Patents

Literature

1416 results about "Electromagnetic stirring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

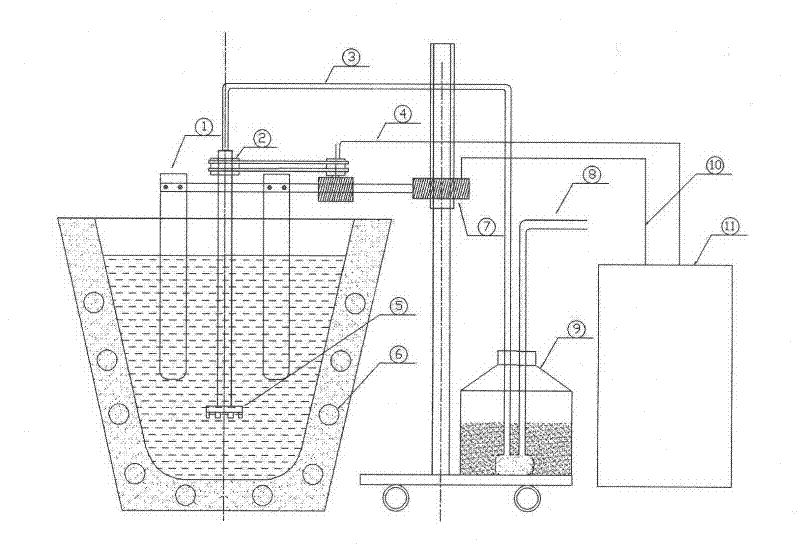

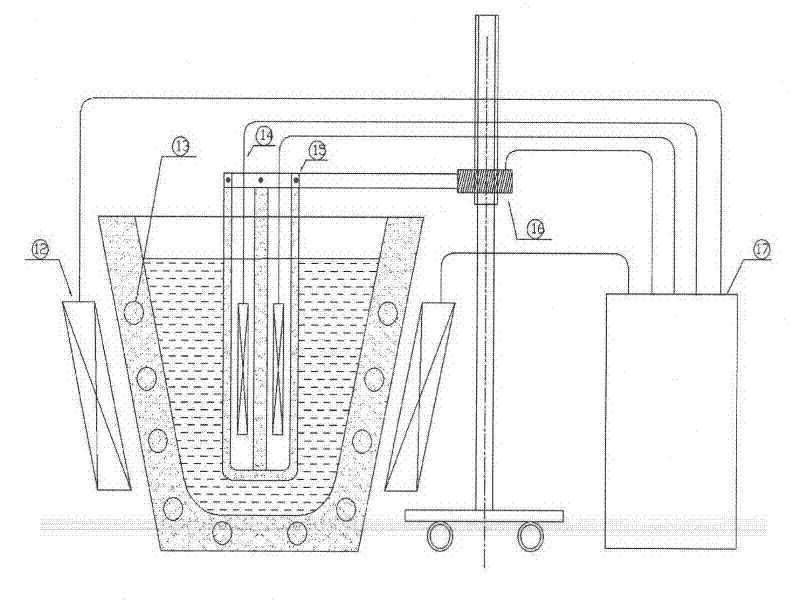

Method for synthesizing metal matrix composition using metal reaction under the coupling action of magnetic field and ultrasonic field

The invention relates to a method for preparing endogenetic particle reinforced metal matrix composites under the coupling effect of a magnetic field and supersonic waves. The method comprises: adjusting the temperature of a metal matrix fused mass to the reaction initial temperature after refining, adding a reactant which can generate a particle phase with the fused mass through the reaction in situ for implementing the synthesis reaction, standing the mixture after the reaction is over, and cooling the mixture to the pouring temperature for pouring; and the method is characterized in that: the magnetic field and the high-intensity ultrasonic field are simultaneously exerted in the reaction synthesis process to realize the synthesis of endogenetic particle reinforced metal matrix composites under the coupling effect of the magnetic field and the high-intensity ultrasonic field. The magnetic field can be an intense pulse magnetic field, a high frequency oscillation magnetic field or a low frequency alternating magnetic field. In the method, the coupling effect of the magnetic field and the ultrasonic field makes the particle sizes be thinned and dispersed evenly; the ultrasonic vibration agitation and electromagnetic stirring functions improve the composite dynamic condition, and the compounding of the particle phase and a base metal interface is better; and the co-action of magnetochemistry and sonochemistry improves the thermodynamic condition of the reaction in situ, as well as speeding up the reaction in situ and controlling the growth of the particle phase.

Owner:JIANGSU UNIV

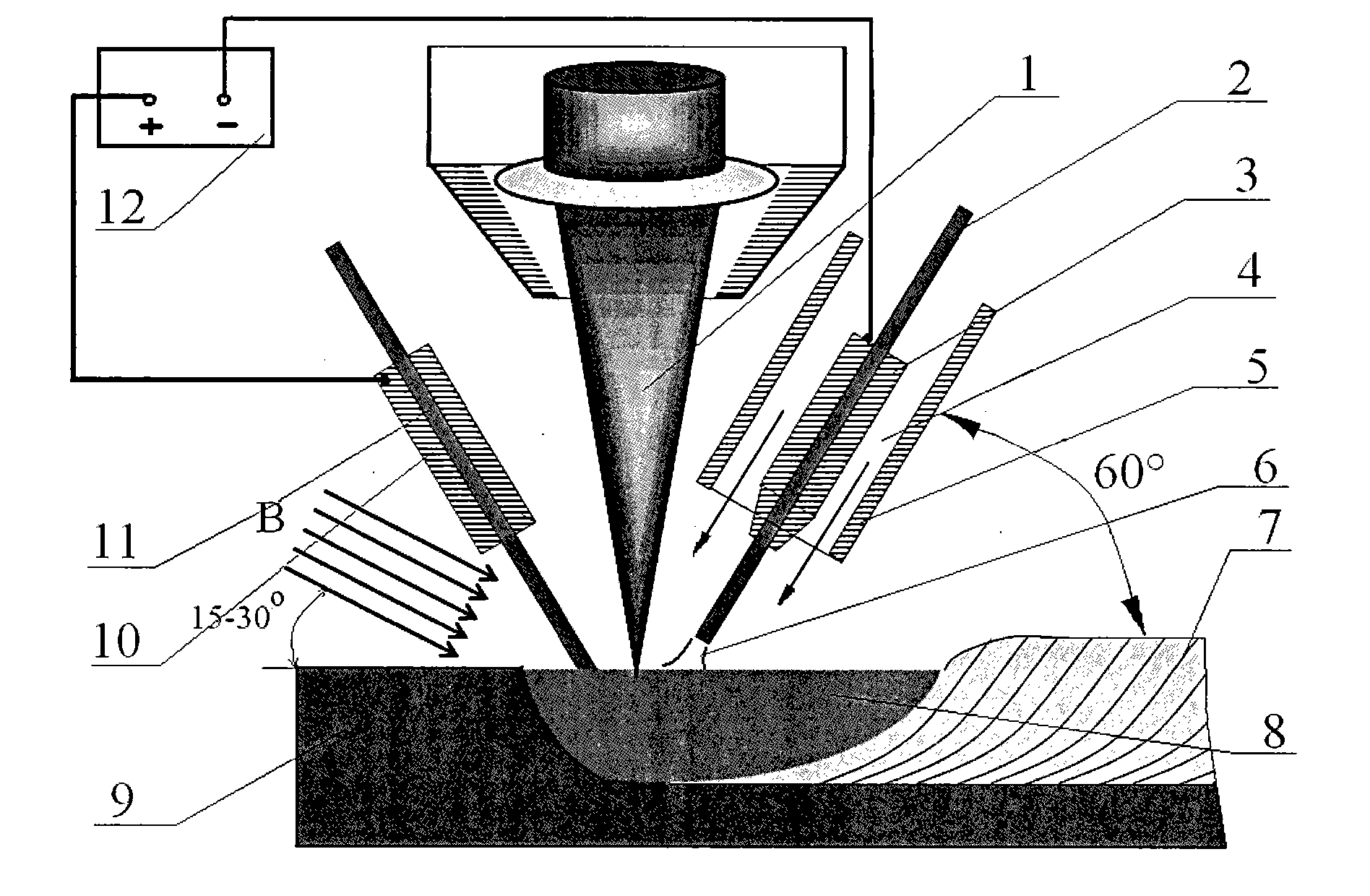

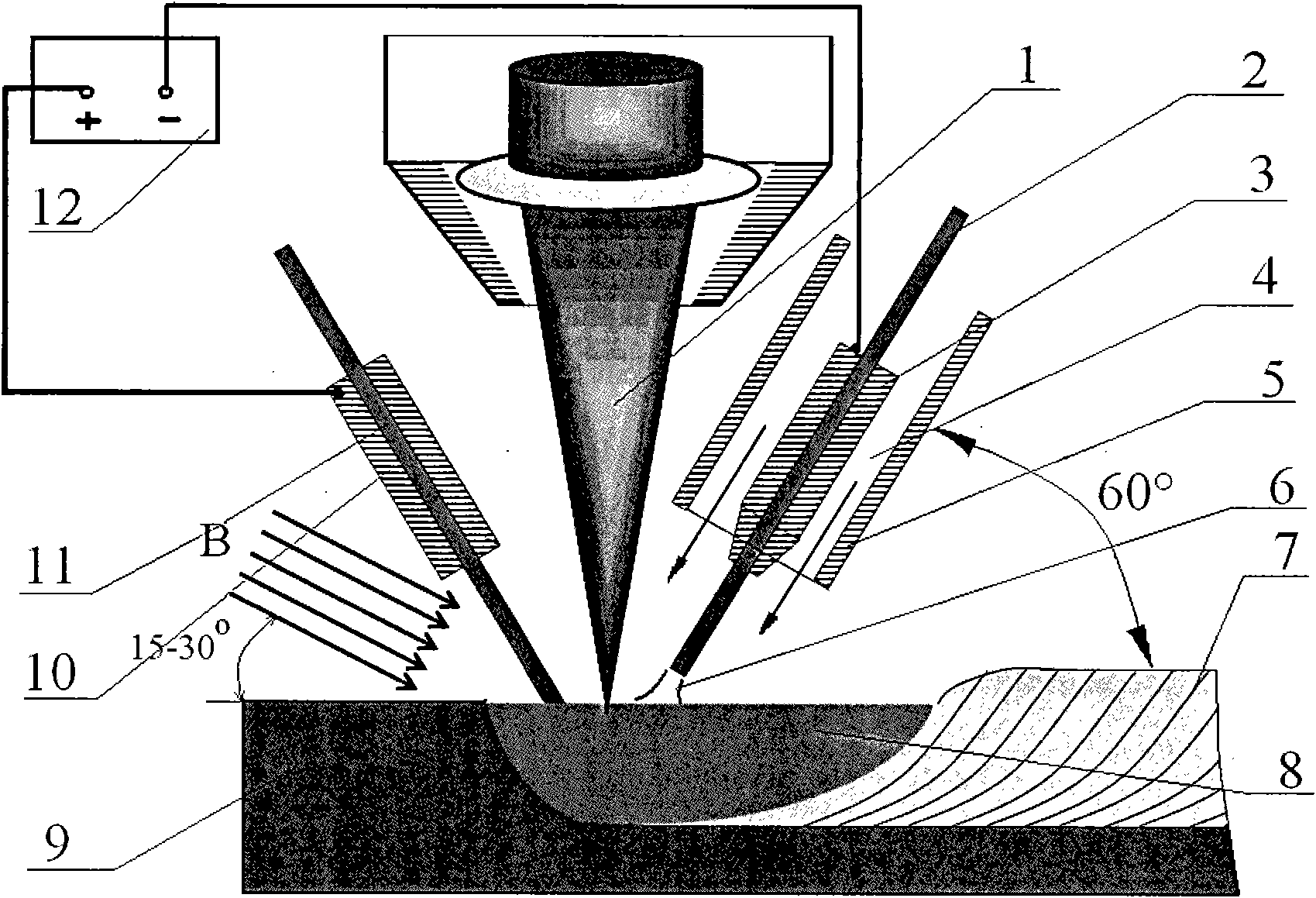

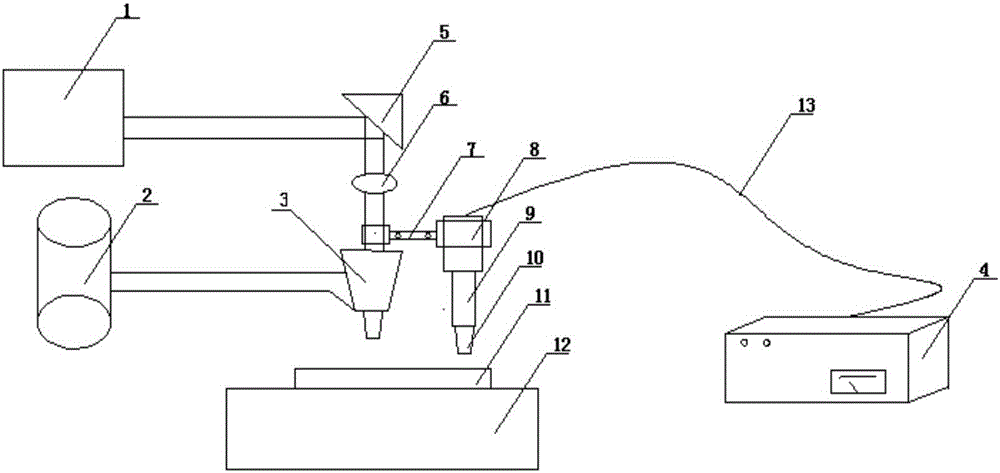

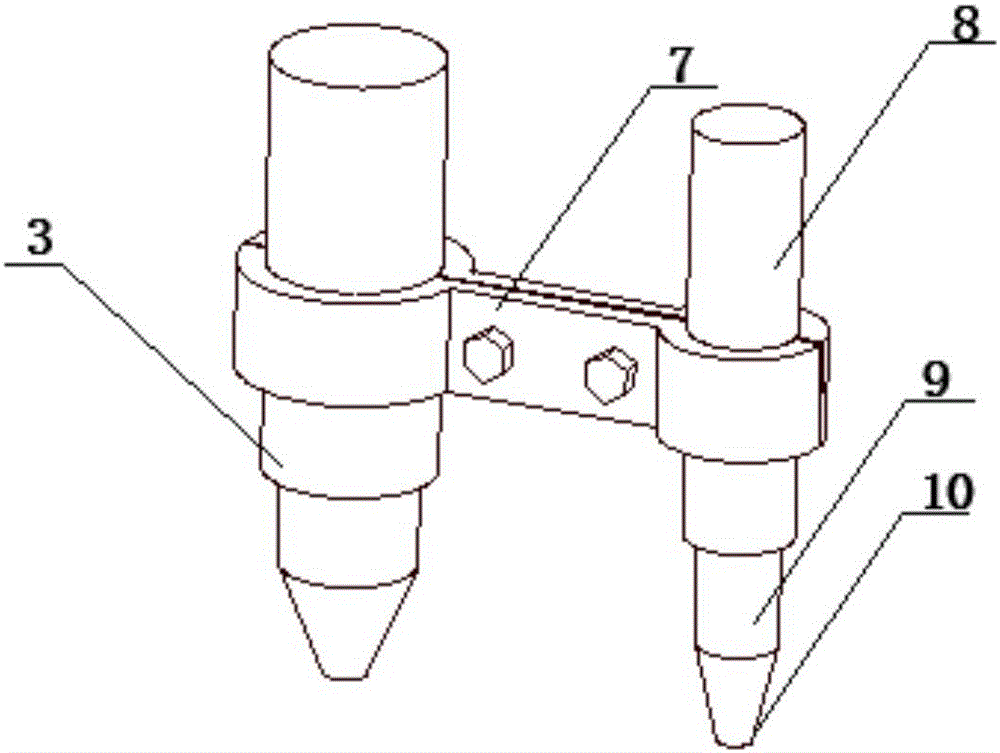

Electromagnetic current coupling field assisted hybrid melting-brazing method for laser-TIG arc and equipment

InactiveCN101862913AImprove connection qualityInhibition formationSoldering apparatusWelding apparatusMetallic materialsWelding defect

The invention discloses an electromagnetic current coupling field assisted hybrid melting-brazing method for a laser-TIG arc and equipment. In addition to the use of the welding zone, an alternating magnetic field is added to control properties of plasma formed through ionization of laser, arc and a raw material metal, thereby improving the laser utilization rate. Under the electric field assisted comprehensive effect, the weld melting depth is increased, and the assistant effect on the melting bath of the liquid-state brazing filler metal for laser-arc melting-brazing is realized through electromagnetic stirring and excitation and enhancement, thereby promoting the orderly flow of the liquid-state brazing filler metal and the rupture, wetting, spreading and proliferation of the liquid-state brazing filler metal on the surface of the high metal material, improving the full mixing of the liquid-state brazing filler metal and the base metal formed by melting the low-melting-point metal material, improving the uniformity of the components of the brazed weld, stabilizing the welding process, reducing welding defects, increasing the welding speed, improving the weld formation, optimizing the structure and performance of the brazed weld, and improving the quality of the brazed joint. Moreover, the equipment has the advantages of simple structure, flexible application, low cost, good effect and easy realization.

Owner:CHONGQING UNIV

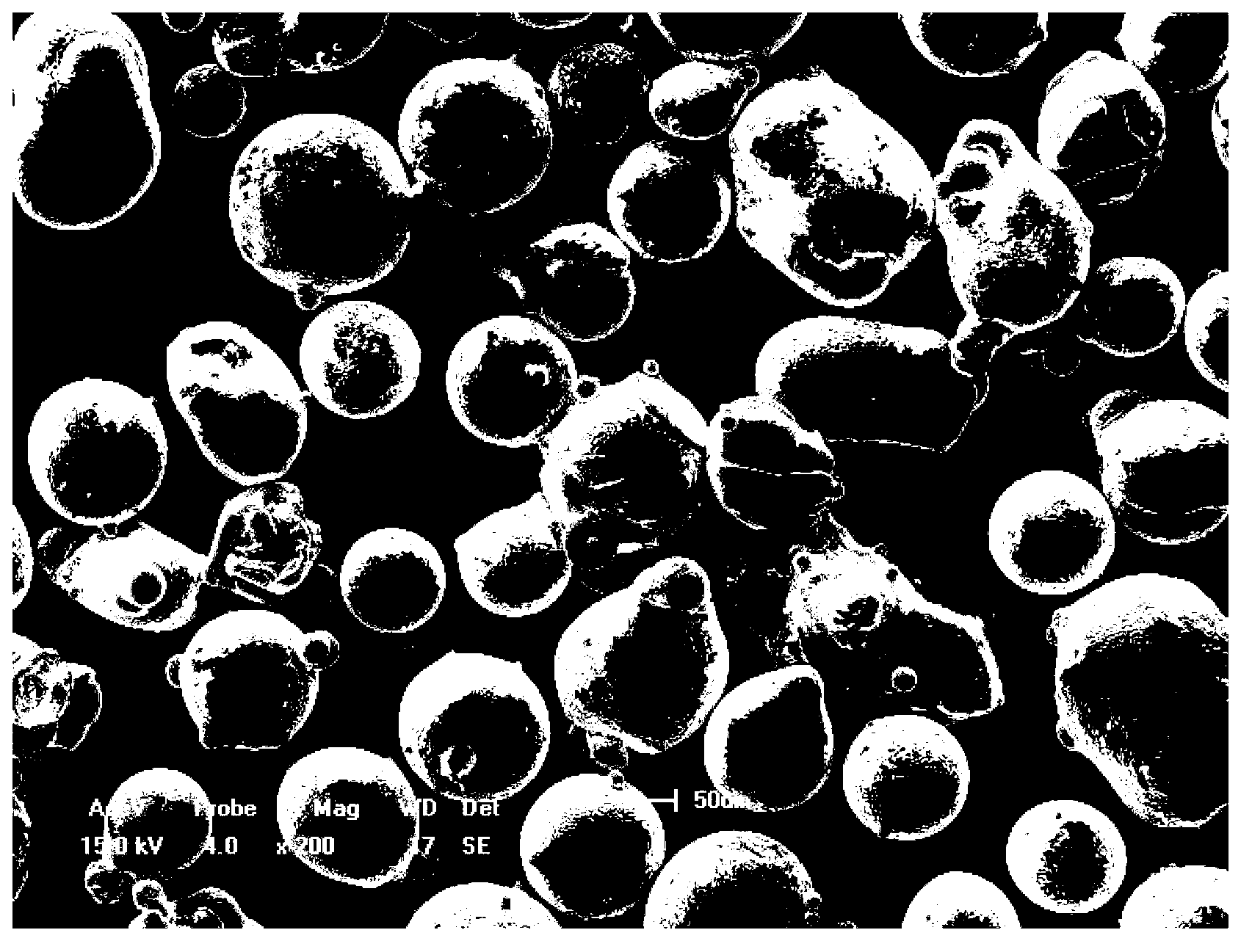

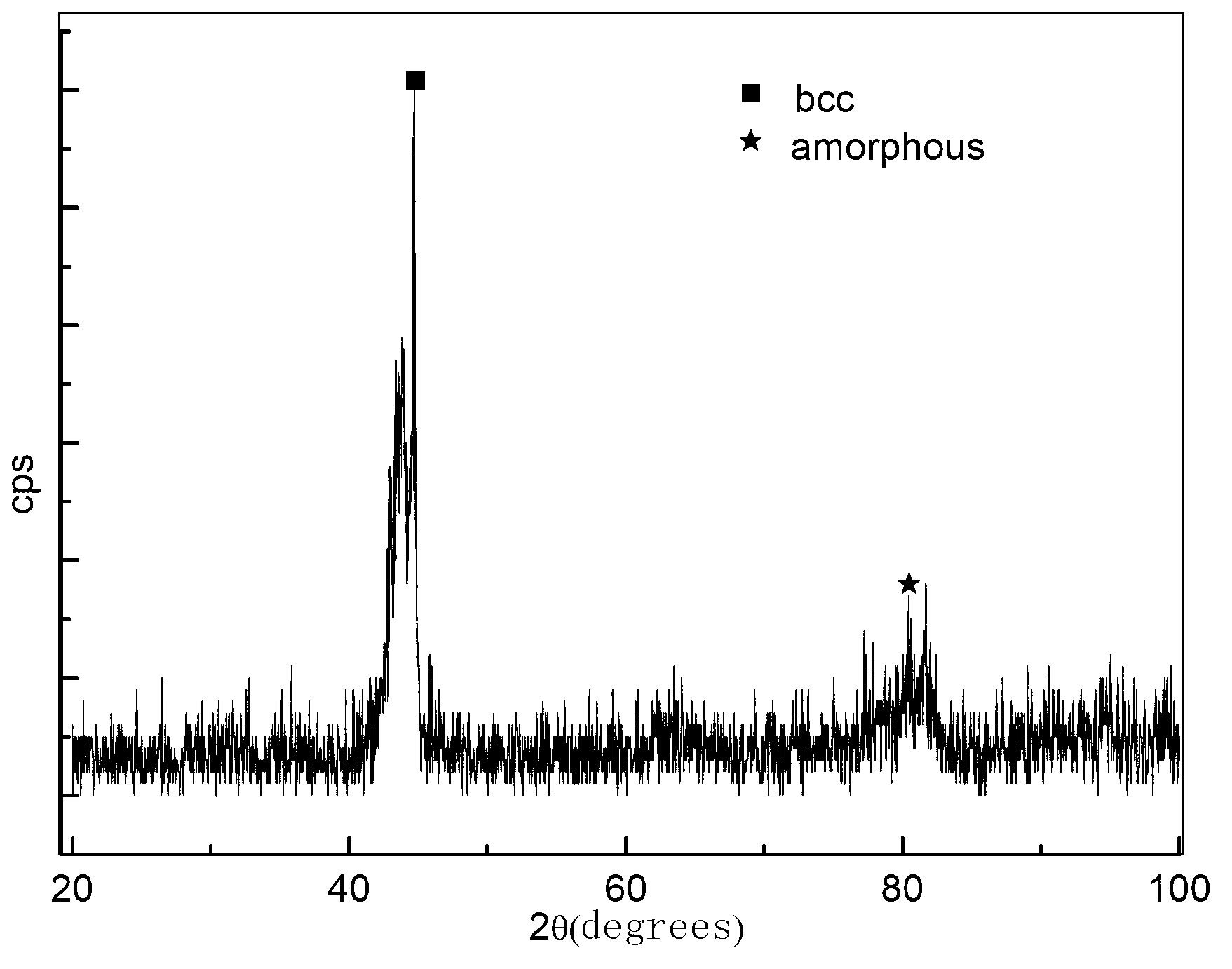

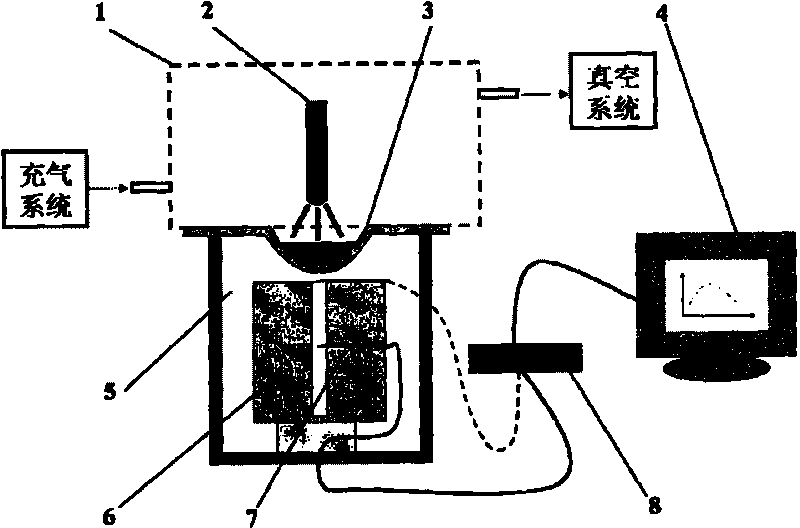

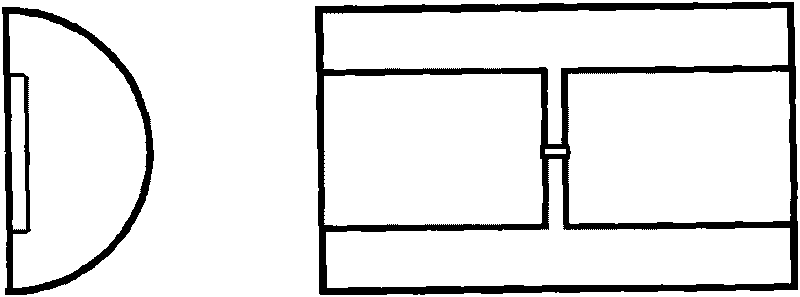

High-entropy alloy powder containing amorphous nanocrystalline and fabrication method thereof

The invention relates to high-entropy alloy powder containing amorphous nanocrystalline and a fabrication method thereof. A high-entropy alloy coating is composed of, by atomic percent, 14.3% of Al, 14.3% of Fe, 14.3% of Co, 14.3% of Ni, 14.3% of Cr, 14.3% of Mo and 14.2% of Si, and the total percentage is 100%. The fabrication method includes the following steps: S1, high-entropy alloy master alloy is fabricated through a medium-frequency induction smelting technique, wherein weighed metallic raw materials are put in a carborundum crucible in sequence and according to melting points from low to high, then the carborundum crucible is vacuumized until the pressure is lower than 6.0*10MPa; argon gas is inflated in the carborundum crucible, the metallic raw materials are melted under the condition that the pressure of the argon air is 3*10-2 Pa, the smelting current is 75A, the melting time is 25min, the alloy composition is segregated with the assistance of electromagnetic stirring, the alloy composition is poured into a magnesia framework after the alloy composition is melted completely, and the high-entropy alloy master alloy which is even in ingredients is obtained; S2, high-entropy alloy powdered materials are fabricated through gas atomization equipment. The fabrication method of the high-entropy alloy powder is used for fabricating the high-entropy alloy coating containing the amorphous nanocrystalline or bulk alloy materials of more superior performance.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

Consumable electrode surfacing method of electromagnetic complex field, and the device and extension application thereof

InactiveCN101032788AStir wellChange the crystallization stateWelding/cutting auxillary devicesArc welding apparatusComposite fieldEngineering

The present invention relates to one kind of composite electromagnetic field build-up welding method, apparatus and expanded application, and is composite electromagnetic field controlled gas protected build-up welding method. The welding apparatus is provided with exciting power source, exciting device, auxiliary electric field device and water cooling system. The exciting device has electromagnetic stirring exciting coil and electromagnetic heat treatment exciting coil; and the auxiliary electric field device includes one pair of movable electrodes. Through electromagnetic stirring, electromagnetic heat treatment and the compound effect of auxiliary electric field and the welding torch, the present invention realizes the build-up welding of alloy material in high efficiency, high quality and low cost.

