Patents

Literature

74714 results about "Sewage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sewage (or domestic wastewater or municipal wastewater) is a type of wastewater that is produced by a community of people. It is characterized by volume or rate of flow, physical condition, chemical and toxic constituents, and its bacteriologic status (which organisms it contains and in what quantities). It consists mostly of greywater (from sinks, tubs, showers, dishwashers, and clothes washers), blackwater (the water used to flush toilets, combined with the human waste that it flushes away); soaps and detergents; and toilet paper (less so in regions where bidets are widely used instead of paper).

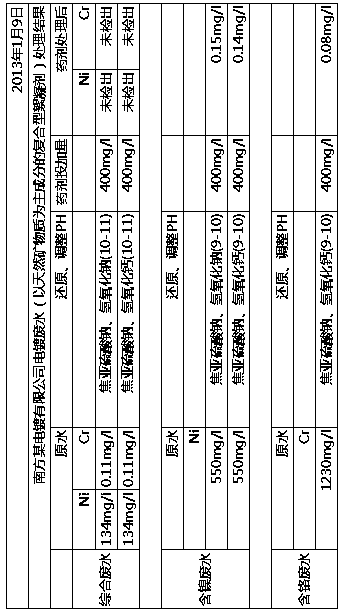

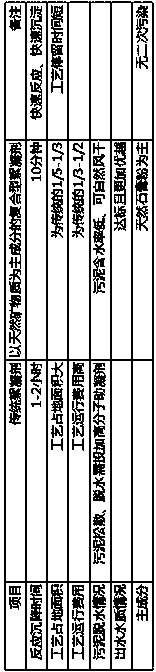

Compound flocculant taking natural minerals as main components

InactiveCN104229957AEfficient removalApplicable to a wide range of PHWater resource protectionWater/sewage treatment by flocculation/precipitationDry weightNatural mineral

The invention discloses a compound flocculant taking natural minerals as main components. The compound flocculant is mainly prepared from the following components by weight percent: 60%-85% of natural minerals, 8%-38% traditional inorganic flocculant and 3%-10% of organic polymer flocculant. According to the invention, key points are as follows: in the compound flocculant taking natural minerals as main components, the weight of the natural minerals, the inorganic flocculant and the organic polymer flocculant is dry weight; and the compound flocculant is implemented to purification of civil engineering wastewater, natural water, industrial wastewater, oily wastewater, fluoride wastewater, food processing wastewater, auto parts processing wastewater, colored wastewater, clean wastewater, semiconductor processing wastewater, restaurant waste water, mine water, slaughter wastewater, grinding wastewater, sewage effluent and the like.

Owner:张家领

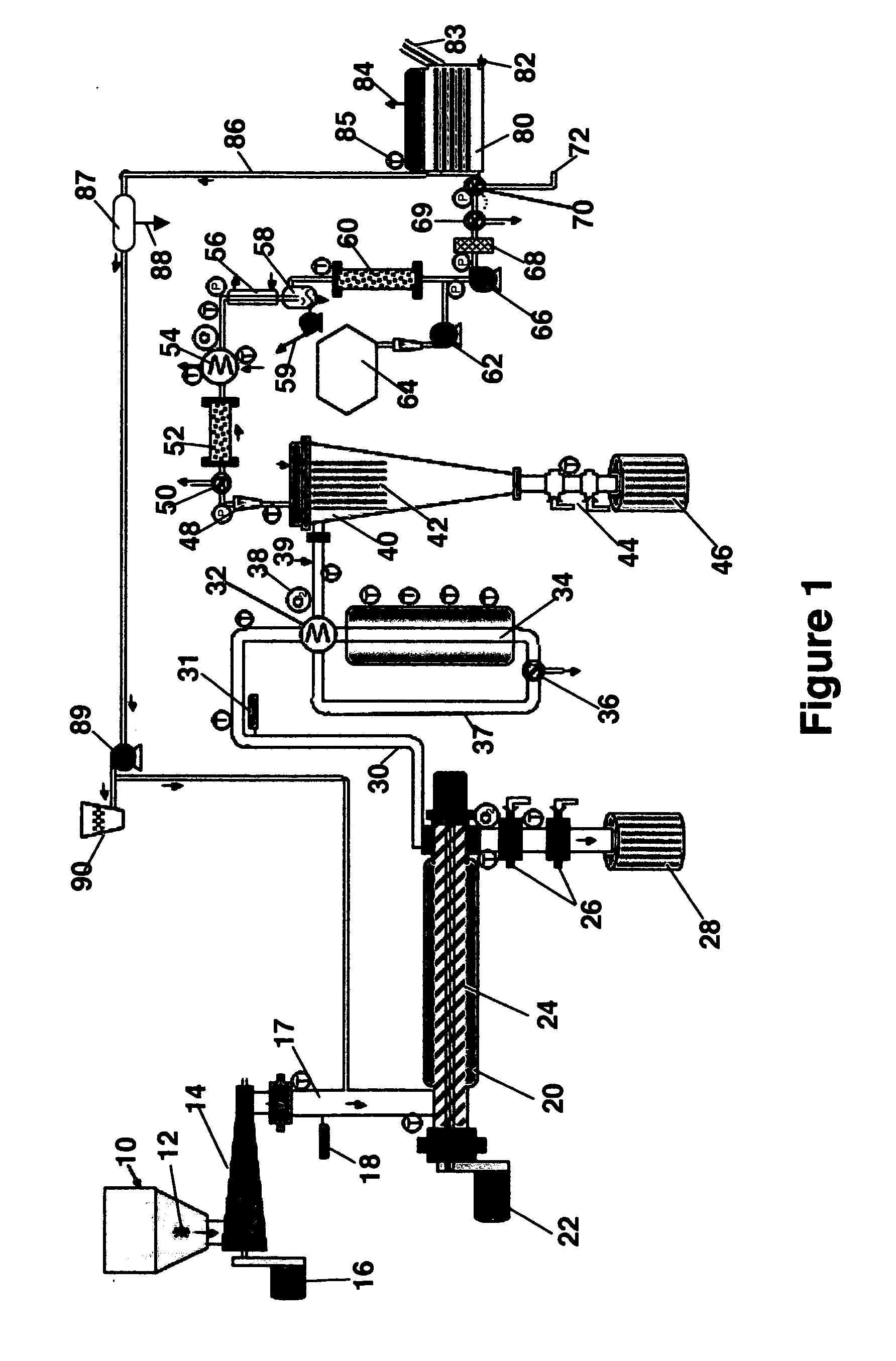

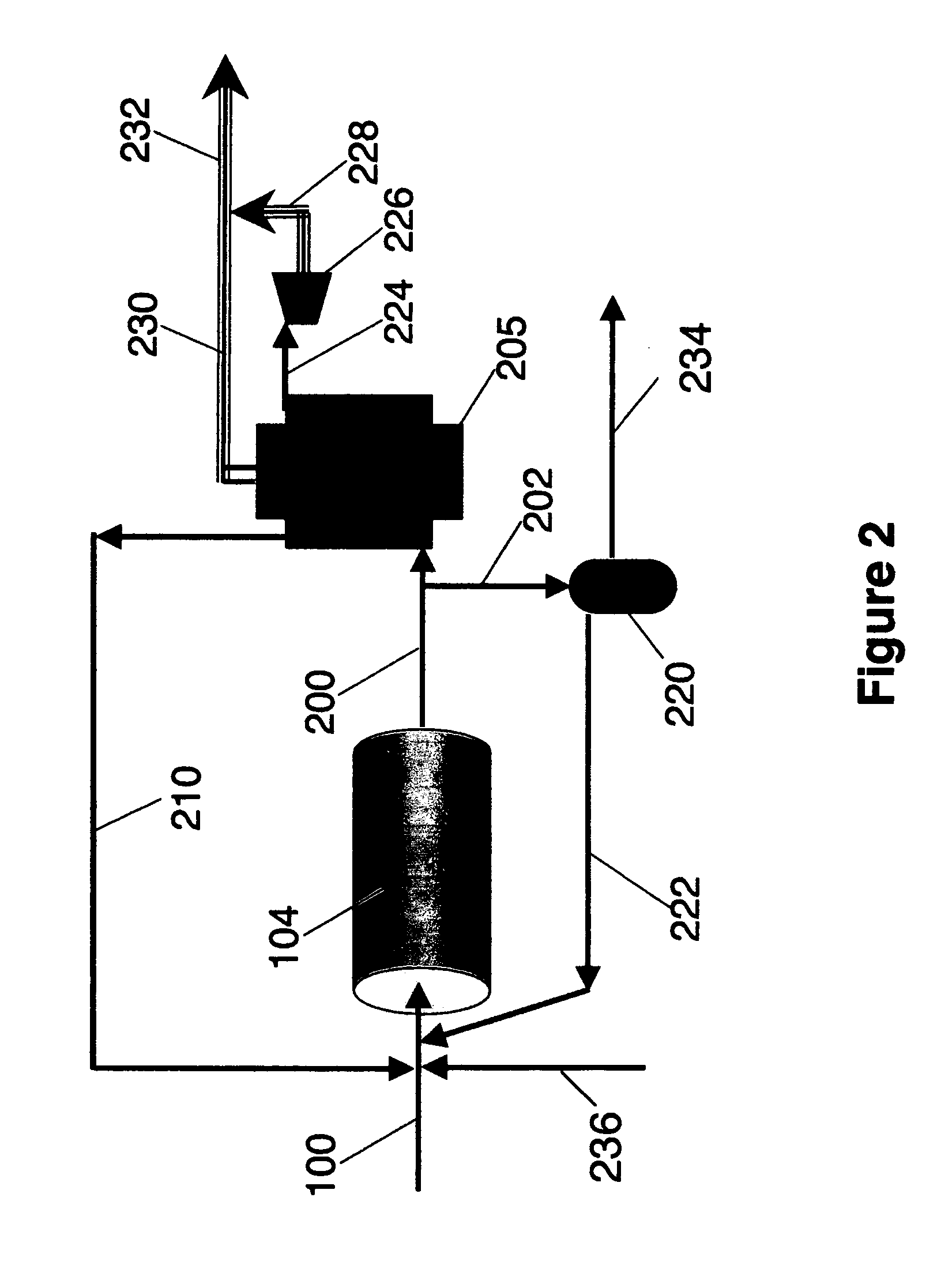

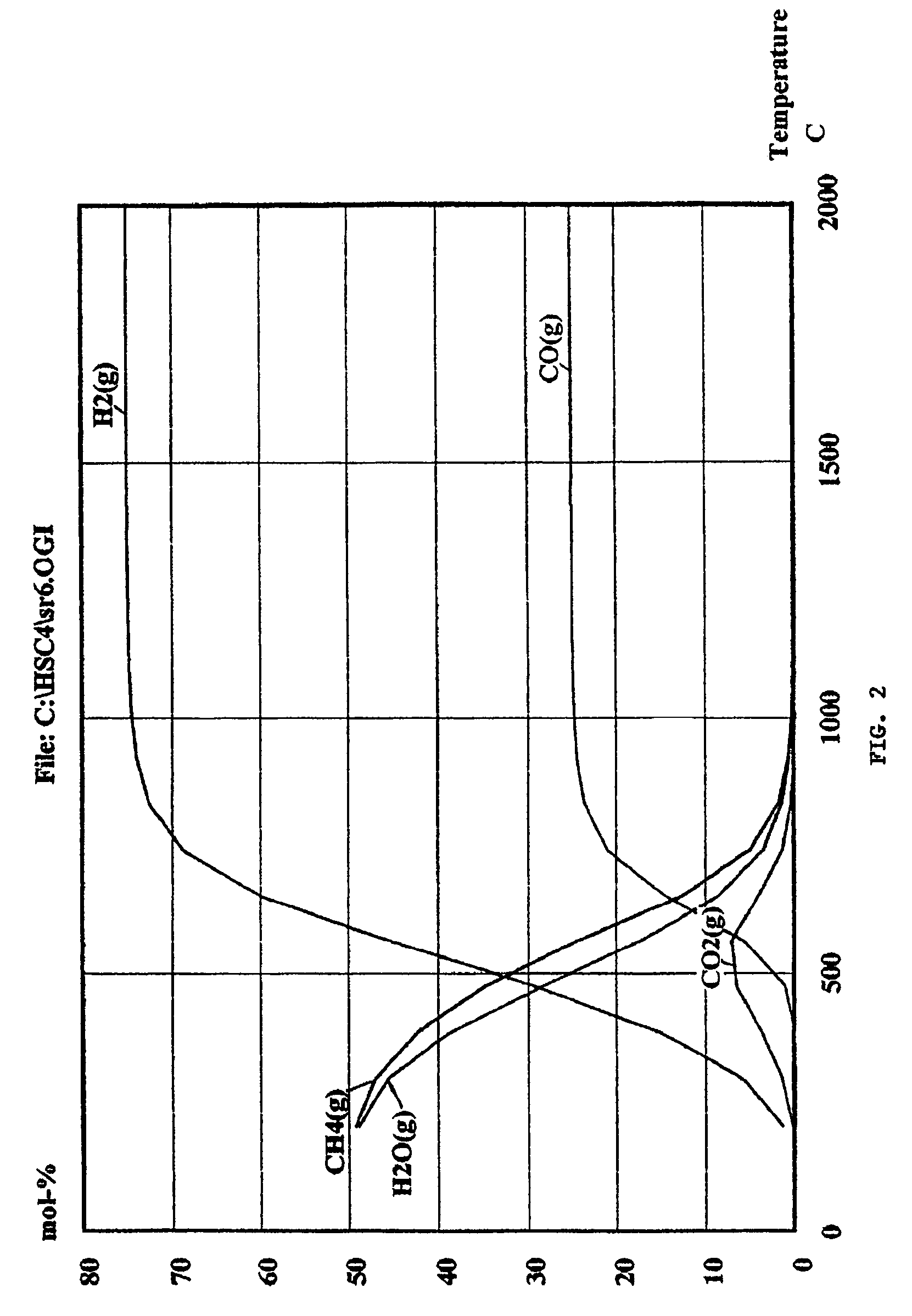

Process and system for converting carbonaceous feedstocks into energy without greenhouse gas emissions

ActiveUS20070099038A1High hydrogen contentFuel cells groupingHydrogen separation using solid contactPetroleum cokePetroleum

The process of the invention converts carbonaceous feedstock such as coal, hydrocarbon oil, natural gas, petroleum coke, oil shale, carbonaceous-containing waste oil, carbonaceous-containing medical waste, carbonaceous-containing military waste, carbonaceous-containing industrial waste, carbonaceous-containing medical waste, carbonaceous-containing sewage sludge and municipal solid waste, carbonaceous-containing agricultural waste, carbonaceous-containing biomass, biological and biochemical waste, and mixtures thereof into electrical energy without the production of unwanted greenhouse emissions. The process uses a steam / CO2 reformer operating in the exit range of at least 700° to about 1600° C. (1300-2900°0 F.) to convert the carbonaceous feedstock and a greenhouse gas stream into a synthesis gas comprising mostly carbon monoxide and hydrogen that contains poisons and the compounds that poison fuel cells. The syngas is sent to an interface zone to remove these poisons and other fouling compounds that are electrochemically oxidized in an electricity-producing fuel cell into an exit gas comprising carbon dioxide and water.

Owner:RAVEN SR INC

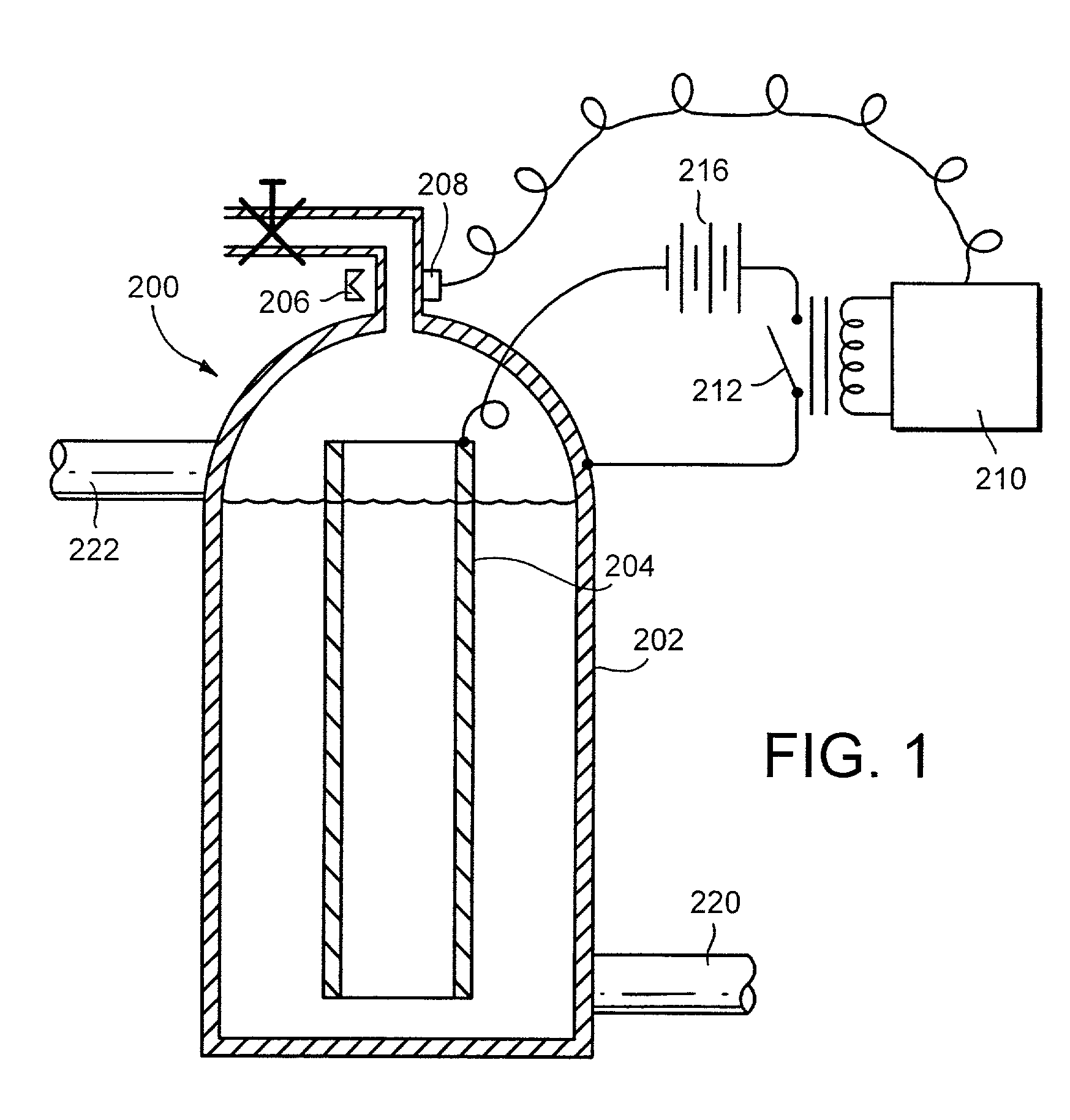

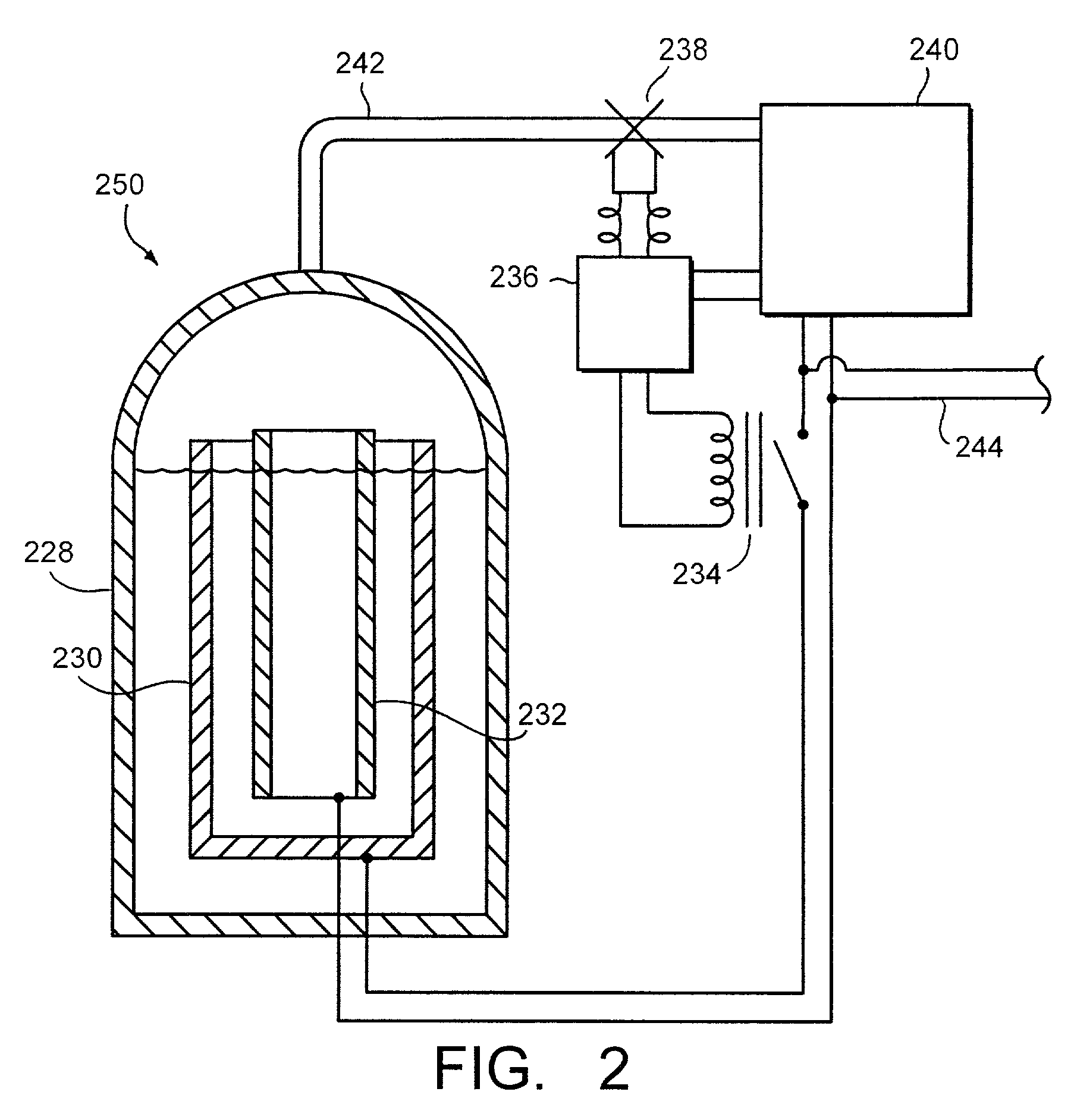

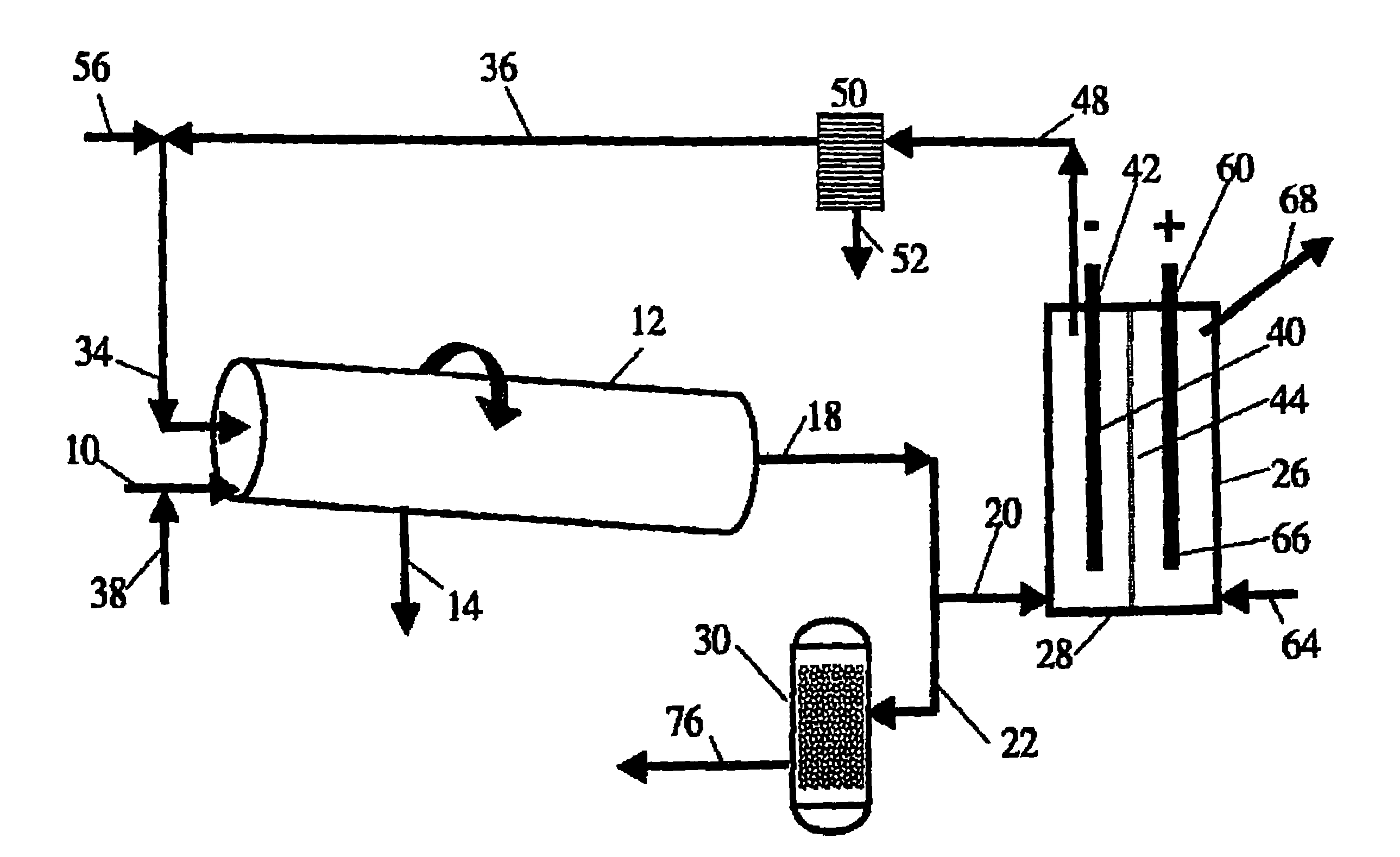

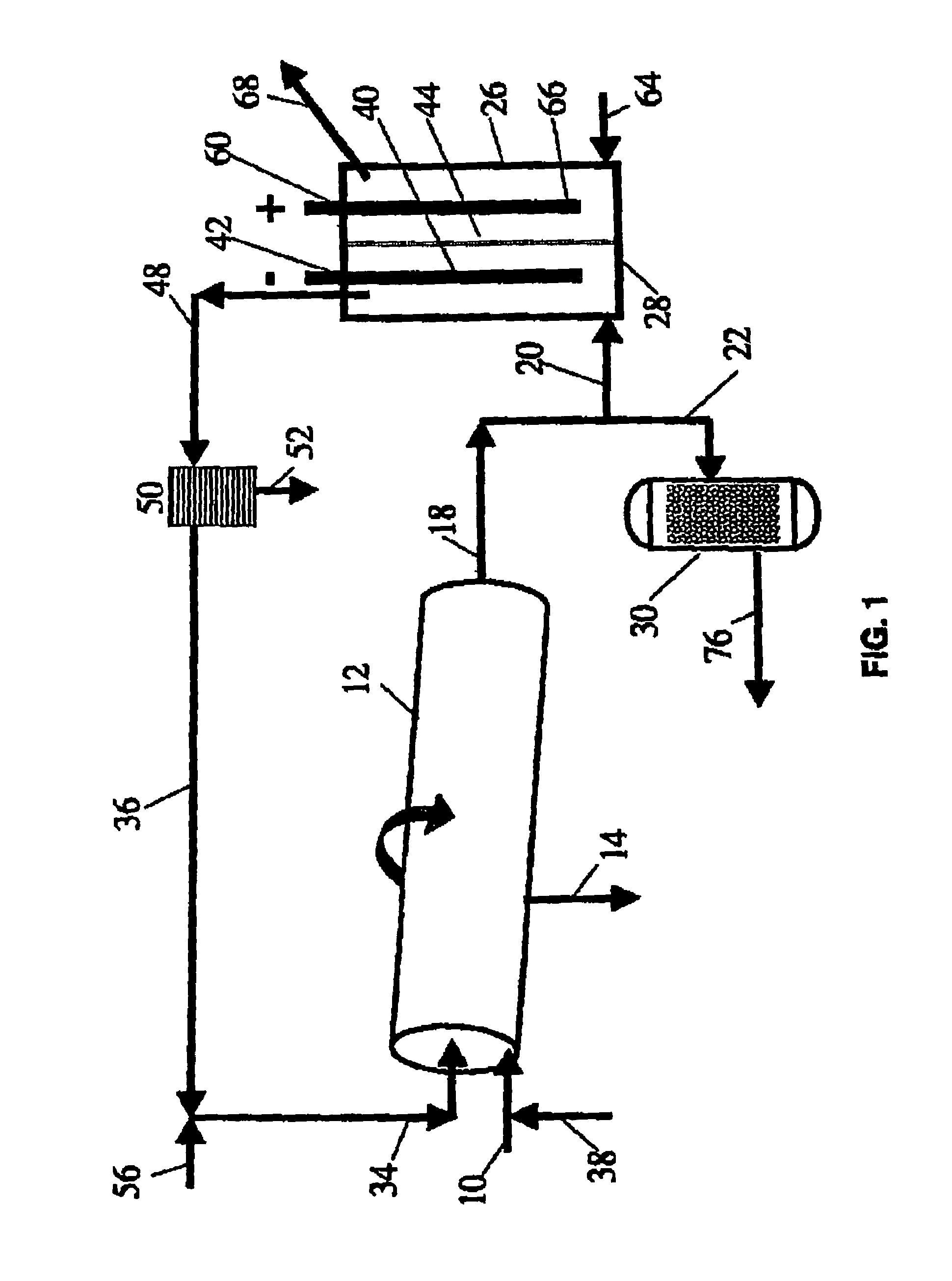

Method and apparatus for sustainable energy and materials

A process for the production of hydrogen from anaerobically decomposed organic materials by applying an electric potential to the anaerobically decomposed organic materials, including landfill materials and sewage, to form hydrogen, and for decreasing the time required to treat these anaerobically decomposed organic materials. The organic materials decompose to volatile acids such as acetic acid, which may be hydrolyzed by electric current to form hydrogen. The process may be continuously run in sewage digestion tanks with the continuous feed of sewage, at landfill sites, or at any site having a supply of anaerobically decomposed or decomposable organic materials.

