Patents

Literature

1313 results about "Vibration response" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and system for analysing tachometer and vibration data from an apparatus having one or more rotary components

ActiveUS7640802B2Avoid problemsEasy to getVibration measurement in solidsVehicle testingForce frequencyVibration amplitude

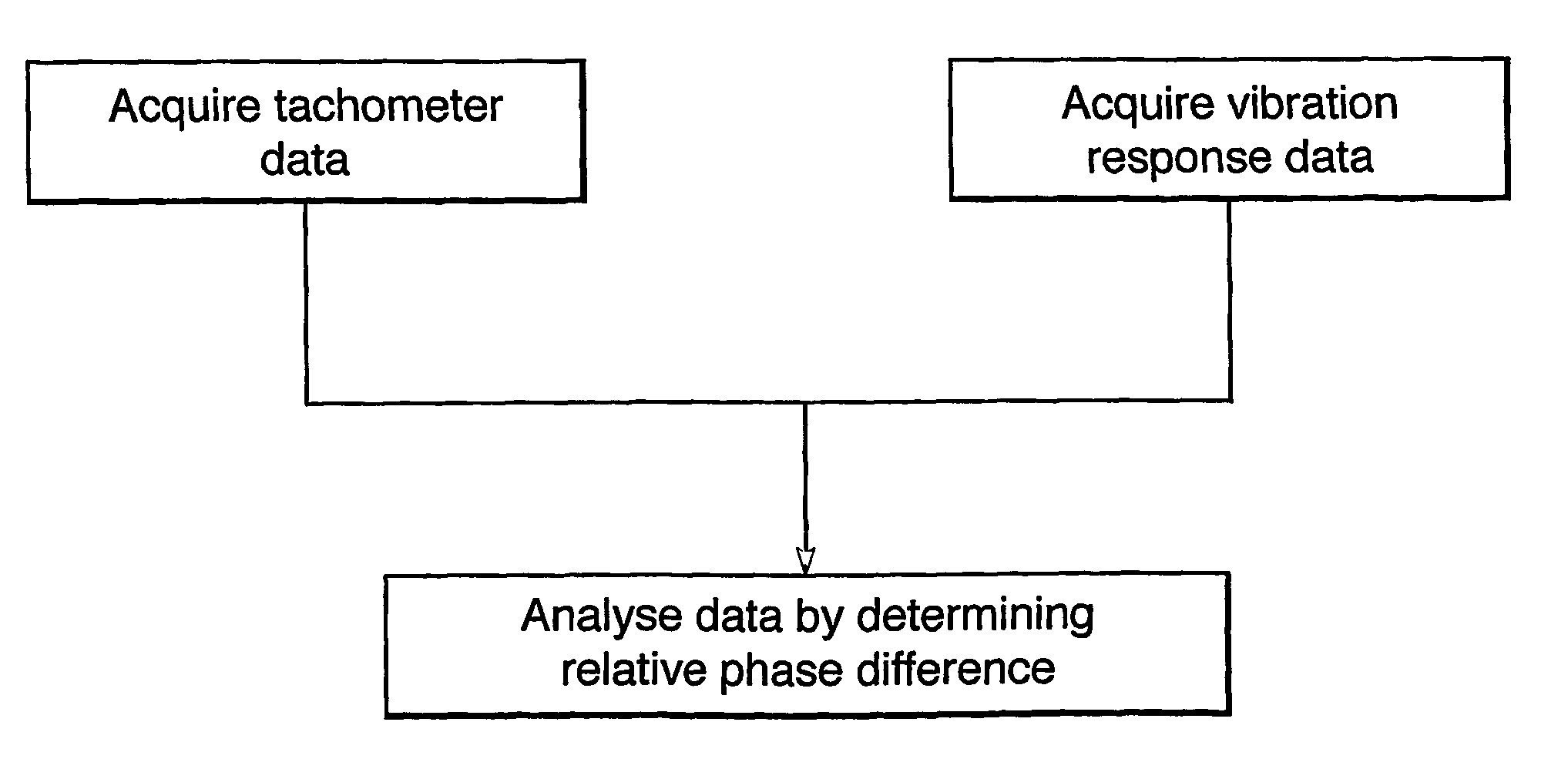

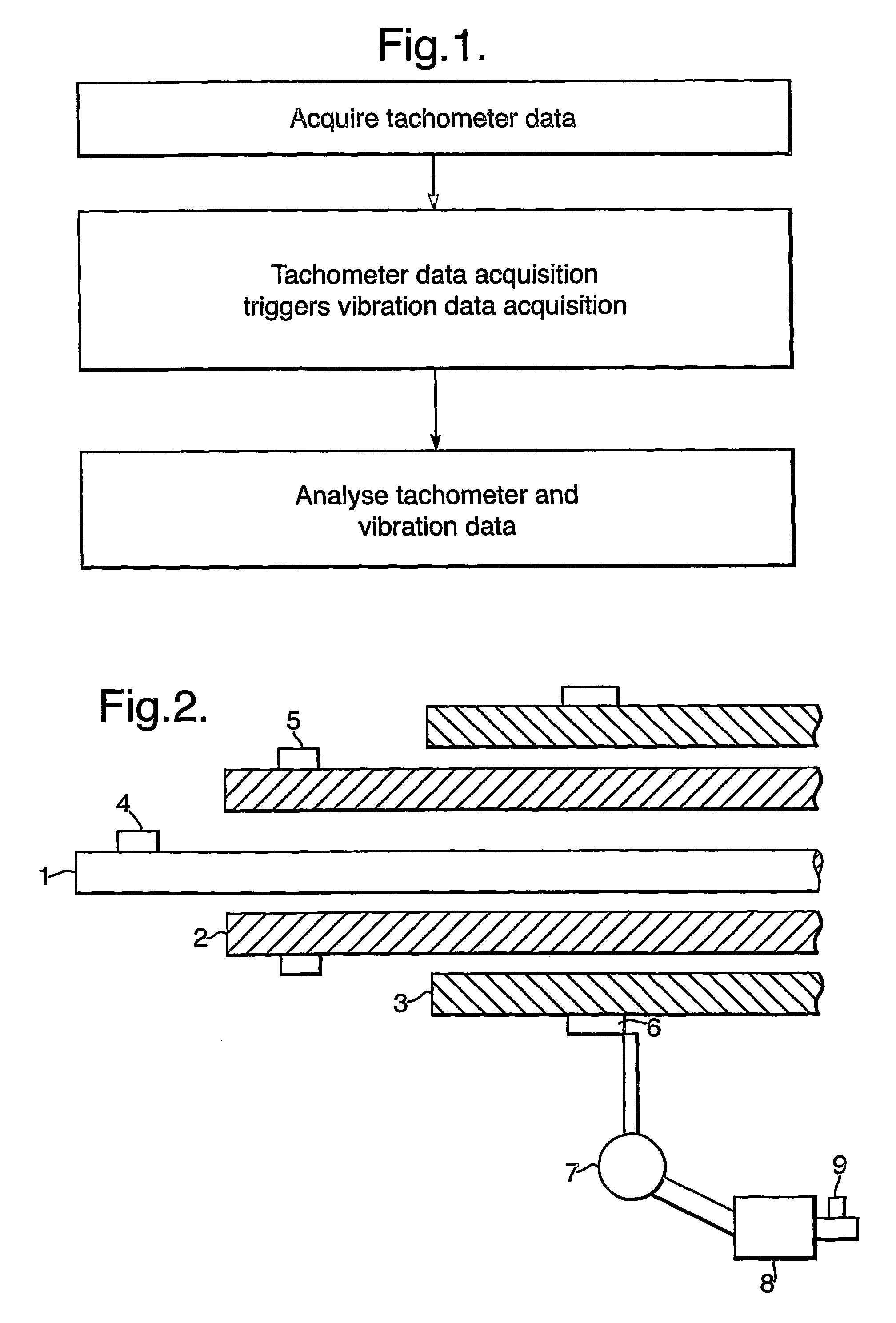

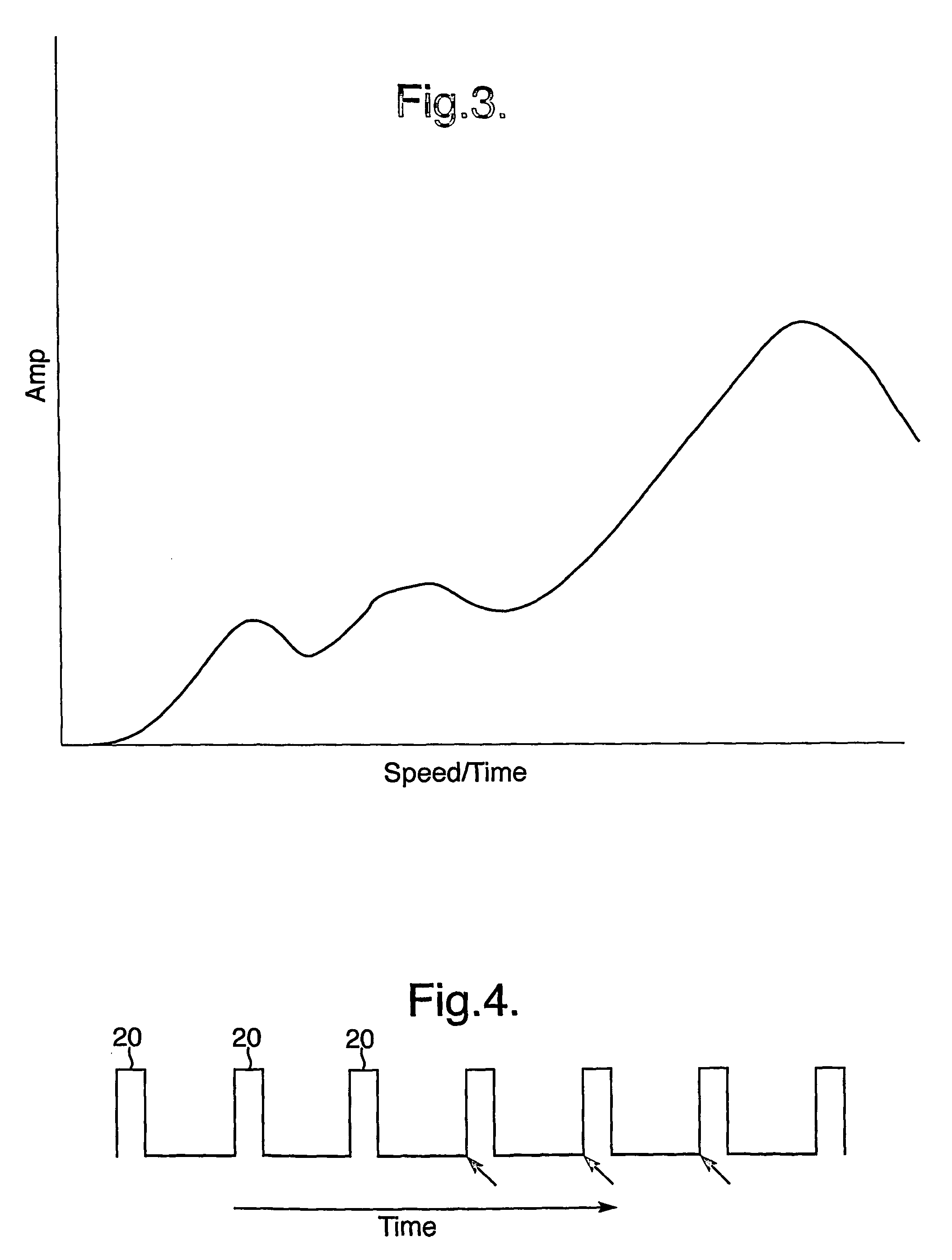

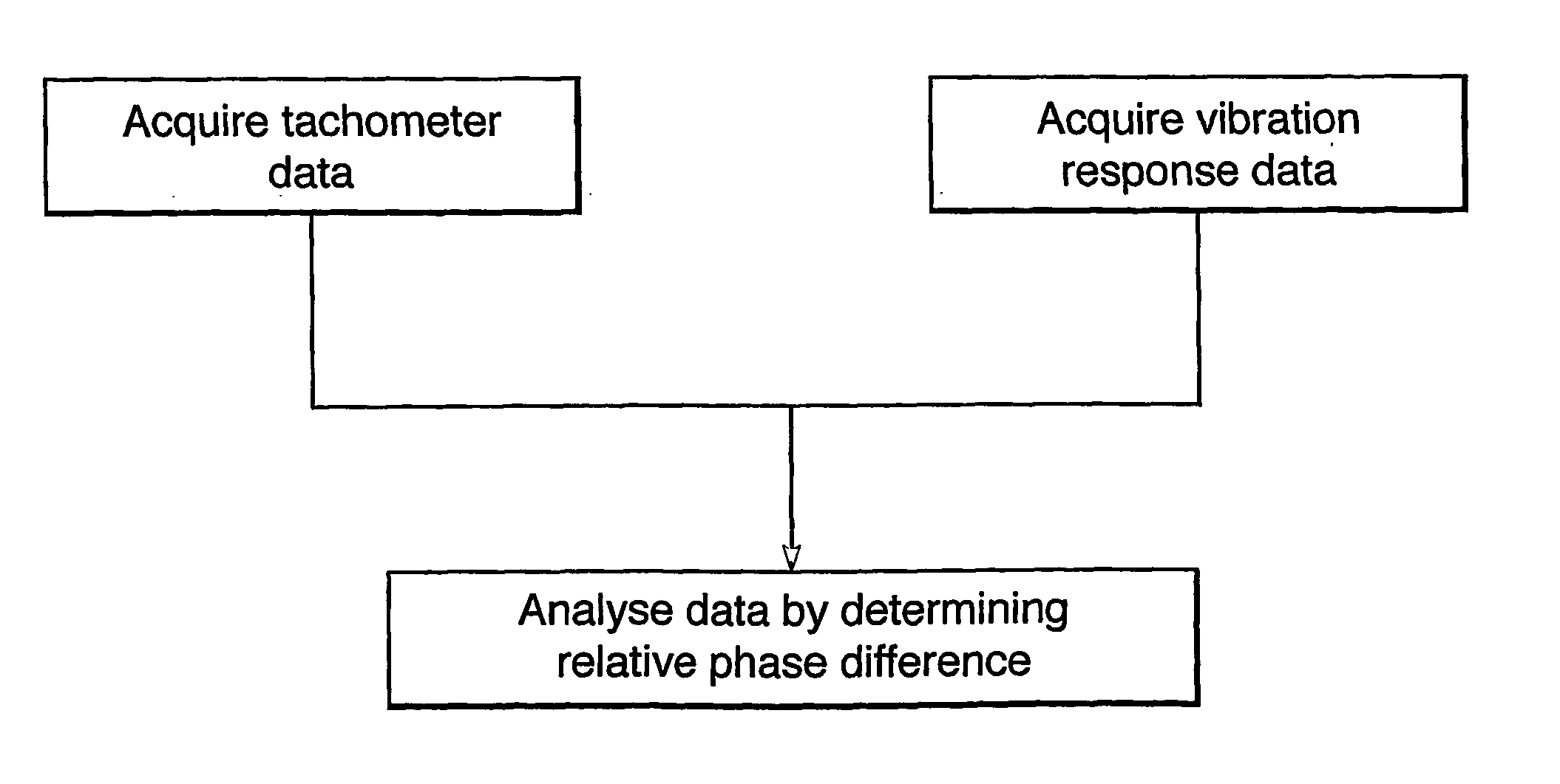

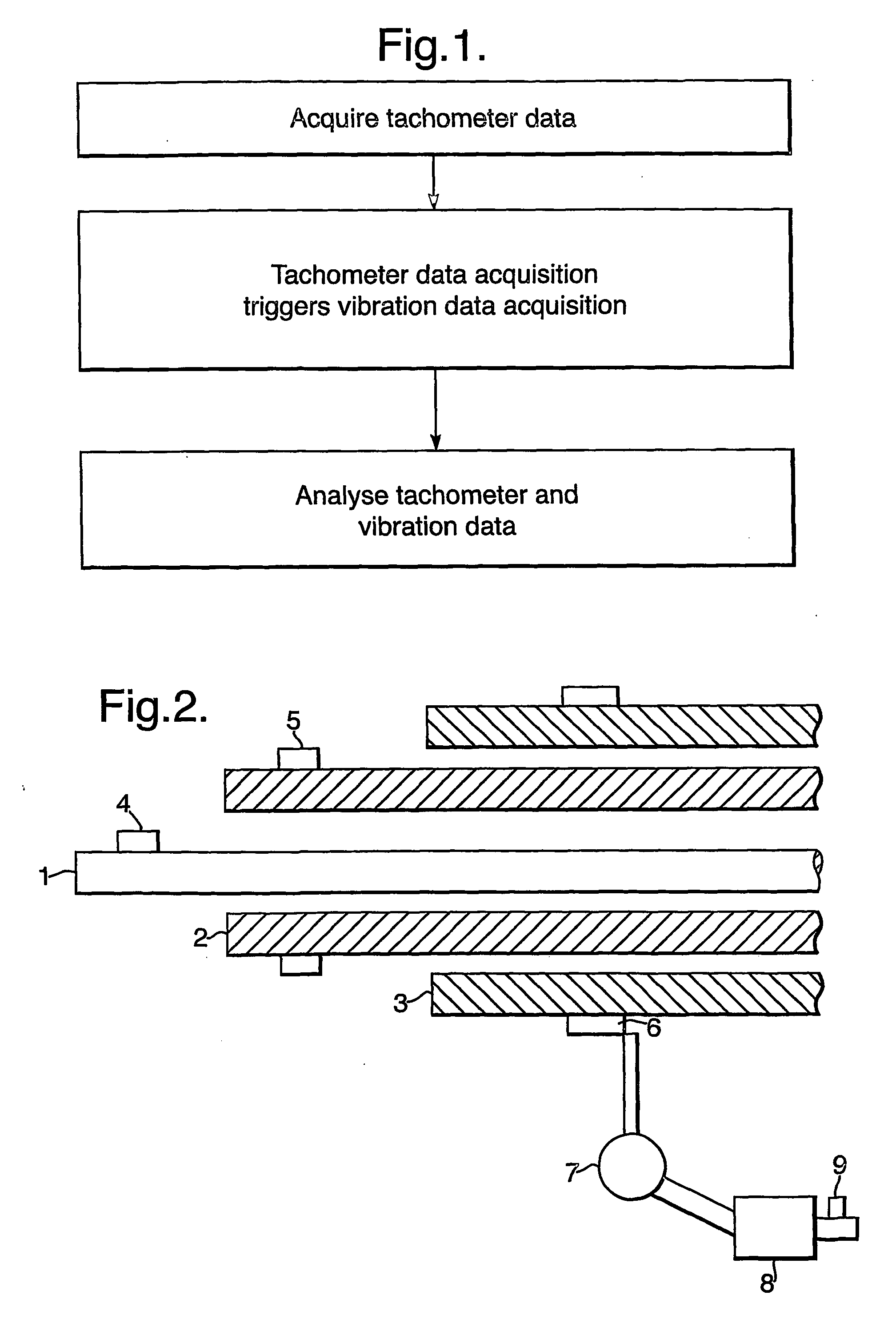

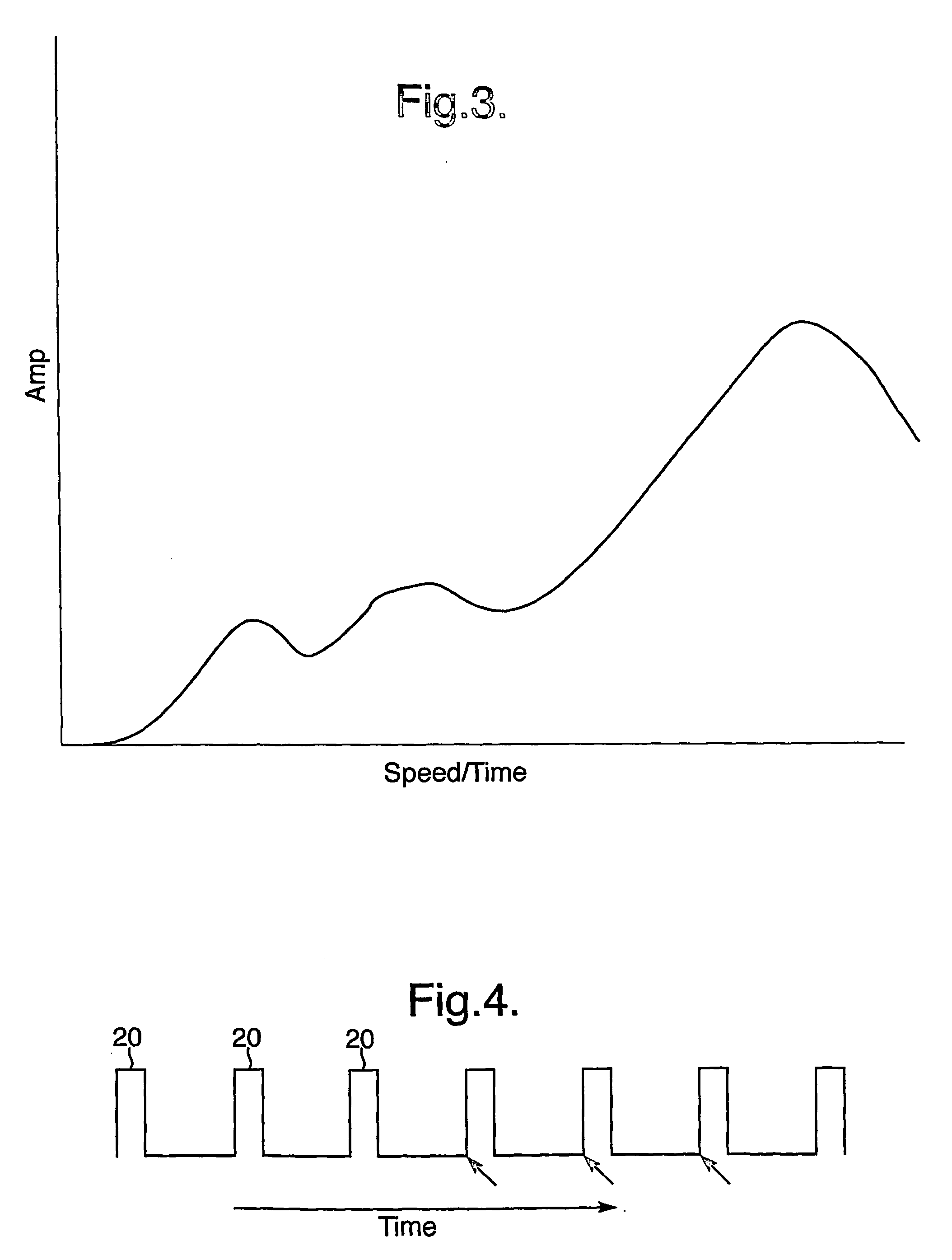

A method of analysing tachometer and vibration response data from an apparatus having one or more rotary components is provided. The method comprises the steps of: providing vibration response data and corresponding tachometer data from the apparatus for a period over which a rotary component of the apparatus varies in rotational speed, the tachometer data being for that component; repeatedly performing at intervals throughout the period the sub-steps of: determining a forcing frequency of the component from the tachometer data and a corresponding vibration response frequency of the apparatus from the vibration response data, comparing the forcing and vibration response frequencies to determine the relative phase difference between the frequencies, and determining the corresponding amplitude of the vibration response from the vibration response data; and plotting the relative phase differences and vibration amplitudes on a polar diagram. The plot trajectory is characteristic of the behavior of the apparatus over the period.

Owner:ROLLS ROYCE PLC +1

Method and system for analysing tachometer and vibration data from an apparatus having one or more rotary components

ActiveUS20070006636A1Avoid problemsEasy to getVehicle testingVibration measurement in solidsForce frequencyVibration amplitude

A method of analysing tachometer and vibration response data from an apparatus having one or more rotary components is provided. The method comprises the steps of: providing vibration response data and corresponding tachometer data from the apparatus for a period over which a rotary component of the apparatus varies in rotational speed, the tachometer data being for that component; repeatedly performing at intervals throughout the period the sub-steps of: determining a forcing frequency of the component from the tachometer data and a corresponding vibration response frequency of the apparatus from the vibration response data, comparing the forcing and vibration response frequencies to determine the relative phase difference between the frequencies, and determining the corresponding amplitude of the vibration response from the vibration response data; and plotting the relative phase differences and vibration amplitudes on a polar diagram. The plot trajectory is characteristic of the behaviour of the apparatus over the period.

