Split ball valve

a ball valve and valve body technology, applied in the direction of fluid removal, sealing/packing, borehole/well accessories, etc., can solve the problems of limiting the control of the drilling or production fluid operations to the whole well bore, the casing or the tubing string is subject to high levels of compressive and tensile stress, and the drilling engineer cannot independently control the drilling or production fluid at different depths within the well bor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] As used herein, the term “casing” shall mean a plurality of connected cylindrical members that are permanently affixed in the well bore and are used in drilling and production operations.

[0024] As used herein, the term “drill pipe” shall mean a plurality of connected cylindrical members that are connected to a drill bit and are rotated to drill the well bore.

[0025] As used herein, the term “line pipe” shall mean a plurality of connected cylindrical members that are positioned on the surface and are used to transport drilling and production fluid to / from the well bore.

[0026] As used herein, the term “tubing” shall mean a plurality of connected cylindrical members that are removably positioned within the well bore and are used in production operations.

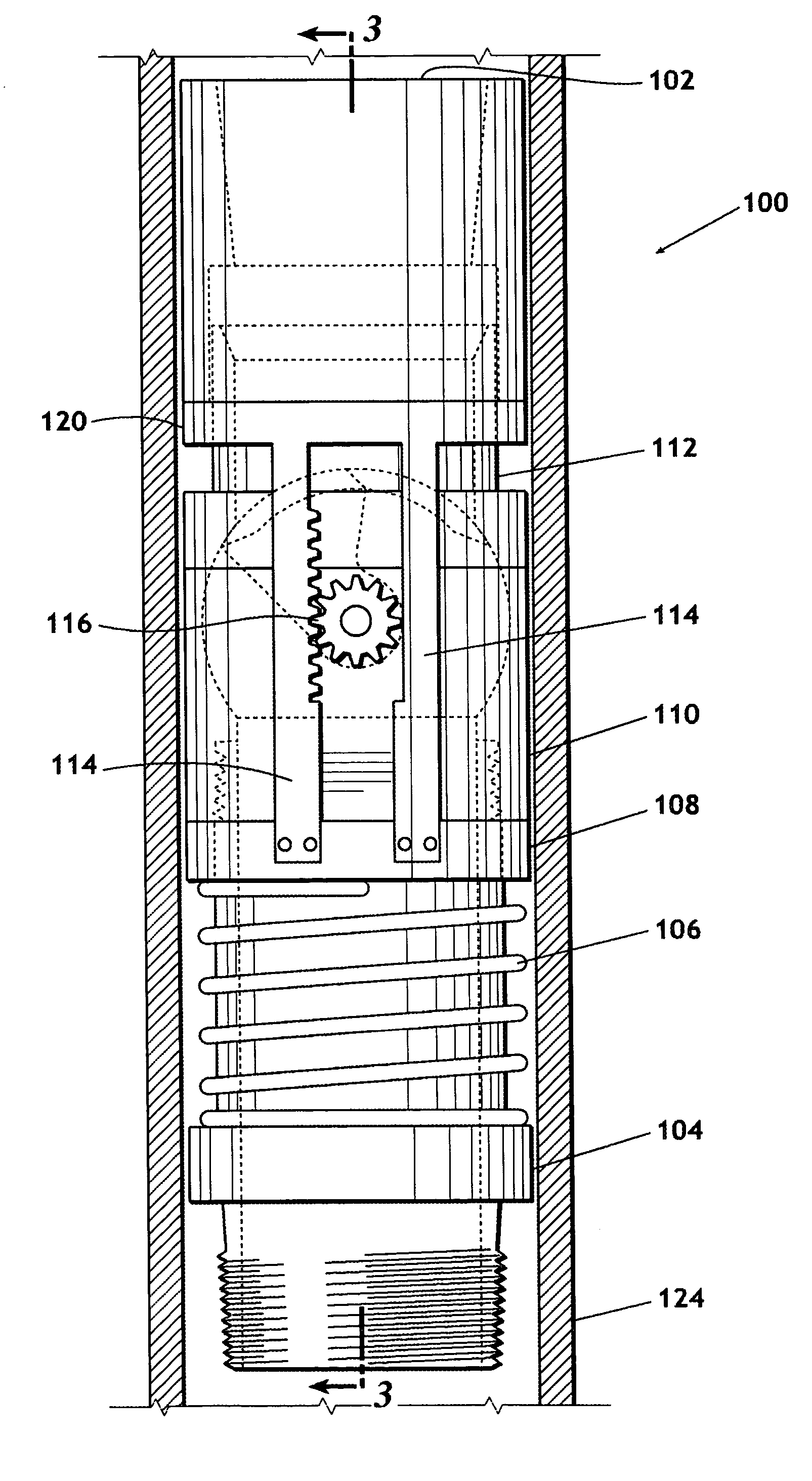

[0027]FIG. 2 is an illustration of an elevation view of split ball valve 100. Split ball valve 100 is shown inside a concentric string of casing 124, which is cutaway in FIG. 2 to show the exterior of split ball valve 100. For...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com