Owner:CHONGQING UNIV

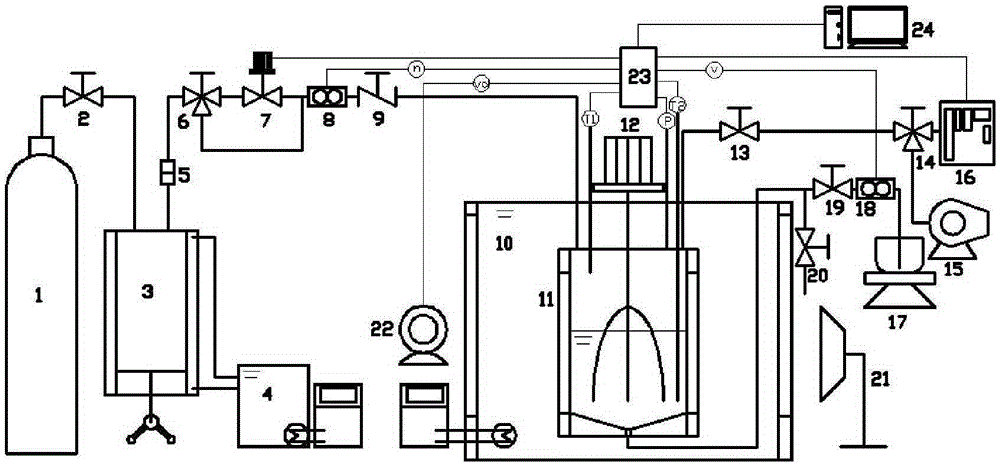

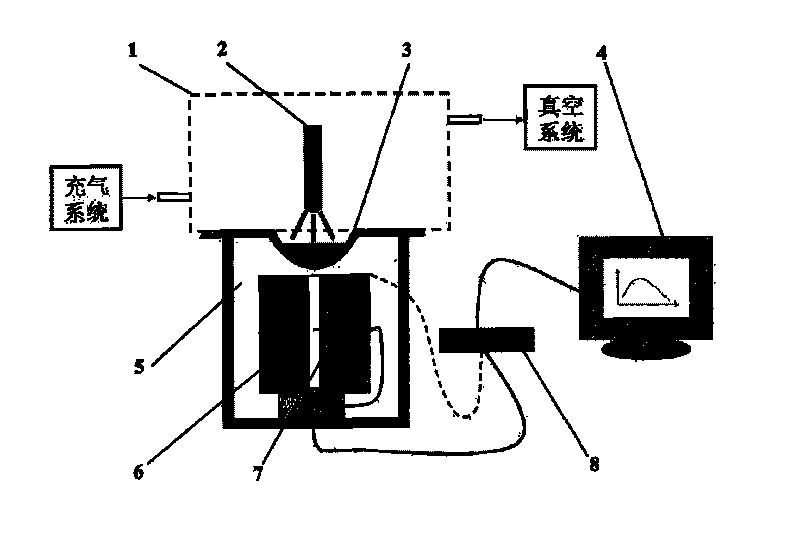

Visual gas hydrate dynamic experimental device

InactiveCN105301205AEasy dischargeEasy to operateChemical/physical/physico-chemical stationary reactorsFeed devicesGrowth phaseTemperature control

The invention provides a visual gas hydrate dynamic experimental device. The visual gas hydrate dynamic experimental device comprises a visual electromagnetic stirring reaction still, a voltage stabilizing pre-cooling gas supplying unit, an gas exhaust unit, a liquid charging / discharging unit, a temperature control unit and a data collecting and processing unit, wherein the visual electromagnetic stirring reaction still is used for mixing experimental gas and experimental liquid in the reaction still for reaction to form and decompose hydrate; the voltage stabilizing pre-cooling gas supplying unit and the gas exhaust unit are used for supplying pre-cooling experimental gas for the visual electromagnetic stirring reaction still and discharging gas; the liquid charging / discharging unit is used for injecting the experimental liquid to the visual electromagnetic stirring reaction still or discharging the experimental liquid; the temperature control unit is used for controlling the temperature change of the visual electromagnetic stirring reaction still; the data collecting and processing unit is used for collecting, processing, saving and analyzing kinetic parameters during a hydrate formation and decomposition process. According to the visual gas hydrate dynamic experimental device, numerous defects of a common hydrate dynamic experimental device are overcome, the kinetic properties in a nucleation phase and a growth phase of gas hydrate can be accurately determined, and the experimental device is simple, economical and convenient to operate.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Method for controlling center porosity of large section heavy rail steel casting blank

The invention relates to the technical field of ferrous metallurgy, in particular to a method for controlling the center porosity of a large section heavy rail steel casting blank. The method comprises the following steps of controlling the superheat degree of medium-package molten steel; controlling the pulling speed in the normal pouring process; pressing down the final solidification end in the pouring process; setting the stirring strength and stirring frequency of electromagnetic stirring of a crystallizer; setting the stirring strength and stirring frequency of electromagnetic stirring at the final solidification end; controlling the cooling water yield and the secondary cooling specific water yield of the crystallizer. The center porosity of the large section heavy rail steel casting blank produced by adopting the method can be effectively controlled, and the remaining internal quality of the casting blank can be effectively guaranteed.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

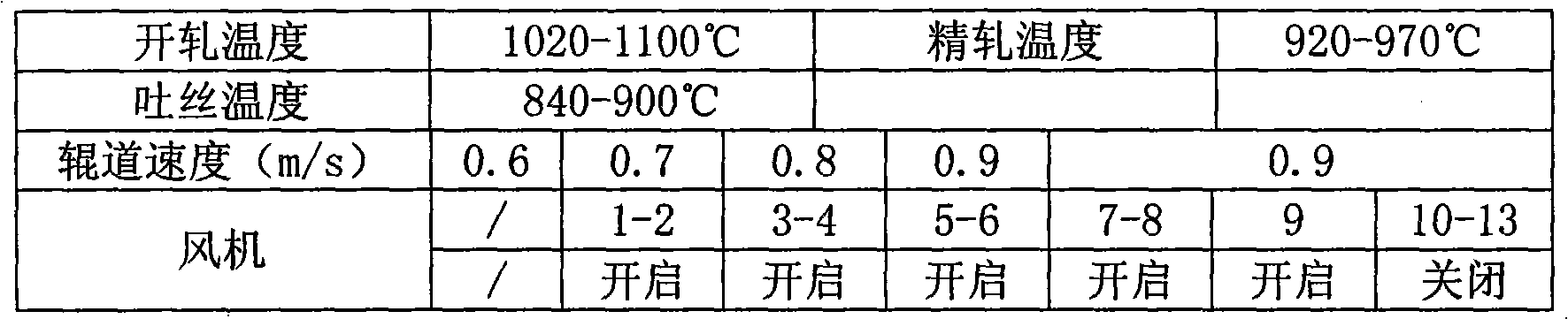

Micro alloying SWRH87B hot rolled wire rod and manufacturing method thereof

InactiveCN101597713AQuality improvementEasy to useTemperature control deviceManufacturing convertersTemperature controlWire rod

The invention provides a micro alloying SWRH87B hot rolled wire rod and a manufacturing method thereof, belonging to the technical field of hot rolled wire rod. In the invention, Cr and V micro alloying are adopted; double slag process high drawing carbon operation is used in a converter; end-point carbon is controlled at 0.40-0.60%, the steel tapping temperature is 1580-1620 DEG C, and the slag-blocked tapping is used; low nitrogen carburant is used for recarburization; Si-Ca-Ba is used for deoxidation; 600-800kg synthetic slag is added into each converter; oxygen activity is controlled below 10ppm by entering into an LF refining station, and the refined finishing slag sum of FeO and MnO is no more than 3%; inclusion modification treatment is carried out on the Ca-Si line; a billet in the size of 160mm*160mm is used, a casting mould is used for coordinating with final electromagnetic stirring (F-EMS); continuous casting machine whole protection, constant drawing speed casting and proper secondary cooling system are adopted; the initial rolling temperature is controlled at 1020-1150 DEG C which is conductive to welding the drawholes and increasing the probability of the drawholes welding; the water pre-cooling and phase transformation strengthening cooling technology is used to control the texture and the performance. The invention has the advantages that the aging time of the wire rod before the follow-up processing is shortened, the tensile strength thereof after aging time is larger than 1280MPa, and the area reduction rate is larger than 25%.

Owner:SHOUGANG CORPORATION

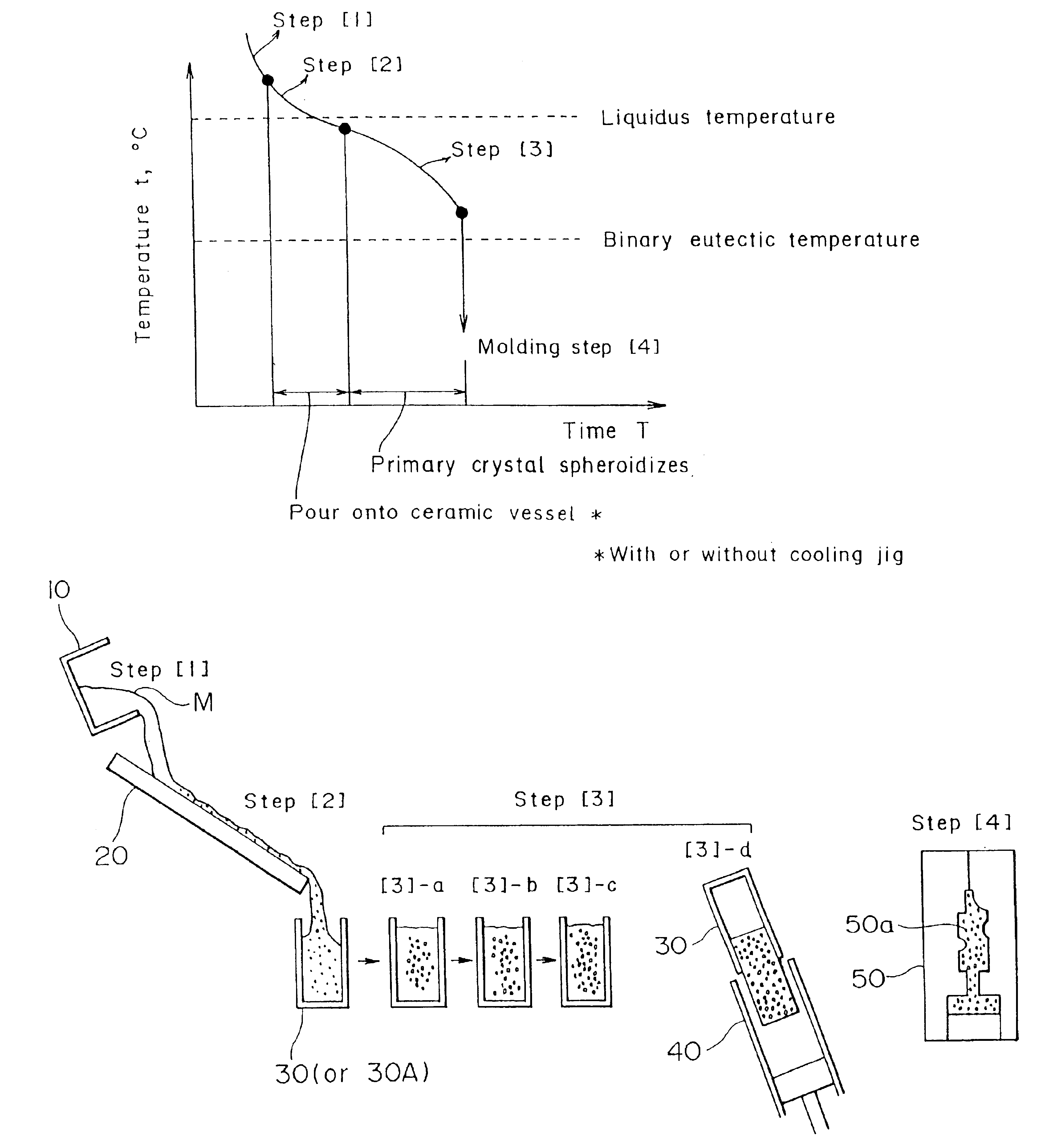

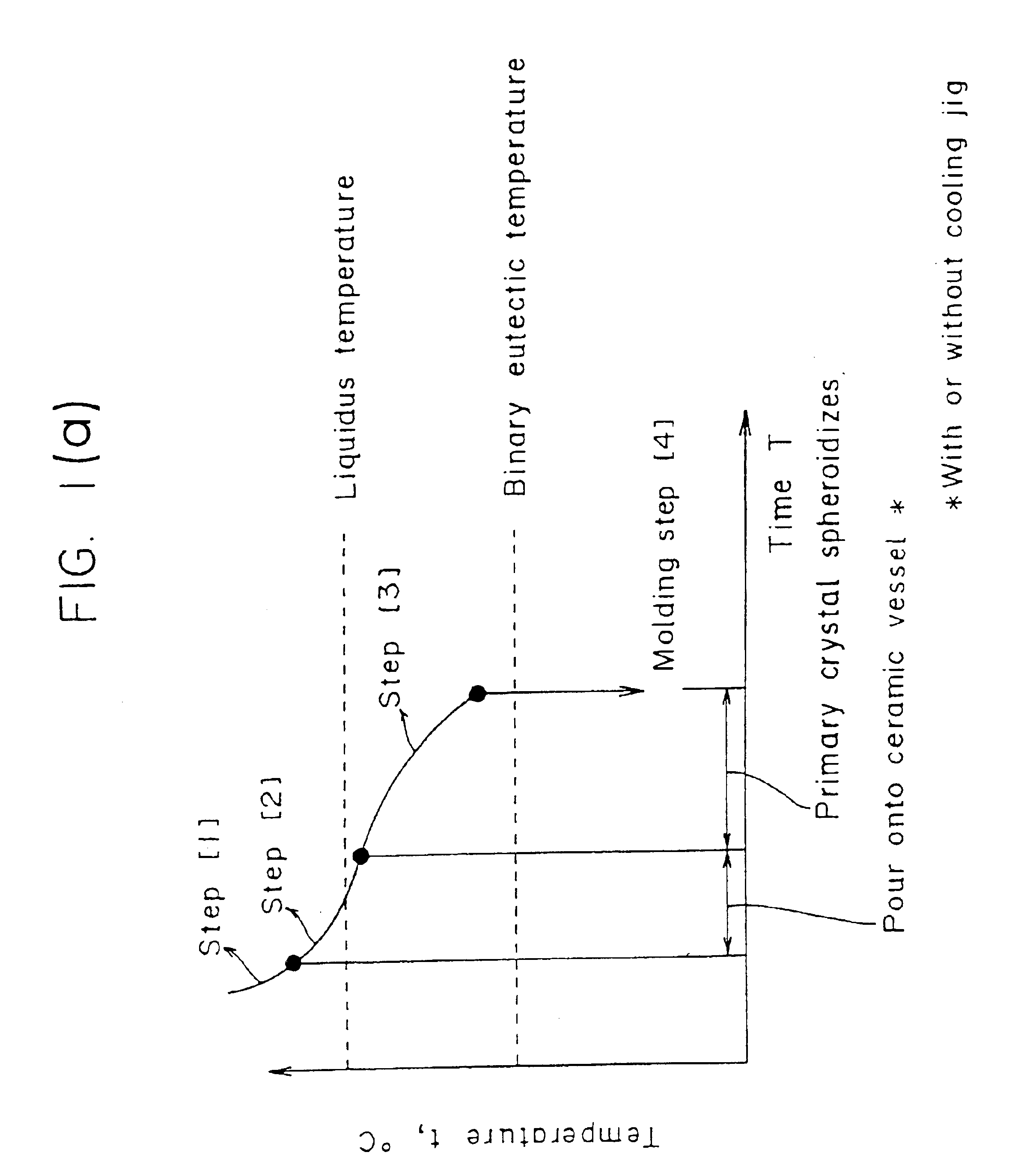

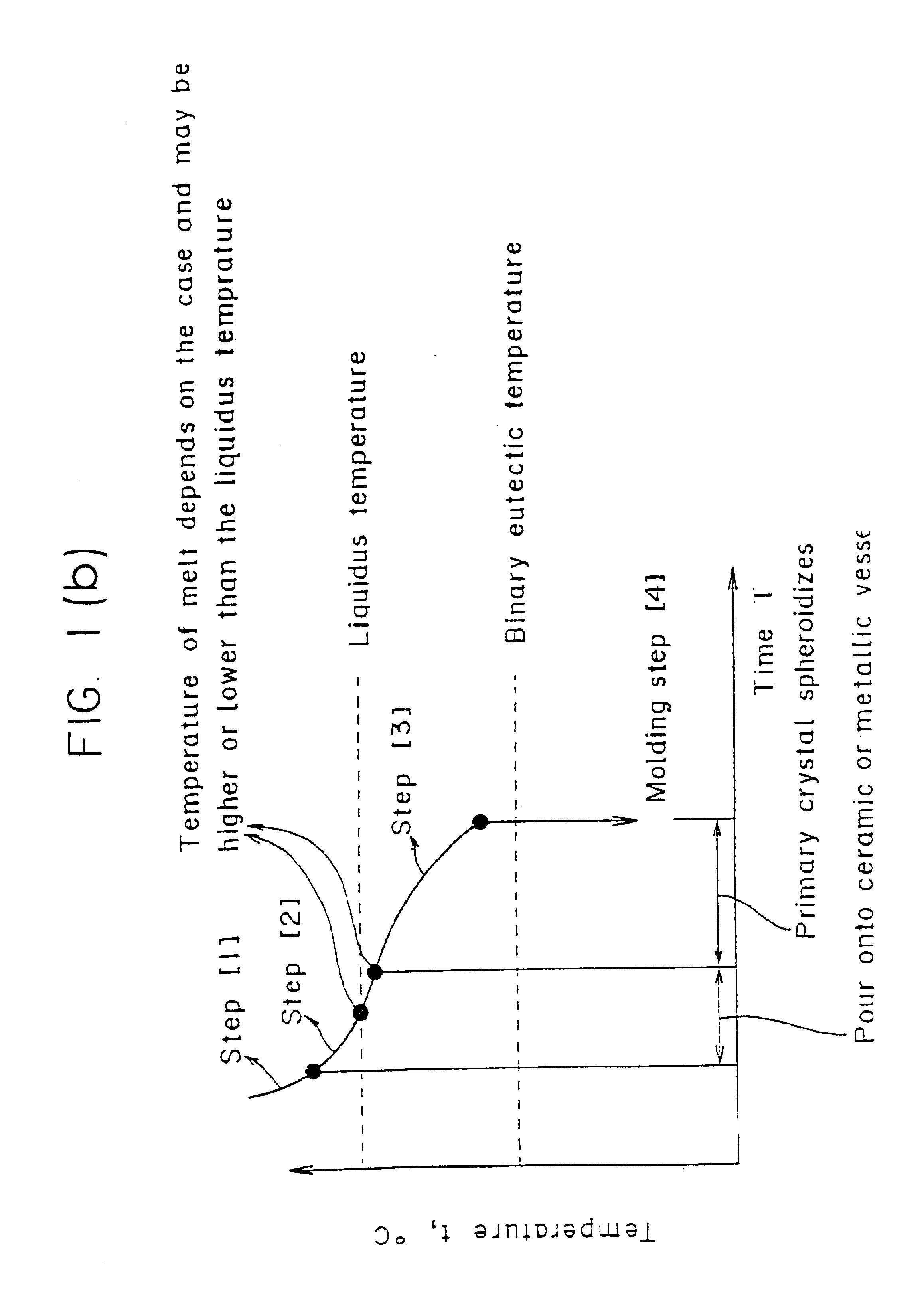

Method of shaping semisolid metals

A method and apparatus for the semisolid forming of alloys to enable shaped parts having a fine-grained, spherical thixotropic structure to be produced in a convenient, easy and inexpensive manner without relying upon the conventional mechanical or electromagnetic agitation. In the method, a molten alloy having crystal nuclei at a temperature not lower than the liquidus temperature or a partially solid, partially molten alloy having crystal nuclei at a temperature not lower than a molding temperature is fed into an insulated vessel and is maintained in the insulated vessel for 5 seconds to 60 minutes as it is cooled to the molding temperature where a specified liquid fraction is established, thereby crystallizing fine primary crystals in the alloy solution, and the alloy is fed into a forming mold, where it is shaped under pressure.

