Patents

Literature

3539results about How to "Fast measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

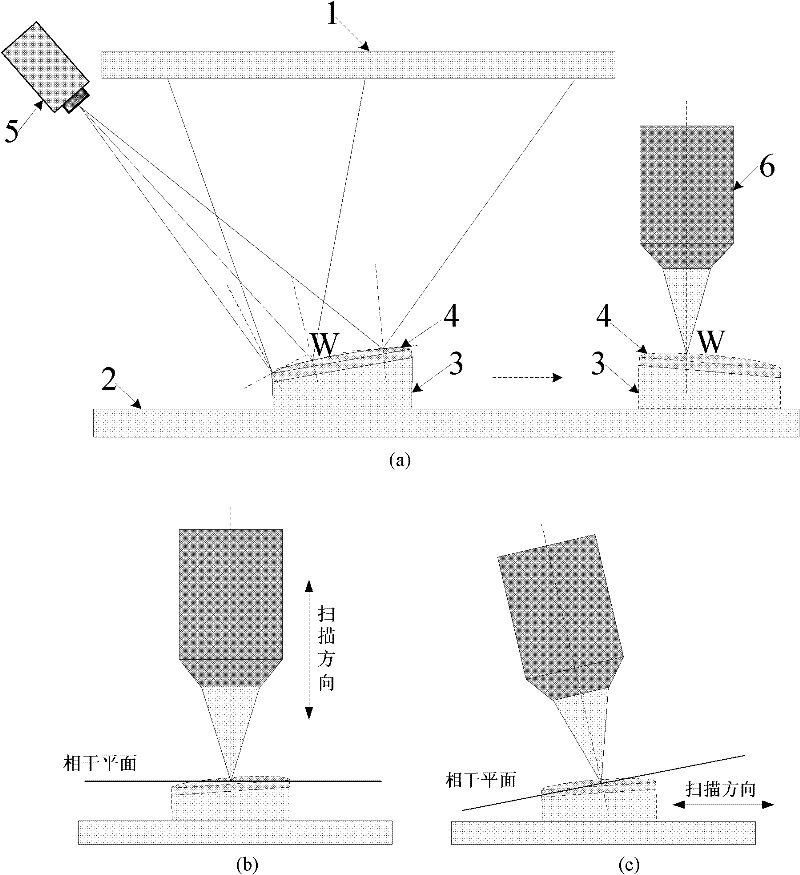

A method of 3D contour measurement of a workpiece on a conveyor belt based on line laser scanning

ActiveCN107578464AHigh measurement accuracyAccurate measurementImage analysisUsing optical meansMobile laser scanningLaser light

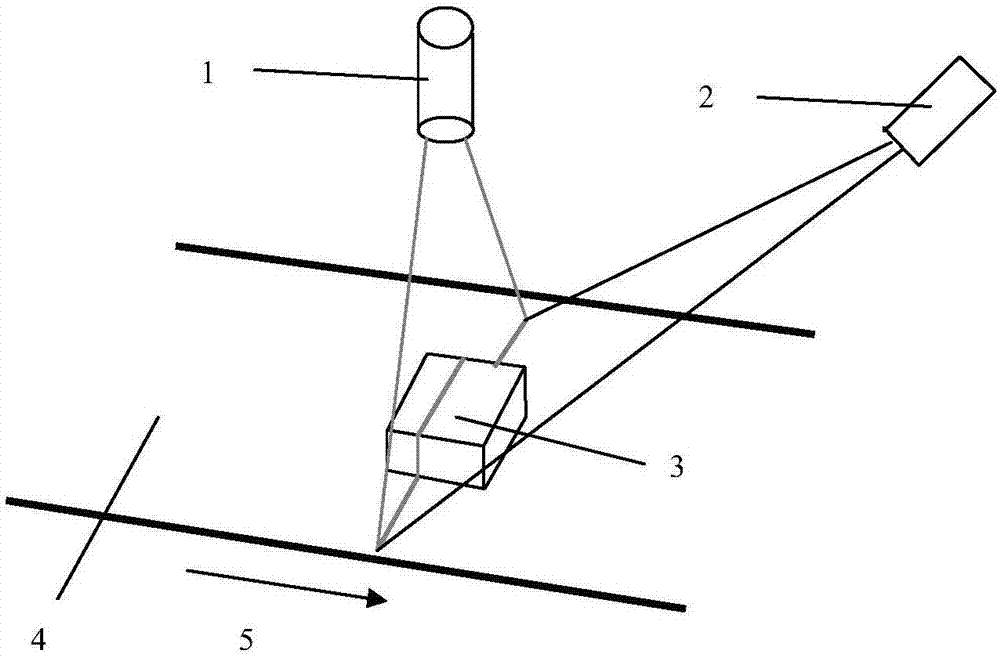

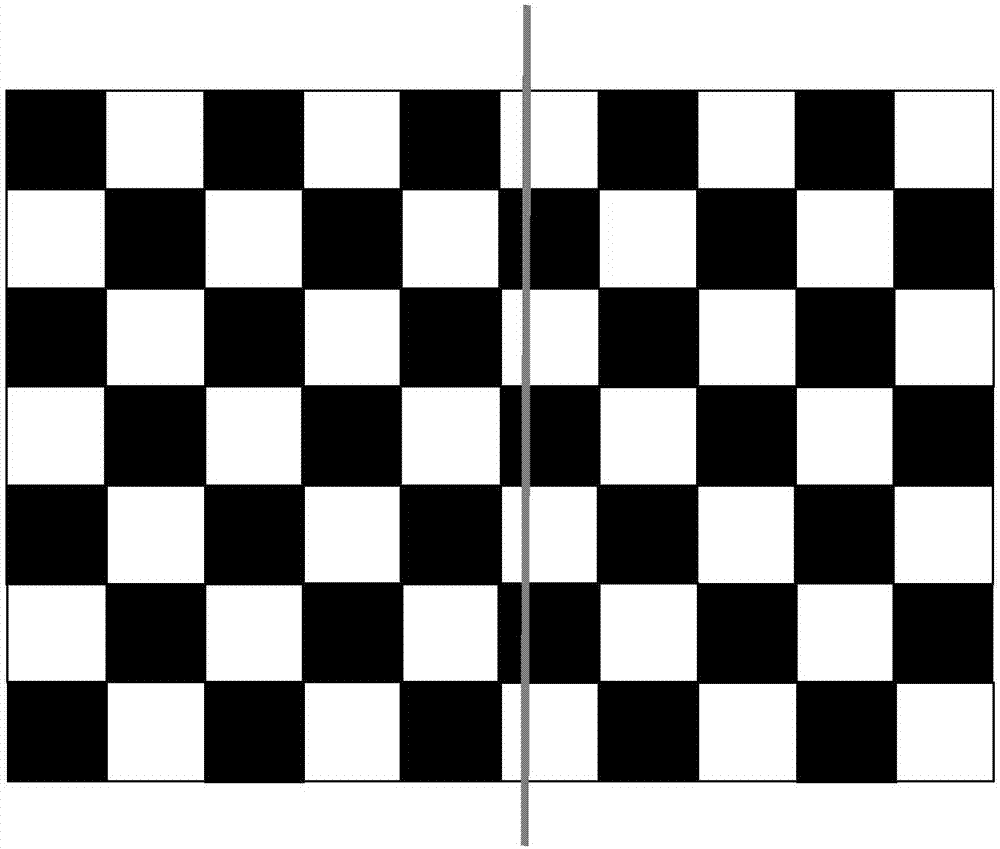

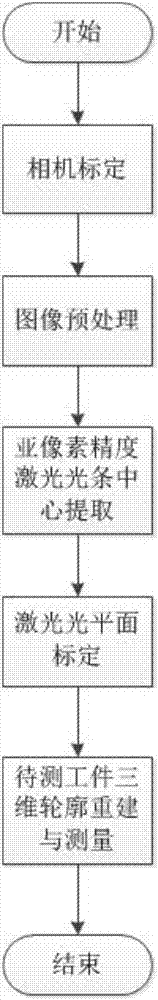

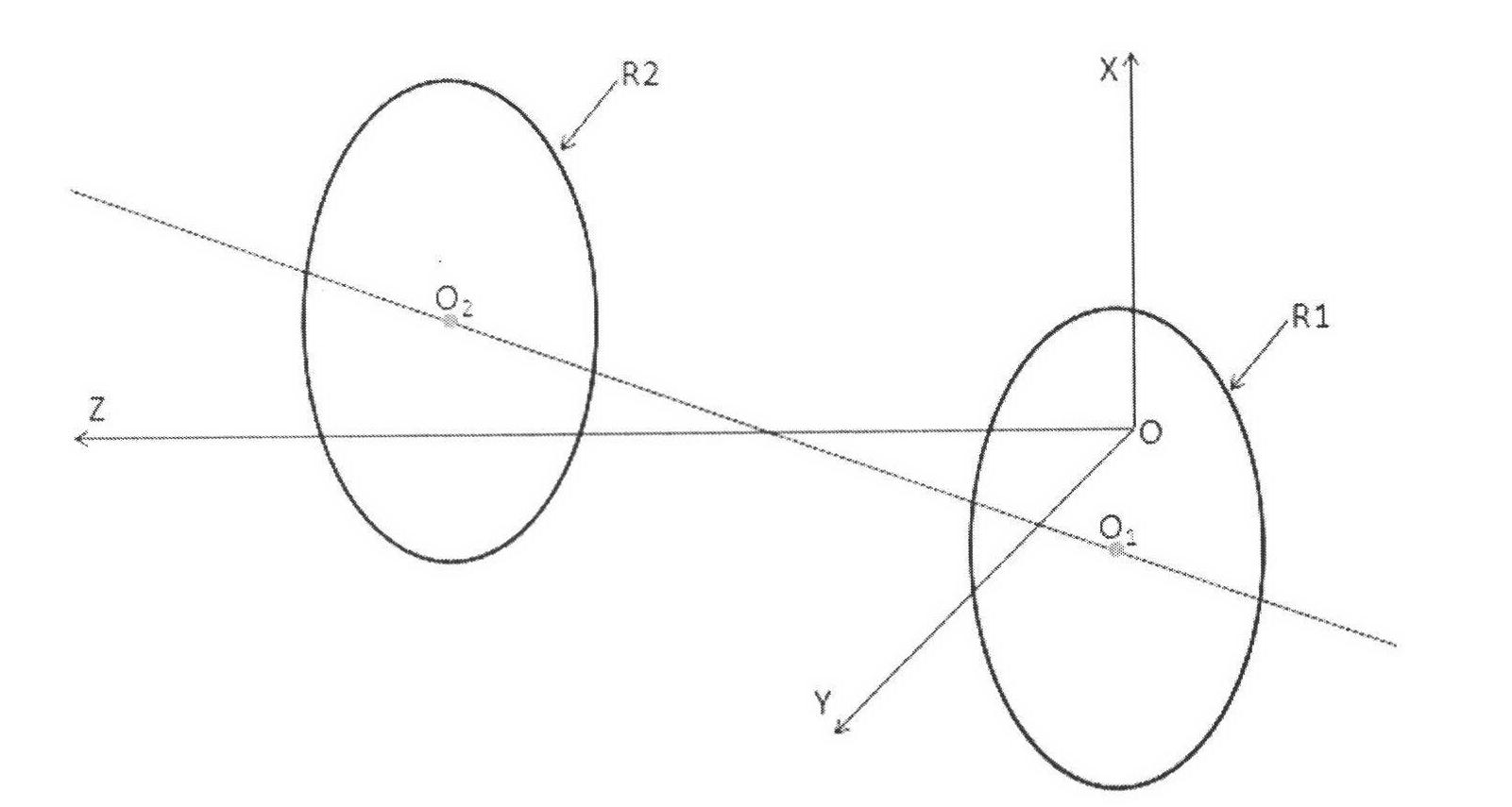

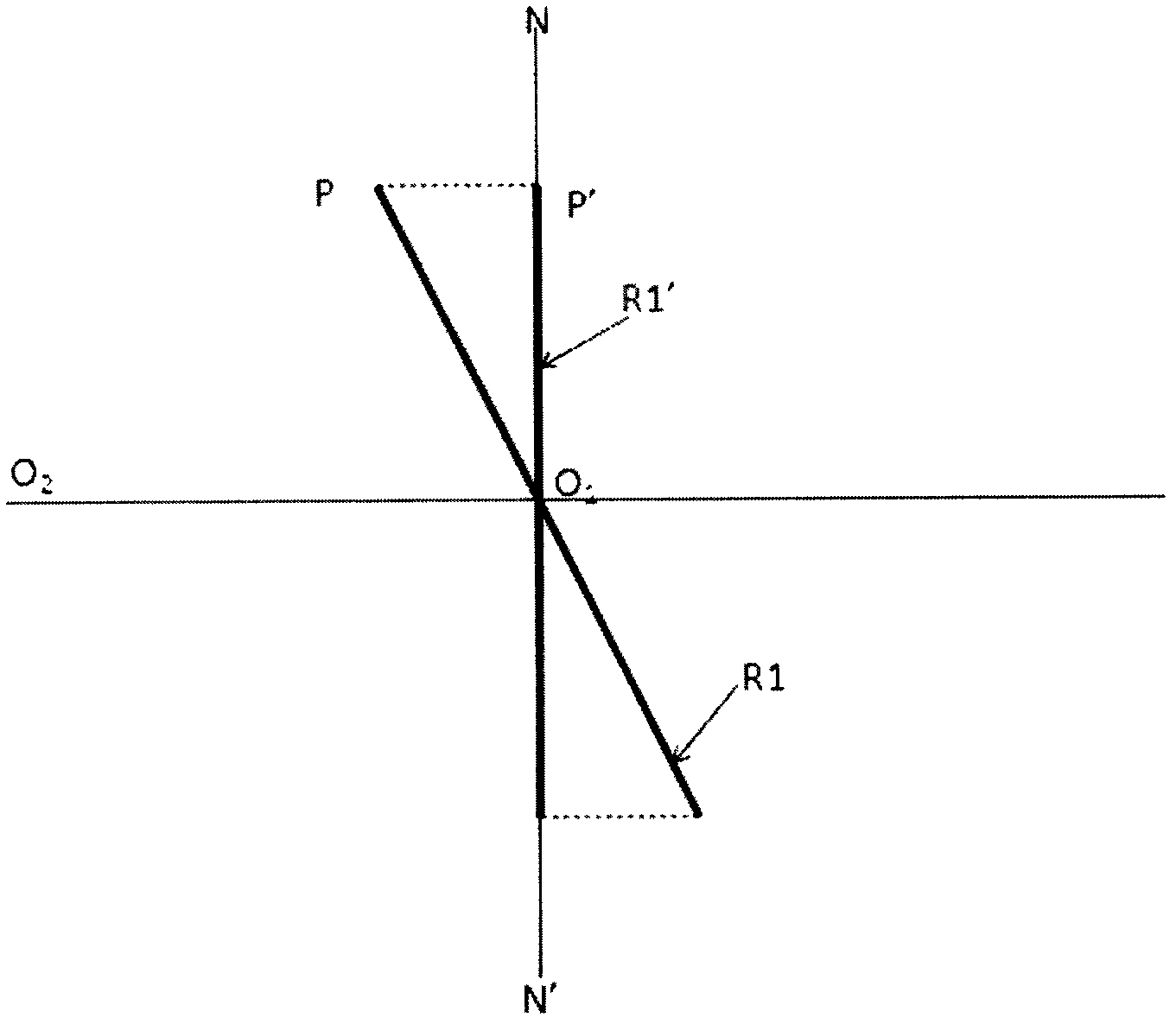

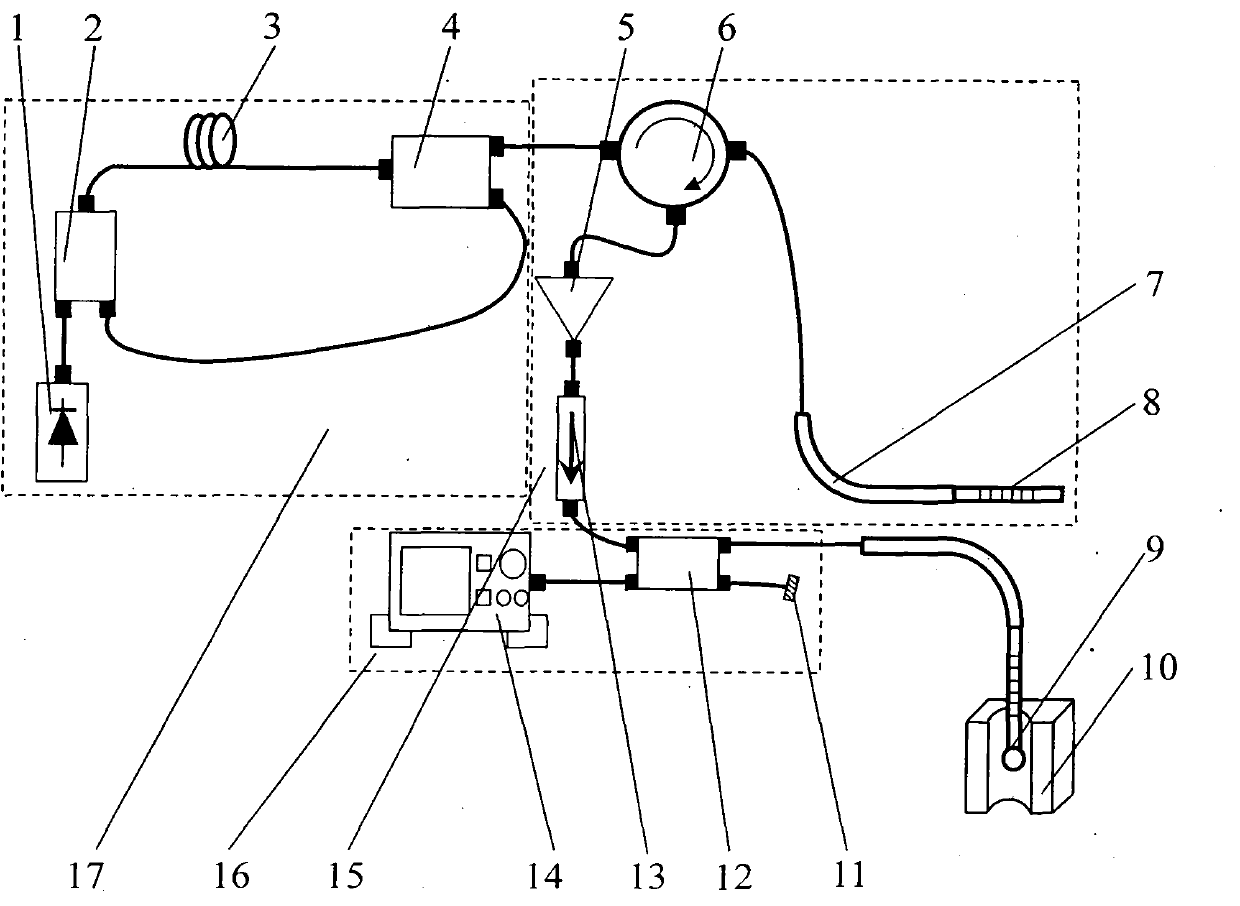

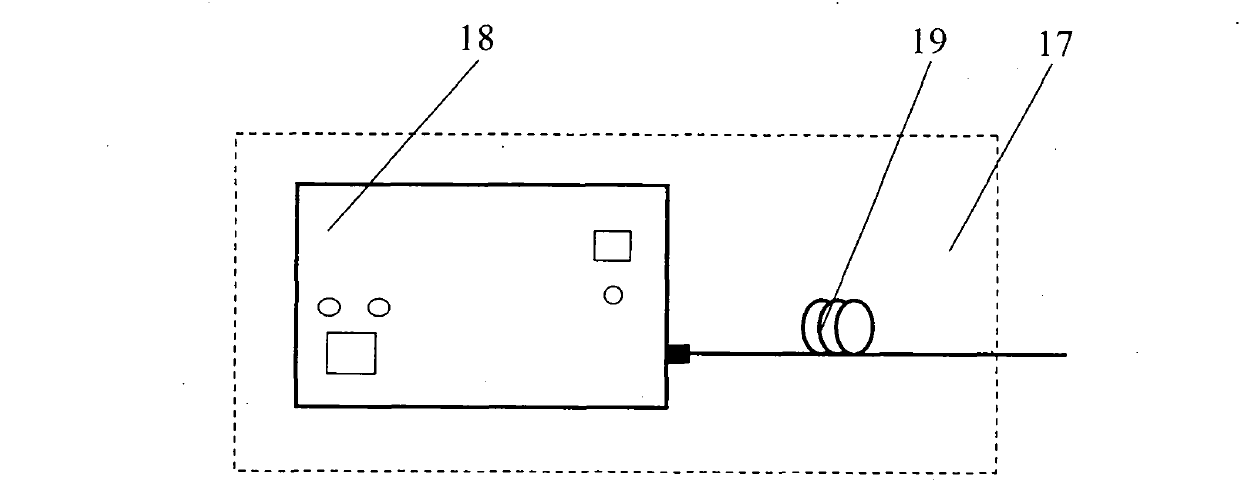

The invention discloses a method of 3D contour measurement of a workpiece on a conveyor belt based on line laser scanning. The method comprises the following steps of obtaining camera internal and external parameters through camera calibration, carrying out filtering and laser light strip center position initial extraction through an image preprocessing step, carrying out sub-pixel precision refinement on the center coordinates of a light bar, obtaining a light plane equation through the laser light plane calibration and finally carrying out reconstruction and measurement of the three-dimensional contour information of a workpiece to be measured. The workpiece 3D contour measurement brought forward by the invention has the following advantages: a high measurement precision which means thethree-dimensional contour information of the workpiece to be measured can be accurately obtained through the laser light bar extraction with sub-pixel precision and 3D reconstruction; a fast measurement speed which means real-time measurement of 3D contour information of the workpiece to be tested can be realized to improve the efficiency of industrial production site operations; and low hardwarecosts which is realized in a hardware implementation mode in which laser is combined with a monocular camera. Accordingly, the technical method of the application has advantages such as being in a non-contact mode, high in measurement precision, fast in speed and low in cost, and can be applied to an industrial automation production process to realize accurate measurement of the 3D contour information of the workpiece on the conveyor belt.

