Patents

Literature

2278 results about "Power ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

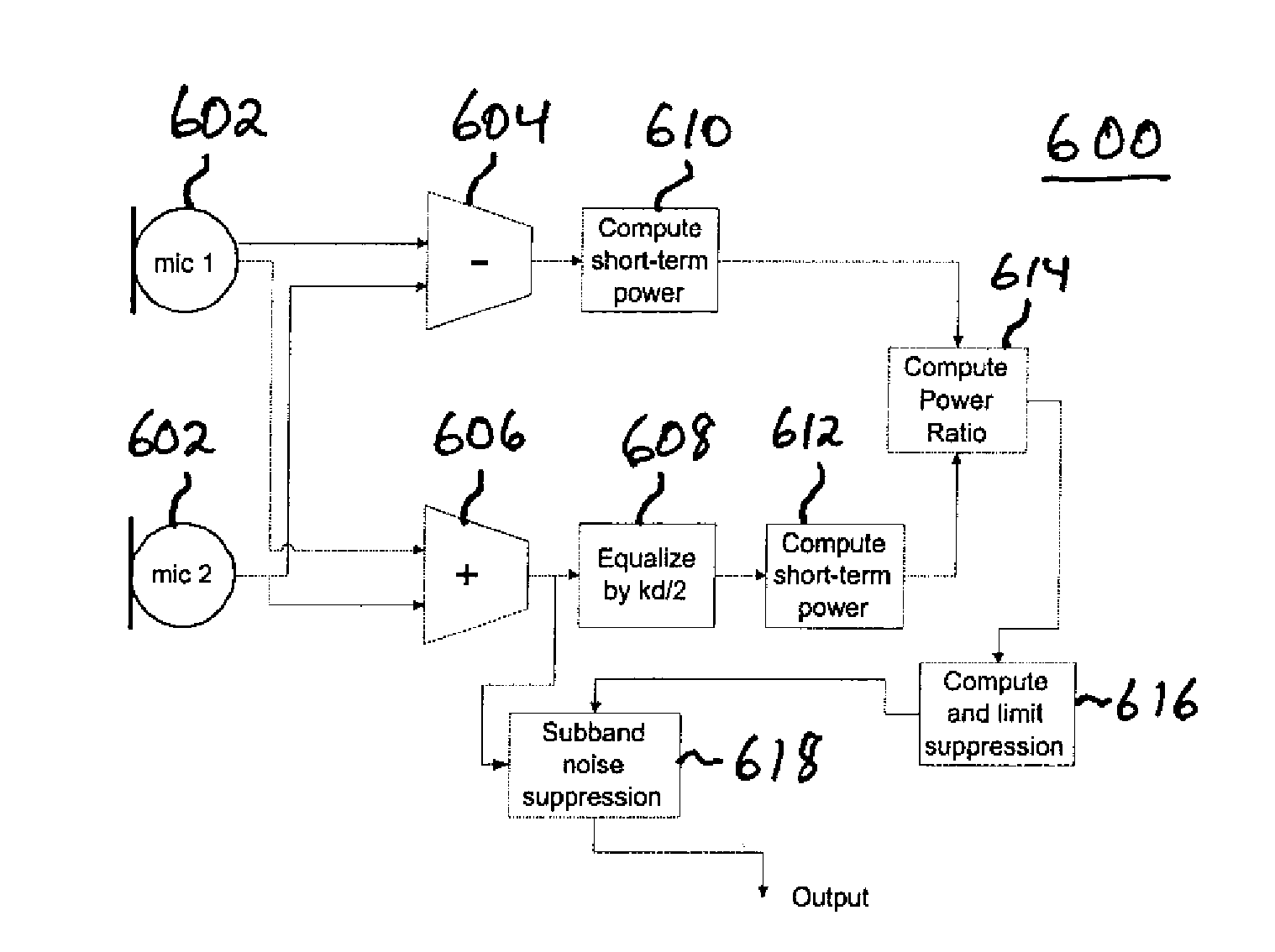

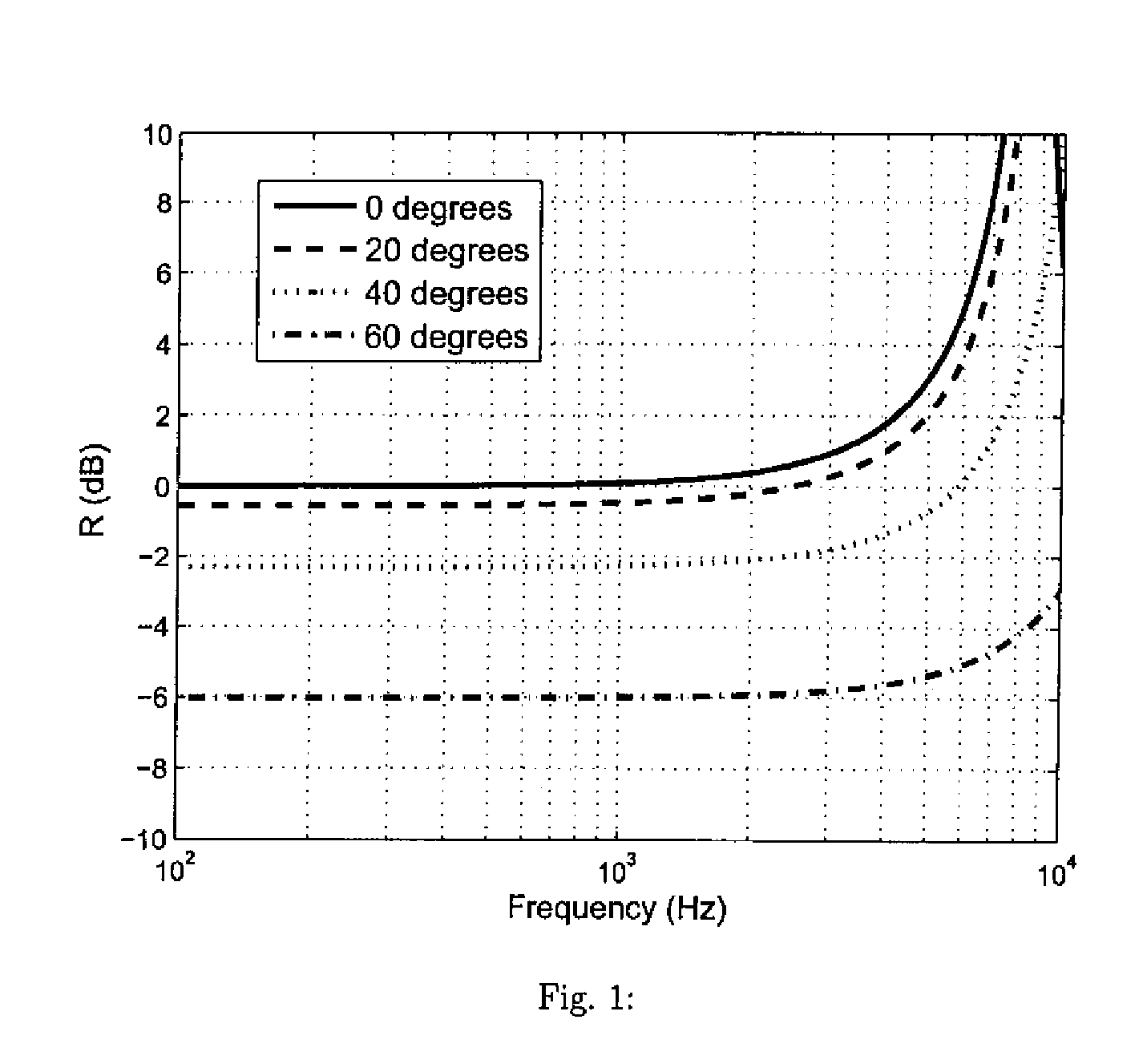

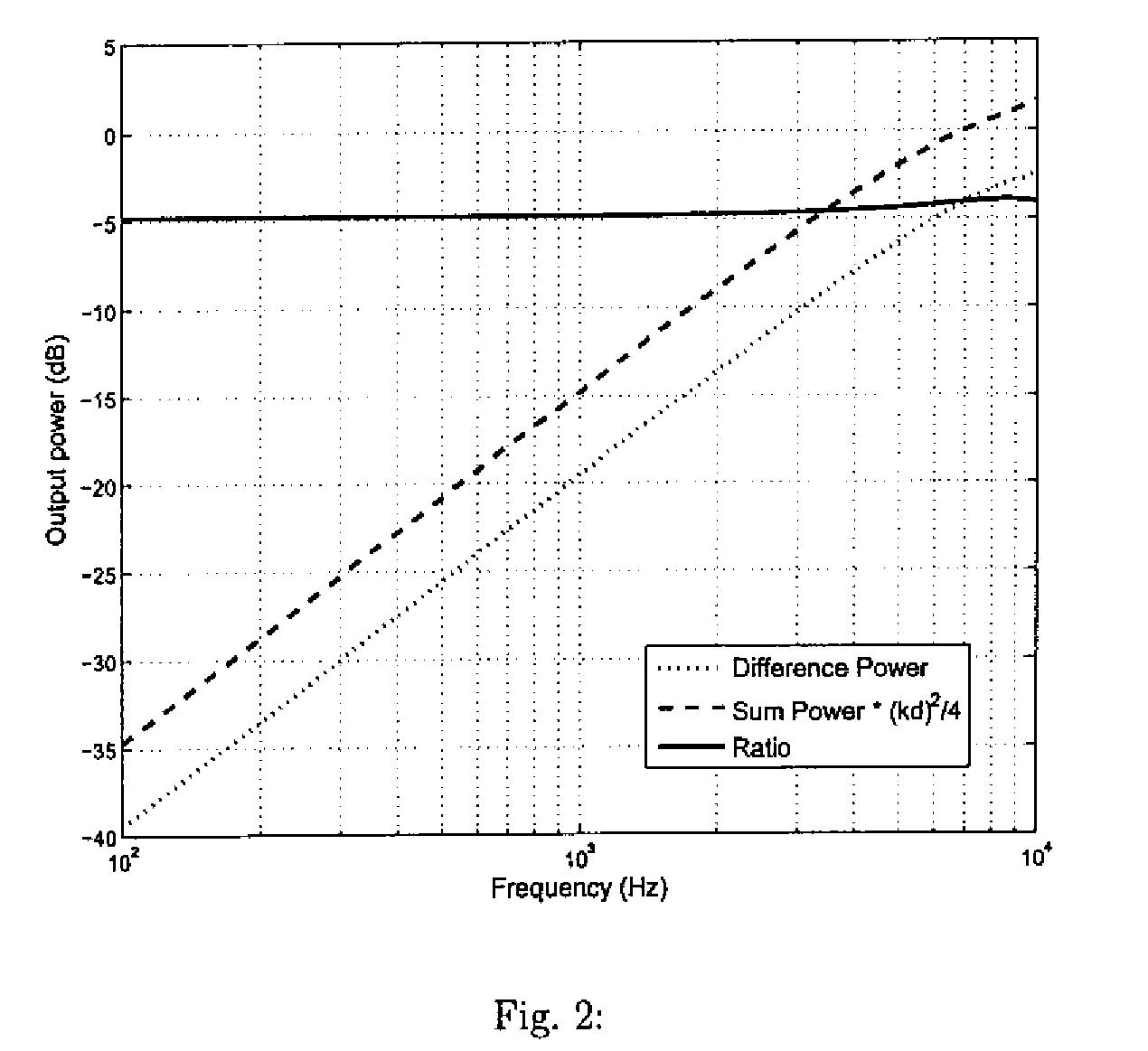

Dual-Microphone Spatial Noise Suppression

Spatial noise suppression for audio signals involves generating a ratio of powers of difference and sum signals of audio signals from two microphones and then performing noise suppression processing, e.g., on the sum signal where the suppression is limited based on the power ratio. In certain embodiments, at least one of the signal powers is filtered (e.g., the sum signal power is equalized) prior to generating the power ratio. In a subband implementation, sum and difference signal powers and corresponding the power ratio are generated for different audio signal subbands, and the noise suppression processing is performed independently for each different subband based on the corresponding subband power ratio, where the amount of suppression is derived independently for each subband from the corresponding subband power ratio. In an adaptive filtering implementation, at least one of the audio signals can be adaptively filtered to allow for array self-calibration and modal-angle variability.

Owner:MH ACOUSTICS

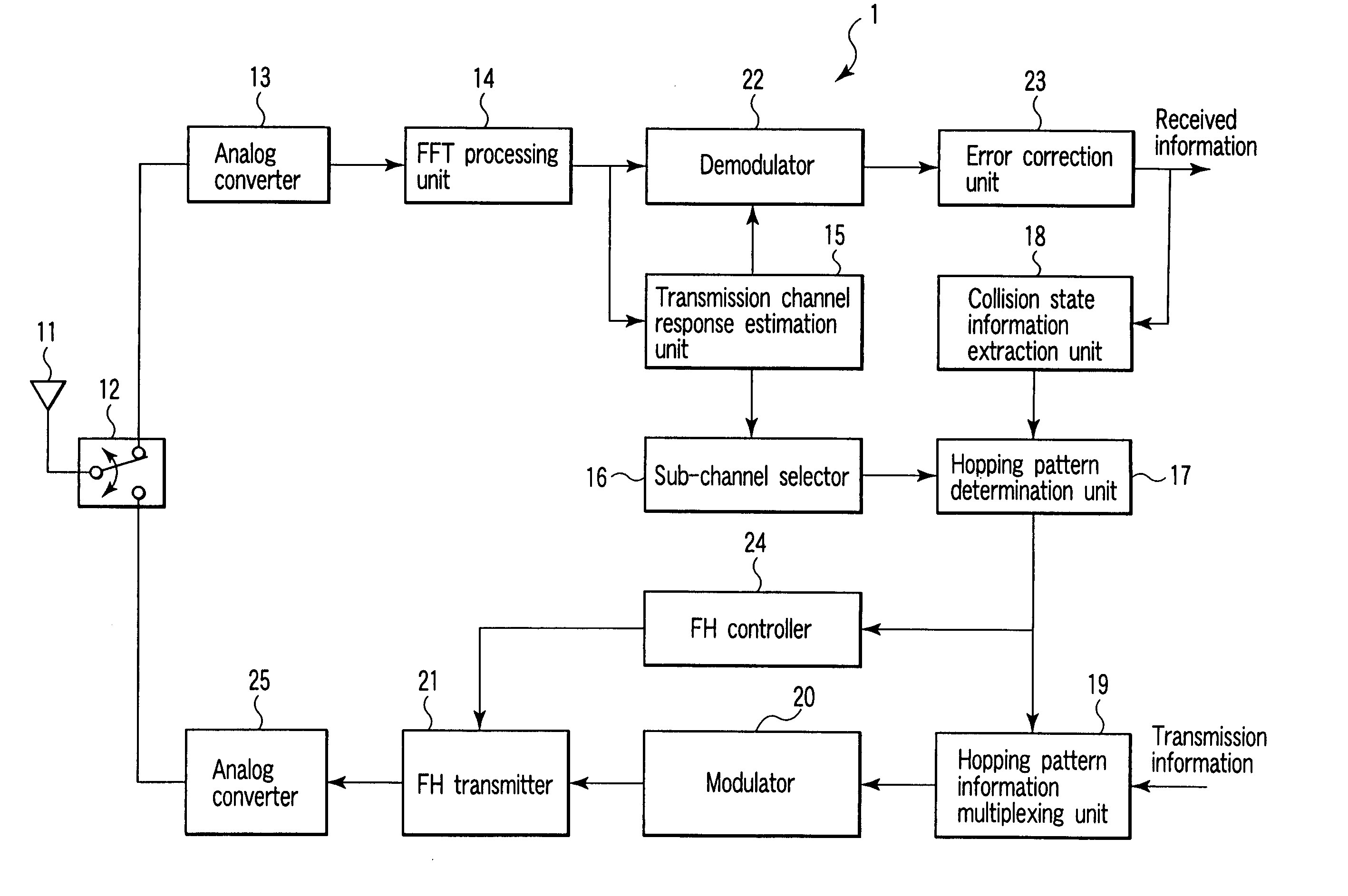

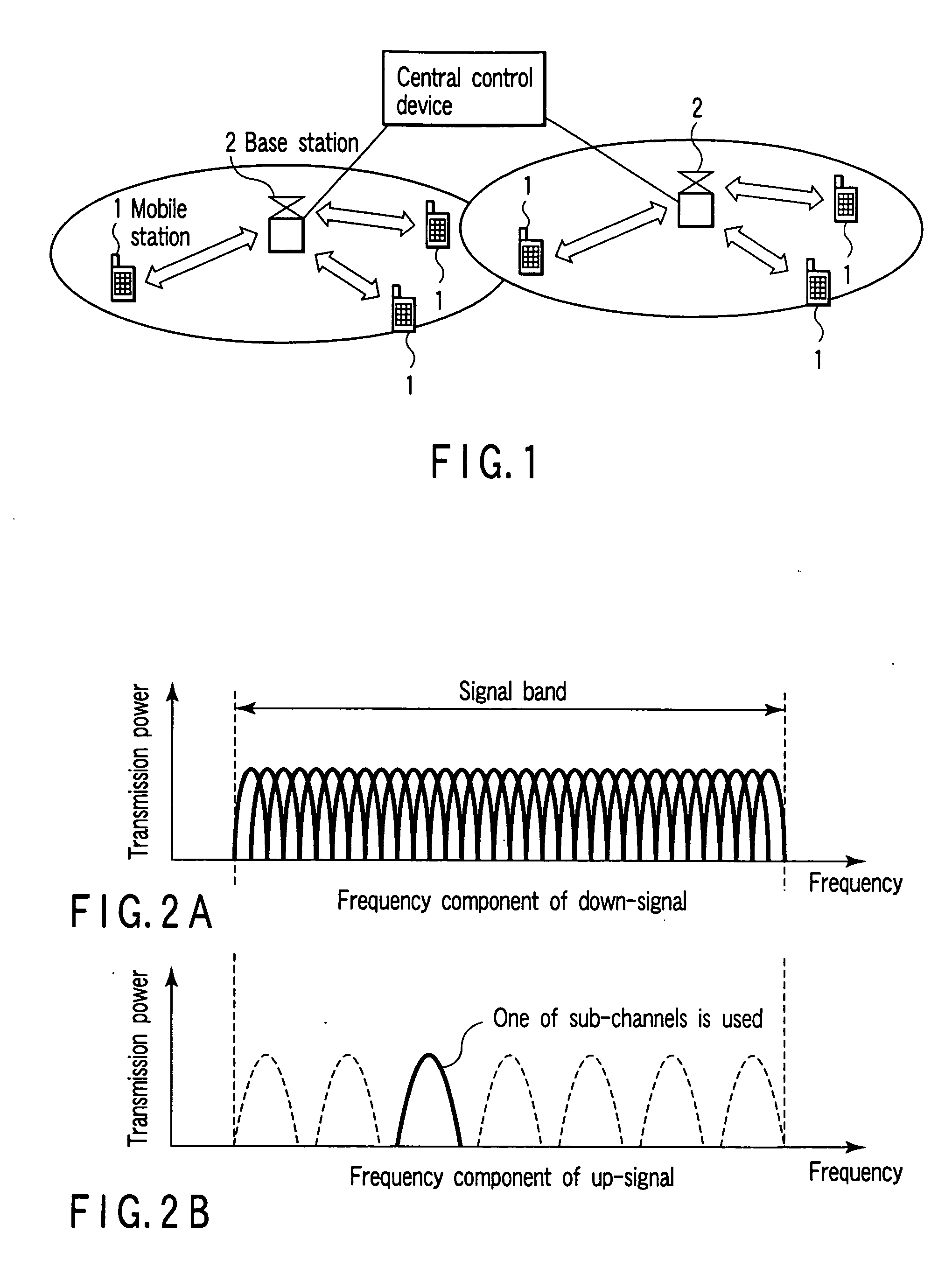

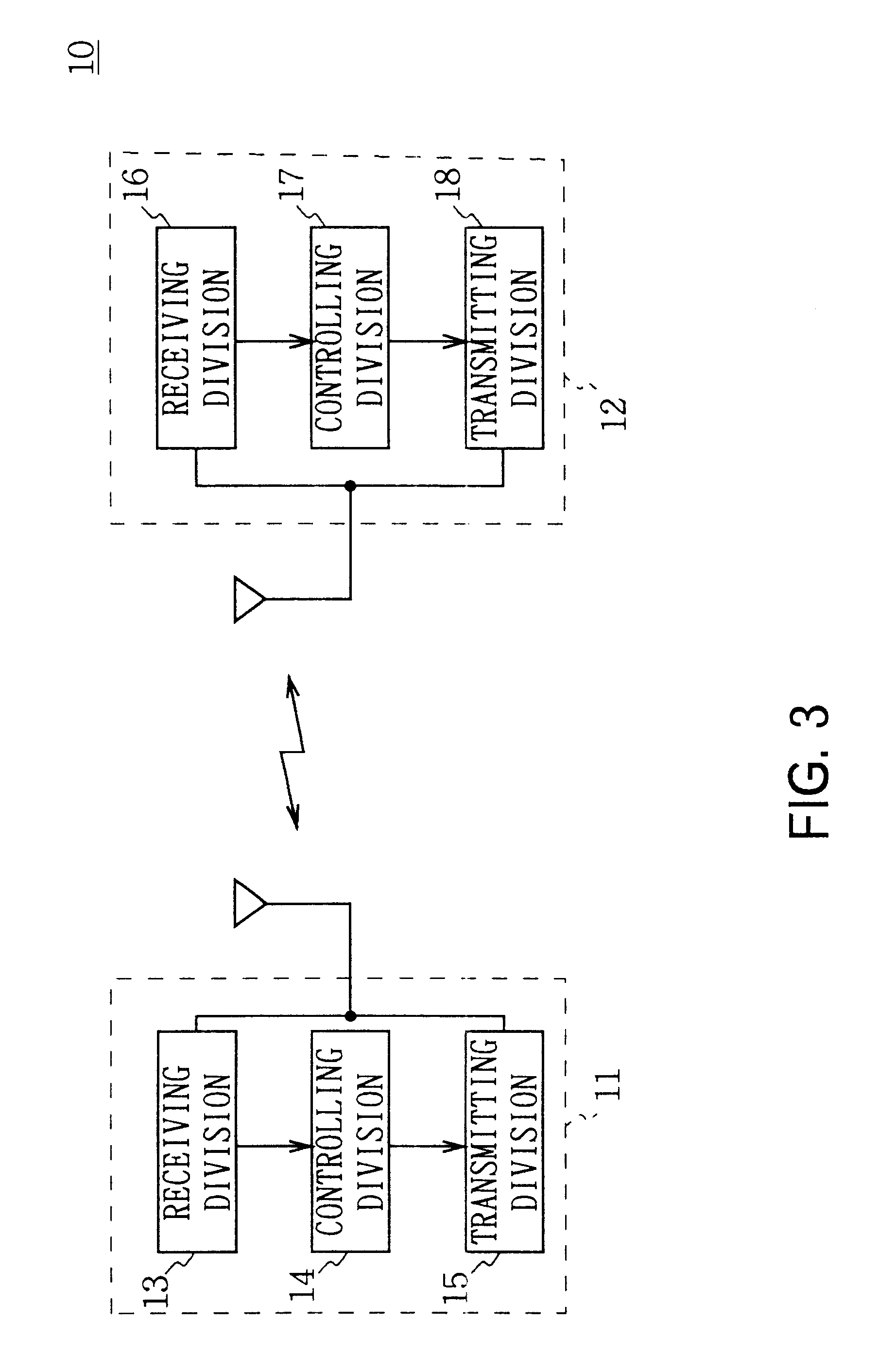

Radio communication apparatus, base station and system

InactiveUS20060013285A1Modulated-carrier systemsOrthogonal multiplexSignal to noise power ratioTransmitter

Radio communication apparatus for receiving OFDM signal from base station and transmitting FH signal to base station, using sub-channels, base station comparing hopping pattern information items indicating hopping patterns from radio communication apparatuses including radio communication apparatus, and generating collision information when hopping patterns include colliding hopping patterns, includes estimation unit configured to estimate channel response values of sub-channels based on OFDM signal, selector which selects, from sub-channels, several sub-channels which have higher channel response values than a value, each of channel response values being expressed by power level, signal-to-noise power ratio, or signal-to-interference ratio, determination unit configured to determine hopping pattern from selected sub-channels, transmitter which transmits, to base station, hopping pattern information item indicating determined hopping pattern, receiver which receives collision information from base station, and correction unit configured to correct hopping pattern based on collision information.

Owner:KK TOSHIBA

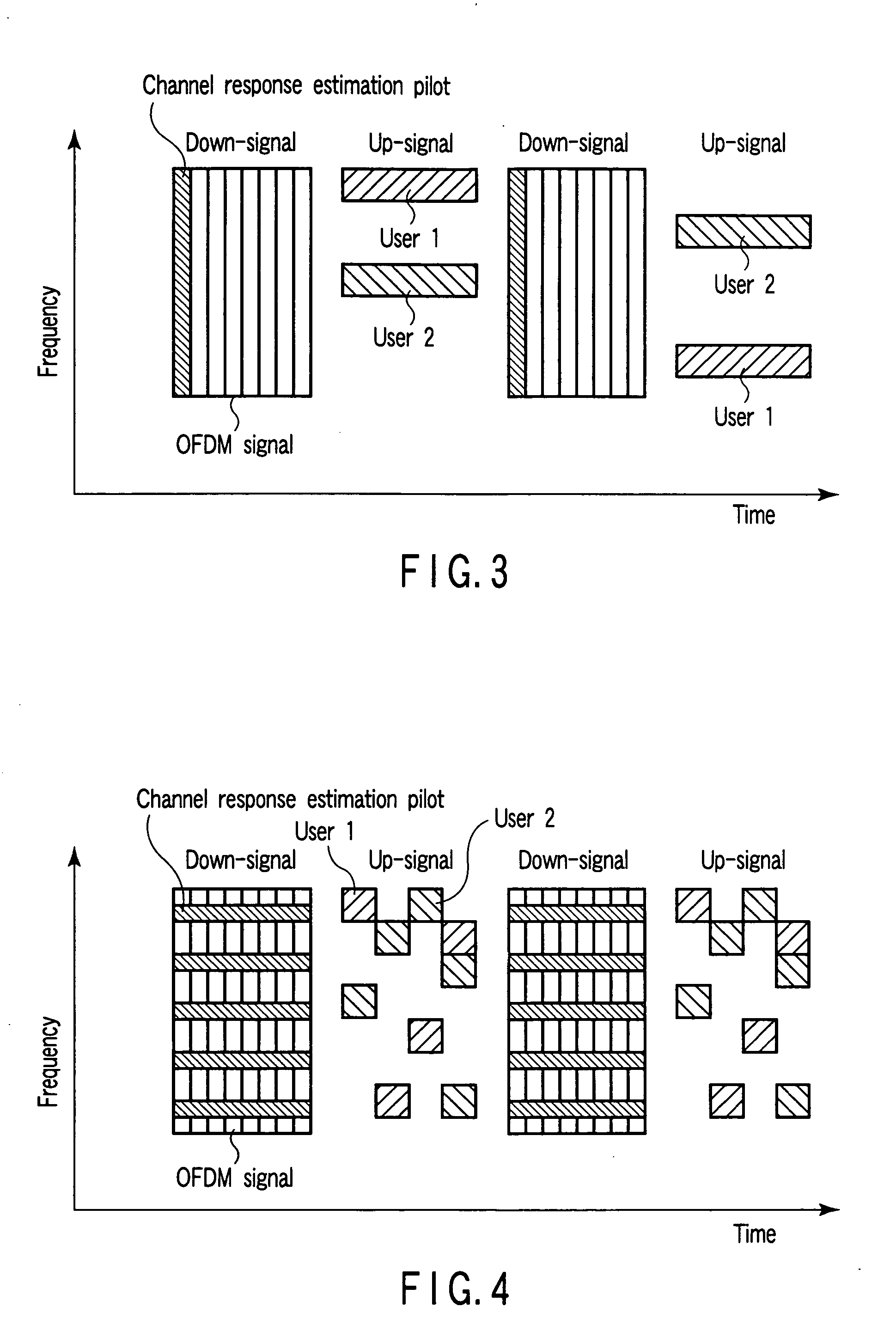

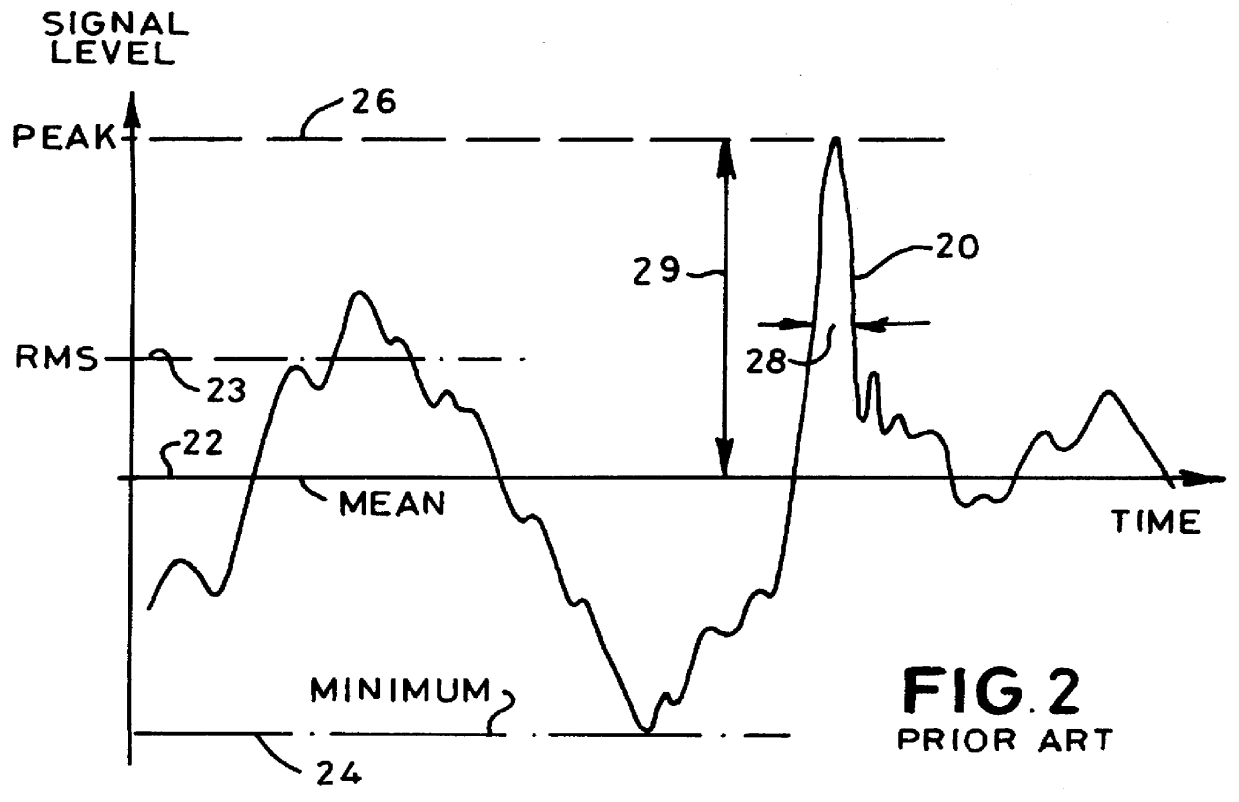

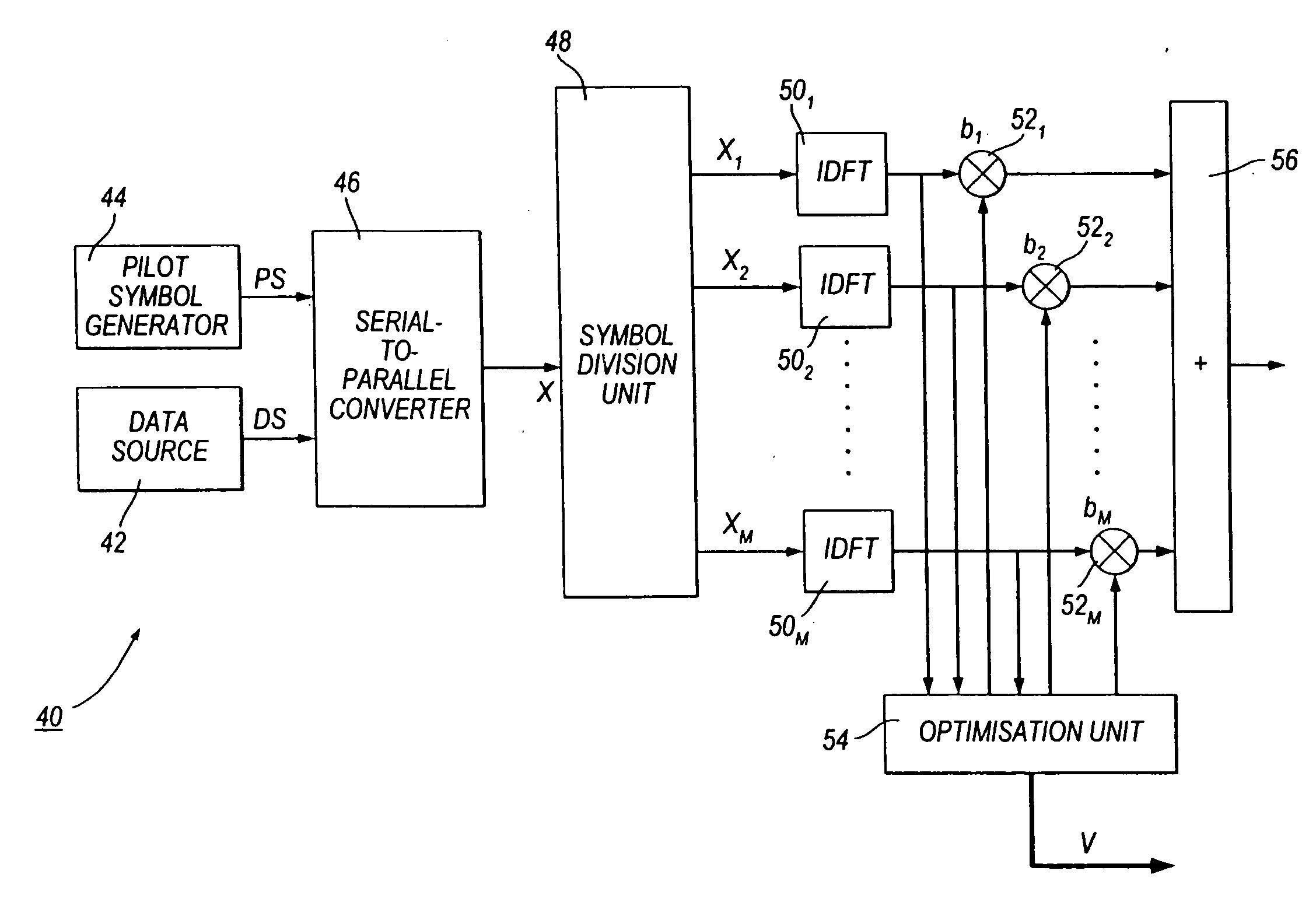

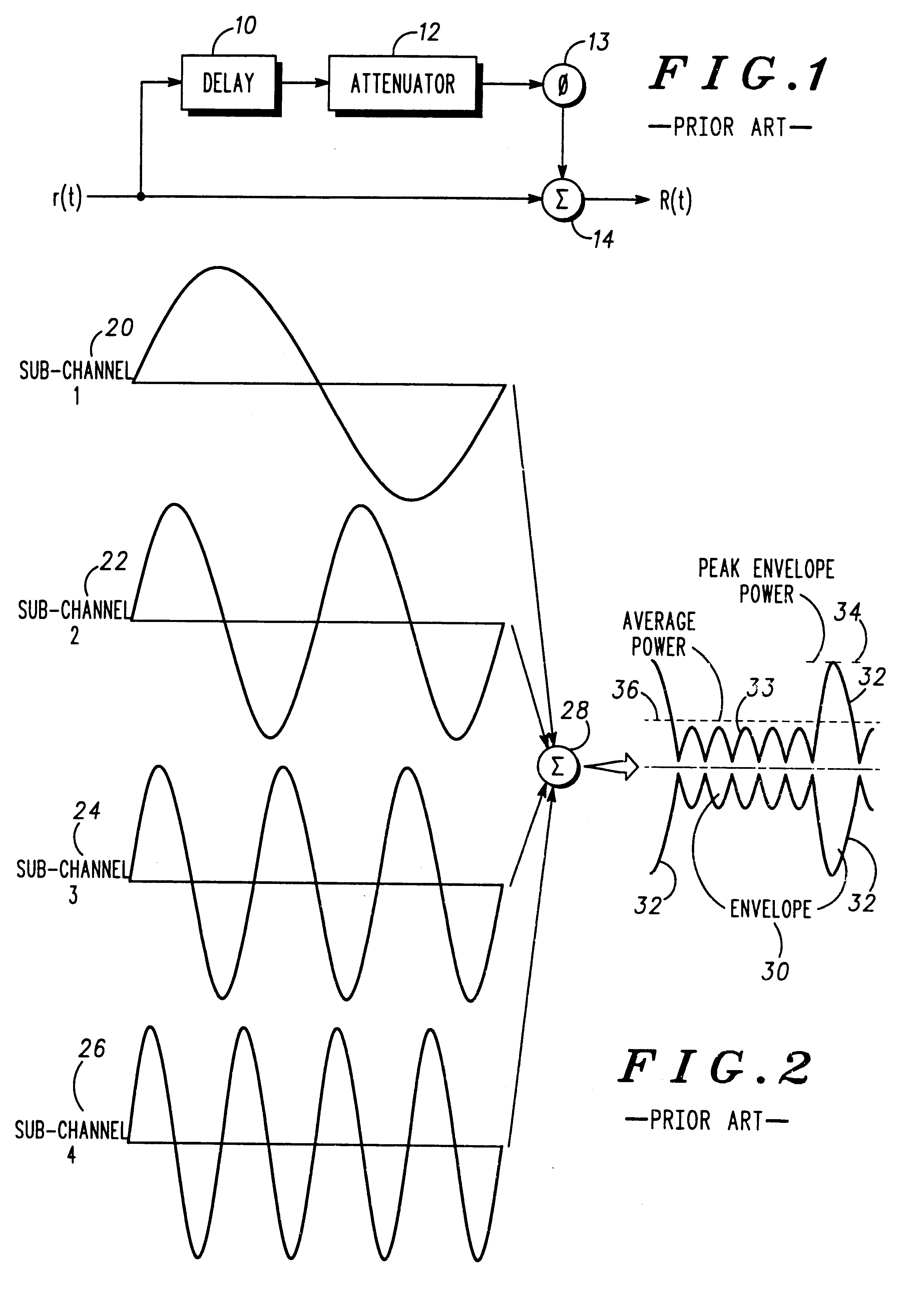

Method and apparatus for reducing the peak-to-average ratio in a multicarrier communication system

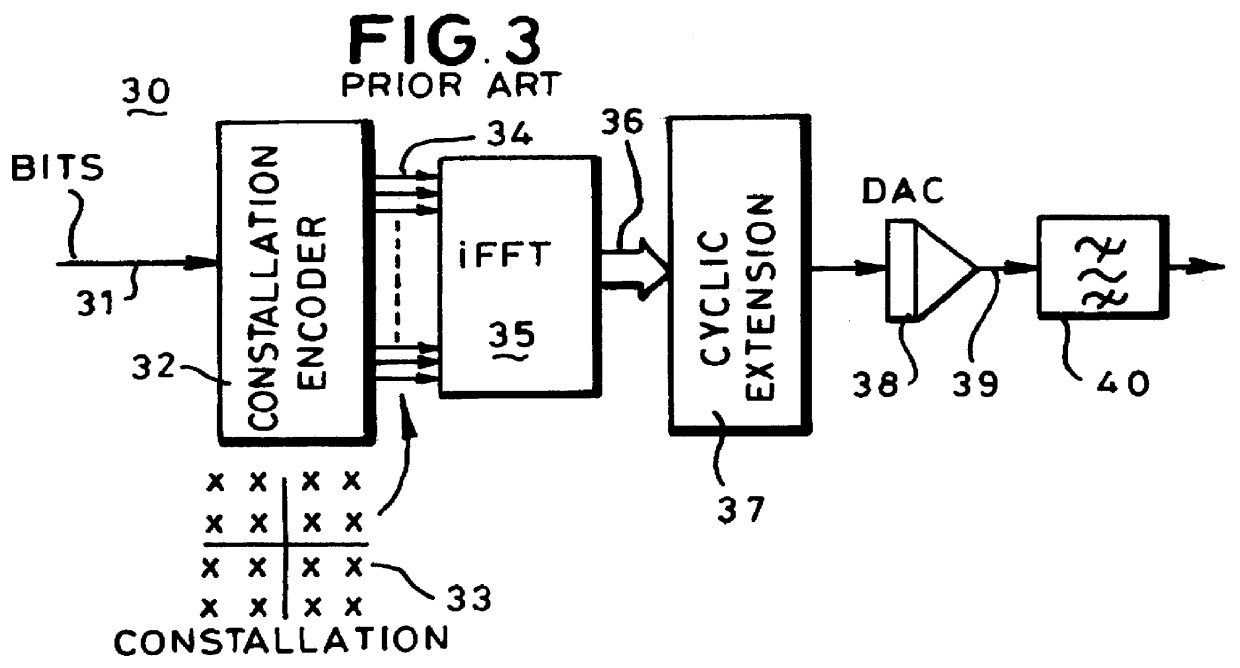

InactiveUS6130918AReduce impactGood dispersionAmplitude-modulated carrier systemsMulti-frequency code systemsTime domainData set

A reduction in a peak-to-mean envelope power ratio of a multicarrier signal, represented as a time domain signal, is achieved by applying (76) an offset, indicative of a difference (74) between a mean signal level and a midpoint level of the time domain signal, to the time domain signal. Alternatively, constellation values of positive and negative frequency components are modified by differing functions to produce a modified data set. Preferably, the negative frequency components are set to a predetermined value (namely zero (124)) to provide an alternate coding scheme Once the multicarrier signal has been converted into a time domain representation, real and imaginary parts (126-128) of the modified data set that consequently only contain positive frequency components and zeros are compared with one another to identify (130) which of the real and imaginary parts has a lower peak-to-average signal ratio (134) for the time domain representation. Then, based upon which of the peak-to-average signal ratios is lowest (136), either the real and imaginary part of the time domain signal is selected for subsequent transmission (138).

