Patents

Literature

2157 results about "Vibration source" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

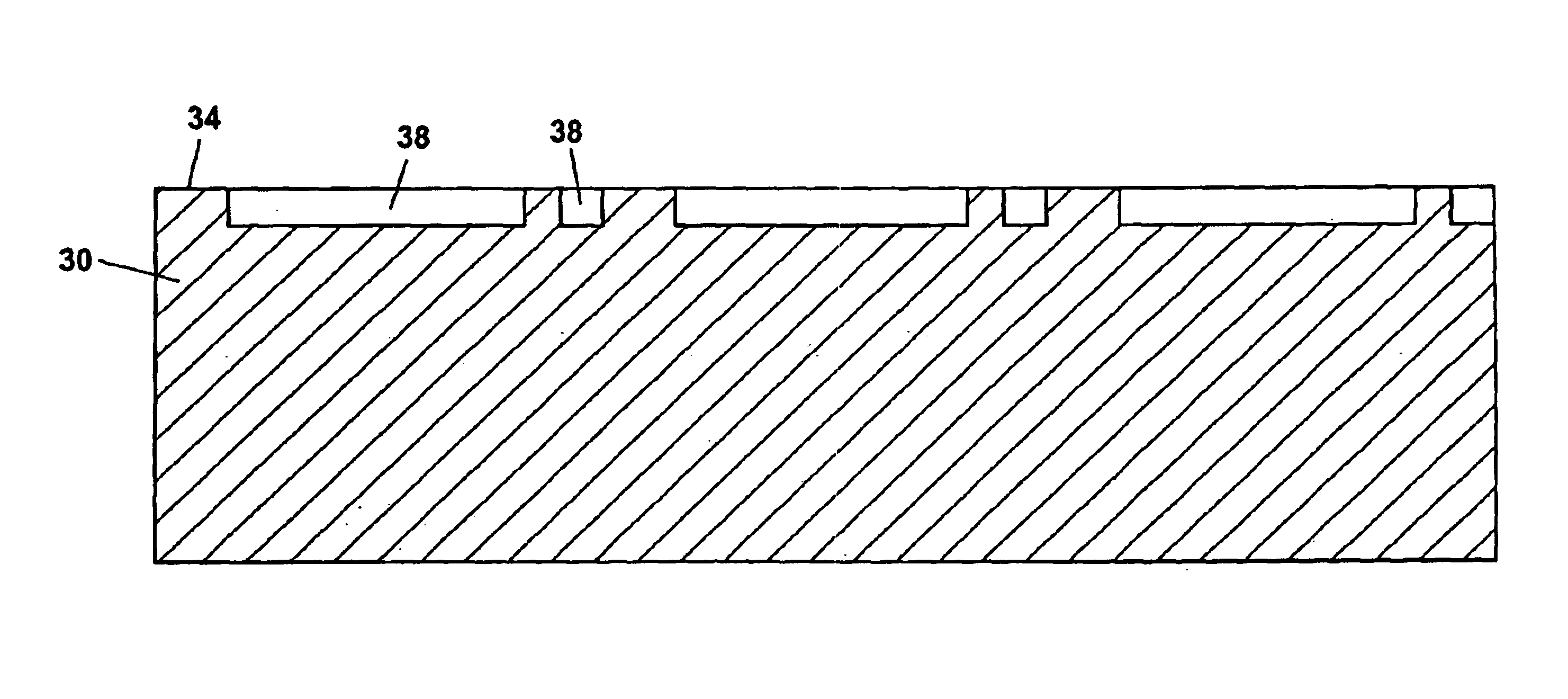

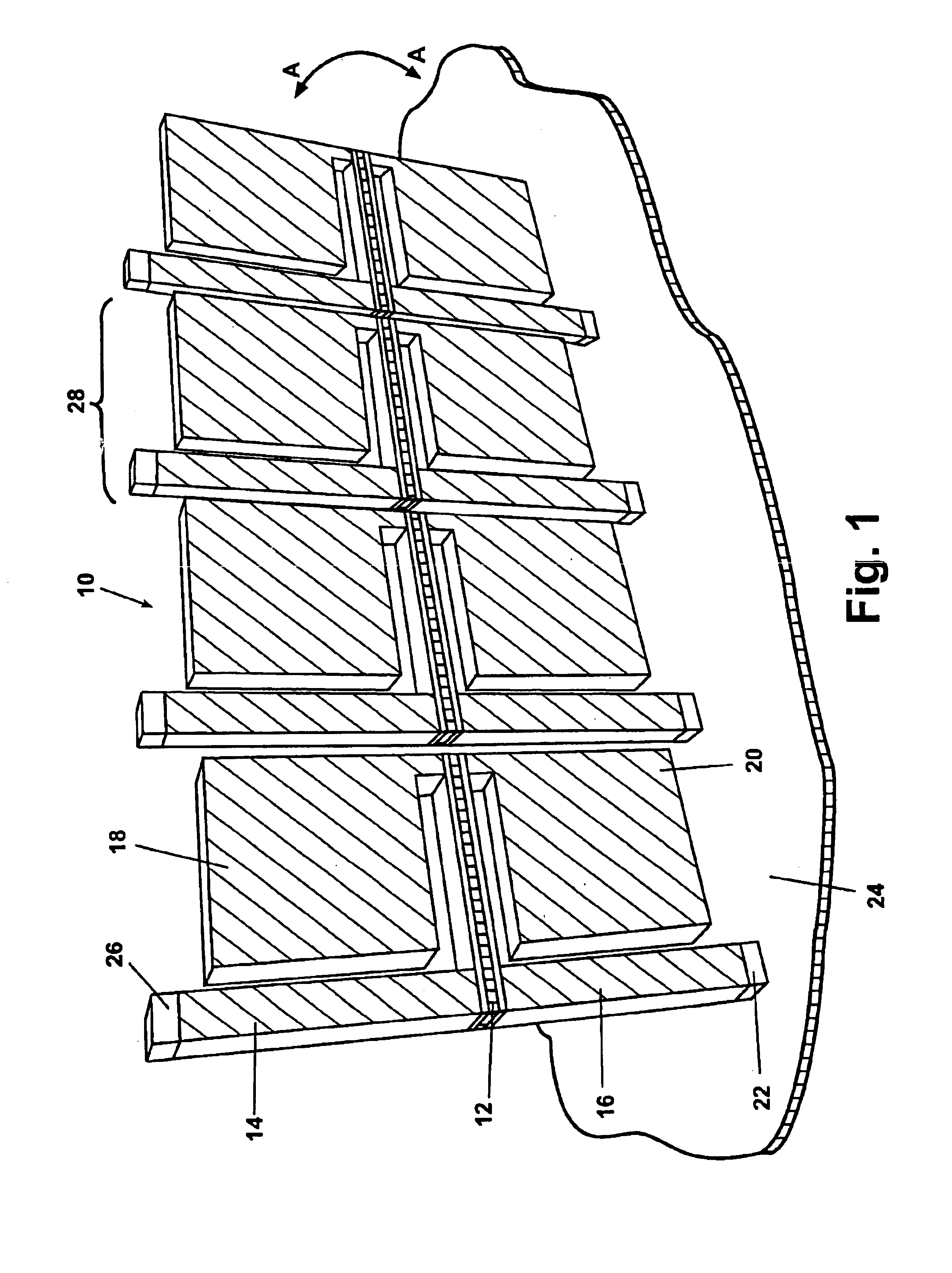

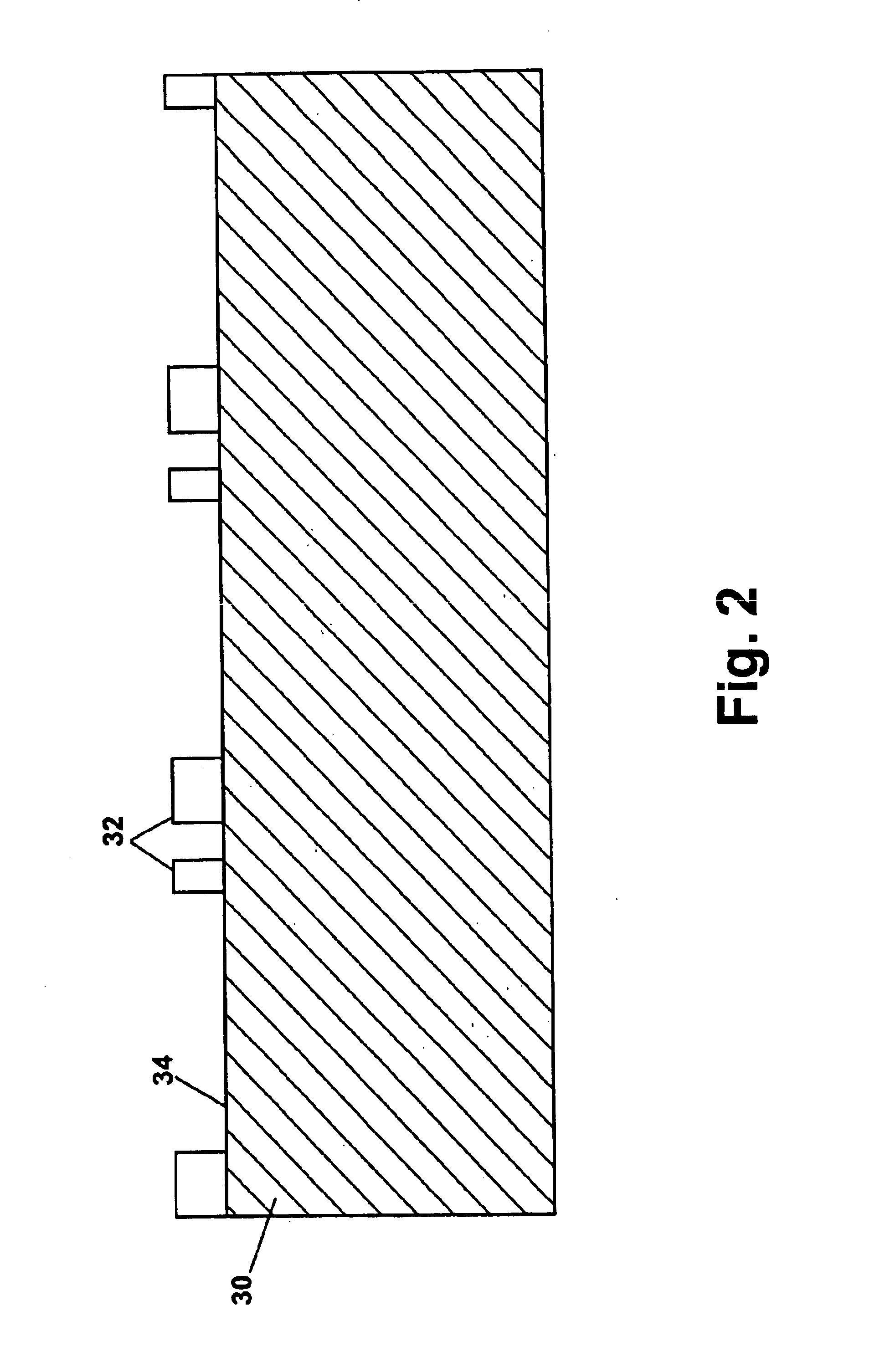

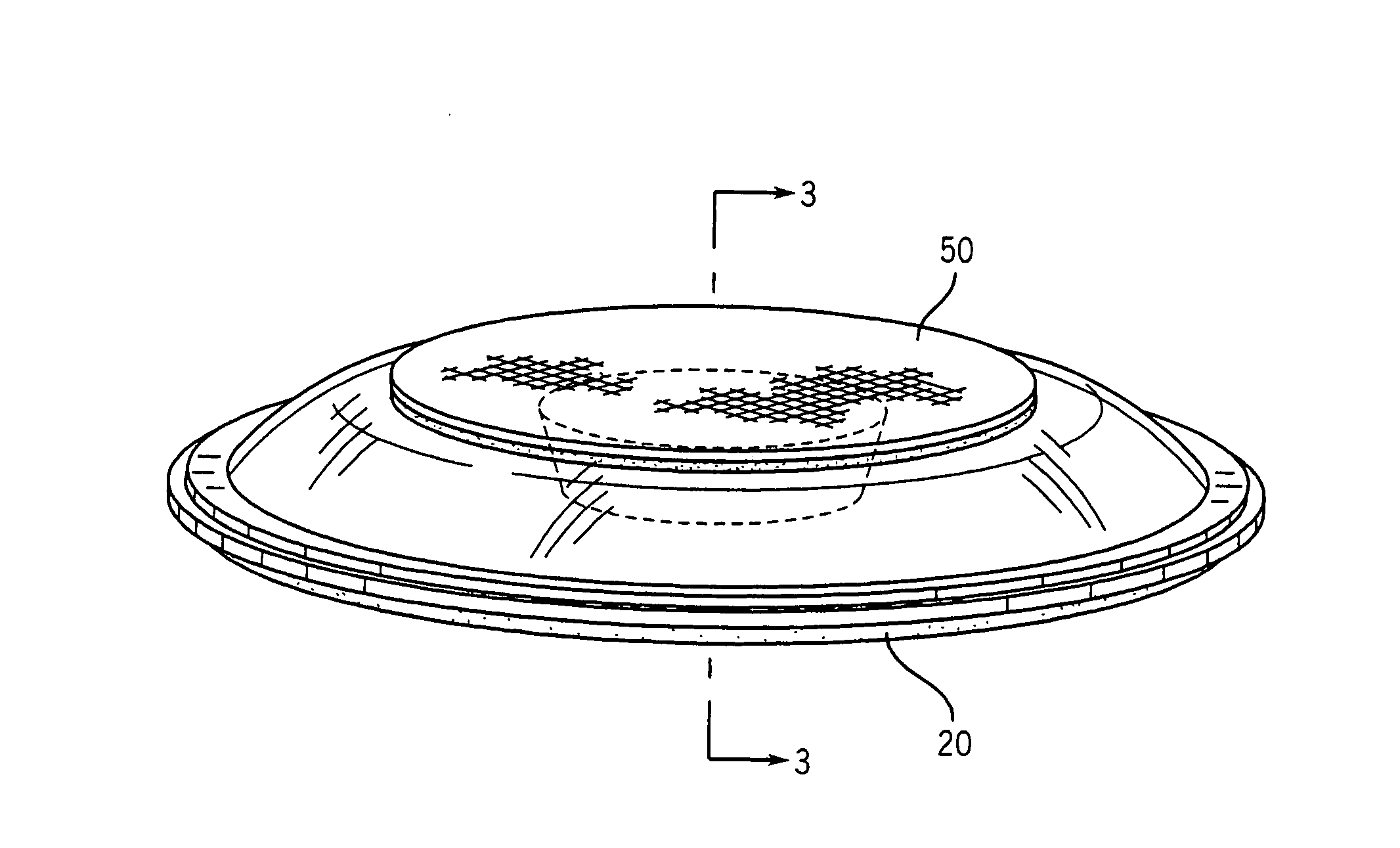

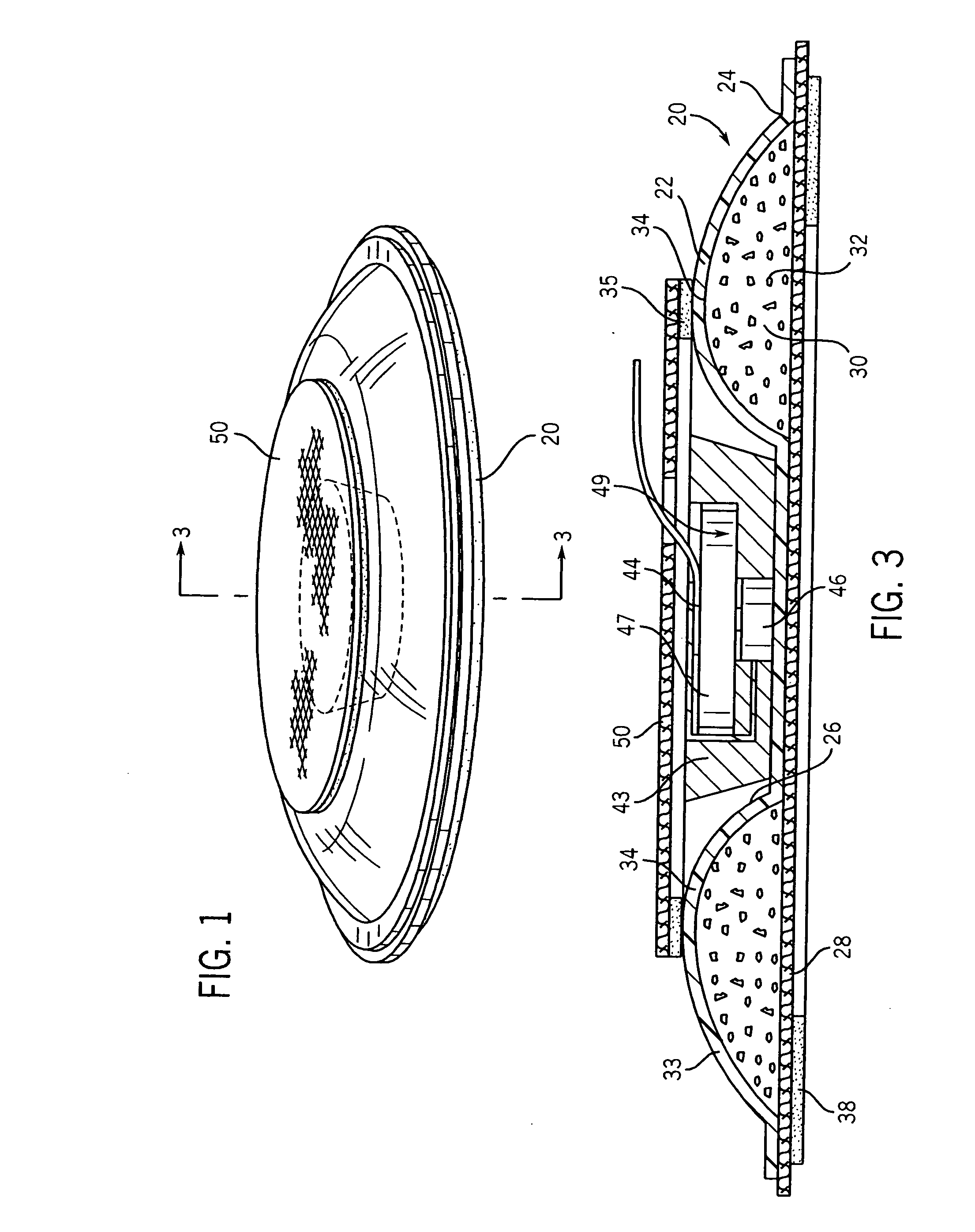

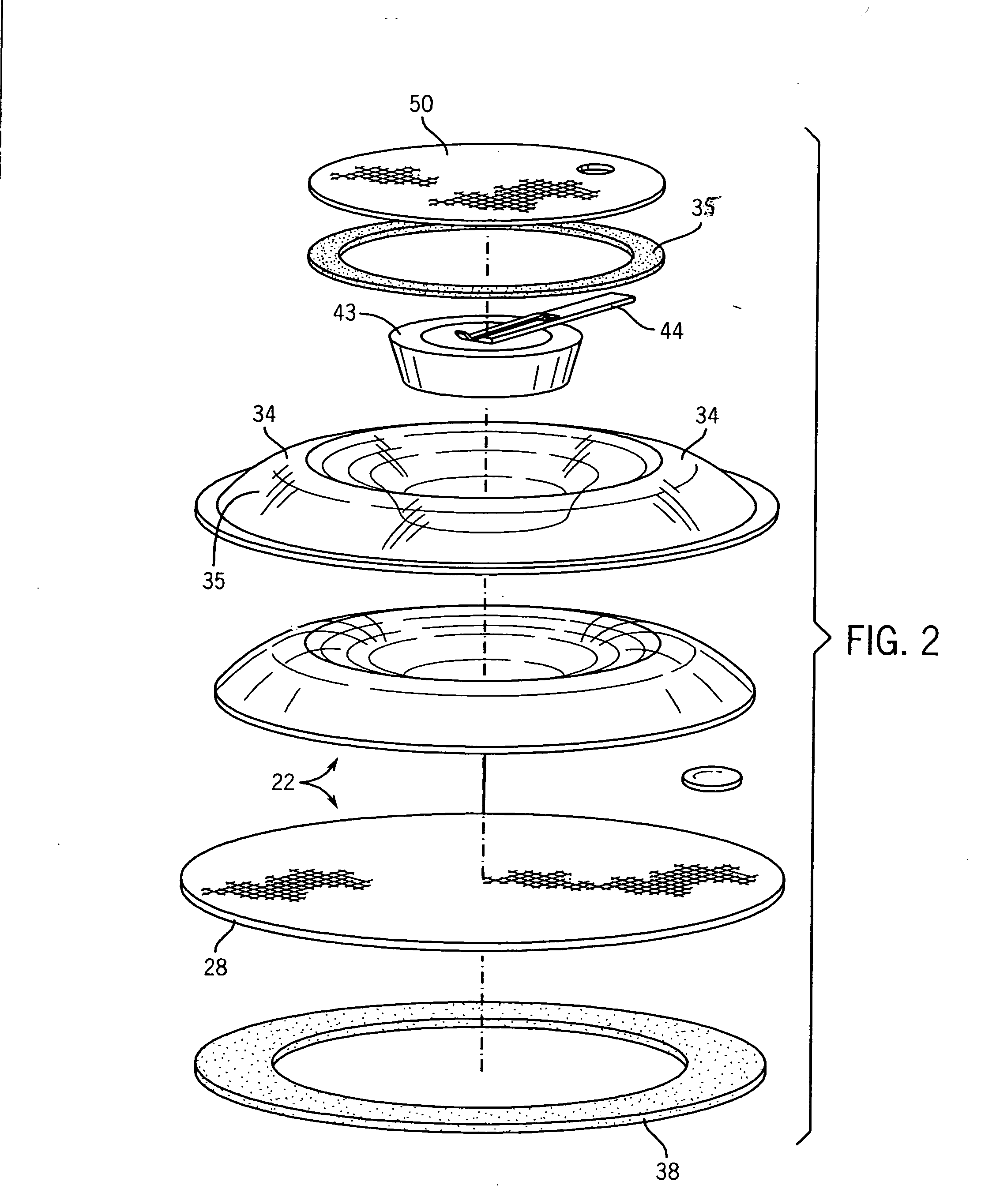

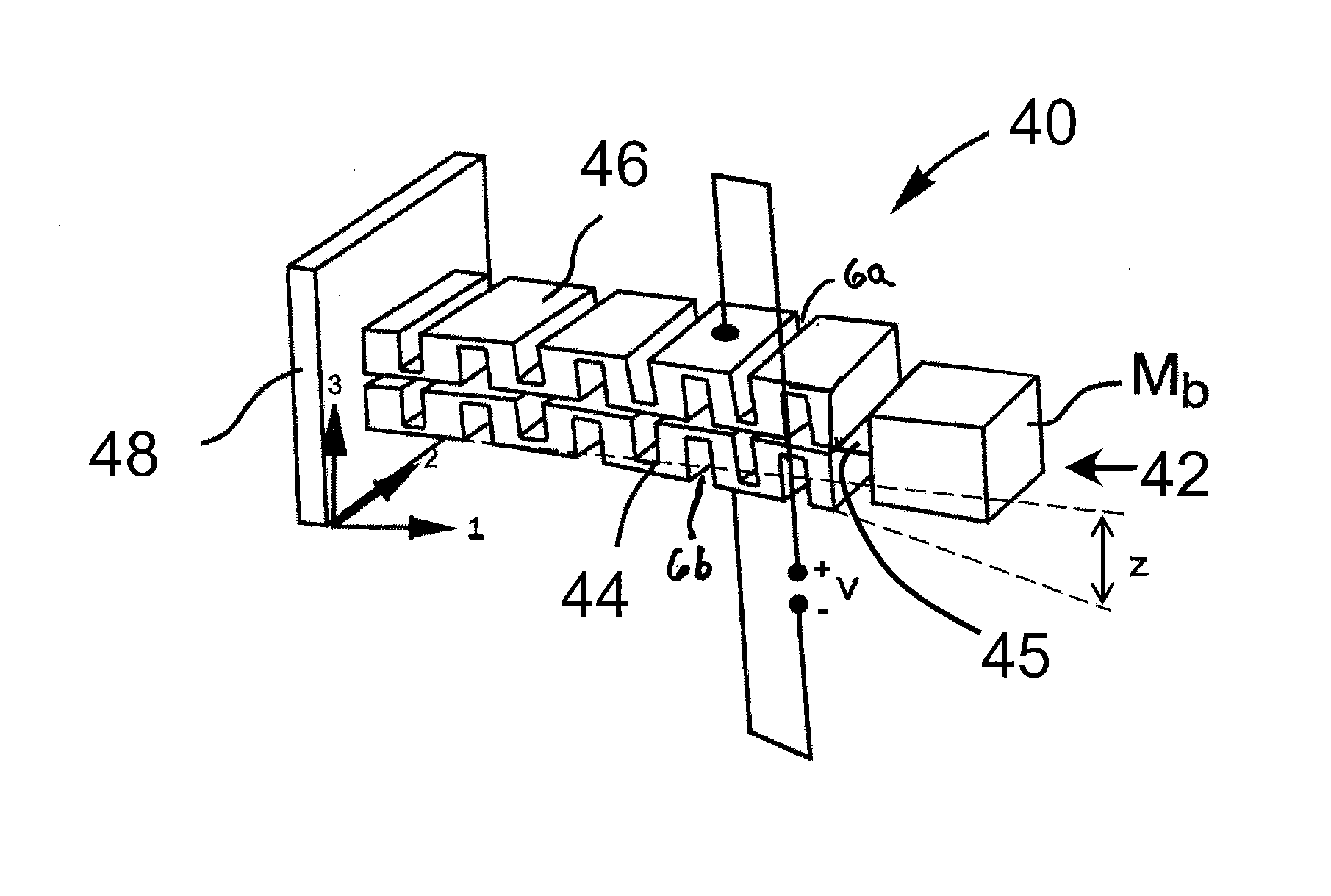

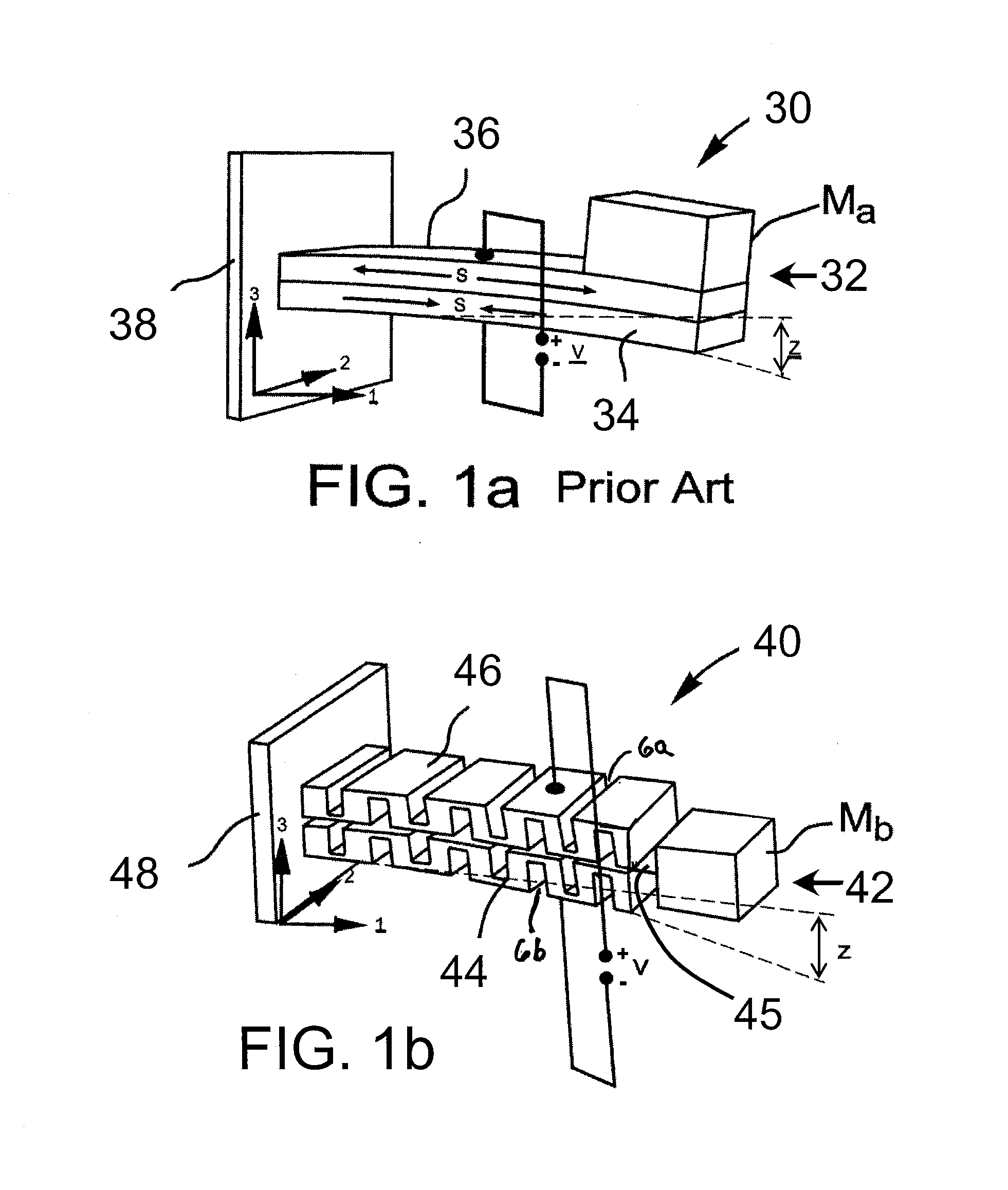

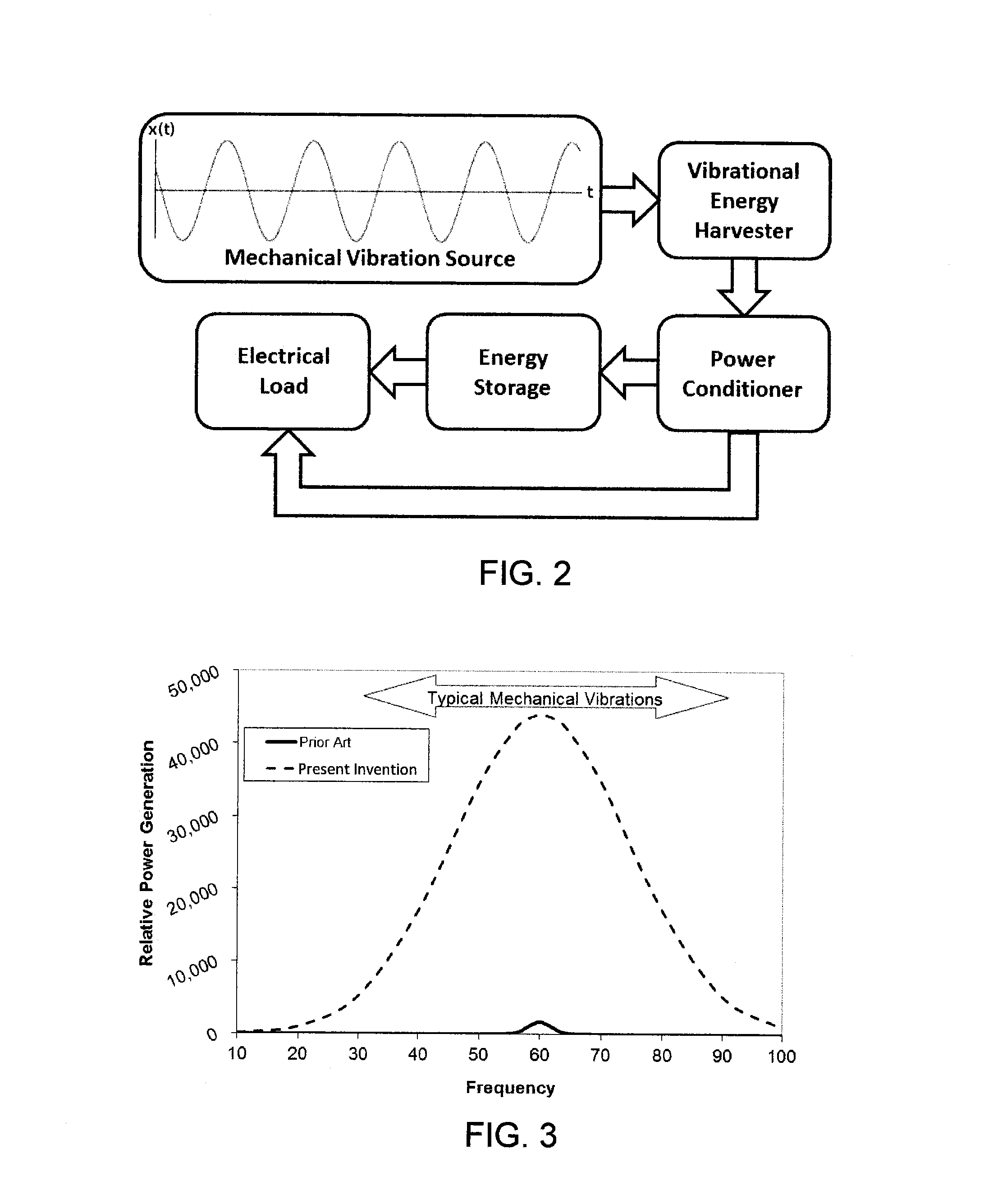

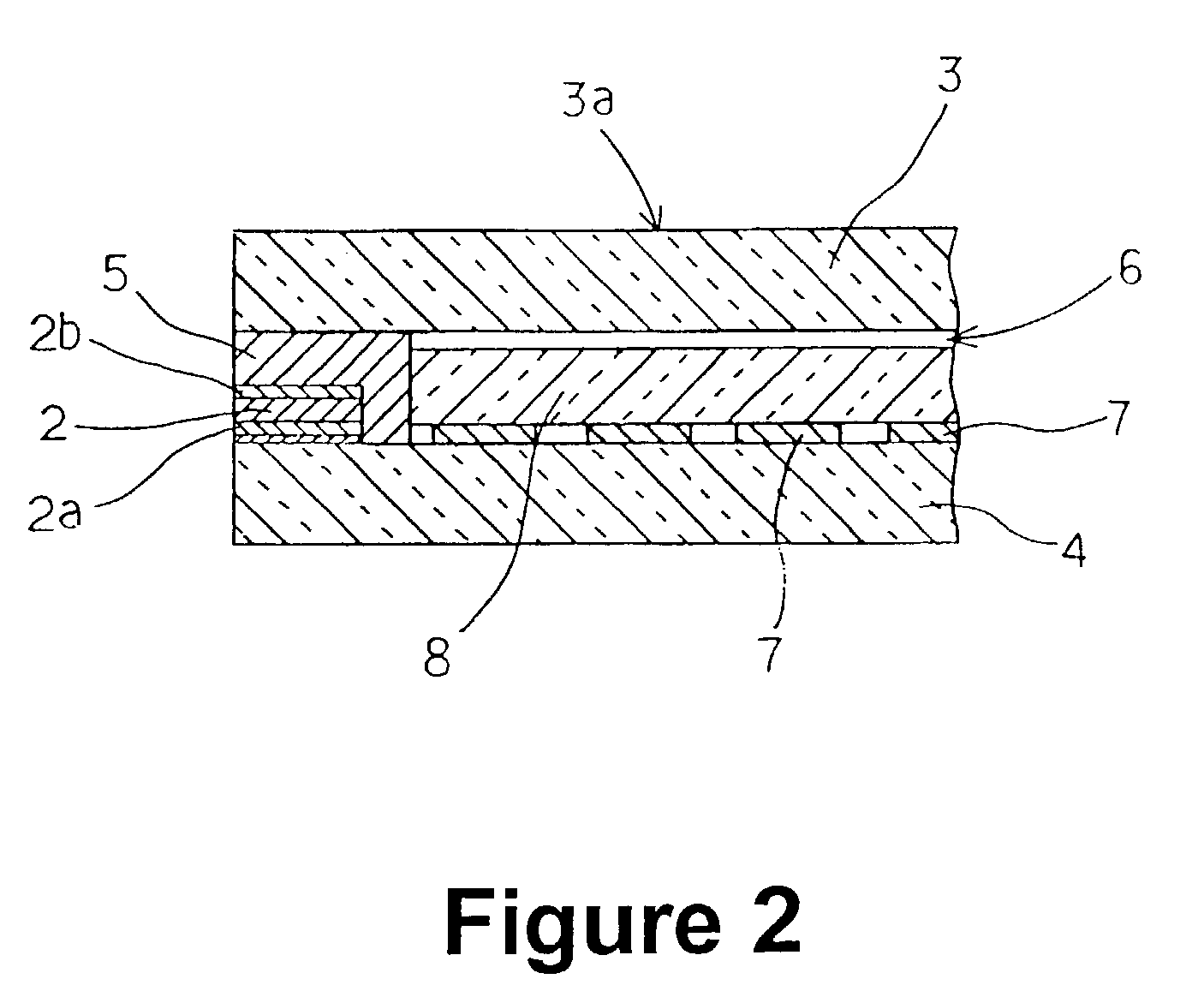

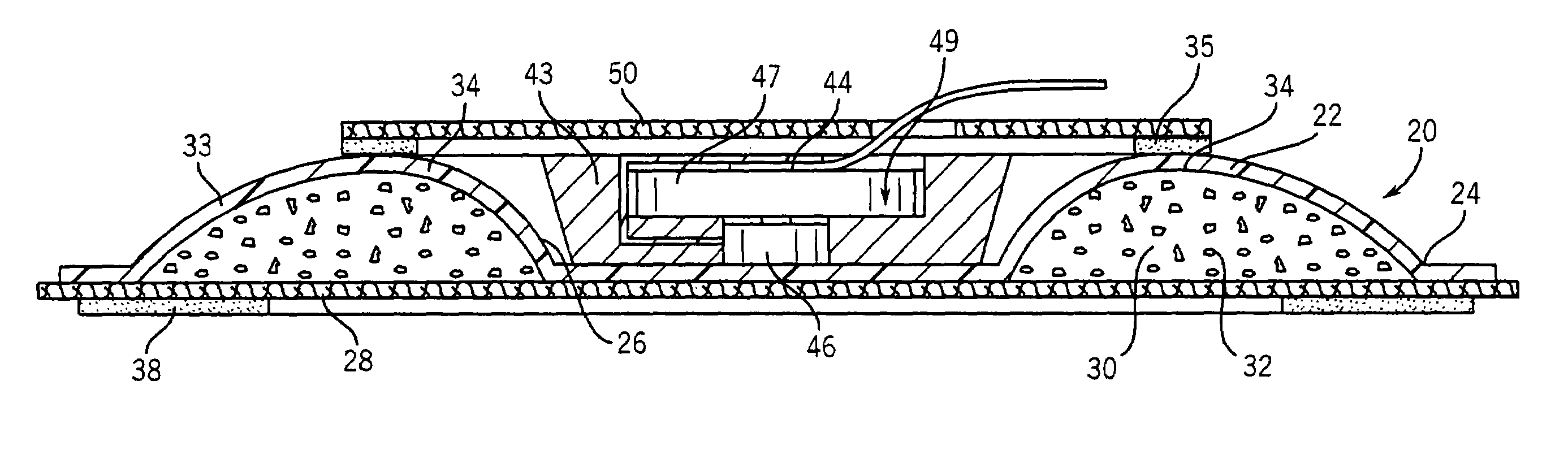

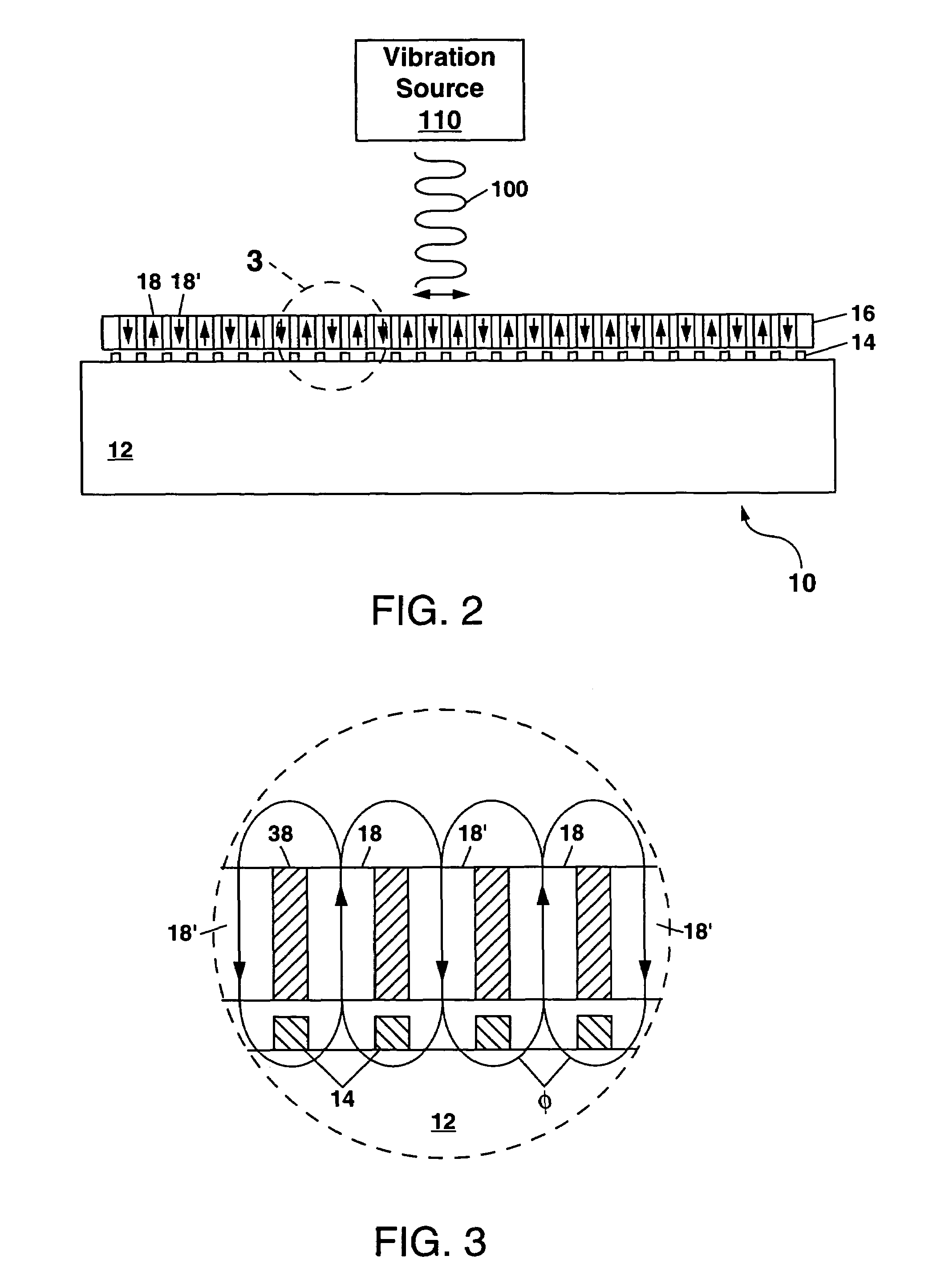

Multi-frequency piezoelectric energy harvester

InactiveUS6858970B2Maximize amount of energyPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive devicesElectricityCantilevered beam

A piezoelectric device connected to a vibration source converts vibration energy to electrical current. A plurality of pairs of oppositely polarized piezoelectric wafers deflect to produce an electrical current. Each pair of wafers are arranged back-to-back and electrically joined together. The plurality of pairs of wafers are each connected to a set of micro-machined parts. Each pair of wafers form a bimorph, configured as a cantilevered beam attached to a set of parts to form an element. Each cantilevered beam has a mass weighted first end and is fixedly attached to one or more flexible sheaths on a second end. A plurality of elements form a cell unit. A plurality of cell units form an array. The electrical current produced varies by the number of elements per cell unit, and / or with the number of cell units per array.

