Patents

Literature

9488 results about "Electric potential" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An electric potential (also called the electric field potential, potential drop or the electrostatic potential) is the amount of work needed to move a unit of charge from a reference point to a specific point inside the field without producing an acceleration. Typically, the reference point is the Earth or a point at infinity, although any point can be used.

Electrochemical cell

InactiveUS6284125B1Improve accuracyImprove reliabilityImmobilised enzymesBioreactor/fermenter combinationsElectricityDiffusion

A method for determining the concentration of a reduced (or oxidised) form of a redox species in an electrochemical cell of the kind comprising a working electrode and a counter electrode spaced from the working electrode by a predetermined distance, said method comprising the steps of: (1) applying an electric potential difference between the electrodes; (2) selecting the potential of the working electrode such that the rate of electro-oxidation of the reduced form (or electro-reduction of the oxidised form) of the species is diffusion controlled, (3) selecting the spacing between the working electrode and the counter electrode so that reaction products from the counter electrode arrive at the working electrode; (4) determining current as a function of time after application of the potential and prior to achievement of a steady state; (5) estimating the magnitude of the steady state current, and (6) obtaining from the change in current with time and the magnitude of the steady state current, a value indicative of the diffusion coefficient and / or of the concentration of the reduced form (or the oxidised form) of the species. Also disclosed is an apparatus for determining the concentration of a redox species in an electrochemical cell comprising: an electrochemical cell having a working electrode and a counter (or counter / reference) electrode, means for applying and electric potential difference between said electrodes, means for measuring the change in current with time, and characterised in that the working electrode is spaced from the counter electrode by less than 500 mum.

Owner:LIFESCAN INC

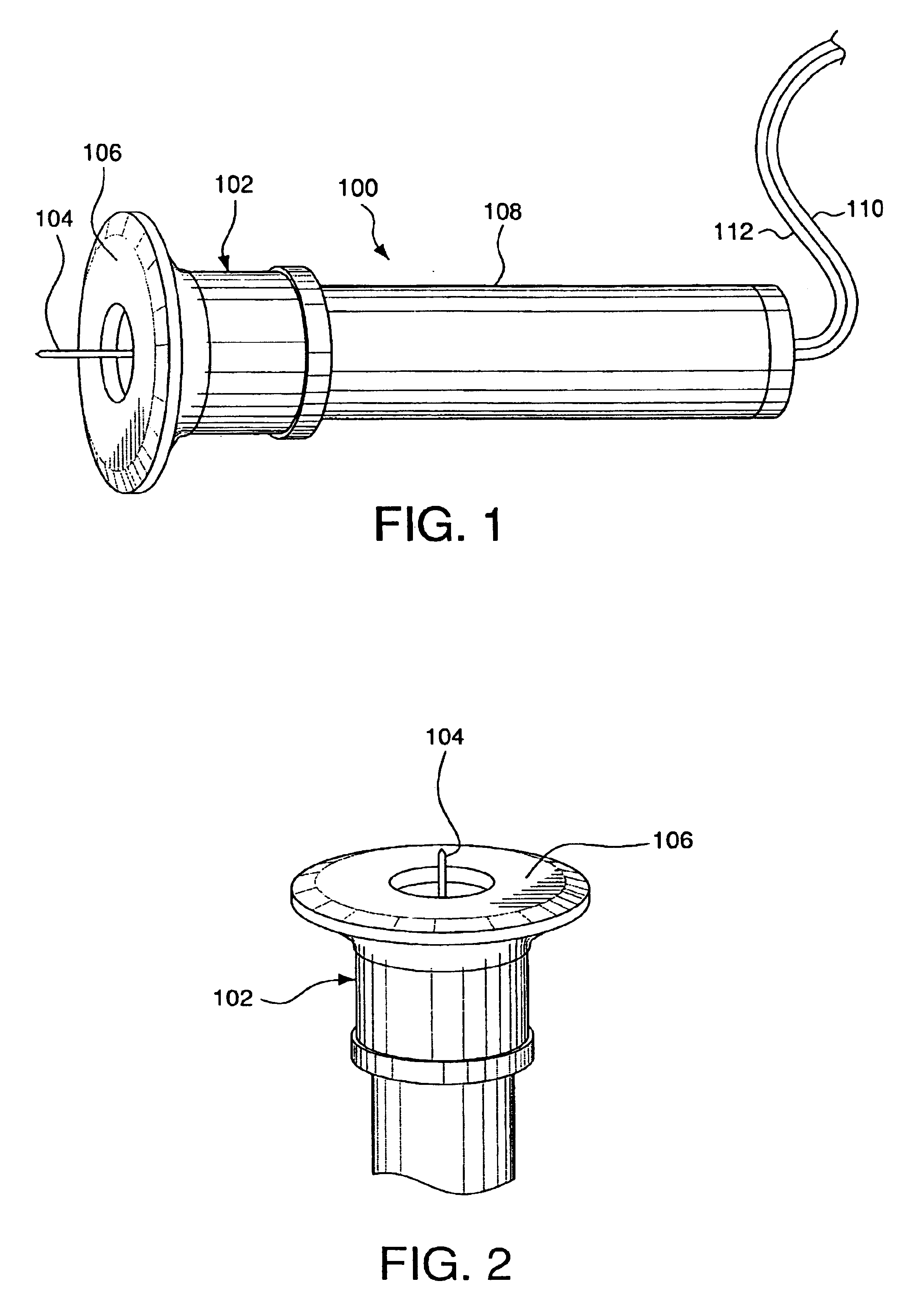

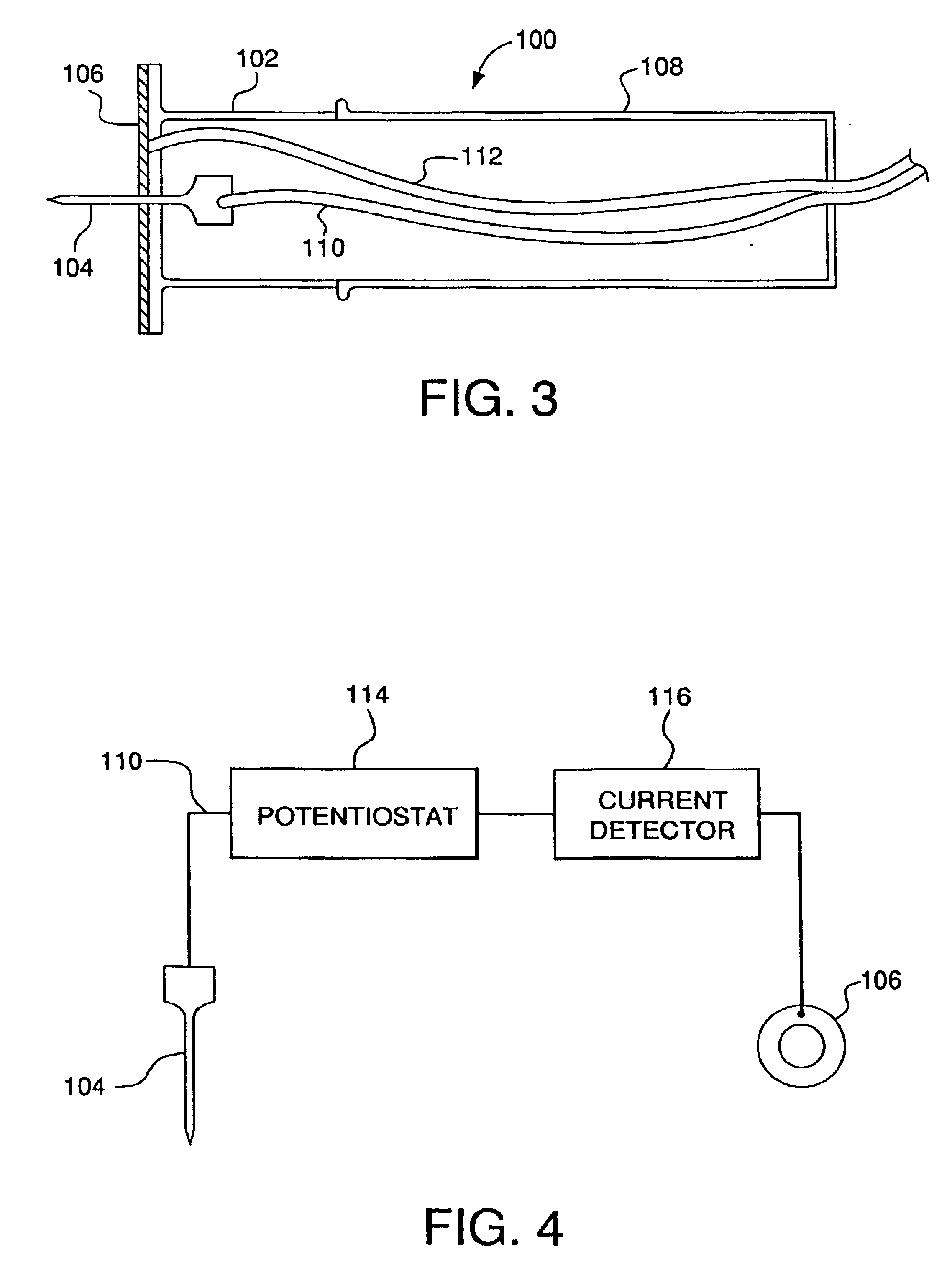

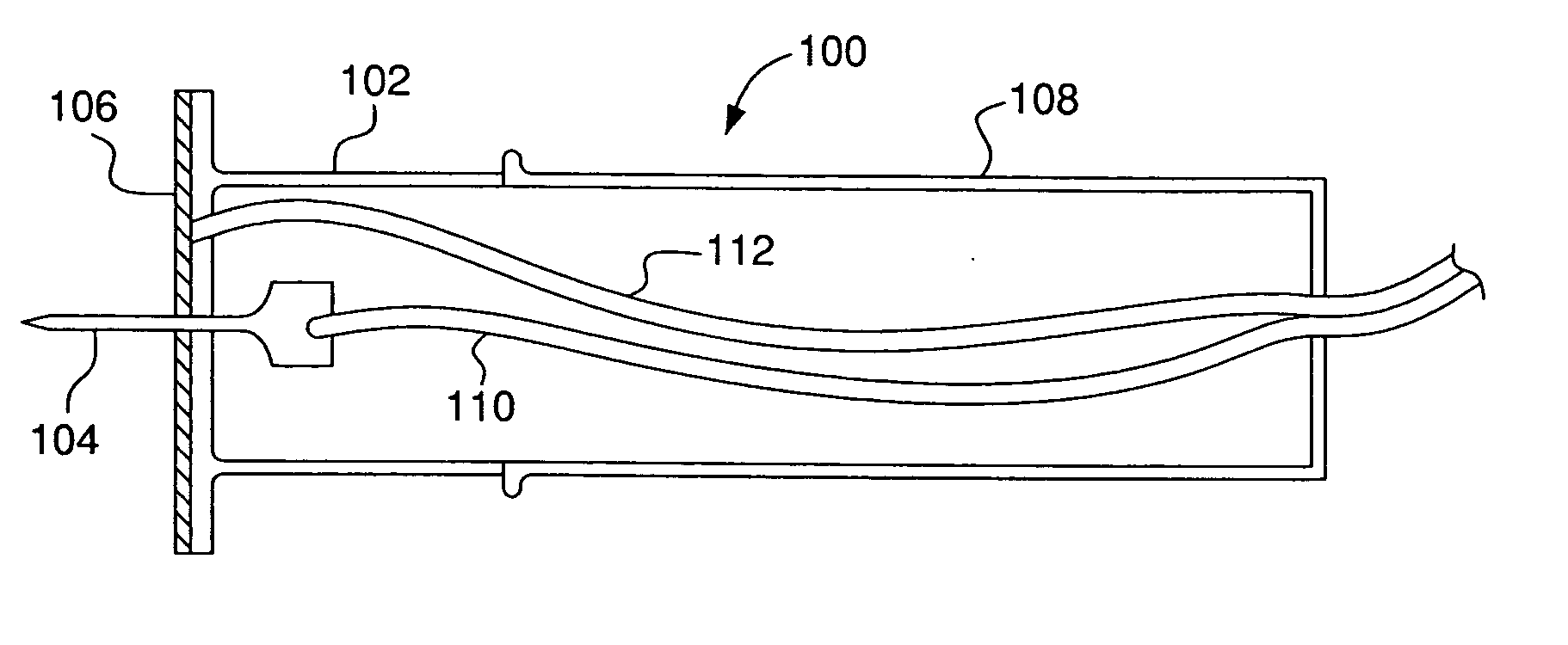

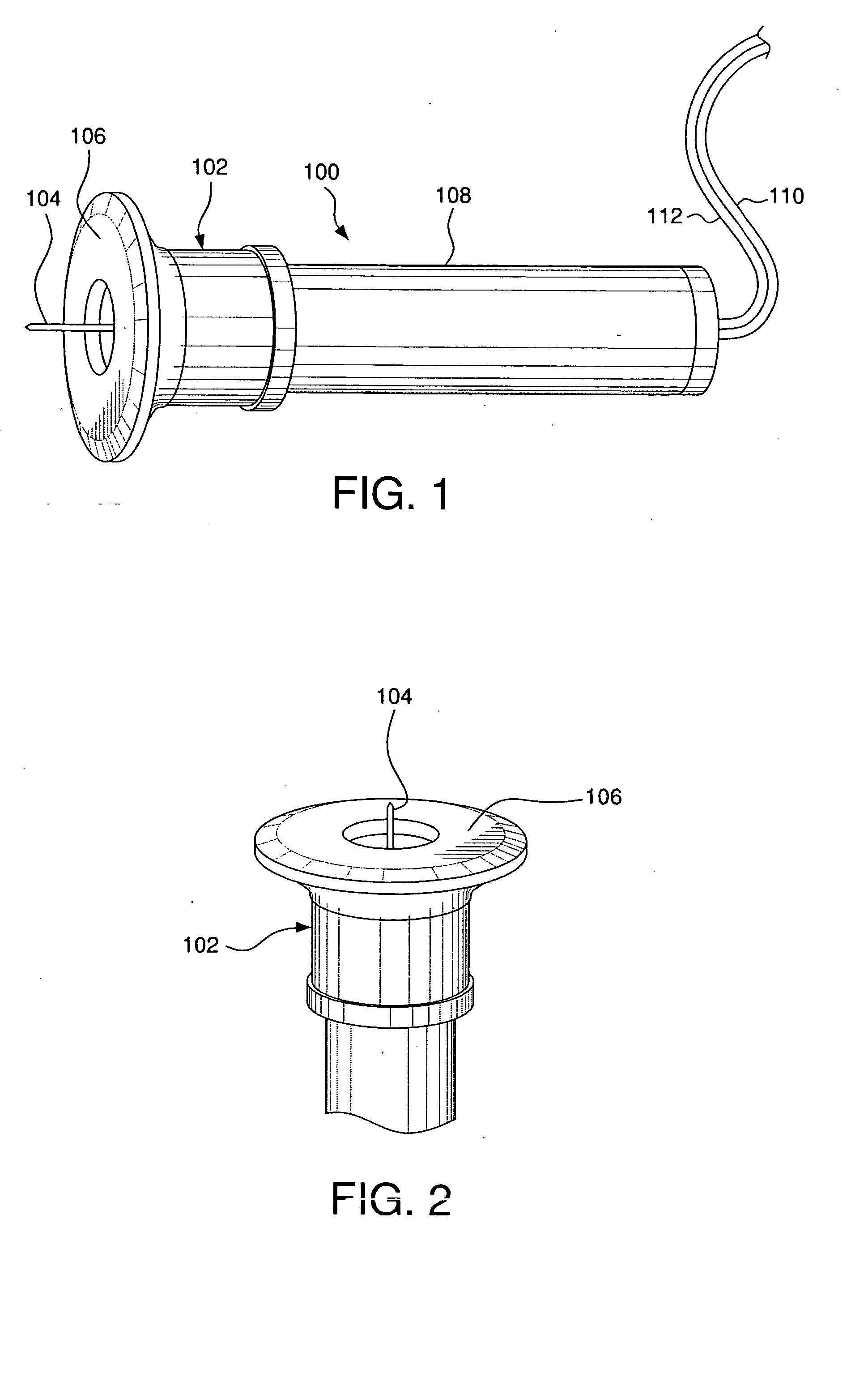

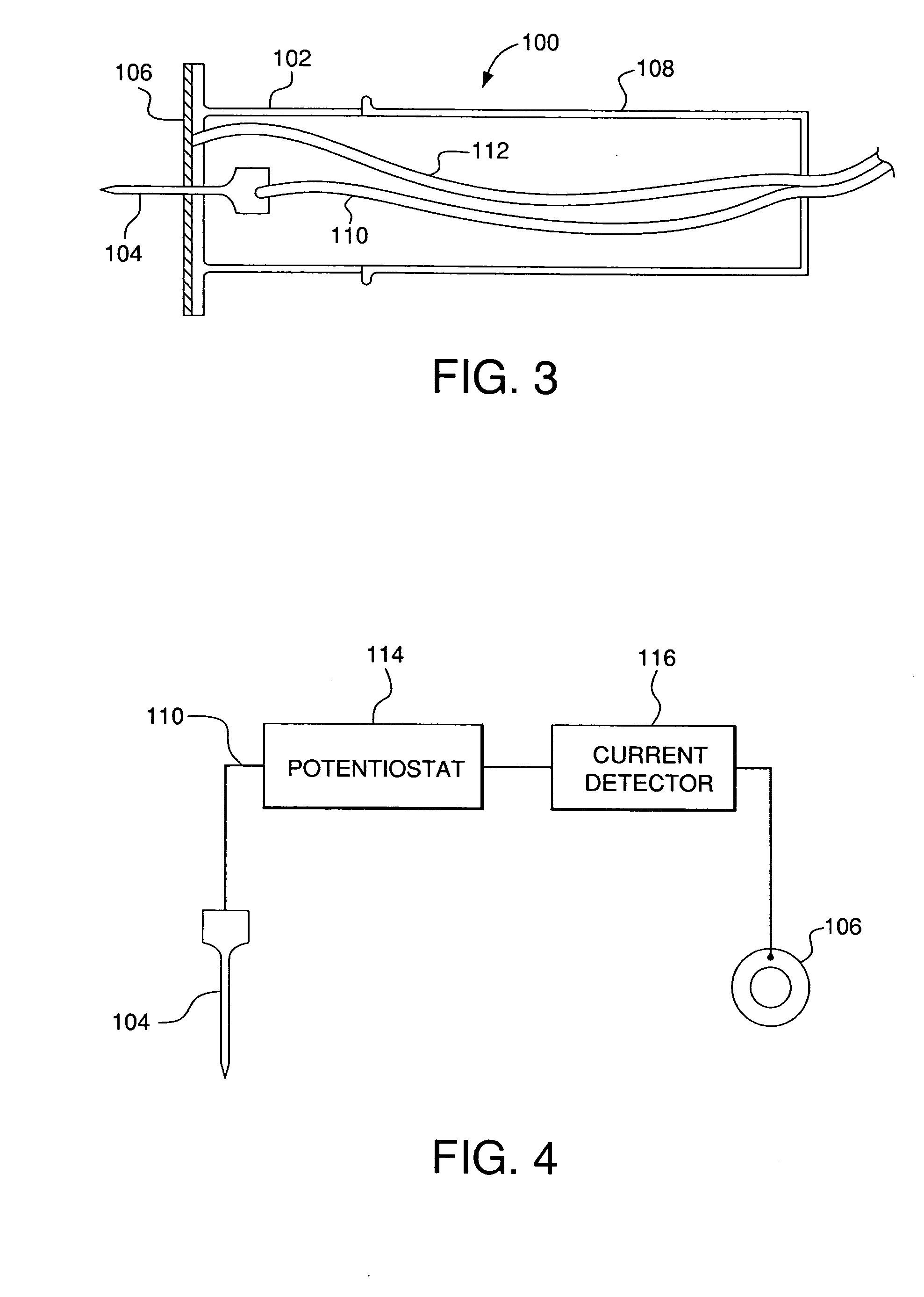

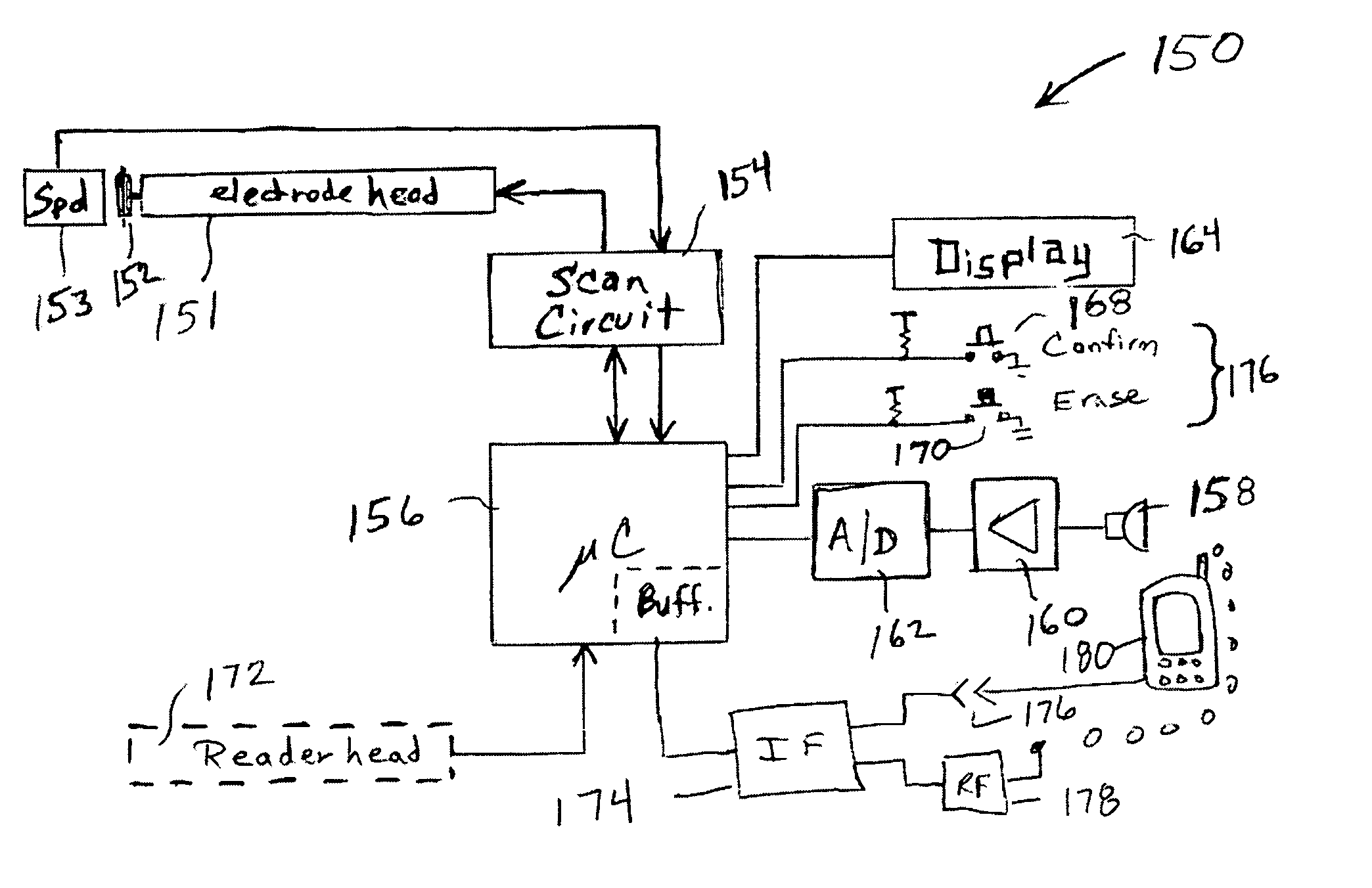

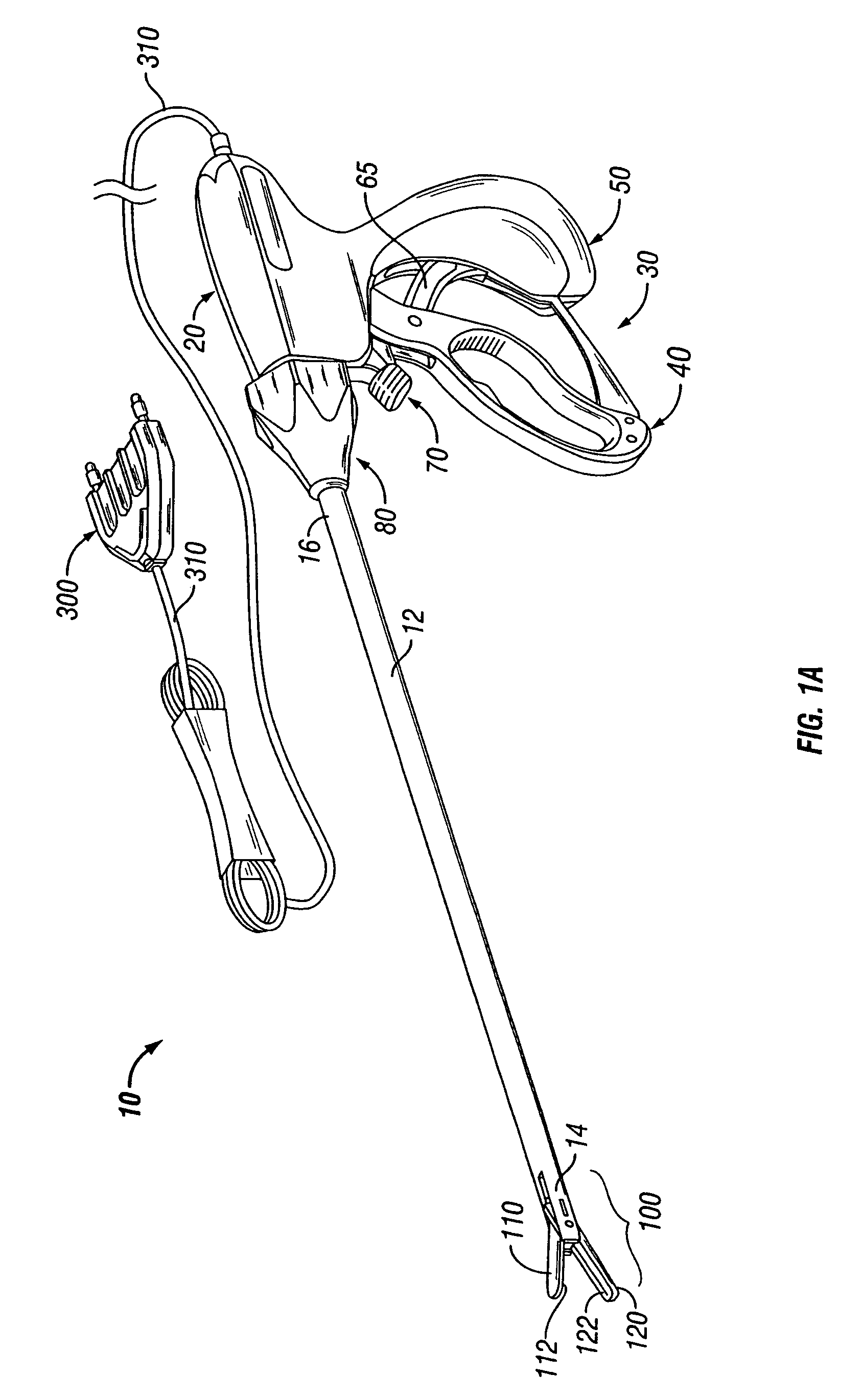

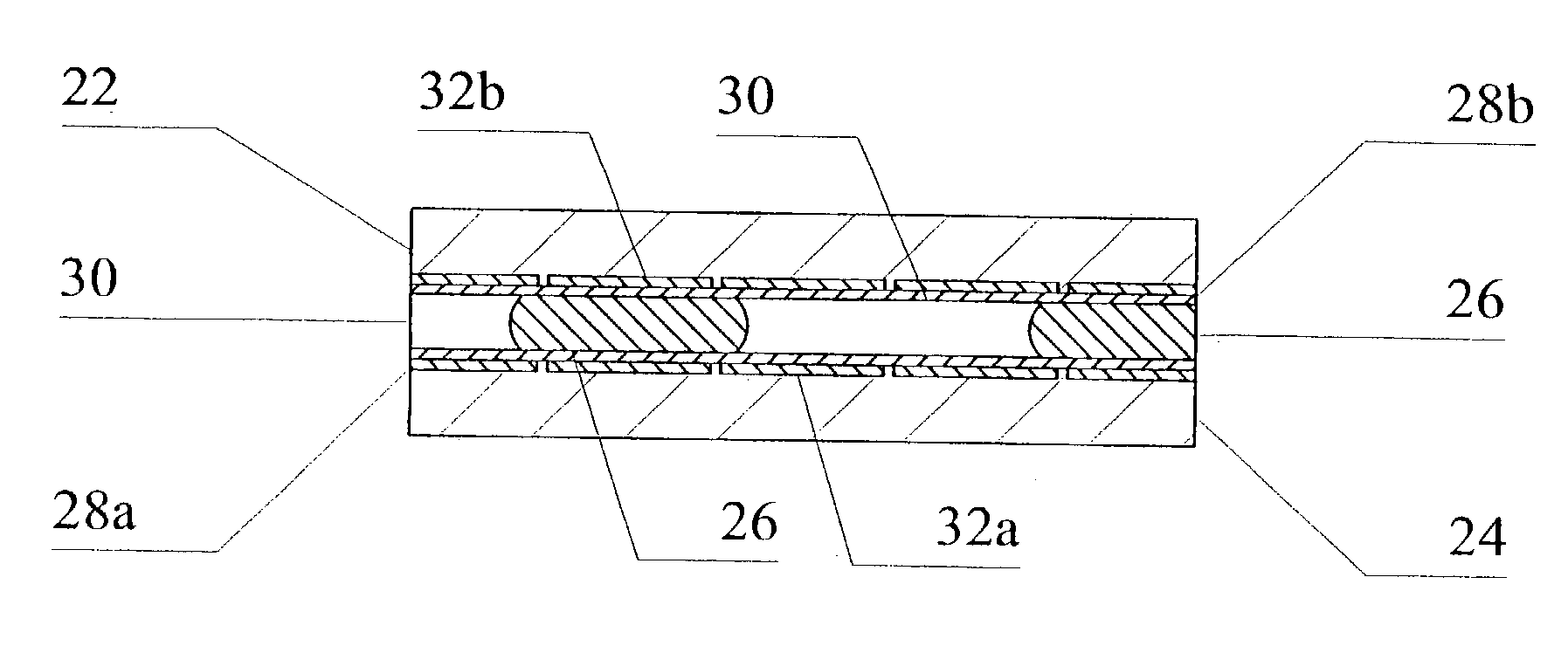

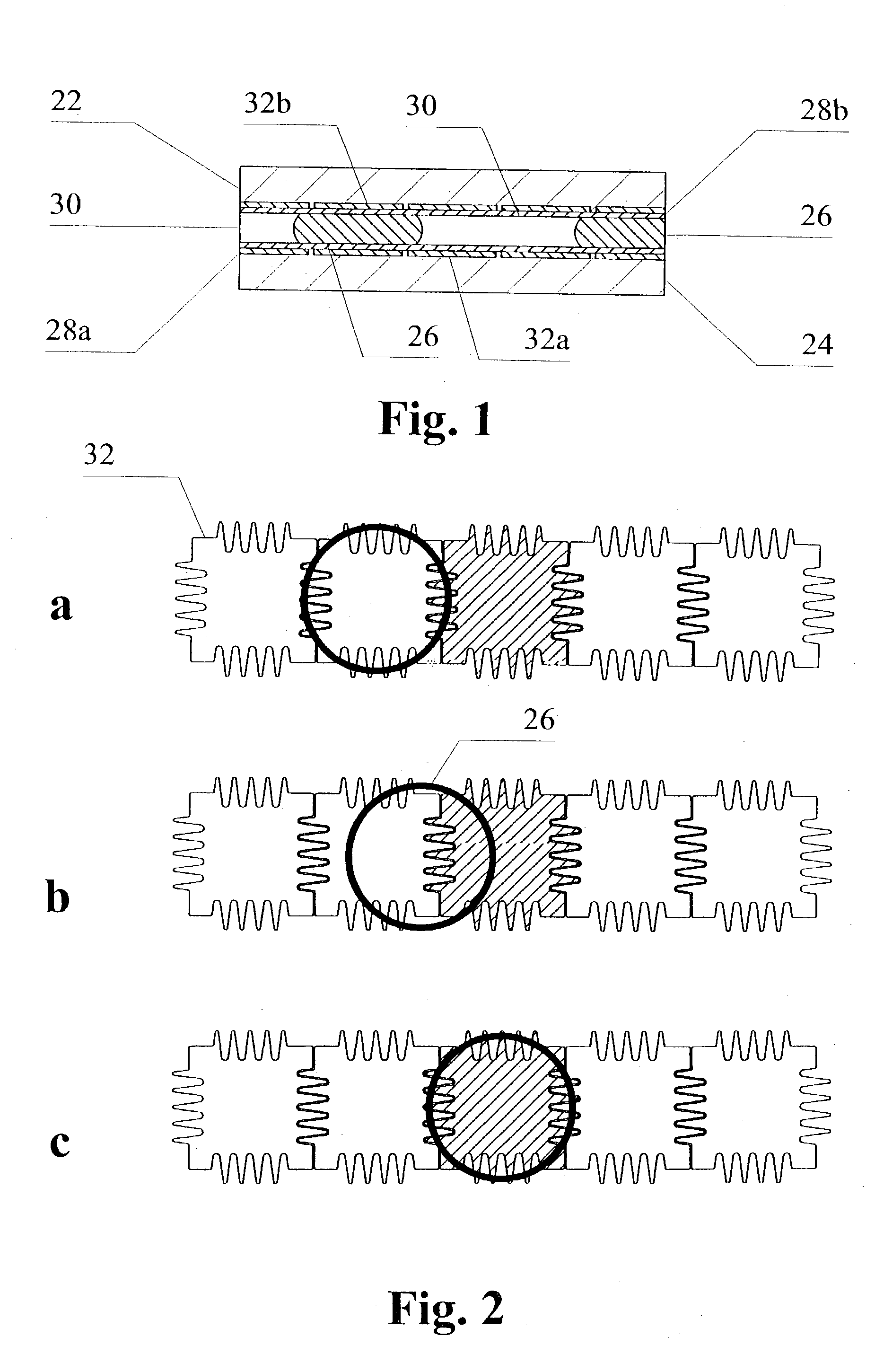

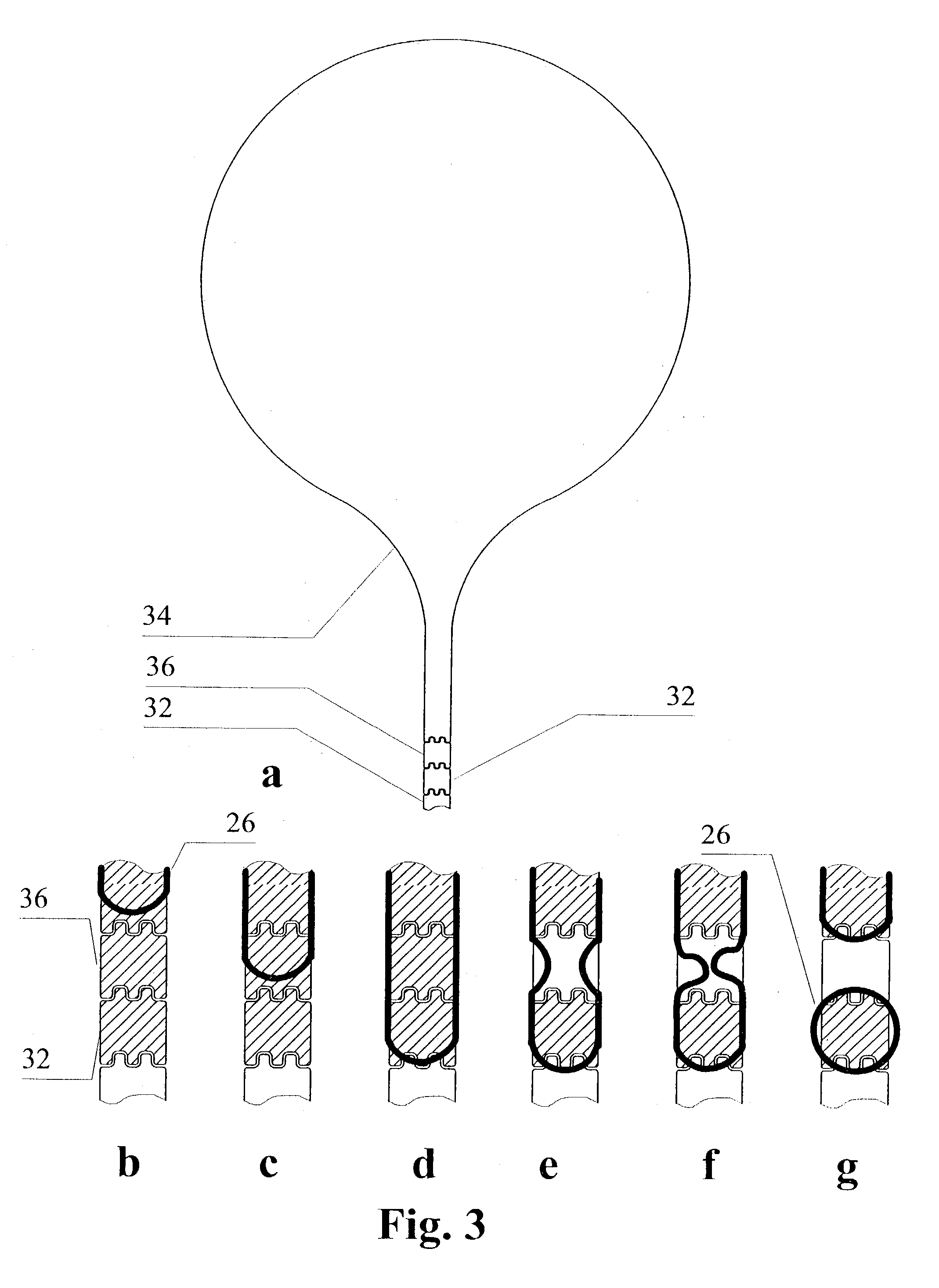

Minimally-invasive system and method for monitoring analyte levels

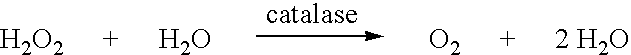

InactiveUS6952604B2Improve responseImprove signal and performanceCatheterSensorsAnalyteStratum corneum

A minimally-invasive analyte detecting device and method for using the same. The system and method employ a device having an active electrode optionally coated with a substance, and a counter-electrode that is configured at least partially surround the active electrode. The configuration of the auxiliary electrode and active electrode improves the current flow through the device and increases the sensitivity of the device. When the device is placed against the patient's skin, the active electrode is adapted to enter through the stratum corneum of a patient to a depth less than a depth in the dermis at which nerve endings reside. An electric potential is applied to the active electrode and the analyte level is determined based on the amount of current or charge flowing through the device.

