Patents

Literature

87 results about "Diversity effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In fact, there are several effects of diversity in communities. The most important effect of diversity is eliminating the discrimination in the community. If the communities have only two races such as black and white people, discrimination will absolutely be exist.

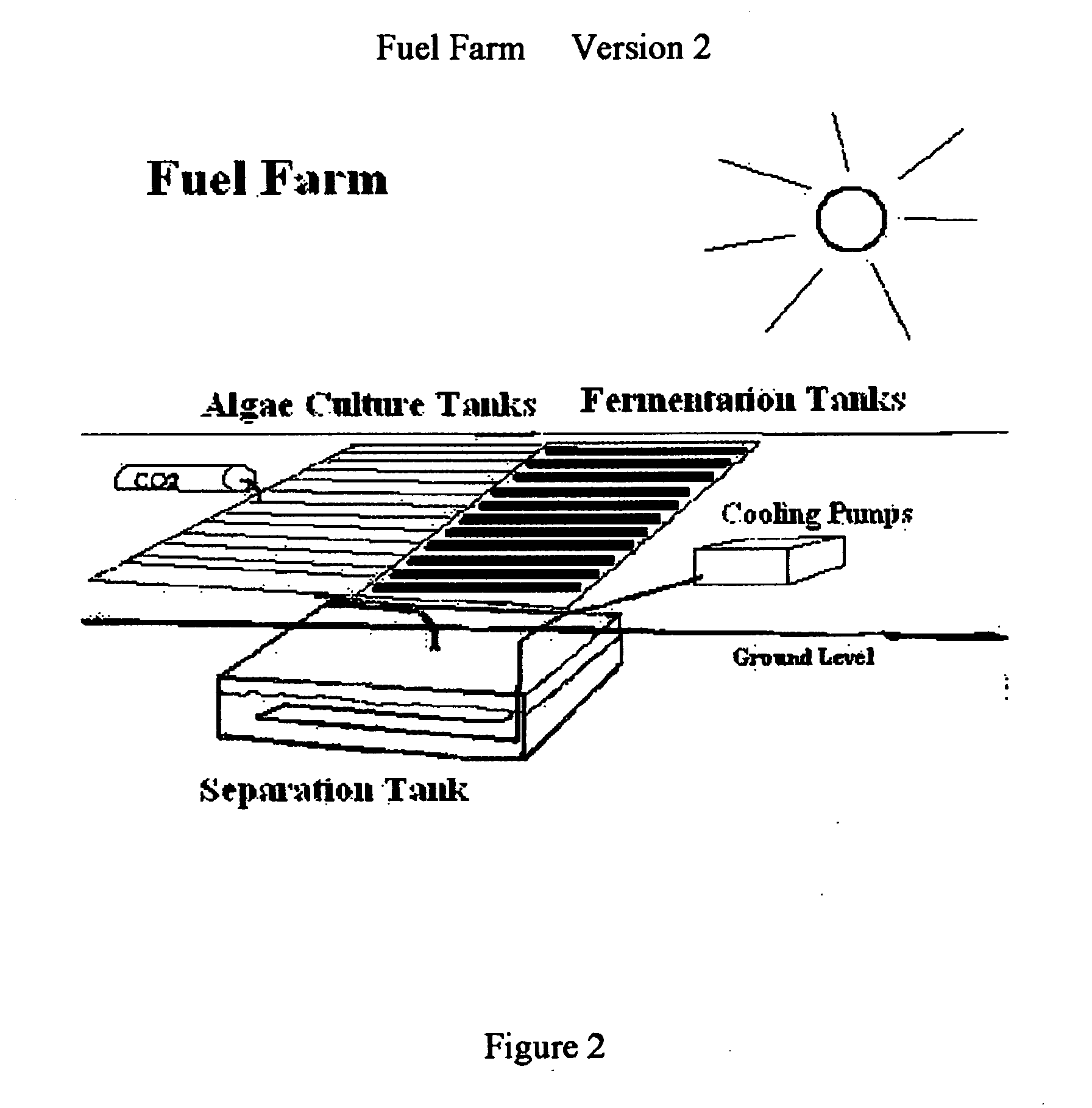

Method and apparatus for transmitting and receiving data in a communication system

ActiveUS20110119568A1Data representation error detection/correctionCode conversionCommunications systemComputer science

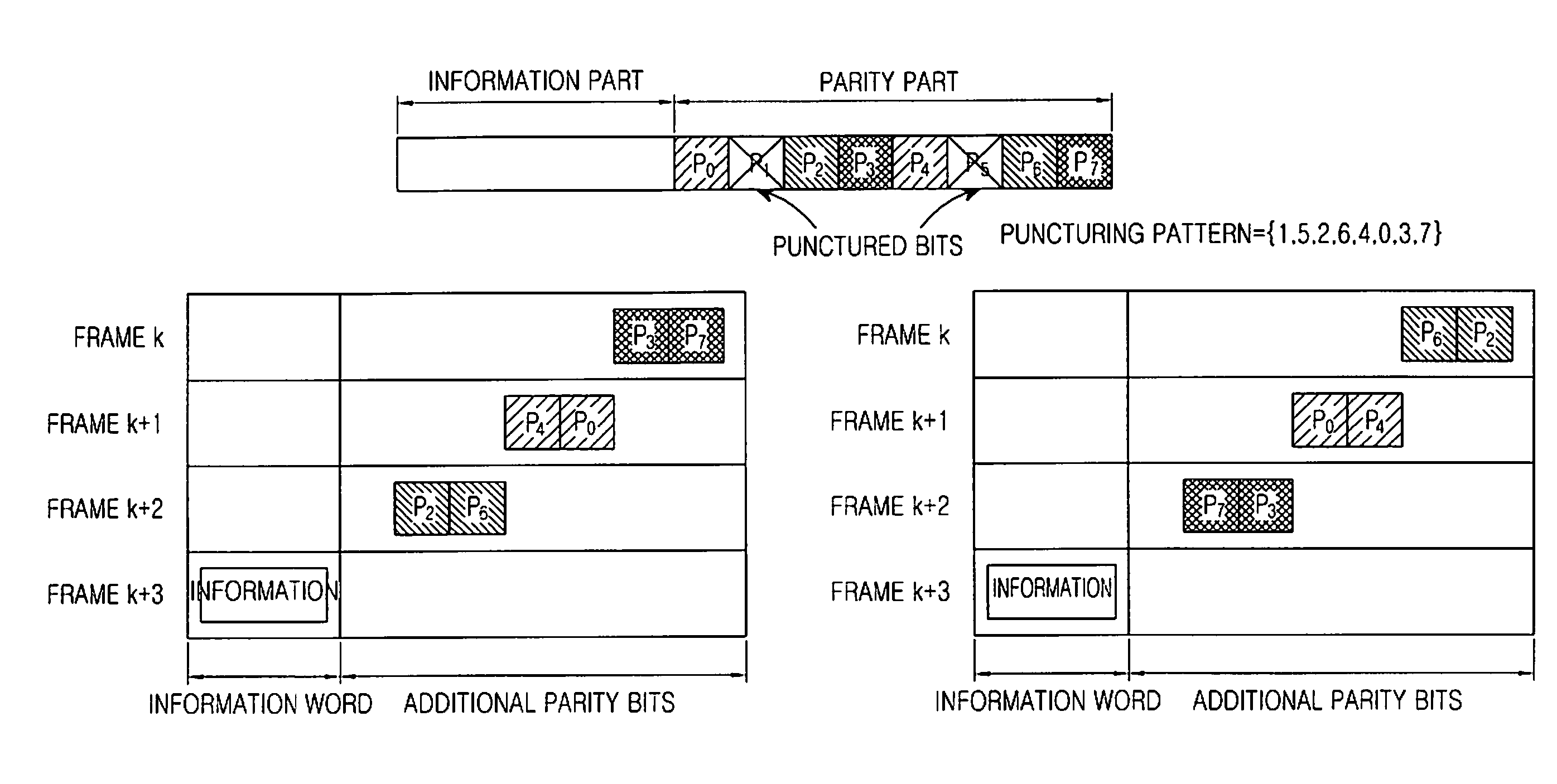

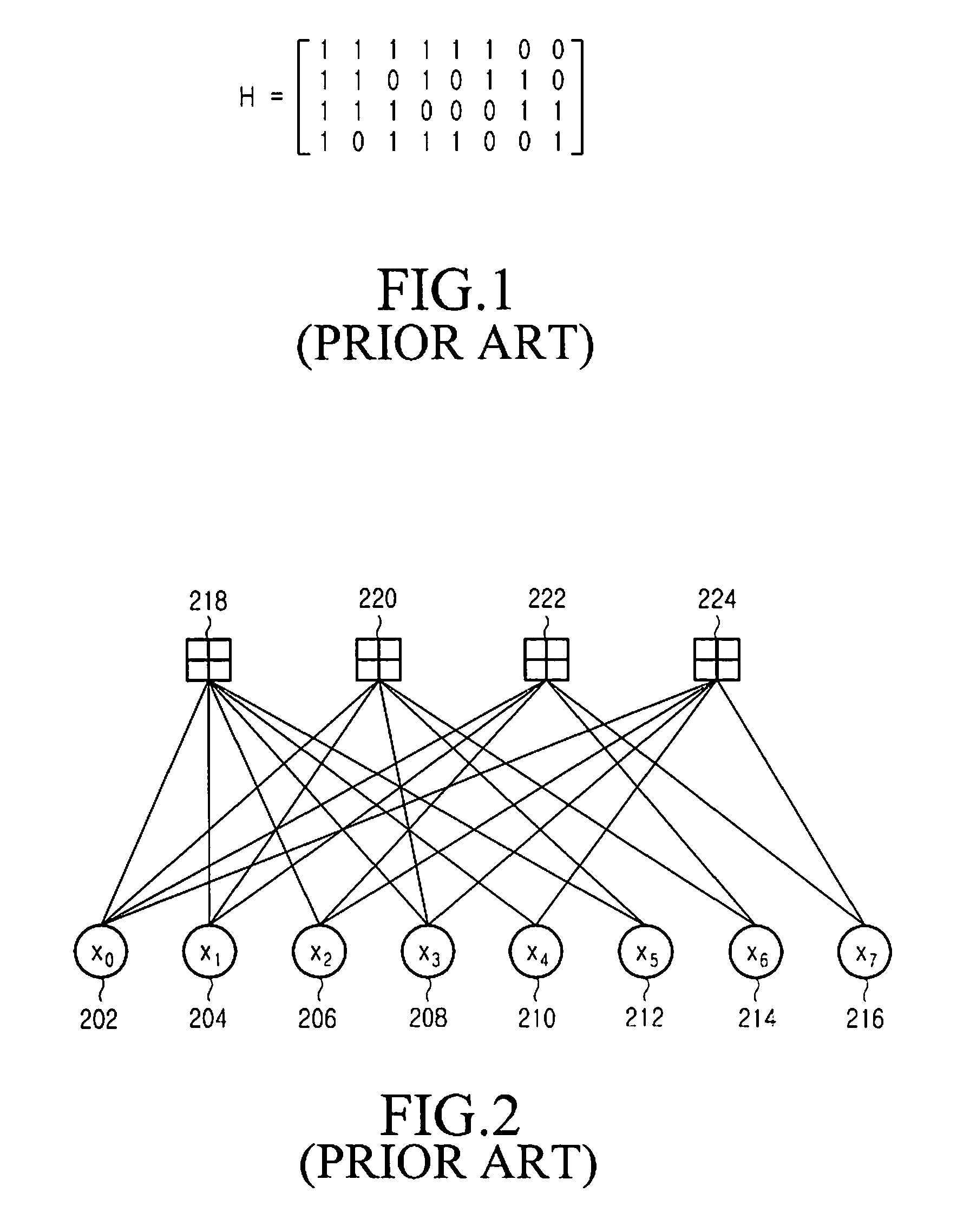

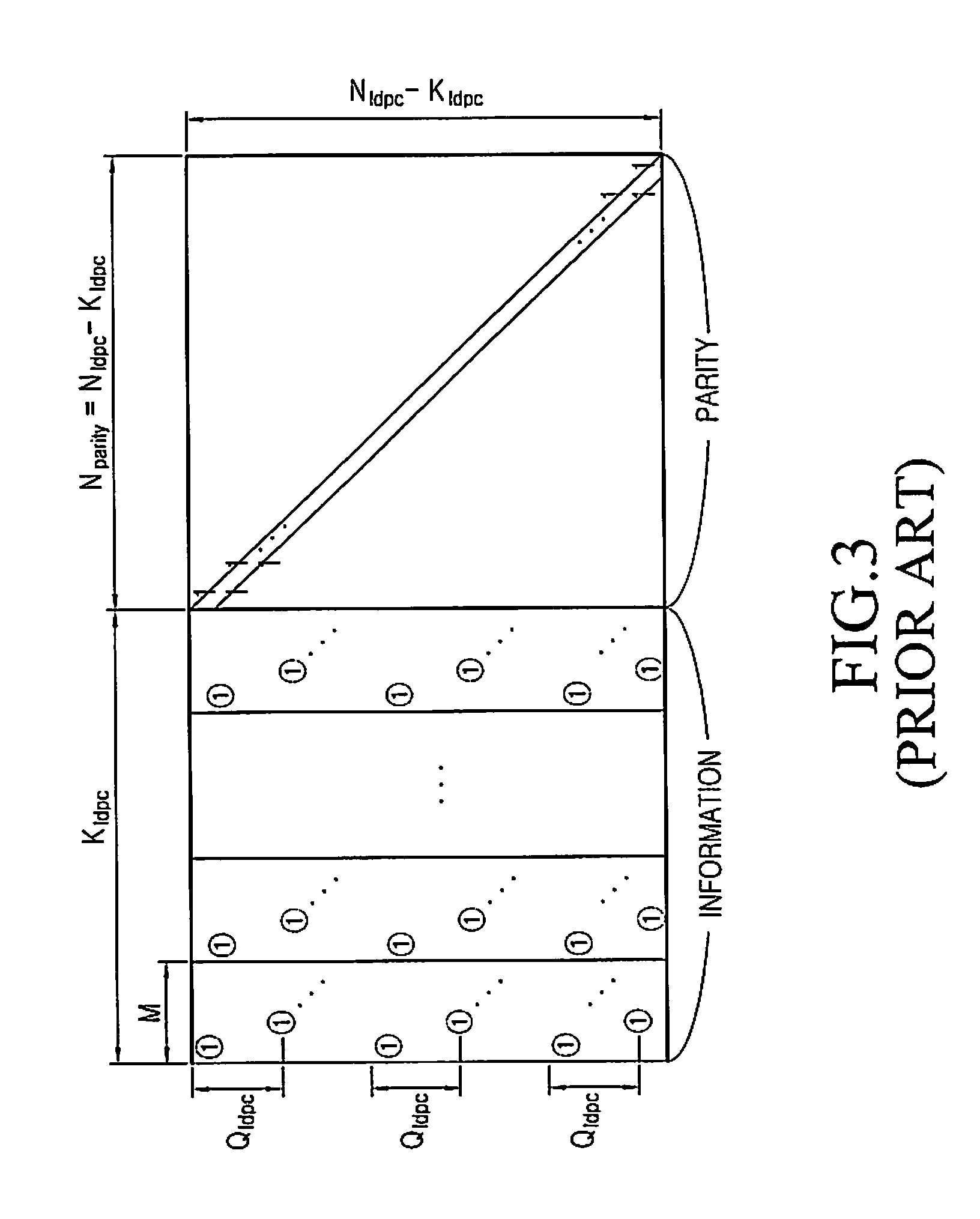

A method is provided for transmitting data, which improves a diversity effect in a communication system. The method includes transmitting an information word including a codeword in a (k+s)-th frame, generating s groups based on parity bits obtained by encoding the information word, and transmitting the s groups in s frames preceding the (k+s)-th frame, in a distributed manner.

Owner:SAMSUNG ELECTRONICS CO LTD

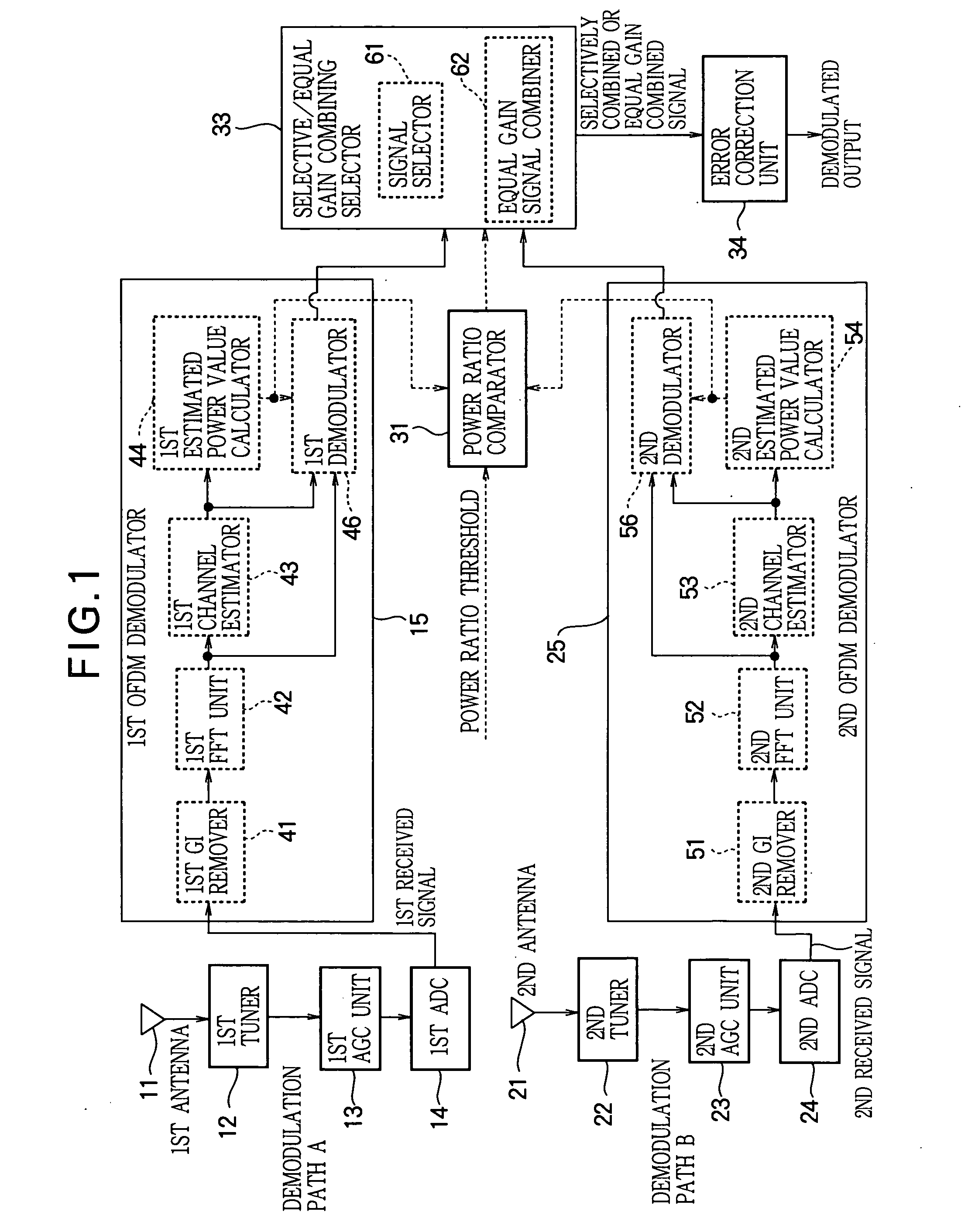

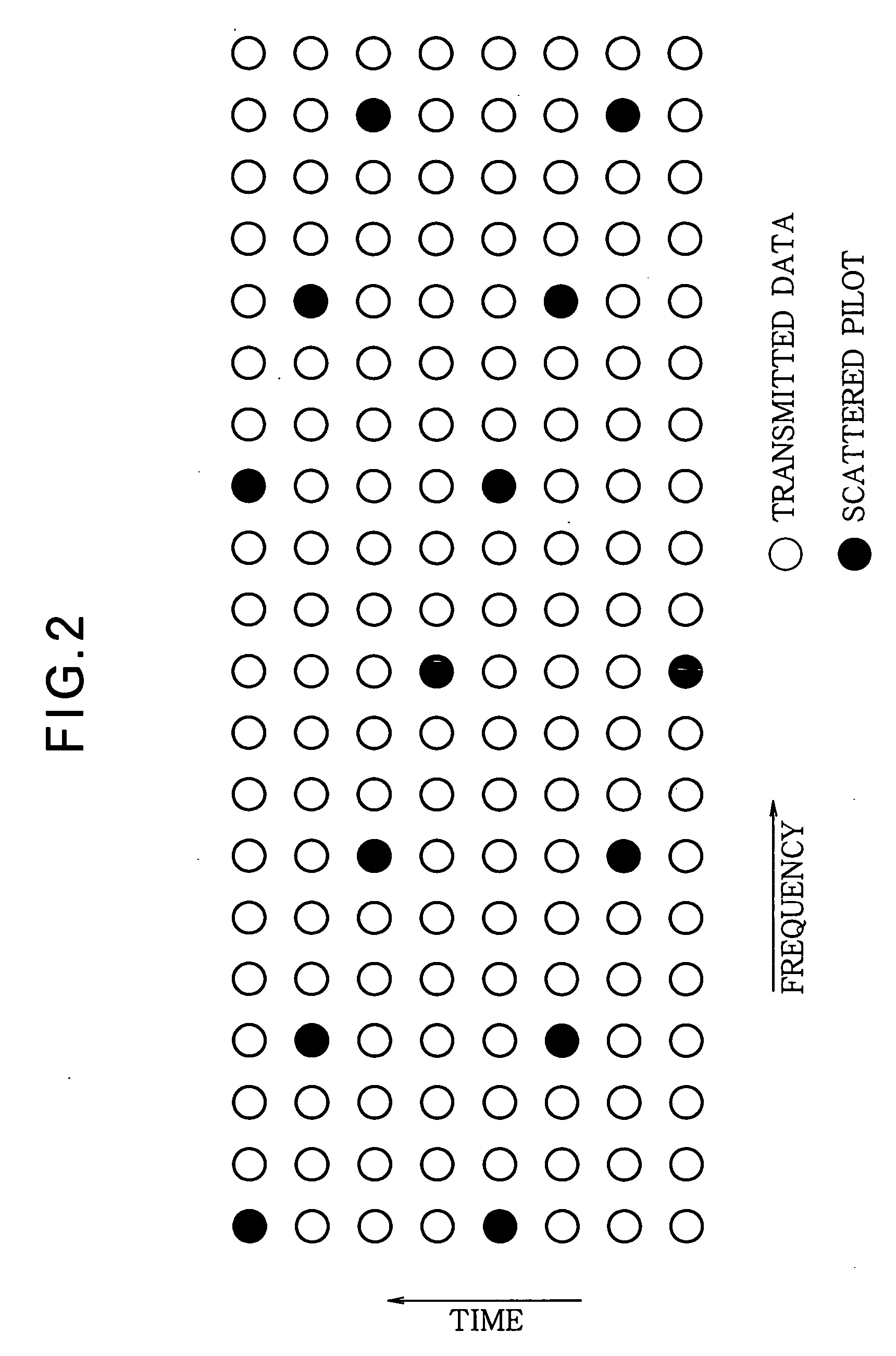

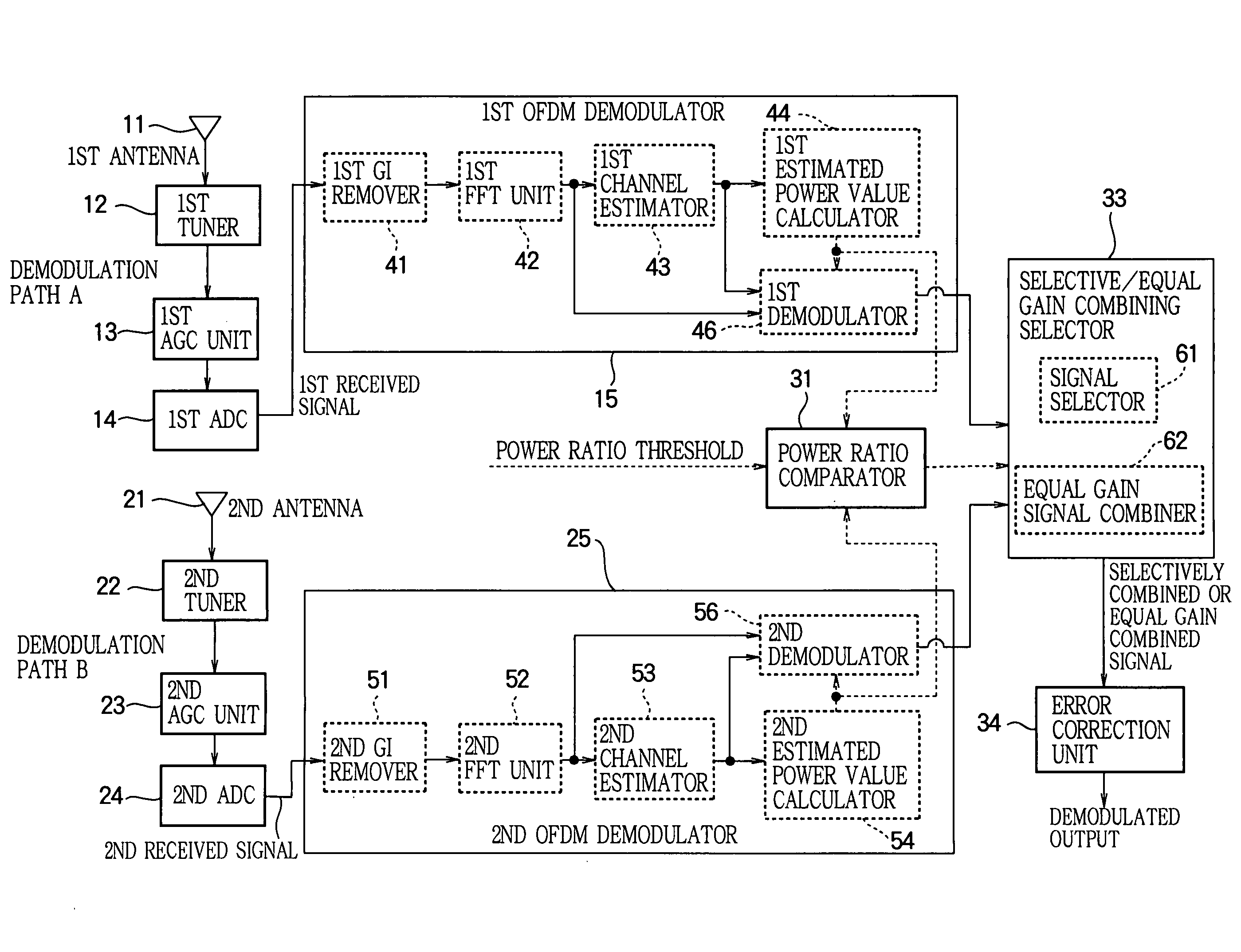

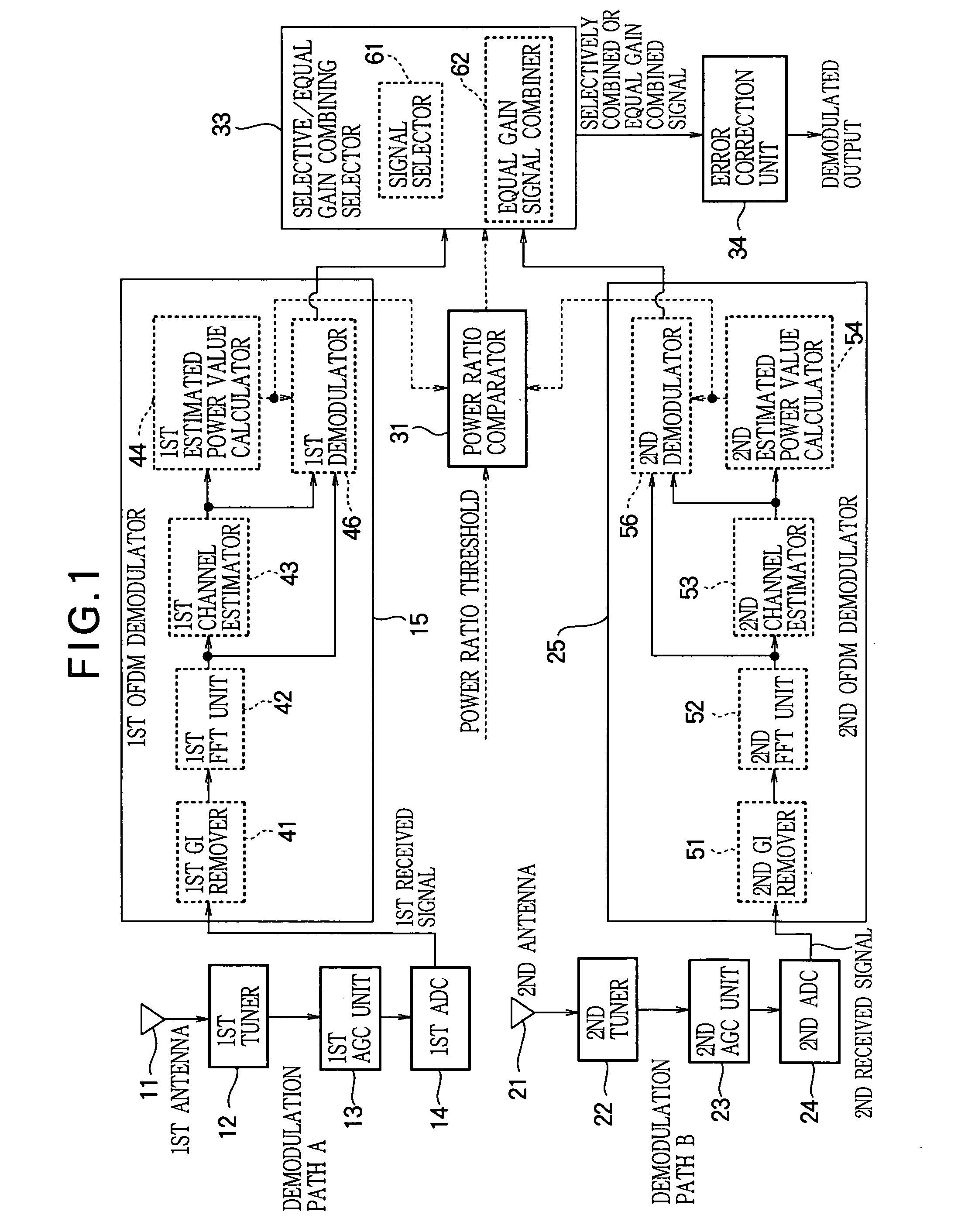

Diversity receprtion device and diversity reception method

InactiveUS20060166634A1Large diversity effectImprove reception performanceSpatial transmit diversityError detection/prevention using signal quality detectorCarrier signalEngineering

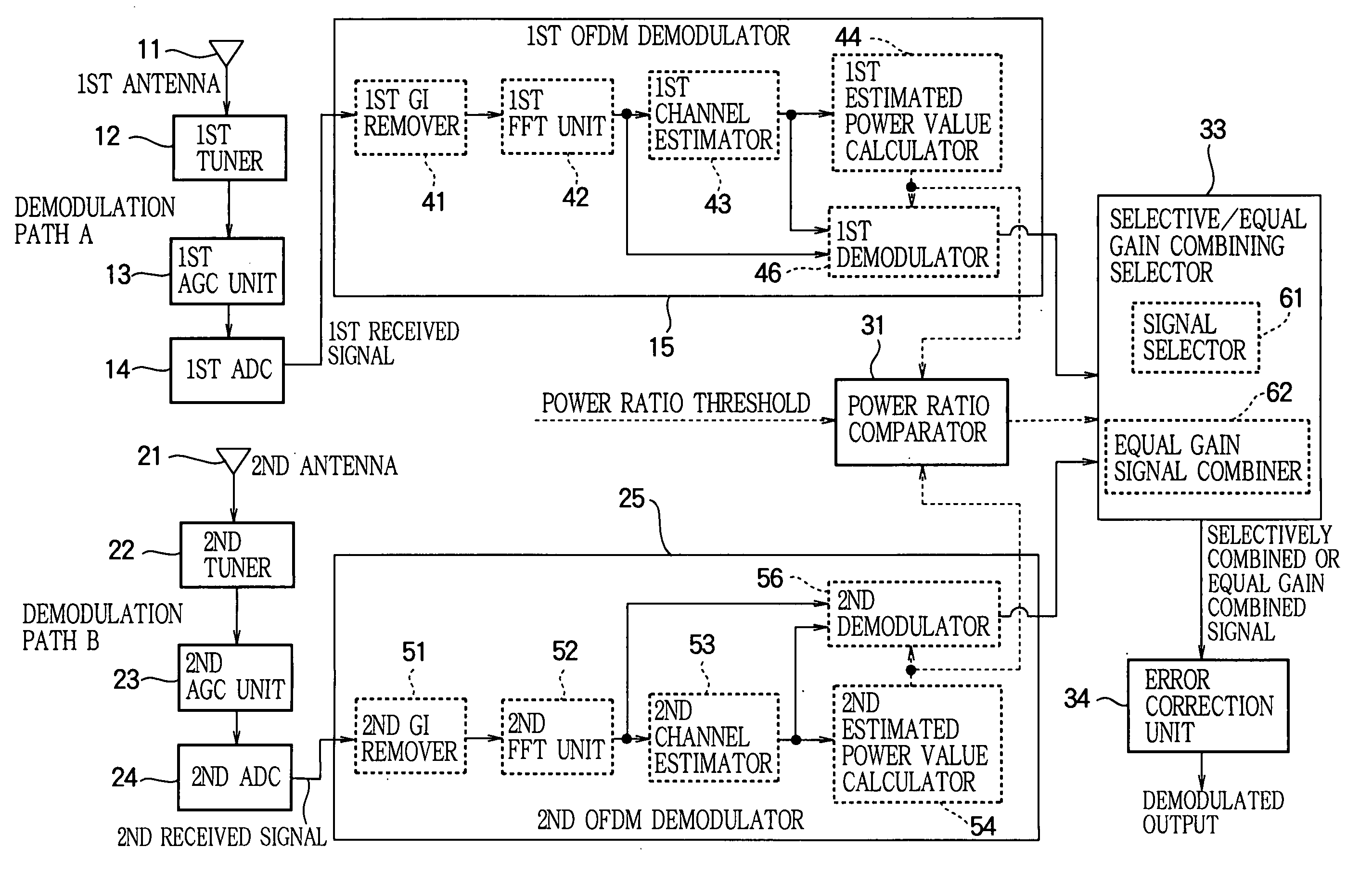

The circuit size of a diversity receiver for an orthogonal frequency division multiplexing signal is reduced, and the diversity effect is increased, by providing a power ratio comparator that calculates a difference value as a ratio of powers derived from channel estimation results for subcarrier components received from two antennas (11), (21) and compares the calculated difference value with a predetermined threshold, and a selective / equal gain combining selector (33) that outputs one of the received demodulated signals when the comparison result indicates that the calculated difference value is greater than the threshold value.