Owner:MCALISTER TECH LLC +1

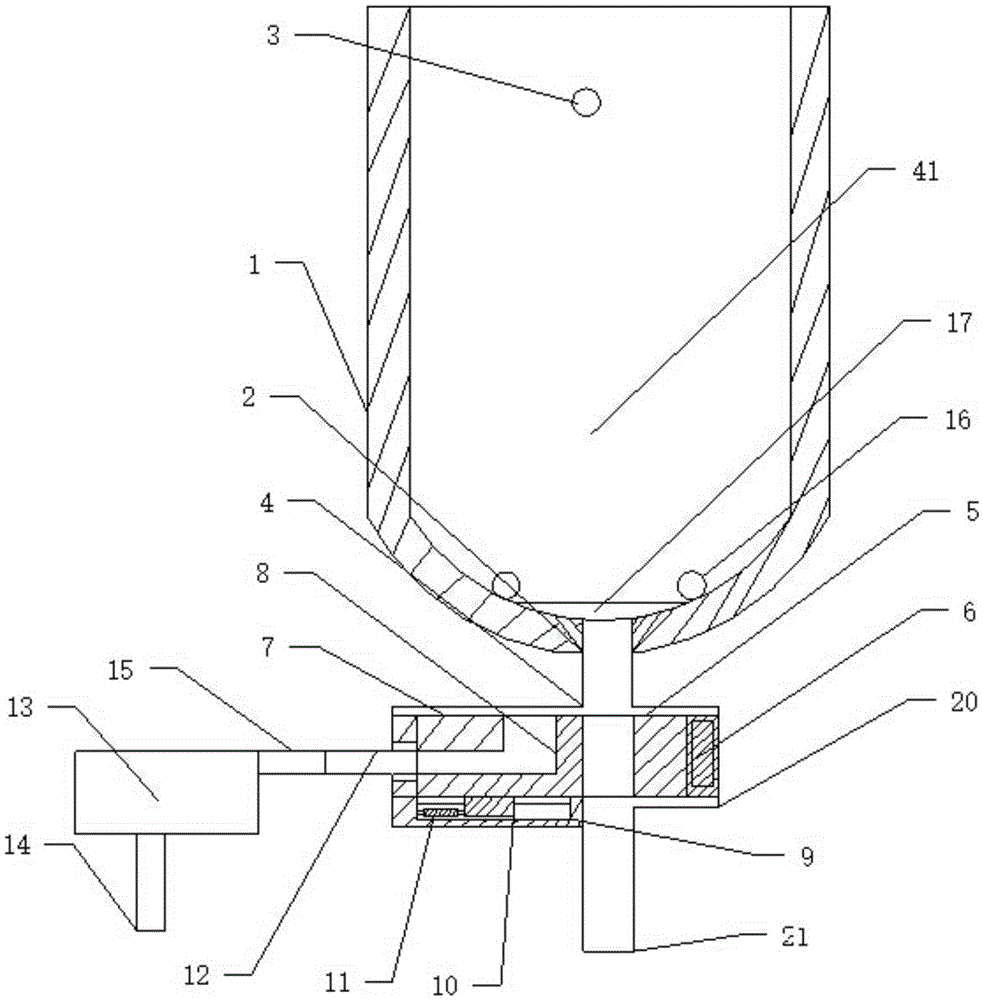

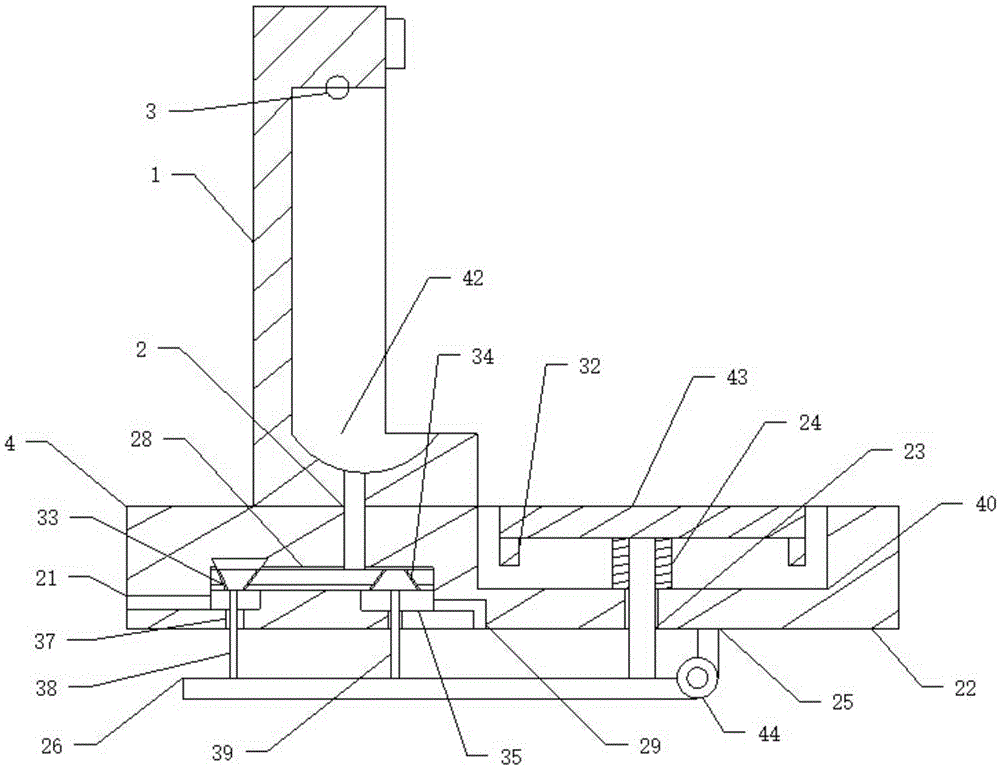

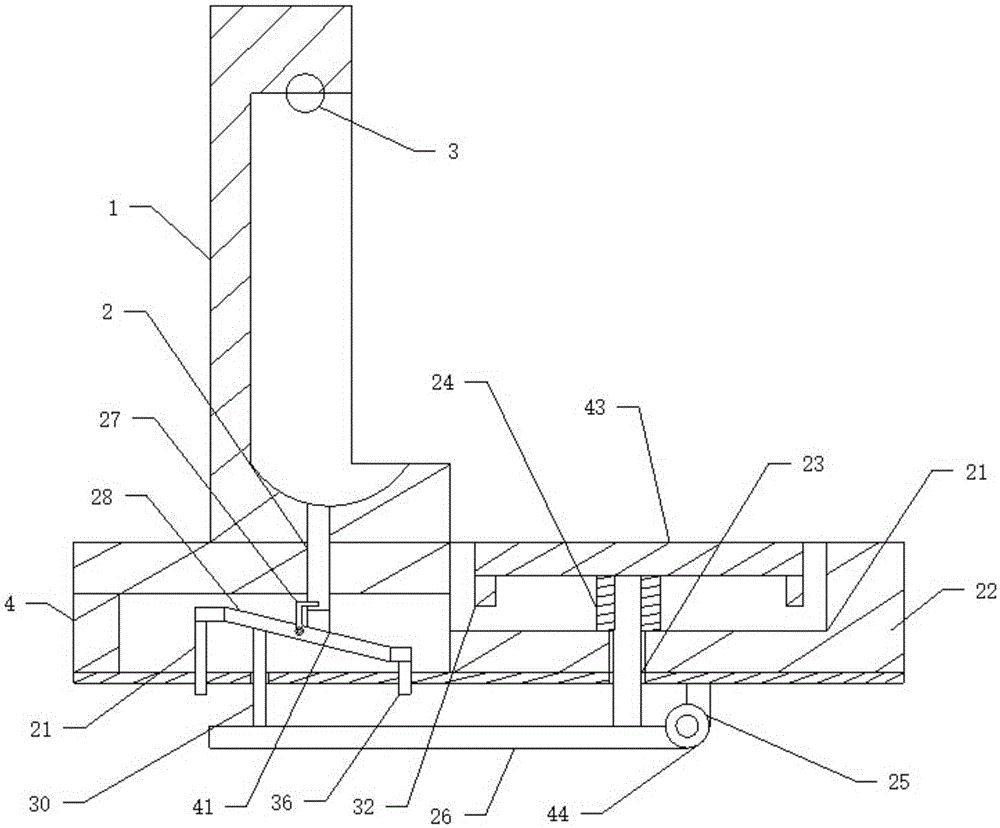

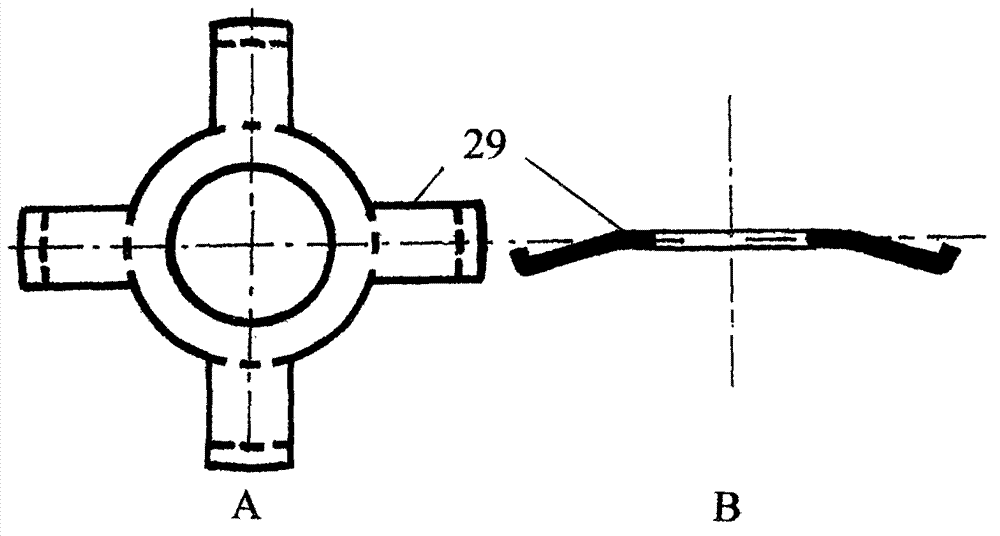

Toilet with function of urine separation

InactiveCN105484336AEasy to separateGuaranteed separation effectUrinalsLavatory sanitorySewageEngineering

The invention discloses a toilet with a function of urine separation. The toilet comprises a toilet body and a urinal. A water pipe for flushing the urinal is arranged at the top of the toile body, a delay infrared induction sensor for controlling the water pipe to close is arranged at the top of the urinal, and the bottom of the urinal is provided with a filter screen. The toilet is characterized in that a sewage pipe a corresponding to the filter screen and a urine separation device connected with the sewage pipe are connected to the bottom of the urinal, a water drain pipe is connected to the bottom of the urine separation device, and a sewage hose a is connected to one end of the urine separation device. The toilet with the function of urine separation is simple in structure and convenient to use, complete urine separation can be realized, and accordingly the problem of incompleteness in urine separation is avoided.

Owner:刁淑红 +1

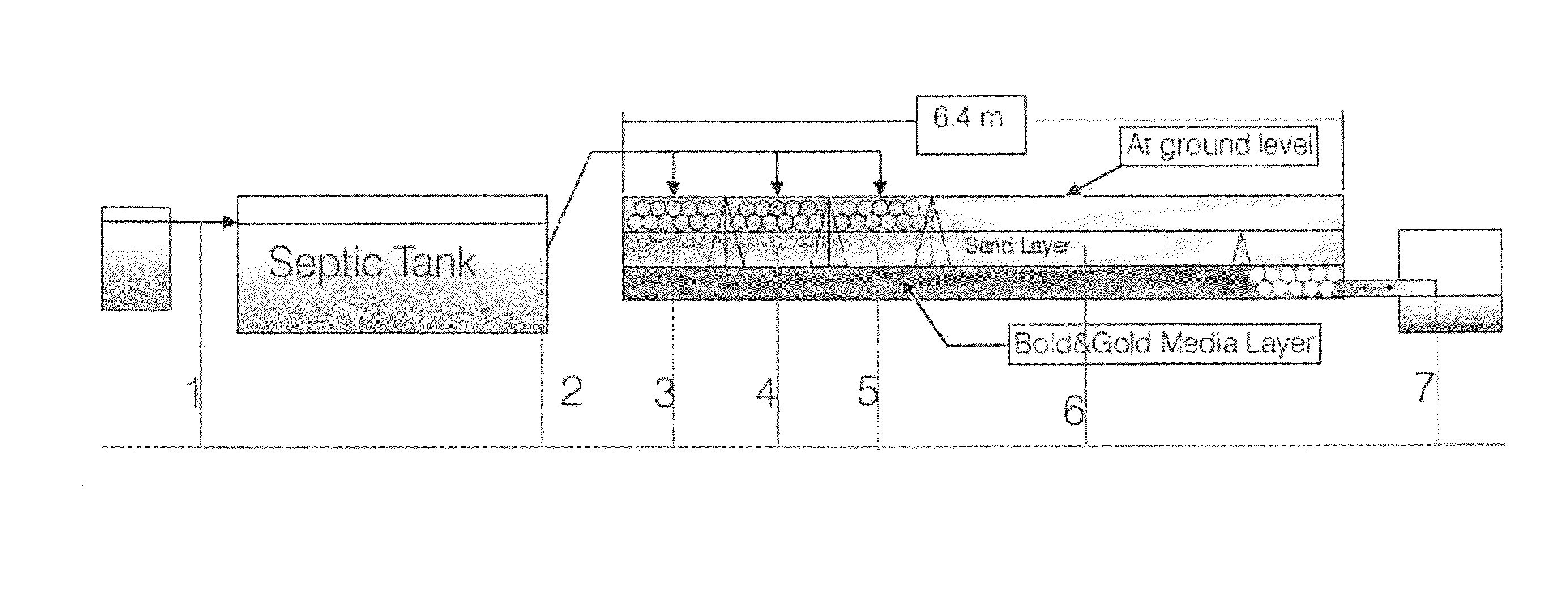

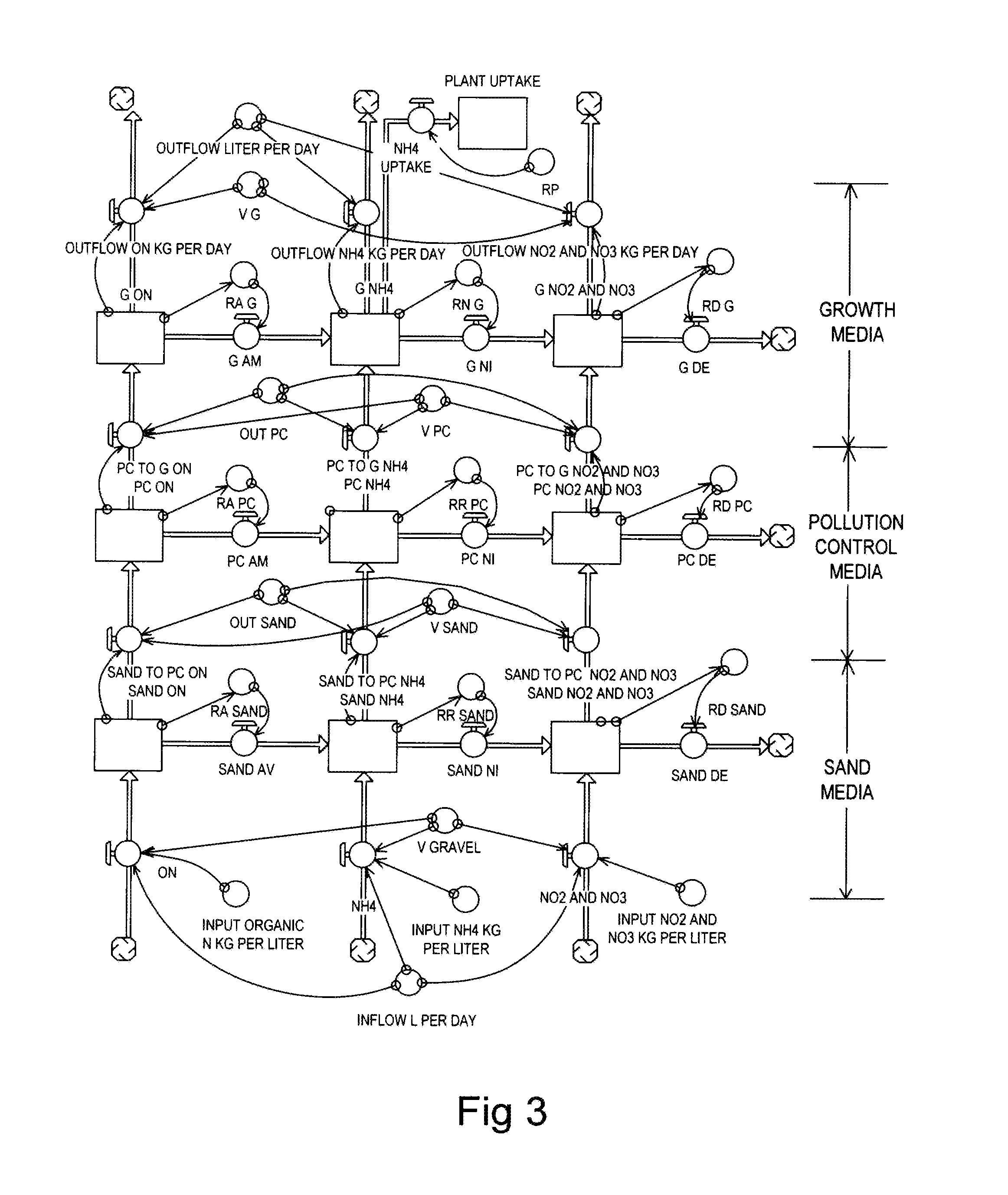

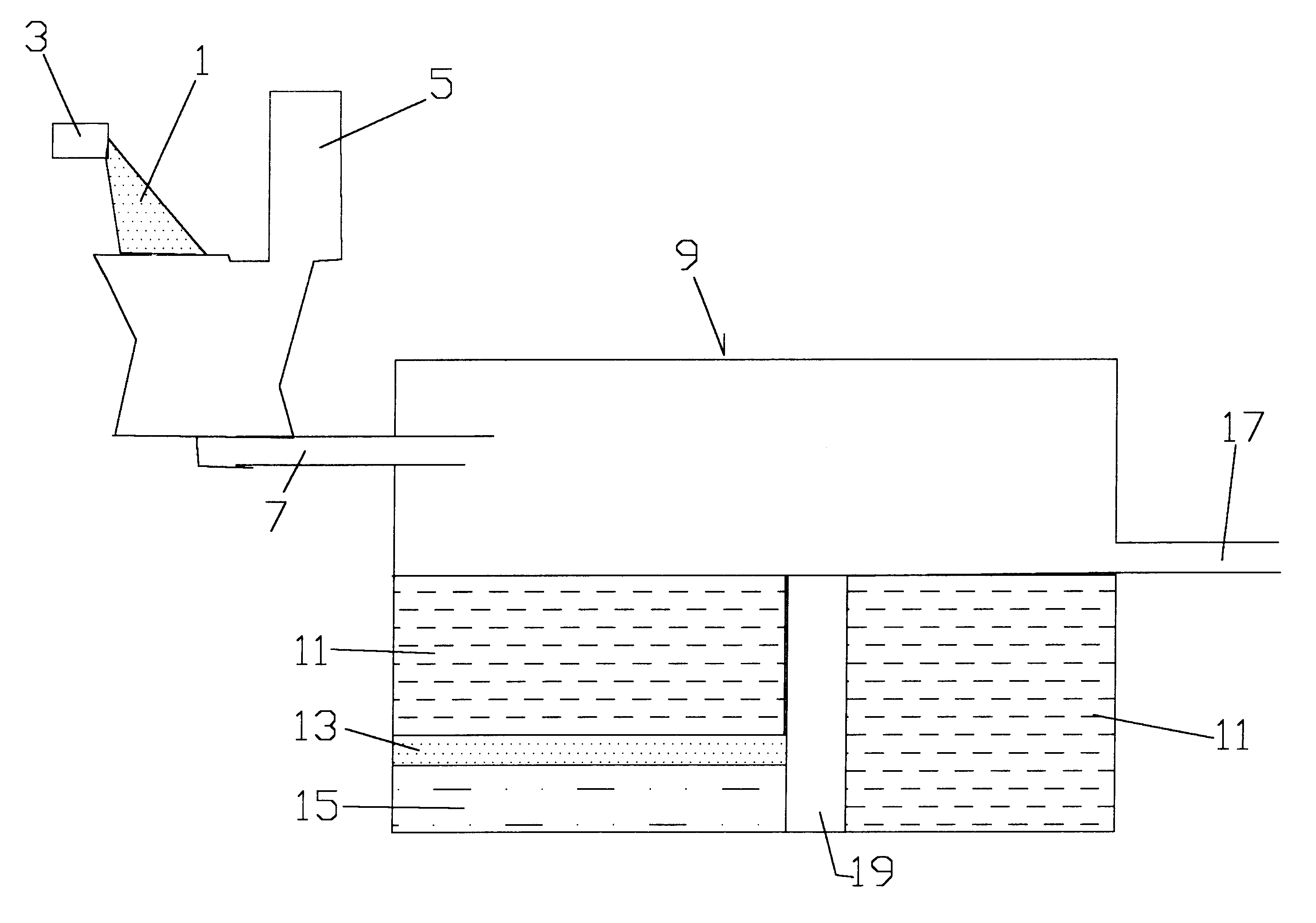

Subsurface upflow wetland system for nutrient and pathogen removal in wastewater treatment systems

ActiveUS8252182B1Low maintenance burdenHigh benefit cost ratioWater cleaningContaminated soil reclamationFecesTotal suspended solids

Methods and systems for a subsurface upflow wetland for wastewater treatment that includes a series of parallel treatment cells, each cell including from bottom to top, a layer of gravel, a layer of sand over the gravel to remove pathogens from a septic effluent, a pollution control medium above the sand layer to remove nutrients, total suspended solid, and biochemical oxygen demand and a growth media mixture layered on top of the pollution control media to grow plants, and a gravity distribution system to distribute effluent to the series of parallel treatment cells. The pollution control medium includes at least one recycled material and at least one naturally occurring material. In an embodiment it includes recycled tire crumb, sand and limestone or recycled tire crumb, compost, sand and limestone.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