Owner:RPX CLEARINGHOUSE

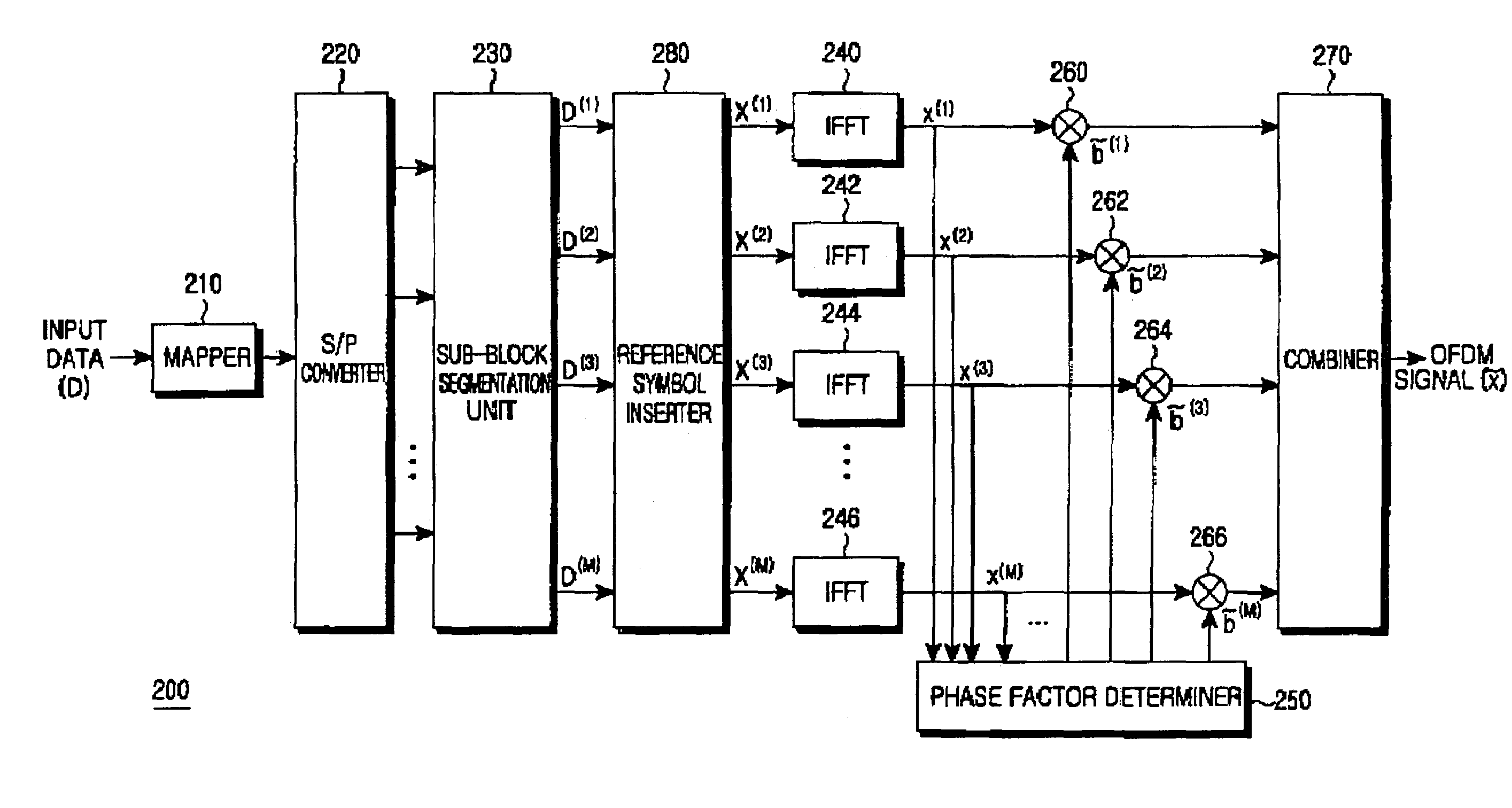

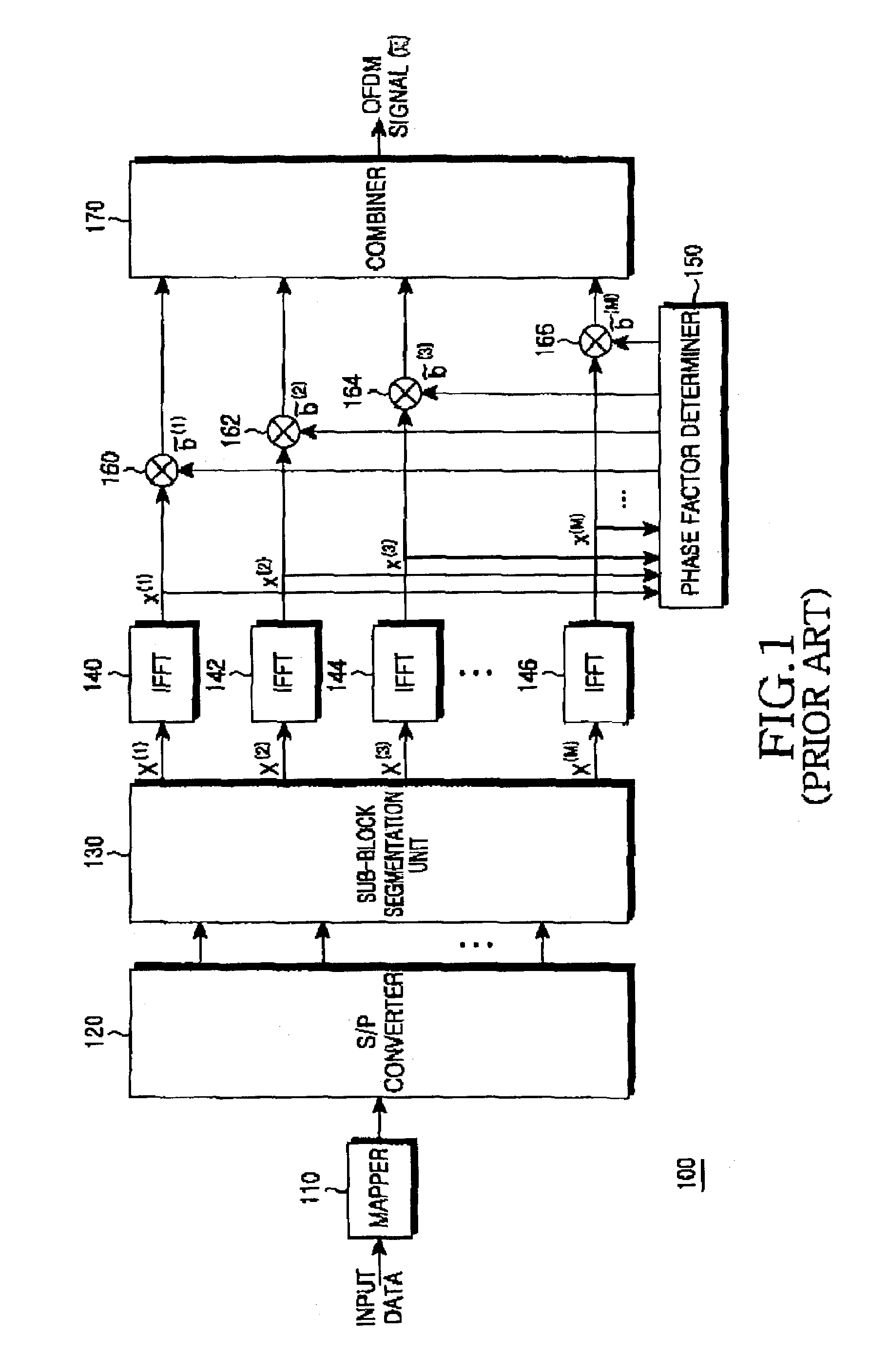

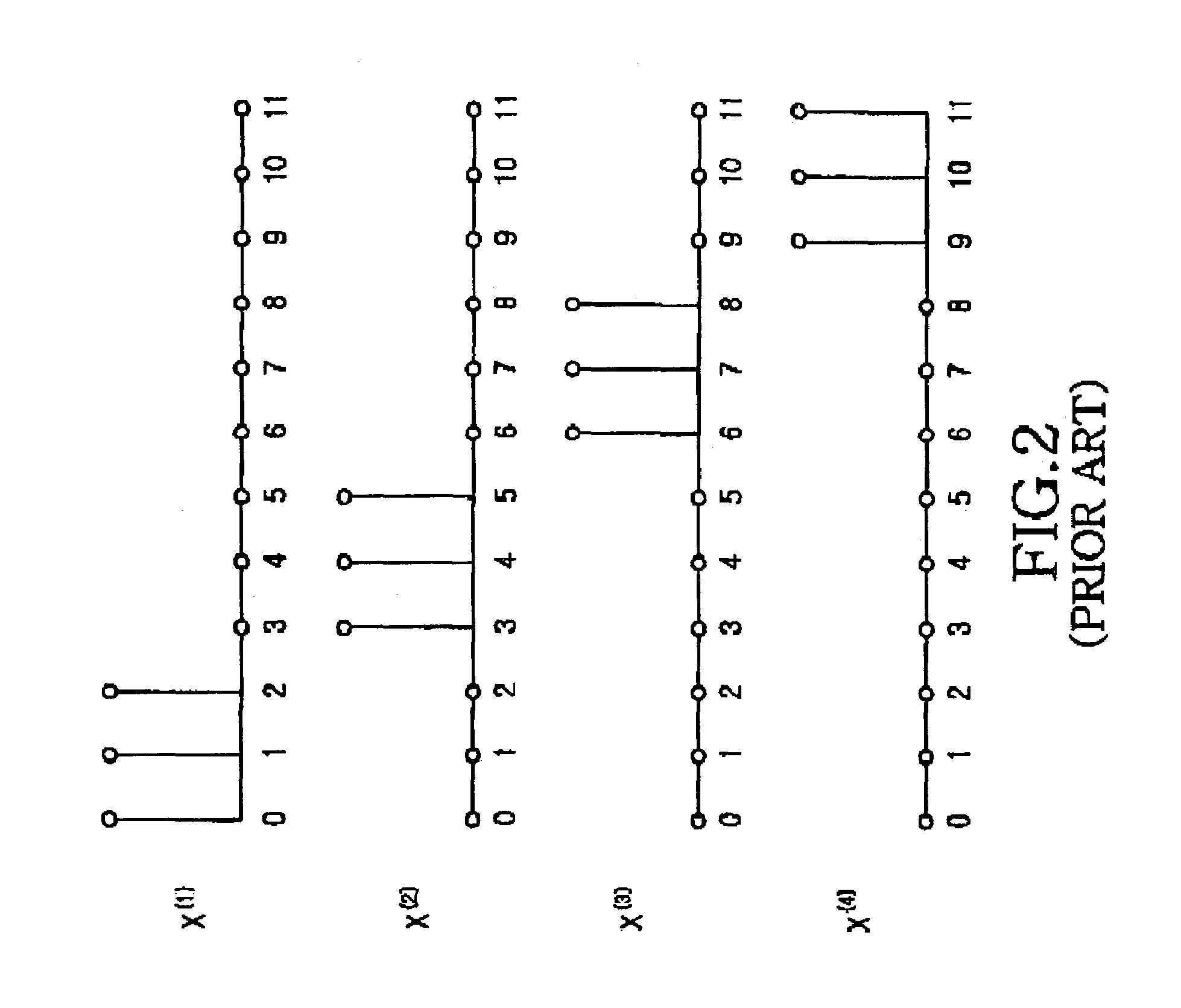

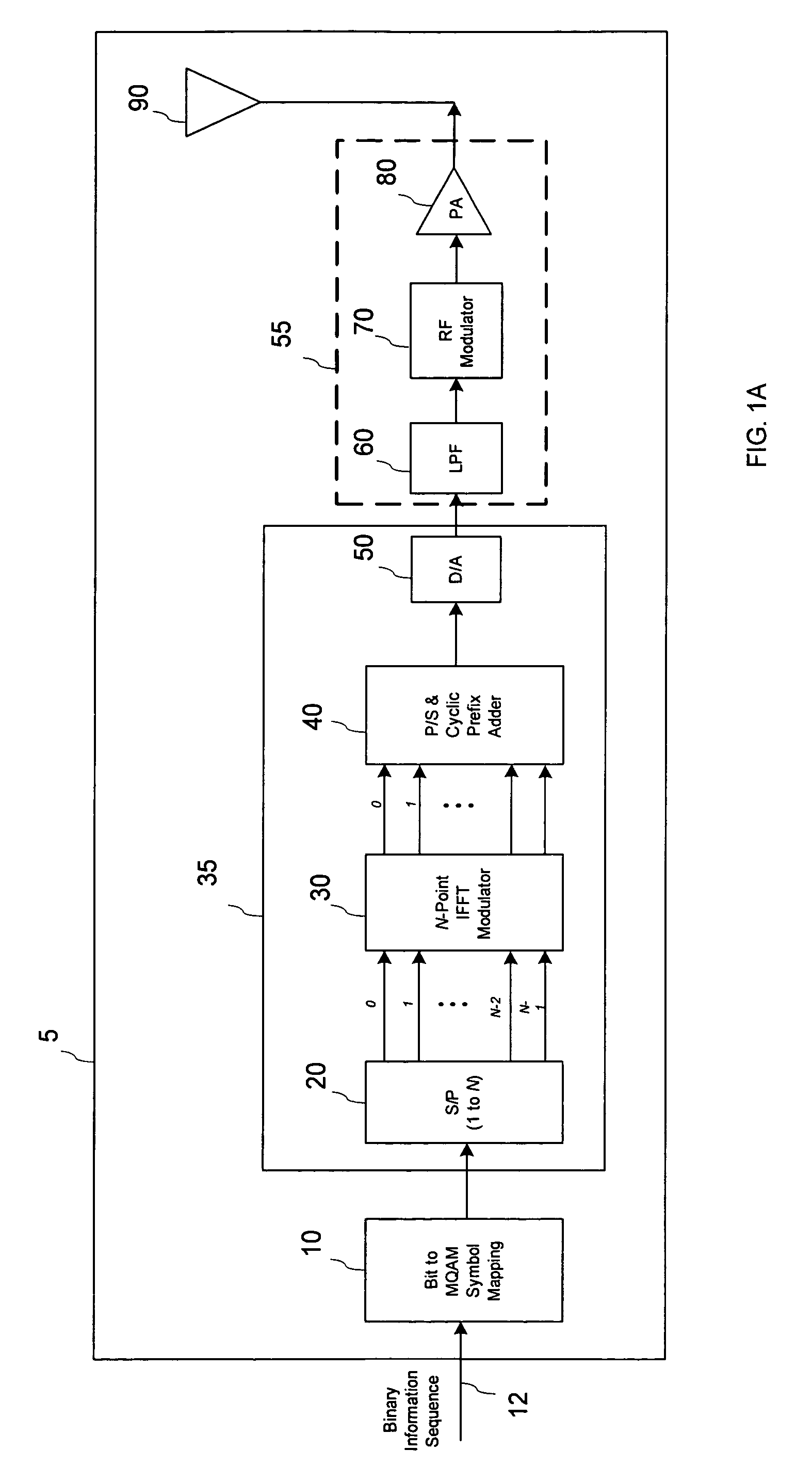

Apparatus and method for transmitting and receiving side information of a partial transmit sequence in an OFDM communication system

ActiveUS7376074B2Minimizing PAPRFrequency-division multiplexCode division multiplexNonlinear distortionData stream

An OFDM (Orthogonal Frequency Division Multiplexing) communication system that multiplexes data with a plurality of orthogonal sub-carrier frequencies, which includes a transmitter for converting a serial data stream into parallel data, and segmenting the parallel data into a plurality of blocks having a plurality of data blocks; inserting reference data having information representing a phase value and a position into which the reference symbol is inserted, into each of the segmented blocks; IFFT (Inverse Fast Fourier Transform)-transforming the respective blocks into time-based signals where sub-carrier frequencies are separately assigned to the data blocks; and determining phase factors of the IFFT-transformed time-based signals to reduce a peak-to-average power ratio (PAPR) where non-linear distortion occurs due to coincidence of phases of the data blocks IFFT-transformed with the sub-carrier frequencies, and phase-rotating the IFFT-transformed signals according to the determined phase factors before transmission.

Owner:SAMSUNG ELECTRONICS CO LTD

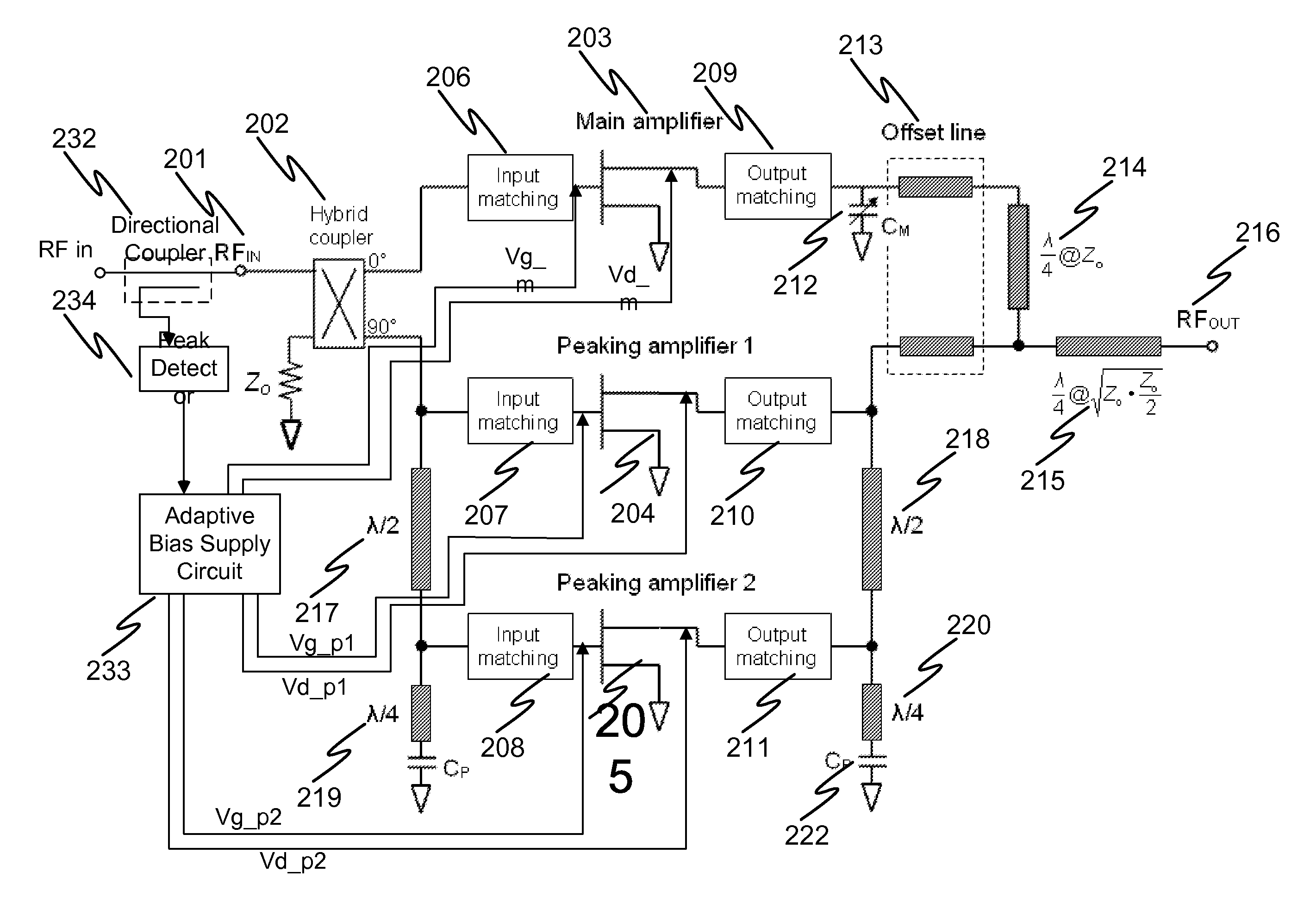

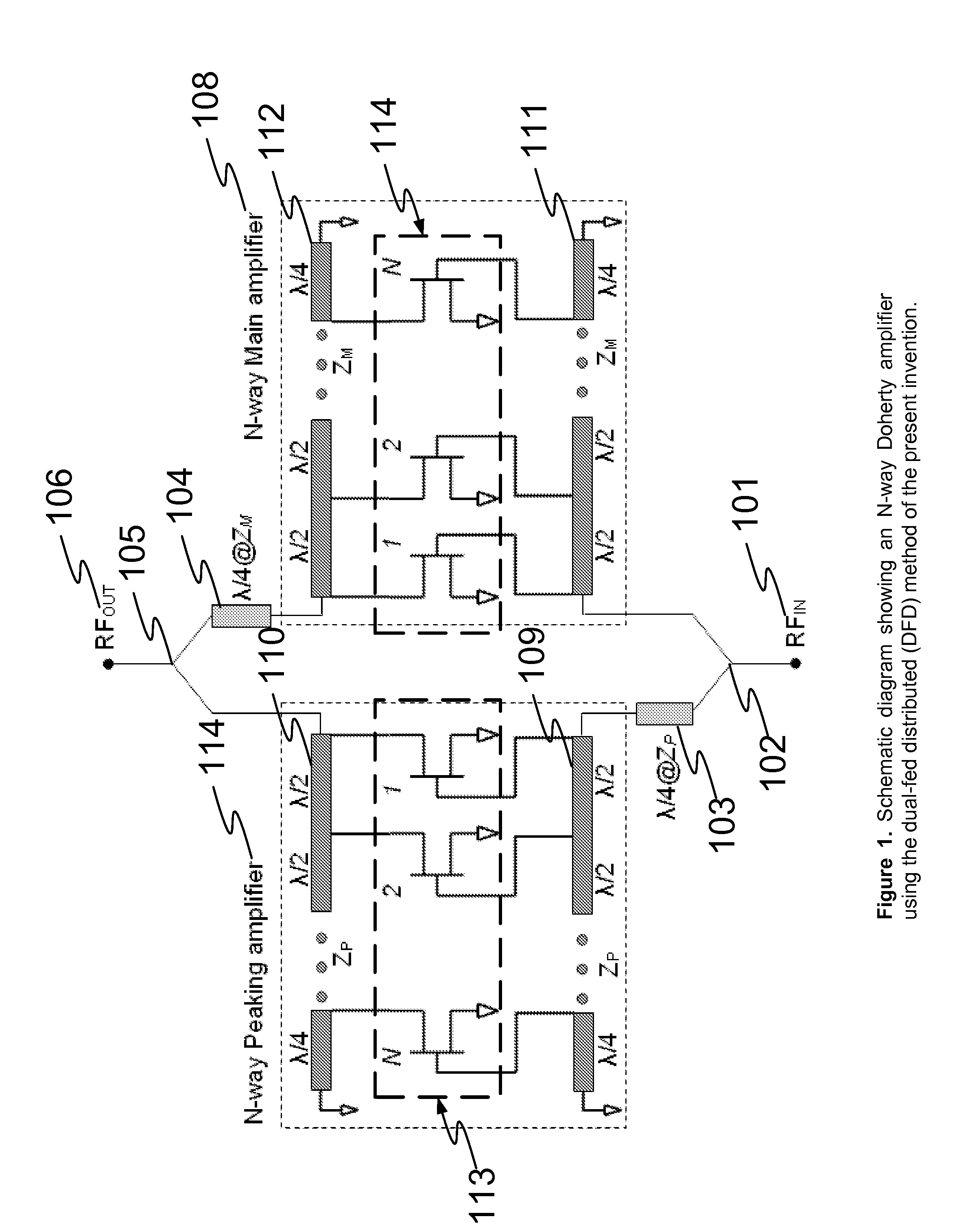

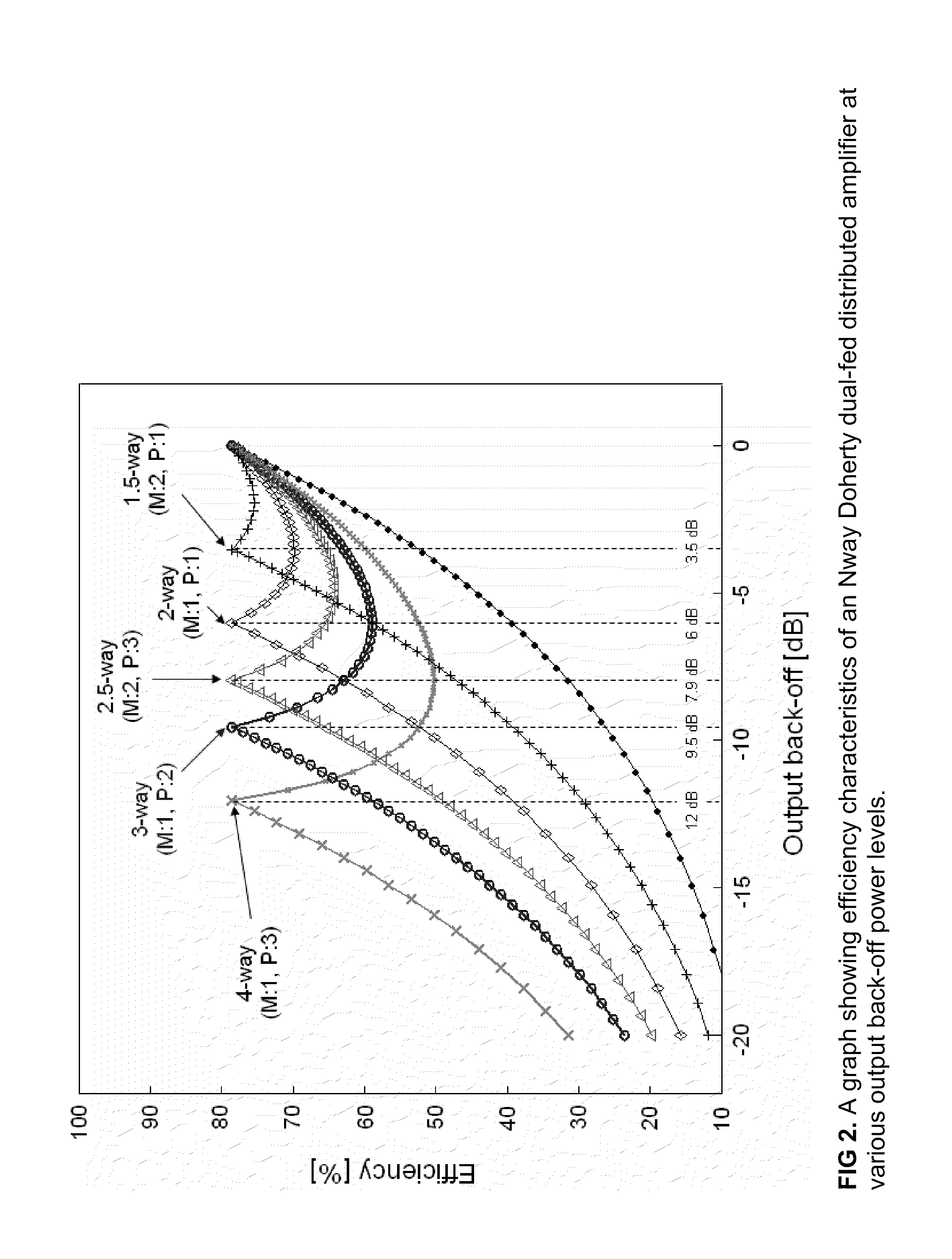

N-way Doherty distributed power amplifier with power tracking

ActiveUS8274332B2Improve performanceIncrease productionNegative-feedback-circuit arrangementsAmplifier combinationsAdaptive biasMultiplexing

