Patents

Literature

665 results about "Production tubing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production tubing is a tube used in a wellbore through which production fluids are produced (travel).

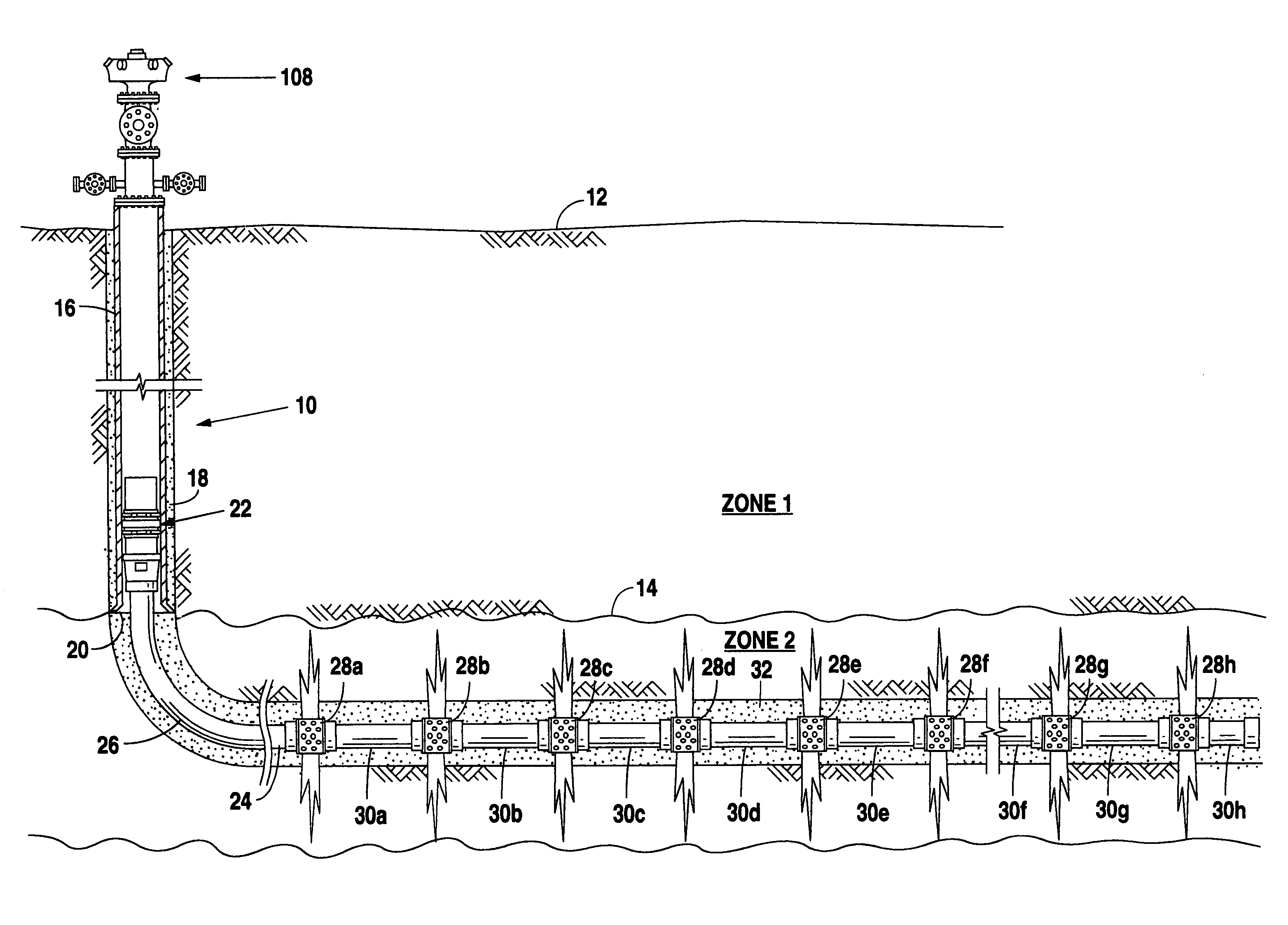

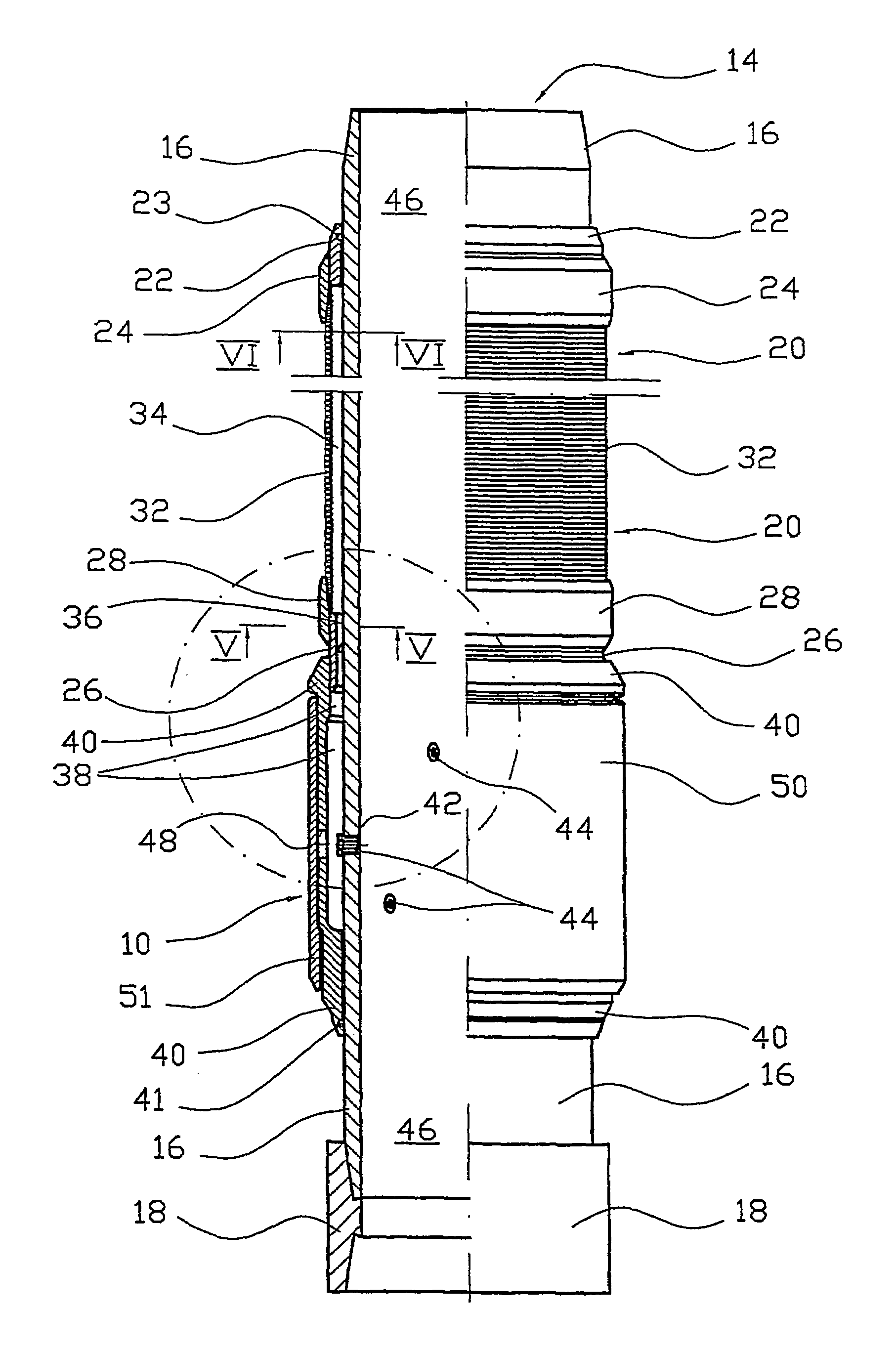

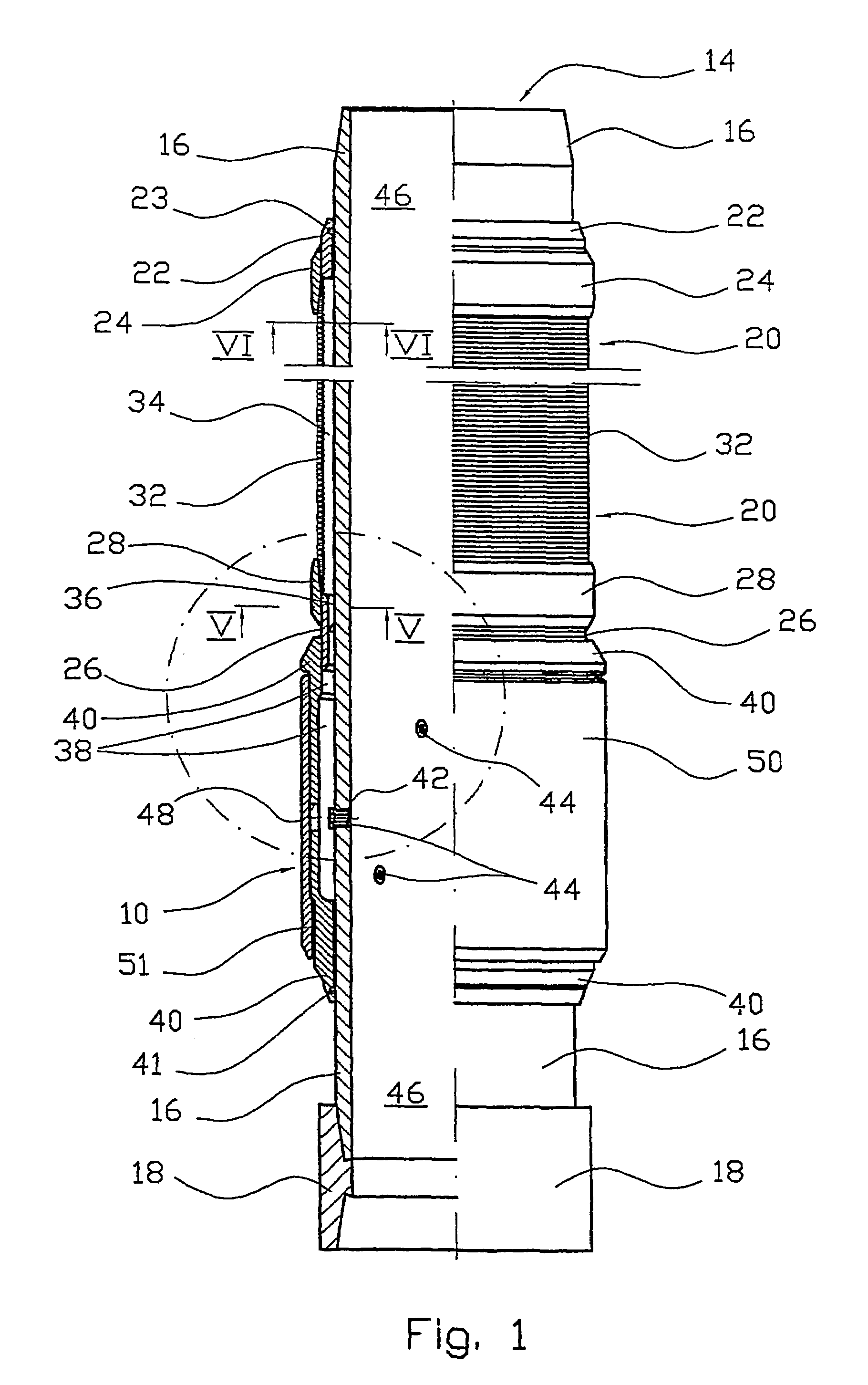

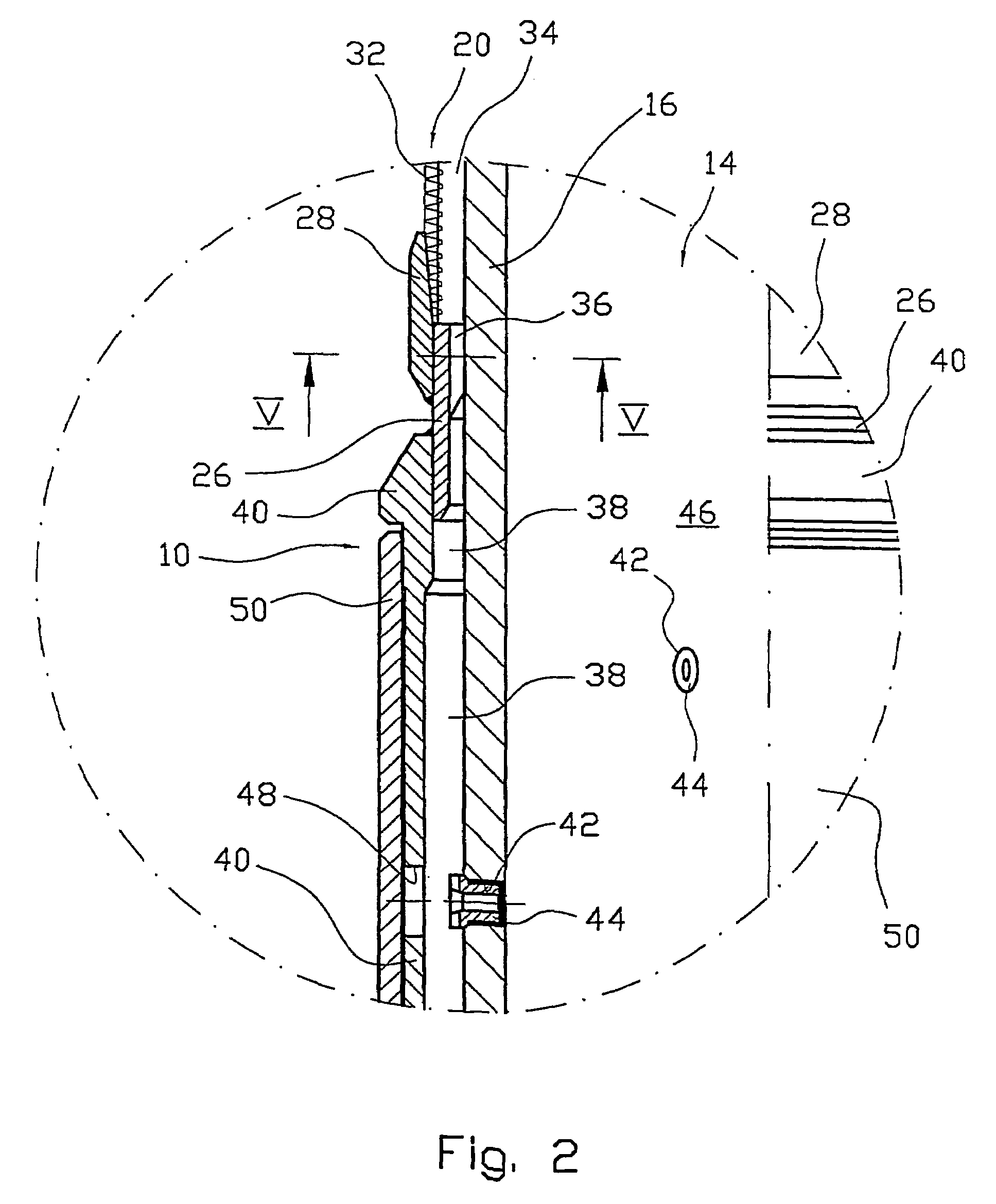

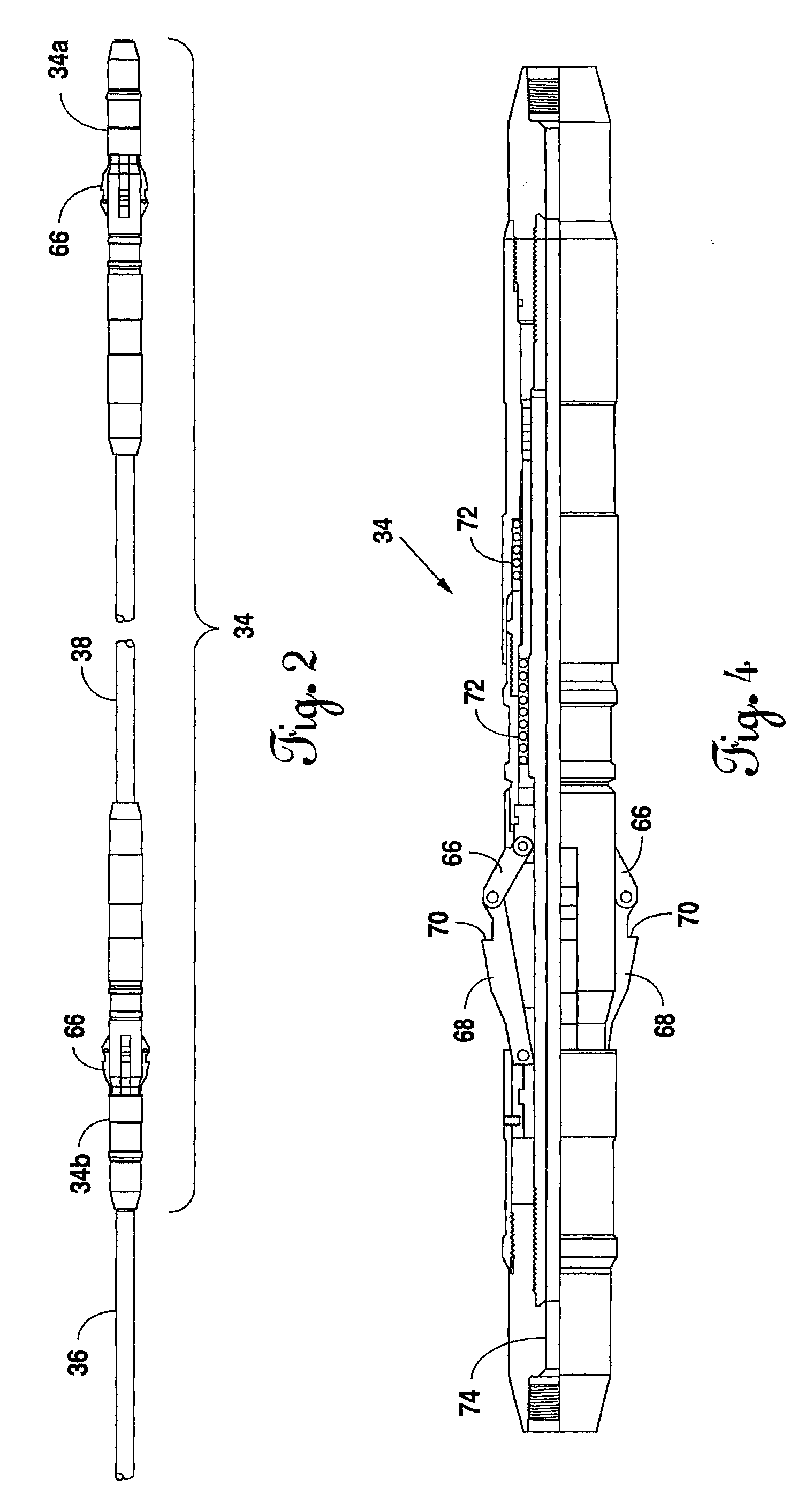

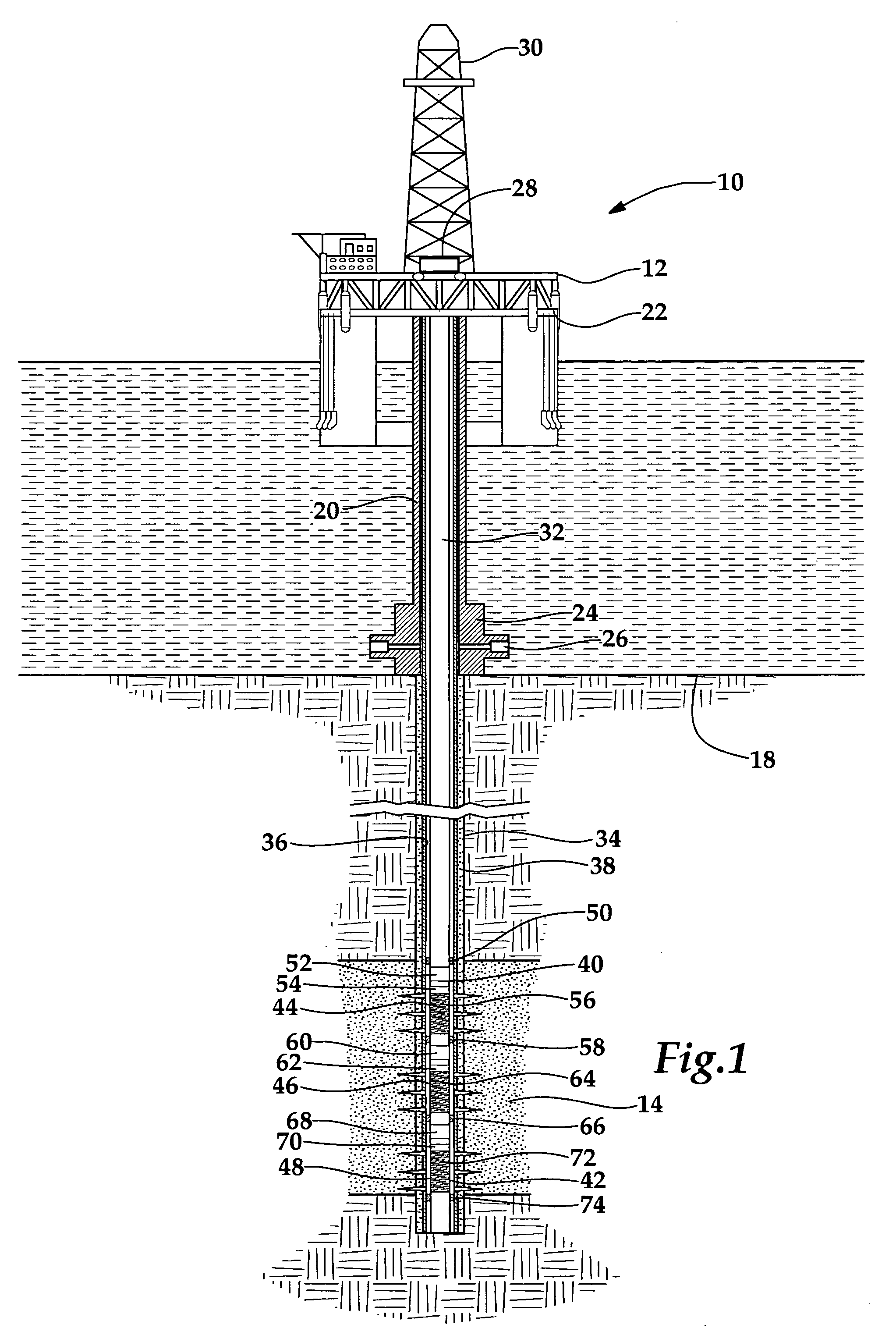

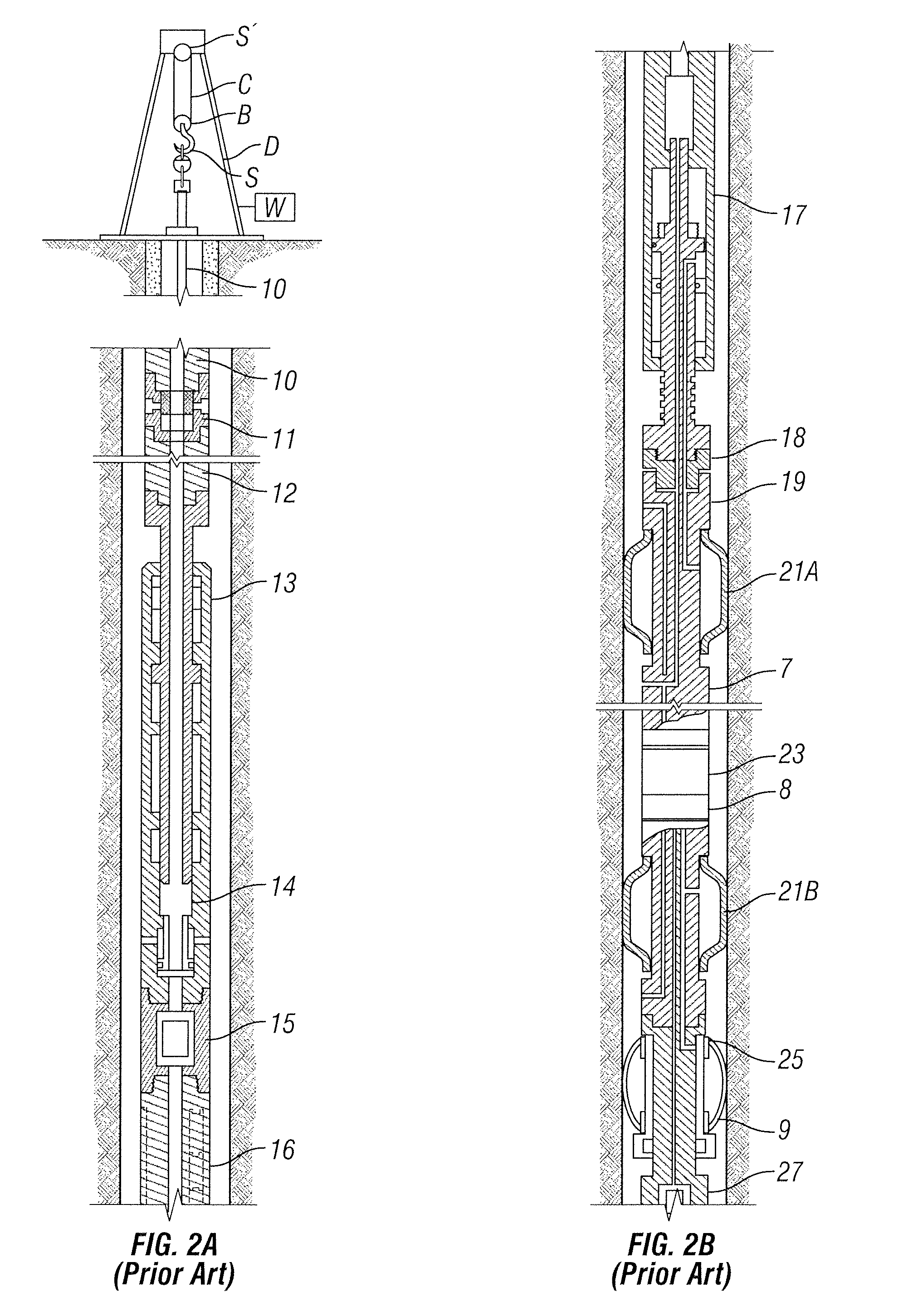

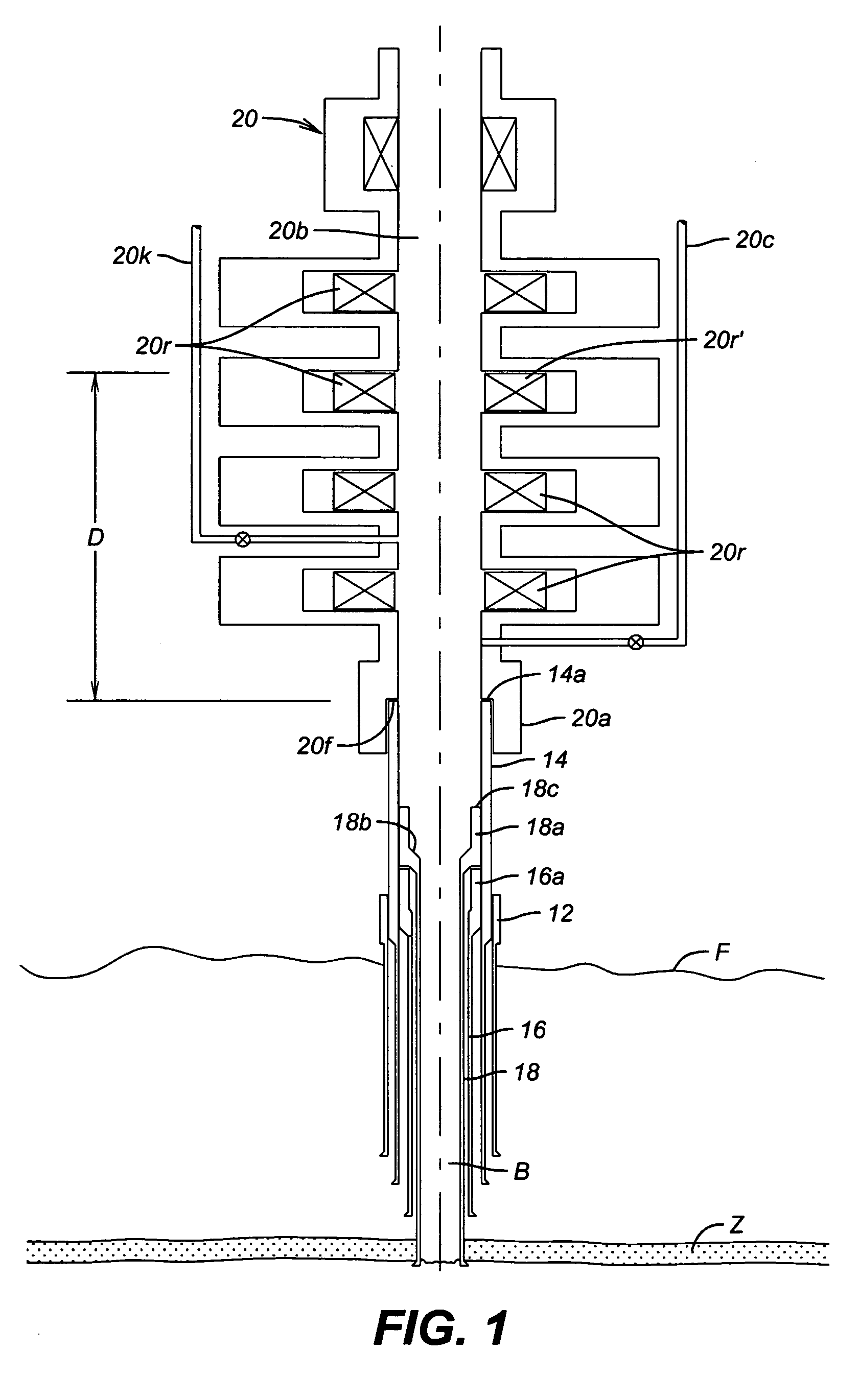

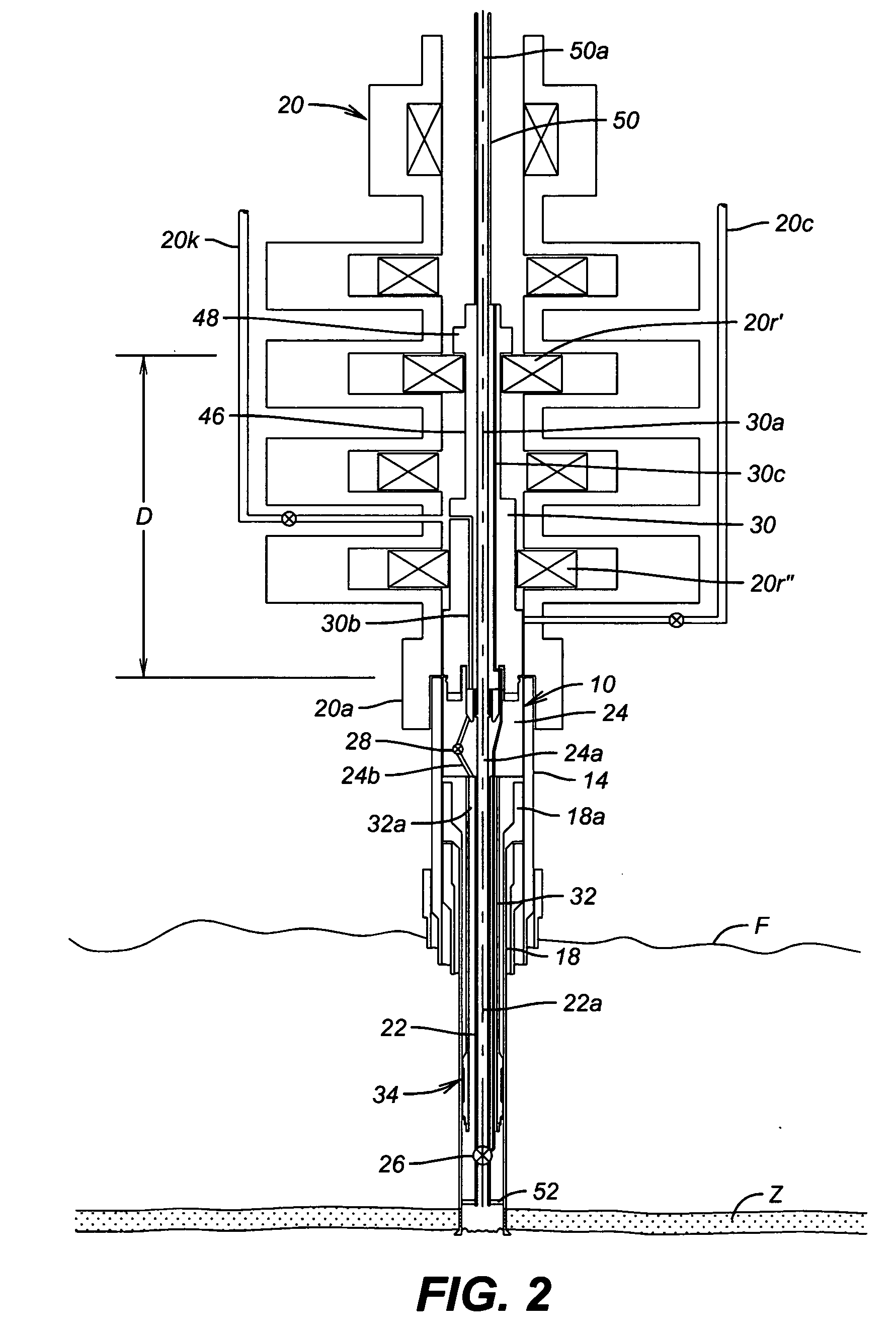

Method of providing hydraulic/fiber conduits adjacent bottom hole assemblies for multi-step completions