Owner:THE BOEING CO

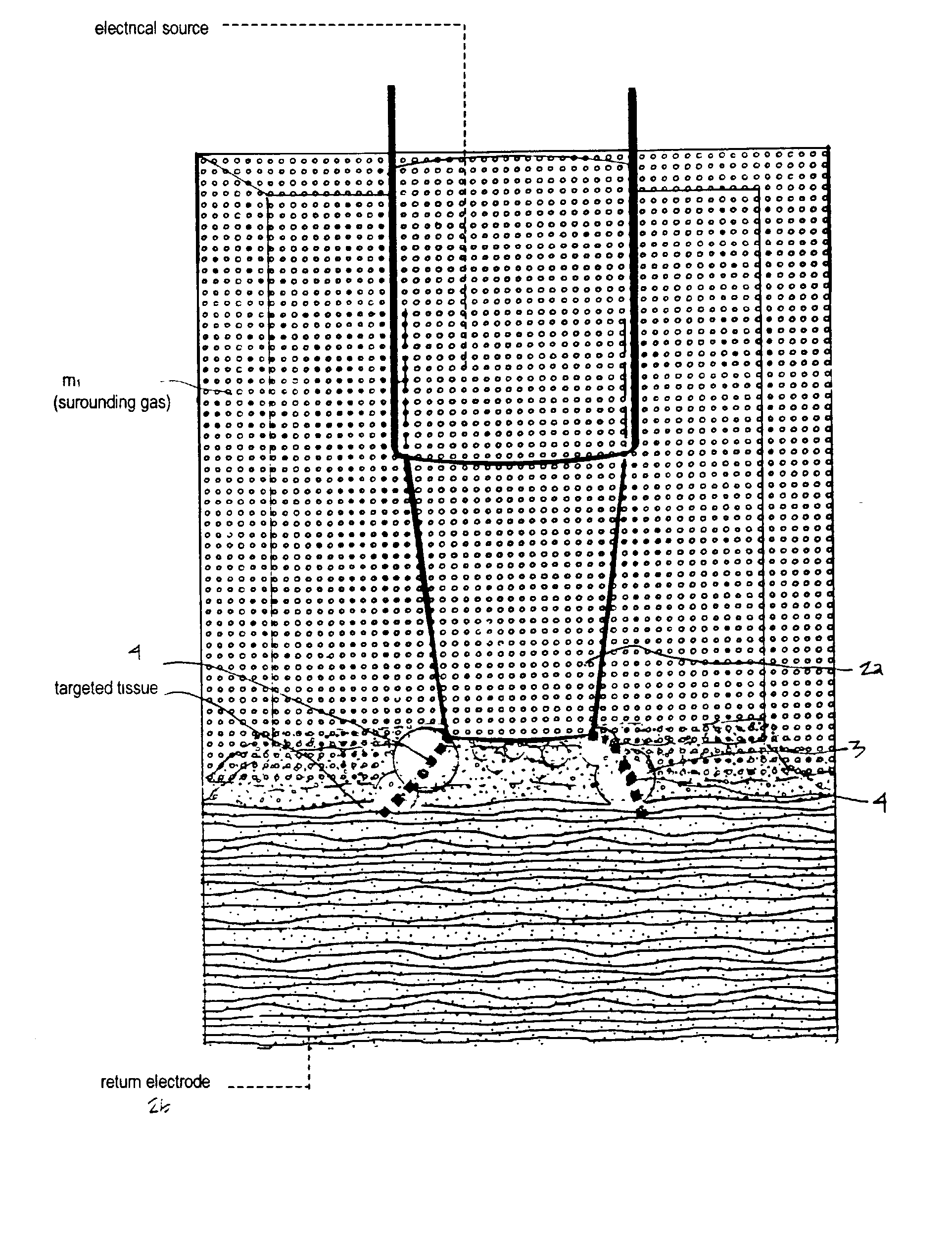

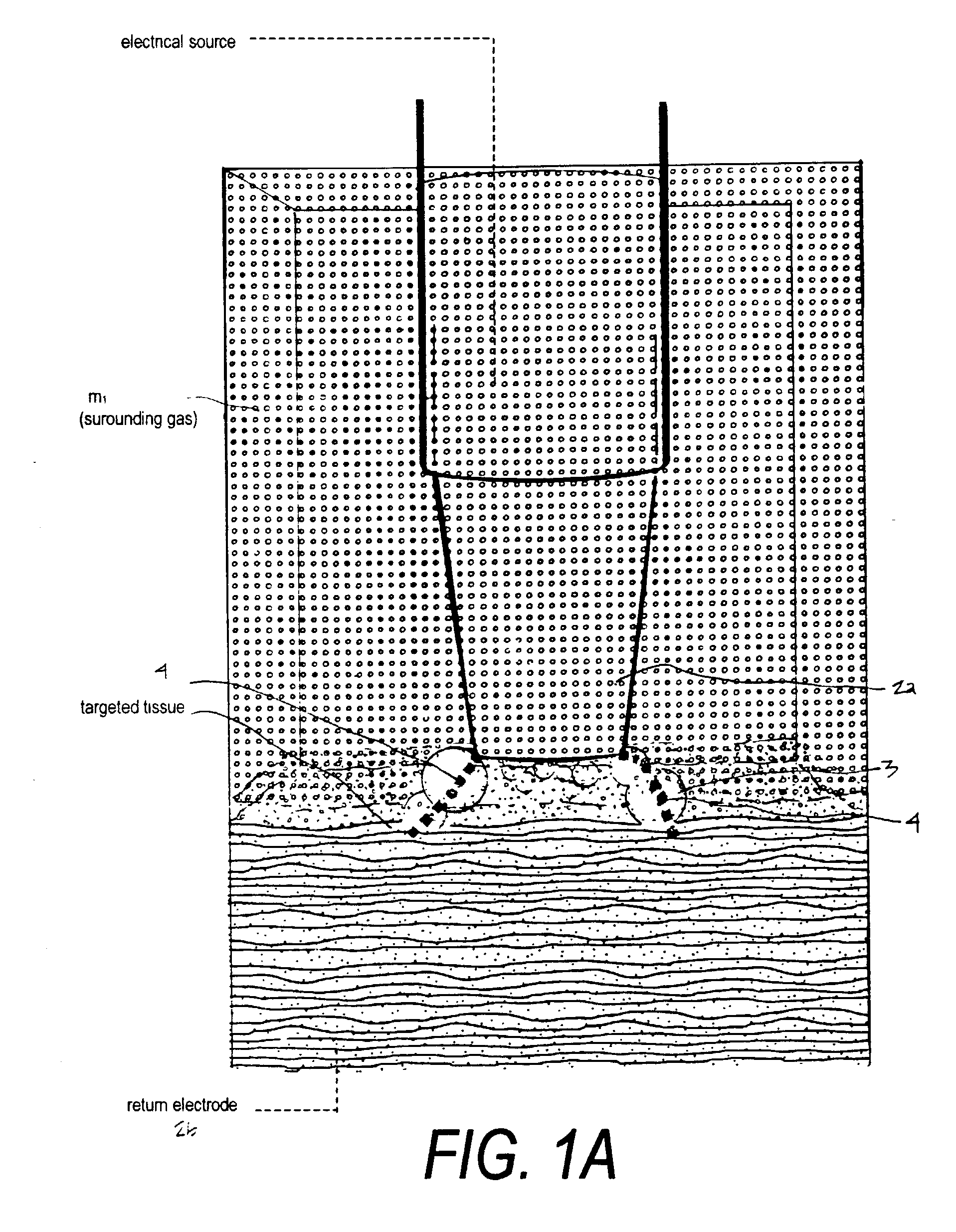

Electrical discharge devices and techniques for medical procedures

InactiveUS20030125727A1Enhance electron avalancheDiagnosticsSurgical instrument detailsTarget tissueMedical procedure

A medical instrument coupled to first and second energy means and a computer controller for the controlled volumetric removal of thin tissue layers. The system provides a source for introducing a gas to controllably form and capture transient gas volumes in a microchannel structure at the working surface of the instrument that interfaces with a targeted tissue site. Each of the microchannel features of the working surface carries an electrode element coupled to the electrical source. The energy may be applied to the targeted site in either of two modes of operation, depending in part on voltage and repetition rate of energy delivery. In one mode of energy application, electrical potential is selected to cause an intense electrical arc across the transient ionized gas volumes to cause an energy-tissue interaction characterized by tissue vaporization. In another preferred mode of energy delivery, the system applies selected levels of energy to the targeted site by means of an energetic plasma at the instrument working surface to cause molecular volatilization of surface macromolecules thus resulting in material removal. Both modes of operation limit collateral thermal damage to tissue volumes adjacent to the targeted site. Another preferred embodiment provides and an ultrasound source or other vibrational source coupled to the working end to cause cavitation in fluid about the working end.

Owner:RELIGN CORP

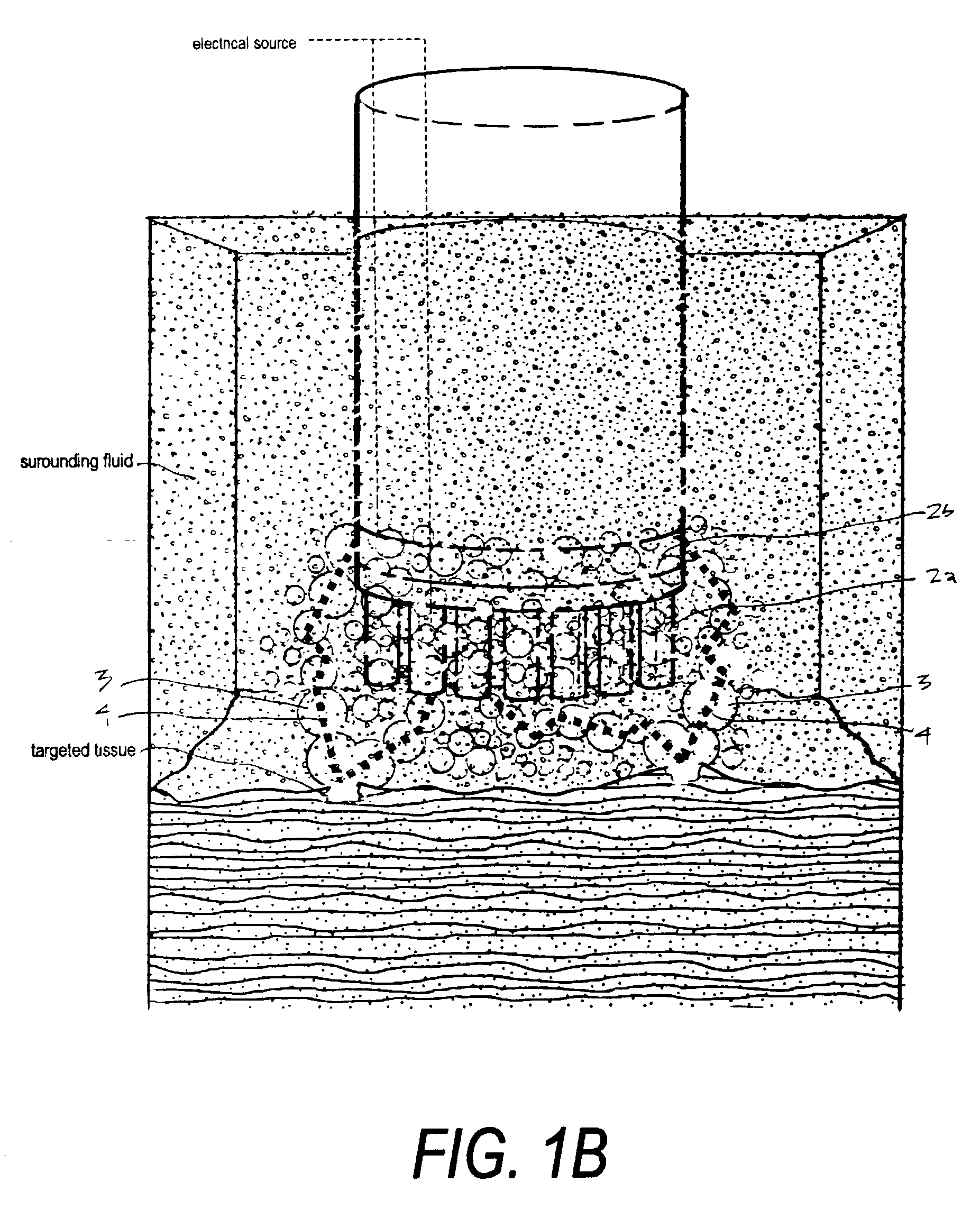

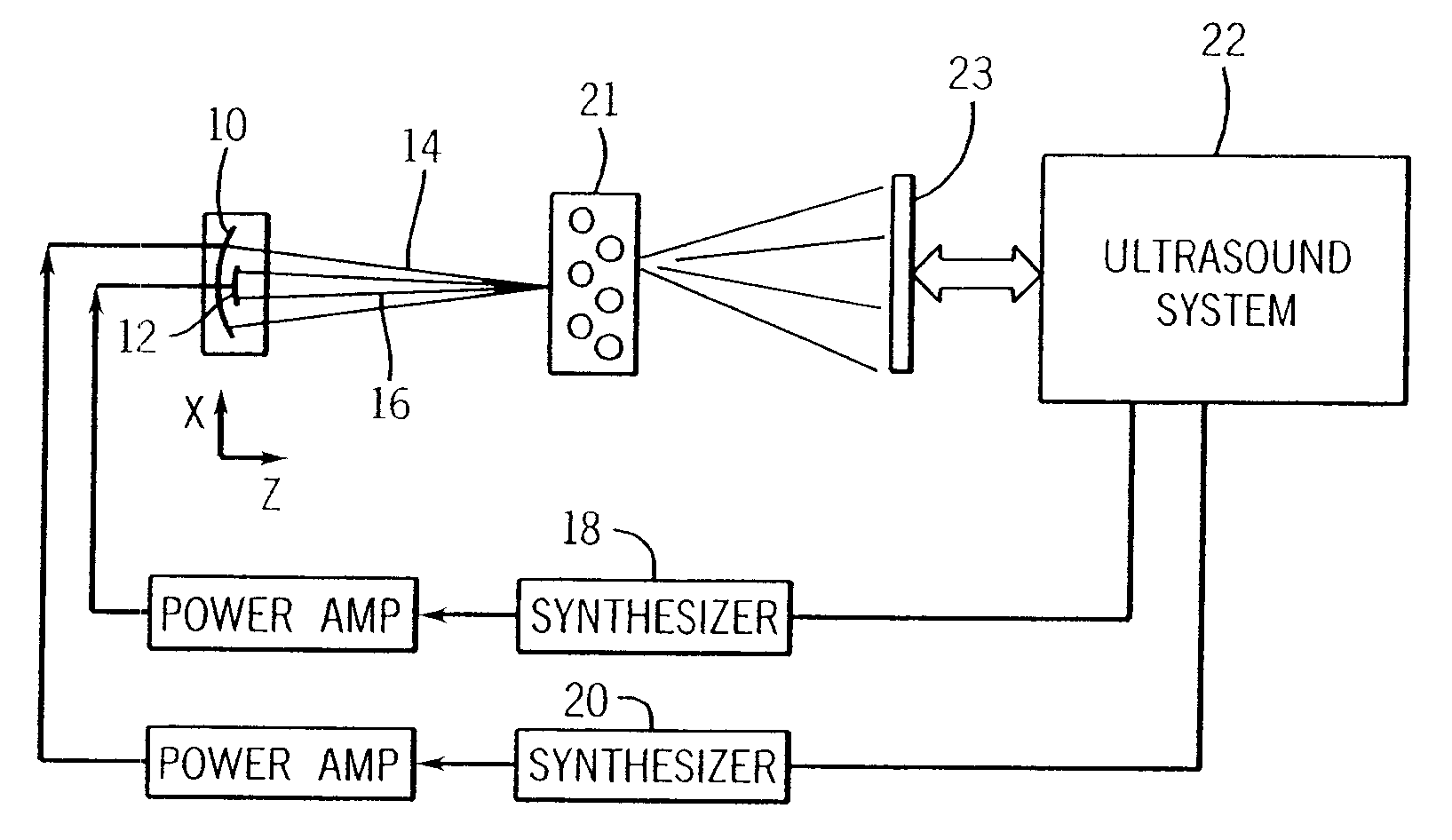

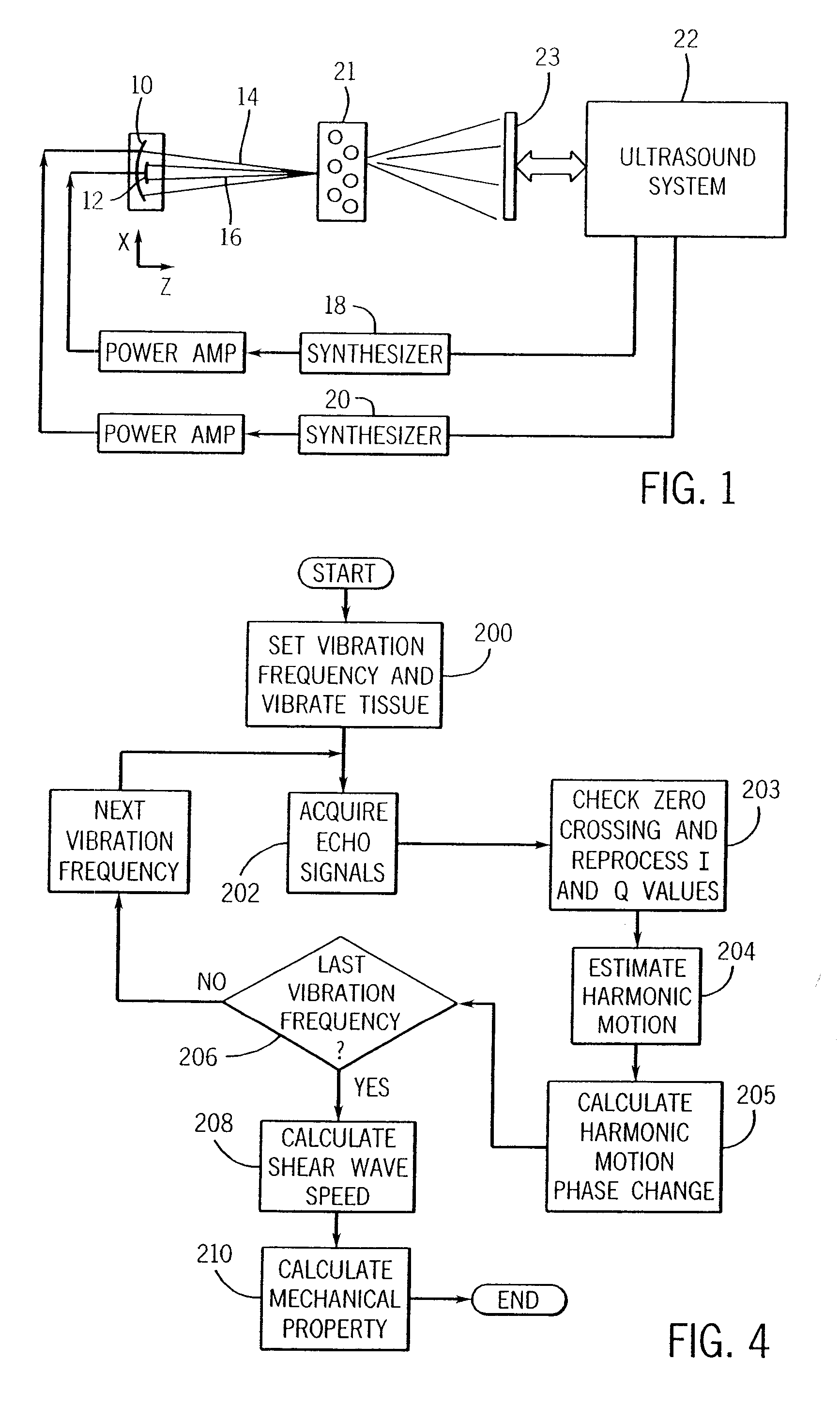

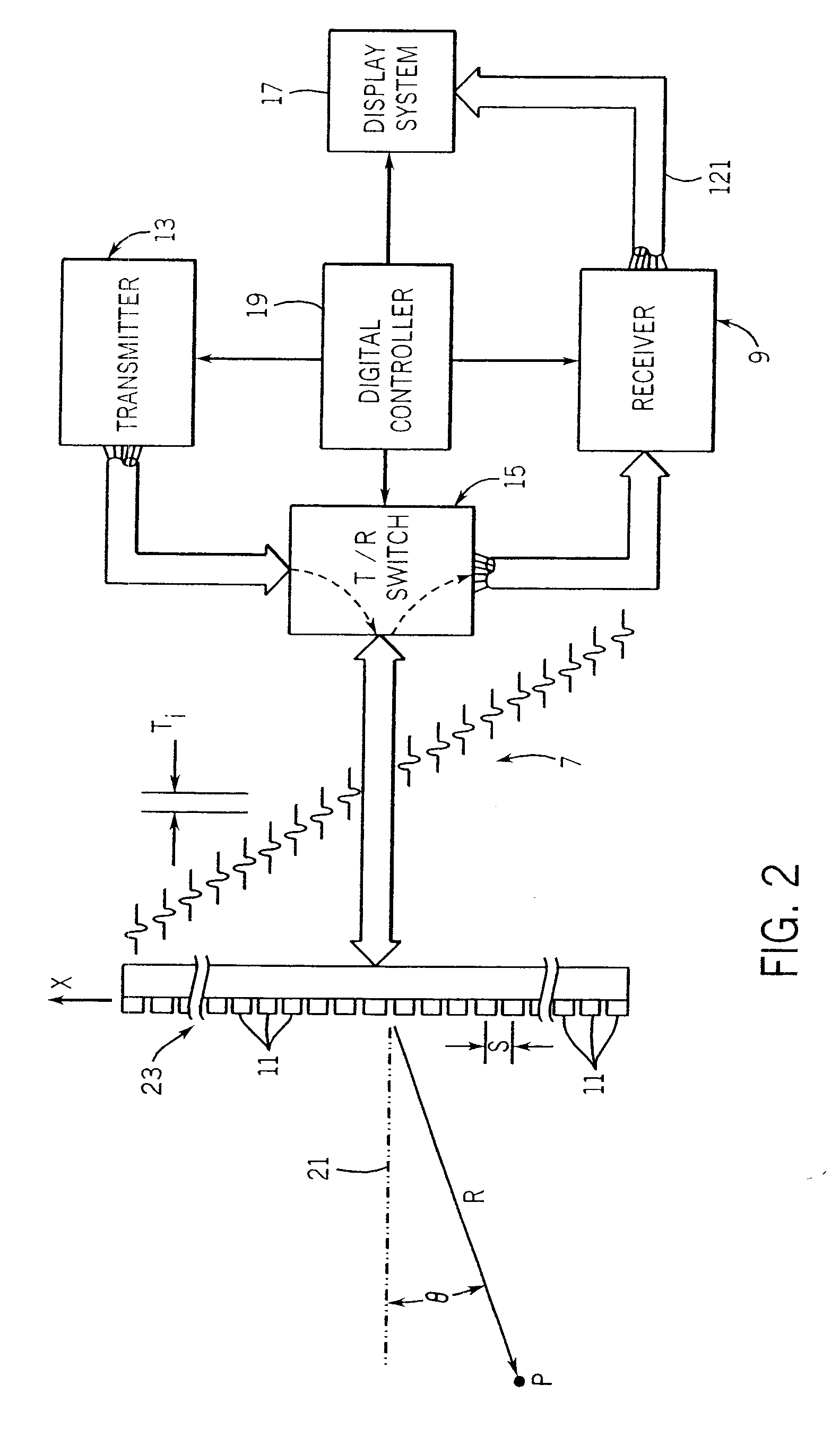

Ultrasound vibrometry

ActiveUS20070038095A1Vibration measurement in solidsUltrasonic/sonic/infrasonic diagnosticsSonificationMechanical property

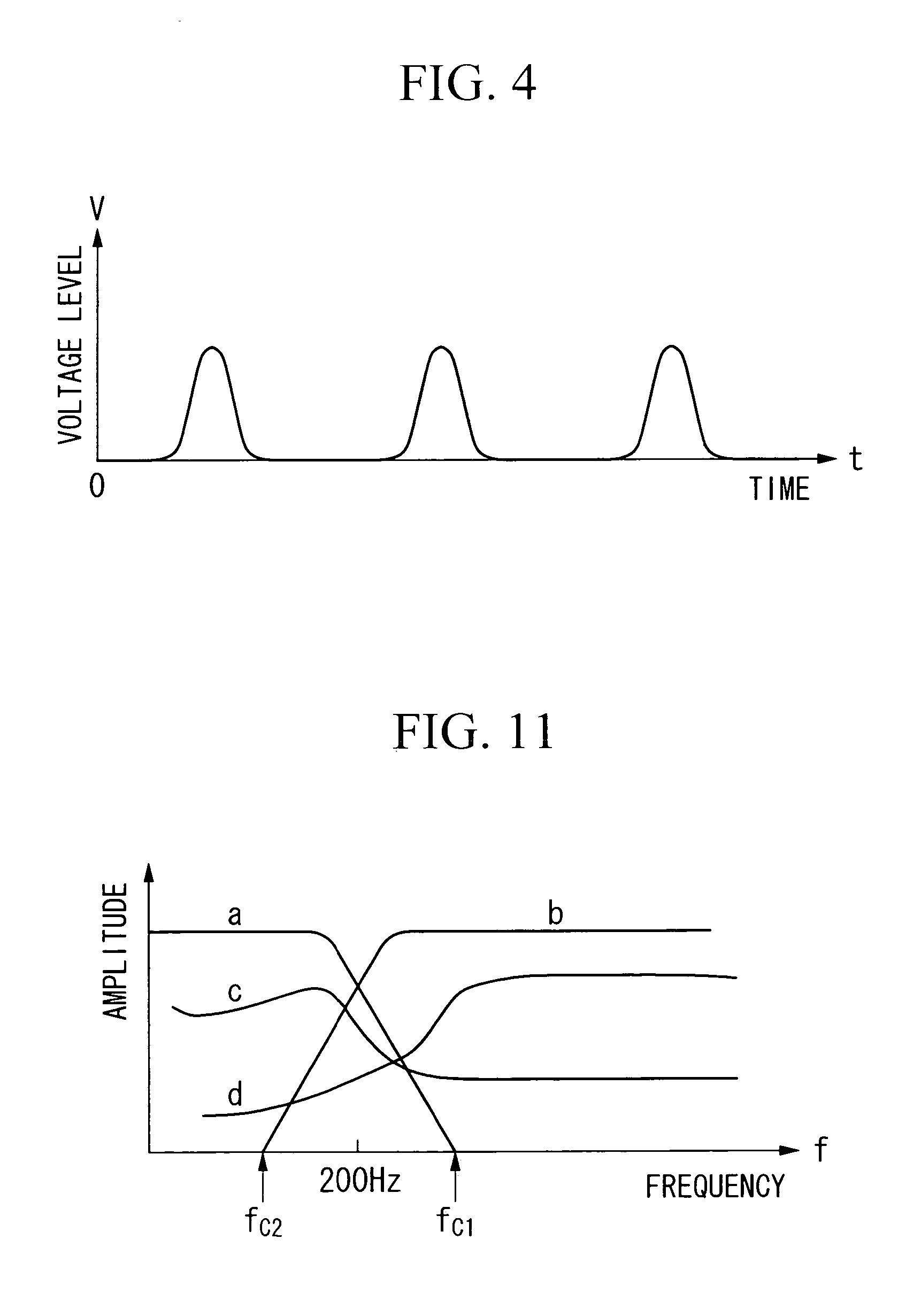

A method for measuring a mechanical property of a subject includes using an ultrasonic transducer to apply ultrasonic vibration pulses to a vibration origin in the subject in an on-off time sequence in order to impart a harmonic motion at a prescribed frequency to the subject, and when the vibration pulses are off, using the same transducer to apply ultrasonic detection pulses to a motion detection point and to receive echo signals therefrom in order to sense the harmonic motion on the subject at the motion detection point. From the harmonic signal information, a harmonic signal is detected and a characteristic such as amplitude or phase of the detected harmonic signal is measured. The mechanical property is calculated using the measured characteristic using for example a wave speed dispersion method.

Owner:MAYO FOUND FOR MEDICAL EDUCATION & RES

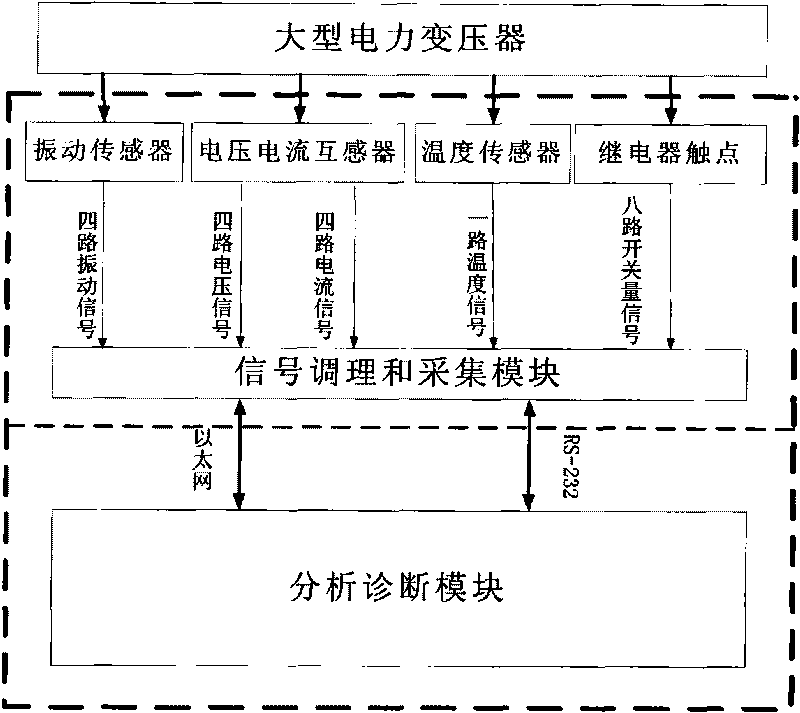

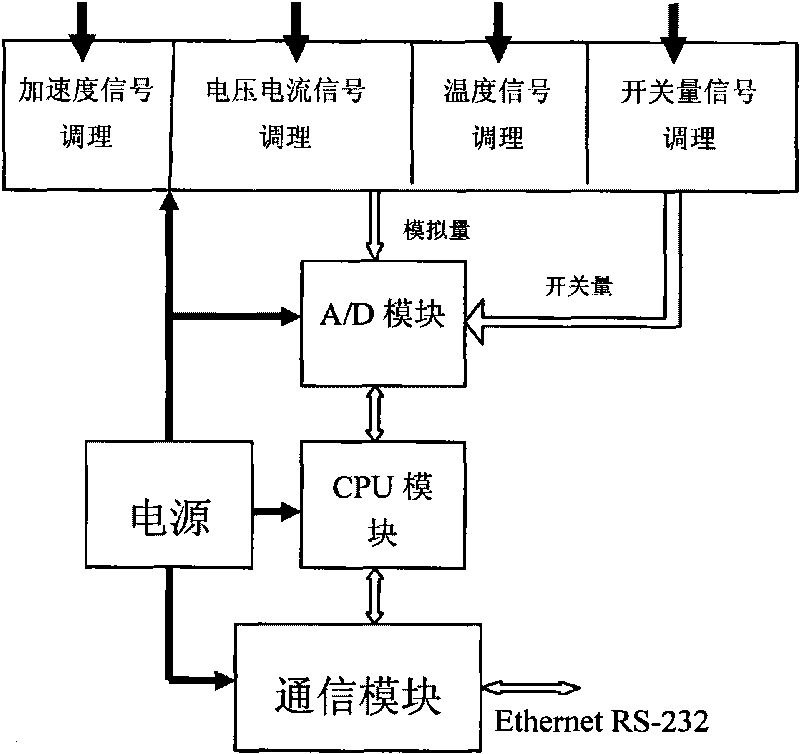

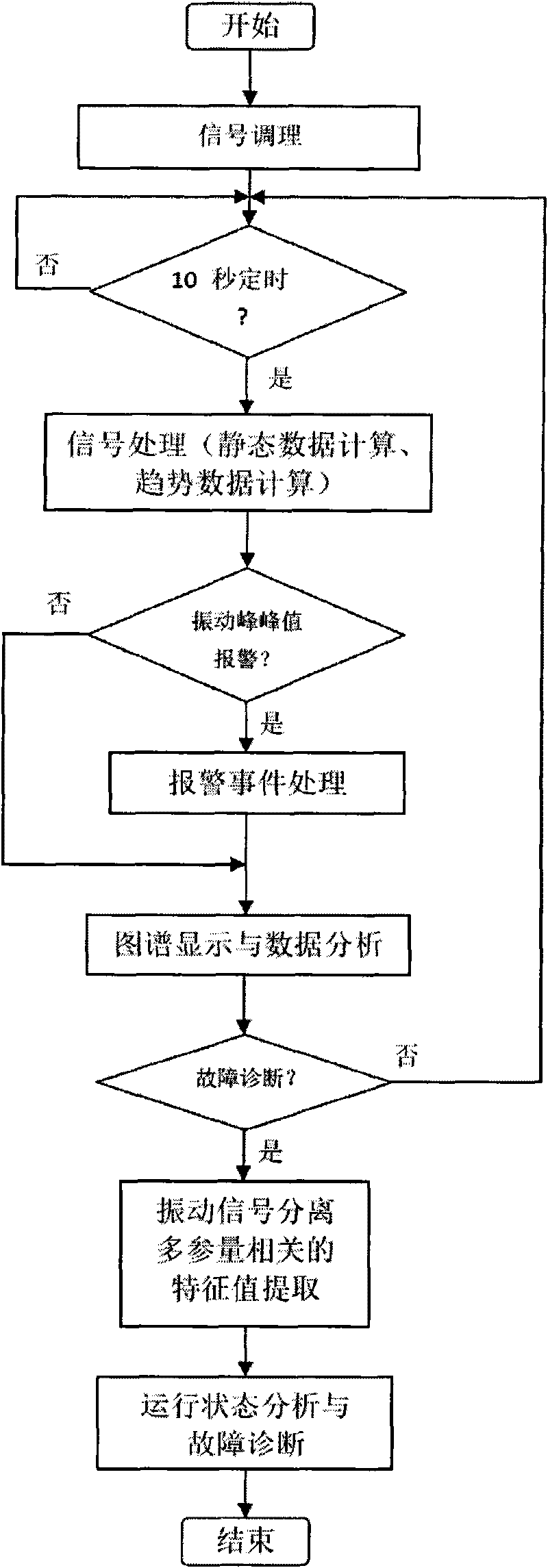

Methods for vibration online monitoring and fault diagnosis of power transformer

InactiveCN101709995ASafe and stable operationImprove accuracyThermometer detailsSubsonic/sonic/ultrasonic wave measurementSignal conditioningEngineering

The invention discloses a method for vibration online monitoring and fault diagnosis of a power transformer. The surface vibration of an oil tank of a transformer, the voltage, the current and the oil temperature of the transformer, and the switching values reflecting the on-states of a vibration source fan and the oil tank of the transformer are taken as basic monitoring parameters to be monitored; after signal conditioning is performed on the monitoring parameters, continuous synchronous waveform data sampling, processing and saving are performed; then the processed waveform data are continuously displayed in real time; signal decomposition, multi-parameter correlation analysis and characteristic vector magnitude extraction are performed on the waveform data; and then various characteristic vector thresholds of a specific transformer are compared to analyze and diagnose the operating state and the fault of the transformer. With the method, the operating state of the power transformer can be monitored in real time, and early warning as well as the analysis and the diagnosis of the fault condition of the transformer are provided, thus guaranteeing the secure and stable operation of the transformer.