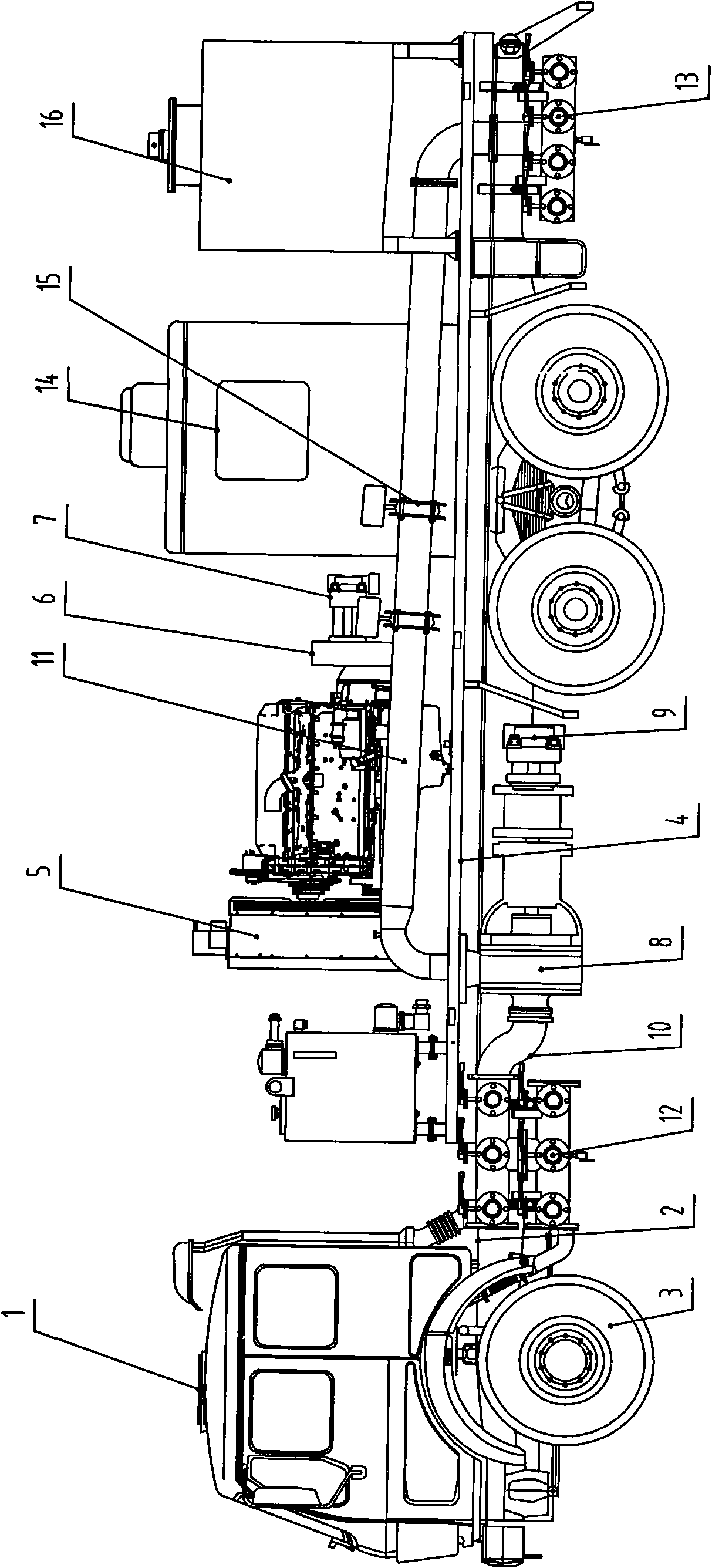

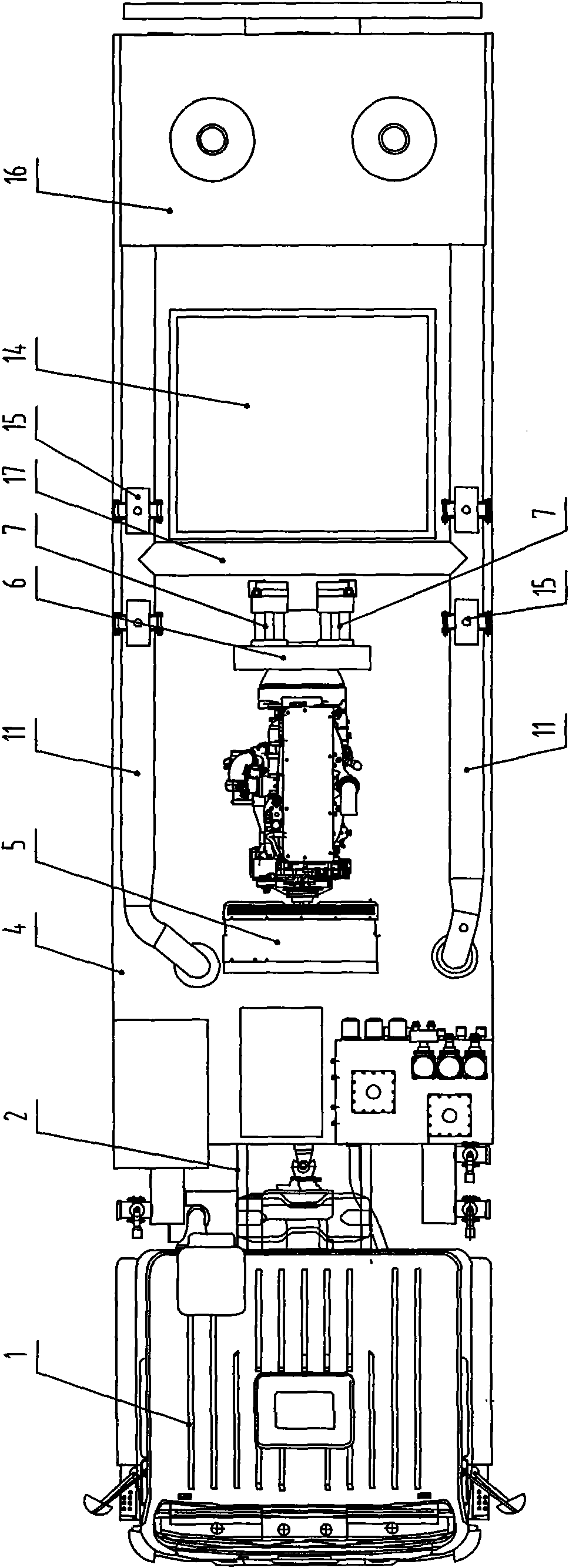

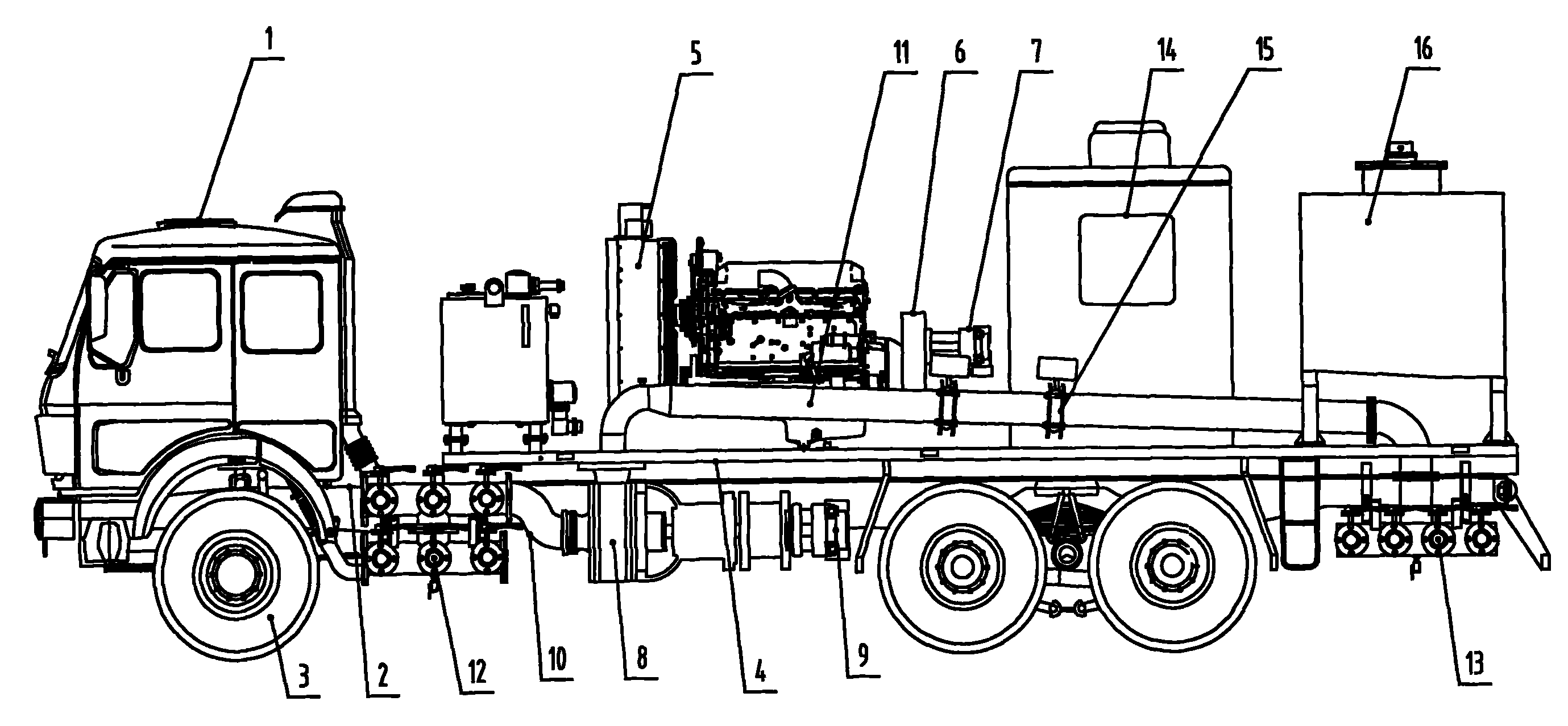

Liquid supply vehicle

ActiveCN101885307ALower suction heightImprove inhalation performanceFluid removalItem transportation vehiclesVehicle frameSewage

The invention discloses a liquid supply vehicle, which comprises a frame with a cab. The lower part of the frame is provided with wheels, the rear upper part of the frame is provided with a bedplate, a power driving device is arranged on the bedplate, a centrifugal pump is arranged below the bedplate, the power driving device is in transmission connection with the centrifugal pump, and an inlet and an outlet of the centrifugal pump are connected with a suction pipe and a discharge pipe respectively. The liquid supply vehicle has the advantages of improving the self-sucking effect of a fracturing truck, improving the operation efficiency of the fracturing truck and shortening the operation time, along with reasonable design, simple structure, easy assembly and manufacture, and also can be used for liquid delivery in other industries of flood drainage, sewage clearing and the like.

Owner:ZYT GASOLINEEUM EQUIP

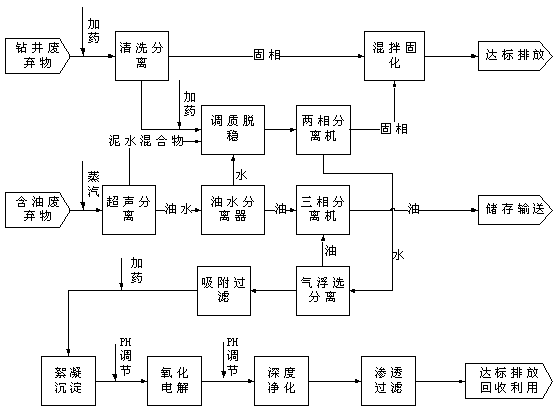

Method for comprehensive treatment of oilfield waste

ActiveCN102849880BSolve the use problemMeet the actual needs of protectionWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesElectrolysisSludge

The invention discloses a method for comprehensive treatment of oilfield waste, which is characterized by comprising the process steps of cleaning and separation, ultrasonic separation, tempering and destabilization, oil-water separation, centrifugal separation, mixed curing, air floatation separation, adsorption filtration, flocculating settling, oxidization electrolysis, deep purification and permeable filtration. Thus, the oilfield waste is treated and utilized in a classified manner, so that sump oil is recovered, the solid phase achieves the discharge standard of oilfield sludge treatment design specifications (SY / T6851-2012) or is reutilized for construction material manufacturing, and the liquid phase achieves the sewage comprehensive discharge standard (GB8978-1996) after being subjected to water treatment.

Owner:RUIJIE ENVIRONMENTAL PROTECTION TECH CO LTD

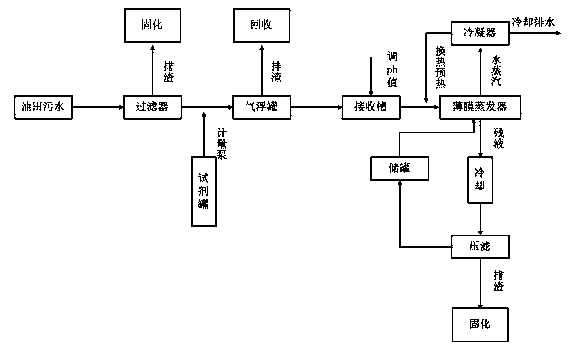

Processing method of sewage in oil fields by using film evaporator

InactiveCN103420532AReduce processing costsReduce consumptionWaste water treatment from quariesMultistage water/sewage treatmentSlagWastewater

The invention discloses a processing method of sewage in oil fields by using a film evaporator. The processing method is characterized by comprising following technology steps: filtering sewage with a filtering device, removing oil by the air-floating method, separating and condensing sewage by the thin-film evaporating method, and processing residual slag, is mainly used for evaporating processing of sewage in oil fields, and is capable of continuously processing oil-containing sewage. The liquid phase and solid phase after being processed can be discharged without causing pollution to the environment.

Owner:JEREH ENERGY SERVICES

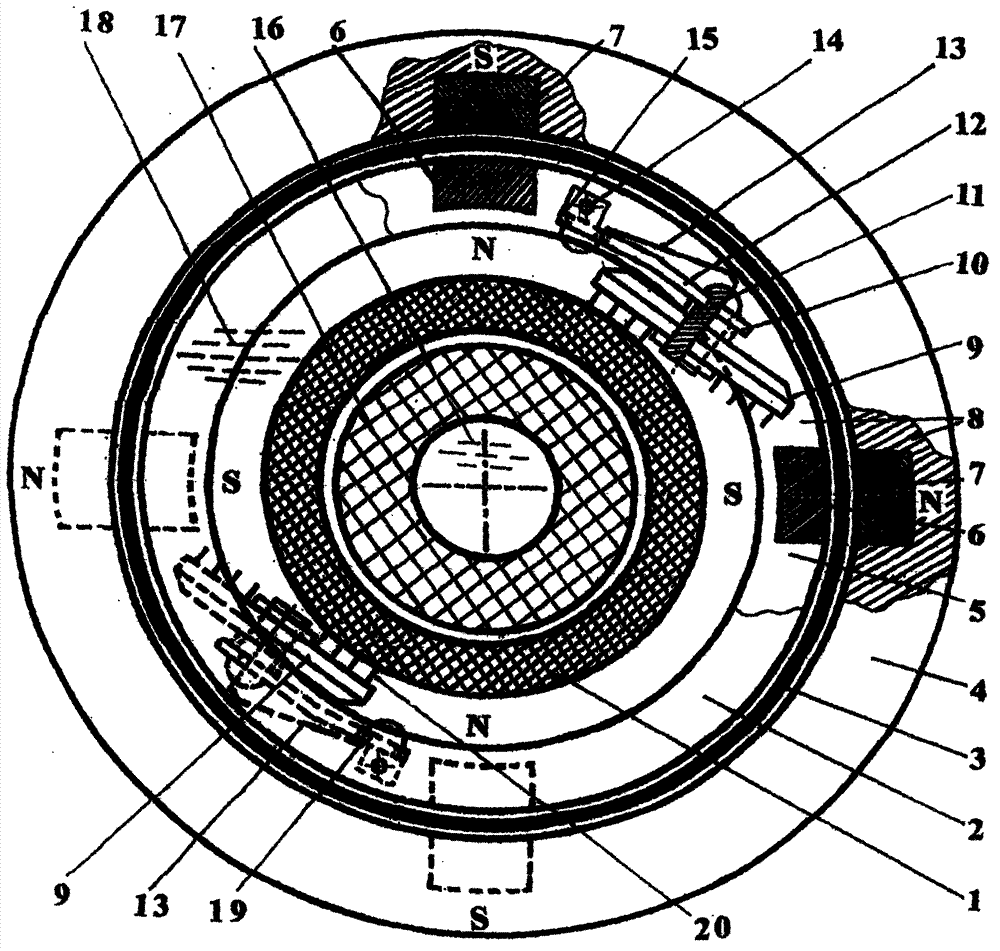

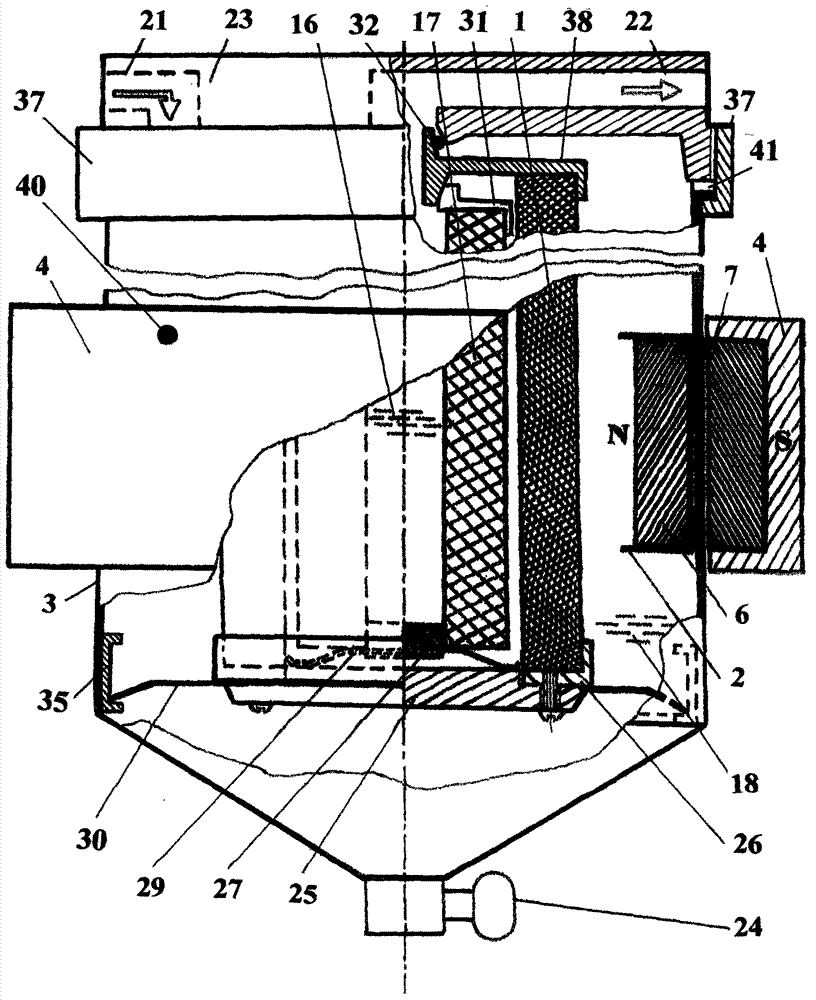

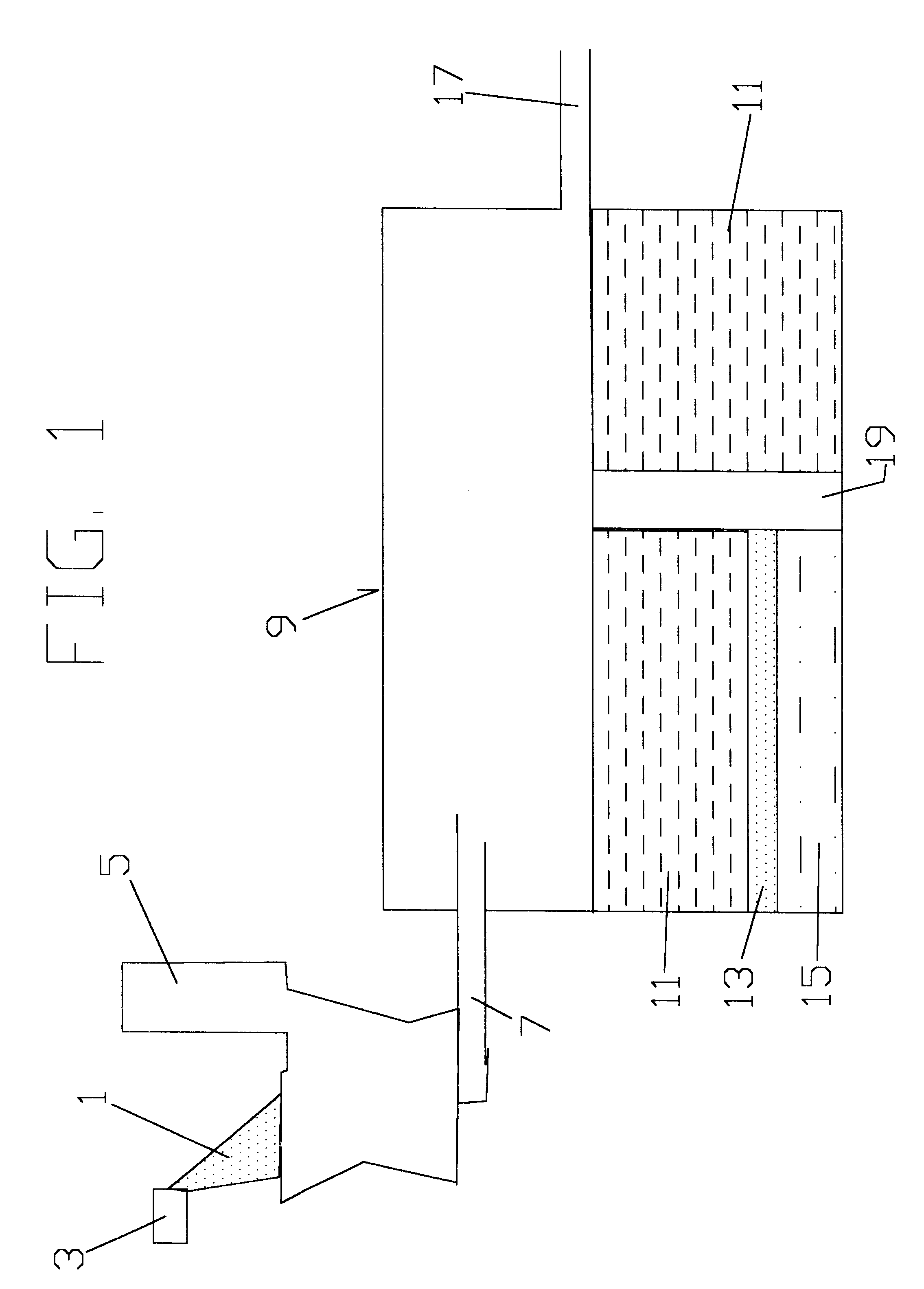

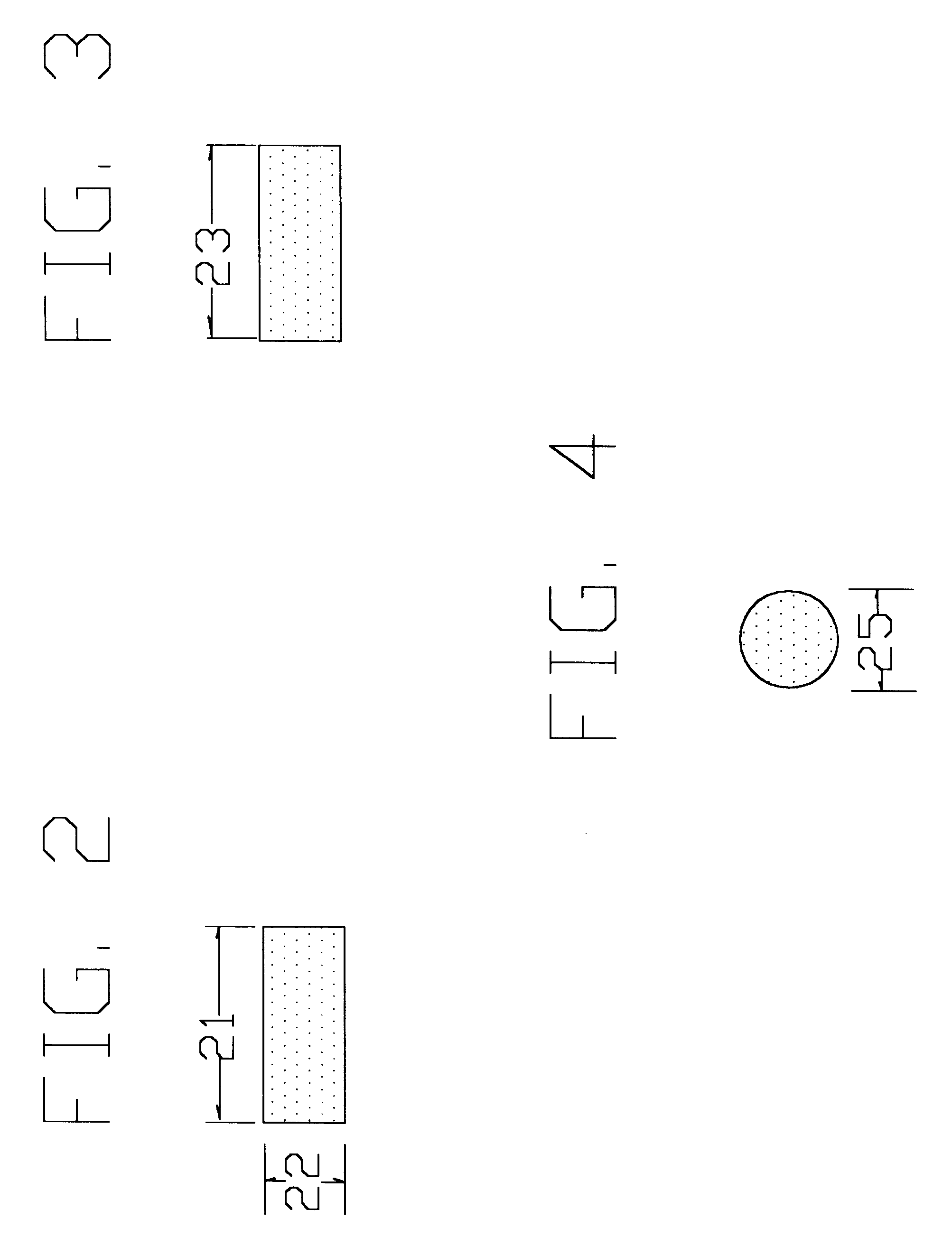

Disassembly-and-washing-free durable ceramic filter element water purifier

InactiveCN103157318AExtended service lifeAvoid damageLoose filtering material filtersGravity filtersWater filterEngineering

The invention discloses a disassembly-and-washing-free durable ceramic filter element water purifier which comprises a base 23, a ceramic filter element 1 and a non-magnetizer shell cylinder 3. The technical scheme is that a washing component is arranged in the shell cylinder 3 and is in mechanical linkage with an inner magnetic ring 2 which can slide along the shell cylinder 3, an outer magnetic ring 4 capable of sliding is sleeved outside the shell cylinder 3, and the two magnetic rings are separated by the cylinder wall and mutually absorbed. The outer magnetic ring 4 is pushed and rotated by hand, the inner magnetic ring 2 can be moved simultaneously and drives the washing component to wash the ceramic filter element 1, and sewage is discharged through a blowdown valve 24. Due to the fact that when the ceramic filter element 1 of the water purifier is washed, the outer cylinder 3 does not need to be disassembled, not only is operation convenient and fast, but also component damage possibly caused in the frequent washing and disassembling process is avoided, moreover, wearing strength imposed on the ceramic filter element by the washing component is reduced to the maximum, and active carbon which is inactive after a long time can be conveniently replaced, and therefore the service life of the water purifier can be greatly prolonged.

Owner:嘉兴市圣路易斯洁具有限公司

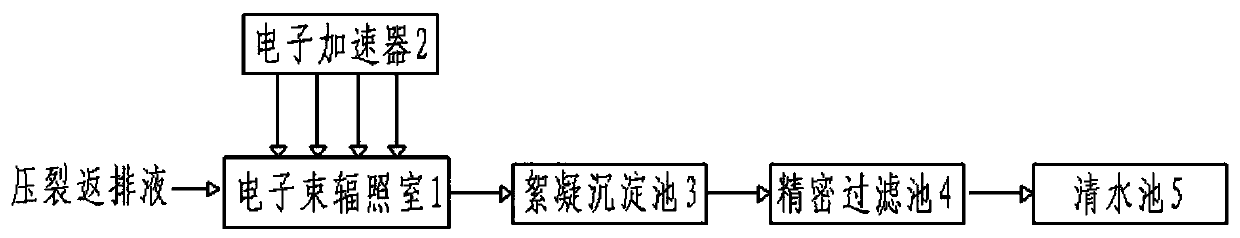

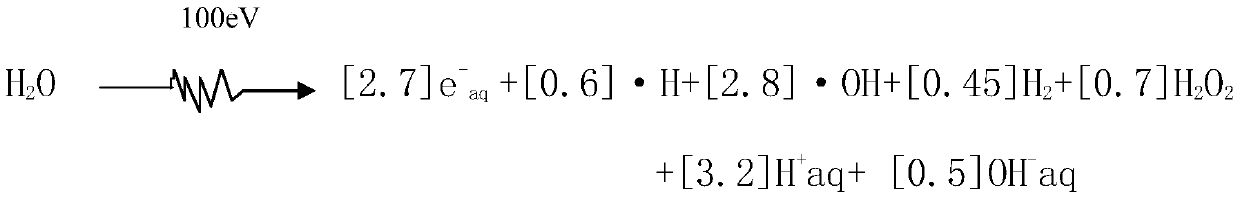

Rapid treatment method for fracturing flowback fluid

PendingCN110467298ARealize online processingLittle side effectsWaste water treatment from quariesTreatment involving filtrationFlocculationFiltration