Owner:CHANGSHA XIANGJI HAIDUN TECH CO LTD

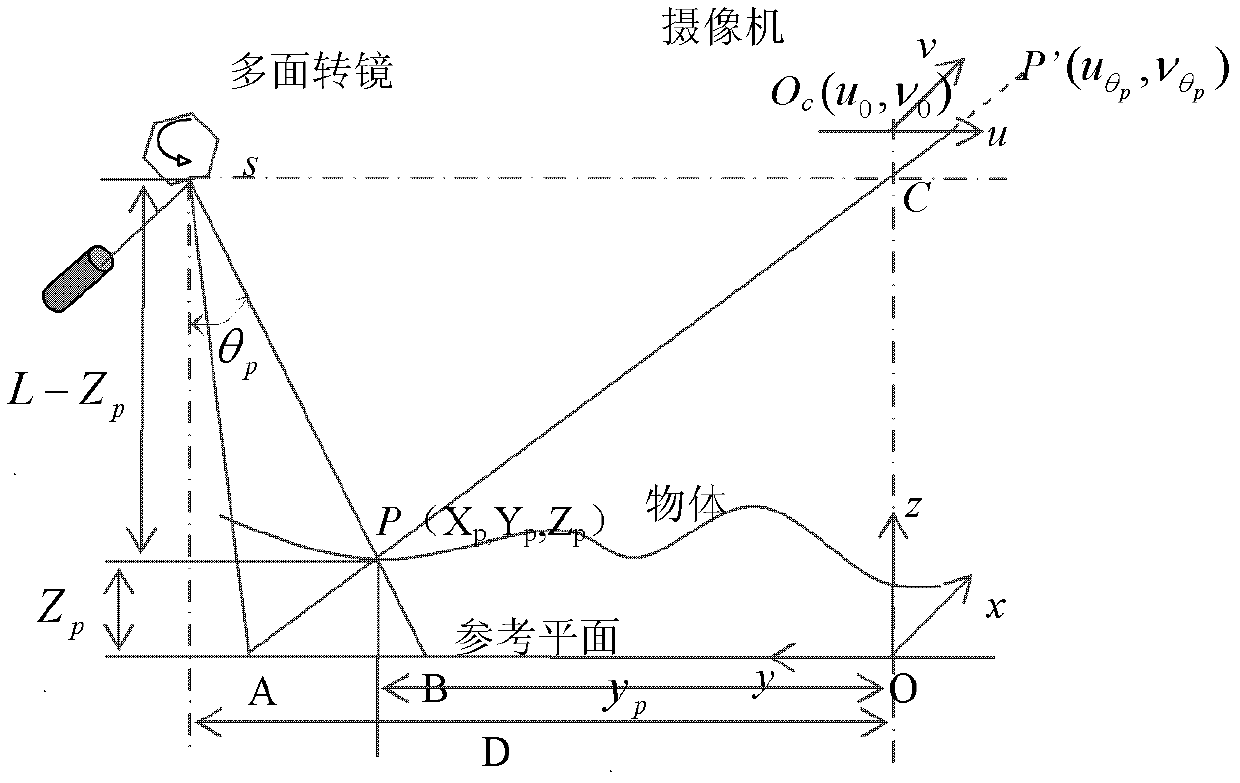

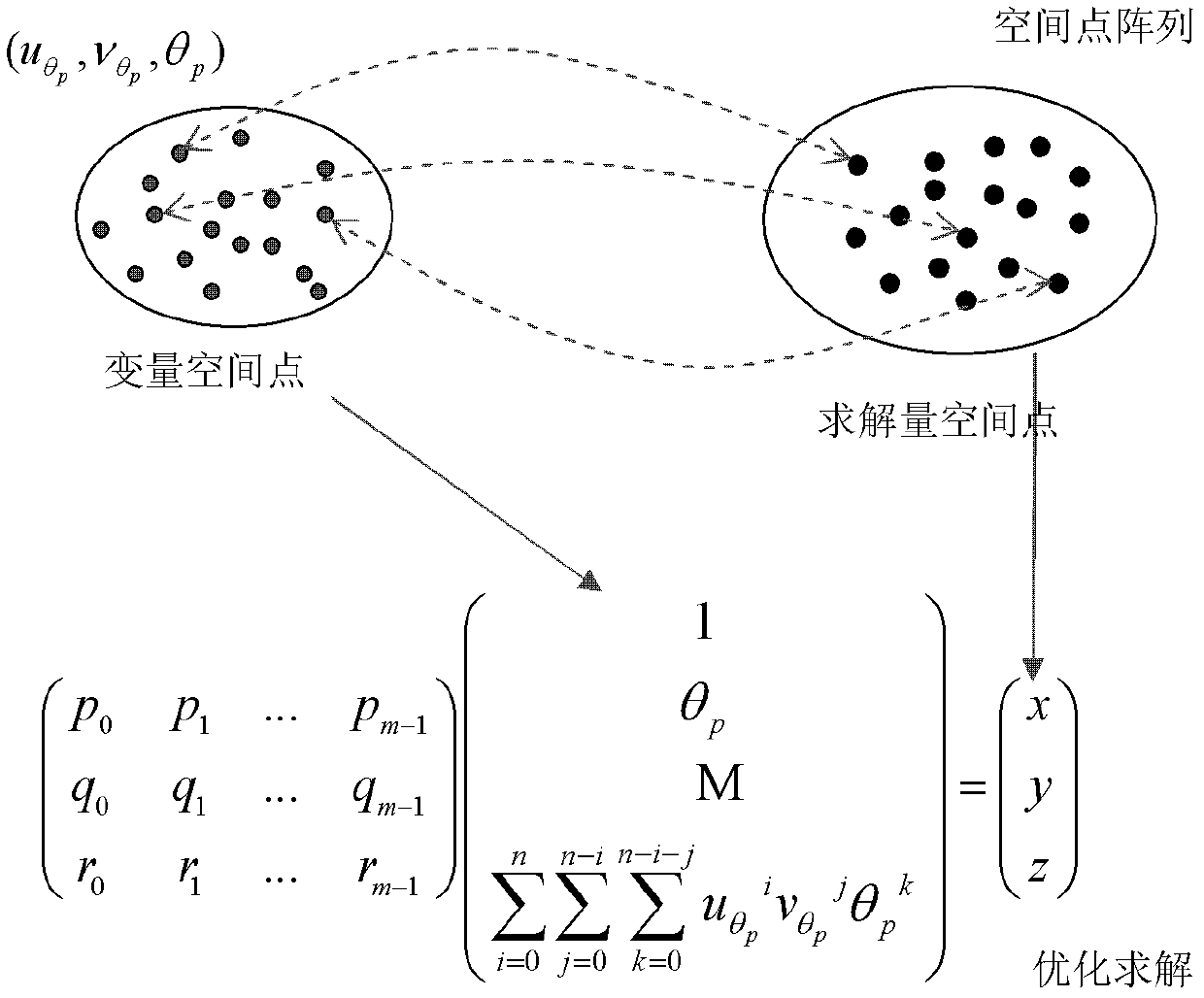

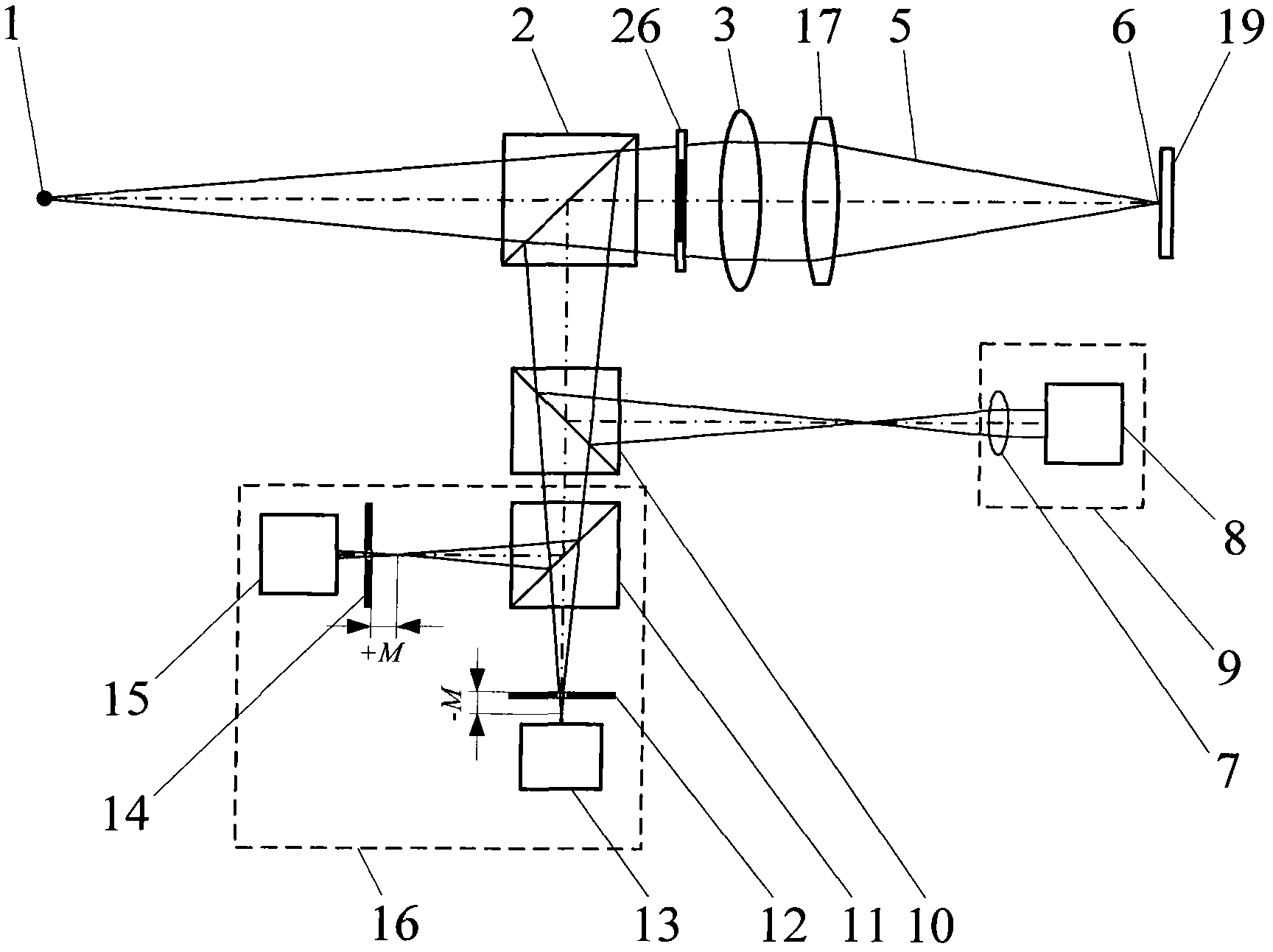

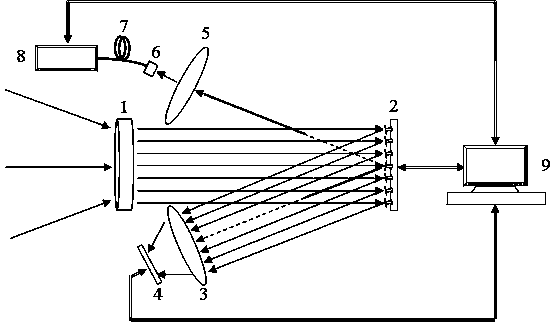

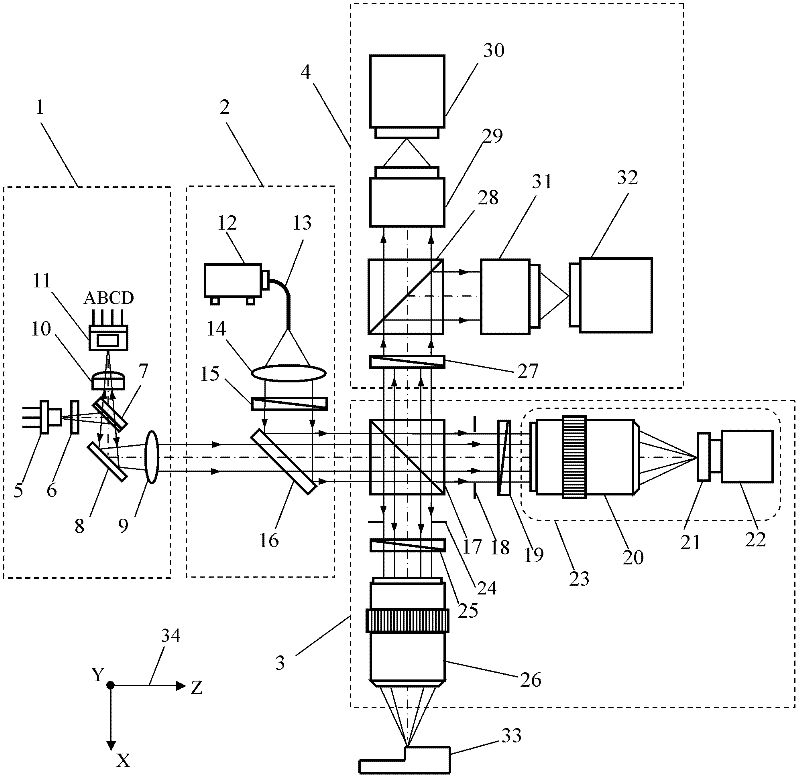

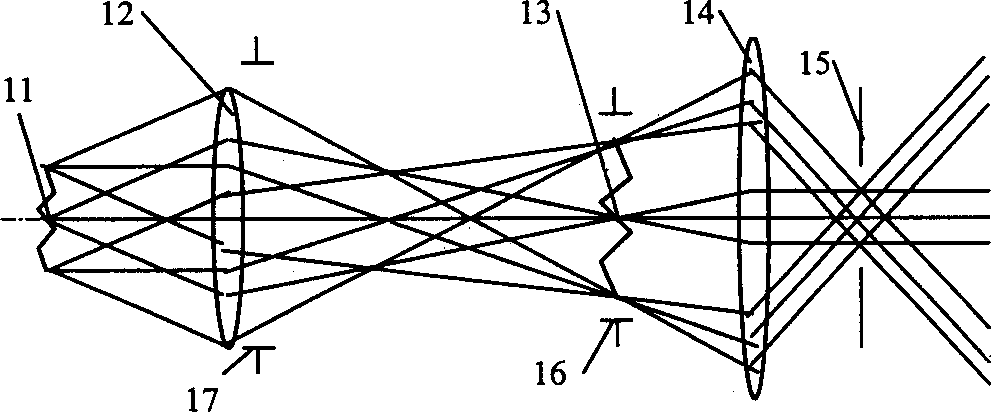

High-speed scanning and overall imaging three-dimensional (3D) measurement method

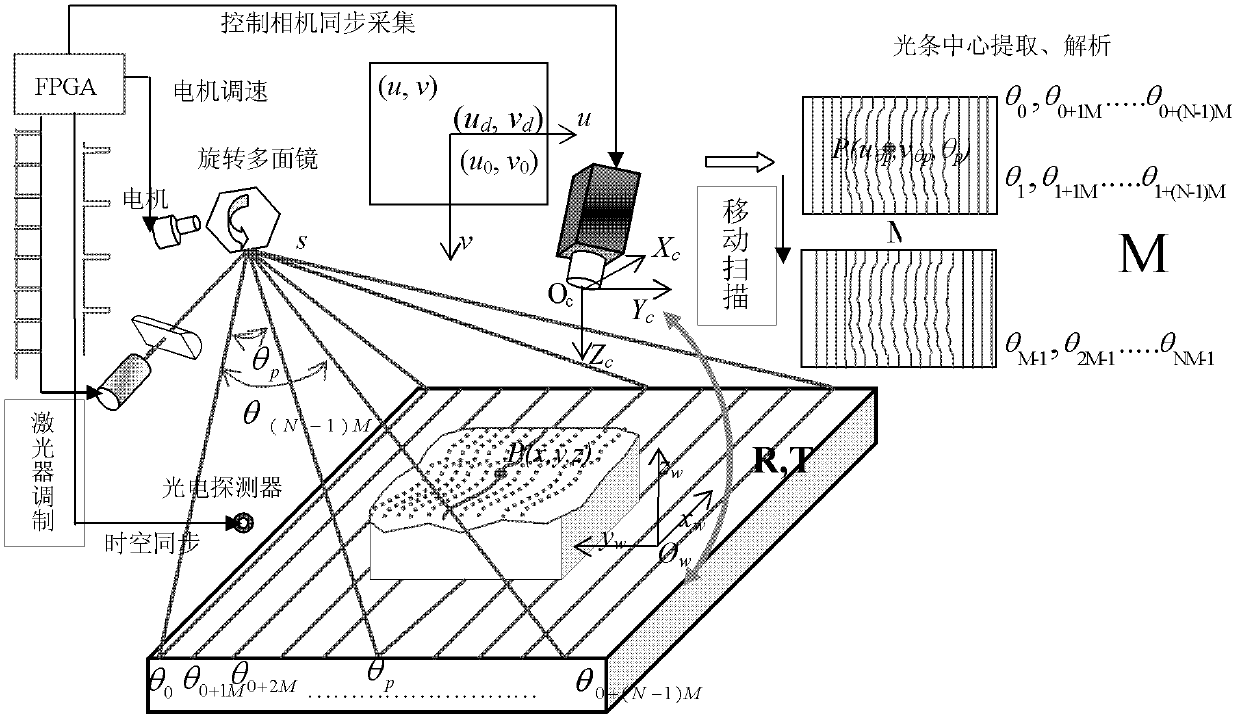

InactiveCN102589476AFast measurementLittle effect on reflectivityUsing optical meansThree dimensional measurementPrism

The invention relates to a visual inspection technology. In order to meet the requirements of fast and high-accurate surface three-dimensional (3D) topography online measurement and the detection requirements of a production line on intelligence, fastness, high accuracy and low cost, the invention adopts the technical scheme that: a high-speed scanning and overall imaging 3D measurement method comprises the following steps of: carrying out external modulation on a driving power supply by using a laser so as to control the output of a word line laser; rotating a multifaceted prism under the drive of a high-speed motor, wherein line-structured light outputted by the laser is reflected and projected to the surface of a measured object by the multifaceted prism; and placing a photoelectric detector at a position which is the limit position projected by the line-structured light during the rotating process of the multifaceted prism, carrying out exposure on an area-array CCD (Charge-Coupled Device) camera during the process that the line-structured light scans the whole area, and establishing a measurement model, wherein the 3D coordinate (xp, yp, zp) of the surface feature point of the measured object is obtained according to a formula by using an image coordinate (u[theta]p, v[theta]p) formed by the area-array CCD camera and [theta]p. The high-speed scanning and overall imaging 3D measurement method is mainly applied to the fast and high-accurate surface 3D topography online measurement.

Owner:TIANJIN UNIV

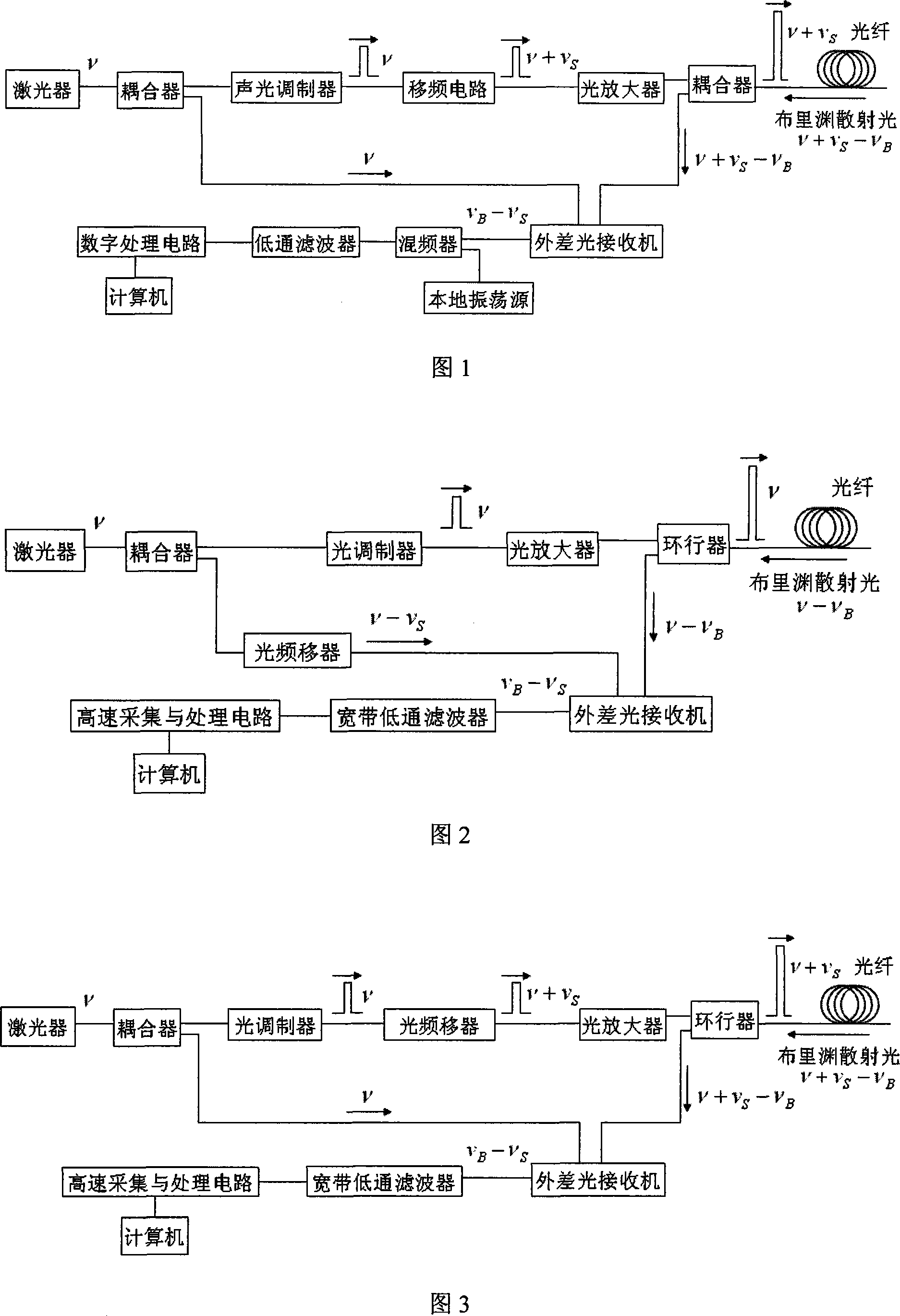

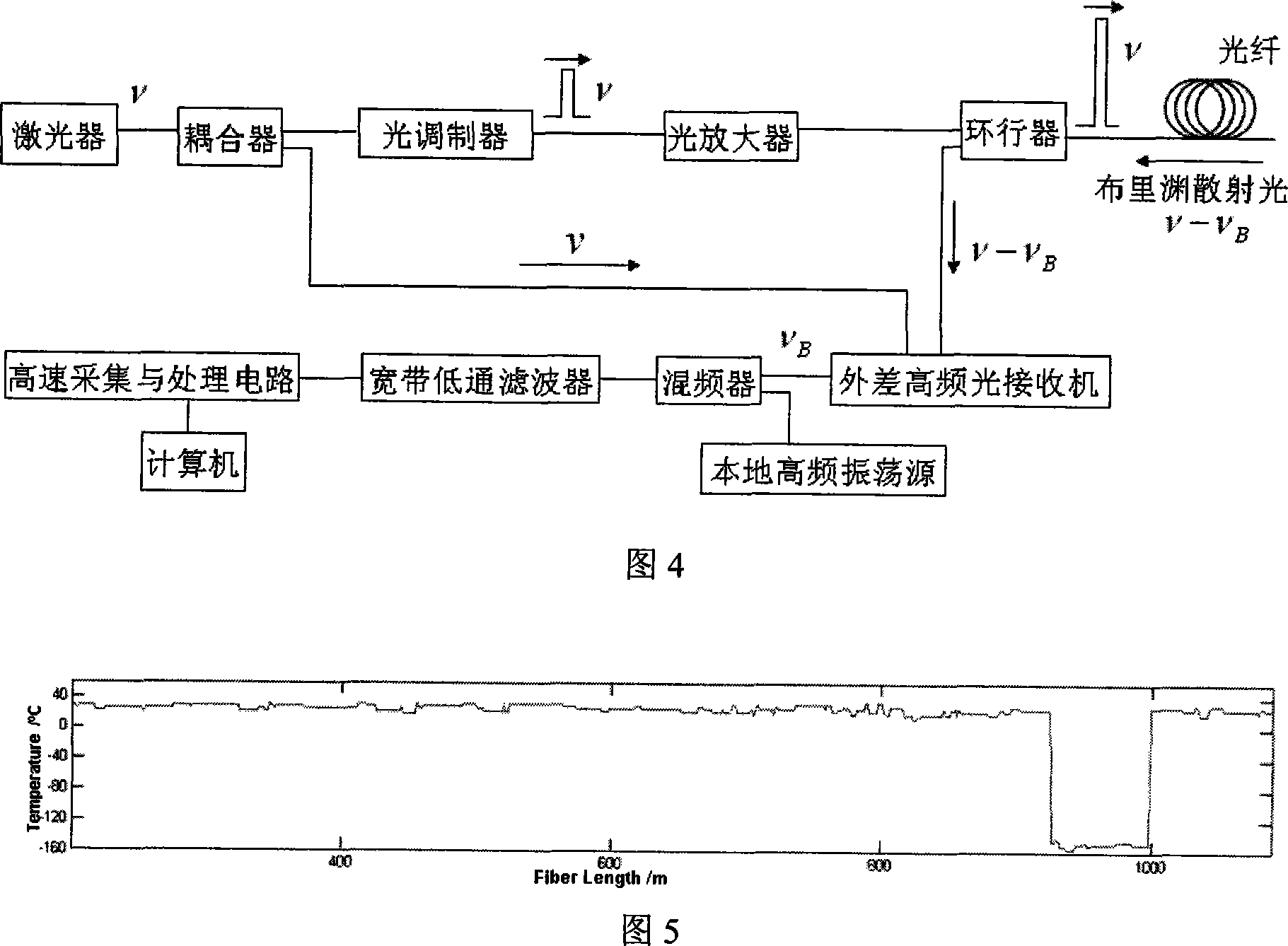

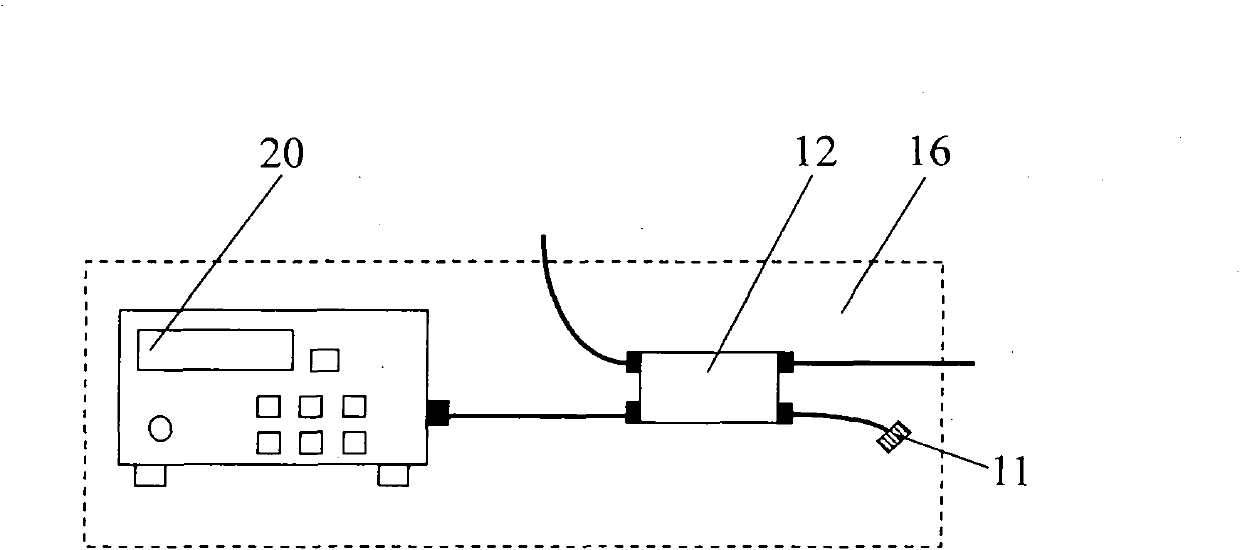

Brillouin optical time domain reflection measuring method based on quick fourier transform

InactiveCN101144729AFast measurementHigh measurement accuracyThermometers using physical/chemical changesUsing optical meansTime domainSignal-to-noise ratio (imaging)

The invention interferes local reference light with Brillouin diffused light transferred back by a sensing optical fiber, a Brillouin diffused spectrum electrical signal generated completely passes through a broadband low pass wave filter, the sampling is performed by the high speed acquisition and the processing circuit, a quick speed Fourier transformation is performed, a Brillouin diffused spectrum is obtained; then a Lorentz fitting is performed, and a Brillouin frequency shift of each unit on the whole optical fiber is obtained finally; the relation of the Brillouin diffused spectrum, and the strain or the temperature is utilized to realize a full-distribution type measurement of the strain or the temperature. The whole Brillouin diffused spectrum on the whole sensing optical fiber can be obtained in an impulse detecting circle by a processing method of the high speed acquisition, and the processing circuit and the quick speed Fourier transformation adopted by the invention, the measuring speed is improved to an order of magnitude compared with the prior technology on the premise of not decreasing the resolution of a measuring space and the measuring accuracy, thereby improving a speech to noise ratio to more than a plurality of times, the measuring accuracy is improved to a great extent, and the structure of the invention device is simple.

Owner:NANJING UNIV

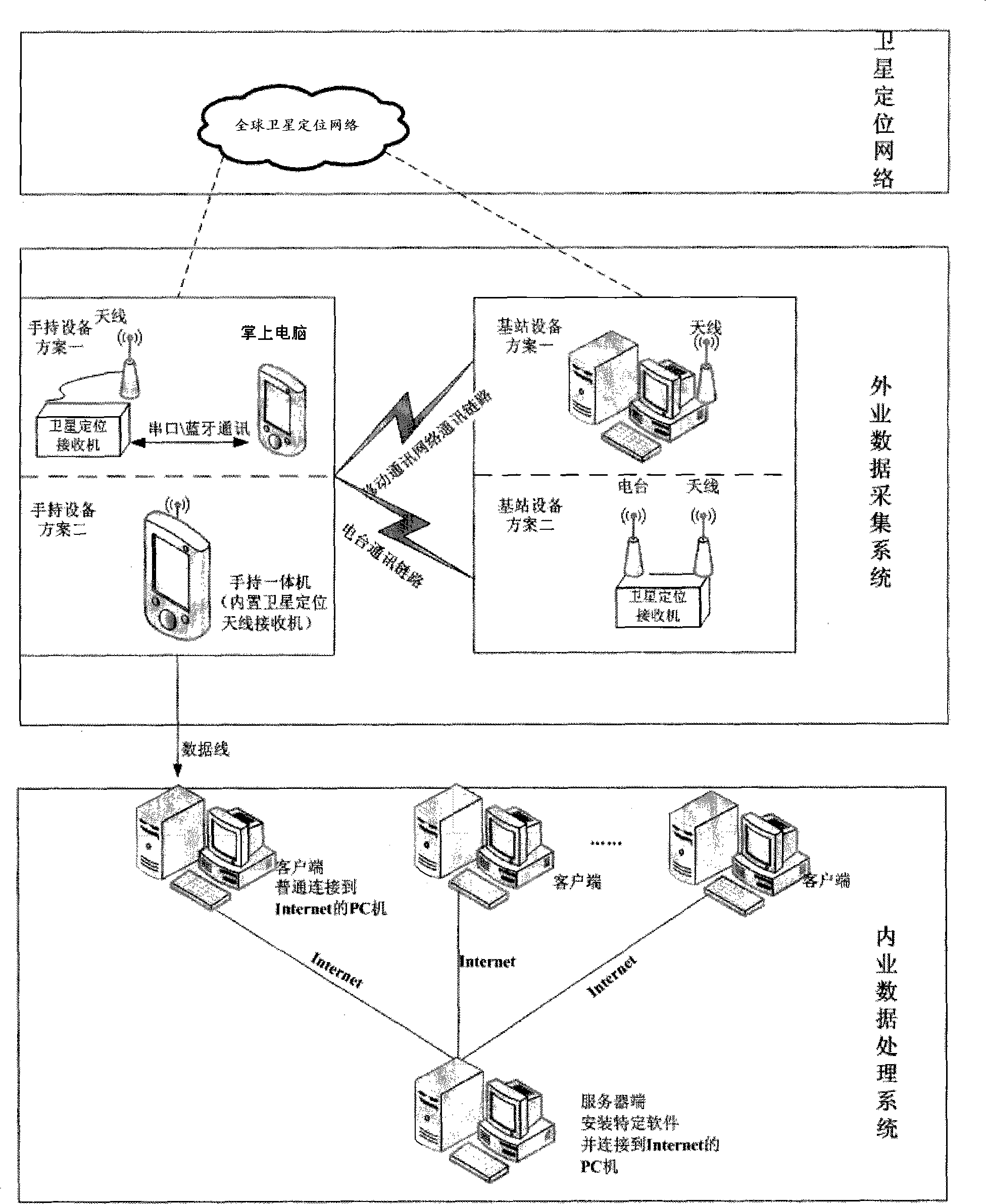

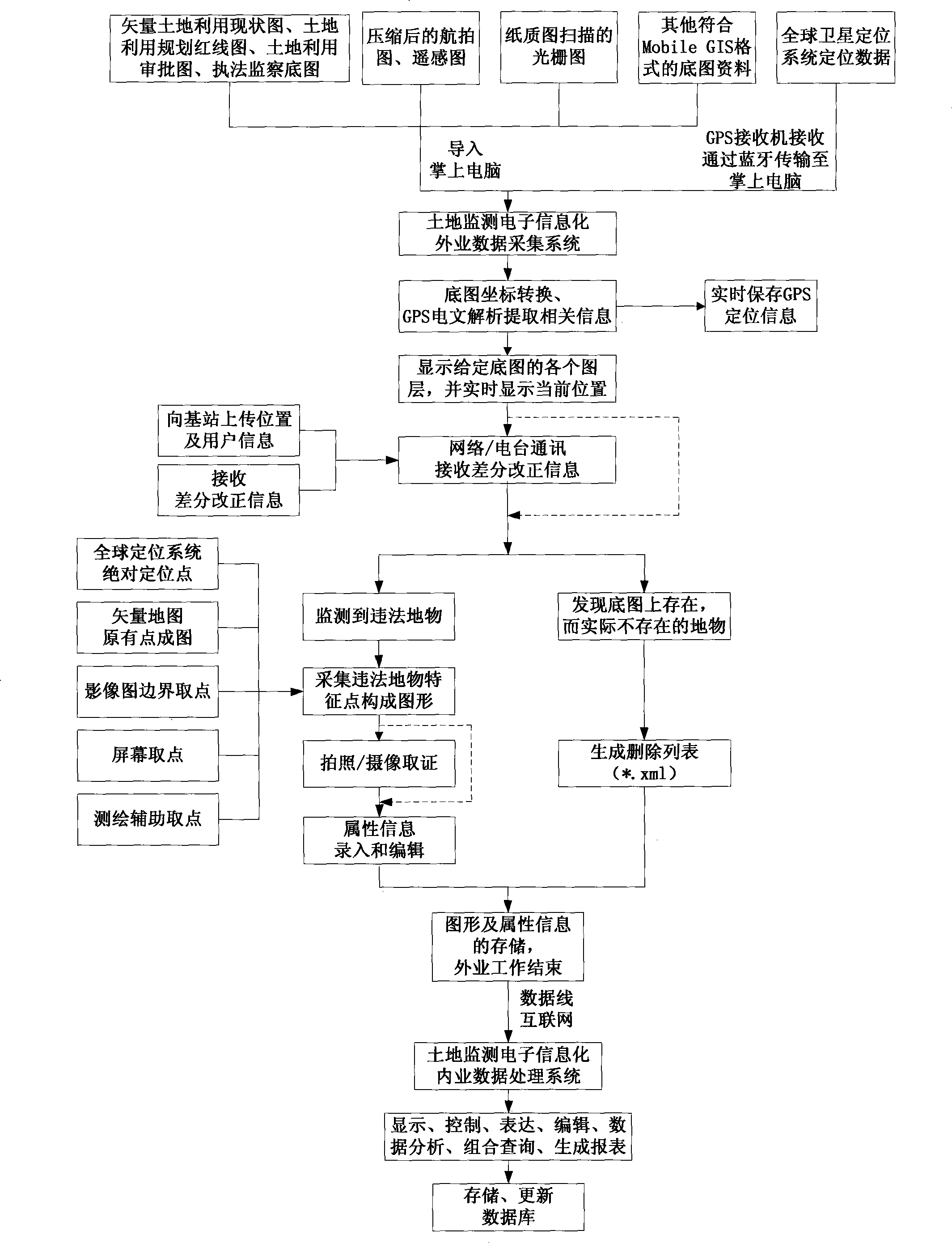

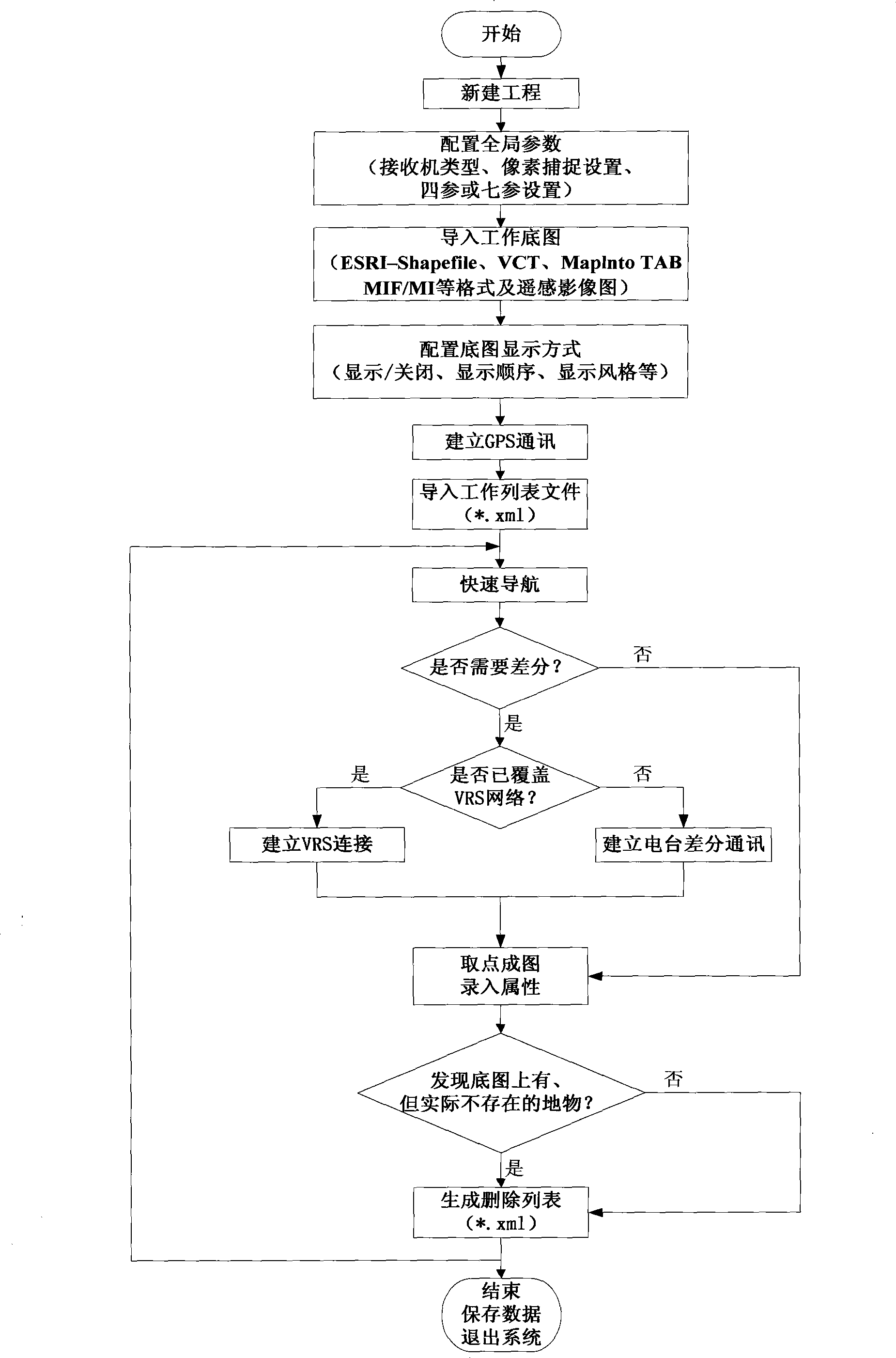

Electronic information system for earth monitor and method thereof

InactiveCN101452072AMeet real needsGuaranteed real-time updatesPosition fixationSatellite radio beaconingTerrainData acquisition

The present invention provides an electronic information system and a method thereof, and constructs two sets of subsystems of field data collecting and indoor data processing. The field data collecting system is based on a Mobile GIS platform and is combined with GPS positioning, GPRS network, bluetooth communication, etc. The field data collecting system realizes high-precision positioning of earth monitoring, uses different methods for executing difference positioning, digital information collecting, eraser list constructing, photograph taking / camera shooting evidence obtaining and terrain hyperlinking for realizing electronic information of field land surveying at the state with / without VRS network. The indoor data processing system is based on SuperMap GIS developing platform and Browser / Server structure, and is combined with XML data interchange, spatial geographical coordinate projection switching, overlapping analyzing, etc. The indoor data processing system realizes multiple functions of indoor multi-source map data expression and operation, combined inquiry, report generation, land monitoring database updating, property formwork customizing, etc., and realizes electronic information of indoor land monitoring operation.