Owner:DALI SYST LTD

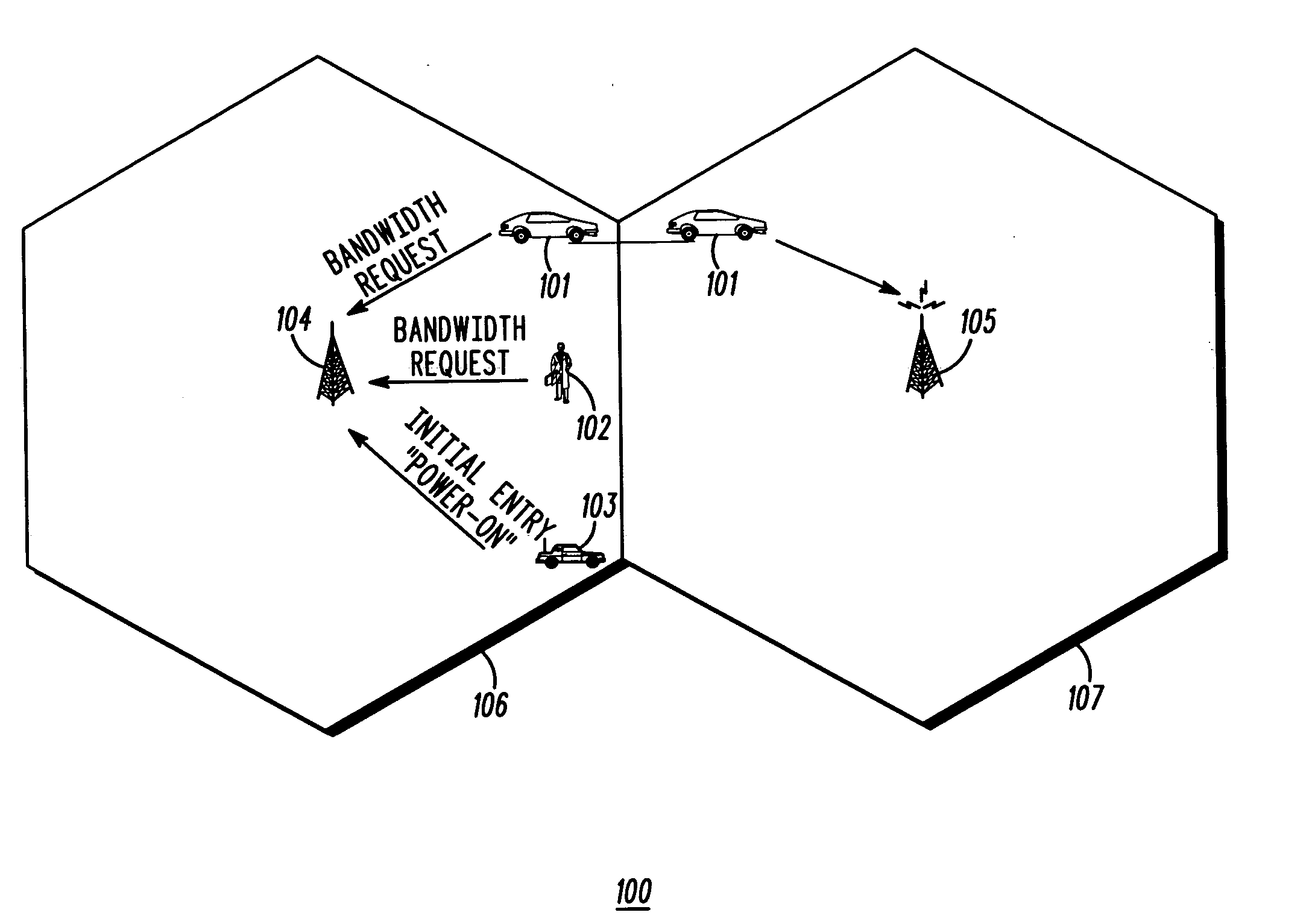

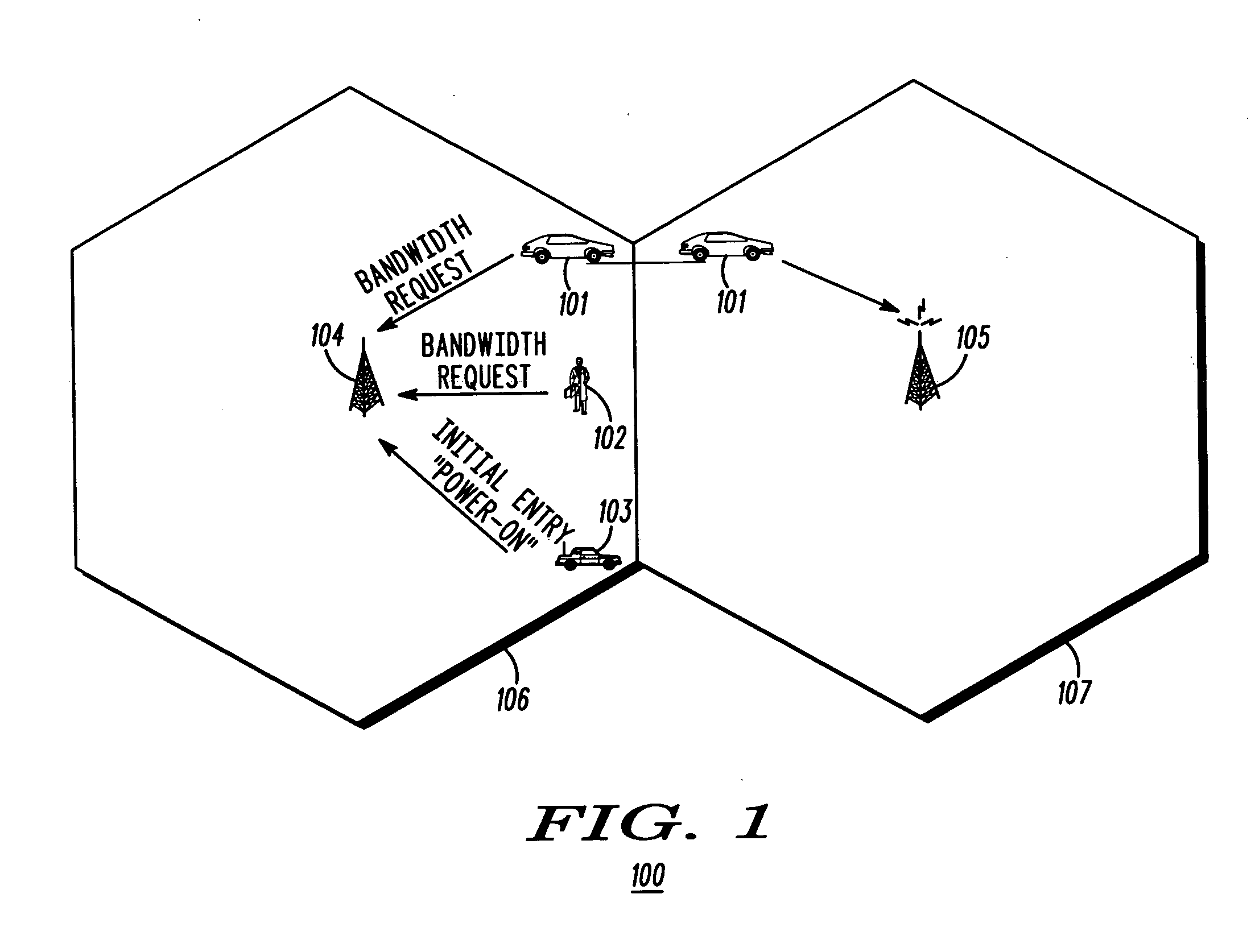

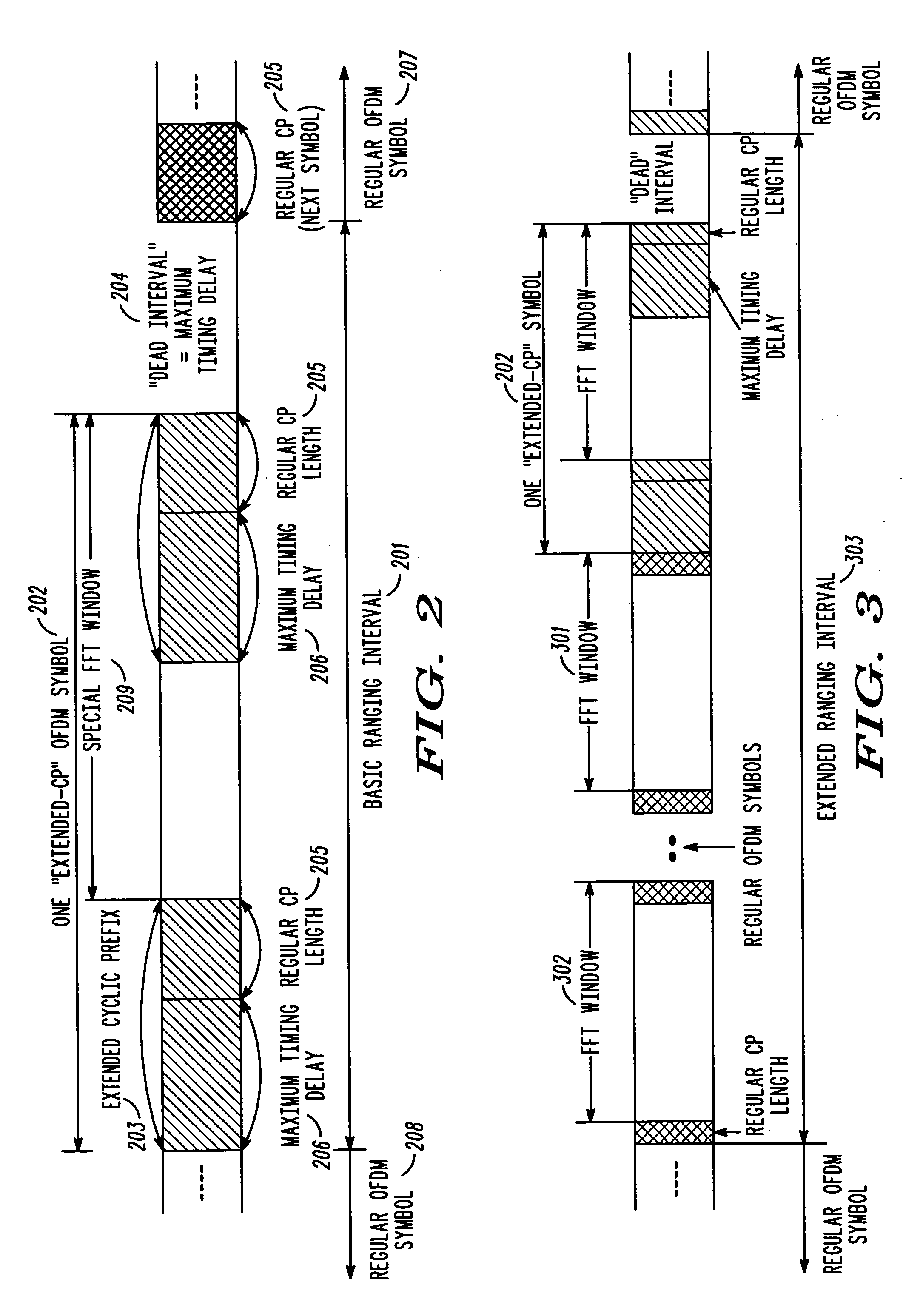

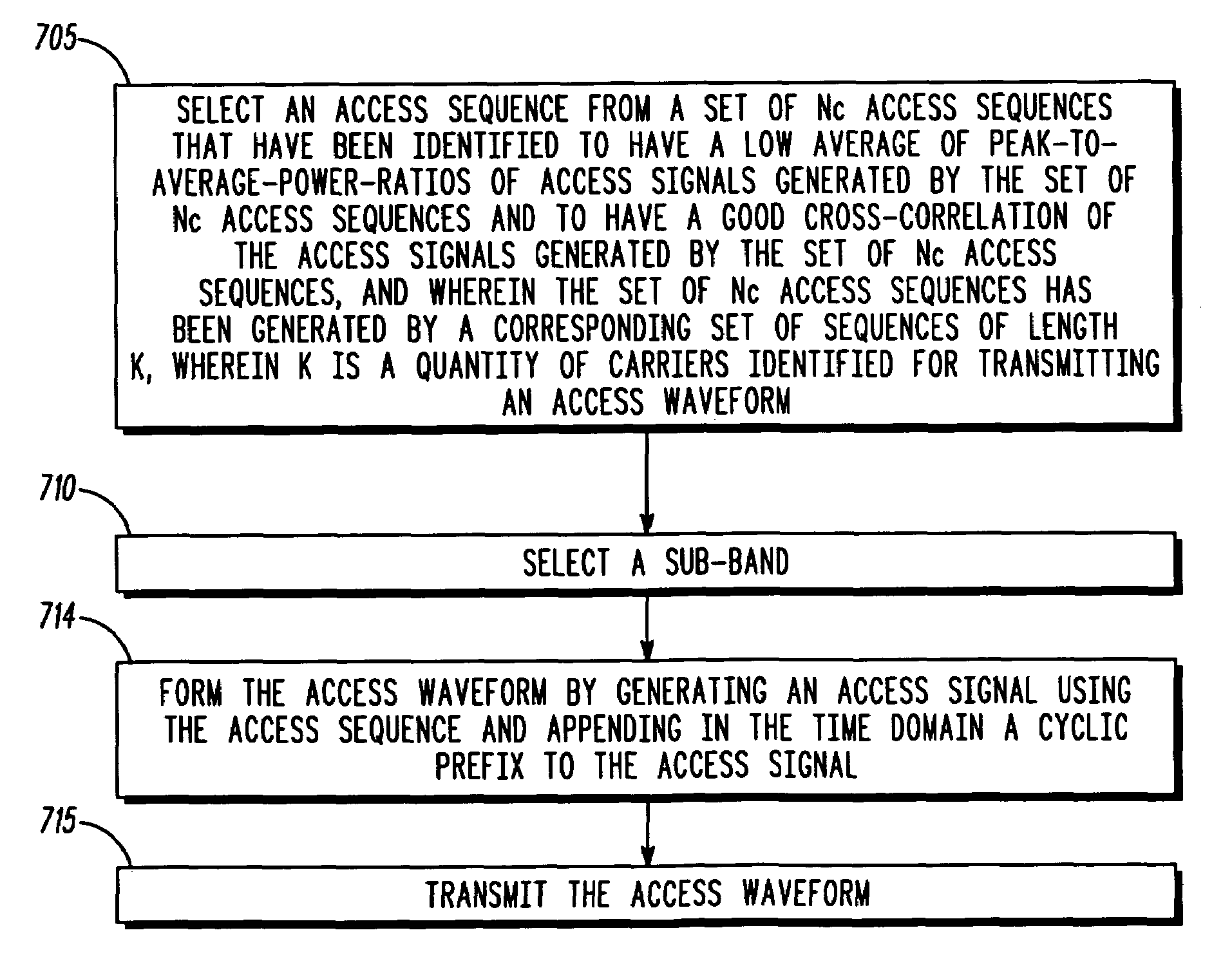

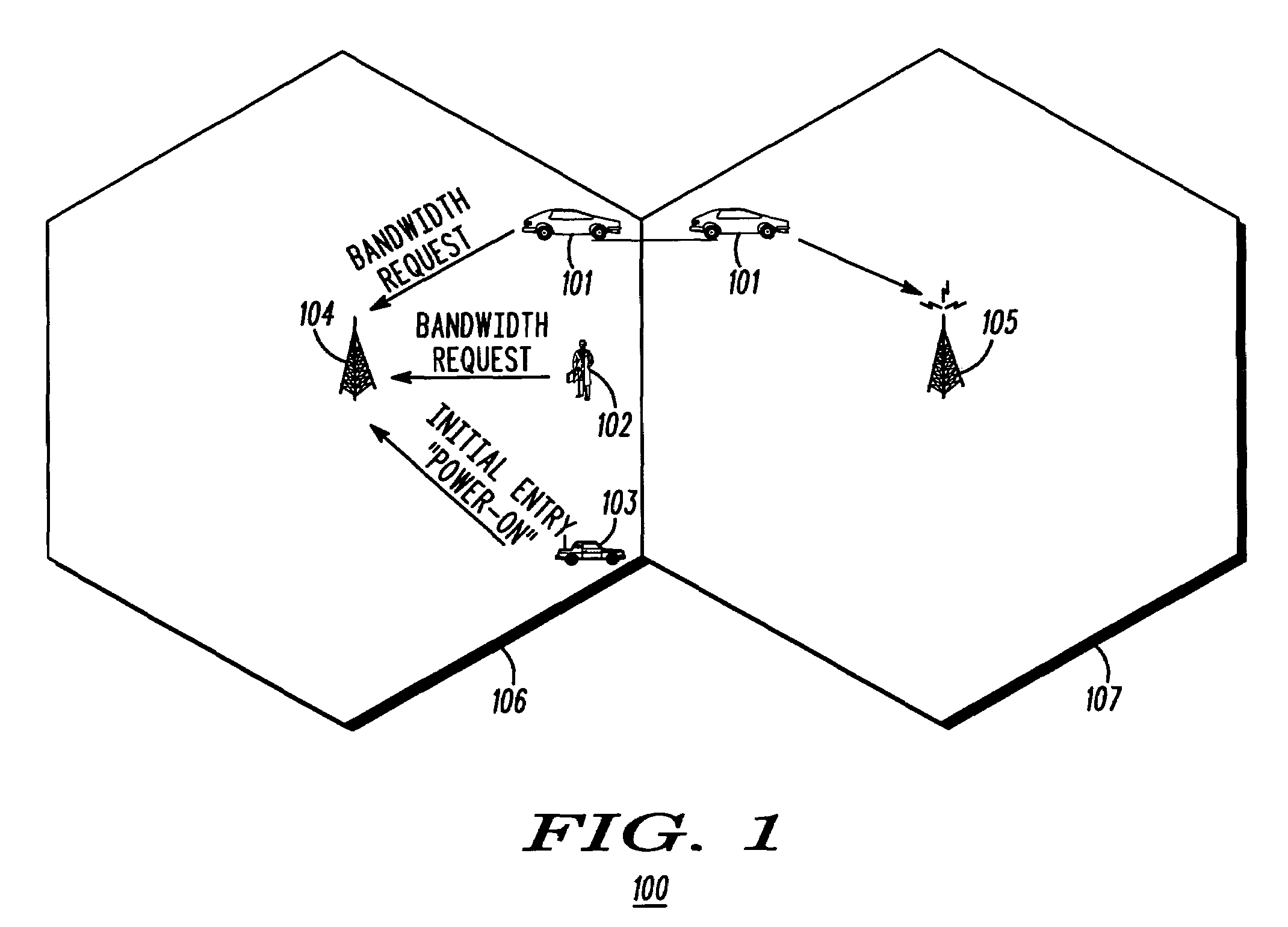

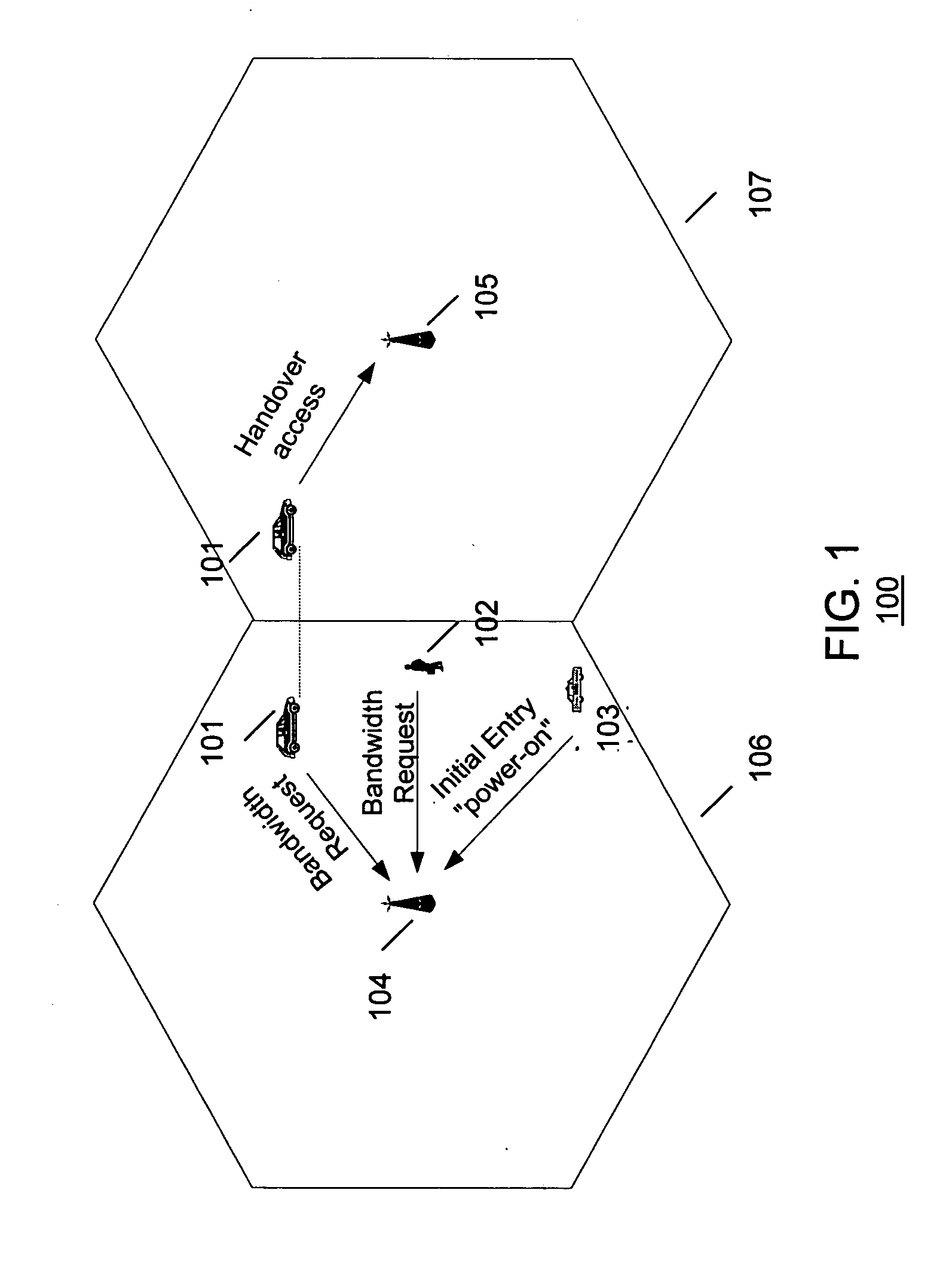

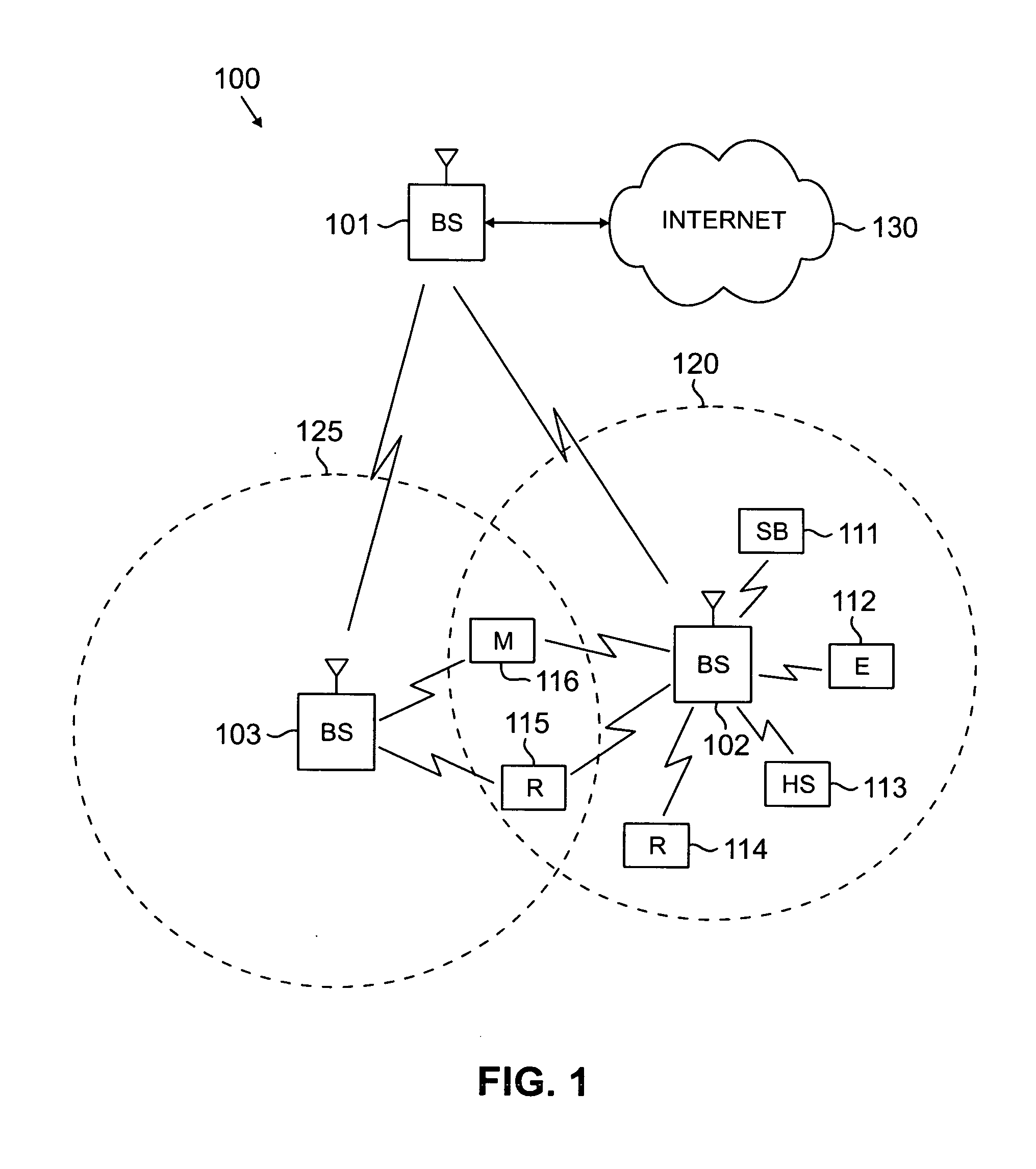

Method and apparatus for accessing a wireless communication system

Access to a wireless communication system (100) by a subscriber station (101-103) is facilitated by selecting (705) an access sequence from a set of sequences that have been identified to have a low average of peak-to-average-power-ratios of access signals generated by the set of sequences and also based on a good cross-correlation of the access signals; forming (714) the access waveform by generating an access signal using the access sequence and appending in the time domain a cyclic prefix to the access signal; and transmitting (715) the access waveform. In some implementations, the access waveform is cyclically shifted (820) before the cyclic prefix is appended, and in some implementations, the signal is transmitted (710, 810) in a randomly selected sub-band of an access interval.

Owner:GOOGLE TECH HLDG LLC

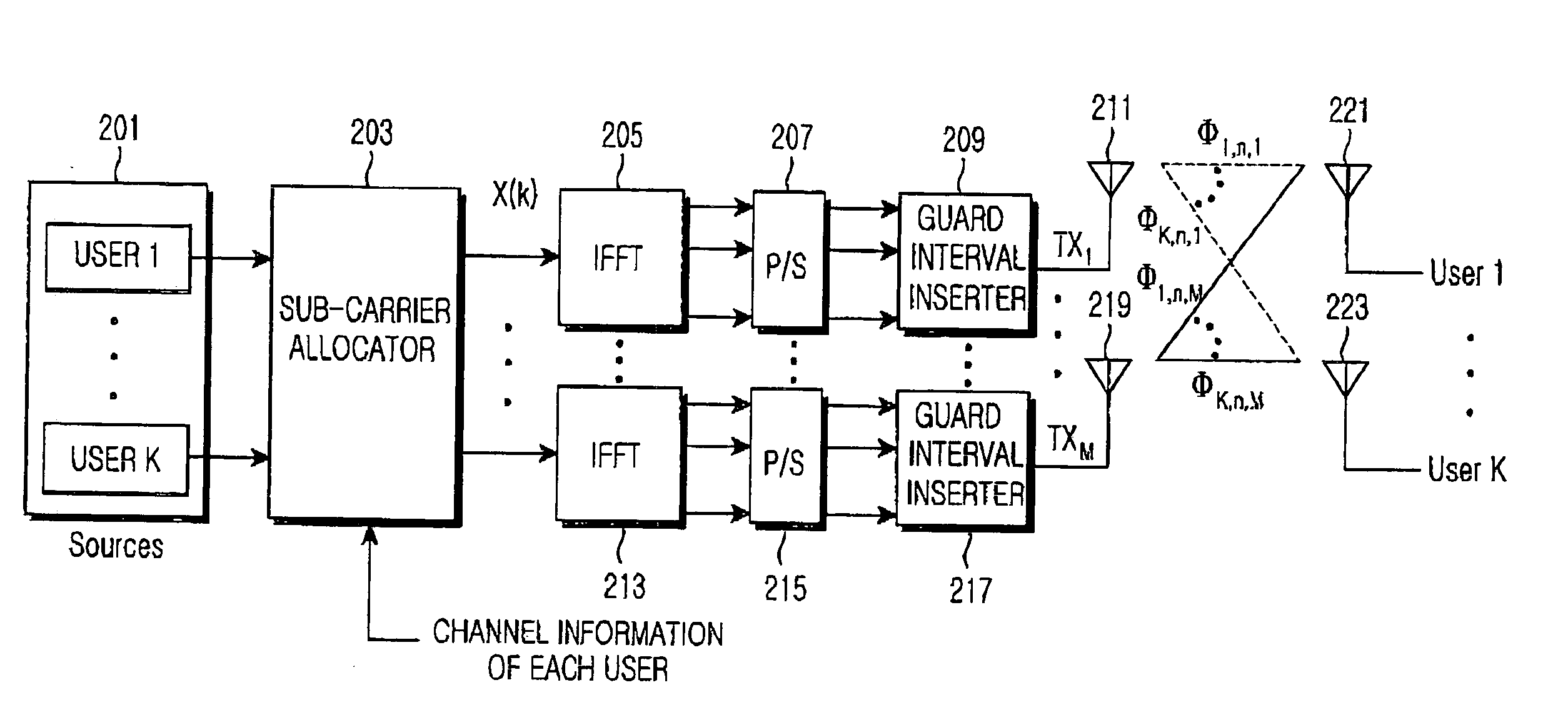

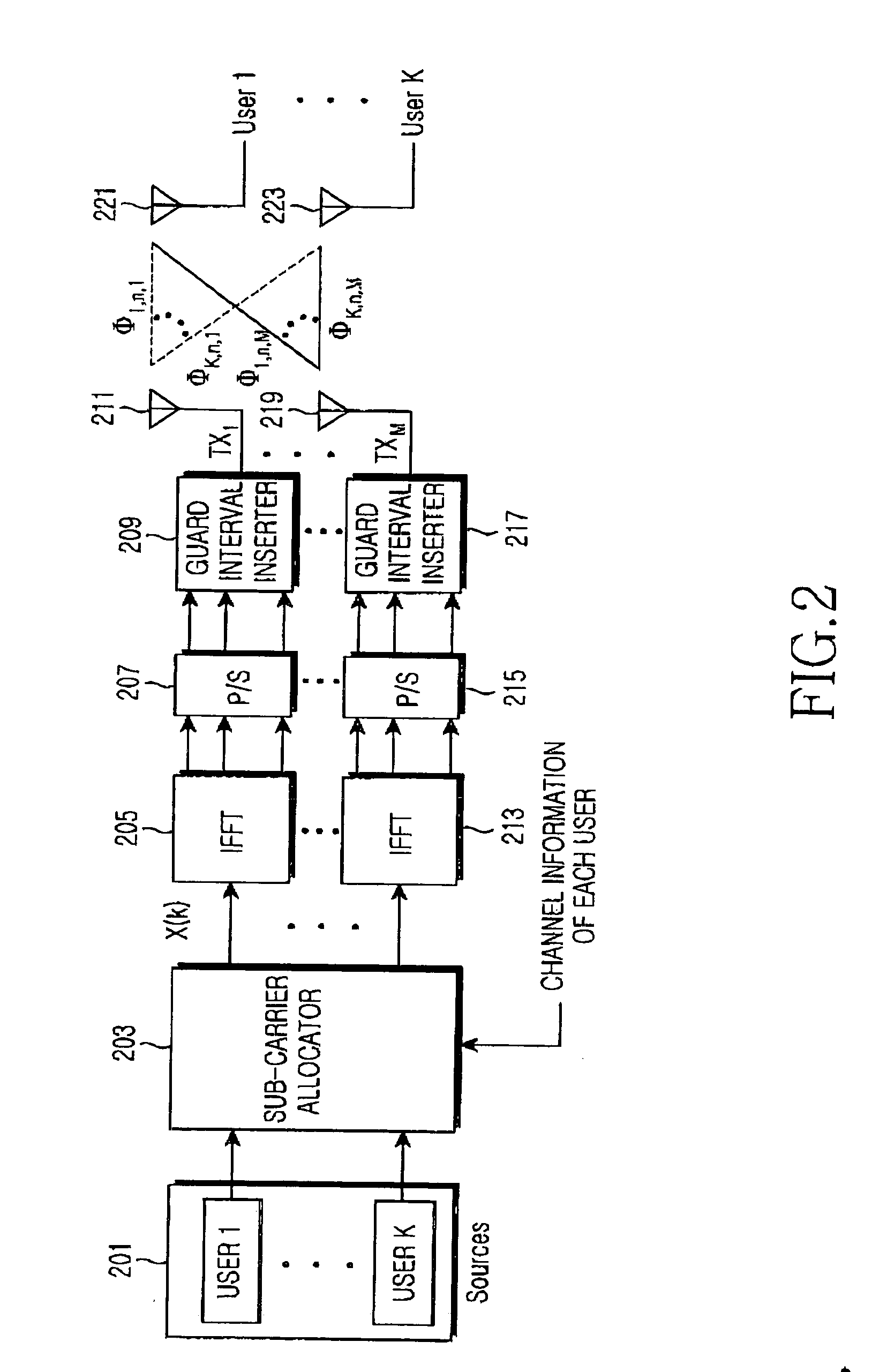

Apparatus and method for sub-carrier allocation in a multiple-input and multiple-output (MIMO) orthogonal frequency division multiplexing (OFDM) communication system

ActiveUS20050099937A1Effective distributionEnergy efficient ICTCriteria allocationQuality of serviceCarrier signal

An apparatus and a method capable of effectively allocating sub-carriers for a plurality of users and transmitting the sub-carriers to users through multiple antennas in an orthogonal frequency division multiplexing (OFDMA) mobile communication system are provided. A sub-carrier allocation method reduces transmission power by taking a desired bit rate and power budget into consideration. The sub-carriers are optimally allocated to each antenna, so that peak to average power ratio (PARR) is reduced and Quality of Service (QoS) is improved. The apparatus and the method are adaptable for multi-users and obtain space diversity gain through multiple antennas.

Owner:SAMSUNG ELECTRONICS CO LTD

Method and apparatus for accessing a wireless communication system

Owner:GOOGLE TECHNOLOGY HOLDINGS LLC

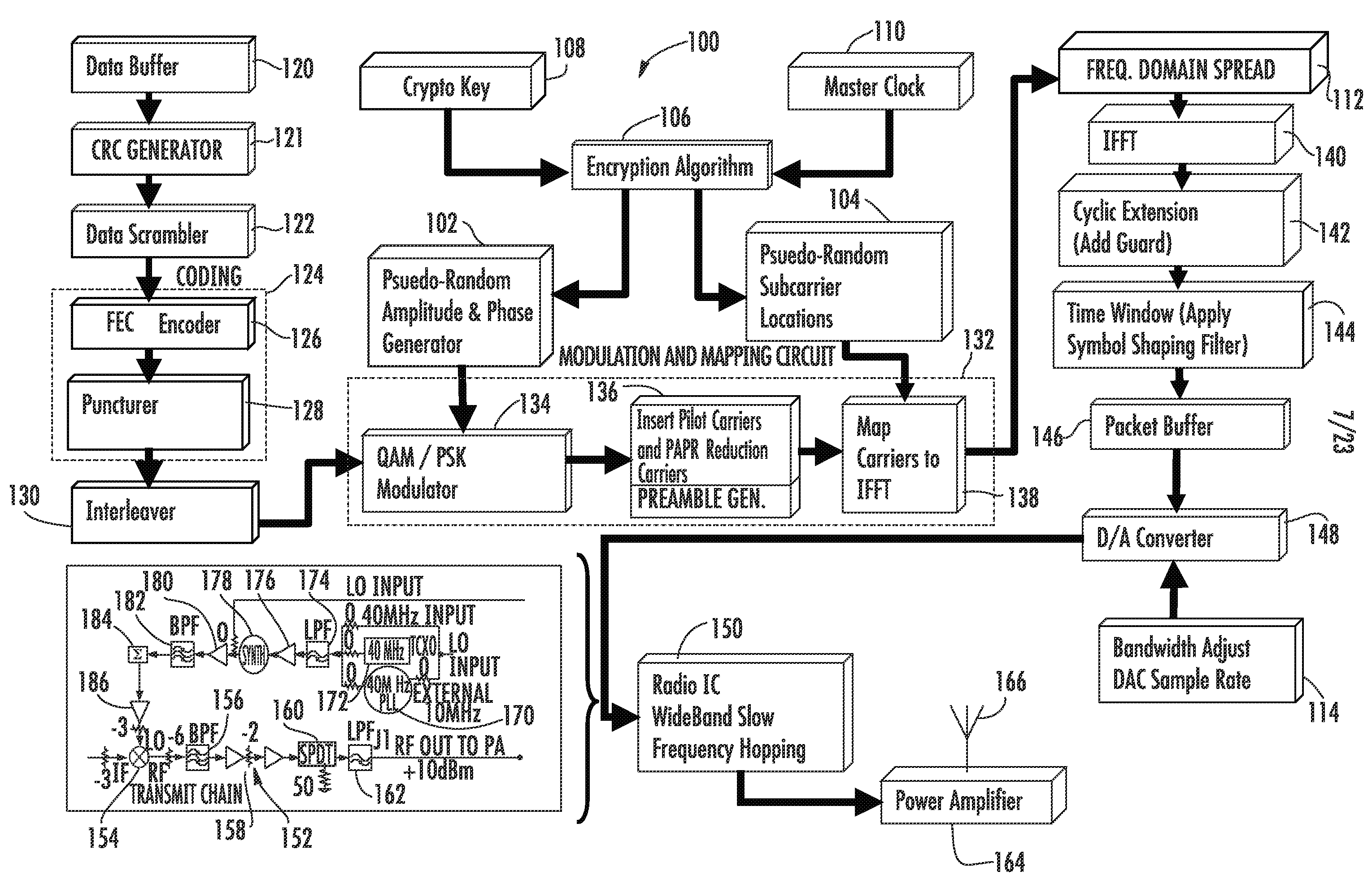

Orthogonal frequency division multiplexing (OFDM) communications device and method that incorporates low papr preamble with circuit for measuring frequency response of the communications channel

ActiveUS20100080312A1Diversity/multi-antenna systemsSecret communicationFrequency spectrumFrequency-division multiplexing

A communications device includes a demapping and demodulation circuit and processes an OFDM communications signal that includes modulated subcarriers carrying communications data forming a data payload and modulated subcarriers carrying a training sequence forming a preamble. Those OFDM subcarriers carrying the training sequence have a sample for each subcarrier at a frequency bin using evenly spaced, equal amplitude subcarriers that have a set phase of each sinusoid to a specific angle with quadratic phase to form a low peak-to-average power ratio (PAPR) preamble with about a PAPR value of 2.6 decibels (dB). A channel estimate circuit is operative for measuring fluctuations within a flat-top spectrum of the received OFDM communications signal corresponding to the preamble to reflect the frequency response of the communications channel.

Owner:SMARTSKY NETWORKS

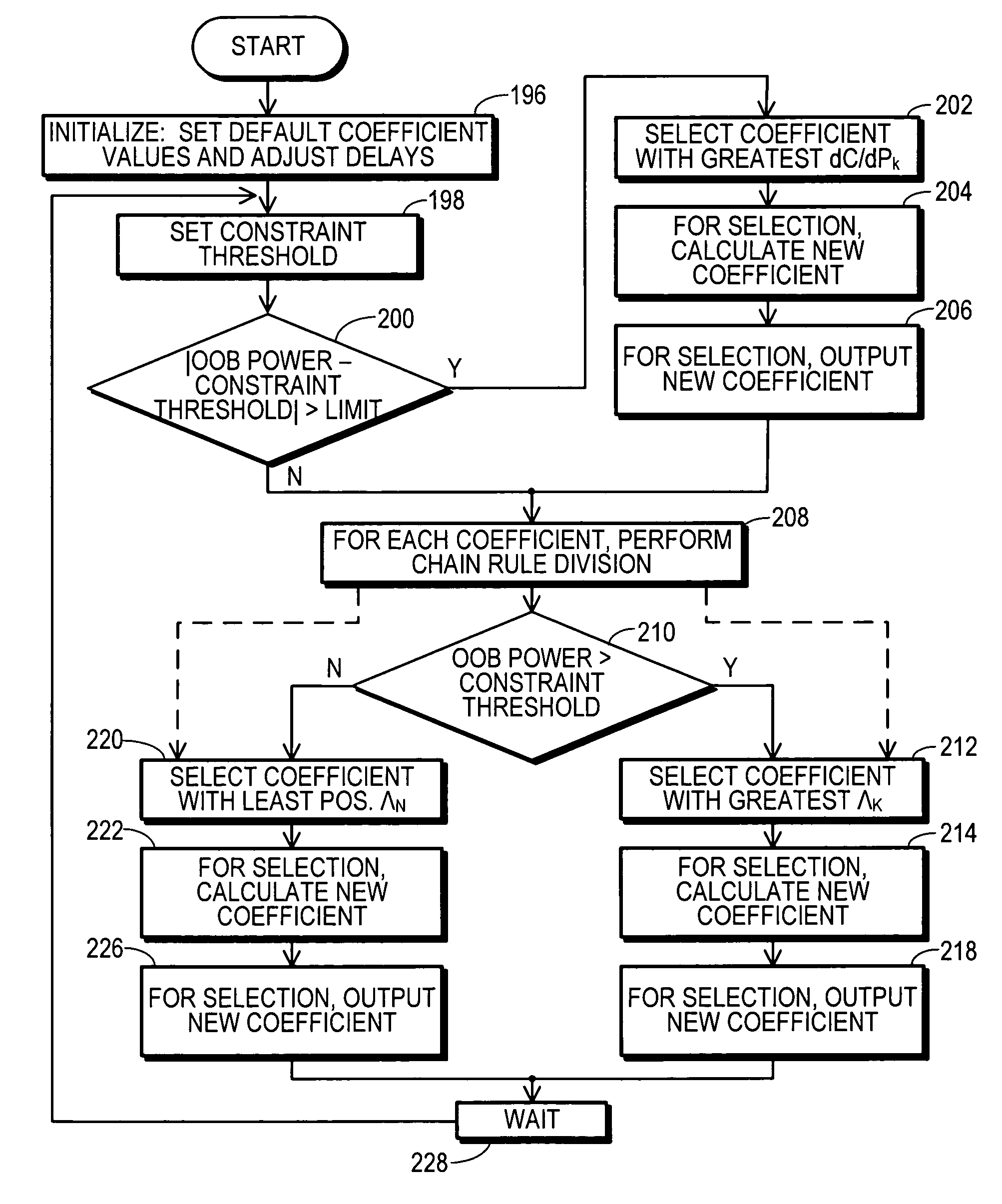

RF transmitter with variably biased RF power amplifier and method therefor

InactiveUS20070281635A1More powerSimultaneous amplitude and angle modulationResonant long antennasPeak valueWide band

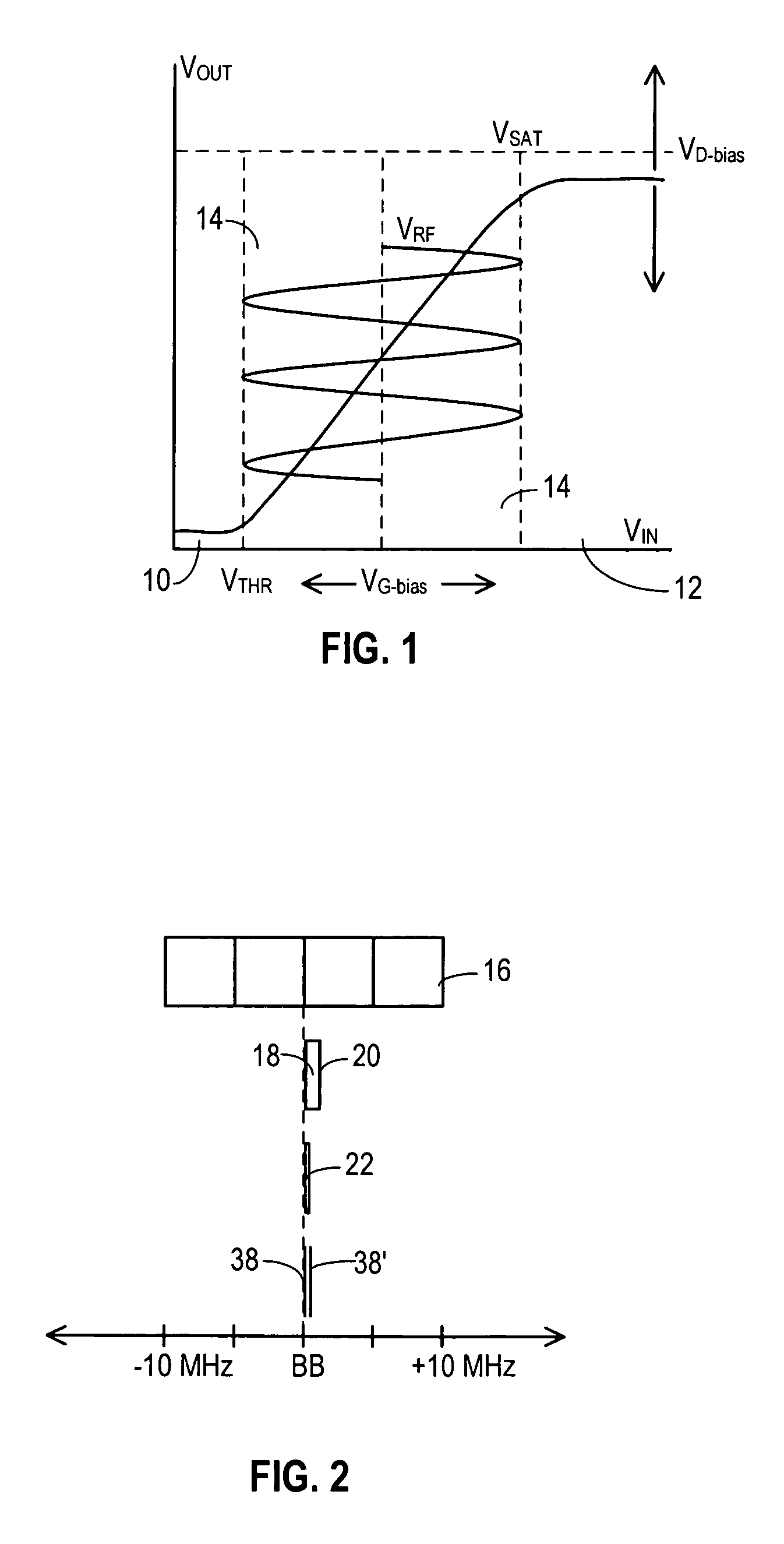

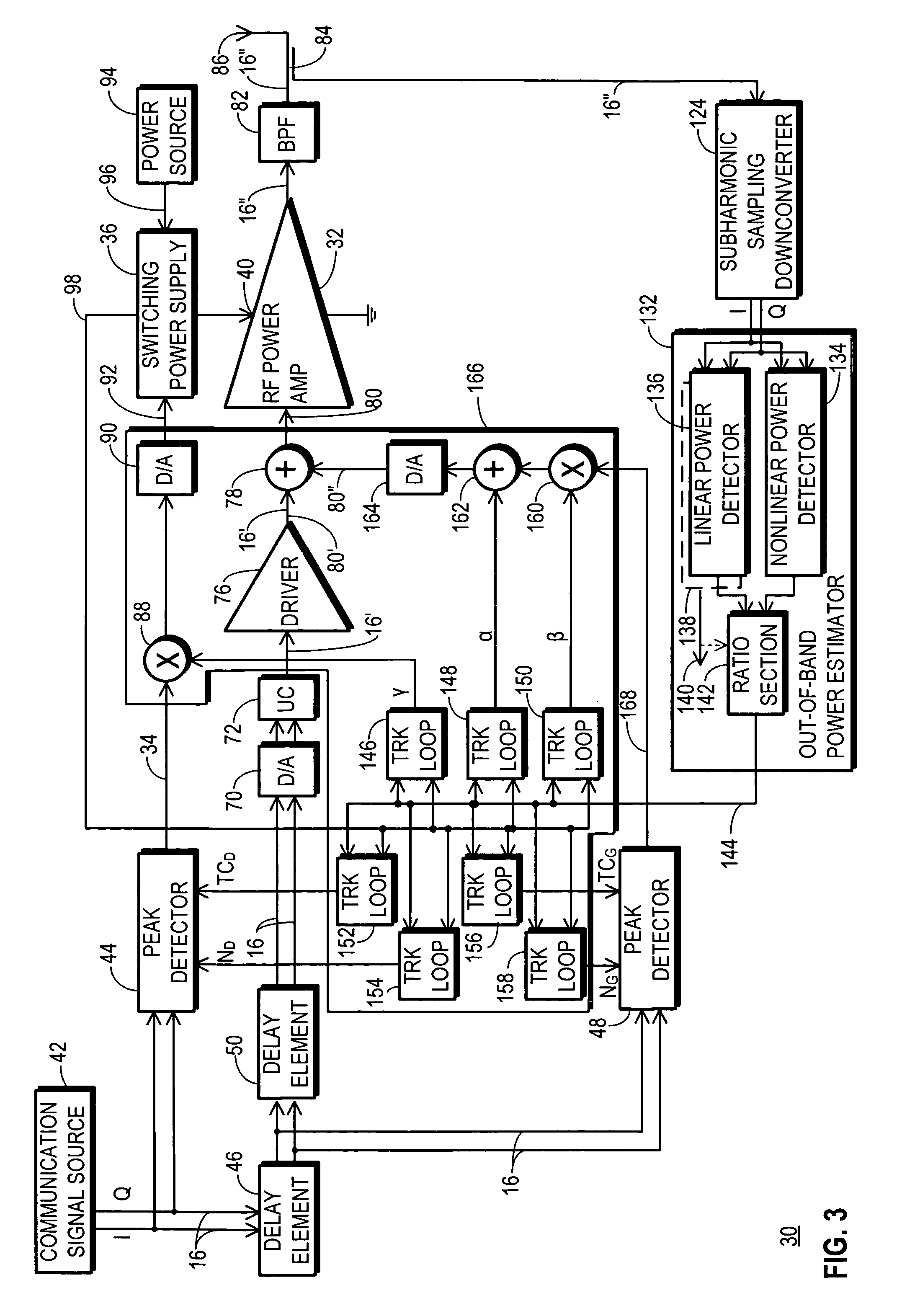

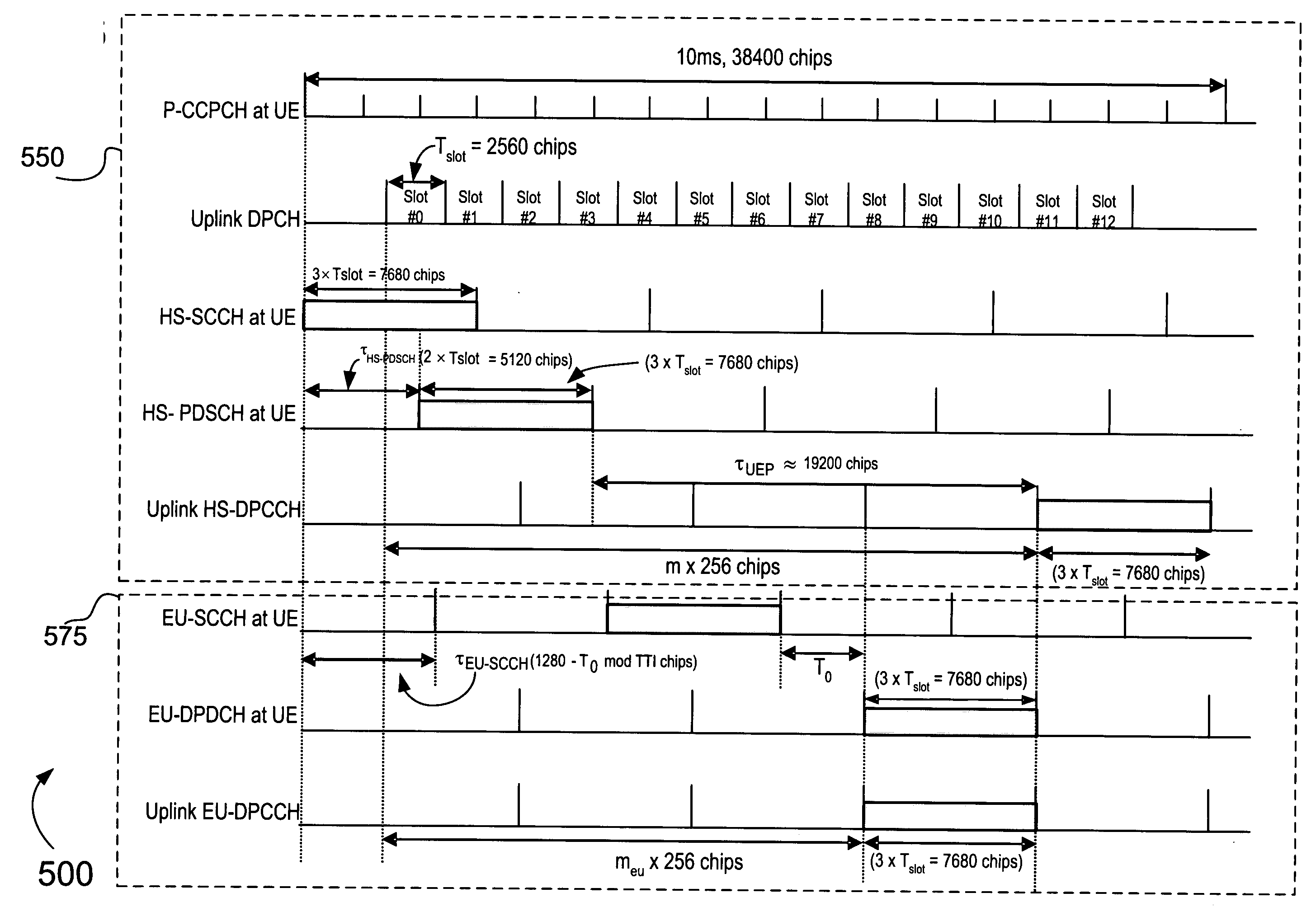

An RF transmitter (30) includes an RF power amplifier (32) for which the power input bias voltage (40) and signal input bias voltage (80) are controlled within feedback loops. A peak detector (44) generates a lowered-spectrum, peak-tracking signal (34) that follows the largest amplitude peaks of a wide bandwidth communication signal (16) but exhibits a lower bandwidth. This signal (34) is scaled in response to the operation of a drain bias tracking loop (146) then used to control a switching power supply (36) that generates the power input bias voltage. The tracking loop (146) is responsive to out-of-band power detected in a portion of the amplified RF communication signal (16″). A ratio of out-of-band power (128) to in-band power (126) is manipulated in the tracking loop (146) so that the power input bias voltage is modulated in a way that holds the out-of-band power at a desired predetermined level.