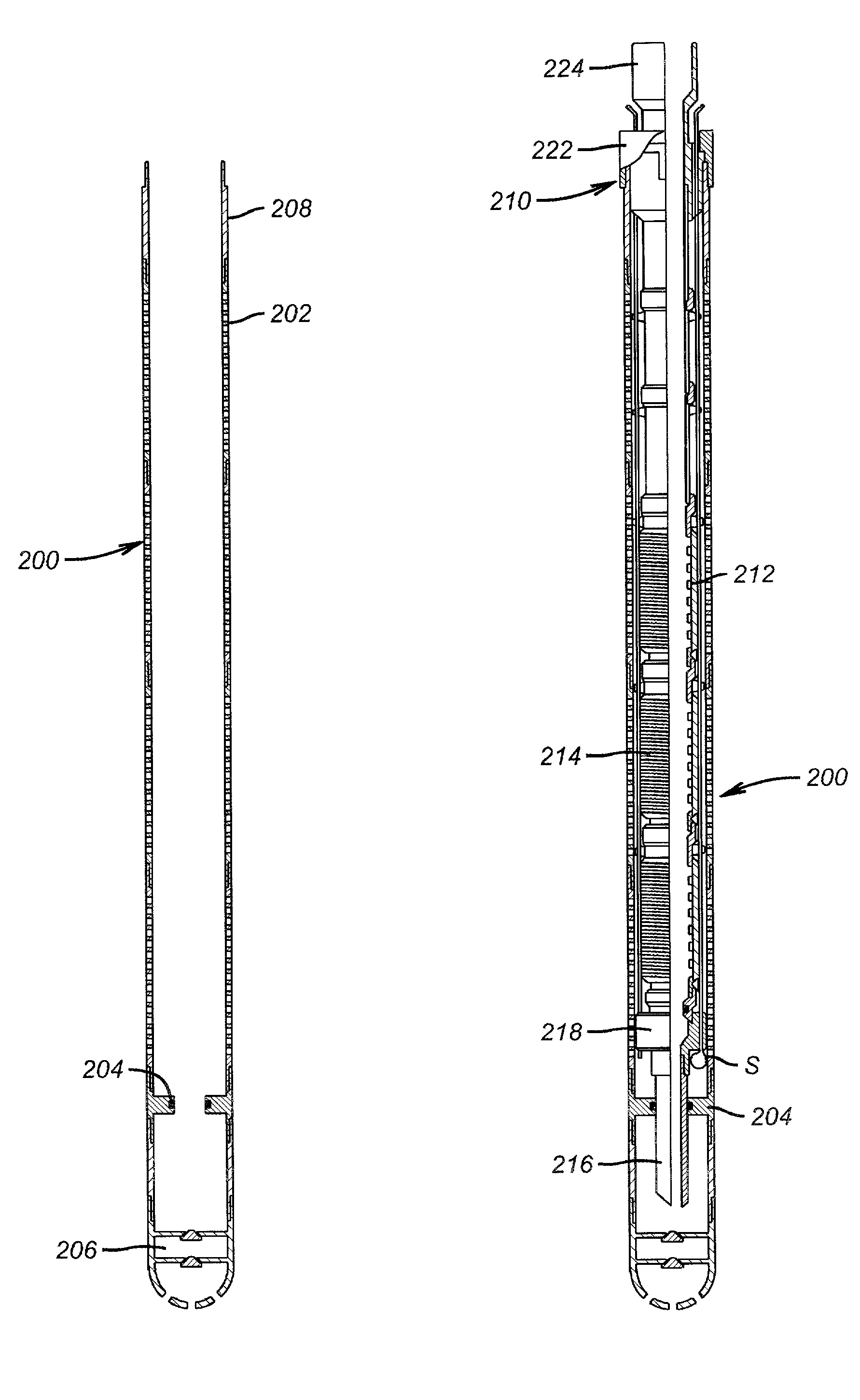

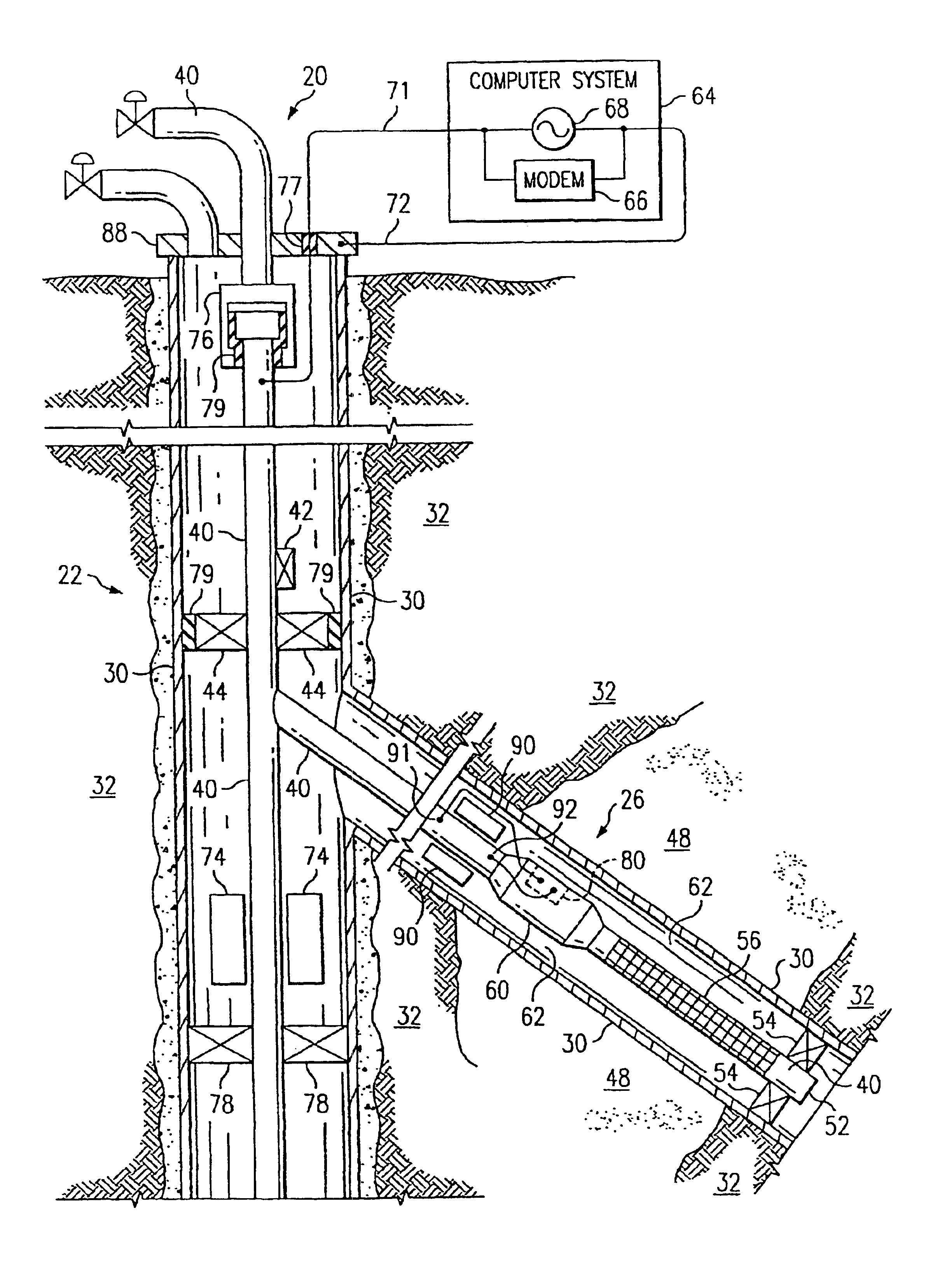

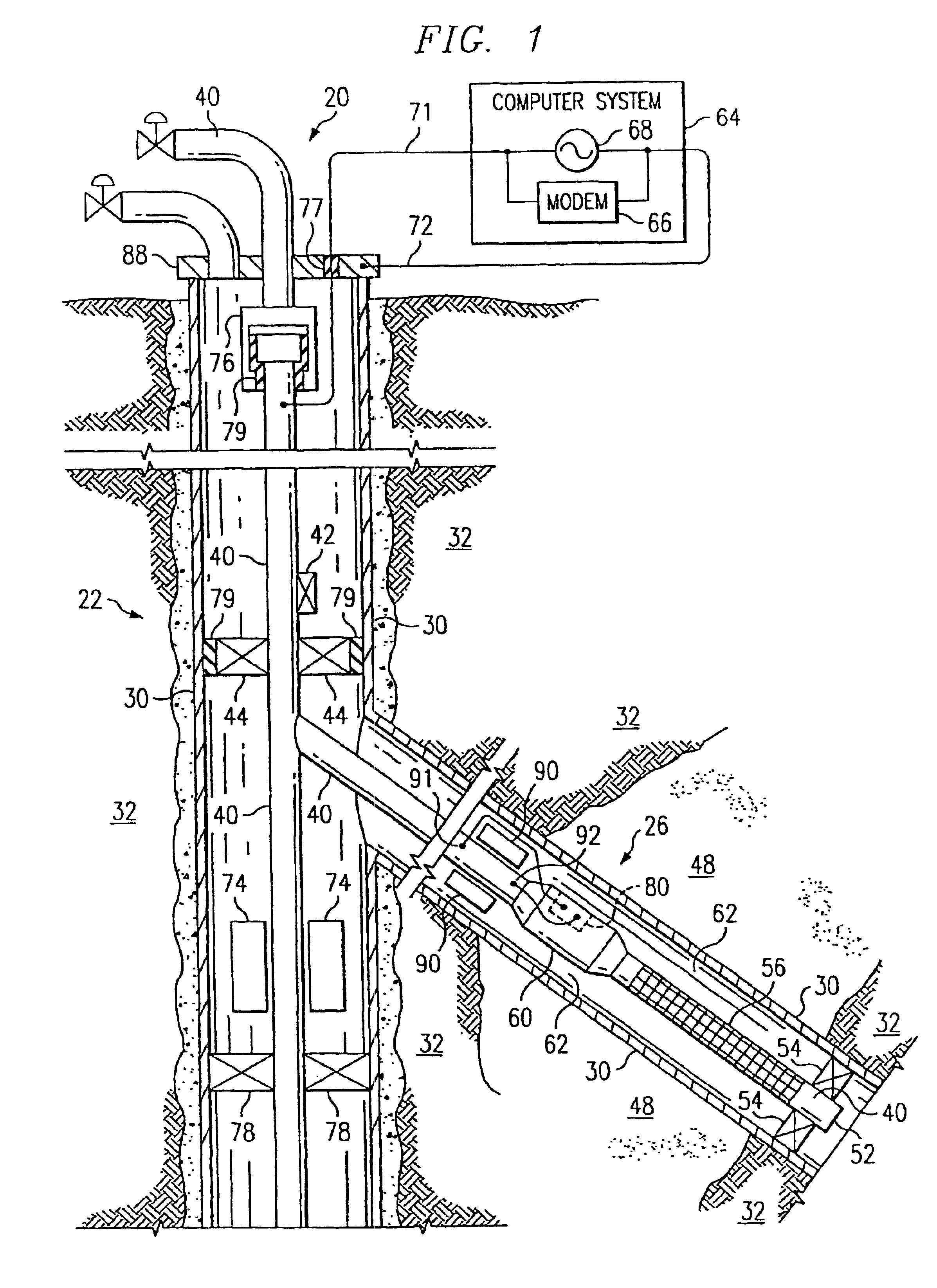

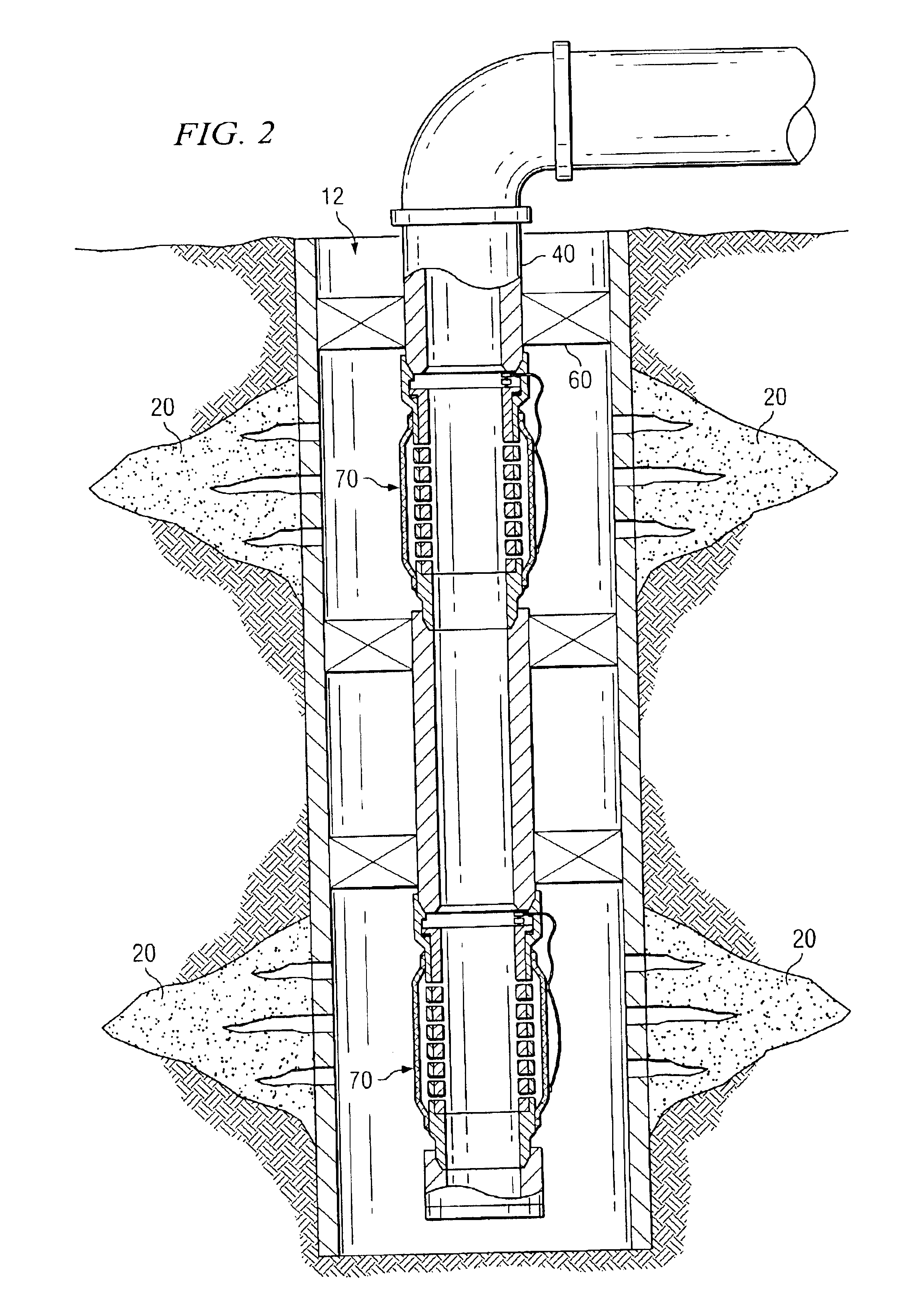

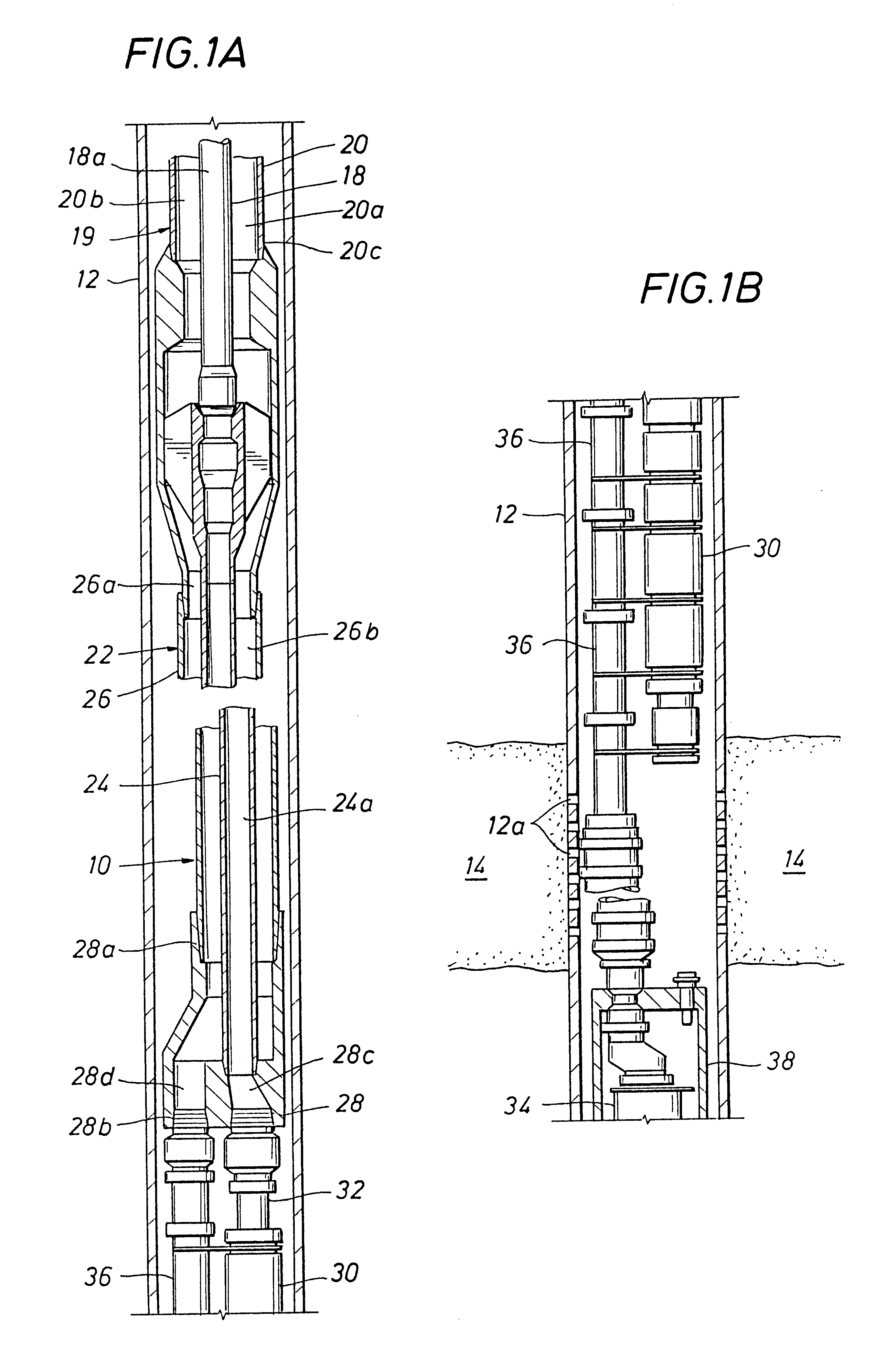

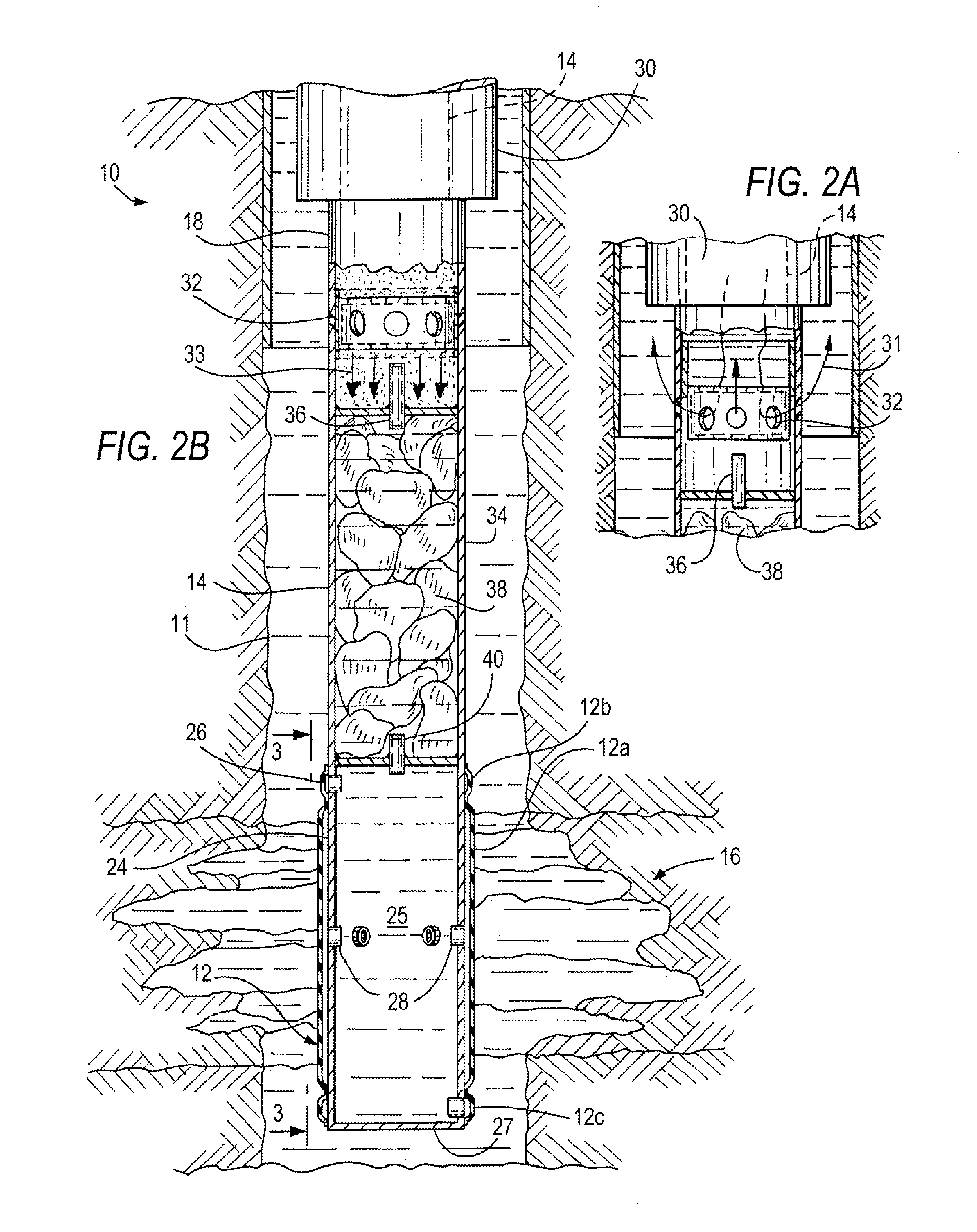

A technique for providing auxiliary conduits in multi-trip completions is disclosed. The technique has particular applicability to liner mounted screens which are to be gravel packed. In the preferred embodiment, a protective shroud is run with the gravel pack screens with the auxiliary conduits disposed in between. The auxiliary conduits terminate in a quick connection at a liner top packer. The gravel packing equipment can optionally be secured in a flow relationship to the auxiliary conduits so as to control the gravel packing operation. Subsequent to the removal of the specialized equipment, the production tubing can be run with an auxiliary conduit or conduits for connection down hole to the auxiliary conduits coming from the liner top packer for a sealing connection. Thereafter, during production various data on the well can be obtained in real time despite the multiple trips necessary to accomplish completion. The various completion and / or production activities can also be accomplished using the auxiliary conduits such as actuation of down hole flow control devices, chemical injection, pressure measurement, distributed temperature sensing through fiber optics, as well as other down hole parameters.

Owner:BAKER HUGHES INC

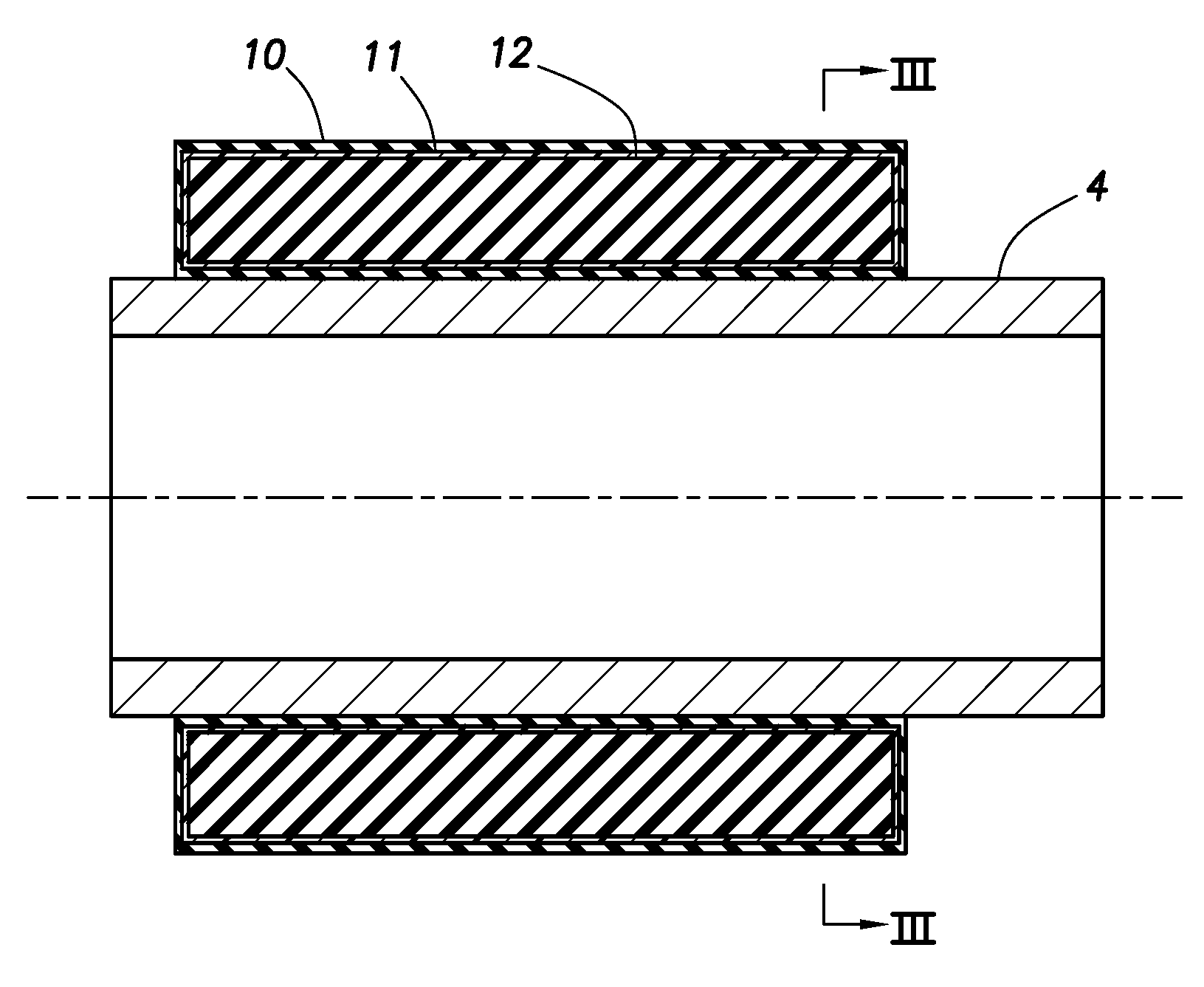

Well packing

InactiveUS7143832B2Less expandedSimple and reliable deviceFluid removalSealing/packingEngineeringProduction tubing

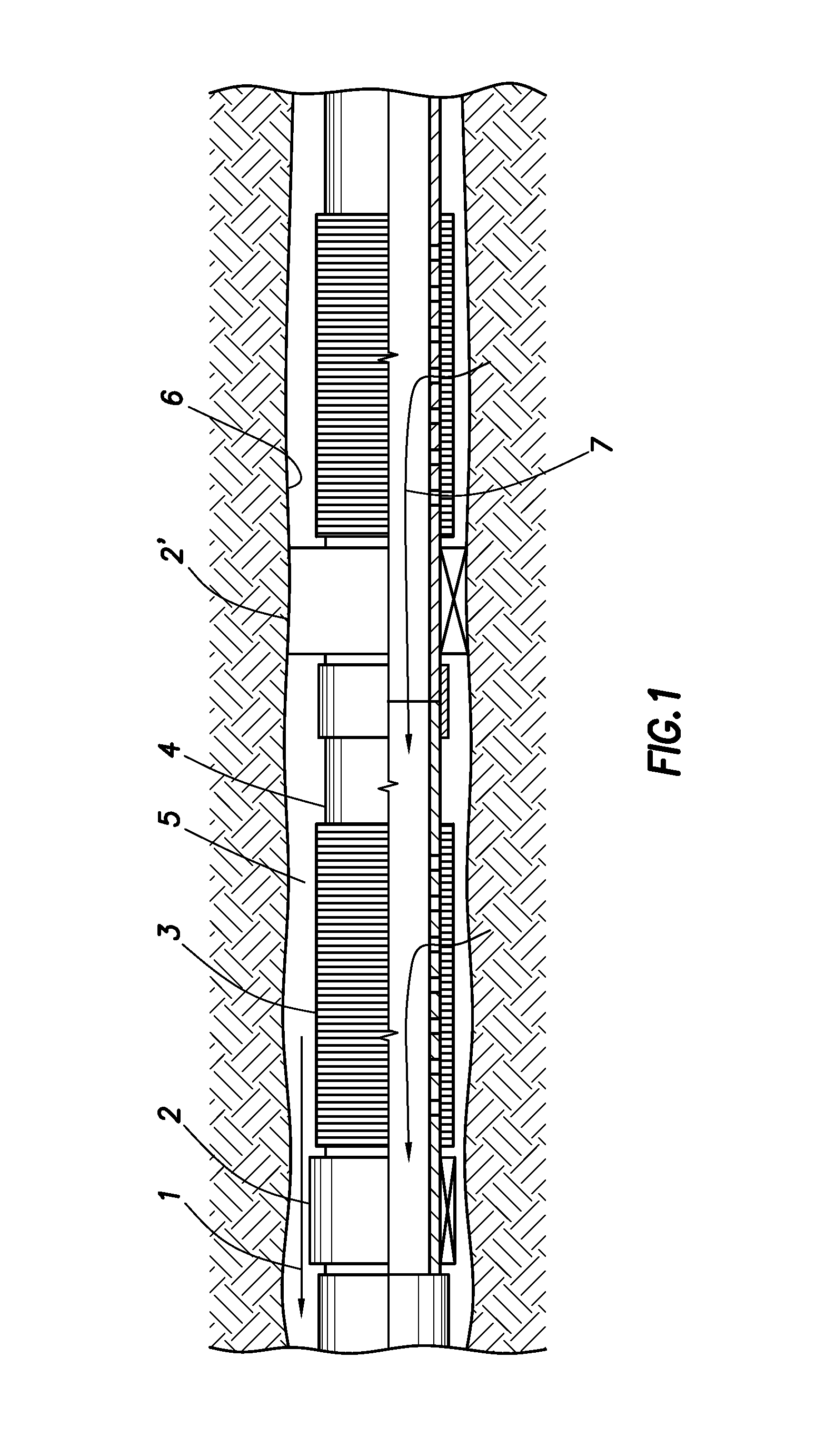

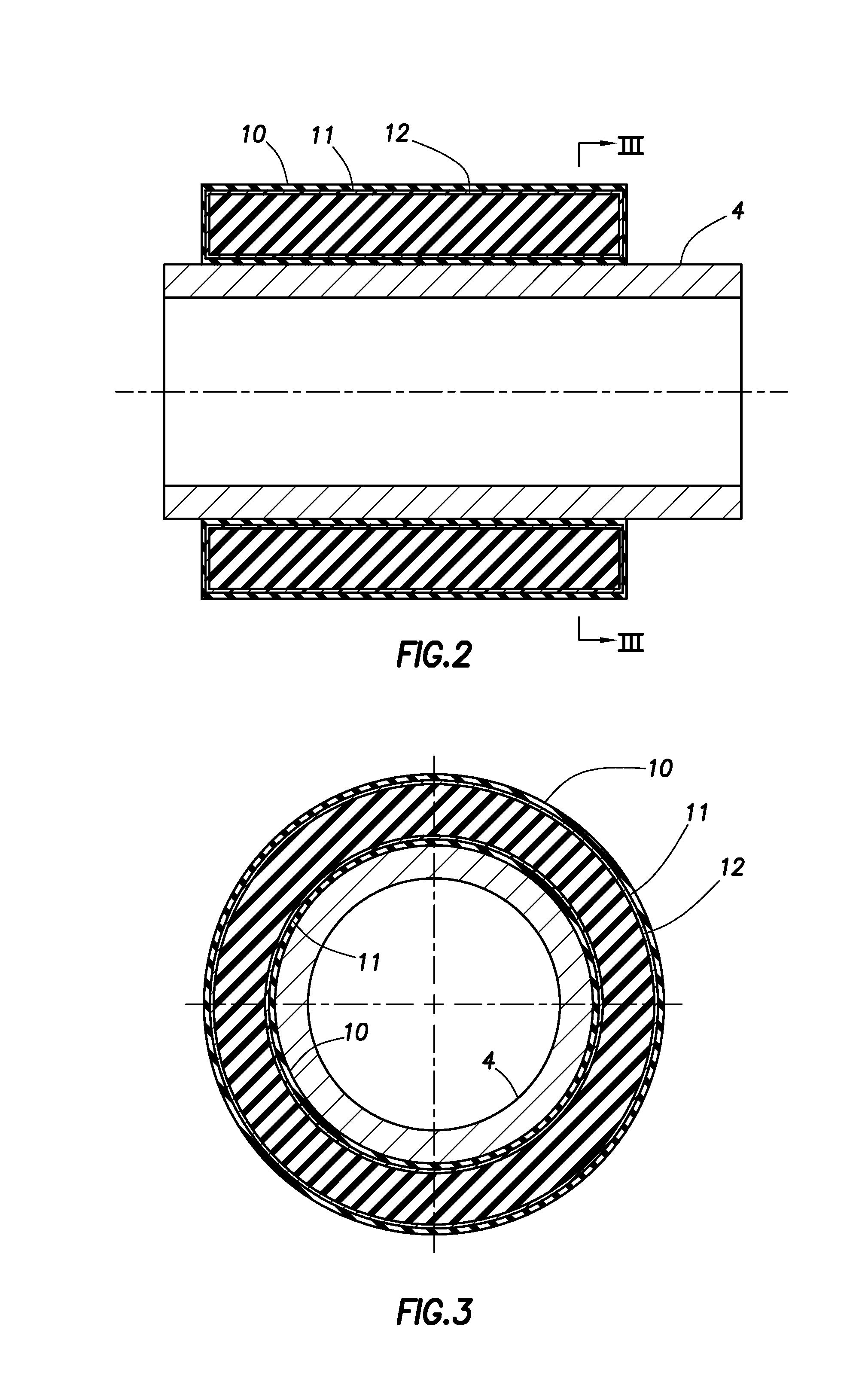

Annular packer (2) arranged on the outside of a production tubing (4) said packer comprises a core (12) comprising elastic polymer swelling by absorption of hydrocarbons. The core (12) may be surrounded by an external mantle of rubber (10), which is permeable to hydrocarbons and may be equipped with a reinforcement (11). The core (12) swells by absorption of hydrocarbons and the packer (2) expands thus in order to seal the annular space (5) between the production tubing (4) and the well wall (6).

Owner:HALLIBURTON ENERGY SERVICES INC

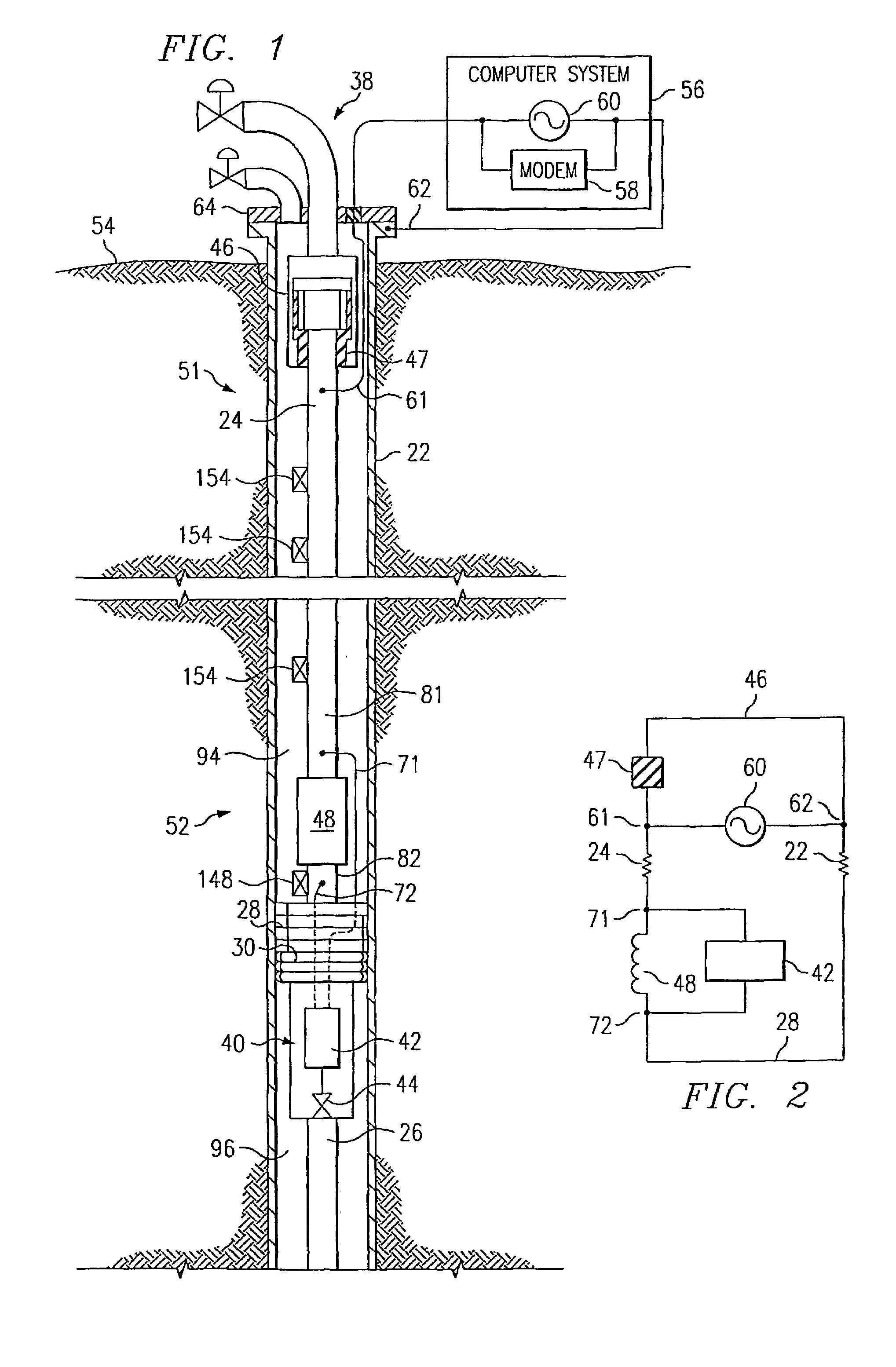

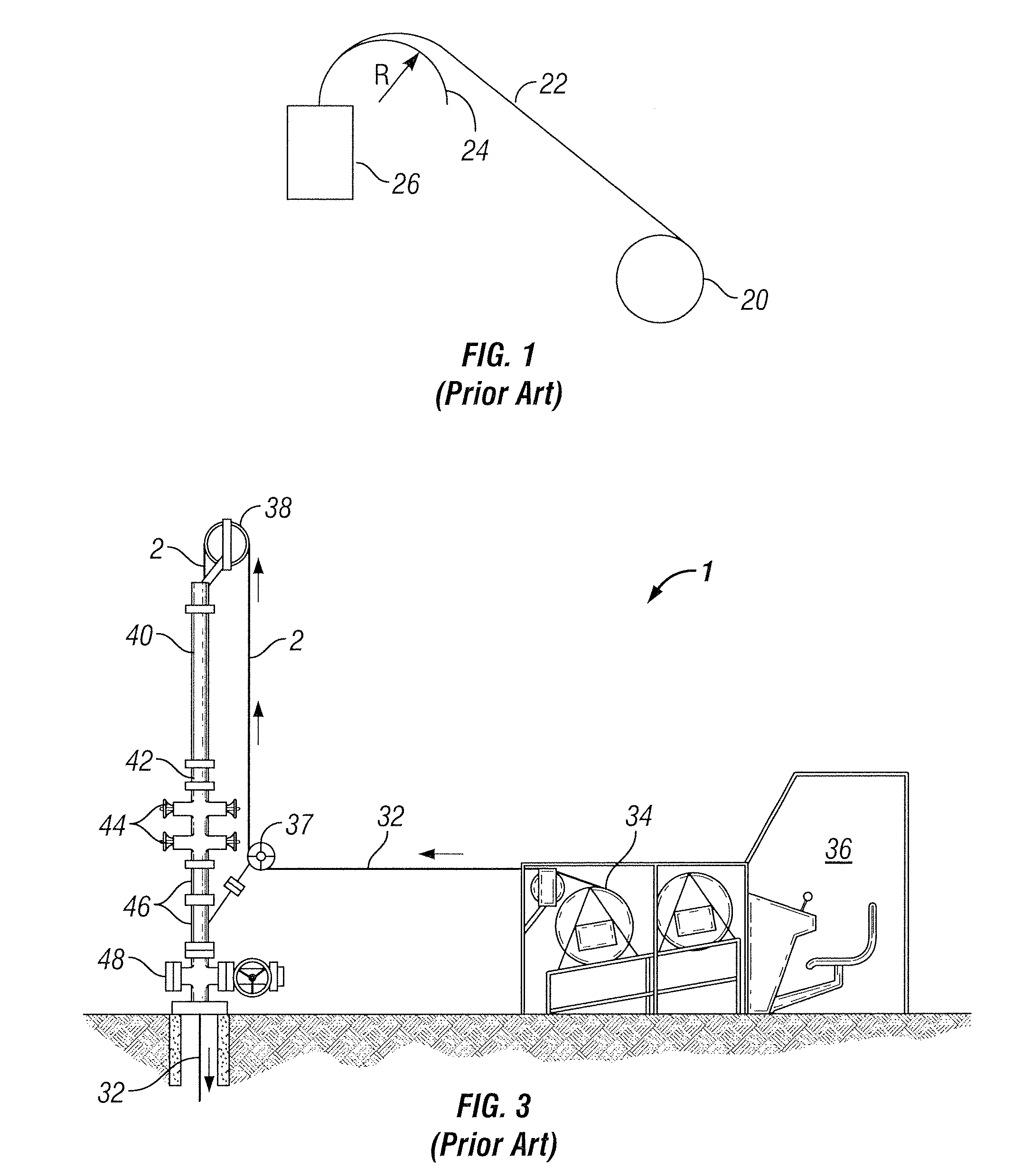

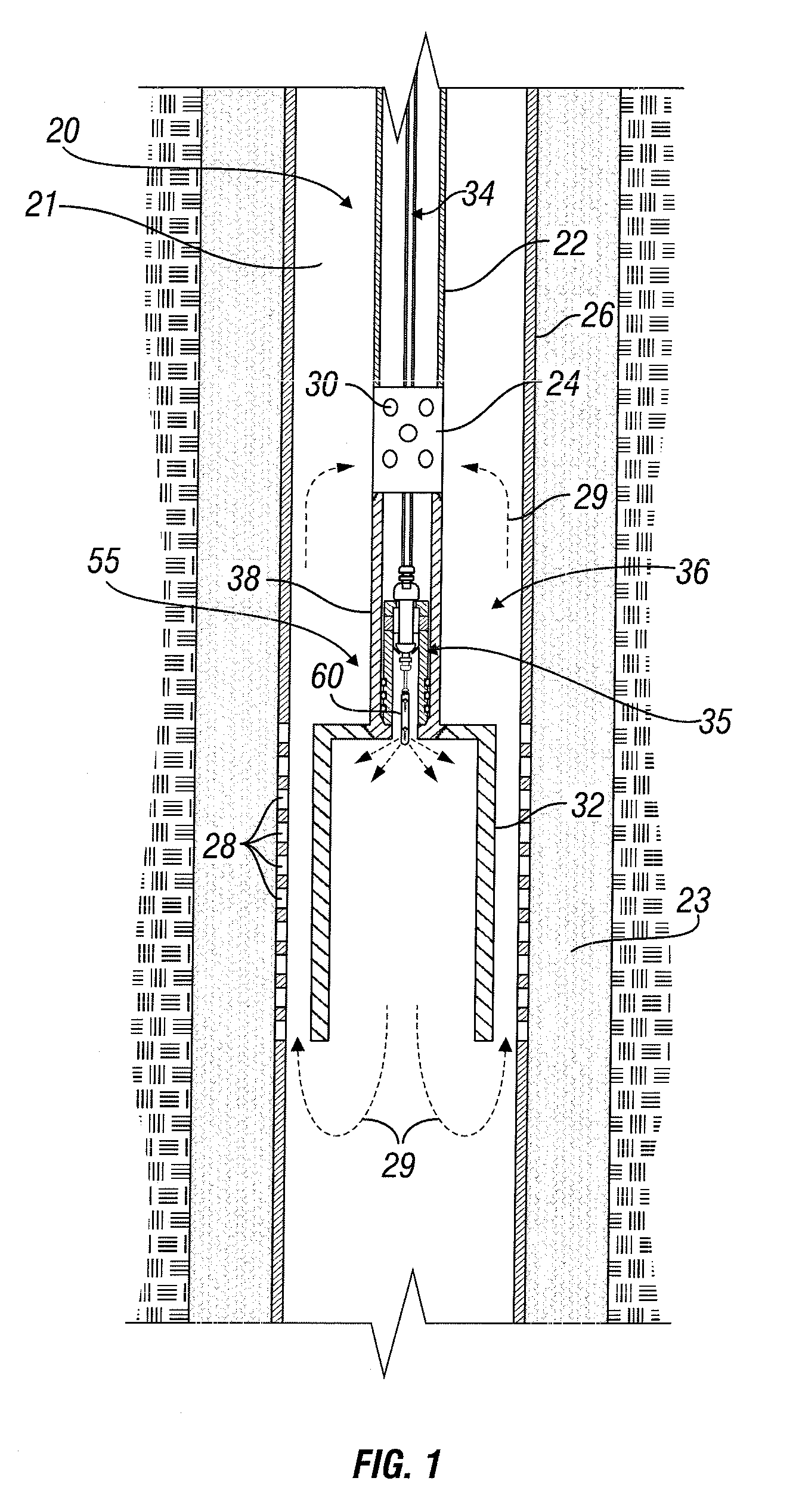

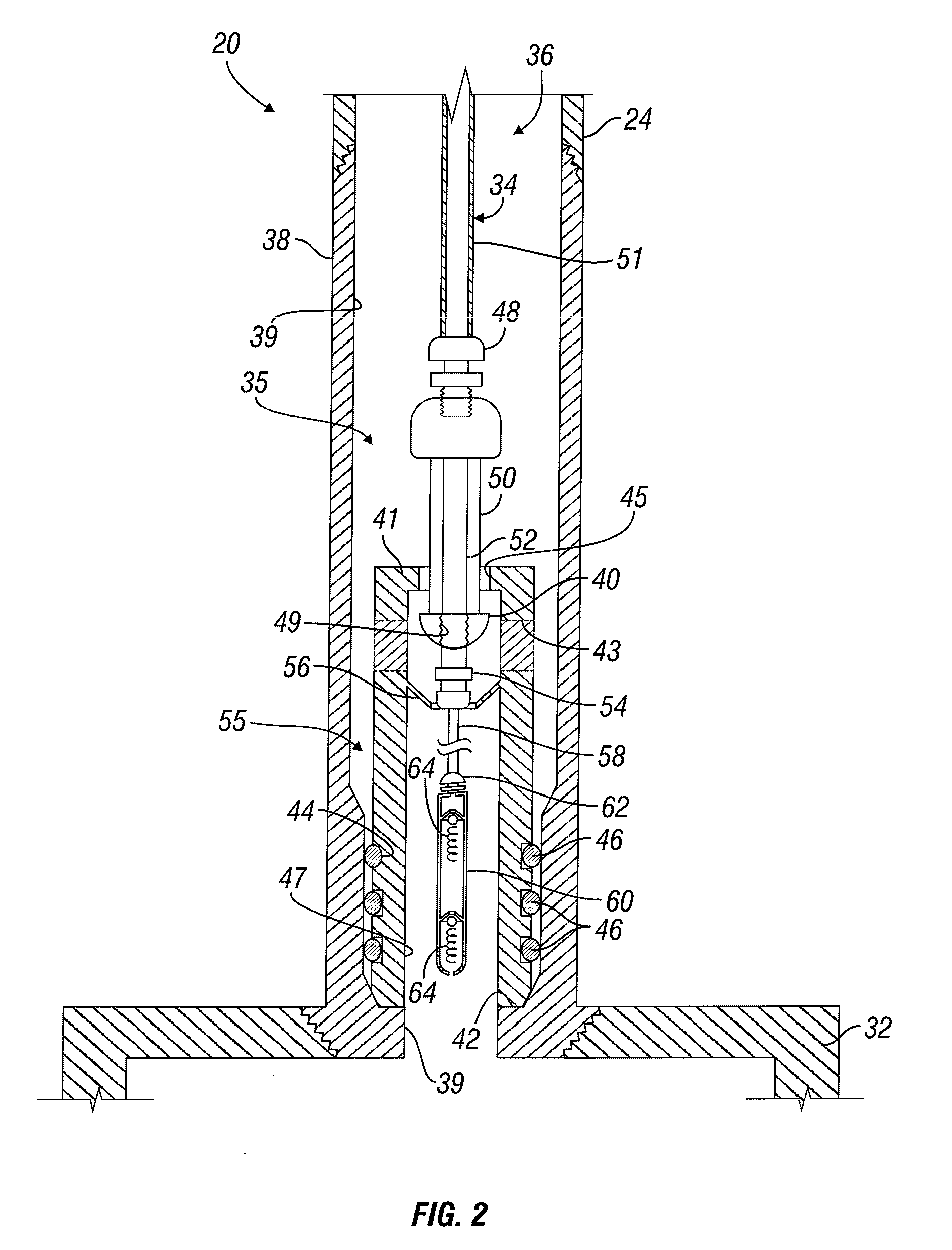

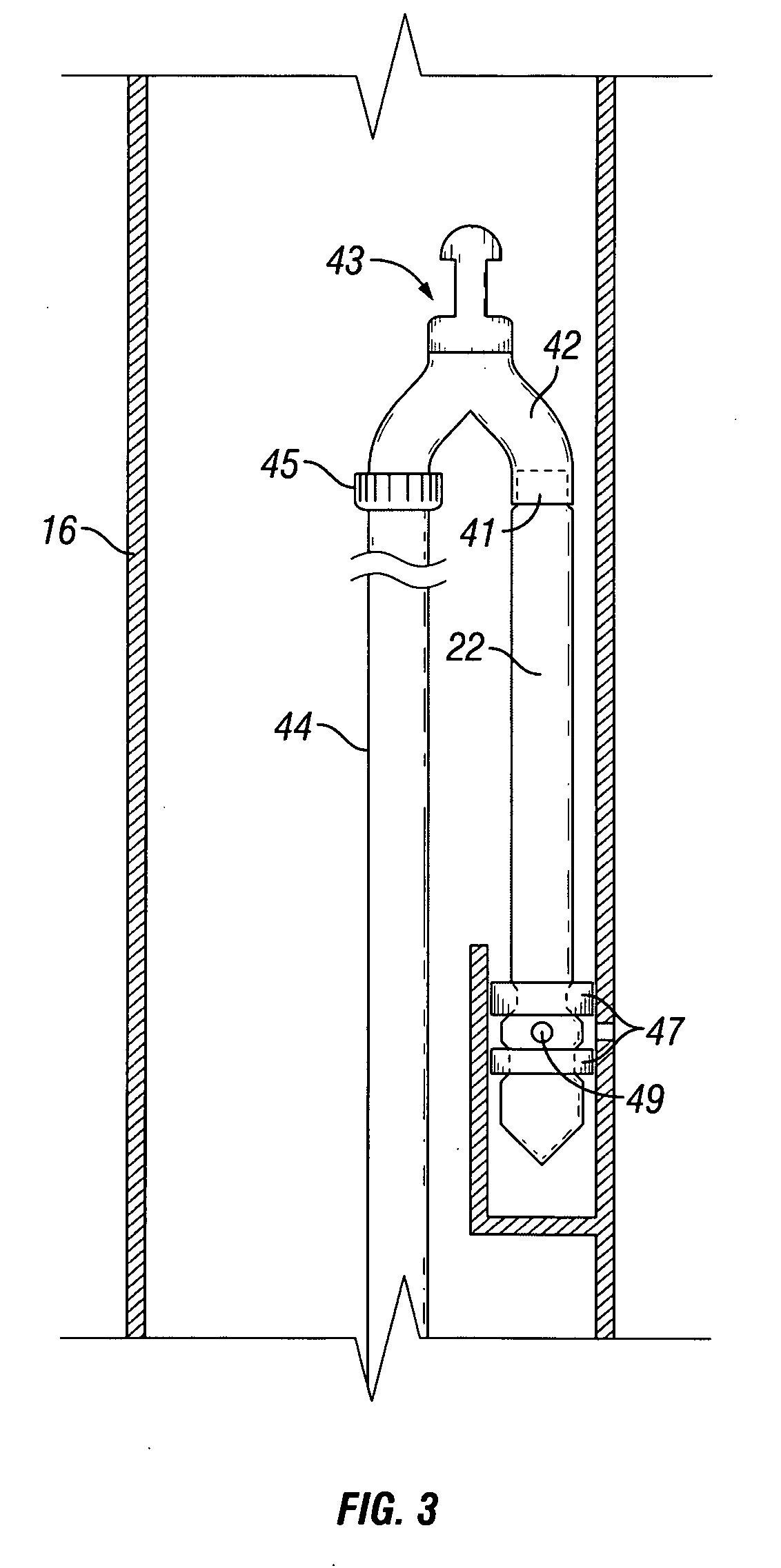

Controlled downhole chemical injection

InactiveUS6981553B2Improve efficiencyImprove flow characteristicsNear-field transmissionSurveyElectrical conductorPetroleum