Owner:ZHEJIANG UNIV

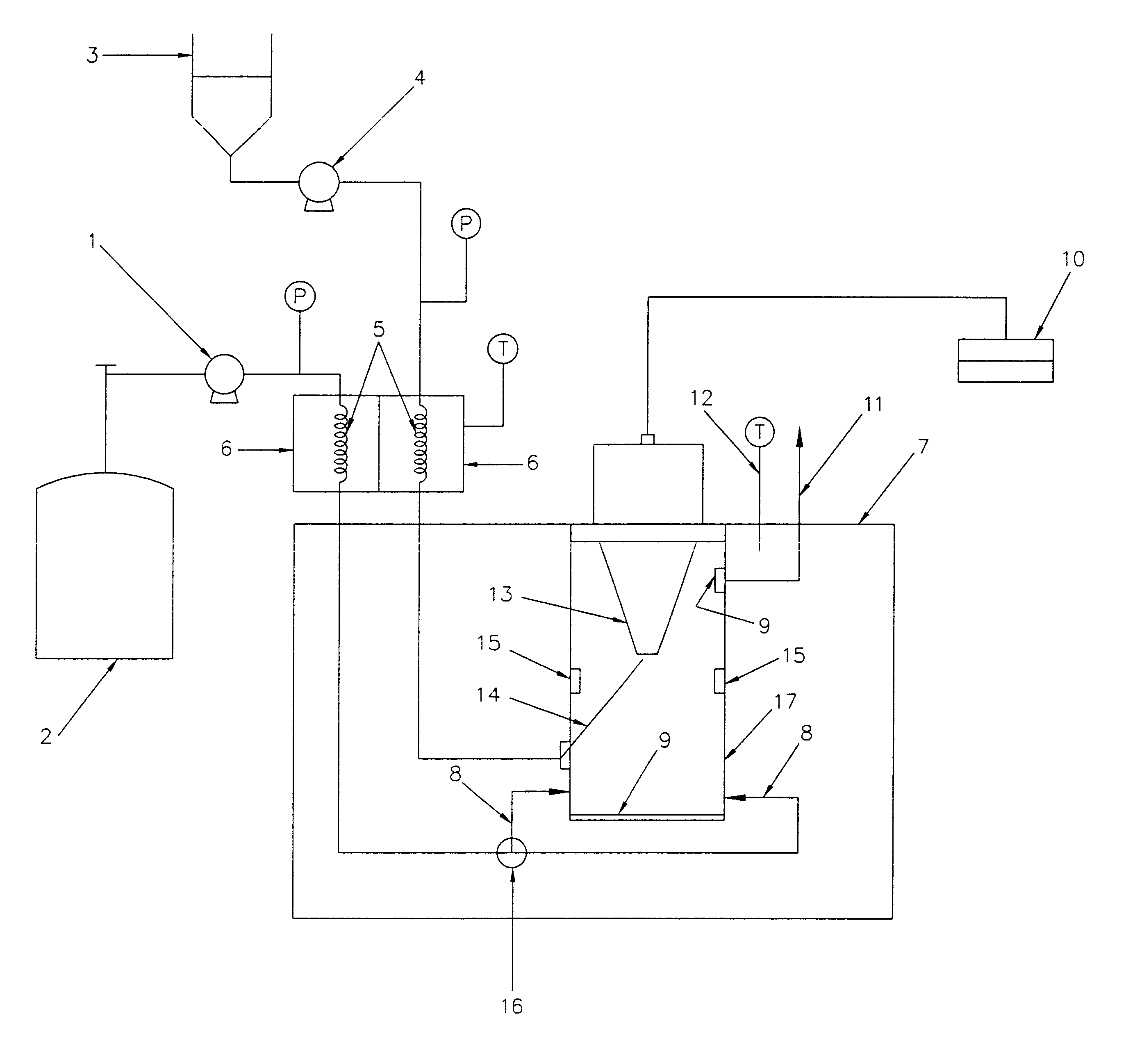

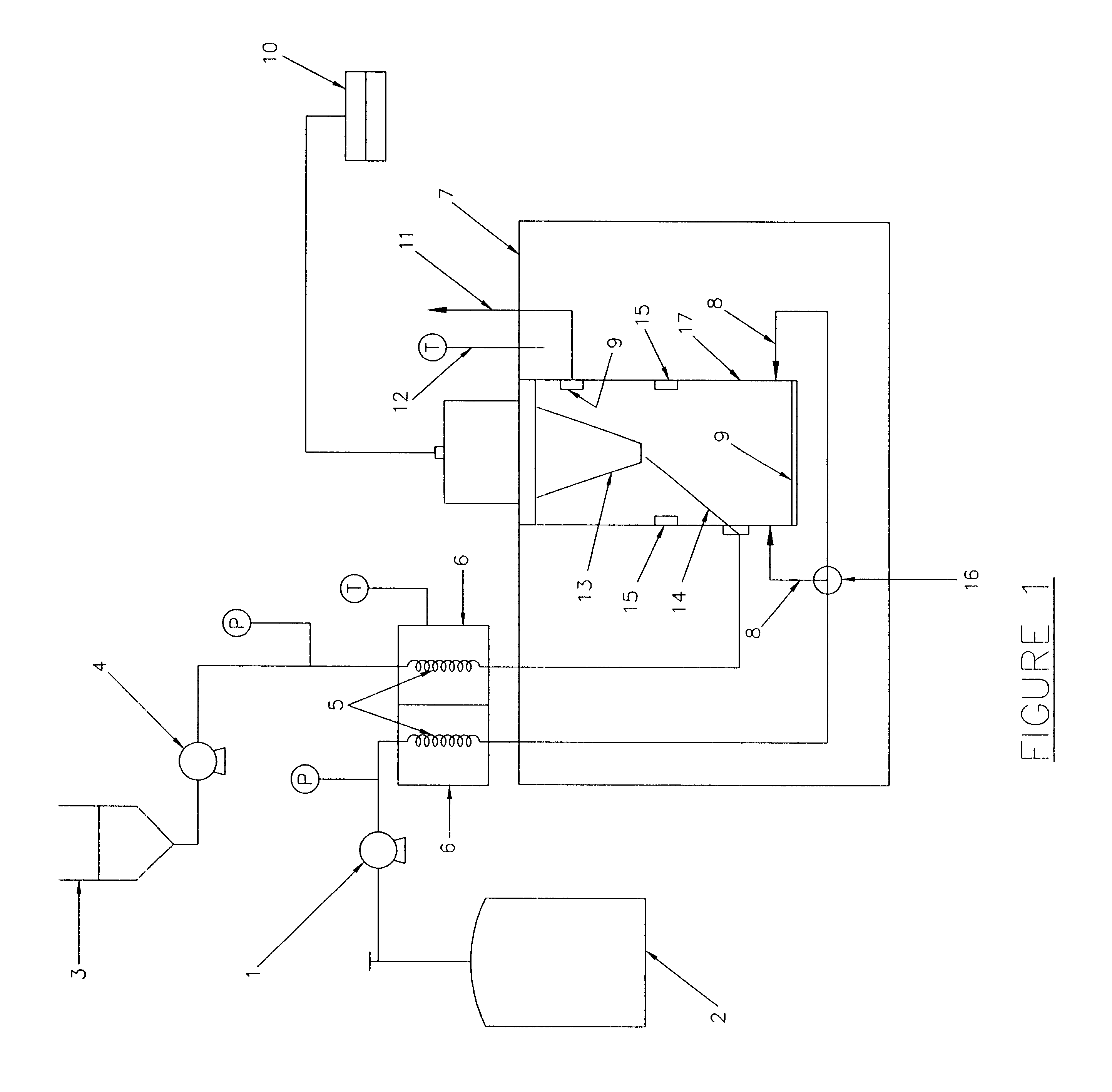

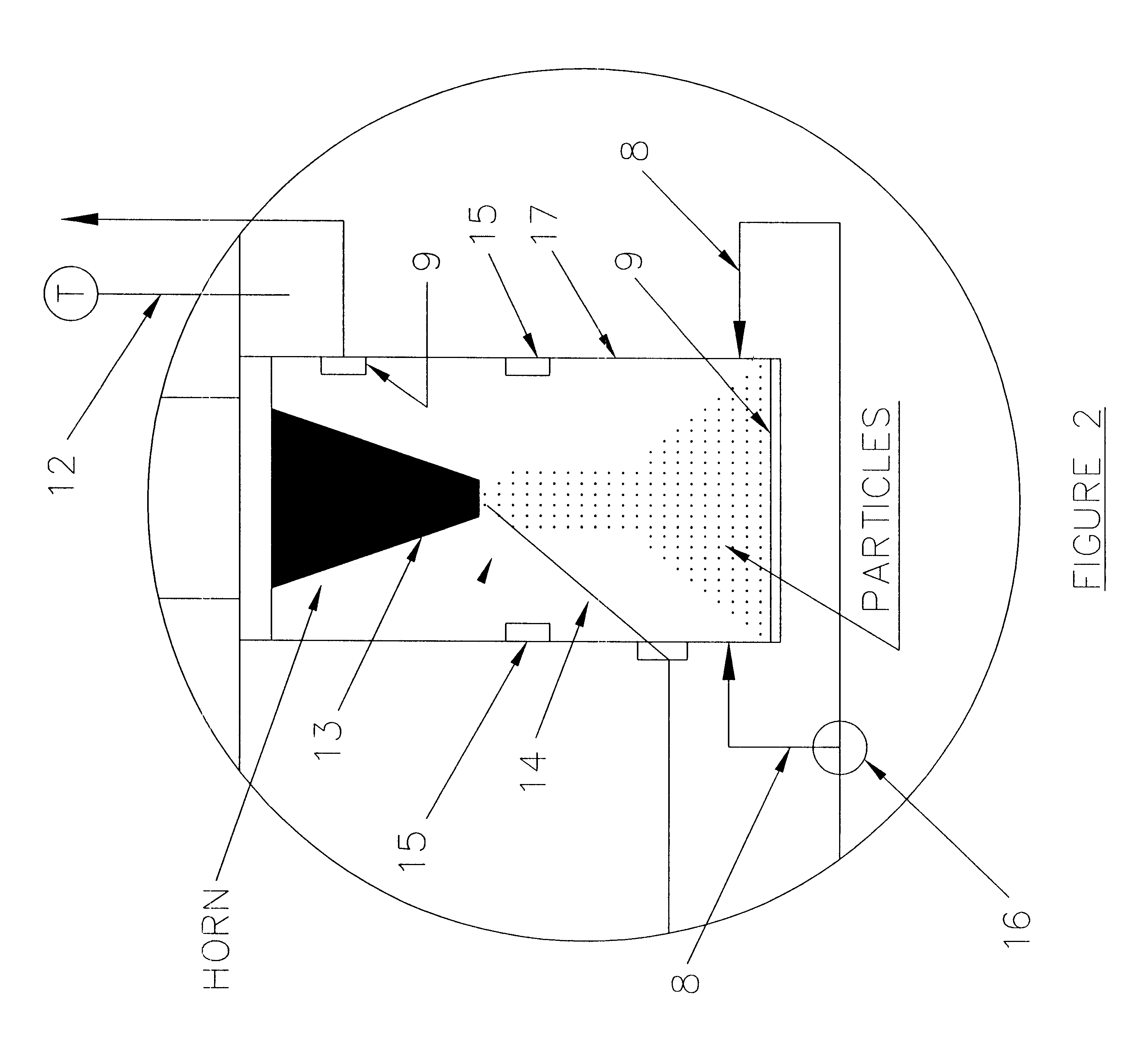

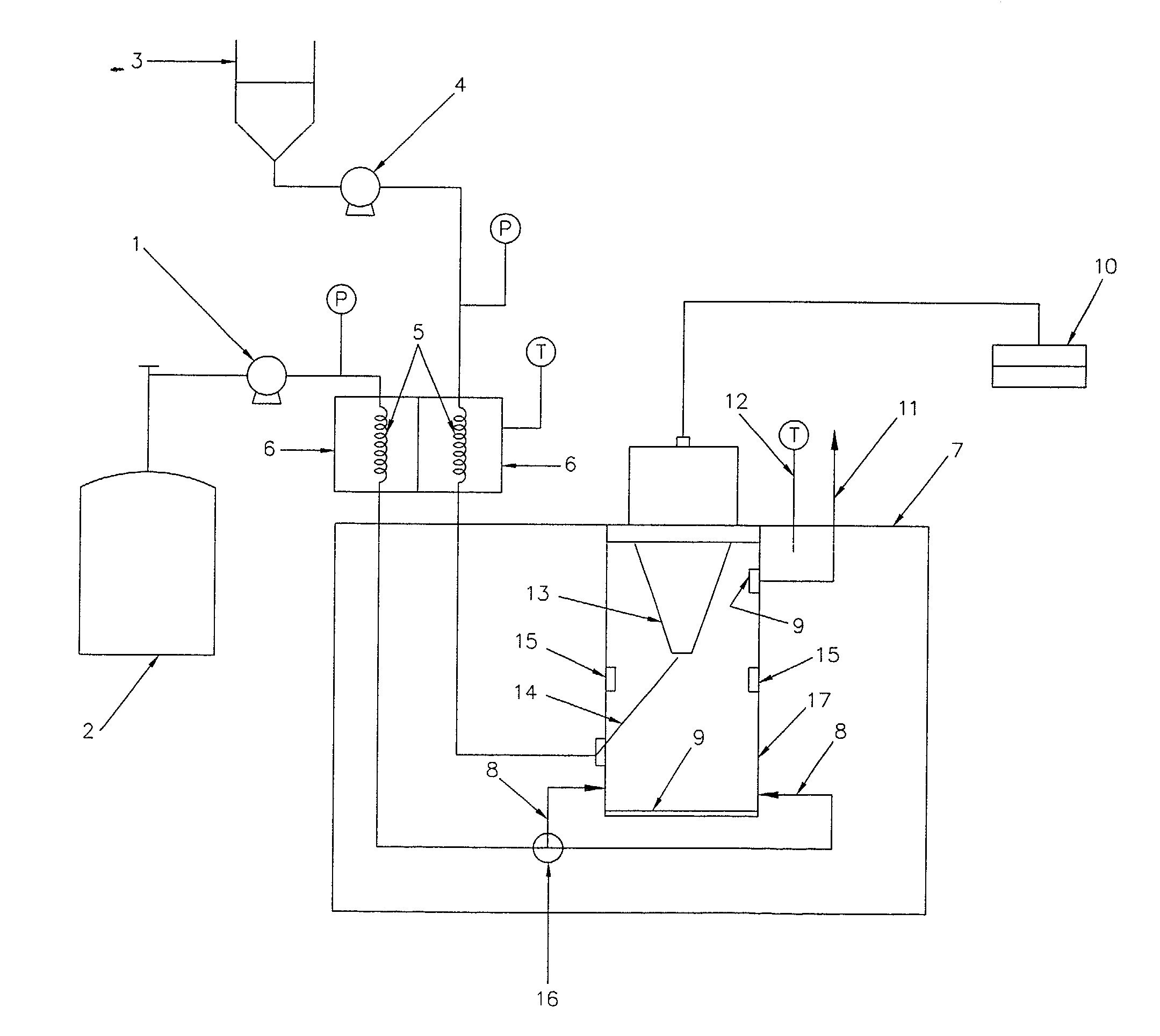

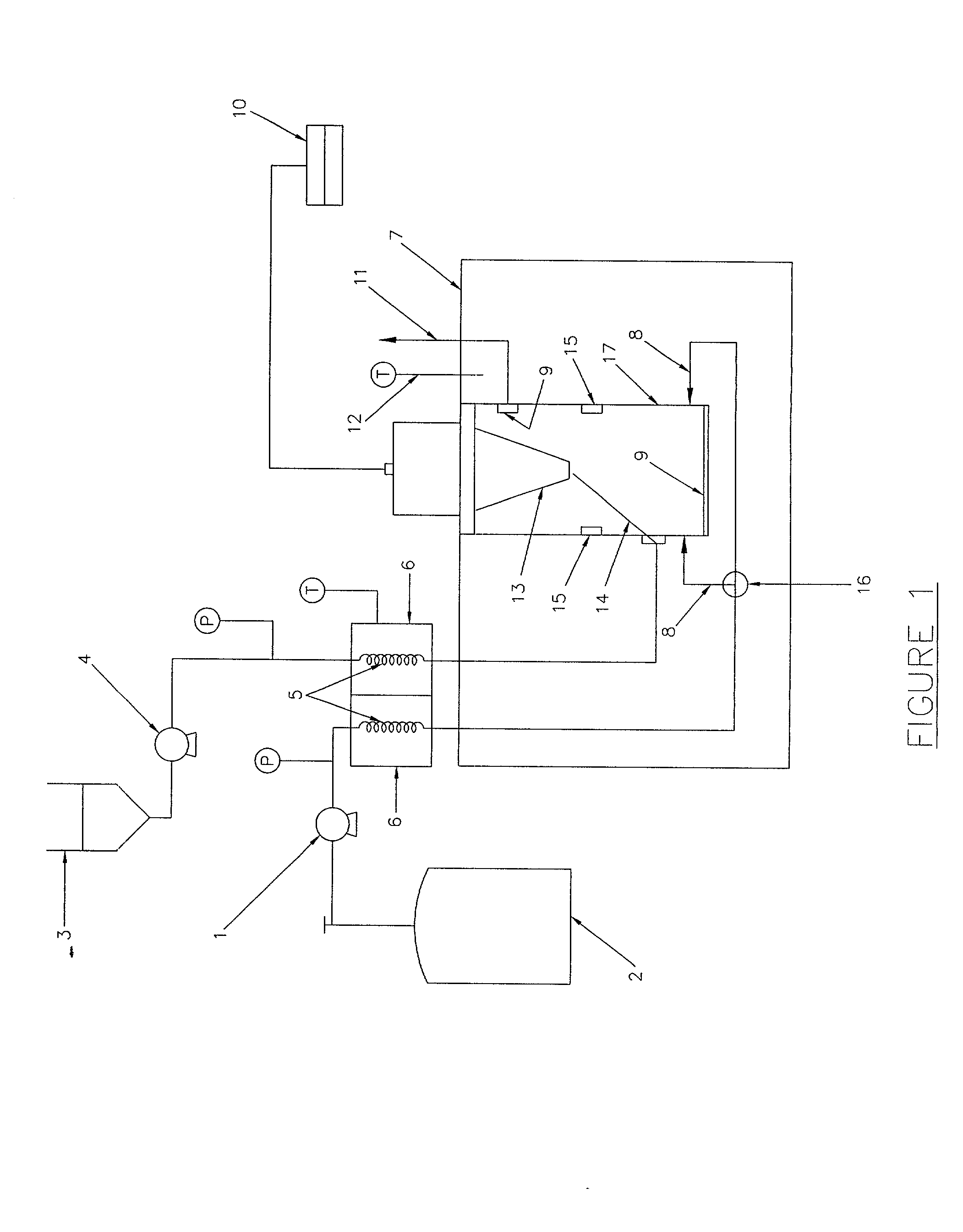

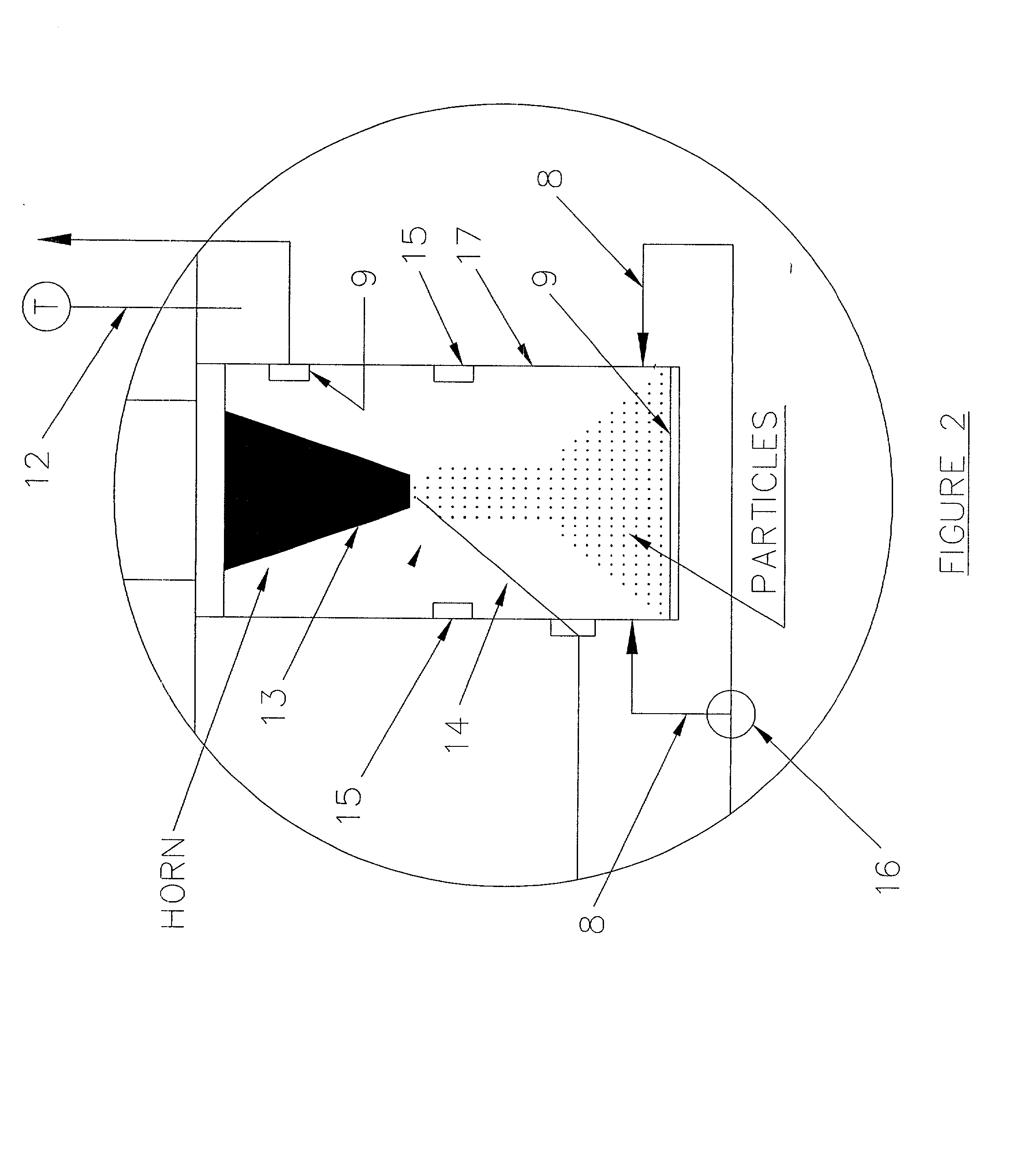

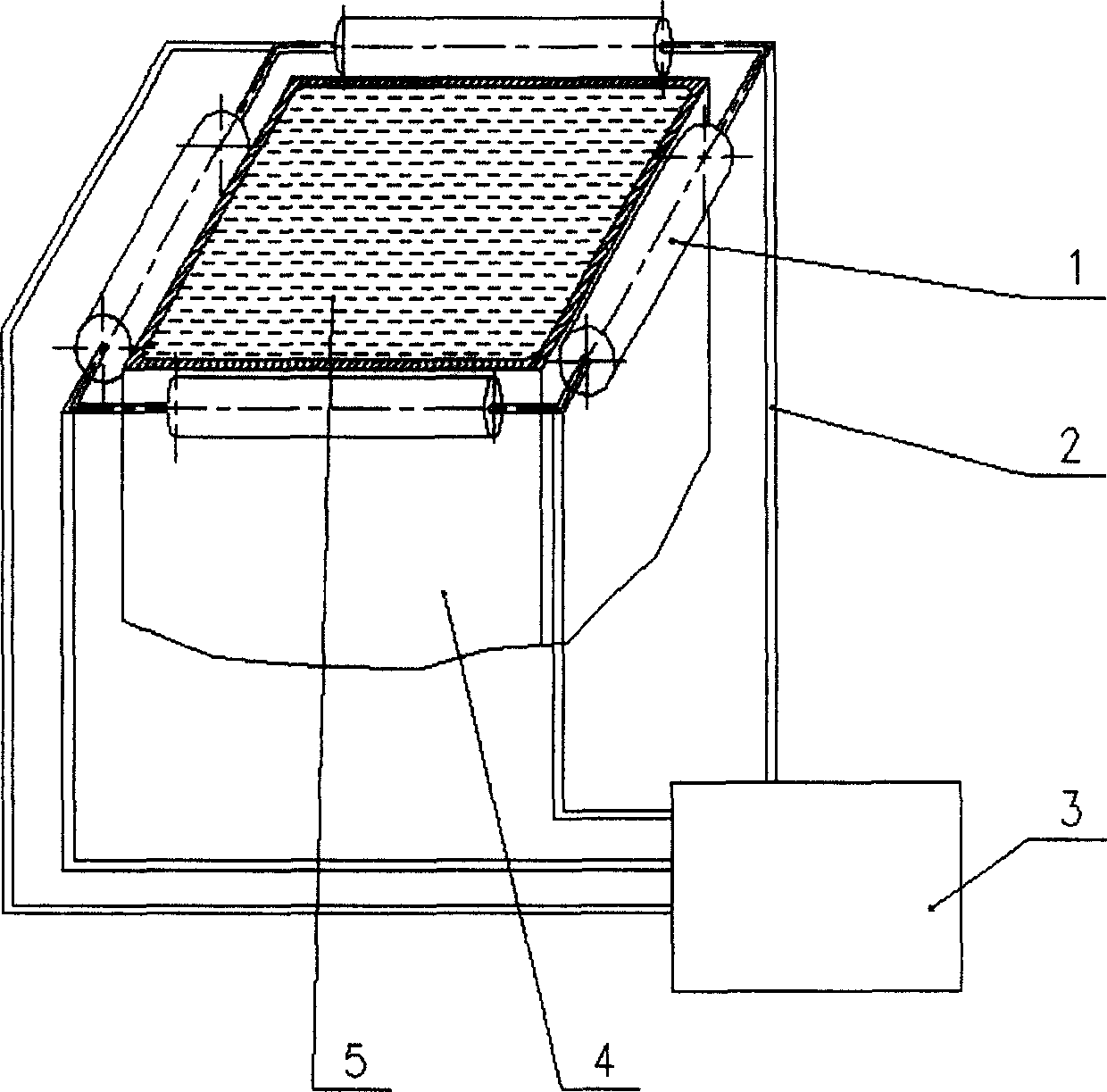

Method of forming nanoparticles and microparticles of controllable size using supercritical fluids with enhanced mass transfer

The current invention, Supercritical Antisolvent Precipitation with Enhanced Mass Transfer (SAS-EM) provides a significantly improved method for the production of nano and micro-particles with a narrow size distribution. The processes of the invention utilize the properties of supercritical fluids and also the principles of virbrational atomization to provide an efficient technique for the effective nanonization or micronization of particles. Like the SAS technique, SAS-EM, also uses a supercritical fluid as the antisolvent, but in the present invention the dispersion jet is deflected by a vibrating surface that atomizes the jet into fine droplets. The vibrating surface also generates a vibrational flow field within the supercritical phase that enhances mass transfer through increased mixing. Sizes of the particles obtained by this technique are easily controlled by changing the vibration intensity of the deflecting surface, which in turn is controlled by adjusting the power input to the vibration source. A major advantage of the SAS-EM technique is that it can be successfully used to obtain nanoparticles of materials that usually yield fibers or large crystals in SAS method. Microencapsulation via coprecipitation of two or more materials can also be achieved using the SAS-EM technique.

Owner:UNIV AUBURN

Method of forming nanoparticles and microparticles of controllable size using supercritical fluids and ultrasound

The current invention, Supercritical Antisolvent Precipitation with Enhanced Mass Transfer (SAS-EM) provides a significantly improved method for the production of nano and micro-particles with a narrow size distribution. The processes of the invention utilize the properties of supercritical fluids and also the principles of virbrational atomization to provide an efficient technique for the effective nanonization or micronization of particles. Like the SAS technique, SAS-EM, also uses a supercritical fluid as the antisolvent, but in the present invention the dispersion jet is deflected by a vibrating surface that atomizes the jet into fine droplets. The vibrating surface also generates a vibrational flow field within the supercritical phase that enhances mass transfer through increased mixing. Sizes of the particles obtained by this technique are easily controlled by changing the vibration intensity of the deflecting surface, which in turn is controlled by adjusting the power input to the vibration source. A major advantage of the SAS-EM technique is that it can be successfully used to obtain nanoparticles of materials that usually yield fibers or large crystals in SAS method. Microencapsulation via coprecipitation of two or more materials can also be achieved using the SAS-EM technique.

Owner:UNIV AUBURN

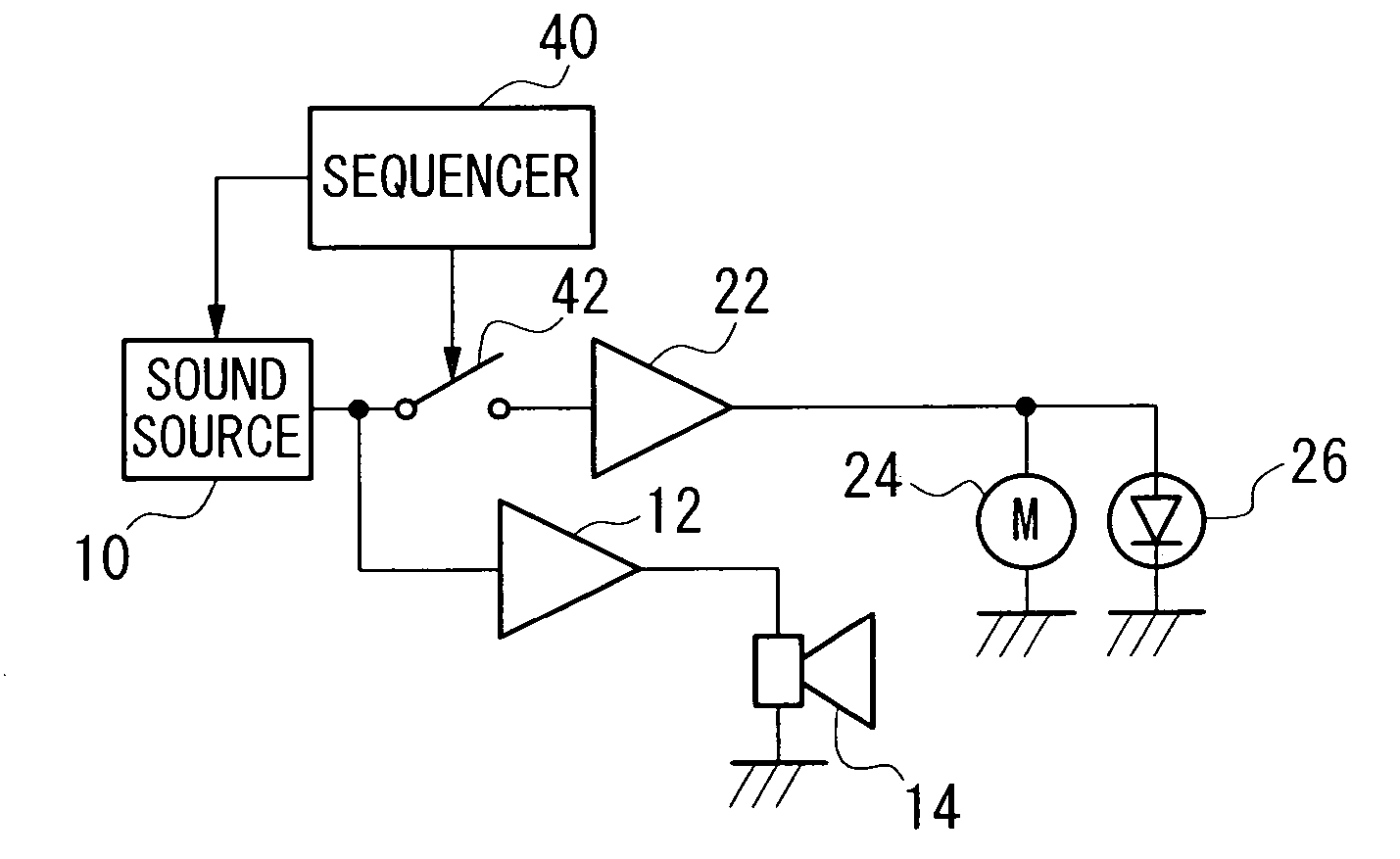

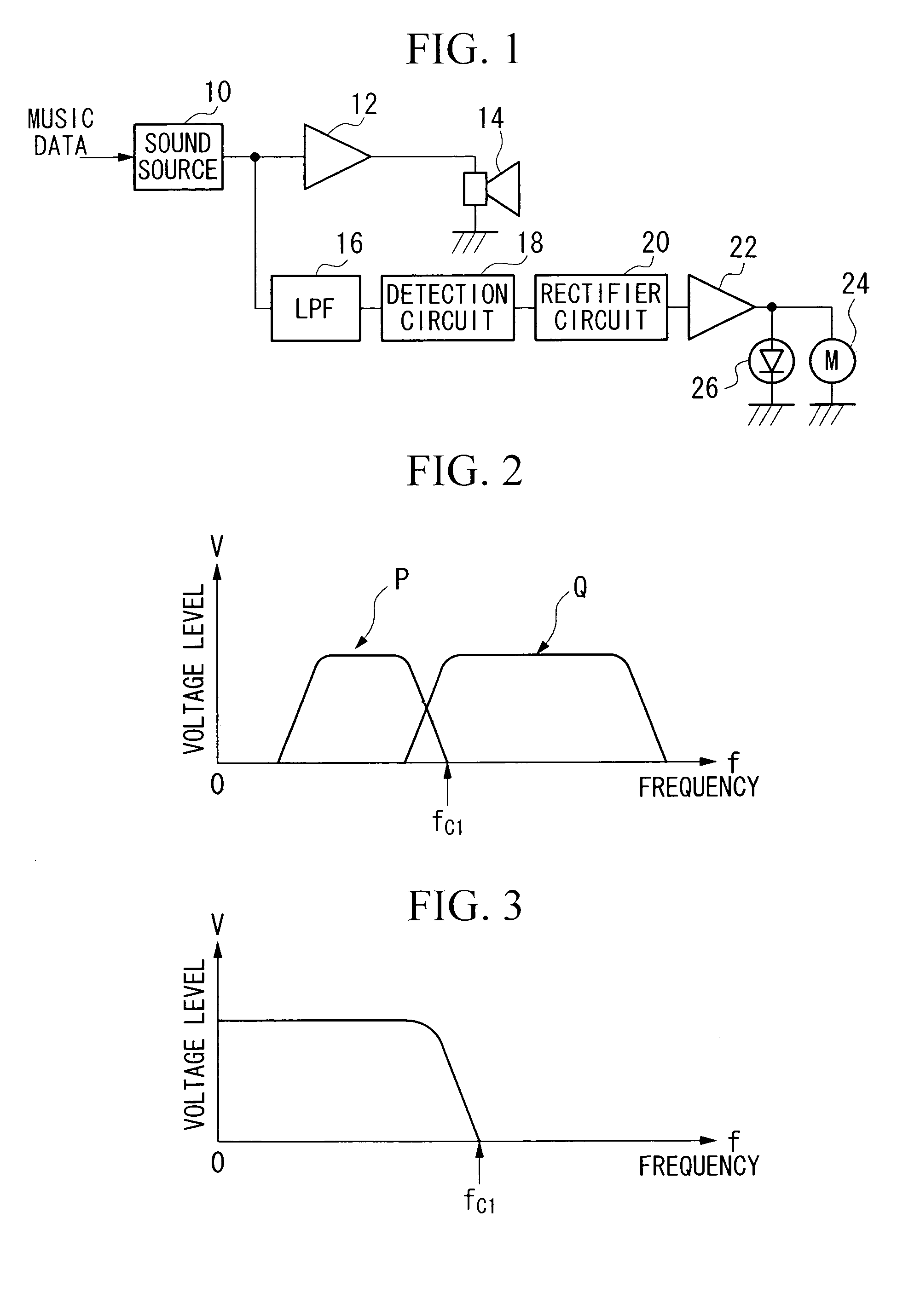

Vibration source driving device

A vibration source driving device that realizes various vibration functions on portable telephones. The vibration source driving device includes a sound source for generating musical tone signals in response to music data. A vibration source to generate vibration, a driver to drive the vibration and a control circuit are further included such that the vibration source may be driven in synchronization with the rhythm signal within the music data.