Owner:ROLLS ROYCE PLC +1

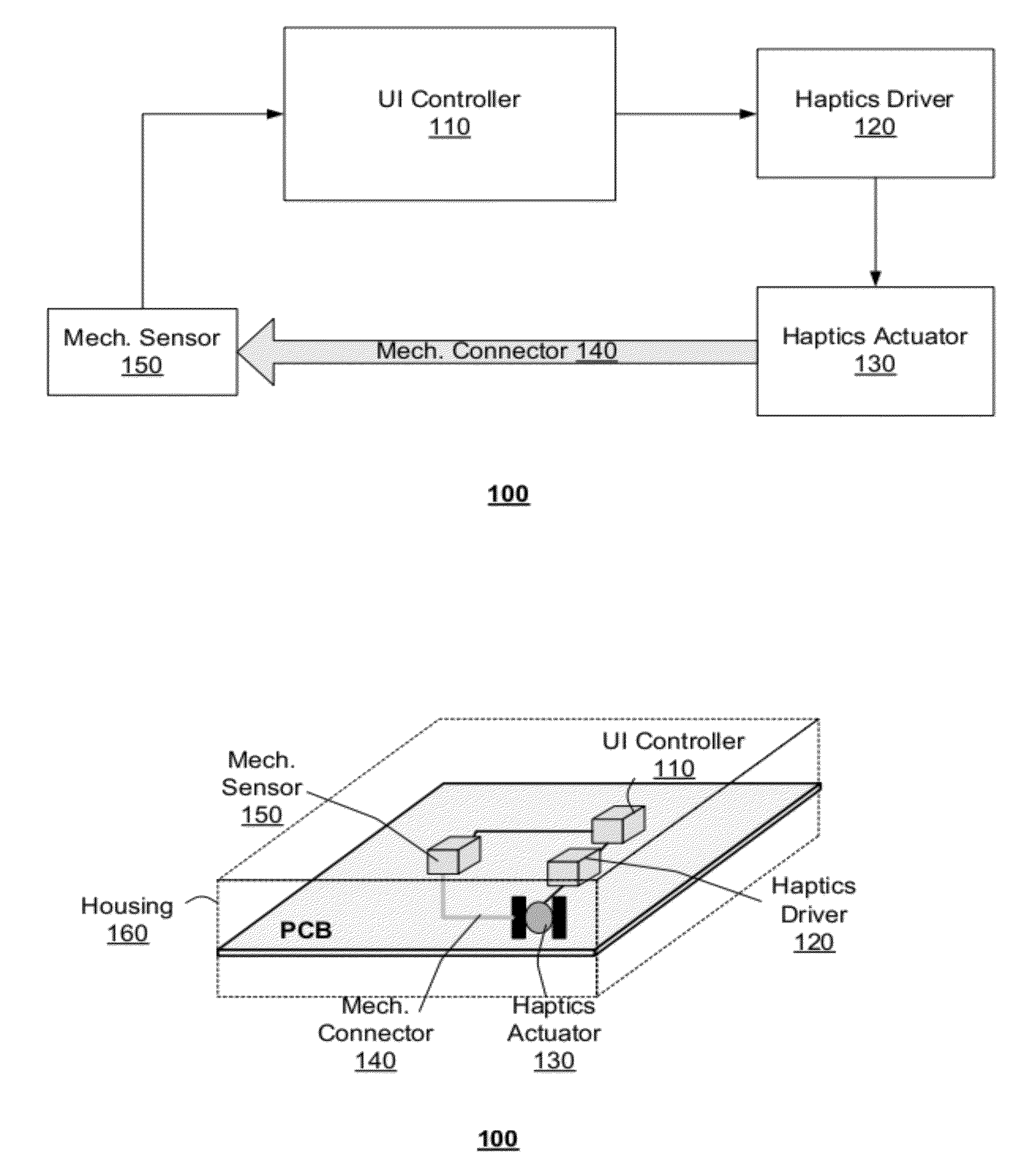

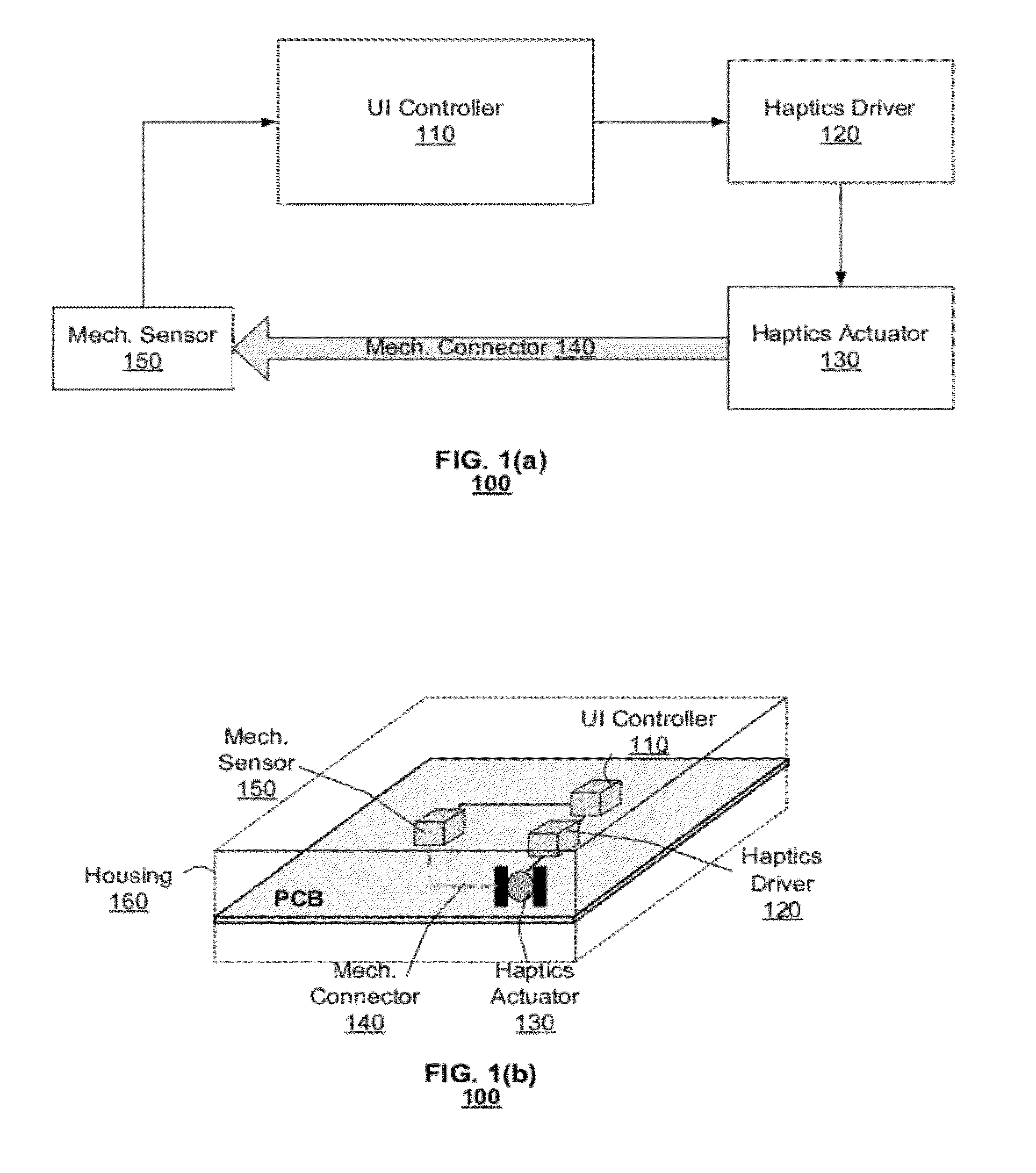

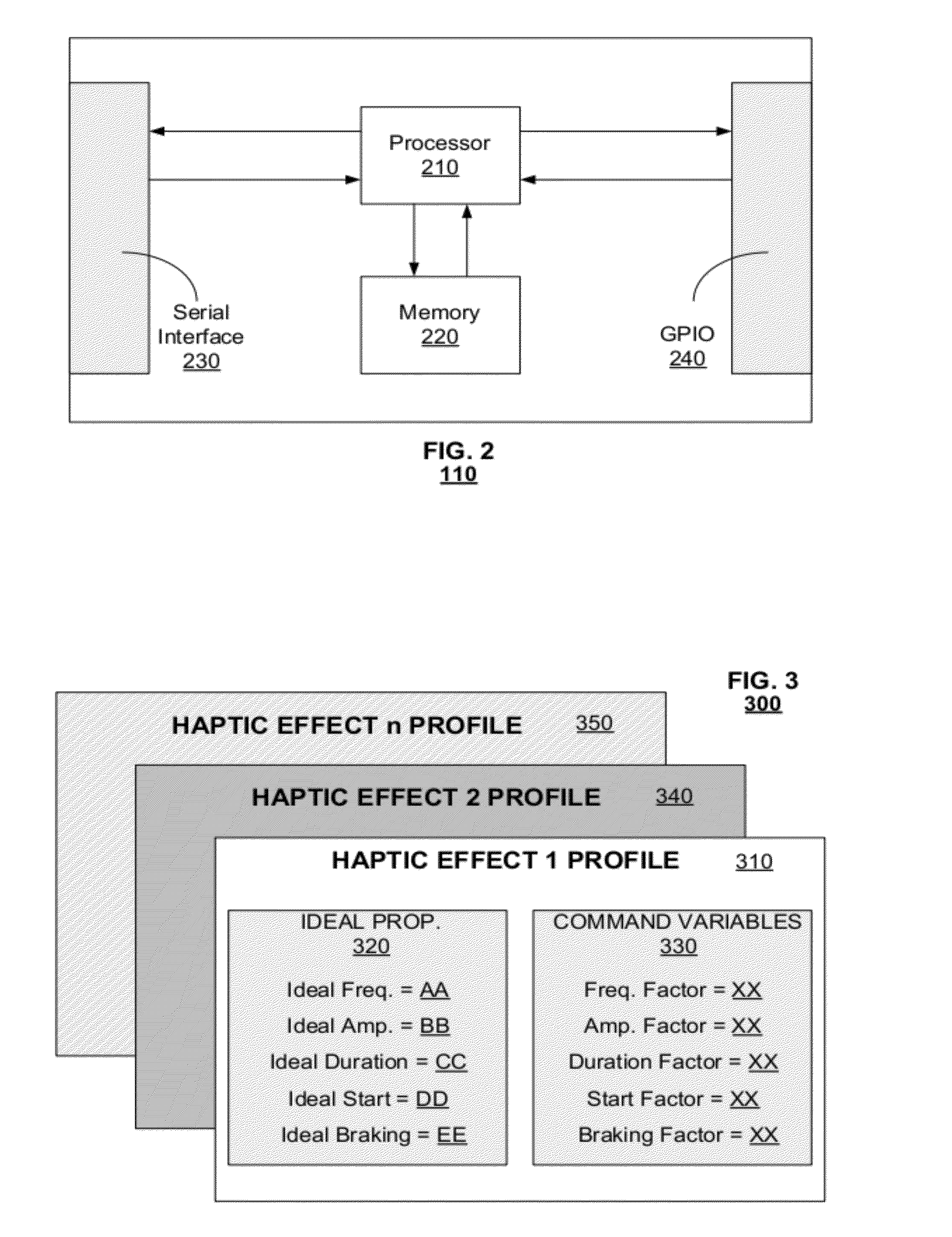

Method and apparatus for haptic vibration response profiling and feedback

ActiveUS20120249462A1Digital data processing detailsRepeater circuitsVibration measurementEngineering

Embodiments of the present invention may provide a device to adaptively generate a haptic effect. The device may include a controller to generate a haptic command associated with a haptic profile and a haptic driver to generate a drive signal based on the haptic command, wherein the drive signal causes an actuator to produce vibrations corresponding to a haptic effect. Further, the device may include a sensor, coupled mechanically to the actuator, to measure at least one property of the vibrations. The controller may adjust the haptic command according to the measured at least one property. Therefore, the device may continuously tune haptic effect generation according to vibration measurements.

Owner:ANALOG DEVICES INC

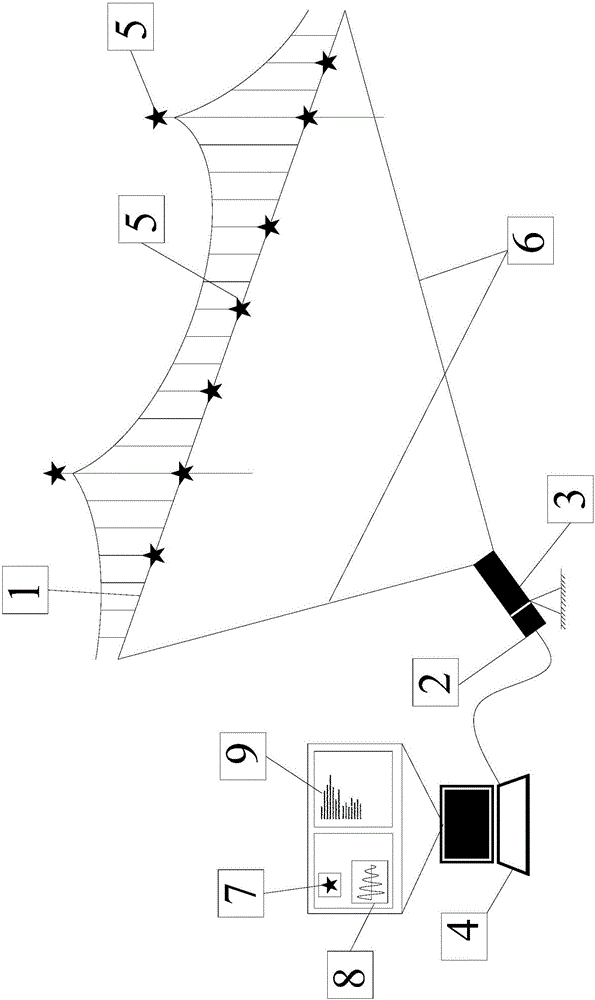

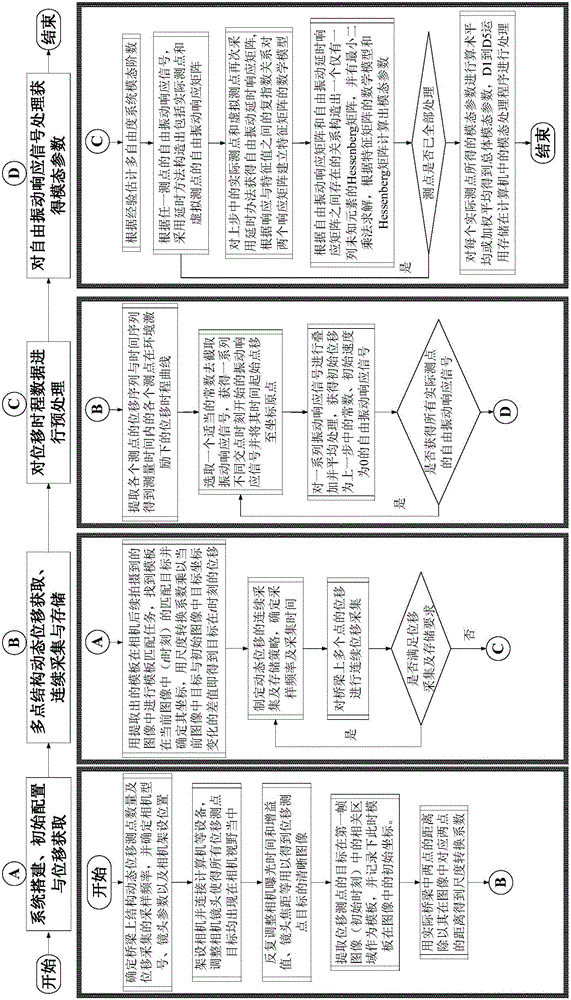

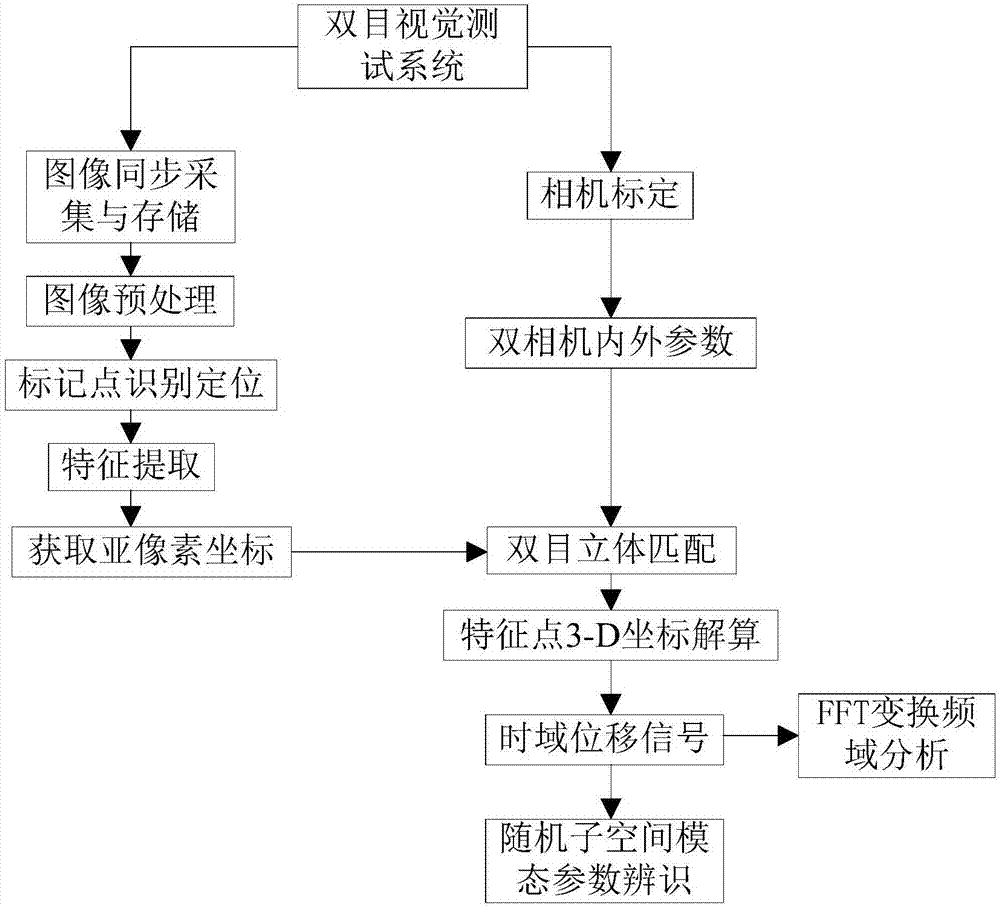

Method for bridge vibration testing and dynamic property recognition based on video monitoring

ActiveCN105865735AEasy to operateWill not adversely affectVibration testingVideo monitoringPattern recognition

A method for bridge vibration testing and dynamic property recognition based on video monitoring comprises a step A of performing system construction, initial configuration and displacement obtaining; a step B of performing multipoint structure dynamic displacement obtaining, continuous collection and storage; a step C of preprocessing displacement time-history data; and a step D of processing free vibration response signals to obtain a modal parameter.

Owner:ZHEJIANG UNIV

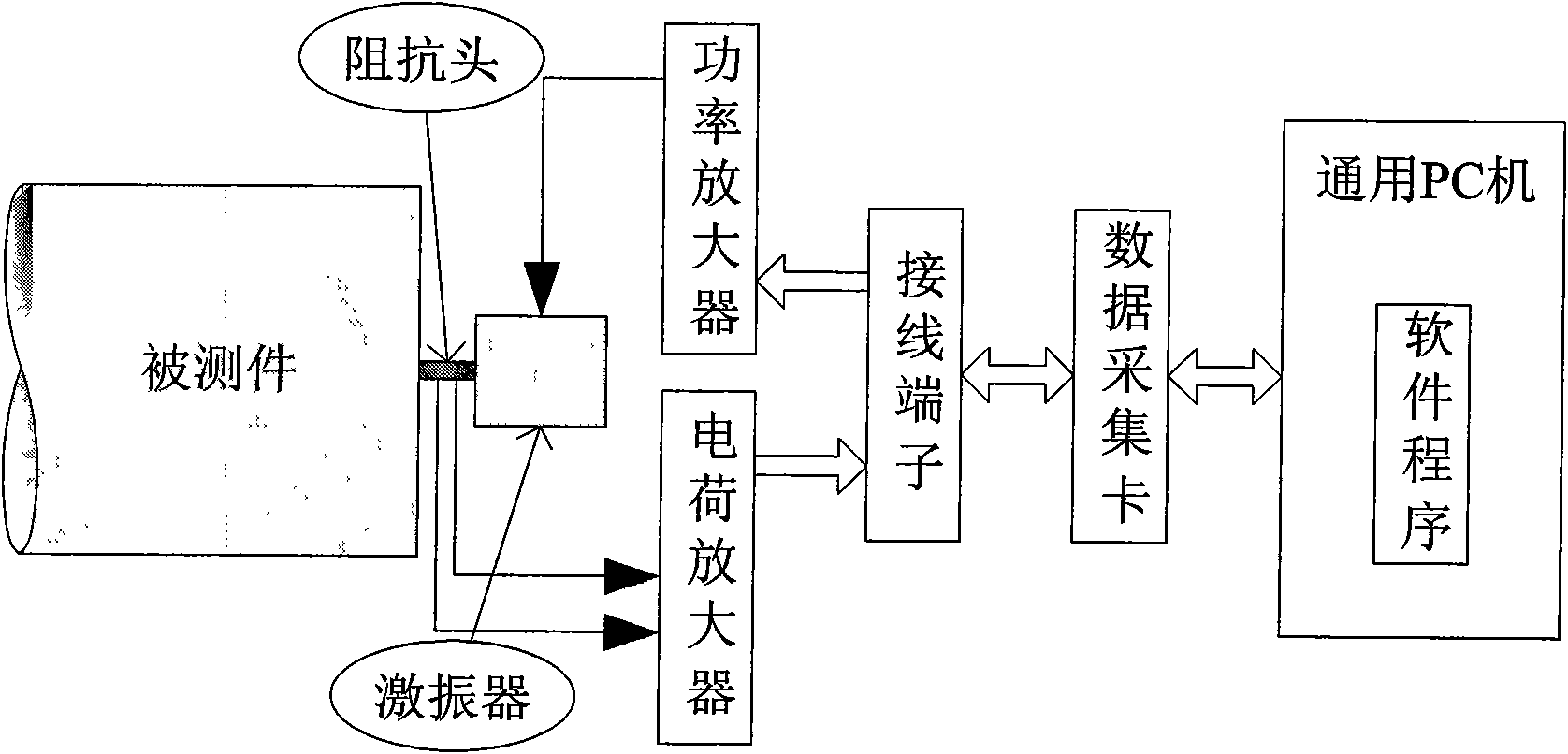

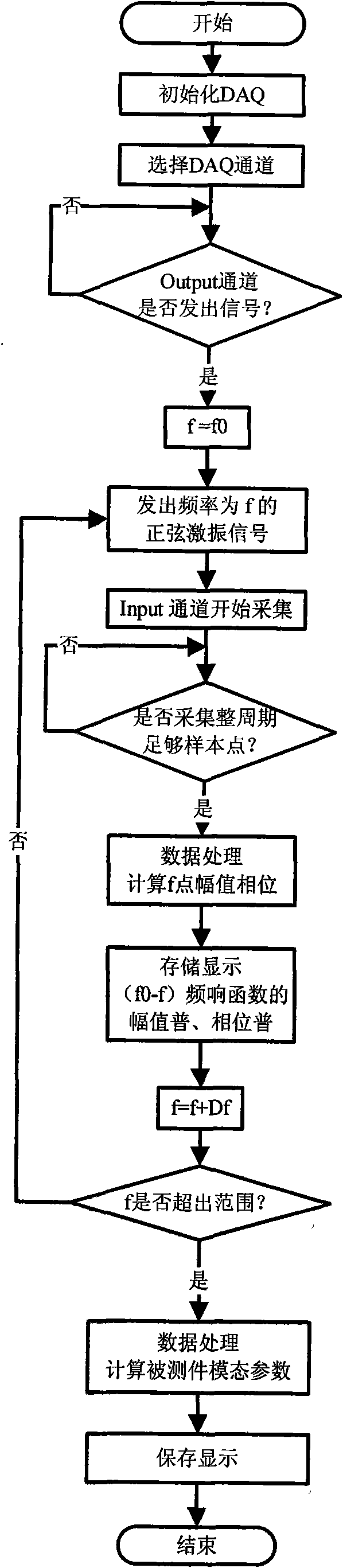

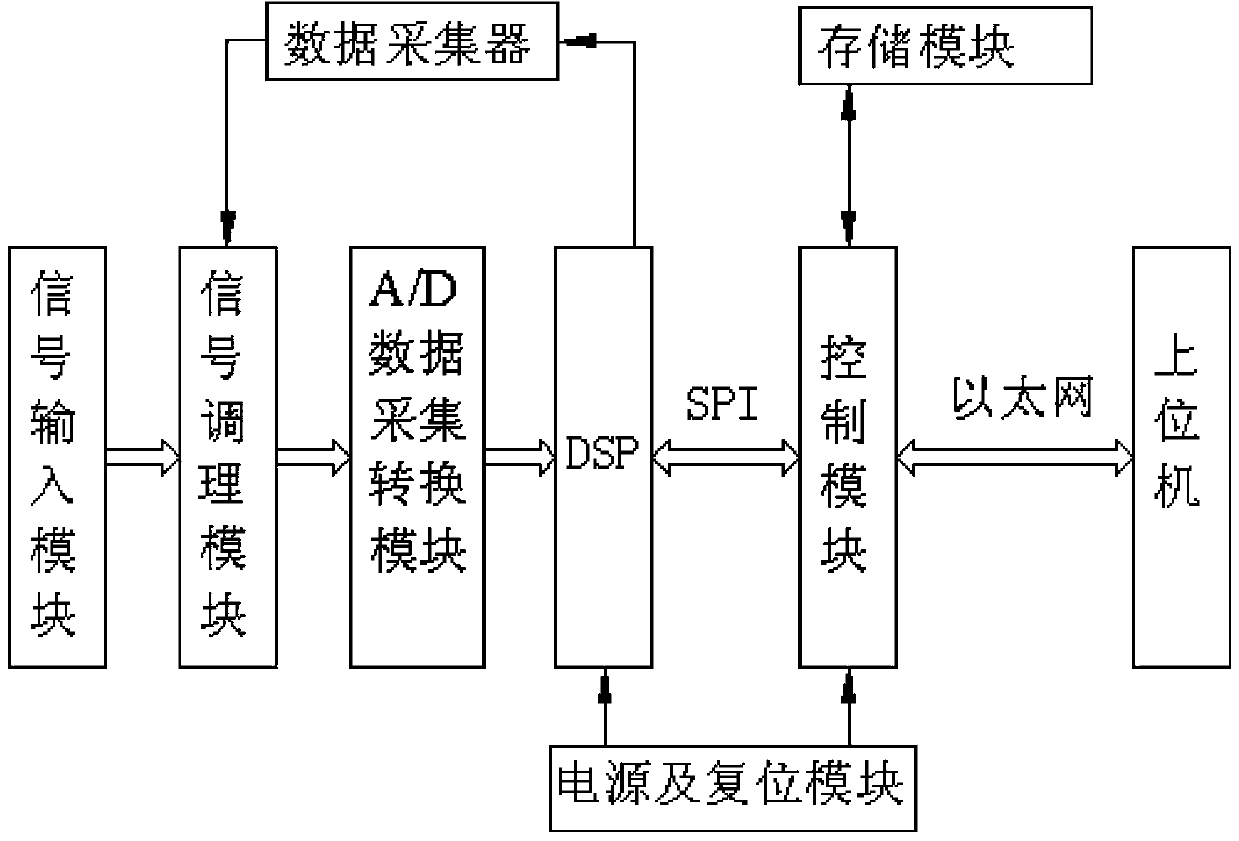

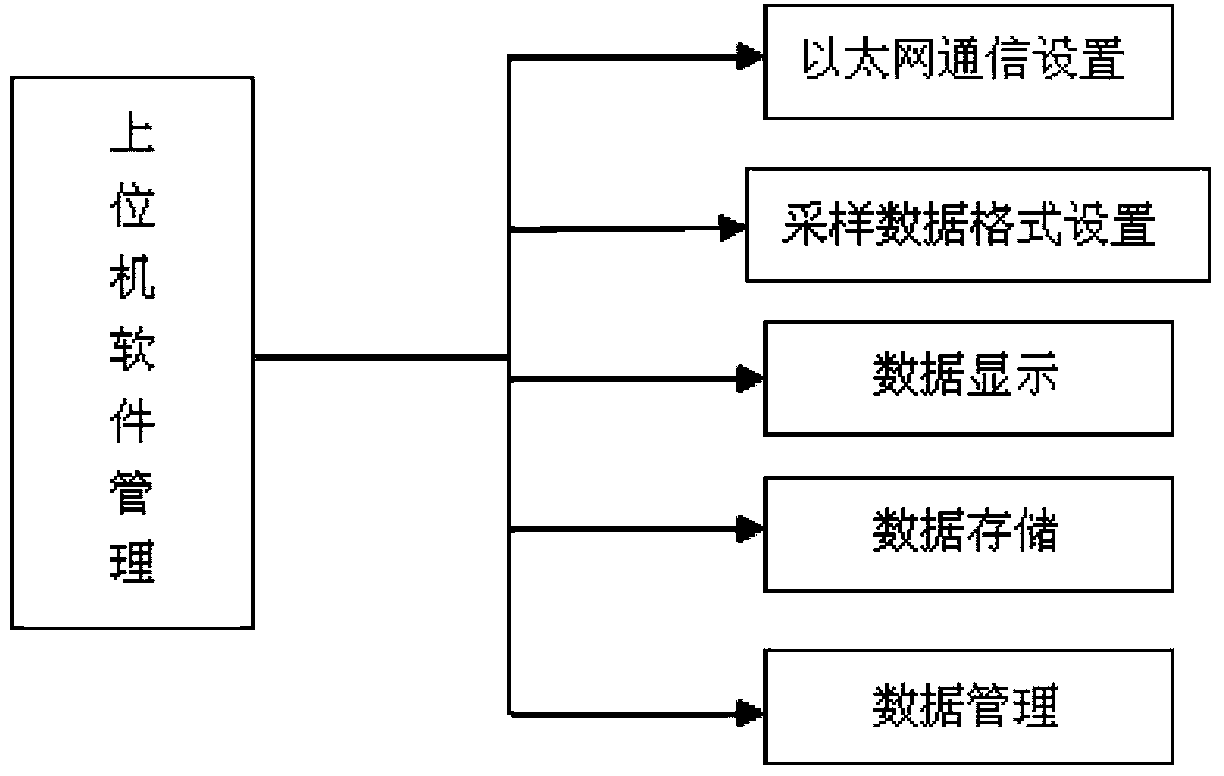

System and method for measuring time-sharing quick steady-state sine sweep excitation frequency response function

InactiveCN101561342AEasy to operateLarge excitation powerVibration testingShielded cableData acquisition

The invention relates to a system and a method for measuring time-sharing quick steady-state sine sweep excitation frequency response function, which belong to the technical field of vibration tests. An excitation system adopts a vibration exciter and a power amplifier. A force sensor and a vibration sensor are adopted to measure an exciting force signal and a vibratory response signal of the system at the same time. A charge amplifier is adopted to condition and filter the signals. A data acquisition system connects a data acquisition card with a connecting terminal through a high-performance shielded cable and is connected with a general computer to acquire and send data. The generation of a sweep signal and the data processing, analysis, storage and display of an exciter response signal are achieved by adopting software based on the general computer. The system and the method achieve quick steady-state sine sweep excitation, the complete cycle sampling of the exciter response signal, and precise and reliable frequency response function curve. The test system is guided by computer programs and is finished automatically, the test method is precise and reliable, and the system and the method have important meaning on testing the dynamic properties of structural elements.

