Patents

Literature

51117 results about "Production line" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A production line is a set of sequential operations established in a factory where components are assembled to make a finished article or where materials are put through a refining process to produce an end-product that is suitable for onward consumption...

Compositions of ethylene/alpha-olefin multi-block interpolymer for elastic films and laminates

Owner:DOW GLOBAL TECH LLC

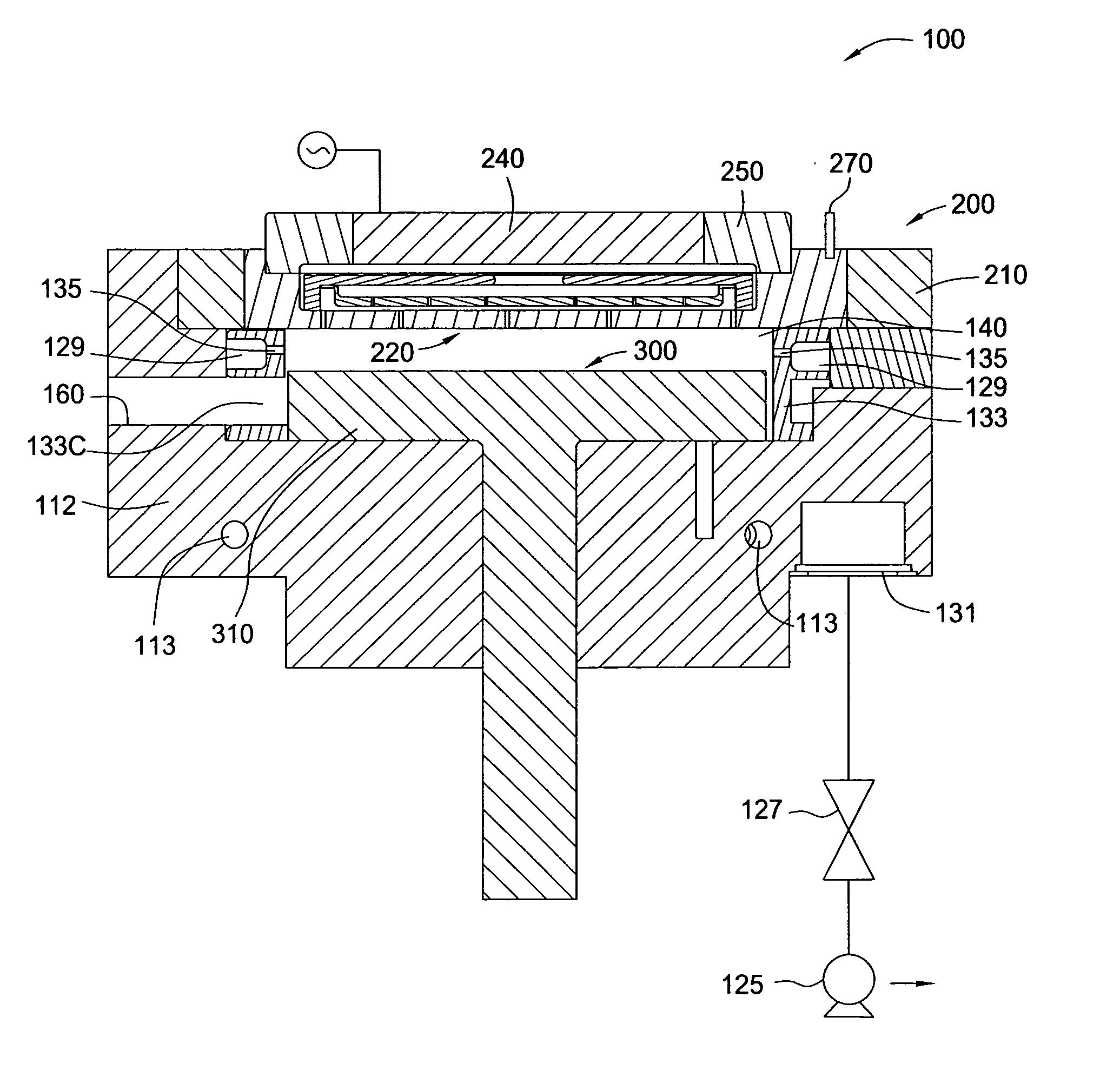

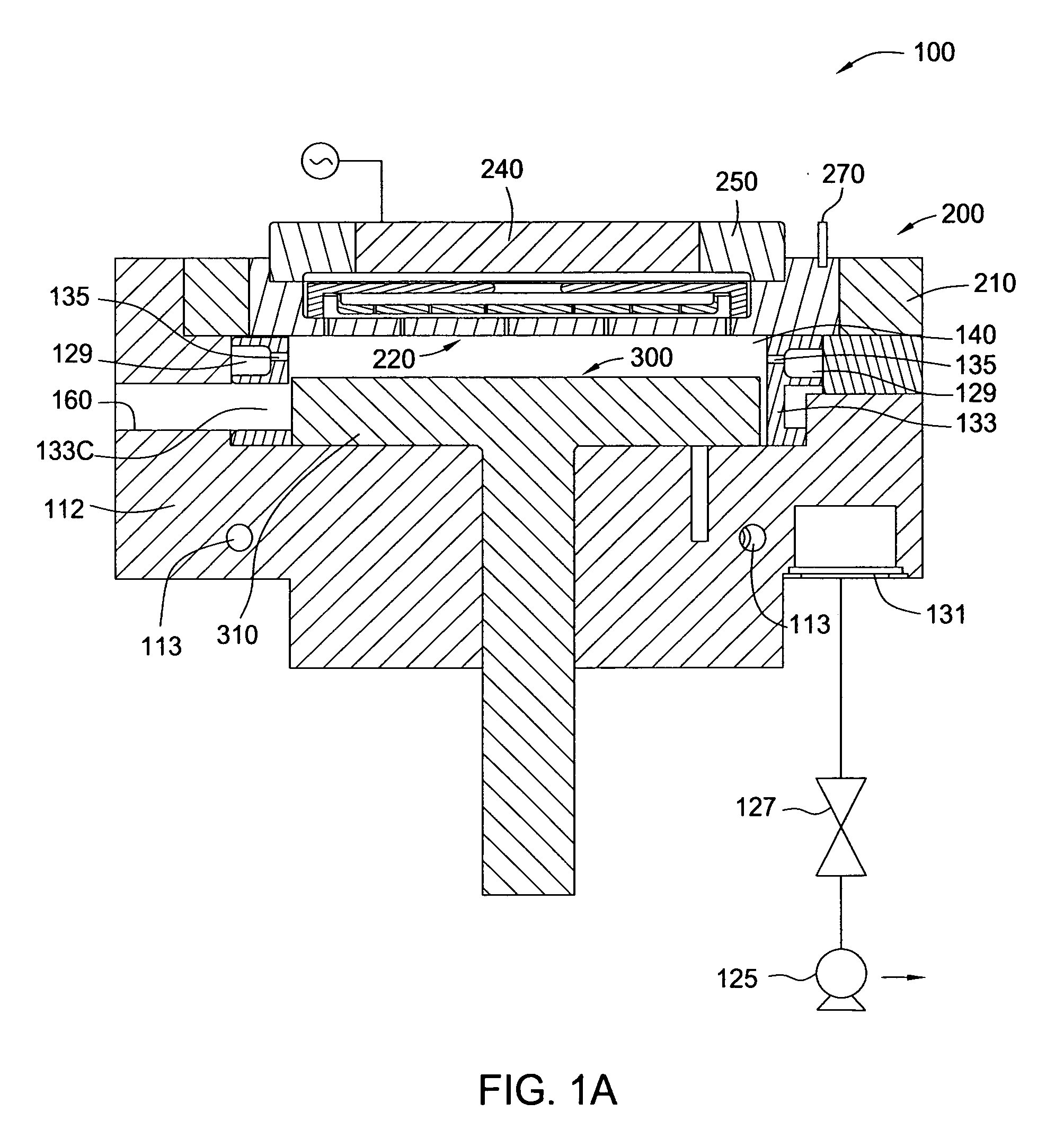

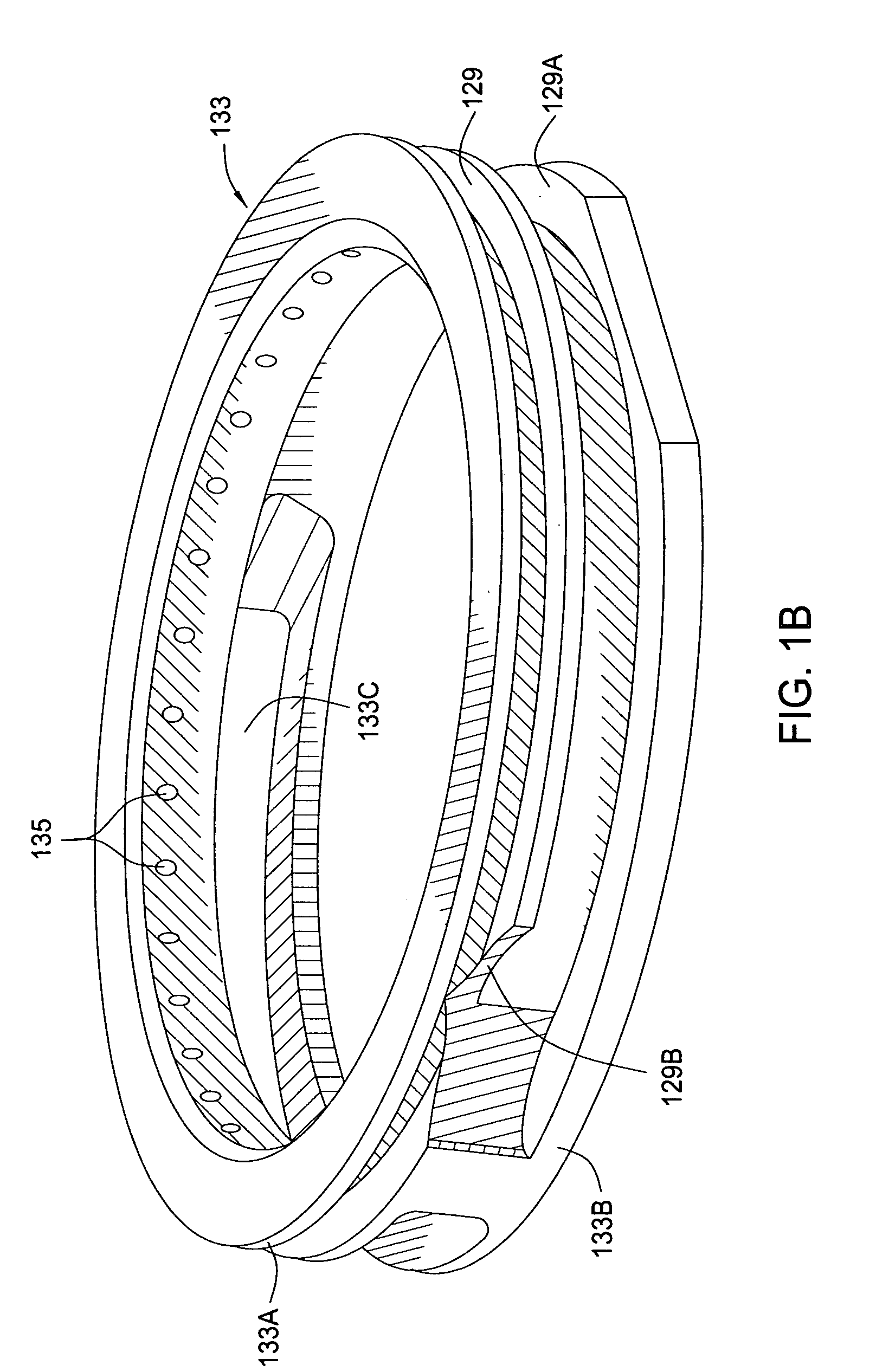

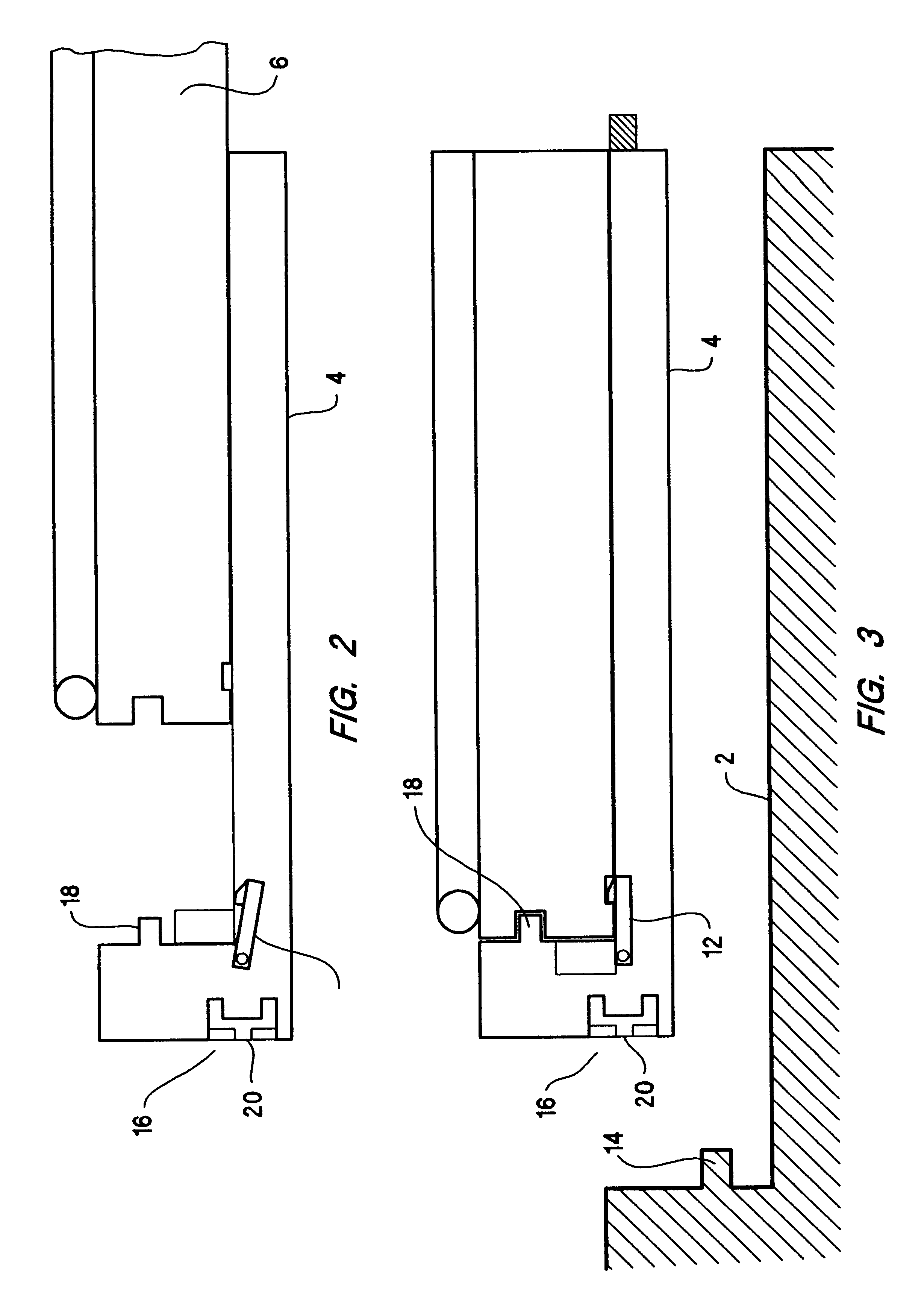

Lid assembly for front end of line fabrication

ActiveUS20050218507A1Electric discharge tubesSemiconductor/solid-state device detailsProduction lineFront end of line

A lid assembly for semiconductor processing is provided. In at least one embodiment, the lid assembly includes a first electrode comprising an expanding section that has a gradually increasing inner diameter. The lid assembly also includes a second electrode disposed opposite the first electrode. A plasma cavity is defined between the inner diameter of the expanding section of the first electrode and a first surface of the second electrode.

Owner:APPLIED MATERIALS INC

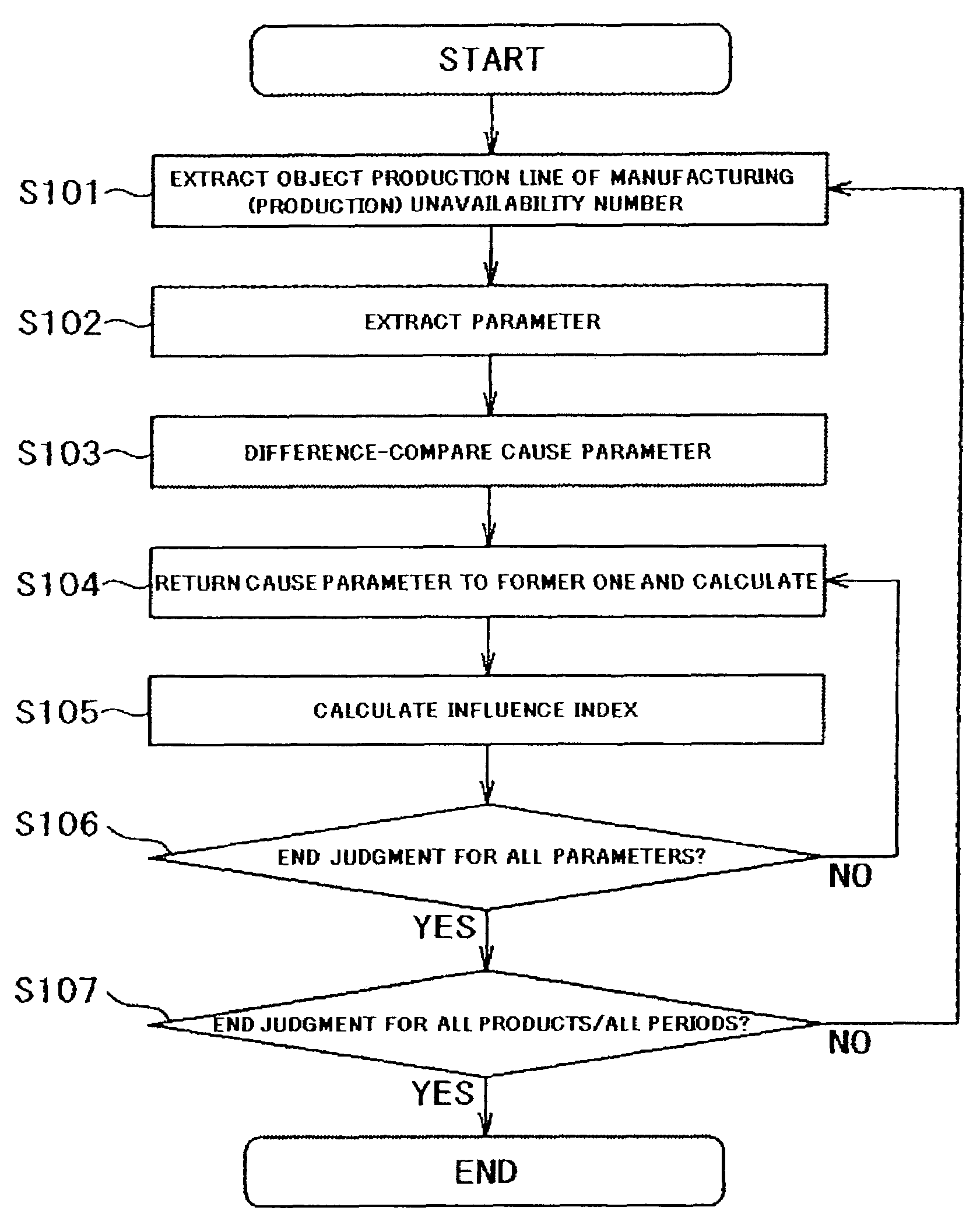

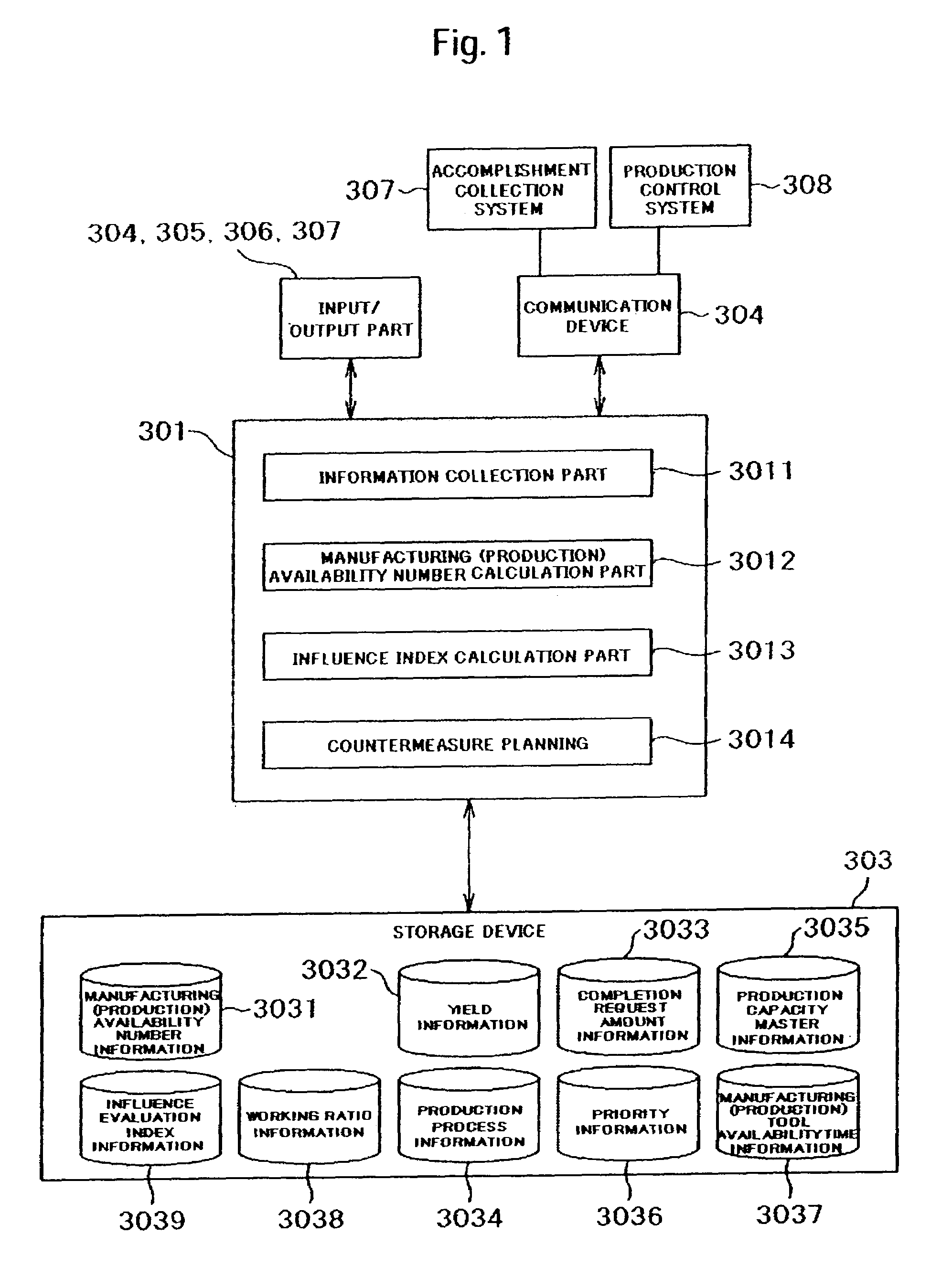

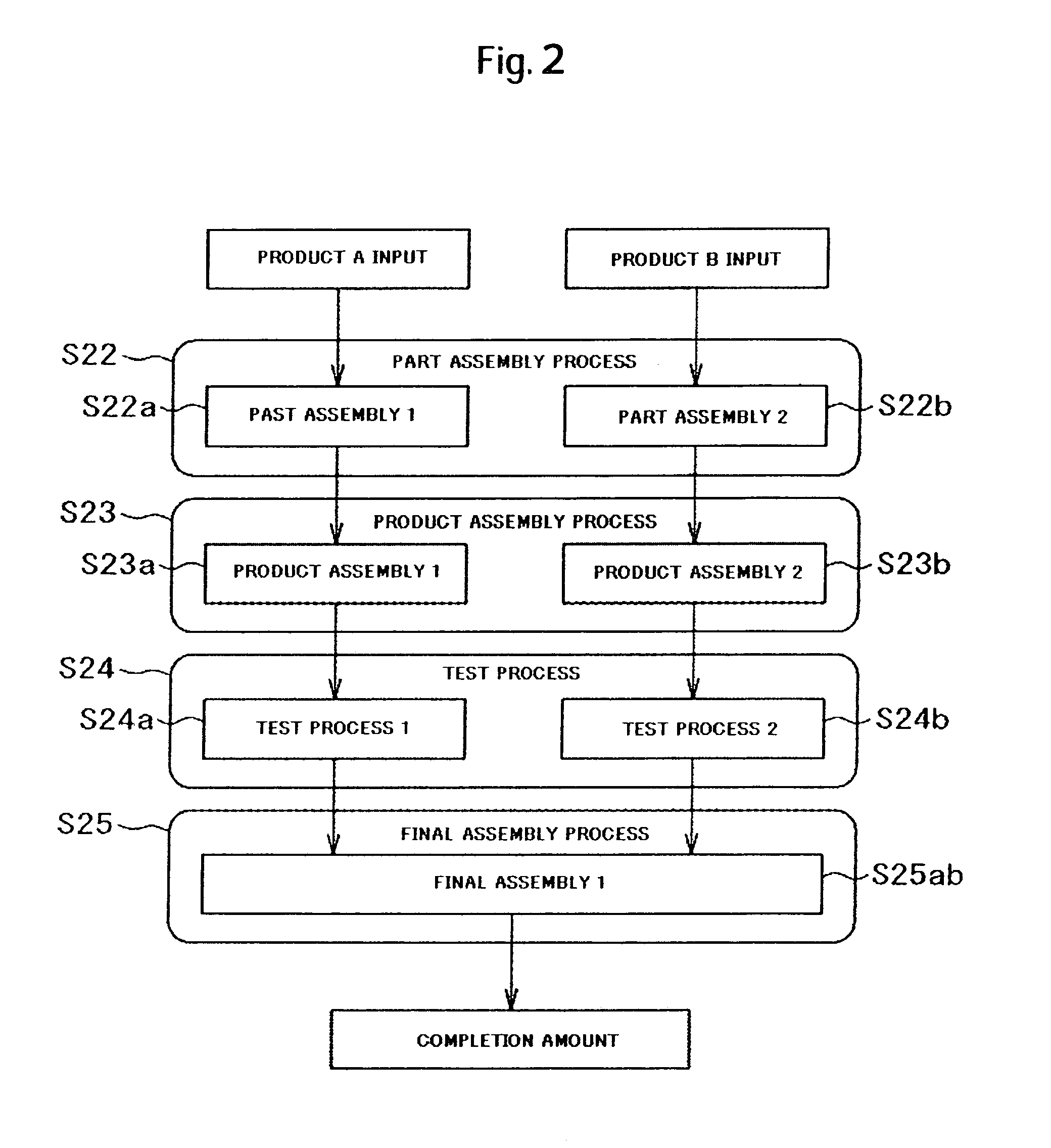

Production planning method and production planning system

InactiveUS7693593B2Change in yield of the production line is vigorousComplicated processingForecastingResourcesProduction lineUnavailability

Embodiments of the present invention provide a production planning method and system. Where a manufacturing apparatus is shared by a plurality of products in a production line, if a manufacturing (production) availability number is changed, a cause parameter is automatically investigated so that a production plan with high precision can be prepared in a short time. With respect to a production plan as the previous / current comparison objects, a production process used in the production plan in which a change occurs, is extracted. From the production process, a parameter item to be used in the production capacity evaluation is extracted for all products, a difference comparison is made between the value of the previous parameter and the value of the current parameter, so that the parameter item as the cause is specified. The combination of the cause parameter items is calculated, and a cause parameter list is prepared. Next, from the specified parameter list, the parameter item is sequentially changed, and the manufacturing (production) availability number is recalculated. An influence index given to the manufacturing (production) unavailability number by the cause parameter, is calculated.

Owner:WESTERN DIGITAL TECH INC

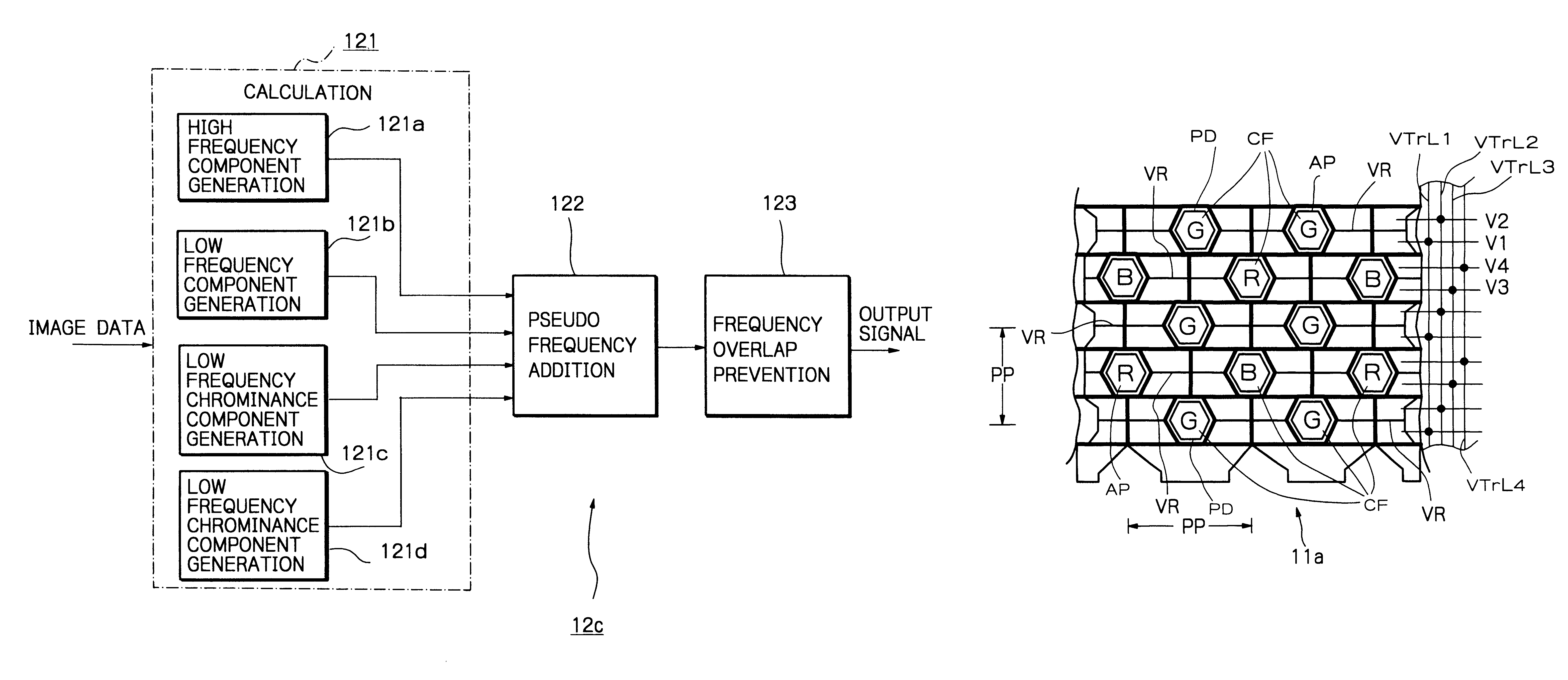

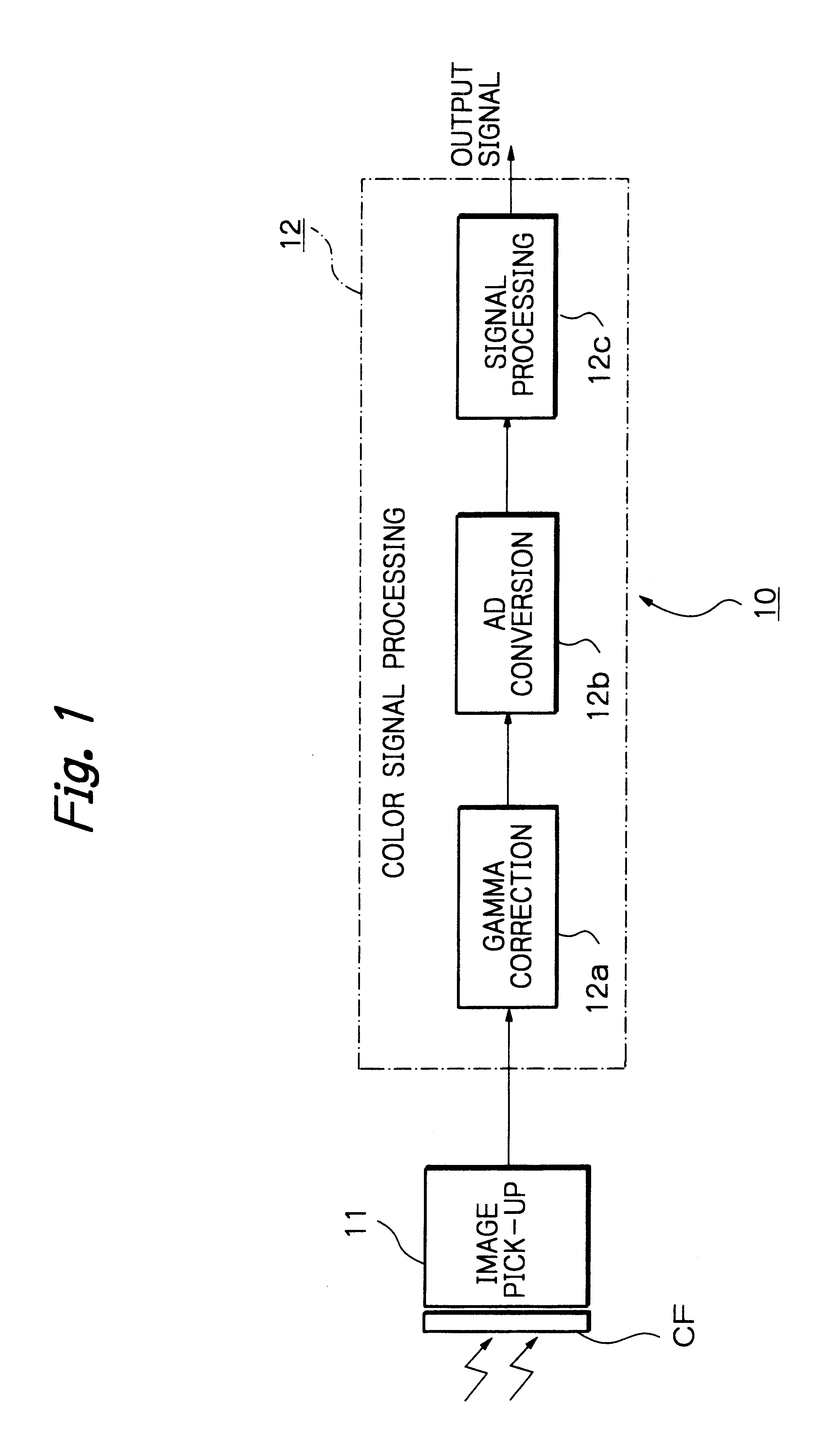

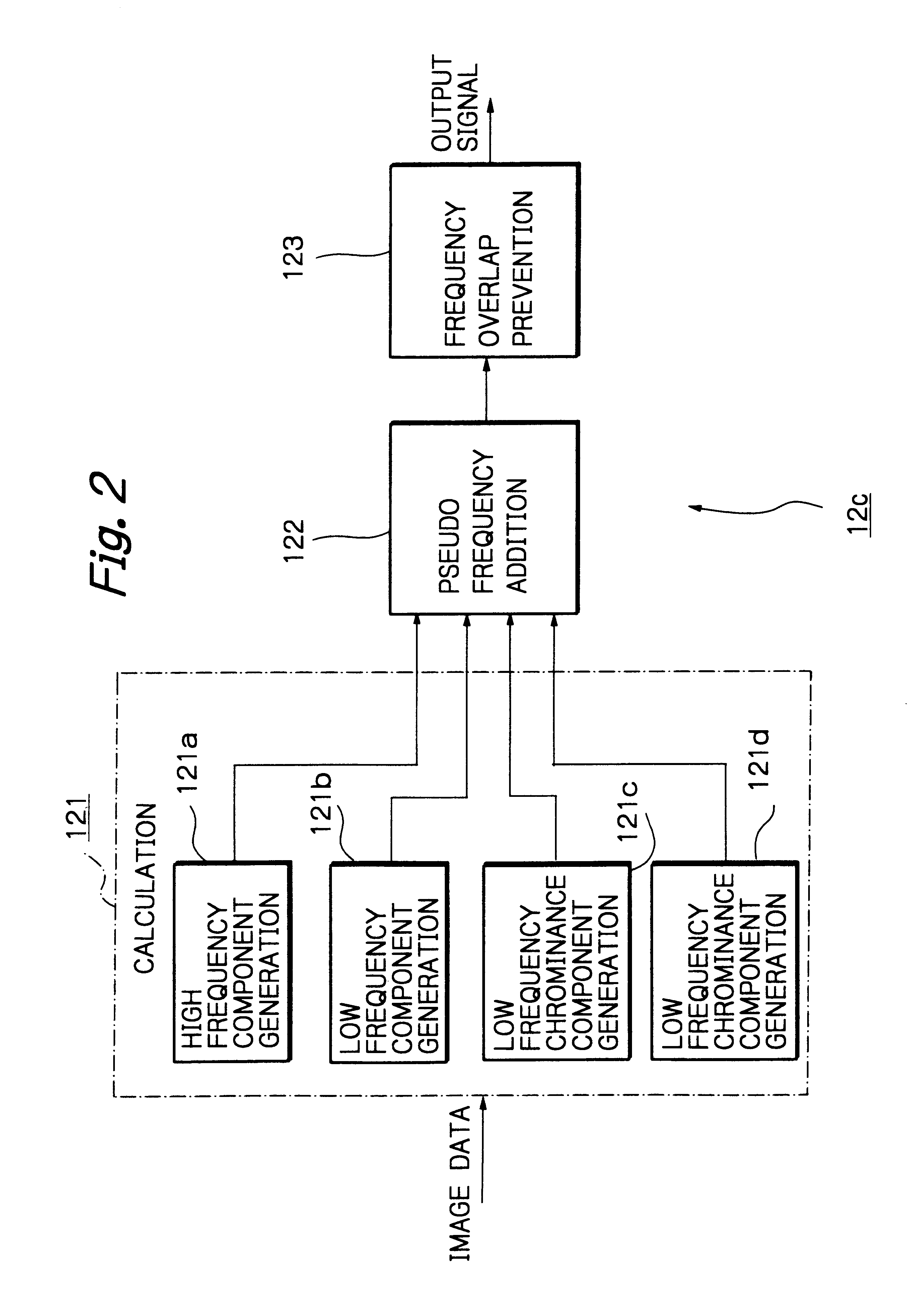

Solid-state imaging apparatus and signal processing method for transforming image signals output from a honeycomb arrangement to high quality video signals

InactiveUS6882364B1High outputWithout delayTelevision system detailsColor signal processing circuitsLow-pass filterFalse color

A solid-state imaging apparatus includes an image pick-up section in which photosensitive devices are arranged in, e.g., a honeycomb G square lattice, RB full-checker pattern due to shifted pixels. Regions void of the photosensitive devices are assumed to be virtual photosensitive devices. A signal processing section generates data for the virtual photosensitive devices by using the data of surrounding photosensitive devices while attaching importance to accurate color reproduction and horizontal and / or vertical resolution. As a result, the number of pixel data are increased in a square lattice arrangement. Therefore, high quality image signals are readily achievable with a smaller number of photosensitive devices than conventional with a conventional apparatus. Interpolation can be executed with the high quality signals to the limit of resolution with an adequate circuit scale. The honeycomb arrangement guarantees the required size of the individual pixel and thereby the sensitivity of the entire apparatus while increasing yield on a production line. False colors particular to a single photosensitive portion can be reduced by, e.g., uniform interpolation. Particularly, when a digital camera is constructed by using an imaging apparatus including optics operable with a silver halide sensitive type of film, false colors can be reduced without resorting to an optical low pass filter.