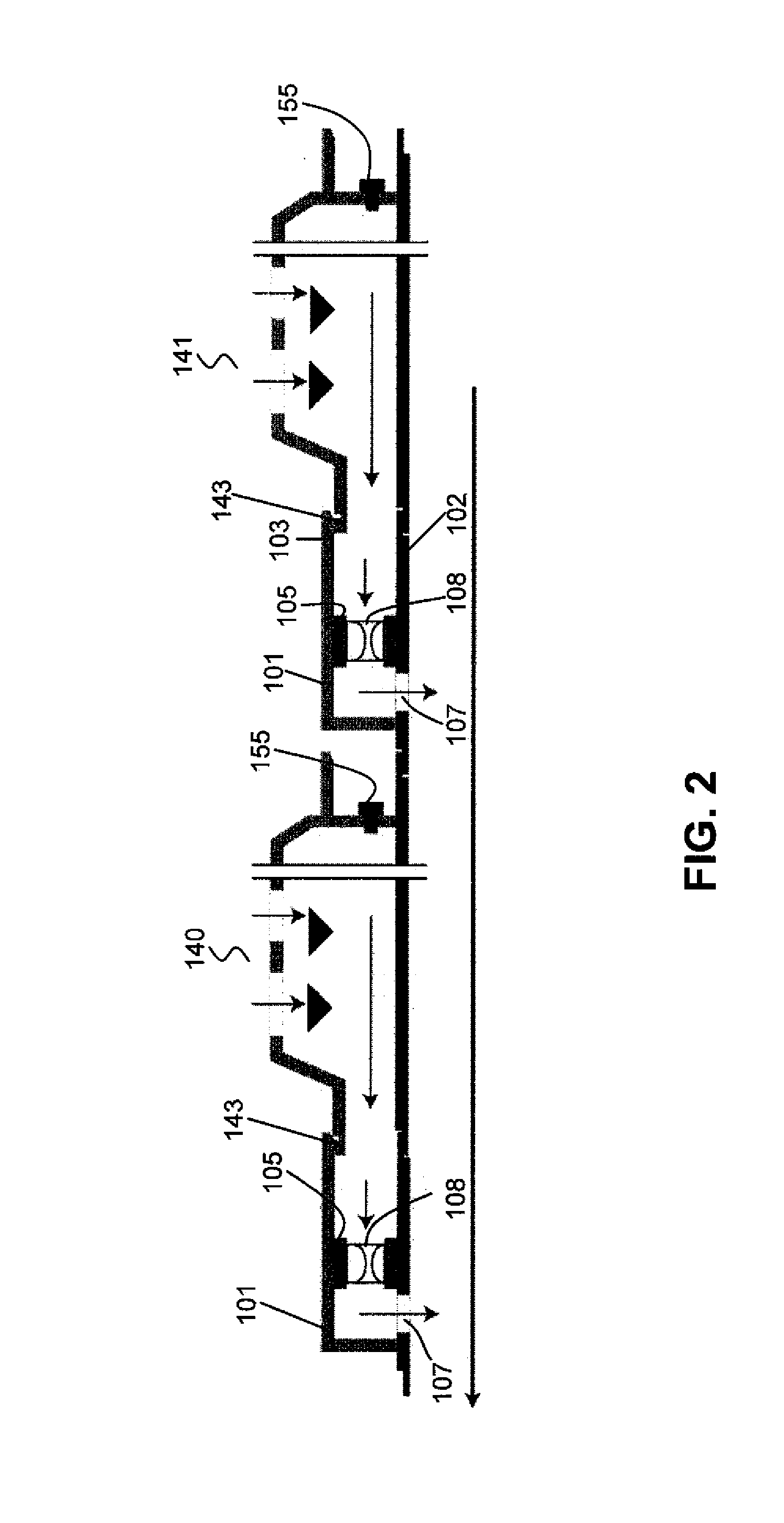

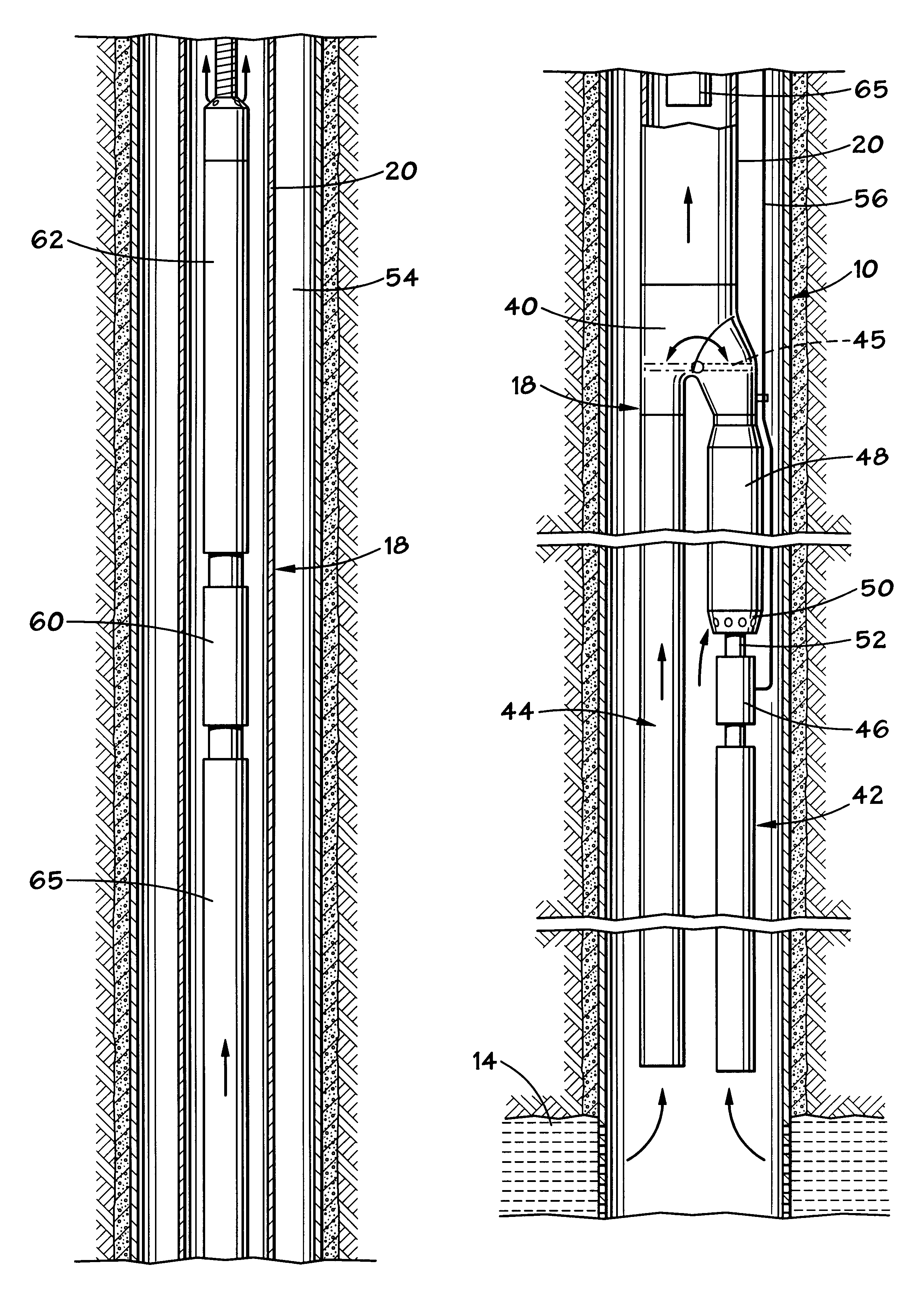

A petroleum well having a well casing, a production tubing, a source of time-varying current, a downhole chemical injection device, and a downhole induction choke. The casing extends within a wellbore of the well. The tubing extends within the casing. The current source is located at the surface. The current source is electrically connected to, and adapted to output a time-varying current into, the tubing and / or the casing, which act as electrical conductors for providing downhole power and / or communications. The injection device having a communications and control module, a chemical container, and an electrically controllable chemical injector. The communications and control module is electrically connected to the tubing and / or the casing. The chemical injector is electrically connected to the communications and control module, and is in fluid communication with the chemical container. The downhole induction choke is located about a portion of the tubing and / or the casing. The chemical injector is electrically connected to the communications and control module, and is in fluid communication with the chemical container. The downhole induction choke is located about a portion of the tubing and / or the casing. The induction choke is adapted to route part of the electrical current through the communications and control module by creating a voltage potential between one side of the induction choke and another side of the induction choke. The communications and control module is electrically connected across the voltage potential. Also, a method is provided for controllably injecting a chemical into the well downhole, which may be used to: improve lift efficiency with a foaming agent, prevent deposition of solids with a paraffin solvent, improve a flow characteristic of the flow stream with a surfactant, prevent corrosion with a corrosion inhibitor, and / or prevent scaling with scale preventers.

Owner:SHELL OIL CO

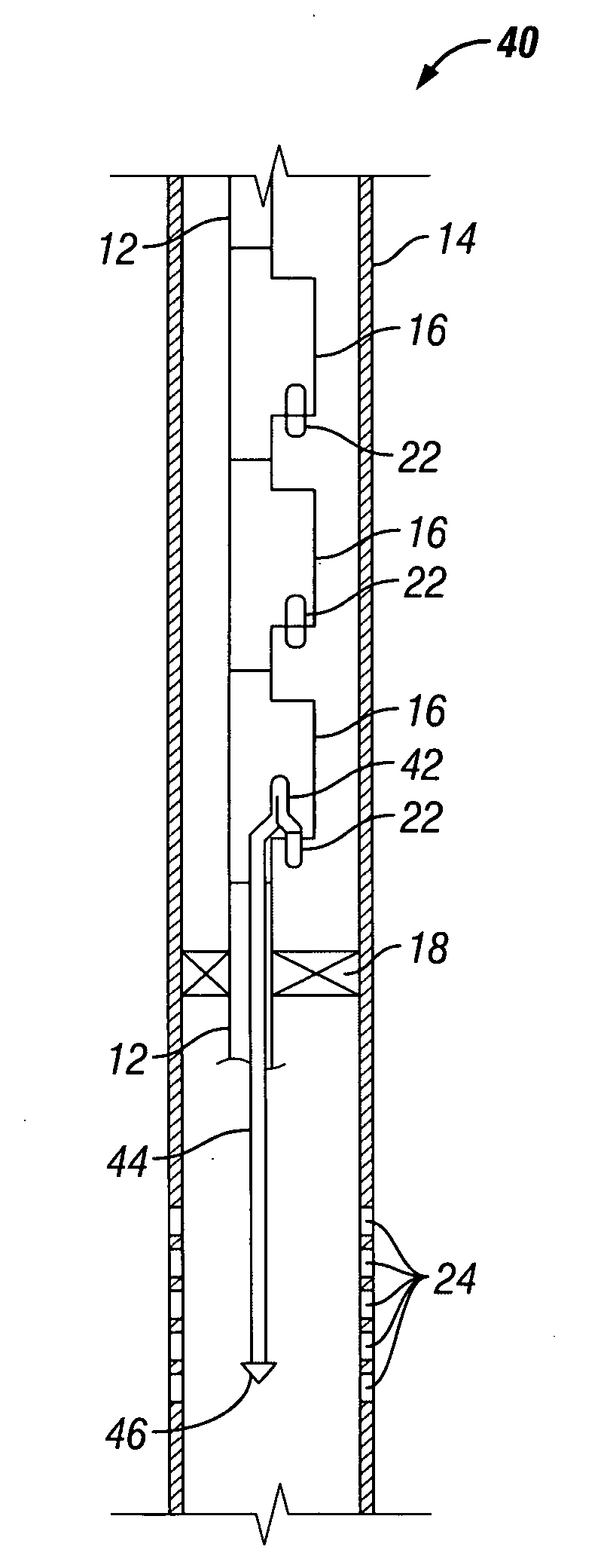

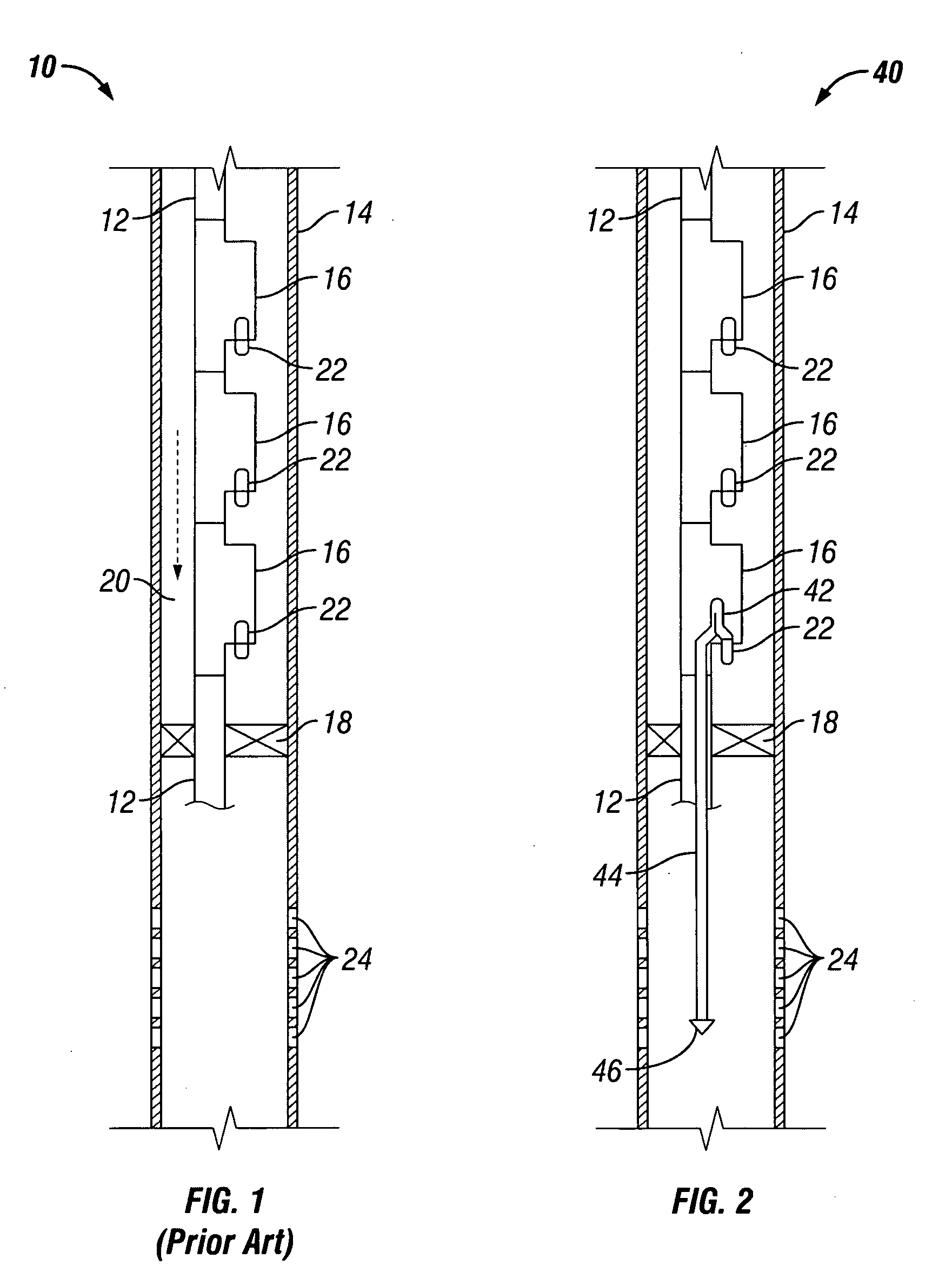

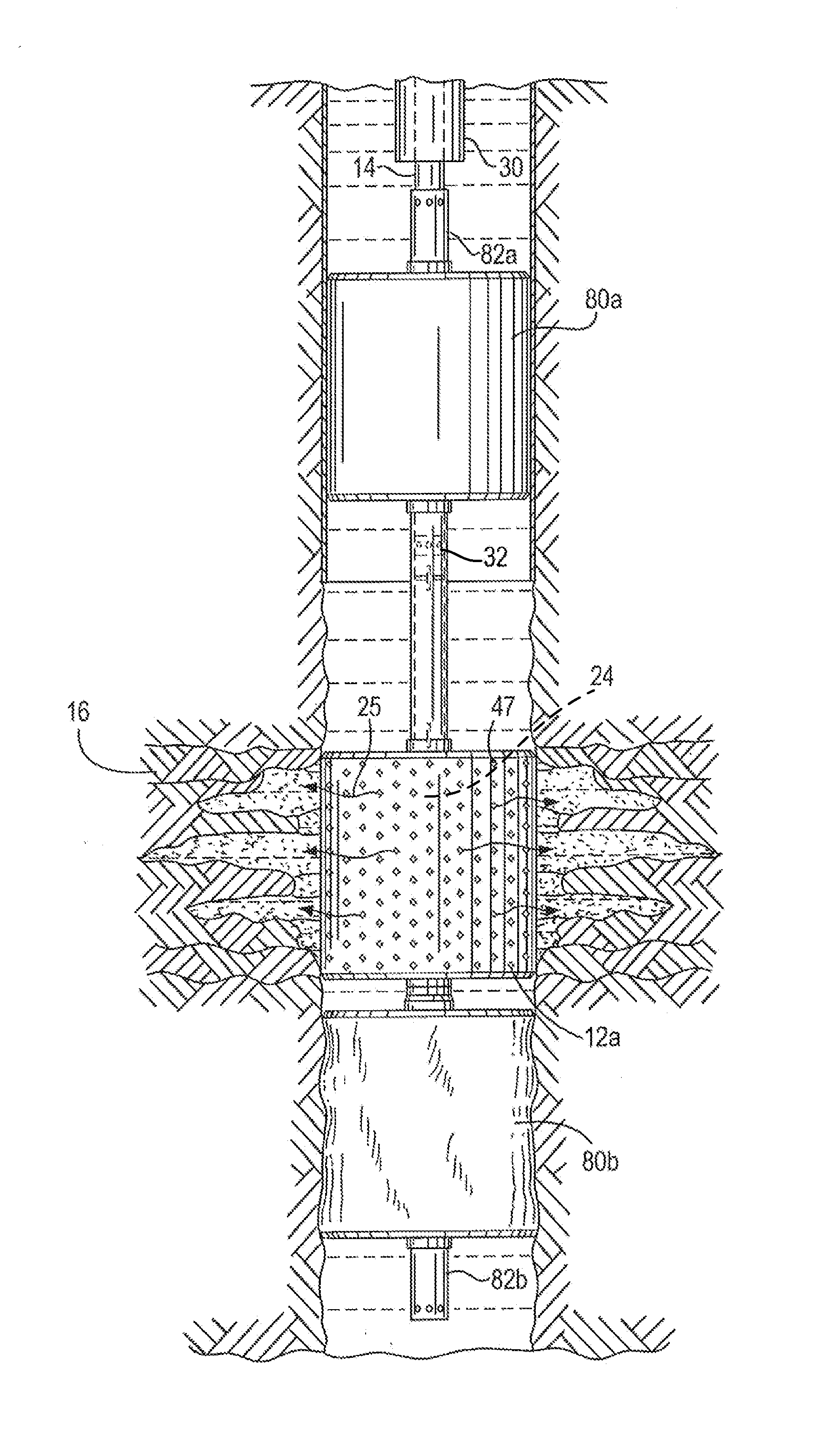

Use of downhole high pressure gas in a gas-lift well and associated methods

InactiveUS7147059B2Simplified installation procedureLow costNear-field transmissionSurveyElectrical conductorPetroleum product

A gas-lift petroleum well and method for producing petroleum products using downhole pressurized gas to provide lift. The gas-lift well having a well casing, a production tubing, a packer, and a gas-lift valve. The well casing extends within a wellbore of the well, and the wellbore extends through oil and gas zones. The production tubing extends within the casing. The tubing having an opening formed therein, which is in fluid communication with an oil zone. The packer is located downhole in the casing and coupled to the tubing. The packer can have an electrically controllable packer valve, which is adapted to control a flow of downhole pressurized gas from one side of the packer to another. The downhole pressurized gas is provided by a gas zone that the wellbore passes through. The downhole gas-lift valve is coupled to the tubing and is adapted to control a flow of downhole pressurized gas into oil in the tubing for lifting the oil. The gas-lift valve can be an electrically controllable valve. The tubing and casing are used as electrical conductors for supplying power and / or communications downhole. The current in the tubing is routed using a ferromagnetic induction choke to create a voltage potential, which provides electrical power to downhole electrical devices. Also, there may be a bypass passageway to route downhole gas to gas-lift valves. There may also be downhole sensors to measure physical quantities (e.g., pressure). Such measurements can be used for feedback control of downhole electrically controllable valves.

Owner:SHELL OIL CO

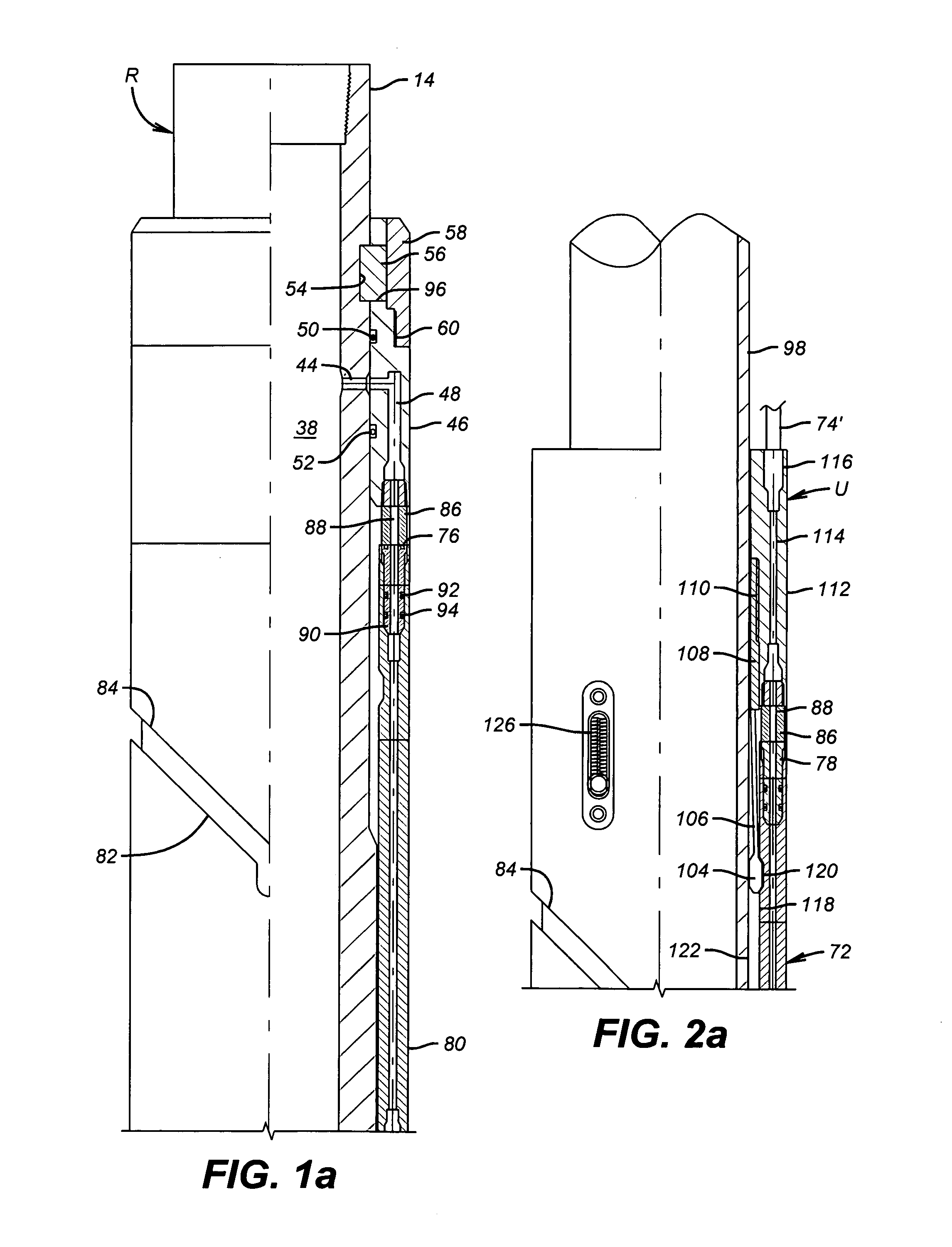

Arrangement for and method of restricting the inflow of formation water to a well

InactiveUS7185706B2Low mobilityNeutral buoyancyDrilling rodsFluid removalWater flowVolumetric Mass Density

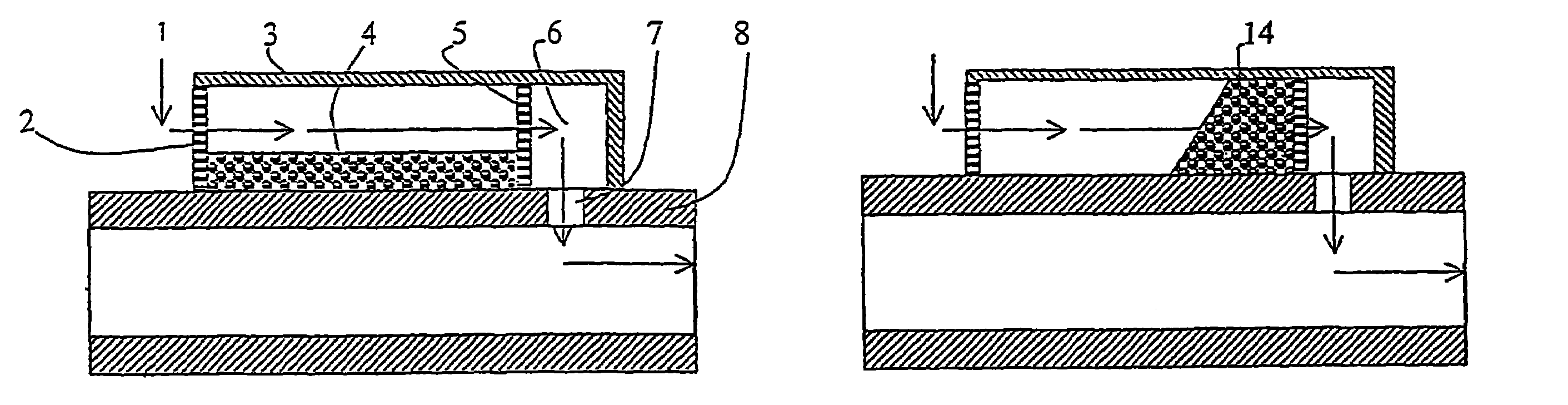

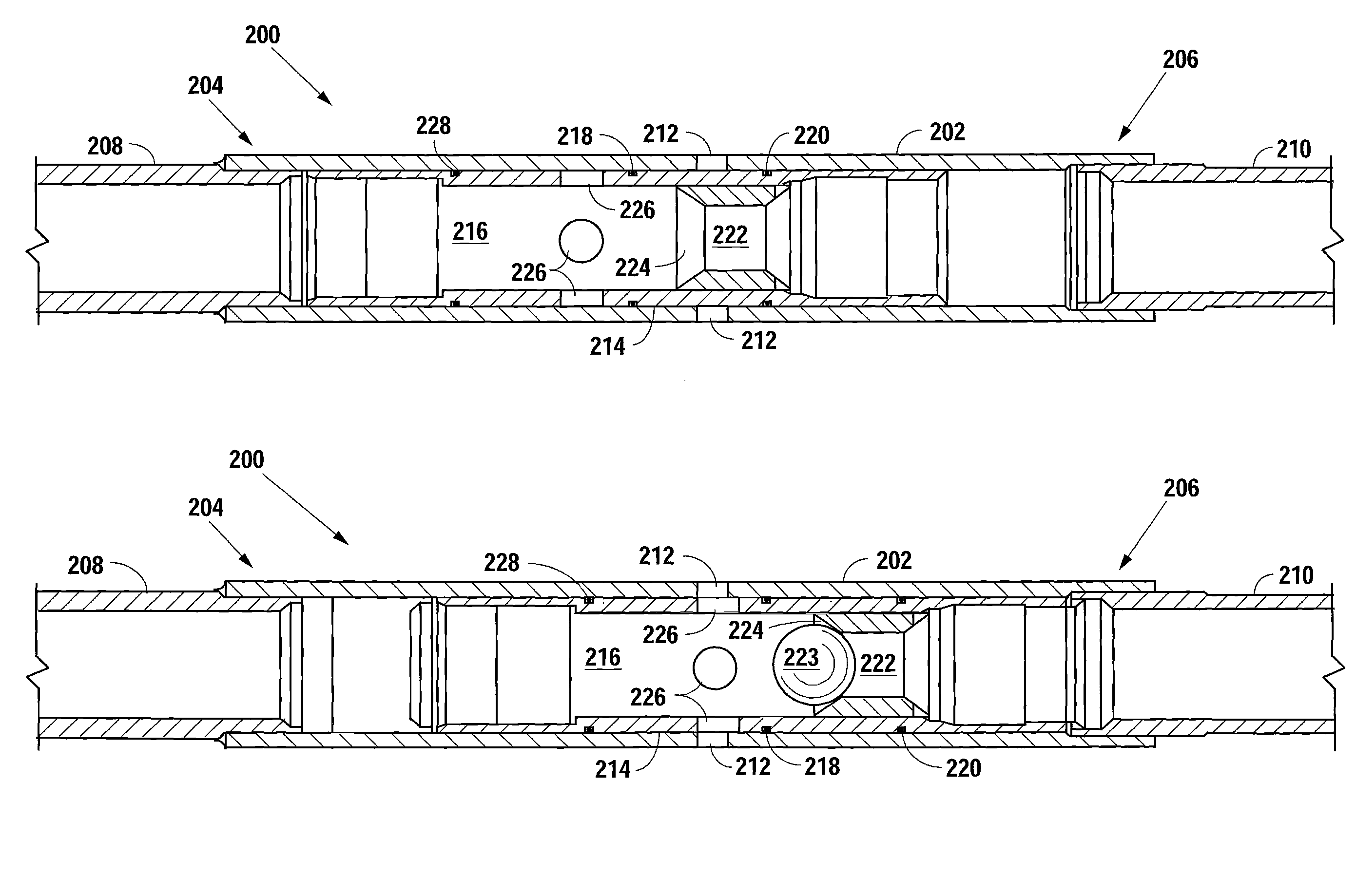

An arrangement for restricting the inflow of formation water from an underground formation to a hydrocarbon producing well, where, between the underground formation and a production tubing (38) located in the well, there is disposed at least one flow chamber (3, 33) connected to the production tubing (38), the flow chamber (3, 33), preferably via a filter (2) in one portion, being open to inflow of formation fluid and in communication with the production tubing (38) via at least one opening (7, 32), and where the flow chamber (3, 33) is provided with at least one free-floating body (4, 34) with approximately the same density as the formation water, the at least one body (4, 34) being designed by means of the closing of at least one opening (32) or choking, to reduce the inflow of formation water to the production tubing (38).

