Inflow control device

a control device and inflow technology, applied in the direction of drilling machines and methods, borehole/well accessories, underwater drilling, etc., can solve the problems of reducing affecting the oil production rate, and affecting the recovery rate of wells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016]It will be appreciated that the present invention may take many forms and embodiments. In the following description, some embodiments of the invention are described and numerous details are set forth to provide an understanding of the present invention. Those skilled in the art will appreciate, however, that the present invention may be practiced without those details and that numerous variations and modifications from the described embodiments may be possible. The following description is thus intended to illustrate and not to limit the present invention.

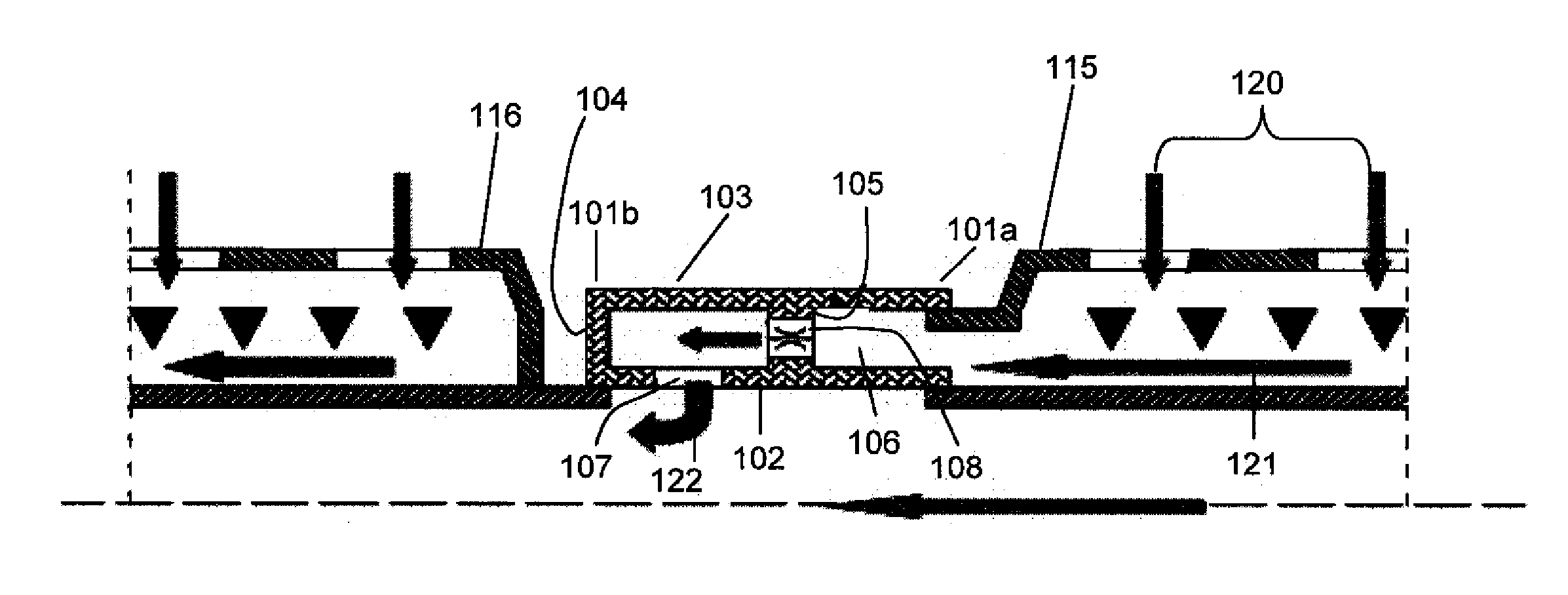

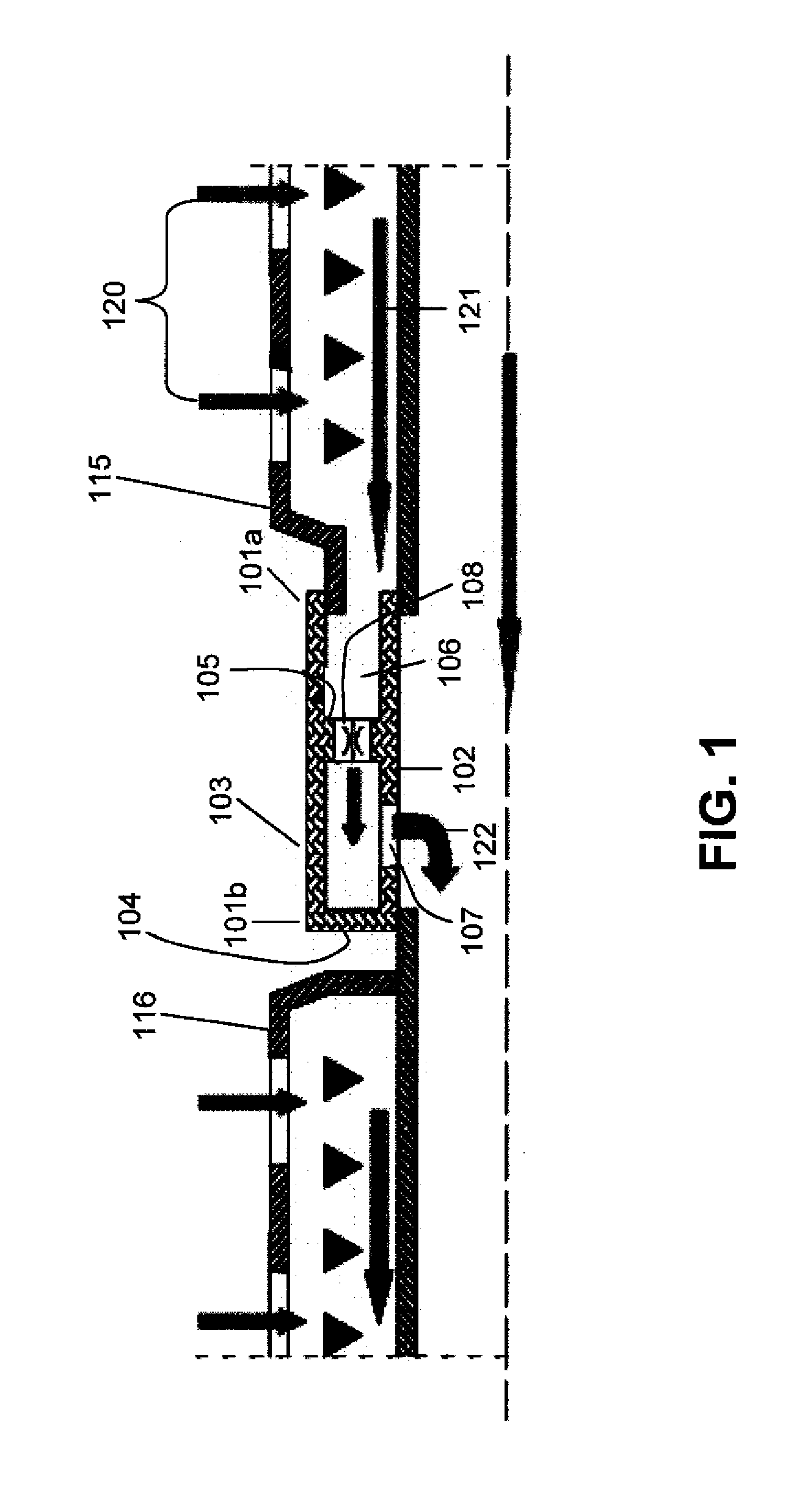

[0017]With reference to FIG. 1, one embodiment of an inflow control device 101 in accordance with the present invention is illustrated. Inflow control device 101 comprises a body with two ends 101a and 101b, and the body comprises inner and outer concentric tubular members 102 and 103, respectively. An annulus 106 is defined between tubular members 102 and 103, with the annulus 106 being closed at end 101b and being open at e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com