Owner:MITSUBISHI ELECTRIC CORP

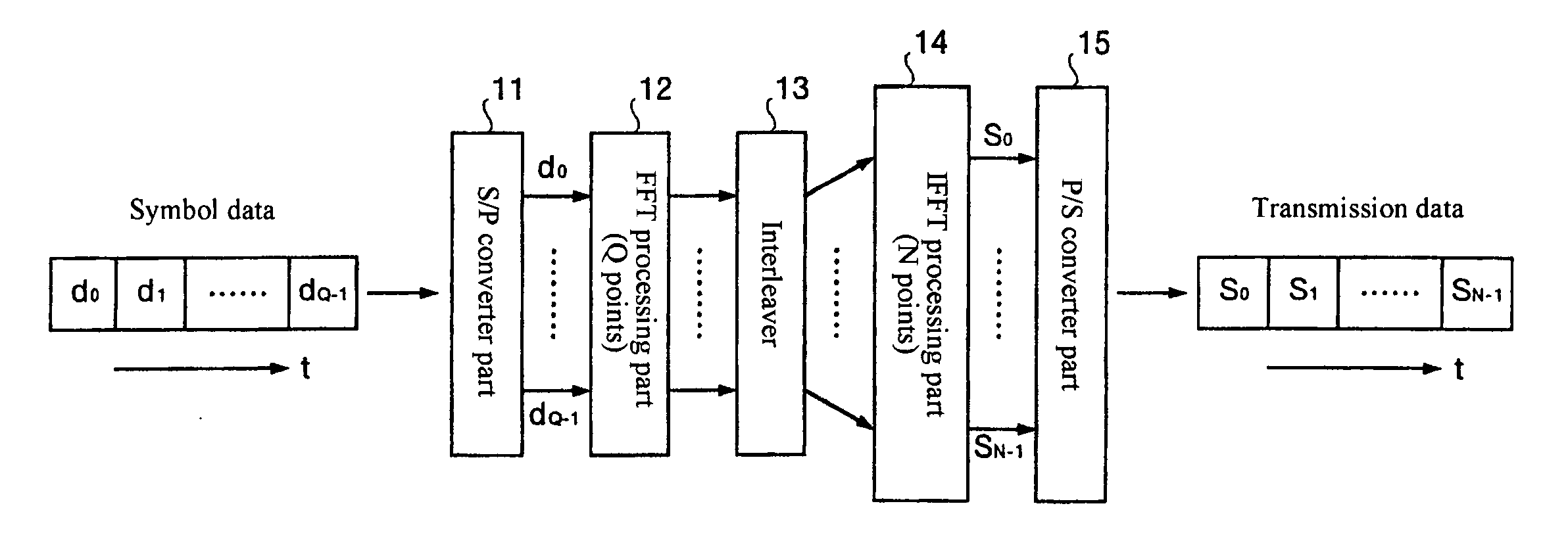

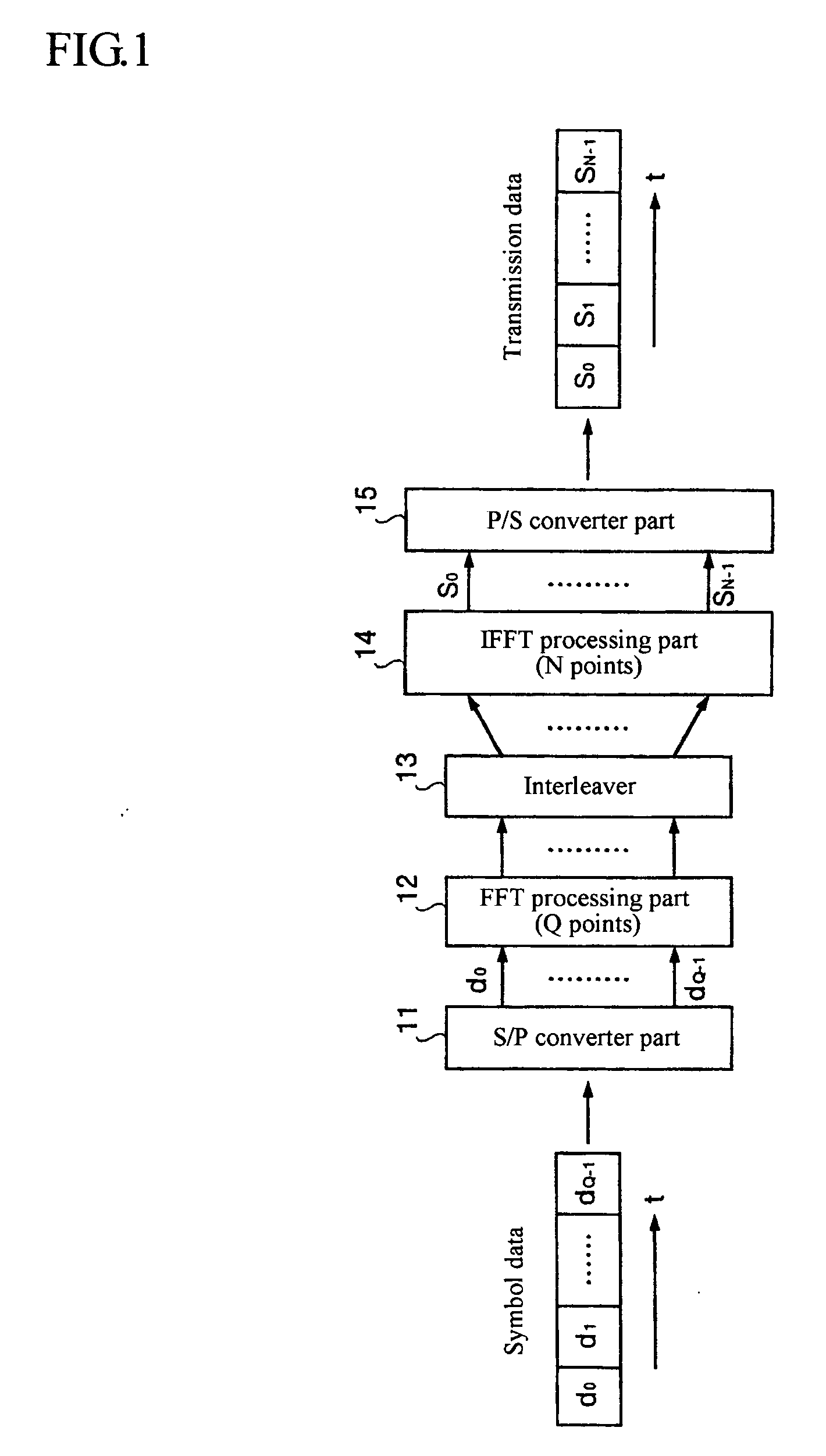

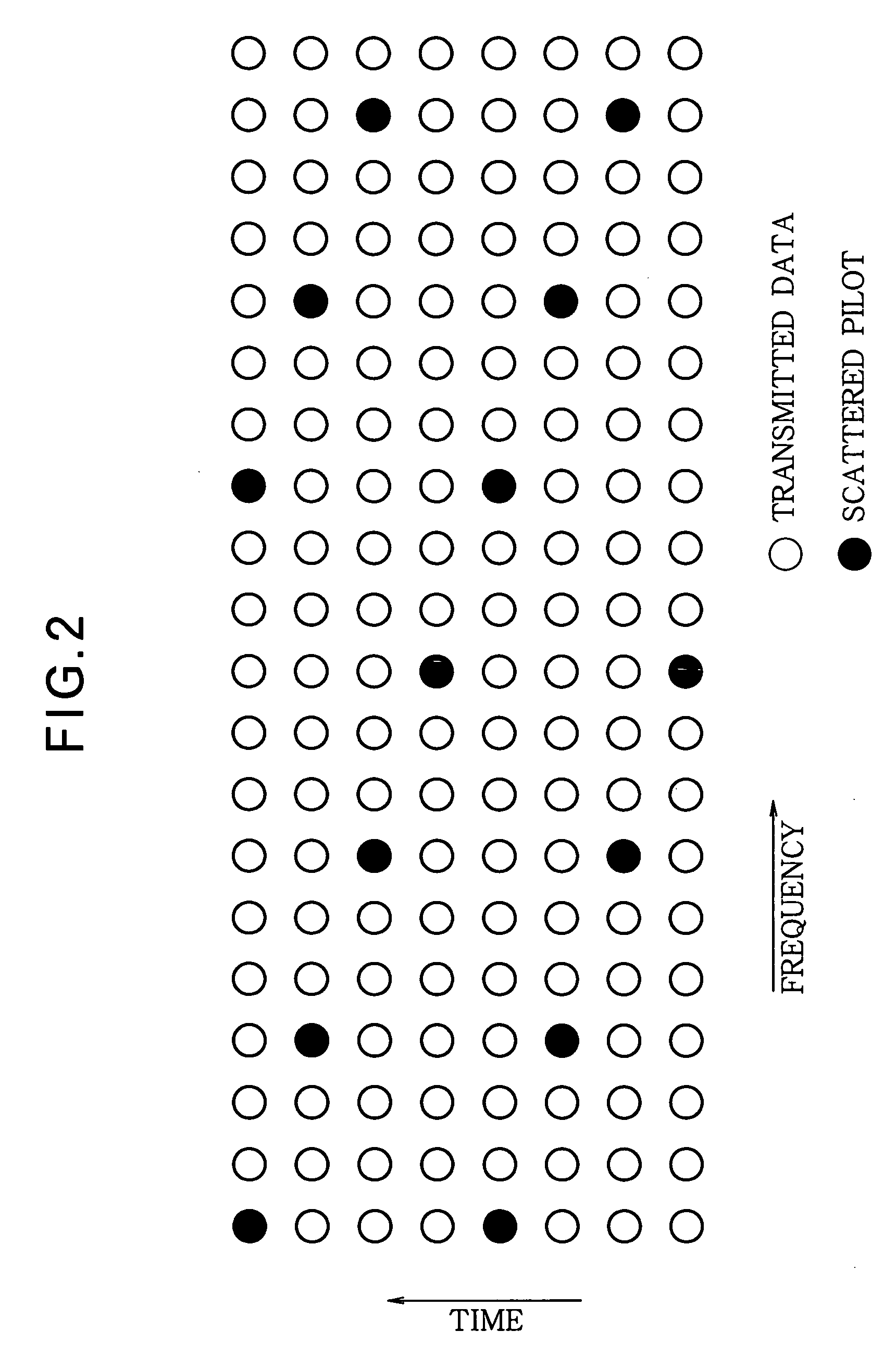

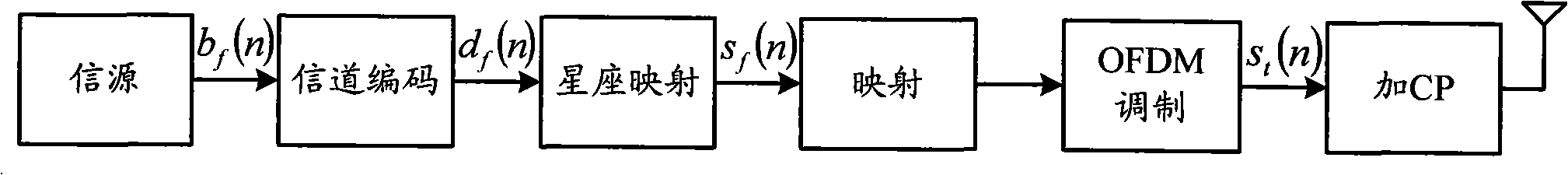

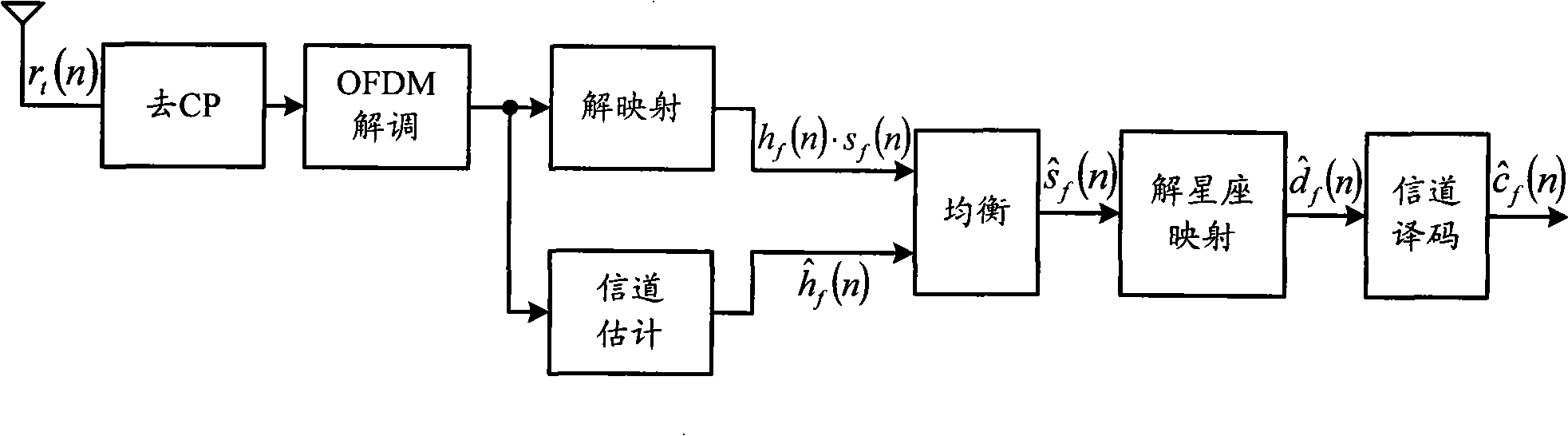

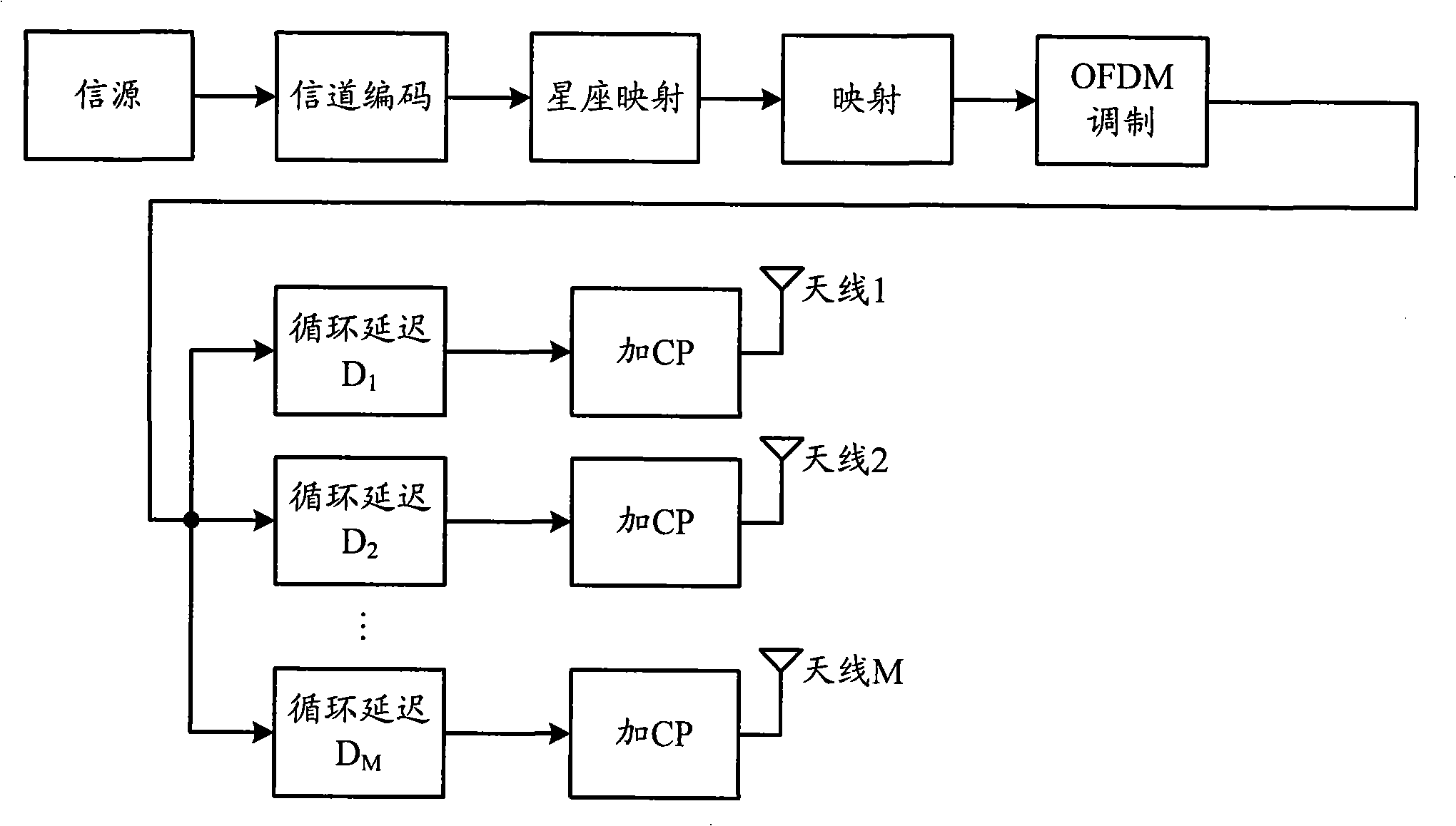

Transmitter apparatus, communication system, and communication method

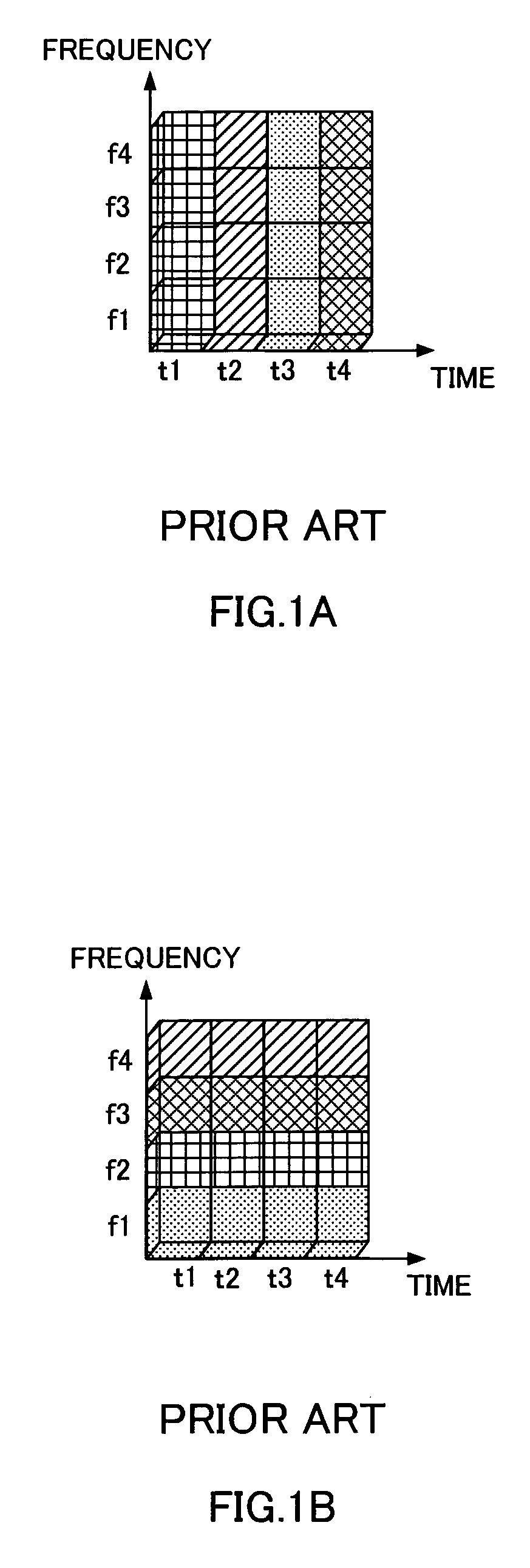

InactiveUS20070053449A1Secret communicationMulti-frequency code systemsTime domainCommunications system

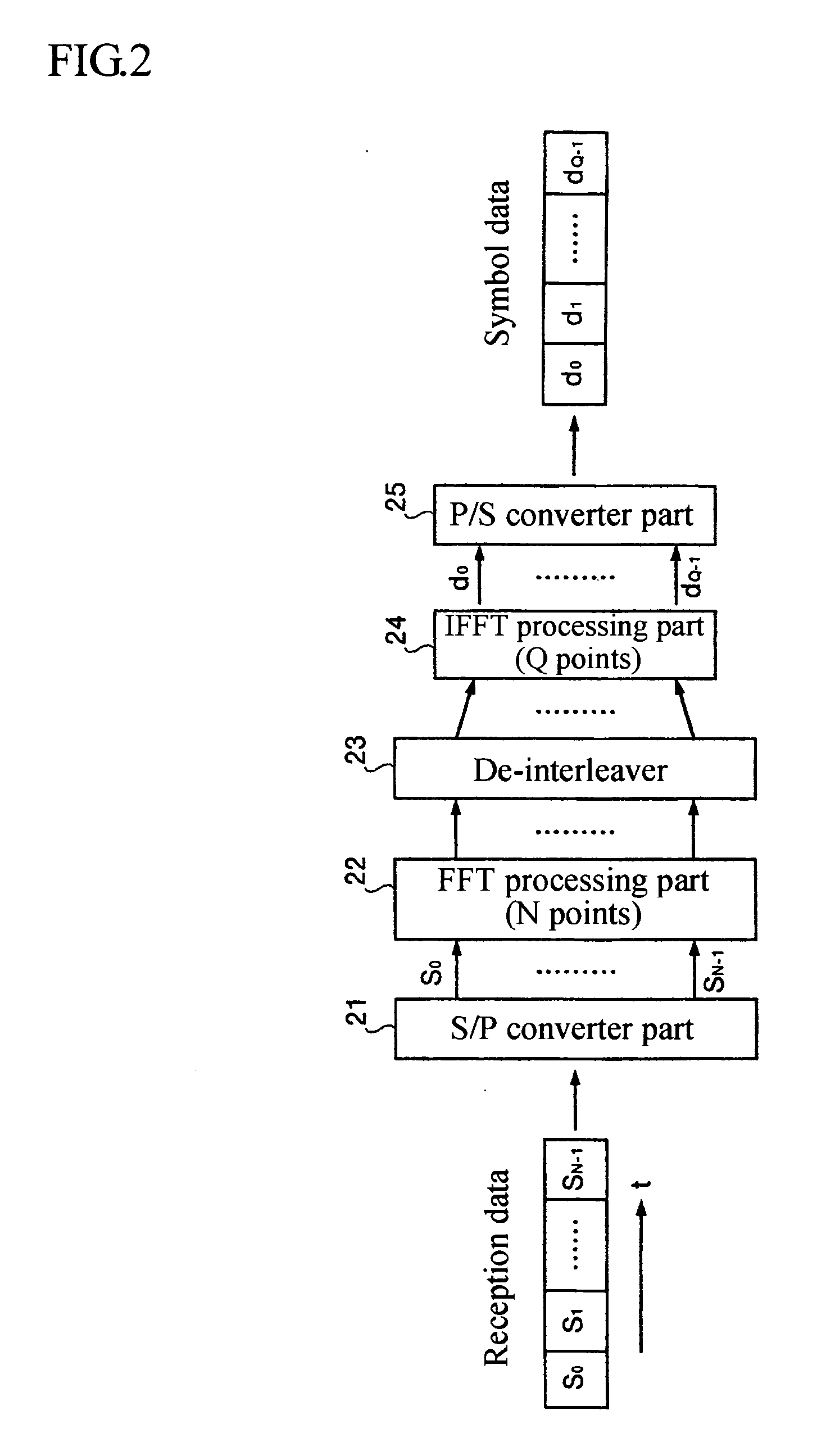

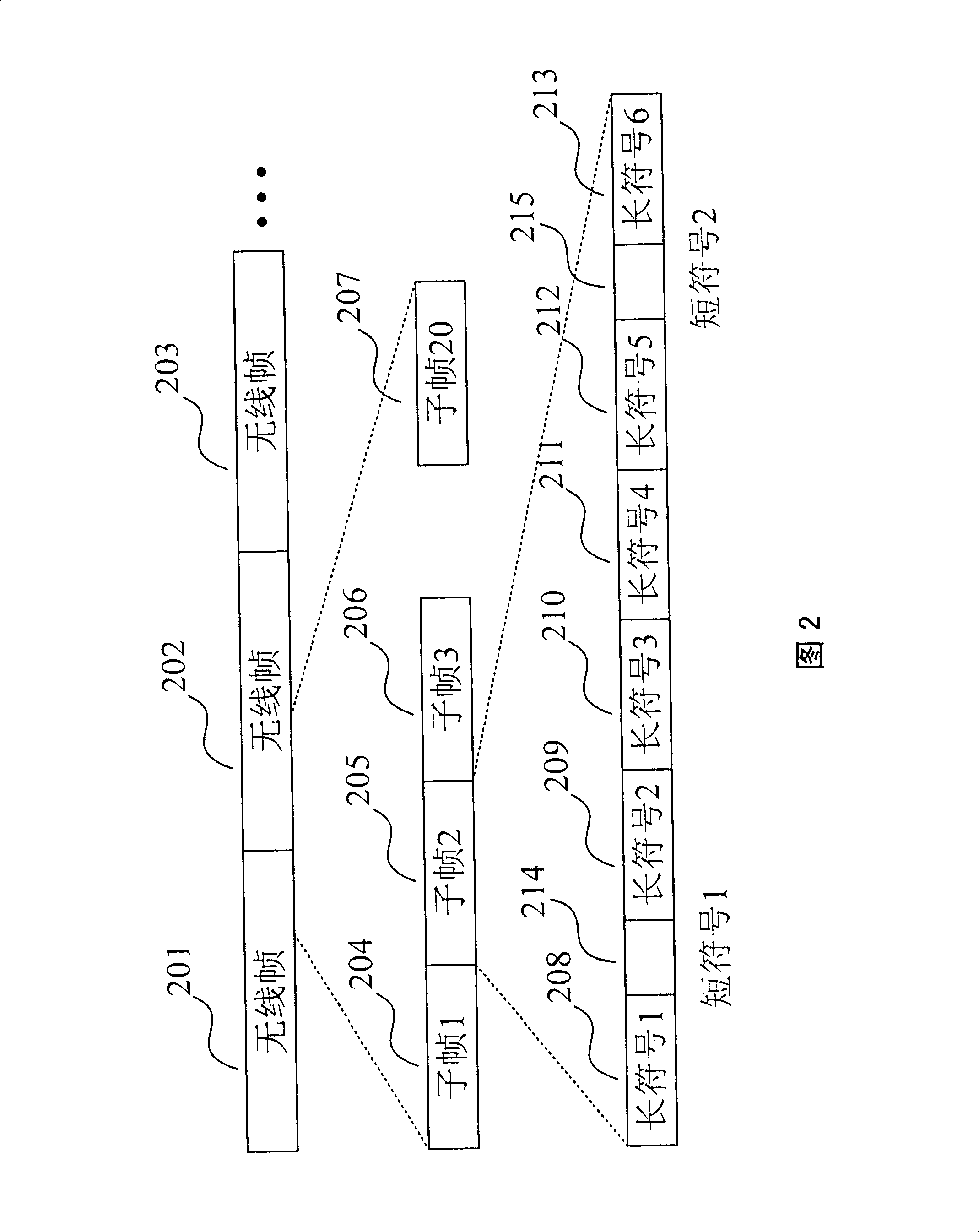

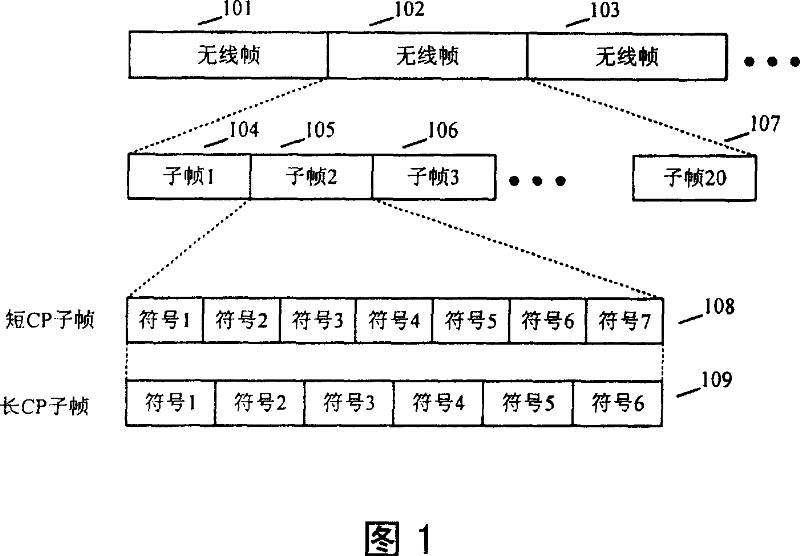

A communication technology for allowing a mobile communication system to accommodate variable rate users, while obtaining a frequency diversity effect. A transmitter apparatus using, for transmission, transmission signals produced based on data symbols of a predetermined transmission method, comprising an FFT processing part for converting the data symbols to frequency domain data; an interleaver for sorting the frequency domain data; and an IFFT processing part for converting the sorted frequency domain data to a time domain signal; wherein the FFT processing part subjects Q received data symbols to Q-point FFT processing, the interleaver produces N data from Q data outputted from the FFT processing part (where N>Q), and the IFFT processing part subjects the N data outputted from the interleaver to N-point IFFT processing.