Owner:HALLIBURTON ENERGY SERVICES INC

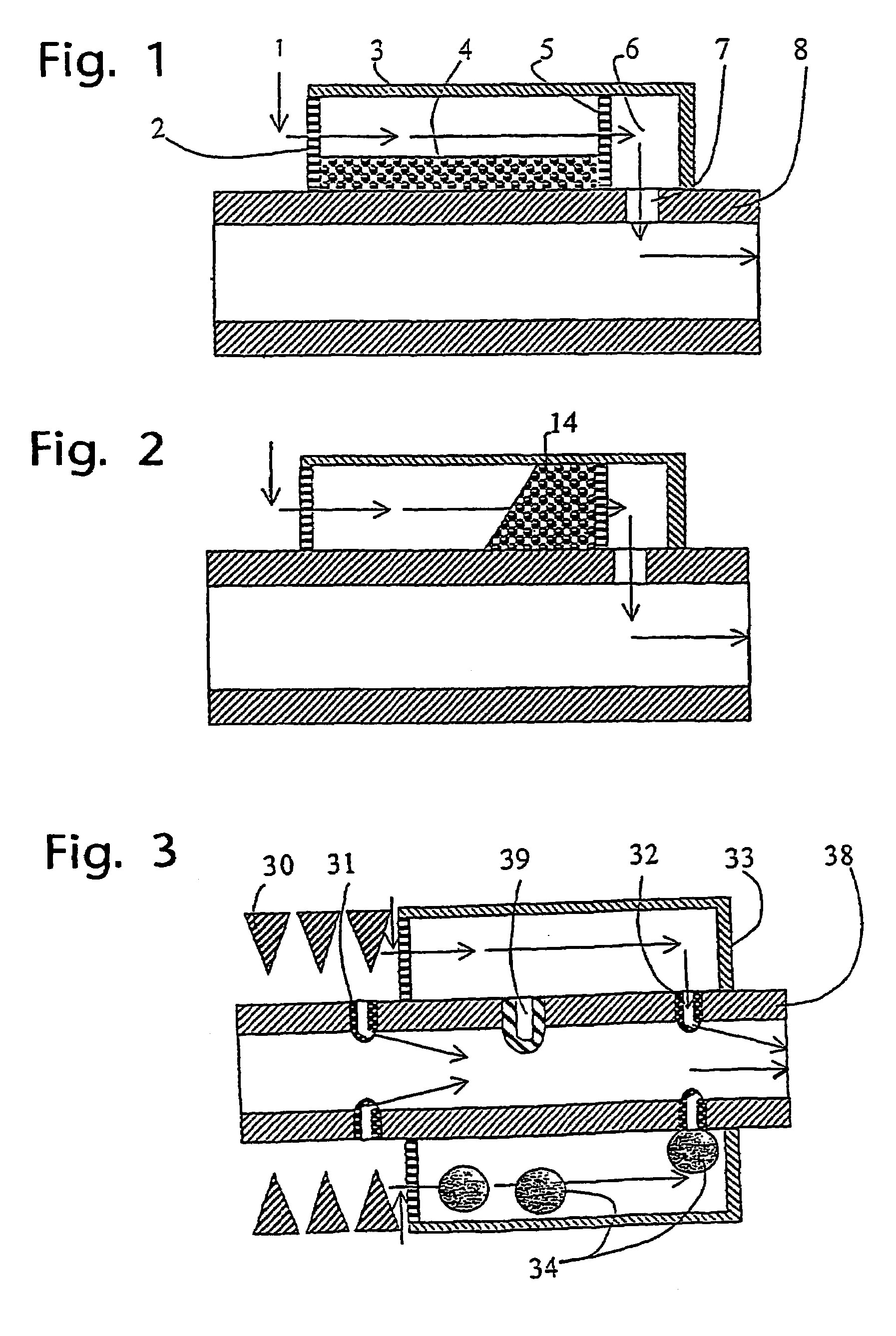

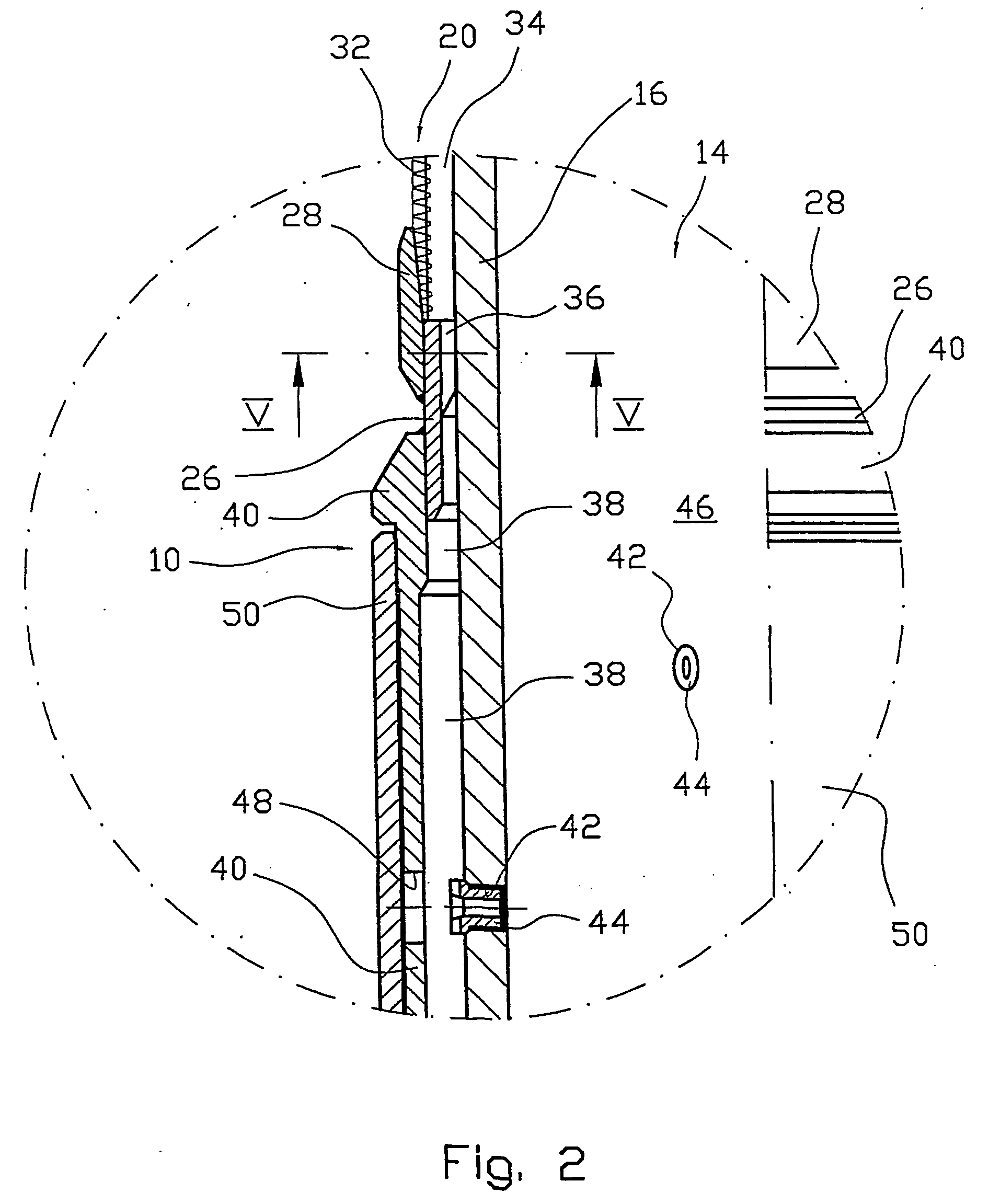

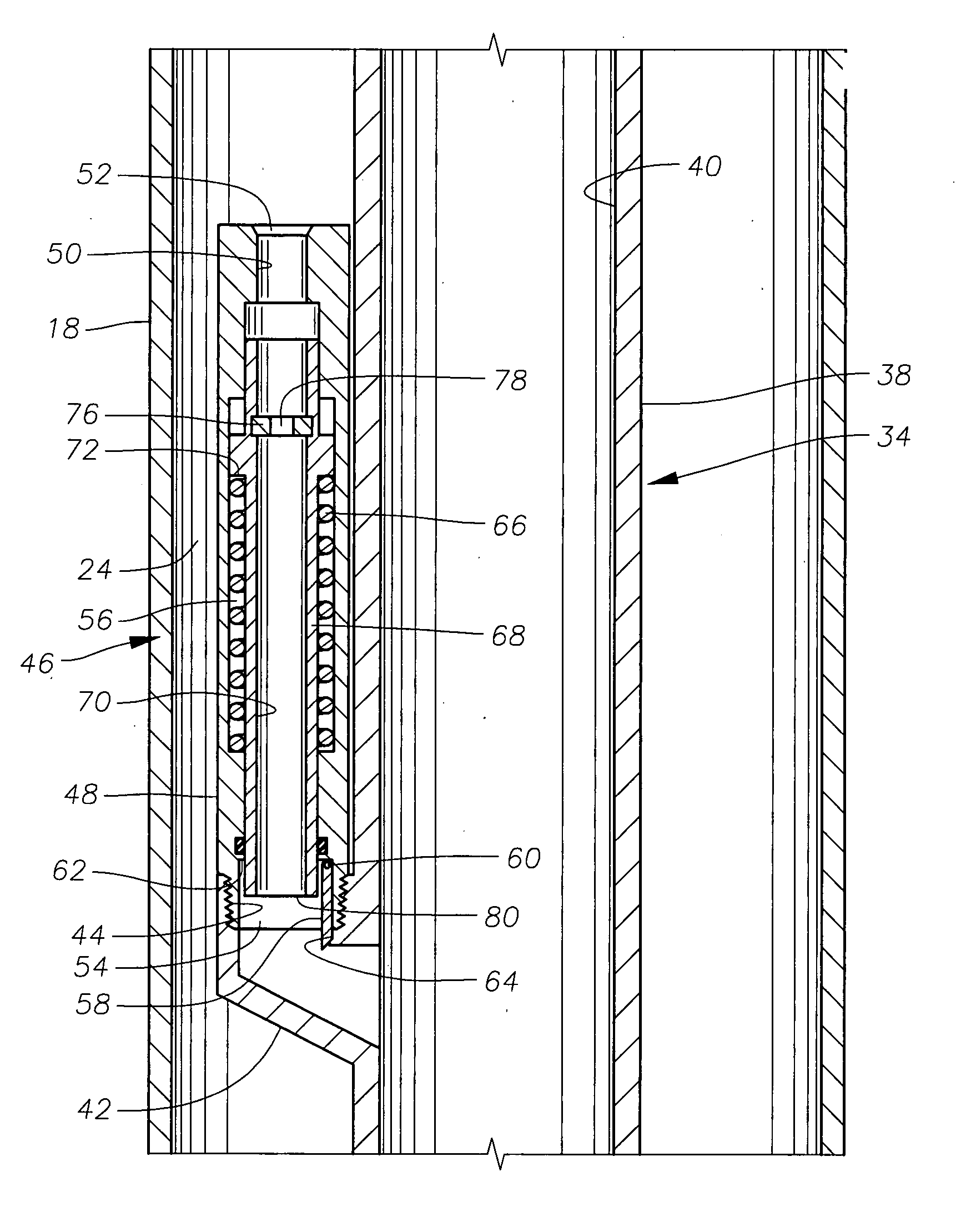

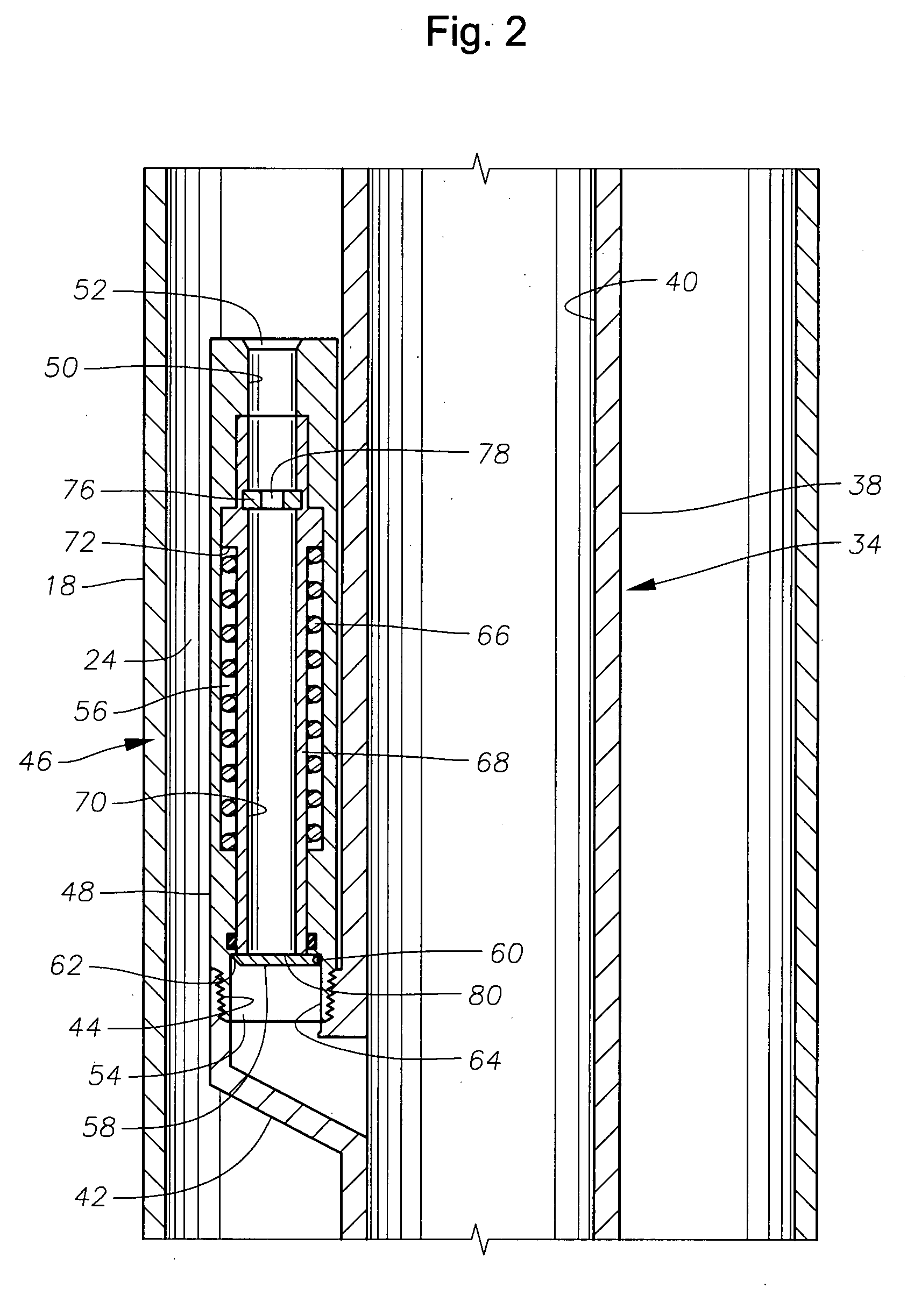

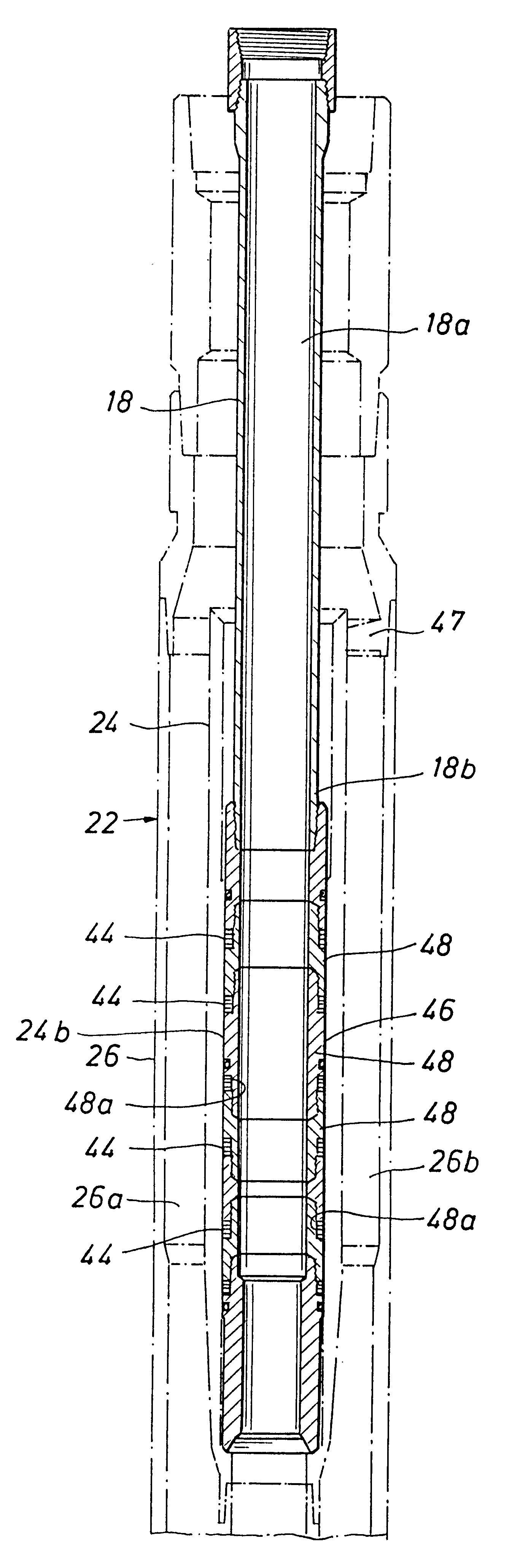

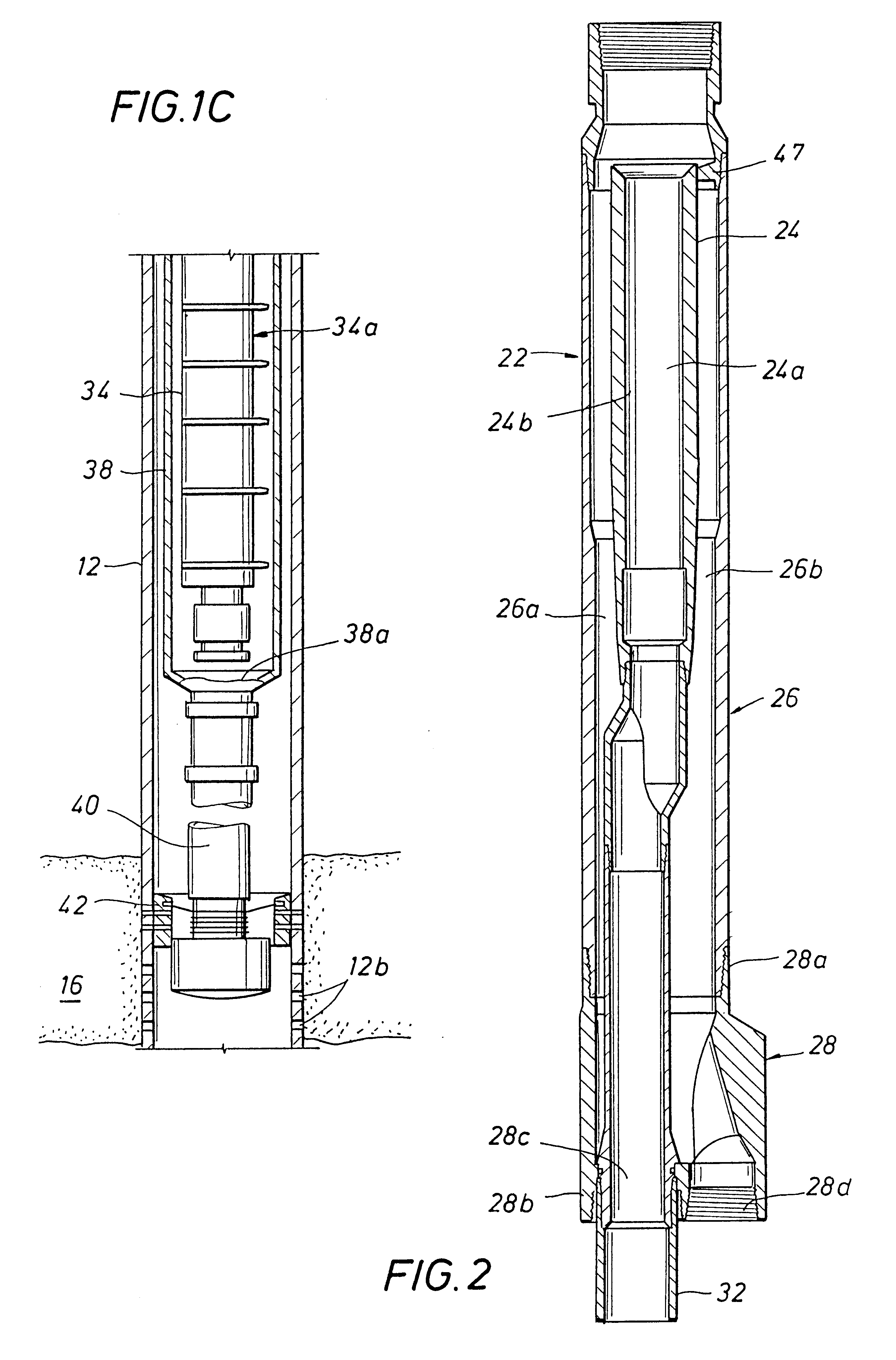

Well device for throttle regulation of inflowing fluids

A flow arrangement (10, 12) for use in a well through one or more underground reservoirs, and where the arrangement (10, 12) is designed to throttle radially inflowing reservoir fluids produced through an inflow portion of the production tubing in the well, the production tubing in and along this inflow portion being provided with one or more arrangements (10, 12). Such an arrangement (10, 12) is designed to effect a relatively stable and predictable fluid pressure drop at any stable fluid flow rate in the course of the production period of the well, and where said fluid pressure drop will exhibit the smallest possible degree of susceptibility to influence by differences in the viscosity and / or any changes in the viscosity of the inflowing reservoir fluids during the production period. Such a fluid pressure drop is obtained by the arrangement (10, 12) comprising among other things one or more short, removable and replaceable flow restrictions such as nozzle inserts (44, 62), and where the individual flow restriction may be given the desired cross section of flow, through which reservoir fluids may flow and be throttled, or the flow restriction may be a sealing plug.

Owner:RESLINK

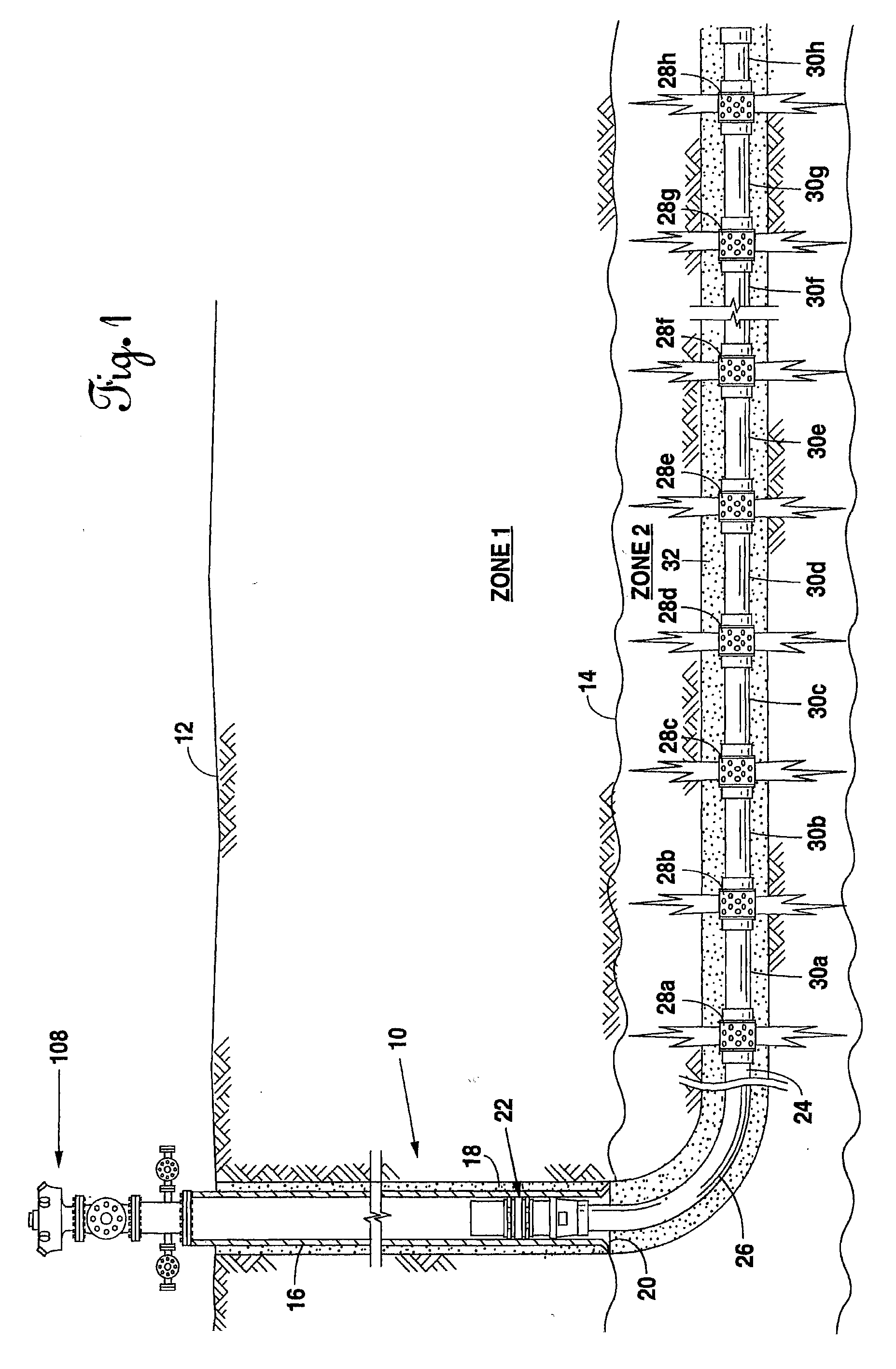

Cemented open hole selective fracing system

A cemented open hole selective fracing system is shown. In the producing zone, an open hole is drilled therein and a production tubing is cemented in place. At preselected locations along the production tubing, the production tubing will have sliding valves located there along. The sliding valves may be selectively opened by a shifting tool, and the cement around the sliding valve dissolved. Thereafter, the formation may be fraced immediately adjacent the opened sliding valve. By selectively opening different combinations of sliding valves, fracing can occur in stages with more fracing pressure and more fracing fluid being delivered deeper into the formation. Just as the sliding valves can be selectively opened with a switching tool, the sliding valves can also be selectively closed to protect the production of the well.

Owner:PEAK COMPLETIONS TECH INC

Flow control device for choking inflowing fluids in a well

A flow arrangement (10, 12) for use in a well through one or more underground reservoirs, and where the arrangement (10, 12) is designed to throttle radially inflowing reservoir fluids produced through an inflow portion of the production tubing in the well, the production tubing in and along this inflow portion being provided with one or more arrangements (10, 12) Such an arrangement (10, 12) is designed to effect a relatively stable and predictable fluid pressure drop at any stable fluid flow rate in the course of the production period of the well, and where said fluid pressure drop will exhibit the smallest possible degree of susceptibility to influence by differences in the viscosity and / or any changes in the viscosity of the inflowing reservoir fluids during the production period. Such a fluid pressure drop is obtained by the arrangement (10, 12) comprising among other things one or more short, removable and replaceable flow restrictions such as nozzle inserts (44, 62), and where the individual flow restriction may be given the desired cross section of flow, through which reservoir fluids may flow and be throttled, or the flow restriction may be a sealing plug.

Owner:RESLINK

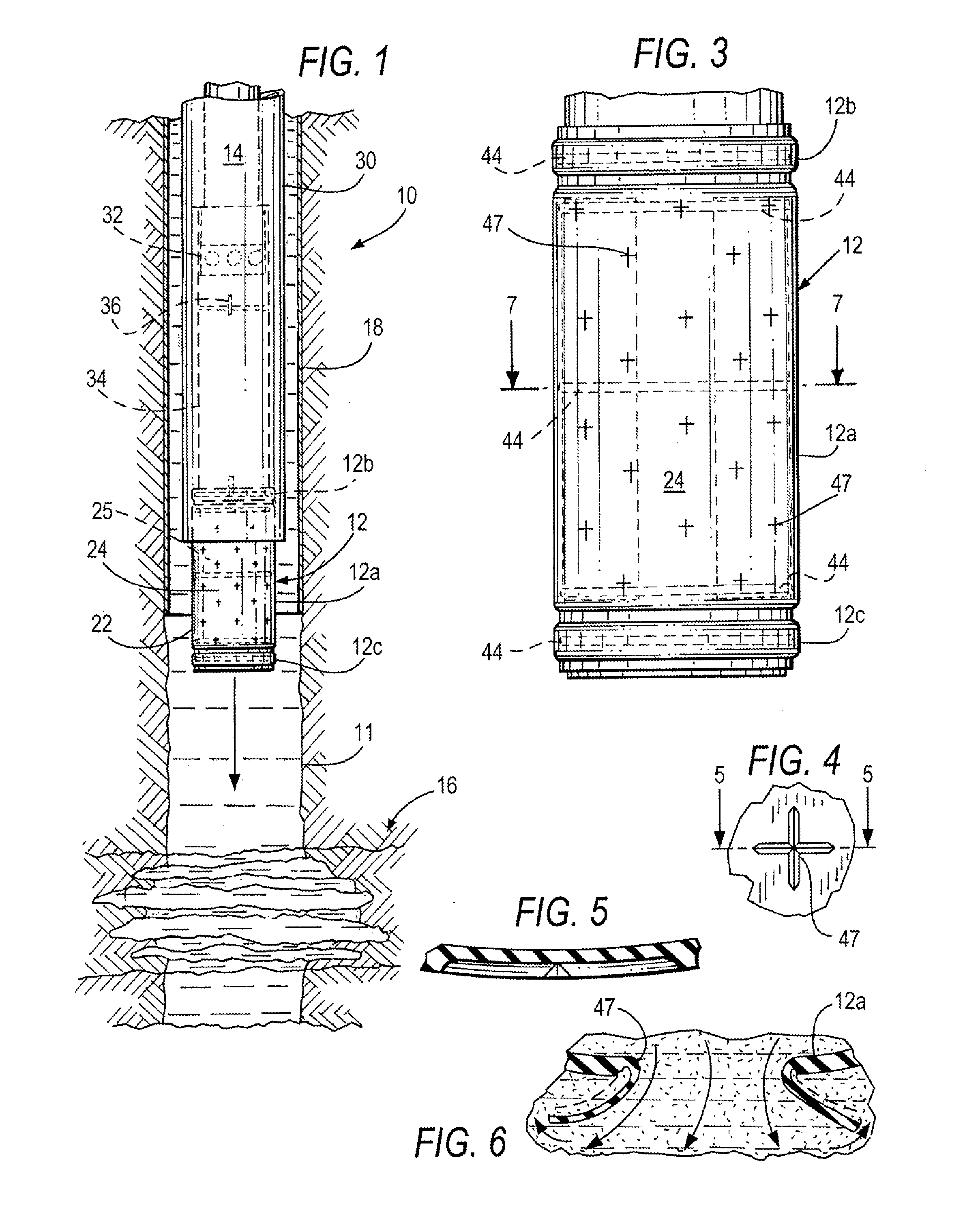

Inflow control device

An inflow control device is disclosed for use in controlling the flow of fluid into a production tubing in a subterranean wellbore. The device is especially adapted for use with sand screen apparatus, but is modular in that it is manufactured separately from the sand screen apparatus. An inflow control device according to the present invention contains an orifice having an opening which is adjustable in size and which is disposed in the device to permit communication of fluid from one end of the body to the other. An inflow control device according to the present invention may be utilized with multiple sand screen assemblies.

Owner:SCHLUMBERGER TECH CORP

Cemented Open Hole Selective Fracing System

A cemented open hole selective fracing system and method are shown. In the producing zone, an open hole is drilled therein and a production tubing is cemented in place. At preselected locations along the production tubing, the production tubing will have sliding valves located there along. The sliding valves may be selectively opened, and the cement around the sliding valve dissolved. Thereafter, the formation may be fraced immediately adjacent the opened sliding valve. By selectively opening different combinations of sliding valves, fracing can occur in stages with more fracing pressure and more fracing fluid being delivered deeper into the formation. Just as the sliding valves can be selectively opened, the sliding valves can also be selectively closed to protect the production of the well.

Owner:PEAK COMPLETION TECH

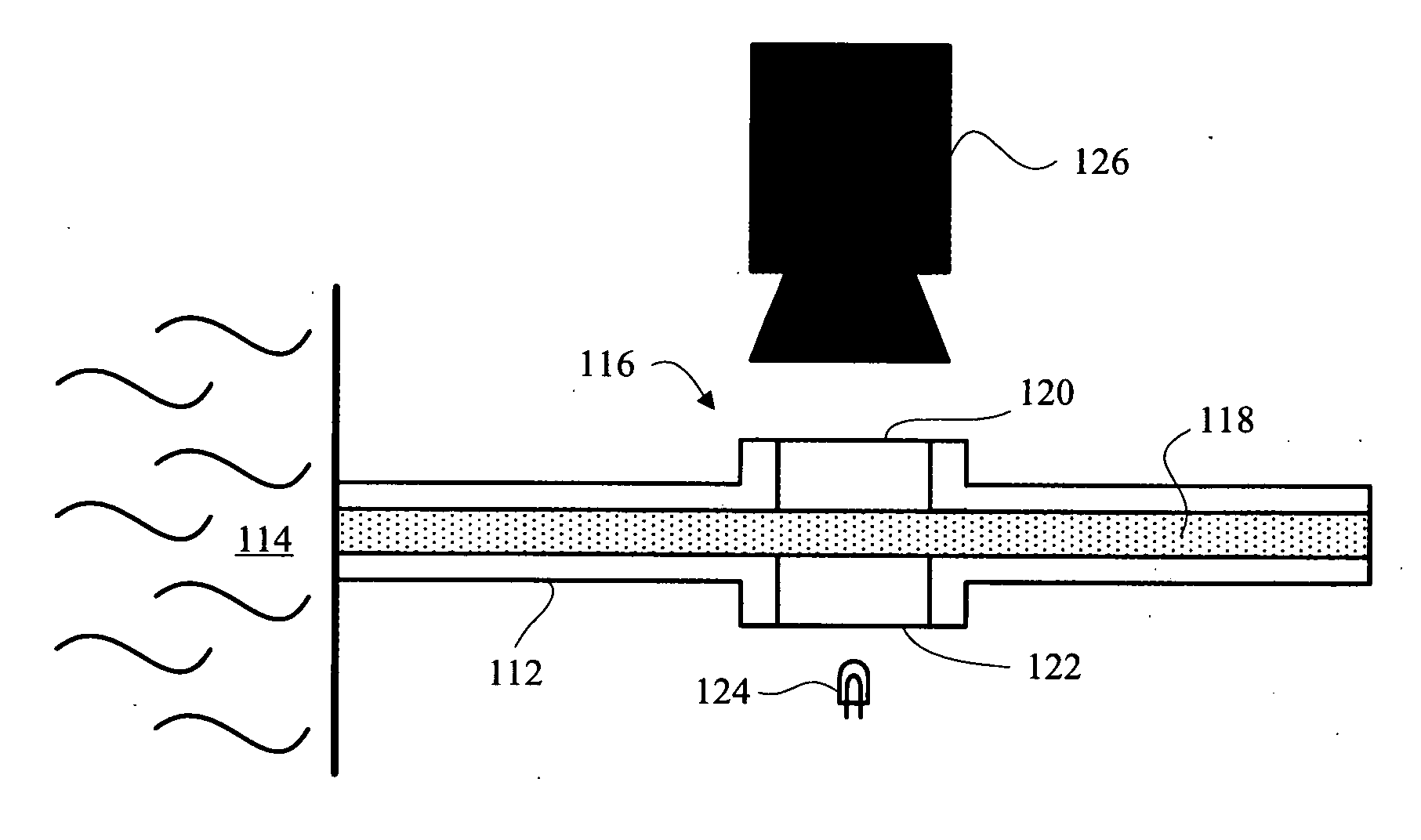

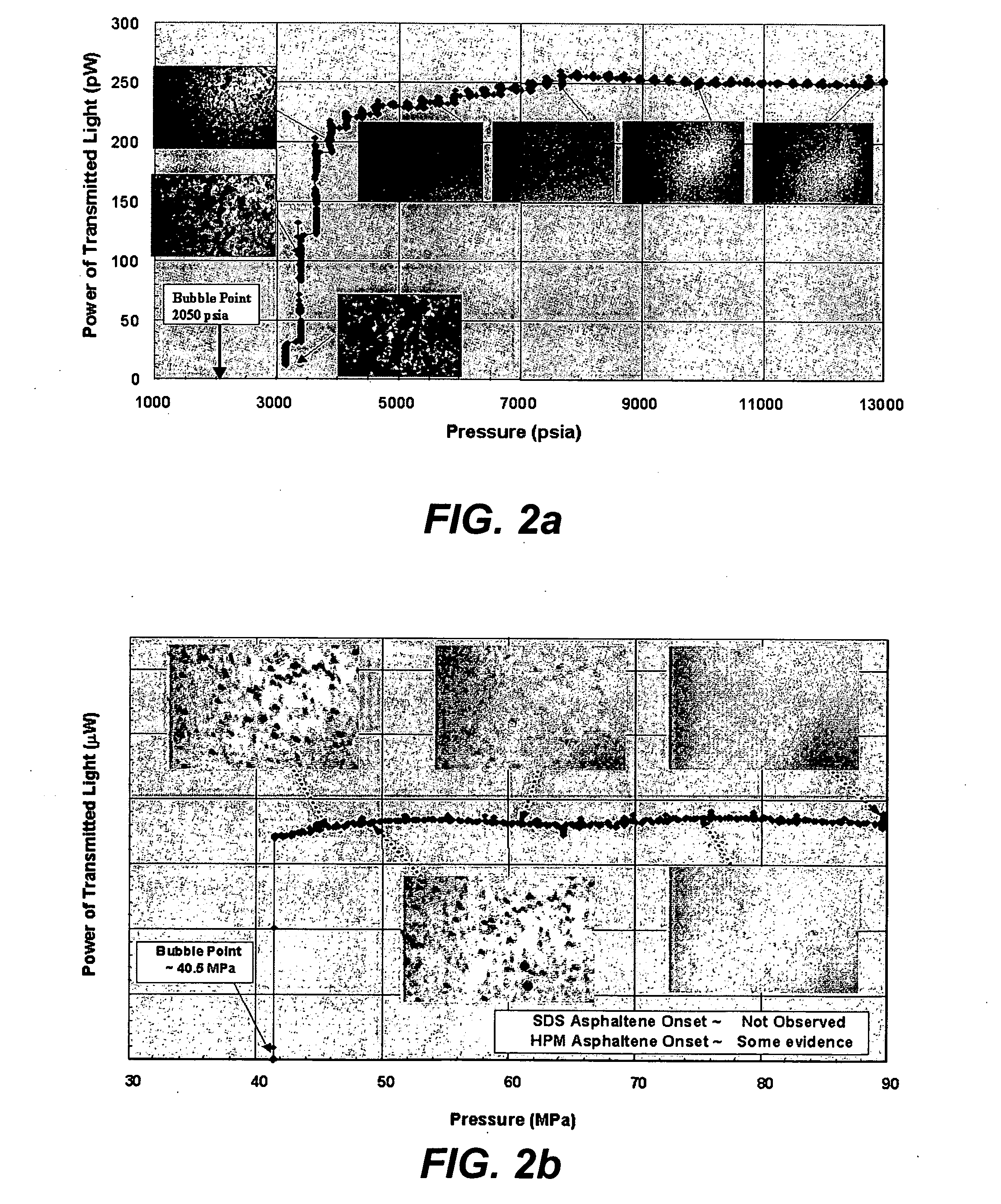

Spectral imaging for downhole fluid characterization

ActiveUS20070035736A1Reduce pressureConstructionsInvestigating moving fluids/granular solidsOcean bottomLine tubing

The present invention contemplates implementation of transitory downhole video imaging and / or spectral imaging for the characterization of formation fluid samples in situ, as well as during flow through production tubing, including subsea flow lines, for permanent and / or long term installations. The present invention contemplates various methods and apparatus that facilitate one-time or ongoing downhole fluid characterization by video analysis in real time. The methods and systems may be particularly well suited to permanent and periodic intervention-based operations.

Owner:SCHLUMBERGER TECH CORP

Casing hanger assembly with rupture disk in support housing and method

A casing hanger support assembly supports an inner casing string within a well containing an outer casing string and a production tubing string. The casing hanger support housing supports the casing hanger in the well, with a casing hanger being secured to an upper end of the inner casing string. One or more of a rupture disk and a blowout plug are provided in a wall of the casing hanger support housing for maintaining the desired pressure differential between an annulus within the outer casing string and an annulus exterior of the outer casing string, thereby preventing casing collapse or burst.

Owner:DRIL QUIP

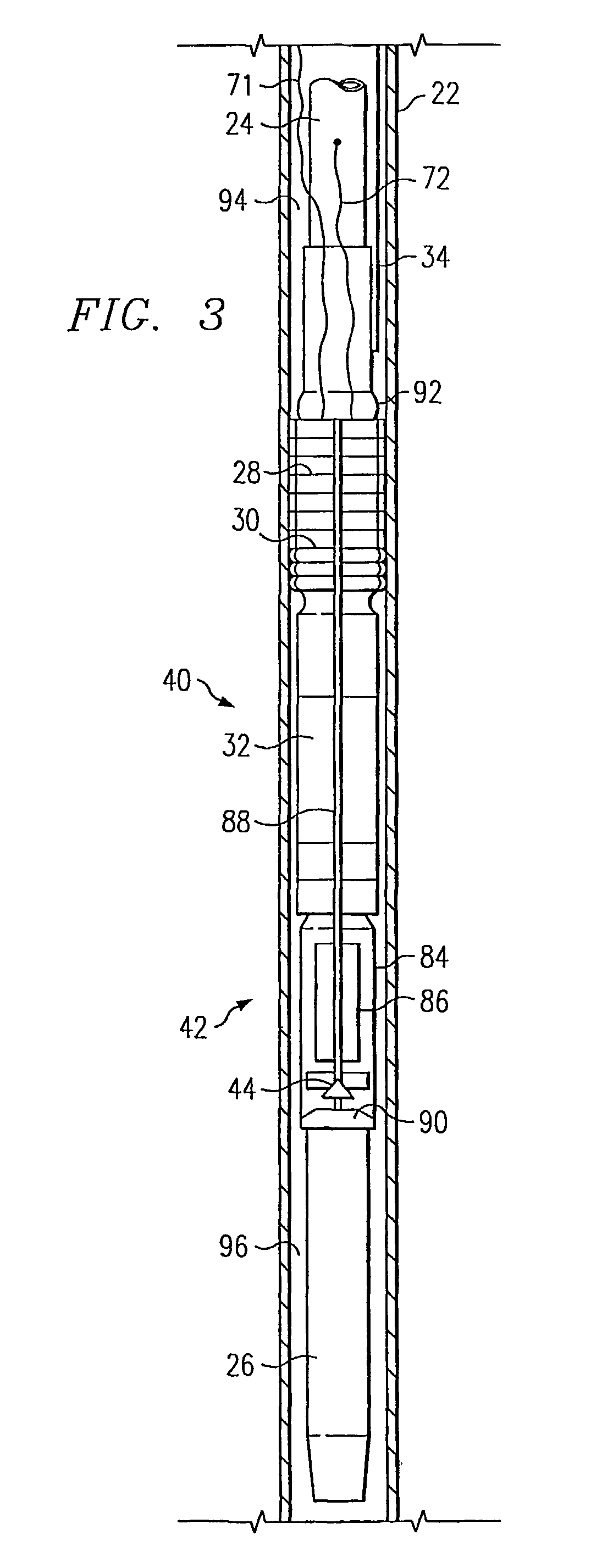

Method and device for downhole flow rate control

InactiveUS6273194B1Extend your lifeImprove reliabilityFluid removalWell/borehole valve arrangementsCouplingActuator

