Patents

Literature

252 results about "% area reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reduction of area. The difference between the original cross-sectional area of a test specimen before being subjected to tension and the area of its smallest cross section after rupture; expressed as a percentage of the original cross-sectional area of the specimen.

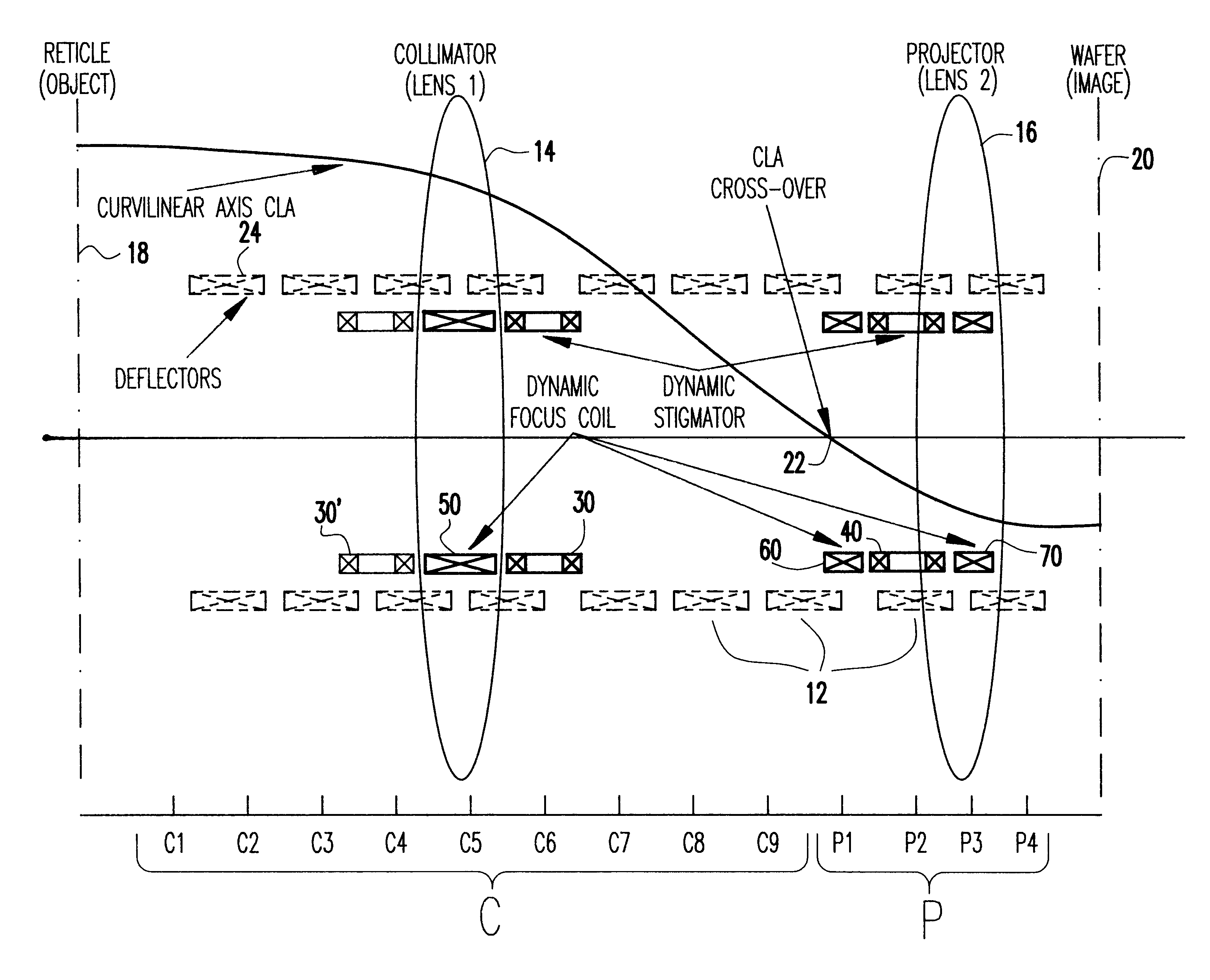

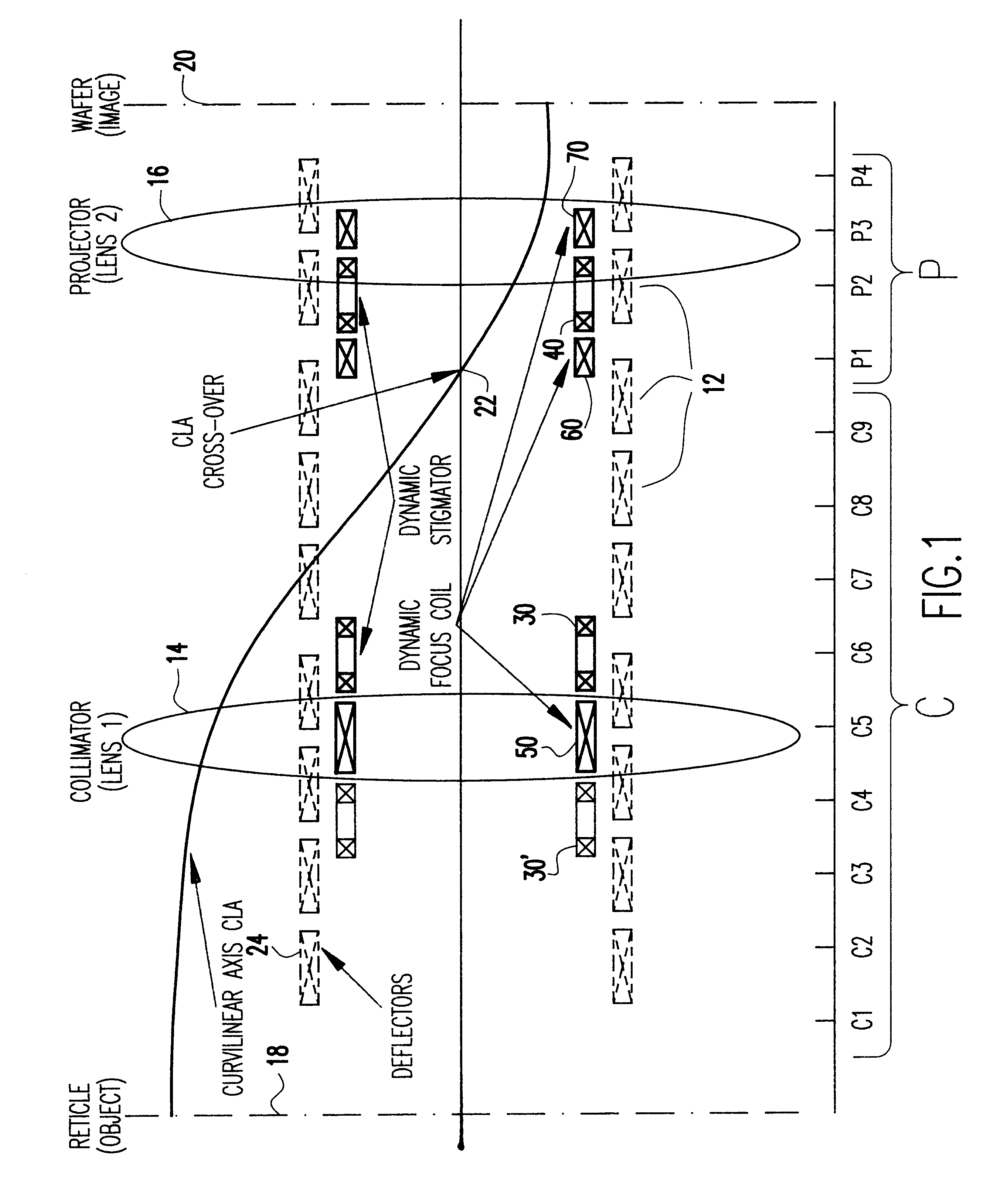

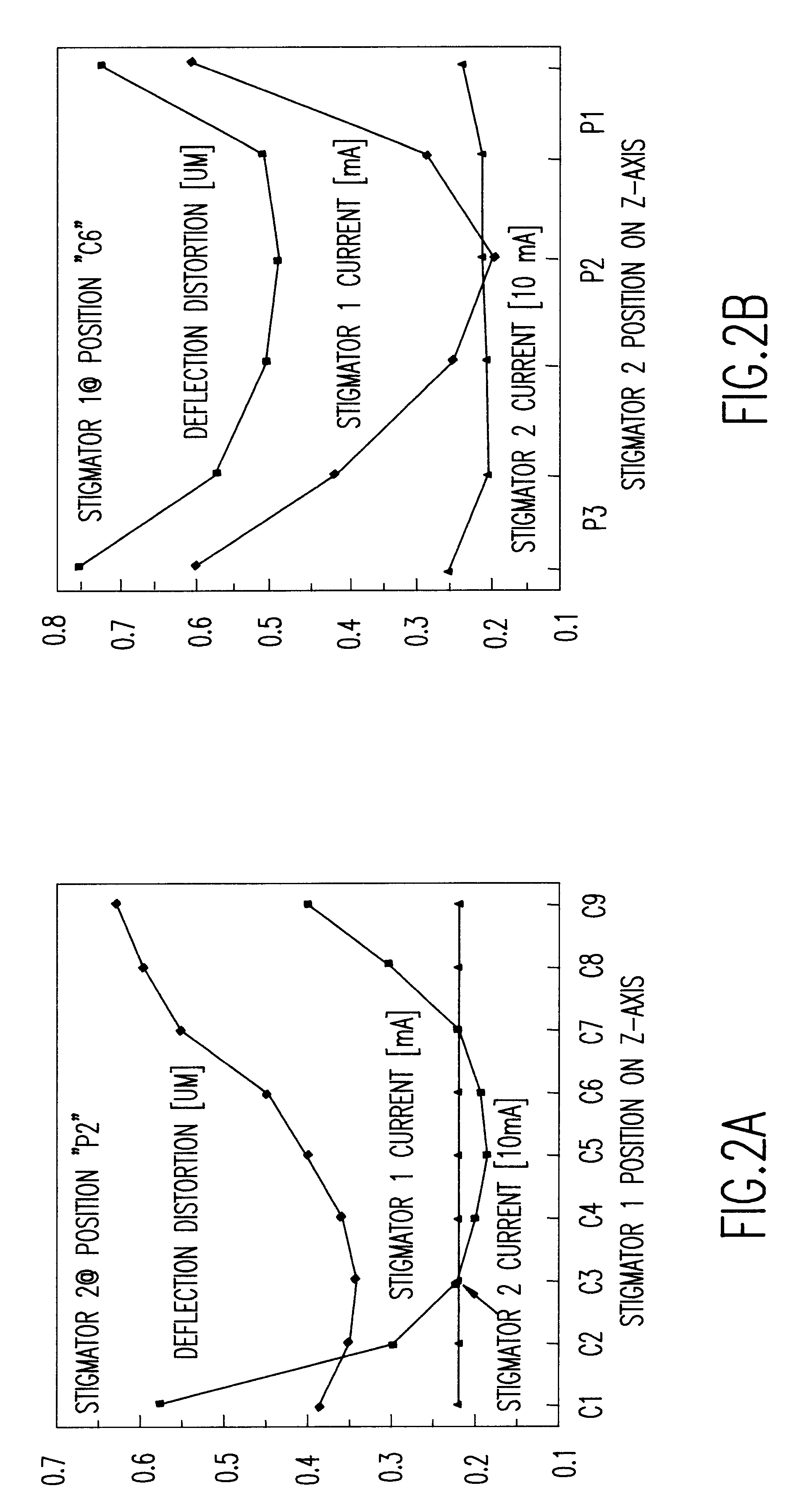

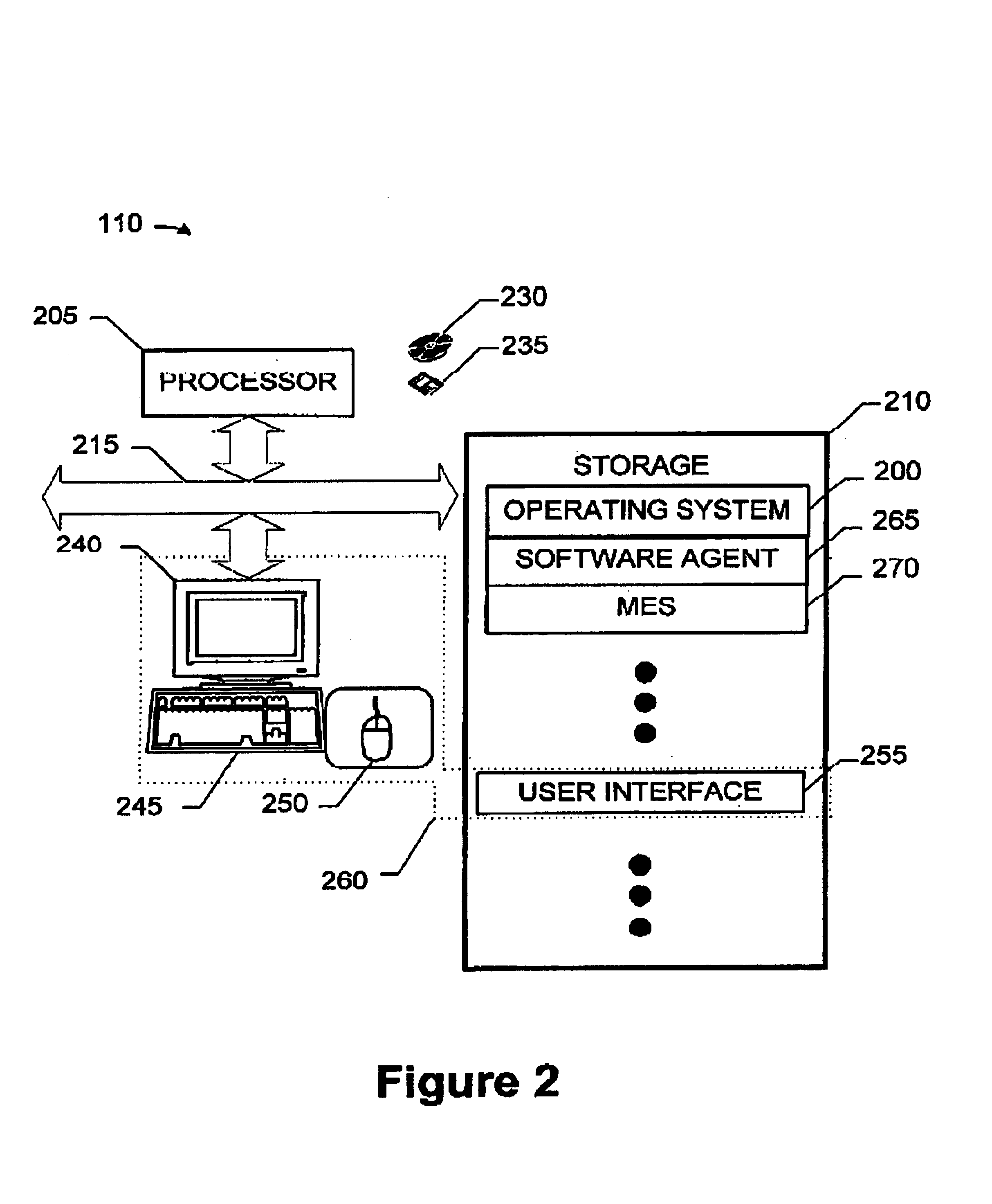

Multi-element deflection aberration correction for electron beam lithography

InactiveUS6180947B1Adjust focusStability-of-path spectrometersBeam/ray focussing/reflecting arrangementsProjection opticsLithographic artist

A method of optimizing locations of correction elements of a charged particle beam system determines respective corrector element currents to achieve optimum correction as a function of individual corrector location. Substantially complete dynamic correction of FSD and SFD can be obtained consistent with efficiency of operation and minimization of deflection distortion. In particular, FSD and SFD corrections can be sufficiently separated for substantially complete correction of SFD and FSD simultaneously with two stigmators. Both of these types of correction can be provided in complex charged particle beam systems employing curvilinear axis (CVA) particle trajectories and or large area reduction projection optics (LARPO) which cause complex hybrid aberrations in order to achieve high throughput consistent with extremely high resolution supporting one-tenth micron minimum feature size lithography regimes and smaller.

Owner:NIKON CORP

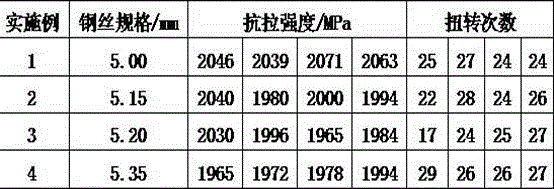

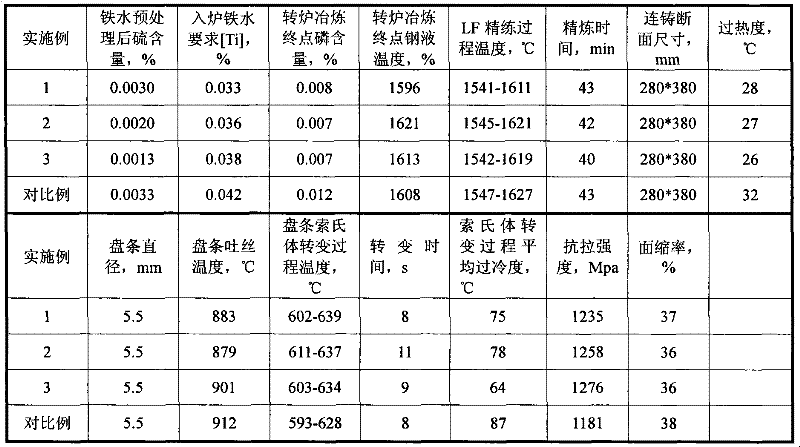

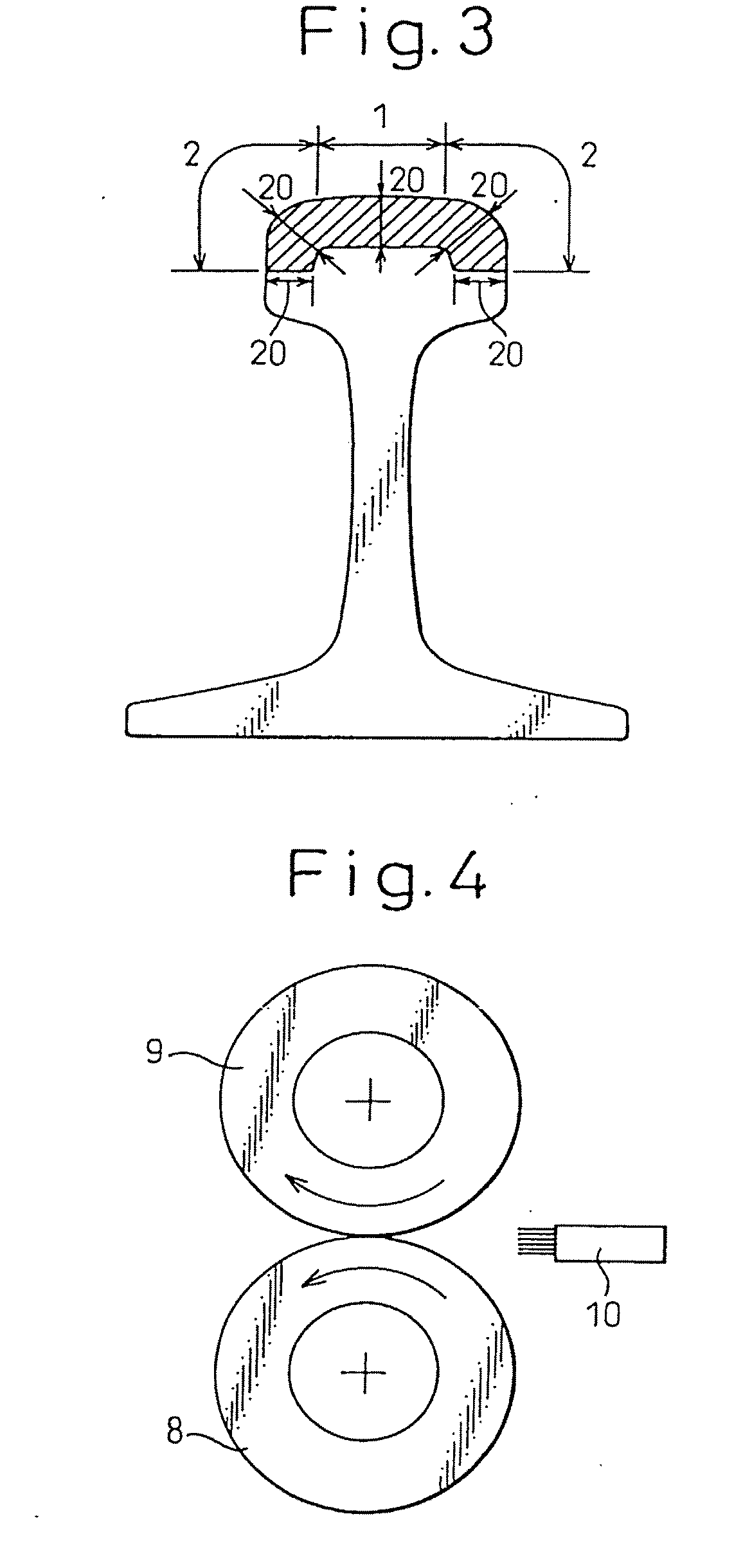

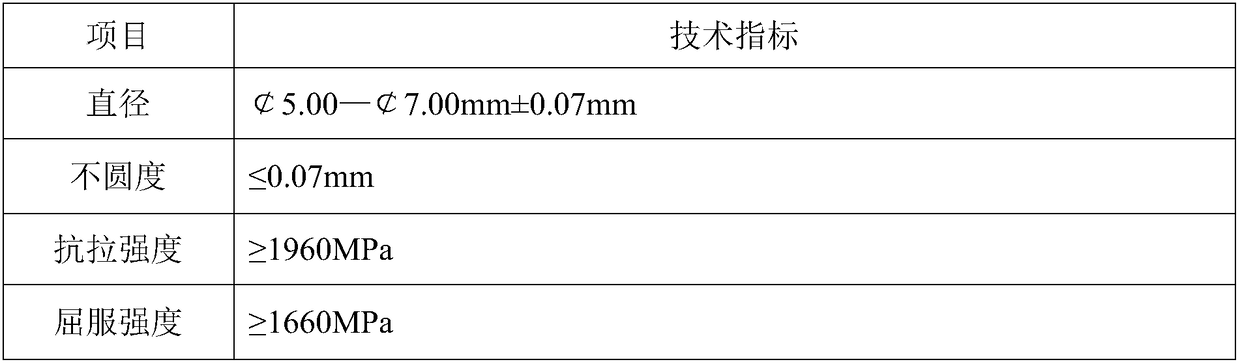

Hot-rolled wire rod for 1,960MPa-level cable rope galvanized steel wire and production method

ActiveCN105671443AGuaranteed torsional performanceHigh tensile strengthWire rodUltimate tensile strength

The invention discloses a hot-rolled wire rod for a 1,960MPa-level cable rope galvanized steel wire and a production method. The hot-rolled wire rod is prepared from, by weight percent, 0.85%-0.91% of C, 0.20%-1.00% of Si, 0.60%-0.90% of Mn, 0.25%-0.35% of Cr, 0.015%-0.040% of Al, not larger than 0.025% of P, not larger than 0.025% of S, 0.02%-0.07% of V, not larger than 0.20% of Cu, not larger than 0.0030% of Ca and the balance Fe and inevitable impurity elements. Reasonable component contents are adopted in the wire rod, the wire rod has the beneficial effects of being high in tensile strength and plasticity, the situation of hardening during machining in the drawing process can be effectively reduced, and the torsional property of the steel wire obtained through drawing is effectively guaranteed. In the wire rod obtained through the method, the sorbite structure proportion reaches 90% to 93%, the tensile strength of the wire rod is larger than or equal to 1,320 MPa, and the area reduction rate is larger than or equal to 40%. After the wire rod obtained through the method is subjected to drawing, galvanizing and stabilizing treatment, the tensile strength of the steel wire is larger than or equal to 1,960 MPa, the torsion index is larger than or equal to 14 times, and the wire rod can be used for producing the 1,960MPa-level bridge cable rope galvanized steel wire and is suitable for ultra-large-span bridges with the ultrahigh requirement for strength.