Owner:INTELLIGENT COSMOS RES INST

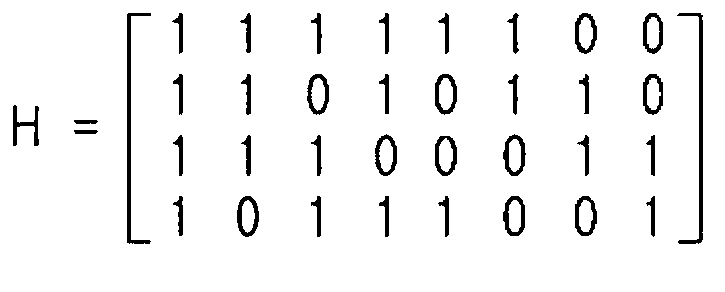

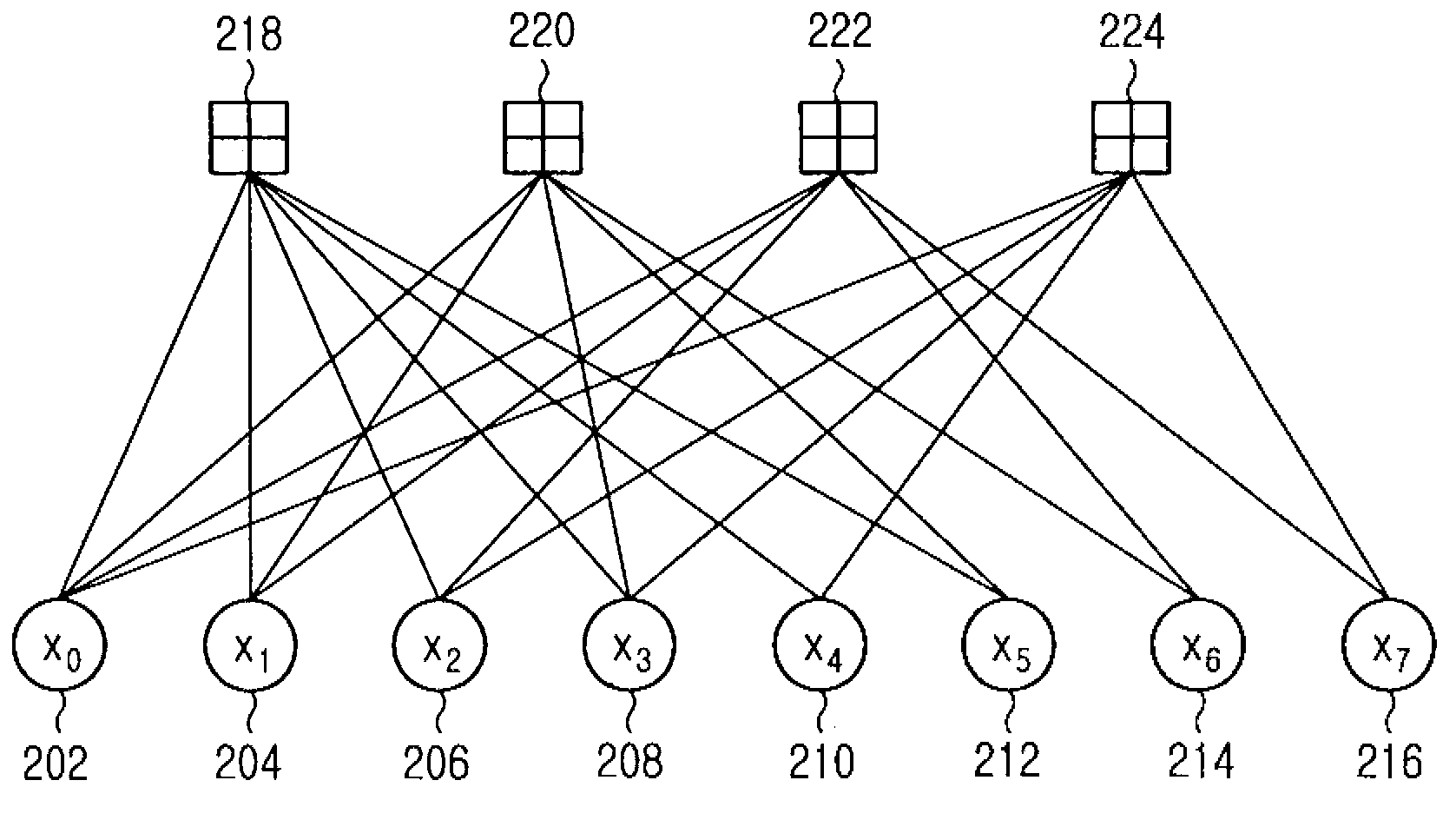

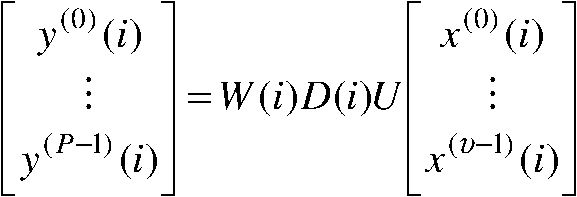

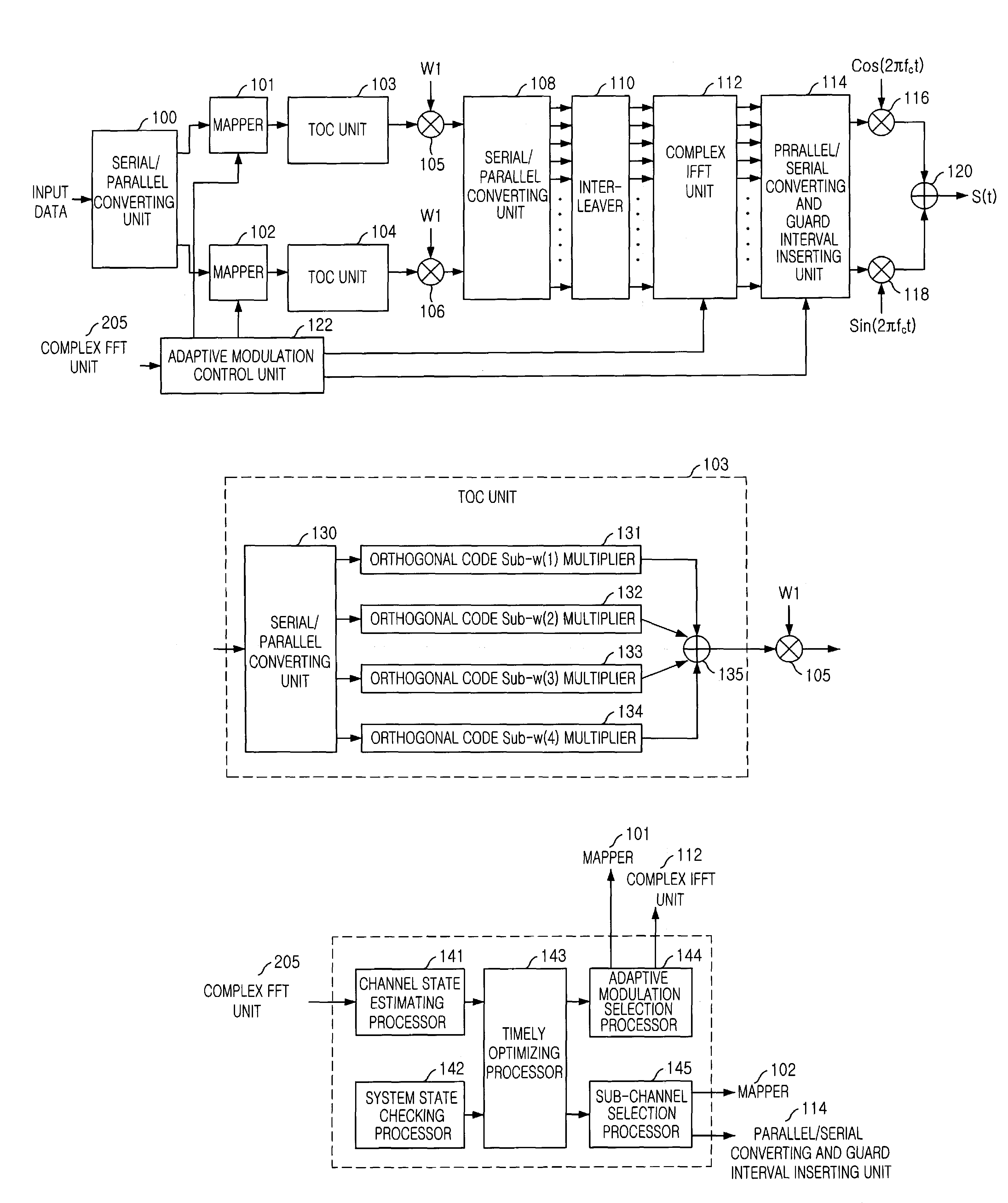

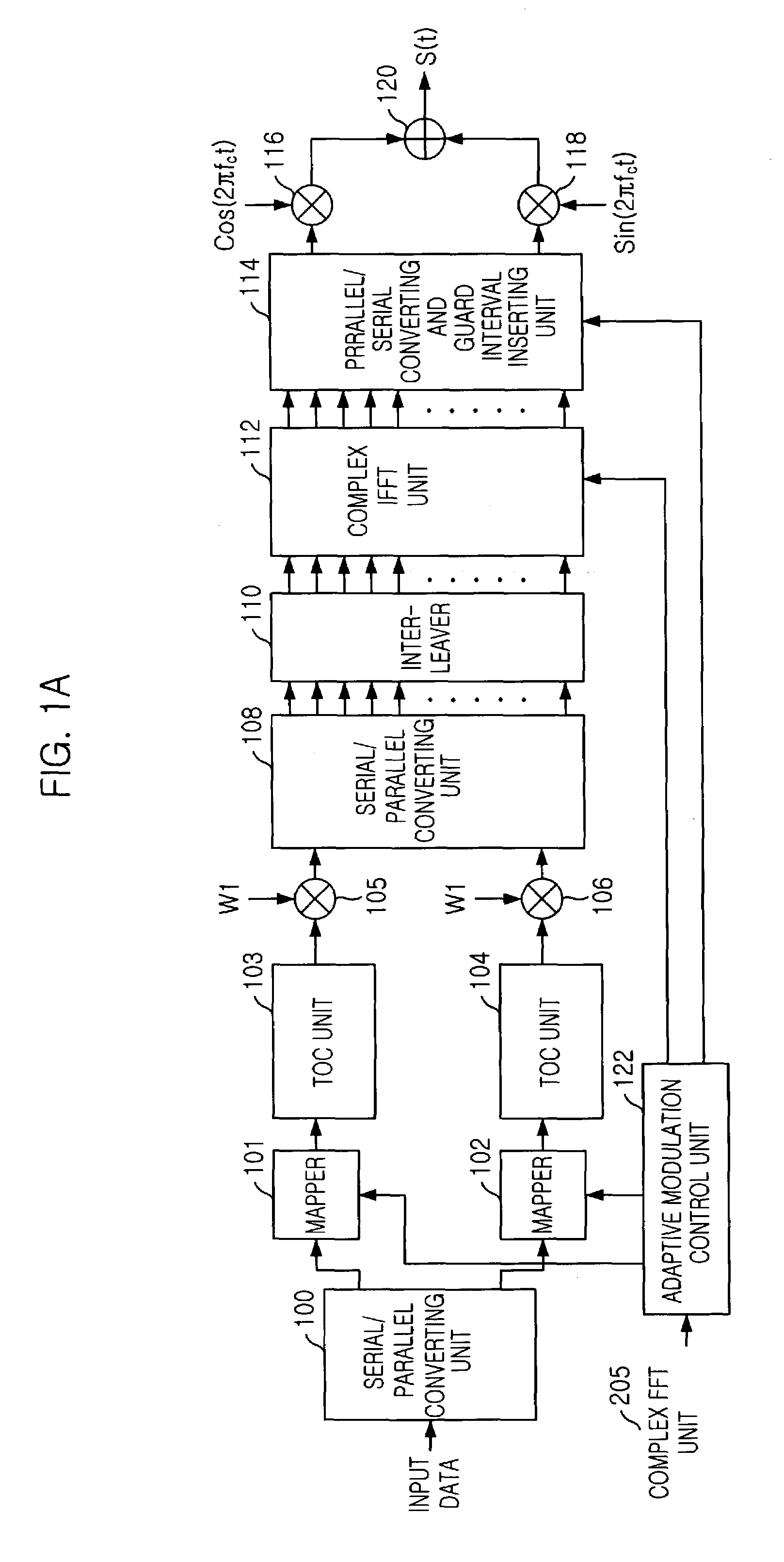

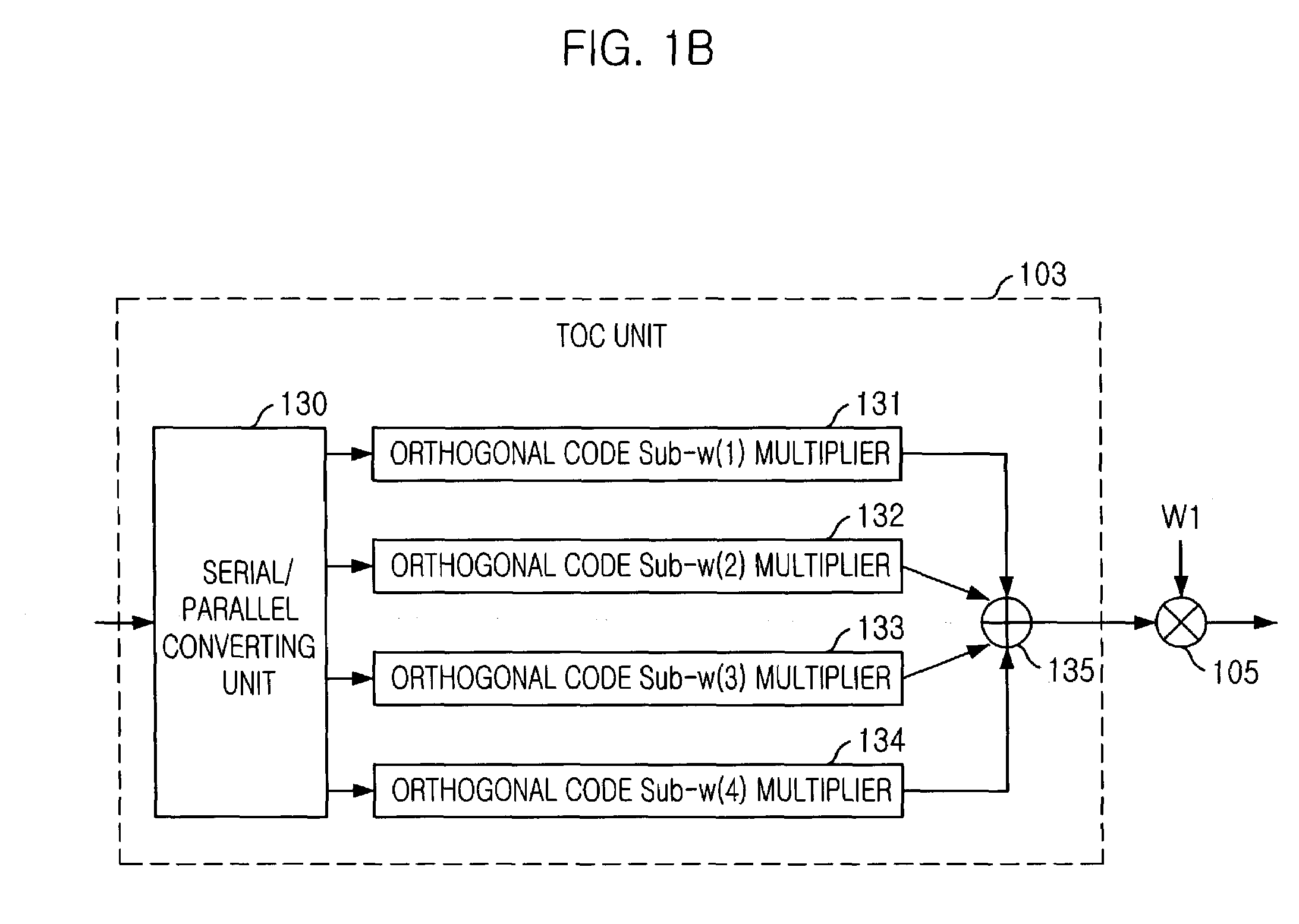

Apparatus for transmitting and receiving signal using orthogonal codes and non-binary values in CDMA/OFDM system and method thereof

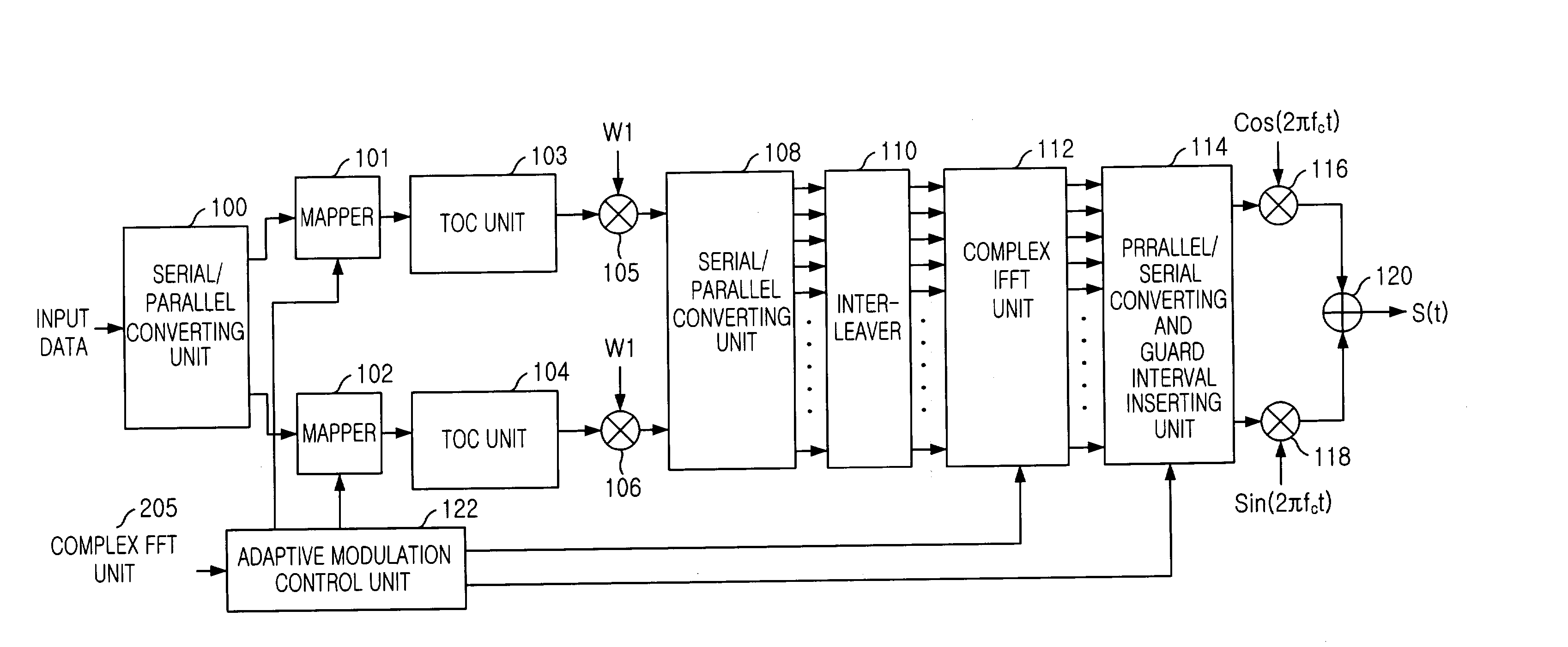

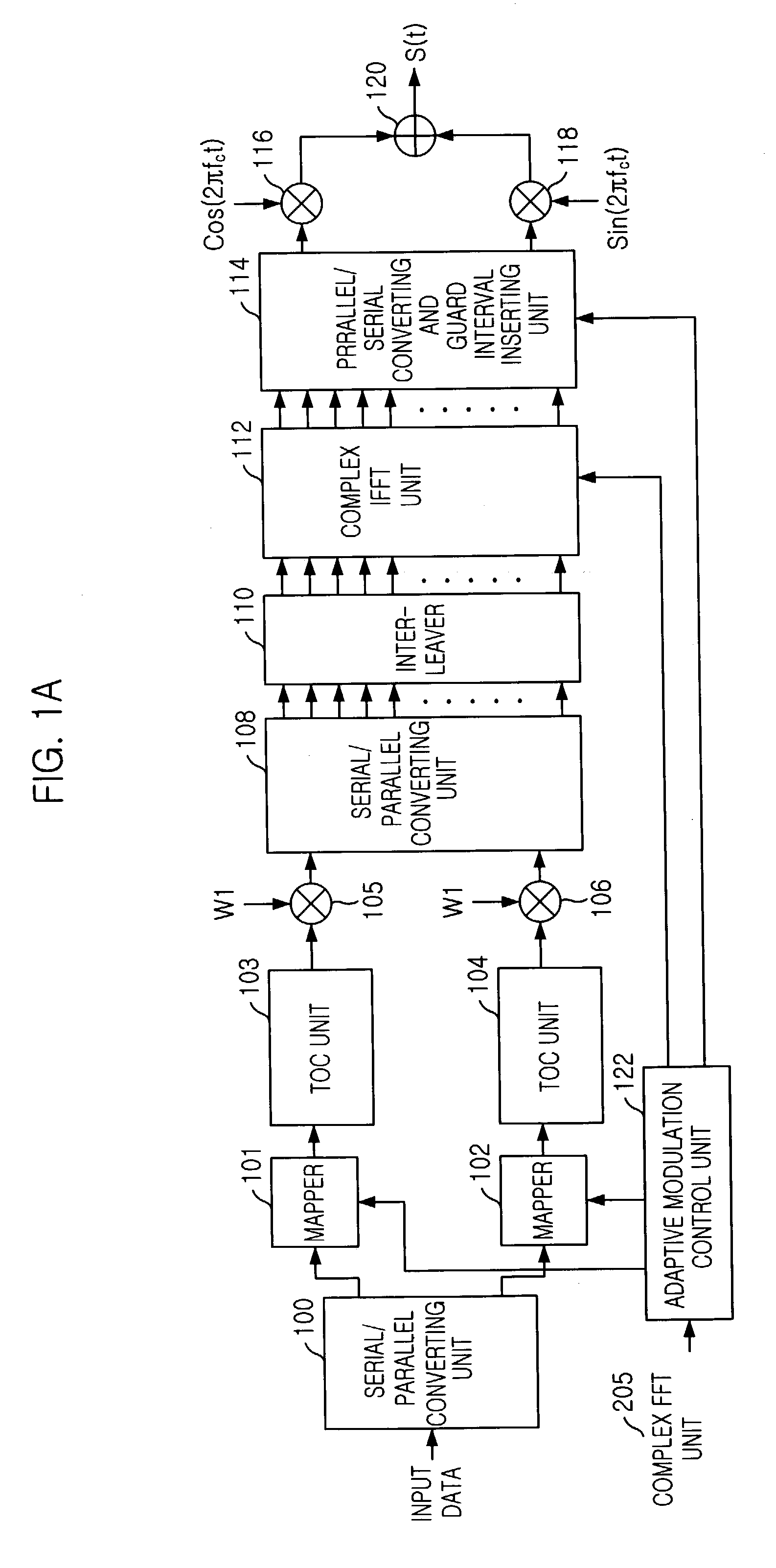

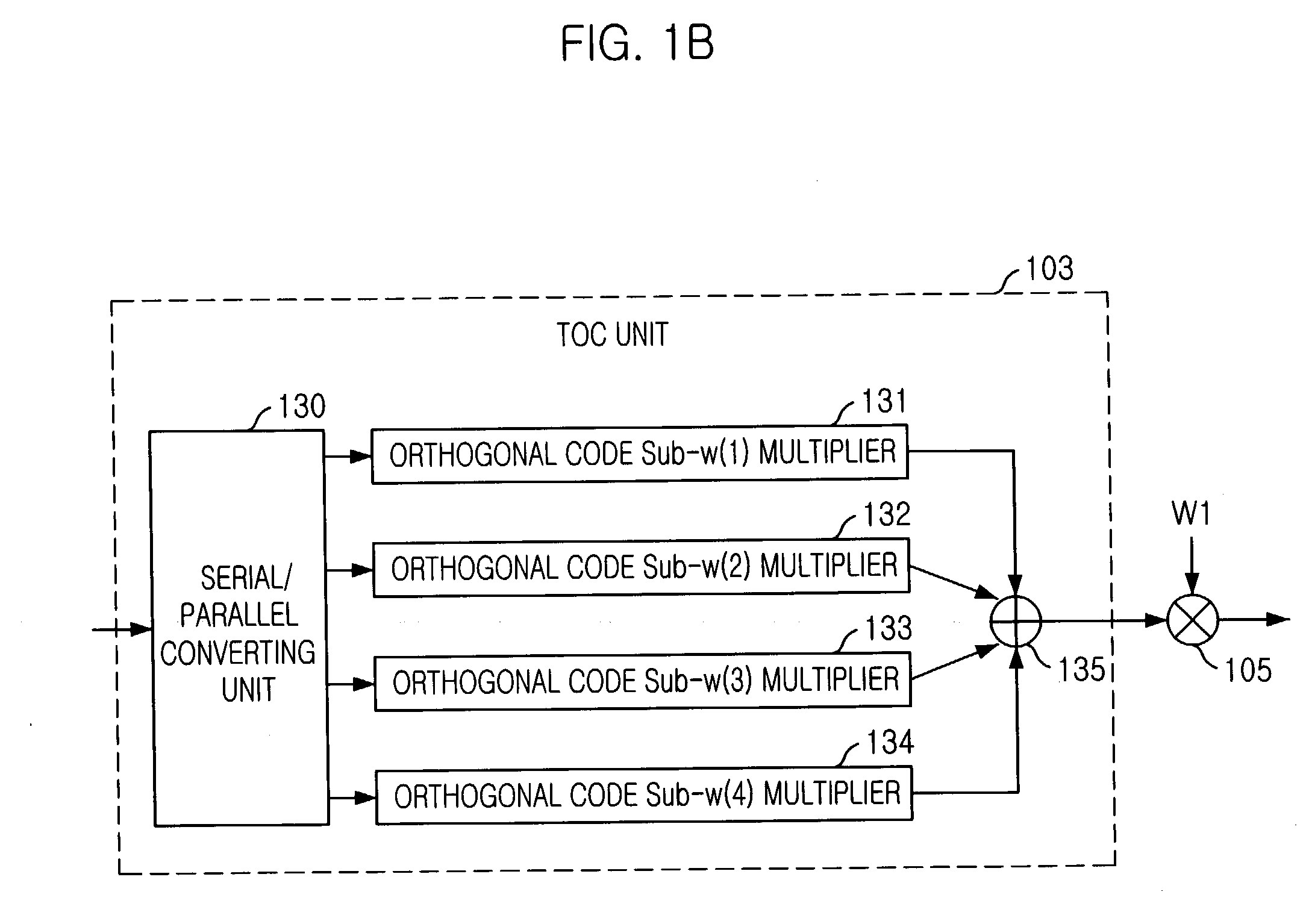

ActiveUS20040085919A1Multiple modulation transmitter/receiver arrangementsCriteria allocationOrthogonal coordinatesCode division multiple access

An apparatus for transmitting and receiving a signal in Code Division Multiple Access / Orthogonal Frequency Division Multiplexing (CDMA / OFDM) system is provided. The apparatus discriminates user signals with a unique spreading code and the orthogonal codes, increases data transmission rate with the non-binary value without increasing of entire bandwidth used by the users, solves signal interference with interleaver and diversity effect of interleaving and OFDM, and maximizes transmission efficiency by varying modulation schemes depending on channel states.

Owner:UNILOC 2017 LLC

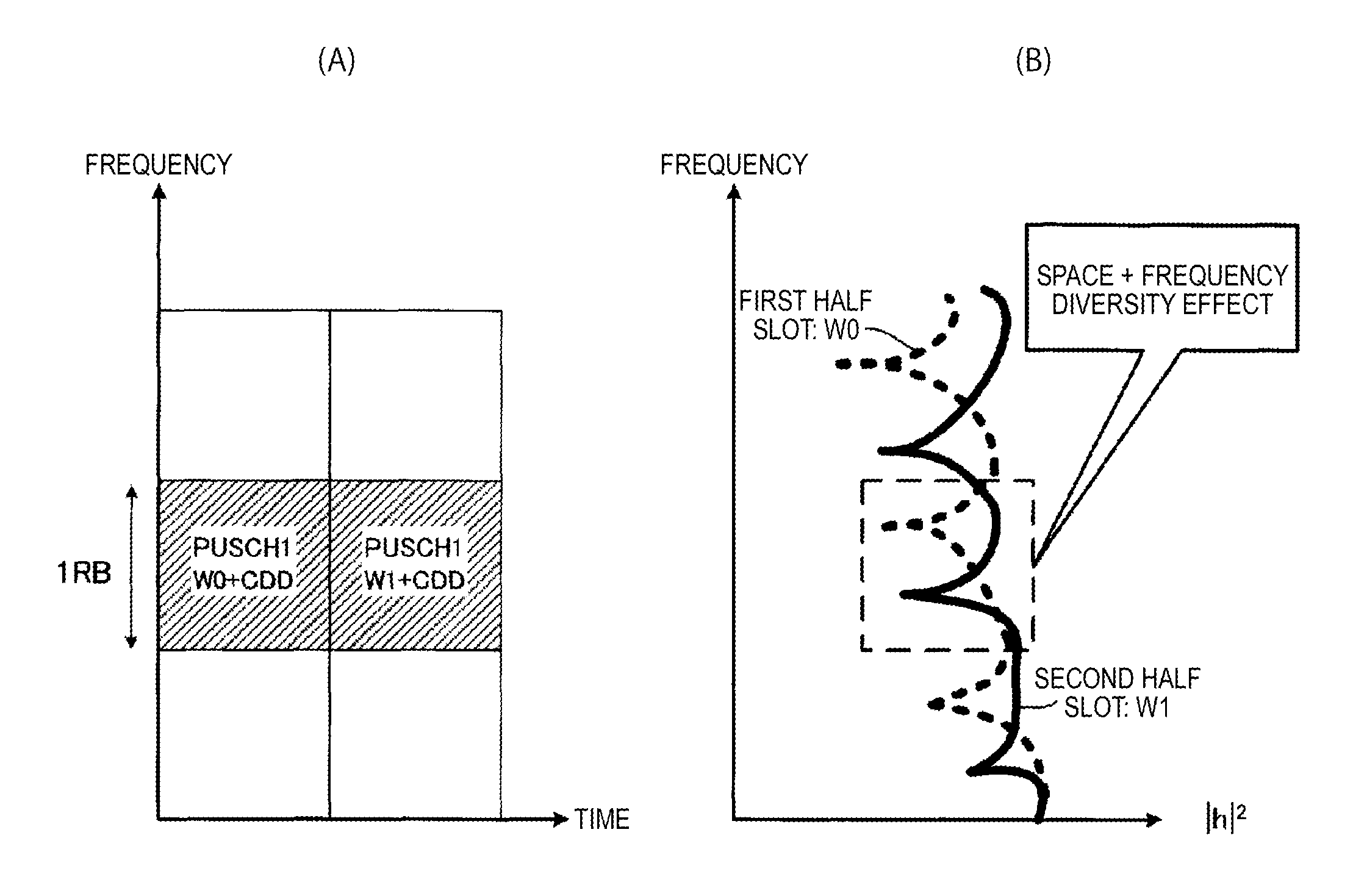

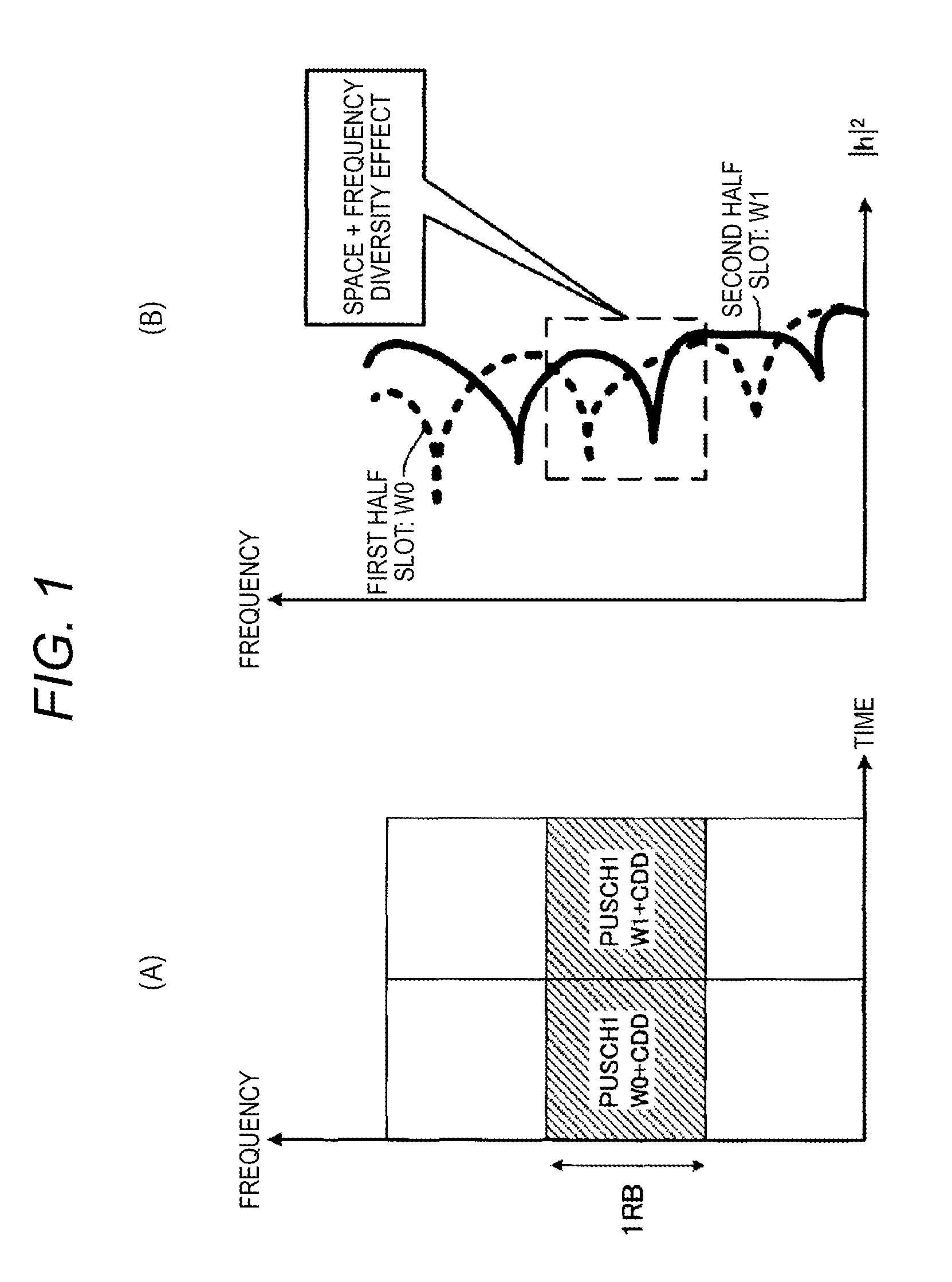

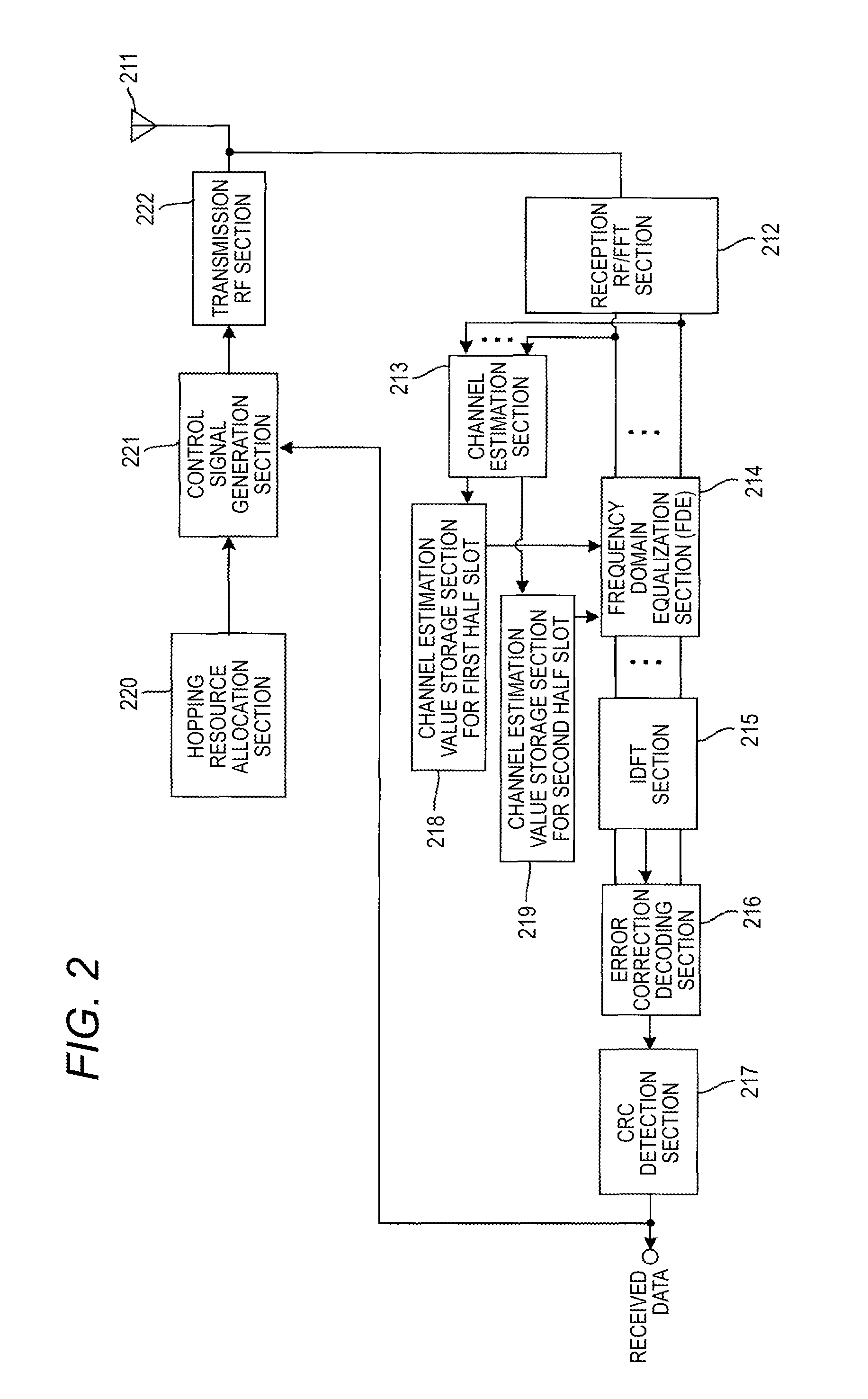

Radio communication device and radio communication method

ActiveUS20110134901A1Avoid complicationsPreventing of use of resourceAmplitude-modulated carrier systemsDiversity/multi-antenna systemsPrecodingPhase shifted

It is possible to obtain the diversity effect in a plurality of slots while preventing complication of a scheduler or inefficient use of resources, to eliminate the phenomenon in which SINR significantly decreases in a specific slot, and to avoid deterioration of demodulation performance. In a radio communication system which performs transmission in a sub-frame unit having two slots temporally continuously arranged, when pre-coding is performed by multiplying a signal to be output to a plurality of antennas by a pre-coding weight, CDD is used to shift a phase such that the phase in the pre-coding weight is cyclically changed on the frequency axis. The phase shift amount to be applied by the CDD is set to change by 2π in an allocated resource block (1RB) of the local device, and PVS is applied such that the phase shift amount differs by π between the weight W0 of the first half slot and the weight W1 of the second half slot in the sub-frame.

Owner:III HLDG 12 LLC

Device and method for transmitting HARQ ACK/NACK

ActiveCN101222304AIncrease frequency diversity effectMaintain single carrier natureError prevention/detection by using return channelCoding blockData signal

The invention discloses a method for transmitting an HARQ ACK / NACK message which comprises the steps that: a first communication node sends the data containing a plurality of code blocks, here each code block is defined as a message block which is independently added with a CRC and a code; a second communication node receives data signals of the first communication node and judges whether each code block correctly receives; the second communication node respectively sends an HARQ ACK or an NACK message aiming at each code block, here each sent ACK / NACK message can occupy I branches or Q branches of at least one part of modulation symbols in the entire physical resources used to transmit the HARQ ACK / NACK messages; the first communication node receives the HARQ ACK / NACK messages sent by the second communication node and correspondingly sends new data or retransmit data. The method of the invention can increase the frequency diversity effect during the transmission of the ACK / NACK messages; when the method is used in the SCFDMA system, the method can maintain the single carrier characteristic of the SCFDMA system.

