Patents

Literature

521 results about "Production string" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The production string is a part of an oil well that is composed of the production tubing and other completion components and serves as the conduit through which the production fluid flows from the oil reservoir to the surface through the wellhead. Its purpose is to both contain the fluids from contaminating the environment or eroding the other well structures, such as the casing.

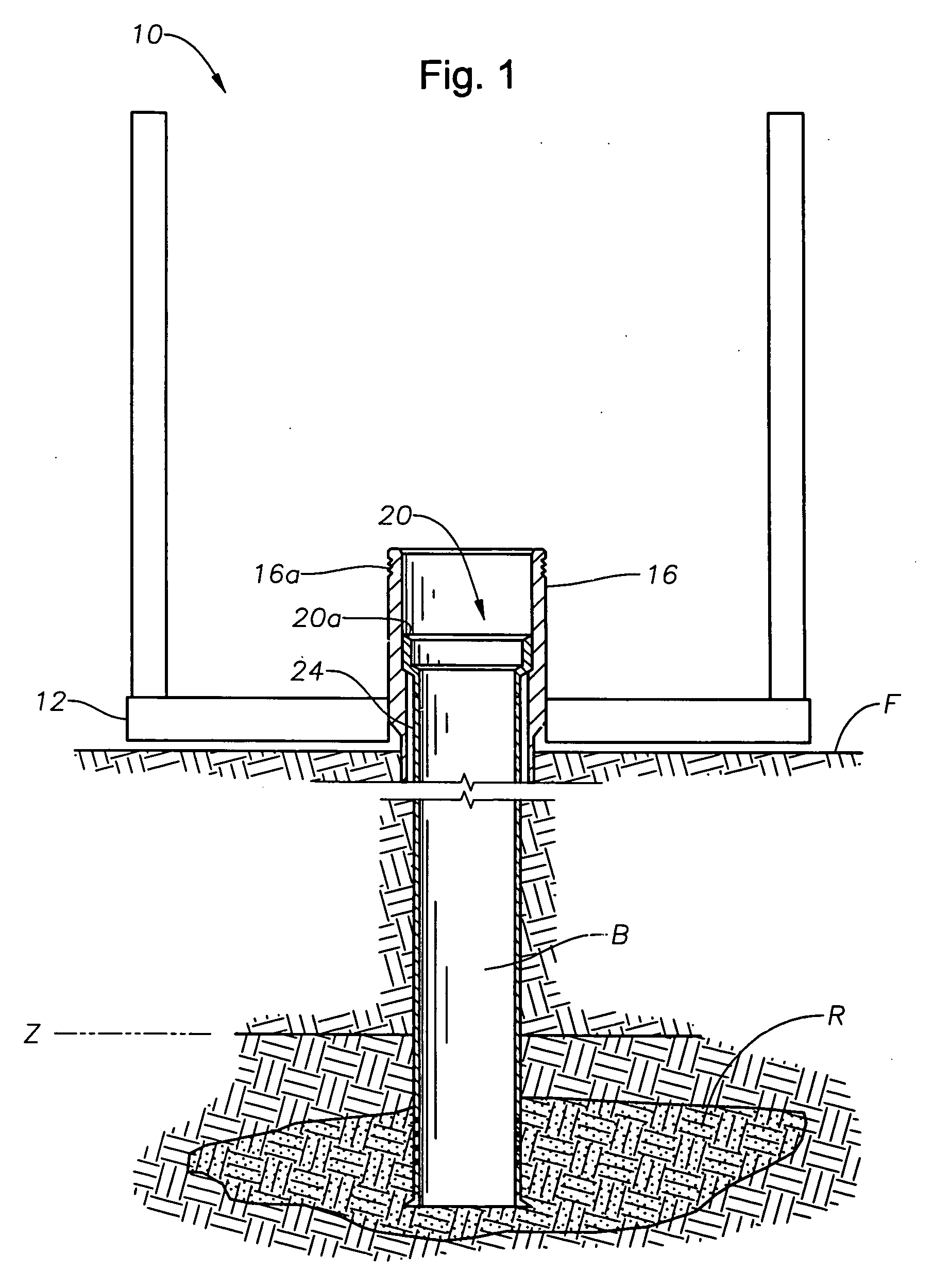

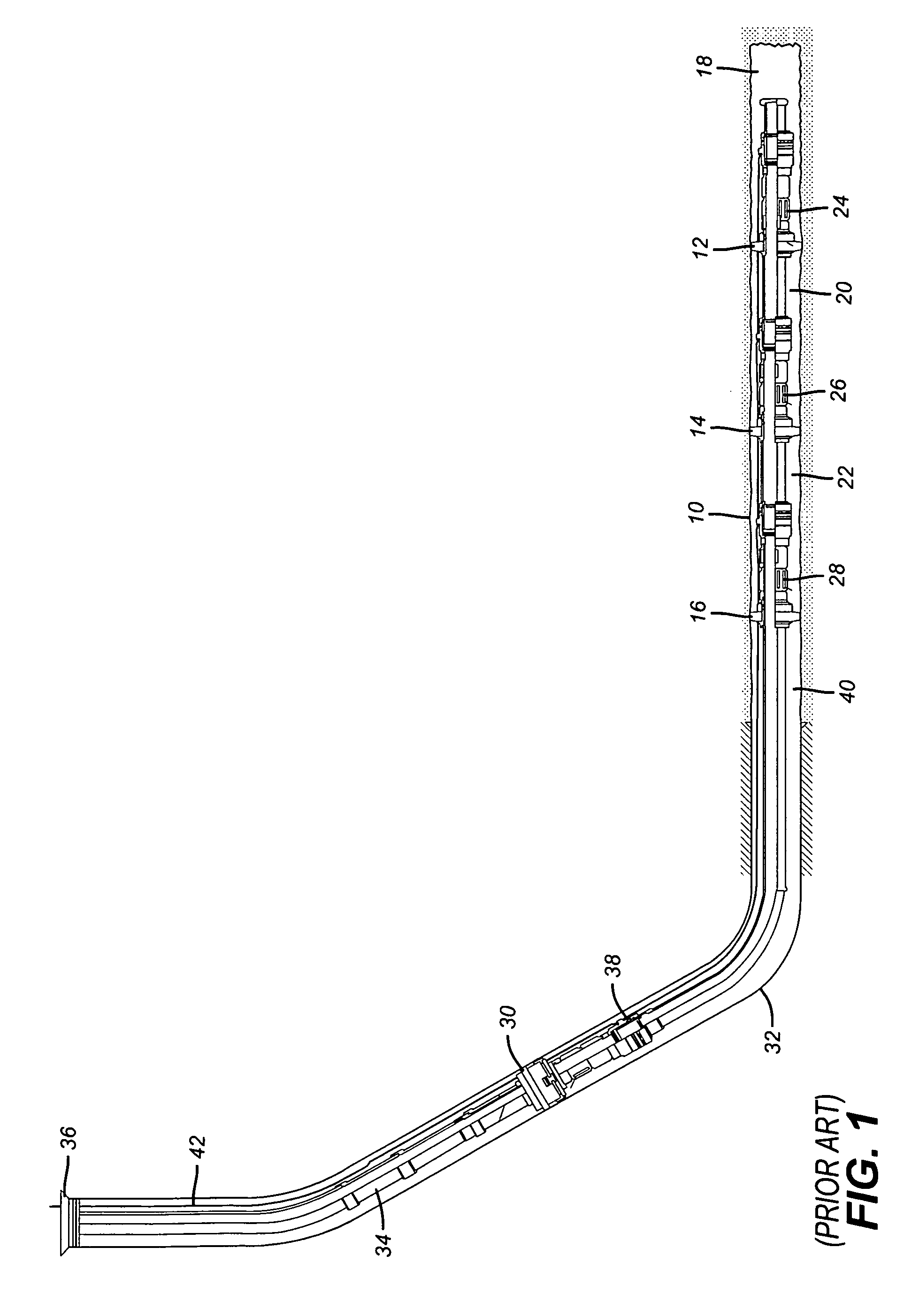

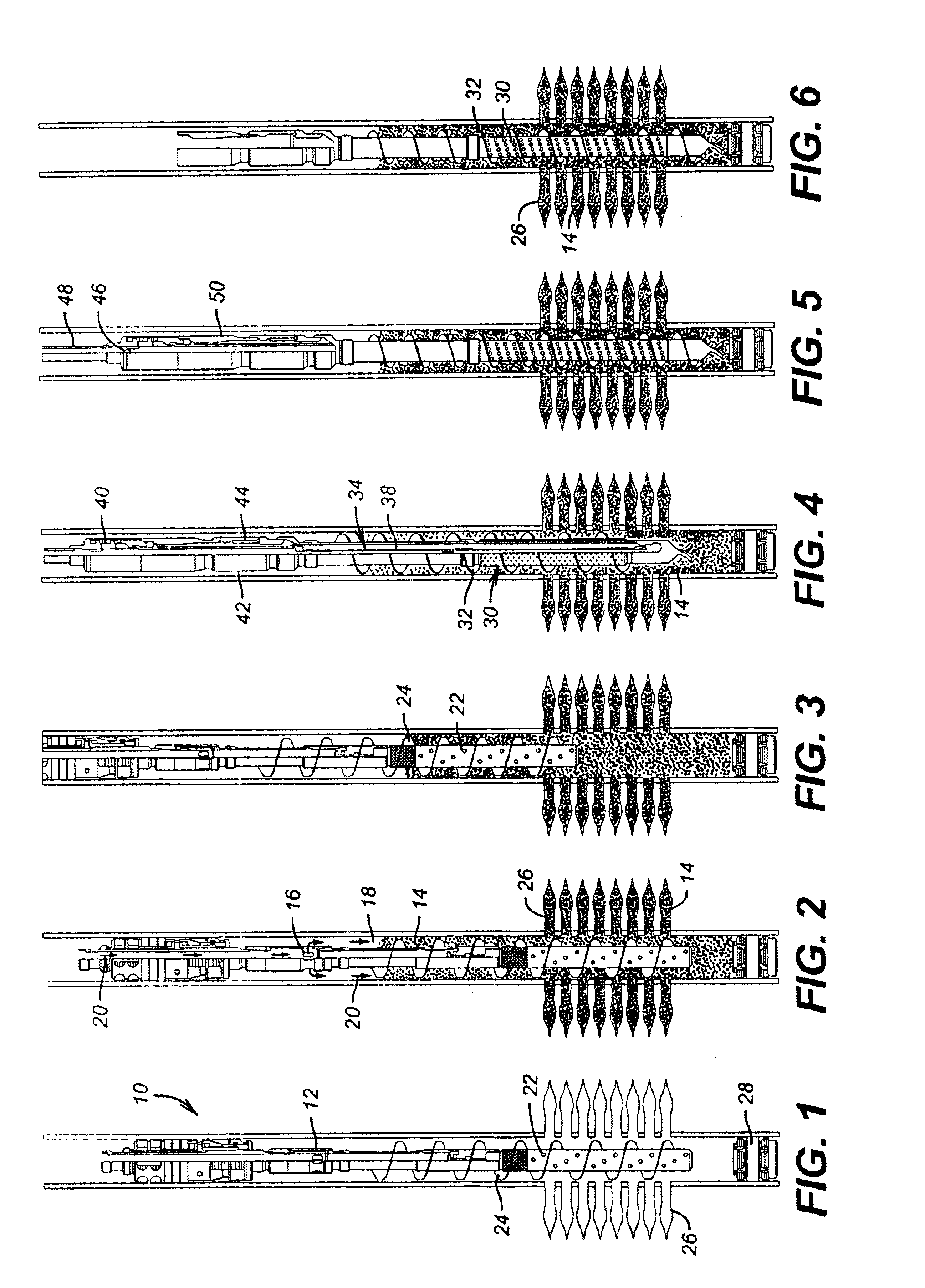

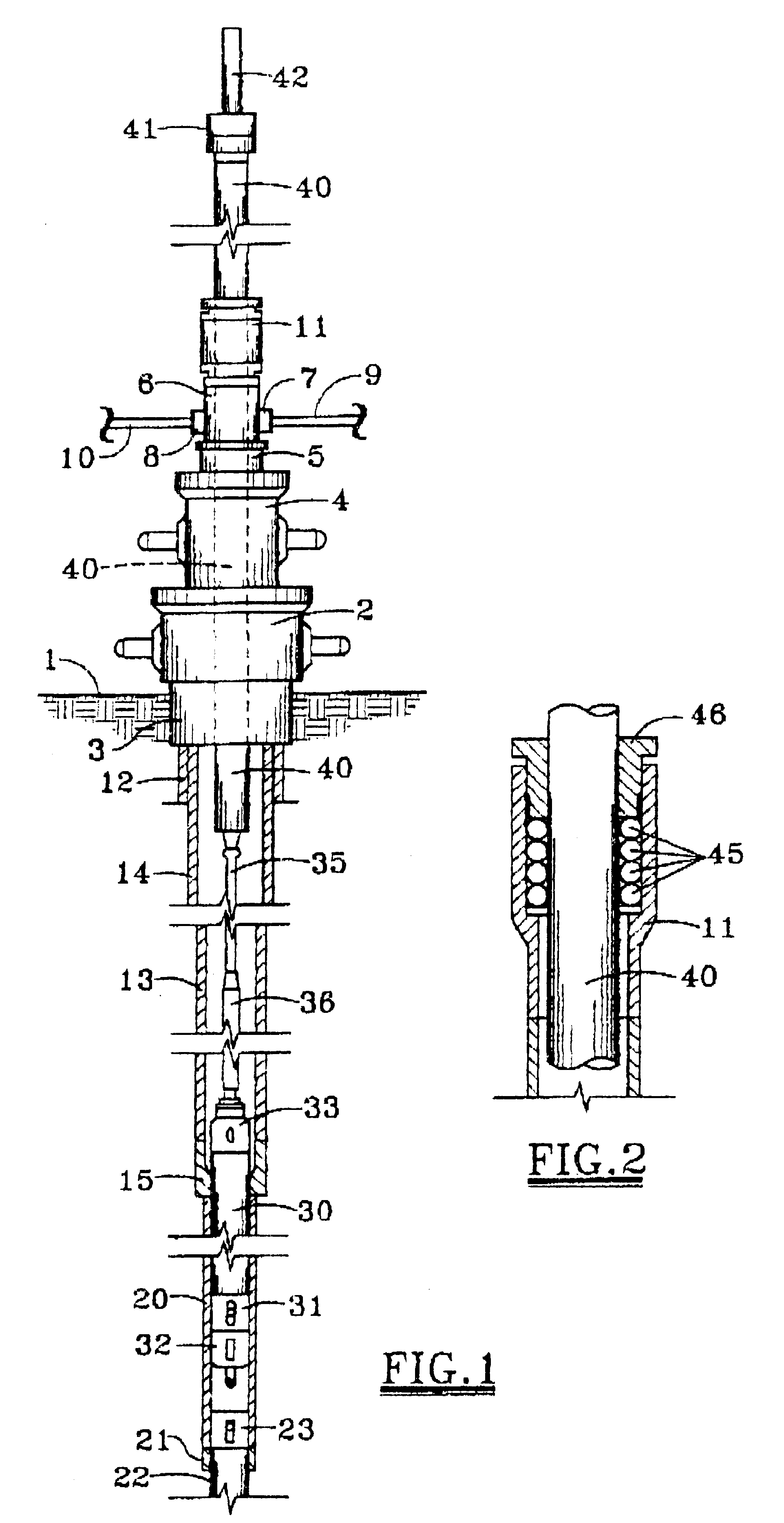

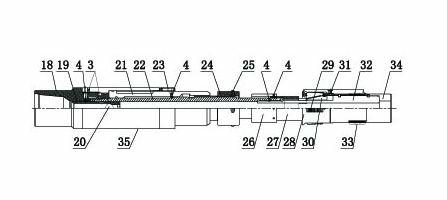

System for installation of well stimulating apparatus downhole utilizing a service tool string