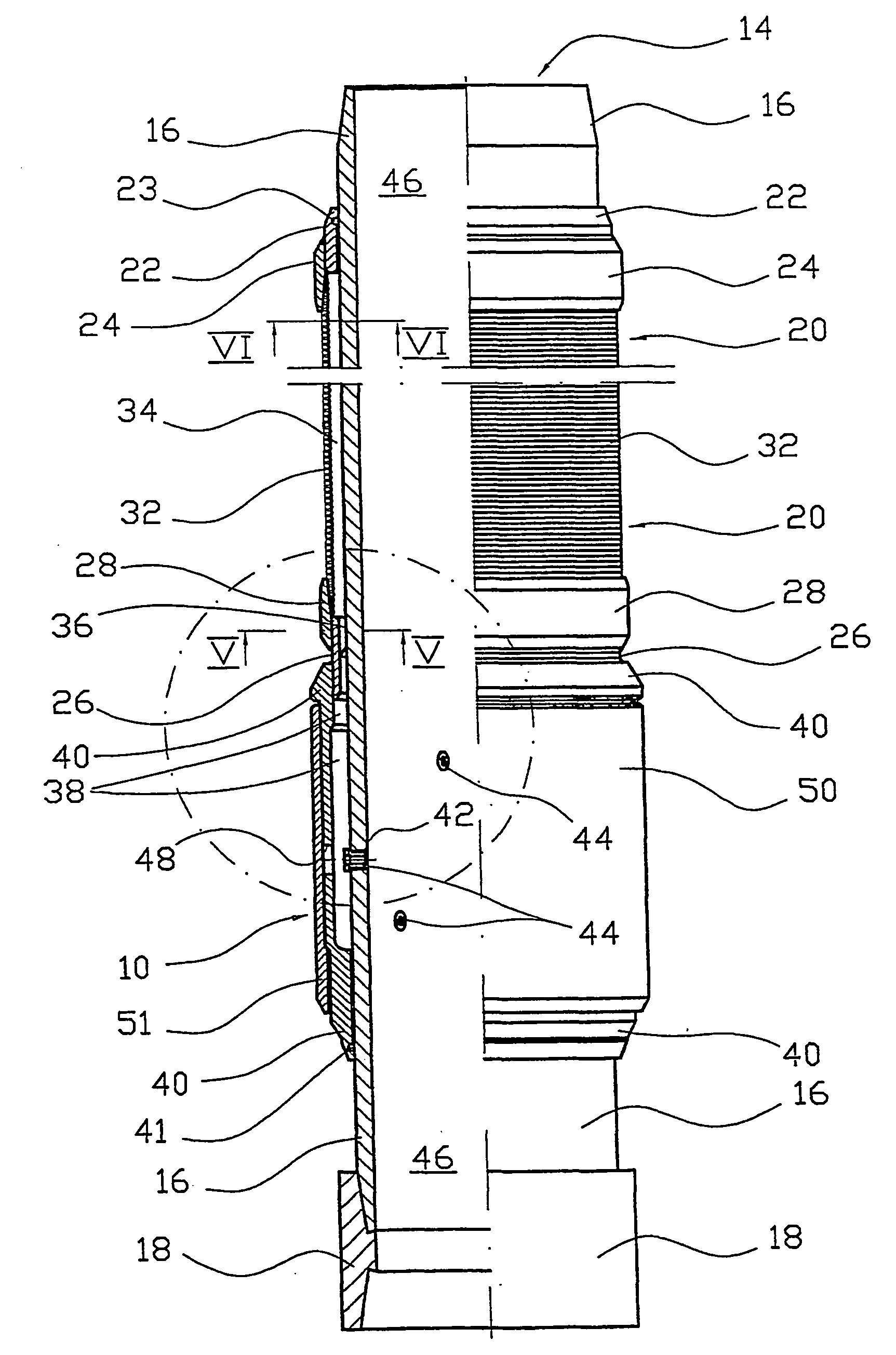

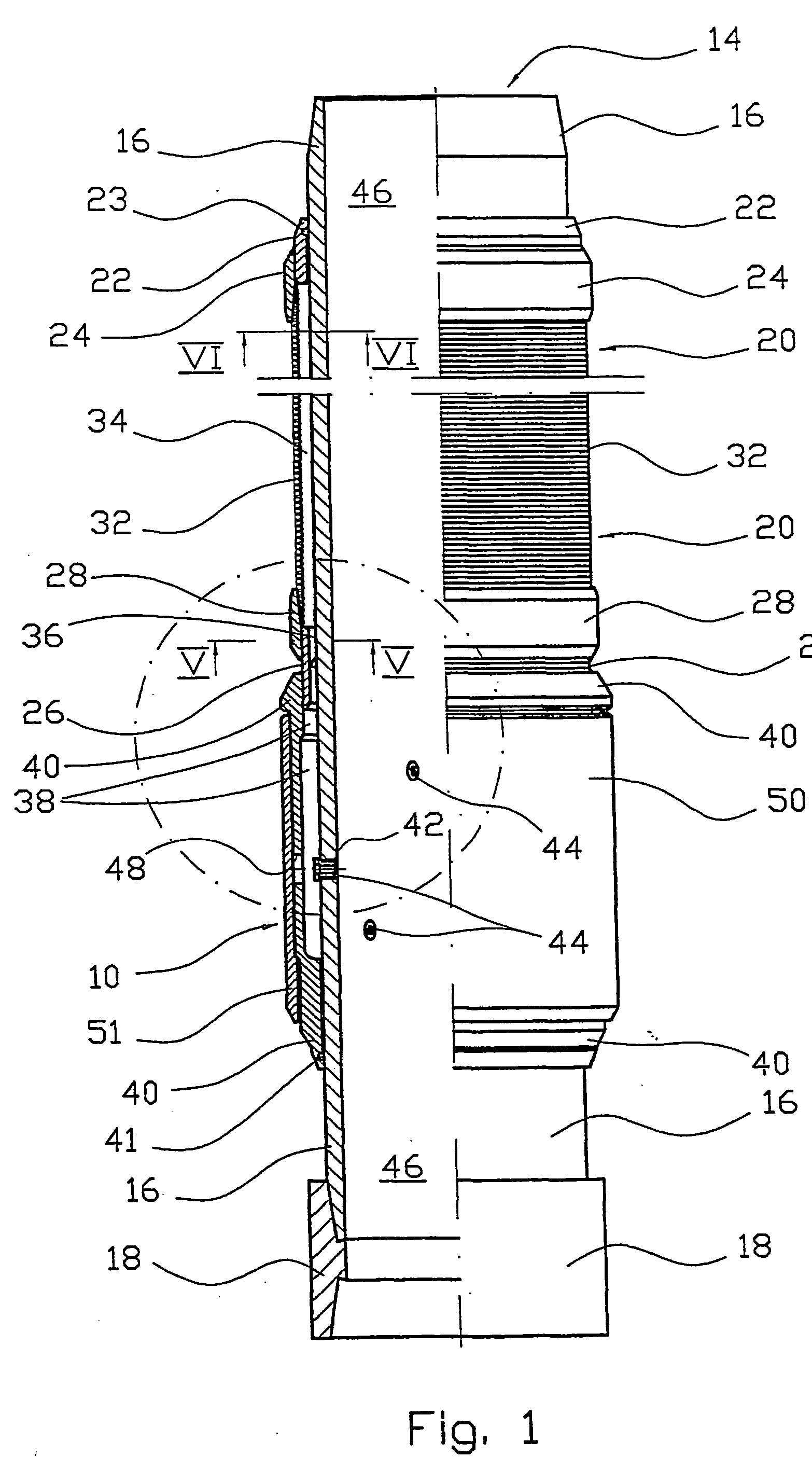

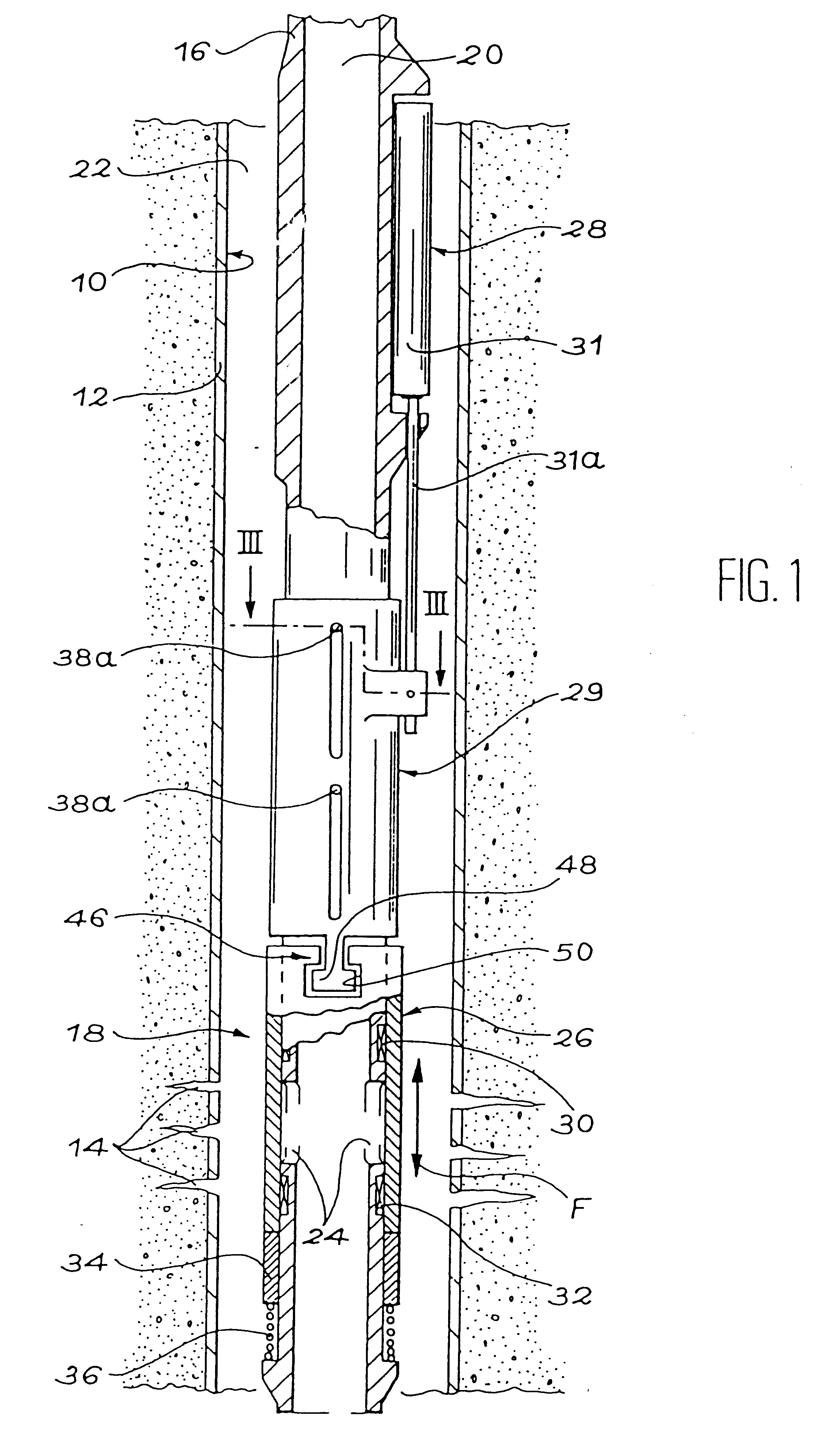

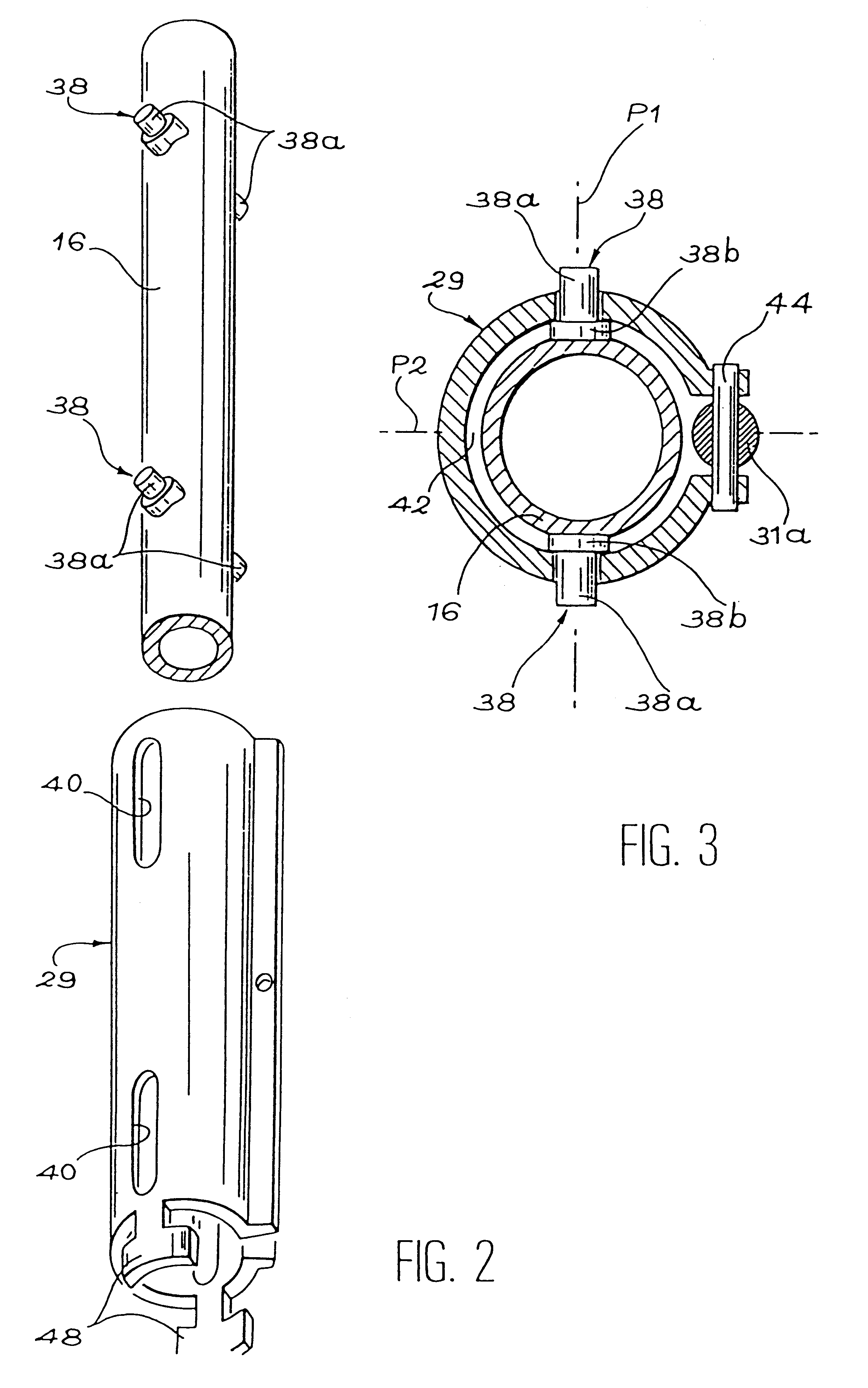

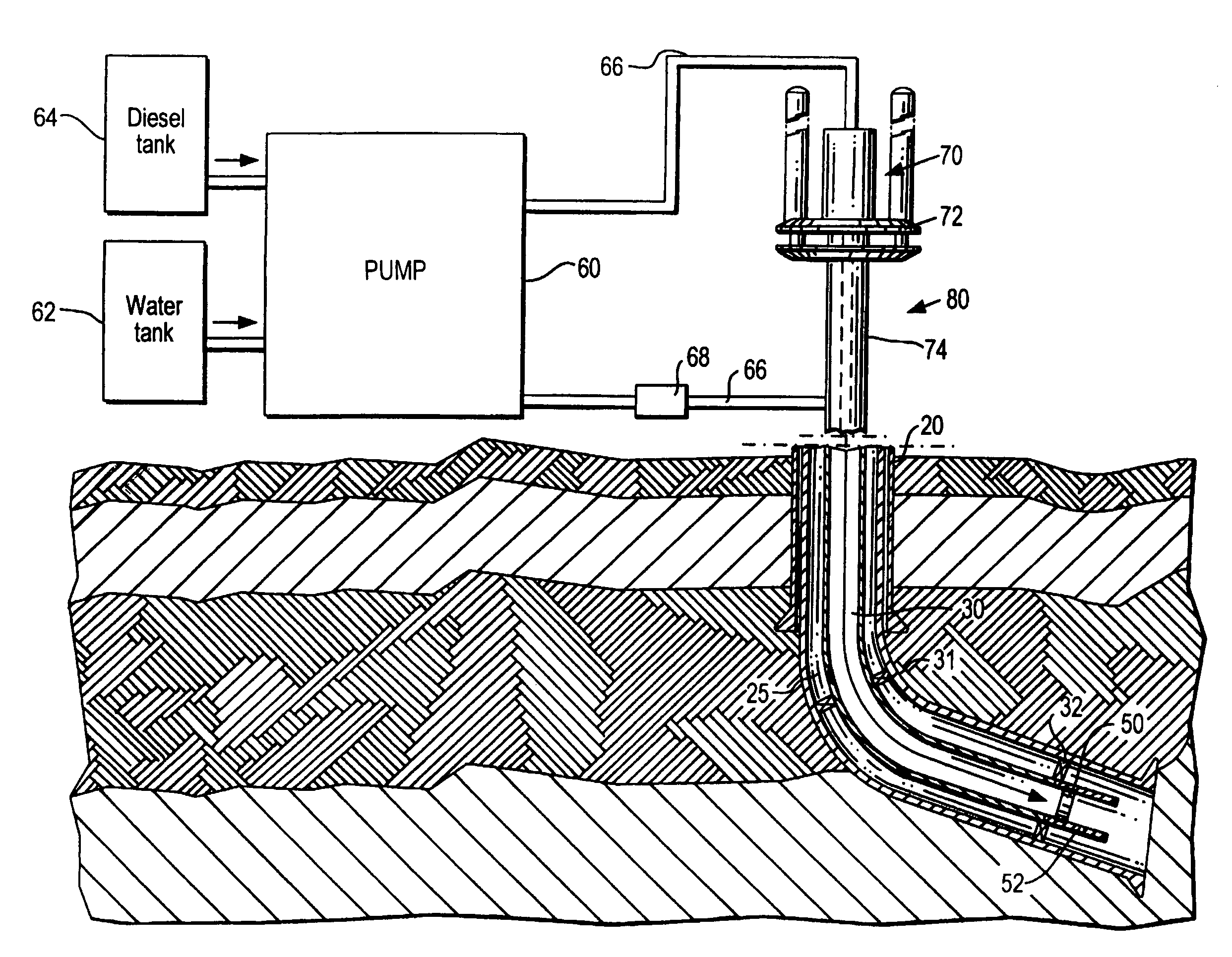

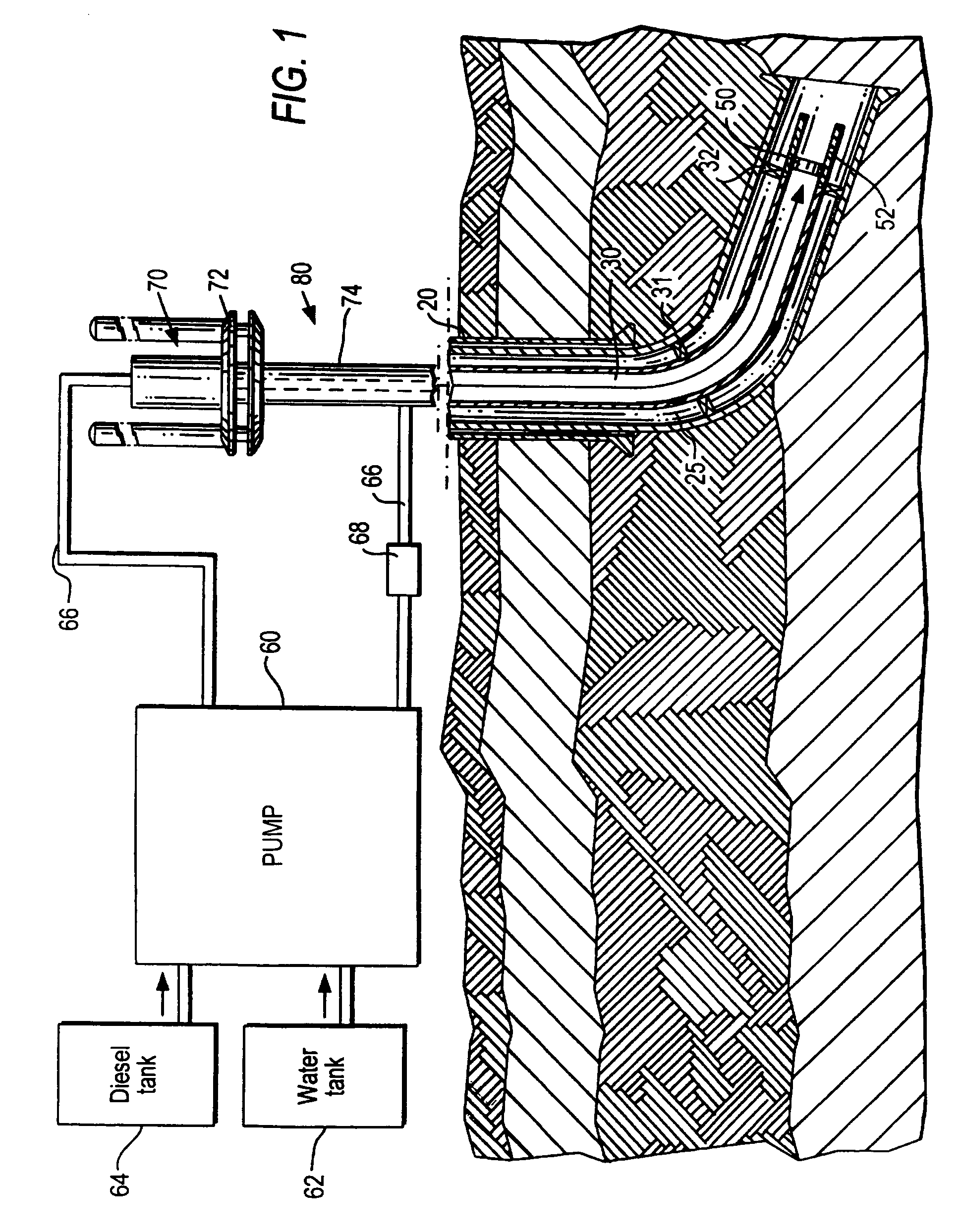

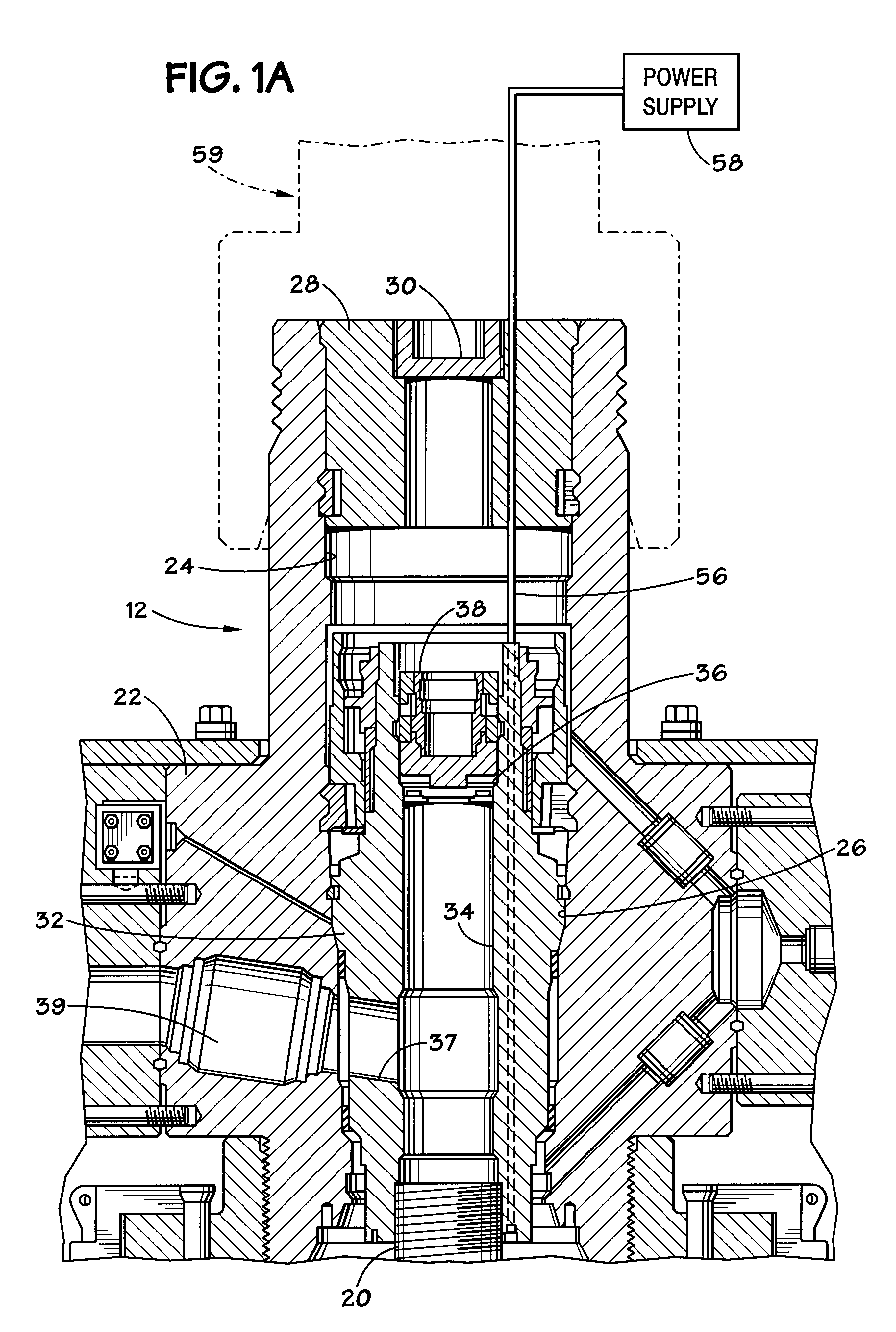

A flow rate control device (18) placed down an oil well in production comprises holes (24) formed in the production tubing (16), a closure sleeve (26) suitable for sliding facing the holes (24), an actuator (31) disposed eccentrically relative to the tubing (16), and an intermediate part (29). The intermediate part (29) is guided on the tubing (16) in a manner such as to withstand the tilting torque due to the eccentricity of the actuator (31). A coupling (46) that is flexible except in the direction in which the sleeve is moved connects the part (29) to the closure sleeve (26) symmetrically about the axis of the tubing (16). The resulting decoupling guarantees that the sleeve (26) is self-centering, which improves the life-span of the device (18) significantly.

Owner:SCHLUMBERGER TECH CORP

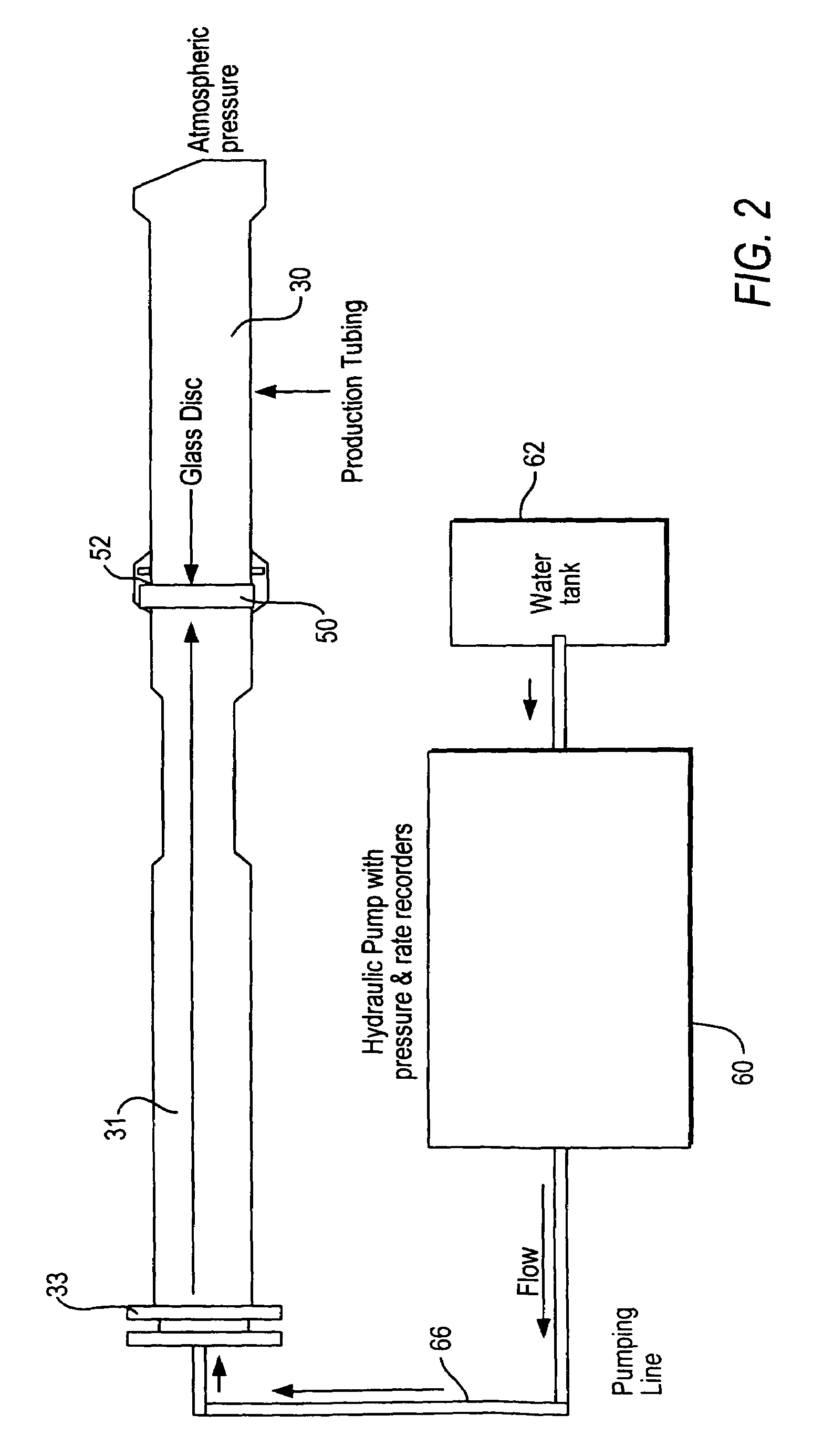

Method for hydraulic rupturing of downhole glass disc

A method for rupturing a glass disc in a well completion tool located downhole in a section of production tubing includes providing a wellhead isolation tool, or tree saver, to isolate the wellhead Christmas tree, adding a pressurized fluid to the tubing / casing annulus and pumping a disc rupturing fluid into the production tubing via the tree saver until the disc is ruptured. Following rupture, the pump can be rapidly stopped, or slowed, and started to create a water hammer effect that removes any glass shards remaining in the disc holder.

Owner:SAUDI ARABIAN OIL CO

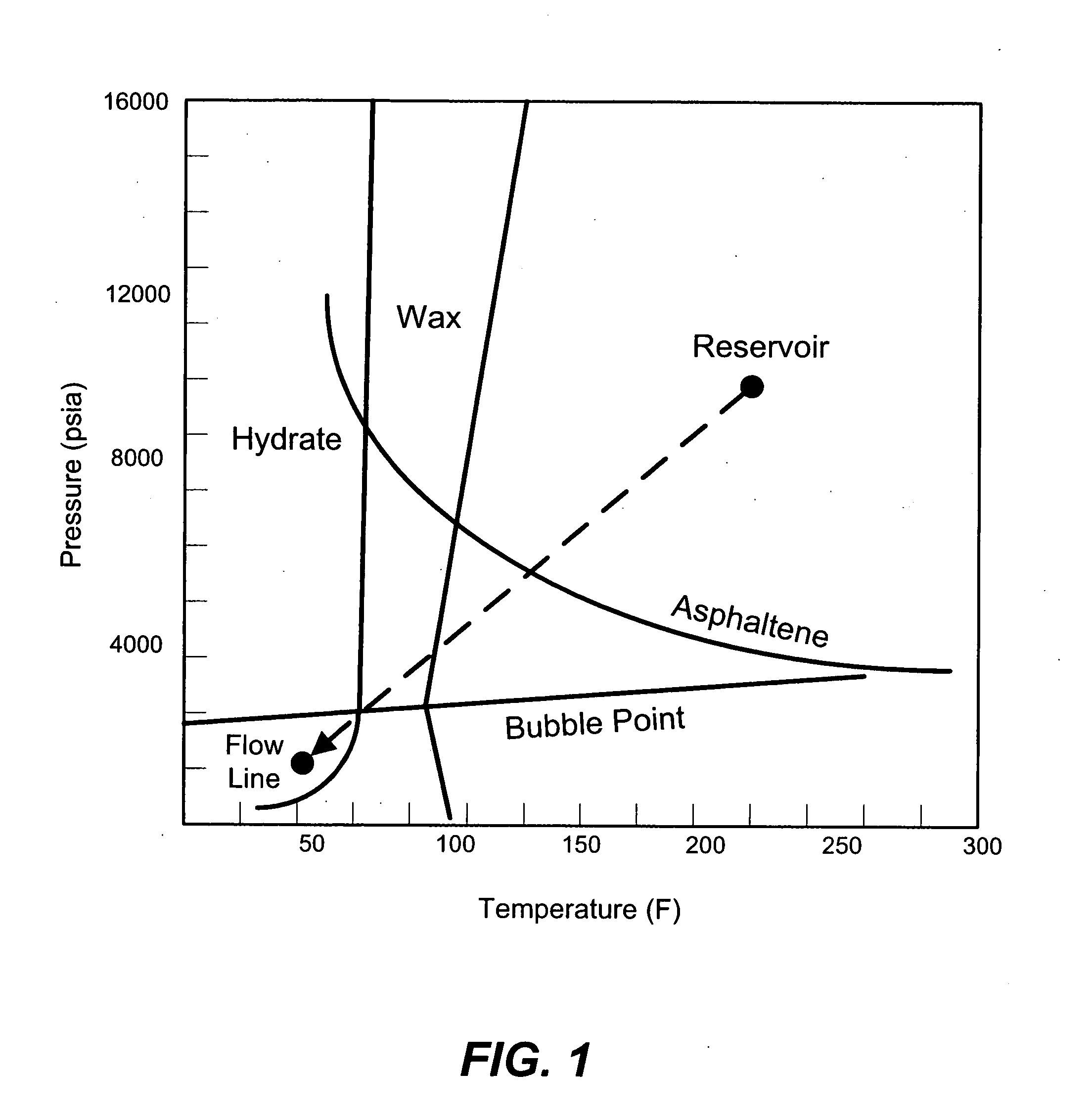

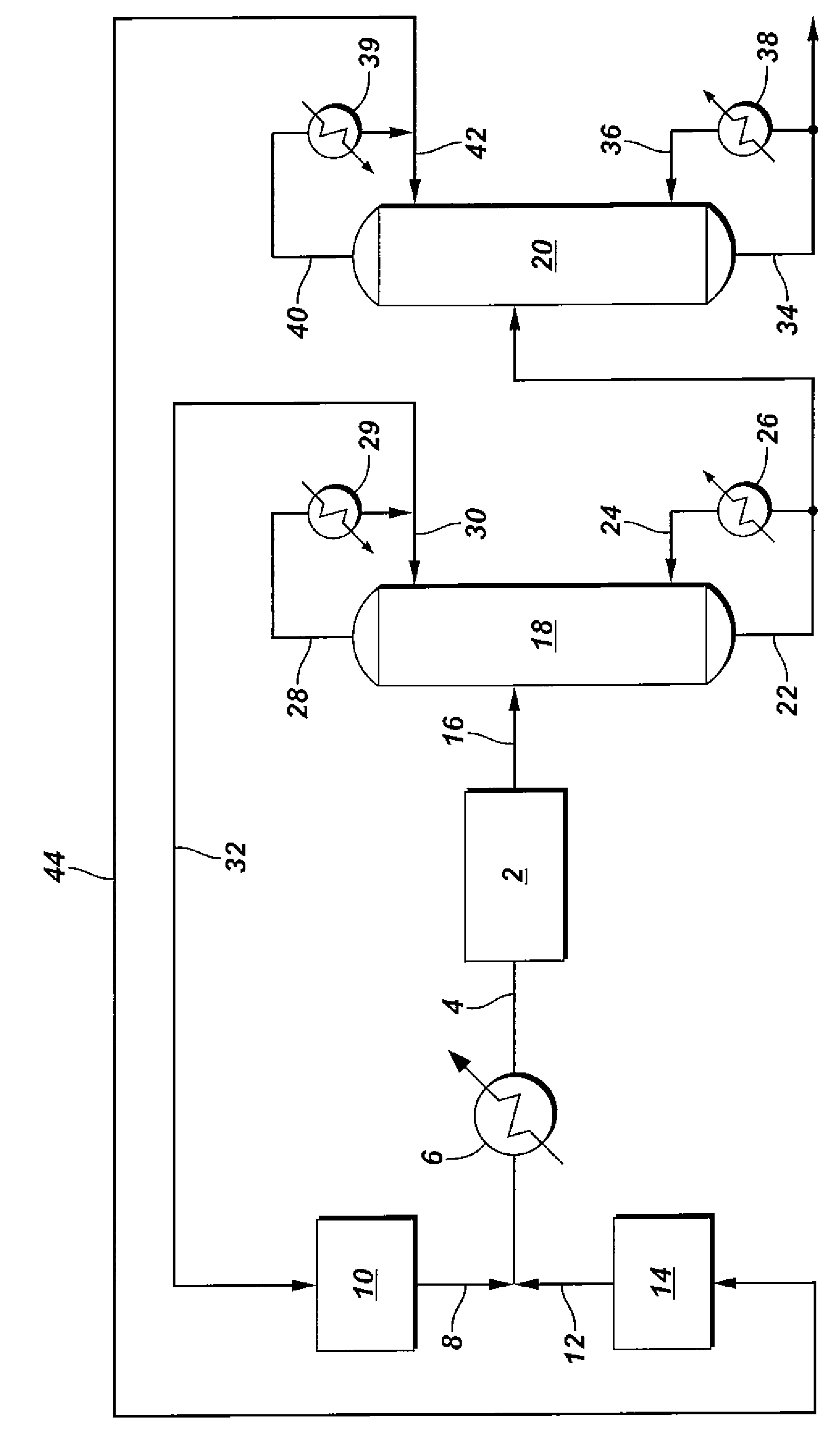

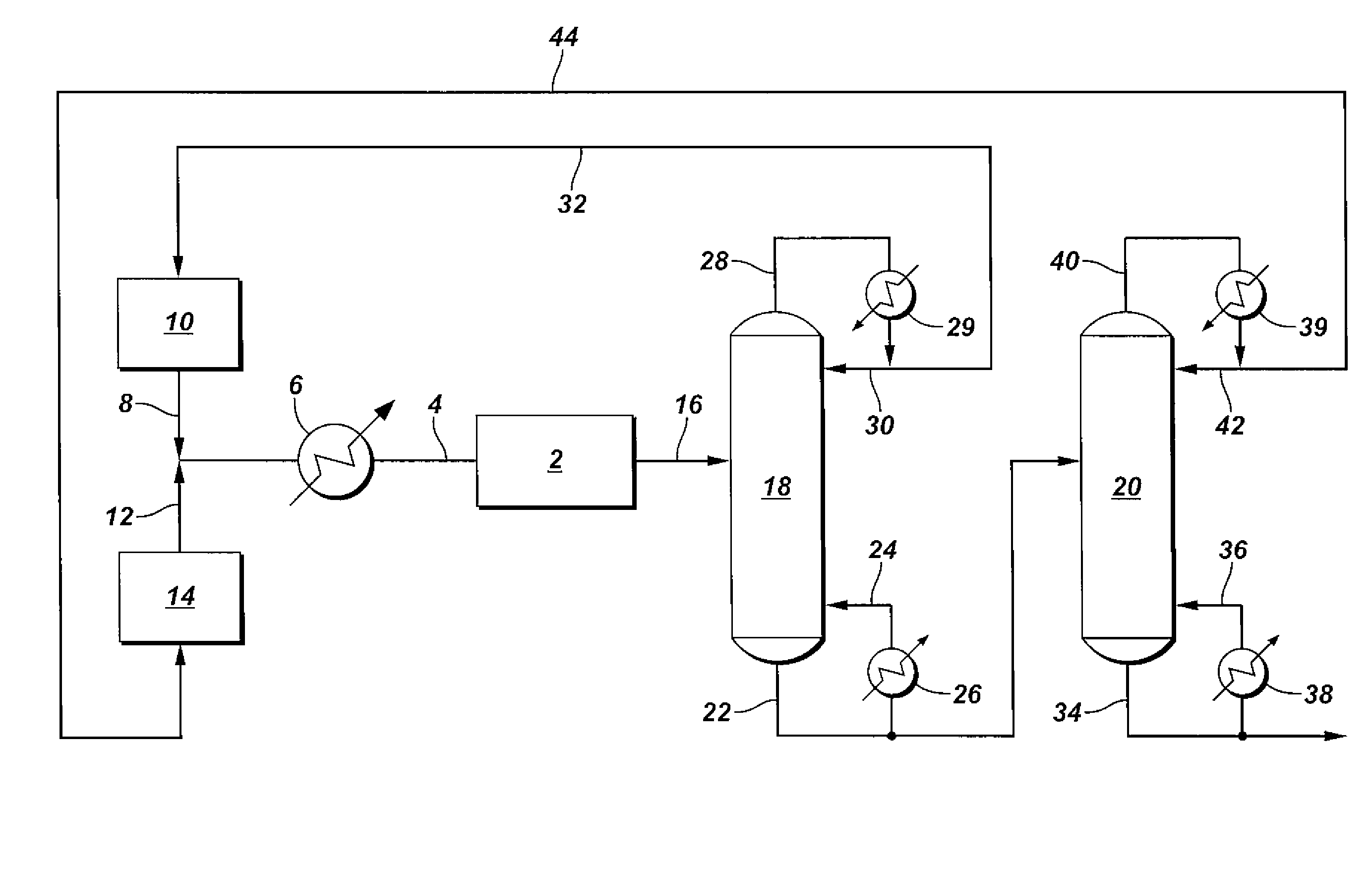

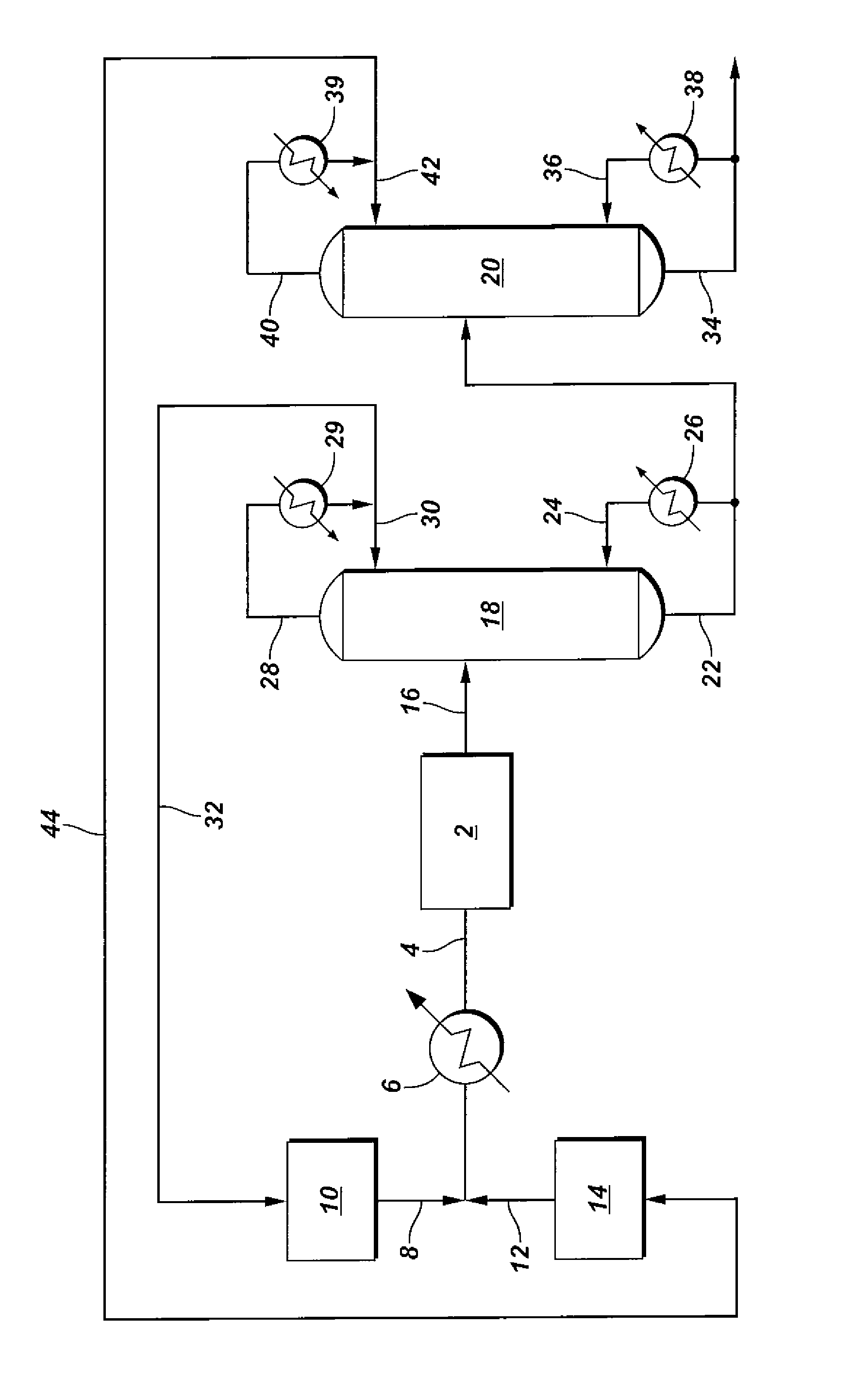

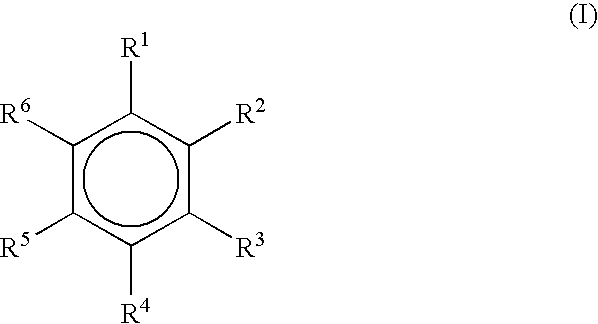

Compositions and methods of using same in producing heavy oil and bitumen

InactiveUS7691788B2Maximize the effectLarge volumeWorking-up pitch/asphalt/bitumen by chemical meansFluid removalFuel oilSolvent

Owner:SCHLUMBERGER TECH CORP

Compositions and Methods of Using Same in Producing Heavy Oil and Bitumen

InactiveUS20070295640A1Reduce energy consumptionMinimal heat lossWorking-up pitch/asphalt/bitumen by chemical meansFluid removalFuel oilSolvent

deposition in a formation, wellbore, near wellbore region, and production tubing. Compositions of the invention comprise an asphaltene solvent and a viscosity reducing agent, the asphaltene solvent and viscosity reducing agent present in a ratio so as to substantially reduce viscosity of an asphaltene-containing material while substantially negating deposition of asphaltenes either in a reservoir, in production tubing, or both when mixed or otherwise contacting the asphaltene-containing material Methods of the invention comprise forcing a composition comprising an asphaltene solvent and a viscosity reducing agent to contact an asphaltene-containing hydrocarbon in an underground geologic formation, and producing from the formation a production composition comprising at least some of the treatment composition and at least some of the asphaltene-containing hydrocarbon under conditions sufficient to substantially negate deposition of asphaltenes in the formation.