Owner:BEIJING SAMSUNG TELECOM R&D CENT +1

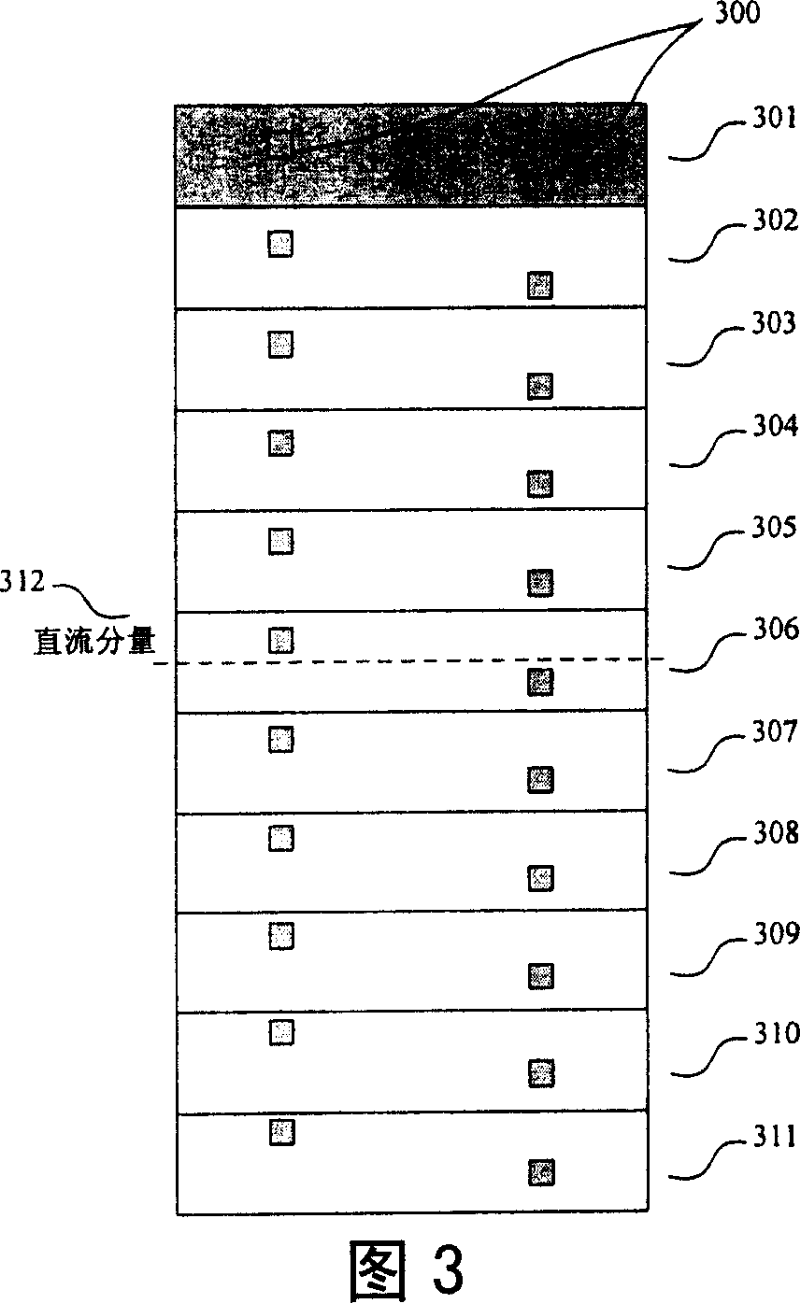

Device and method for dividing resource blocks of wireless communication system

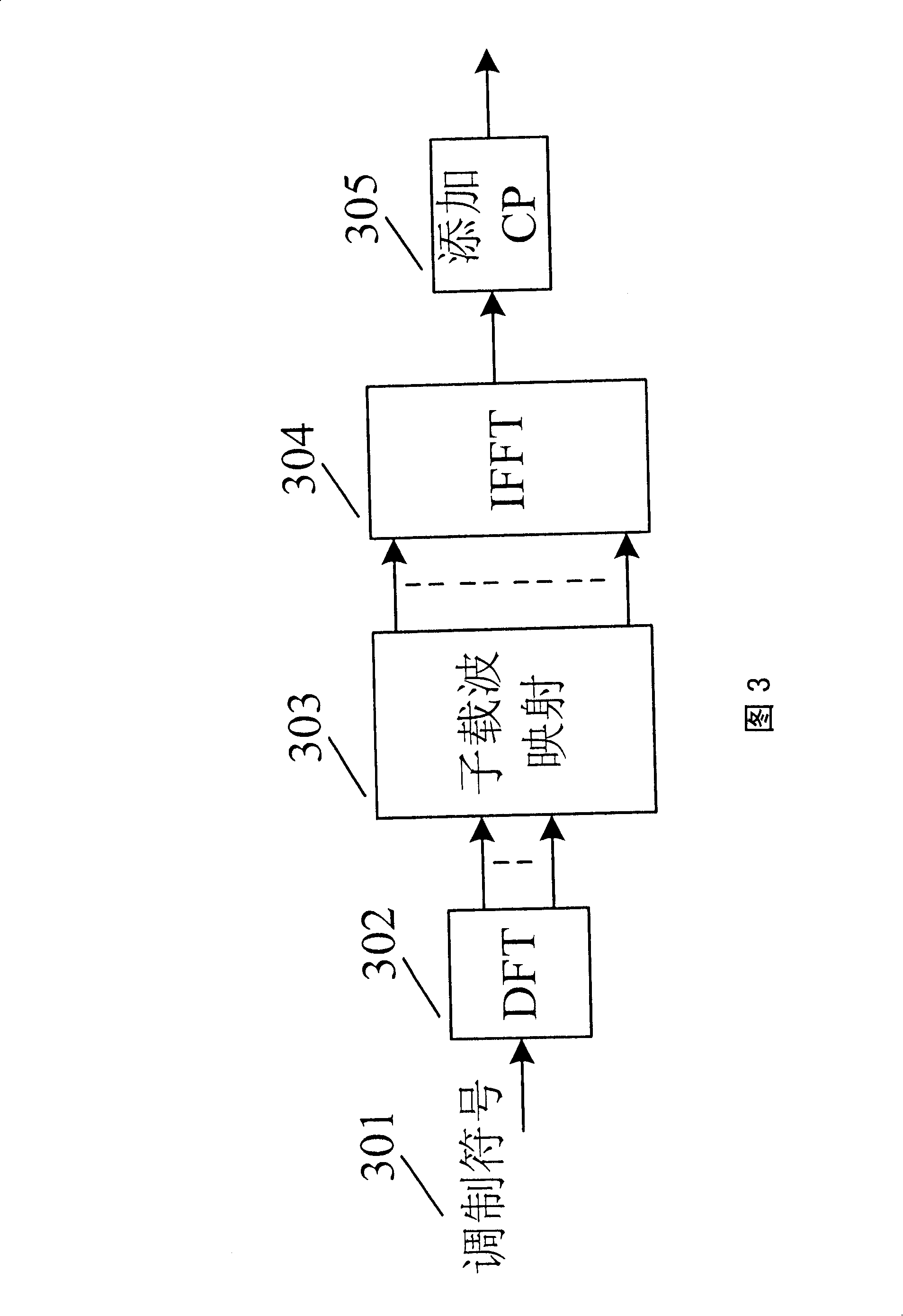

InactiveCN101043495AGood frequency diversityReduce the impactRadio transmission for post communicationMulti-frequency code systemsCommunications systemResource block

The division method for channel resource in a wireless communication system comprises: pre-dividing some resource from system physical time-frequency source to carry at least one distributed physical resource unit for distributed transmission, setting the number as n; dividing the residual resource into (N-n) local physical resource units for local distributed transmission; and mapping the distributed / local virtual resource block to the distributed / local physical resource unit, respectively. This invention can provide well frequency diversity effect, and affects little to local transmission user.

Owner:BEIJING SAMSUNG TELECOM R&D CENT +1

Diversity reception device and diversity reception method

InactiveUS7310503B2Less circuitryRemarkable effectSpatial transmit diversityError detection/prevention using signal quality detectorCarrier signalDiversity scheme

The circuit size of a diversity receiver for an orthogonal frequency division multiplexing signal is reduced, and the diversity effect is increased, by providing a power ratio comparator that calculates a difference value as a ratio of powers derived from channel estimation results for subcarrier components received from two antennas (11), (21) and compares the calculated difference value with a predetermined threshold, and a selective / equal gain combining selector (33) that outputs one of the received demodulated signals when the comparison result indicates that the calculated difference value is greater than the threshold value.

Owner:MITSUBISHI ELECTRIC CORP

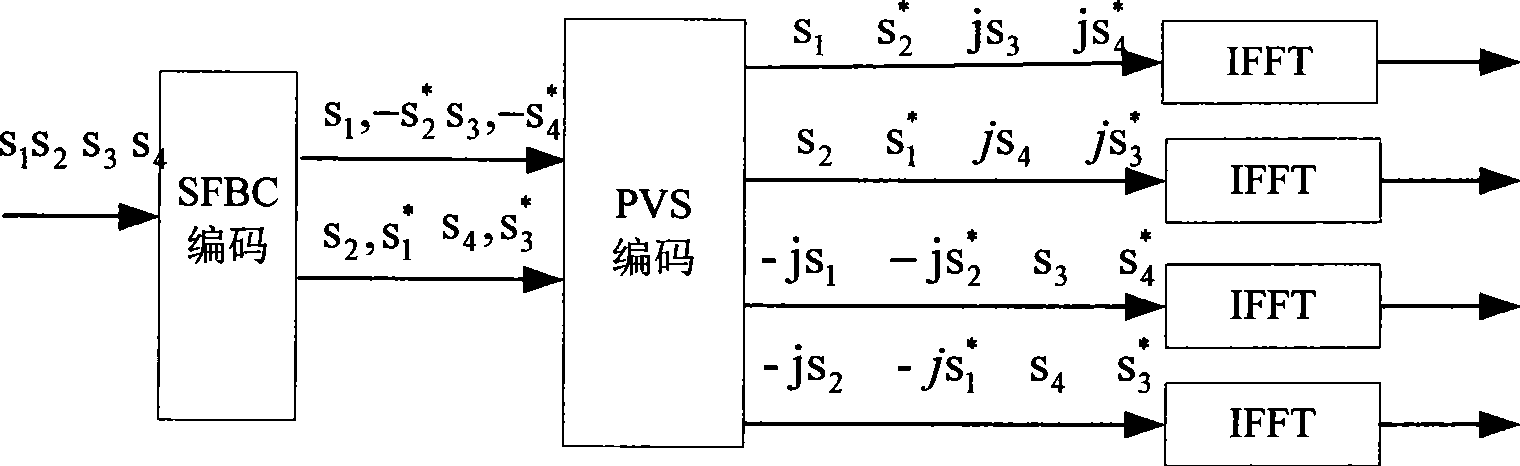

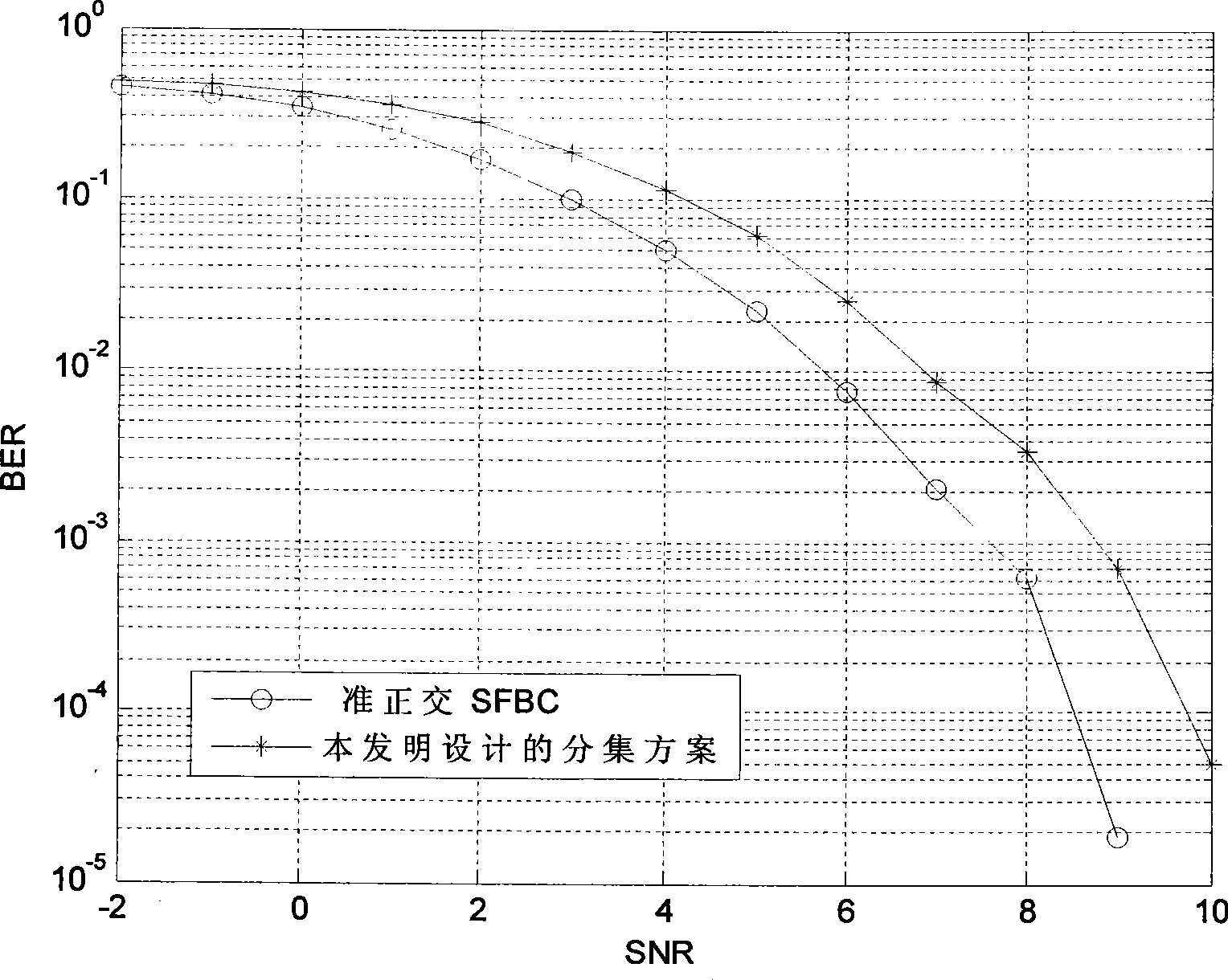

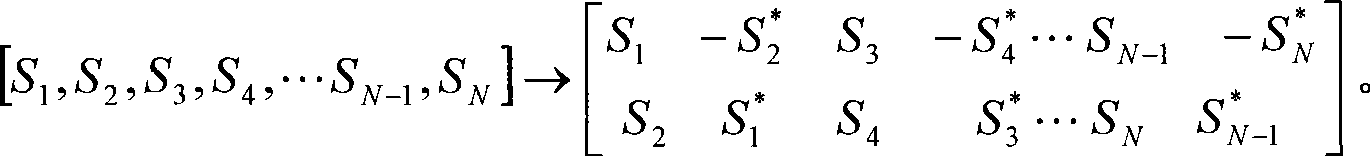

Transmission diversity method base on null-frequency encode

InactiveCN101378299ASimple designEasy to decodeSpatial transmit diversityMulti-frequency code systemsData streamEuclidean vector

The invention discloses a transmission diversity method based on space-frequency coding, which is applicable to an MIMO-OPDM system with a sending antenna which is more than 2. The method takes a combination of the SFBC and pre-coding weighing switching as a diversity mode of SFBC+PVS, taking the objective factor into the account that the stronger the channel correlation is, the weaker the diversity effect is, and uses a weighted vector to remove the effect resulted by the inclination angle between antennae and the channel correlation between different antennae. The method comprises the following steps: step one, two paths of data streams are obtained by carrying out SFBC coding to an input bit stream; step two, two groups of pre-coding weighing vectors are selected; and step three, a coding matrix after pre-coding weighing switching is obtained after the pre-coding weighing vector is adopted to carry out weighing to an SFBC coding data block, and finally an in-time signal obtained by inverse fast Fourier transform is transmitted. By adopting the diversity method, the space diversity effect can be utilized better and the effect on coding gains can be reduced.

Owner:ZTE CORP

Wireless Transmission Device, Wireless Reception Device, And Symbol Arranging Method

ActiveUS20080031307A1Maintain interference resistanceImproving error rate performanceMultiple modulation transmitter/receiver arrangementsNetwork traffic/resource managementWireless transmissionInterference resistance

Owner:OPTIS WIRELESS TECH LLC

Method and apparatus for transmitting and receiving data in a communication system

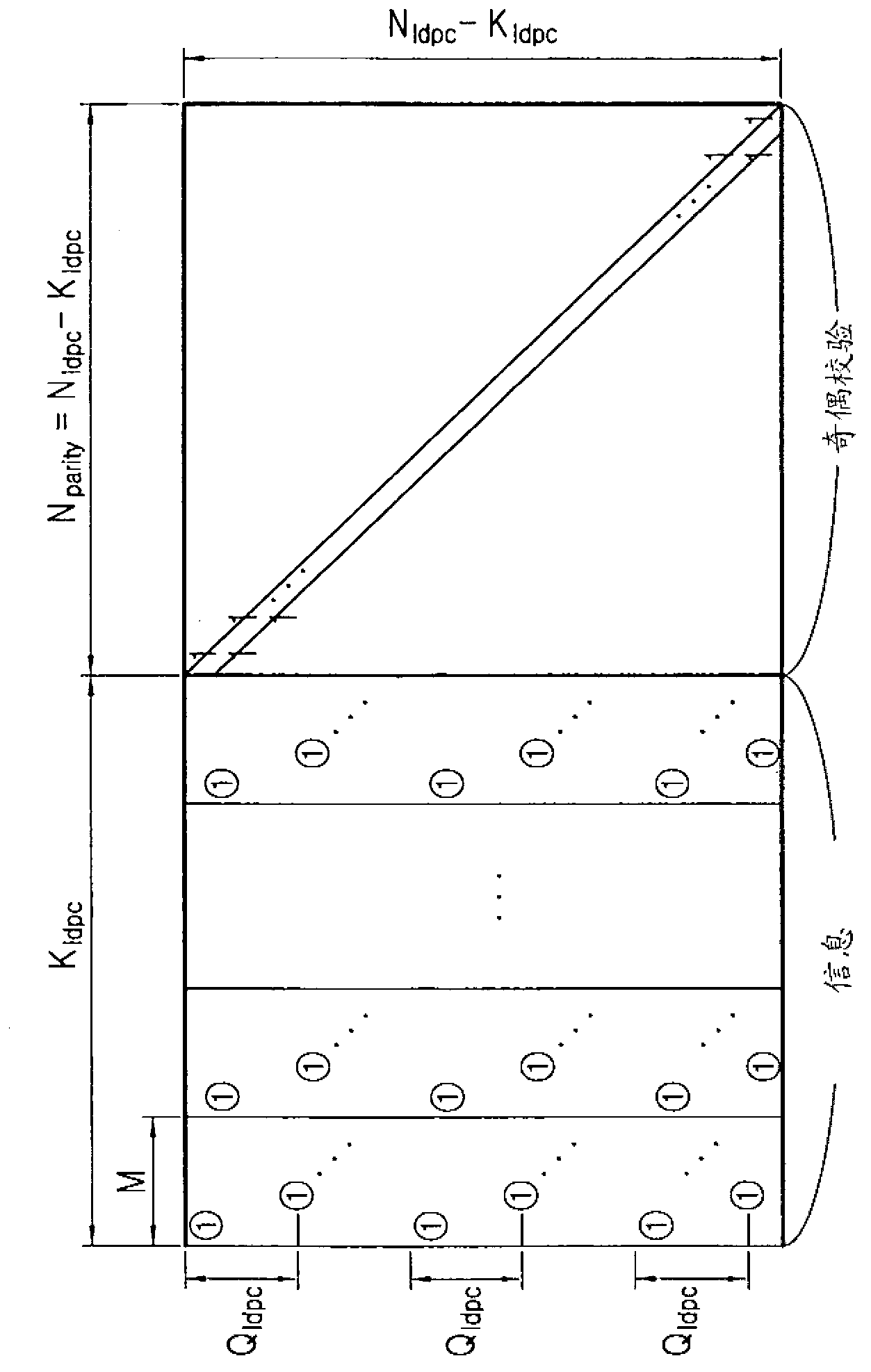

ActiveCN102714504ASolve the real problemSpatial transmit diversityError correction/detection using LDPC codesCommunications systemParity bit

A method is provided for transmitting data, which improves a diversity effect in a communication system. The method includes transmitting an information word including a codeword in a (k+s)-th frame, generating s groups based on parity bits obtained by encoding the information word, and transmitting the s groups in s frames preceding the (k+s)-th frame, in a distributed manner.

Owner:SAMSUNG ELECTRONICS CO LTD

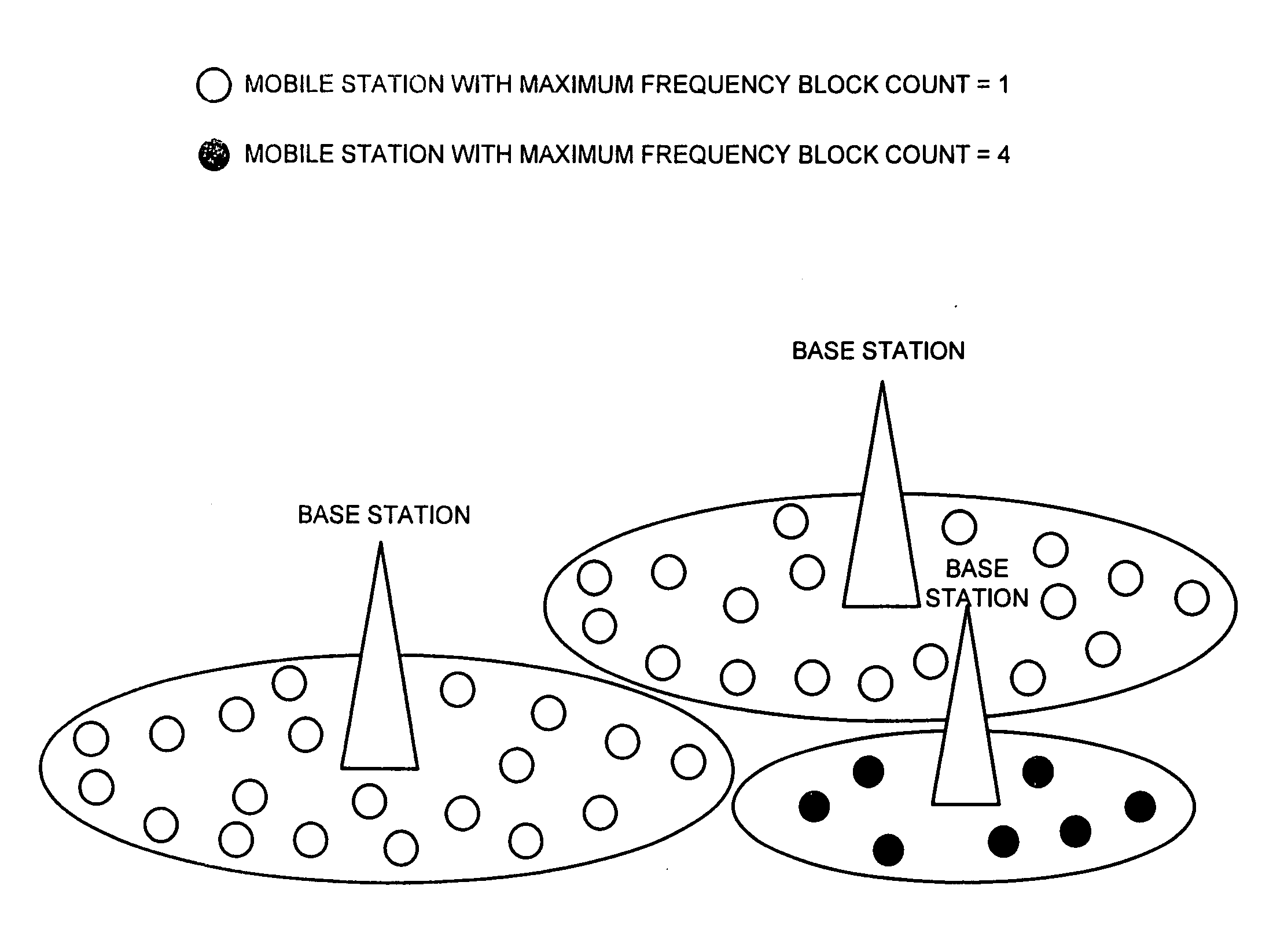

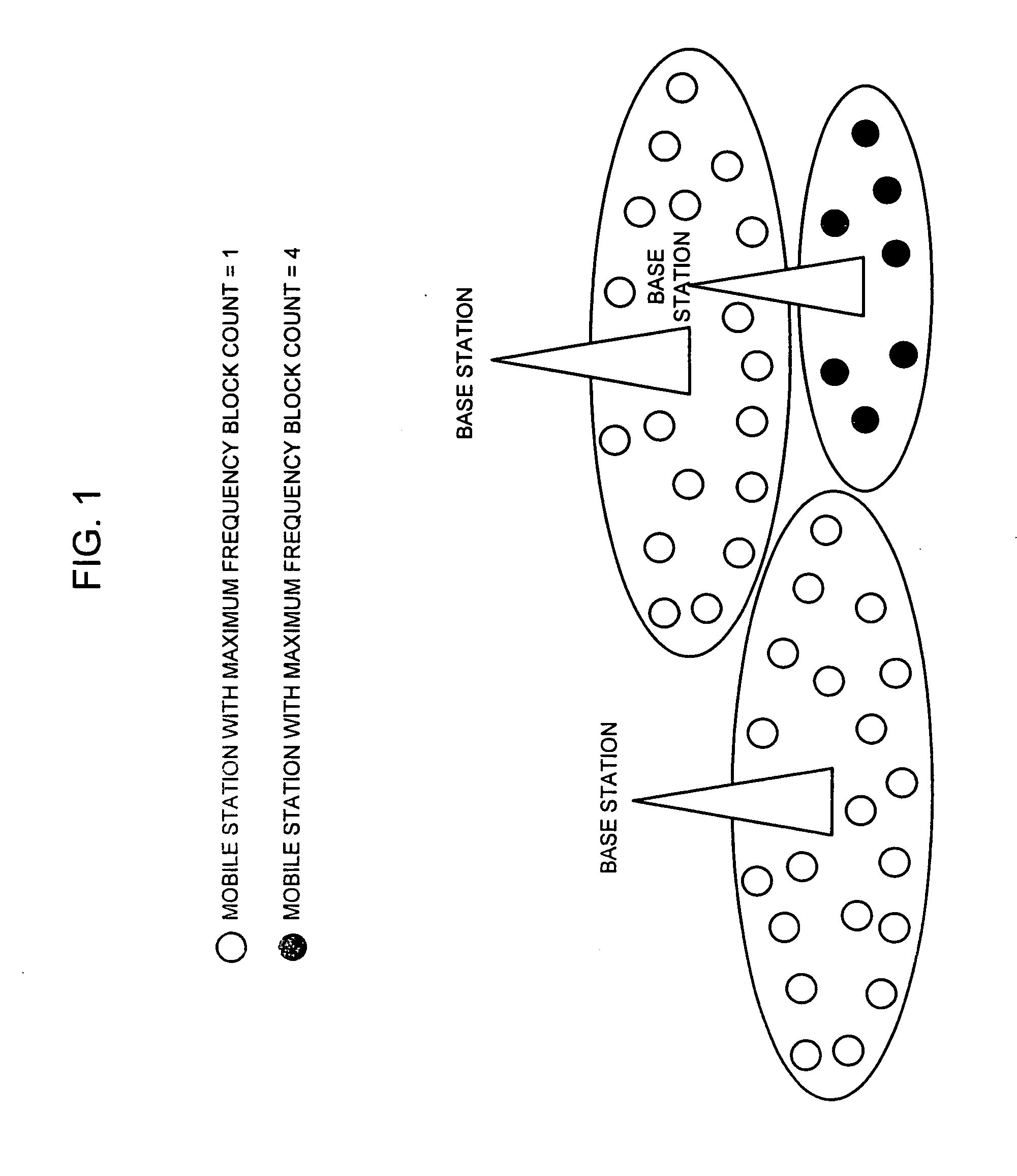

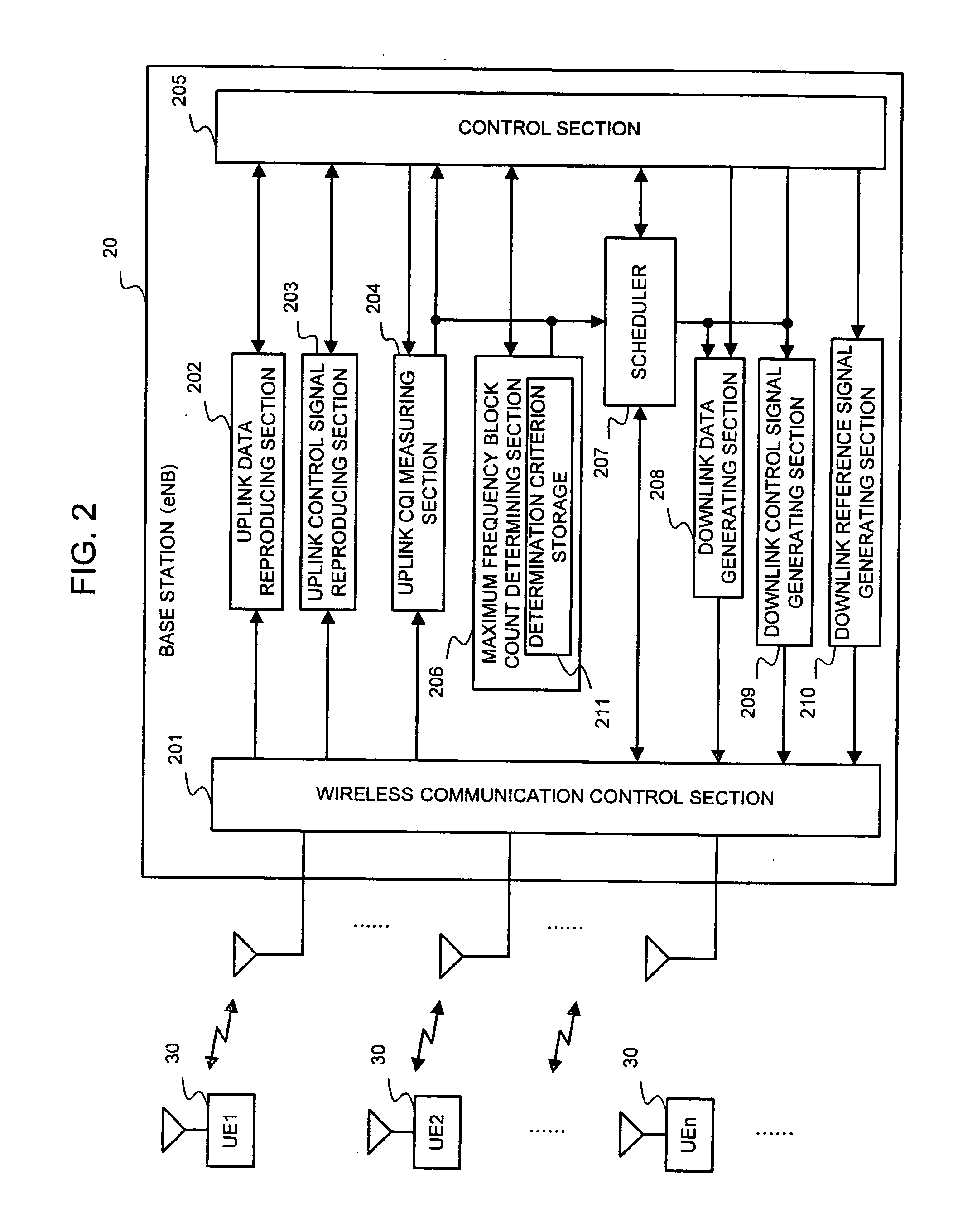

Wireless communication system, wireless communication setting method, base station, mobile station, and program

ActiveUS20110002282A1Improve system throughputIncrease overheadModulated-carrier systemsTransmission path divisionCommunications systemResource block

The problem is that, in a mobile wireless system, when more than one frequency block composed of resource blocks that are consecutive on a frequency axis is assigned to one mobile station, the multi-diversity effect due to scheduling increases by the number of assigned frequency blocks being increased, but the overhead caused by the scheduling information increases. Accordingly, there is a tradeoff between the multi-diversity effect and the scheduling overhead. However, when the aforementioned tradeoff was considered with OFDM and SC-FDMA, the same fixed number of frequency blocks would have been used for all mobile stations. Accordingly, an optimization that takes into account the tradeoff between the multi-diversity effect and scheduling overhead has not been sufficiently achieved. In a wireless communication system, the maximum frequency block number, which is the maximum number of the aforementioned frequency blocks assigned to the same mobile station, is set based on system information, which is information pertaining to the base station installation environment and the mobile station or the mobile station's communication status, and the base station assigns no more resource blocks than the aforementioned maximum frequency block number.

Owner:NEC CORP

Combined feedback method and device of uplink control information

ActiveCN102437901AImplement Joint FeedbackIncrease frequency diversity effectError prevention/detection by using return channelError prevention/detection by diversity receptionChannel state informationControl channel

The invention relates to the communication field and discloses a combined feedback method and device of uplink control information. The method comprises the following steps of: obtaining ACK(Acknowledgement) / NACK (Negative Acknowledgement) information and period CSI (Channel State Information) to be fed back and determining uplink sub-frames for bearing the ACK / NACK information and the period CSI; an performing block interleaving treatment on the ACK / NACK information and period CSI, and mapping interleaved data to a physical resource corresponding to a PUCCH (Physical Uplink Control Channel) in the uplink sub-frames and then feeding back the data to a network side, wherein in each time slot occupied by the physical resource corresponding to the PUCCH, the mapped ACK / NACK information is continuously arrayed and the mapped CIS is continuously arrayed. Therefore, according to the method and the device provided by the invention, the combined feedback of the ACK / NACK information and the CIS is realized and the frequency diversity effect in the process of sending the data is increased, so that the system performance is improved in the process of transmitting the ACK / NACK information and the CIS.

Owner:DATANG MOBILE COMM EQUIP CO LTD

Multi-antenna system and data transmission method thereof

ActiveCN101325442ASolve the problem of precoding performance degradationSpatial transmit diversityMulti-frequency code systemsPrecodingCommunications system

The invention relates to a wireless communication system, which discloses a multi-antenna system and a data transmitting method. In the invention, the plural phase sequence in the MIMO precoding system of CDD is improved, to cause the phase shift in the whole system bandwidth equal to CDD, meanwhile the variable step of the plural phase sequence is set to be equal to the corresponding sub-carrier of the precoding feedback bandwidth, thereby keeping higher precoding performance when the feedback bandwidth is greater relative to the whole frequency band ratio. The virtual cycle time delay can be changed along the time, thereby obtaining the diversity effect on the time. When the channel frequency has small selectivity, the virtual cycle time delay makes the minimum to obtain the dispatching gain.