Owner:UBE IND LTD

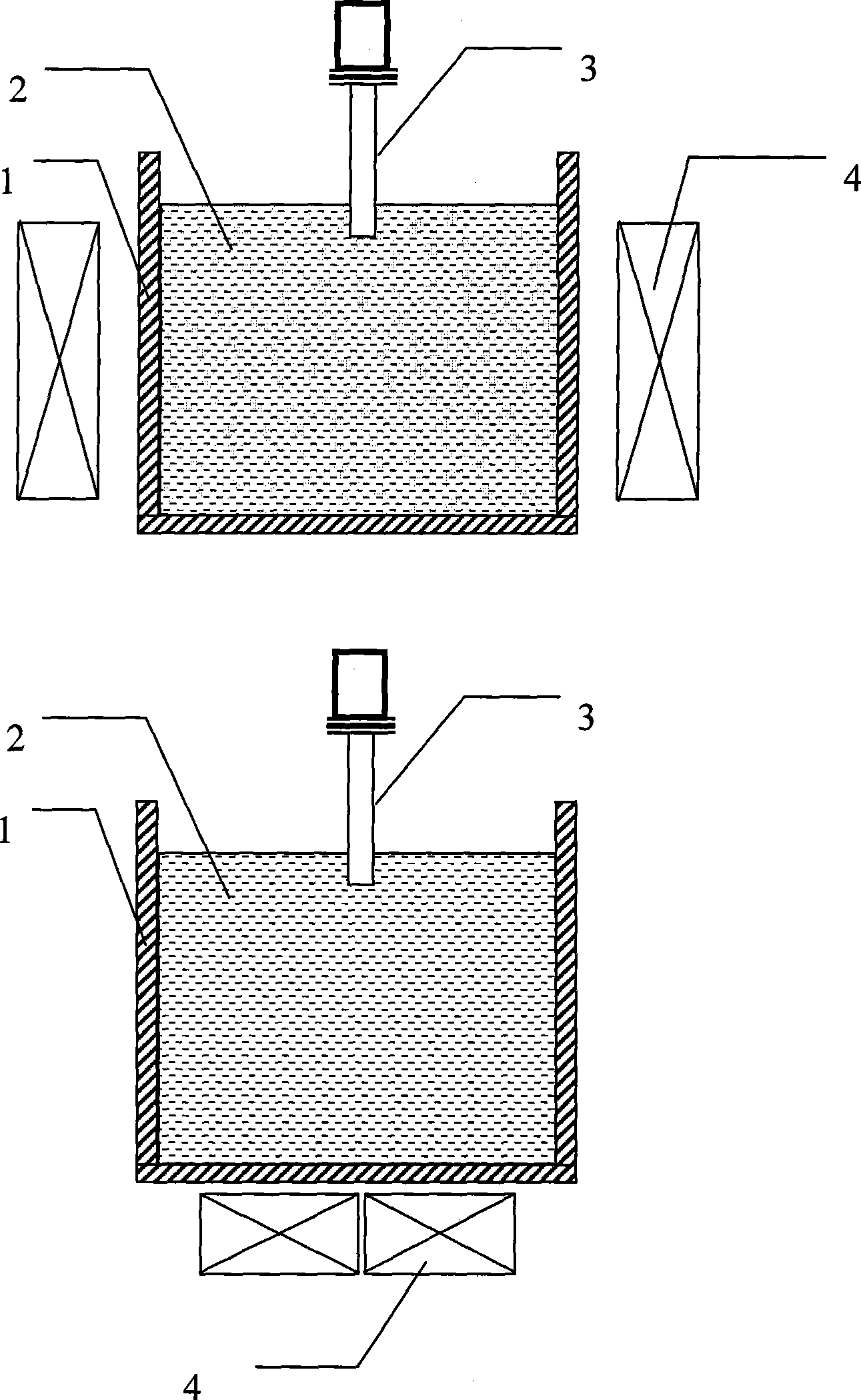

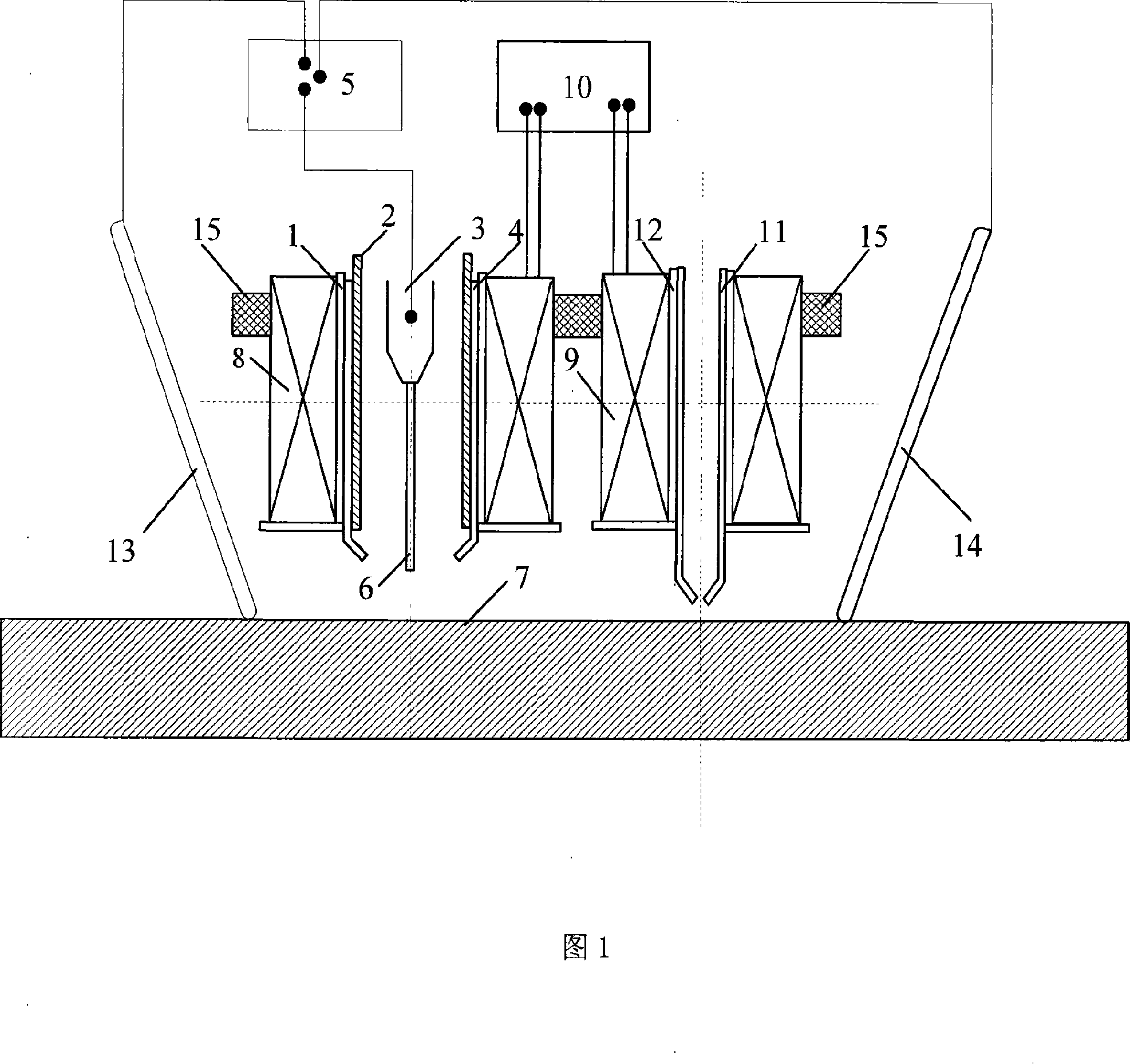

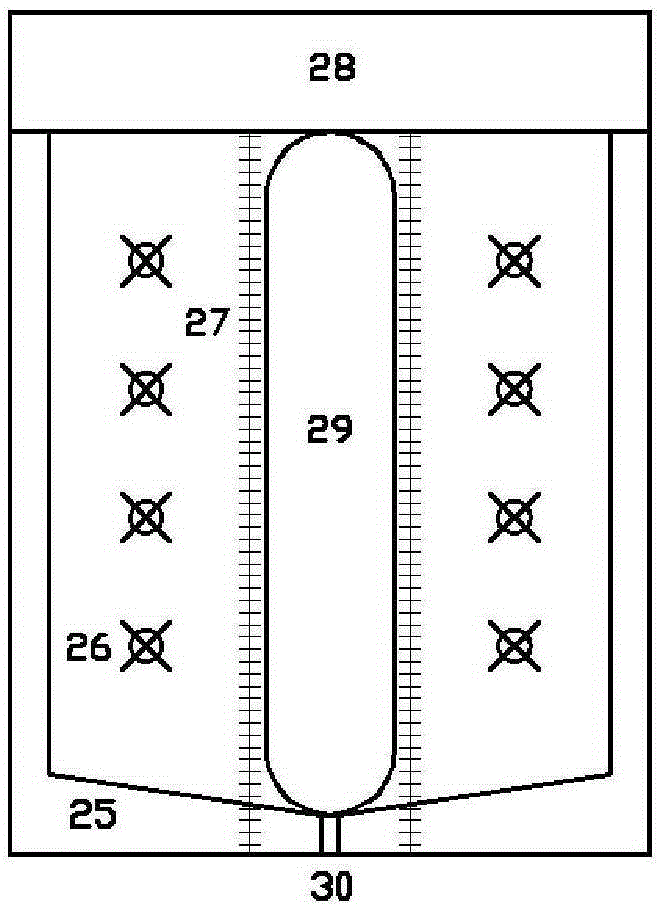

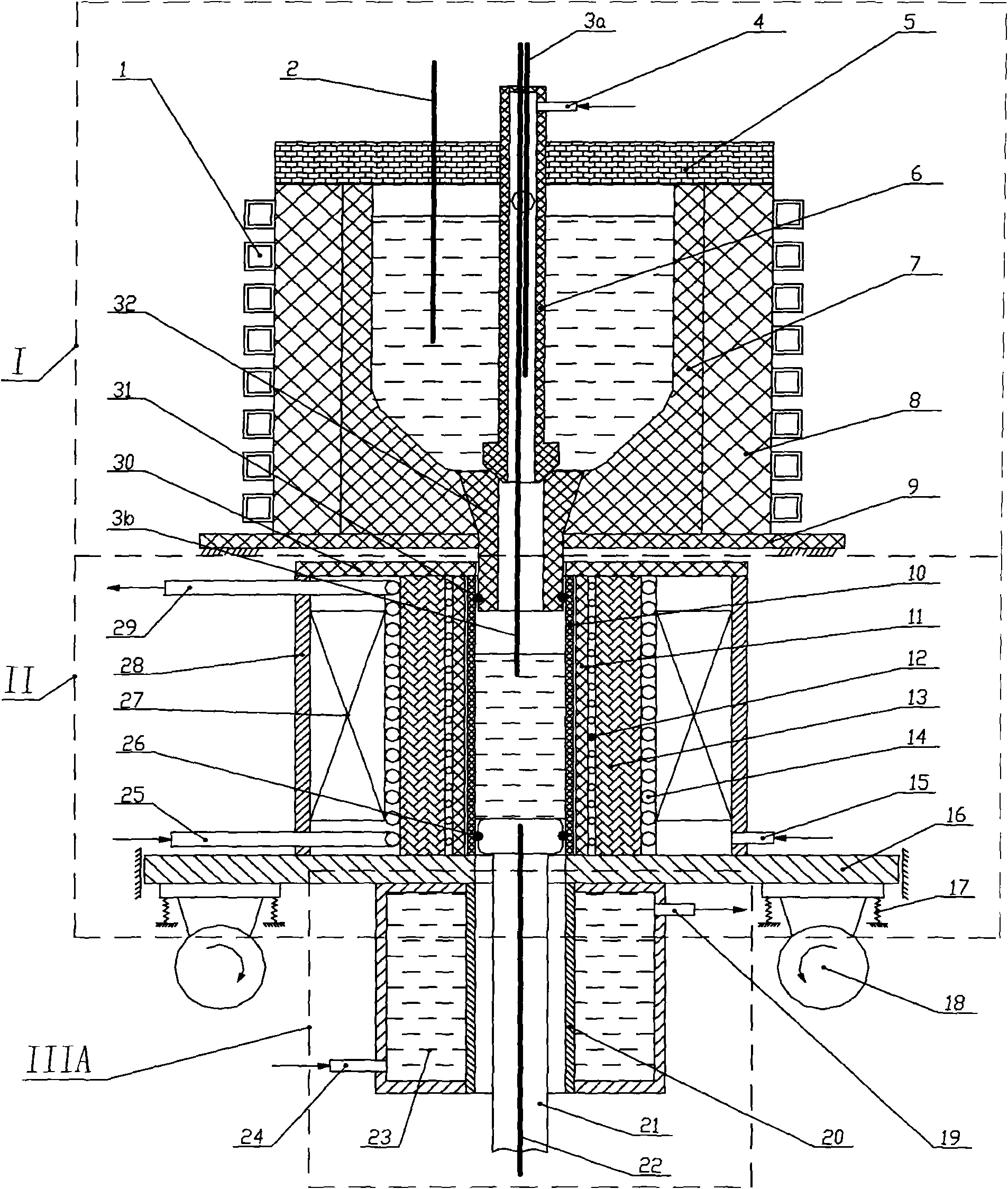

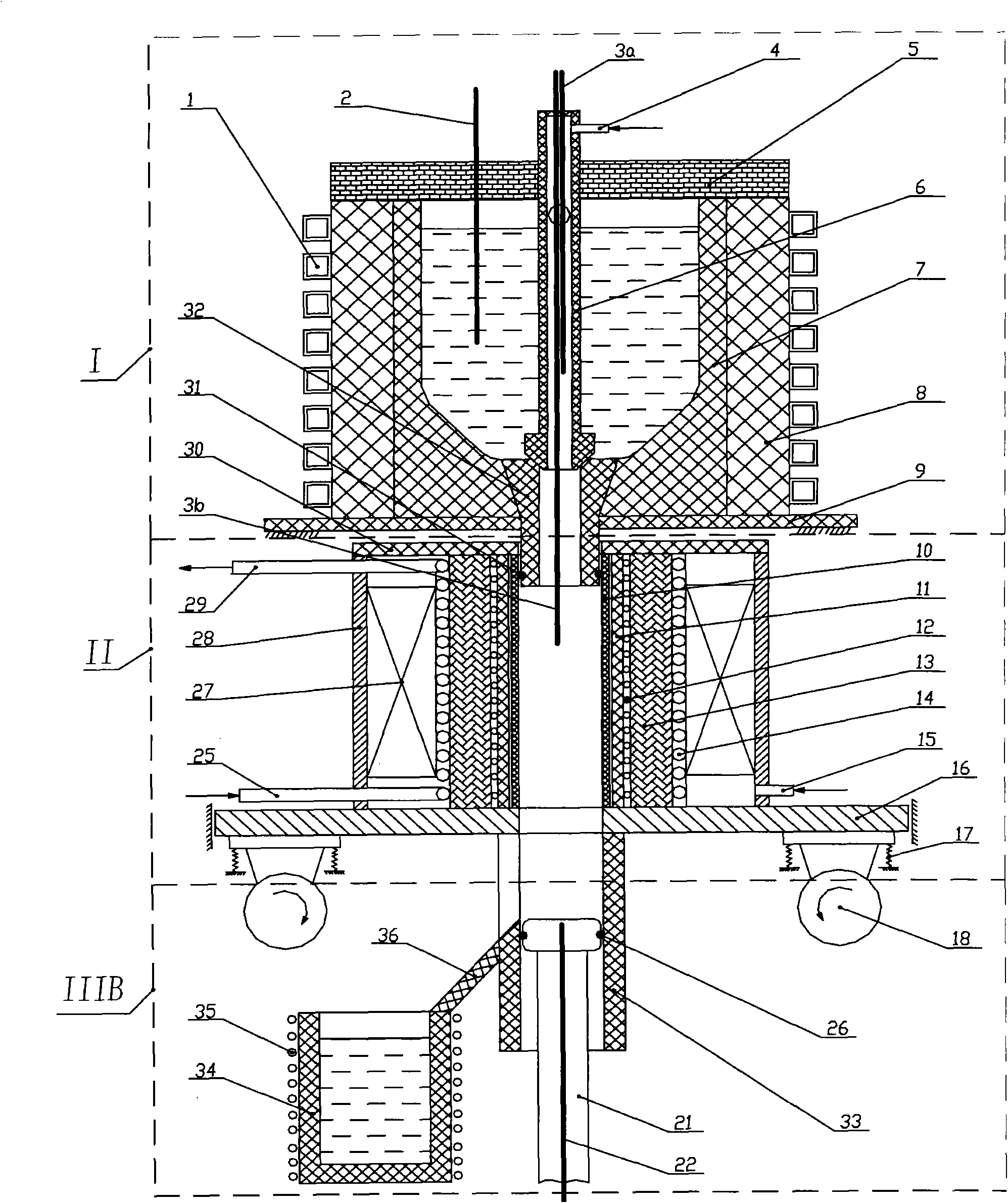

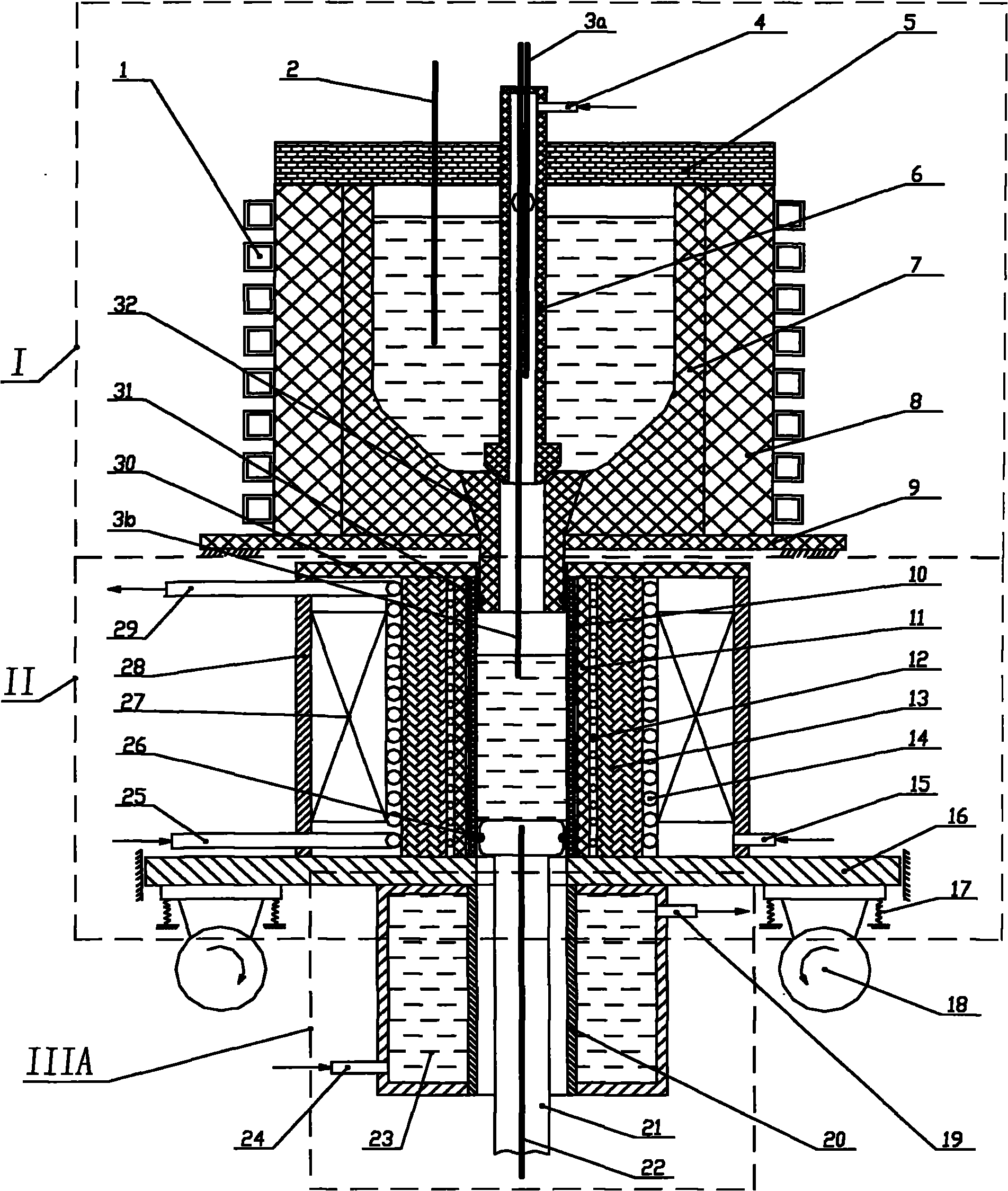

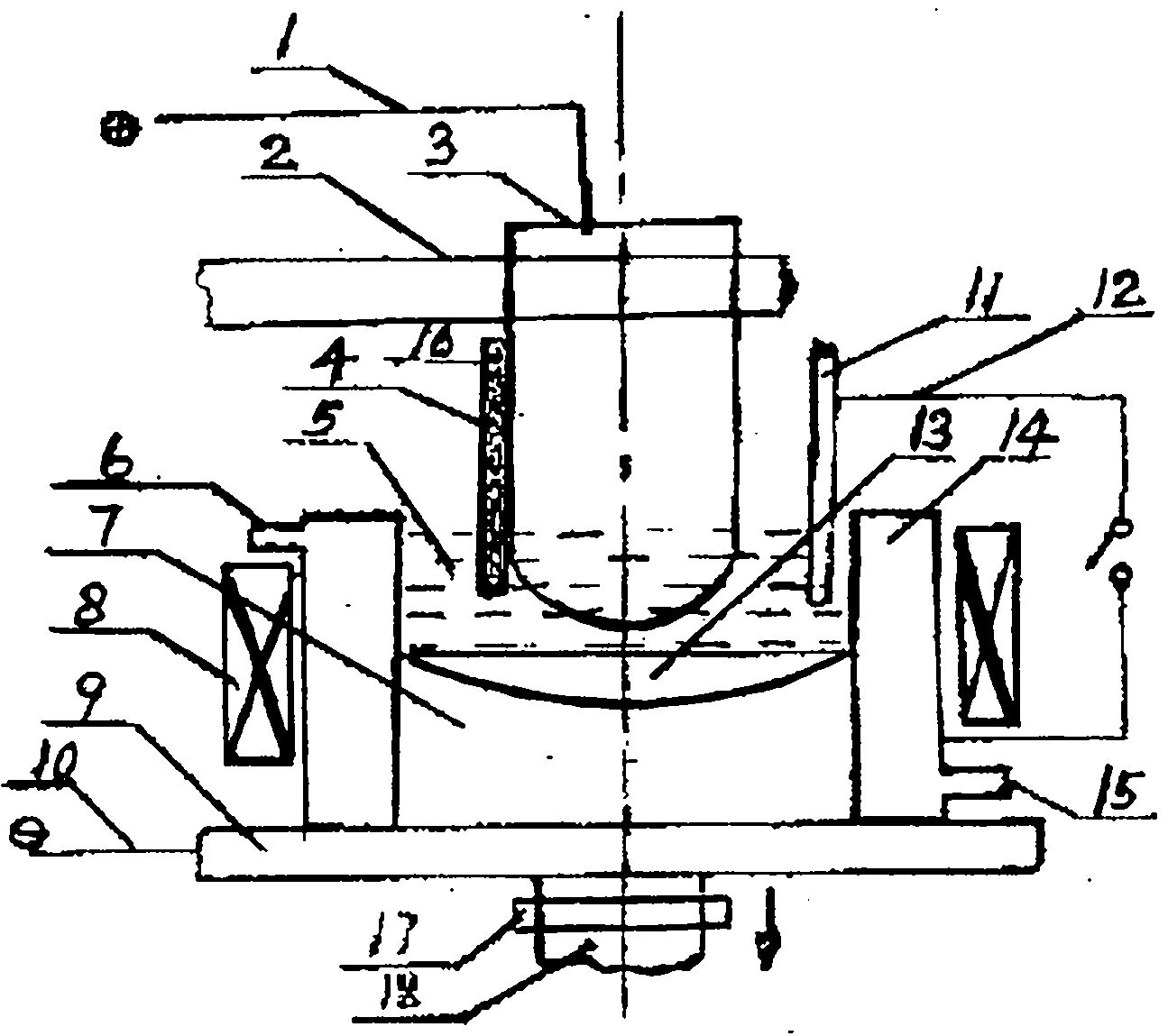

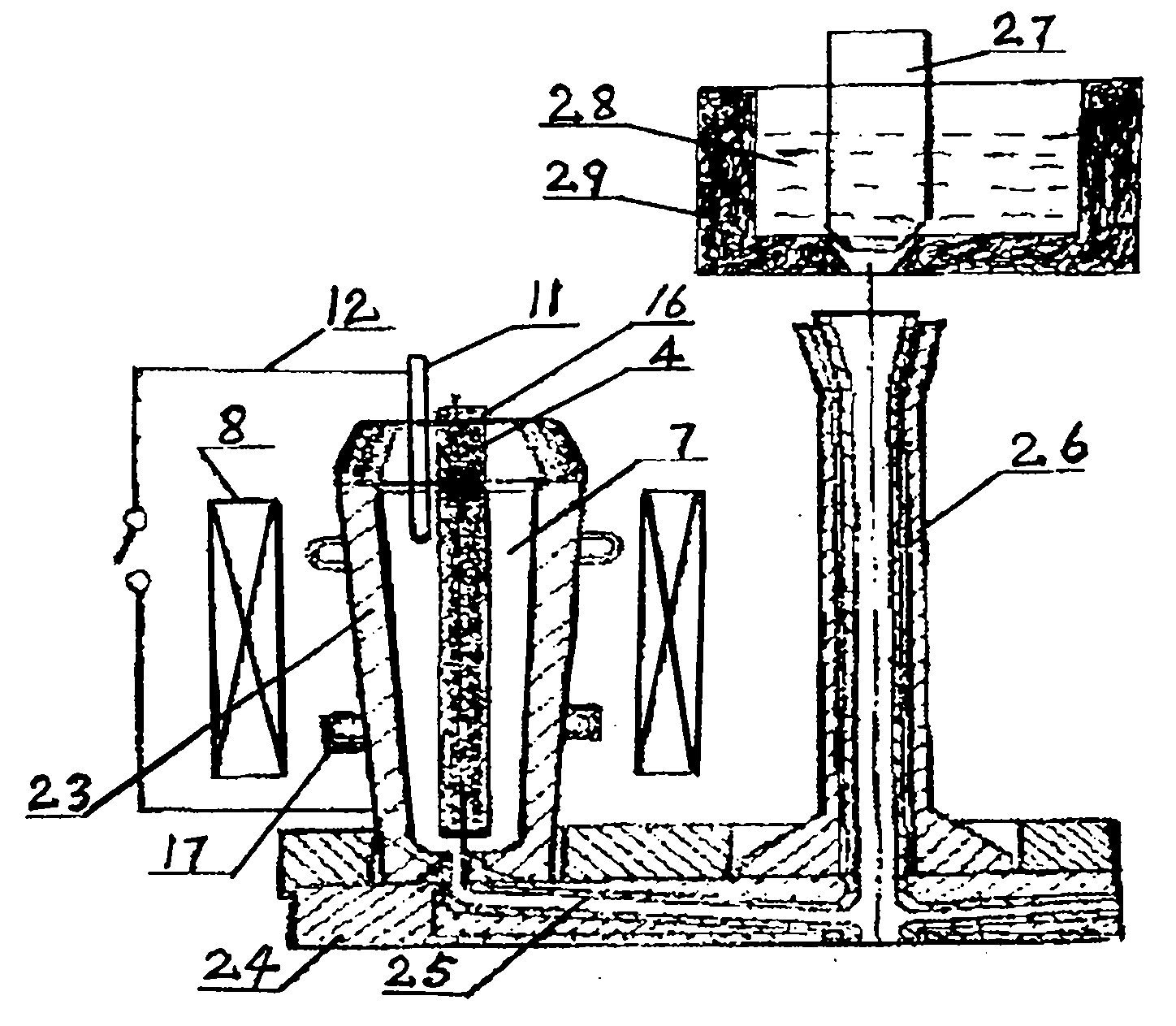

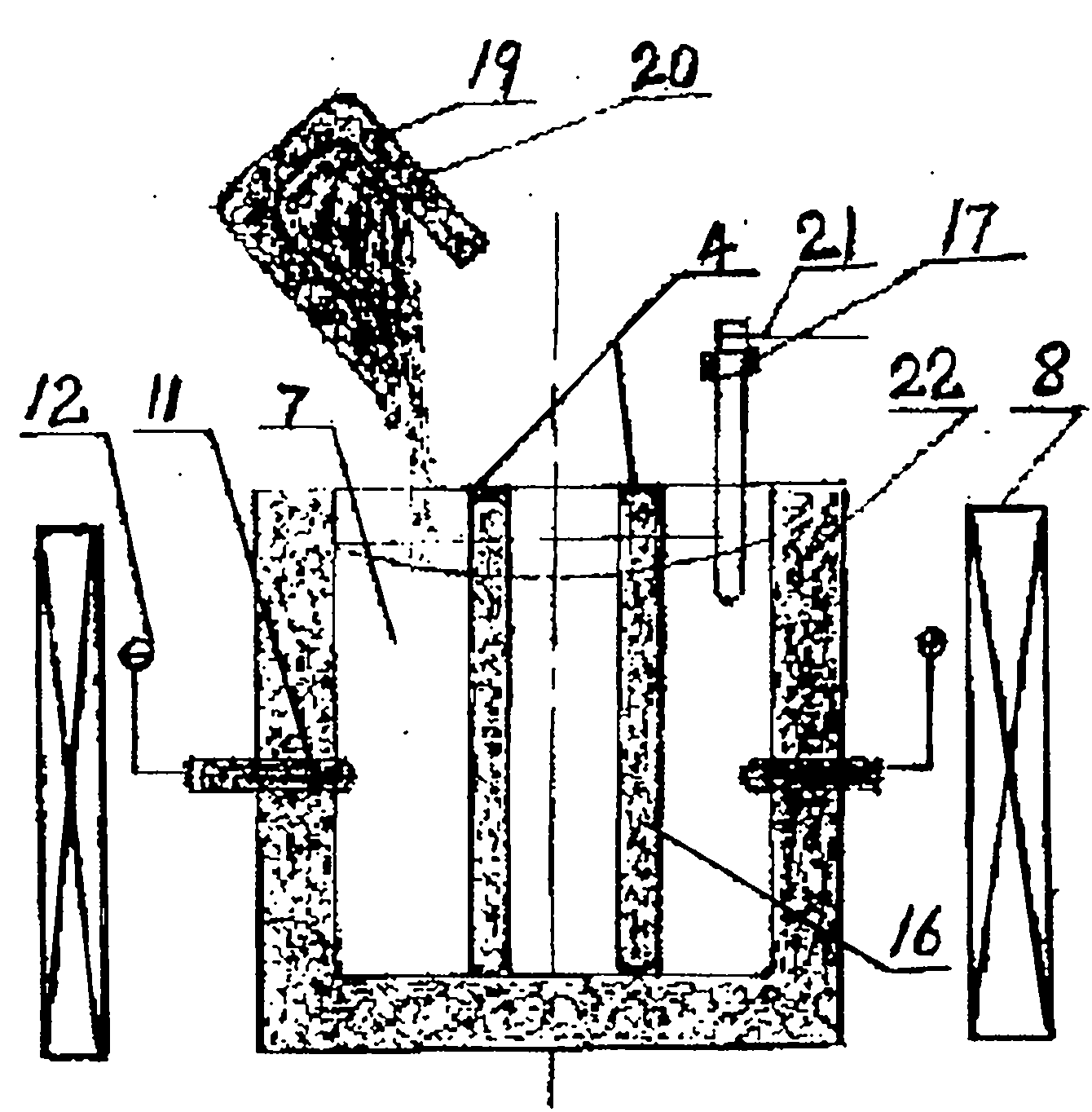

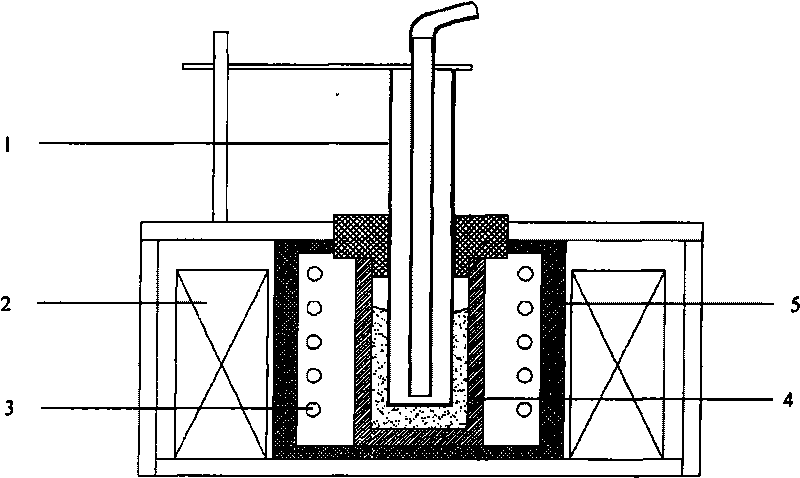

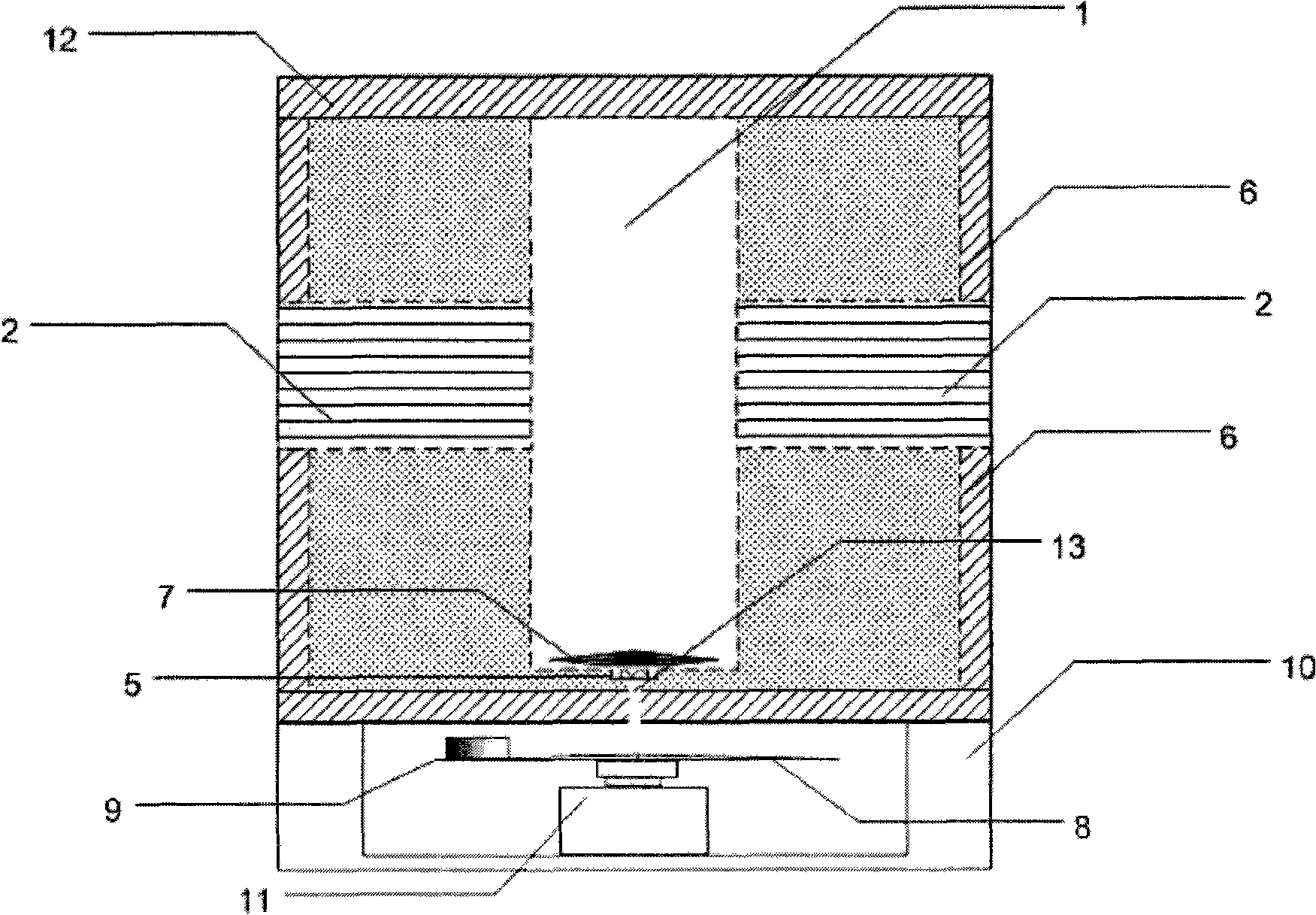

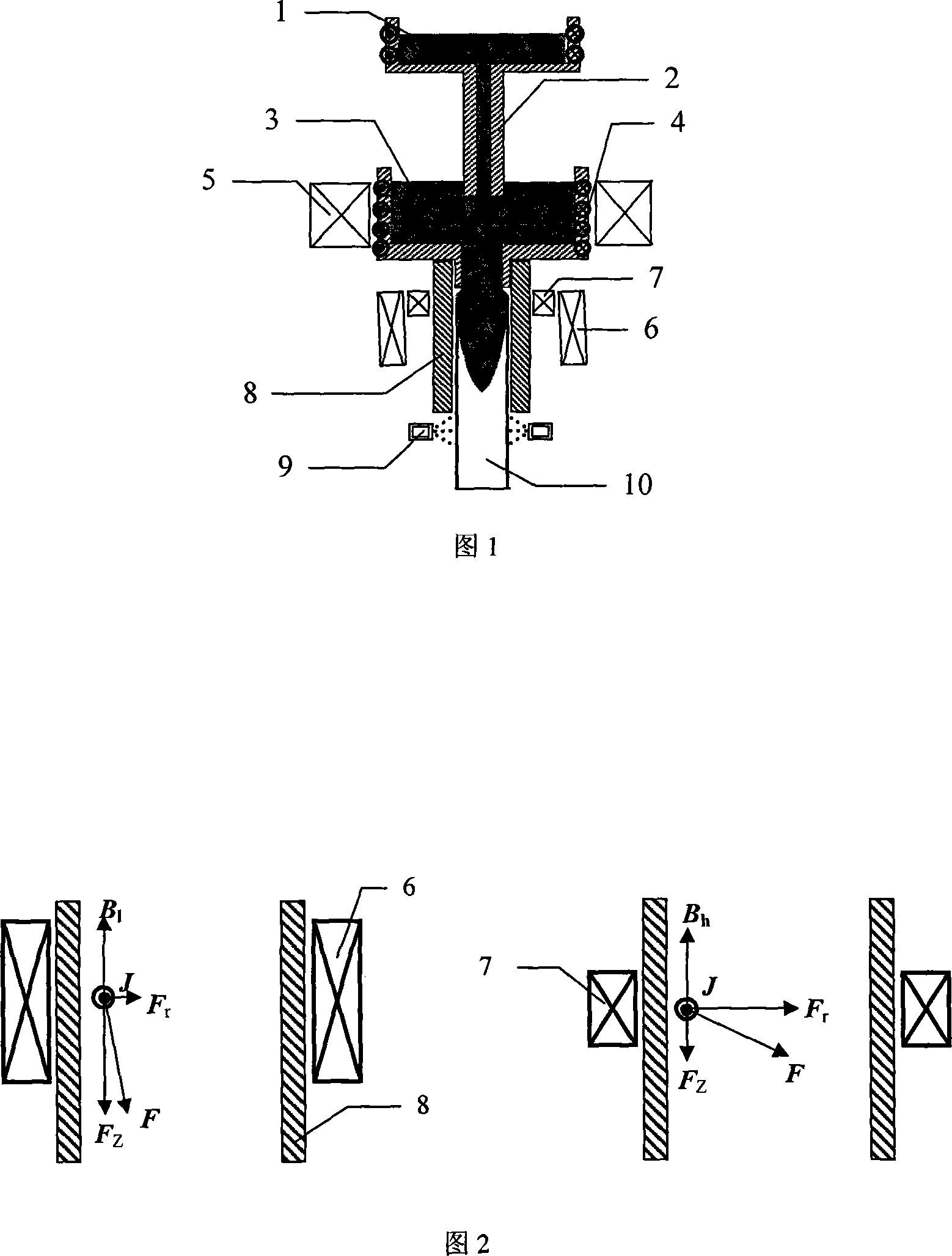

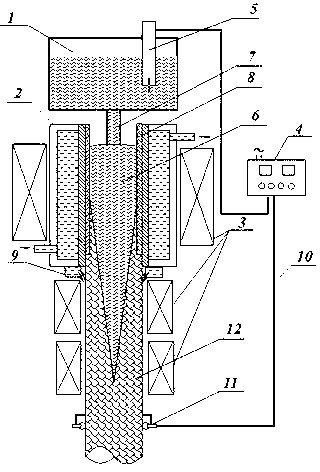

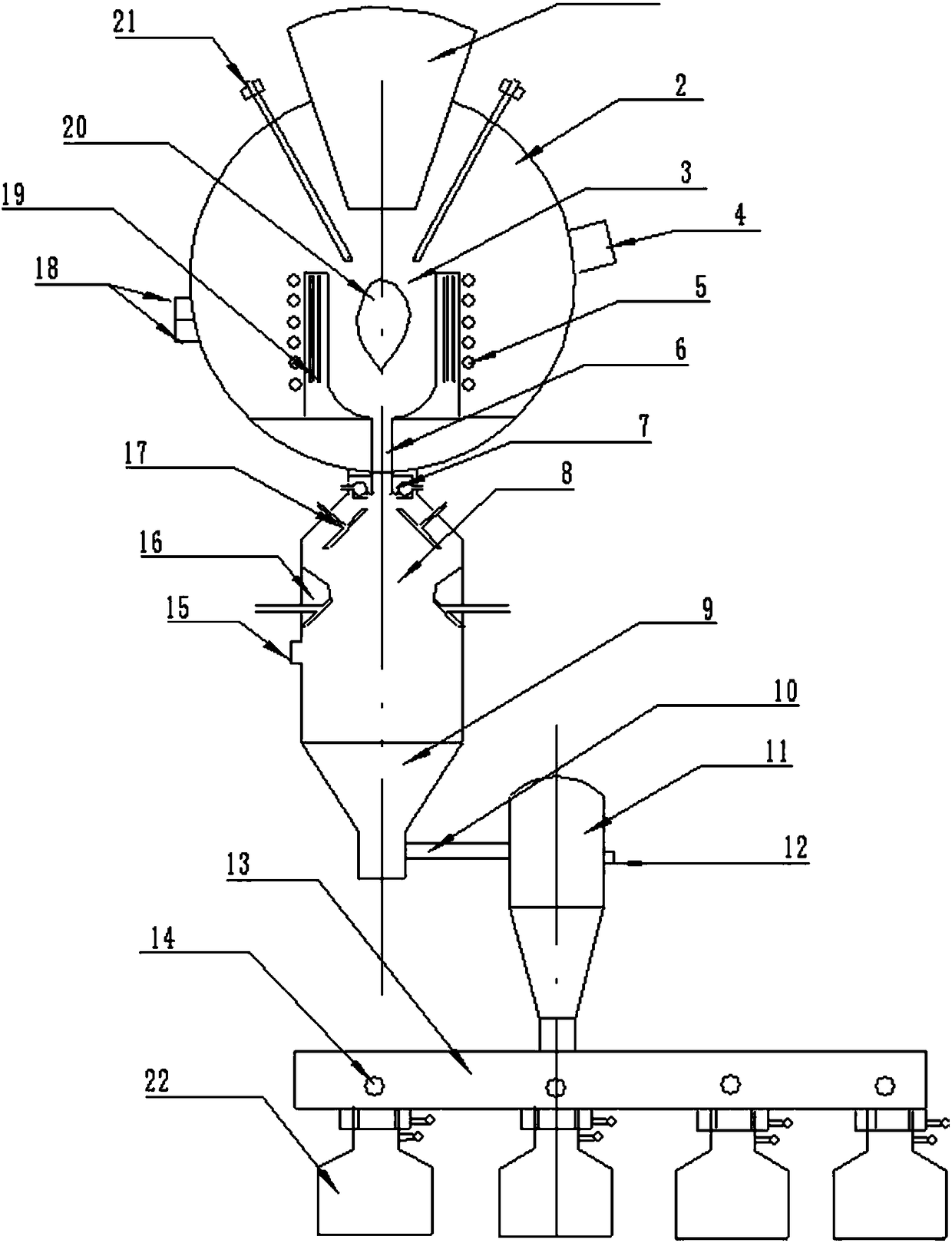

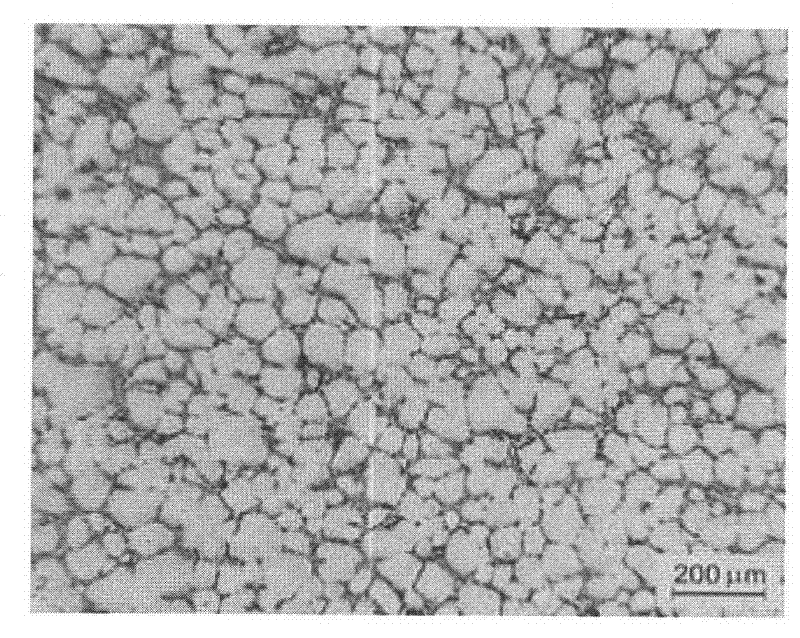

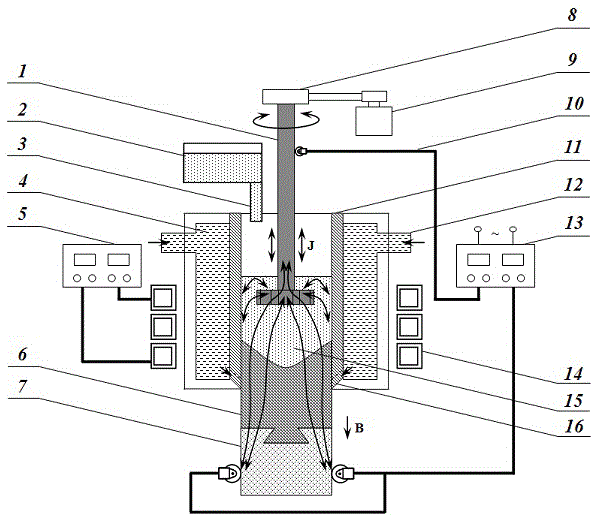

Electromagnetic stirring and vibration combined device for preparing semi-solid slurry of black metal

The invention relates to an electromagnetic stirring and vibration combined device for preparing semi-solid slurry of a black metal. The device comprises three main sections: a melting furnace, a stirring chamber, and a crystallizer or a rheologic conveyor, wherein the melting furnace is arranged at the upper part of the stirring chamber, and the crystallizer or the rheologic conveyor is arranged at the lower part of the stirring chamber. When molten metal is poured into the melting furnace, a medium-frequency induction heater is used for maintaining temperature and uniformly heating; when the temperature of the molten metal is within the liquidus temperature range, the molten metal is poured into a stirring crucible in a quantitative amount, and a non-dendritic fine equiaxial spherical or nearly spherical microstructure is obtained by electromagnetically stirring and mechanically vibrating the molten metal; and the prepared fine nearly spherical semi-solid slurry is poured into the crystallizer, then cooled and solidified