Owner:FUJIFILM CORP

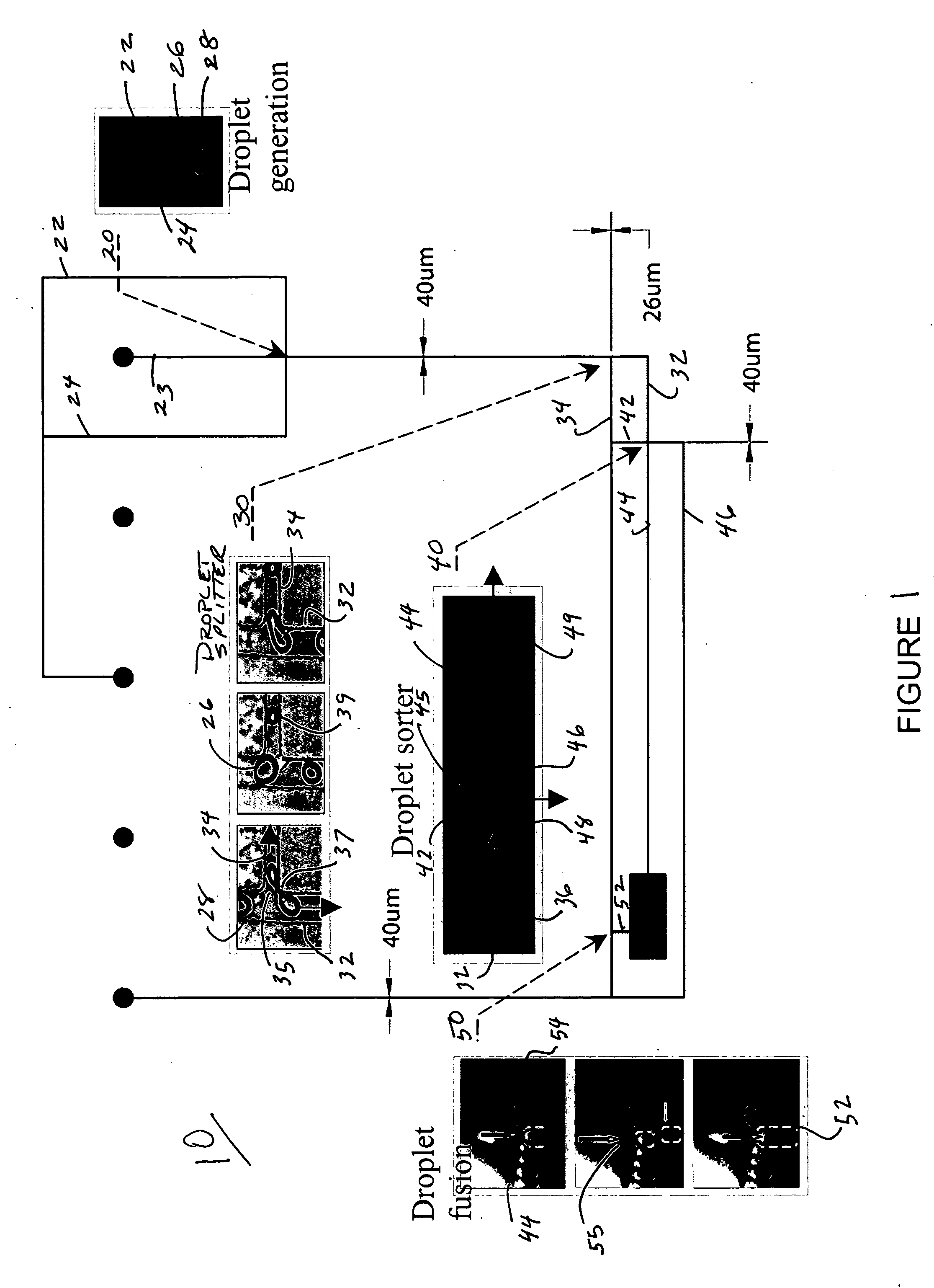

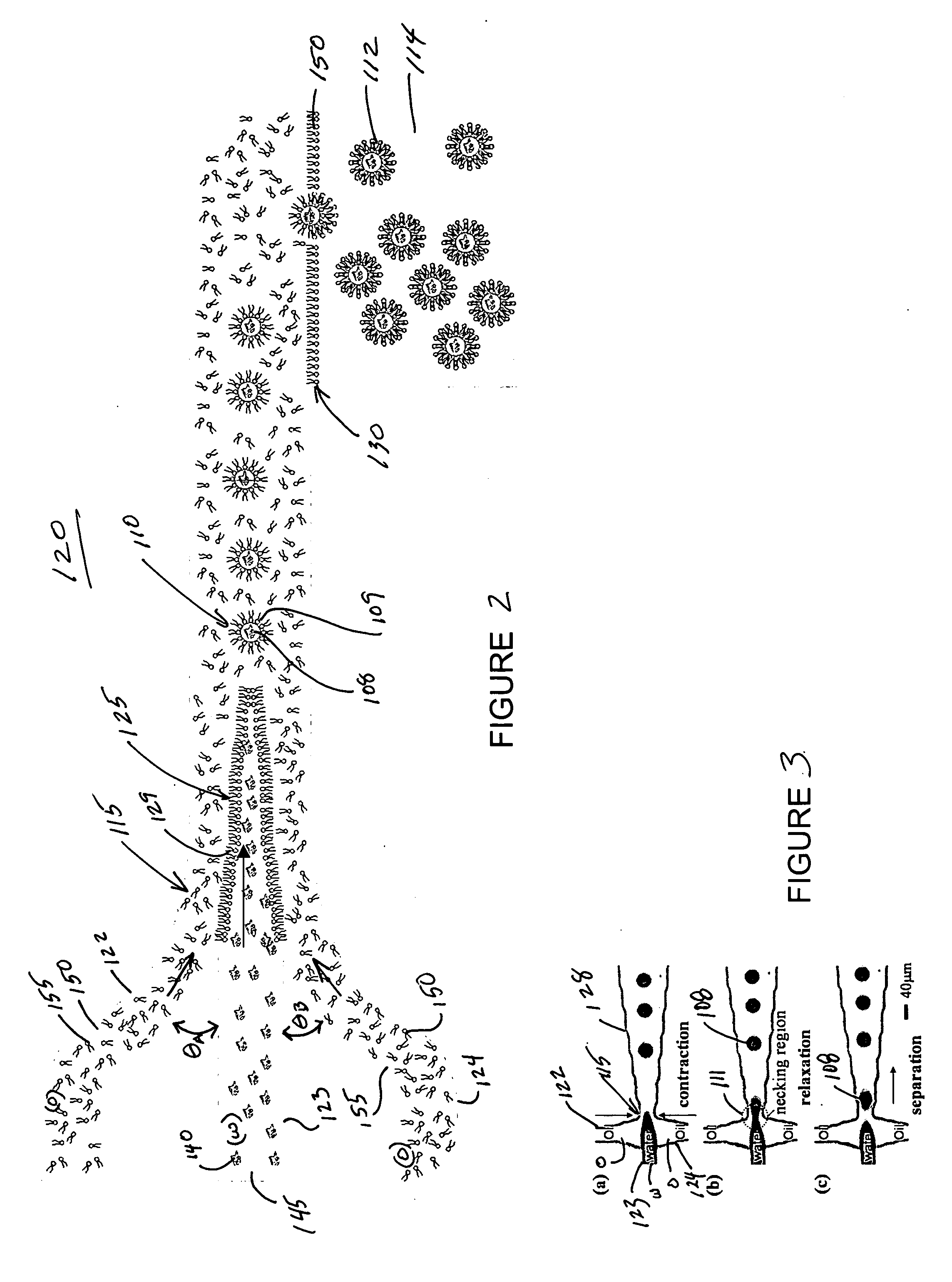

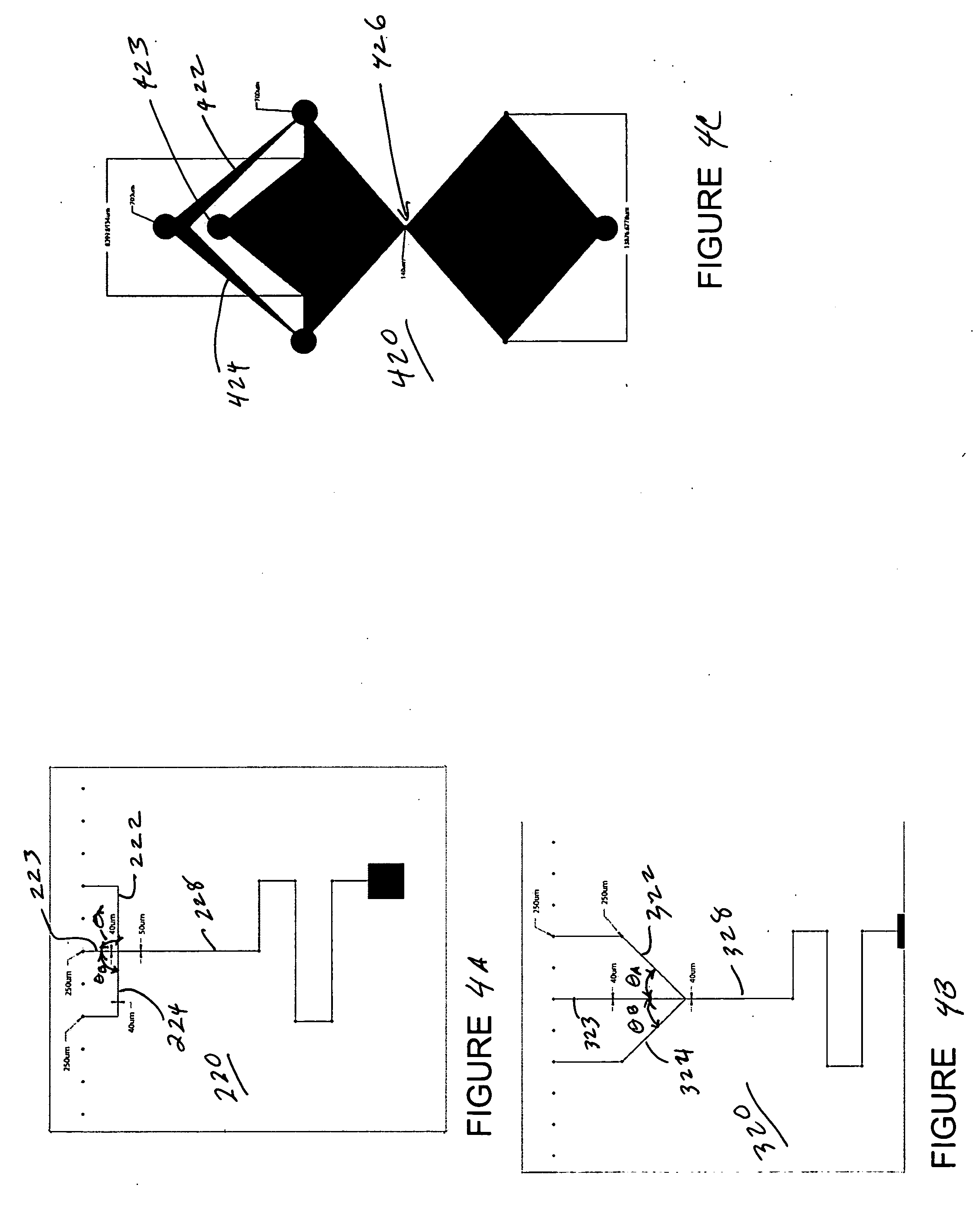

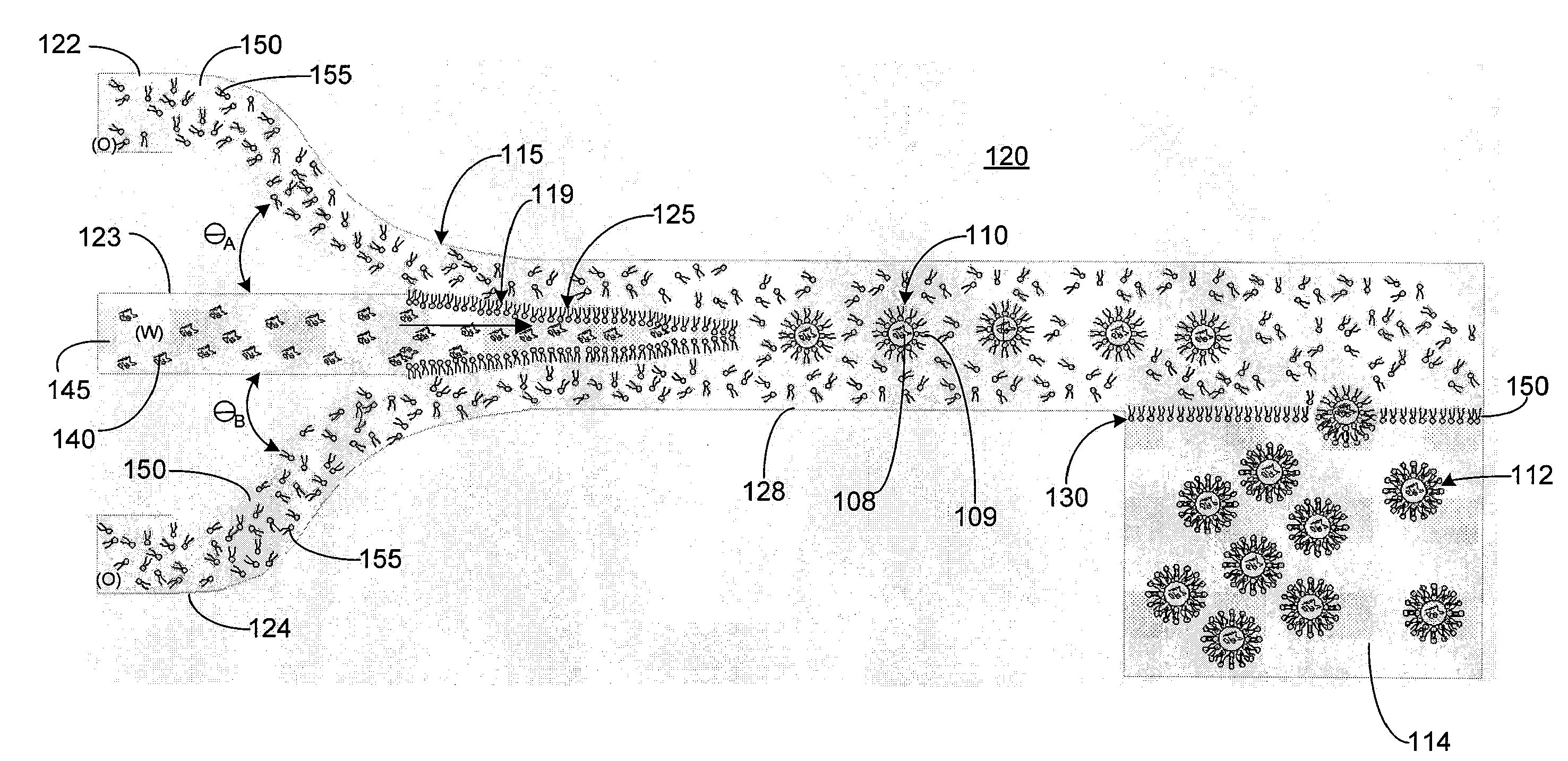

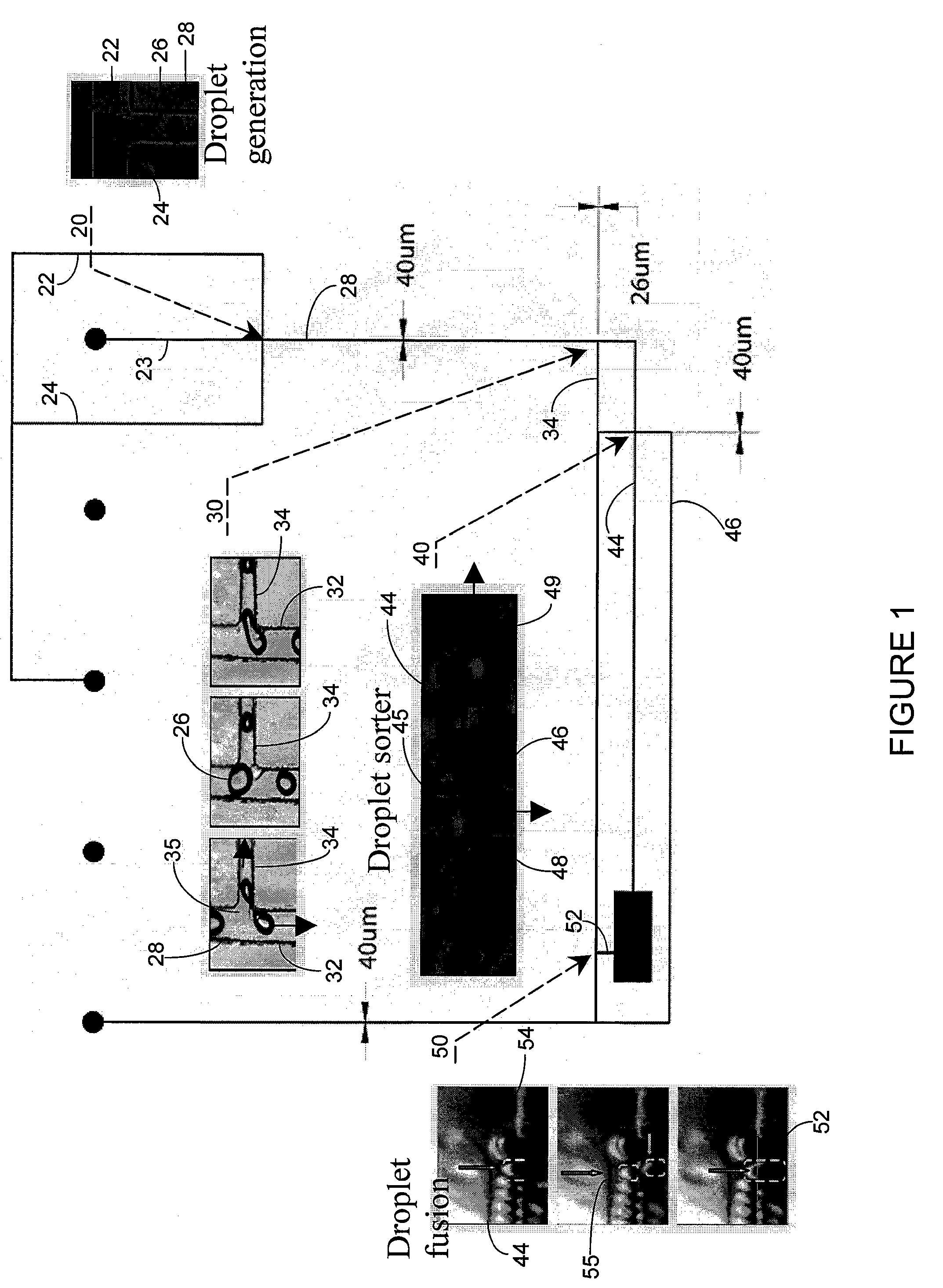

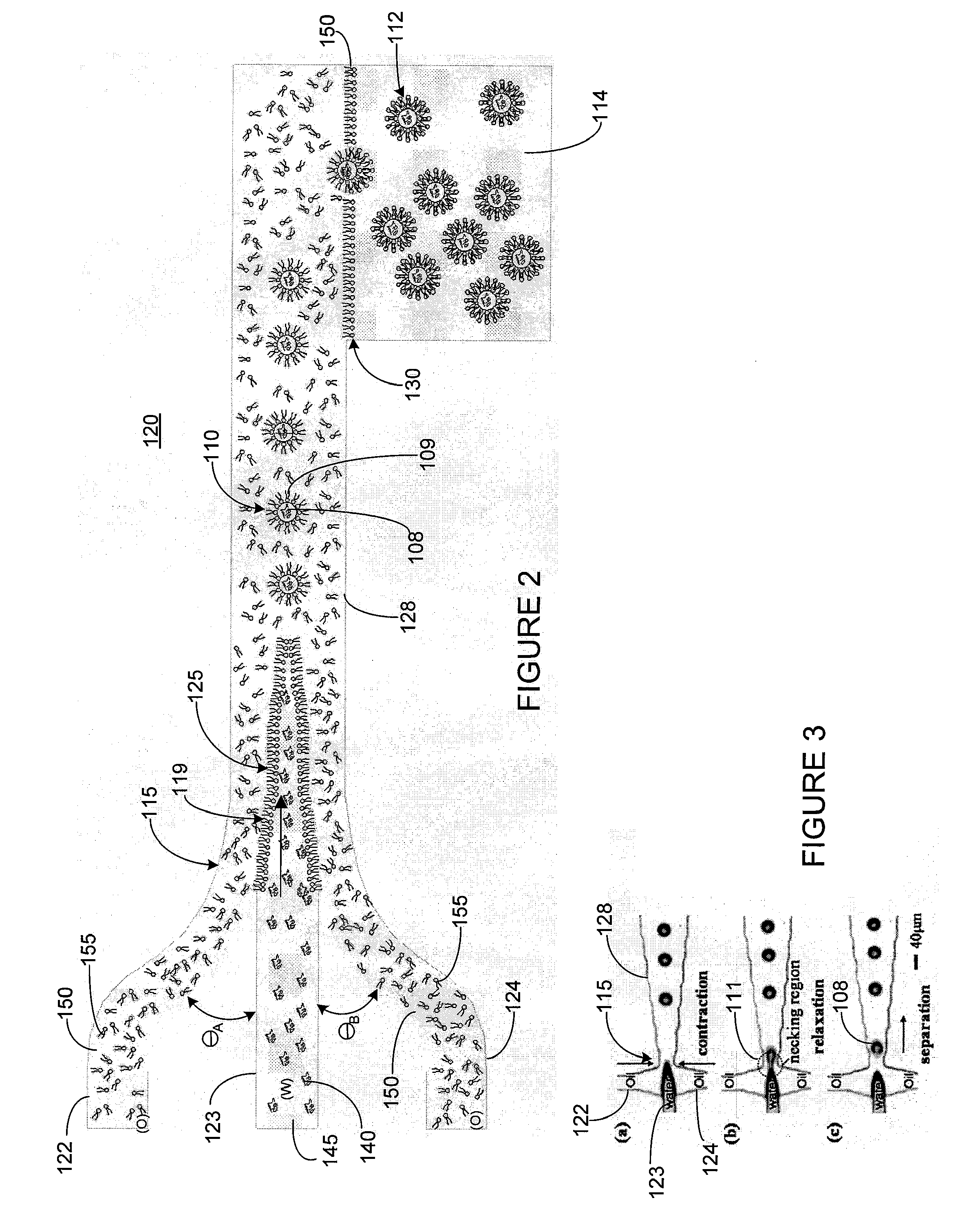

Microfluidic devices for controlled viscous shearing and formation of amphiphilic vesicles

ActiveUS20050032240A1Facilitates programmable control of sizeIncrease shear forceMixing methodsTransportation and packagingViscous shearEngineering

Systems and methods that control the size and composition of emulsified droplets, multi-lamellar and asymmetric vesicles, encapsulation of reagents, membrane proteins, and sorting of vesicles / droplets. More particularly, microfluidic devices for controlled viscous shearing of oil-water emulsions of micro- and nano-scale droplets, the subsequent formation of amphiphilic vesicles such as liposomes, polymer vesicles, micelles, and the like, the post-assembly and post-processing of the droplets including splitting, fusing, sorting and the like, polymer emulsions, and the integration of amphiphilic vesicle production-line on a single microfluidic chip. Preferably, the microfluidic device enables oil-water co-flows with tunable viscous shear forces higher than the immiscible interfacial tension forces that generate favorable conditions for droplet formation.

Owner:RGT UNIV OF CALIFORNIA

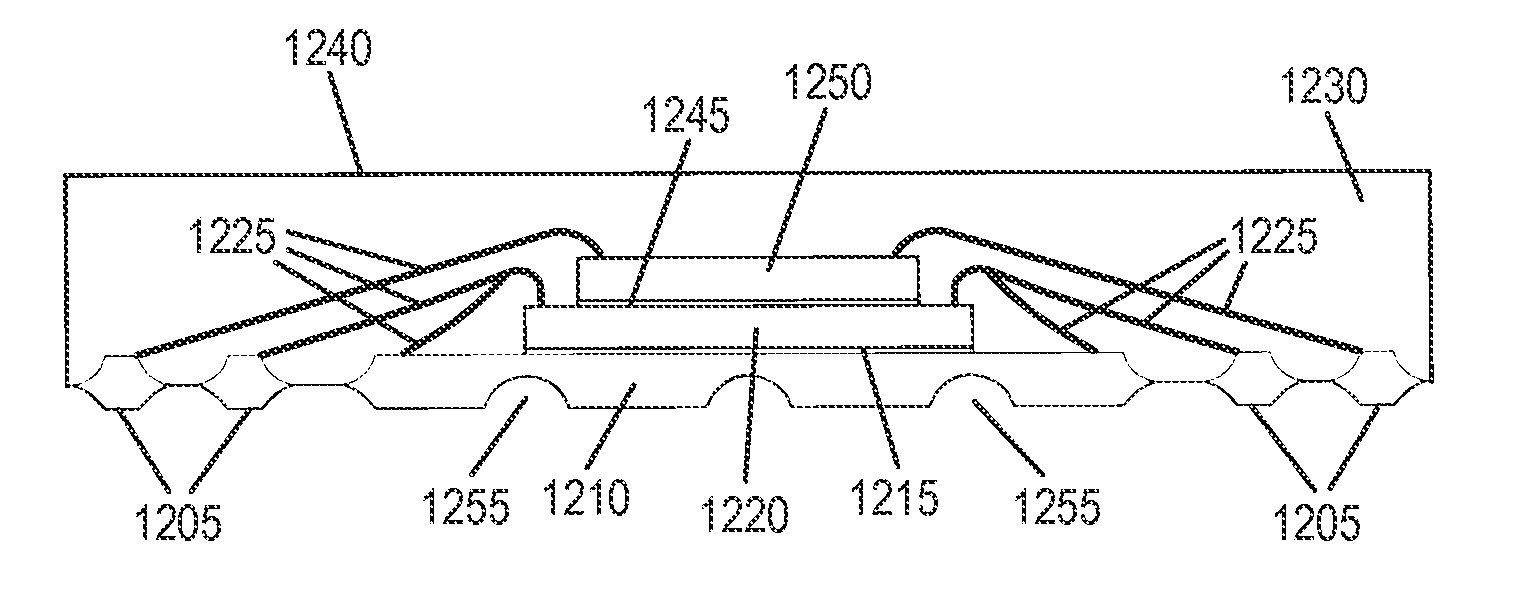

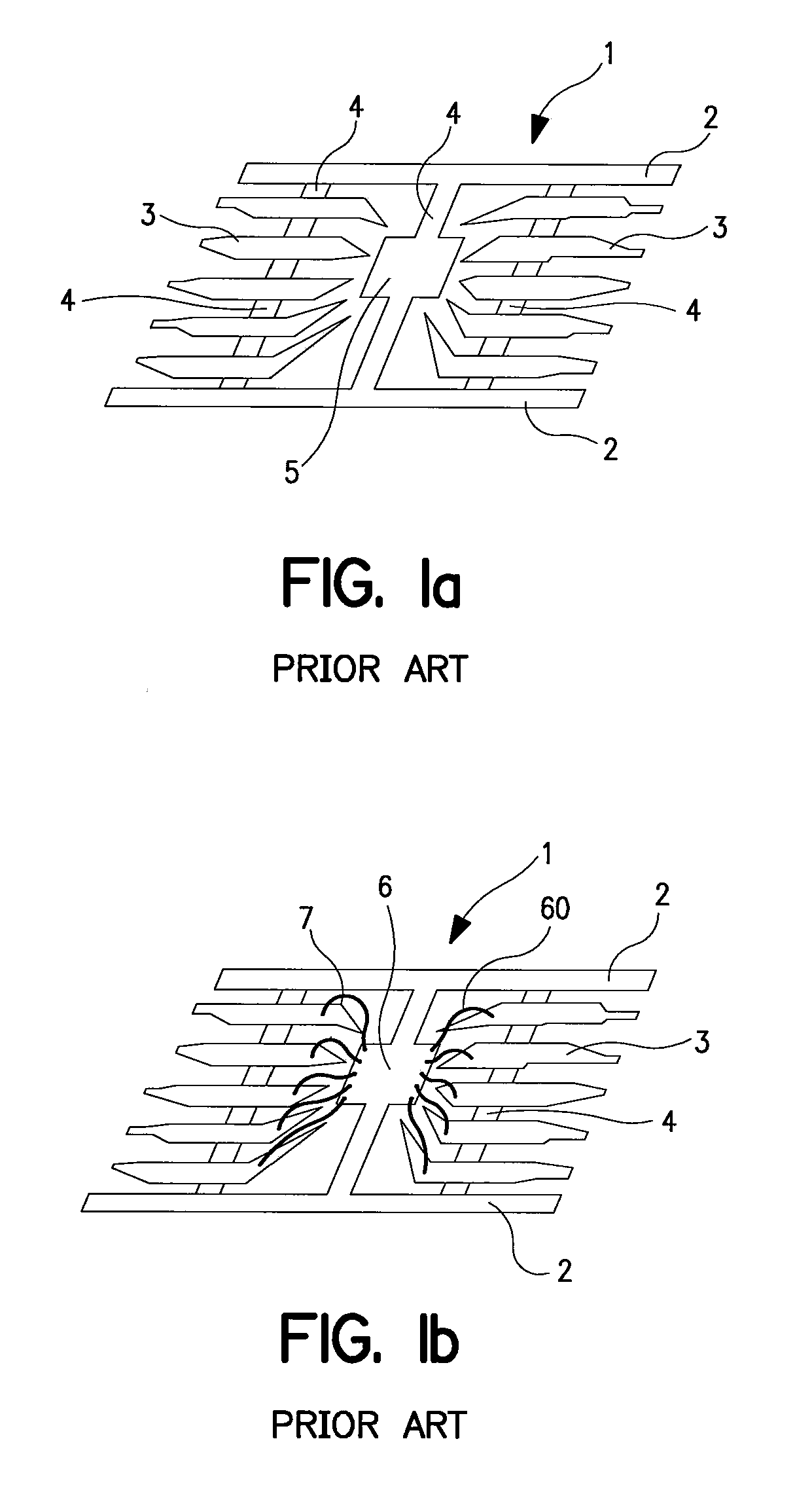

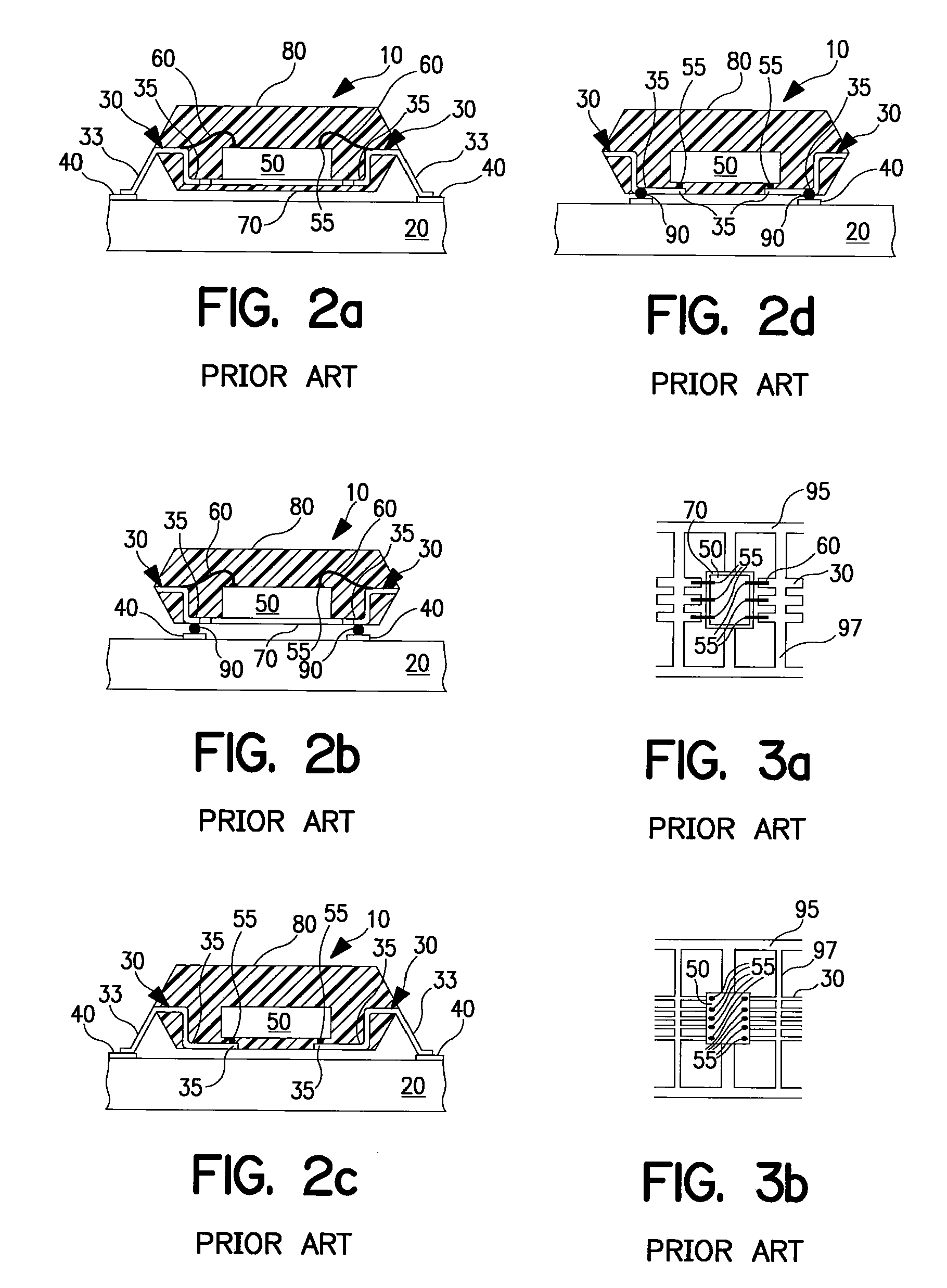

Partially patterned lead frames and methods of making and using the same in semiconductor packaging

InactiveUS20080258278A1Reduce thicknessImprove structural rigiditySemiconductor/solid-state device detailsSolid-state devicesLead bondingBonding process

A method of making a lead frame and a partially patterned lead frame package with near-chip scale packaging lead-count, wherein the method lends itself to better automation of the manufacturing line and improved quality and reliability of the packages produced therefrom. A major portion of the manufacturing process steps is performed with a partially patterned strip of metal formed into a web-like lead frame on one side so that the web-like lead frame is also rigid mechanically and robust thermally to perform without distortion or deformation during the chip-attach and wire bond processes, both at the chip level and the package level. The bottom side of the metal lead frame is patterned to isolate the chip-pad and the wire bond contacts only after the front side, including the chip and wires, is hermetically sealed with an encapsulant. The resultant package being electrically isolated enables strip testing and reliable singulation.