Owner:BEIJING UNIV OF TECH

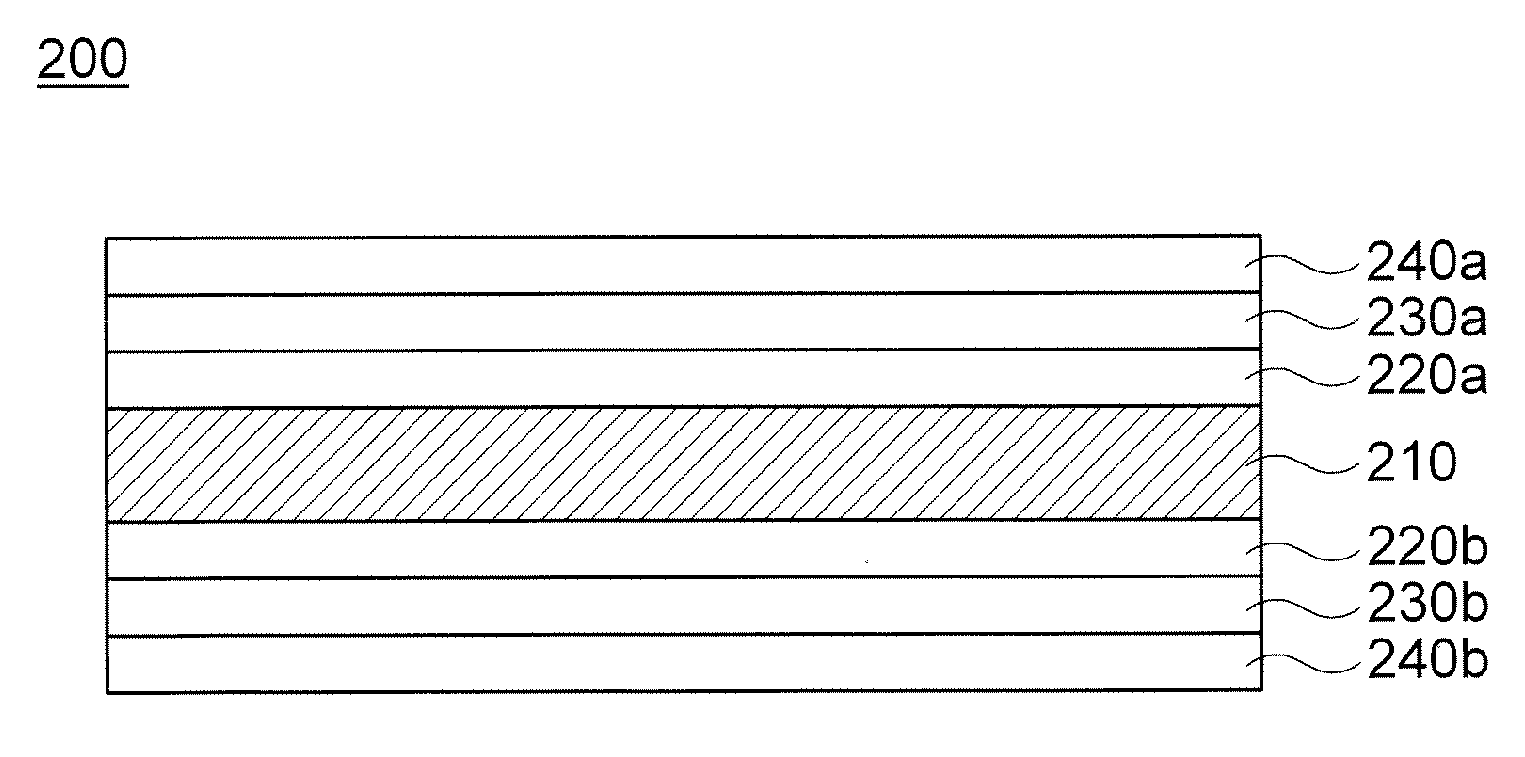

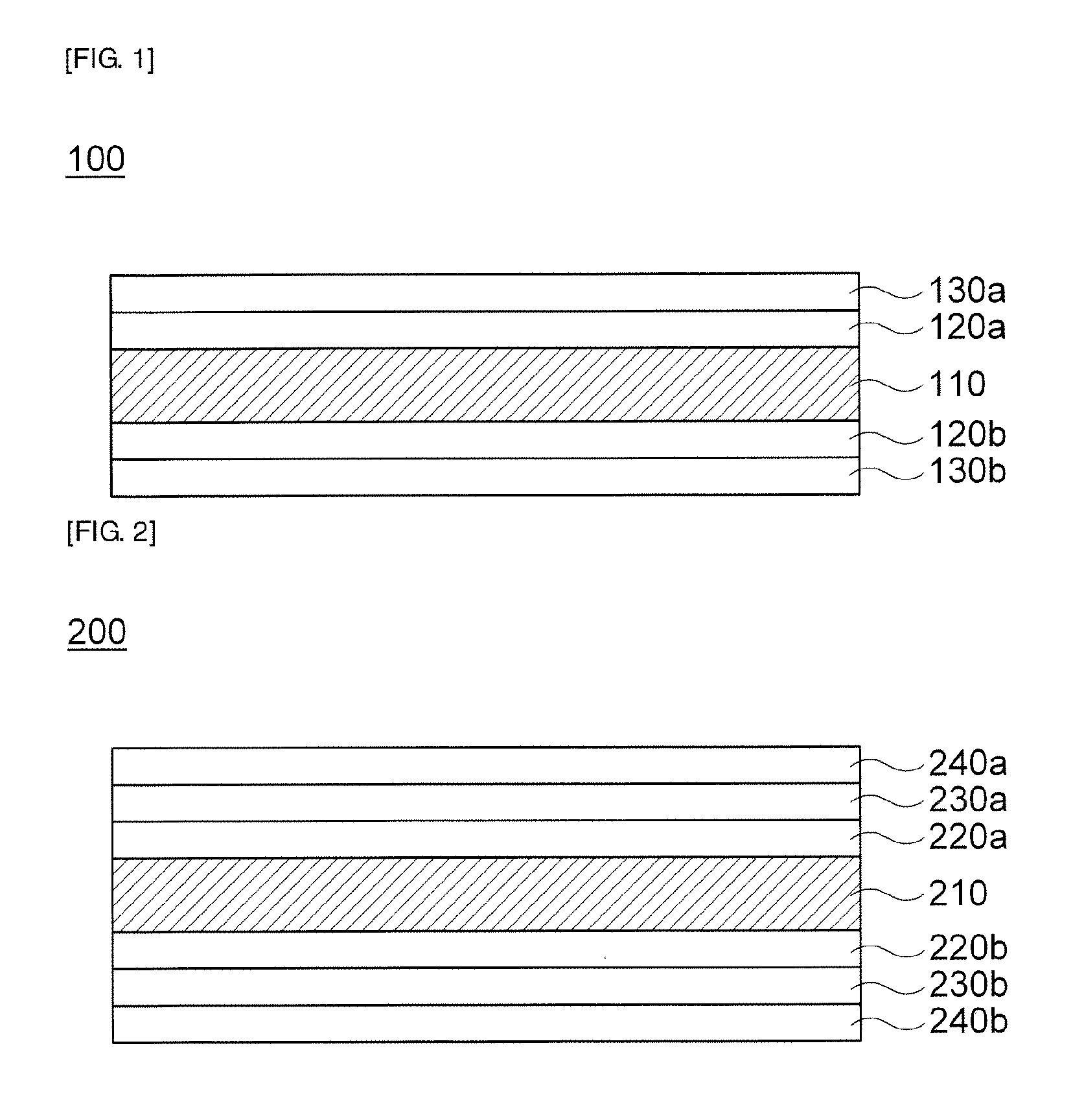

Piezoelectric device of polymer

InactiveUS20130127299A1Material nanotechnologyPiezoelectric/electrostriction/magnetostriction machinesOptoelectronicsGraphene

The present invention relates to a piezoelectric device of a multi-layered structure on which first electrodes and second electrodes are sequentially stacked on a piezoelectric polymer and single surfaces or both surfaces of piezoelectric polymer.In accordance with the present invention, the vibration response characteristics of the piezoelectric polymer can be improved by using the graphene or the composite thereof as a surface electrode material to the piezoelectric polymer; and, there are effects that the response characteristics of the piezoelectric device are excellent and the reliability thereof is excellent by forming a second electrode having an excellent conductivity and a protection electrode thereof.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

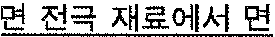

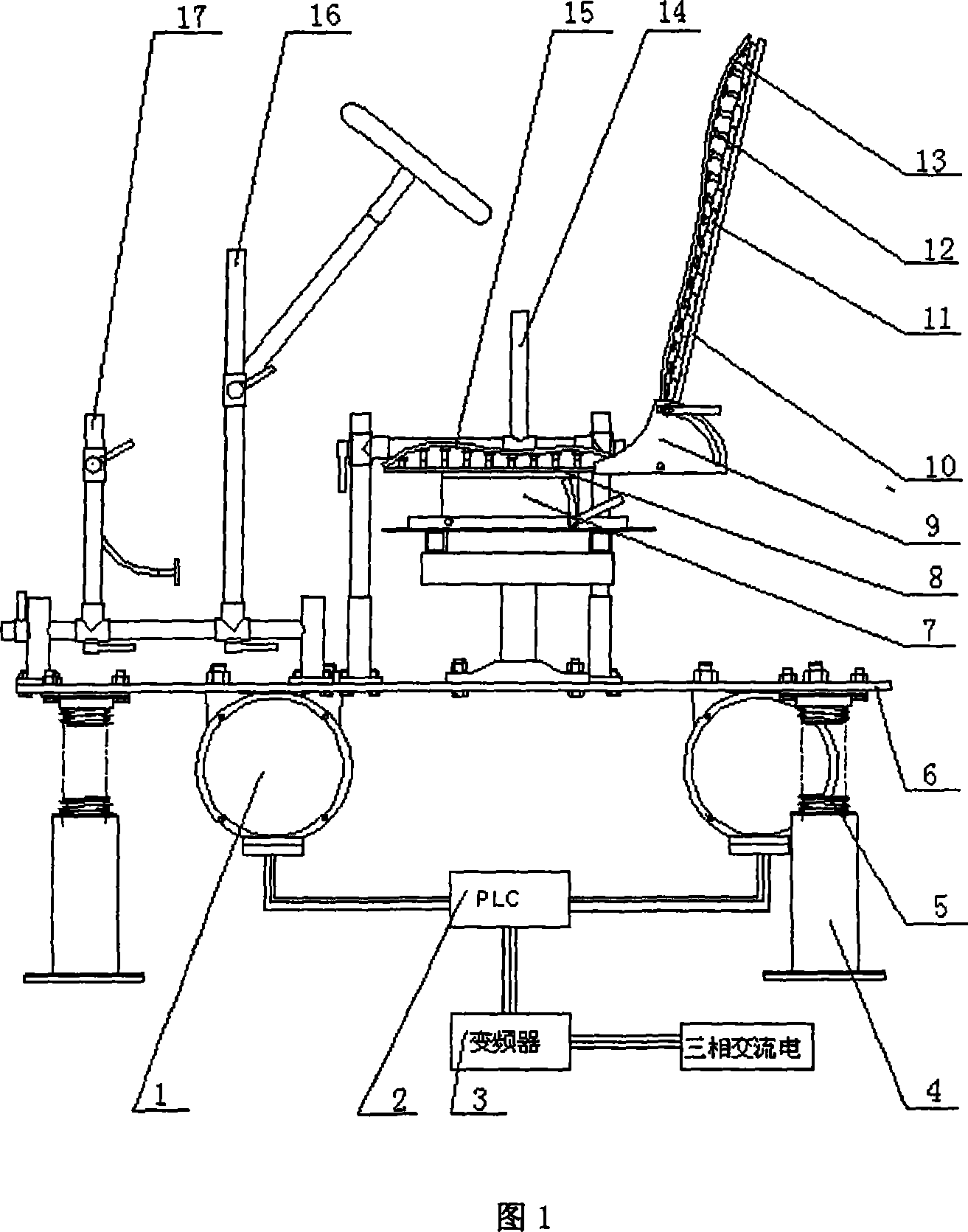

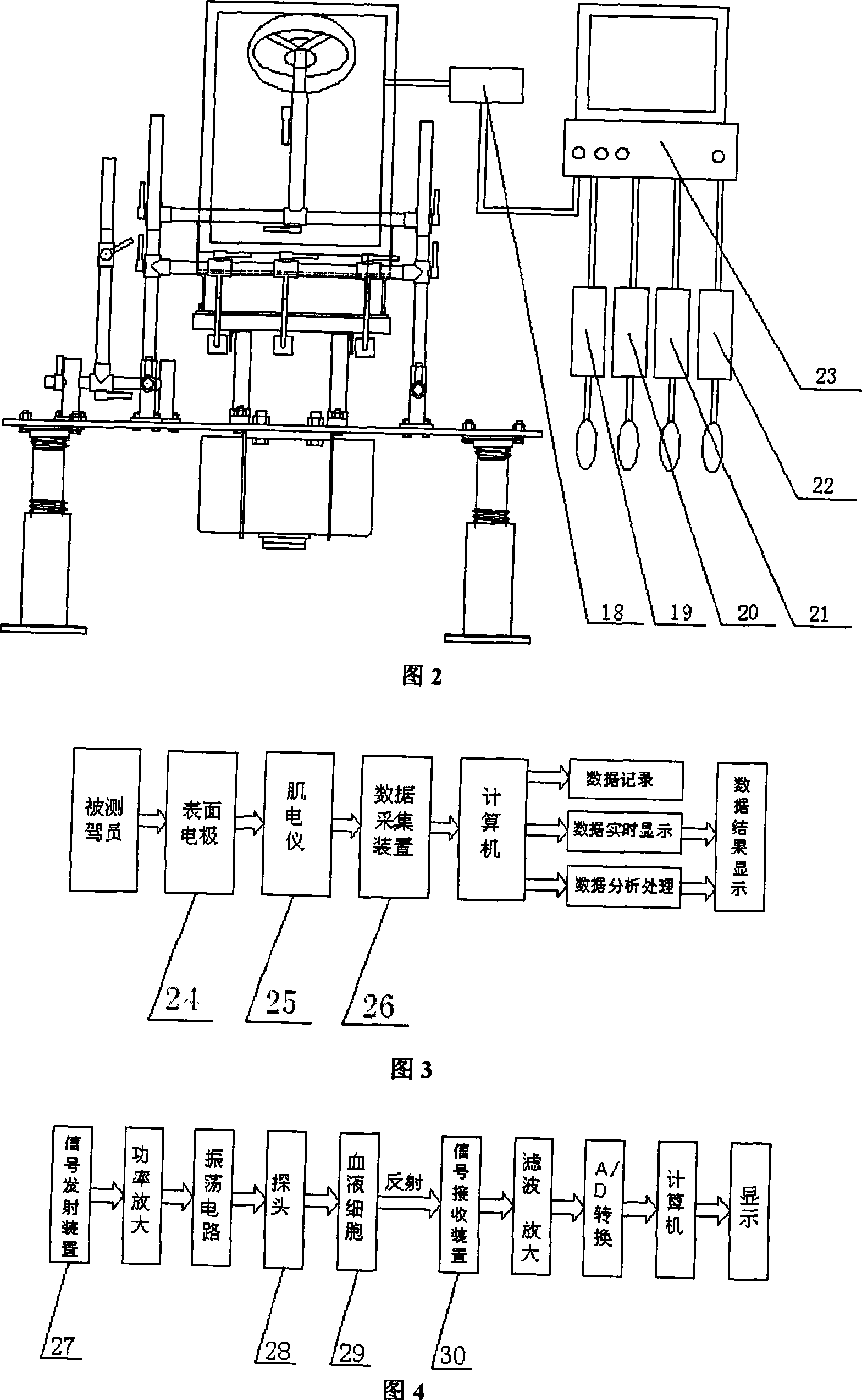

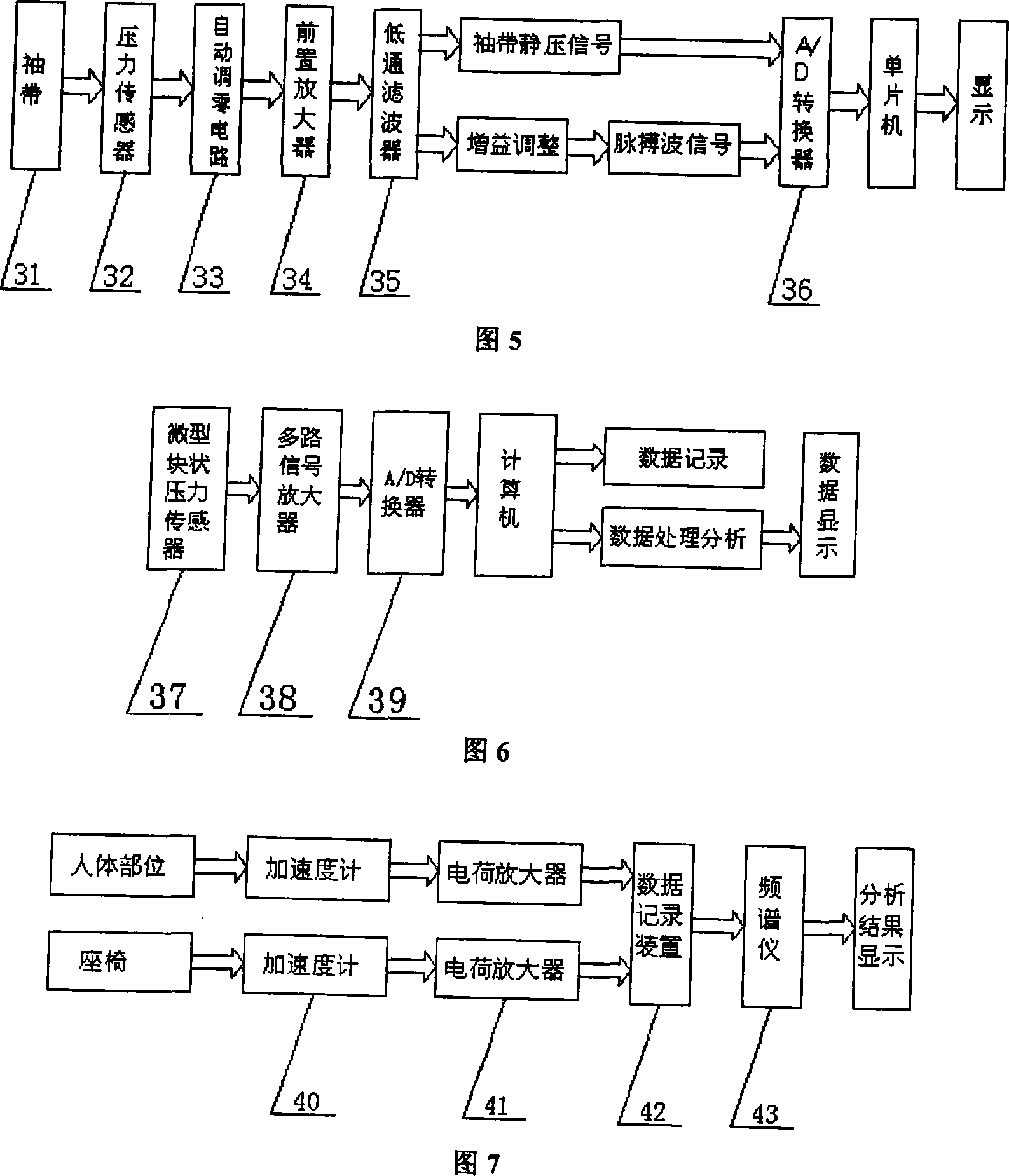

Dynamic riding-driving circumstance human body physiological character and biomechanics testing platform

InactiveCN101214143AEasy to measureEasy to operateVehicle testingDiagnostic recording/measuringHuman bodyButtocks

The invention discloses a dynamic driving environment human physiological characteristics and biomechanics test platform which mainly consists of a dynamic excitation system, a three-dimensional digital adjustable seat system, a three-dimensional adjustable driving mechanism and a human physiological characteristics and biomechanics test system. The invention can simulate the dynamic environment (vibration environment) of automobiles, which means to implement the stepless frequency conversion, the amplitude, the frequency fixation and frequency sweep vibration for the variable acceleration; simulate the posture operation of the automobiles in various driving environment; measure the human physiological character indexes of the human electromyography signals, the human arterial blood flow, the human blood pressure response, the human heartbeat number of a driver, etc., and the vibration response of every human part, the contact stress of a human-chair interface and the body pressure distribution of human buttock and back; study and comprehensively test the human physiological characteristics and the human biomechanics of the driving postures of different populations. Through the stimulation on a dynamic driving environment human physiological characteristics and biomechanics test system, scientific data required by the automobile human-machine interface design for populations with different shapes can be obtained.

Owner:XI AN JIAOTONG UNIV

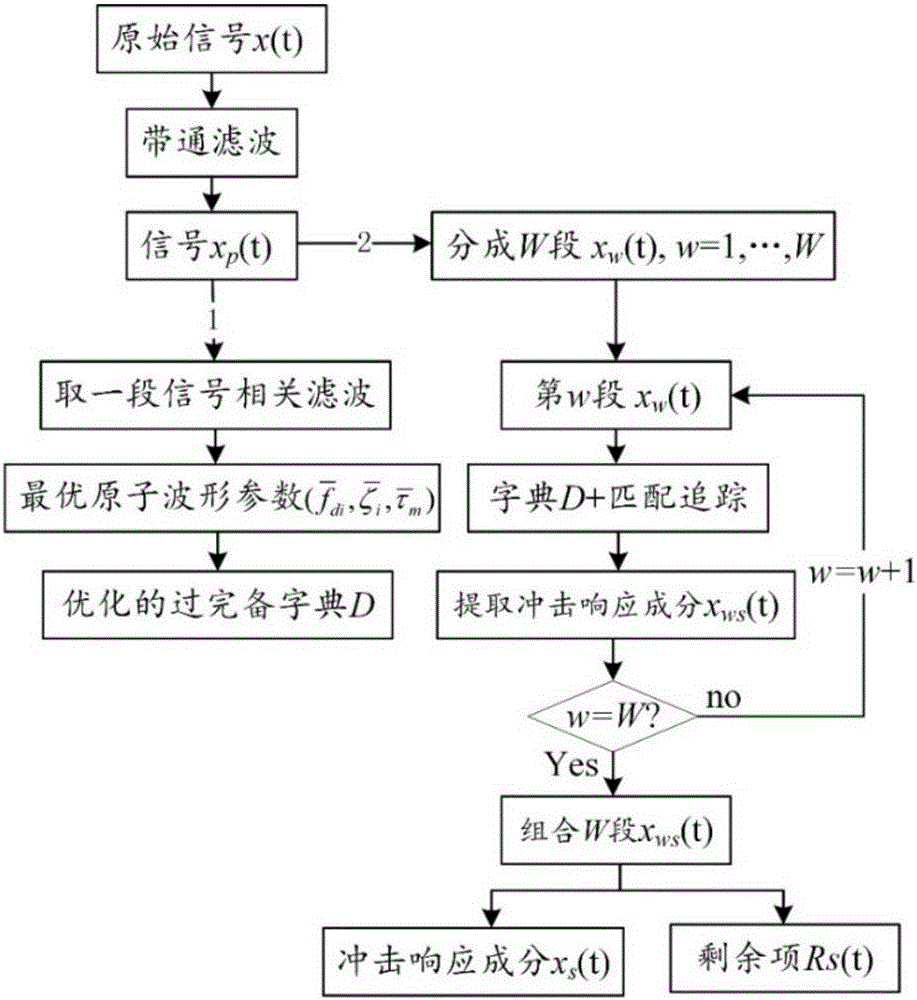

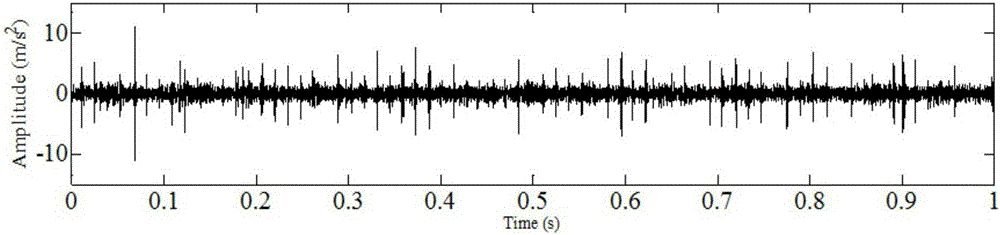

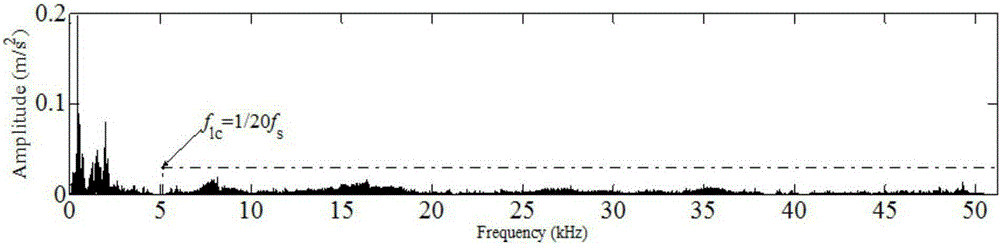

Rolling bearing fault feature extraction method based on signal sparse representation theory

InactiveCN105241666AWide versatilityReduce pointsMachine bearings testingDamping ratioAdaptive method

The invention discloses a rolling bearing fault feature extraction method based on the signal sparse representation theory, and the method comprises the following steps: constructing an over-complete dictionary representing local damages of a rolling bearing through employing a multi-stage inherent frequency unit impulse response function; recognizing the multi-stage inherent frequency and damping ratio of the rolling bearing and a sensor system from a vibration response signal through a related filtering method, and obtaining an optimized dictionary; solving a sparse coefficient through employing a matching tracking algorithm, and improving the solving speed and precision through reasonable segmentation; reconstructing an impact response signal of each segment, and obtaining the sparse representation of a fault feature signal; carrying out time domain index statistic characteristic analysis of time intervals of adjacent impact response components in a sparse signal, and diagnosing the type of a fault through combining a mean value and a mean square deviation value. The method has the advantages of an analytical method and an adaptive method, improves the precision of waveform features, and can iron out the defects that a conventional method based on Fourier transform is not suitable for rotating speed fluctuation.