Owner:SCHLUMBERGER TECH CORP

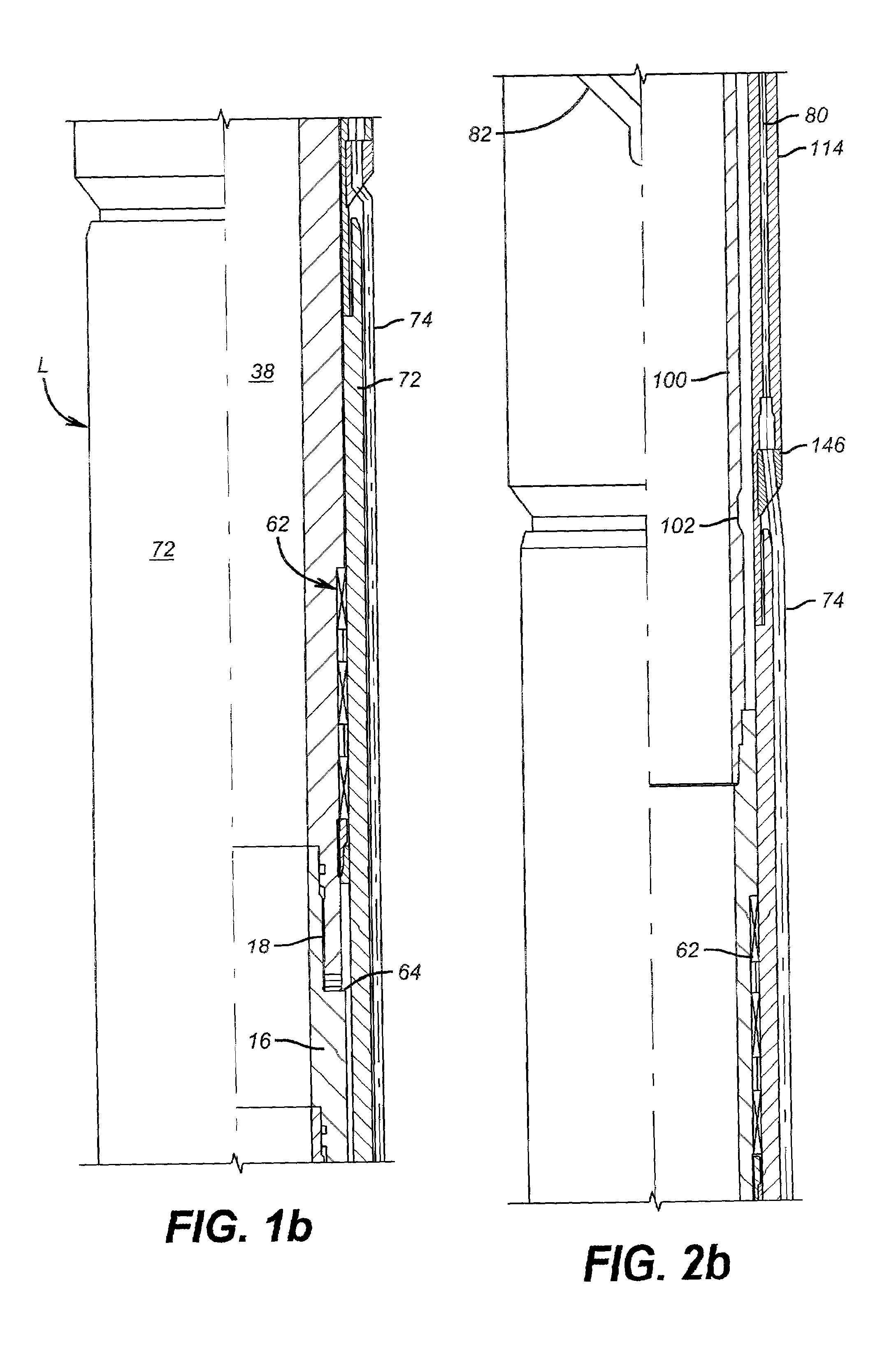

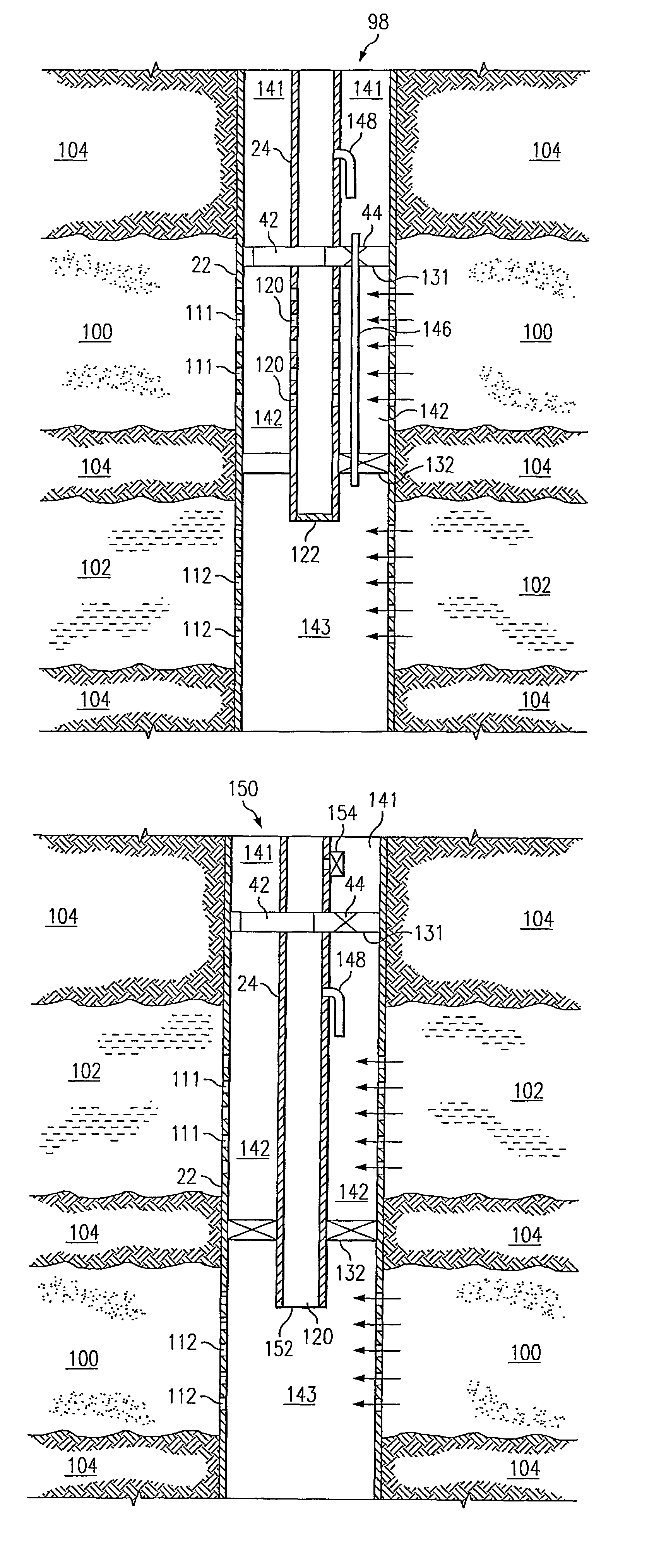

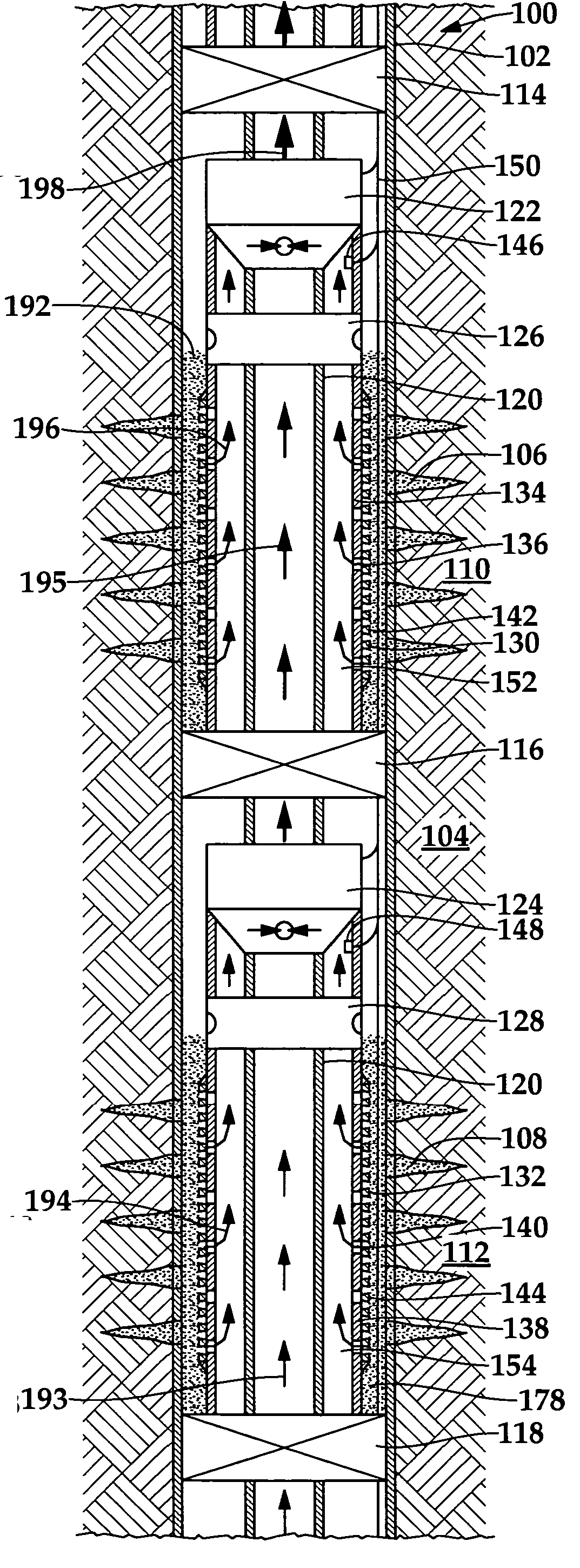

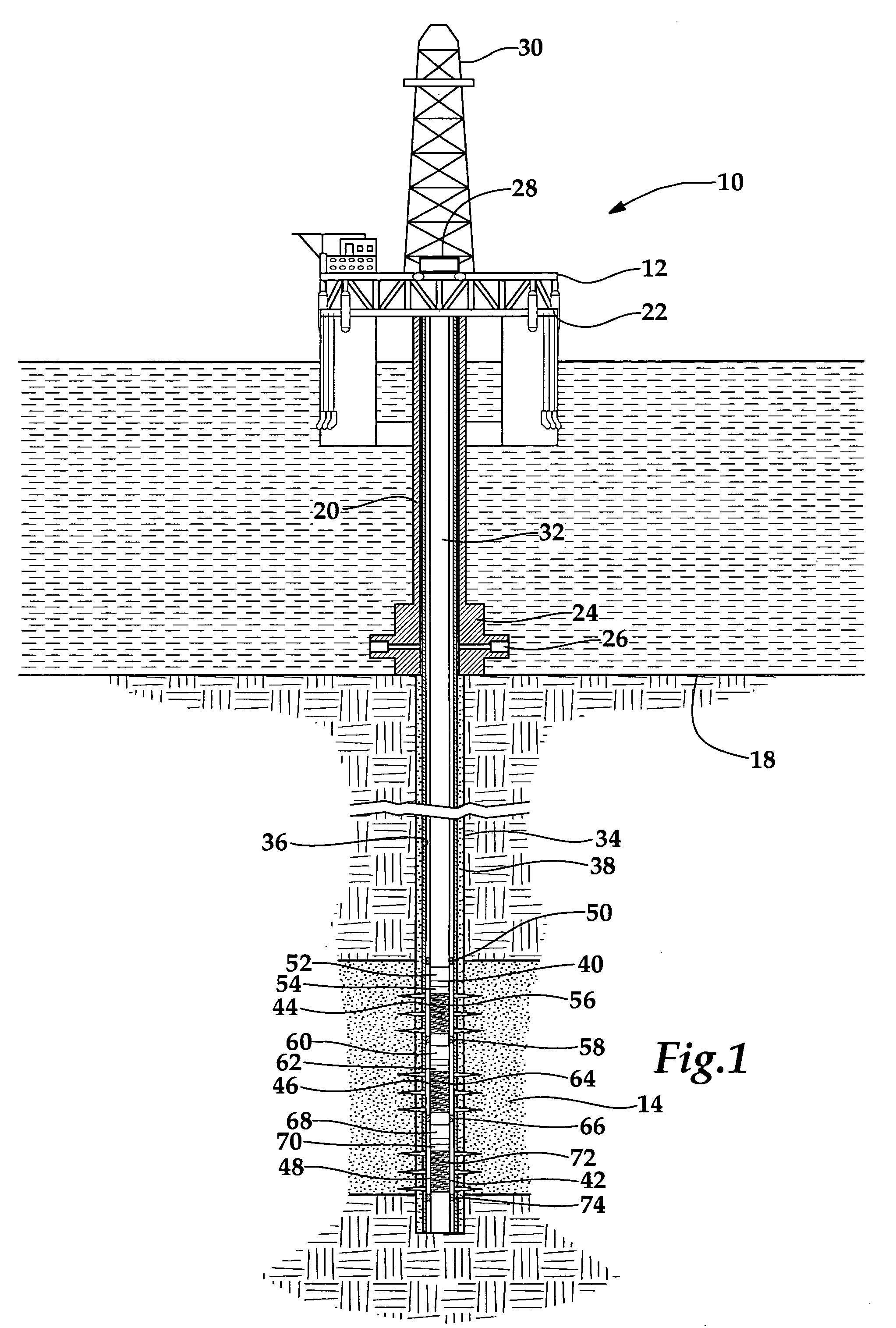

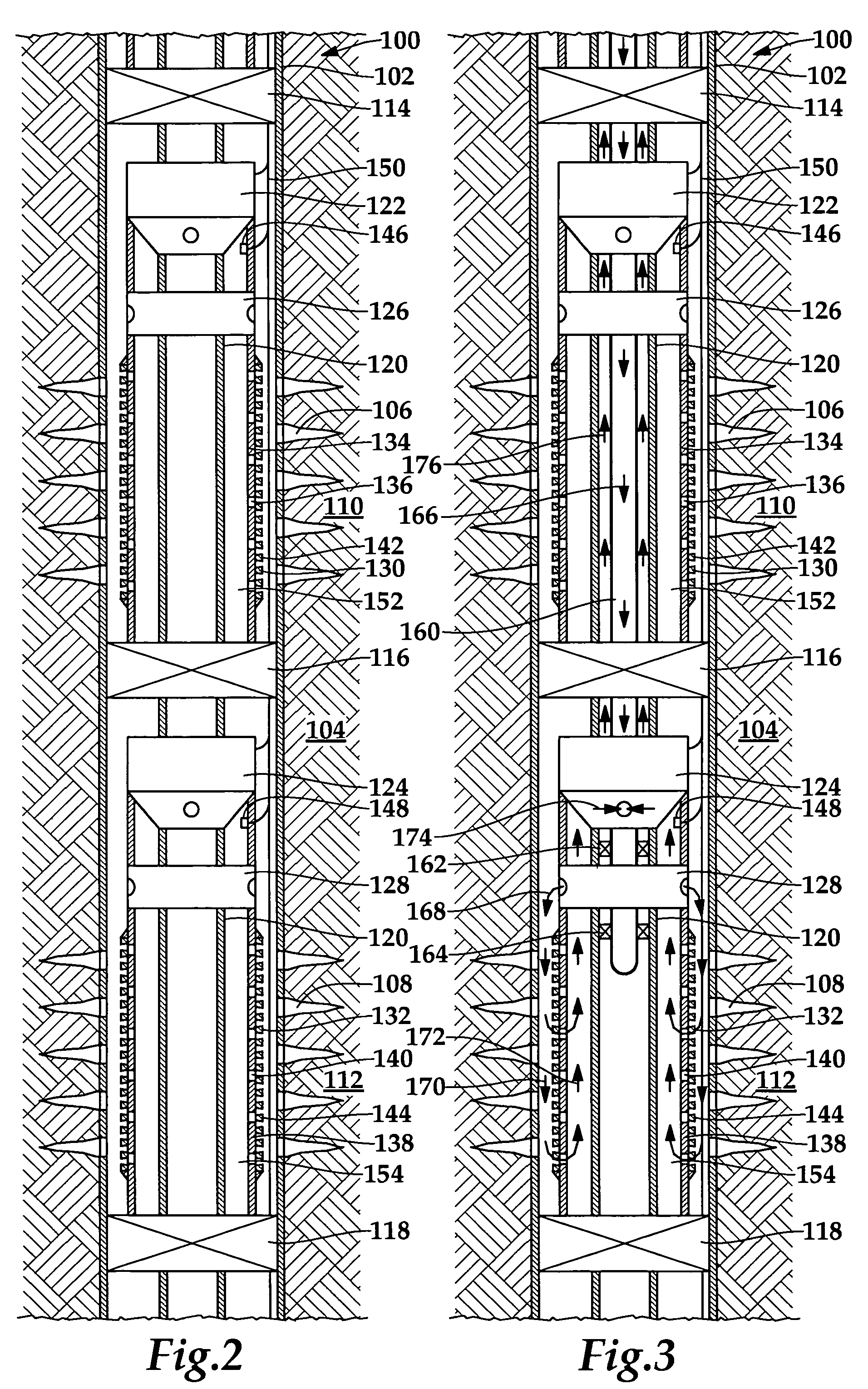

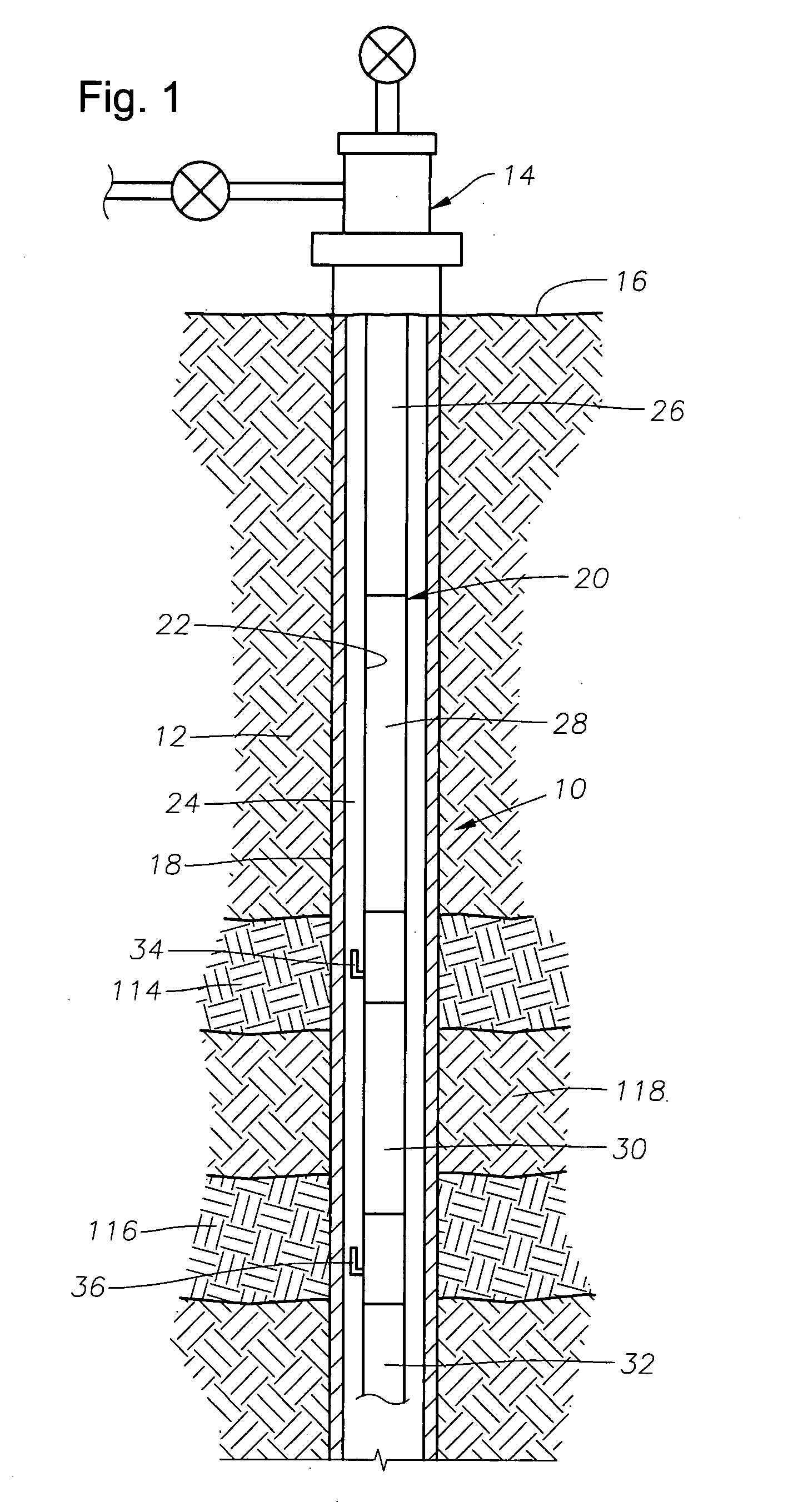

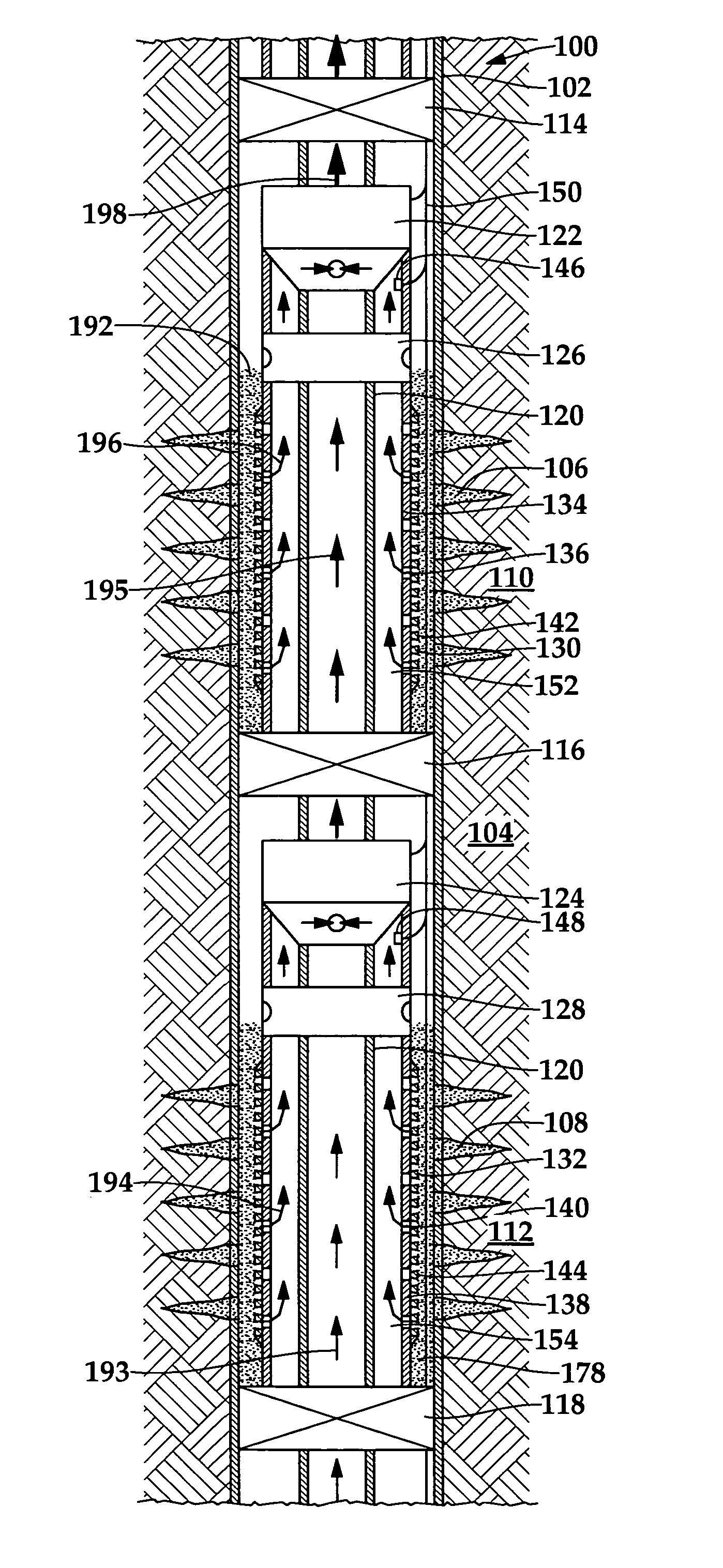

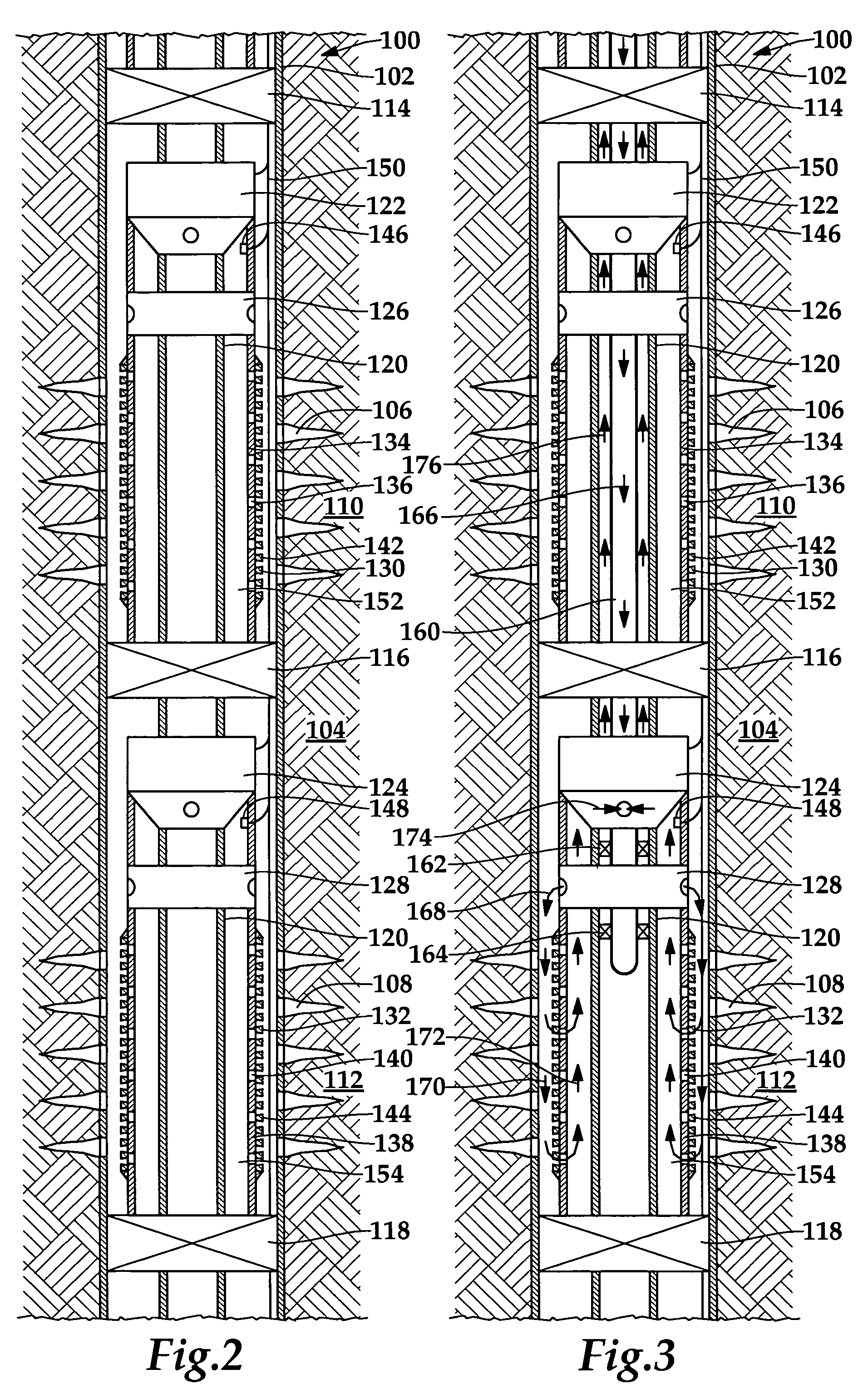

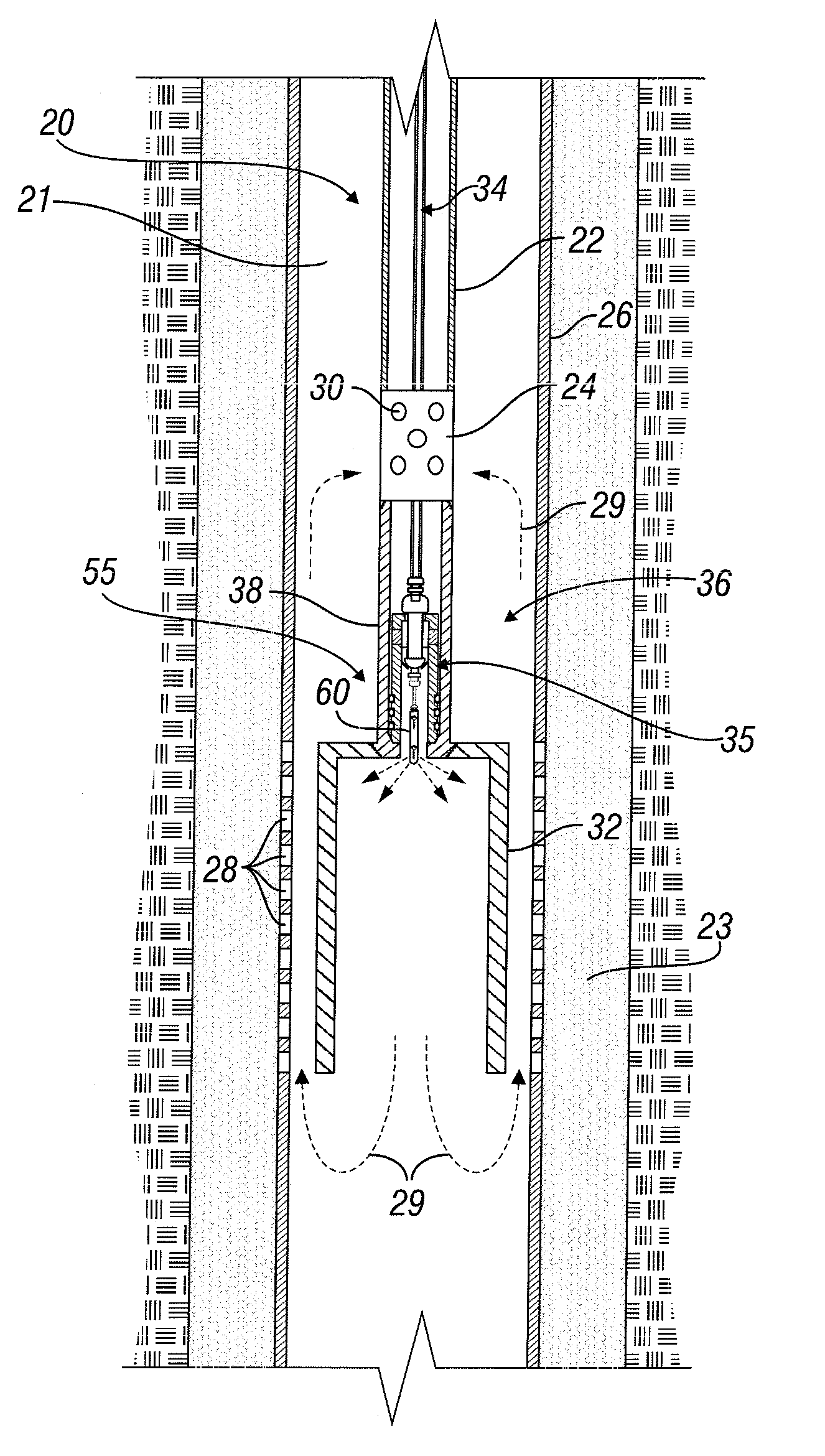

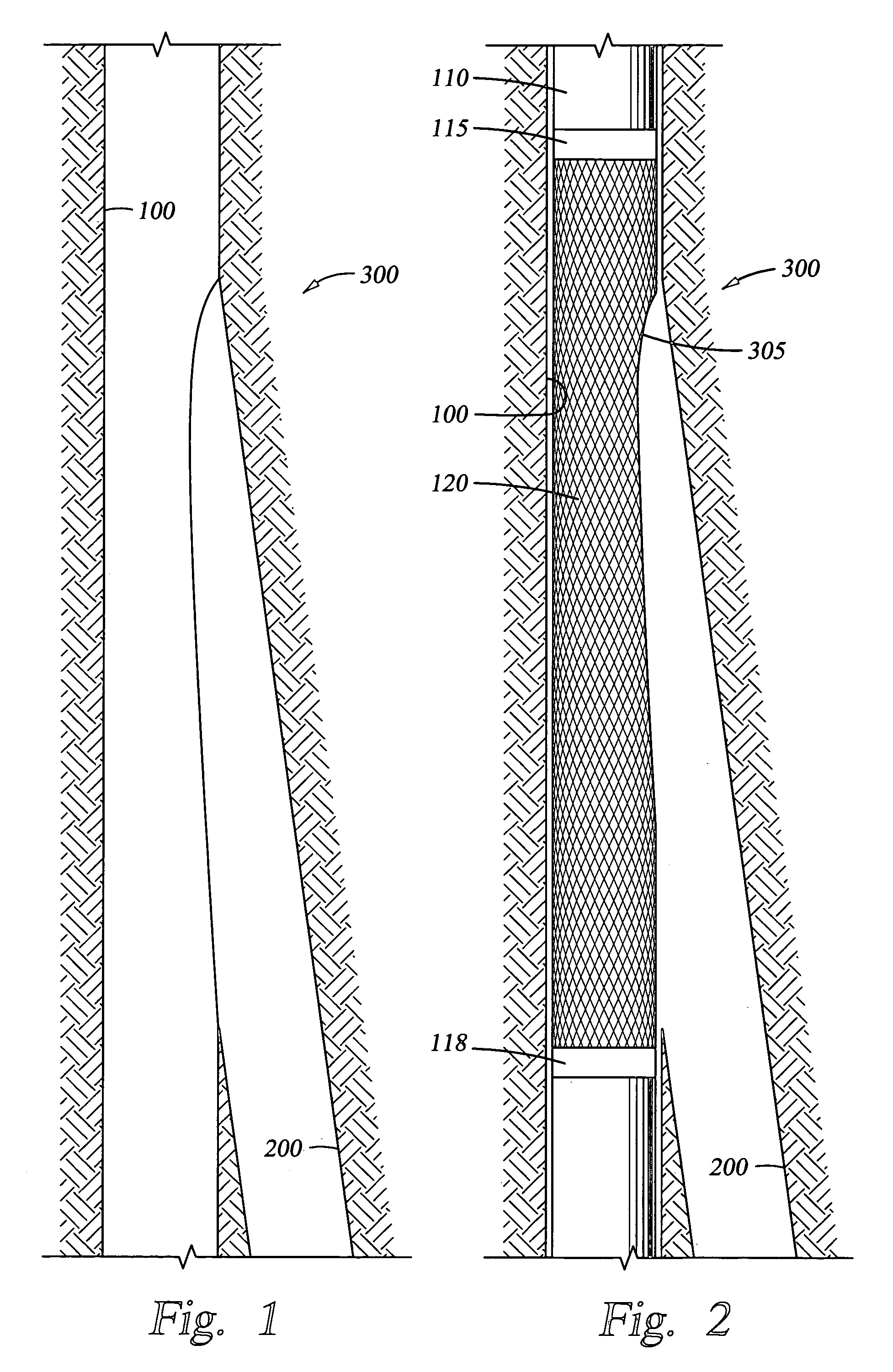

Sand control completion having smart well capability and method for use of same

ActiveUS20060060352A1Preventing fluid lossFluid loss is preventedFluid removalDrinking water installationEngineeringControl valves

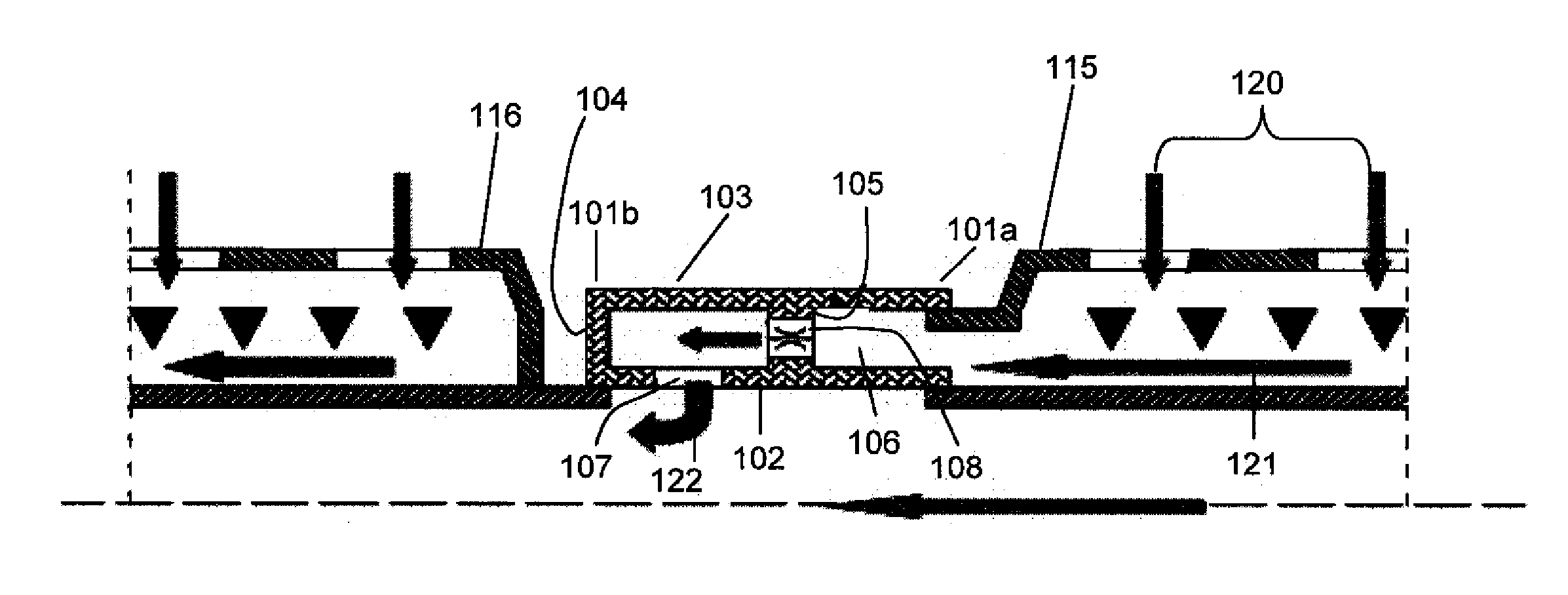

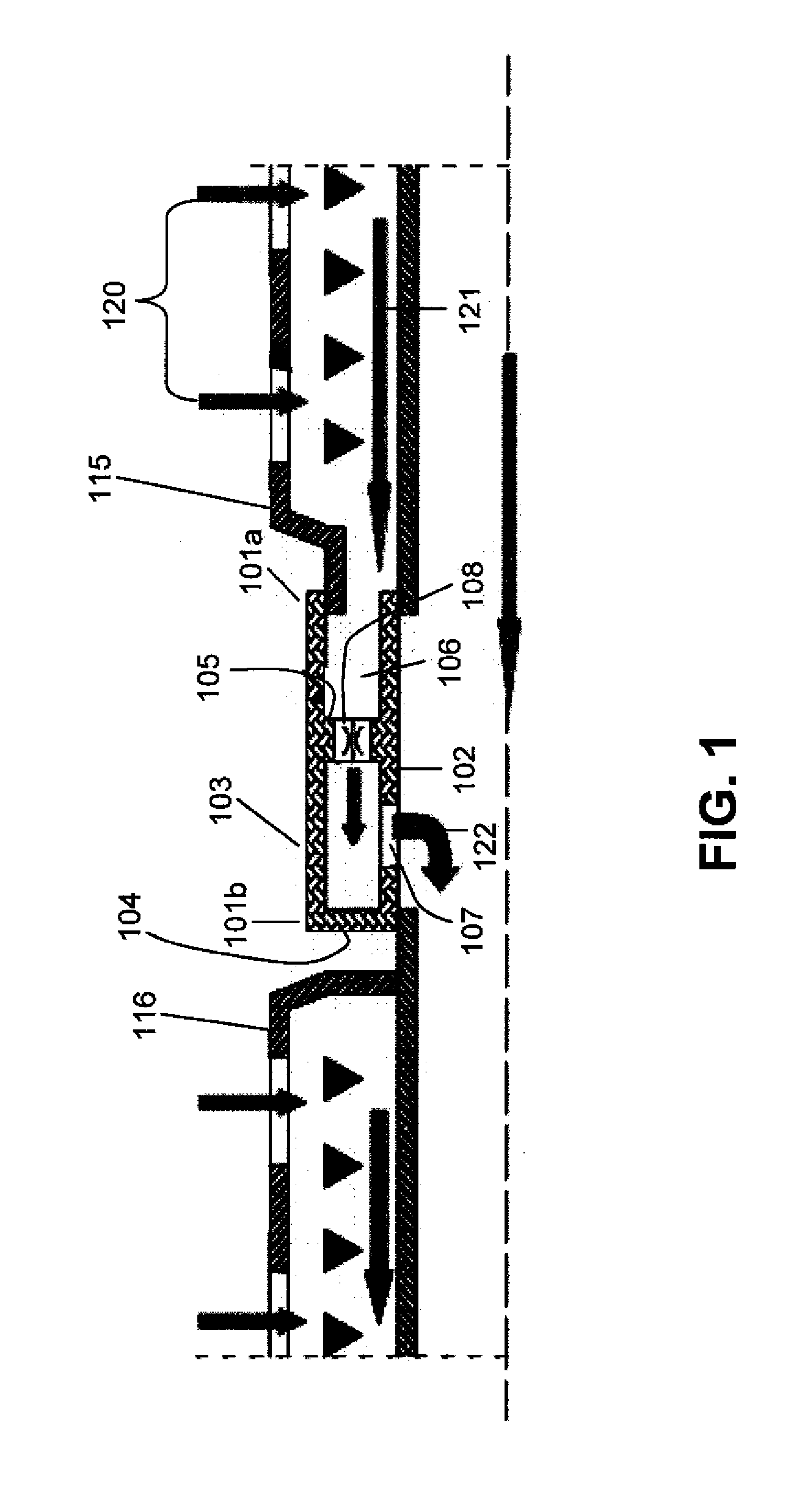

A sand control completion (100) for installation in a wellbore (102) includes first and second packers (114, 116) that define a first zone (110) in the wellbore (102). A production tubing (120) extends substantially through the first zone (110). Positioned between the first and second packers (114, 116) are a sand control screen (130), an inflow control valve (122) and a crossover valve (126). The sand control screen forms a first annulus (152) with the production tubing (120) and a second annulus with the wellbore (102). The inflow control valve (122) is operable to selectively allow and prevent fluid communication between the first annulus (152) and the interior of the production tubing (120). The crossover valve (126) is operable to selectively allow and prevent fluid communication between the production tubing (120) and the second annulus.