Owner:UNISEM M BERHAD

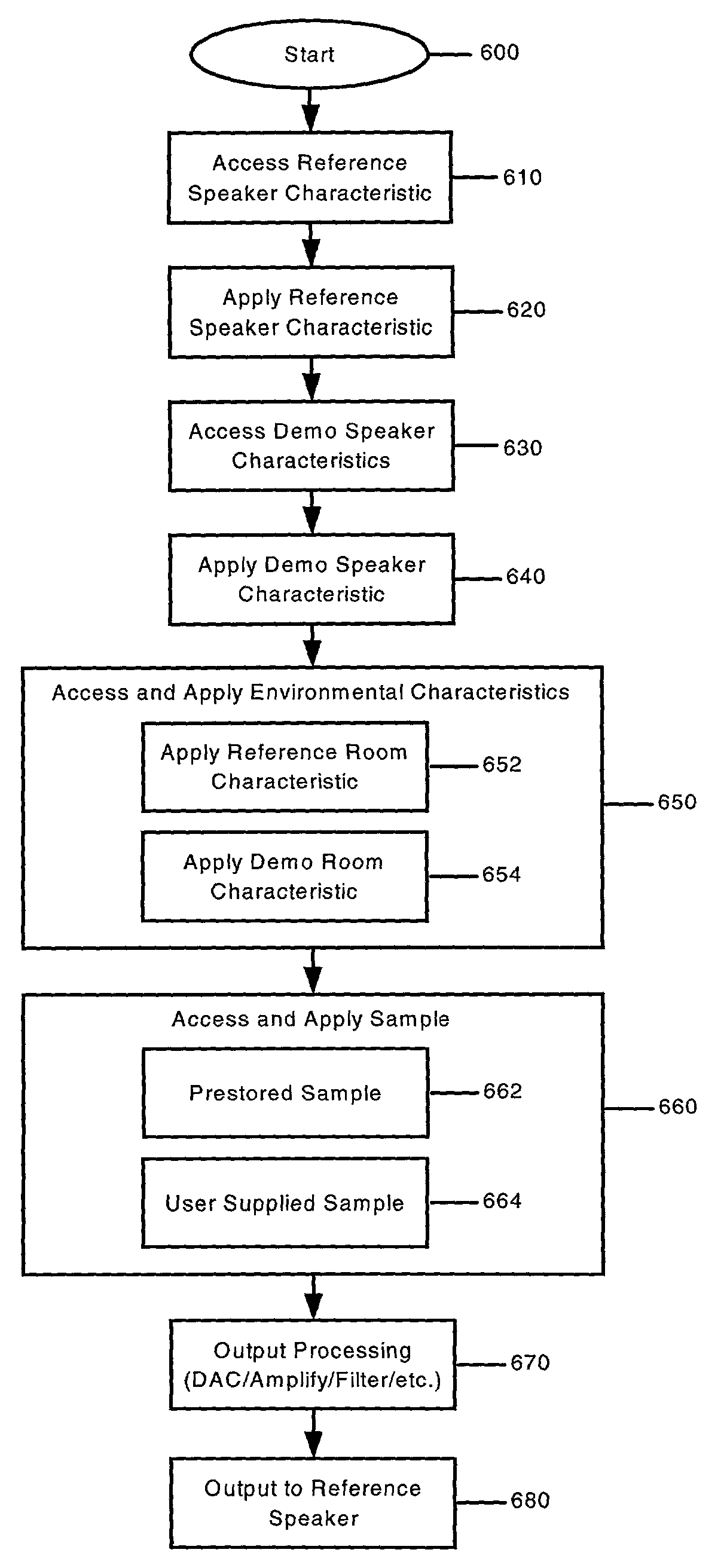

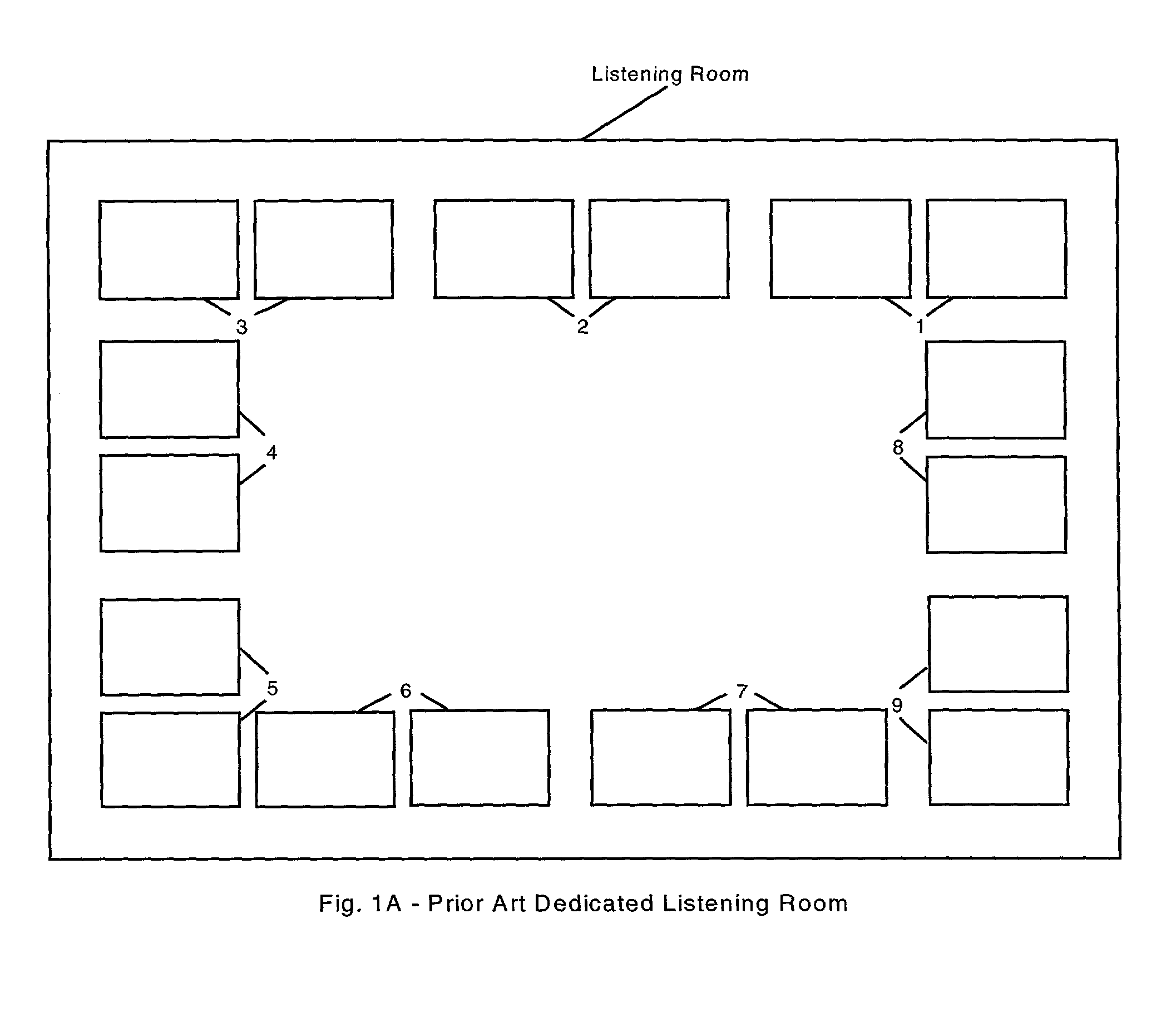

Virtual speaker demonstration system and virtual noise simulation

ActiveUS7096169B2Reduce the amount requiredReduce complexityNear-field transmissionEar treatmentProduction lineLoudspeaker

A virtual speaker demonstration system is disclosed that permits a retail outlet to use a reference speaker to demonstrate the performance of multiple different demonstration speakers. A user interface permits a user to select a demonstration speaker and signal processing is performed so that the output from the reference speaker simulates the output of the selected demonstration speaker. The invention provides benefits to all three of the consumer, the retailer, and the manufacturer. The consumer can listen to and compare multiple demonstration speakers easily and conveniently from the same reference speaker. The retailer to use a single (or few) reference speaker to demonstrate the performance of multiple demonstration speakers, saving costs and space. The manufacturer to be able to display and demonstrate to consumers a broader range of the manufacturer's product line.

Owner:CRUTCHFIELD

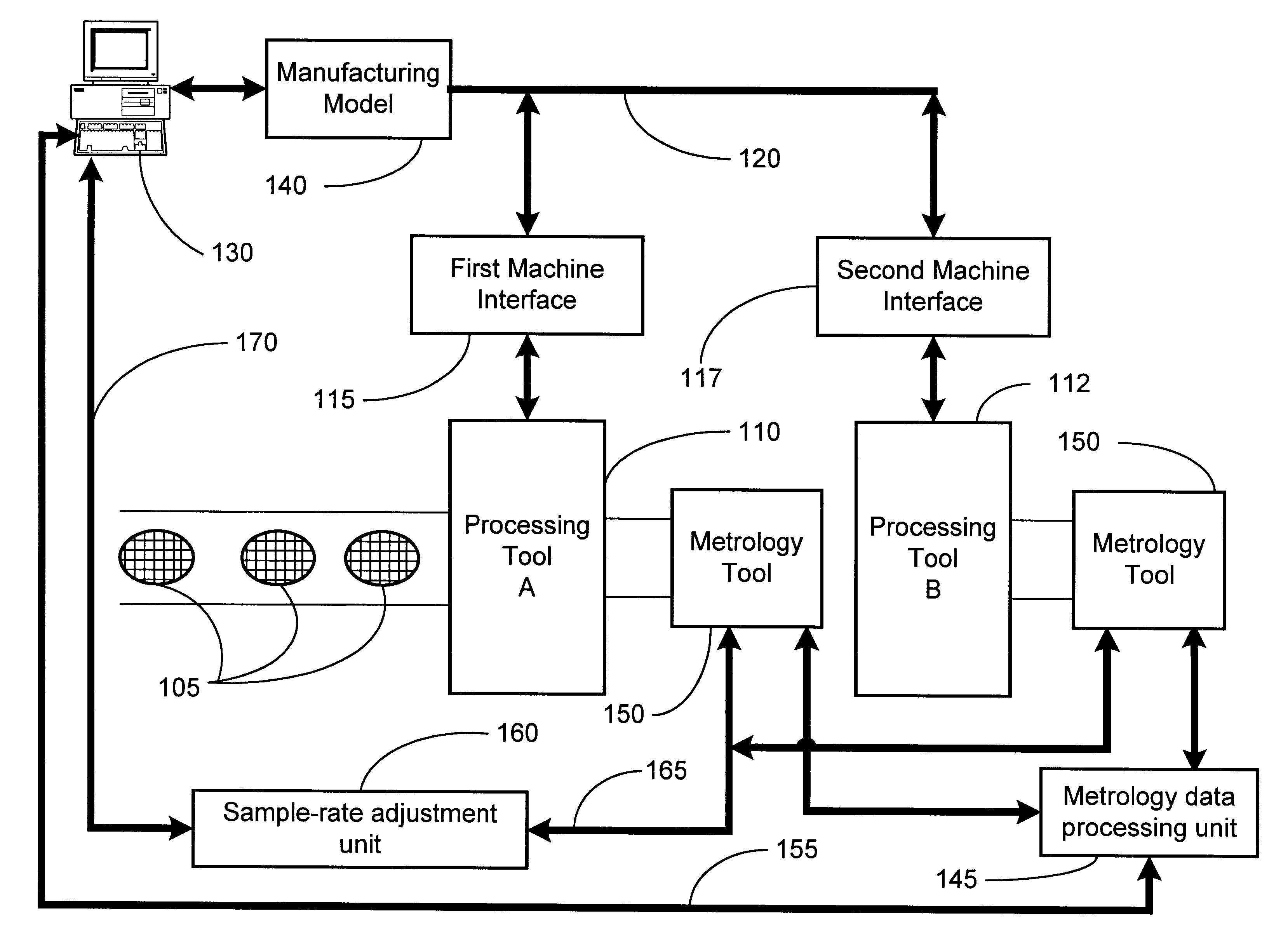

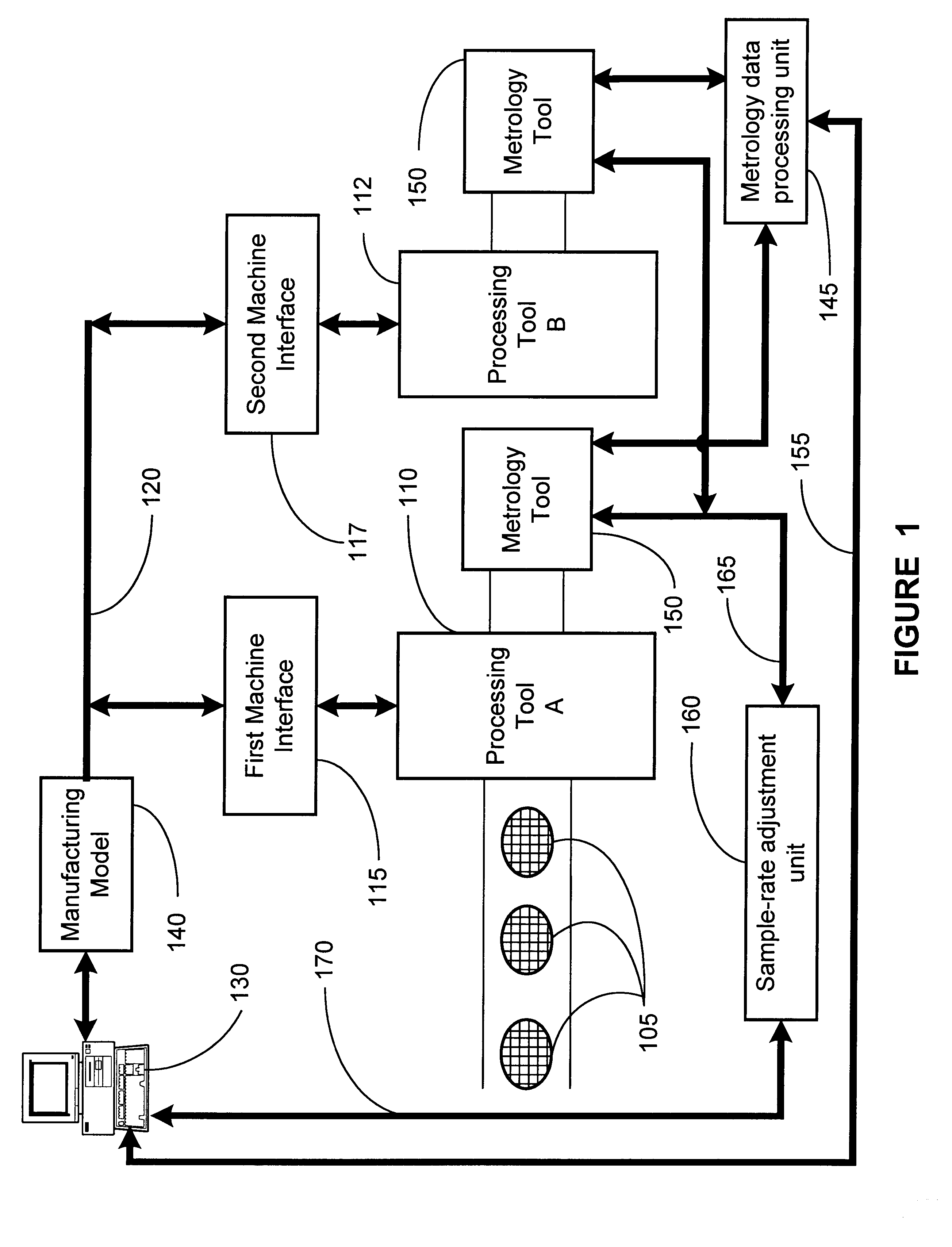

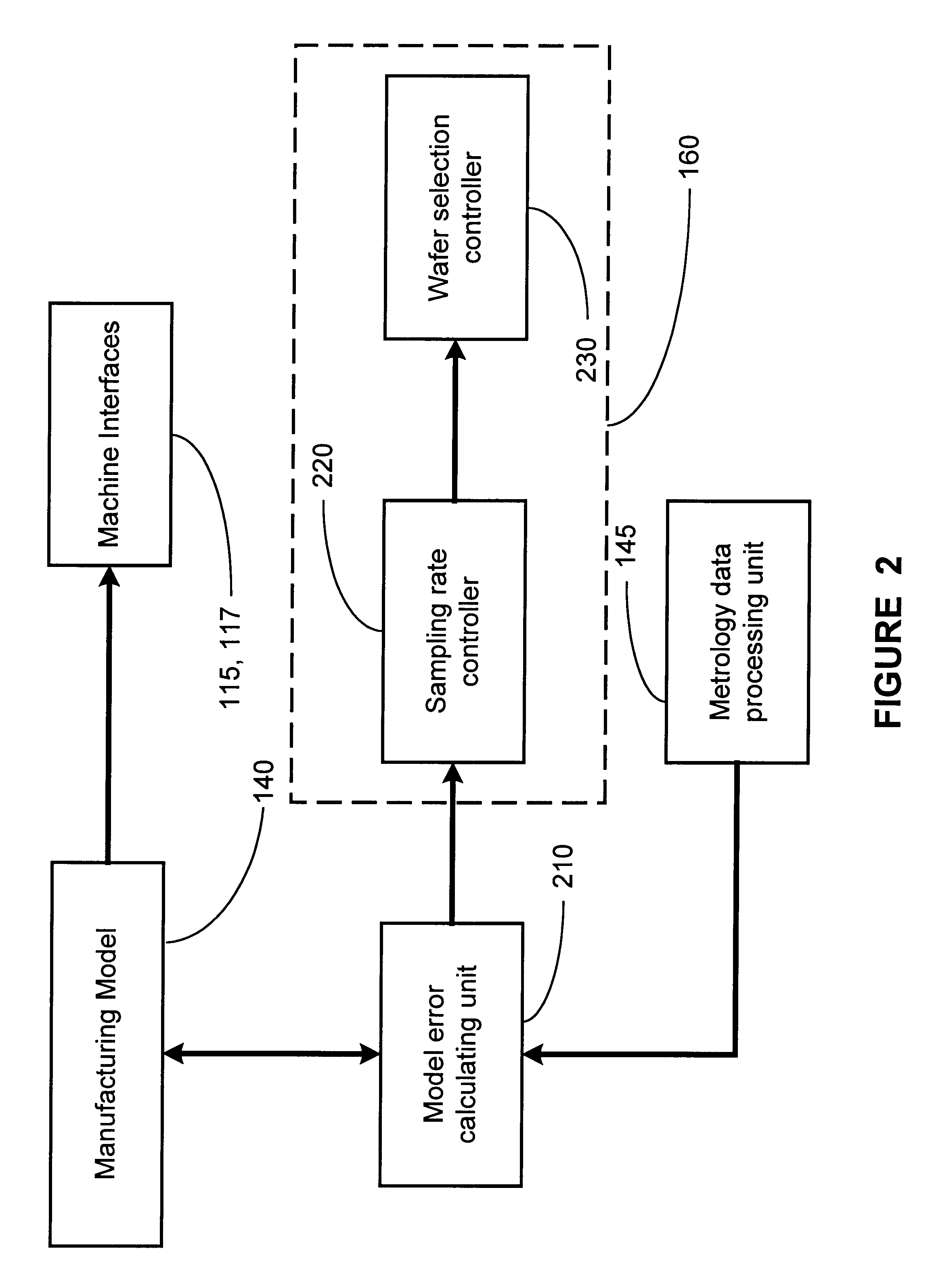

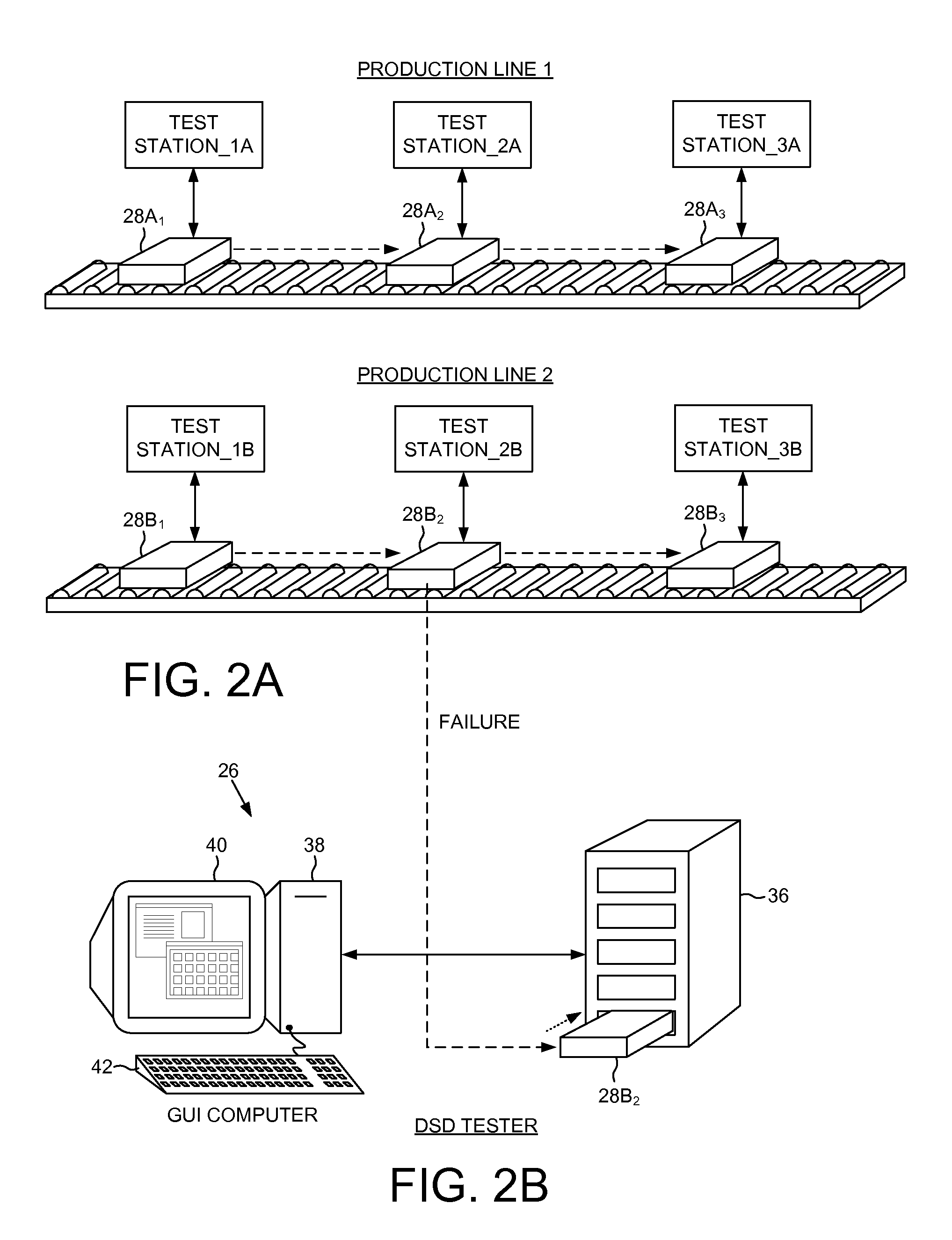

Method and apparatus for dynamic sampling of a production line

InactiveUS6442496B1Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingProduction lineEngineering

The present invention provides for a method and an apparatus for performing dynamic sampling of a production line. A first plurality of semiconductor wafers are processed. A minimum sampling rate of semiconductor wafers is calculated. Wafers from the first plurality of the semiconductor wafers are selected and analyzed at the calculated sampling rate. The performance of the processing of the first plurality of semiconductor wafers is quantified, based upon the analyzed wafers. A dynamic sampling process is performed based upon the quantification of the performance of the processing of semiconductor wafers.

Owner:GLOBALFOUNDRIES INC

Storage systems and methods for retrieving units from a storage system

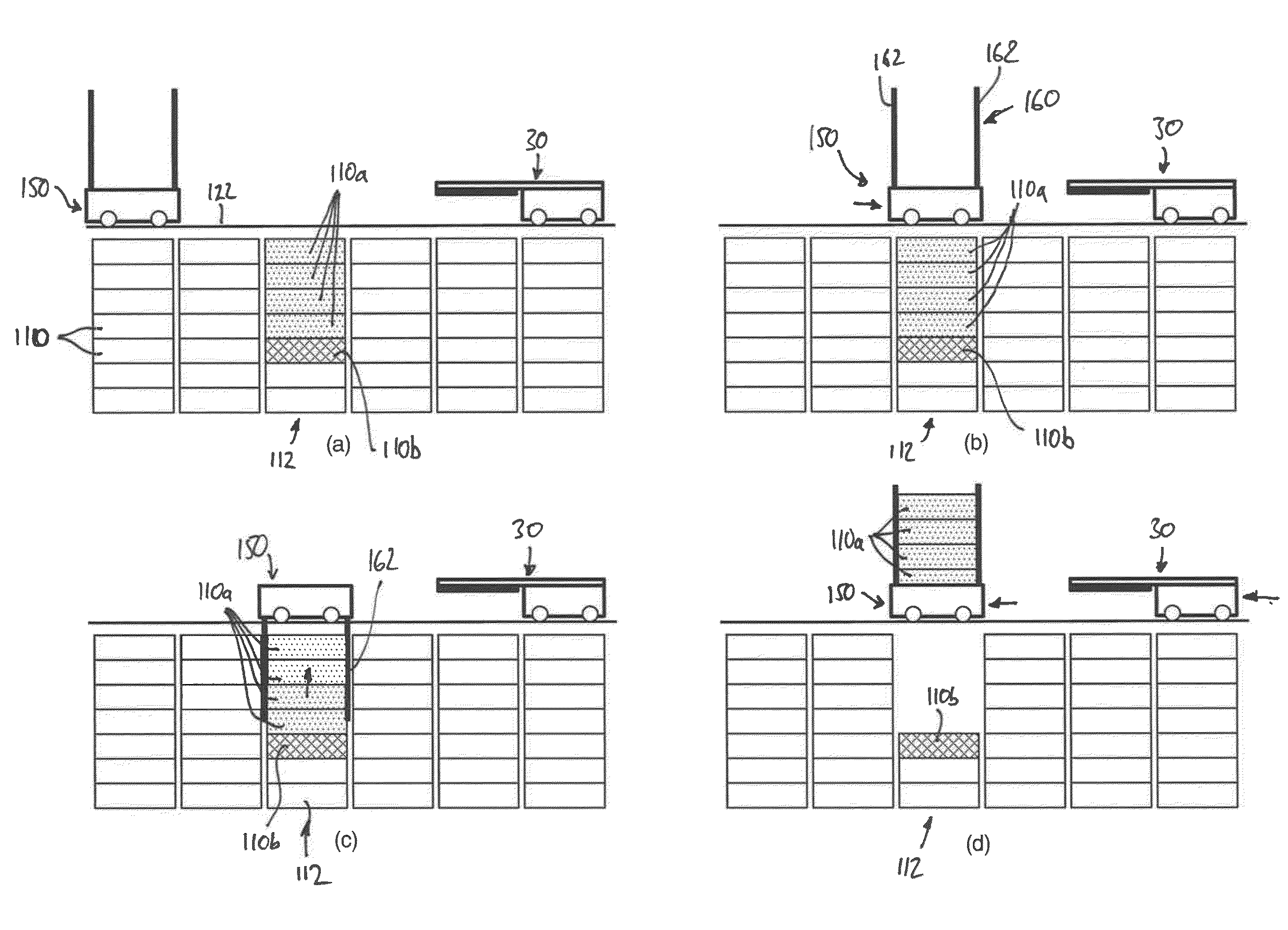

ActiveUS20150127143A1Efficient retrievalEasy to solveComputer controlDigital data processing detailsProduction lineEngineering

A system and method suitable for storing multiple product lines in an automated warehouse environment are disclosed. The storage system includes a frame containing a plurality of stacks of containers, a first handling device capable of lifting a plurality of containers from a stack in a single operation, and a second independently moveable handling device capable of lifting a single container and moving the container laterally. The first and second handling devices can work together to remove a target container quickly and with minimum use of resources.