Owner:SOUTH CHINA UNIV OF TECH

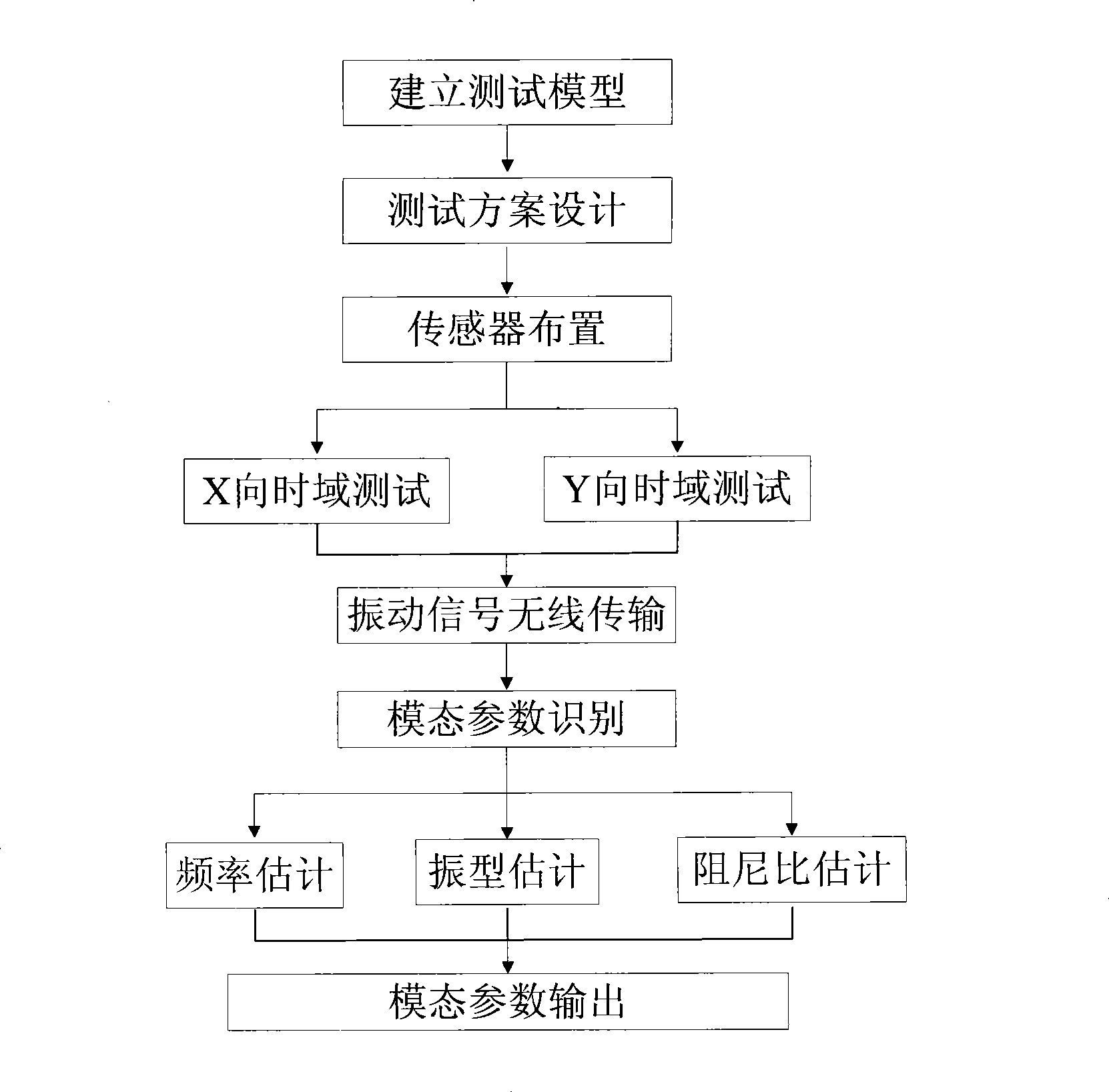

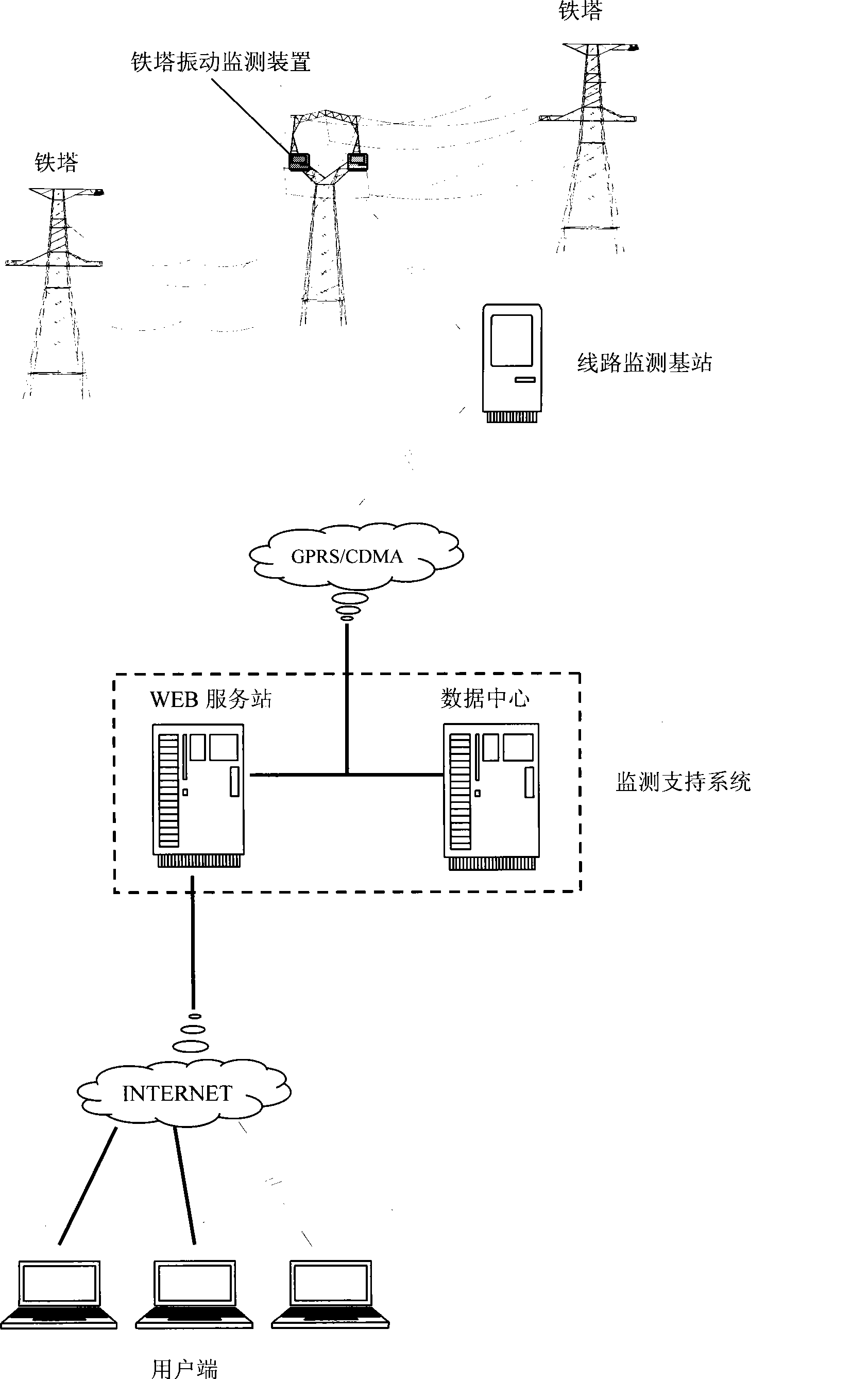

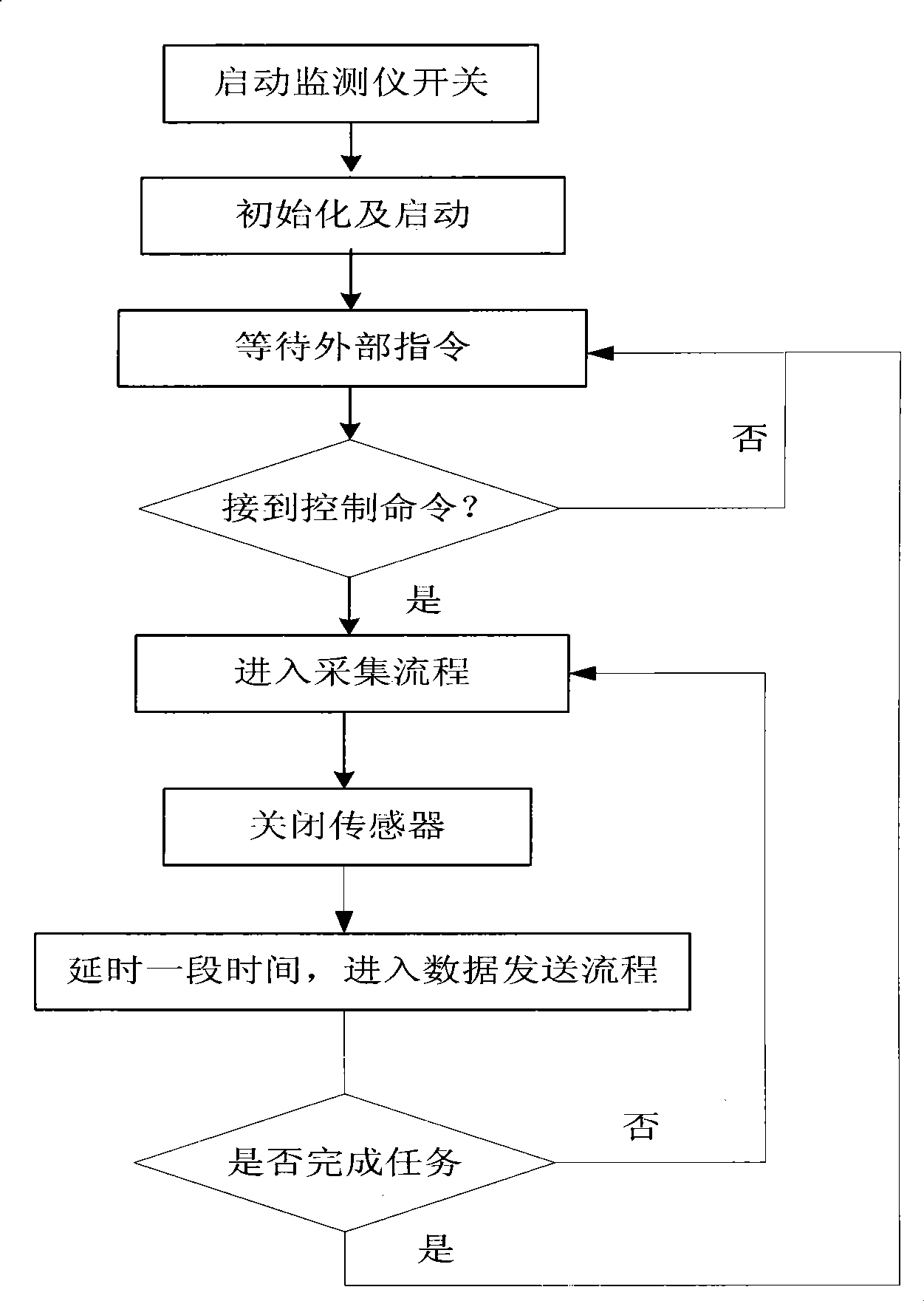

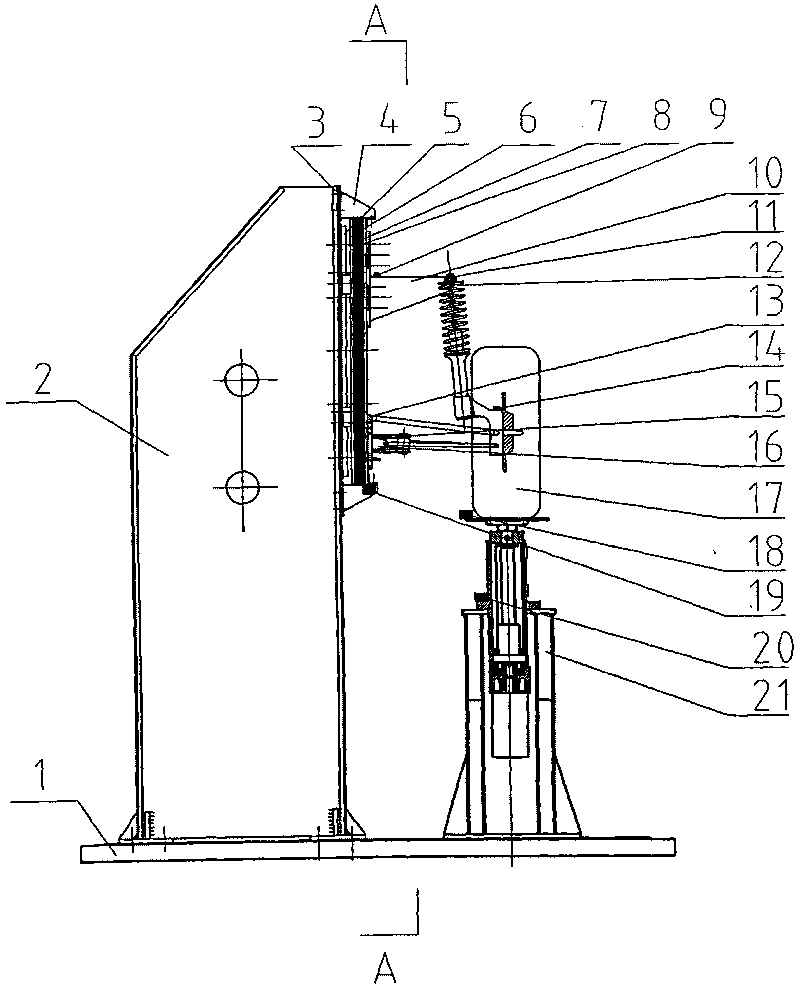

Method for testing vibration of high-tower structure of transmission line

InactiveCN101446517AHigh precisionEasy to operateVibration testingWireless sensor networkingMonitoring system

The invention provides a testing method of a vibration response test for a high-tower structure of transmission line of transmission of vibration signals and stimulation by taking wind load as external environment in a wireless mode. The method has the characteristics of simple and convenient operation and analysis and higher precision compared with the traditional vibration response testing means in a wired transmission and hammer method. Therefore, relational environment parameters motivated by environment are confirmed through a meteorological environment monitoring device, the vibration response of an iron tower is tested by the selected accelerating sensor, the test data of the vibration response of the high-tower structure of transmission line is transmitted by applying the wireless sensor, and finally modal mode parameters of the high-tower structure of transmission line is confirmed through the back-end process of the monitoring system.

Owner:CHINA ELECTRIC POWER RES INST +1

Vibration sensor and audio equipment

PendingCN108513241AGood vibration responseImprove effects applied to the audio domainSubsonic/sonic/ultrasonic wave measurementUsing electrical meansMems microphoneEngineering

The invention discloses a vibration sensor and audio equipment. The vibration sensor comprises a shell which is provided with an accommodating cavity with an opening; a circuit board component that isfixedly connected with the shell and blocks the opening; an MEMS microphone that is arranged on one surface of the circuit board component, positioned in the accommodating cavity, and electrically connected with the circuit board component; a first vibration film that is arranged on the inner wall surface of the accommodating cavity; a mass block that is fit with the surface of the first vibration film, wherein when a vibration signal or a pressure signal is input from one side, far away from the accommodating cavity, of the shell, the first vibration film and the mass block vibrate, so as todrive the air pressure in the accommodating cavity to change. The technical scheme provided by the invention aims at enabling the vibration sensor to have good vibration response to high frequency vibration and low frequency vibration, and thus the effect of the vibration sensor applied to the audio field is enhanced.

Owner:WEIFANG GOERTEK MICROELECTRONICS CO LTD

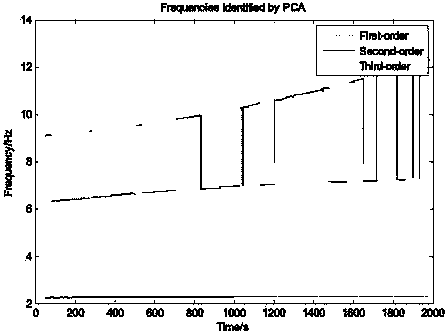

Method and device for identifying operating modal parameters of linear time-varying structure and application of the device

ActiveCN104698837AProof of existenceReal-time effective monitoring of dynamic change characteristicsAdaptive controlVibration controlPrincipal component analysis

The invention relates to method for identifying operating modal parameters of a linear time-varying structure based on memory-restricted principal component analysis. According to the method, the operating modal parameters of a dynamical system with time-varying structural characteristics can be identified by only using unsteady vibration response signals, the operating modal parameters of the structure are identified, and the dynamical variation characteristics of the system can be effectively monitored in real time, thus the method can be applied to vibration control, equipment fault diagnosis, health monitoring, and system structure analysis and optimization. The method is characterized in that the parameter characteristics of the system are identified by only using actual measured response signals, load signals aren't measured, and the method is proven according to mathematical theoretical analysis and experiment, so that a physical significance is endowed to the method. The invention further relates to an operating modal measuring device based on the method, and the device is used for measuring vibration response signals and identifying the operating modal parameters to obtain the real-time online dynamical characteristic change of the system structure, thus the device can be applied to fault diagnosis and health monitoring analysis of a large complex engineering structure (bridge, rail and the like).

Owner:HUAQIAO UNIVERSITY

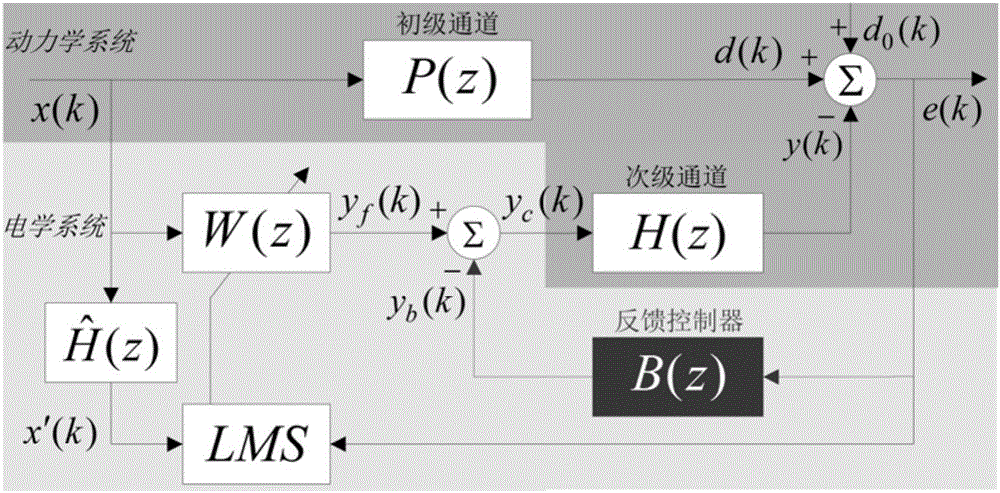

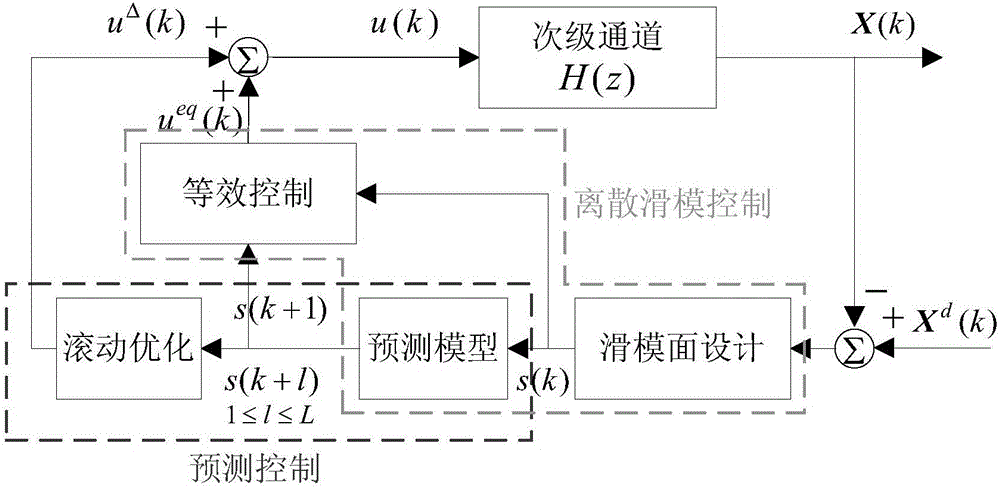

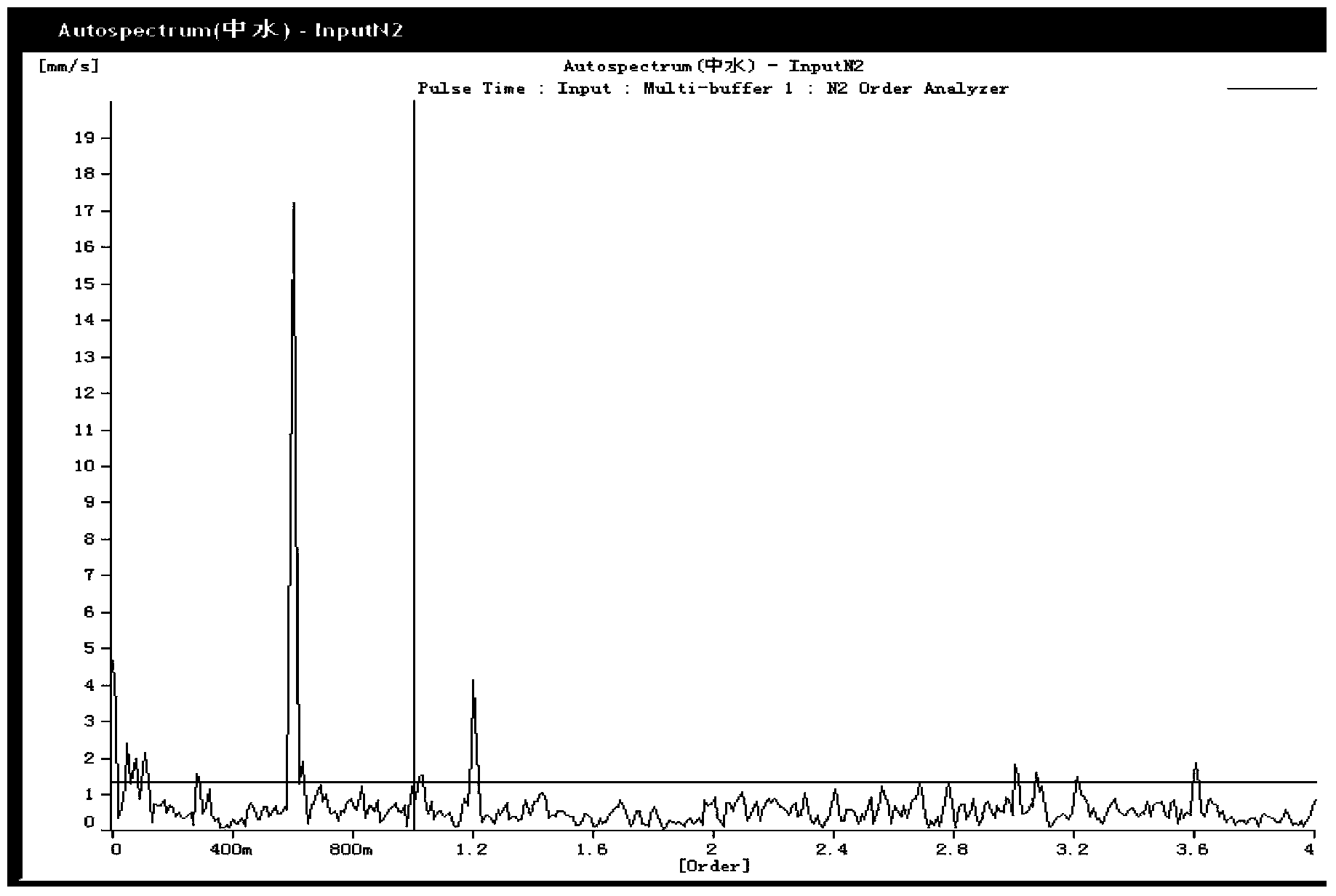

Helicopter multi-frequency vibration active control method

InactiveCN105843270AReduce order requirementsAvoiding Frequency Modulation ProblemsMechanical oscillations controlEngineeringActuator

The invention discloses a method for actively controlling multi-frequency vibration of a helicopter, including system identification, collecting the control voltage of the actuator and the acceleration response at the controlled point, using the recursive least squares algorithm for system identification, and finally obtaining the discrete state space of the secondary channel Equation; feedback controller design, using the secondary channel discrete state space equation obtained in step 1 to carry out discrete predictive sliding mode feedback controller design; reference signal and error signal acquisition, according to the helicopter rotor characteristics and speed characteristics, extract the rotor excitation frequency, synthesize reference signal, and collect the vibration response error signal at the controlled point; the feedforward-feedback hybrid control algorithm iterates, and uses the reference signal and error signal obtained in step 3 to iterate the feedforward controller and the feedback controller to obtain the feedforward-feedback Feedback the mixed control voltage signal; output the control quantity; use the mixed control voltage obtained in step 4 as the input signal at the next moment, drive the actuator to produce the required response, and return to step 3.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

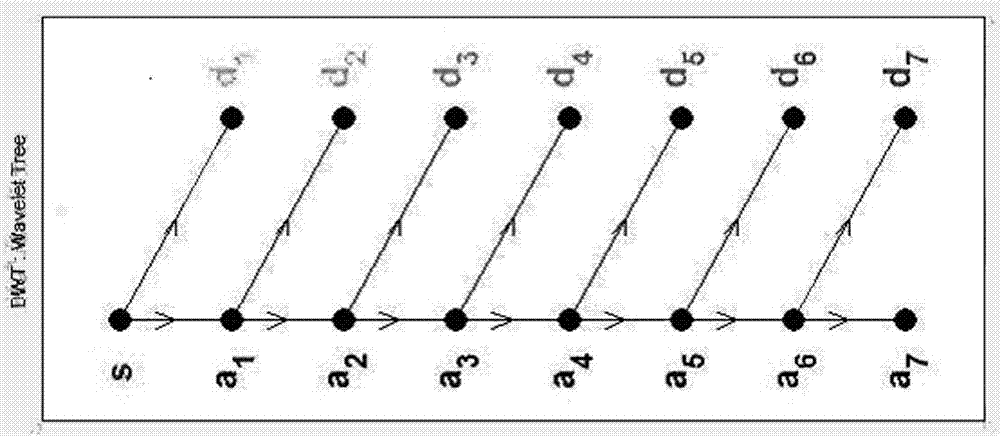

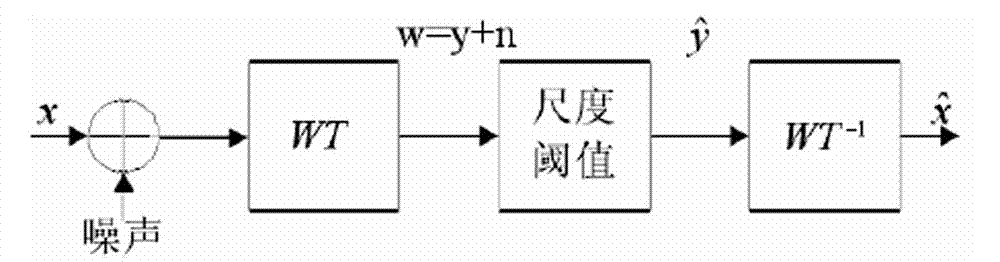

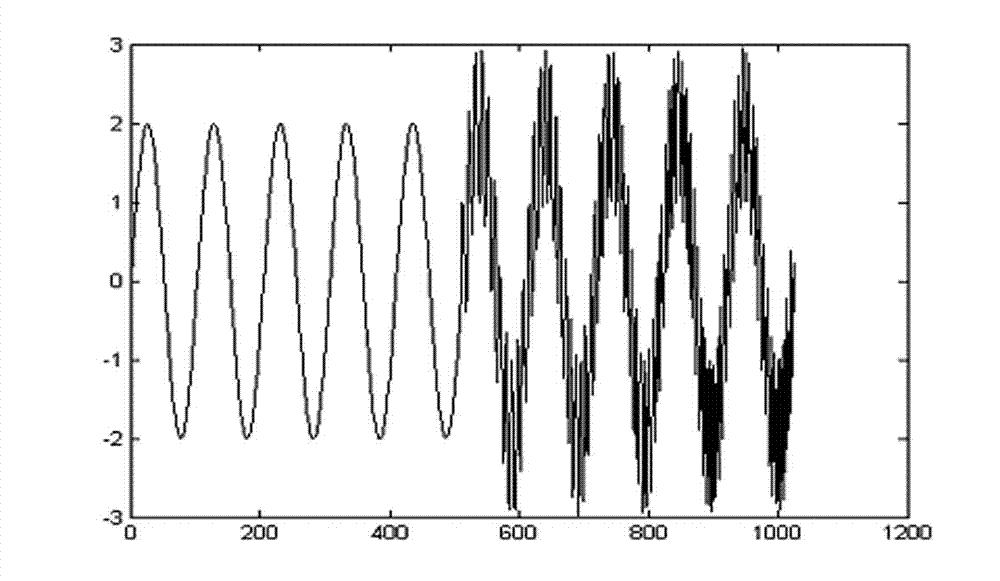

Method for denoising acoustic testing data of porcelain insulator vibration based on wavelet decomposition threshold denoising

InactiveCN102928517AEffective filteringImprove accuracyProcessing detected response signalTime domainMulti resolution

The invention discloses a method for denoising acoustic testing data of porcelain insulator vibration based on wavelet decomposition threshold denoising. The method comprises the following steps: using a vibration acoustic method to detect a porcelain insulator to acquire a porcelain insulator vibration response signal containing noise; selecting a suitable wavelet basis function for the porcelain insulator vibration response signal containing noise and then carrying out multi-resolution wavelet decomposition, and transforming the vibration response from a time domain to a wavelet domain; rationally selecting a threshold function and a threshold, and machining a wavelet coefficient corresponding to the noise according to the threshold function; carrying out wavelet reconstruction, transforming the vibration response after denoising treatment to the time domain from the wavelet domain; storing the de-noised vibration response and sorting an acoustic testing result of the porcelain insulator vibration. According to the method, the noise in the acoustic testing data of the porcelain insulator vibration can be effectively filtered, so that sorting accuracy is improved.

Owner:STATE GRID HEBEI ELECTRIC POWER RES INST +2

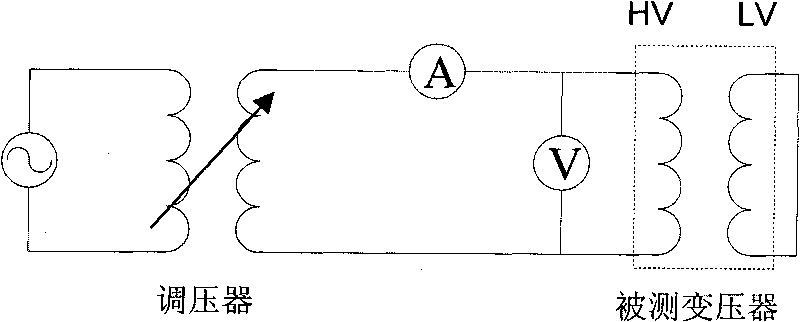

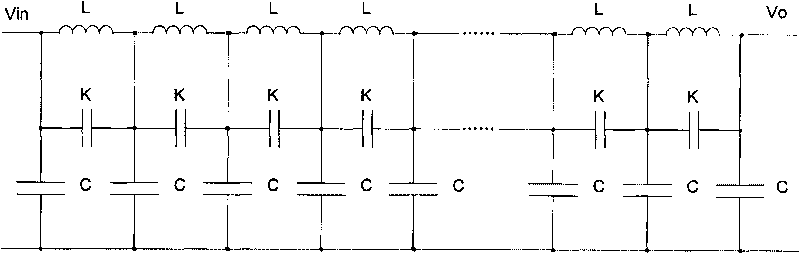

System and method for detecting transformer winding state by using constant-current sweep frequency power source excitation

ActiveCN101738567ASensitive looseSensitive deformationTransformers testingFrequency spectrumConductor Coil

The invention relates to system and method for detecting the transformer winding state by using constant-current sweep frequency power source excitation. A measurement and control analysis module controls sweep frequency power source and applies output constant-current sweep frequency excitation signals by an exciting transformer at a high-voltage side of the transformer to be detected; a vibration sensor measures vibration response signals of a transformer winding to be detected at different excitation frequencies; a vibration signal collector collects and preprocesses the signals measured by the vibration sensor; and the measurement and control analysis nodule carries out spectrum analysis to the received and processed vibration response signal data, displays and records a resonant frequency curve of the transformer winding on a frequency domain, compares with the resonant frequency curve previously measured and recorded as well as the vibration frequency curve of a transformer three-phase coil, and judges the state of the transformer winding to obtain the measuring result. The invention can effectively and sensitively detect the states of looseness or deformation of the transformer winding for prompt repair or replacement so as to avoid a fault of abrupt short circuit of the transformer caused by damage of the winding structure.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

