Aero-engine body vibration characteristic analysis method

A technology of aero-engine and vibration characteristics, applied in the direction of internal combustion engine testing, etc., can solve the problems of less joint research on the characteristics of rotating and static systems, weak engineering guidance, and poor consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

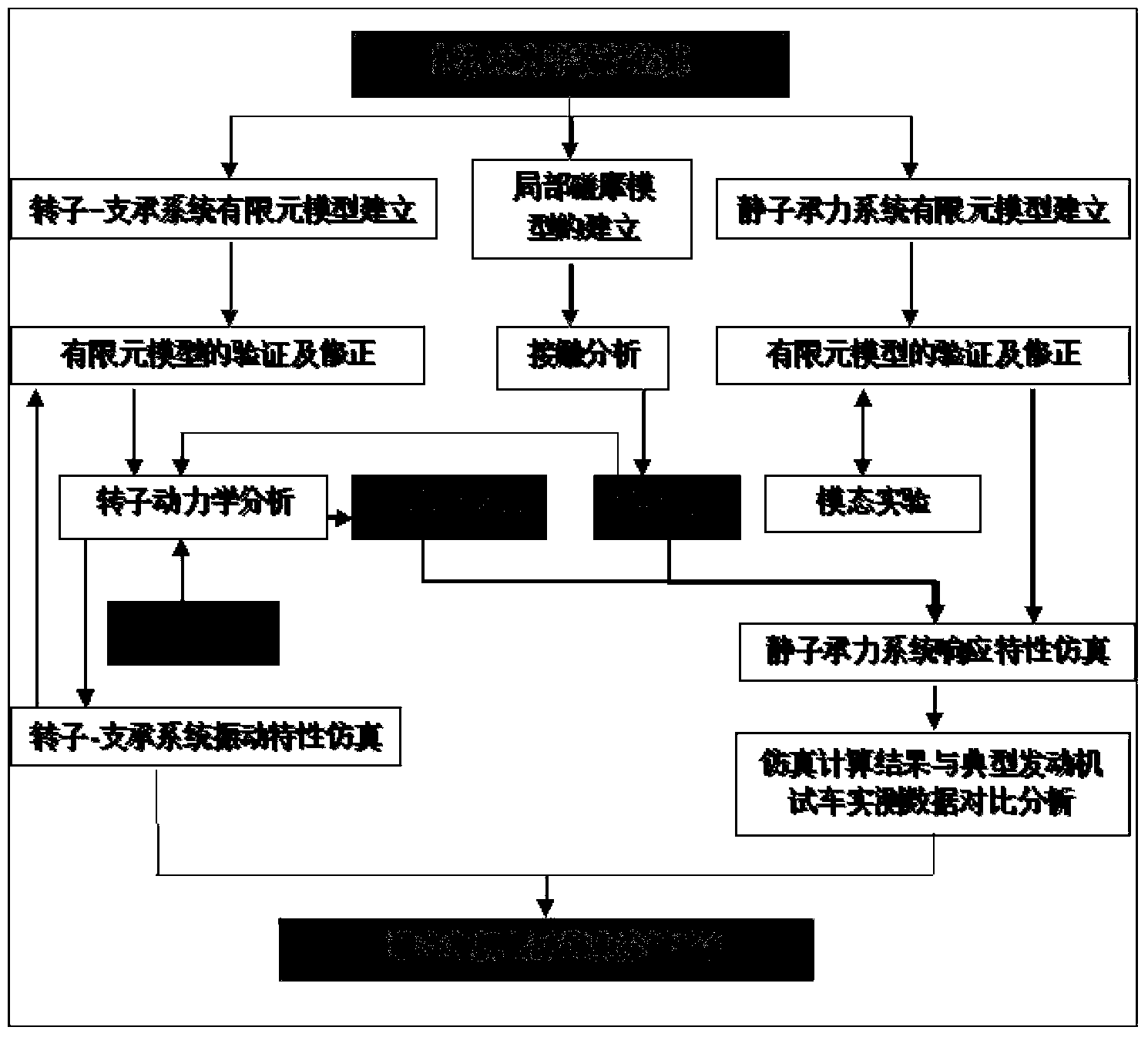

[0025] This embodiment provides a method for analyzing the vibration characteristics of a complete aircraft engine, which is characterized in that: the complete engine system is isolated into a rotor system and a stator system, the two are coupled through a fulcrum system, and the dynamic characteristics of the rotor and stator systems are used co-simulation;

[0026] Firstly, the mechanical analysis of the whole engine system is carried out. The rotor system is the vibration source, and the stator system is the response body. The vibration energy of the rotor is transmitted to the stator system through the fulcrum in the form of support reaction force, and the response of the stator system can reflect the vibration characteristics of the whole machine. Divide a complex and almost unanalyzable huge system into analyzable subsystems, and organically combine each system through dynamic characteristic co-simulation, truly reflect the actual state of the whole machine, and realize ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com