Owner:OCADO INNOVATION

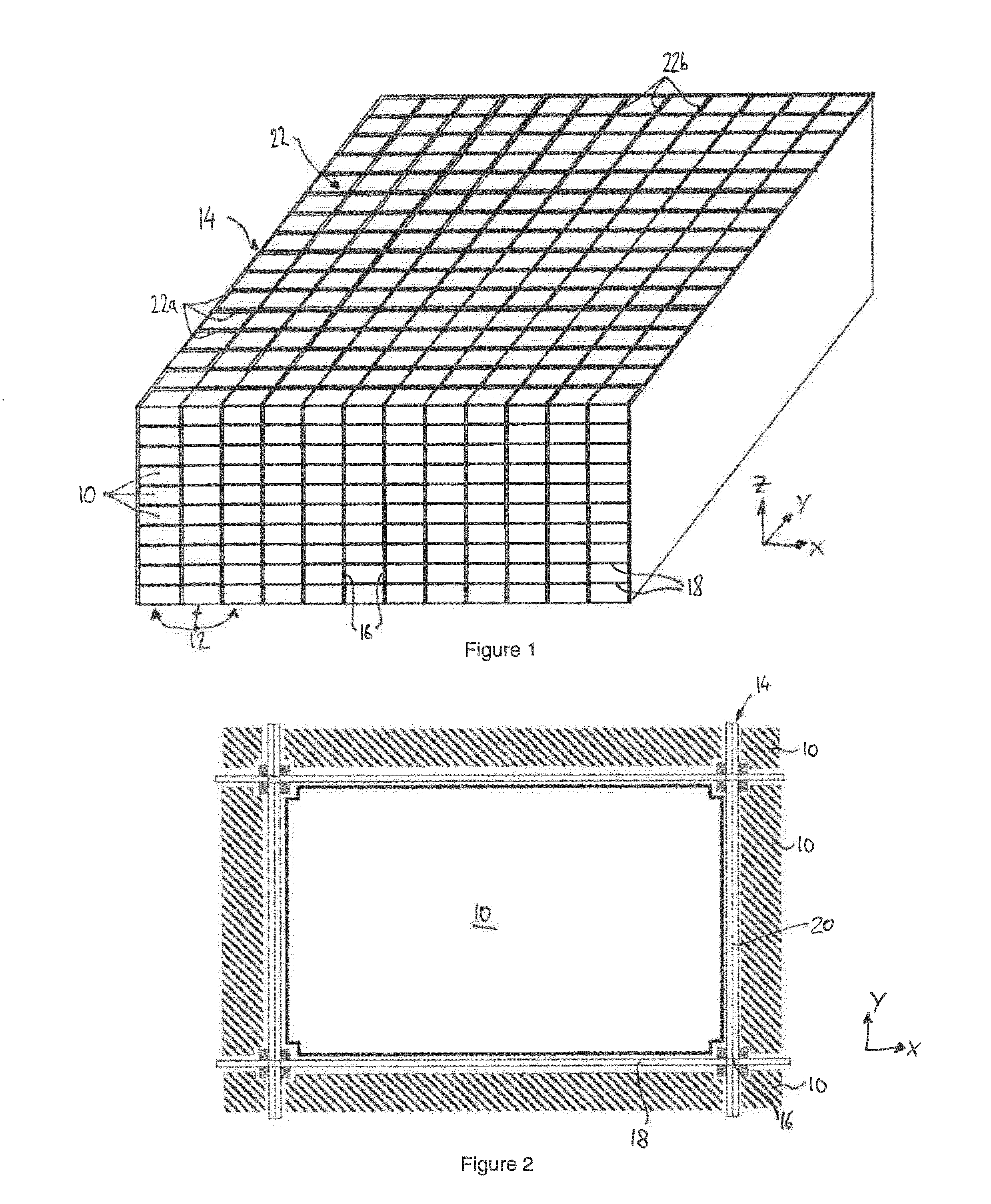

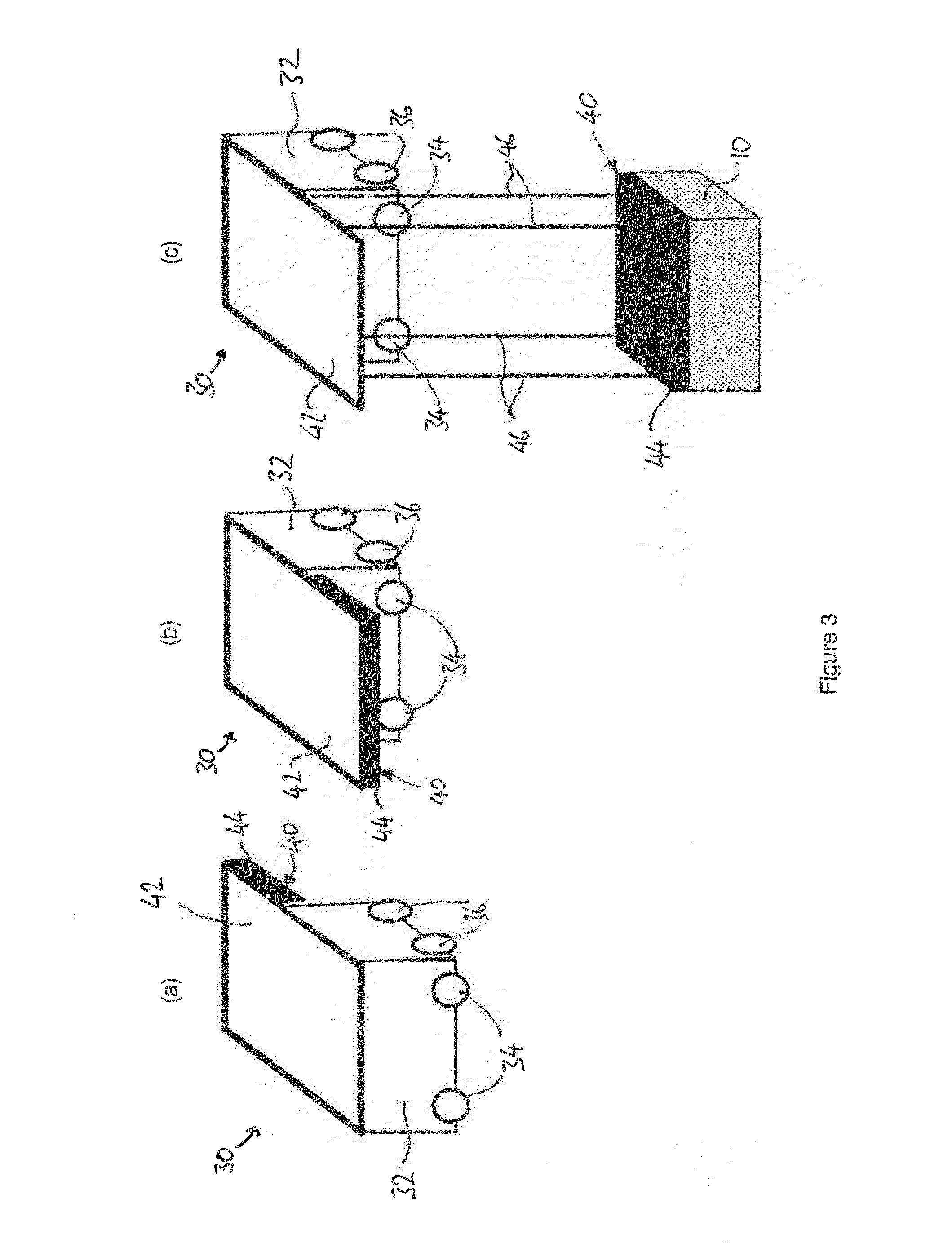

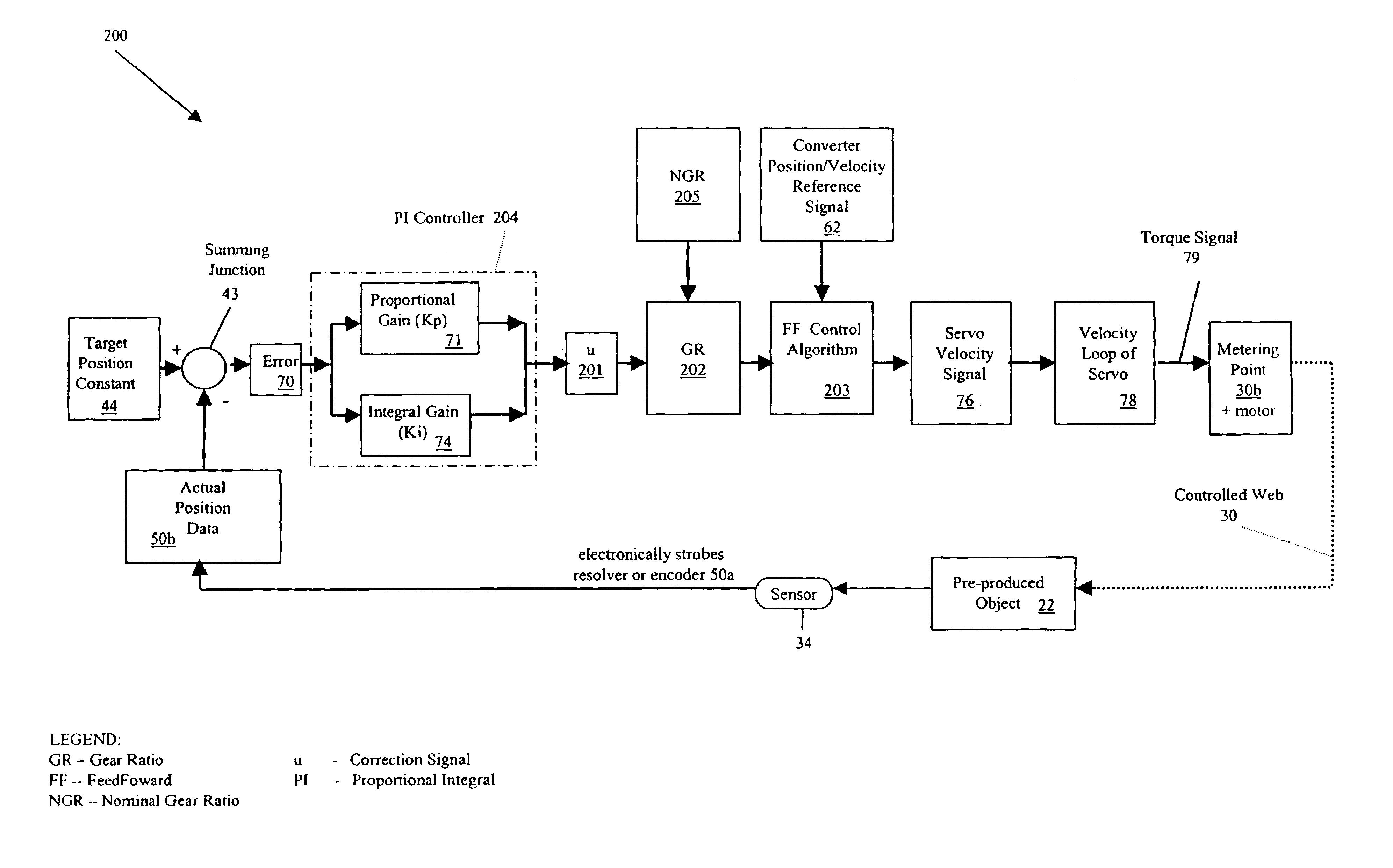

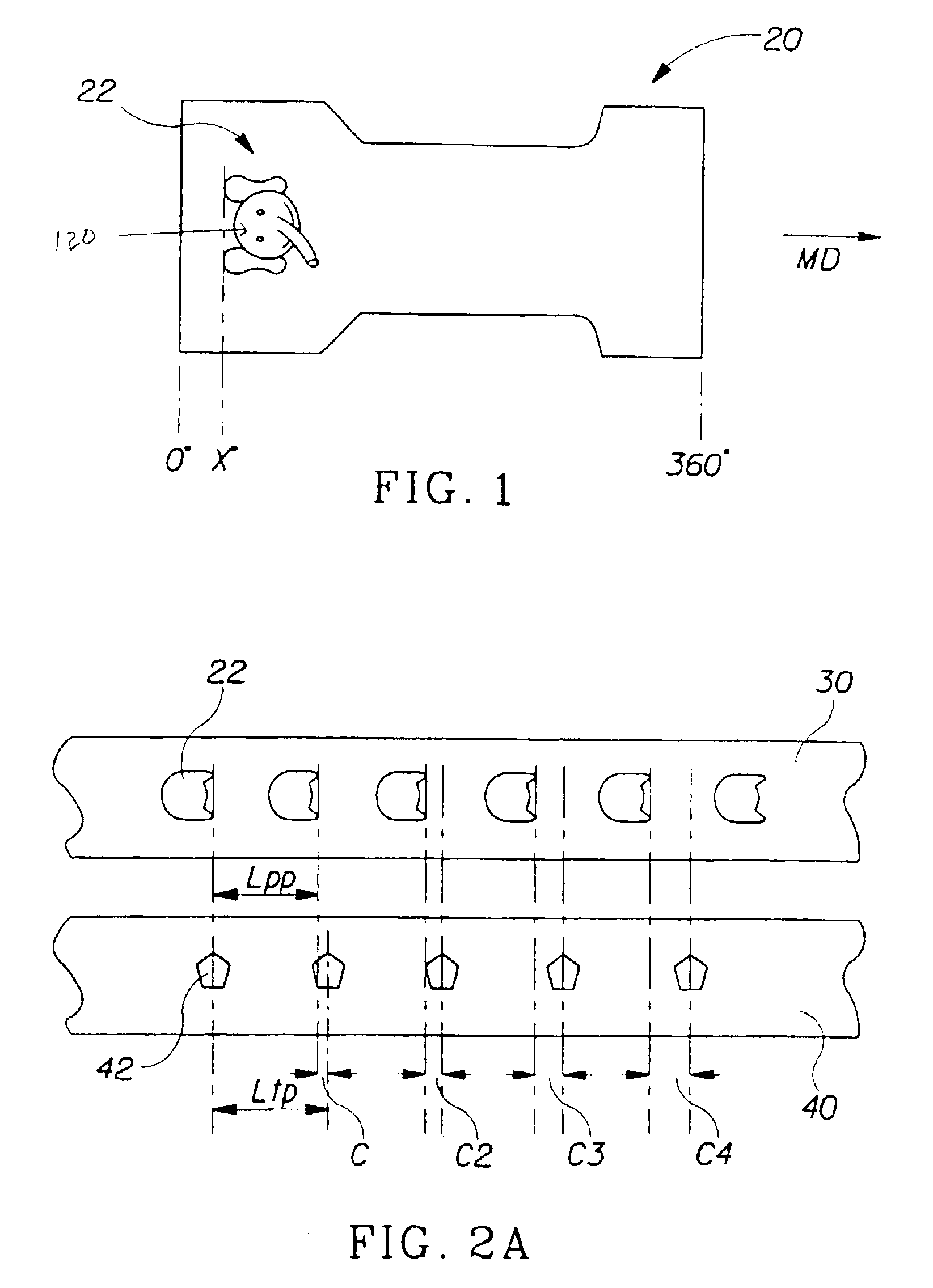

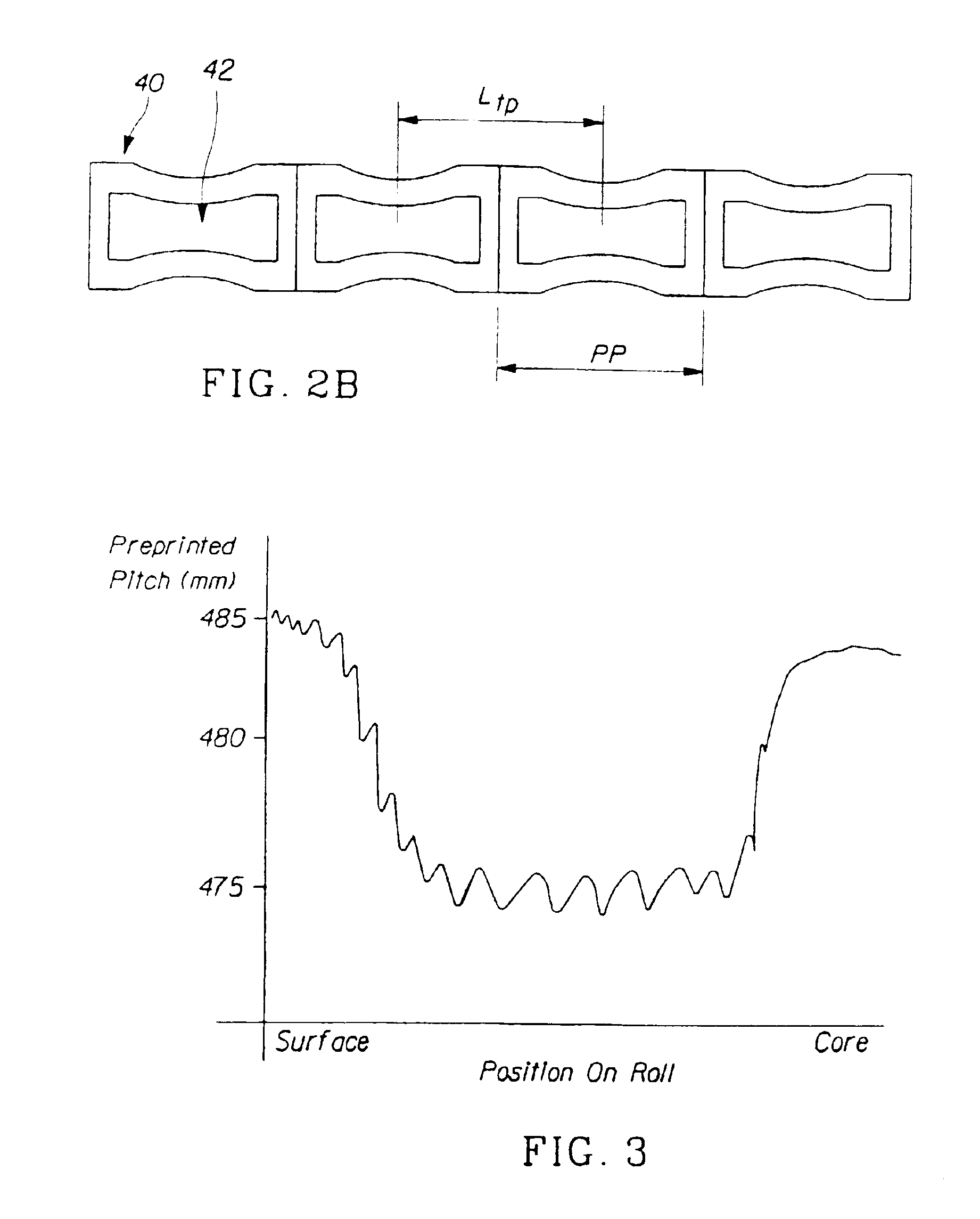

Method and system for registering pre-produced webs with variable pitch length

A new machine control method and system for registering pro-produced webs into a converting line producing disposable absorbent articles such as diapers, pants, feminine hygiene articles or a component thereof. The pre-produced web can include a multiplicity of pre-produced objects spaced on the web at a pitch interval in the web direction. The pre-produced web being manipulated in order for the pre-produced object of the web to be registered in relation to a target position constant. The present invention includes three embodiments, where the first embodiment is expressed as a generic claim. The first embodiment includes a closed-loop feedback registration system; the second and third embodiments, in addition, include an open-loop feedforward phasing system. In addition, the third embodiment uses a machine vision system to recognize any element of a complex pre-produced object (e.g., colorful graphics).

Owner:THE PROCTER & GAMBLE COMPANY

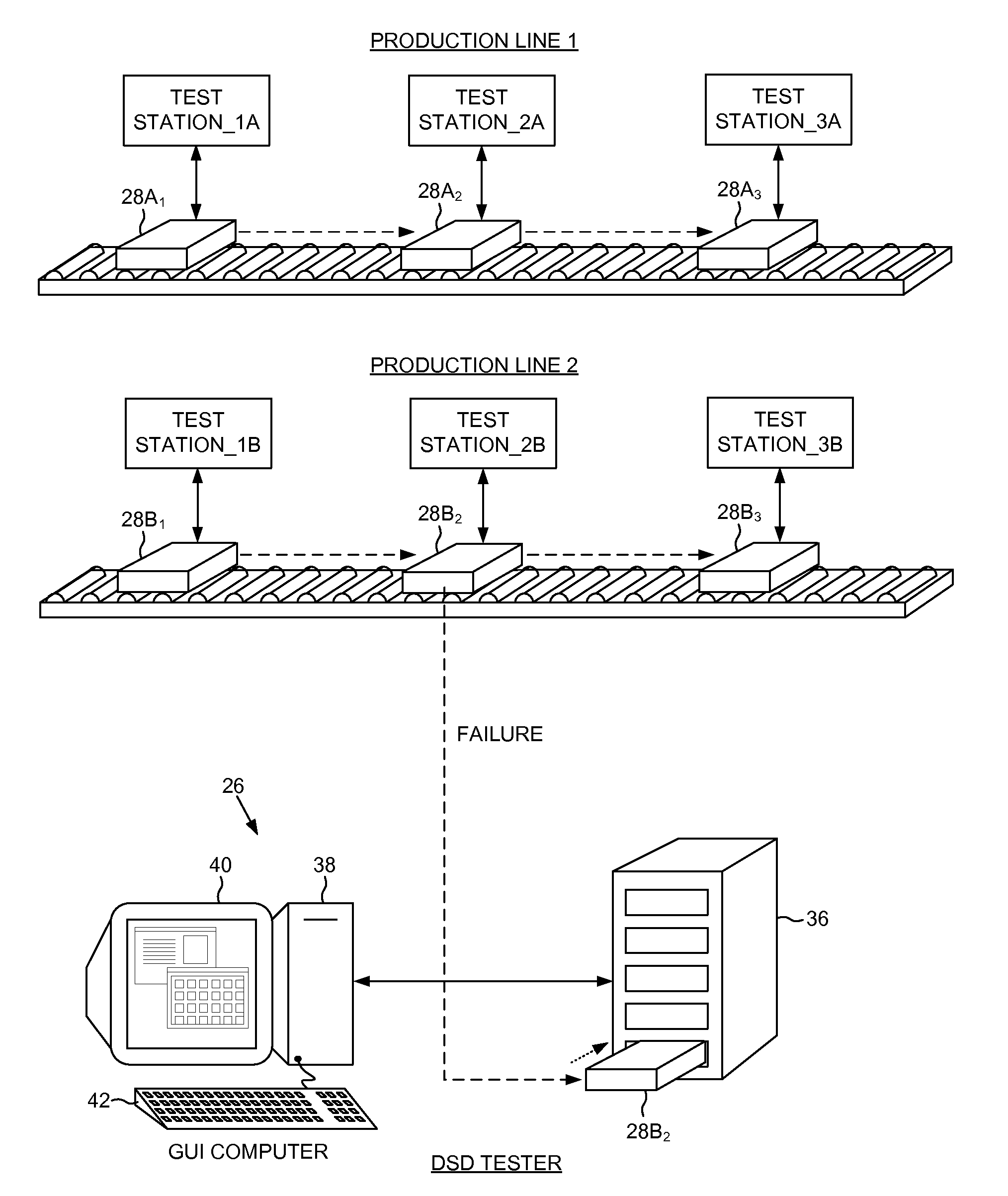

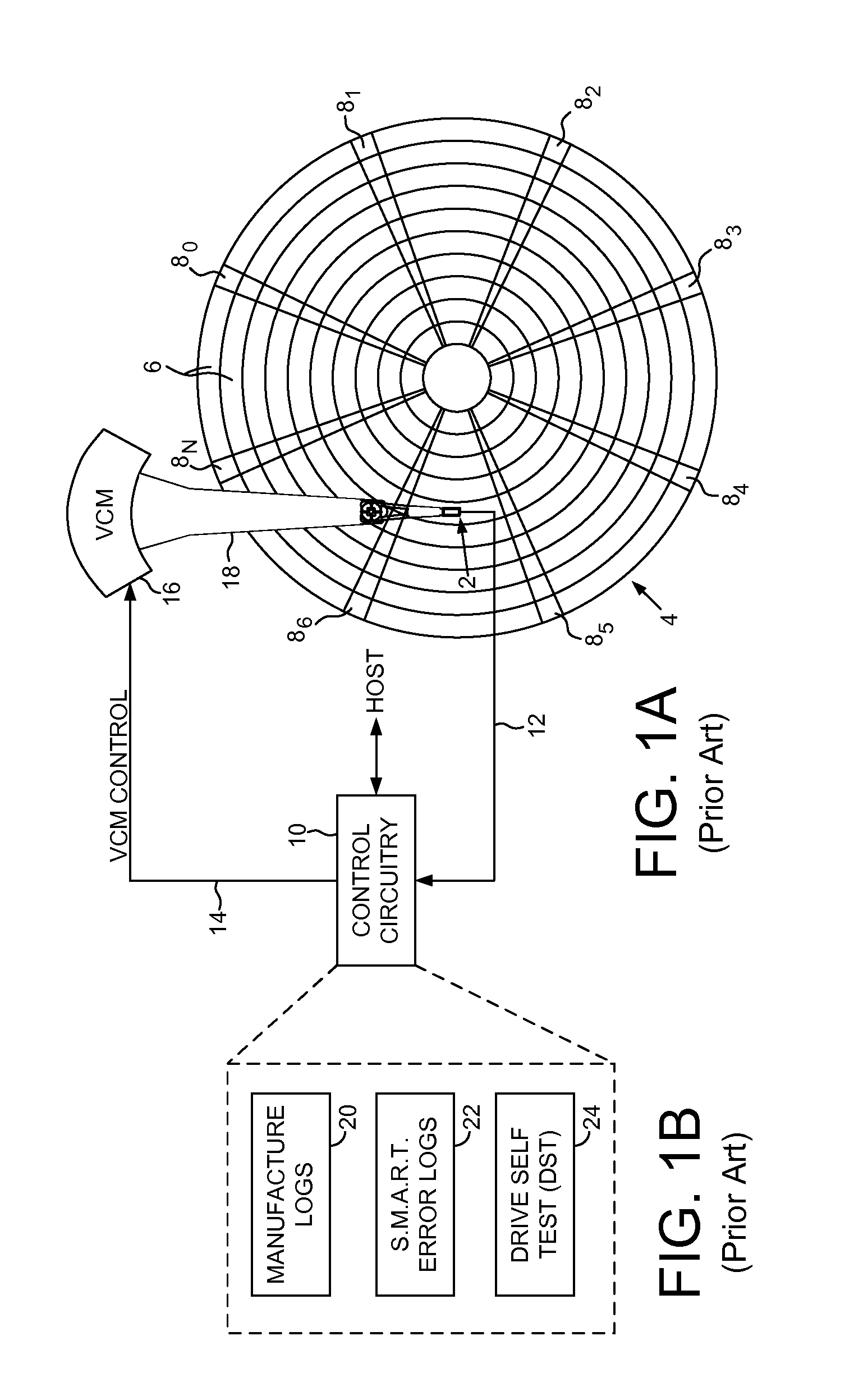

Data storage device tester

A data storage device (DSD) tester is disclosed for testing a DSD. The DSD tester comprises control circuitry operable to receive production line data through an interface, wherein the production line data is related to the DSD. The control circuitry executes a DSD test on the DSD, and transmits failure data generated by the DSD test and the production line data to a failure information database.