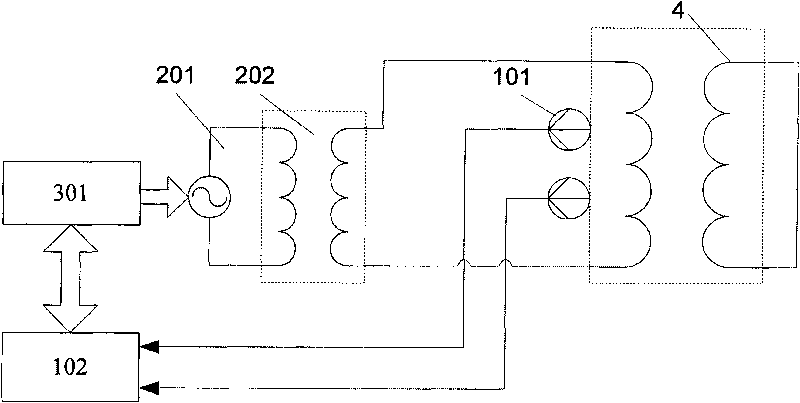

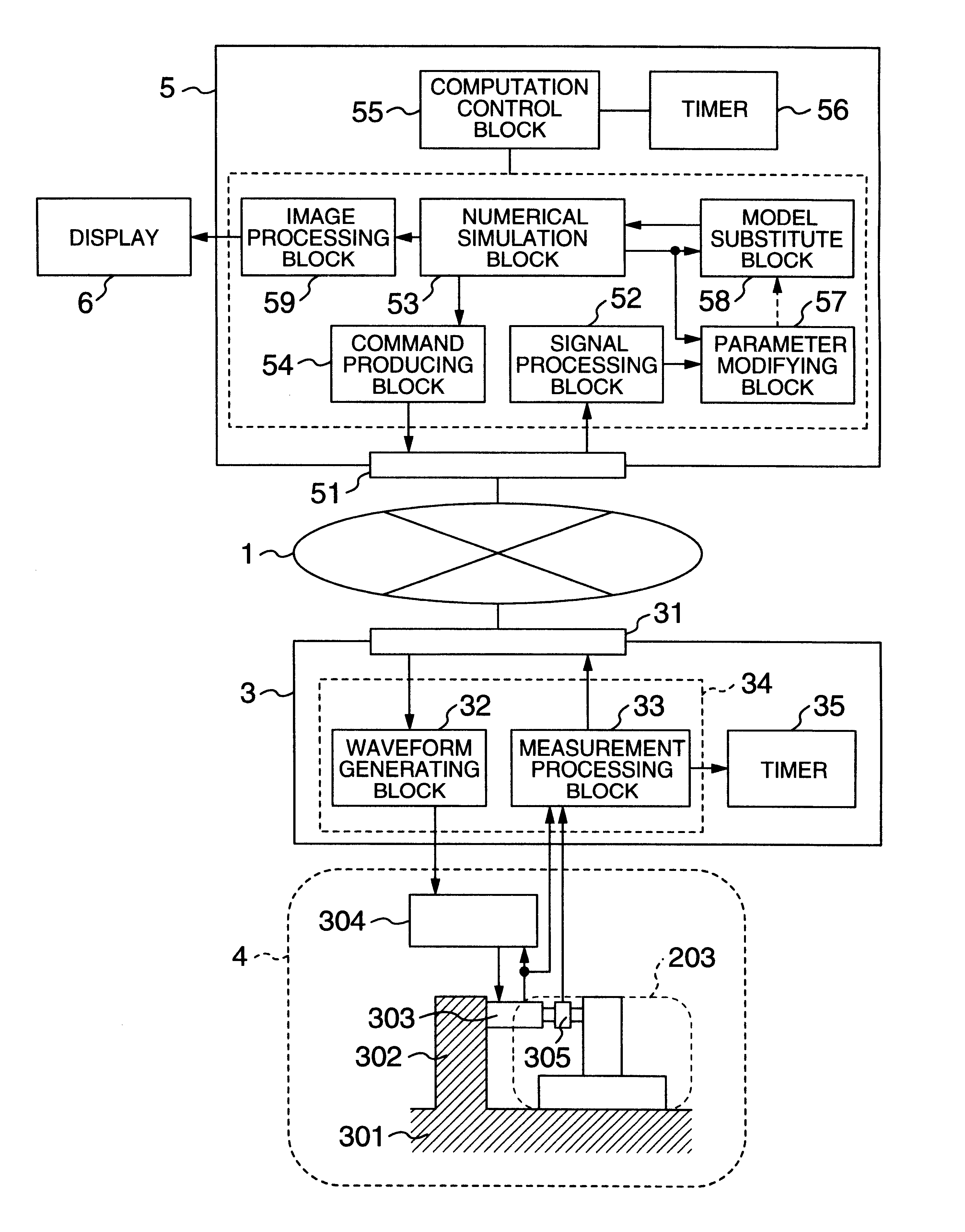

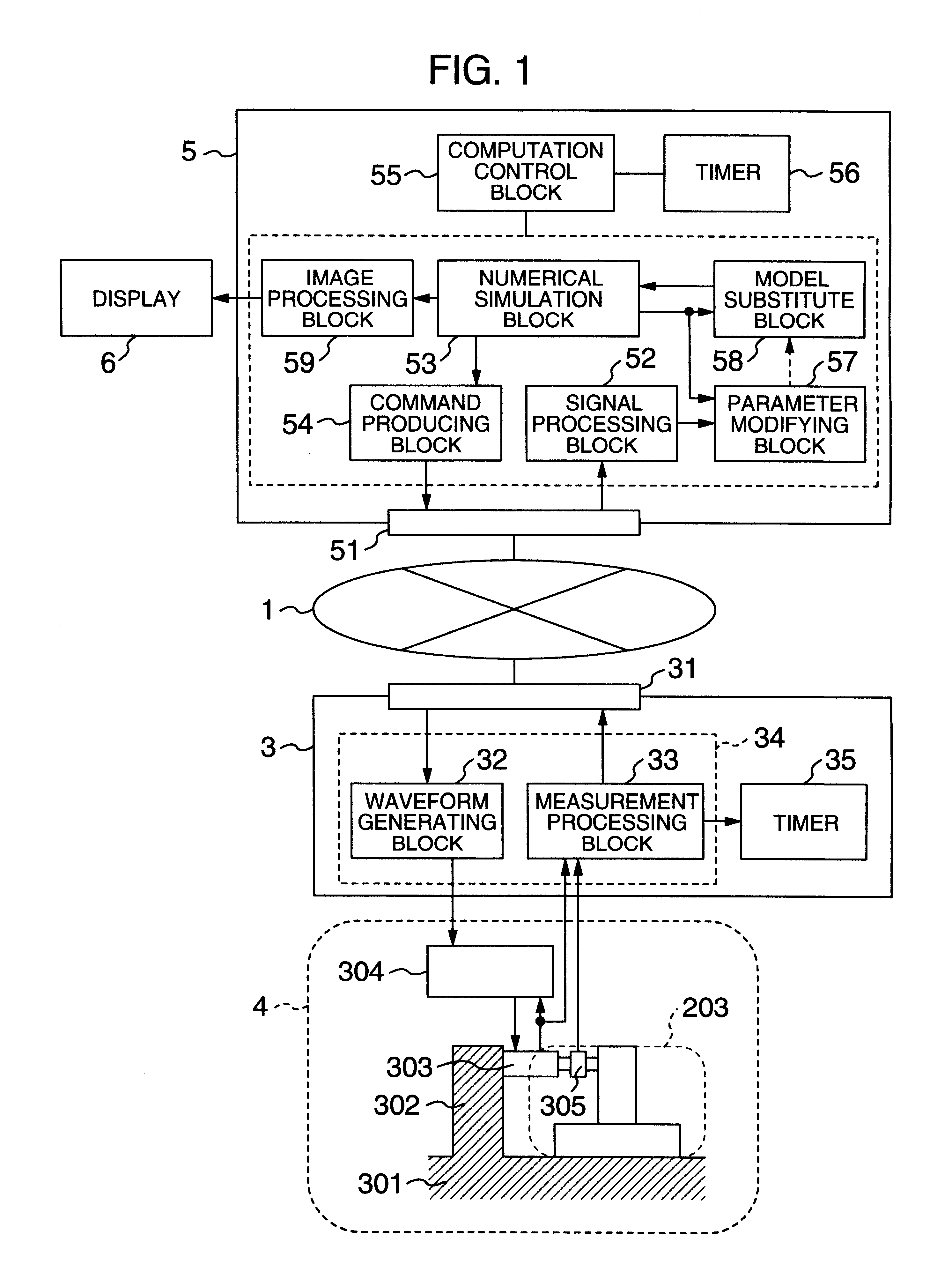

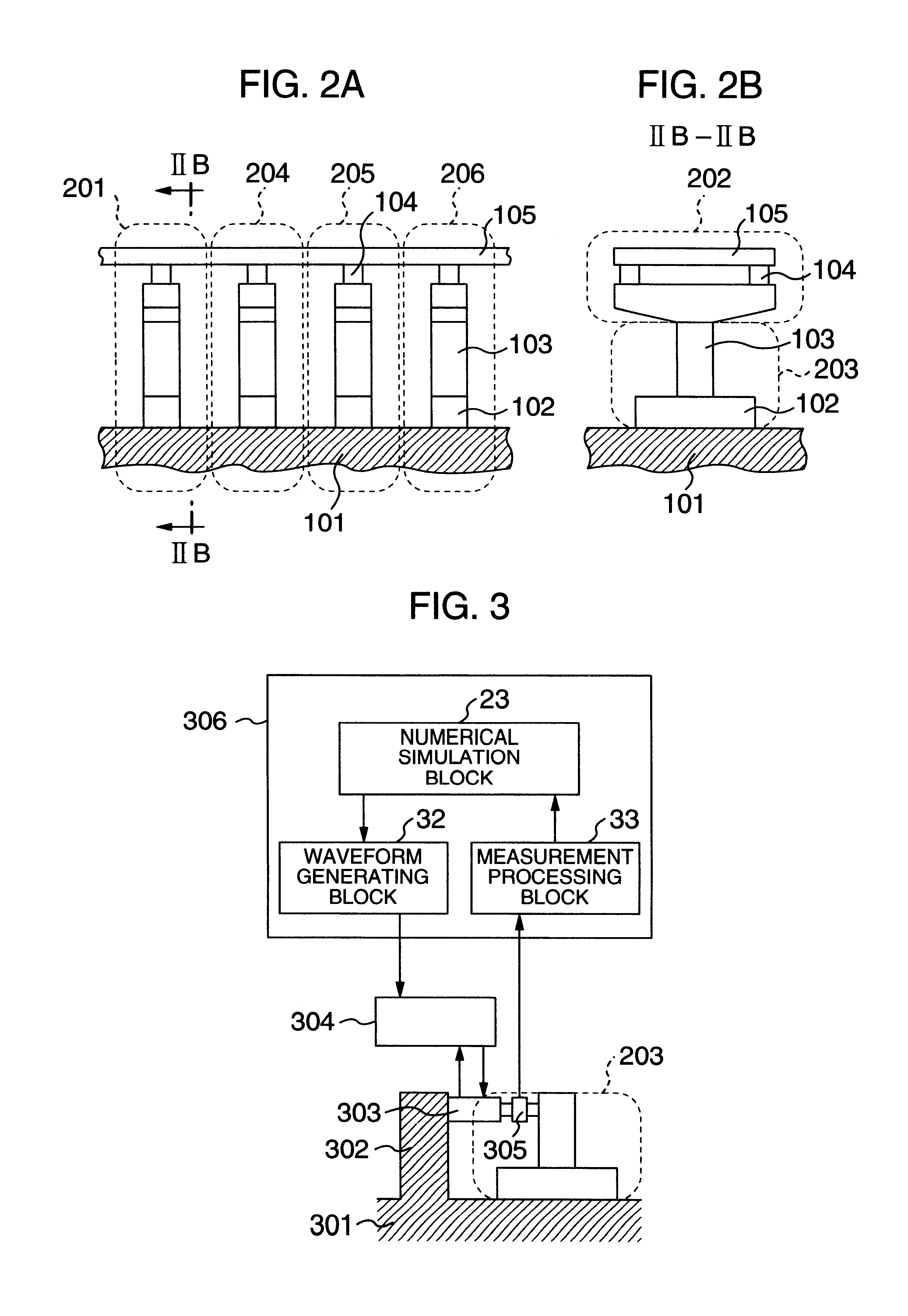

Vibration testing device and vibration response evaluating method

A vibration testing device includes a computer system having: a measurement processing block for inputting an output of the monitoring sensor and processing the output; a model substituting block for modeling characteristics of the test piece, calculating a response quantity corresponding to a drive condition of an actuator, and inputting the calculation result to a numerical simulation block and the parameter changing block; the parameter changing block for comparing the calculation result of the model substituting block with the processing result of the measurement processing block, and changing the parameter; the numerical simulation block for calculating a vibration response in accordance with a previously input structure numerical model; and a waveform generating block for calculating a time function of a deformation to be applied to the test piece, and outputting the time block to the actuator controlling device.

Owner:HITACHI IND PROD LTD

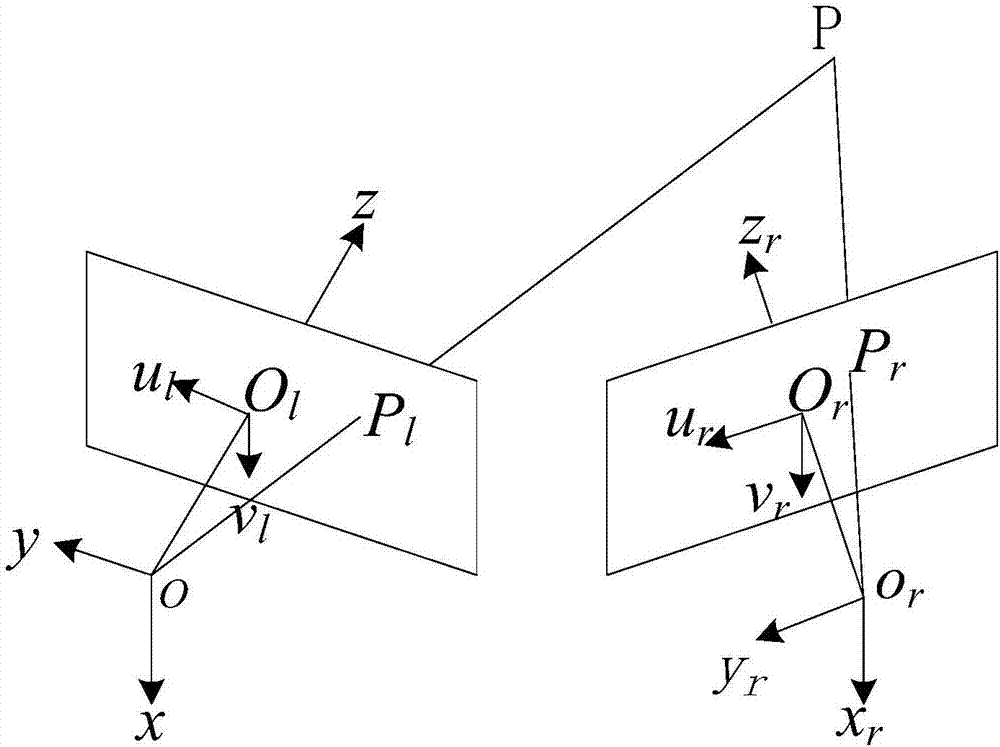

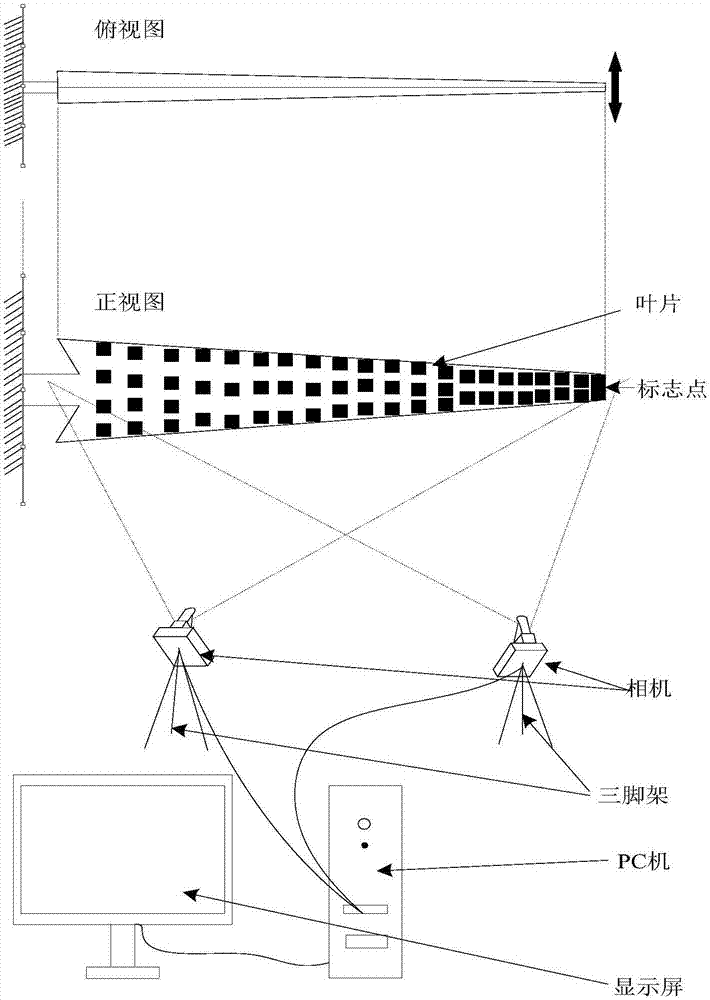

Modal test method of large draught fan blade based on photography measurement technology

ActiveCN106989812AThe influence of dynamic characteristicsRealize non-contact measurementSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansMeasurement pointFourier transform on finite groups

The invention discloses a modal test method of a large draught fan blade based on the photography measurement technology. The method comprises steps of using a pair of CMOS / CCD industrial cameras to carry out synchronous shooting on surface images of the draught fan blade under random excitation vibration; identifying and positioning multiple marking points in the images; extracting central sub-pixel level coordinates of the marking points and carrying out stereo matching of the double cameras; calculating three-dimensional coordinates of each measurement point through the three-dimensional reconstruction technology; carrying out micro-division processing on displacement data to obtain required vibration response (speed and accelerated speed) signals; through the Fourier transform, converting time domain signals into observation peak values in frequency domains to find corresponding modal frequencies; by combining analyzed frequency values, further using the stochastic subspace identification method (SSI) to precise calculate modal parameters of the blade; and acquiring the fixed frequency, the vibration mode and the damping ratio of the blade. According to the invention, by use of non-contact type multi-point synchronous vibration measurement, rapid high-precision model test on the draught fan blade can be achieved.

Owner:HUNAN UNIV OF SCI & TECH

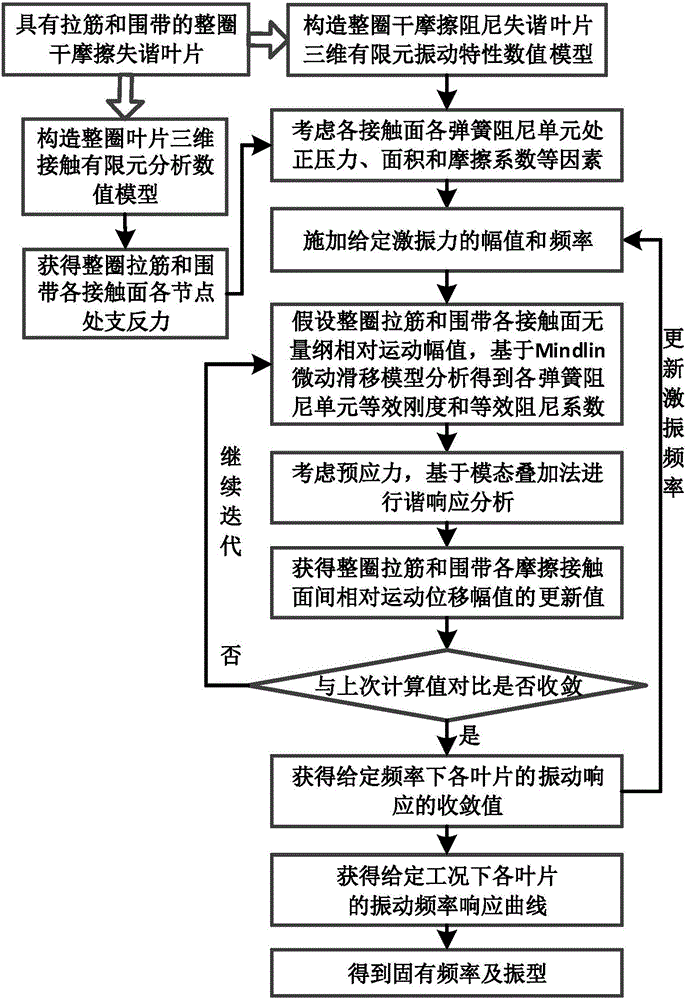

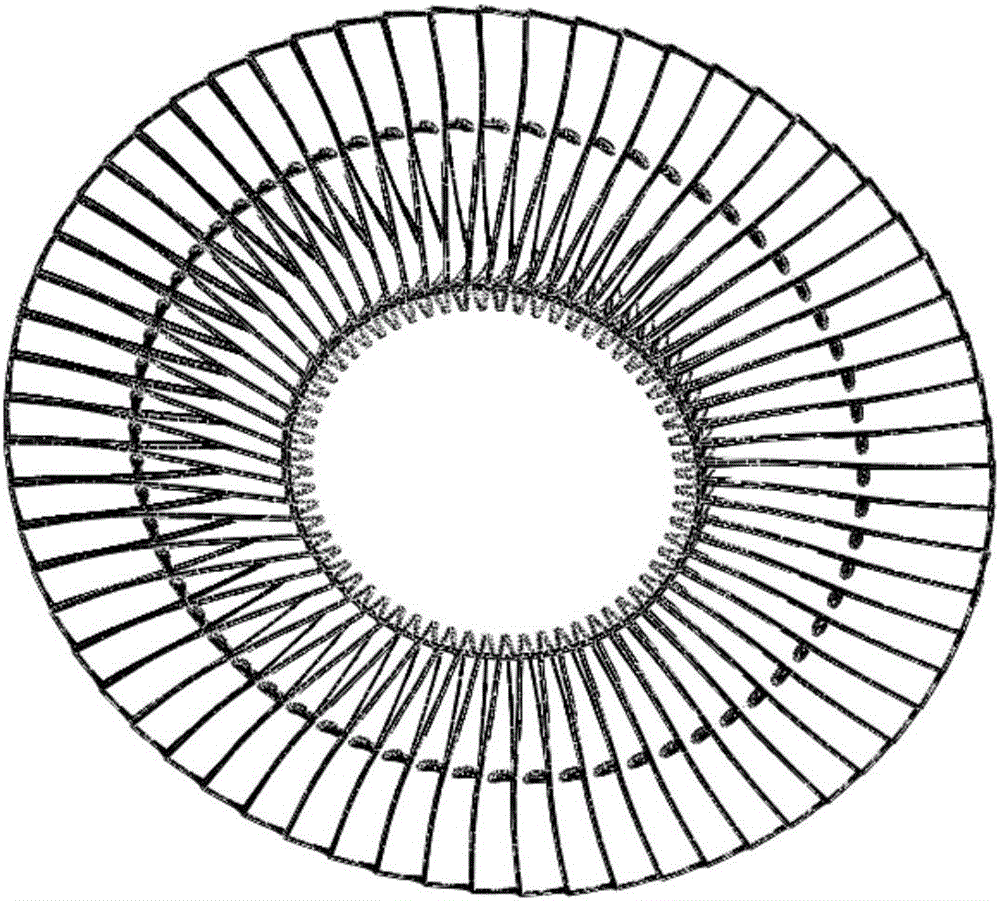

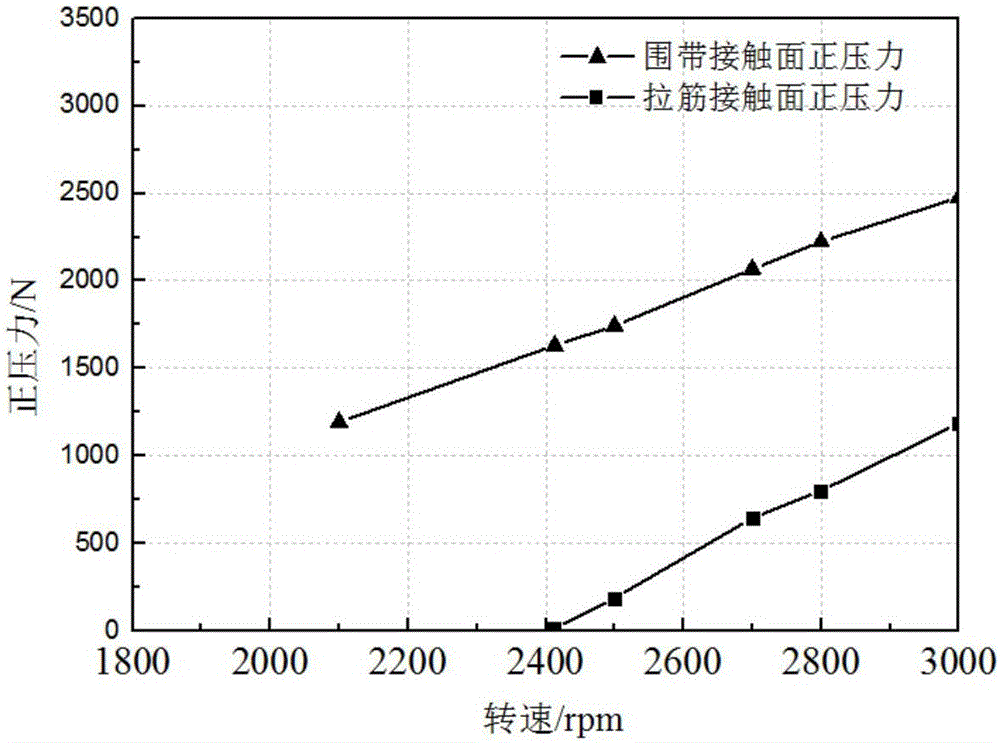

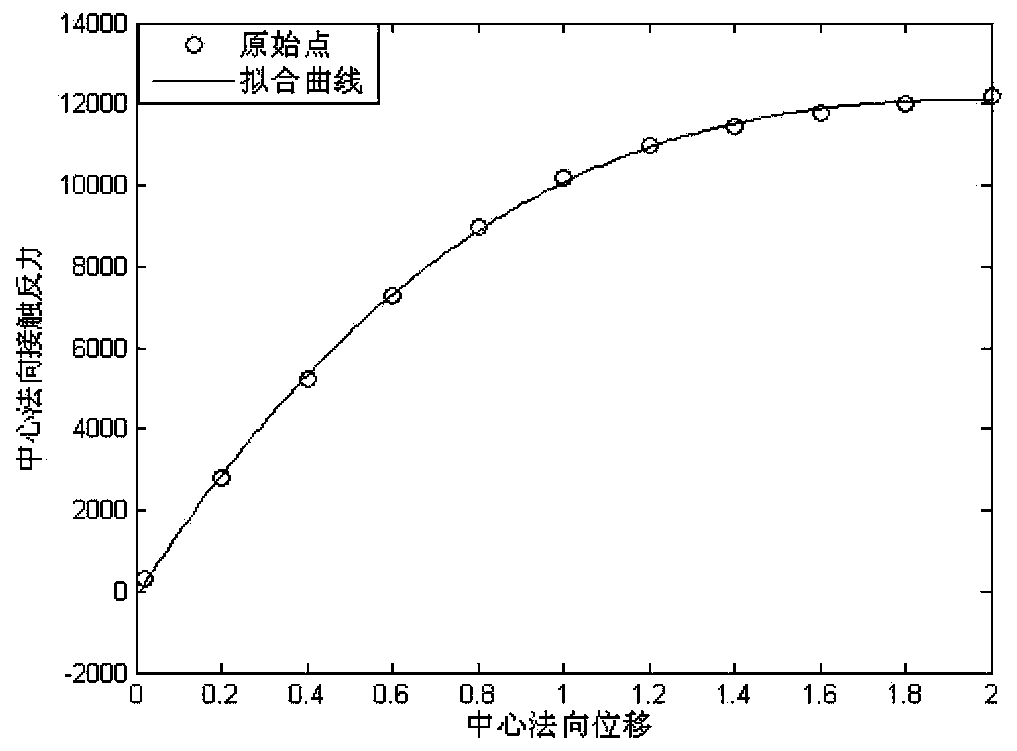

Vibration analysis method for dry frictional damping mistuned blades with tendons and shroud bands

ActiveCN106528982AHigh precisionShort analysis timeGeometric CADDesign optimisation/simulationVibration amplitudeFrictional coefficient

The invention discloses a vibration analysis method for dry frictional damping mistuned blades with tendons and shroud bands. The method comprises the steps of for actual mistuned states of the blades of a steam turbine, performing three-dimensional contact finite element analysis firstly to obtain support reactions of nodes of contact surfaces of the tendons and the shroud bands of the entire circle of the blades; secondly establishing a contact surface relationship by adopting spring damping units, considering positive pressures, areas and frictional coefficients at the spring damping units, and building a dry frictional damping mistuned vibration analysis model based on a Mindlin micro-sliding friction model and a harmonic balance method; thirdly considering a pre-stress and adopting harmonic response analysis for obtaining convergency values of vibration responses of the blades through iterative solving; and through cyclic calculation, obtaining vibration amplitude response curves of the dry frictional mistuned blades, and performing further extraction to obtain an inherent frequency and a vibration mode. The method is of important significance for dry frictional damping mistuned analysis of the blades and improvement of mistuned bladed disk vibration.

