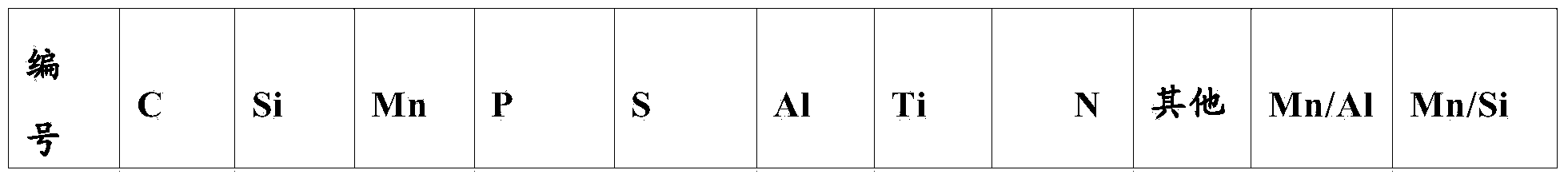

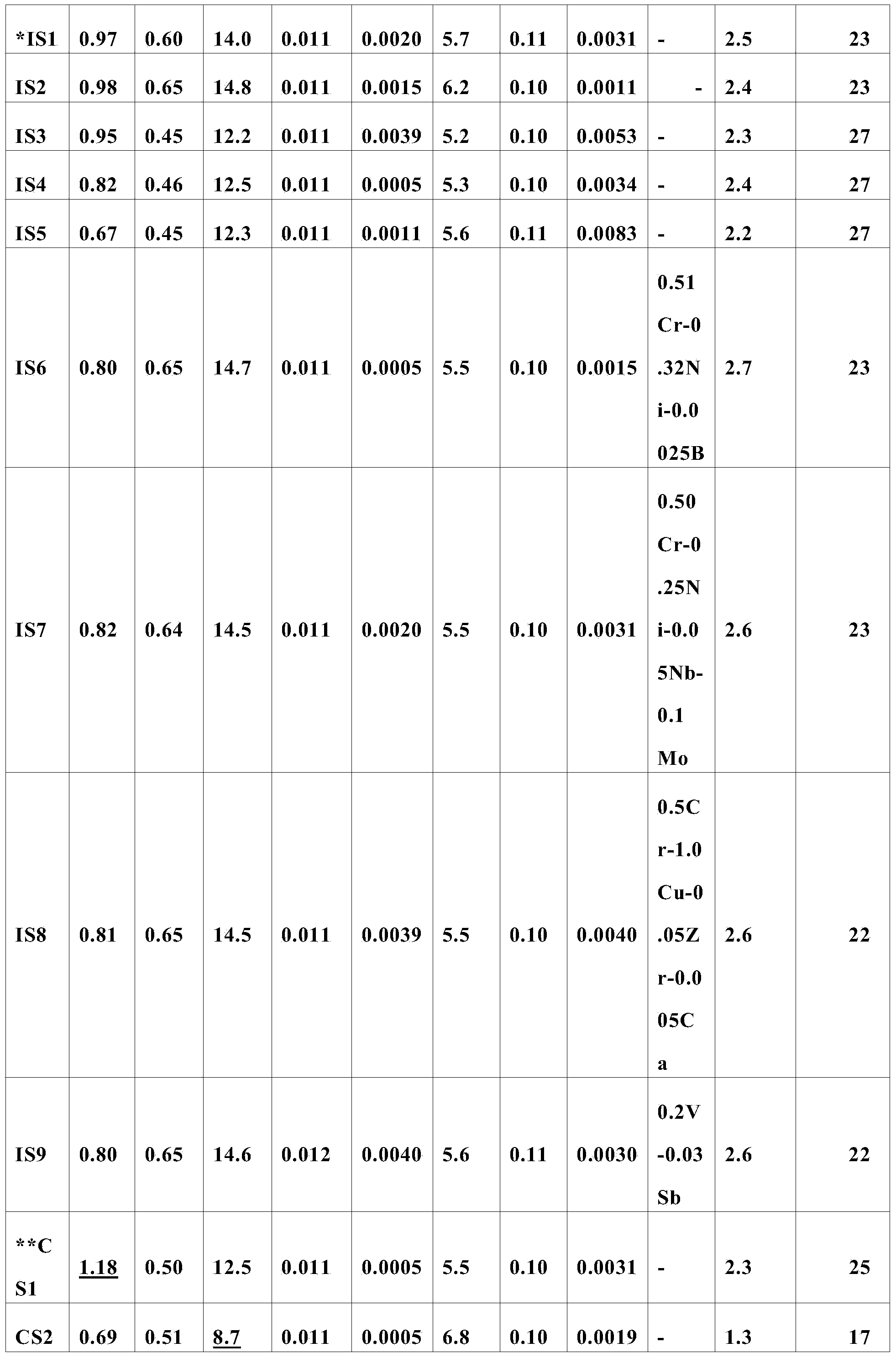

Austenitic, lightweight, high-strength steel sheet of which the yield ratio and flexibility are outstanding and a production method therefor

ActiveCN103370434AHigh yield ratioImprove ductilityHot-dipping/immersion processesThin material handlingPliabilityManganese

The present invention relates to an austenitic, lightweight, high-strength steel sheet having a high yield ratio and ductility and a method for producing the same, and more particularly, to a high-strength steel sheet for automotive interior panels, exterior panels, and structural parts, and a method for producing the steel sheet. An aspect of the present invention provides austenitic, lightweight, high-strength hot rolled steel sheet , cold rolled steel sheet and coated steel sheet having a high yield ratio and ductility and a method for producing thereof including appropriate concentrations of alloying elements such as Mn, Si, and Al to obtain a tensile strength of 800 MPa or greater, an elongation of 30% or greater, and a yield ratio of 60% or greater that are difficult to obtain from high-carbon, high-manganese steel sheets or high-manganese, lightweight steel sheets of the related art. The present invention provides a steel sheet having a low specific gravity, a high yield ratio, and high ductility as compared to high-strength steel sheets of the related art such as advanced high strength steels (AHSS). The steel sheet of the present invention is effective in maintaining the rigidity of a structural member and have good press processing characteristics so that the steel sheet can be used for manufacturing automotive parts to reduce the weight of automobiles and combining a plurality of parts into a single module or as one part to simplify machining or assembly processes.