Owner:CRESTCOM INC

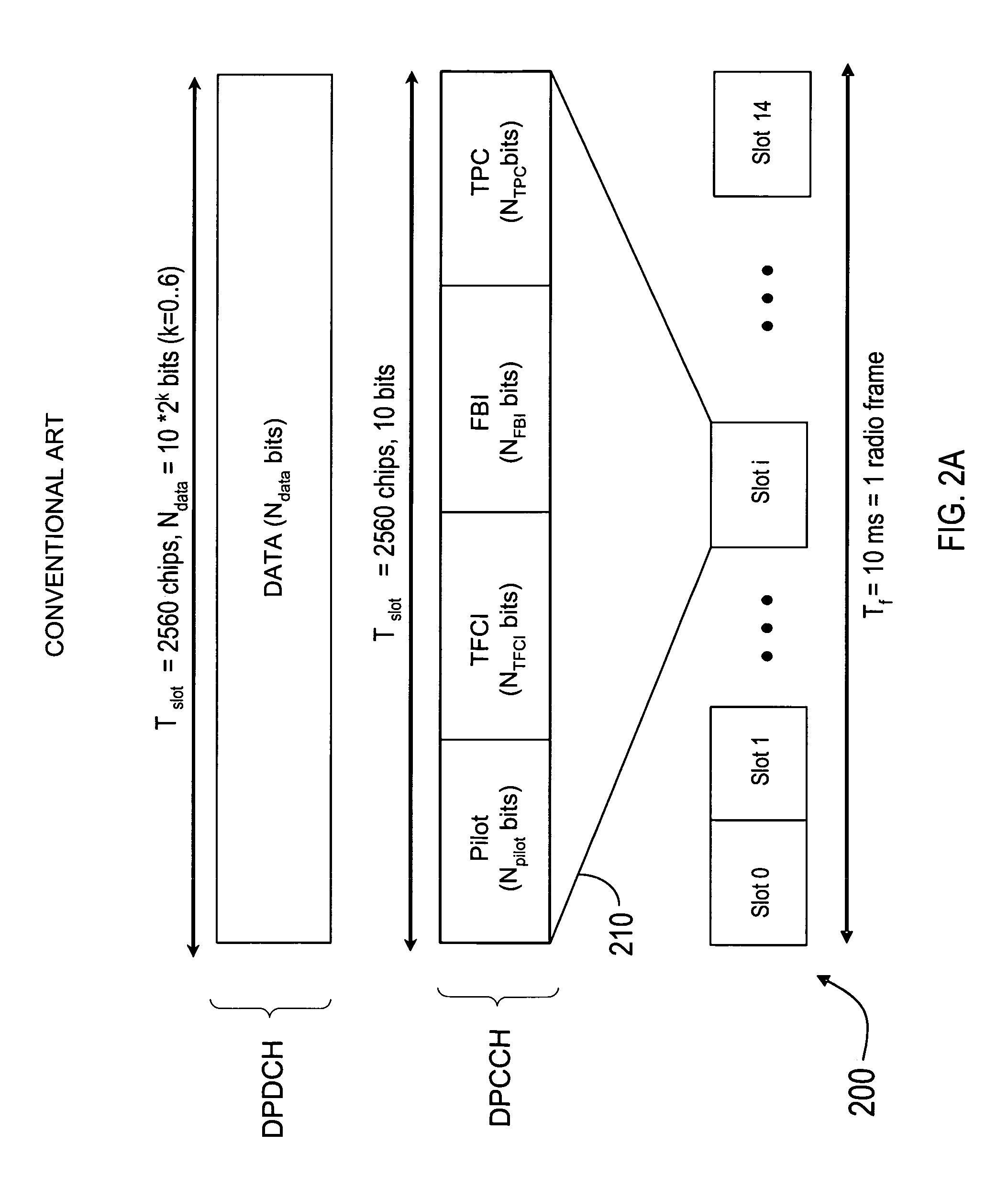

Method of aligning physical channels for uplink transmission

ActiveUS20050068990A1Increase in peak-to-average power ratio my be avoided and/or reducedTime-division multiplexCode division multiplexUplink transmissionEngineering

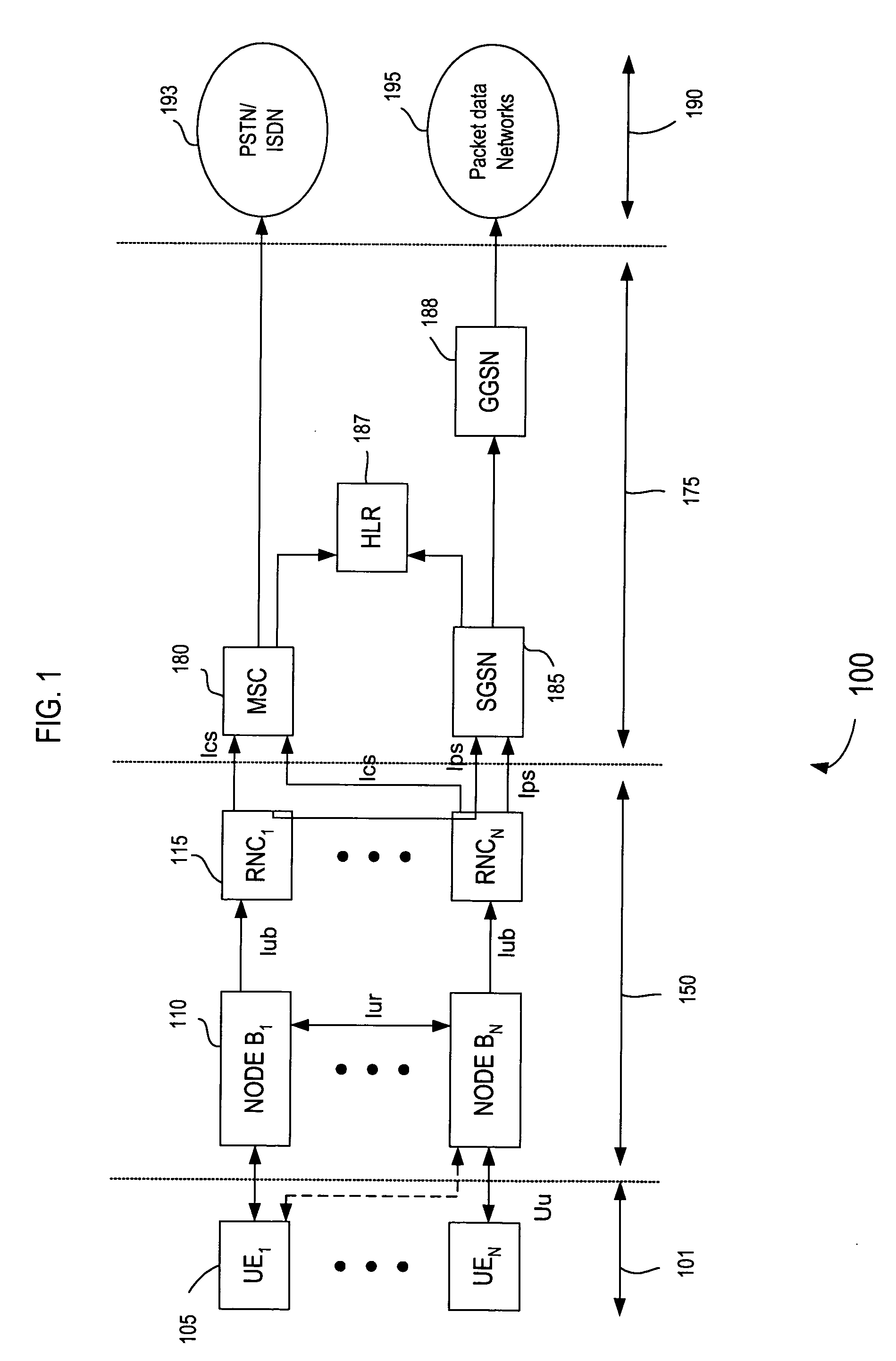

In a method for aligning a plurality of physical channels for uplink transmission two or more physical channels may be aligned based on a timing offset so that the two channels are transmitted in the uplink at a time instant different than a time of uplink transmission for a third physical channel. Accordingly, the two physical channels may be code multiplexed with additional physical channels other than the third physical channel to generate a code-multiplexed signal to be used for uplink transmission. The timing offset information may be assigned to the user from a base station, for example, in order to align the two physical channels. Accordingly, an increase in peak-to-average power ratio my be avoided and / or reduced if multiplexing the two physical channels with other physical channels for uplink transmission.

Owner:ALCATEL-LUCENT USA INC

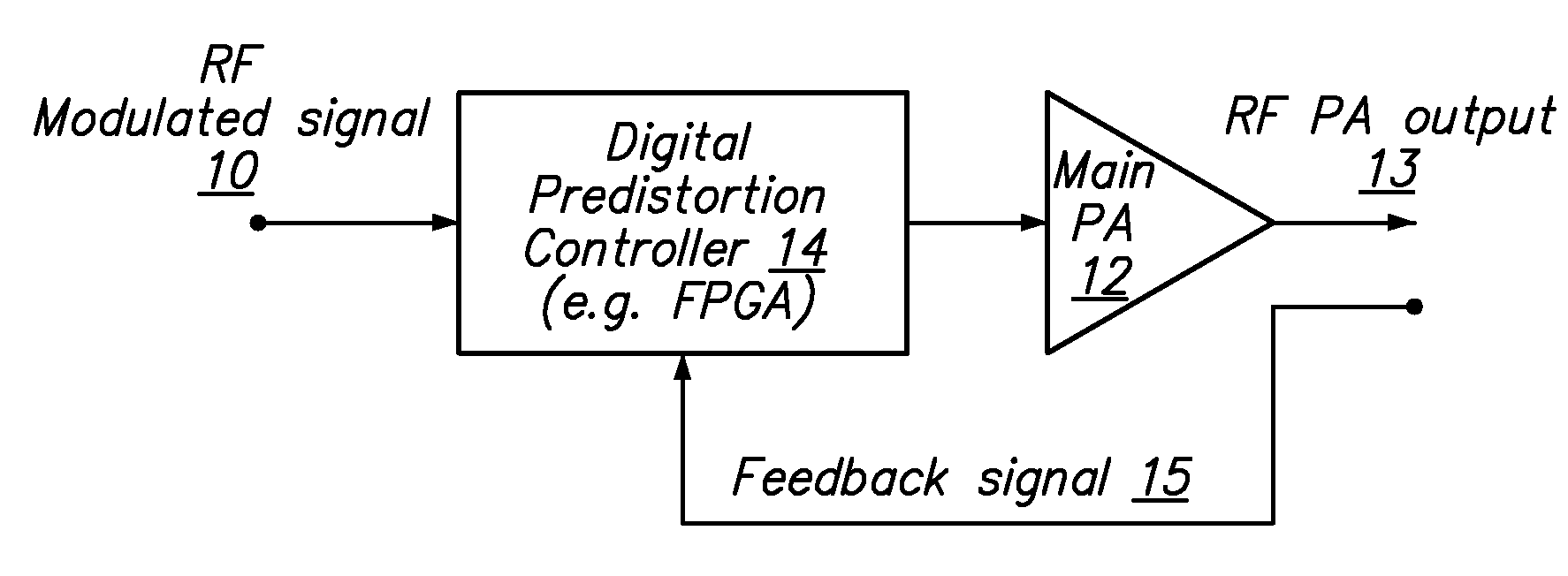

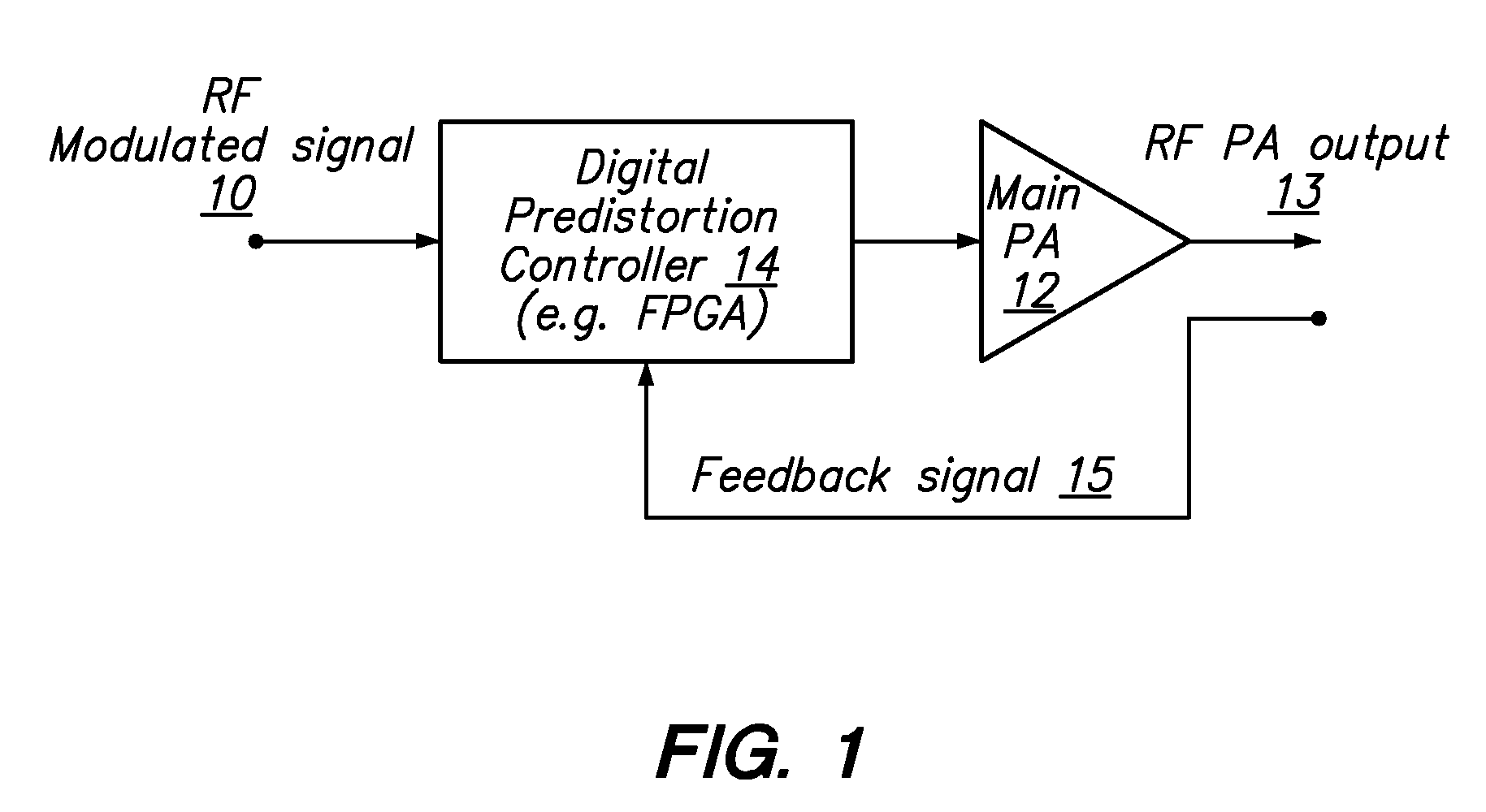

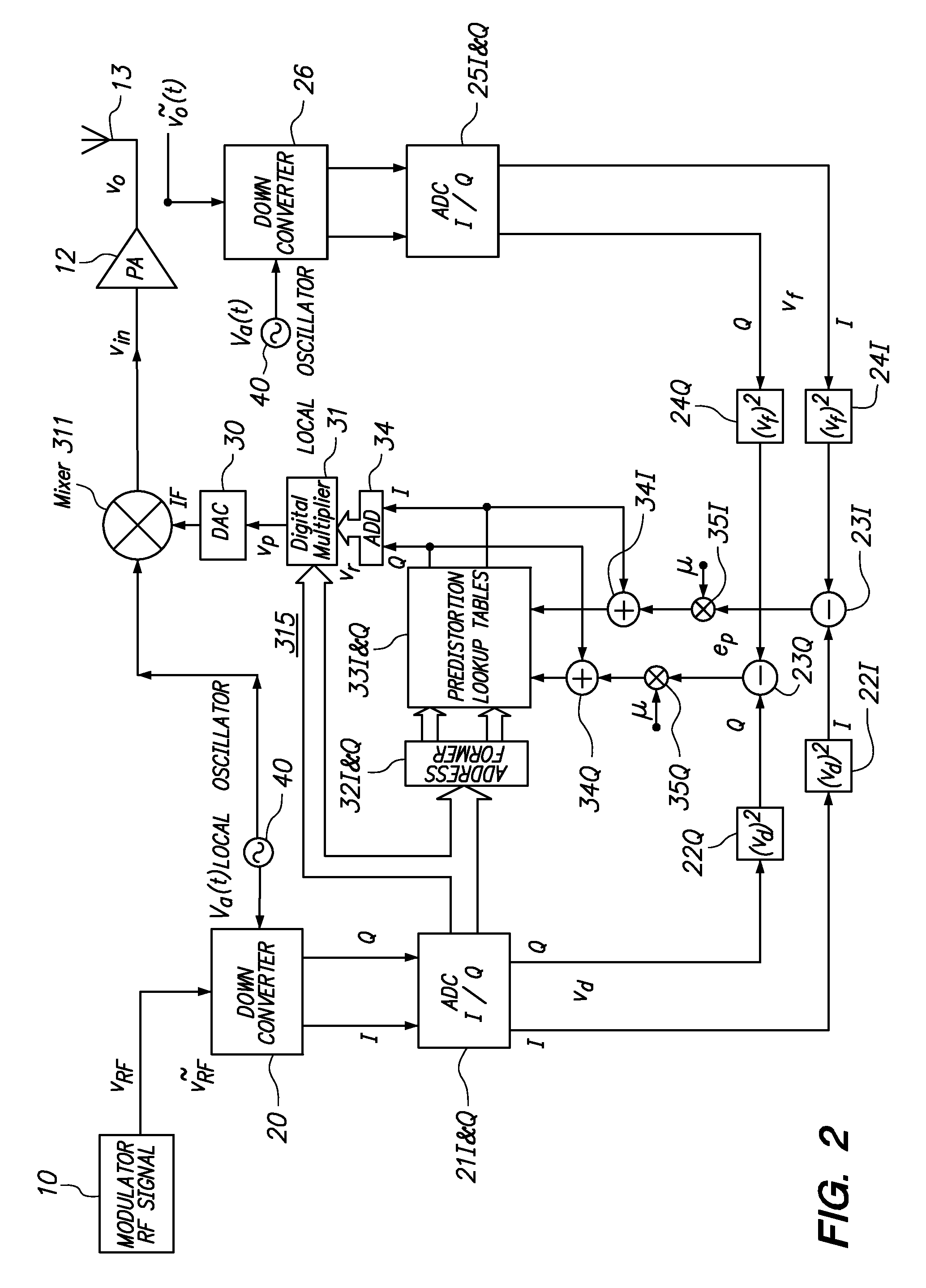

Digital Hybrid Mode Power Amplifier System

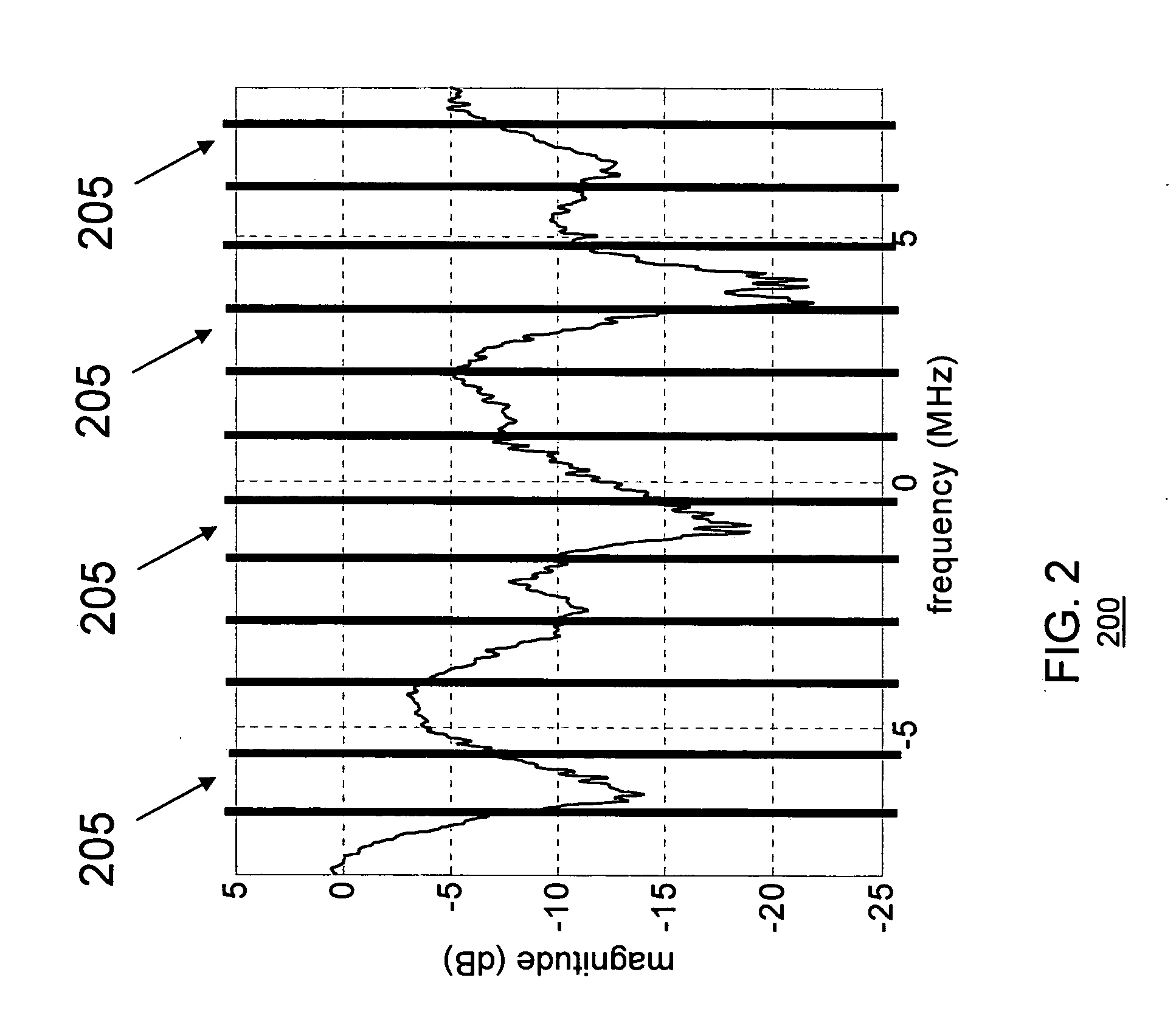

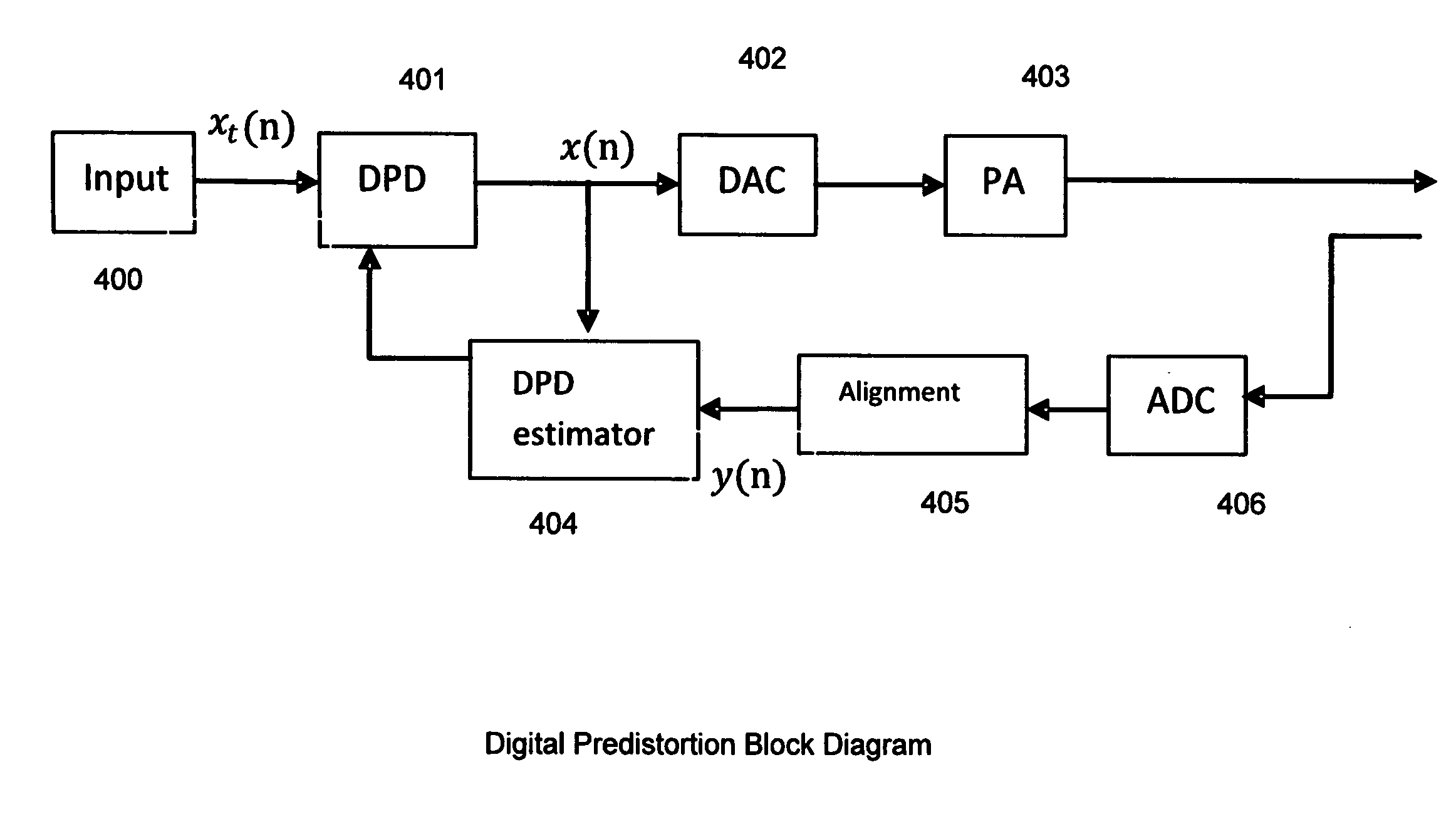

InactiveUS20080265996A1High performance and cost-effectiveImprove linearityAmplifier modifications to reduce non-linear distortionHigh frequency amplifiersPeak valueMulti carrier

A RF-digital hybrid mode power amplifier system for achieving high efficiency and high linearity in wideband communication systems is disclosed. The present invention is based on the method of adaptive digital predistortion to linearize a power amplifier in the RF domain. The power amplifier characteristics such as variation of linearity and asymmetric distortion of the amplifier output signal are monitored by the narrowband feedback path and controlled by the adaptation algorithm in a digital module. Therefore, the present invention could compensate the nonlinearities as well as memory effects of the power amplifier systems and also improve performances, in terms of power added efficiency, adjacent channel leakage ratio and peak-to-average power ratio. The present disclosure enables a power amplifier system to be field reconfigurable and support multi-modulation schemes (modulation agnostic), multi-carriers and multi-channels. As a result, the digital hybrid mode power amplifier system is particularly suitable for wireless transmission systems, such as base-stations, repeaters, and indoor signal coverage systems, where baseband I-Q signal information is not readily available.

Owner:DALI SYST LTD

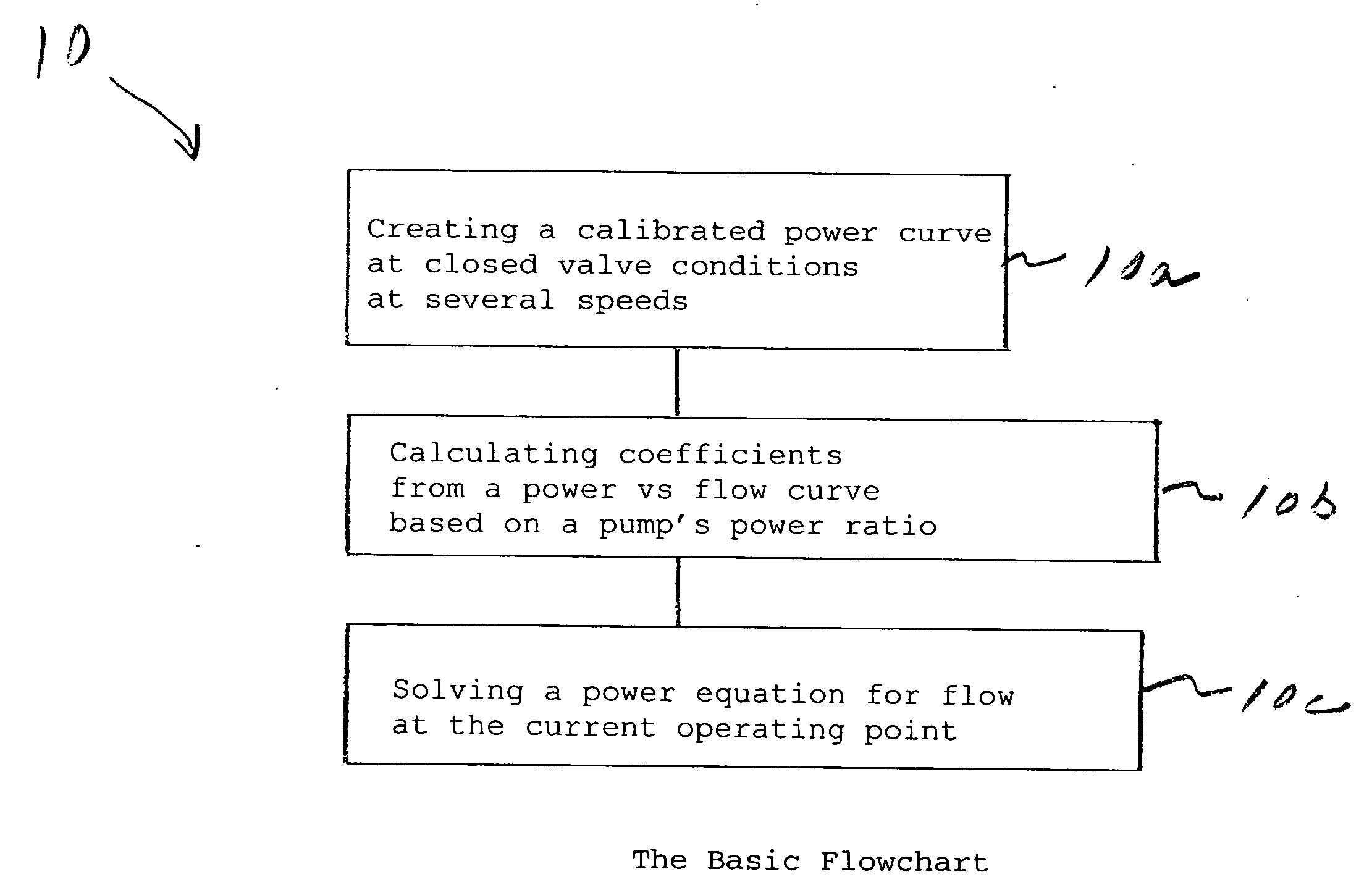

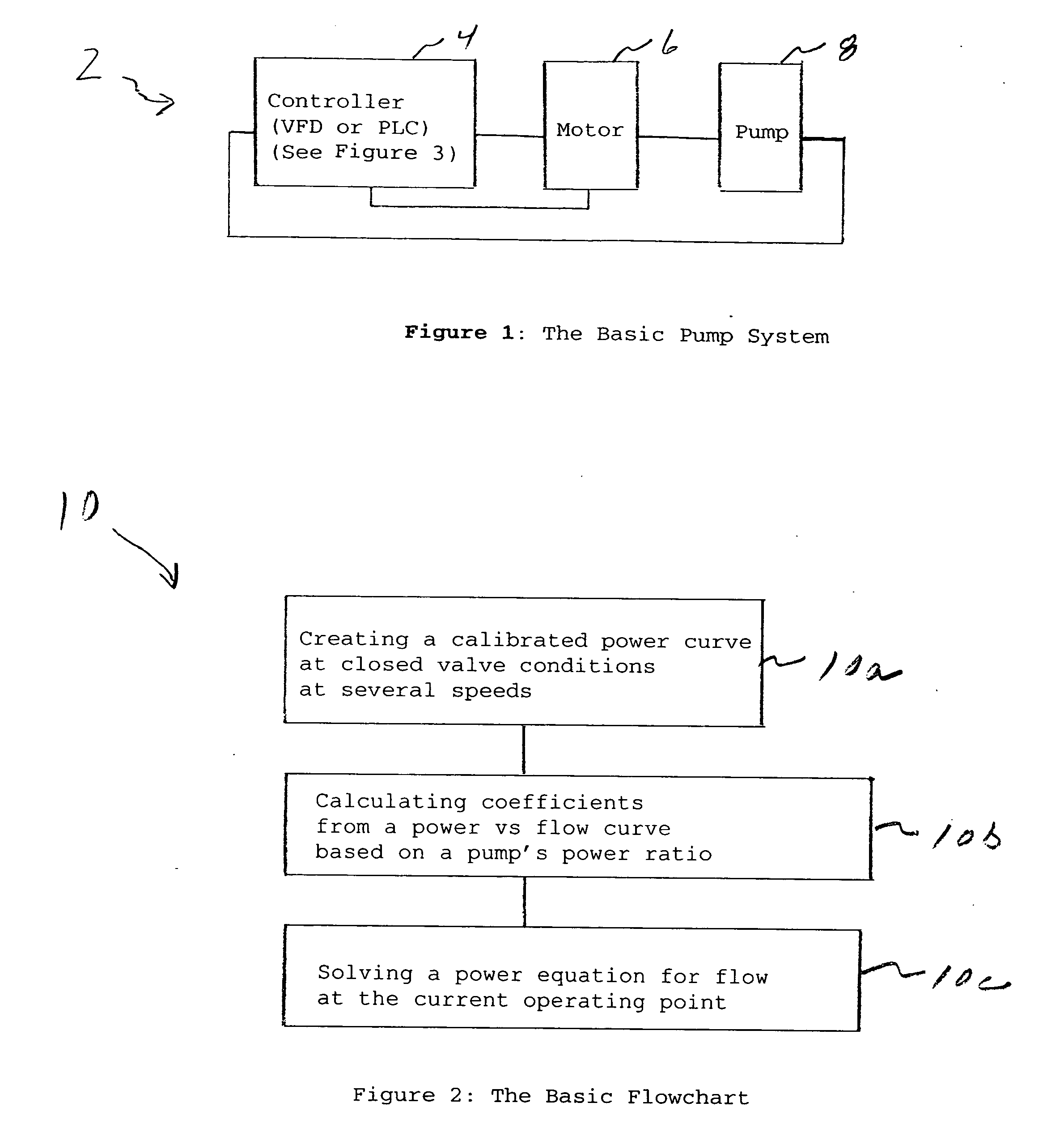

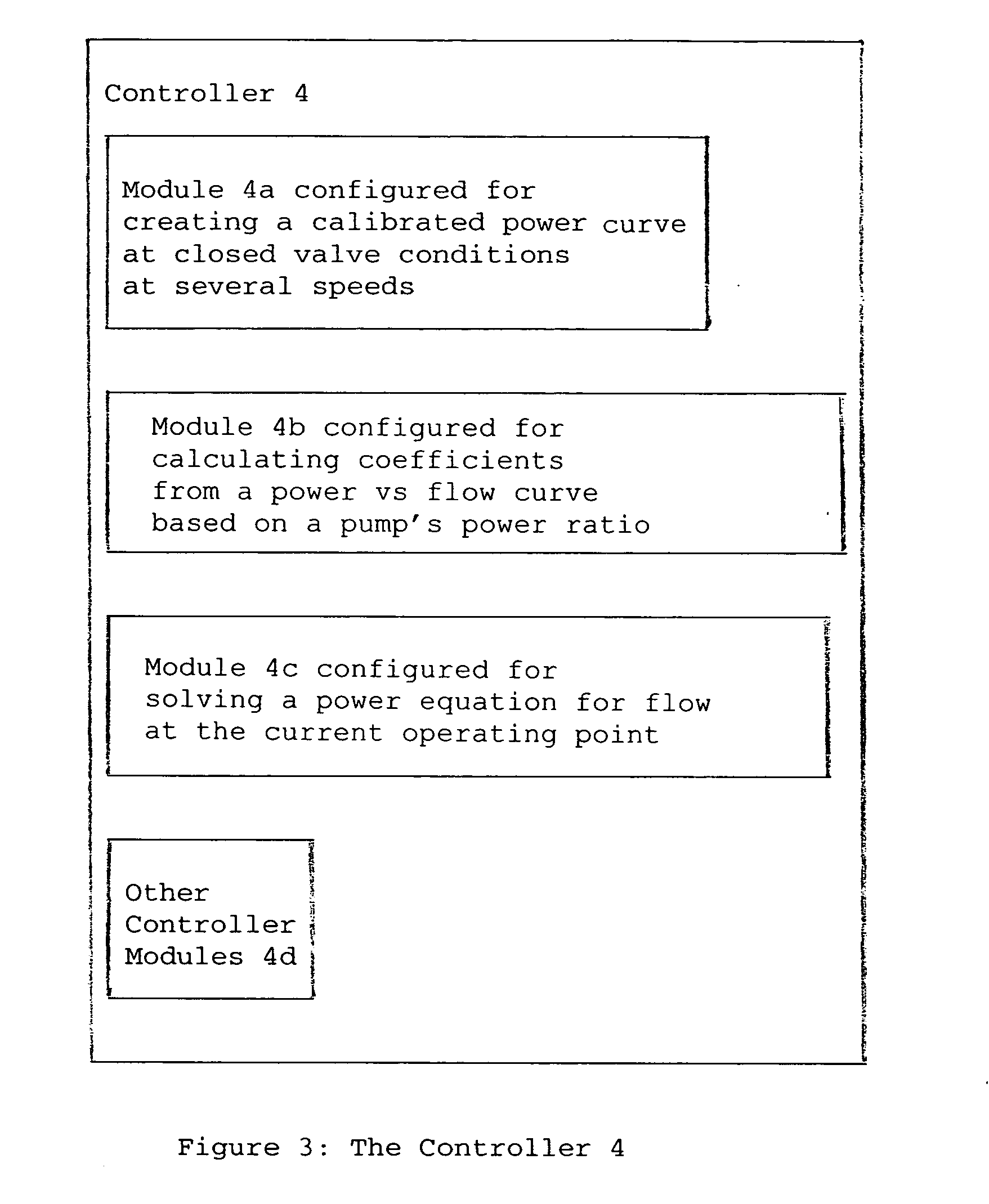

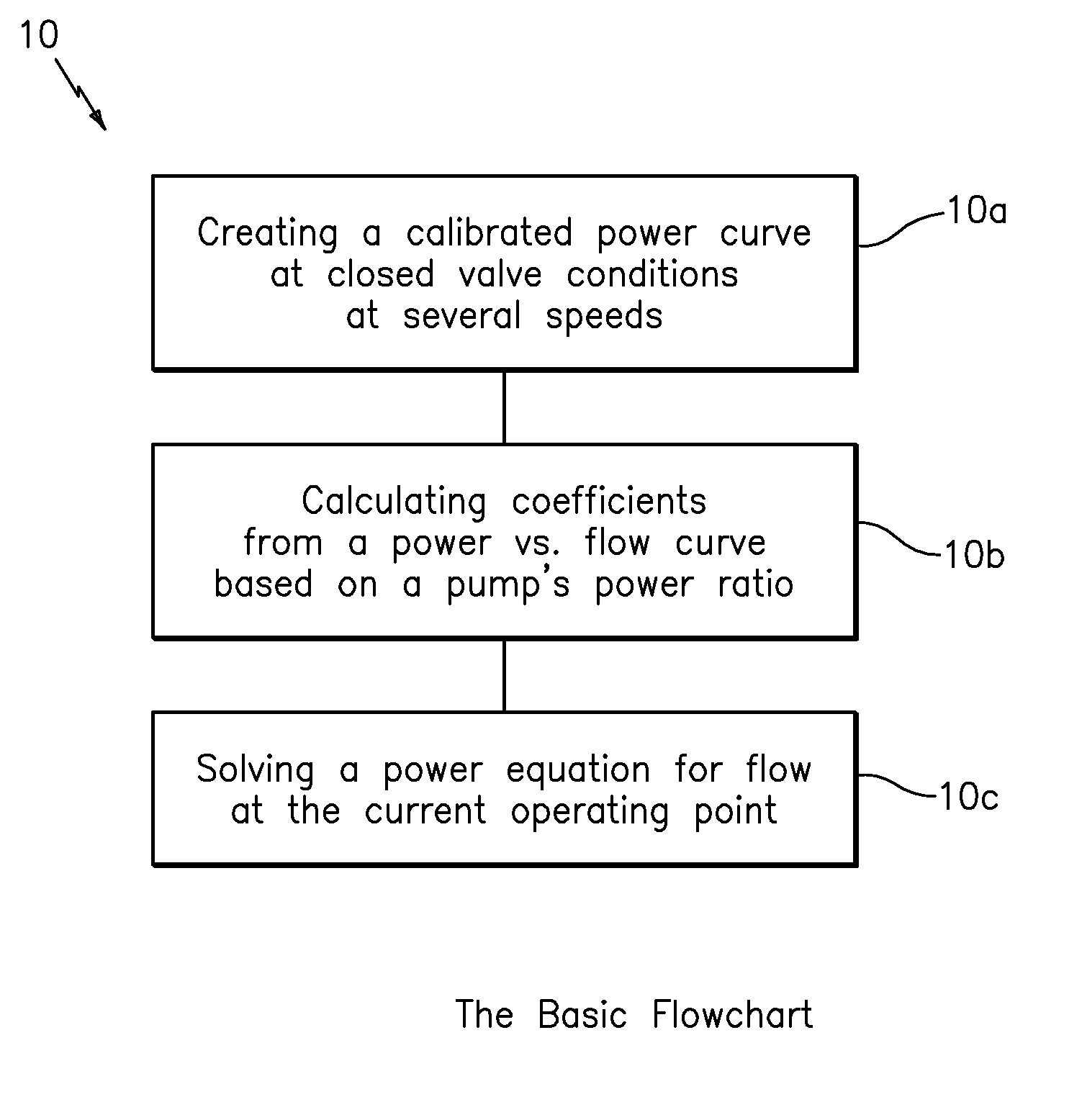

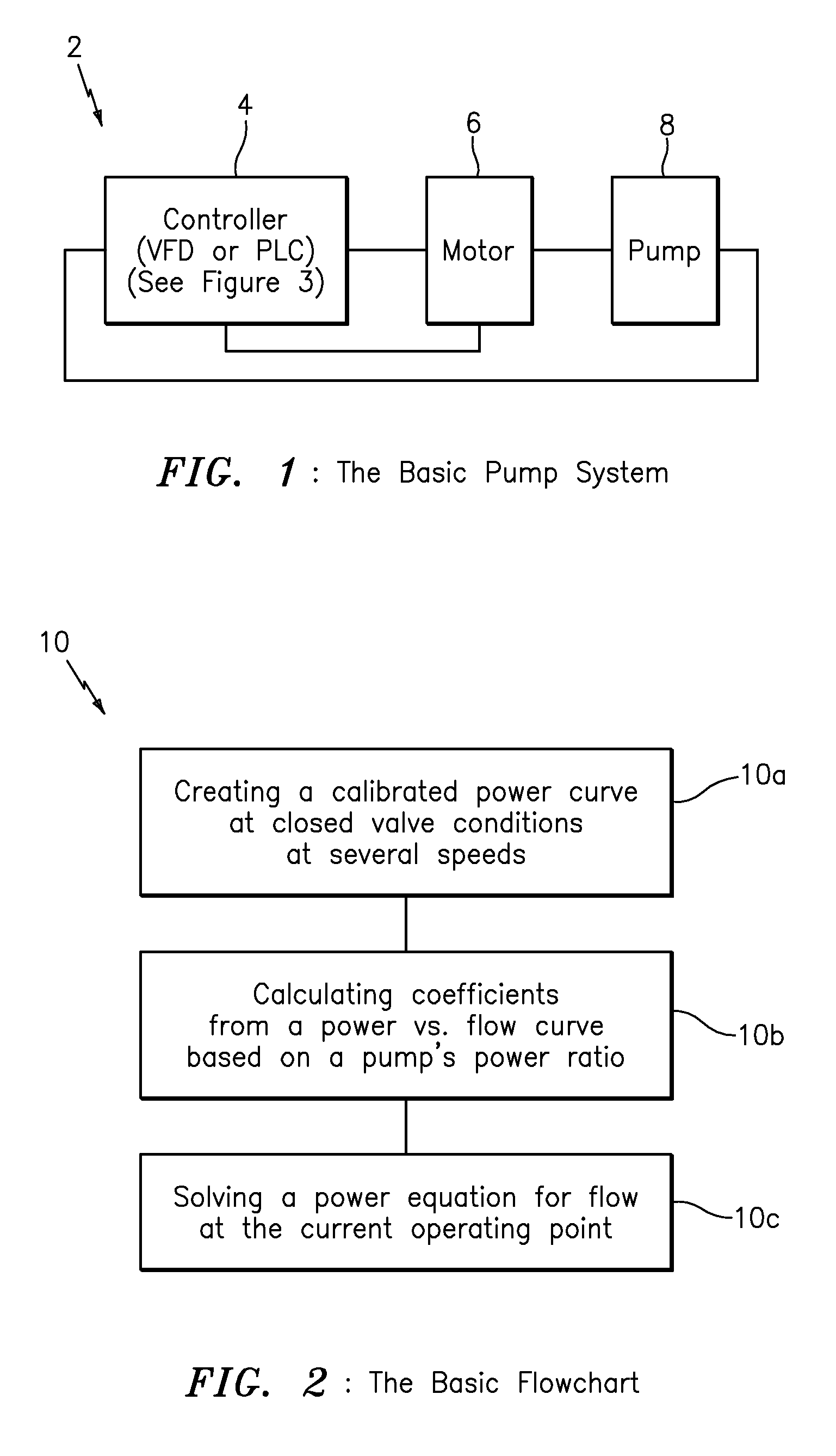

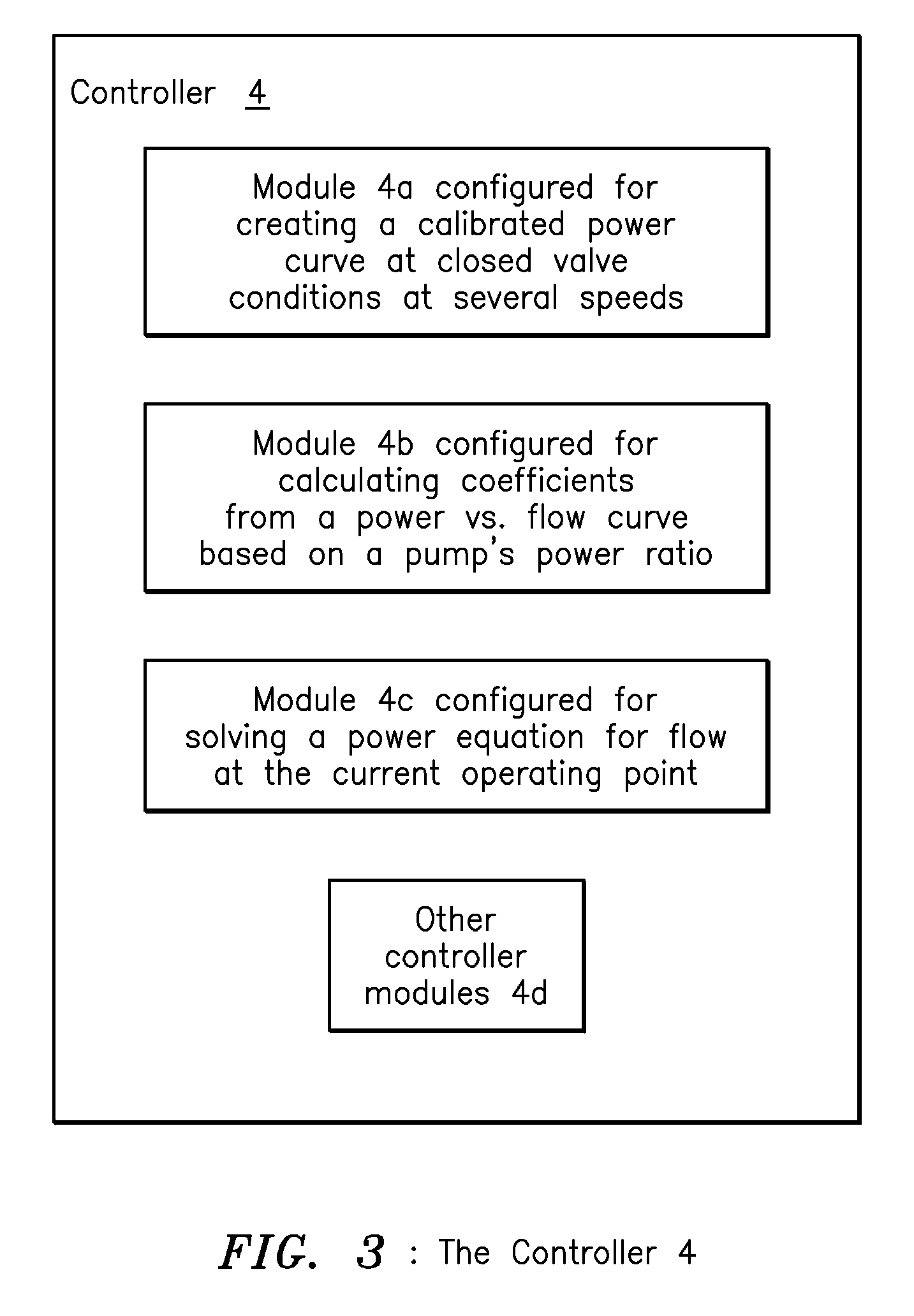

Method for determining pump flow without the use of traditional sensors

ActiveUS20070212210A1Testing/calibration apparatusAmplifier modifications to reduce noise influenceOperating pointMuller's method