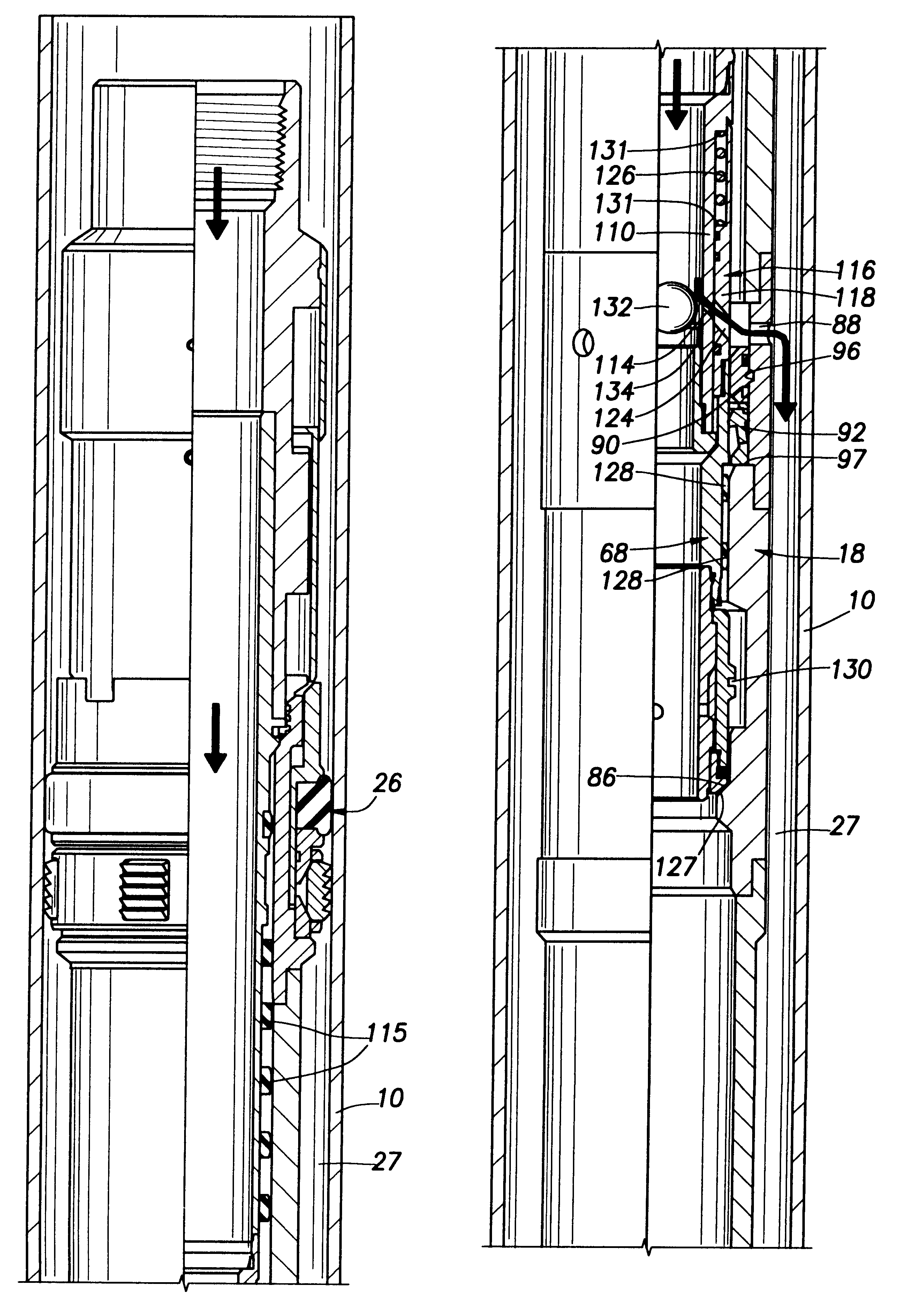

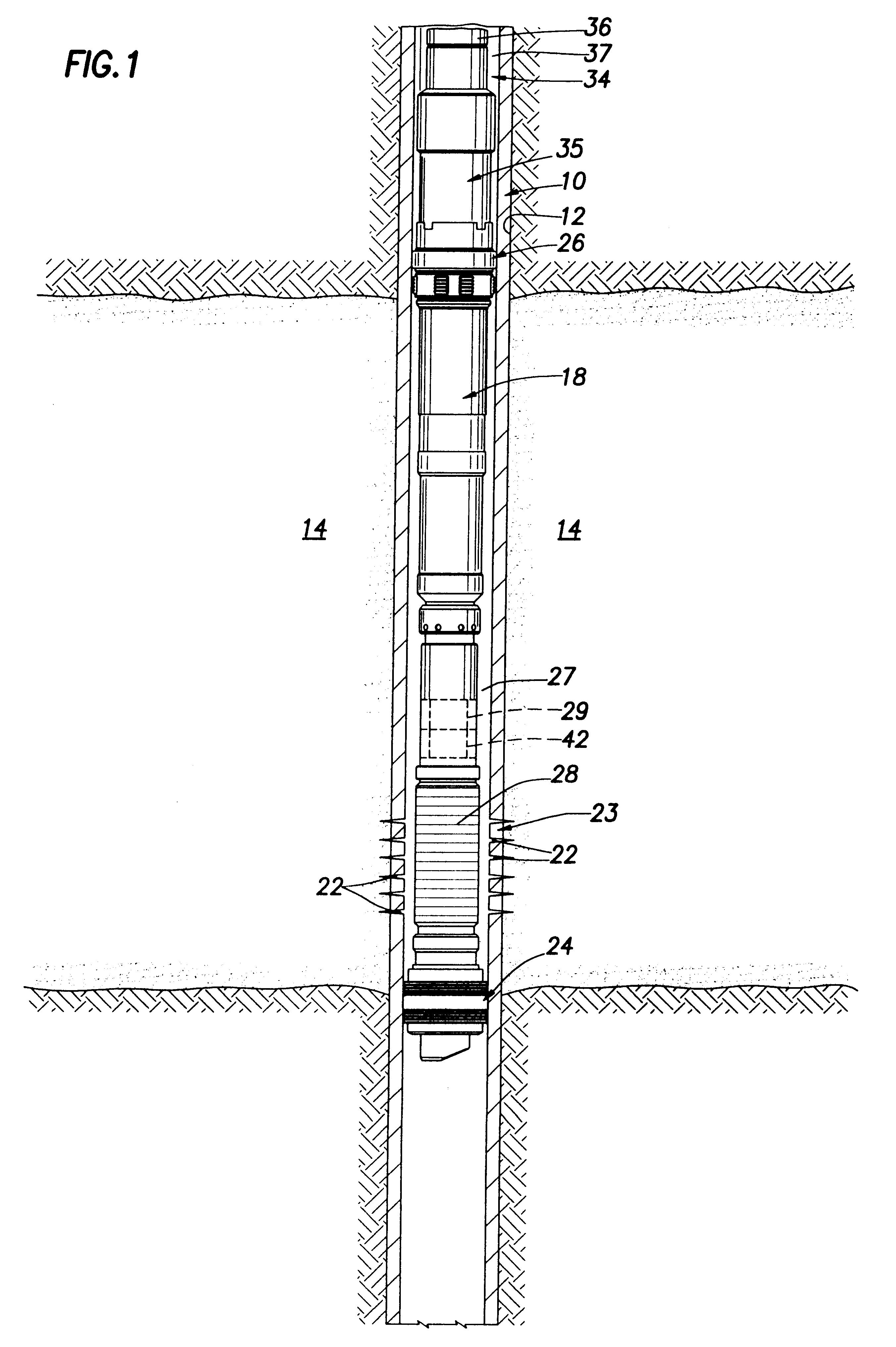

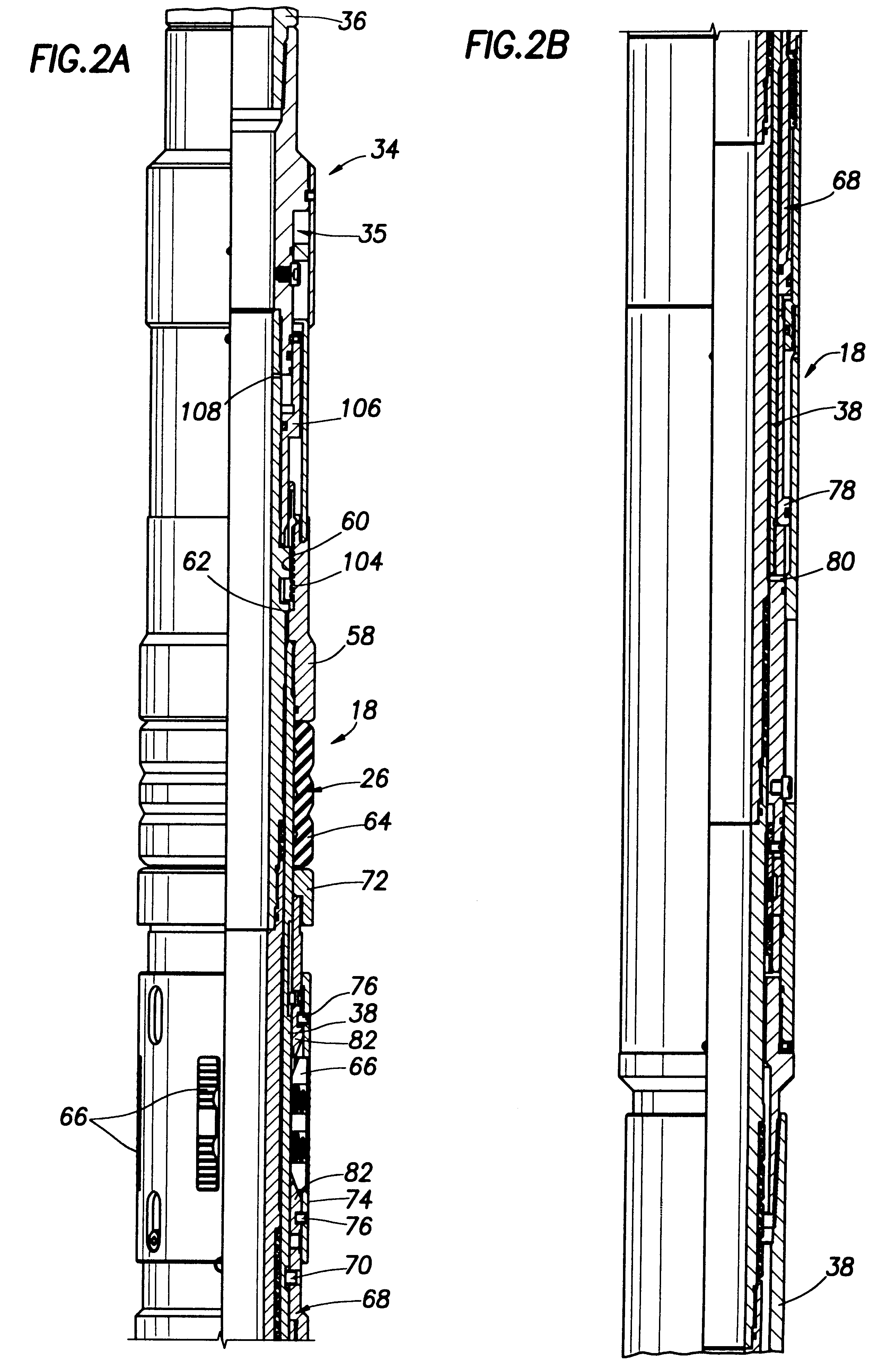

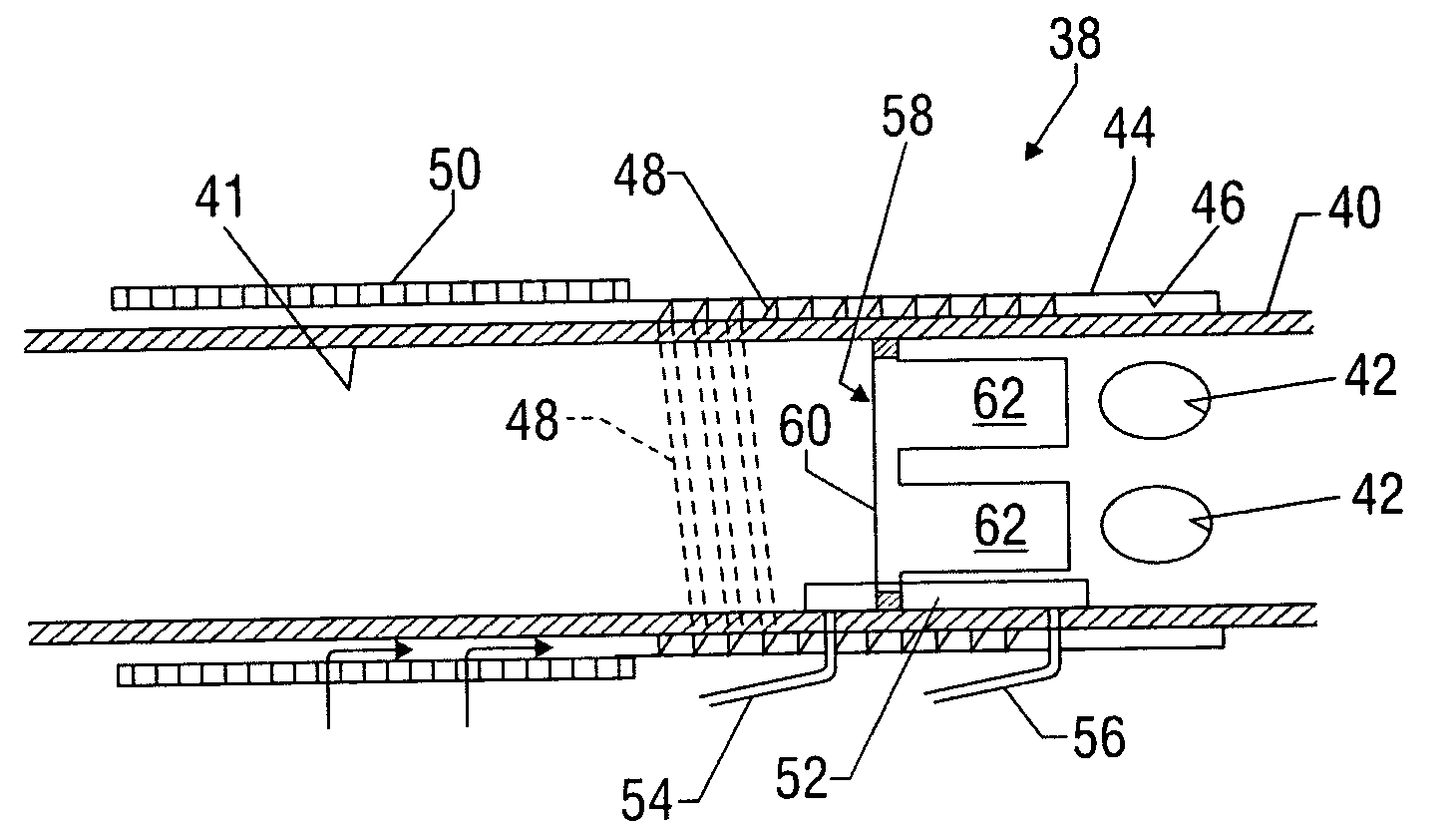

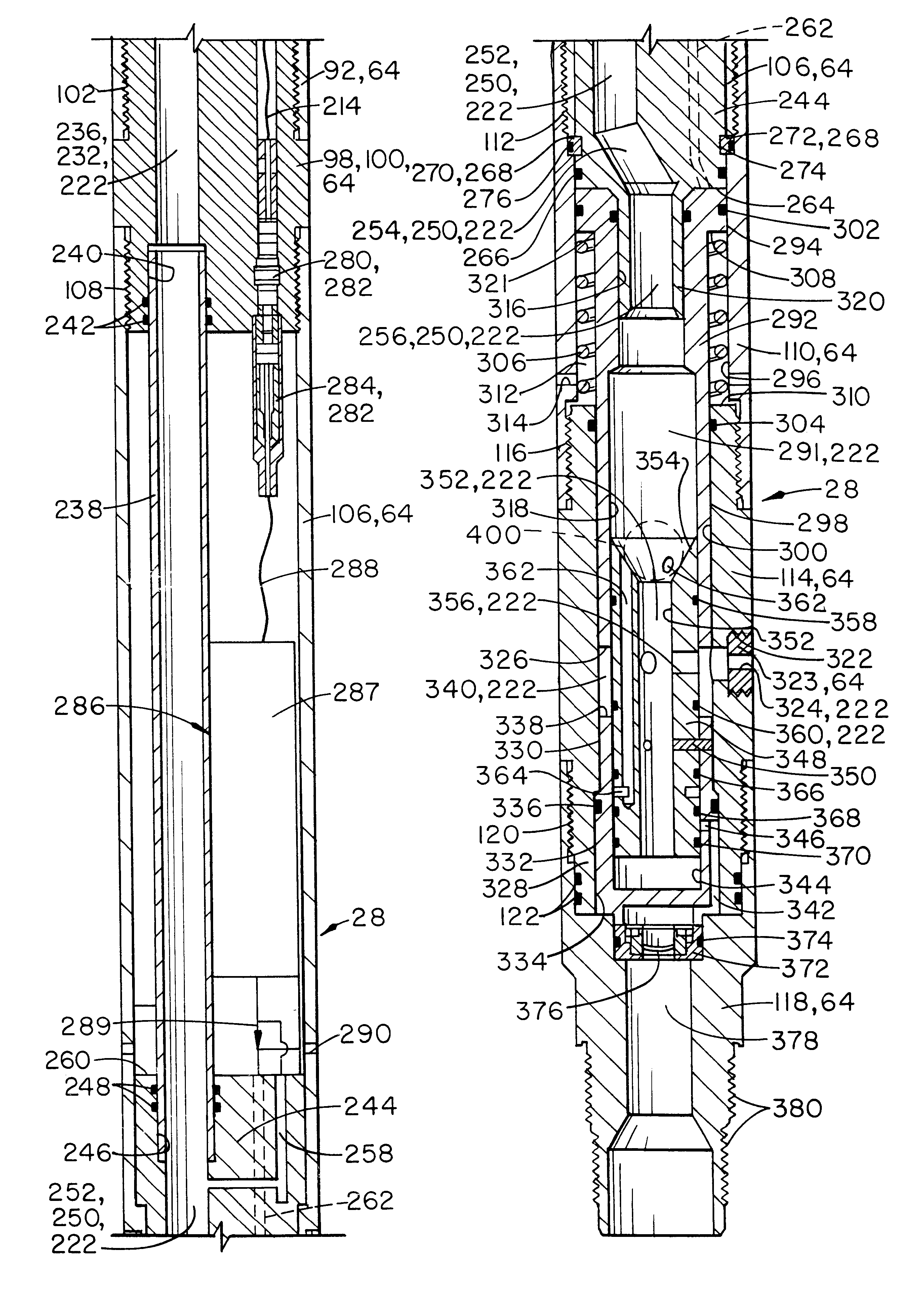

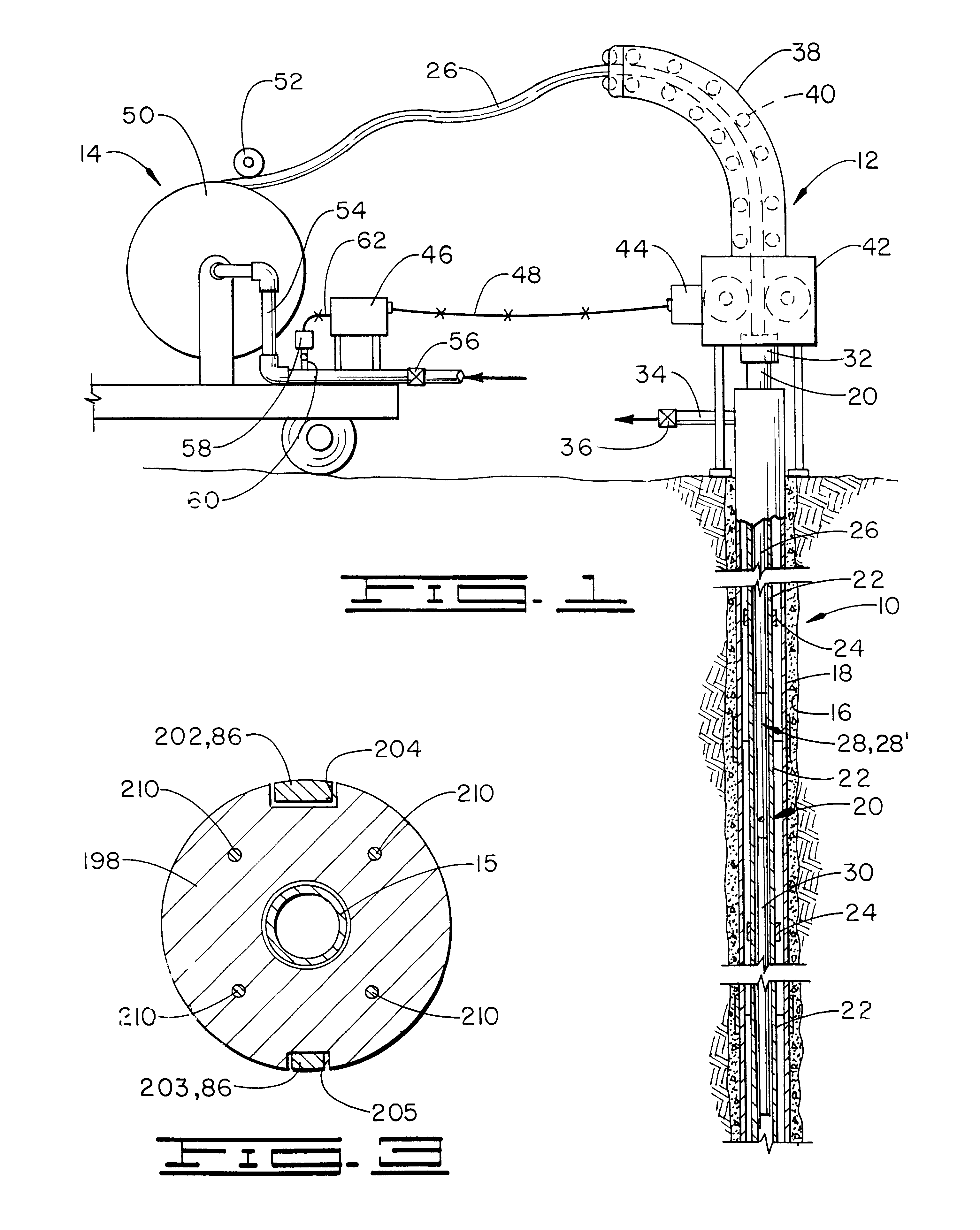

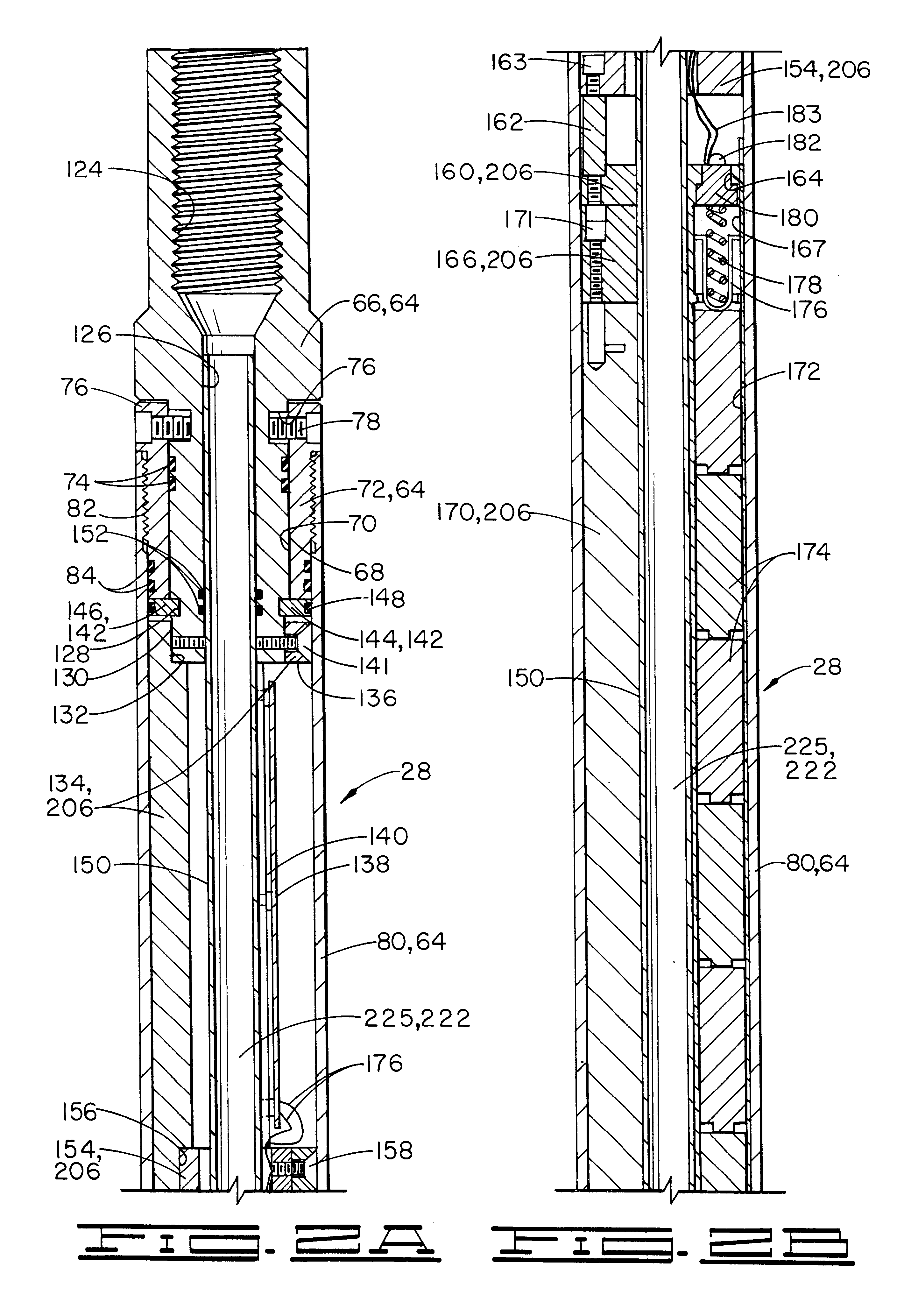

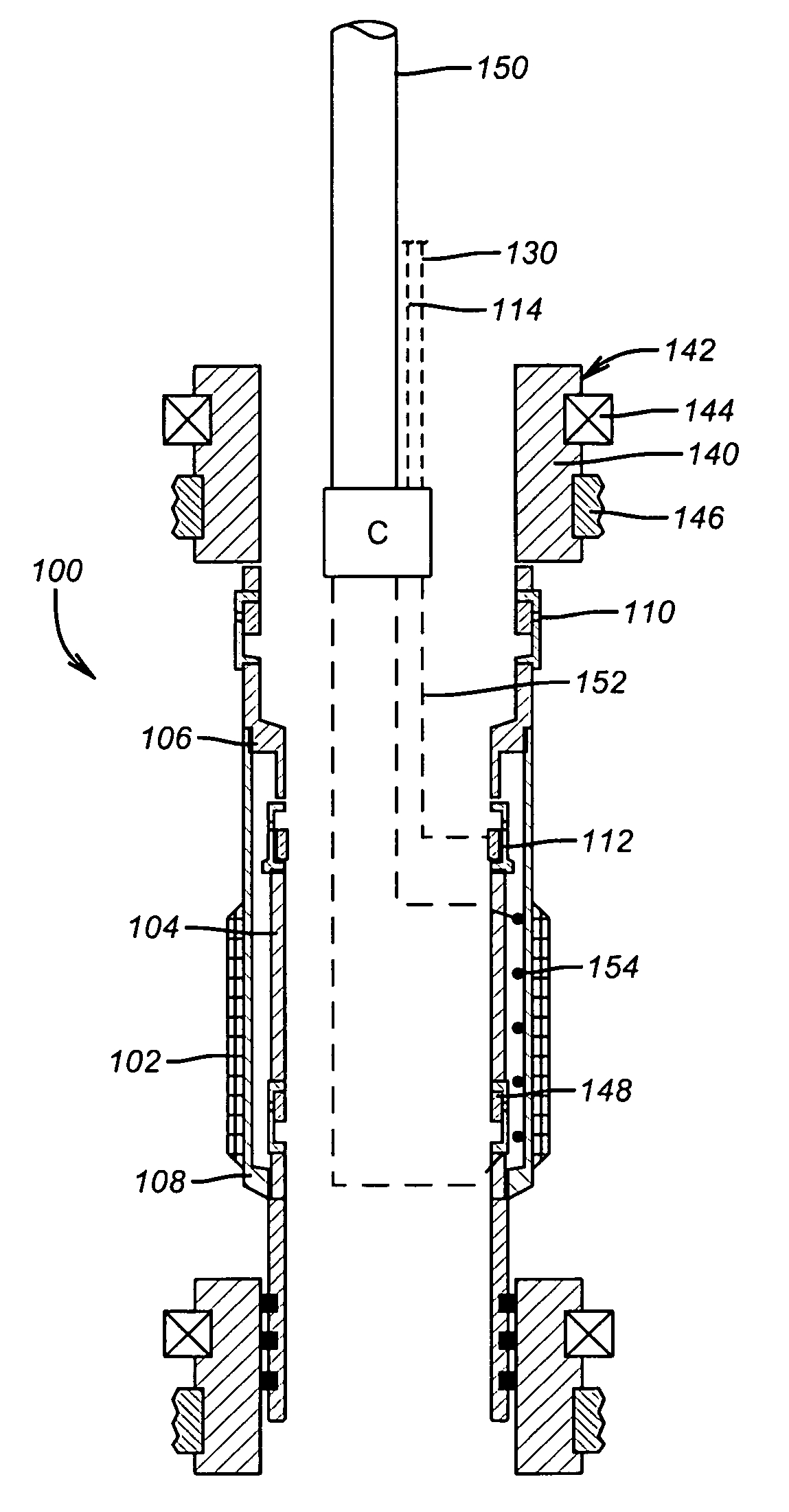

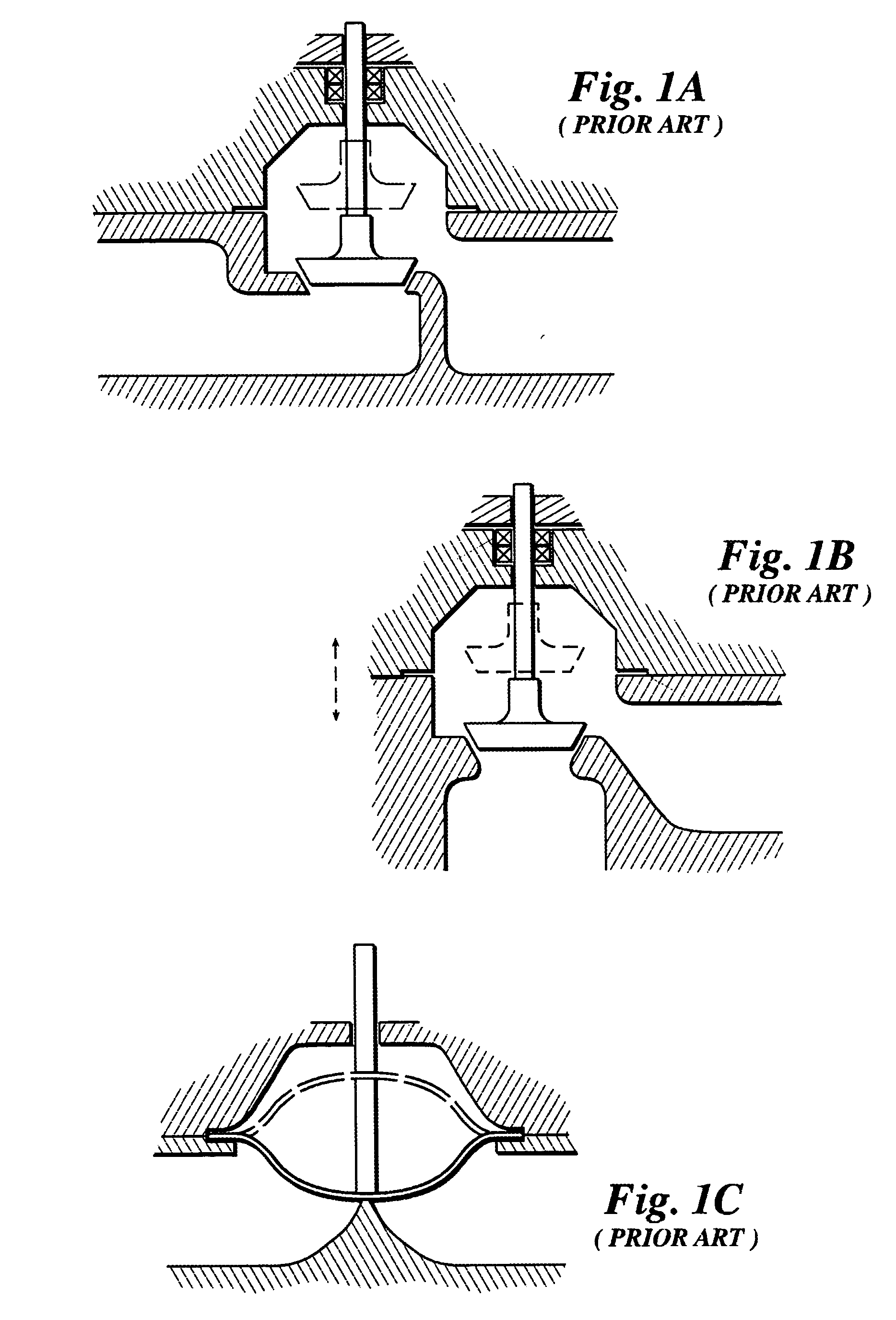

A service tool string (34) is releasably attached to a bottom hole assembly (18) and forms a production string as well as a work string. The tool (35) has a mandrel (102) and a slide valve assembly (68) mounted on the mandrel for relative sliding movement. Crossover ports (114, 124) are provided in the mandrel (102) and the slide valve assembly (68). Slide valve assembly (68) moves by gravity and spring action when not contacted by the bottom hole assembly (18) to a position in which ports (114, 124) are blocked as shown in FIG. 7B. Upon contact of slidable valve assembly (68) with the bottom hole assembly (18), slide valve assembly is moved upwardly for alignment of ports (114, 124) as shown in FIGS. 5B and 6B. An equalizing valve (29) as shown in FIGS. 10-12 is effective to equalize the fluid pressure within the bottom hole assembly (18) with the fluid pressure outside the perforated casing section (23) so that in a reverse position as shown in FIG. 7B, the service tool (35) can be lifted to a position above the upper packer assembly (26) and above the bottom hole assembly (18). A diverter ball (132) seated on a ball catcher (134) is effective to divert the fracturing fluid outwardly through crossover ports (114, 124) as shown in FIG. 6B for downward flow through the annulus (27) into the formation adjacent the perforated casing section (23).