Owner:YAMAHA CORP

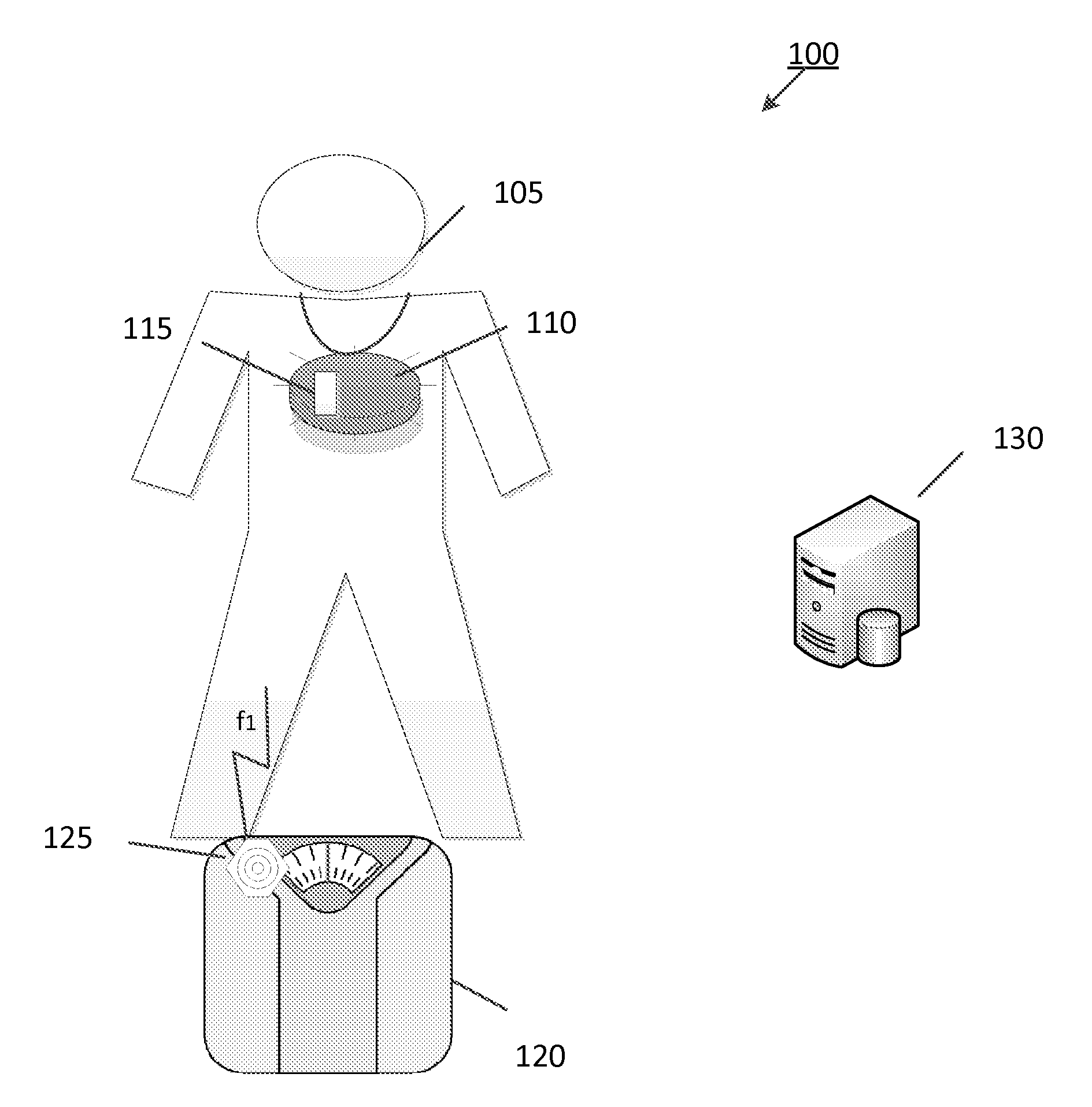

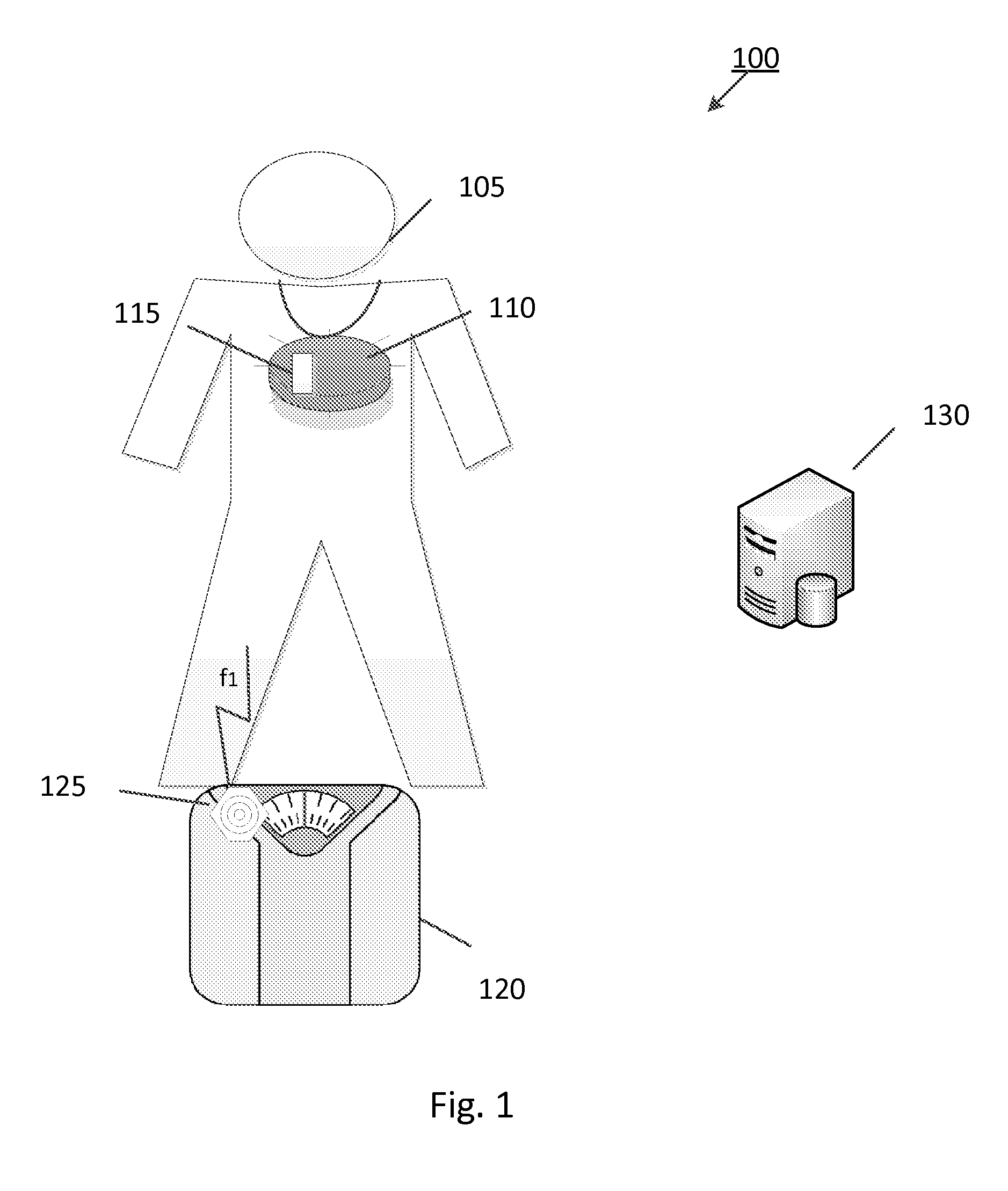

Physiological data acquisition utilizing vibrational identification

InactiveUS20120146795A1ElectrocardiographyLocal control/monitoringAccelerometerPhysiological monitoring

The present invention utilizes an accelerometer (included within a wireless physiology monitoring device or as part of a separate device such as, but not limited to a smartphone, e.g., iPhone, or other mobile device) to link a patient with a separate medical data acquisition device such as a weight scale or a blood pressure monitor in order to collect and transmit a range of medical data associated with the user. The medical data acquisition device includes a vibration source for emitting a vibration at a predetermined or random frequency. When the acquisition device is activated, a vibration is transmitted from the through the patient and is detected by the accelerometer. The accelerometer then measures the particular frequency of vibration and transmits this information to a centralized monitoring unit (CMU). Based on the measured frequency, the CMU is able to know that the same patient wearing / holding the device is also the same patient using the data acquisition device. The vibration source may revolve through a number of predetermined frequencies (as determined on its own or instructed via the CMU) or simply generate a random frequency.

Owner:MATHAI TOM +1

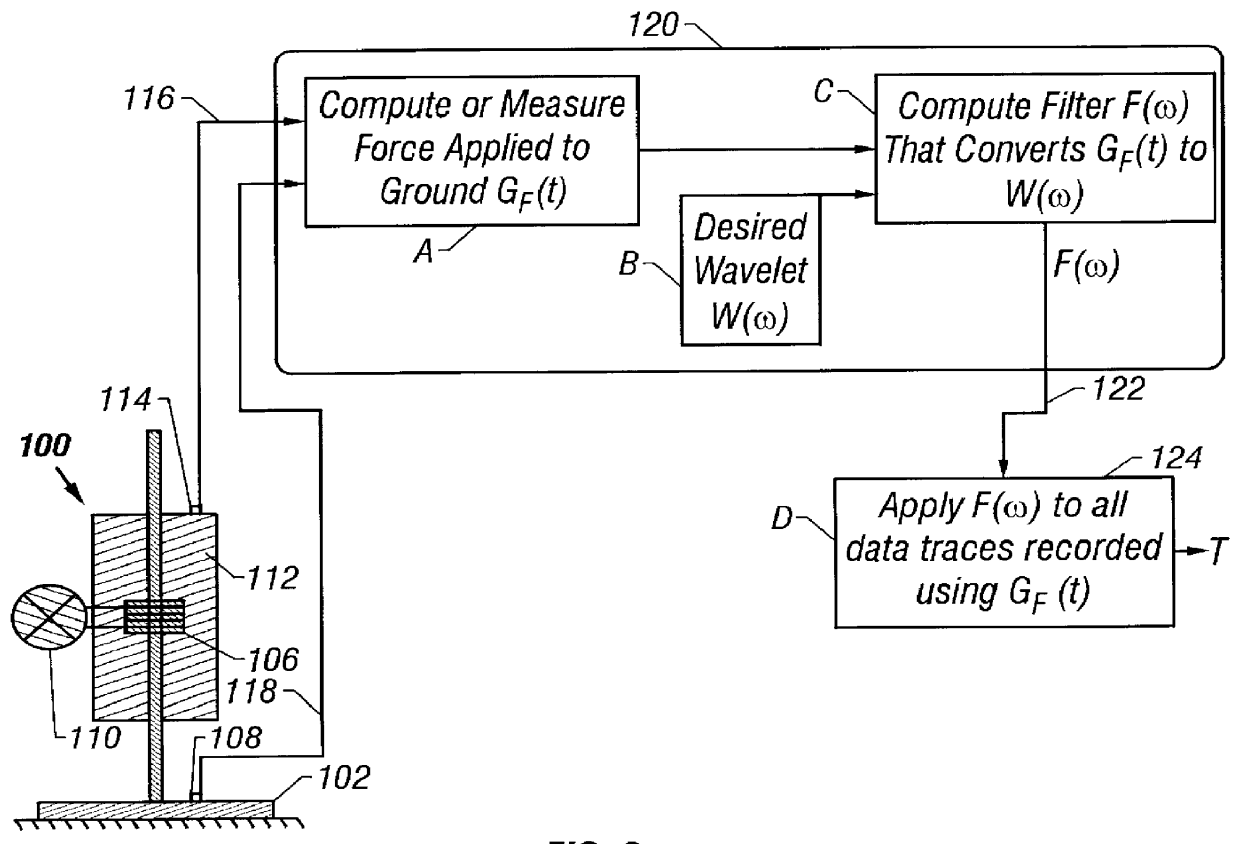

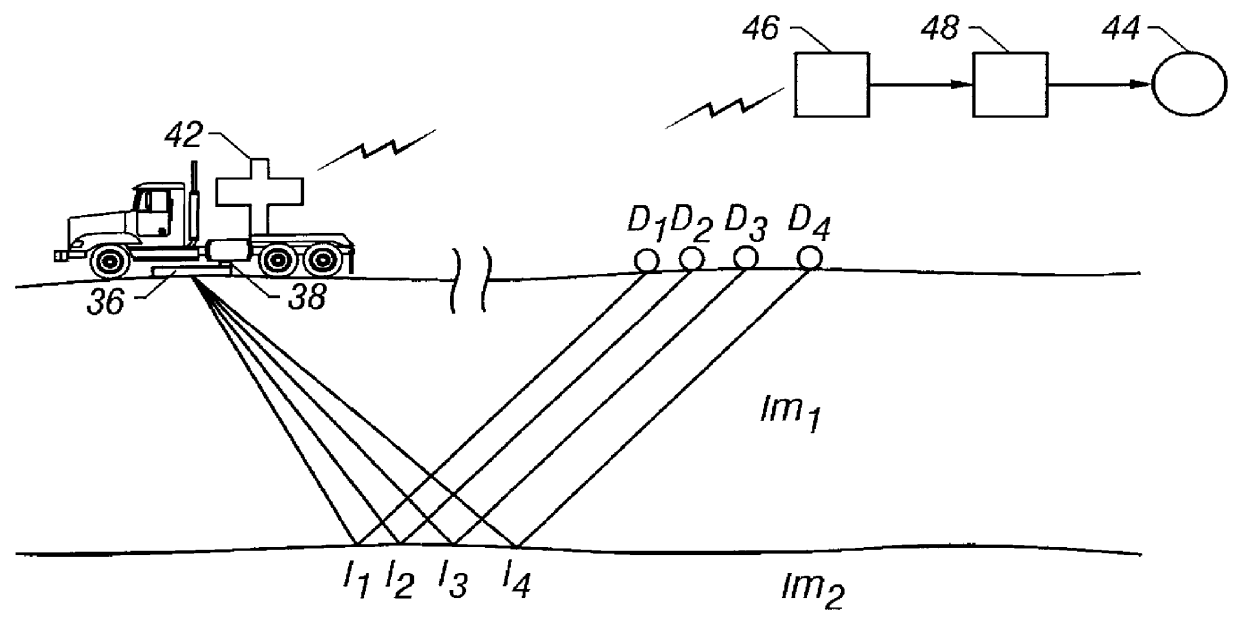

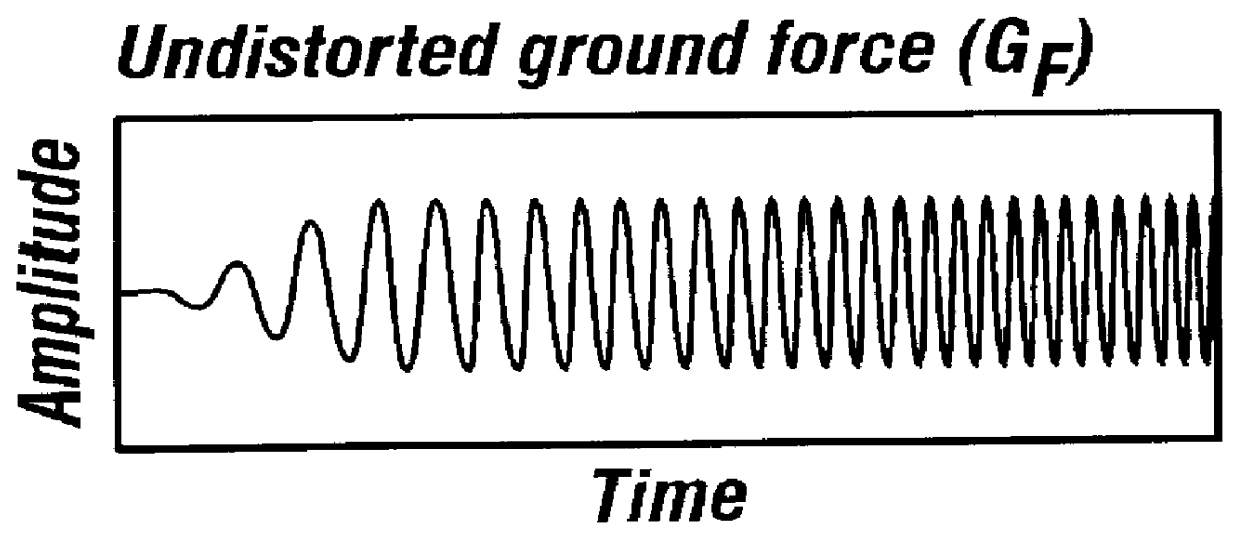

Seismic data acquisition and processing using non-linear distortion in a vibratory output signal

InactiveUS6161076AImprove stabilityCancel noiseBeacon systems using ultrasonic/sonic/infrasonic wavesSeismic signal processingNonlinear distortionRelative phase

A method for improving vibratory source seismic data uses a filter which converts a recorded seismic groundforce signal (including harmonic distortion therein) into a desired short-duration wavelet. A plurality of surveys may be carried out using a plurality of sweeps from plurality of vibrators that have their relative phases encoded, the groundforce signal of each vibrator being measured. The recorded seismic reflection signals are then processed to separate out the signals from each vibrator. In another aspect, harmonics of upto any desired order may be canceled while carrying out multiple surveys with a plurality of vibrators. In a marine environment, the recorded signal from a vibrator towed by a moving vessel is used to derive a Doppler shift correction filter that is applied to reflection seismic data.

Owner:WESTERNGECO LLC +1

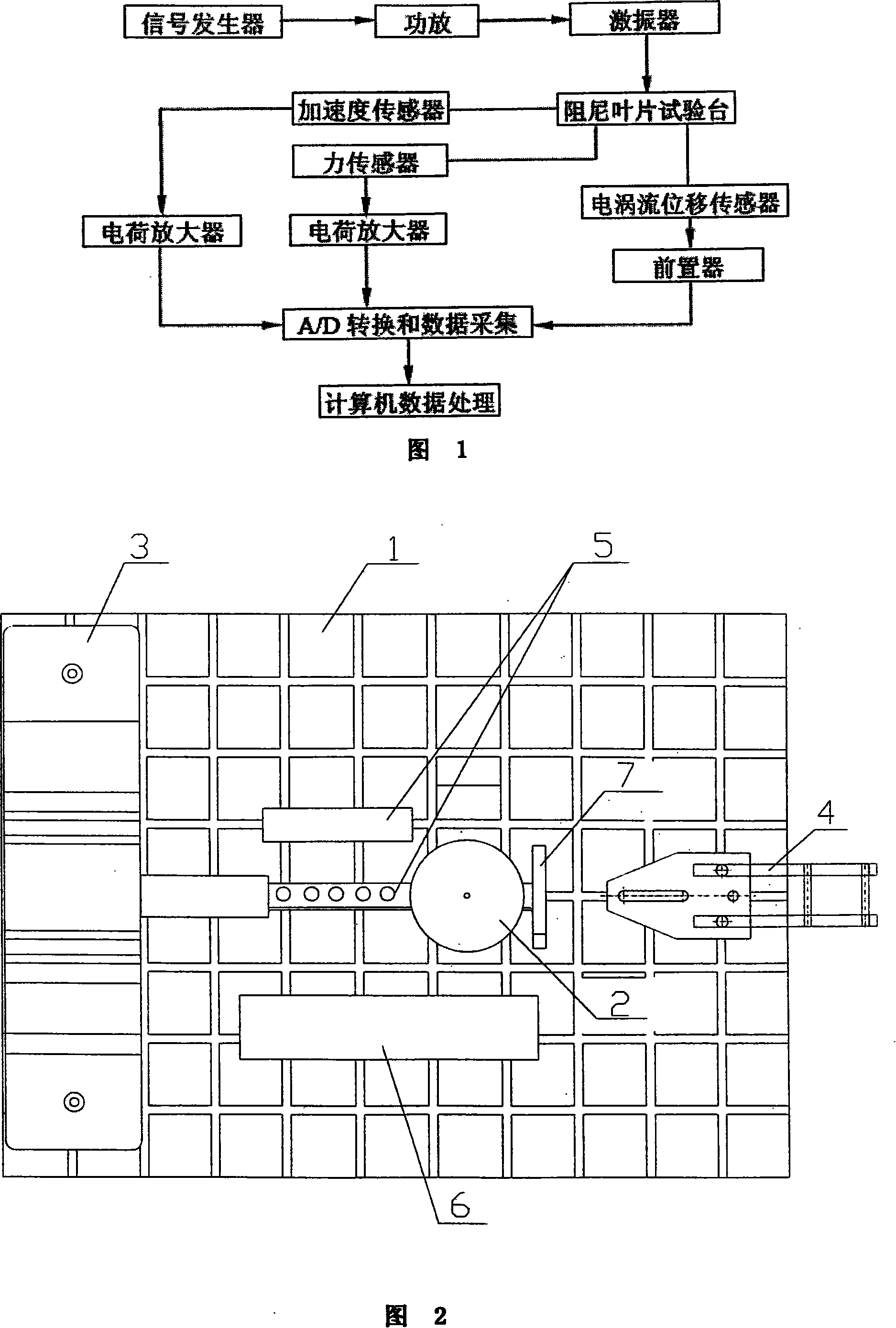

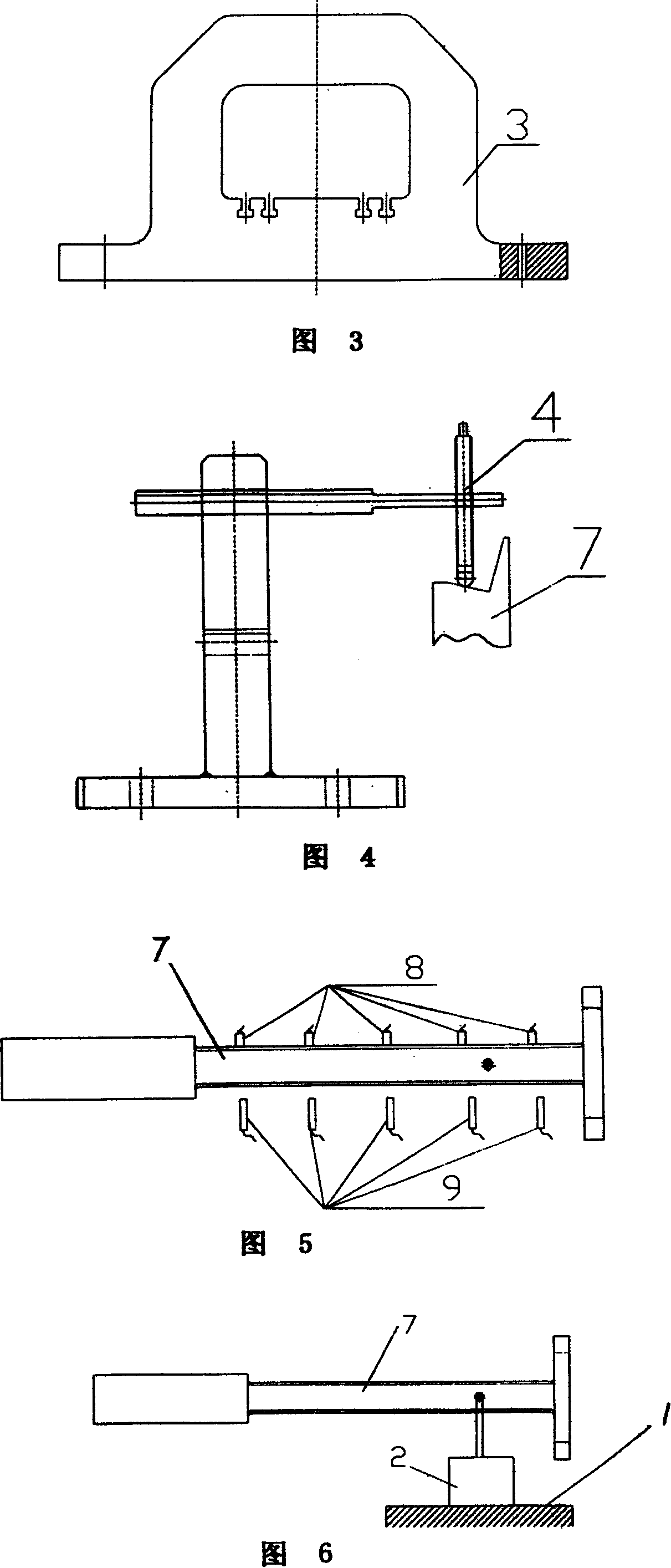

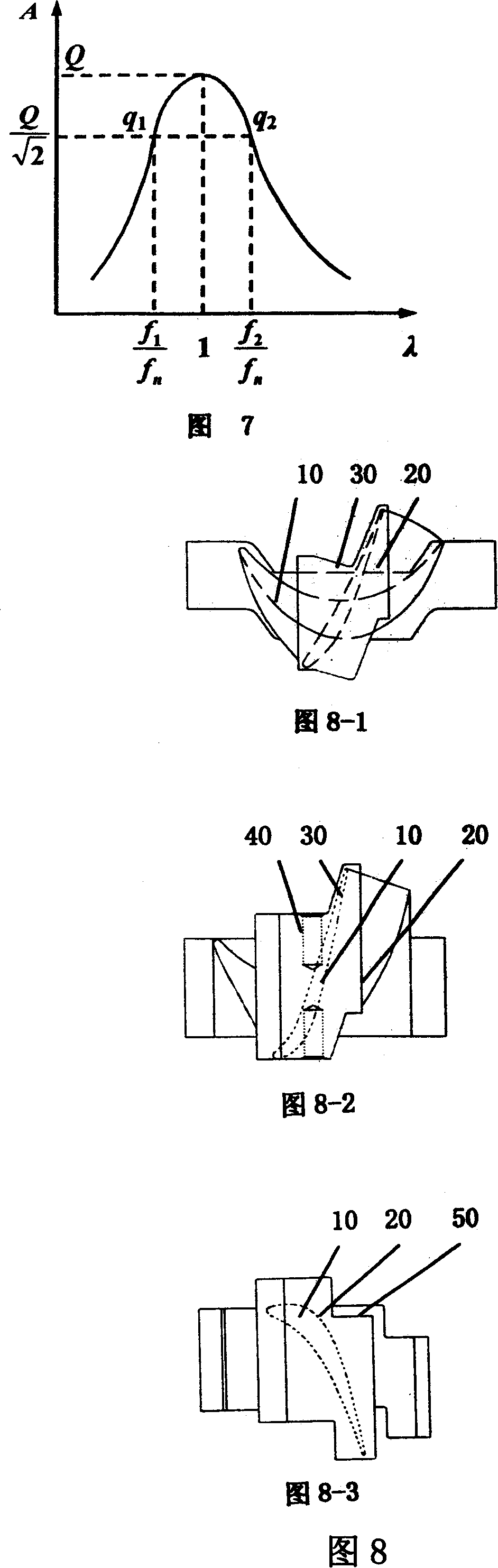

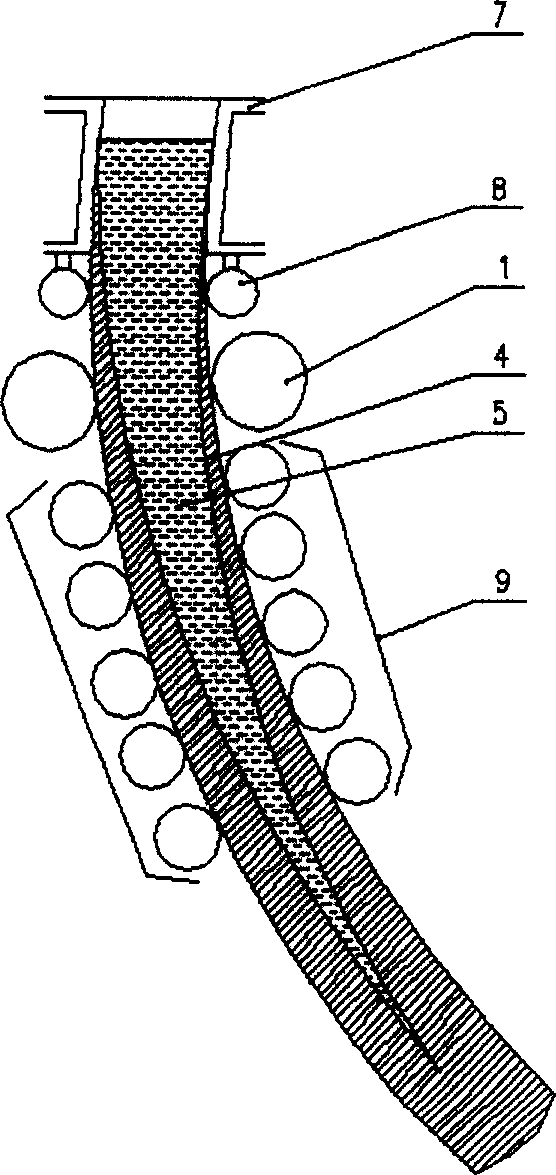

Turbine blade vibration test method and device

ActiveCN101122541AProven Vibration MechanismReasonable designVibration testingElasticity measurementMathematical modelEngineering

The invention discloses a steam turbine blade vibration test method and device. The method steps are that firstly, a blade force vibration status is analyzed and a blade excitation force mathematical model is built. Secondly, an excitation force is imposed on the blade by a vibration source. The frequency of the excitation force is regulated until resonance is generated between the blade and the vibration source. Vibration characteristics parameters values of the blade under the excitation force are measured. Thirdly, blade damping characteristics parameters, including modal damping ratio, damper contact stiffness and blade dynamic stress, are worked out according to the vibration characteristics parameters values. The device includes a test bed, a blade clamping mechanism arranged on the test bed, an excitation generator, a vibration parameter detector and a data processing system. The excitation vibration generator is fixed on the test bed. The excitation vibration head of the excitation vibration generator is fixed with the blade. Corresponding to the blade, the vibration parameter detector transforms the vibration signals of the blade into electric signals, which are input into the data processing system. The invention proves the vibration mechanism of the damping blade. A calculation model of the damping blade is constructed through the test parameters. Experience design is terminated. The blade design is standardized to step into a scientific design orbit.

Owner:DONGFANG TURBINE CO LTD +1

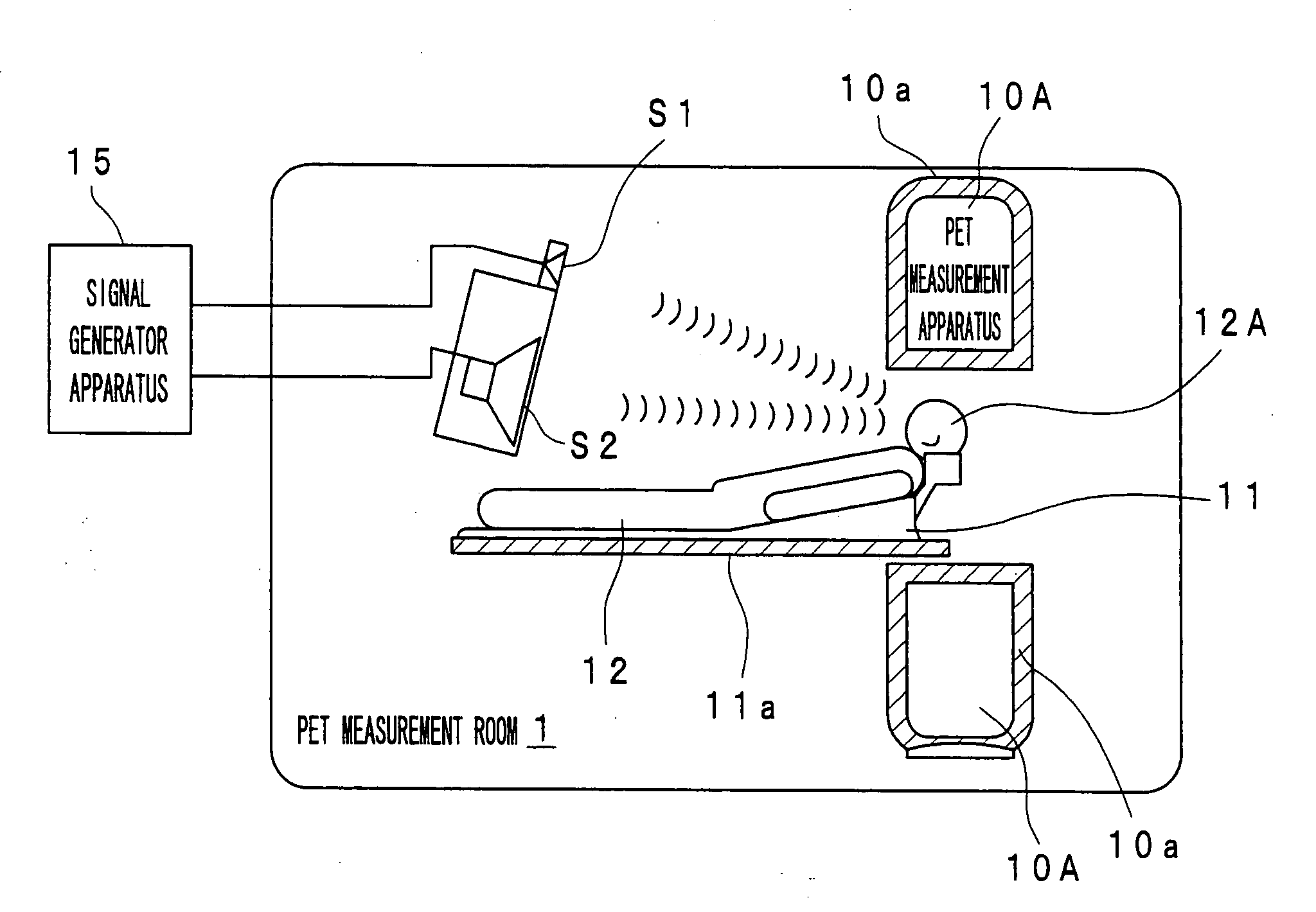

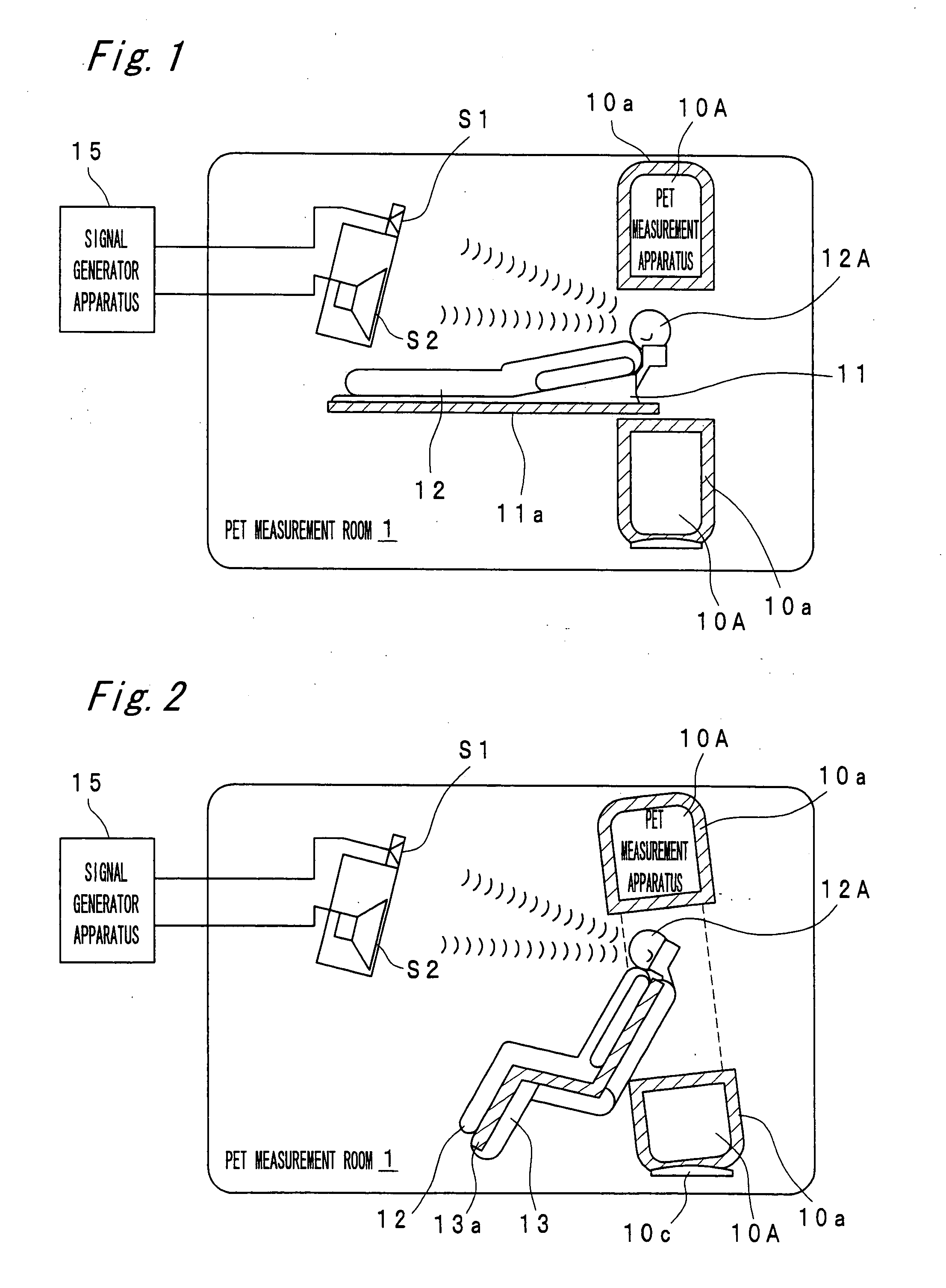

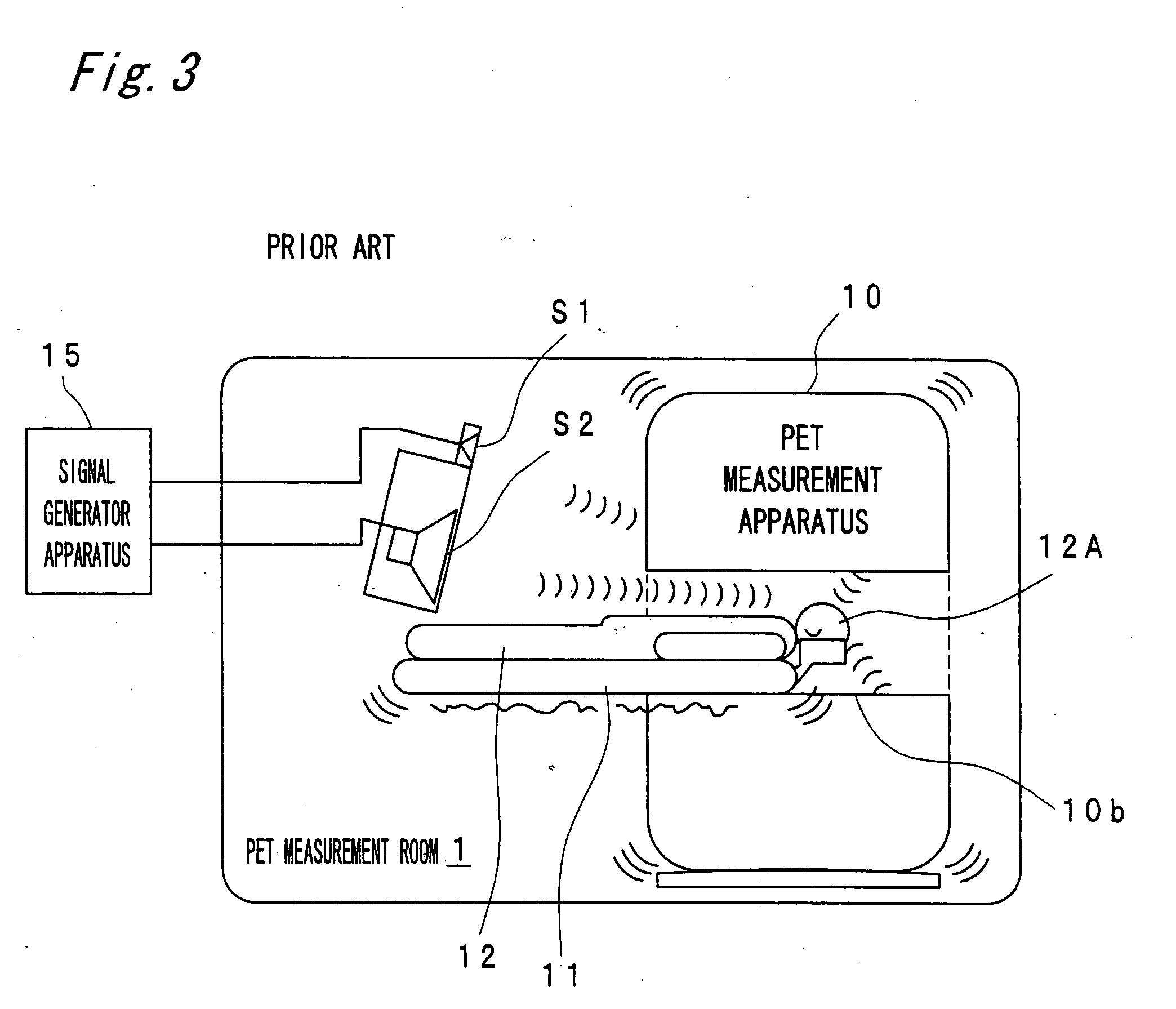

Oscillation representing system for effectively applying hypersonic sound

InactiveUS20080281238A1Simply effectively applyingPrevent slippingChiropractic devicesVibration massageBiological bodyAuditory sense

A vibration presenting system includes a first vibration applying device for applying a vibration that is generated by a first vibration source and has frequency components within an audible range perceivable as a sound by an auditory sense system of a living body to the auditory sense system of the living body, and a second vibration applying device for applying a vibration that is generated by a second vibration source different from the first vibration source and has superhigh frequency components exceeding the audible range unperceivable by the auditory sense system of the living body to a living body component region other than the auditory sense system of the living body. The living body component region other than the auditory sense system of the living body is a body surface of the living body, which may include a head thereof.