A technique for determining pump flow without using traditional sensors features steps and modules for creating a calibrated power curve at closed valve conditions at several speeds; calculating coefficients from a normalized power curve based on a pump's power ratio; and solving a polynomial power equation for flow at the current operating point. The calibrated power curve may be created by increasing the speed of the pump from a minimum speed to a maximum speed and operating the pump with a closed discharge valve. This data is used to correct published performance for shutoff power and best efficiency point power at rated speed in order to determine the pump's power ratio. It is also used to accurately determine closed valve power at the current operating speed. The pump's power ratio is determined by the equation: Pratio=Pshutoff @100% / PBEP<sub2>—< / sub2>corr. The polynomial power equation may, for example, include a 3rd order polynomial equation developed using coefficients from the normalized power versus flow curve, and corrections may be made for speed, hydraulic efficiency and specific gravity in the polynomial power equation. Complex roots may be determined to solve the 3rd order polynomial equation using either Muller's method or some other suitable method, and the calculated actual flow may be determined for a specific operating point.

Owner:ITT MFG ENTERPRISES LLC

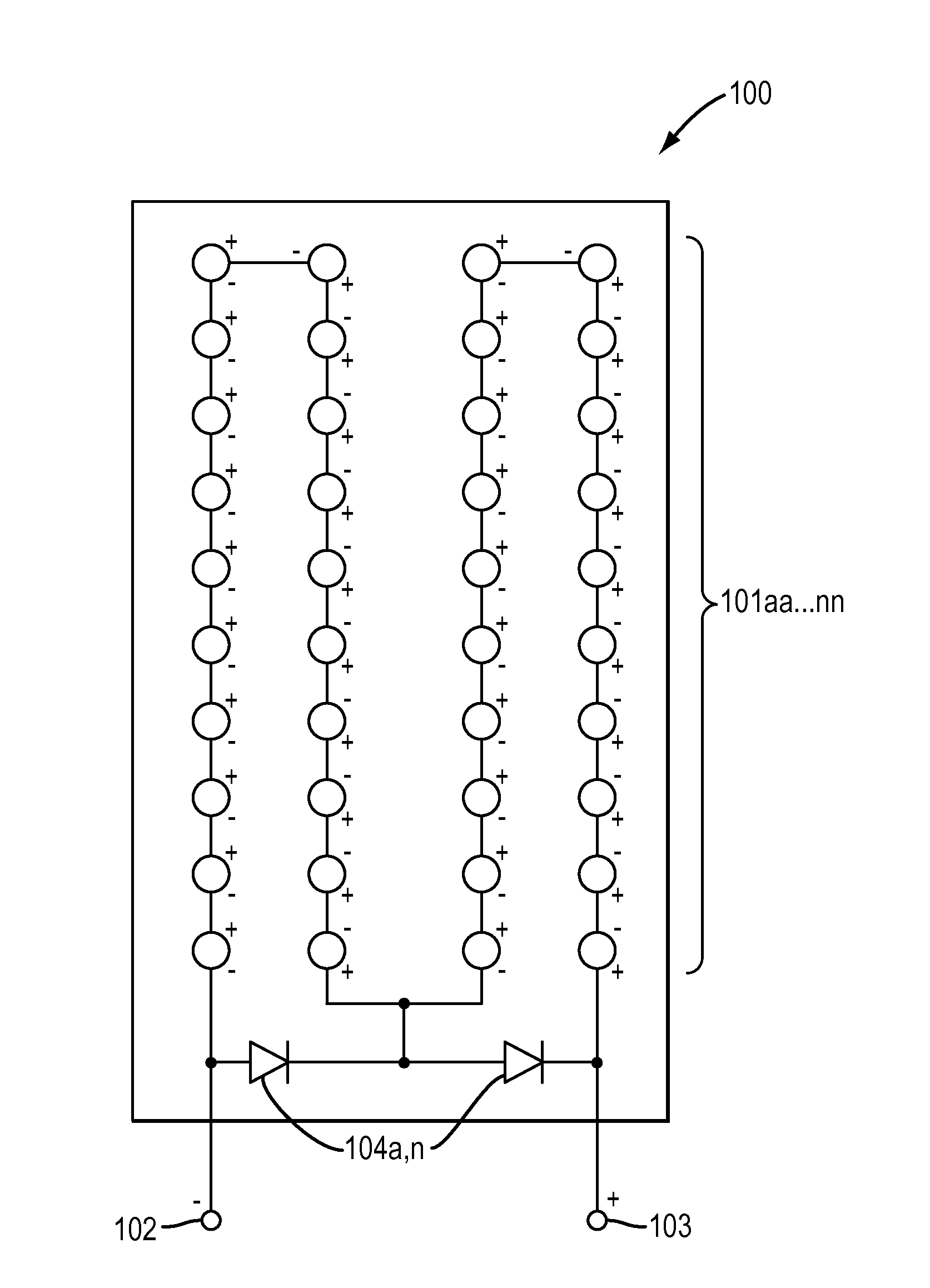

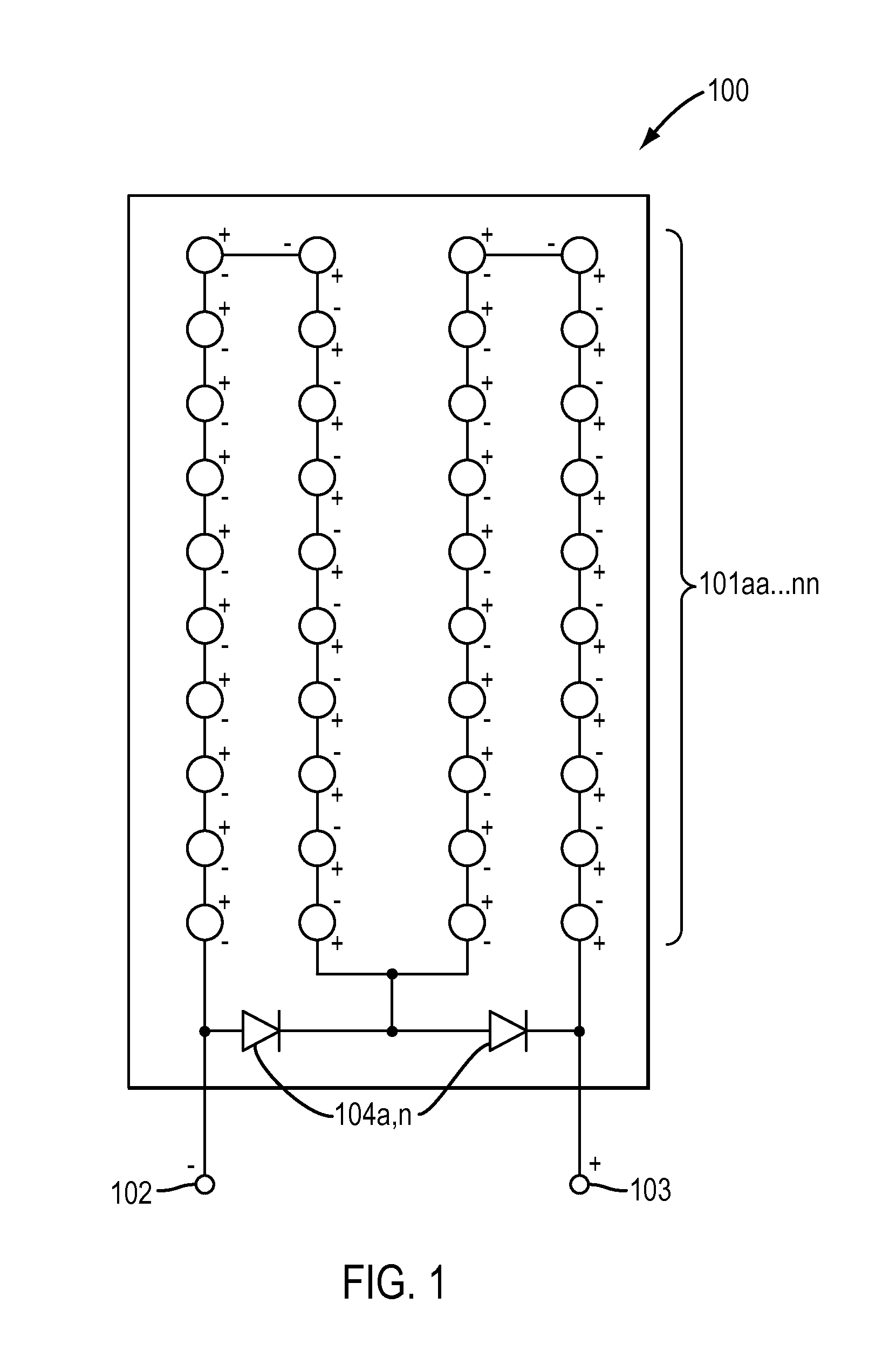

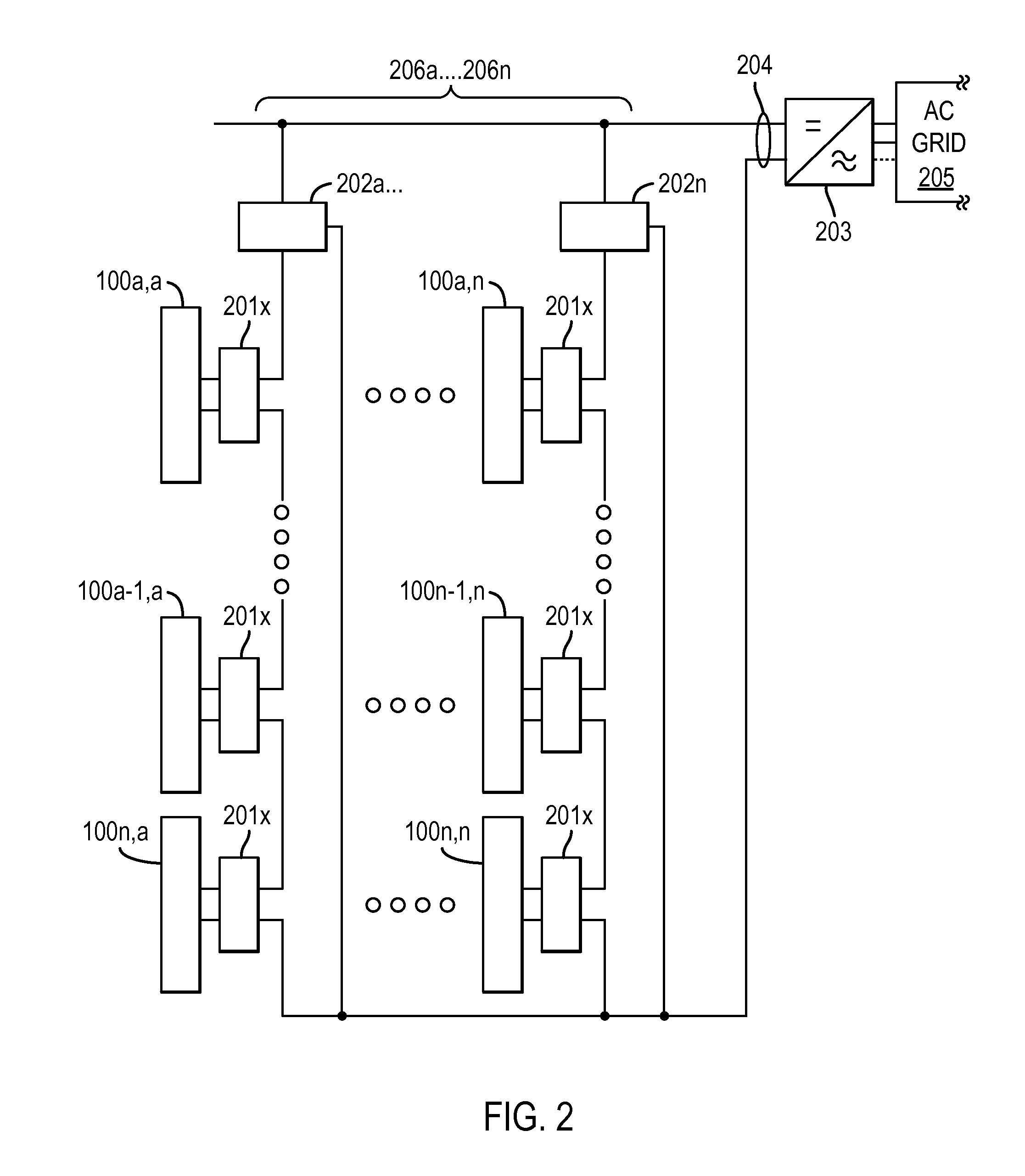

Enhanced System and Method for Matrix Panel Ties for Large Installations

InactiveUS20130192657A1PV power plantsSemiconductor/solid-state device manufacturingLow voltageEngineering

A low voltage / power ratio photovoltaic power generation panel includes a plurality of photovoltaic cells, wherein at least a subset of the cells are arranged in an array of “x” columns and “y” rows of cells connected in a two dimensional matrix configuration, wherein the cells in each row are connected in parallel and the cells in each column are connected in series. The cells in the panel are connected by arranging the plurality of cells in a plurality of columns, each column having a number of cells; arranging the plurality of columns in the number of rows; and connecting the plurality of cells together in a two dimensional matrix configuration by connecting the cells in each row together in parallel and the cells in each column in series.

Owner:TIGO ENERGY

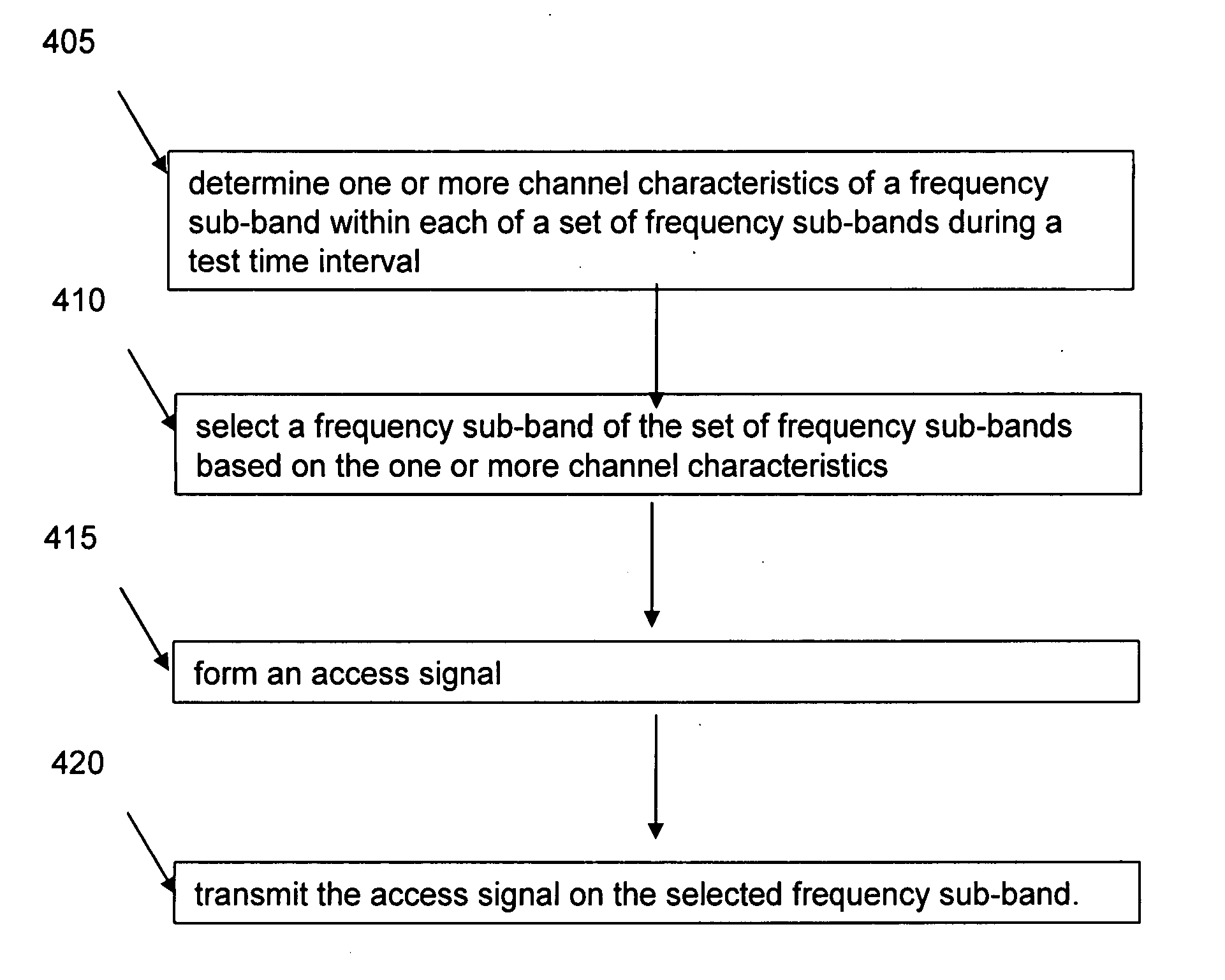

Method and apparatus for accessing a wireless multi-carrier communication system

A subscriber station (101-103) accesses a multicarrier communication system (100) by determining (505) one or more channel characteristics that is indicative of a range of the subscriber station from a base station, selecting (510) an access code that generates an access signal having a peak to average power ratio, using the one or more channel characteristics, generating (515) an access signal from the access code, and transmitting (525) the access signal and also by determining (405) one or more channel characteristics of each frequency sub-band of a set of frequency sub-bands, selecting (410) a frequency sub-band of the set of frequency sub-bands based on the one or more channel characteristics, and transmitting (420) the access signal on the selected frequency sub-band.

Owner:MOTOROLA INC +1

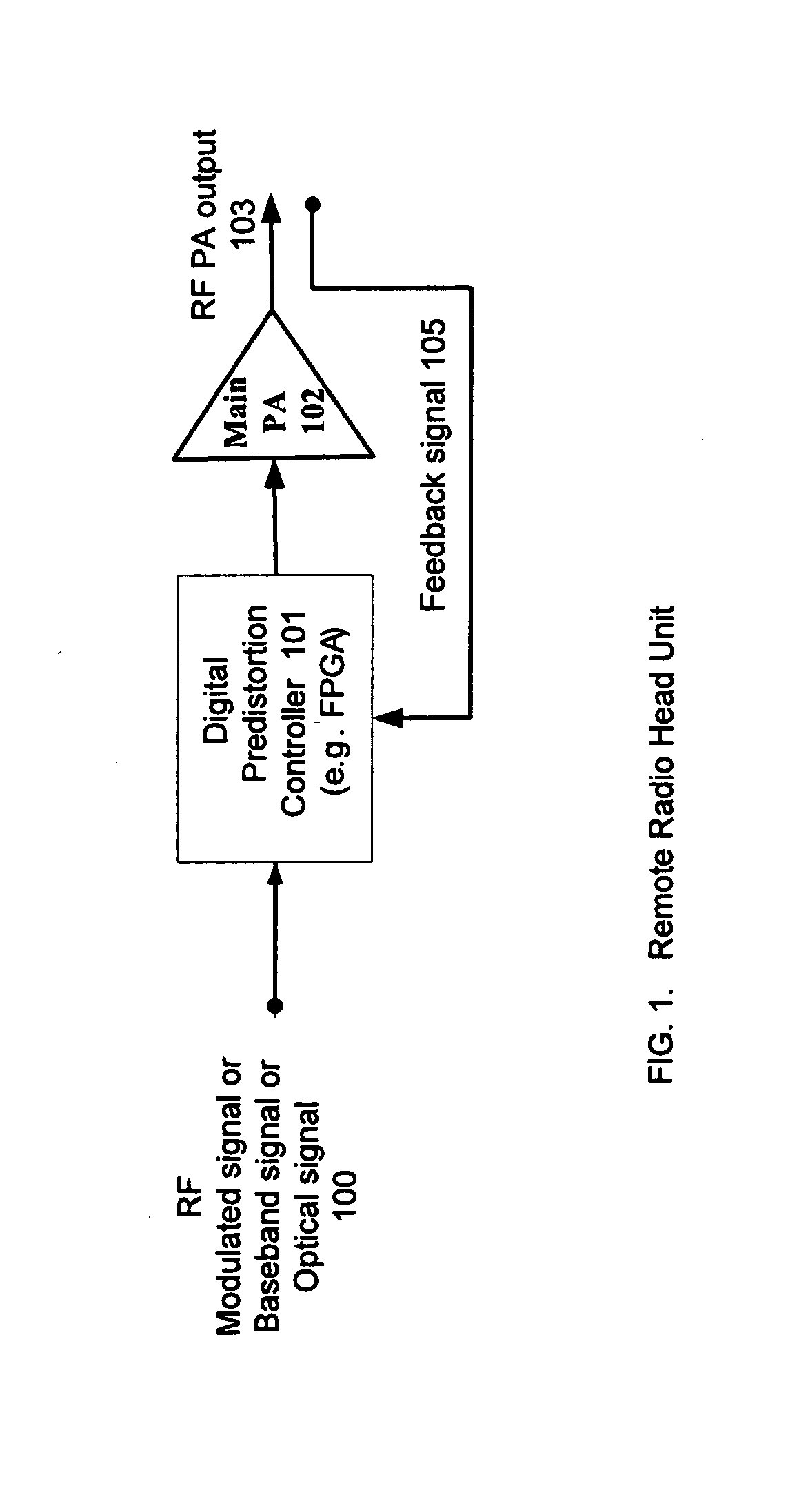

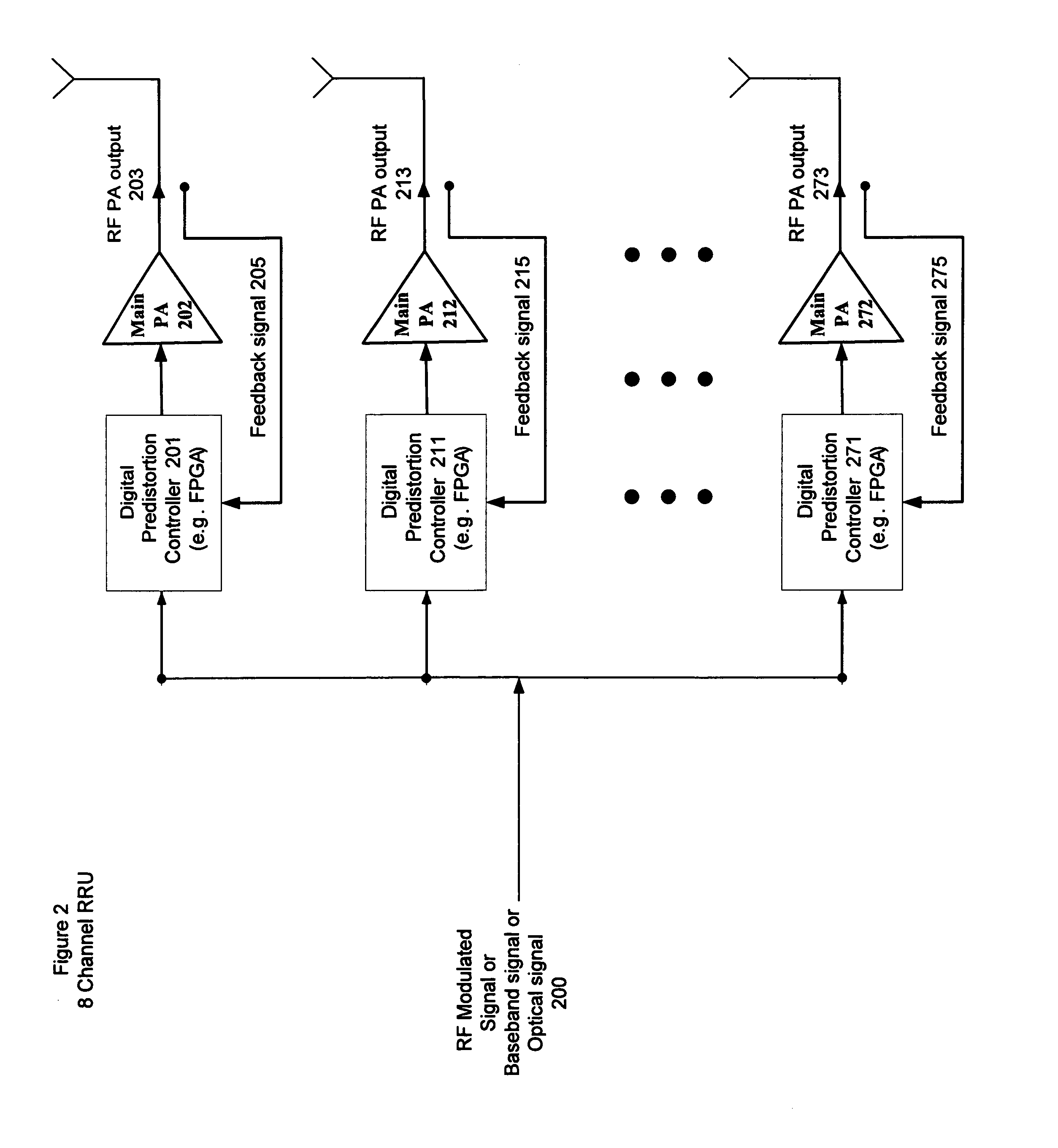

High efficiency, remotely reconfigurable remote radio head unit system and method for wireless communications

ActiveUS20120155572A1High performance and cost-effectiveImprove linearityEnergy efficient ICTPower amplifiersUnit systemEngineering

A remote radio head unit (RRU) system for achieving high efficiency and high linearity in wideband communication systems is disclosed. The present invention is based on the method of adaptive digital predistortion to linearize a power amplifier inside the RRU. The power amplifier characteristics such as variation of linearity and asymmetric distortion of the amplifier output signal are monitored by a wideband feedback path and controlled by the adaptation algorithm in a digital module. Therefore, embodiments of the present invention can compensate for the nonlinearities as well as memory effects of the power amplifier systems and also improve performance, in terms of power added efficiency, adjacent channel leakage ratio and peak-to-average power ratio. The present disclosure enables a power amplifier system to be field reconfigurable and support multi-modulation schemes (modulation agnostic), multi-carriers, multi-frequency bands and multi-channels. As a result, the remote radio head system is particularly suitable for wireless transmission systems, such as base-stations, repeaters, and indoor signal coverage systems.

Owner:DALI SYST LTD

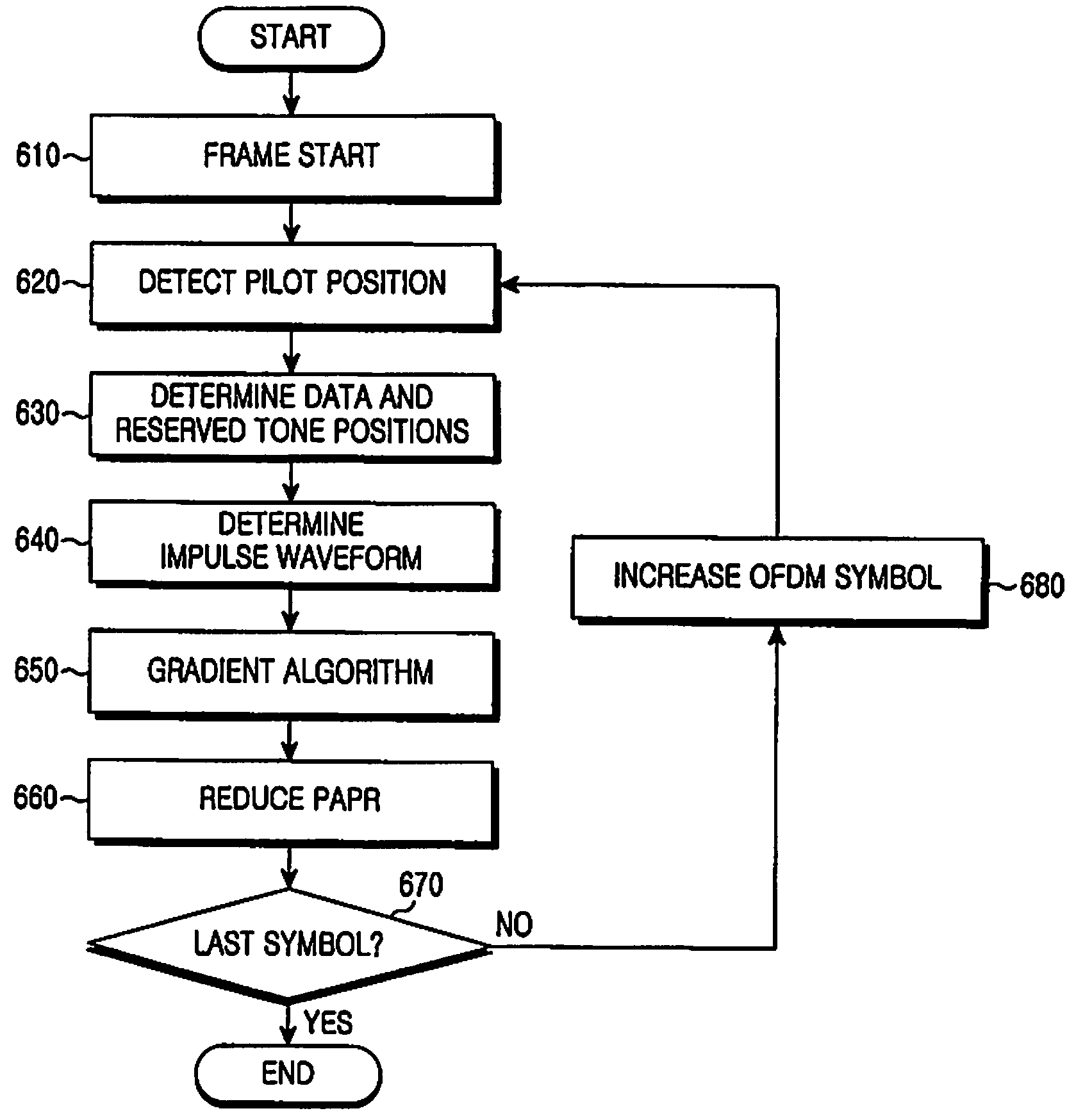

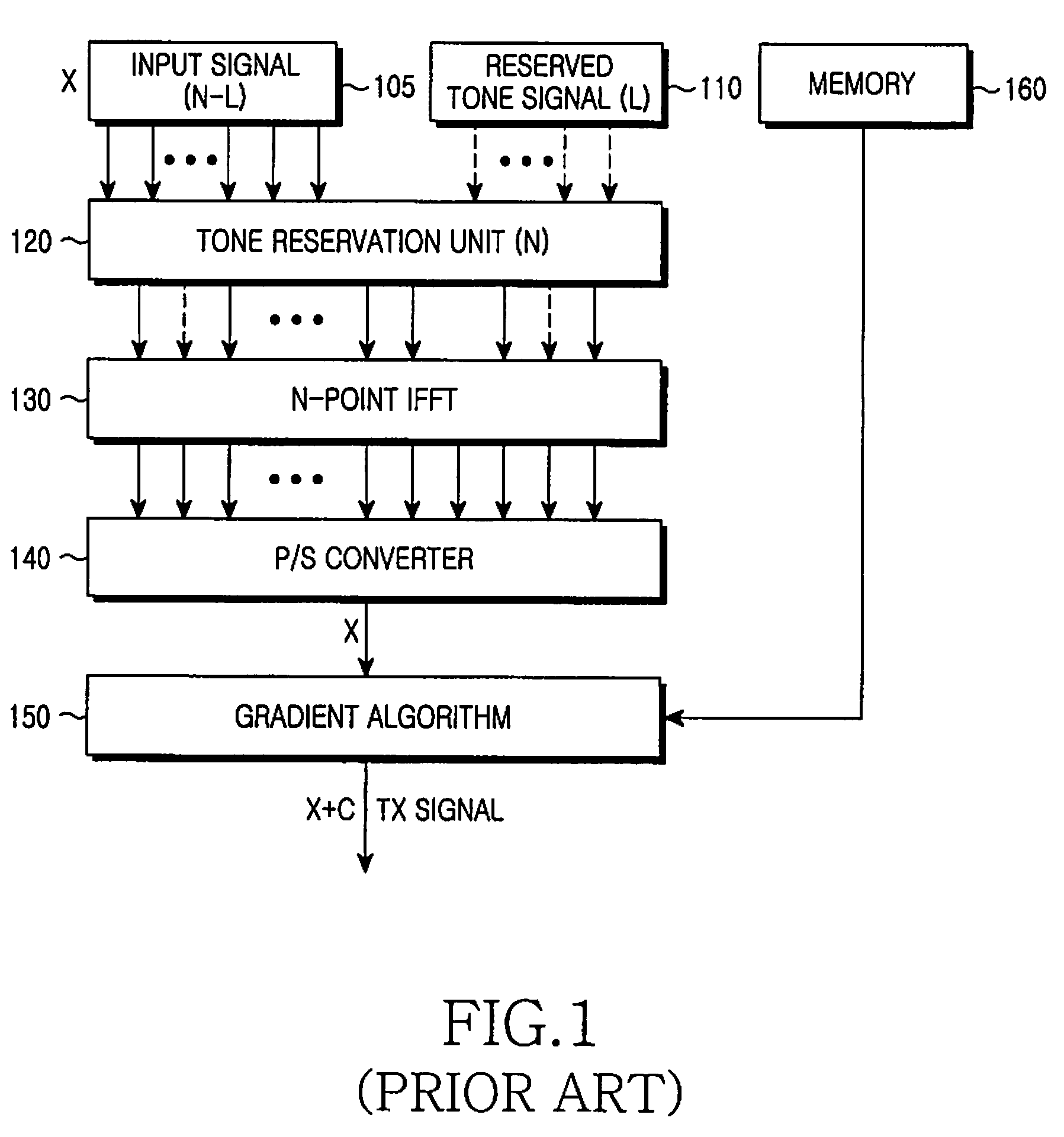

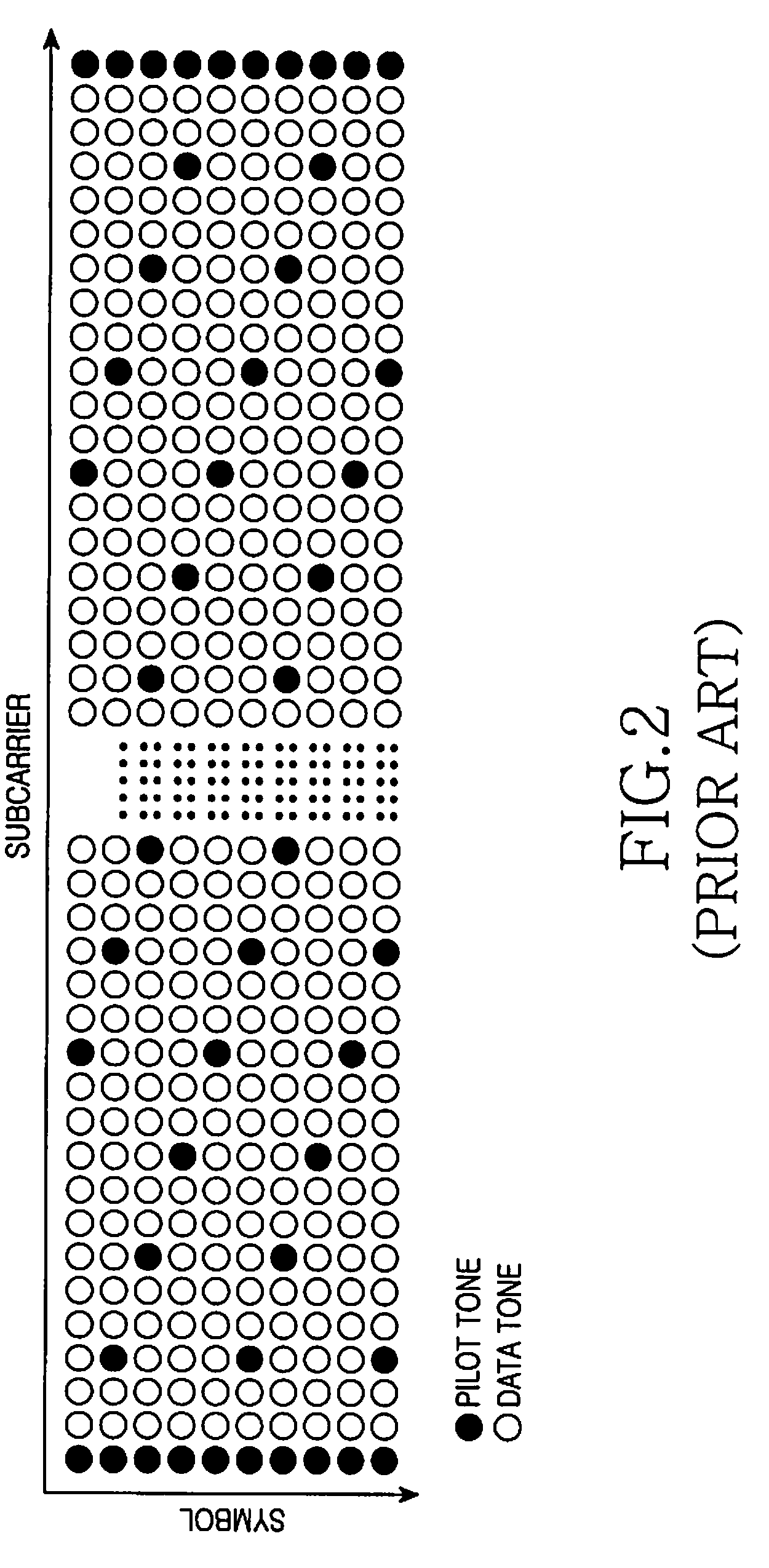

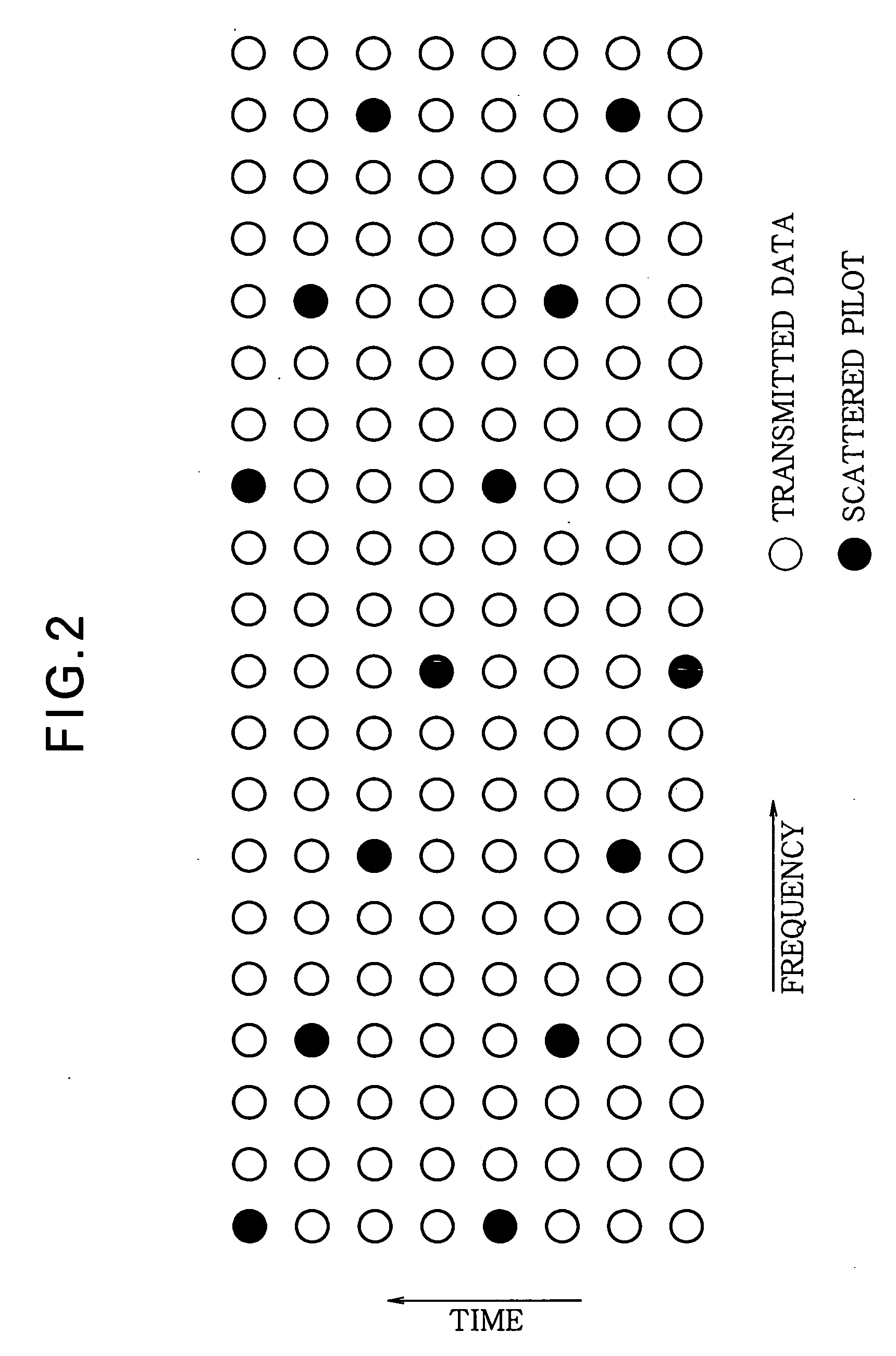

Apparatus and method for reducing peak to average power ratio in an orthogonal frequency division multiplexing system

ActiveUS20080298490A1Avoid collisionSecret communicationMulti-frequency code systemsCommunications systemComplex valued

A method for reducing a Peak to Average Power Ratio (PAPR) using reserved tones in a transmission apparatus of an Orthogonal Frequency Division Multiplexing (OFDM) communication system is provided. The method includes detecting a subcarrier spacing interval and the number of spaced symbols based on a predetermined pilot pattern upon signal reception, and determining positions of shifted reserved tones obtained by shifting positions of reserved tones allocated to a predetermined symbol during the number of the spaced symbols at intervals of the spacing interval; determining an impulse waveform obtained by rotating a phase of a complex value of an impulse stored in a memory, using the determined positions of frequency-domain reserved tones of each symbol; calculating a subtrahend for a PAPR of an output signal using the phase-rotated impulse waveform; and reducing a PAPR of an input signal by performing a gradient algorithm using the phase-rotated impulse waveform.