Owner:RUIJIE ENVIRONMENTAL PROTECTION TECH CO LTD

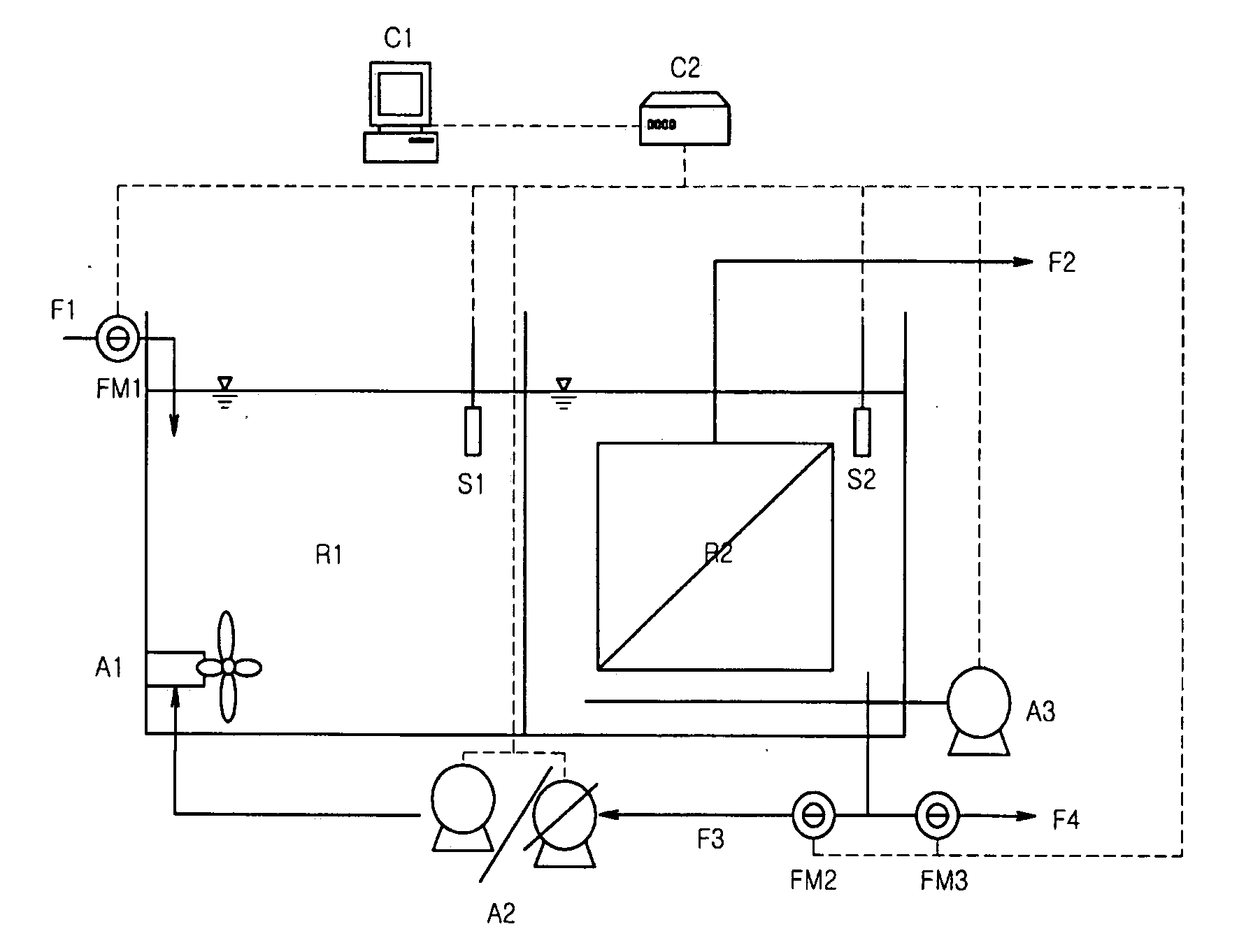

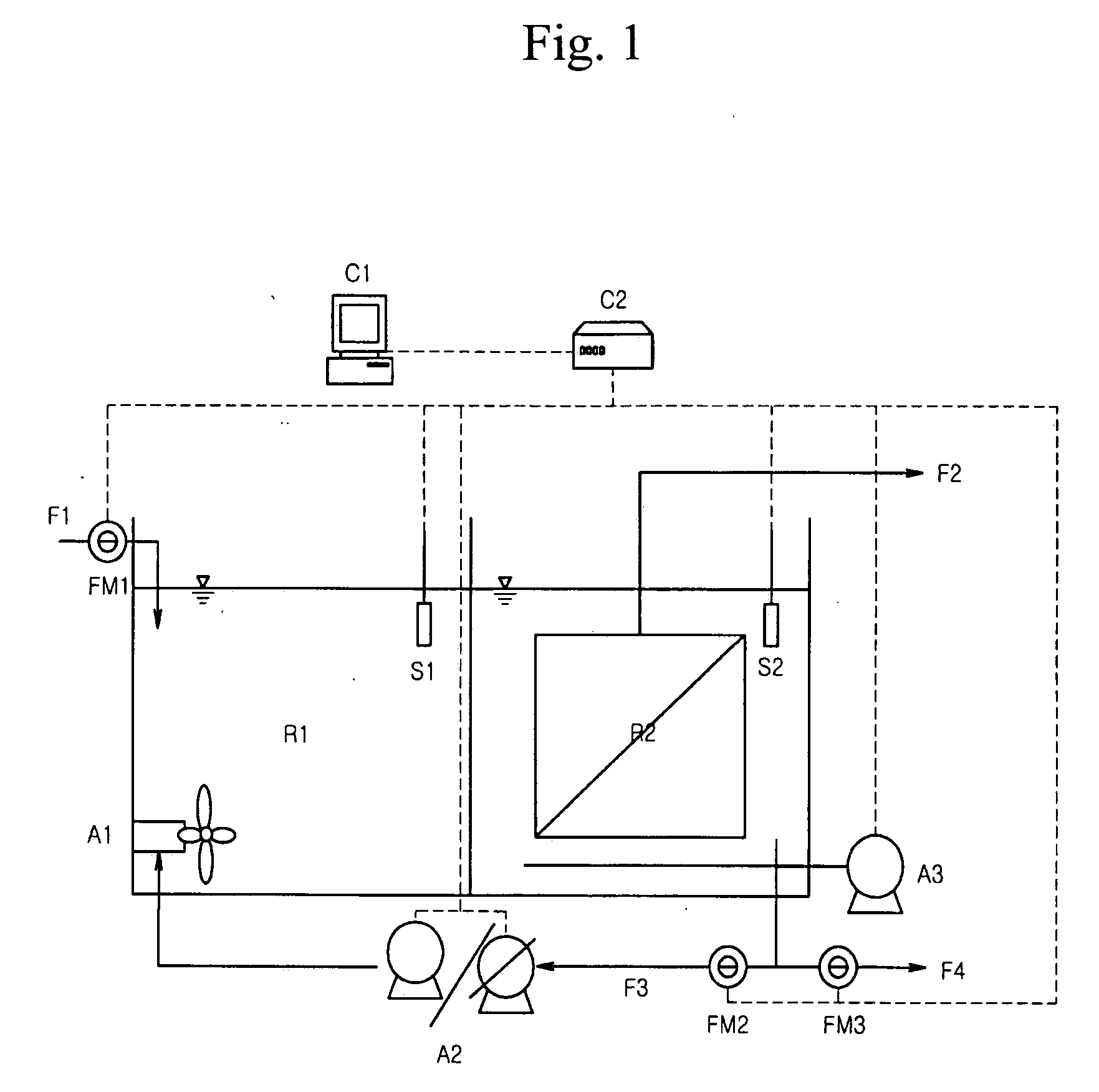

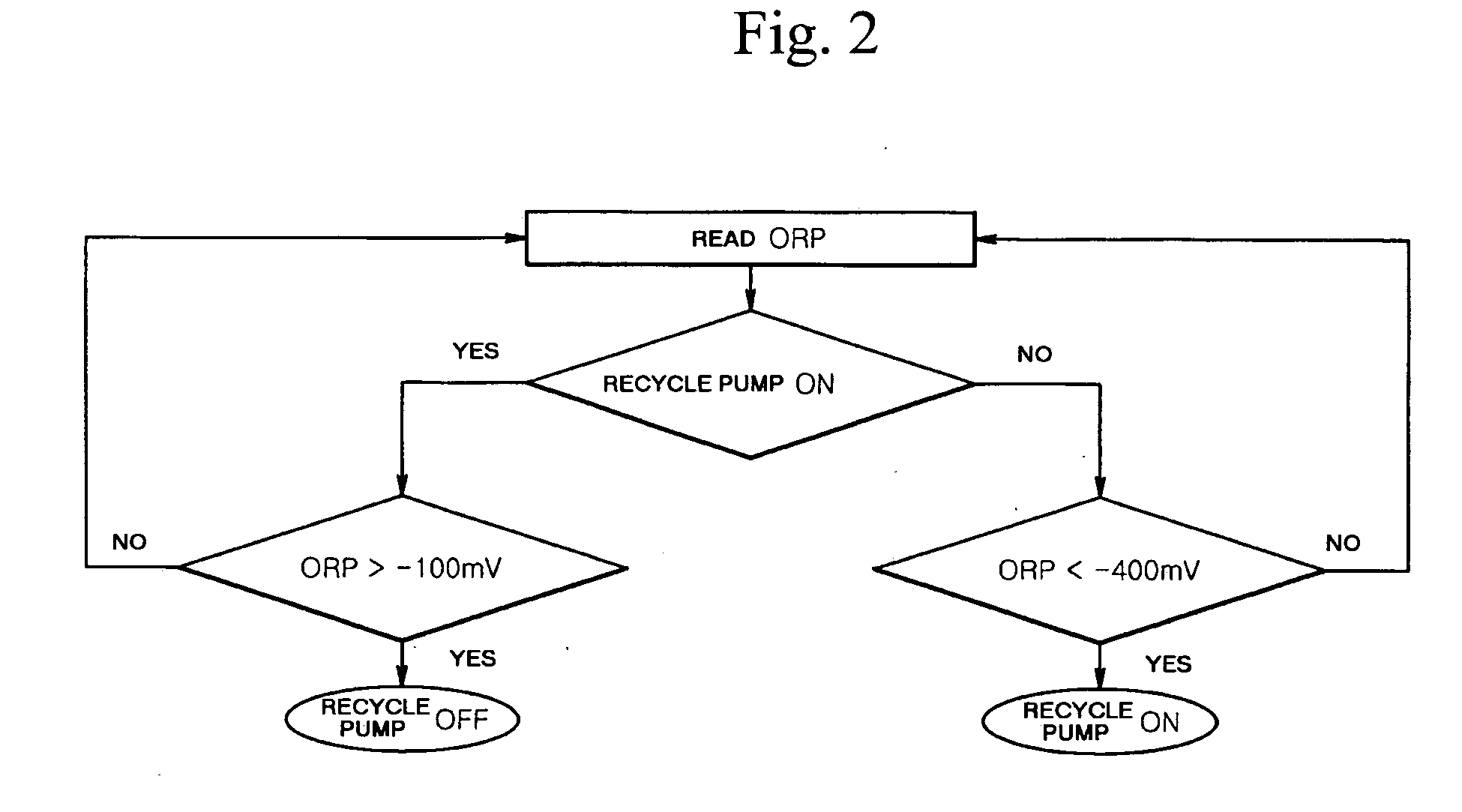

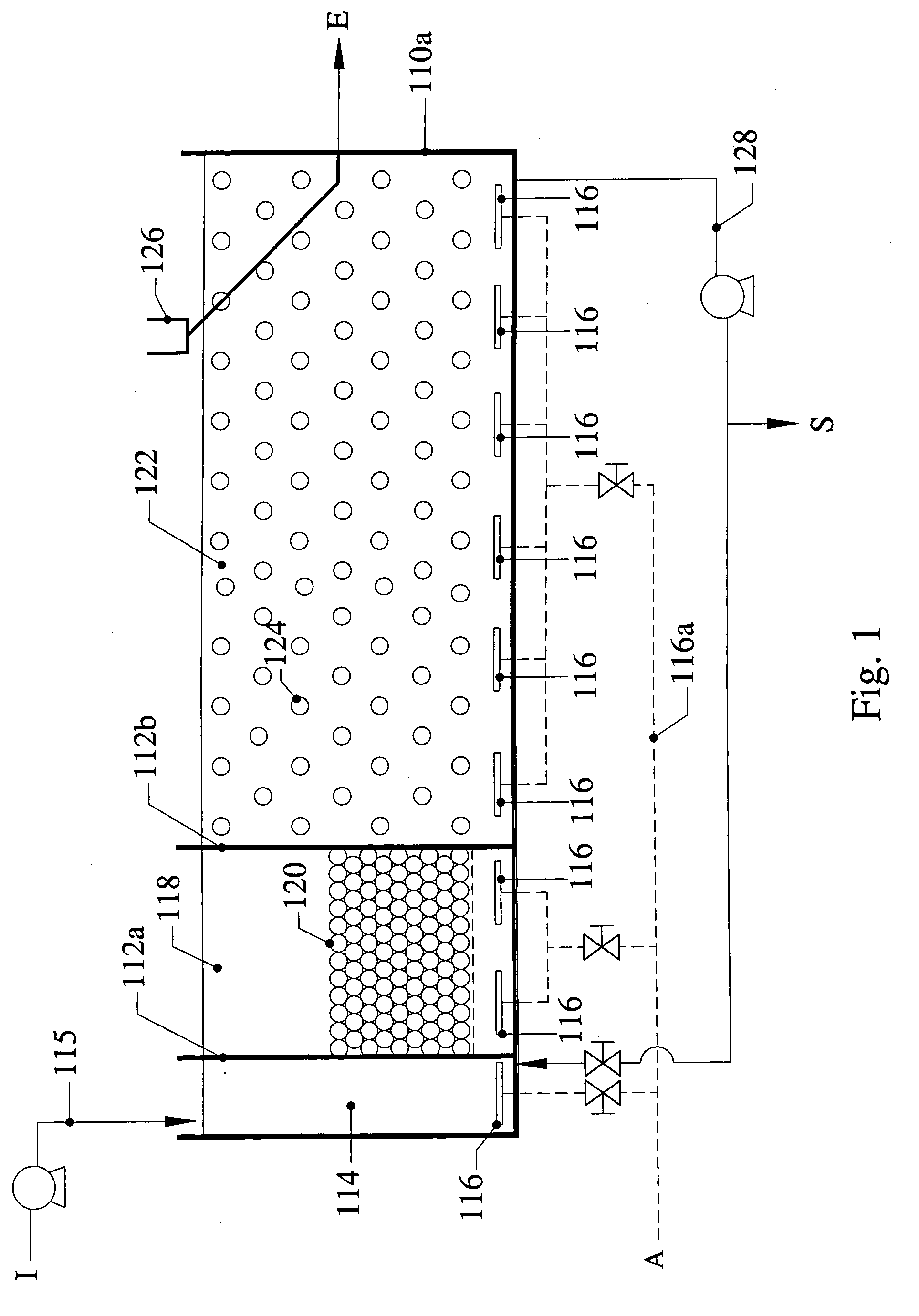

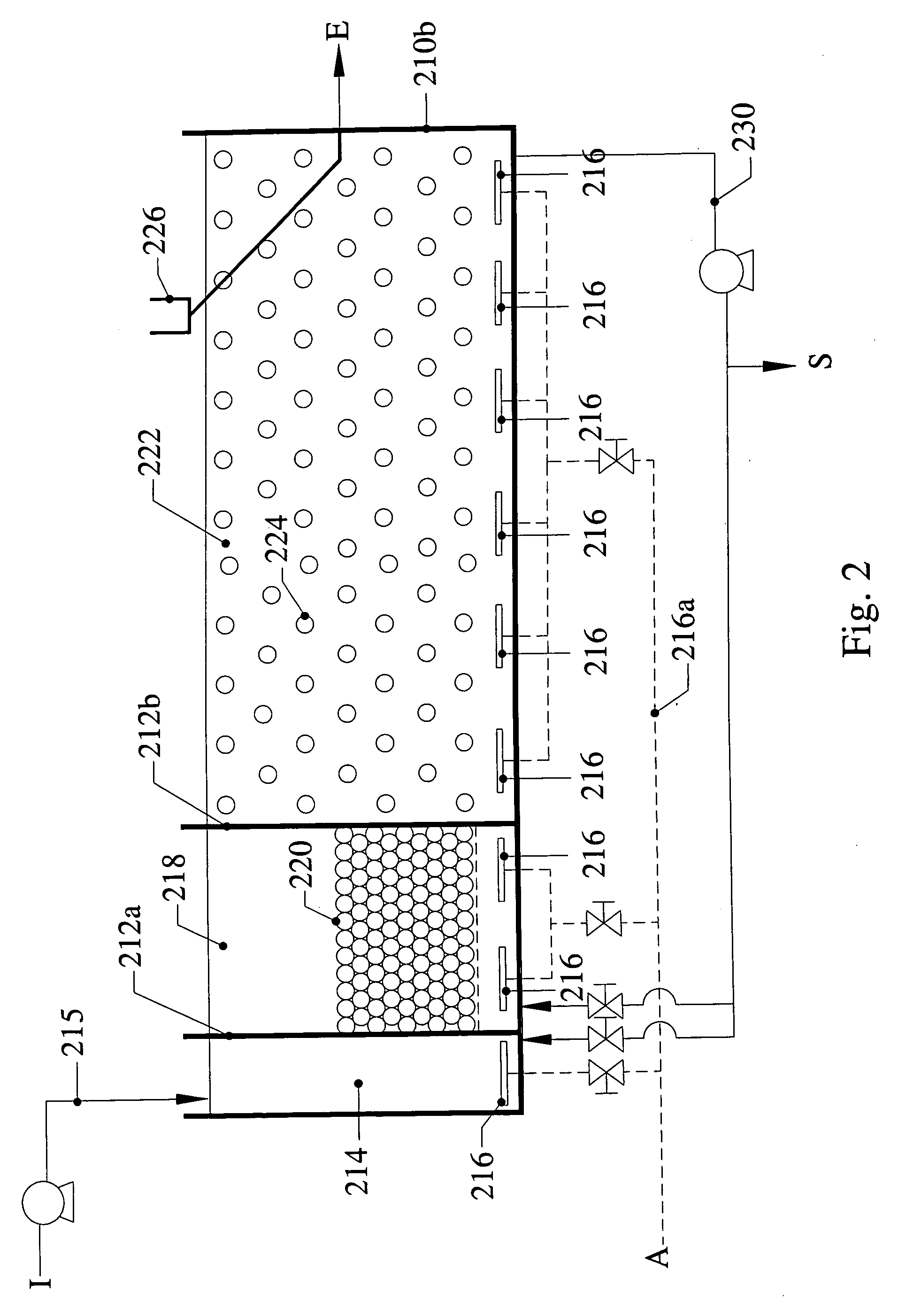

Membrane coupled activated sludge method and apparatus operating anoxic/anaerobic process alternately for removal of nitrogen and phosphorous

ActiveUS20070108125A1Quality improvementSimple processTreatment using aerobic processesMixing methodsActivated sludgeNitrogen

Disclosed are a membrane coupled activated sludge method and apparatus operating anoxic / anaerobic processes alternately for removal of nitrogen and phosporus, wherein nitrogen and phosphorous together with organics in the sewage, wastewater, filthy water etc. can be simultaneously removed with an economic and efficient manner, an operation thereof is easy and efficient, a capacity thereof is high and the method is economic due to the reduced operating costs with performing measurement and control of a recycle rate, a recycle time of alternate operation of the anoxic and anaerobic process, an amount of sludge, an amount of aeration and an operation of a blower for an intermittent membrane cleaning.

Owner:KOREA INST OF SCI & TECH

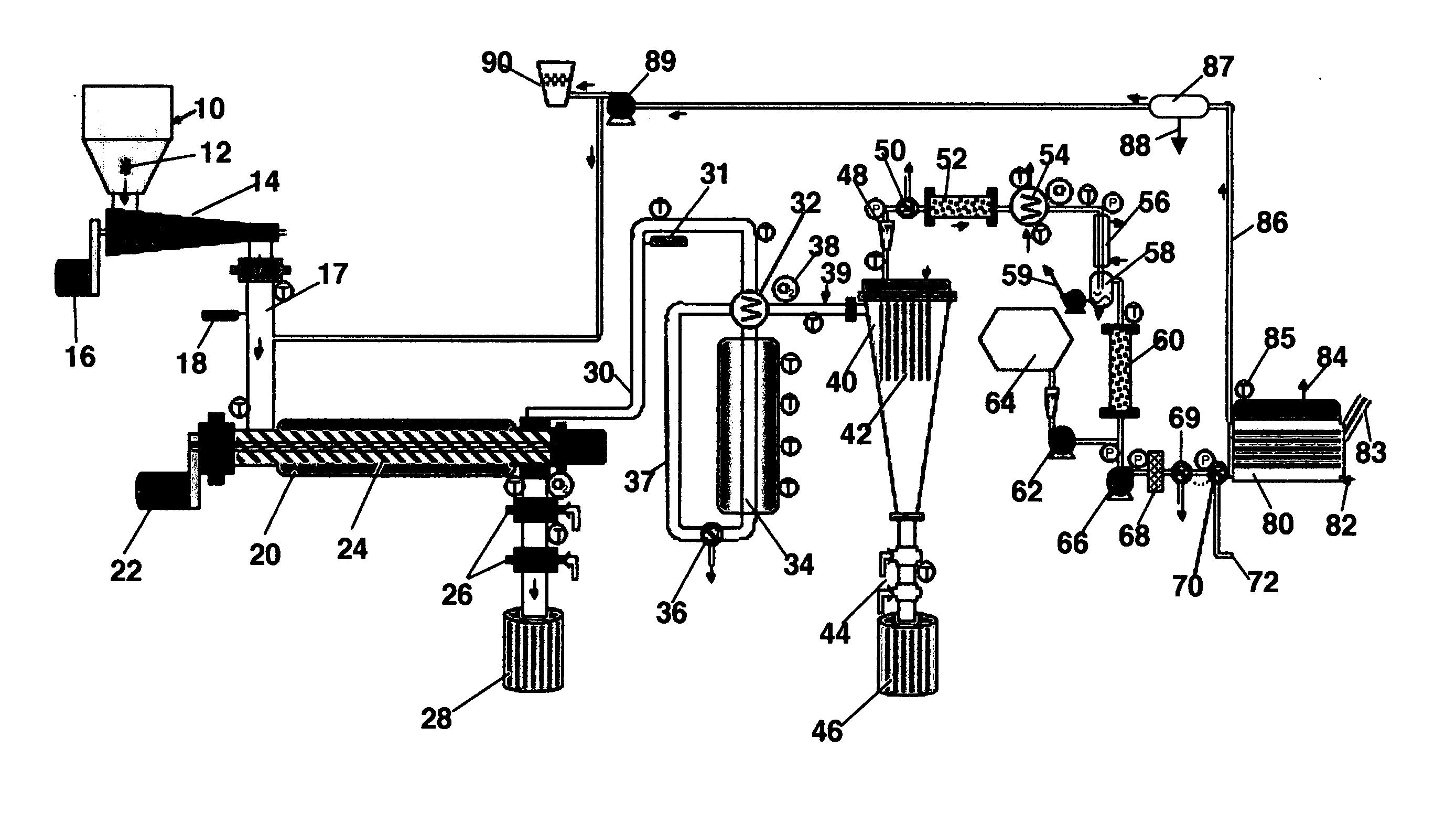

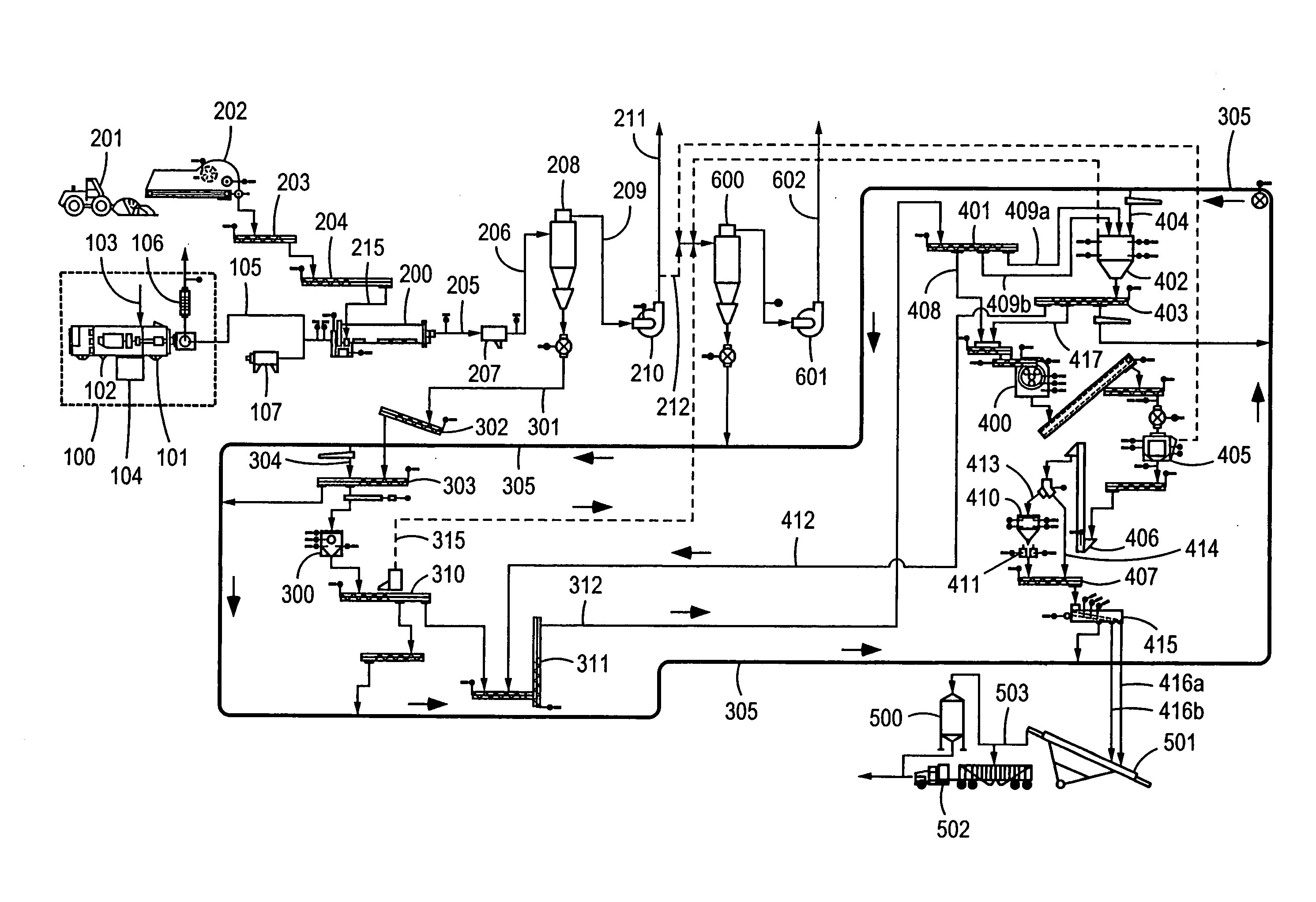

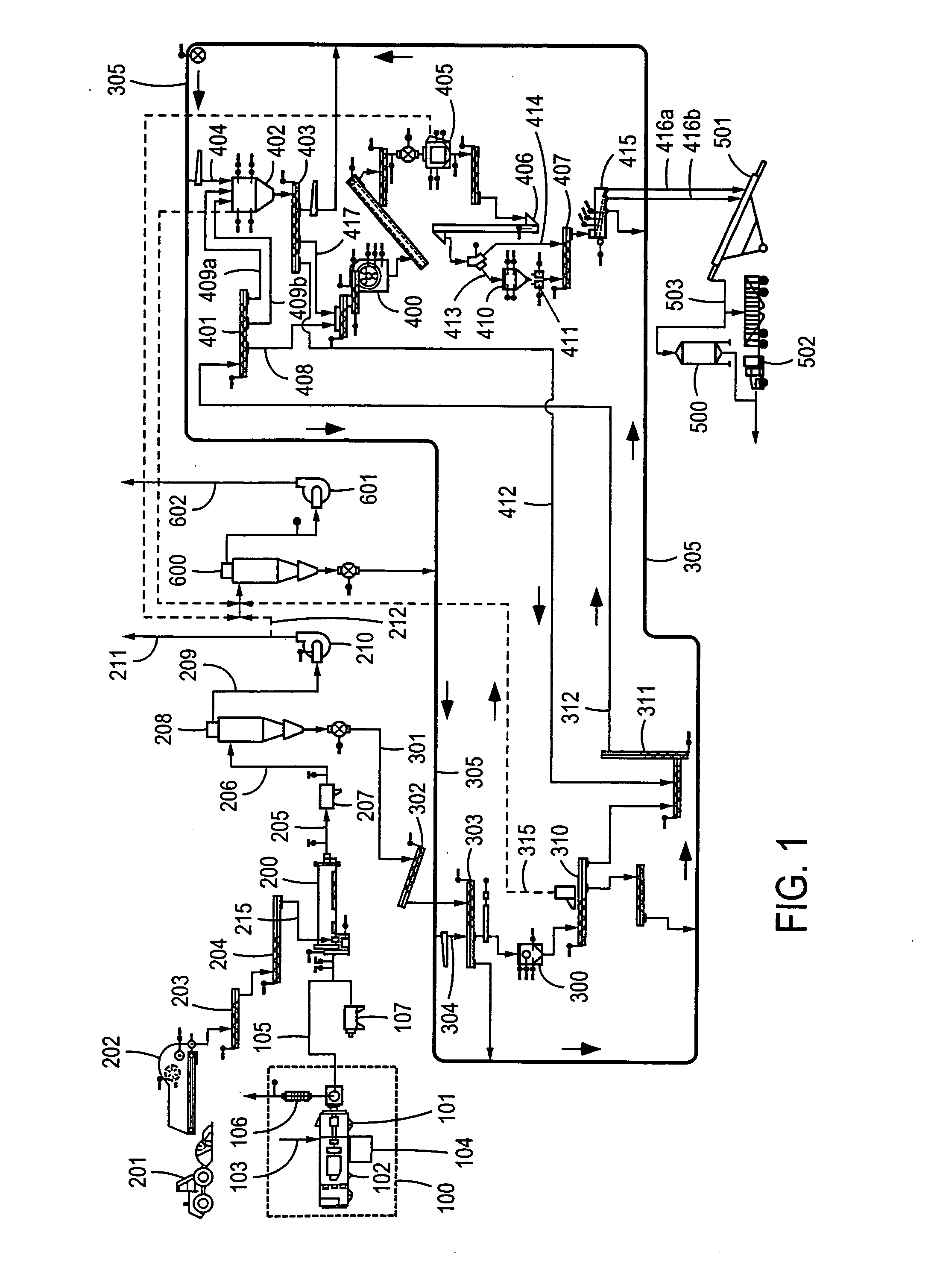

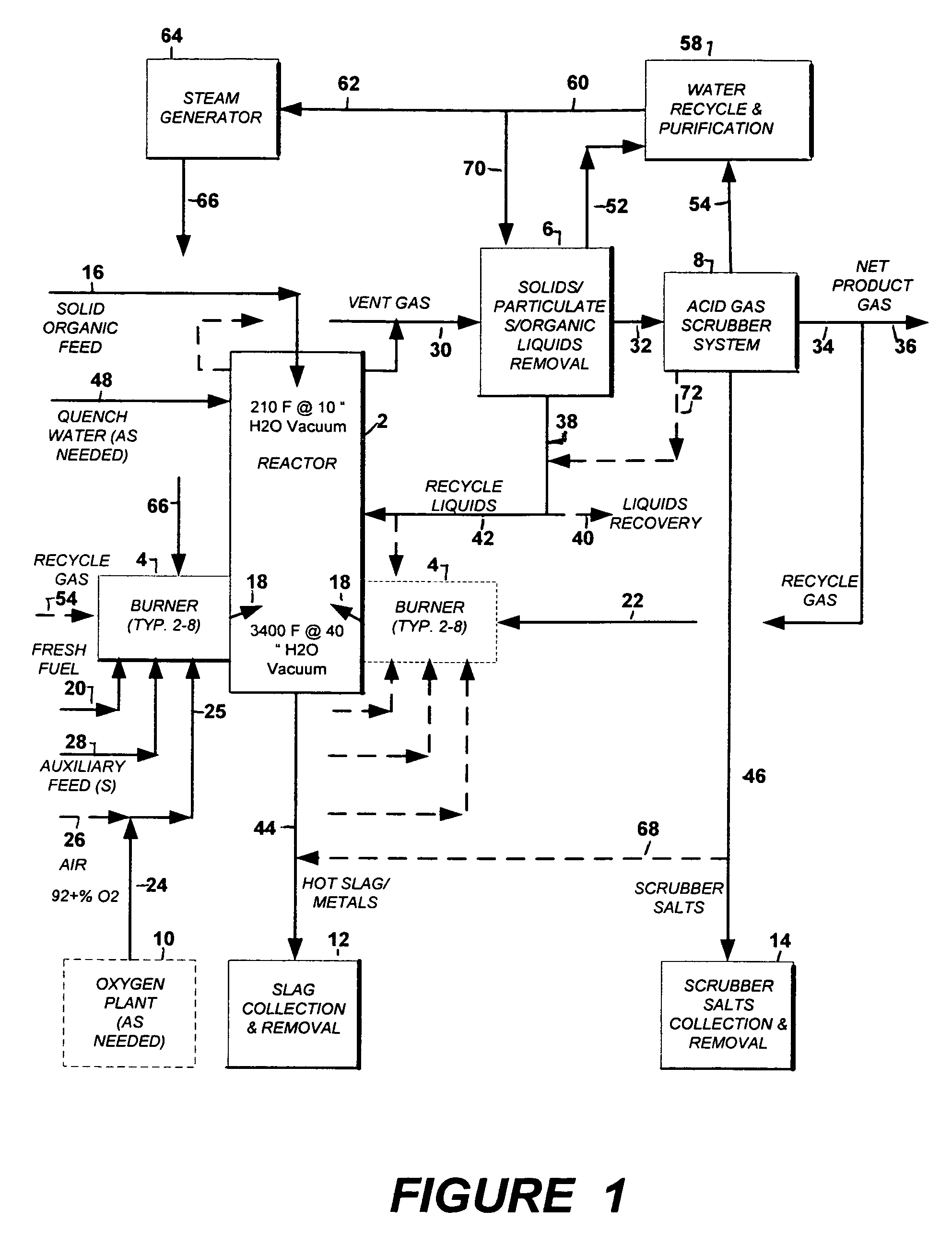

Process and system for converting carbonaceous feedstocks into energy without greenhouse gas emissions

InactiveUS7220502B2Improve efficiencyHigh hydrogen contentFuel cell auxillariesWaste based fuelPetroleum cokeToxic industrial waste

The process and system of the invention converts carbonaceous feedstock such as coal, hydrocarbon oil, natural gas, petroleum coke, oil shale, carbonaceous-containing waste oil, carbonaceous-containing medical waste, carbonaceous-containing military waste, carbonaceous-containing industrial waste, carbonaceous-containing medical waste, carbonaceous-containing sewage sludge and municipal solid waste, carbonaceous-containing agricultural waste, carbonaceous-containing biomass, biological and biochemical waste, and mixtures thereof into electrical energy without the production of unwanted greenhouse emissions. The process and system uses a combination of a gasifier, e.g., a kiln, operating in the exit range of at least 700° to about 1600° C. (1300-2900° F.) to convert the carbonaceous feedstock and a greenhouse gas stream into a synthesis gas comprising mostly carbon monoxide and hydrogen without the need for expensive catalysts and or high pressure operations. One portion of the synthesis gas from the gasifier becomes electrochemically oxidized in an electricity-producing fuel cell into an exit gas comprising carbon dioxide and water. The latter is recycled back to the gasifier after a portion of water is condensed out. The second portion of the synthesis gas from the gasifier is converted into useful hydrocarbon products.