Owner:XI AN JIAOTONG UNIV

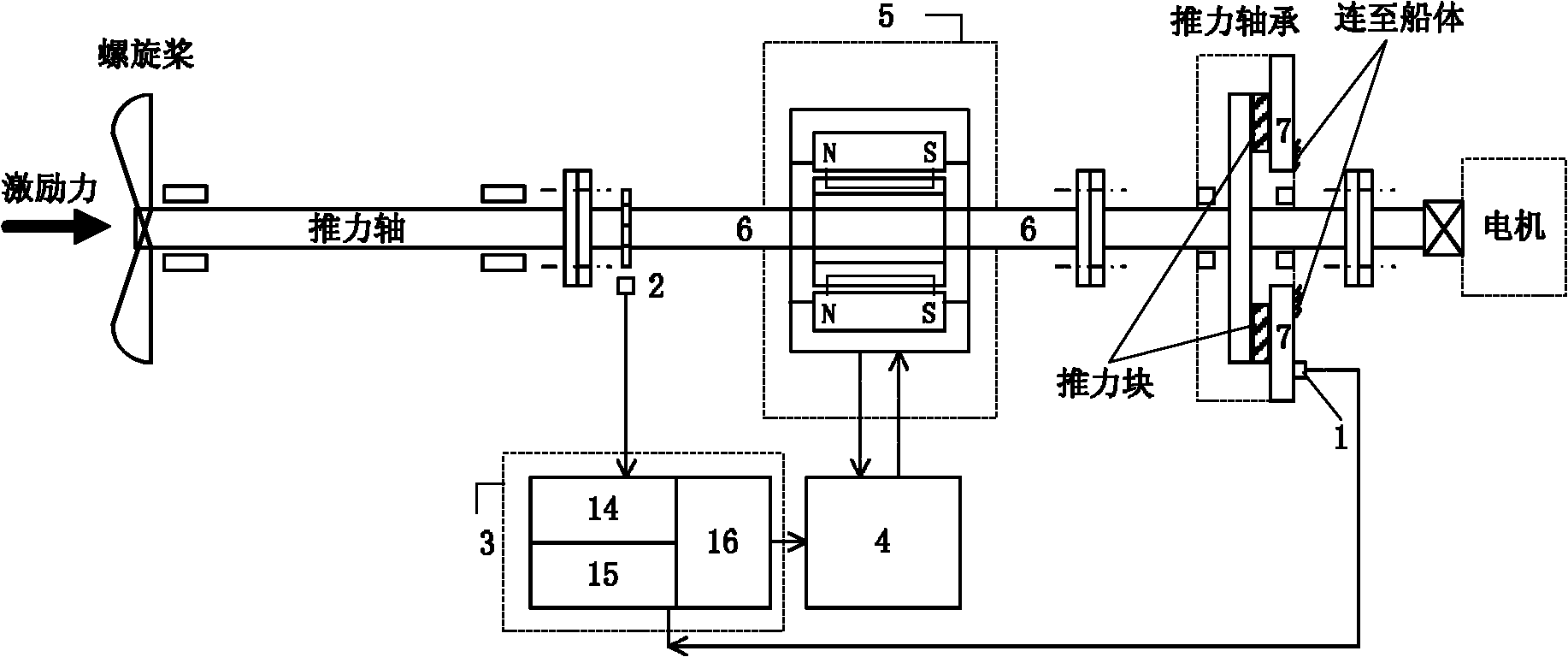

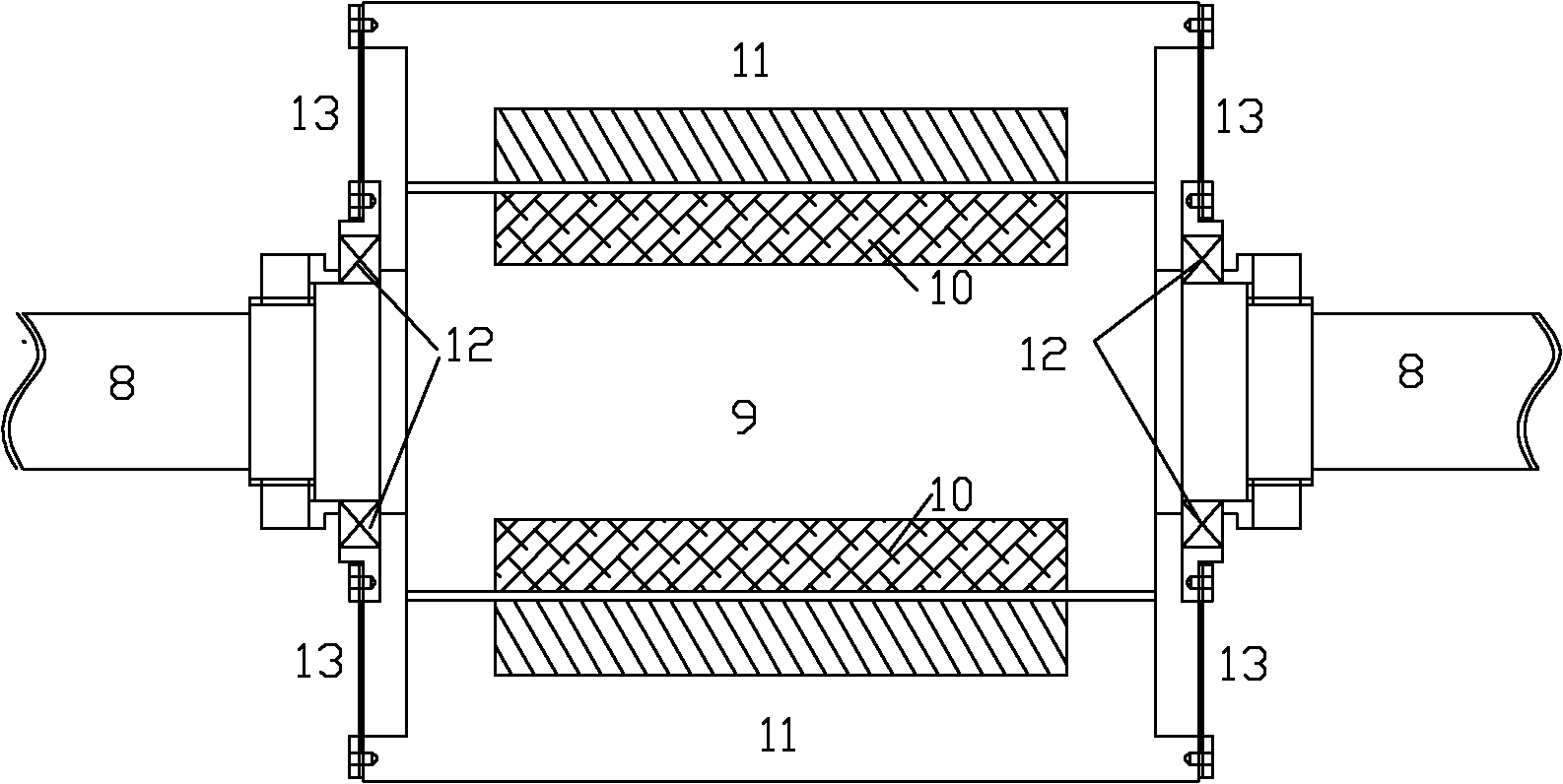

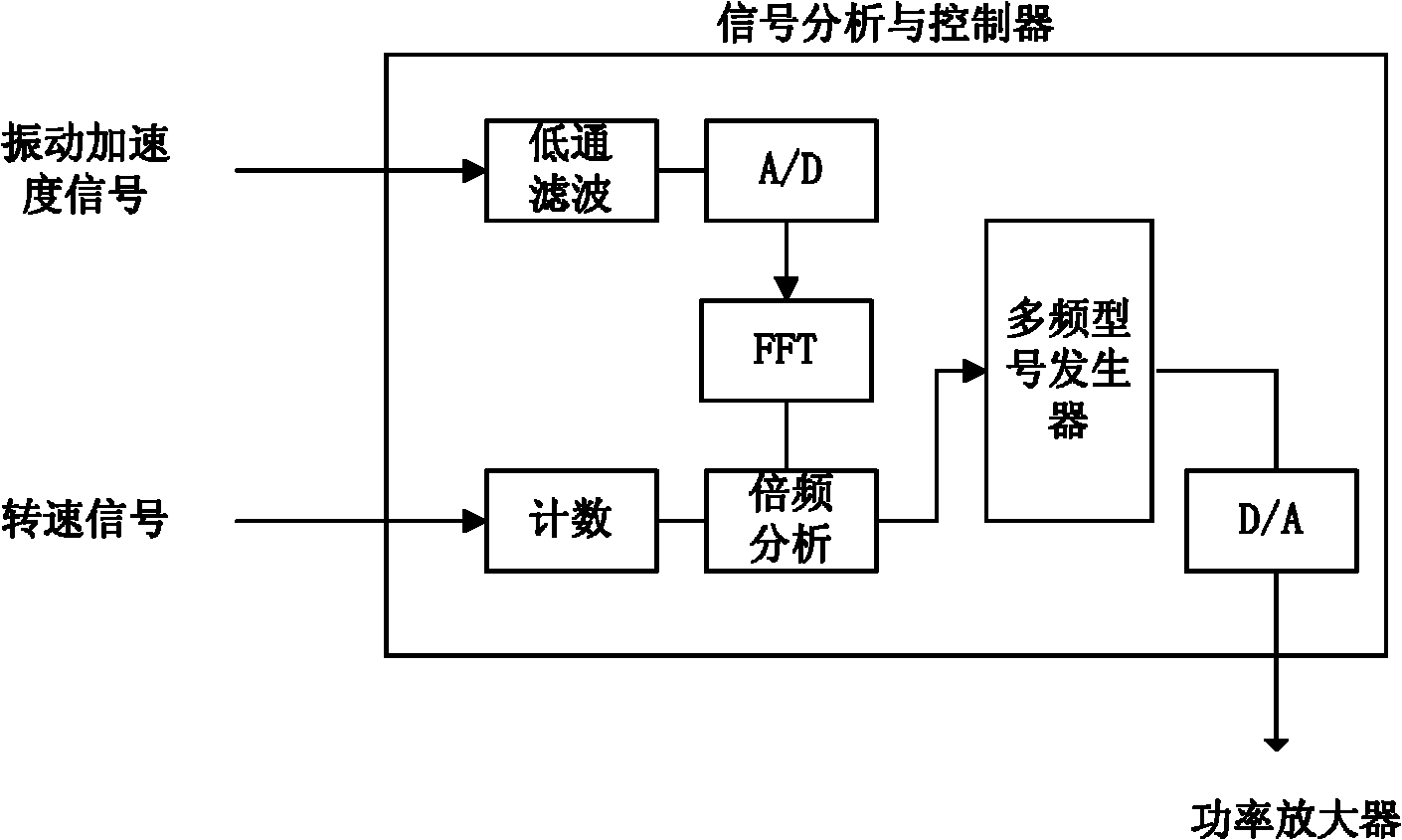

Electromagnetic active control device for longitudinal vibration of marine shafting

InactiveCN102072276AAvoid the disadvantages of vibration amplitude amplificationDoes not change intrinsic stiffness propertiesNon-rotating vibration suppressionWater acting propulsive elementsFrequency spectrumVibration acceleration

An electromagnetic active control device for longitudinal vibration of a marine shafting, belonging to the technical field of oceanographic engineering, comprises: an acceleration transducer, a tachometer, a signal analysis and control module, a power amplifier and an electromagnetic actuator, wherein the acceleration transducer and the tachometer are respectively located on a thrust bearing base and a middle shaft and output a measured vibration acceleration electric signal of the base and a photoelectric signal of the shafting to the signal analysis and control module; the signal analysis and control module receives the vibration acceleration electric signal and the photoelectric signal, performs spectrum analysis and characteristic signal extraction on the received signals to generate corresponding action control signals, and outputs the action control signals to the power amplifier for amplification; and the electromagnetic actuator is arranged on the middle shaft and receives the amplified control signals to generate a corresponding longitudinal actuation force applied on the middle shaft, thereby implementing the control for the longitudinal vibration of the shafting. The electromagnetic active control device for longitudinal vibration of the marine shafting effectively reduces the longitudinal vibration of the shafting, so that vibration response of a marine structure is reduced finally, and the control device not only is effective to low frequency line spectra, but also has excellent control effect on broadband random excitation.

Owner:SHANGHAI JIAO TONG UNIV

Impact and vibration method for measuring natural frequency of bridge lower structure

InactiveCN1804563AEasy to operateEasy to testVibration measurement in solidsSubsonic/sonic/ultrasonic wave measurementFrequency spectrumEngineering

The invention relates to an impulse vibrating method for testing the bridge substructure natural frequency of vibration which uses avoirdupois weight to stroke the pier and tests the vibrating response of the pier to analyze and compute the natural frequency of vibration. It uses avoirdupois weight to stroke the pier top part and tests the speed and hastens response of the bridge. It usually dose multi-stroke and uses the recording wave mode superposition to dispel the noise to obtain the accurate response wave mode. It reads the response wave mode to do Fourier analysis to ascertain Fourier frequency spectrum and combines with the peak spectrum to ascertain the natural frequency of vibration of bridge.

Owner:BEIJING JIAOTONG UNIV

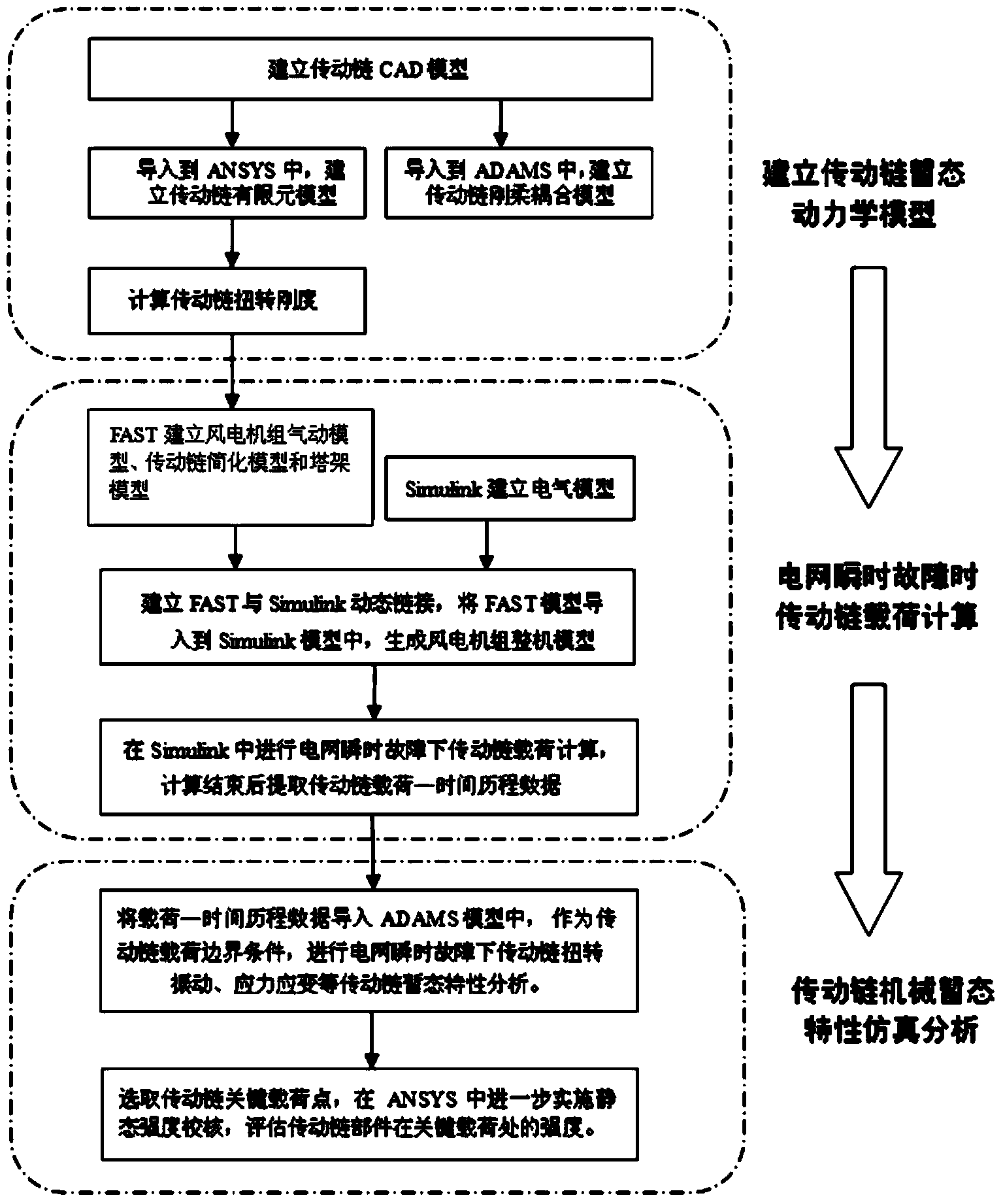

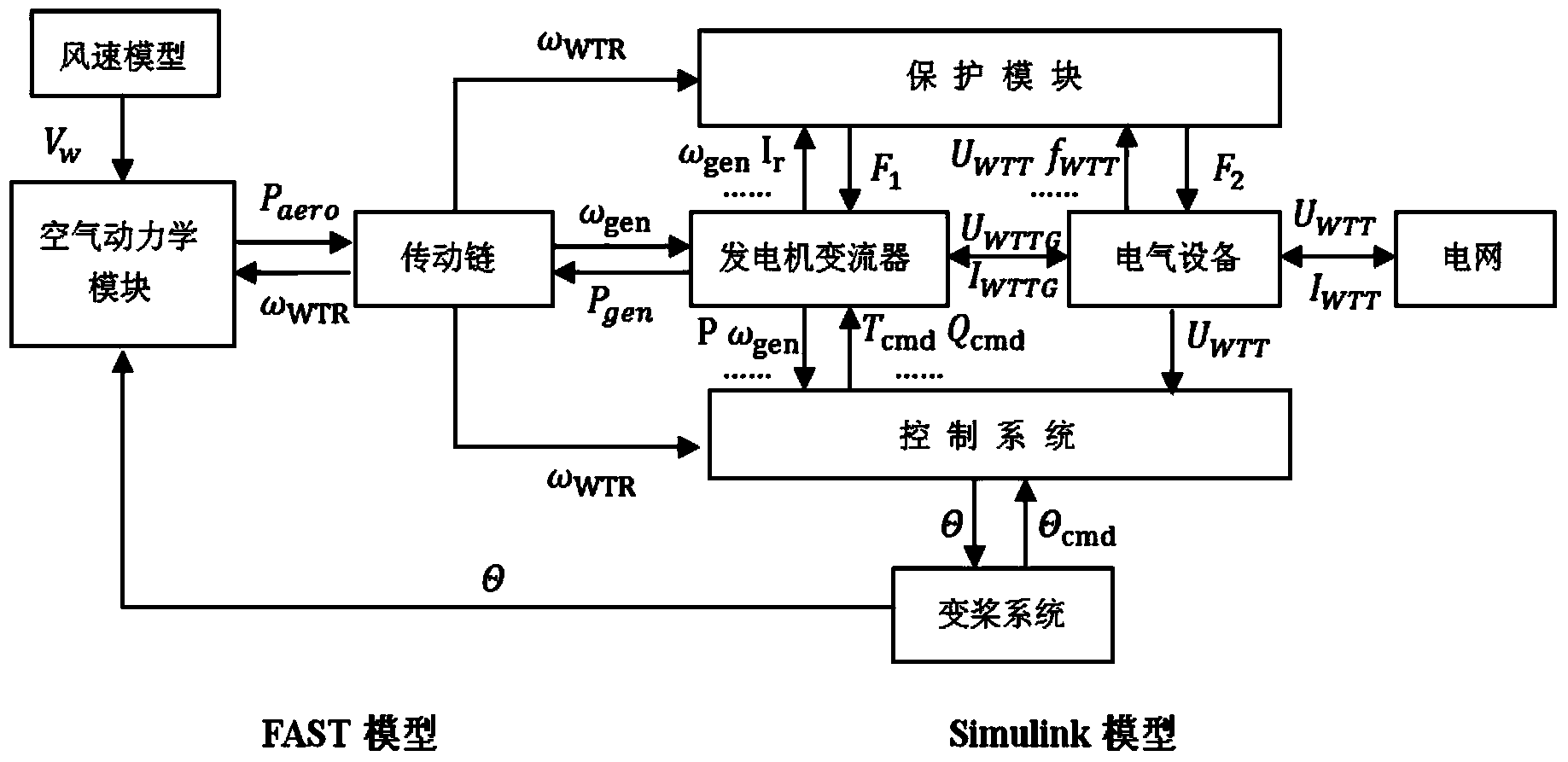

Modeling and simulating method for mechanical transient characteristics of transmission chain of wind generating set

ActiveCN103745070AOvercoming the disadvantages of mechanical transient characteristicsAnalyzing Mechanical Transient EffectsSpecial data processing applicationsInformation technology support systemElement modelSimulation

The invention discloses a modeling and simulating method for mechanical transient characteristics of a transmission chain of a wind generating set. The method comprises the following steps: (1) building a three-dimensional model of the transmission chain of the wind generating set; (2) importing the three-dimensional model of the transmission chain into ANSYS and ADAMS, and building a finite element model and a rigid-flexible coupling model of the transmission chain, wherein the rigid-flexible coupling model considers the flexibility of a main shaft, a planet carrier, a transmission shaft and an output shaft; (3) building a wind generating set model, calculating a transmission chain load when a power grid has a transient fault, and simulating the power grid fault through a voltage sag generator, wherein a torque-time history of the transmission chain is extracted after calculation; (4) loading the torque-time history of the transmission chain into an ADAMS model to serve as the load boundary condition for simulating the mechanical transient characteristics of the transmission chain, performing simulation analysis on the mechanical transient characteristics such as the torque vibration response and stress of the transmission chain when the power grid has the transient fault in ADAMS, and checking and evaluating the mechanical transient characteristics of the transmission chain; (5) selecting a key load point of the transmission chain and performing static strength check analysis in ANSYS.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

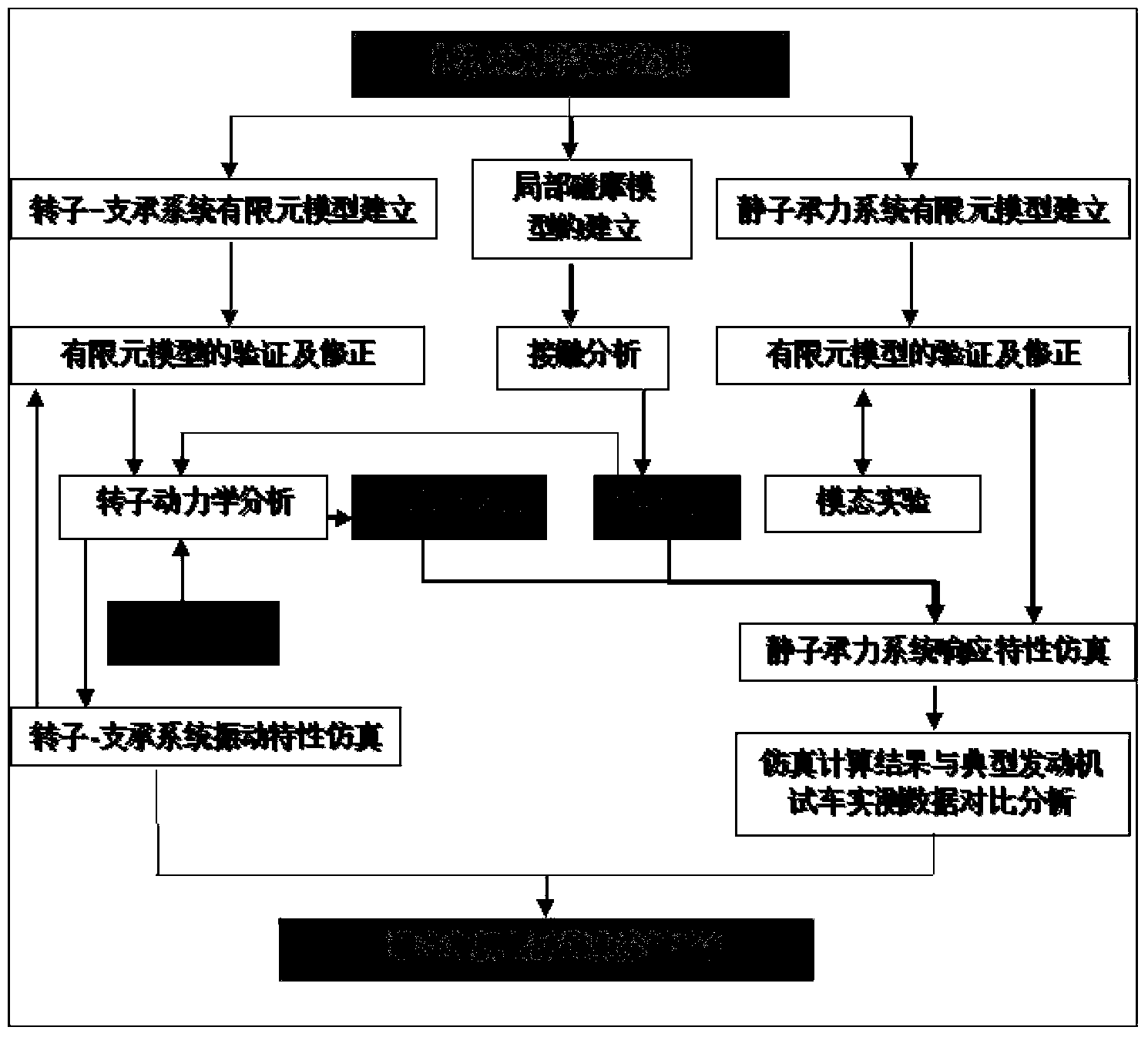

Aero-engine body vibration characteristic analysis method

ActiveCN103471854AReduce the hidden danger of failureImprove overall technical qualityInternal-combustion engine testingAviationResearch Object

The invention discloses an aero-engine body vibration characteristic analysis method. An engine body system is separated into a rotor system and a stator system, the rotor system and the stator are coupled through a fulcrum system and are simulated jointly through dynamic characteristics of the rotor system and the stator system; the engine body system is separated into the two study objects, i.e., a rotor bearing system and a stator bearing system, and then vibration response and dynamic bearing reaction of the rotor bearing system are simulated and analyzed through a finite element analysis platform under the action of unbalanced exciting force and rub-impact force to acquire excitory input of the stator system; at last, the acquired dynamic bearing reaction and the rub-impact force are loaded on the stator bearing system, and the vibration response characteristics of the stator bearing system is simulated and analyzed to acquire engine body vibration characteristics. The aero-engine body vibration characteristic analysis method has the advantages of reducing hidden fault danger in the design of aero-engines and providing decision bases and technical support for engine vibration faults.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

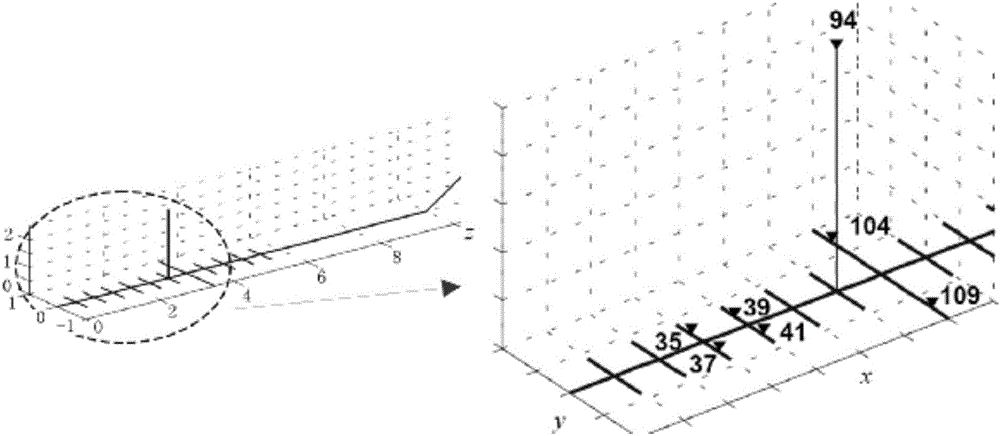

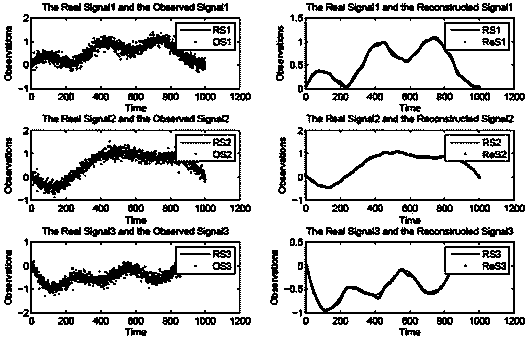

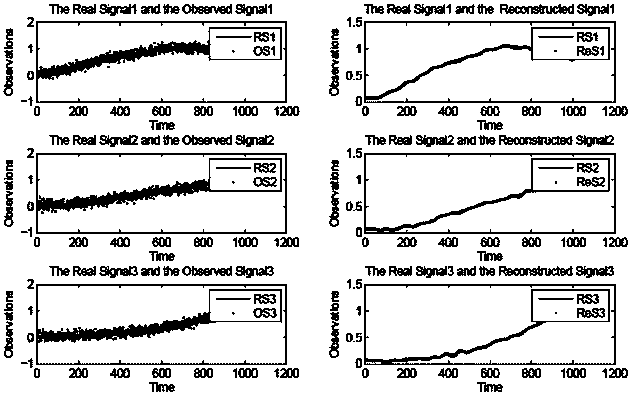

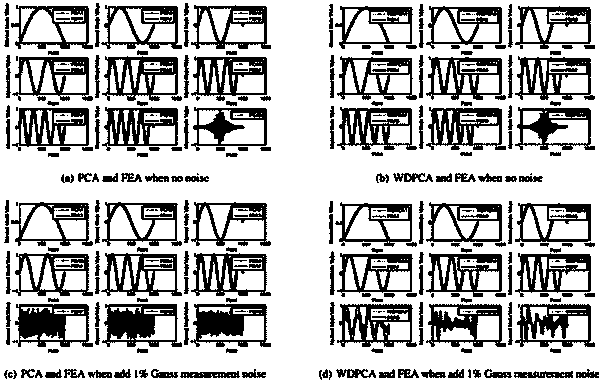

Operating modal parameter identification method for principal component analysis on basis of wavelet threshold denoising

ActiveCN104112072AHigh precisionActive connectionSpecial data processing applicationsPrincipal component analysisEngineering

The invention relates to an operating modal parameter identification method for principal component analysis on basis of wavelet threshold denoising. Measurement noise in vibration response signals of a small damping mechanical structure can be effectively filtered out, the operating mode (a modal inherent frequency and modal vibration shape) of a system can be identified, operating modes (modal inherent frequency and modal vibration shapes) with small contribution amount in the response signal can be even identified, and a PCA modal parameter identification algorithm and physical significance interpretation and certification are endowed. The method is applied to three-dimensional operating modal parameter identification as well as equipment fault diagnosis and health condition monitoring. The invention further relates to an operating modal parameter analysis meter based on the method. Multiple vibrating sensors are arranged on key points of the mechanical structure, operating modal parameter identification is carried out on the vibration response signals obtained through measurement, changes of characteristics of the system structure can be understood, and the operating modal parameter analysis meter can be applied to fault diagnosis and health condition monitoring of large-scale project structures.

Owner:HUAQIAO UNIVERSITY

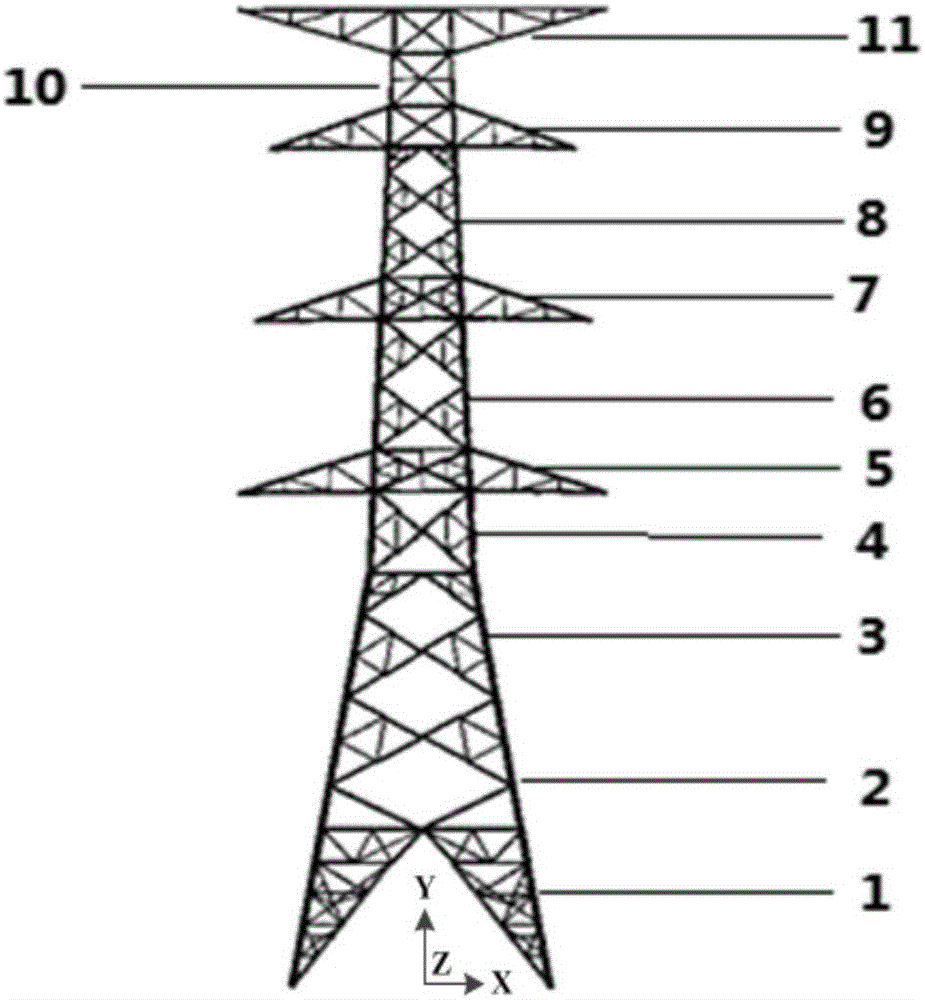

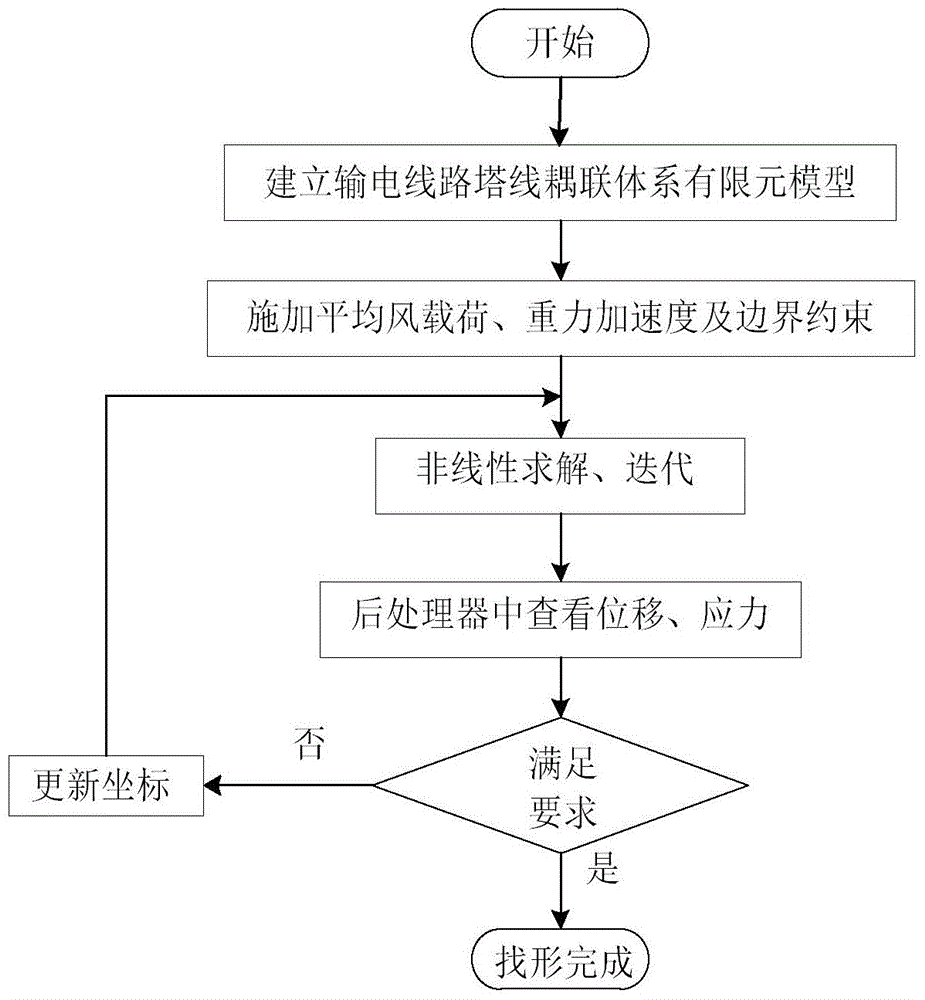

Power transmission line wind vibration calculation method under random wind load

ActiveCN105740548ASolve the problem of many iterations and difficult convergenceReduce computing timeDesign optimisation/simulationSpecial data processing applicationsElement modelEngineering

The invention discloses a power transmission line wind vibration calculation method under random wind load. The power transmission line wind vibration calculation method comprises the following steps: 1: carrying out formfinding on a tower line coupled system finite element model under dead load and average wind load; 2: simulating a pulsation wind speed field to obtain a pulsation wind speed time history; and 3: carrying out wind vibration response calculation: transforming the pulsation wind speed time history obtained in 2) into wind load, applying the wind load to the finite element model which finishes formfinding under the dead load and the average wind load in 1), carrying out transient solving, and extracting a displacement and stress result to finish wind vibration calculation after solving. In the power transmission line wind vibration calculation, average wind speed and pulsation wind speed are separably processed, the pulsation wind speed is applied to a coupled model which finishes formfinding under the average wind load to carry out calculation so as to solve the problem of high iterations and small possibility of convergence of a traditional wind vibration analysis method, and calculation time is shortened.