Owner:BECTON DICKINSON & CO

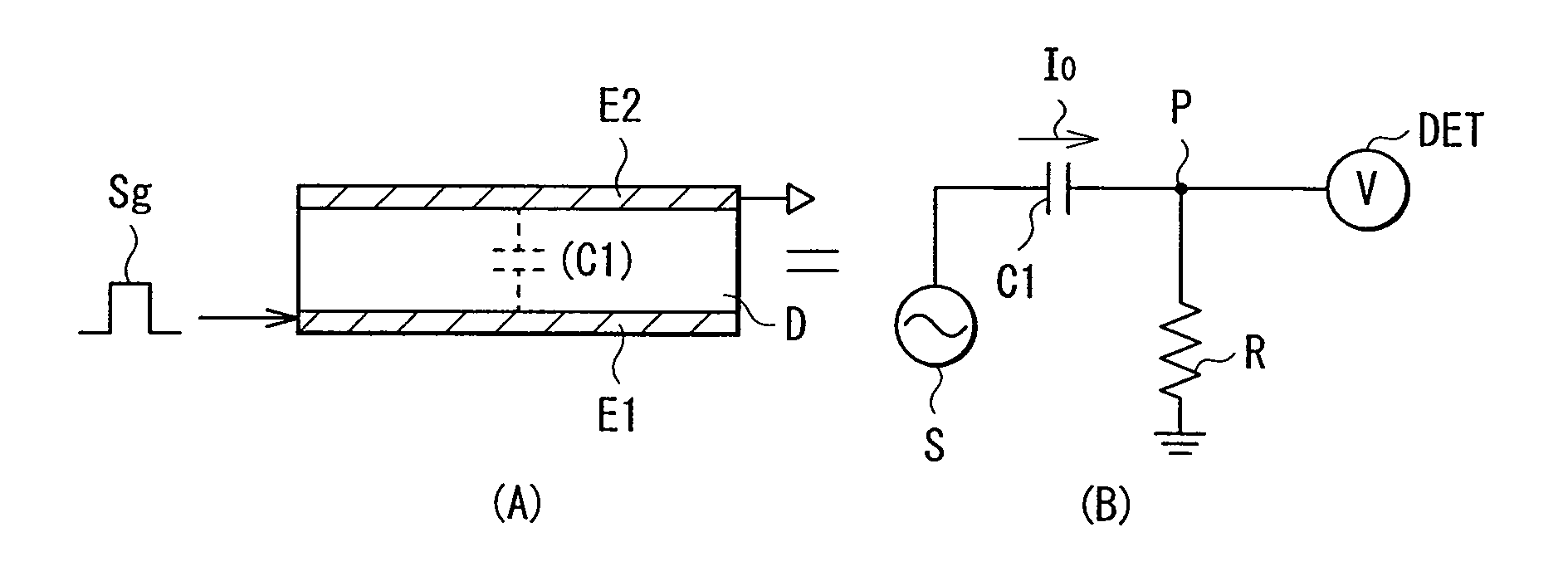

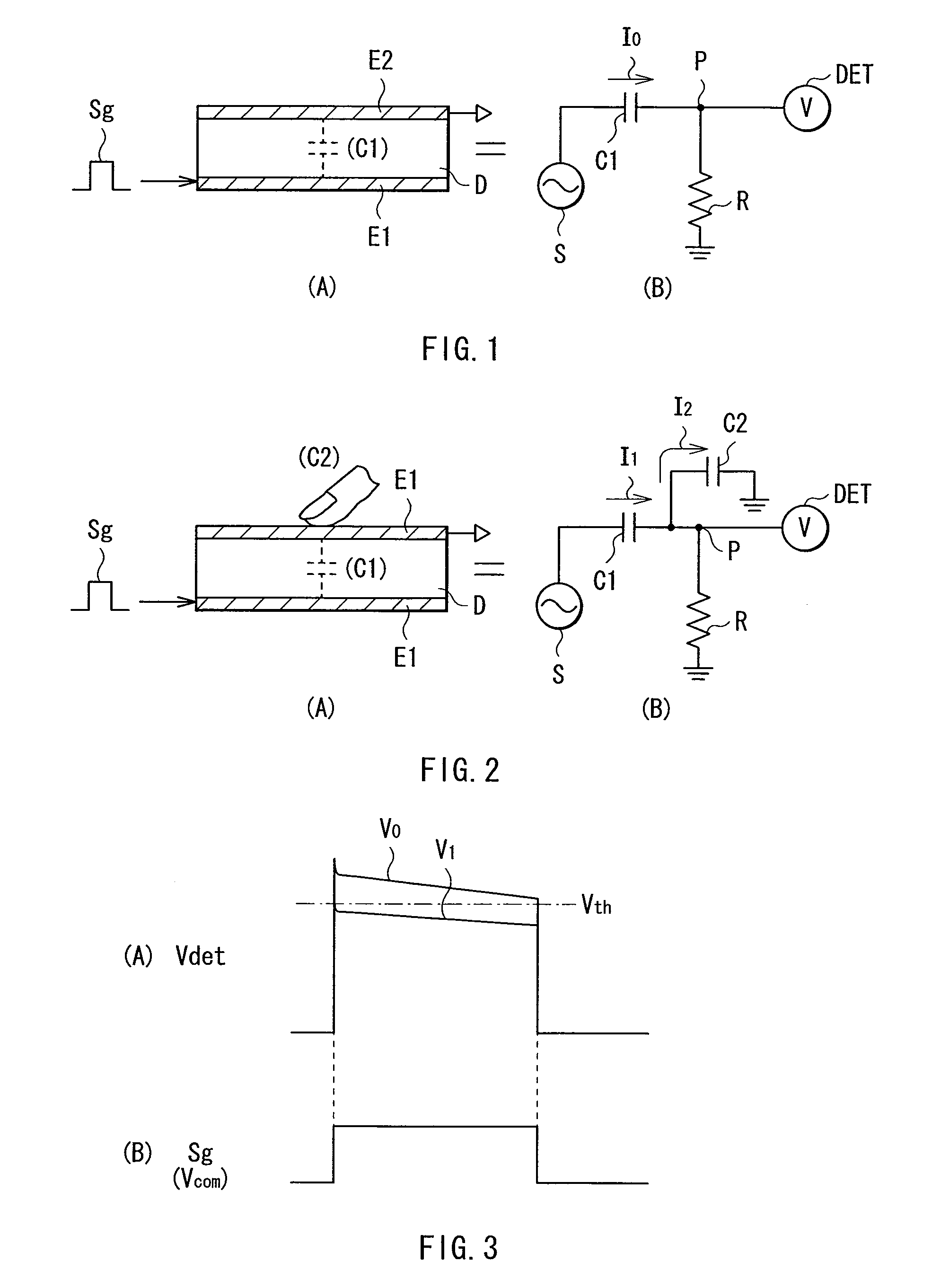

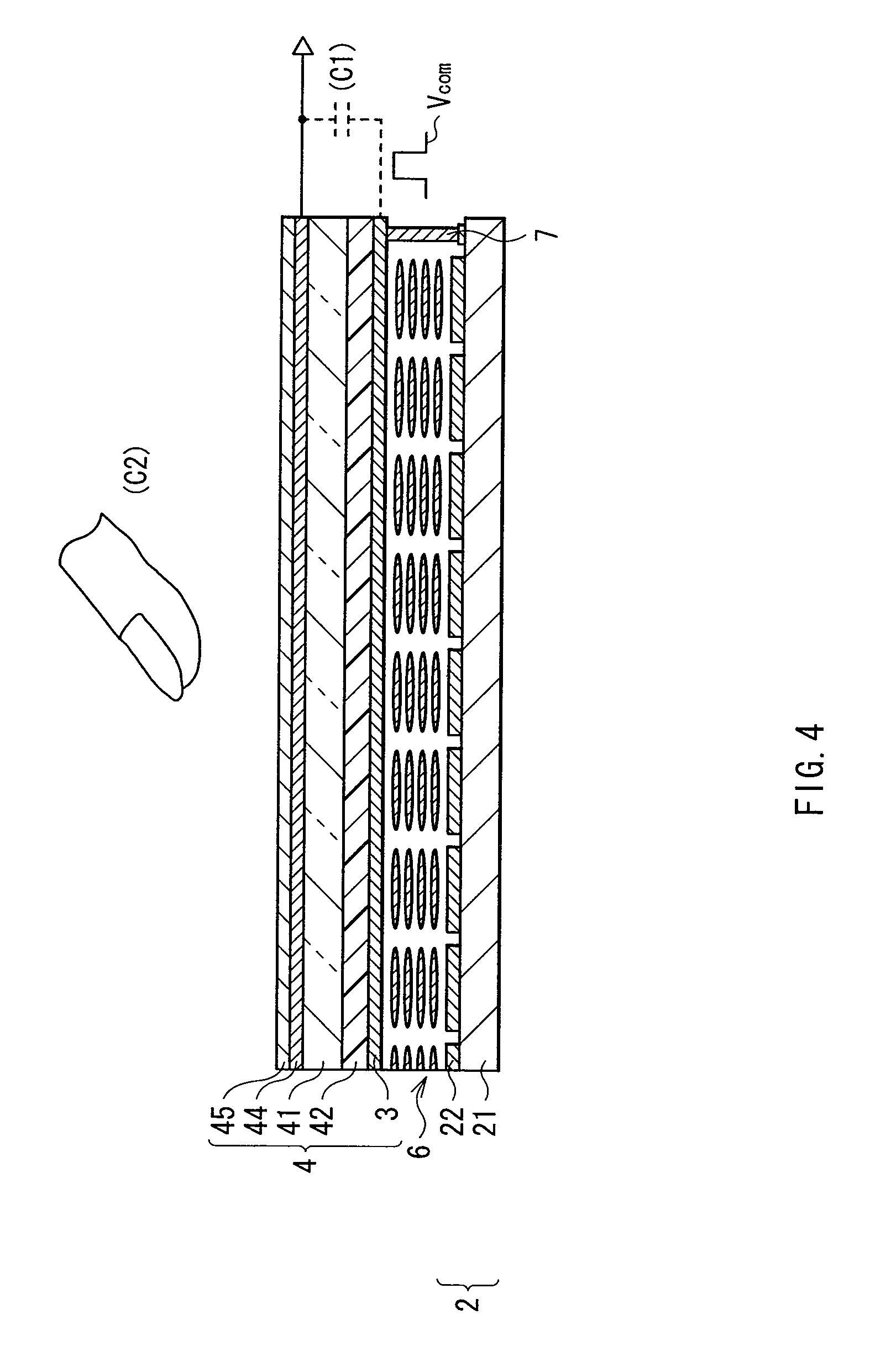

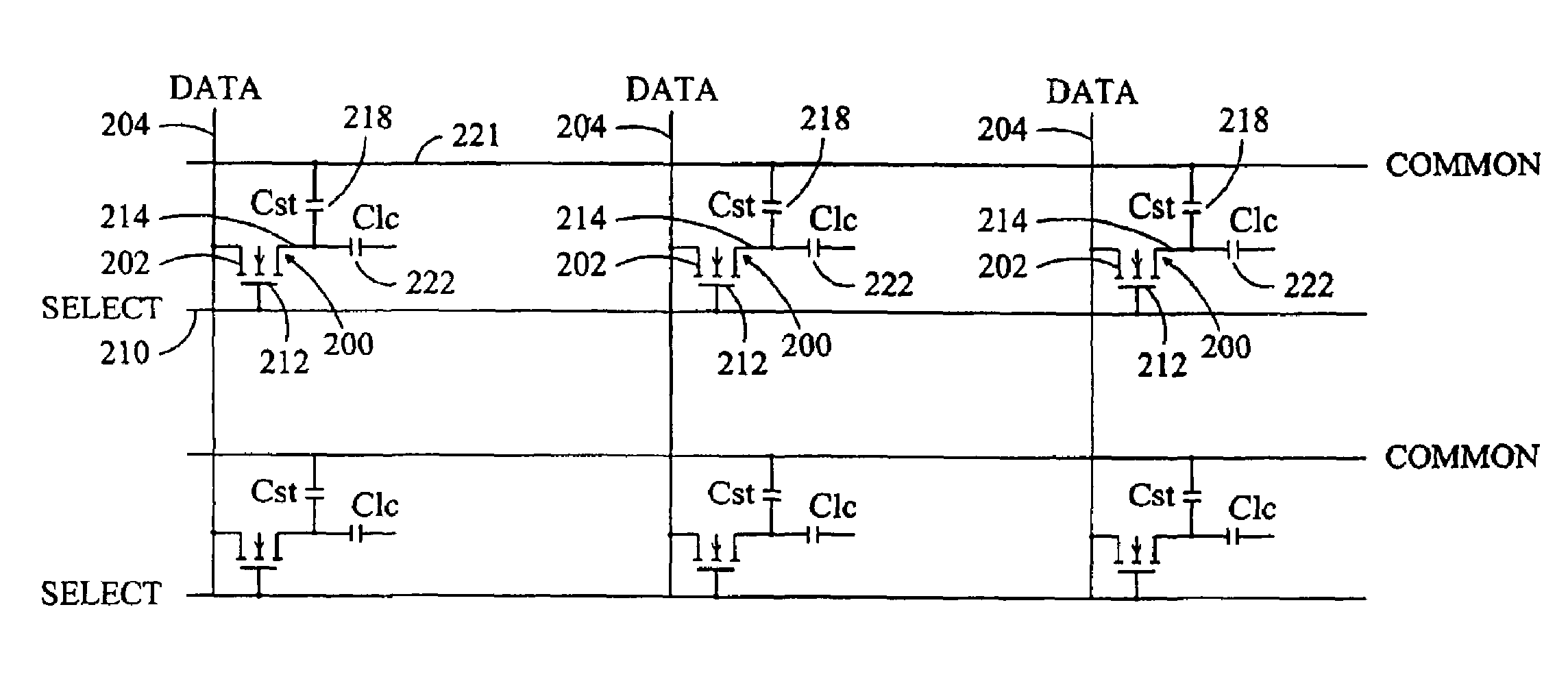

Display device with touch sensor

ActiveUS20100182273A1Improve design flexibilityEasy to integrateStatic indicating devicesNon-linear opticsCapacitanceLiquid-crystal display

A common electrode 43 for display, which is originally provided in a liquid crystal display element, is also used as one (drive electrode) of a pair of electrodes for a touch sensor, and the other (detection-electrode-for-the-sensor 44) of the pair of electrodes is newly formed. An existing common drive signal Vcom as a drive signal for display is used in common for a drive signal for the touch sensor. A capacitance is formed between the common electrode 43 and the detection-electrode-for-the-sensor 44, and touch detection is performed by utilizing a change of this capacitance caused by a finger touch of a user. Thus, a display device with a touch sensor is also applicable to a mobile device in which electric potential of the user is inconstant in many cases. The newly-provided electrode is only the detection-electrode-for-the-sensor 44, and it is unnecessary to newly prepare a drive signal for the touch sensor. Therefore, the configuration is simple.

Owner:JAPAN DISPLAY INC

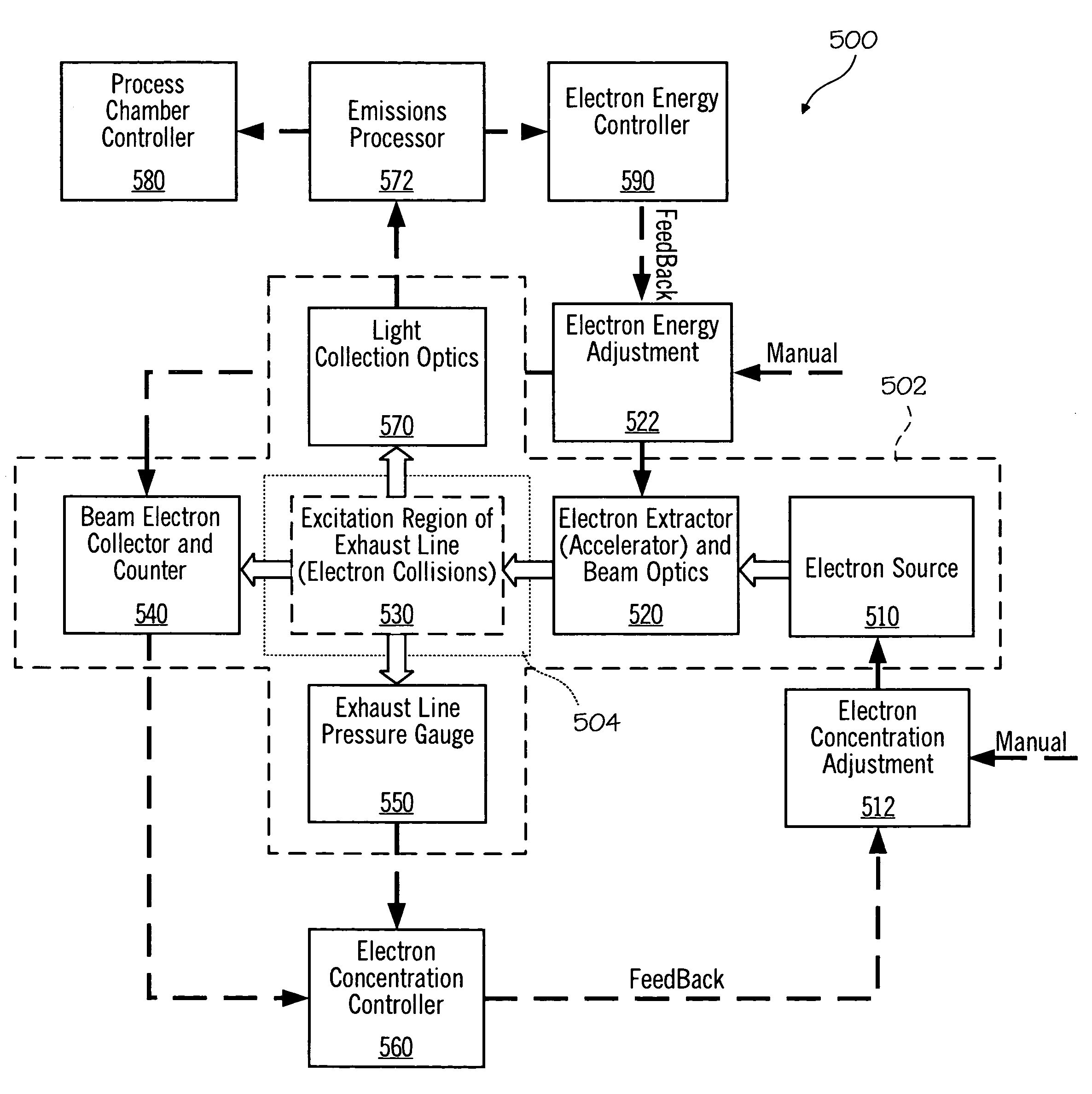

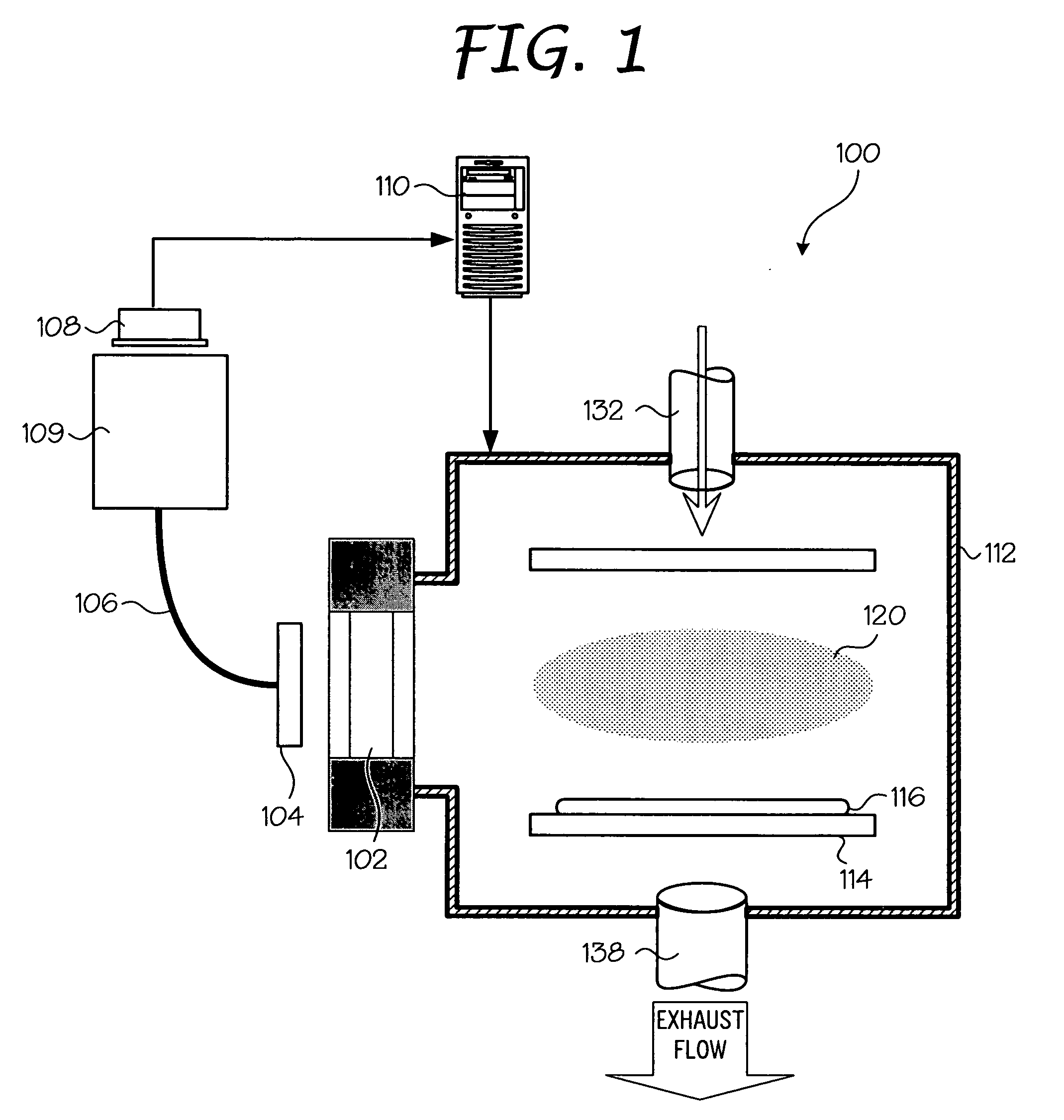

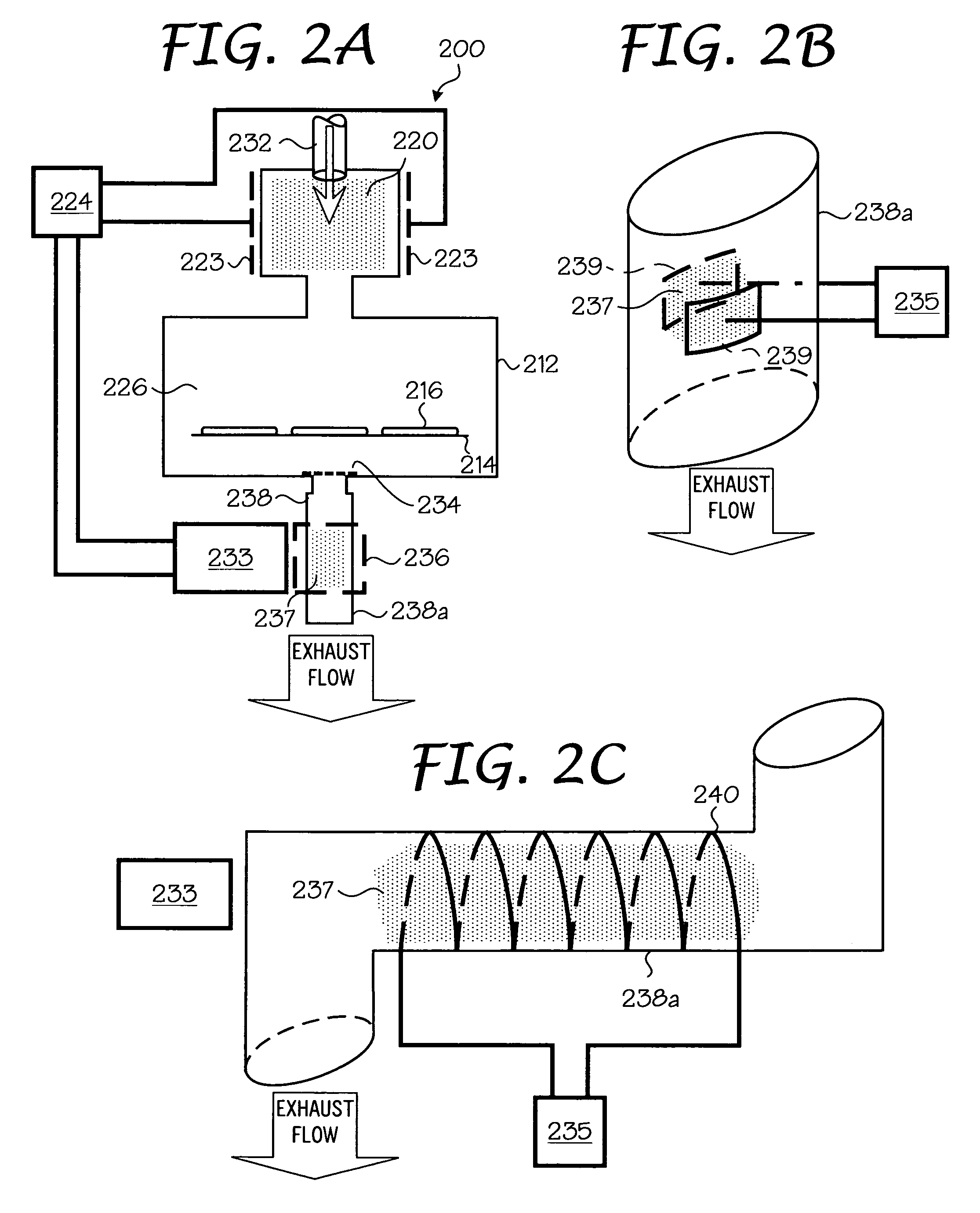

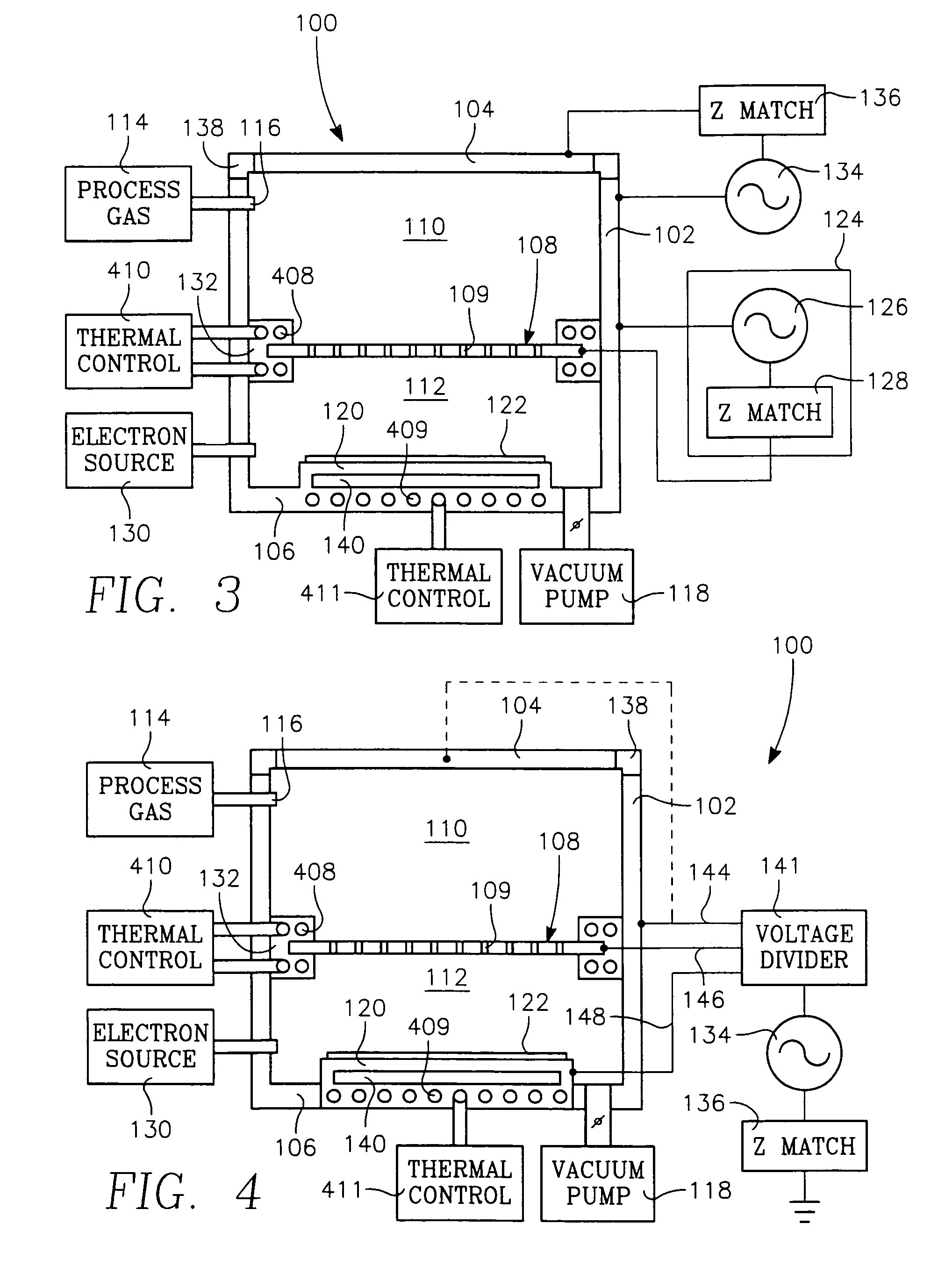

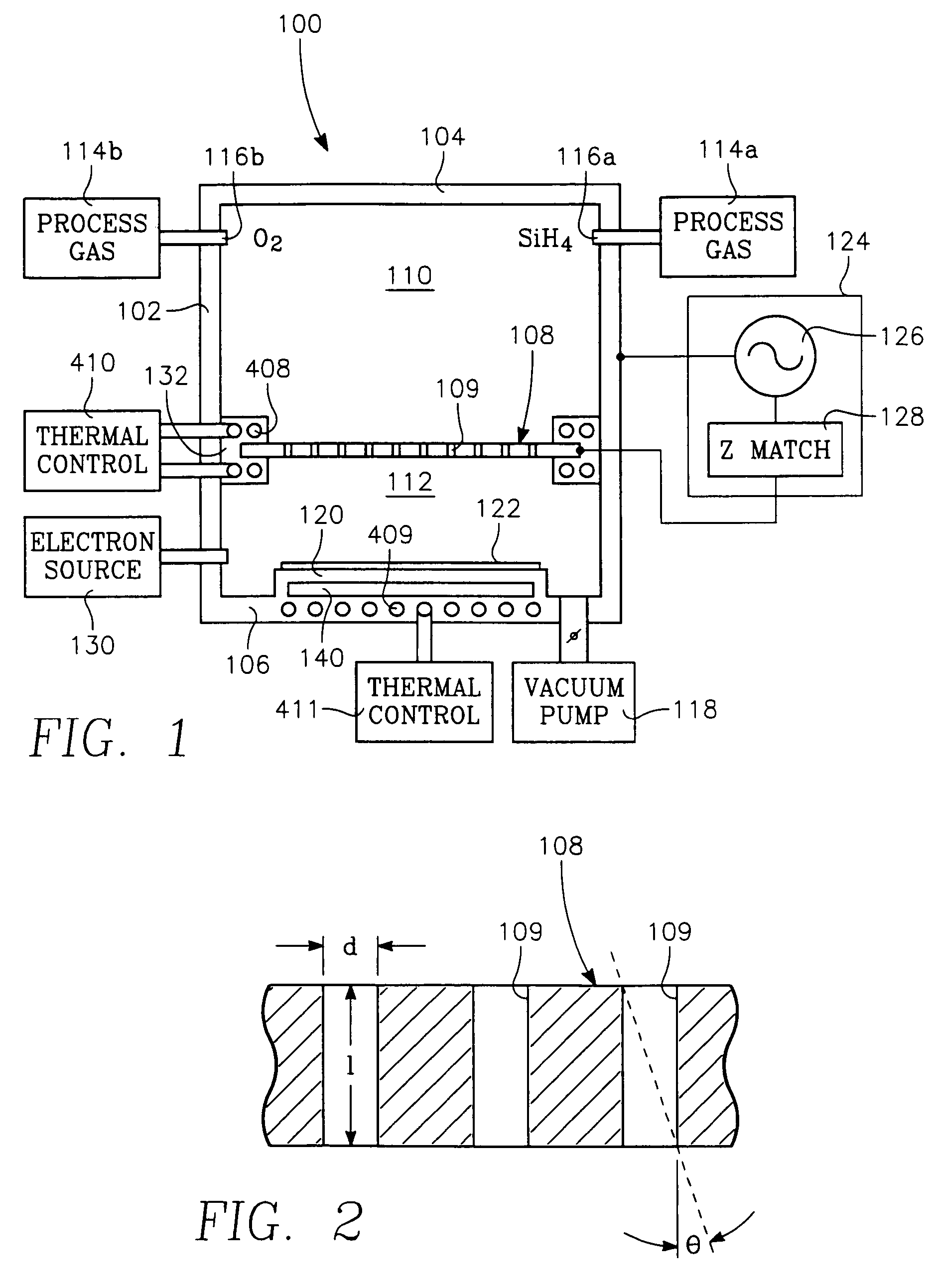

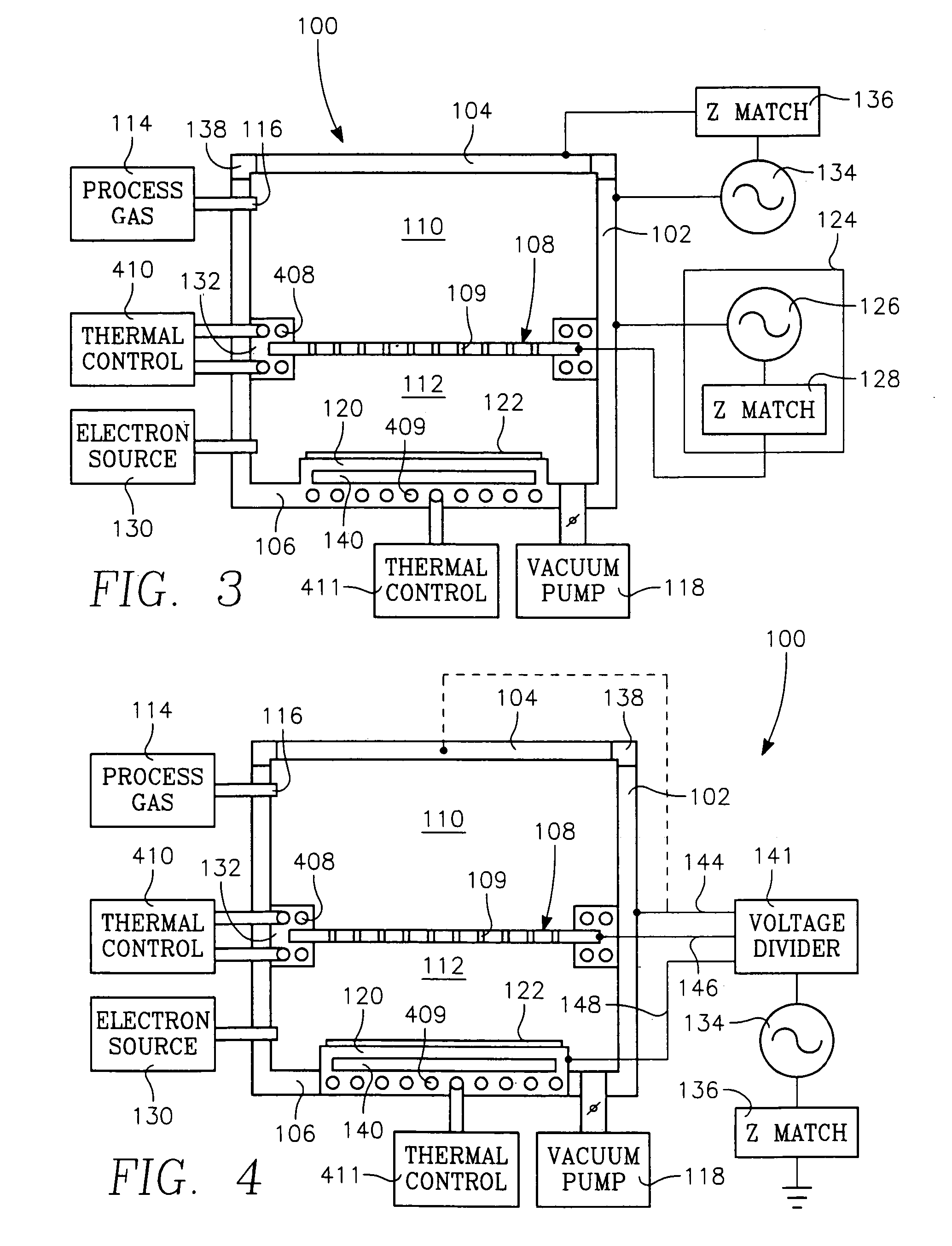

Electron beam exciter for use in chemical analysis in processing systems

ActiveUS20100032587A1Disparity will become so greatHigh electron energyCathode ray tubes/electron beam tubesRadiation therapyElectron sourceFluorescence

The present invention is directed to a gas line electron beam exciter, gas line electron beam excitation system and method for exciting a gas using an electron beam exciter. The electron beam exciter generally comprises a variable density electron source for generating a cloud of electrons in an electron chamber and a variable energy electron extractor for accelerating electrons from the electron chamber as an electron beam and into an effluent stream for fluorescing species in the effluent. The electron density of the electron beam is variably controlled by adjusting the excitation power applied to the variable density electron source. The electrons in the electron chamber reside at a reference electrical potential of the chamber, typically near ground electrical potential. The electron energy of the electron beam is variably controlled by adjusting an electrical potential across the variable energy electron extractor, which energizes the electrons through an extraction hole of the chamber and toward the extractor. The greater the difference in the electrical potential between the electron extractor and the electron source, the higher the energy imparted to the electrons in the electron beam. The excitation power applied to the electron source can be adjusted independently from the electron energy of the electron beam, thereby altering the electron density of the electron beam without changing the energy level of the electrons of the electron beam.

Owner:VERITY INSTR +1

Minimally-invasive system and method for monitoring analyte levels

A minimally-invasive analyte detecting device and method for using the same. The system and method employ a device having an active electrode optionally coated with a substance, and a counter-electrode that is configured at least partially surround the active electrode. The configuration of the auxiliary electrode and active electrode improves the current flow through the device and increases the sensitivity of the device. When the device is placed against the patient's skin, the active electrode is adapted to enter through the stratum corneum of a patient to a depth less than a depth in the dermis at which nerve endings reside. An electric potential is applied to the active electrode and the analyte level is determined based on the amount of current or charge flowing through the device.

Owner:BECTON DICKINSON & CO

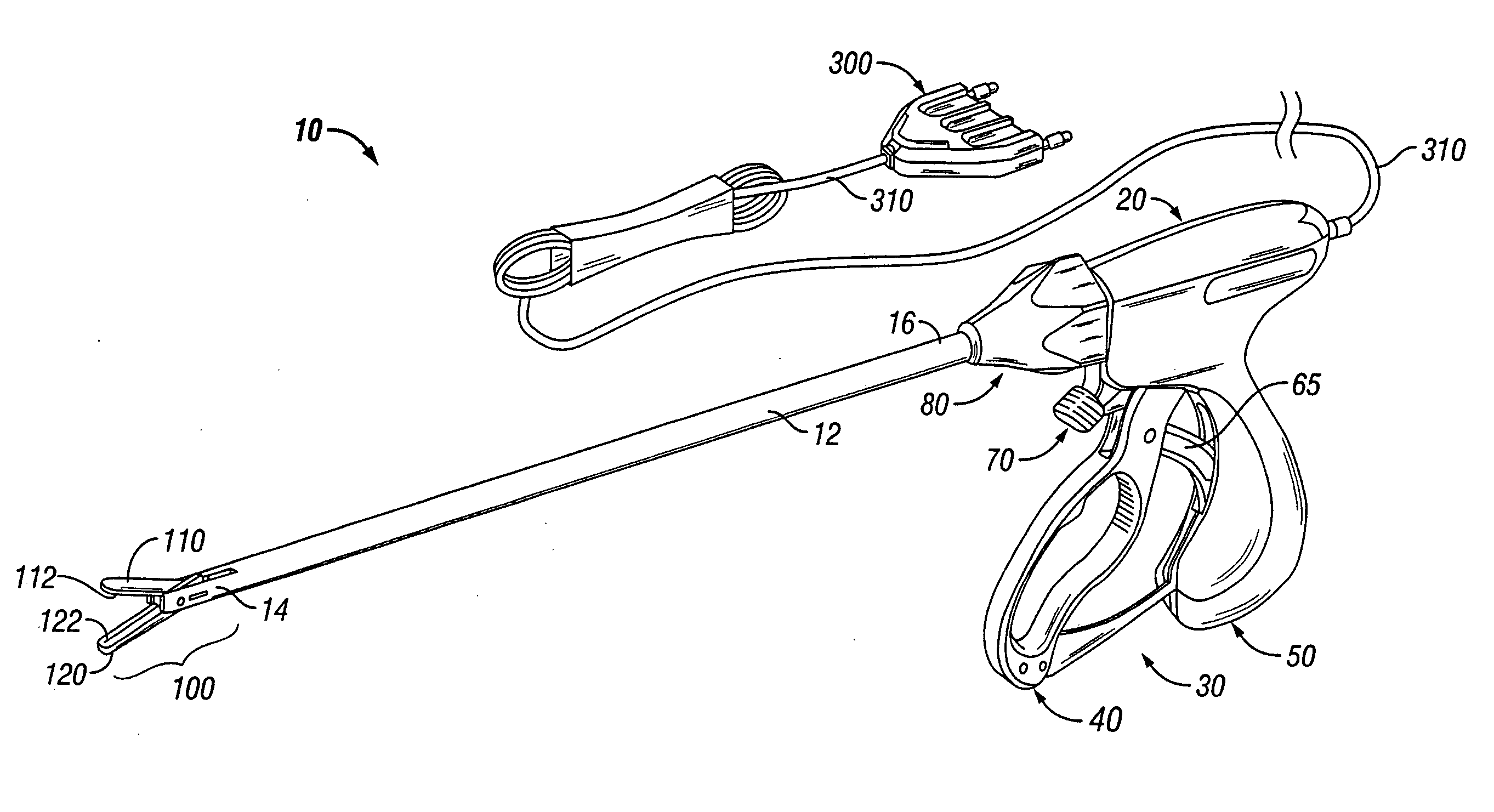

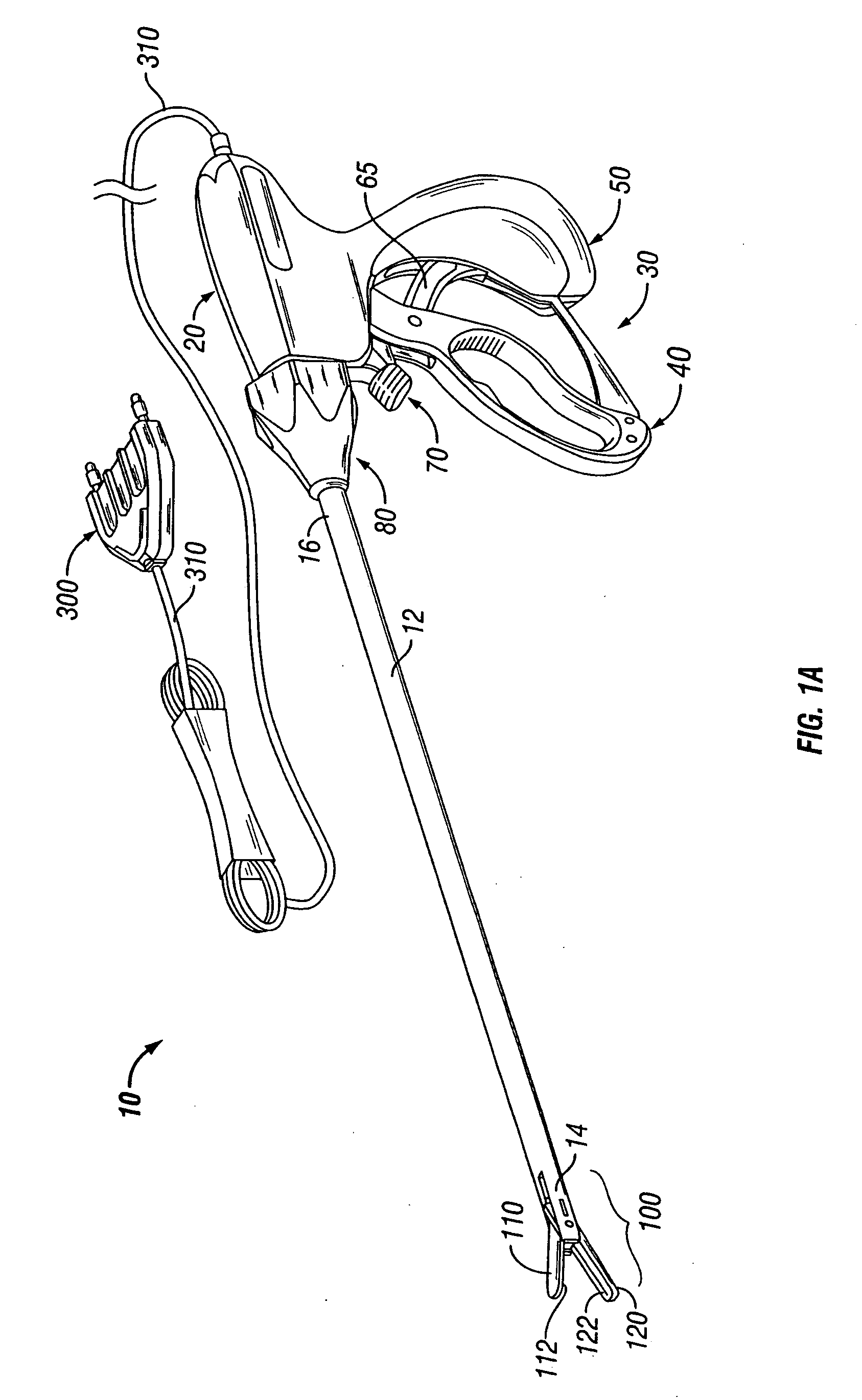

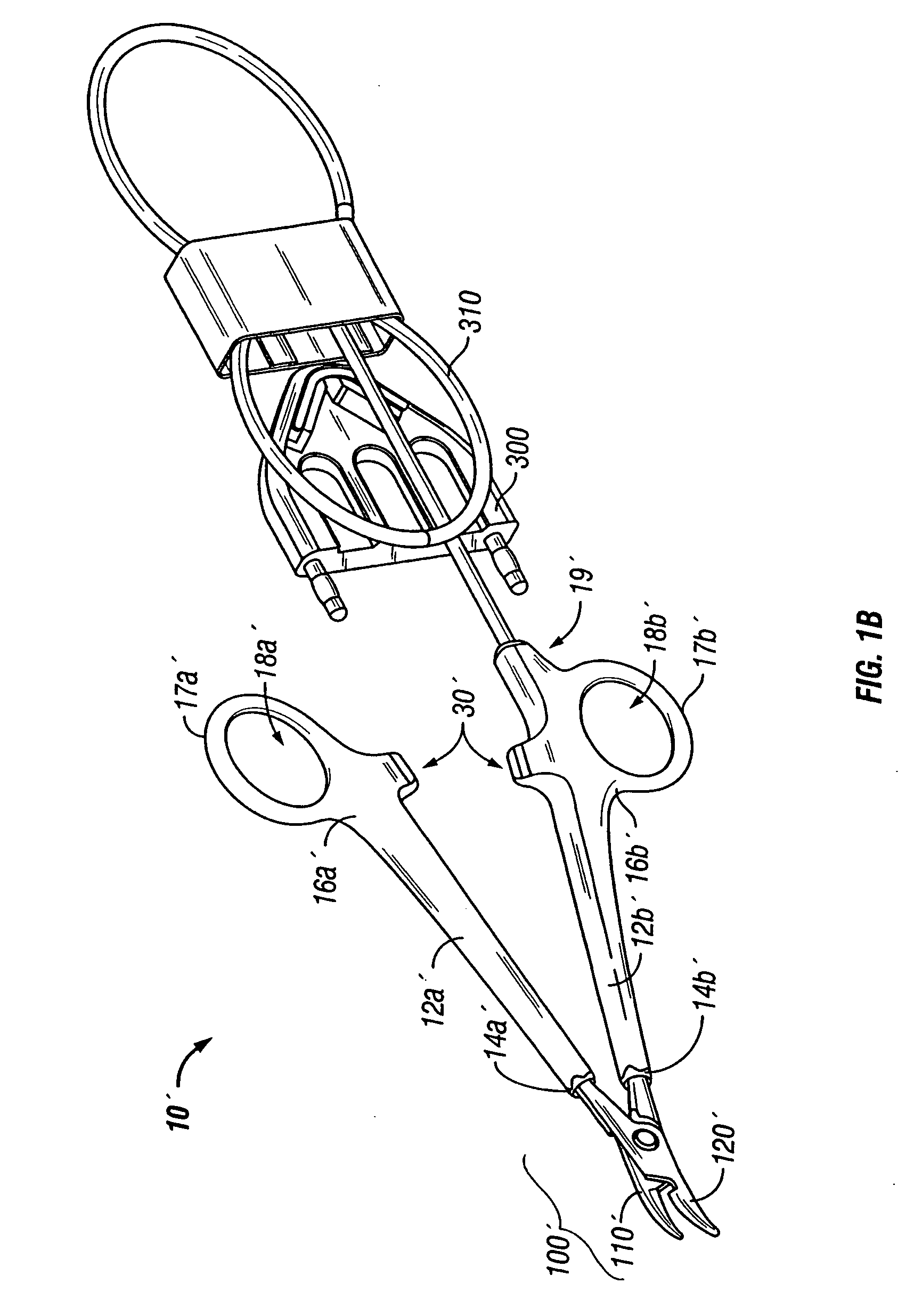

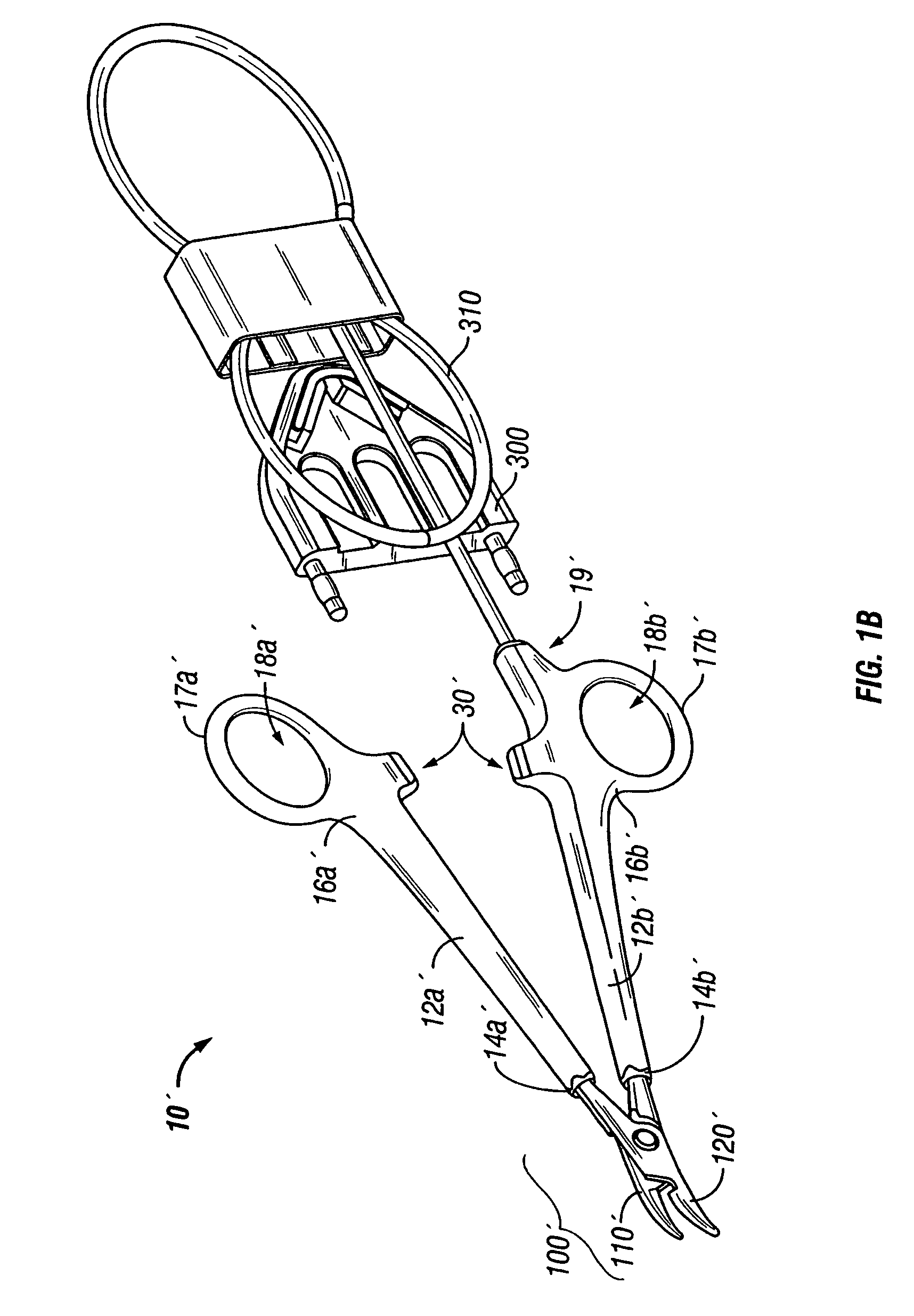

Incorporating rapid cooling in tissue fusion heating processes

ActiveUS20060052778A1Rapid coolingSurgical instruments for heatingSurgical forcepsElectricityThermoelectric cooling