Owner:SOUTHEAST UNIV

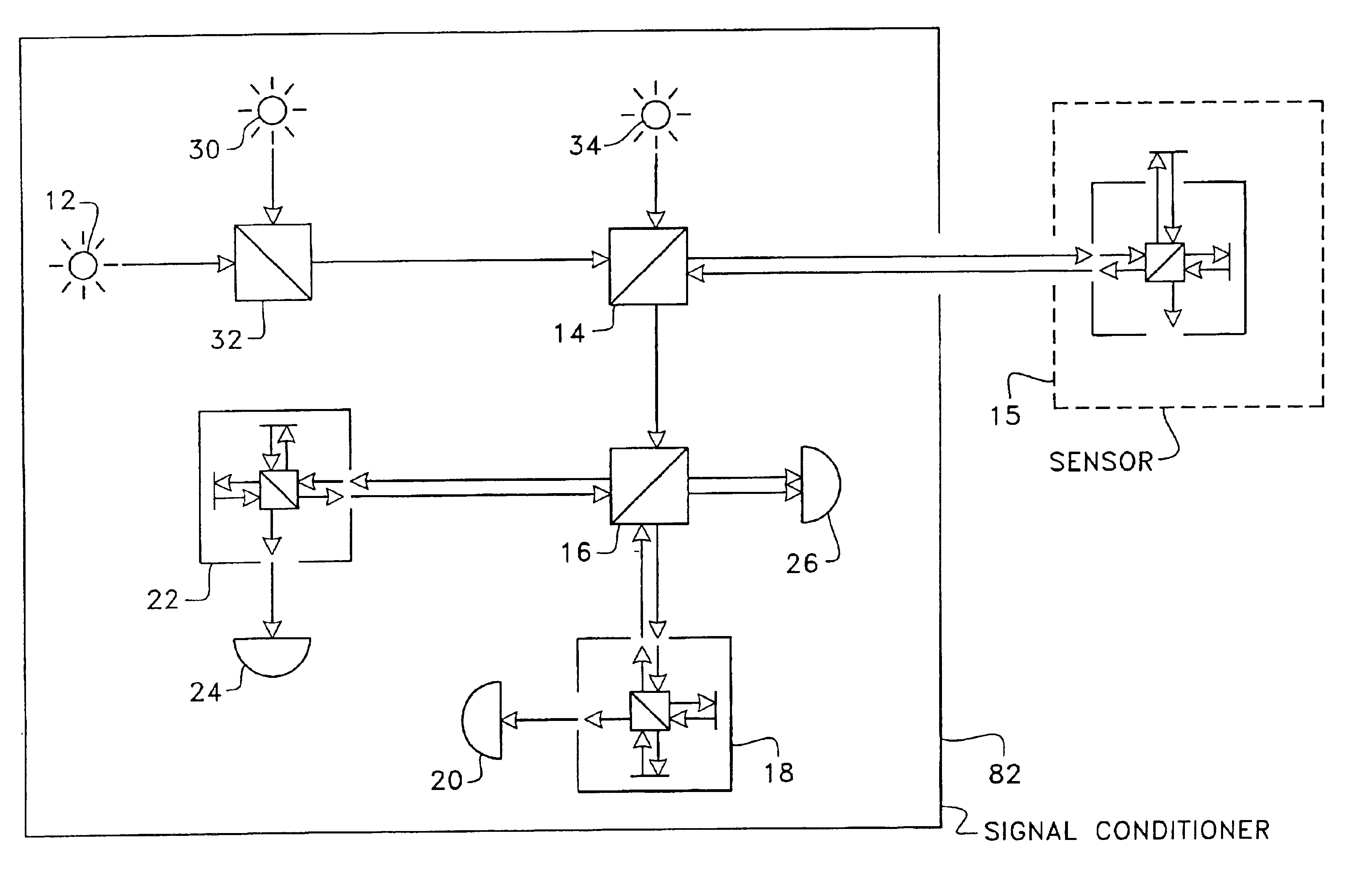

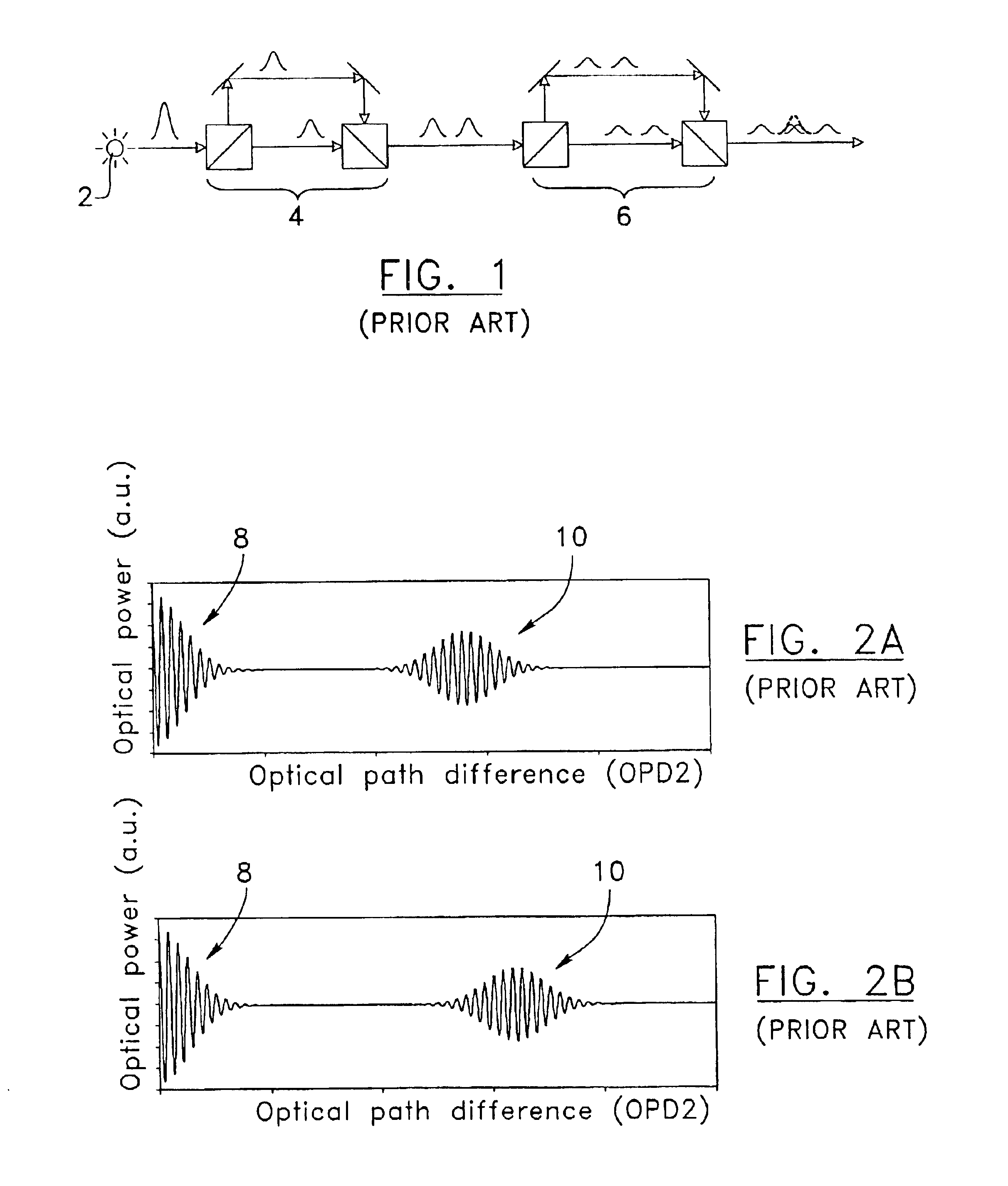

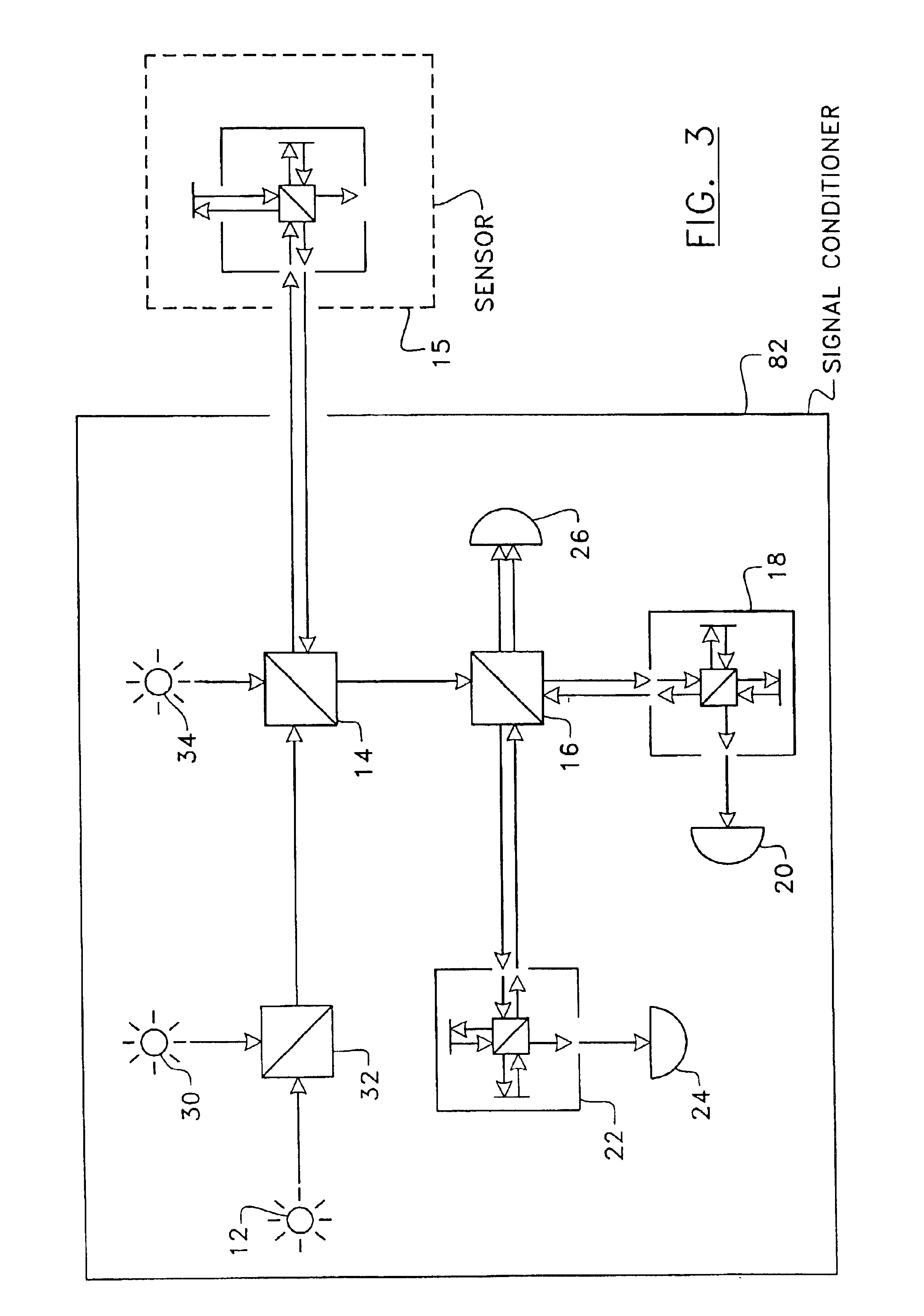

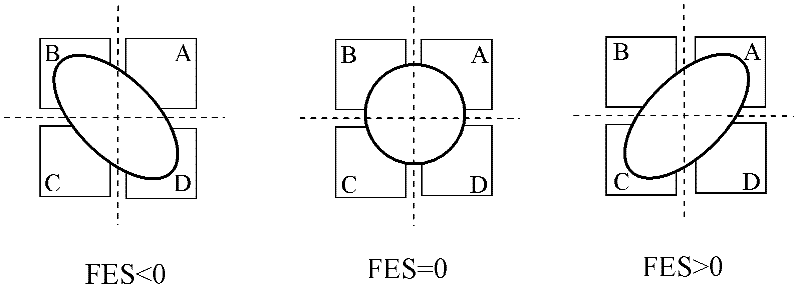

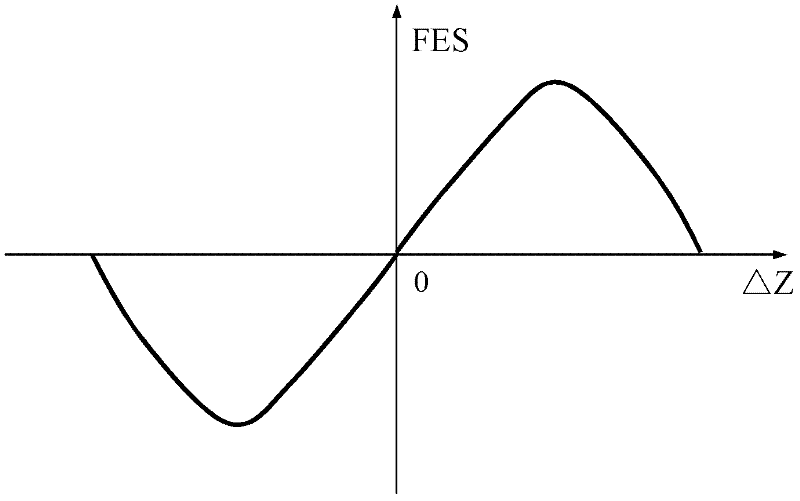

System and method for measuring an optical path difference in a sensing interferometer

ActiveUS6842254B2Robust and reliable measurementFast measurementInterferometersUsing optical meansLight beamAbsolute measurement

An apparatus and a method of measuring an optical path difference in a sensing interferometer. Light from a source is directed in the sensing interferometer. The light reflected from the sensing interferometer is splitted into first and second beams respectively directed into two reference interferometers having optical path differences greater than the coherence length of the source and such that the optical signals are in quadrature. The intensities of the light transmitted by the reference interferometers and recombined light reflected from the reference interferometers are detected for measuring the optical path difference in the sensing interferometer. Additional light sources allow for correction of internal perturbations and absolute measurement of the optical path difference in the sensing interferometer.

Owner:FISO TECH

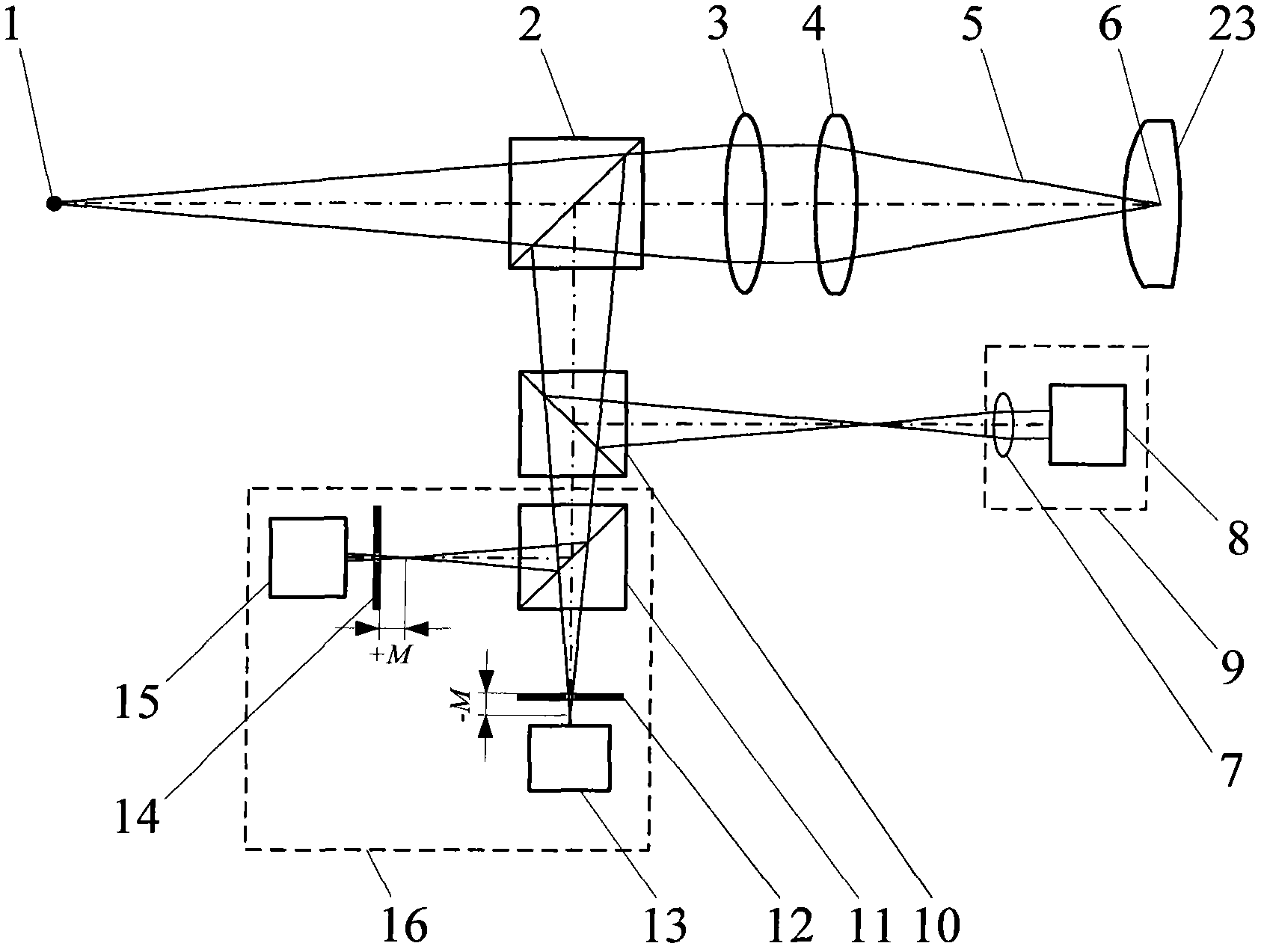

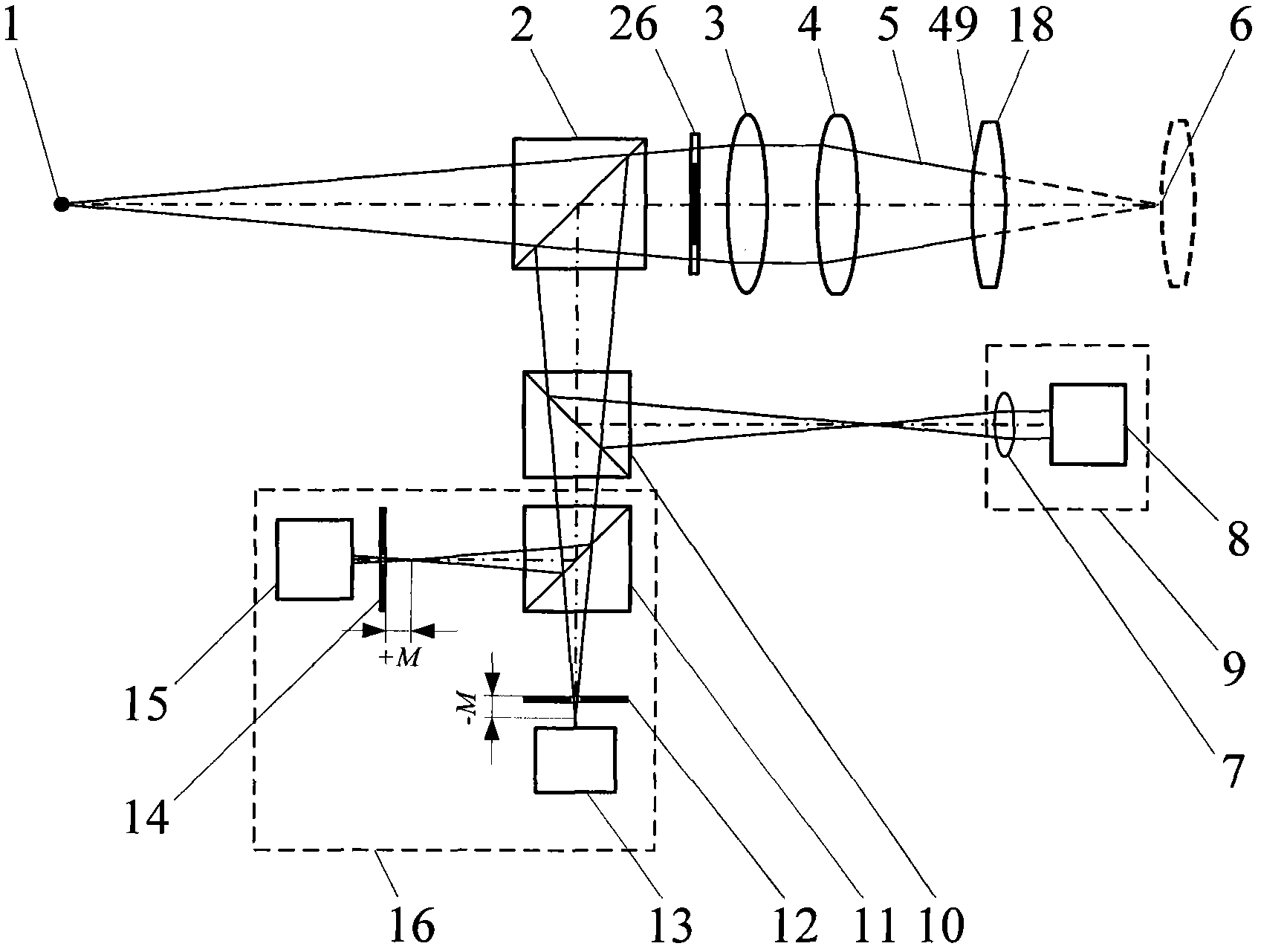

Method and device for measuring multiple element parameters in differential con-focus interference manner

ActiveCN102147240ARealize simultaneous measurementAchieve precise positioningPhase-affecting property measurementsUsing optical meansConsMeasurement precision