Owner:WESTERN DIGITAL TECH INC

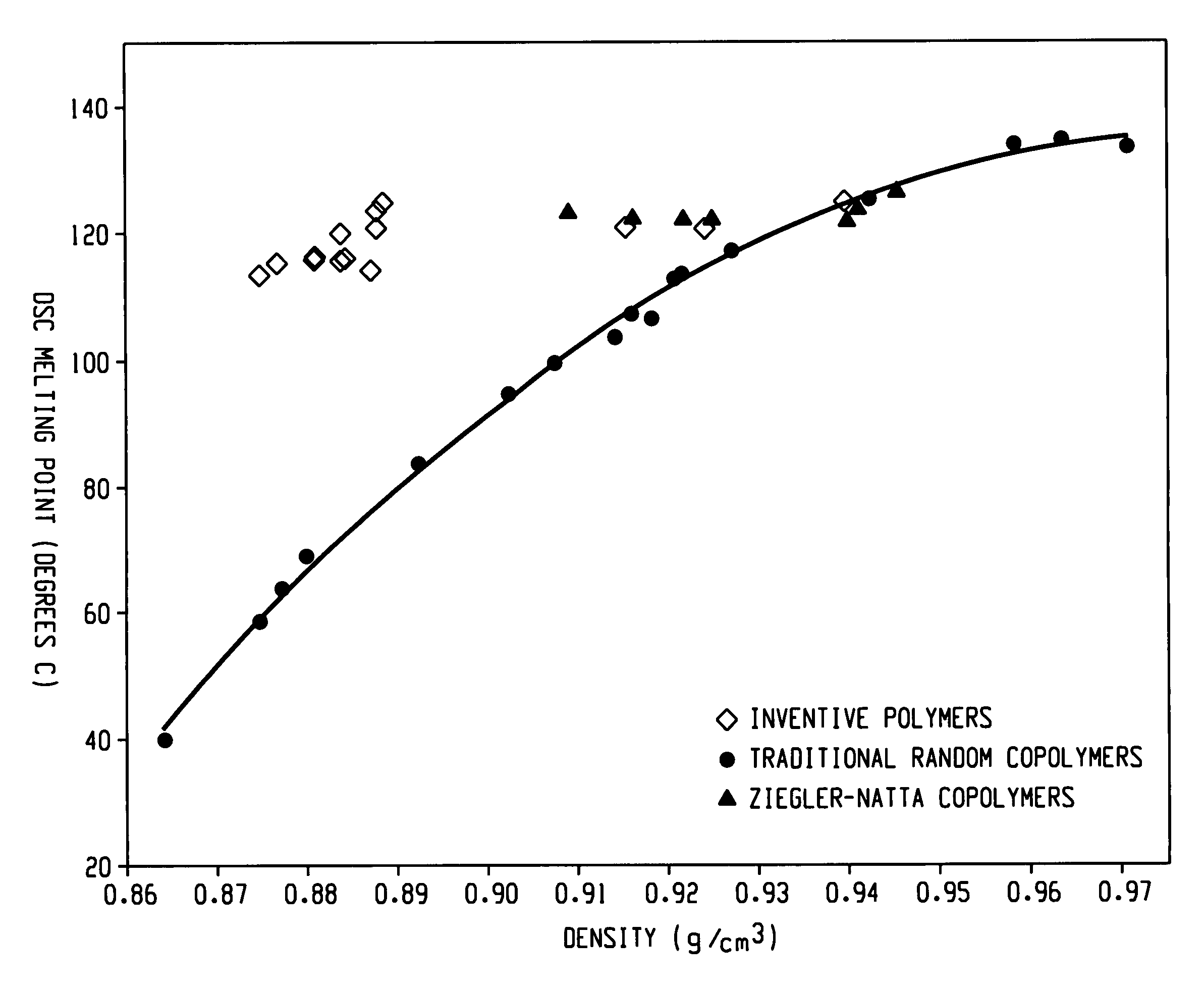

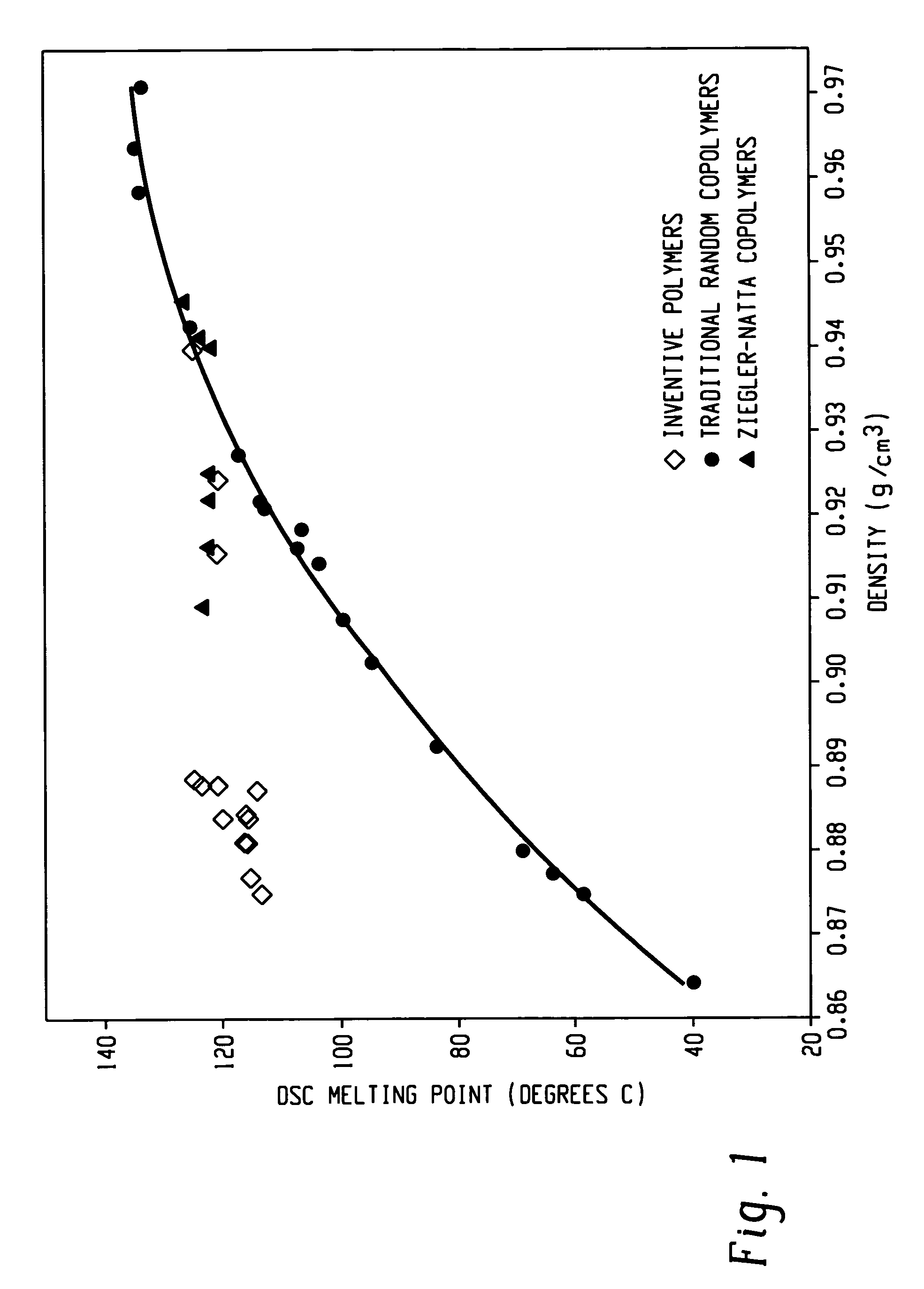

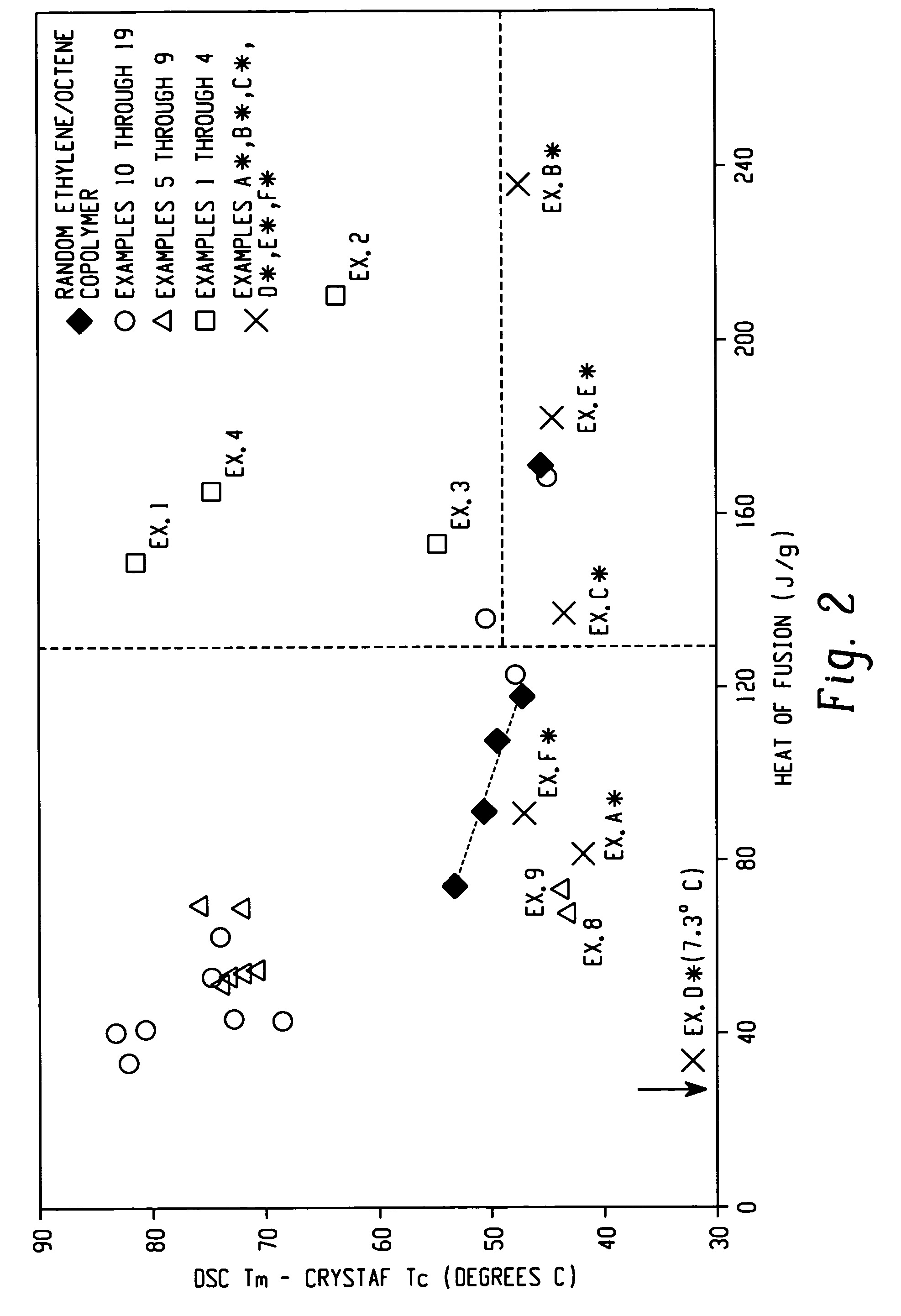

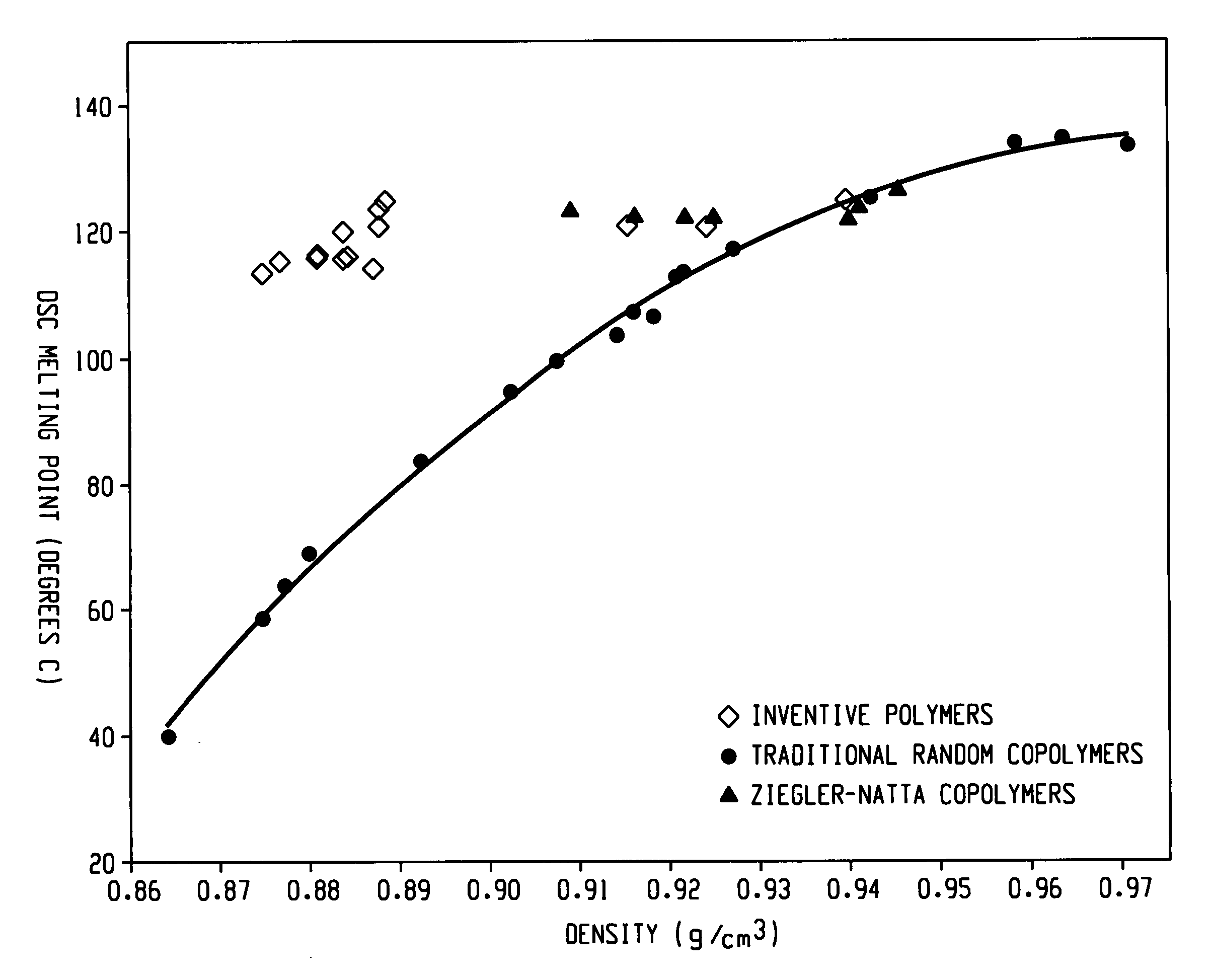

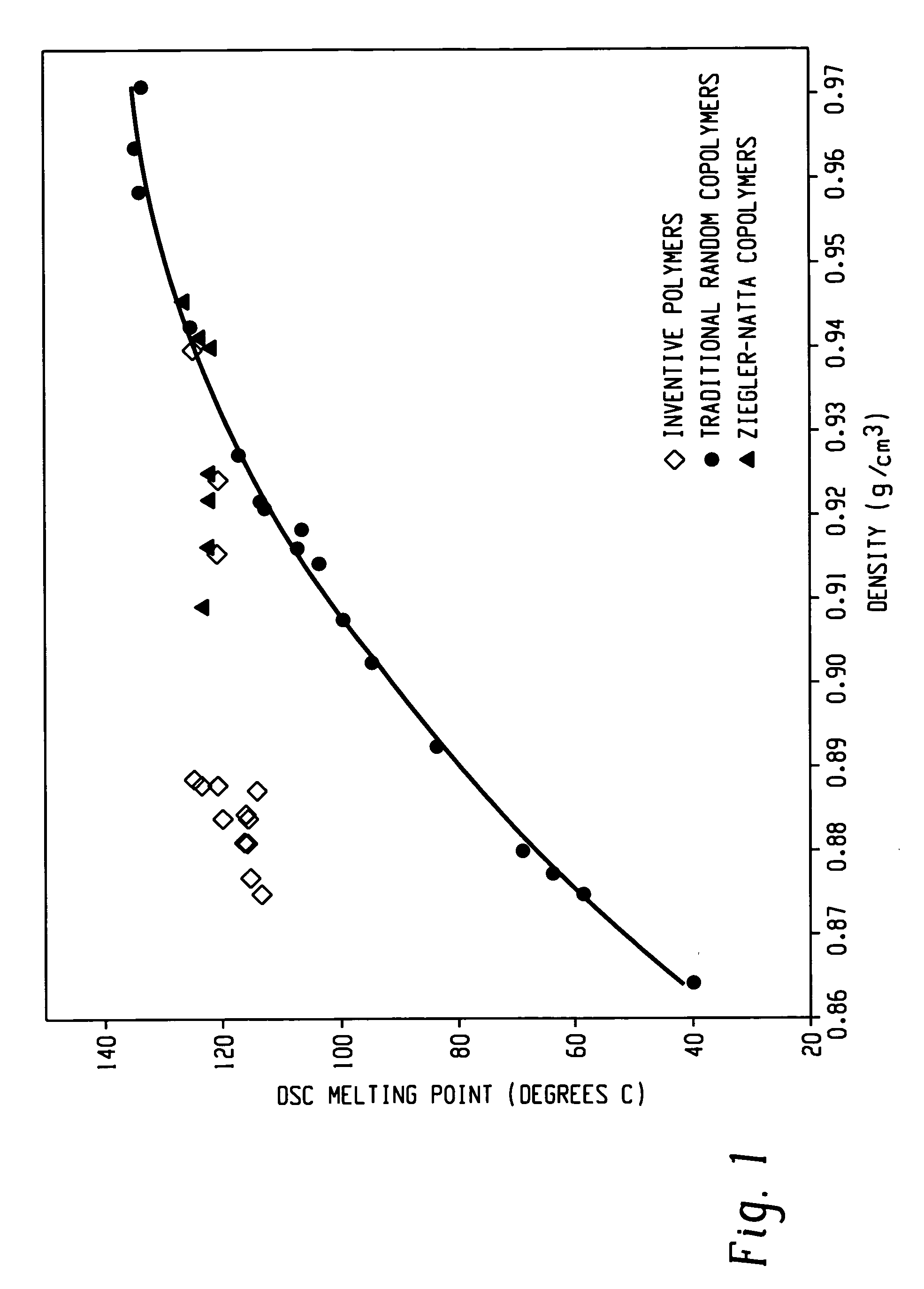

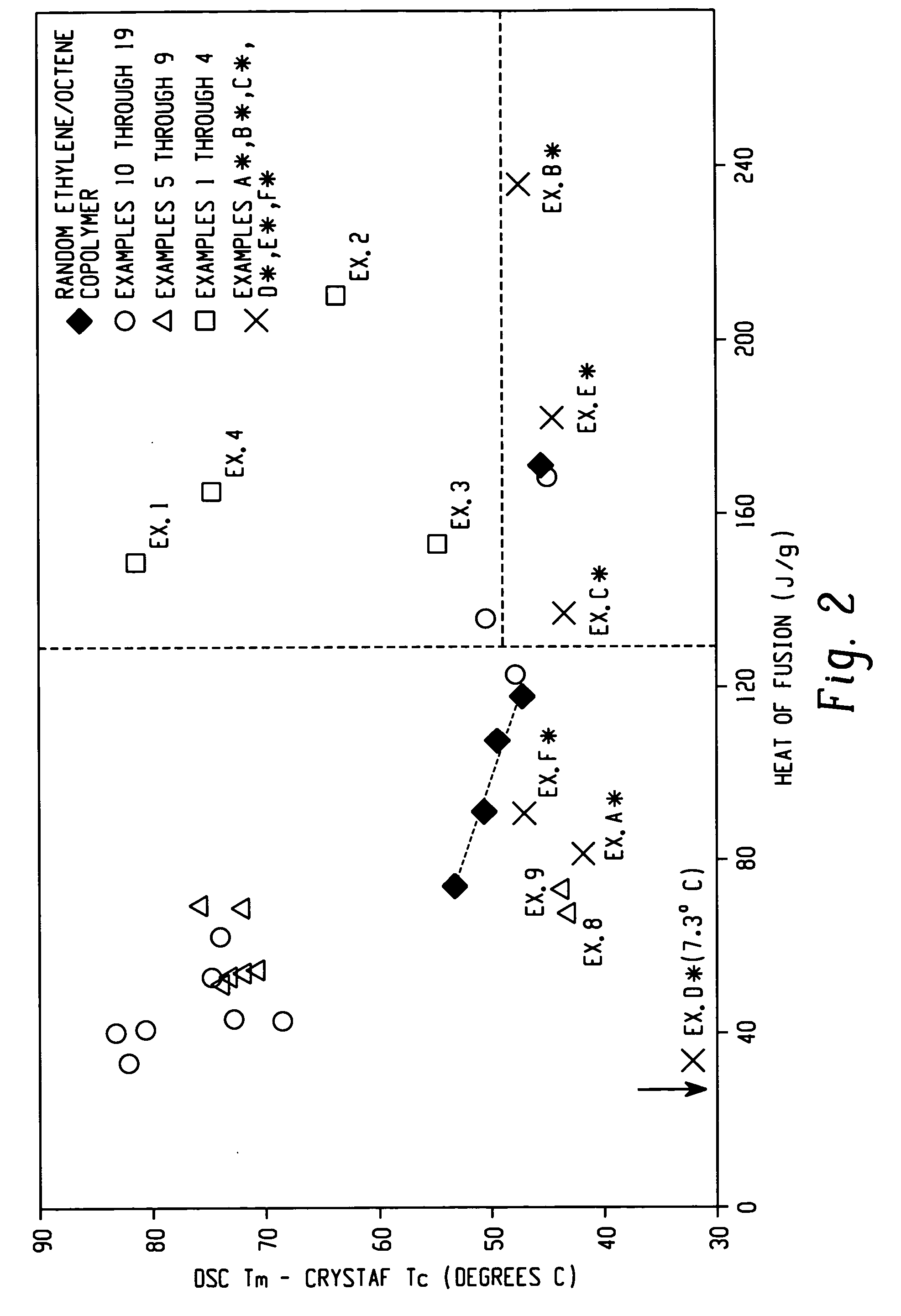

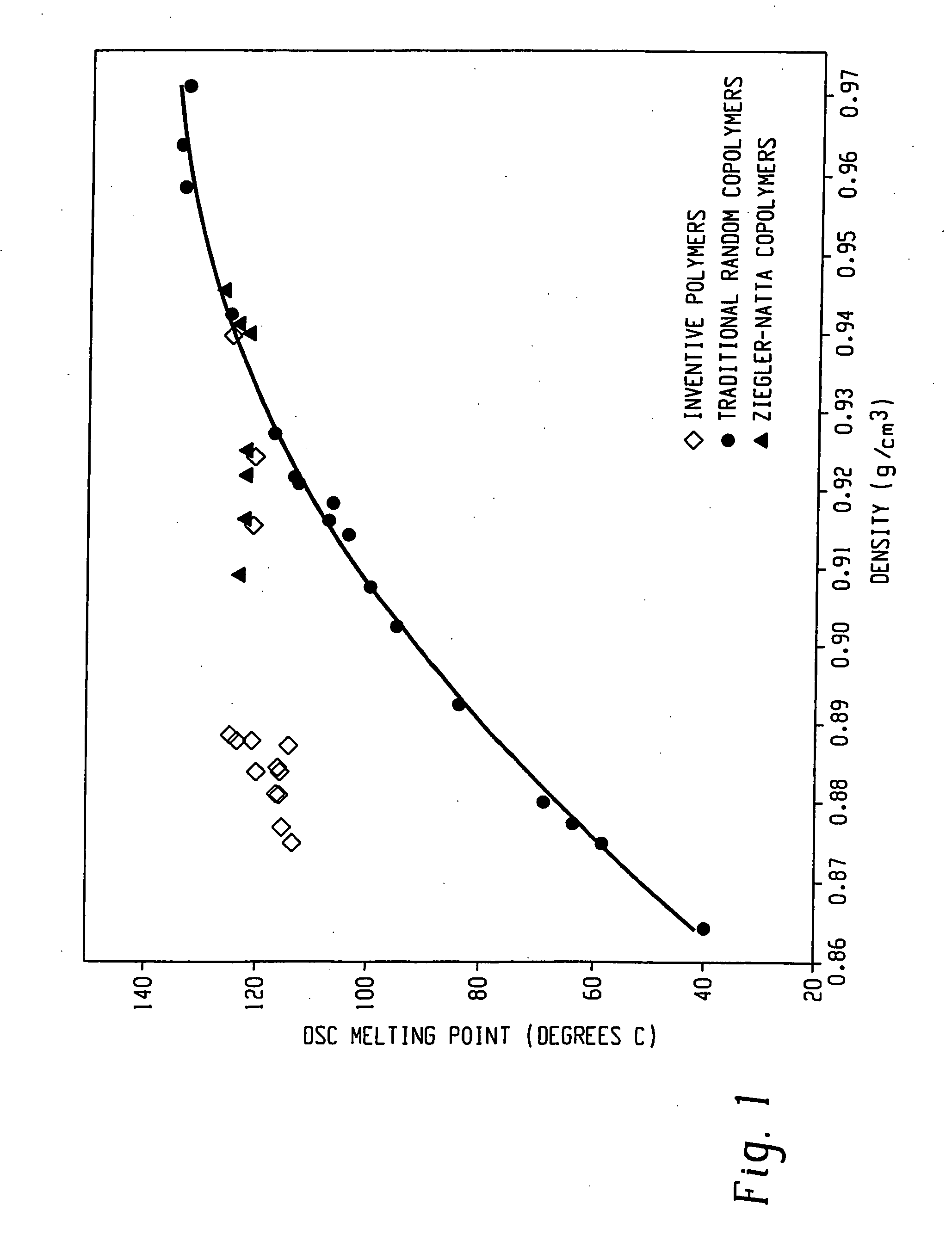

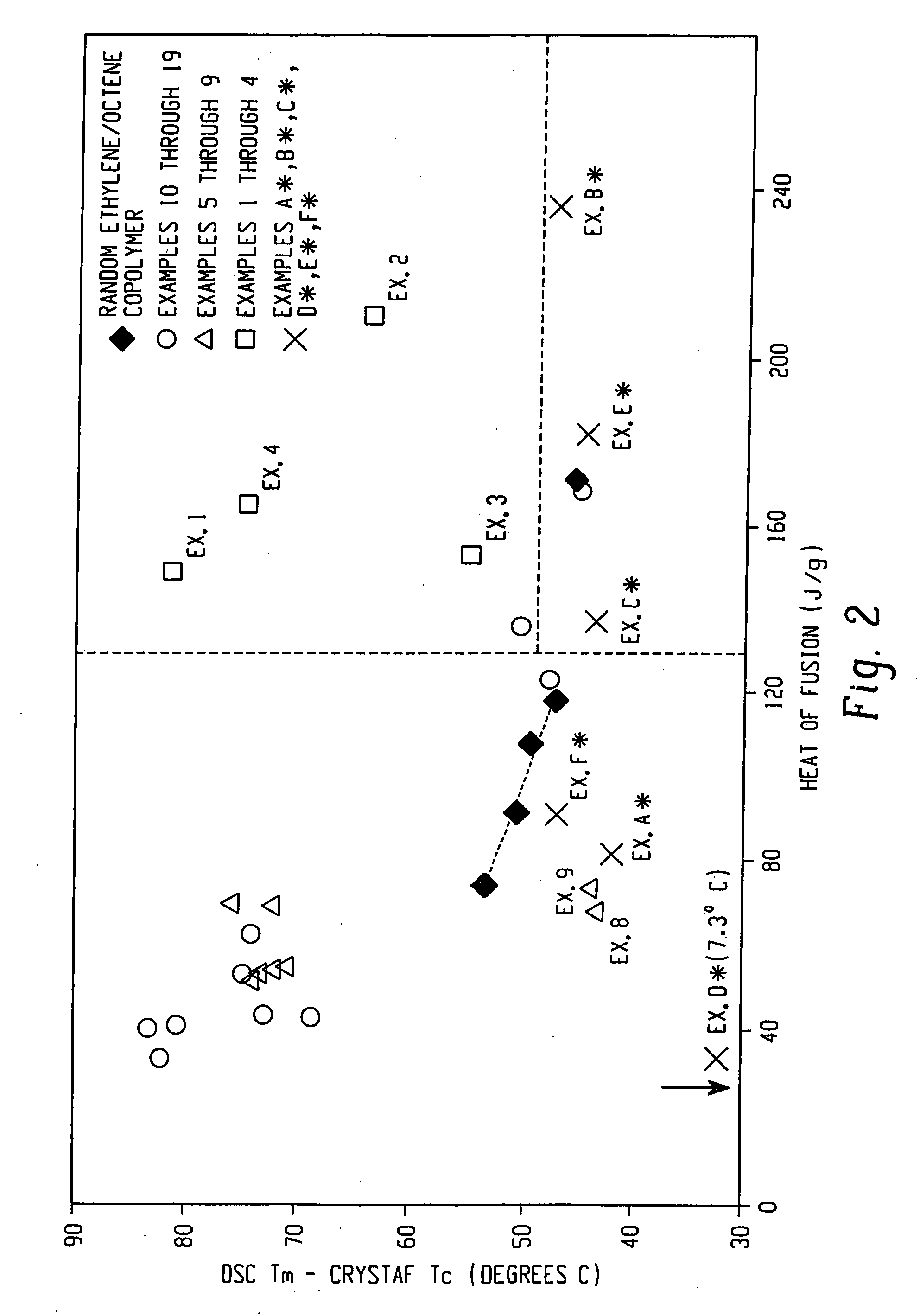

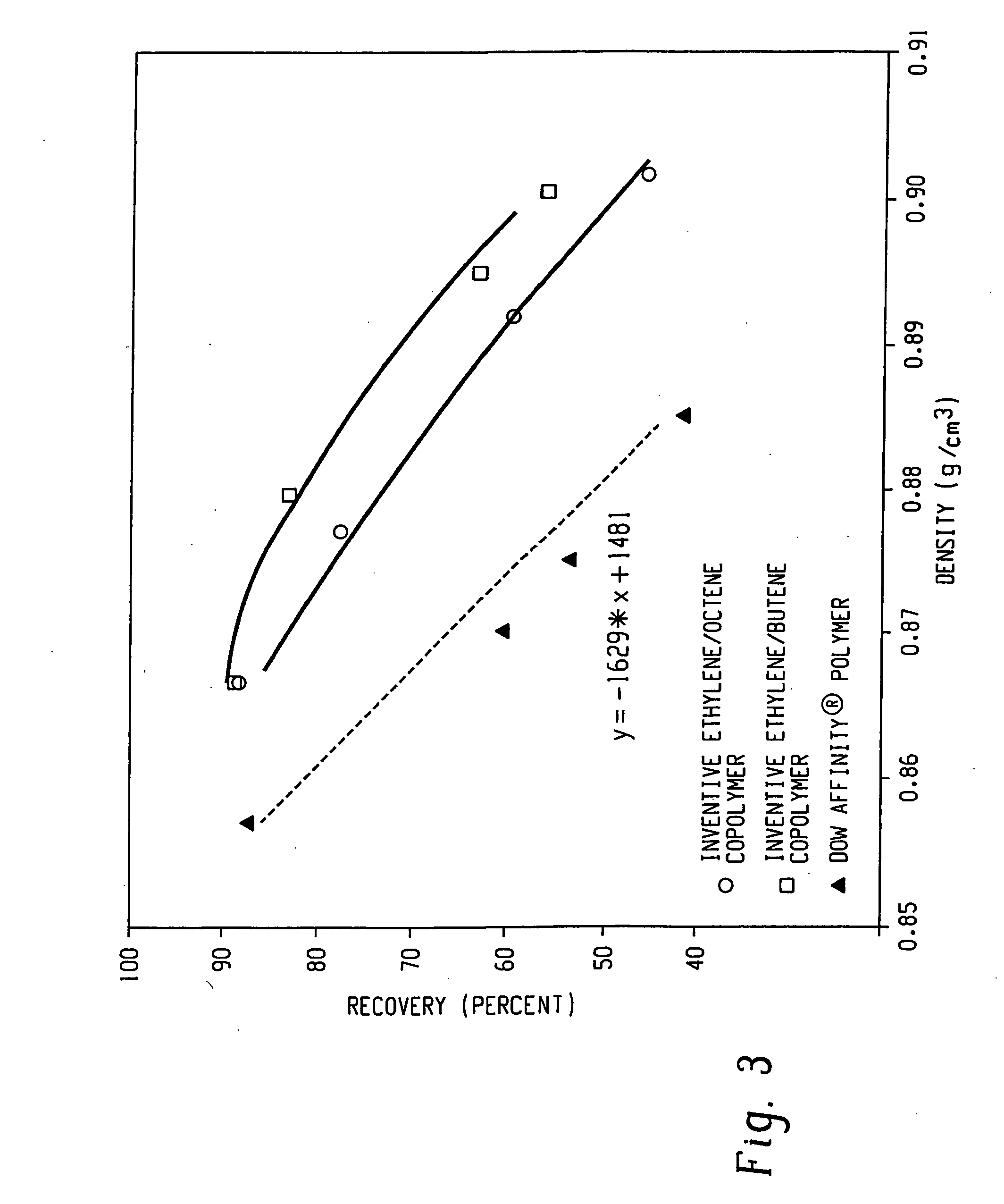

Compositions of ethylene/alpha-olefin multi-block interpolymer for elastic films and laminates

This invention relates to polyolefin compositions. In particular, the invention pertains to elastic polymer compositions that can be more easily processed on cast film lines, extrusion lamination or coating lines due to improved resistance to draw resonance. The compositions of the present invention preferably comprise an elastomeric polyolefin resin and a high pressure low density type resin.

Owner:DOW GLOBAL TECH LLC

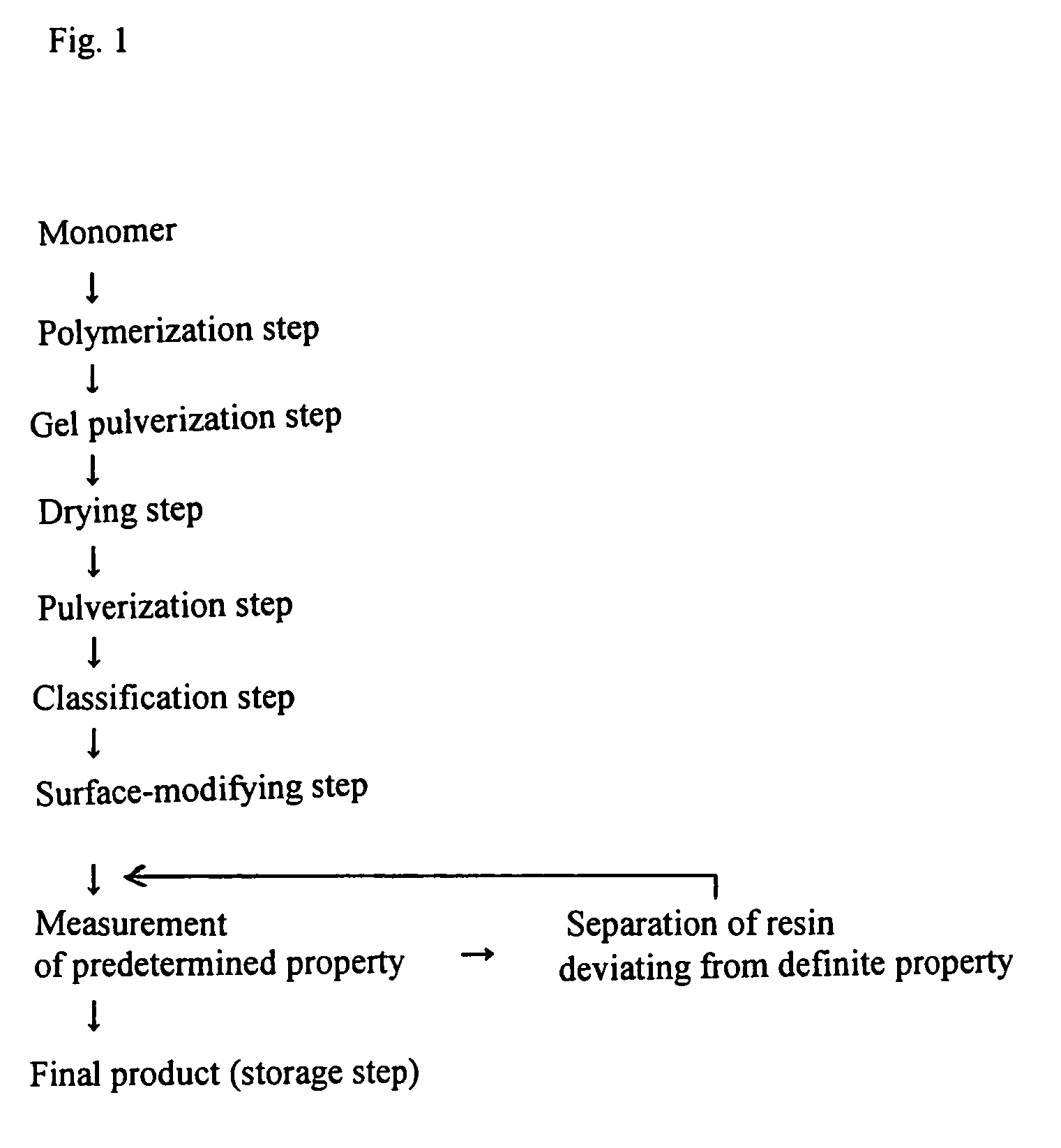

Process for continuous production of water-absorbent resin product

ActiveUS7193006B2Quality improvementHigh propertySynthetic resin layered productsCellulosic plastic layered productsProduction linePolymer science

There is disclosed a process for continuous production of a water-absorbent resin product by which the water-absorbent resin product having high properties can continuously be produced easily and inexpensively with stable constant quality. In addition, there is disclosed a water-absorbent resin product having high properties and being stable in quality. The process comprises the following steps of: (A) measuring a water-absorbent resin by its predetermined property and / or its predetermined component content, wherein the water-absorbent resin comes being continuously produced via a classification step and / or a surface-modifying step; (B) separating a predetermined amount of water-absorbent resin (a) from the water-absorbent resin that comes being continuously produced, wherein the water-absorbent resin (a) is a water-absorbent resin which displays not less than a definite value and / or a water-absorbent resin which displays not more than a definite value as to the predetermined property and / or the predetermined component content in accordance with results of the aforementioned measurement; and (C) mixing at least a portion of the aforementioned separated predetermined amount of water-absorbent resin (a) into a water-absorbent resin that comes being continuously produced via a classification step and / or a surface-modifying step on the same or another production line.

Owner:NIPPON SHOKUBAI CO LTD

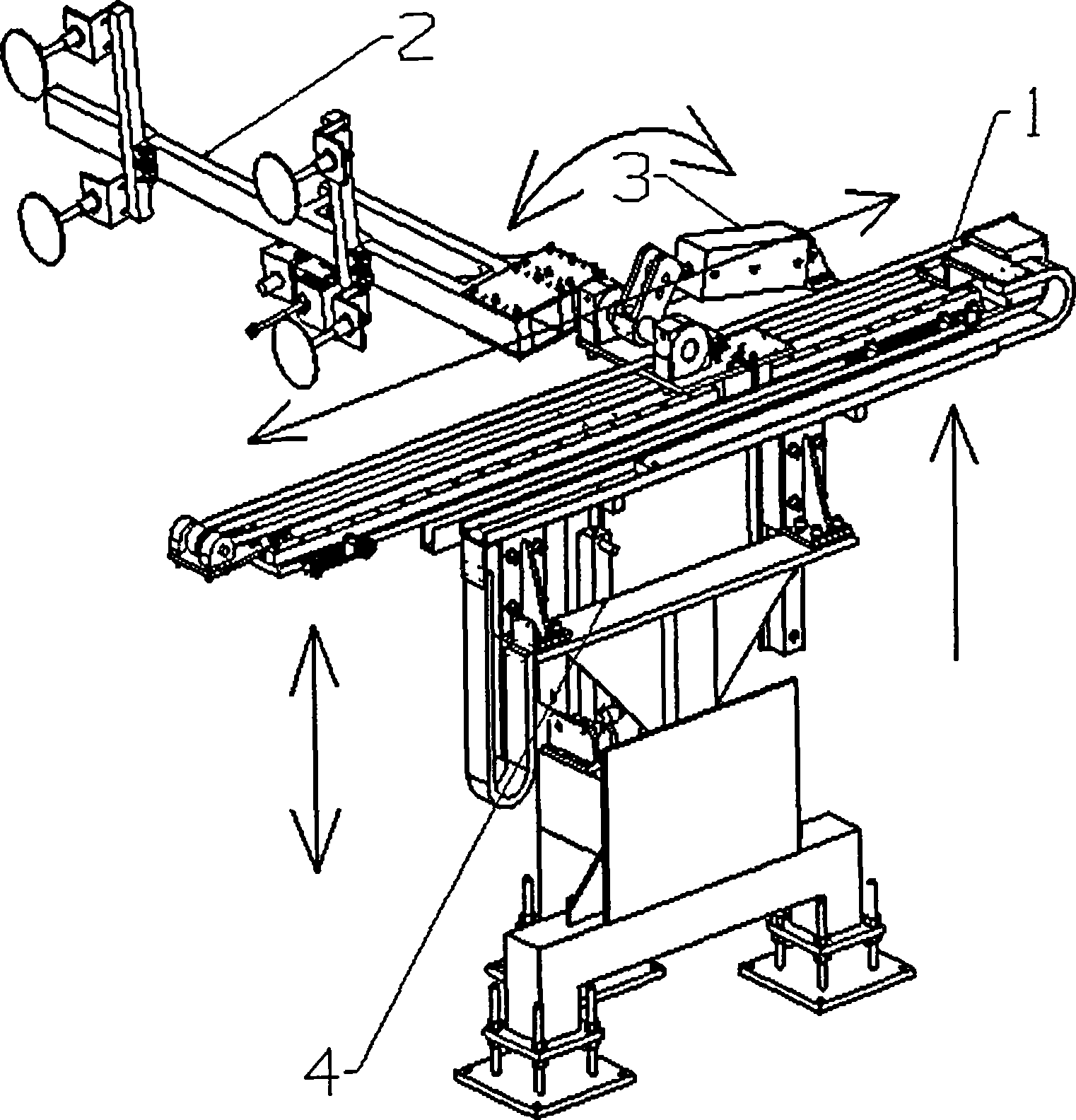

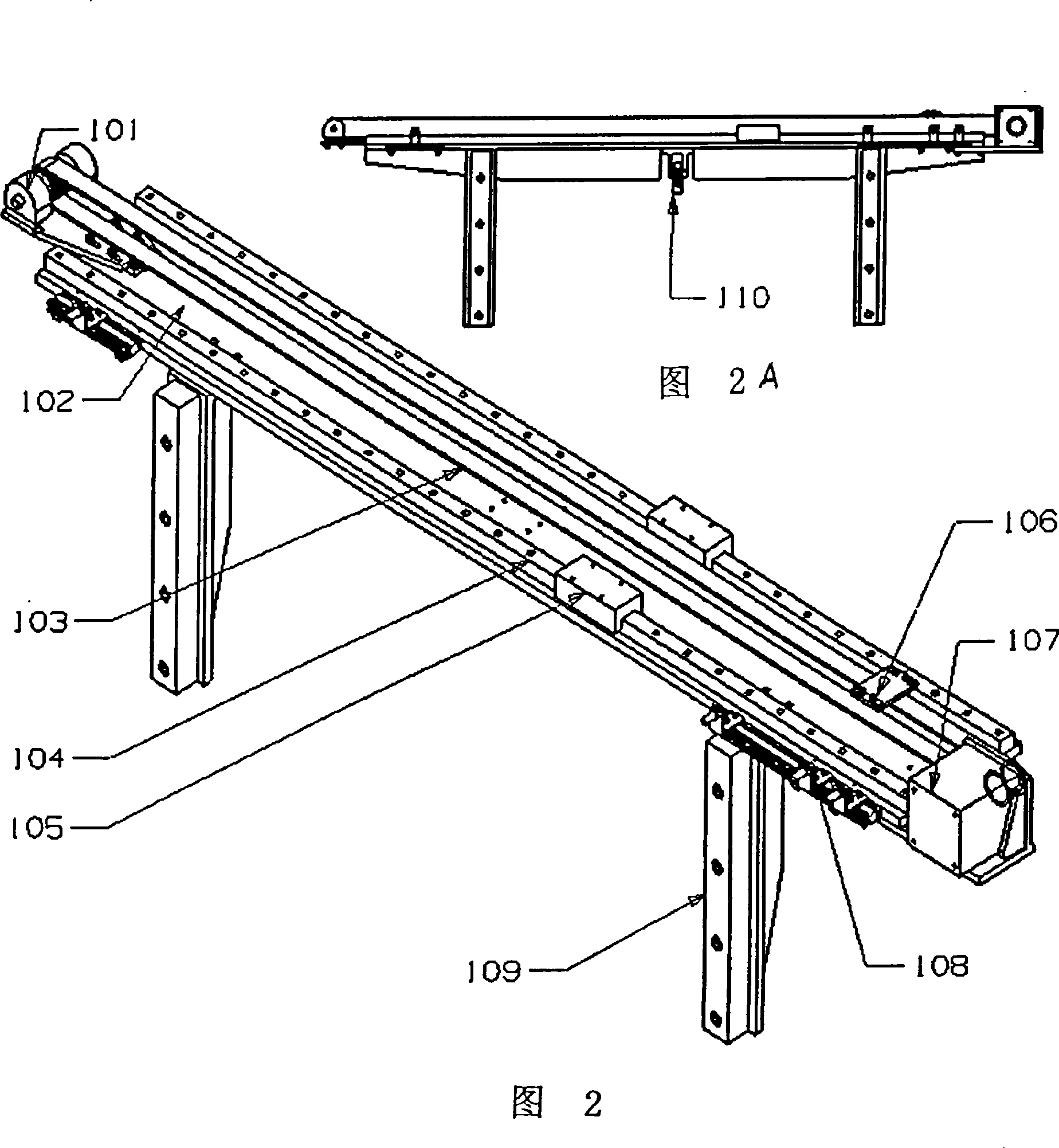

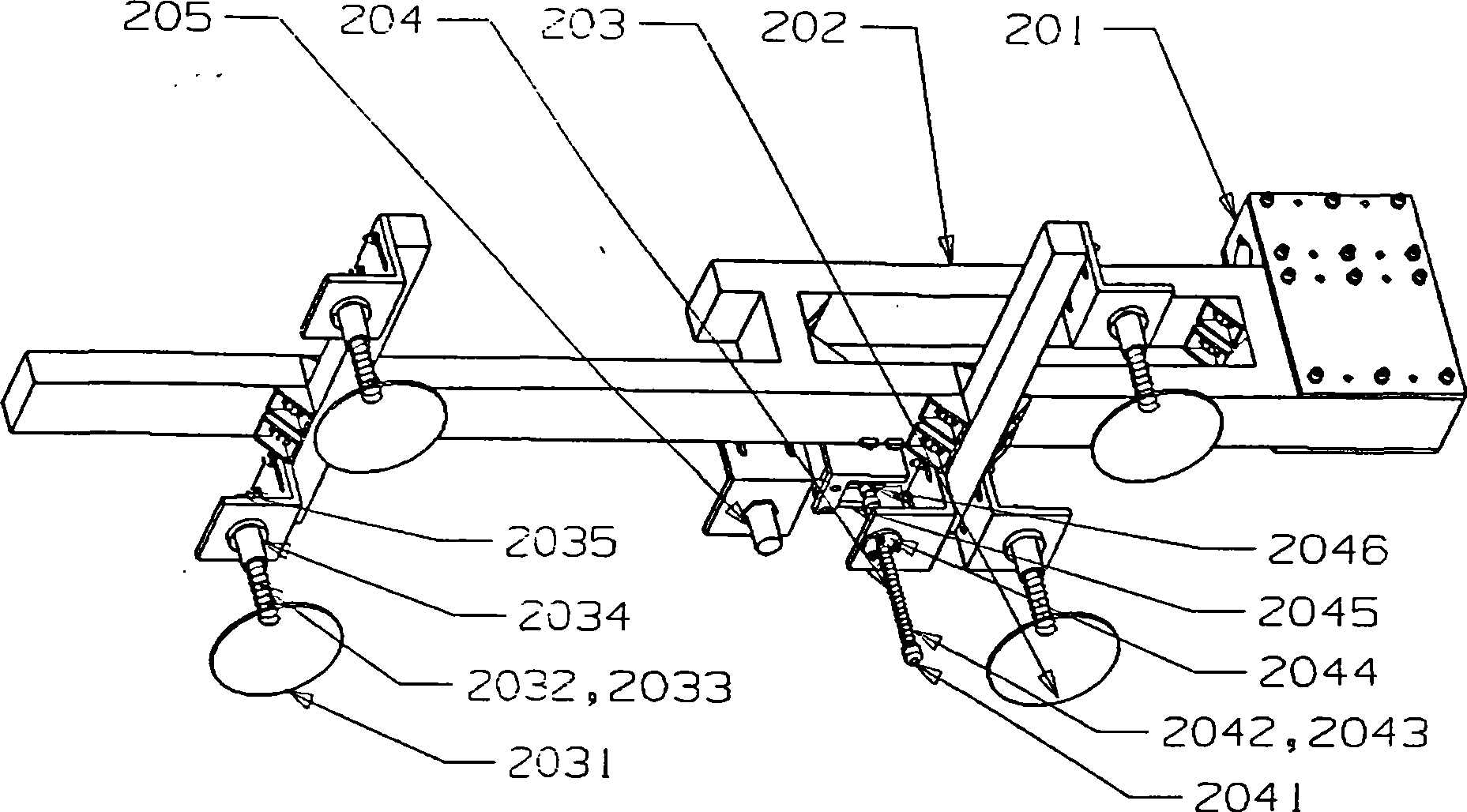

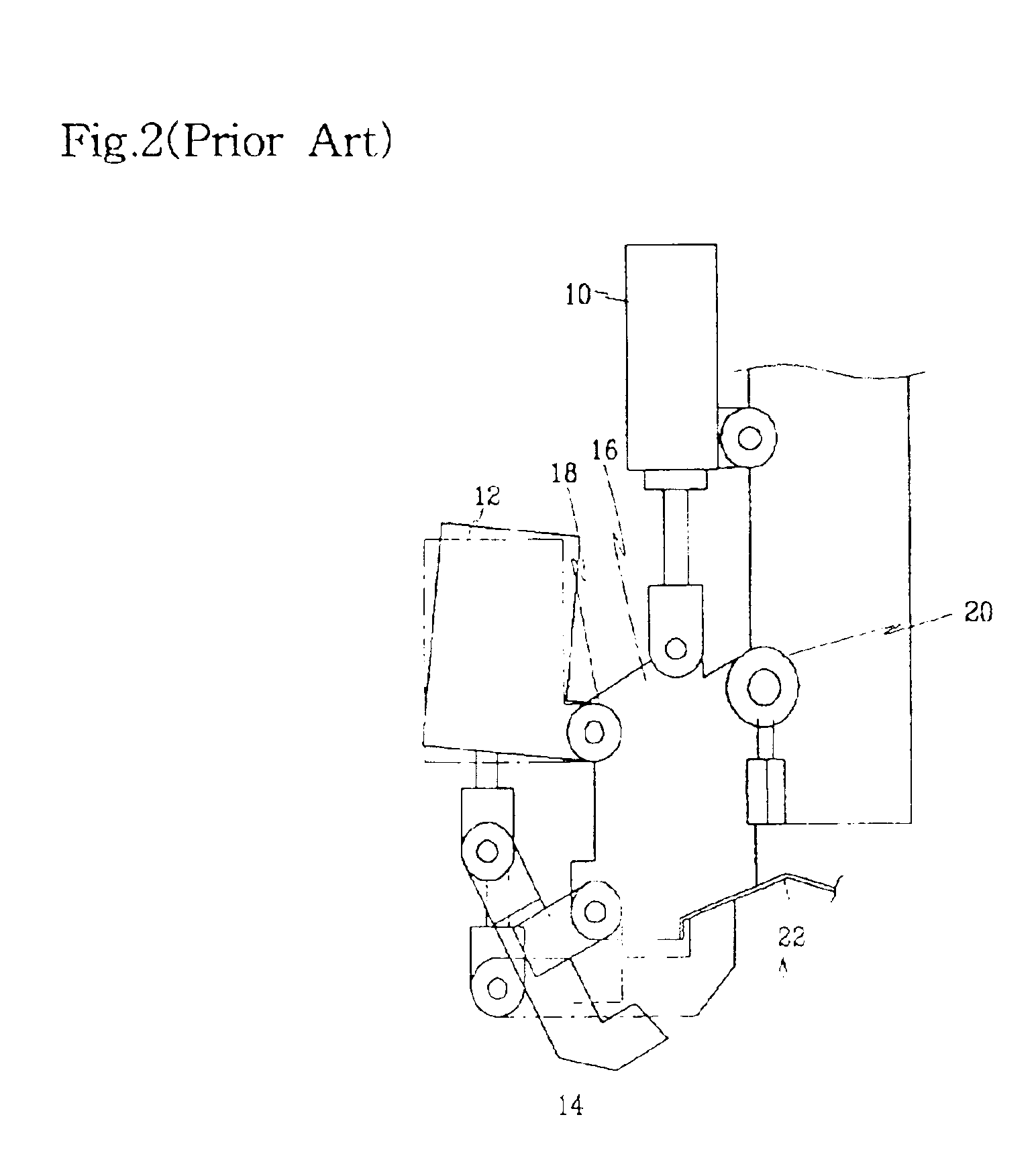

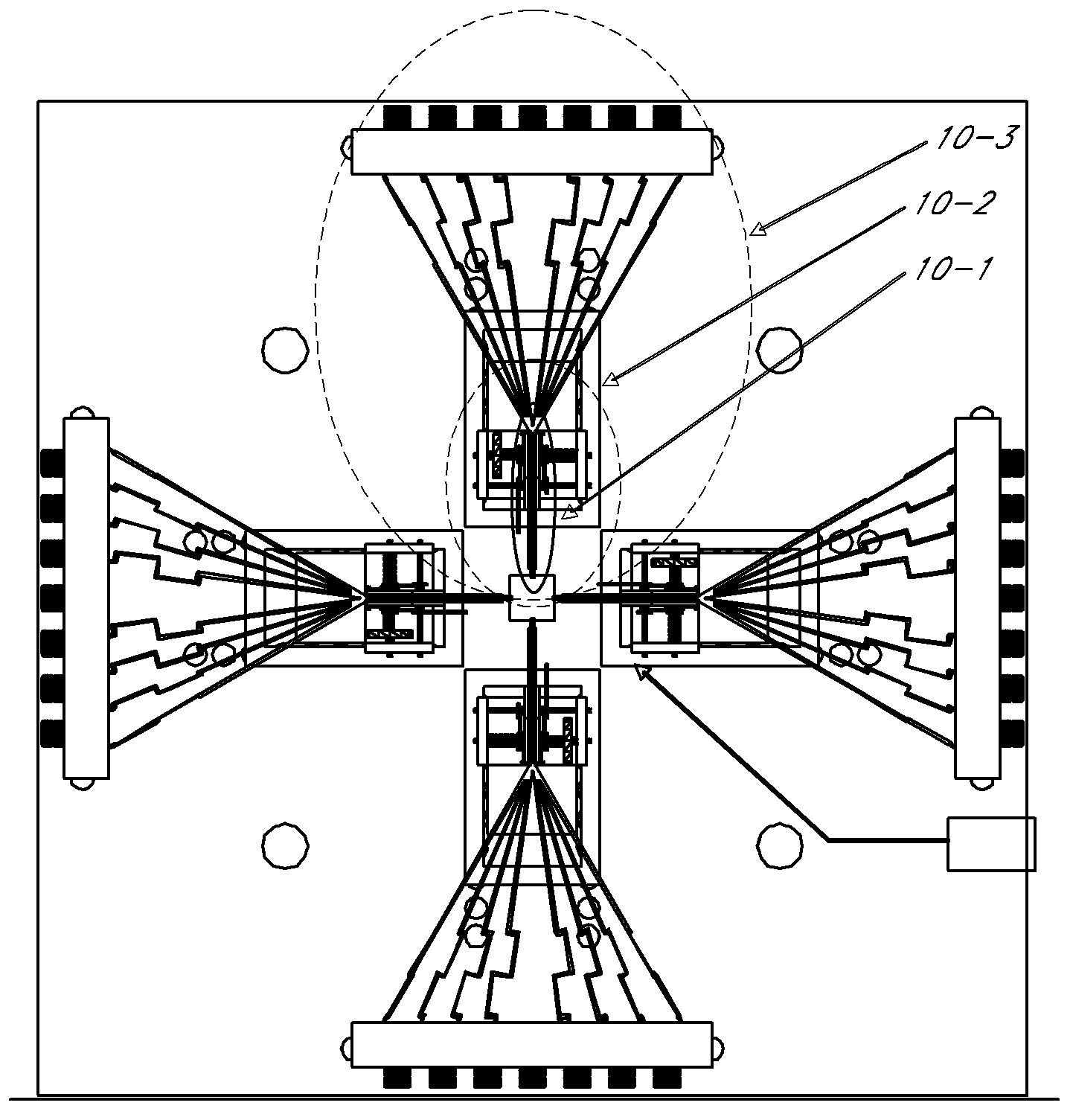

Automatic original-glass fetching manipulator of automobile glass pre-treatment production line

InactiveCN101417422ADecrease productivityExtended duty cycleProgramme-controlled manipulatorJointsRotational axisProduction line

The invention relates to an automatic loading machine hand of car glass pre-treatment production lines, comprising a driving mechanism platform, a grabbing arm and a sense touch mechanism, an arm rotary mechanism and a rising and falling buffering mechanism; wherein, the driving mechanism platform is arranged on the rising and falling buffering mechanism which consists of 3 three-foot single-leg frames; the grabbing arm and the sense touch mechanism are connected with a rotation axis of the arm rotary mechanism. The invention has the advantages that the rising and falling movements along a Z shaft direction are carried out by using a dual action cylinder to drive the driving mechanism platform to move from left to right along an X shaft direction, when rising, the grabbing glass is lifted by 300mm so as to separate glass on a stacking frame and avoid a ledge on the stacking frame; when falling, the grabbing glass is led to fall by 300mm to put the glass on a conveyer moving in a Y shaft direction; the device is delicate and aesthetic in shape, and small in occupation space; the design concept is innovative, novel, practical and prospective; the structure is simple; therefore, the machine hand can be easily made, assembled, and programmed and the manufacturing price is low.