An electrode sealing assembly for use with an electrosurgical instrument for sealing tissue includes first and second jaw members which are movable from a first position in spaced relation relative to one another to at least one second position for grasping tissue. The jaw members include electrically conductive sealing plates designed to selectively transmit electrosurgical energy to tissue disposed between the sealing plates. The jaw members also include a thermoelectric cooling plate having a first surface in direct contact with an outer surface of the sealing plate. The thermoelectric cooling plate includes first and second electrical connections on opposite sides of the jaw member. The first connection is configured to selectively transmit a first electrical potential and the second connection is configured to selectively transmit a second electrical potential such that heat generated by the sealing plates is transferred away from the tissue via the thermoelectric cooling plate.

Owner:COVIDIEN AG

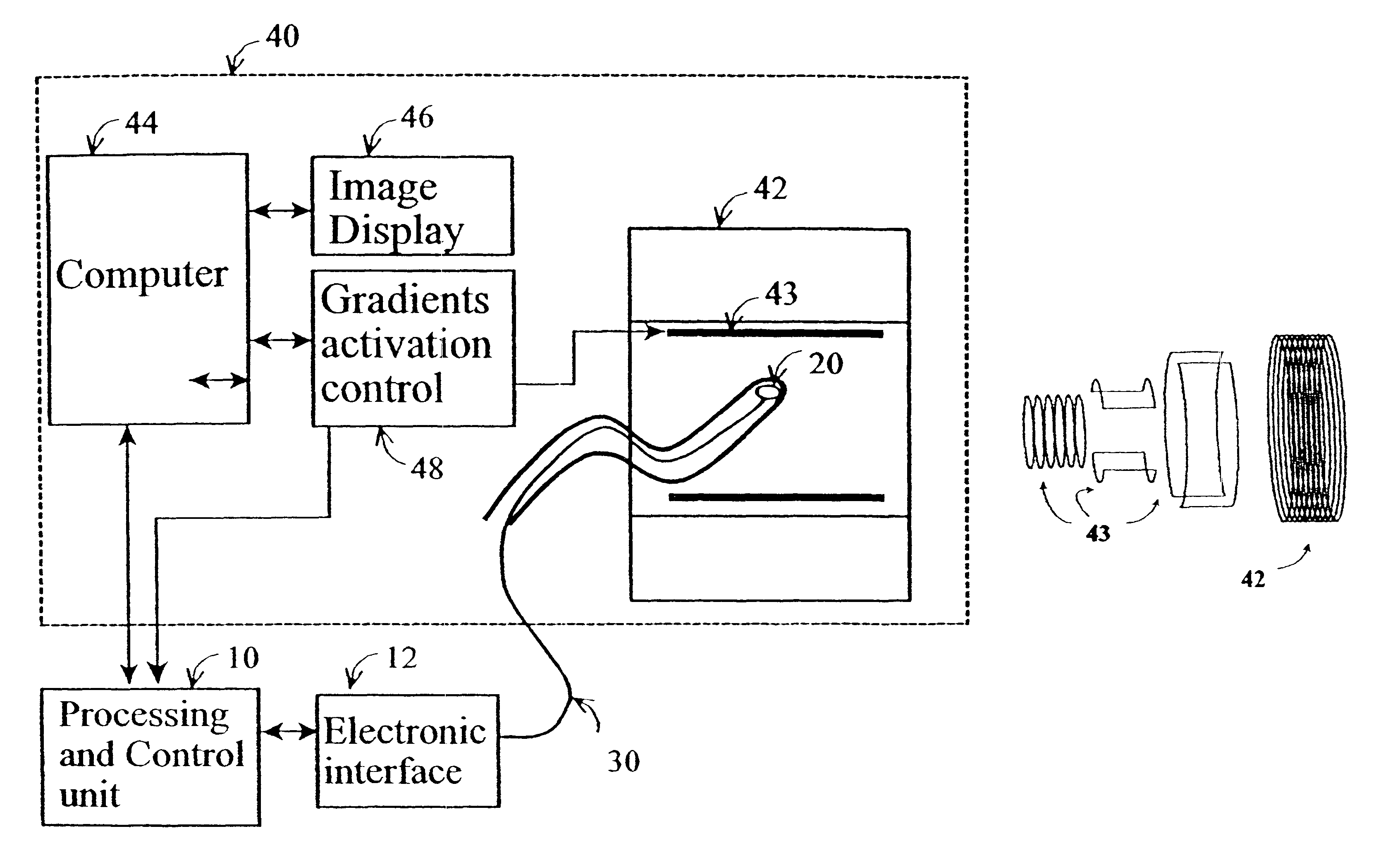

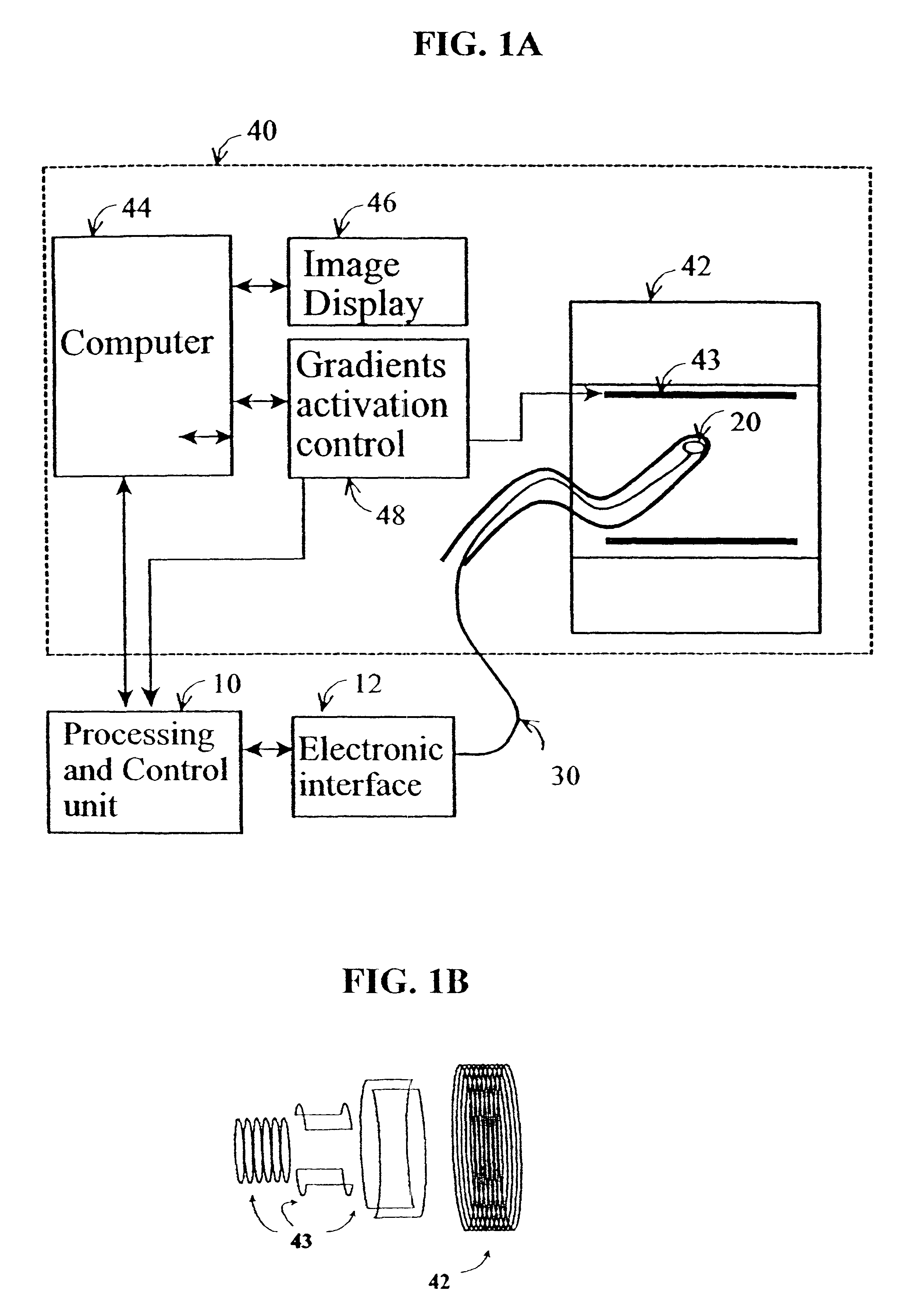

Method and apparatus to estimate location and orientation of objects during magnetic resonance imaging

InactiveUS6516213B1Limited accuracy of orientationSatisfies requirementDiagnostic recording/measuringSensorsMagnetic field gradientThree-dimensional space

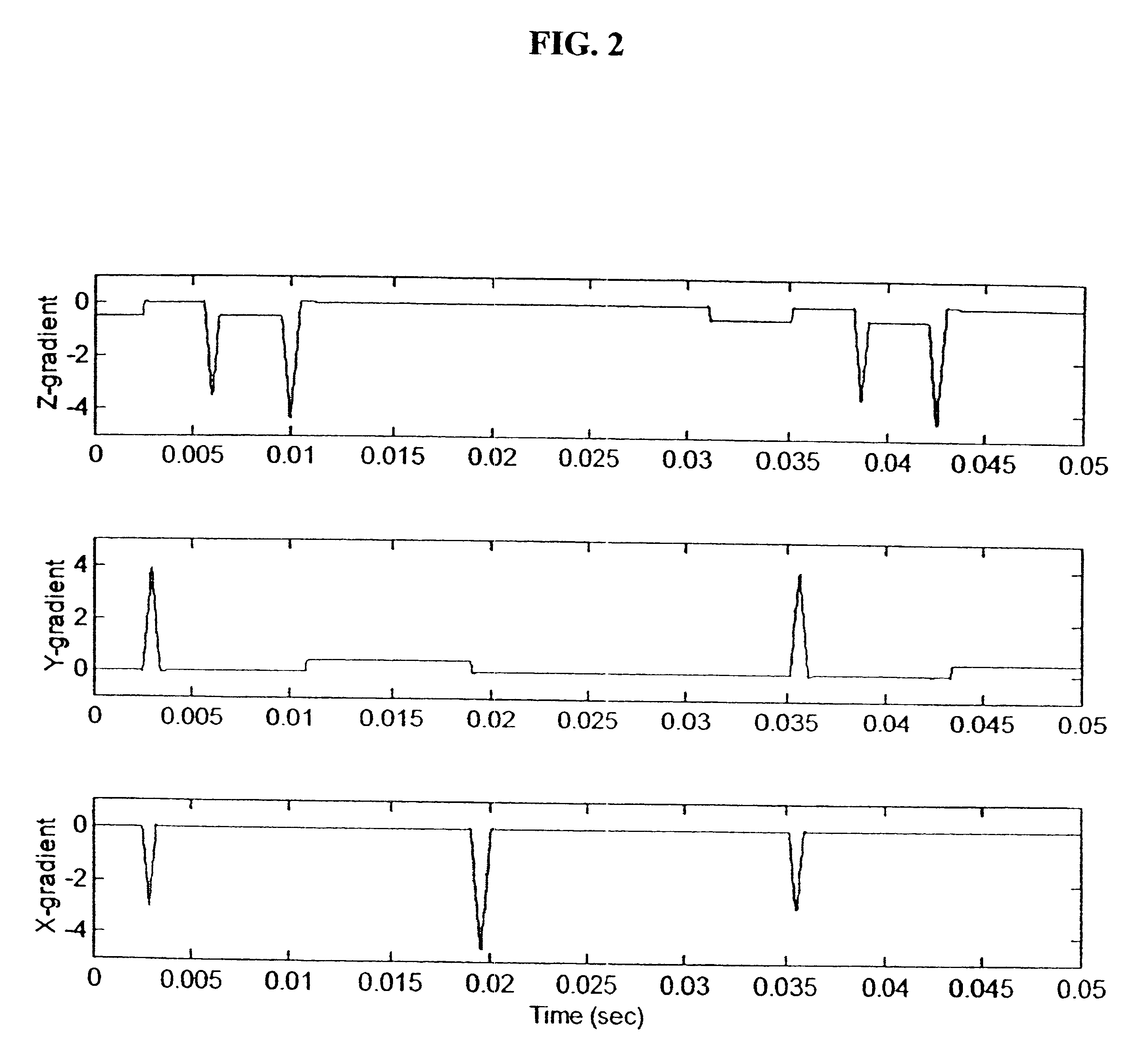

Method and apparatus for determining the instantaneous location, the orientation of an object moving through a three-dimensional space by applying to the object a coil assembly including a plurality of sensor coils (20) having axes of known orientation with respect to each other including components in the three orthogonal planes; generating a time-varying, three-dimensional magnetic field gradient having known instantaneous values of magnitude and direction; applying the magnetic field gradient to the space, and object moving therethrough to induce electrical potentials in the sensor coils; measuring the instantaneous values of the induced electrical potentials generated in the sensor coils; processing the measured instantaneous values generated in the sensor coils together with the known magnitude, direction of the generated magnetic field gradient, the known relative orientation of the sensor coils in the coil assembly to compute the instantaneous location, orientation of the object within the space.

Owner:ROBIN MEDICAL

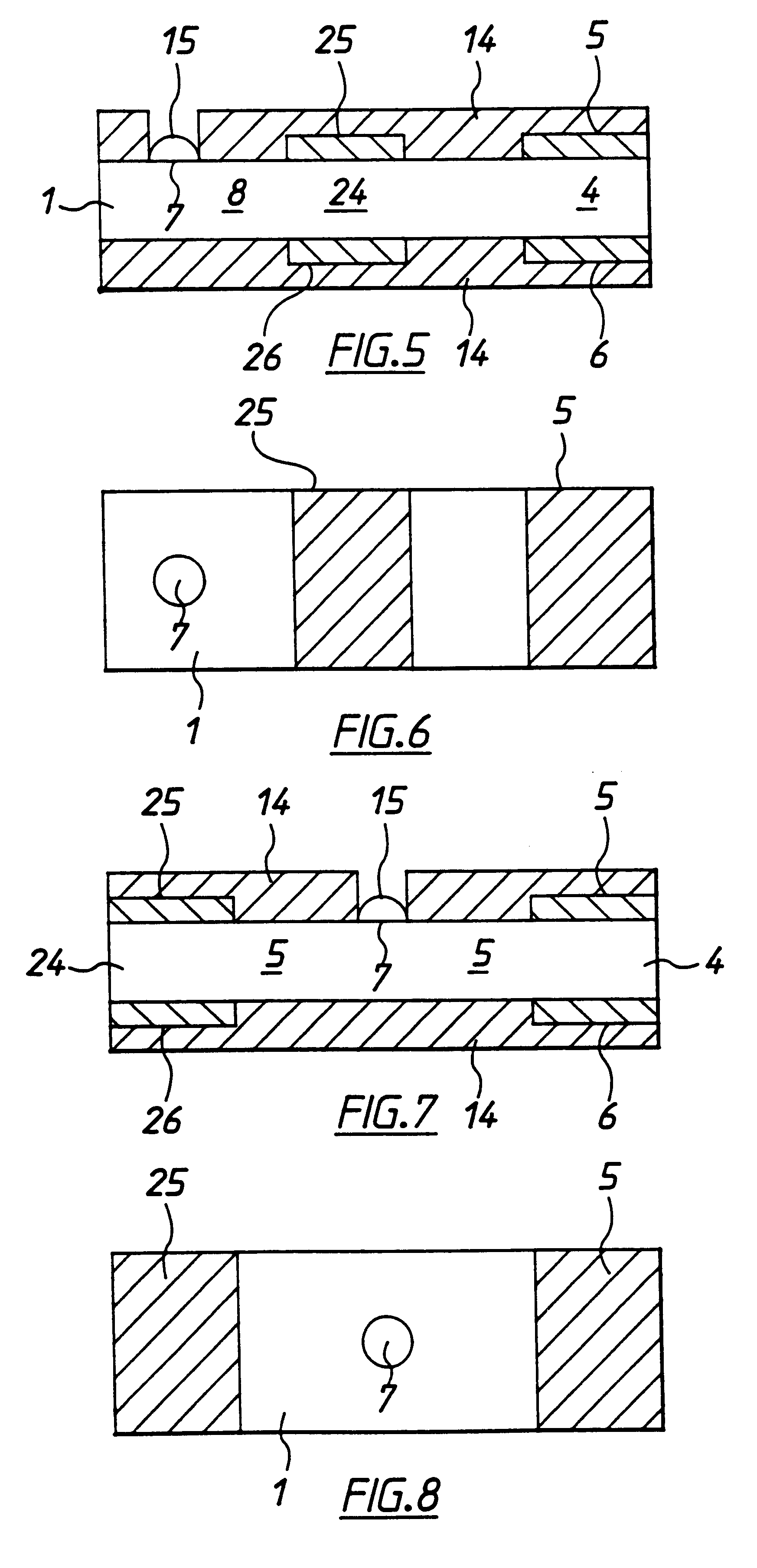

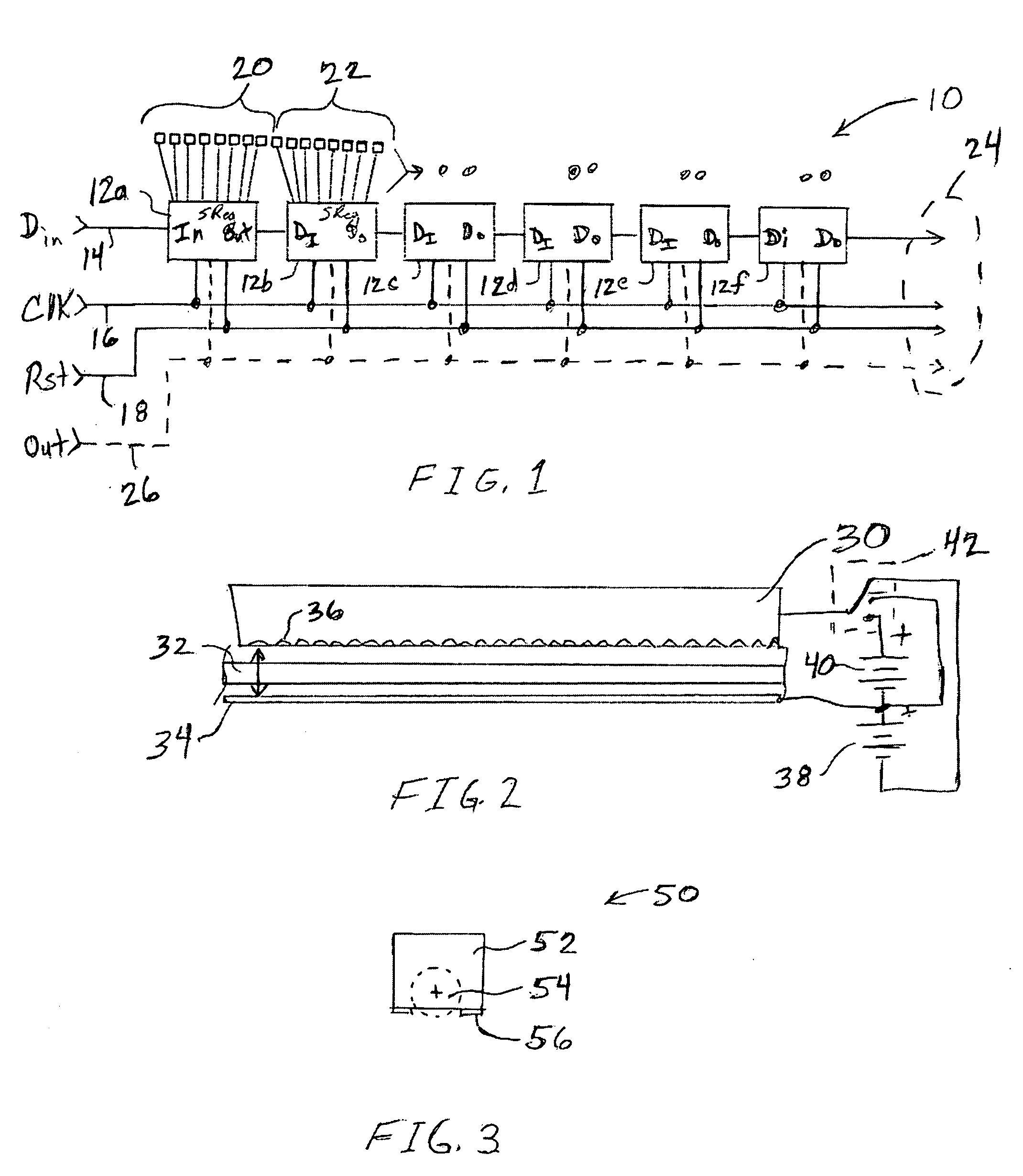

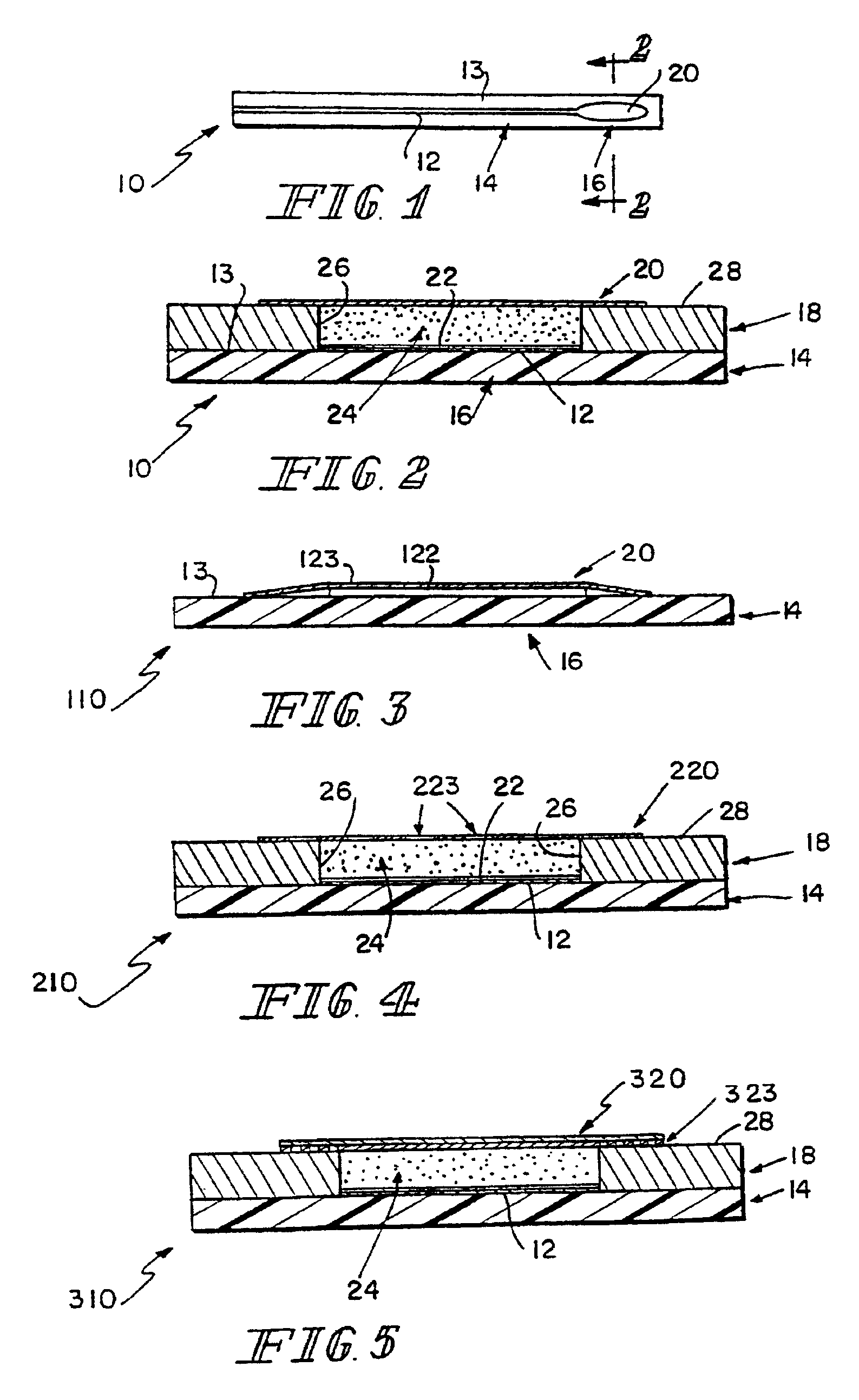

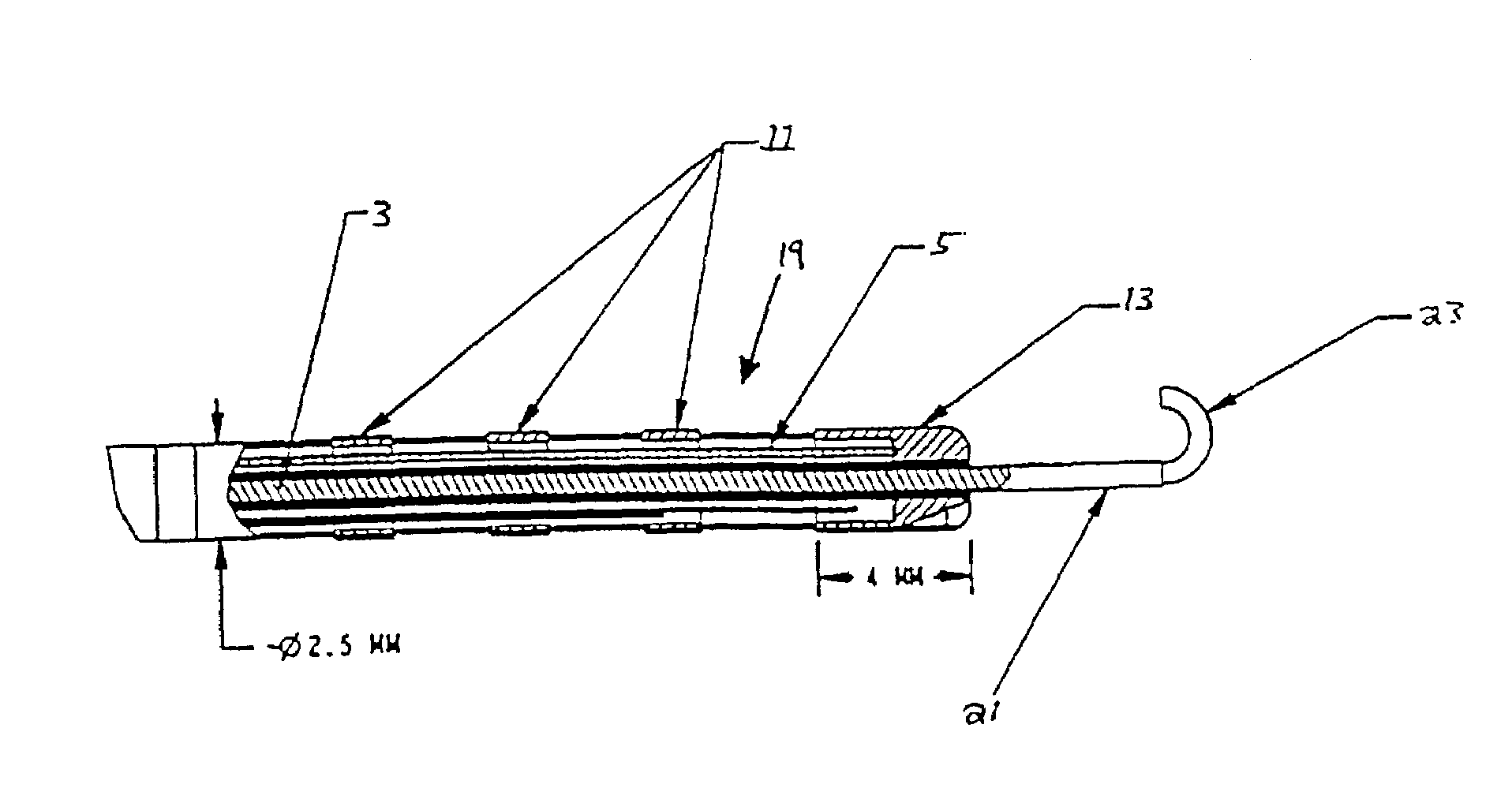

Sliver type autonomous biosensors

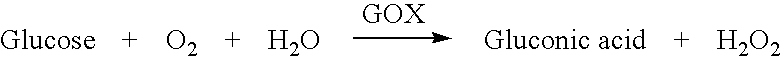

InactiveUS20040180391A1Bioreactor/fermenter combinationsBiological substance pretreatmentsIn vivoElectrochemistry

In vivo or in vitro monitoring of chemical and biochemical species (e.g., pH, or glucose levels) in the interstitial fluid of patients or in a sample of a fluid to be analyzed is provided by a probe (10, 70, 210, 270). For in vivo monitoring, the probe is readily inserted by a minimally invasive method. Optical or electrochemical sensing methods are employed to detect a physical or chemical change, such as pH, color, electrical potential, electric current, or the like, which is indicative of the concentration of the species or chemical property to be detected. Visual observation by the patient may be sufficient to monitor certain biochemicals (e.g., glucose) with this approach. A CAP membrane allows high enzyme loadings, and thus enables use of microminiature probes, and / or diagnosis of low levels of the analyte(s), with sufficient signal-to-noise ratio and low background current.

Owner:CASE WESTERN RESERVE UNIV

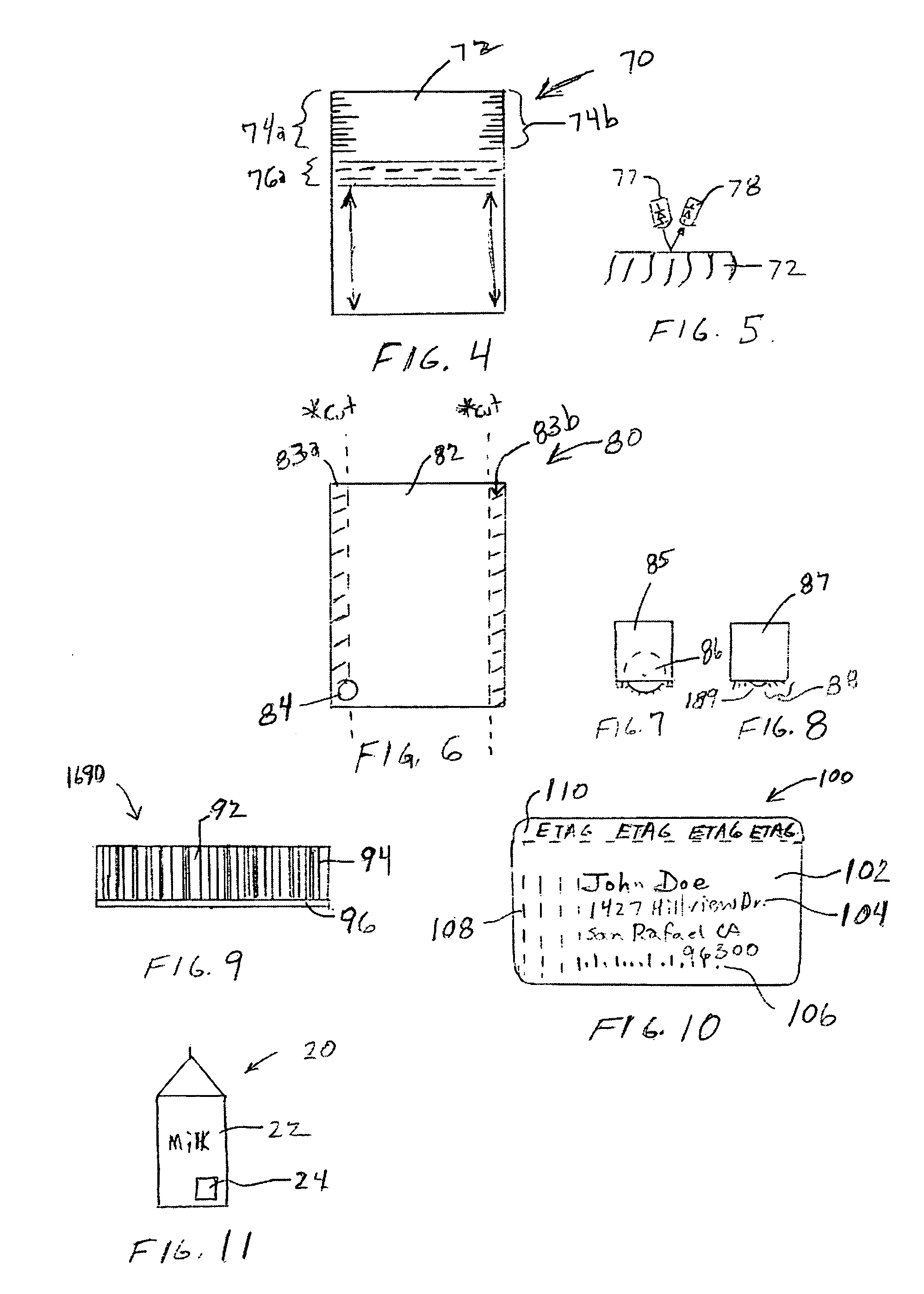

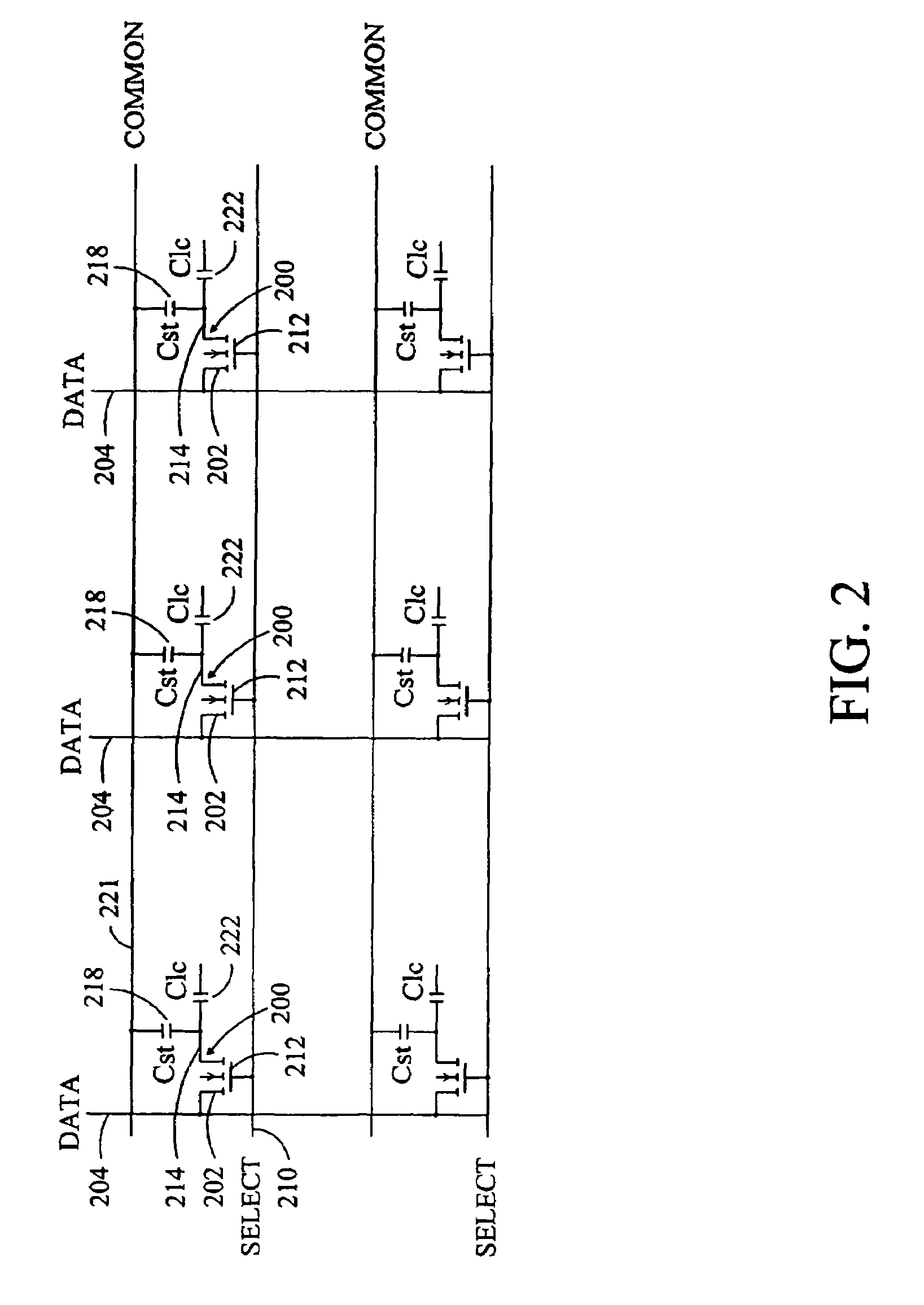

Apparatus and methods for static and semi-static displays

InactiveUS20060020469A1Low costReduce component countStatic indicating devicesSpeech analysisDisplay deviceData signal

A display device for modulating light intensity in response to programmed data output. Tapered cells within a base material containing a fluid within which are contained electrostatically responsive particles. Electrodes couple data signals to opposing portions of the cells, whereupon the position of the particles is modulated in response to the electric potential applied to said electrodes. A number of electronic ink displays, systems and method aspects are described.