Owner:SAMSUNG ELECTRONICS CO LTD

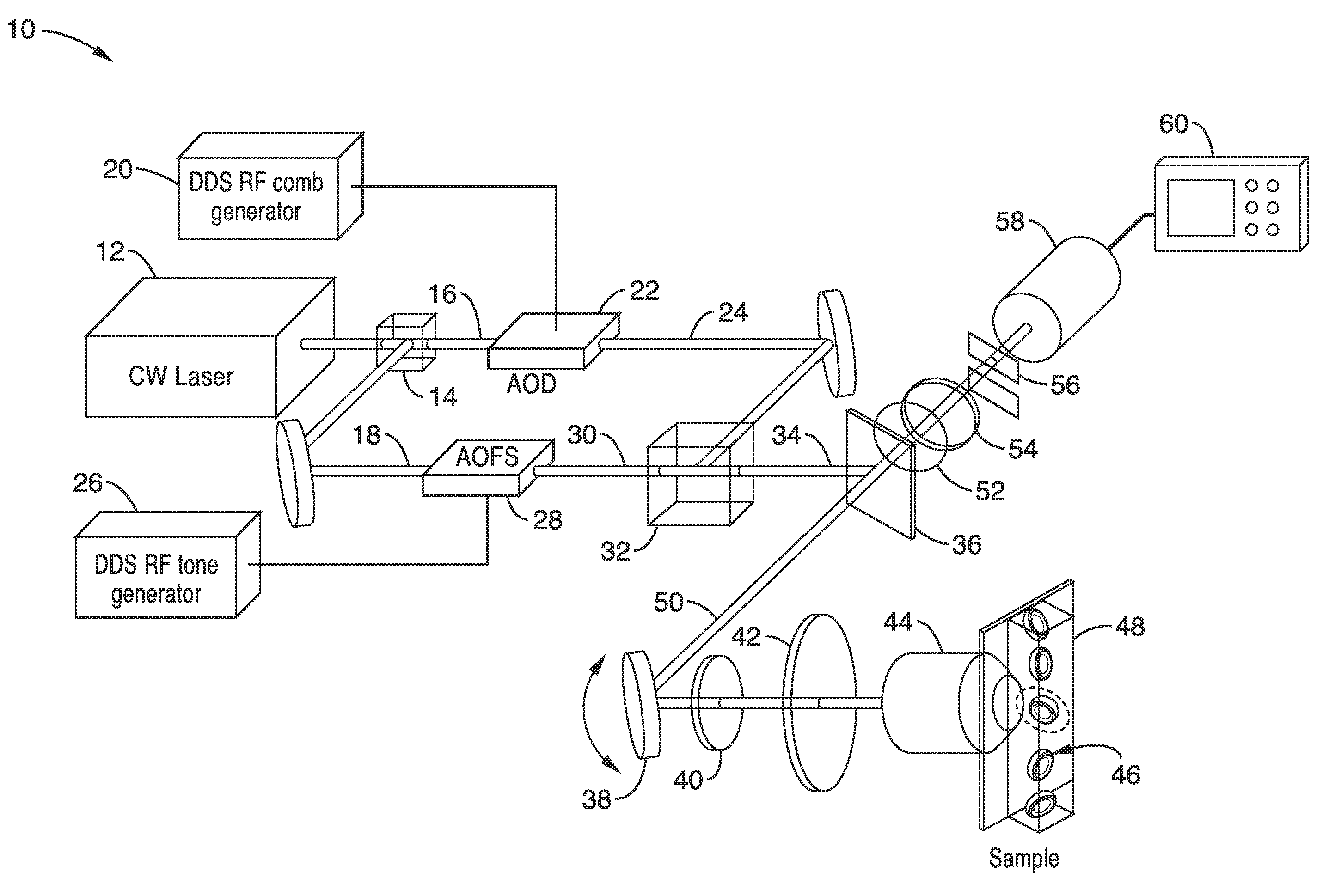

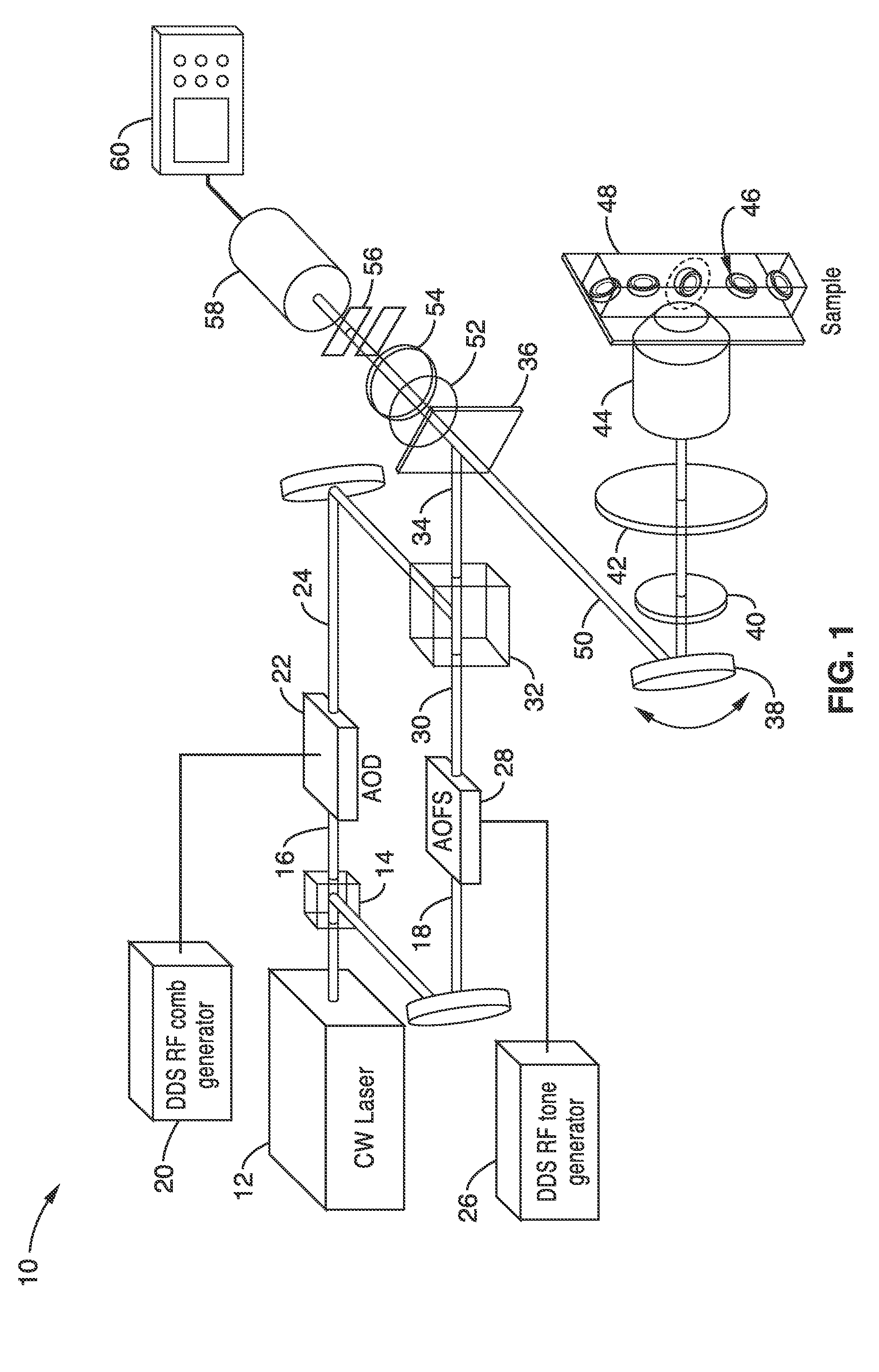

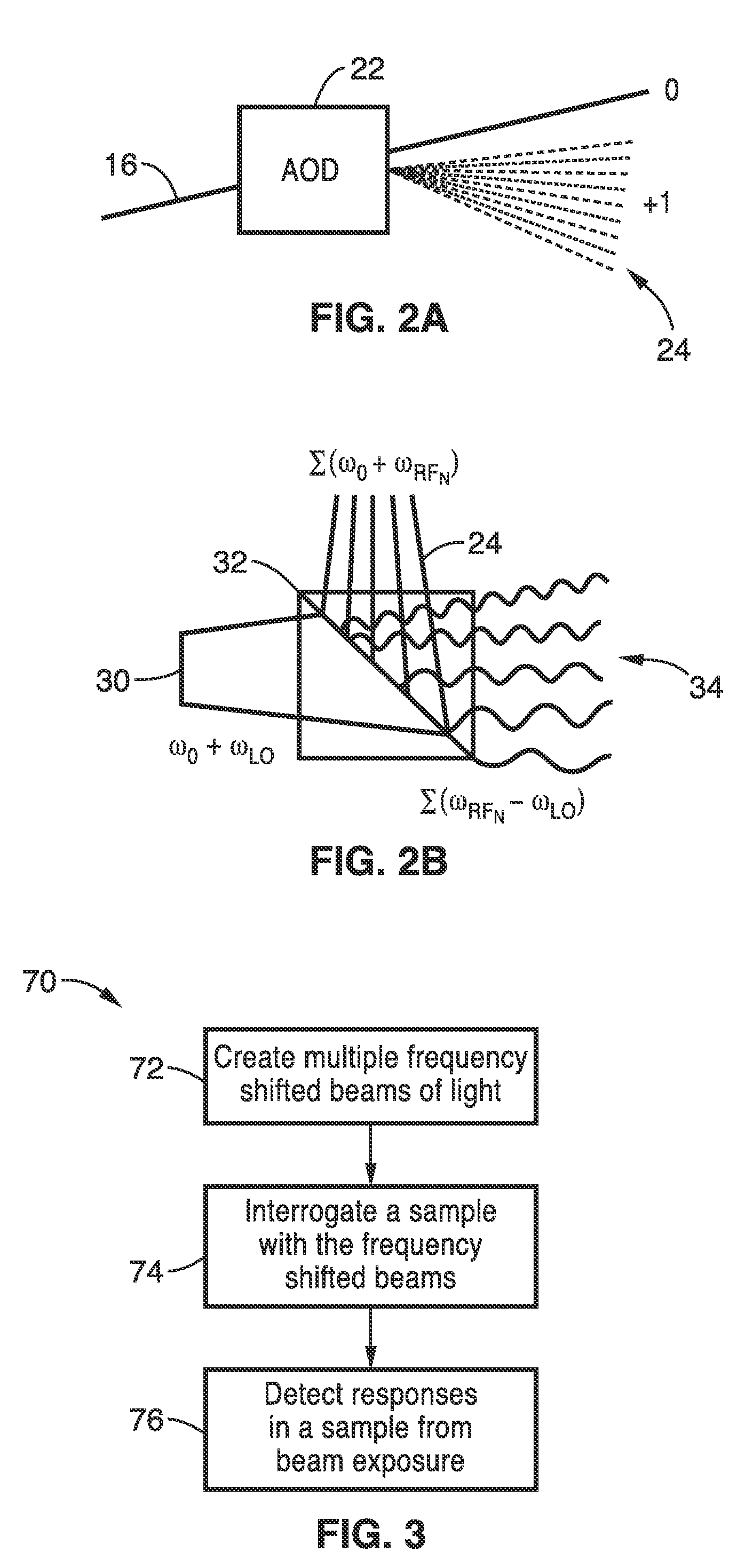

Apparatus and methods for fluorescence imaging using radiofrequency-multiplexed excitation

ActiveUS9423353B2Reduce image noiseScalable approachMicroscopesFluorescence/phosphorescenceBeam splitterLaser scanning microscope

Apparatus and methods for fluorescence imaging using radiofrequency multiplexed excitation. One apparatus splits an excitation laser beam into two arms of a Mach-Zehnder interferometer. The light in the first beam is frequency shifted by an acousto-optic deflector, which is driven by a phase-engineered radiofrequency comb designed to minimize peak-to-average power ratio. This RF comb generates multiple deflected optical beams possessing a range of output angles and frequency shifts. The second beam is shifted in frequency using an acousto-optic frequency shifter. After combining at a second beam splitter, the two beams are focused to a line on the sample using a conventional laser scanning microscope lens system. The acousto-optic deflectors frequency-encode the simultaneous excitation of an entire row of pixels, which enables detection and de-multiplexing of fluorescence images using a single photomultiplier tube and digital phase-coherent signal recovery techniques.

Owner:RGT UNIV OF CALIFORNIA

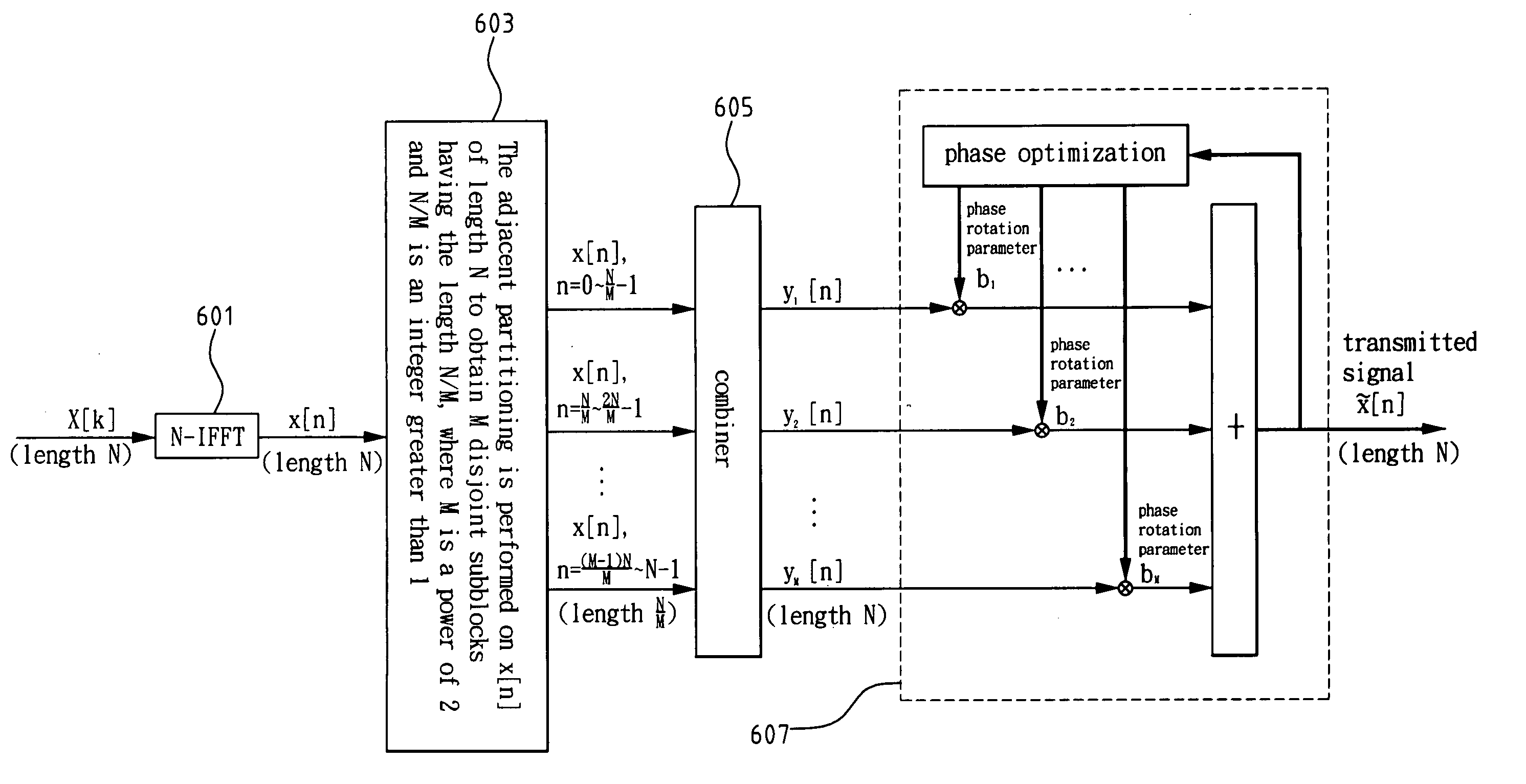

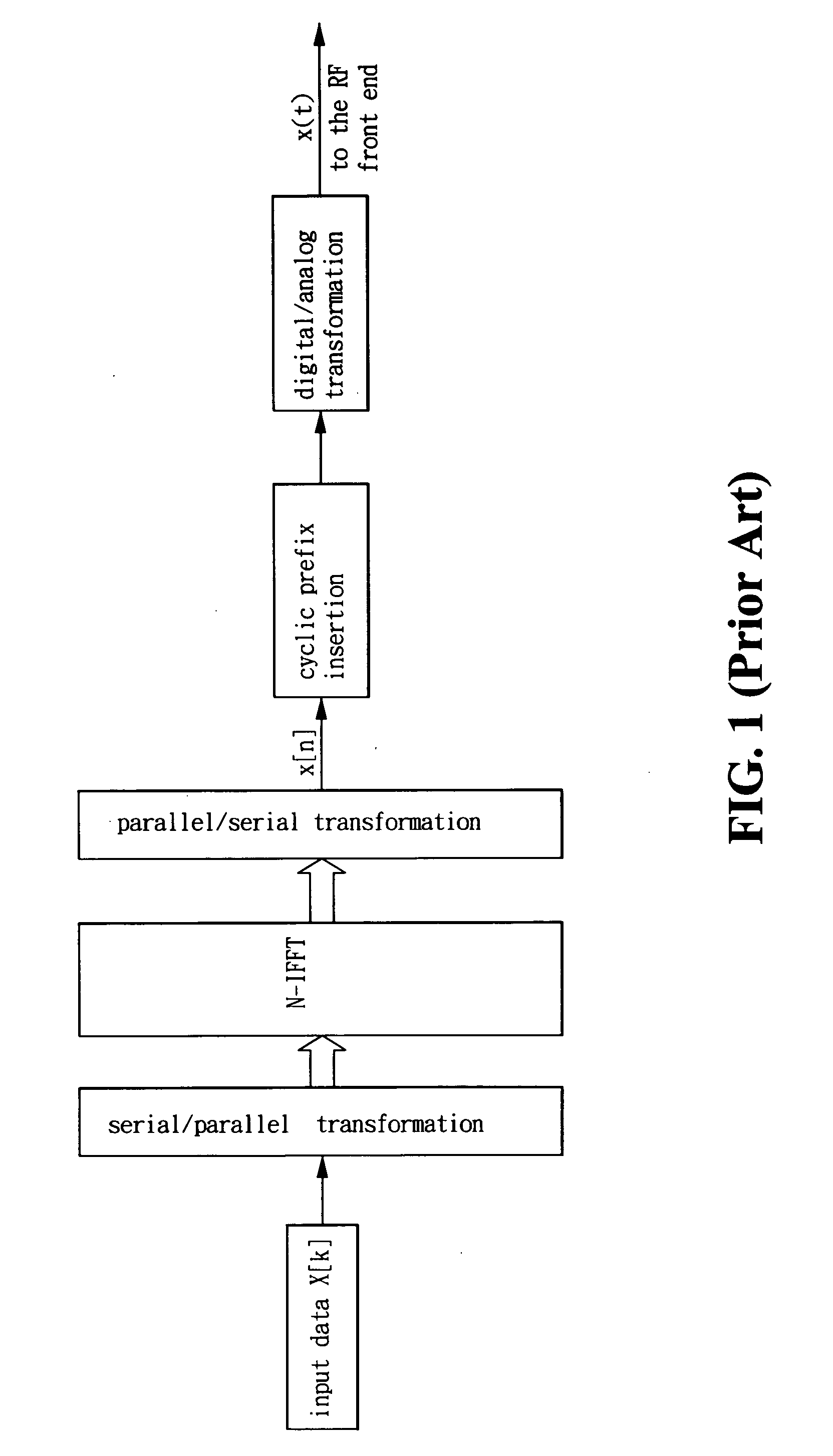

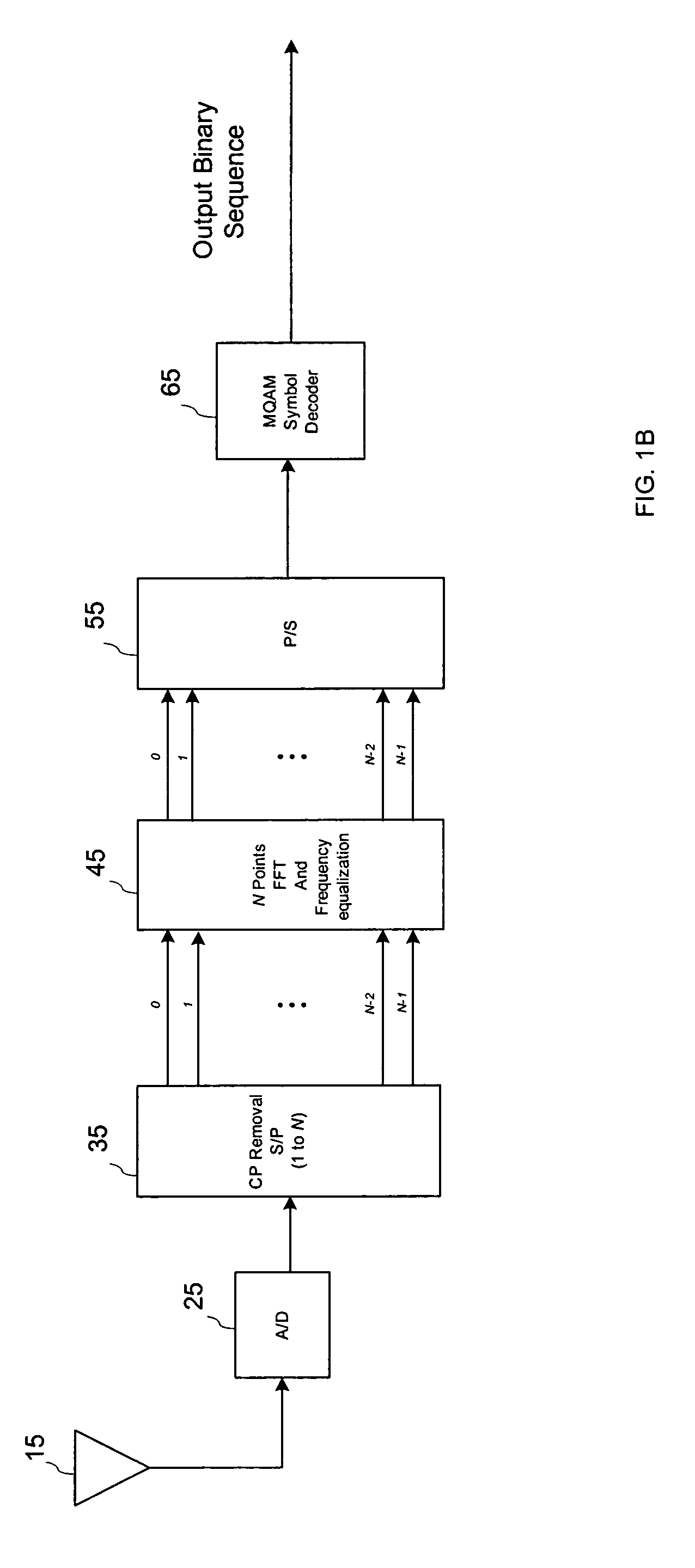

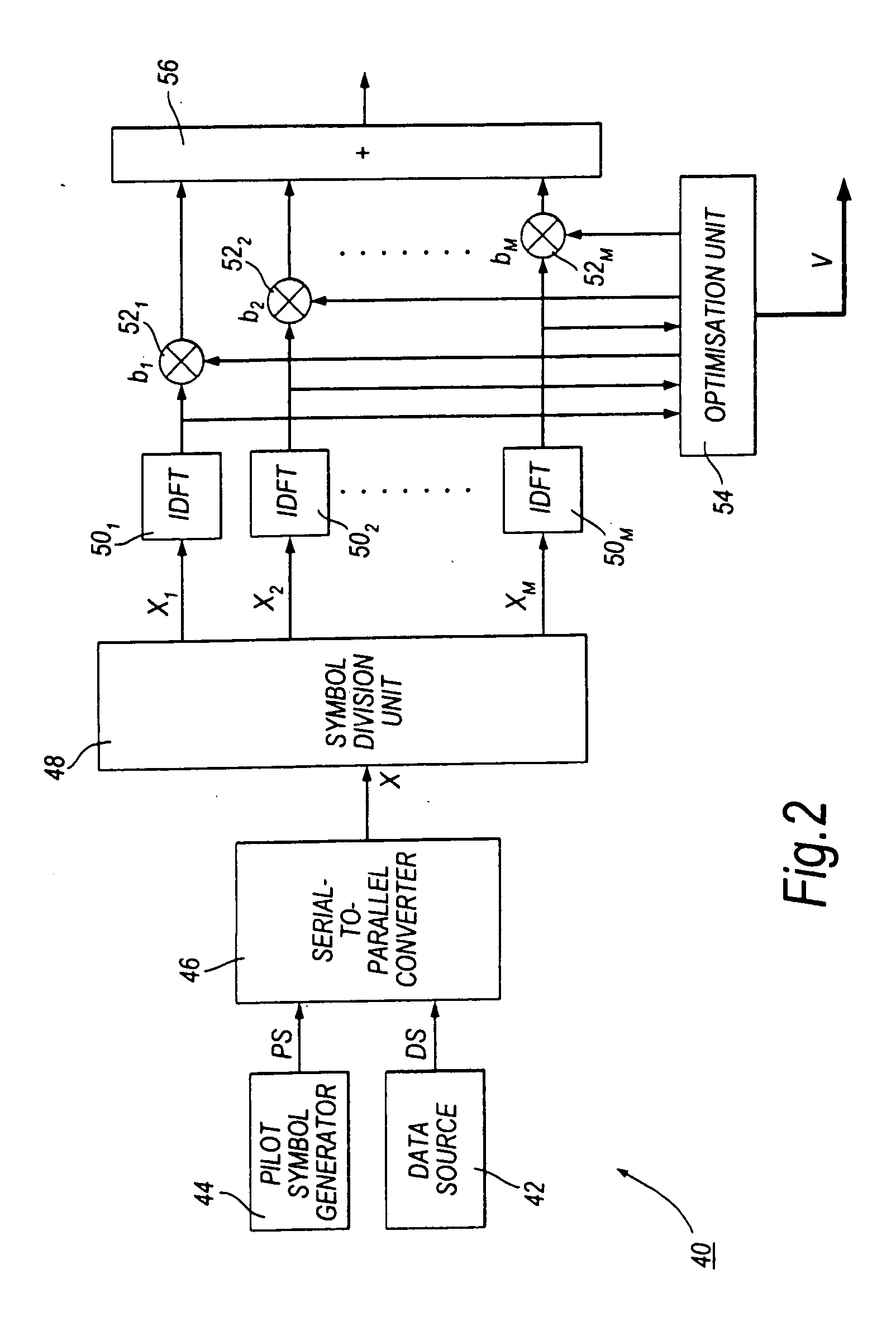

Method and apparatus for PAPR reduction of an OFDM signal

InactiveUS20050270968A1Shorten the lengthReduce the amount of calculationSecret communicationMulti-frequency code systemsTime domainFast Fourier transform

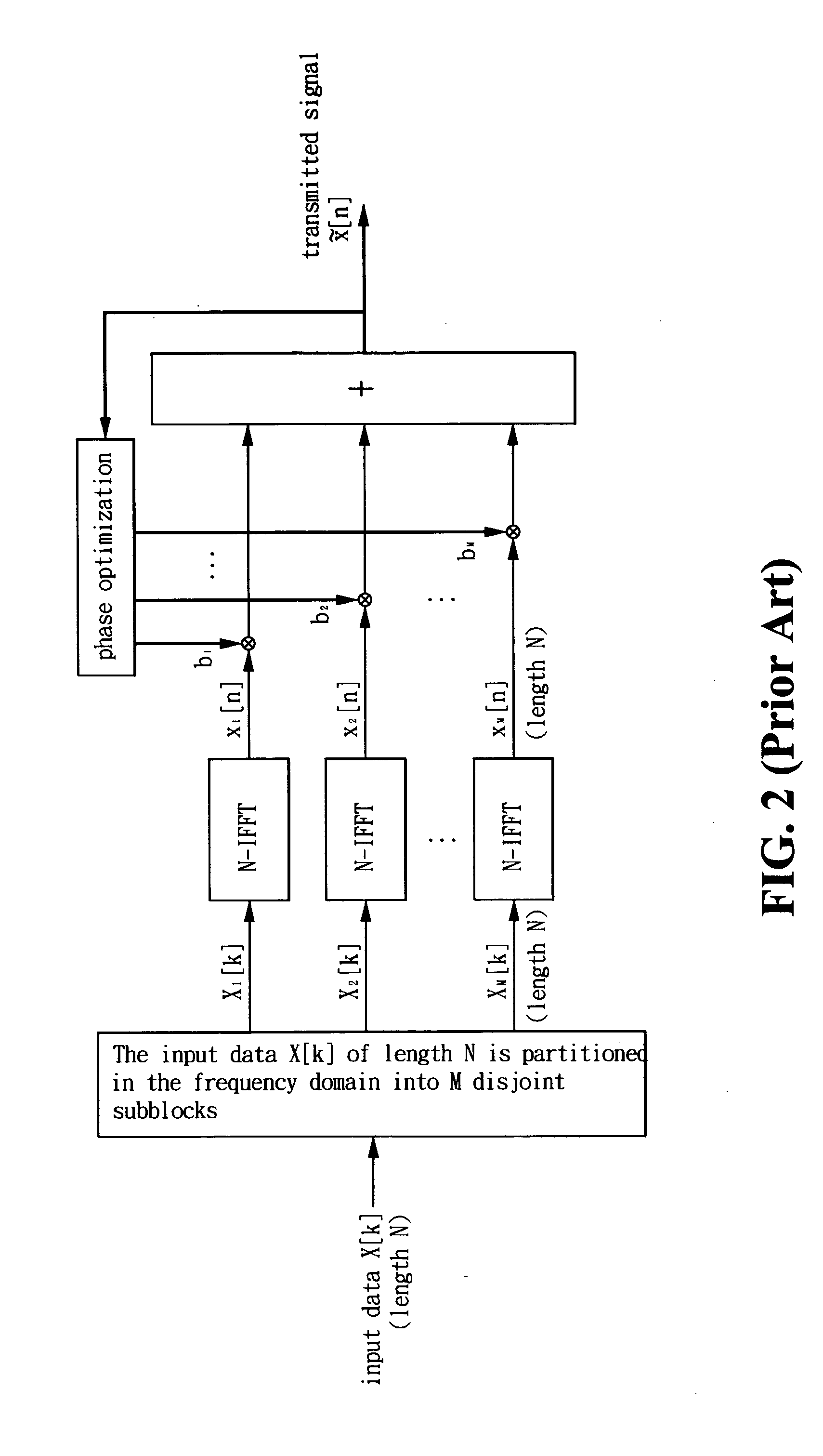

An apparatus and a method for peak-to-average power ratio reduction of an OFDM signal are disclosed. The method uses the interleaved characteristics of partial transmit sequences to partition input data x[n] of length N into several disjoint subblocks in time domain, and a complete N-point signal {tilde over (x)}[n] is composed after phase optimization, where N is the length of an OFDM signal and n=0, 1, . . . , N−1. Accordingly, the apparatus comprises an N-point inverse fast Fourier transform (N-IFFT), a de-multiplexer, a combiner, a set of memory and an adder. This invention uses only one N-IFFT, whereby it can achieve significant computation reduction. This invention requires (N / 2)log2 N complex multiplications and N memory units. It also preserves the inherent property as well as advantages of an OFDM system.

Owner:IND TECH RES INST

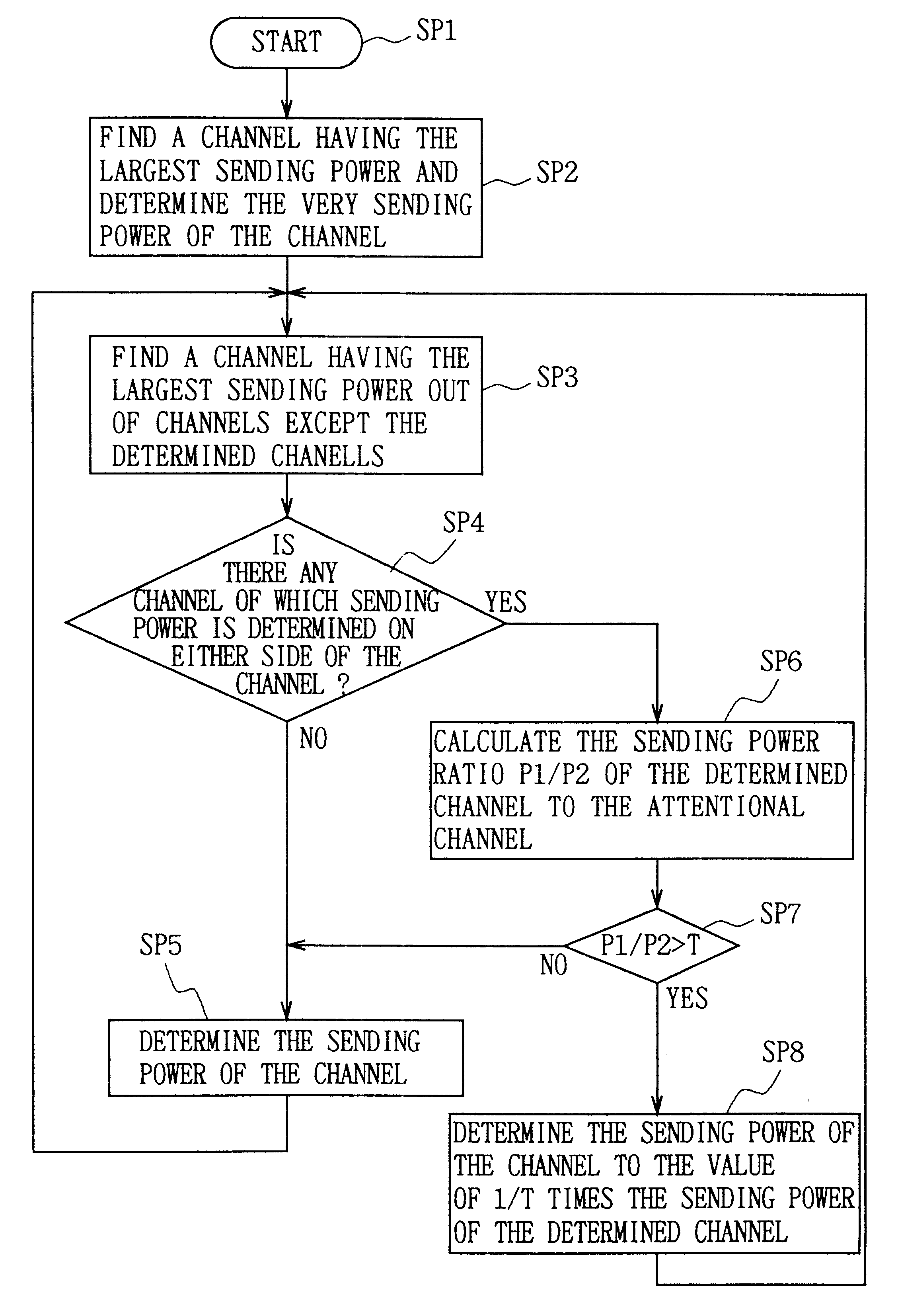

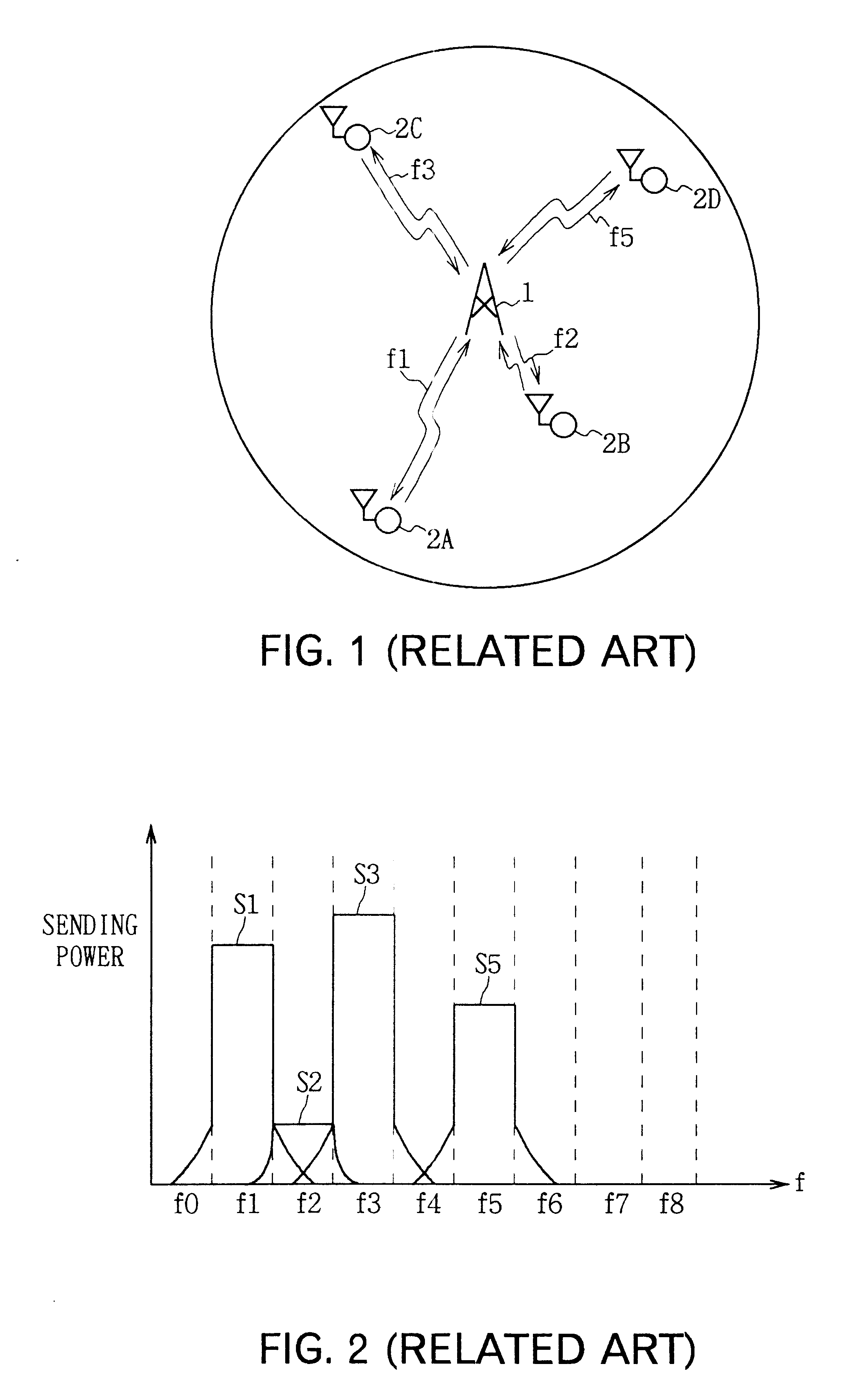

Transmitting method and apparatus, and sending power controlling method

In a transmitting method, it is possible to avoid influences of adjacent-channel interference to perform communication satisfactorily. In the case of performing transmission with a previously set sending power, the transmission is performed with the set sending power with respect to a channel having the largest sending power. With respect to a channel having the next largest sending power, if its adjacent channel is the determined channel, the transmission is performed such that the sending power is corrected on the basis of the sending power of the determined channel. Thereby, it is possible to prevent the signal-to-interference wave power ratio C / I of the channel from deteriorating due to the leakage signal (interference wave) from the adjacent channel. Thus, it is possible to avoid the influences of adjacent-channel interference to thereby perform communication satisfactorily.