Owner:POSCO CO LTD

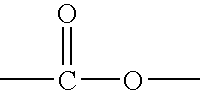

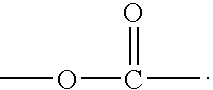

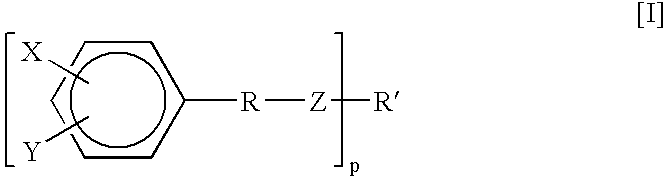

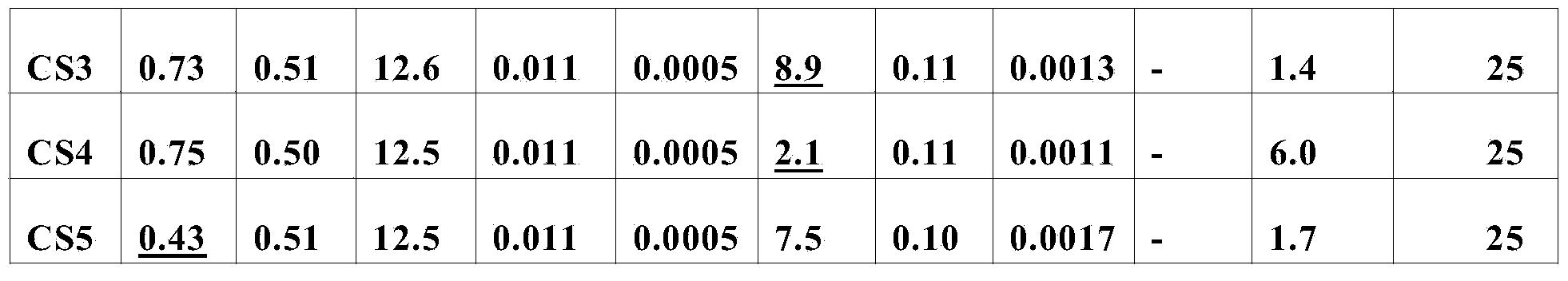

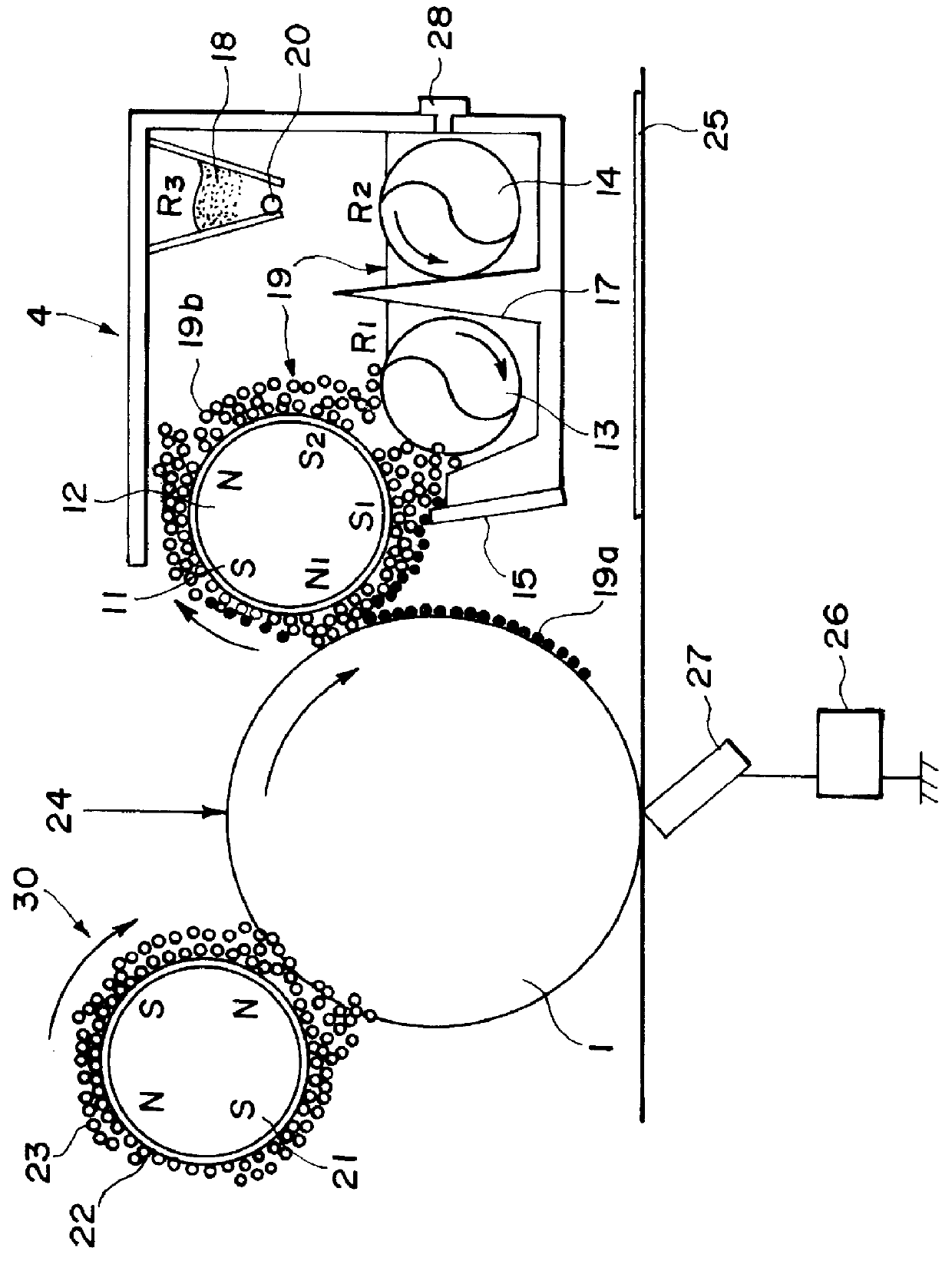

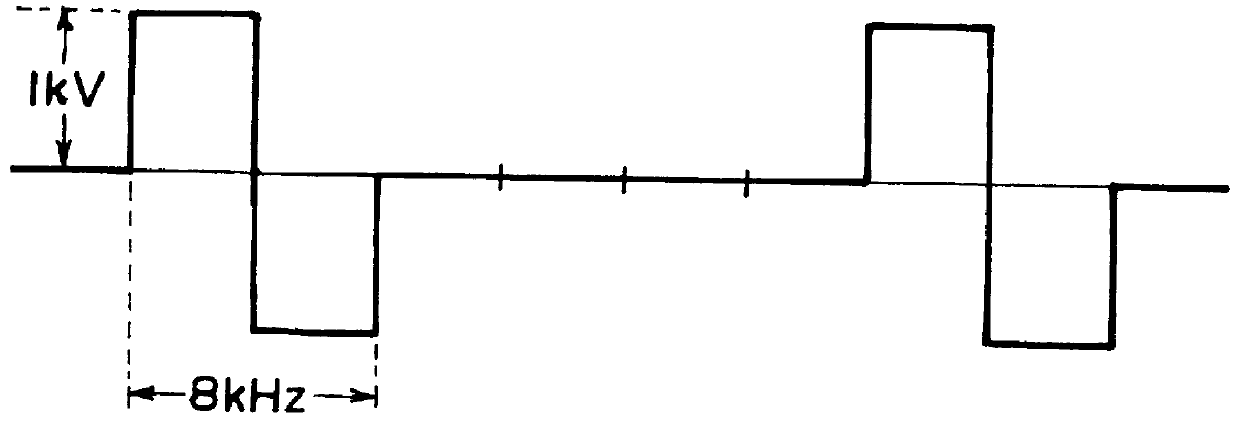

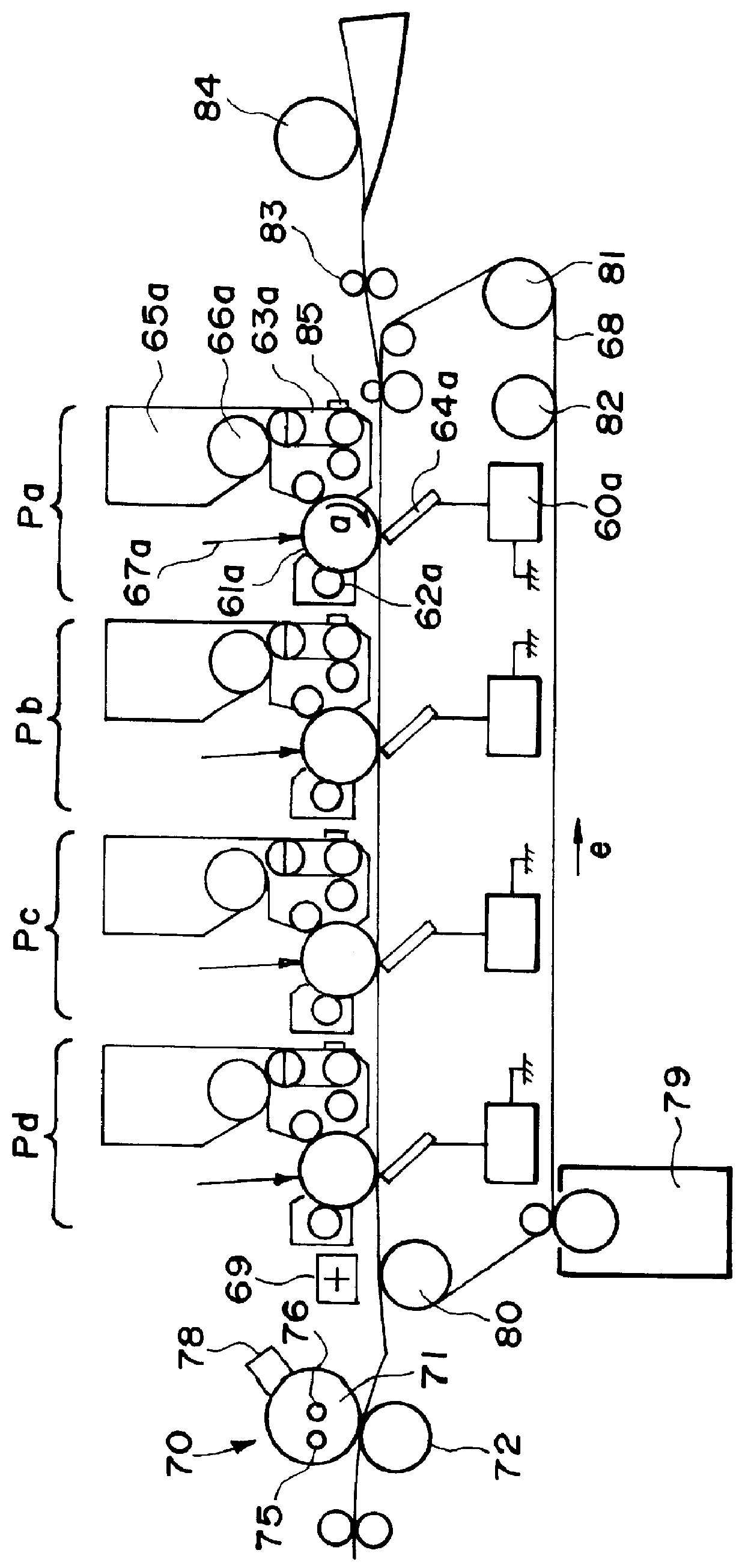

Magnetic carrier, two-component developer and image forming method

InactiveUS6124067AHigh-quality tonerHigh image densityElectrographic process apparatusDevelopersEngineeringPolymer

A magnetic carrier constituting a two-component developer for use in an electrophotographic image forming method is formed of a carrier core comprising a first resin and magnetic fine particles dispersed in the first resin, and a second resin surface-coating the carrier core. (a) The magnetic carrier has a true specific gravity of 2.5-4.5, a magnetization sigma 1000 as measured in a magnetic field of 1000x(103 / 4 pi )xA / m (1000 oersted) of 15-60 Am2 / kg (emu / g), a residual magnetization sigma r of 0.1-20 Am2 / kg (emu / g) and a resistivity of 5x1011-5x1015 ohm.cm. (b) The first resin has a polymer chain including a methylene unit (-CH2-). (c) The second resin has at least a fluoro-alkyl unit, a methylene unit (-CH2-) and an ester unit. (d) The carrier core is surface-coated with (i) a mixture of the second resin and a coupling agent having at least an amino group and a methylene unit, or (ii) a coupling agent having at least an amino group and a methylene unit, and then with the second resin.