into a blank, or the slurry is poured into the rheologic conveyor and then is rapidly conveyed to a forming mold for rheoforming. The device can be used for preparing semi-solid slurry of a black metal and nonferrous metal, which improves the efficiency and the quality for preparing metal semi-solid slurry and shortens the preparation time. The device is especially suitable for rheoforming.

Owner:XI AN JIAOTONG UNIV

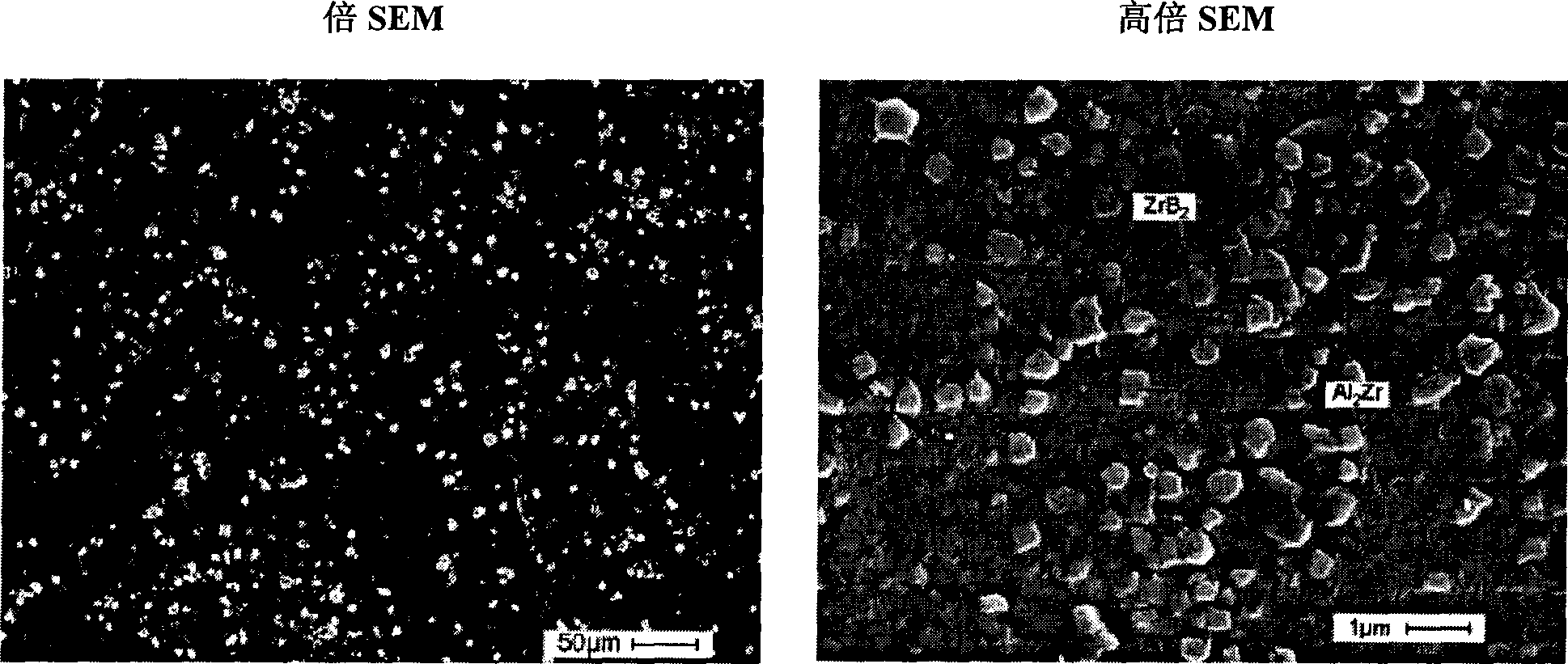

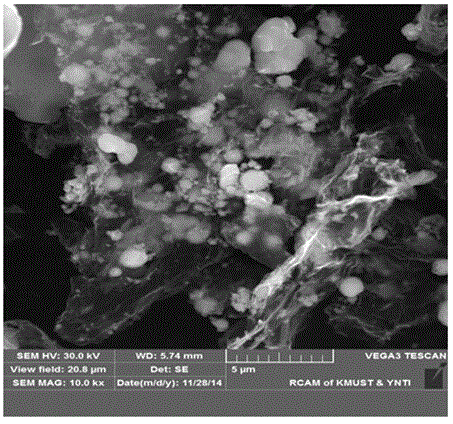

Process and equipment for preparing nanoparticle-reinforced metal matrix composite material

The invention discloses a process and equipment for preparing a nanoparticle-reinforced metal matrix composite material. The process comprises the following steps of: mixing reinforcing nanoparticles with matrix metals and a grain growth inhibitor in a stirring ball mill together, and then loading the mixture into a steel pipe; casting the mixture together with the matrix metals in a water cooling crystallizer or casting and forming the mixture together with a molten metal in a casting mould; and performing quick solidification and crystallization after electromagnetic stirring and ultrasonic vibration to ensure that the two phase materials achieve complete metallurgical bonding, wherein because of the electromagnetic stirring and the ultrasonic vibration, the two phase materials are mixed more uniformly, and all properties of the composite material can be further improved. by using the process and the equipment, a production process is simple, the cost is low, the efficiency is high, the product performance is high, the process is easy to control, the external dimensions of products are not limited by the process, and large-sized nanoparticle-reinforced metal matrix composite materials can be manufactured.