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

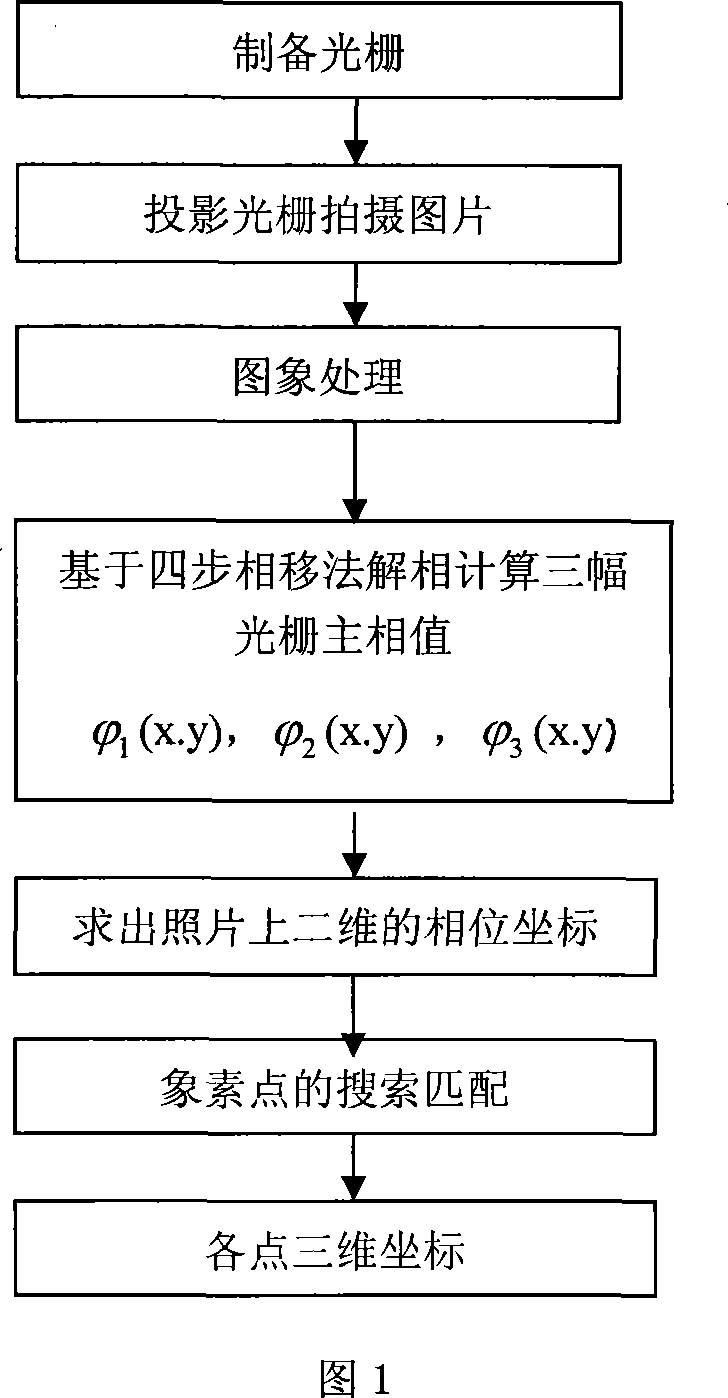

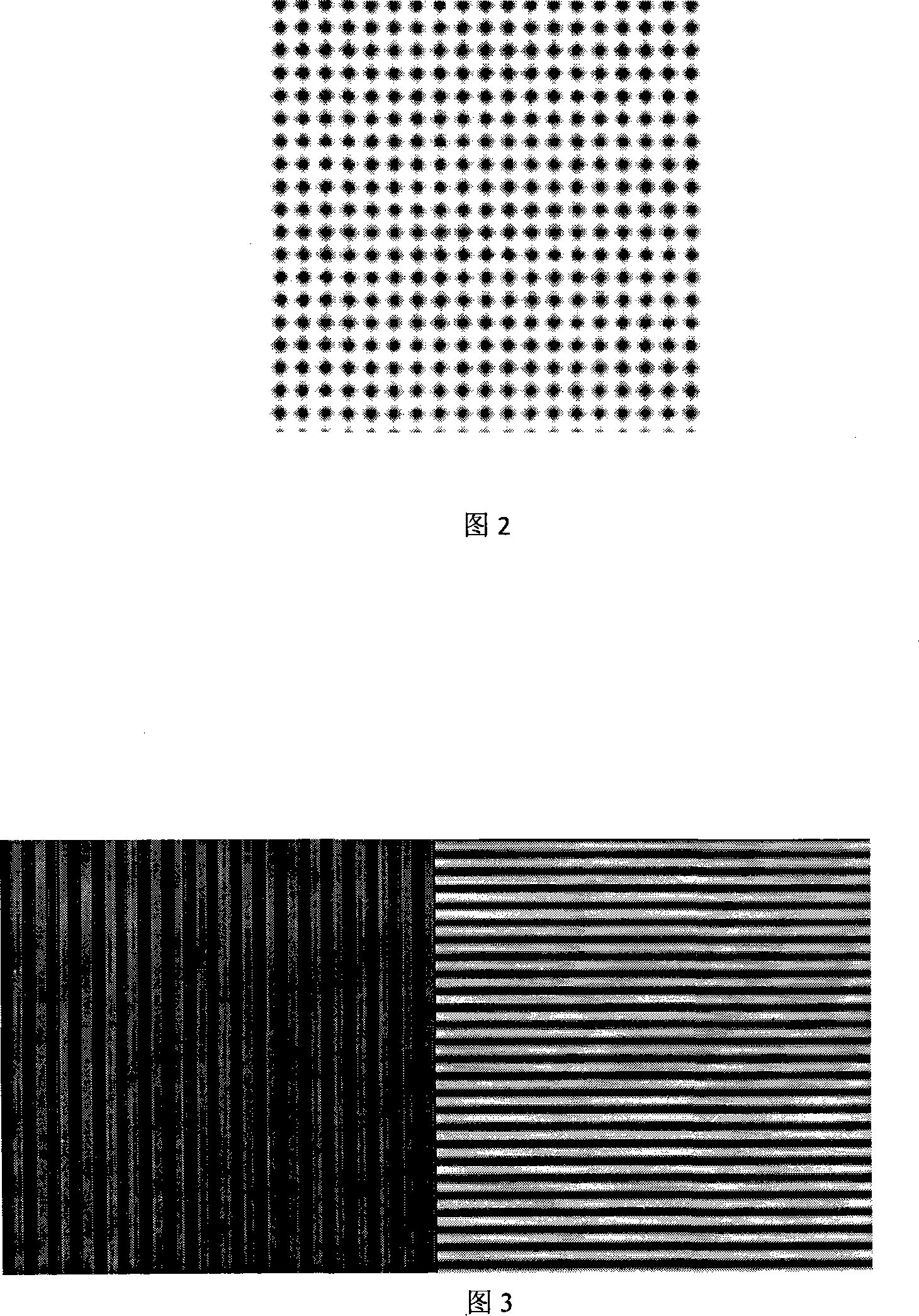

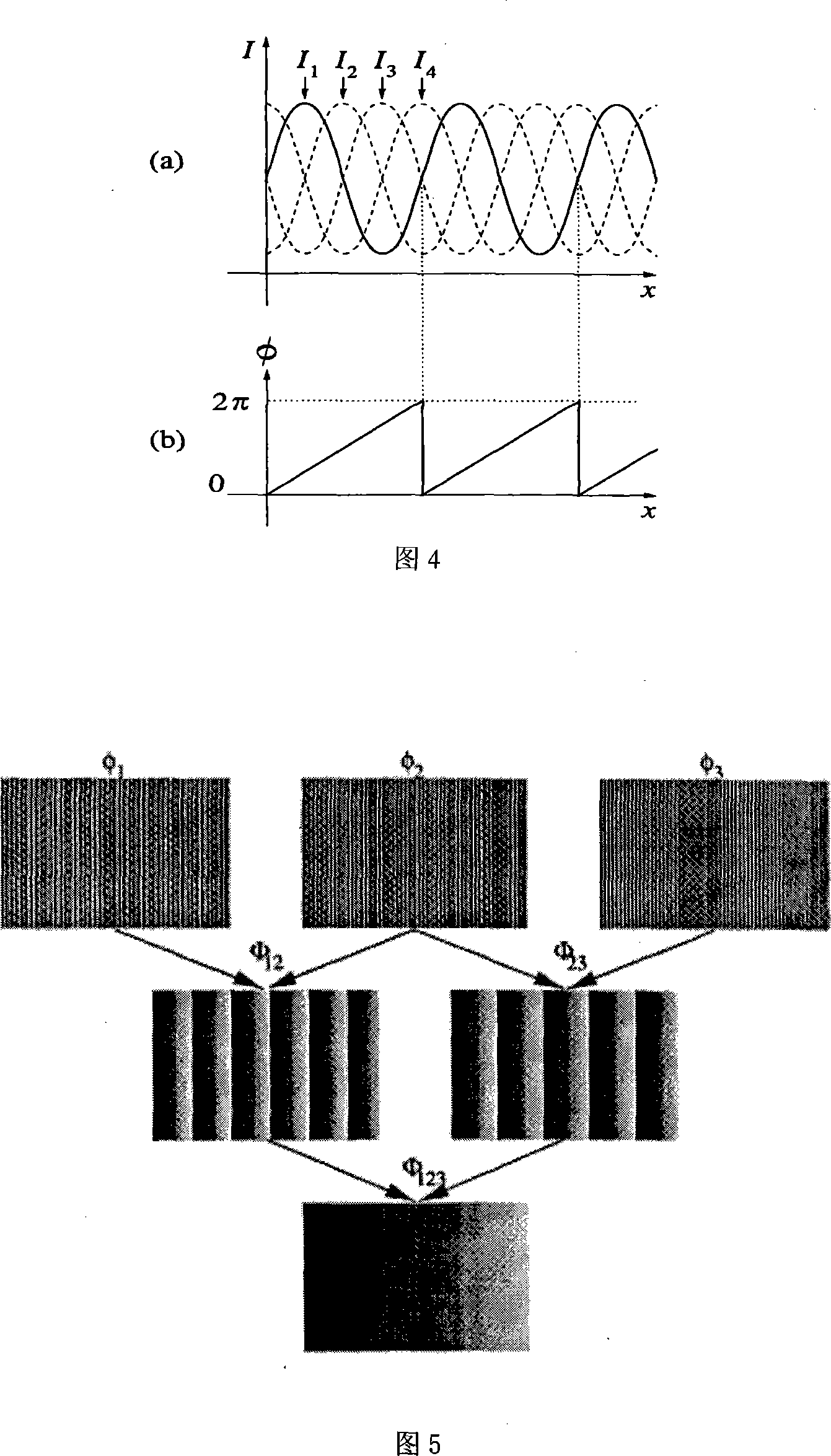

Two-diensional three-frequency dephase measuring method base on color structural light

InactiveCN101089547AAvoid measurement errorsOvercoming Coding FlawsUsing optical meansPicture interpretationObservational errorGrating

A 2-D three-frequency diphase measuring method based on colored- structure light includes preparing three gratings by complexing different three primary color sine light with three the same frequencies, projecting said gratings on object to be measured, utilizing two the same CCD vide cameras to make shooting for obtaining 24 pieces of pictures, dephasing said pictures to obtain phase values at X and Y direction on each pixel pf each picture and matching two phase values for calculating out 3-D coordinate of each point.

Owner:HUAZHONG UNIV OF SCI & TECH

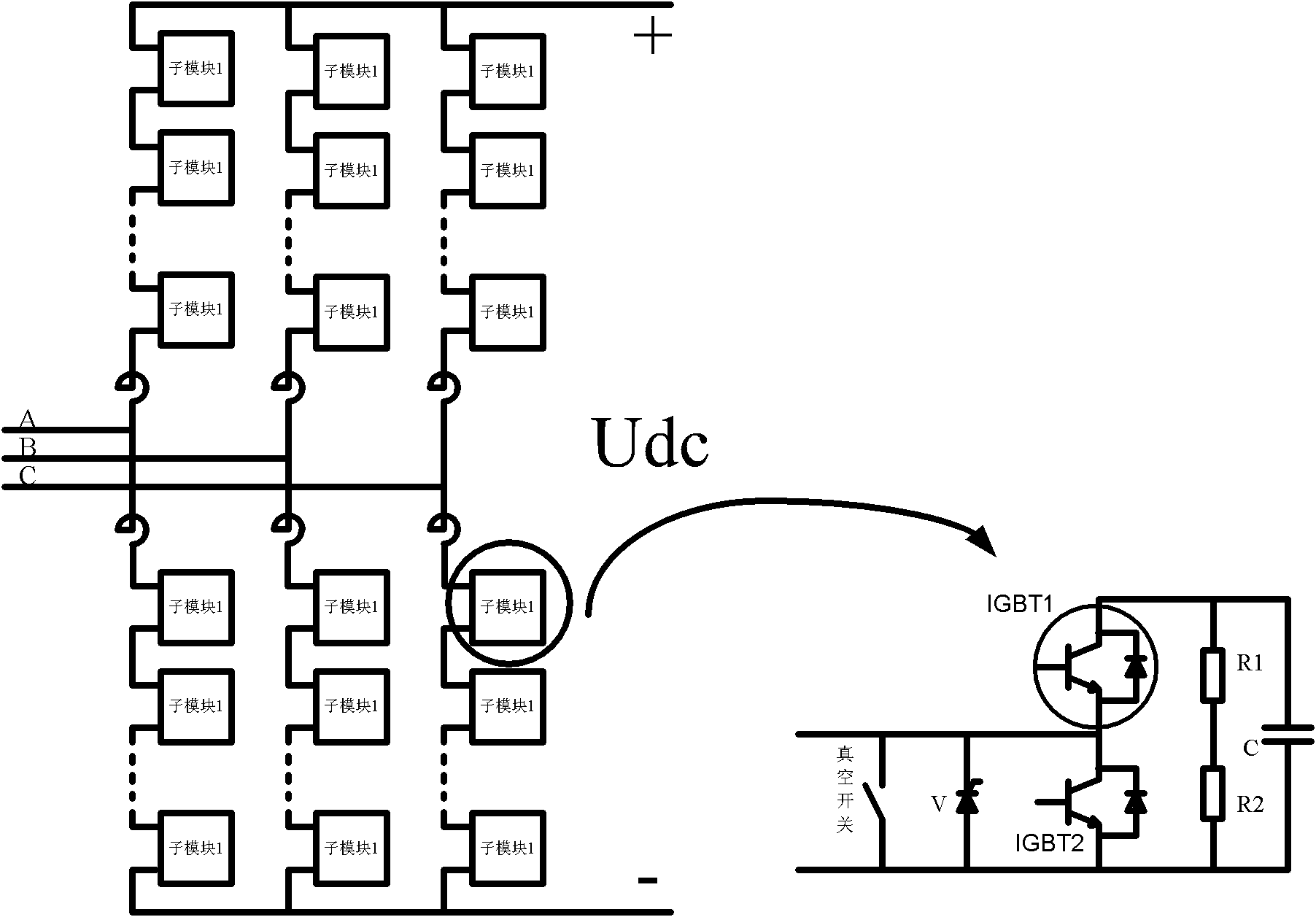

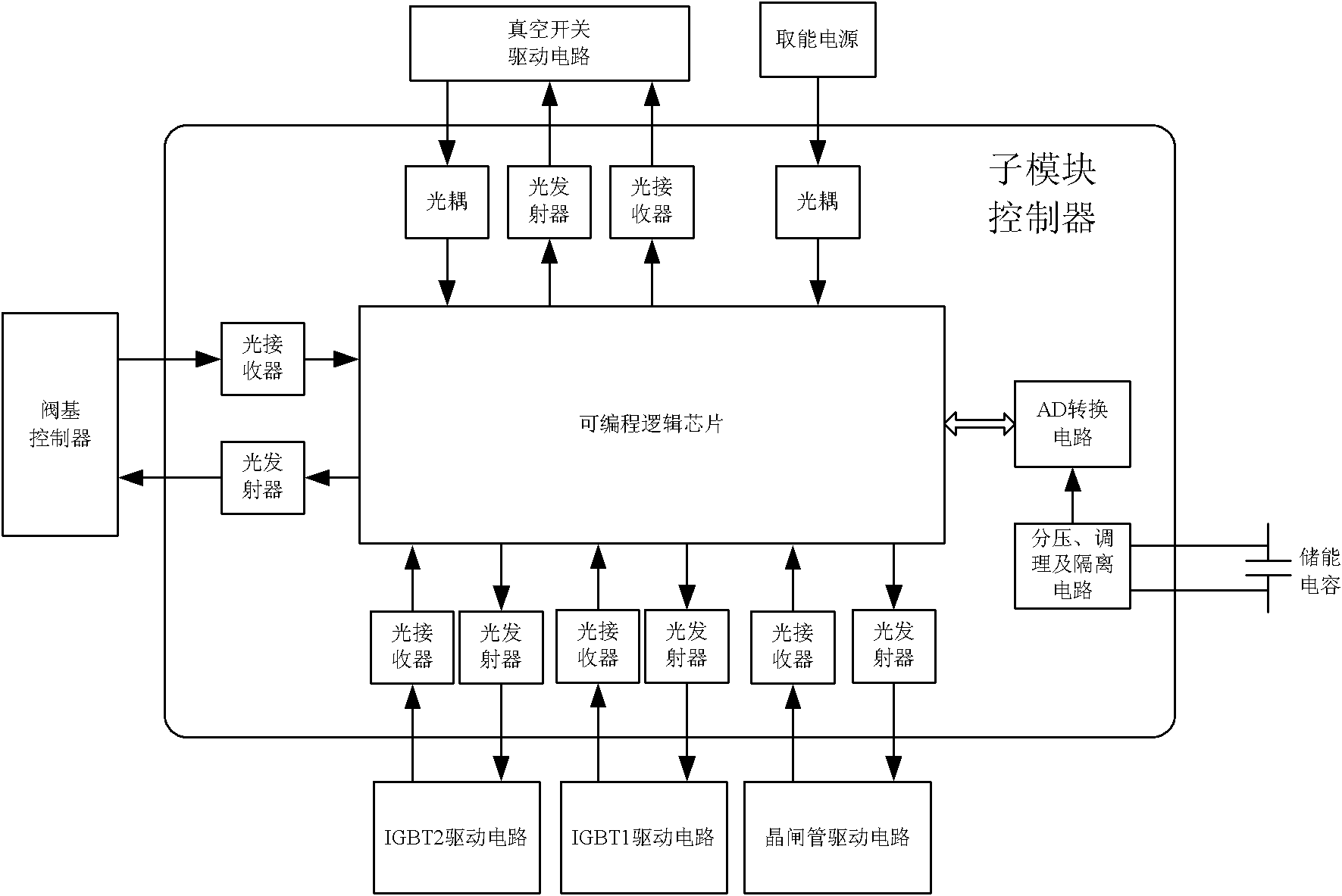

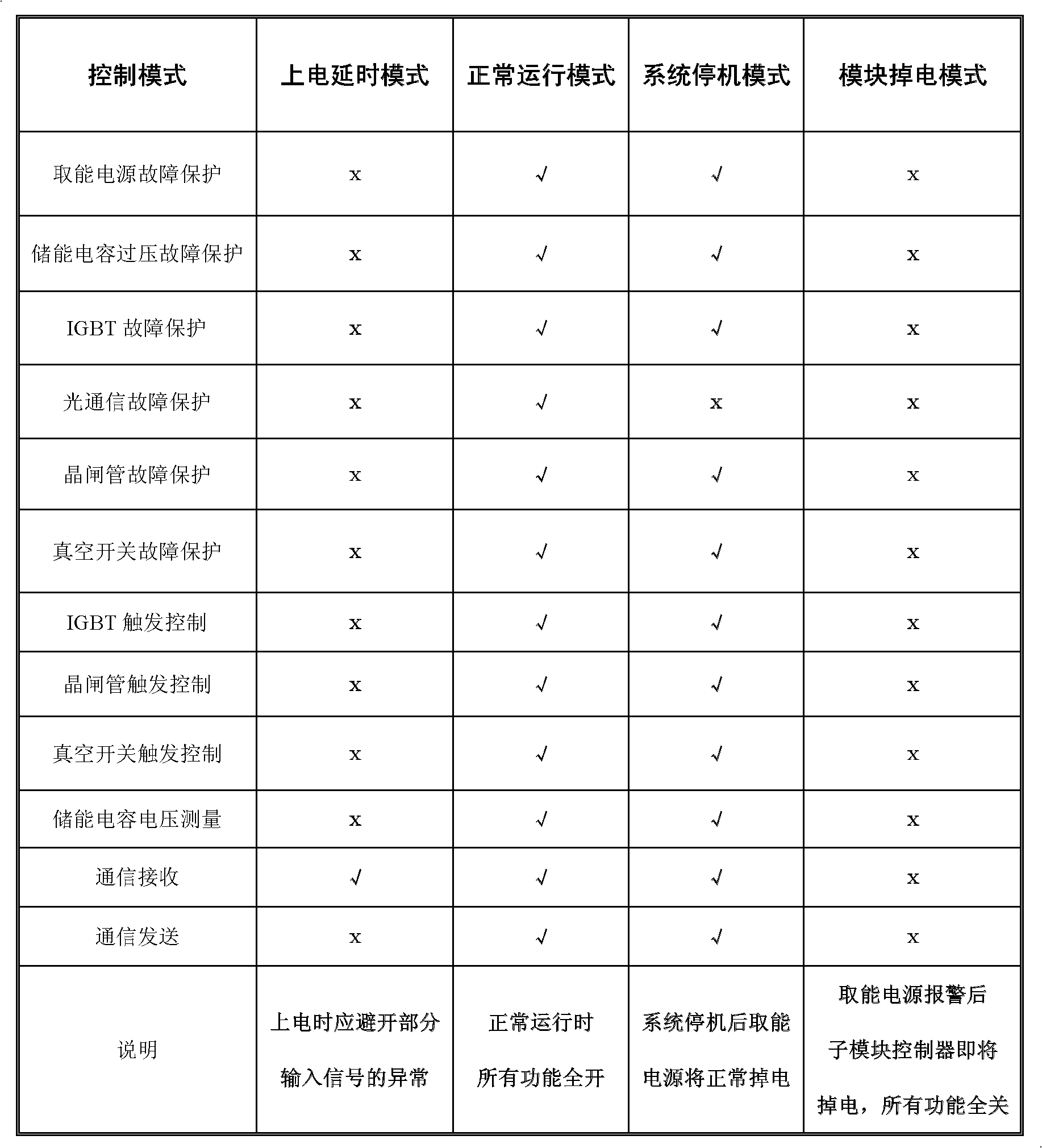

Modularized multi-level converter sub-module control and protection method

ActiveCN102118019AAchieve relatively independent controlGuaranteed reliabilityEmergency protective circuit arrangementsAc-dc conversionAsynchronous serial communicationComputer module

The invention relates to a modularized multi-level converter sub-module control and protection method. The control and protection method comprises the following processing modes: in four control models of a sub-module, executing different control and protection logics by using a sub-module controller; generating a sub-module internal interface output signal, detecting an input signal and diagnosing a plurality of faults; executing control and protection actions by using the sub-module controller according to an action priority level; detecting the voltage of an energy storage capacitor C by using the sub-module controller; and performing asynchronous serial communication between the sub-module controller and a valve-based controller. In the method, a complete and intelligent control and protection scheme is designed aiming at the structure of the modularized multi-level converter sub-module, the coordinated control and protection of the overall sub-module can be realized, so that the stable and reliable operation of the sub-module in a converter and the coordinated matching with an overall control and protection system of the converter are ensured.

Owner:CHINA ELECTRIC POWER RES INST +1

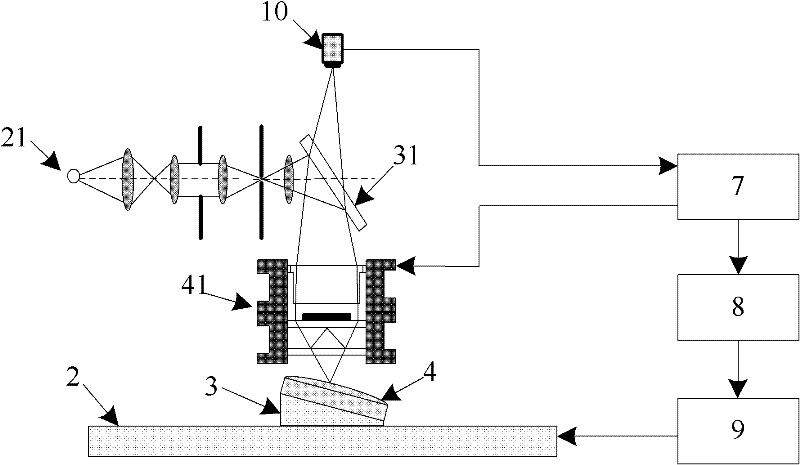

High-precision non-contact measurement method and device for three-dimensional profile of optical freeform curved surface

InactiveCN102305601AImprove detection accuracyImprove resolutionUsing optical meansGratingError separation

The invention relates to high-precision in-situ detection for complicated curved-surface parts with high-curvature surface form. In order to provide non-contact for the parts and detection for the surfaces of the parts, the invention provides the following technical scheme, namely a high-precision non-contact measurement method and a high-precision non-contact measurement device for a three-dimensional profile of an optical freeform curved surface. A grating projection device is used for projecting a sine grating stripe onto the surface of a measured object; an image acquisition device acquires a deformed stripe pattern modulated by the surface of the measured object and sends the deformed stripe pattern into a computer to recover the three-dimensional profile of the surface of the measured object; a white light scanning interference measuring head is used for scanning and measuring local characteristics of the measured object in nano-scale precision; a white light scanning image acquisition device acquires an interfered stripe pattern and sends the interfered stripe pattern into the computer to acquire data of the three-dimensional profile of a measurement region; and a result can be obtained according to data obtained by measurement of a grating projection vision detection unit and a white light scanning interference measurement unit through a multi-sensor massive data combination algorithm and corresponding error separation and compensation measures. The invention is mainly applied to the high-precision in-situ detection of the parts.

Owner:TIANJIN UNIV

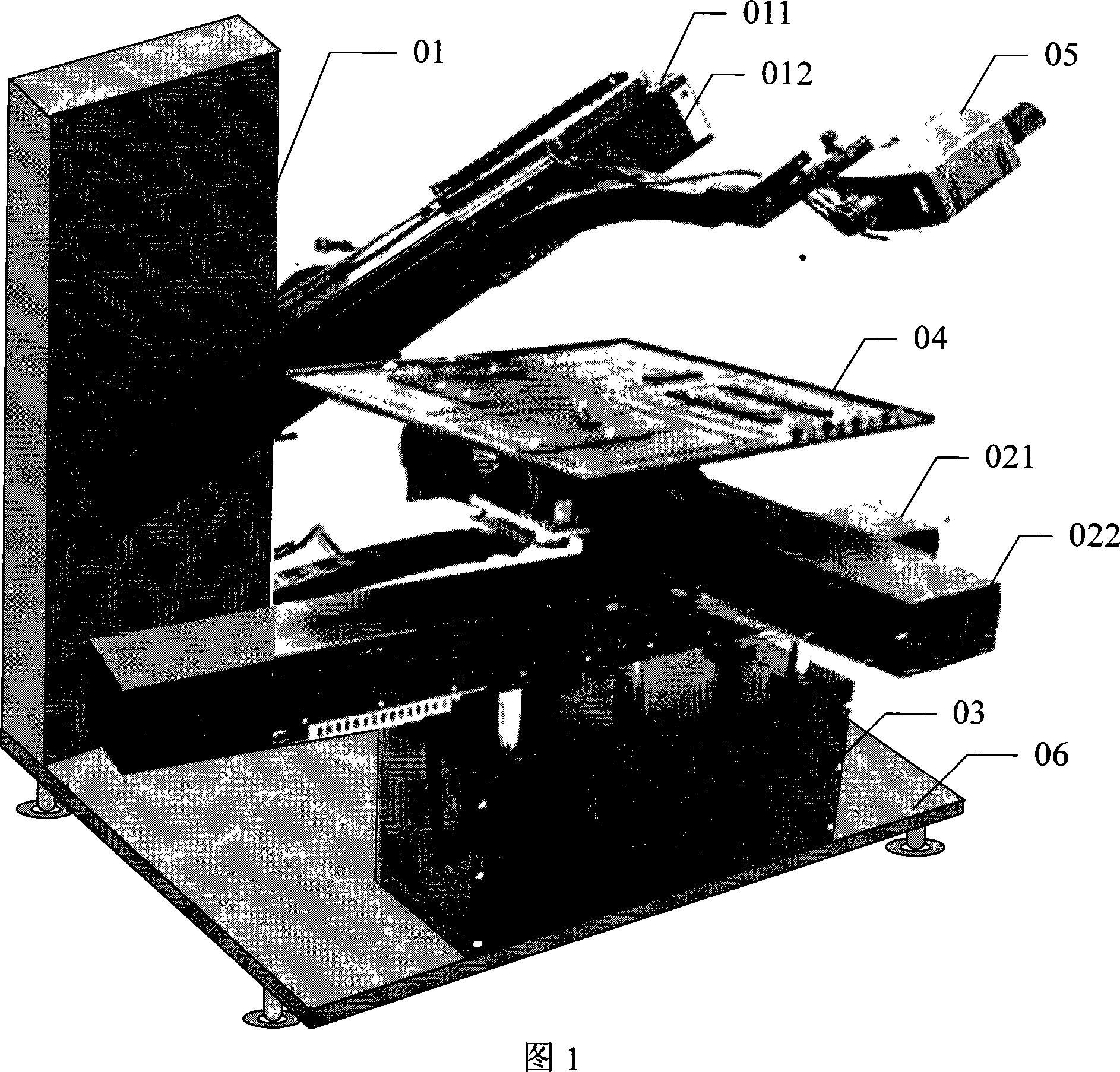

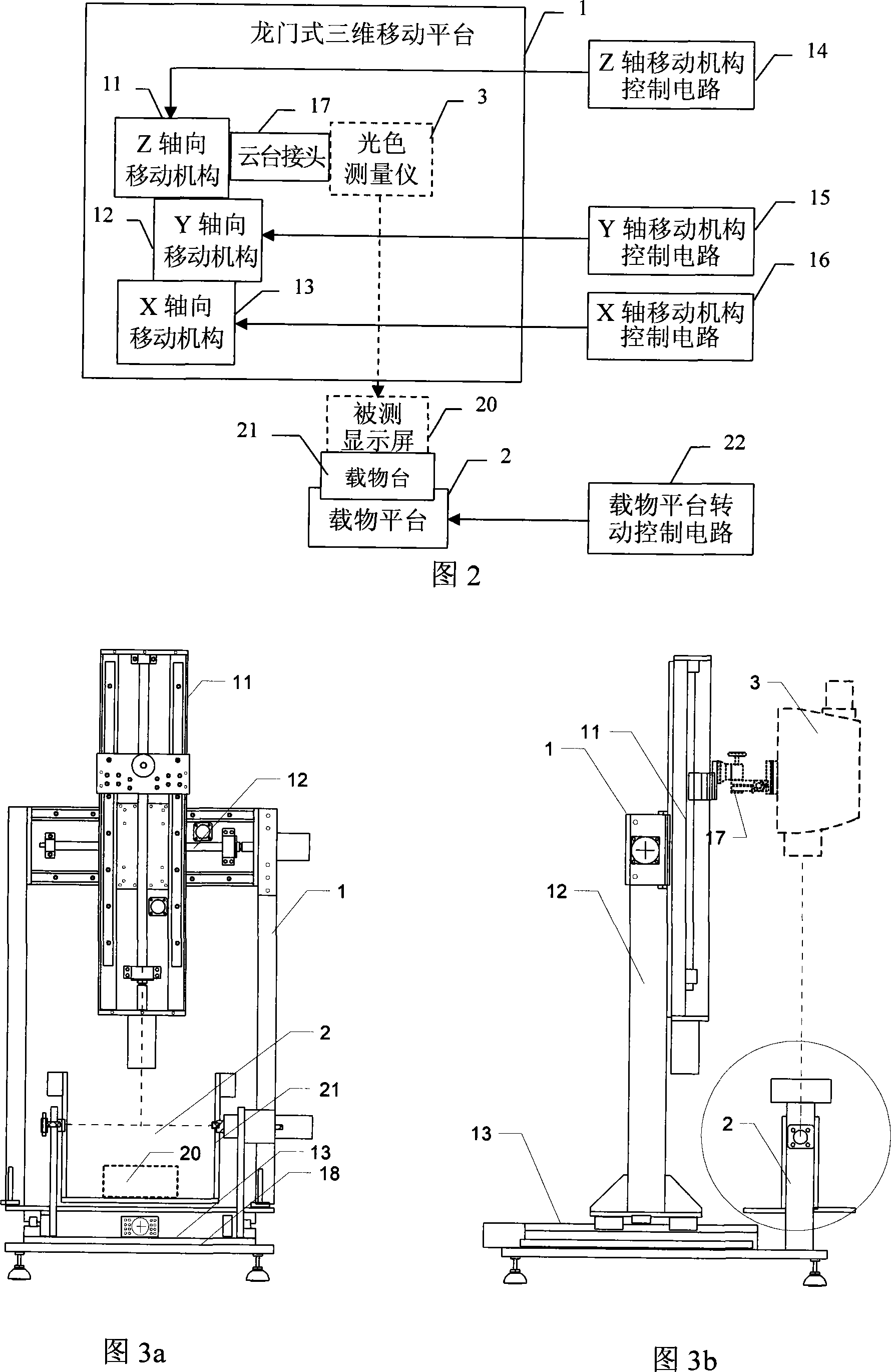

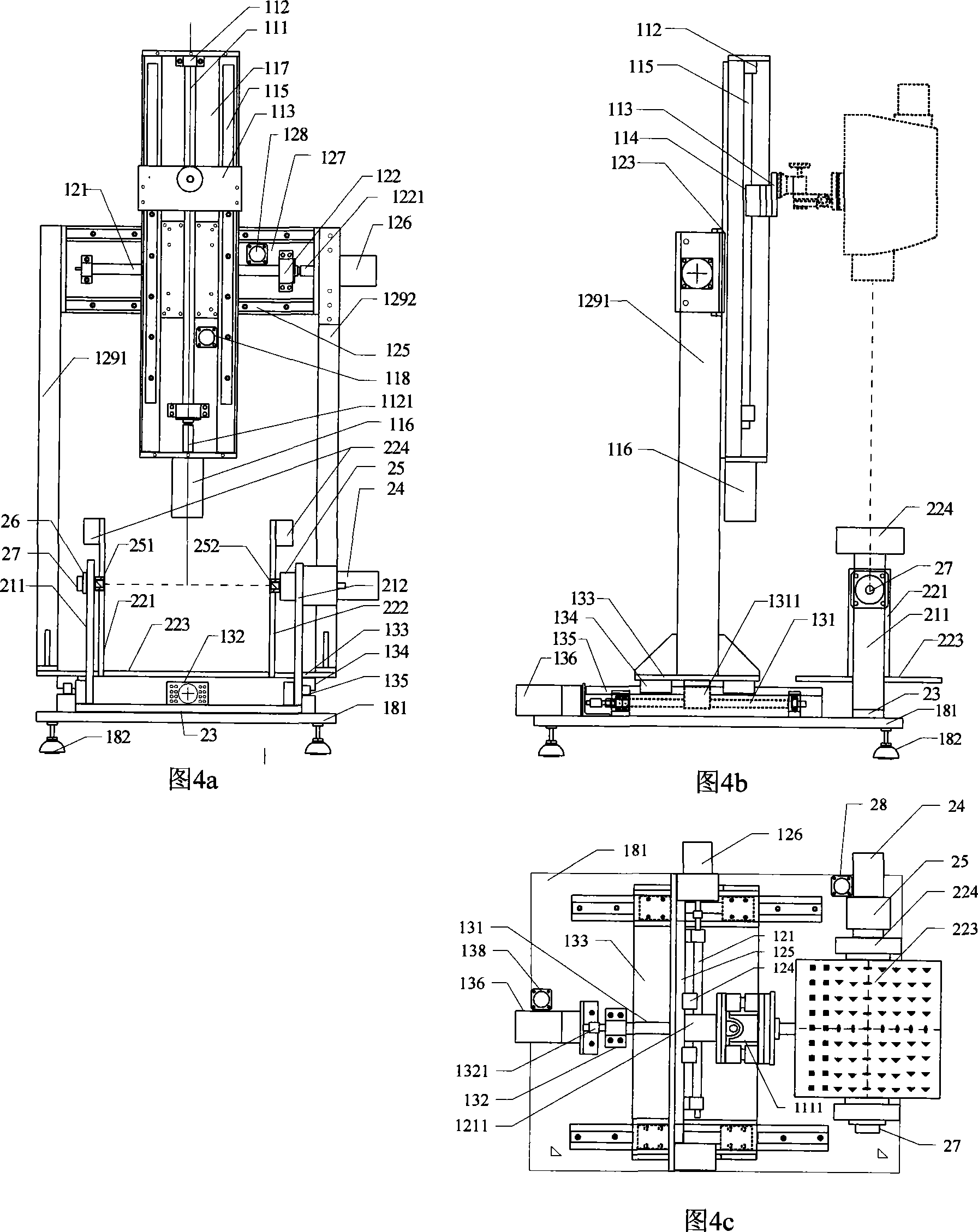

Gantry type four dimensional automatic measurement used for detecting display screen color performance

InactiveCN101118719AImprove stabilityReduce weightColor measuring devicesStatic indicating devicesMeasuring instrumentTelevision screen

The present invention discloses a composition method of a gantry four-dimensional automatic measurement platform for detecting photochromic performance of display screens and a gantry four-dimensional automatic measurement platform using the method. The present invention relates to the automatic measuring technology of the photochromic performance of display screens, and comprises a platform base, a gantry frame, an X-axis moving mechanism, a Y-axis moving mechanism, a Z-axis lifting mechanism, and a display screen-carrying rotating platform. By moving the mechanisms to control the circuit, the four-dimensional automatic measurement platform for detecting photochromic performance of display screens is flexibly controlled to accomplish the three-dimensional move of the photochromic measuring instrument and the accurate one-dimensional rotation of the display screen to be measured, the present invention is characterized in stable movement of the photochromic measuring instrument, small rotation radium of the display screen, novel structure, small driving power needed, small size, light weight, low cost, rapid measuring speed, high reliability and so on. The present invention can be widely applied to the photochromic automatic detecting system of LCD or LED television screen, display screen, or mobile phone screen and so on, and the present invention can precisely adjust the coordinate position of the test points and the angle of the display screen intelligently according to the detecting requirement of photochromic performance of the display screens under the computer management, and rapidly accomplish the detection of photochromic performance.