Owner:CANON KK

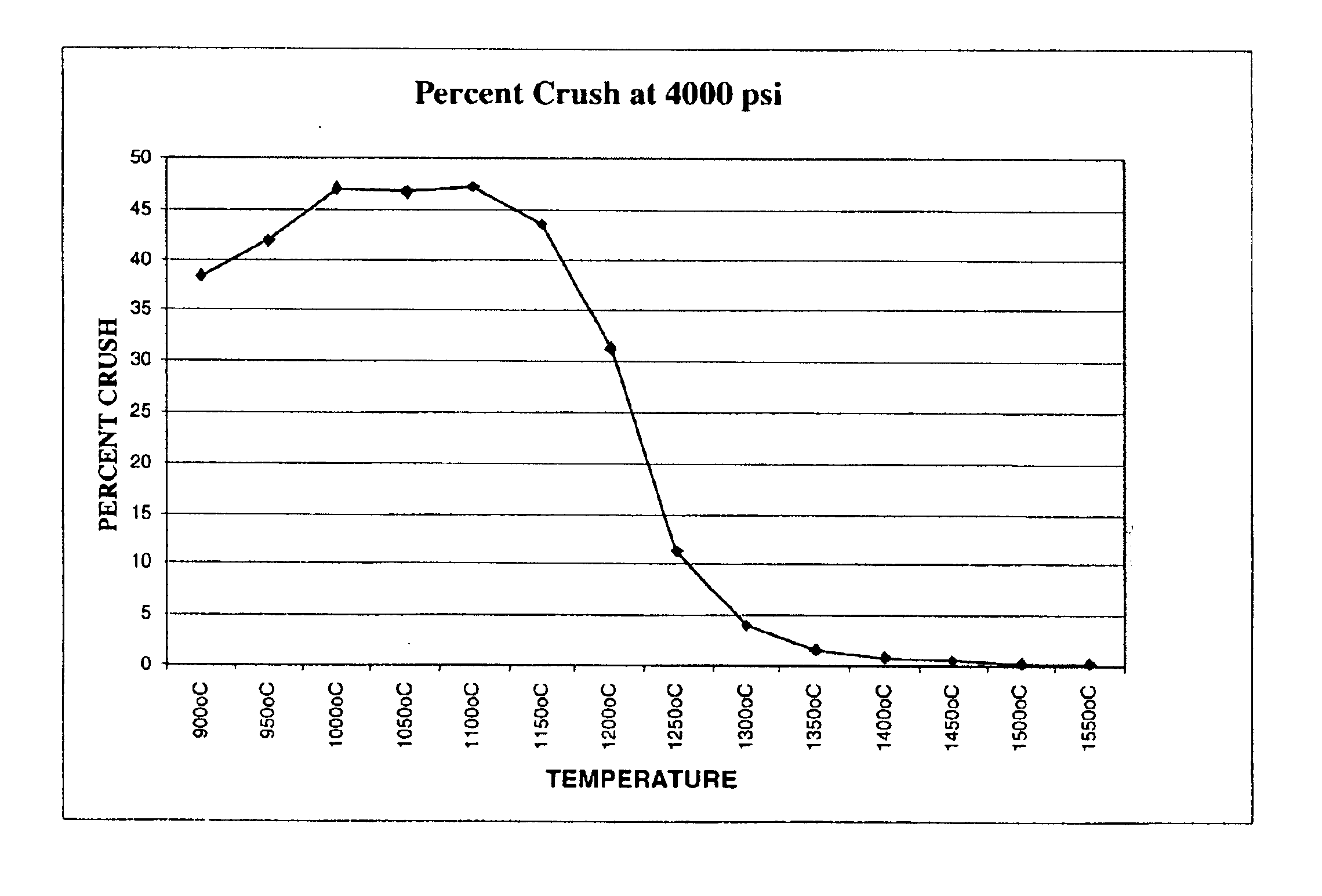

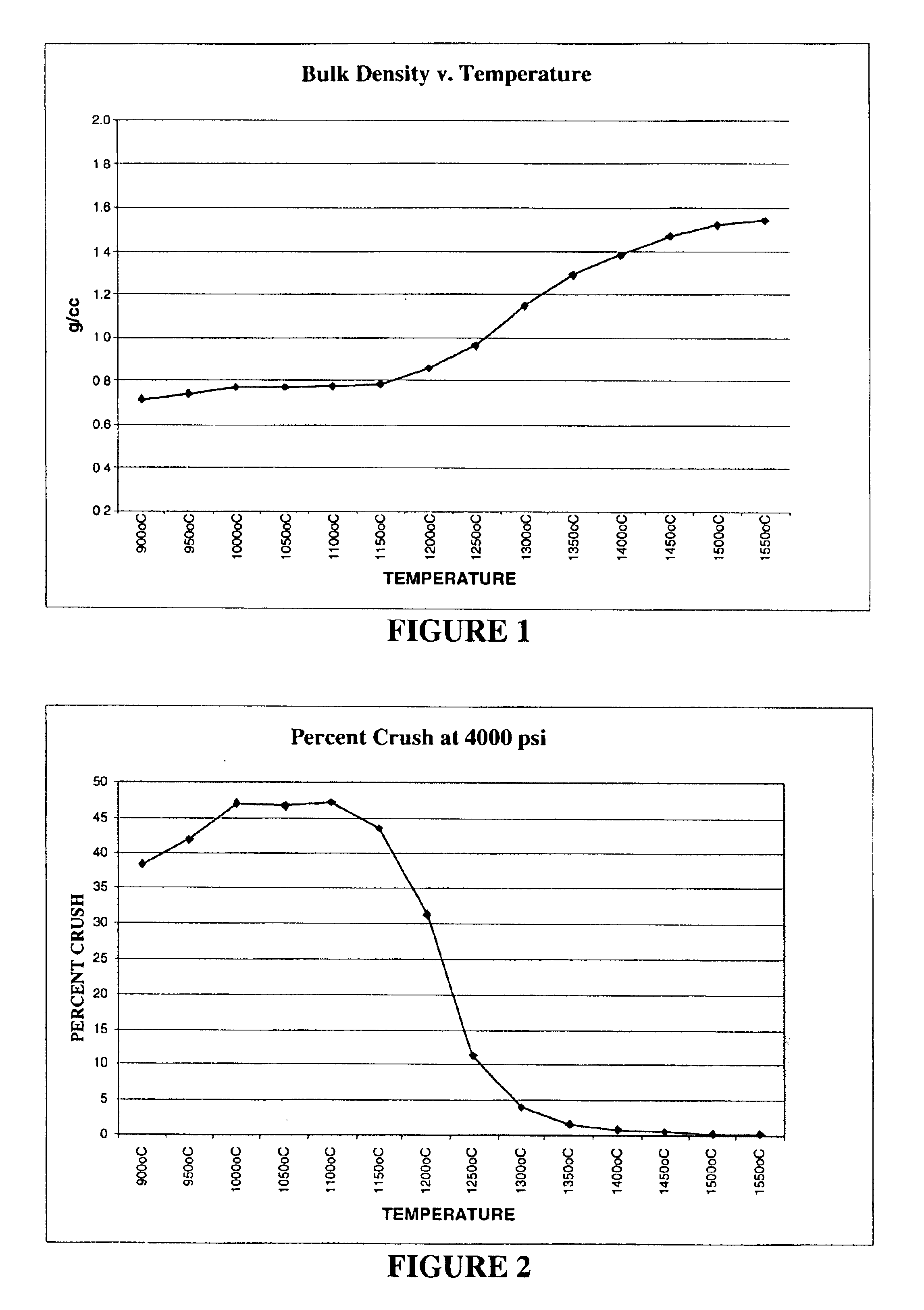

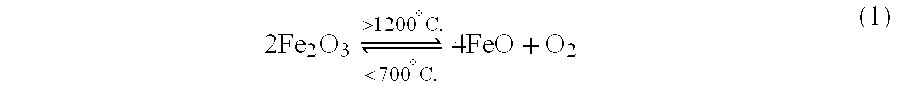

Ceramic proppant with low specific weight

InactiveUS20080070774A1Avoid product qualitySintering range is again narrowedFluid removalCeramic shaping apparatusMagnesium orthosilicateUltimate tensile strength

A precursor composition for the production of granulated ceramic material, particularly for ceramic proppants, comprises 20 to 55% by weight of magnesium orthosilicate, 20 to 35% by weight of MgO, and 2.5 to 11% by weight of Fe2O3. The resulting lightweight proppant material shows high mechanical strength. To further decrease the specific density of the proppant, the formation of small pores can be increased by adding 0.3 to 2.4% carbon as a gas-forming agent.

Owner:OBSCHESTVO S OGRANICHENNOY OTVETSTVENNOSTYU FORES

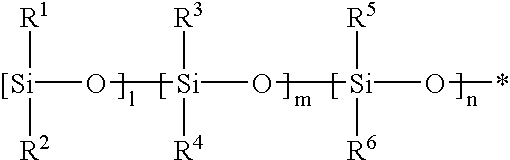

Injectable intraocular accommodating lens

InactiveUS20020071856A1Reduce post-injection manipulationInjection is simpleHair cosmeticsPharmaceutical delivery mechanismMedicineRefractive index

The present invention relates to compositions comprising polysiloxanes suitable for the preparation of accommodating intraocular lenses, having a specific gravity of greater than about 1.0, a refractive index suitable for restoring the refractive power of the natural crystalline lens and a viscosity suitable for injection through a standard cannula. The present invention includes intraocular lenses made from said polysiloxane compositions having a Young's modulus less than about 10 kPa.

Owner:AMO GRONINGEN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com