Owner:丁家伟

Preparation method of graphene-reinforced copper-based composite

ActiveCN105624445AImprove performanceEasy to organizeTransportation and packagingMetal-working apparatusSlurryCobalt

The invention discloses a preparation method of a graphene-reinforced copper-based composite and belongs to the field of preparation of high-strength and high-conductivity composites. The method comprises steps as follows: graphene, nano copper powder and cobalt powder in the required mass ratio are mixed in absolute ethyl alcohol, the mixture is physically dispersed under electromagnetic stirring, and then physically dispersed mixed slurry is added to a ball milling tank for mechanical ball milling; after evenly mixed slurry is centrifugally dried, obtained mixed powder is annealed and then subjected to hot-pressing SPS (spark plasma sintering) forming; an obtained block blank is annealed and then subjected to hot extrusion, and the graphene-reinforced copper-based composite is obtained. The graphene-reinforced copper-based composite prepared through the method has the good mechanical property, uniform structure and good heat and electricity conductivity.

Owner:KUNMING UNIV OF SCI & TECH

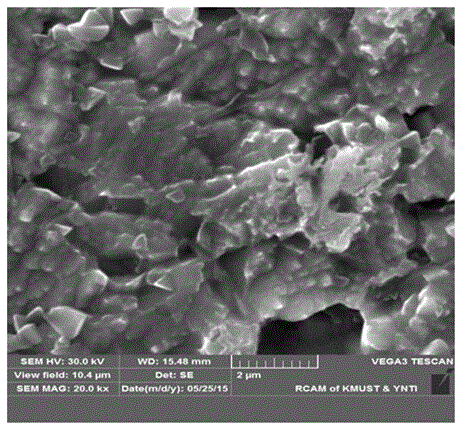

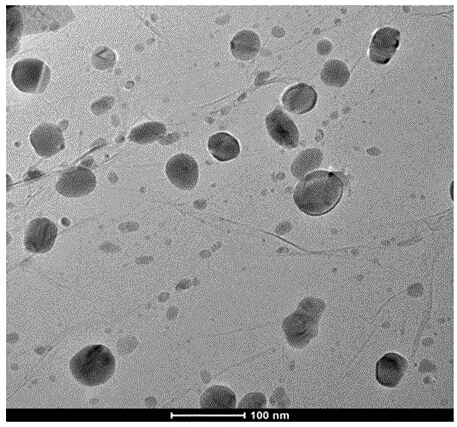

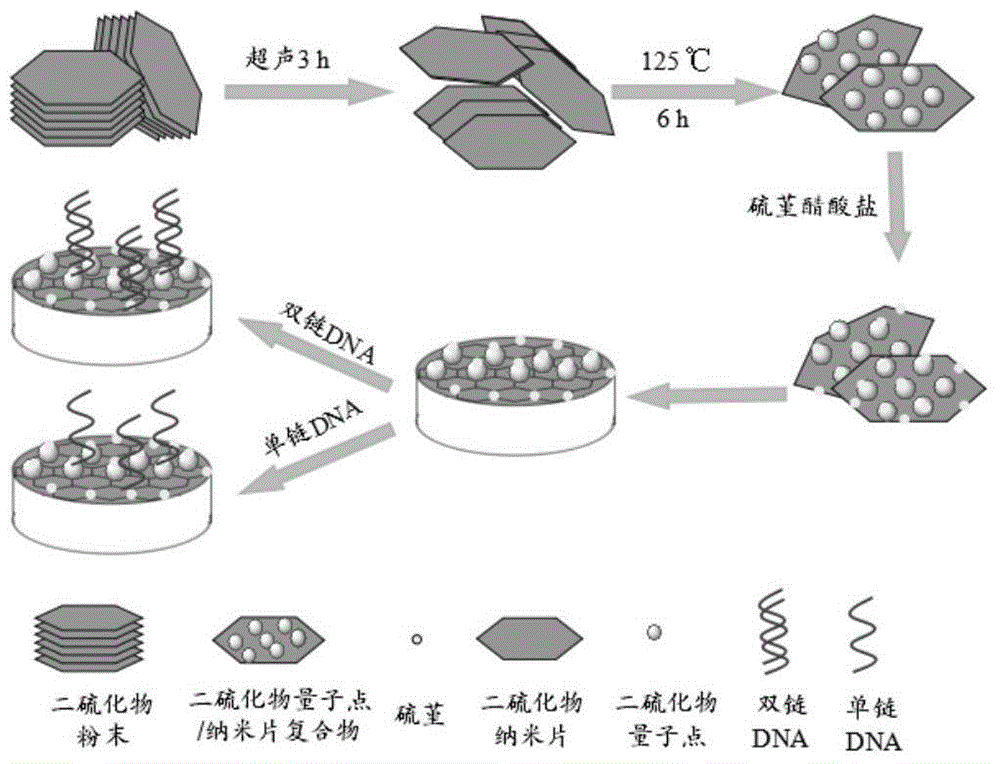

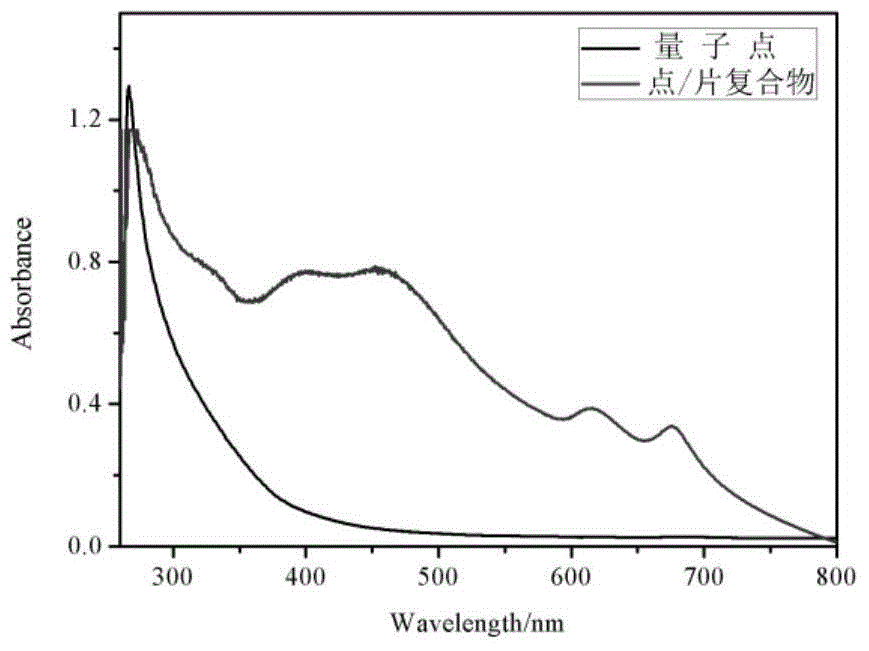

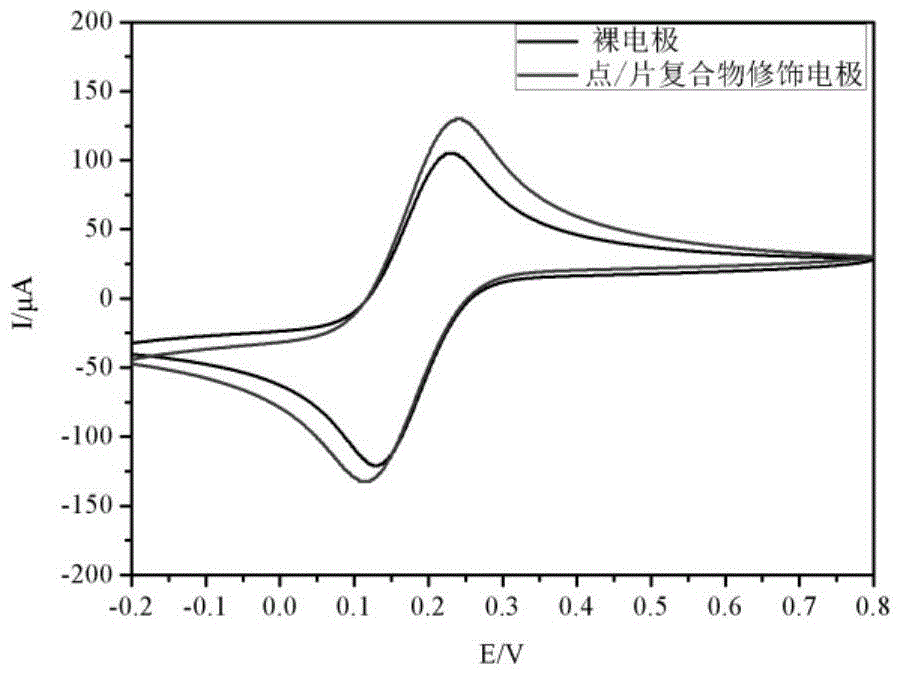

Preparation method of disulfide dot/nanosheet compound DNA electrochemical probe

ActiveCN105004775AHigh sensitivityImprove stabilityMaterial analysis by electric/magnetic meansOrganic solventQuantum dot

The invention relates to a preparation method of a disulfide dot / nanosheet compound DNA electrochemical probe. The method concretely comprises the following steps: 1, carrying out ultrasonic peeling on transition metal disulfide powder, carrying out high-temperature electromagnetic stirring to prepare a transition metal disulfide quantum dot / nanosheet compound, and carrying out ultrasonic treatment on the compound in a thionine and ionic liquid dispersion liquid to prepare a thionine functionalized compound; 2, dispersing the compound prepared in step 1 in an organic solvent to prepare a suspension, dispensing the suspension on an electrode, and drying to obtain a compound modified electrode; and 3, carrying out electrochemical test on a three-electrode system formed by the electrode produced in step 2 in a buffer solution, injecting different concentrations of a DNA solution, testing, recording the change of the electrochemical signal of the electrode, and constructing a DNA electrochemical probe system. The probe has the advantages of high sensitivity, good stability, wide linear range and low detection limit, can be used in detection of DNA in serum, and has wide application prospect in biological analysis and clinic diagnosis fields.

Owner:QINGDAO UNIV

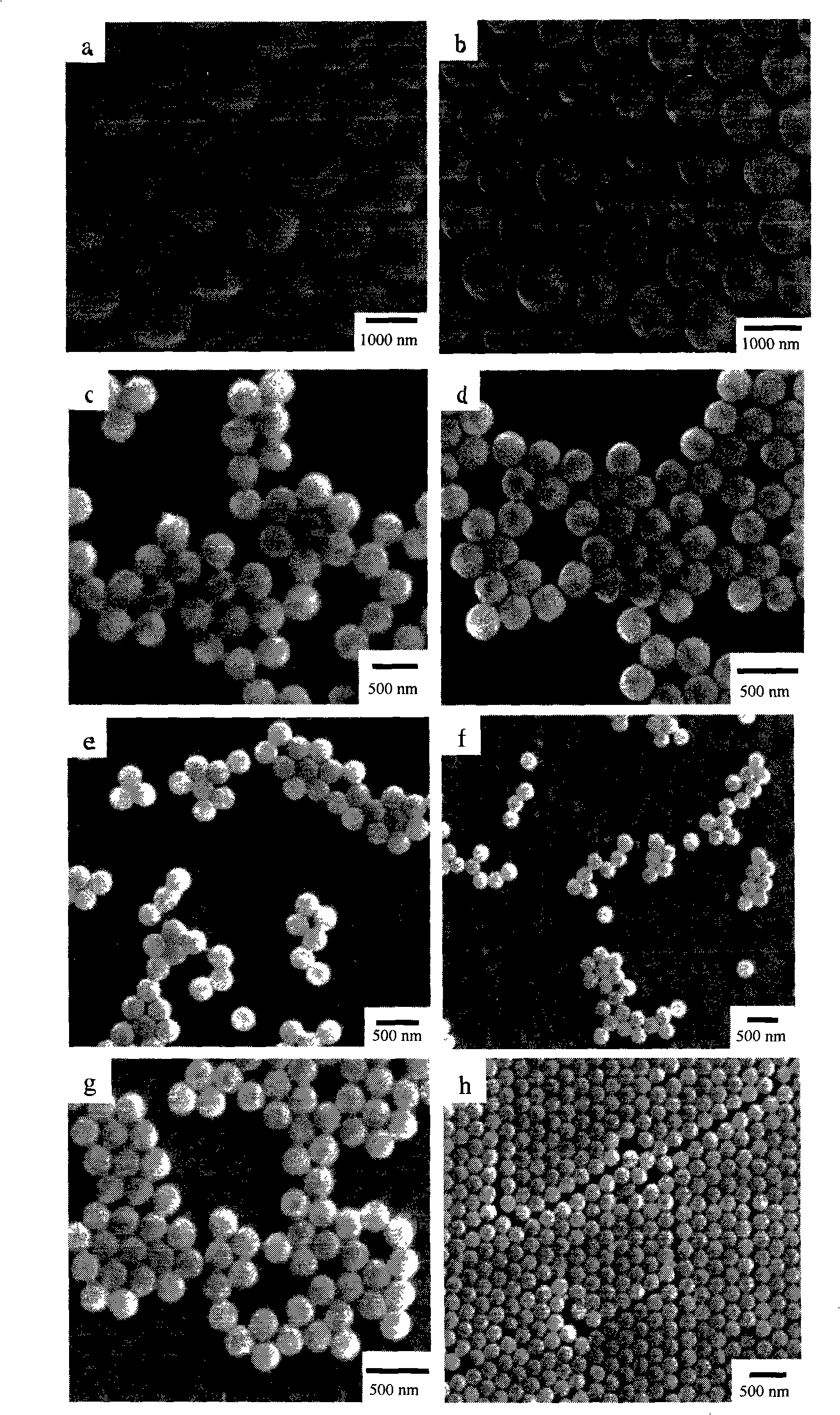

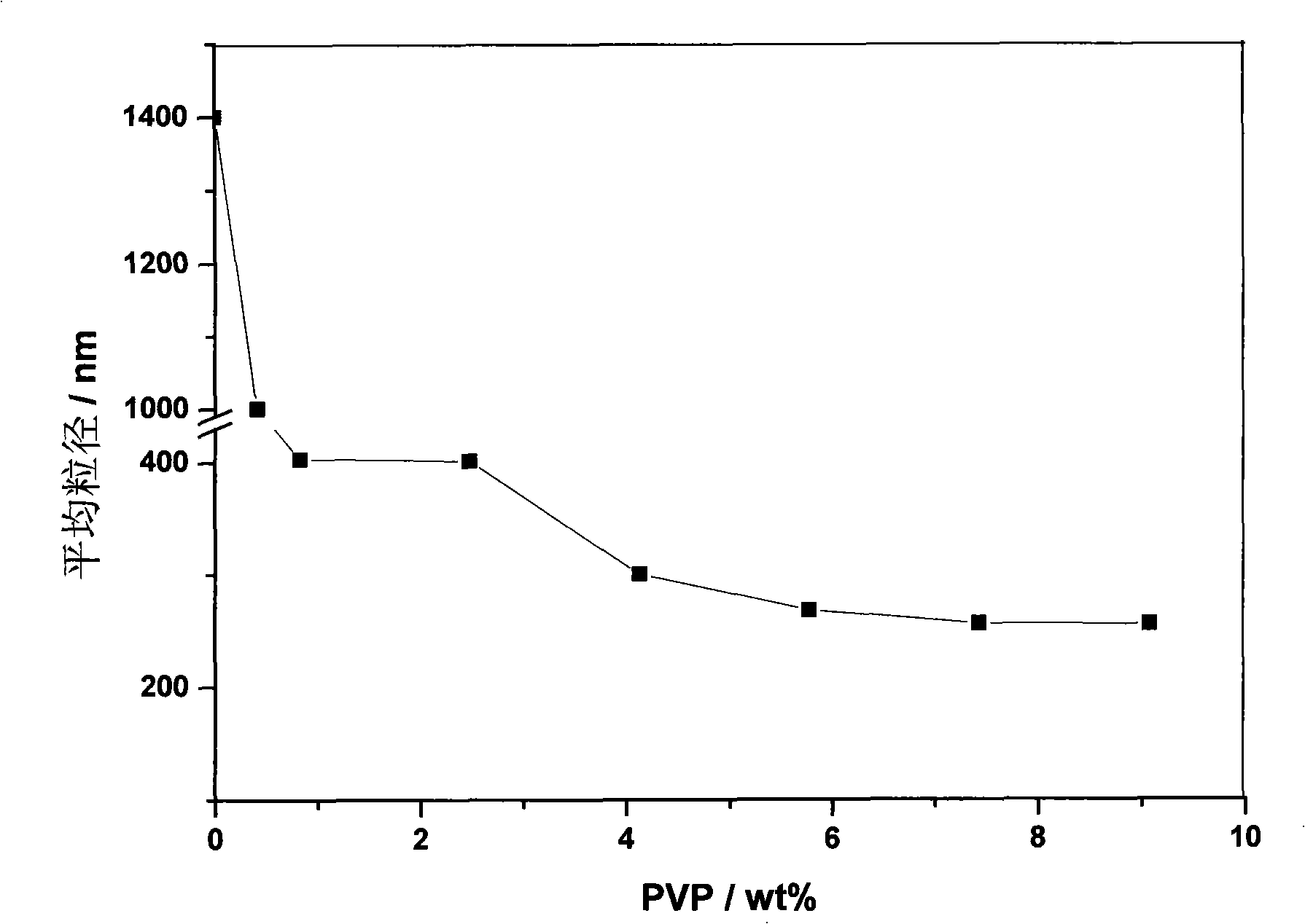

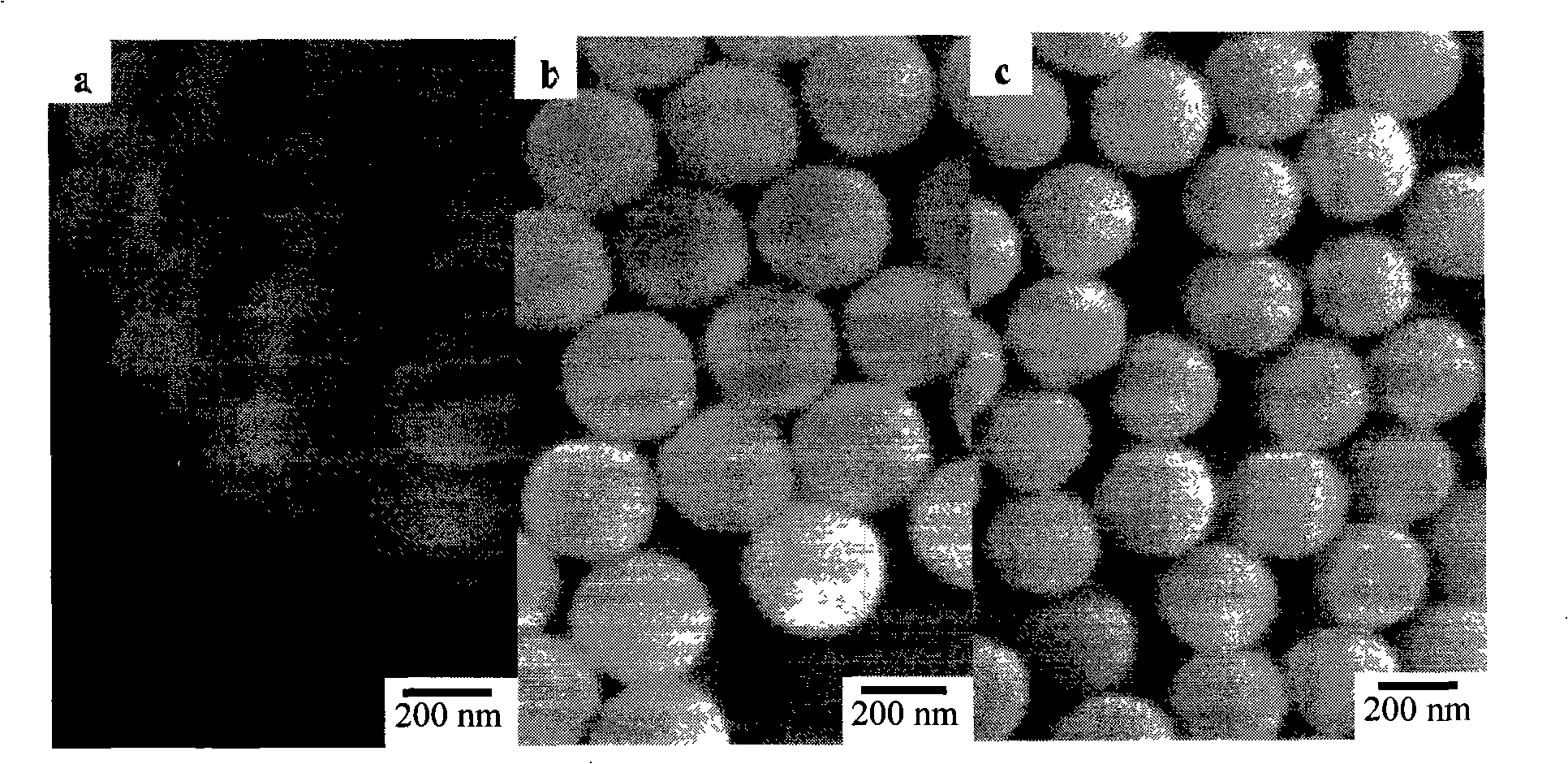

Method for preparing monodisperse polystyrene microsphere with controllable grain diameter

InactiveCN101293936ALow purity requirementGood monodispersityHydrocarbon purification/separationHydrocarbonsPotassium persulfateMicrosphere

The invention belongs to the technology field of nanometer materials preparation, particularly relates to a preparation method of monodisperse polystyrene microspheres capable of controlling the particle size of the polystyrene microspheres within a certain range by changing the use amount of a stabilizer. The invention prepares polystyrene microspheres with simply purified styrene as a monomer, potassium persulfate as an initiator, water as a reaction medium and polyvinylpyrrolidone as a stabilizer by using soap-free emulsion polymerization. The preparation method uses electromagnetic stirring instead of electric stirring; and has the advantages of relatively low requirements for the uniformity of stirring speed, no need of surfactant, simple process, and low cost. The obtained polystyrene microspheres have good monodispersity, and the particle size thereof can be controlled within the range of 250-1,400nm by changing the use amount of the stabilizer. The monodispersed polystyrene microspheres have important application value as a module or template in construction of photonic crystals, inorganic / organic nanometer composite materials and hollow micrometer / nanometer spheres.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