Owner:XINGTAI IRON & STEEL

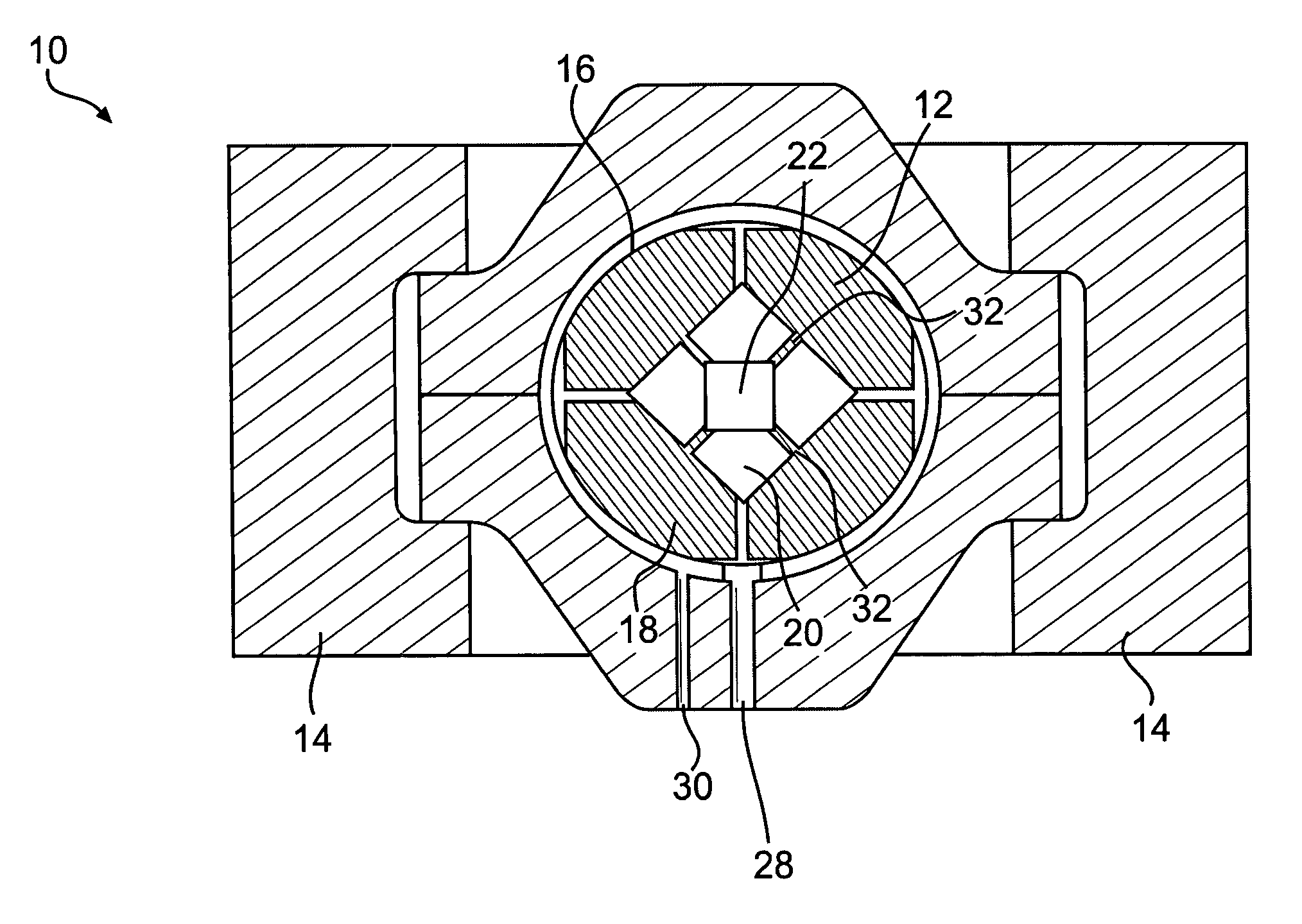

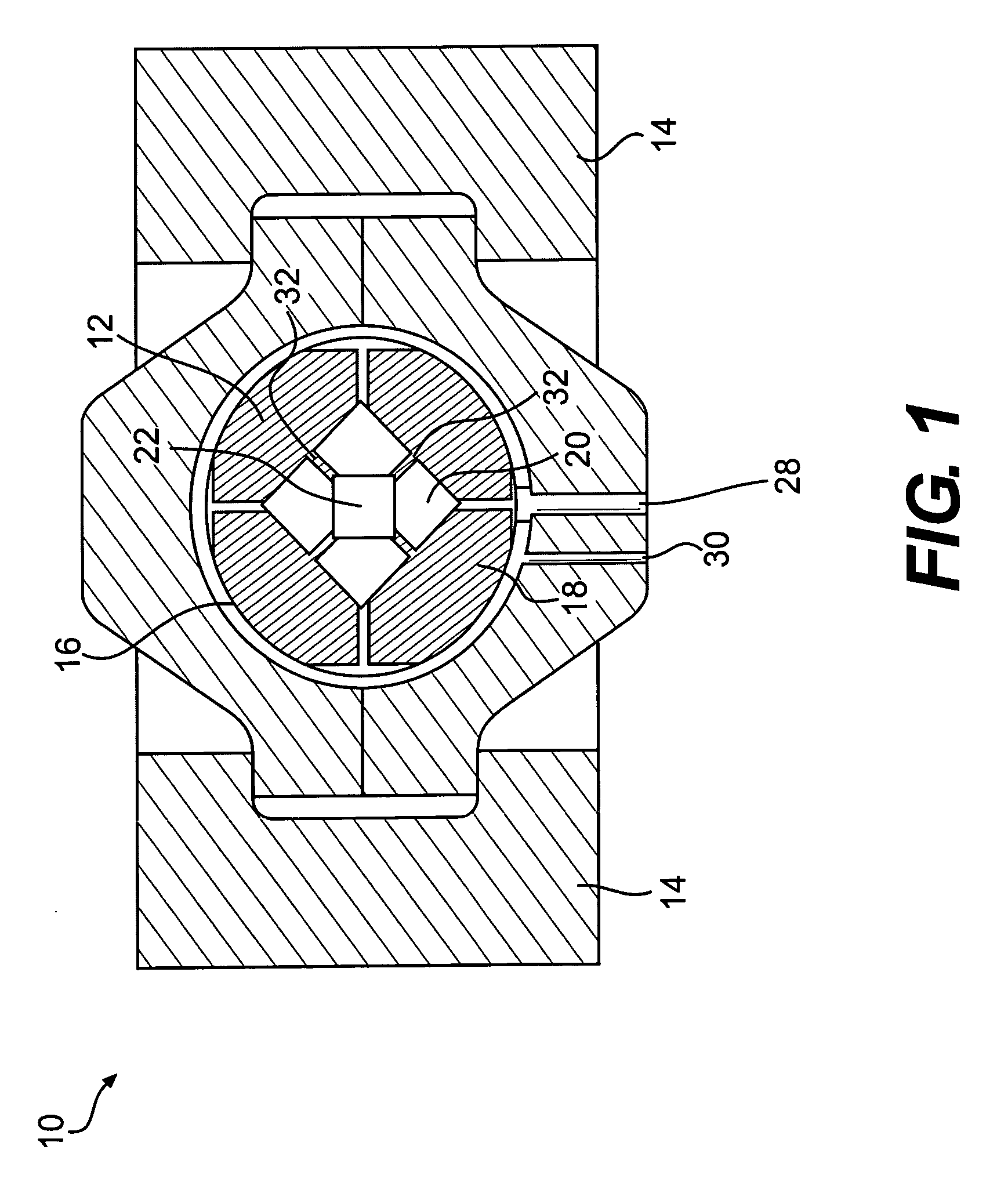

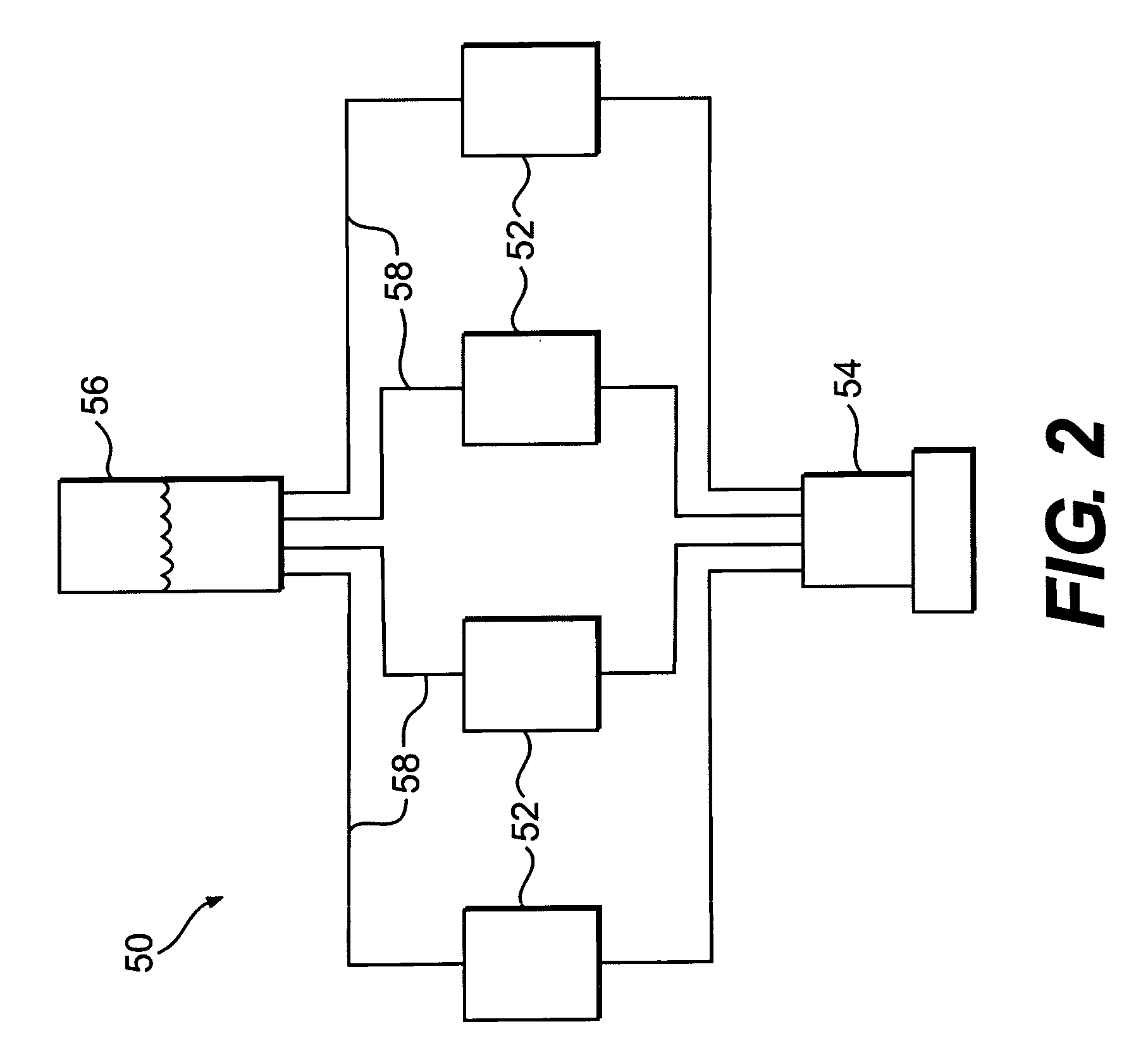

System and high pressure, high temperature apparatus for producing synthetic diamonds

An apparatus for growing a synthetic diamond comprises a growth chamber, at least one manifold allowing access to the growth chamber, and a plurality of safety clamps positioned on opposite sides of the growth chamber; wherein the growth chamber and the plurality of safety clamps are comprised of a material having a tensile strength of about 120,000-200,000 psi, a yield strength of about 100,000-160,000 psi, an elongation of about 10-20%, an area reduction of about 40-50%, an impact strength of about 30-40 ft-lbs, and a hardness greater than 320 BHN.

Owner:THE GEMESIS CORP

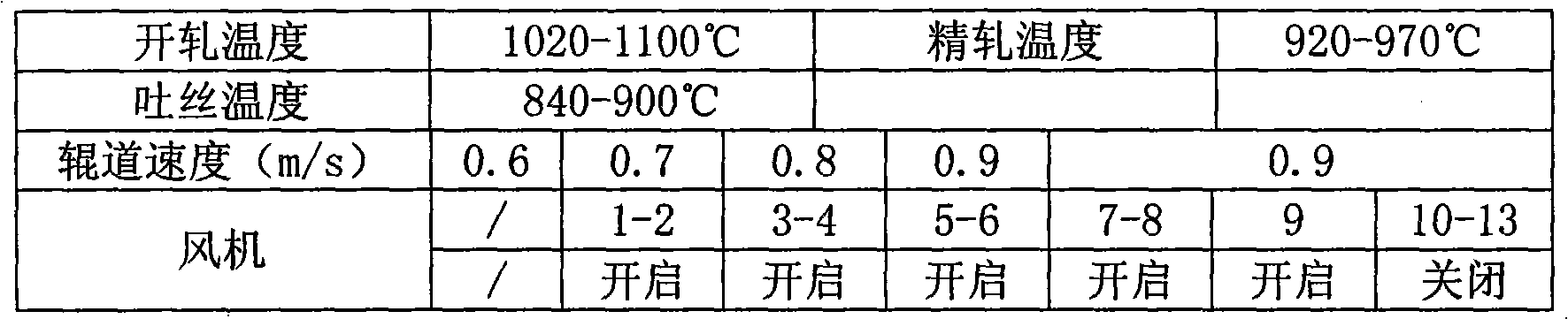

Micro alloying SWRH87B hot rolled wire rod and manufacturing method thereof

InactiveCN101597713AQuality improvementEasy to useTemperature control deviceManufacturing convertersTemperature controlWire rod

The invention provides a micro alloying SWRH87B hot rolled wire rod and a manufacturing method thereof, belonging to the technical field of hot rolled wire rod. In the invention, Cr and V micro alloying are adopted; double slag process high drawing carbon operation is used in a converter; end-point carbon is controlled at 0.40-0.60%, the steel tapping temperature is 1580-1620 DEG C, and the slag-blocked tapping is used; low nitrogen carburant is used for recarburization; Si-Ca-Ba is used for deoxidation; 600-800kg synthetic slag is added into each converter; oxygen activity is controlled below 10ppm by entering into an LF refining station, and the refined finishing slag sum of FeO and MnO is no more than 3%; inclusion modification treatment is carried out on the Ca-Si line; a billet in the size of 160mm*160mm is used, a casting mould is used for coordinating with final electromagnetic stirring (F-EMS); continuous casting machine whole protection, constant drawing speed casting and proper secondary cooling system are adopted; the initial rolling temperature is controlled at 1020-1150 DEG C which is conductive to welding the drawholes and increasing the probability of the drawholes welding; the water pre-cooling and phase transformation strengthening cooling technology is used to control the texture and the performance. The invention has the advantages that the aging time of the wire rod before the follow-up processing is shortened, the tensile strength thereof after aging time is larger than 1280MPa, and the area reduction rate is larger than 25%.

Owner:SHOUGANG CORPORATION

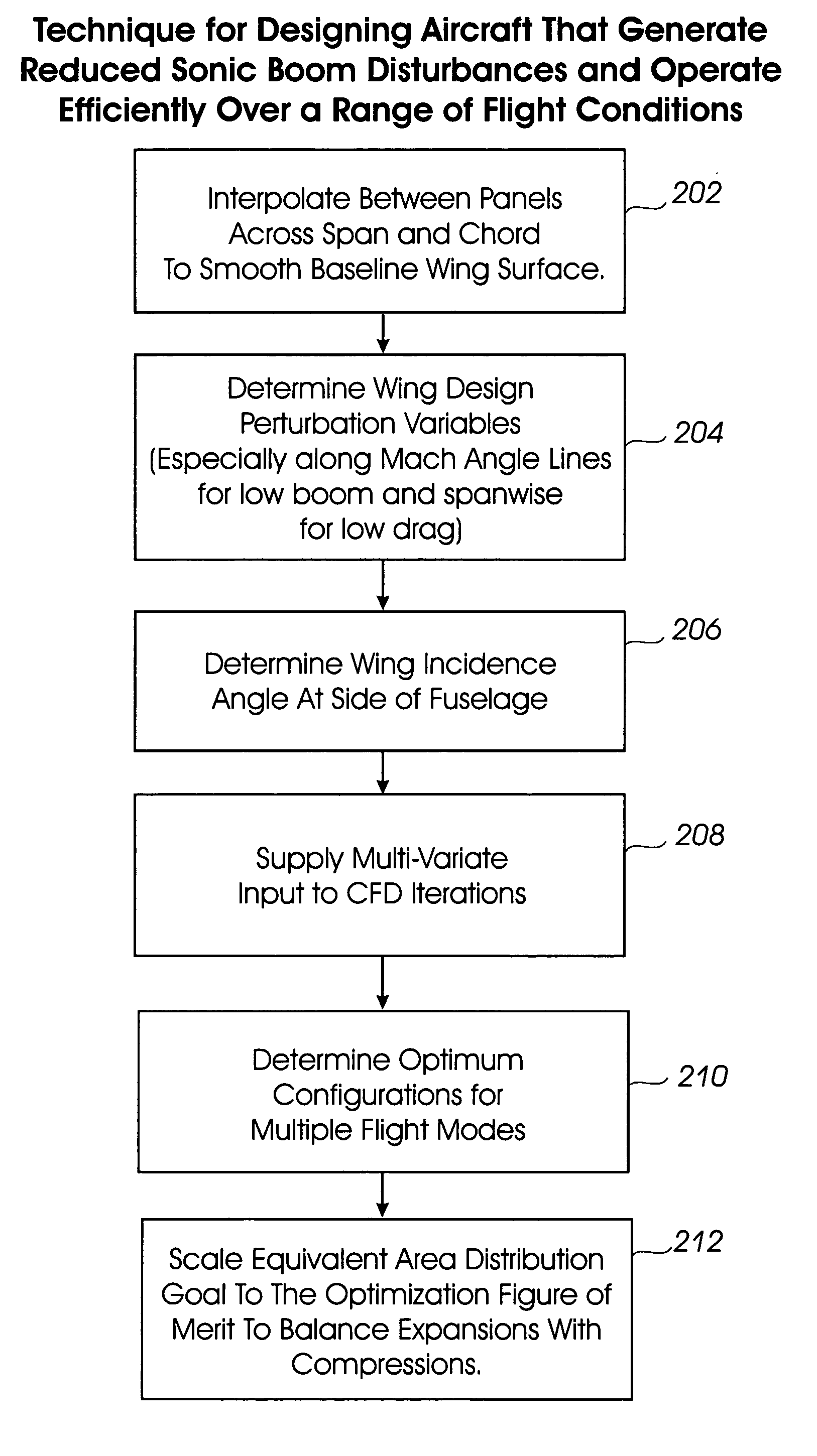

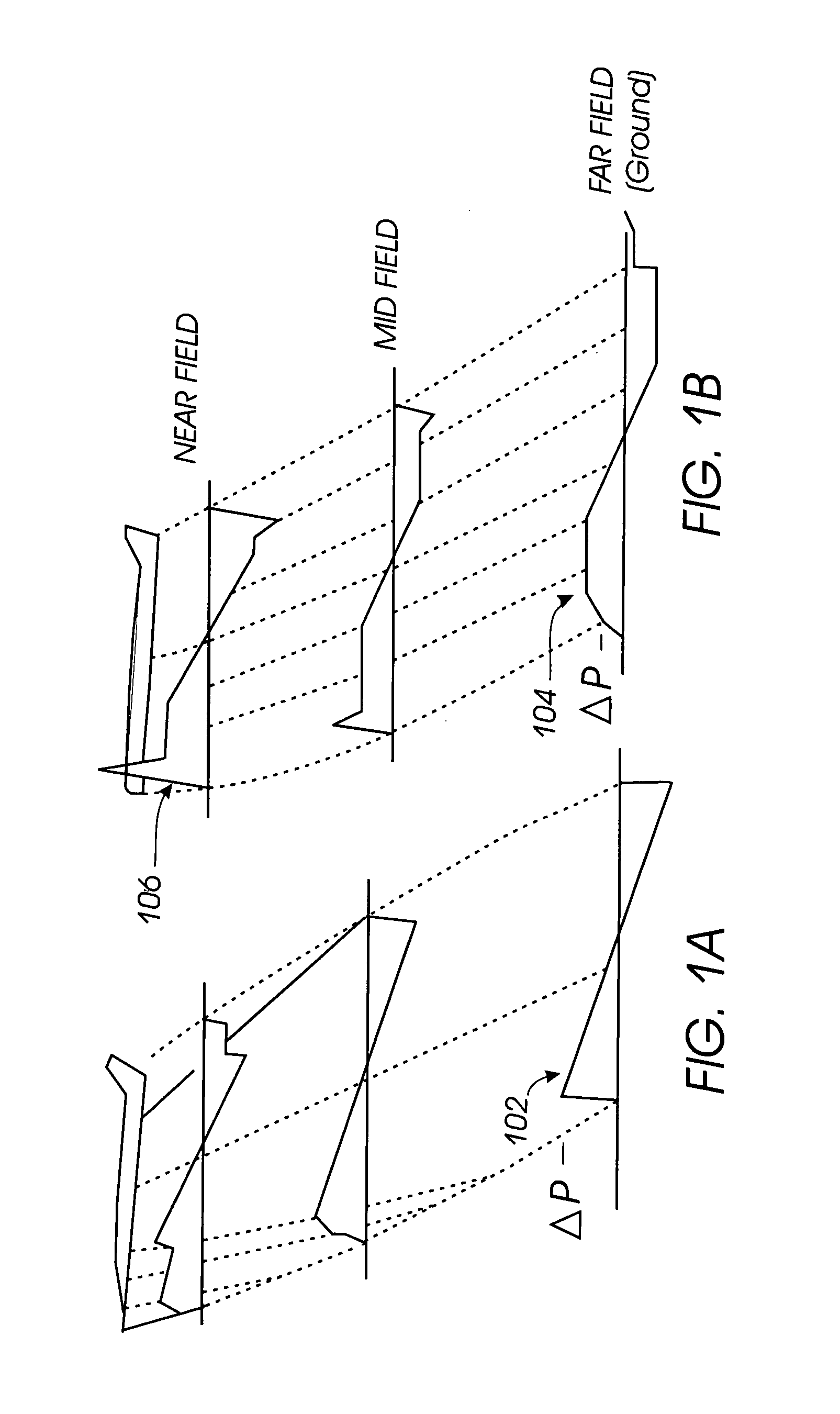

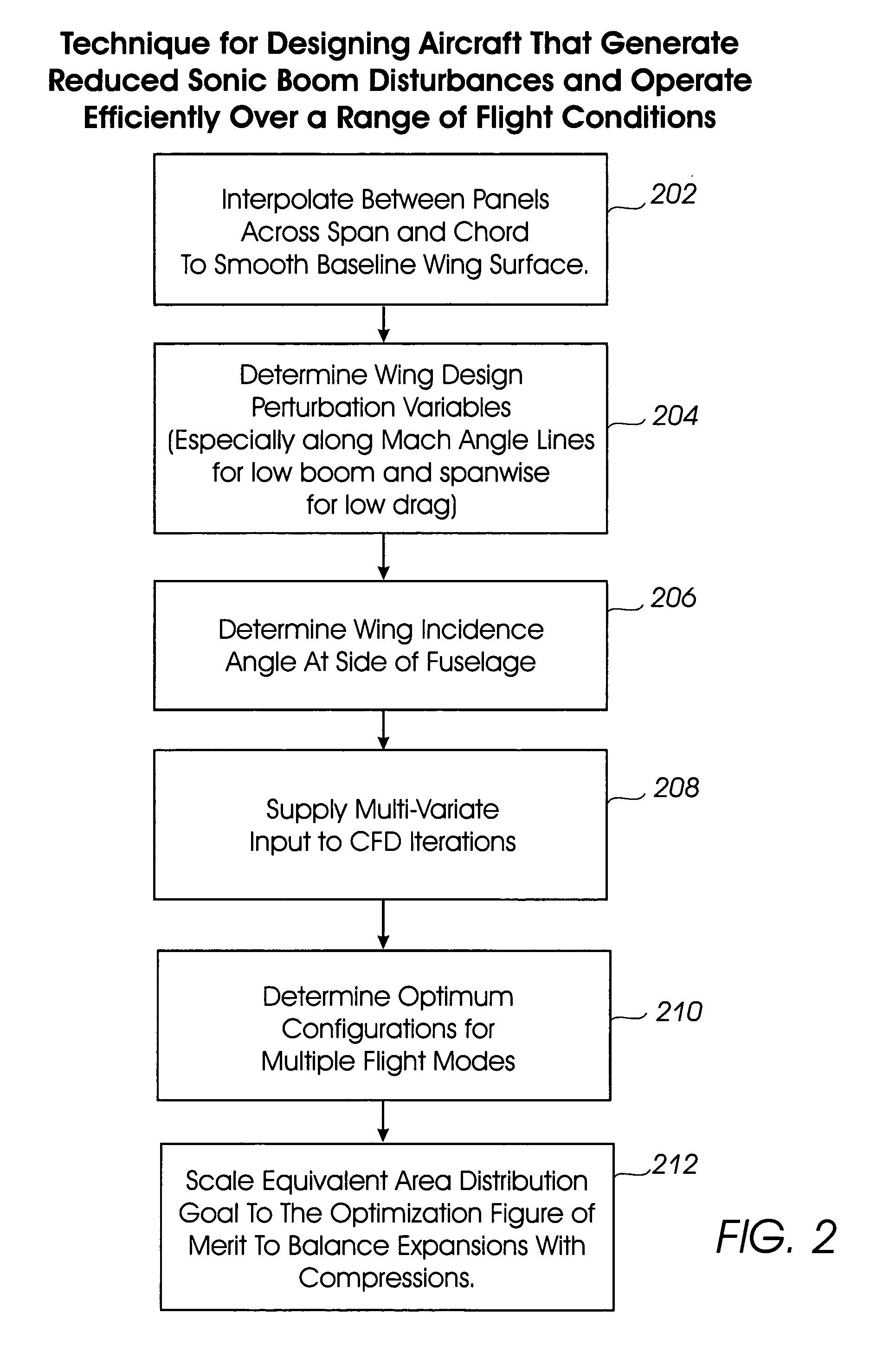

System, apparatus, and method for redistributing forces to meet performance goals and shock wave disturbance constraints

A system and method for configuring an aircraft for low sonic boom supersonic flight conditions includes redistributing lift of a wing by configuring the wing with one or more areas of far-field expansion ahead of areas of far-field compression. An equivalent area distribution goal curve is scaled to account for the equivalent area reduction due to excursions below to goal curve. A relaxed constraint allows the equivalent area distribution of the aircraft to be at or below the equivalent area distribution goal curve to enable multiple parameters to be configured to meet the equivalent area distribution constraint, as well as other constraints. The system and method can be adapted to aid in the design of any type of vehicle whose surfaces are subject to supersonic fluid flow, especially to reduce sonic boom.