Owner:ACTION RES

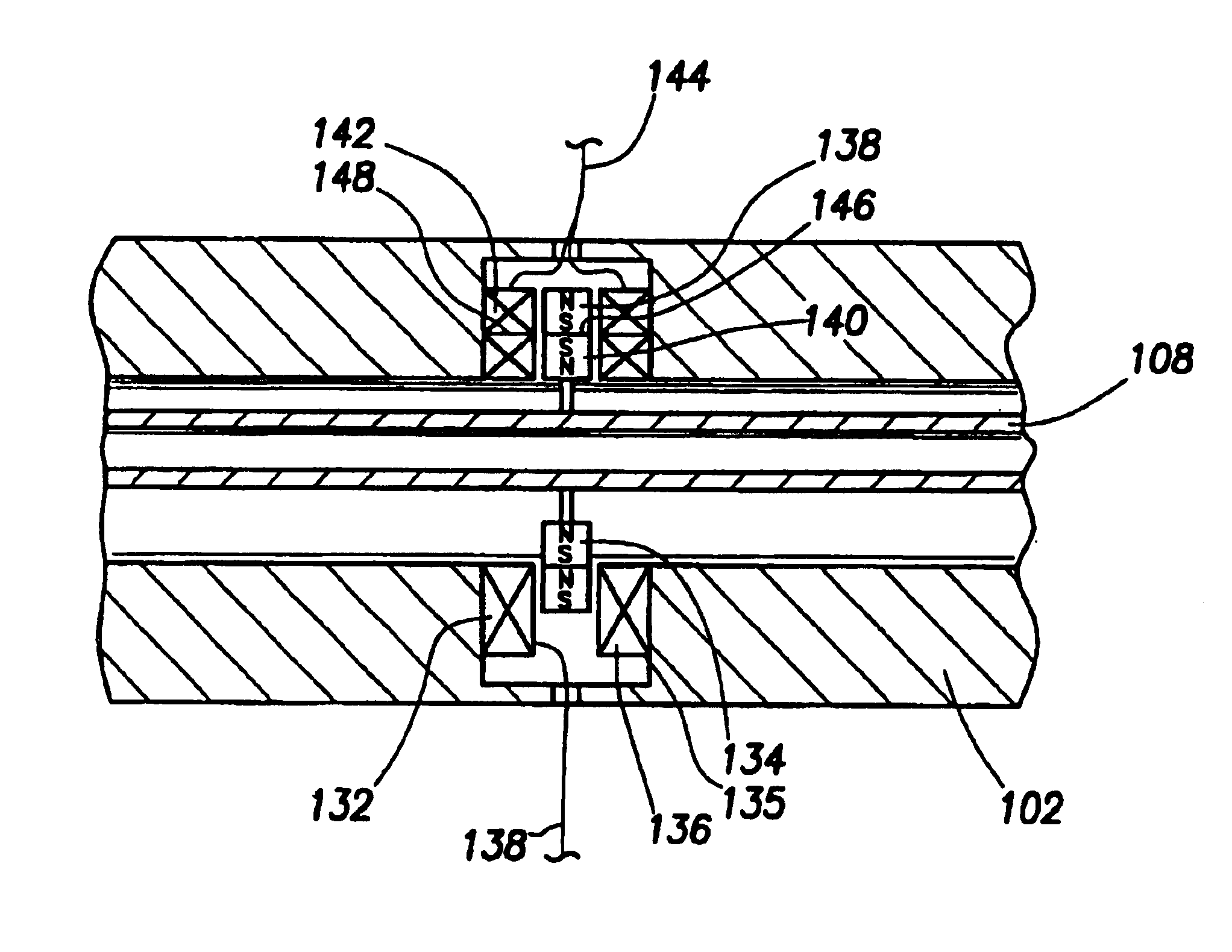

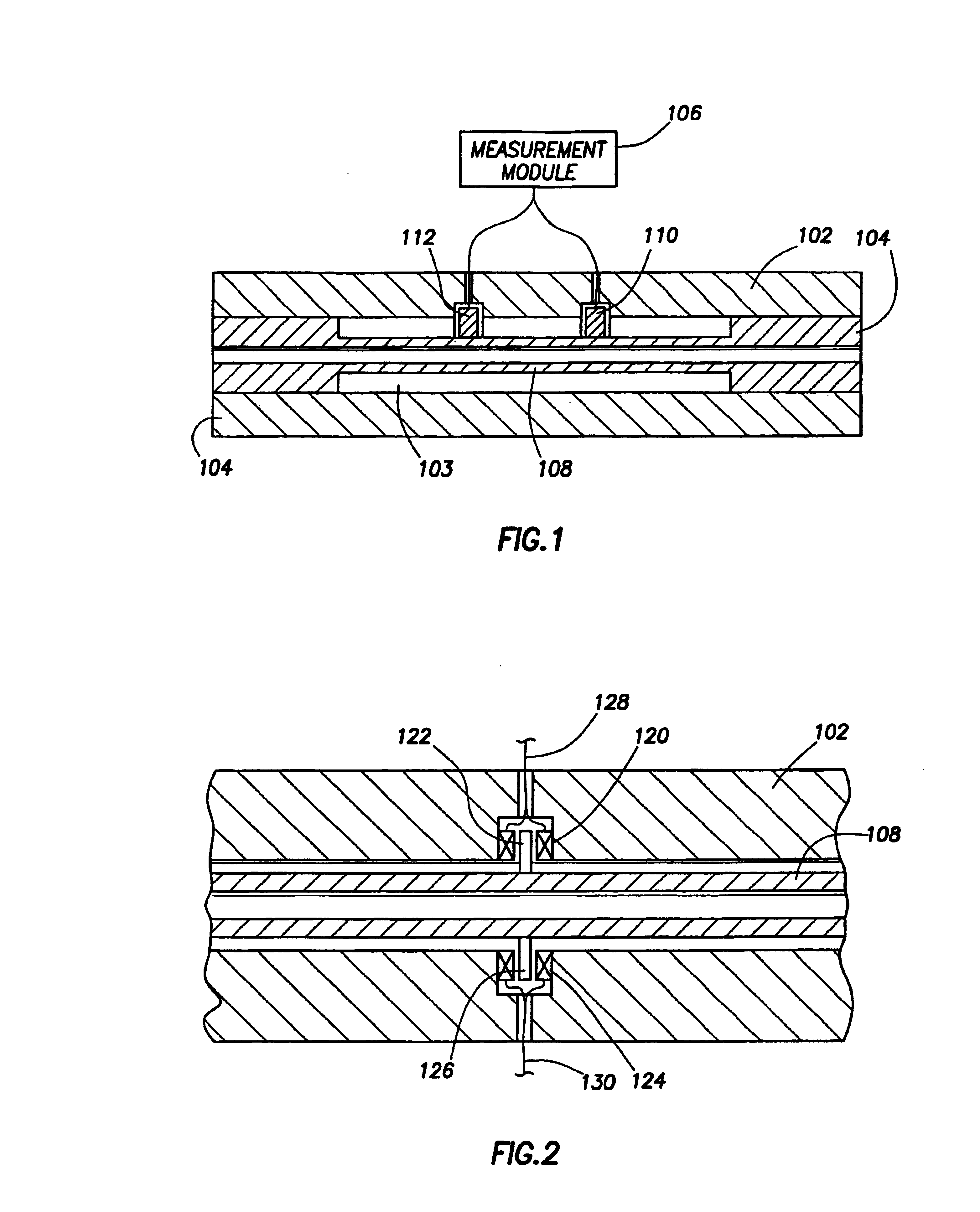

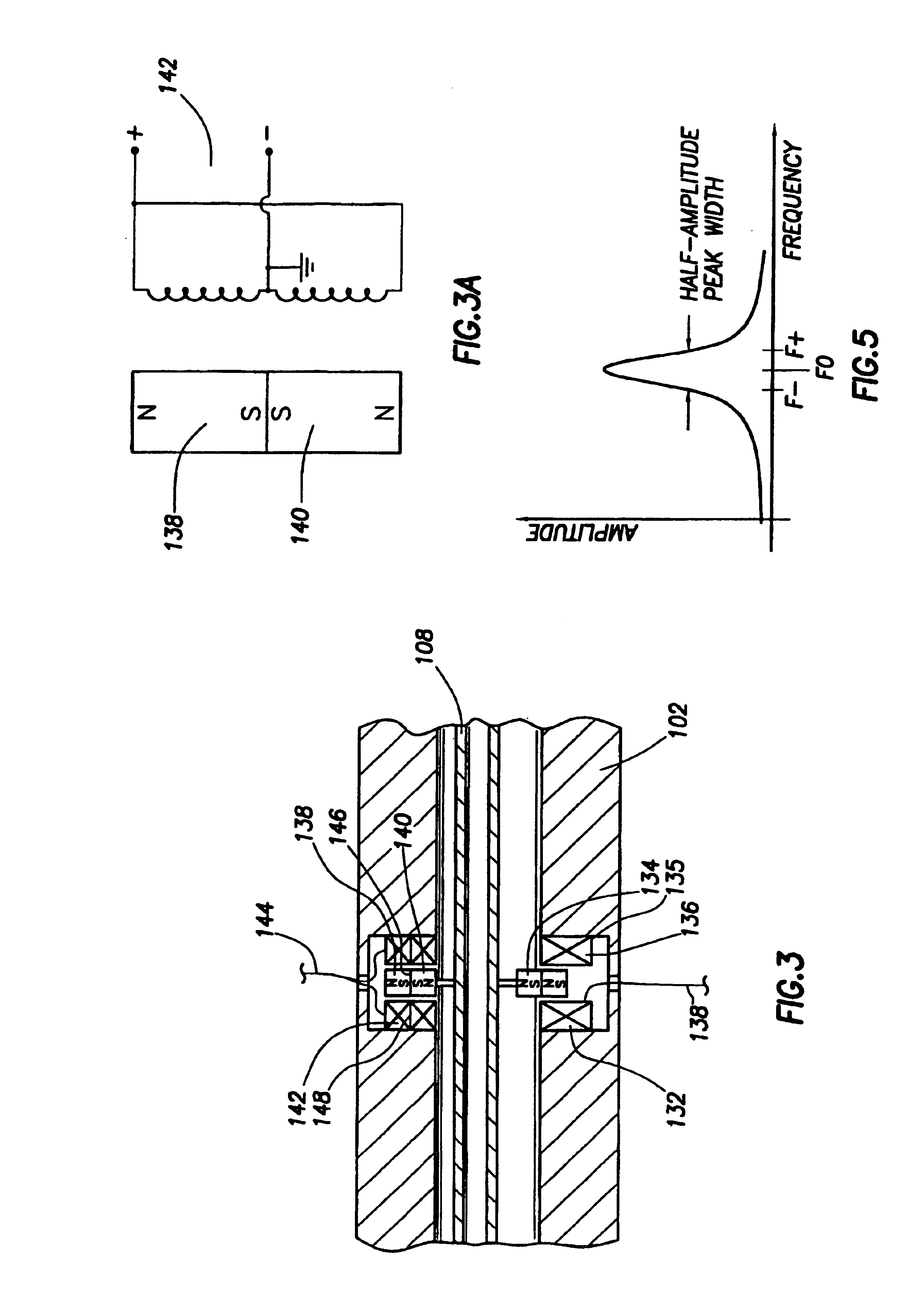

Single tube densitometer

InactiveUS6912904B2Improve accuracyImprove reliabilityVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesMeasurement deviceComputer module

A measurement device is provided that determines fluid properties from vibration frequencies of a sample cavity. In one embodiment, the measurement device includes a sample flow tube, vibration source and detector mounted on the tube, and a measurement module. The sample flow tube receives a flow of sample fluid for characterization. The measurement module employs the vibration sources to generate vibrations in the tube. The measurement module combines the signals from the vibration detector on the tube to determine properties of the sample fluid, such as density, viscosity, compressibility, water fraction, and bubble size. The measurement module may further detect certain flow patterns such as slug flow, for example. To measure the sample fluid density, the measurement module determines the resonant frequency of the sample flow tube. The density can then be calculated according to a formula that compensates for the temperature and pressure of the system.

Owner:HALLIBURTON ENERGY SERVICES INC

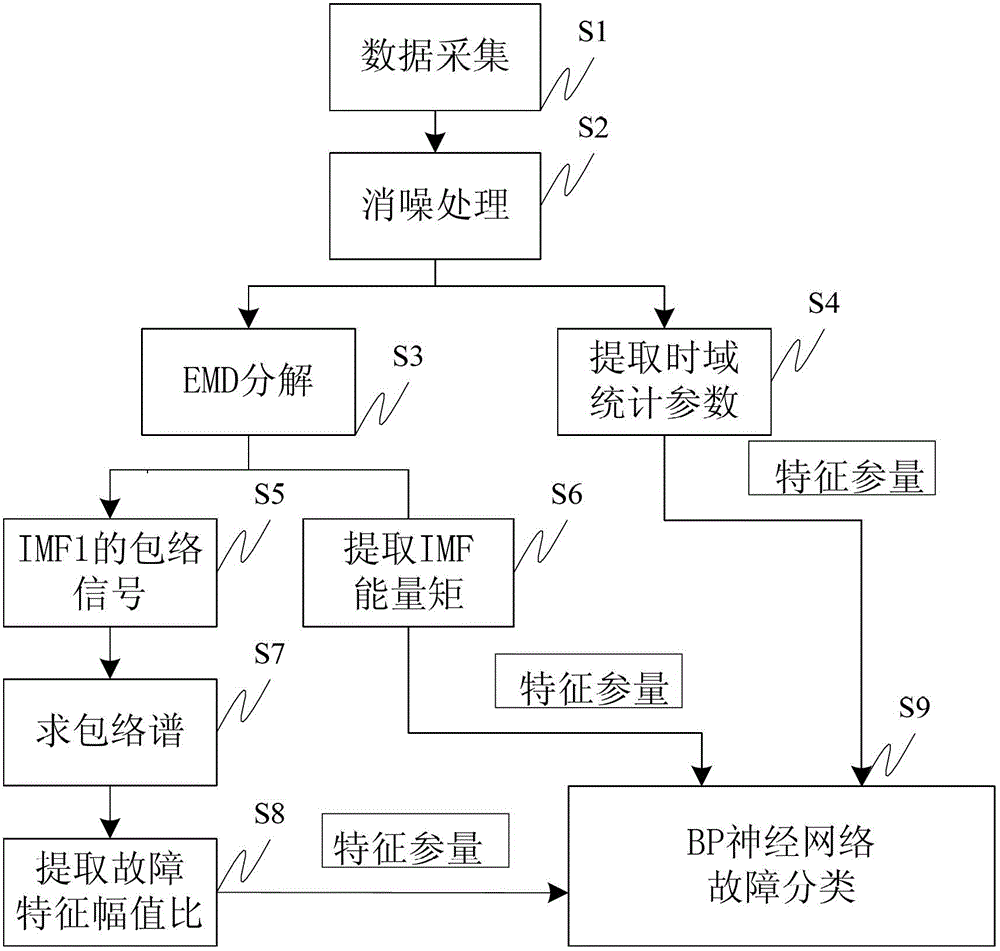

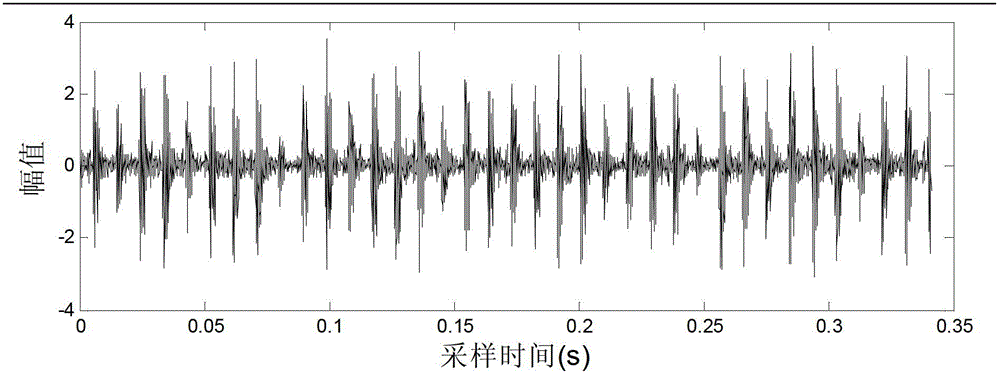

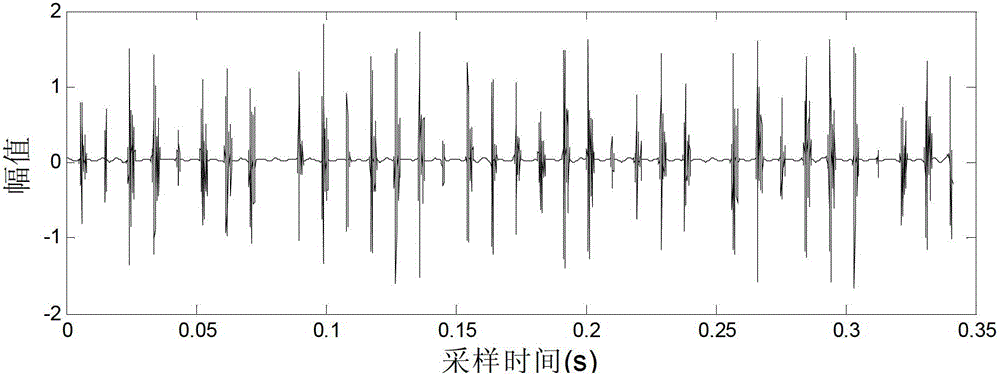

Rolling bearing failure diagnostic method based on multi-characteristic parameter

ActiveCN102721545AReflect work statusImprove diagnostic accuracyMachine bearings testingBiological neural network modelsTime domainVibration source

The invention discloses a rolling bearing failure diagnostic method based on a multi-characteristic parameter, which comprises the following steps of: (1) pre-processing the collected vibrating signals, and removing the interference of the noise and other vibrating sources; (2) extracting a time domain statistical parameter capable of reflecting different working conditions of the rolling bearing from the vibrating signals; (3) figuring out the envelope signal of the pre-processed vibrating signals, decomposing the envelope signal through an improved empirical mode decomposition method to obtain a series of intrinsic mode functions; (4) selecting multiple intrinsic mode functions concentrating most part of energy, and calculating an energy torque; (5) performing envelope spectrum analysis on the first decomposed intrinsic mode function, and calculating the failure characteristic amplitude ratio; and (6) serving a plurality of characteristic parameters extracted in the step as input vector of a BP neural network, and outputting the diagnosis result through the network. The rolling bearing failure diagnostic method disclosed by the invention can fully reflect the operation condition of the rolling bearing, improve the diagnosis accuracy and facilitate realization of the online monitoring of the rolling bearing.

Owner:BEIJING JIAOTONG UNIV

Therapy patch

Therapy patches are disclosed which are designed to deliver vibration and heat (or cold) to human skin so as to provide muscle relief. These patches have a chemical pouch that generates heat or cold upon initiation. They also have a motor and battery to provide a vibration source. Forms of the invention have an adhesive so that the patch can be attached to the skin (and thus need not be manually held in place during use). Kits are also provided in which the motor and battery can be used with a string of linked, severable replacement pouches. Methods of using these patches are also disclosed.

Owner:SC JOHNSON & SON INC

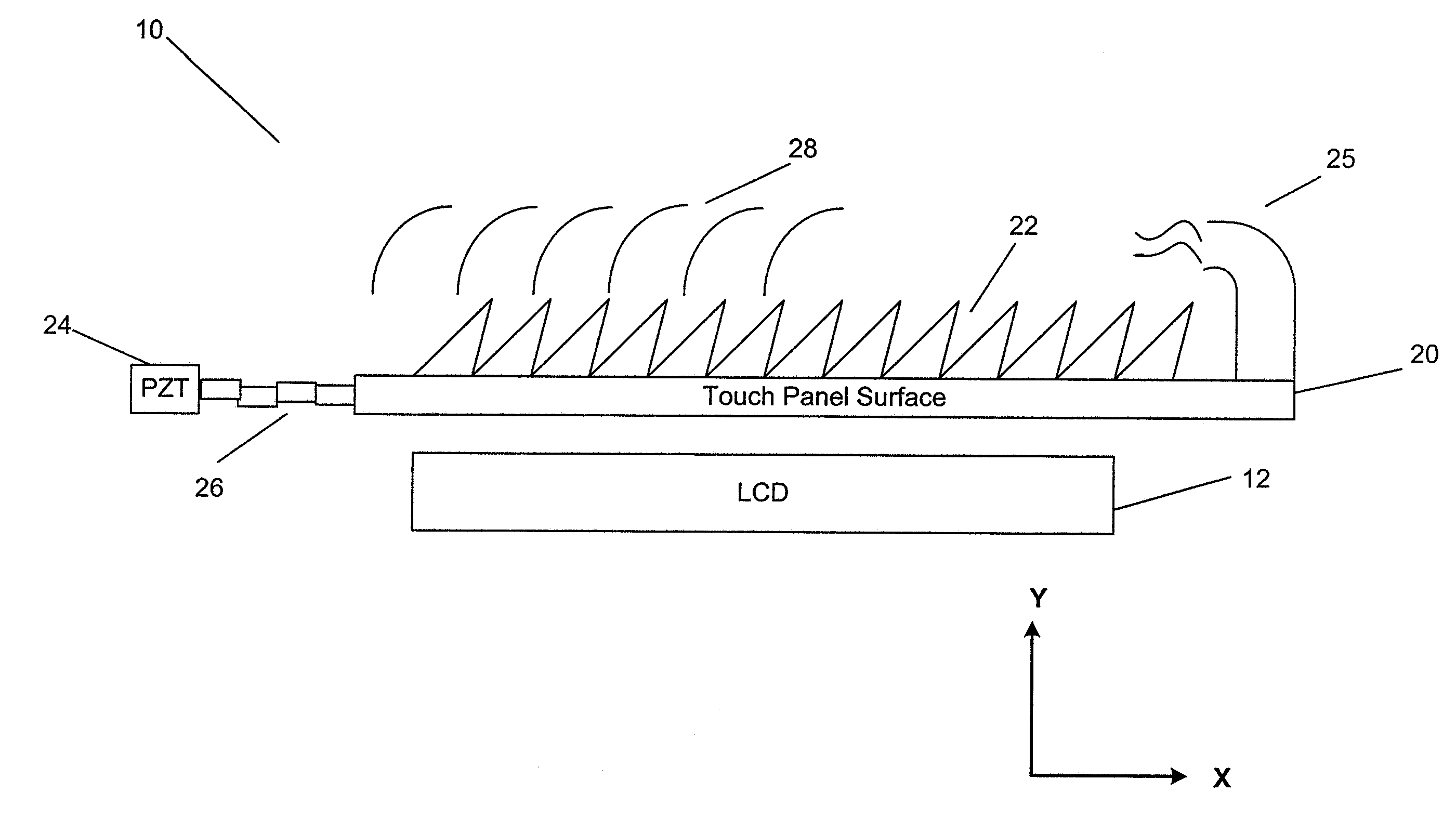

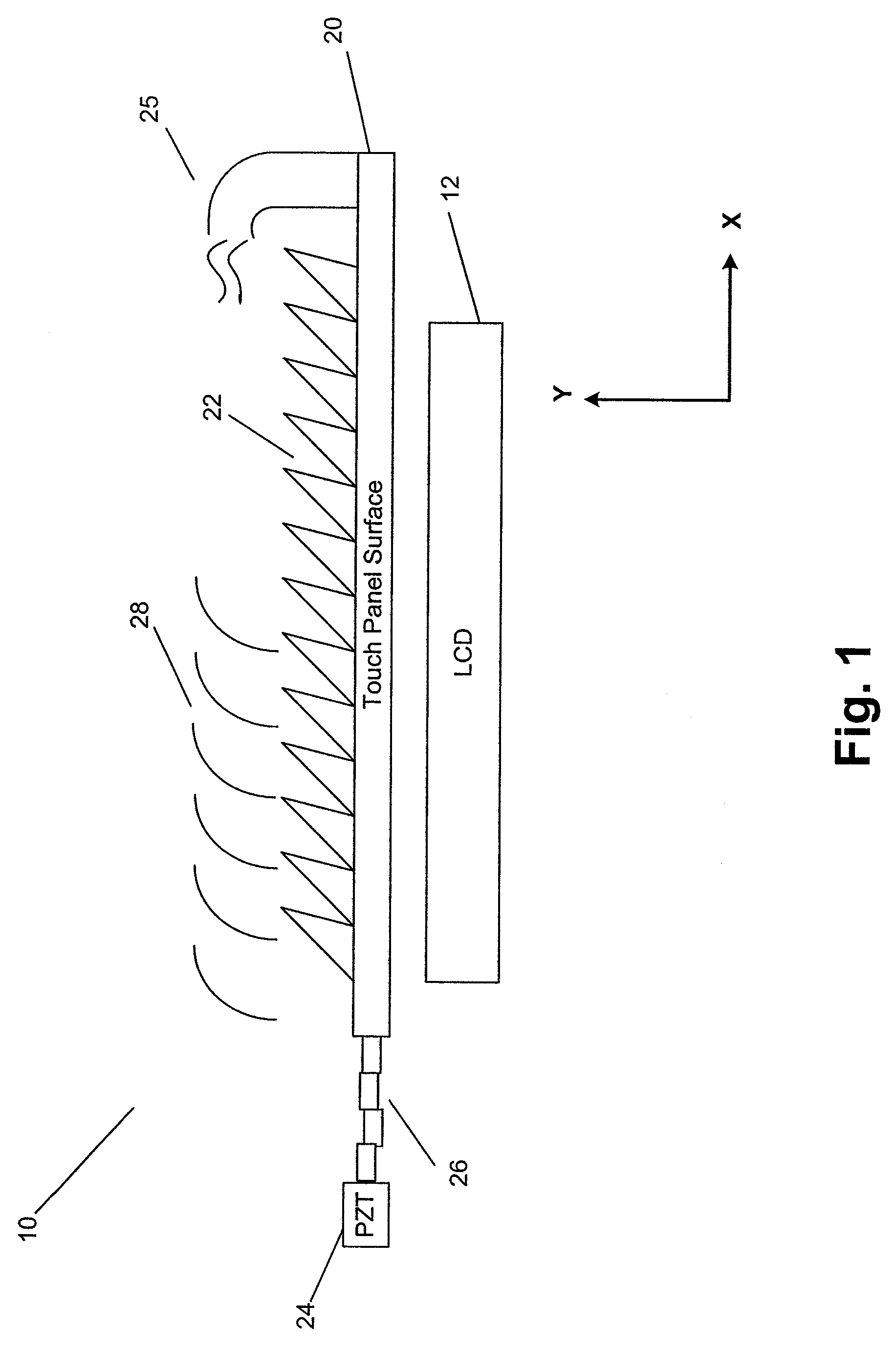

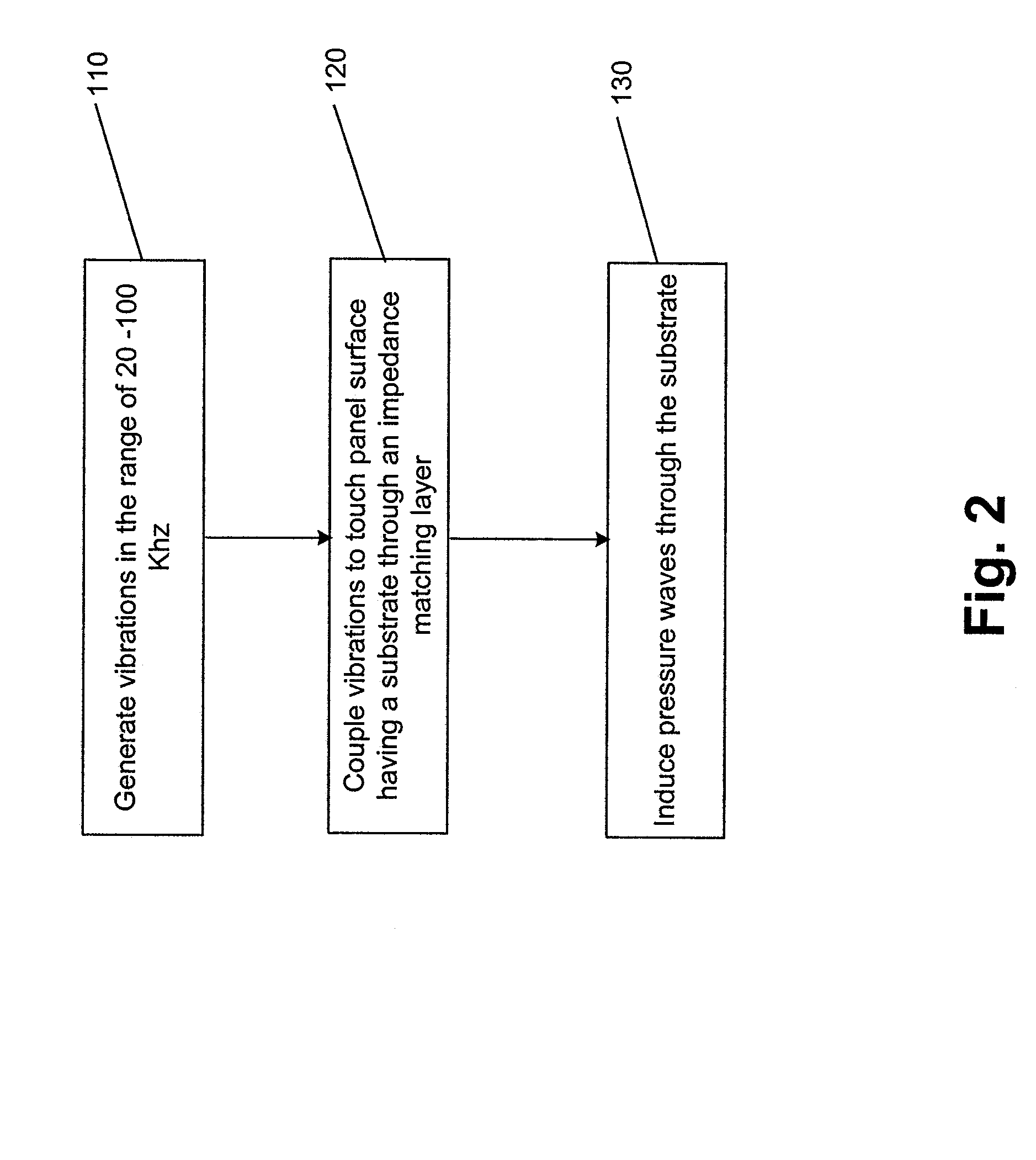

Sanitizing a touch panel surface

A touch panel system that sanitizes a touch panel surface includes a substrate coupled to the touch panel surface. The system further includes an impedance interface coupled to the touch panel surface and a vibration source coupled to the impedance interface. The vibration source vibrates the substrate to generate pressure waves which destroy contaminants on the touch panel surface.