Owner:RAST RODGER H

Incorporating rapid cooling in tissue fusion heating processes

ActiveUS7708735B2Rapid coolingSurgical instruments for heatingSurgical forcepsElectricityThermoelectric cooling

Owner:COVIDIEN AG

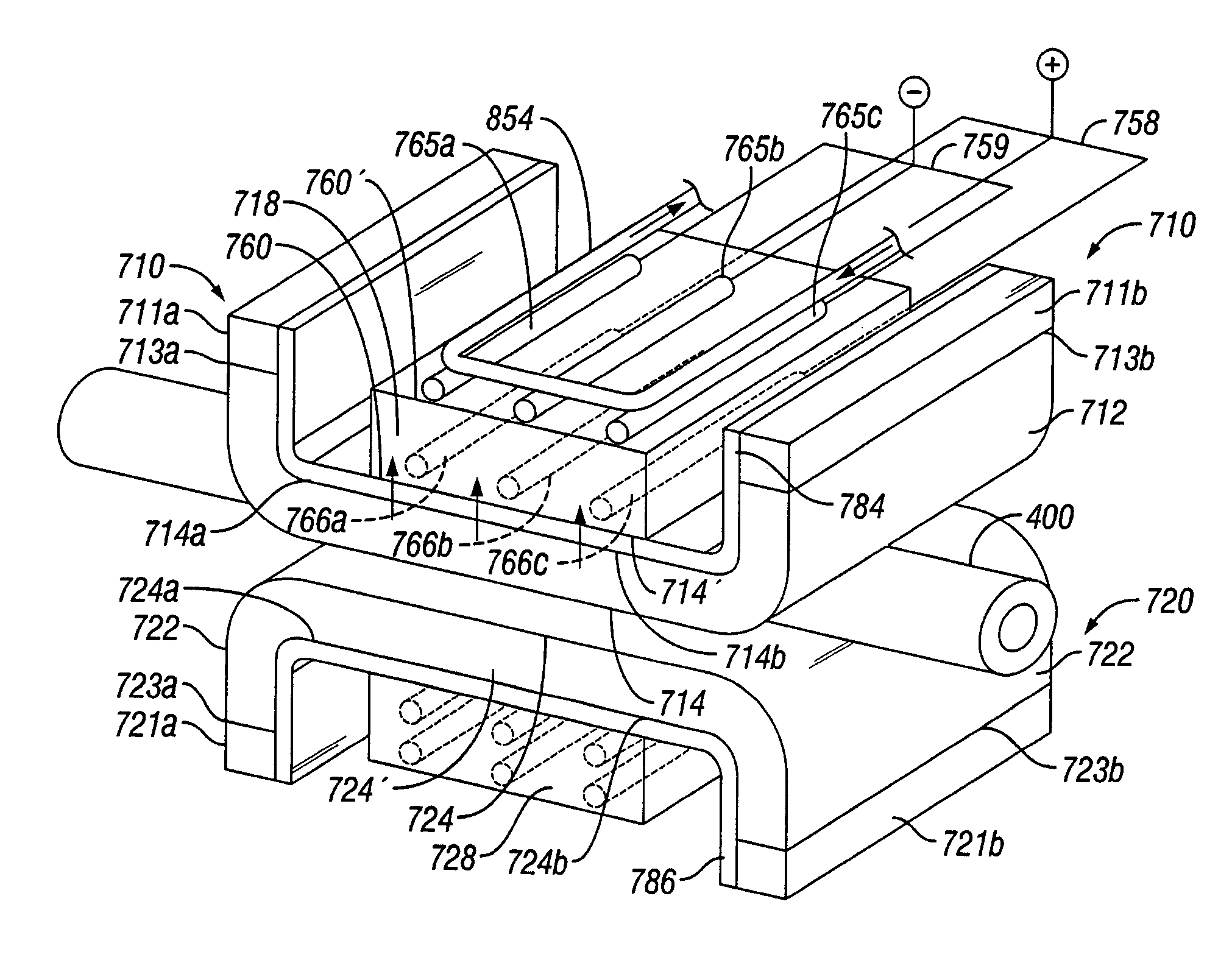

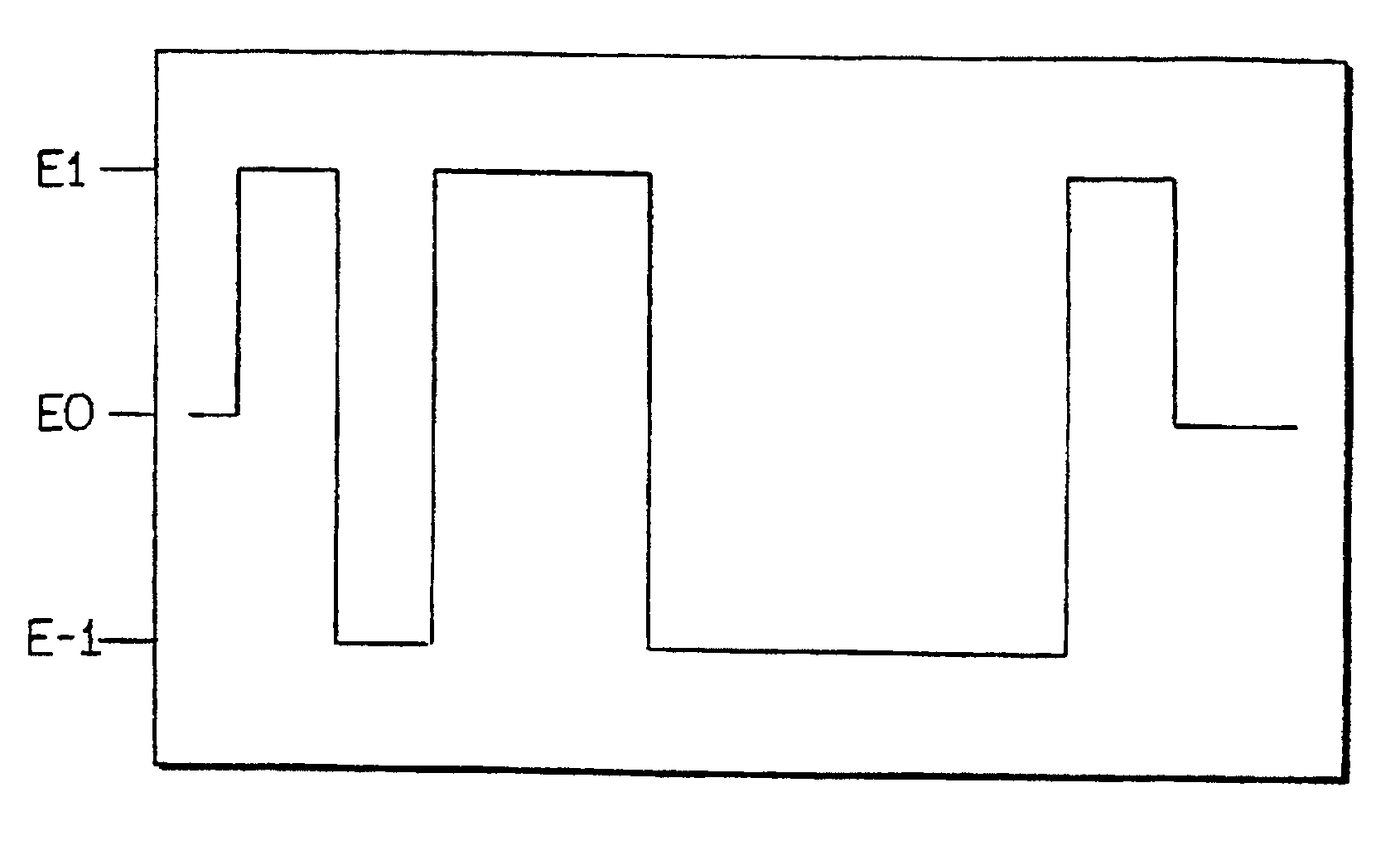

Small volume biosensor for continuous analyte monitoring

InactiveUS7045054B1Increase ratingsMinimize periodImmobilised enzymesBioreactor/fermenter combinationsRedox enzymesContinuous analysis

Sensors (10, 110, 210, 310, 410) and a method for detecting an analyte are described. Sensors (10, 110, 210, 310, 410) each have a volume of a hydrophilic medium (24) that retains an amount of analyte proportionate to the concentration of analyte in a biological fluid, electrodes (12) and a redox enzyme in contact with medium (24), and an electron transfer mediator. The fluid contacts sensors (10, 110, 210, 310, 410) and at initially predetermined intervals intermittently applies a potential to electrode (12) sufficient to oxidize the mediator and sensing current through electrode (12) as a function of the duration of the applied potential. The applied mediator oxidizing applied potential is maintained for a period of time sufficient to determine the rate of change of current with time through electrode (12). The current flow is correlated with the current flow for known concentrations of the analyte in medium (24).

Owner:ROCHE DIABETES CARE INC

Electronic device and driving method

InactiveUS20020011799A1Static indicating devicesSolid-state devicesElectrical resistance and conductanceEngineering

An electro-optical device is provided having a pixel portion with a novel structure, and in which display irregularities such as crosstalk, which develop due to a drop in voltage caused by the wiring resistance of electric current supply lines in an electro-optical device, are improved upon. Attention is drawn to the fact that during a period in which write in of a signal to a pixel from a signal line is not performed, a signal is not input to a source signal line and to a gate signal line, but are at a fixed electric potential. An electric current supply line and a source signal line, or an electric current supply line and a gate signal line, are connected through a switching transistor. A signal is input to a connection control line during a sustain period, and the connection transistor is made conductive. The source signal line or the gate signal line is therefore utilized as a pathway for supplying electric current to the EL element.

Owner:SEMICON ENERGY LAB CO LTD

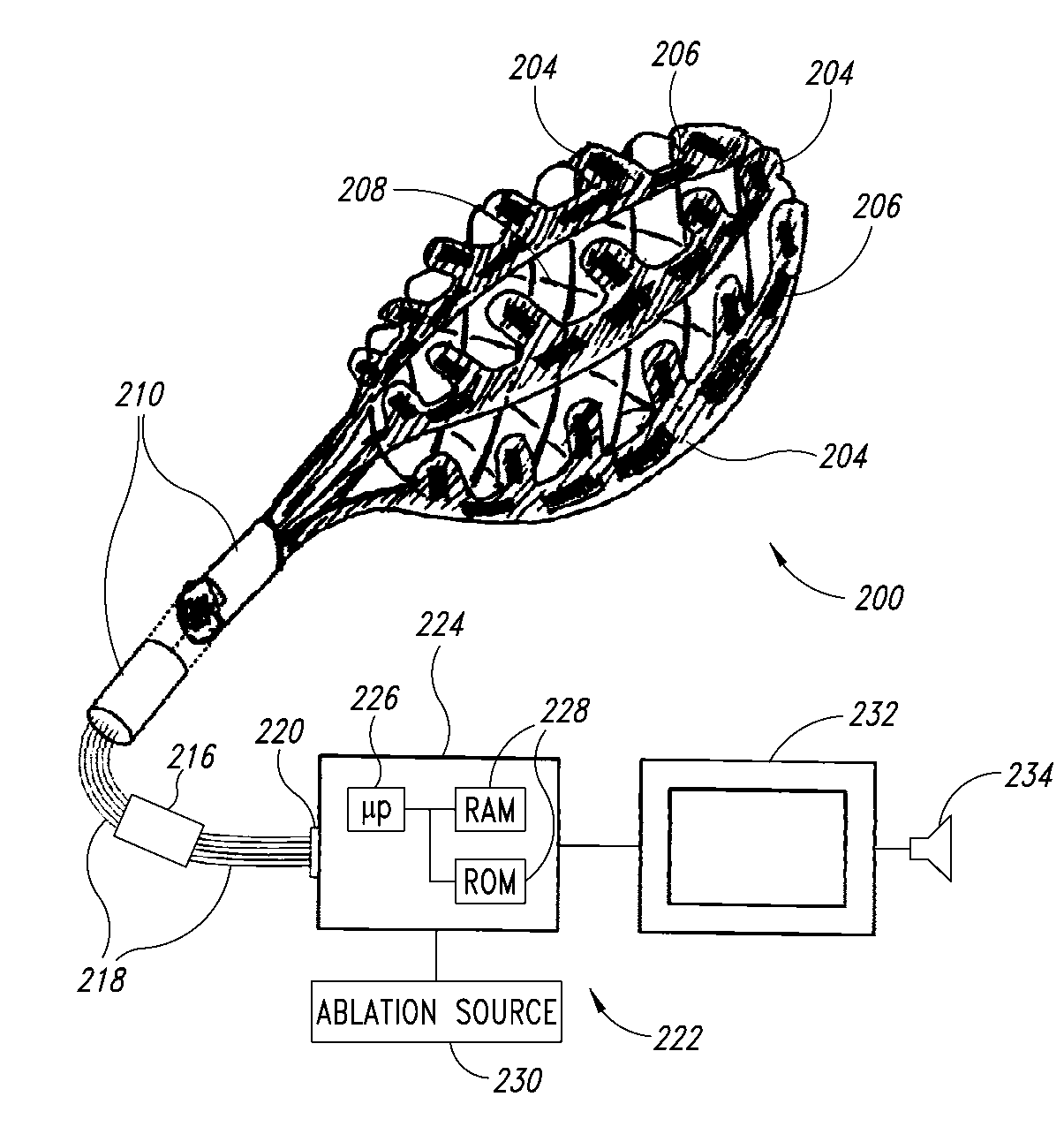

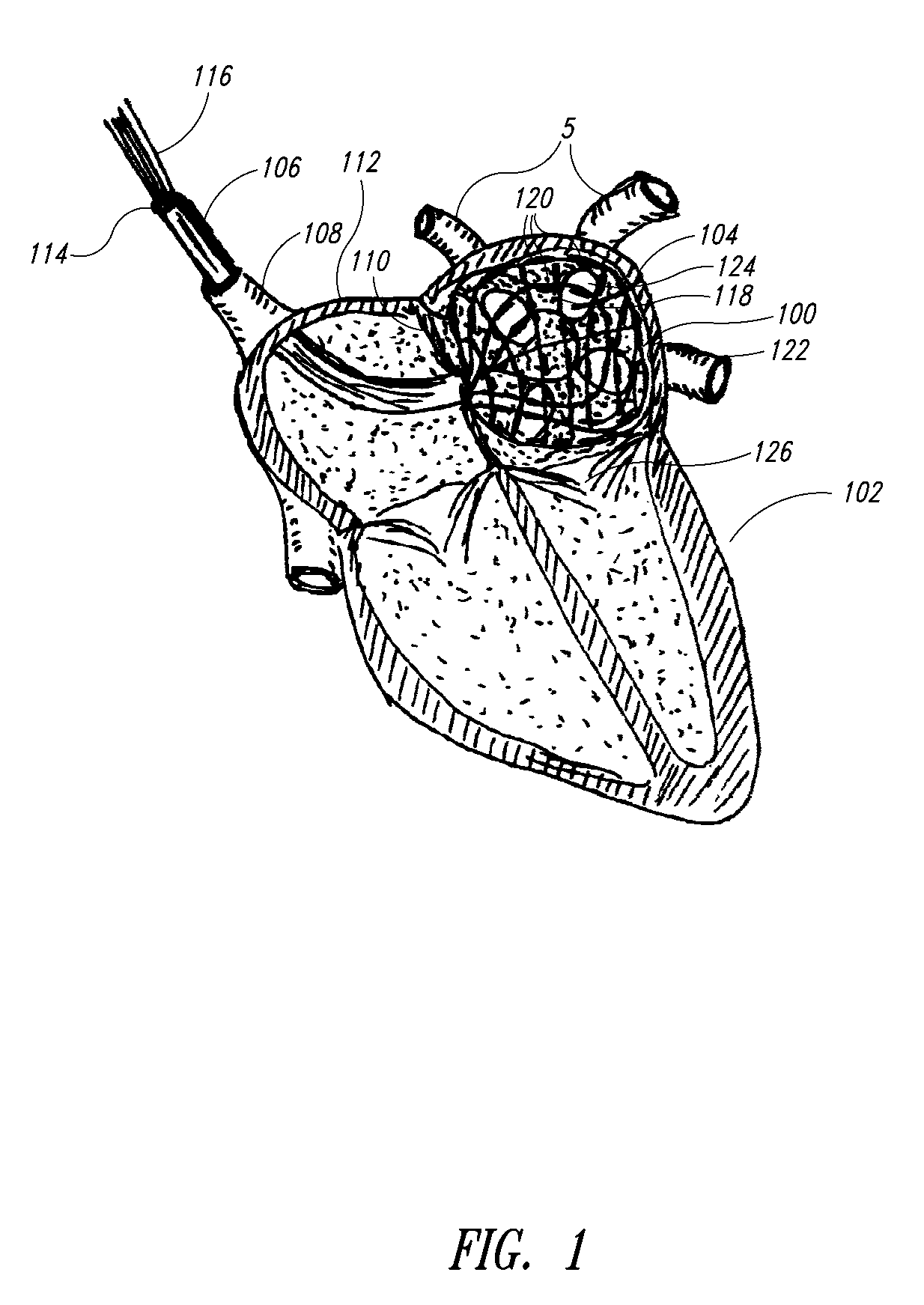

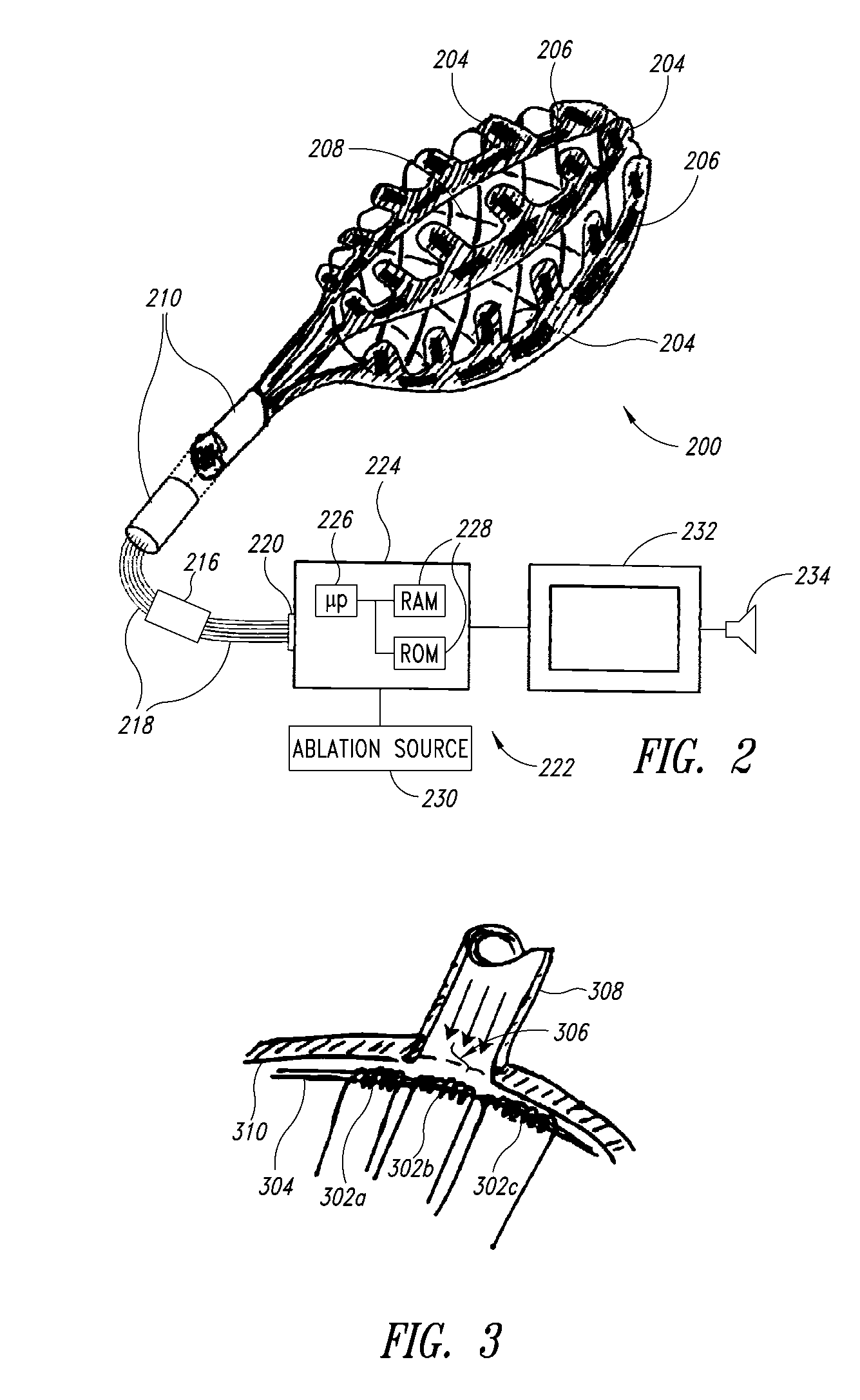

Medical device for use in bodily lumens, for example an atrium

ActiveUS20090131930A1Improve abilitiesConvenient location informationDiagnostic recording/measuringSensorsAtrial cavityPermittivity

A device positionable in a cavity of a bodily organ (e.g., a heart) may discriminate between fluid (e.g., blood) and non-fluid tissue (e.g., wall of heart) to provide information or a mapping indicative of a position and / or orientation of the device in the cavity. Discrimination may be based on flow, or some other characteristic, for example electrical permittivity or force. The device may selectively ablate portions of the non-fluid tissue based on the information or mapping. The device may detect characteristics (e.g., electrical potentials) indicative of whether ablation was successful. The device may include a plurality of transducers, intravascularly guided in an unexpanded configuration and positioned proximate the non-fluid tissue in an expanded configuration. Expansion mechanism may include helical member(s) or inflatable member(s).

Owner:KARDIUM

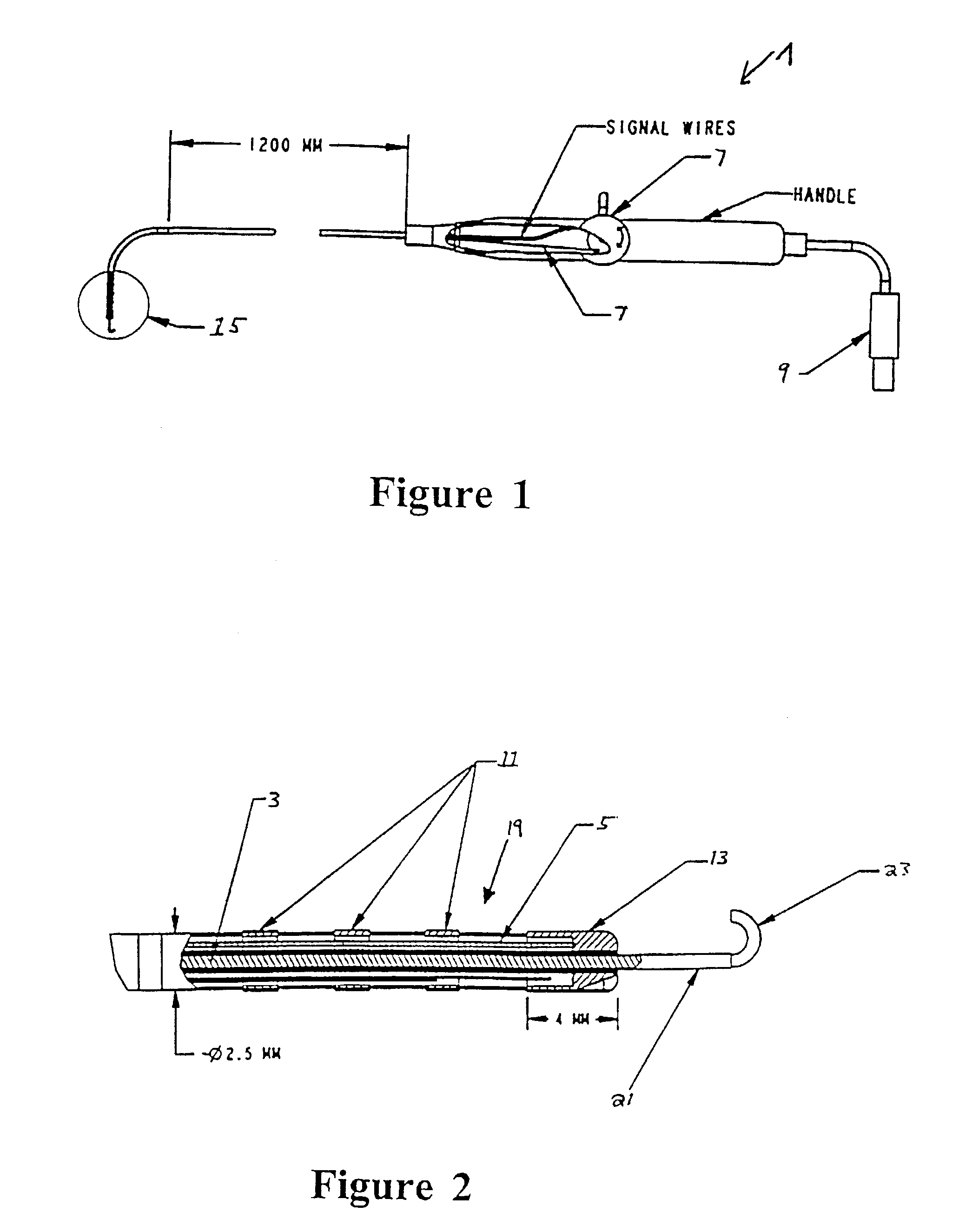

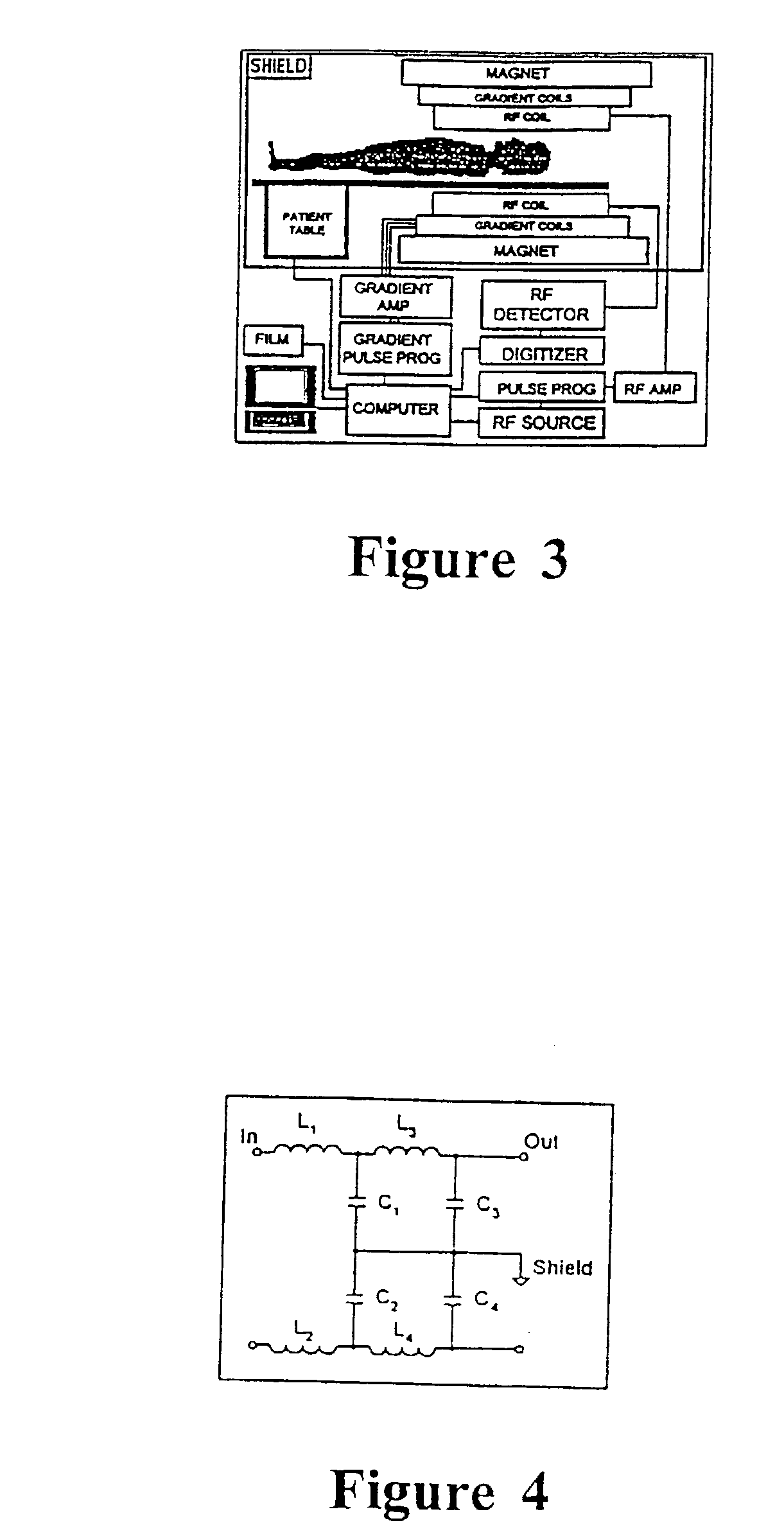

System and method for magnetic-resonance-guided electrophysiologic and ablation procedures

InactiveUS7155271B2Increased resolution and reliabilityImprove accuracySurgical instrument detailsDiagnostic recording/measuringMr guidanceMr contrast agent

A system and method for using magnetic resonance imaging to increase the accuracy of electrophysiologic procedures is disclosed. The system in its preferred embodiment provides an invasive combined electrophysiology and imaging antenna catheter which includes an RF antenna for receiving magnetic resonance signals and diagnostic electrodes for receiving electrical potentials. The combined electrophysiology and imaging antenna catheter is used in combination with a magnetic resonance imaging scanner to guide and provide visualization during electrophysiologic diagnostic or therapeutic procedures. The invention is particularly applicable to catheter ablation, e.g., ablation of atrial fibrillation. In embodiments which are useful for catheter ablation, the combined electrophysiology and imaging antenna catheter may further include an ablation tip, and such embodiment may be used as an intracardiac device to both deliver energy to selected areas of tissue and visualize the resulting ablation lesions, thereby greatly simplifying production of continuous linear lesions. The invention further includes embodiments useful for guiding electrophysiologic diagnostic and therapeutic procedures other than ablation. Imaging of ablation lesions may be further enhanced by use of MR contrast agents. The antenna utilized in the combined electrophysiology and imaging catheter for receiving MR signals is preferably of the coaxial or “loopless” type. High-resolution images from the antenna may be combined with low-resolution images from surface coils of the MR scanner to produce a composite image. The invention further provides a system for eliminating the pickup of RF energy in which intracardiac wires are detuned by filtering so that they become very inefficient antennas. An RF filtering system is provided for suppressing the MR imaging signal while not attenuating the RF ablative current. Steering means may be provided for steering the invasive catheter under MR guidance. Other ablative methods can be used such as laser, ultrasound, and low temperatures.

Owner:THE JOHNS HOPKINS UNIVERSITY SCHOOL OF MEDICINE

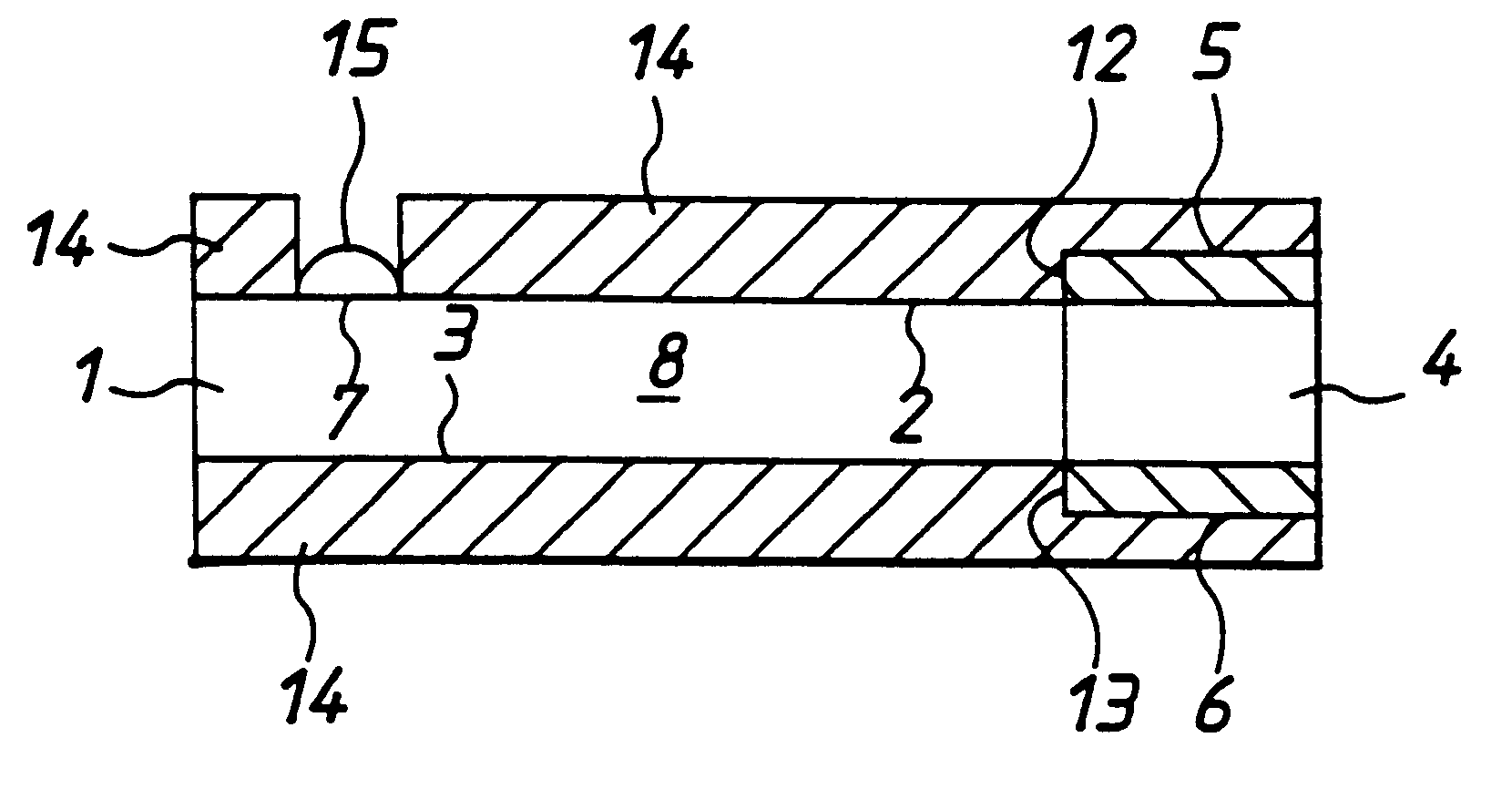

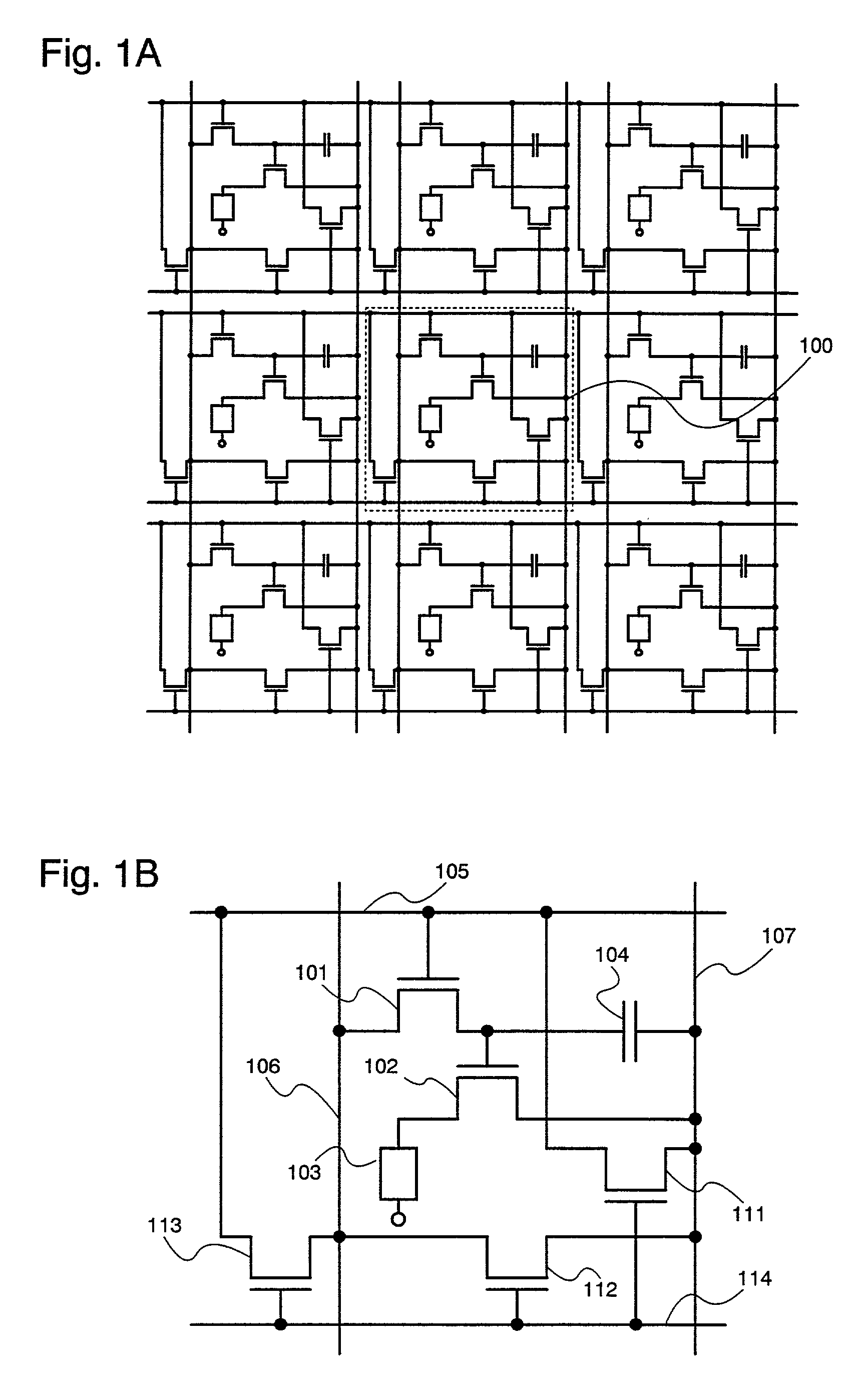

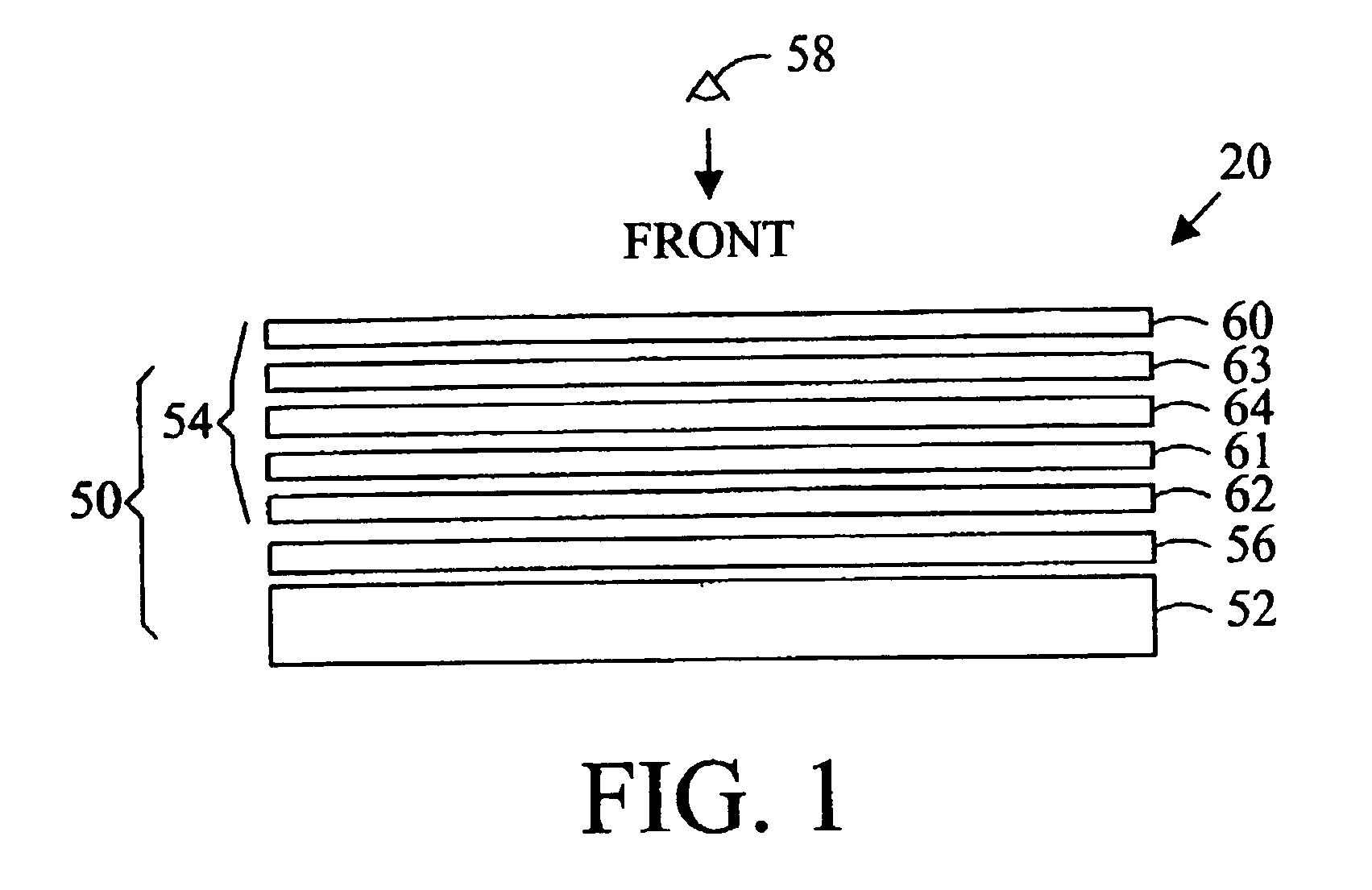

Integrated optical light sensitive active matrix liquid crystal display

ActiveUS7009663B2Static indicating devicesNon-linear opticsActive-matrix liquid-crystal displayLiquid-crystal display

A liquid crystal device including a front electrode layer, rear electrode layer, a liquid crystal material located between the front electrode layer and the rear electrode layer. A polarizer is located between the liquid crystal material and the front electrode layer and changing an electrical potential between the rear electrode layer and the front electrode layer modifies portions of the liquid crystal material to change the polarization of the light incident thereon. A plurality of light sensitive elements are located together with the rear electrode layer and a processor determines the position of at least one of the plurality of light sensitive elements that has been inhibited from sensing ambient light.