Owner:HUAWEI TECH CO LTD

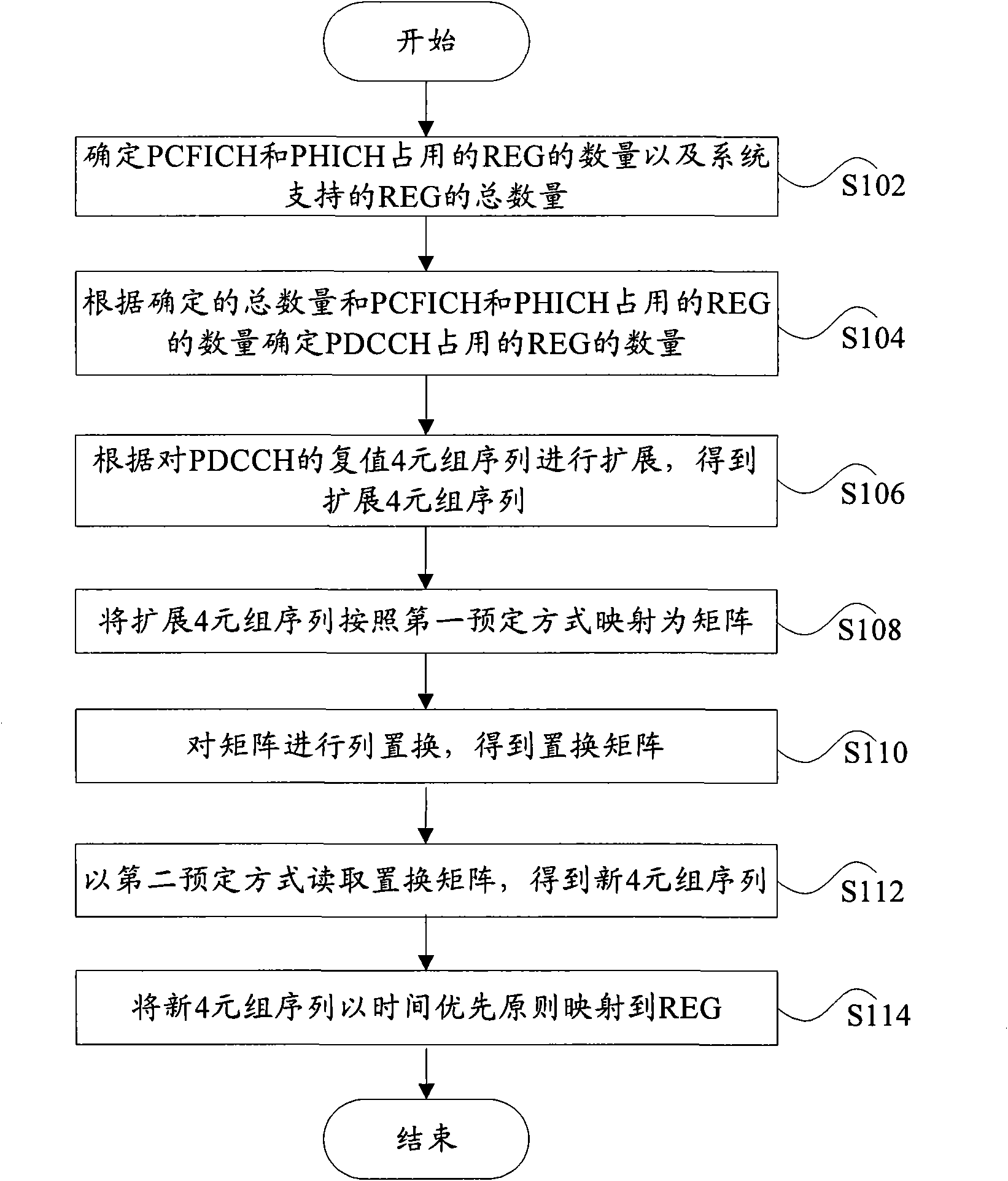

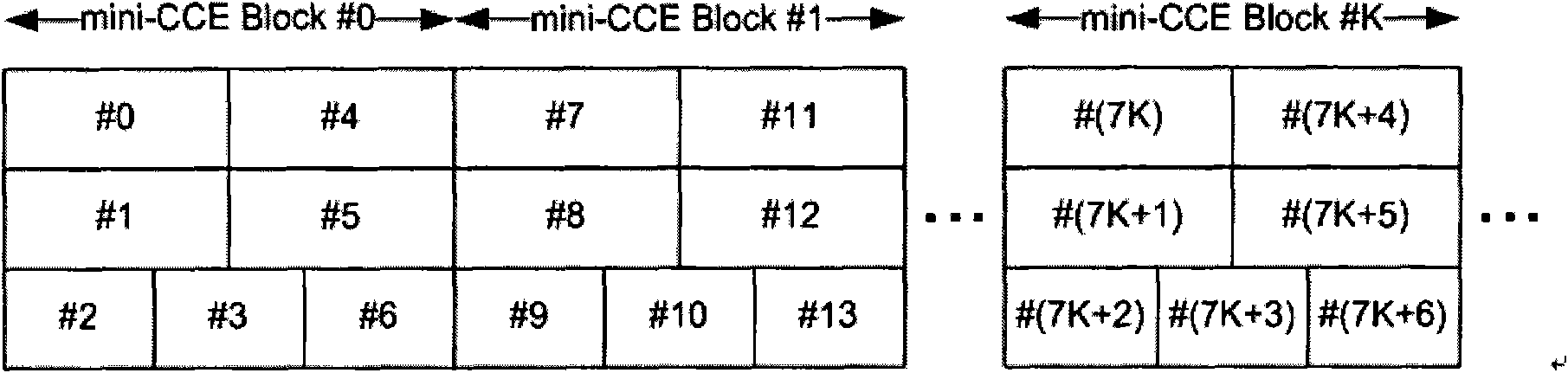

Method and device for mapping control channel sources

ActiveCN101605023AReduce distractionsIncrease diversity effectError prevention/detection by using return channelMulti-frequency code systemsAutomatic repeat requestResource element

The invention discloses a method for mapping control channel sources. The method comprises the following steps: confirming the number of source element groups occupied by a physical control format indicator channel (PCFICH) and a physical hybrid automatic repeat request indicator channel (PHICH) and the total number of the source element groups supported by a system; confirming a number NREG of the source element groups occupied by a physical downlink control channel (PDCCH) according to the confirmed total number and the number of the source element groups occupied by the PCFICH and the PHICH; expanding a complex value 4-tuple sequence of the PDCCH according to the NREG to obtain an expanded 4-tuple sequence; mapping the expanded 4-tuple sequence into a matrix according to a first preset mode; permuting the columns of the matrix to obtain a permutation matrix; reading the permutation matrix in a second preset mode to obtain a new 4-tuple sequence; and mapping the new 4-tuple sequence to the source element groups by a time priority principle. The invention also discloses a device for mapping the control channel sources. The invention can reduce the mutual interference among the control channels and improve the diversity effect of an OFDM technology.

Owner:ZTE CORP

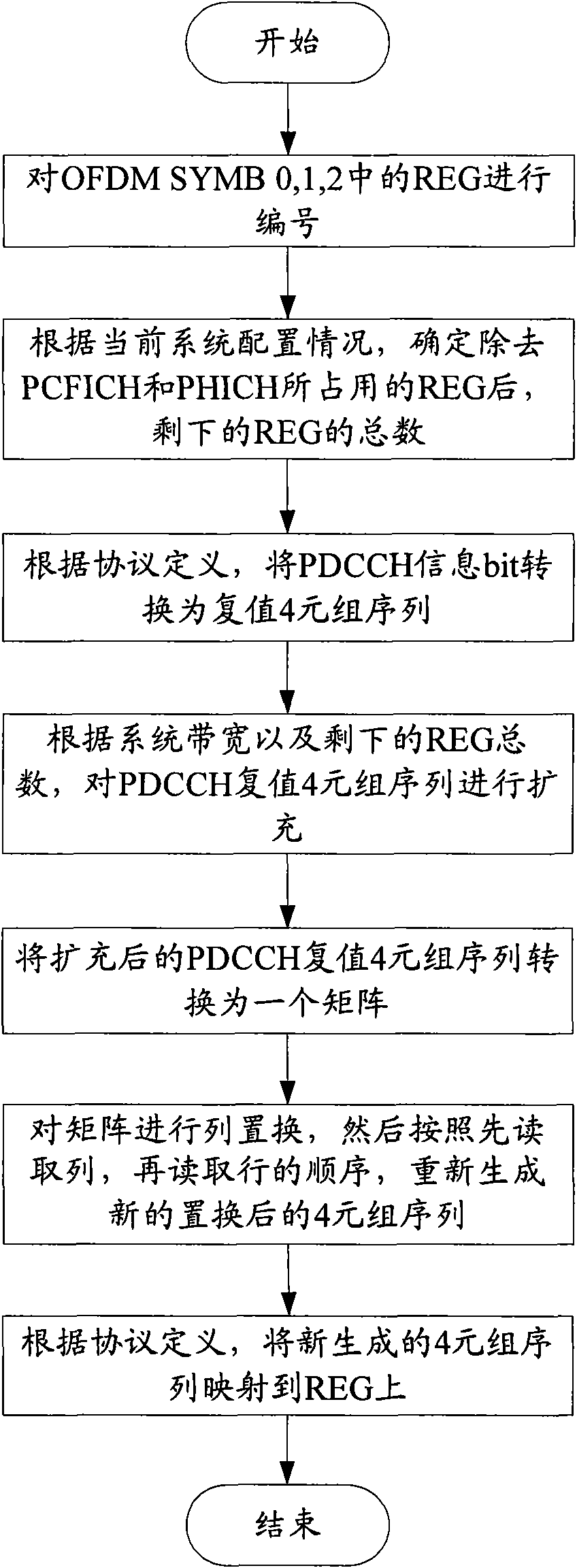

Resource mapping method of control channel in orthogonal frequency division multiplexing system

ActiveCN101610586AIncrease distanceReduce distractionsError prevention/detection by using return channelWireless communicationTelecommunicationsControl channel

The invention discloses a resource mapping method of a control channel in an orthogonal frequency division multiplexing system. The method comprises the following steps of: (1) dividing a wireless channel resource into a logic resource and a physical resource of which the total numbers are both N, coding the resources as L = l1, l2, ellipsis and lN, and P = p1, p2, ellipsis and pN respectively, and coding an OFDM SYMB of the wireless channel as 0, 1, ellipsis and N-1; (2) determining a frequency hopping function f (L), and obtaining offset v shift corresponding to the OFDM SYMB according to a formula v shift = ((NSC / n).(mod (NID, n* NRB))) / (2*m); (3) allocating the logical resource for PCFICH, and mapping the logical resource to the physical resource; and (4) allocating the logical resource when a vacant logic resource is PHICH and PDCCH in sequence, and mapping both logic resources to the physical resource according to a mapping function P = mod (f (L) +v shift, N). The method ensures that logically adjacent control channels with the same type in the same cell keep a distance as far as possible in a frequency domain, and the same control channel of the adjacent cells keeps a distance as far as possible in the frequency domain, reduces the interference among all the control channels, and improves the diversity effect of the OFDM technology.

Owner:ZTE CORP

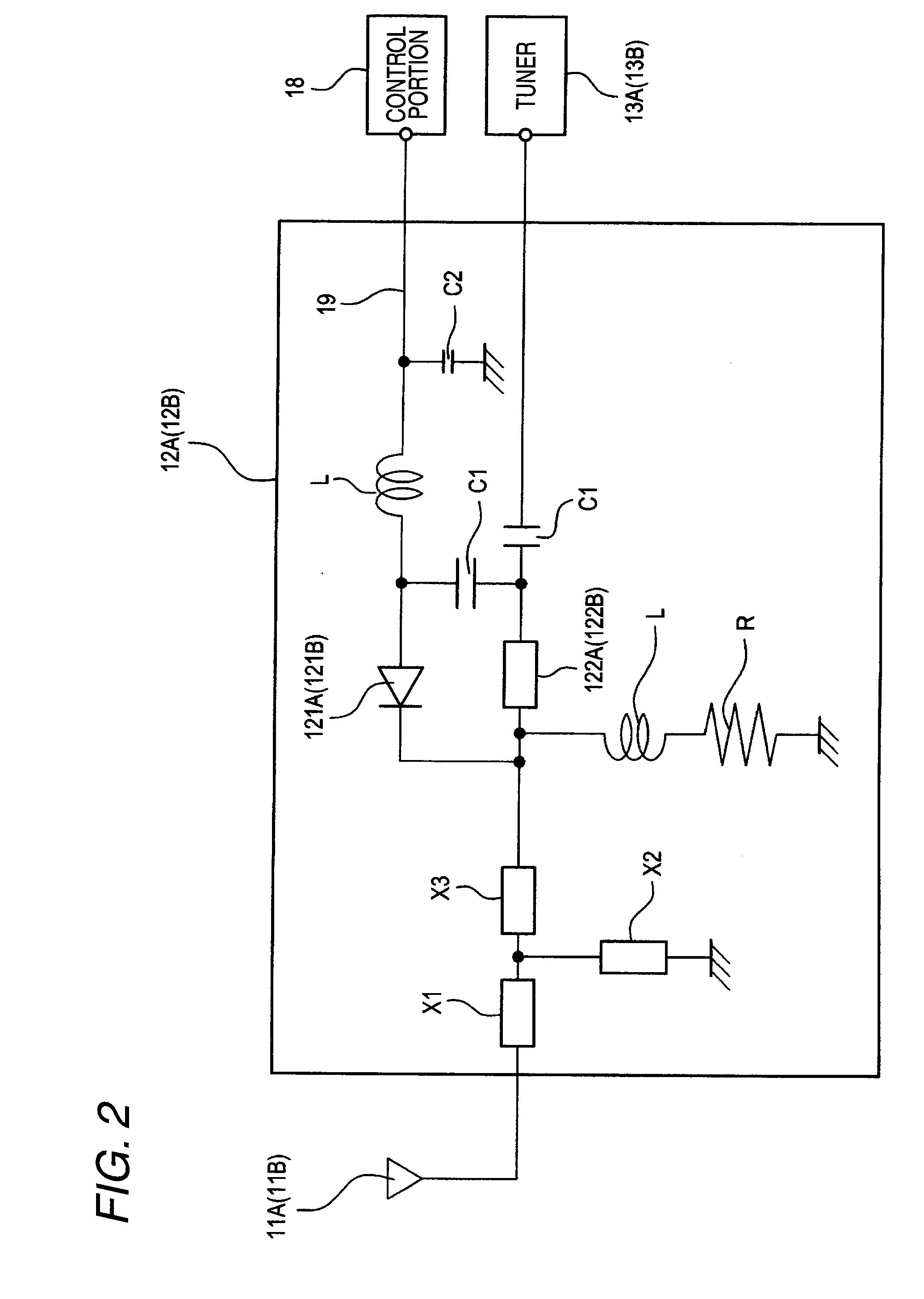

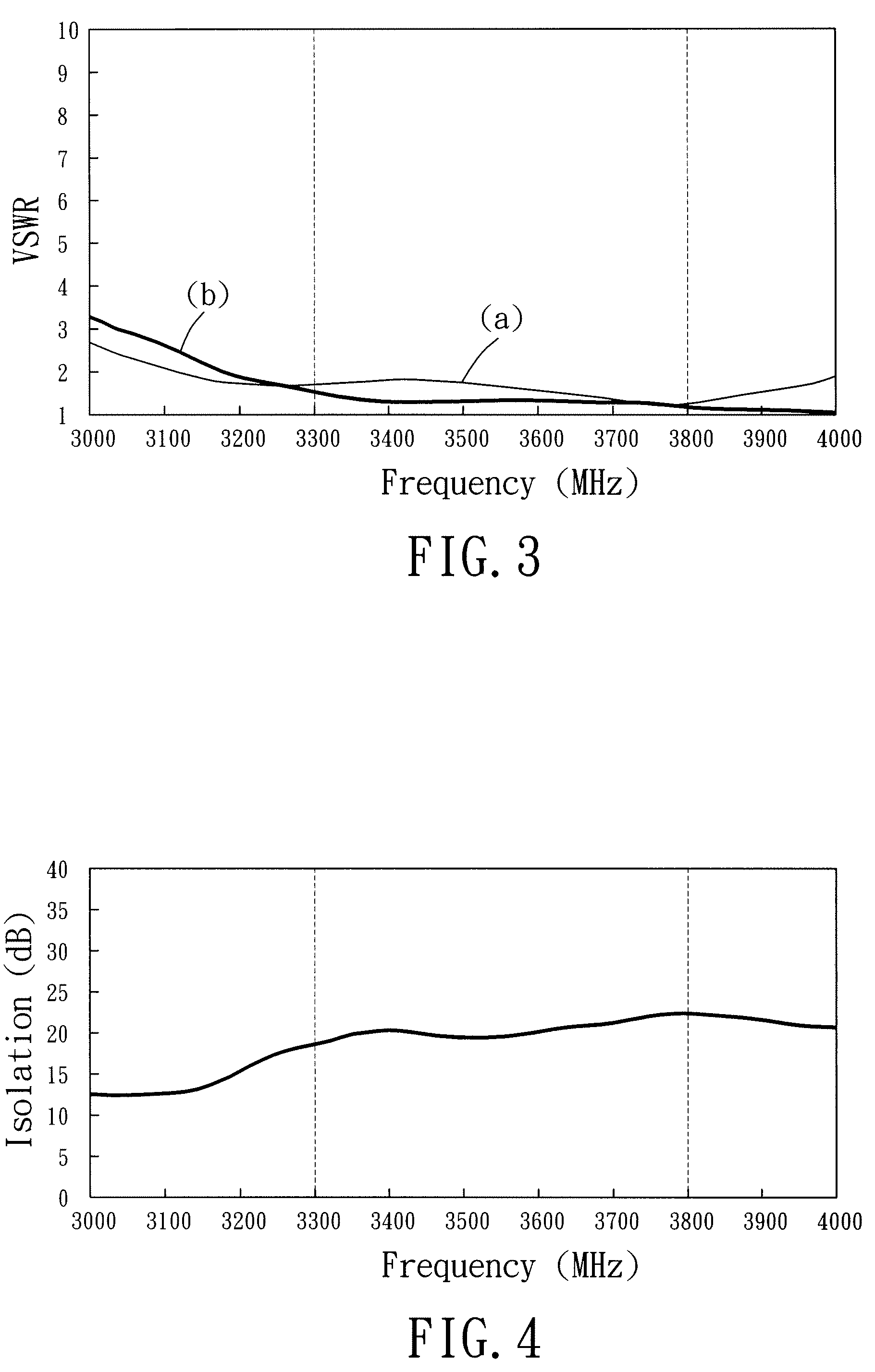

Portable wireless apparatus

InactiveUS20090267842A1Reduce deteriorationIncrease transfer speedAntenna supports/mountingsRadio transmissionElectromagnetic couplingEngineering

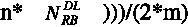

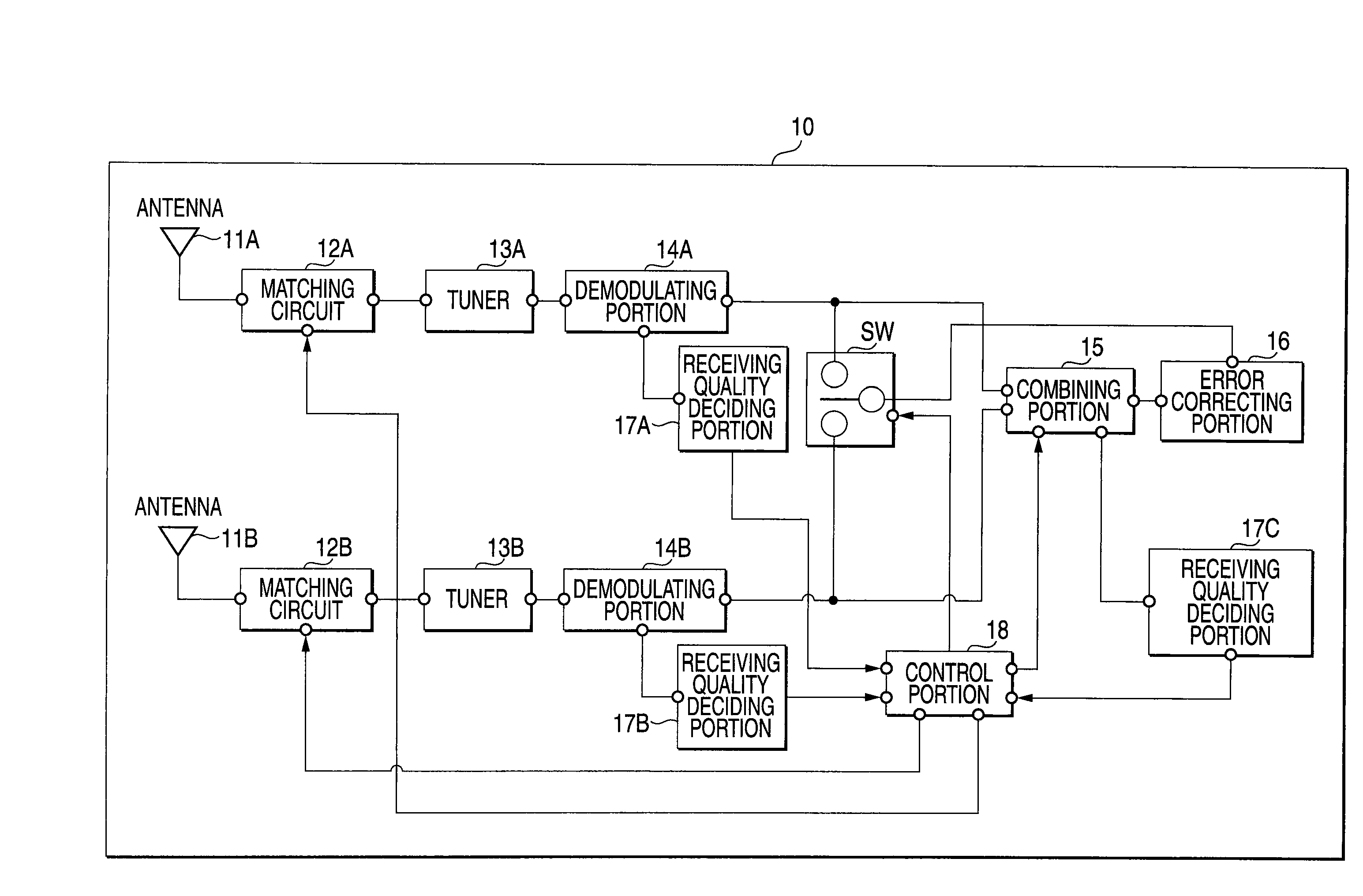

It is an object to relieve deterioration in efficiency due to the influence electromagnetic coupling between antennas and to obtain a high diversity gain, and a high transmission speed and a large communication capacity in an MIMO system. In a portable wireless machine including two types of antennas 11A and 11B for receiving a digital modulating signal, matching circuits 12A and 12B set individually to the antennas 11A and 11B respectively, tuners 13A and 13B, demodulating portions 14A and 14B, a combining portion 15 for combining a demodulated signal, and receiving quality deciding portions 17A, 17B and 17C for outputting receiving qualities in respective branches and after a combination, a diversity effect decision is made by using the receiving quality after the combination and a receiving quality in a single branch receipt, and a matching condition of the matching circuit 12A or the matching circuit 12B of the antenna 11A or the antenna 11B is controlled corresponding to a result.

Owner:PANASONIC CORP

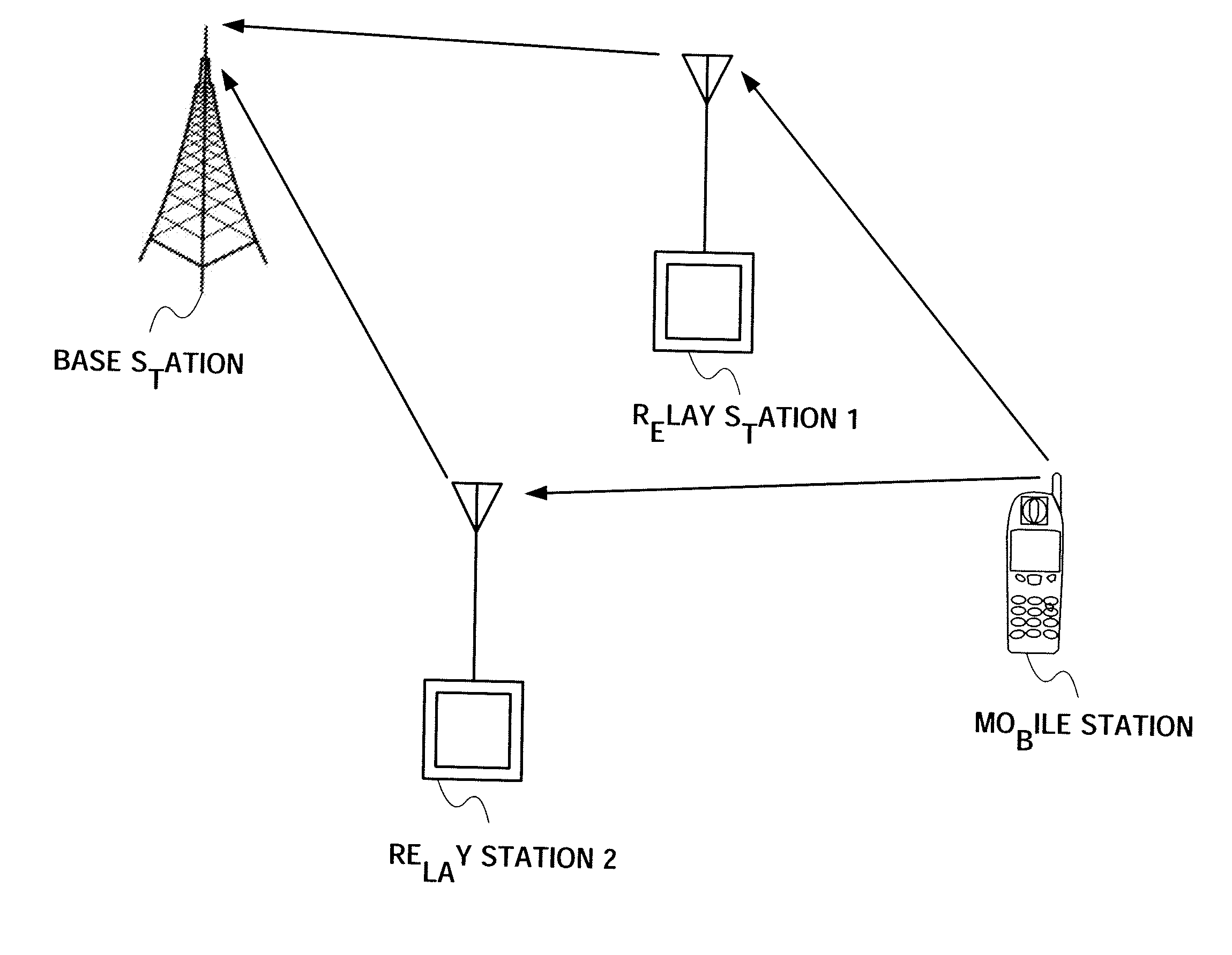

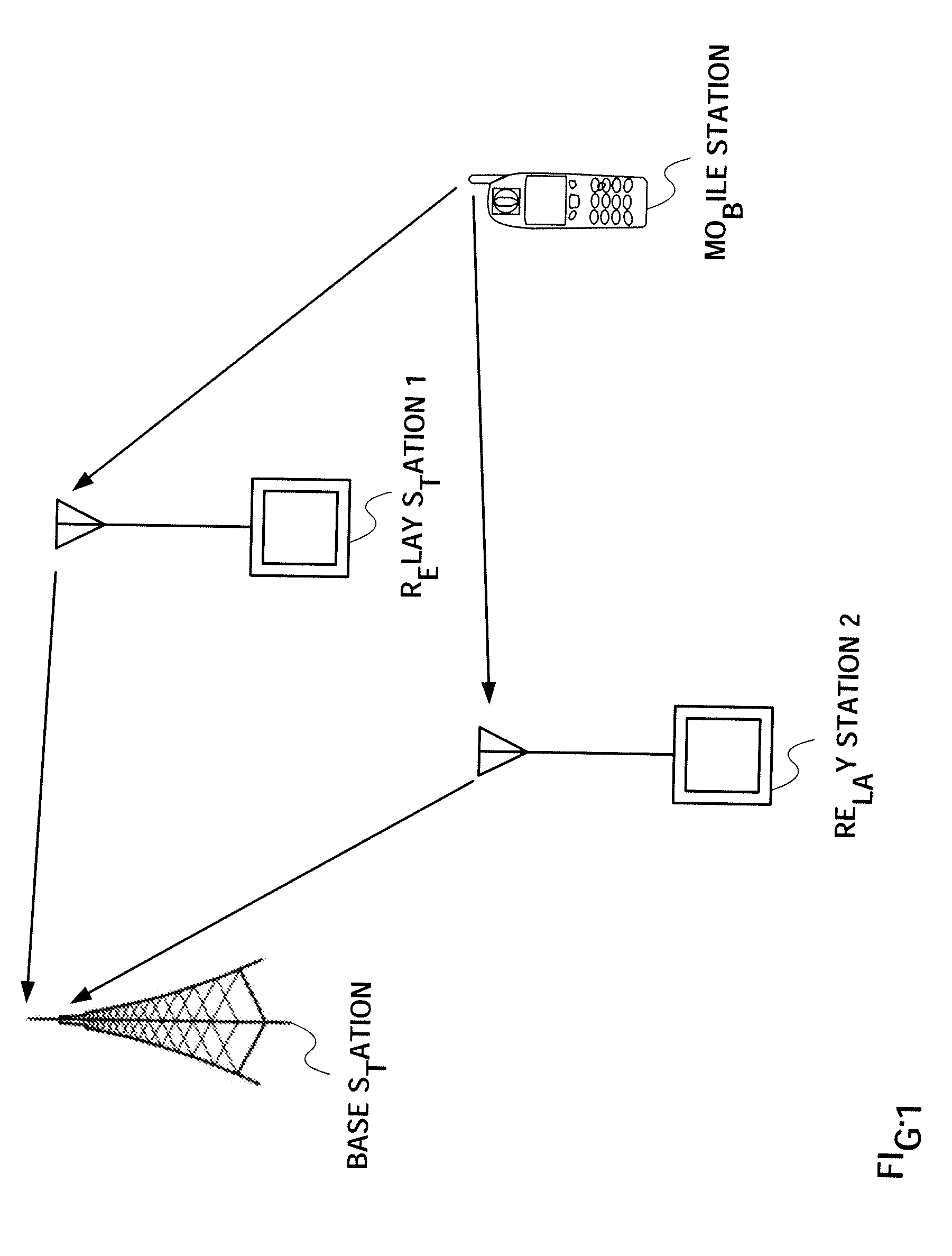

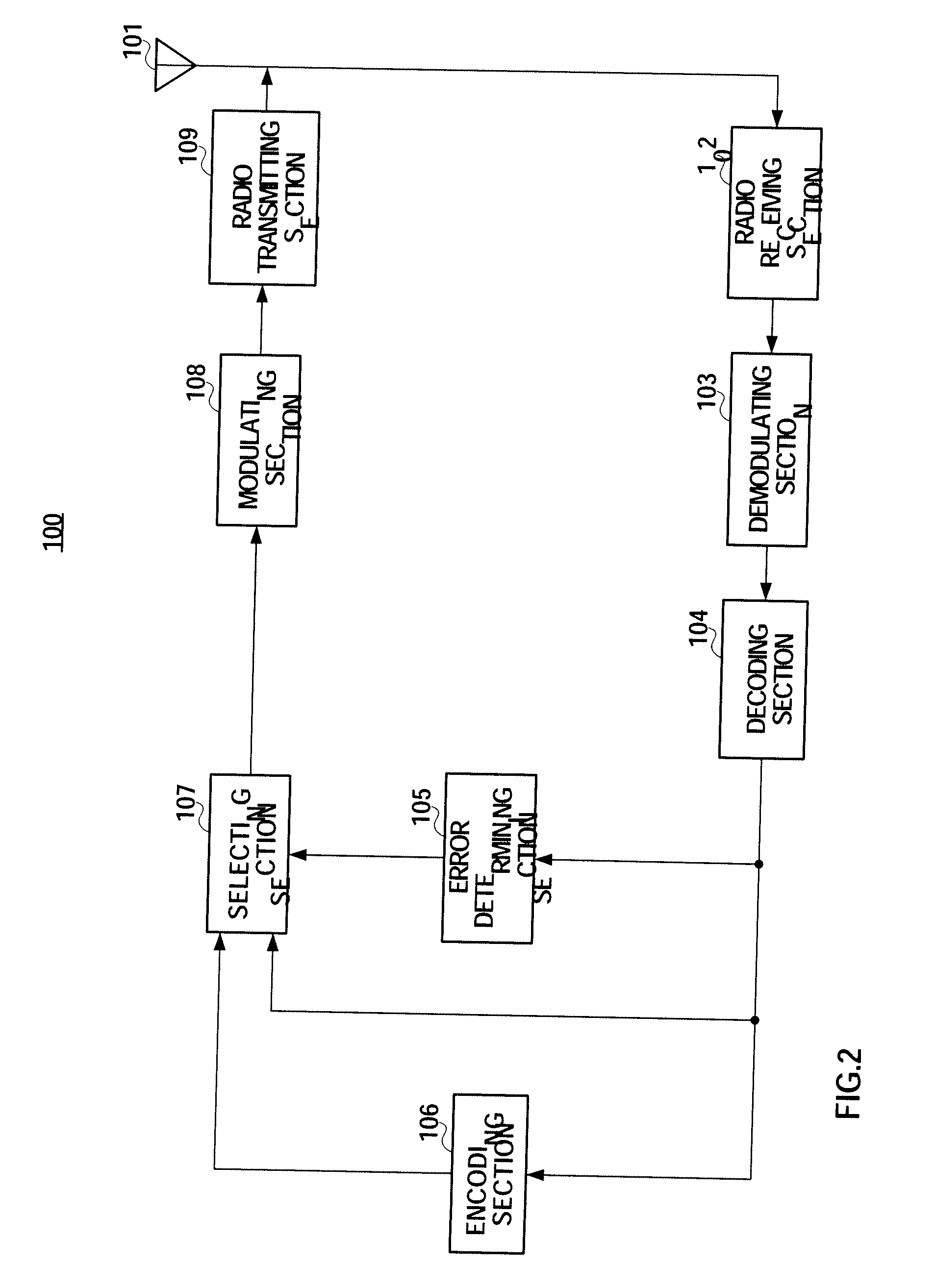

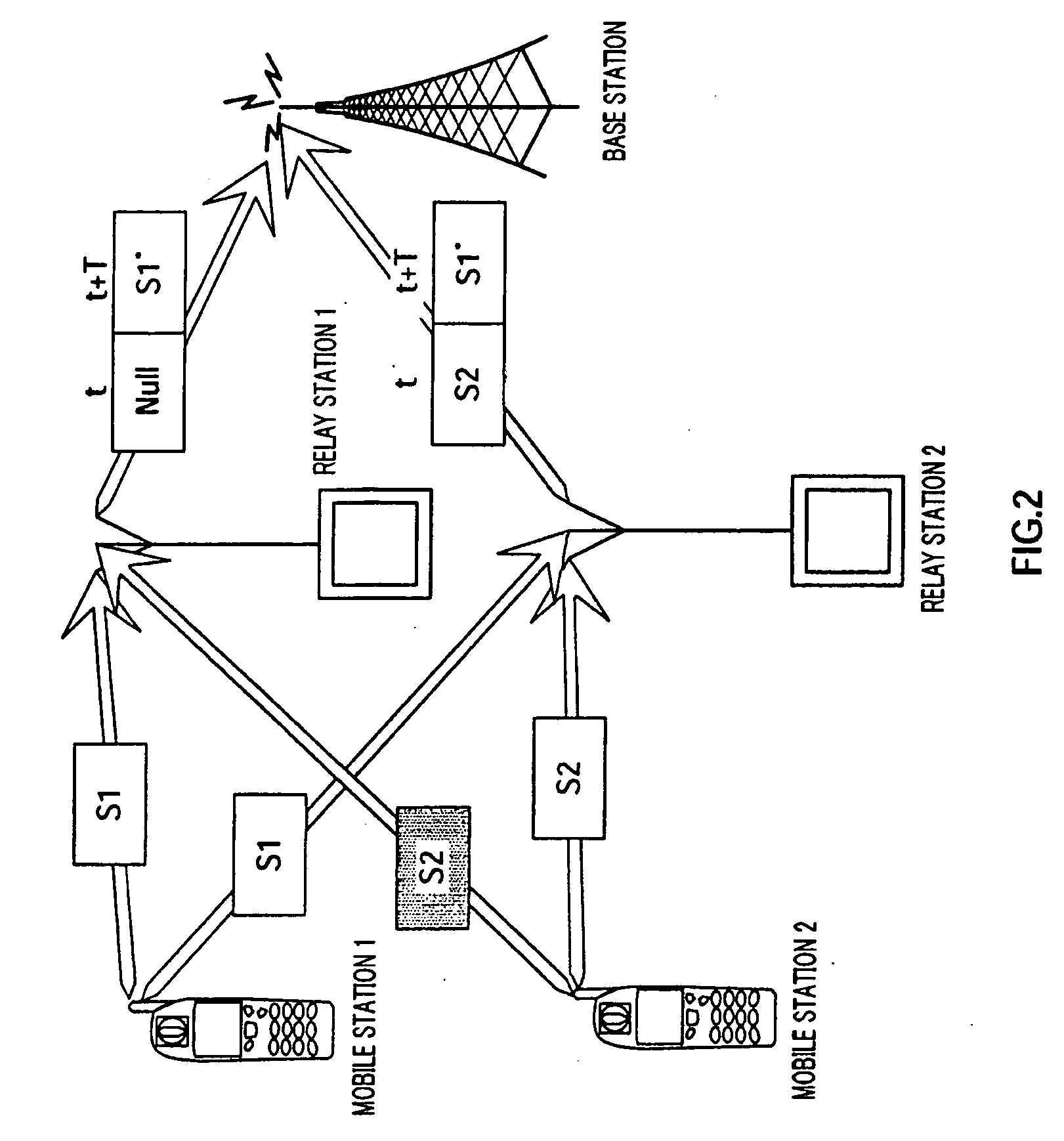

Radio communication apparatus and relay transmission method

ActiveUS20090036051A1Diversity effectError prevention/detection by using return channelTransmission systemsMobile stationComputer science

Provided is a relay transmission method capable of obtaining the diversity effect even when a relay station has detected an error in a relay signal when performing communication between a base station and a mobile station via a relay station. In the relay station used in this method, a decoding unit (104) performs error-correction-decoding of a systematic bit by performing repeated decoding such as a turbo decoding by using a parity bit and obtains a decoding result formed by a systematic bit after the error-correction-decoding. An error judging unit (105) judges whether the decoded result has an error by using CRC (Cyclic Redundancy Check). An encoding unit (106) performs error-correction-encoding of the decoded result and obtains a systematic bit after error-corrected-encoded and a parity bit. A selection unit (107) selects the decoded result inputted from the decoding unit (104) or the bit string inputted from the encoding unit (106) according to the judgment result obtained by the error judging unit (105) and outputs it to a modulation unit (108).