Owner:XI AN JIAOTONG UNIV +1

Multifunctional test bed for simulating condition by one-quarter suspension of vehicle

InactiveCN101718632AVerify control effectSmall footprintVehicle suspension/damping testingMagnetic currentSemi active

The invention discloses a multifunctional test bed for simulating condition by a one-quarter suspension of a vehicle, comprising a T-shaped groove base, a test bed support frame, an actuating bench assembly and a vehicle suspension assembly. The test bed support frame is arranged on one side of the T-shaped groove base; and the actuating bench assembly is arranged on the other side of the T-shaped groove base. The vehicle suspension assembly is arranged on a working disk of the actuating bench assembly; and the vibration response of a vehicle body and unsprung mass can be obtained by simulating the road surface vibration through the output of an actuating bench. The multifunctional test bed has multiple functions, can meet simulation condition tests of transverse arm type, multi-link type and Macphersan type suspension systems in the suspension forms, meet simulation condition tests of passive, semi-active and active suspension systems in the types and meet actual condition tests and pseudo-dynamic tests in the simulation modes. According to the test results, the invention not only can analyze the performance of single vibration absorber, but also can analyze the overall performance of the suspension and can verify control effects of magnetorheological semi-active suspension under different control strategies.

Owner:ZHEJIANG UNIV

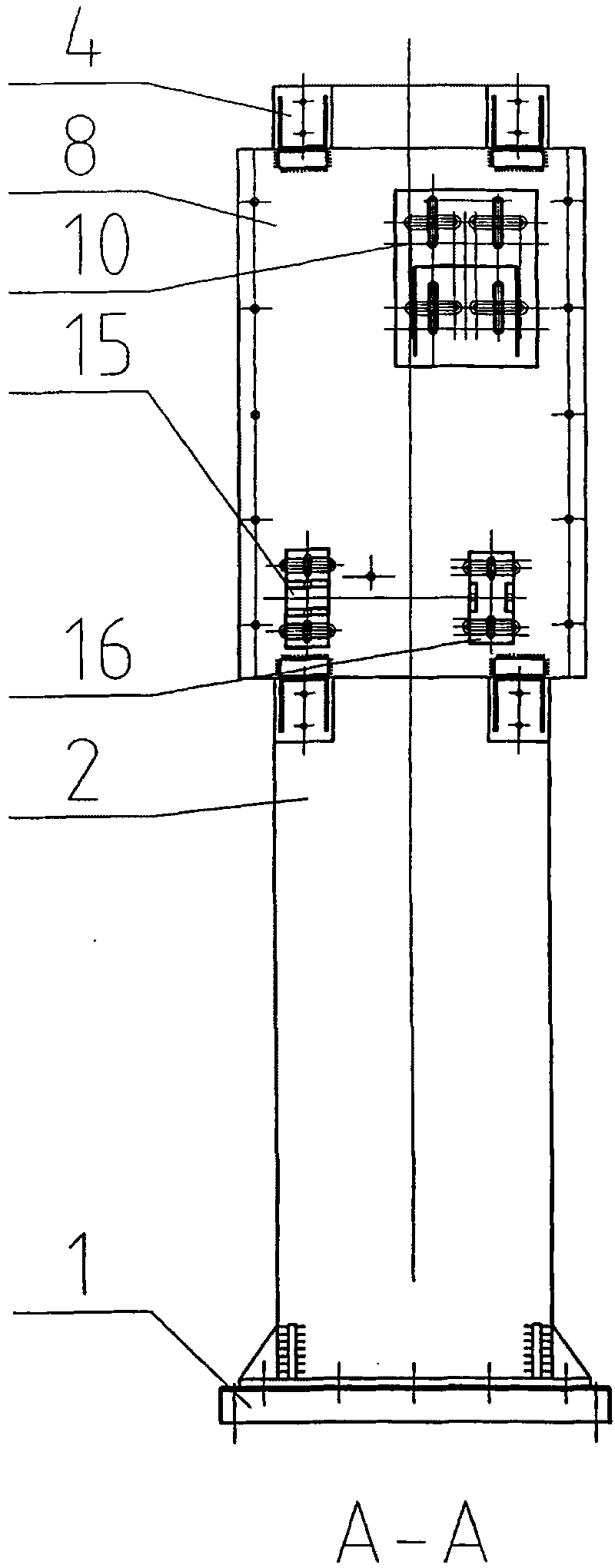

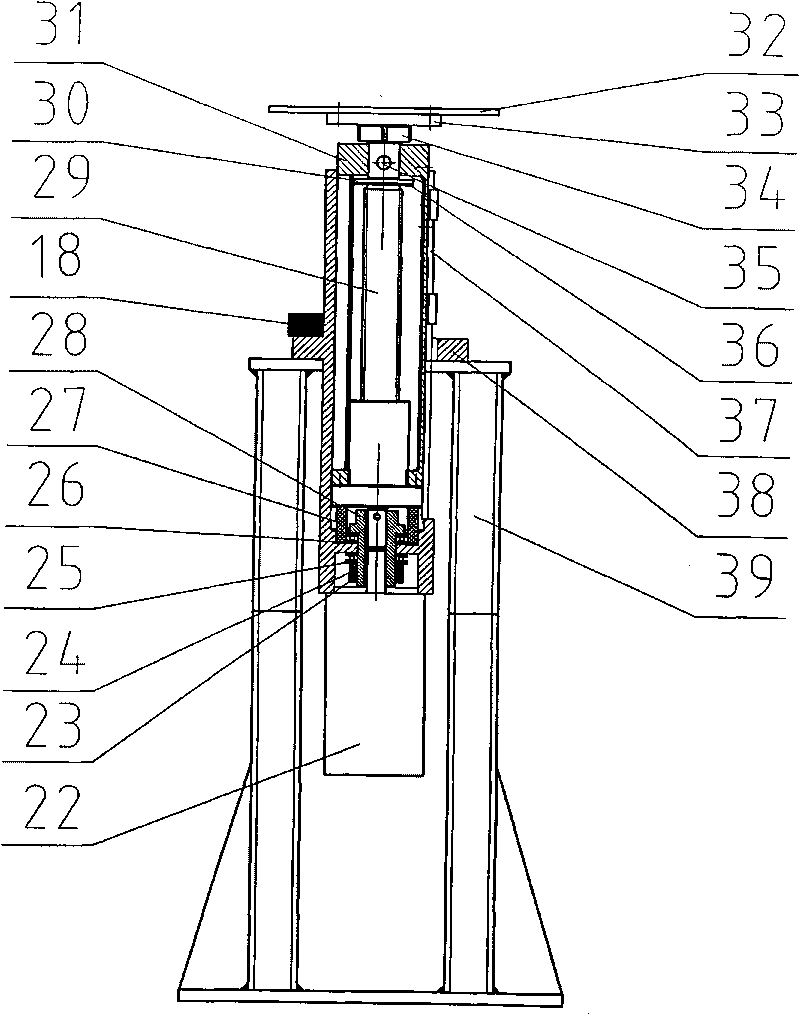

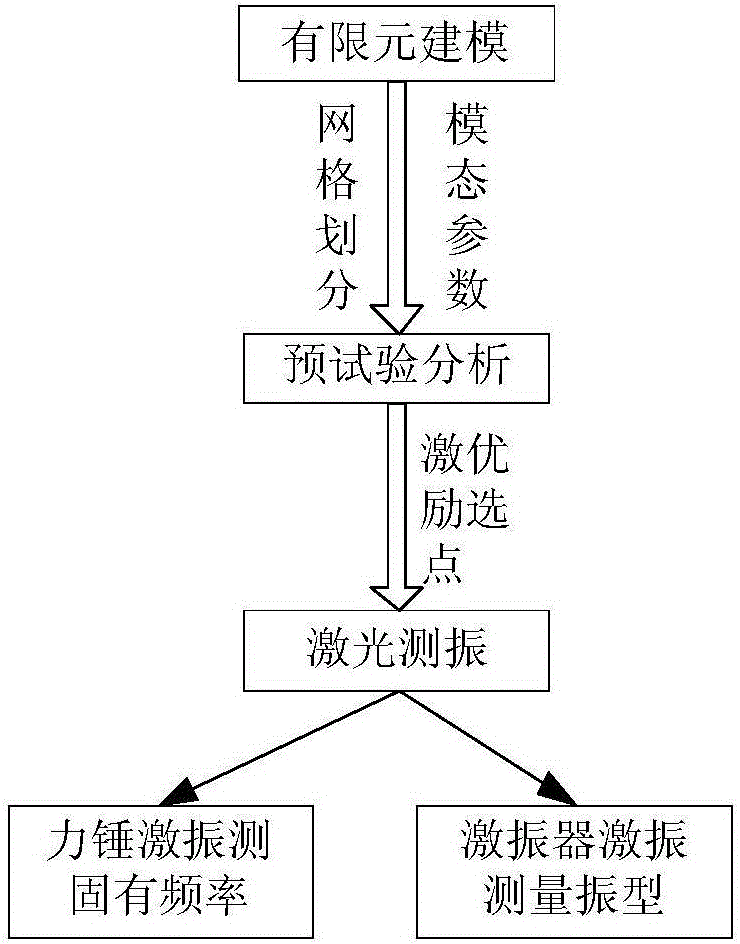

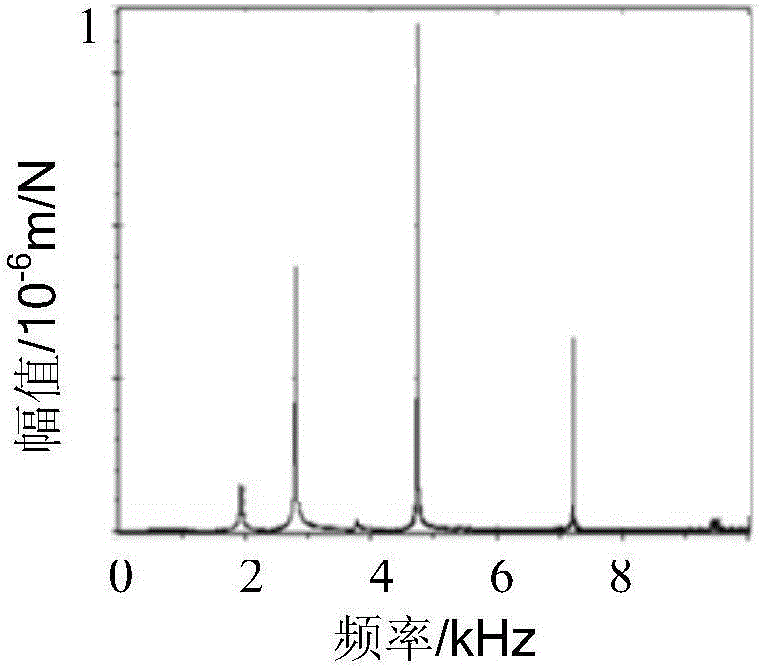

Small impeller mode testing method based on exciting point optimization and vibration measurement with laser

InactiveCN106596011ASolving Modal Testing ChallengesOvercome the problem of additional quality impactVibration testingVibration measurementModal testing

The invention discloses a small impeller mode testing method based on exciting point optimization and vibration measurement with laser. With the method, a technical problem of low testing precision of the existing small impeller mode testing method can be solved. The method is characterized in that an inherent frequency and a vibration mode of an impeller are obtained by finite element stimulation calculation; a mesh division model and a mode calculation result of the impeller are introduced into LMS Virtual.lab software to carry out a preliminary test analysis; and an impeller mode exciting position is selected preferably by using a driving point residue (DPR) method. An impeller is fixed at a support elastically; morphological data of a plate and blades are obtained by using a morphological scanning unit of a laser vibration measurement instrument; and a scanning region is defined at an image directly and point distribution is carried out. With a single-point hammering method, a vibration response signal on the free boundary condition is obtained; the inherent frequency of the impeller is measured; and point-to-point scanning is carried out by using an exciter on the condition of single-frequency shock excitation so as to obtain all-order vibration. Therefore, the testing precision can be improved.

Owner:中国船舶重工集团公司第七0五研究所

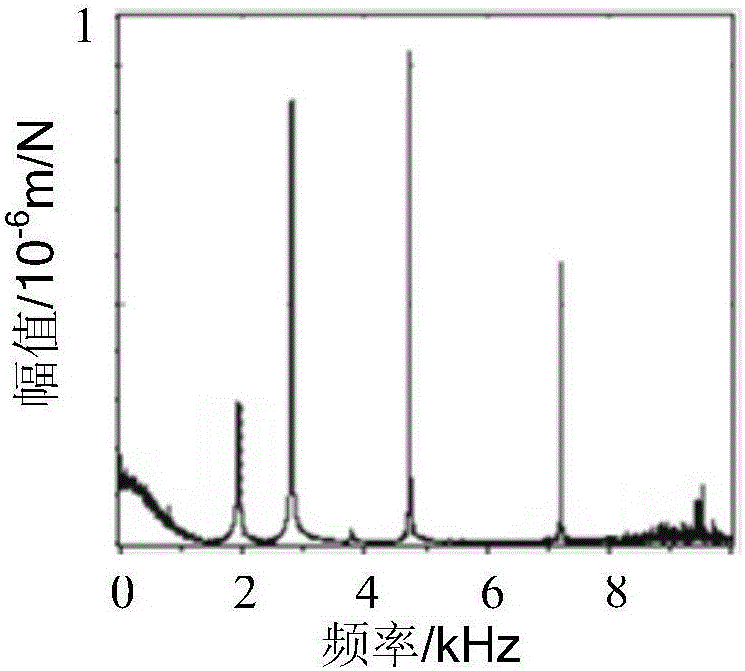

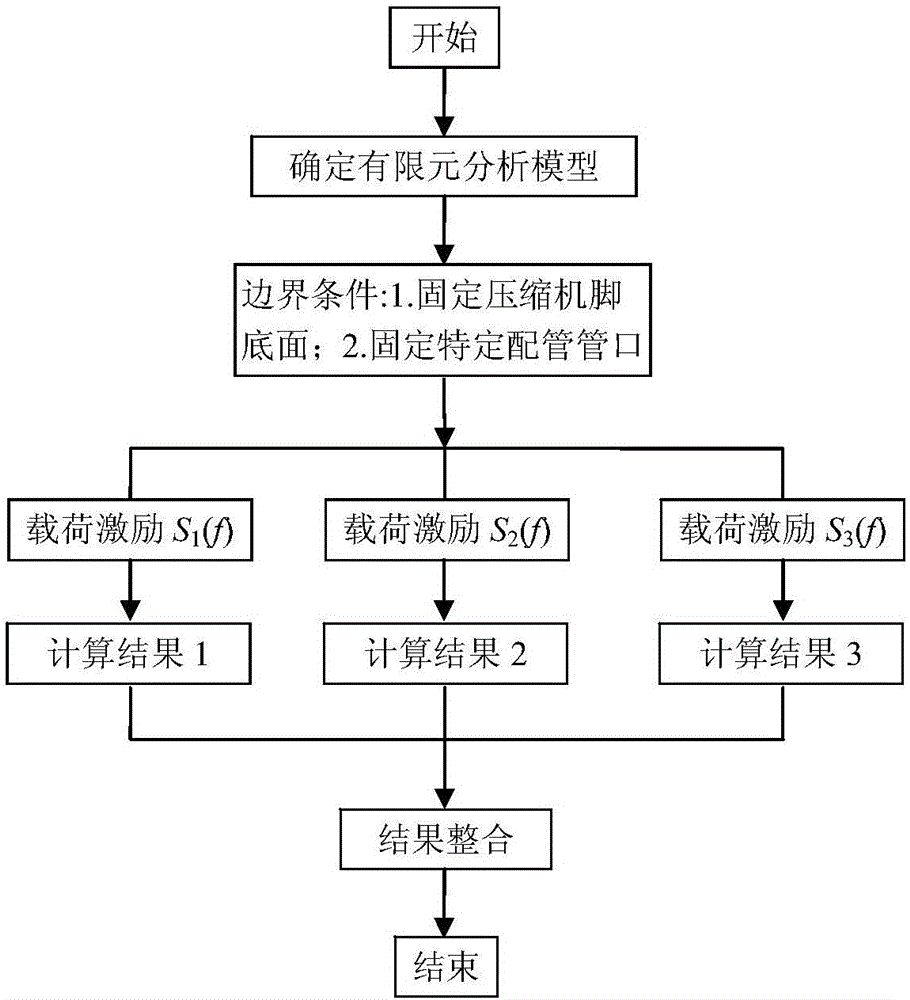

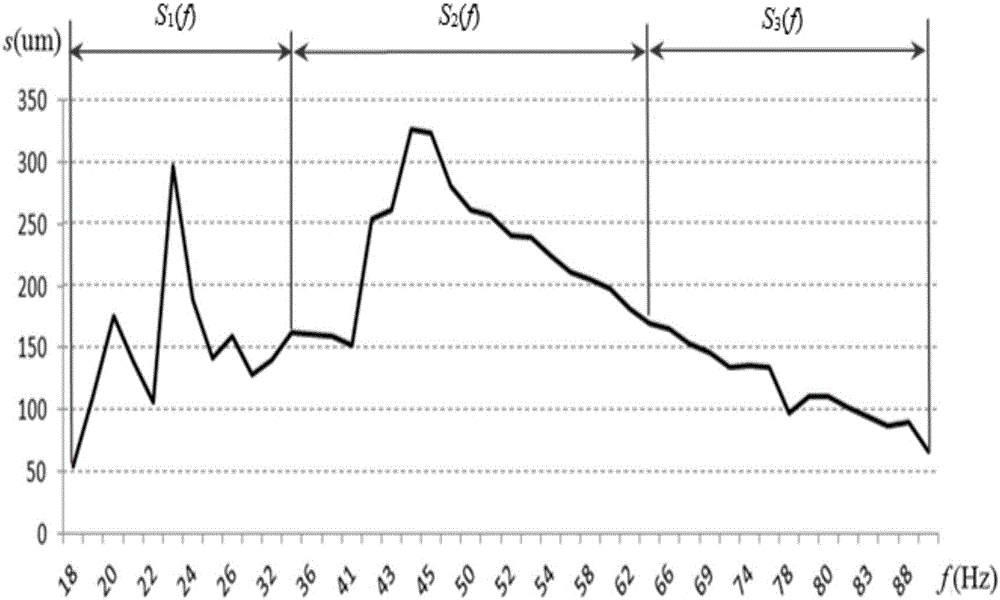

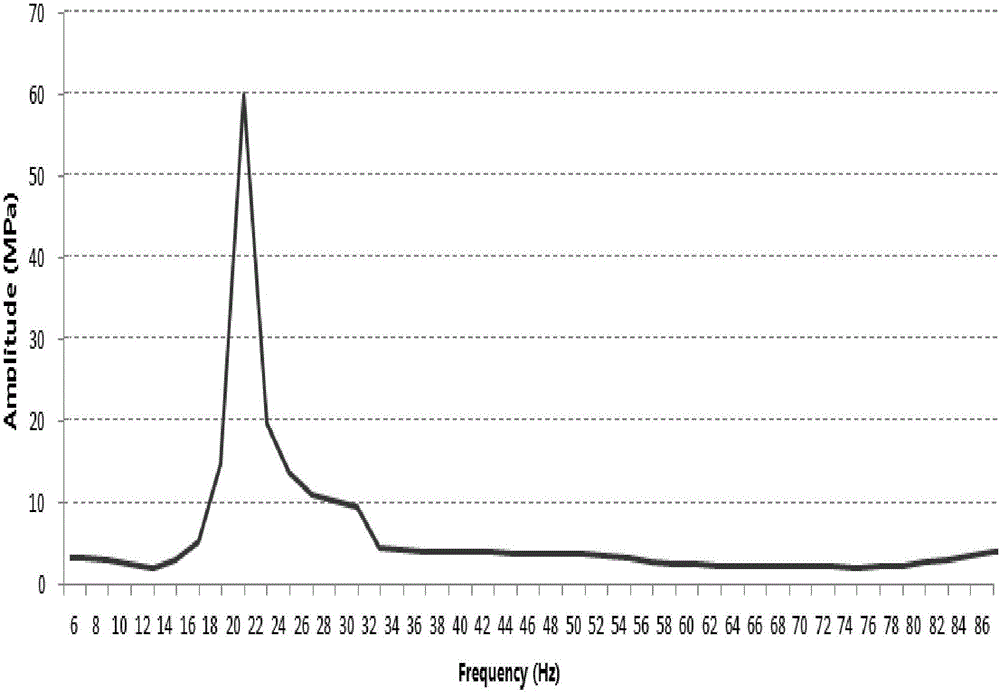

Pipe vibration simulation method for air conditioner compressor

ActiveCN106529048AComprehensive simulation resultsSimulation is accurateDesign optimisation/simulationSpecial data processing applicationsElement analysisEngineering

The invention relates to air conditioner parameter simulation, discloses a pipe vibration simulation method for an air conditioner compressor, and solves the problems of large simulation calculation amount and low calculation accuracy of a pipe vibration simulation method for the air conditioner compressor in a conventional technology. The method comprises the steps of A, determining a finite element analysis model of a compressor pipe structure according to an modal experiment and comparison with a modal simulation result; B, obtaining a compressor surface vibration displacement response function S(f) through experiment testing, wherein f is a frequency; C, dividing the compressor surface vibration displacement response function S(f) into a plurality of frequency band functions Si(f) (i is greater than or equal to 1 and is an integer); D, extracting a surface vibration displacement maximum Sj(fj) (j=i), in each frequency band range, of the compressor to serve as node load excitation of a whole analysis system, and segmentally performing simulation; and E, integrating simulation results to obtain a vibration response result, in a compressor full-frequency-band running range, of the compressor pipe.

Owner:四川长虹空调有限公司

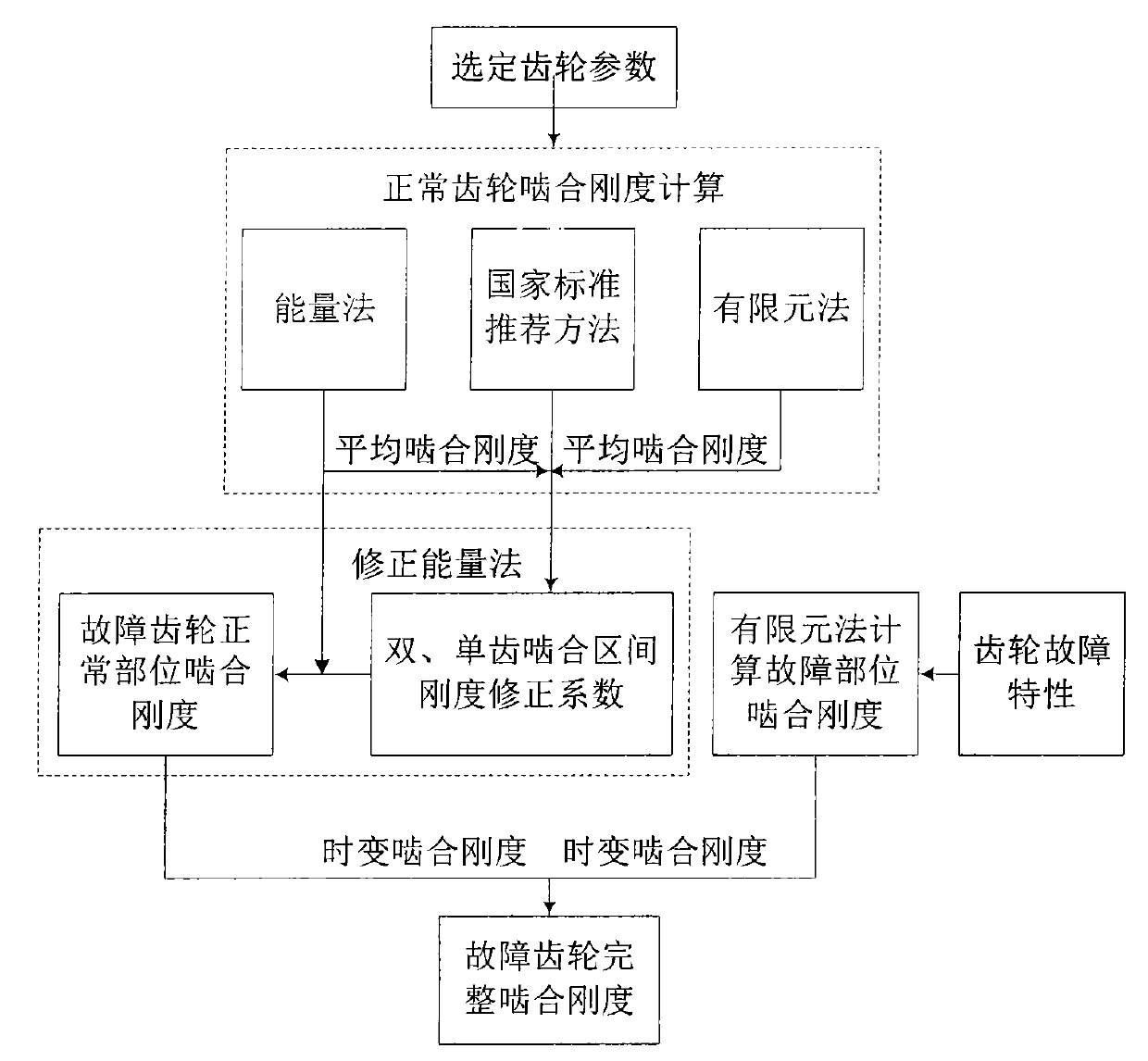

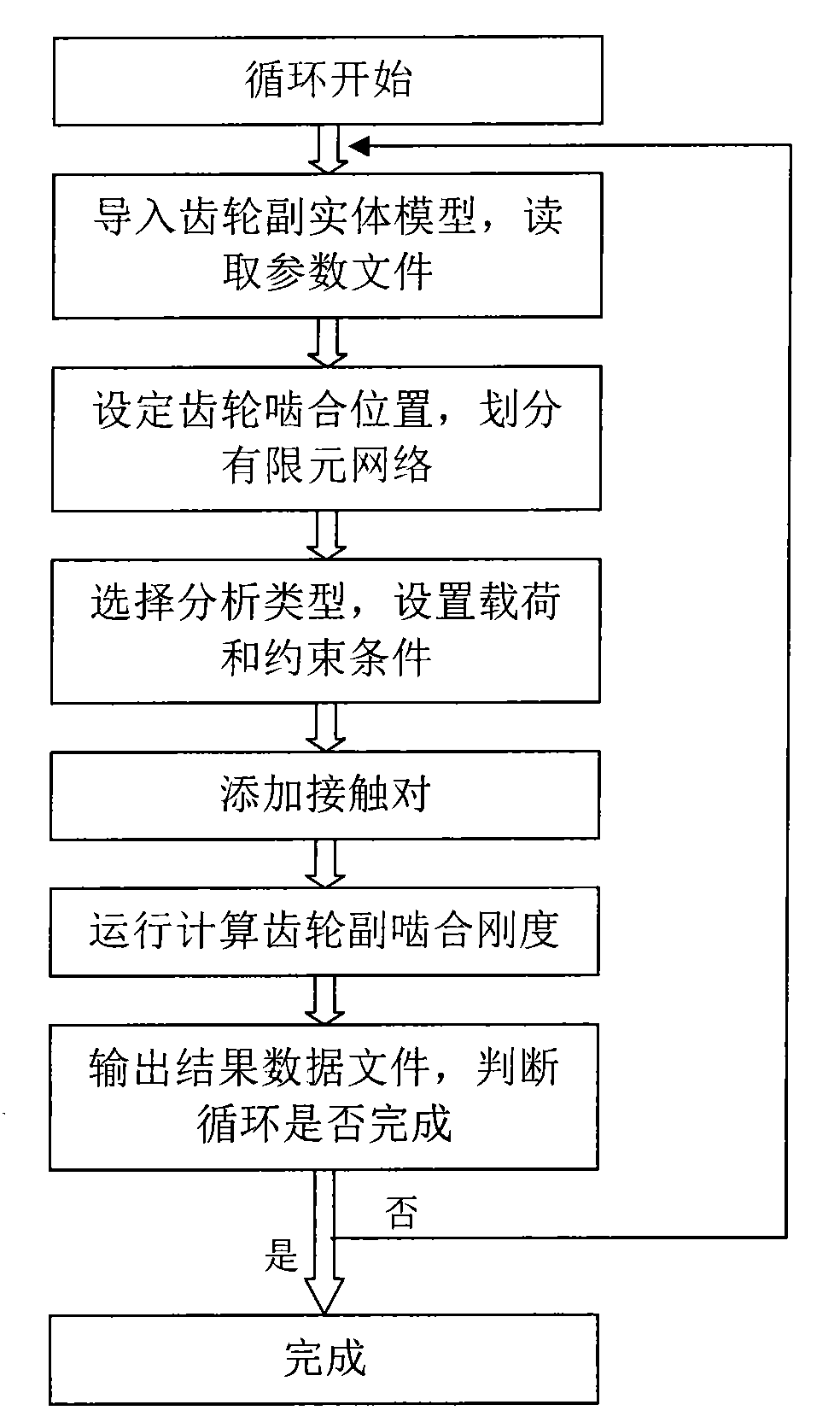

Method for simulation analysis on meshing stiffness of cylindrical spur gear undergoing damaged single-tooth failure

InactiveCN101770538AIncrease stiffnessReliable theoretical basisMachine gearing/transmission testingSpecial data processing applicationsElement modelSimulation

The invention relates to a method for the simulation analysis on the meshing stiffness of a cylindrical spur gear undergoing damaged single-tooth failure. The method comprises the following steps: firstly, setting the correction coefficient of the meshing stiffness of single-tooth and double-tooth meshing section on the basis of the calculation results of the average stiffness according to the finite element method and the national standard method, so as to improve the calculation accuracy of the meshing stiffness of a normal gear according to the energy method; secondly, establishing a finite element model of the spur gear undergoing damaged failure targeting on the failure location of the spur gear by combining the three-dimensional modeling software and the finite-element analysis software, and compiling a simulation calculation program by using the computer language, so as to calculate the time-varying meshing stiffness; and finally, integrating the calculation results of the two steps to obtain the integrated meshing stiffness of the spur gear. By fully integrating the advantages of the corrected energy method and the finite element method, the invention can not only guarantee the calculation accuracy, but also improve the calculation efficiency. The method of the invention for the simulation calculation of the meshing stiffness of the gear undergoing damaged single-tooth failure is effectively applicable in the research on the vibration response mechanism of a gear system.