Owner:SONY CORP

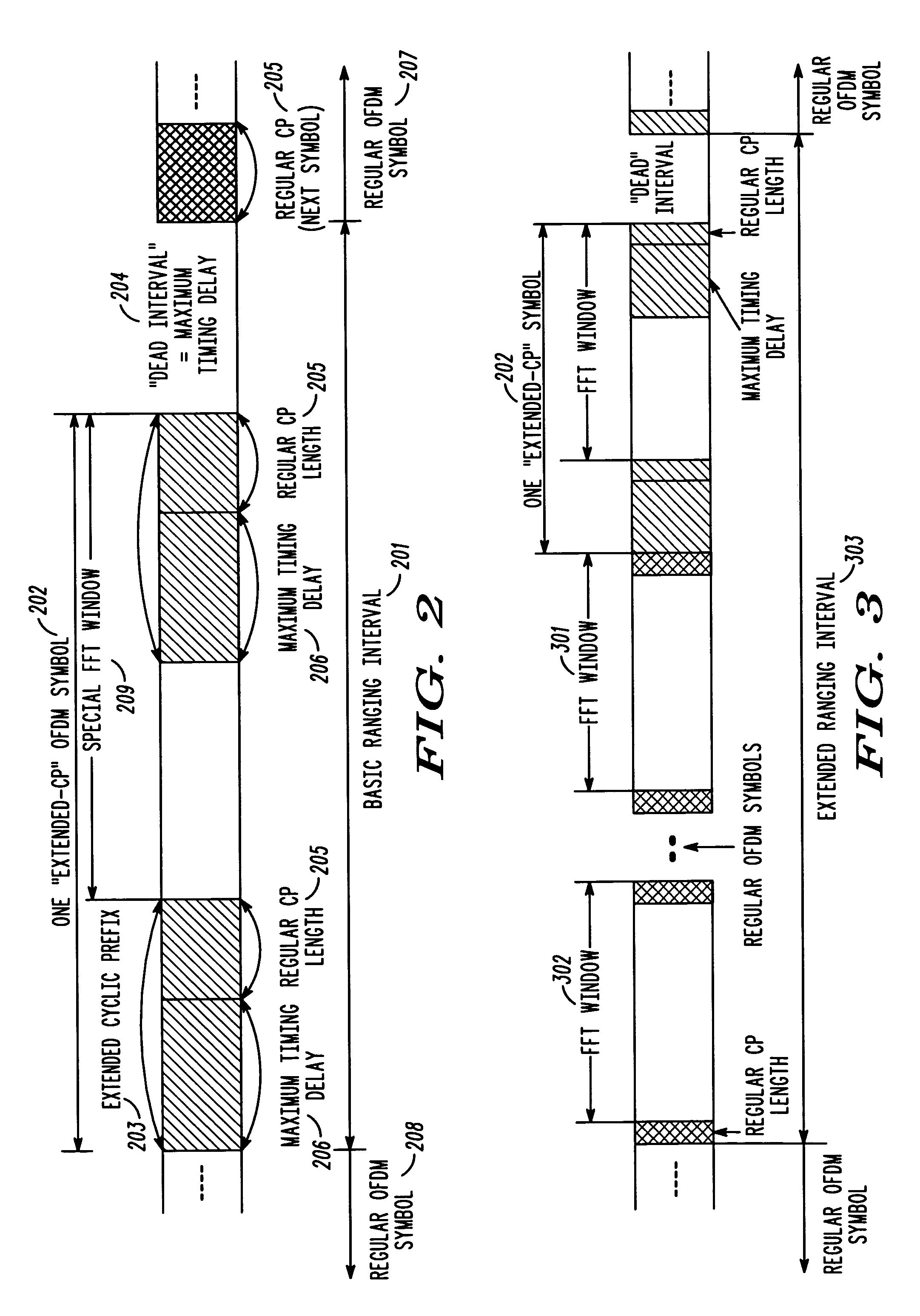

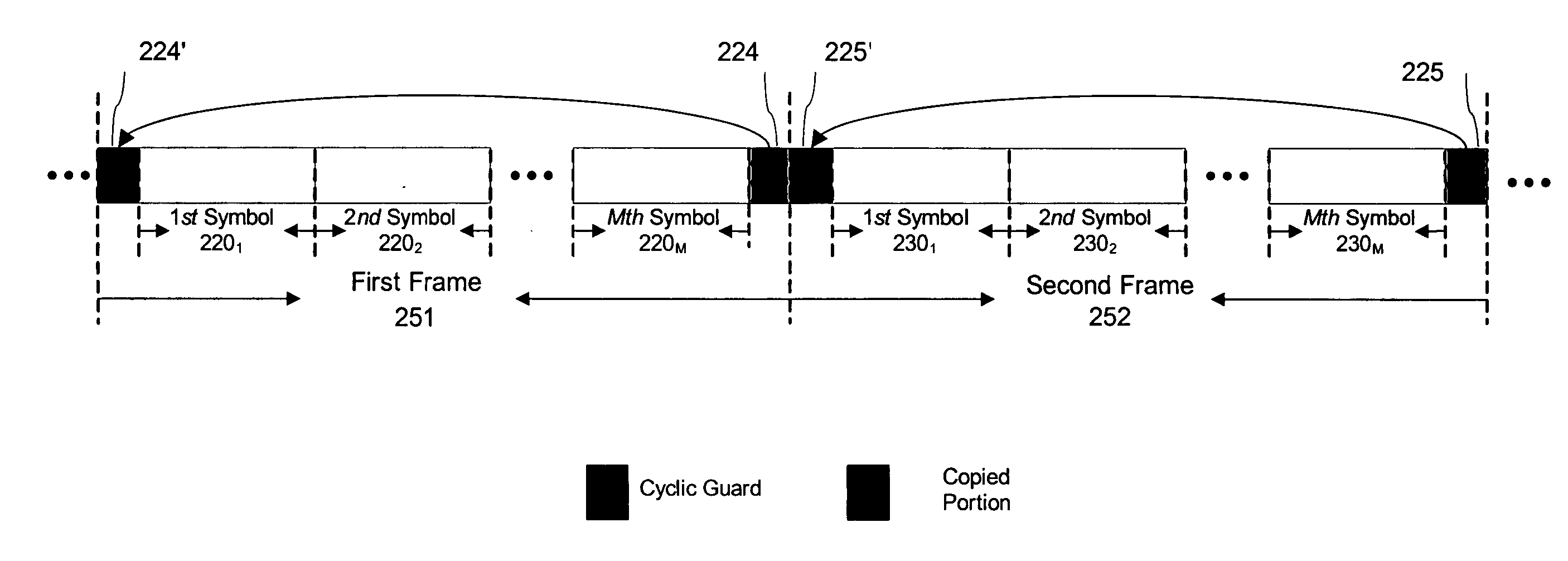

Multi-symbol encapsulated OFDM transmission

InactiveUS20050068886A1Improve bandwidth efficiencyReduce frequency offsetFrequency-division multiplexMulti-frequency code systemsHigh bandwidthCyclic prefix

A method and system for communication of information in OFDM format are disclosed. The method employs multi-symbol encapsulation (MSE), wherein multiple OFDM symbols are grouped together in cyclic frames having a single cyclic guard portion, for example a cyclic prefix, with multiple OFDM symbols sandwiched between each two consecutive cyclic guard portions. All OFDM symbols of one frame are equalized together at the receiver in a frequency domain using a single DFT / IDFT operation sequence. Embodiments of the MSE OFDM system are disclosed enabling high bandwidth efficiency, high tolerance to carrier frequency offset and low peak-to-average power ratio.

Owner:HER MAJESTY THE QUEEN & RIGHT OF CANADA REPRESENTED BY THE MIN OF IND THROUGH THE COMM RES CENT

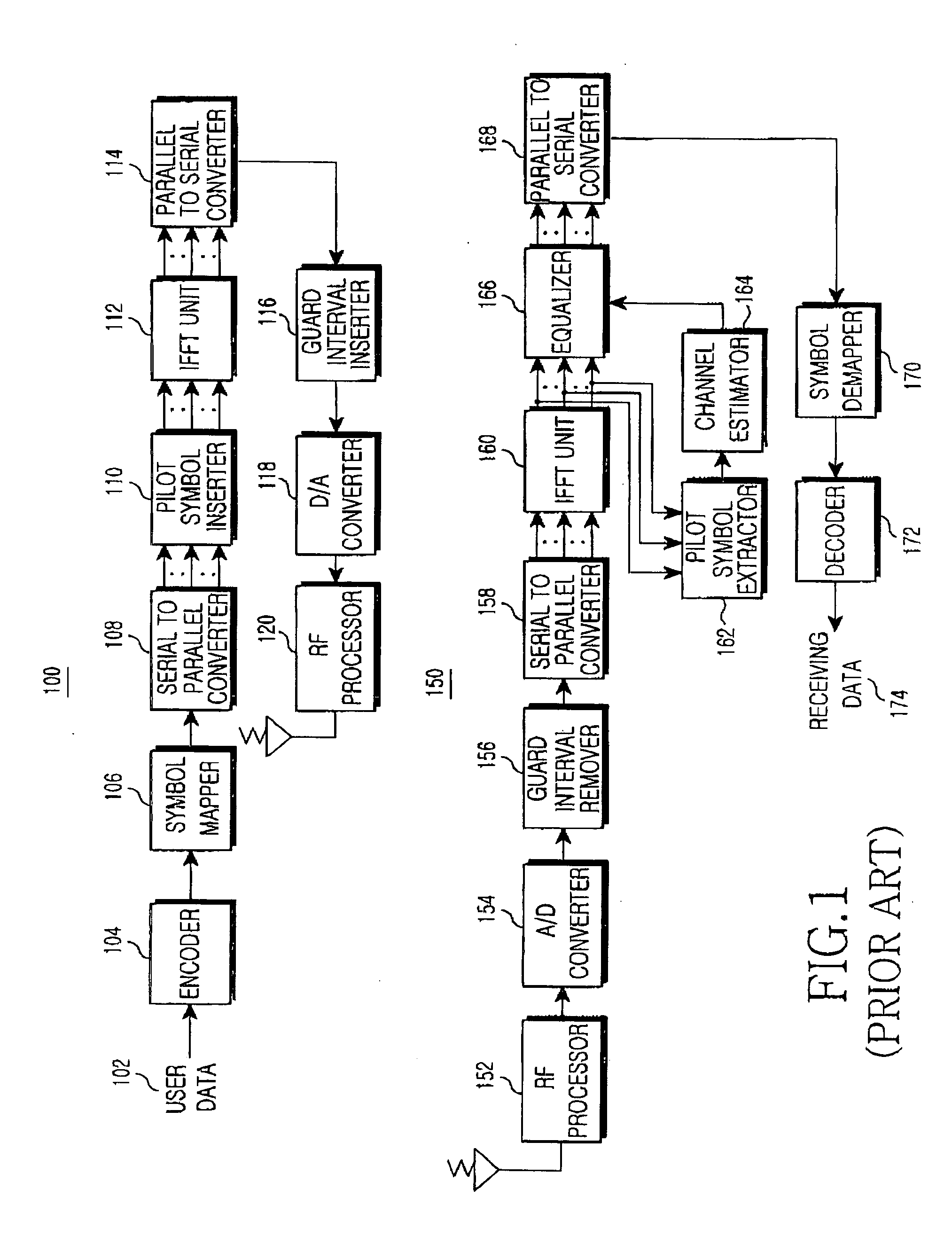

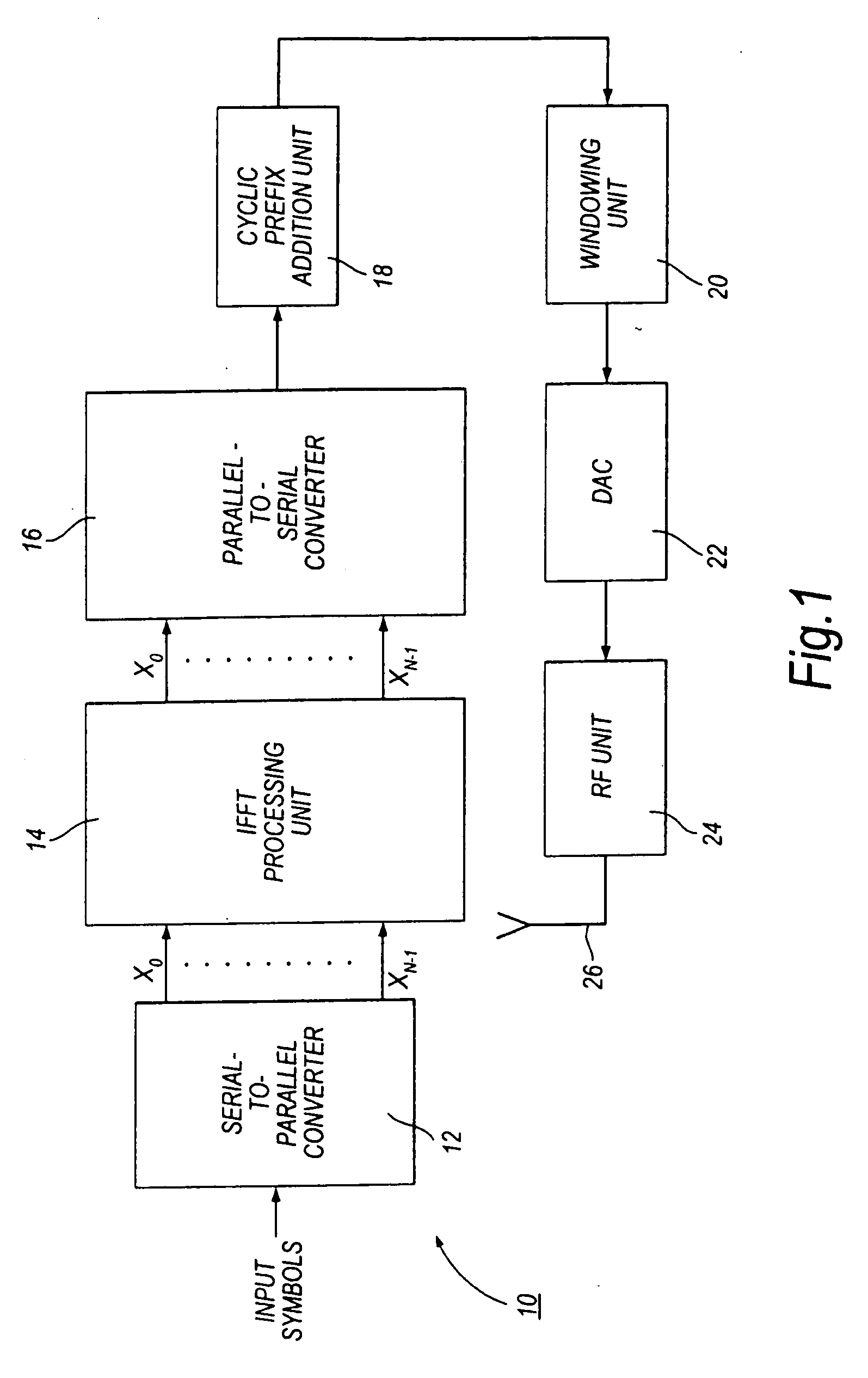

OFDM communication systems, transmitters and methods

InactiveUS20070217329A1Improve performanceModulated-carrier systemsFrequency-division multiplexCarrier signalOfdm communication system

A transmitter 100 transmits an orthogonal frequency division multiplexing (OFDM) signal. A control unit 104 receives a group of input symbols (X0 to XN-1) based on which the transmitted signal is to be generated. The control unit selects, from among a plurality of available allocations of input symbols to sub-carriers, one allocation to apply to the received group of input symbols. Each available allocation serves to allocate the input symbols to respective sub-carriers in a different way from each other available allocation. The allocation selection is based on predicted values of a predetermined property, e.g. a peak-to-average power ratio (PAPR), of the transmitted signal for different available allocations. The available allocations may be different rotations. Further elements 102, 14, 16 of the transmitter generate the transmitted signal using the selected allocation.

Owner:FUJITSU LTD

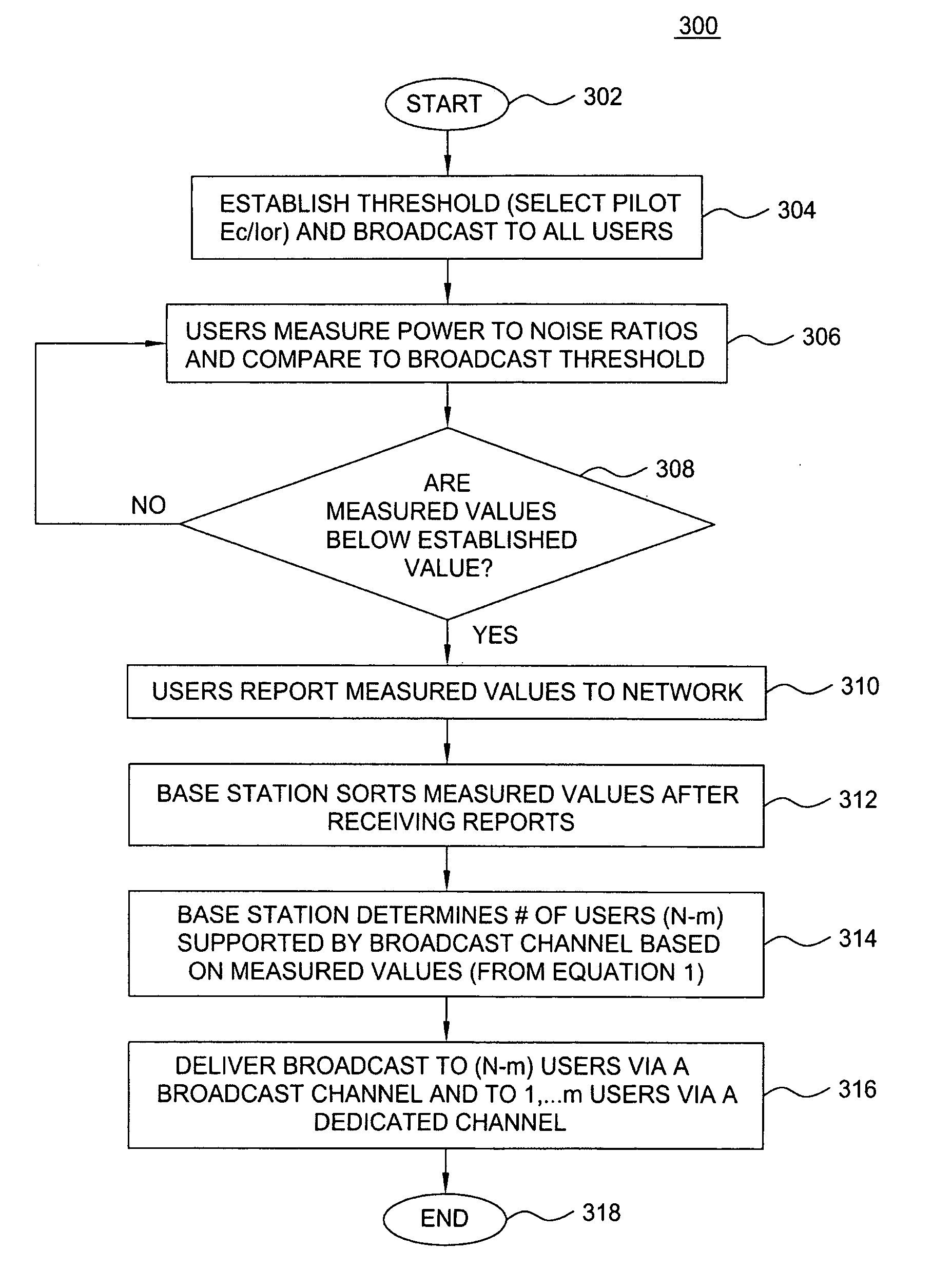

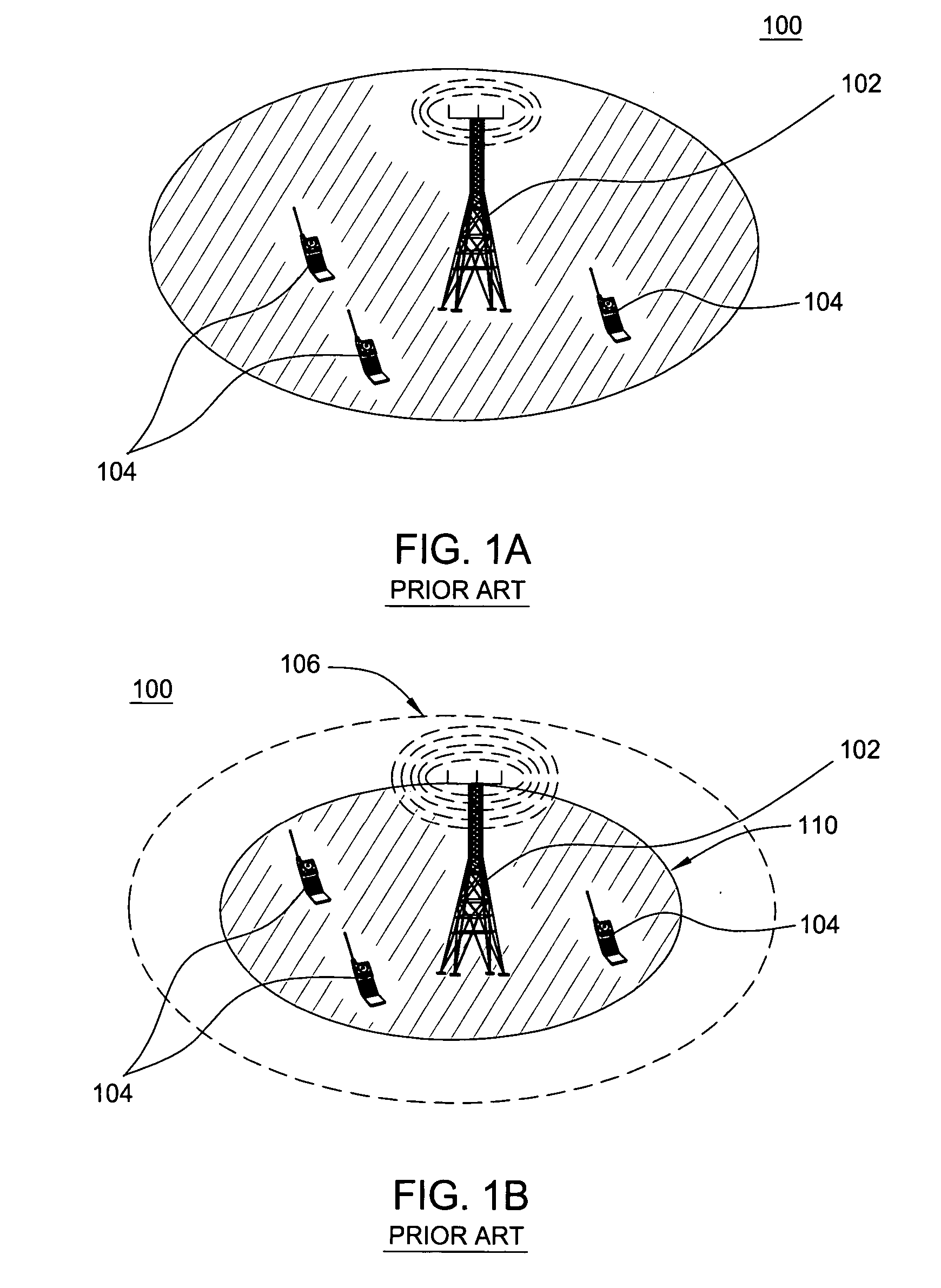

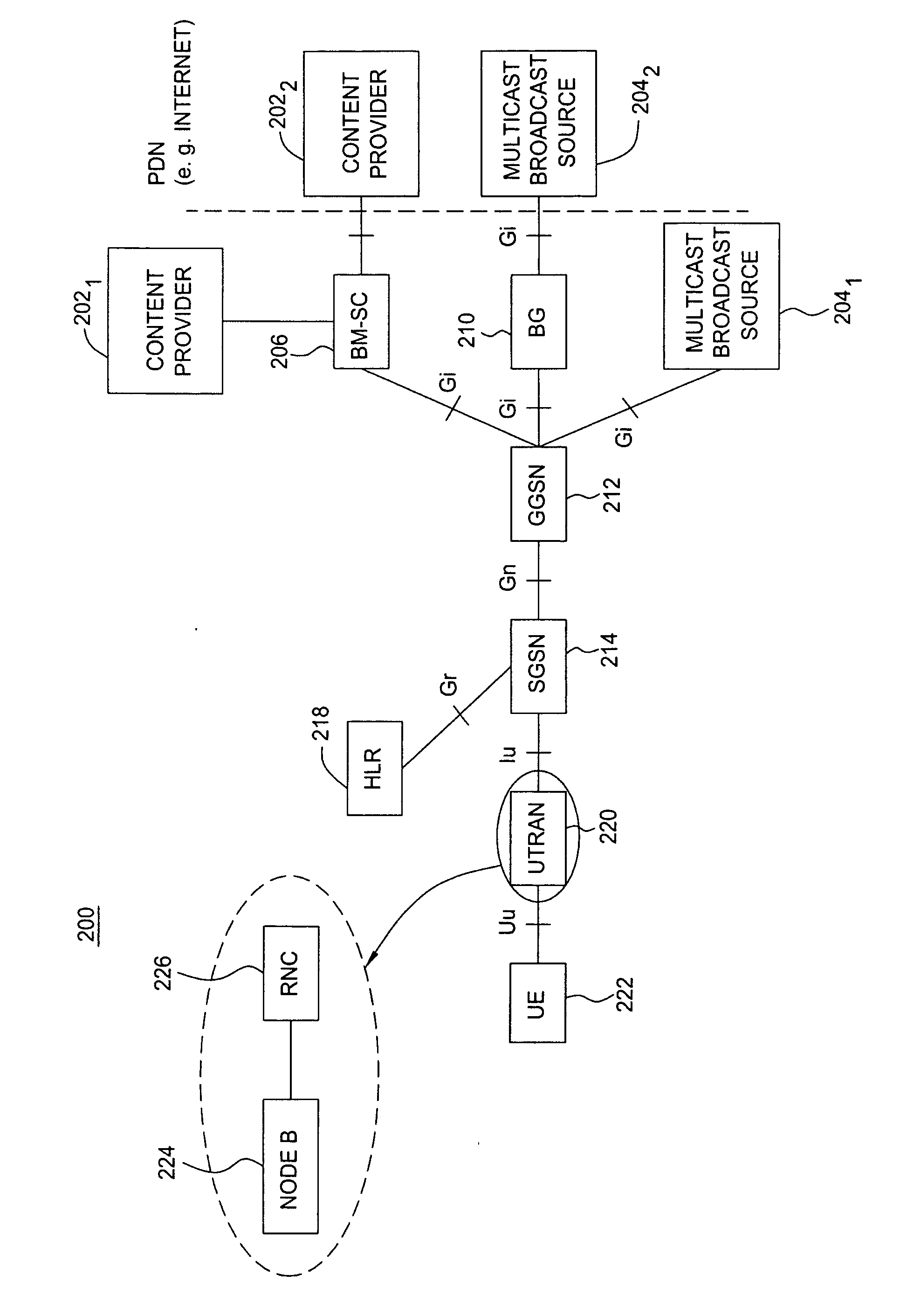

Method and apparatus for providing multicast services in a wireless communication environment

ActiveUS20050085254A1Power managementBroadcast service distributionBroadcast channelsCommunications system

Method for multicasting messages to users of a wireless communication system includes the steps of establishing a power ratio threshold for transmitting the messages, measuring respective power ratios of the users, comparing the established power ratio threshold to the measured power ratios, determining a first subset of the users and a second subset of the users based upon the measured power ratios and delivering the messages to the first subset of the plurality of users via a first transmission scheme. The first transmission scheme delivers the messages to all of the users of the first subset via a broadcast channel. The method also has a step of delivering the messages to the second subset of the users via a second transmission scheme. The second transmission scheme delivers the messages to each of the users of the second subset via respective dedicated channels.

Owner:ALCATEL-LUCENT USA INC +1

Method for determining pump flow without the use of traditional sensors

ActiveUS7945411B2Testing/calibration apparatusProcess and machine controlOperating pointMuller's method

A technique for determining pump flow without using traditional sensors features steps and modules for creating a calibrated power curve at closed valve conditions at several speeds; calculating coefficients from a normalized power curve based on a pump's power ratio; and solving a polynomial power equation for flow at the current operating point. The calibrated power curve may be created by increasing the speed of the pump from a minimum speed to a maximum speed and operating the pump with a closed discharge valve. This data is used to correct published performance for shutoff power and best efficiency point power at rated speed in order to determine the pump's power ratio. It is also used to accurately determine closed valve power at the current operating speed. The pump's power ratio is determined by the equation: Pratio=Pshutoff @100% / PBEP<sub2>—< / sub2>corr. The polynomial power equation may, for example, include a 3rd order polynomial equation developed using coefficients from the normalized power versus flow curve, and corrections may be made for speed, hydraulic efficiency and specific gravity in the polynomial power equation. Complex roots may be determined to solve the 3rd order polynomial equation using either Muller's method or some other suitable method, and the calculated actual flow may be determined for a specific operating point.

Owner:ITT MFG ENTERPRISES LLC

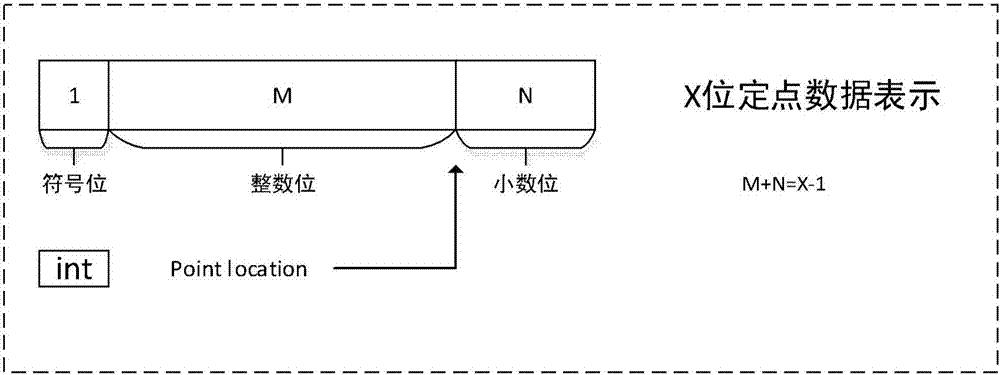

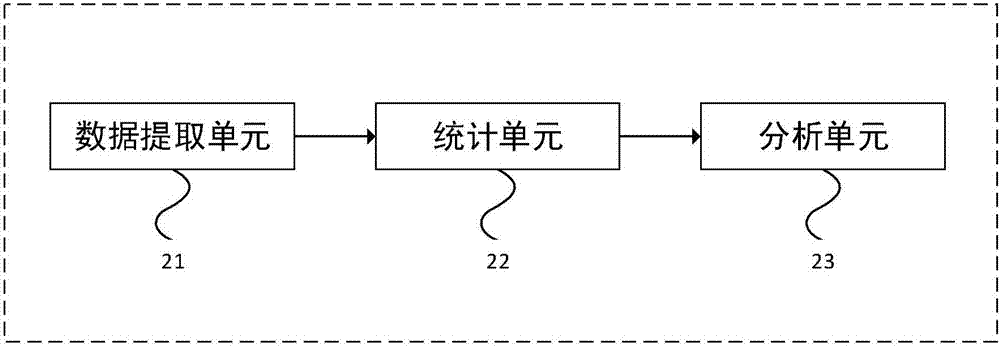

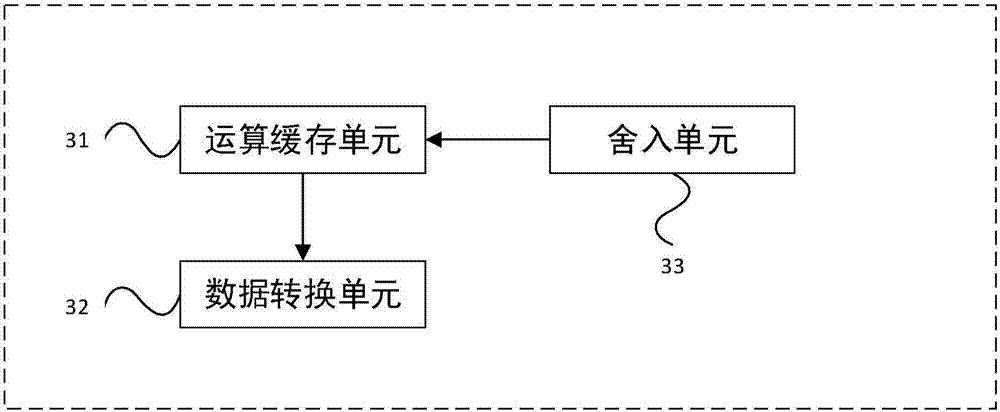

Device and method for executing forward operation of artificial neural network

PendingCN107330515ASmall area overheadReduce area overhead and optimize hardware area power consumptionDigital data processing detailsCode conversionData operationsComputer module

The invention provides a device and a method for executing a forward operation of an artificial neural network. The device comprises the components of a floating point data statistics module which is used for performing statistics analysis on varies types of required data and obtains the point location of fixed point data; a data conversion unit which is used for realizing conversion from a long-bit floating point data type to a short-bit floating point data type according to the point location of the fixed point data; and a fixed point data operation module which is used for performing artificial neural network forward operation on the short-bit floating point data. According to the device provided by the invention, through representing the data in the forward operation of the multilayer artificial neural network by short-bit fixed points, and utilizing the corresponding fixed point data operation module, forward operation for the short-bit fixed points in the artificial neural network is realized, thereby greatly improving performance-to-power ratio of hardware.

Owner:CAMBRICON TECH CO LTD

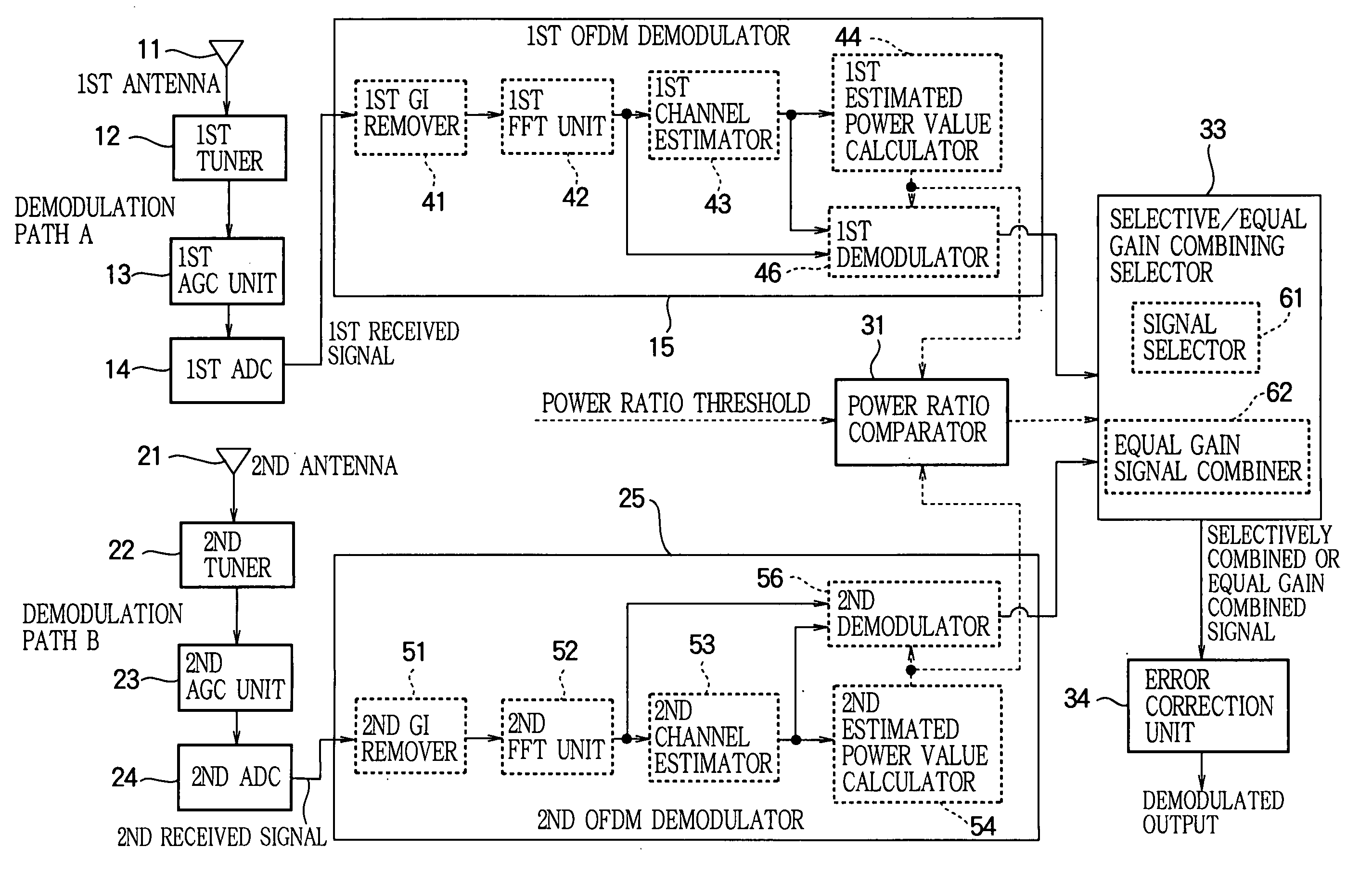

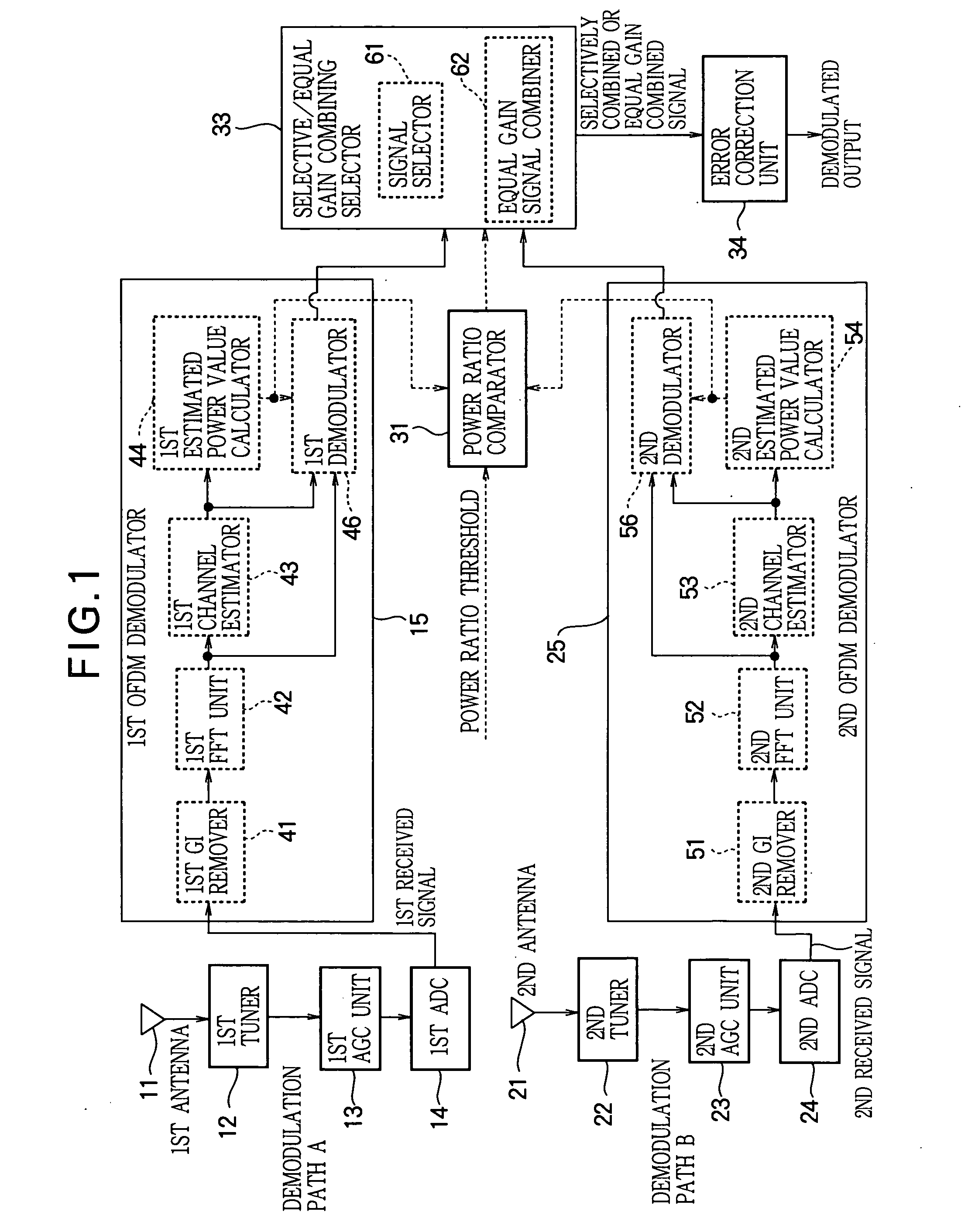

Diversity receprtion device and diversity reception method

InactiveUS20060166634A1Large diversity effectImprove reception performanceSpatial transmit diversityError detection/prevention using signal quality detectorCarrier signalEngineering

The circuit size of a diversity receiver for an orthogonal frequency division multiplexing signal is reduced, and the diversity effect is increased, by providing a power ratio comparator that calculates a difference value as a ratio of powers derived from channel estimation results for subcarrier components received from two antennas (11), (21) and compares the calculated difference value with a predetermined threshold, and a selective / equal gain combining selector (33) that outputs one of the received demodulated signals when the comparison result indicates that the calculated difference value is greater than the threshold value.