Owner:上海耀皮康桥汽车玻璃有限公司

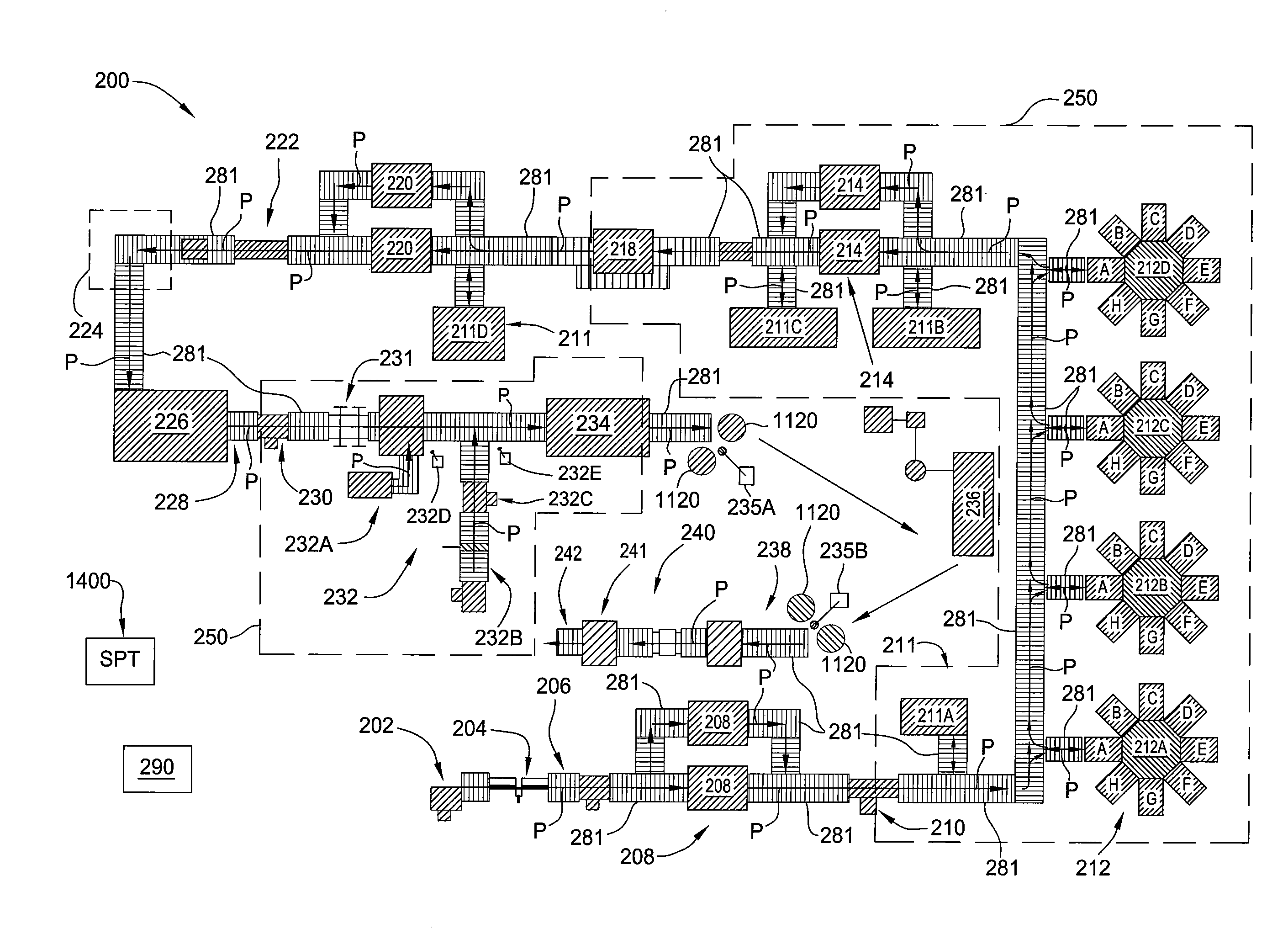

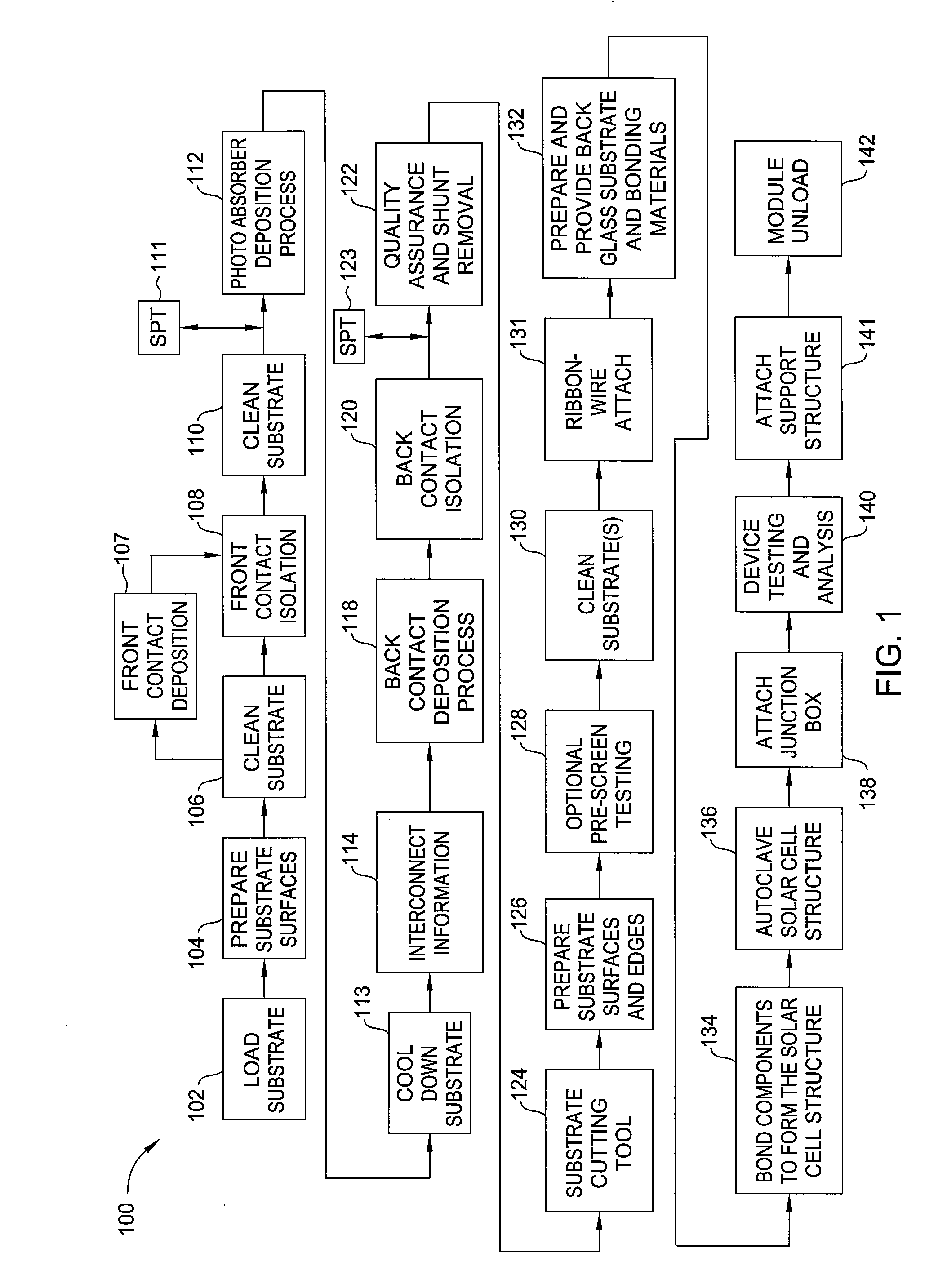

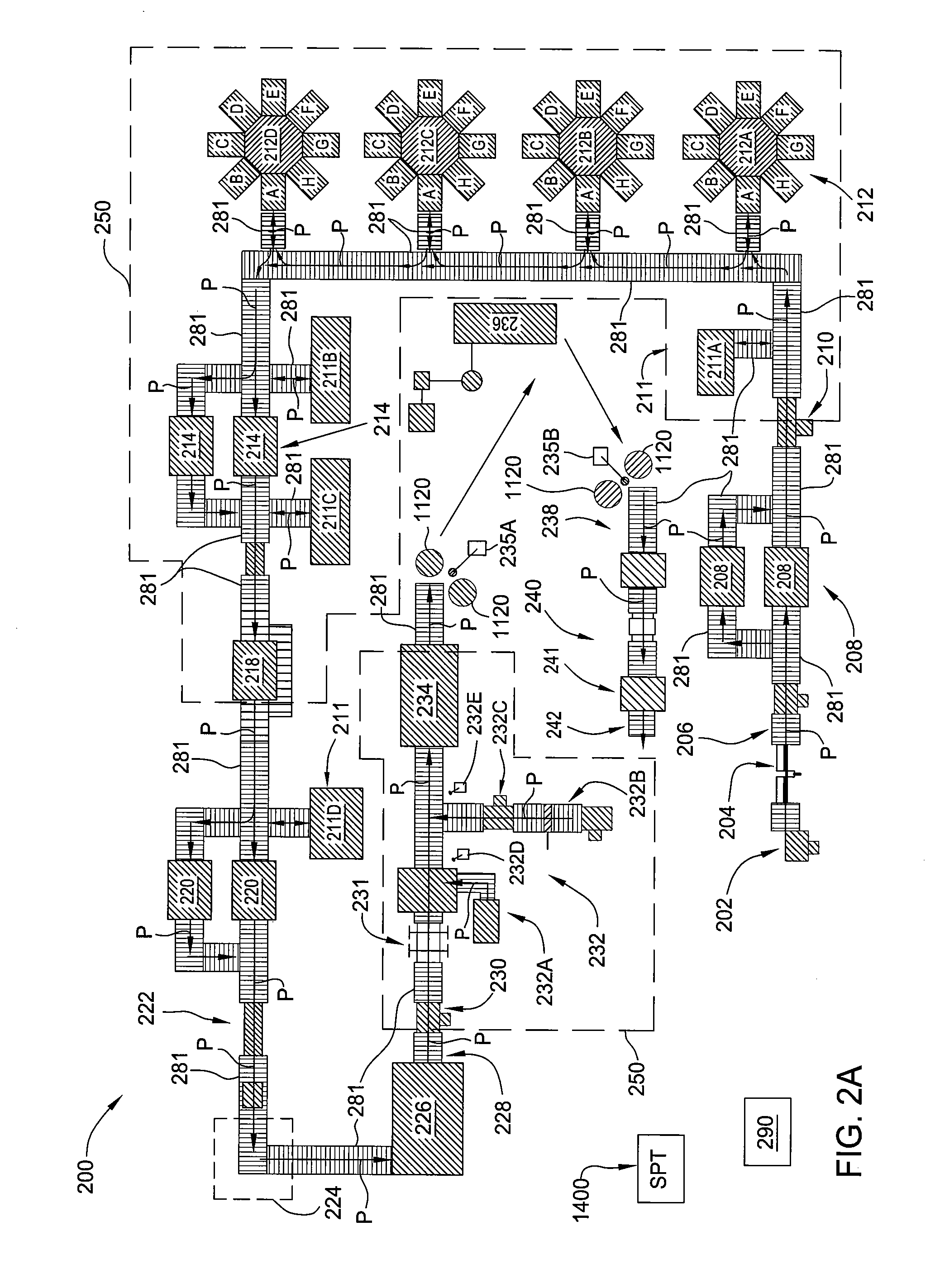

Photovoltaic production line

InactiveUS20090077805A1Improve bindingPhotovoltaic monitoringWave amplification devicesProduction lineQuality assurance

The present invention generally relates to a system that can be used to form a photovoltaic device, or solar cell, using processing modules that are adapted to perform one or more steps in the solar cell formation process. The automated solar cell fab is generally an arrangement of automated processing modules and automation equipment that is used to form solar cell devices. The automated solar fab will thus generally comprise a substrate receiving module that is adapted to receive a substrate, one or more absorbing layer deposition cluster tools having at least one processing chamber that is adapted to deposit a silicon-containing layer on a surface of the substrate, one or more back contact deposition chambers, one or more material removal chambers, a solar cell encapsulation device, an autoclave module, an automated junction box attaching module, and one or more quality assurance modules that are adapted to test and qualify the completely formed solar cell device.

Owner:APPLIED MATERIALS INC

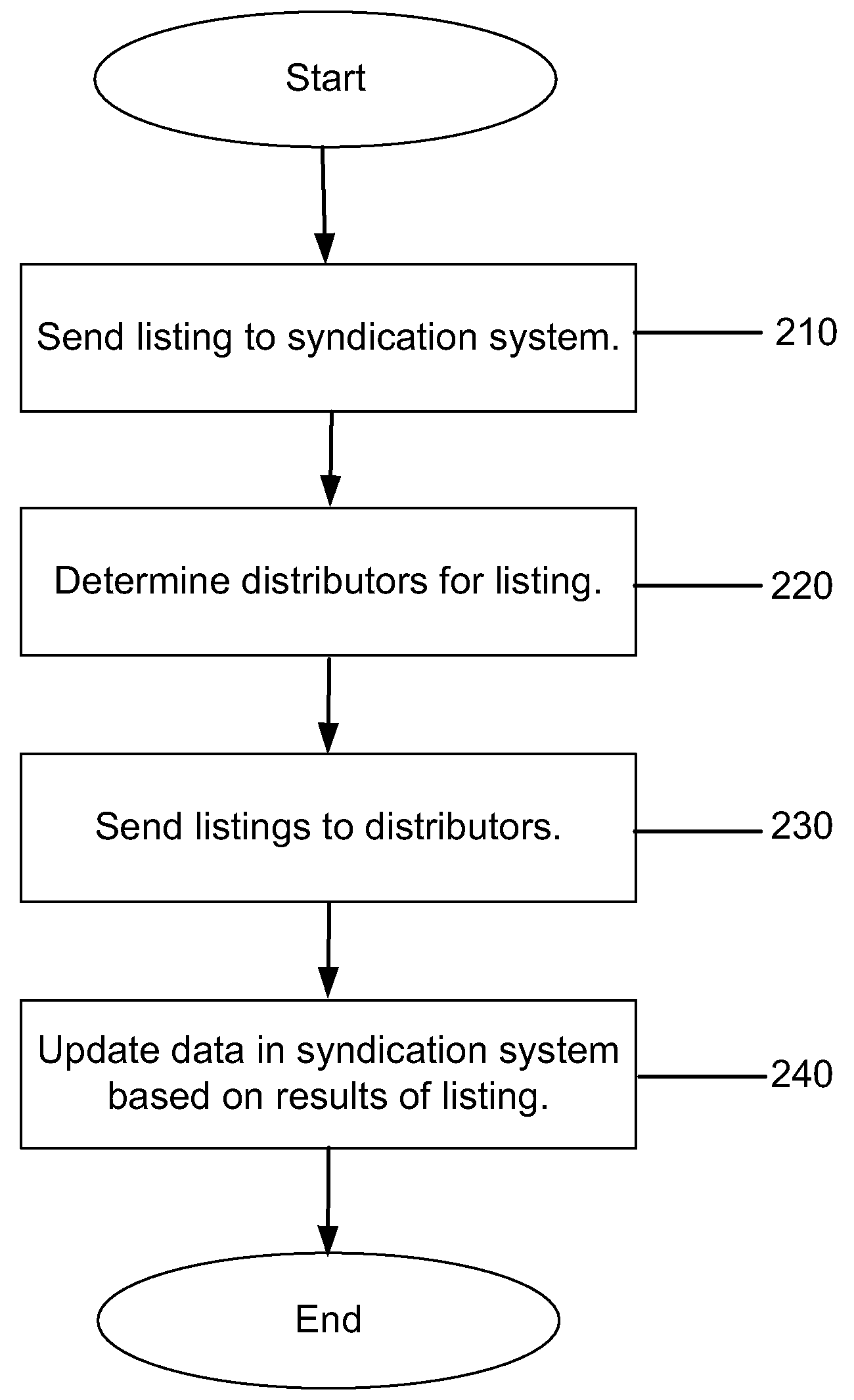

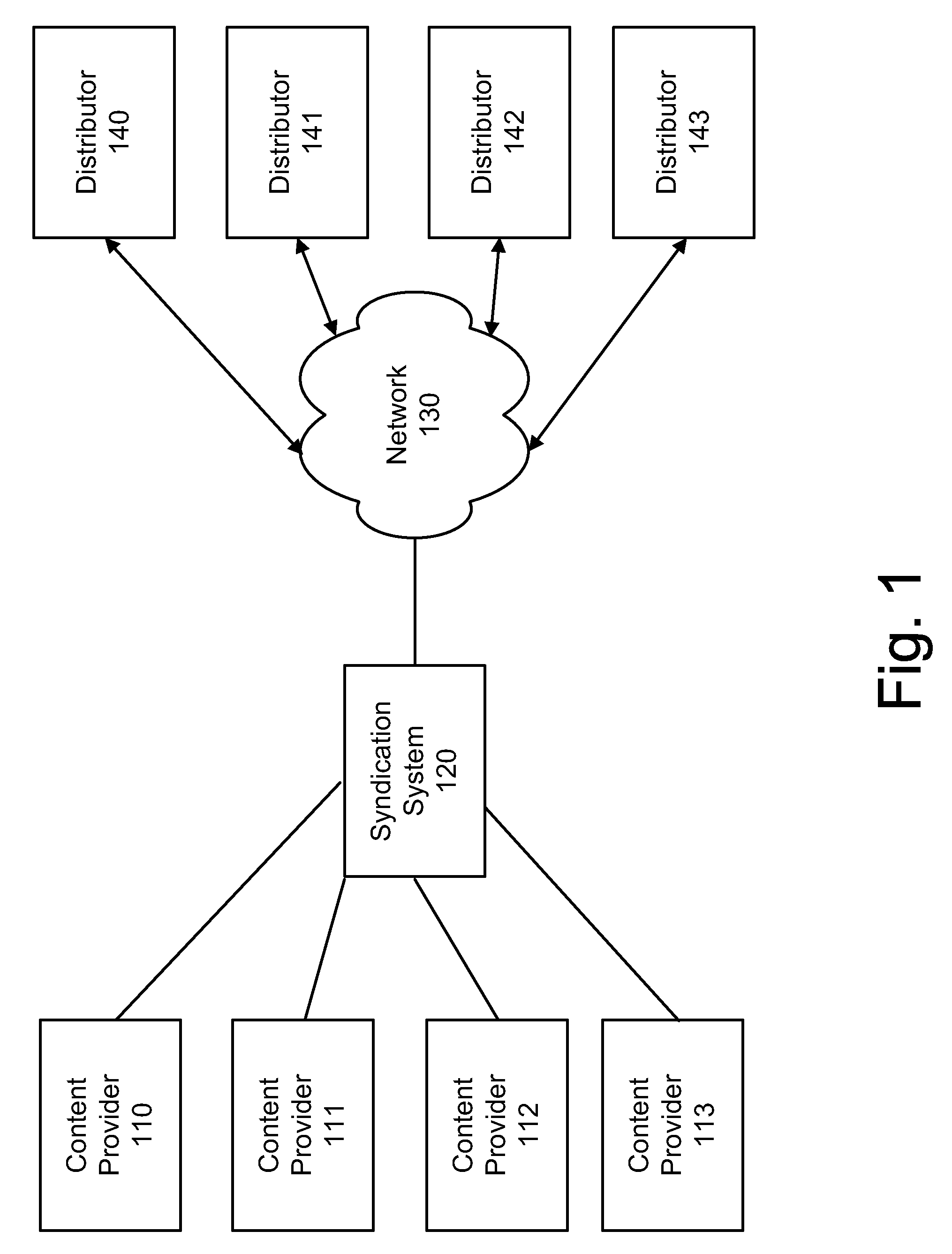

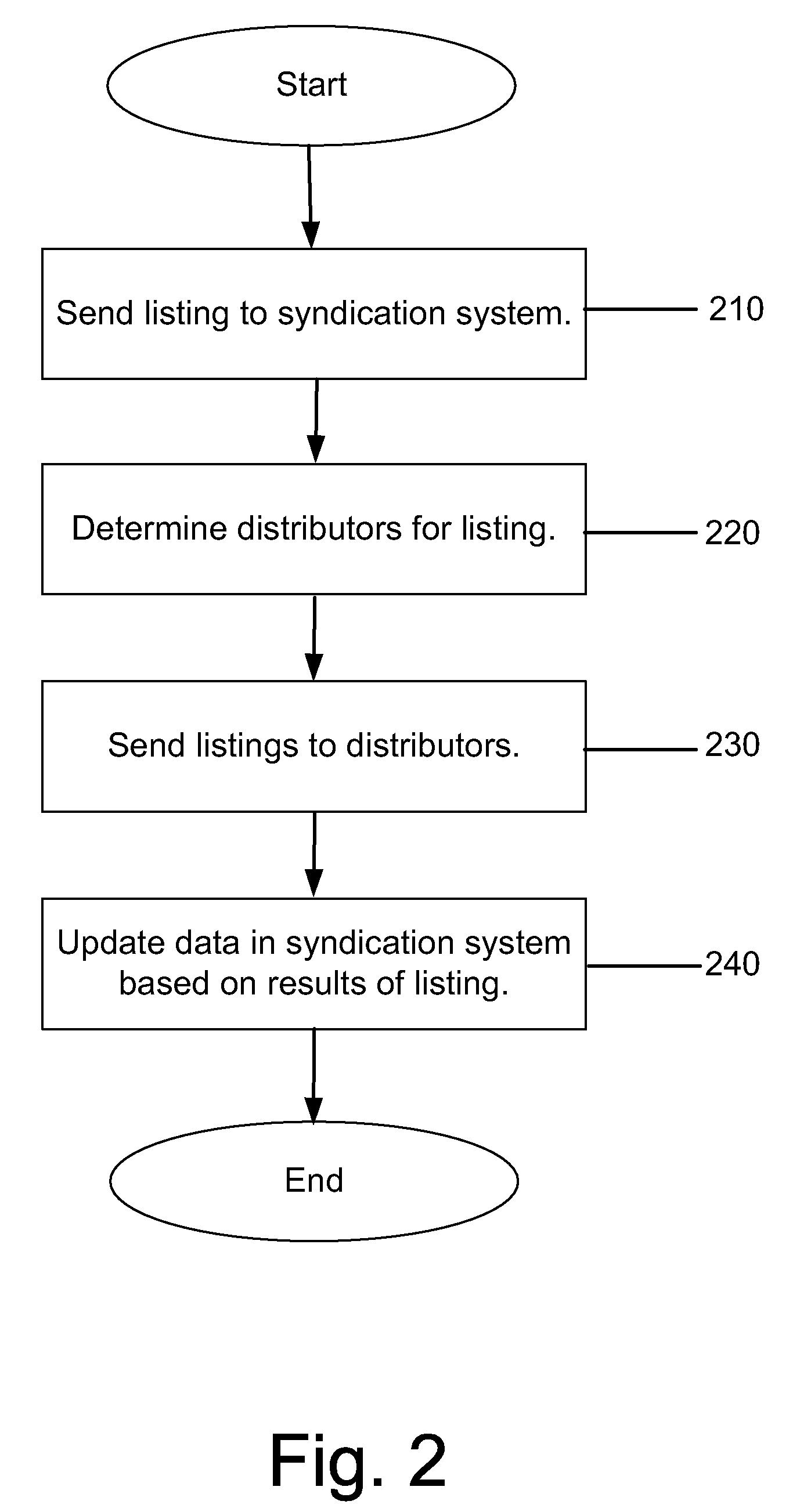

Syndication optimization system

InactiveUS20090012996A1Automate processingSpecial data processing applicationsMarketingProduction lineGranularity

Aspects of the present invention include automating the process of determining the optimal channels for syndicating content. The automation process can be based on a plurality of factors weighted in accordance with a user's preferences. A further aspect of the present invention calls for dynamically updating the process of channel selection by continually updating the data used in the decision making process. Aspects of the present invention allow a user to apply their chosen factors at various levels of granularity such as for individual products, product lines, category of products, or company-by-company.

Owner:OATH INC

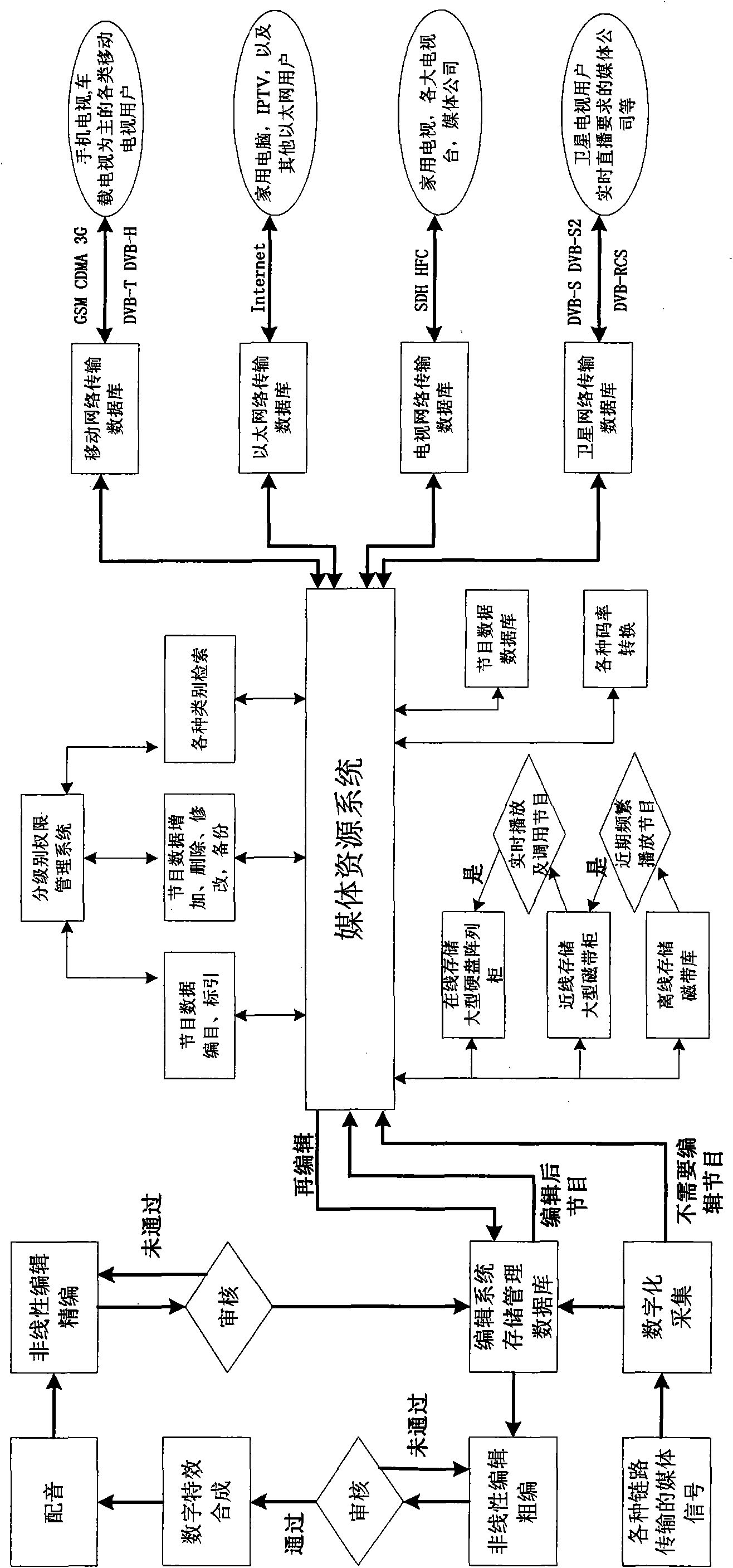

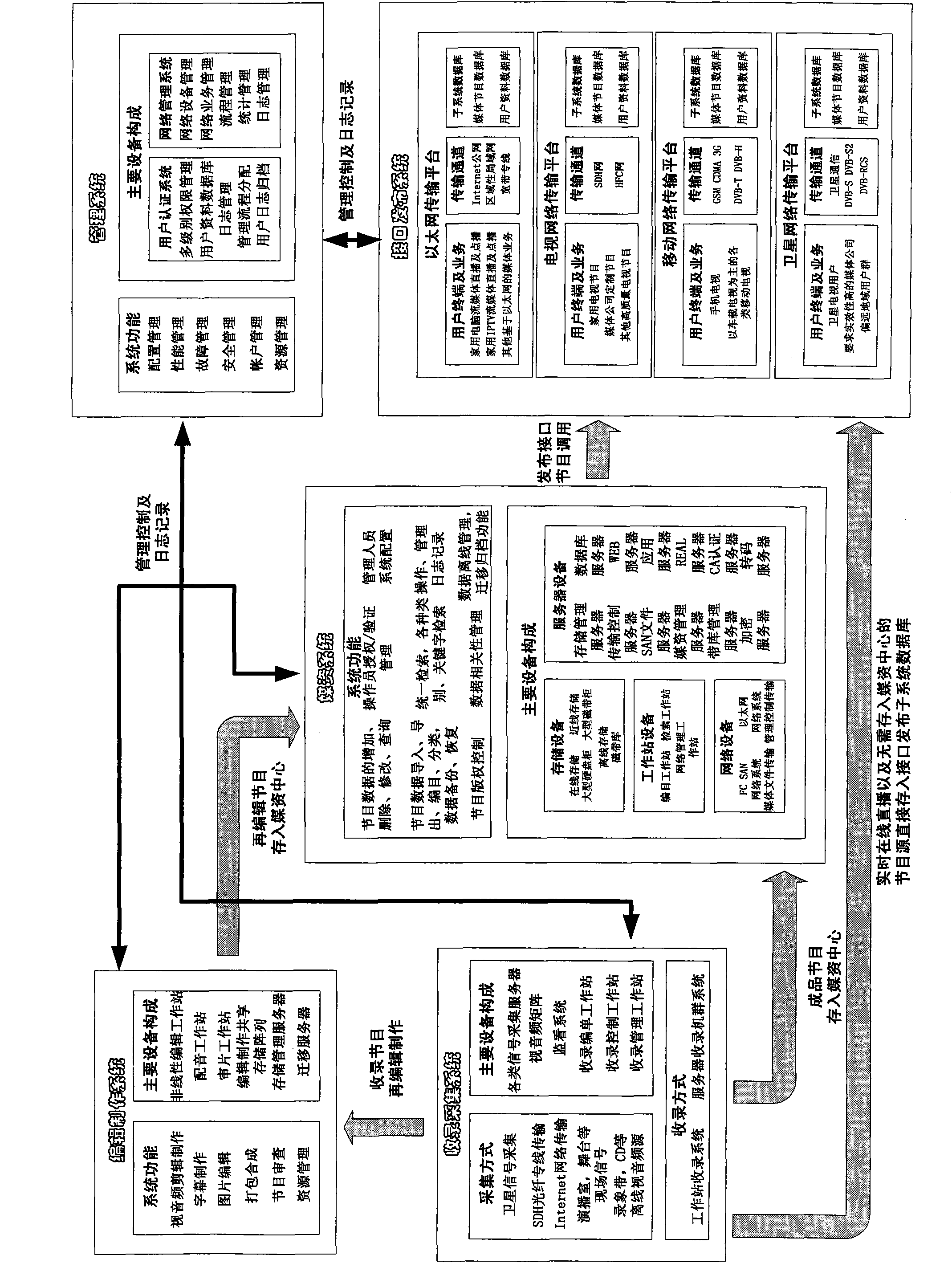

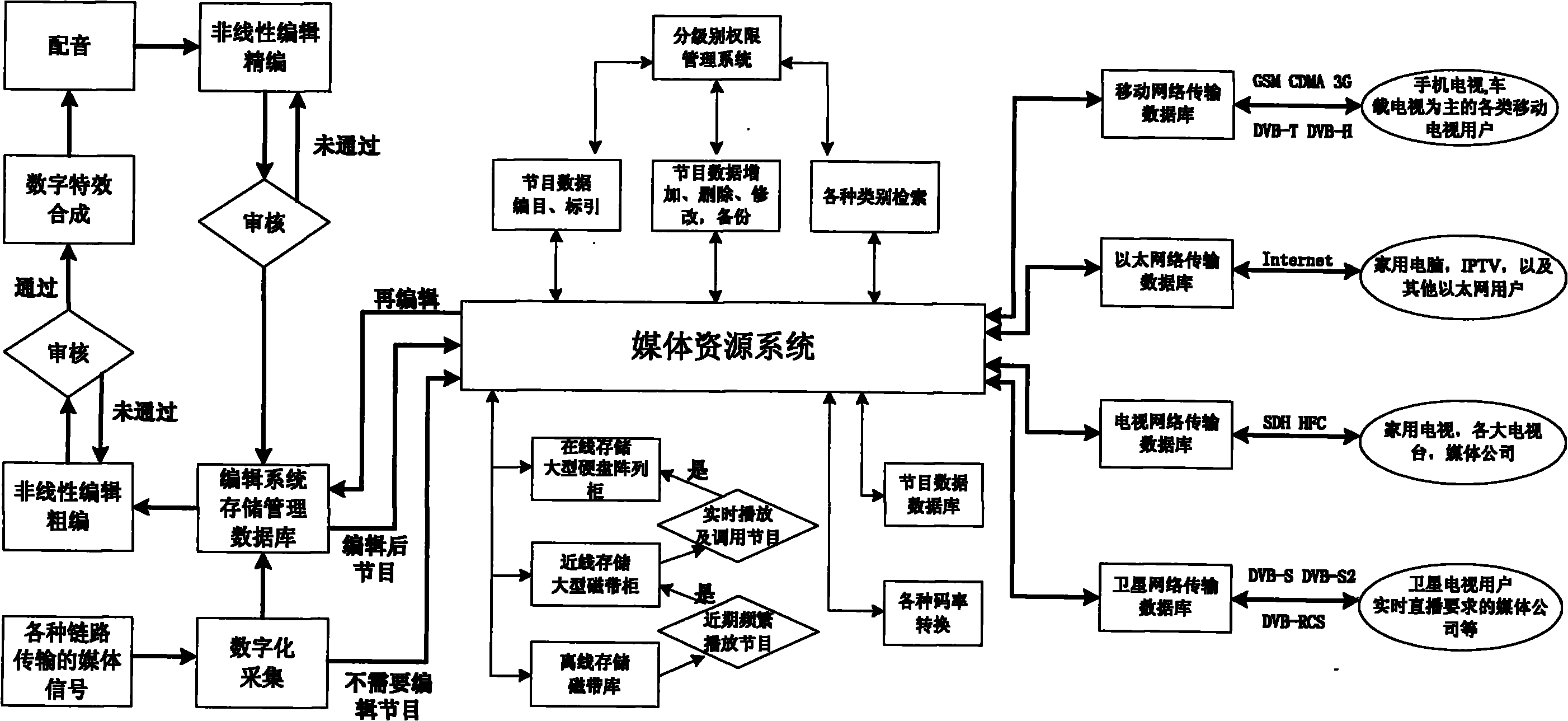

Digital multimedia information transmission platform

InactiveCN101783873ASupport automatic technical review functionImprove review efficiencyTelevision system detailsColor television detailsSystems managementCataloging

The invention discloses a digital multimedia information transmission platform, which comprises an acquisition system, a manufacturing system, a media resource system, a management system and a release system, wherein the acquisition system consists of control equipment, outside network material receiving server and an foreign signal, studio signal and magnet tape material acquisition and collection subsystem; the manufacturing system consists of a program editing system, a program examination system, a background packing and synthesizing system and a resource manager; the media resource system consists of a media resource cataloging and searching work station, a transcoding server, a database server, a storage management and migration server and a system management working station; the management system consists of a uniform user identification system and a network management system; the release system serving as an external interface module of a multimedia center encrypts finished products in multiple formats and executes related release according to outside service demands; and the platform is an integrated production line of digital media contents and also a digital media resource comprehensive service system platform and can realize overall media resource sharing.

Owner:BEIJING INFV MEDIA TECH

Compositions of ethylene/alpha-olefin multi-block interpolymer for elastic films and laminates

ActiveUS20070155900A1Easy to processHigh tensile strengthPersonal careLayered product treatmentProduction linePolyolefin

This invention relates to polyolefin compositions. In particular, the invention pertains to elastic polymer compositions that can be more easily processed on cast film lines, extrusion lamination or coating lines. The compositions of the present invention preferably comprise an elastomeric polyolefin resin and a high pressure low density type resin.

Owner:DOW GLOBAL TECH LLC

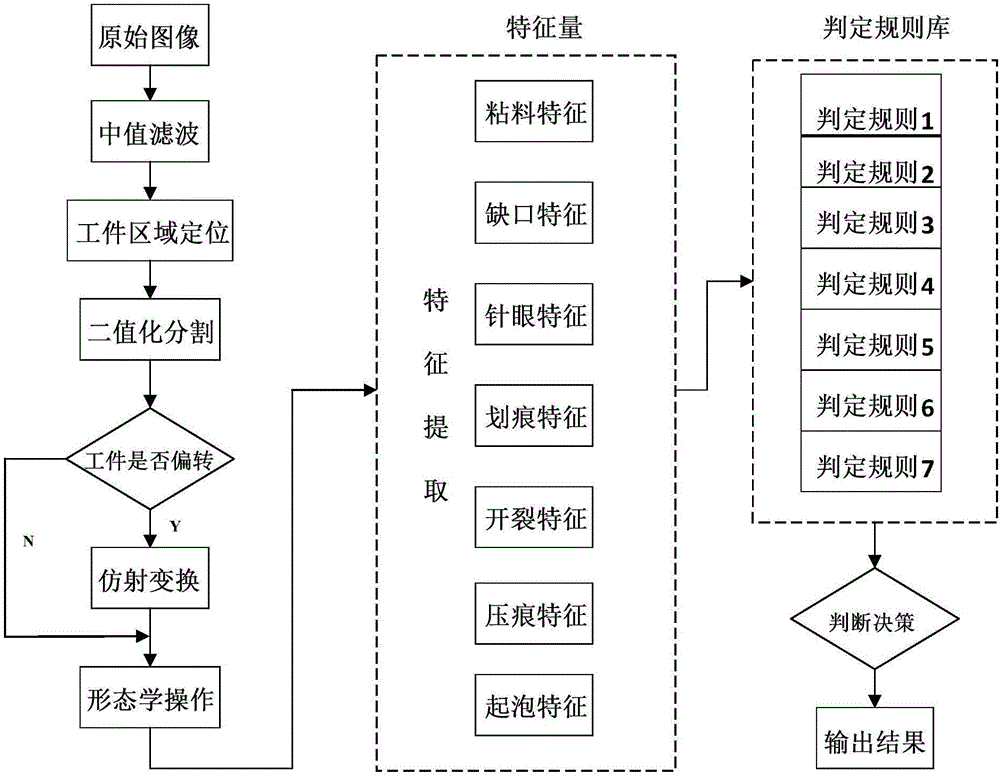

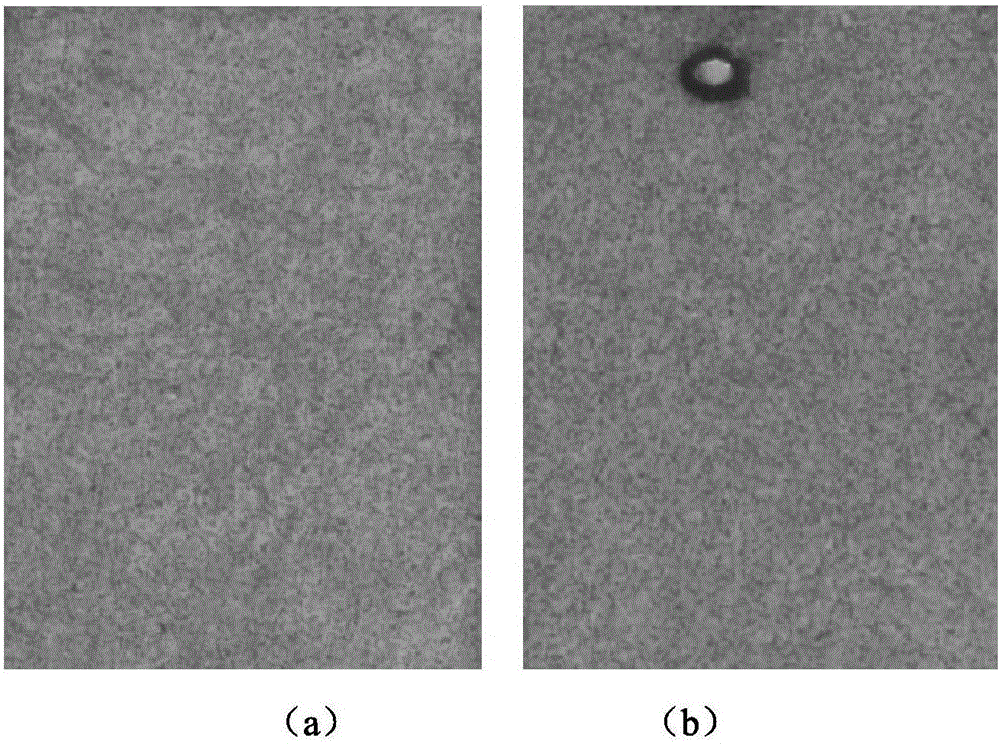

System for visually detecting workpiece appearance defects based on image processing

ActiveCN106053479AFast positioningHigh precisionImage enhancementImage analysisDiffuse reflectionVisual perception

The invention discloses a system for visually detecting workpiece appearance defects based on image processing, comprising an industrial personal computer, a coaxial light source, a CCD (charge coupled device) industrial camera, an image acquisition card and a rejecting mechanism; both the coaxial light source and the rejecting mechanism are connected with the industrial personal computer; the CCD industrial camera is connected with the industrial personal computer through the image acquisition card; wherein the coaxial light source is used for providing a diffuse reflection light source for a workpiece to be detected; the CCD industrial camera is used for taking an image of the workpiece at a detection station; the rejecting mechanism is used for rejecting from a production line, workpieces detected to be defective; the industrial personal computer has a defect detection module based on image processing; the system is high in detection efficiency and easy to implement.