Owner:SCHLUMBERGER TECH CORP

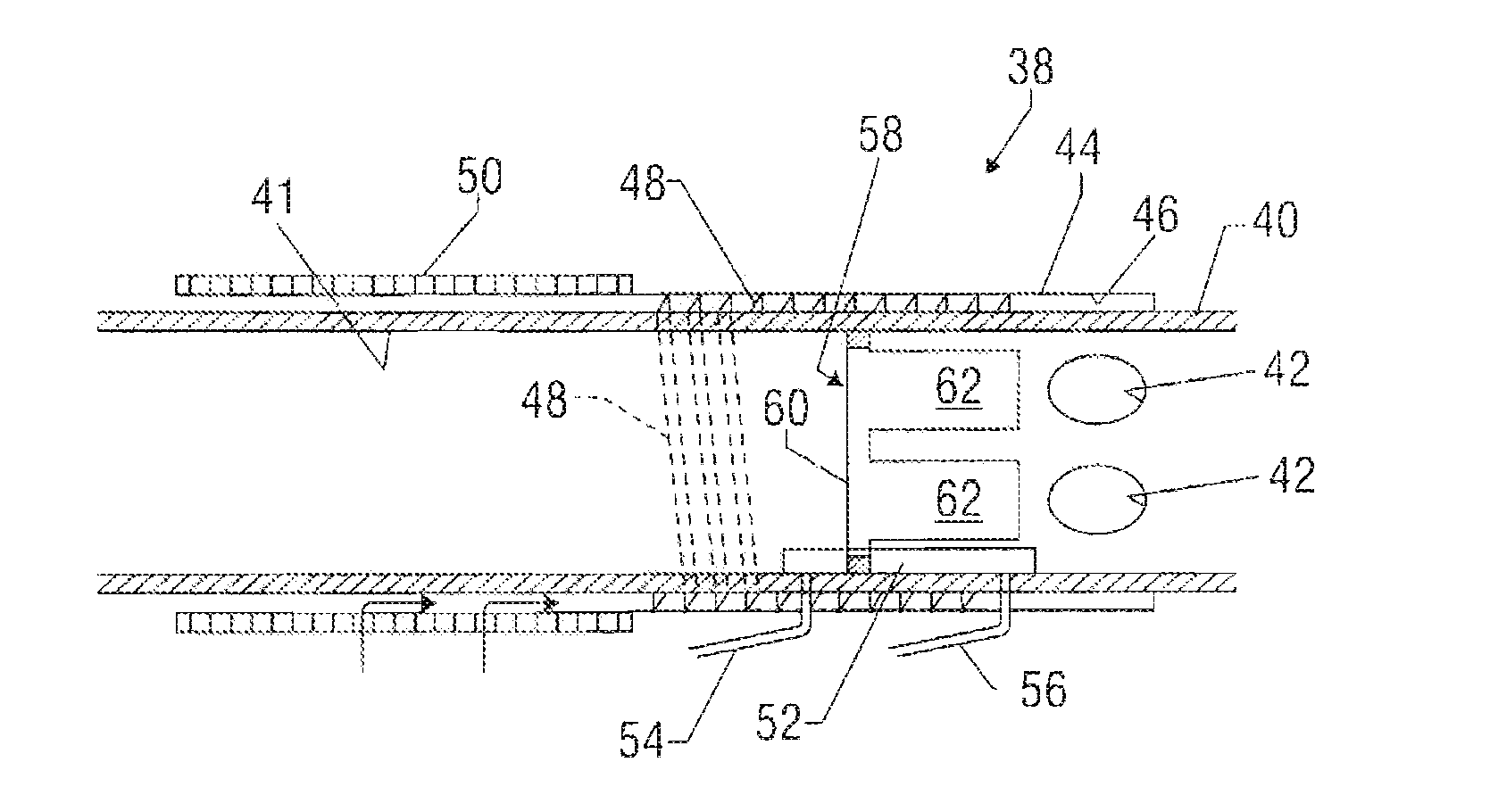

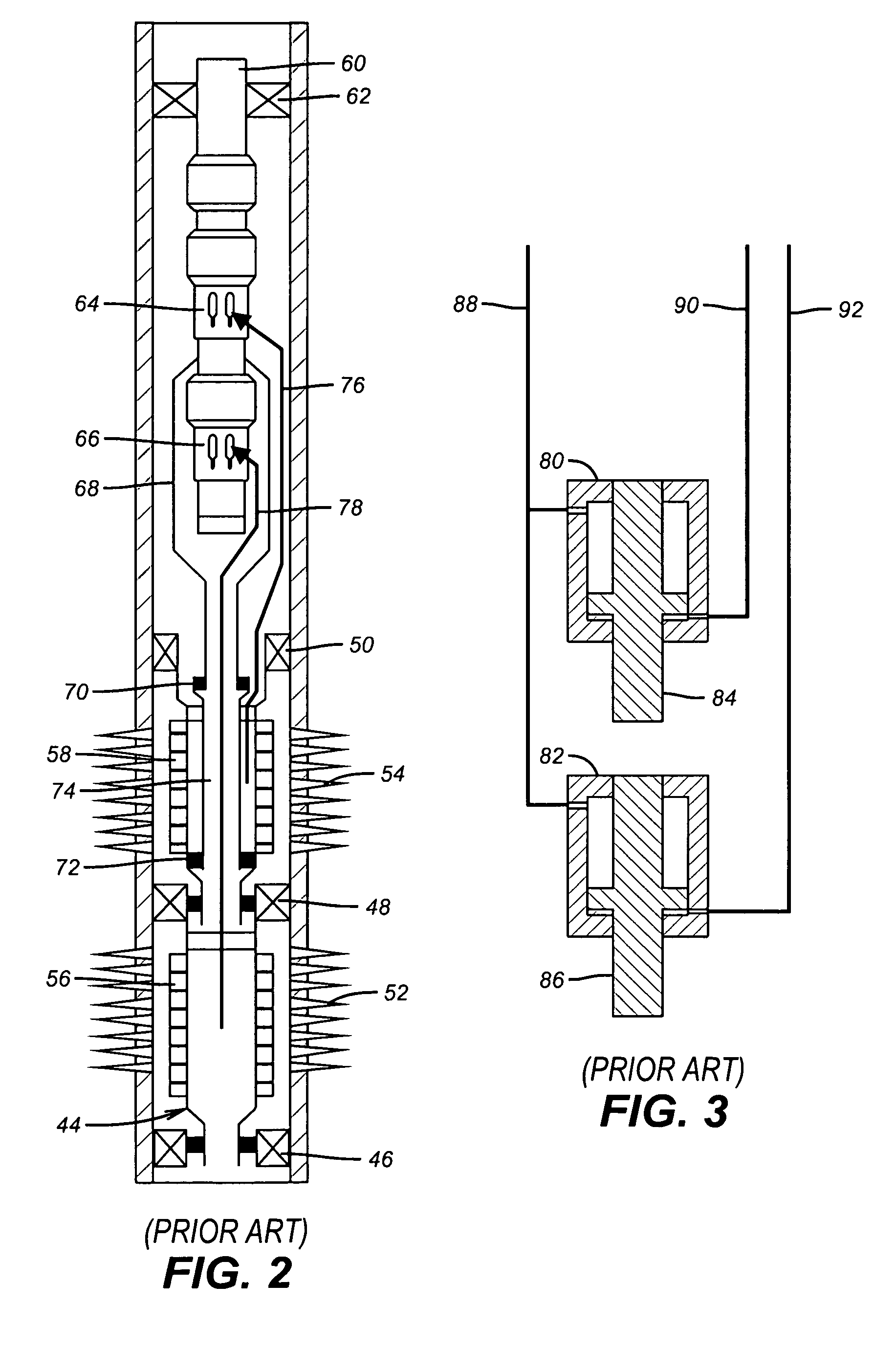

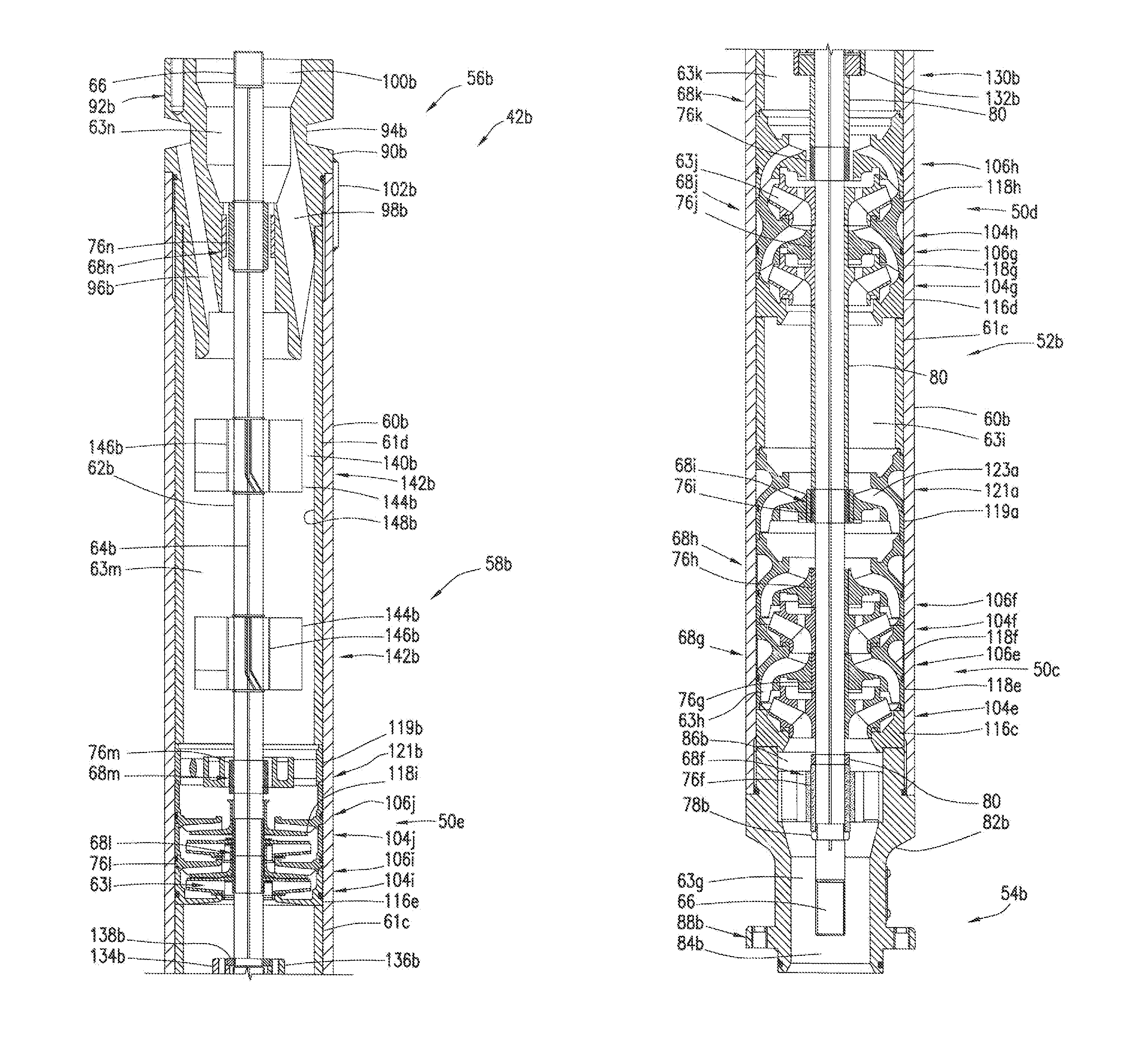

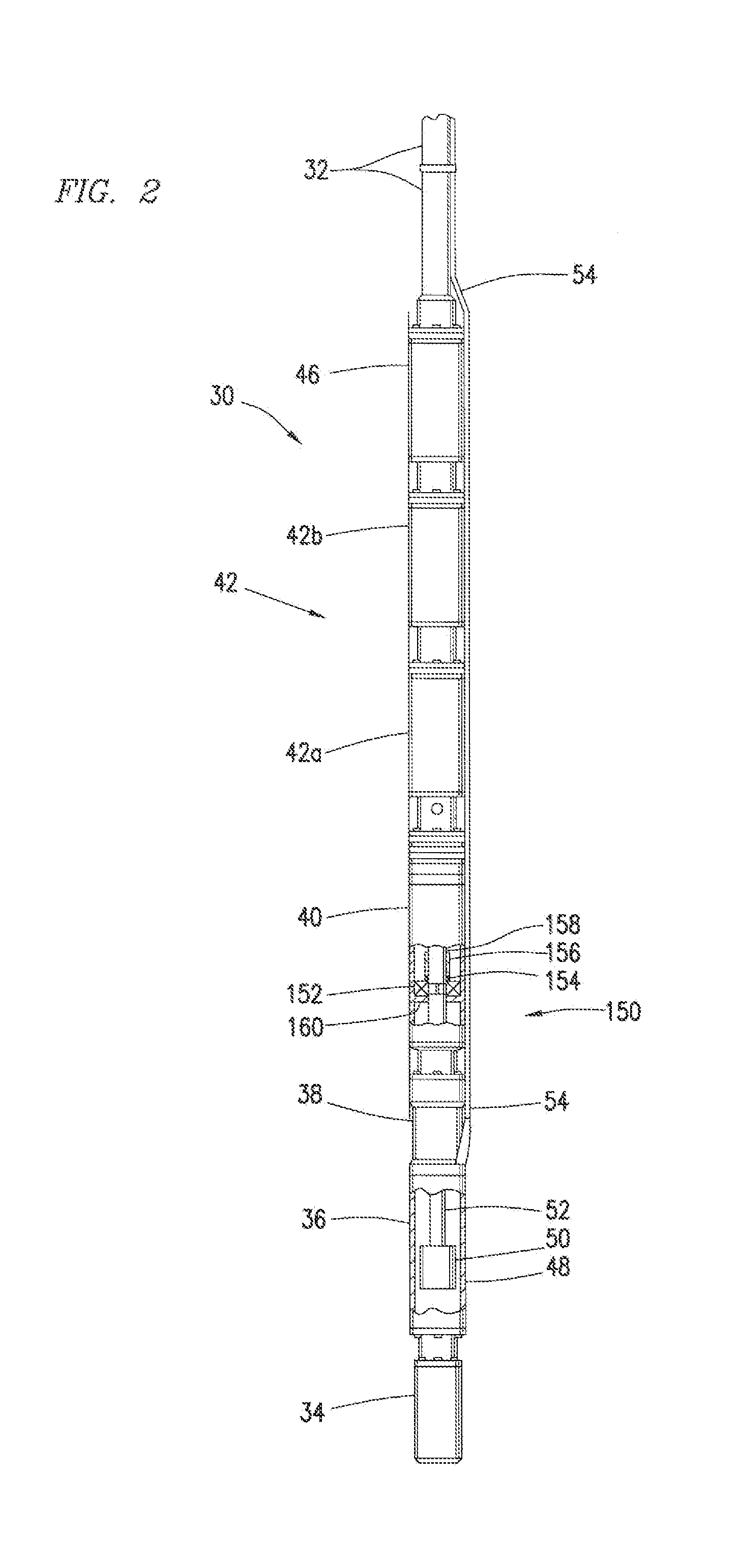

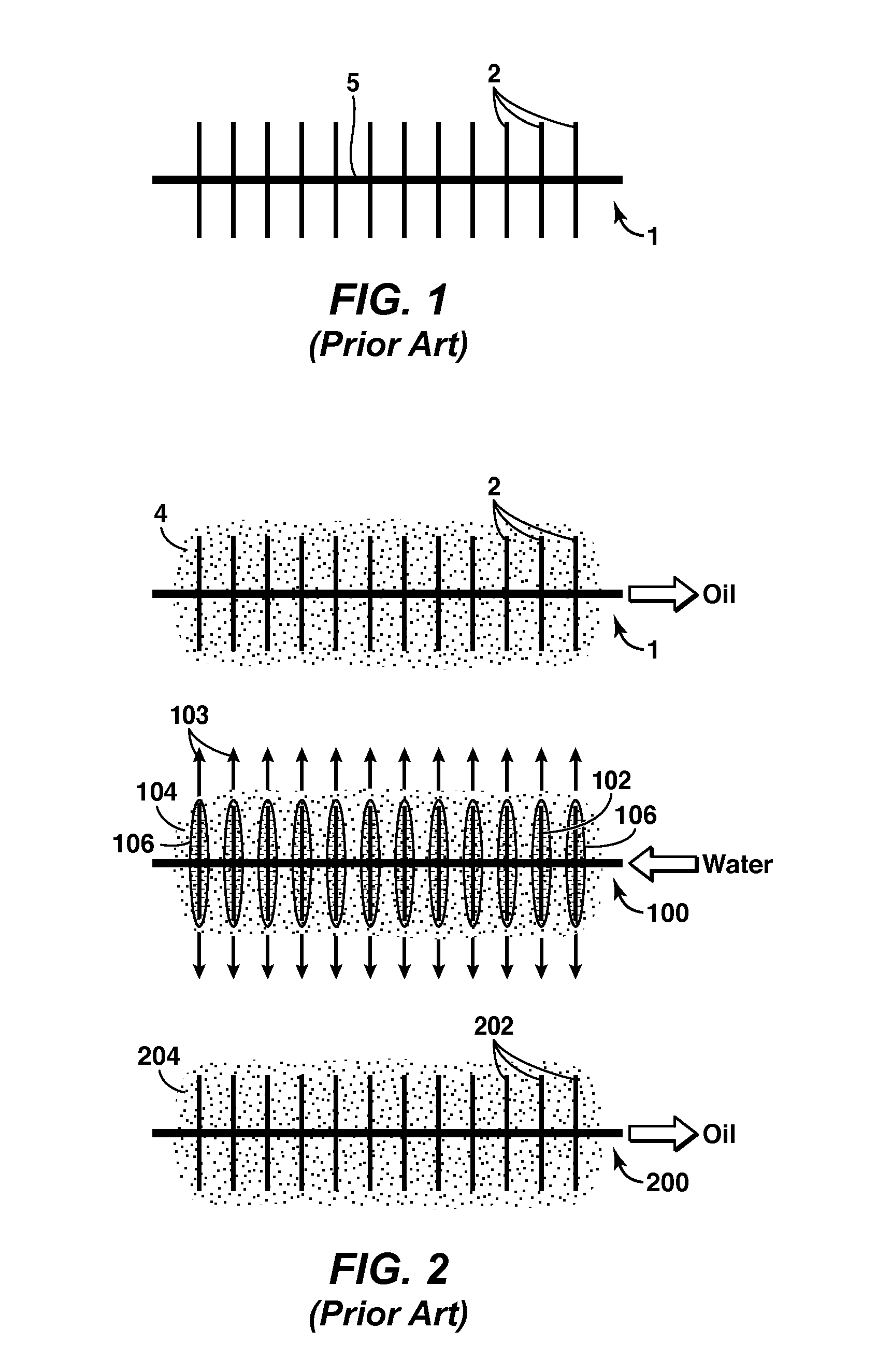

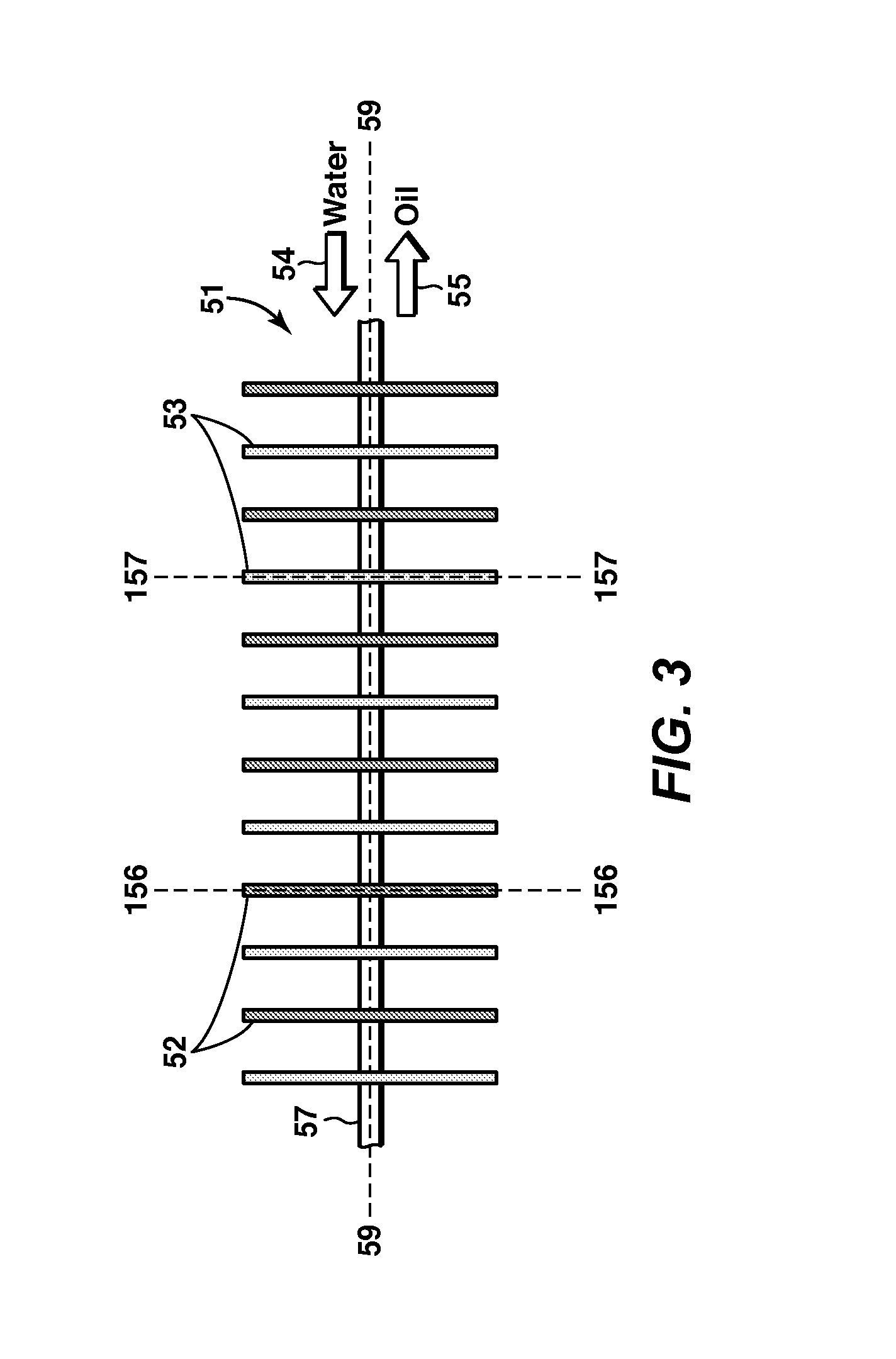

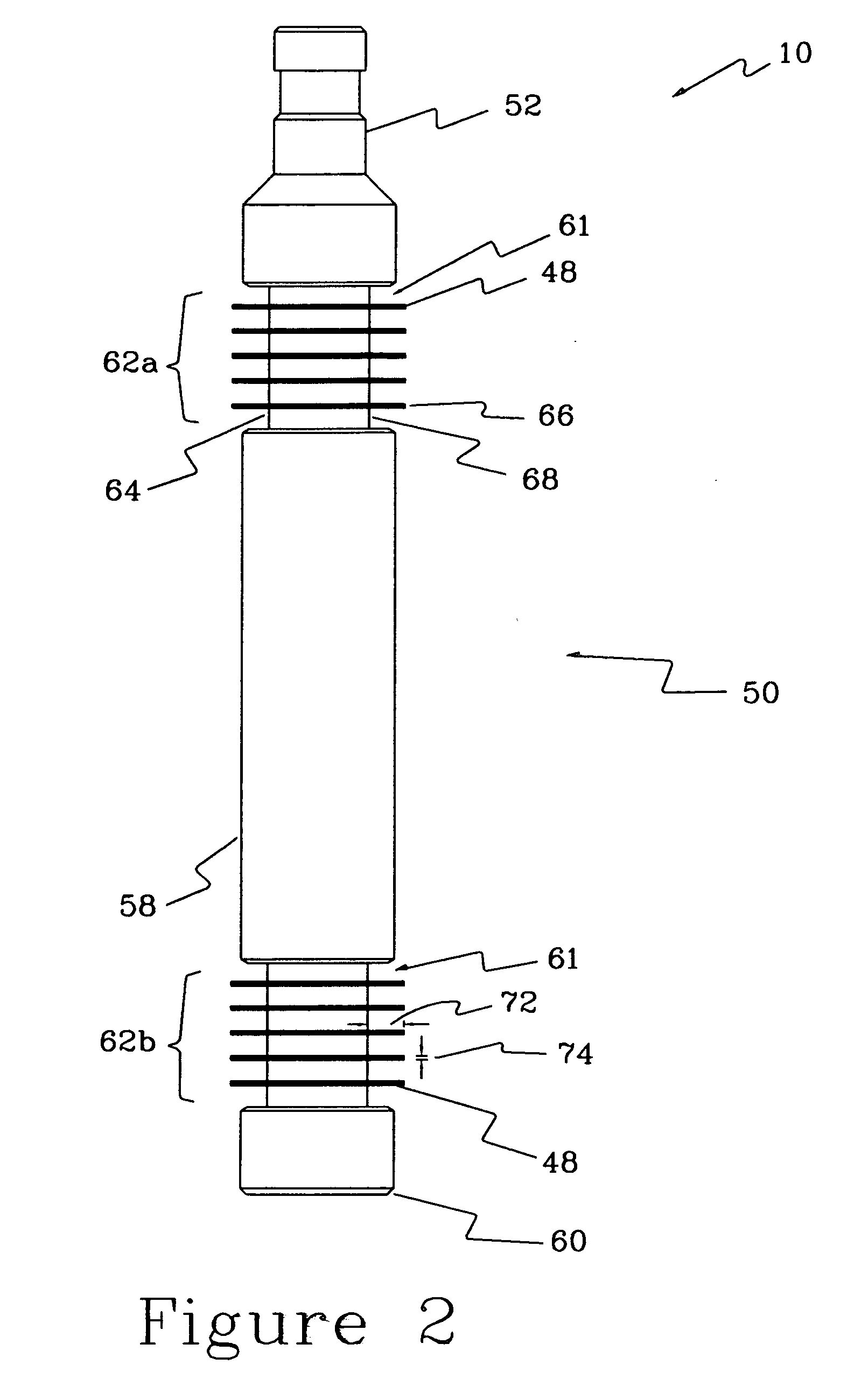

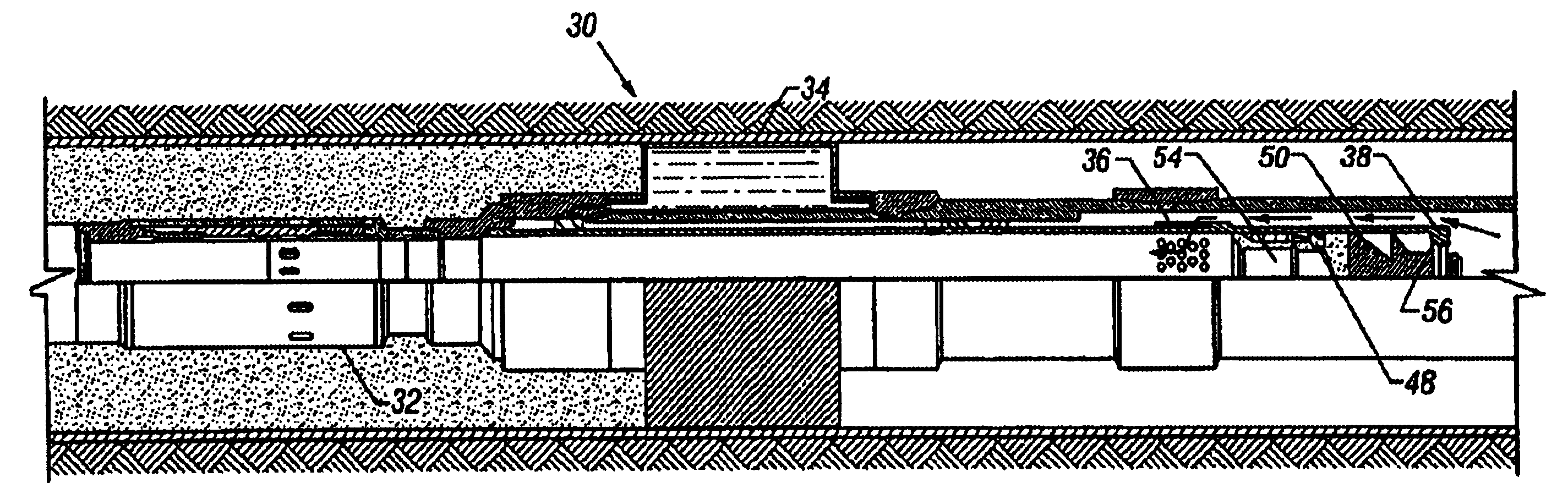

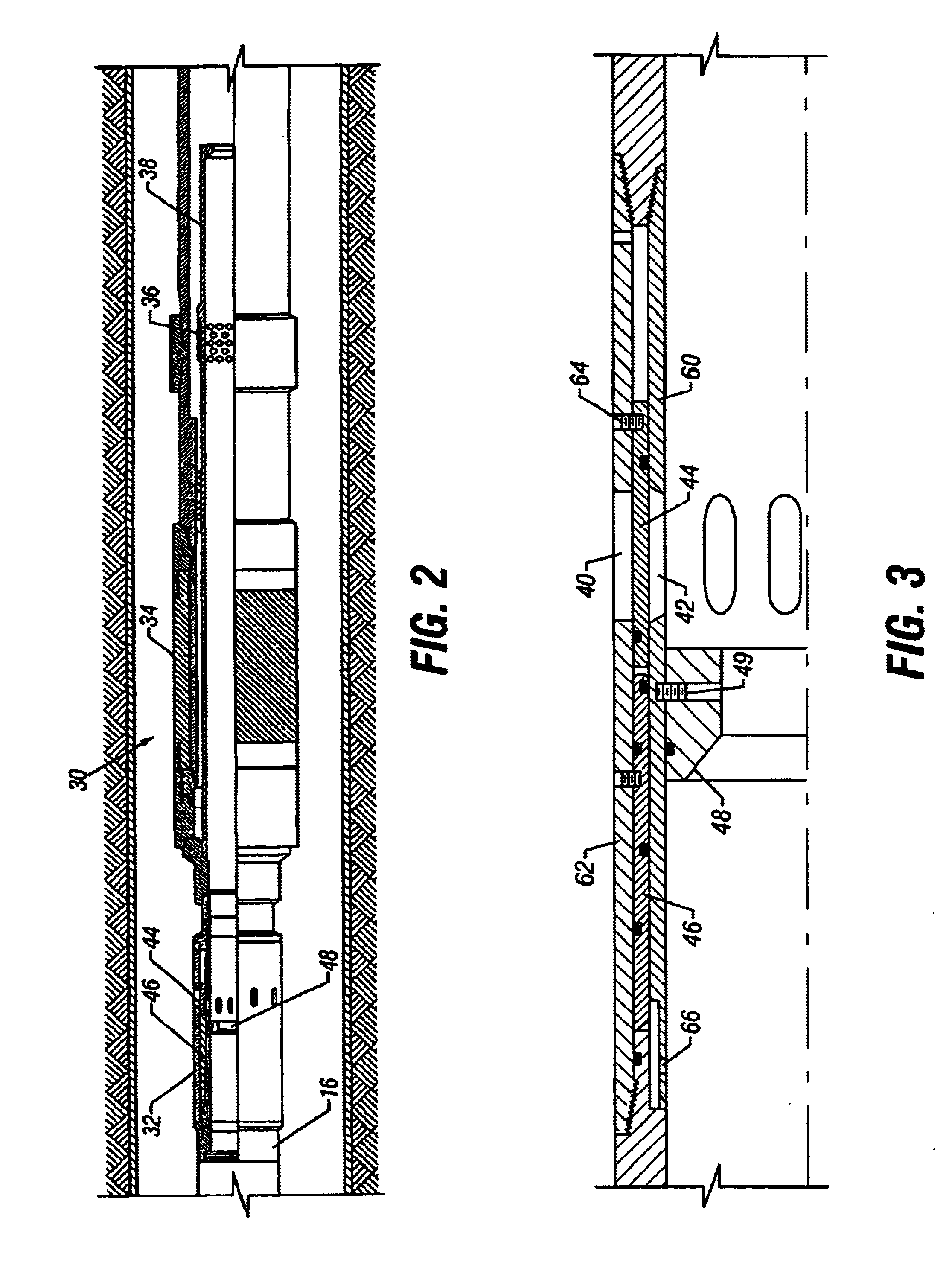

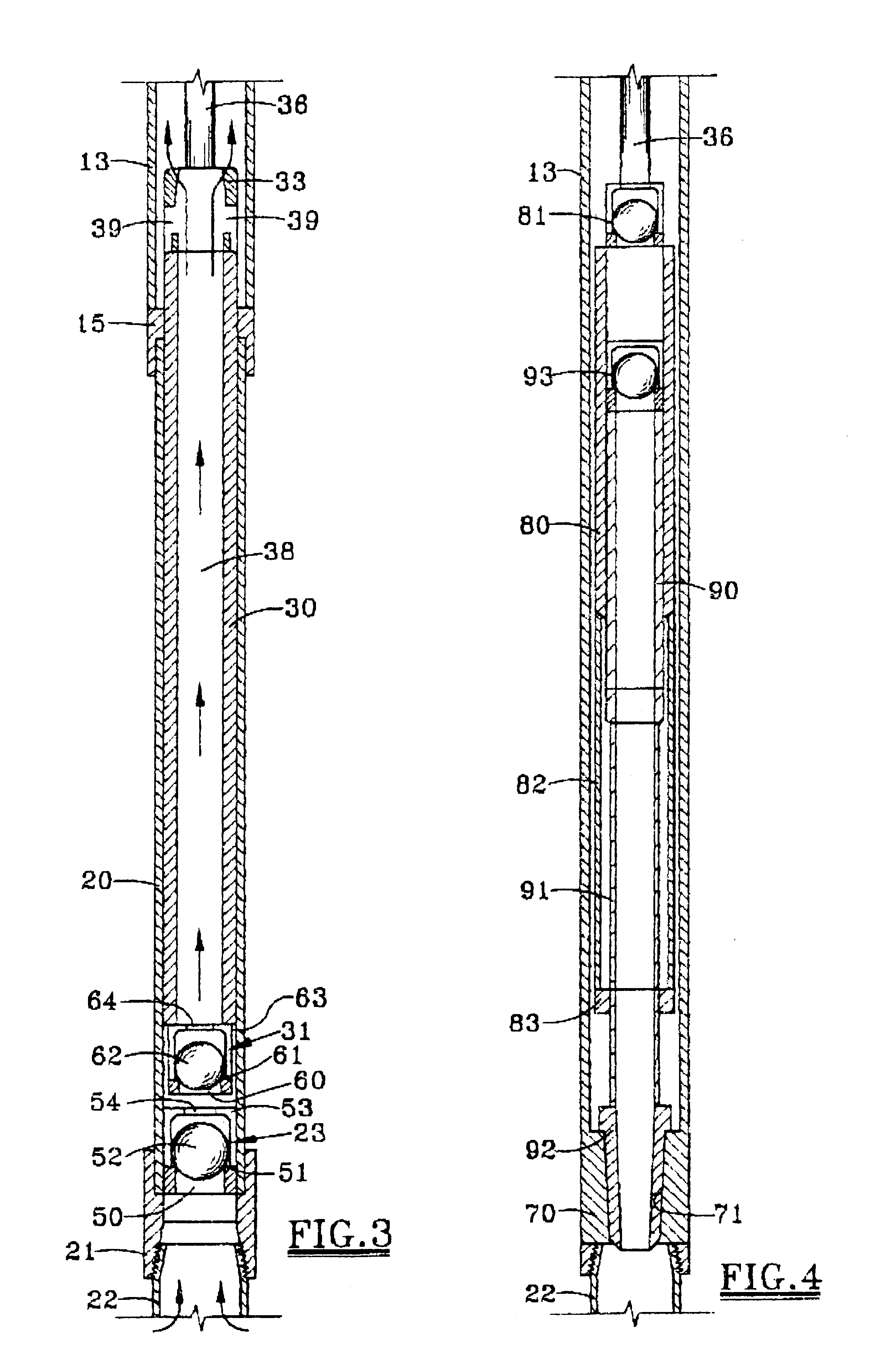

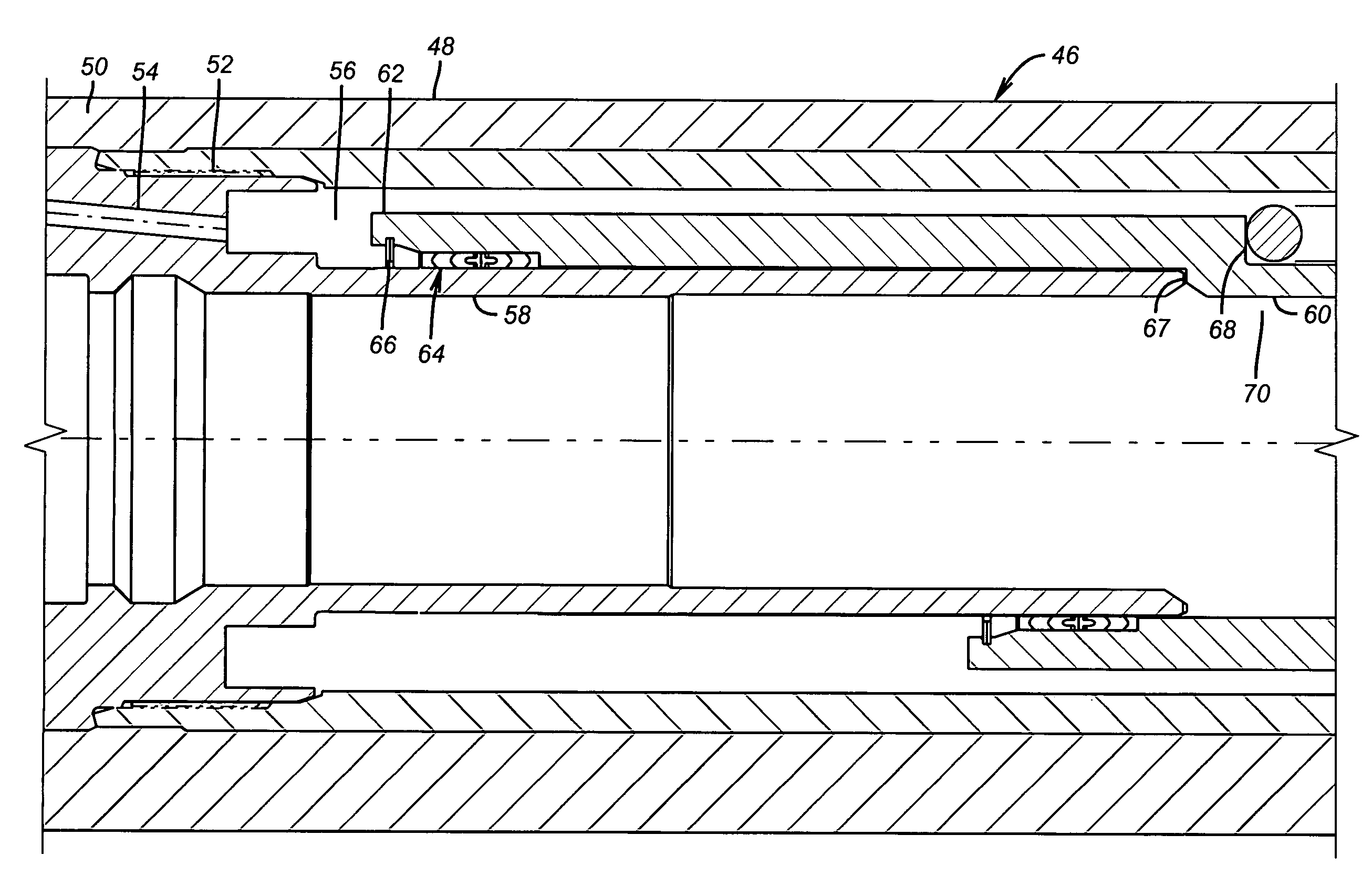

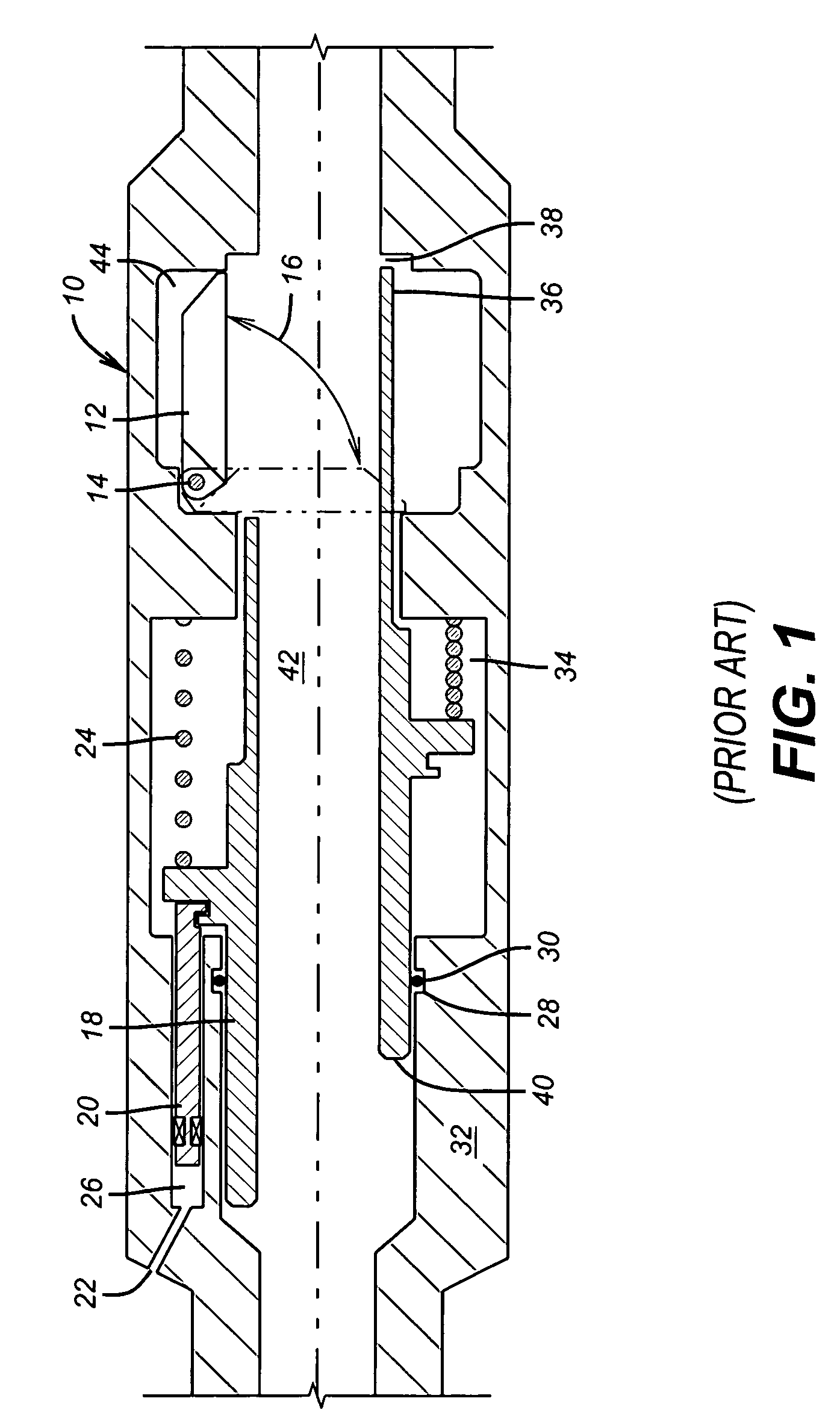

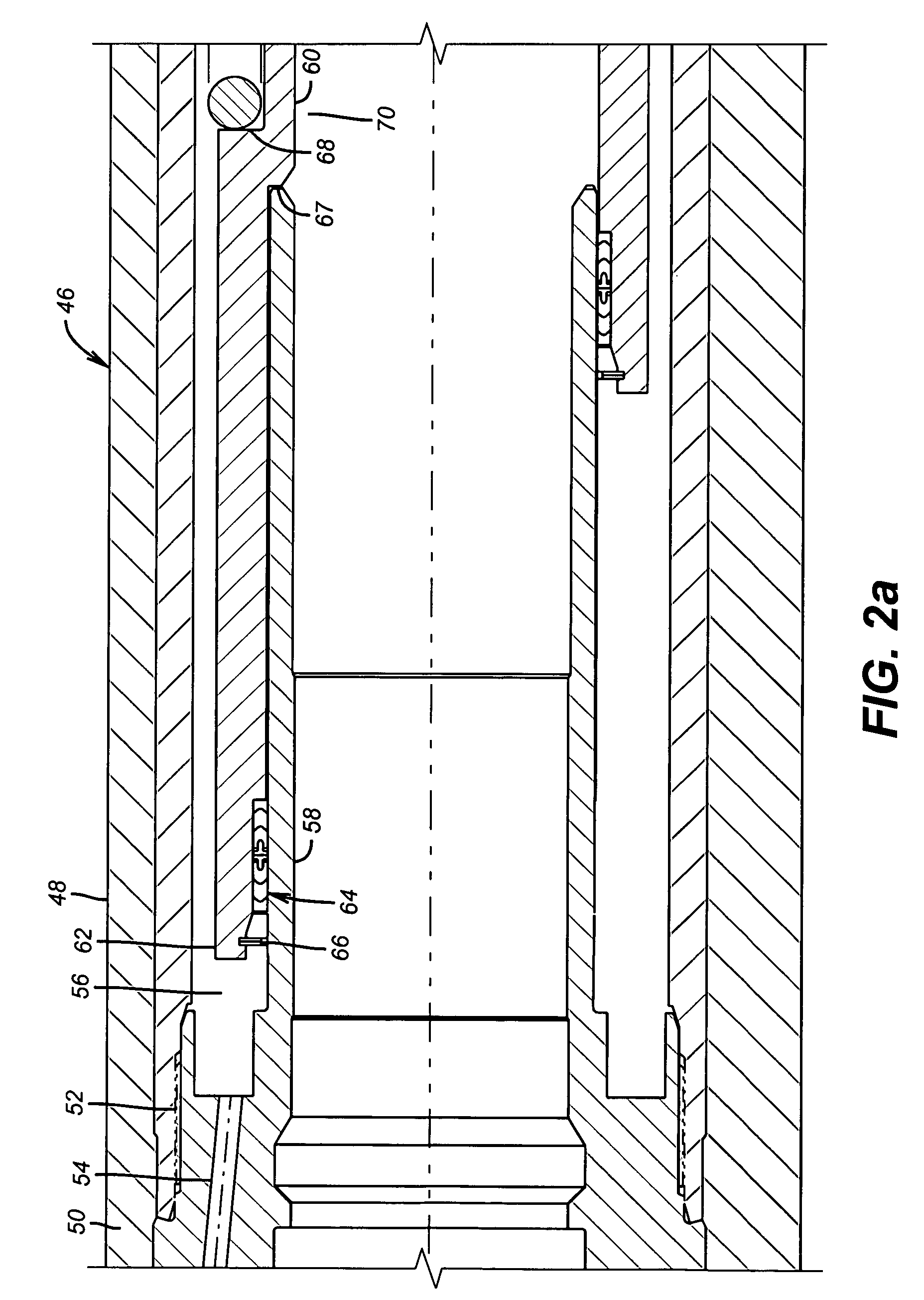

Downhole inflow control device with shut-off feature

InactiveUS20060113089A1Fluid removalWell/borehole valve arrangementsControl flowChemical composition

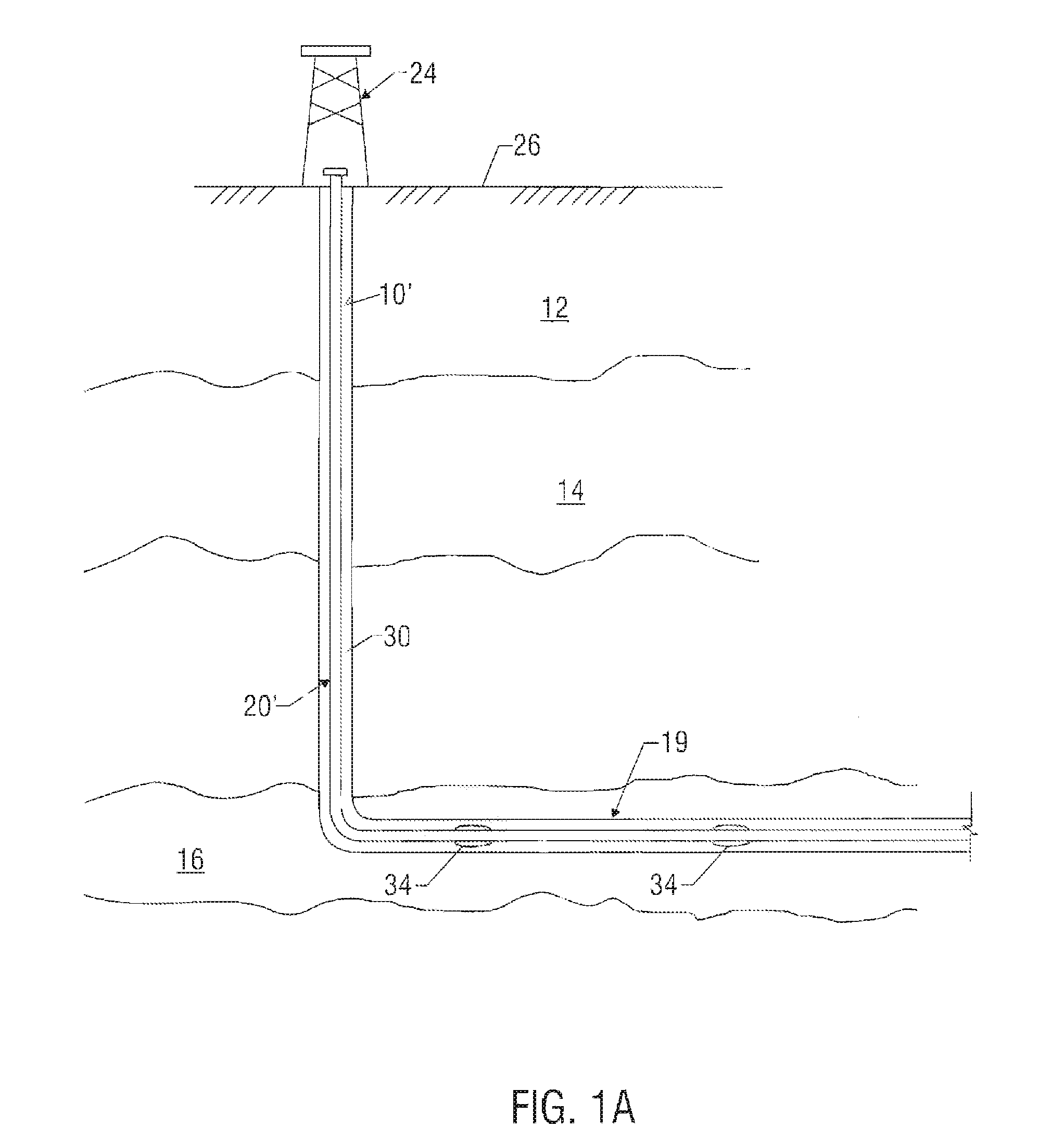

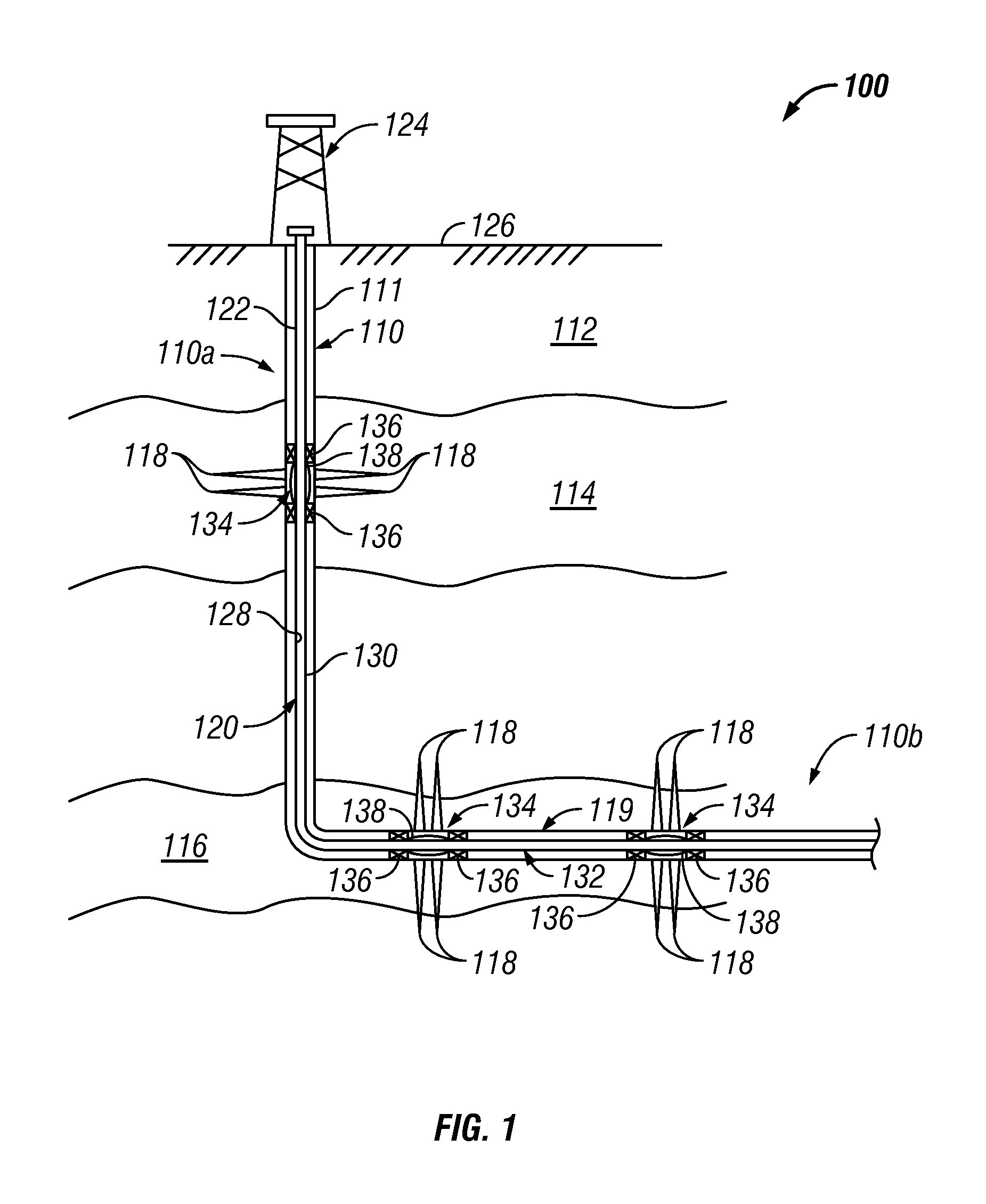

A system and method for controlling inflow of fluid into a production string. In aspects, the invention provides a downhole sand screen and inflow control device with a gas or water shut-off feature that can be operated mechanically or hydraulically from the surface of the well. The device also preferably includes a bypass feature that allows the inflow control device to be closed or bypassed via shifting of a sleeve. In embodiments, the flow control device can be adaptive to changes in wellbore conditions such as chemical make-up, fluid density and temperature. Exemplary adaptive inflow control devices include devices configured to control flow in response to changes in gas / oil ratio, water / oil ratio, fluid density and / or the operating temperature of the inflow control device. In other aspects of the present invention, inflow control devices are utilized to control the flow of commingled fluids drained via two or more wellbores.

Owner:BAKER HUGHES INC

Downhole Inflow Control Device with Shut-Off Feature

A system and method for controlling inflow of fluid into a production string. In aspects, the invention provides a downhole sand screen and inflow control device with a gas or water shut-off feature that can be operated mechanically or hydraulically from the surface of the well. The device also preferably includes a bypass feature that allows the inflow control device to be closed or bypassed via shifting of a sleeve. In embodiments, the flow control device can be adaptive to changes in wellbore conditions such as chemical make-up, fluid density and temperature. Exemplary adaptive inflow control devices include devices configured to control flow in response to changes in gas / oil ratio, water / oil ratio, fluid density and / or the operating temperature of the inflow control device. In other aspects of the present invention, inflow control devices are utilized to control the flow of commingled fluids drained via two or more wellbores.

Owner:BAKER HUGHES INC

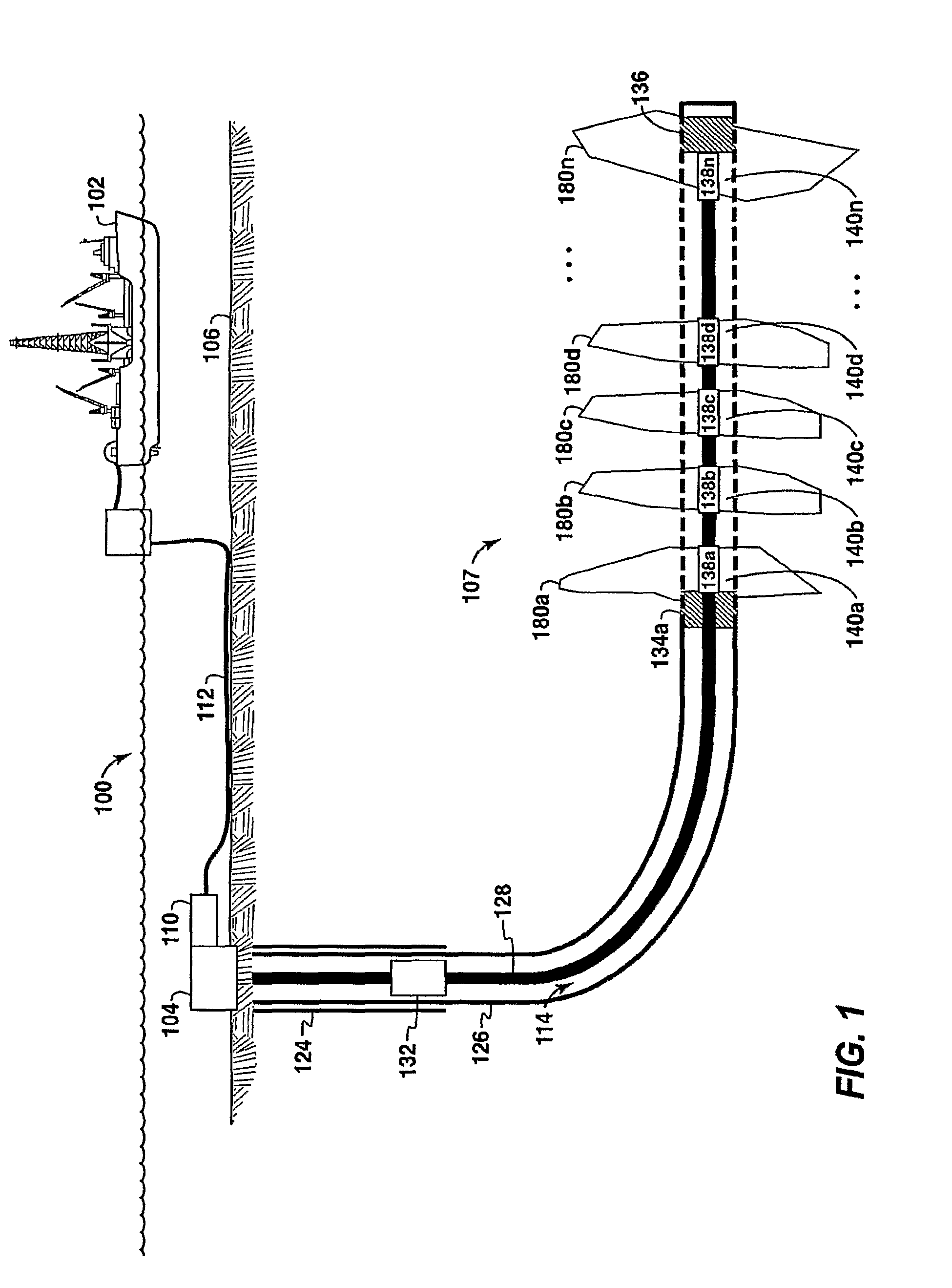

Method of Providing Flow Control Devices for a Production Wellbore

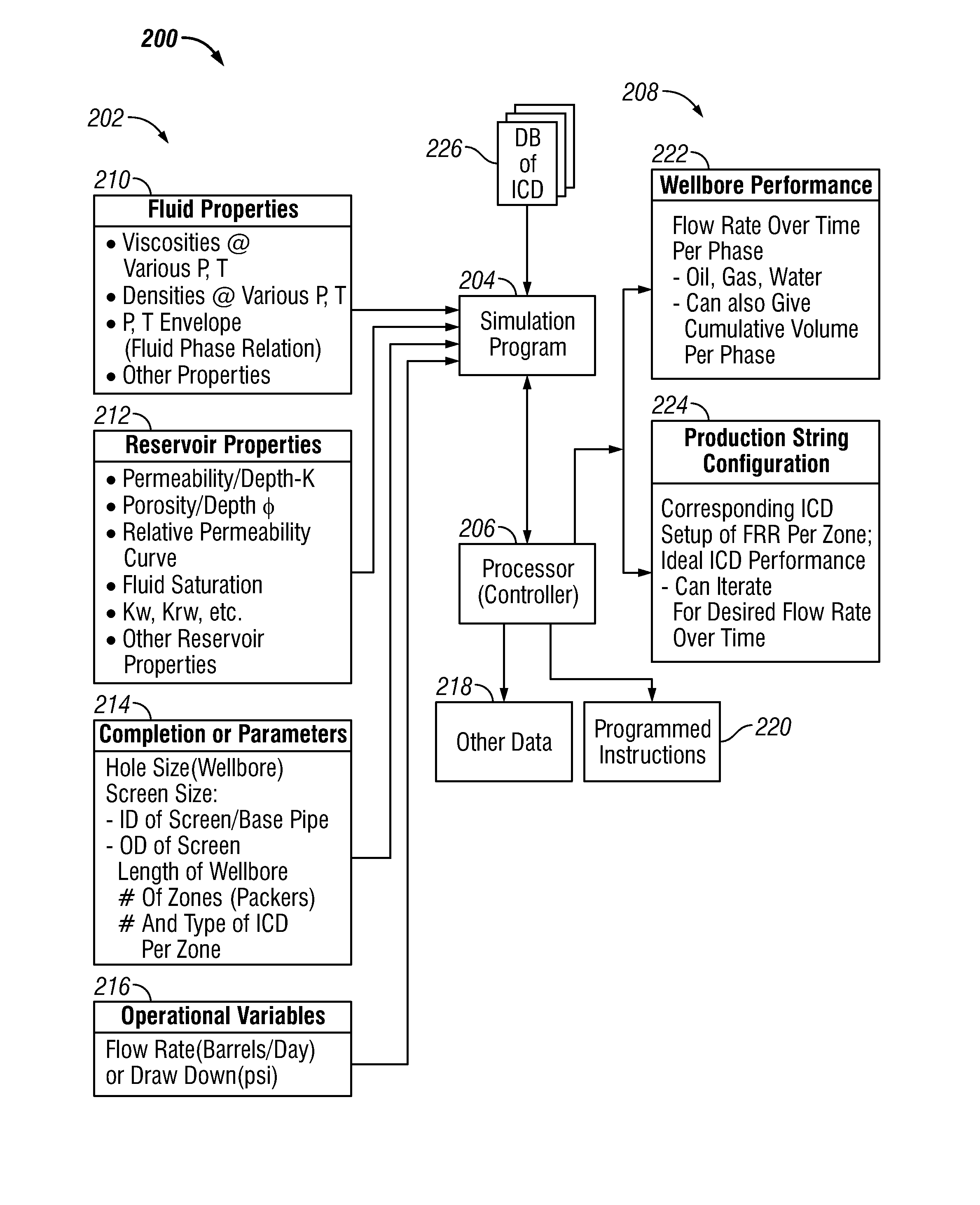

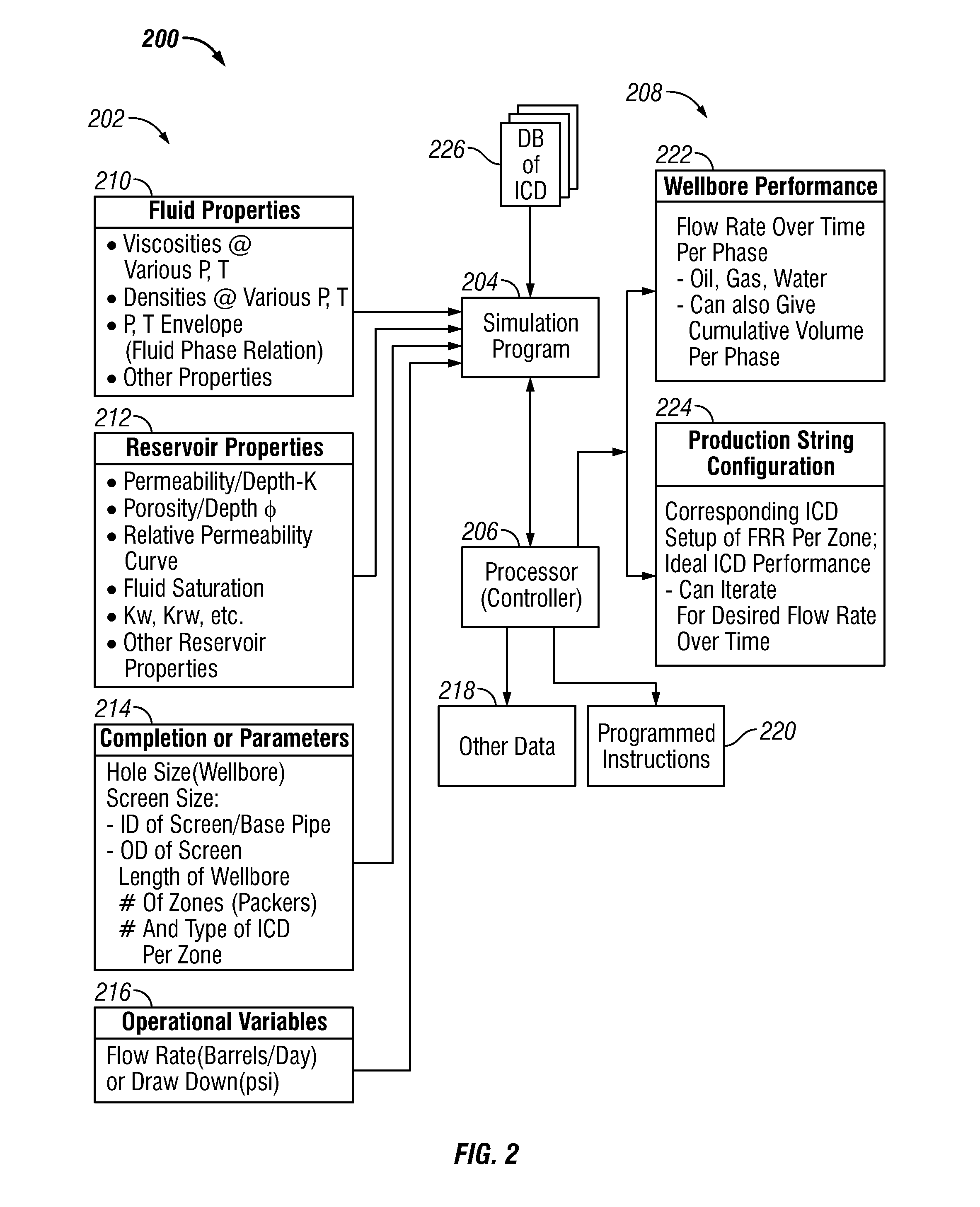

A method of providing a production string for a wellbore formed in a formation is disclosed. The method, in one embodiment may include: defining a performance criterion for flow of a fluid from a formation into a wellbore; performing a simulation using a processor, a simulation program, a parameter of the fluid, a parameter of the formation and a parameter of the wellbore to determine a first flow characteristic of the flow of the fluid from the formation into the wellbore corresponding to an initial set of flow control devices arranged in the wellbore; performing one or more additional simulations using the processor, the simulation program and the parameters of formation, fluid and wellbore to determine a new flow characteristic of the flow of the fluid from the formation into the wellbore for a new set of flow control devices until a new determined characteristic of the flow of the fluid from the formation into the wellbore meets the performance criterion; and storing results of simulation results relating to the flow control devices in a suitable storage medium.