Owner:MITSUBISHI ELECTRIC CORP

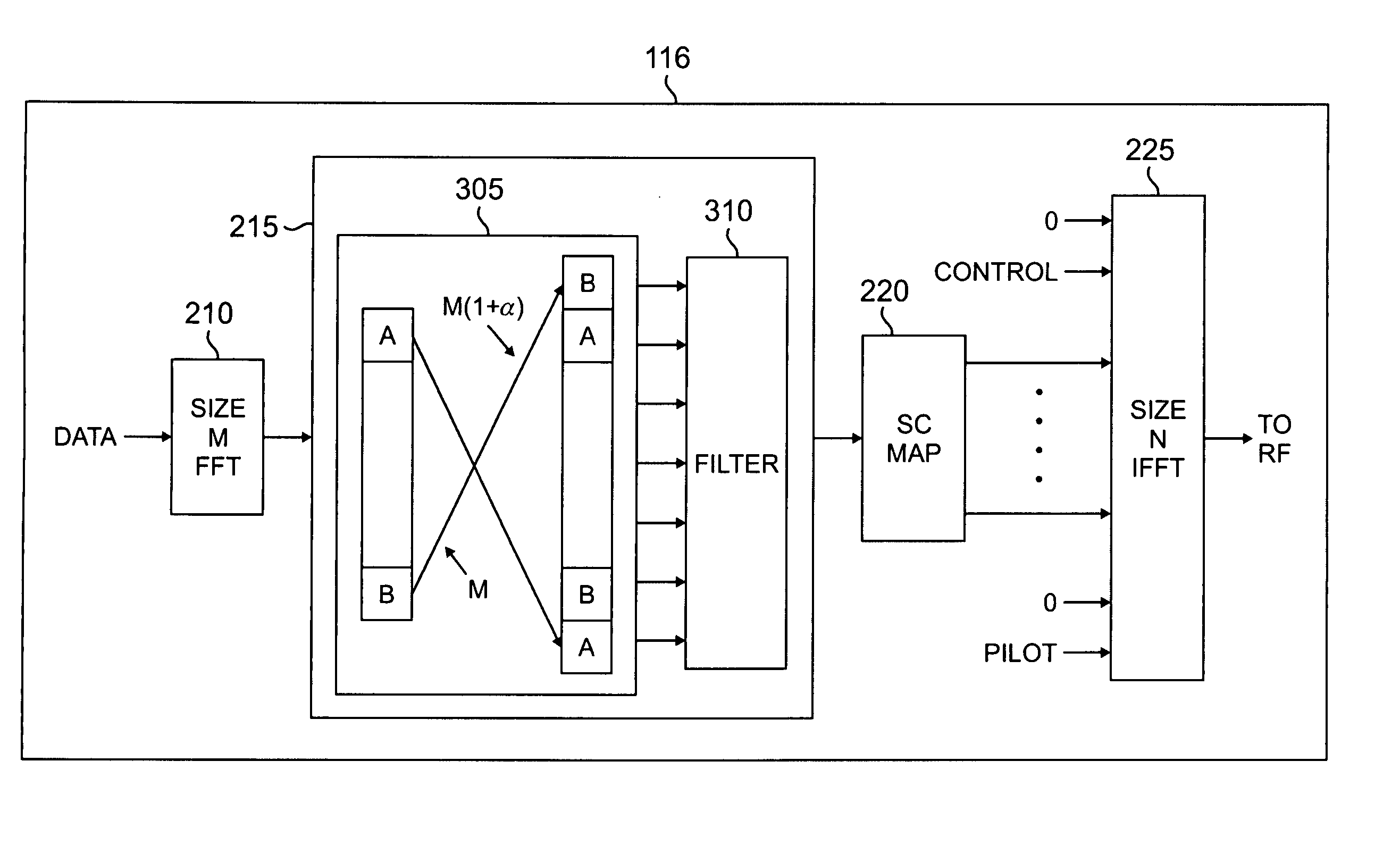

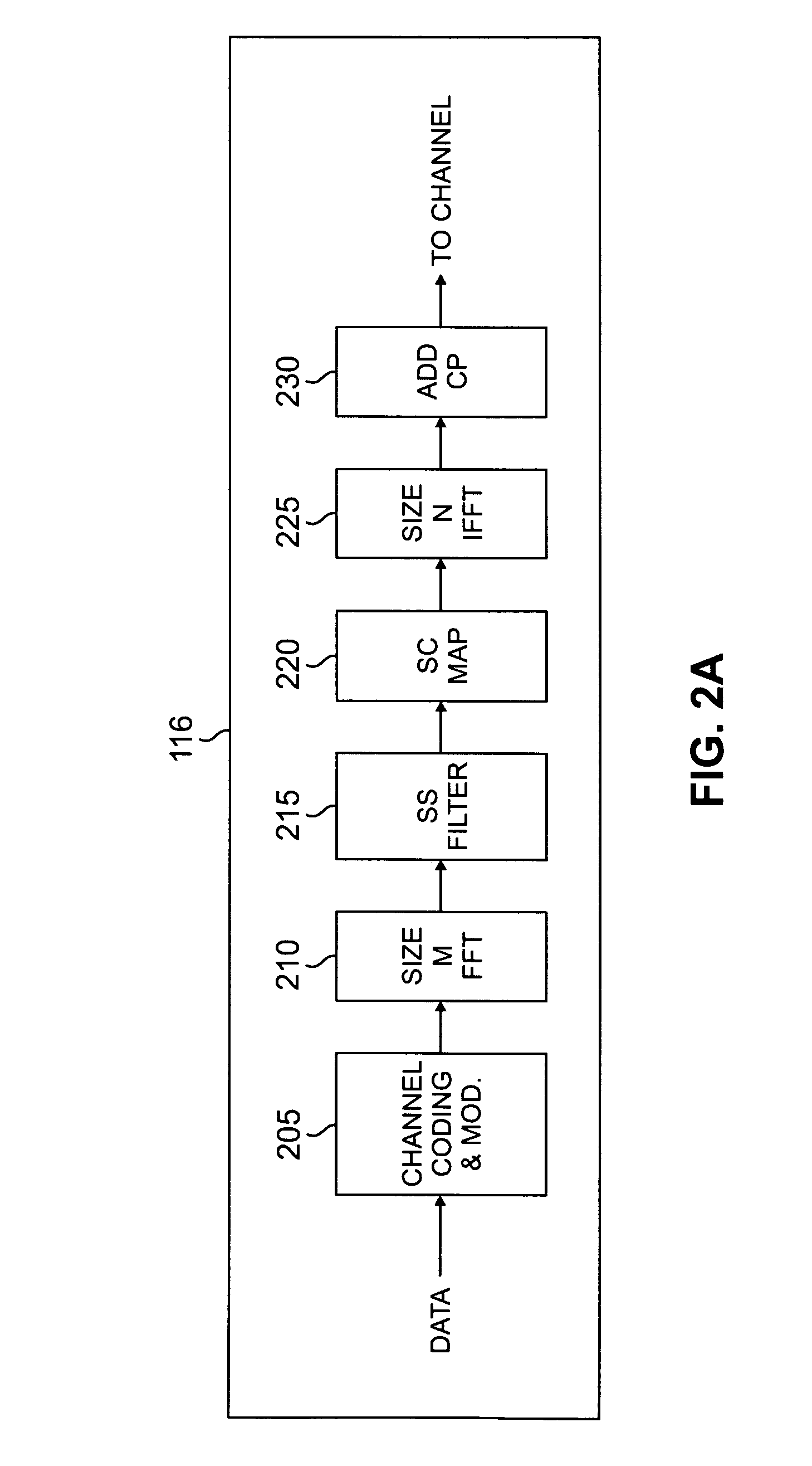

Apparatus and method for reduced peak-to-average-power ratio in a wireless network

InactiveUS20070081604A1Modulated-carrier systemsPolarisation/directional diversityTelecommunicationsFrequency spectrum

A wireless transmission device capable of communicating with a receiver according to a DFT-spread OFDM protocol. The wireless transmission device comprises a configurable spectral shaping filter block capable of performing spectral shaping of an outgoing signal. The wireless transmission device configures the configurable spectral shaping filter block to perform spectral shaping according to a peak-to-average power (PAPR) value associated with the outgoing signal. The multi-carrier protocol comprises one of orthogonal frequency division multiple access (OFDMA) and orthogonal frequency division multiplexing (OFDM).

Owner:SAMSUNG ELECTRONICS CO LTD

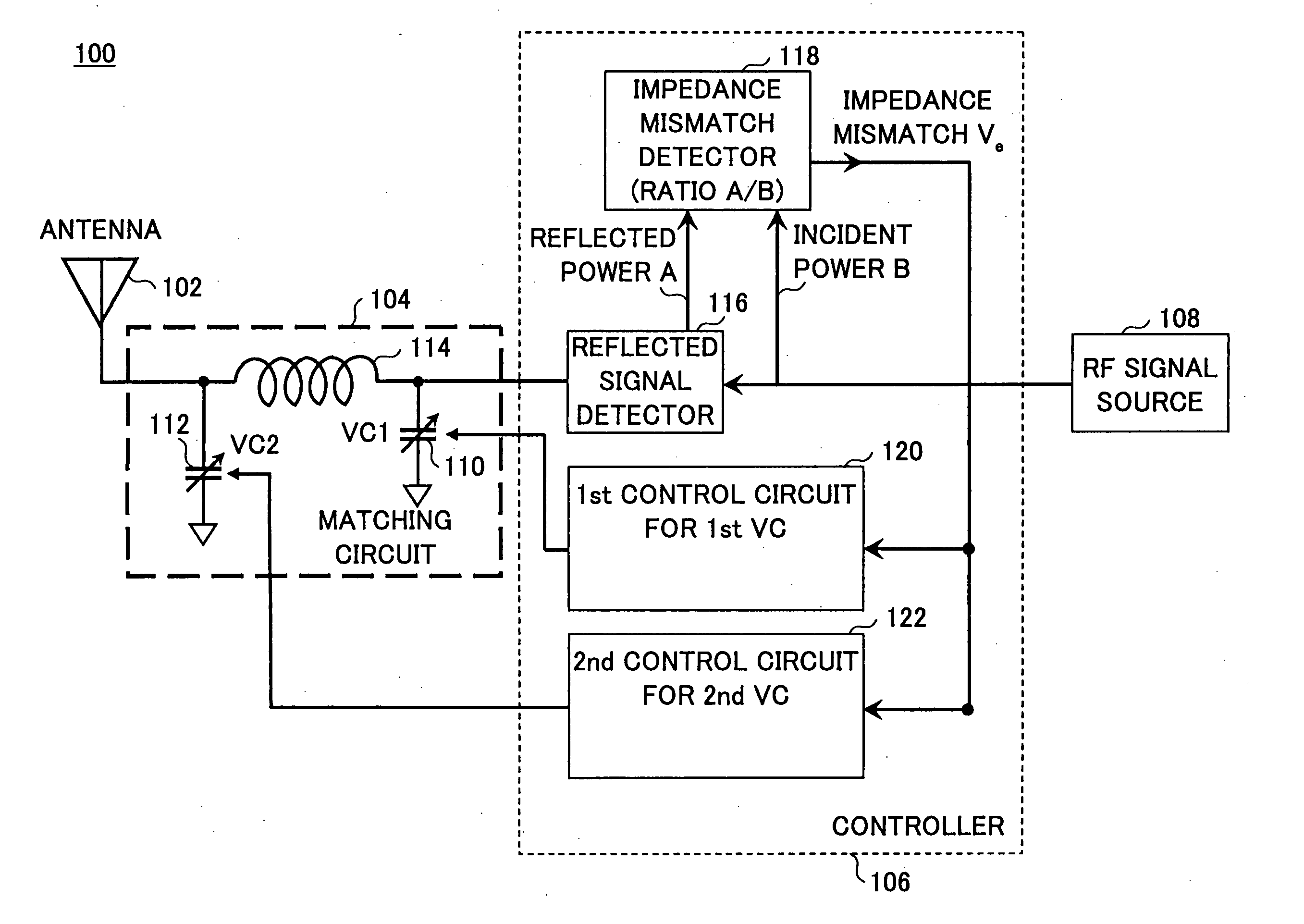

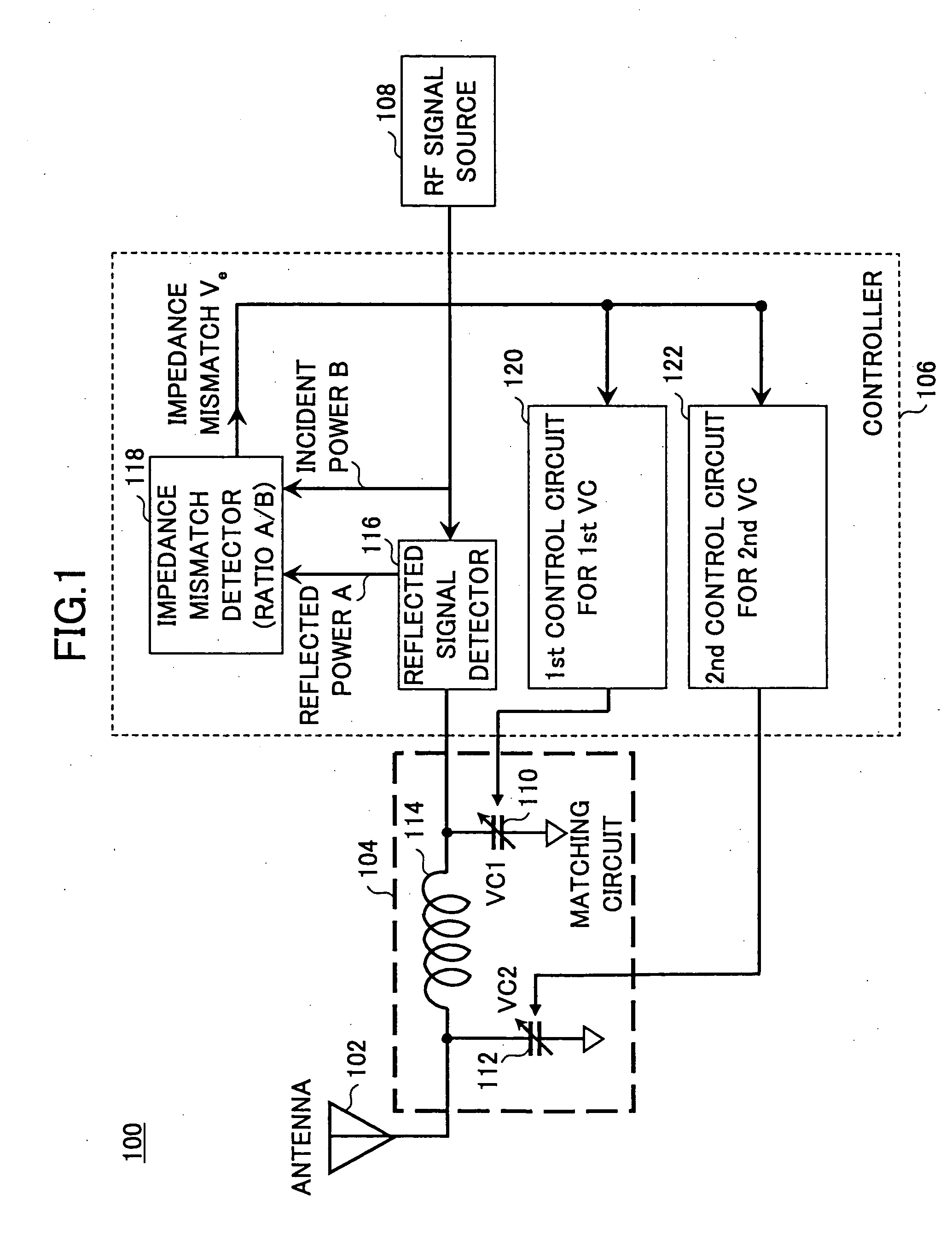

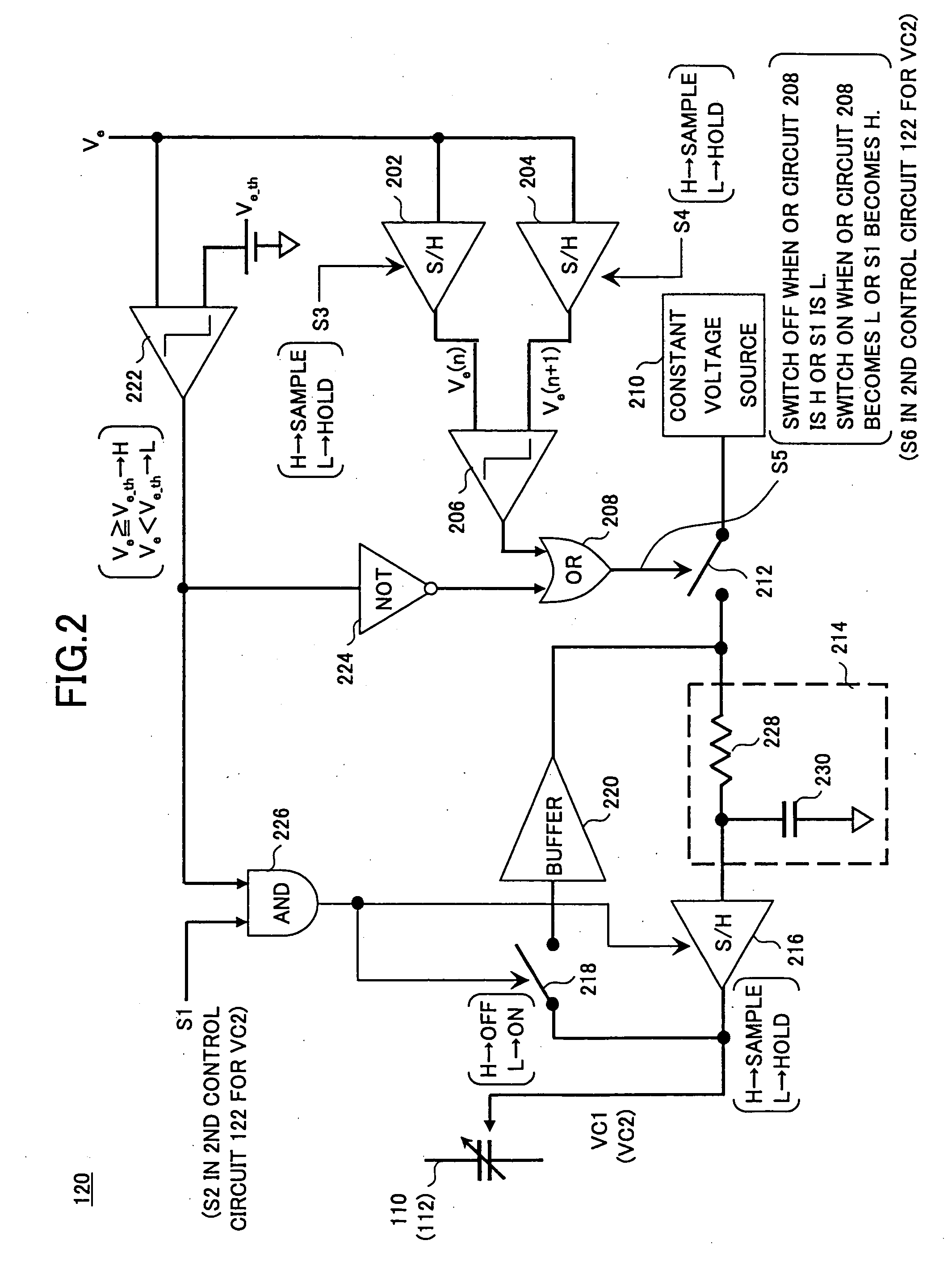

Control device for antenna matching circuit

ActiveUS20050184922A1Multiple-port networksDiversity/multi-antenna systemsEngineeringElectrical impedance

A control device for an antenna matching circuit is configured to output an adjusting signal for changing impedance of an element in the antenna matching circuit based on change over time in signal power ratio of a reflected signal from the antenna matching circuit to an incident signal to the antenna matching circuit.

Owner:FUJITSU LTD

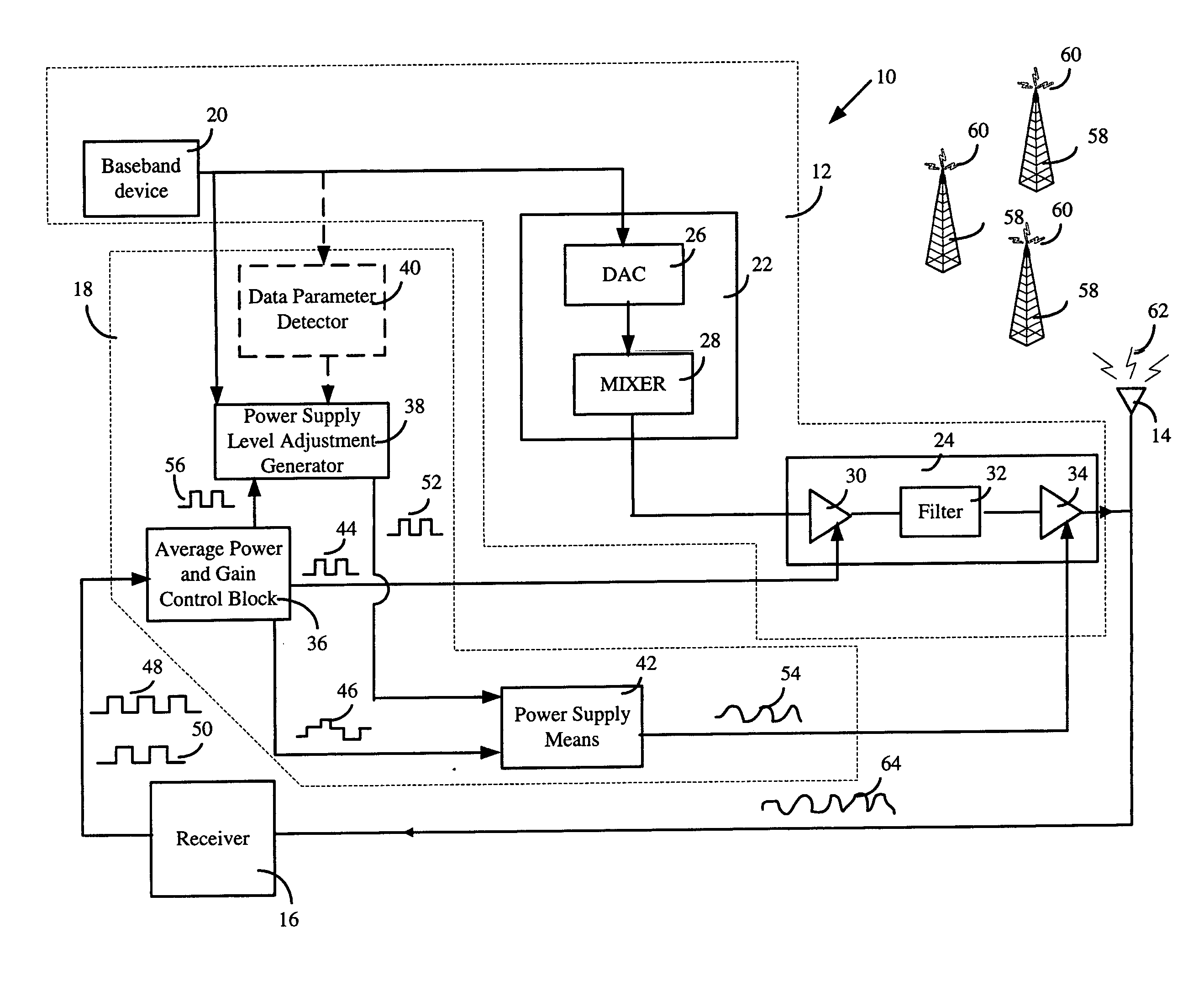

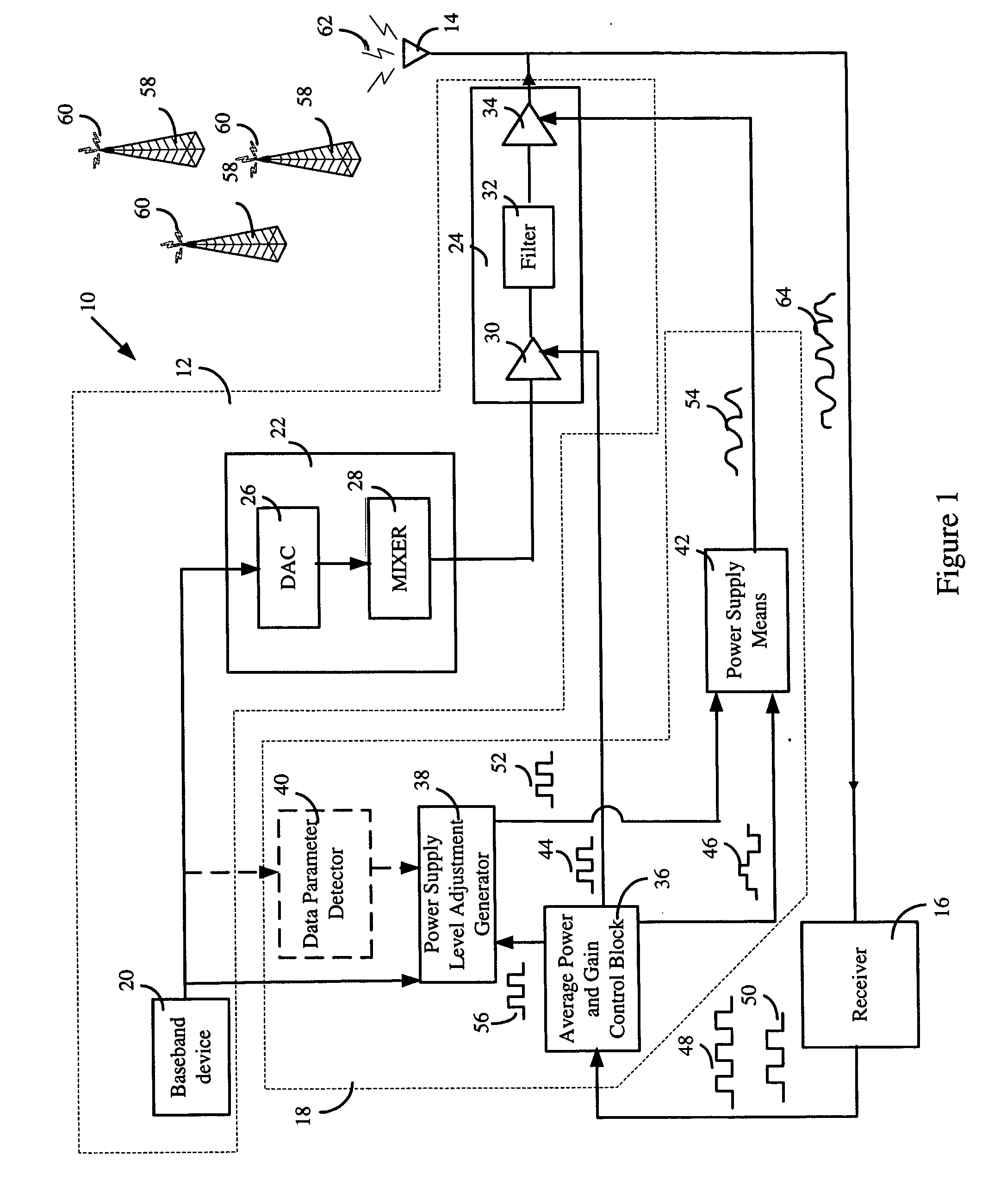

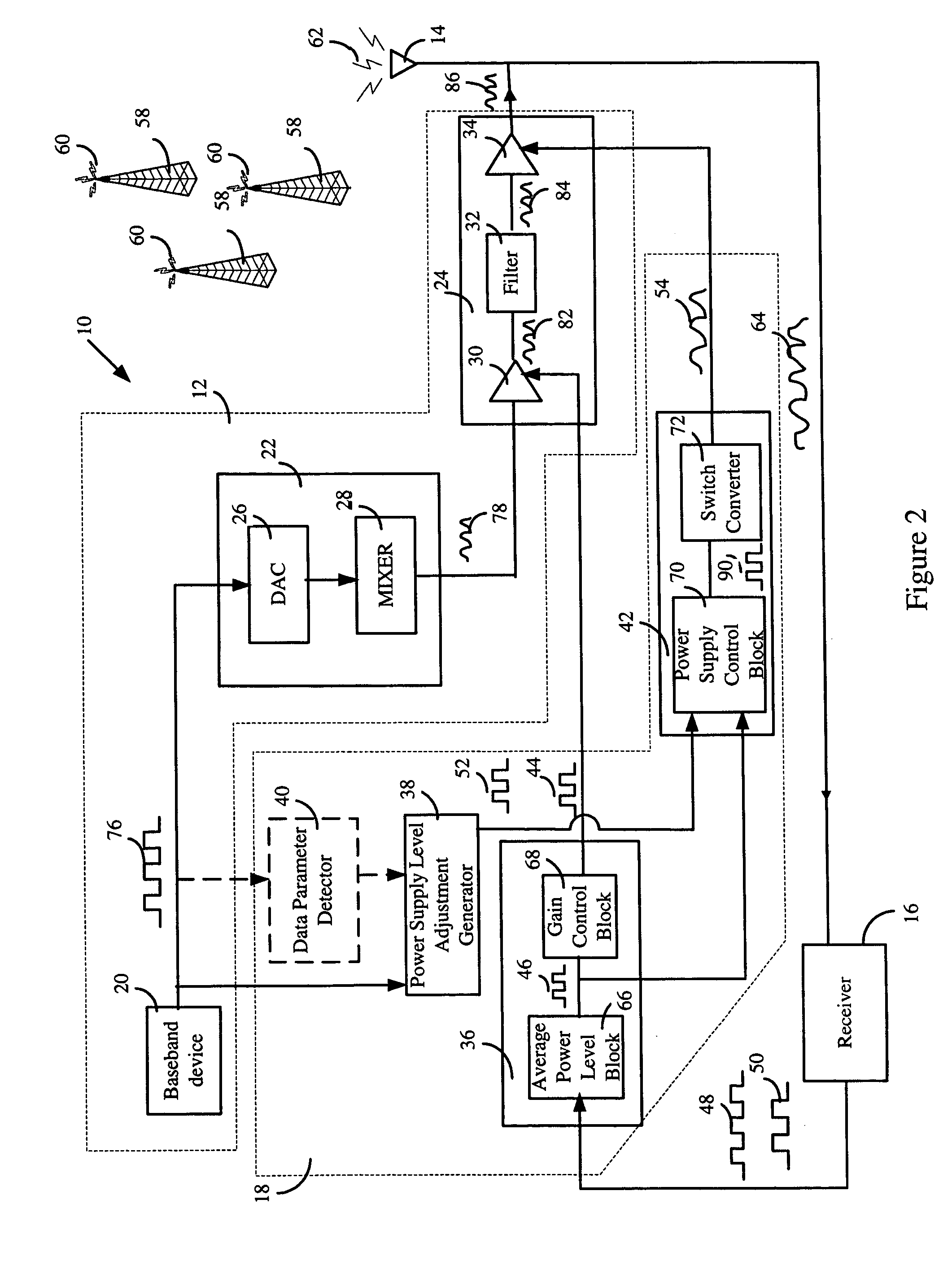

Method and apparatus for improving power amplifier efficiency in wireless communication systems having high peak to average power ratios

ActiveUS20050186923A1Reduce power lossAugment estimated desired power levelEnergy efficient ICTPower managementData streamHigh peak

A power management system and method for a wireless communication device generates an average desired transmit power signal based on at least one of a received signal strength indicator signal and a power control instruction signal from a base station. A power supply level adjustment signal is generated based on the data parameters of an outgoing data stream and at least one environmental information signal. A combination of the power supply level adjustment signal and the average desired transmit power or a gain control signal and an altered version of the power supply level adjustment signal is used to generate a variable power supply signal that is provided to an output amplifier block for sufficiently generating outgoing wireless device radio signals while reducing power loss in the output amplifier block.

Owner:MALIKIE INNOVATIONS LTD

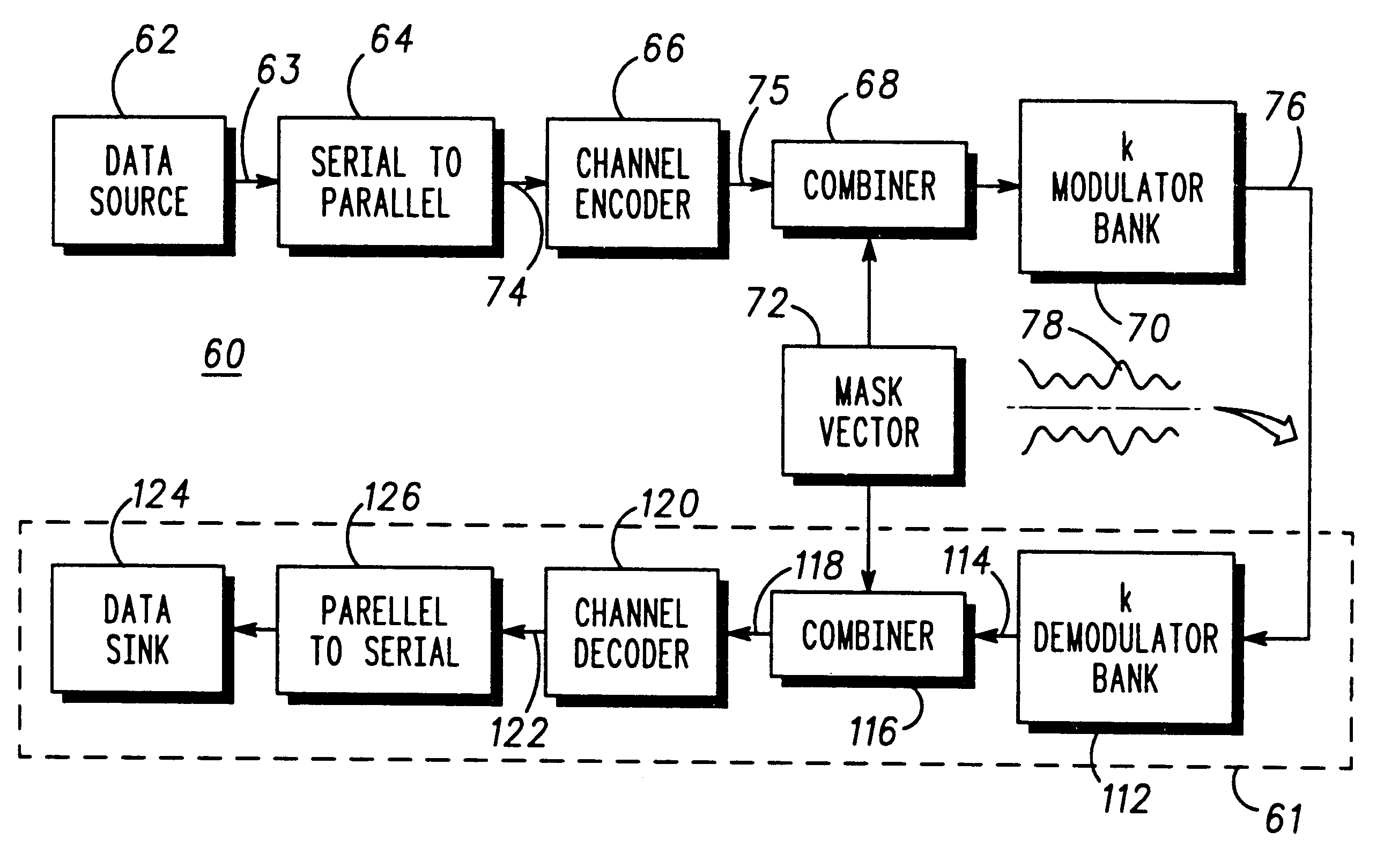

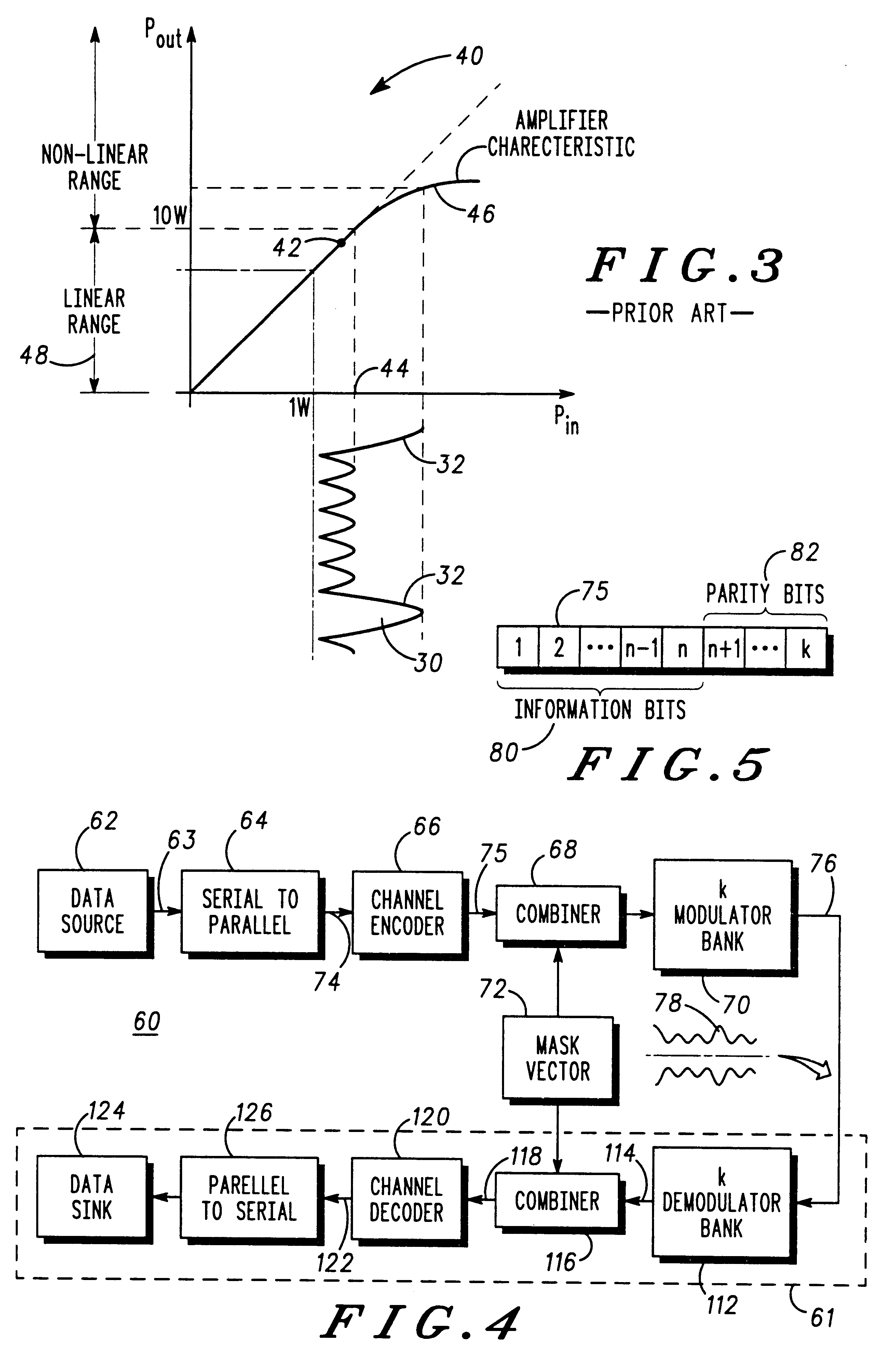

Multicarrier communication system and method for peak power control

InactiveUS6307892B1Remove distortion effectsImprovement in PMEPRSecret communicationMulti-frequency code systemsCommunications systemPeak value

A communication device for simultaneously transmitting information on multiple sub-channels encodes information for each of the multiple sub-channels with a coding scheme to produce channel encoded information. A mask vector derived from a redundancy in the coding scheme, encodes the channel encoded information to transform the channel encoded information into codewords having pairwise Euclidean distance properties identical to those of the channel encoded information, Modulation of the sub-channels in accordance with the codewords in a modulator then produces a composite signal envelope having a peak-to-mean error power ratio (PMEPR) reduced relative to a PMEPR for correspondingly modulated channel encoded information.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com