Owner:APPLE INC

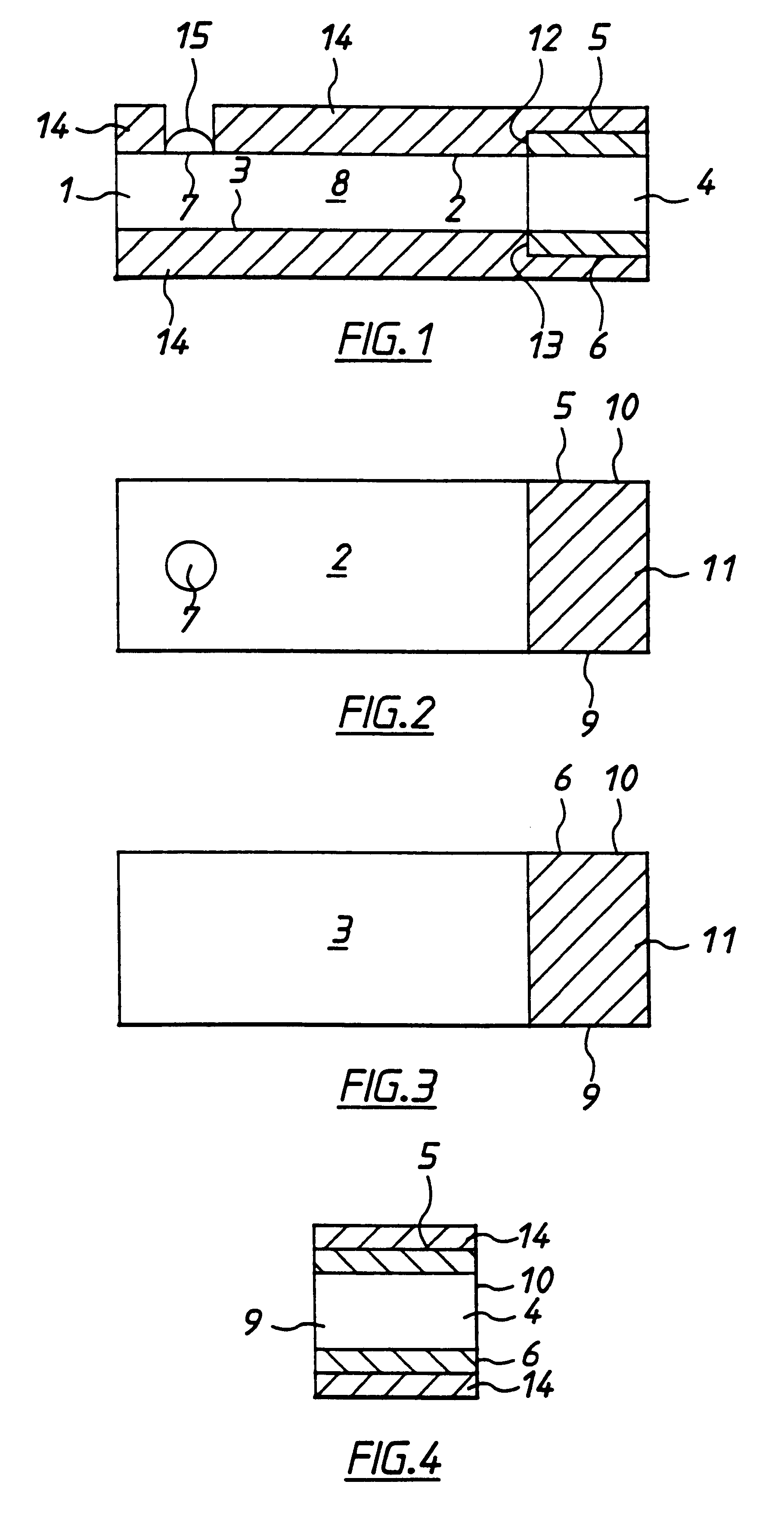

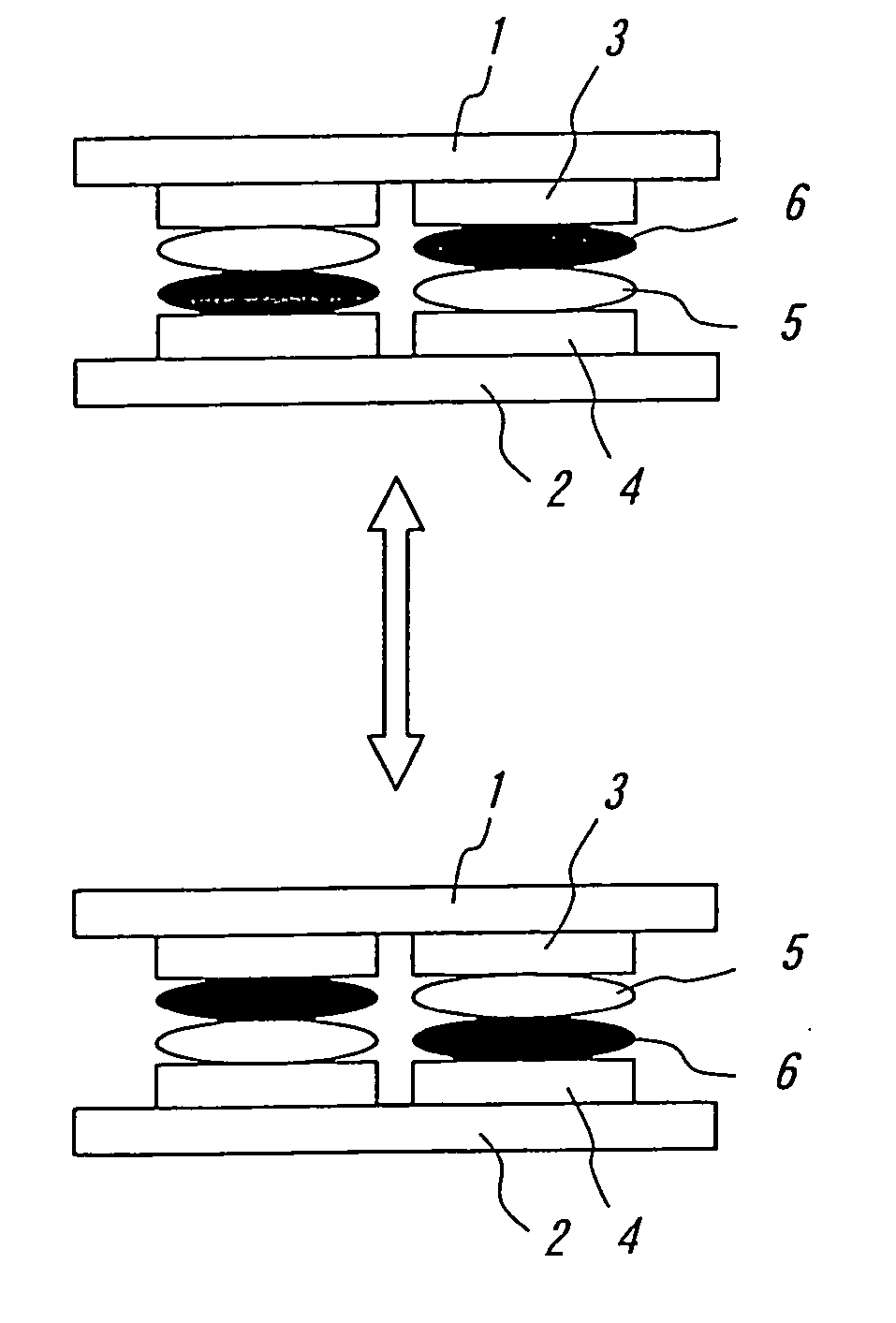

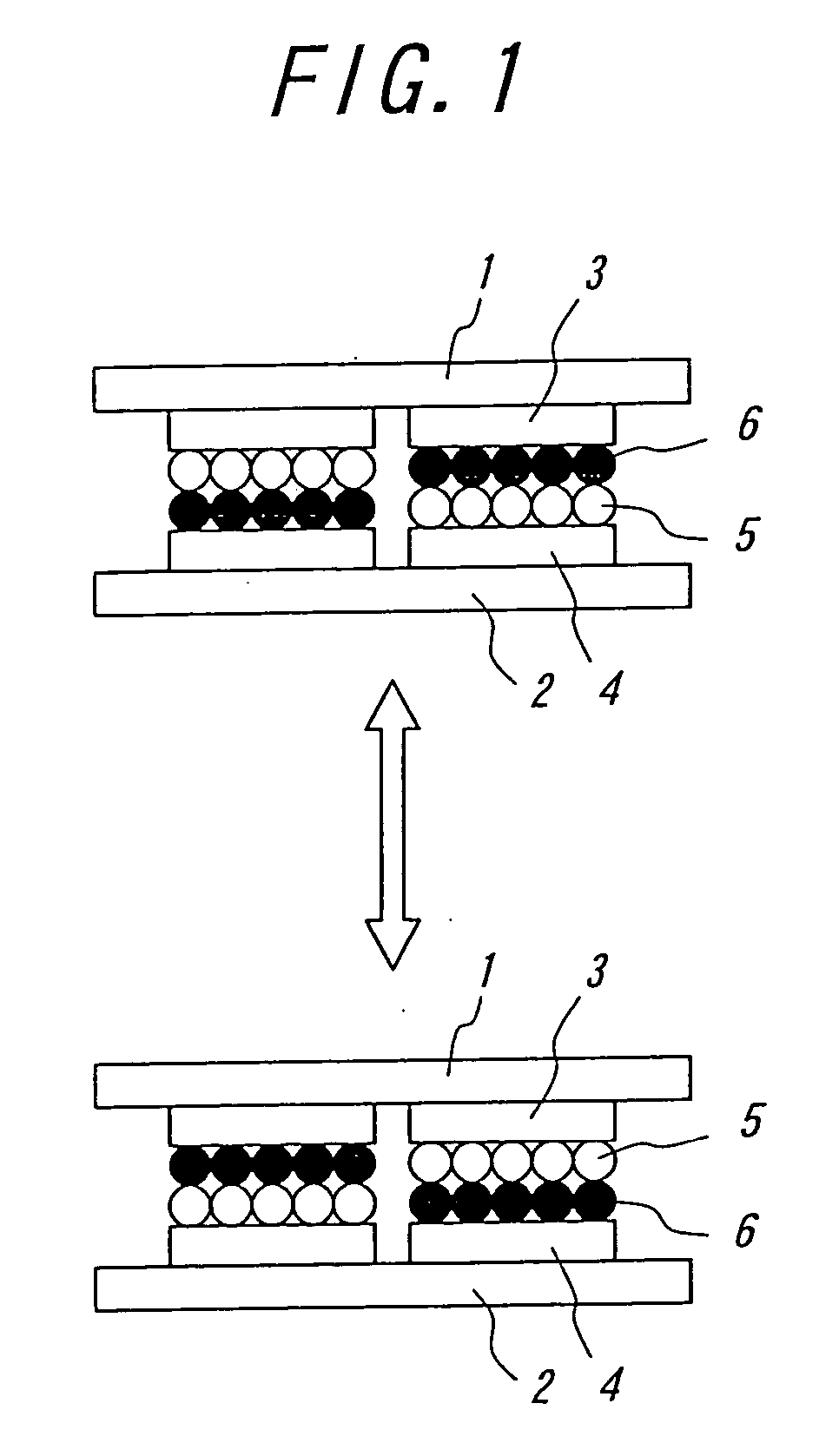

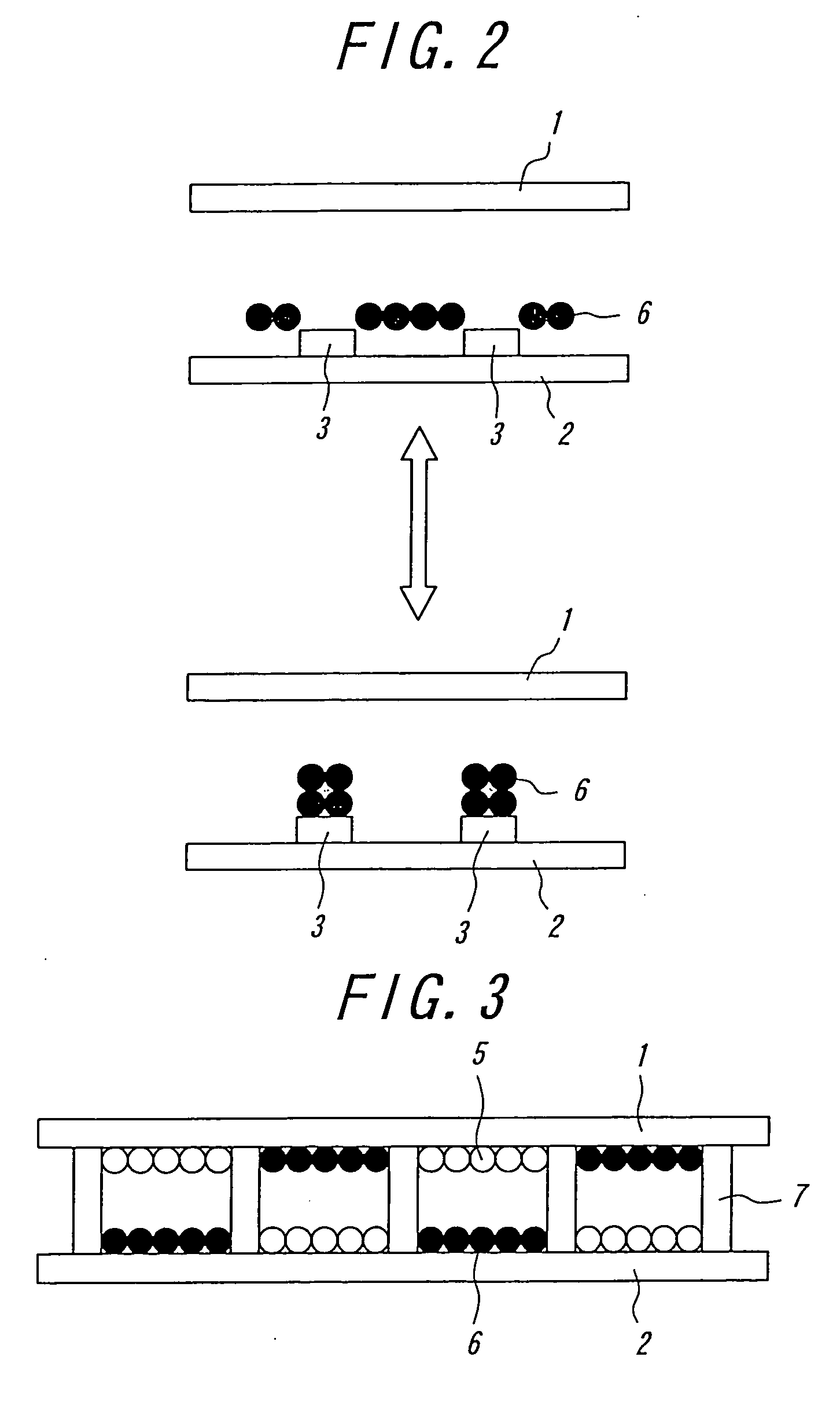

Image display and method for manufacturing image display

InactiveUS20060087479A1Improve performanceRapid responseStatic indicating devicesNon-linear opticsAnisotropic conductive filmDisplay device

In a first aspect of the invention, an image display device, in which one or more groups of particles or liquid powders are sealed between opposed two substrates, at least one of two substrates being transparent, and, in which the particles or the liquid powders, to which an electrostatic field produced by two groups of electrodes having different potentials is applied, are made to move so as to display an image, has a construction such that a member for transmitting a signal, which is applied to circuits for an image display, is provided to the substrate by means of an anisotropic conductive film and members such as the electrode are provided to a substrate opposed to a transparent substrate. In second to sixth aspects of the invention, an image display device has a construction such that the electrode is arranged to a surface of the substrate through a transparent elastic member, or, an anti-reflection layer is arranged, or, a connection operation between two substrates through a partition wall is optimized.

Owner:BRIDGESTONE CORP

Method of using actuators for microfluidics without moving parts

InactiveUS7255780B2Maximize area overlapEffectively converting the surface into more hydrophilicSludge treatmentFlow mixersElectricityMicrofluidics

A series of microactuators for manipulating small quantities of liquids, and methods of using these for manipulating liquids, are disclosed. The microactuators are based on the phenomenon of electrowetting and contain no moving parts. The force acting on the liquid is a potential-dependent gradient of adhesion energy between the liquid and a solid insulating surface.

Owner:ADVANCED LIQUID LOGIC

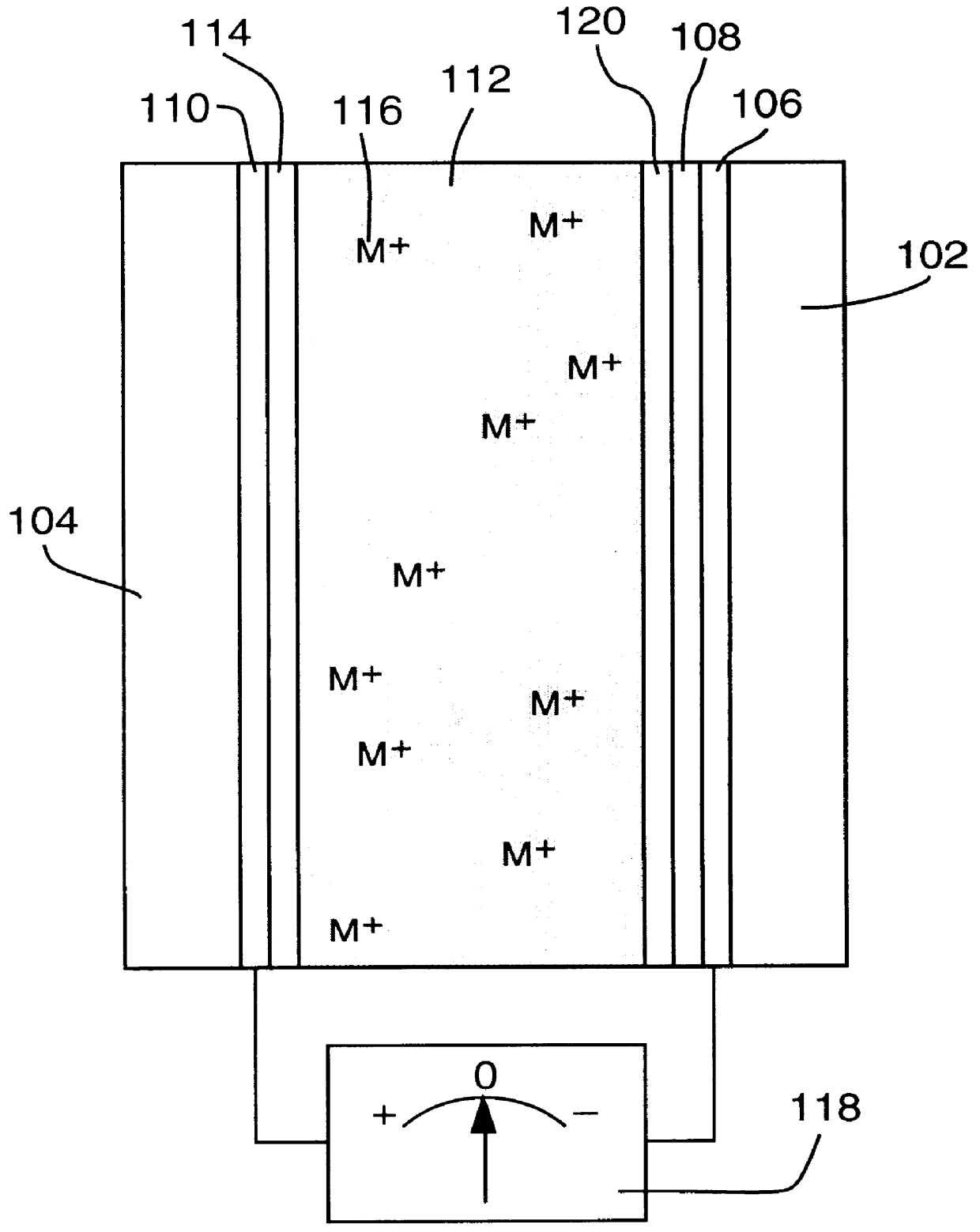

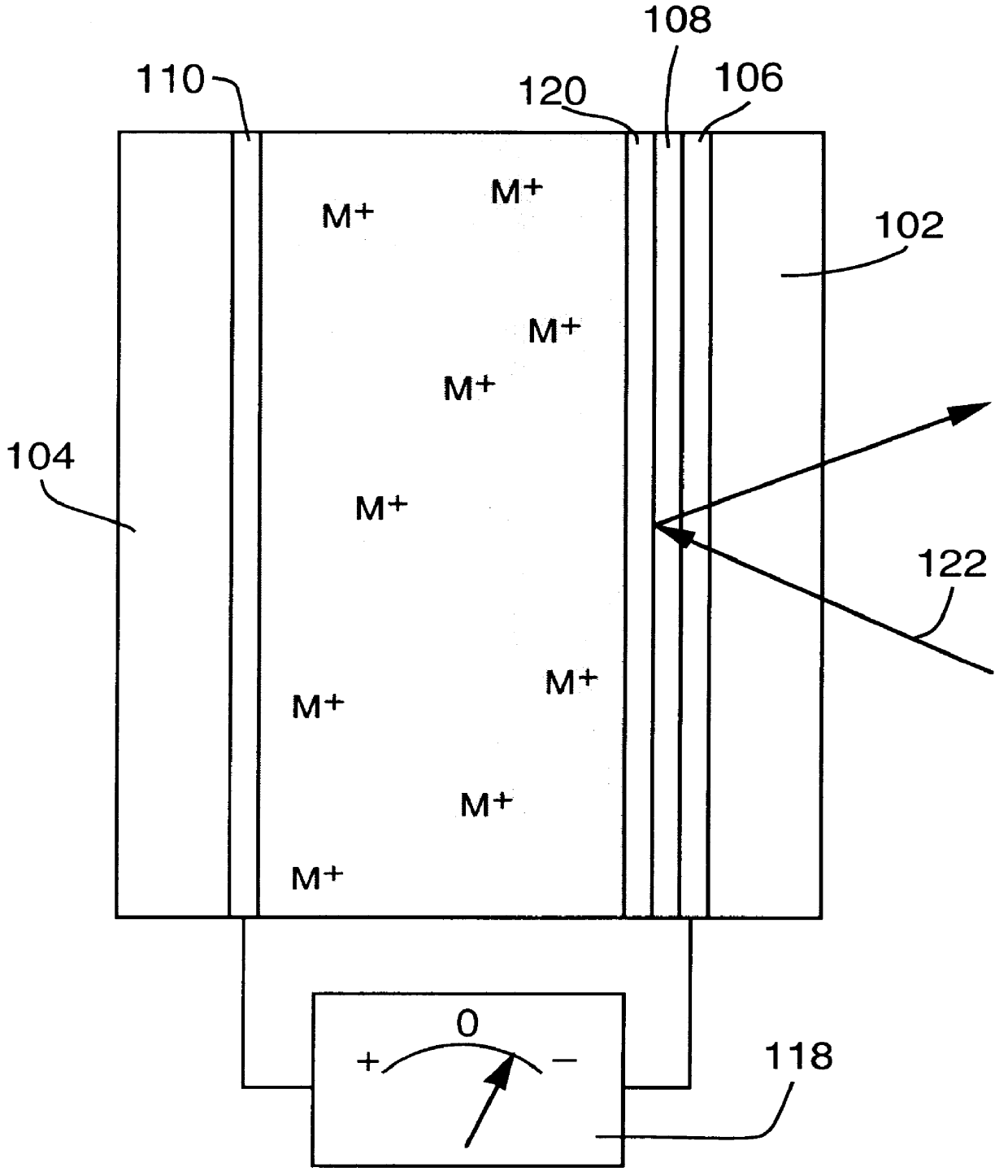

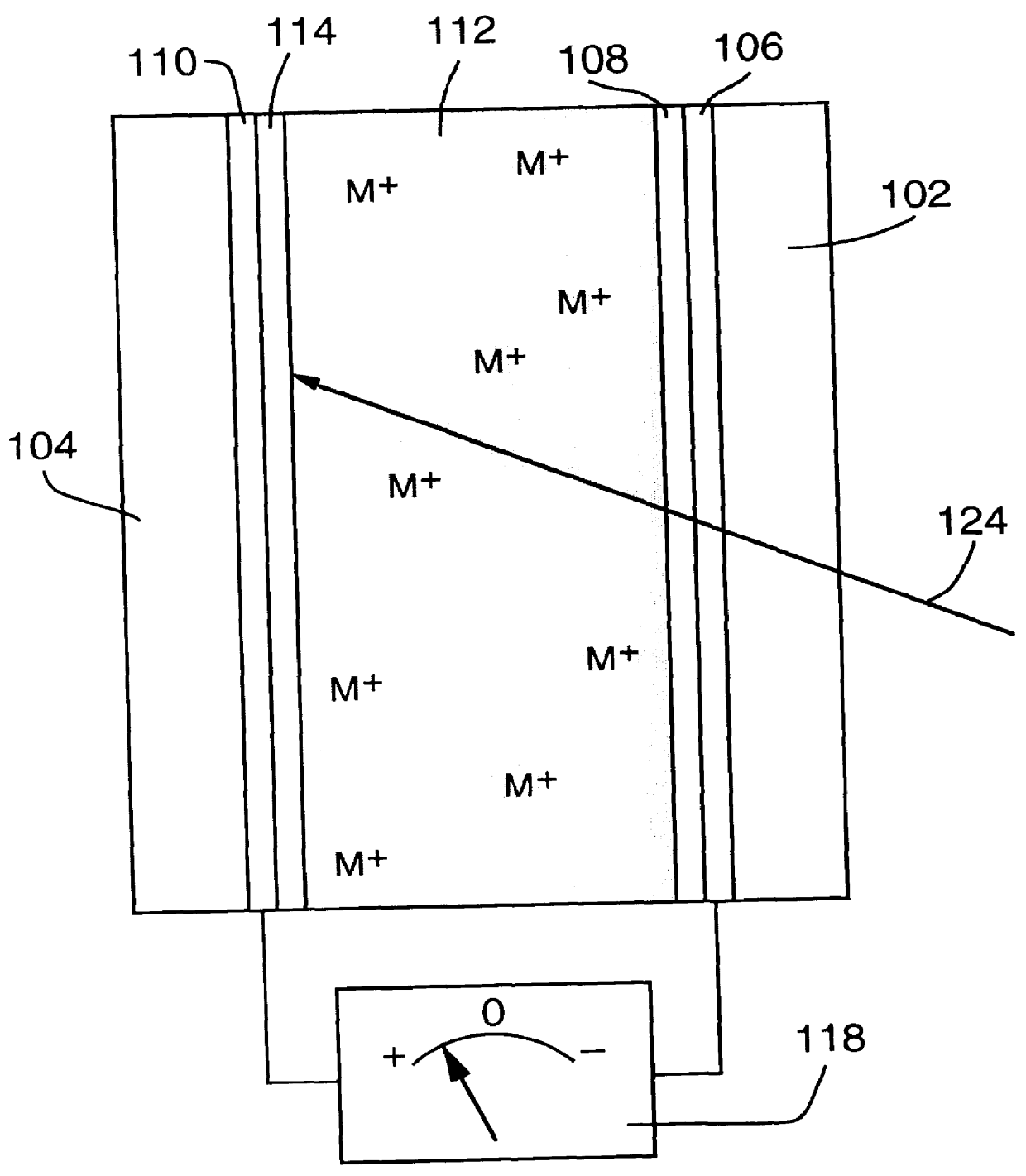

Reversible electrochemical mirror for modulation of reflected radiation

InactiveUS6166847APrecise and Efficient ControlUniform nucleationNon-linear opticsElectricityElectromagnetic radiation

An electrochemical mirror includes a transparent first electrode and a second electrode. An electrolytic solution, disposed between the first and second electrodes, contains ions of a metal which can electrodeposit on the electrodes. A negative electrical potential applied to the first electrode causes deposited metal to be dissolved from the second electrode into the electrolytic solution and to be electrodeposited from the solution onto the first electrode, thereby affecting the reflectivity of the mirror for electromagnetic radiation. A surface modification layer applied to the first electrode ensures that the electrodeposit is substantially uniform, resulting in a mirror layer which increases the reflectivity of the mirror. A positive electrical potential applied to the first electrode causes deposited metal to be dissolved from the first electrode and electrodeposited from the solution onto the second electrode, thereby decreasing the reflectivity of the mirror.

Owner:TELEDYNE SCI & IMAGING

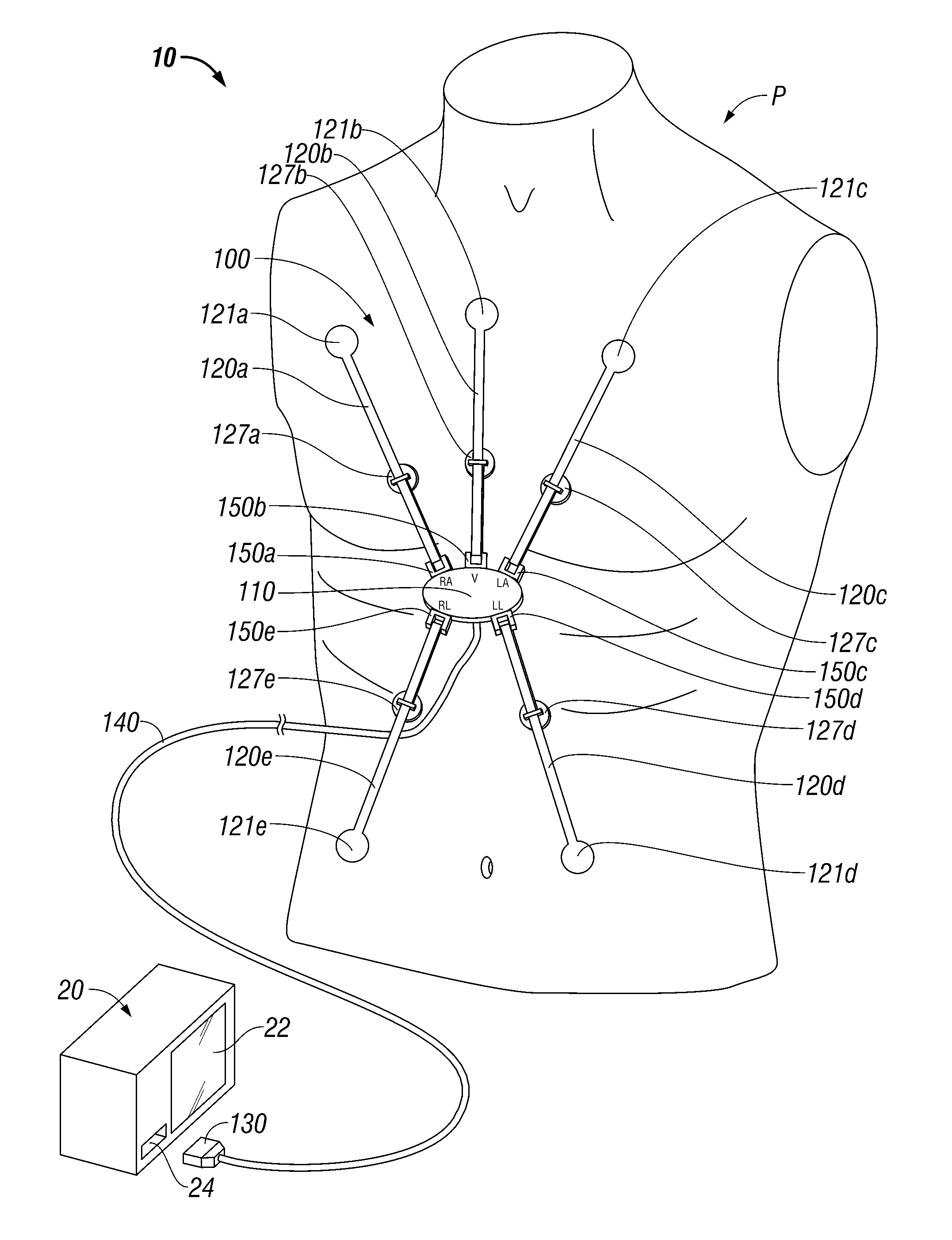

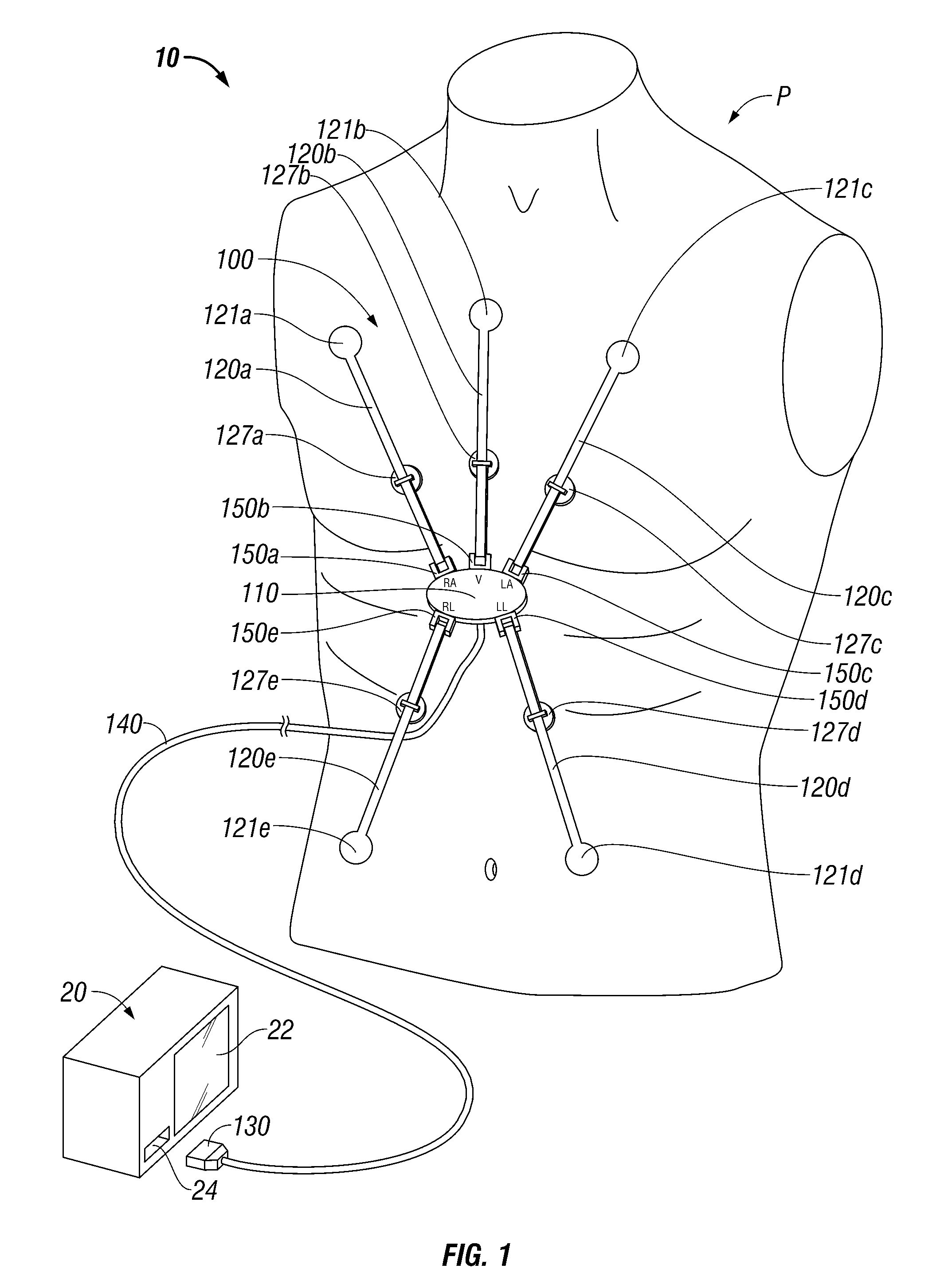

ECG lead wire organizer and dispenser

Owner:KPR U S LLC

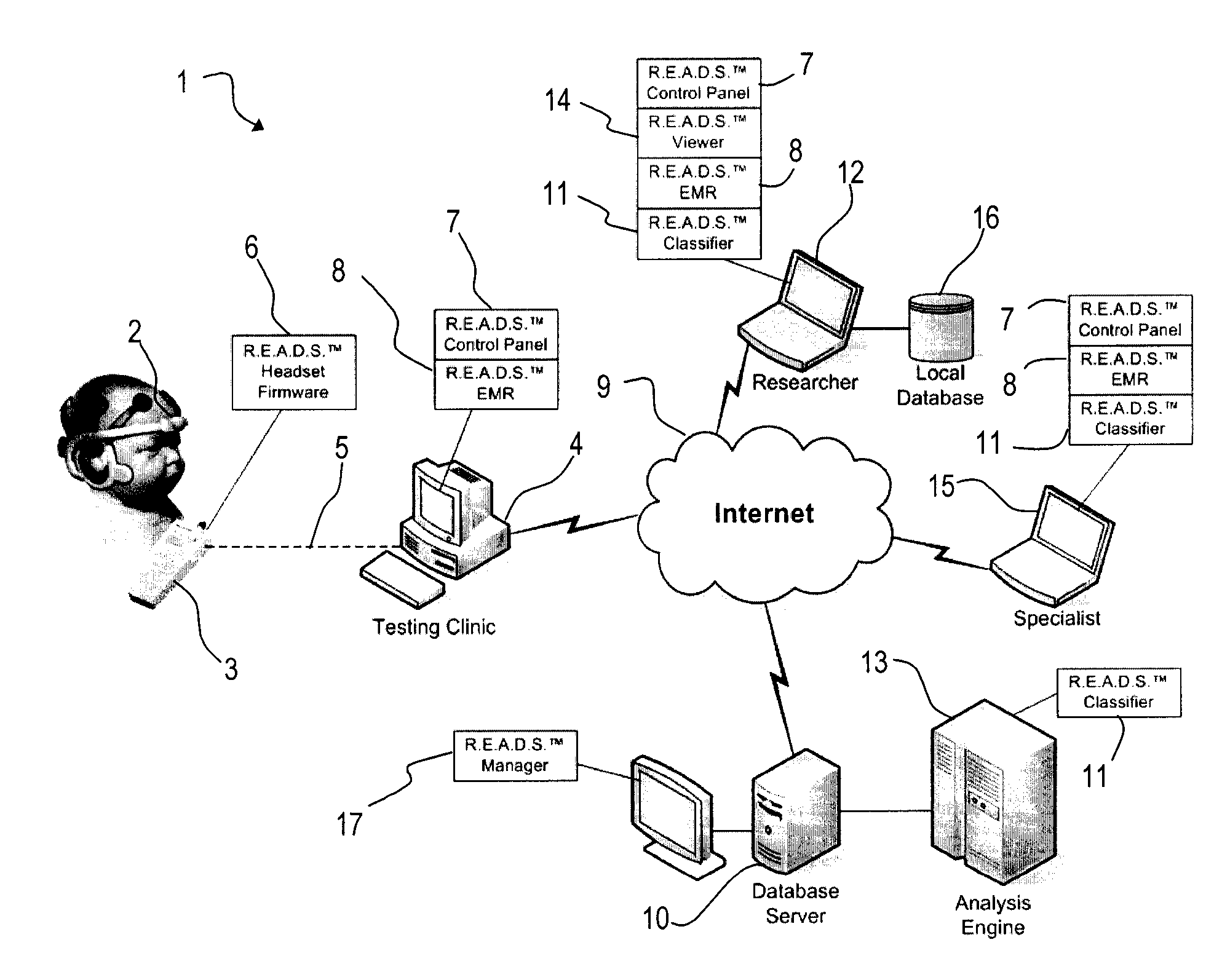

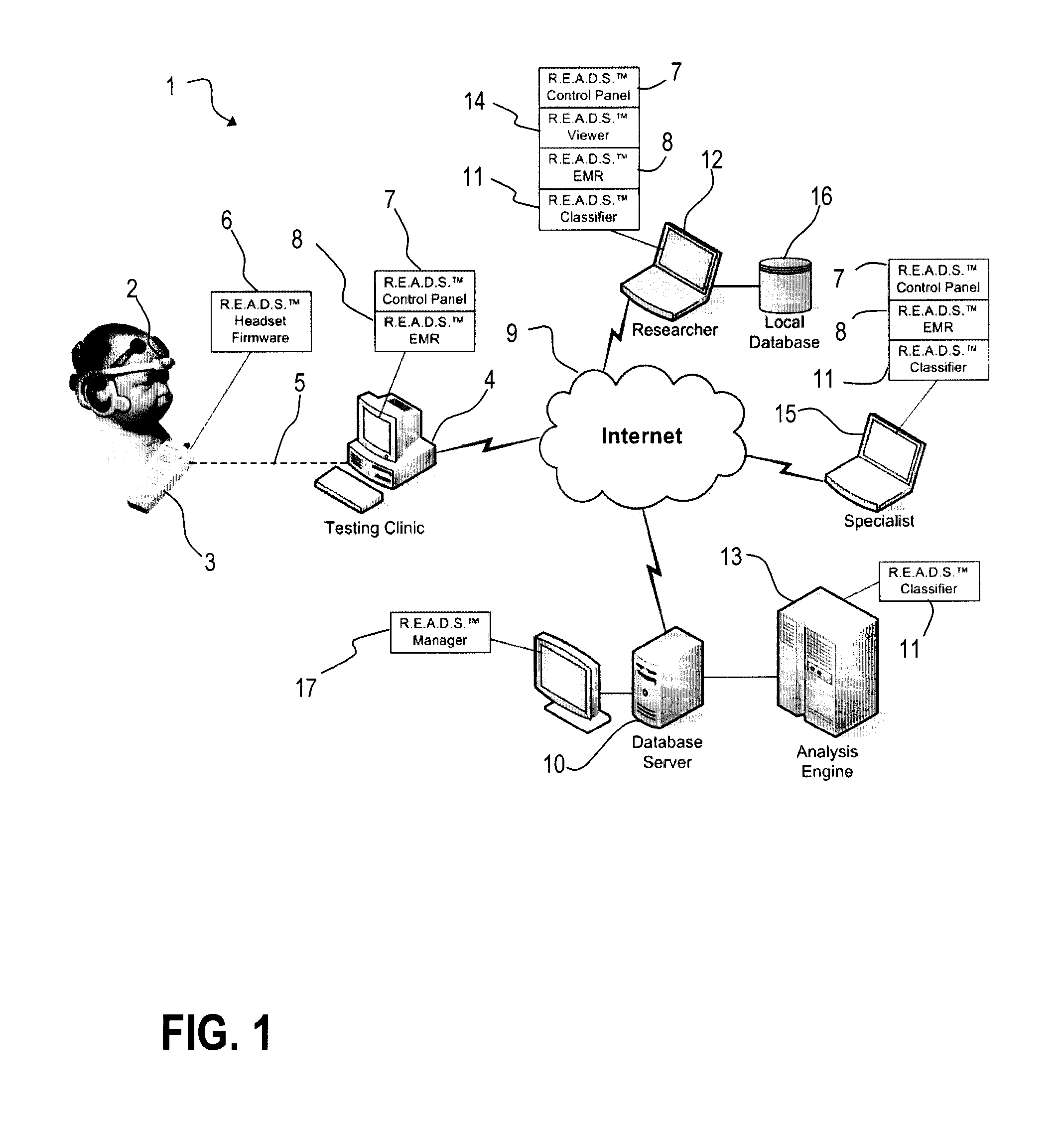

Biopotential Waveform Data Fusion Analysis and Classification Method

InactiveUS20080208072A1Improve classification accuracyElectroencephalographyMedical data miningTraining phaseData source

Biopotential waveforms such as ERPs, EEGs, ECGs, or EMGs are classified accurately by dynamically fusing classification information from multiple electrodes, tests, or other data sources. These different data sources or “channels” are ranked at different time instants according to their respective univariate classification accuracies. Channel rankings are determined during training phase in which classification accuracy of each channel at each time-instant is determined. Classifiers are simple univariate classifiers which only require univariate parameter estimation. Using classification information, a rule is formulated to dynamically select different channels at different time-instants during the testing phase. Independent decisions of selected channels at different time instants are fused into a decision fusion vector. The resulting decision fusion vector is optimally classified using a discrete Bayes classifier. Finally, the dynamic decision fusion system provides high classification accuracies, is quite flexible in operation, and overcomes major limitations of classifiers applied currently in biopotential waveform studies and clinical applications.