Owner:BAKER HUGHES INC

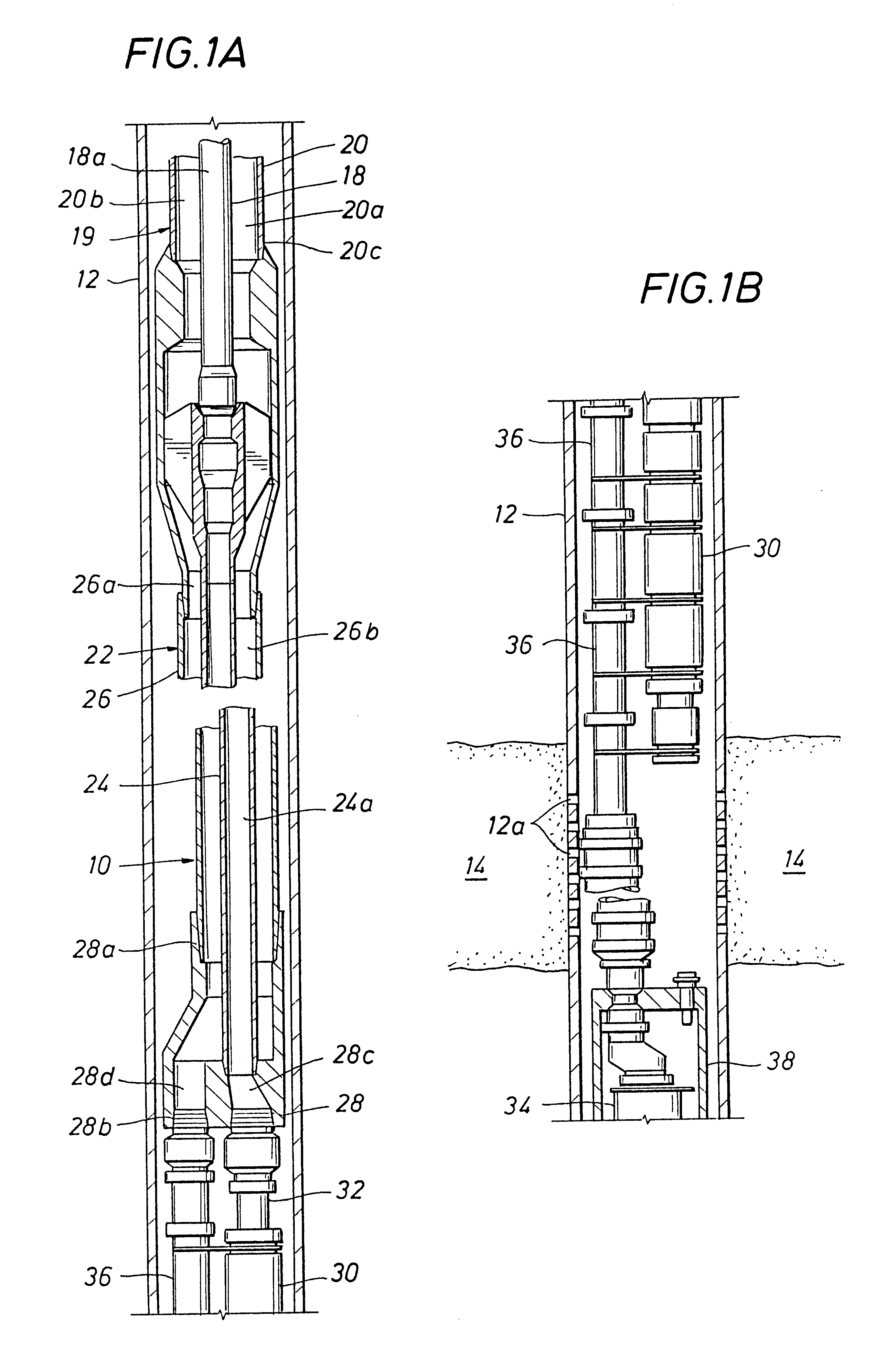

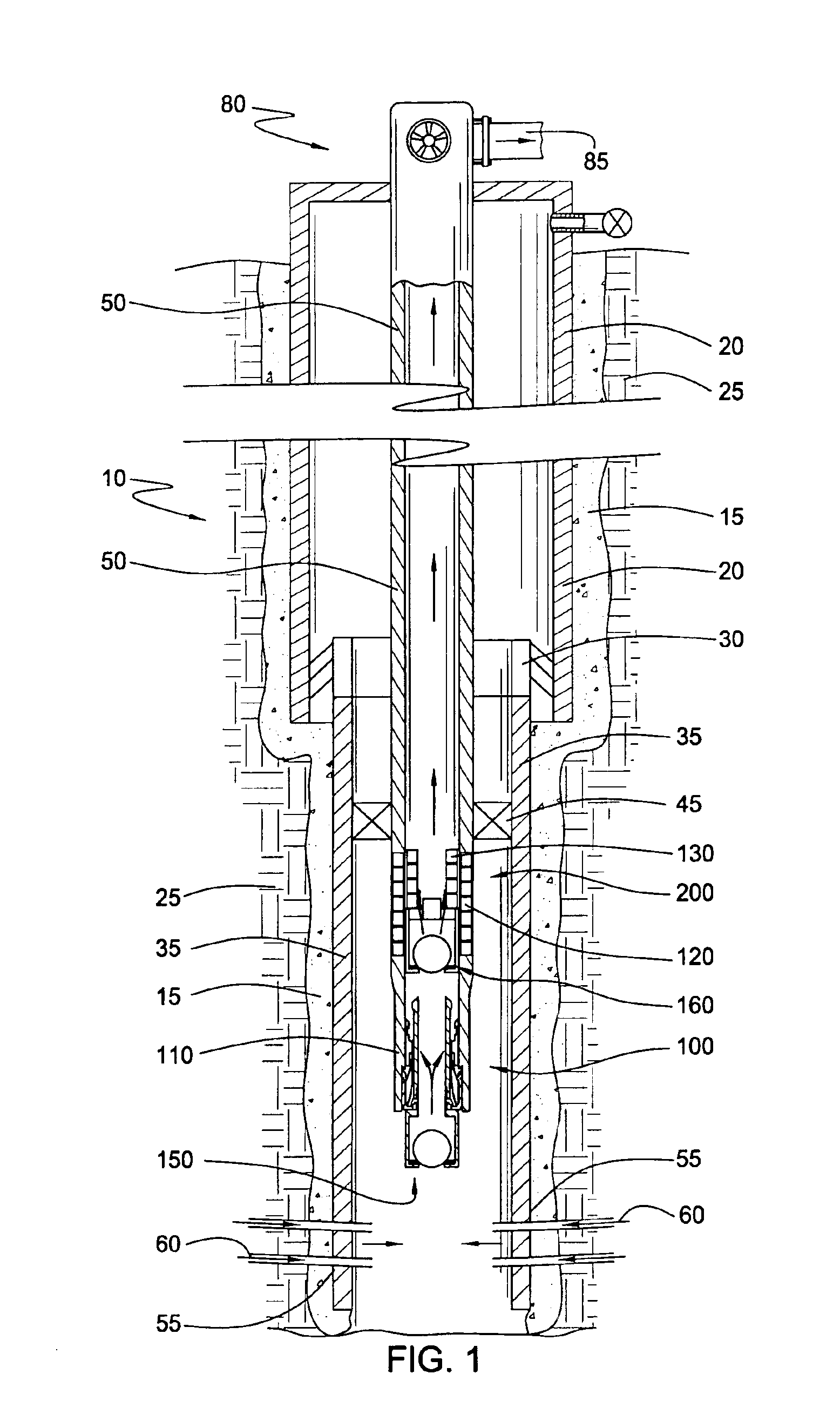

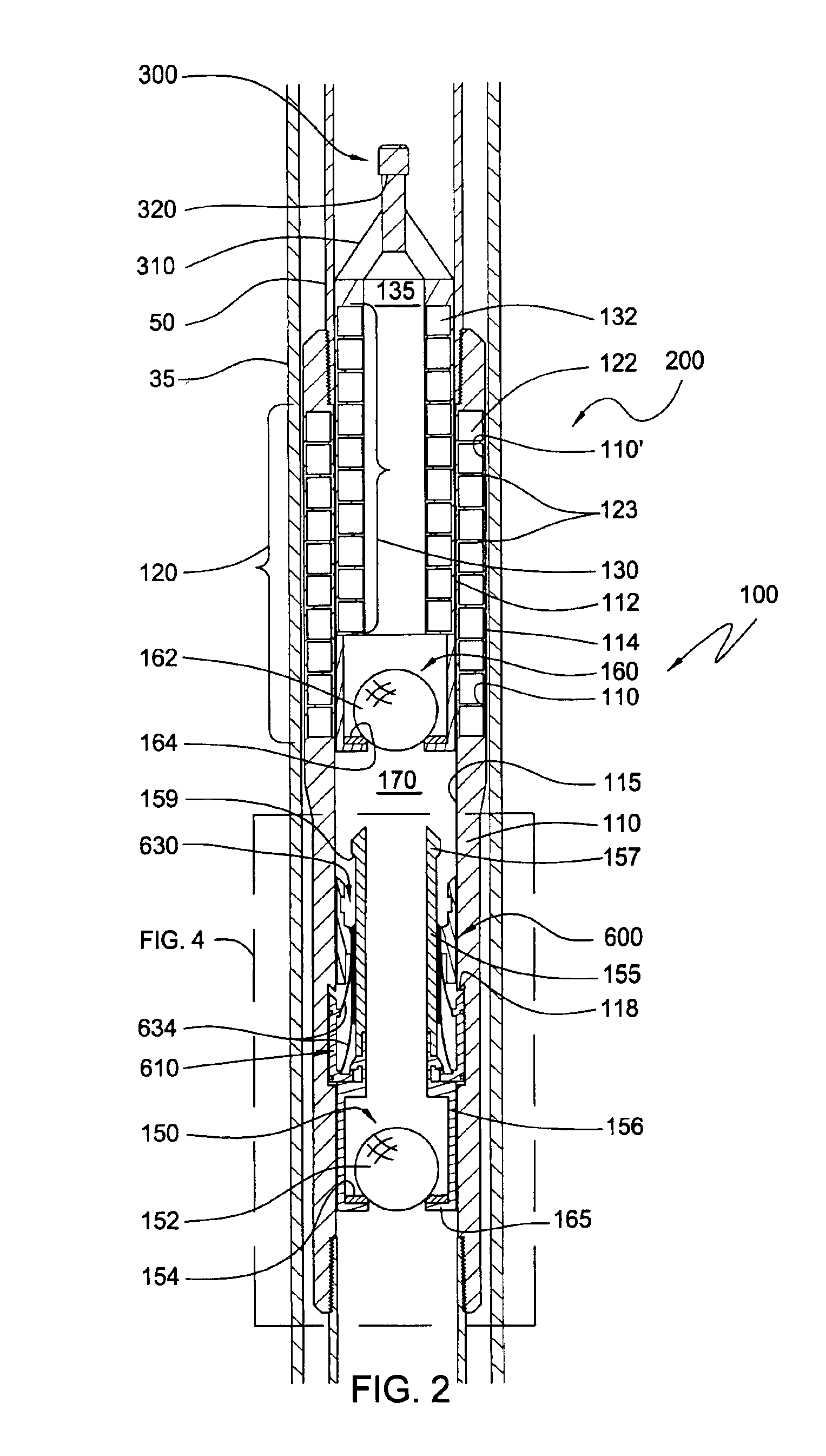

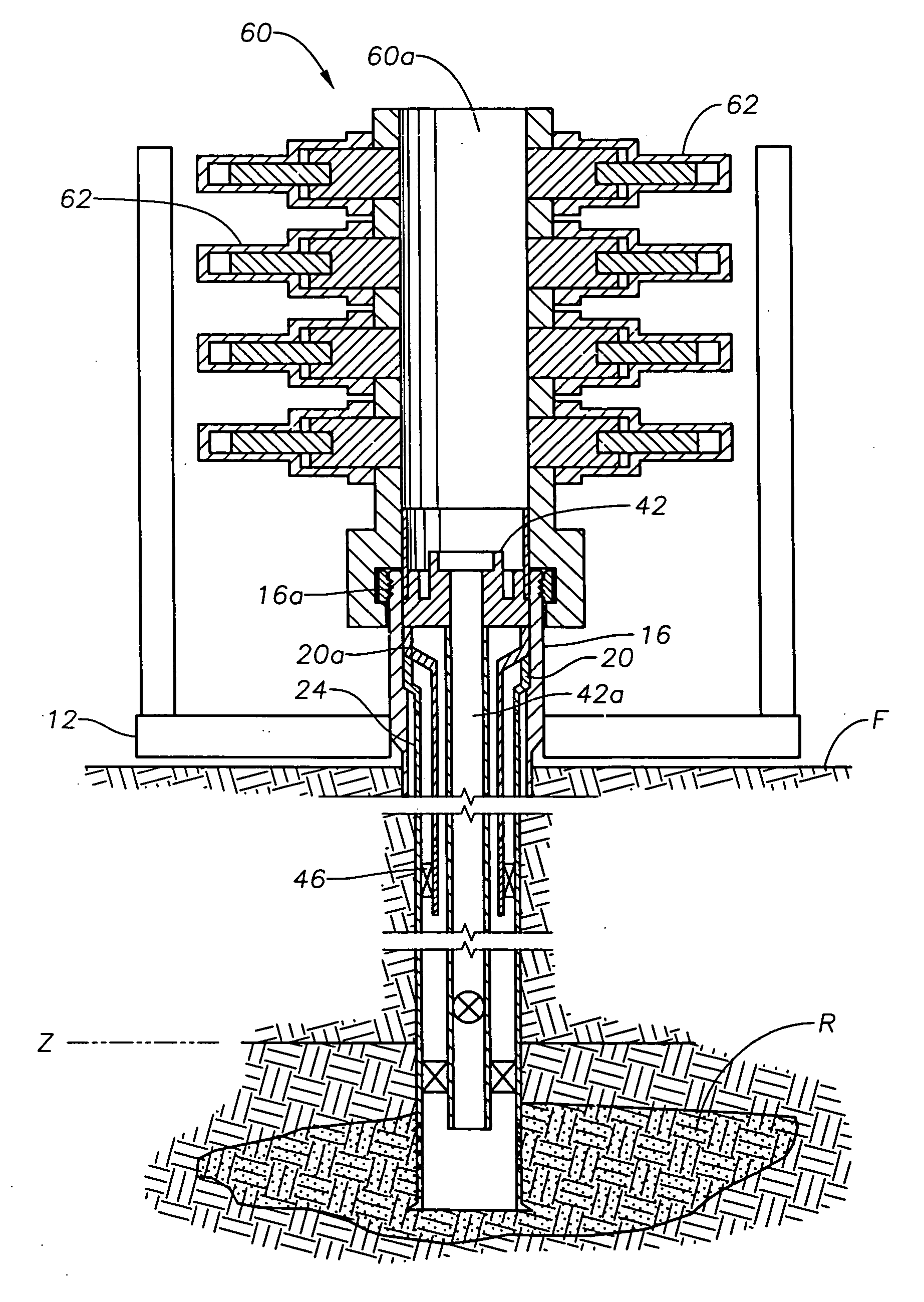

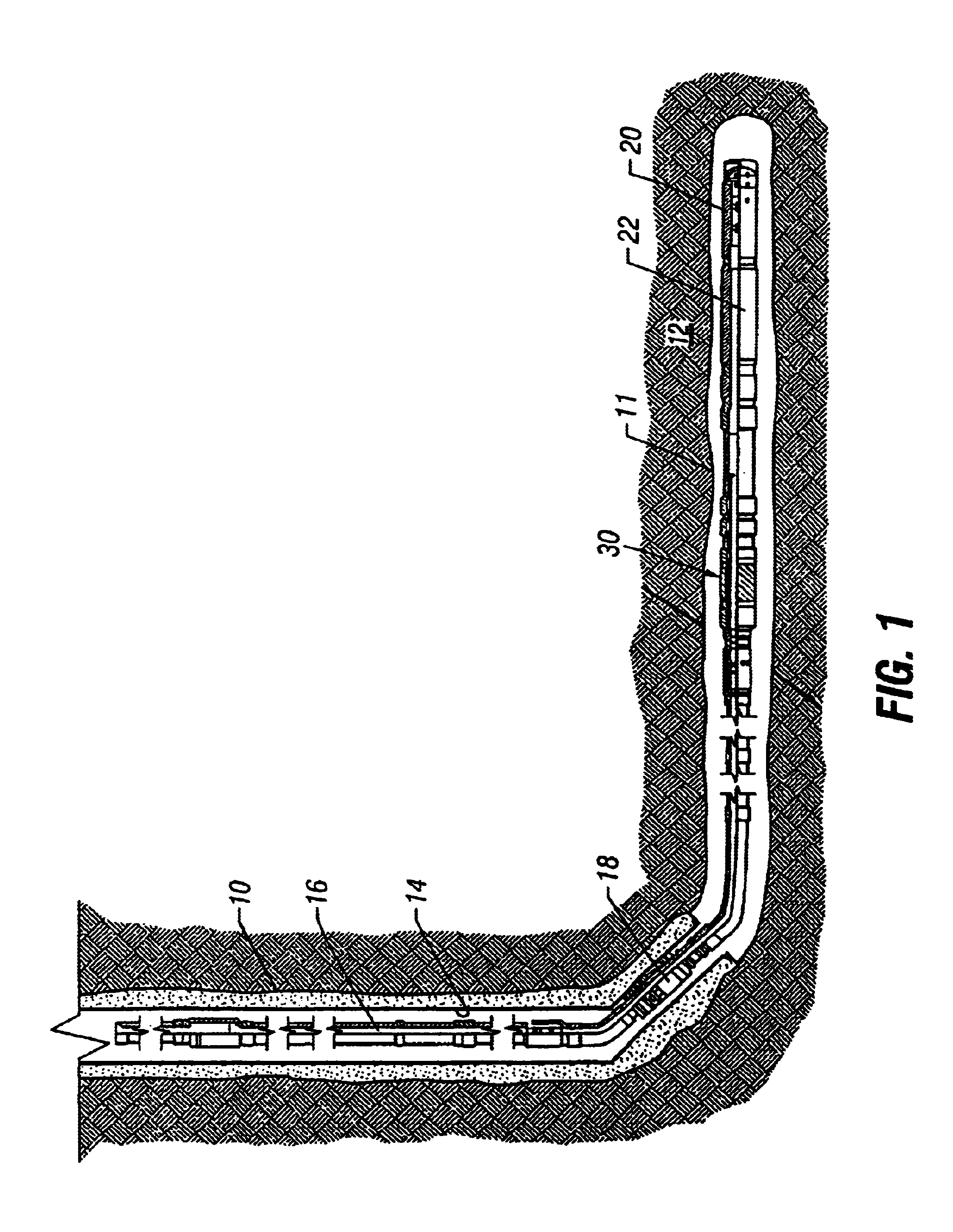

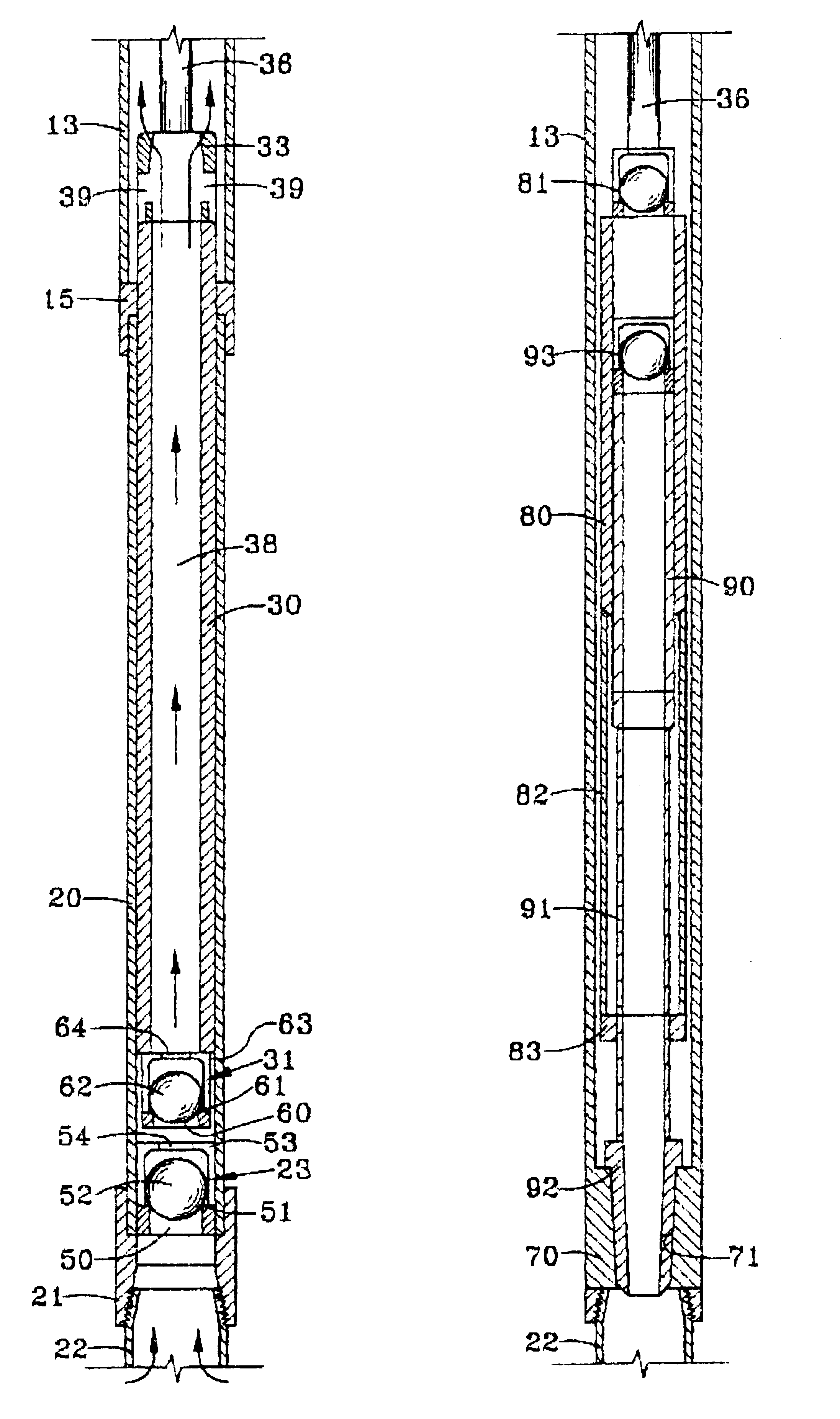

Artificial lift, concentric tubing production system for wells and method of using same

An artificial lift, concentric tubing production system for a well and method of using same. The system including an upper concentric tubing string portion comprising an inner production tubing string positioned within an outer production tubing string. A flow crossover assembly is connected to the upper concentric tubing string portion. The flow crossover assembly has first and second passageways. The inner production tubing string is in fluid communication with the first passageway and the outer production tubing string in fluid communication with the second passageway. An upper transducer is in fluid communication with one of the passageways of the flow crossover assembly and a lower apparatus is in fluid communication with the other of the passageways of the flow crossover assembly. The upper transducer may be a pump such as an electric submersible pump or a progressive cavity pump. The lower apparatus may be a pump, including an electric submersible pump, or a liquid / gas separator.

Owner:YPF INT

Submersible electric pump

InactiveUS6926504B2Quickly and economically expandedIncrease motivationPositive displacement pump componentsFlexible member pumpsRotary pumpComputer module

An improved electrical pump is first provided for use in a wellbore. The pump comprises a stator and a stator housing, and an armature and an armature housing. The stator housing and the armature housing define concentrically nested tubular bodies. The armature housing is configured to permit production fluids to flow therethrough. In one aspect, the stator and armature are assembled in connectible and interchangeable sections called “modules” that can be attached in series. In one aspect, the electrical operation of coils within the stator is protected from individual coil short-circuiting or failure by wiring them in parallel, rather than in series. In addition, each module may be wired in parallel. In this way, a failure of one stator module will not result in the failure of another stator module. In an embodiment of the present invention, the valves of the pump are capable of being retrieved by a wireline, without pulling the entire production string. A method for using a plurality of electrical pumps is also provided. The configuration of the electrical pumps allows multiple linear pumps to be placed in series with the production tubular member. Alternatively, a rotary pump design is provided which allows multiple rotary pumps to be placed in series with the production tubular member.

Owner:SHELL INT EXPLORATION & PRODN +2

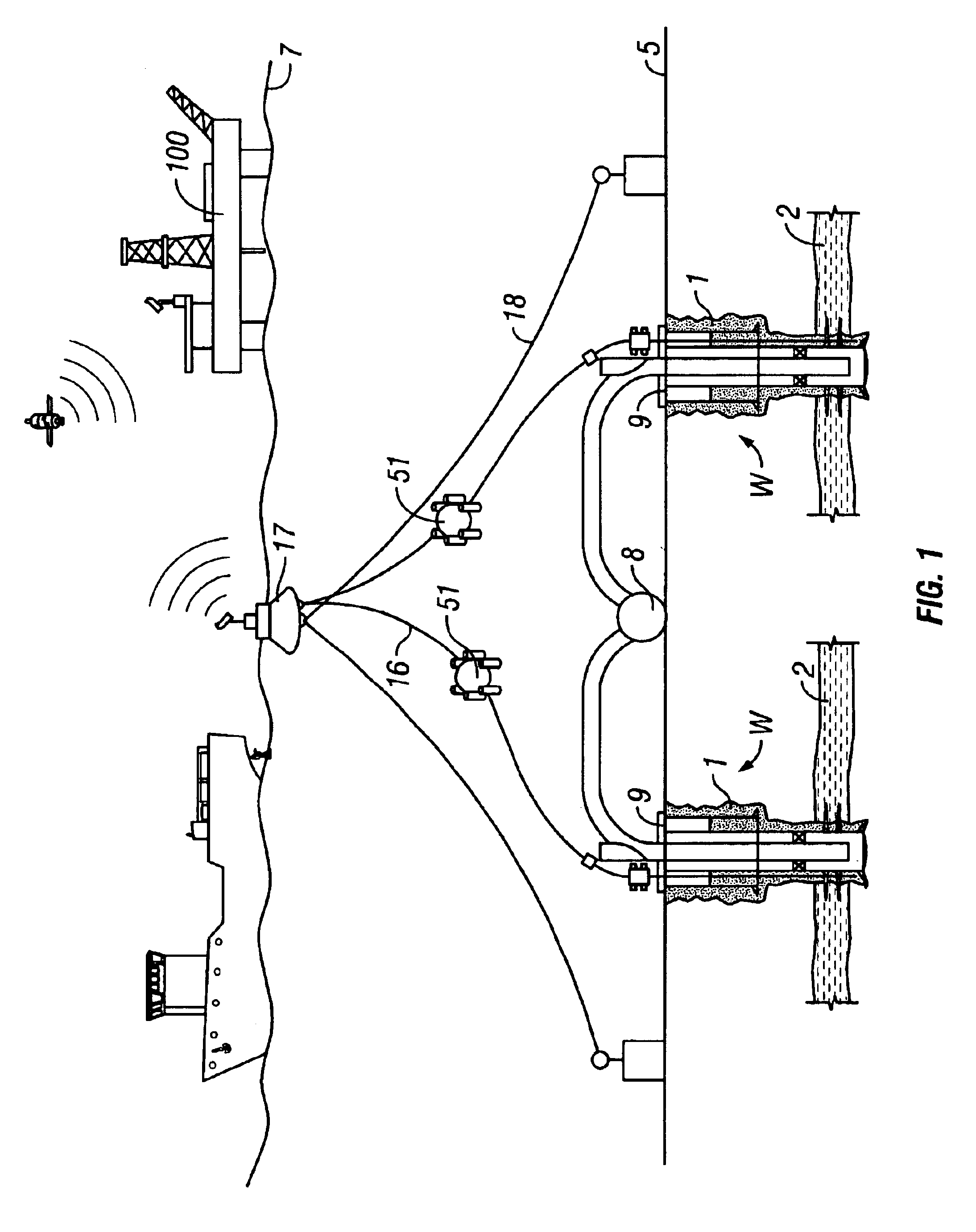

Method and apparatus to monitor, control and log subsea oil and gas wells

A method and apparatus for logging, controlling, or monitoring a subsea well or group of wells through a path not within production tubing. Preferred embodiments allow logging tools, wire rope, optic fibers, electrical cables, monitoring and measuring instruments and other items known to those skilled in the art of oil and gas production to be disposed into the well without interfering with the flow path through the production string. A further preferred embodiment includes the mooring or tethering of an instrument pod over the subsea well. The instrument pod is designed to provide on-board data storage, data processing, data receiving, and data transmission equipment, such that data from the well can be transmitted back to a receiving network where the data may be stored and processed into useful information for reservoir operators.

Owner:SENSOR HIGHWAY LTD

Wireless coiled tubing joint locator

A wireless coiled tubing joint locator for locating joints or collars in a production tubing string. An electromagnetic coil assembly or giant magnetoresistive digital field sensor senses the increased mass of a pipe joint, and provides a signal to an electric circuit which generates a signal received by a pilot solenoid valve. The solenoid valve momentarily opens a pilot passageway which activates a piston to close a circulation port in the joint locator, resulting in an increase in a surface pressure reading observable by the operator. In one embodiment, a rupture disk is provided so that pressure cannot be applied to any downhole tool below the joint locator prematurely. A seat sleeve prevents premature communication of fluid to the rupture disk but can be opened by dropping a ball into the joint locator. A second embodiment may be used for either logging or washing operations or both. The electronic circuit can provide a selected one of a plurality of time delays. A fixed test period in the circuit delays activation of the time delay so that the joint locator may be tested before it is run into the well. The electric circuit and power supply are provided in a removable case.

Owner:HALLIBURTON ENERGY SERVICES INC

Remedial system to flush contaminants from tubing string

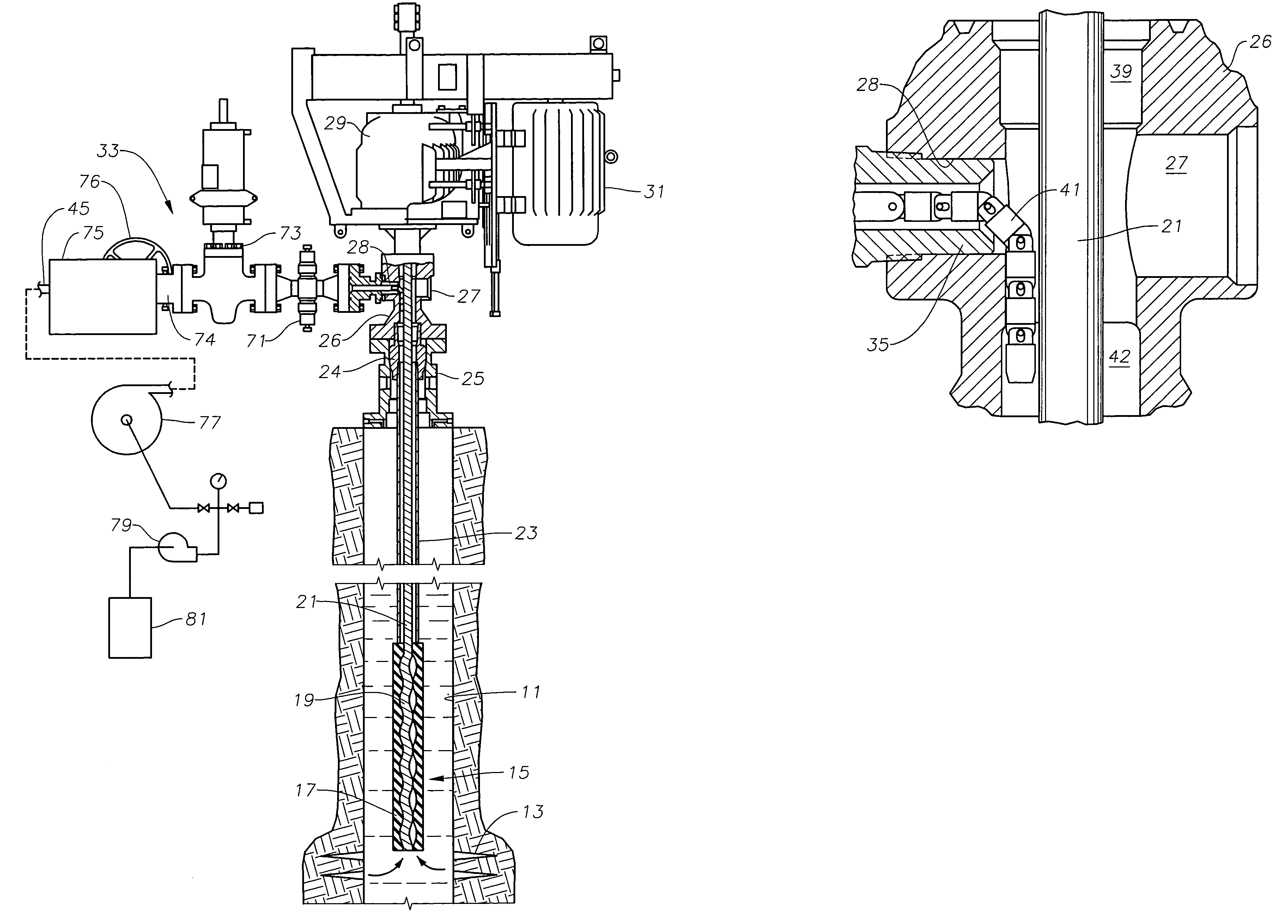

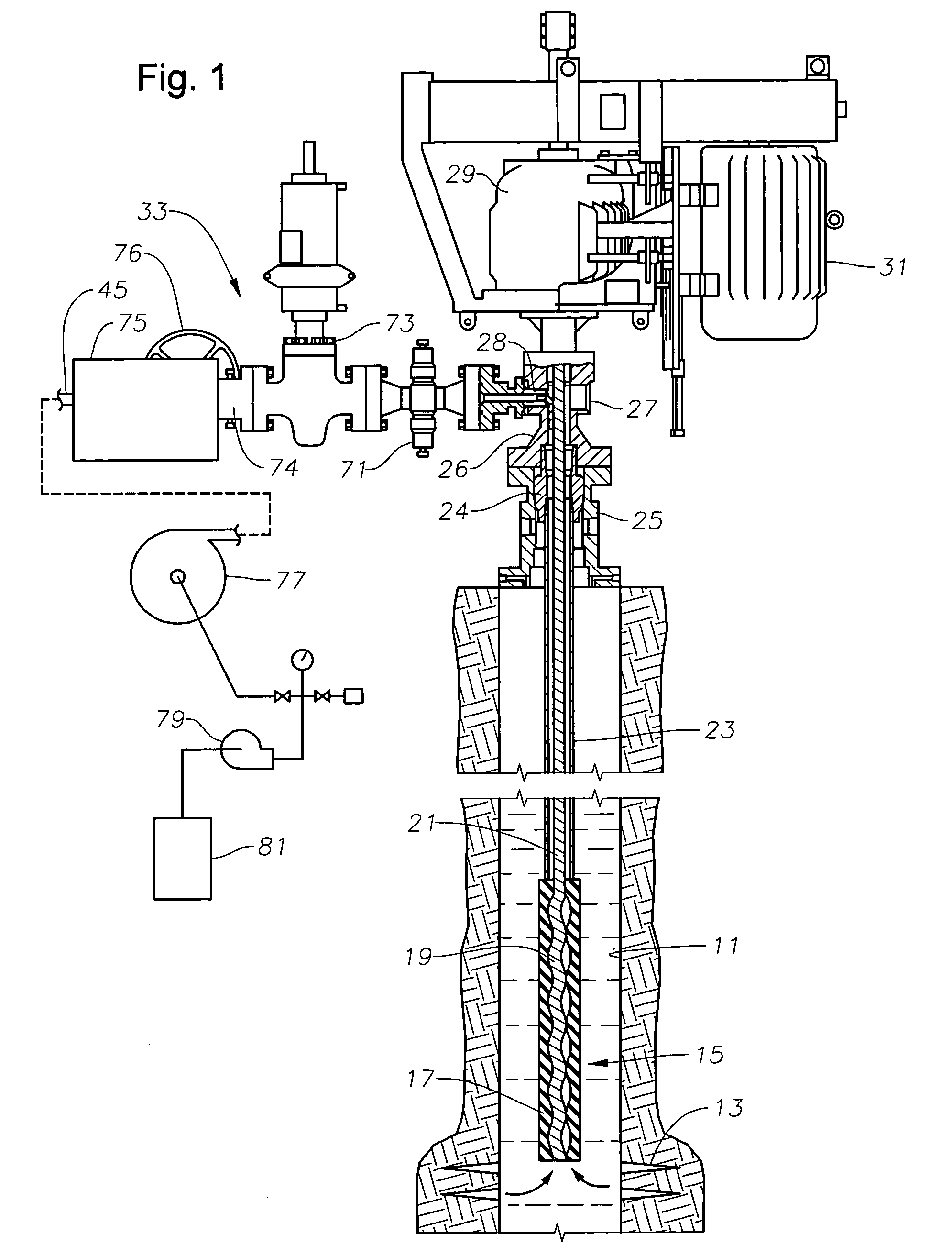

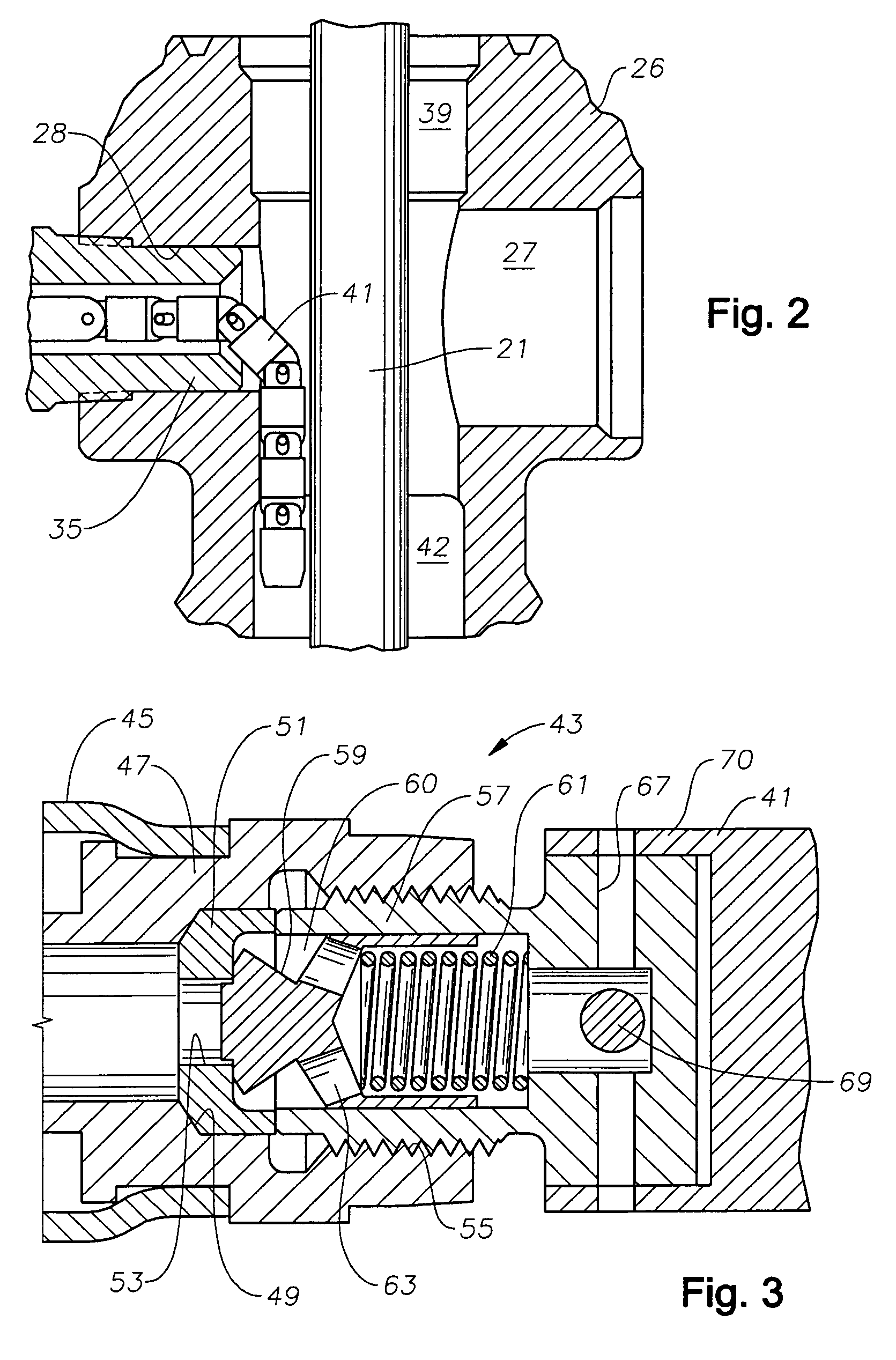

A method of cleaning debris from a string of production tubing in a well enables removal without pulling the string of rods that extend through the tubing. A rotary pump is suspended to a lower end of the tubing for pumping well fluid through the tubing to a wellhead at the surface. A motor assembly at the surface rotates the rods to drive the pump. A closure member is placed on a lower end of an elastomeric hose that will open when a selected level of internal fluid pressure is applied. The operator applies internal pressure to the hose at a pressure less than the selected level to increase rigidity of the hose. The operator inserts the hose through a port in a sidewall of the wellhead, the hose deflecting downward and into the tubing. At a desired point, the operator increases the internal pressure in the hose to open the closure member, then discharges a cleansing fluid into the tubing, which flows back up the tubing along with debris.