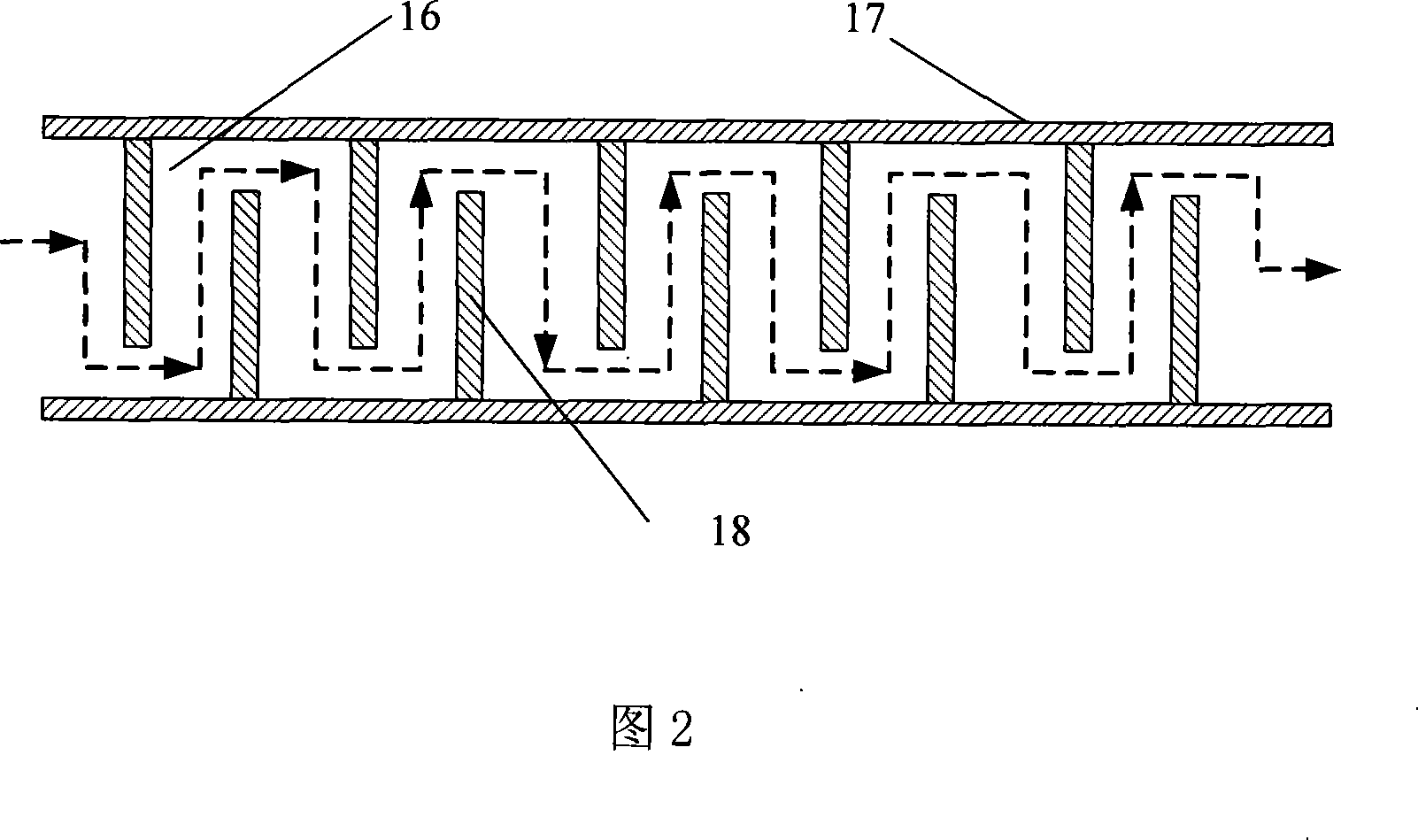

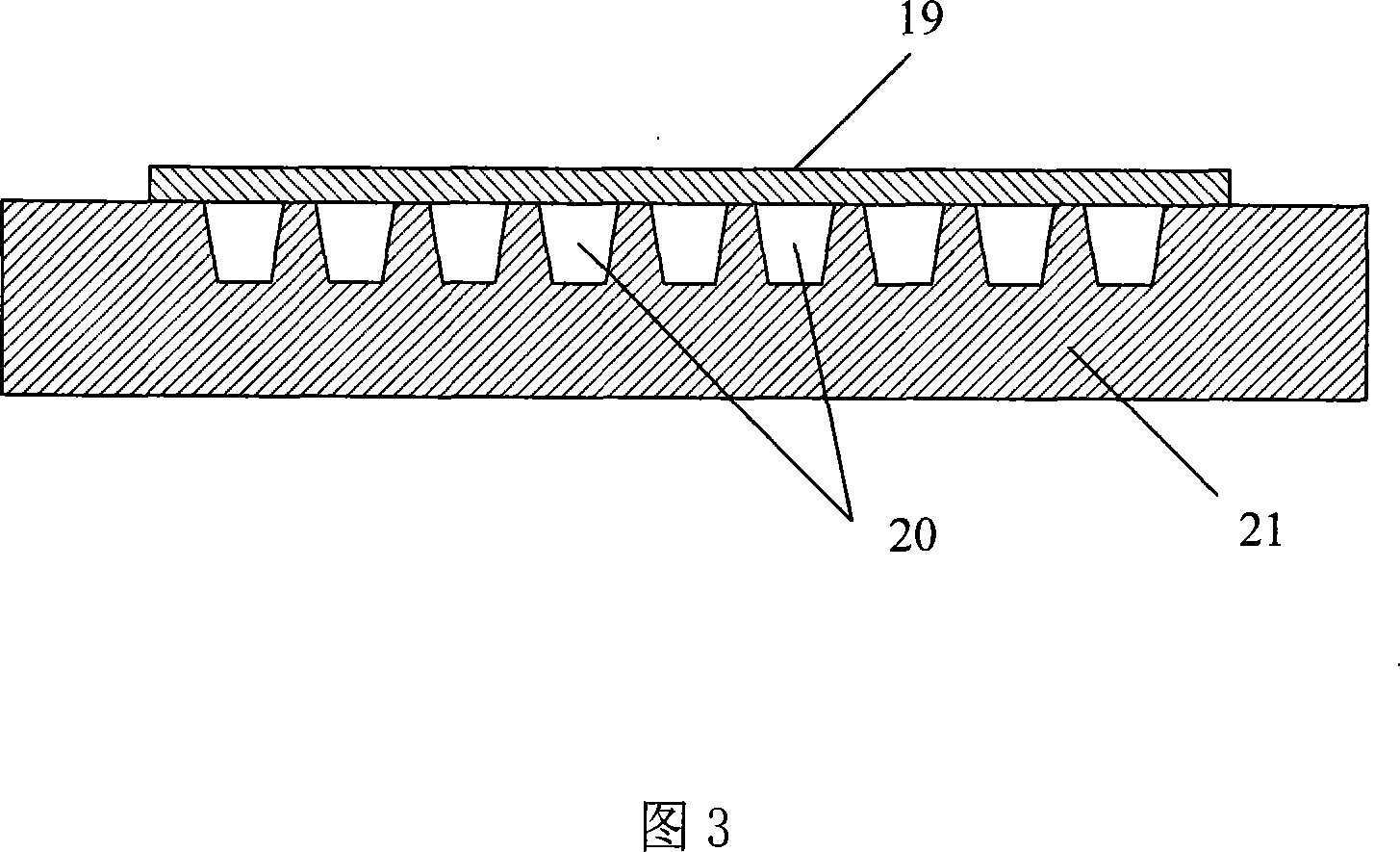

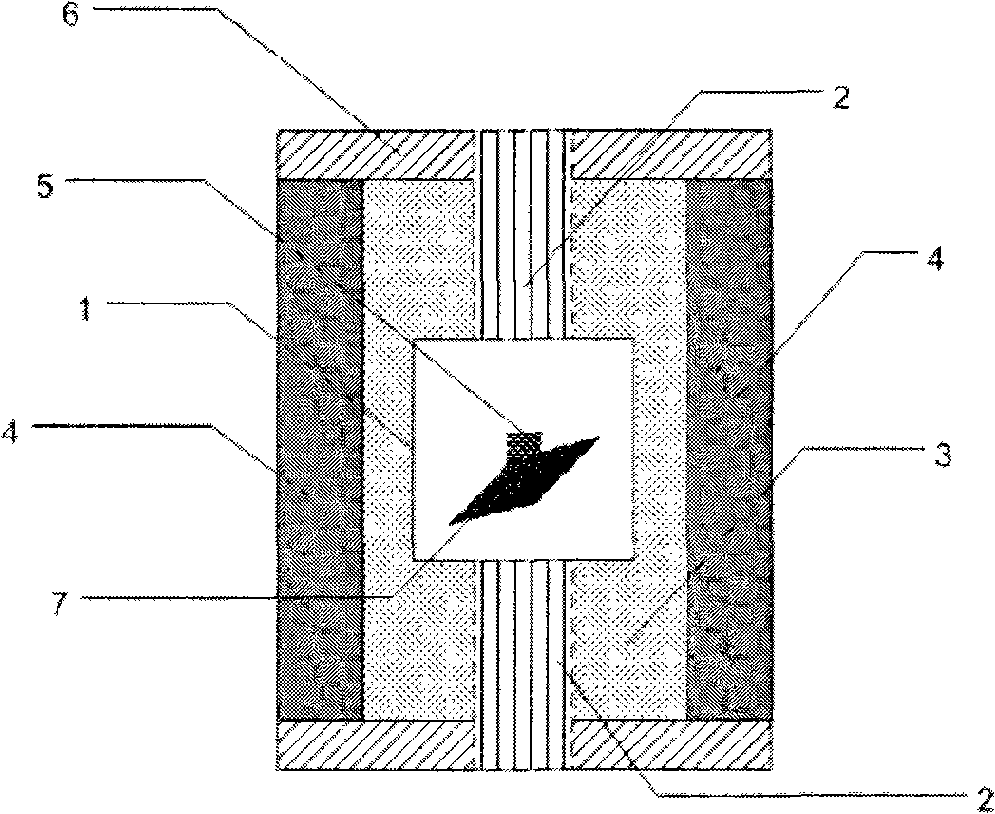

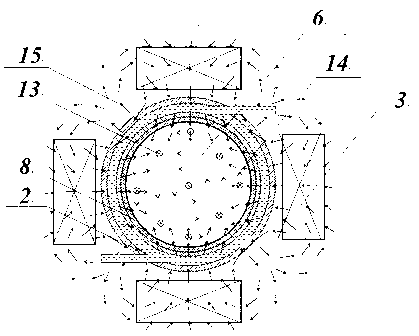

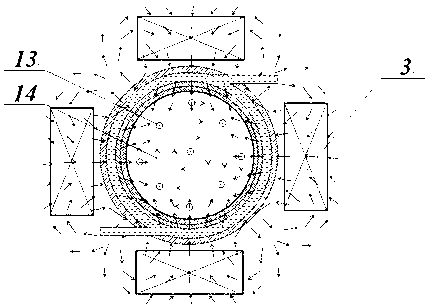

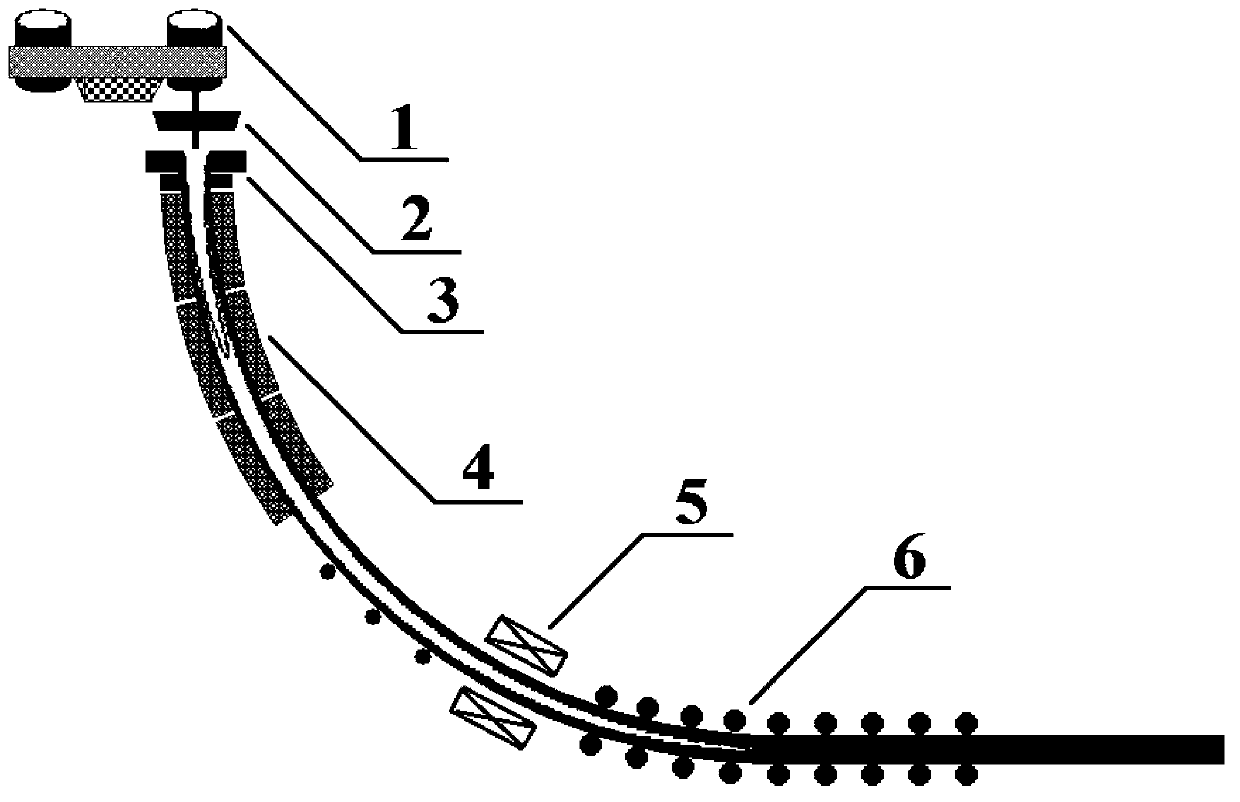

Method for preparing semi-solid alloy rheological slurry or billet through annular-gap type electromagnetic stirring

A method for preparing semi-solid metal or alloy slurry or billet through annular-gap type electromagnetic stirring is hereinafter referred to as an annular-gap type electromagnetic stirring method in which the liquid metal or alloy liquid with 5-100 DEG C higher than the liquidus temperature is cast in an annular gap formed between an inner side wall of a slurrying chamber and an outer wall of an internal cooling controller. The metal or the alloy liquid is strongly stirred under the action of an electromagnetic induction rotary stirrer. Meanwhile, the cooling medium flowing in an external cooling controller and the internal cooling controller lead the temperature field of the slurry to be more uniform, thereby obtaining the fine and uniform semi-solid structure. The method is characterized in that the width of the annular gap formed between the inner side wall of the slurrying chamber and the outer wall of the internal cooling controller is 3-100mm. During preparation, the cooling medium is flowed in the external cooling controller and the internal cooling controller so as to lead the temperature field of the slurry to be uniform. The preparation method leads the stirring force field and the temperature field of the slurry to be more uniform, thereby obtaining the high-quality semi-solid slurry. The method has the advantages of simple preparation process, convenient operation, excellent shape of the semi-solid structure, uniformity and fineness and low preparation cost, and is particularly applicable to preparation of semi-solid aluminum or aluminum alloy, magnesium and magnesium alloy and other metal and alloy or composite material slurry or billet.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