Owner:NEURONETRIX SOLUTIONS

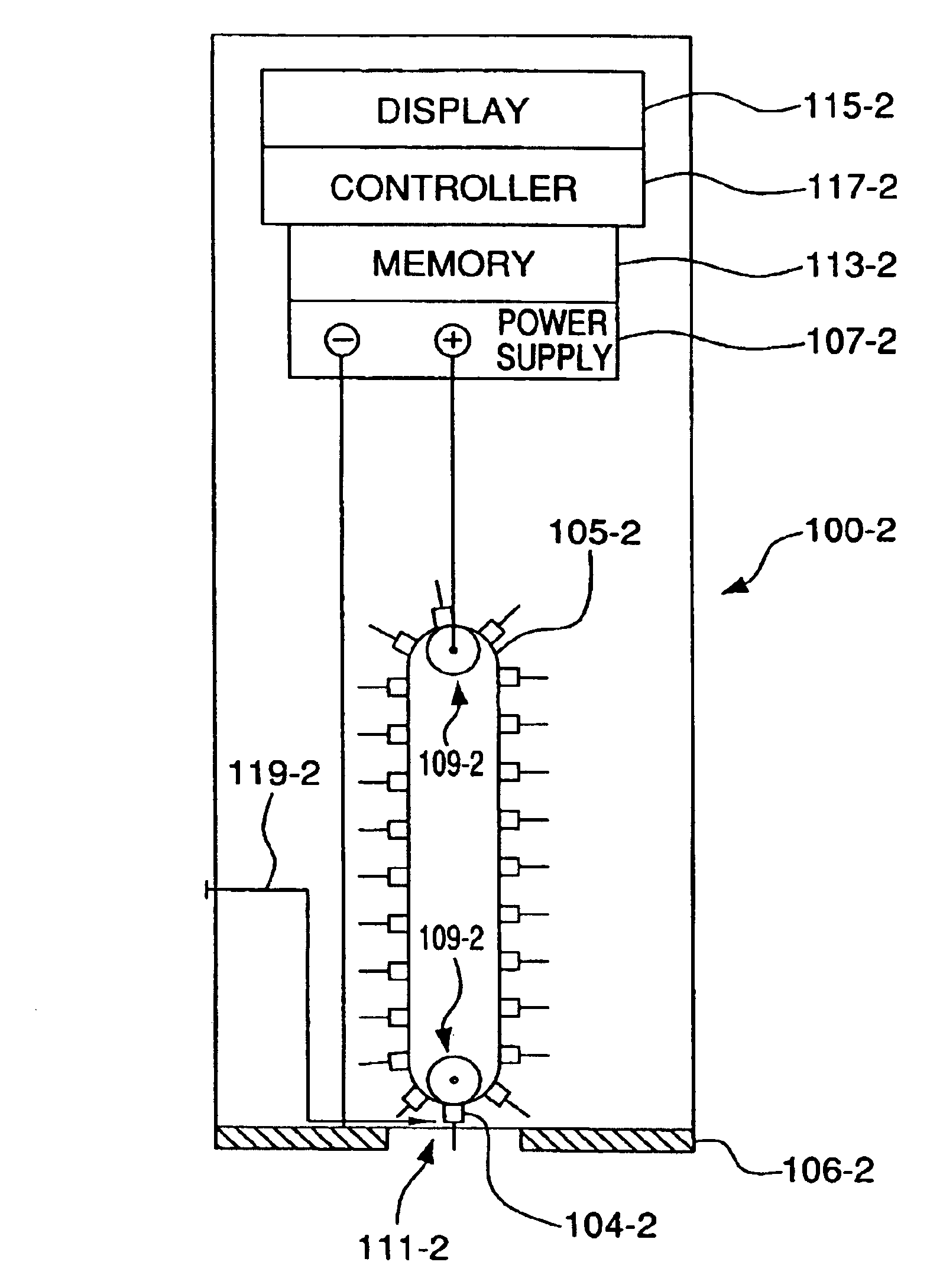

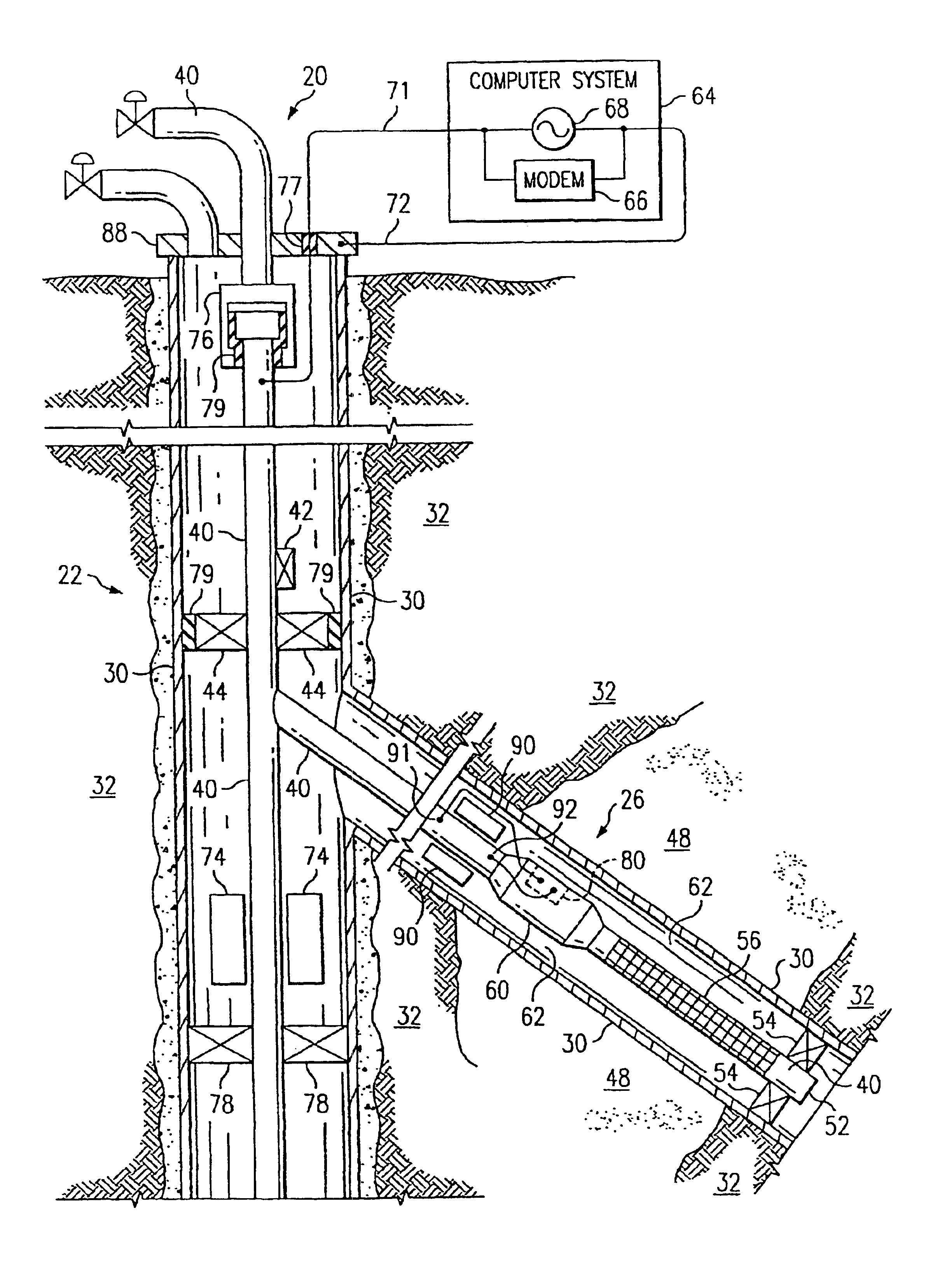

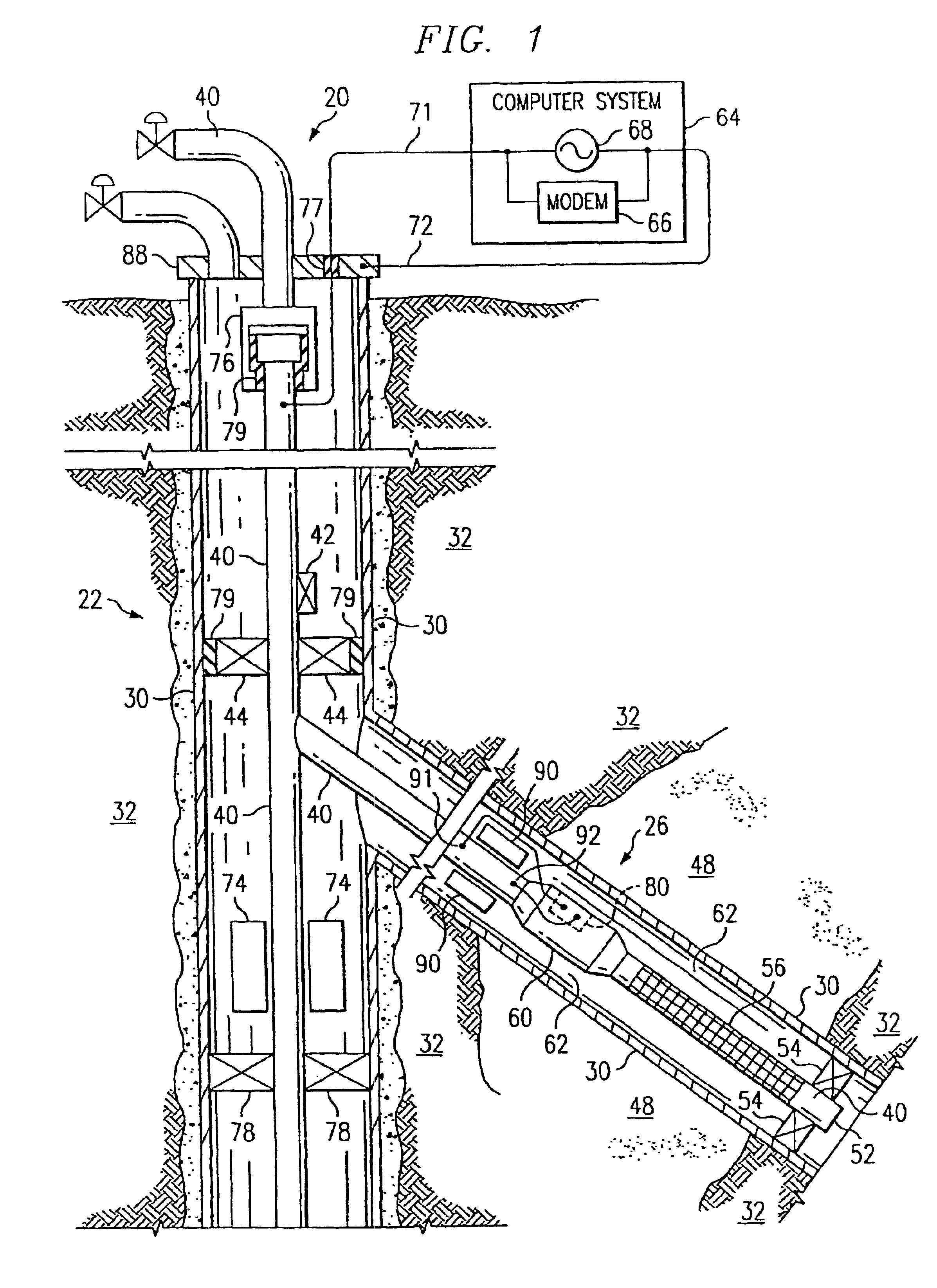

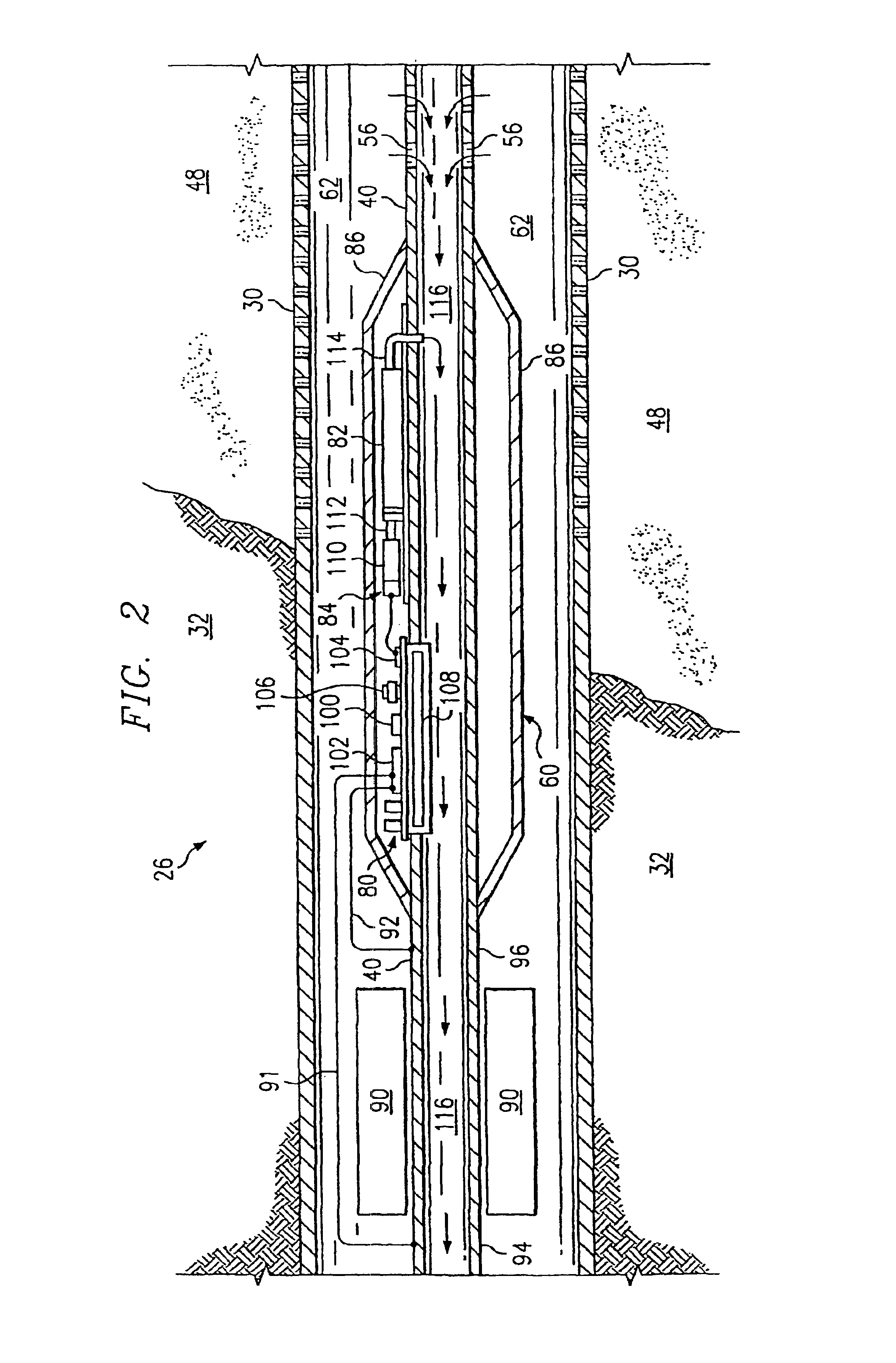

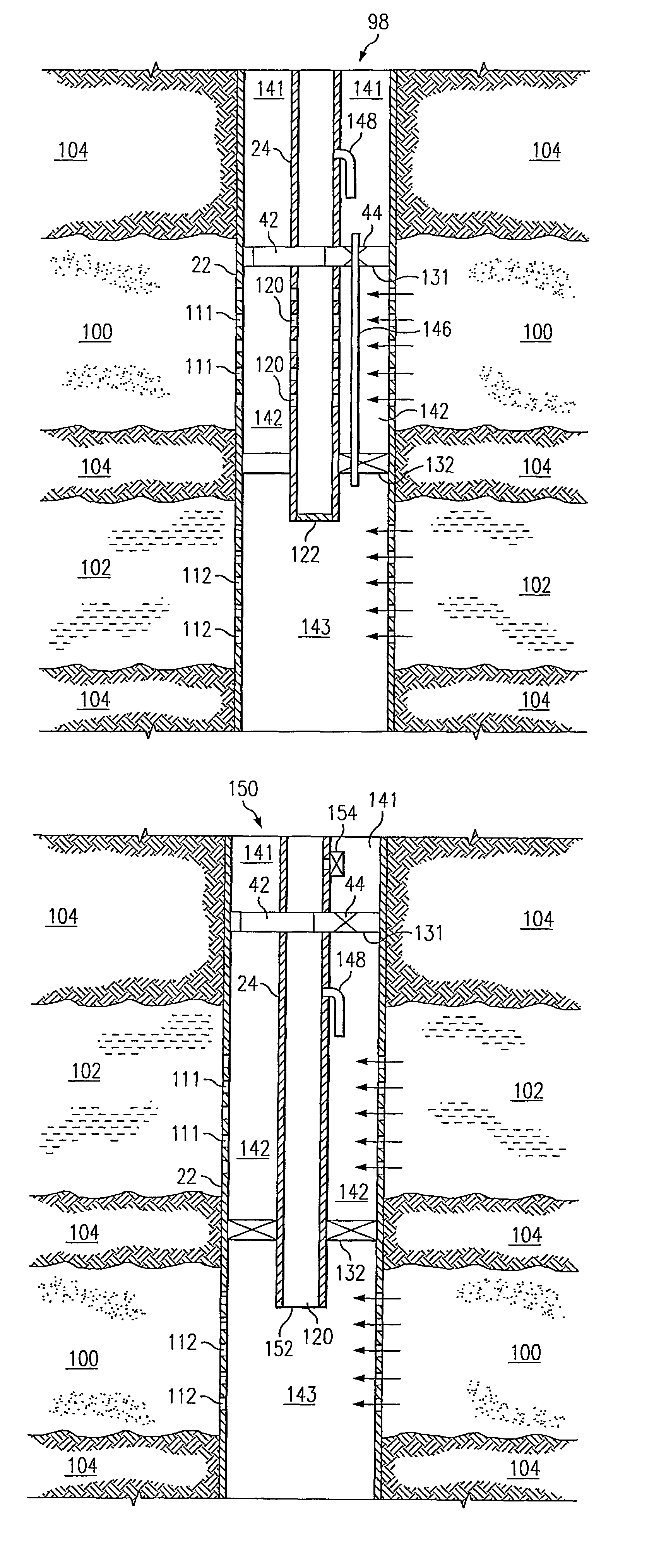

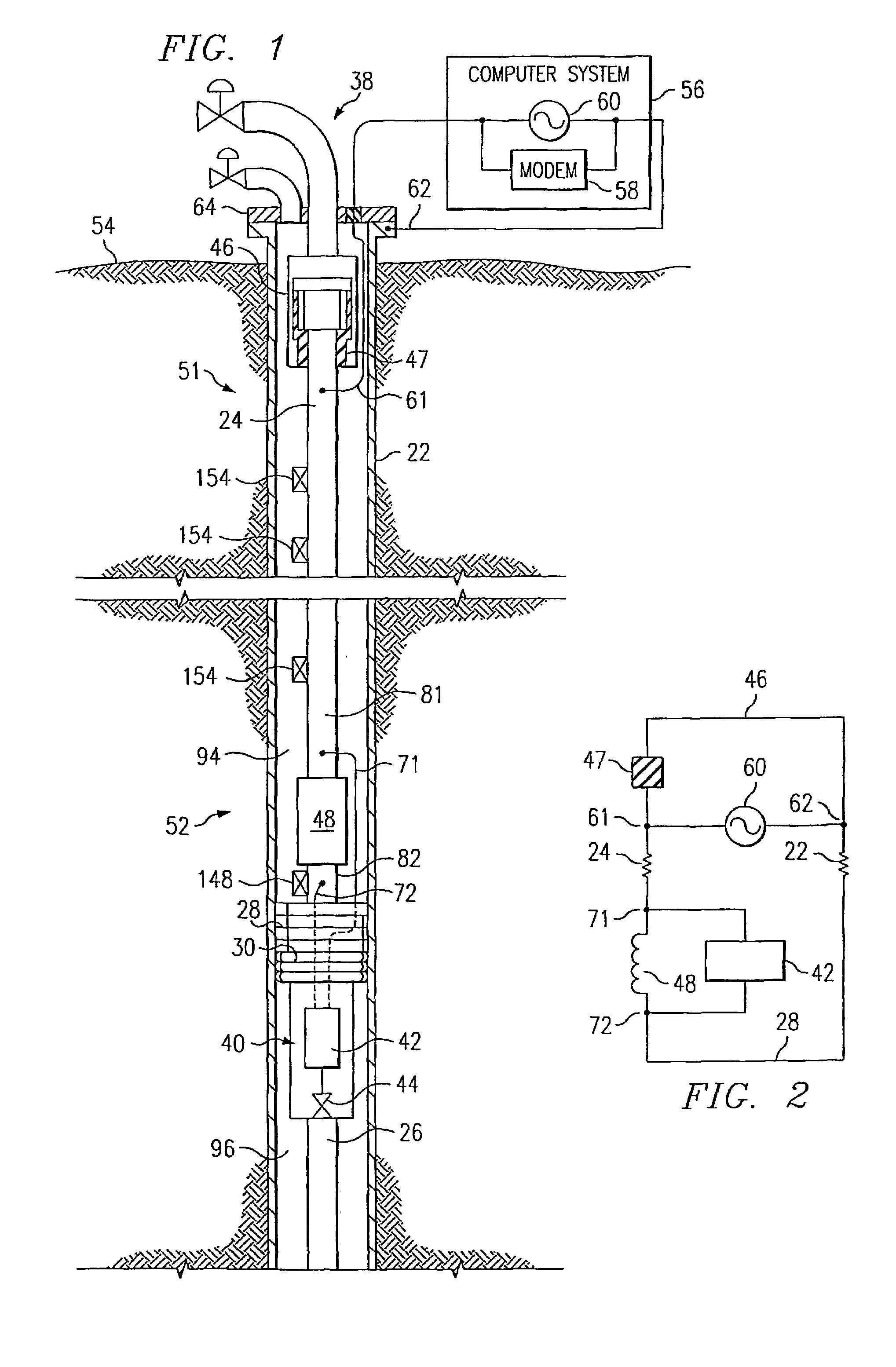

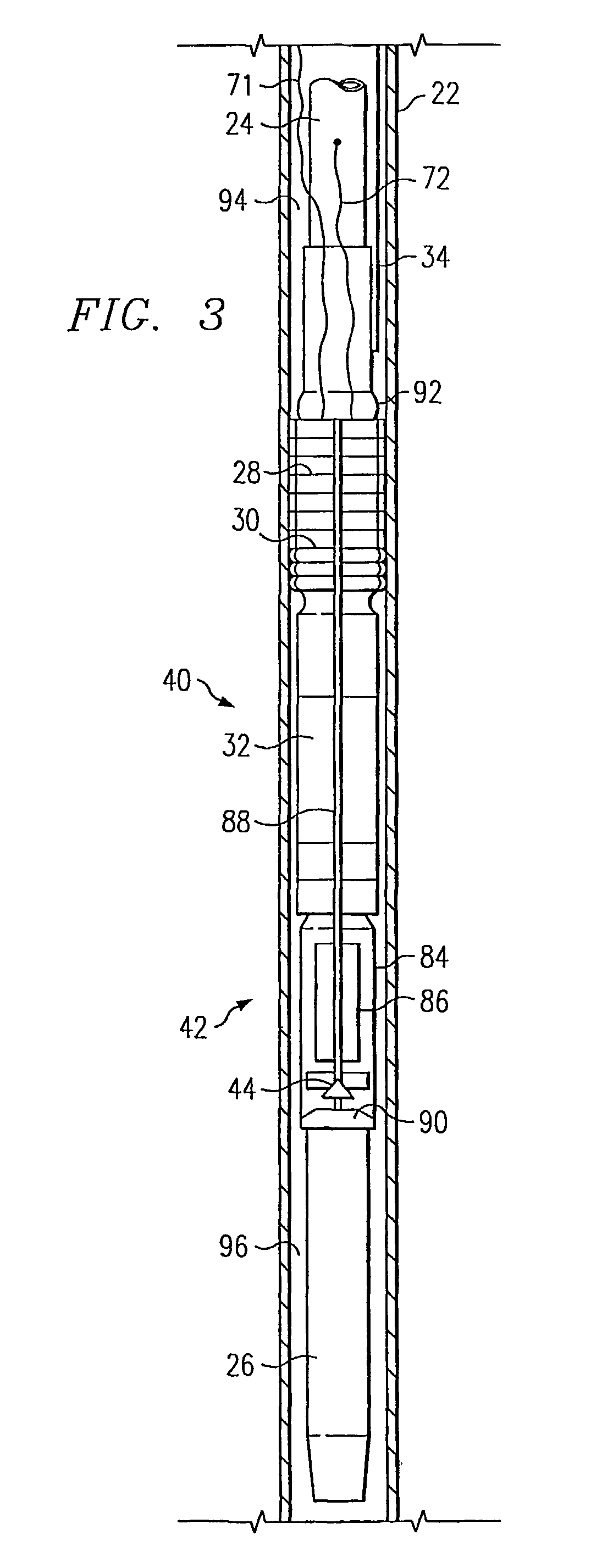

Controlled downhole chemical injection

InactiveUS6981553B2Improve efficiencyImprove flow characteristicsNear-field transmissionSurveyElectrical conductorPetroleum

A petroleum well having a well casing, a production tubing, a source of time-varying current, a downhole chemical injection device, and a downhole induction choke. The casing extends within a wellbore of the well. The tubing extends within the casing. The current source is located at the surface. The current source is electrically connected to, and adapted to output a time-varying current into, the tubing and / or the casing, which act as electrical conductors for providing downhole power and / or communications. The injection device having a communications and control module, a chemical container, and an electrically controllable chemical injector. The communications and control module is electrically connected to the tubing and / or the casing. The chemical injector is electrically connected to the communications and control module, and is in fluid communication with the chemical container. The downhole induction choke is located about a portion of the tubing and / or the casing. The chemical injector is electrically connected to the communications and control module, and is in fluid communication with the chemical container. The downhole induction choke is located about a portion of the tubing and / or the casing. The induction choke is adapted to route part of the electrical current through the communications and control module by creating a voltage potential between one side of the induction choke and another side of the induction choke. The communications and control module is electrically connected across the voltage potential. Also, a method is provided for controllably injecting a chemical into the well downhole, which may be used to: improve lift efficiency with a foaming agent, prevent deposition of solids with a paraffin solvent, improve a flow characteristic of the flow stream with a surfactant, prevent corrosion with a corrosion inhibitor, and / or prevent scaling with scale preventers.

Owner:SHELL OIL CO

Use of downhole high pressure gas in a gas-lift well and associated methods

InactiveUS7147059B2Simplified installation procedureLow costNear-field transmissionSurveyElectrical conductorPetroleum product

A gas-lift petroleum well and method for producing petroleum products using downhole pressurized gas to provide lift. The gas-lift well having a well casing, a production tubing, a packer, and a gas-lift valve. The well casing extends within a wellbore of the well, and the wellbore extends through oil and gas zones. The production tubing extends within the casing. The tubing having an opening formed therein, which is in fluid communication with an oil zone. The packer is located downhole in the casing and coupled to the tubing. The packer can have an electrically controllable packer valve, which is adapted to control a flow of downhole pressurized gas from one side of the packer to another. The downhole pressurized gas is provided by a gas zone that the wellbore passes through. The downhole gas-lift valve is coupled to the tubing and is adapted to control a flow of downhole pressurized gas into oil in the tubing for lifting the oil. The gas-lift valve can be an electrically controllable valve. The tubing and casing are used as electrical conductors for supplying power and / or communications downhole. The current in the tubing is routed using a ferromagnetic induction choke to create a voltage potential, which provides electrical power to downhole electrical devices. Also, there may be a bypass passageway to route downhole gas to gas-lift valves. There may also be downhole sensors to measure physical quantities (e.g., pressure). Such measurements can be used for feedback control of downhole electrically controllable valves.

Owner:SHELL OIL CO

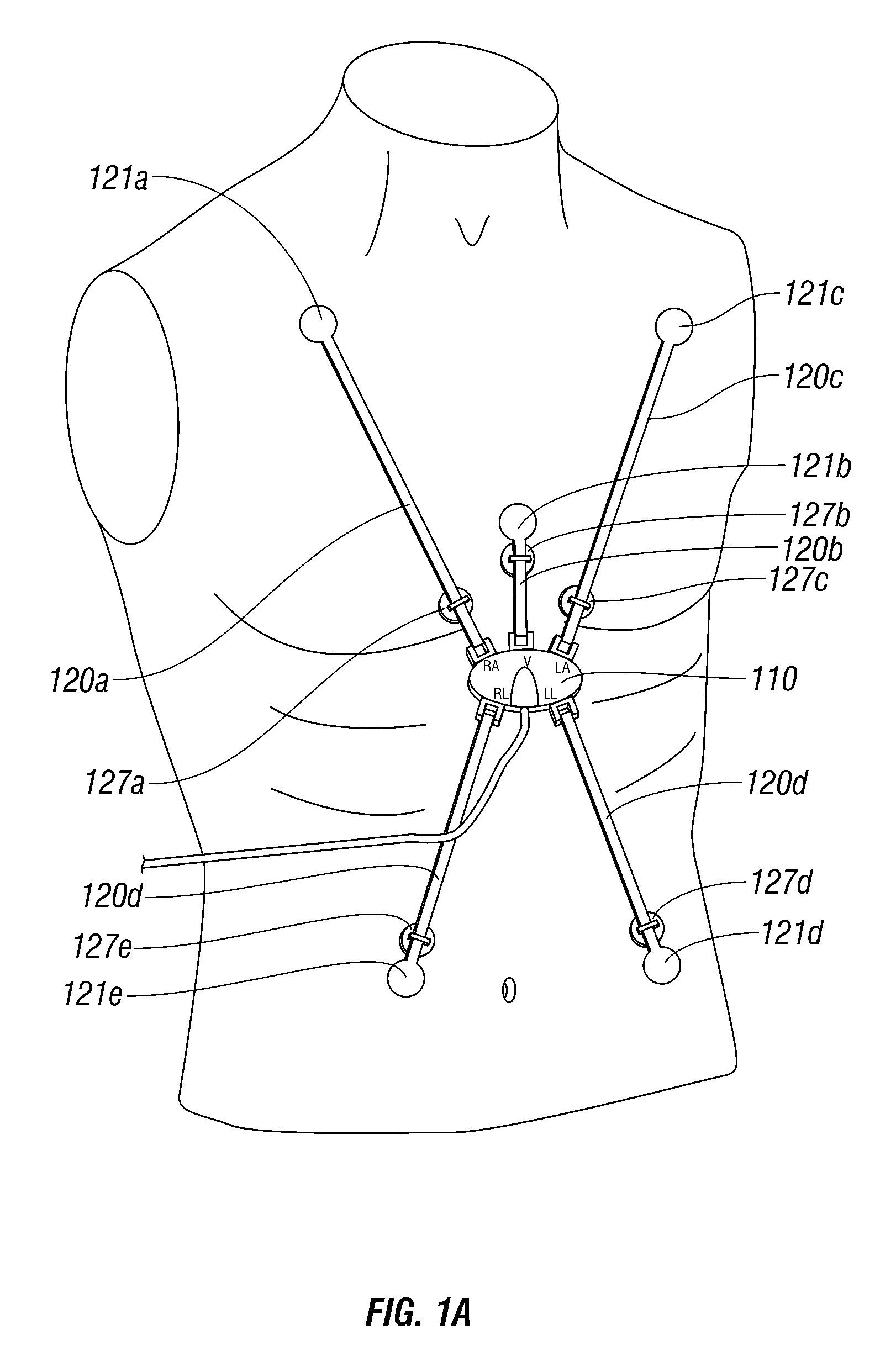

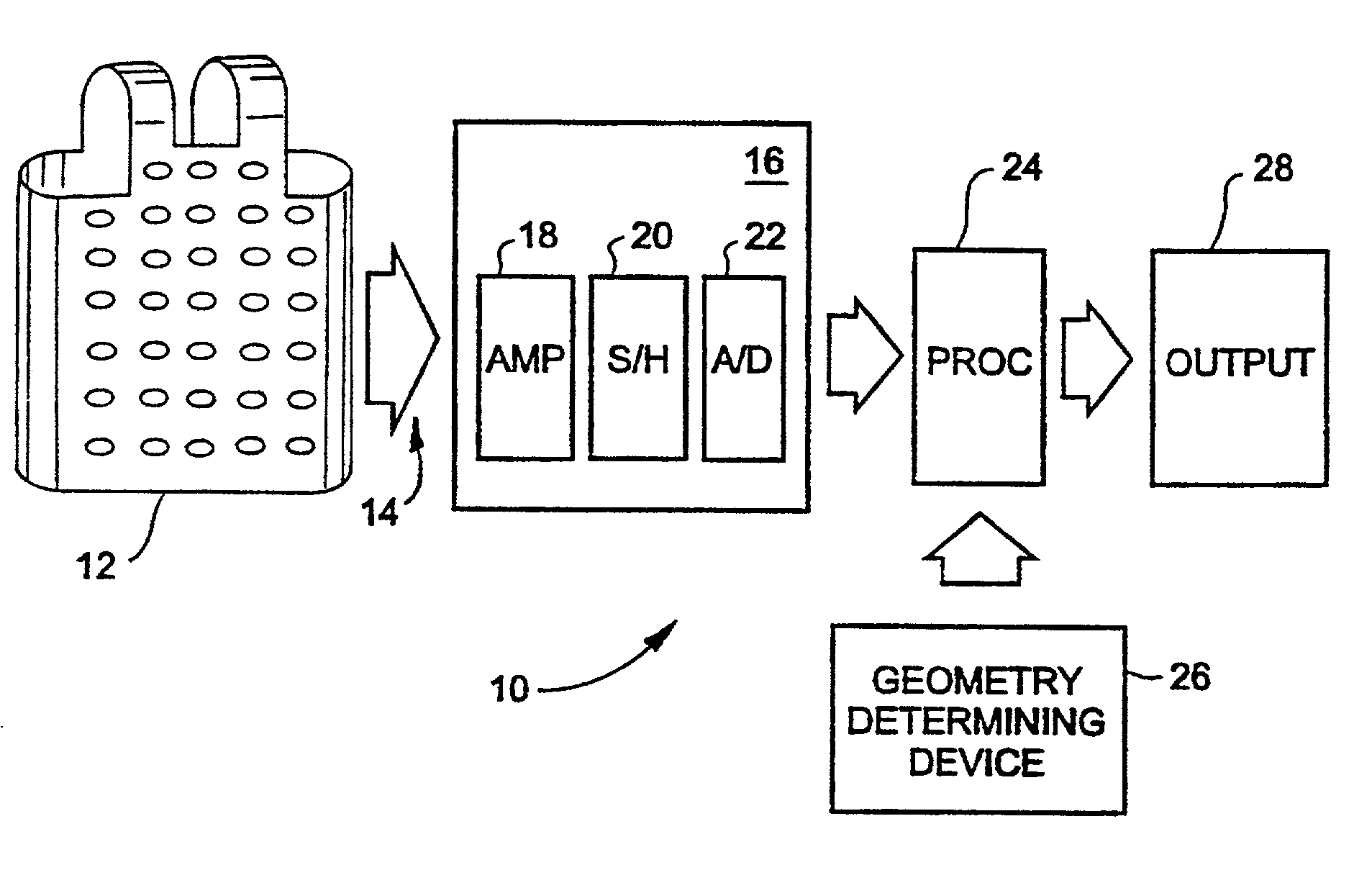

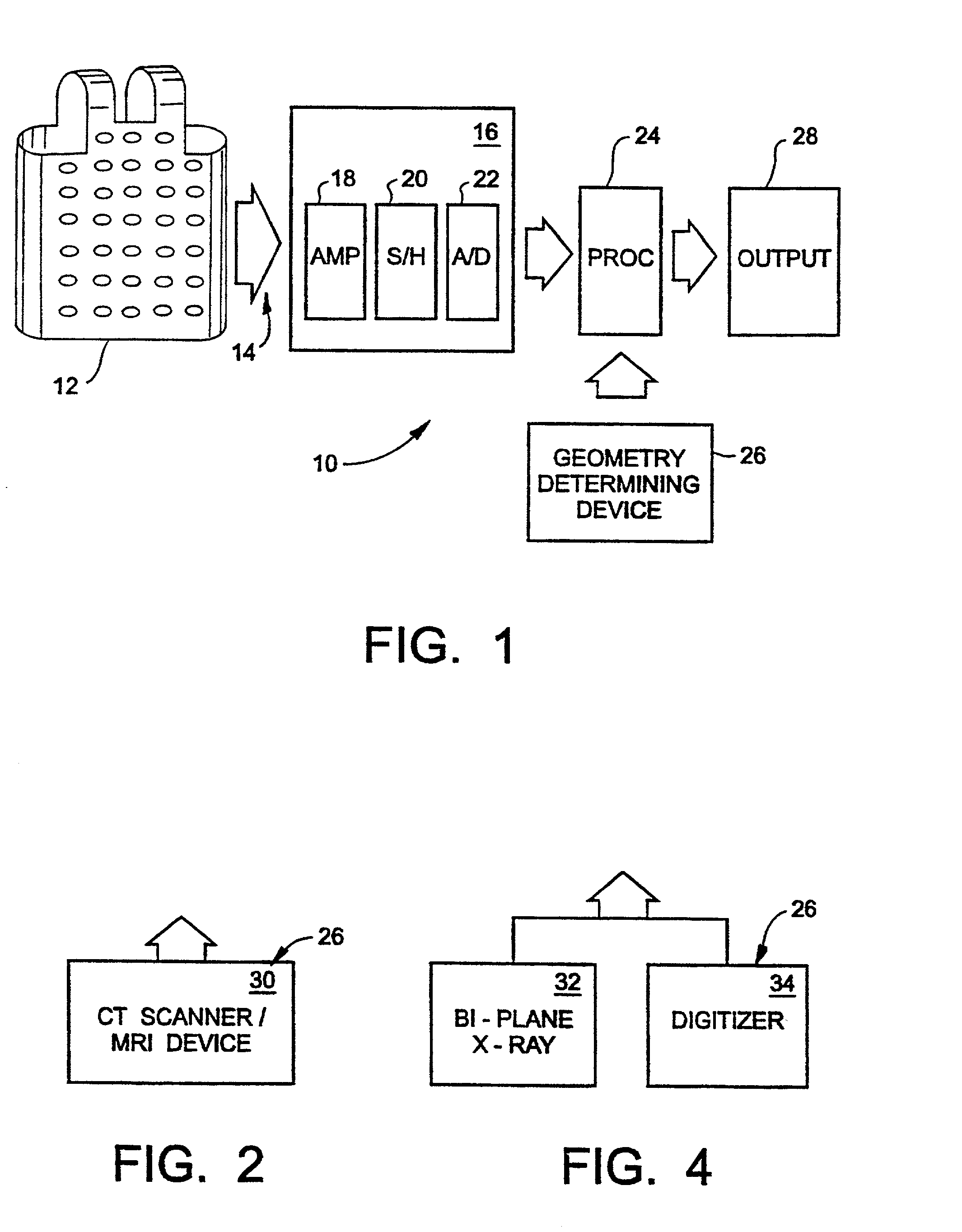

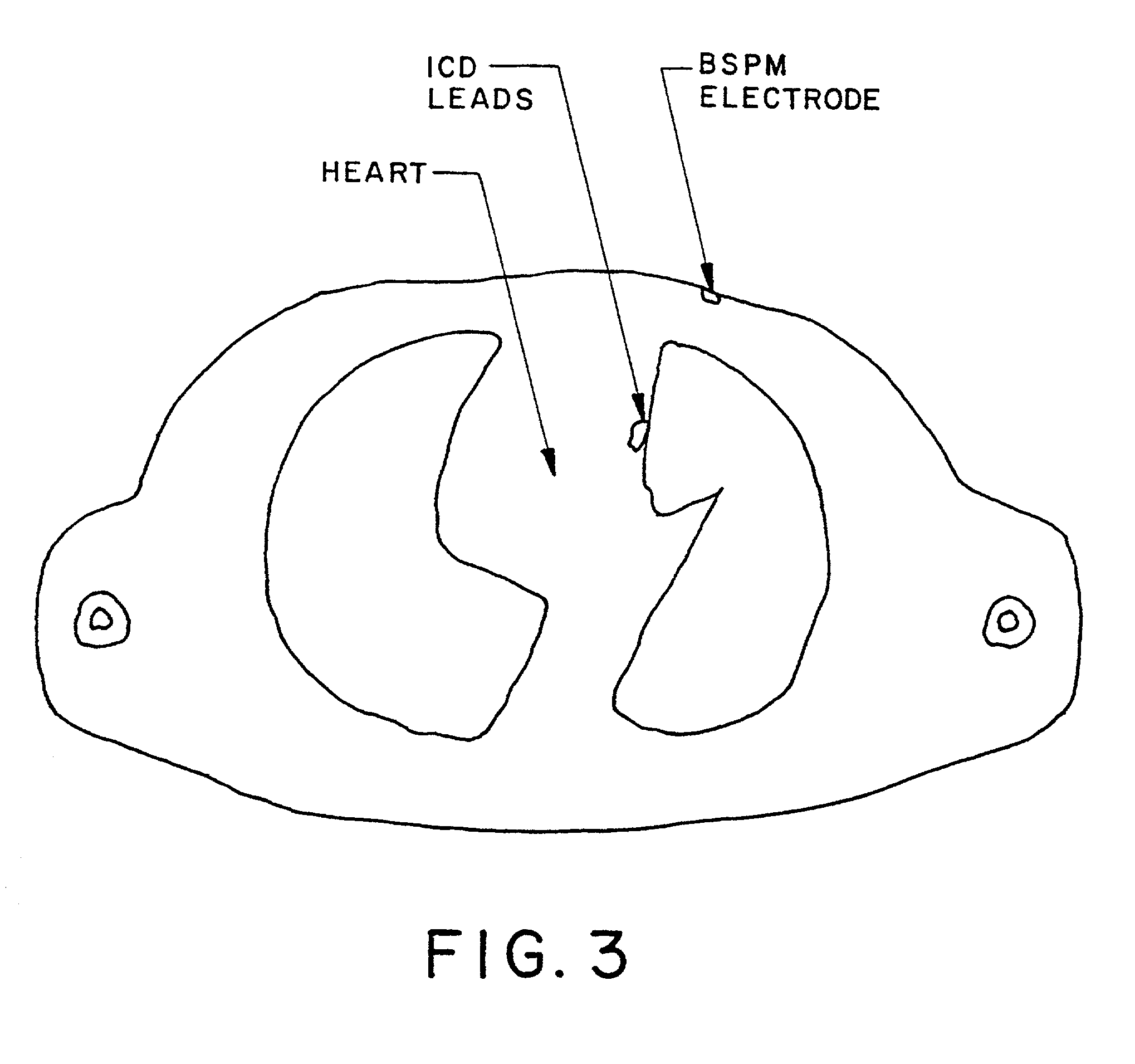

System and method for non-invasive electrocardiographic imaging

A system and method is provided for non-invasively determining electrical activity of the heart of a human being. Electrical potentials are measured on the body surface via an electrode vest (12), and a body surface potential map is generated. A matrix of transformation based on the geometry of the torso, the heart, locations of electrodes, and position of the heart within the torso is also determined with the aid of a processor (24), and a geometry determining device (26). The electrical potential distribution over the epicardial surface of the heart is then determined based ona regularized matrix of transformation, and the body surface potential map. Using the epicardial potential distributions, epicardial electrogram, isochronal are also reconstructed, and displayed via an output device (28).