Owner:ZHEJIANG UNIV

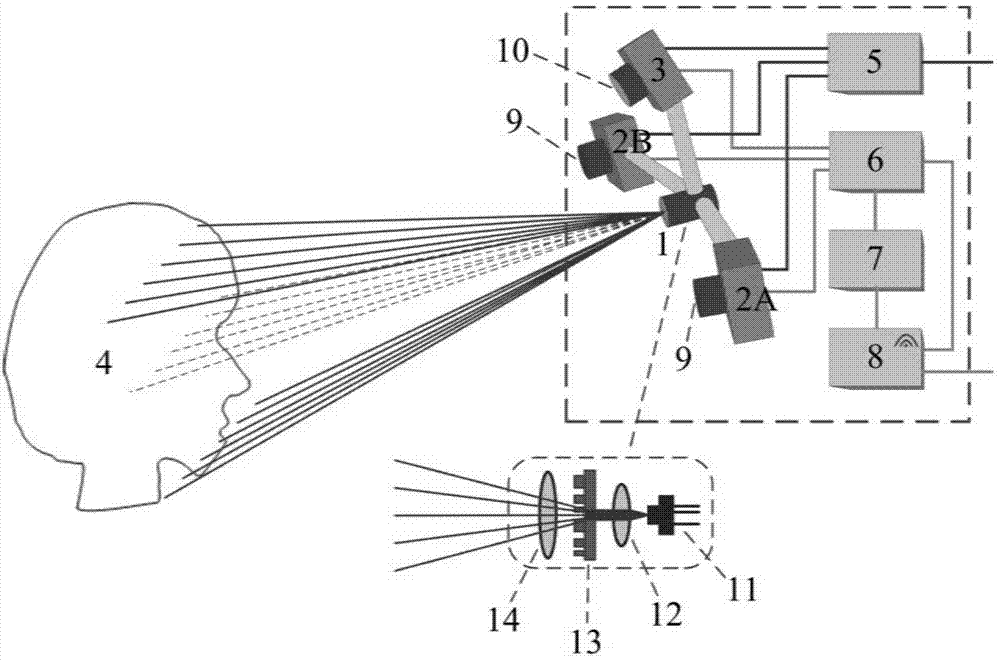

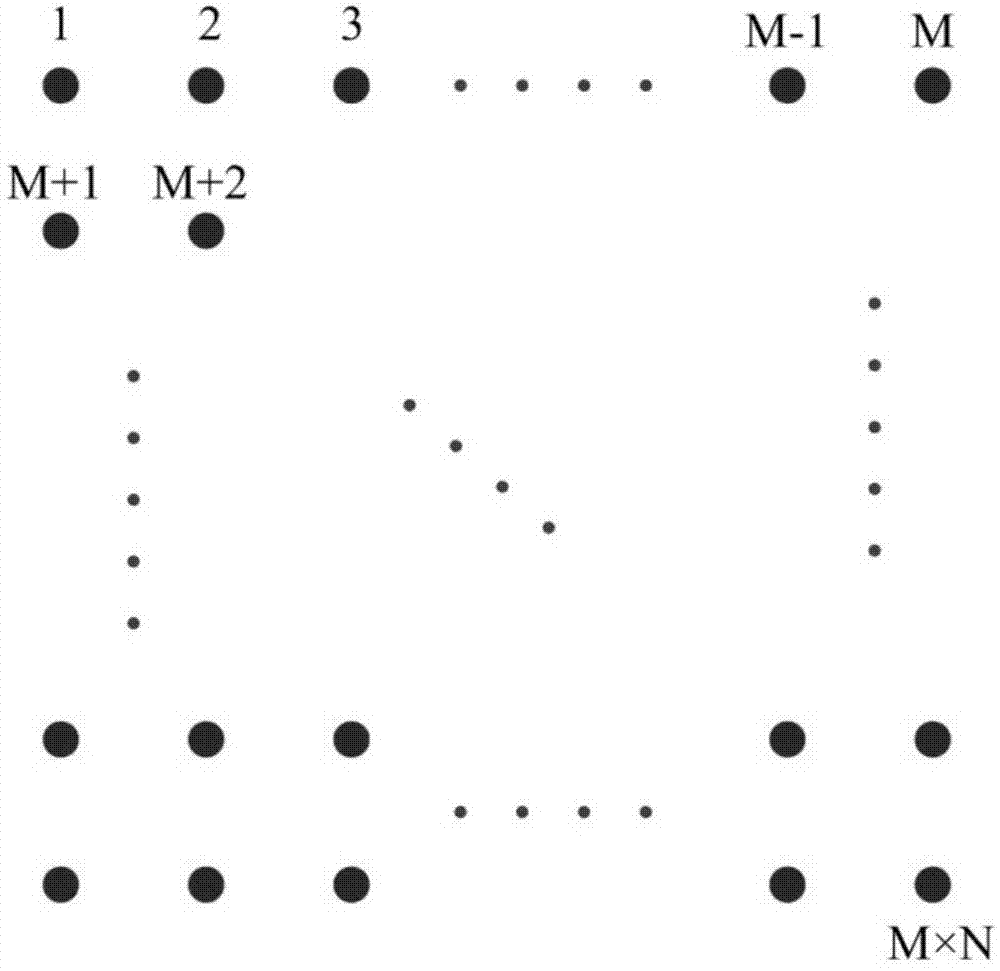

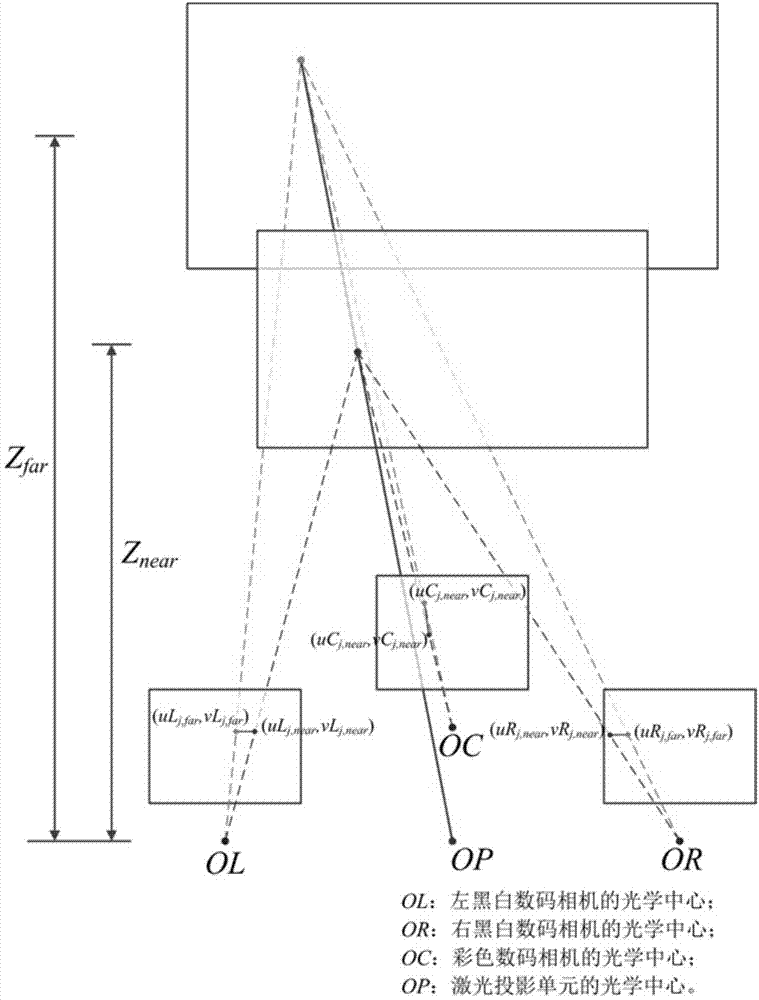

Color three-dimensional profile measuring device and method based on Dammann grating

The invention discloses a color three-dimensional profile measuring device and method based on a Dammann grating. According to the color three-dimensional profile measuring device, the Dammann grating is adopted as a core optical component, a laser beam emitted by an infrared laser is split into a regular laser spot array, and the measurement is performed by using the laser spot array as a protection structure. Two black and white digital cameras with narrow band-pass filters are used for shooting a laser dot matrix to reconstruct a three-dimensional profile of an object to be tested, and one color digital camera with an infrared cut-off filter is used for recording true color information of the object to be tested. The color three-dimensional profile measuring device has the advantages of small volume, low cost, high measurement speed and the like, and is expected to be widely applied to fields such as three-dimensional modeling, object identification, object tracking, action capturing, and human-computer interaction.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Image spectrum detection method and system

InactiveCN103925999AFast measurementSimple system structureSpectrum investigationOptical spectrometerCcd camera

The invention discloses an image spectrum detection method and system. The system comprises an imaging lens set, a DMD, imaging lenses, an area array CCD camera, a convergent lens set, an optical fiber coupler, an optical fiber, a fiber optical spectrometer and a processor. Both the CCD camera and the fiber optical spectrometer are connected to the processor. A micromirror in a micromirror device has the opening state and the closed state. Incident image signals transmit the imaging lens set to form incident light signals and then enter the micromirror device. When the micromirror in the micromirror device is in the closed state, reflecting light signals are imaged to the surface of the CCD camera through the imaging lenses; when the micromirror in the micromirror device is in the opening state, the light signals are reflected to the convergent lens set, converged to the optical fiber coupler, coupled to the optical fiber, and transmitted to the fiber optical spectrometer for spectrum measurement. The image spectrum detection system can be provided with any fiber optical spectrometer, broadband spectrum measurement is achieved, and the spectral resolution can be increased to 0.0001 order of magnitude through the image spectrum detection system according to the technical parameters of an existing commercial fiber optical spectrometer.

Owner:SUN YAT SEN UNIV

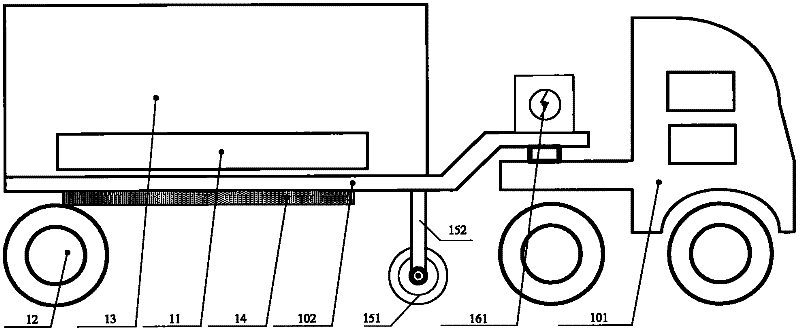

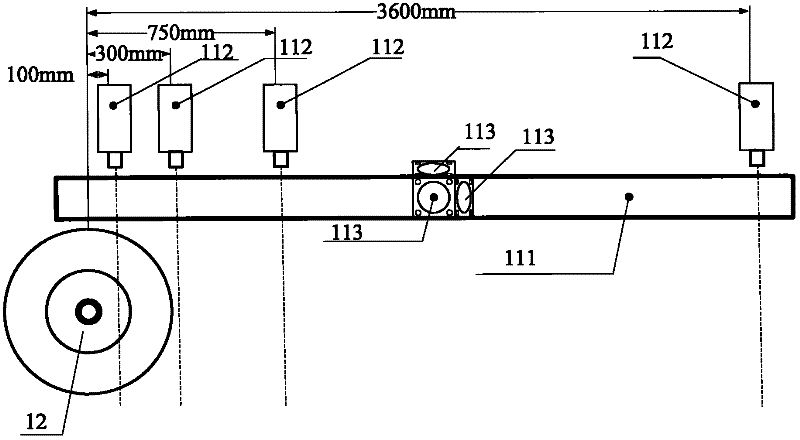

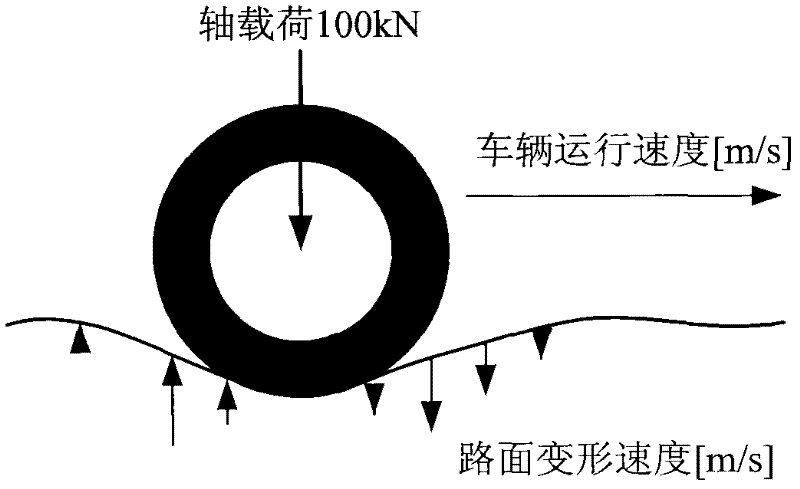

Laser dynamic deflection survey vehicle

ActiveCN102162217AFast measurementWide range of measurement speed variationUsing optical meansRoads maintainenceAccelerometerDoppler velocity

The invention provides a laser dynamic deflection survey vehicle. The survey vehicle comprises a mobile measuring table, a measuring cross beam, a running wheel, a velocity measuring wheel, an accelerometer and a data acquiring and processing device. The laser dynamic deflection survey vehicle provided by the invention has the following advantages: according to the laser Doppler velocity measurement principle and the inertia measurement principle, during the driving process of the vehicle at a normal traffic velocity (15-80km / h), a plurality of laser Doppler vibration meters arranged in the front of loading wheels of the vehicle synchronously measure the relative movement velocity of various measuring points on a road surface; the instantaneous deflection deformation velocity of the road surface is obtained through inertia compensation calculation; and a dynamic deflection value of the road surface is obtained through inversion by utilizing a road layered elastic mechanical model and used for general investigation and assessment of the bearing capacity of a road network.

Owner:WUHAN WUDA ZOYON SCI & TECH

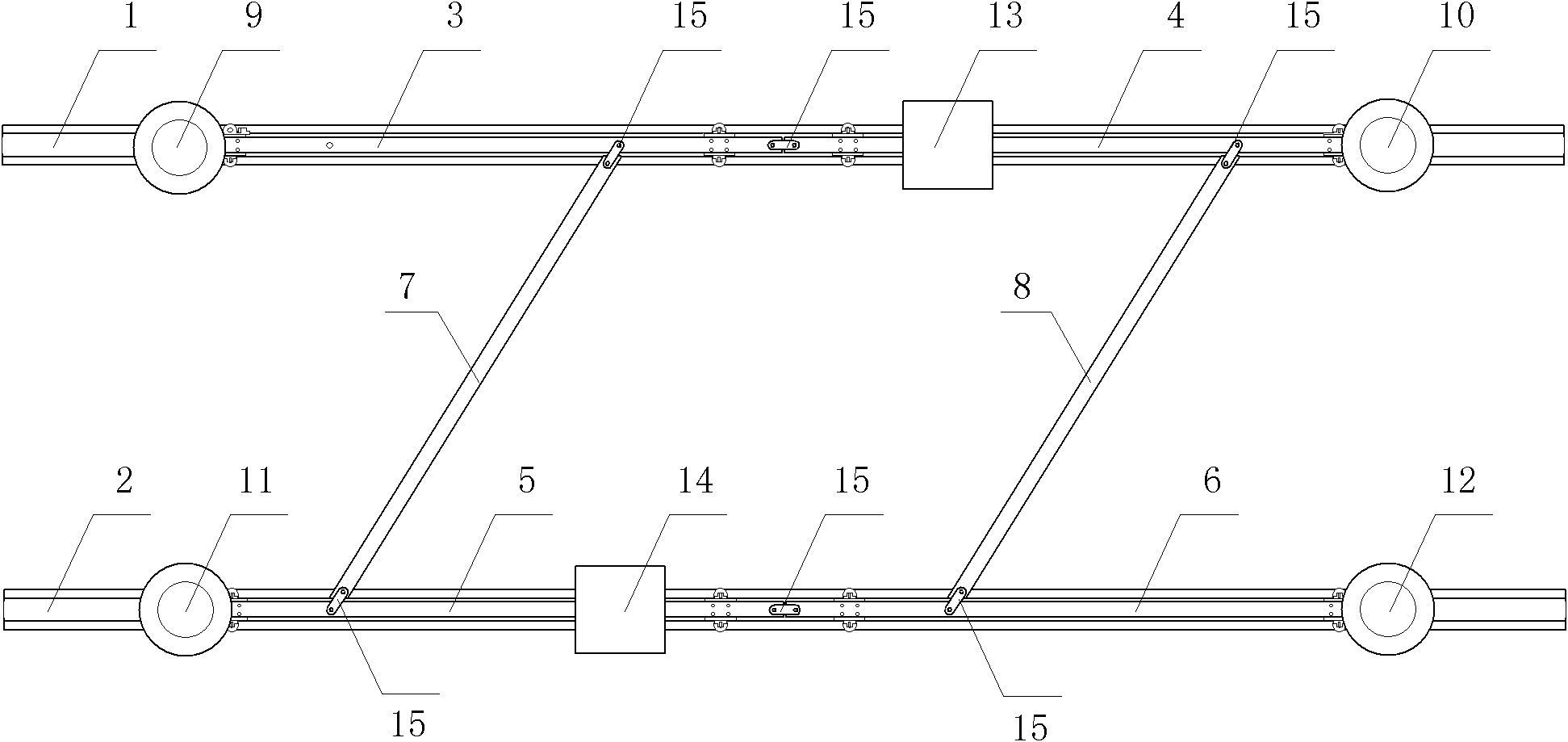

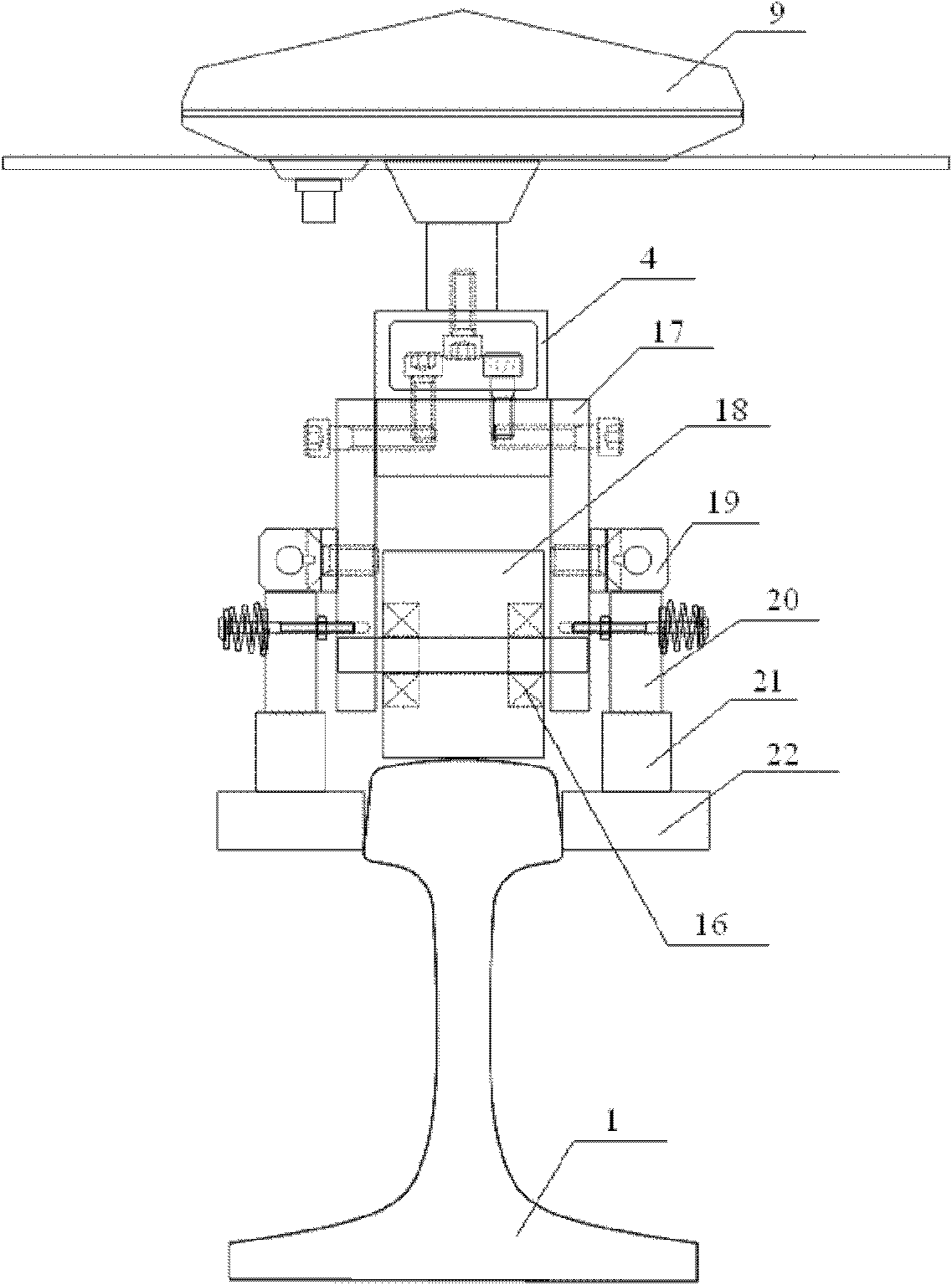

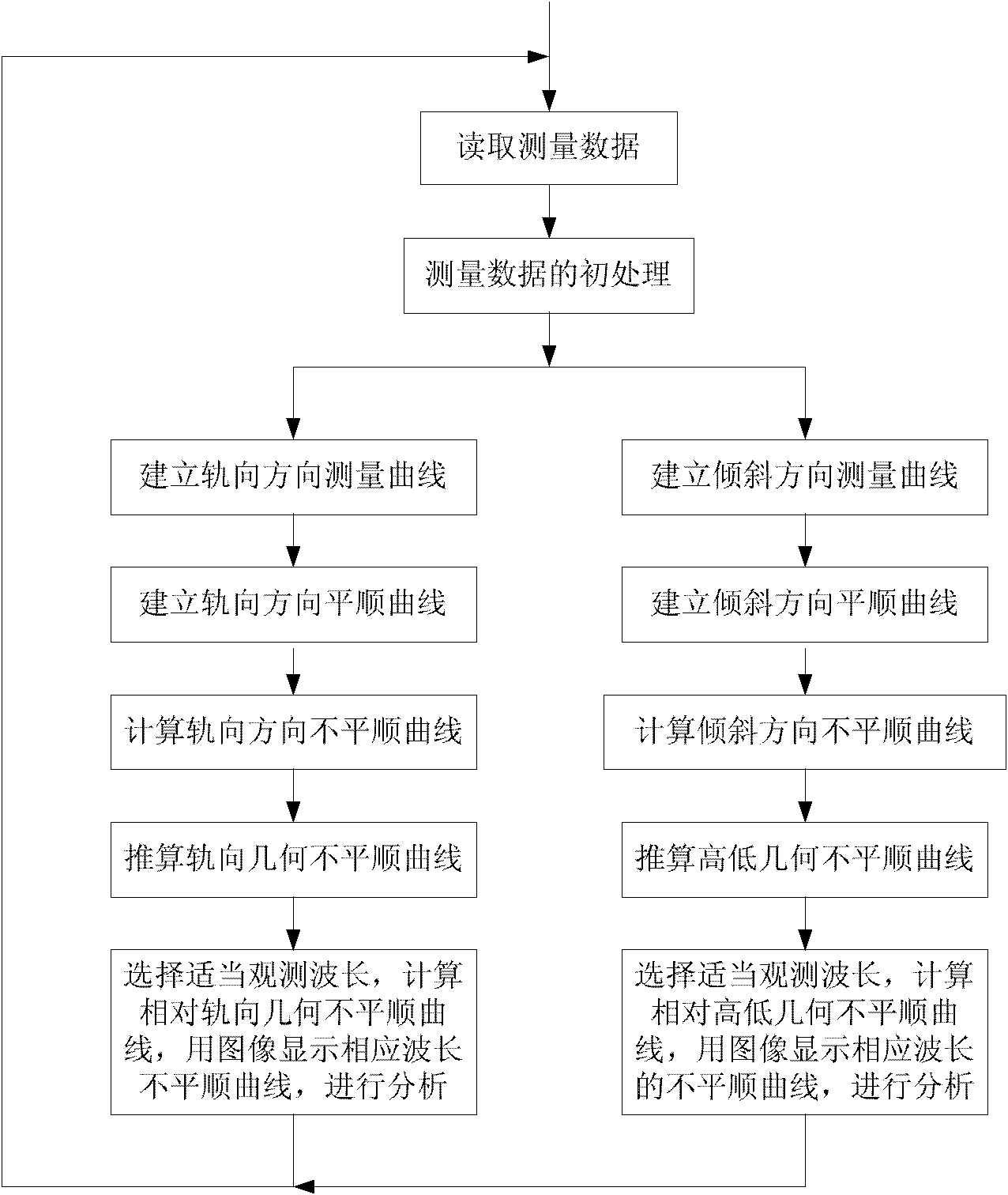

GPS (Global Positioning System) track irregularity detection system and method

ActiveCN102337710AHandling location information is simpleImprove work efficiencyMeasuring apparatusAccuracy and precisionEnvironmental geology

The invention discloses a GPS (Global Positioning System) track irregularity detection system and method. The system comprises a measuring unit and a data postprocessing unit, wherein the measuring unit comprises a moving bracket movably arranged on the surface of a track, and a measuring device; the measuring device is rigidly fixed on the moving bracket and comprises two independently-arranged measured data acquisition recorders; the measured data acquisition recorders are used for measuring state data of the moving bracket in real time and recording the state data measured at every time to a data recording unit according to a time sequence arrangement; and the data postprocessing unit is used for processing the state data recorded in the data recording unit in an off-line way. The GPS (Global Positioning System) track irregularity detection system and method disclosed by the invention have the advantages of high measurement precision, high measurement speed and complete measuring functions.

Owner:SAFEWAY XIAN NAVIGATION TECH

Two-dimensional and three-dimensional integrated imaging measurement system

ActiveCN102589463AFast measurementHigh degree of automationUsing optical meansBiological tissueAstigmatism

The invention discloses a two-dimensional and three-dimensional integrated imaging measurement system, which is characterized by being composed of an astigmatism automatic focusing unit, a light source unit, a Linnik interference unit and an image receiving unit. According to the two-dimensional and three-dimensional integrated imaging measurement system, disclosed by the invention, a fixed system framework is used for integrating a plurality of advanced imaging technologies so as to efficiently meet various precise measurement requirements; the two-dimensional and three-dimensional integrated imaging measurement system is mainly applied to testing of two-dimensional geometrical parameters of a micro-part structure, detecting of the machining, the quality and the surface appearance of MEMS (Micro-electromechanical Systems), IC (Integrated Circuit) and optical micro-devices, and medical measurement of biological tissues and the like.