Owner:RAVEN SR INC

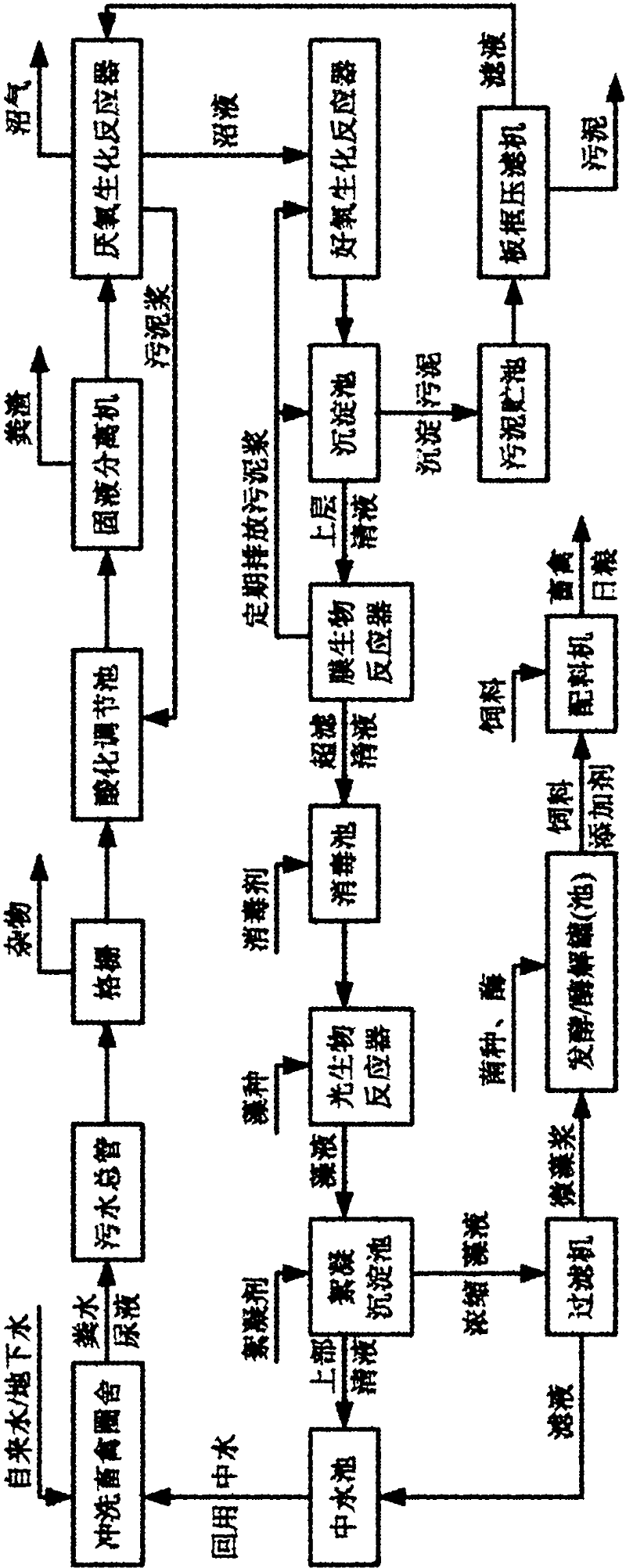

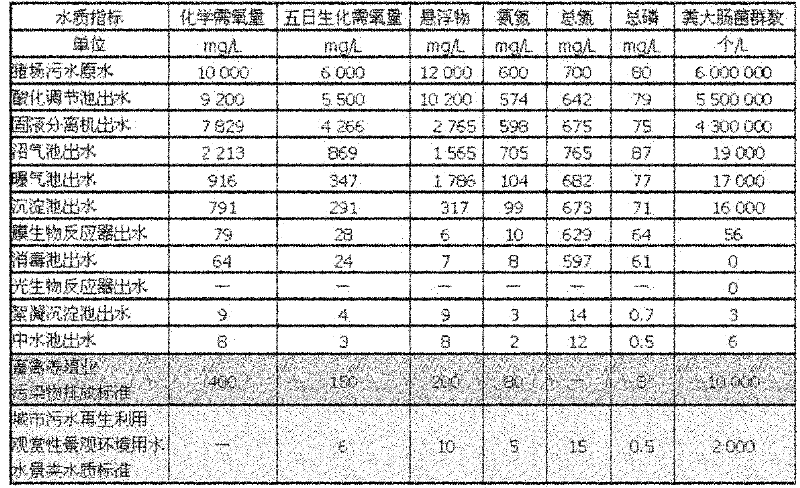

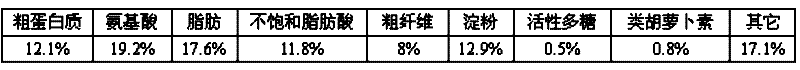

Method for producing feed additive from livestock and poultry breeding wastewater and purifying breeding wastewater to reclaimed water

InactiveCN102161550AReduce water consumptionAchieving zero emissionsWaste water treatment from animal husbandryAnimal feeding stuffUltrafiltrationSlurry

The invention relates to the fields of environmental technology and the breeding and processing of microalgae, in particular to a method for producing feed additive from livestock and poultry breeding wastewater and purifying breeding wastewater to reclaimed water. The method is characterized by comprising the following steps that: wastewater enters an acidification adjusting tank through a grille, and the acidified wastewater enters an anaerobic biochemical reactor for treatment and then enters an aerobic biochemical reactor; after the aerobic biochemical treatment, the obtained biogas slurry enters a settling tank for settling, the supernatant enters a membrane bioreactor for further aerobic treatment and is filtered by an ultrafiltration membrane, the generated ultrafiltration clear liquid is sterilized and neutralized and then enters a photobioreactor, algae are added into the photobioreactor to perform microalgae cultivation, and the algae liquid is discharged from the photobioreactor and then enters a flocculation and settling tank; and after flocculation and settling, the supernatant is used for water recycling, the concentrated algae liquid at the bottom enters a filter, and the separated microalgae slurry enters a fermentation / enzymolysis pot (tank) to perform fermentation / enzymolysis to be used as the feed additive. The invention has the advantages of high economic adaptability, zero discharge and the like.

Owner:蔡志武 +1

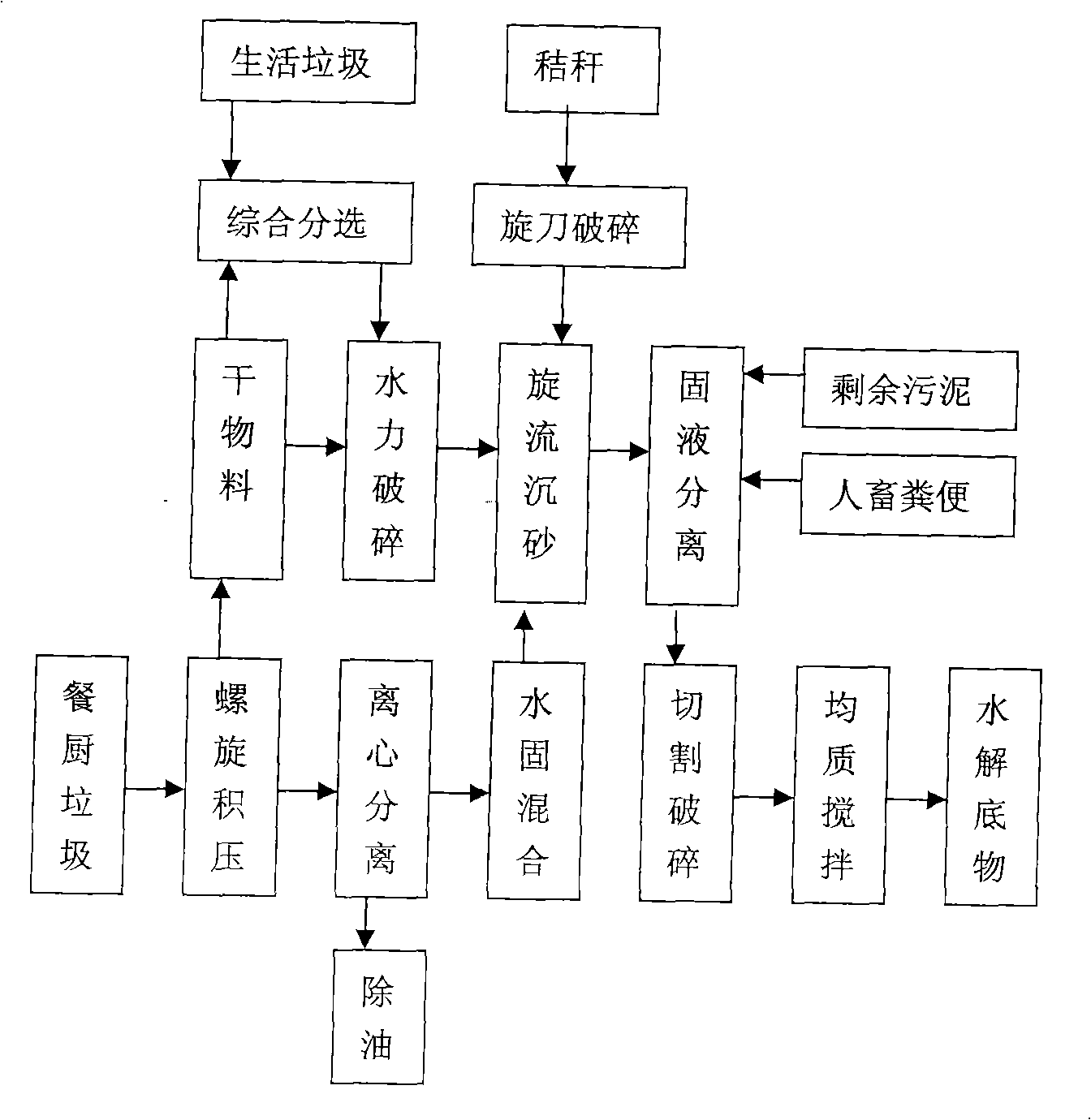

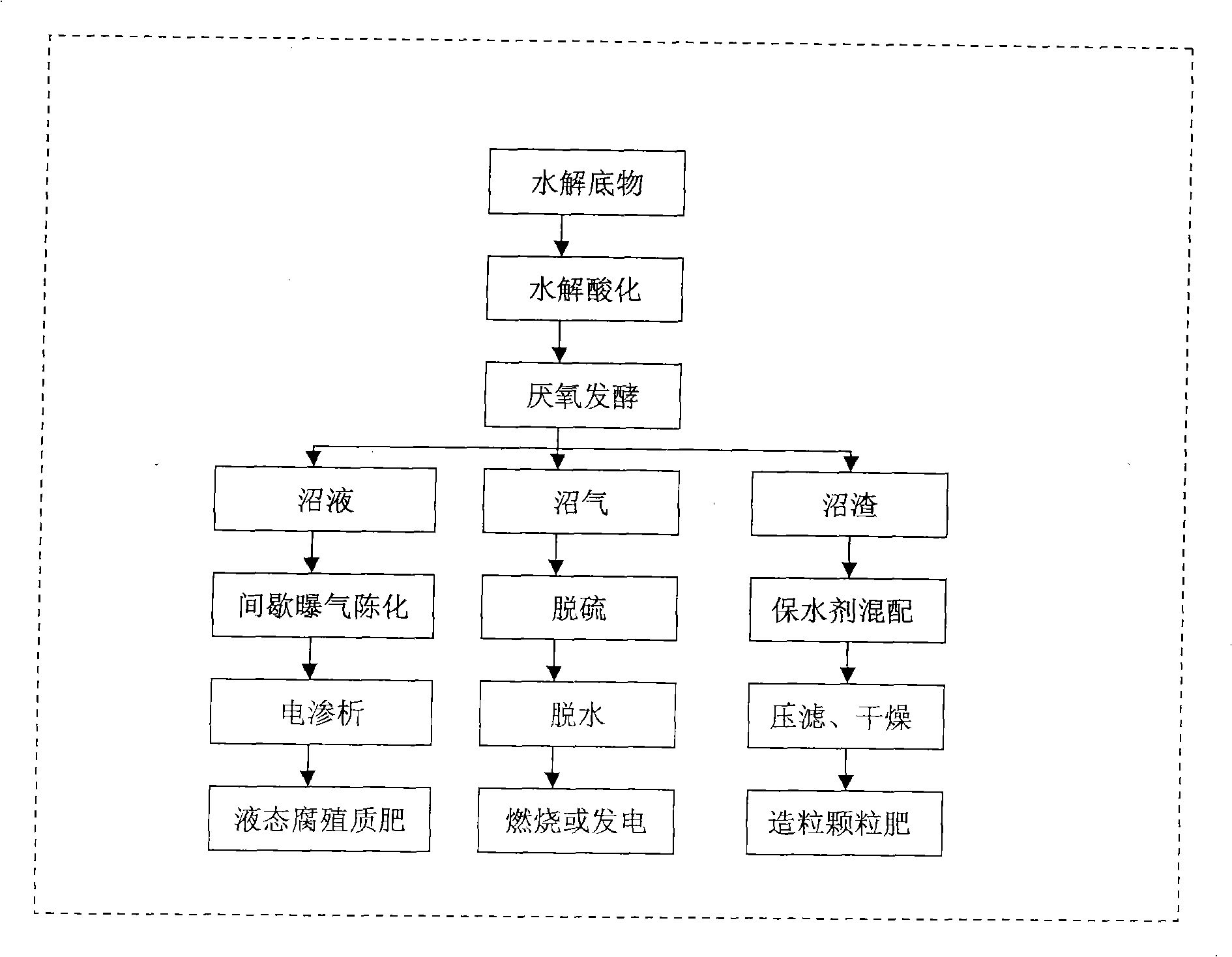

Combined anaerobic fermentation process for organic solid wastes

InactiveCN101337838AReduce consumptionImprove mass transfer efficiencyBio-organic fraction processingClimate change adaptationSludgeAnimal feces

The invention discloses a combined anaerobic fermentation method of organic solid wastes. The organic solid wastes used for the combined anaerobic fermentation include domestic wastes, excess sludge, feces, kitchen waste, straws, etc. The method comprises the following steps: carrying out different pre-processing processes to obtain organic materials with a granularity less than 5 mm; passing through a cutting pump, adjusting the C / N ratio, adjusting the water content, etc. to obtain a homogeneous fermentation substrate with a solid holdup of 2 to 10%; hydrolyzing and acidifying the fermentation substrate in the presence of a hydrolase; fermenting for a period of 15 to 25 days under the condition of stirring at a middle temperature of 32-38 DEG C to obtain biogas, which can be used for energy supply or output of a system; aging and desalting the biogas liquid to obtain a liquid humic acid fertilizer; and processing the biogas residues to a granular humic acid fertilizer. The fermentation substrate has proper C / N ratio to obviate feedback suppression of the substrate during the fermentation of a single material and simultaneously can enhance the hydrolysis effects of celluloses, lignin, hemicelluloses, etc. The method has the advantages of easy flow pattern control, low energy consumption, and no generation of sewages, and can obtain the high-quality biogas fluid and the high-quality granular humic acid fertilizer.

Owner:鄂尔多斯市城市矿产研究开发有限责任公司

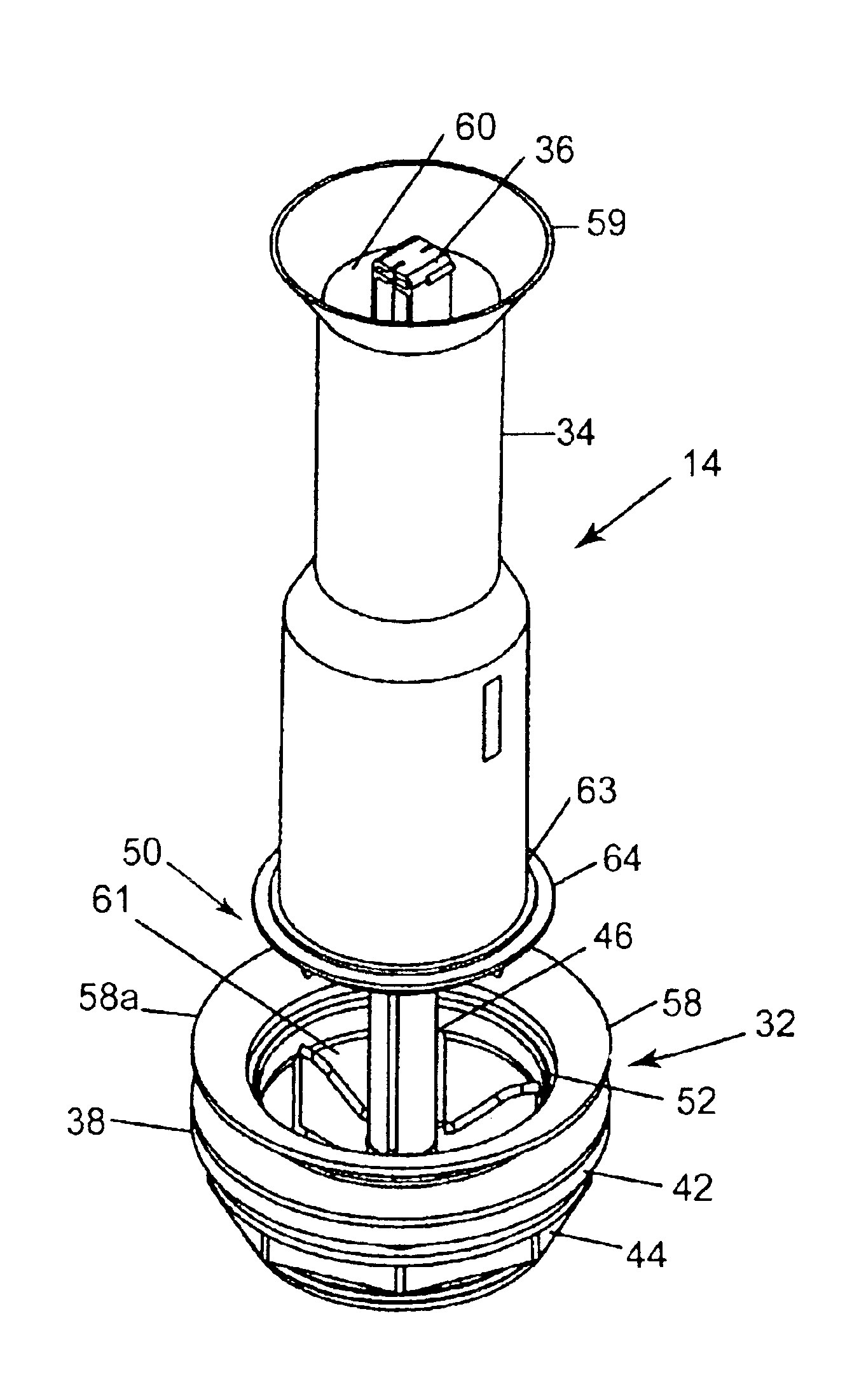

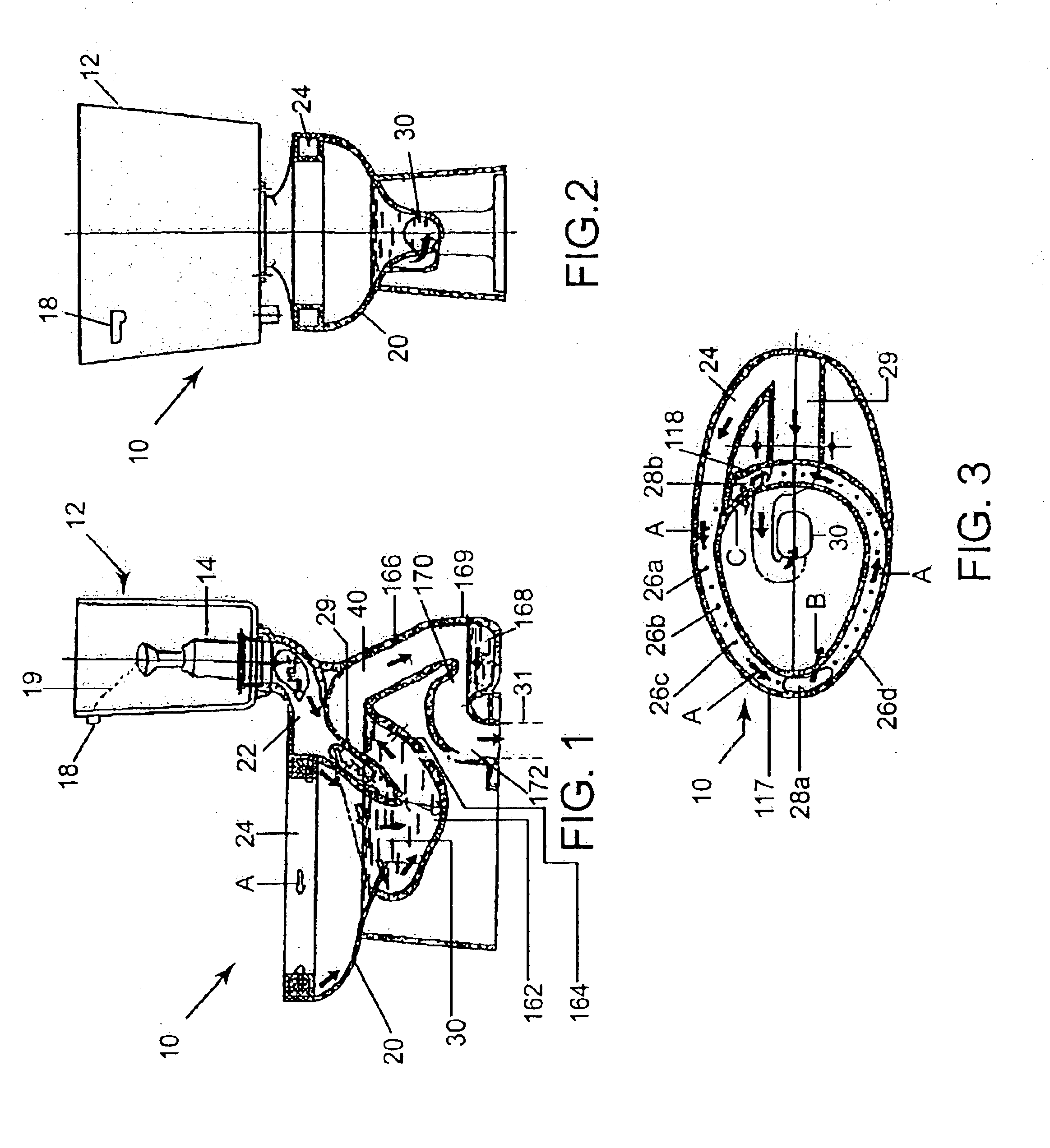

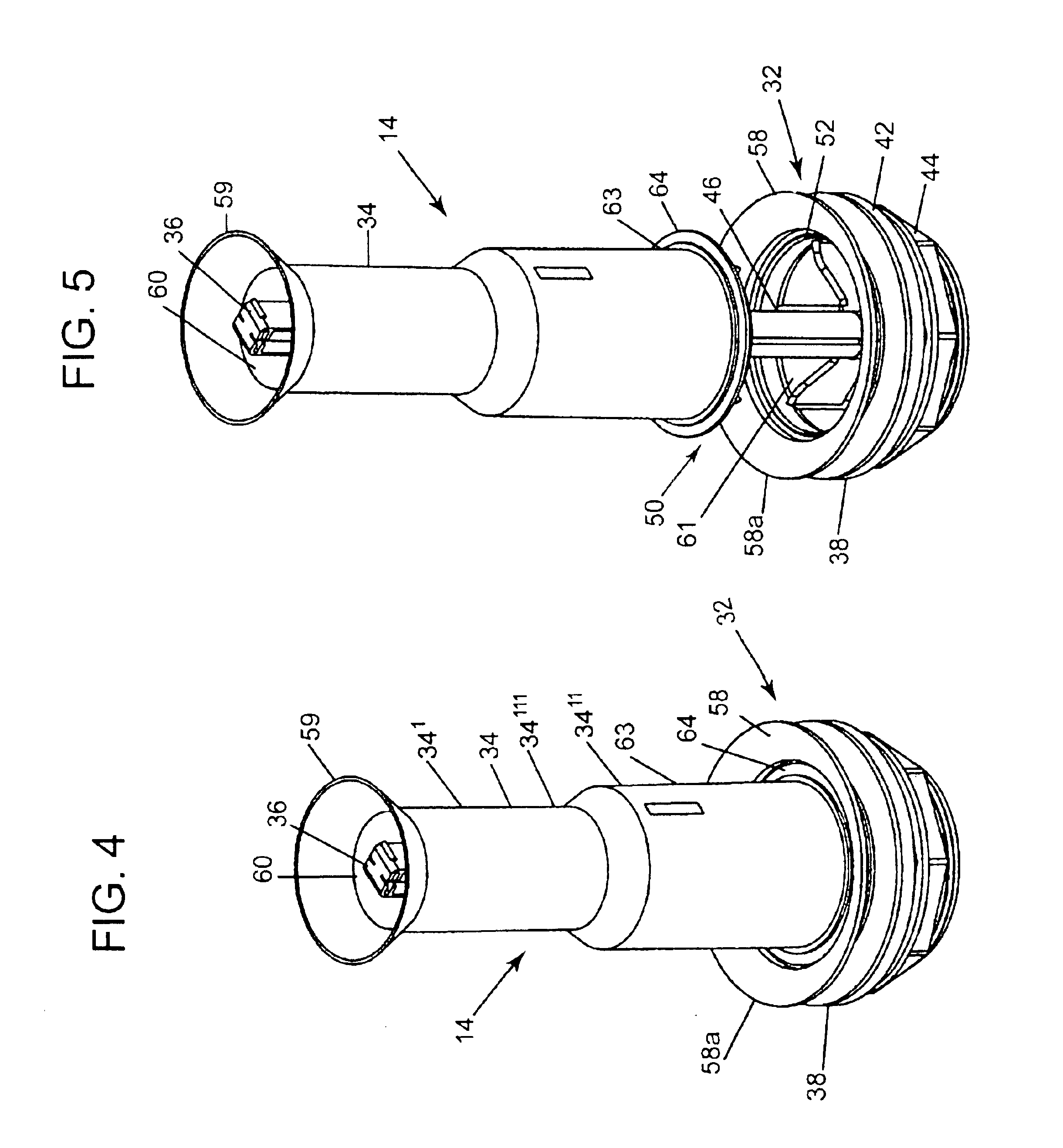

Toilet assembly

InactiveUS6715162B2No reduction in cross sectional areaIncrease capacityUrinalsWater closetsWater dischargeWater flow

A toilet includes a toilet bowl assembly having a toilet bowl and a trapway extending from the bottom of the toilet bowl to a sewage line. The toilet bowl has a rim channel provided along an upper perimeter portion thereof. In this toilet, the flush water flows through the rim channel in a path which is asymmetric and unidirectional along the entire perimeter portion thereof. The rim channel includes a plurality of rim openings distributed evenly along the perimeter of the rim channel. Flush water passing through the plurality of rim openings pre-wets the entire perimeter of the toilet bowl. The rim channel further includes a pair of water discharge slots which directs water directly into the toilet bowl in two powerful streams. The flush valve allowing passage of water from the water tank to the toilet bowl assembly is in the form of a valve inlet having a radiused port to generate greater energy throughput of the flush water.