Owner:VETCO GRAY LLC

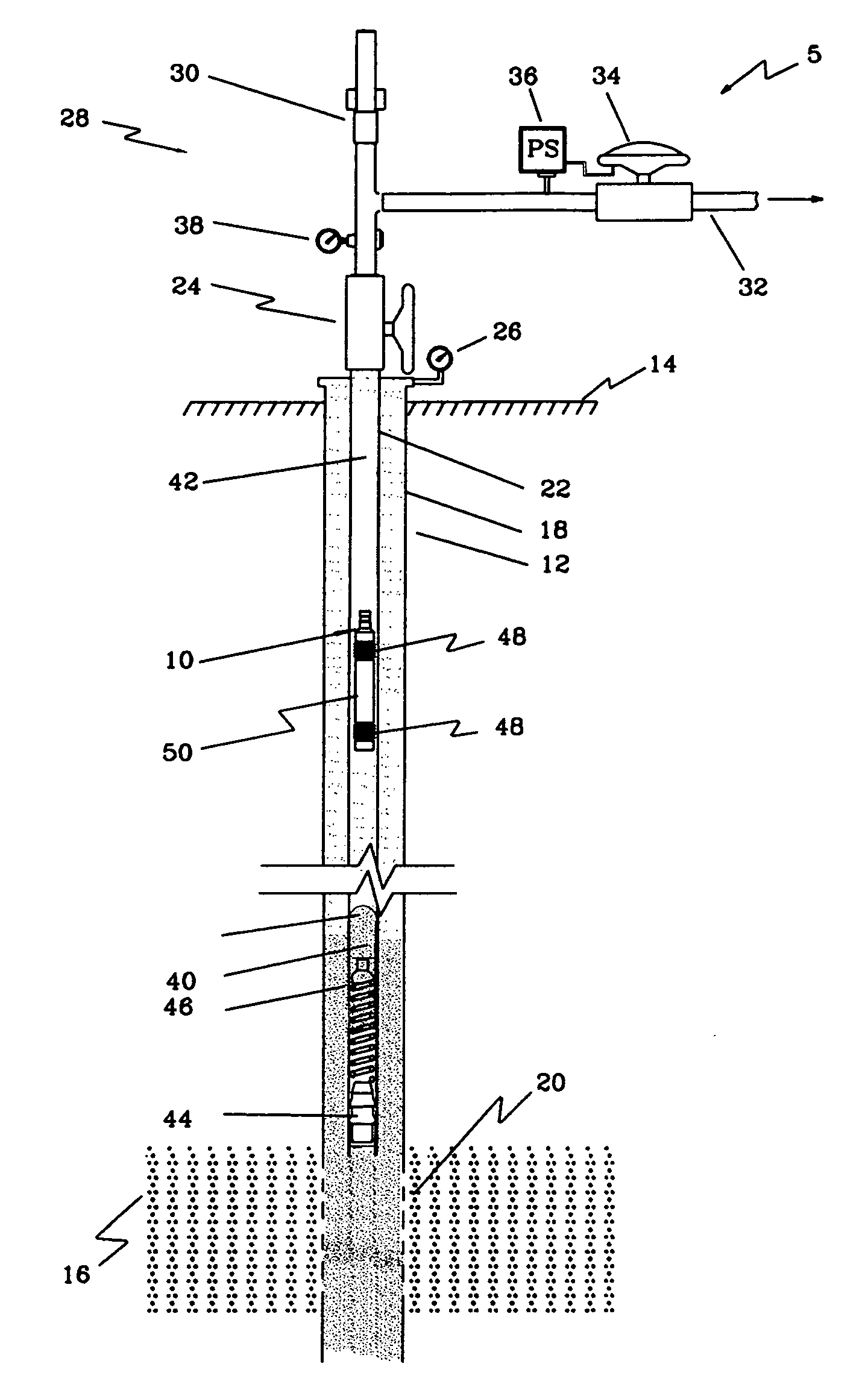

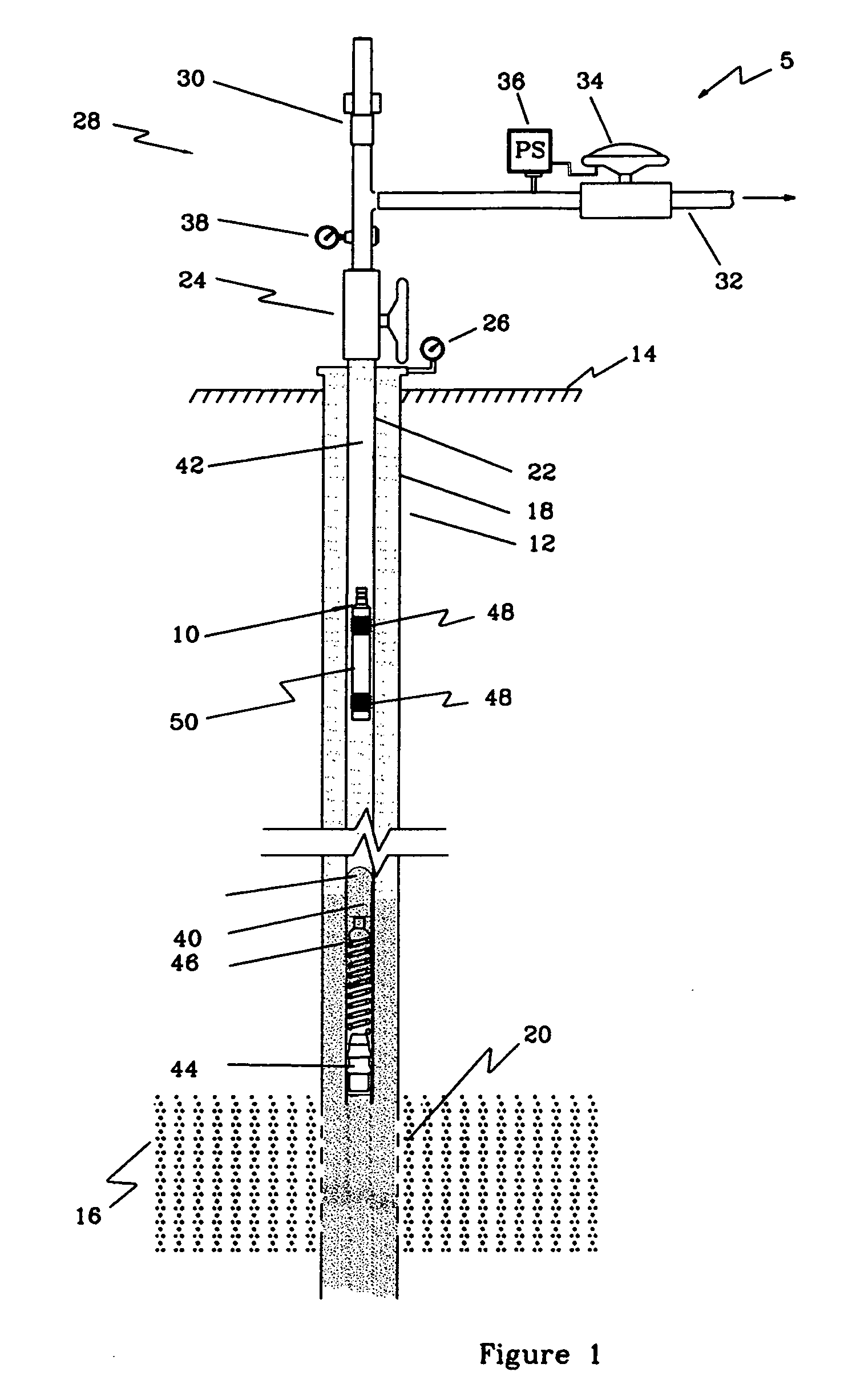

Oil and gas well completion system and method of installation

A completion system, and a corresponding method, for completing a subsea well, where the well includes a wellhead and a tubing hanger disposed in the wellhead and supports a string of production tubing, allows for angular alignment-free assembly of the subsea well. The completion system includes a series of circumferential channels formed in a well completion device at a boundary between the tubing hanger and the well completion device. The circumferential channels provide complete circular fluid paths with respect to the tubing hanger and the well completion device. At least one supply bore is in communication with each circumferential channel and is and oriented to supply a fluid to the circumferential channel, and at least one drain bore in communication with each circumferential channel and is oriented to remove fluid from the circumferential channel. Finally a circumferential electrical connector couples the tubing hanger and the completion device. The circumferential channels and bores provide fluid services between the completion device and the tubing hanger and the electrical connector provides electrical services to the tubing hanger. The completion system allows the fluid and electrical services to be provided without requiring any angular alignment between the tubing hanger and the completion device.

Owner:DRIL QUIP

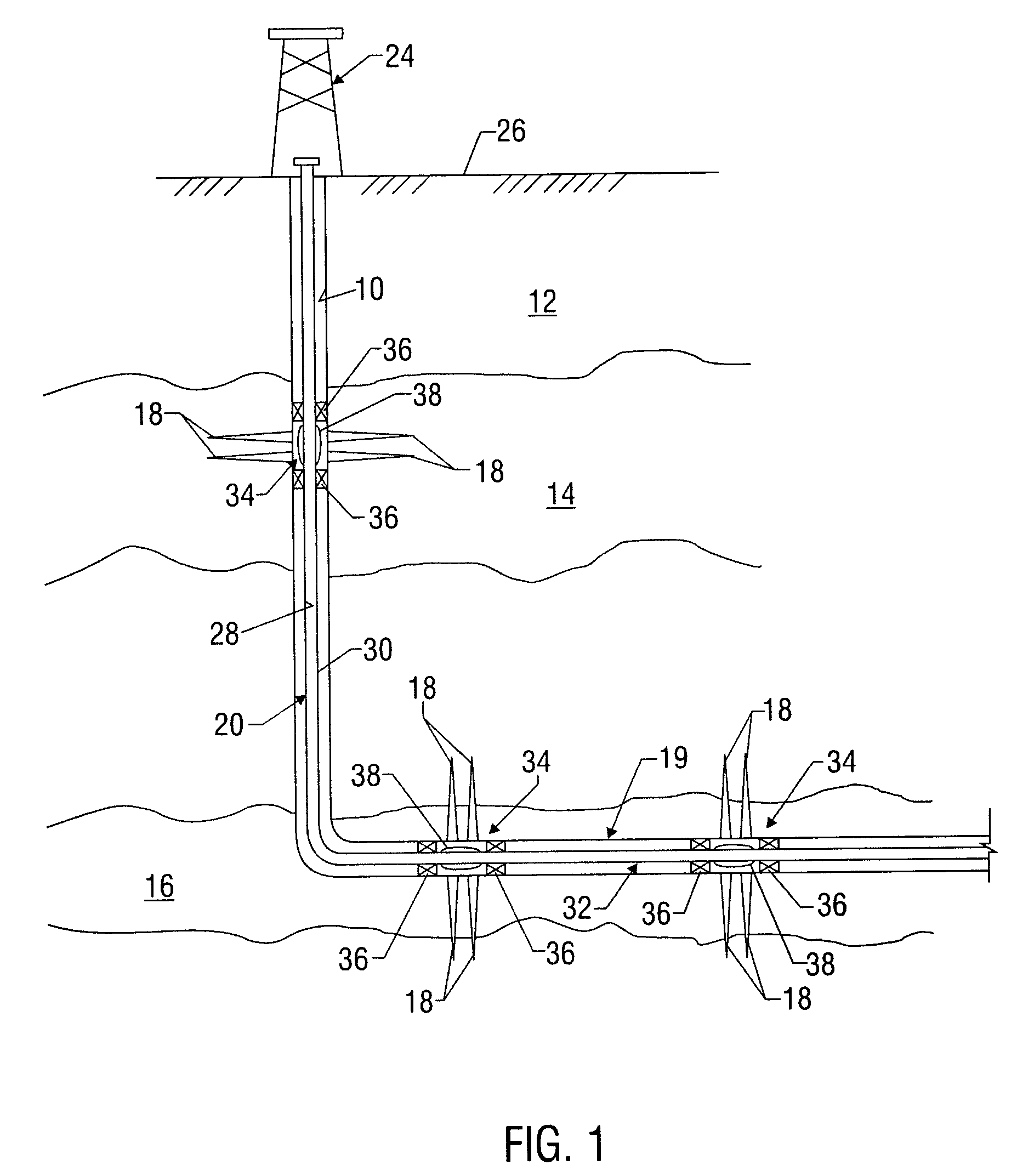

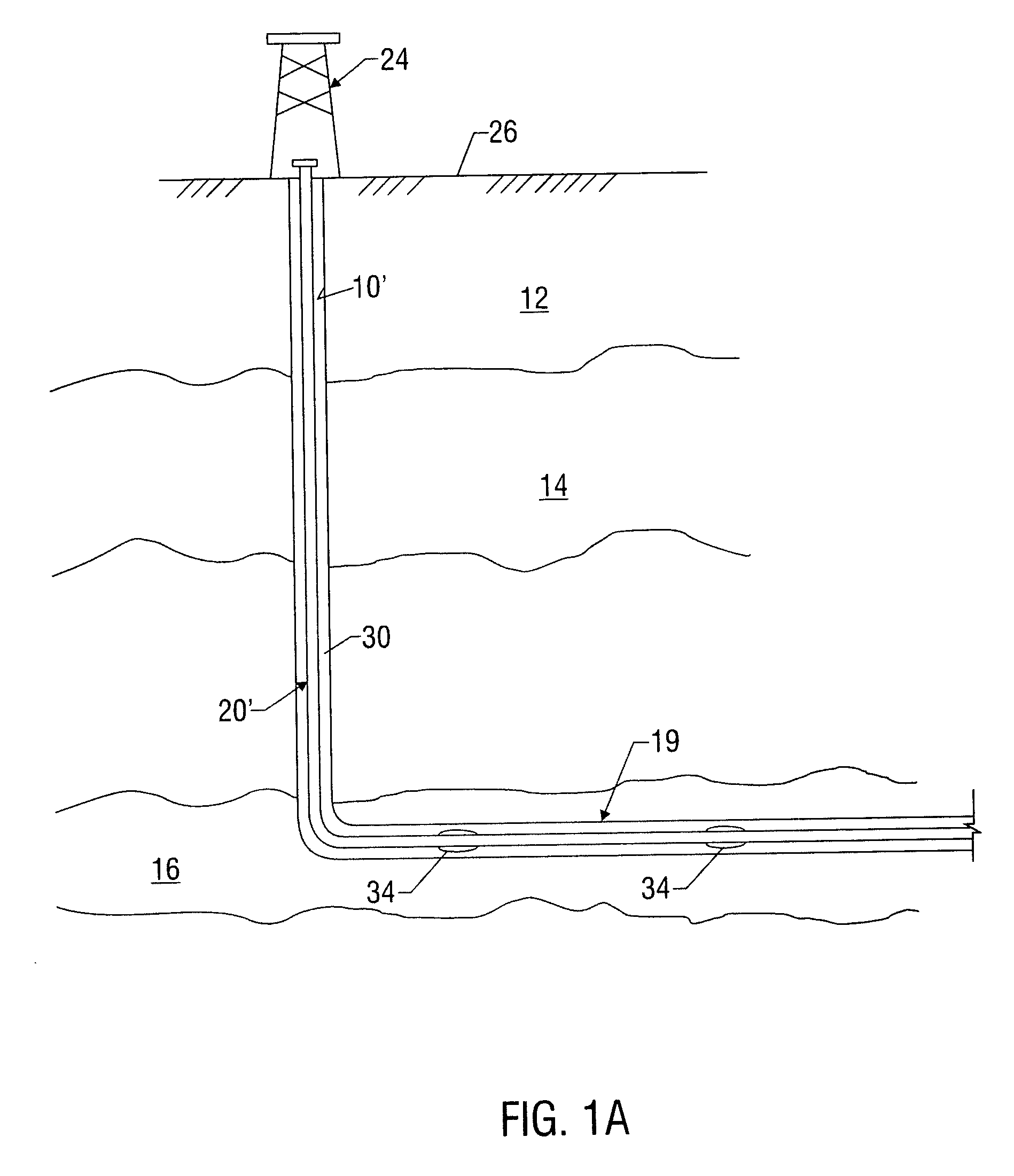

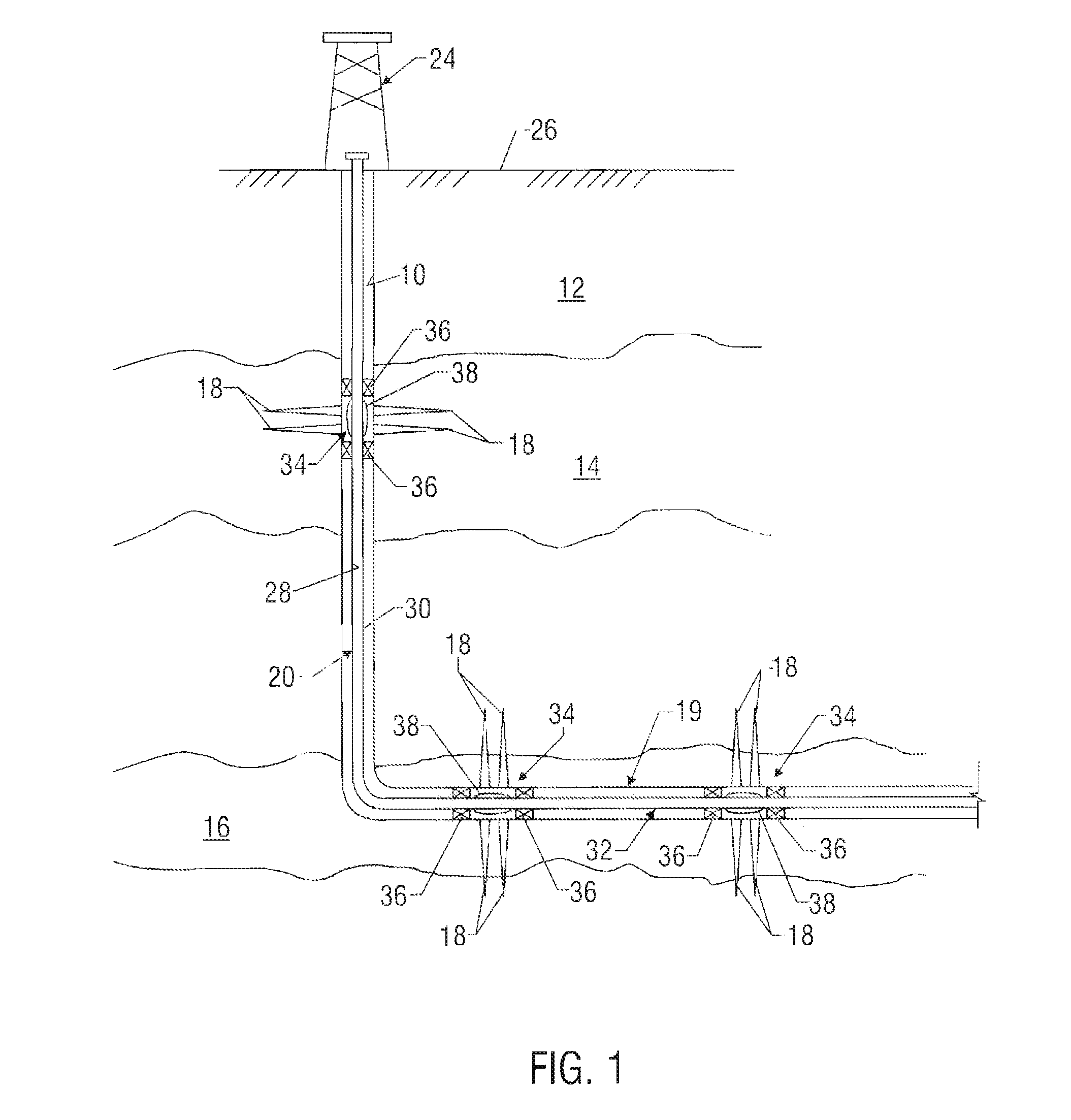

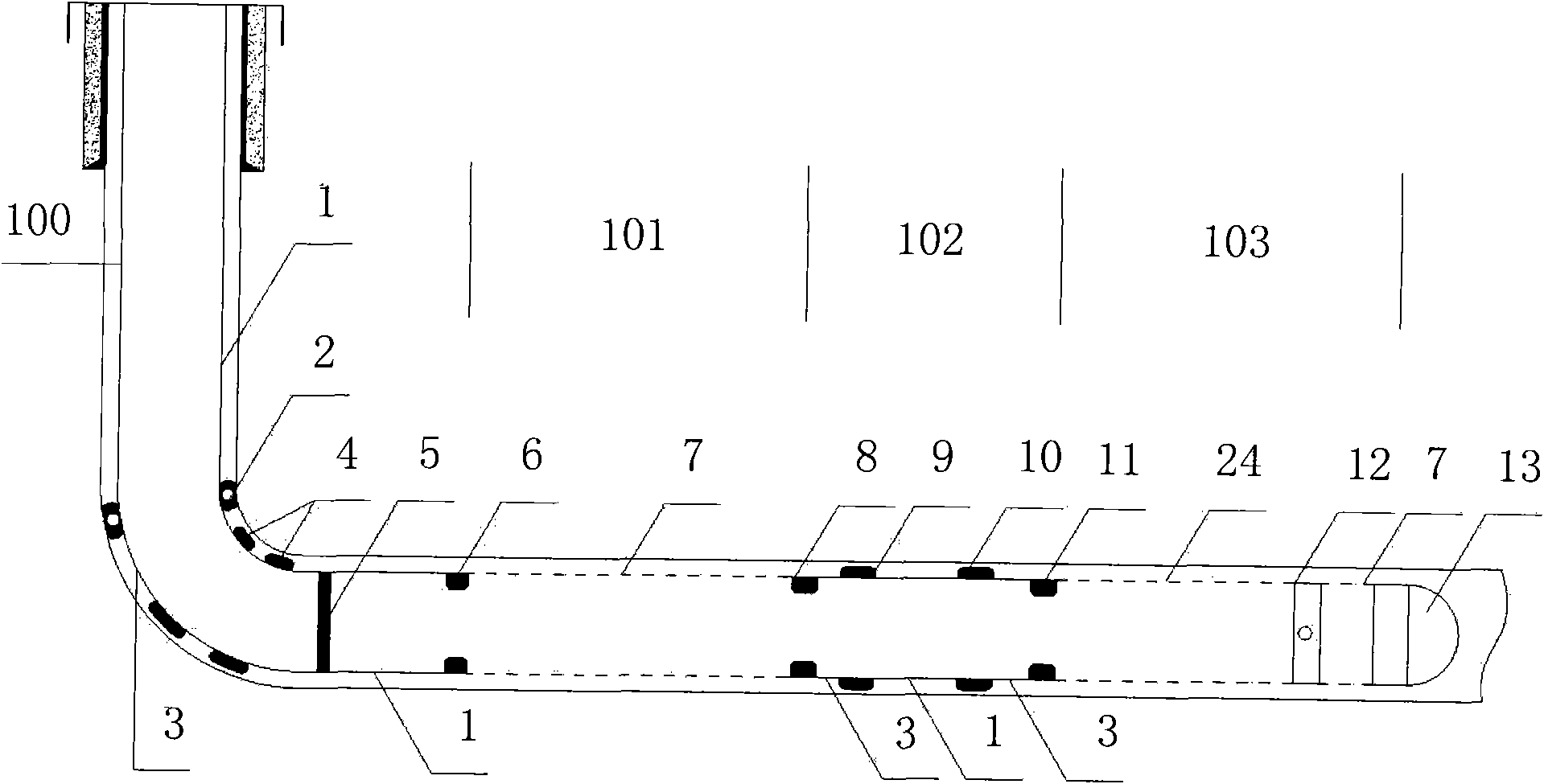

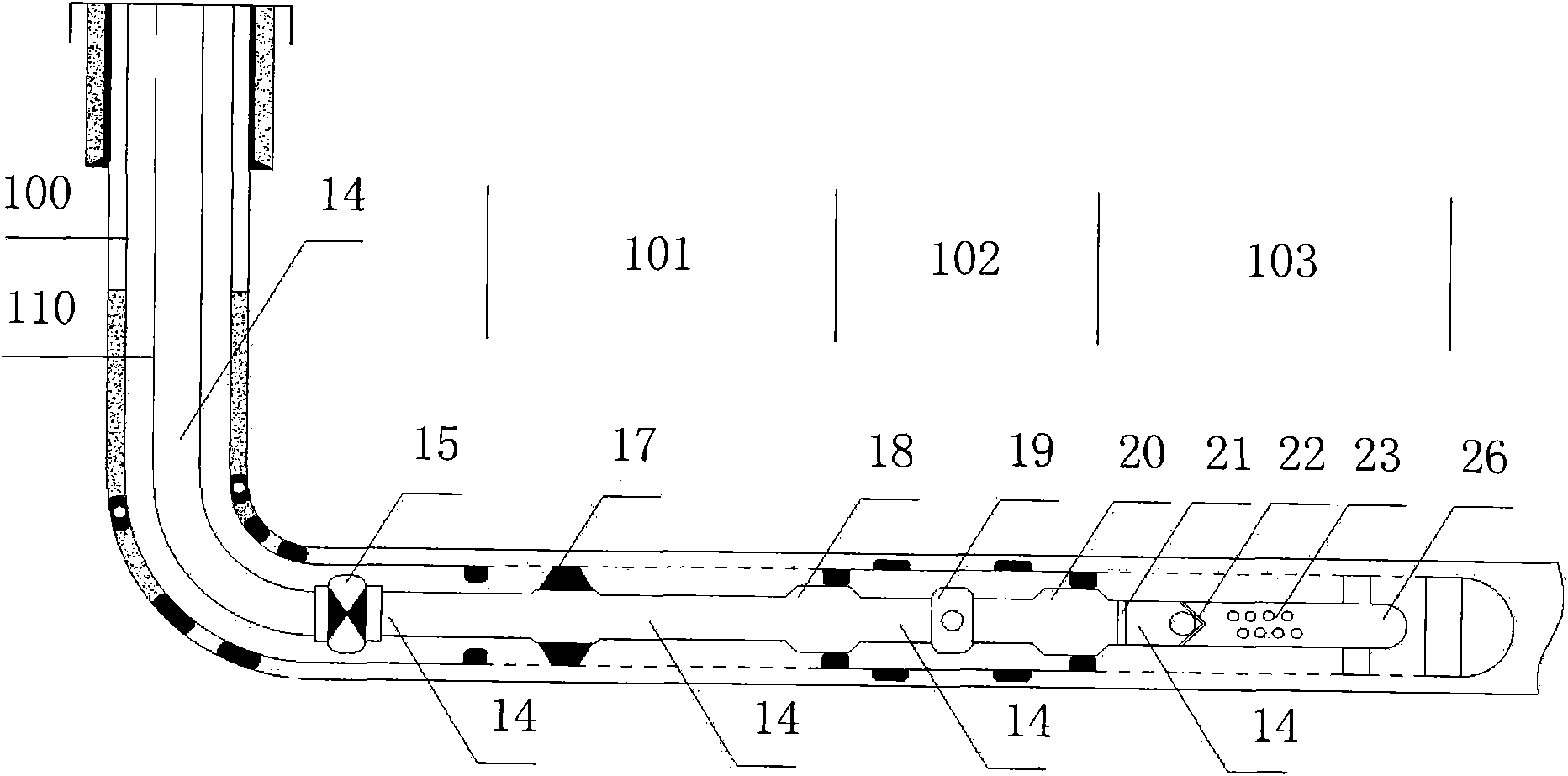

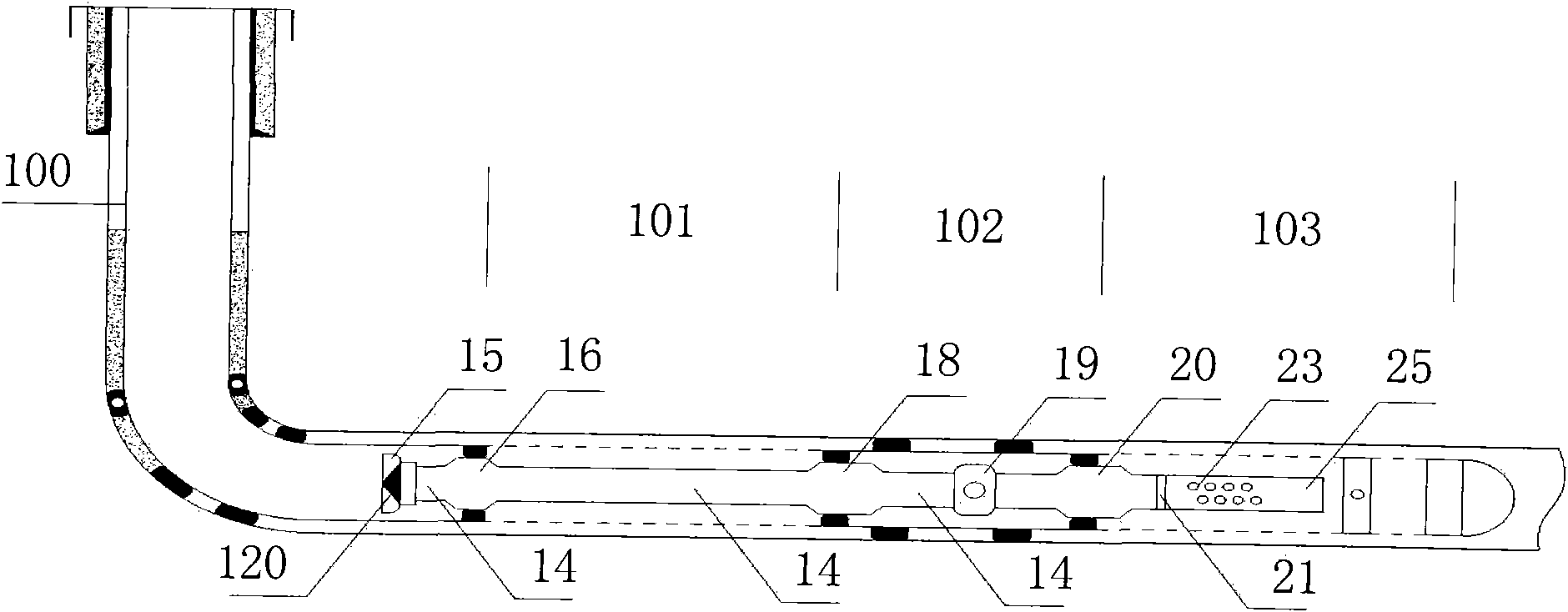

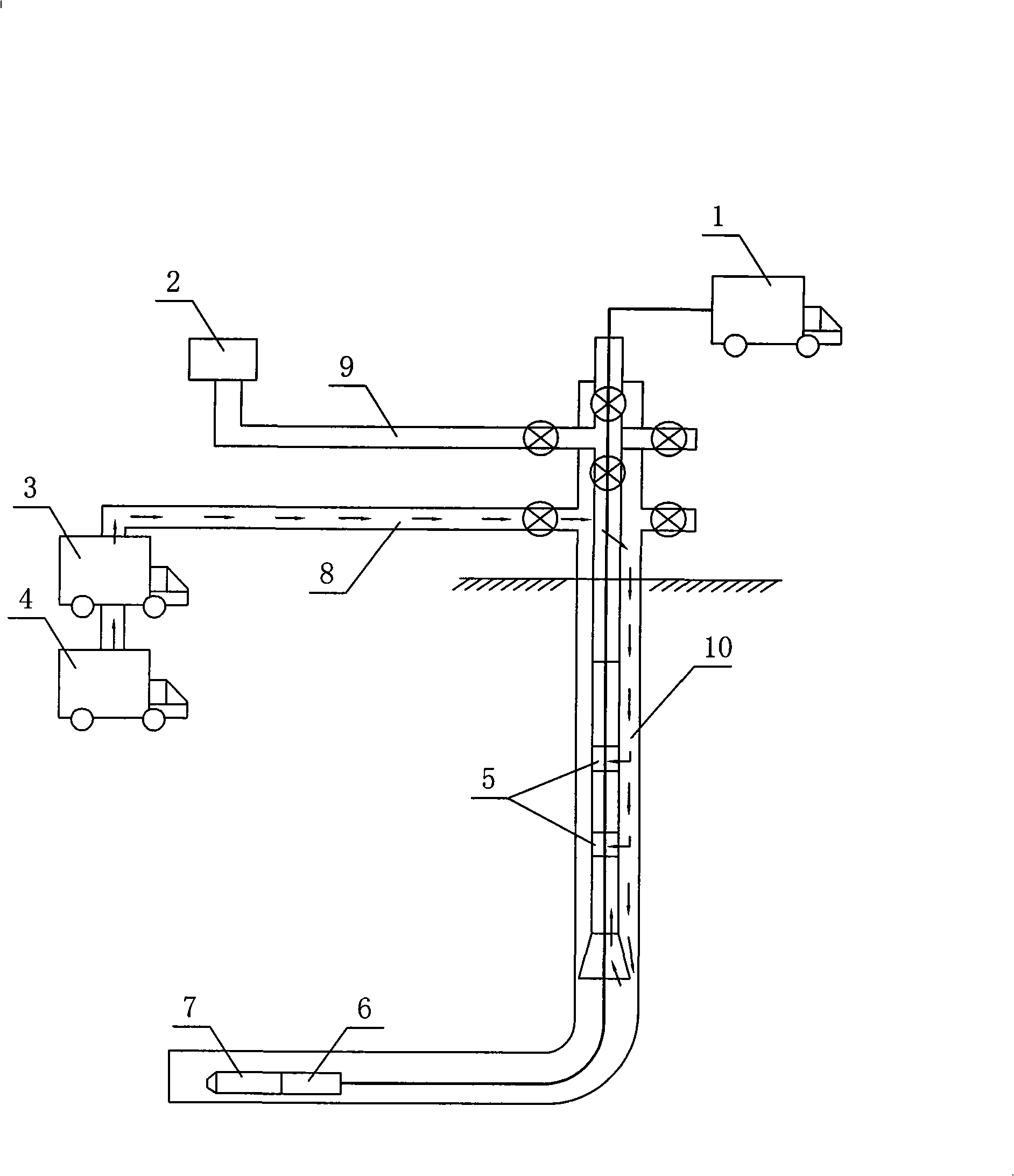

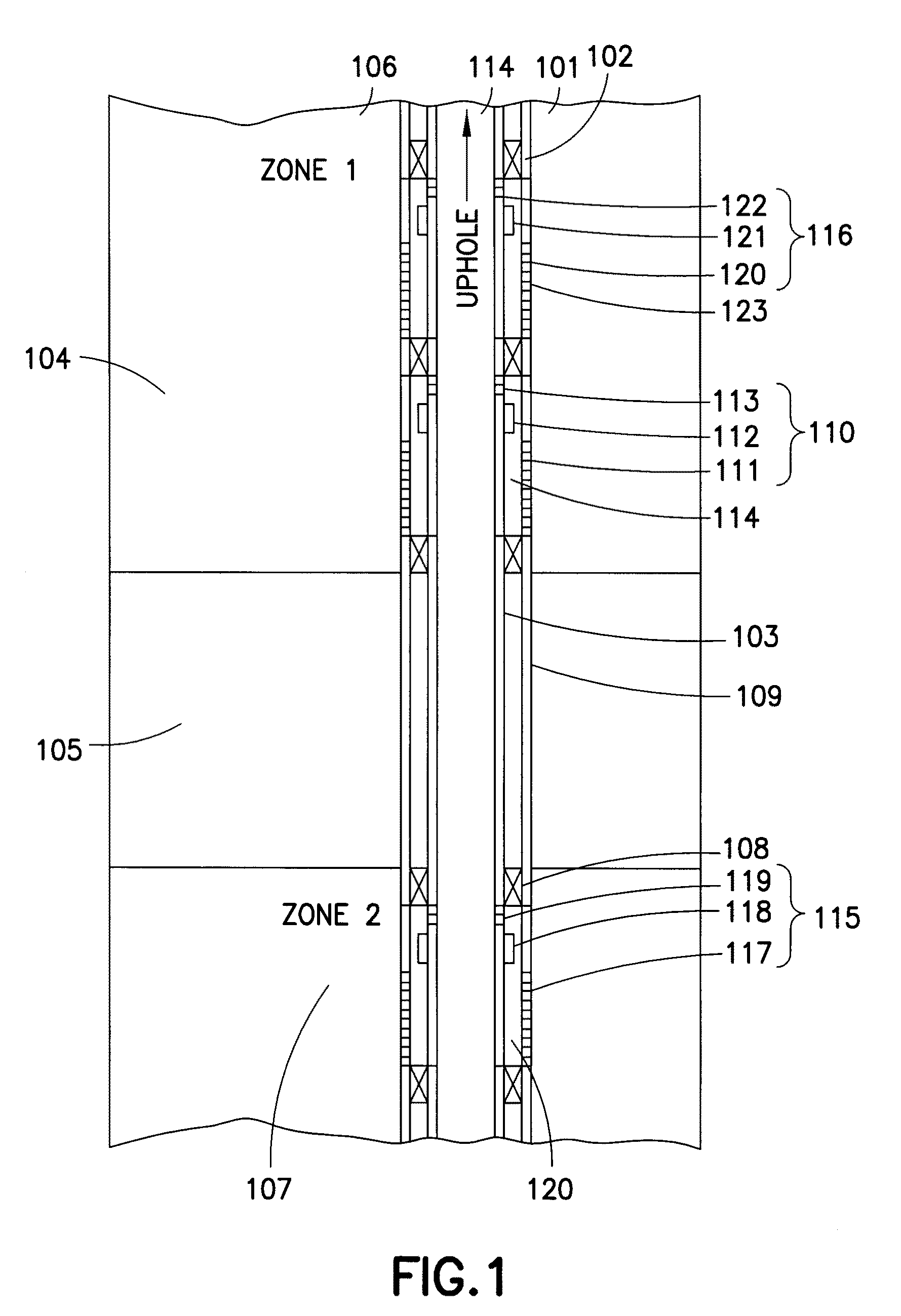

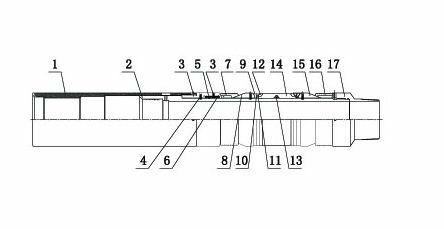

Well completion and oil production string of horizontal well and well completion and oil production processes thereof

ActiveCN101864921AImprove segmental sealing effectDelayed ConingDrilling rodsFluid removalAcid washingOil water

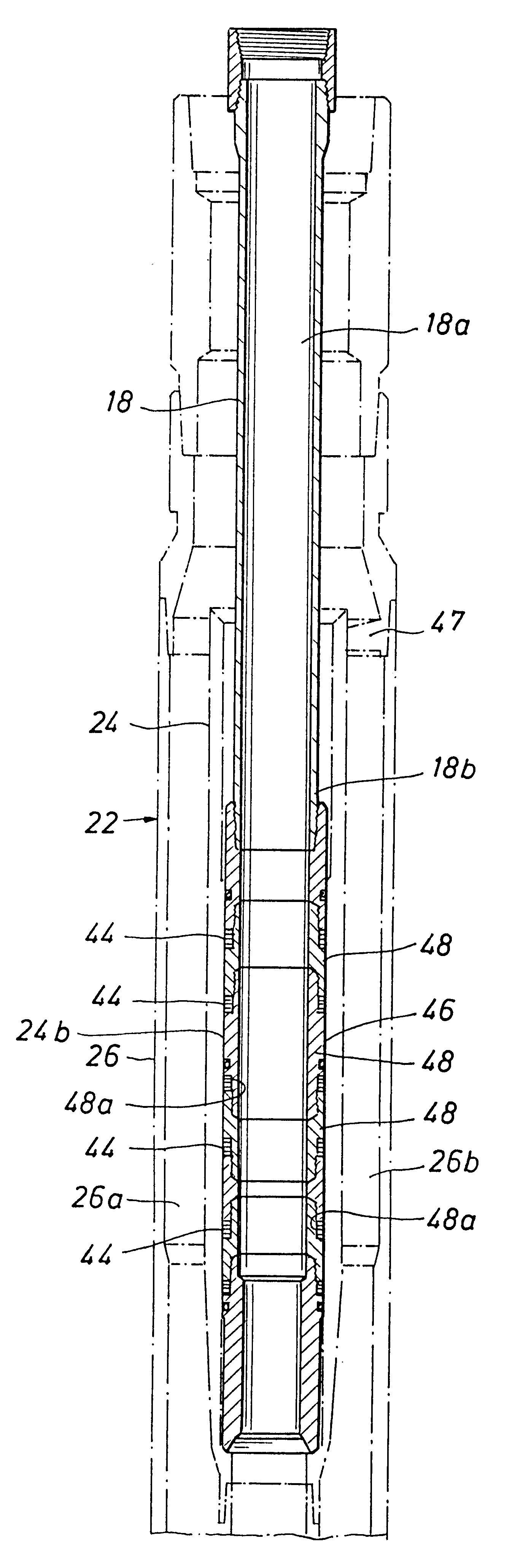

The invention relates to a well completion and oil production string of a horizontal well and well completion and oil production processes. In order to overcome the defect that in traditional horizontal well open hole sand-proof screening pipe well completion construction, an open hole packer at a horizontal section cannot effectively seal and separate oil and water layers because of irregular well diameter, a well completion string is fixedly arranged at the horizontal well section in an open hole well bore; a grading hoop, a casing short section, an external casing packer I, a blind plate, a casing, a layered seal tube I, an upper screening pipe, a layered seal tube II, a second casing short section, an external casing packer II, the other casing, an external casing packer III, a third casing short section, a layered seal tube III, a lower screening pipe, a wash-down valve, the lower screening pipe and a guiding shoe of the well completion string are sequentially and fixedly connected; and an acid washing string, a string for sealing up and producing oil from down, a string for sealing down and producing oil from up or a commingled production string is arranged in the well completion string. The invention has the beneficial effects that the well completion process of the horizontal well is combined with a post oil production technology, the sectioned sealing effect between the well completion string and the open hole well bore is improved, bottom water coning is delayed, and the purposes of controlling water and increasing oil are achieved.