Owner:HEFEI UNIV OF TECH

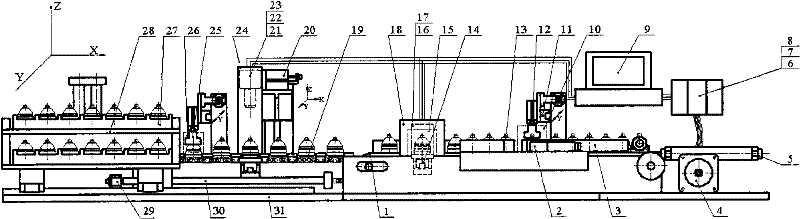

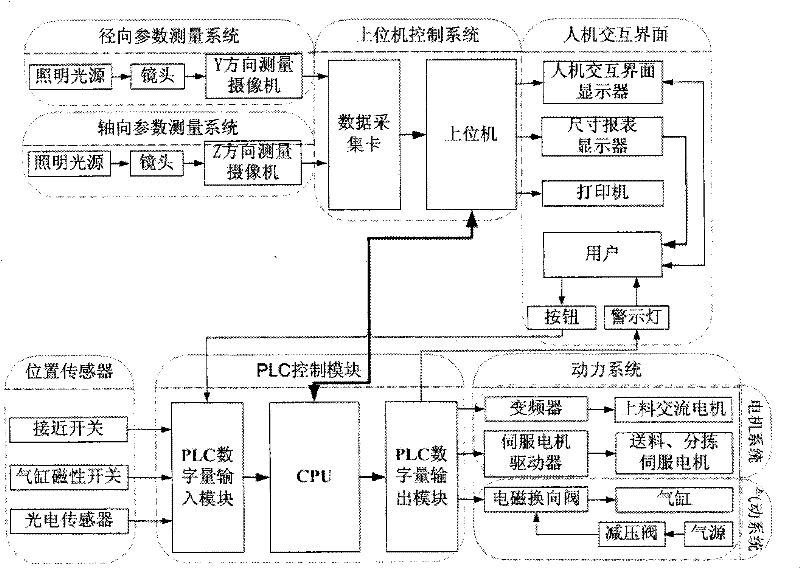

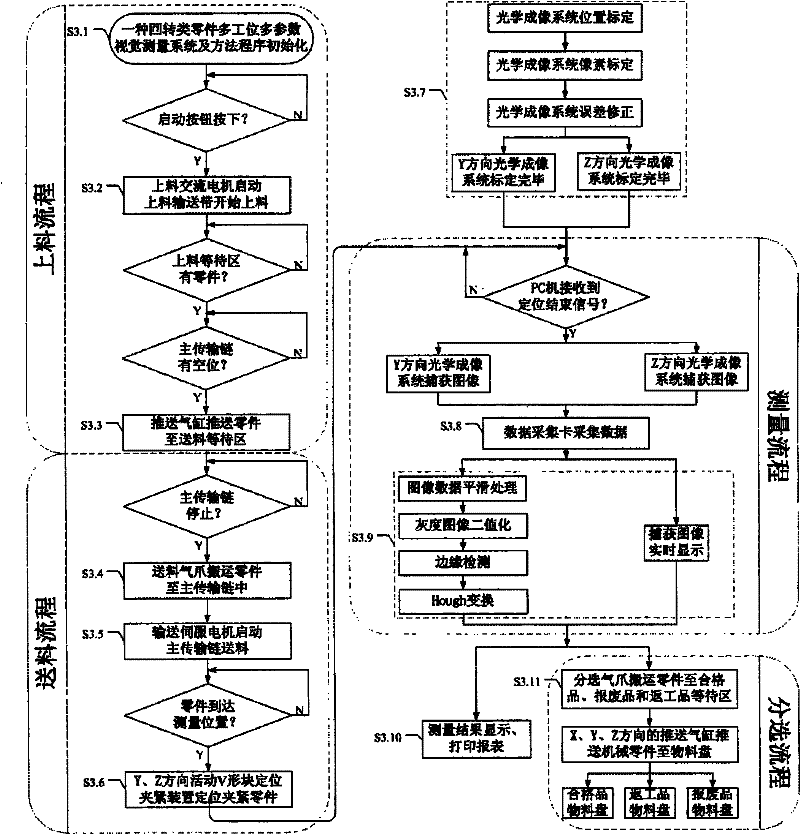

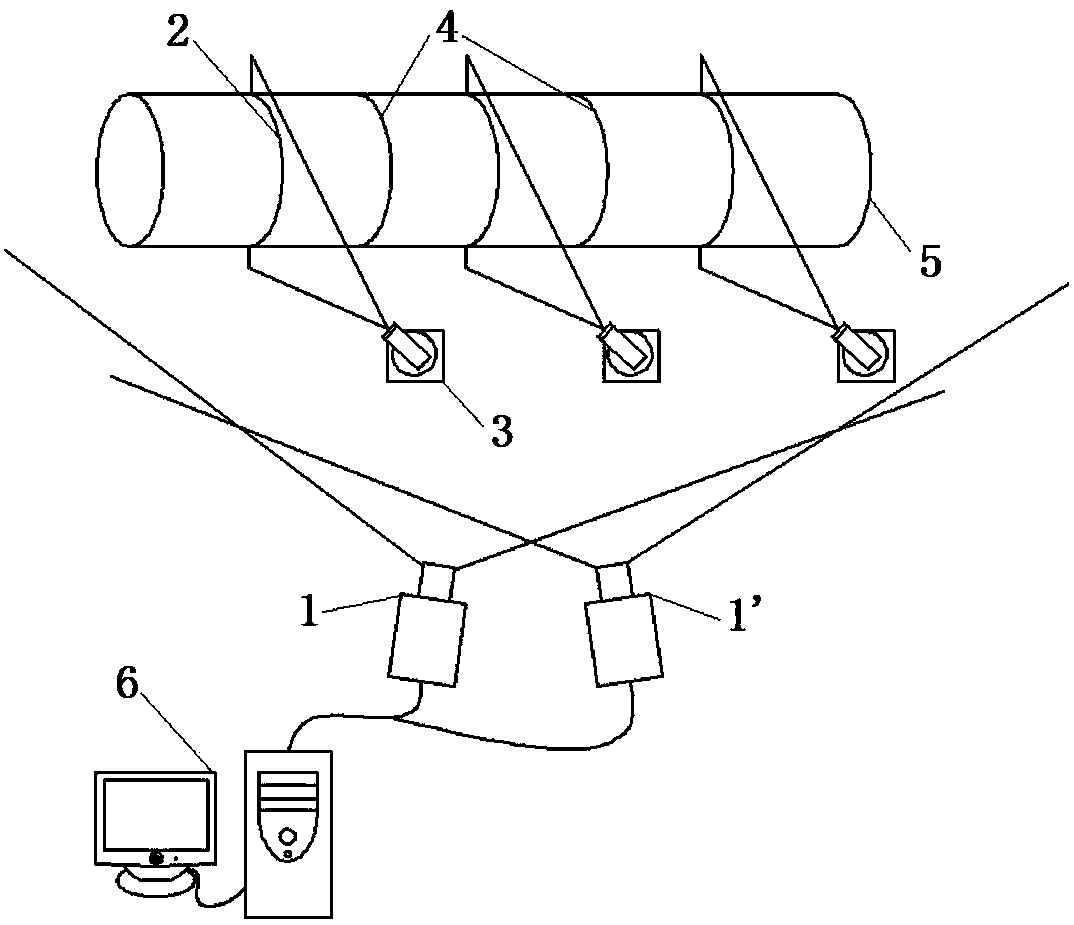

Multi-station and multi-parameter vision measuring system and method for rotary parts

InactiveCN102553833AHigh degree of automationFast measurementUsing optical meansSortingMeasuring equipmentQuality control

The invention discloses a multi-station and multi-parameter vision measuring system and method for rotary parts. The multi-station and multi-parameter vision measuring system comprises a Y-shaped feeding mechanism, a multi-station chain type feeding mechanism, a radial parameter measuring device, an axial parameter measuring device, a warehousing type three-dimensional sorting mechanism, a PLC (Programmable Logic Controller) control module, a human-machine interaction interface and an upper computer control system. The invention can provide geometrical quantity precision measuring equipment for the quality control of processing of the rotary parts on industrial field. The geometrical quantity precision measuring equipment can be used for detecting the geometric dimension error, shape error and position error and counting and analyzing the detection result of the same batch of parts to grasp the fluctuation condition of the batch quality of products. Meanwhile, the equipment has functions of automatically feeding parts and automatically sorting according to the measuring result and can be directly connected in series to the production line in series for on-line and full-detection of the parts.

Owner:ZHEJIANG UNIV

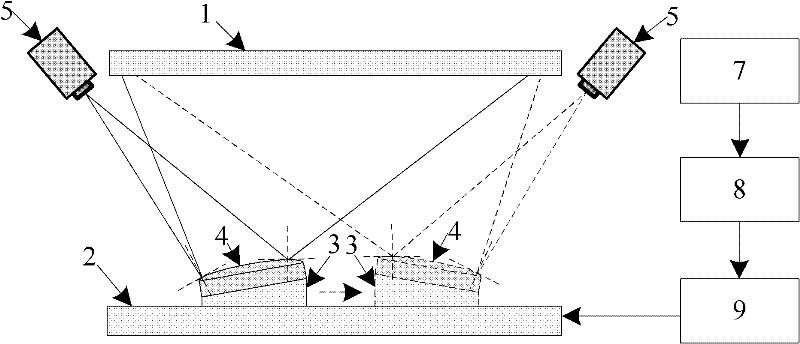

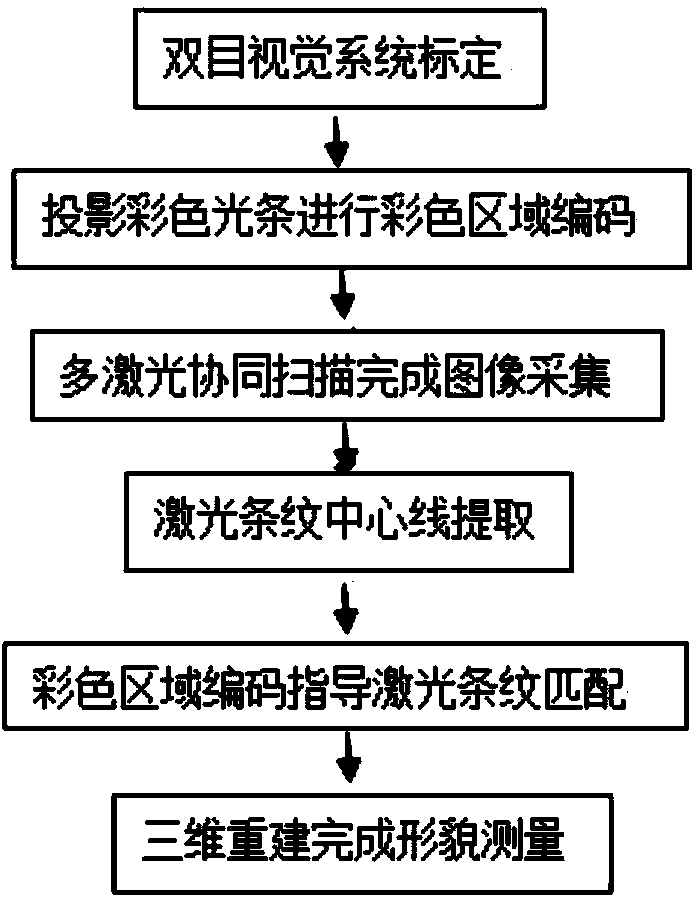

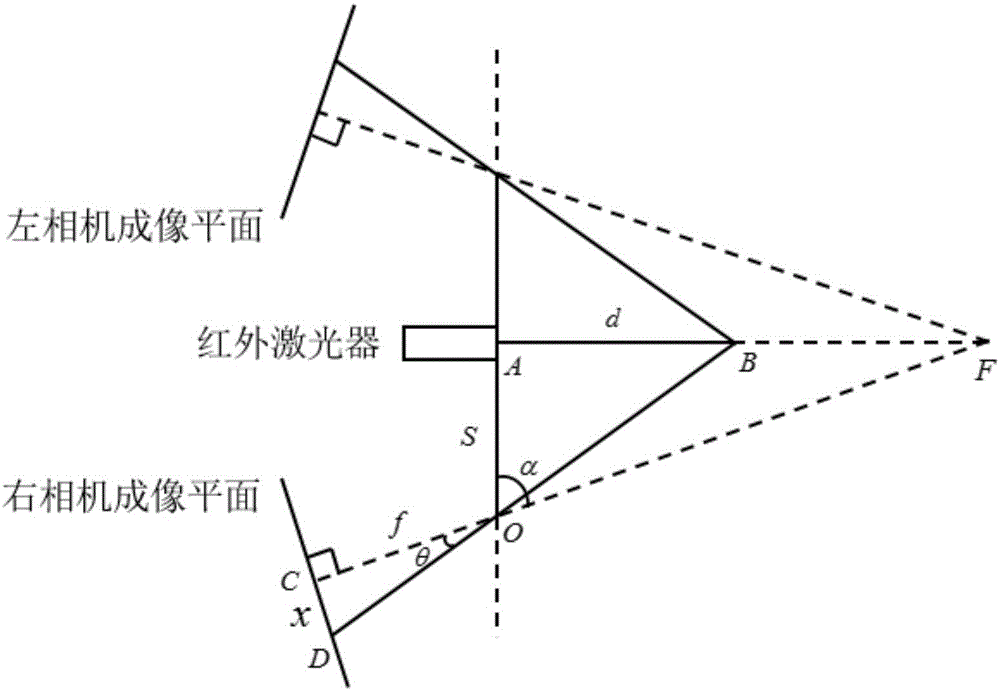

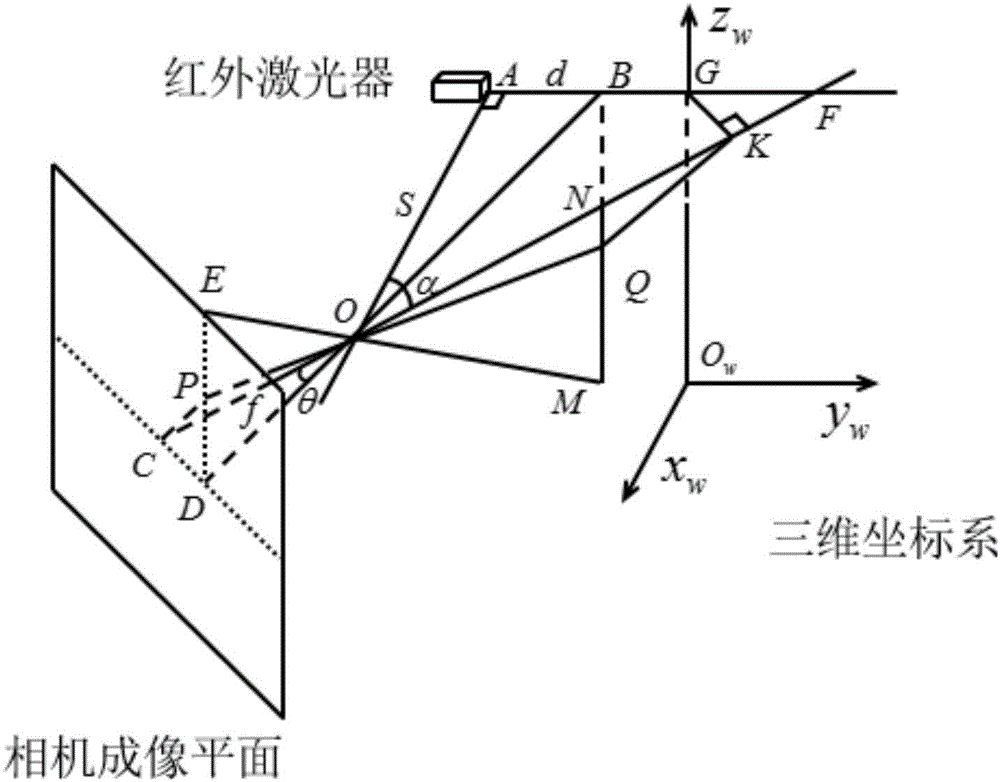

Quick morphology vision measuring method in multi-laser synergic scanning mode

InactiveCN103940369AIncrease brightnessImprove linearityUsing optical meansImage extractionSystematic measurement

The invention discloses a quick morphology vision measuring method in a multi-laser synergic scanning mode, belongs to the technical field of computer vision measurement and relates to a quick big component morphology measuring method in the multi-laser synergic scanning mode. The method comprises the steps that firstly, colorful light bars are projected to the surface of an object to be measured, and then color area coding within a measurement range is conducted; secondly, multiple lasers are projected to the surface of a component to be measured, the multiple lasers are scanned simultaneously by controlling a rotating platform, laser stripes are subjected to image extraction and matching according to the binocular vision measurement theory, and then quick measurement of morphology is achieved finally. By the adoption of the quick morphology vision measuring method in the multi-laser synergic scanning mode, quick and accurate big component morphology measurement without any processing on a target object is achieved, and the image acquisition quality is improved through high brightness and high condensation of the lasers; besides, color area coding is used for assisting in accurate matching of the multiple laser stripes, so that the matching requirement and the calculated amount are greatly lowered, and the measurement efficiency of the whole system is improved.

Owner:DALIAN UNIV OF TECH

Method for rapidly detecting cracks of tunnel lining

InactiveCN104019742AWill not interfere with normal trafficGood test resultUsing optical meansRailway tunnelData acquisition

The invention relates to a method for rapidly detecting cracks of a tunnel lining. The method comprises the steps that the surface of a tunnel is scanned by a vehicle-mounted CCD camera to obtain a crack image and the image is transmitted to an image acquisition card in real time; data of the crack image are transmitted to a computer by the image acquisition card; image discriminatory analysis processing is conducted on the data of the image by the computer, and therefore tunnel crack information is obtained, wherein the tunnel crack information comprises the positions, the lengths, the widths and the shapes of the cracks. The method is suitable for a road tunnel and a railway tunnel through different vehicle-mounted platforms and the application range is wide. Detection is conducted on the vehicle-mounted platform with the speed larger than 60km / h, an ideal detection result is obtained, and therefore detection cannot interfere in normal traffic in the tunnel. Fully-automatic data acquisition and processing are adopted, manual interference is not needed, detection speed is high, accuracy is high, and cost is low. The method is large in economic value and social value in the technical field of tunnel crack detection and is worthy of wide popularization and application.

Owner:WUHAN WUDA ZOYON SCI & TECH

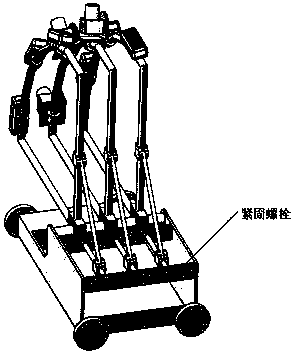

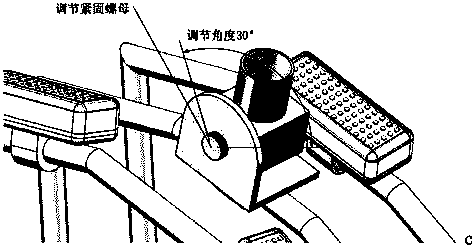

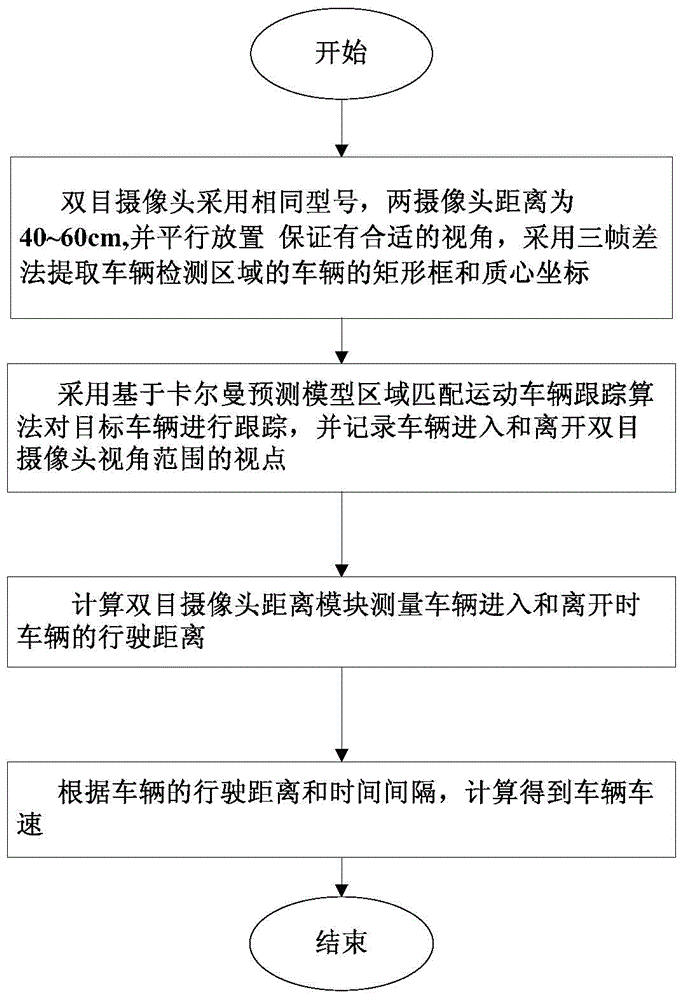

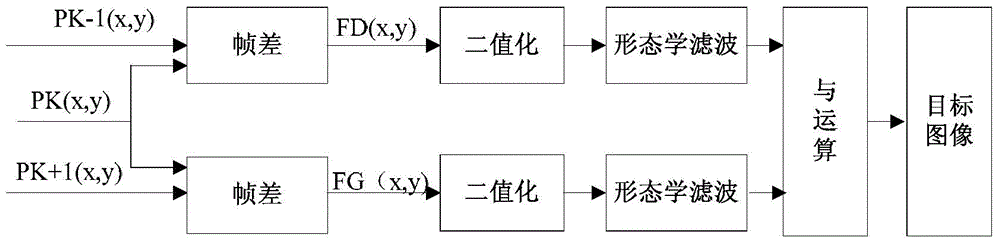

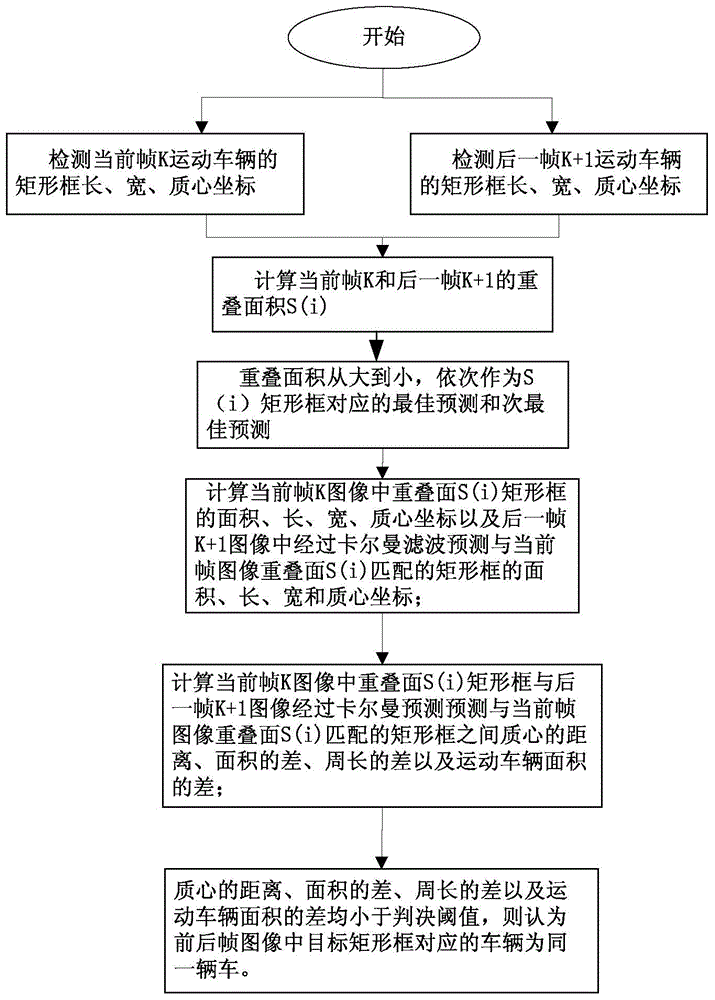

Detecting method and system based on binocular camera for real-time vehicle speed

InactiveCN104155470AFast measurementHigh precisionDevices using time traversedElectromagnetic wave reradiationParallaxViewpoints

The invention discloses a detecting method and system based on a binocular camera for real-time vehicle speed. The detecting method comprises the following steps: 1) extracting a rectangular frame and a barycentric coordinate entering a visual angle range of the binocular camera, and tracking a target vehicle; 2) recording the position and the time of a vehicle entering or leaving the visual angle range of the binocular camera; 3) pre-building a parallax depth chart of the binocular camera and a proportional relation chart of perpendicular lengths from viewpoints at the depths of the binocular camera to an optical axis and the pixel count of imagery; 4) acquiring parallax of the vehicle entering the viewpoints of the visual angle range of the binocular camera and leaving the viewpoints of the visual angle range of the binocular camera to obtain the perpendicular lengths from the viewpoints of an entering position or a leaving position of the vehicle to the optical axis; 5) calculating a traveling distance between the viewpoints of the entering position and the leaving position of the vehicle, and obtaining the vehicle speed of the vehicle according to the traveling distance and the time of the vehicle. The detecting method and system have the advantages that the speed measuring precision is high, and speed measurement can be performed on multiple vehicle objectives on multilane at the same time.

Owner:SOUTH CHINA UNIV OF TECH

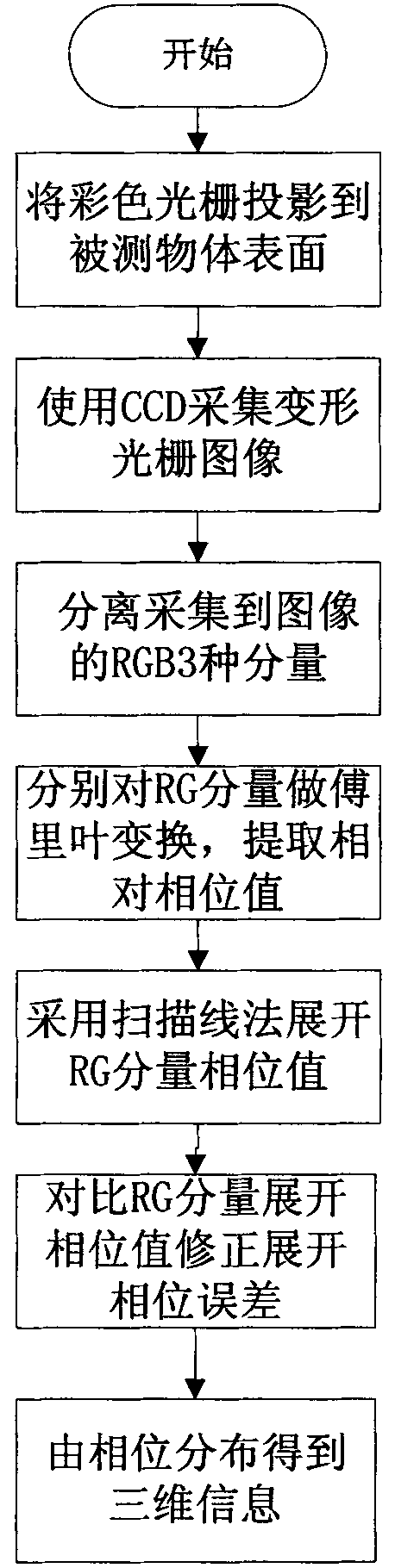

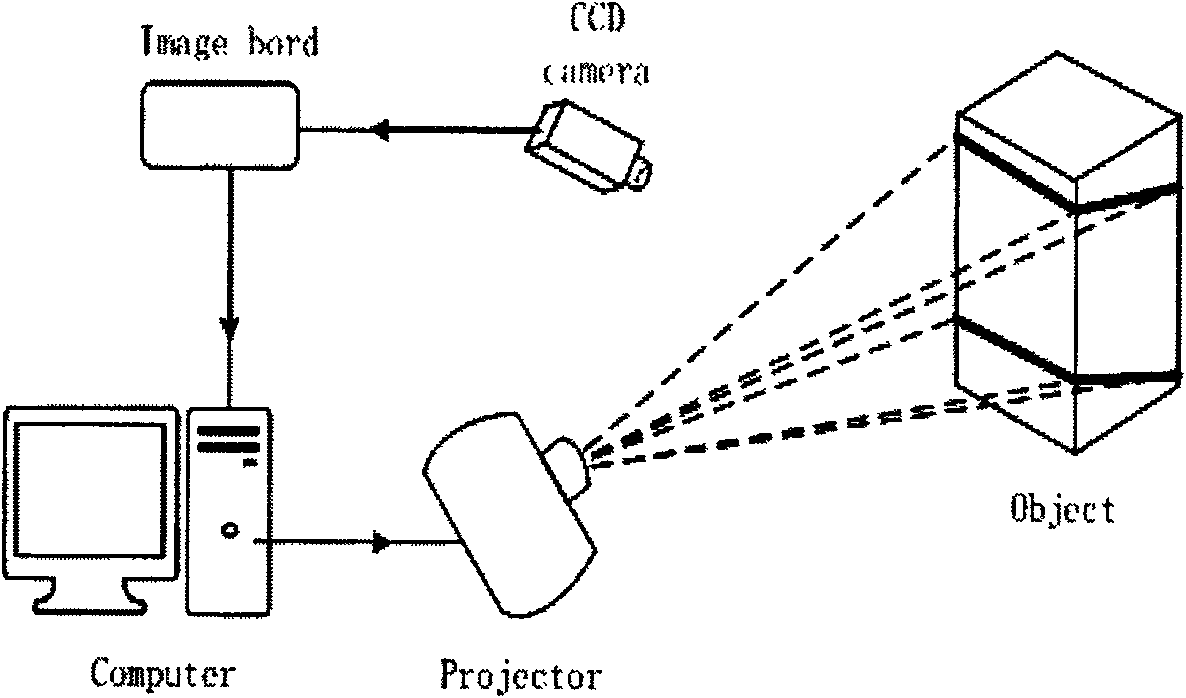

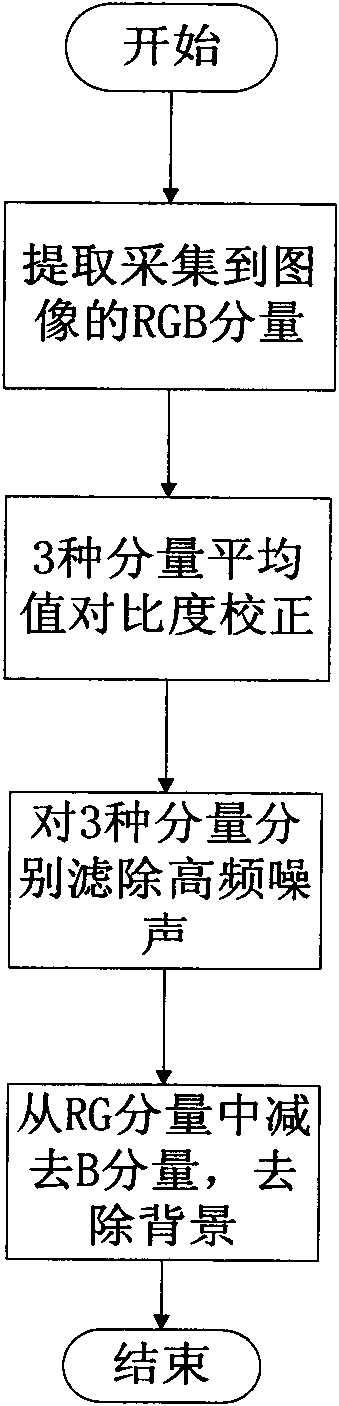

Tricolor raster projection-based Fourier transform three-dimensional measuring method

InactiveCN101986098AReduce the numberQuick measurementUsing optical meansPattern recognitionComputer graphics (images)

The invention discloses a new tricolor raster projection-based Fourier transform three-dimensional measuring method, which mainly aims to accurately work out the phase distribution of raster images, and then obtain the three-dimensional topography information of objects according to the phase distribution. The method is implemented through the steps of setting the gray values of R and G components in a projected raster to follow a sinusoidal variation regulation with two different frequencies, and setting a B component as the average value of the R component or the G component, and forming a color raster image to be projected on an object to be measured; and separating the three components of an acquired deformed color raster image, then processing the separated three gray images, meanwhile, restraining background components and high-frequency noises when the Fourier transform is used to calculate relative phases, and carrying out comparison and calibration on the three gray images with the relative phase values under the two frequencies when the phases are unwrapped so as to achieve the purpose of precisely calculating absolute phases containing height information. Only one raster image is required to be projected in the whole measuring process, therefore, the method of the invention is good in real-time.