Owner:SUPERSONIC AEROSPACE INT

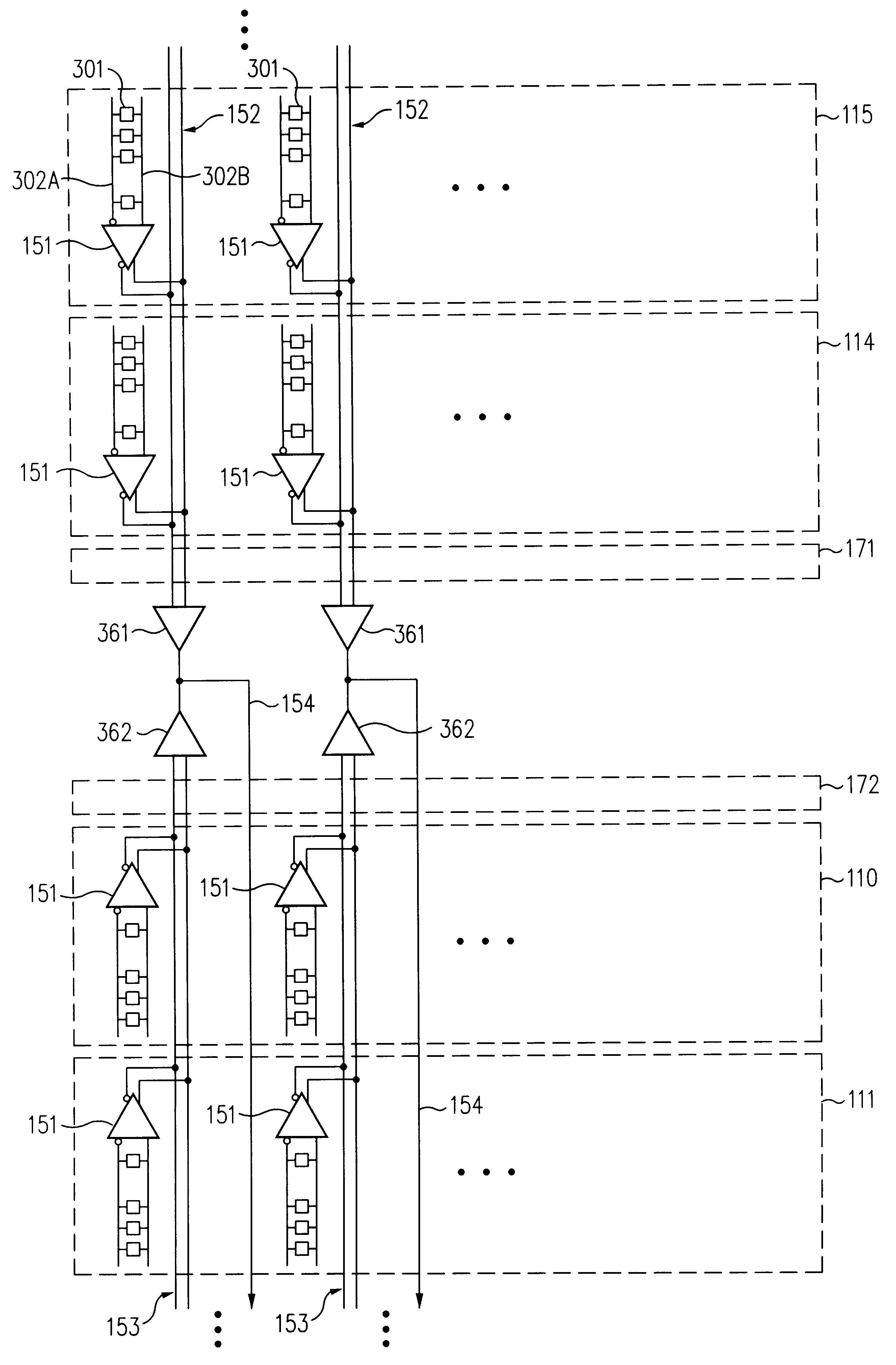

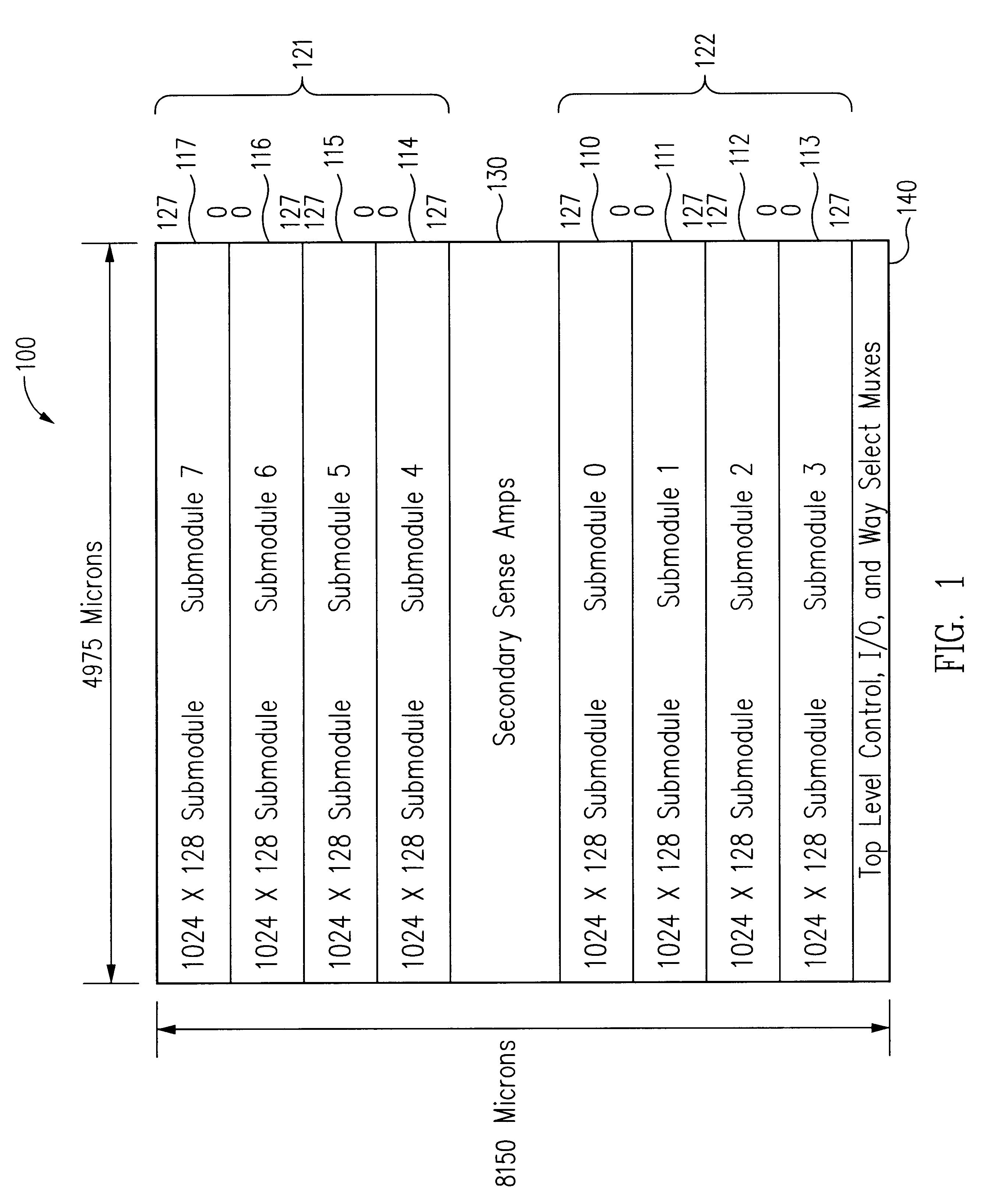

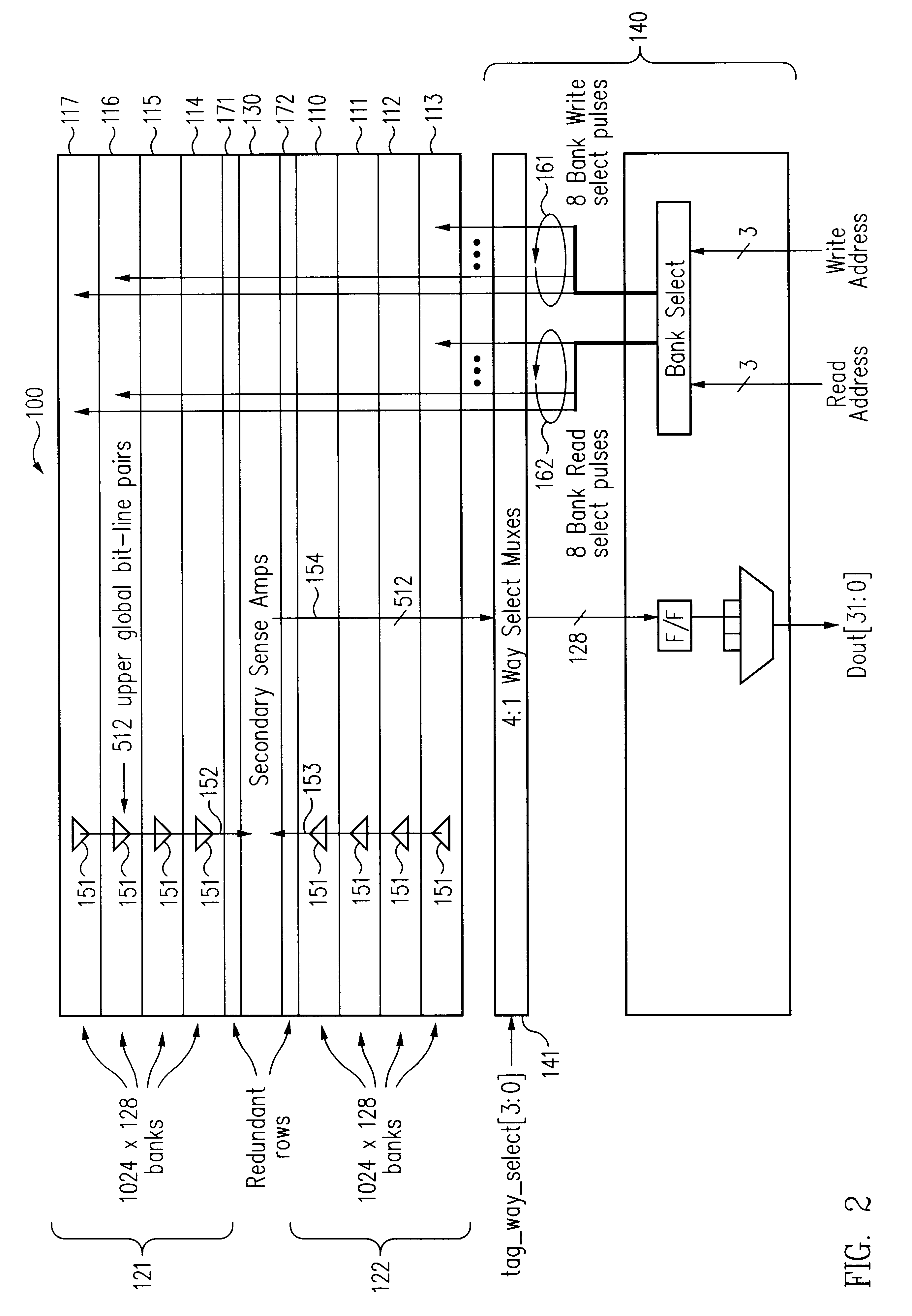

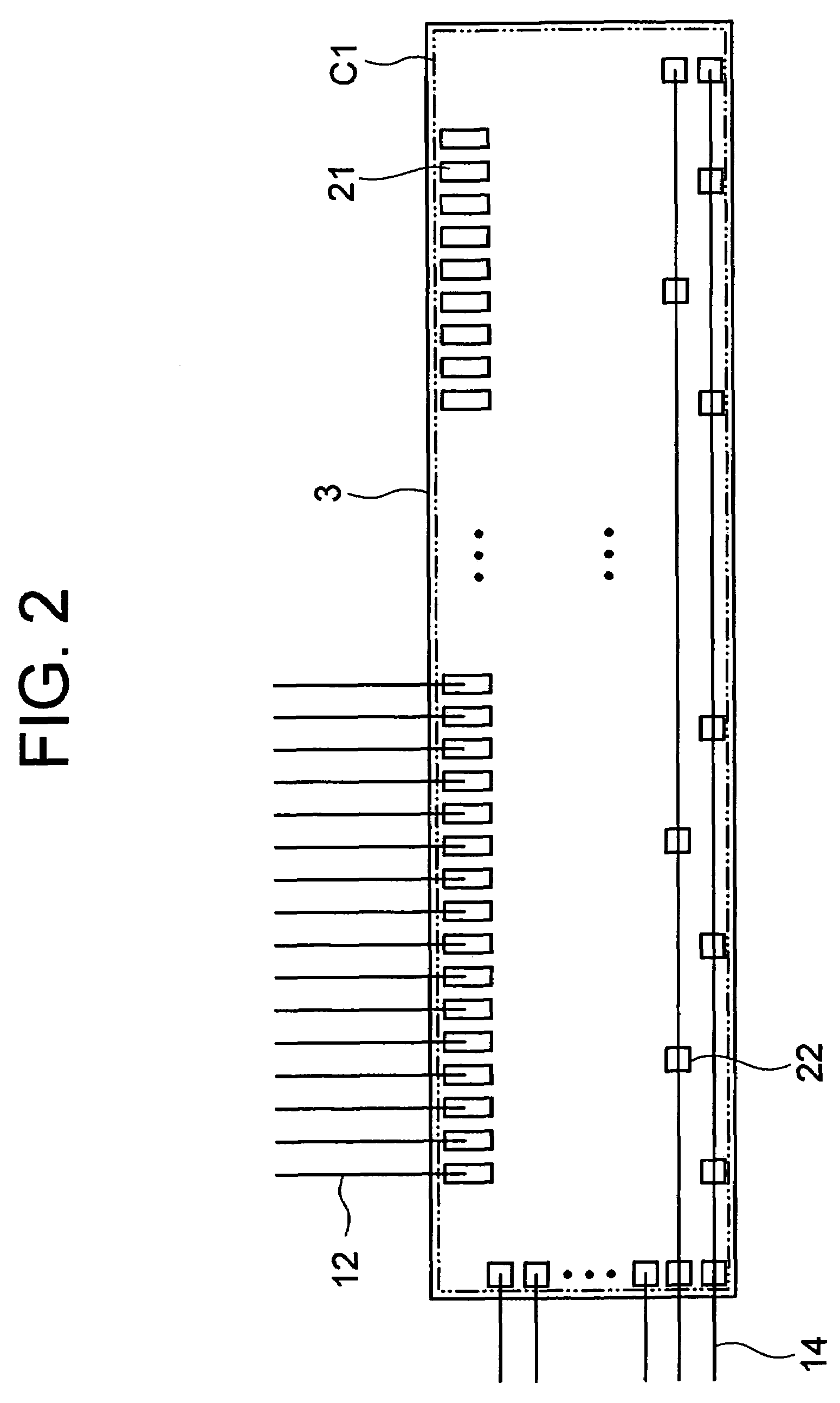

Layout for semiconductor memory including multi-level sensing

InactiveUS6188596B1Reduce the differenceReduce power consumptionDigital storageBit lineAudio power amplifier

A memory module configuration has been developed, which employs multi-level sensing, low-voltage-swing differential signal paths, and array layout techniques to better optimize area / speed / power tradeoffs. In some configurations two-level sensing is employed with secondary sense amplifiers positioned toward a middle of the memory module with memory banks or submodules positioned therearound. Primary sense-amplifiers in the submodules or banks sense differential signals on local bit-lines spanning the corresponding submodule or bank and drive a low-voltage-swing differential signal onto global bit-lines that span a subset of the submodules or banks. The global bit-lines are sensed by secondary sense amplifiers that drive data outputs across a subset of the submodules or banks toward output circuits. In some configurations the memory module is divided into upper and lower portions with upper global bit-lines spanning the upper portion and lower global bit-lines spanning the lower portion. Corresponding upper and lower global bit-lines are disjoint and are sensed by corresponding upper and lower secondary sense amplifiers. By this arrangement, the minimum to maximum variation in access time between the different rows of the memory module is reduced. Moreover, smaller drivers and lower power is achieved by use of such a two-level arrangement. In particular, area reductions and power reductions are achieved for submodule- or bank-resident primary sense amplifiers.

Owner:GLOBALFOUNDRIES INC

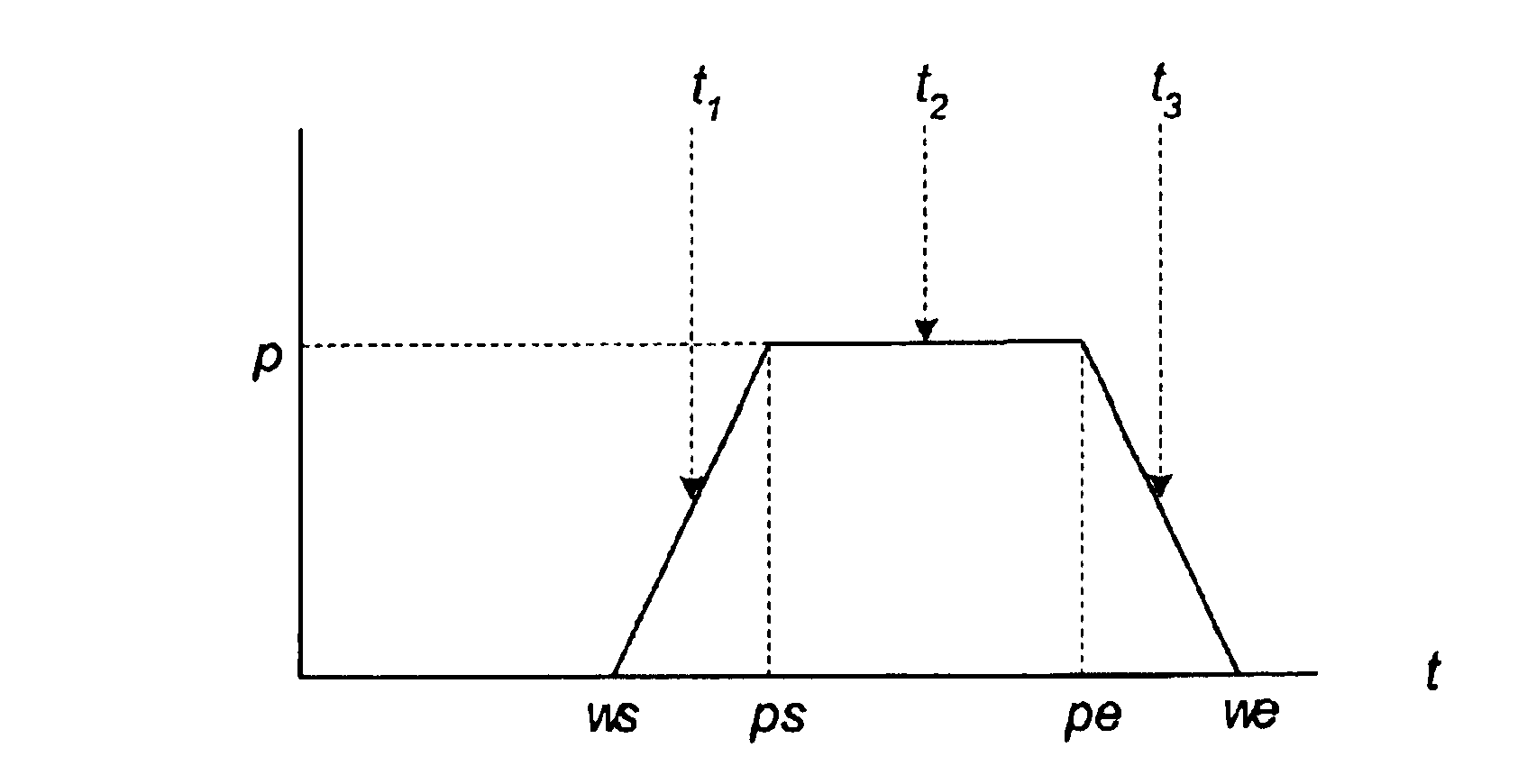

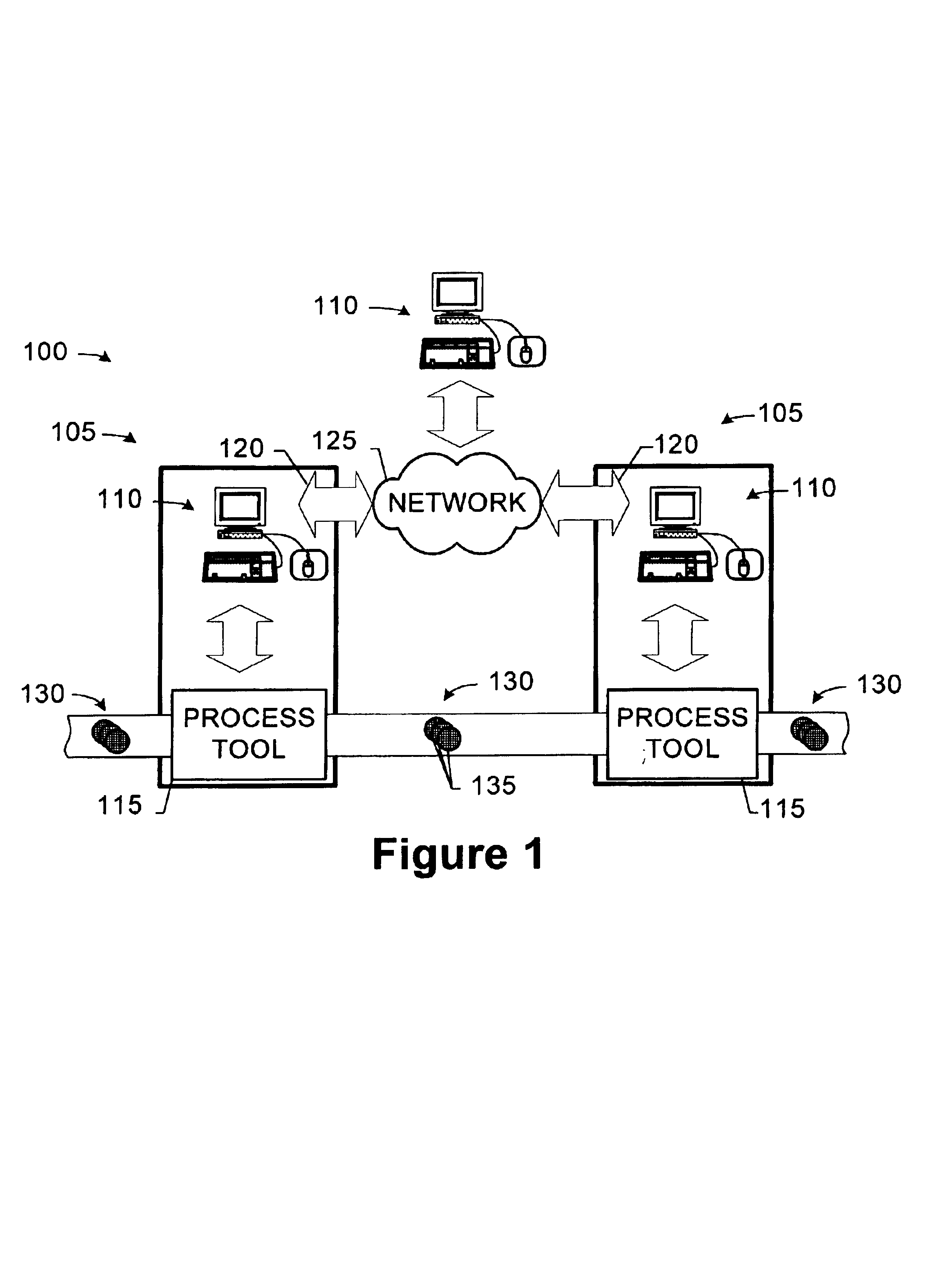

Method and apparatus for reducing scheduling conflicts for a resource

A method includes providing a schedule of engagements for a resource. Each engagement has a working window and an associated engagement density function. The engagement density functions of the scheduled engagements are combined to generate a committed capacity function for the resource. A region of violation in the committed capacity function is identified where the committed capacity of the resource exceeds a capacity threshold. An area of a region of overlap between the working window of a selected one of the engagements and the region of violation is determined. An area reduction amount for the selected engagement is determined based on a portion of the area of the region of overlap. The working window of the selected engagement is changed based on the area reduction amount.