Owner:IMMERSION CORPORATION

Shaped high frequency vibratory source

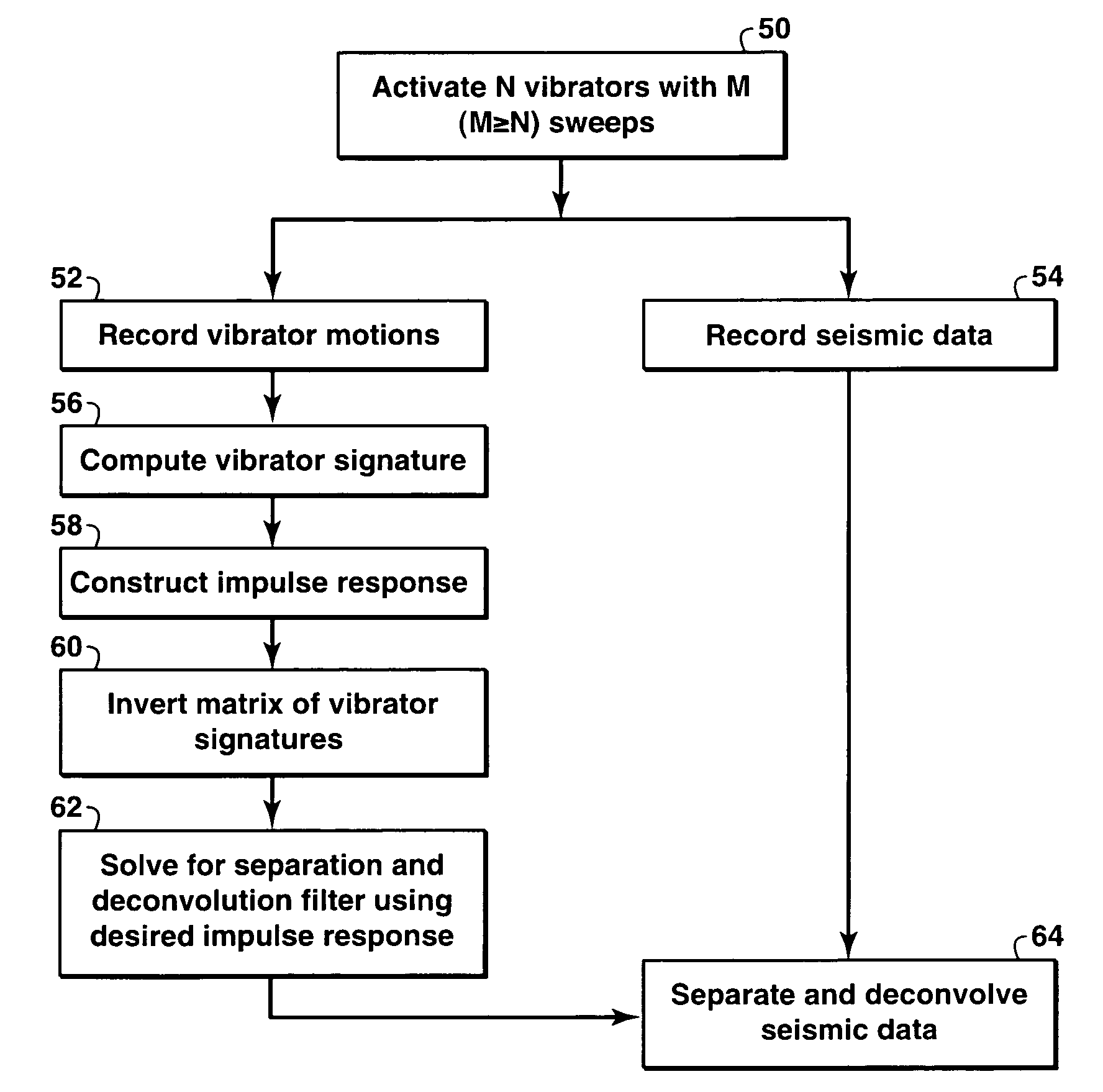

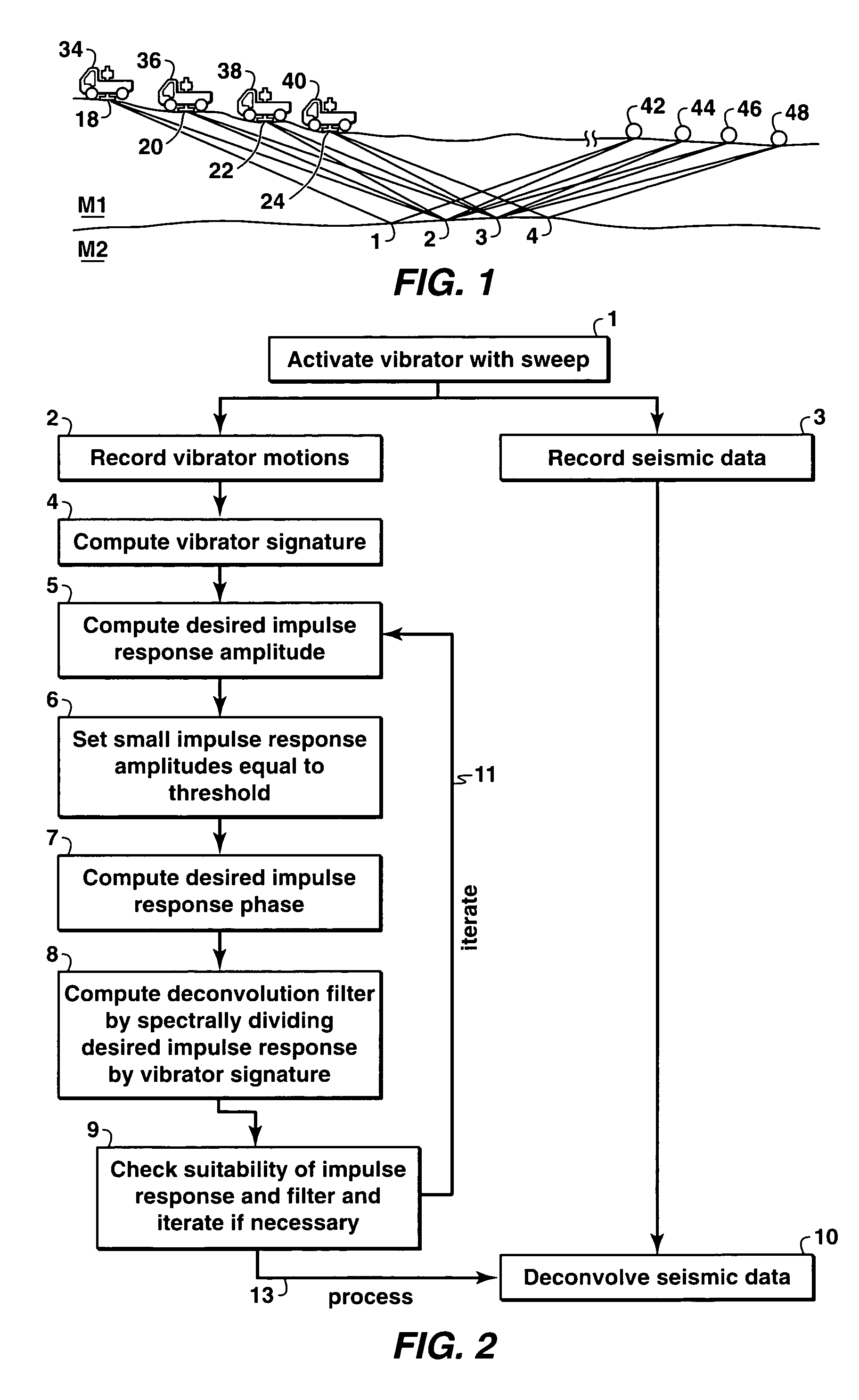

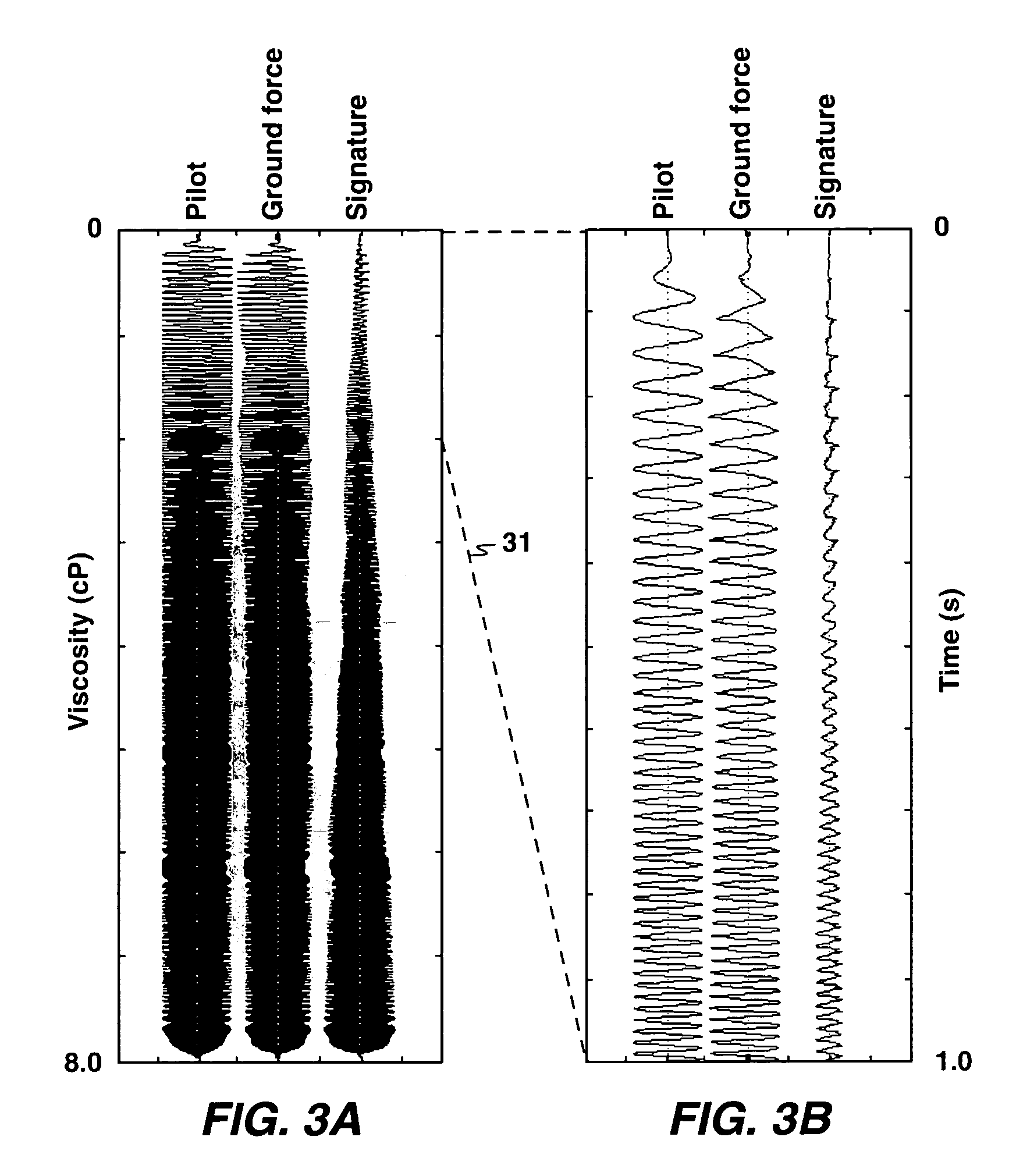

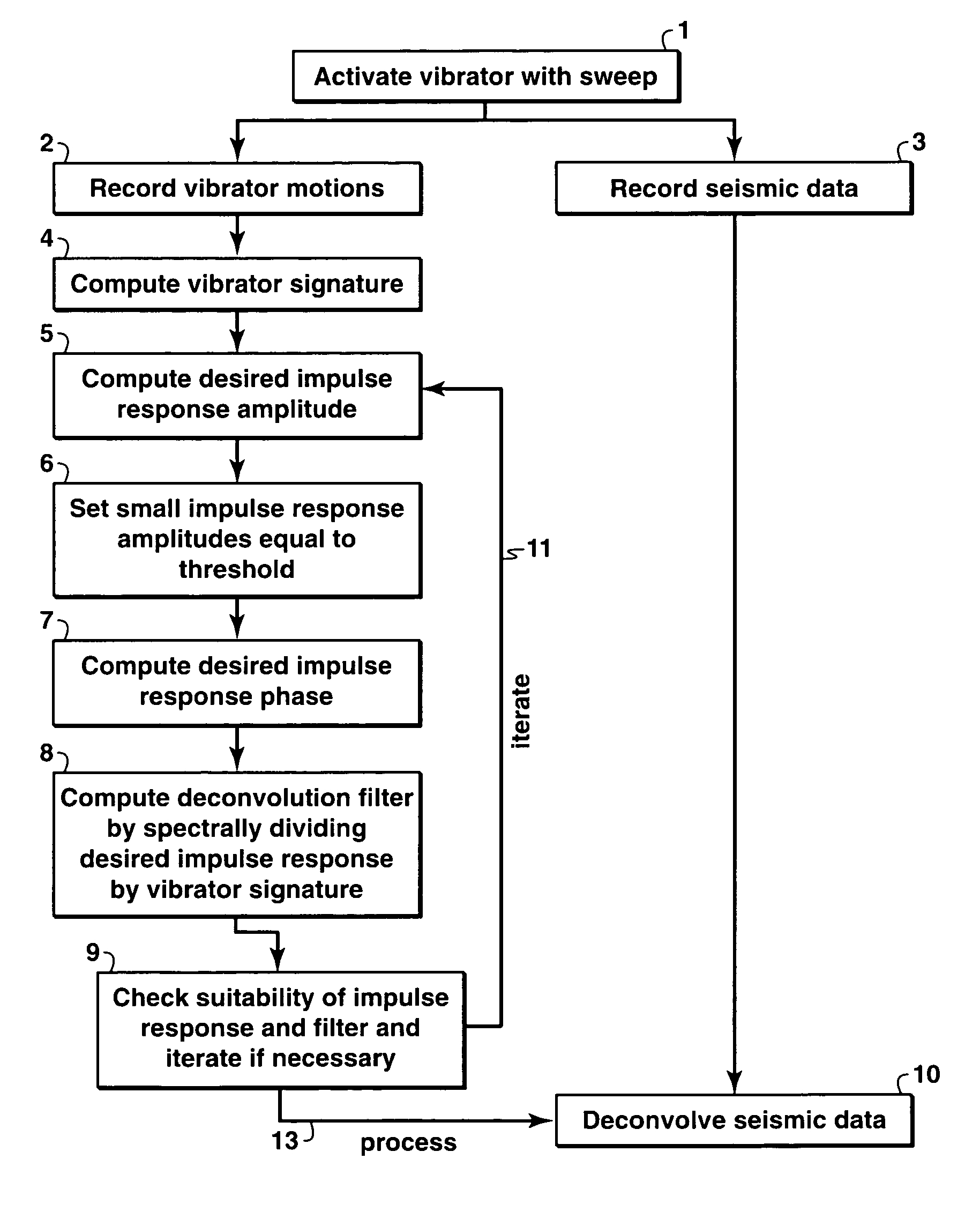

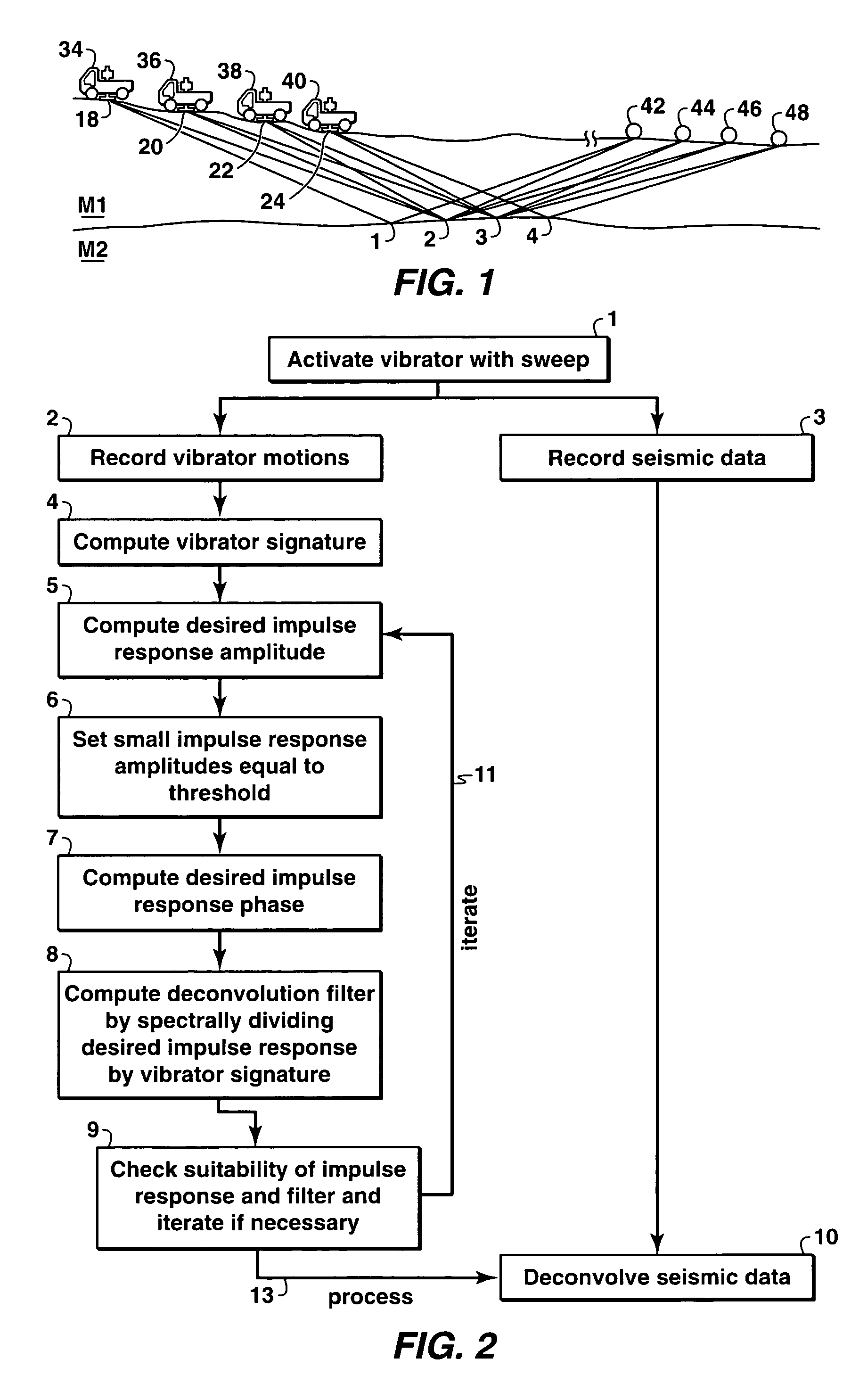

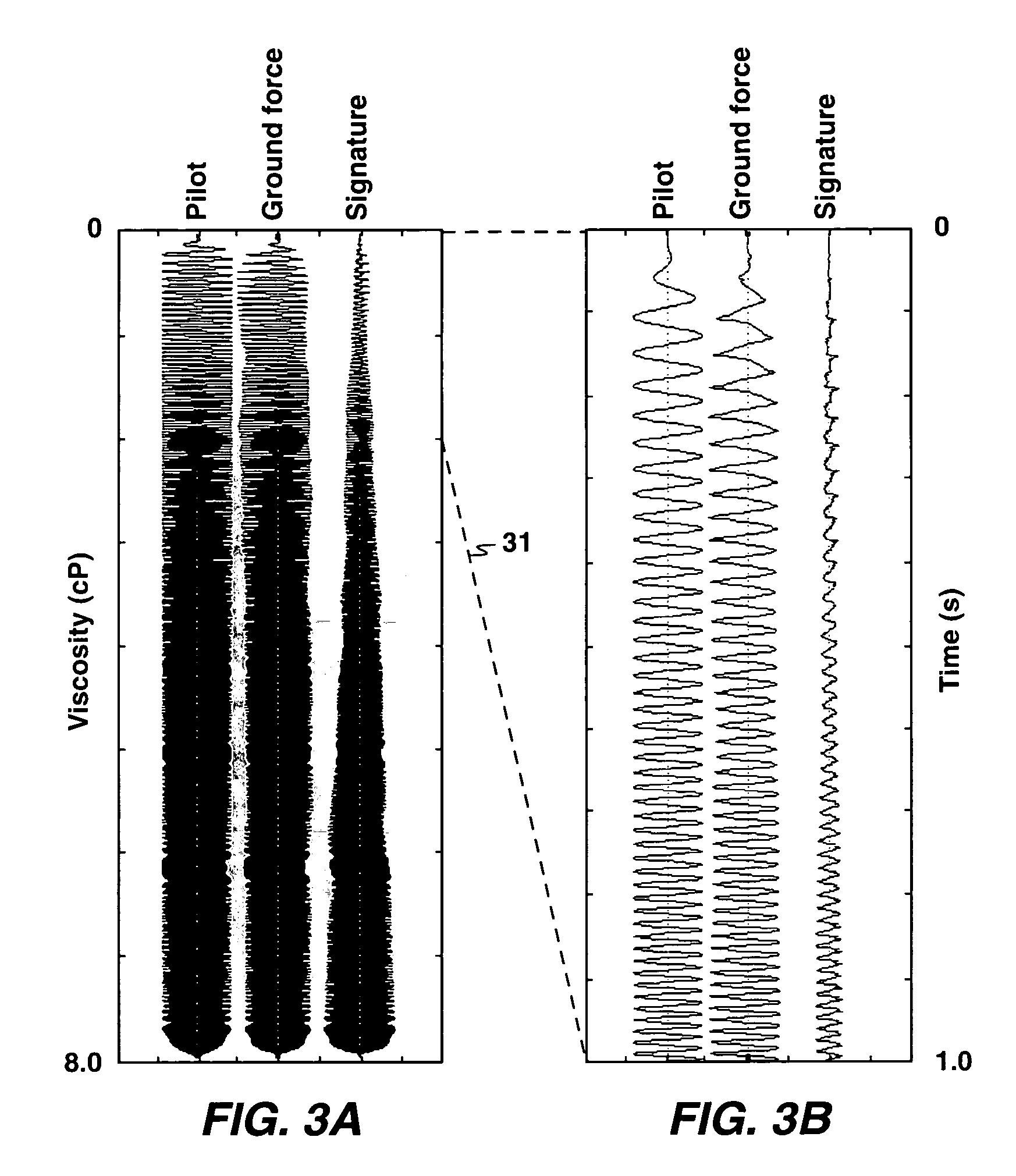

ActiveUS7436734B2Improved noise suppressionSeismic data acquisitionSeismic signal processingConvolution filterBiological activation

The present invention is a method of processing seismic data in which one or more seismic vibrators are activated with one or more pilot signals and vibrator motions are recorded along with seismic data. Vibrator signatures are computed from measured vibrator motions, such as the ground force signal. A desired impulse response is specified from either a measured vibrator motion or from test data or field data from a location near the location from which the seismic data was acquired. A deconvolution filter is computed from the impulse response and the vibrator signature. Alternatively, a single separation and deconvolution filter is derived from the impulse response and from vibrator signatures from multiple vibrators and sweeps. The deconvolution or deconvolution and separation filter is used to process the seismic data. The vibrators are then moved to a new location, and the activation is repeated.

Owner:EXXONMOBIL UPSTREAM RES CO

Shaped high frequency vibratory source

ActiveUS20060250891A1Improved noise suppressionSeismic data acquisitionSeismic signal processingConvolution filterBiological activation

The present invention is a method of processing seismic data in which one or more seismic vibrators are activated with one or more pilot signals and vibrator motions are recorded along with seismic data. Vibrator signatures are computed from measured vibrator motions, such as the ground force signal. A desired impulse response is specified from either a measured vibrator motion or from test data or field data from a location near the location from which the seismic data was acquired. A deconvolution filter is computed from the impulse response and the vibrator signature. Alternatively, a single separation and deconvolution filter is derived from the impulse response and from vibrator signatures from multiple vibrators and sweeps. The deconvolution or deconvolution and separation filter is used to process the seismic data. The vibrators are then moved to a new location, and the activation is repeated.

Owner:EXXONMOBIL UPSTREAM RES CO

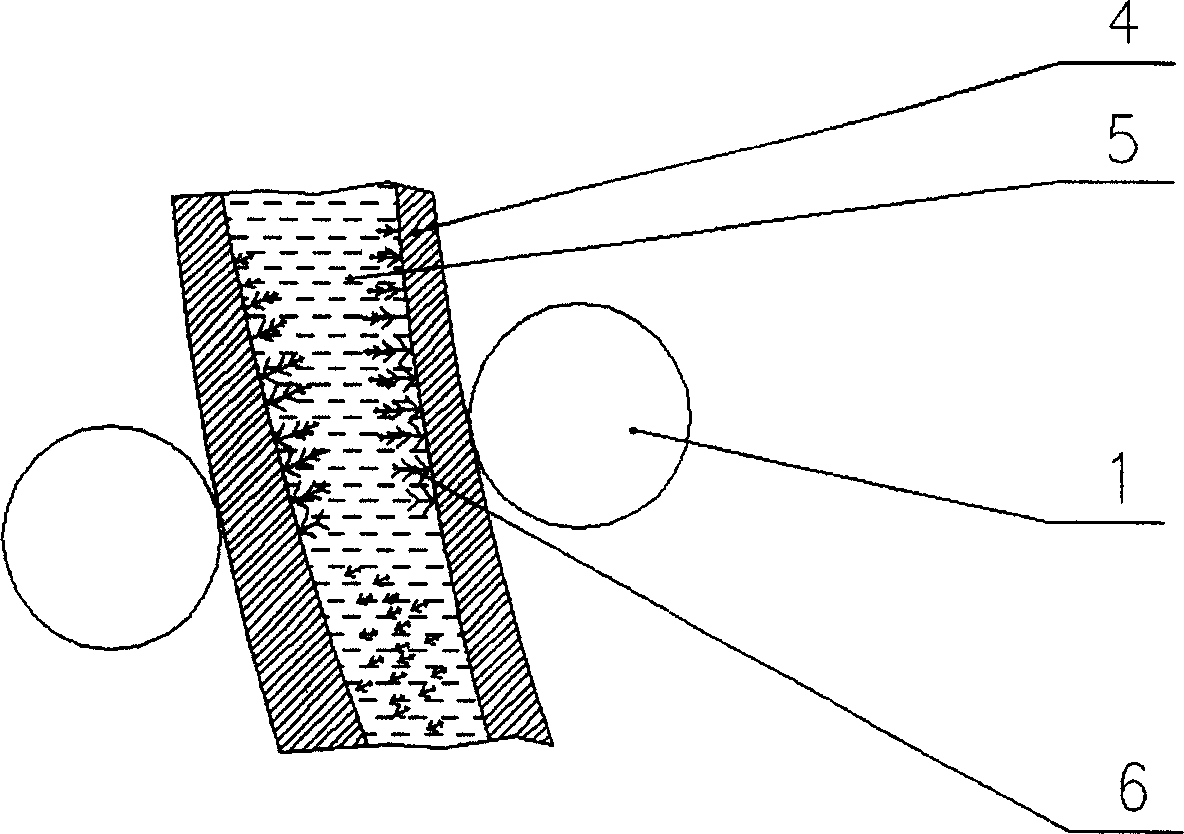

Method for improving continuous casting blank quality and vibration support roller device

The present invention belongs to the field of continuous metal blank casting technology, and is especially the method of raising continuous cast blank quality and the vibrating support roller apparatus. While the vibrating support roller closely contacting the casing of the continuously cast blank casing rotates synchronously with cast blank, it vibrates in the direction perpendicular to the cast blank thickness or in the direction parallel to the blank drawing under the drive of the vibration source, and the vibration is transferred to the solidifying shell of the liquid core via contact. The vibrating support roller apparatus consists of vibrating support roller, vibration transferring pipeline and vibration generating source. The present invention can improve the quality of the continuous cast blank obviously.

Owner:CENT IRON & STEEL RES INST

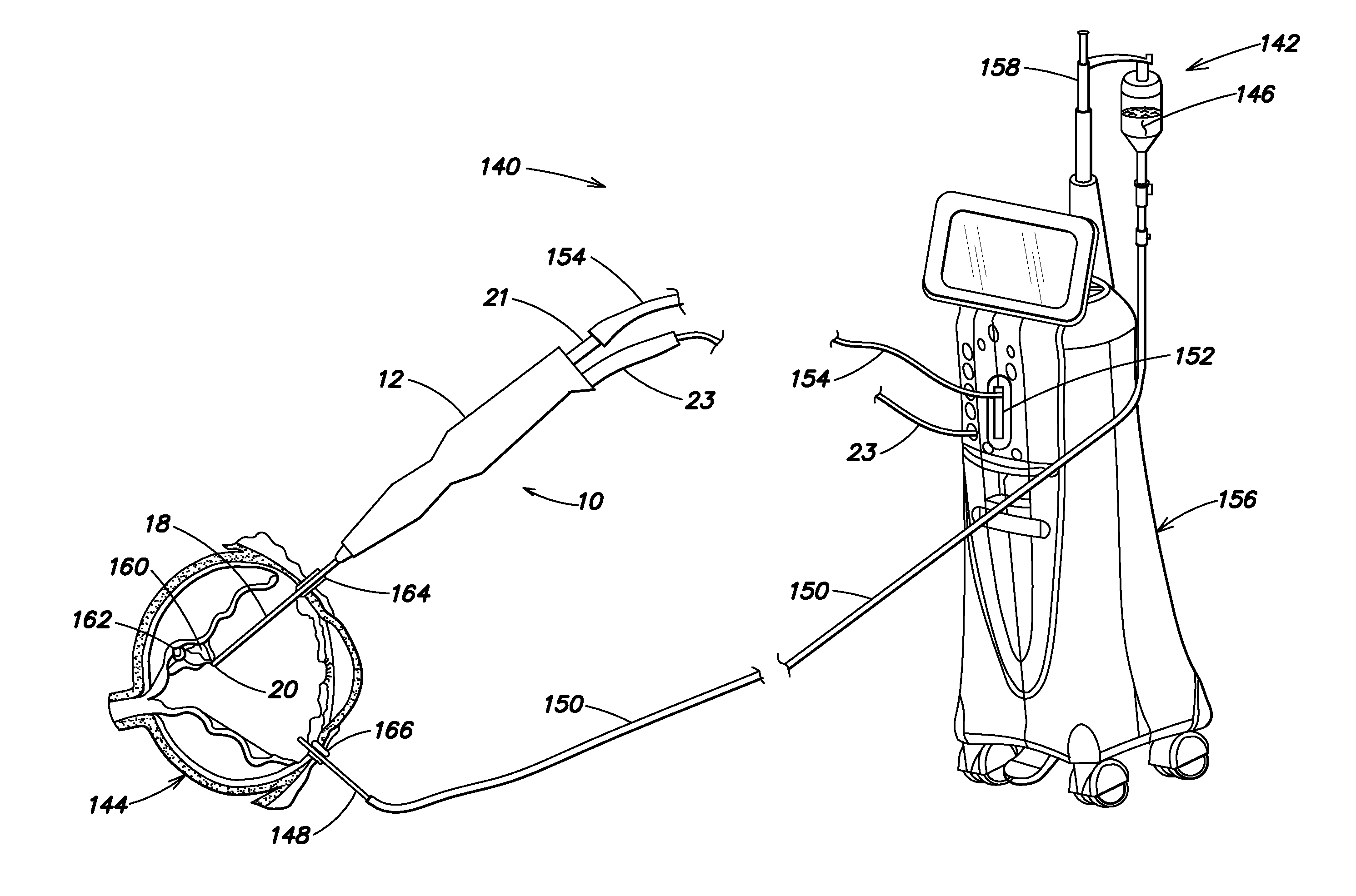

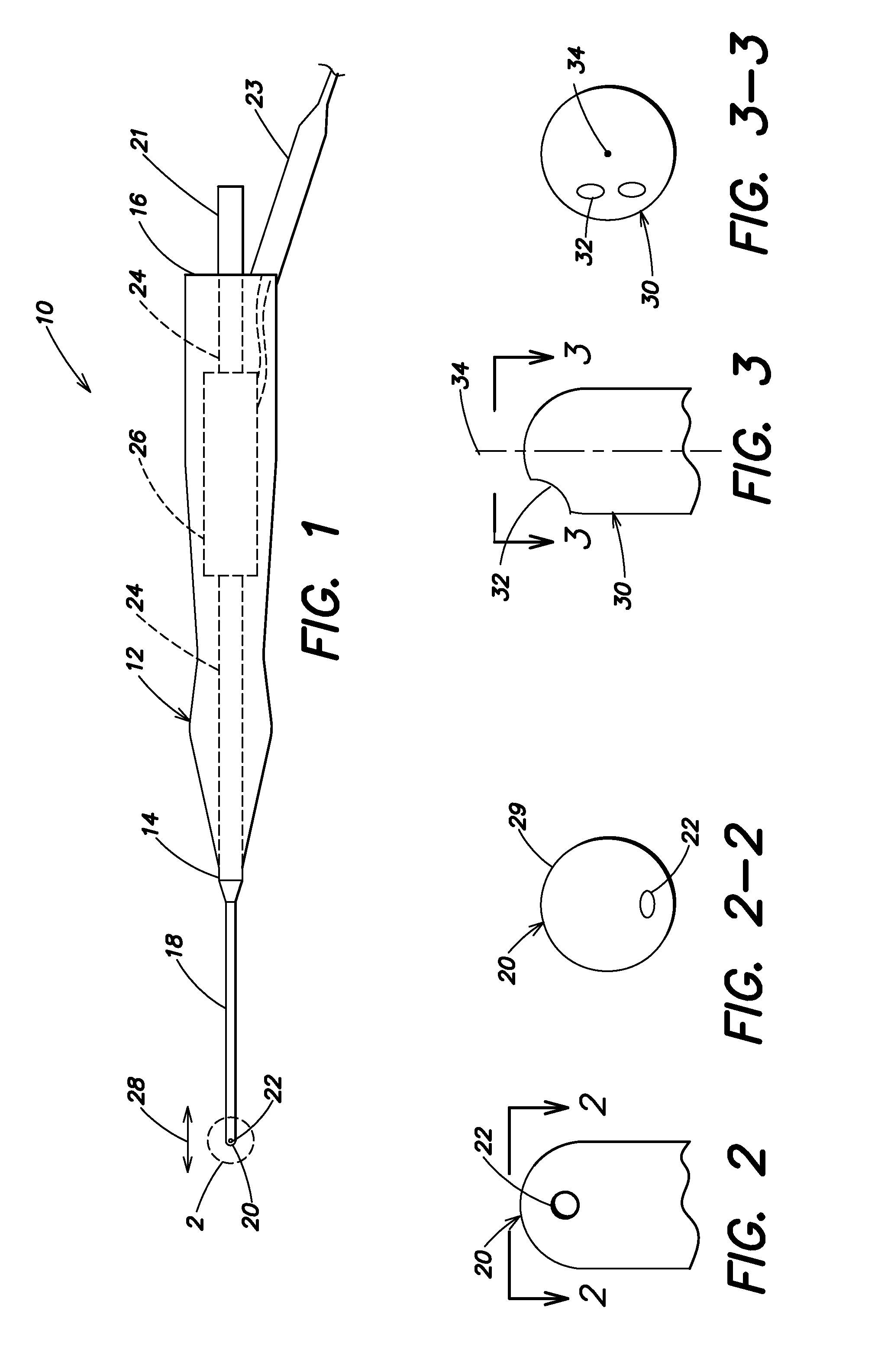

Vibrating Surgical Device for Removal of Vitreous and Other Tissue

An ophthalmic surgical device 10 includes a housing 12 having a distal end 14 and a proximal end 16. A cannula 18 is attached to the housing distal end 14 and has a distal tip 20 with at least one port 22 in communication with a lumen 19 extending through the cannula 18 and in communication with an aspiration path 24 in the housing 12. A vibration source 26 is held within the housing 12 for vibrating the distal tip 20 for assisting in vitreous and other tissue removal. An aspiration source 152 connected to the aspiration path 24 for applying a negative pressure to the lumen 19 and the at least one port 22 for removing fluids and the vitreous and other tissue from the eye. The vibration source 26 and the aspiration source 152 together create a periodic bi-directional flow of tissue through the port 22 without creating cavitation externally of the distal tip 20.

Owner:BAUSCH & LOMB INC

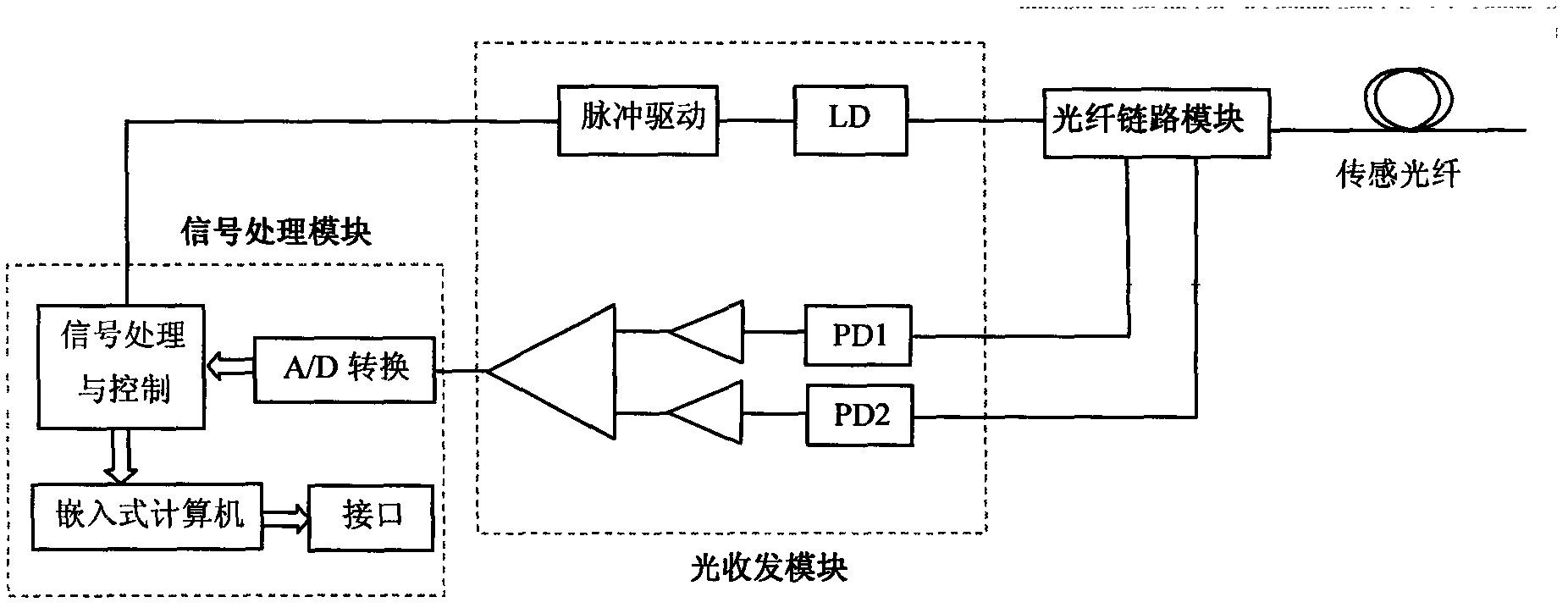

Multi-point localizable distribution-type optical-fiber vibration sensor based on polarization-state differential detection

InactiveCN102809421AHigh detection sensitivityHigh positioning accuracySubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansTime domainPhotovoltaic detectors

The invention discloses a distribution-type optical-fiber vibration sensor which is based on polarization-state differential detection and can localize multiple points of vibration sources, and the sensor is characterized in that on the basis of the traditional optical time domain reflectometer, a polarization beam splitter is used for detecting a polarization state of backward scattered light in sensing optical fibers, two beams of orthogonal polarization light which is outputted by the polarization beam splitter are respectively photoelectrically converted by two photoelectric detectors, then differential operation and amplification processing is conducted for two detected signals, the signals are sampled by an analog / digital (A / D) converter, and the sample is sent into an embedded computer to be data analyzed and computed so as to realize the precise localization of the vibration sources which are distributed along the axial direction of the optical fibers. Due to adopting the multi-point localizable distribution-type optical-fiber vibration sensor, the simultaneous localization of multi-point weak vibration sources which are distributed along the axial direction of the optical fibers can be realized. The multi-point localizable distribution-type optical-fiber vibration sensor is simple and reliable, easy to implement and maintain and suitable for the detection and precise localization of the weak vibration signal sensed by the long-distance laid optical fibers.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