Owner:XIANGTAN UNIV

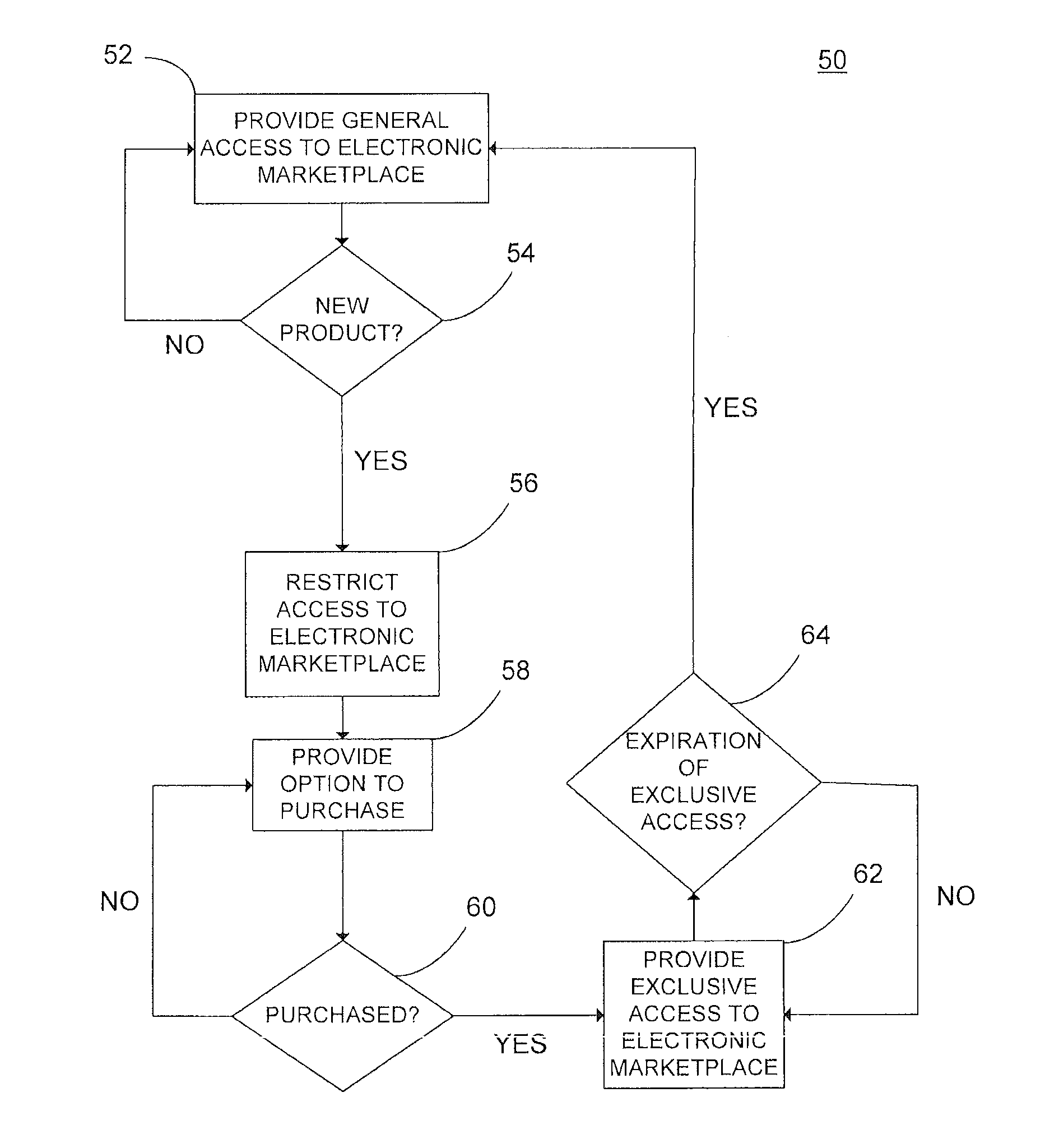

Interactive electronic marketplace

A promotional marketing method for an electronic marketplace, wherein a user gains exclusive, limited access to the marketplace upon purchase of a membership item. Systems and methods for assigning a virtual prize to a buyer within an electronic marketplace. Systems and methods for creating a product line of collectibles and shipping materials based on a theme established from an image of a graphic.

Owner:JENSEN TIFFANY

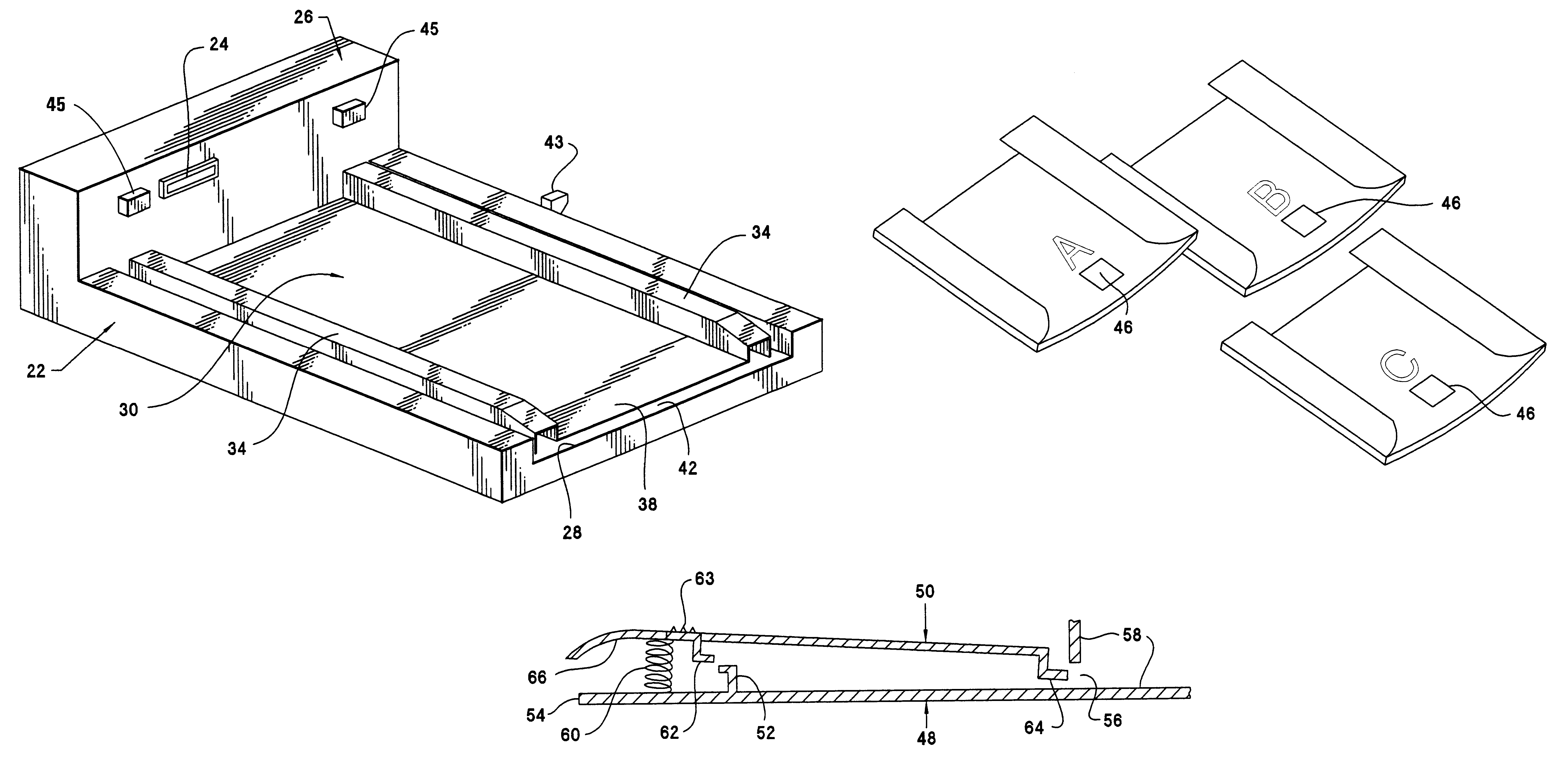

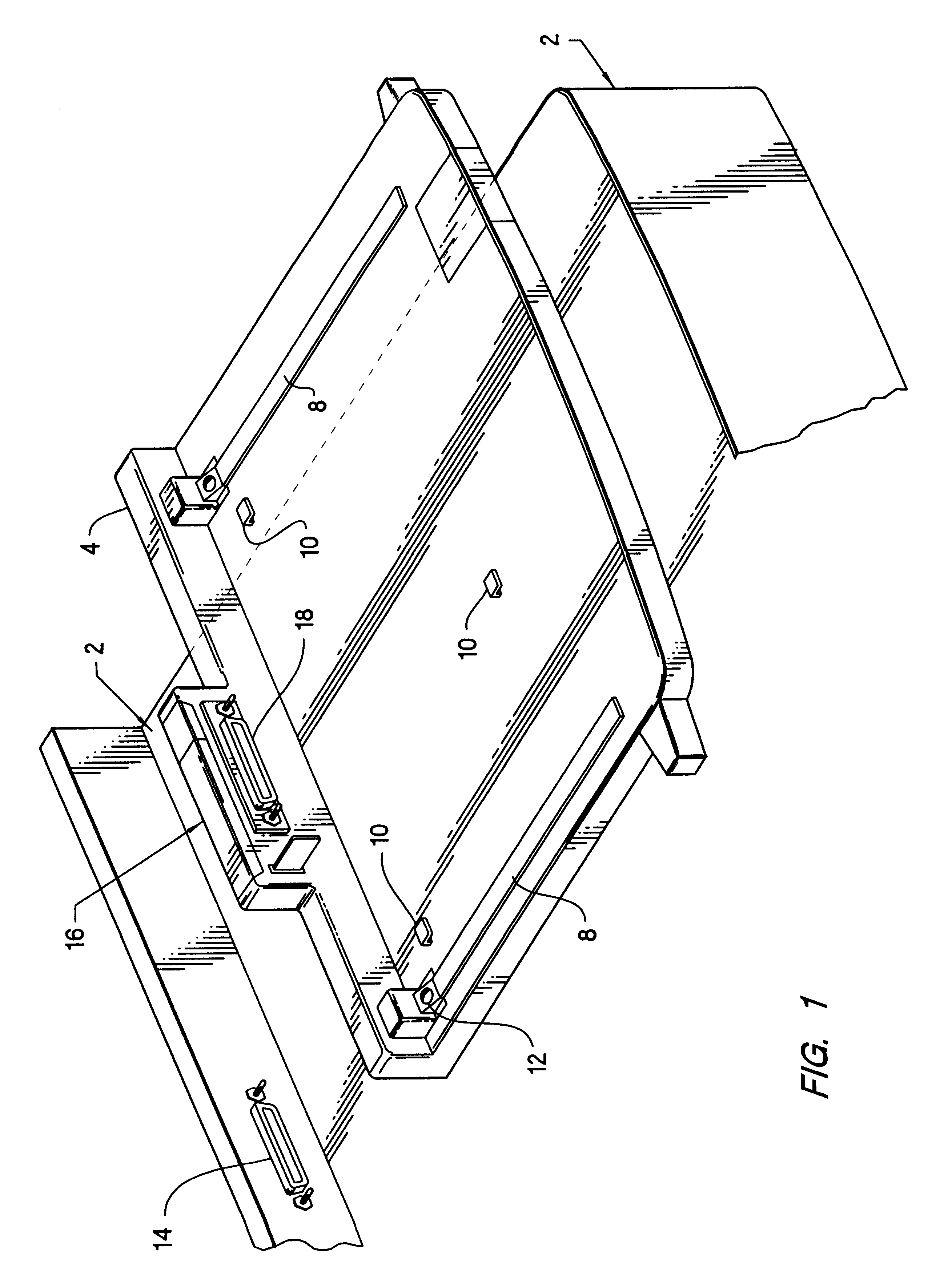

Docking station having a plurality of adapter trays for a plurality of portable computers

InactiveUS6301106B1Few structuresReduce manufacturing costBatteries circuit arrangementsDigital data processing detailsDocking stationProduction line

The invention provides a single docking station structure which is usable for a set of different pieces of equipment having essentially similar interfaces, such as a manufacturer's line of portable ("notebook" or "laptop") computer product models. A common first module supports interfaces with peripheral devices or the like. A model-specific second module, second from a set of second modules that correspond with various models from the line of portable computers, is coupled with the first module to support the portable computer. The second module supports the portable computer, so as to interface it directly with the interface on the first module. The second modules, preferably configured as trays for holding the portable computers, are very simple and inexpensive to manufacture. The trays can be stored next to the docking station (like magazines on a bookshelf). An identification system, which labels the different trays and cross-references them to the corresponding portable computers, allows for future changes in the manufacturer's product line, in which a new model of portable computer requires either a new tray or one of the previously existing trays. The invention is advantageous to manufacturers because it reduces the number and variety of docking station products required for use with the manufacturer's portable computers.

Owner:HEWLETT PACKARD DEV CO LP

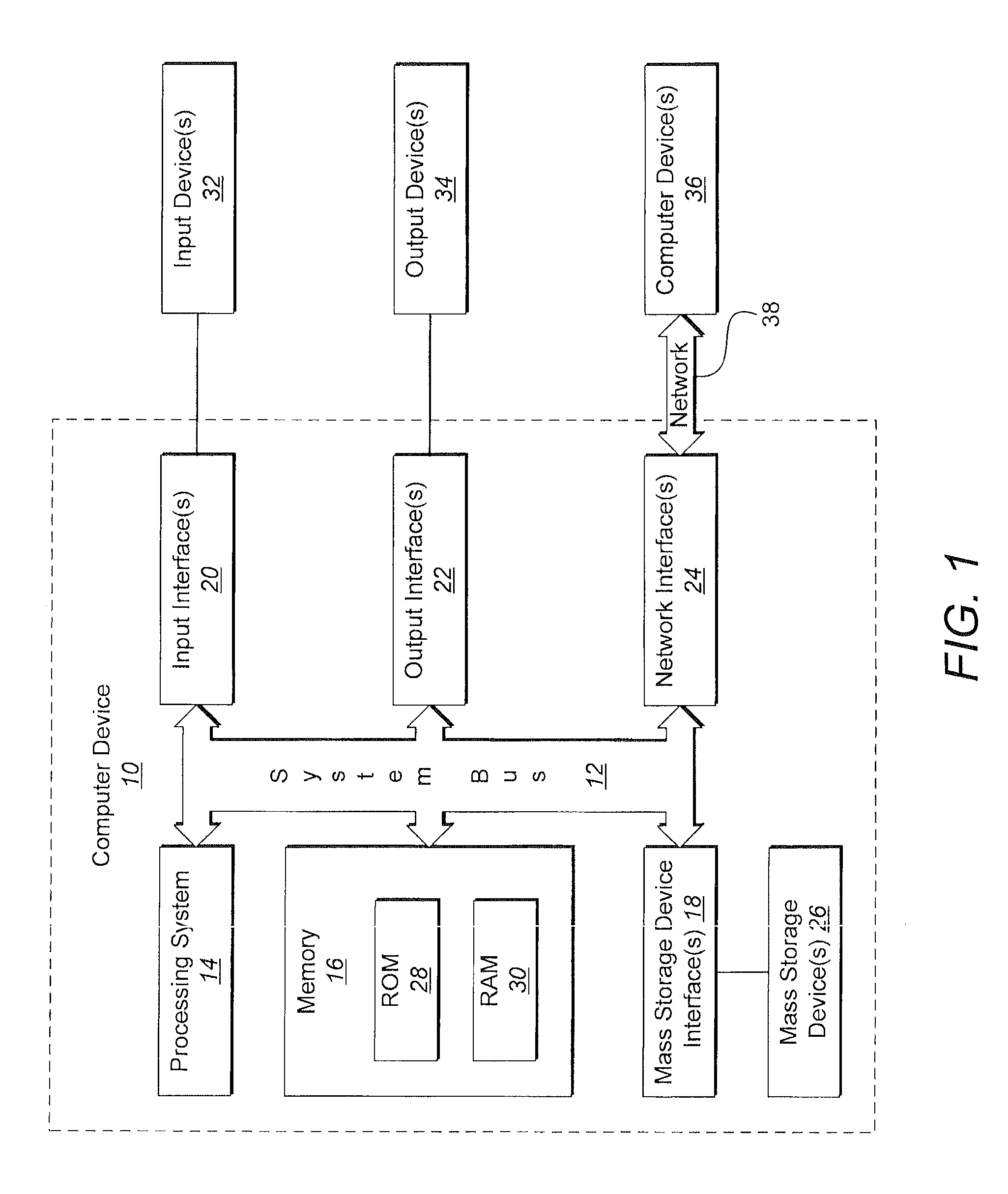

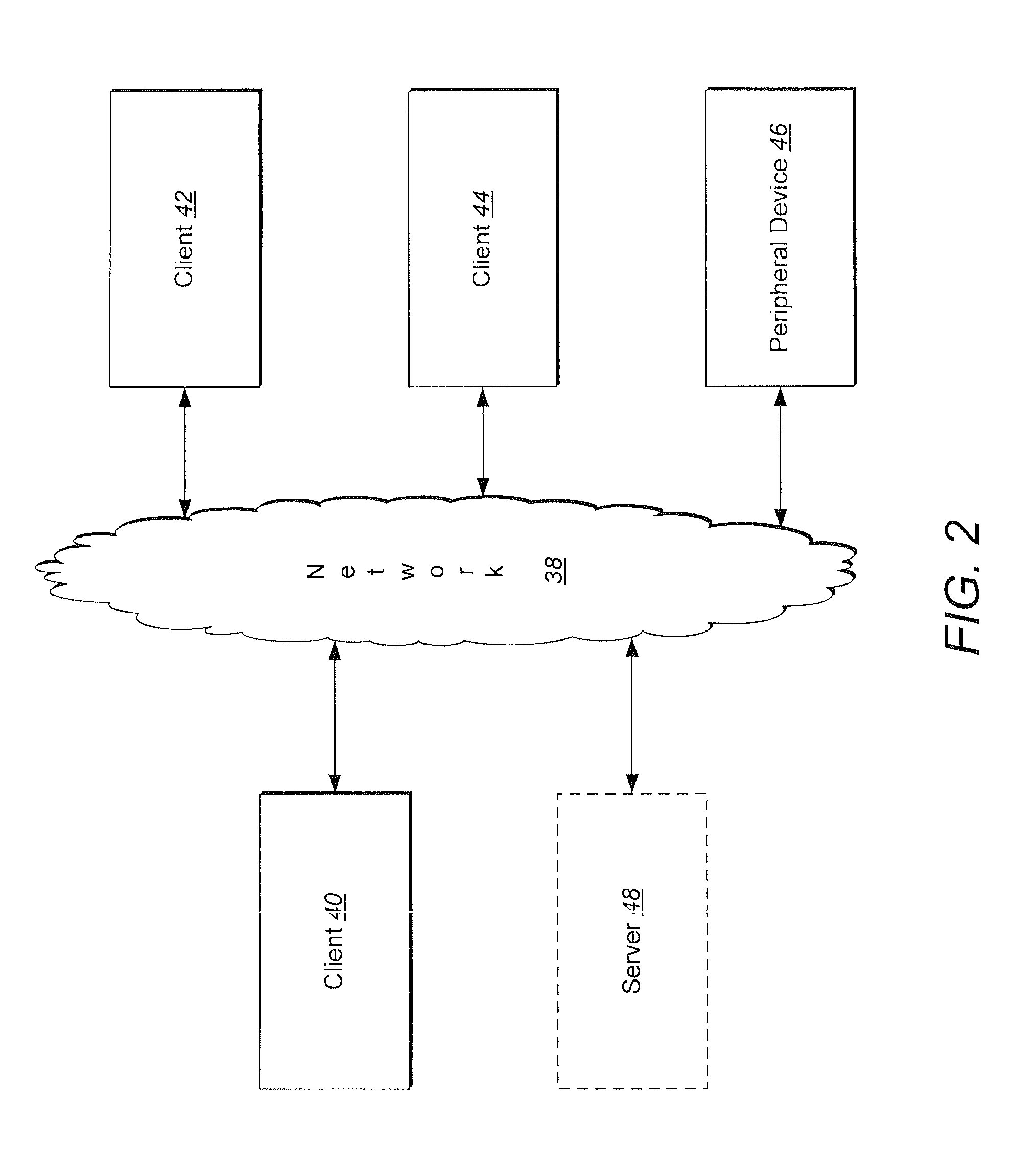

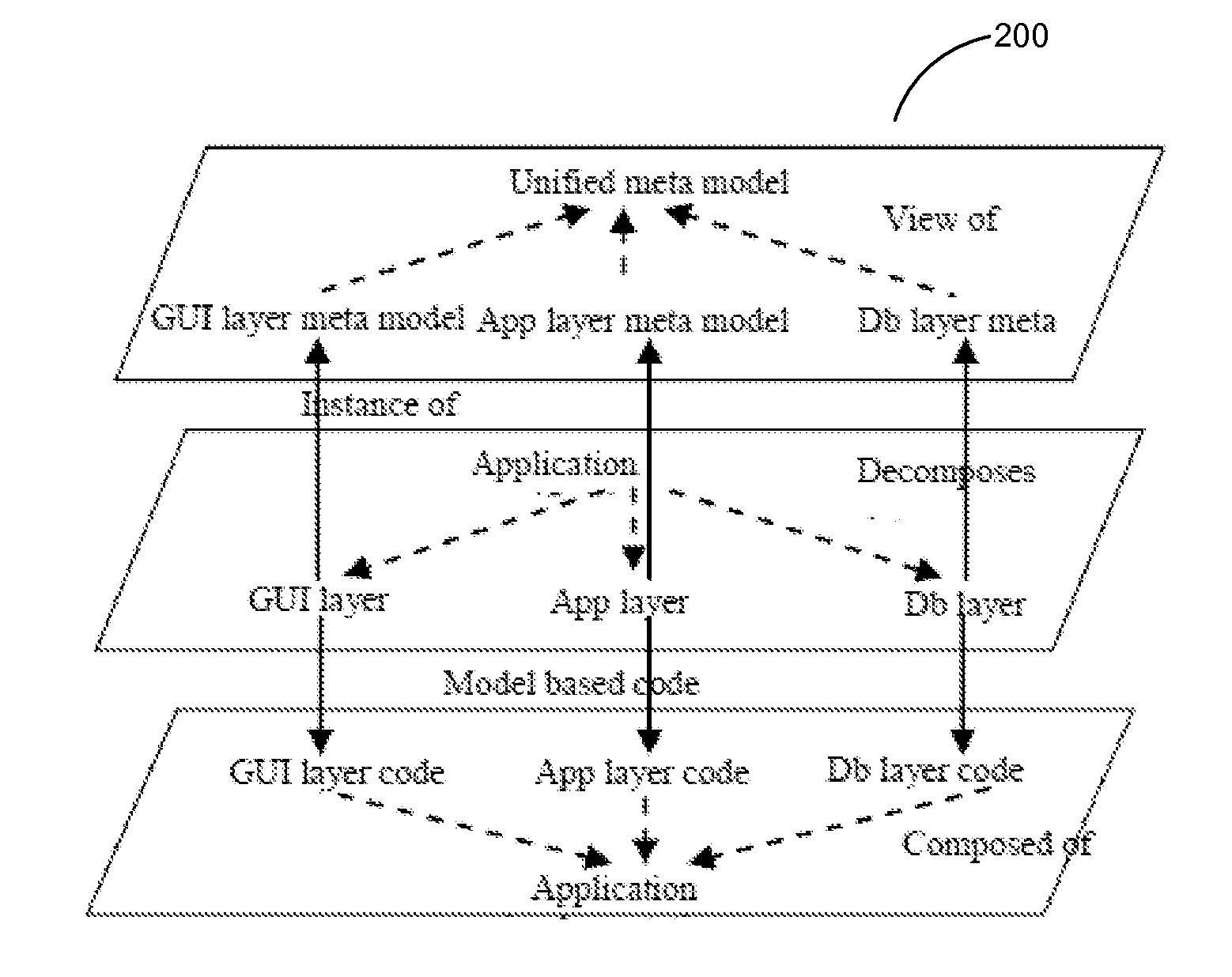

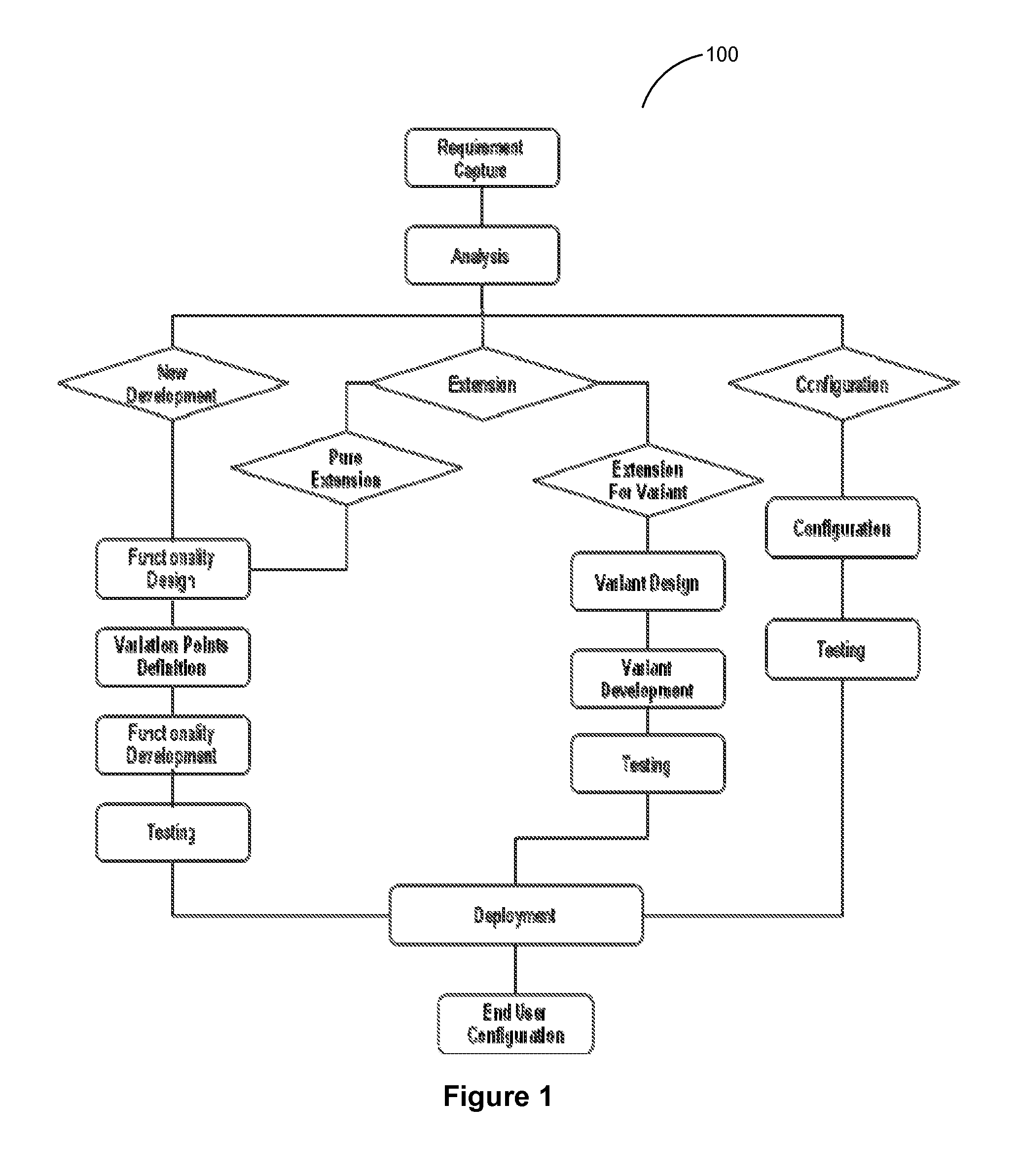

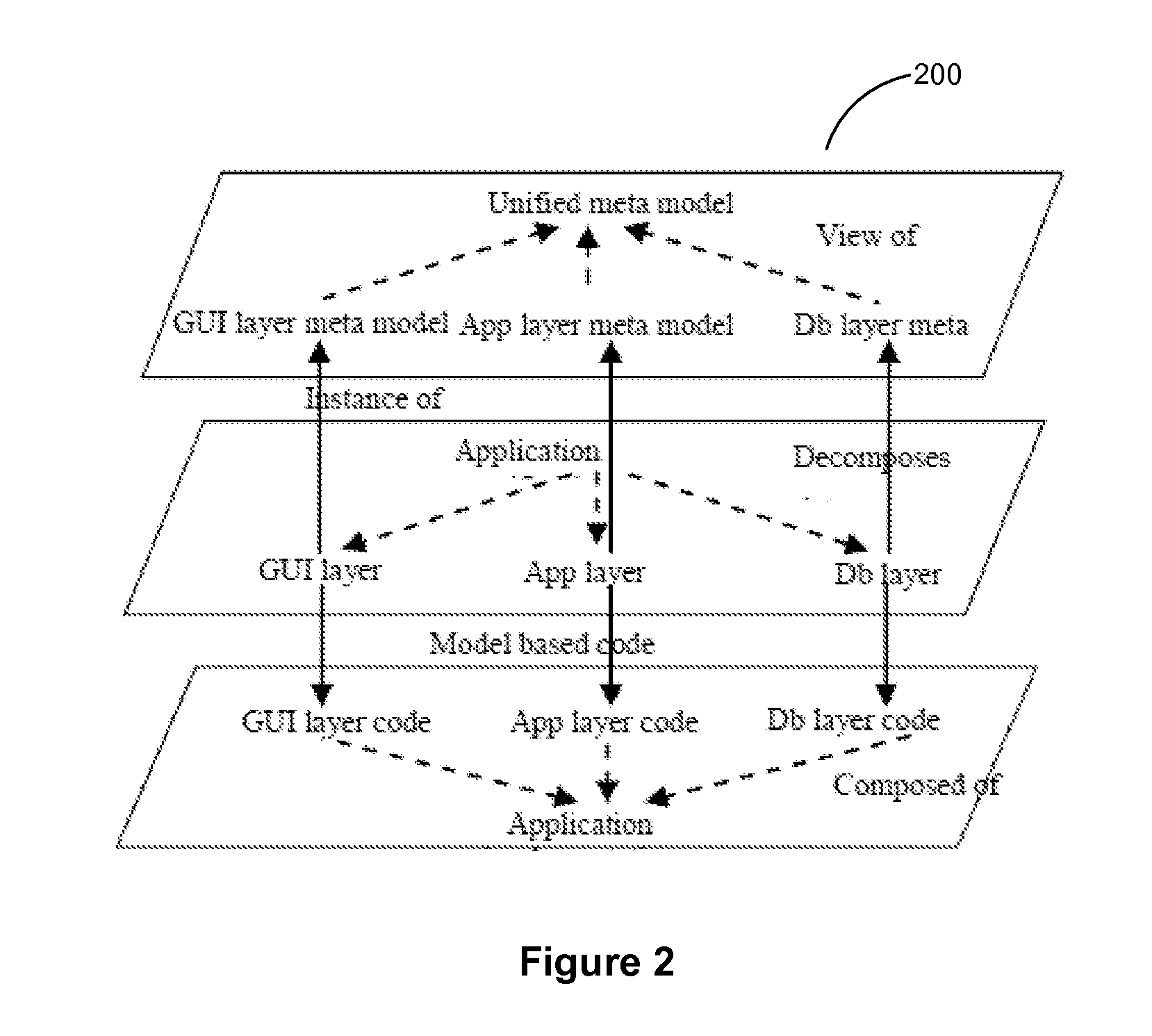

Computationally efficient system for developing configurable, extensible business application product lines using model-driven techniques

ActiveUS20120102451A1Address extensibilityAddress configurabilitySoftware designSpecific program execution arrangementsProduction lineExtensibility

The present invention provides a computationally efficient system for developing configurable, extensible business application product lines using model-driven techniques. The invention enables to create a common business application with a set of pre-defined variants, selection of a suitable variant from the pre-defined set, and composition of the common application with the selected variant into a purpose-specific business application and also provides for modeling of commonality and variability thus leading to a single specification. The invention provides model-based solution to address extensibility and configurability of both structural and behavioral aspects in a functionality dimension of database intensive business application and it supports configuration process at three different stages of application development (i.e. design time, installation time and run time) of database intensive business application. The invention reduces the cost as well as computational time for creating new business applications, and leads to effective maintenance and smooth evolution.

Owner:TATA CONSULTANCY SERVICES LTD

Industrial character identification method based on convolution neural network

ActiveCN106650721AQuick identificationEfficient identificationNeural architecturesCharacter recognitionProduction lineGraphics

The invention provides an industrial character identification method based on a convolution neural network. The method comprises the steps of establishing character data sets, carrying out data enhancement and preprocessing on the character data sets and establishing a CNN (Convolution Neural Network) integrated model, wherein the model comprises three different individual classifiers, training is carried out through utilization of the model, the training is finished by two steps, a first step is offline training, an offline training model is obtained, a second step is online training, the offline training model is used for initialization, a special production line character data set is trained, and an online training model is obtained; carrying out preprocessing, character positioning and single character image segmentation on a target image; sending the segmented character images to the trained online training model, and probability values of classifying the single target images into classes by the three classifiers in the CNN integrated model is obtained; final decision is carried out in a voting mode, thereby obtaining a classification result of test data. According to the method, characters on different production lines can be identified rapidly and efficiently.

Owner:吴晓军

Microfluidic devices for controlled viscous shearing and formation of amphiphilic vesicles

ActiveUS7595195B2Facilitates programmable control of sizeIncrease shear forceMixing methodsTransportation and packagingViscous shearEngineering

Systems and methods that control the size and composition of emulsified droplets, multi-lamellar and asymmetric vesicles, encapsulation of reagents, membrane proteins, and sorting of vesicles / droplets. More particularly, microfluidic devices for controlled viscous shearing of oil-water emulsions of micro- and nano-scale droplets, the subsequent formation of amphiphilic vesicles such as liposomes, polymer vesicles, micelles, and the like, the post-assembly and post-processing of the droplets including splitting, fusing, sorting and the like, polymer emulsions, and the integration of amphiphilic vesicle production-line on a single microfluidic chip. Preferably, the microfluidic device enables oil-water co-flows with tunable viscous shear forces higher than the immiscible interfacial tension forces that generate favorable conditions for droplet formation.

Owner:RGT UNIV OF CALIFORNIA

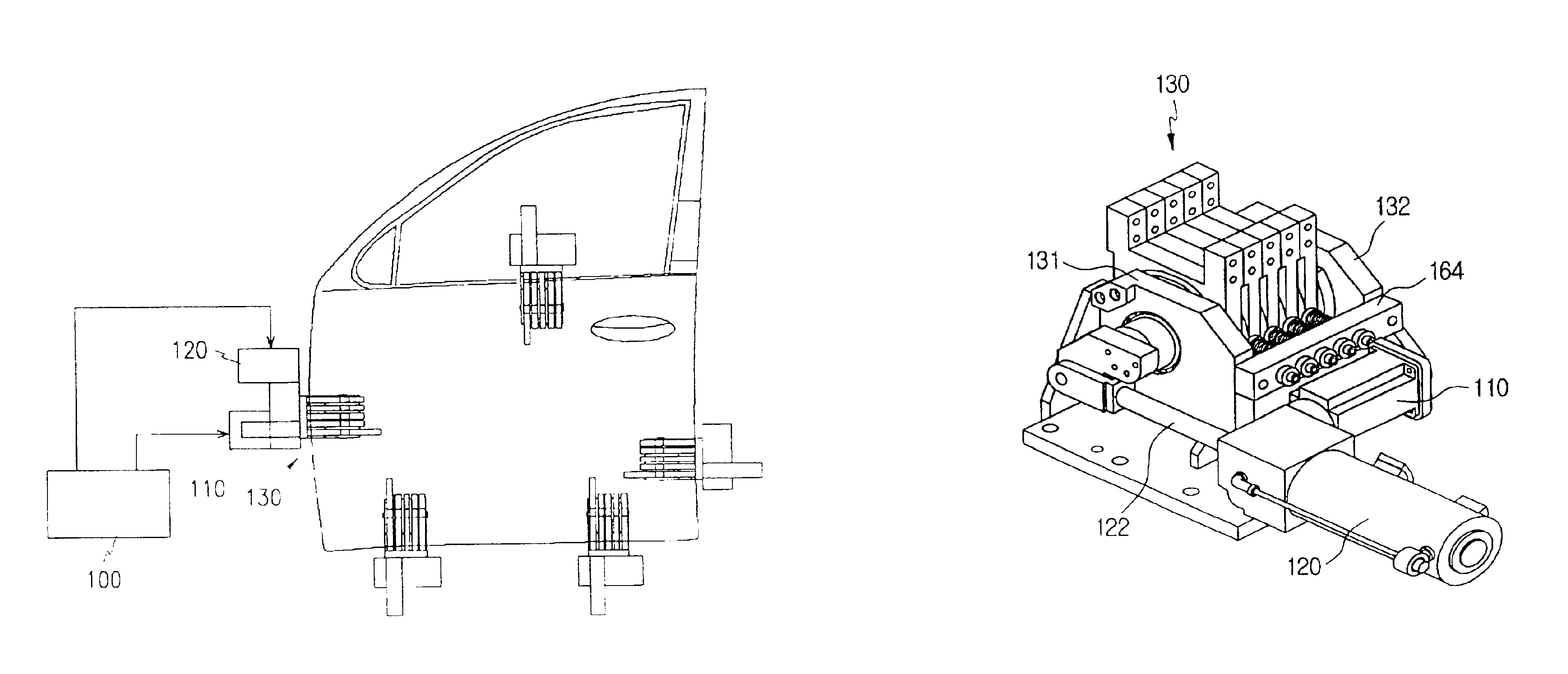

Panel-securing system for various vehicle types

A panel-securing system for various vehicle types is provided, in which various clamps and fingers for different panel shapes may be selected for operation by a single cylinder, the amount of space utilized to install the system is minimized, and parts used in the system are simplified. The panel-securing system for use in a production line for various vehicle types comprises a controller having stored therein panel information for various vehicle types, the controller generating and outputting a locator-selection control signal and a panel-securing control signal corresponding to panel information of the correct vehicle type; a first actuator for selecting a locator corresponding to the locator-selection control signal output by the controller; a second actuator for driving a locator corresponding to the panel-securing control signal output by the controller; and a panel-securing assembly including a plurality of locators, which correspond to panels of the various vehicle types.