Owner:CASE WESTERN RESERVE UNIV

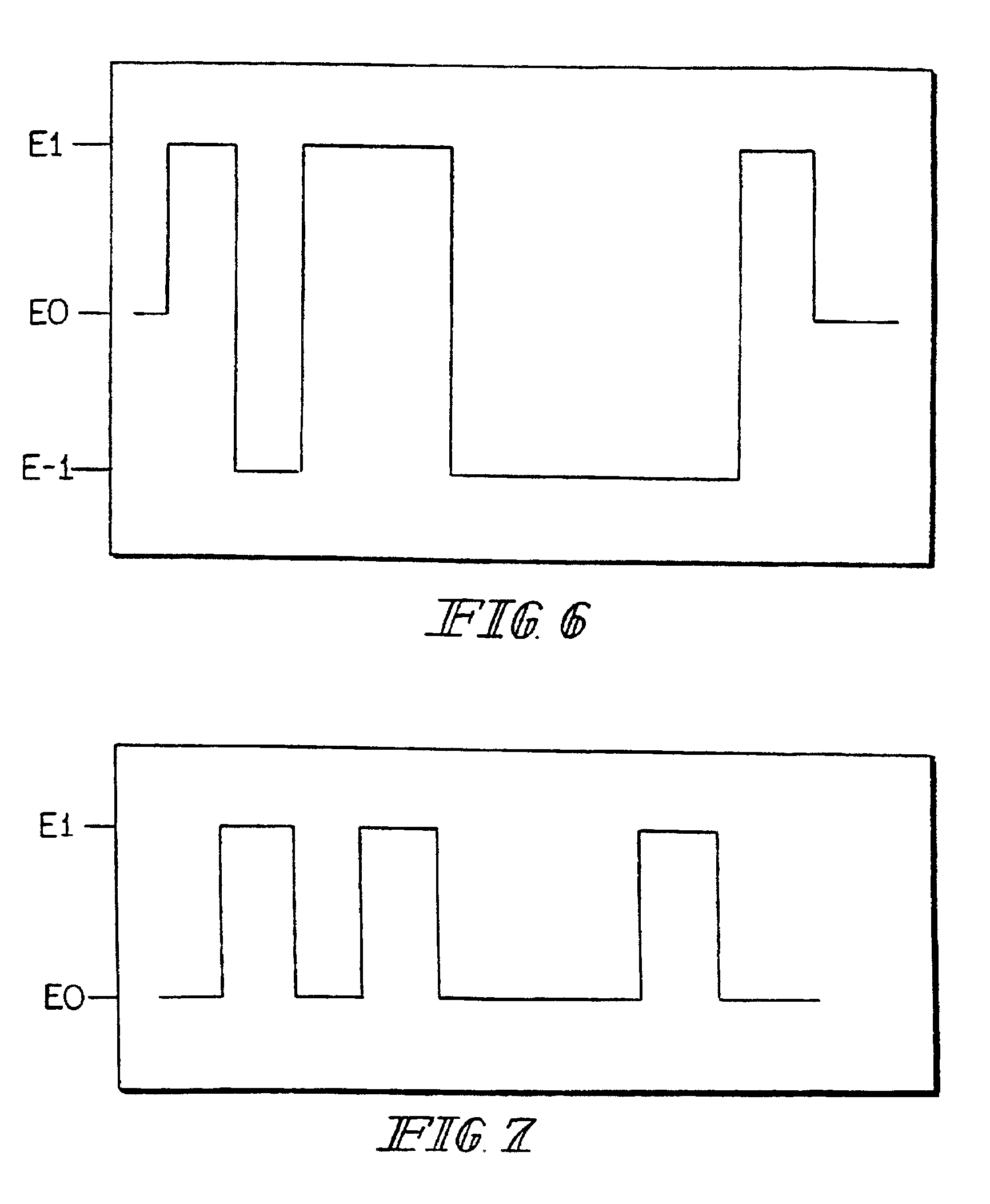

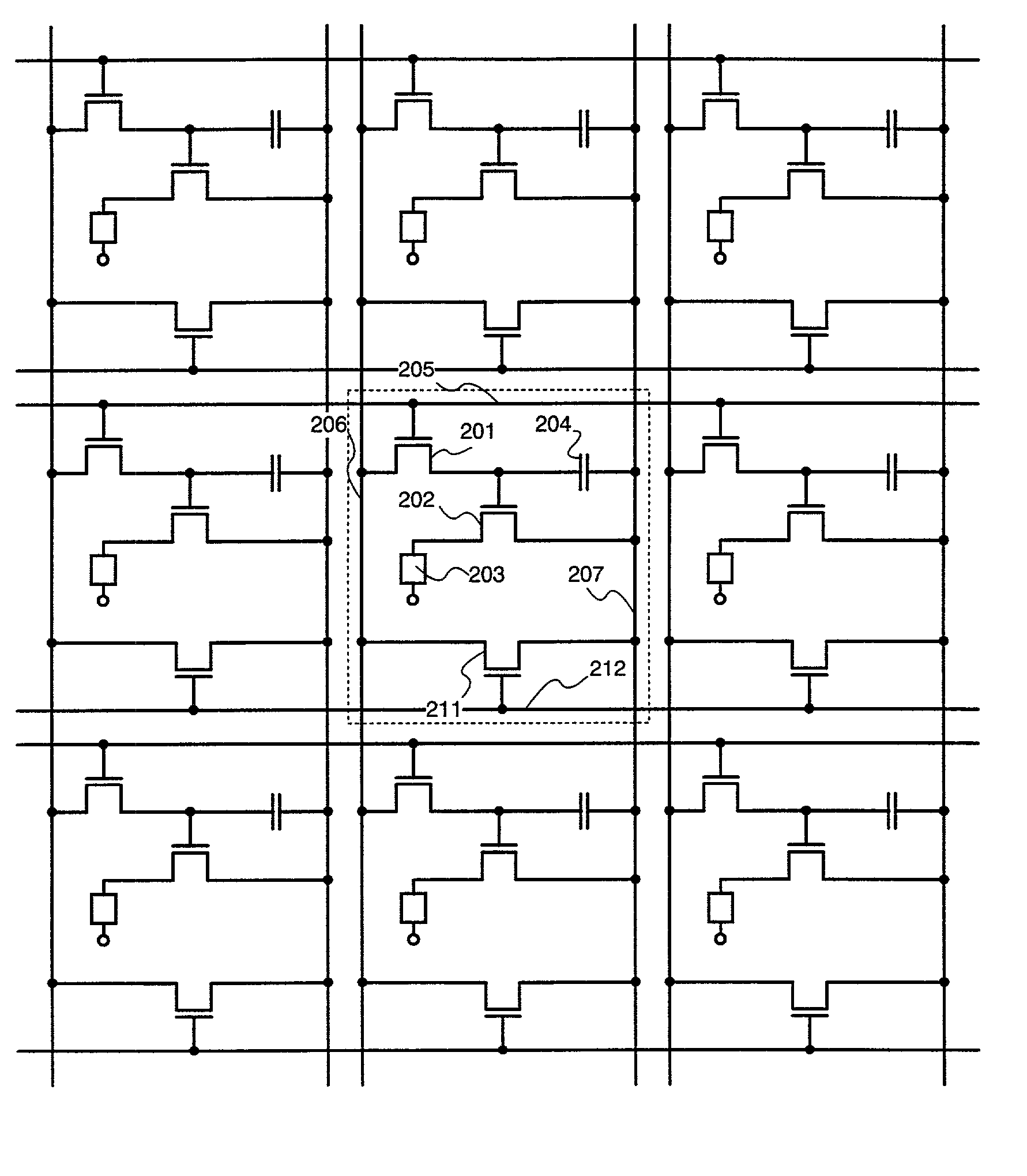

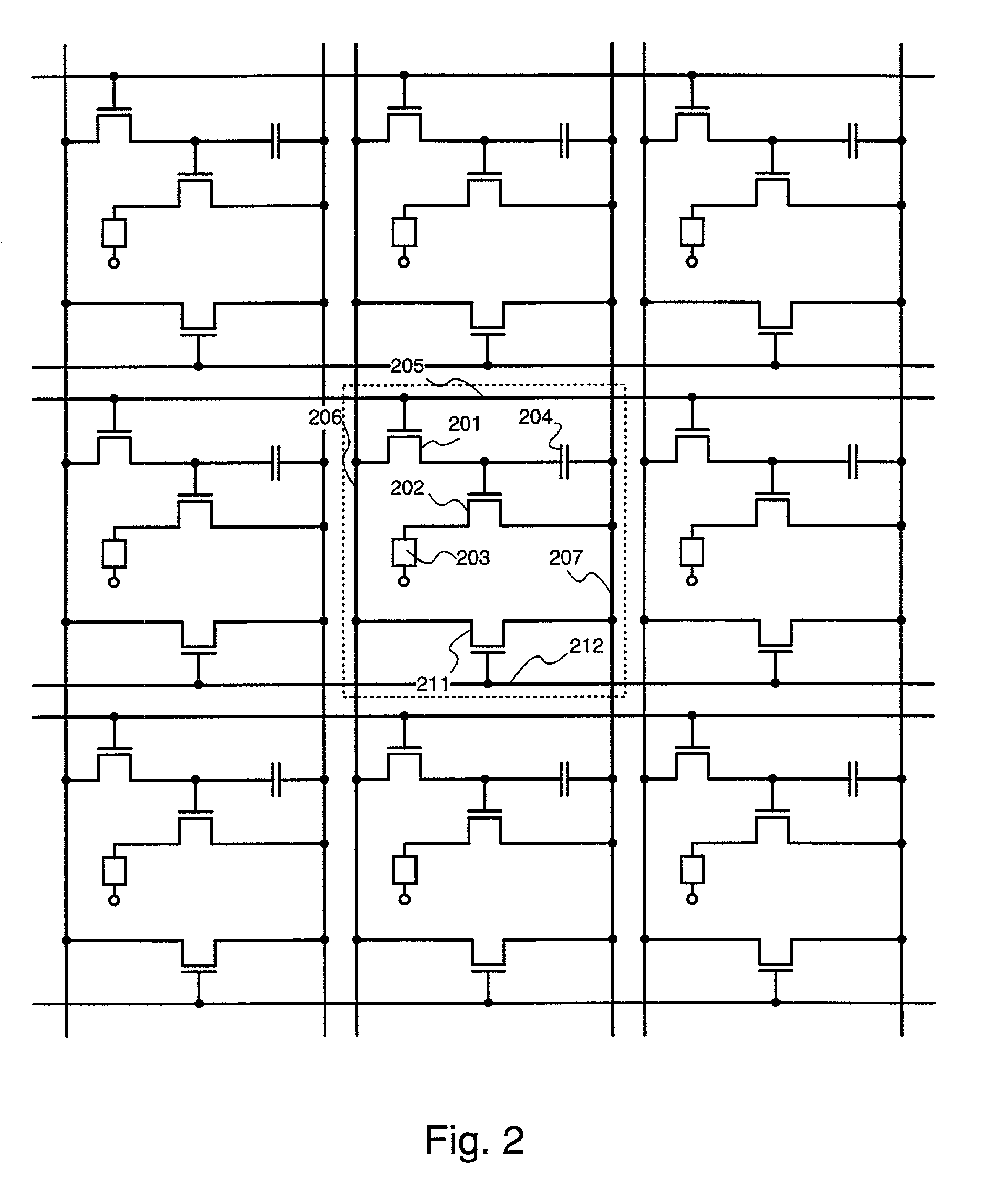

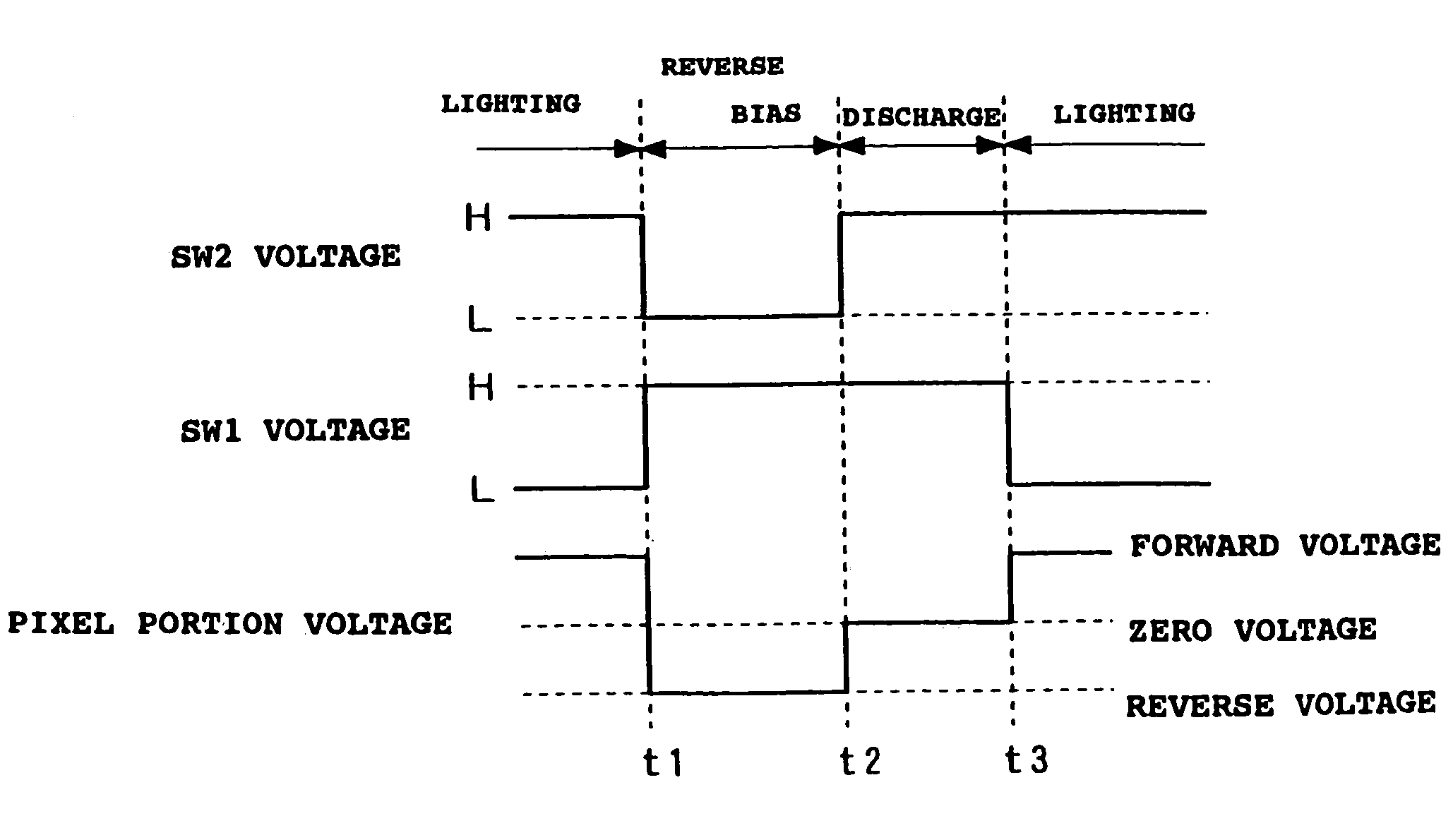

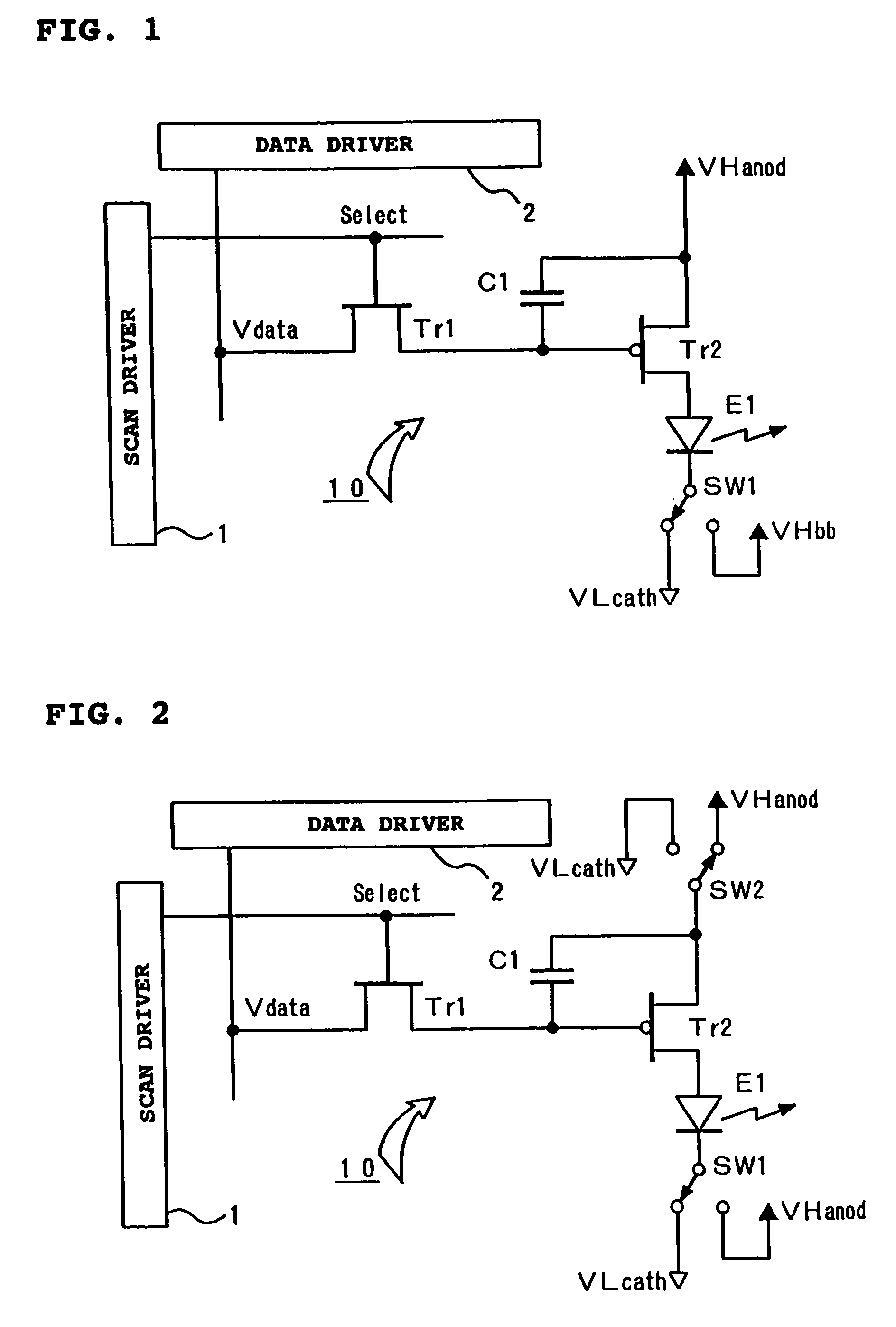

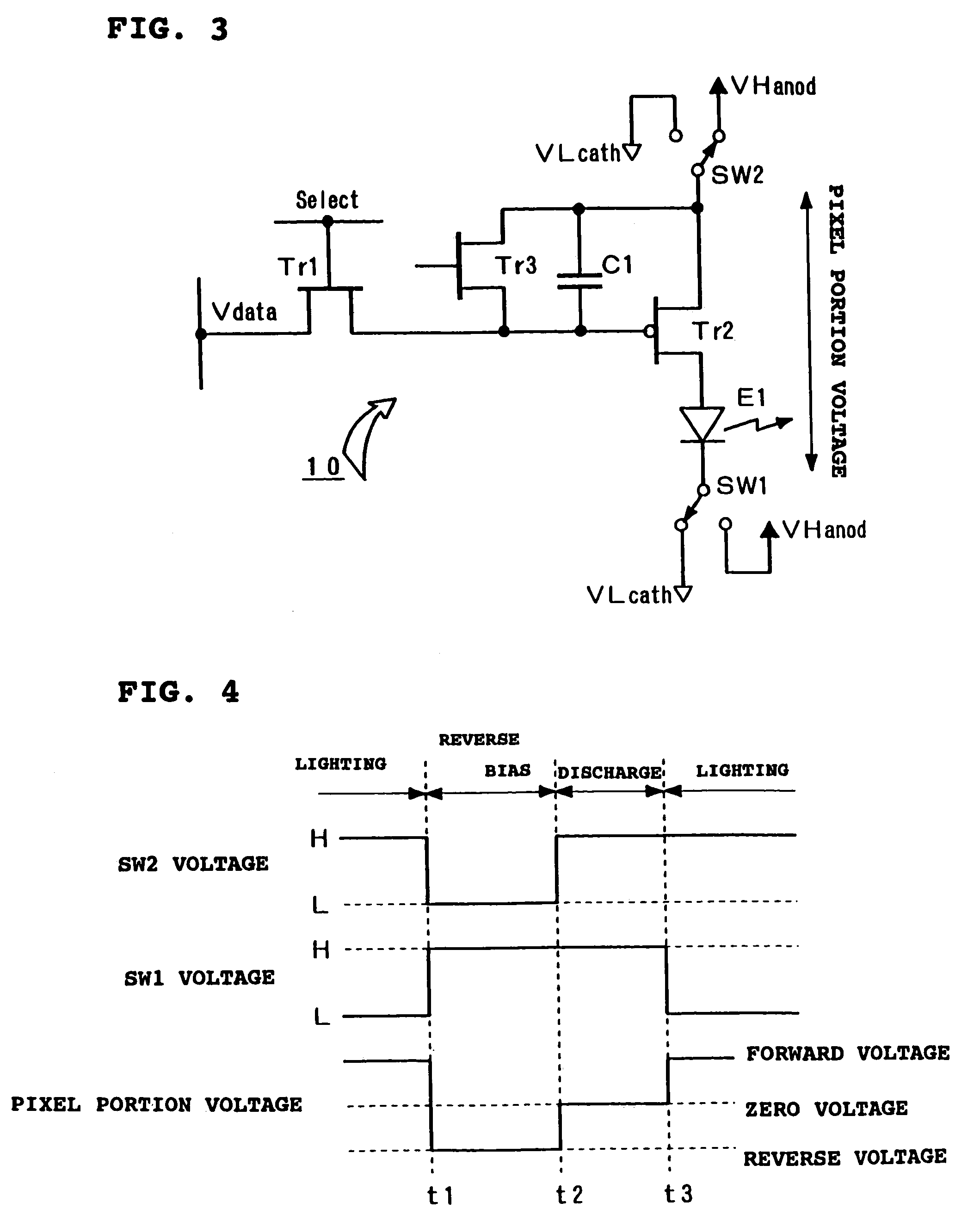

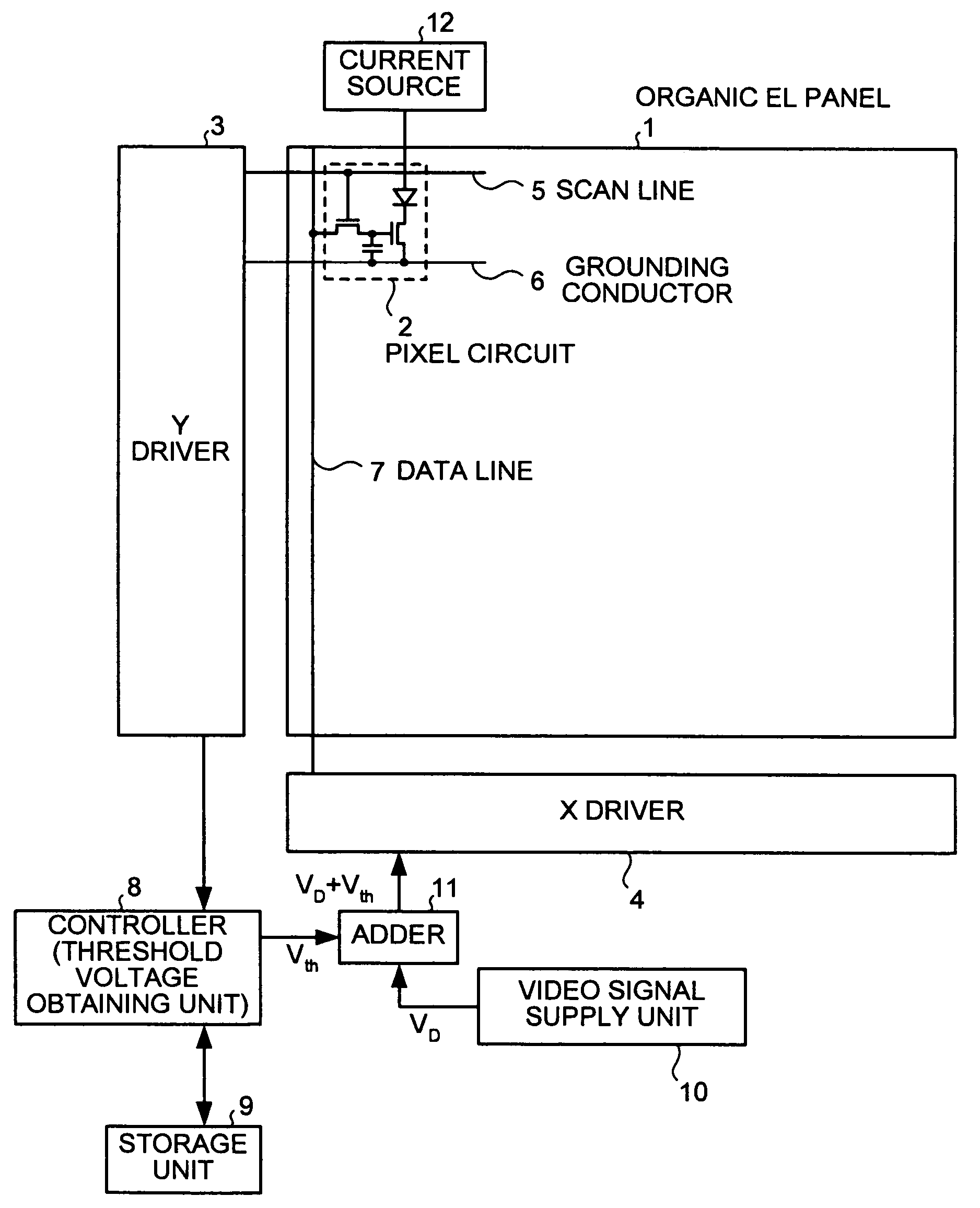

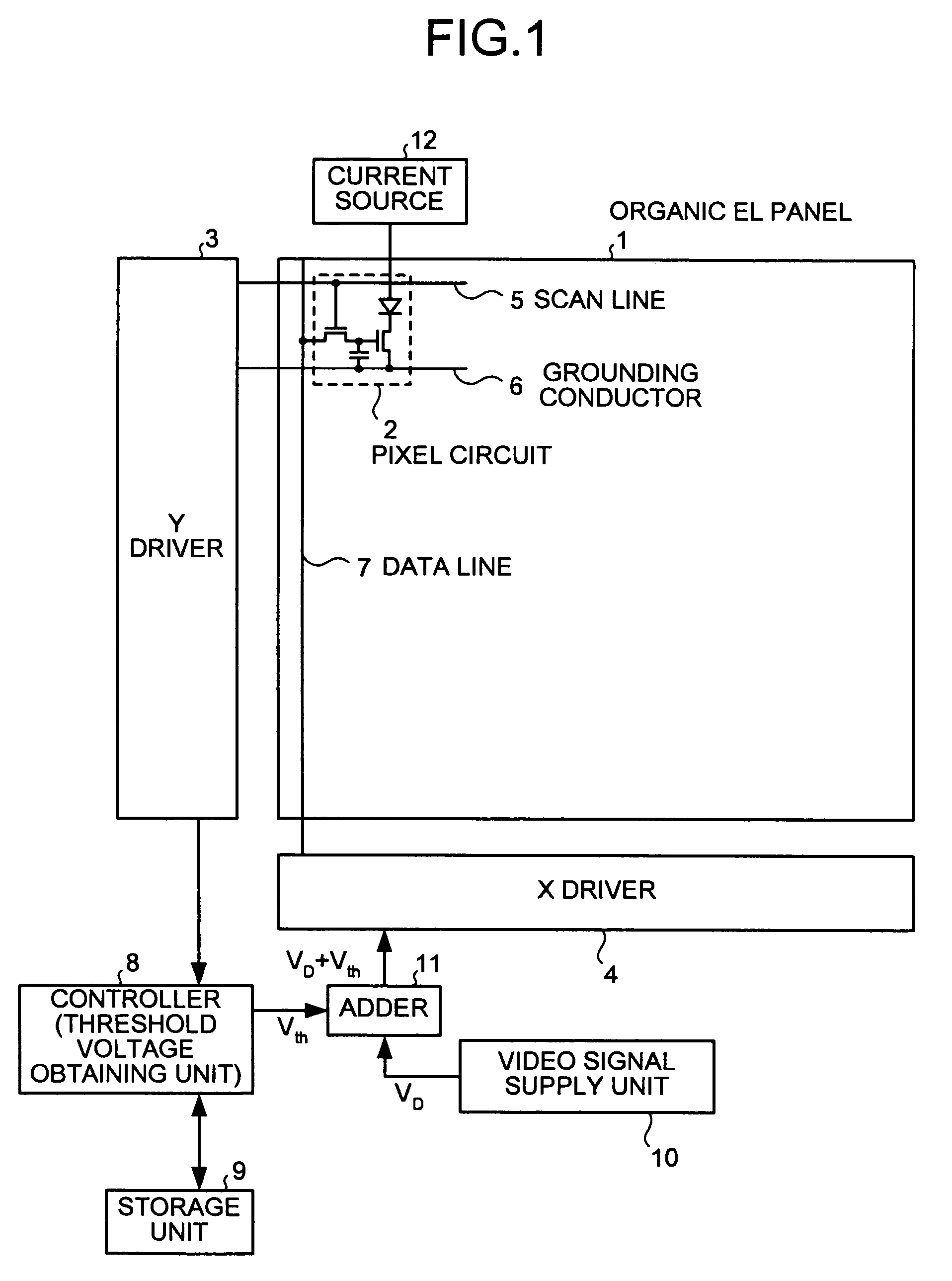

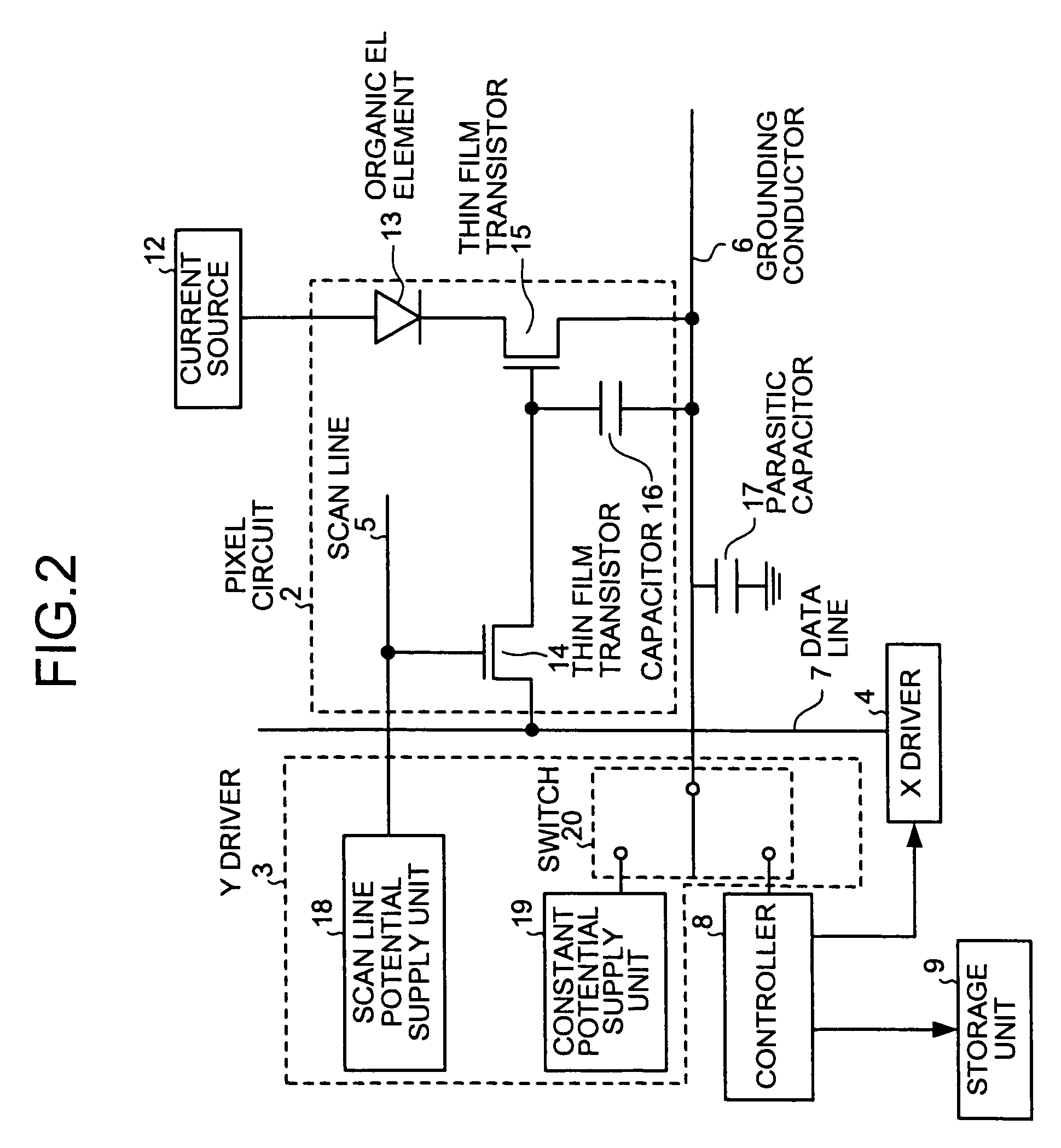

Drive methods and drive devices for active type light emitting display panel

InactiveUS7193589B2Static indicating devicesElectroluminescent light sourcesEffect lightParasitic capacitance

In a drive device for an active type light emitting display panel which can apply a reverse bias voltage to an EL element, in order to be able to compensate deterioration in light-emitting efficiency of the EL element accompanied by applying of the reverse bias voltage and the like, one pixel 10 is composed of a controlling TFT (Tr1), the driving TFT (Tr2), a capacitor C1, and the EL element E1. Switching switches SW1, SW2 mutually enables a supplying state of a forward current to the EL element E1 and an applying state of the reverse bias voltage to be selected. In one control form according to the present invention, when the applying state of the reverse bias voltage shifts to the supplying state of the forward current, by switching one switch first, the anode and cathode of the EL element E1 are made to the same electrical potential to allow electrical charges to be discharged. Thus, charge of the forward current for a parasitic capacitance of the EL element E1 can be performed rapidly, and rising of the lighting operation of the EL element can be advanced.

Owner:TOHOKU PIONEER CORP

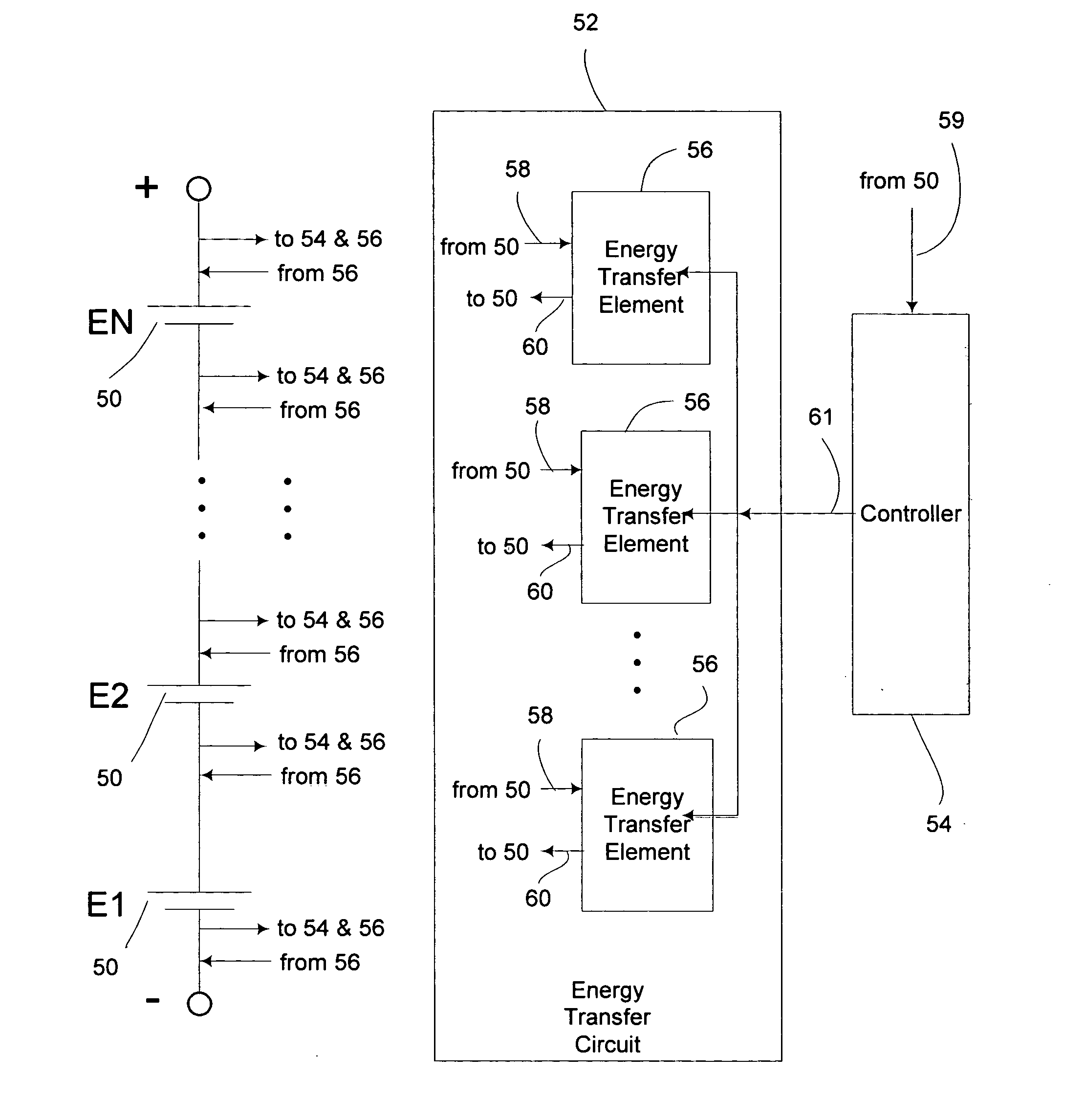

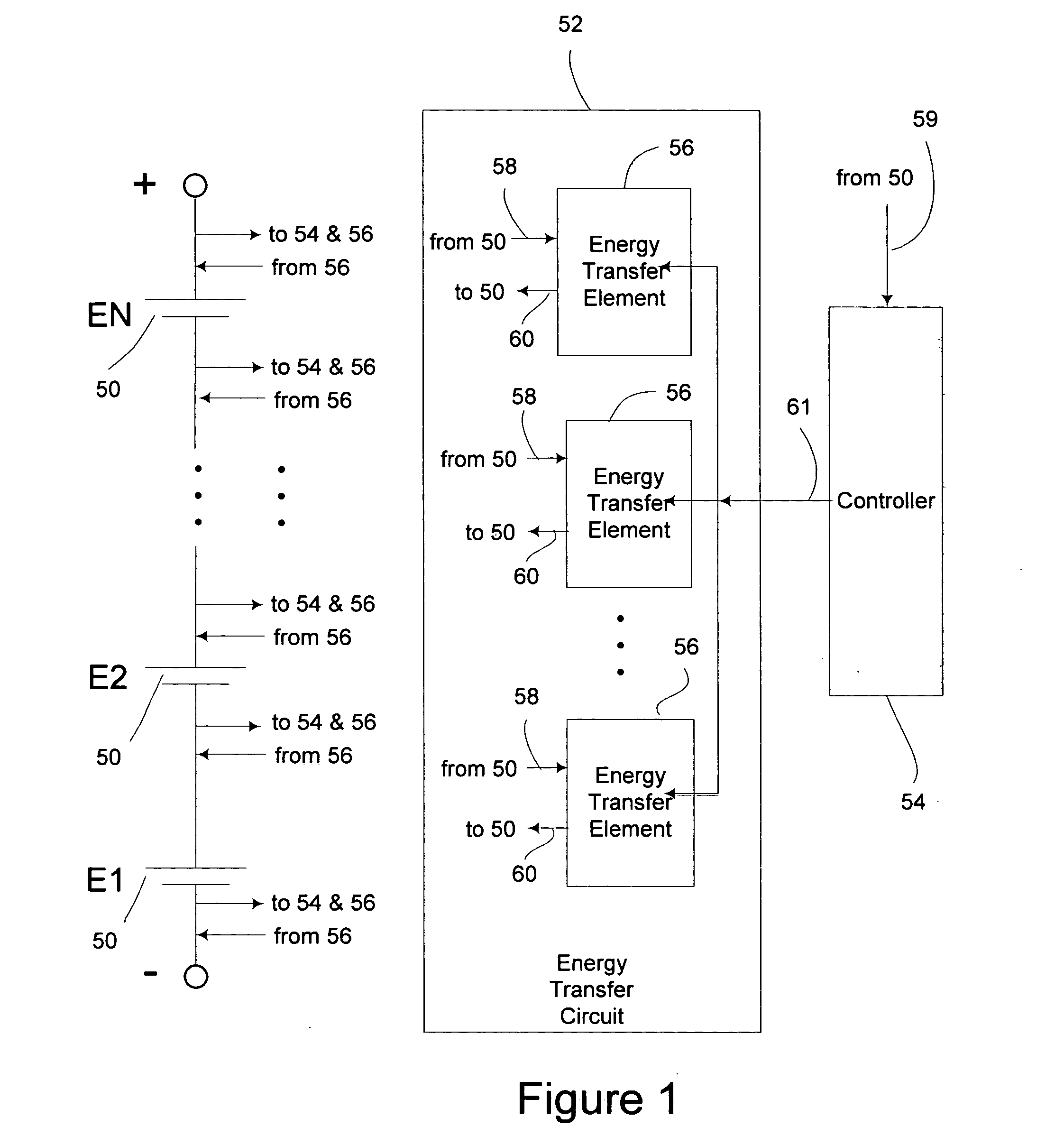

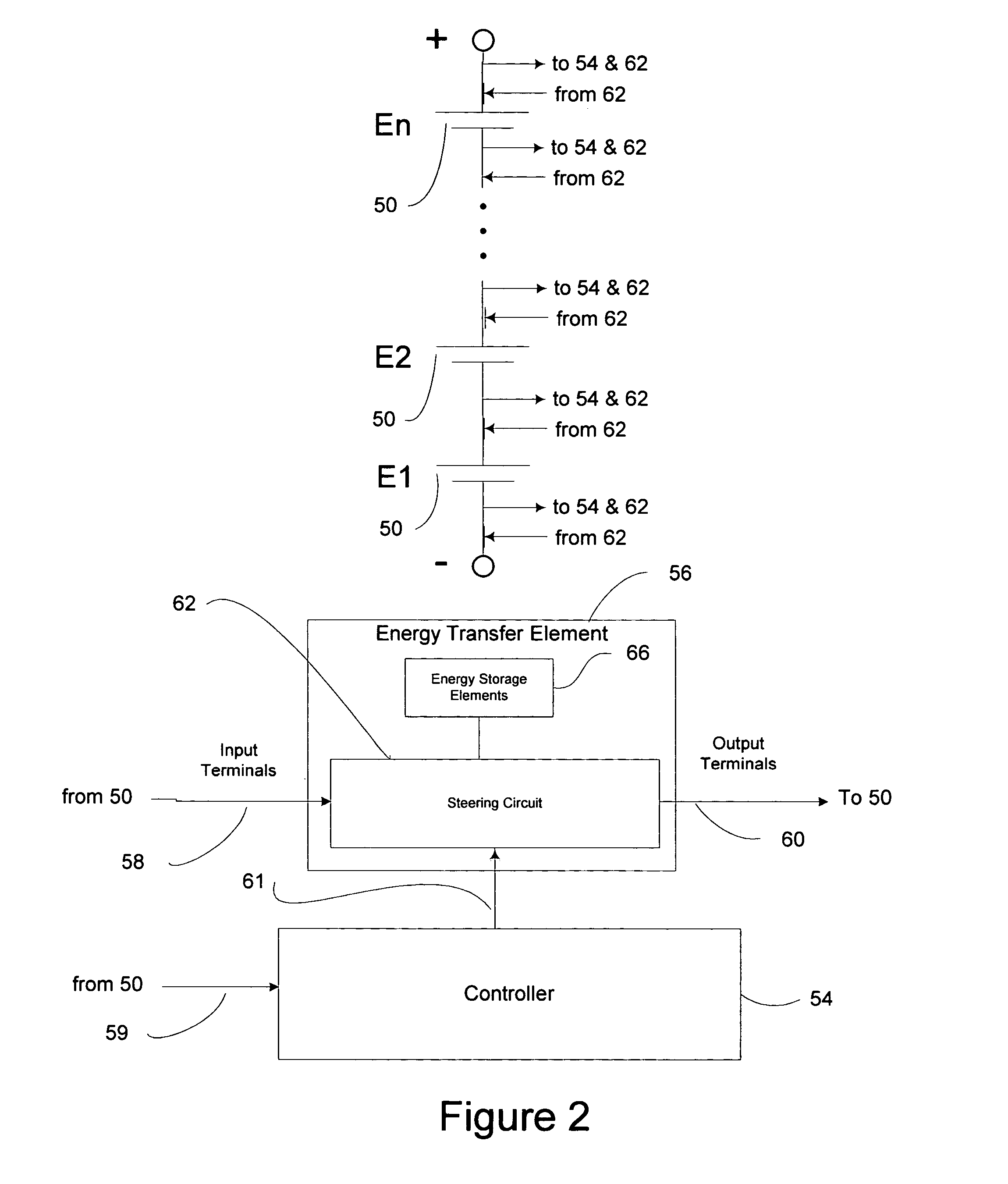

Energy transfer device for series connected energy source and storage devices

InactiveUS20050077879A1Extended service lifeImprove energy storage performanceCharge equalisation circuitElectric powerTransformerEnergy device

A low cost, efficient, and rapid means for transferring energy or balancing charge among multiple, series connected batteries, capacitors, photovoltaic cells, fuel cells, and other types of energy source or storage devices is provided. Modules that transfer energy by moving charge from one or more series connected energy devices directly to one or more other energy devices in the string are disclosed. The modules utilize steering circuits comprised of switches and rectifiers, and energy storage elements such as inductors and transformers, to transfer energy between multiple energy devices in the string. The modules may be used in combination with string charging devices and loads. The modules provide a means to balance charge or potential of the energy devices, which is known to provide benefits of increased life and capacity.