Owner:HALLIBURTON ENERGY SERVICES INC

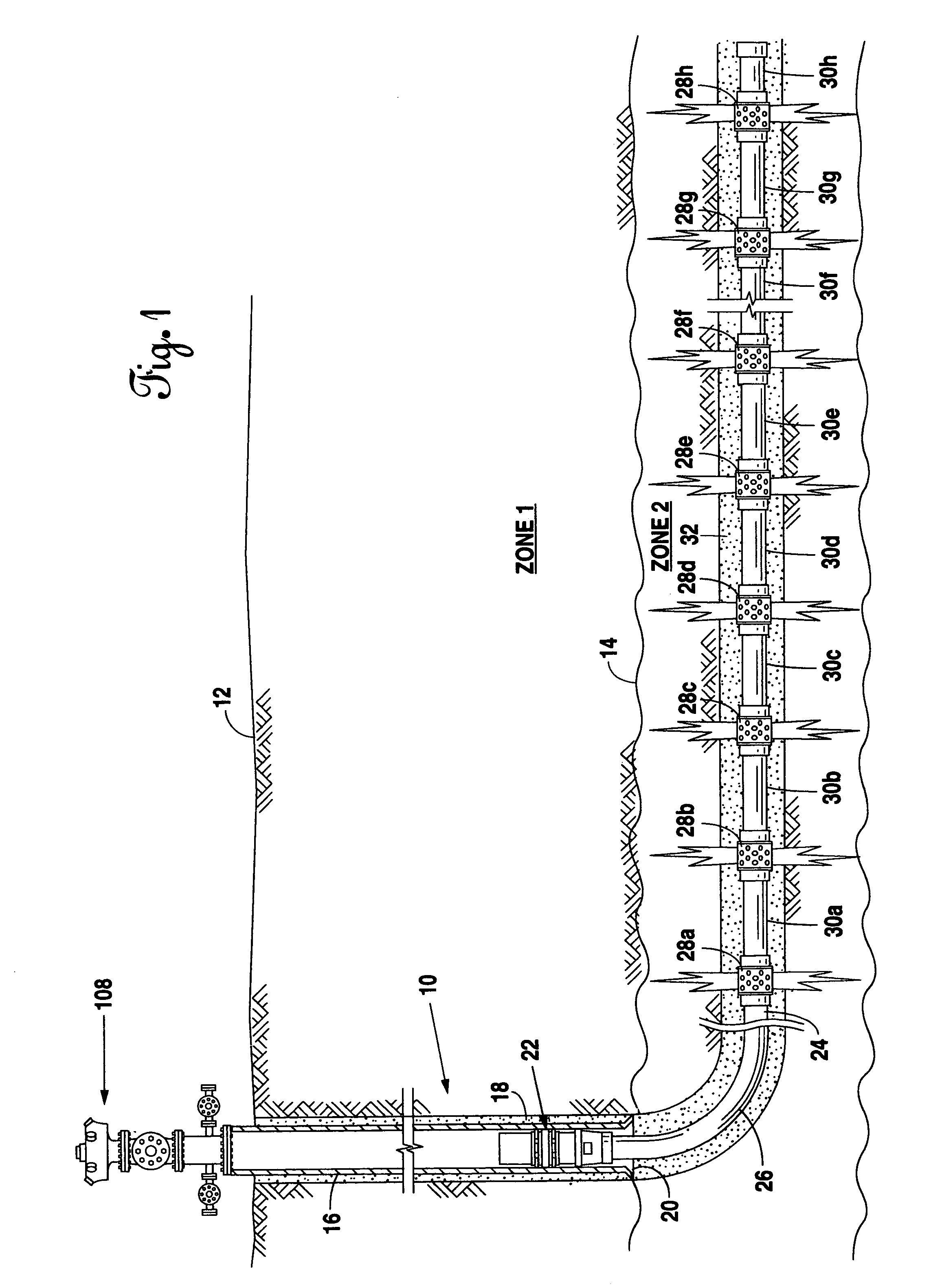

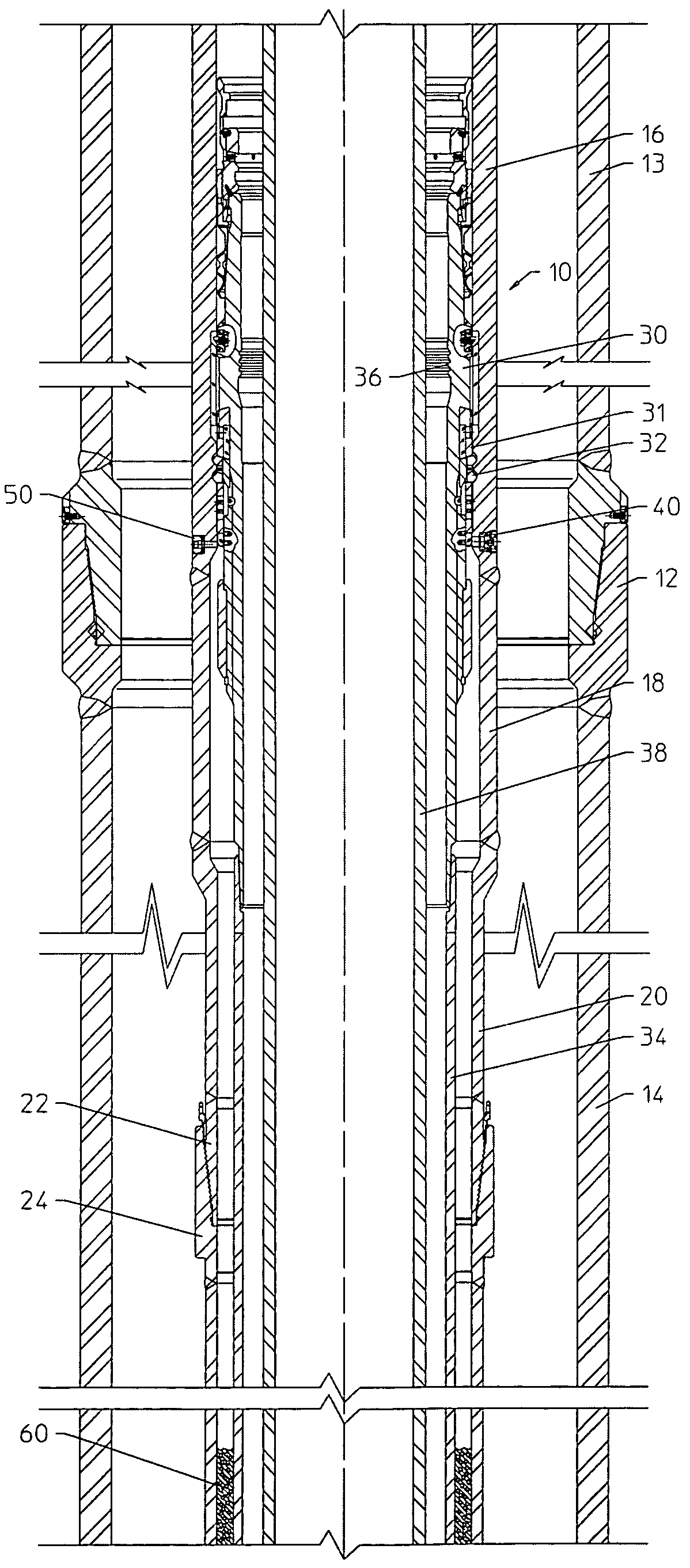

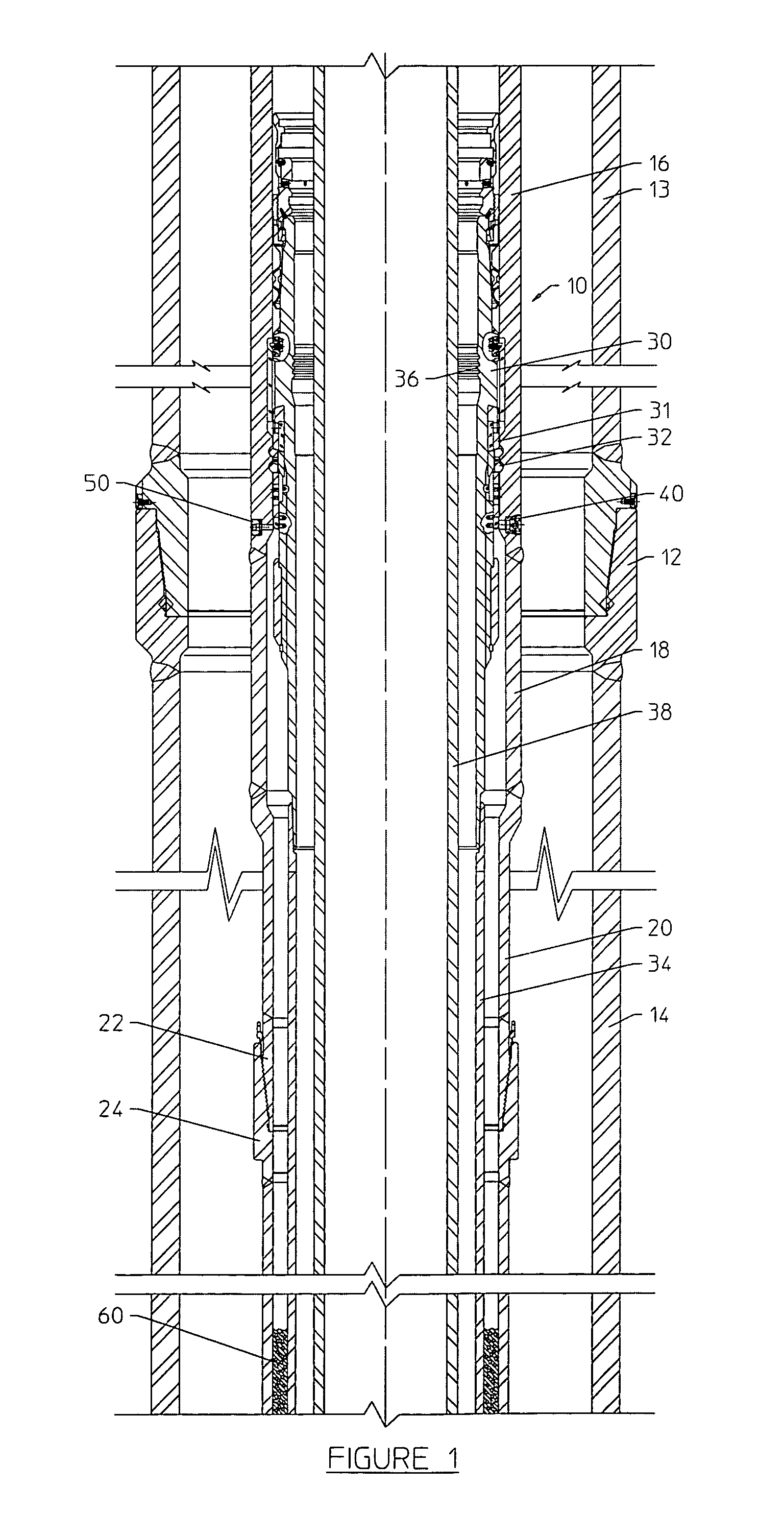

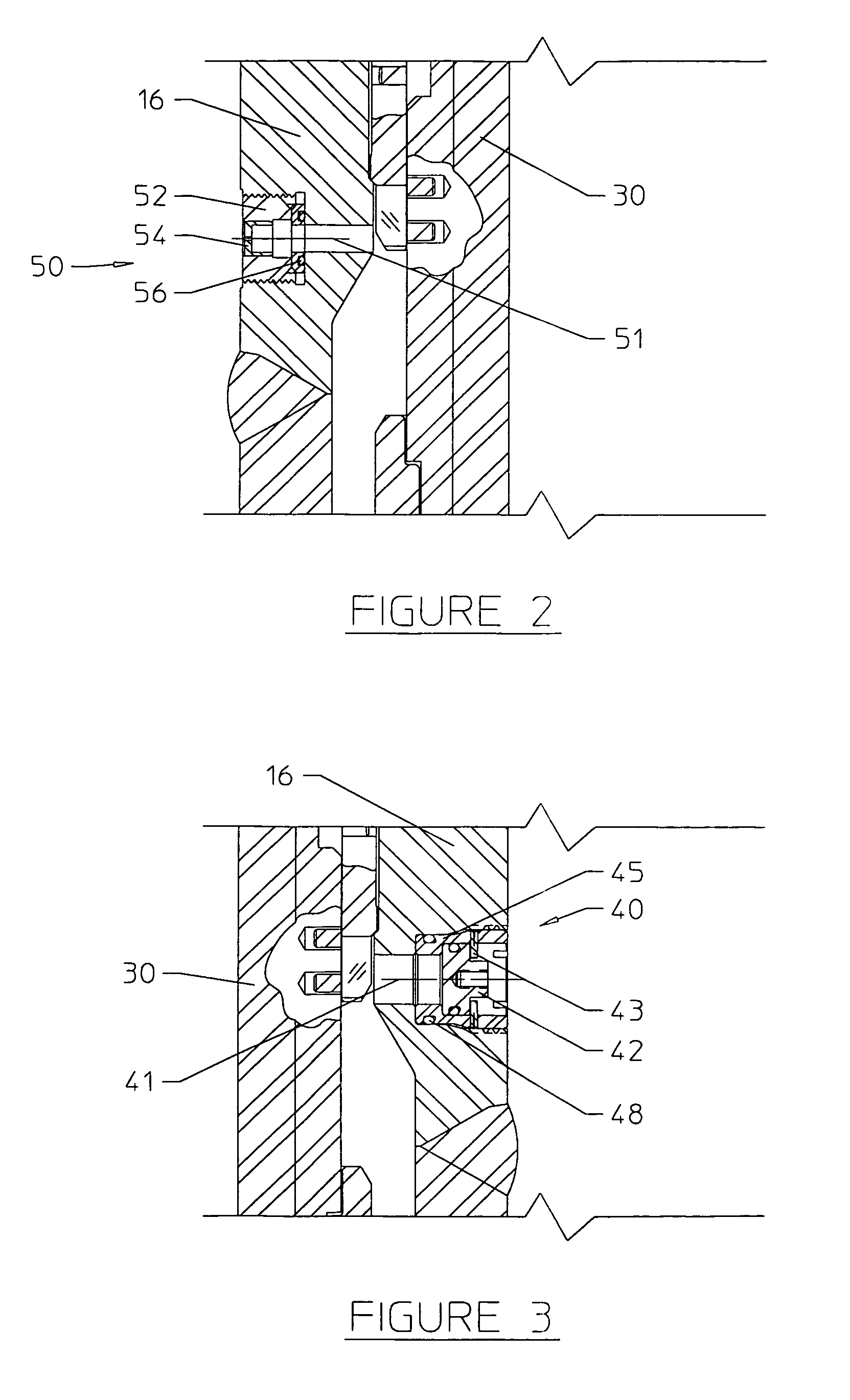

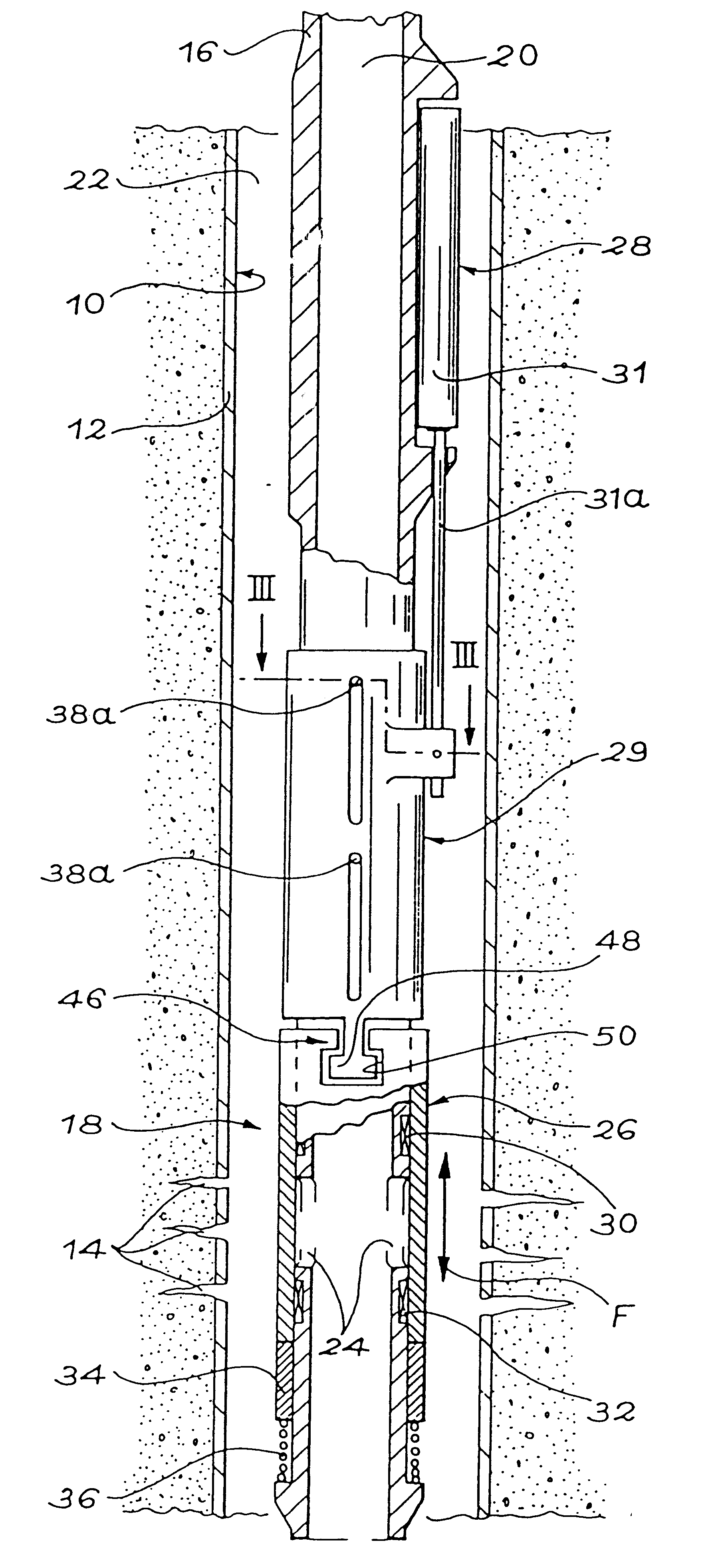

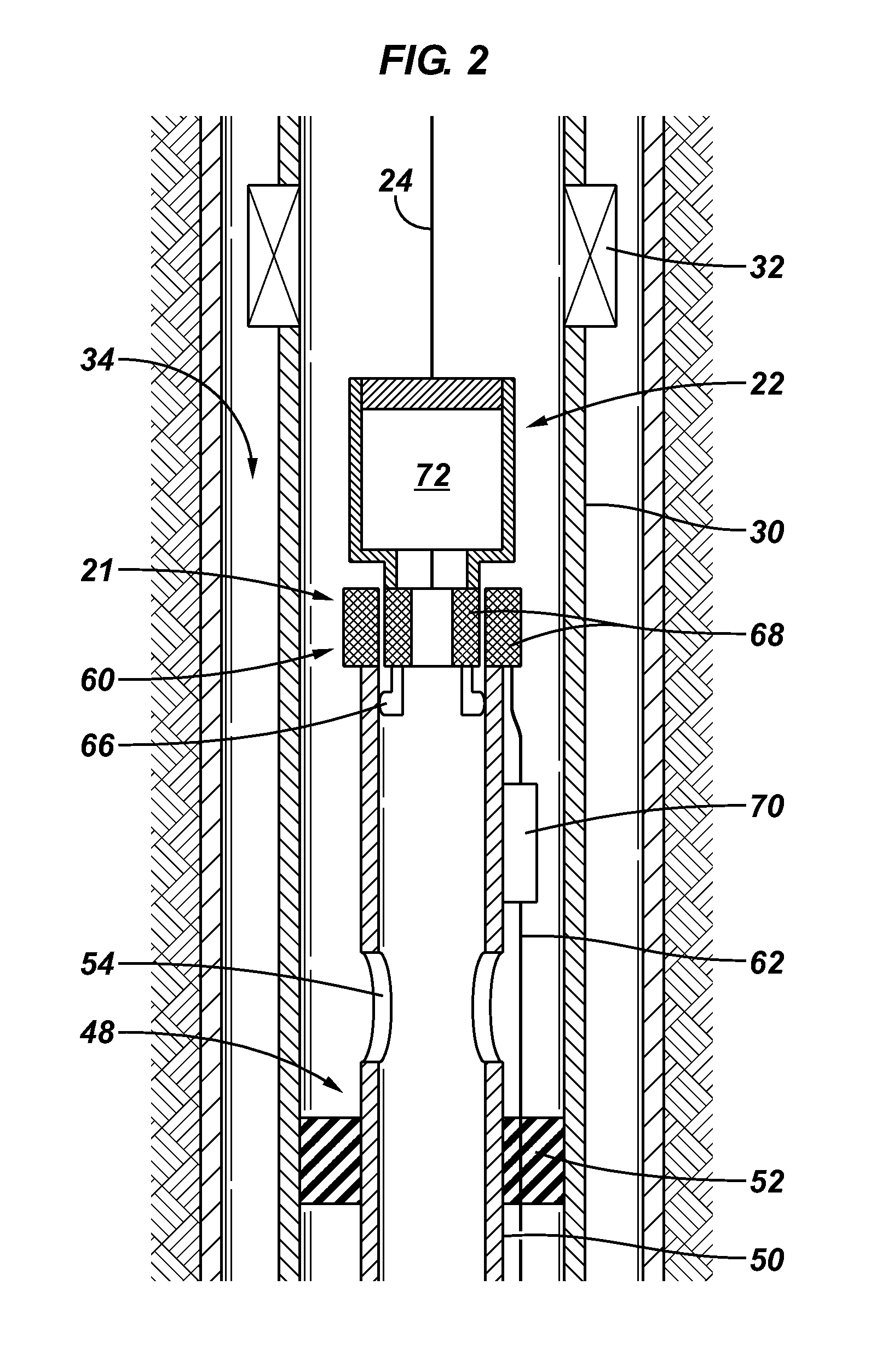

Through tubing intelligent completion system and method with connection

A technique facilitates use of a through tubing completion system run in a lateral borehole. The through tubing completion may comprise production tubing coupled to a flow control valve and one or more sensors measuring at least one characteristic of the lateral borehole. The through tubing completion also comprises a connection system which facilitates the transfer of signals between the through tubing completion extending into the lateral borehole and a surface location or other location.

Owner:SCHLUMBERGER TECH CORP

Barrier orifice valve for gas lift

ActiveUS20070181312A1Increase flow ratePrevent backflowPressure pumpsFluid removalEngineeringGas lift

Gas lift valve designs and gas lift systems are described that feature a positive closure mechanism that is highly resistant to significant wear or damage that would result in fluid leakage. A pivotable flapper member is incorporated into a gas lift valve and used as a flow control mechanism. The flapper member provides a positive barrier to fluid flow from the production tubing to the annulus, even after substantial wear or damage.

Owner:BAKER HUGHES INC

Wellbore evaluation system and method

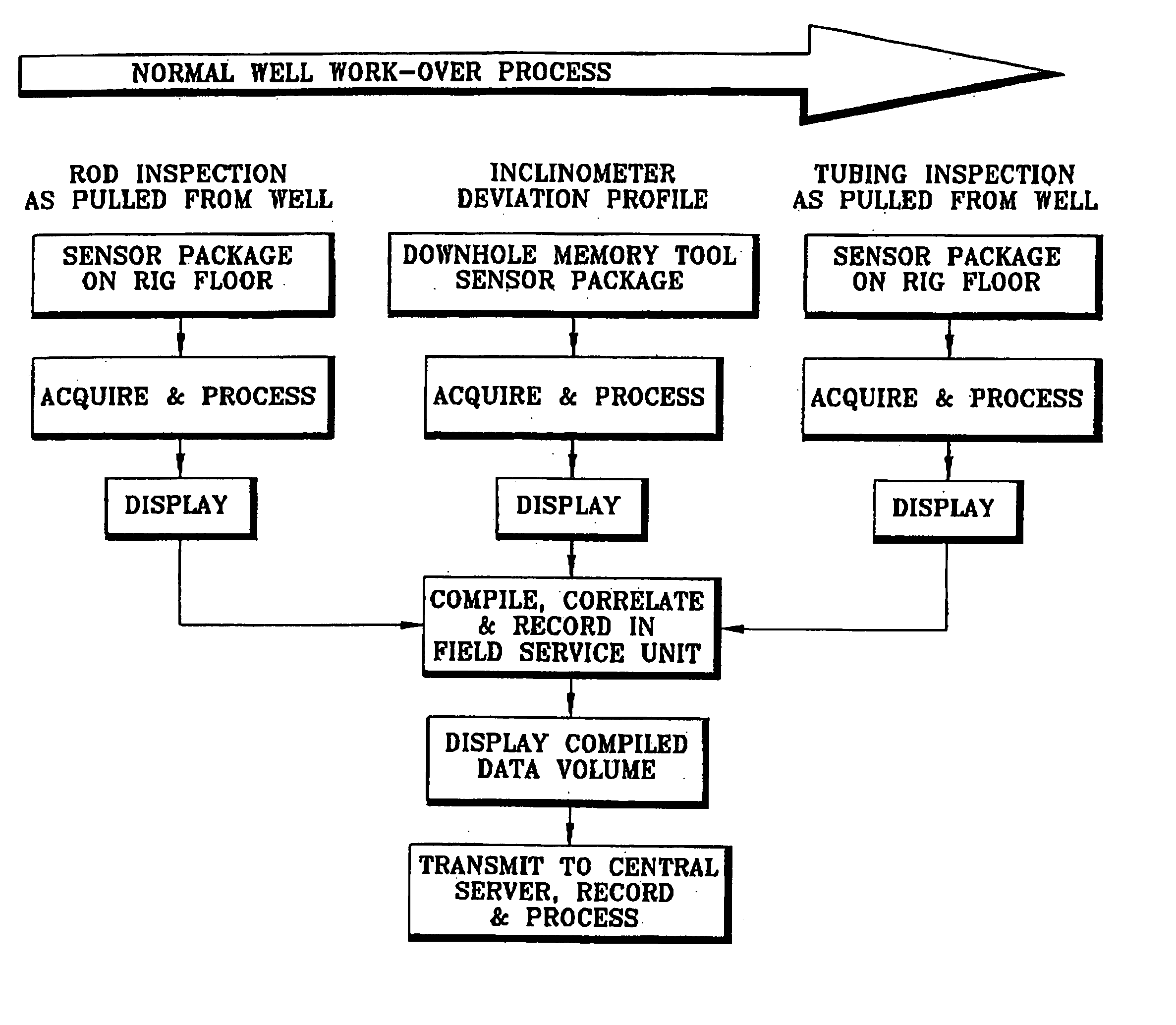

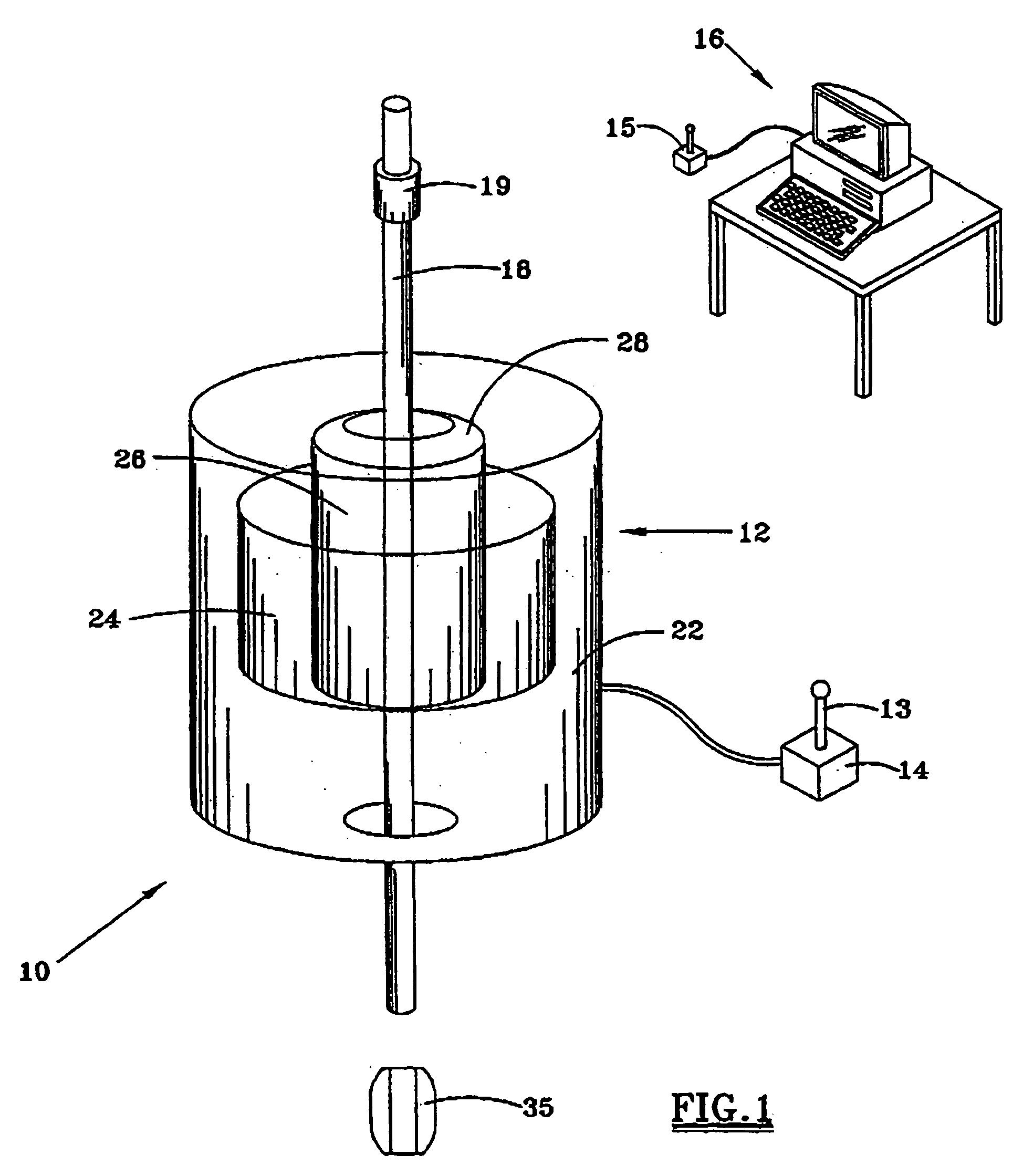

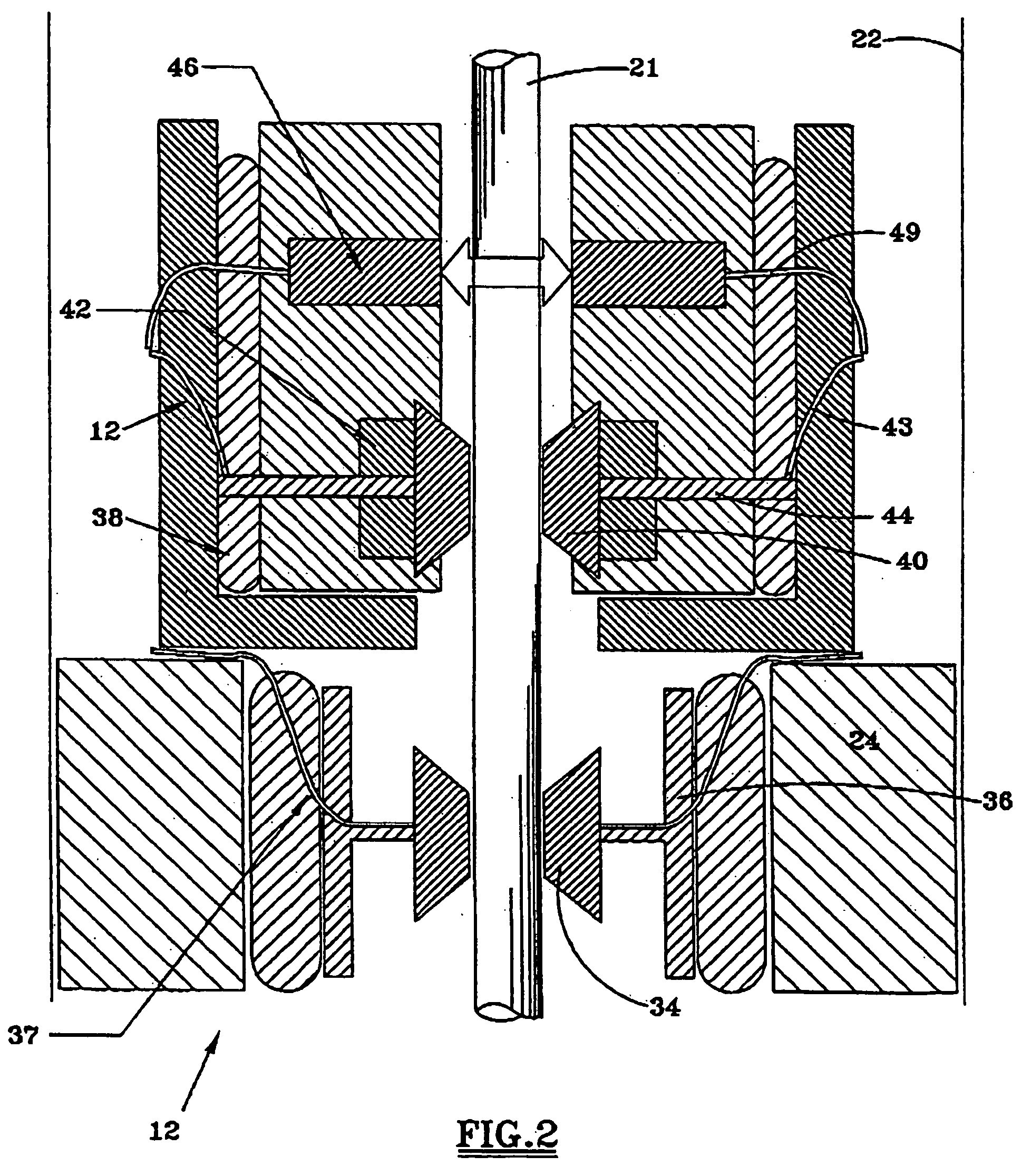

ActiveUS20060271299A1Electric/magnetic detection for well-loggingSurveySection planeData acquisition

A wellbore evaluation system evaluates mechanical wear and corrosion to components of a well system including a production tubing string positionable in a well and a sucker rod string movable within the production tubing string. A deviation sensor determines a deviation profile of the production tubing string in the well, and a rod sensor senses and measures wear and corrosion to the sucker rod string as it is removed from the well to determine a rod profile. A data acquisition computer is in communication with the sensors for computing and comparing the deviation profile and the rod profile as a function of depth in the well. A 3-dimensional image of wellbores, with isogram mapping, may be generated and examined over the internet.

Owner:ROBBINS & MYERS ENERGY SYST

Sand control completion having smart well capability and method for use of same

ActiveUS7367395B2Fluid loss is preventedPreventing fluid lossFluid removalDrinking water installationEngineeringControl valves

A sand control completion (100) for installation in a wellbore (102) includes first and second packers (114, 116) that define a first zone (110) in the wellbore (102). A production tubing (120) extends substantially through the first zone (110). Positioned between the first and second packers (114, 116) are a sand control screen (130), an inflow control valve (122) and a crossover valve (126). The sand control screen forms a first annulus (152) with the production tubing (120) and a second annulus with the wellbore (102). The inflow control valve (122) is operable to selectively allow and prevent fluid communication between the first annulus (152) and the interior of the production tubing (120). The crossover valve (126) is operable to selectively allow and prevent fluid communication between the production tubing (120) and the second annulus.

Owner:HALLIBURTON ENERGY SERVICES INC

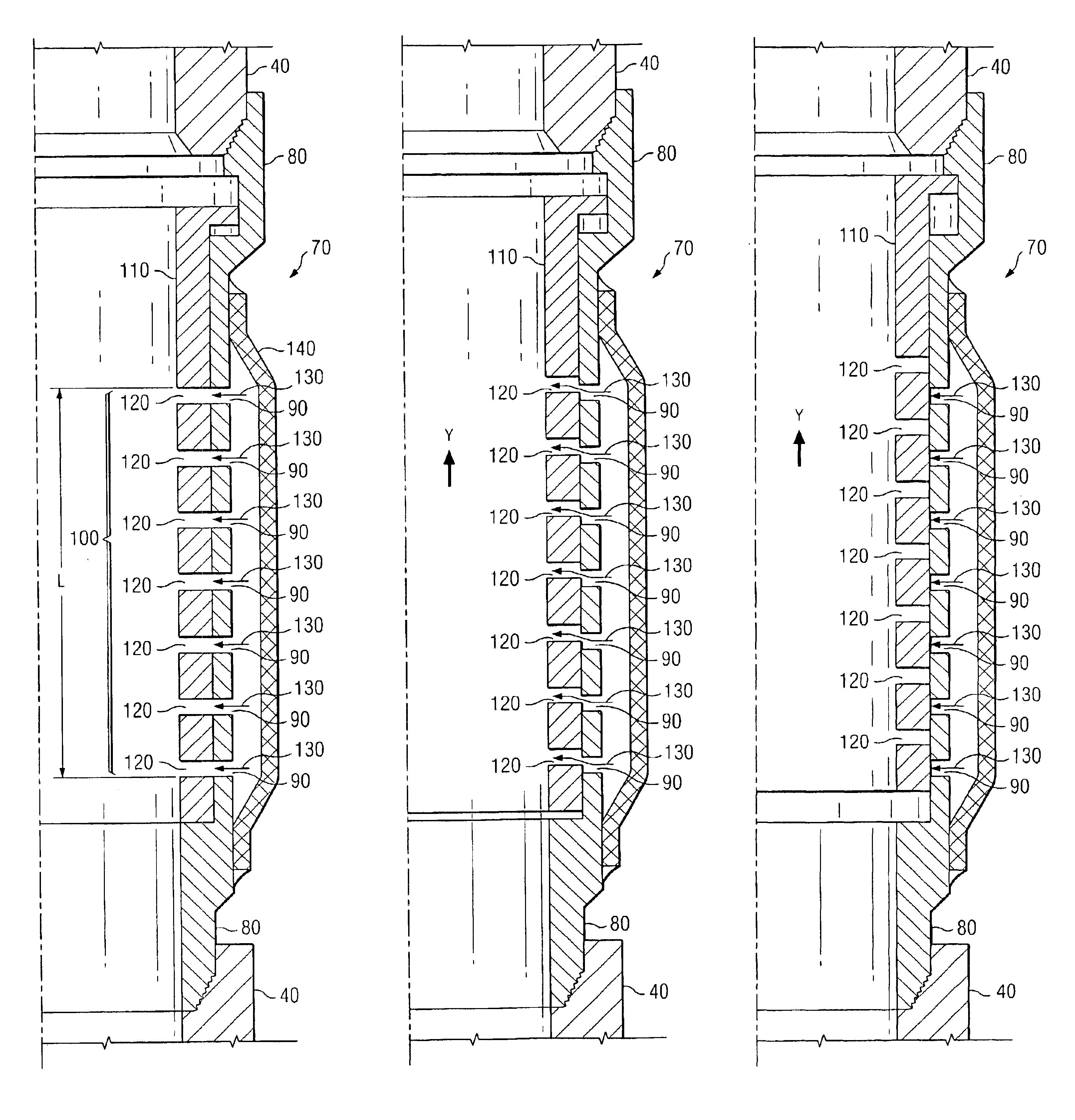

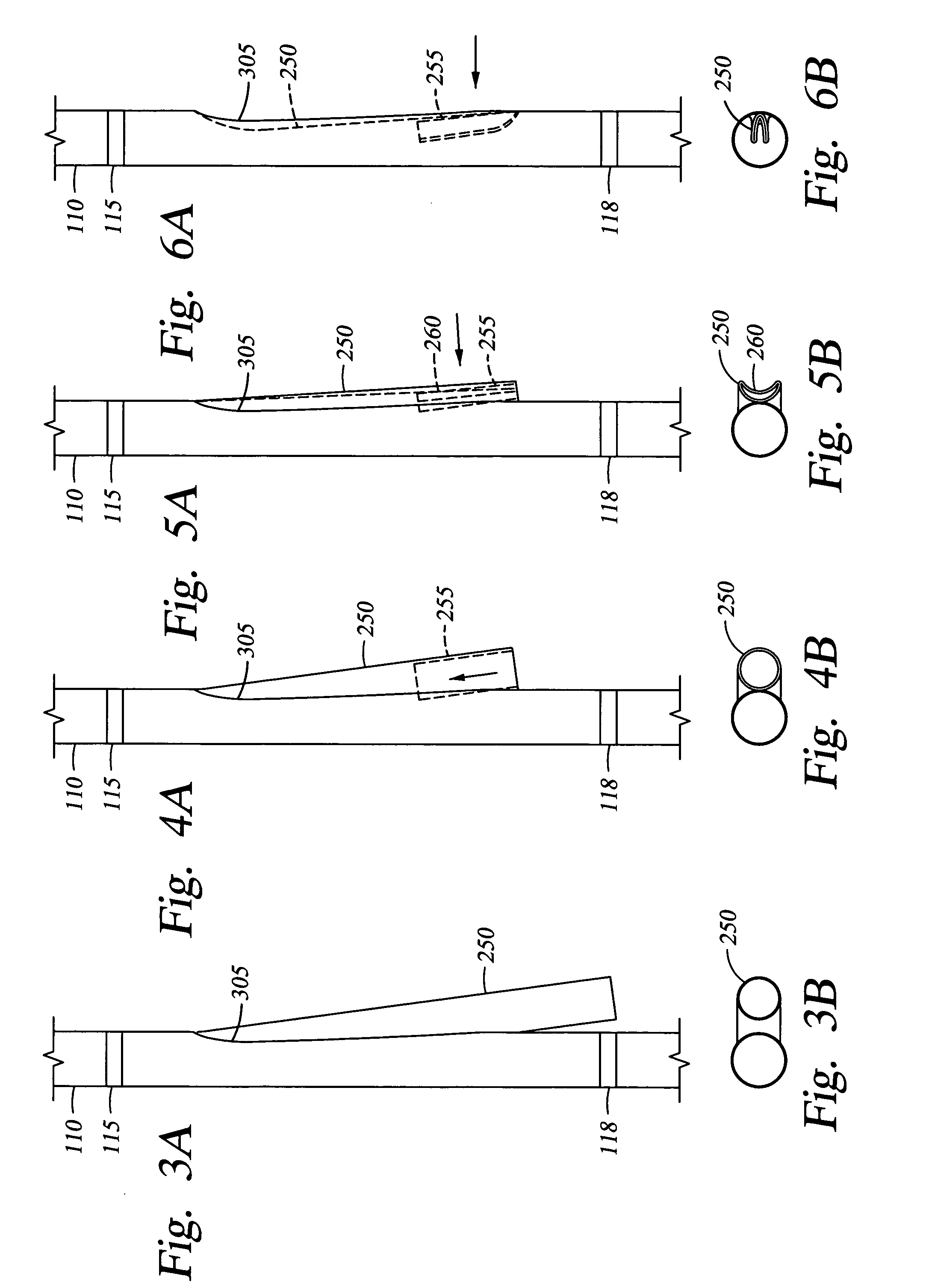

Well screen assembly and system with controllable variable flow area and method of using same for oil well fluid production

A well screen assembly (70) with a controllable variable flow area. The well screen assembly (70) comprises an outer tubular section (80), the outer tubular section (80) containing a first plurality of openings (90) disposed in a pattern (100) throughout a length “L” of the outer tubular section (80); an inner tubular section (110) that is disposed within the outer tubular section (80), the inner tubular section (110) containing a second plurality of openings (120) disposed in the same pattern (100) throughout a length L of the inner tubular section (110), and when the first plurality of openings (90) and second plurality of openings (120) align, the openings form a plurality of passageways (130) through the outer tubular section (80) and inner tubular section (110). The well screen assembly (70) may therefore, vary the flow of production fluid through it and upwards through the interior of a production tubing (40).