Owner:GLOBALFOUNDRIES US INC

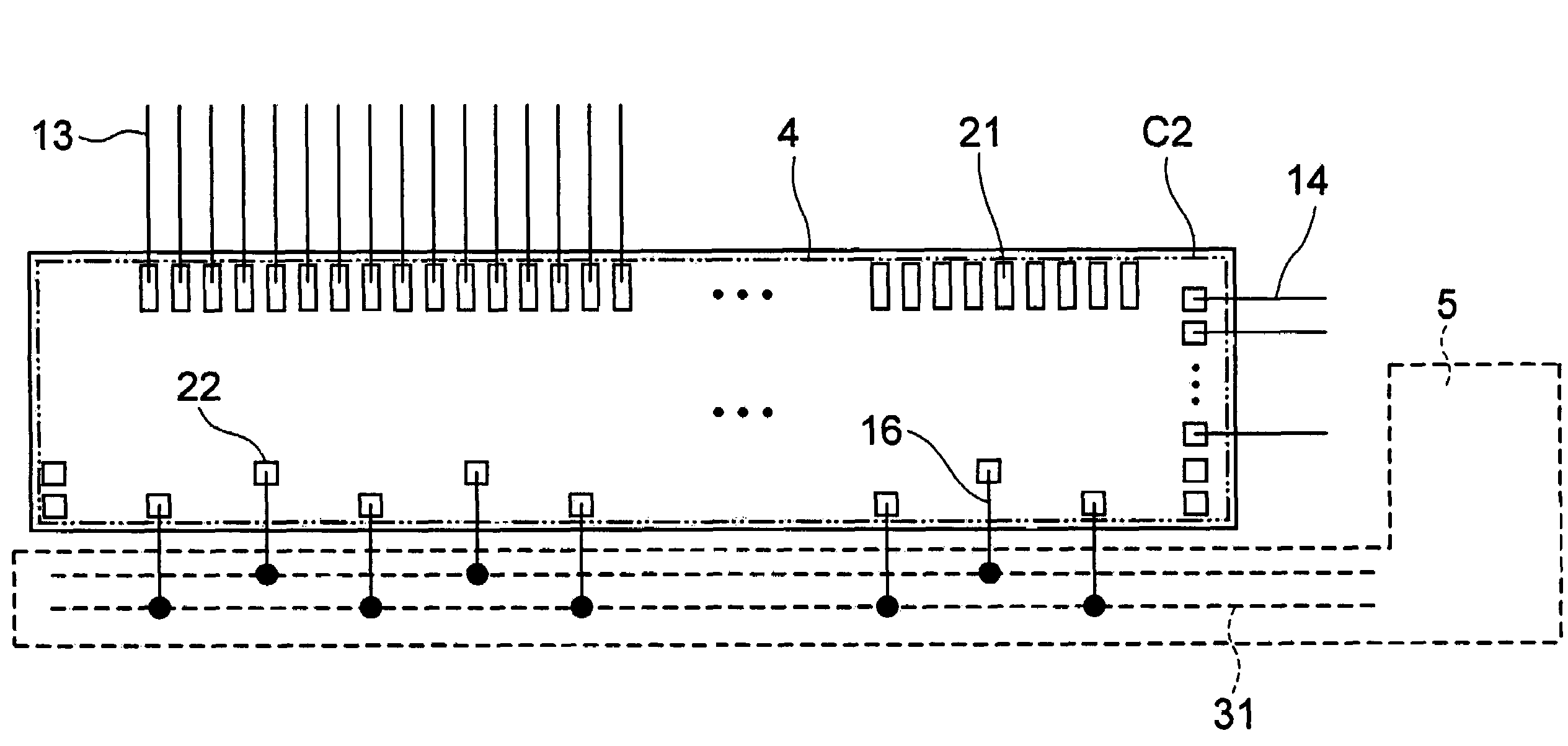

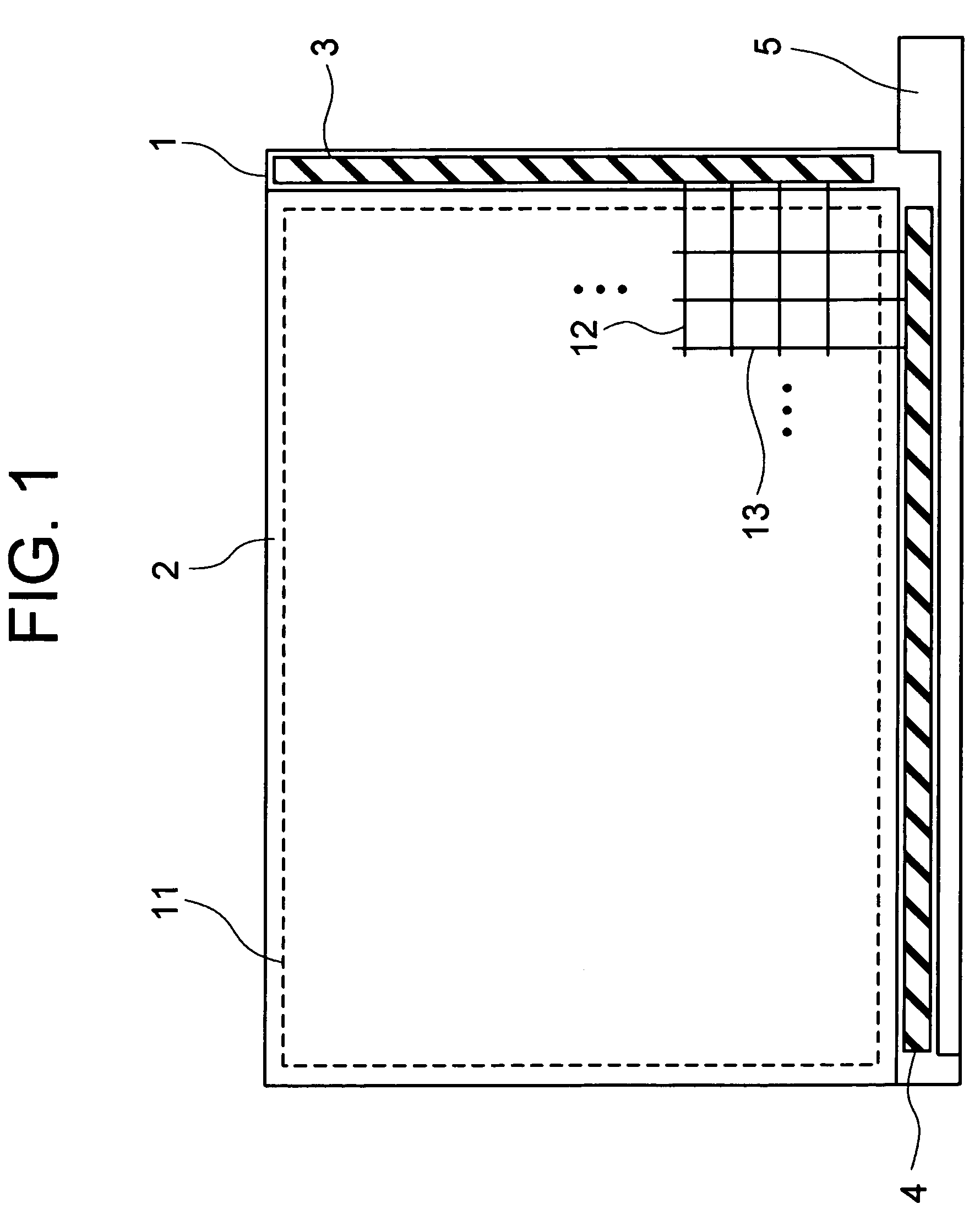

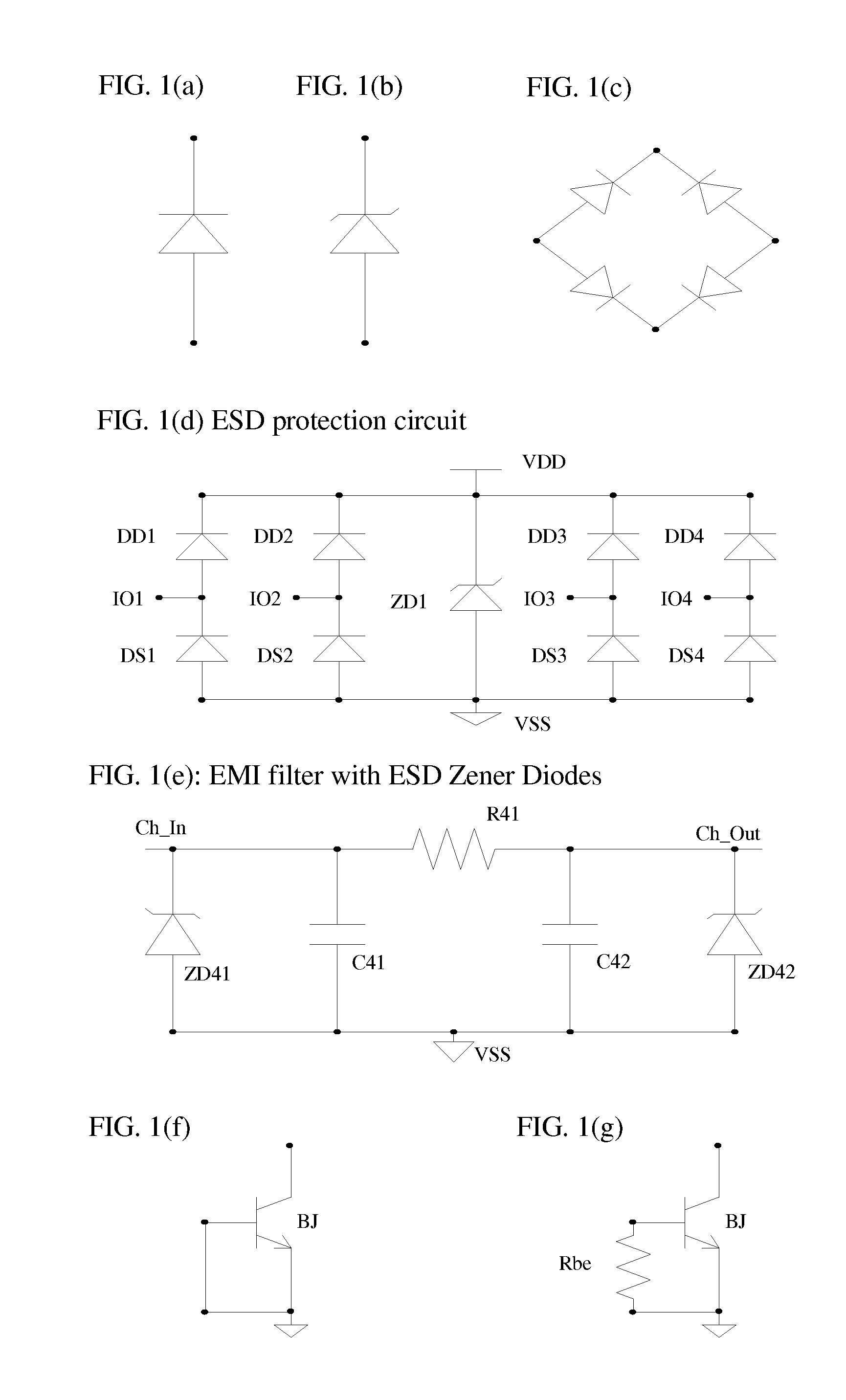

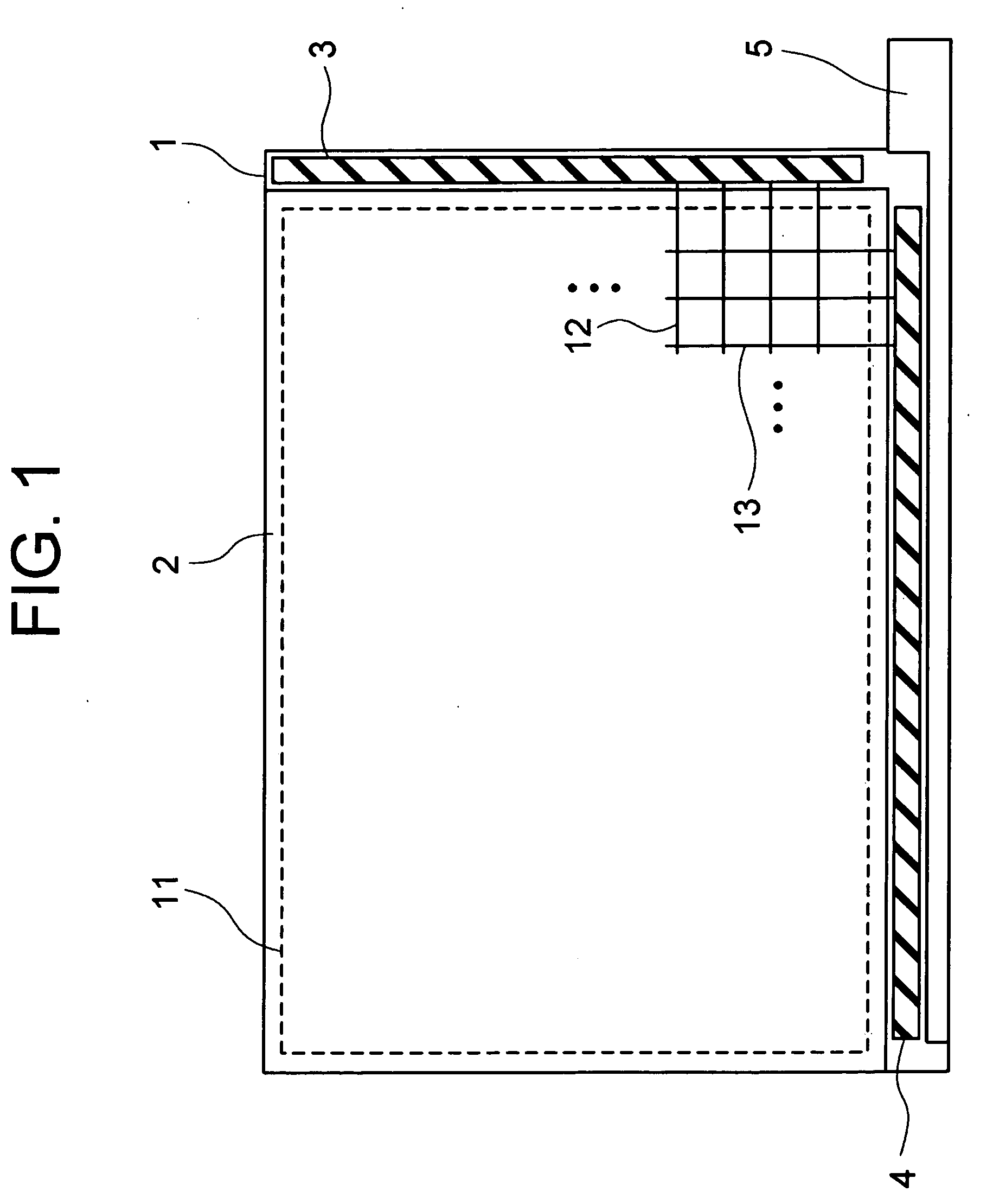

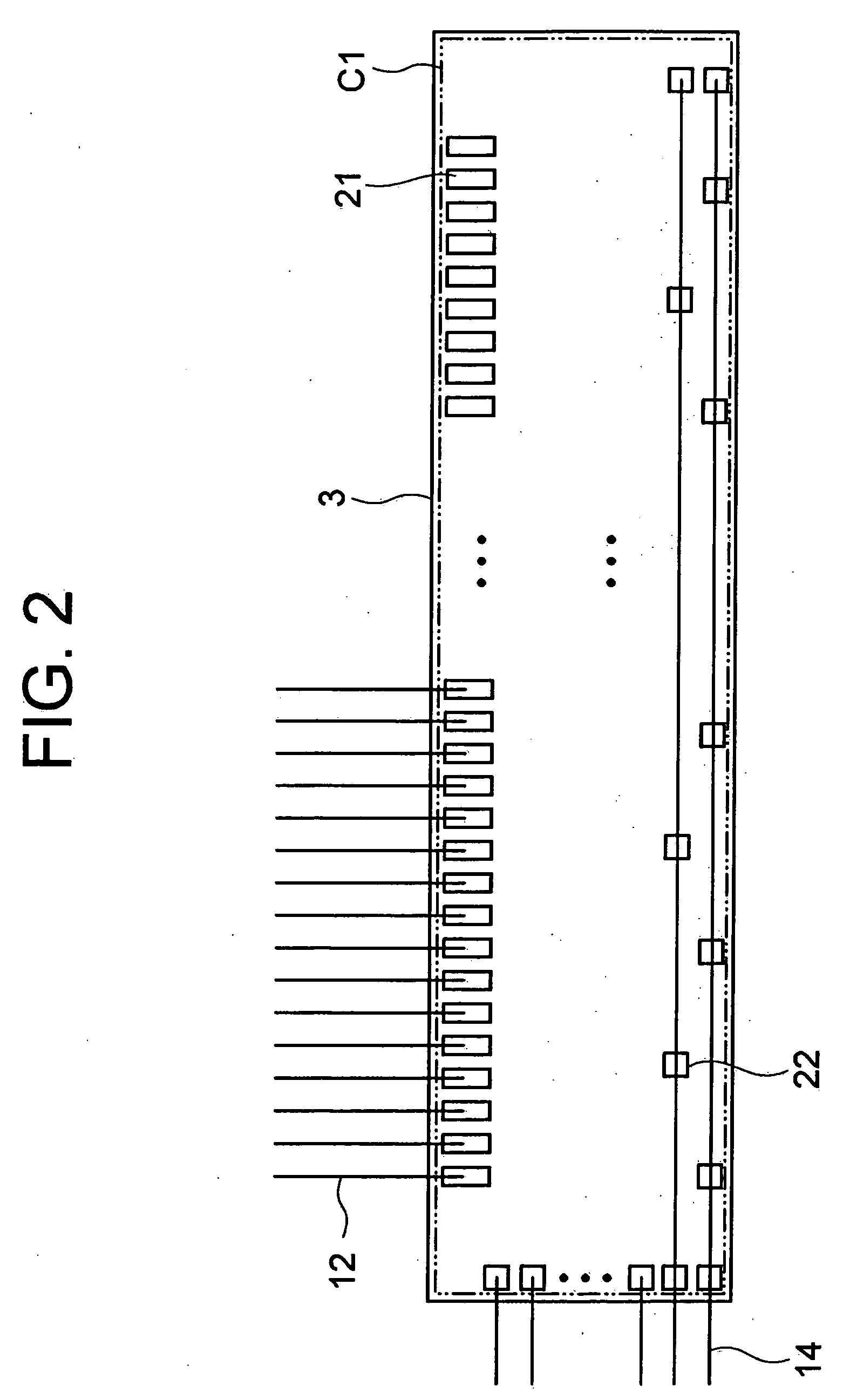

Semiconductor chip and display device using the same

ActiveUS7251010B2Narrow frameStatic indicating devicesSemiconductor/solid-state device detailsElectricityDevice material

To realize an area reduction of a semiconductor chip without adding a process, and to provide a semiconductor chip structure having an excellent pressure balance when mounted.In the structure of a semiconductor chip in which control / power supply lines are formed on a glass substrate, connecting terminals for electrically connecting with the control / power supply lines are provided in alignment in the longitudinal direction of the semiconductor device, whereby the wiring length within the semiconductor chip can be suppressed to be minimum. Since the wiring length is shortened, the width of the wirings within the semiconductor chip is narrowed, so that the area of the semiconductor chip is reduced.

Owner:HANNSTAR DISPLAY CORPORATION

Method and system for quantification of arterial stenosis

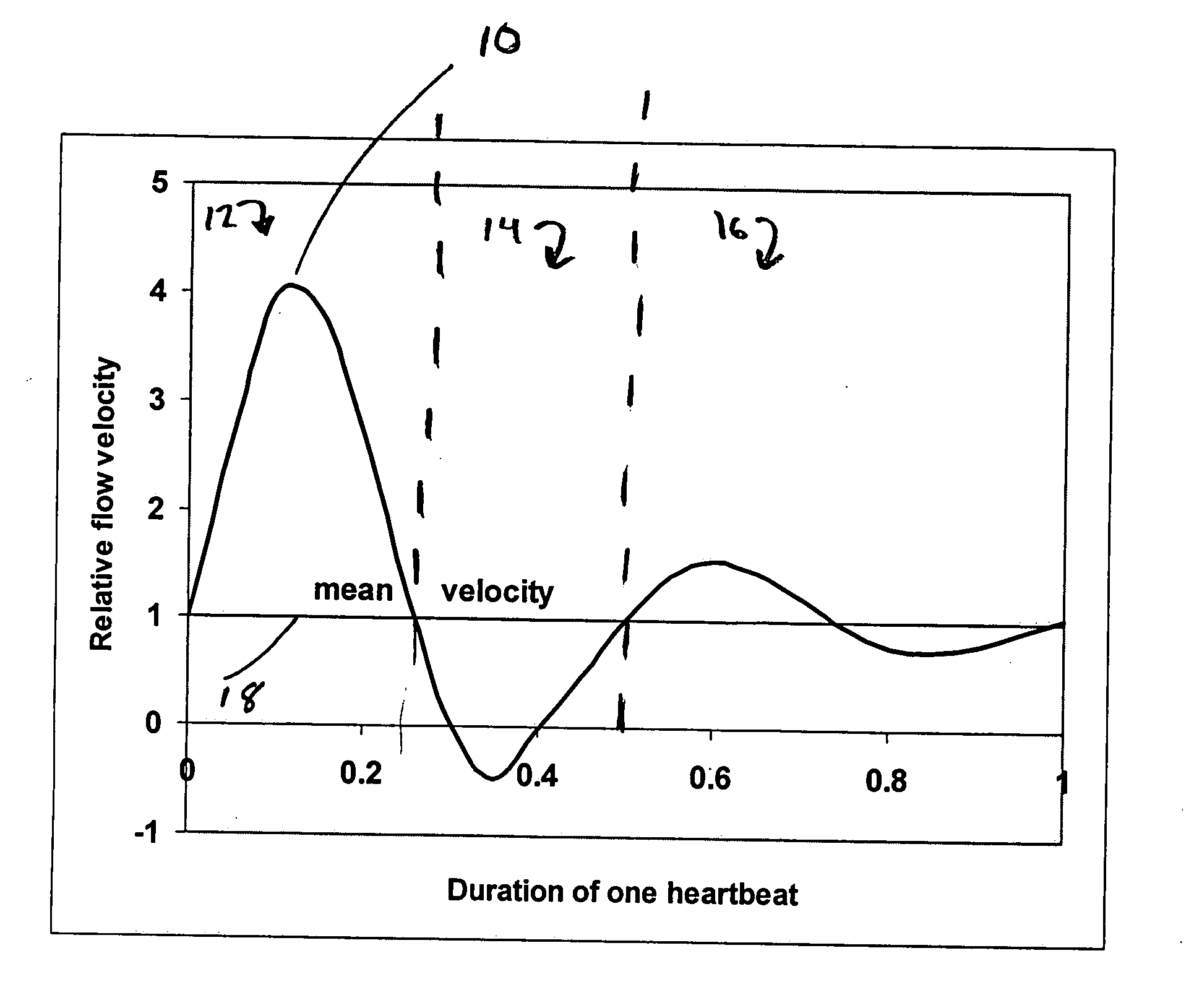

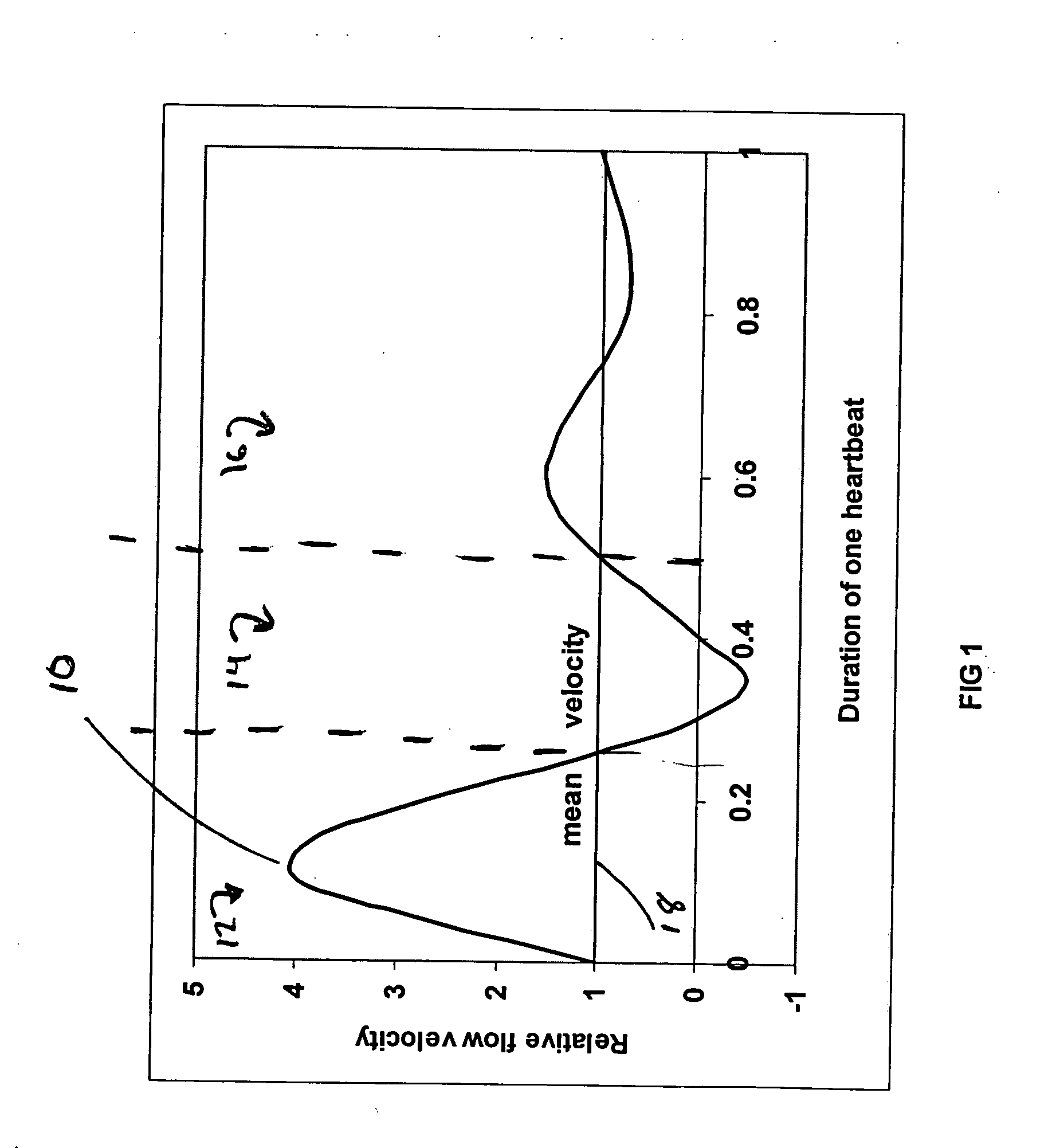

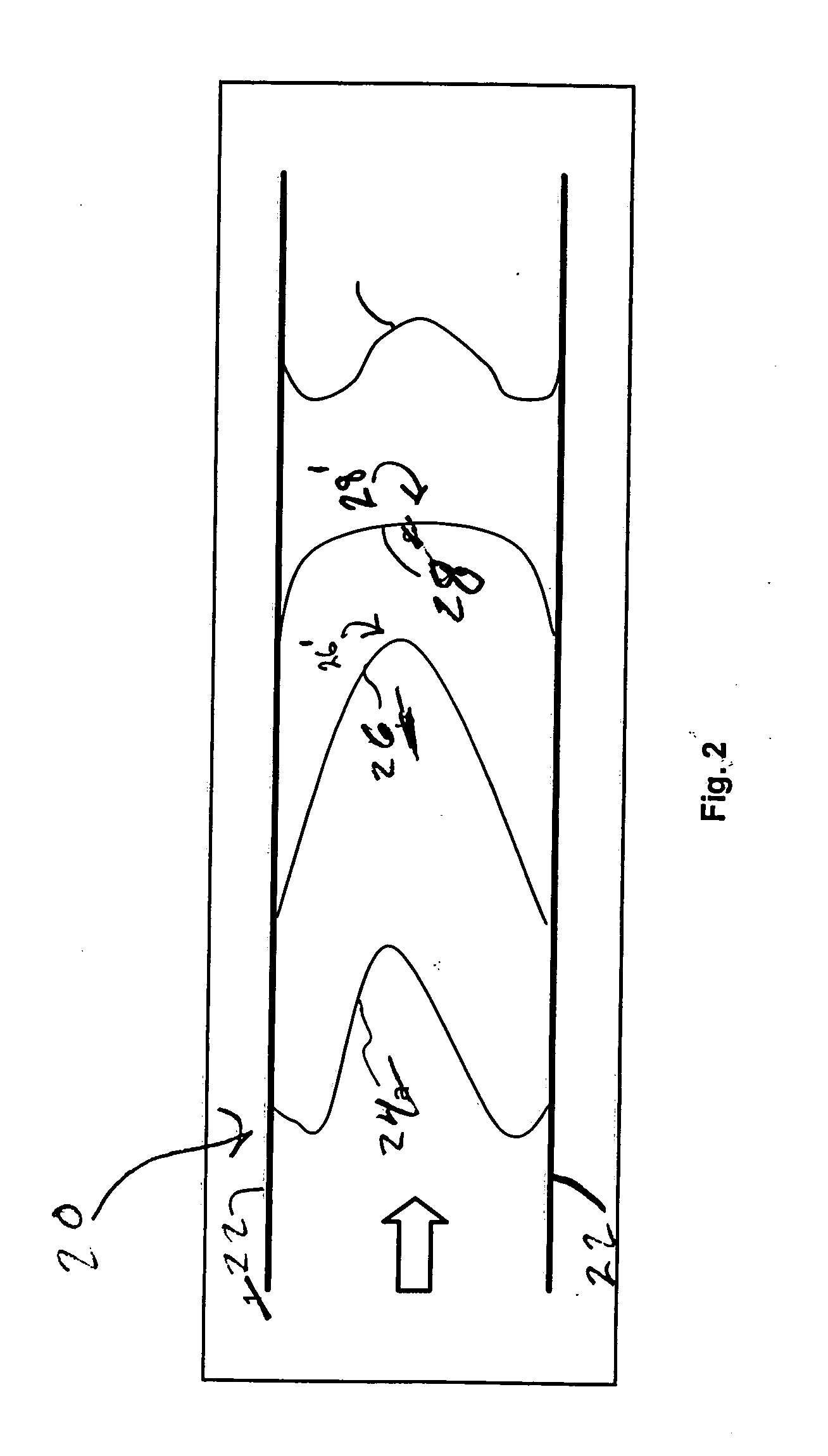

InactiveUS20050119573A1Accurately determineBlood flow measurement devicesDiagnostic recording/measuringFrequency spectrumArterial stenosis

A method is proposed that identifies and quantifies stenoses in arteries based on an analysis of Doppler frequency shifts from several heartbeats. It is non-invasive and individual insensitive. Pulsatile flow through a blood vessel with wall roughness and / or variable lumen area generates flow disturbances, which lead to variations in the shape of the Doppler shift frequency spectrum. One or several frequency bands that are affected by these flow disturbances are selected from the overall Doppler shift frequency spectrum. Next, one or several parameters, which characterize the selected frequency bands and vary with the degree of stenosis, are used in a linear function to calculate the percentage of lumen area reduction. This method applies in the clinically important range of lumen area reduction of 10-70% with a standard error of 5% or less. For lumen area reductions greater than about 70%, the standard error is larger. A system for practical implementation is also proposed.

Owner:VAS SCAN

Ultra-low carbon steel wire rod for electric conduction and production method thereof

InactiveCN103469061AMeet the use requirementsReduce manufacturing costMetal/alloy conductorsWire rodChemical composition

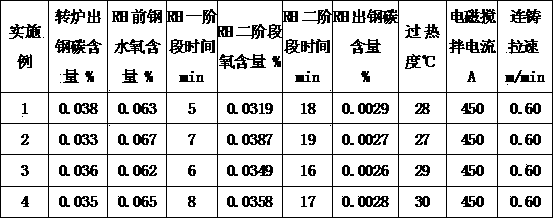

The invention provides an ultra-low carbon steel wire rod for electric conduction and a production method thereof. The ultra-low carbon steel wire rod for electric conduction comprises the following chemical compositions: 0.002-0.005% of C, 0.004-0.010% of Si, 0.05-0.15% of Mn, less than or equal to 0.015% of P, less than or equal to 0.010% of S, 0.0050-0.0080% of total oxygen, and less than or equal to 0.0050% of total aluminum. The carbon content of smelted steel tapped from a converter is less than or equal to 0.040%, and the oxygen content of molten steel is 0.060-0.070%; natural decarburization is performed for 5-8 minutes in the first stage of RH refining; in the second stage of RH refining, after the carbon content is reduced to below 0.0030%, oxygen blowing is performed for 15-20 minutes, and a low-carbon or carbon-free steel ladle is adopted for smelting; the superheat degree of molten steel of a continuous casting tundish is less than or equal to 30 DEG C, the electromagnetic stirring current is greater than or equal to 400A, and the pulling rate is 0.5-0.7 m / min; the temperature of an entry double-module is 880-900 DEG C, the spinning temperature is 900-920 DEG C, the roller-bed speed is 0.2-0.4 m / s, and fans are completely closed. The electric conductivity of the wire rod disclosed by the invention is greater than or equal to 15%, the tensile strength is less than or equal to 300 MPa, and the area reduction index is greater than or equal to 80%, and the wire rod can partially replace copper conducting materials, thereby reducing the production cost.

Owner:ANGANG STEEL CO LTD

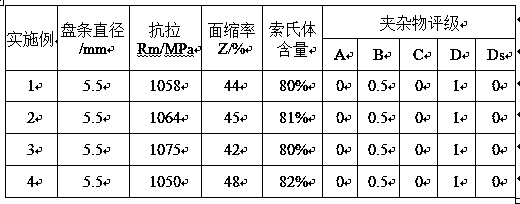

High-strength high-carbon steel wire rod and production method thereof

The invention provides a high-strength high-carbon steel wire rod and a production method thereof. The high-strength high-carbon steel wire rod comprises the following components by weight percentage: 0.85%-0.90% of C, 0.1%-1.0% of Si, 0.3%-1.0% of Mn, less than or equal to 0.015% of P, less than or equal to 0.010% of S, less than or equal to 0.0010% of Ti and the rest Fe. The production method comprises the following steps of: 1), smelting: preprocessing molten iron, controlling sulfur to be less than 0.005%, and feeding less than or equal to 0.040% of Ti into a convertor, wherein the smelting final-point phosphorus content of the convertor is less than or equal to 0.010%, the final-point molten steel temperature of the convertor is at 1,570-1,680 DEG C, the refining process temperature is at 1,530-1,625 DEG C, and the refining time is for 20-50minutes; 2), continuous casting: adopting a large square ingot for the continuous casting, wherein the tundish molten steel superheating temperature is not more than 30 DEG C; and 3), continuous rolling and wire rod rolling, wherein the diameter of the wire rod is 5.5-8.0mm, the laying temperature is 870-910 DEG C, the sorbite transformation process temperature of the wire rod is controlled at 640-600 DEG C, the transformation time is controlled at 7-12seconds, and the sorbite transformation process average supercooling temperature of the wire rod is controlled at 60-80 DEG C. Due to the adoption of the high-strength high-carbon steel wire rod disclosed by the invention, the tensile strength can reach 1,200 MPa-1,300MPa, and the area reduction index is not less than 30%.

Owner:ANGANG STEEL CO LTD

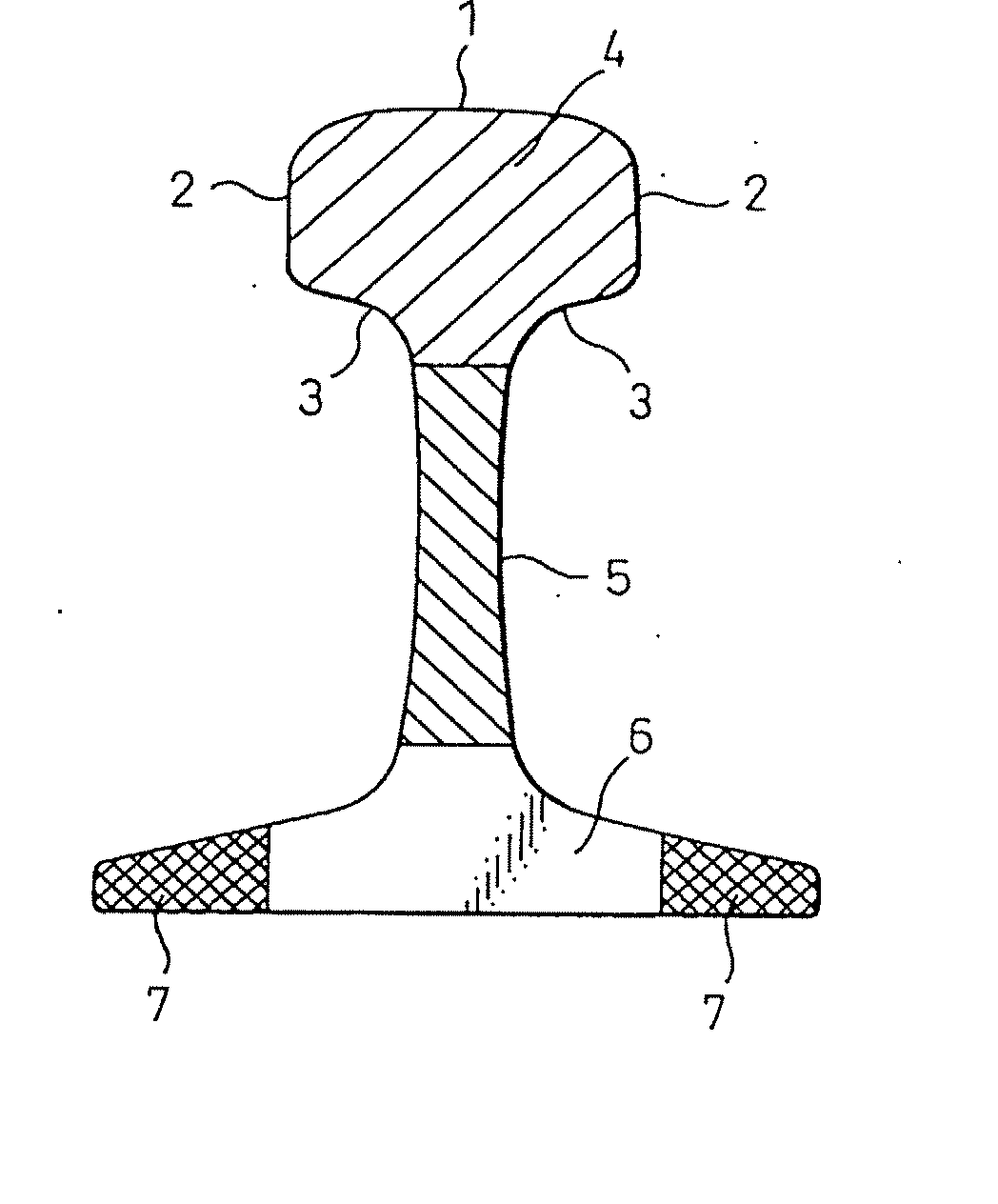

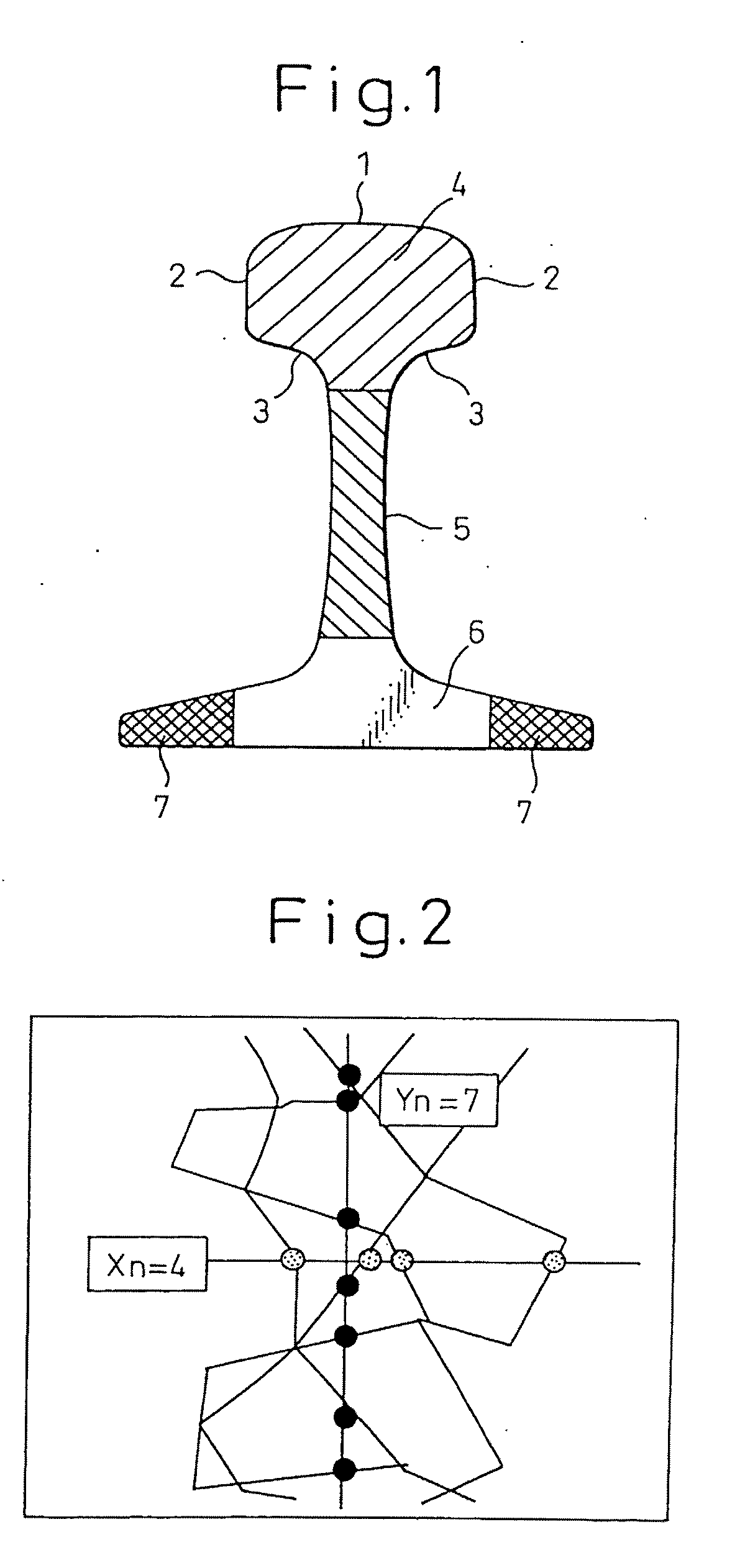

Pearlitic steel rail excellent in wear resistance and ductility and method for producing same

