Production method of high-strength and long-fatigue-life spring steel

A fatigue life and production method technology, applied in the field of metallurgy, can solve the problems of inability to meet ultra-high cycle fatigue life, poor plastic deformation of inclusions, influence of plastic deformation ability of inclusions, etc., to increase investment and production costs, and reduce alloy content. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

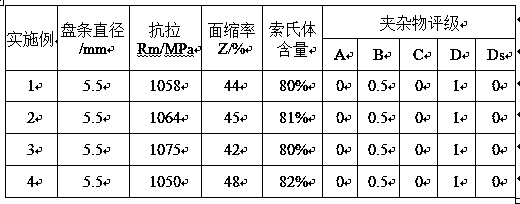

example 1

[0024] The production method of high-strength and high-fatigue life spring steel, the chemical composition of steel is: carbon=0.56%, silicon=1.45%, manganese=0.62%, phosphorus=0.009%, sulfur=0.010%, aluminum=0.004%, Chromium = 0.68%, titanium = 0.0033%, niobium = 0.013%, and the rest is Fe and unavoidable impurities.

[0025] Smelting: Converter tapping [P]=0.006%, [C]=0.10%, using LF+VD refining process, LF furnace refining process argon blowing, slag deoxidation, first add 500kg of alkaline slag, then add acid slag 160kg, refining slag alkalinity CaO / SiO 2 =1.2; VD vacuum degassing treatment, the vacuum degree is below 0.5tor, the vacuum holding time is 21min, the outbound molten steel [H]=1.7ppm, and the constant [O]=15ppm;

[0026] Continuous casting: full protection casting is adopted, the superheat of the tundish is 28°C, the fluctuation of the liquid level is controlled at ±2.5%, the size of the slab is 150*150mm; the slab [N]=35ppm.

[0027] The surface of the slab ...

example 2

[0030] The production method of high-strength and high-fatigue life spring steel, the chemical composition of the steel is: carbon = 0.56%, silicon = 1.42%, manganese = 0.65%, phosphorus = 0.008%, sulfur = 0.011%, aluminum = 0.0041%, Chromium = 0.69%, titanium = 0.0044%, niobium = 0.005%, and the rest is Fe and unavoidable impurities.

[0031] Smelting: Converter tapping [P]0.007%, [C]0.11%, using LF+VD refining process, LF furnace refining the whole process of argon blowing, slag deoxidation, first add 520Kg of basic slag, then add 165kg of acidic slag, Basicity of refining slag CaO / SiO 2 =1.1; VD vacuum degassing treatment, when the vacuum degree is below 0.5tor, the vacuum holding time is 20min, the outbound molten steel [H] 1.6ppm, [O] 11ppm; The surface fluctuation is controlled at ±2.8%, and the billet size is 150mm×150mm. Slab [N]=34ppm.

[0032] The surface of the billet is first polished with pellets, and then the defect mark is detected by magnetic particle inspec...

example 3

[0035] The production method of high-strength and high-fatigue life spring steel, the chemical composition of the steel is: carbon=0.58%, silicon=1.47%, manganese=0.63%, phosphorus=0.0010%, sulfur=0.008%, aluminum=0.0047%, Chromium = 0.69%, titanium = 0.0046%, niobium = 0.007%, and the rest is Fe and unavoidable impurities.

[0036] Smelting: Converter tapping [P]=0.009%, [C]=0.08%, using LF+VD refining process, LF furnace refining whole process of argon blowing, slagging and deoxidation, adding 480kg of basic slag first, then adding acidic slag 180kg, refining slag alkalinity CaO / SiO 2 =1.0; VD vacuum degassing treatment, when the vacuum degree is below 0.5tor, the vacuum holding time is 20min, the outbound molten steel [H]=1.1ppm, [O]=11ppm; continuous casting adopts full protection casting, and the superheat of the tundish is 27℃ , the liquid level fluctuation is controlled at ±2.9%, the billet size is 150mm×150mm, and the billet [N]=31ppm.

[0037] Polish the surface of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com