Owner:DAGANG OIL FIELD GRP +1

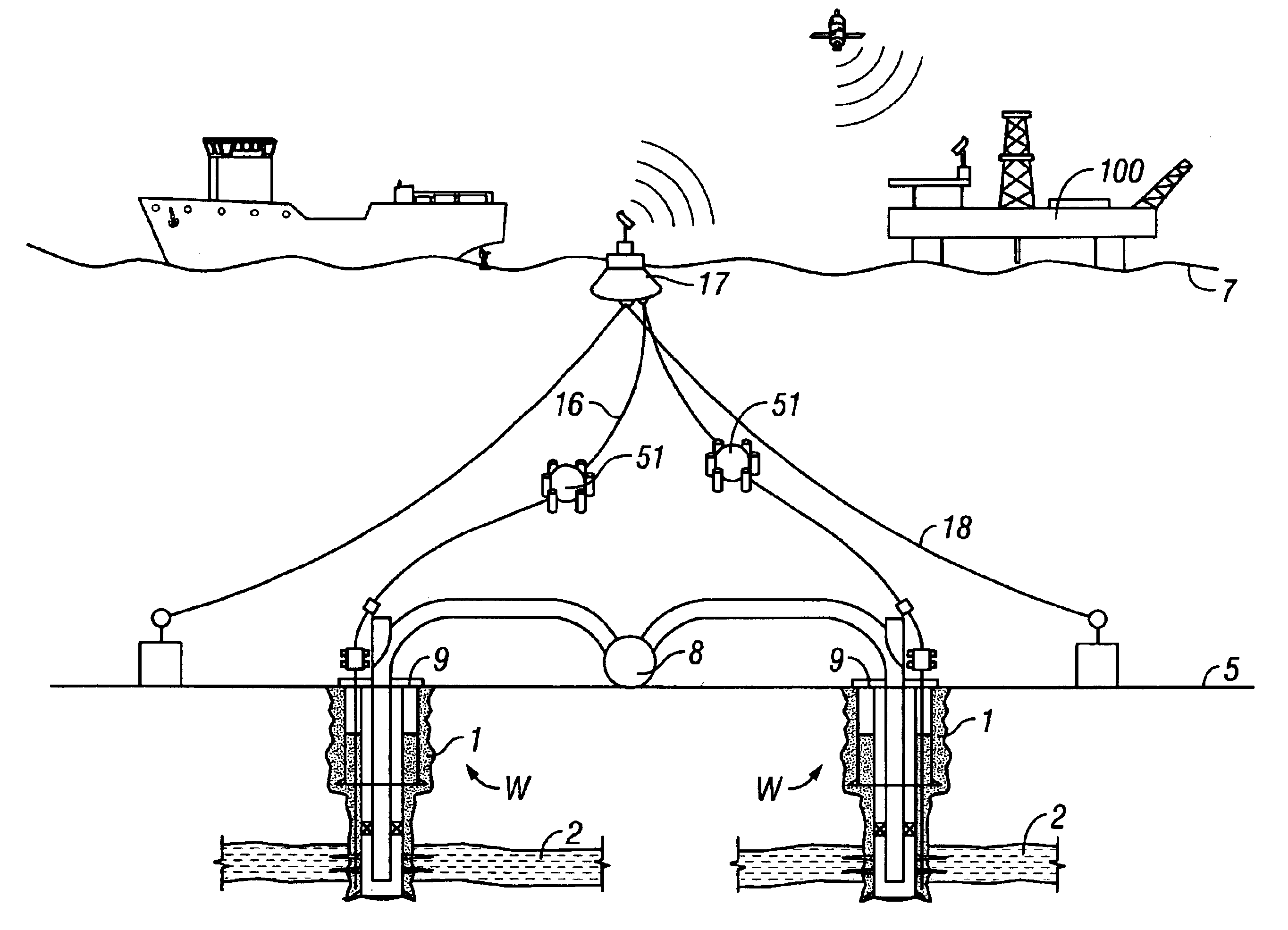

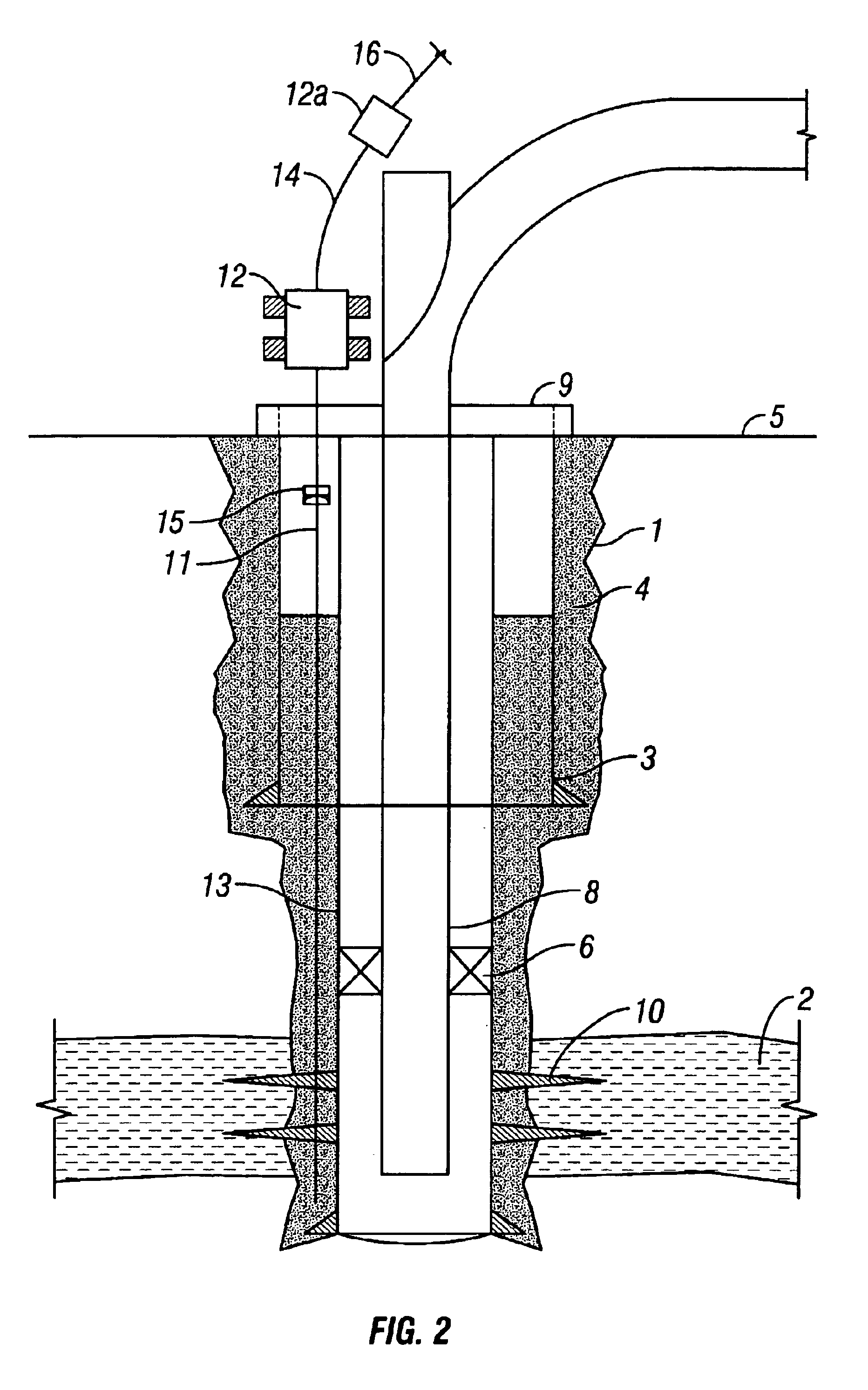

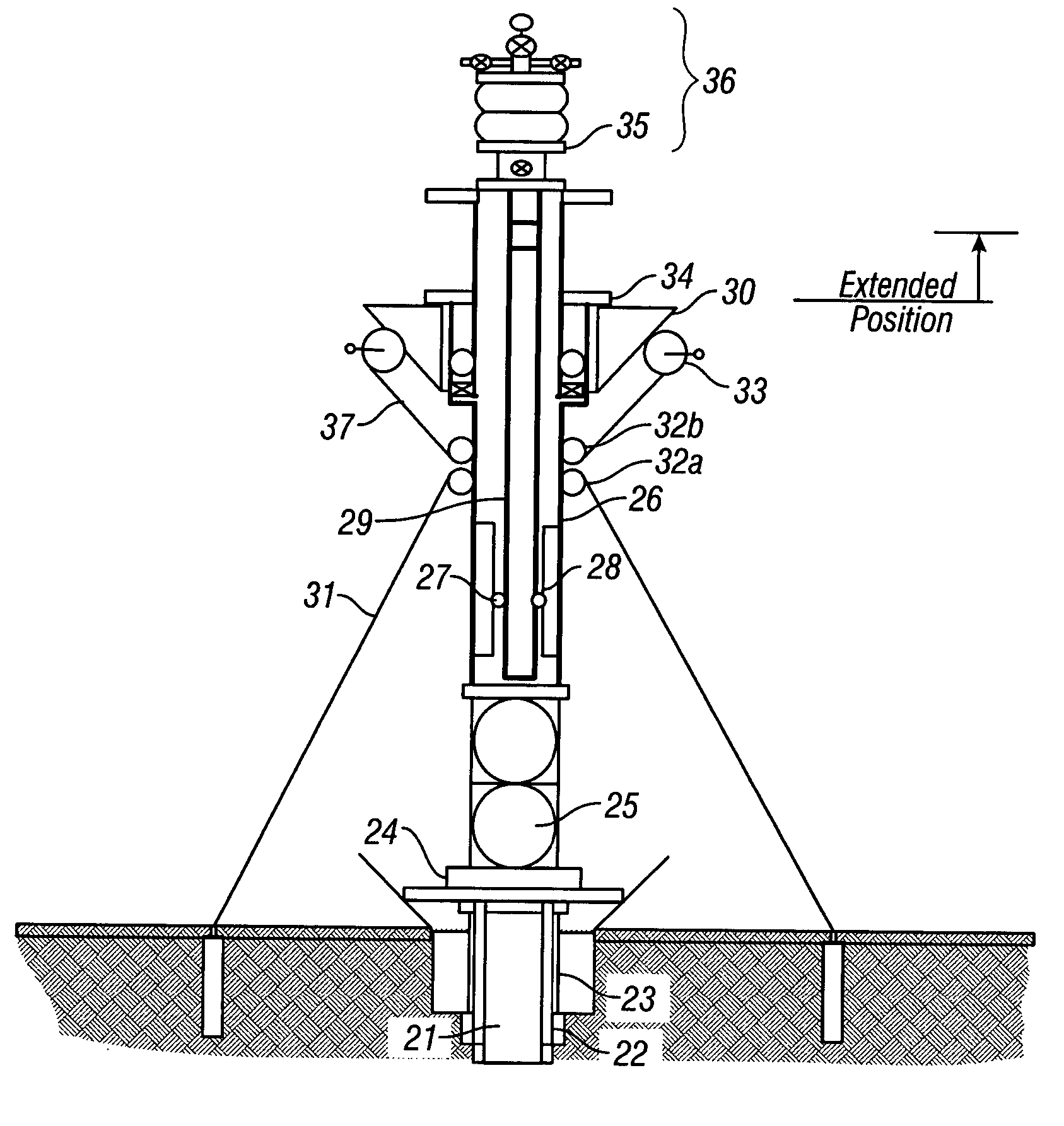

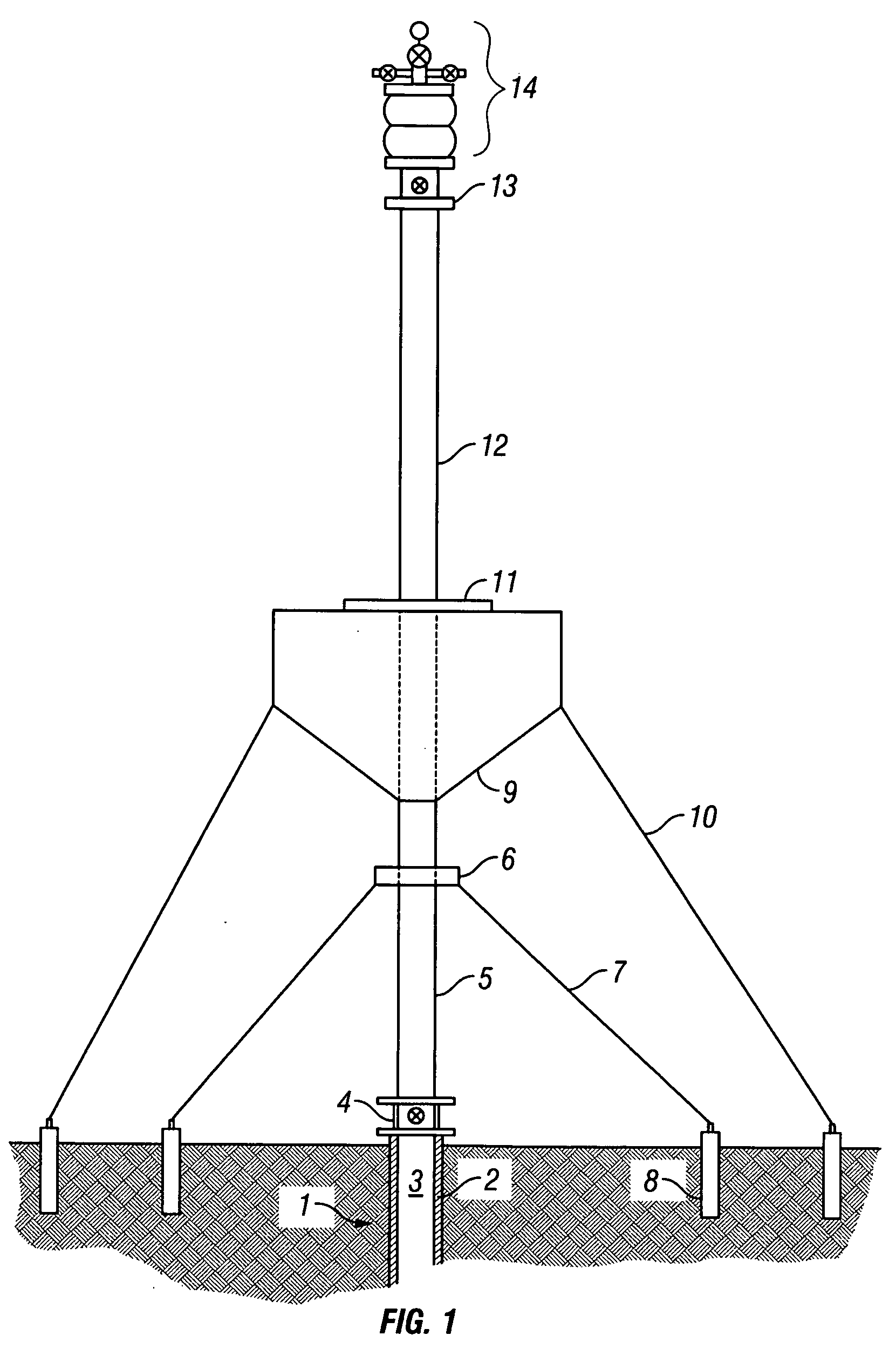

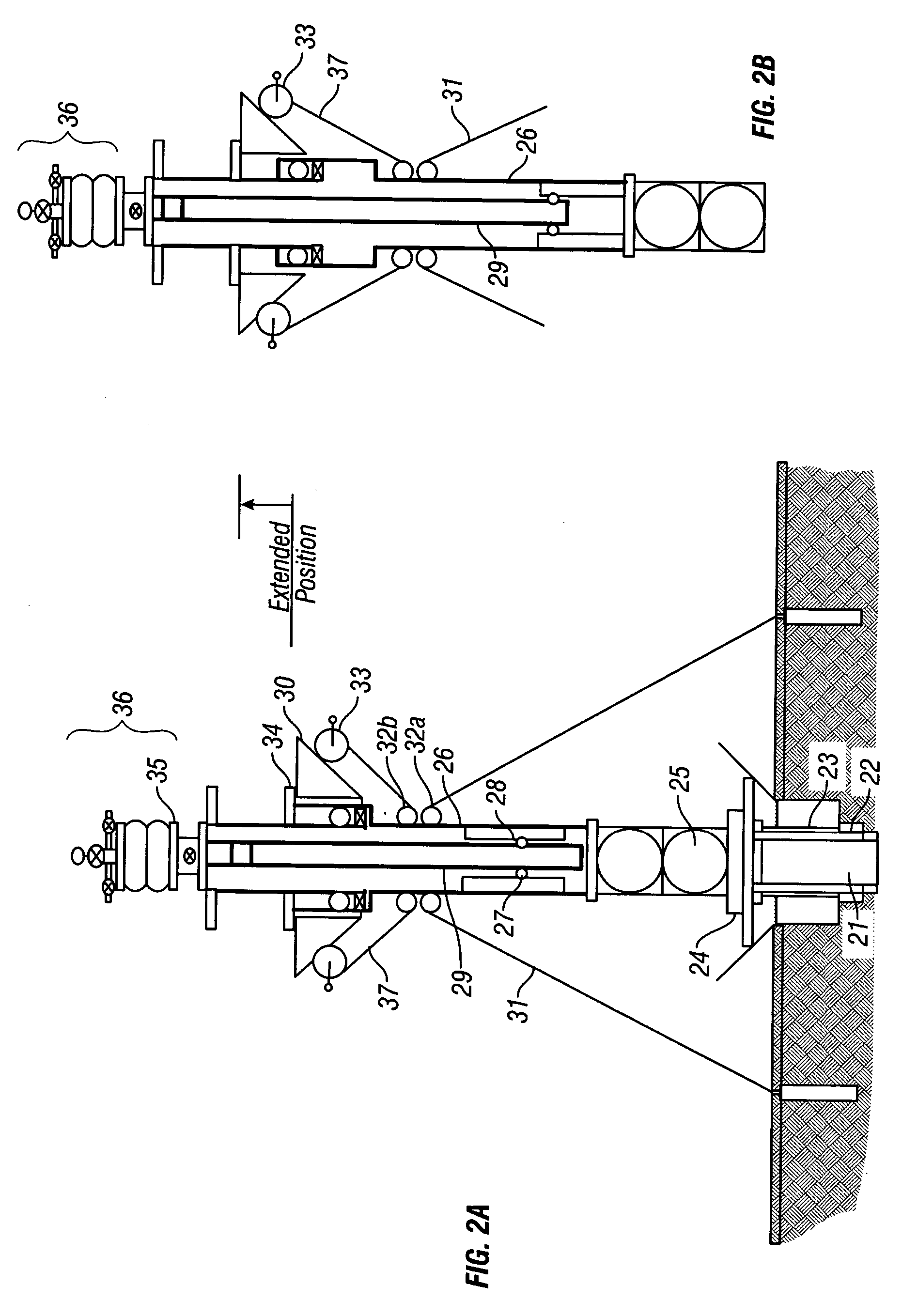

System and method of installing and maintaining an offshore exploration and production system having an adjustable buoyancy chamber

A system and method of establishing an offshore exploration and production system is disclosed, in which a well casing is disposed in communication with an adjustable buoyancy chamber and a well hole bored into the floor of a body of water. A lower connecting member joins the well casing and the chamber, and an upper connecting member joins, the adjustable buoyancy chamber and a well terminal member. The chamber's adjustable buoyancy enables an operator to vary the height or depth of the well terminal member, and to vary the vertical tension imparted to drilling and production strings throughout exploration and production operations. Also disclosed is a system and method of adjusting the height or depth of a wellhead while associated vertical and lateral forces remain approximately constant. A variety of well isolation members, lateral stabilizers and anchoring means, as well as several methods of practicing the invention, are also disclosed.

Owner:ANADARKO PETROLEUM CORPORATION

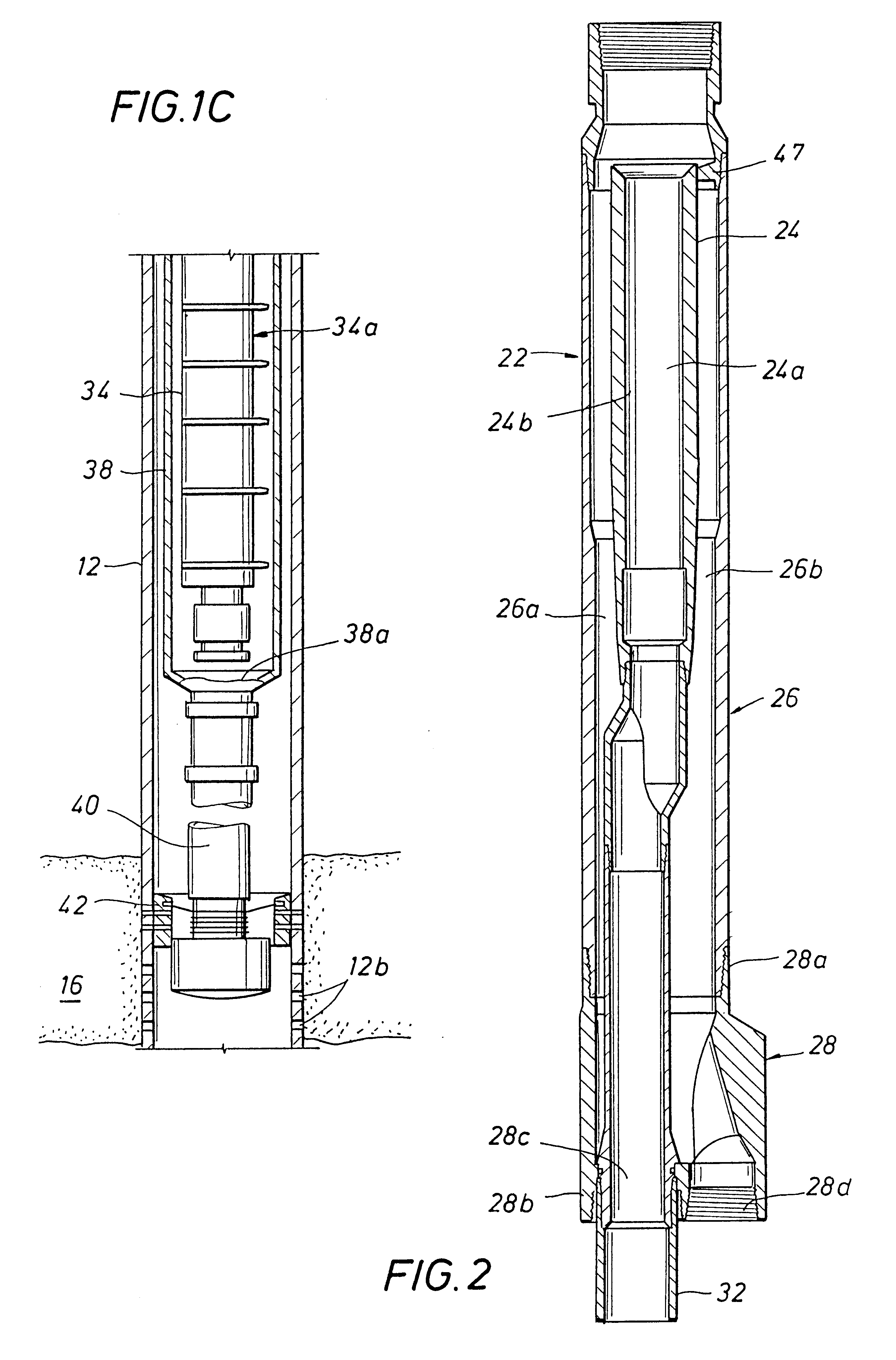

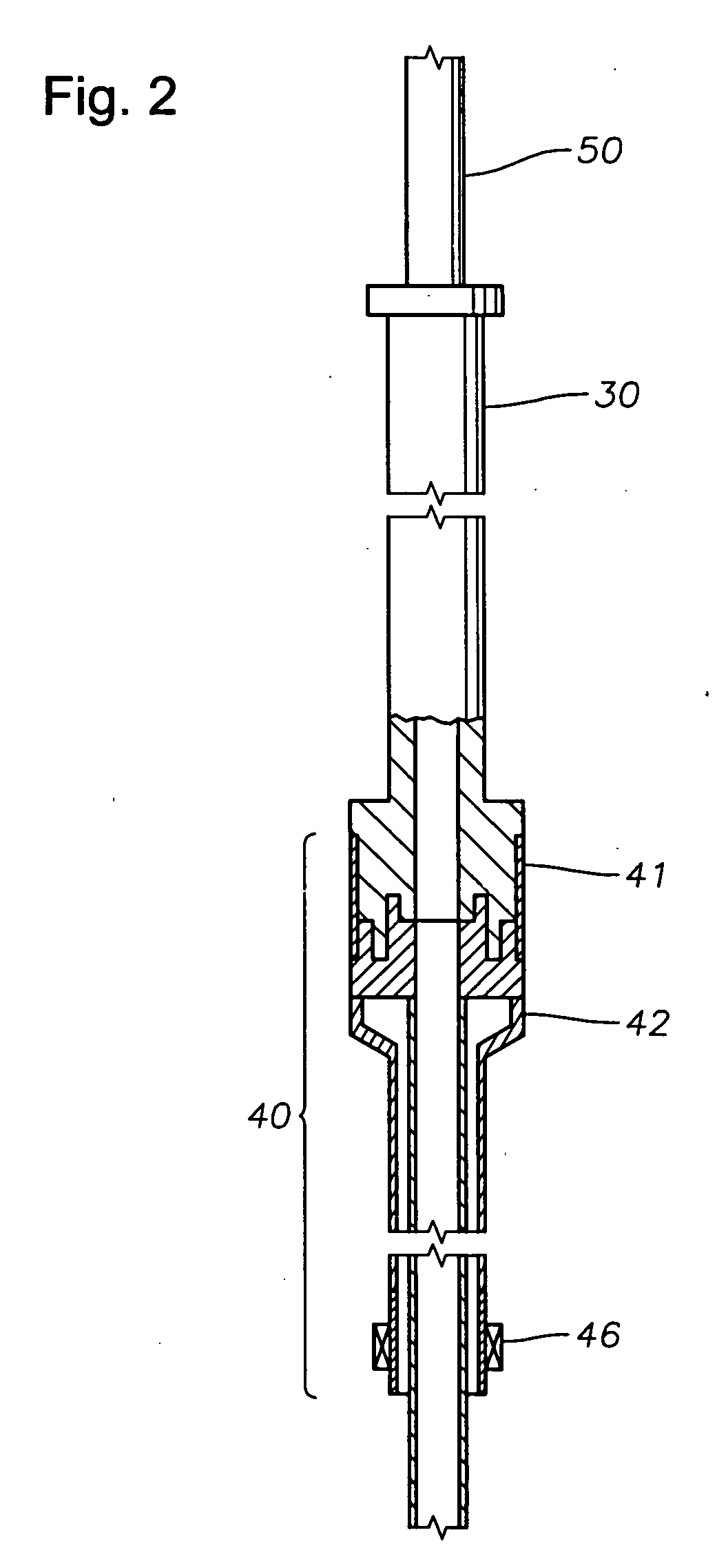

Tubular expansion fluid production assembly and method

InactiveUS7124829B2Reliable settingsConstructed moreFluid removalSealing/packingCasing stringEngineering

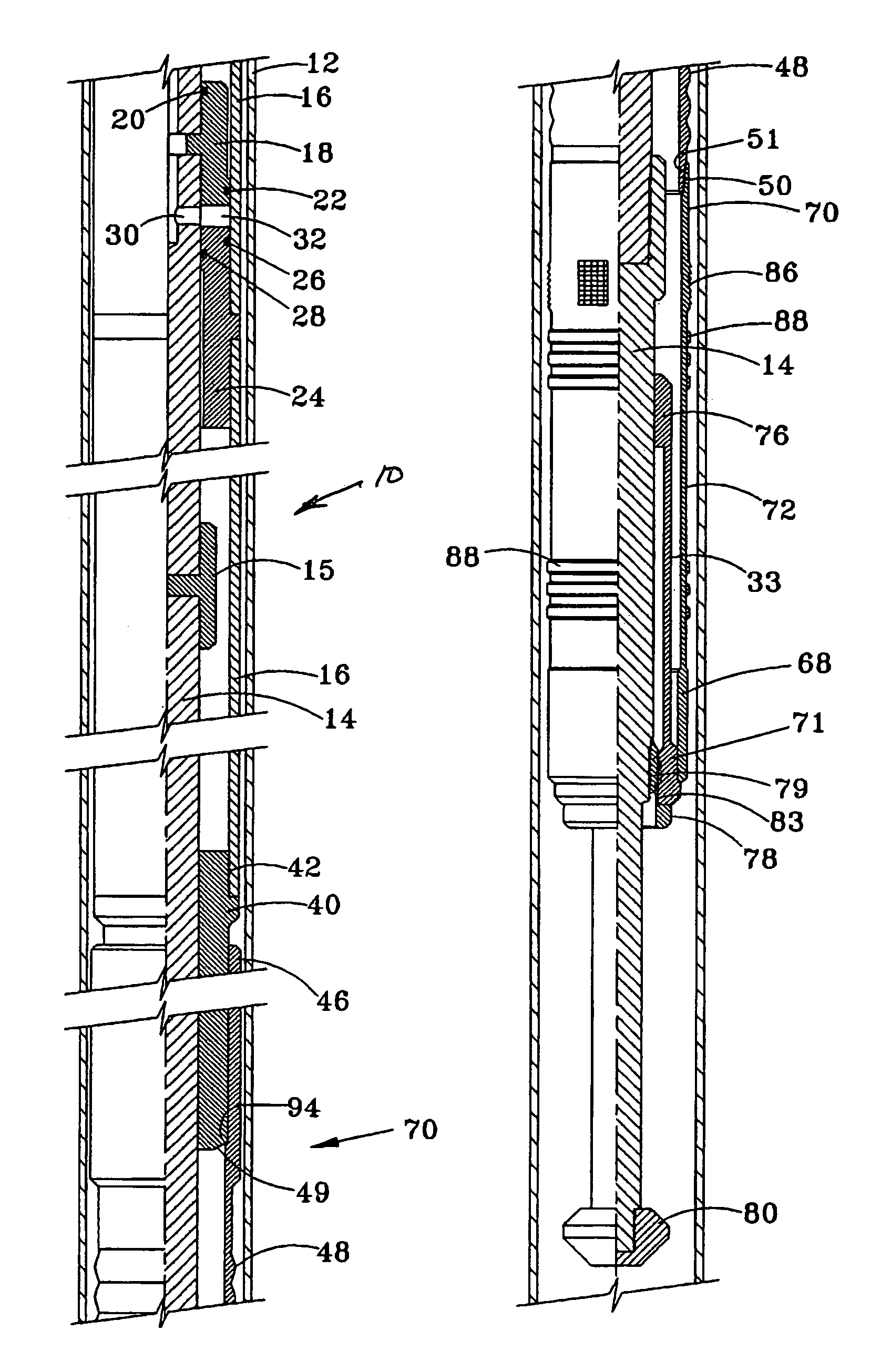

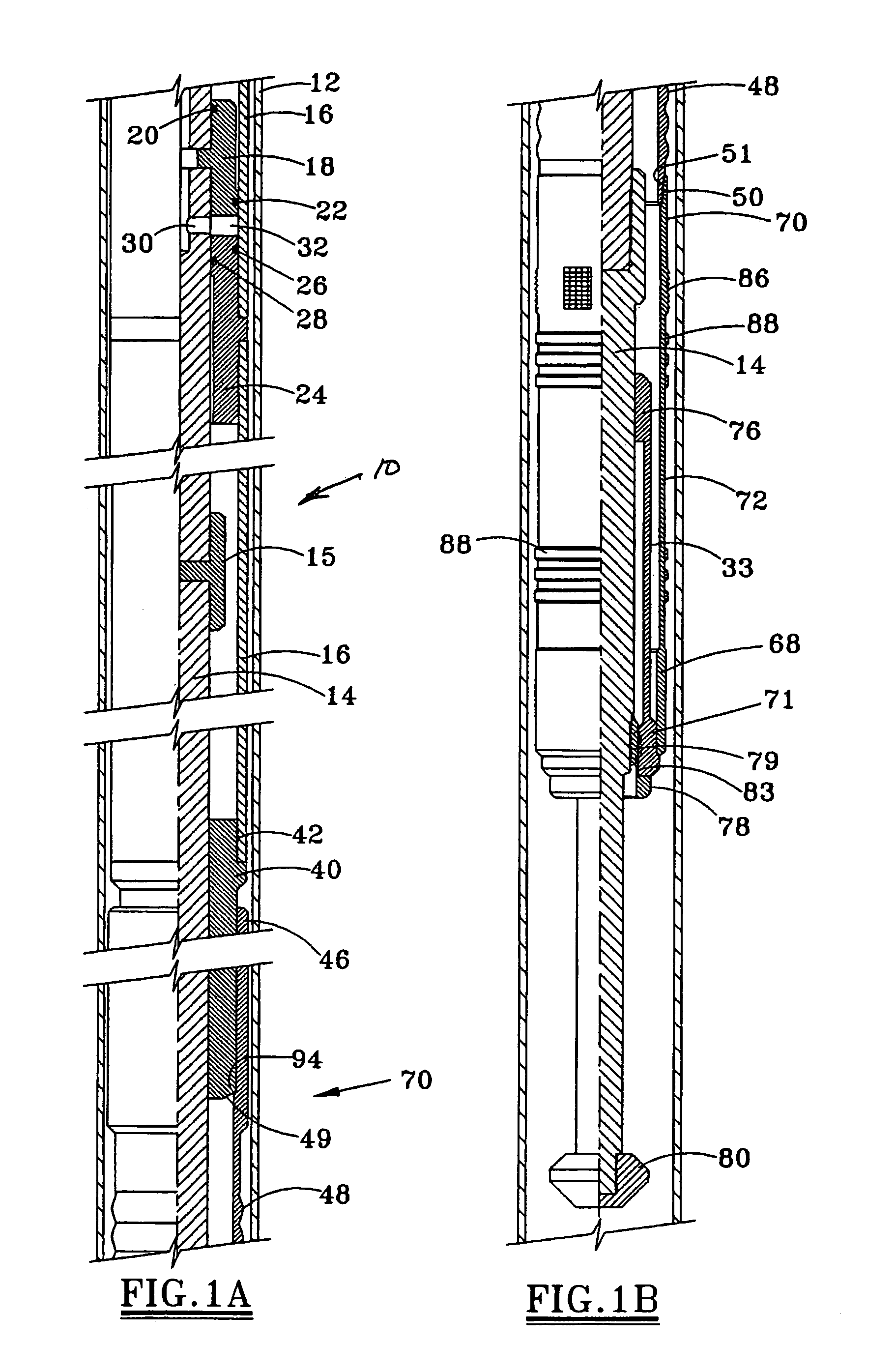

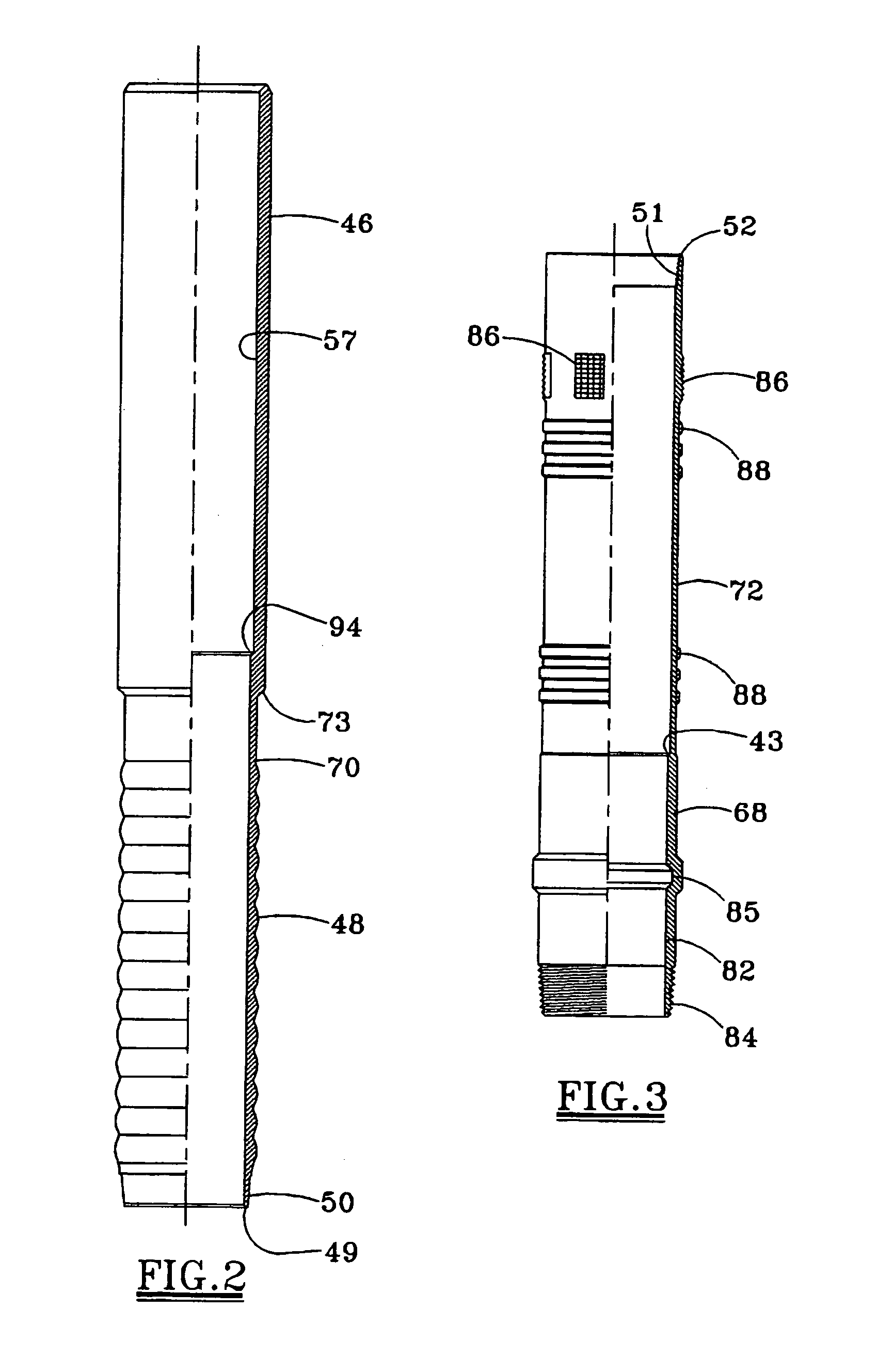

An expansion-set fluid production assembly transfers well fluids from a casing string 12 to a production tubing string 112. A tubular anchor 72 and tubular expander 70 may be positioned downhole on a running tool at a desired depth along the casing string 12. An actuator assembly 10 may forcibly move the tubular expander 70 into the tubular anchor 72, expanding the tubular anchor 72 to seal and secure the tubular anchor 72 against the casing string 12. The running tool actuator assembly 10 may be removed, leaving the expanded tubular anchor 72 and tubular expander 70 downhole. A seal nipple 122 may be sealed with the tubular expander 70 and to the production tubing string 112. Fluids may then be recovered from the wellbore through the casing string 12, through the fluid production assembly, and into the production tubing string 112.