Owner:NEAR TIMOTHY PAUL

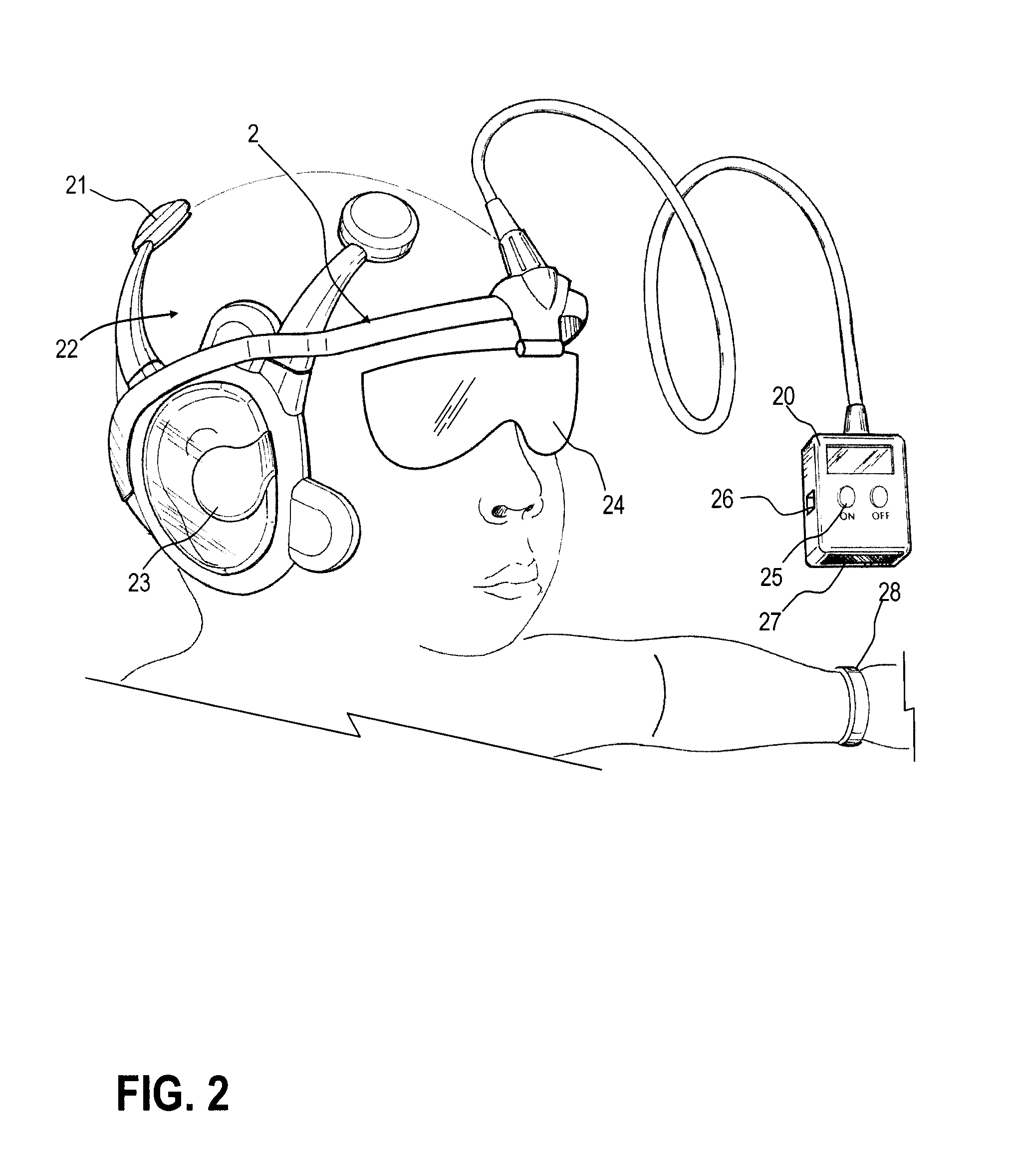

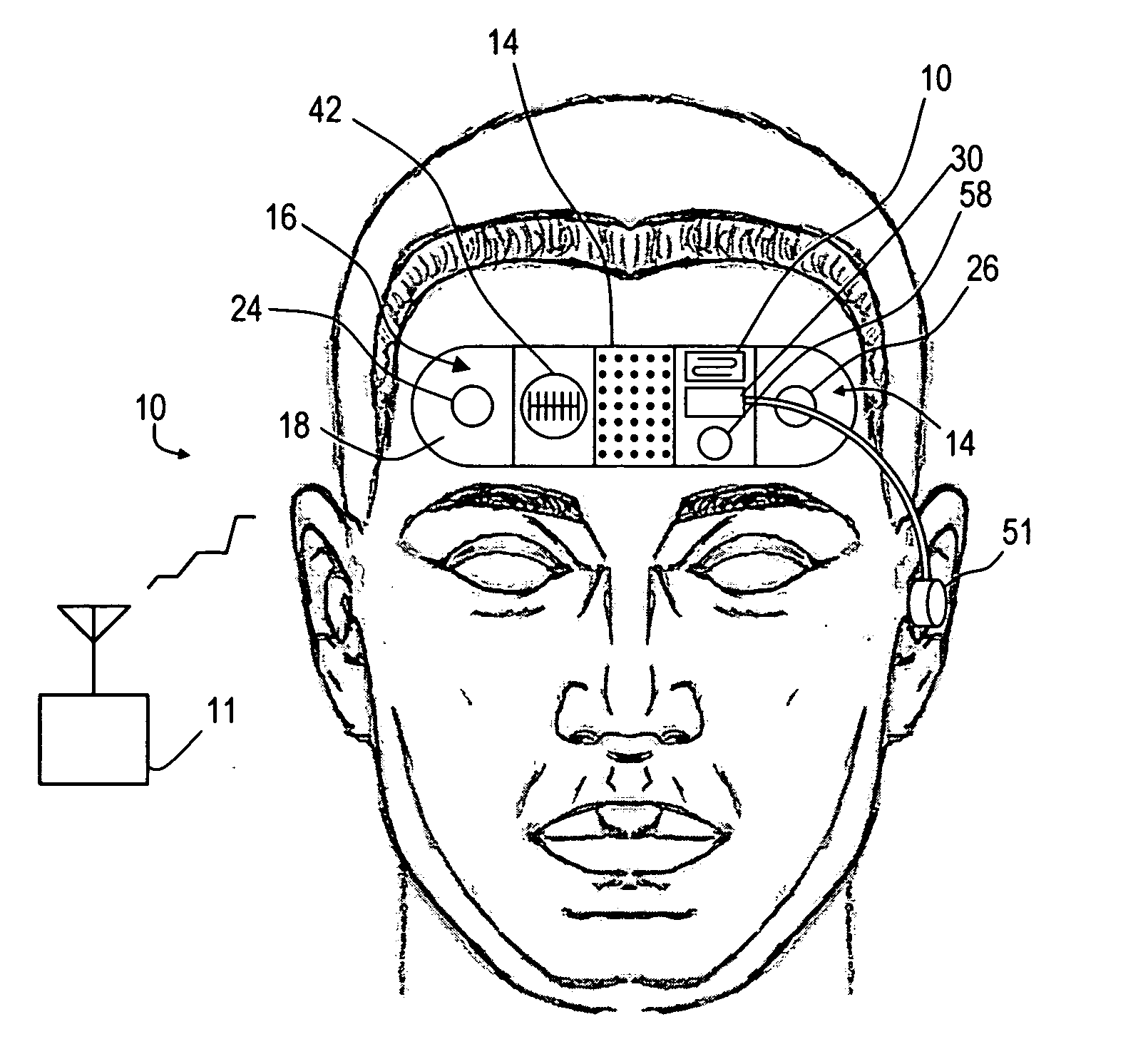

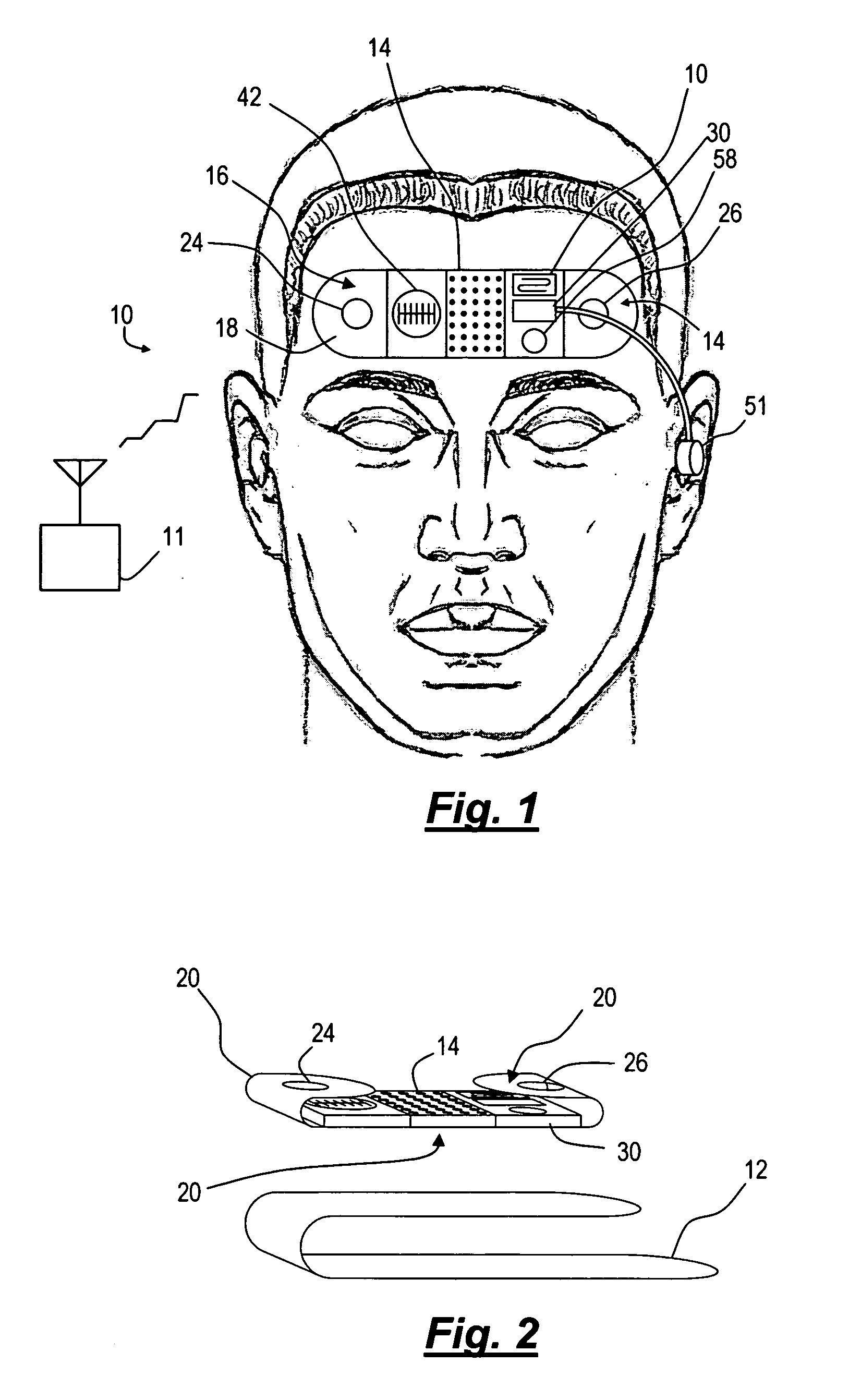

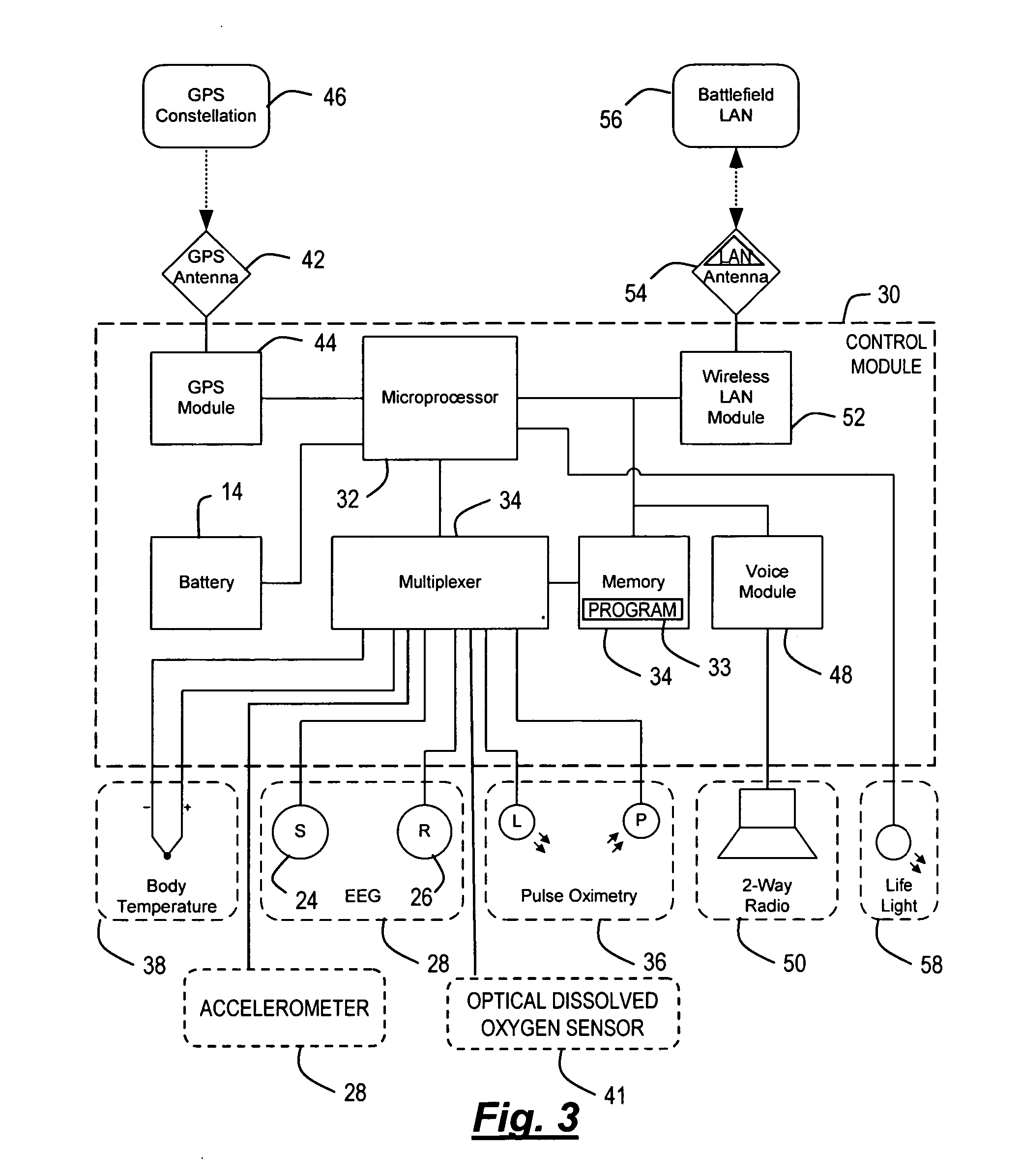

Device and method for transmitting physiologic data

InactiveUS20050280531A1ElectrocardiographyRadio/inductive link selection arrangementsGps receiverMonitoring system

A wireless biopotential monitoring system composed of a wireless electrode module which can be attached to a disposable electrode strip. Such a device can be conveniently affixed to a patient's skin and will transmit the physiological signals to a remote receiver where the signals can be monitored by a clinician. The device is powered by a fuel-air battery. The device would remain packaged in an airtight package until it needs to be applied at which time either the wounded soldier would apply the device himself / herself or it would be applied by another soldier or corpsman. The device would begin to measure brainwave activity, heart rate, and dissolved oxygen level. The device would also identify the wounded soldier's location using the onboard GPS receiver. The physiologic data along with the soldier's position would then be transmitted to a remote receiver.

Owner:NEURONETRIX SOLUTIONS

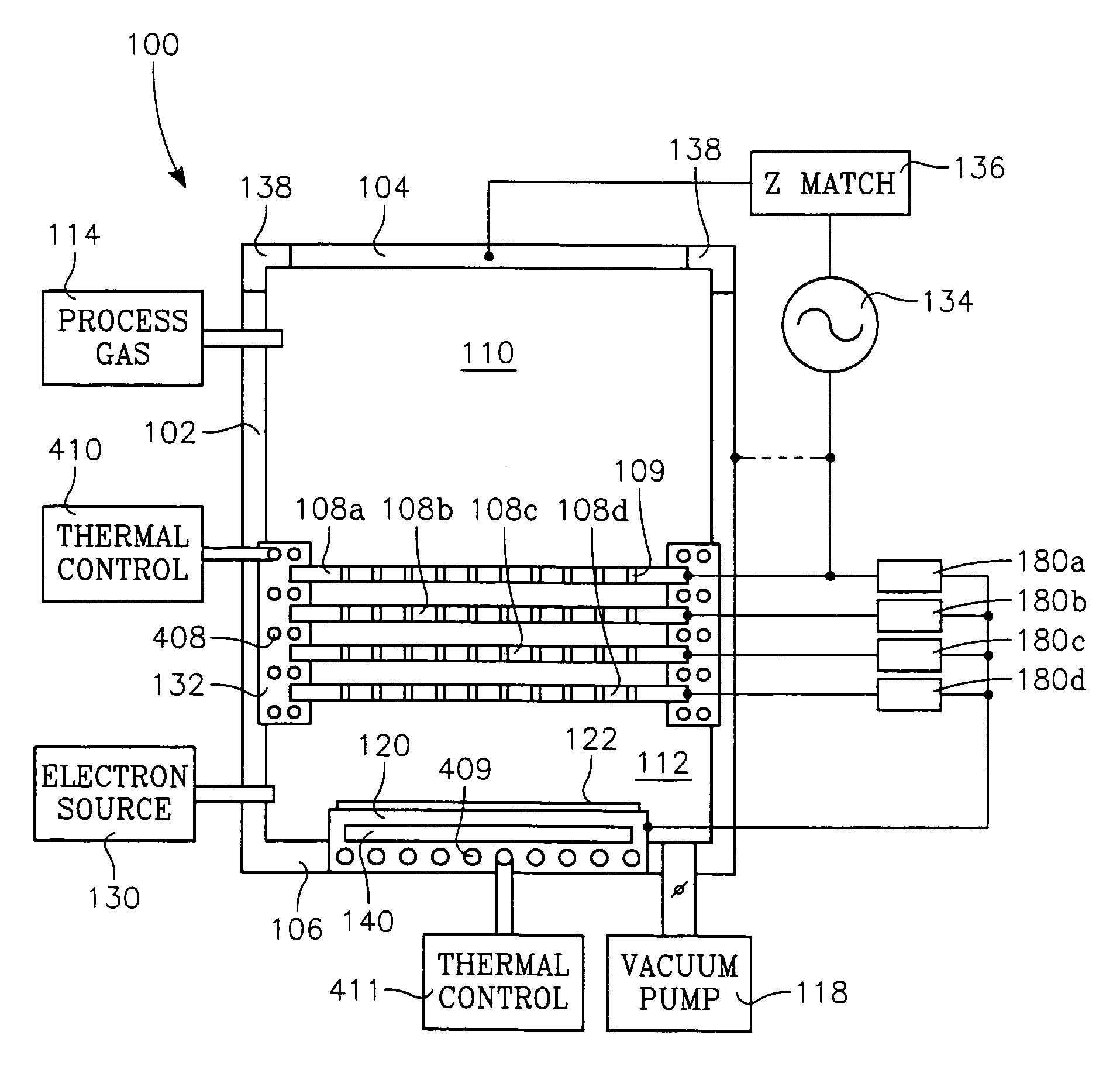

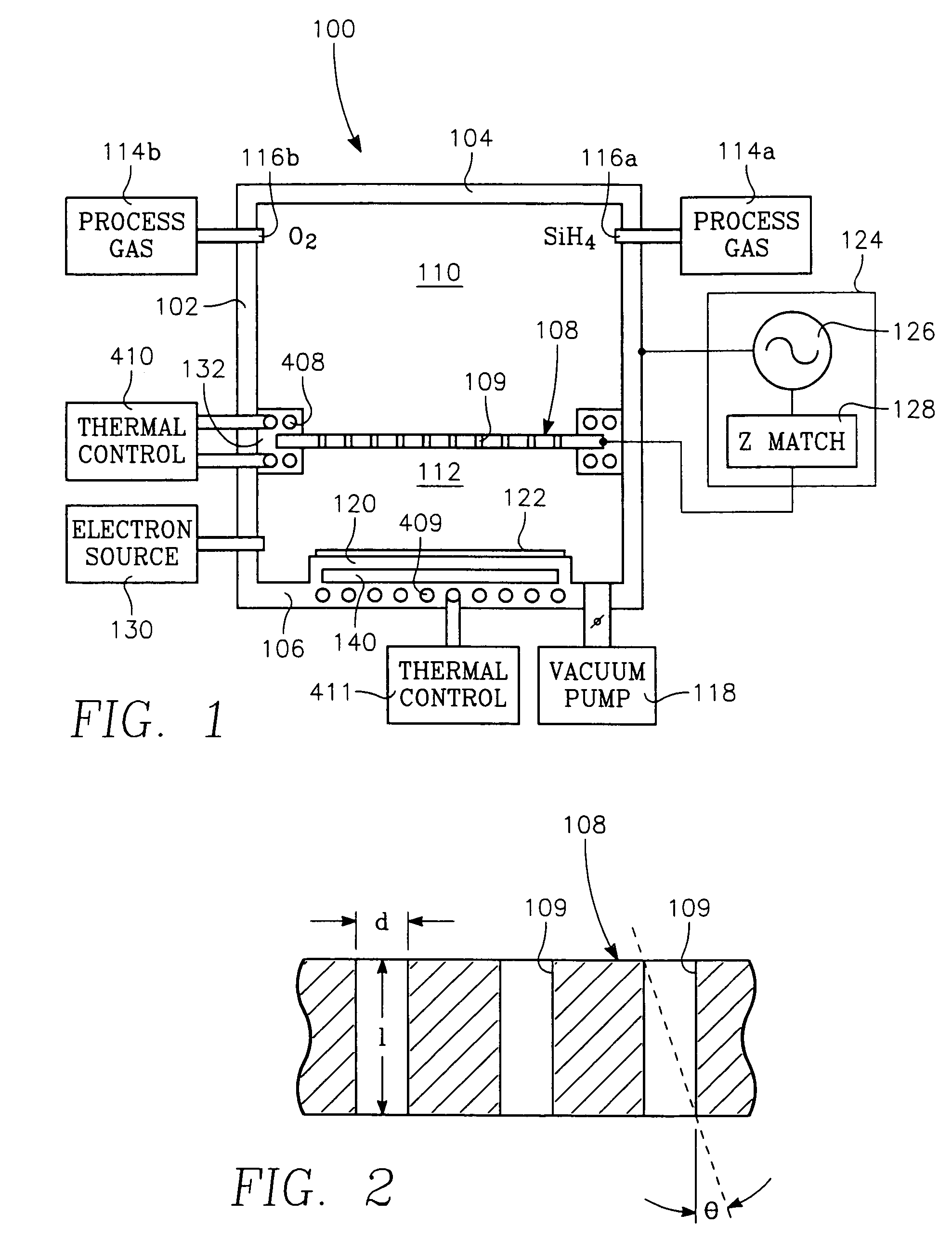

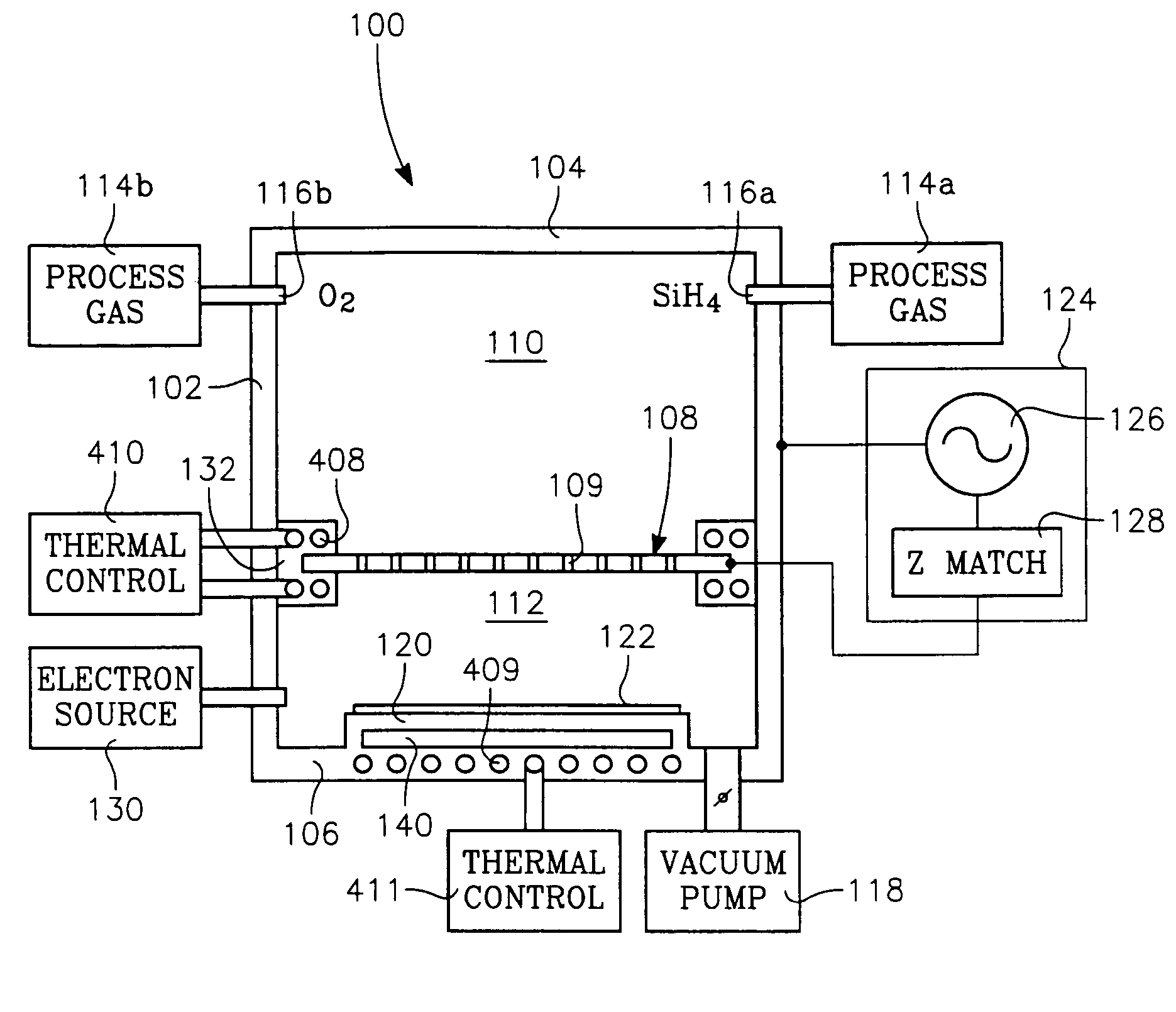

Chemical vapor deposition plasma process using an ion shower grid

A chemical vapor deposition process is carried out in a reactor chamber with an ion shower grid that divides the chamber into an upper ion generation region and a lower process region, the ion shower grid having plural orifices oriented in a non-parallel direction relative to a surface plane of the ion shower grid. A workpiece is placed in the process region facing the ion shower grid, the workpiece having a workpiece surface generally facing the surface plane of the ion shower grid. A gas mixture is furnished comprising deposition precursor species into the ion generation region and the process region is evacuated at an evacuation rate sufficient to create a pressure drop across the ion shower grid from the ion generation region to the process region whereby the pressure in the ion generation region is at least several times the pressure in the process region. A layer of material of a desired thickness is deposited on the workpiece by: (a) applying plasma source power to generate a plasma of the deposition precursor species in the ion generation region, and (b) applying a grid potential to the ion shower grid to create a flux of ions from the plasma through the grid and into the process region.

Owner:APPLIED MATERIALS INC

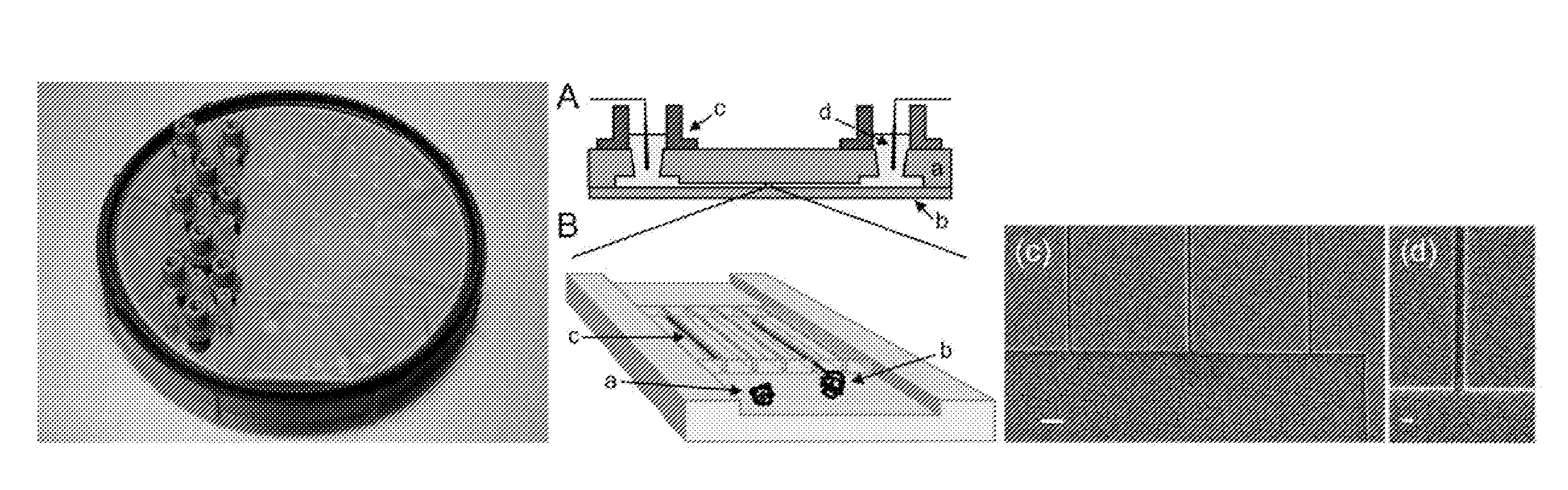

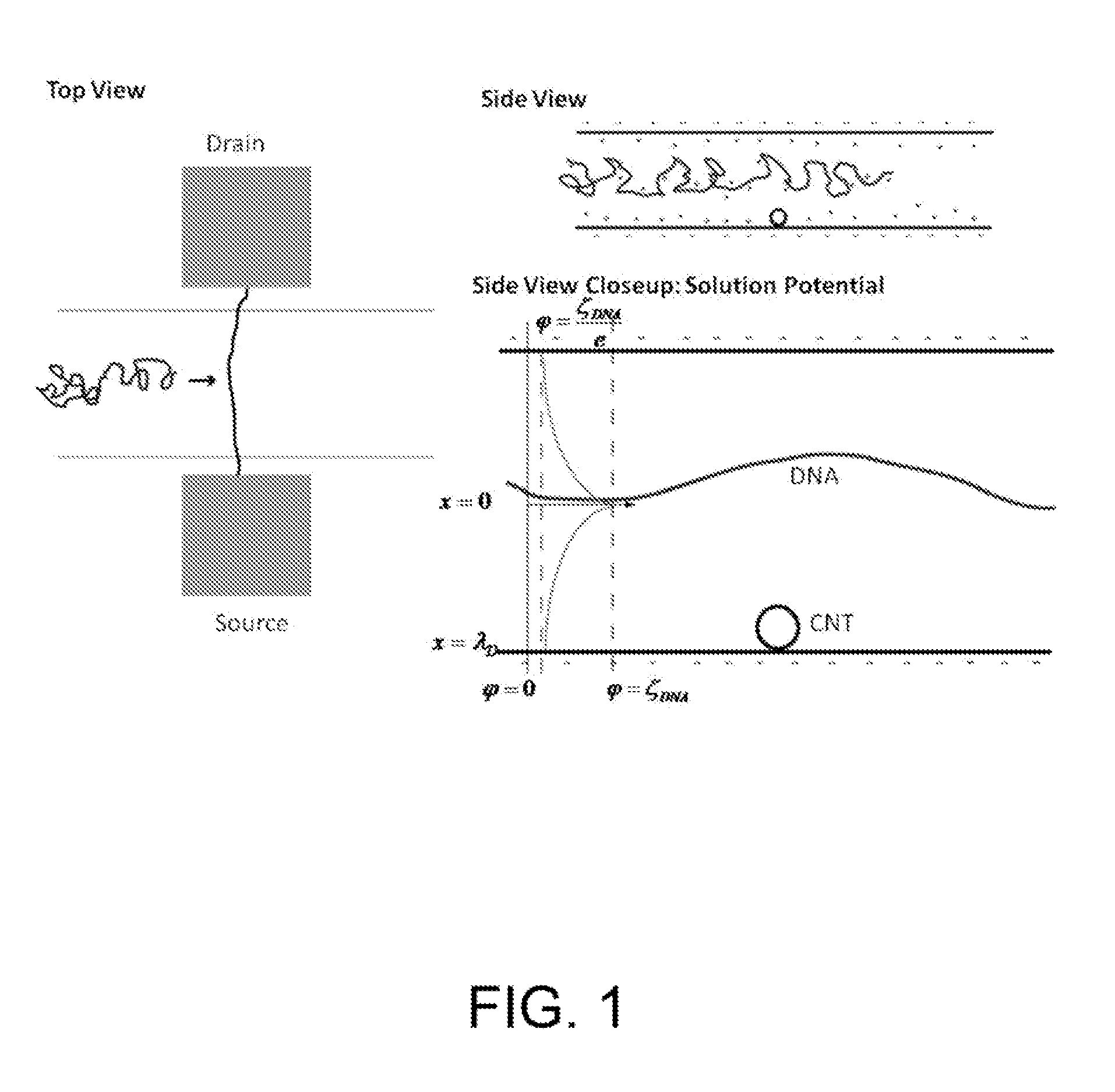

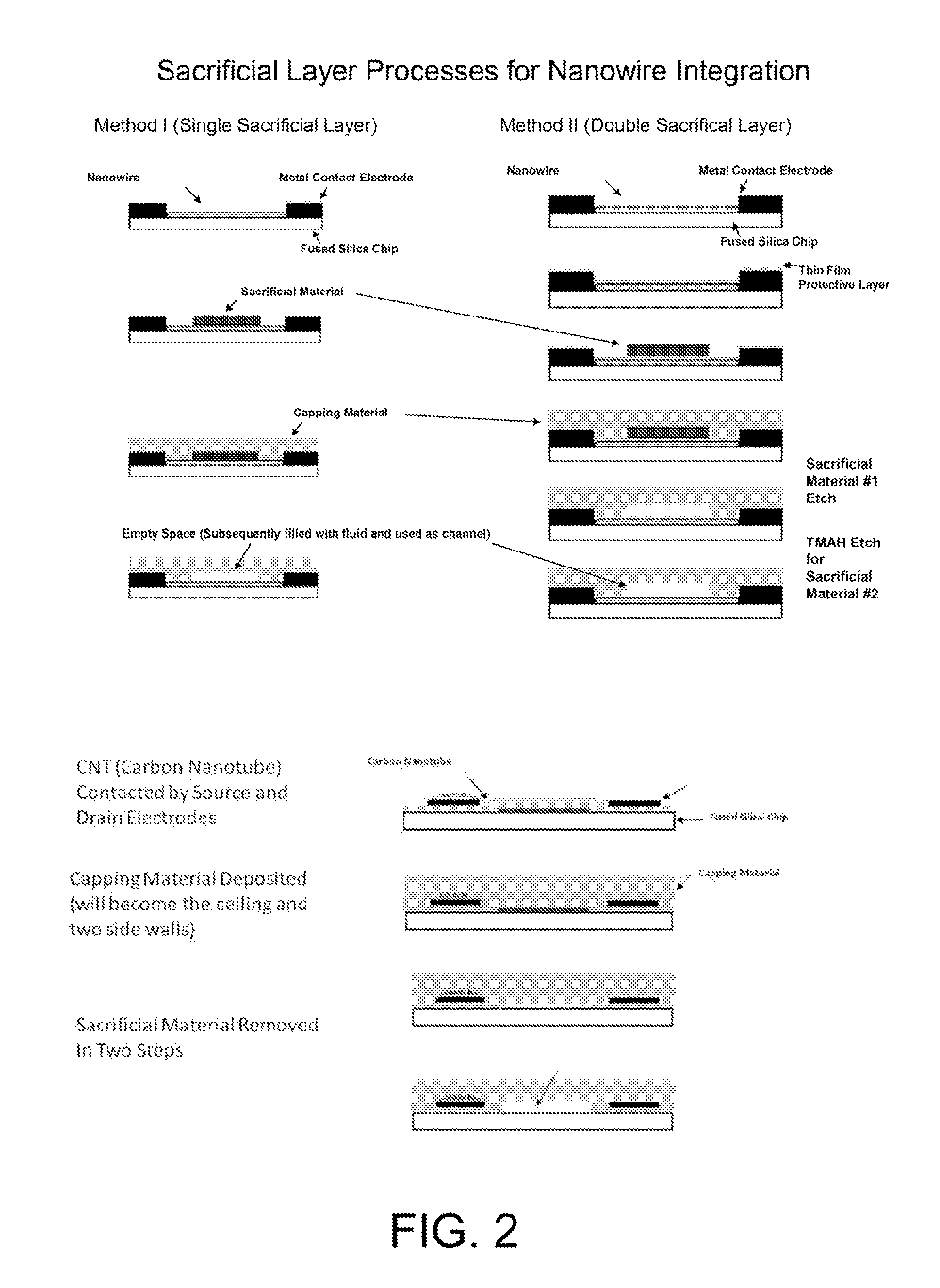

Nanofluidic channels with integrated charge sensors and methods based thereon

An electrical detector is provided that comprises a nanofluidic channel with an integrated nanoscale charge sensor. The charge sensor can be an unfunctionalized nanowire, nanotube, transistor or capacitor and can be of carbon, silicon, carbon / silicon or other semiconducting material. The nanofluidic channel depth is on the order of the Debye screening length. Methods are also provided for detecting charged molecules or biological or chemical species with the electrical detector. Charged molecules or species in solution are driven through the nanofluidic channel of the electrical detector and contact the charge sensor, thereby producing a detectable signal. Methods are also provided for detecting a local solution potential of interest. A solution flowing through the nanofluidic channel of the electrical detector contacts the charge sensor, thereby producing a detectable local solution potential signal.

Owner:CORNELL UNIVERSITY

Image display apparatus using current-controlled light emitting element

InactiveUS7358941B2Solve problemsUnified controlElectroluminescent light sourcesSolid-state devicesElectricityElectric light

A pixel circuit includes a driver element that is supplied with a potential from a data line. The driver element controls a value of current passing through an electric light emitting element. Upon obtaining a threshold voltage, a conductive member connected to the electric light emitting element is made to be a floating state to cause the driver element to become on-state, variations in the potential of the conductive member caused by charges passing through the driver element to flow into the conductive member are detected by a threshold voltage detector to obtain the threshold voltage of the driver element.

Owner:INNOLUX CORP

Chemical vapor deposition plasma process using plural ion shower grids

A chemical vapor deposition process is carried out in a reactor chamber having a set of plural parallel ion shower grids that divide the chamber into an upper ion generation region and a lower process region, each of the ion shower grids having plural orifices in mutual registration from grid to grid, each orifice being oriented in a non-parallel direction relative to a surface plane of the respective ion shower grid. A workpiece is placed in the process region, so that a workpiece surface of the workpiece is generally facing a surface plane of the nearest one of the ion shower grids, and a gas mixture comprising a deposition precursor species is furnished into the ion generation region. The process region is evacuated at an evacuation rate sufficient to create a pressure drop across the plural ion shower grids between the ion generation and process regions whereby the pressure in the ion generation region is several times the pressure in the process region. The process further includes applying plasma source power to generate a plasma of the deposition precursor species in the ion generation region and applying successive grid potentials to successive ones of the grids.

Owner:APPLIED MATERIALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com