Owner:HYUNDAI MOTOR CO LTD

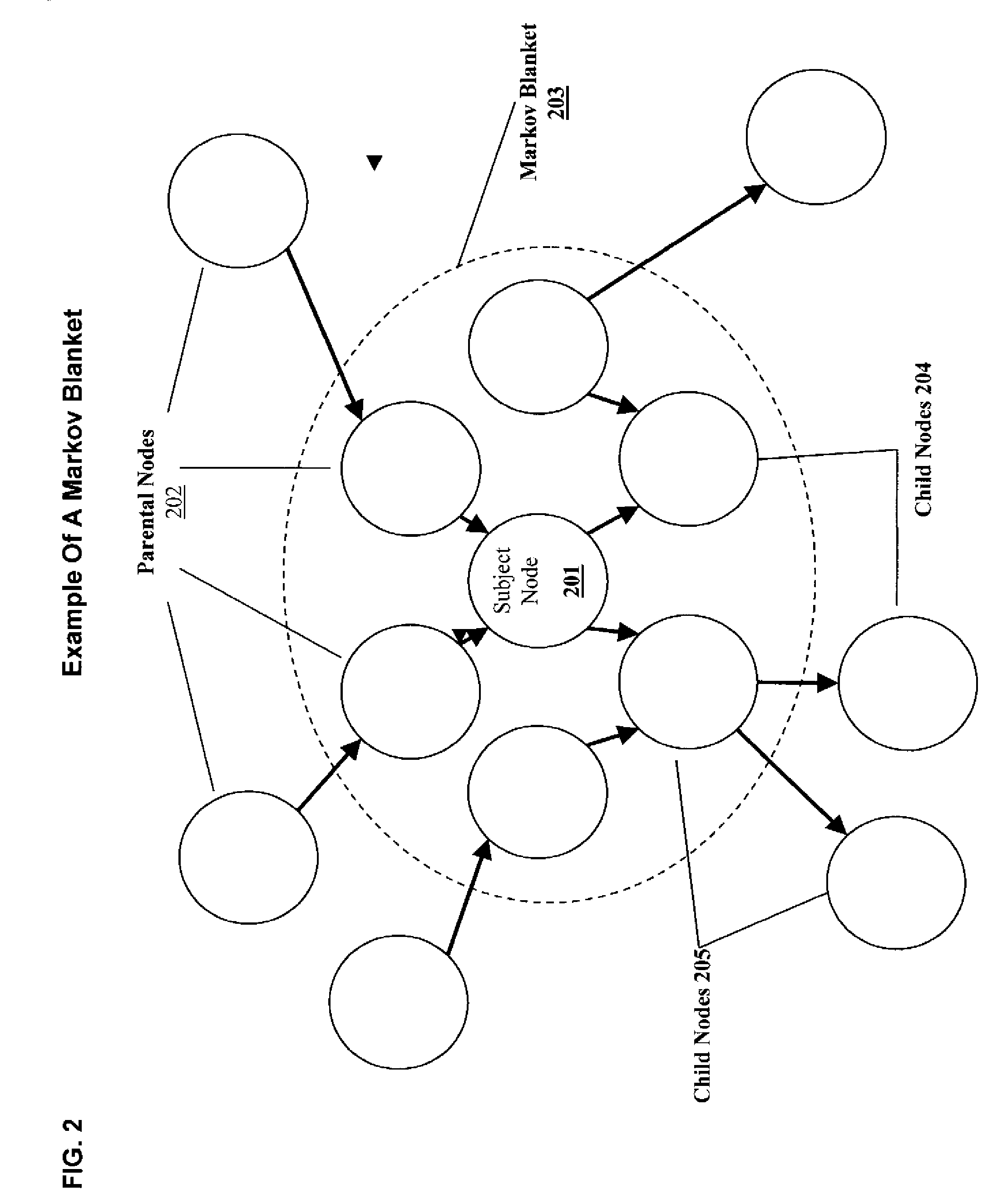

Extensible bayesian network editor with inferencing capabilities

A system for the representation, editing, evaluation, and inference of graphical models is disclosed which can be used to construct and evaluate a graphical model or graphical network and to calculate inference values. An efficient method of updating graphical models is demonstrated, and provides the basis for an improved system for manipulation and evaluation of probabilistic models. The graphical network editor is useful in the construction of graphical modes such as Bayesian Networks. The graphical network and network graphical user interface (GUI) are used in conjunction with each other to model a system wherein failure probabilities and the current state of components are taken into account to monitor the health and progress of a system for an engineer or engineering software to evaluate and monitor. The evaluation is useful in the monitoring of assets and other real systems having multiple, dependent, and independently operating components such as a pump, a manufacturing plant, a production line, an assembly line, where asset health and quality control is a concern. The asset components each influencing some overall outcome of a system or situation. Success or failure or probability of success, probability of failure and health of the system can be monitored and manipulated by altering the values of prior probability and posterior probability values. Failure correlation between components can be evaluated wherein failure rates of asset is unknown. Production and quality can be monitored and altered.

Owner:QUANTUM LEAP RES

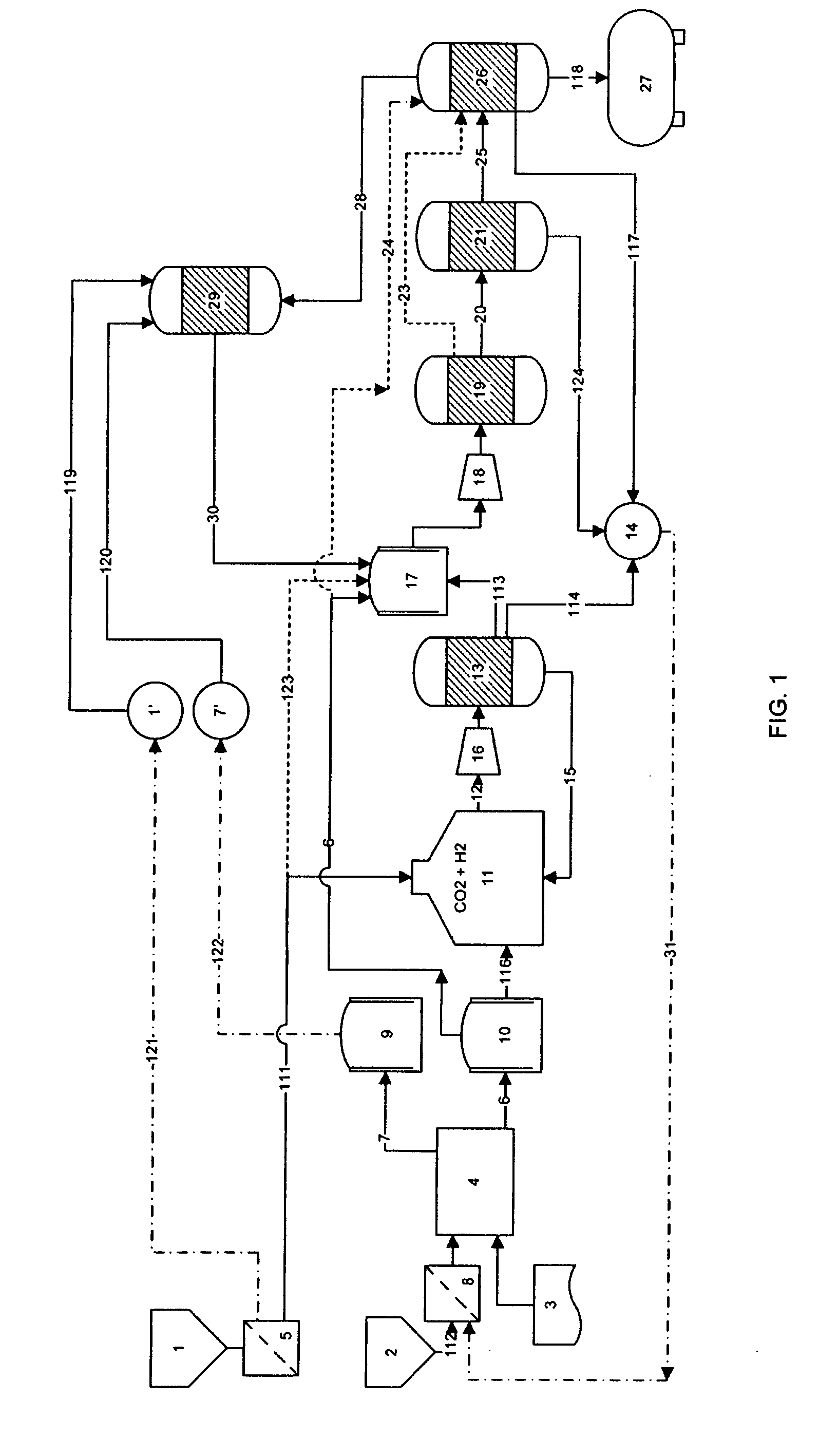

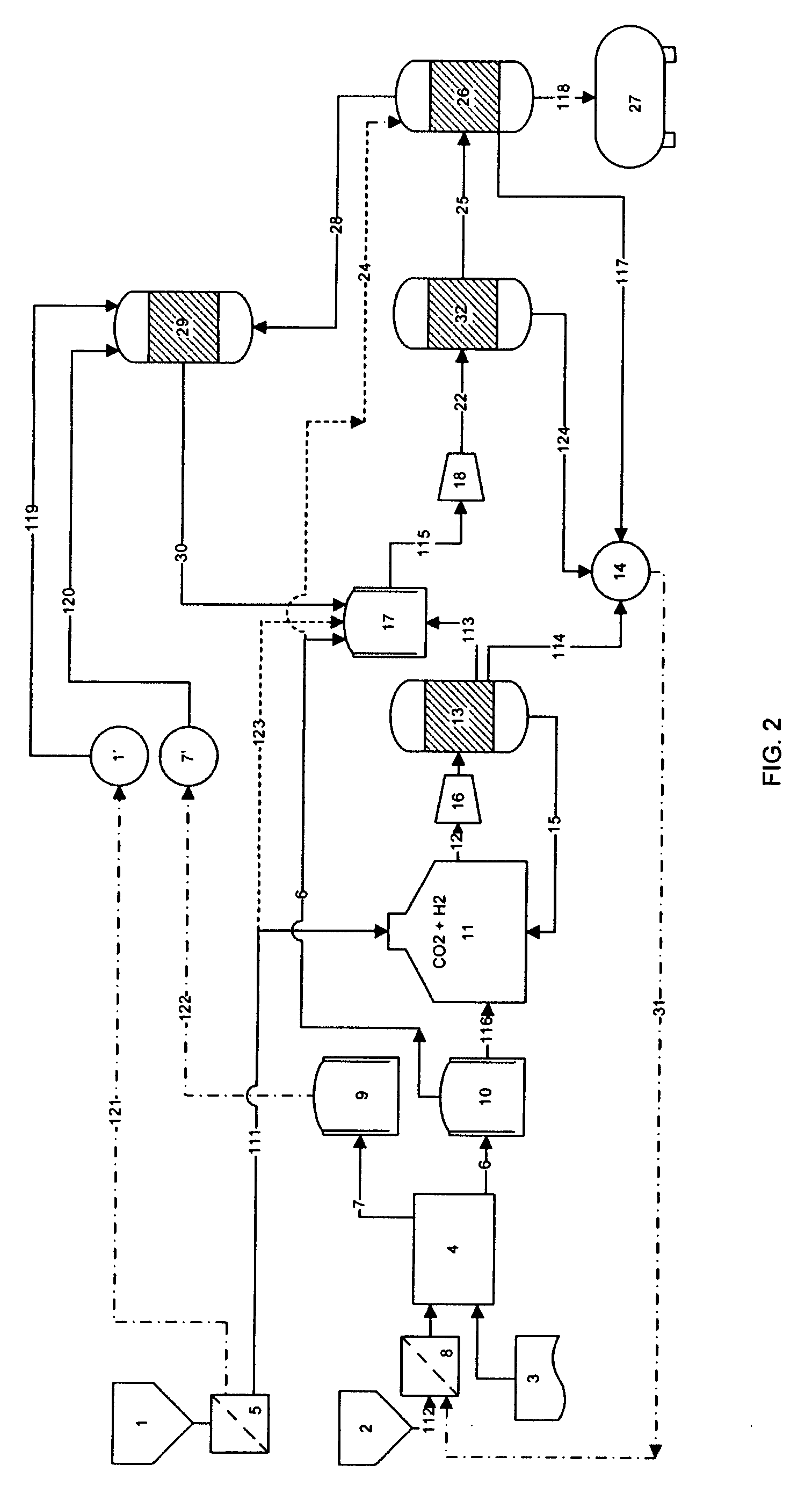

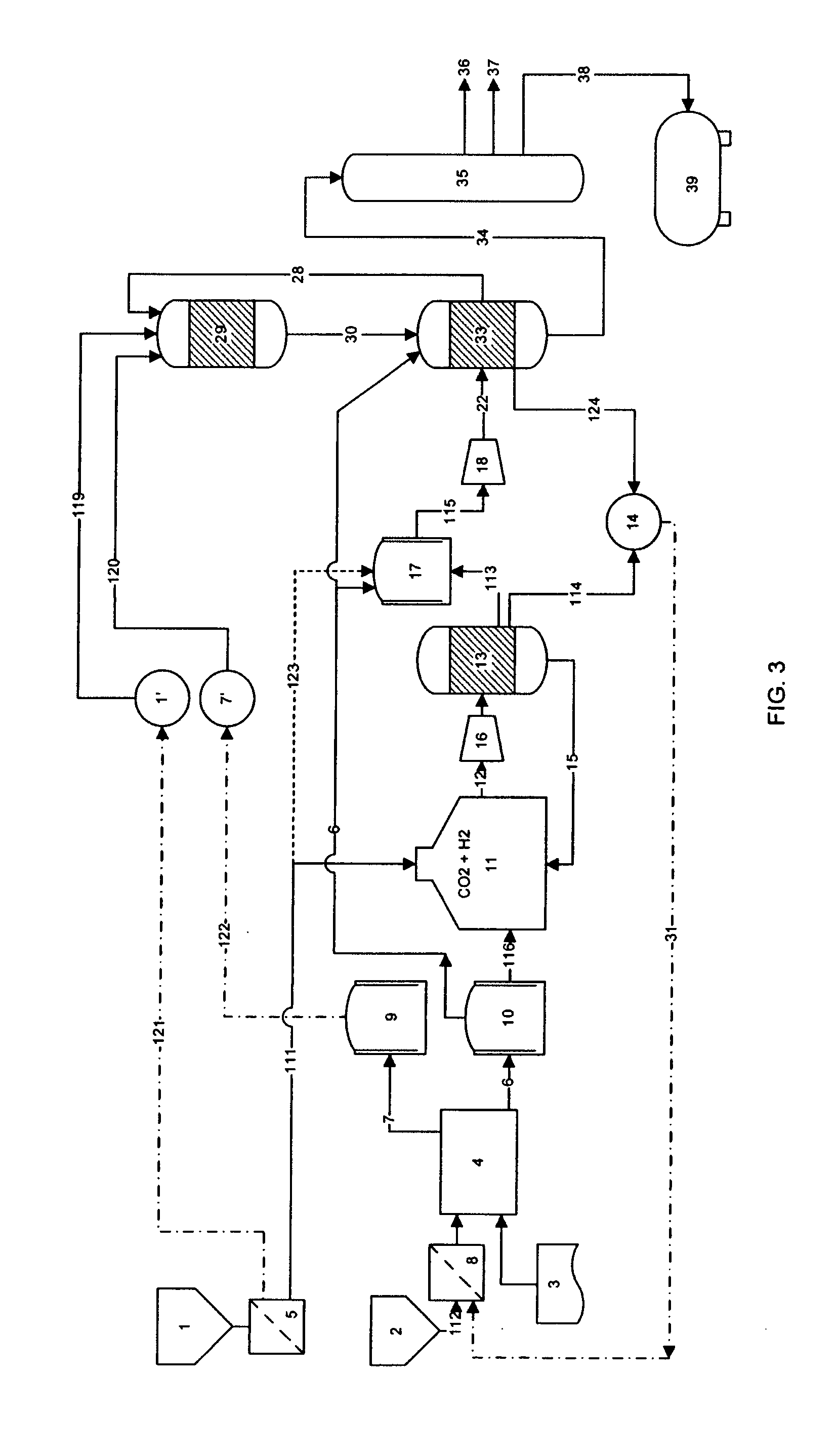

Process for producing liquid fuel from carbon dioxide and water

ActiveUS20070244208A1Combustible gas chemical modificationOrganic compounds purification/separation/stabilisationHydrocotyle bowlesioidesLiquid fuel

A process for producing high octane fuel from carbon dioxide and water is disclosed. The feedstock for the production line is industrial carbon dioxide and water, which may be of lower quality. The end product can be high octane gasoline, high cetane diesel or other liquid hydrocarbon mixtures suitable for driving conventional combustion engines or hydrocarbons suitable for further industrial processing or commercial use. Products, such as dimethyl ether or methanol may also be withdrawn from the production line. The process is emission free and reprocesses all hydrocarbons not suitable for liquid fuel to form high octane products. The heat generated by exothermic reactions in the process is fully utilizes as is the heat produced in the reprocessing of hydrocarbons not suitable for liquid fuel.

Owner:CRI EHF

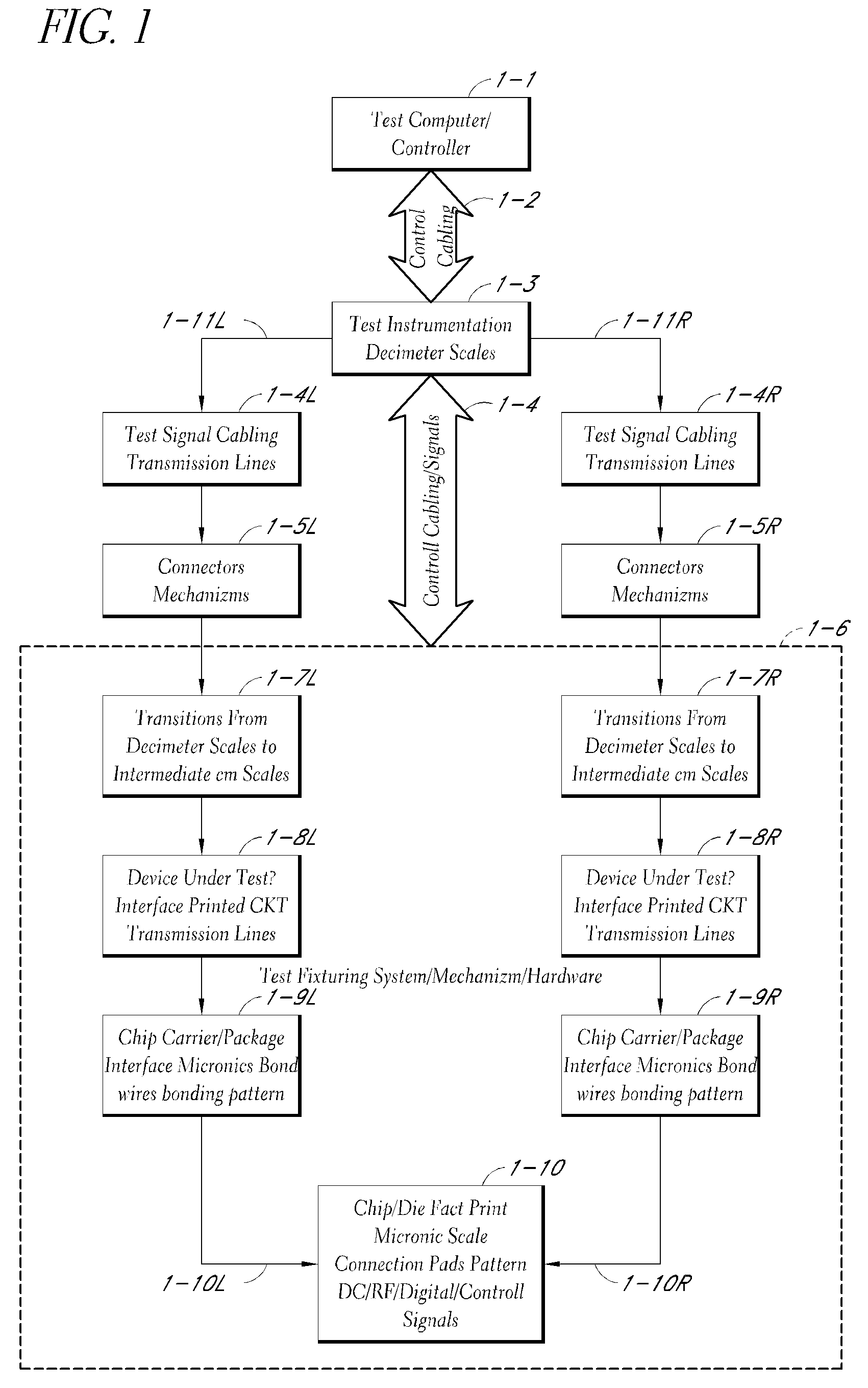

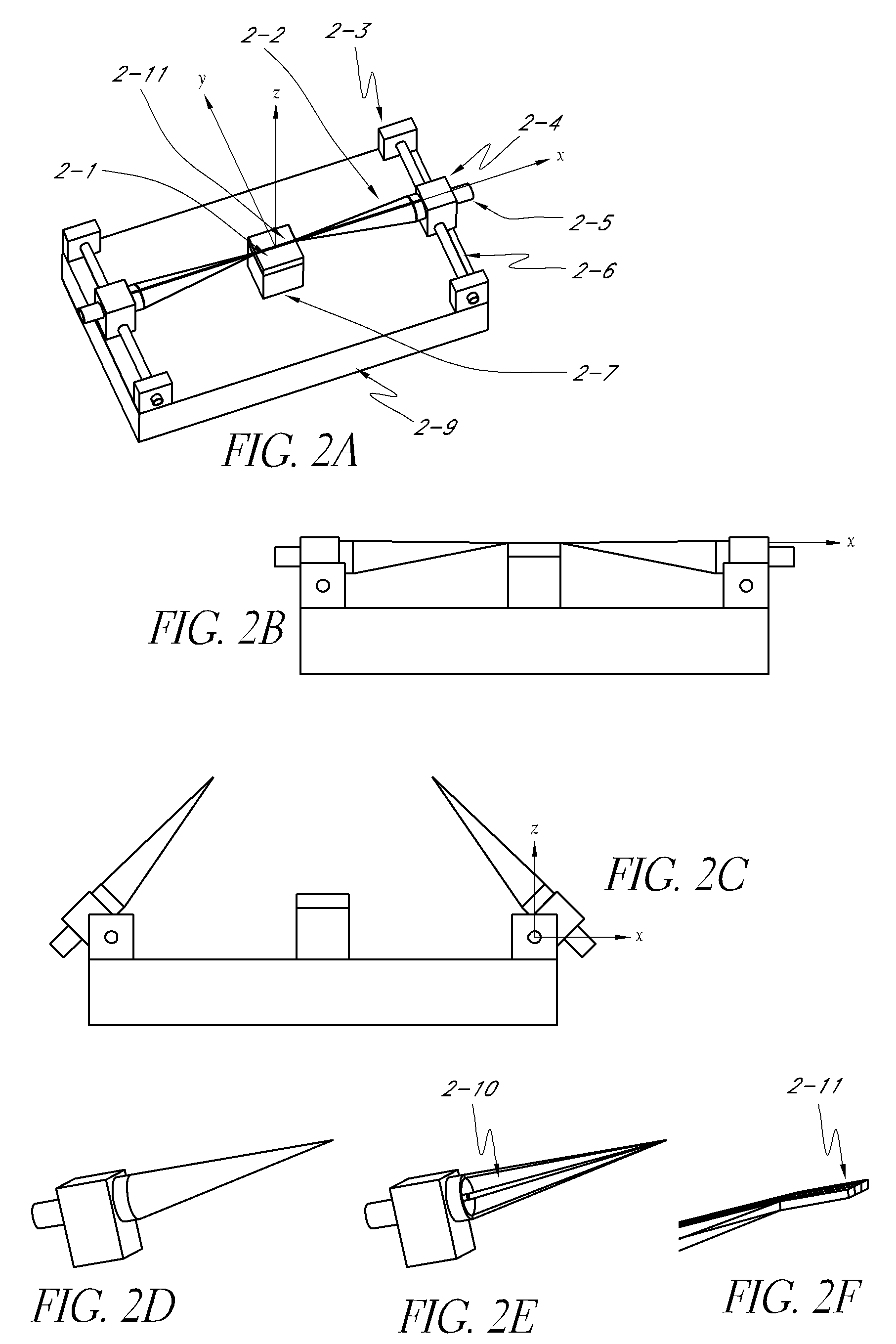

Scalable wideband probes, fixtures, and sockets for high speed IC testing and interconnects

ActiveUS20080265919A1Reducing cross talk and prasiticsIncrease speedElectrical measurement instrument detailsSolid-state devicesRadiation lossPicosecond

We introduce a new Periodic micro coaxial transmission line (PMTL) that is capable of sustaining a TEM propagation mode up to THz band. The PMTL can be manufactured using the current photolithographic processes. This transmission line can be embedded in microscopic layers that allow many new applications. We use the PMTL to develop a wideband highly scalable connector that is then used in a Probe that can be used for connecting to microscopic scale Integrated Circuits with picoseconds High Speed Digital and near THz Analogue performance in various stages of development from R&D to production testing. These probes, in one embodiment, provide a thin pen-like vertical probe tip that matches the die pad pattern precisely that can be as agile as a high speed plotter pen, connecting on the fly to any die pattern on a wafer. This approach allows the most valuable part of the test, namely the wafer to remain stationary and safe, and the least costly part of the test, namely the probe to take most of the wear and tear. We further use the embedded PMTL to develop a modular, scaleable and fully automated Universal Test Fixture for testing chips in various stages of development mainly for digital IC chips that can be utilized in production lines with pick and place of chips on tape to test every chip before insertion into circuits. One embodiment includes a low profile wideband Signal Launcher and an alligator type RF Clip that can be used at the edge of PCB's directly for validation broads. The Signal Launcher is used to develop a new versatile Flush Top Test Fixtures for individual device testing in various stages of development from die, to packaged, to Module, to Circuit Boards. The PMTL can also provide Confined Field Interconnects (CFI) between various elements on semiconductor wafers to reduce parasitic and radiation losses and practically eliminating cross talk, thus, increasing the speed of digital IC's. The PMTL is also used to develop a Universal Test Socket, and a Hand Probe with performance up to 220 GHz.

Owner:WAYMO LLC

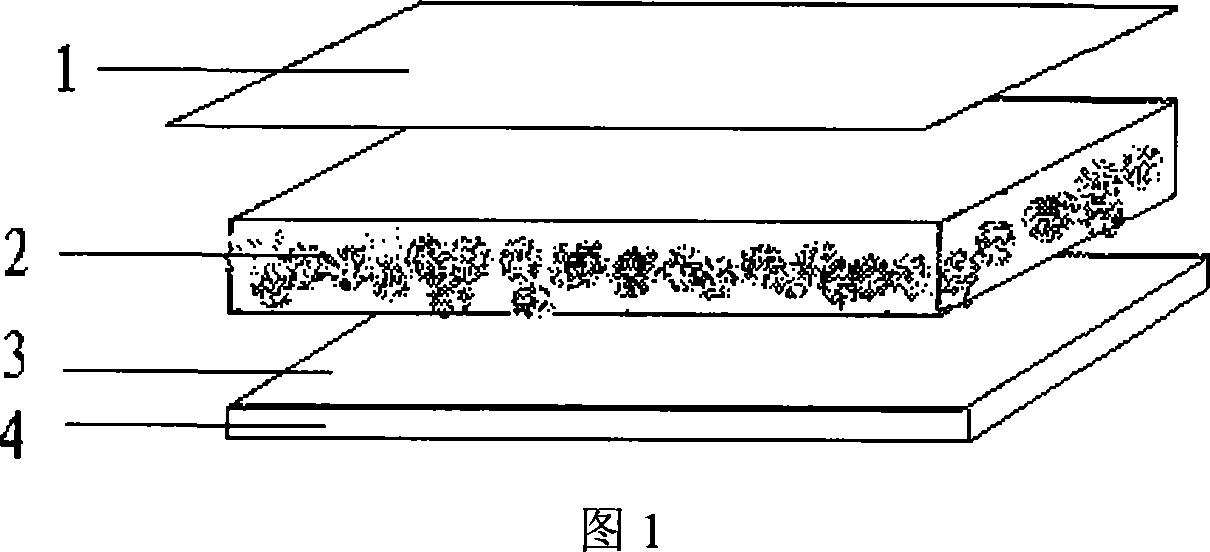

Polyurethane composite thermal insulation board, manufacturing method and application of the same

InactiveCN101220614AImprove thermal insulation performanceImprove fire and flame retardant performanceCovering/liningsLaminationProduction lineAlcohol

The invention provides a polyurethane compound heated board and a manufacturing method and application, which relates to a heated board and supplies a polyurethane compound heated board that has good heat-insulating effect, high fire-fighting and flame-retardant performance, convenient using performance and high constructing efficiency and the manufacturing method and the application. The invention includes a polyurethane rigid foam insulating layer, a bonding layer and an inorganic material composite board; the bonding layer is arranged between the polyurethane rigid foam insulating layer and the inorganic material composite board; the thickness of the polyurethane rigid foam insulating layer is 20-80mm and the thickness of the inorganic material composite plate is 3-10mm. The inorganic material composite board can be continuously produced for further use; an adhesive treatment agent is coated on the inorganic material composite board; polyhydric alcohol combination material and isocyanate combination material are added into the continuous production line for mixed foaming and curing to obtain the polyurethane compound heated board; the mass ratio of the polyhydric alcohol combination material and the isocyanate is 100:95-160.

Owner:厦门高特高新材料有限公司

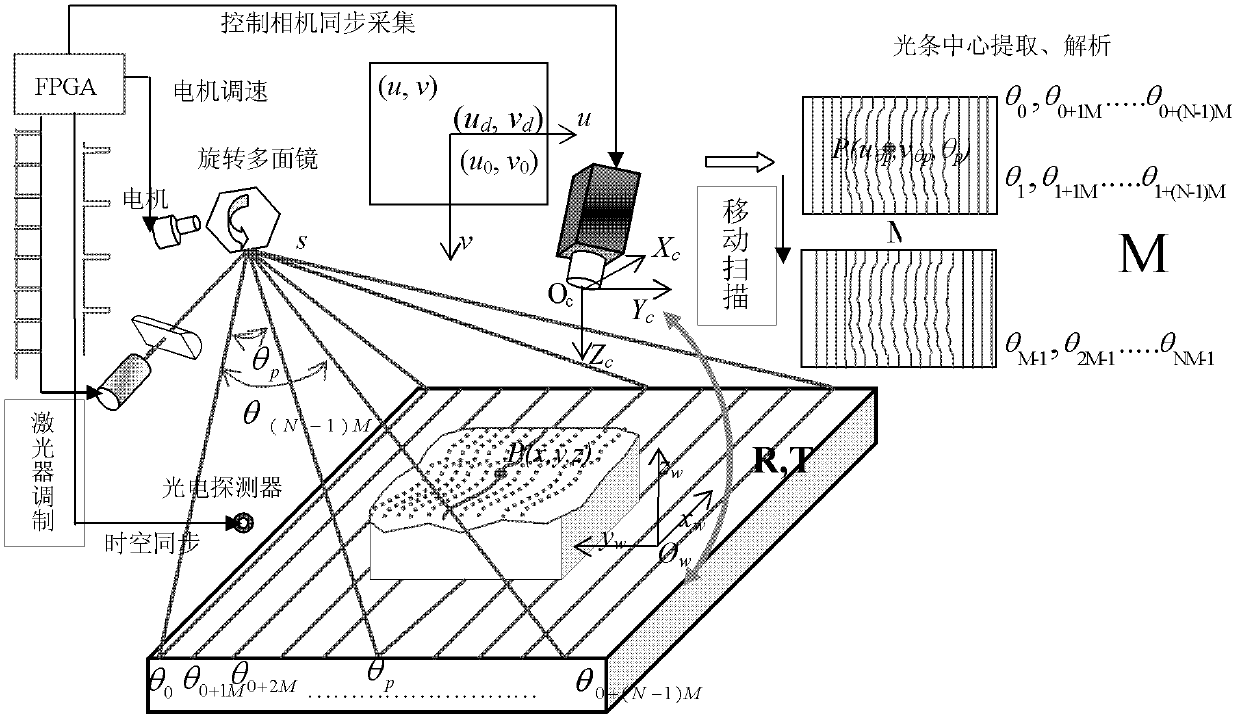

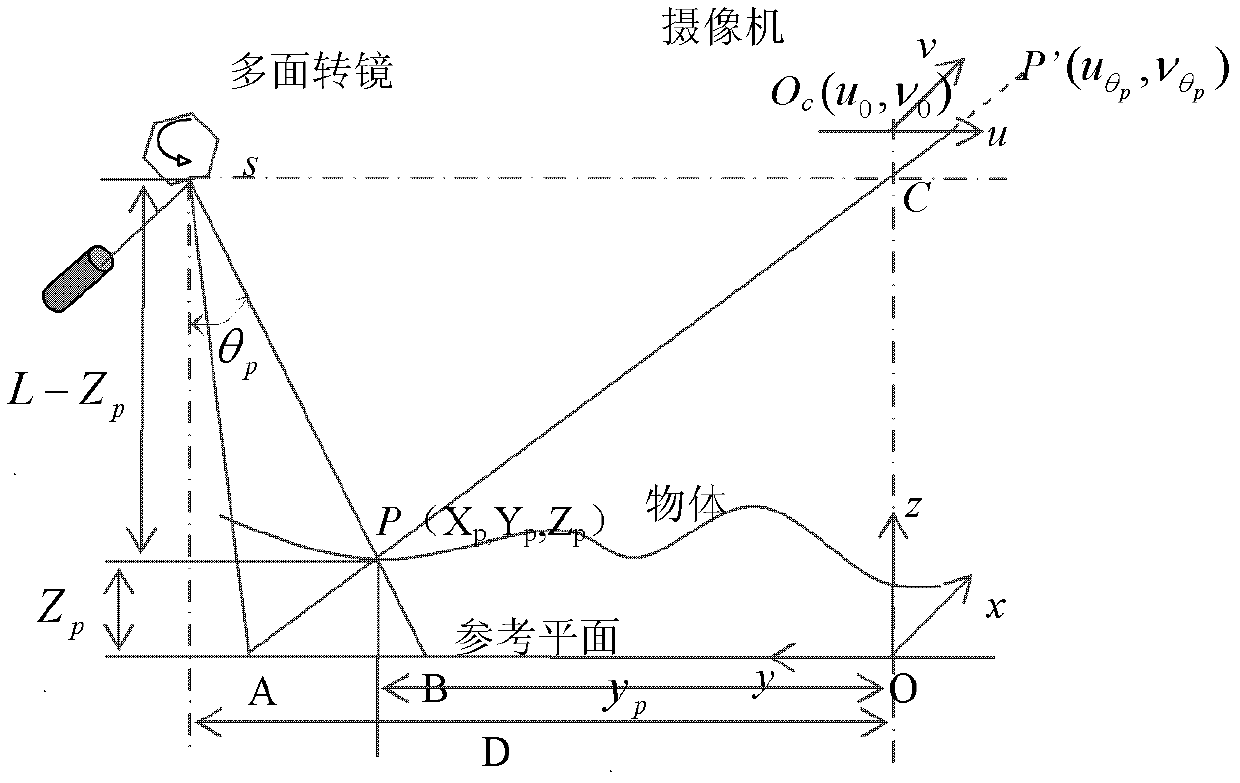

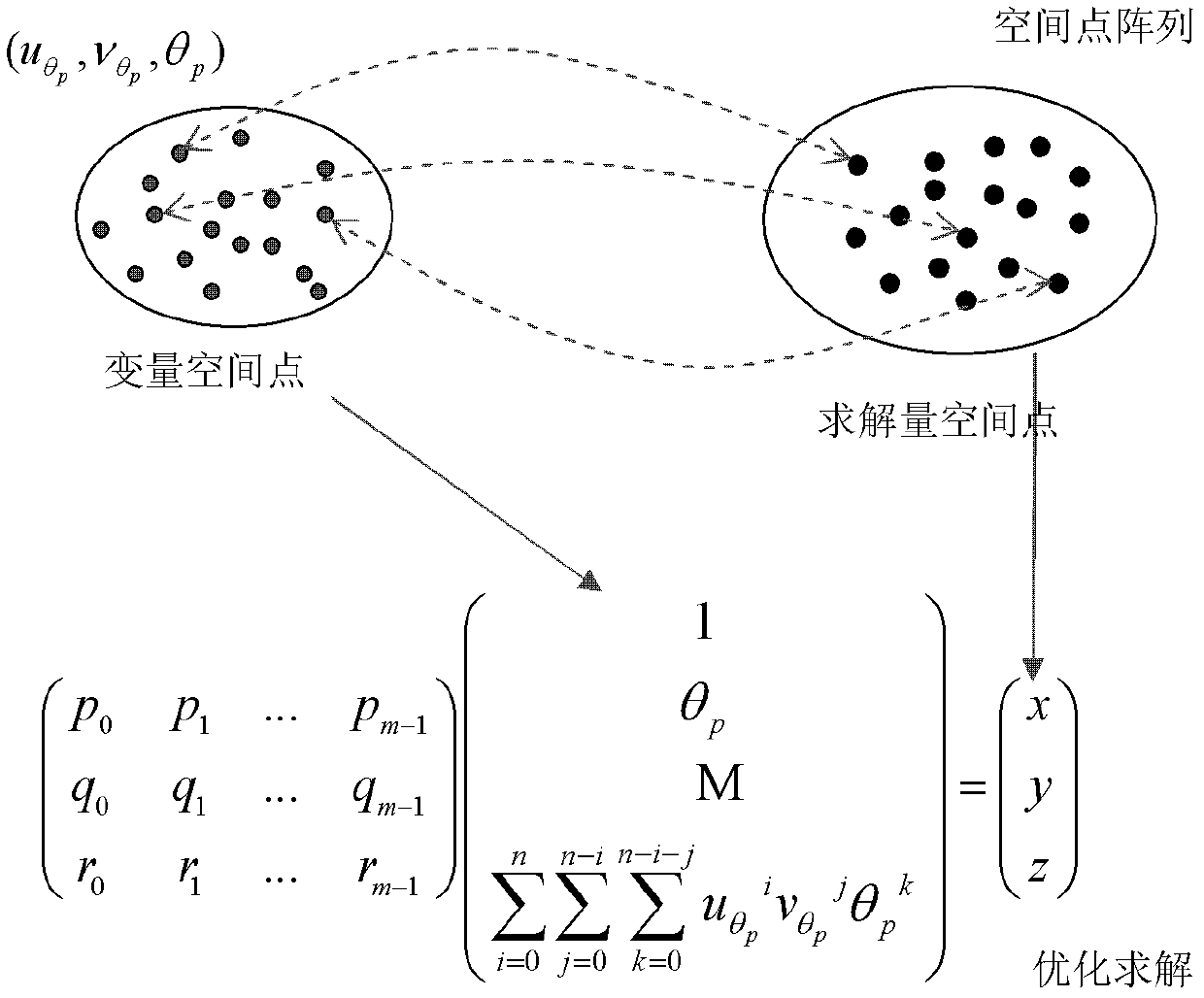

High-speed scanning and overall imaging three-dimensional (3D) measurement method

InactiveCN102589476AFast measurementLittle effect on reflectivityUsing optical meansThree dimensional measurementPrism

The invention relates to a visual inspection technology. In order to meet the requirements of fast and high-accurate surface three-dimensional (3D) topography online measurement and the detection requirements of a production line on intelligence, fastness, high accuracy and low cost, the invention adopts the technical scheme that: a high-speed scanning and overall imaging 3D measurement method comprises the following steps of: carrying out external modulation on a driving power supply by using a laser so as to control the output of a word line laser; rotating a multifaceted prism under the drive of a high-speed motor, wherein line-structured light outputted by the laser is reflected and projected to the surface of a measured object by the multifaceted prism; and placing a photoelectric detector at a position which is the limit position projected by the line-structured light during the rotating process of the multifaceted prism, carrying out exposure on an area-array CCD (Charge-Coupled Device) camera during the process that the line-structured light scans the whole area, and establishing a measurement model, wherein the 3D coordinate (xp, yp, zp) of the surface feature point of the measured object is obtained according to a formula by using an image coordinate (u[theta]p, v[theta]p) formed by the area-array CCD camera and [theta]p. The high-speed scanning and overall imaging 3D measurement method is mainly applied to the fast and high-accurate surface 3D topography online measurement.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com