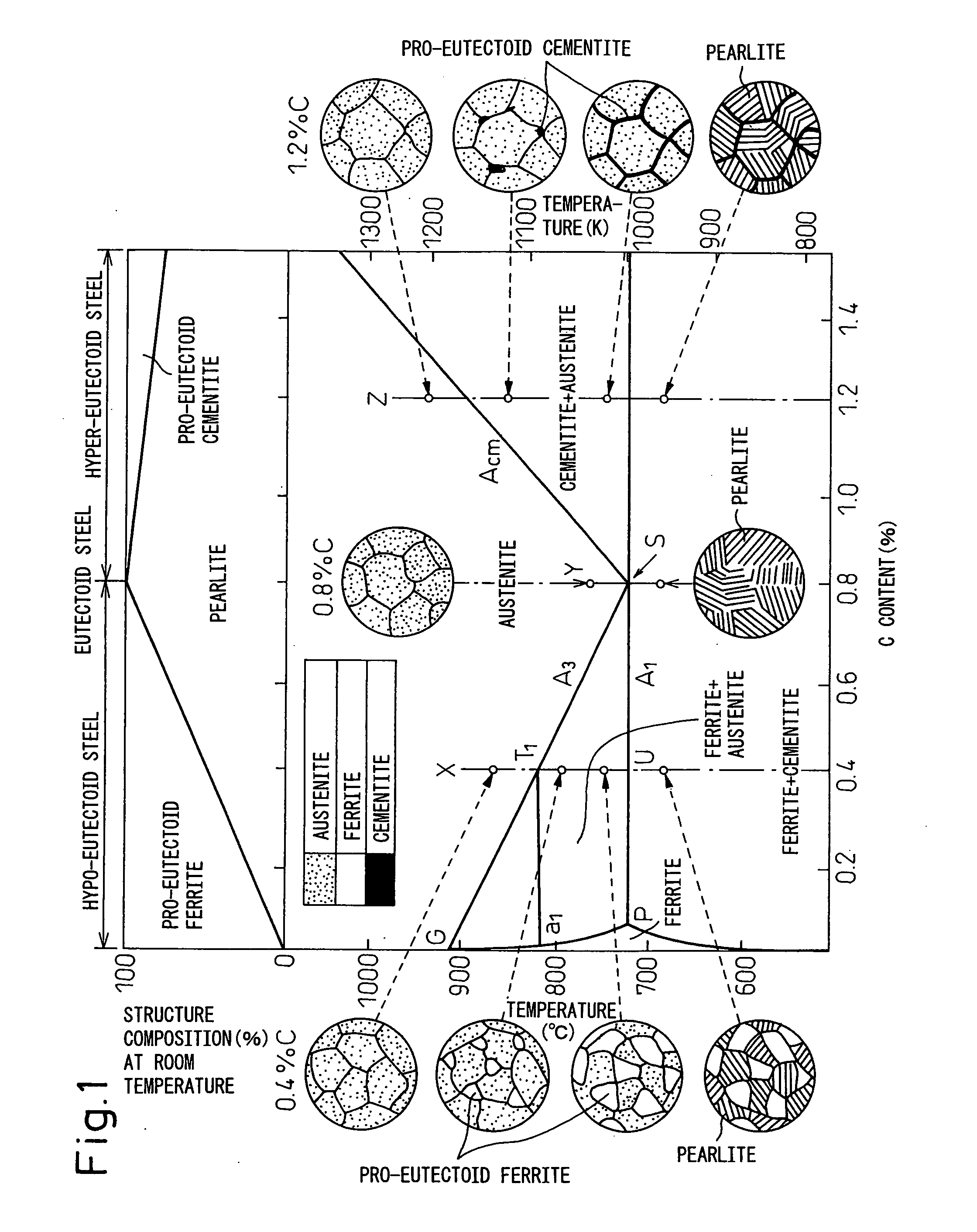

InactiveUS20080011393A1High carbon contentInhibition formationFurnace typesHeat treatment furnacesGranularityPearlite

The present invention is: a pearlitic steel rail excellent in wear resistance and ductility, characterized in that, in a steel rail having pearlite structure containing, in mass, 0.65 to 1.40% C, the number of the pearlite blocks having grain sizes in the range from 1 to 15 μm is 200 or more per 0.2 mm2 of an observation field at least in a part of the region down to a depth of 10 mm from the surface of the corners and top of the head portion; and a method for producing a pearlitic steel rail excellent in wear resistance and ductility, characterized by, in the hot rolling of said steel rail, applying finish rolling so that the temperature of the rail surface may be in the range from 850° C. to 1,000° C. and the sectional area reduction ratio at the final pass may be 6% or more, and then applying accelerated cooling to the head portion of said rail at a cooling rate in the range from 1 to 30° C. / sec. from the austenite temperature range to at least 550° C.

Owner:NIPPON STEEL CORP

Hot continuous rolling process of high-sulfur (sulfur-phosphorus) free cutting structural steel

InactiveCN1608758ASolve technical problems that are easy to slipHigh yieldFurnace typesMetal rolling arrangementsSulfurWater flow

The present invention is hot continuous rolling process of high-sulfur (sulfur-phosphorus) easy-to-cut structural steel, and features that the billet is hot rolled into rod or wire by means of controlling billet heating, coarse rolling speed, area reduction and cooling water flow rate. The present invention solves the difficult problem of rolling easy-to-cut structural steel with high high-sulfur (sulfur-phosphorus) content without producing crack, and has high production efficiency, stable quality and high material utilization.

Owner:宝钢特钢有限公司

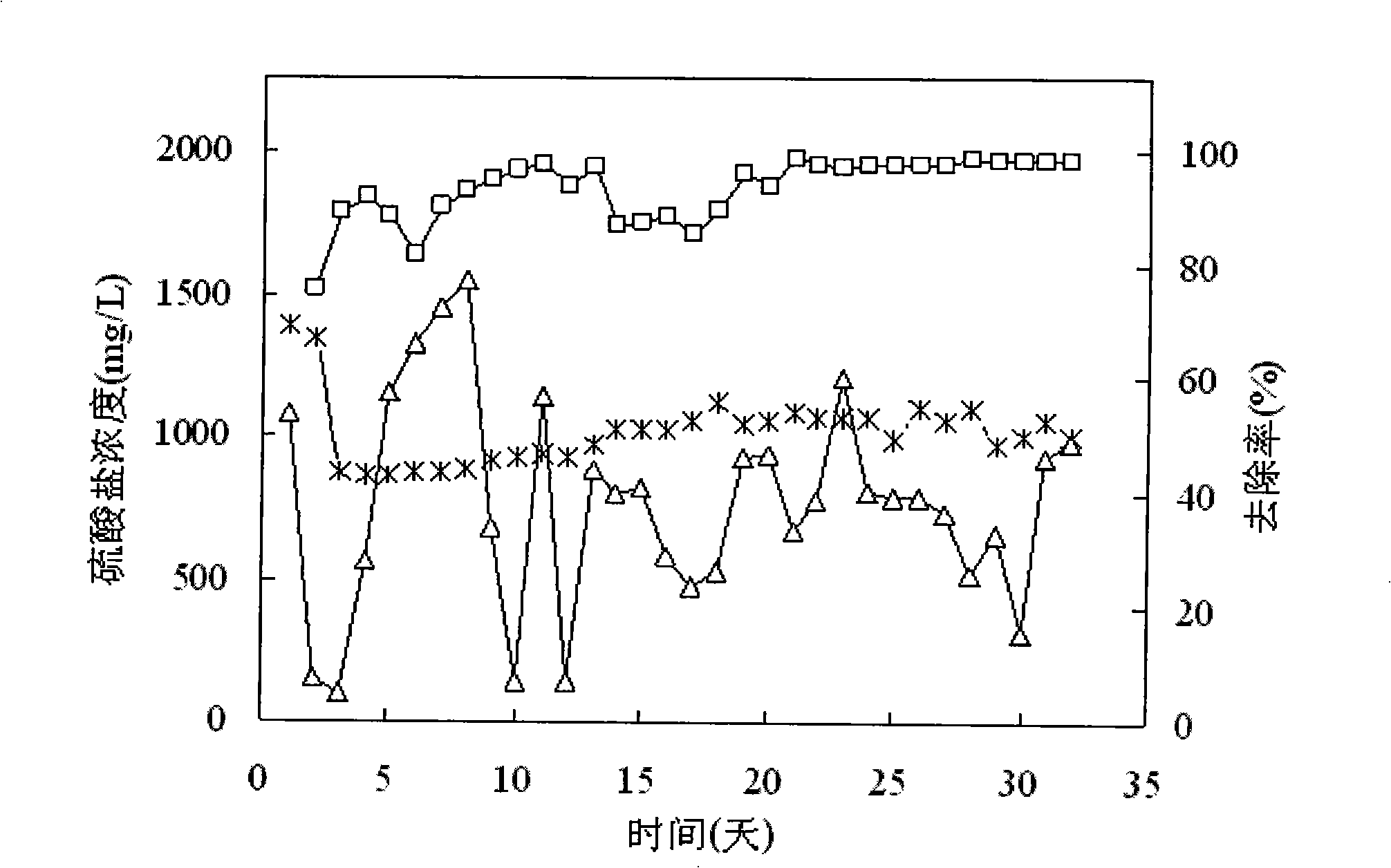

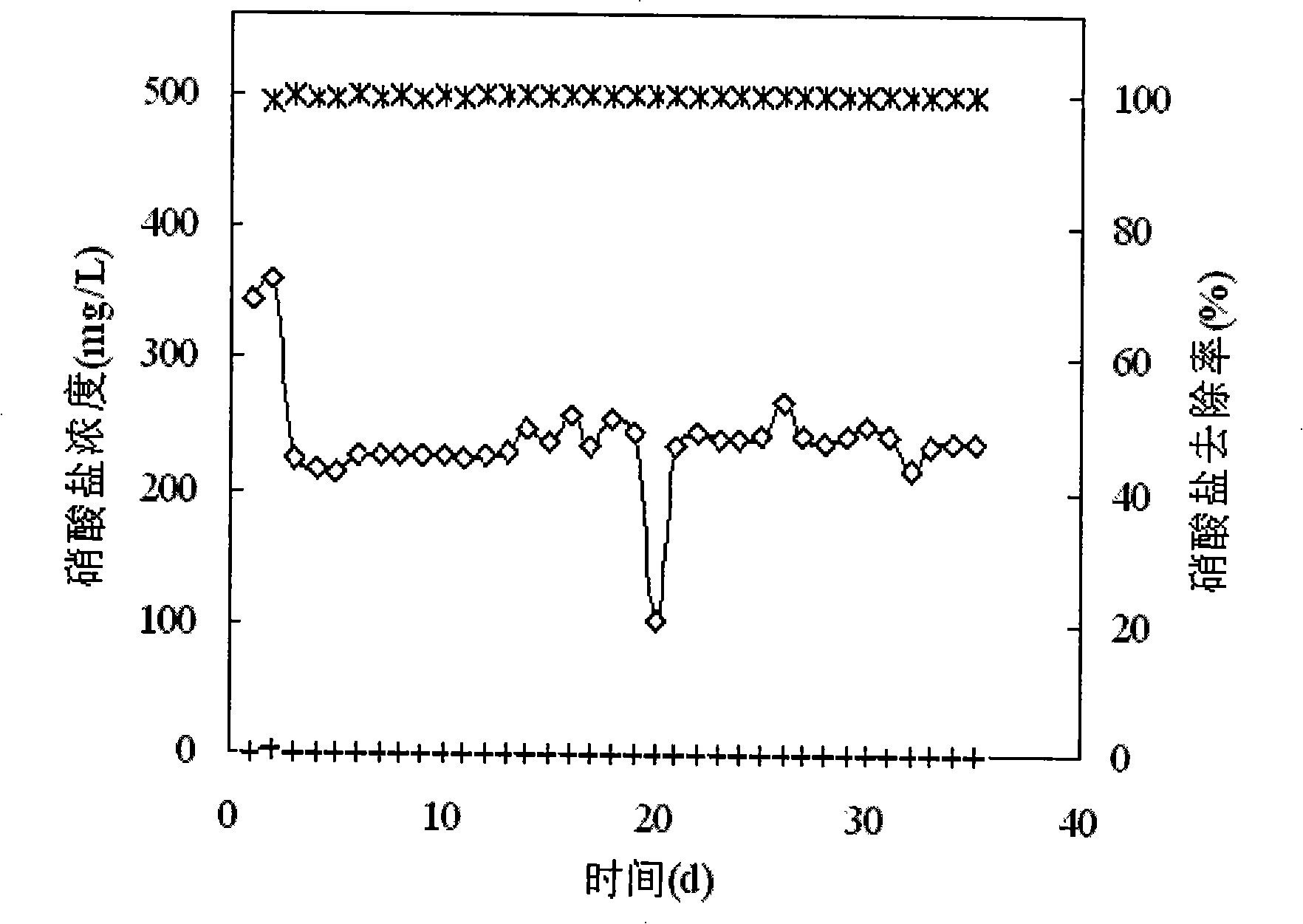

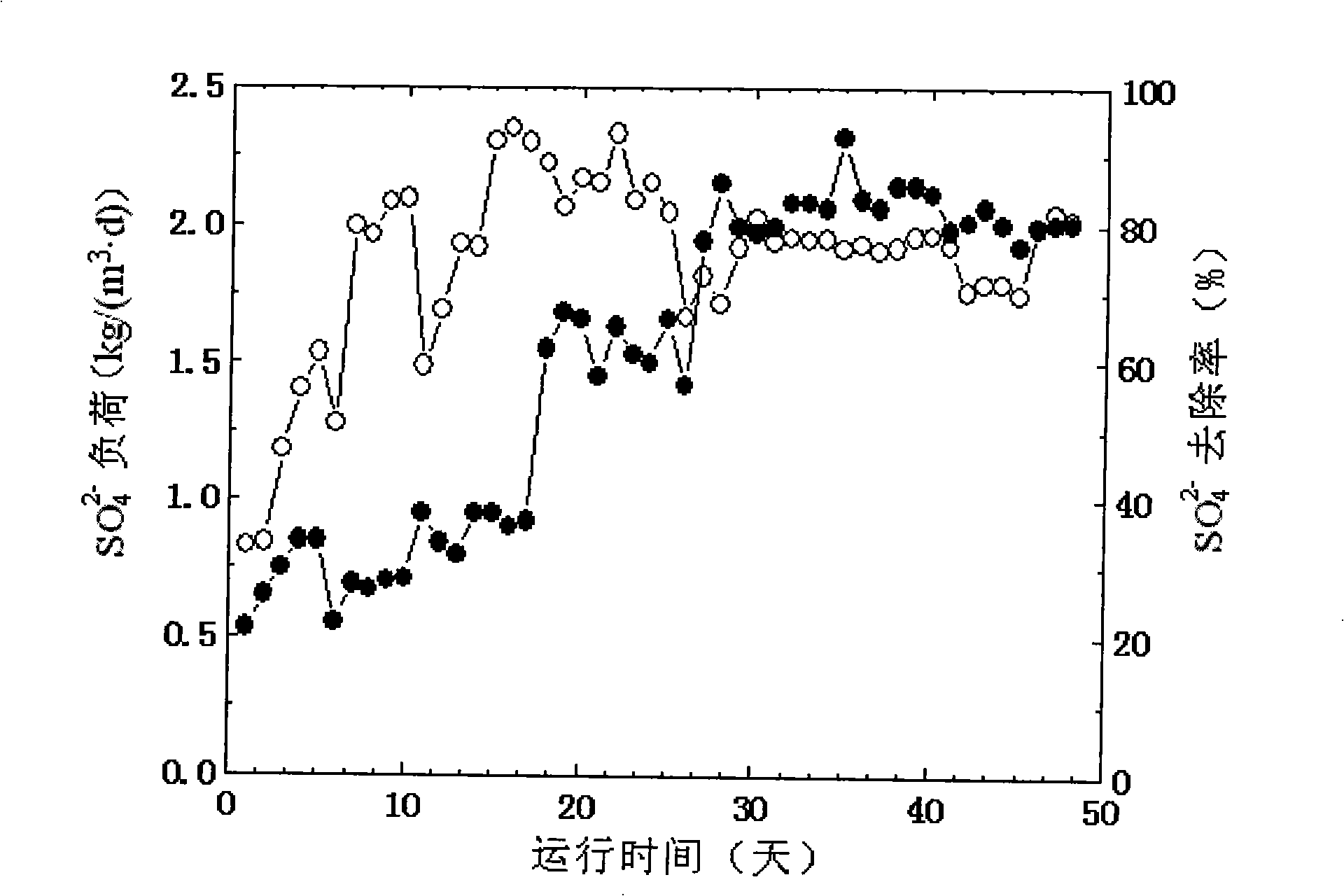

Method for removing sulphur and nitrogen in inorganic waste water synchronously

ActiveCN101302058AReduce yieldSimple processTreatment with anaerobic digestion processesActivated sludgeSuspended particles

The invention provides a method for synchronously removing sulfur and nitrogen in inorganic wastewater, relating to the method for treating the inorganic wastewater. The method overcomes the defects of complicated process, high energy consumption, high cost and easily caused secondary pollution in the prior process for removing the sulfur and the nitrogen in the inorganic wastewater. The method comprises the following steps of: 1. adding anaerobic activated sludge into a reactor for biofilm formation, or for cultivating granular sludge; 2. feeding the inorganic wastewater into the reactor, and adding an organic carbon source into the wastewater, so that sulfate in wastewater in a biofilm or in the granular sludge is transformed into sulfide, the surface of the sulfide diffusion biofilm or the surface of the granular sludge is oxidized into elemental sulfur, and nitrate in the wastewater is denitrified into nitrogen; 3. discharging the wastewater which is treated via the second step, and separating and recycling suspended particles of the elemental sulfur; therefore, synchronous removal of the sulfur and the nitrogen in the inorganic wastewater can be completed. The method has the advantages of simple process, convenient operation, high treatment efficiency, no secondary pollution, occupied area reduction, low operating cost, low sludge yield and small energy consumption.

Owner:HARBIN INST OF TECH

Production method of high-strength and long-fatigue-life spring steel

The invention discloses a production method of high-strength and long-fatigue-life spring steel. The chemical compositions of the spring steel comprise, by weight, 0.51-0.59% of carbon, 1.40-1.60% ofsilicon, 0.50-0.80% of manganese, 0.012% or less of phosphorus, 0.010% or less of sulphur, 0.02% of or less niobium, 0.005% or less of titanium, 0.005% or less of aluminum, 0.50-0.80% of chromium andthe balance Fe and unavoidable impurities. The production method comprises the technological steps that (1) smelting is conducted; (2) continuous casting is conducted; (3) coping is conducted; and (4)rolling and controlled cooling are conducted, and the high-strength and long-fatigue-life wire spring steel taking a sorbite structure as a matrix is produced. According to the production method of the high-strength and long-fatigue-life spring steel, the diameter of a representative steel type, namely an X55SiCrA steel wire rod, is 5.5 mm, the tensile strength is 1000 MPa or over, the area reduction is 40% or over, the grade A, the grade B, the grade C and the grade D of inclusions are all smaller than 1.0, a DS type inclusion is not contained, and the using requirements of a valve spring for an automobile can be well met.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

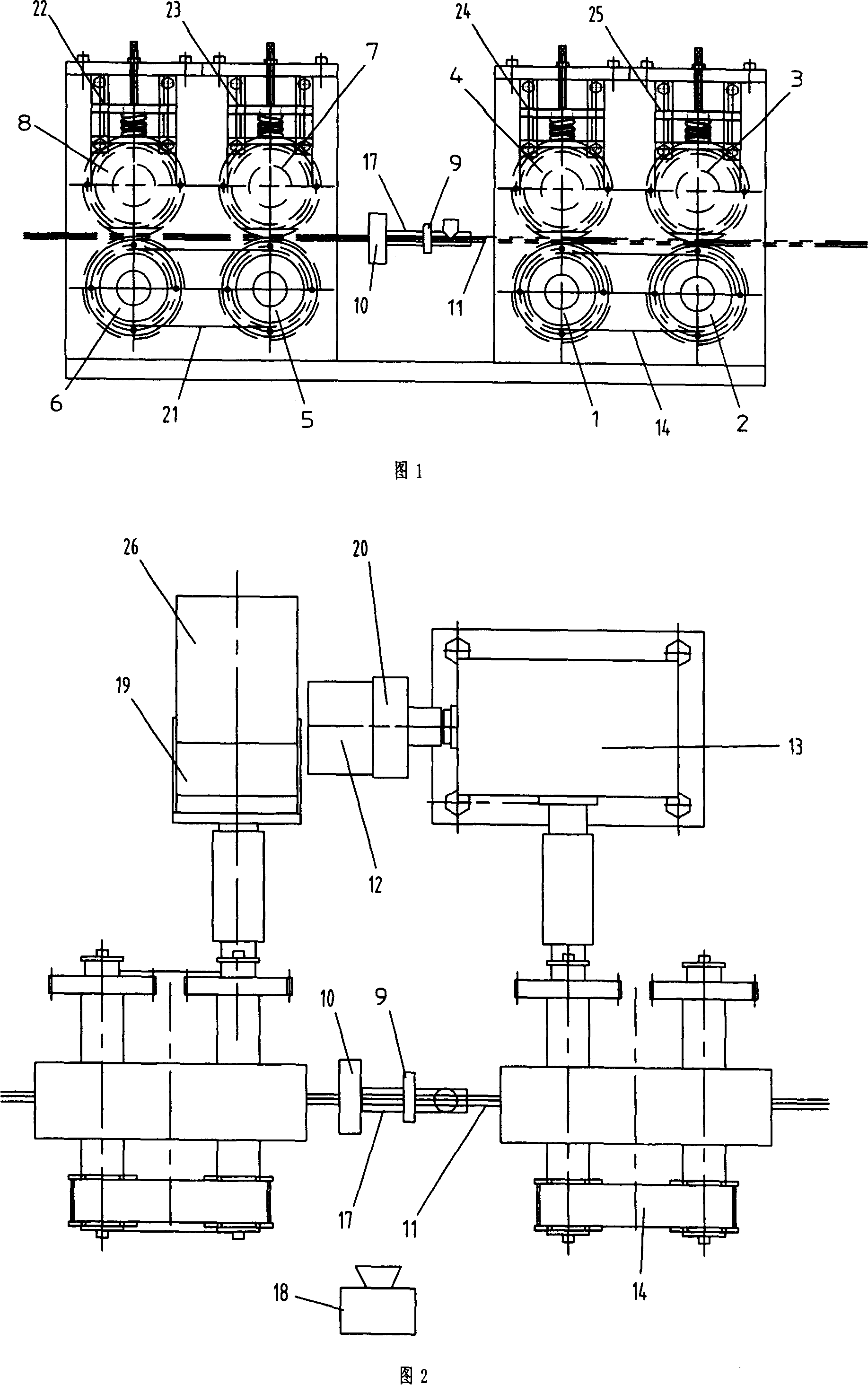

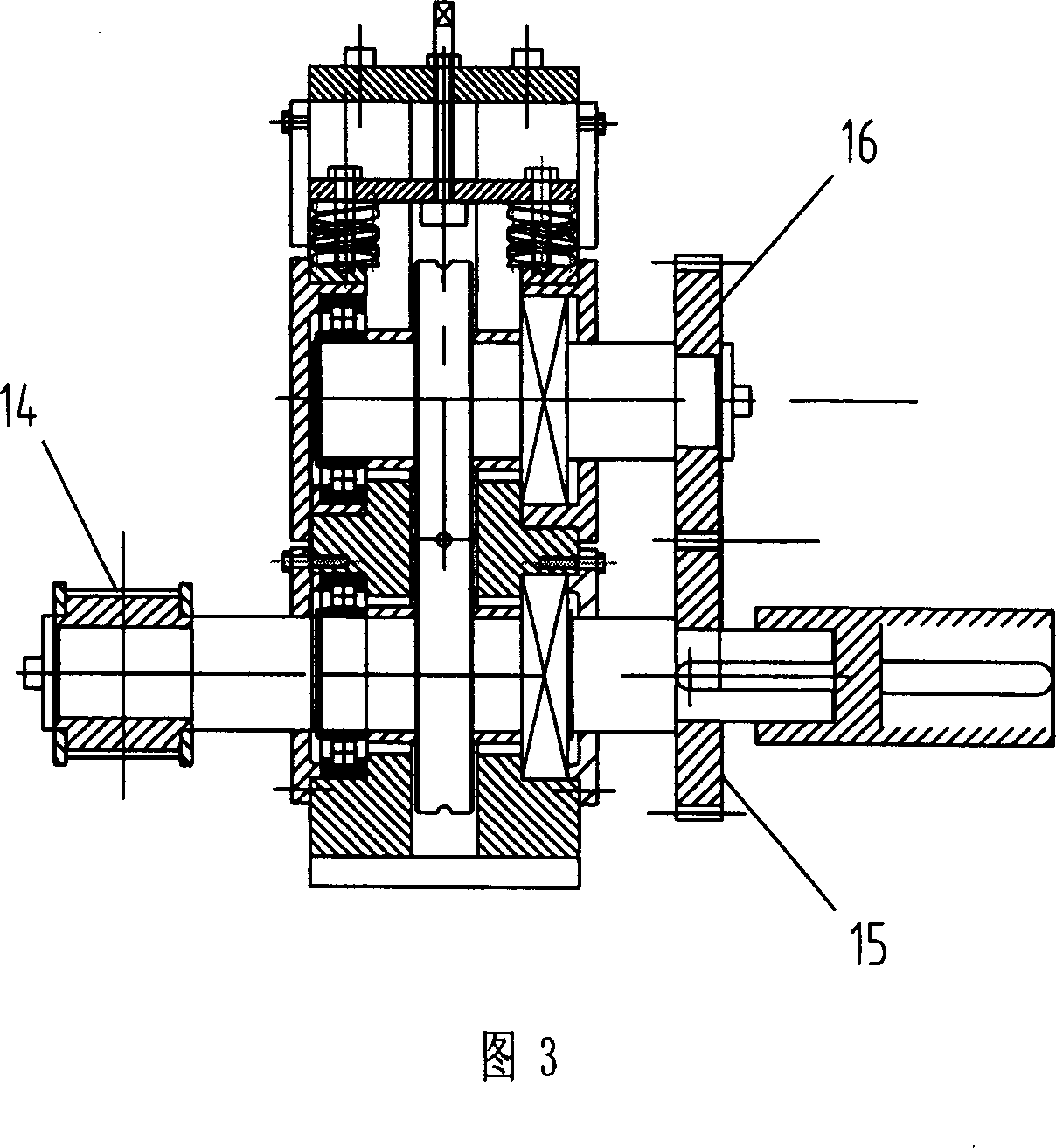

Intelligent no-mold drawing formation apparatus and process

ActiveCN101020197APrevent unstable deformationStable continuous formingMetal-working feeding devicesTemperature control using electric meansAutomatic controlControl system

The present invention is intelligent no-mold drawing formation apparatus and process, and belongs to the field of metal pressing work technology. The apparatus includes an intelligent automatic control system, a feeding and drawing system, a heating and temperature measuring system, a cooling system and a protecting gas supplying system. The technological process includes loosening the automatic hold-down device, passing the drawn material through the feeding rolls, heating, applying the automatic hold-down device to hold down the material, and moving the material forwards under the computer control to obtain predicted area reduction. The present invention has raised stability and high product size precision, and is suitable for high efficiency work of producing wires and rods.