Owner:AS IP HOLDCO LLC

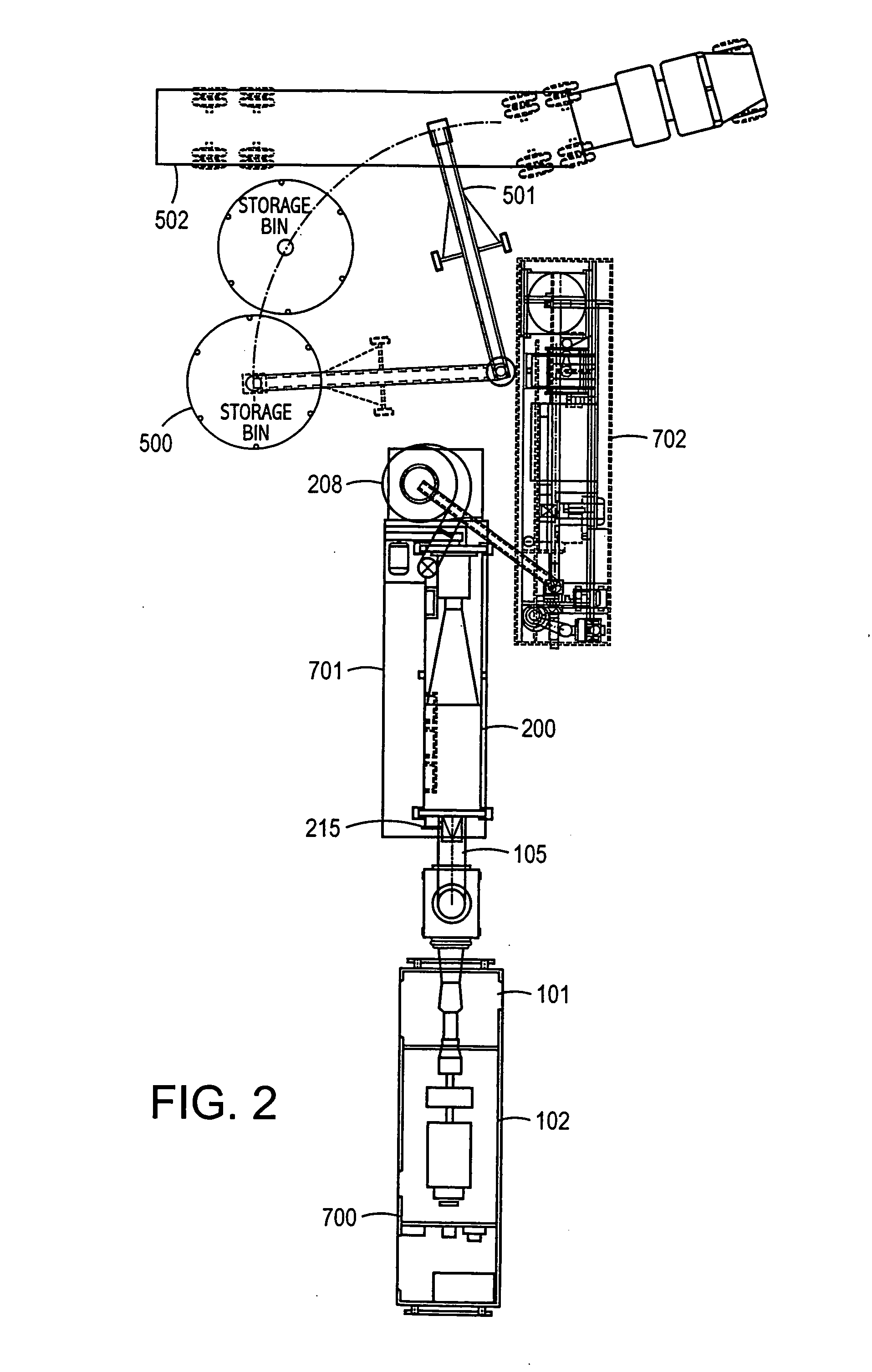

Process and apparatus for manufacture of fertilizer products from manure and sewage

InactiveUS20060010712A1Drying using combination processesBio-organic fraction processingOrganic farmingSewage

This invention discloses systems and methods for conversion of manure to novel fertilizer and / or soil builder products useful as input for organic farming operations. The equipment systems comprise a gas turbine generator unit (preferred heat source), a dryer vessel and a processing unit, wherein the connection between the gas turbine and the dryer vessel directs substantially all the gas turbine exhaust into the dryer vessel and substantially precludes the introduction of air into the dryer vessel. The dryer vessel receives the manure for contact with the turbine exhaust gases to convert the manure to a dry material, which is passed to the processing unit where it is formed into granules, pellets or other desired form for the final dry fertilizer product. The method comprises drying, heating and converting the manure to form novel self binding fertilizer and soil builder type products for organic farming and other uses.

Owner:EARTHRENEW INC

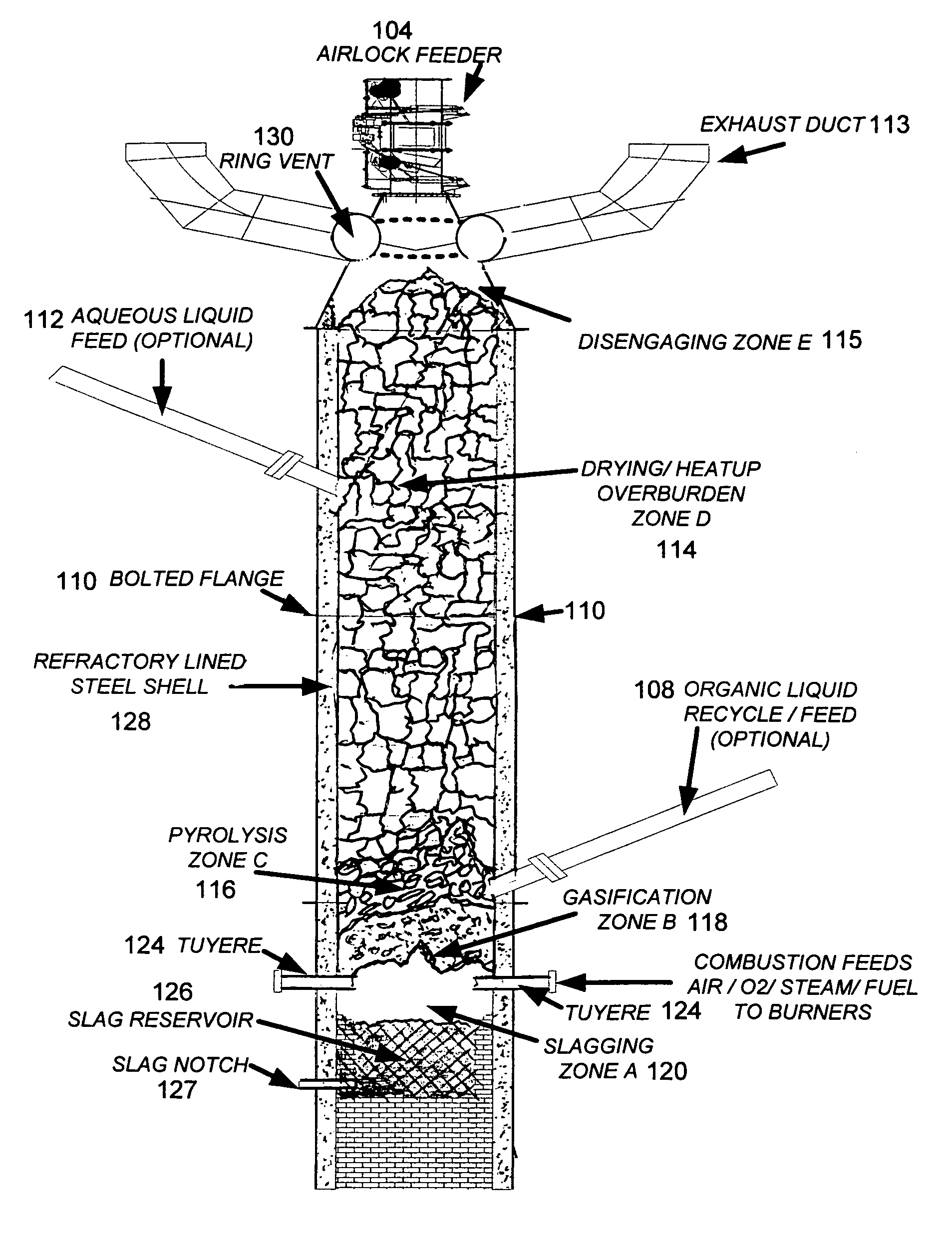

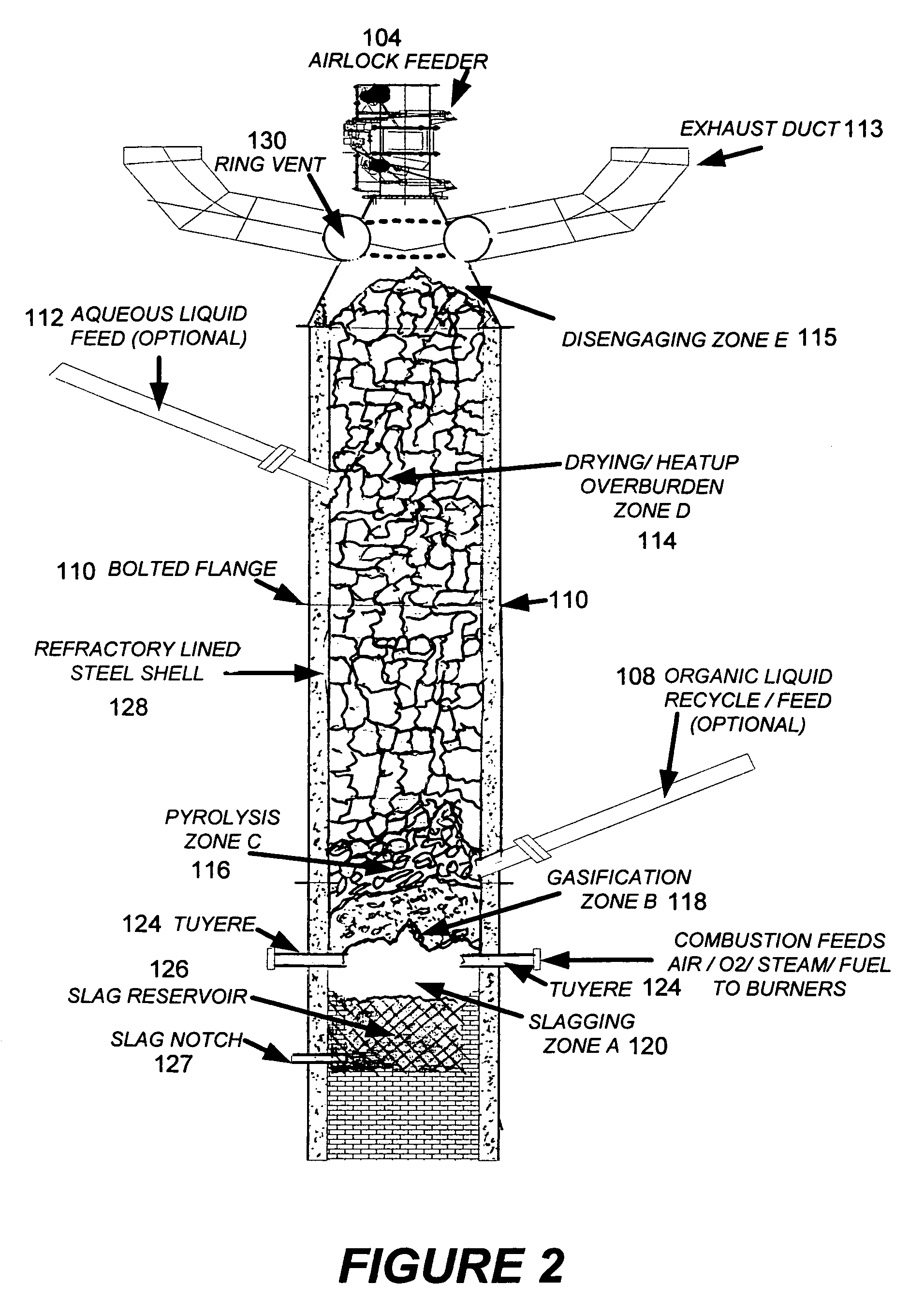

Process for pyrolytic heat recovery enhanced with gasification of organic material

InactiveUS7452392B2Improve throughputInhibition formationGas modification by gas mixingWaste based fuelThermal energyForming gas

This invention is a reactor and a process for the conversion of organic waste material such as municipal trash, sewage, post-consumer refuse, and biomass to commercially salable materials.The invention produces the following:1. Maximum energy conversion from the organic material2. High volume consumption of the organic feed material3. Less pollution of gaseous products than prior art systems4. Solid residuals for disposal are minimal and non-hazardous.The conversion is accomplished by combining anaerobic gasification and pyrolysis of the feed organic material and making it into synthetic gas. The synthetic gas is a mixture of hydrocarbons (CxHy), hydrogen, and carbon monoxide with small amounts of carbon dioxide and nitrogen. An essential feature of the invention is a hot driver gas, devoid of free oxygen and rich in water, which supplies the entire thermal and chemical energy needed for the reactions. This hot driver gas is produced by complete sub-stoichiometric combustion of the fuel (CxHy) before it enters the reactor.

Owner:NICK PETER A +4

Black-odor river pollution treatment method

InactiveCN101417840AEfficient removalControl and reduce the total amount receivedTreatment using aerobic processesWater aerationMicrobial agentSelf purification

The invention discloses a method for managing town black and olid river pollution in situ by utilizing biological repair technology, which takes the steps and measures of aerating and oxygenizing in riverway, adding a complex microbial agent, biologically repairing bottom sediment, arranging a bio-nest system and the like, so as to control and eliminate the exogenous and endogenous pollution of the river, purify the water quality of the river, improve the self-purification ability of the water body and achieve the purpose of eliminating black and olid. The method does not need to build structures in the riverway or lead the river water out of the riverway to be treated, or dredge the bottom sediment in the river, therefore the method is generally applicable to incomplete sewage interception and dredging or the rivers which can not be intercepted sewage or dredged temporarily, and the in situ treatment to the riverway which is affected by tide and has complicated fluid variation. Therefore, the method which can lead the water body to recover normal ecological function provides the practical, economic and convenient treatment method for various town black and olid rivers.

Owner:黎赓桓 +1

Extensive wastewater treatment capture agent

InactiveCN104071880ASimple application processQuick resultsWater/sewage treatment by flocculation/precipitationChemical adsorptionSewage

The invention discloses an extensive wastewater treatment capture agent. The capture agent is prepared from an organic coagulant, an inorganic coagulant, a coagulant aid, a binder and a modifier. The colloid charge balance in sewage is broken by ionization of the capture agent in water, and pollutants are subjected to physical and chemical adsorption and subjected to consolidation settlement, so as to achieve the target of reducing chemical oxygen demand (COD), biochemical oxygen demand (BOD) and storativity (SS). The extensive wastewater treatment capture agent is simple in application process, quick to take effect, wide in adaptability and broad in market prospect.

Owner:NANCHANG GERUN ENVIRONMENTAL PROTECTION SCI &TECH CO LTD

Recirculating marine aquaculture process

A high efficiency recirculating marine aquaculture process for producing fish at variable yield densities of up to 60 kg / meter3 of the aquaculture tank, including fish that spawn under short photoperiods such as gilthead seabream (Sparus aurata) as well as fish that spawn under long photoperiods such as striped bass (Morone saxatilis). The process involves broodstock conditioning, spawning / reproduction, larval growth, nursery, and adult grow-out operations. The process is characterized by high-rate growth at optimal process conditions requiring less than 10% daily water exchange, thereby enabling effluent waste from the system to be discharged to a municipal sewer after disinfection treatment, which in turn permits siting of the aquaculture process facility in urban / suburban locations where aquaculture processes have been previously infeasible.

Owner:UNIV OF MARYLAND BALTIMORE COUNTY

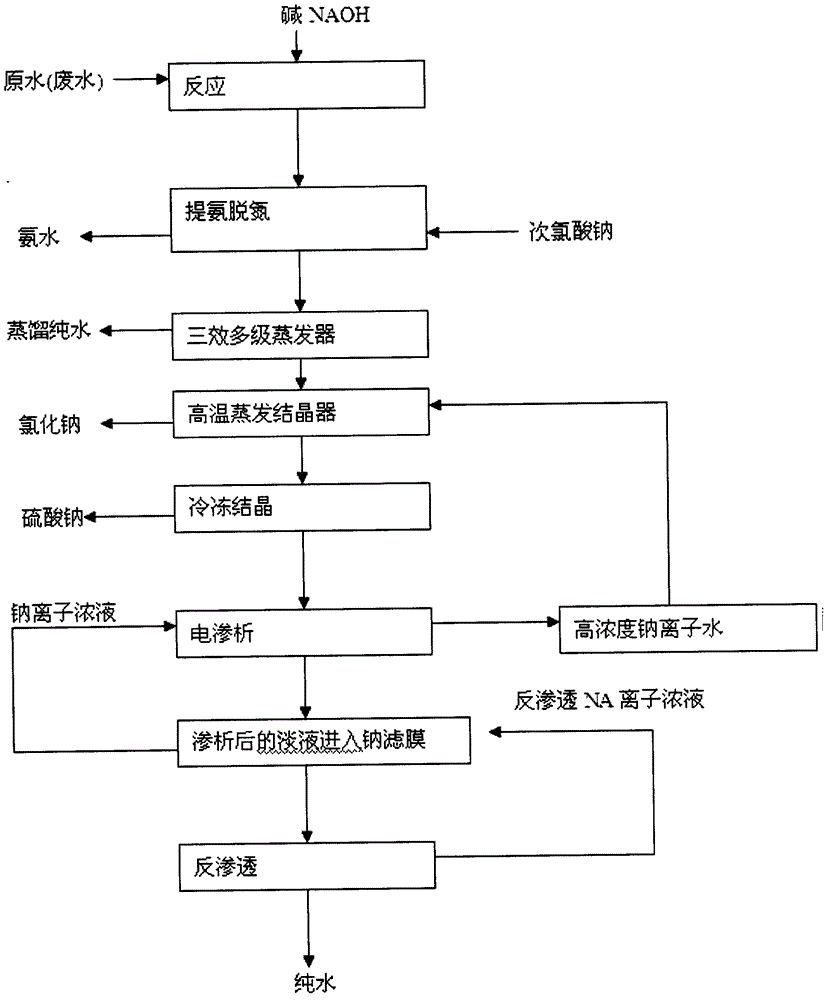

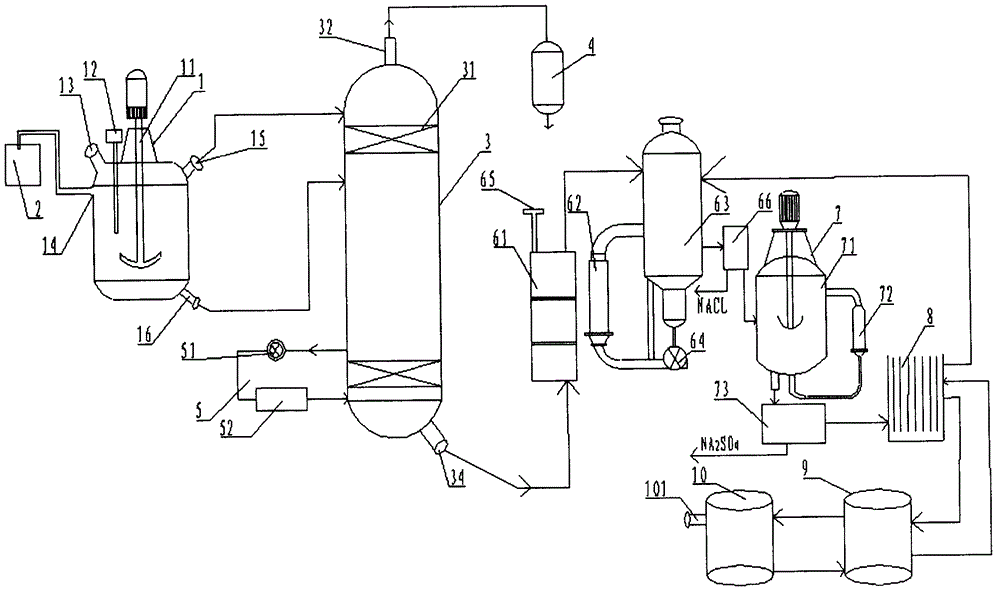

Method and device for utilizing sewage containing ammonia and sodium

ActiveCN104609633AReduce energy consumptionSave energyWater contaminantsMultistage water/sewage treatmentResource utilizationReverse osmosis

The invention discloses a method and device for utilizing sewage containing ammonia and sodium. The method comprises the steps of deamination reaction, denitrification reaction, gas-liquid separation, triple-effect multistage evaporation, evaprative crystallization and freezing crystallization, electrodialysis and sodium filteration membrane, and concentration of reverse osmosis membrane, so that distilled water and membrane deion pure water are recovered, and the resource utilization of sole sodium chloride and sodium sulfate is realized.

Owner:RUANSHI CHEM CHANGSHU

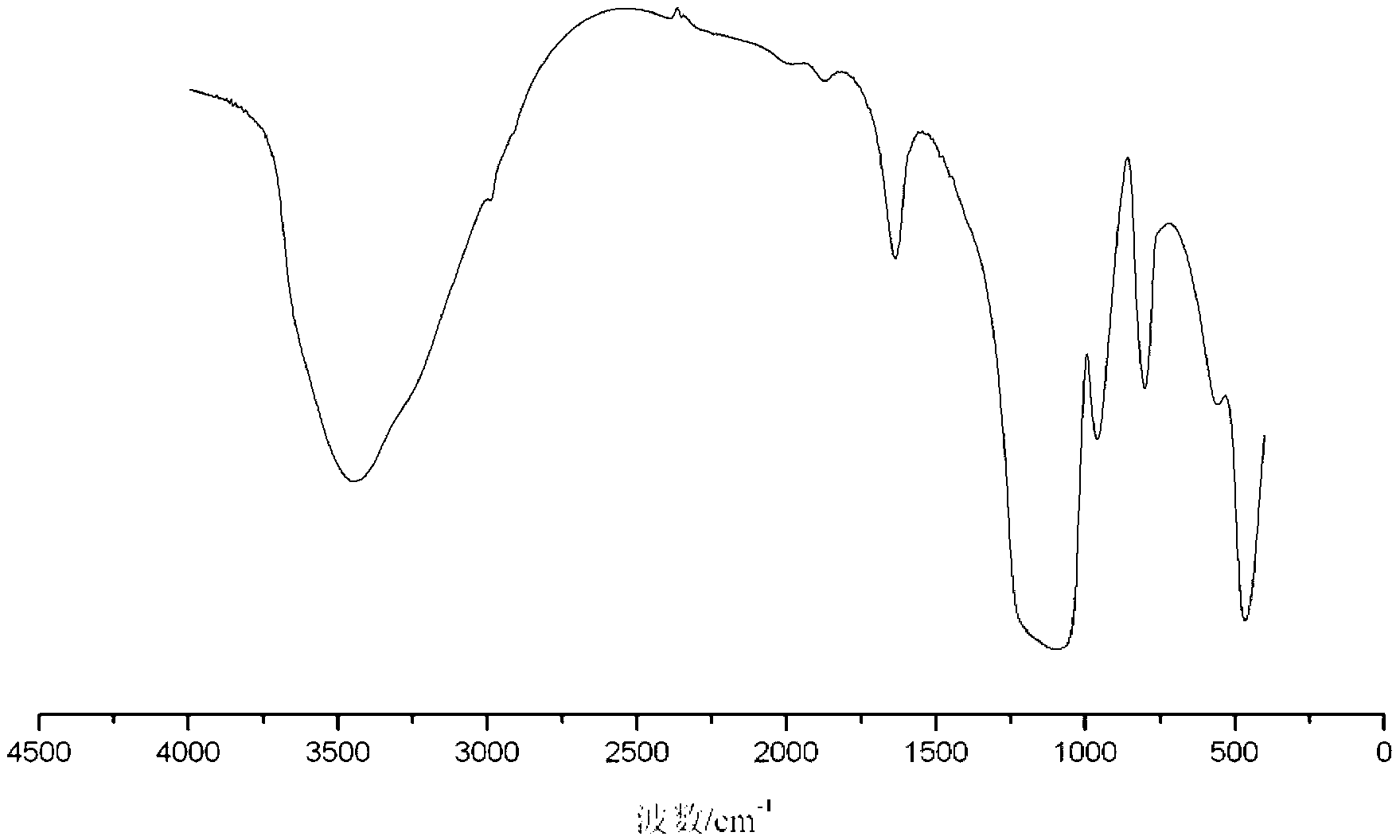

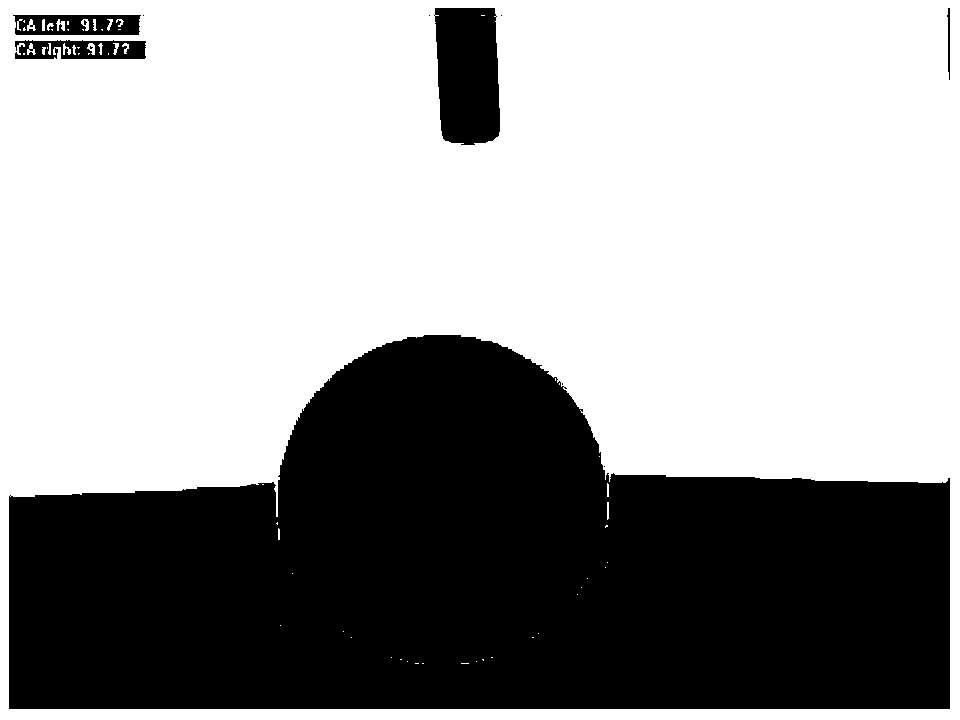

Super-hydrophilic and underwater-super-oleophobic oil-water separation mesh membrane, and preparation method and application thereof

InactiveCN103316507AHas super oleophobic propertiesLow costFatty/oily/floating substances removal devicesLiquid separationHydrophilic polymersSewage

The invention discloses a super-hydrophilic and underwater-super-oleophobic oil-water separation mesh membrane, and a preparation method and an application thereof. According to the method, fabric mesh with a specification of 100-300 meshes is subjected to ultrasonic cleaning, and is air-dried under normal temperature; a hydrophilic polymer water-sensitive agent and a cross-linking agent are dissolved in water according to a ratio of 1:9-9:1; the mixture is well mixed by magnetic stirring, such that a solution with a concentration of 1-99% is prepared; nano-sol is prepared with a sol-gel method; the solution and the nano-sol are prepared into a mixed solution with a concentration of 1-99%, and the solution is well dispersed through ultrasonic dispersion; the mesh is soaked in the mixed solution and is vertically lifted, or the mesh is directly sprayed by using a high-pressure spraying gun; and the mesh is bake-dried, such that the super-hydrophilic and underwater-super-oleophobic oil-water separation mesh membrane is obtained. Contact angles of the super-hydrophilic and underwater-super-oleophobic oil-water separation mesh membrane with water and oil in air are both 0 DEG, and the membrane is super-hydrophilic. Under water, the contact angle of the membrane with oil drops is larger than 150 DEG, and the membrane has an oil drop low adhesion characteristic. The mesh membrane provided by the invention can be used in oil-water mixture separation and oil-containing sewage processing.

