Method for improving continuous casting blank quality and vibration support roller device

A technology of supporting rolls and continuous casting slabs, which is applied in the field of metal continuous casting, can solve problems such as cracks at the solidification front of slabs, central looseness and segregation, and are not easy to control, so as to reduce slab segregation and avoid rolling cracks , to reduce the effect of segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

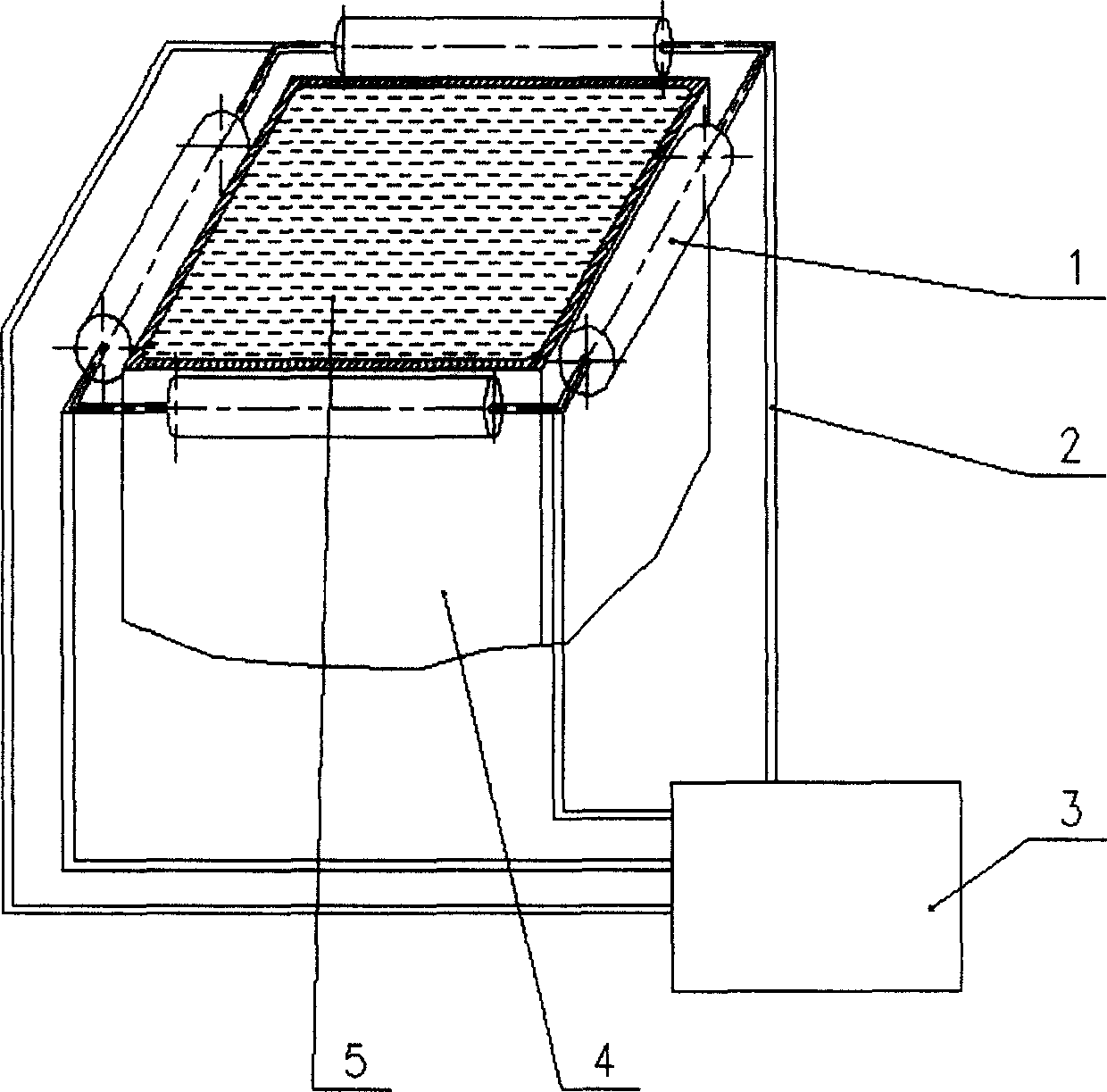

[0027] figure 1 Among them, the vibration support roll device is composed of a vibration support roll 1 that is closely attached to the four walls of the continuous casting slab, and a vibration transmission pipeline 2 and a vibration generation source 3 connected to it.