Owner:UNIV OF SCI & TECH BEIJING

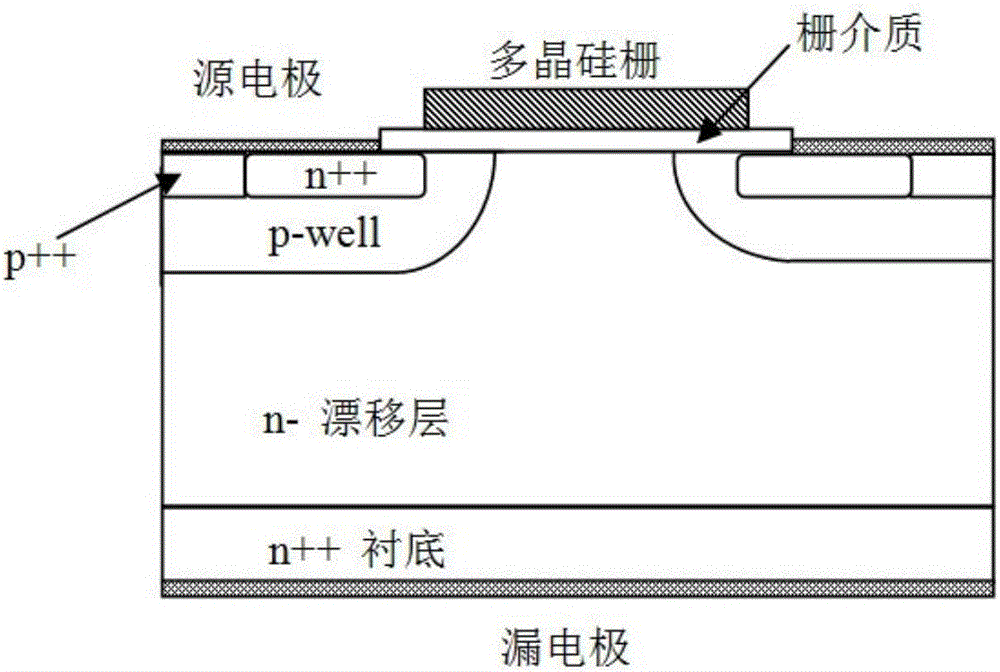

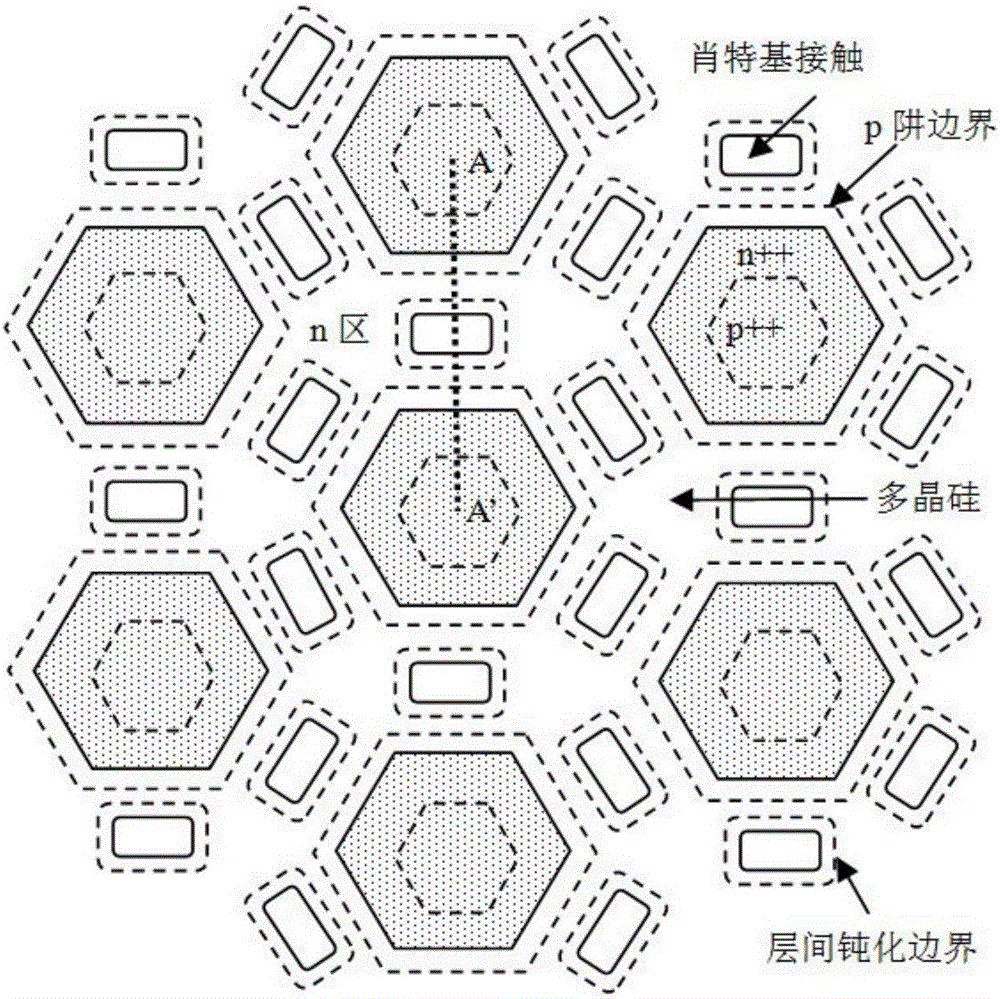

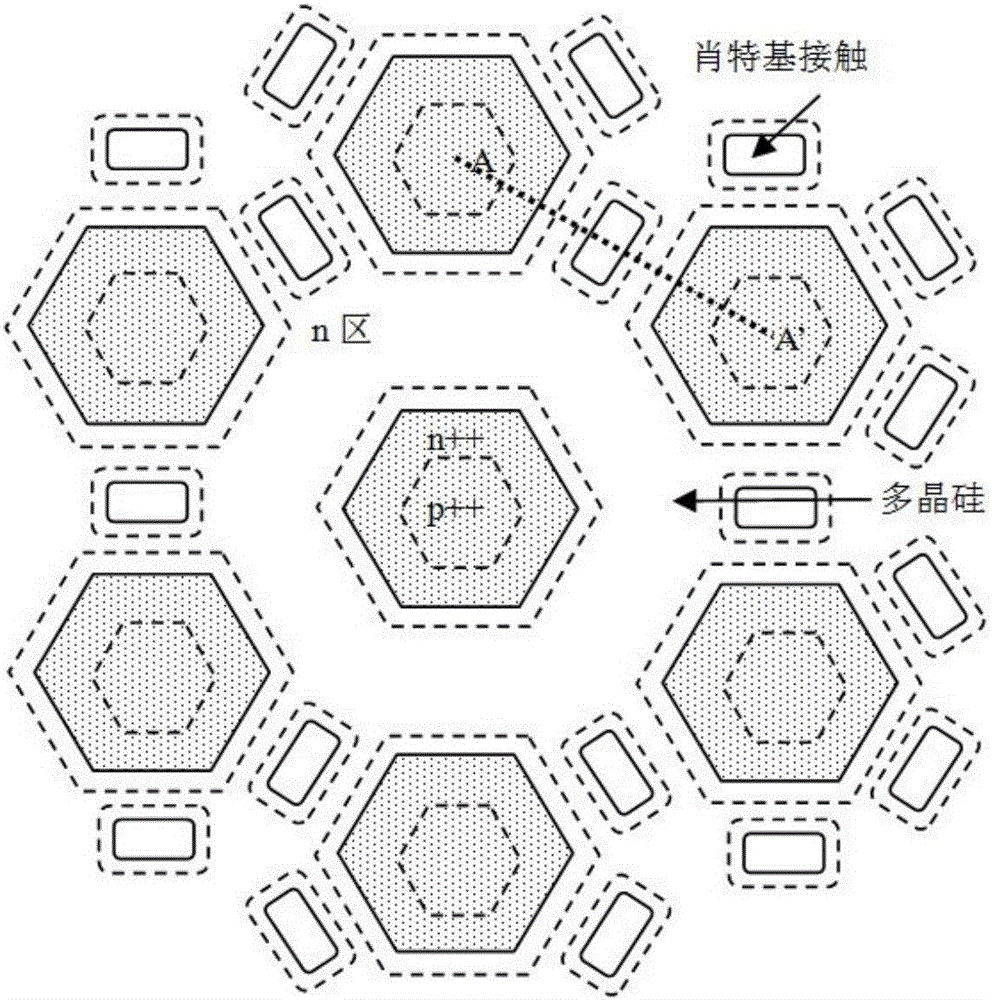

SiC MOSFET device with integrated schottky diode

InactiveCN106784008AImprove switching performanceHighly integratedSemiconductor devicesCapacitanceMOSFET

The invention discloses a SiC MOSFET device with an integrated schottky diode, wherein an original cell structure of a source region from top to bottom is a drain electrode, a substratum, a buffer layer, a drift layer and two P well regions symmetrically from the left and the right. The adjacent n++ area and P++ area arranged on the P well regions from left to right are sequentially provided with a source electrode, a grid electrode, a schottky metal, the grid electrode and the source electrode. The source electrode is positioned above the n++ area and P++ area. The surface part of the P well regions is fully covered with the grid electrode. One side of the grid electrode overlaps with the n++ area and the other side of the grid electrode overlaps with a JFET area. The schottky metal is positioned above the JFET area. The SiC MOSFET device with the integrated and inverse parallel schottky diode is provided, wherein the integrated schottky diode is located in the JFET area, adjacent to the grid electrode area. The SiC MOSFET device with higher original cell integration and density has the advantage of effectively utilizing the proportion of the JFET area. Meanwhile, compared with conventional MOSFET, the current MOSFET is capable of effectively reducing grid capacitance and input-output capacitance and improving switching performance of the device due to the area reduction of the gate capacitance.

Owner:BEIJING CENTURY GOLDRAY SEMICON CO LTD

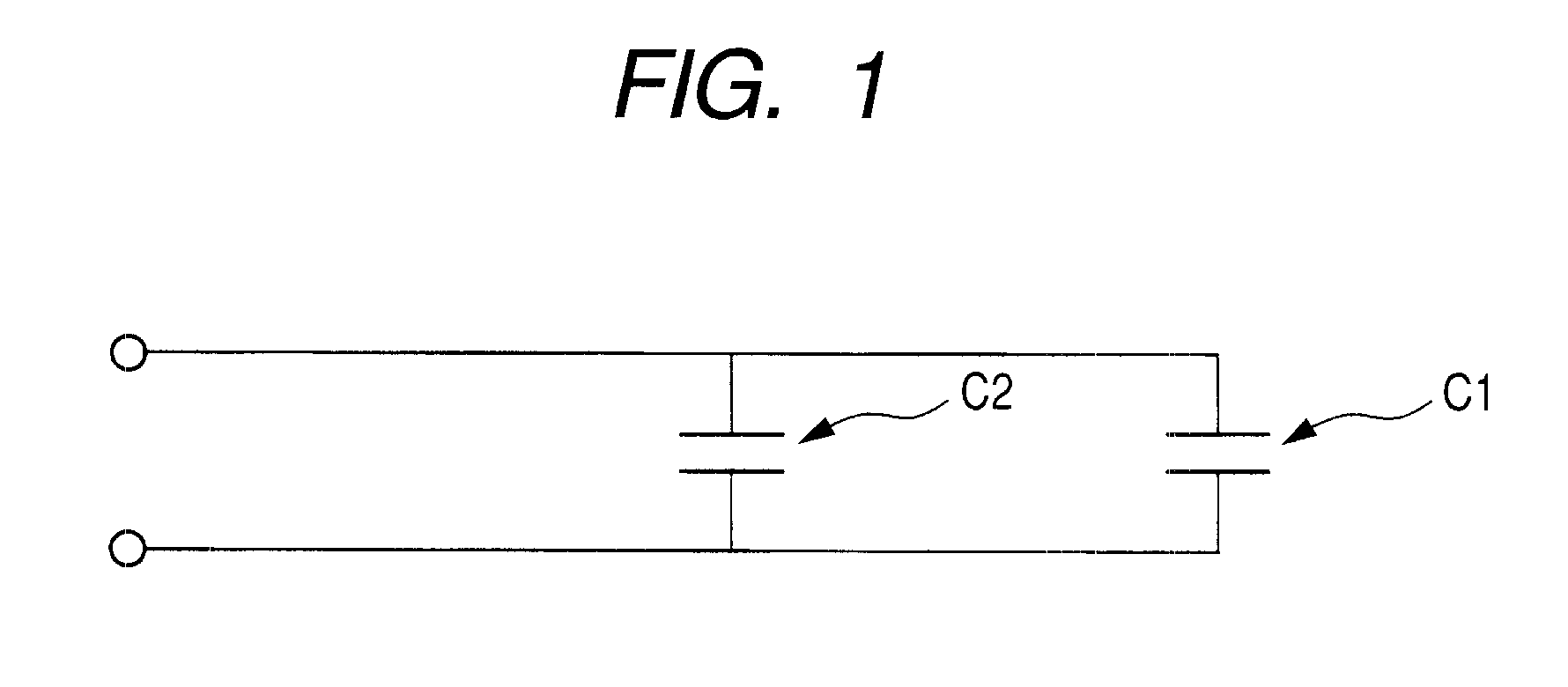

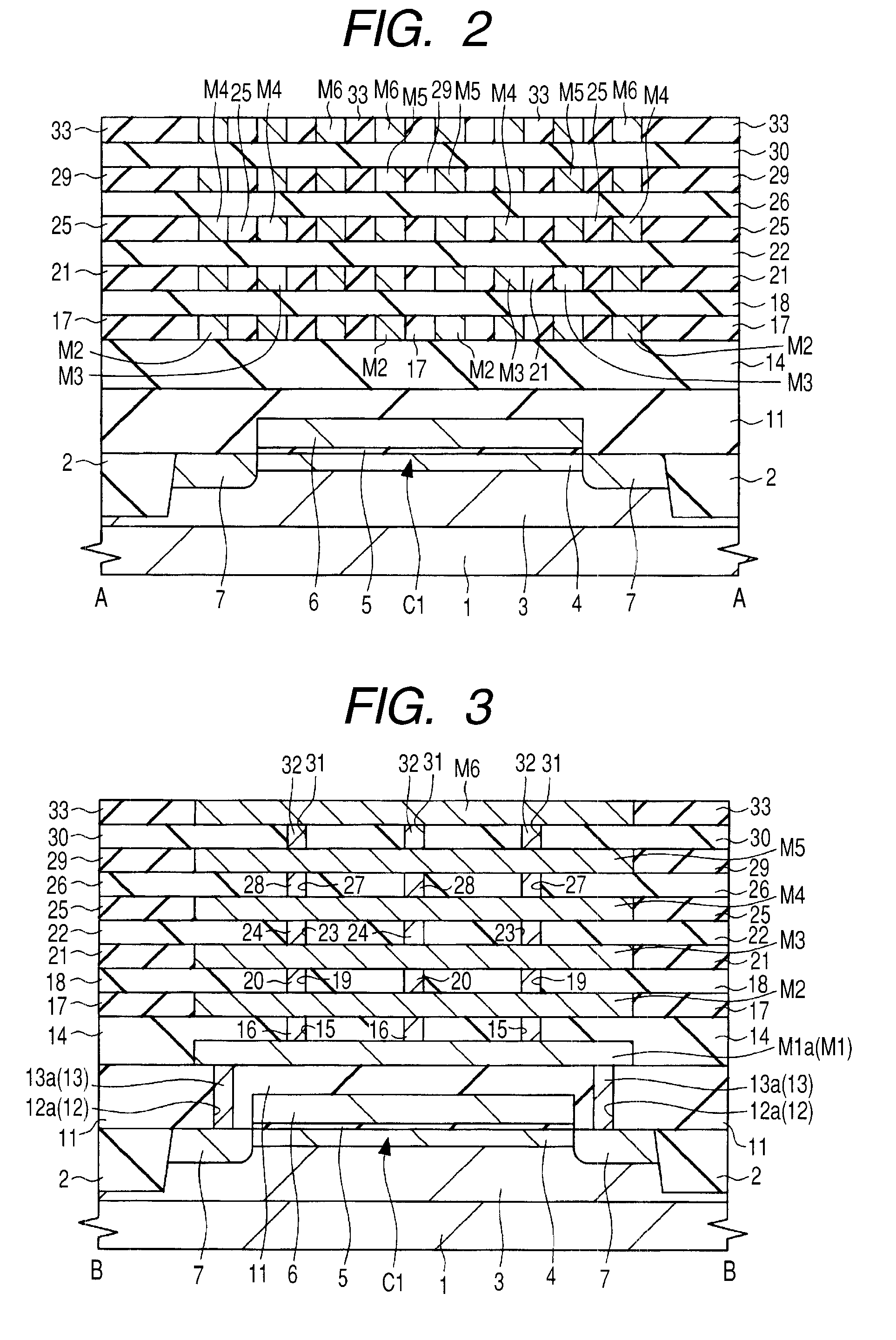

Semiconductor device

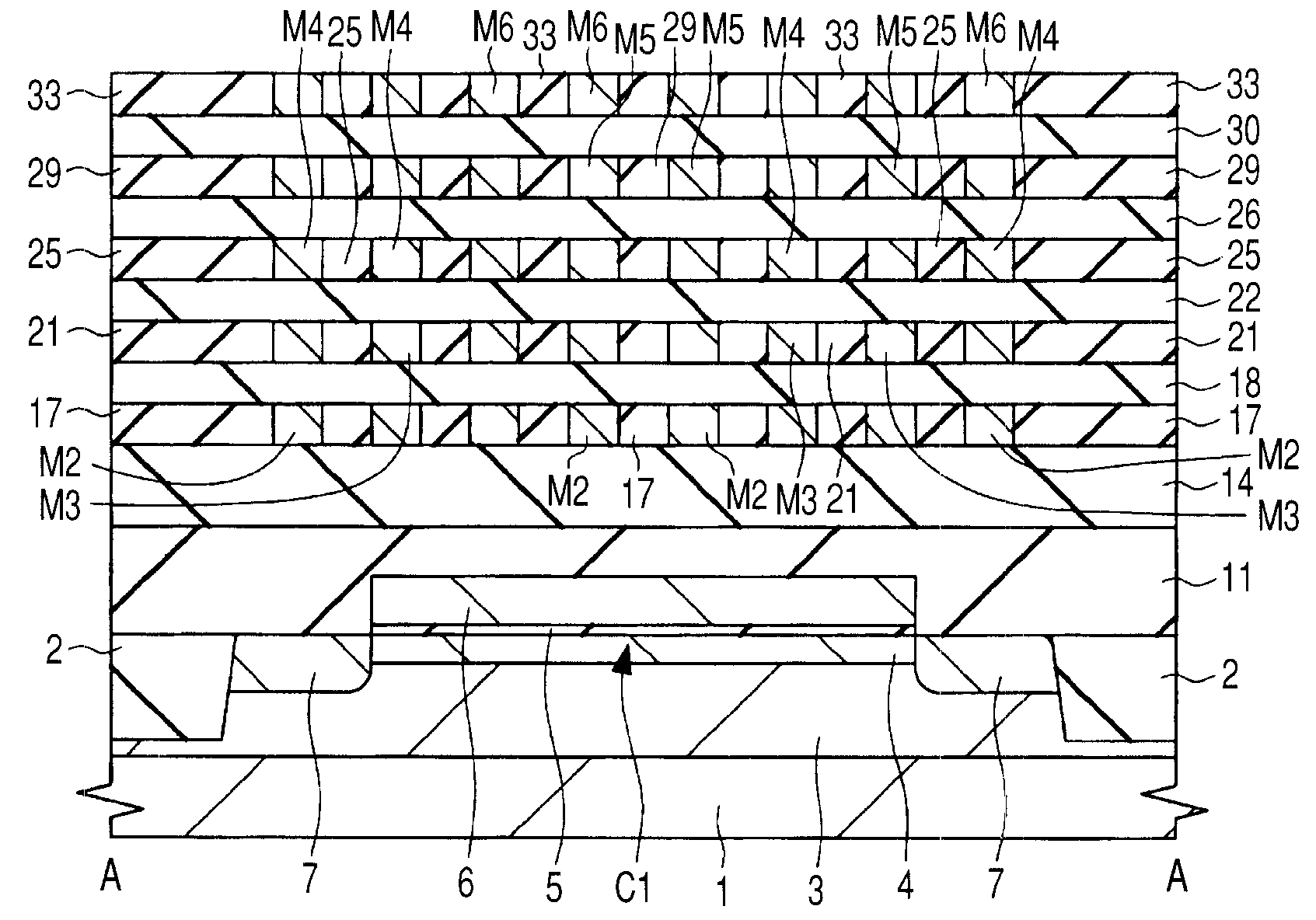

InactiveUS20080230820A1Reduce plane sizeReduce areaTransistorSemiconductor/solid-state device detailsCapacitanceDevice material

Coexistence of the realization of high-capacity of a capacitive element and the area reduction of a semiconductor device is aimed at. A plurality of capacitive elements from which a kind differs mutually are accumulated and arranged on a semiconductor substrate, and they are connected in parallel. These capacitive elements are arranged to the same plane region, and make a plane size almost the same. A lower capacitive element is an MOS type capacitive element which uses as both electrodes the n-type semiconductor region formed in the semiconductor substrate, and the upper electrode formed via the insulation film on the n-type semiconductor region. The MIM type capacitive element formed with the pattern of the comb-type of a wiring is arranged in the upper part of a lower capacitive element, and this is connected with a lower capacitive element in parallel.

Owner:RENESAS ELECTRONICS CORP

Method for manufacturing stainless steel wire for spectacle frame

ActiveCN102828122ABright surfaceNo defects in appearanceFoundry mouldsFoundry coresHardnessStainless steel wire

The invention discloses a method for manufacturing the stainless steel wire for a spectacle frame, comprising the following steps: (1) treating the skin film; (2) drying; (3) drawing for the first time and carrying out bright annealing on line for the first time, wherein the area-reduction rate during drawing for the first time is 40-60%, the temperature of carrying out bright annealing on line for the first time is 1,000-1,100 DEG C, and the speed is 3-9m / min; (4) drawing for the second time and carrying out bright annealing on line for the second time, wherein the area-reduction rate during drawing for the second time is 40-60%, the temperature of carrying out bright annealing on line for the second time is 1,000-1,100 DEG C, and the speed is 5-12m / min; and (5) drawing for the third time and carrying out bright annealing on line for the third time, wherein the area-reduction rate during drawing for the third time is 45-75%, the temperature of carrying out bright annealing on line for the third time is 1,000-1,100 DEG C, and the speed is 5-12m / min. The stainless steel wire manufactured by the method has a bright surface, is free from the surface defect, has high tensile strength temperature and good extensibility and has the following mechanical properties: the yield strength of 300-400N / mm<2>, the tensile strength of 550-650N / mm<2> or higher, the elongation of 50-60% and the hardness value (HV) of 200-300.

Owner:浙江腾龙不锈钢棒线有限公司

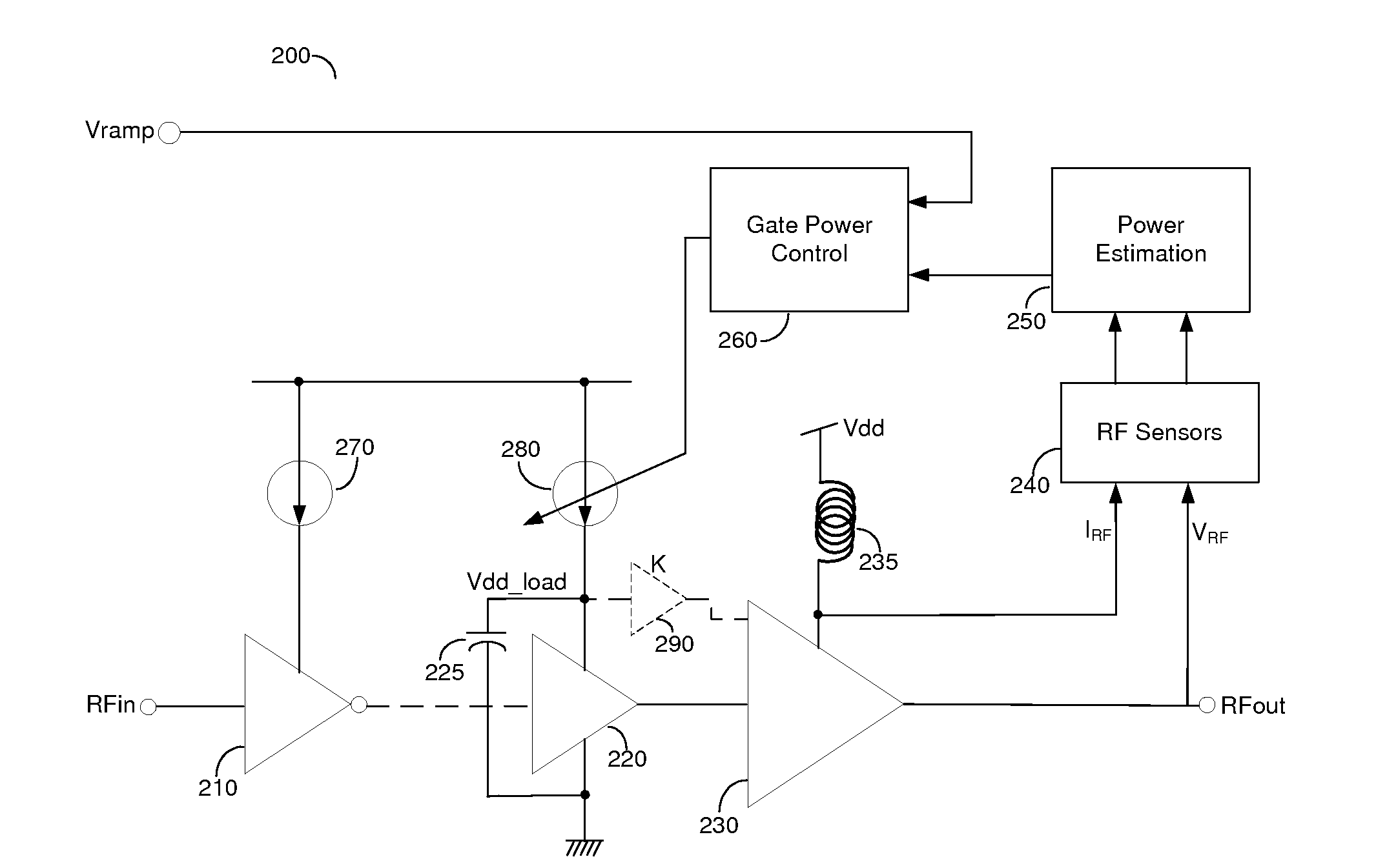

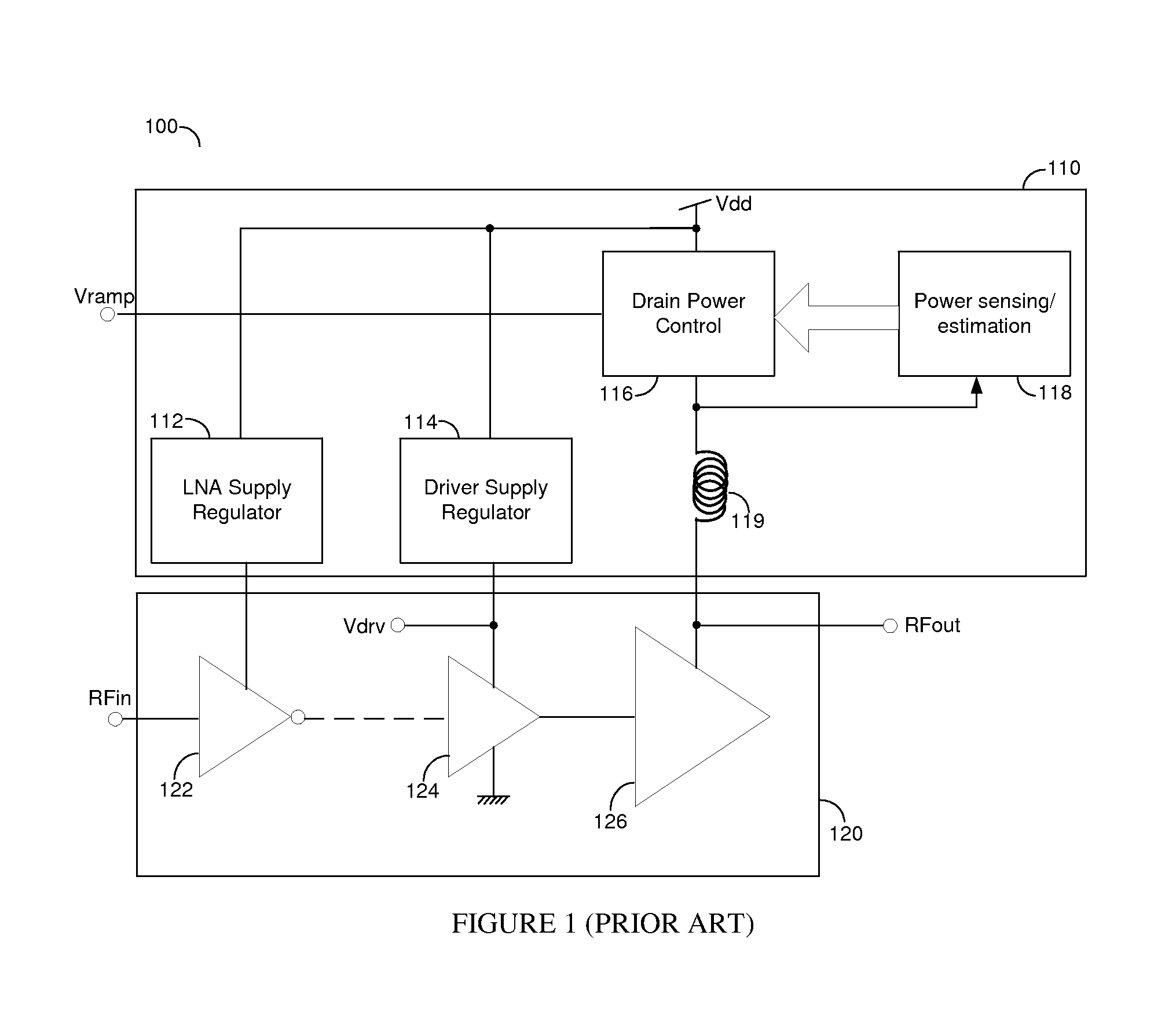

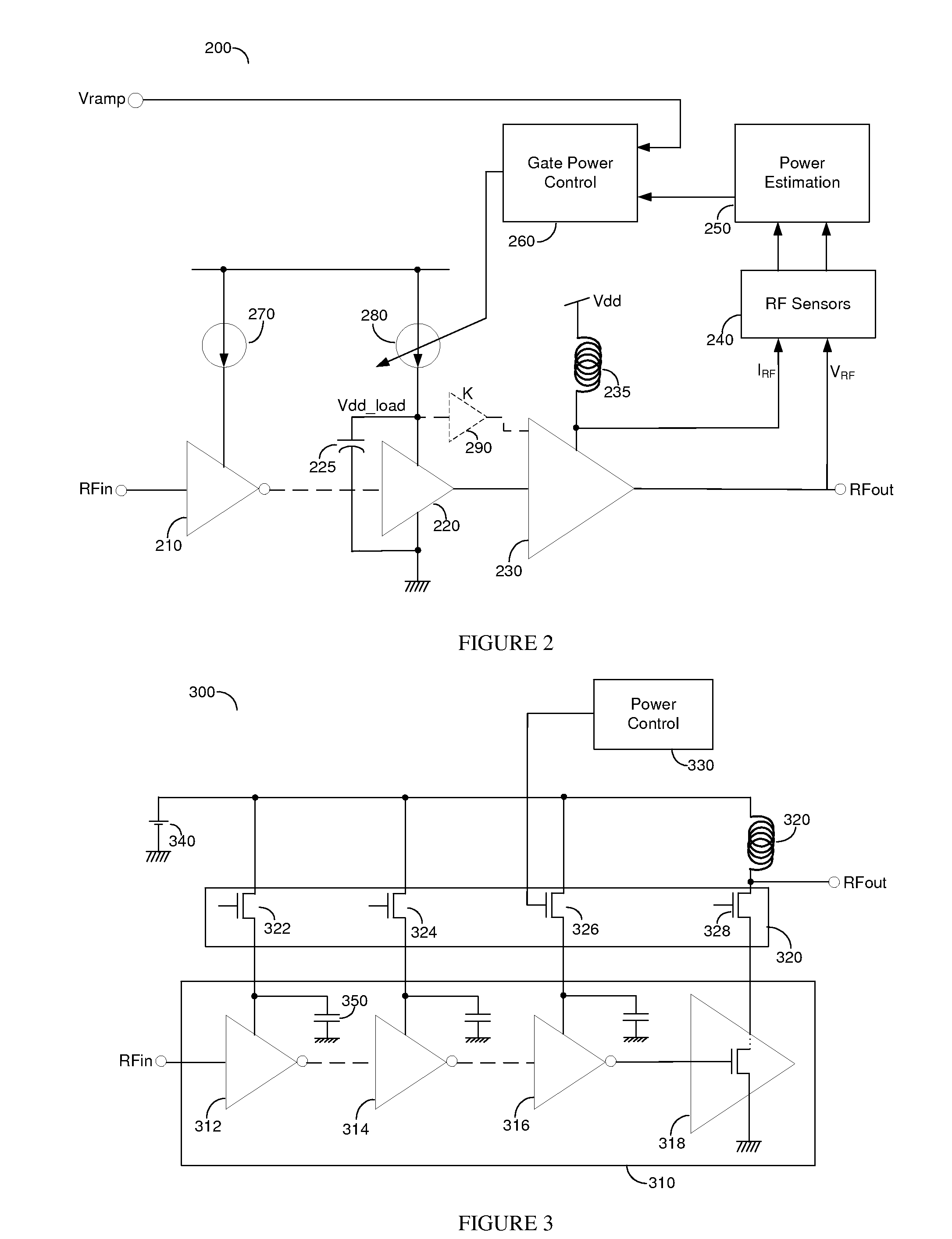

Power Amplifier System with a Current Bias Signal Path

Power amplifier (PA) systems are typically comprised of a signal path integrated circuit (IC) and a power control IC. Advanced CMOS technologies may allow smart integration of such ICs into a single IC and provide an opportunity to improve performance and cost. Specifically, the radio frequency (RF) signal path is designed to enable local biasing of the gain stages that comprise the RF signal path. By using current-mode biasing instead of the prior art voltage-mode biasing significant area reduction is achieved as well as better isolation between the stages which reduces noise, and improves stability.