Owner:TIW

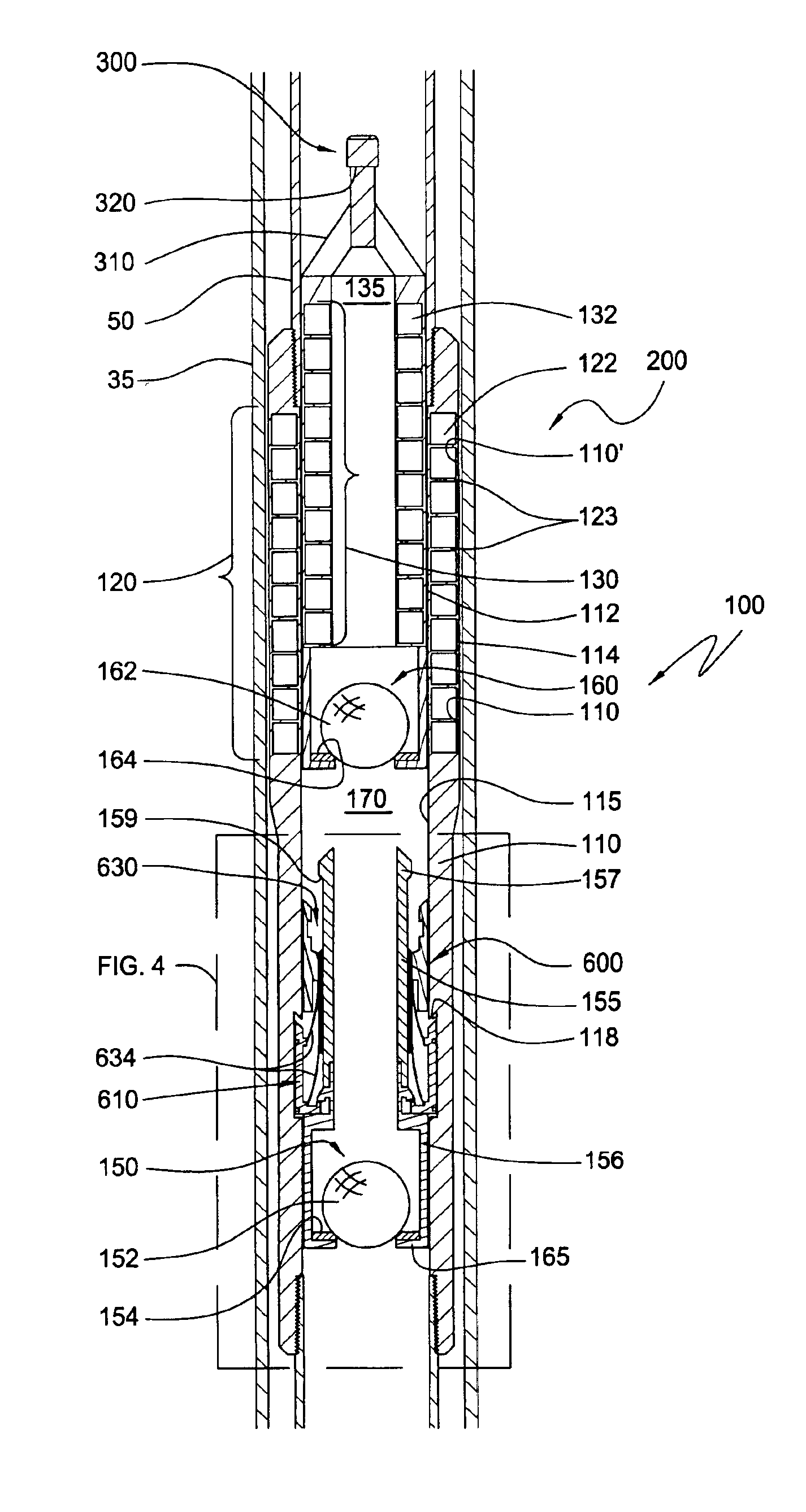

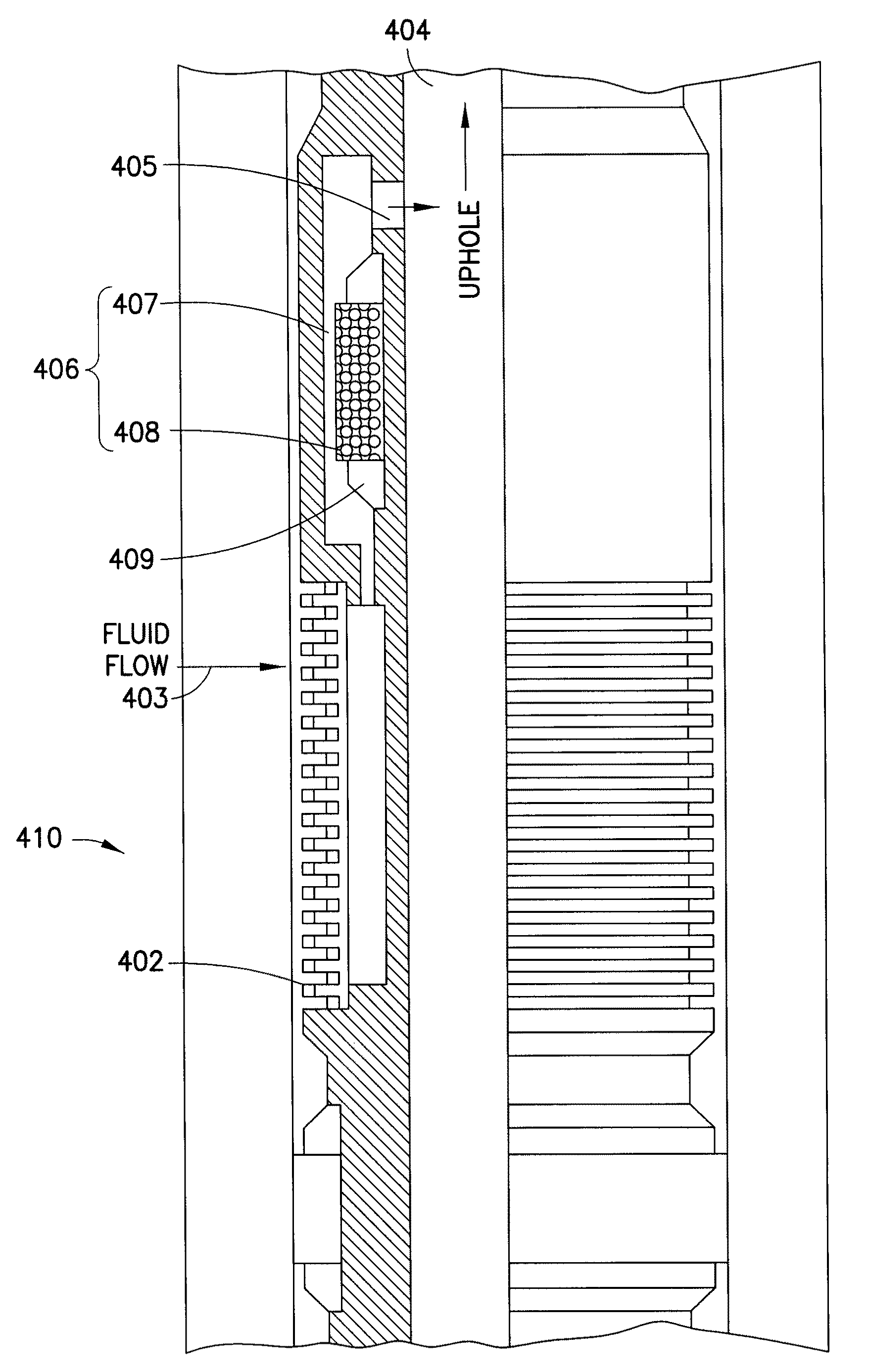

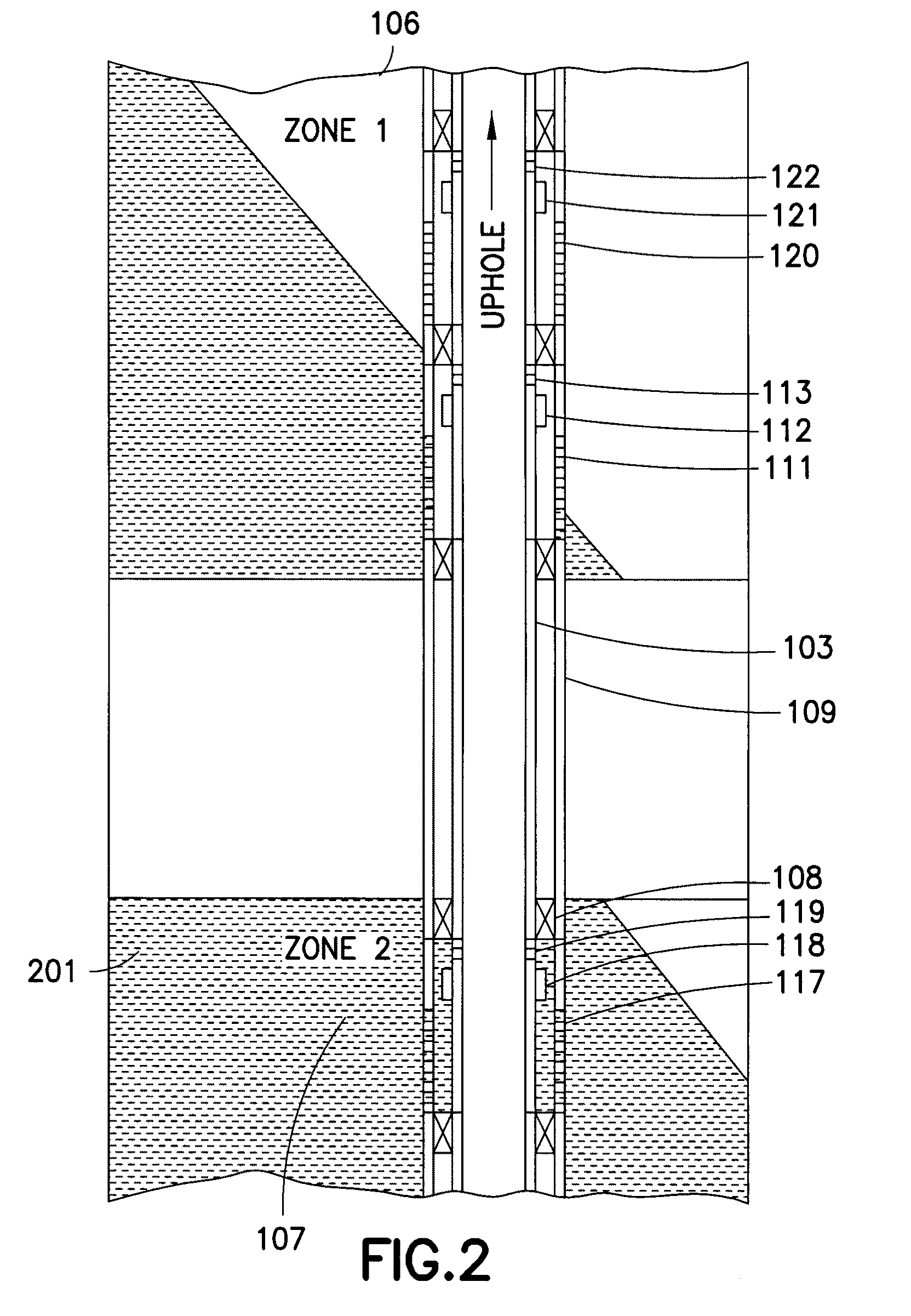

Intelligent Well Control System for Three or More Zones

An intelligent well system can service three or more zones that have gravel packed screens. A modular system features a screen and a surface controlled production valve on an internal blank pipe that internally straddles the screen. A gravel exit valve is disposed above the blank pipe and the blank pipe can optionally have a fluid loss control valve. A gravel pack / fracturing assembly can engage each module and close the fluid loss valve and gravel outlet valve on the way out of a module. Optionally the fluid loss valve can be eliminated if the gravel packing and fracturing string has the ability to power the production valve. The modules can be connected by wet connects as can the production string to make the intelligent well system functional from the surface.

Owner:BAKER HUGHES INC

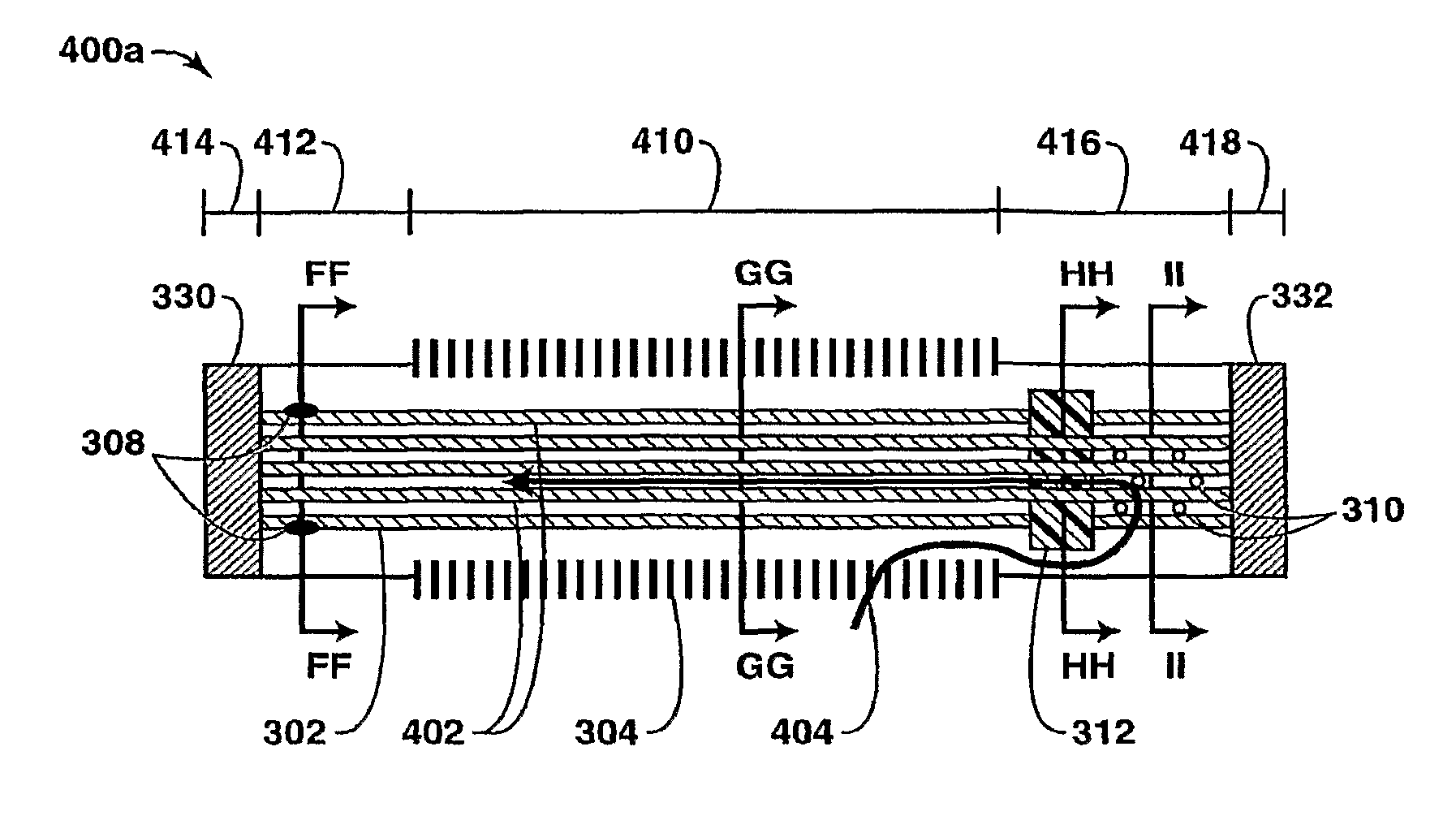

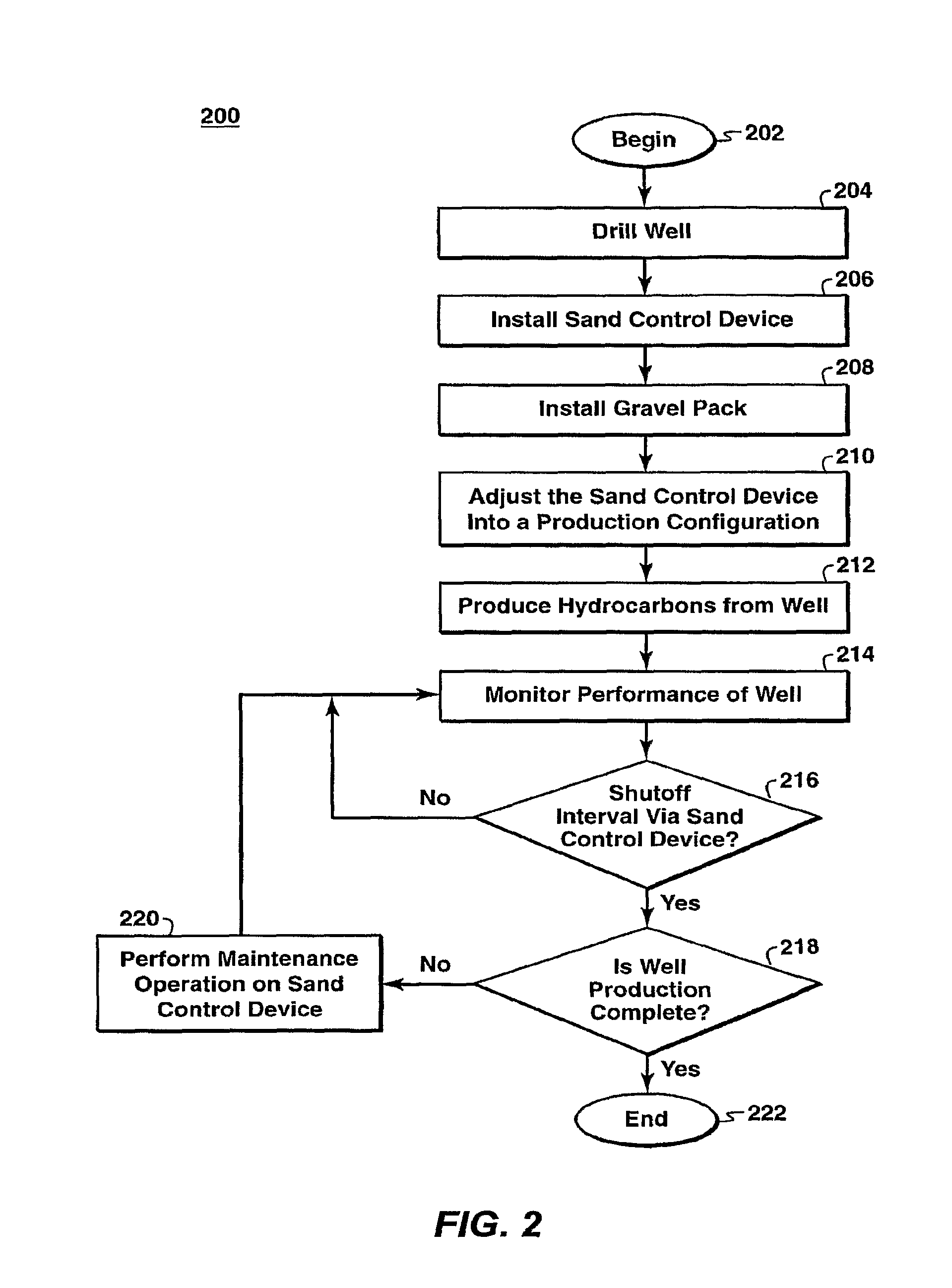

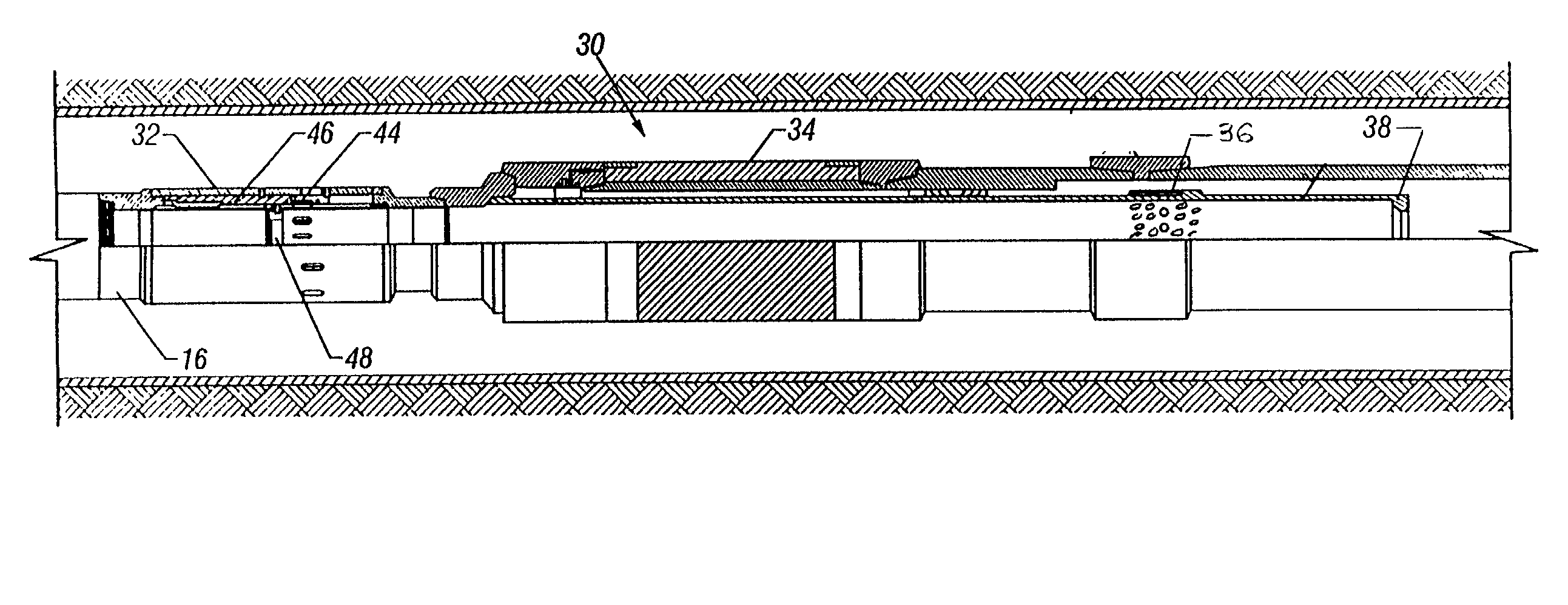

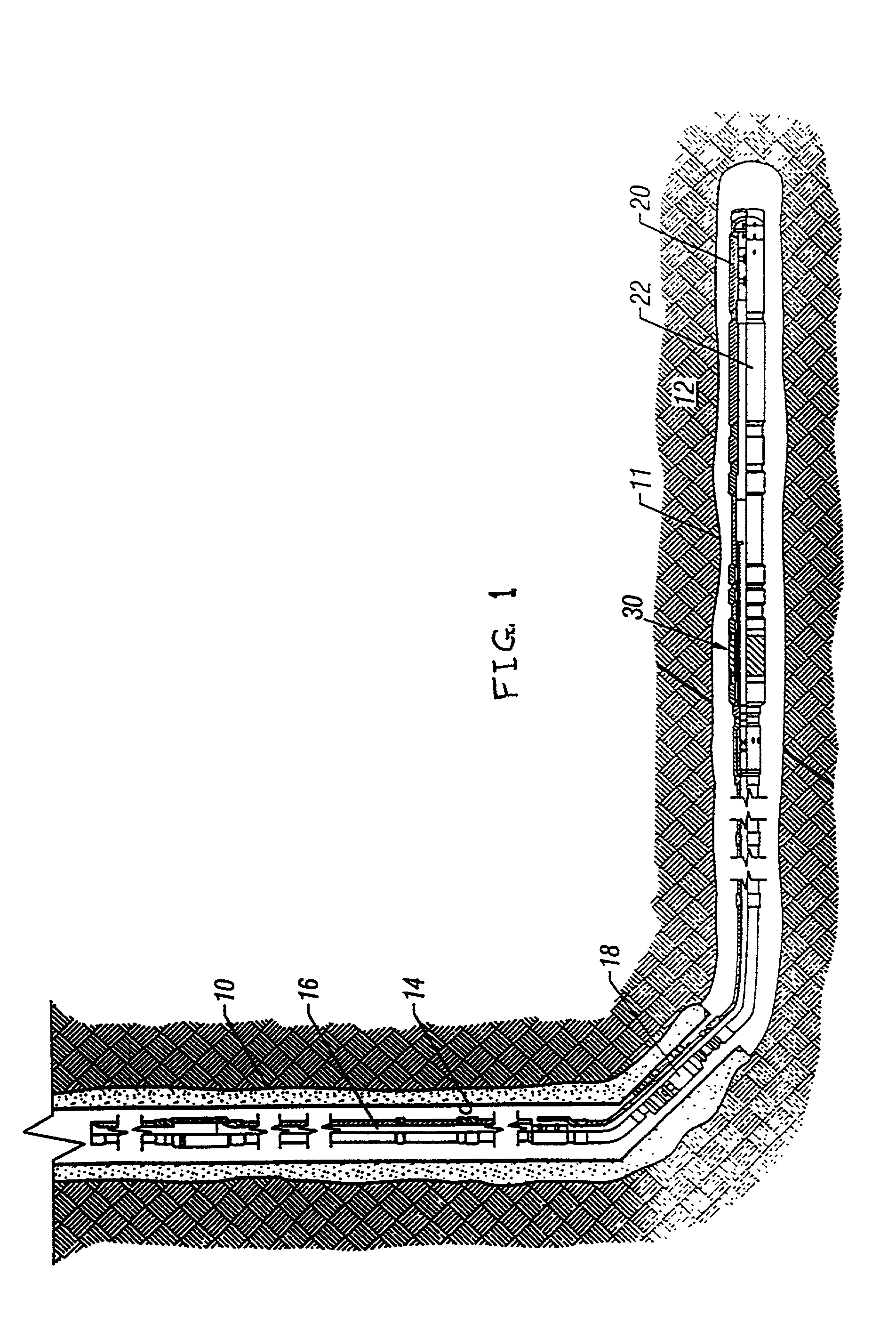

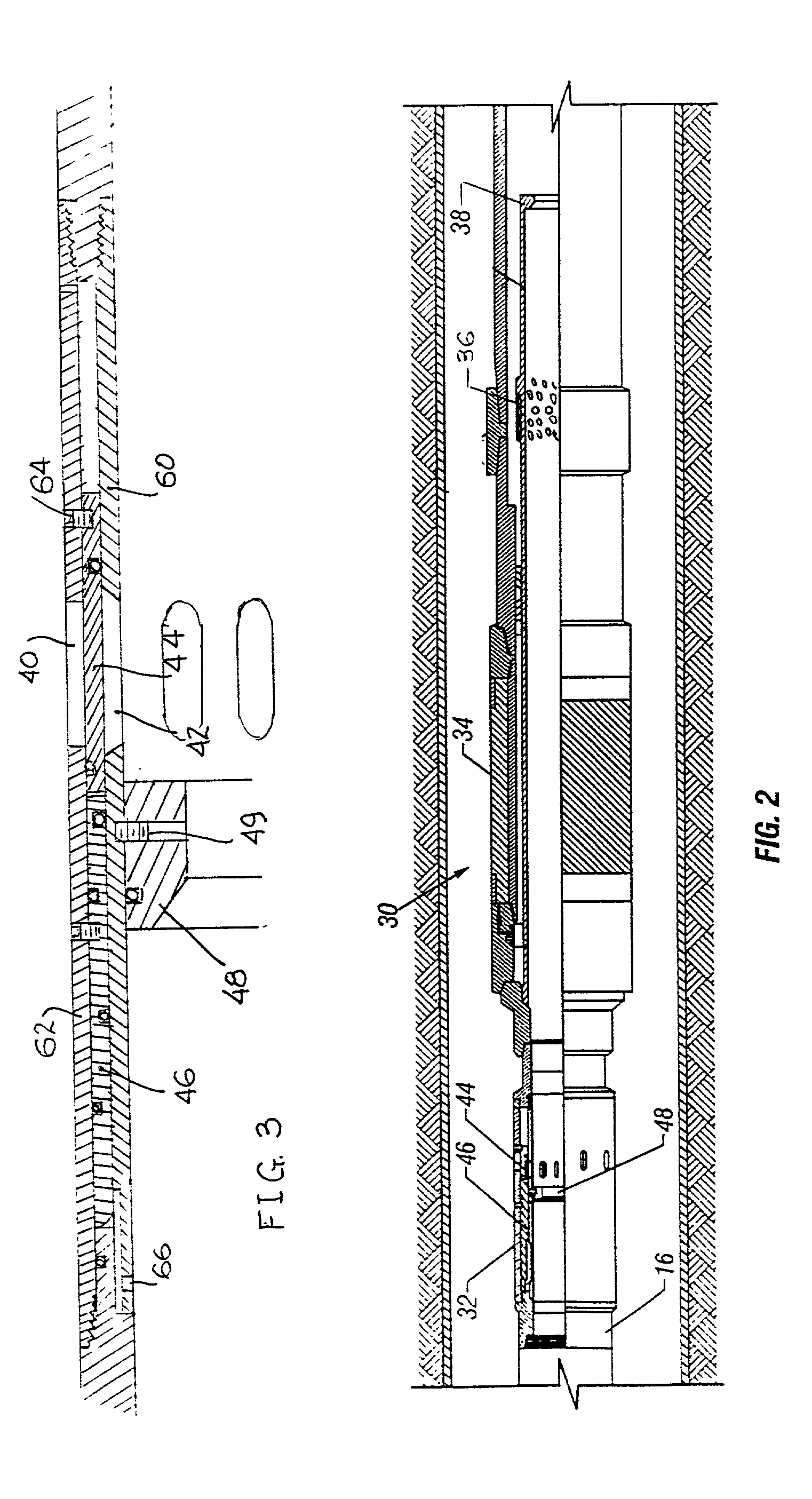

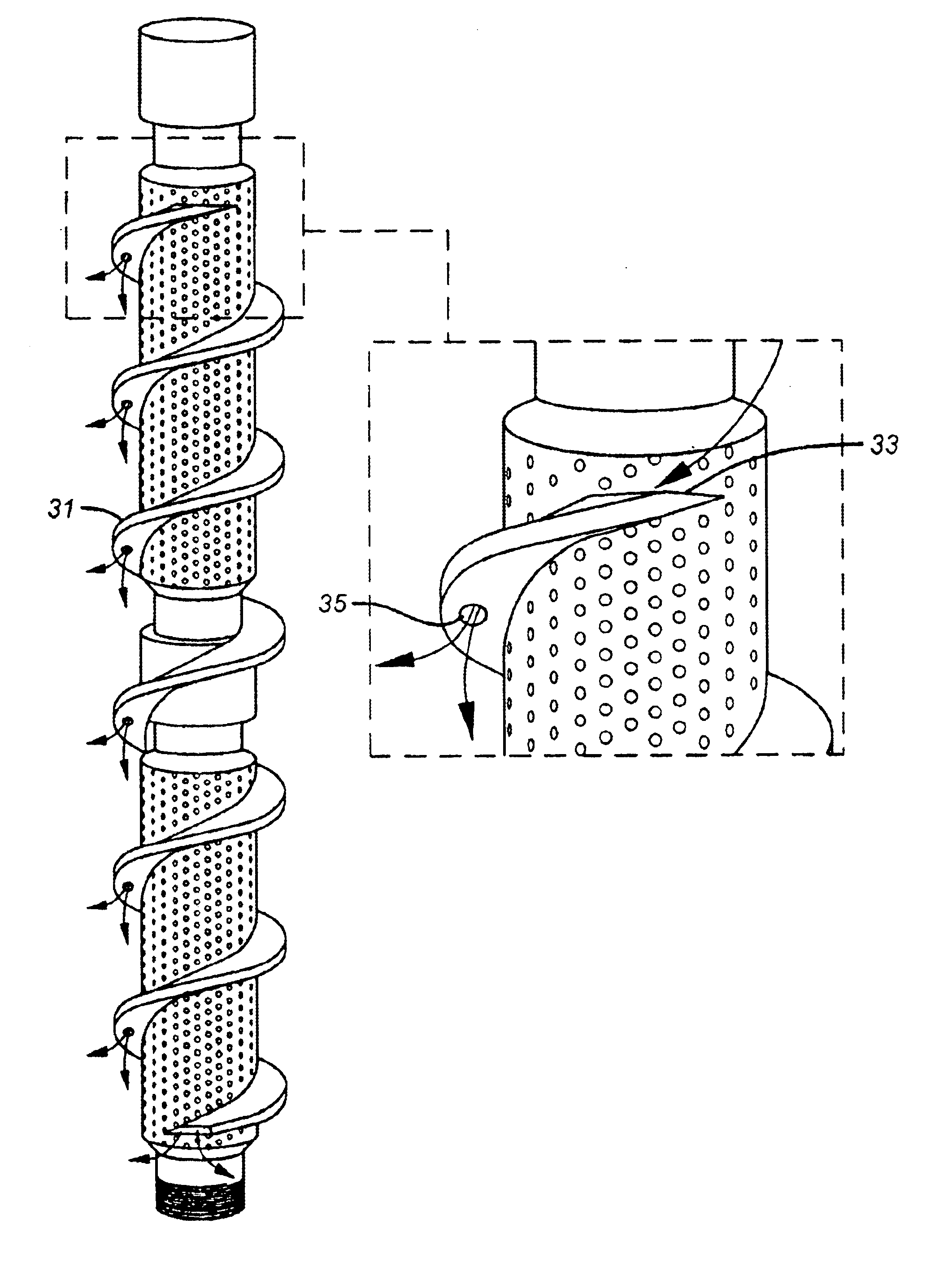

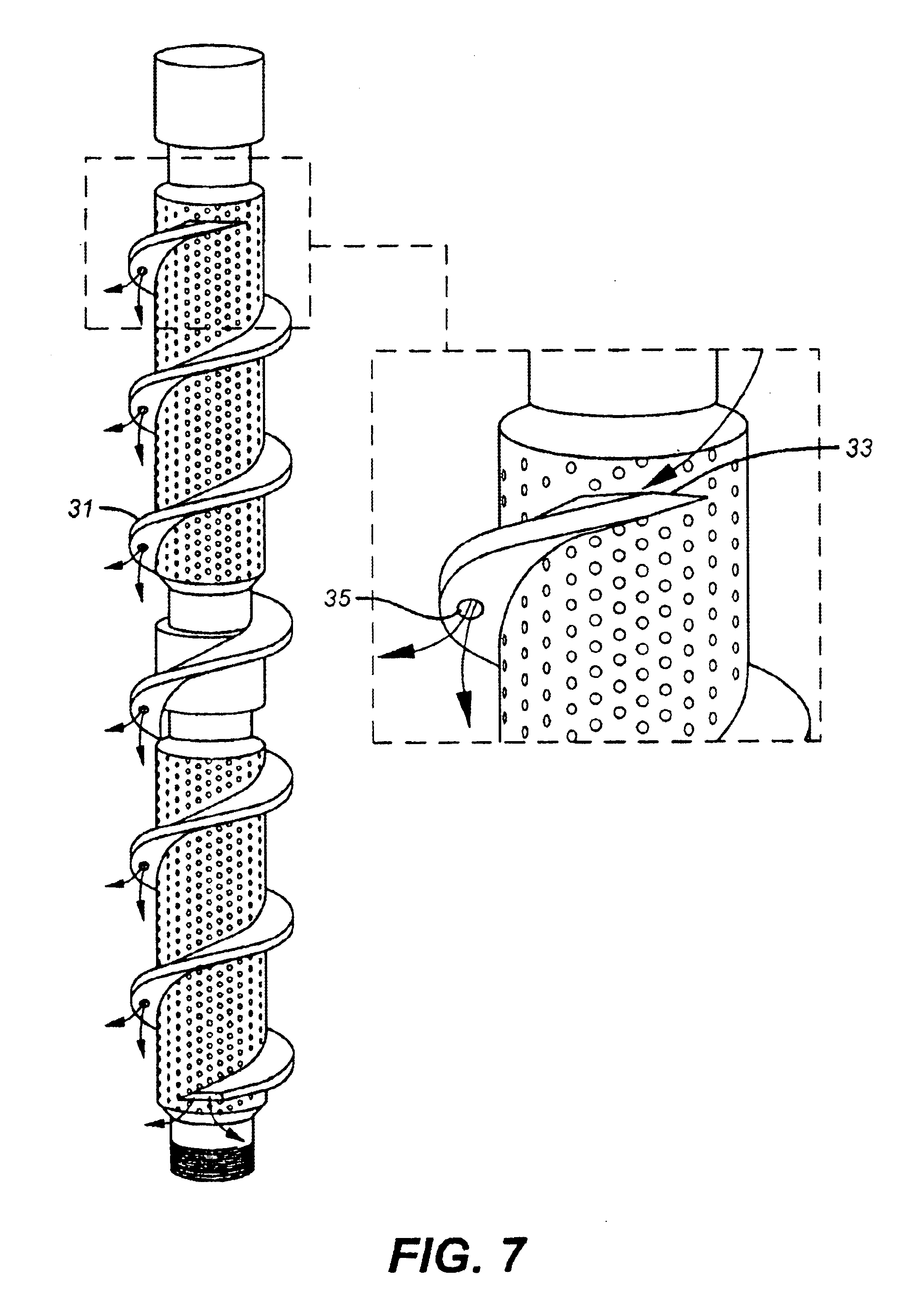

Wellbore method and apparatus for sand and inflow control during well operations

A method, system and apparatus associated with the production of hydrocarbons are described. The system includes a wellbore that accesses a subsurface reservoir; a production tubing string disposed within the wellbore; and one or more sand control devices coupled to the production tubing string and disposed within the wellbore. At least one of the sand control devices includes a first tubular member having a permeable section and a non permeable section; a second tubular member disposed within the first tubular member. The second tubular member has a plurality of openings and an inflow control device that each provide a flow path to the interior of the second tubular member. Also, the at least one of the sand control devices includes a sealing mechanism disposed between the first tubular member and the second tubular member. The sealing mechanism is configured to provide a pressure loss during gravel packing operations that is less than the pressure loss during at least some of the production operations.

Owner:EXXONMOBIL UPSTREAM RES CO

Zero drill completion and production system

Owner:BAKER HUGHES INC

Downhole gas compression separator assembly

Downhole Electric Submersible Pumps (ESP) in a production string often experience gas lock caused by free gas present in the production liquids which reduces intake pressure below the operating parameters of the ESP. A gas compression separator assembly, having a series of compressors and separation chambers, entrains or dissolves the free gas component of the production fluid and separates free gas for downhole disposal. The production fluid fed to the ESP intake has an increased fluid pressure, a reduced volumetric fluid flow, and a lower free gas content, and is less likely to induce gas lock of the ESP.