Owner:HAIAN COUNTY SHENLING ELECTRICAL APPLIANCE MFG +1

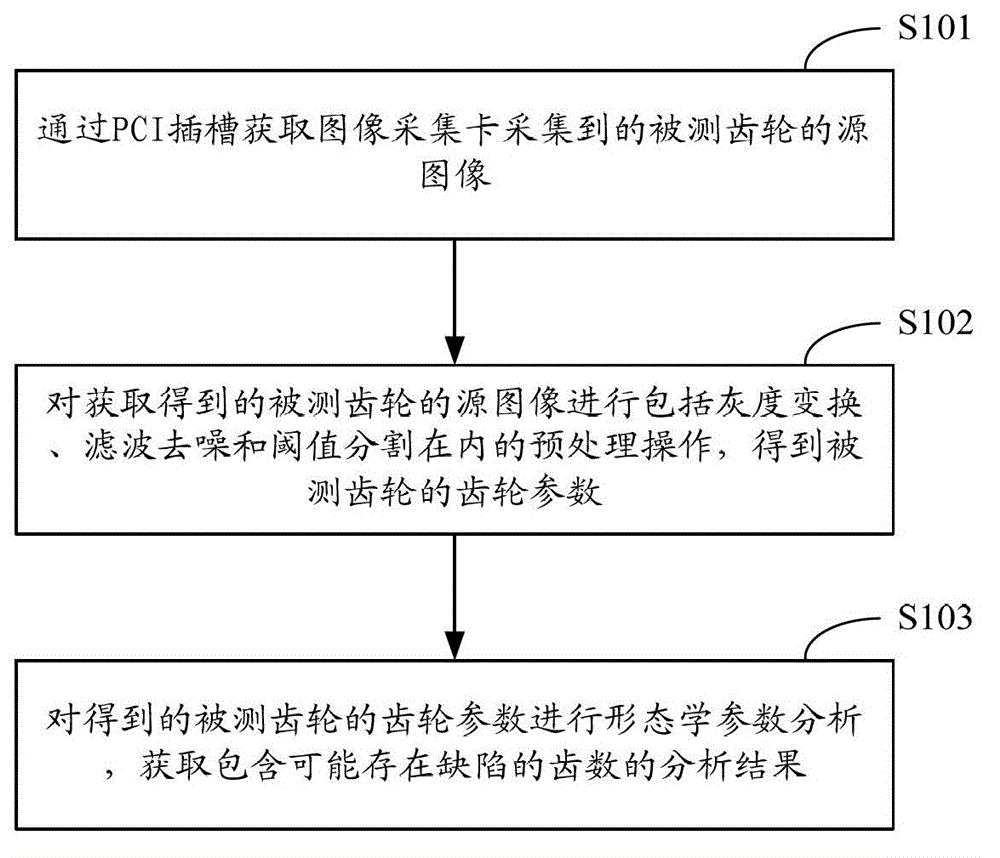

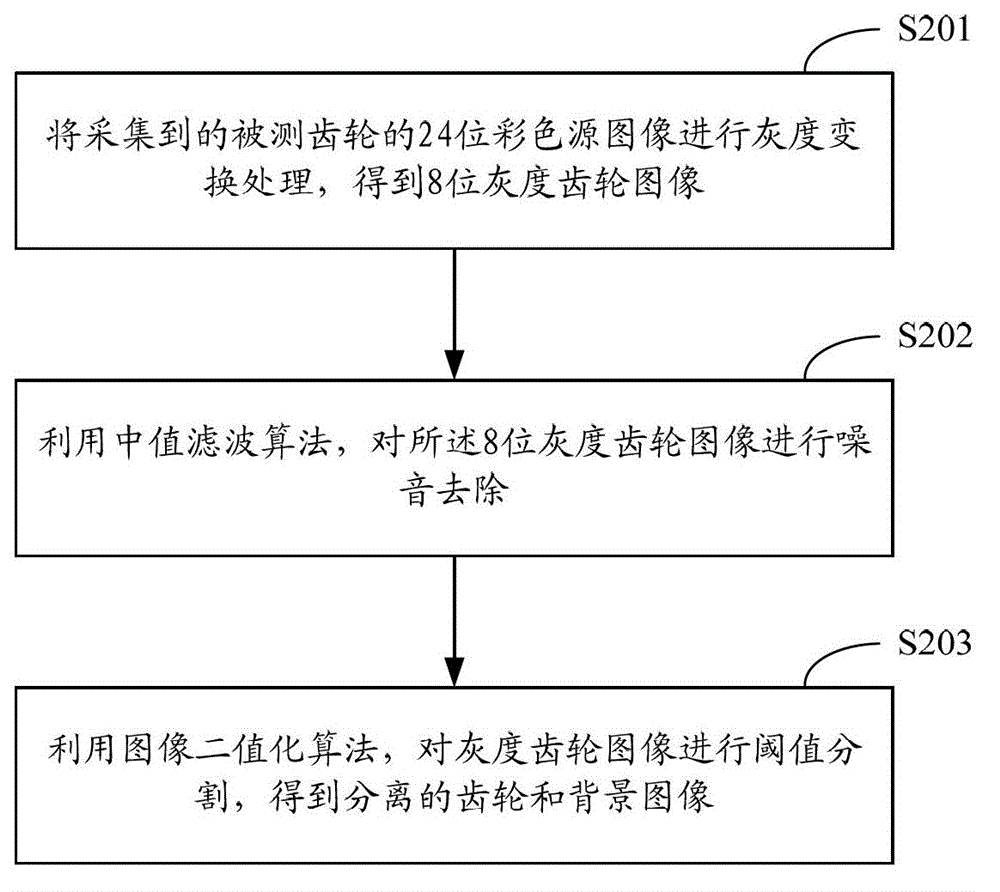

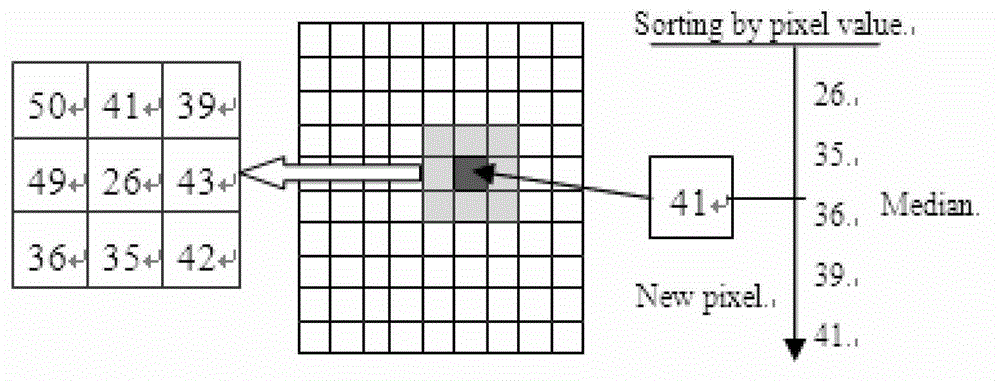

Gear defect detection method and system based on computer vision

ActiveCN102914545AMeet the functional requirements of routine parametric measurementsMeet the functional requirements of the measurementOptically investigating flaws/contaminationUsing optical meansImaging processingNoise reduction

The invention relates to the technical field of image processing and provides a gear defect detection method and system based on computer vision. The method comprises the following steps of: acquiring a source image of a detected gear acquired by an image acquisition card through a peripheral component interconnect (PCI) slot; performing preprocessing operation comprising grey level transformation, filtering and noise reduction and threshold segmentation on the source image of the detected gear, and obtaining gear parameters of the detected gear; and performing morphological parameter analysis on the gear parameters of the detected gear, and acquiring an analysis result of the teeth where the defects possibly exist. The gear defect detection method is high in measurement speed and high in precision, the functional requirements of the conventional gear parameter measurement are met, the production efficiency and production automation degree can be greatly improved in the large-scale industrial production process, the measurement precision requirement in the actual production can be met, the measurement time is only several seconds, the requirement on the measurement speed in industrial measurement can be met, and the method has high theoretical and practical values.

Owner:WEIFANG UNIVERSITY

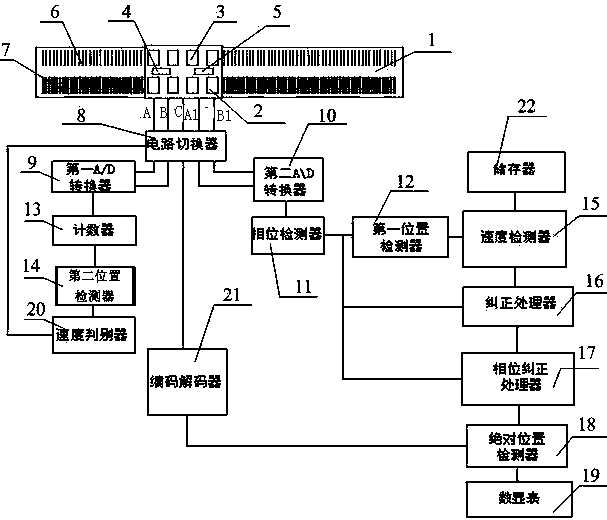

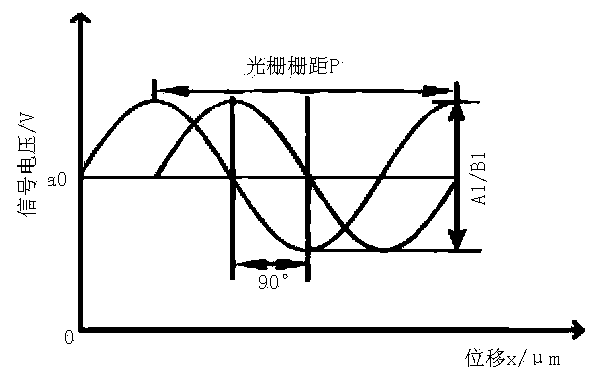

Image collecting circuit of high-speed absolute grating ruler

ActiveCN103512500AFast measurementIncrease productivityUsing optical meansConverting sensor outputGratingCoding decoding

The invention relates to an image collecting circuit of a high-speed absolute grating ruler. Coarse code channels and high-precision absolute code channels are engraved in the grating ruler. A photoelectricity converter for reading images and two LED light sources are further installed on the grating ruler. Multiple data reading windows are arranged in the photoelectricity converter. The image collecting circuit comprises a circuit switching device, a first A / D converter, a second A / D converter, a phase detector, a first position detector, a counting device, a second position detector, a speed detector, a correcting processor, a phase correcting processor, an absolute position detector, a speed judging device, a coding and decoding device and a storage device. Phases output by the photoelectricity converter are used for finely dividing adjacent absolute coding engraving line intervals to improve measuring precision of the grating ruler, macro-micro composite reading on low-precision incremental code channels and high-precision absolute code channels is achieved with a reading head. In a low-precision measuring stage, high measuring speed is achieved and low-speed high-precision measuring is carried out by switching when an endpoint is close.

Owner:GUANGDONG UNIV OF TECH

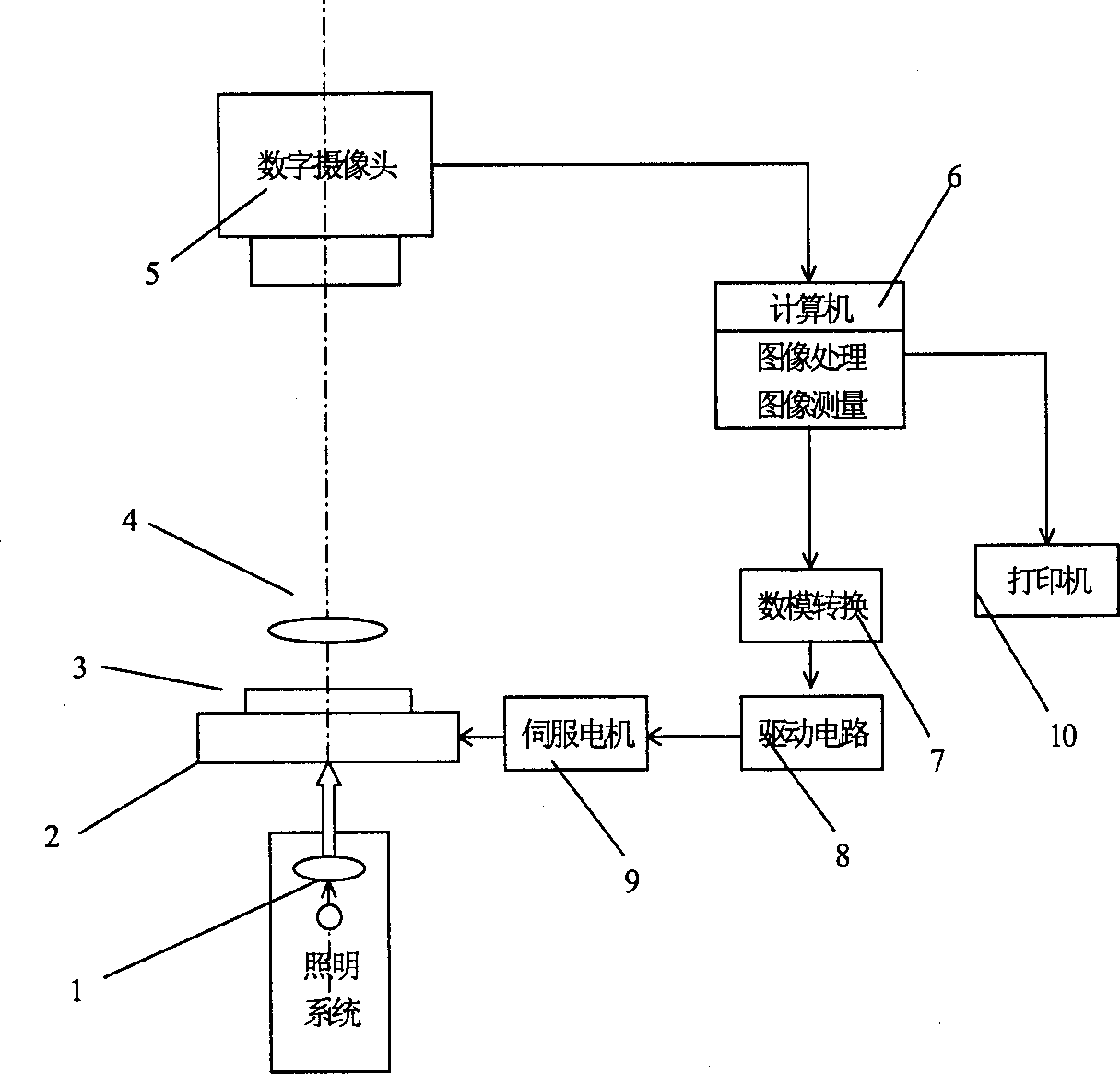

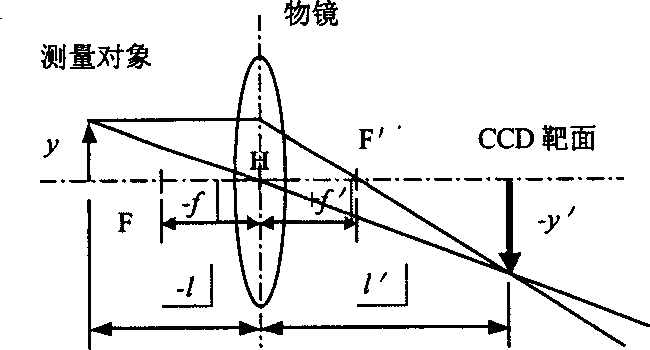

Method and system for measuring wool fiber fineness measurement

InactiveCN1359006AMany measurement parametersReliable resultsMaterial analysis by optical meansContinuous measurementSingle fibre

The present invention relates to a method for measuring wool fibre fineness and its system. Digital camera head (CCD) is adopted to convert the amplified fibre image into digital image, and transfer it into computer to mare real time processing to obtain fibre outline and calculate single fibre fineness, then it counts up the data of average fineness and fineness distribution of all the measured fibres. In said ivnention, general light source is used and the proper alogirhtm and software are designed with can measure animal fibre with the measurement range of 4-300 micrometers, and its measurement speed is 140 fibre / sec.

Owner:TSINGHUA UNIV

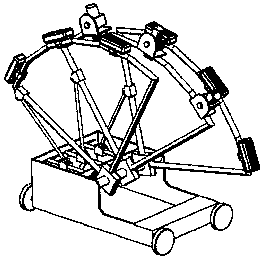

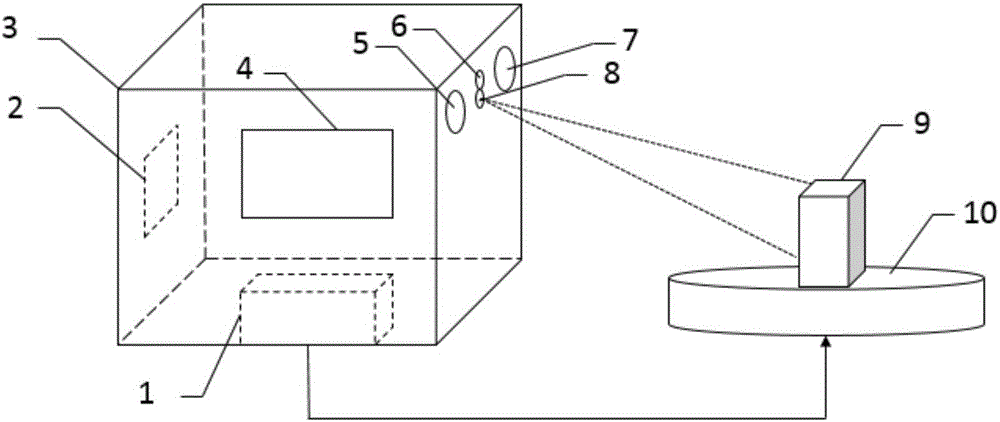

Binocular three-dimensional reconstruction method and binocular three-dimensional reconstruction system

InactiveCN106780725AAvoid blind spotsGuaranteed measurement accuracyDetails involving processing stepsUsing optical meansPoint cloudReconstruction method

The invention discloses a binocular three-dimensional reconstruction method and a binocular three-dimensional reconstruction system. The binocular three-dimensional reconstruction method includes acquiring certain portions of a person or an object on a turntable by the aid of two cameras; turning the turntable by a circle to obtain three-dimensional point cloud data of the scanned object and reconstructing three-dimensional curved surface models of the scanned object; driving a 3D (three-dimensional) printer to carry out printing so as to obtain three-dimensional models of the measured object. The acquired certain portions of the person or the object on the turntable are irradiated by line infrared light. The core thoughts include that the position of the to-be-measured object on the turntable is corrected by a line laser device, so that the to-be-measured object can be positioned in the center of a rotary shaft; an industrial personal computer is connected with two cameras to acquire the portions, which are irradiated by the line infrared light, of the measured object, and the turntable rotates at the constant speed by the circle under the control of the industrial personal computer; acquired images are extracted by an infrared center, and point cloud data can be generated; binocular point cloud data are fused and denoised; curved surfaces are reconstructed according to the fused point cloud data; the three-dimensional models of the measured object are printed. The binocular three-dimensional reconstruction method and the binocular three-dimensional reconstruction system have the advantages that the person or the object can be three-dimensionally reconstructed, the three-dimensional models of the person or the object can be printed, the binocular three-dimensional reconstruction method and the binocular three-dimensional reconstruction system are speedy and stable and are high in precision, and application requirements on quickly acquiring three-dimensional models of measured objects can be met.

Owner:XI AN JIAOTONG UNIV

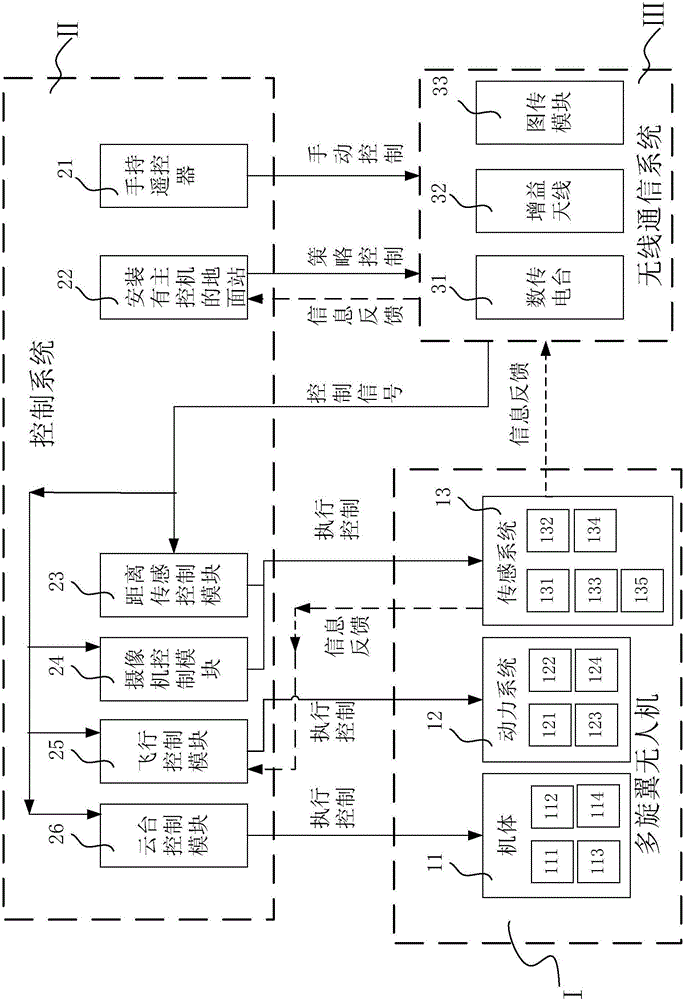

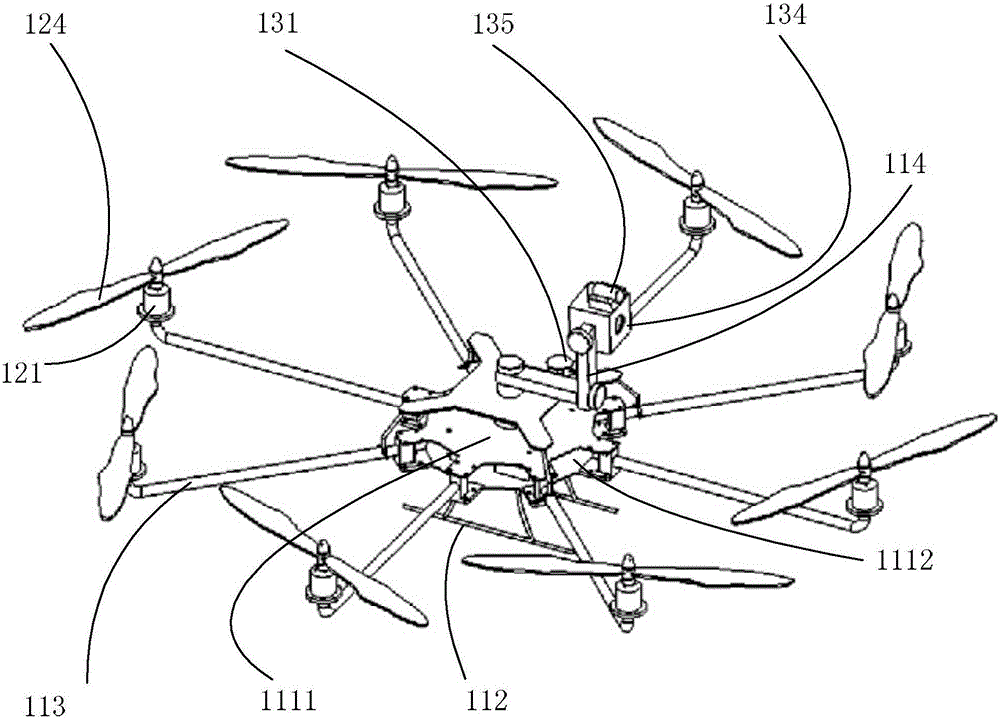

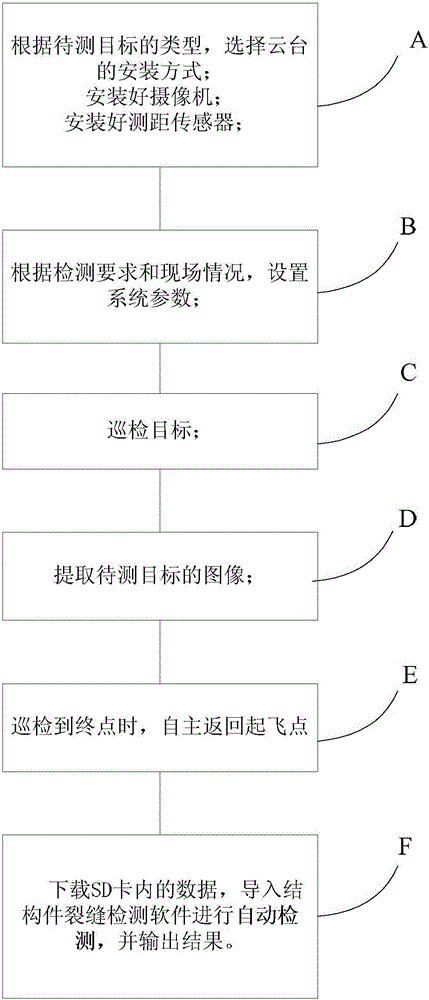

Multi-rotor unmanned aerial vehicle detection platform system for detecting surface cracks of structural member and method for detecting surface cracks of structural member with multi-rotor unmanned aerial vehicle detection platform system

ActiveCN106124517AHigh degree of automationSave time at workAircraft componentsOptically investigating flaws/contaminationHand heldVehicle detection

The invention discloses a multi-rotor unmanned aerial vehicle detection platform system for detecting surface cracks of a structural member. The multi-rotor unmanned aerial vehicle detection platform system comprises a multi-rotor unmanned aerial vehicle, a control system and a wireless communication system; the multi-rotor unmanned aerial vehicle for providing a task load and detecting the surface cracks of the structural member comprises a vehicle body, a power system and a sensing system; the control system comprises an upper computer, a lower computer and a hand-held remote control unit; the upper computer is a ground station provided with a main control computer; the lower computer is an execution control module arranged on the multi-rotor unmanned aerial vehicle; the wireless communication system comprises a data transfer radio, a gain antenna and an image transmission module; the main control computer arranged on the ground station transmits information by means of the data transfer radio and controls the flight of the multi-rotor unmanned aerial vehicle through the execution control module arranged on the multi-rotor unmanned aerial vehicle. The platform detecting system is high in degree of automation; by use of a method for detecting the surface cracks of the structural member with the platform detecting system, the working time required by detecting can be effectively saved, and the detection cost is greatly reduced; the multi-rotor unmanned aerial vehicle detection platform and the method are particularly suitable for detection work of cracks on the surface of a large-sized structural member.