Owner:QORVO INT PTE LTD

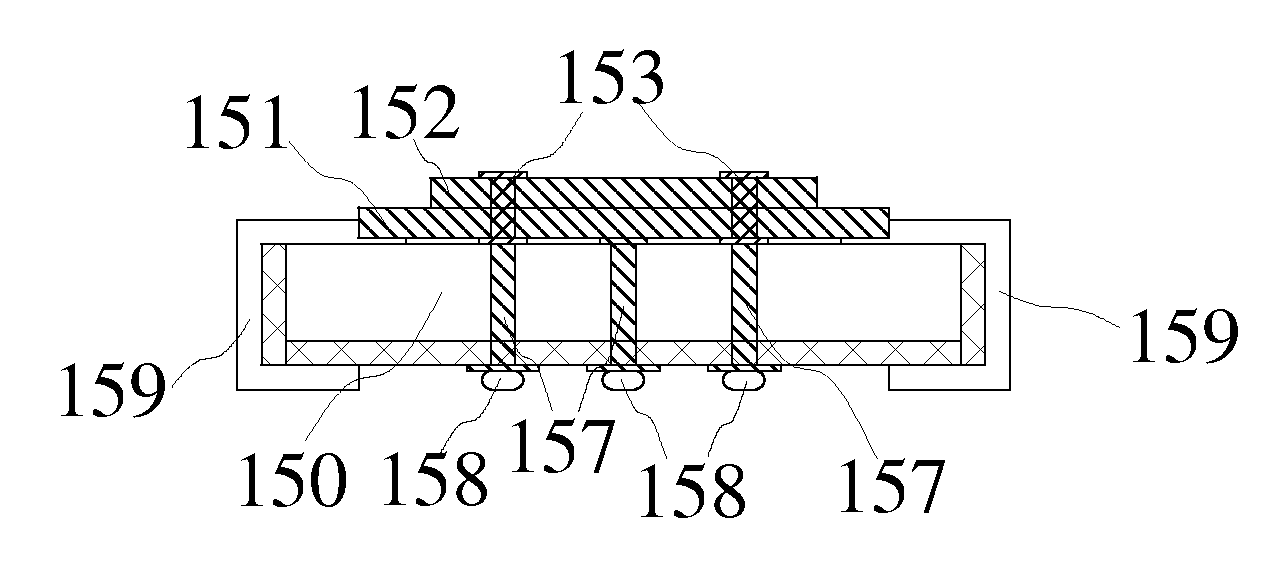

Area reduction for surface mount package chips

InactiveUS20110133337A1Reduce areaCost-effectiveSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorSurface mounting

Using side-wall conductor leads deposited on the side-walls of a base substrate to form package level conductor leads for active circuits manufactured on silicon substrate(s) stacked on the base substrate, the preferred embodiments of the present invention significantly reduces the areas of surface mount package chips. Besides area reduction, these methods also provide significant cost saving and reduction in parasitic impedance.

Owner:SHAU JENG JYE

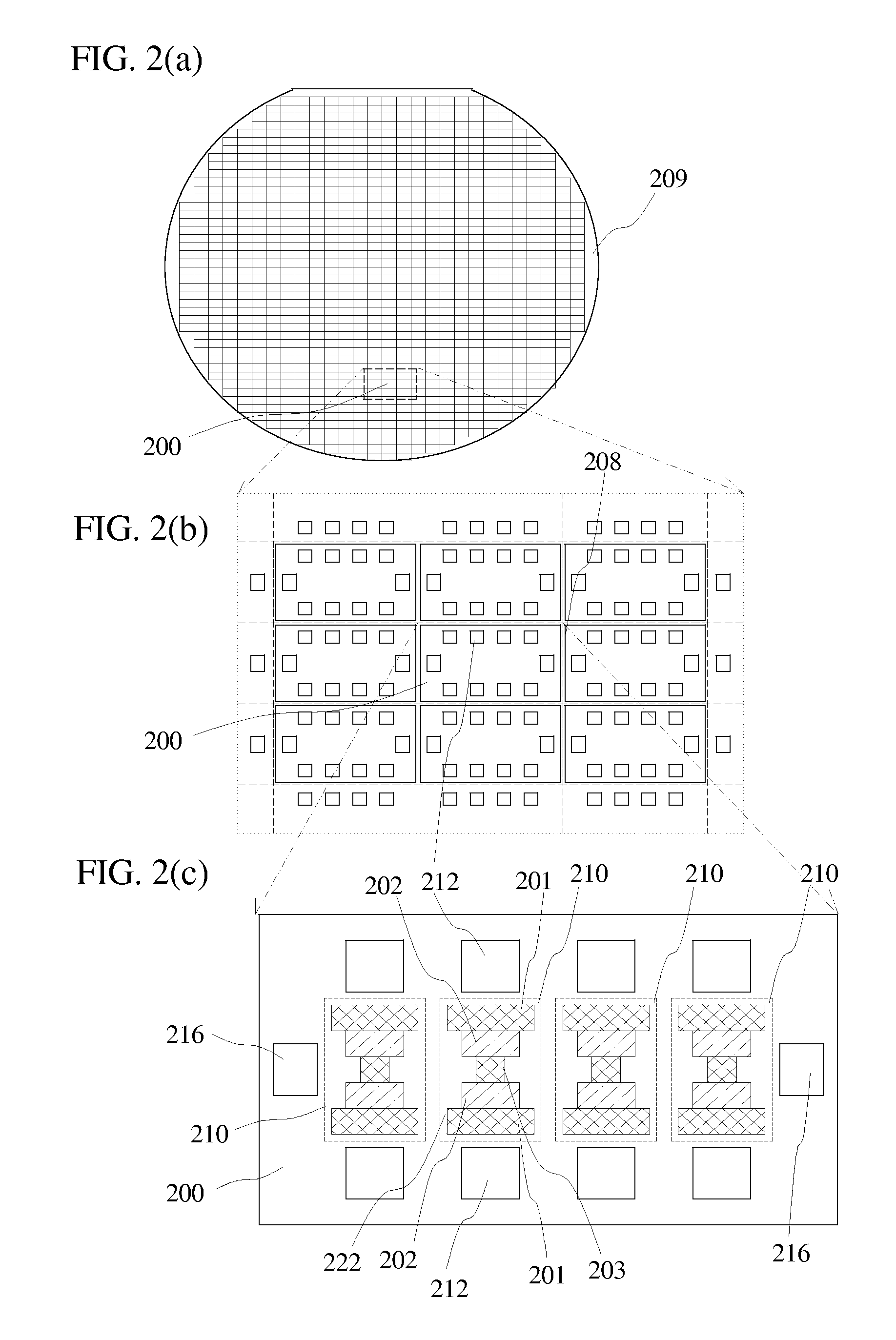

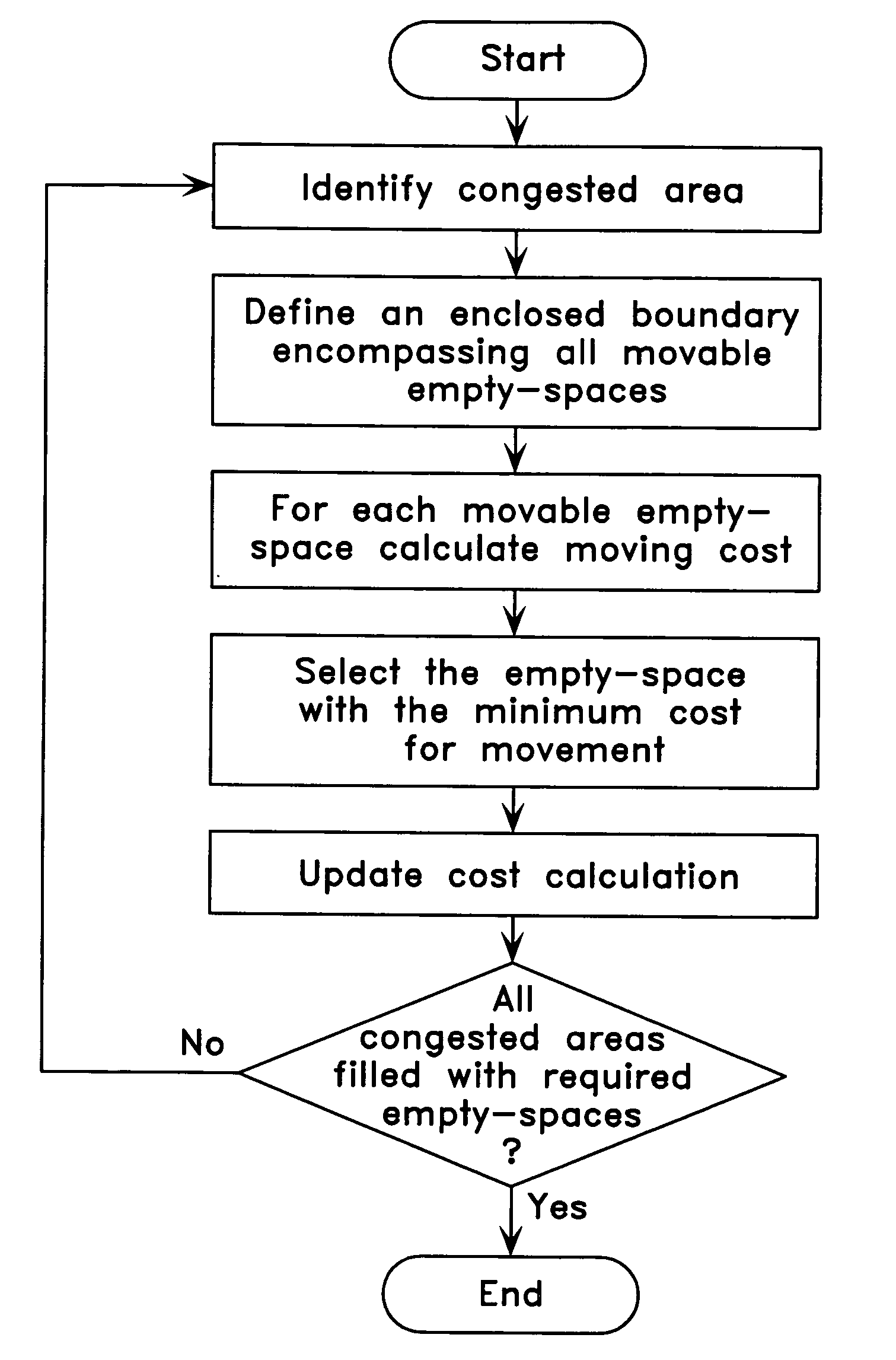

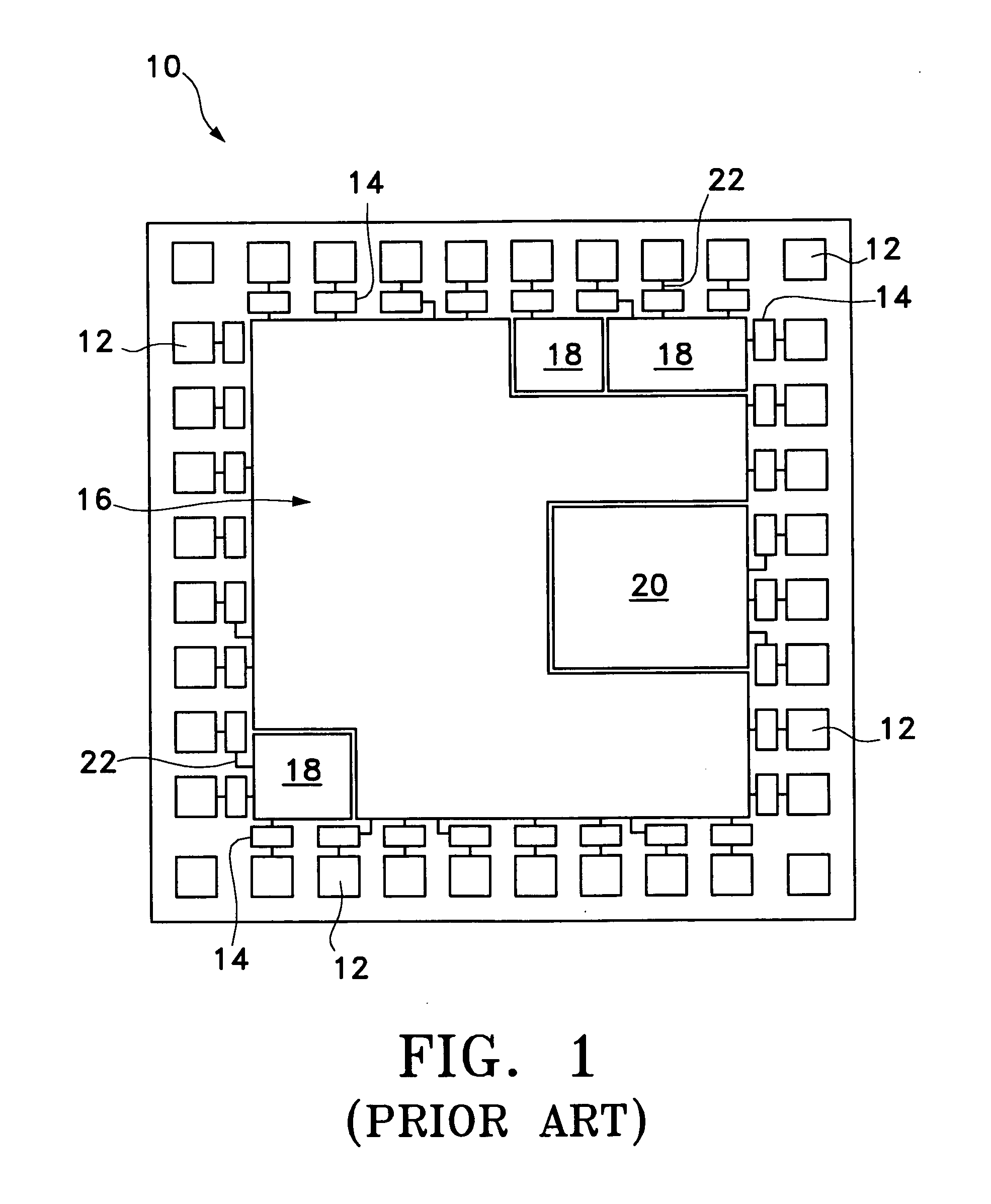

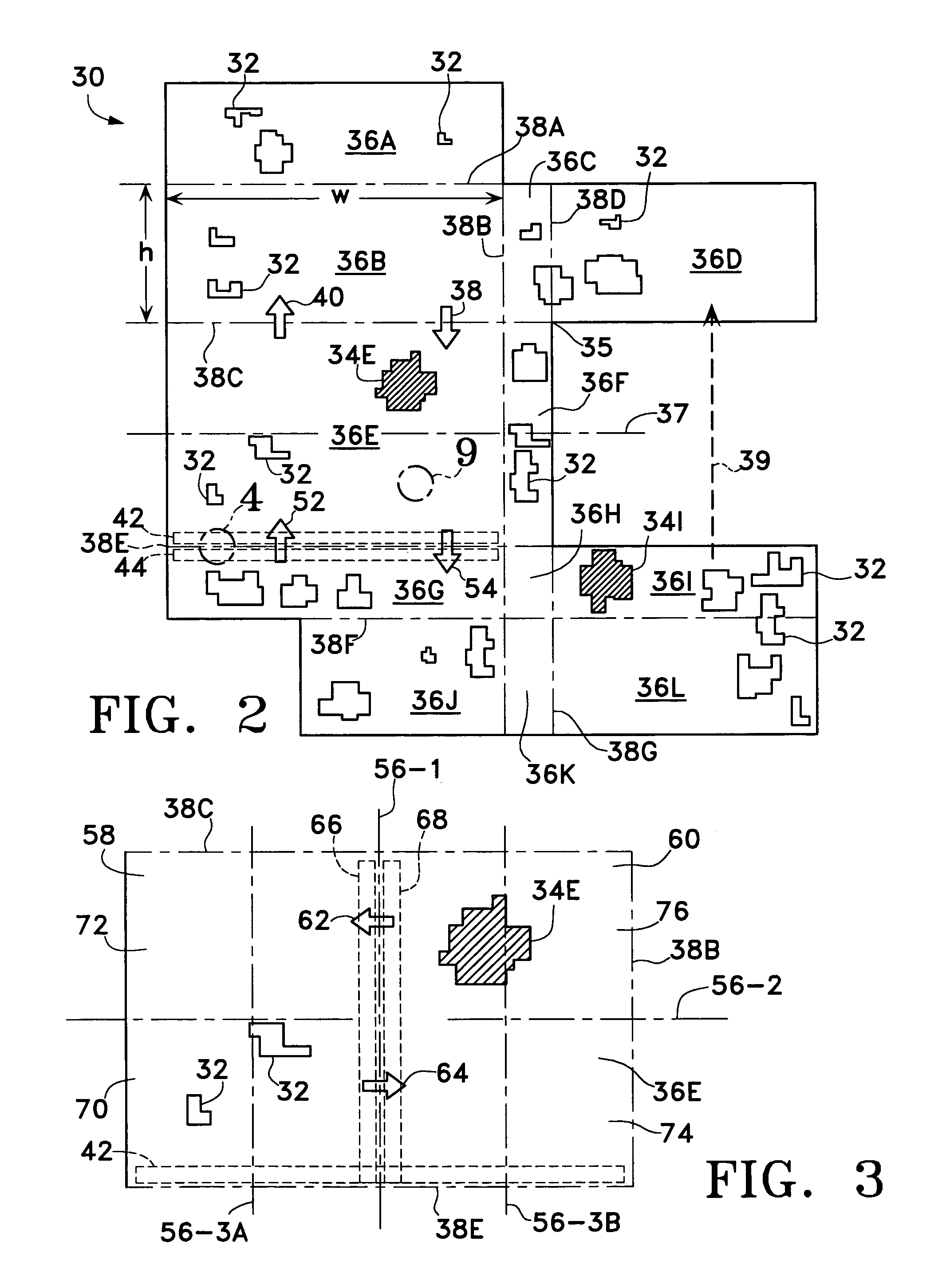

Chip-area reduction and congestion alleviation by timing-and-routability-driven empty-space propagation

InactiveUS7200827B1Reduce chip sizeDecreased routabilityMulti-objective optimisationSoftware simulation/interpretation/emulationChip sizeComputer science

An EDA (Electronic Design Automation) process which collects and moves empty-spaces among cells on a circuit layout to one or more target areas for productive use, such as chip-size reduction and routability congestion alleviation. The process includes globally moving the empty-spaces to the target area and thereafter locally moving the empty-spaces as refinement.

Owner:APEX DESIGN SYST

Heat-resisting steel material used as vane or bolt of supercritical steam turbine and preparation method thereof

InactiveCN101525726AMeet the design requirementsMeet the use requirementsBlade accessoriesScrewsChemical compositionSteam turbine blade

The invention discloses a heat-resisting steel material used as a vane or a bolt of a supercritical steam turbine. The chemical composition of the material (in percentage by weight) is: 0.12 to 0.16 percent of C, 0.30 to 0.70 percent of Mn, 0.35 to 0.65 percent of Ni, 10.0 to 11.0 percent of Cr, 0.30 to 0.5 percent of Mo, 1.5 to 1.9 percent of W, 0.14 to 0.20 percent of V, 0.05 to 0.11 percent of Nb, 0.04 to 0.08 percent of N, and the balance of Fe and impurities. The chemical property of the material is that: tensile strength sigma b is more than or equal to 930MPa; yield strength sigma 0.2 is more than or equal to 765MPa; tensile stretch delta is more than or equal to 14 percent; percentage of area reduction psi is more than or equal to 32 percent; ballistic work AKv is more than or equal to 20J; and hardness HB is between 277 and 331.

Owner:SICHUAN JIANGYOU LIUHE STEAM TURBINE MATERIAL

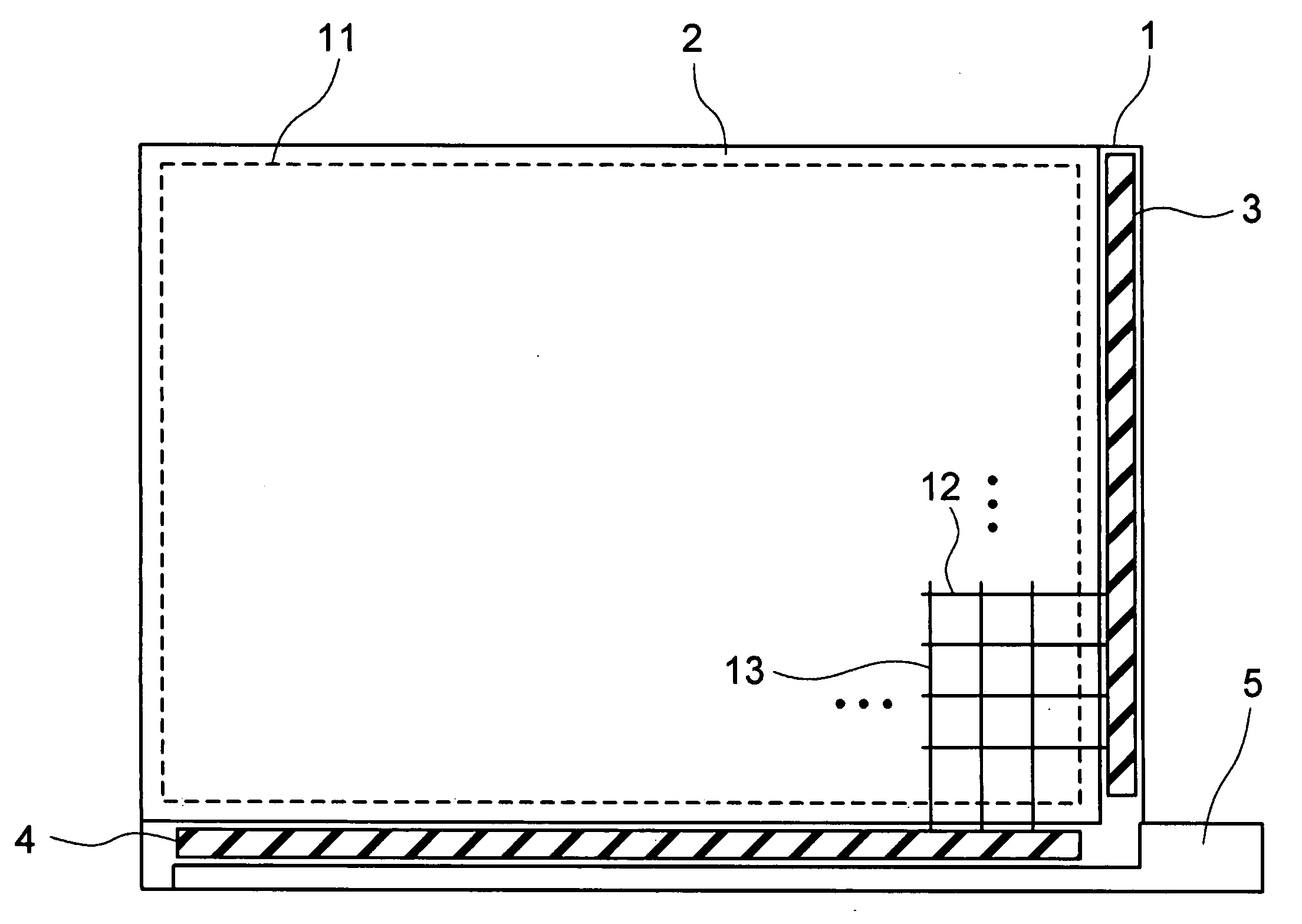

Semiconductor chip and display device using the same

ActiveUS20050205888A1Narrow frameStatic indicating devicesSemiconductor/solid-state device detailsSemiconductor chipDisplay device

To realize an area reduction of a semiconductor chip without adding a process, and to provide a semiconductor chip structure having an excellent pressure balance when mounted. In the structure of a semiconductor chip in which control / power supply lines are formed on a glass substrate, connecting terminals for electrically connecting with the control / power supply lines are provided in alignment in the longitudinal direction of the semiconductor device, whereby the wiring length within the semiconductor chip can be suppressed to be minimum. Since the wiring length is shortened, the width of the wirings within the semiconductor chip is narrowed, so that the area of the semiconductor chip is reduced.

Owner:HANNSTAR DISPLAY CORPORATION

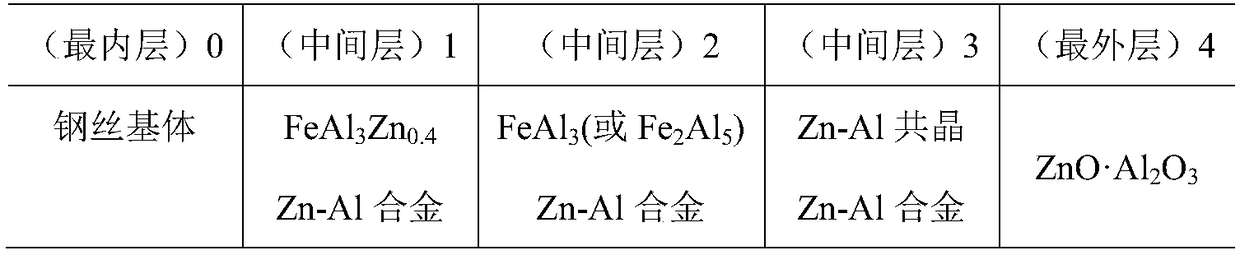

High-strength and ductility durable type large-diameter 1960 MPa stage zinc-aluminum alloy coating steel wire for bridge cable

InactiveCN108239735AHigh strengthIncreased durabilityHot-dipping/immersion processesWater bathsHigh carbon

The invention relates to a high-strength and ductility durable type large-diameter 1960 MPa stage zinc-aluminum alloy coating steel wire for a bridge cable. A steel wire rod is an ultra-pure hyper-eutectoid steel high-carbon steel wire rod obtained after sorbite treatment (water bath, lead bath and salt bath), the strength of extension is larger than or equal to 1290 MPa, the area reduction rate is larger than or equal to 30%, and the elongation is larger than or equal to 10%; and the steel wire rod is drawn into a bright steel wire with the diameter ranging from 4.90 mm to 6.90 mm, then hot galvanizing zinc-aluminum alloy coating is carried out, and technological processes include lead bath degreasing, hot water washing, chlorohydric acid pickling, hot water washing, weak base washing, hot water washing, ammonium chloride and zinc chloride solvent plating assisting, hot-dip galvanizing-nitrogen smearing, zinc-aluminum alloy hot galvanizing, nitrogen smearing and wire collecting. The steel wire rod is subject to stabilization treatment, and the strength, the linearity, the relaxation rate and the steel wire axial homogeneity of the large-diameter ultrahigh-strength Zn95Al5 alloy coating steel wire are guaranteed.