Owner:PANASONIC INTELLECTUAL PROPERTY CORP OF AMERICA

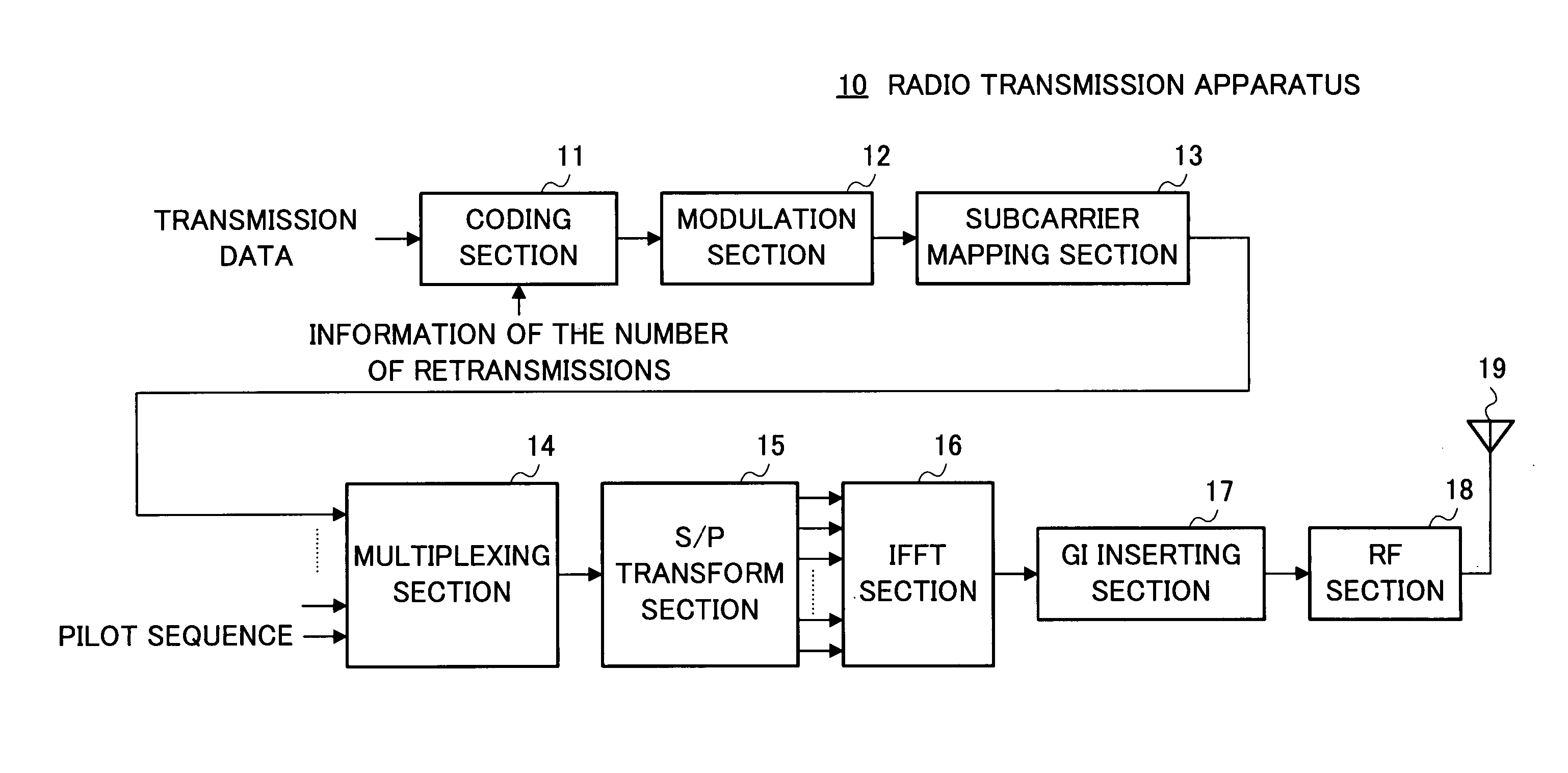

Radio transmitter apparatus, radio receiver apparatus, and radio transmission method

InactiveUS20060195756A1Enhancing effect of improving error rate characteristicGood effectError prevention/detection by using return channelOther error detection/correction/protectionRadio receiverCoding decoding

Transmission data in a different interleaving pattern is input for each retransmission via interleaver 31 to outer coding processing section 32 that performs coding processing with a strong correction capability for the burst error such as Reed-Solomon coding. Inner coding processing section 33 performs coding processing with a strong correction capability for the random error such as turbo coding. Different outer code parity bits are thus transmitted for each retransmission, and the decoding side is capable of performing outer code decoding processing using different outer code parity bits corresponding to the number of retransmissions, and thus improves the correction capability for the burst error. As a result, it is possible to acquire both the combining gain due to the inner coding processing and the diversity effect due to the outer code by retransmission, and it is thus possible to effectively reduce both the random error and burst error while taking full advantage of retransmission.

Owner:PANASONIC CORP

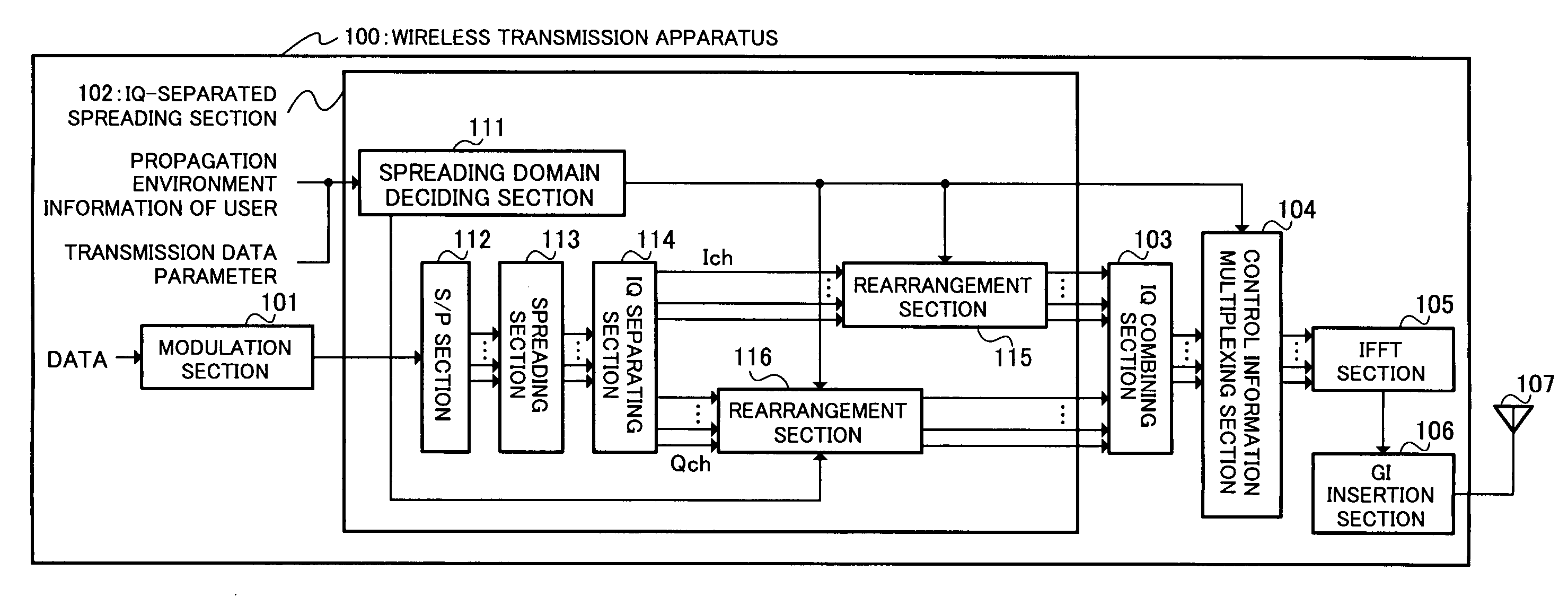

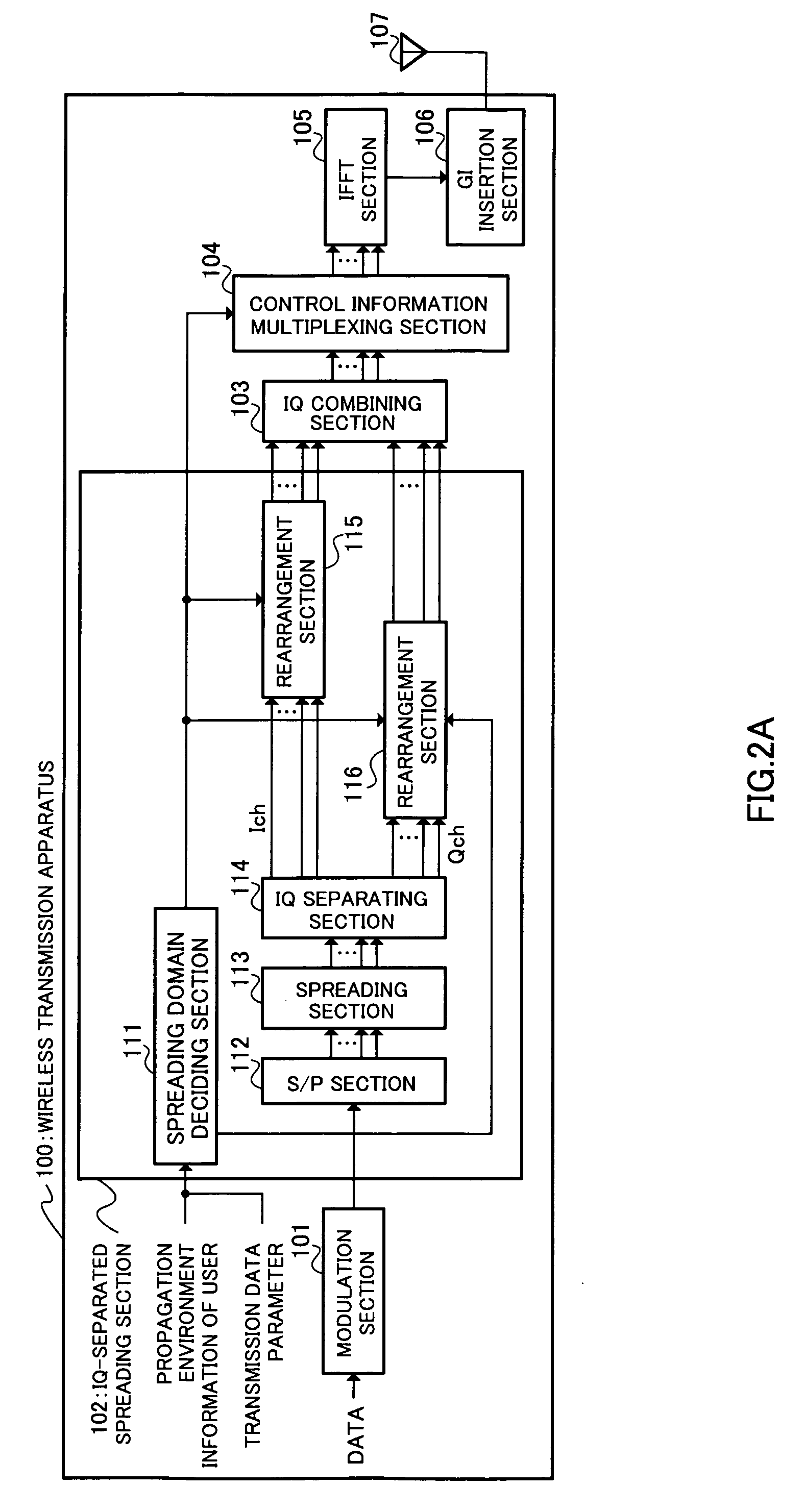

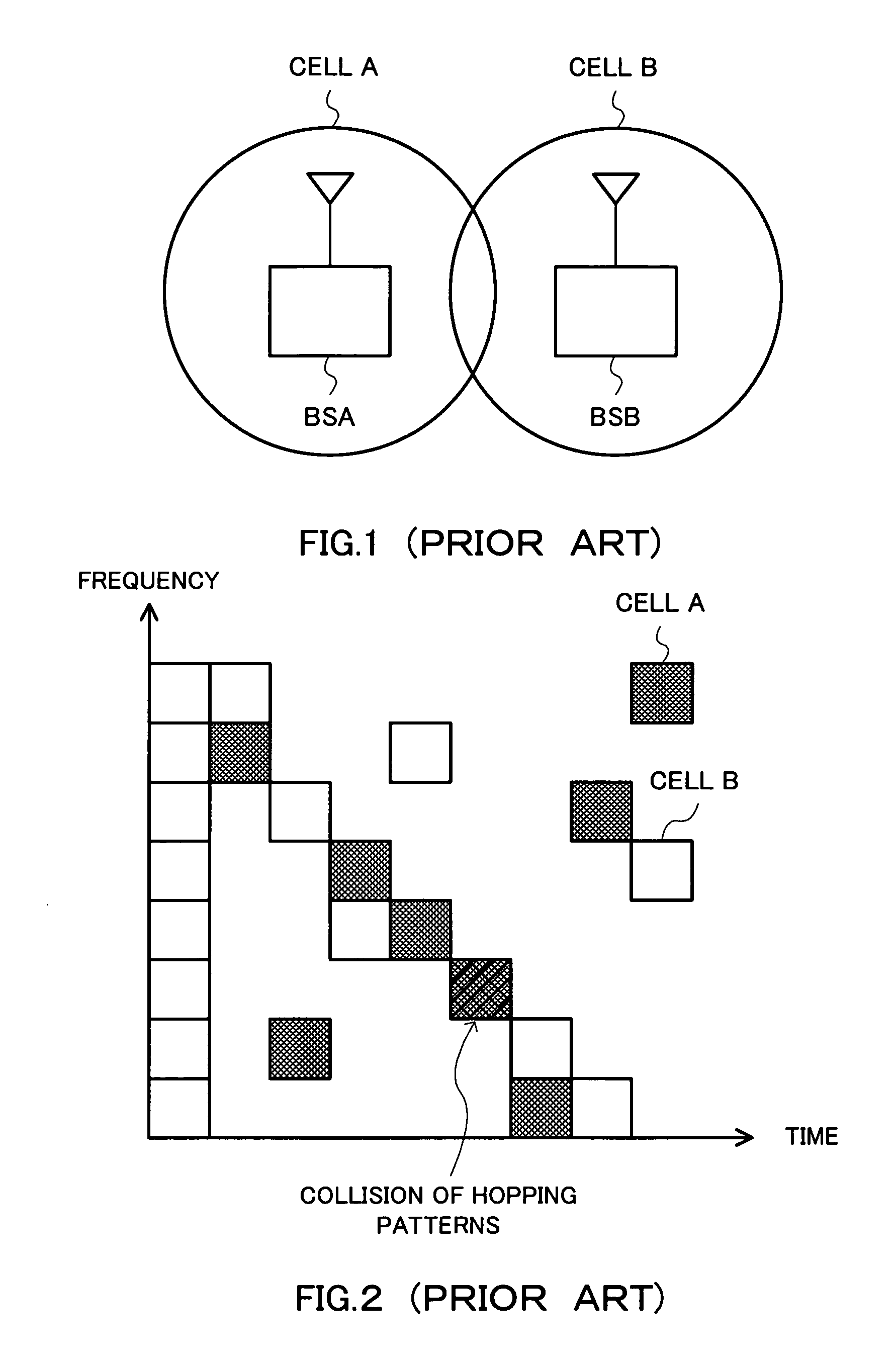

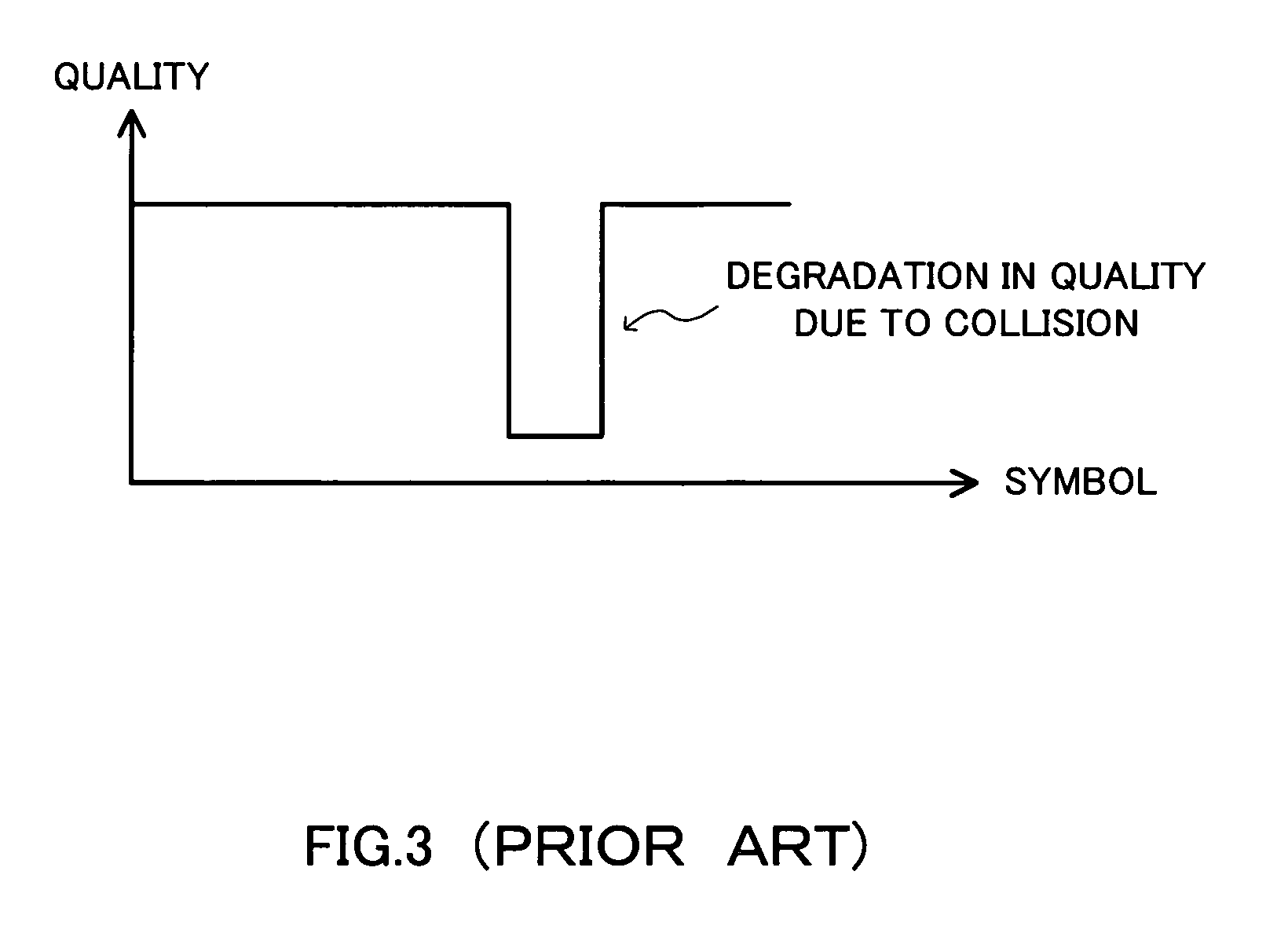

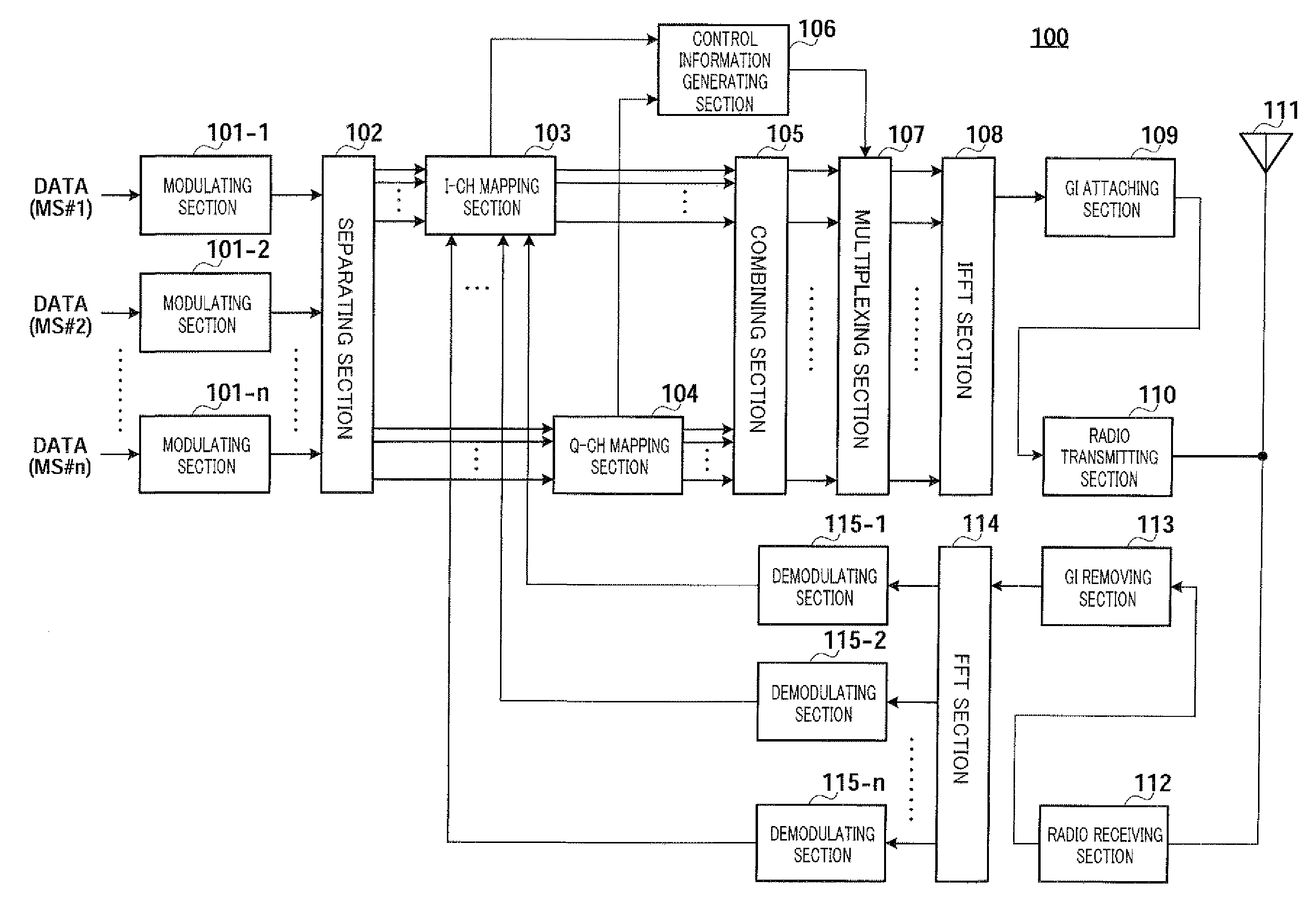

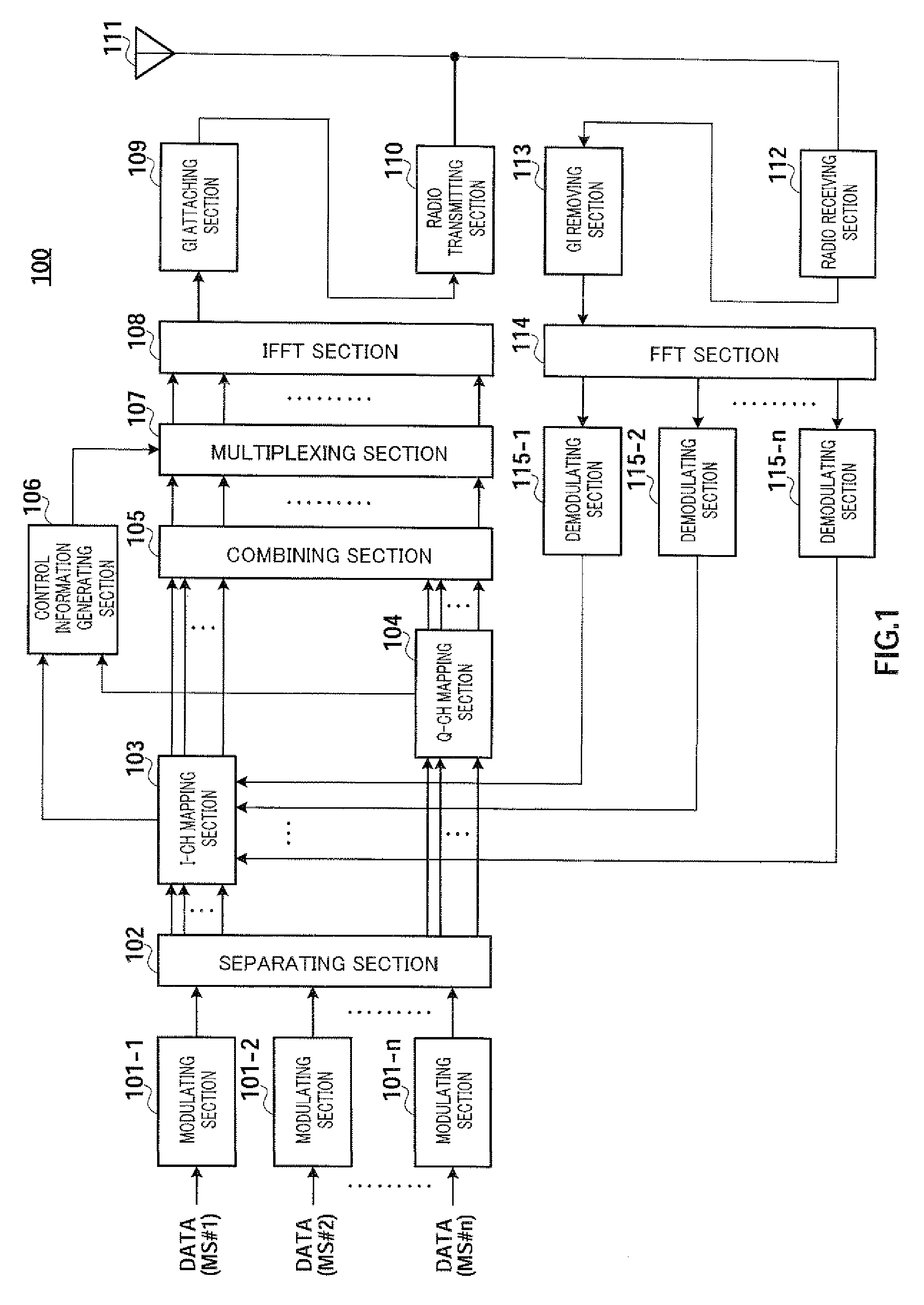

Radio communication base station apparatus and radio communication method in multi-carrier communications

Provided is a radio communication base station device capable of acquiring both a multi-user diversity effect and a frequency diversity effect simultaneously in multi-carrier communications. In this devices modulation units (101-1 to 101-n) modulate data to mobile stations (MS#1 to MS#n) individually to create data symbols. A separation unit (102) separates each data symbol inputted, into an Ich (in-phase components) and a Qch (orthogonal components). An Ich arrangement unit (103) and a Qch arrangement unit (104) arrange the Ich and Qch, respectively, in a plurality of sub-carriers constituting an OFDM symbols, and output the same to a synthesization unit (105). This synthesization unit (105) synthesizes the Ich and Qch arranged for each sub-carrier, to create the synthesized symbol.

Owner:INTERDIGITAL PATENT HLDG INC

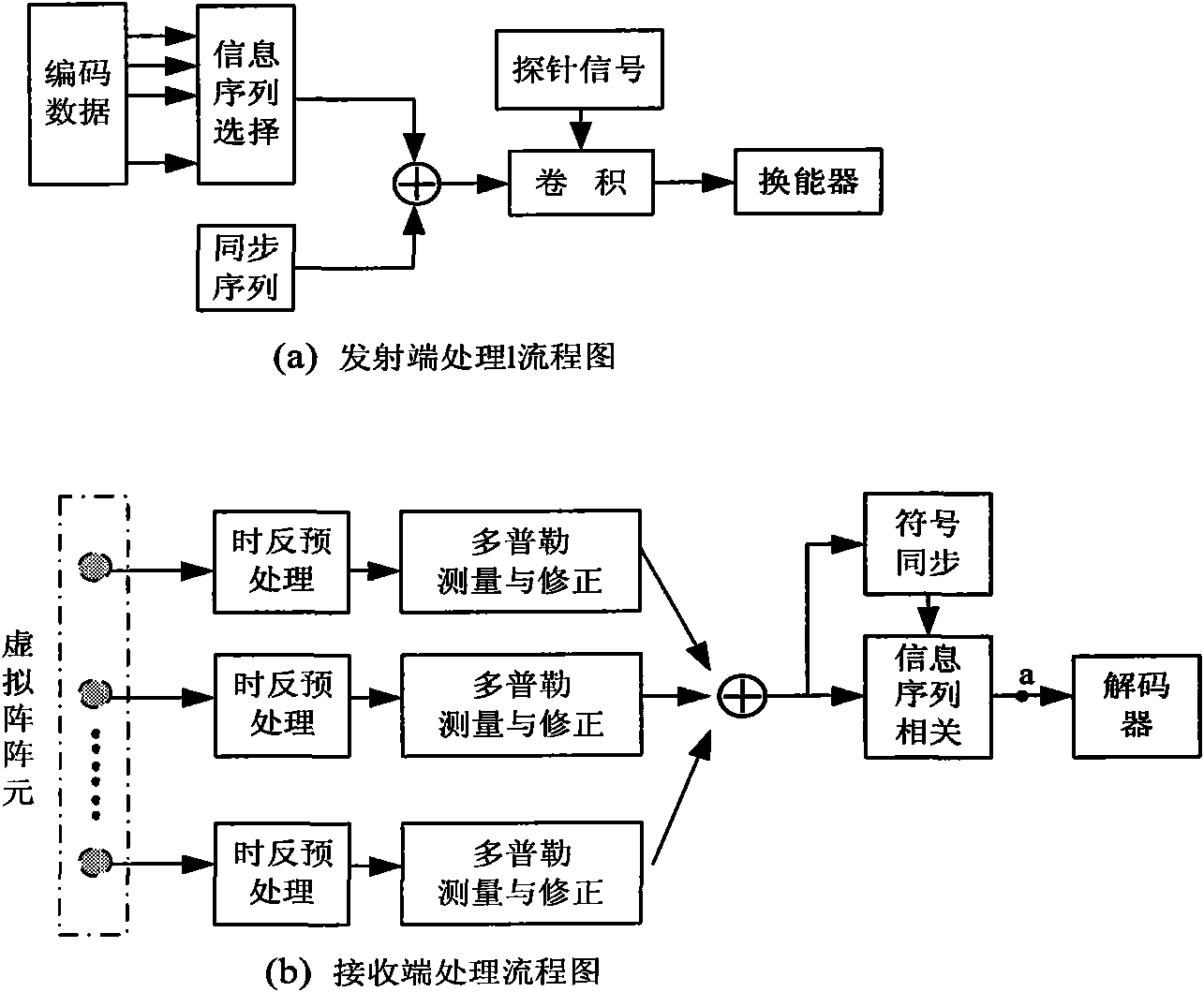

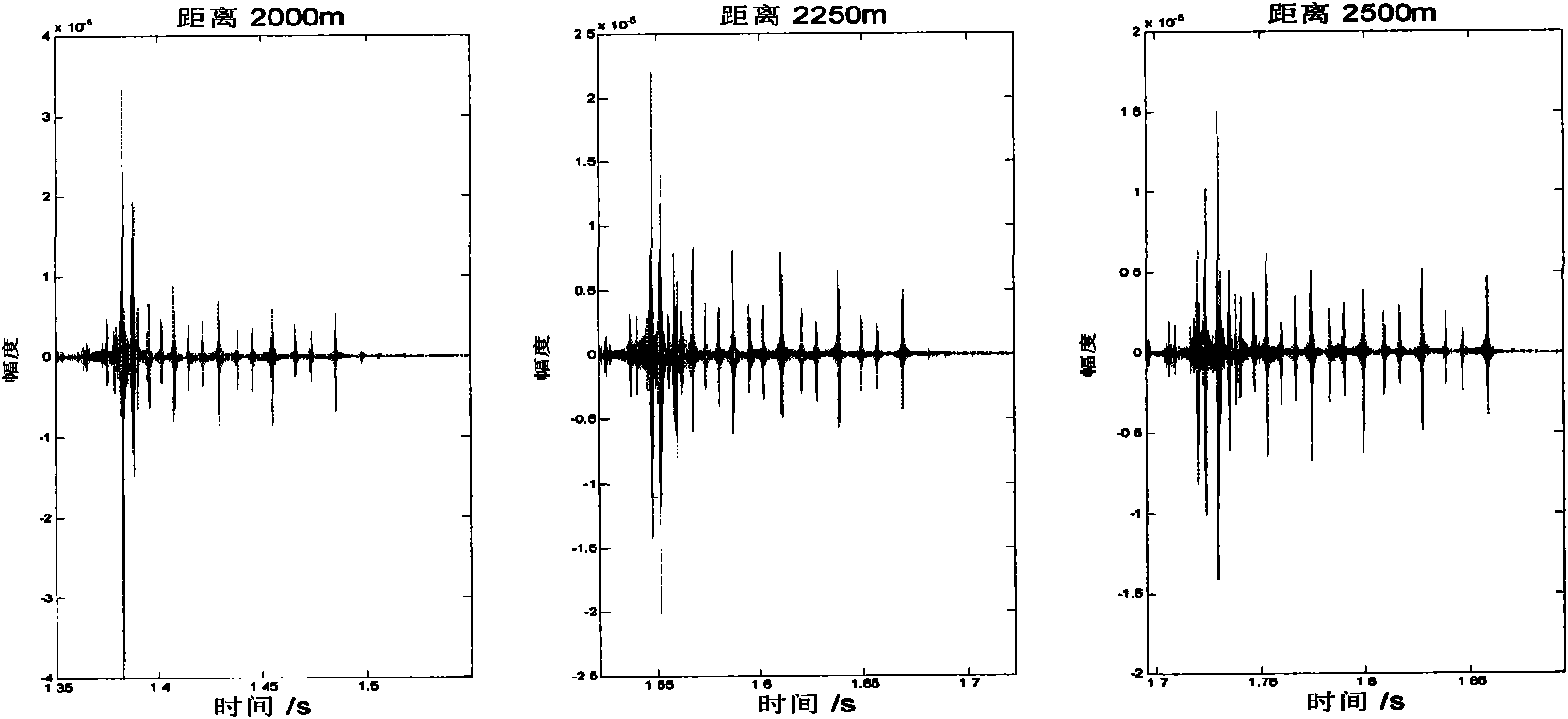

Passive time reversal underwater sound communication method suitable for mobile platform

InactiveCN102025423AGood space diversity effectGain Time Diversity GainTransmissionArray elementEngineering

The invention discloses a passive time reversal underwater sound communication method suitable for a mobile platform, wherein at least a receiver or a sender moves, the same information frame is repeatedly emitted on different position points, and channel transfer functions on different position points have lower correlation. A receiving end carries out pretreatment, such as frame synchronization, time reversal convolution, Doppler correction and the like, to a received signal, then merges a plurality of pretreated signals received on different opposite positions, and recovers emission information by operations, such as symbol synchronization, spread spectrum sequence correlation and the like. The invention has the beneficial effects that level correlation of a underwater sound communication channel is weakened by using position changes to provide a space diversity effect for time reversal treatment; the configuration of the time reversal communication system is lowered, and for the minimum configuration, the receiving end and the sending end are needed to be provided with only one real object array element respectively. Meanwhile, the same information frame is repeatedly emitted at different time points to obtain the time diversity effect, thereby obviously improving the reliability of the underwater sound communication system in the complex environment.