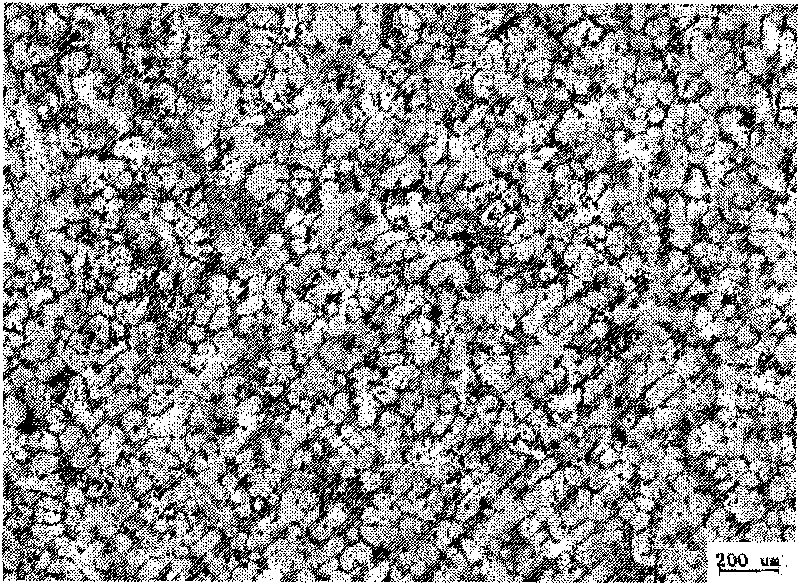

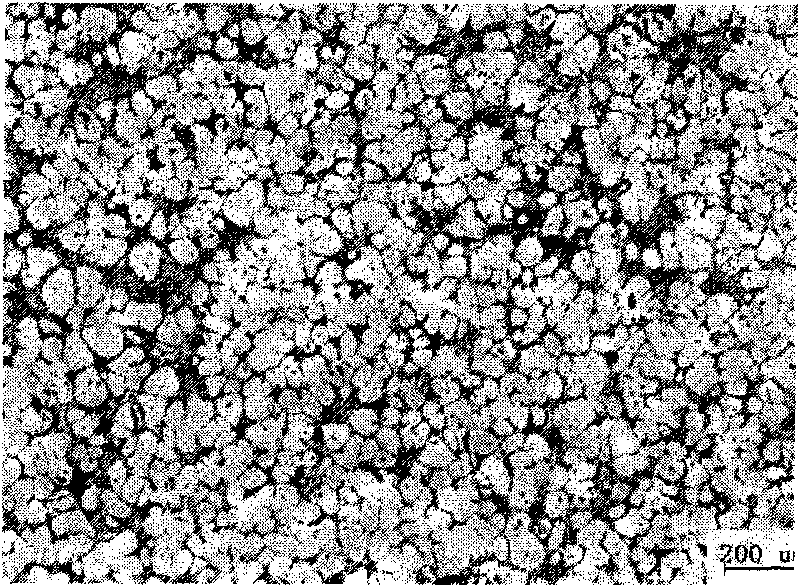

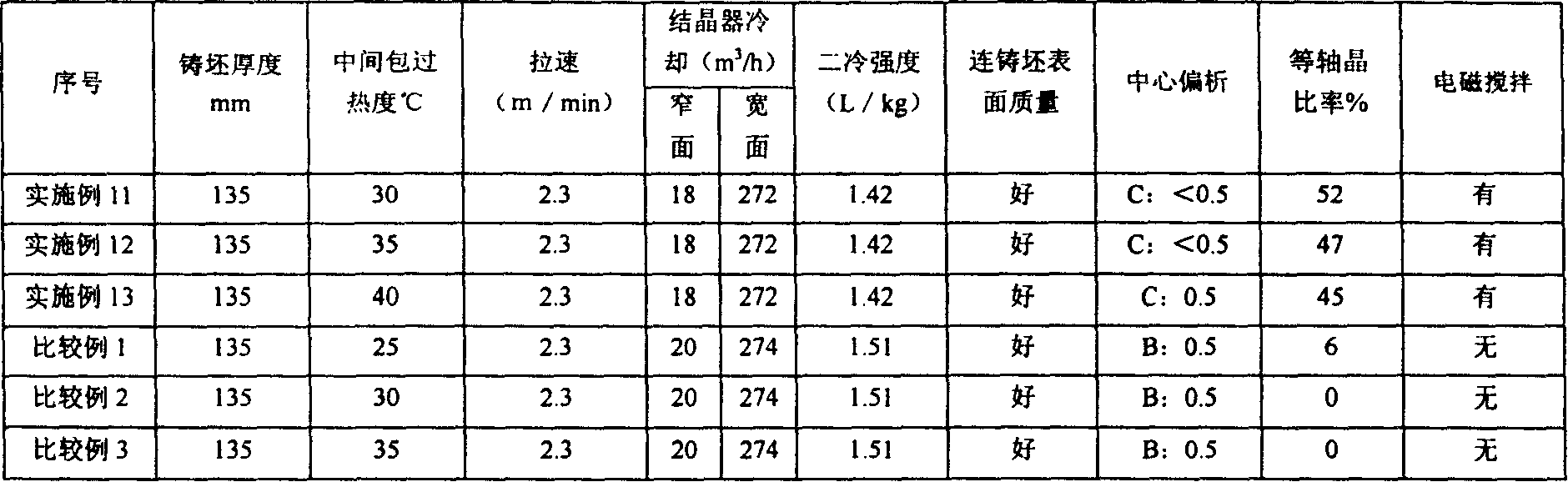

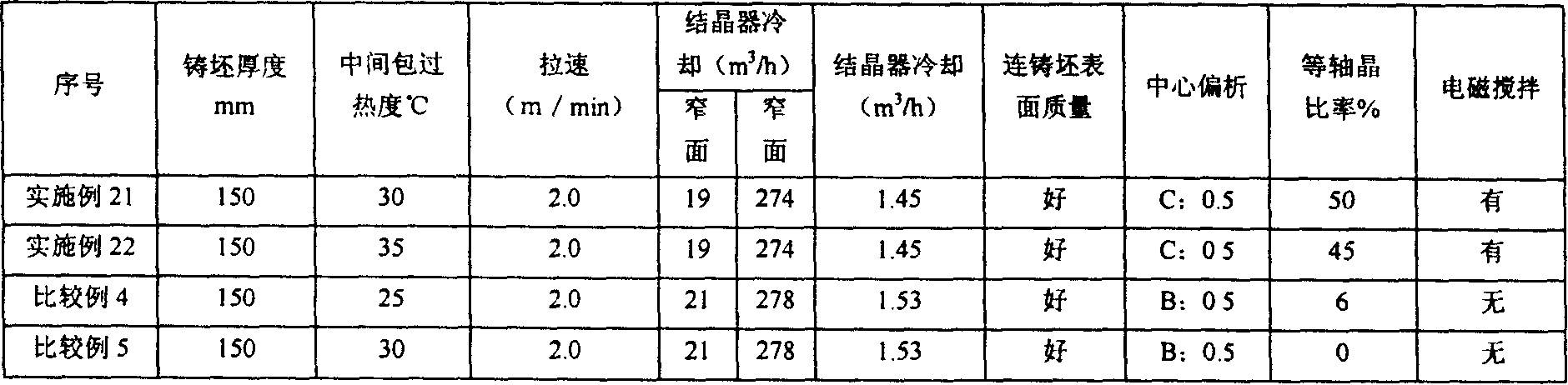

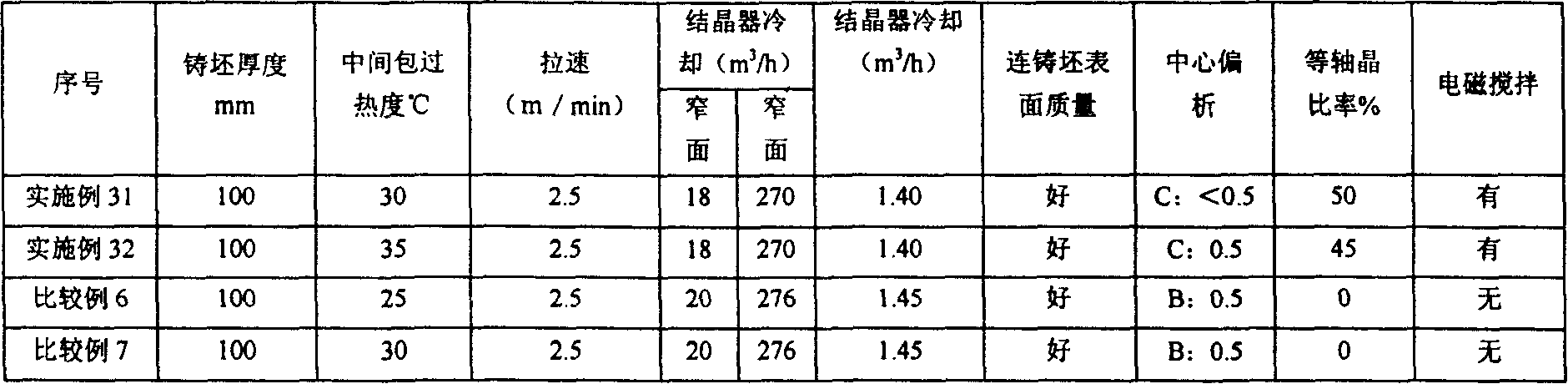

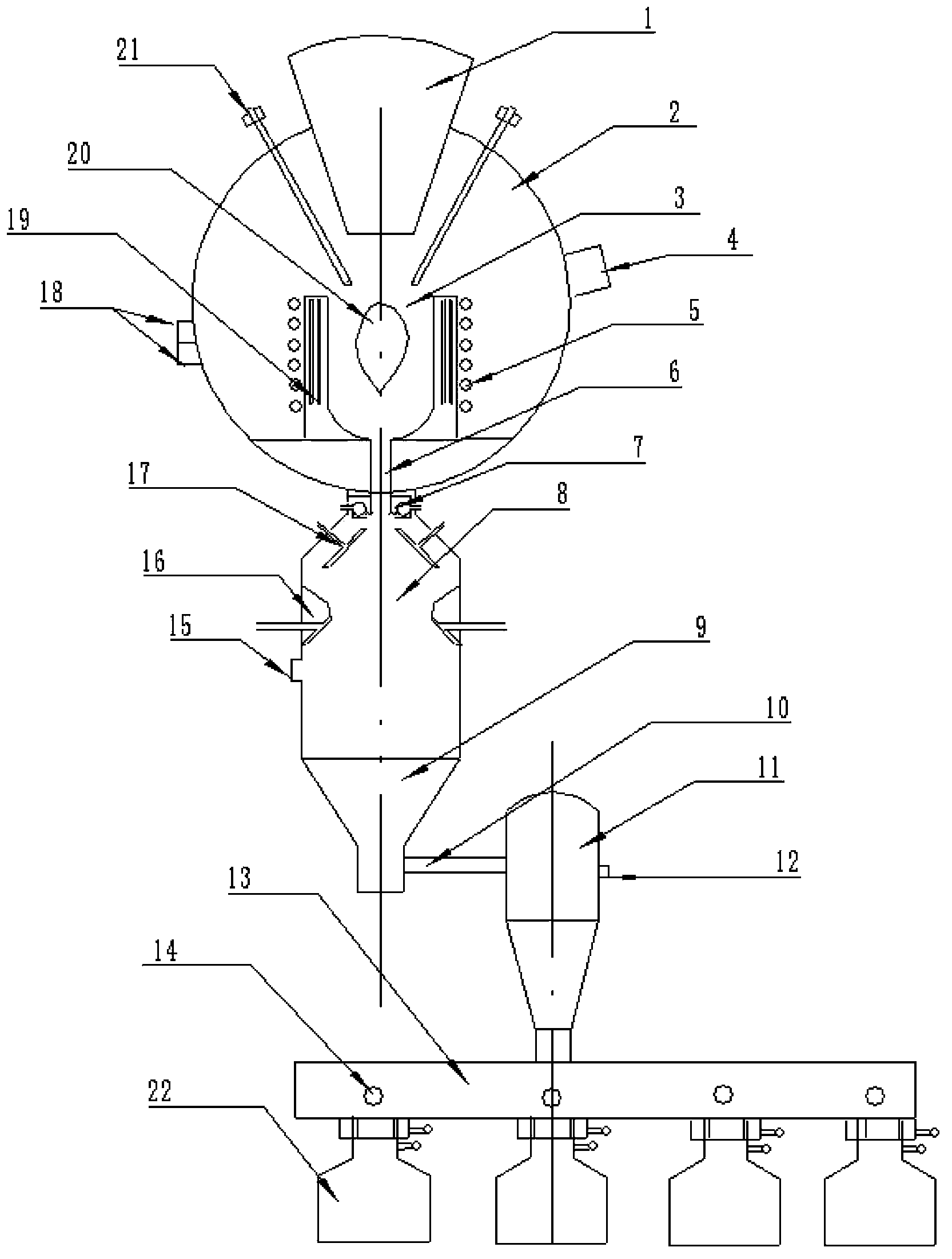

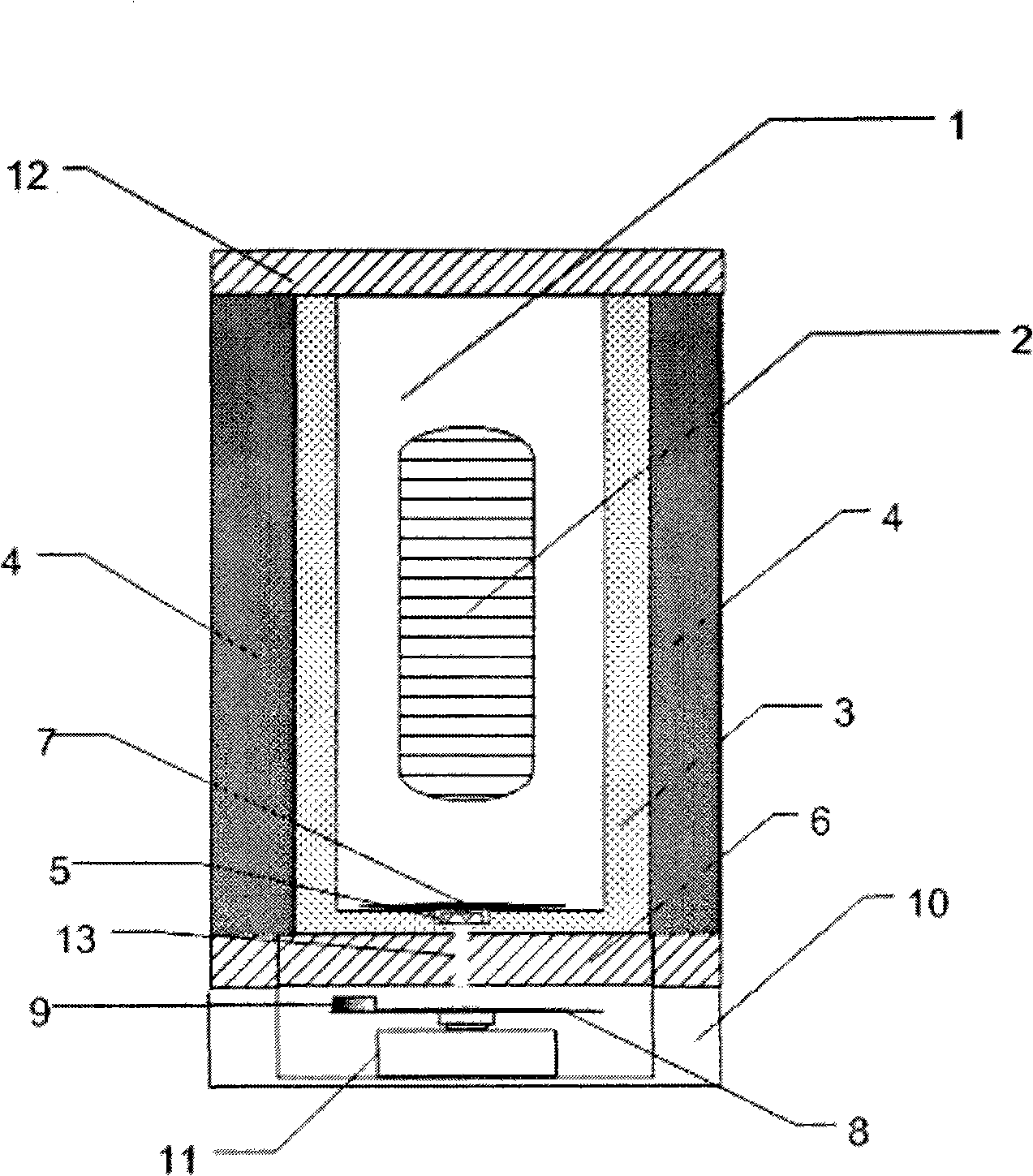

Continuous casting method for increasing equal thickness continuous casting plate billet equal axial crystal rate in non-oriented silicon steel

InactiveCN101164720AImprove mechanical propertiesImprove dynamic conditionsSiliconElectromagnetic stirring

The present invention provides a continuous casting method capable of increasing non-oriented silicon steel medium-thickness continuous cast slab equiaxial crystal rate. It is characterized by that it adopts a medium-thickness slab continuous casting machine, in the continuous casting second cooling zone it adopts a roller electromagnetic stirring equipment. The casting billet size of continuous casting machine is 100-150mmX850-1550mm, pouring speed is 1.5-3.5m / min, the cooling pattern: the narrow edge of crystallizer is 14-25m3 / h, the wide edge of crystallizer is 250-290m3 / h and second cooling intensity is 1.3-1.8L / kg. The described electromagnetic stirring equipment includes 2-4 pairs of introroller built-in traveling wave magnetic field type electromagnetic stirring devices which are assembled into two groups and mounted.

Owner:ANGANG STEEL CO LTD

Ti-based powder preparing device and Ti-based powder preparing method

The invention discloses a Ti-based powder preparing device and a Ti-based powder preparing method. The device comprises a vacuum chamber, a magnetic suspension melting furnace, an atomization power processing chamber and a screening system. During working, when the magnetic suspension melting furnace is energized with high frequency alternating current, a high frequency alternating magnetic field can be produced in space around a coil, and the high frequency alternating magnetic field causes induction vortex in furnace charge. The induction vortex and the external alternating magnetic field interact with each other to produce suspension force for the furnace charge, and the suspension force is balanced with the dead weight of the furnace charge so as to enable the furnace charge to suspend; meanwhile, a vortex circuit generates a great deal of heat to melt the furnace charge, and the molten mass is subjected to deslagging, degassing and purification under the fierce function of electromagnetic stirring. The purified molten mass can fall into a gas atomization chamber by virtue of controlling the magnetic field; under the functions of a supersonic speed high-pressure argon atomizer and a cooling device, the molten mass is atomized into spherical Ti-based powder with high degree of sphericity, oxygen content of less than 1800 ppm and nitrogen content of less than 300 ppm.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Quick changeable temperature small-sized constant temperature sample pool

InactiveCN101281121APrecise and fast temperature controlMeet the requirements of constant temperatureMaterial analysis by optical meansWater/sand/air bathsTemperature controlMetallic materials

The invention relates to a quick variable temperature miniature thermostatic sample cell, which is made of metallic material, an opening is formed in the center of the metallic material and is used as a sample cavity, a light through hole is formed on a metallic shell along the center of the sample cavity, a transparent material is embedded in the light through hole, a Peltier temperature control element is glued on the non-light surface of the metallic material, a groove is arranged on the bottom of the metallic shell for laying aside a temperature sensor, the coat of the metal shell has a heat insulation outer frame, the center of a base connected with the bottom of the heat insulation outer frame is provided with a miniature motor, a small magnet is arranged at the edge of the leaf of a spiral leaf on the shaft of the motor, a stirring magneton is laid aside at the bottom in the sample cavity, the inner wall of the sample cavity and the outer faces of the sensor and the stirring magneton is carried on chemical inertia processing. The invention replaces the water heat conduction with the metal, and changes the system temperature with a thermo-element; the sensor directly observes the temperature of the sample, the heat conduction is speeded up by a miniature electromagnetic stirring system has accelerated; the invention is characterized in having small volume, accurate the temperature measurement, quick variable temperature, and good stability, etc, being able to be placed in analytical instrument such as spectrophotometer, etc., and realizing the quick variable temperature and the accurate thermostatic control of the temperature of the sample.

Owner:SHANGHAI JIAO TONG UNIV

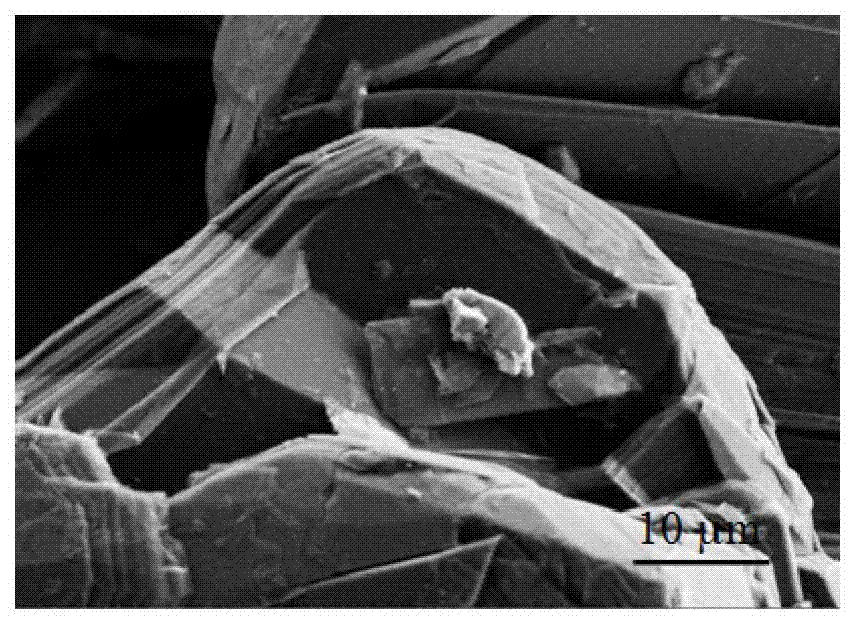

Method and device for preparing crack-free cladding layer through ultrasonic vibration-assisted laser cladding

InactiveCN106350817AIncrease temperatureIncrease stressMetallic material coating processesStress distributionCavitation

The invention discloses a method and a device for preparing a crack-free cladding layer through ultrasonic vibration-assisted laser cladding. Ultrasonic vibration aging is directly introduced into a molten pool micro-area, a direct cavitation effect, a mechanical effect and a heat effect of an ultrasonic wave are utilized for promoting the uniformity of a cladding layer stress field and the refining of grain tissues, and the generation of cracks is inhibited from the root; the ultrasonic wave can be directly acted on a molten pool, a promoting effect on temperature and stress distribution uniformity is higher than an overall vibration effect of a workpiece far away from the molten pool, and the three effects of the ultrasonic wave have a better stirring effect than that of an electromagnetic stirring elimination method, so that the new method has essential difference relative to previous methods, and has better superiority. By repeated experiments, an effect of refining the grain tissues can be achieved so as to prepare the crack-free cladding layer with a favorable surface appearance.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

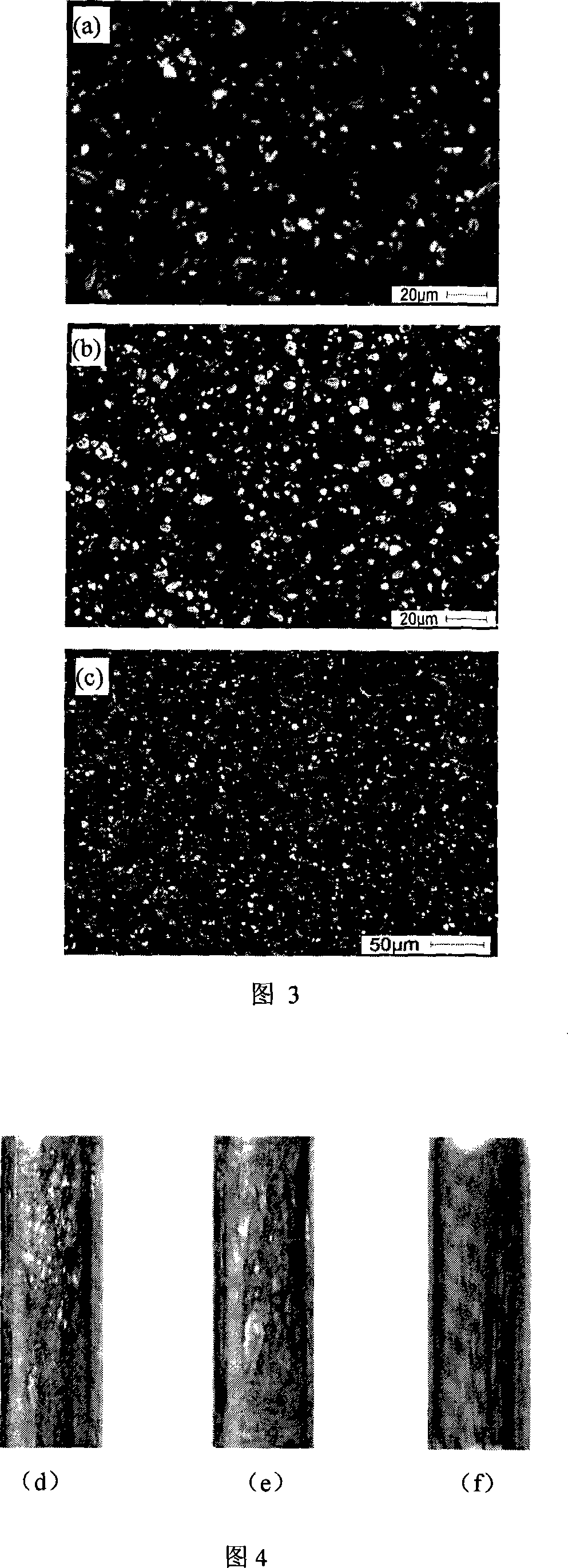

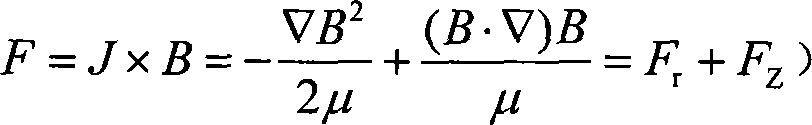

Method of continuous casting particulate reinforced metal matrix composites on different frequency multi-electromagnetic field

Disclosed is a method of particle reinforced metal matrix composite continuous casting in compound magnetic field at different frequency, relating to material processing technology field; in the process of the preparation of the composites melt, low-frequency alternating magnetic field is applied: the frequency is from 5 to 50 Hz, the power range is from 5 to 60 kW; electromagnetic stirring is carried out, making the particles to be fined and evenly distributed; in the process of continuous casting, low-frequency alternating magnetic field is applied to the crystallizer zone: the frequency is from 5 to 50 Hz, the power range is from 5 to 20 kW; electromagnetic stirring is carried out to improve the internal quality; meanwhile, the high-frequency alternating magnetic field is applied in initial solidification zone in crystallizer: the frequency is from10 to 50 kHz, the power range is from 20 to 100Kw, soft contact is applied to improve the surface quality of casting billet. The composites article reinforcement prepared by the method are evenly distributed and fined, the internal organization is compact without any structural defects such as rarefaction or shrinkage hole, the casting billet has high surface finish without any defects.

Owner:JIANGSU UNIV

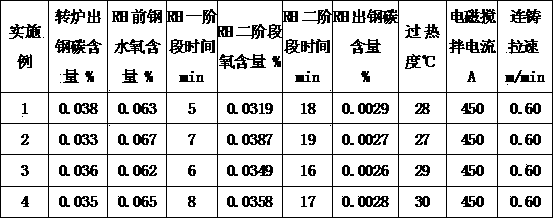

Ultra-low carbon steel wire rod for electric conduction and production method thereof

InactiveCN103469061AMeet the use requirementsReduce manufacturing costMetal/alloy conductorsWire rodChemical composition

The invention provides an ultra-low carbon steel wire rod for electric conduction and a production method thereof. The ultra-low carbon steel wire rod for electric conduction comprises the following chemical compositions: 0.002-0.005% of C, 0.004-0.010% of Si, 0.05-0.15% of Mn, less than or equal to 0.015% of P, less than or equal to 0.010% of S, 0.0050-0.0080% of total oxygen, and less than or equal to 0.0050% of total aluminum. The carbon content of smelted steel tapped from a converter is less than or equal to 0.040%, and the oxygen content of molten steel is 0.060-0.070%; natural decarburization is performed for 5-8 minutes in the first stage of RH refining; in the second stage of RH refining, after the carbon content is reduced to below 0.0030%, oxygen blowing is performed for 15-20 minutes, and a low-carbon or carbon-free steel ladle is adopted for smelting; the superheat degree of molten steel of a continuous casting tundish is less than or equal to 30 DEG C, the electromagnetic stirring current is greater than or equal to 400A, and the pulling rate is 0.5-0.7 m / min; the temperature of an entry double-module is 880-900 DEG C, the spinning temperature is 900-920 DEG C, the roller-bed speed is 0.2-0.4 m / s, and fans are completely closed. The electric conductivity of the wire rod disclosed by the invention is greater than or equal to 15%, the tensile strength is less than or equal to 300 MPa, and the area reduction index is greater than or equal to 80%, and the wire rod can partially replace copper conducting materials, thereby reducing the production cost.

Owner:ANGANG STEEL CO LTD

Low-energy-consumption electromagnetic stirring method for continuous casting and metal continuous casting device

The invention discloses a low-energy-consumption electromagnetic stirring method for continuous casting. The hot top composite novel low-energy-consumption electromagnetic stirring technique is used. A hot top is arranged in a crystallizer, a steady magnetic field with no energy consumption and low energy consumption is exerted on the periphery simultaneously, an electrode bar is inserted in a tundish, a roller electrode is arranged at the solidifying tail end of a continuous casting billet, and therefore alternating current can be exerted on all non-solidification metal melts between the crystallizer and the solidifying tail end. The alternating current and an additional steady magnetic field are acted with each other so as to enable all the non-solidification metal melts in the whole continuous casting billet in a continuous casting process to generate electromagnetic stirring force for driving the continuous casting melts to rotate clockwise and counterclockwise, thereby stirring non-solidification structures, smashing dendrites of solidification front edges of the melts, refining the solidification structures, reducing segregation and cracks. The invention further provides a metal continuous casting device which can be applied to a continuous casting process of various molten metals prone in segregation and draw an alloy continuous casting billet with refined solidification structure, small segregation and no crack.

Owner:SHANGHAI UNIV +1

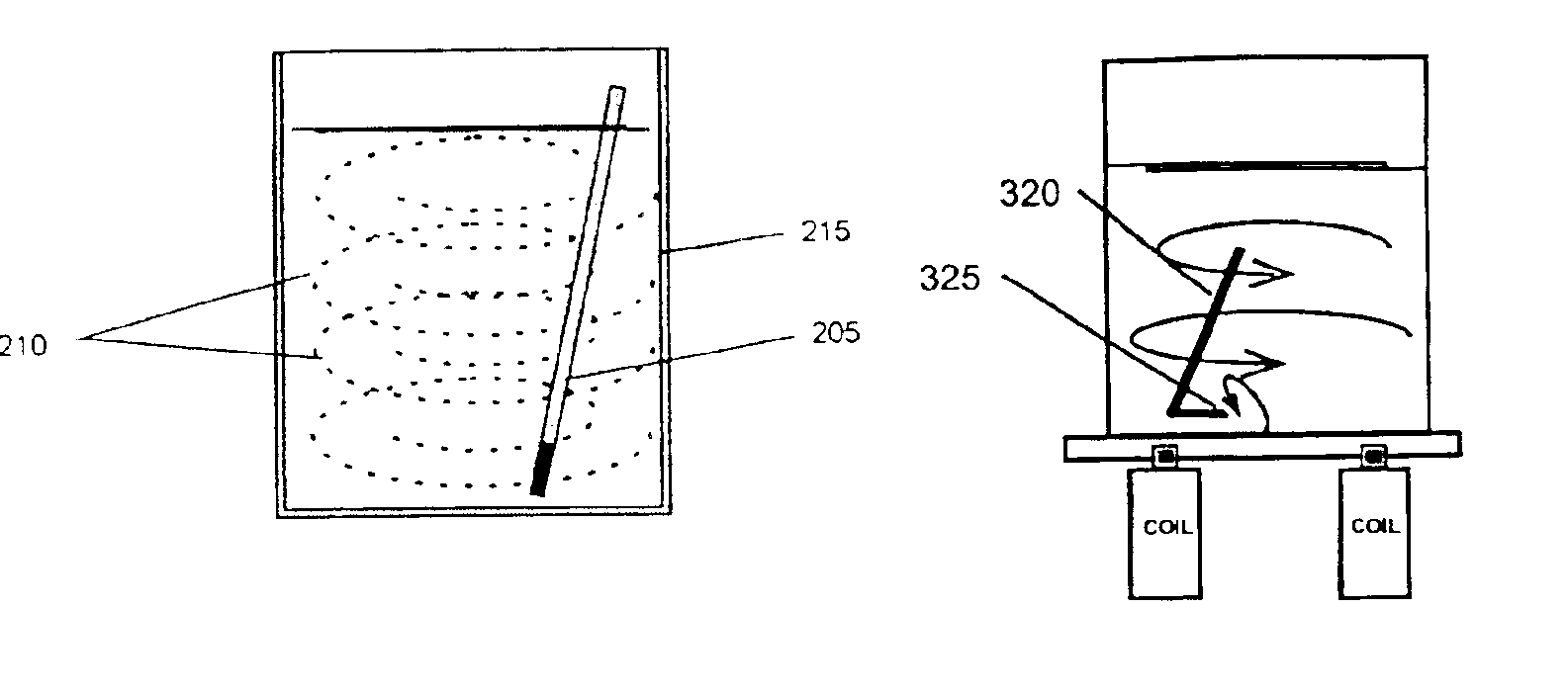

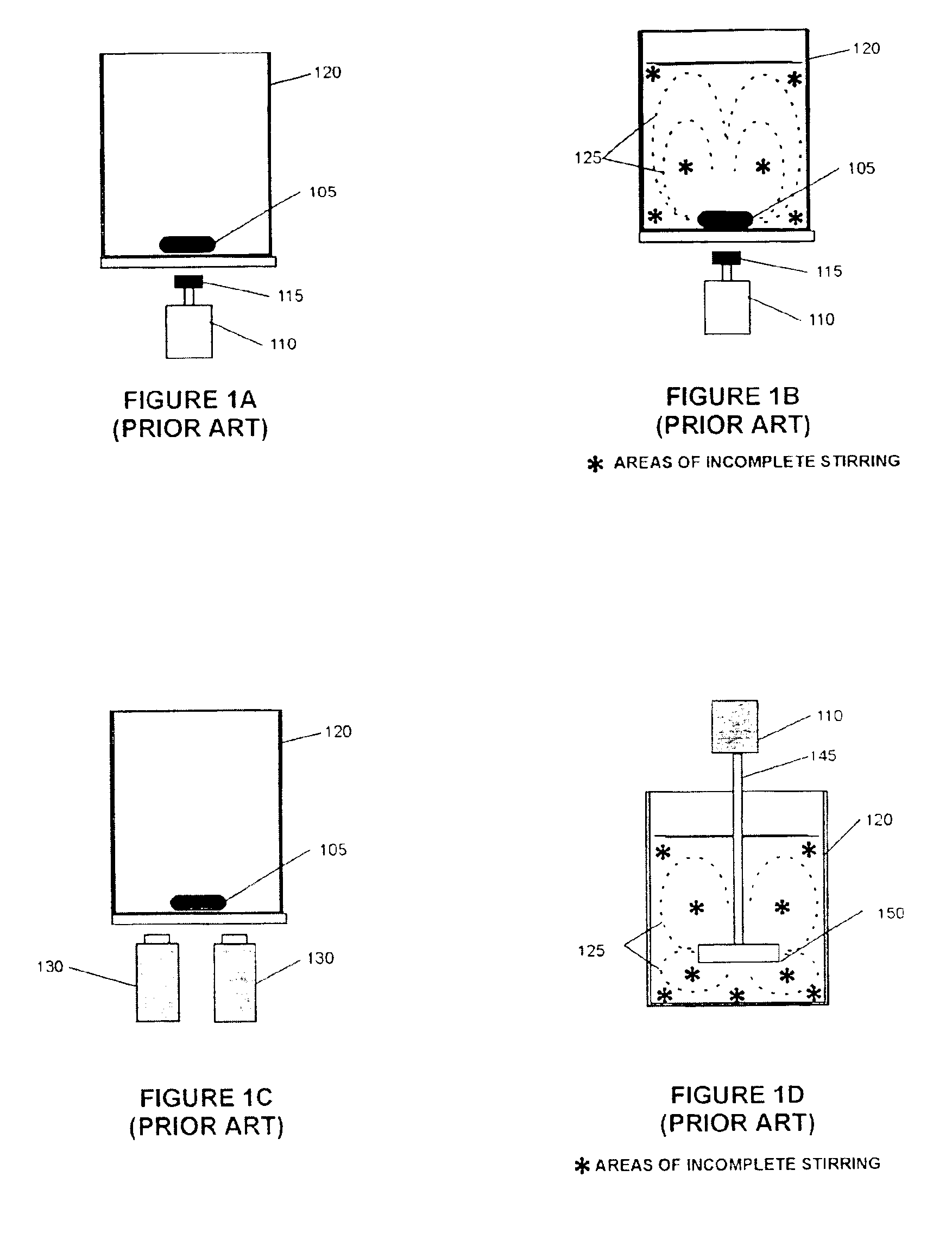

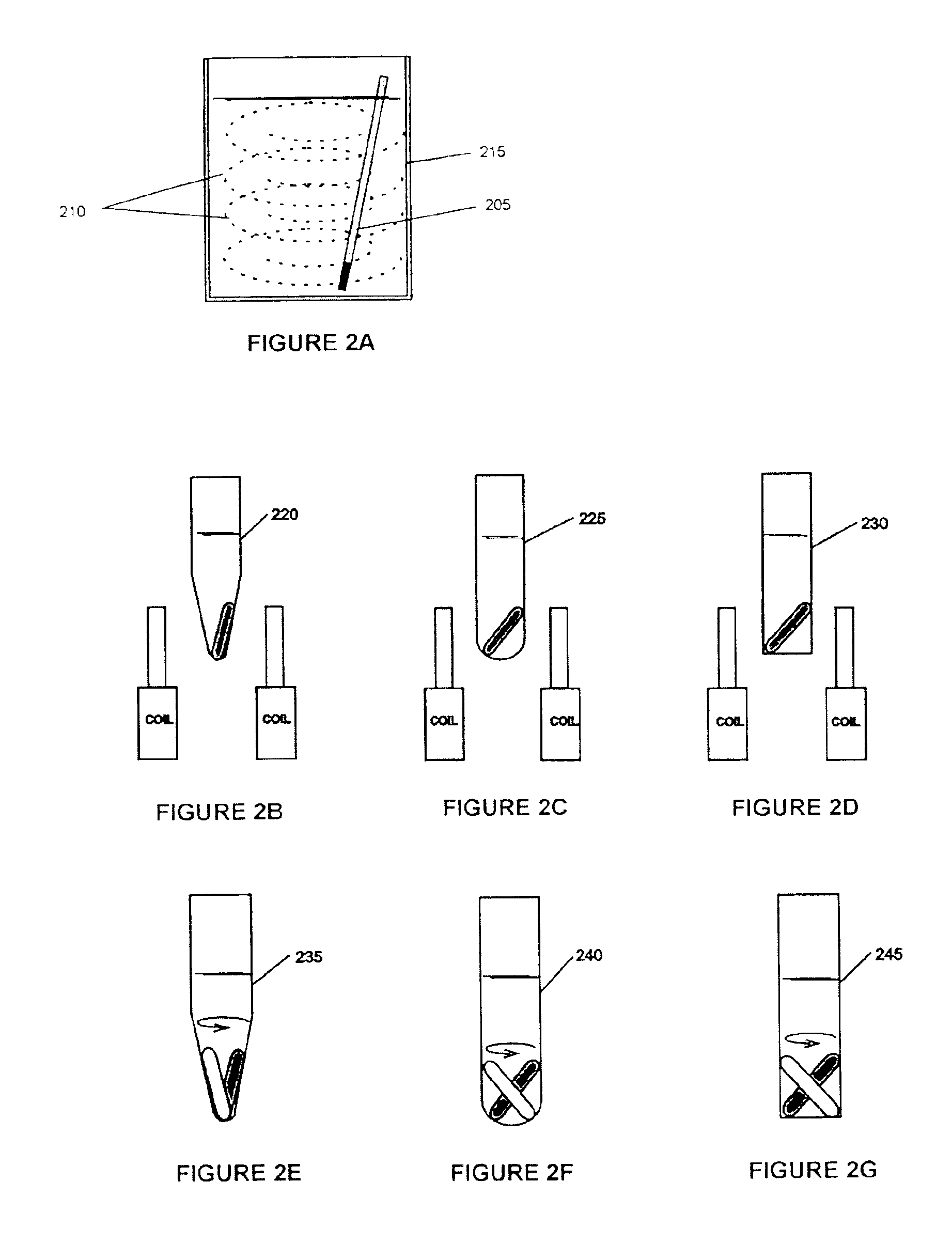

Method and apparatus for using vertical magnetic stirring to produce turbulent and chaotic mixing in various states, without compromising components