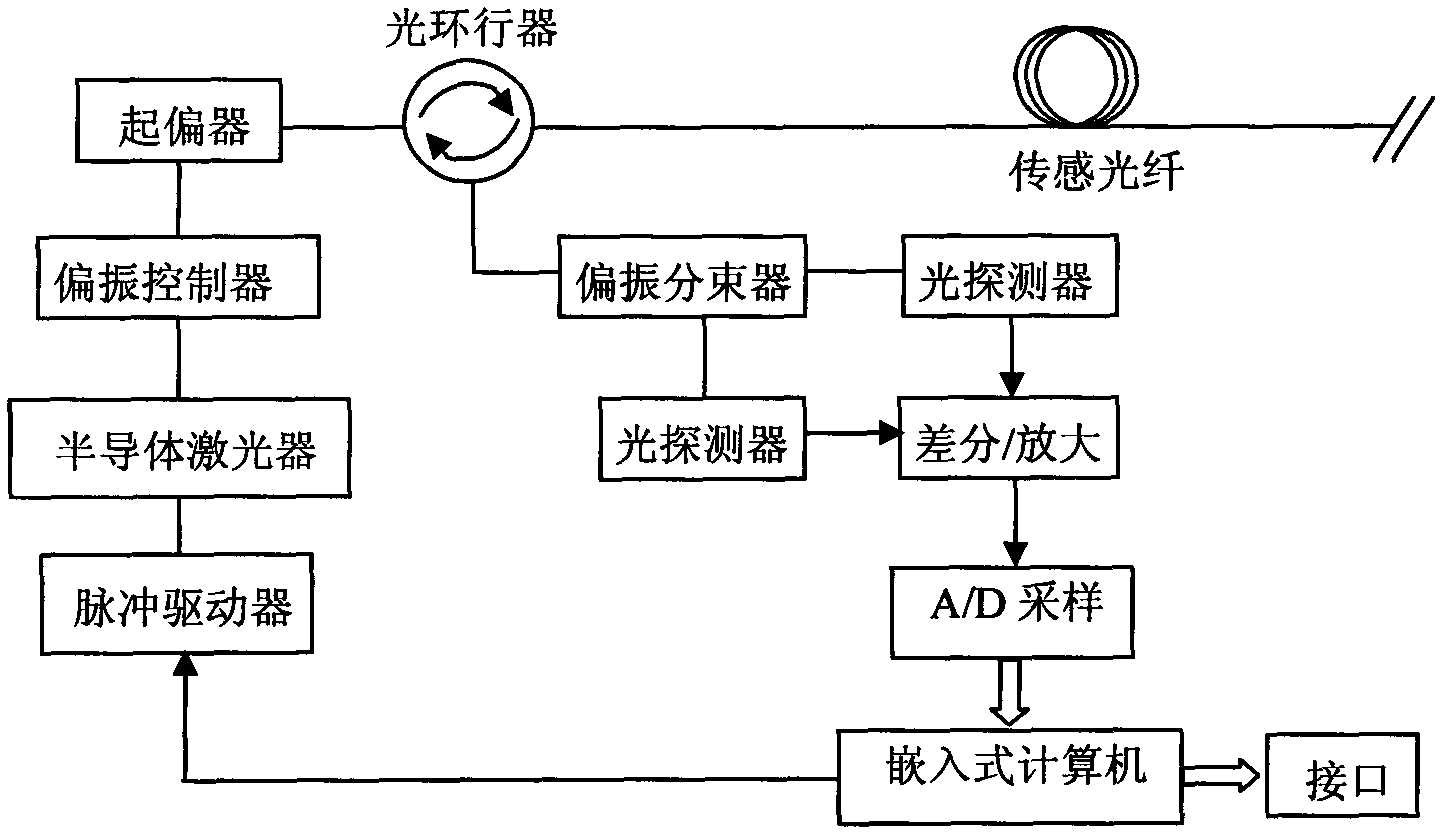

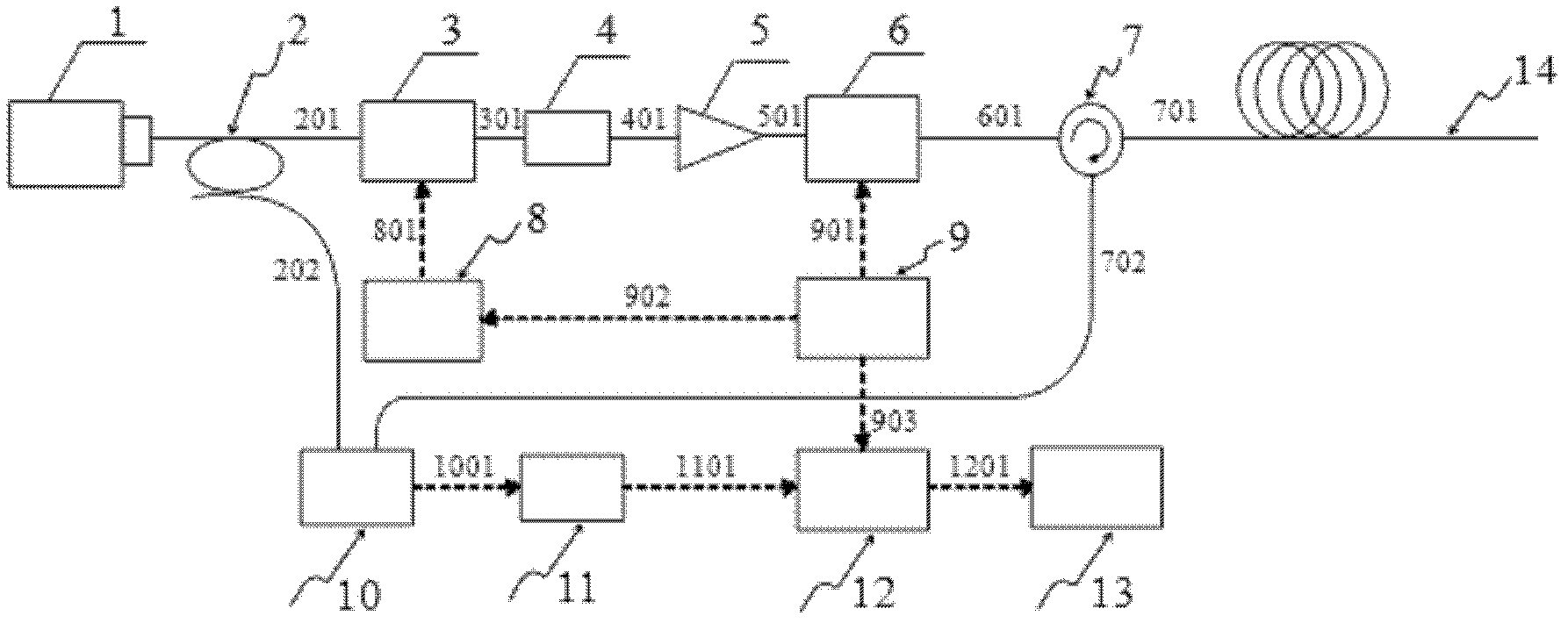

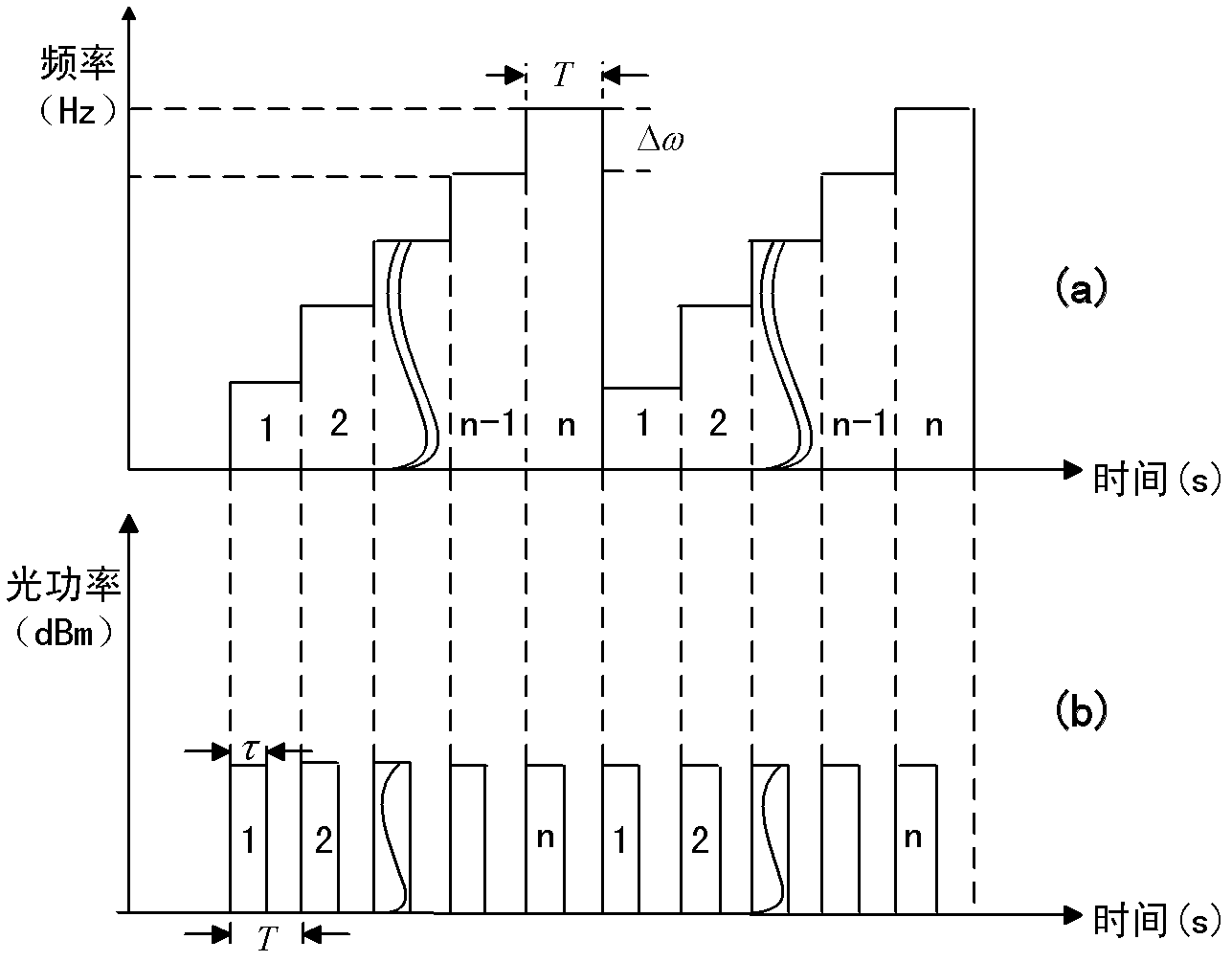

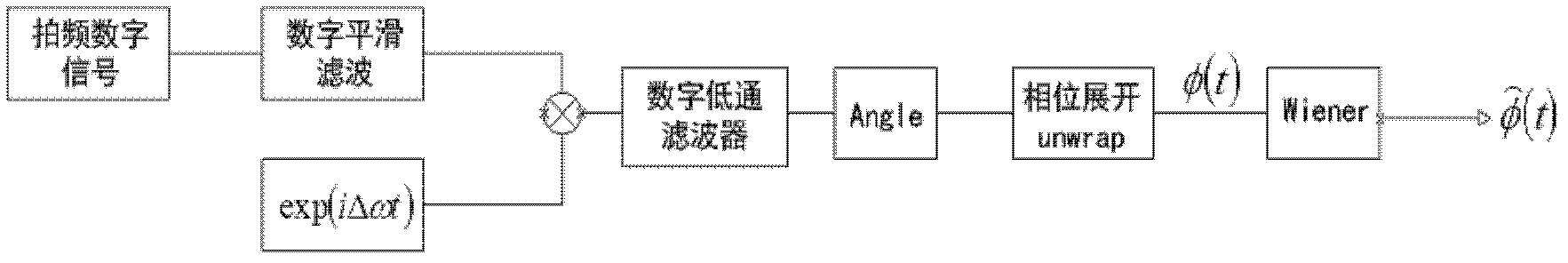

Optical frequency division multiplexing phase-sensitive optical time domain reflectometer

InactiveCN102645268AHigh sensitivityImprove dynamic rangeSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansLine widthLow-pass filter

The invention discloses an optical frequency division multiplexing phase-sensitive optical time domain reflectometer which comprises a narrow line width laser, an optical fiber coupler, a phase modulator, a scrambler, an erbium-doped optical fiber amplifier, an acoustic optical modulator, an optical fiber circulator, a signal generator module, a trigger source, a double balance detector, a low pass filter, a data acquisition card, a computer and a long-distance sensing optical fiber. According to the optical frequency division multiplexing phase-sensitive optical time domain reflectometer, the fundamental contradictions between the measuring distance and sampling rate in a distributed sensing system can be solved, and remoter or higher-frequency vibration is detected; and moreover, due to amplitude and phase information, the characteristics of a vibration source are judged at the first time, and the early warning can be provided immediately.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

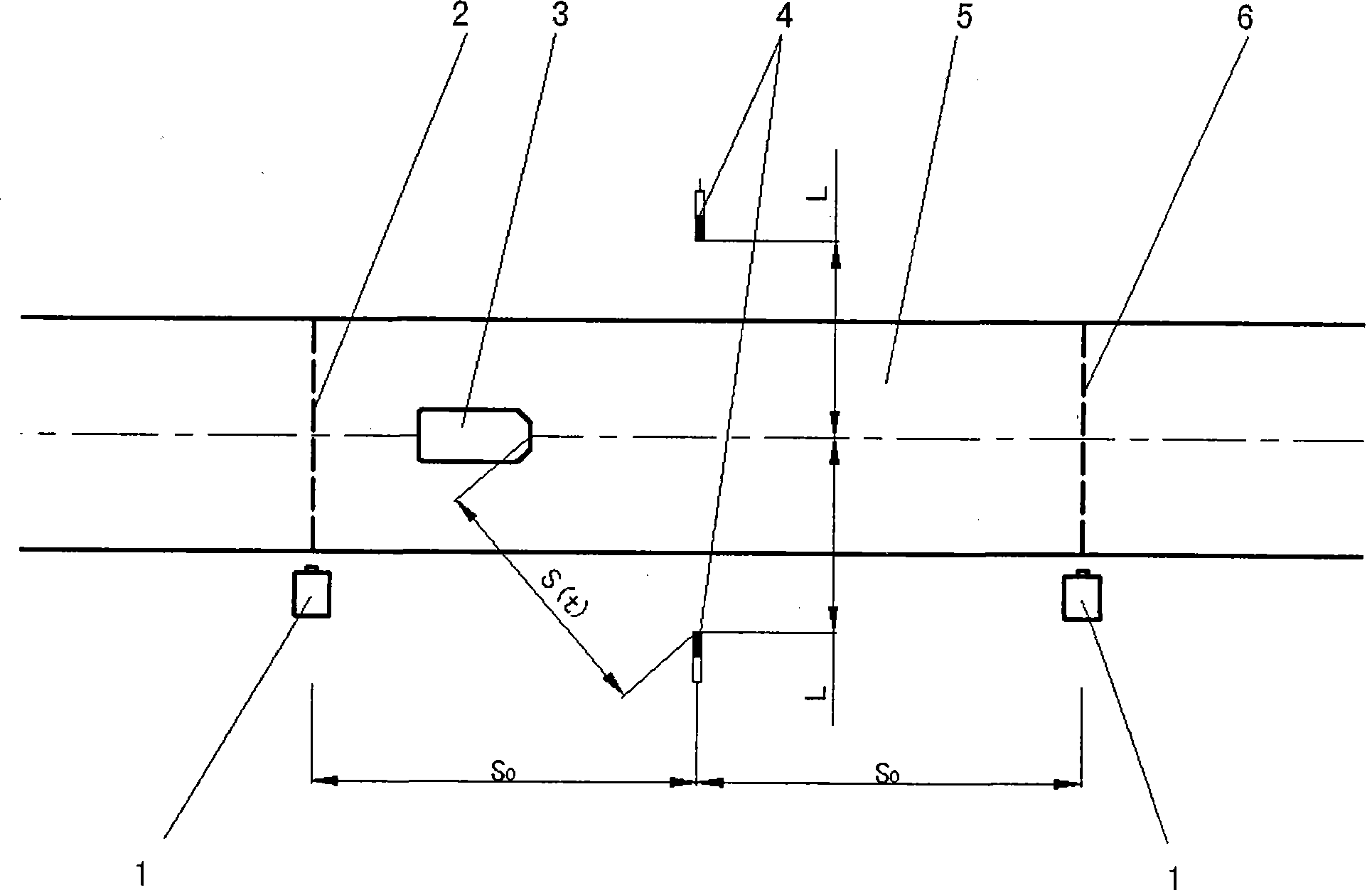

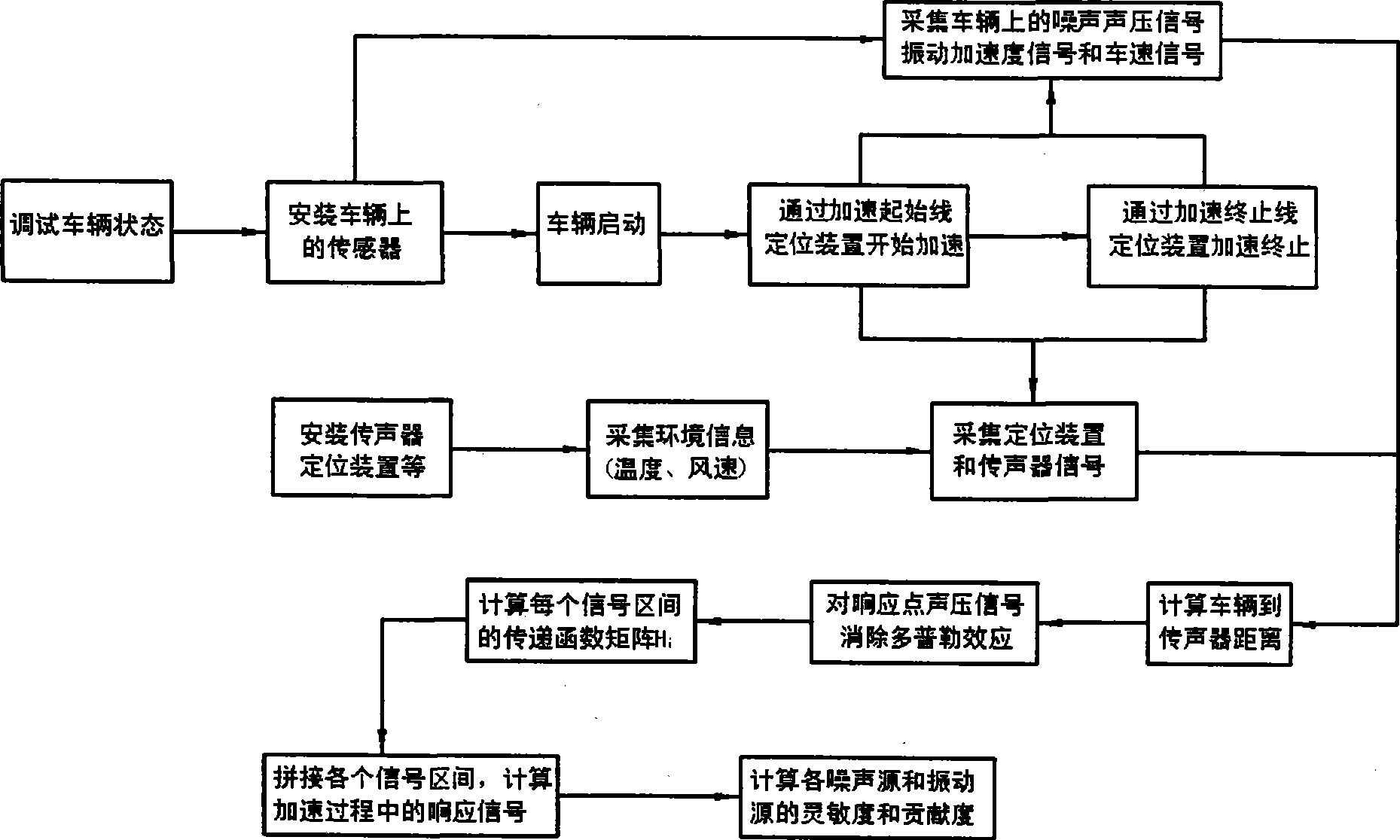

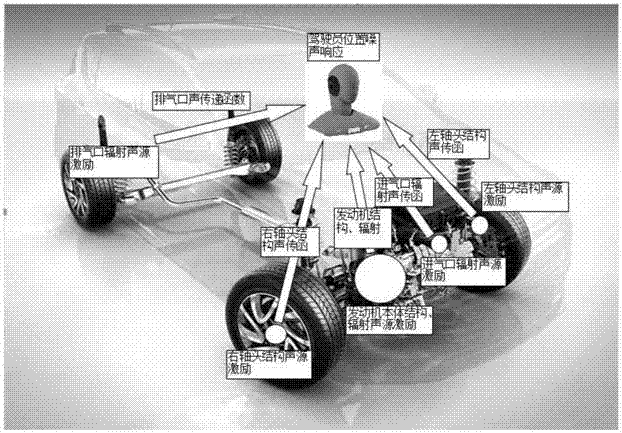

Noise source recognition method for vehicle acceleration noise

InactiveCN101464168AImproves acceleration noiseSubsonic/sonic/ultrasonic wave measurementUsing electrical meansNoise controlTransfer function matrix

The invention relates to a method for indentifying a noise source that produces noise when a vehicle accelerates, and belongs to the technical field of vehicle noise control. The method comprises the following steps: when the vehicle accelerates or travels at a uniform speed, the noise source signal, the vibration source signal, the speed signal, the response point sound pressure signal, the vehicle position signal and the like are collected; the transfer function matrix from the noise source and the vibration source to the response point is calculated; the changing response point sound pressure during the process of acceleration is synthesized and computed; and the sensitivity and the contribution degree of each noise source and vibration source are calculated. The invention has the following advantages: the noise source signal, the vibration source signal, the vehicle travelling state signal, and the ground response point sound pressure signal, which are collected during the running of the vehicle, can be utilized for accurately identifying the noise source that produces noise during the acceleration; and the quantitative relationship between the response point noise signal and each noise source is obtained and can provide a reliable basis for the reduction of noise produced by the acceleration of a running vehicle.

Owner:TSINGHUA UNIV

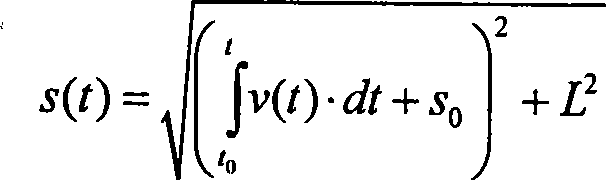

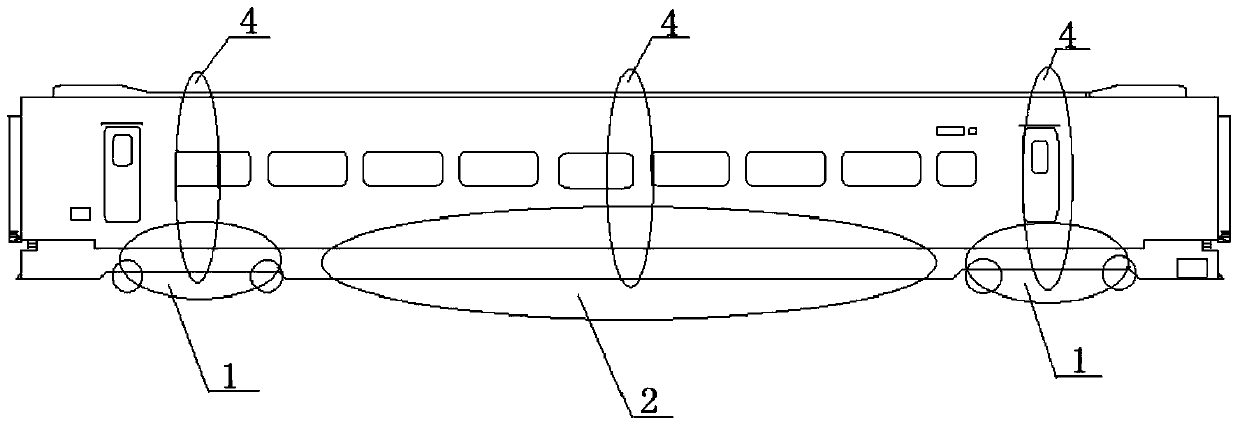

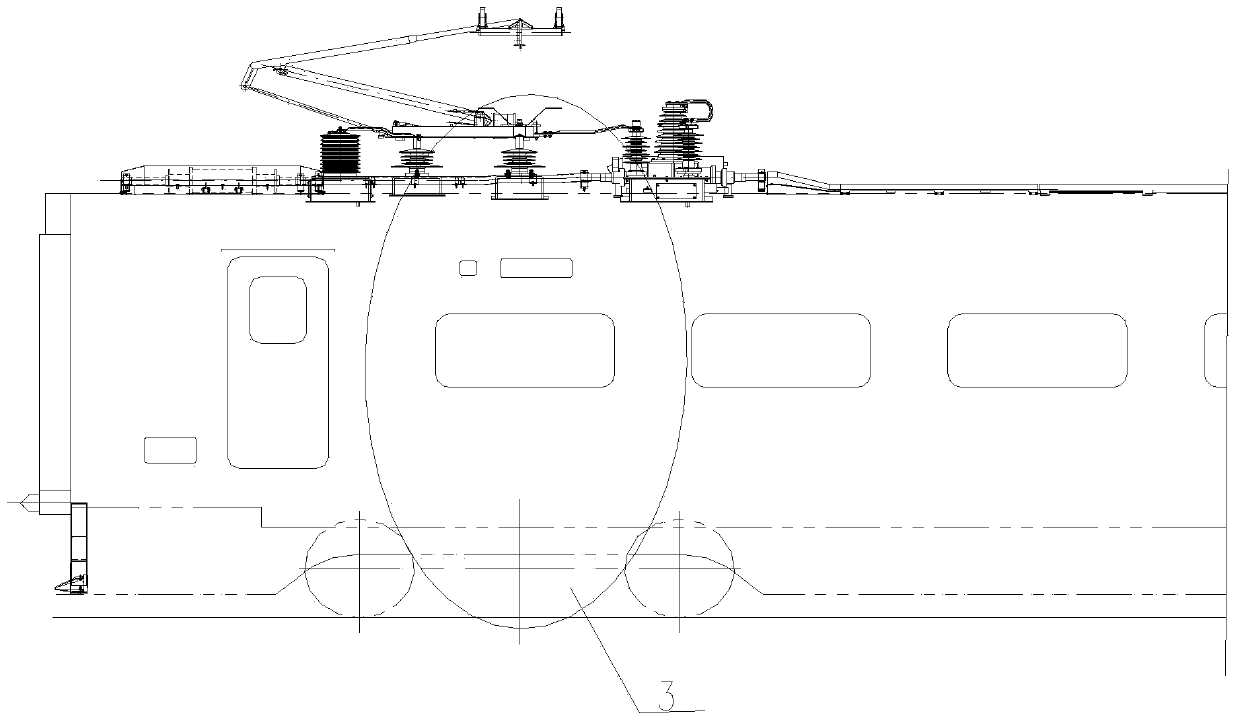

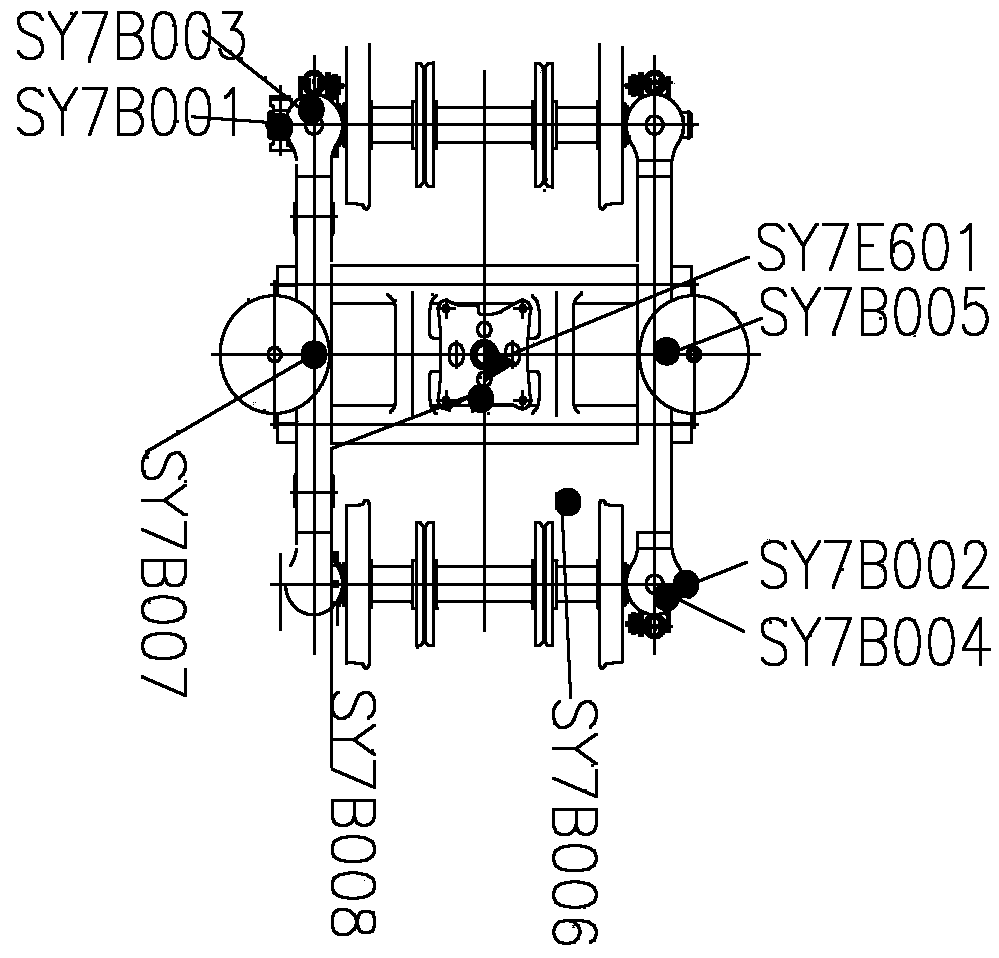

Noise source identifying and testing method for high speed train

ActiveCN103630232ARealize sound source controlImplement path controlSubsonic/sonic/ultrasonic wave measurementBogieSound sources

The invention relates to a noise source identifying and testing method for high speed train. The method comprising the following steps: partitioning noise sources into a steering frame wheel track noise testing area, an equipment noise testing area, a pantograph noise testing area and a pneumatic noise testing area; distributing testing points respectively according to the transmission paths of air sound and structure sound in each area; acquiring testing point data; analyzing through sound and vibration transmission paths; separating the air sound from the structure sound; calculating the contribution of each noise source to interior noise. According to the noise source identifying and testing method, sound sources and vibration sources causing interior noise of the high speed train can be identified, the contribution of each noise source and each vibration source to the interior noise is determined, sound source control and path control of the interior noise are realized fundamentally, and a scientific basis is laid for the vibration and noise reduction structural design of the high speed train.

Owner:CRRC QINGDAO SIFANG CO LTD

Power generator

InactiveUS20130207520A1Low costNegatively impact reliabilityPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesEngineering physicsEnergy storage

An electrical power generator has one or more serpentine elements that are made of a poled piezoelectric or electrostrictive ceramic, one or more electrically conductive shims or foils and at least two electrically conductive electrode coatings on the serpentine element. The conductive electrodes are further electrically connected to an electrical load or energy storage device or both, and the serpentine element is mechanically affixed to a source of compression or vibration or both.

Owner:GENZIKO

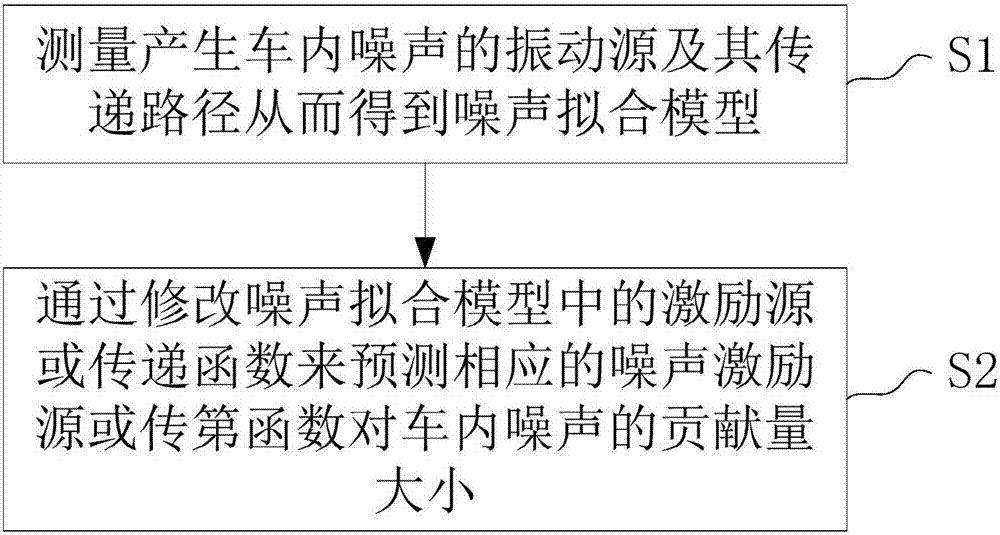

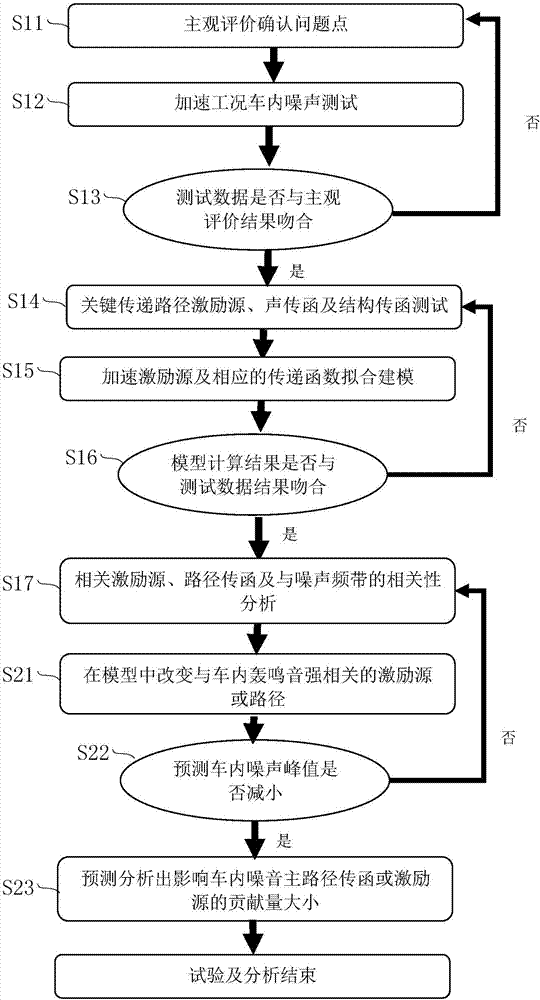

Method for predicting size of acceleration condition in-vehicle noise contribution

InactiveCN106996828ASimple methodReduce computationVehicle testingGeometric CADIn vehicleCorrelation analysis

The invention discloses a method for predicting the size of acceleration condition in-vehicle noise contribution. The method comprises the following steps that a vibration source generating in-vehicle noise and the transfer path thereof are measured so as to obtain a noise fitting model; and the excitation source or the transfer function in the noise fitting model is modified so as to predict the size of contribution of the corresponding noise excitation source or the transfer function on the in-vehicle noise. The in-vehicle noise model is established by using the measured acceleration excitation source and the noise transfer function thereof and correlation analysis is performed on the relevant excitation source, the path transfer function and the noise frequency band to determine the strongly correlated vibration source of the in-vehicle noise and the path transfer function thereof so as to perform troubleshooting, and the method is simple and rapid, the computing burden can be substantially reduced and the processing efficiency can be enhanced.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

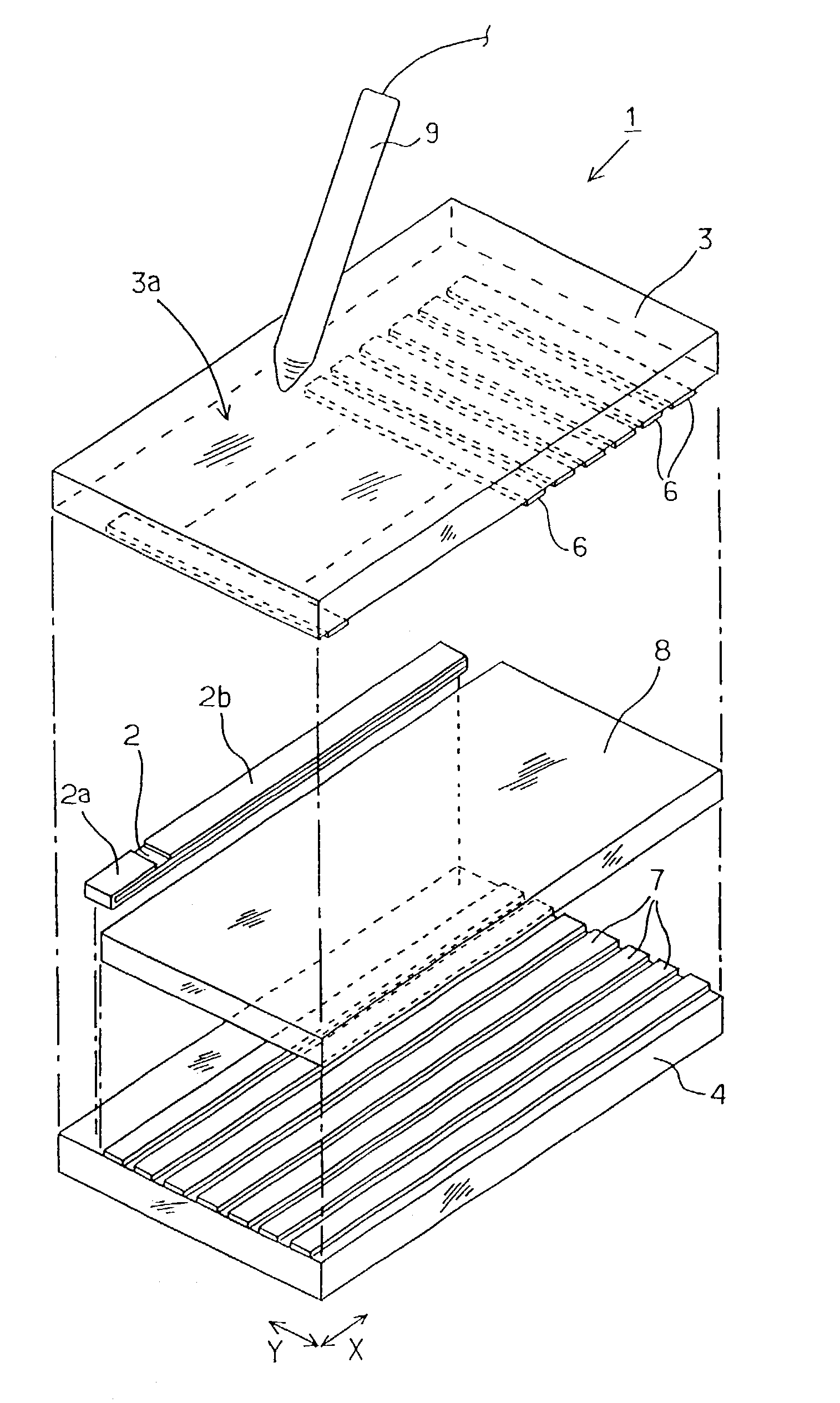

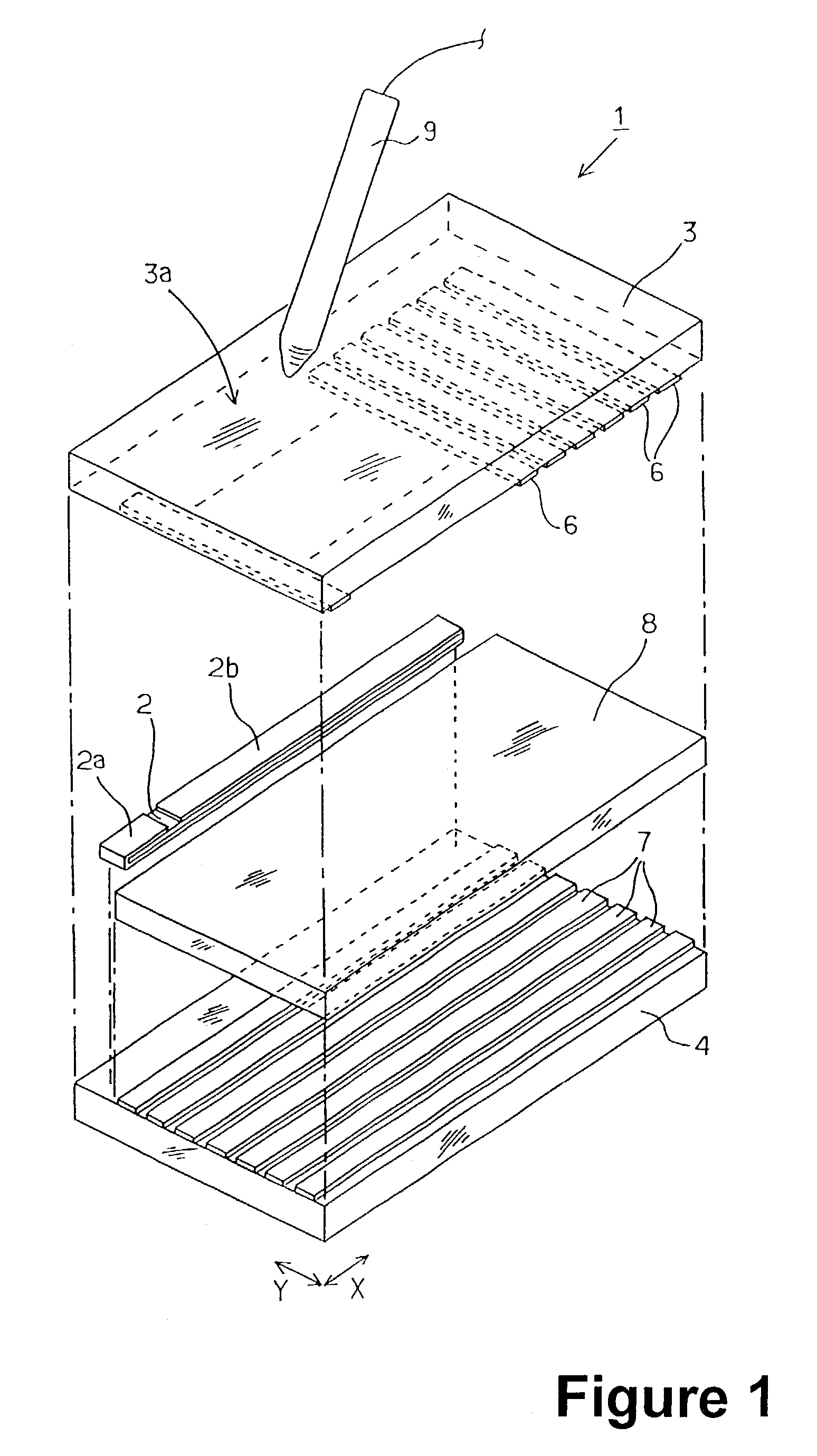

Digitizing tablet

ActiveUS7119798B2Without increasing size of tabletDesign is limitedInput/output for user-computer interactionCathode-ray tube indicatorsSoftware engineeringMechanical engineering

A digitizing tablet that can control the vibration of an operation panel or a support substrate is disclosed. A piezoelectric substrate having a pair of drive electrodes fixed to the front and rear surfaces of the piezoelectric substrate is fixed directly or via one of the drive electrodes to the operation panel or the support substrate. A drive voltage is applied to the pair of drive electrodes after an input as been detected, and the drive voltage causes the expandable piezoelectric substrate to vibrate the operation panel or the support substrate. An additional vibration source is not required. Therefore, the vibration energy is not dissipated and there is no time delay in transmission since the operation panel or the support substrate are vibrated directly by the piezoelectric substrate. The expansion and contraction of the piezoelectric substrate can be controlled so that the vibration can be controlled precisely.