Owner:BEIJING UNIV OF TECH

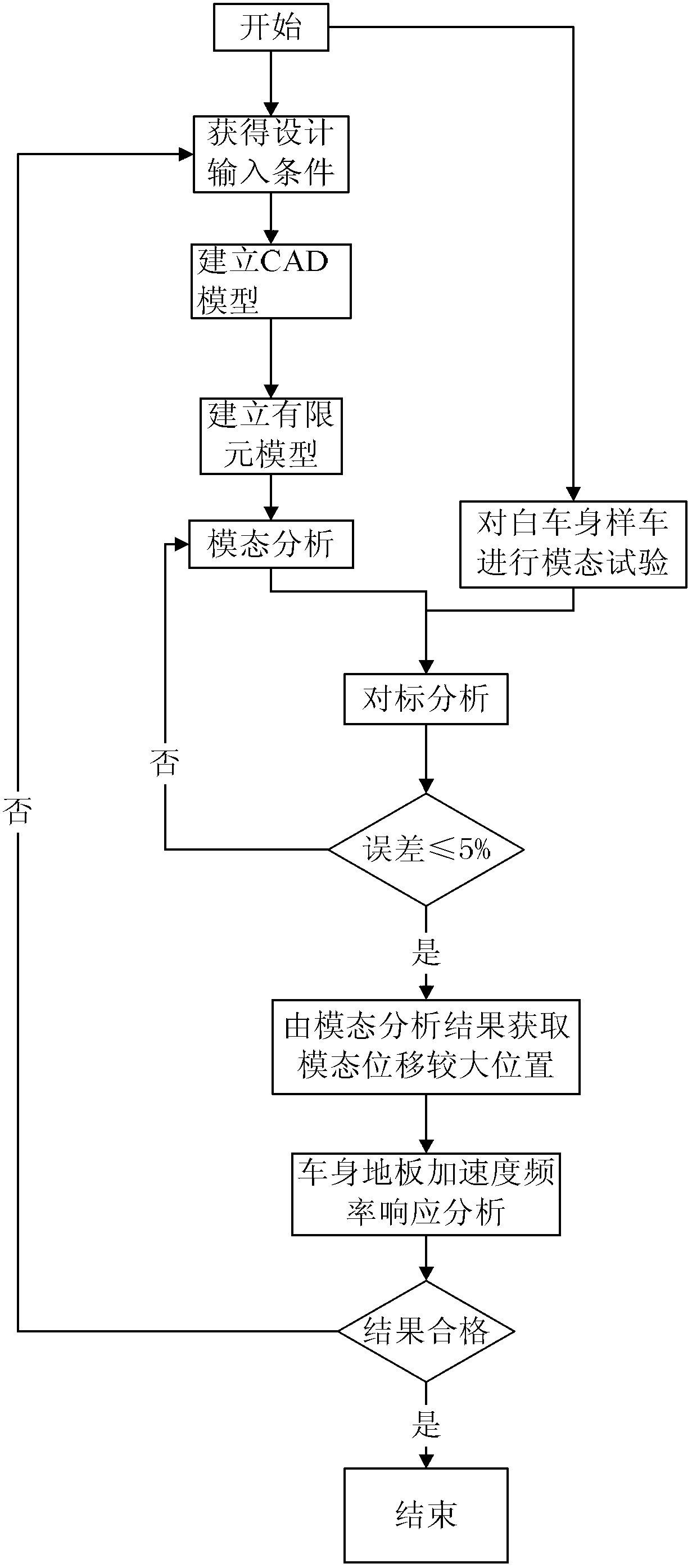

Acceleration frequency response analysis-based body floor optimal design method

ActiveCN102867075AReduce mistakesImprove noiseSustainable transportationSpecial data processing applicationsComputer Aided DesignElement model

The invention discloses an acceleration frequency response analysis-based body floor optimal design method, which comprises the following steps of: acquiring a body floor design input condition; establishing a CAD (Computer Aided Design) model; establishing a finite element model; performing mode CAE (Computer Aided Engineering) analysis on the finite element model to perform mode test on a white body sample; performing benchmarking; checking and verifying the finite element model according to a benchmarking result; searching a region of a large vibration displacement of the white body floor in the finite element model according to a mode CAE analysis result, extracting an inspection point from the region, and performing acceleration frequency response analysis on the inspection point; and modifying the floor design input condition according to the acceleration frequency response analysis result until the vibration response requirement is met. The method has the characteristics of shortening the development time, reducing the development cost, improving the entire noise, the vibration and the comfort, reducing the error between the finite element model and the floor sample and keeping high design quality.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

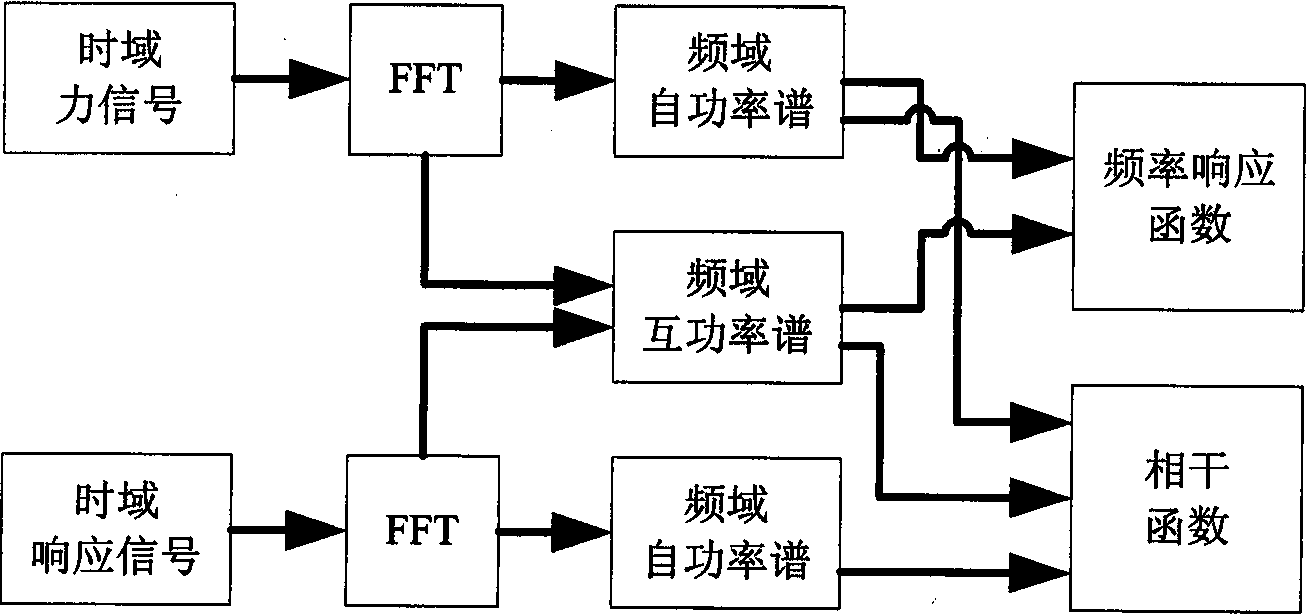

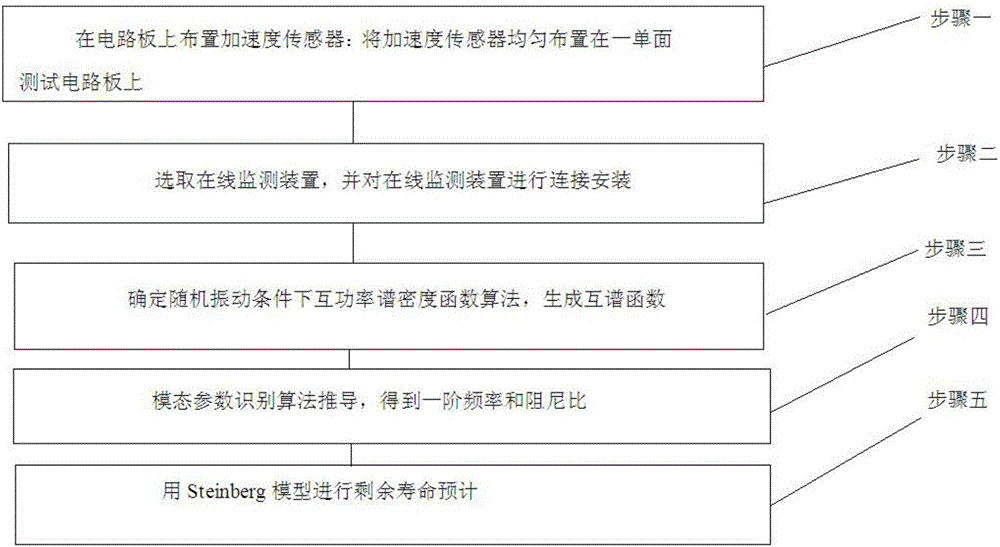

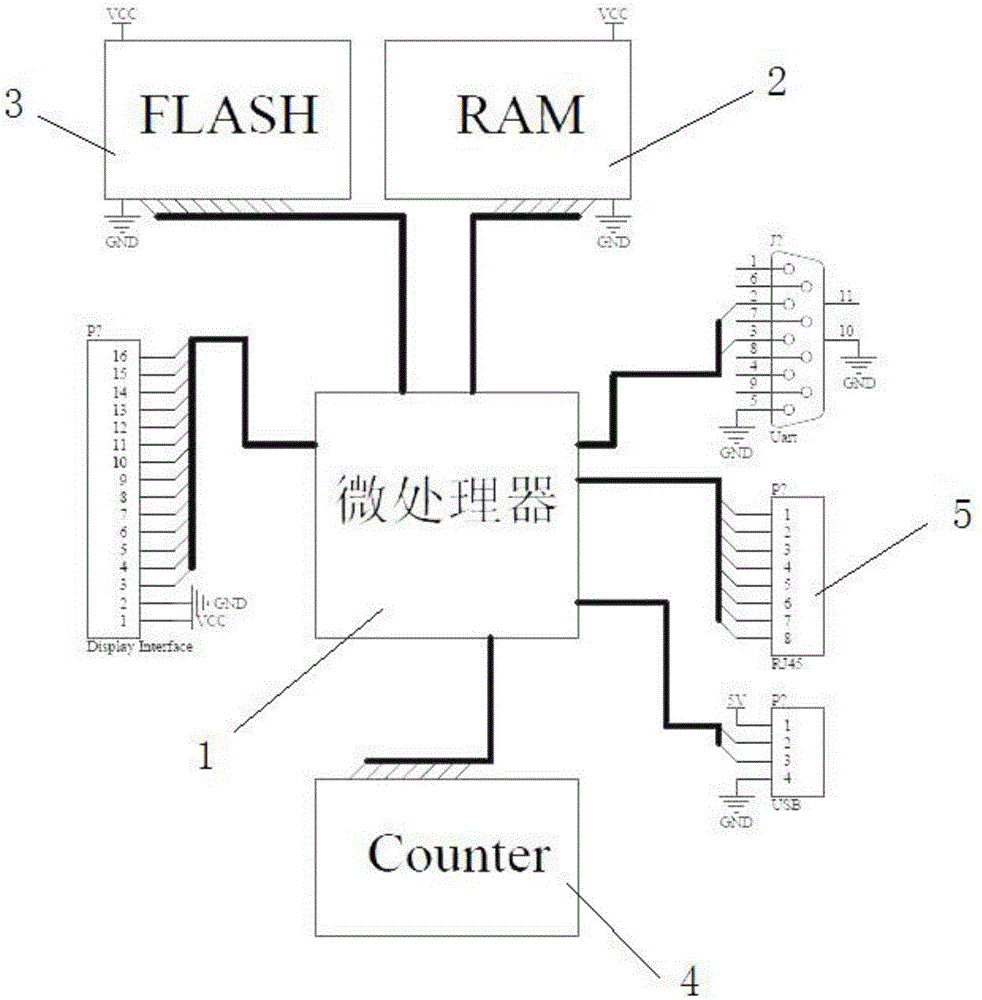

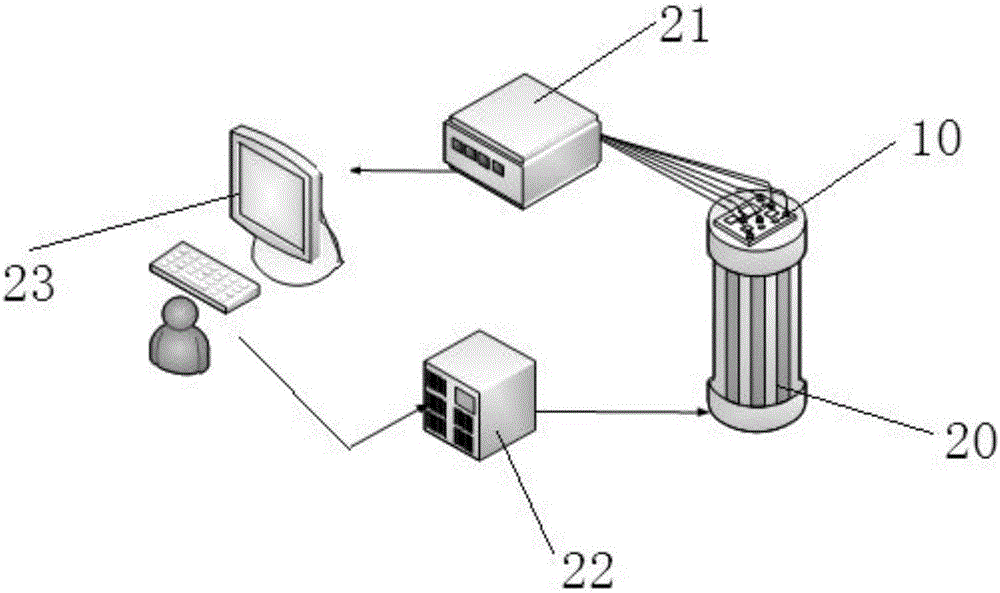

Electronic product vibration DLP method based on cross-power spectrum function mode parameter identification

ActiveCN106482827AAvoid disadvantagesAccurate Vibration Remaining Life Prediction ResultsSubsonic/sonic/ultrasonic wave measurementFinite element analysis softwareDamping ratio

The invention provides an electronic product vibration DLP method based on cross-power spectrum function mode parameter identification. The method comprises the following steps of arranging acceleration sensors on a circuit board; uniformly arranging the acceleration sensors on a single-surface testing circuit board; selecting an online monitoring device, and performing connecting mounting on the online monitoring device; determining a cross-power spectrum function algorithm on a random vibration condition, and generating a cross-power spectrum density function; performing derivation of a mode parameter identification algorithm, and obtaining a first-order frequency and a damping ratio; and performing residual service life estimation by means of a Steinberg model. According to the electronic product vibration DLP method, finite-element analysis software such as vibration analysis software and simulation software are not required for simulating a vibration response mode. A vibration response data collecting operation can be finished just through the acceleration sensors and data collecting equipment. The electronic product vibration DLP method overcomes a defect that partial parameters of existing service life prediction software are empirical parameters which cannot be accurately calculated. Furthermore the first-order frequency and the damping ratio can be calculated through applying a mode identification method.

Owner:BEIHANG UNIV

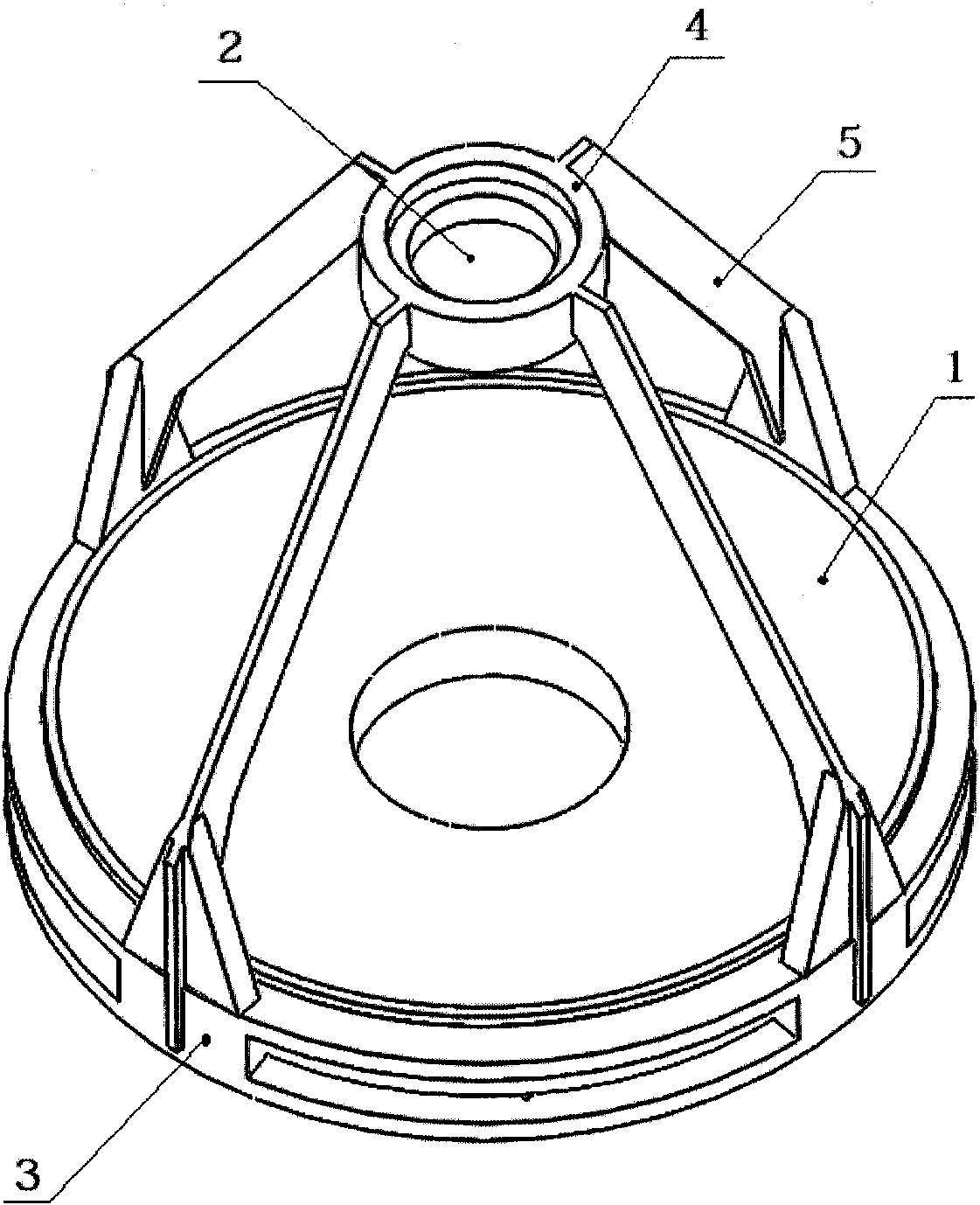

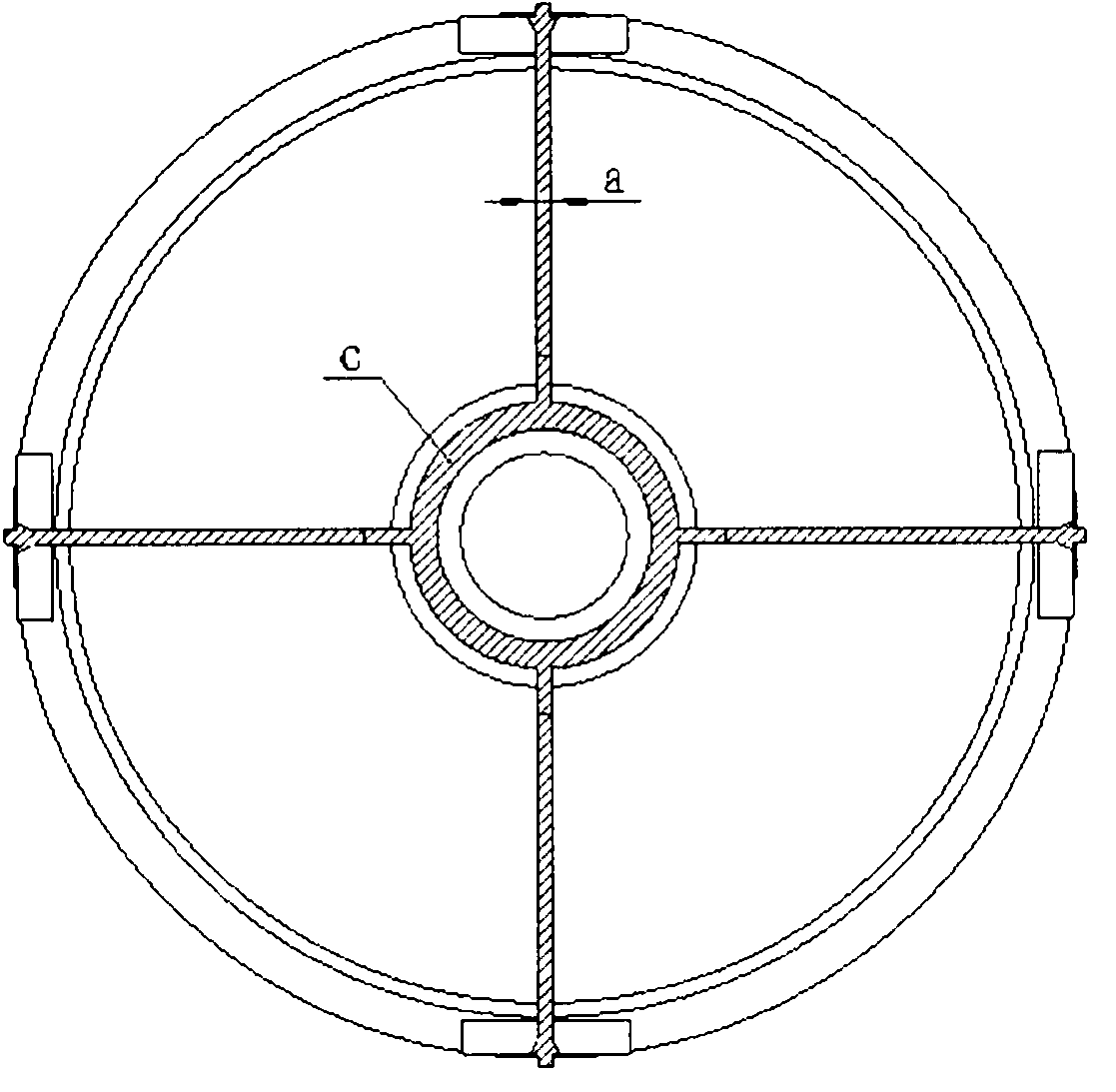

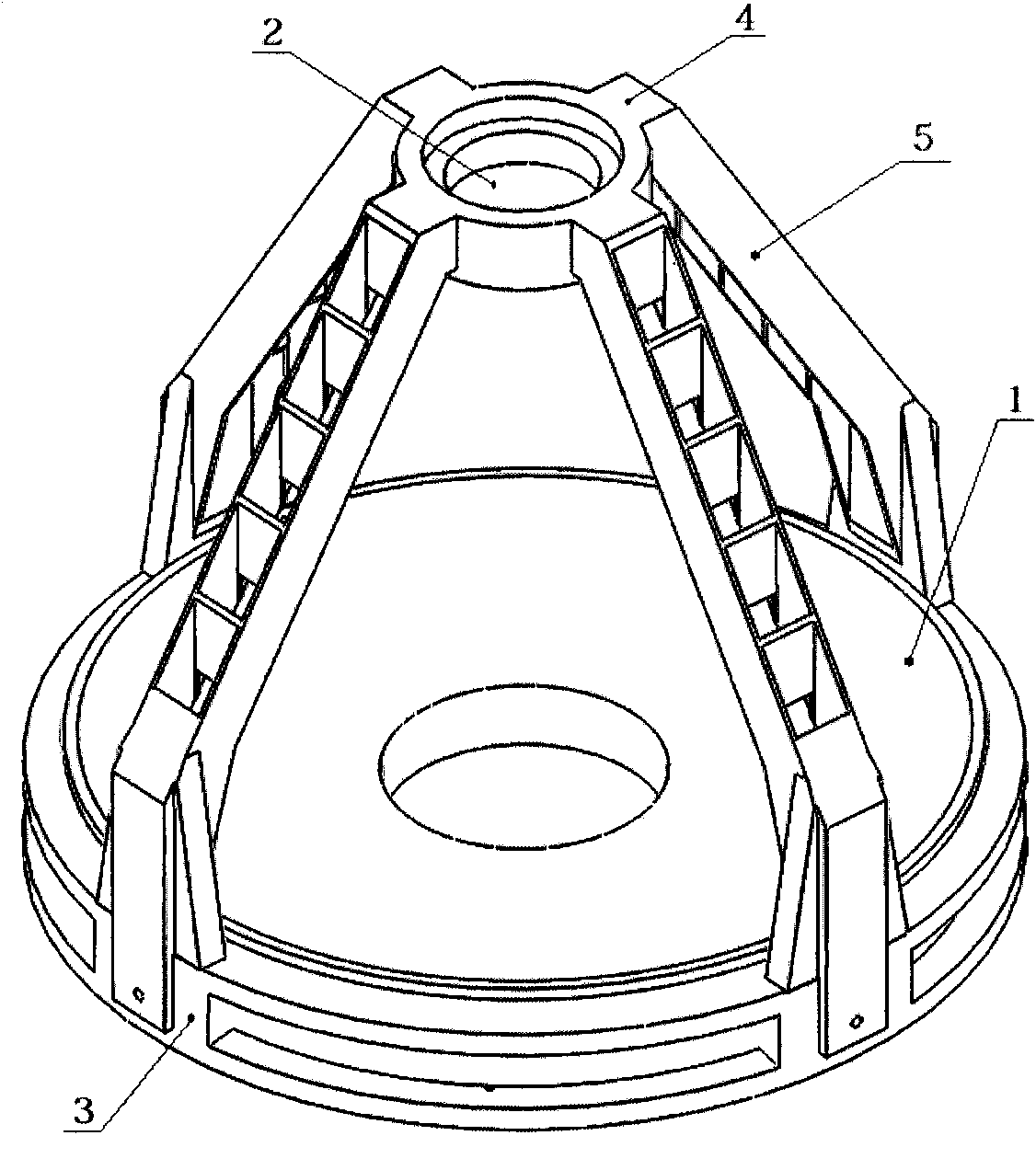

Secondary mirror support structure of space optical remote sensor

InactiveCN102162891AMeet demanding requirementsImprove structural rigidityWave based measurement systemsMountingsOptical axisSingle plate

A secondary mirror support structure of a space optical remote sensor comprises a primary mirror, a secondary mirror, a primary mirror frame, a secondary mirror frame, and secondary mirror support bars, wherein the secondary mirror frame is connected with the primary mirror frame through the secondary mirror support bars, and is parallel to the primary mirror frame; the primary mirror is fixedly mounted on the primary mirror frame; the secondary mirror is fixedly mounted on the secondary mirror frame; the primary mirror is parallel to the secondary mirror; each secondary mirror support bar includes two single plates and a plurality of stiffening ribs; both ends of the single plate are respectively connected with the secondary mirror frame and the primary mirror frame; and the stiffening ribs are arranged between the two single plates of each secondary mirror support bar. The secondary mirror support structure resolves the contradiction of small obstruction ratio, light weight and high rigidity of the support bars. Under the condition of the same obstruction ratio and the same weight, the double-plate structure provided by the invention can greatly improve the rigidity and the thermal stability of the structure in comparison to the conventional single-plate structure; and the specific manifestations are that the fundamental frequency is improved by more than one time, the deformation displacement in the optical axis direction is reduced to about 10% that of the conventional single-plate structure, and the double-plate structure has lower vibration response and less thermal deformation.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com