Owner:SOUTH CHINA UNIV OF TECH

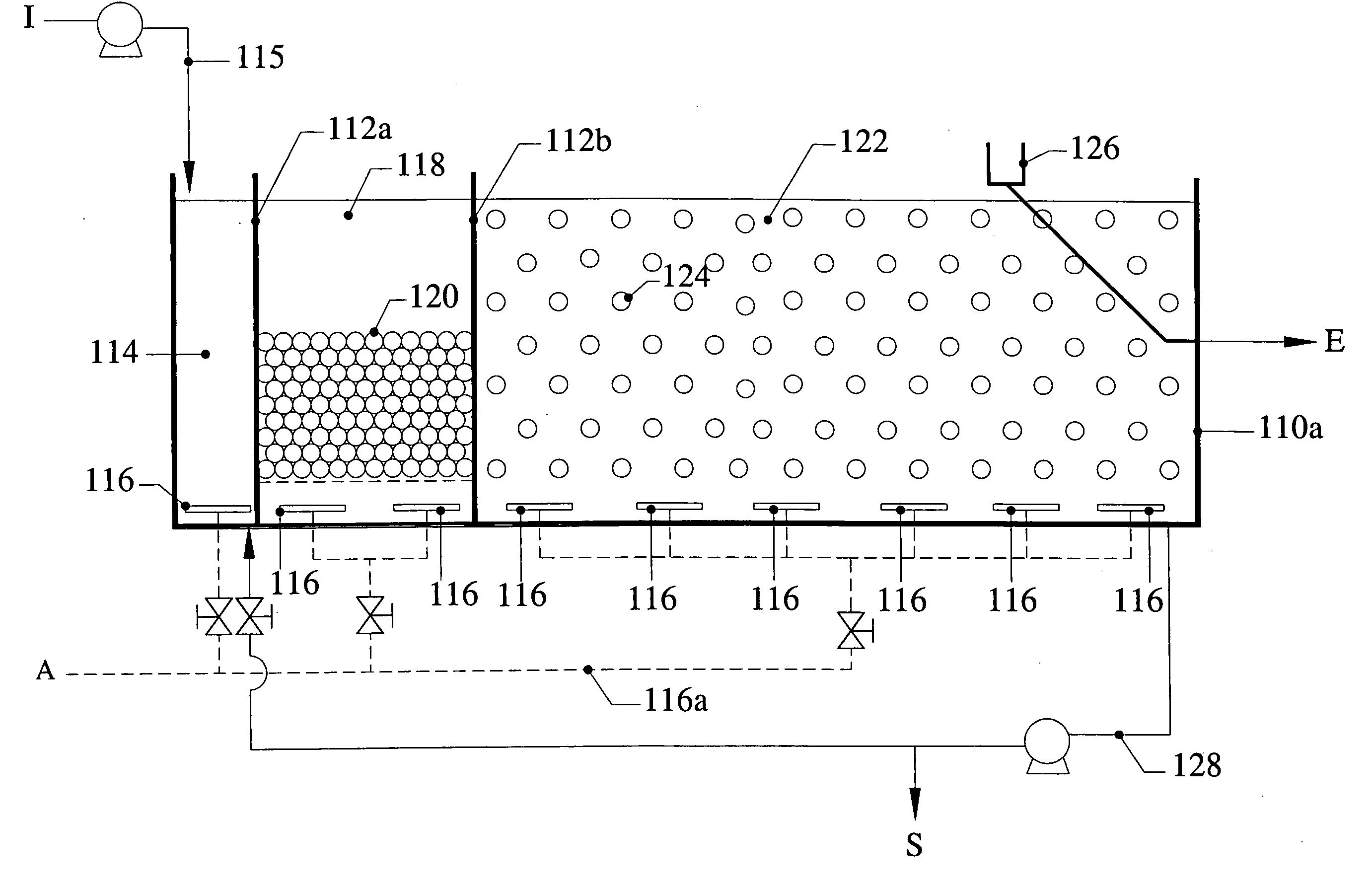

Combined activated sludge-biofilm sequencing batch reactor and process

InactiveUS20040206699A1Similar oxygen transfer efficiencyRemoval can be promoted and increasedTreatment using aerobic processesSeparation devicesSequencing batch reactorActivated sludge

A new biofilm-activated sludge Sequencing Batch Reactor (SBR) treatment process for sewage or wastewater has successfully been developed as the third generation SBR (SBR3). This new SBR3 process utilizes a multi-stage and multi-sludge SBR configuration receiving either continuous or intermittent inflow of wastewater. Each stage has individually controlled continuous or alternating anaerobic / anoxic / aerobic operation, with or without mixing and recycling from the other stage(s). The configuration and operation is dependent upon the treatment objectives and effluent discharge requirements. In the preferred embodiment, carriers are used to facilitate control of operating conditions.

Owner:KINGSFORD ENVIRONMENTAL H K

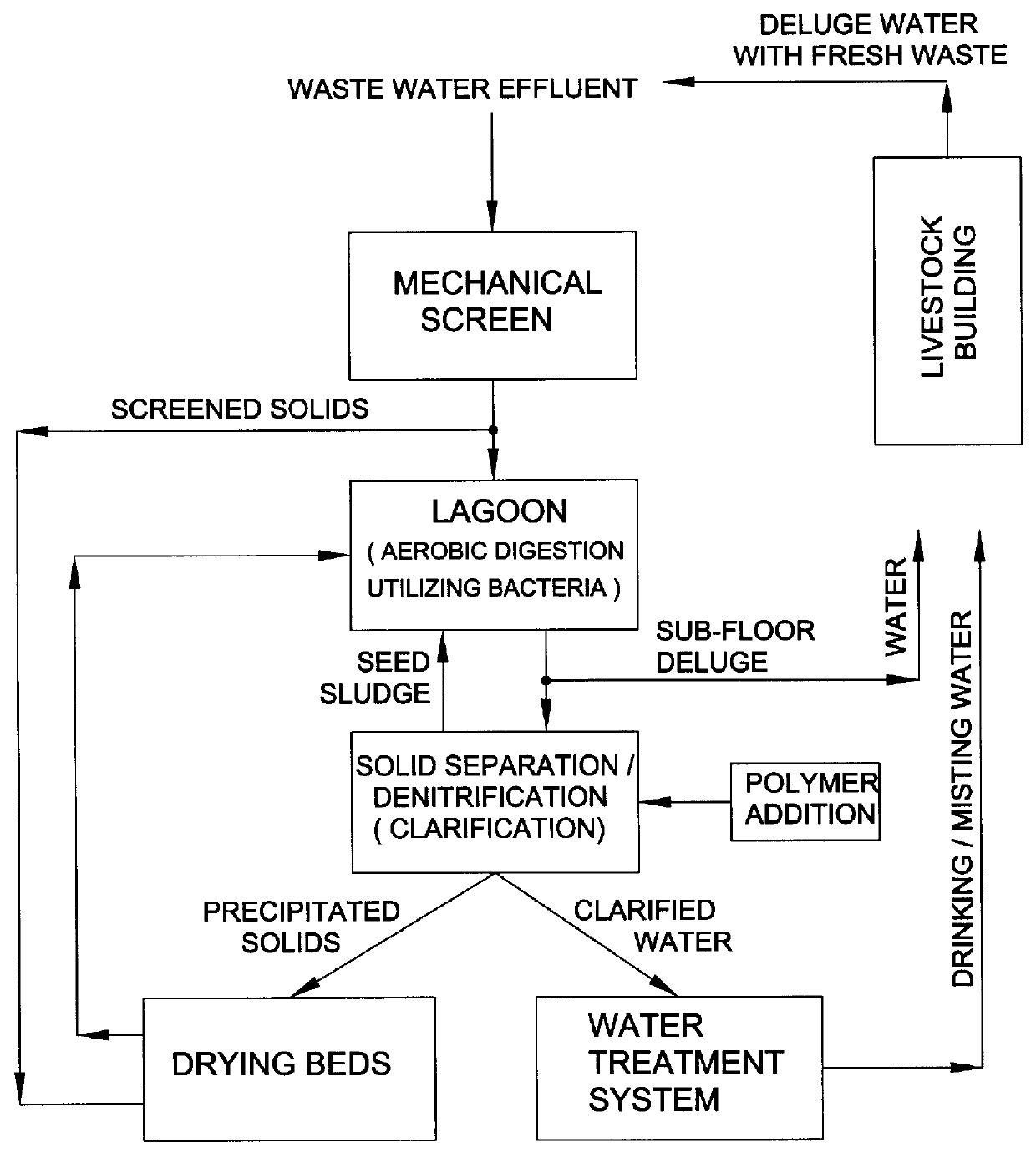

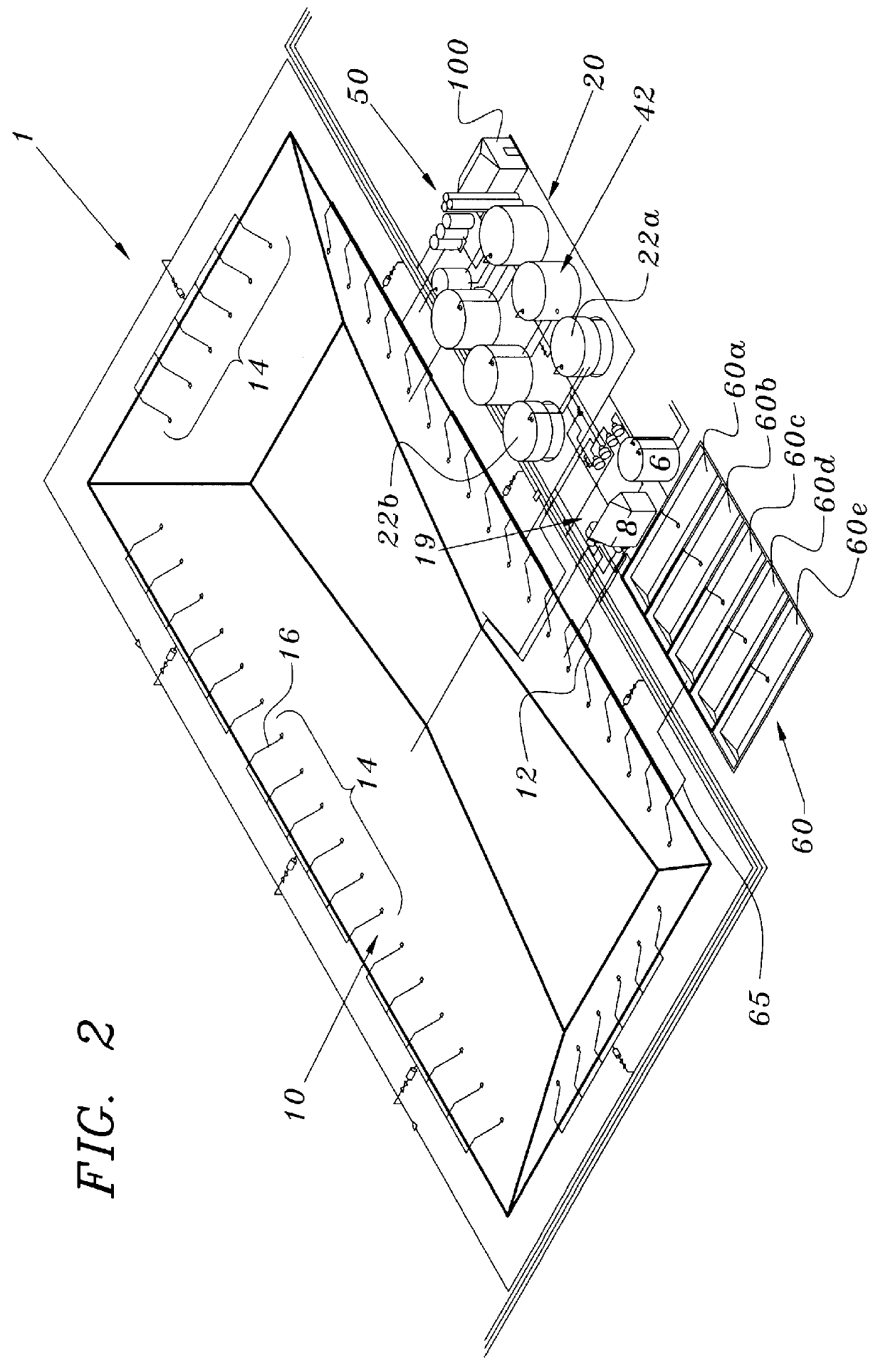

Apparatus and method for purification of agricultural animal waste

InactiveUS6039874AEffective treatment of wastewaterReducing fertilizer nutrientTreatment using aerobic processesOther chemical processesAbove groundFiltration

An apparatus and method for treating and reusing the wastewater discharged from agricultural animal farms. The apparatus and method of the present invention is designed to be a zero discharge system in which no wastewater will be discharged or spray irrigated. The wastewater effluent is first passed through a mechanical screen were bulk solids are separated and partially de-watered. The screened effluent is then directed to a primary plastic-lined earthen lagoon where it undergoes aerobic digestion utilizing specially selected bacteria. After treatment in the primary lagoon, the wastewater effluent is used to wash the floors of the hog houses or undergoes a purification phase including solids separation / denitrification, filtration and sterilization. The solids separation / denitrification phase (clarification) preferably takes place in an anoxic environment in preferably above-ground tanks where suspended solids removal will occur as well as denitrification for nitrate reduction. The clarification process may be facilitated through use of polymer addition. The majority of solids will be sent to a plurality of drying beds for de-watering and subsequent removal.

Owner:AGRIMOND USA CORP

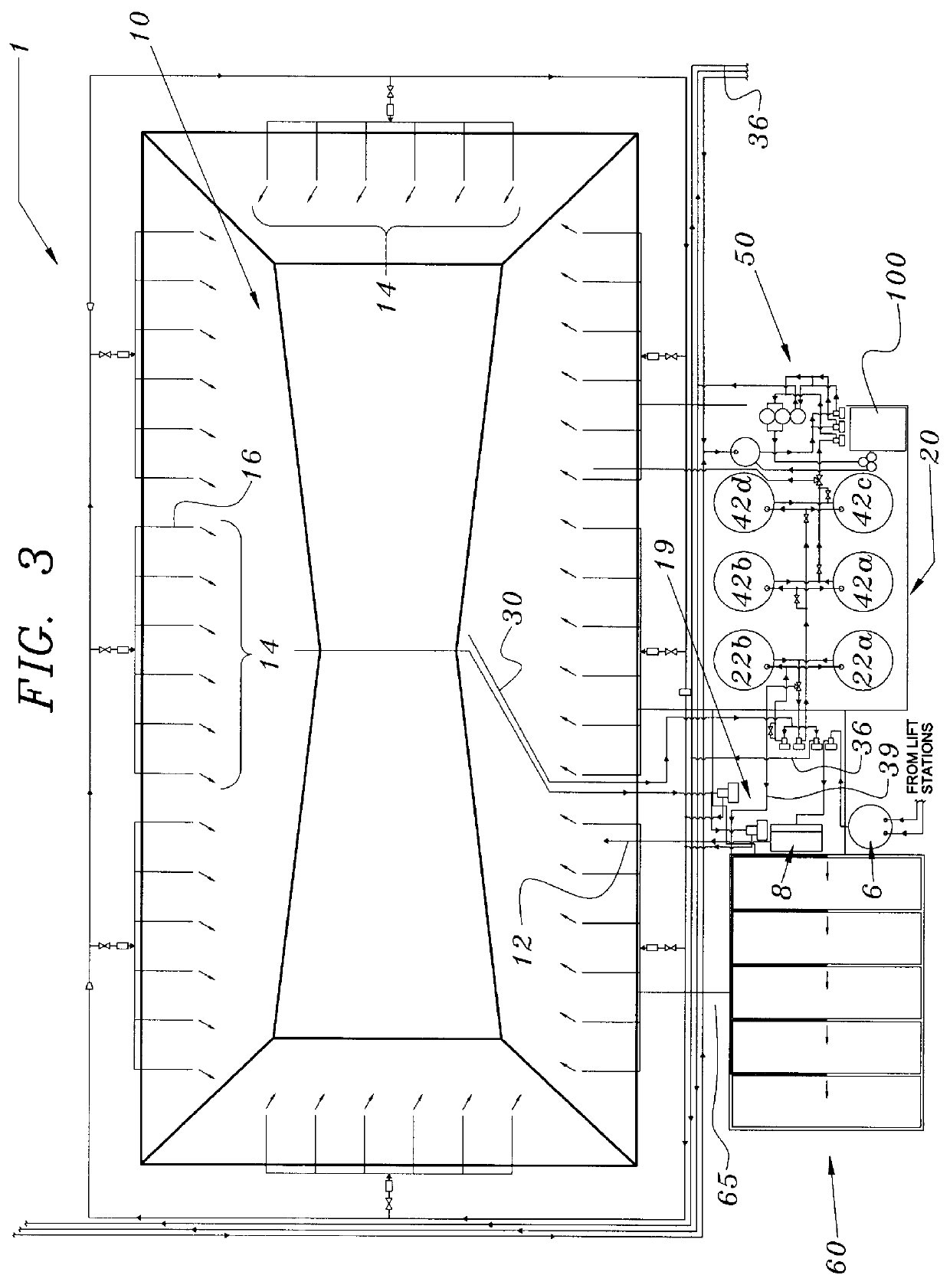

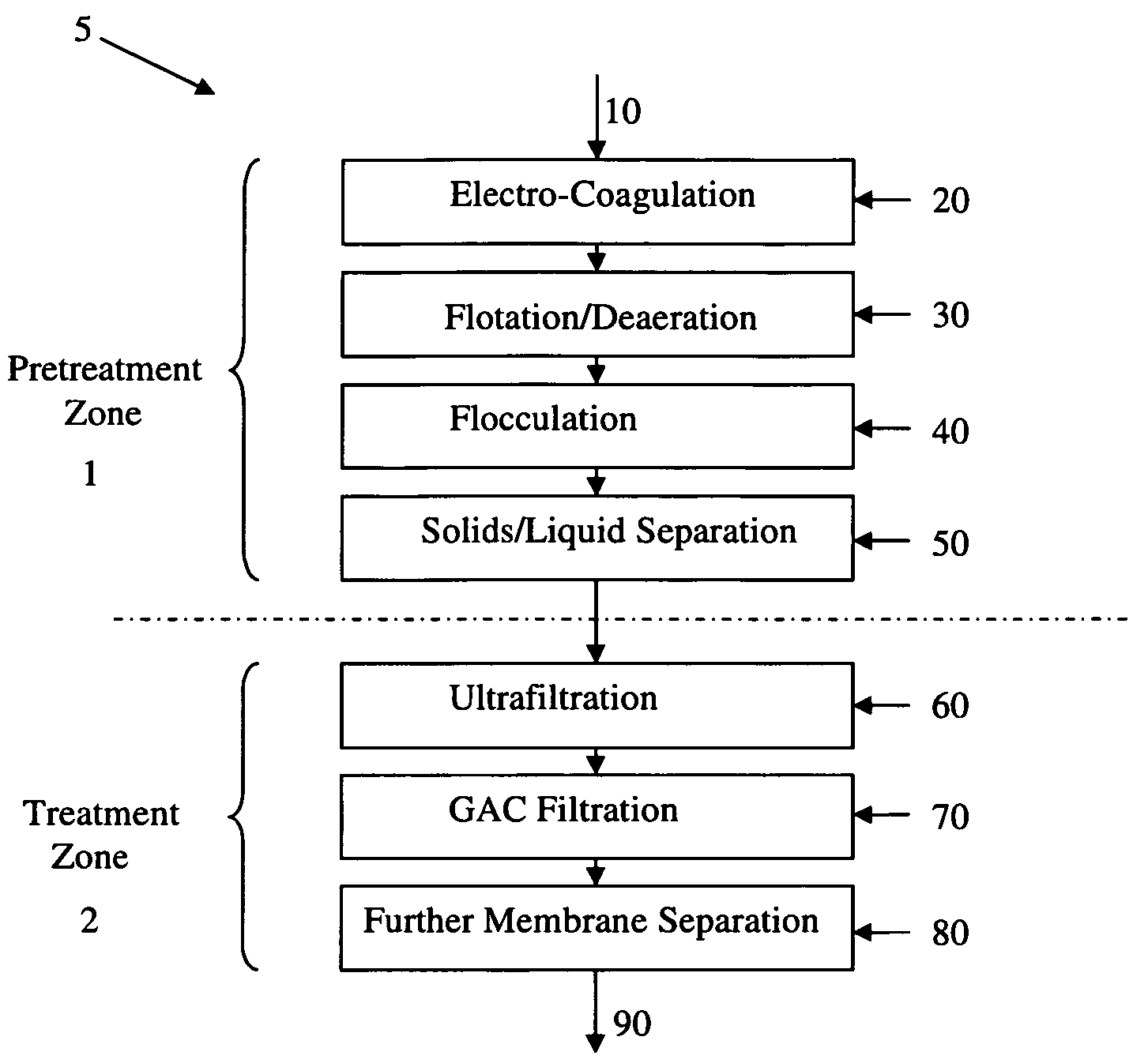

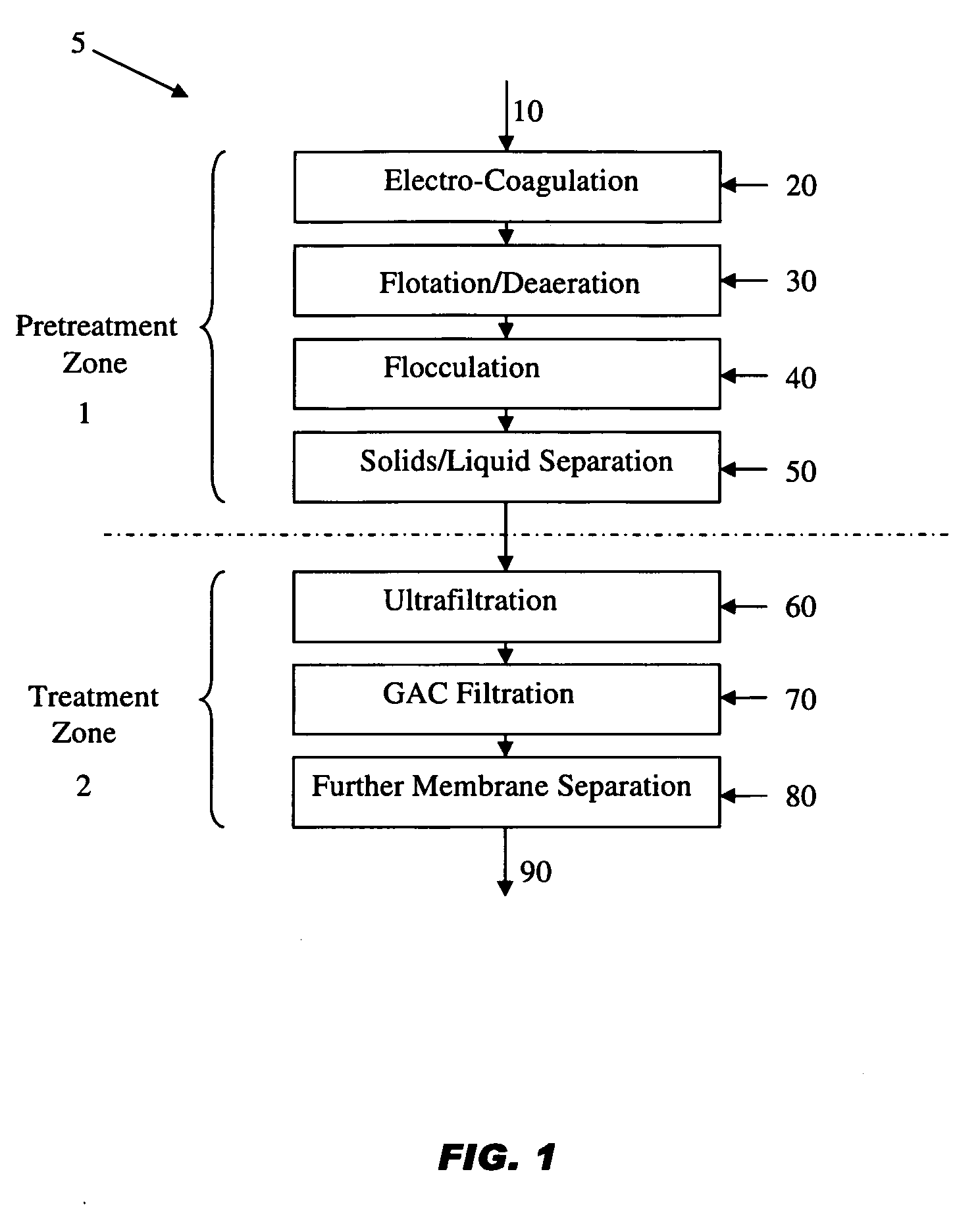

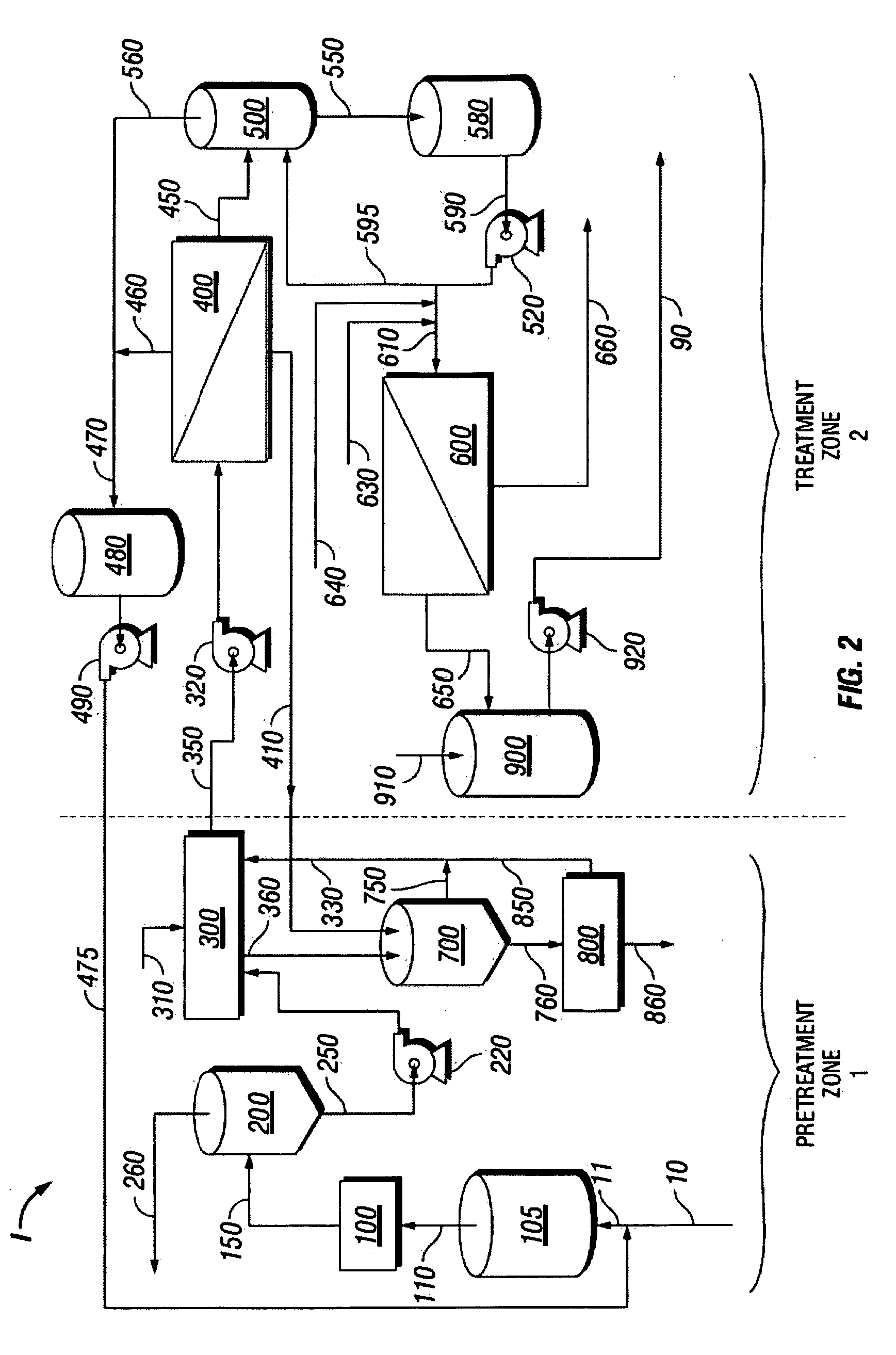

Treatment process and system for wastewater, process waters, and produced waters applications

A method for the removal of contaminants from a contaminated water stream, by pretreating the contaminated water stream to yield a pretreated water stream, wherein pretreating comprises passing the contaminated water stream to at least one electrocoagulation cell wherein coagulation of contaminants is promoted, yielding an electrocoagulated stream; and separating coagulated contaminants from the electrocoagulated stream.An electrocoagulation reactor comprising a plurality of electrodes positioned parallel to each other and provided with a means of energizing each electrode; a fluid inlet for an inlet stream comprising contaminated water; a fluid outlet for an outlet stream comprising electrocoagulated products; a flow distributor system; and a gas distribution system for injecting a gas into the electrocoagulation reactor. An electrocoagulation system for treating a contaminated water stream, the system comprising at least one electrocoagulation reactor.