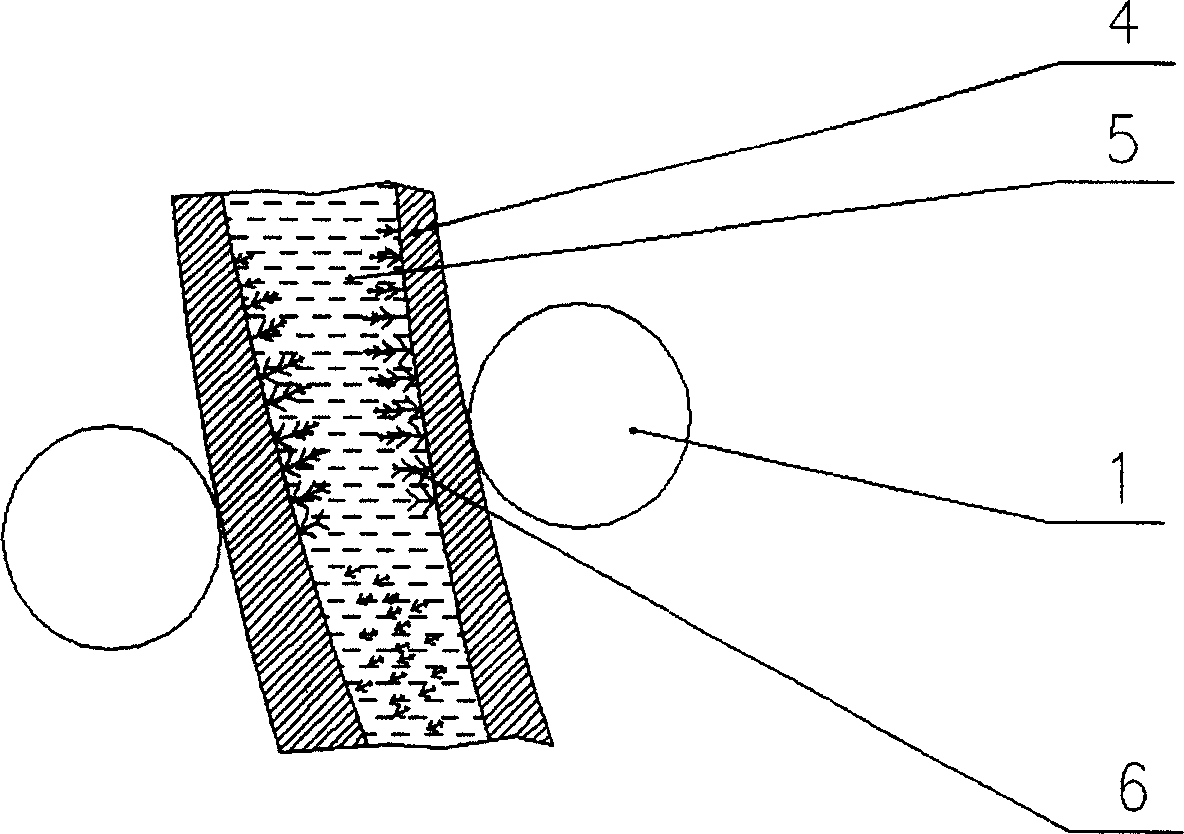

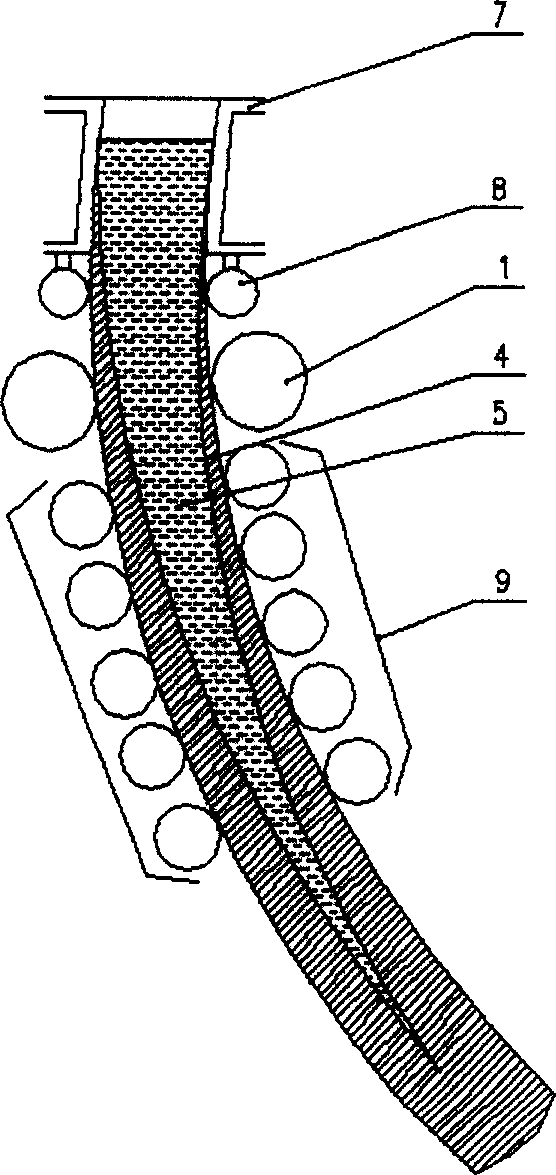

[0028] figure 2 In this process, the vibrating support roller 1 that is closely attached to the four walls of the continuous casting slab keeps rotating synchronously with the surface of the solidification shell 4 of the continuous casting slab, and at the same time, driven by the vibration source 3, it is perpendicular to the thickness direction of the slab or parallel to the drawing High-frequency and small-amplitude vibration in the billet direction, and transmit this vibration to the solidified shell 4 with the liquid core 5 through contact. The dendrites 6 growing at the solidification front of the solidification shell will be broken and broken under the action of this vibration. The vibration amplit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com