Owner:SMK CORP

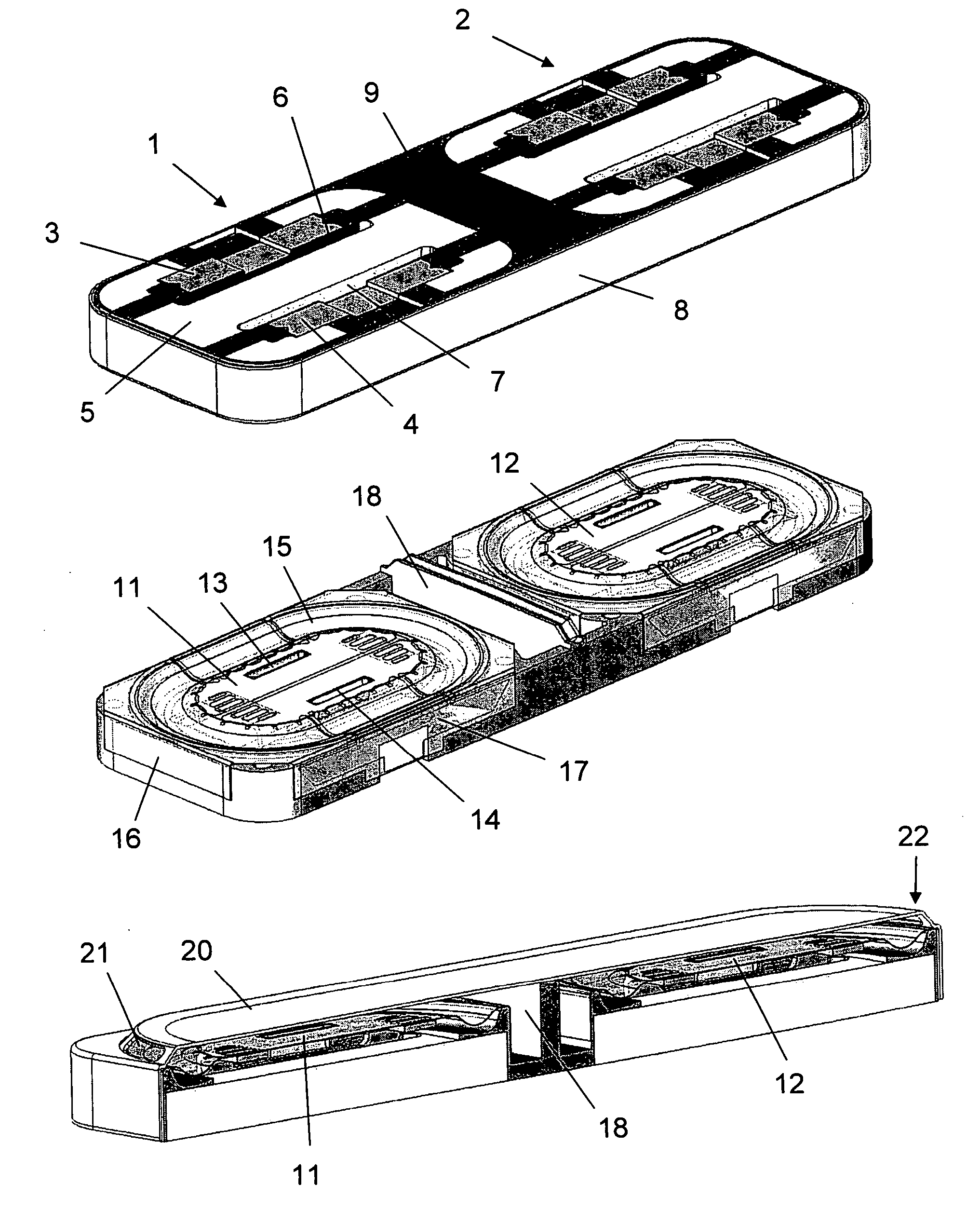

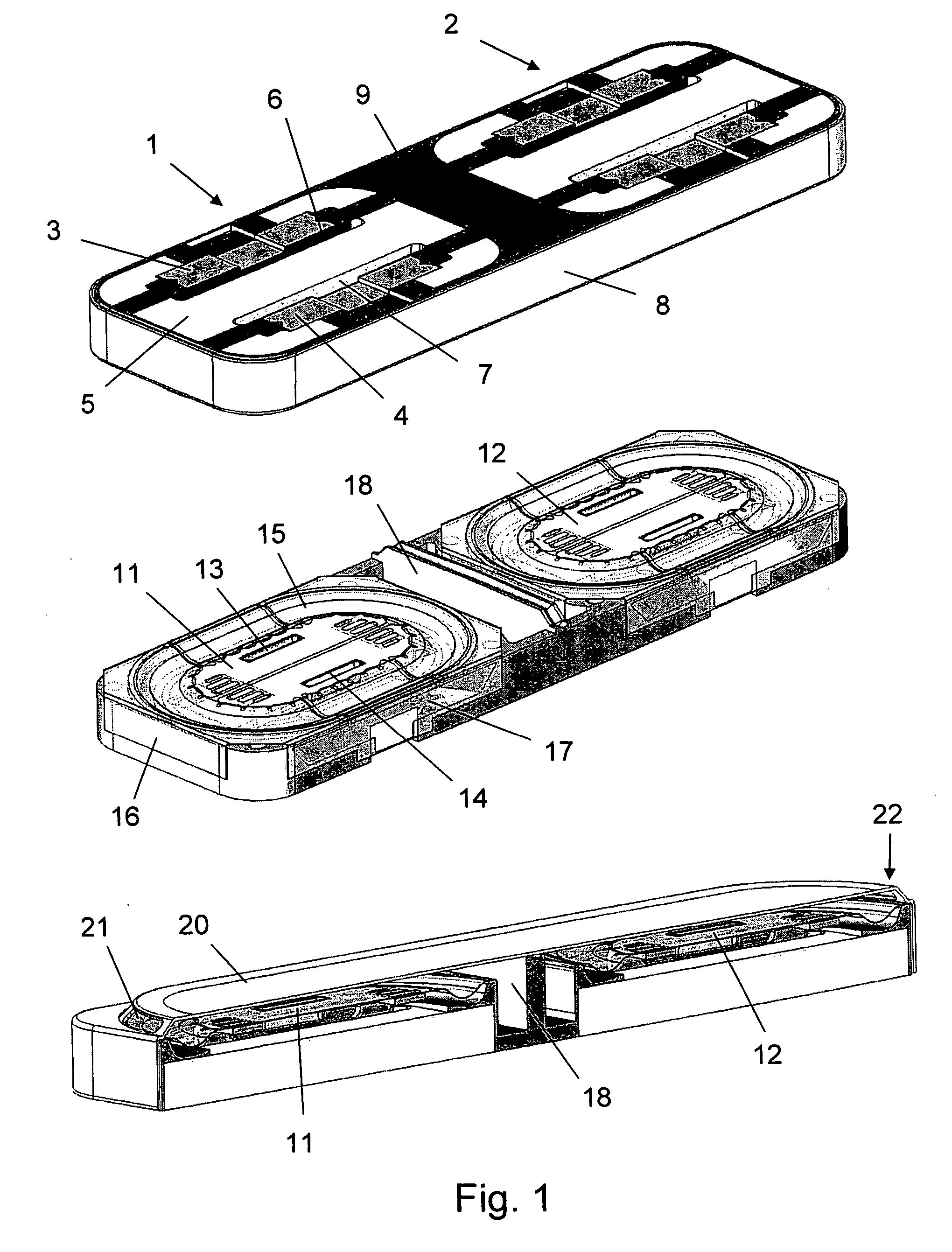

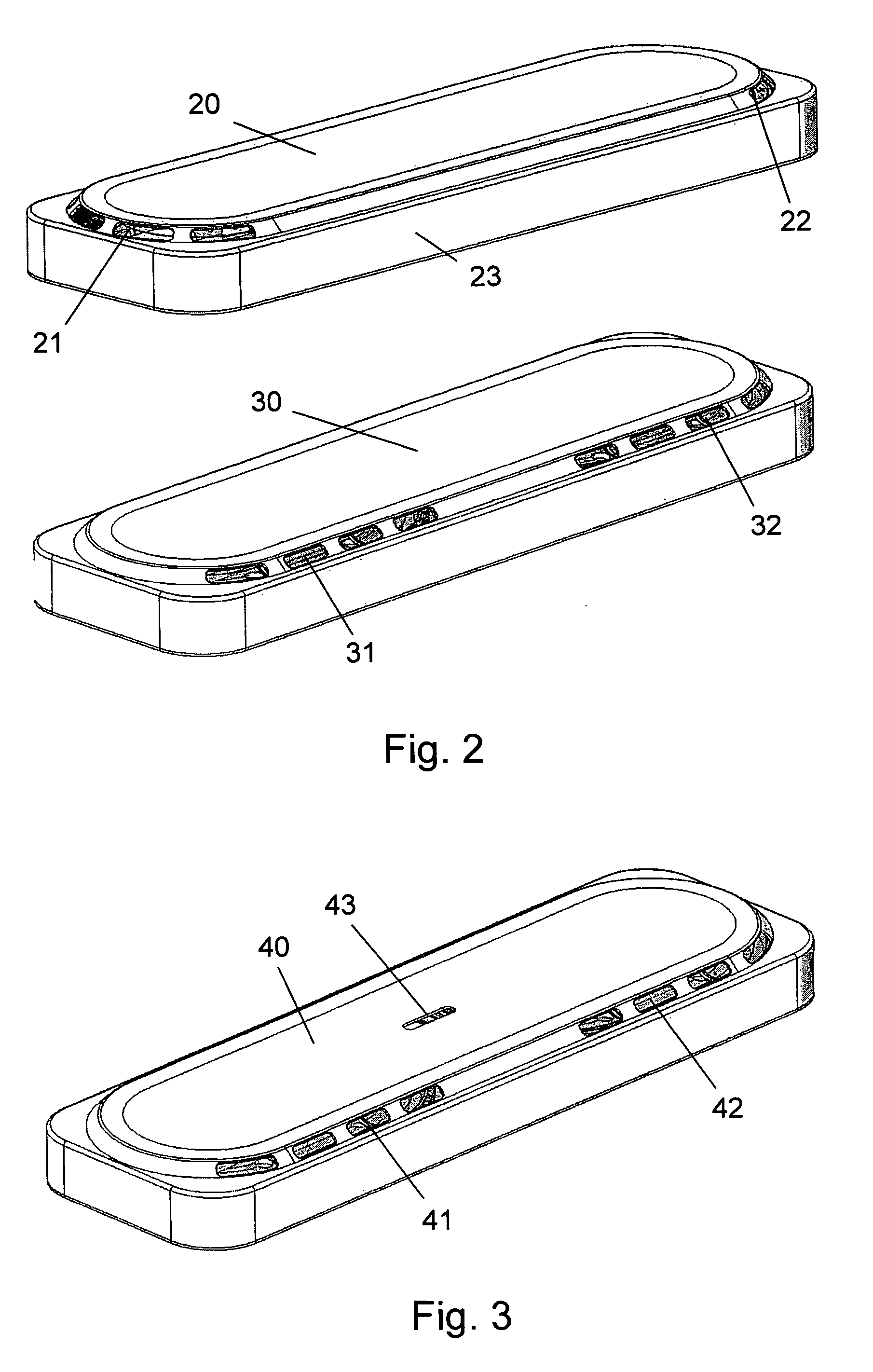

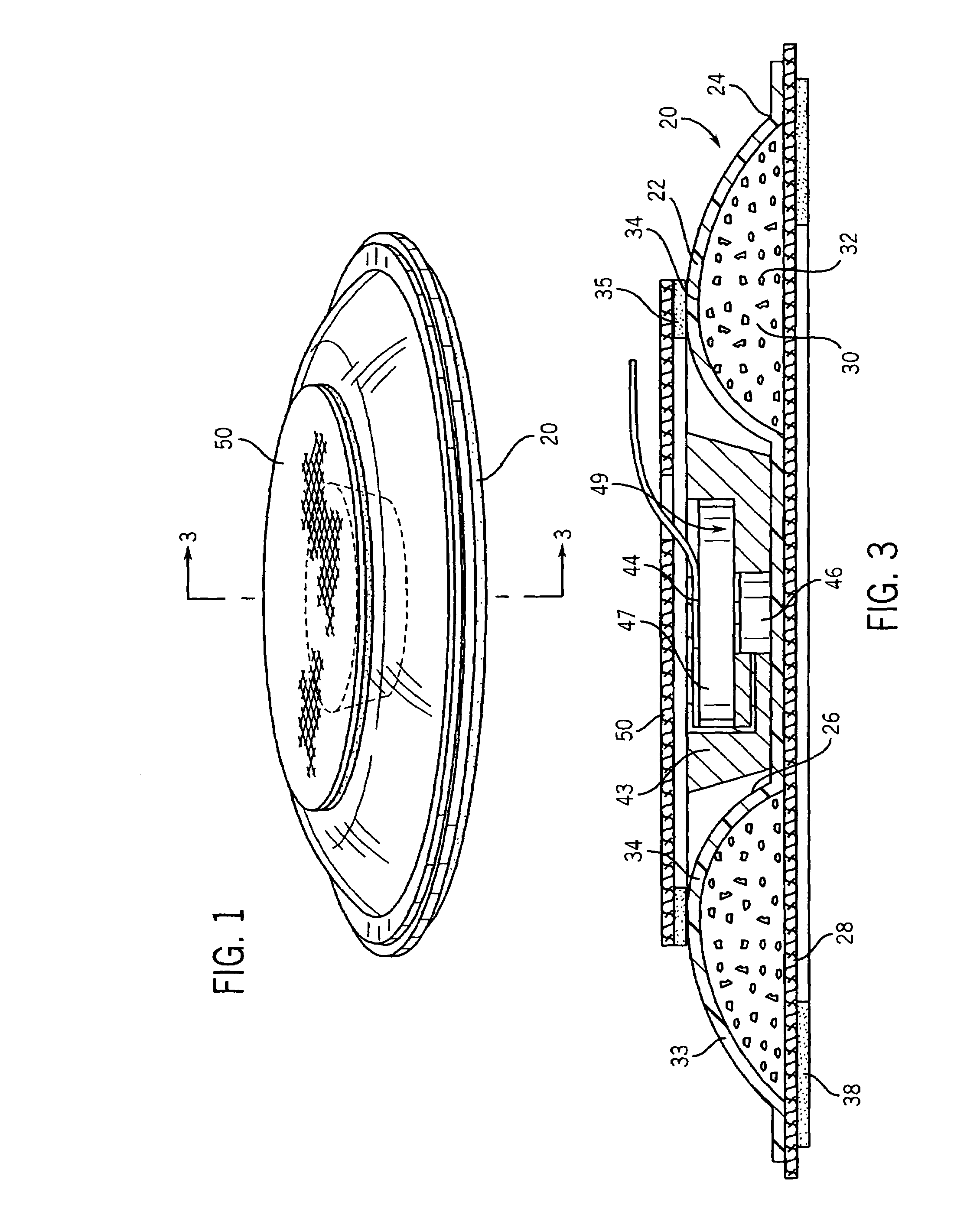

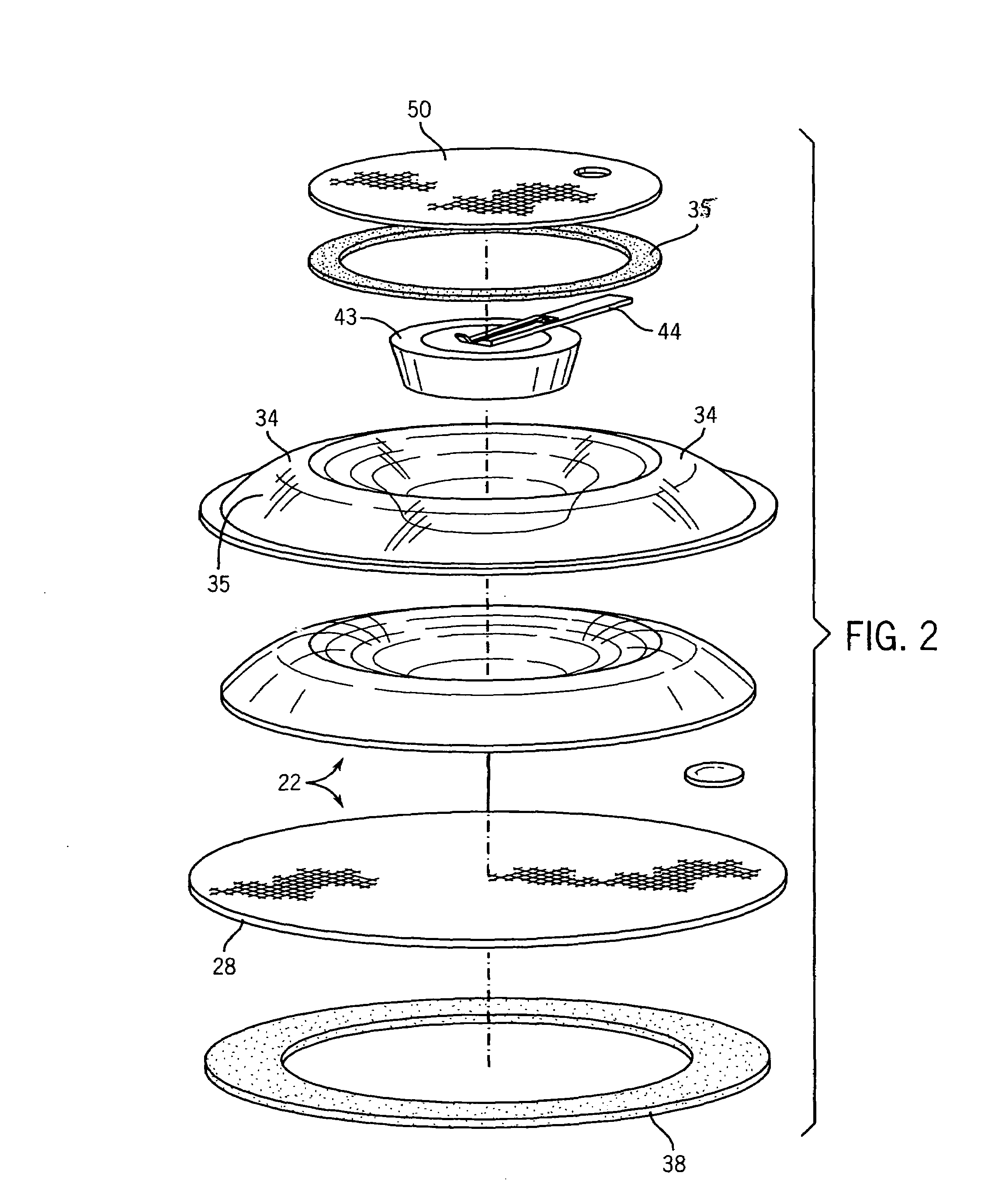

Miniature multi-loudspeaker module

InactiveUS20060188126A1Low costStereo soundMicrophonesTransducers for sound channels pluralityEngineeringLoudspeaker

A miniature multi-loudspeaker module comprising a housing including a magnetic circuit having magnetic means and a magnetically conducting body defining a magnetic field, and first and second coplanar diaphragm and coil assemblies, which are separately movable. The housing is attached to a front cover, which includes first and second sound outlet openings leading to the first and second diaphragms. Preferably, parts of the magnetic circuit can be shared by the two diaphragm and coil assemblies. Preferred embodiments have two diaphragm and coil assemblies that can be separately electrically terminated to enable stereo sound reproduction and can be operated out of phase to serve as a vibration source. Such modules may be utilized for providing stereo sound in, e.g. mobile phones. The front cover may also comprise a sound outlet opening. The receiver signal can be generated by the two diaphragms or by a separately movable third diaphragm and coil assembly.

Owner:SONION HORSENS

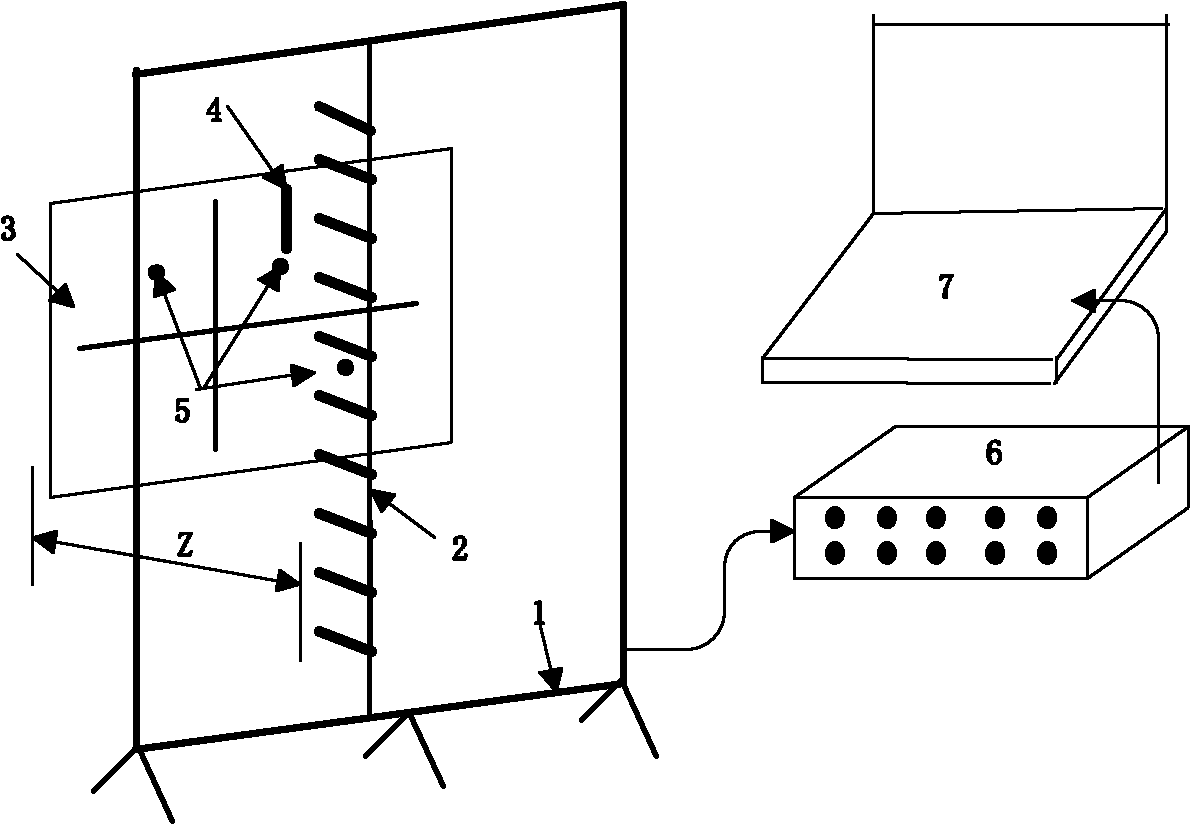

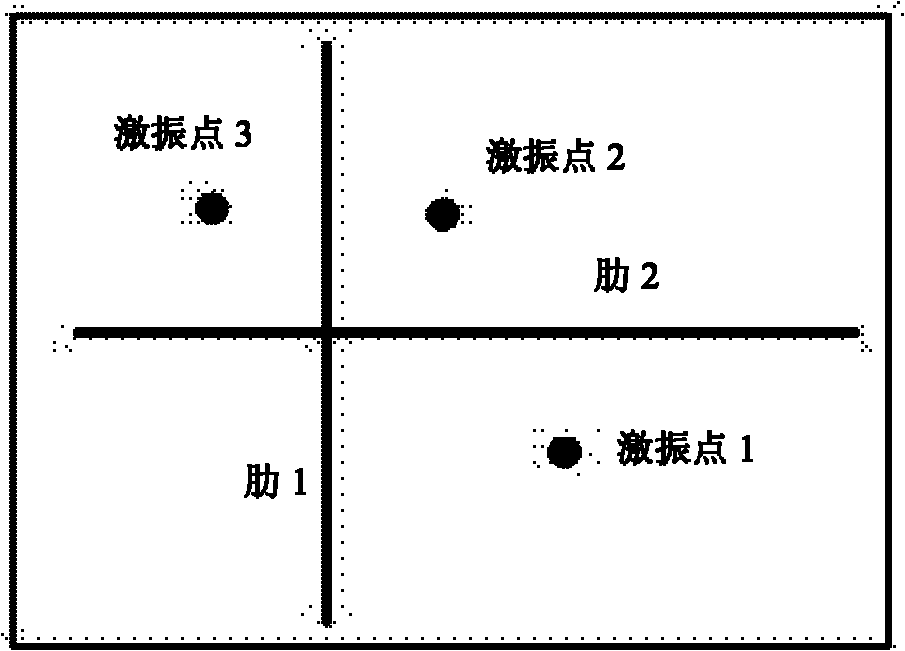

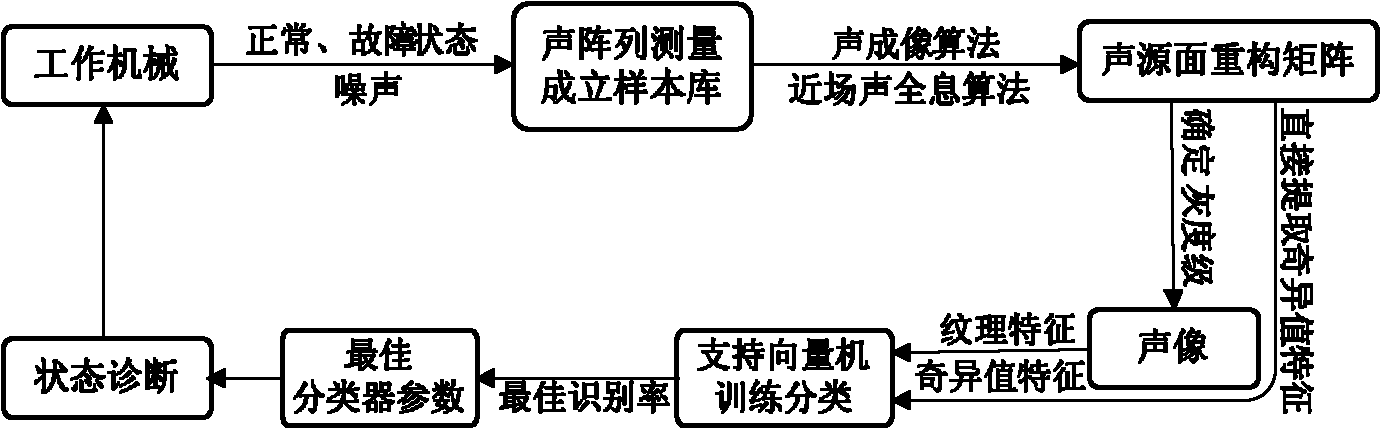

Fault detecting device of near field acoustic holography sound image mode identification and detecting method thereof

InactiveCN101865789AHigh feasibilitySubsonic/sonic/ultrasonic wave measurementStructural/machines measurementSound imageFeature extraction

The invention discloses a fault detecting device of near field acoustic holography sound image mode identification and a detecting method thereof in the field of industrial detection. The device comprises a microphone array, a scanner frame, a reference source, a clamped rib plate, an excitation source and a data acquiring system. The invention adopts sound pressure amplitude and distribution changes under mechanical normal and fault states, borrows ideas from applications of an image diagnosis technology in other fields and utilizes image processing, feature extracting and mode identifying technologies to process a near field acoustic holography image. Experiments show that the method is effective, vibration source positioning and identifying functions coordinated with the holographic imaging technology is proven, the image feather extracting and mode identifying technologies are combined with the acoustic imaging technology, thus broadening the application range of the acoustic imaging technology and bringing a set of effective acoustic fault diagnosis technologies and feasibility of being widely used in engineering thereof.

Owner:SHANGHAI JIAO TONG UNIV

Therapy patch

Therapy patches are disclosed which are designed to deliver vibration and heat (or cold) to human skin so as to provide muscle relief. These patches have a chemical pouch that generates heat or cold upon initiation. They also have a motor and battery to provide a vibration source. Forms of the invention have an adhesive so that the patch can be attached to the skin (and thus need not be manually held in place during use). Kits are also provided in which the motor and battery can be used with a string of linked, severable replacement pouches. Methods of using these patches are also disclosed.

Owner:SC JOHNSON & SON INC

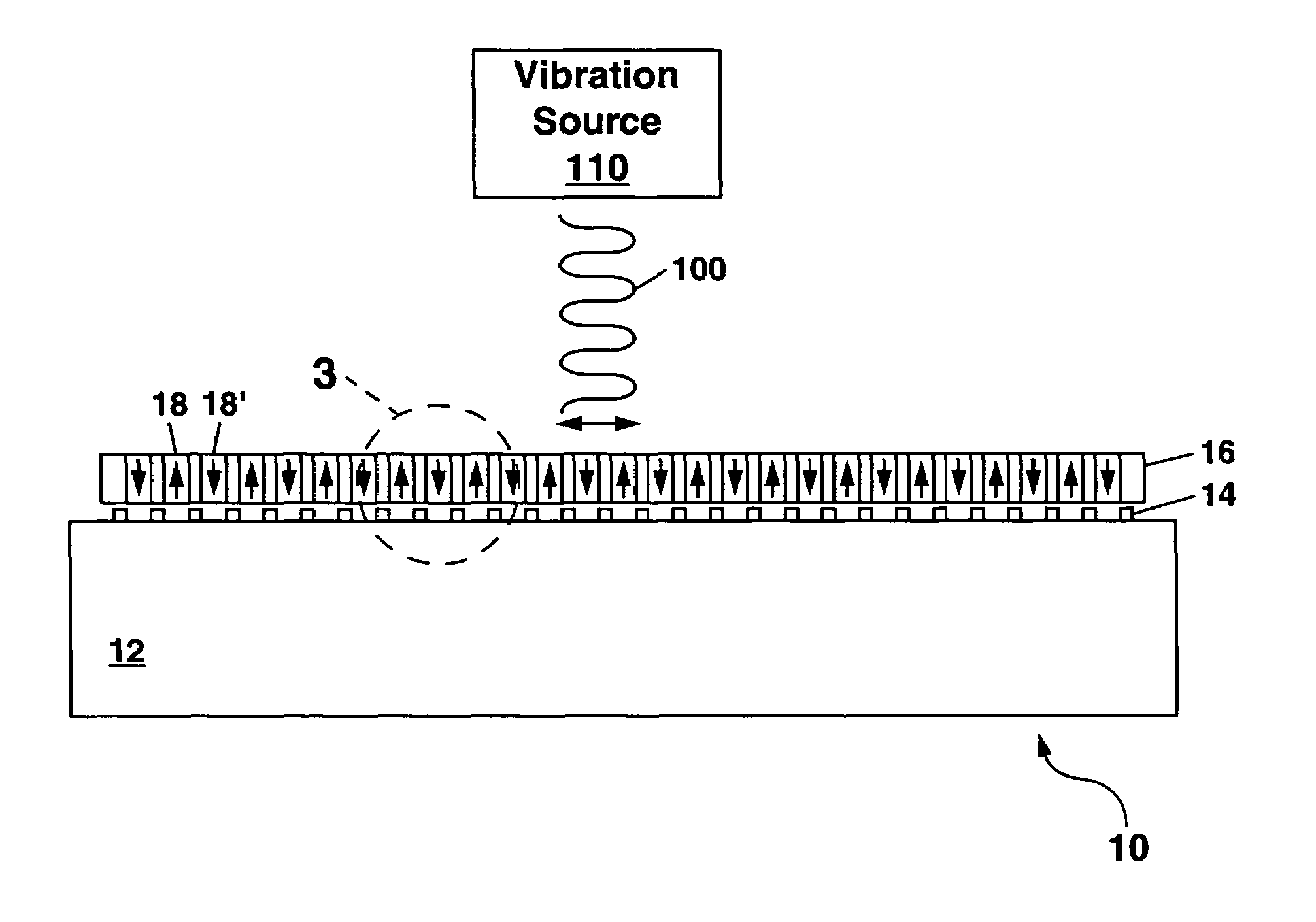

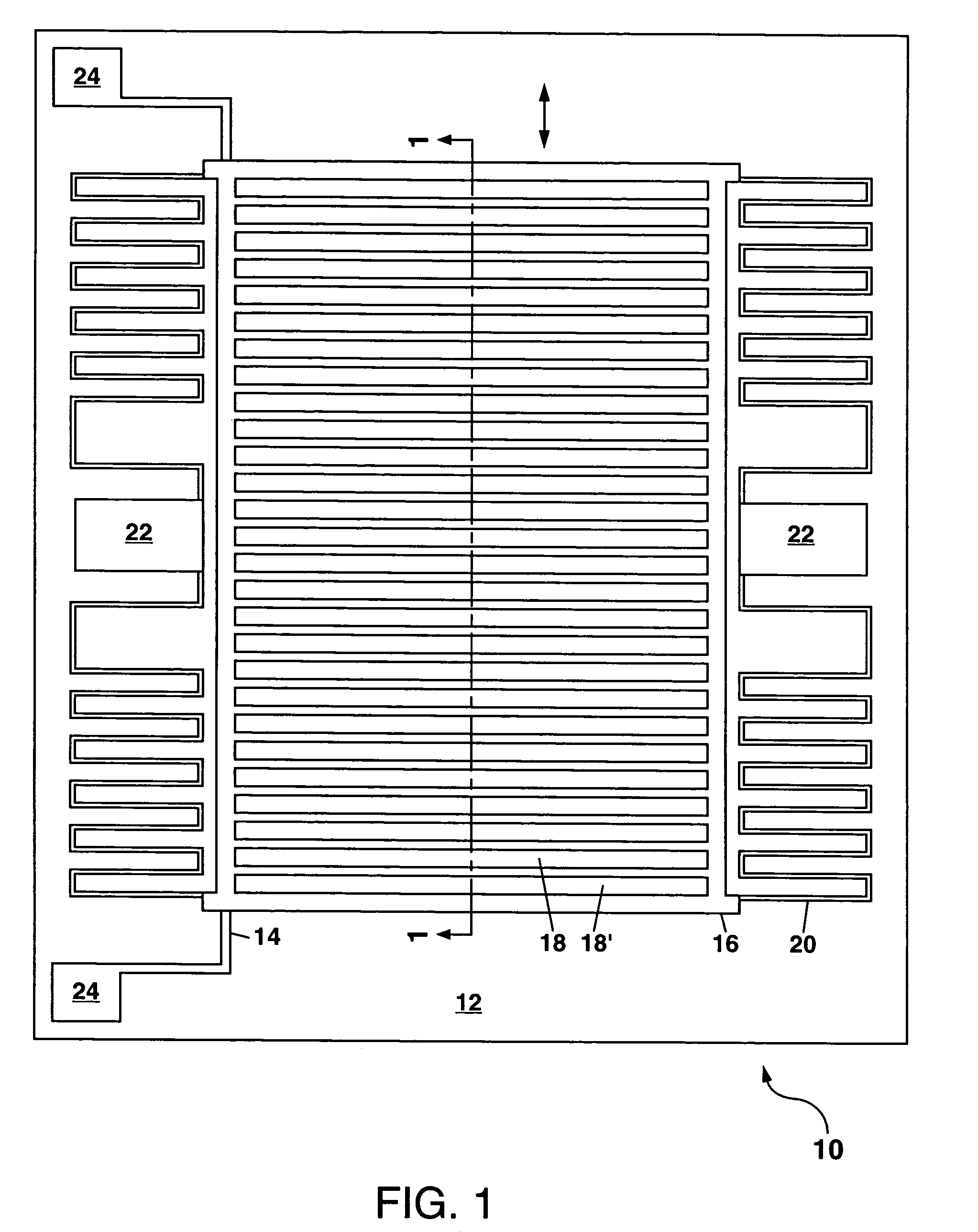

Microelectromechanical power generator and vibration sensor

InactiveUS7142075B1Easy to operateHigh voltageDynamo-electric machinesElectrostrictive/piezoelectric relaysMicromachiningsVibration source

A microelectromechanical (MEM) apparatus is disclosed which can be used to generate electrical power in response to an external source of vibrations, or to sense the vibrations and generate an electrical output voltage in response thereto. The MEM apparatus utilizes a meandering electrical pickup located near a shuttle which holds a plurality of permanent magnets. Upon movement of the shuttle in response to vibrations coupled thereto, the permanent magnets move in a direction substantially parallel to the meandering electrical pickup, and this generates a voltage across the meandering electrical pickup. The MEM apparatus can be fabricated by LIGA or micromachining.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com