Owner:ITS ENGINEERED SYST

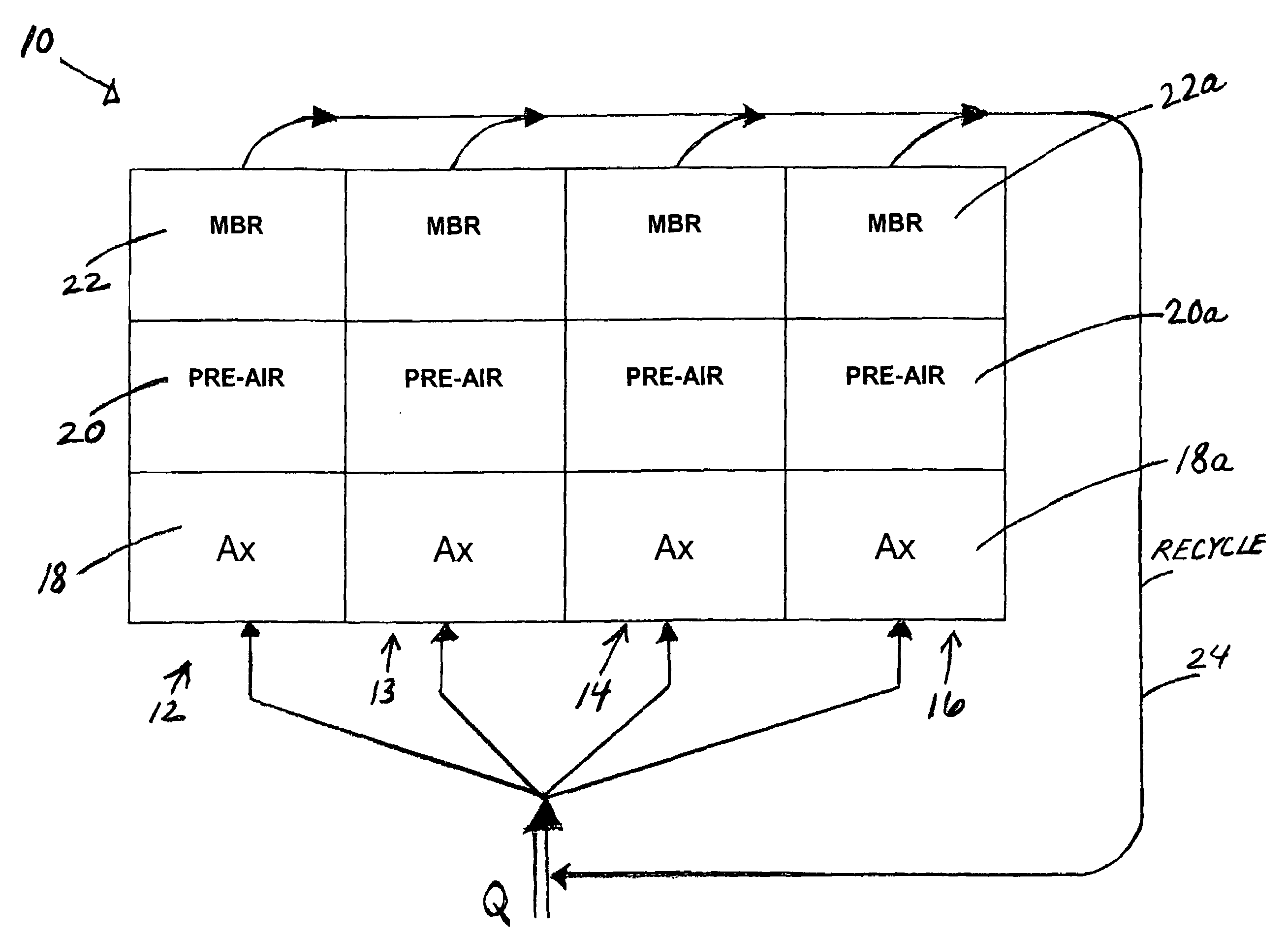

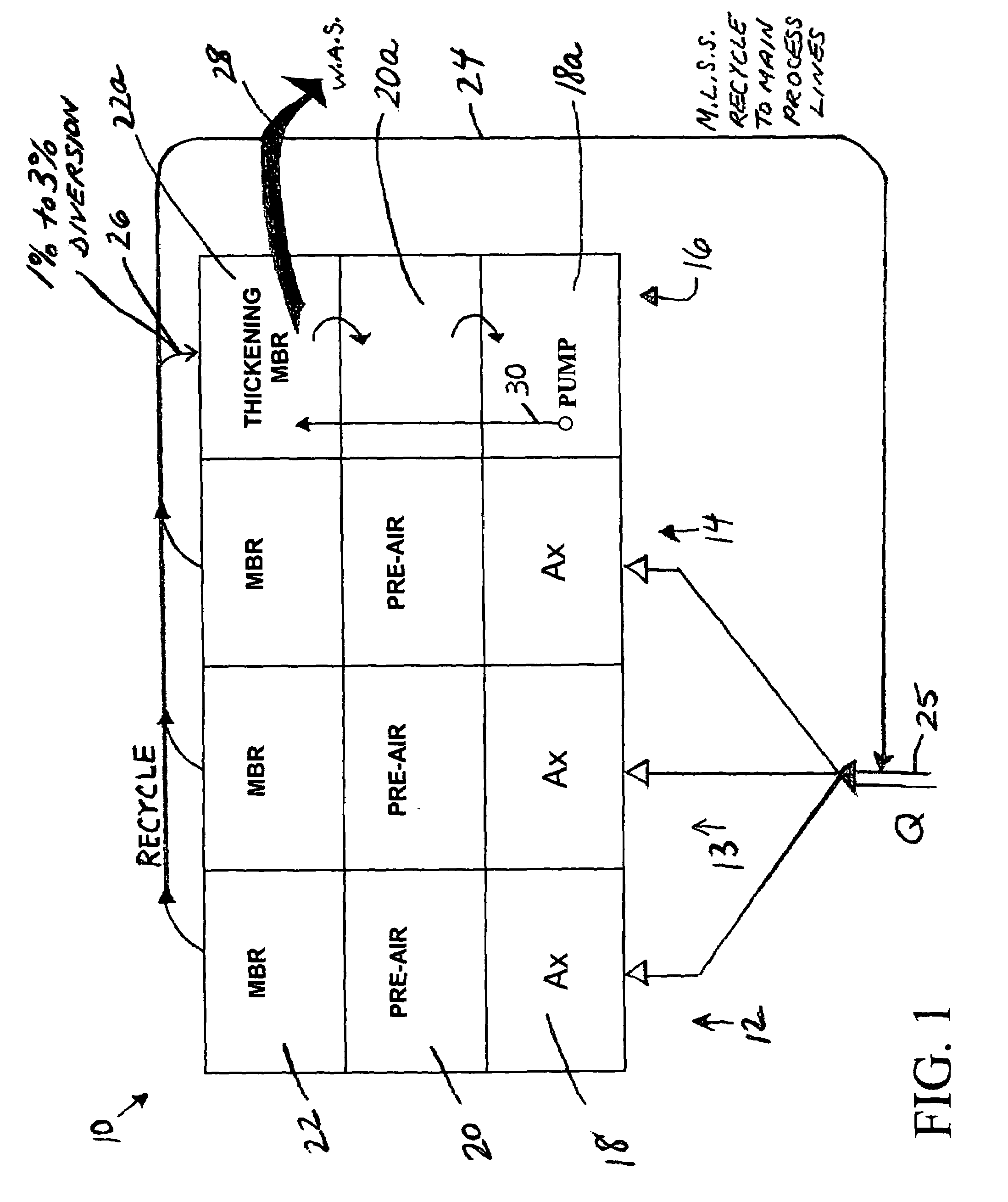

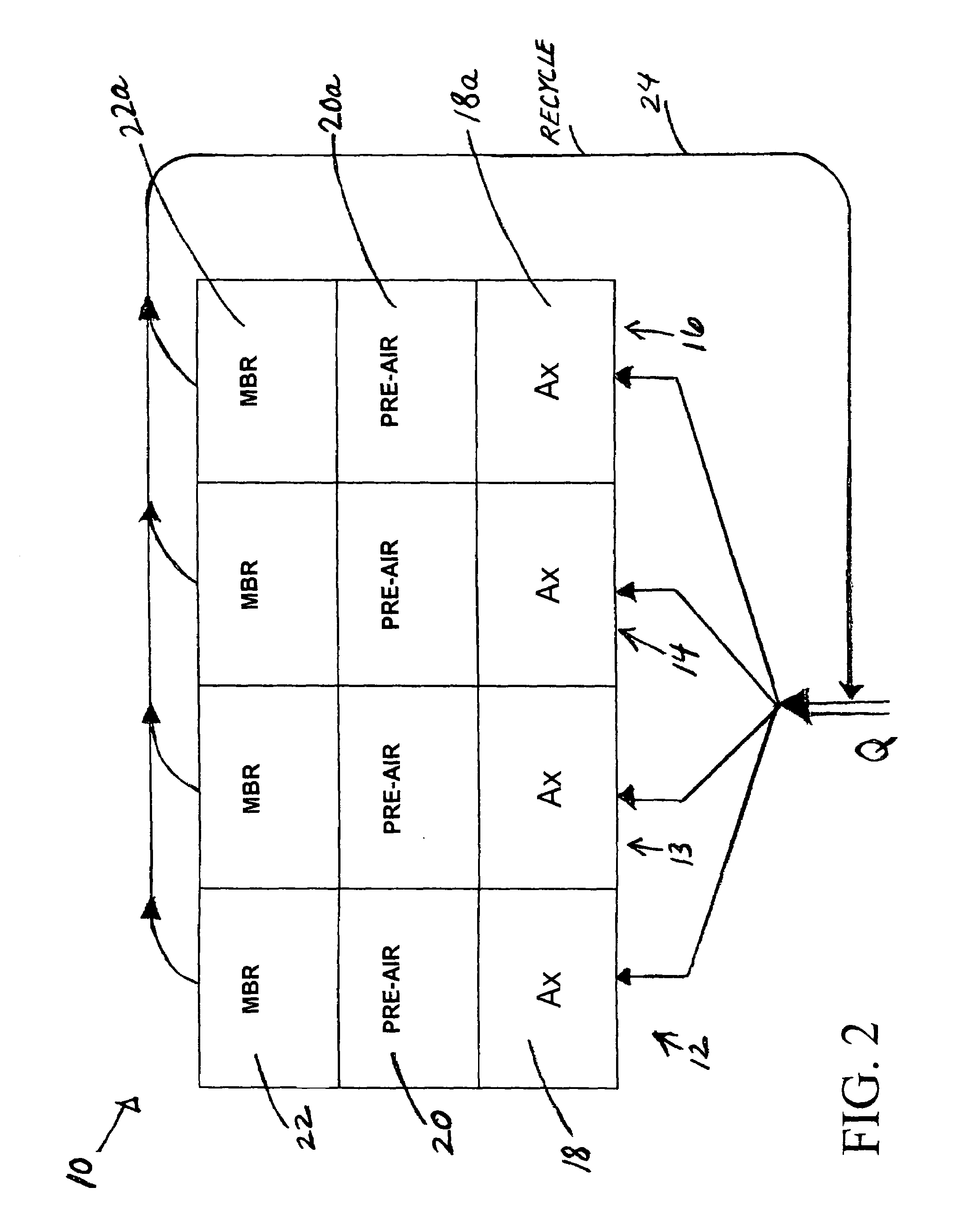

Wastewater treatment system with membrane separators and provision for storm flow conditions

ActiveUS7147777B1Increase biomassTreatment using aerobic processesTreatment with aerobic and anaerobic processesStreamflowTreatment system

In a wastewater treatment system and process utilizing membrane bioreactors (MBRs), multiple, parallel series of tanks or stages each include, an MBR stage. Under conditions of normal flow volume into the system, influent passes through several parallel series of stages or process lines, which might be, for example, an anoxic stage, an aeration stage and an MBR stage. From the MBR stages a portion of M.L.S.S. is cycled through one or more thickening MBRs of similar process lines, for further thickening and further processing and digesting of the sludge, while a majority portion of the M.L.S.S. is recycled back into the main process lines. During peak flow conditions, such as storm conditions in a combined storm water / wastewater system, all of the series of stages with their thickening MBRs are operated in parallel to accept the peak flow, which is more than twice normal flow. M.L.S.S. is recycled from all MBR stages to the upstream end of each of all the parallel process lines, mixing with influent wastewater, and the last one or several process lines no longer act to digest the sludge. Another advantage is that with the thickened sludge in the last process line of basins, which ordinally act to digest the sludge, there is always sufficient biomass in the system to handle peak flow, the biomass being available if needed for a sudden heavy flow or an event that might bring a toxic condition into the main basins.

Owner:OVIVO INC

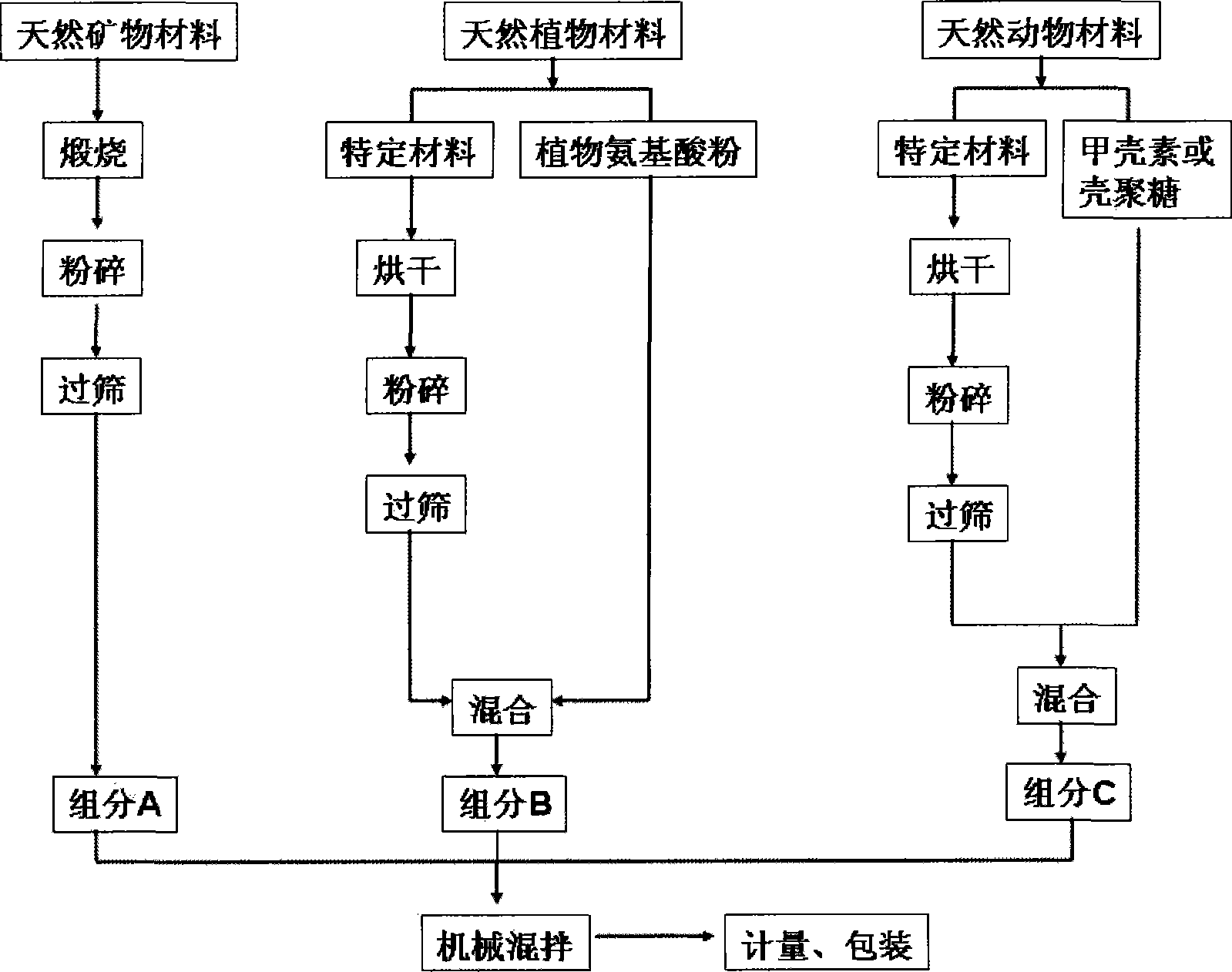

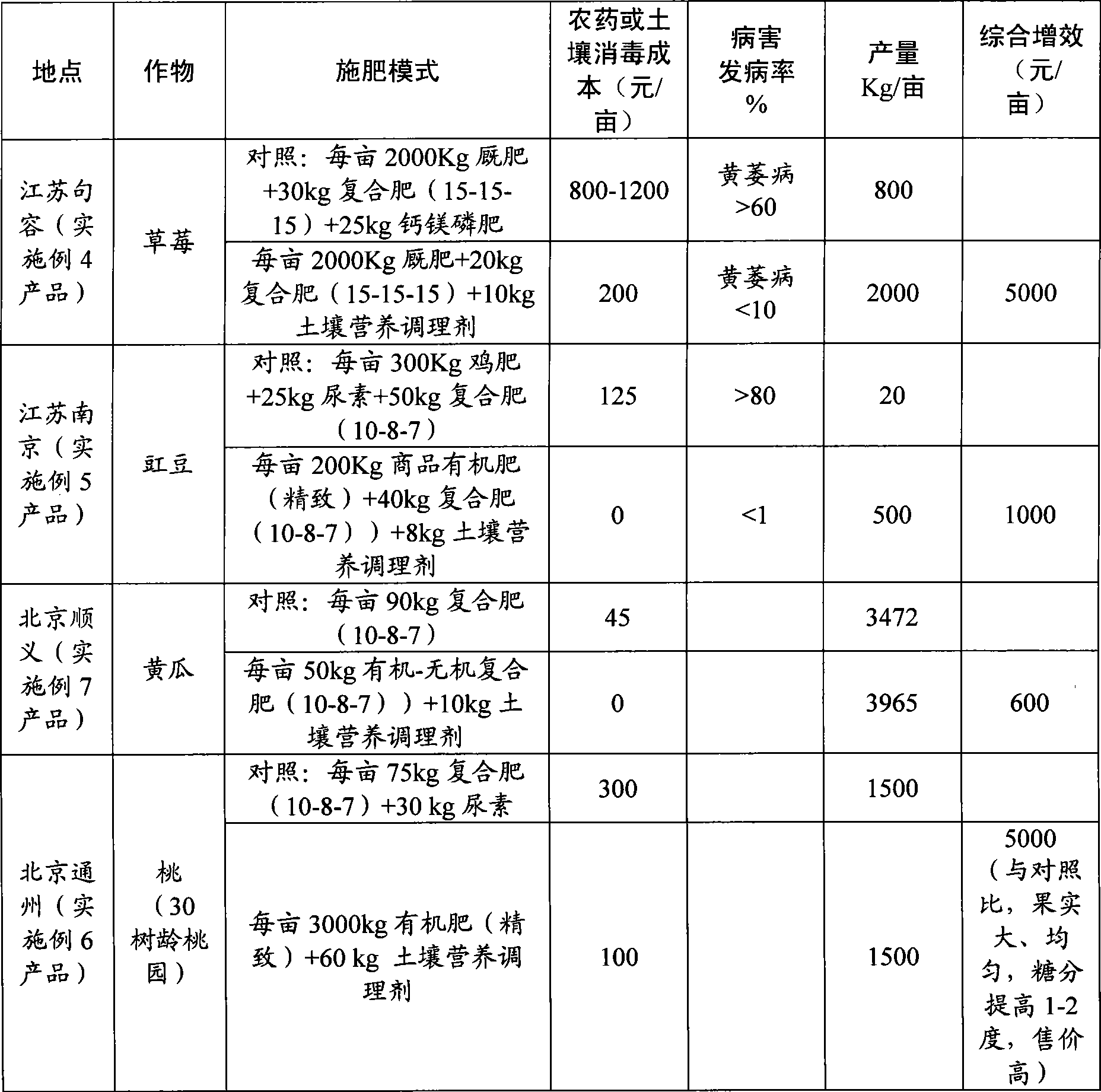

Soil fertility amendment and preparation method thereof

The invention provides a multifunctional soil nutrient conditioner formula with low cost, practicality and effectiveness and a preparation method thereof aiming at the technical problems. The production technology is simple, the production cost is low, and no harmful gas and sewage are generated during production. The product can effectively provide dozens of nutritive elements required for plant growth, is applied by being combined with a common fertilizer and an organic fertilizer, and can obviously improve the utilization rate of the fertilizer, so as to reduce the fertilizer input; and simultaneously the product can obviously stimulate action of beneficial floras of the soil, inhibit action of causal organisms, and increase the disease suppression of the soil and the resistance of plants, and then can effectively control generation of physiological diseases and soil-borne diseases, so as to reduce the pesticide input. The fertilizer input and the pesticide input can be reduced by more than 15 to 30 percent, and the yield can be increased by more than 15 to 30 percent, and simultaneously the product quality is obviously improved and cost conservation and synergism are obvious. Moreover, the soil improvement effect is obvious, and the sustainable utilization capacity can be obviously enhanced.

Owner:仲元(北京)绿色生物技术开发有限公司 +1

Enzyme and bacterial combination in a slowly dissolvable matrix for septic tanks, grease traps and waste treatment

Sewage waste digestive bacteria and enzymes are incorporated into a slow release material and delivered to the site of the waste to digest the solid waste. The slow release material is made heavy so the enzymes and bacteria will be delivered to the sludge in the bottom of a sewage digester chamber and made fat soluble so that the enzymes and bacteria will be delivered to the grease in the waste system to be digested. This selective delivery system prevents the enzymes and bacteria from being diluted in grey water rendering them less effective and discharged from the sewage system without digesting waste.

Owner:NOVOZYMES AS

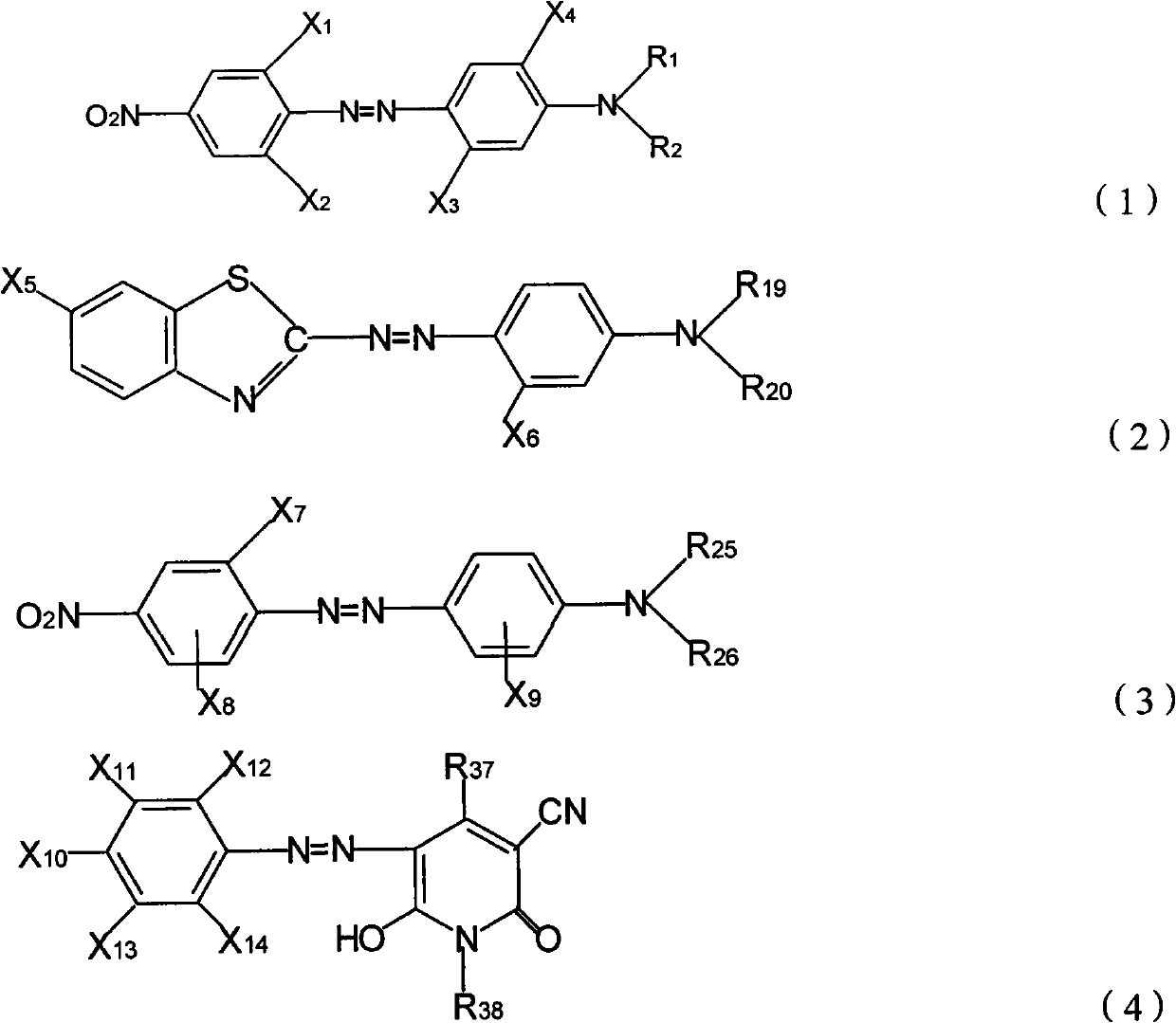

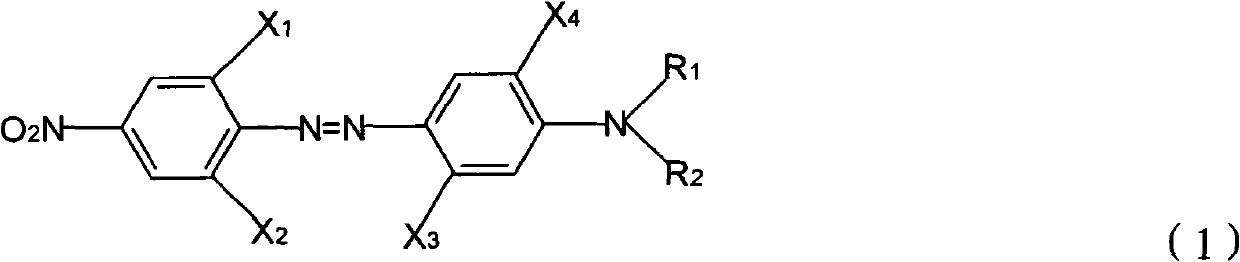

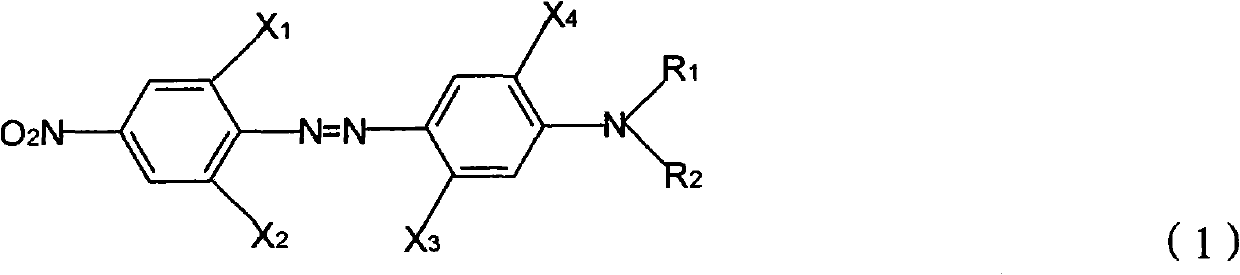

Environment-friendly disperse dye composition

ActiveCN101768376AIncrease profitProtect the environmentOrganic dyesDyeing processDisperse dyeSewage

The invention discloses an environment-friendly disperse dye composition, which comprises the following components by weight percent: 10-75% of dye monomer A as shown in formula (1), 2-35% of dye monomer B as shown in formula (2), 8-50% of dye monomer C as shown in formula (3), and 1-10% of dye monomer D as shown in formula (4). The disperse dye composition can be regulated to obtain colored lights such as black, blue, grey, brown and the like; the obtained dye composition is an environment-friendly dye, and has wide suitable range of the pH value, good pile-on property, strong covering performance, good lifting power, colour yield, levelling property and various fastness, and can greatly improve the utilization rate of the dye and reduce the dye sewage.

Owner:ZHEJIANG RUNTU

Biological deodorization and purification agent, and its use

A biologic deodoring and cleaning agent for treating the refuse to prepare fertilizer and cleaning and activating water area contains high-safety yeast, lactobacillus, nitrogen-fixing bacteria, functional bacillus, and photosynthetic bacteria.

Owner:CHINA AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com