Owner:THE 715TH RES INST OF CHINA SHIPBUILDING IND CORP

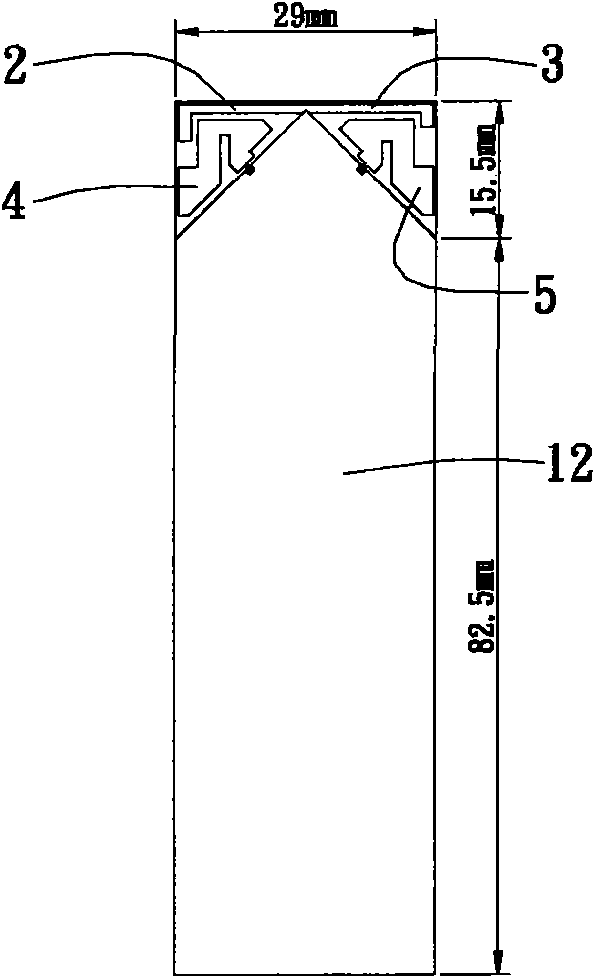

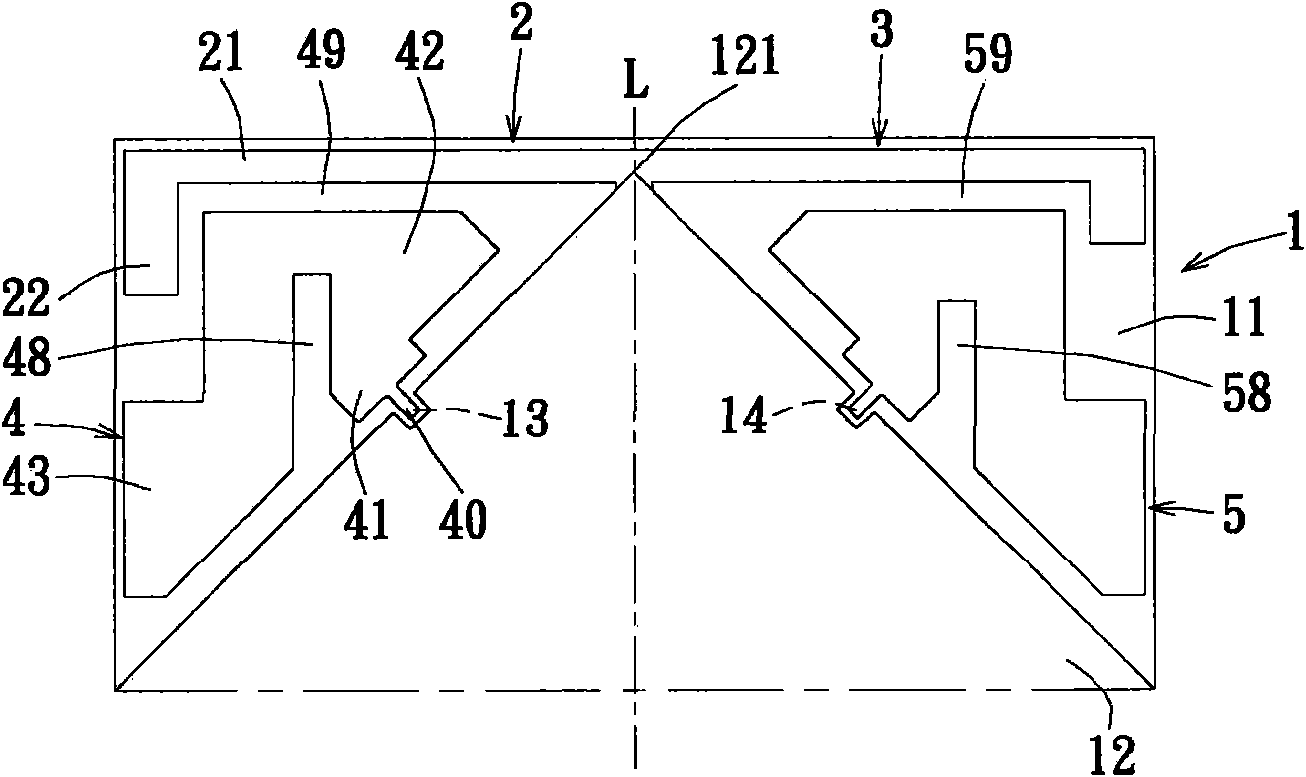

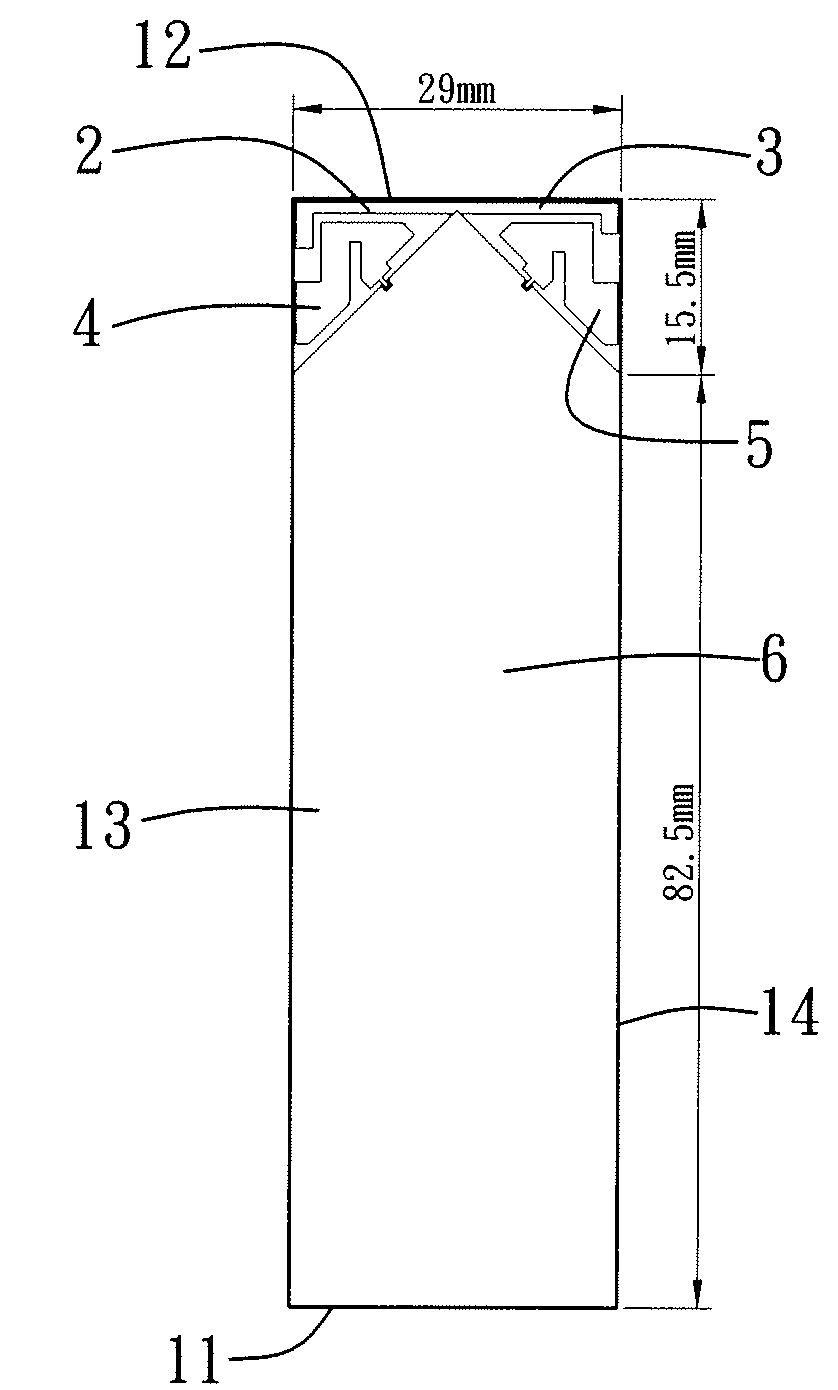

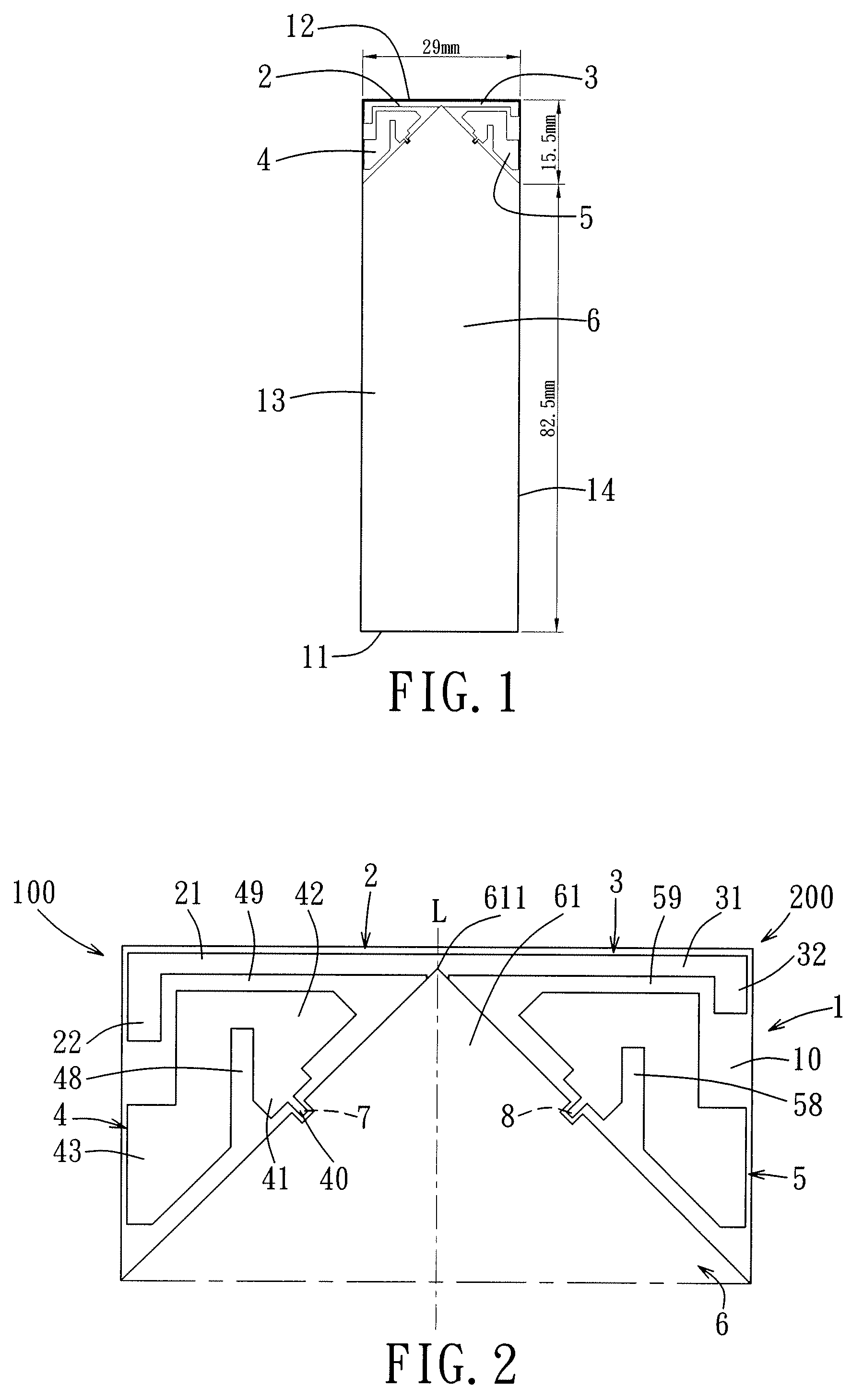

Antenna unit

InactiveCN101577364AImprove performanceReduce poor signal conditionsRadiating elements structural formsIndependent non-interacting antenna combinationsEngineeringMulti path

The invention relates to an antenna unit which comprises a basal plate, a first grounding part, a second grounding part, a first radiation part and a second radiation part, wherein the basal plate is provided with a surface, a grounding face formed on the surface as well as a first feed-in point and a second feed-in part which are formed on the surface; the first grounding part extends outwards from a first end of the grounding face; the shape of the second grounding part is similar to that of the first grounding part, and the second grounding part extends towards a direction opposite to the first grounding part from the first end of the grounding face. The invention can achieve a diversity effect by the first grounding part and the first radiation part as well as the second grounding part and the second radiation part, thereby being capable of reducing the situation of a bad signal caused by the multi-path effect to a large extent and increasing the effectiveness of the whole antenna.

Owner:QUANTA COMPUTER INC

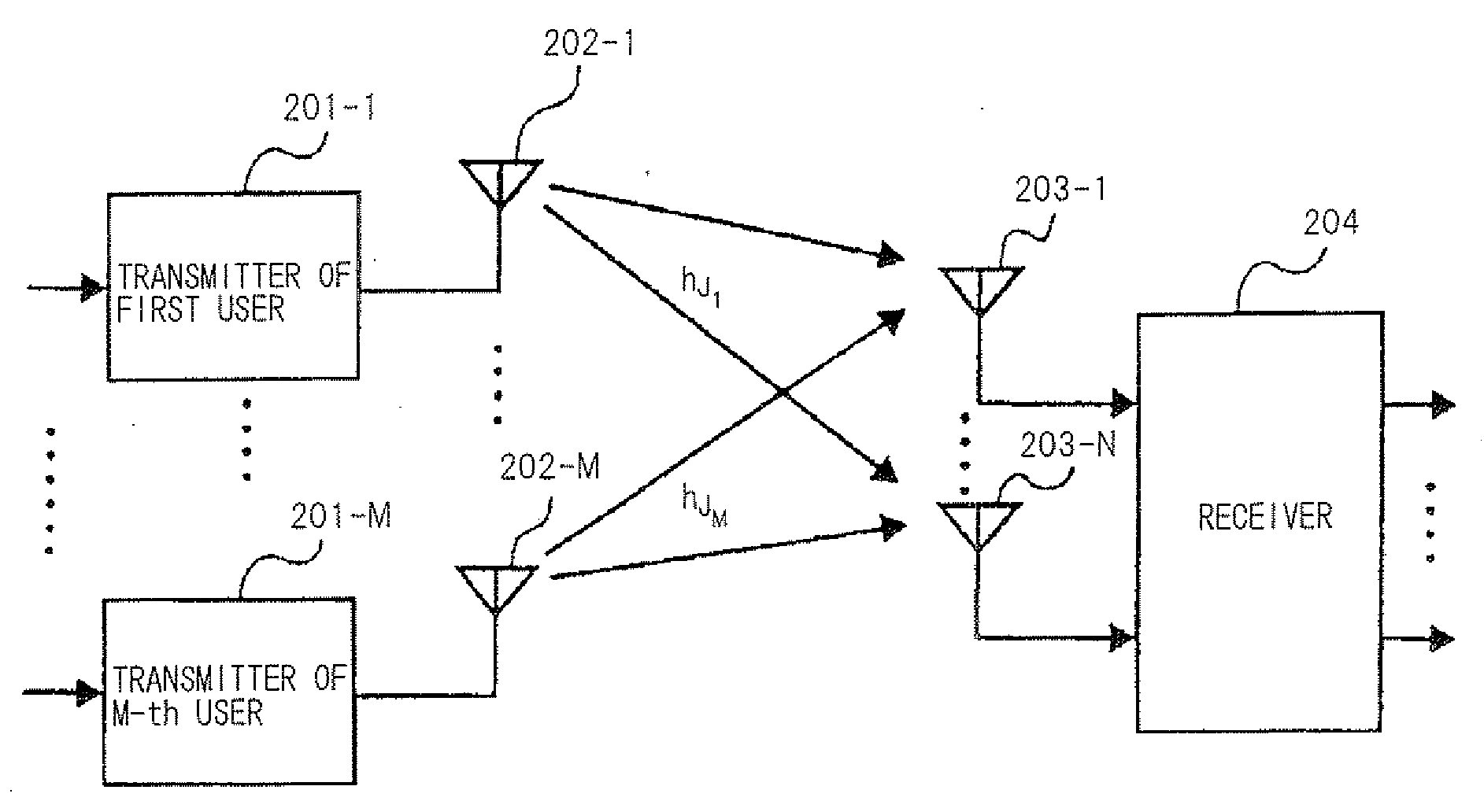

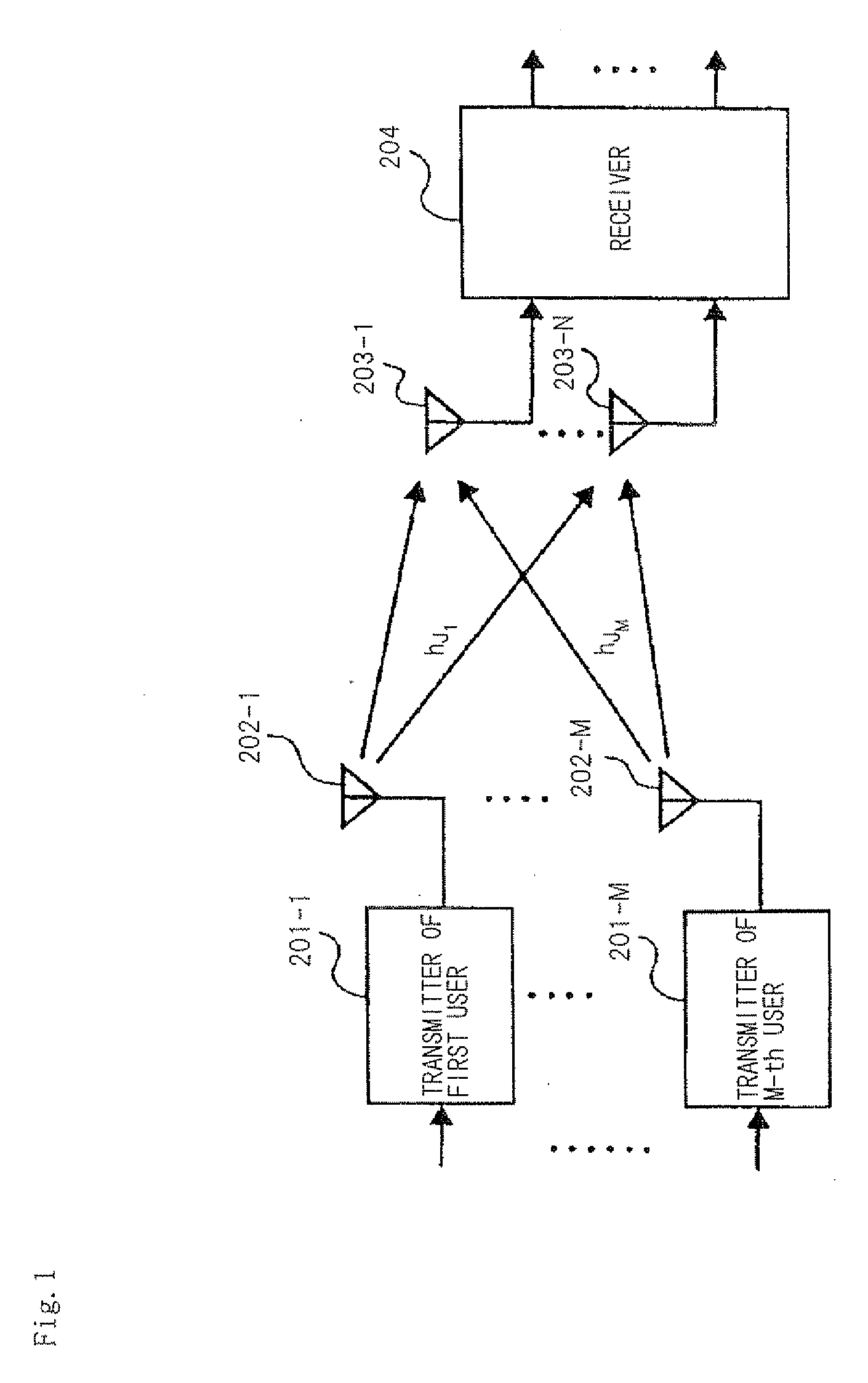

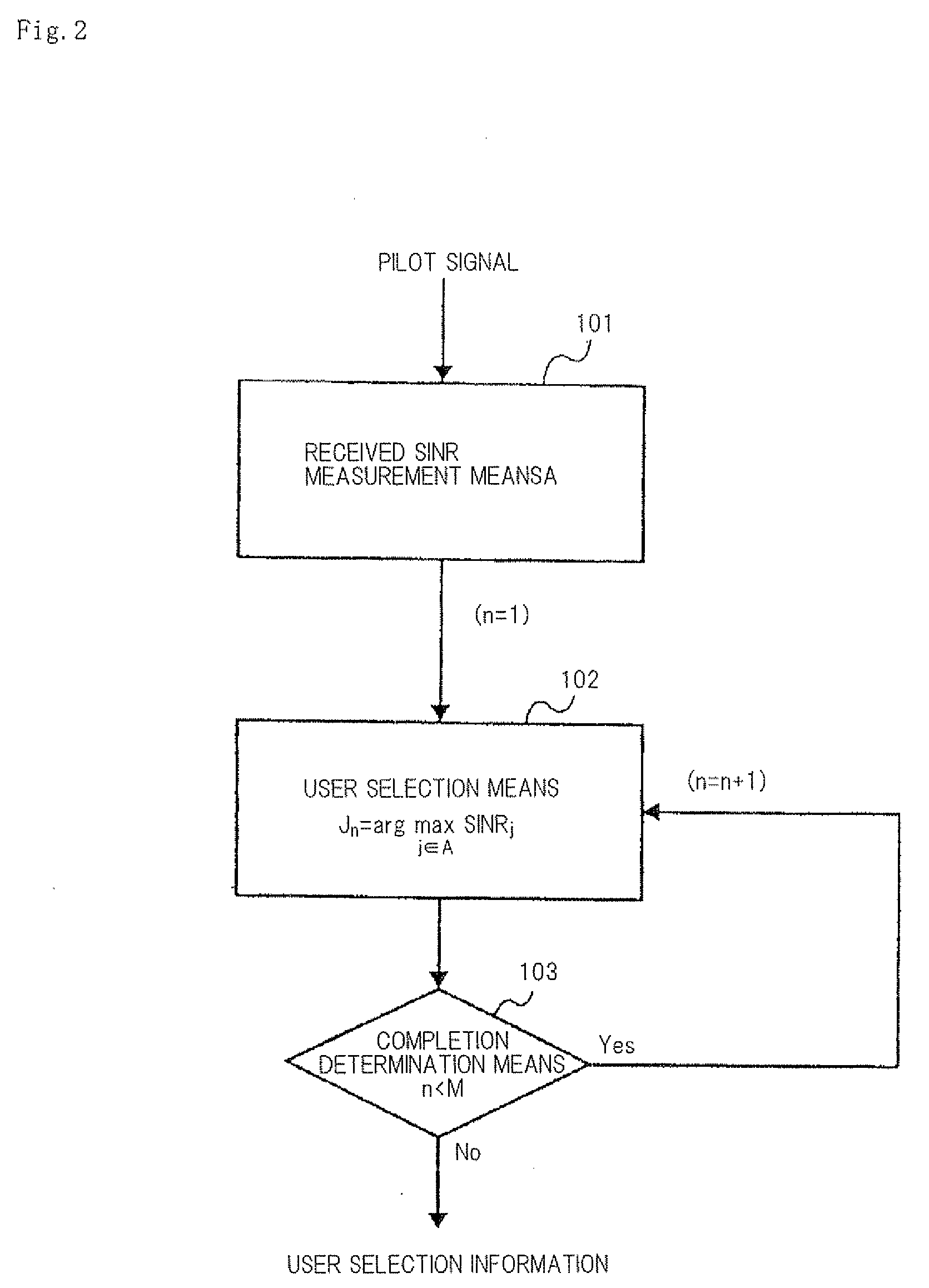

User selection method and user selection device for multiuser MIMO communication

ActiveUS20090010369A1Remarkable effectMultiuser diversity effectSpatial transmit diversityError preventionMimo communicationArtificial intelligence

The present invention aims to provide a user selection method which can provide a large, multiuser diversity effect with a small amount of calculation in multiuser MIMO systems, the method being a user selection method for multiuser MIMO communication, in which an orthogonal coefficient is calculated using a received SINR from a projection channel vector by using GS orthogonalization, and using the orthogonal coefficient, a correction SINR is calculated, and using this correction SINR, user selection is performed, and for a next user selection, the projection channel vector is updated, and the above processes are applied to all users.

Owner:NEC CORP

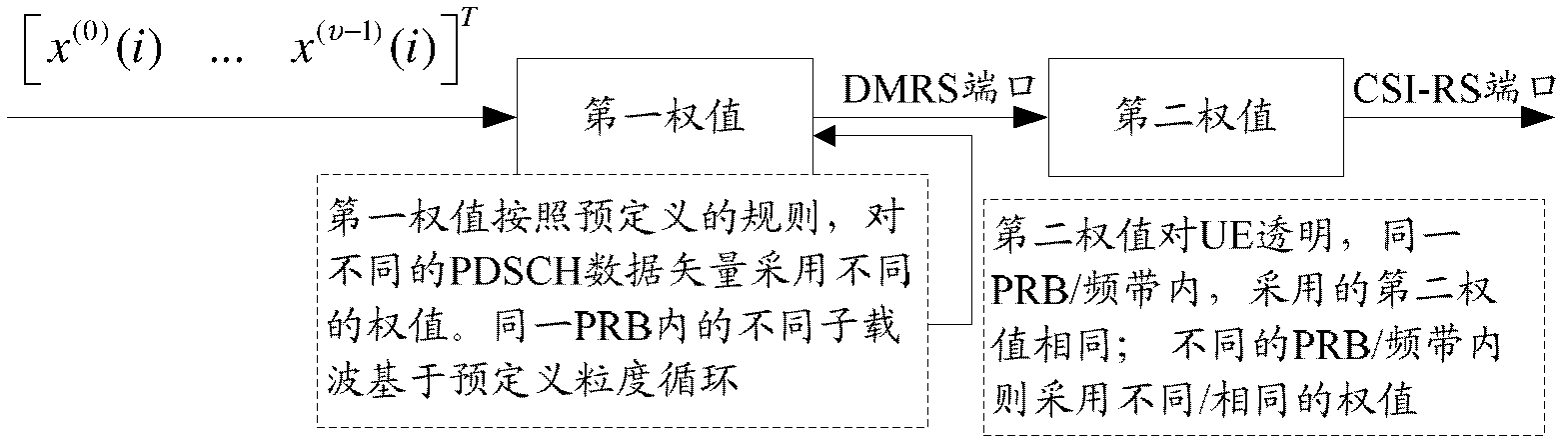

Method and device for open-loop MIMO (multi-input multi-output) transmission on basis of demodulation reference signal

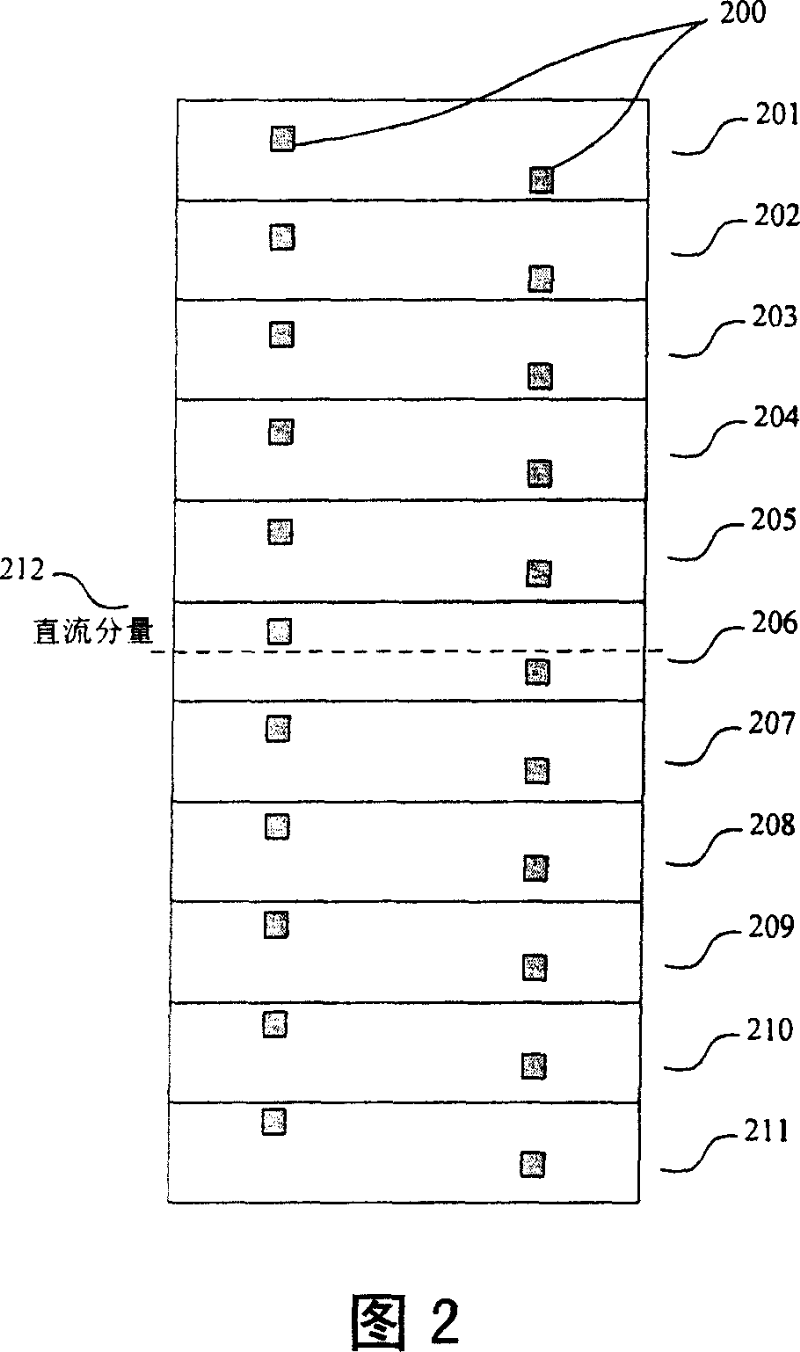

InactiveCN103001742AIncrease diversity gainImprove diversity effectError prevention/detection by diversity receptionMulti inputMimo transmission

The invention discloses a method for open-loop MIMO (multi-input multi-output) transmission on the basis of a demodulation reference signal. The method includes the steps of mapping data to be transmitted in every level to a DMRS (demodulation reference signal) port via a first weight value according to regulations set by both a transmitter and a receiver, mapping DMRS port data to a CSI-RS (channel state information-reference signal) port or a physical antenna via a second weight value, and transmitting. The invention further discloses a device for the open-loop MIMO transmission on the basis of the demodulation reference signal. The limit that a same PRB (physical resource block) must utilize an identical precoding weight value is avoided, and larger diversity gain can be obtained. The characteristics that direction information in a communication system evolves slowly and phase information in different polarizing directions evolves quickly is fully utilized. In addition, on different PRB or frequency bands, different second weight values can be utilized to realize the mapping from the DMRS port to the CSI-RS port, and thereby diversity effect is further improved.

Owner:ZTE CORP

Apparatus for transmitting and receiving signal using orthogonal codes and non-binary values in CDMA/OFDM system and method thereof

ActiveUS7215635B2Improve data transfer rateMaximize transfer efficiencyMultiple modulation transmitter/receiver arrangementsCriteria allocationOrthogonal coordinatesCode division multiple access

An apparatus for transmitting and receiving a signal in Code Division Multiple Access / Orthogonal Frequency Division Multiplexing (CDMA / OFDM) system is provided. The apparatus discriminates user signals with a unique spreading code and the orthogonal codes, increases data transmission rate with the non-binary value without increasing of entire bandwidth used by the users, solves signal interference with interleaver and diversity effect of interleaving and OFDM, and maximizes transmission efficiency by varying modulation schemes depending on channel states.