Owner:HALLIBURTON ENERGY SERVICES INC

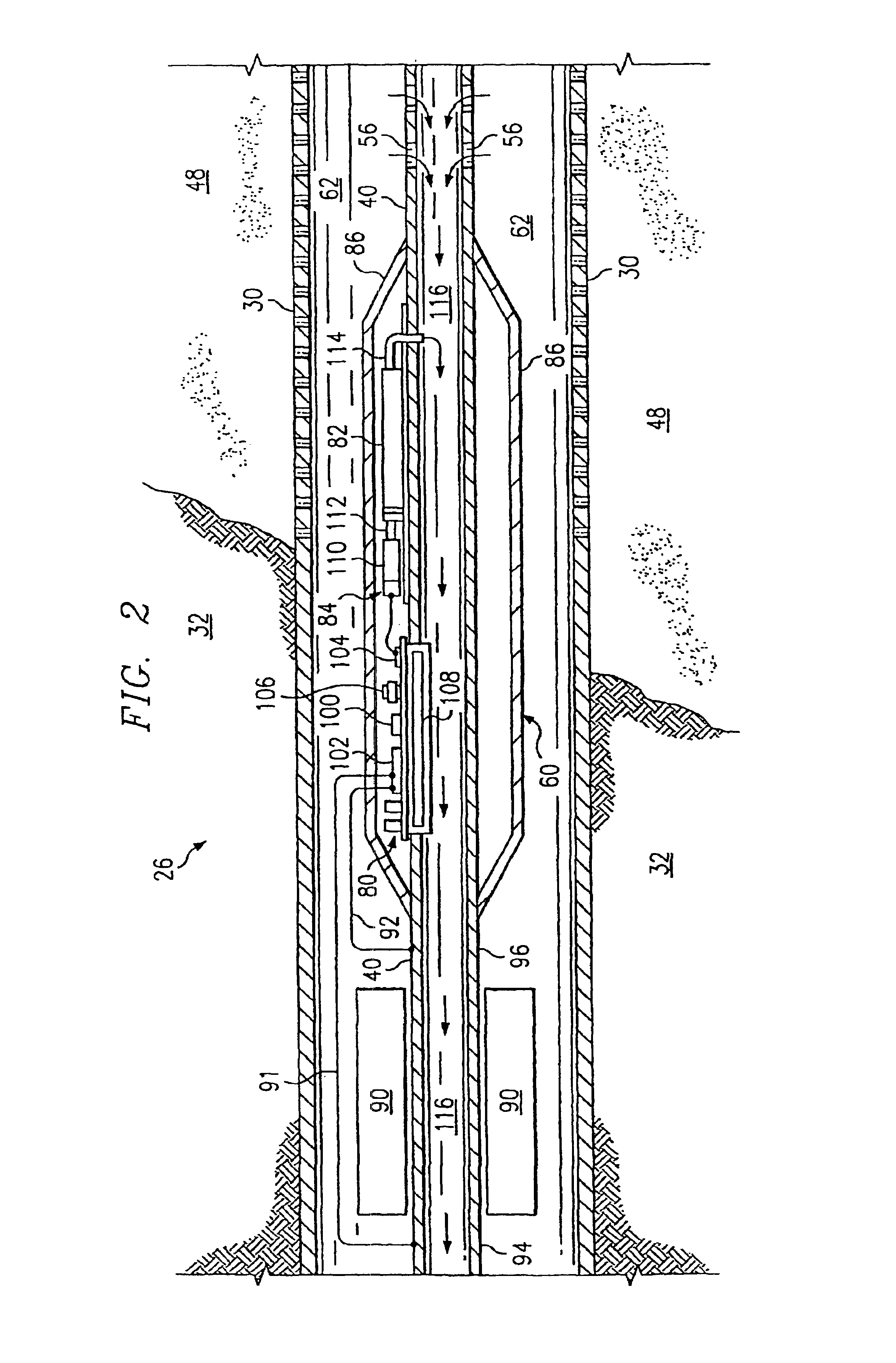

Progressive production methods and system

Methods for staged production from a wellbore include pumps sequentially operated during the life of the well. In described embodiments, production assemblies are used for progressive staged production process in which the production tubing is bifurcated to provide a pair of legs. One of the legs includes a first pump that may be selectively actuated to flow fluid through one of the legs. Means are also provided, including a sliding sleeve and a flapper valve diverter, for blocking production fluid flow through one leg or the other. A second fluid pump is lowered inside of the production tubing to pump fluid after the first pump has failed.

Owner:BAKER HUGHES INC

Methods, systems and apparatus for coiled tubing testing

A method and apparatus for testing a multi-zone reservoir while reservoir fluids are flowing from within the wellbore. The method and apparatus enables isolation and testing of individual zones without the need to pull production tubing. This abstract allows a searcher or other reader to quickly ascertain the subject matter of the disclosure. It may not be used to interpret or limit the scope or meaning of the claims.

Owner:SCHLUMBERGER TECH CORP

Dead string completion assembly with injection system and methods

ActiveUS20090242208A1Avoid flowFluid removalWell/borehole valve arrangementsEngineeringProduction tubing

In some embodiments, apparatus useful for providing fluids or equipment into a subterranean well through a production tubing and associated dead string includes an injection system that is movable into and out of the well without removing the production tubing. The injection system includes a stopper that forms the seal that creates the dead string.

Owner:BAKER HUGHES INC

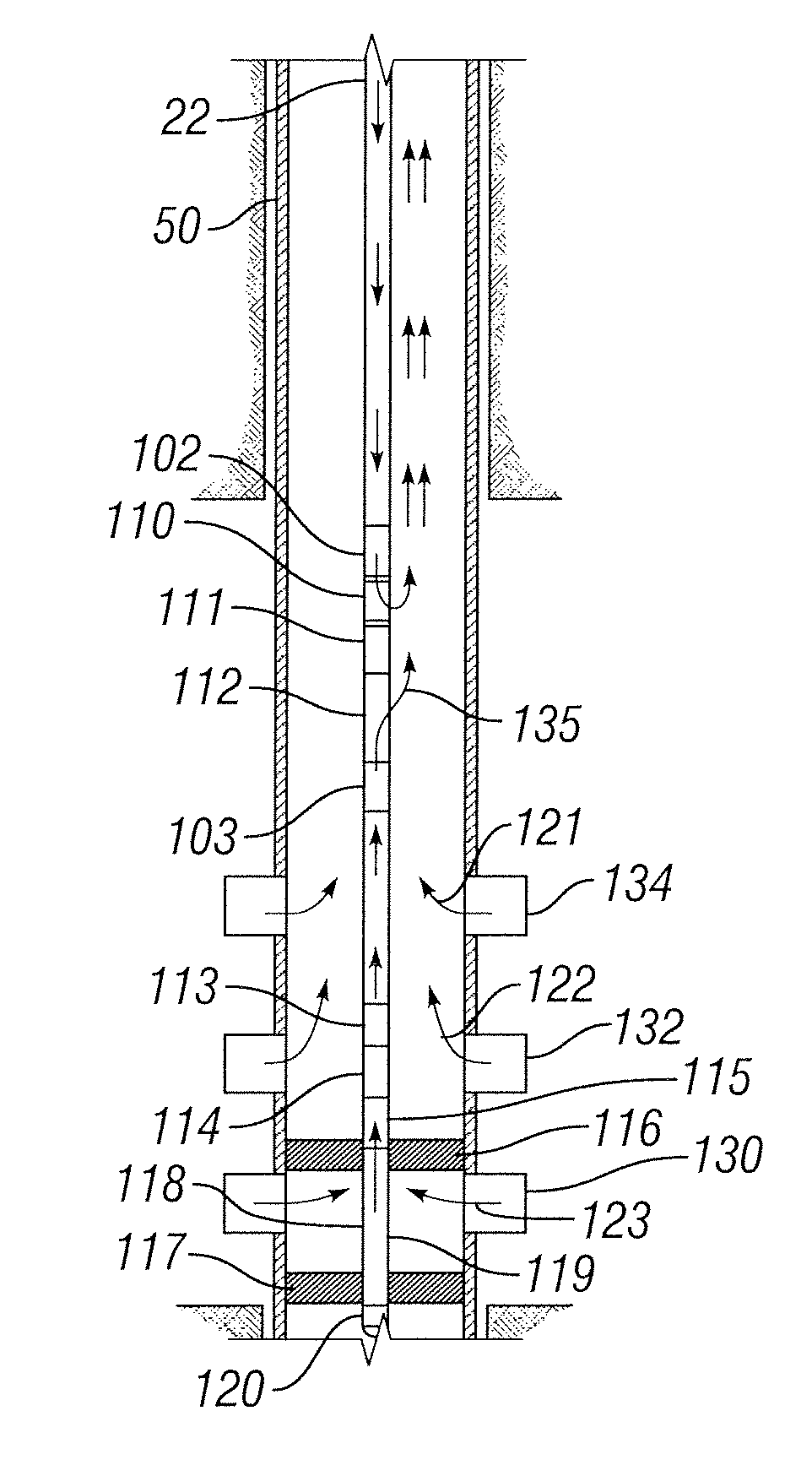

System and method for thru tubing deepening of gas lift

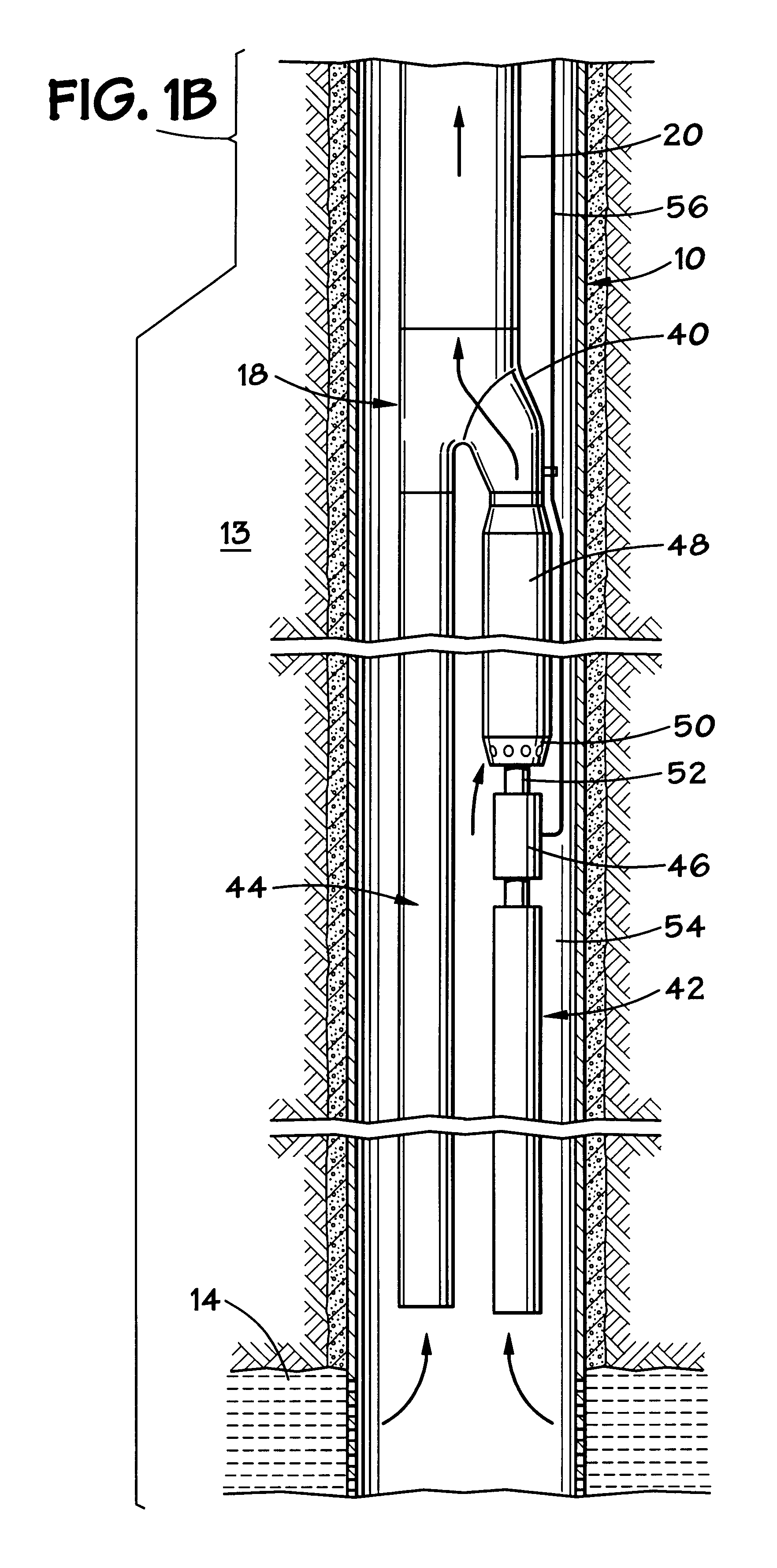

ActiveUS20090255684A1Blowout preventionFluid removalWell/borehole valve arrangementsProduction packerInjection point

The present disclosure is directed to a gas lift system adapted to provide a gas injection point to a deeper location in a wellbore. A turn-over suspension mandrel can be landed inside a side pocket mandrel and connected to a gas lift valve on one end and a coil on the other end. A length of production tubing can extend from the side pocket mandrel. The production tubing can include a production packer to seal the annulus between the tubing and the well casing. The turn-over suspension mandrel can be constructed such that gas entering the gas lift valve is directed down through the coil and into the wellbore beneath the production packer. A plug can be placed at the bottom of the coil in order to prevent blowouts during installation of the gas lift system. An alternative embodiment of the present disclosure provides a coil and plug hung from a gas lift valve of a pack-off assembly.

Owner:BAKER HUGHES INC

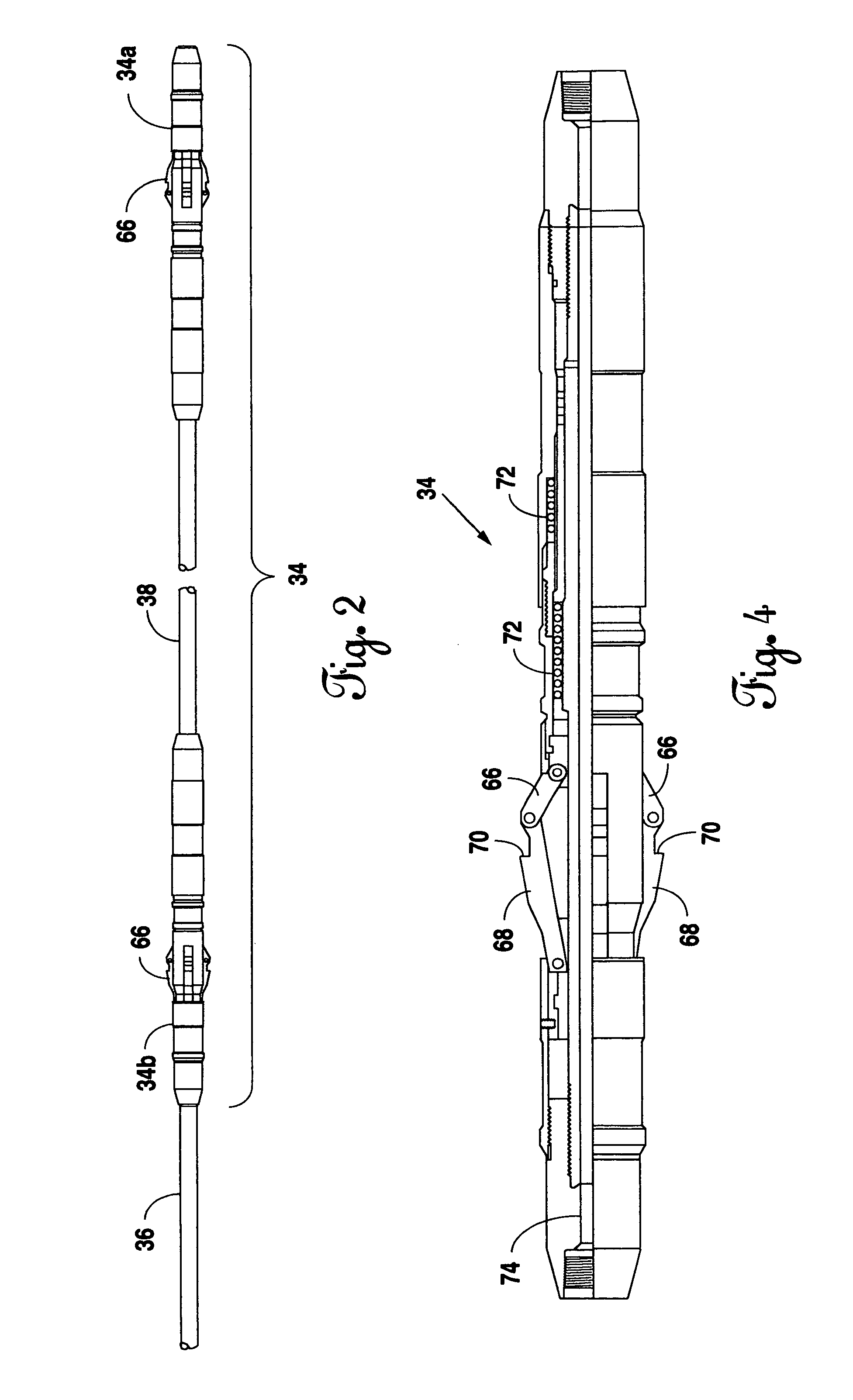

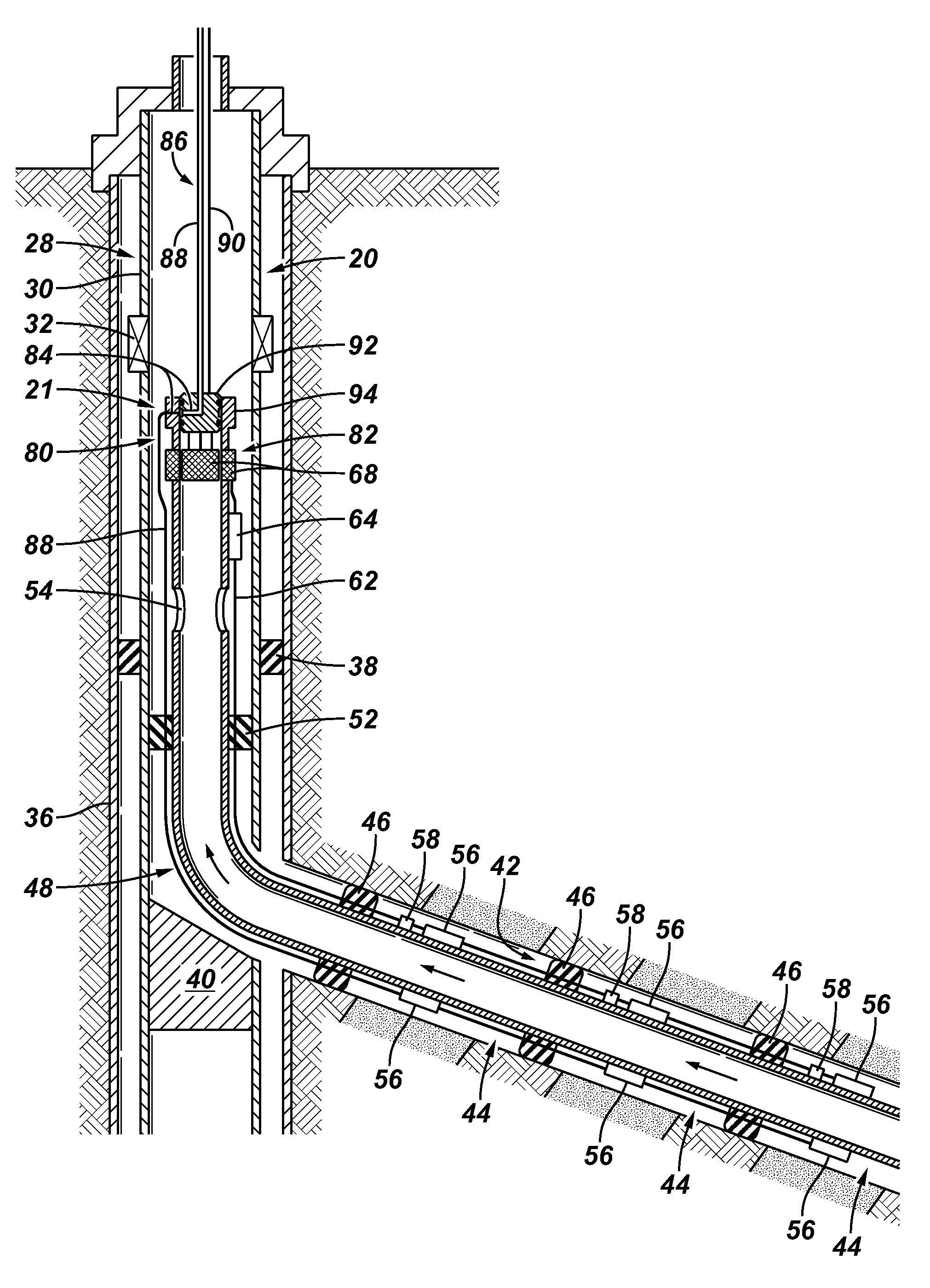

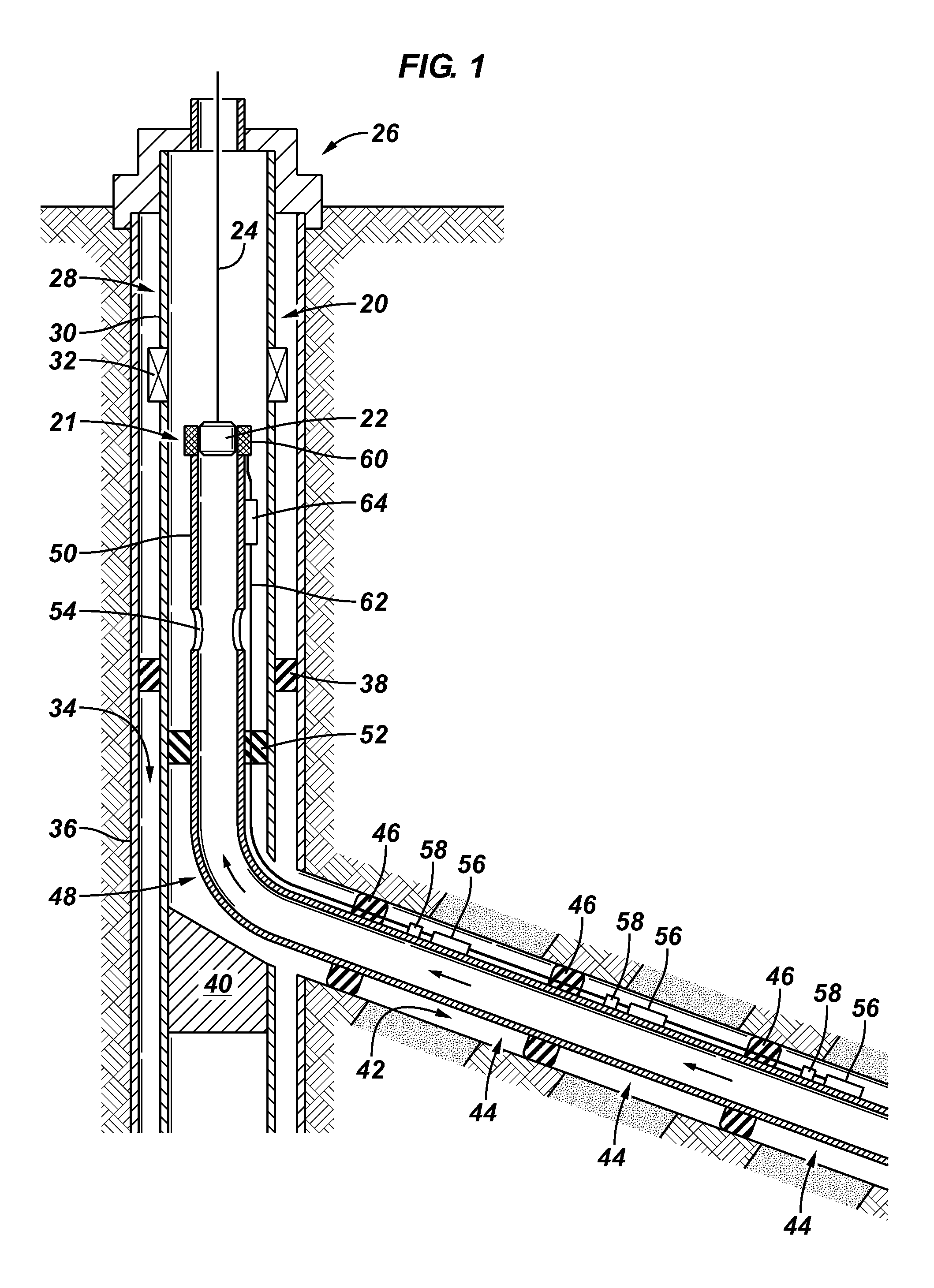

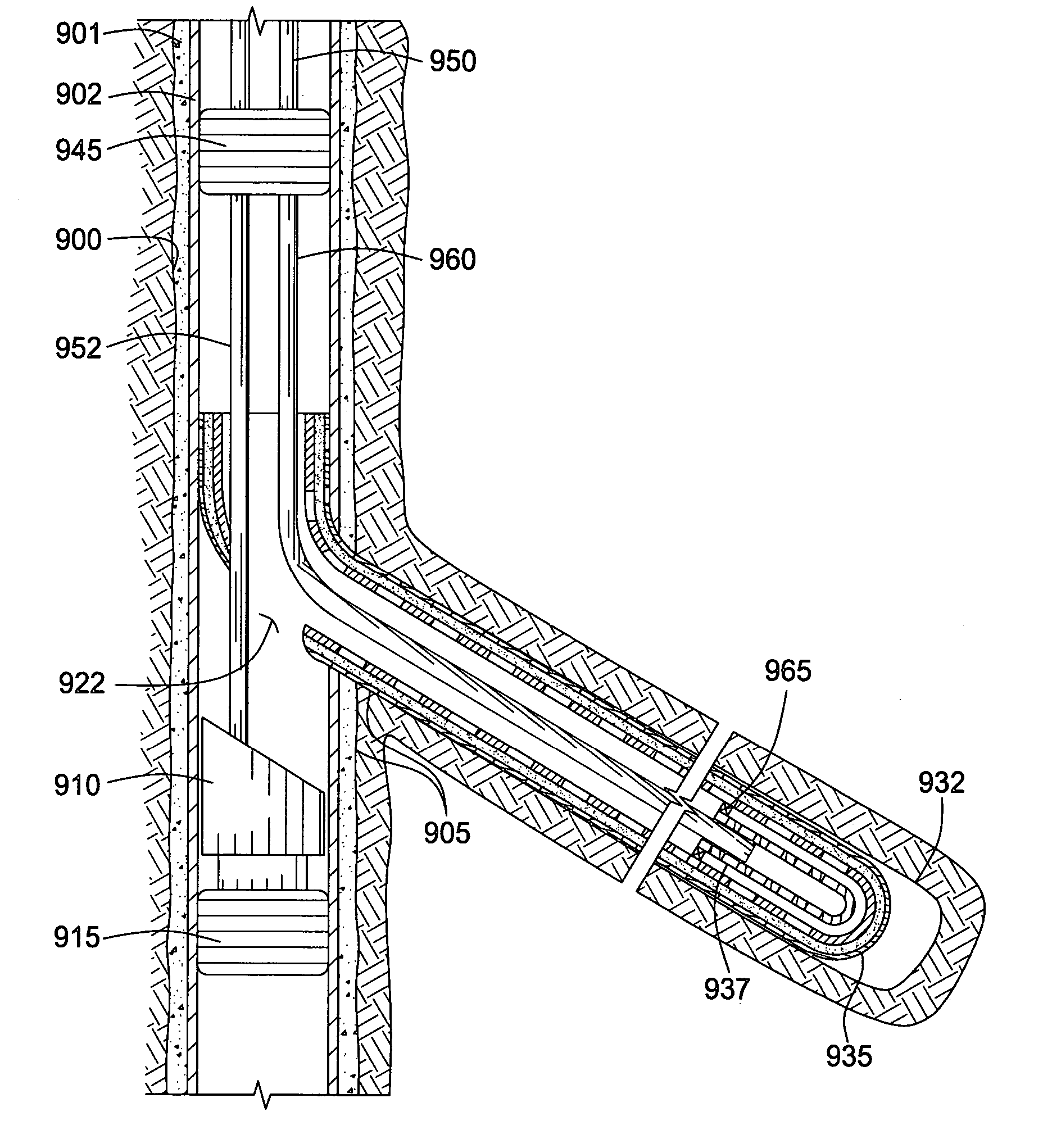

Apparatus and methods to complete wellbore junctions

A method and apparatus for completing a wellbore junction is provided. In one embodiment, a first leg of a screen is fastened within a first tubular with a preformed window. The first tubular houses a whipstock with a cut-out portion containing a folded second leg of the screen. The first tubular is lowered into a junction of a central and a lateral wellbore. A second tubular is lowered within the first tubular and catches an end of the folded second leg of the screen thereby unfolding and expanding the screen as the second tubular is guided into the lateral wellbore. In another embodiment, an expandable sand screen junction component with expandable sand screen production tubing is lowered through a junction of a central and lateral wellbore into the lateral wellbore and expanded into place. A central wellbore access port is milled into the junction component. Various additional methods and apparatuses for providing selective production among the central wellbore, junction, and / or lateral wellbore are provided.

Owner:WEATHERFORD TECH HLDG LLC

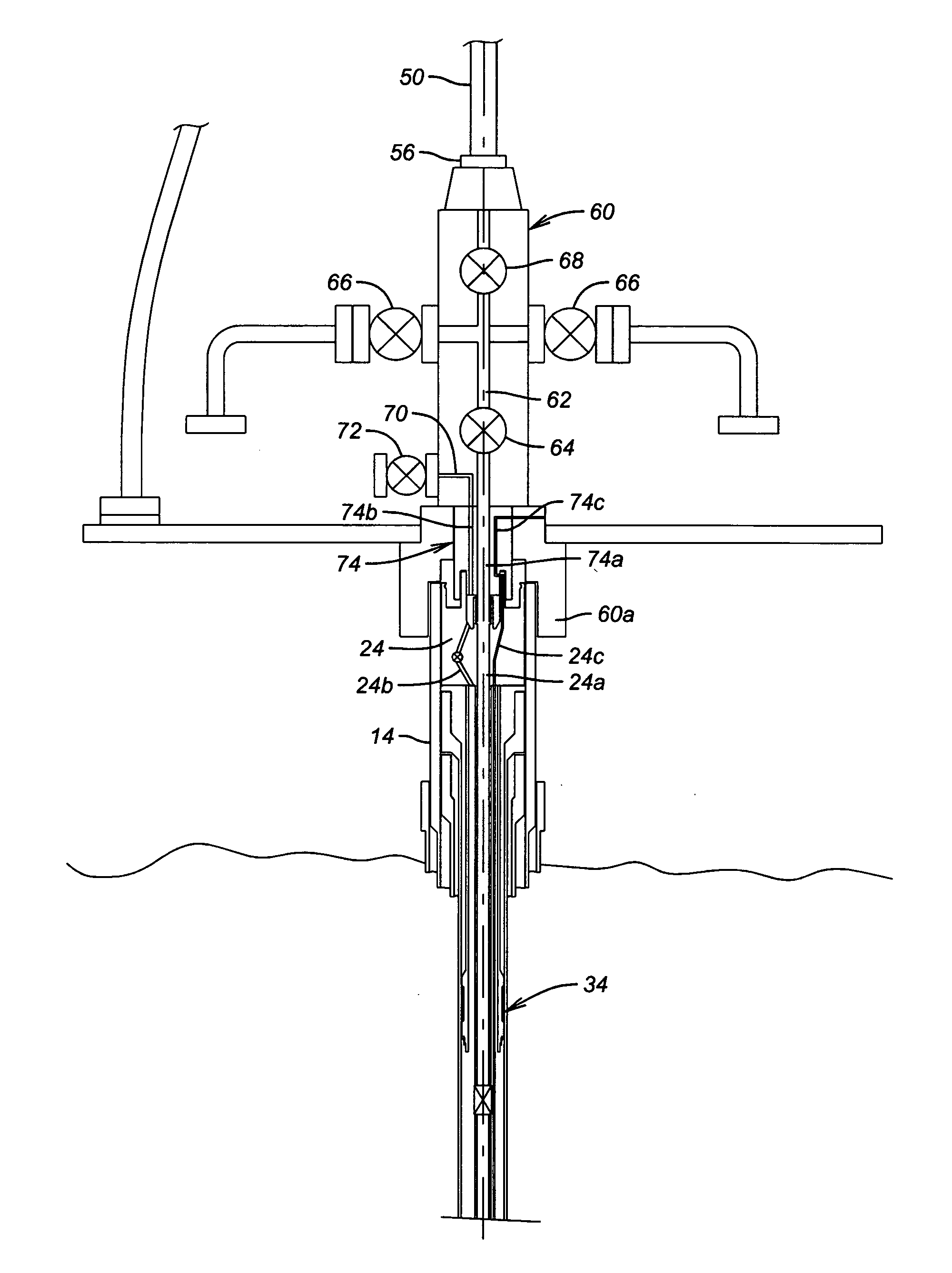

Universal tubing hanger suspension assembly and well completion system and method of using same

The present invention includes a tubing hanger suspension assembly for an oil and gas well completion system and a method of installing same. The tubing hanger suspension assembly includes a tubing hanger housing which is positioned in the wellhead housing. The tubing hanger assembly includes a sealing and lockdown mechanism capable of providing sealing and load support of the production tubing in the production casing string. A stab sub assembly connected to the upper end of the tubing hanger suspension assembly and lower end of the Christmas tree assembly provides downhole hydraulic and electric functionality and annulus access to the production tubing.

Owner:DRIL QUIP +1

Artificial lift, concentric tubing production system for wells and method of using same

An artificial lift, concentric tubing production system for a well and method of using same. The system including an upper concentric tubing string portion comprising an inner production tubing string positioned within an outer production tubing string. A flow crossover assembly is connected to the upper concentric tubing string portion. The flow crossover assembly has first and second passageways. The inner production tubing string is in fluid communication with the first passageway and the outer production tubing string in fluid communication with the second passageway. An upper transducer is in fluid communication with one of the passageways of the flow crossover assembly and a lower apparatus is in fluid communication with the other of the passageways of the flow crossover assembly. The upper transducer may be a pump such as an electric submersible pump or a progressive cavity pump. The lower apparatus may be a pump, including an electric submersible pump, or a liquid / gas separator.

Owner:YPF INT

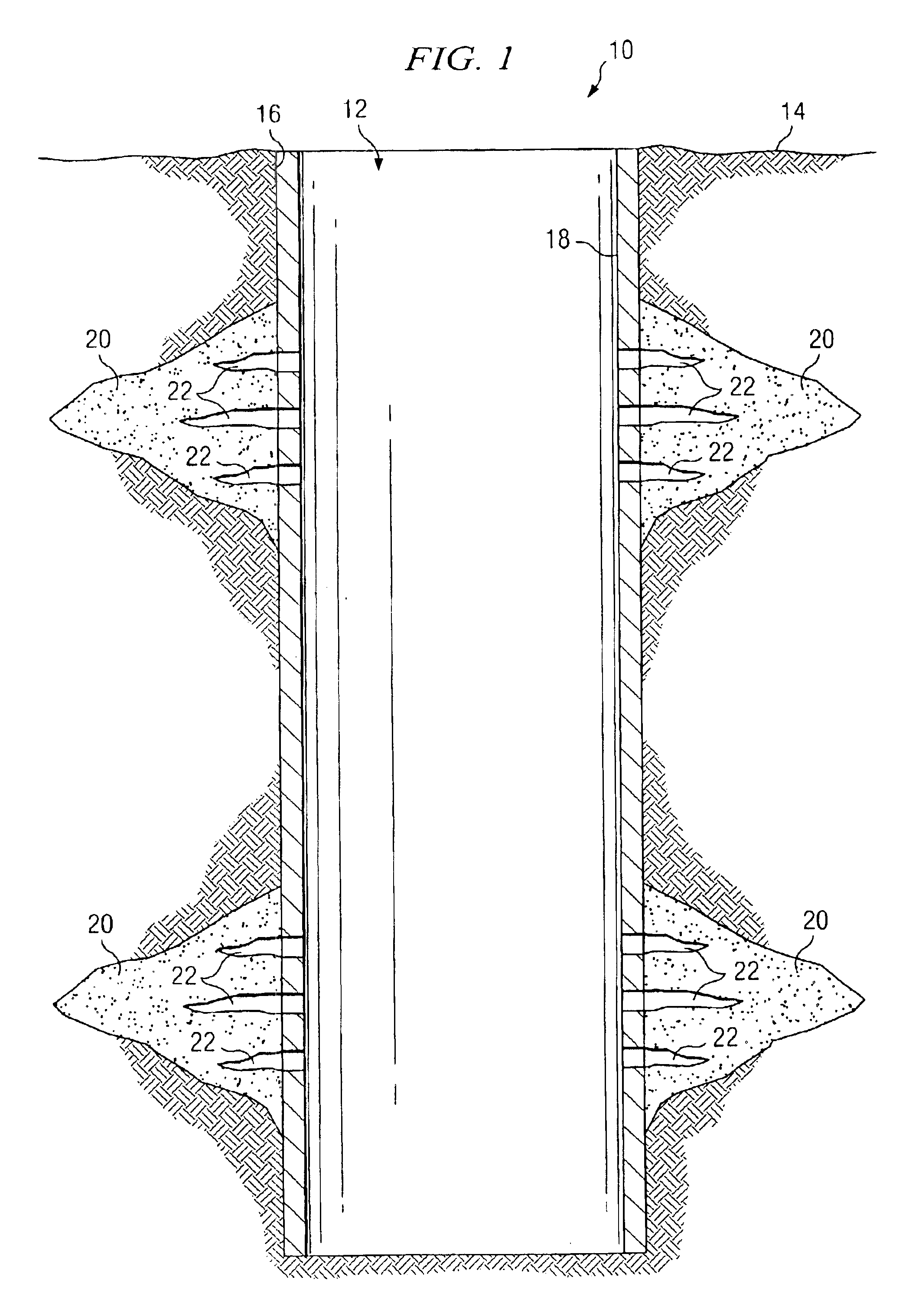

Method and apparatus for sealing an undesirable formation zone in the wall of a wellbore

A method and apparatus are provided for intentionally inducing “formation plugging” in a partially damaged section, water layer, or an otherwise undesirable target zone in the wall of a wellbore. The rigless apparatus is deployed to the target zone by coiled tubing and includes a pair of adjacent inflatable packers or a multi-section inflatable thermoplastic balloon component which is in valved fluid communication with an inflating container filled with formation plugging fluid. The inflating container is in valved fluid communication with a reactant-filled chemical container, the reactant being activated by contact with reactant fluid pumped through the coiled tubing via a circulation valve. The hot pressurized exothermic reaction products pass into the inflation container and displace the formation plugging fluid into the balloon sections and through weakened portions of a central balloon to penetrate the walls of the target zone. The expanded central balloon is melted by the heat of the chemical reaction and a portion adheres to the formation wall thereby sealing the undesirable target zone; thereafter, the remaining balloon sections are deflated or ruptured to permit the apparatus to be withdrawn through the production tubing.

Owner:SAUDI ARABIAN OIL CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com