Owner:JIANGSU FASTEN STEEL CABLE CO LTD +1

ER70S-6 hot rolled wire rod and preparation method thereof

ActiveCN104498818AHigh in calciumLower calcium levelsProcess efficiency improvementWire rodThermal insulation

The invention relates to the technical field of steel and iron materials and in particular relates to an ER70S-6 hot rolled wire rod and a preparation method thereof. In the process steps, deoxidation treatment is performed on the liquid steel by use of a non-calcium alloy material to avoid the increase of the calcium content in the steel, and furthermore, splashing in the process of welding is avoided. The carbon content in the steel is reduced so that the strength of the wire rod can be reduced; the percentage of area reduction and the percentage elongation of the wire rod are increased, in other words, the plasticity of the wire rod is improved, and consequently, the wire rod can be drawn into a welding wire directly without annealing and the production cost of a welding wire factory is reduced; besides, in the preparation process, the quality of the ER70S-6 hot rolled wire rod is improved by controlling the contents of various elements, such as carbon, silicon and magnesium, so that the welding property of the welding wire is improved; in the cooling process of rolling, draught fans on an air cooling line are all turned off and thermal insulation covers are all closed so that the highest tensile strength of the wire rod does not exceed 550MPa and the plasticity of the wire rod is good.

Owner:SHOUGANG SHUICHENG IRON & STEEL GRP

Steel wire for reinforcement of rubber articles, method of manufacturing the same, and steel cord using the same

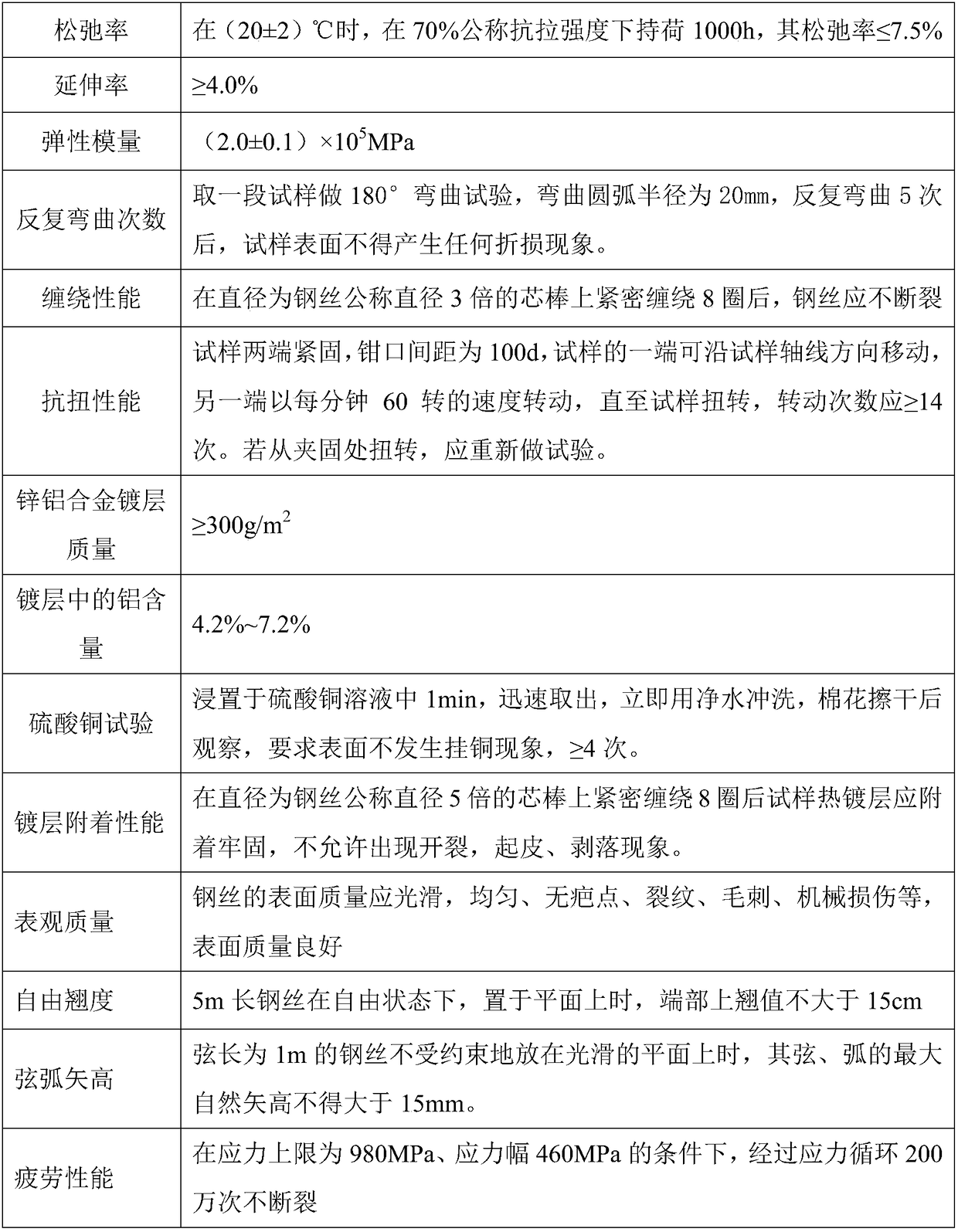

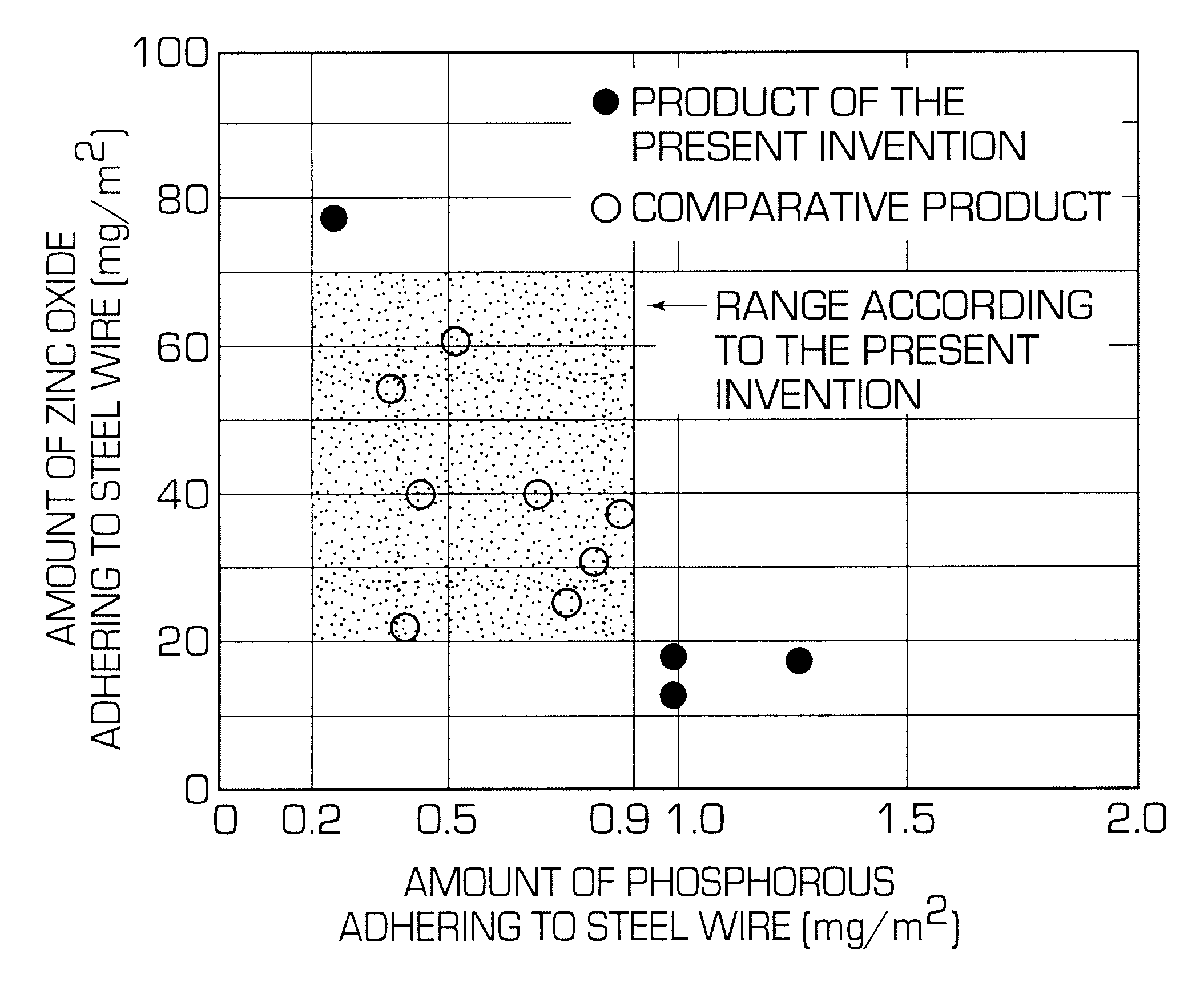

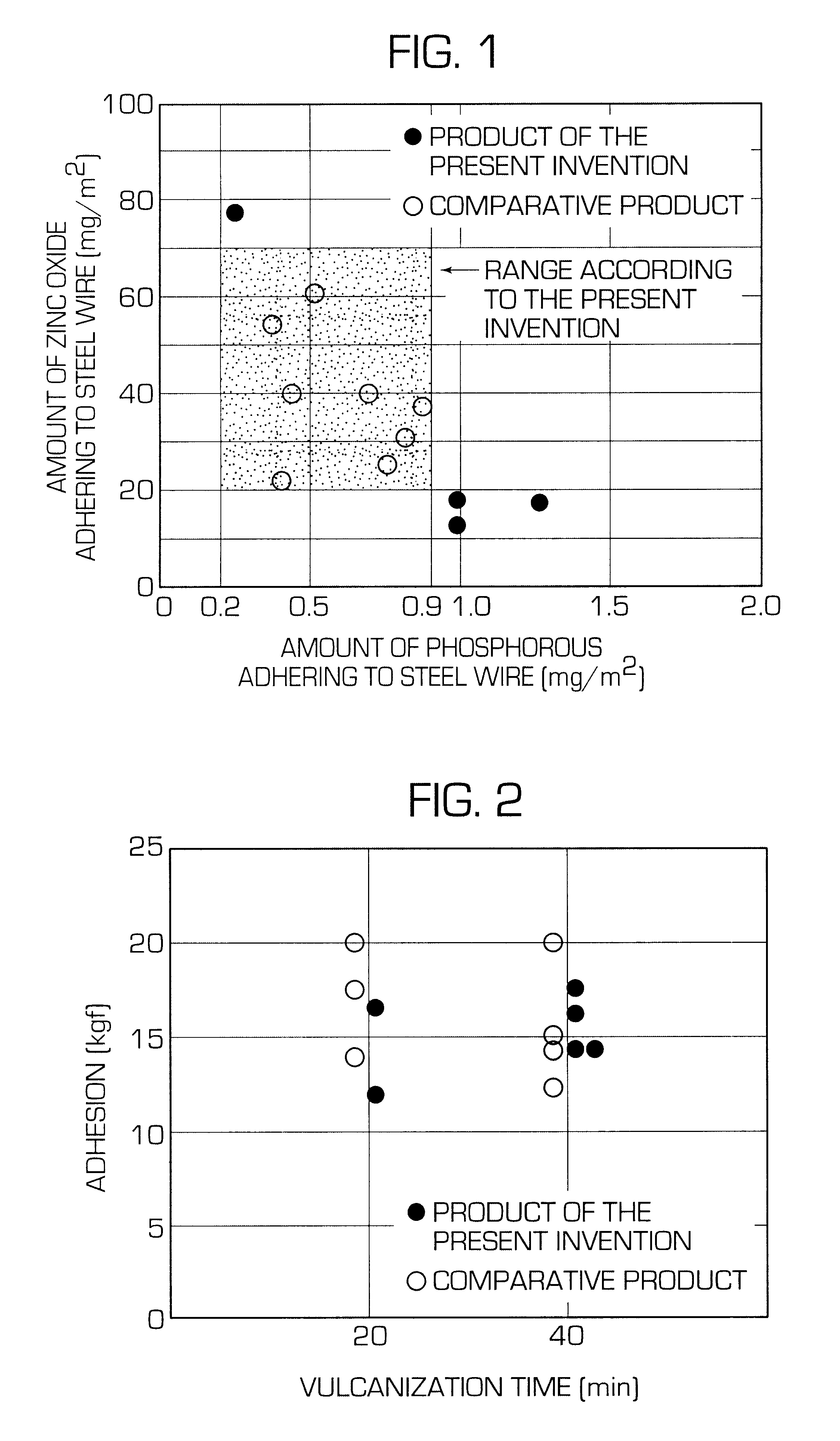

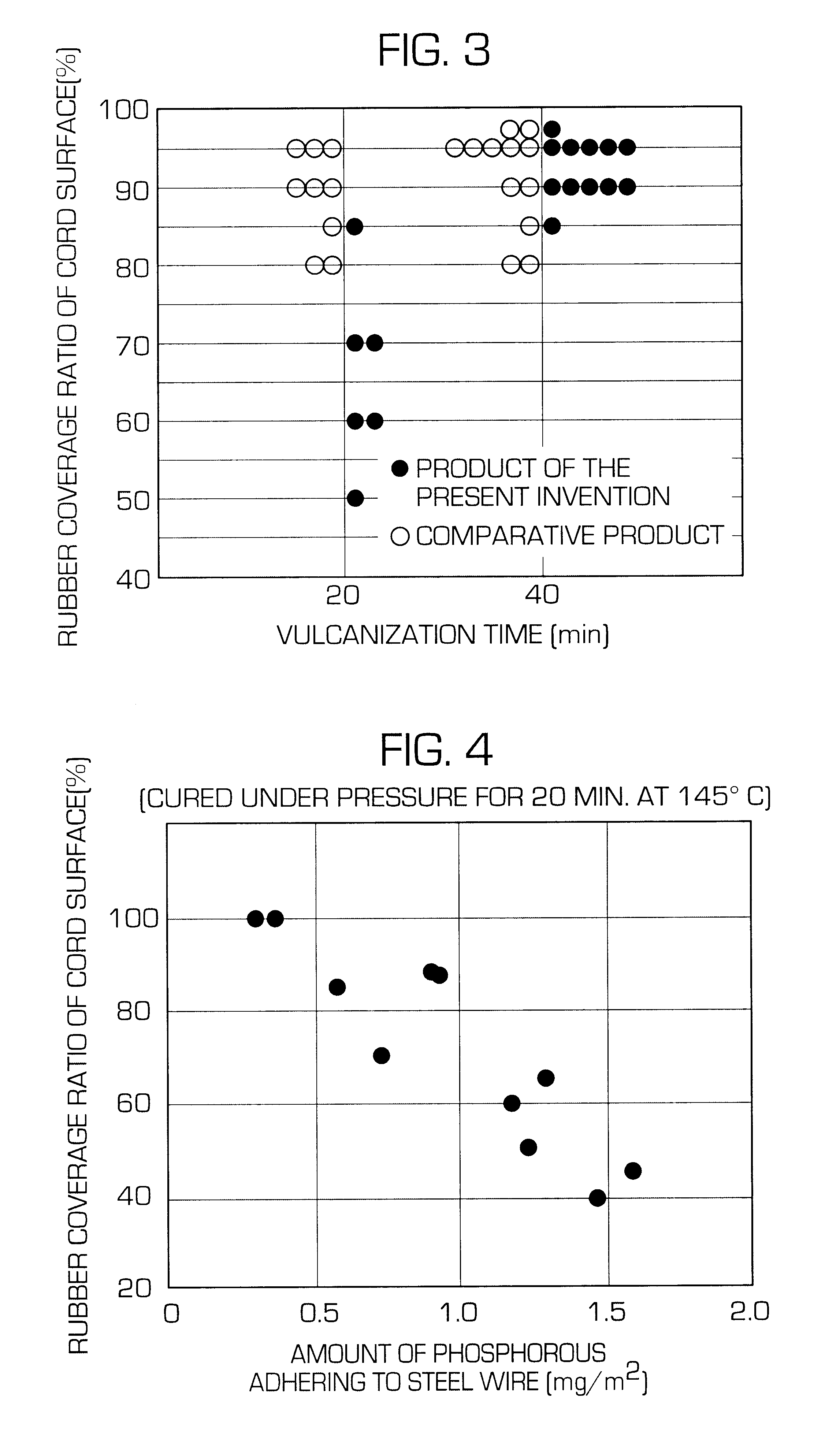

A method of manufacturing steel wire for reinforcement of rubber articles comprises the steps of passing a wire rod plated with brass, through a group of dies immersed in a lubricant containing phosphate in continuous wet processing, winding the resulting steel wire around a spool, mounting the spool on a pay of unit of a twister assembly, and drawing the steel wire by the use of one or more dies arranged between the pay of unit and twisting unit of the twister assembly and having an area reduction per die of at least 5%, to reduce the diameter of the steel wire. Phosphor compound in the coating film formed on the brass plating of the steel wire contains phosphor in the range of 0.2 to 0.9 mg / m2 and zinc oxide in the range of 20.0 to 70.0 mg / m2. Also, provided is a steel cord which comprises twisted steel wires. The initial adhesion of the steel wire or steel cord for reinforcement of rubber articles to rubber is well and economically improved, shortening the curing time and enabling economical production of rubber products.

Owner:BRIDGESTONE CORP

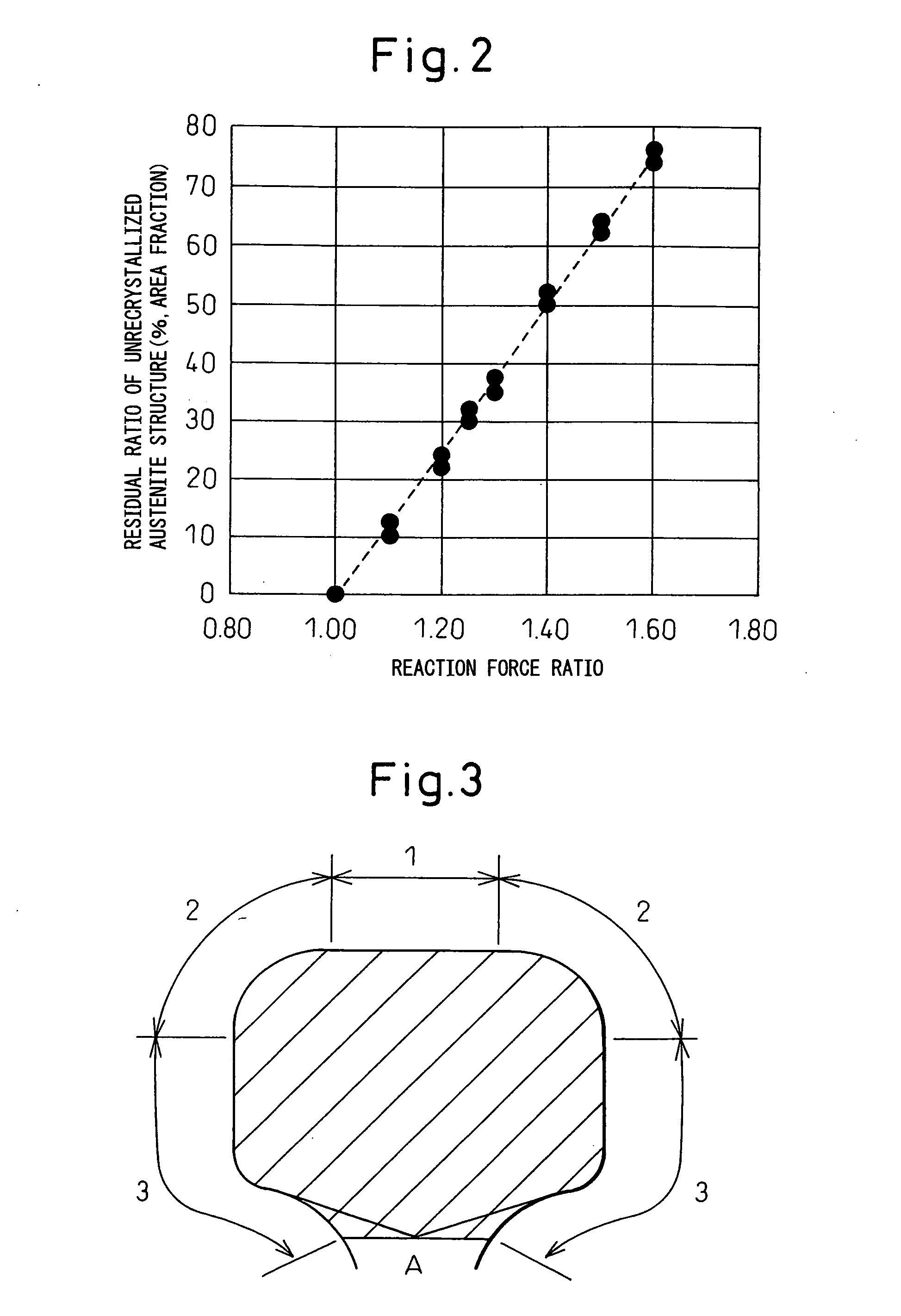

Method for producing pearlitic rail excellent in wear resistance and ductility

ActiveUS20090314049A1Improve ductilityImprove wear resistanceShaping toolsFurnace typesHardnessPearlite

The invention provides a method for producing a pearlitic rail by subjecting to at least rough hot rolling and finish hot rolling a billet comprising, in mass %, C: 0.65-1.20%, Si: 0.05-2.00%, Mn: 0.05-2.00%, and a remainder of iron an unavoidable impurities, wherein the finish hot rolling is conducted by rolling at a rail head surface temperature in a range of not higher than 900° C. to not lower than Ar3 transformation point or Arcm transformation point to produce a head cumulative reduction of area of not less than 20% and a reaction force ratio of not less than 1.25, and the finish hot rolled rail head surface is subjected to accelerated cooling or spontaneous cooling to at least 550° C. at a cooling rate of 2 to 30° C. / sec, thereby refining the rail head structure to attain a hardness within a predetermined range and improving rail wear resistance and ductility.

Owner:NIPPON STEEL CORP

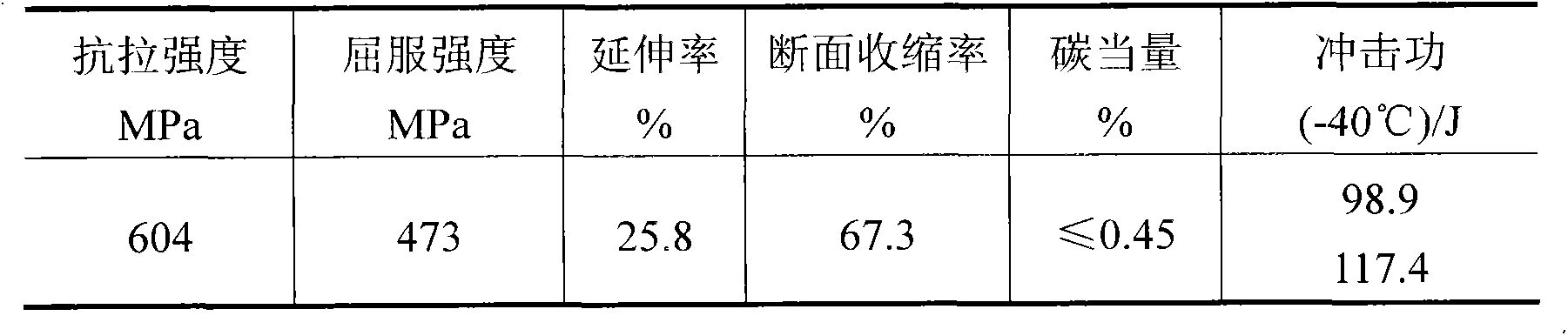

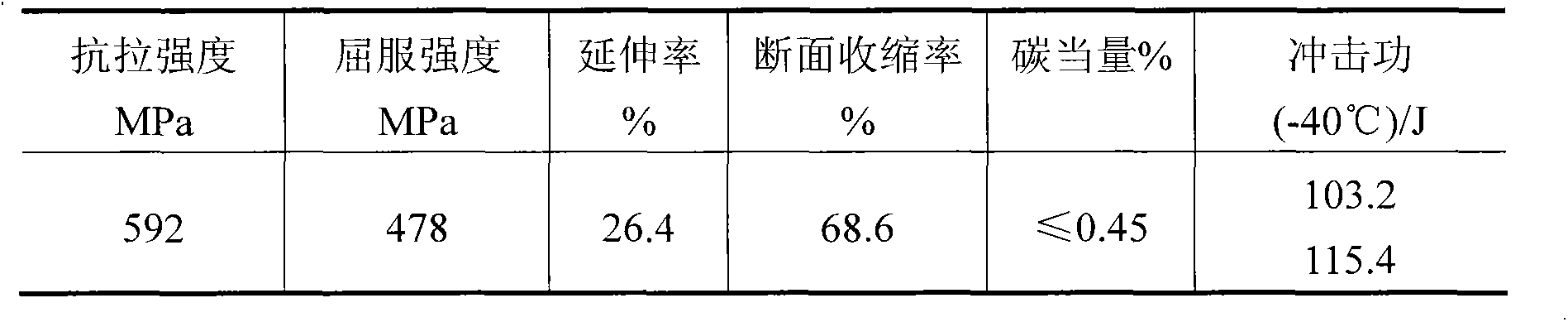

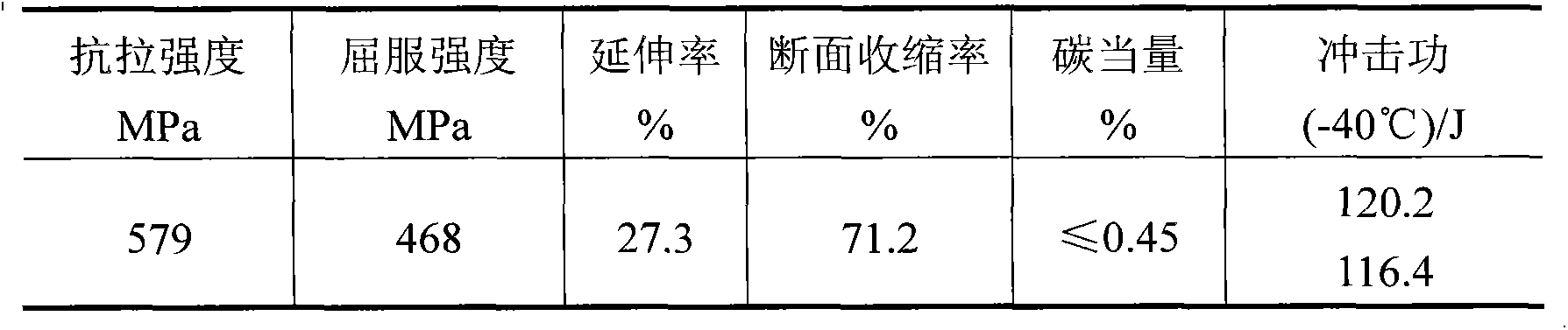

Low-alloy high-strength cast steel for low temperature and preparation method thereof

InactiveCN103194687AEasy to useSufficient low temperature toughnessManganeseArgon oxygen decarburization

The invention discloses a low-alloy high-strength cast steel for low temperature, and the cast steel comprises the following components in percentage by weight: 0.10%-0.15% carbon, 0.30%-0.60% of manganese, 0.10%-0.50% of silicon, 0%-0.015% of phosphorus, 0%-0.025% of sulfur, 1.0%-1.4% of nickel, 0.20%-0.35% of chromium, 0.20%-0.35% of molybdenum, 0.03%-0.06% of vanadium, 0%-0.01% of copper, 0%-0.08% of aluminum and the balance of iron. The low-alloy high-strength cast steel is prepared through electric furnace and argon oxygen decarburization duplex smelting and pouring and normalizing and high-temperature tempering treatment. The cast steel disclosed by the invention achieves the tensile strength of 570-590 Mpa, the yield strength of 460-475 MPa, the elongation percentage of 25%-27%, the area reduction percentage of 67%-70%, the carbon equivalent less than or equal to 0.45% and the impact energy of 110J at -40 DEG C, has the advantages of high strength, good toughness, excellent low-temperature toughness and welding property especially, less alloy element addition, simple heat treatment process and lower cost and is especially suitable for manufacturing high-strength steel casting materials which have severe requirements on low-temperature toughness and welding.

Owner:CENT SOUTH UNIV

Method for manufacturing free-cutting stainless steel wire for ball-point pen head

The invention discloses a method for manufacturing the free-cutting stainless steel wire for a ball-point pen head, comprising the following steps: (1) treating the skin film; (2) drying; (3) drawing for the first time and carrying out bright annealing on line for the first time, wherein the area-reduction rate during drawing for the first time is 40-60%, the temperature of carrying out bright annealing on line for the first time is 700-900 DEG C, and the annealing speed is 3-9m / min; (4) drawing for the second time and carrying out bright annealing on line for the second time, wherein the area-reduction rate during drawing for the second time is 40-60%, the temperature of carrying out bright annealing on line for the second time is 700-900 DEG C, and the annealing speed is 5-12m / min; and (5) drawing for the third time, wherein the area-reduction rate during drawing for the third time is 25-45%. The free-cutting stainless steel wire manufactured by the method has a bright surface, is free from the defects of black and yellow lines, drawing stamps, cracks, folding lines, peeling and the like and has the following mechanical properties: the yield strength of 500-800N / mm<2>, the tensile strength of 700N / mm<2> or higher, the elongation of 3-6% and the hardness value (HV) of 240-280.

Owner:NINGBO BEIFA GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com