Owner:UNILOC 2017 LLC

Antenna having a diversity effect

InactiveUS7714789B2Antenna supports/mountingsRadiating elements structural formsElectromagnetic couplingDielectric substrate

Owner:QUANTA COMPUTER INC

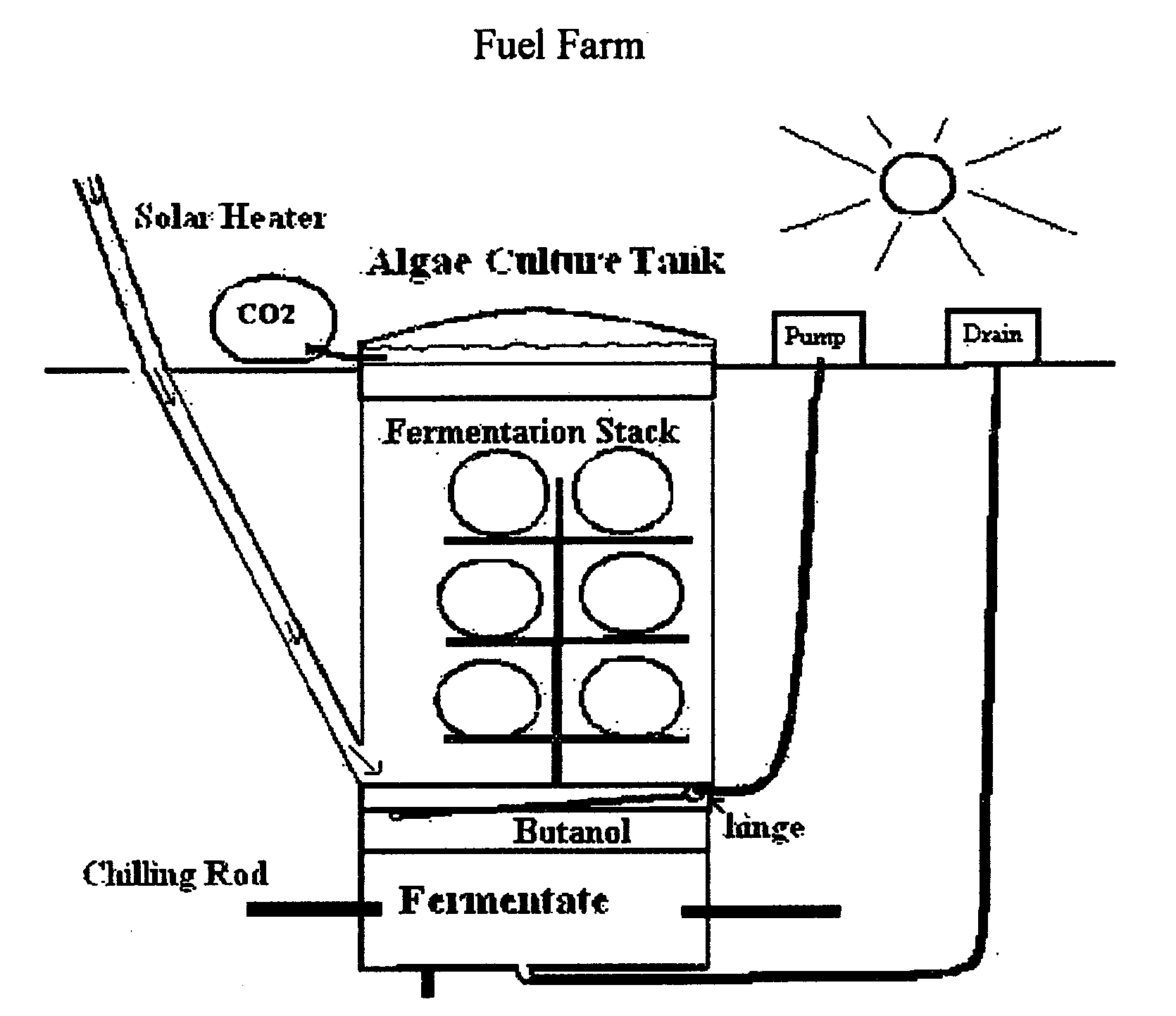

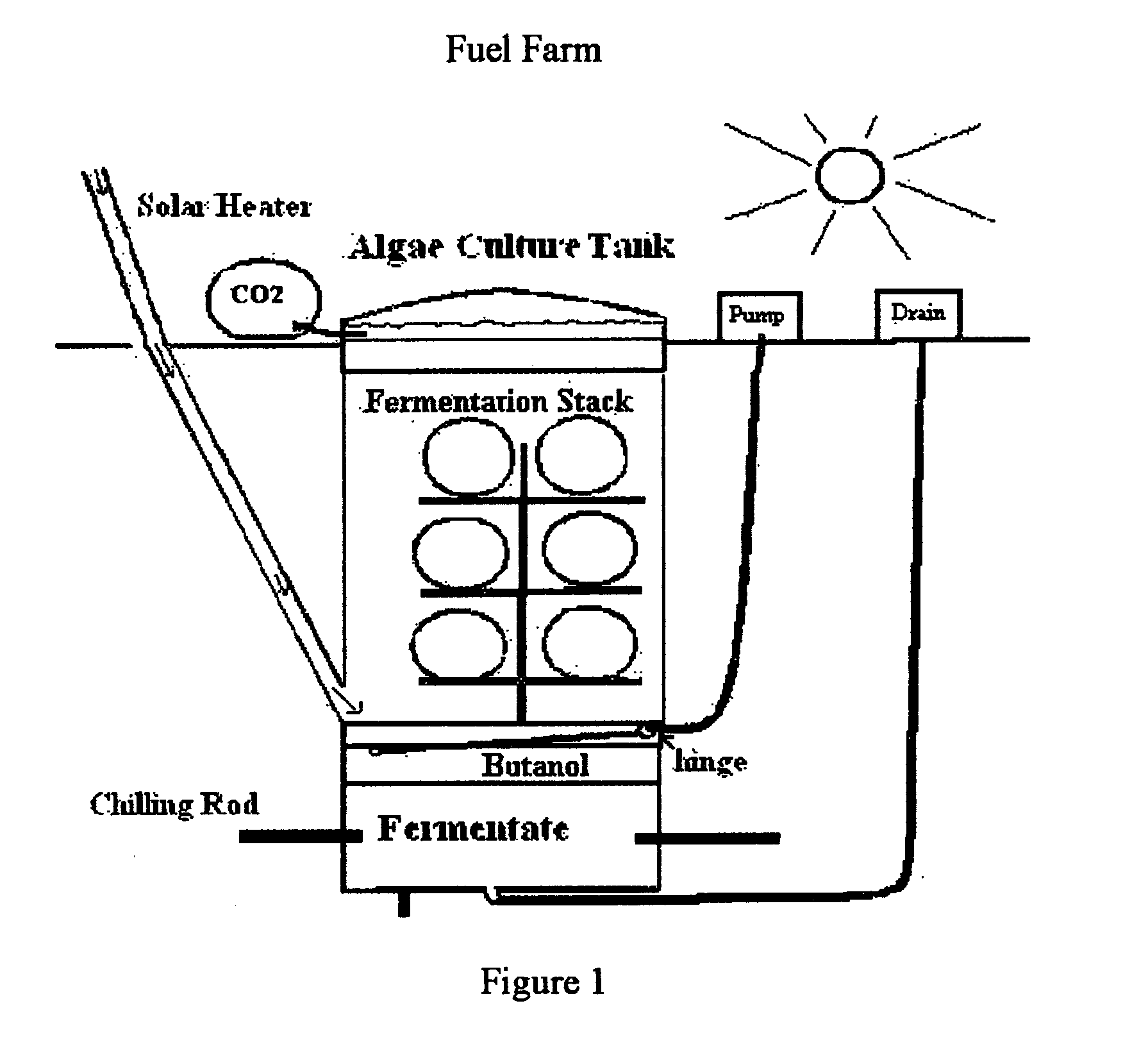

Fuel farm

InactiveUS20090317901A1Improve usabilityBioreactor/fermenter combinationsBiological substance pretreatmentsCanyonOrganism

Three billion years ago single celled plants used sunlight and CO2 to make molecules in which much of the energy was stored that we use today. The first algae cells were very much like today's algae and are still the most efficient converters of sunlight to stored energy. Simple equipment and materials in air and earth are all we need to make a liquid, gasoline-replacing fuel with aqueous culturing and fermenting tanks. One such facility, 14 miles square, on land or floating in a bay could make enough butanol to supply the motor fuel we need. But, it is better to divide production into several thousand Fuel Farms™” to reduce transportation and increase national security.The prototype small business fuel farm uses two acres of land for growing trays, fermentation and storage tanks. A box canyon of land not suitable for agriculture or residential use, hence cheap, but with a a well producing six gallons of water per minute of any quality is all we need. Sewage district effluent with nitrogenous wastes is ideal. Commonly occurring biological entities are the active producers of all the liquid energy we need. Fuel Farms™ can be attractive, safe facilities owned by small entrepreneurs making a fuel free market. Algae and bacteria cultures are available, but better found locally to emploit adaptation and the “diversity effect.” Nonetheless, we should further refine the cultures in a continuing program.Every generation of algae and bacteria makes new variations better able to deal with conditions and make more of what we want. Isolating superior strains is a simple, but never-ending process that is part of the Fuel Farm™ system. As well, the end-product is a wet mixture that cannot be recycled for algae culture as included butanol is poisonous to simple, green plants. This product may find other uses before we have to deal with it as garbage. It may be used to treat wood, protecting it from algae growth. It could be useful in clearing algae bound lakes, a problem yet unsolved.

Owner:VANCE ADRIAN GEORGE

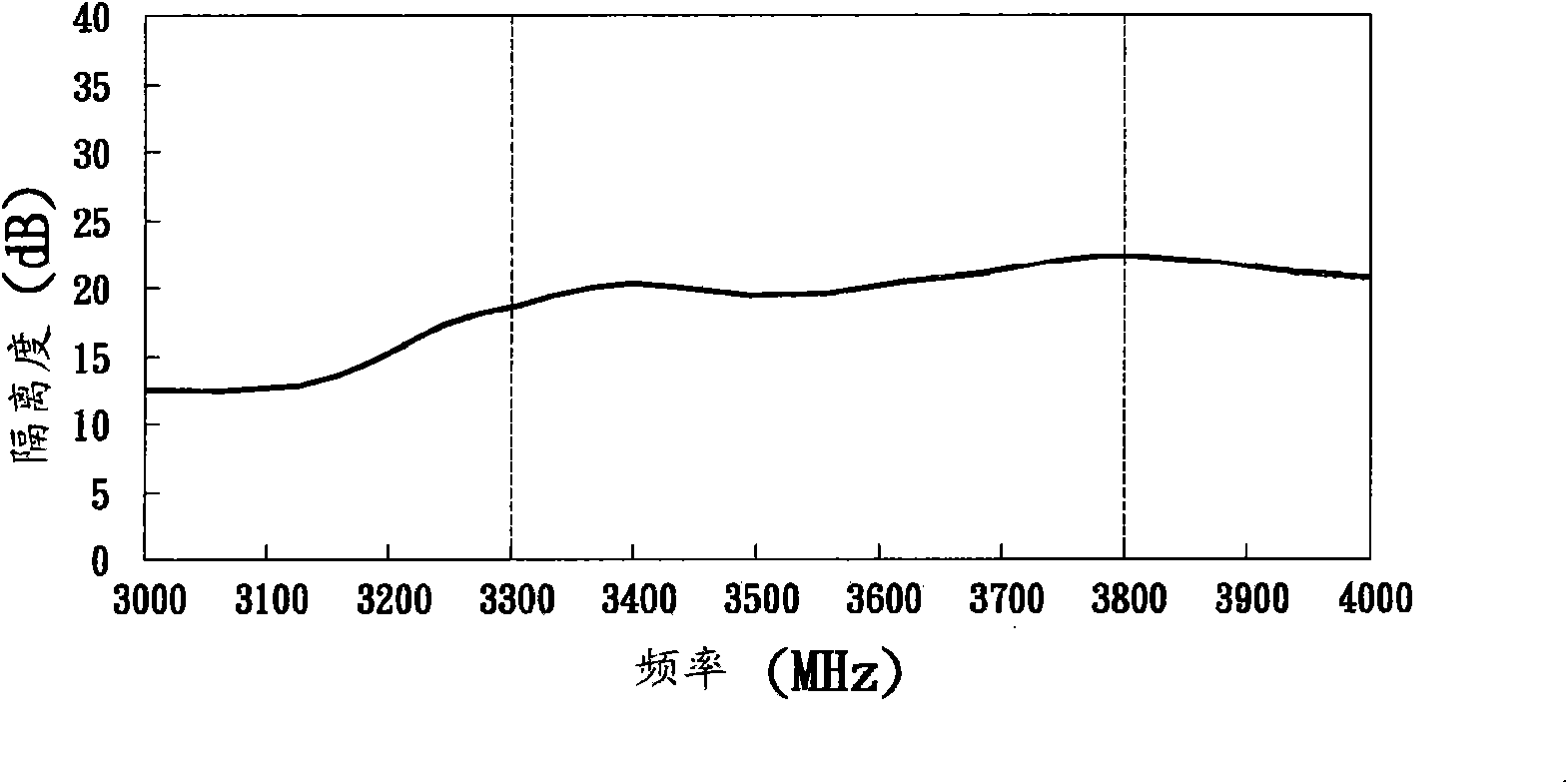

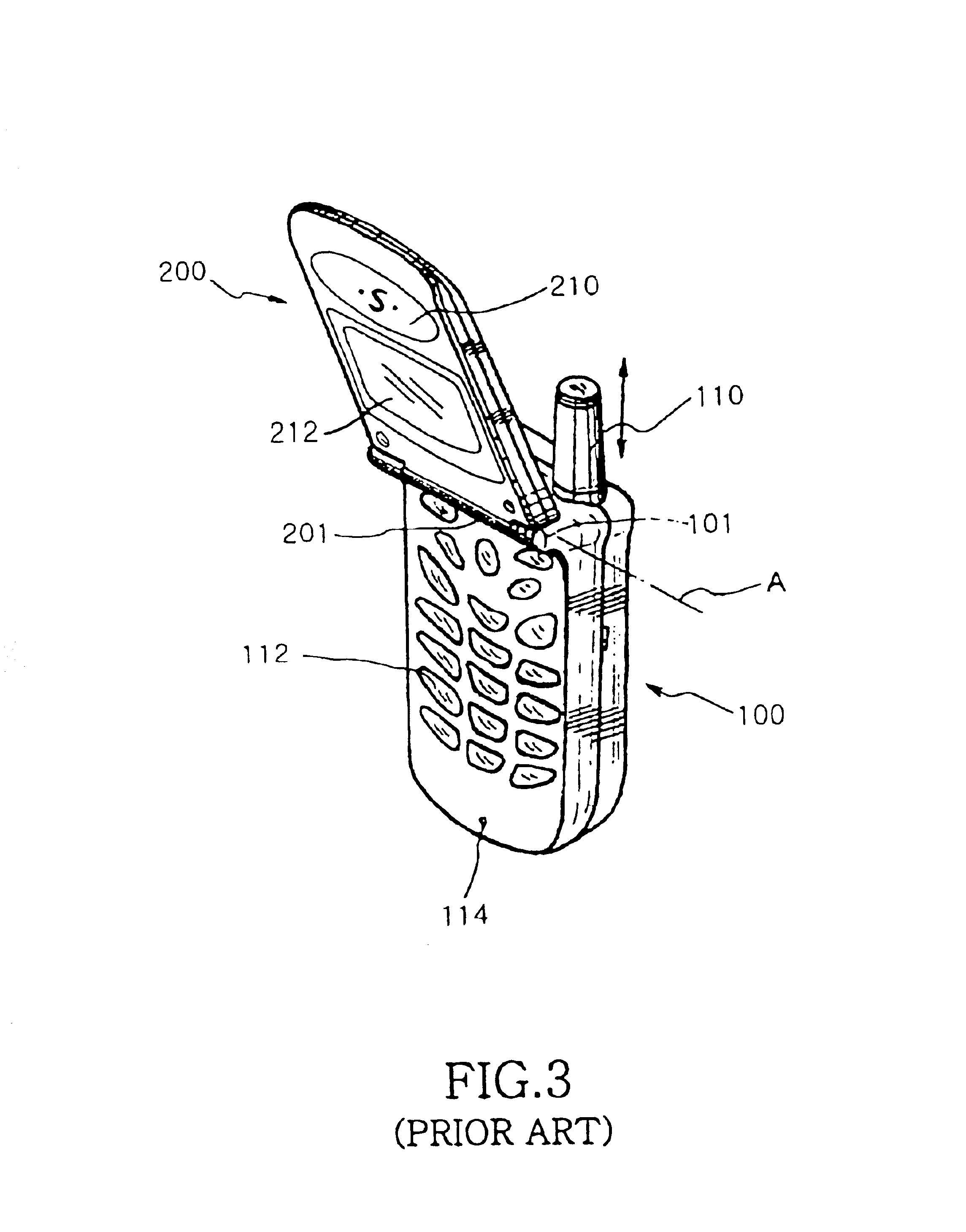

Antenna apparatus for folder type mobile phone

InactiveUS6897825B2Easy to carryAvoid damageSpatial transmit diversityAntenna supports/mountingsEngineeringMobile phone

An antenna apparatus for a folder type mobile phone, wherein a first antenna is installed in a main body of the folder type mobile phone, and a second antenna is installed in the folder. The folder type mobile phone installs a main antenna apparatus in the main body, and an antenna apparatus for maximizing the diversity effect in the folder. As a result, it becomes more convenient to carry the folder type mobile phone based on the diversity mode, while securing a broader separation distance between two antennas at the same time.

Owner:SAMSUNG ELECTRONICS CO LTD

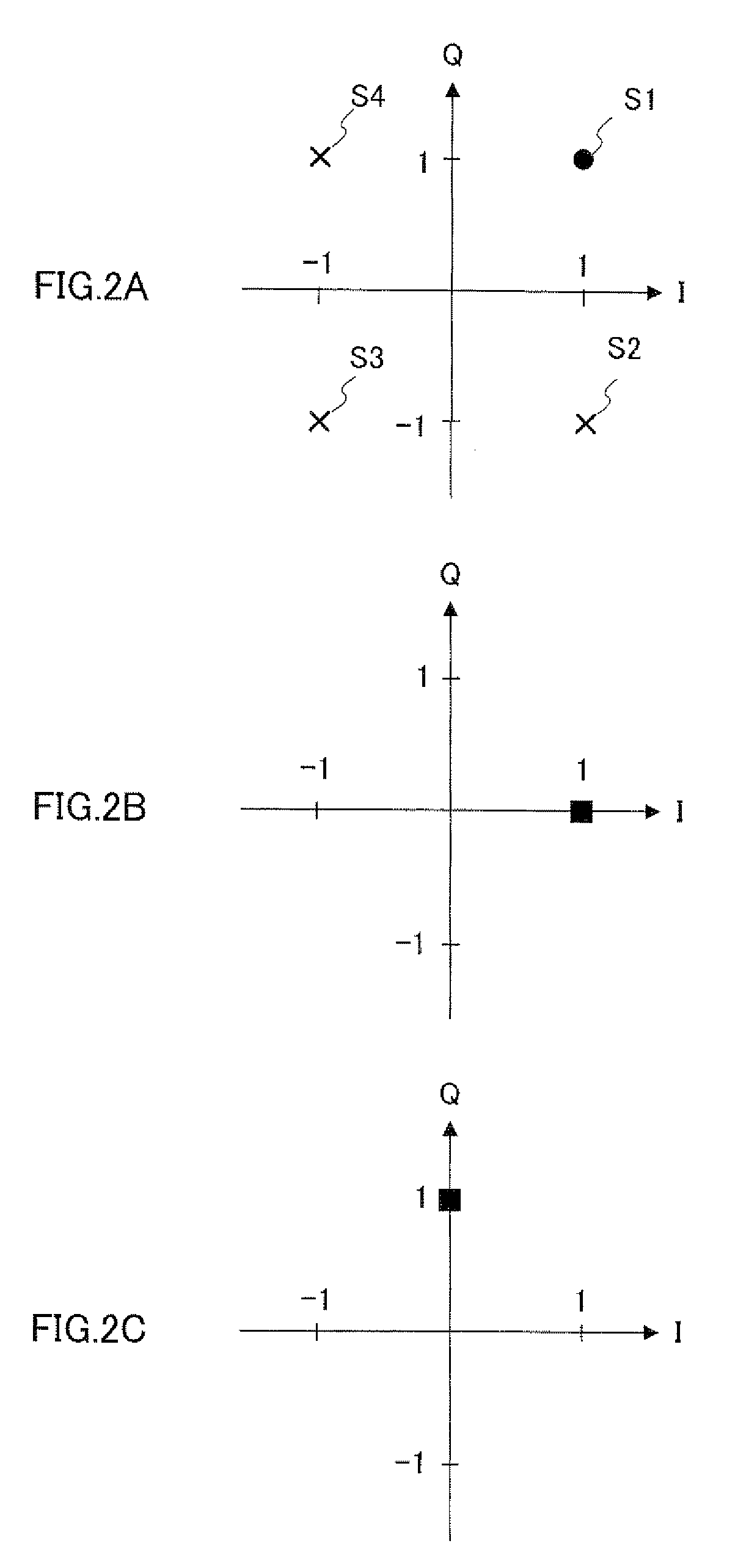

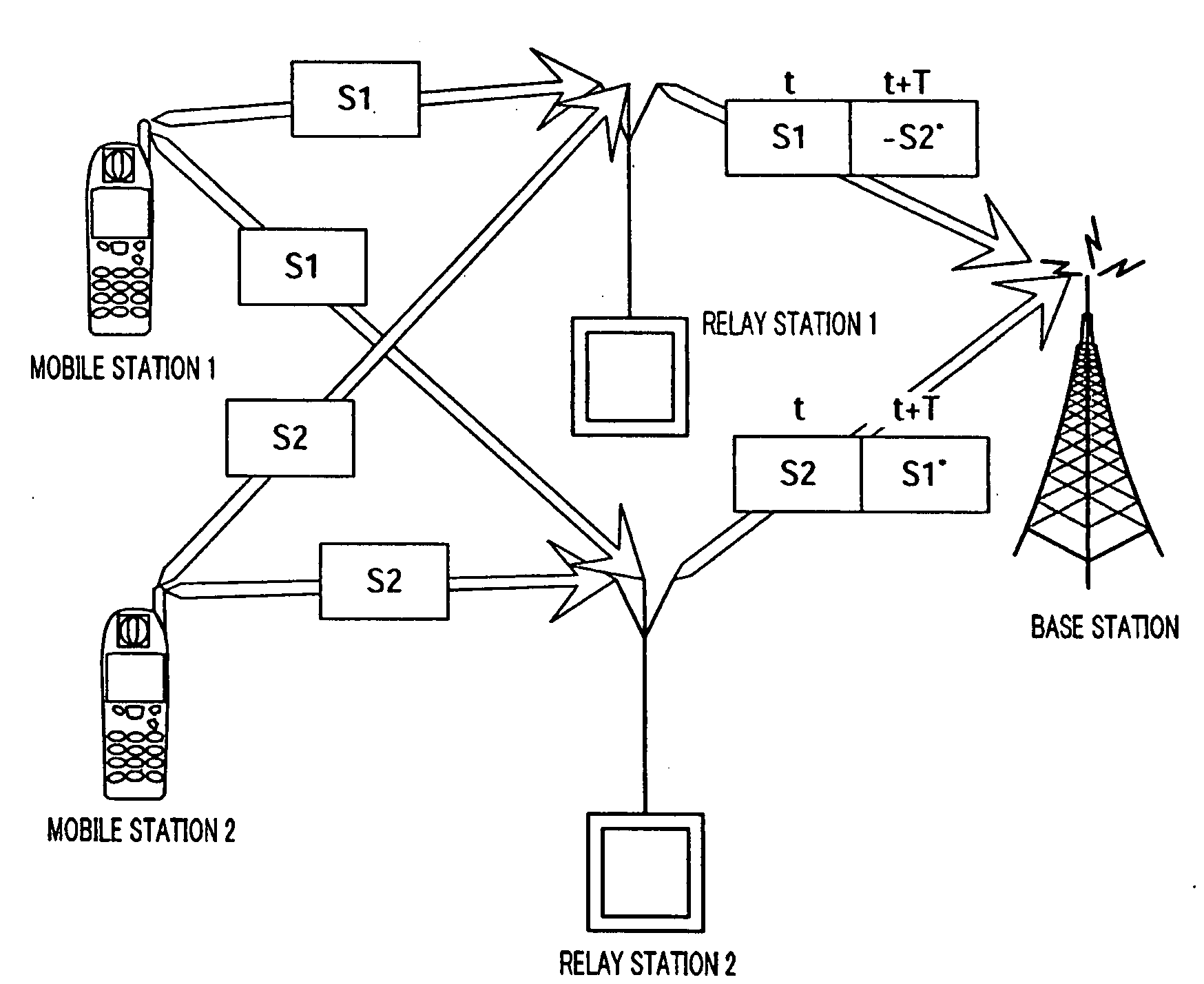

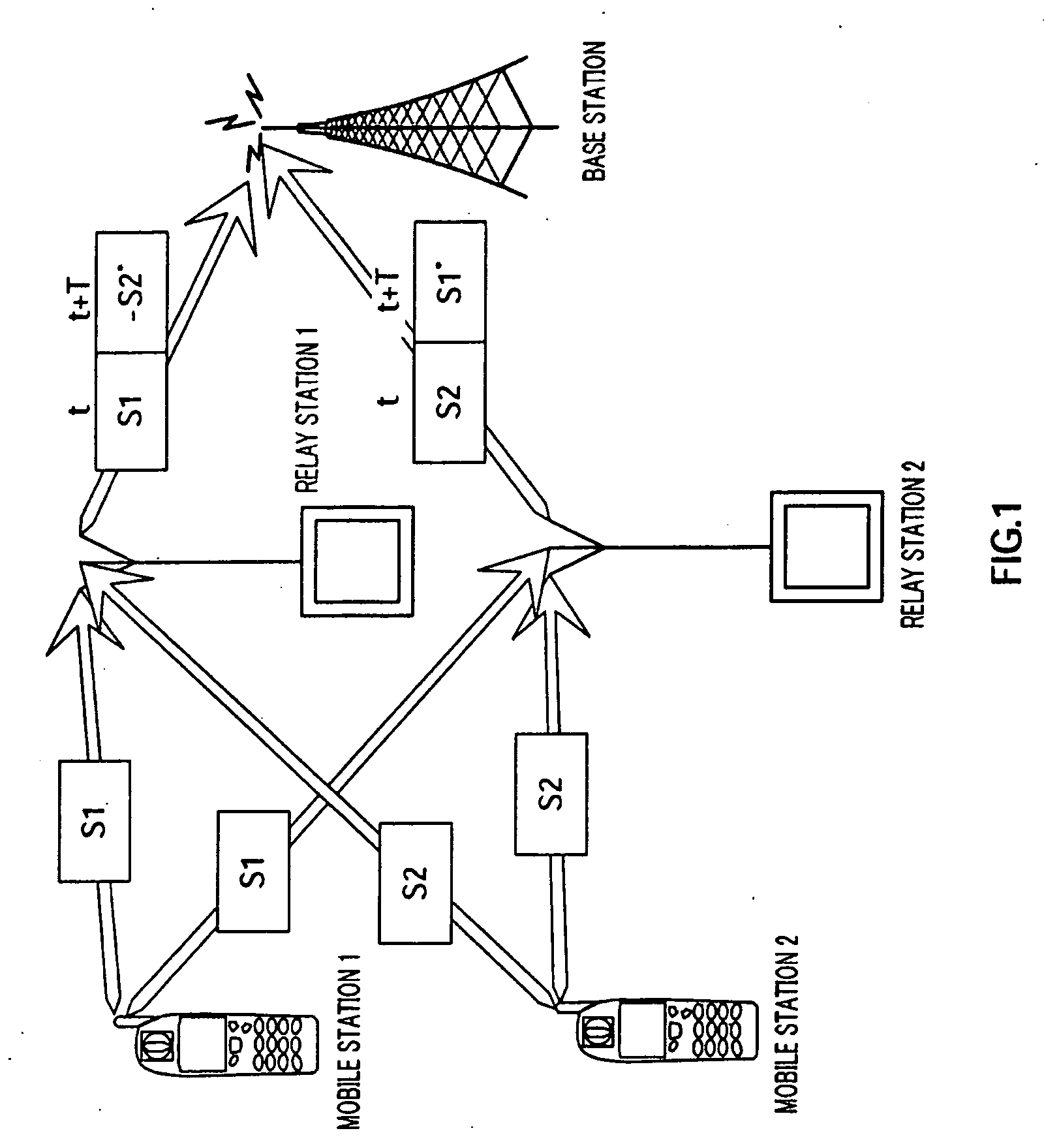

Radio communication apparatus and radio communication method

ActiveUS20090130975A1Site diversityFrequency-division multiplex detailsCommunications systemEngineering

Provided is a mobile communication system capable of obtaining a diversity effect even when a signal received by a relay station has an error in a corporate relay to which time space encoding is applied. In this mobile communication system, when S1 has no error and S2 has an error, a relay station (1) does not perform relay transmission at time t (Null) and relay-transmits S1* to a base station at time t+T. That is, in this case, the relay station (1) relay-transmits at time t+T only S1 to be transmitted at time t when no error is contained in either S1 or S2. Moreover, when S1 has an error and S2 has no error, the relay station (1) relay-transmits S2 at time t and does not perform relay transmission at time t+T (Null). That is, in this case, the relay station (1) relay-transmits only S2 to be transmitted at time t+T at time t if no error is contained in either S1 or S2.

Owner:PANASONIC INTELLECTUAL PROPERTY CORP OF AMERICA

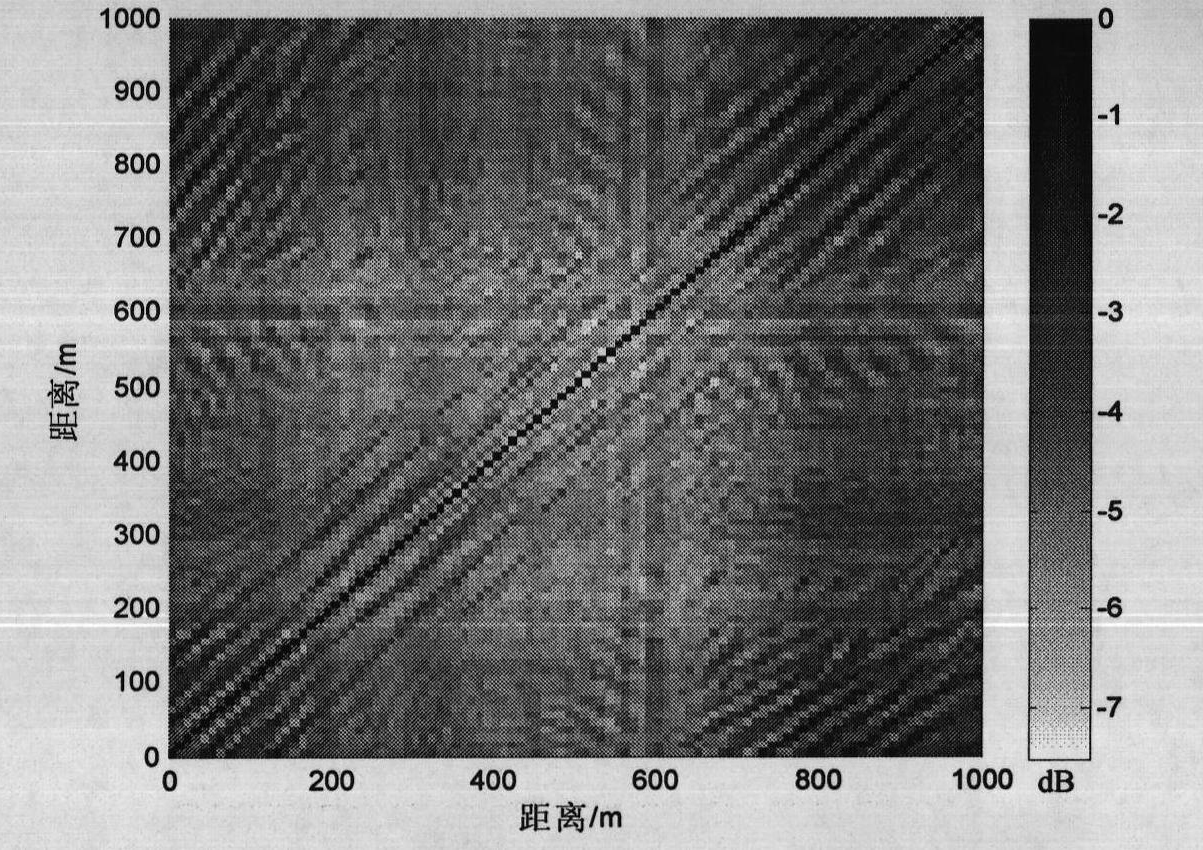

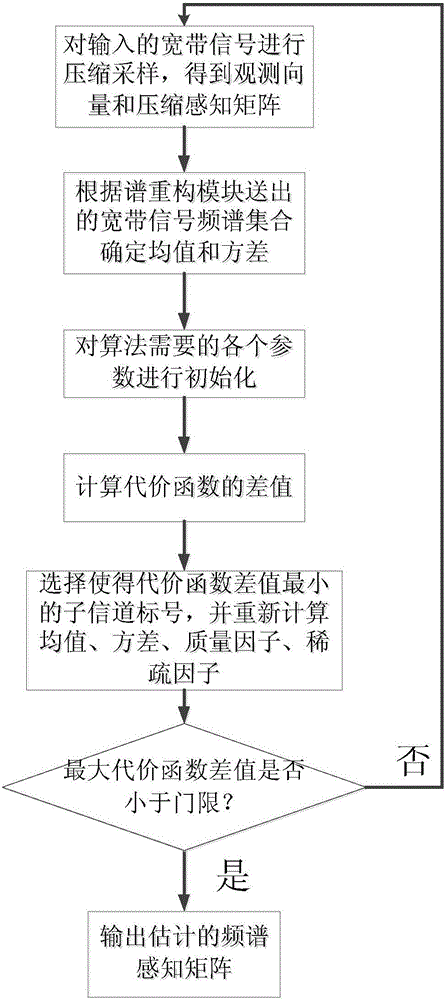

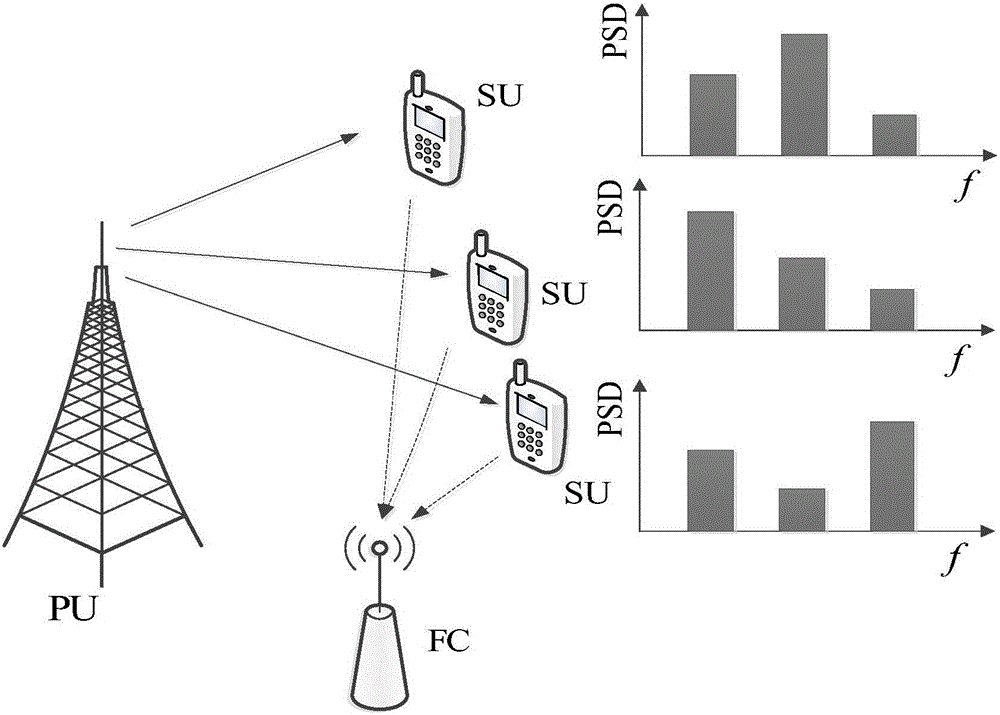

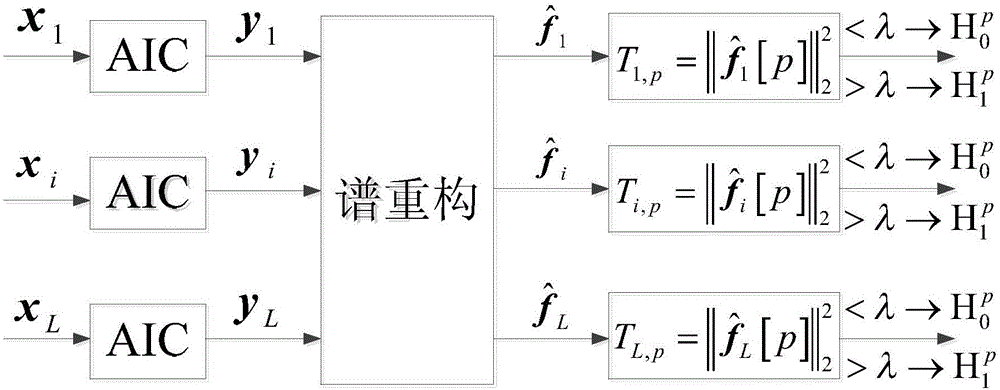

Broadband collaboration spectrum sensing method

ActiveCN105119670AImprove detection rateIncrease the normalized mean square errorTransmission monitoringFrequency spectrumNormalized mean square error

The invention discloses a broadband collaboration spectrum sensing method, which utilizes the block sparse structure of the broadband signal, and utilizes fast marginal likelihood function maximization to perform fast parameter estimation, so as to improve the detection probability, reduce the normalized mean squared error and decrease the detection time consumption of the conventional algorithm. Moreover, a frequency diversity effect is achieved among the nodes of the multi-node wideband cooperative spectrum sensing algorithm, so as to overcome the disadvantages of low detection accuracy and poor real-time performance caused by single node detection.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com