Owner:HALLIBURTON ENERGY SERVICES INC

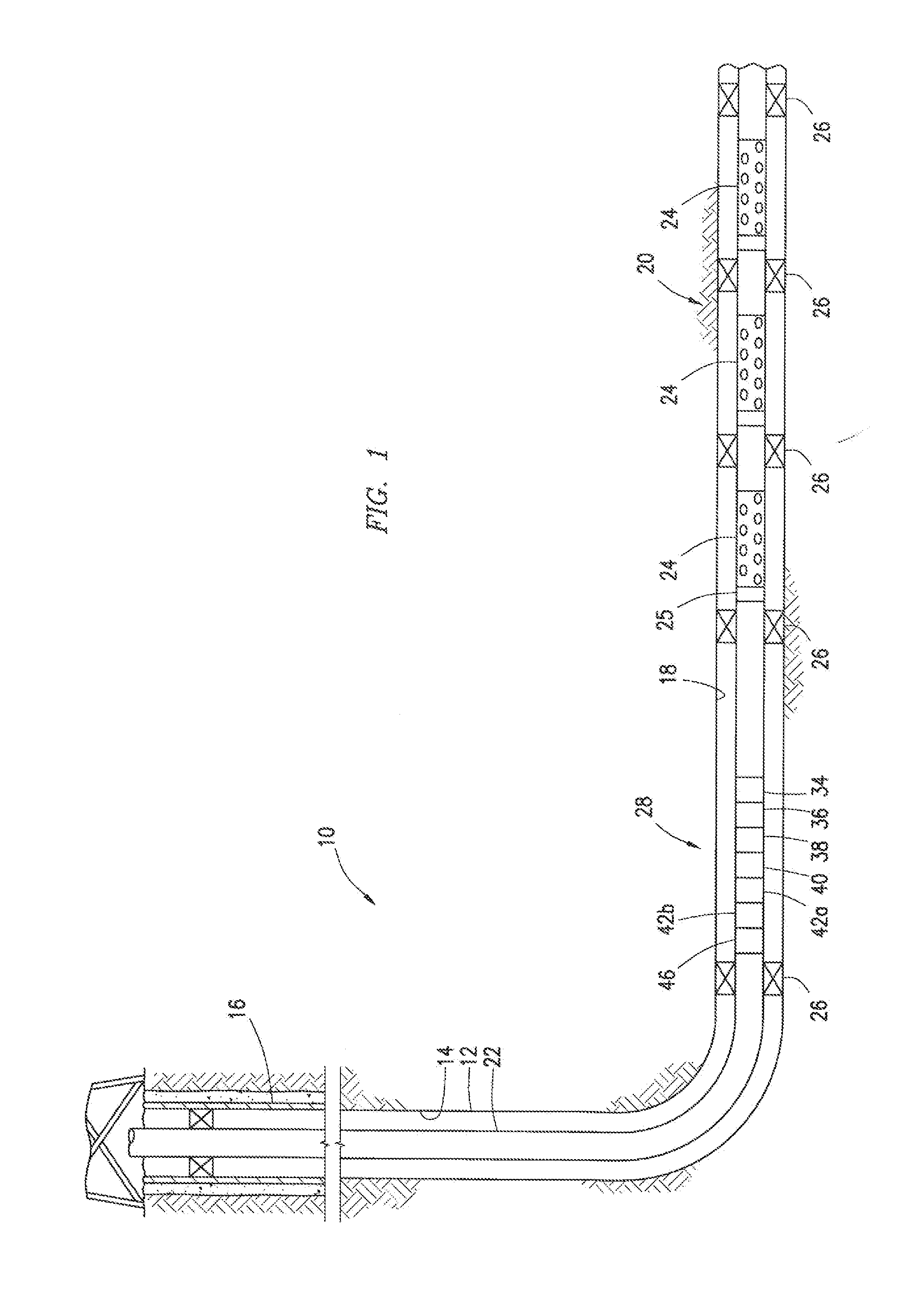

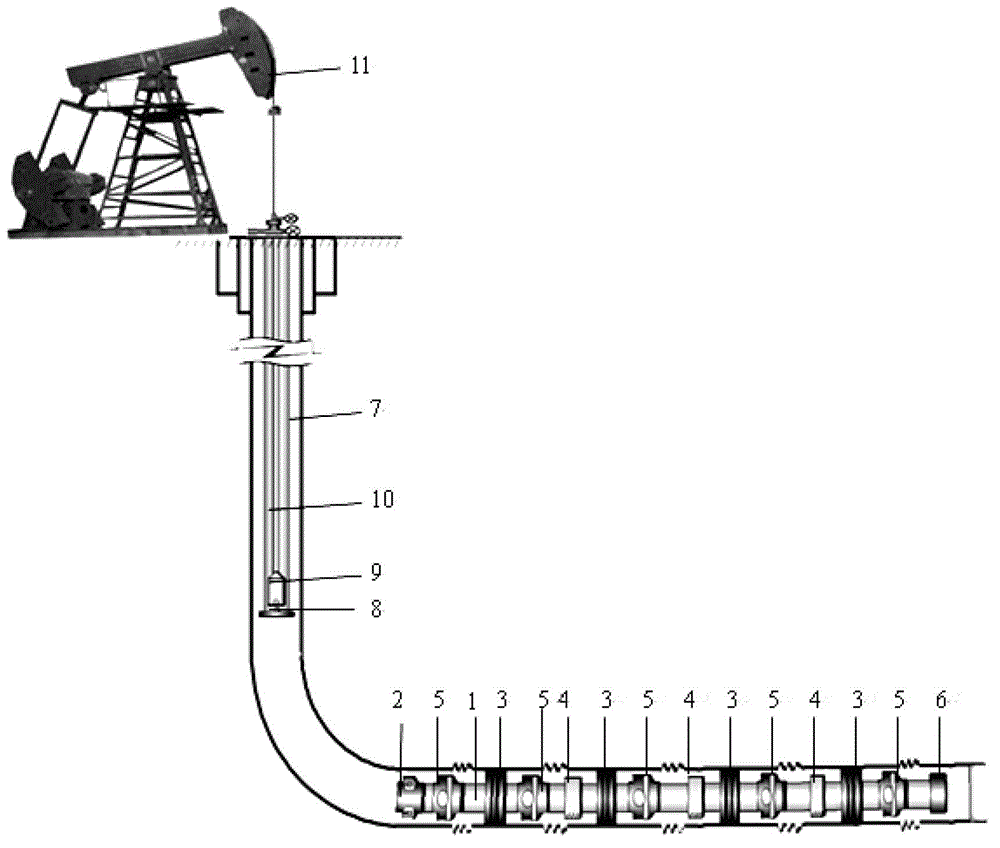

Gas lift method production fluid section plane test technique of mechanical mining horizontal well

InactiveCN101403292ASmall footprintImplement output profile testingSurveyFluid removalLine tubingSection plane

The invention relates to a produced fluid profile logging technique method of a mechanical recovery horizontal well by a pneumatic lifting method, aiming at solving the problem that the existing horizontal well can not carry out profile testing in normal production state. The method is characterized in that: a. a pneumatic lifting production string (10) is put into the well, and a gas transmission line (8) and a pipe laying (9) are connected; b. a tester (7) and a traction apparatus (6) are put into the well by the pneumatic lifting production string (10); and c. a nitrogen gas generation locomotive (4) and a compressing locomotive (3) are started for carrying out oil extraction, and a cable is lifted up to carry out testing when the oil extraction production is stable. The produced fluid profile logging technique method of the mechanical recovery horizontal well by the pneumatic lifting method can leave enough testing channel for the tester, thereby finally realizing the produced fluid profile testing of the horizontal well in normal production state.

Owner:DAQING OILFIELD CO LTD

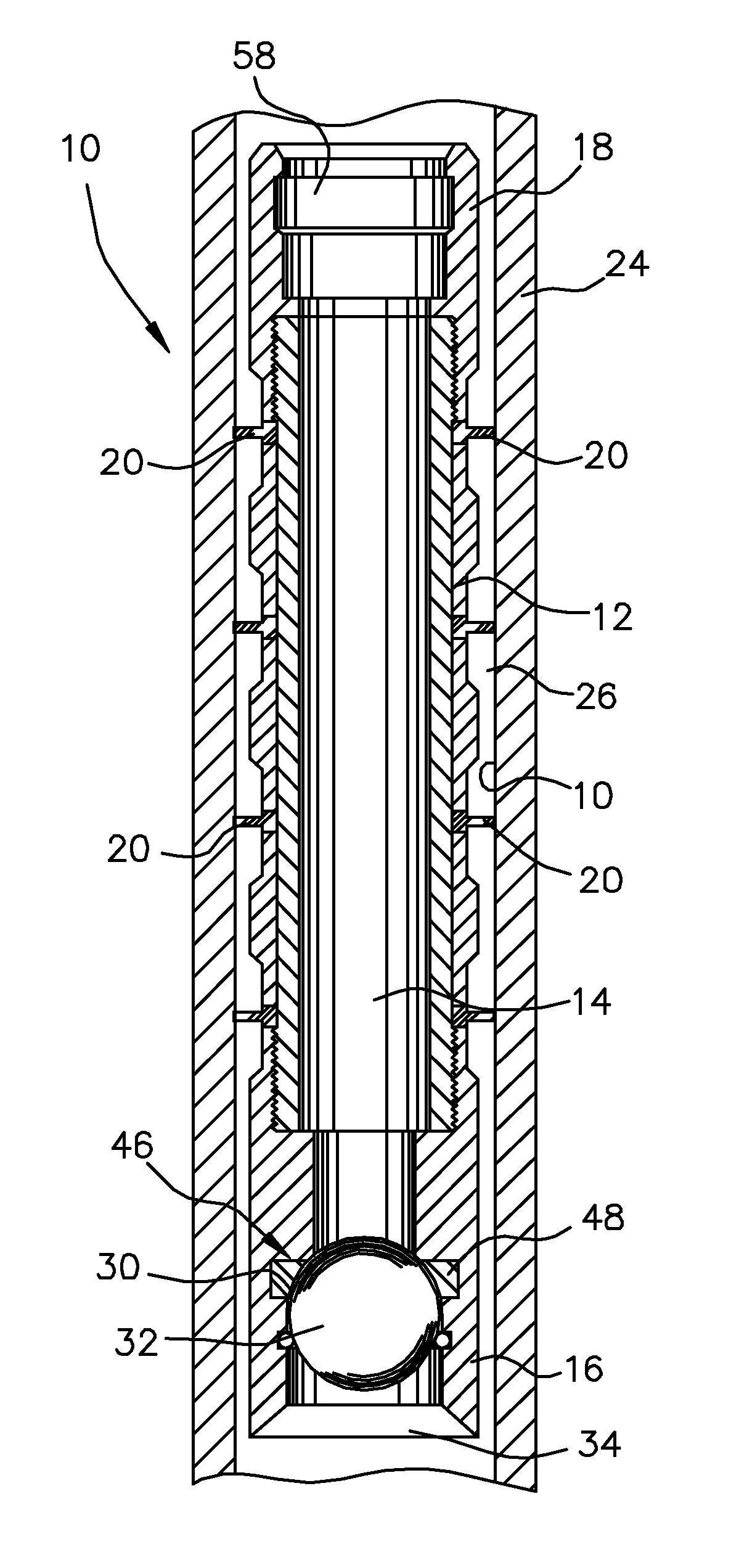

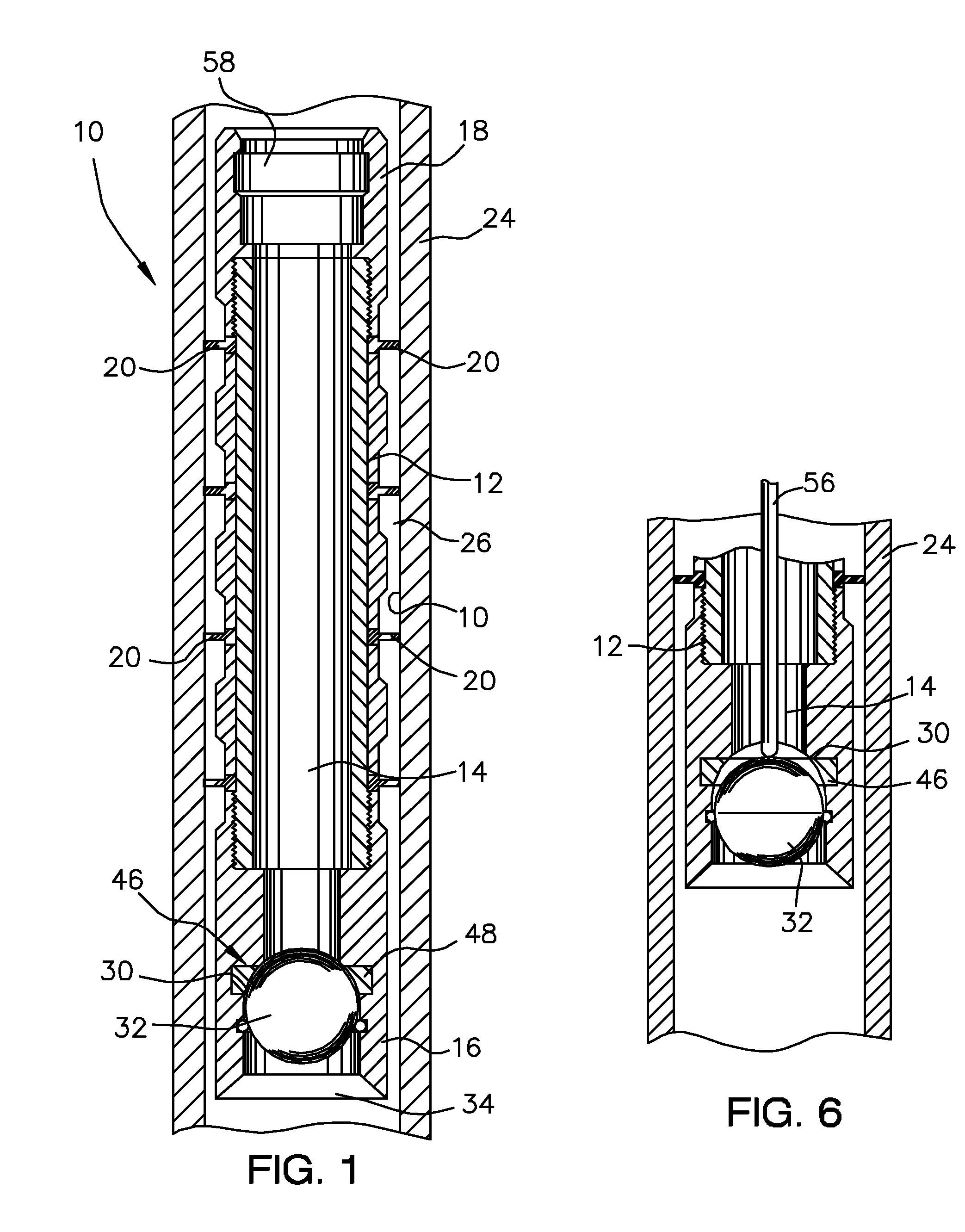

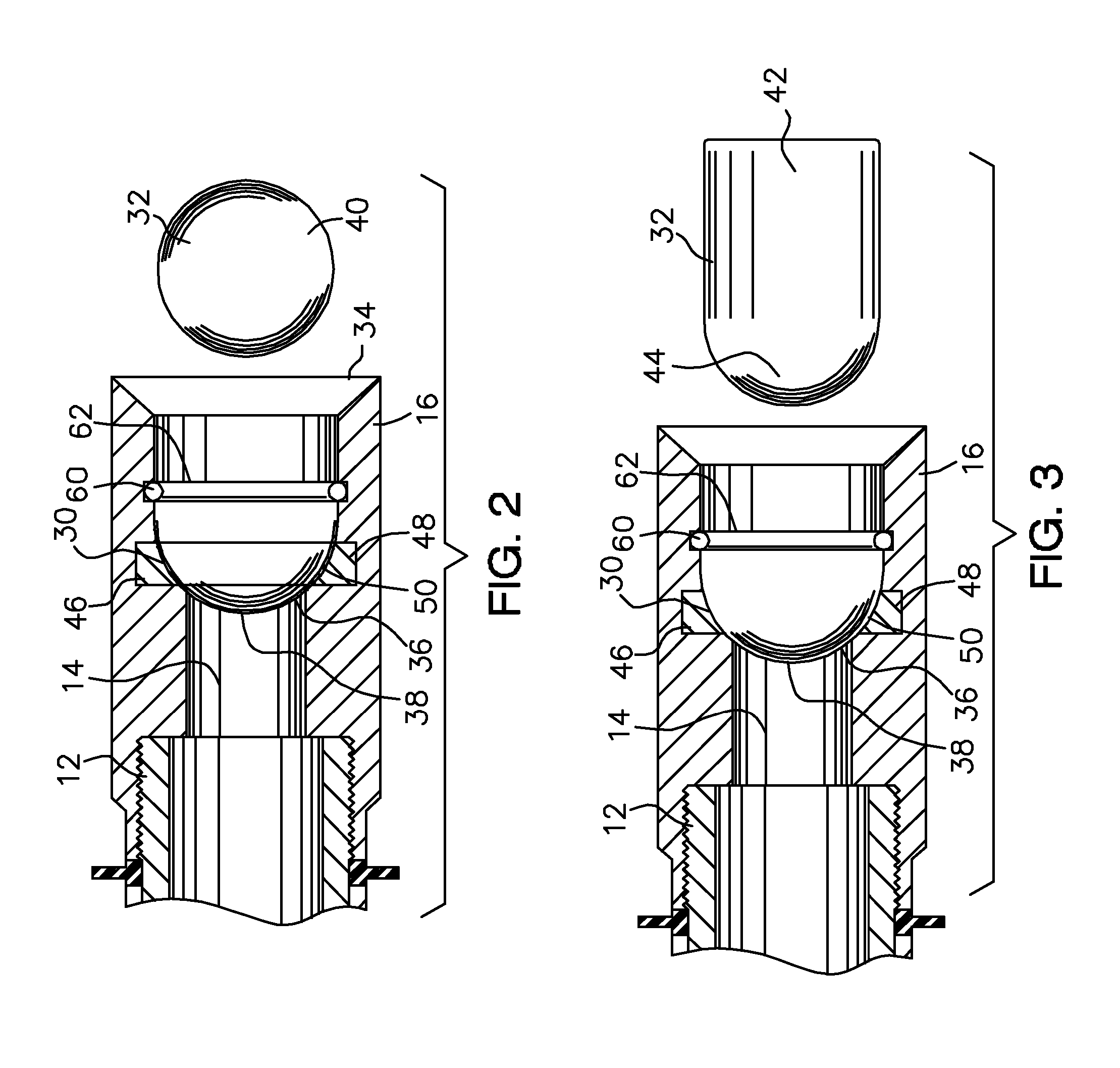

Split ball valve

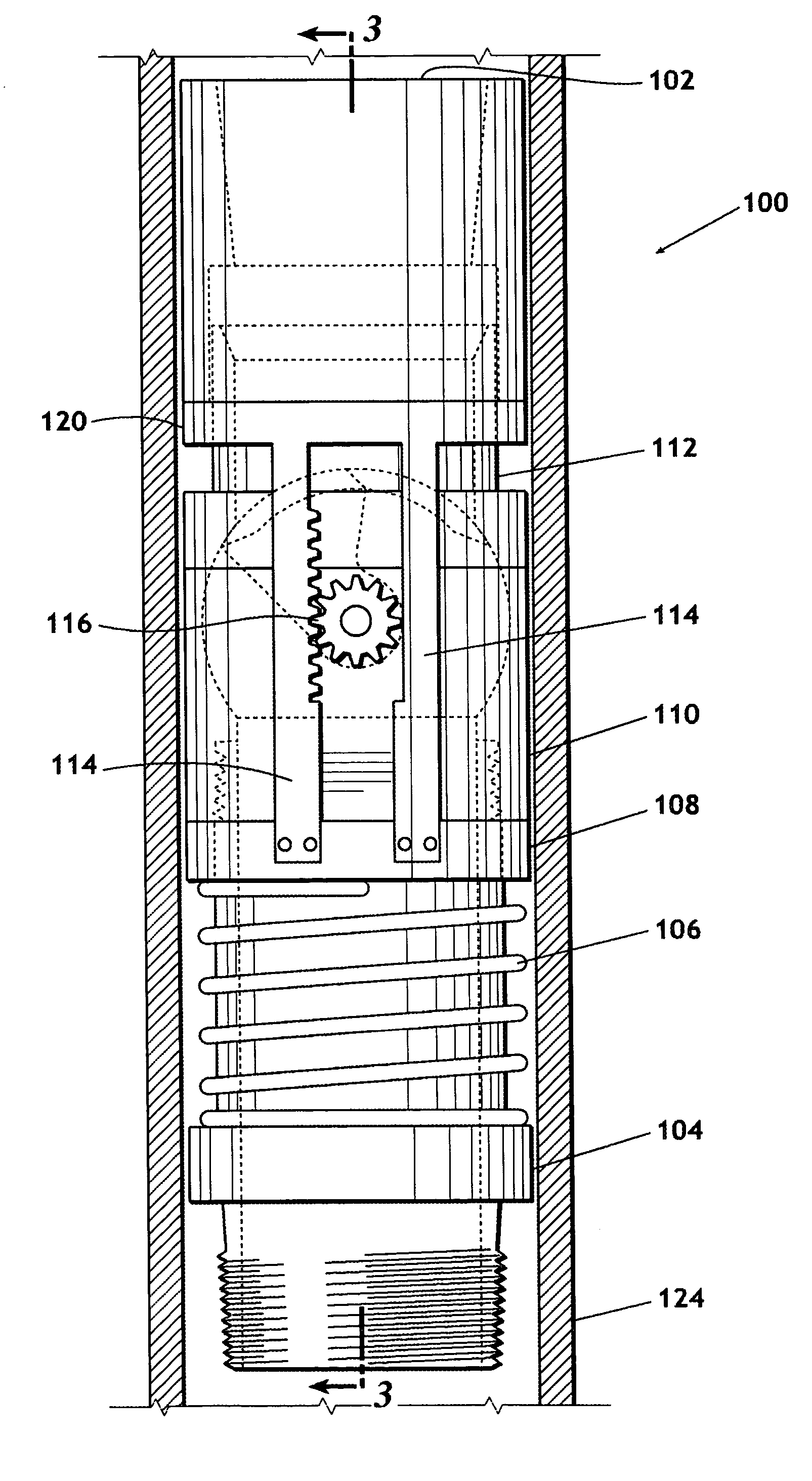

A split ball valve that may be positioned in a production string of line pipe, casing, or tubing. The split ball valve comprises a lower valve assembly and an upper valve assembly. Each of two valve doors in the lower valve assembly is connected to a pinion gear that intermeshes with racks on the upper valve assembly. The upper valve assembly can be vertically displaced relative to the lower valve assembly. A spring keeps the upper valve assembly extended away from the lower valve assembly and thus keeps the valve doors closed. When a downward force is applied to the upper valve assembly, the upper valve assembly is downwardly displaced causing the pinion gears to rotate, which opens the valve doors. The valve doors recede into cavities in the valve body. When open, the split ball valve is fully ported.

Owner:SUNSTONE

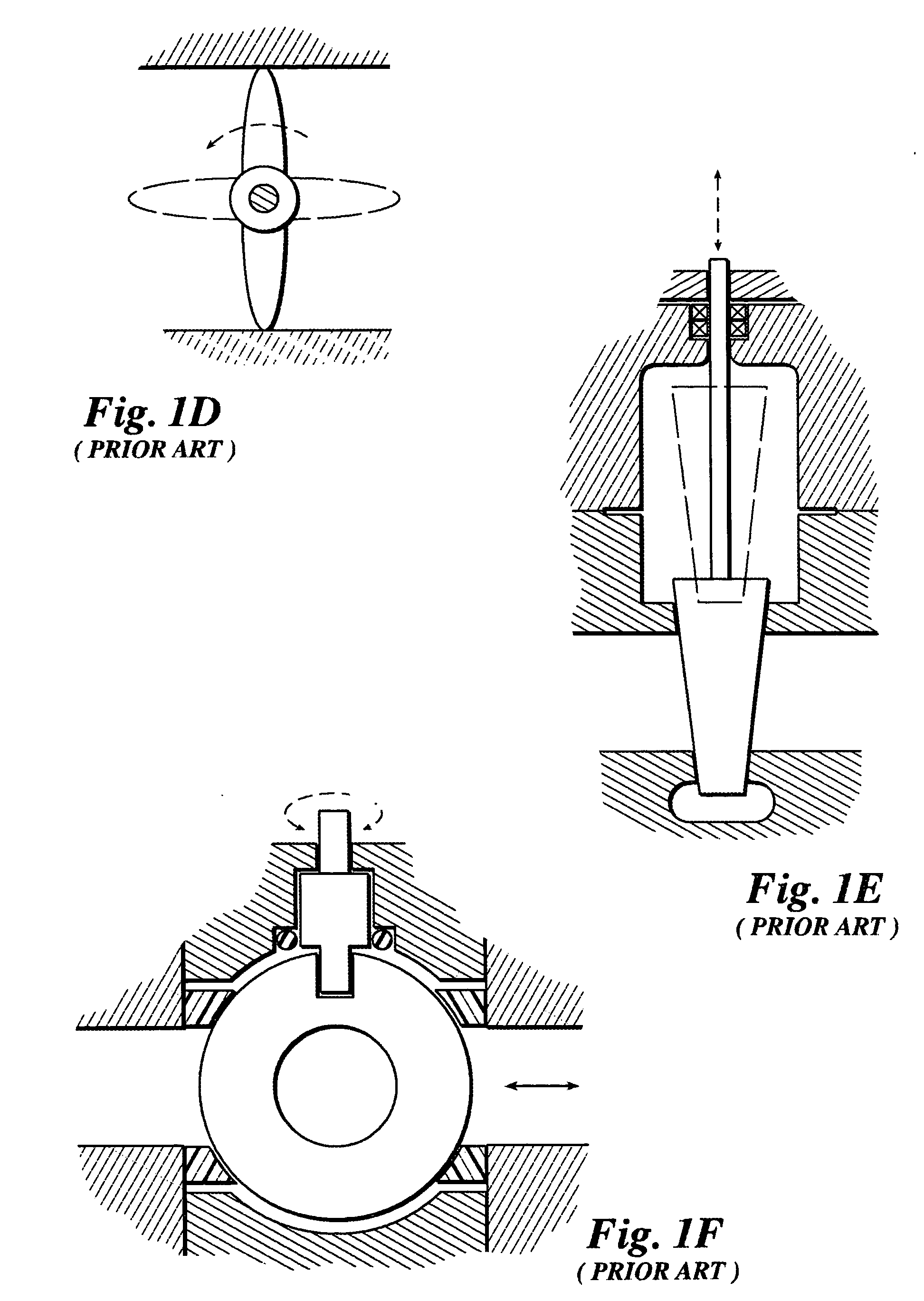

Producing Hydrocarbons from a Formation

A system for and methods of producing hydrocarbons from a formation. A method may include drilling a wellbore in a formation, forming a first fracture in the formation that emanates from the wellbore, forming a second fracture in the formation that emanates from the wellbore and is approximately parallel to the first fracture, and simultaneously (a) injecting a fluid from an injection tubing string in communication with the second fracture and (b) producing hydrocarbons that travel from the first fracture into a production tubing string that is substantially parallel to the injection tubing string. The wellbore may be substantially horizontal. The fluid may increase pressure in an area of the formation adjacent to the first fracture.

Owner:BOONE THOMAS J +3

Interference-seal plunger for an artificial lift system

InactiveUS20070158061A1Increase physical activityFluid removalSealing/packingInterference fitEngineering

A plunger for an artificial lift system and embodiment of the plunger includes a solid body adapted to travel within a production string positioned in a wellbore. At least one sealing ring connected about the body. The at least one sealing ring having an inner surface, an outer surface, a width and a thickness. The width is sufficient such that when the body is disposed in the production string the outer surface contacts and substantially forms a seal between the body and an inner wall of the production string. The at least one sealing ring having an outside diameter greater than the inner diameter of the production tubing within which the body is adapted to travel such that when the body is disposed within the production string an interference fit causes the sealing rings to roll-form into a constricted shape and diameter that exerts the sealing contact with the production string.

Owner:CASEY DANNY M

Gravel packing method using vibration and hydraulic fracturing

A gravel packing method combining fracturing is described. A gun having an exterior auger is used to perforate. With the gun in place, the gravel is positioned around it and the formation is fractured, pushing the gravel into the fractures. The gun is rotated out of the gravel using the auger. A screen with an external auger is run in and rotated into the packed gravel in the wellbore while being vibrated at the same time. After the screen is advanced into position the vibrator is removed and a flapper closes to minimize fluid loss into the formation. A production string and packer are tagged into the screen and production begins.

Owner:BAKER HUGHES INC

Zero drill completion and production system

Owner:BAKER HUGHES INC

Downstroke sucker rod pump and method of use

InactiveUS6497561B2Reduce electricity costsPositive displacement pump componentsFlexible member pumpsReciprocating motionEngineering

Owner:SKILLMAN MILTON

Utilizing swellable materials to control fluid flow

ActiveUS20100108148A1Increase productivityCheck valvesEqualizing valvesProcess engineeringProduction string

Methods and related systems are described for controlling inflow of fluid into a production string. In aspects, the invention provides an inflow control device with a shut-off feature that is operated automatically utilizing swellable materials.

Owner:SCHLUMBERGER TECH CORP

Multi-stage segmented release water exploration pipe column and method for casing well completion multi-stage fractured horizontal well

InactiveCN102747967AHigh efficiency for water testingUnlimited testing levelsSurveyDrilling rodsPeristalsisHigh pressure

Owner:PETROCHINA CO LTD

Plunger Lift Apparatus

A plunger of improved construction for reciprocating in a production string of a gas or oil well to remove fluid from the well. The plunger includes a sleeve having a through passage extending longitudinally from a first end to a second end, the second end forming a seat, a sealing means carried by the sleeve for engaging the inner surface of the production string, a detachable valve member releasably received by the seat to seal the through passage, and a catch positioned to releasably couple the detachable valve member to the sleeve within the seat. The catch retaining the detachable valve member until the detachable valve member is impacted at the surface of the well by a trip rod. The improved construction provides for the use of a heavier or more dense detachable valve member and a lighter or less dense sleeve than previously used in prior plungers, which results in a plunger having an increased efficiency and a greater cycle frequency.

Owner:SCHNEIDER GLENN +1

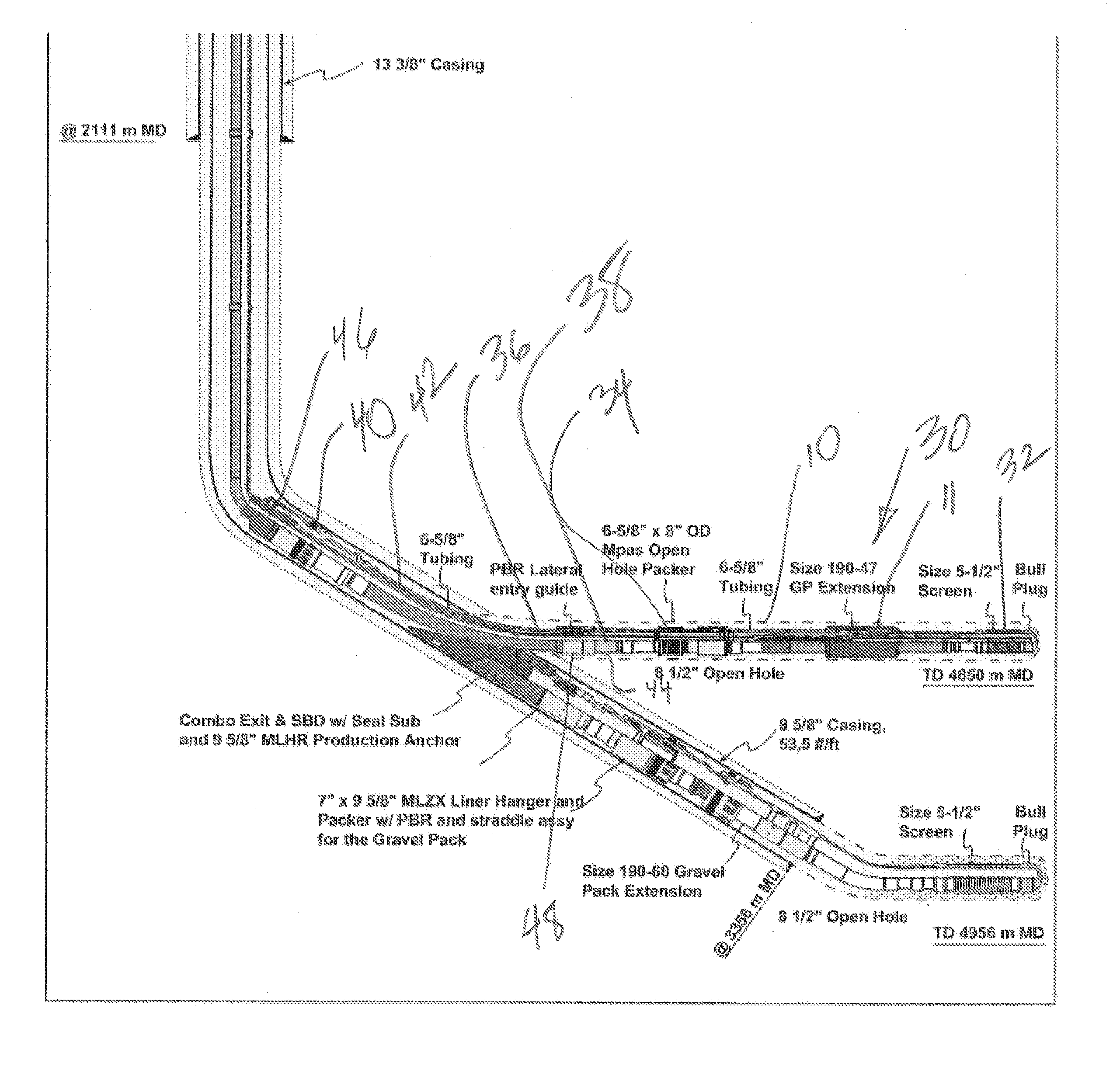

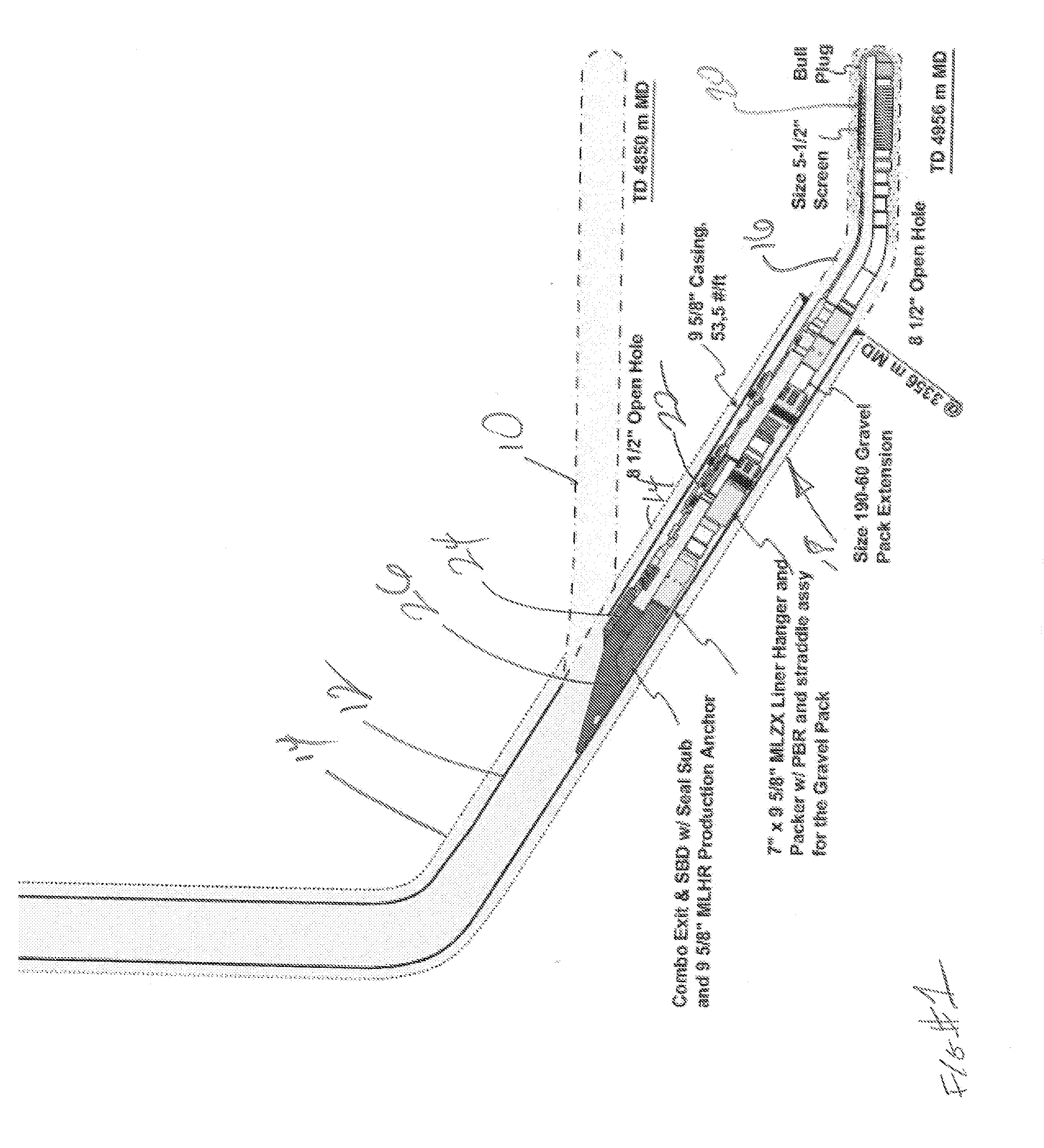

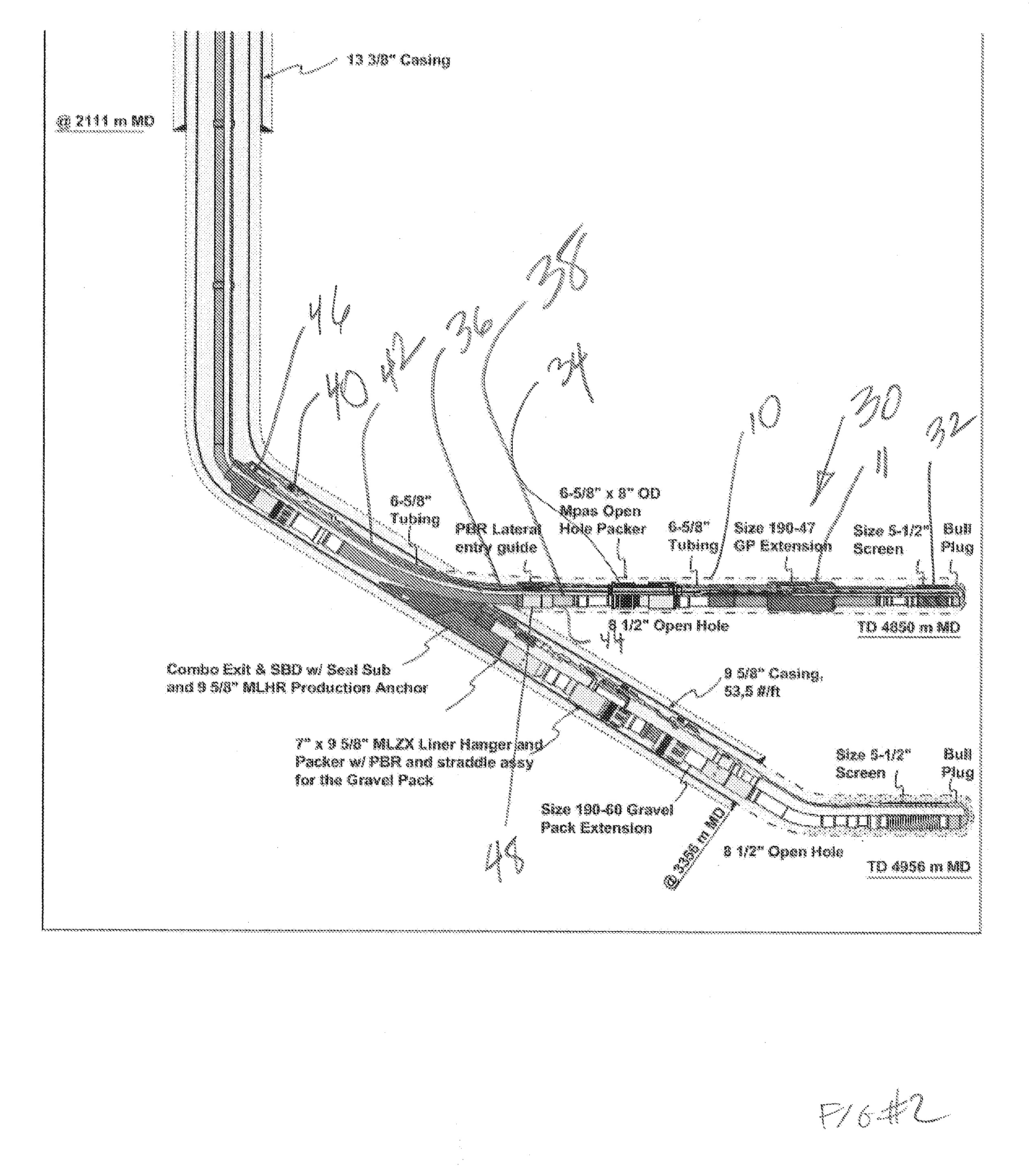

Gravel Packing Method for Multilateral Well Prior to Locating a Junction

A lateral is gravel packed without a junction in place in a single trip into the wellbore. A disconnect is provided between the isolation packer in the lateral and a main bore packer. The inner string assembly in the gravel packing completion releases a disconnect with a shift tool and then releases the main bore packer so that the inner string assembly takes out the main bore packer and the upper portion of the disconnect when pulling out of the hole. A junction is then placed into the main and lateral legs with a packer having a seal bore into which the production string is sealingly stabbed to produce out of the main bore and / or the just completed lateral.

Owner:BAKER HUGHES INC

Cement control ring

A sealing system for a flow tube keeps cement from getting around it to the flapper when the safety valve is in the open position. Seals are provided at opposed ends of the flow tube so that the power spring and the flapper will not get fouled with cement pumped through the flow tube in wells that are completed through a production string with the safety valve in place. The seals may be mounted to the flow tube or the surrounding body. A unique seal construction separates cement from the flapper behind the flow tube. The force acting on the flow tube to hold the valve open also helps to apply a force against the lower seal adjacent the flapper.

Owner:BAKER HUGHES INC

Liner hanger and setting tool

Owner:荆州市赛瑞能源技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com