InactiveUS6988825B2Shorten the timeAffect volumeBioreactor/fermenter combinationsBiological substance pretreatmentsMagnetic tension forceStochastic motion

Vertical electromagnetic stirring is used to produce low shear, stress, turbulent and chaotic mixing of a liquid material or suspension in a container regardless of the volume or container geometry. Movement of a magnetic stir bar is controlled by multiple magnetic fields. The magnetic fields are produced by a series of sequentially or non-sequentially activated inductor coils which produce asymmetrical stirring dynamics and random motions of the stir bar, causing the liquid material to be gently and effectively mixed throughout the container. Moving the stir bar in random and irregular patterns during the stirring operation creates turbulent and chaotic mixing dynamics. The stir bars used for supporting vertical magnetic stirring are specifically designed to optimize the effectivity of the mixing process by maximizing the length of the stir bar to quickly and gently mix the materials.

Owner:BIODATA

Physical simulation method and physical simulation device utilizing suction casting to research solidification of strip continuous casting

The invention relates to a physical simulation method of the solidification process of strip continuous casting and a realization device thereof, which belong to the field of physical simulation and control of growth process of metal solidification structures. The invention provides a physical simulation method of the solidification process of the strip continuous casting process, so that a physical simulation test can reach the cooling rate of actual strip continuous casting to simulate the heat transfer process of the strip continuous casting; and the method researches an evolution law of solidification structures of the strip continuous casting and a basic law of the solidification by adjusting alloy element components and strip thickness, and can contrastively research an influence law of a rolling force on the solidification during the strip continuous casting. The invention provides a set of equipment which can realize physical simulation on the solidification process of the strip continuous casting. The invention designs a physical simulation device which has a concise structure and small scale and is flexible and smart, wherein main parameters of the device comprise that: the final vacuum is 6.6*10-4Pa, the radius of four water-cooled copper crucibles is 25mm, the working current is between 800 and 1,000A, and the rotating speed of electromagnetic stirring is between 0 and 200rpm.

Owner:SHANGHAI UNIV

Continuous casting bloom soft press technology based on tail end electromagnetic stirring

ActiveCN103121092AReduce dependenceThe effect of electromagnetic stirring is greatThermodynamicsHeat transmission

The invention provides a continuous casting bloom soft press technology based on tail end electromagnetic stirring and belongs to the field of metal casting. The continuous casting bloom soft press technology based on the tail end electromagnetic stirring is characterized in that after a tail end electromagnetic stirring device is arranged on a second cooling area, a previous air cooling area is straightened. The thickness of a liquid core controlling the position of the stirring device occupies 30% to 55% of the thickness of a casting blank through a solidification heat transmission mathematical model. Stirring current of the tail end electromagnetic stirring device is 350A to 750A and stirring frequency is 3Hz to 8Hz. When soft press and straightening are conducted simultaneously, complete solidification of liquid phase among columnar crystals is guaranteed and meanwhile total press amount of a press intersection is controlled to be 10mm to 25mm, liquid steel superheat degree of a tundish is 20 DEG C to 30DEG C, dragging speed of a continuous casting machine is 0.35m / min to 0.75m / min, and therefore internal quality of a continuous casting bloom is remarkably improved and high quality rolled metal is guaranteed. Continuous casting bloom bearing steel manufactured through the technology is continuously manufactured for over 10 boilers, occurrence of internal cracks is avoided, a central organization is dense and even, the rate that a center contracting hole <=1.0 reaches 97.54%, center C segregation is controlled to be under 1.06 and thus the internal quality of the bearing steel is remarkably improved.

Owner:UNIV OF SCI & TECH BEIJING

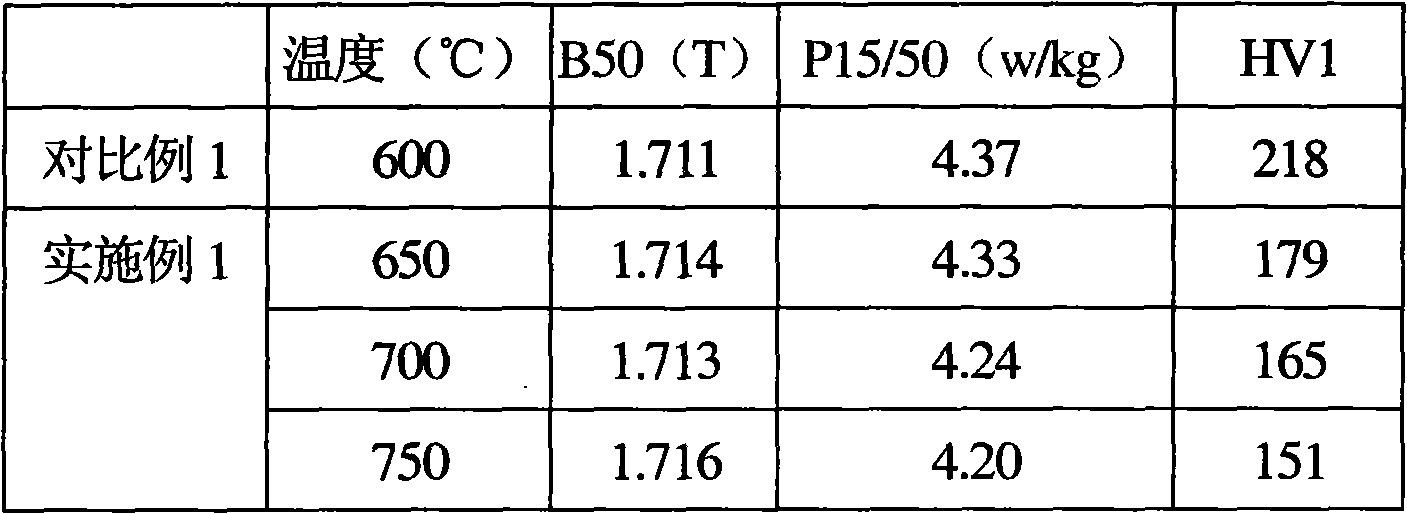

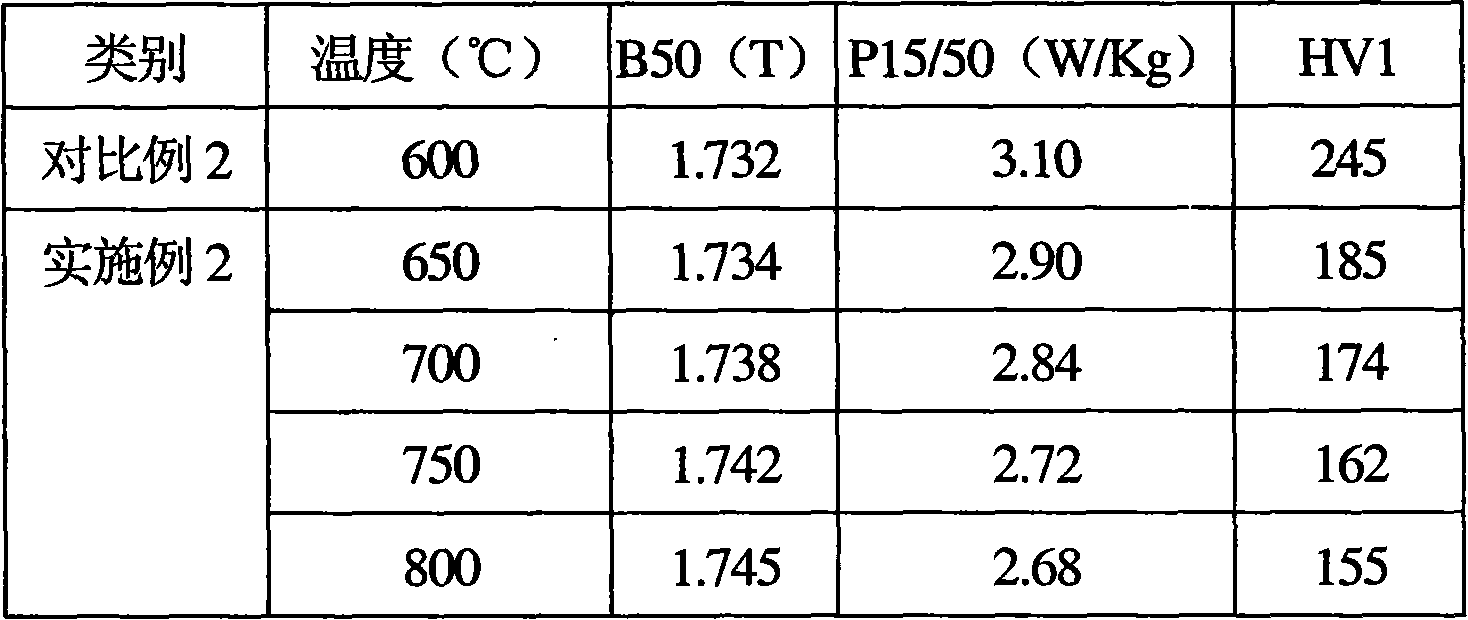

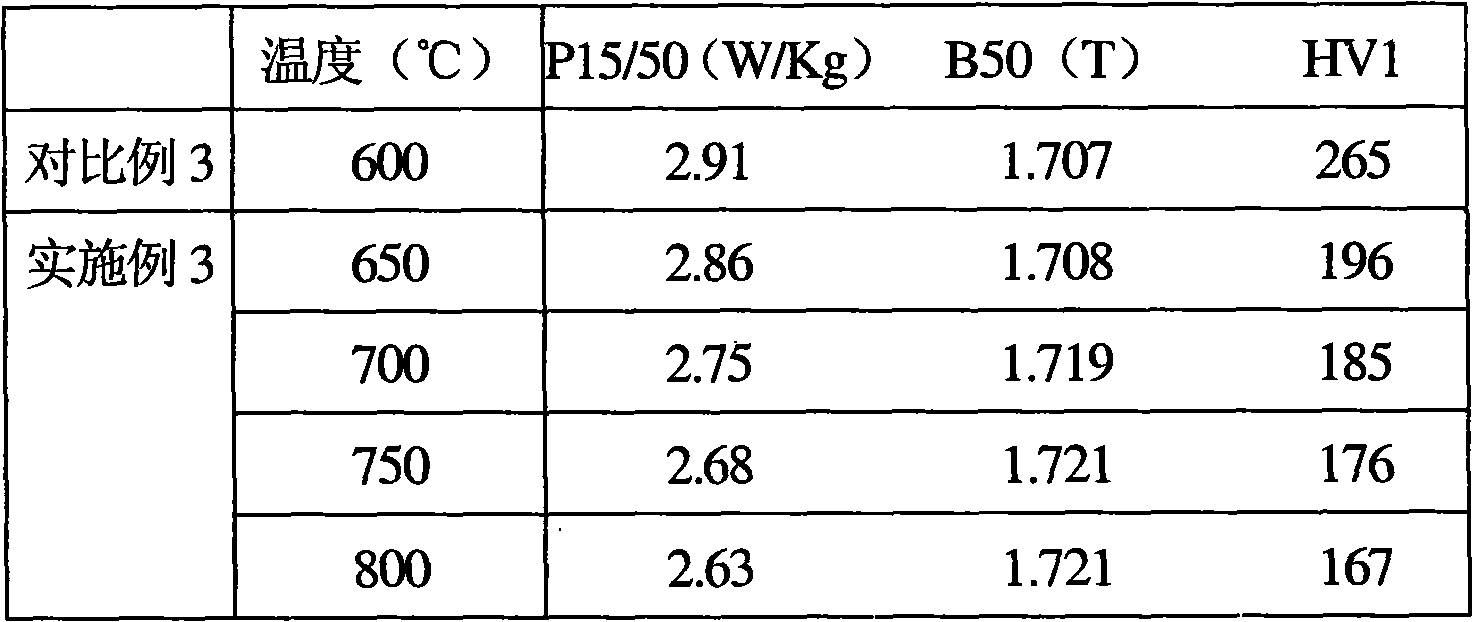

Coated semi-processed non-oriented electrical steel sheet and manufacturing method thereof

InactiveCN101654757AFulfil requirementsReduce iron lossFurnace typesHeat treatment furnacesChemical compositionSheet steel

The invention provides a coated semi-processed non-oriented electrical steel sheet and a manufacturing method thereof. The steel sheet comprises the following chemical compositions in percentage by mass: less than or equal to 0.003 percent of C, 1.00 to 2.30 percent of Si, 0.20 to 1.00 percent of Mn, 0.01 to 0.10 percent of P, 0.20 to 0.80 percent of Al, less than or equal to 0.005 percent of S, less than or equal to 0.005 percent of N, and the balance of Fe and inevitable impurities. The manufacturing method does not need electromagnetic stirring in slab continuous casting; when the content of Si is between 1.65 to 2.30 percent, a normalizing treatment procedure is added before the step of pickling; and an annealing condition is that: a temperature is between 650 and 800 DEG C, the annealing time is between 1 and 4 minutes and the annealing is carried out in a dry atmosphere of whole nitrogen. The coated semi-processed non-oriented electrical steel sheet has low iron loss, high magnetic induction, good mechanical property, simple procedure and low production cost.

Owner:BAOSHAN IRON & STEEL CO LTD

Titanium-based powder material preparing device

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

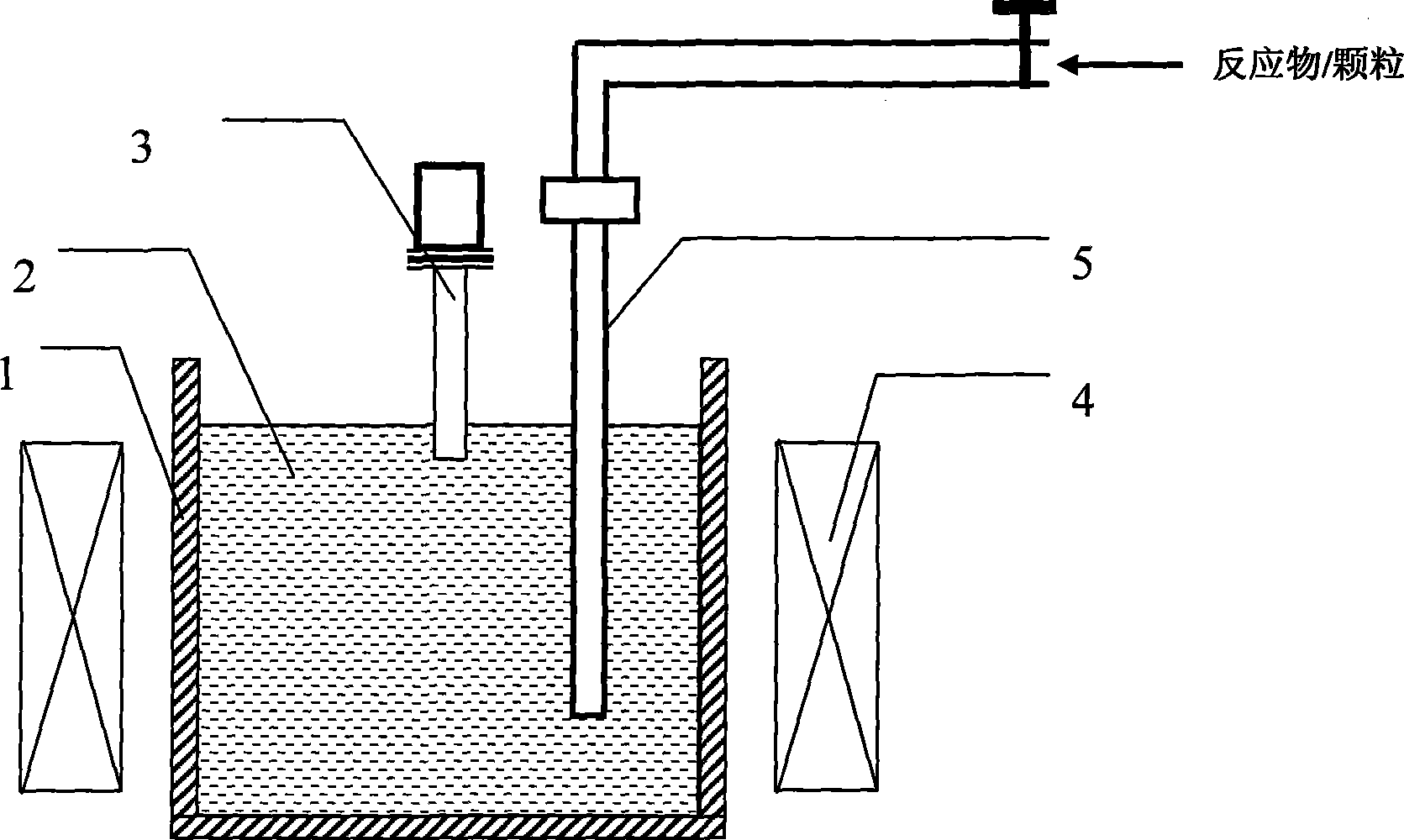

Method and apparatus for preparing semisolid slurry for automobile aluminium wheel through compound modification refinement and electromagnetic stirring

A method and an apparatus for preparing a semisolid slurry for an automobile aluminium wheel through compound modification refinement and electromagnetic stirring. The method comprises steps of: transferring alloy with degree of superheat of 100-120 DEG C into a transit bag, adding a refinement modification agent with high purity nitrogen by an injecting device, wherein the refiner is Al-Zr-B-O intermediate alloy with a granularity of 150-200 um, and the alterant is Al-Sr-RE complex alloy with a granularity of 200-2505 um; standing for 5-8 min, pouring into an electromagnetic stirring crucible when a temperature is 40-50 DEG above a liquidus, putting the crucible in an electromagnetic stirrer, and carrying out composite stirring through a crucible peripheral stirrer and central stirrer, wherein the peripheral stirrer has a frequency of 10-20 Hz, a power of 12 kw, a rate of 300-500 rmp and a time of 2-3 min, and the central stirrer has a frequency of 5-15 Hz, a power of 1-2 kw, a rate of 300-800 rmp and a time of 2-3 min; stopping stirring, when a melt temperature drops to 10-15 DEG C below the liquidus, to obtain a near sphaerocrystal structure semisolid aluminium alloy slurry. The method solves problems of nonuniform slurry and low pulping efficiency.

Owner:JIANGSU KAITE AUTO PARTS

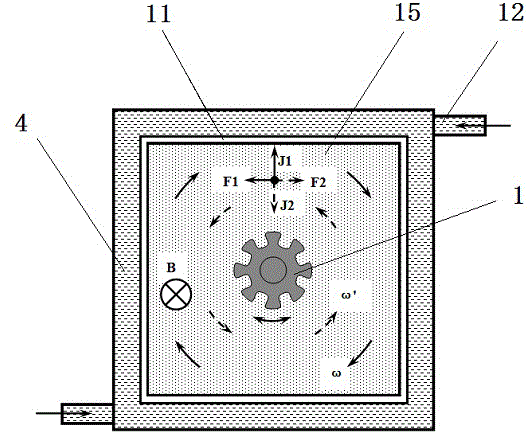

Continuous steel casting process and device with function of electromagnetic excitation compound mechanical stirring

The invention discloses a continuous steel casting process with a function of electromagnetic excitation compound mechanical stirring. According to the process, when alloy melt solidifies, microscopic and macroscopic strong shear flows are generated to break dendritic crystal by the electromagnetic excitation compound mechanical stirring technology, and accordingly, solidification structure refinement, full-equiaxed crystallization and solute segregation reduction are achieved, and alloy properties are improved. The invention further provides a continuous steel casting device mainly comprising a crystallizer, a rotor stirring paddle, a wheel, a program control motor, a magnetic field generator, a coil, and a voltage-regulating frequency-modulating alternating current source. The microscopic flows generated by electromagnetic excitation and macroscopic flows generated by mechanical stirring form complex chaotic flows which form strong shear flows to brake the dendritic crystal, crystal nucleus proliferation is prompted, temperature gradient is reduced, and ultrafine full-equiaxed crystal structure is achieved; meanwhile, segregation of alloy elements is significantly reduced or completely suppressed. The continuous steel casting process and method has the advantages that the energy consumption is significantly lower than that of conventional electromagnetic stirring and energy conservation is significantly effective.

Owner:新兴发展集团有限公司

Continuous casting process for high-class high-quality chain steel

The invention discloses a continuous casting process for high-class high-quality chain steel. According to the continuous casting process, a method of process control is adopted, a large billet caster is adopted for continuous casting, the portion from a large ladle to a tundish and the portion from the tundish to a crystallizer are poured in a protecting mode, argon gas is filled in the tundish before pouring, the portion from the steel ladle to the tundish is poured in a protecting mode through a long nozzle argon seal, the portion from the tundish to the crystallizer is poured in a protecting mode through a high-quality whole internally-installed submerged nozzle, a high-quality current stabilizer is adopted in the tundish impact area, a covering agent is used in molten steel in the tundish, the temperature of the tundish is measured continuously, automatic water distribution is carried out in the crystallizer and for secondary cooling, and the crystallizer is stirred in an electromagnetic mode and pressed dynamically and slightly. According to the continuous casting process, the internal and external quality of a casting blank is good, no connection blanks and slag pits exist in the surface, and performance of cogging rolled steel meets requirements of users.

Owner:NANJING IRON & STEEL CO LTD

Preparation method of nitrogen-doped reducing graphene oxide aerogel

The invention discloses a preparation method of nitrogen-doped reducing graphene oxide aerogel. The method takes common natural graphite powder as a carbon source and comprises the steps of preparing graphite oxide, and performing ultrasonic stripping in deionized water to obtain graphene oxide hydrosol; adding a hexamethylenetetramine crystal into the graphene oxide hydrosol to form mixed liquid; heating the mixed liquid to 70-90 DEG C for 2-4 hours under an electromagnetic stirring condition in a fume cupboard to obtain the mixed liquid of nitrogen-doped reducing graphene oxide aerogel; standing the obtained mixed liquid of nitrogen-doped reducing graphene oxide aerogel for several hours; washing the mixed liquid of hydrogel by use of deionized water for several times; then performing freeze drying or supercritical drying to obtain foamed nitrogen-doped reducing graphene oxide aerogel. By adopting the method disclosed by the invention, the prepared aerogel has a relatively large specific surface area as well as a three-dimensional structure; with an excellent adsorption property, the aerogel can become an ideal water quality purifier, a catalyst carrier and an efficient composite material.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com