Owner:LIUZHOU OVM MASCH CO LTD

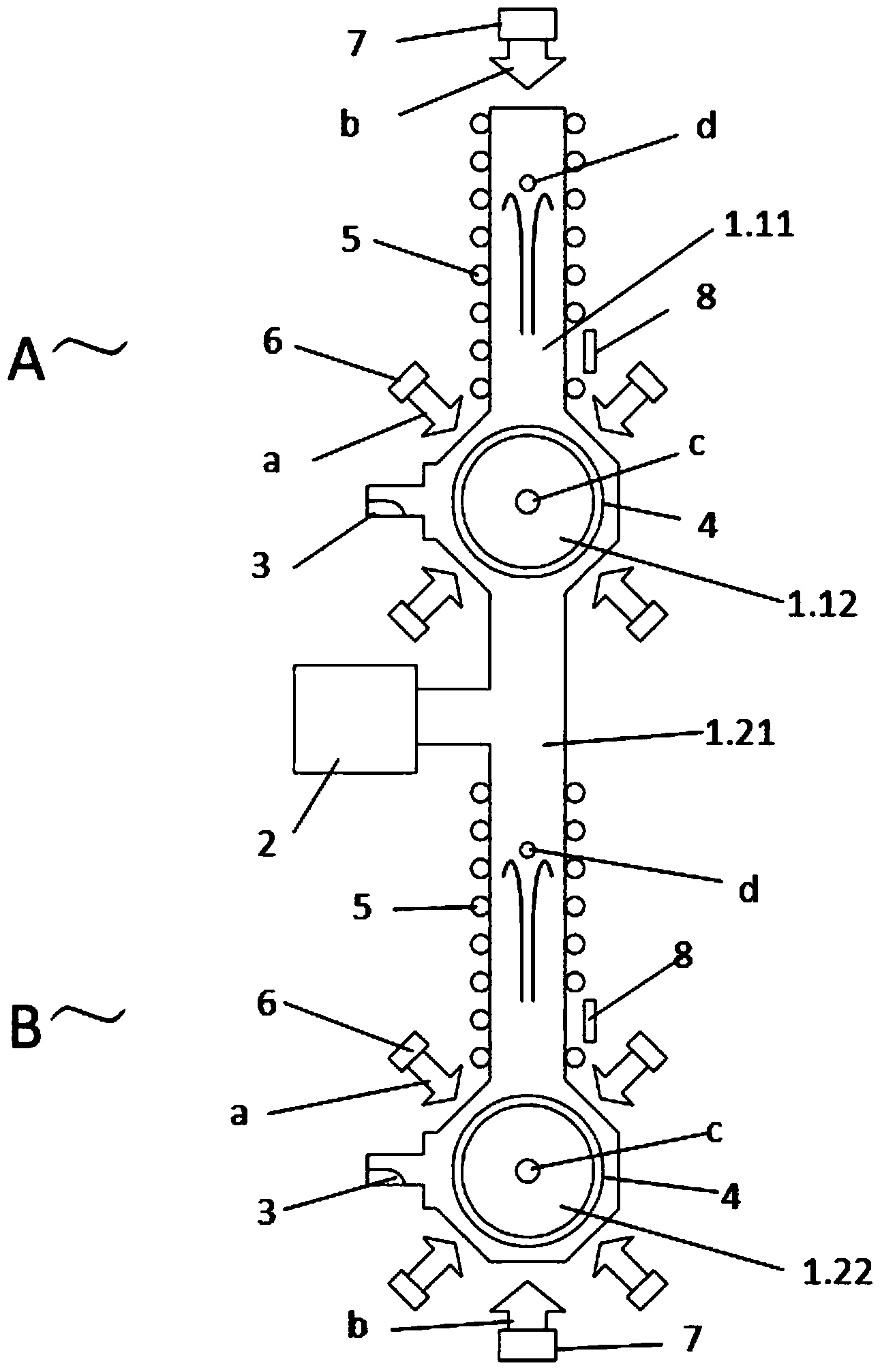

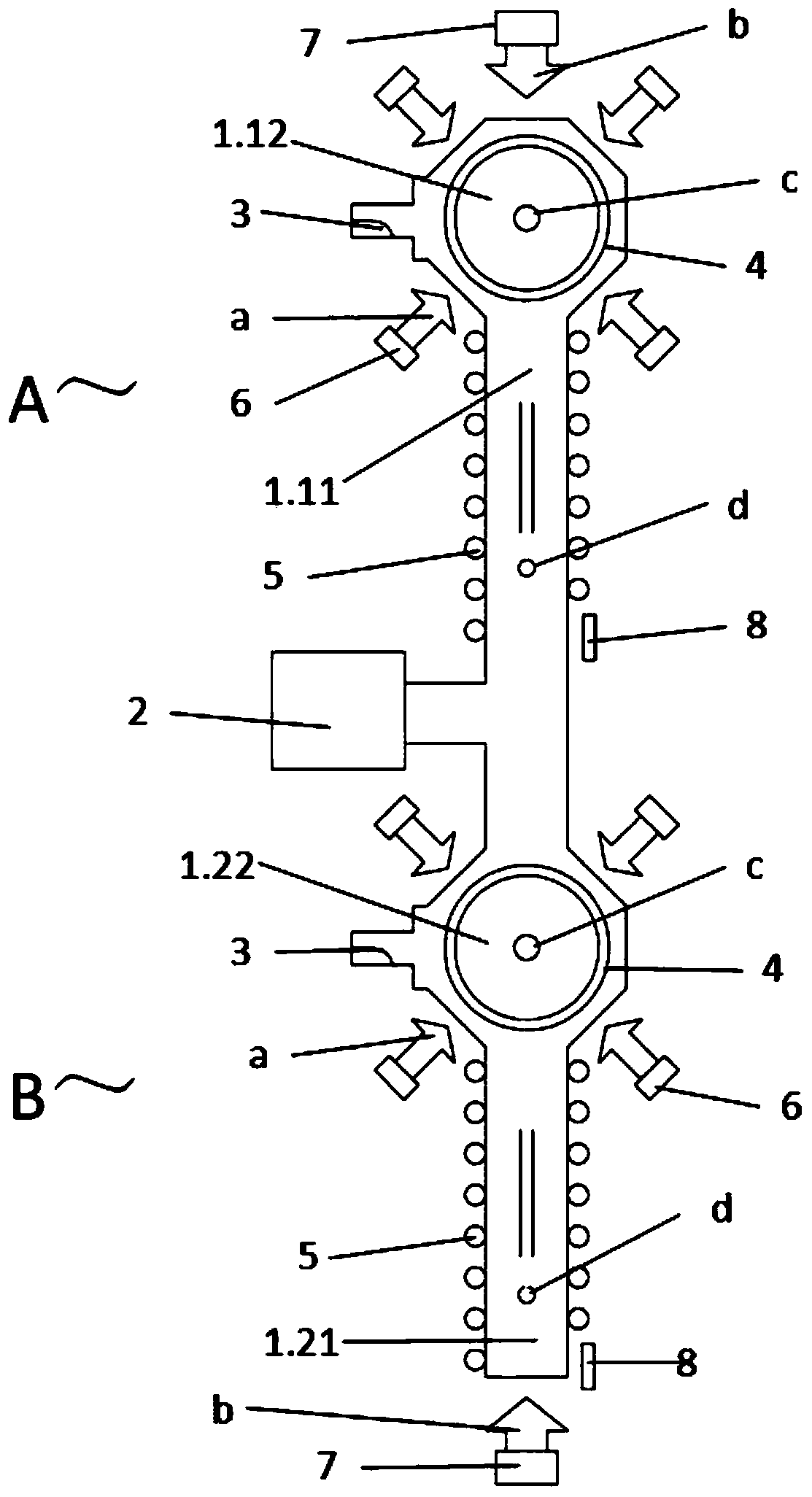

Vertical gravity gradient measuring sensor based on atom interference effect

ActiveCN103472495ARealize synchronized measurementsCancellation noiseGravitational wave measurementAtomic groupUnit device

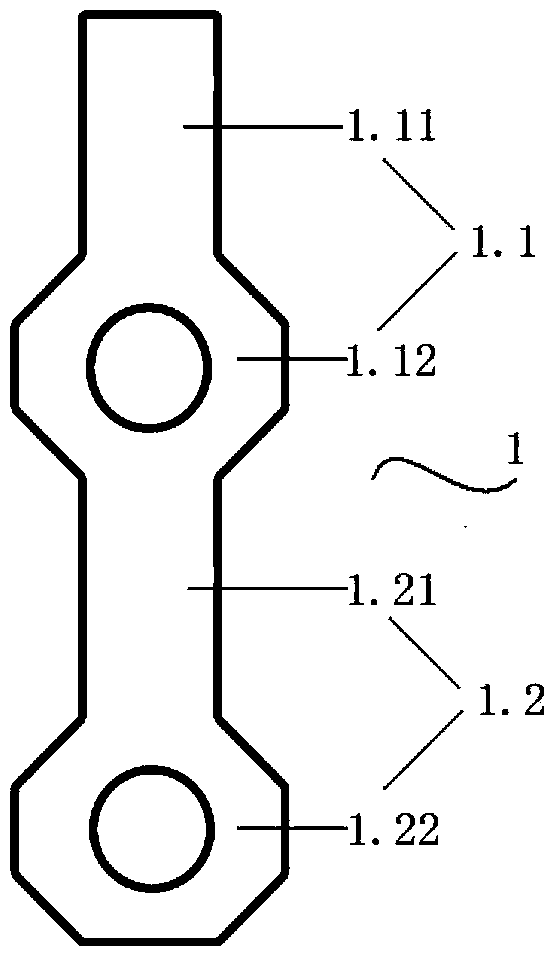

The invention discloses a vertical gravity gradient measuring sensor based on an atom interference effect, and belongs to the technical field of gravity surveying. The sensor comprises a first unit device (A) and a second unit device (B) of the same structures, and is characterized in that a first vacuum container (1.1) and a second vacuum container (1.2) are connected end to end in the mode that central axes are overlapped in the gravity direction to form a vacuum container (1), and the hollow part inside the first vacuum container (1.1) and the hollow part inside the second vacuum container (1.2) are communicated into a whole; two Raman laser beam emitters (7) are respectively arranged on the vacuum container (1) along the central axis of the gravity field direction, and the Raman laser beam emitters (7) carry out opposite emitting and point to the preparation regions of cold atomic groups (c), and the two unit devices share the pair of Raman laser beam emitters (7). The vertical gravity gradient measuring sensor enables noise and deviation from environment and Raman laser phase positions to be offset in a common-mode mode, and reduces the complexity, the size, the mass and the power consumption of a physical system.

Owner:WUHAN INST OF PHYSICS & MATHEMATICS CHINESE ACADEMY OF SCI

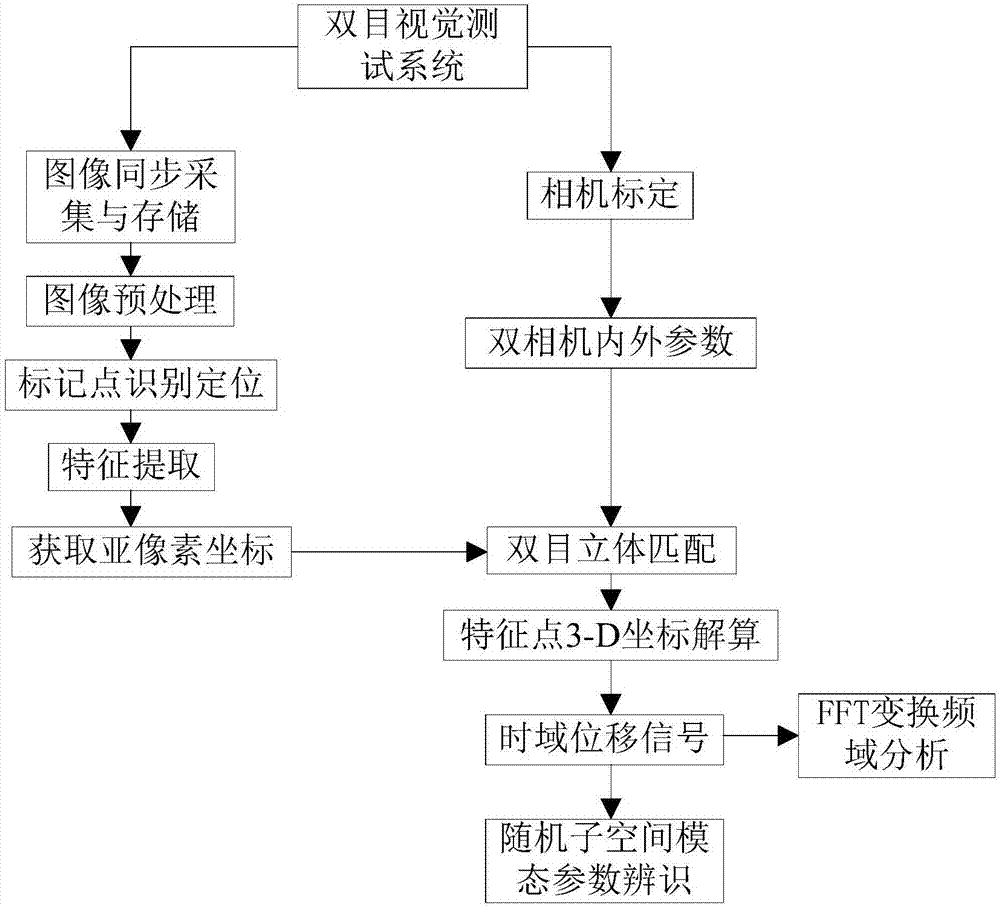

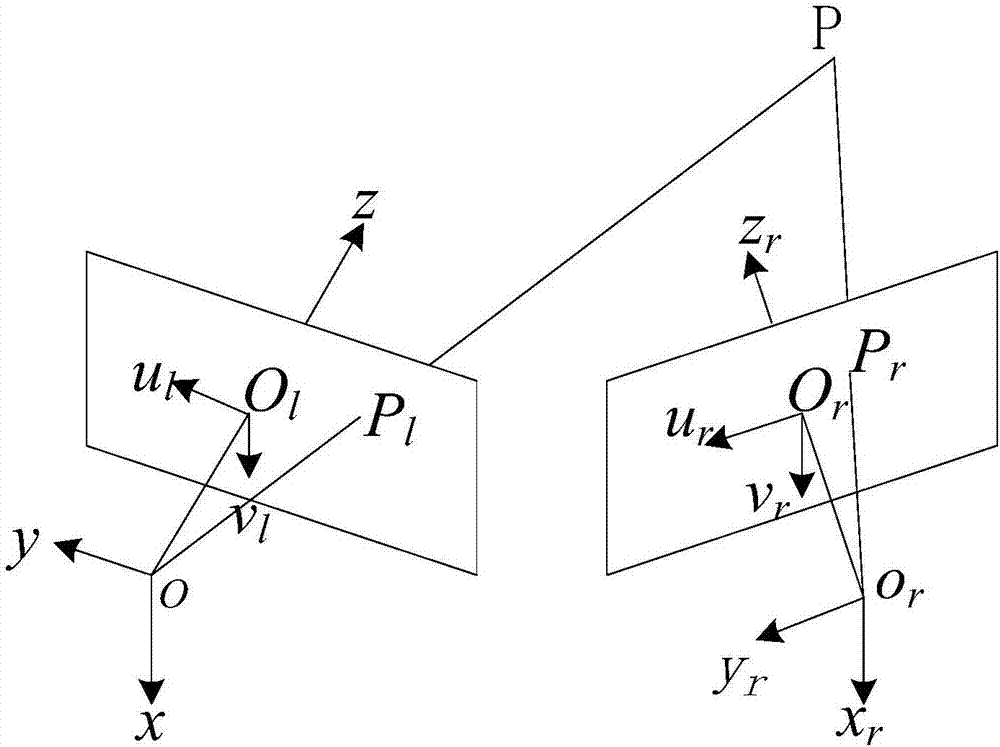

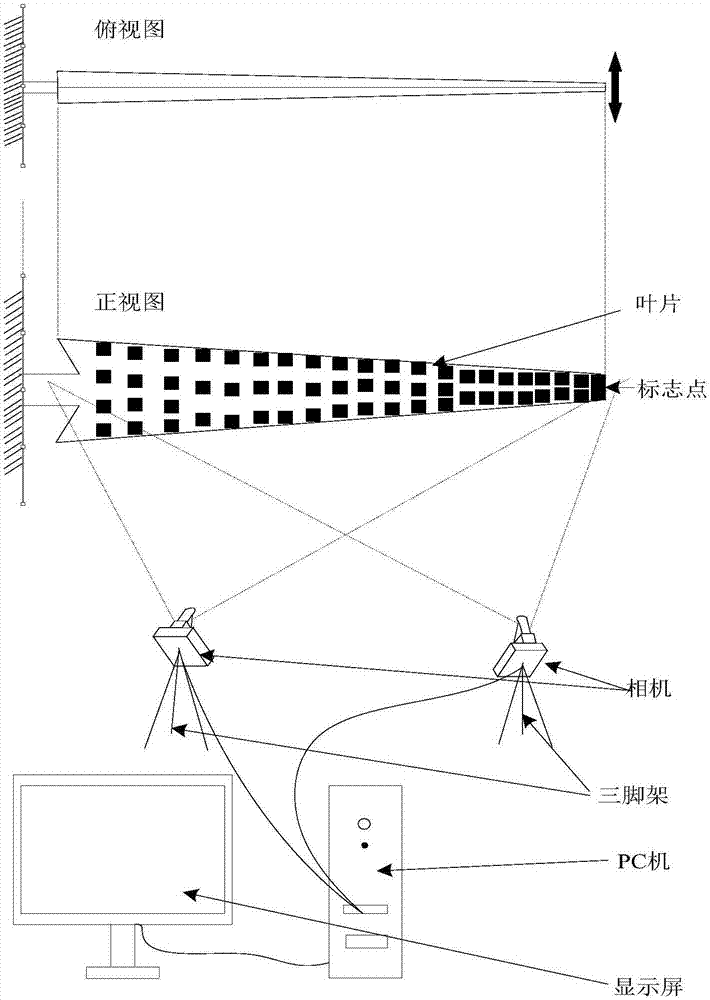

Modal test method of large draught fan blade based on photography measurement technology

ActiveCN106989812AThe influence of dynamic characteristicsRealize non-contact measurementSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansMeasurement pointFourier transform on finite groups

The invention discloses a modal test method of a large draught fan blade based on the photography measurement technology. The method comprises steps of using a pair of CMOS / CCD industrial cameras to carry out synchronous shooting on surface images of the draught fan blade under random excitation vibration; identifying and positioning multiple marking points in the images; extracting central sub-pixel level coordinates of the marking points and carrying out stereo matching of the double cameras; calculating three-dimensional coordinates of each measurement point through the three-dimensional reconstruction technology; carrying out micro-division processing on displacement data to obtain required vibration response (speed and accelerated speed) signals; through the Fourier transform, converting time domain signals into observation peak values in frequency domains to find corresponding modal frequencies; by combining analyzed frequency values, further using the stochastic subspace identification method (SSI) to precise calculate modal parameters of the blade; and acquiring the fixed frequency, the vibration mode and the damping ratio of the blade. According to the invention, by use of non-contact type multi-point synchronous vibration measurement, rapid high-precision model test on the draught fan blade can be achieved.

Owner:HUNAN UNIV OF SCI & TECH

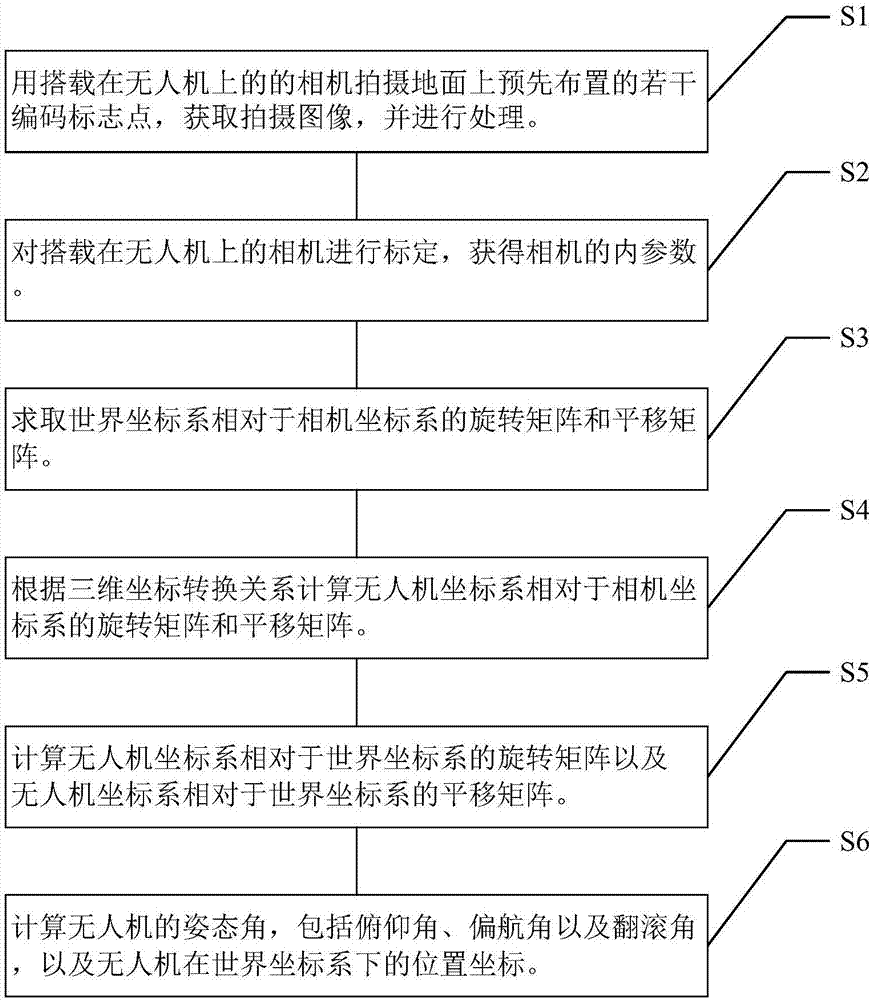

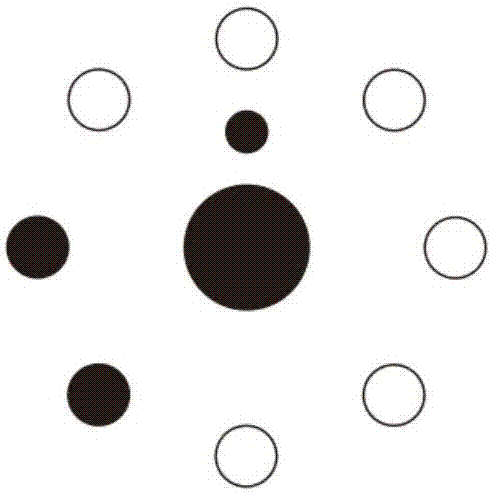

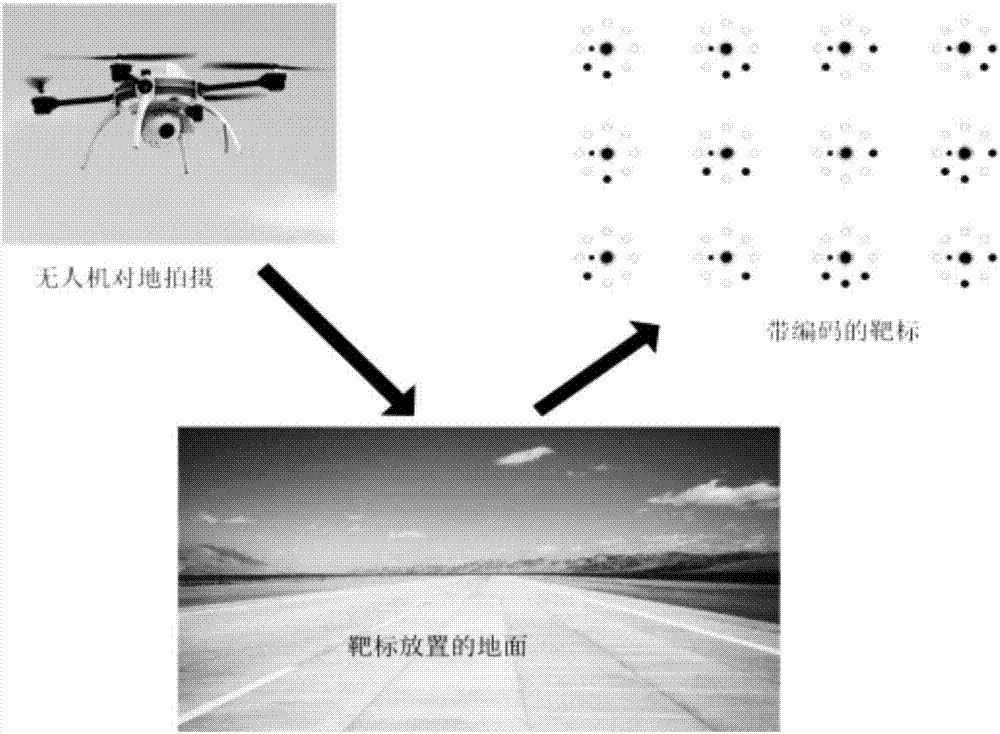

Coded target point based UAV positioning and attitude angle measuring method

ActiveCN107314771AExpand the field of viewIncrease flexibilityNavigational calculation instrumentsIndication/recording movementComputer visionComputer science

The invention provides a coded target point based UAV positioning and attitude angle measuring method. The method comprises the following steps: shooting a plurality of coded target points which are pre-arranged at the ground through a camera which is mounted on an UAV, and obtaining and processing the shot images; calibrating the camera mounted on the UAV, and obtaining internal parameters of the camera; resolving a rotation matrix and a translation matrix of a world coordinate system relative to a camera coordinate system, the rotation matrix and the translation matrix of an UAV coordinate system relative to the camera coordinate system, and the rotation matrix and the translation matrix of the UAV coordinate system relative to the world coordinate system; and then calculating UAV attitude angles, including a pitching angle, a yaw angle and, an overturning angle, and the location coordinate of the UAV under the world coordinate system. According to the method, a binary coding cooperation points with primary points are adopted, and the coordinate transformation relation among the UAV coordinate system, the camera coordinate system and the world coordinate system are adopted, so that the algorithm is simple and easily realized, and meanwhile, the accuracy demand is met.

Owner:HEFEI UNIV OF TECH

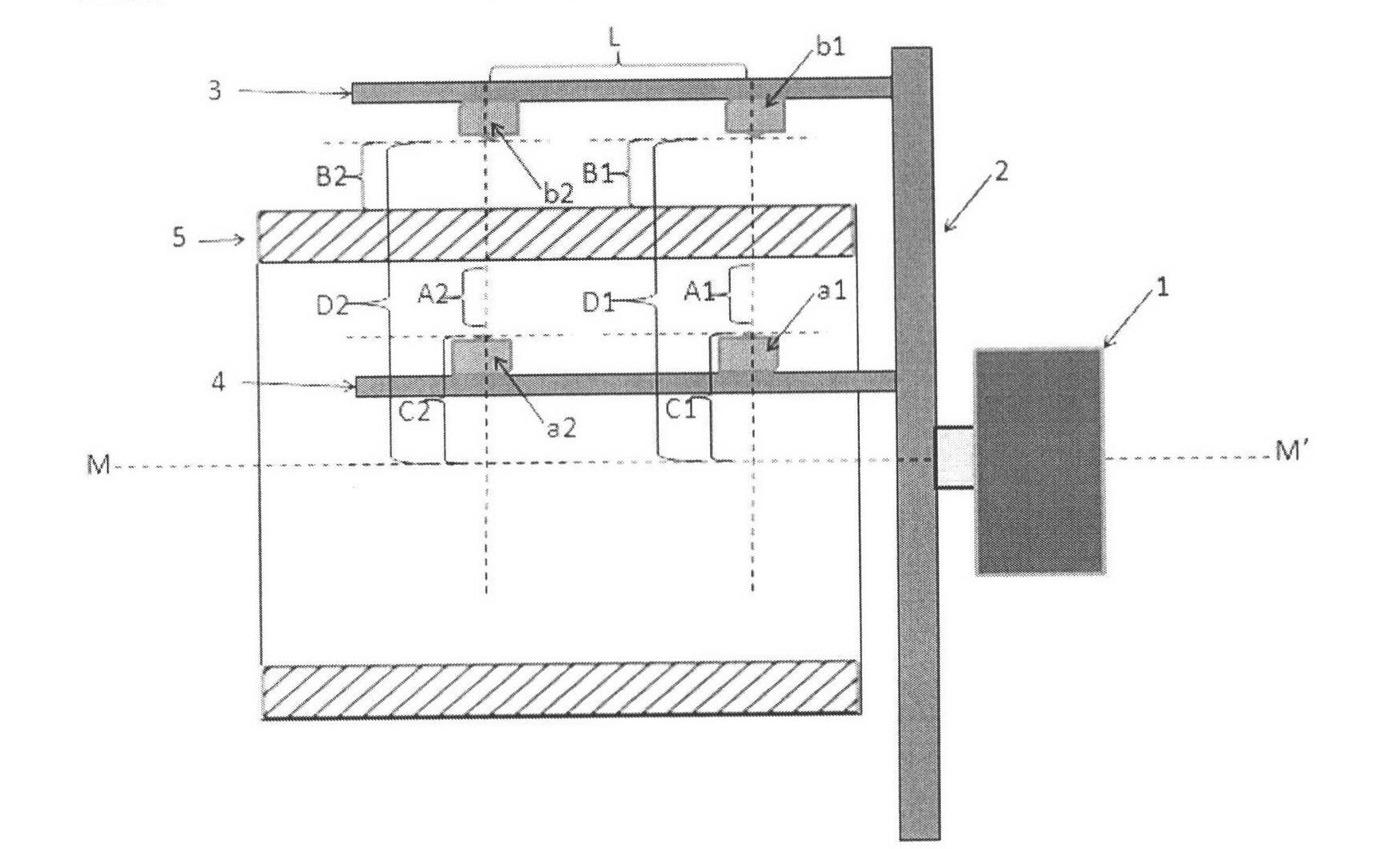

Two-arm four-probe measurement device and method for measuring inner and outer diameters of end of steel tube

ActiveCN102607438AEliminate misalignment deviationReduce the number of turnsUsing optical meansLaser rangingRotary stage

The invention discloses a two-arm four-probe measurement device and method for measuring inner and outer diameters of an end of a steel tube. The measurement device comprises a rotary table (1), a rotary table fixing plane (2), two fixing arms (3) and (4), four laser ranging probes (a1), (a2), (b1) and (b2). According to the measurement method, the four probes rotate around the central axis M-M' of the rotary table, inner and outer diameters of two sections of the steel tube are measured at the same time, a virtual central axis and a virtual space vertical plane of the steel pipe are fitted, the measured section data of the steel tube is projected to the virtual space vertical plane so that the offset when the rotating central axis of the rotary table is not coincident with the central axis of the steel tube can be eliminated, the measurement accuracy is improved, the number of turns of the rotary table is reduced and the measurement speed is improved further. The device and the method can be used for realizing the rapid non-contact automated measurement of inner and outer diameters of the end of the steel tube, eliminating influences from subjective factors of a human and improving automation degree of the production process of steel tubes.

Owner:NANKAI UNIV

Contact type temperature non-inductive three-dimensional detection sensor based on fiber Bragg grating (FBG)

InactiveCN102589439ACapable of 3D detectionRealize three-dimensional space position signal detectionUsing optical meansFiberGrating

The invention discloses a contact type temperature non-inductive three-dimensional detection sensor based on a fiber Bragg grating (FBG) and belongs to the technical field of precision instrument manufacturing and precision test measurement. The sensor comprises a broadband light source system which consists of a pump laser, a wavelength division multiplexing (WDM) coupler, an erbium-doped fiber and a beam splitter, a temperature compensation system which consists of an erbium-doped fiber amplifier (EDFA), a first circulator, a guide pipe, a reference FBG and a fiber barrier, a probe, and a signal receiving system which consists of an optical spectrum analyzer, a fiber coupler and an index-matching fluid, wherein the reference FBG of the temperature compensation system is arranged in a spatial distance of 30 cm of the probe. By the sensor, three-dimensional sensing is realized, and the environmental adaptability of the sensor is greatly improved. The sensor has the characteristics of simple structure and high real-time performance and is easy to practically use. The sensor has the advantage of quick and ultra-precise measurement and calibration of small cavity size.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com