Patents

Literature

4384 results about "Alkalinity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alkalinity (from Arabic "al-qalī") is the capacity of water to resist changes in pH that would make the water more acidic. (It should not be confused with basicity which is an absolute measurement on the pH scale.) Alkalinity is the strength of a buffer solution composed of weak acids and their conjugate bases. It is measured by titrating the solution with a monoprotic acid such as HCl until its pH changes abruptly, or it reaches a known endpoint where that happens. Alkalinity is expressed in units of meq/L (milliequivalents per liter), which corresponds to the amount of monoprotic acid added as a titrant in millimoles per liter.

Stable solid block detergent composition

InactiveUS6177392B1Fit tightlyEasy to cleanInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsAlkalinityIndustrial setting

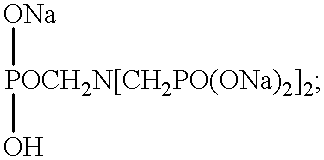

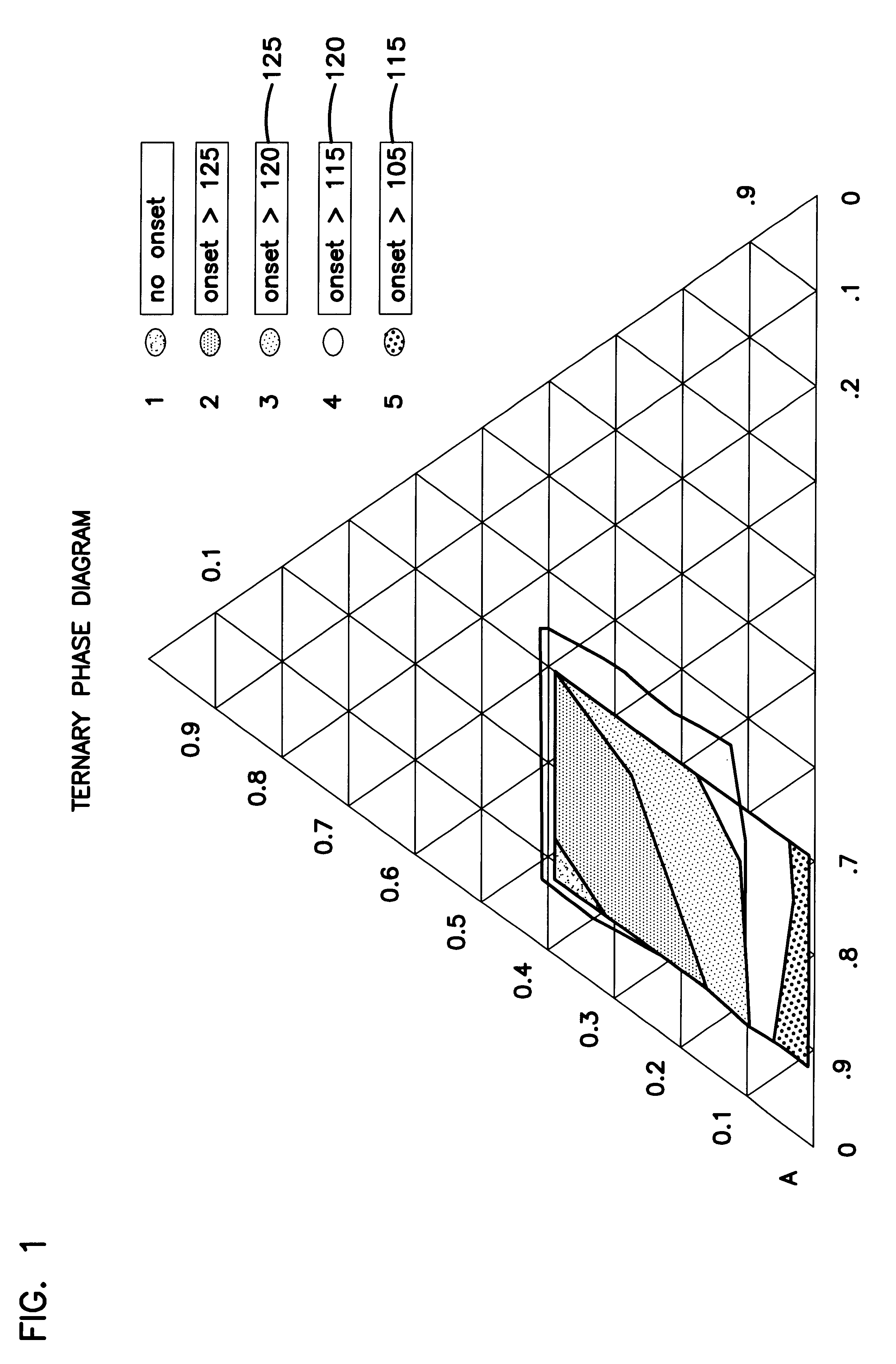

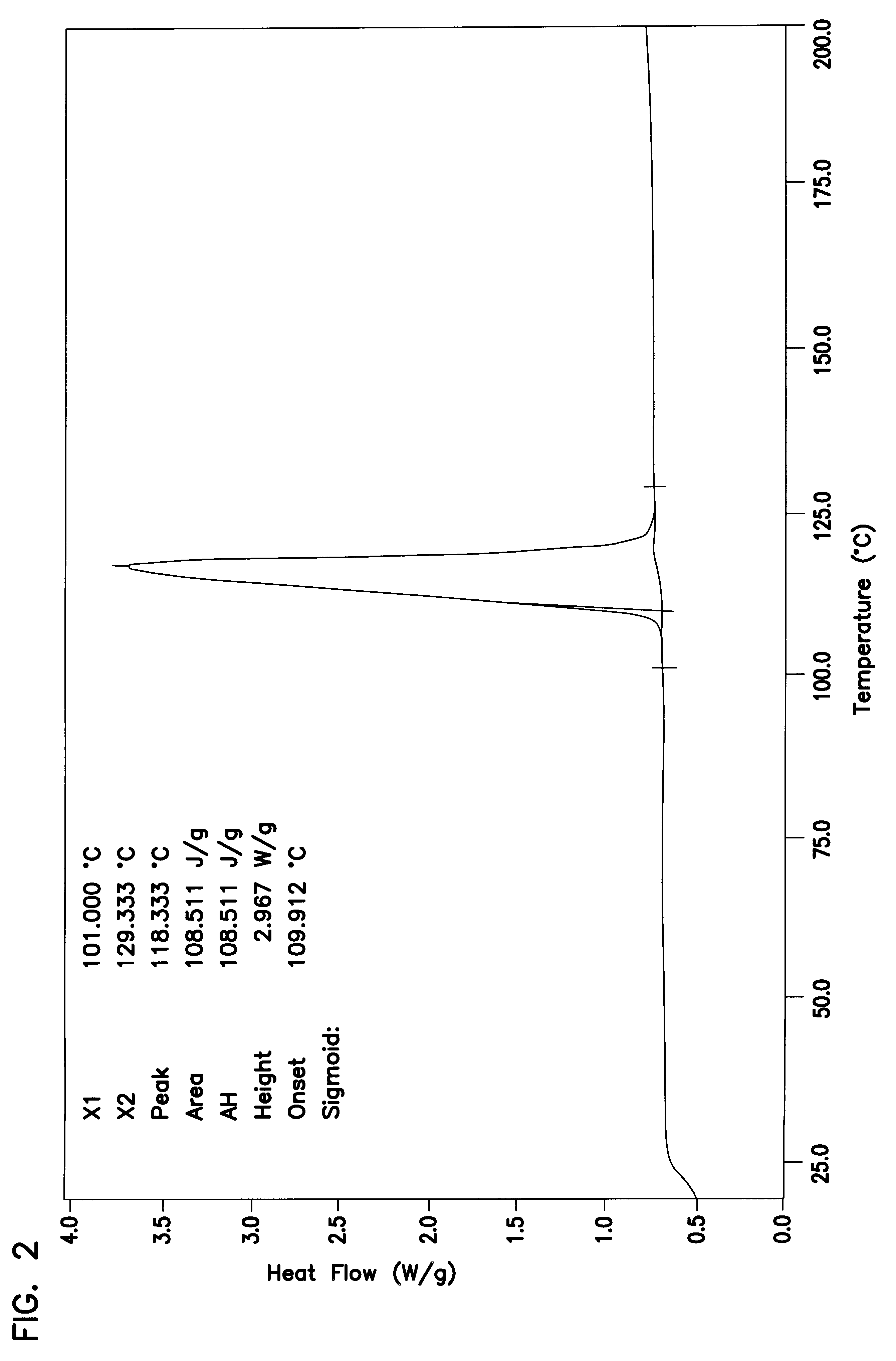

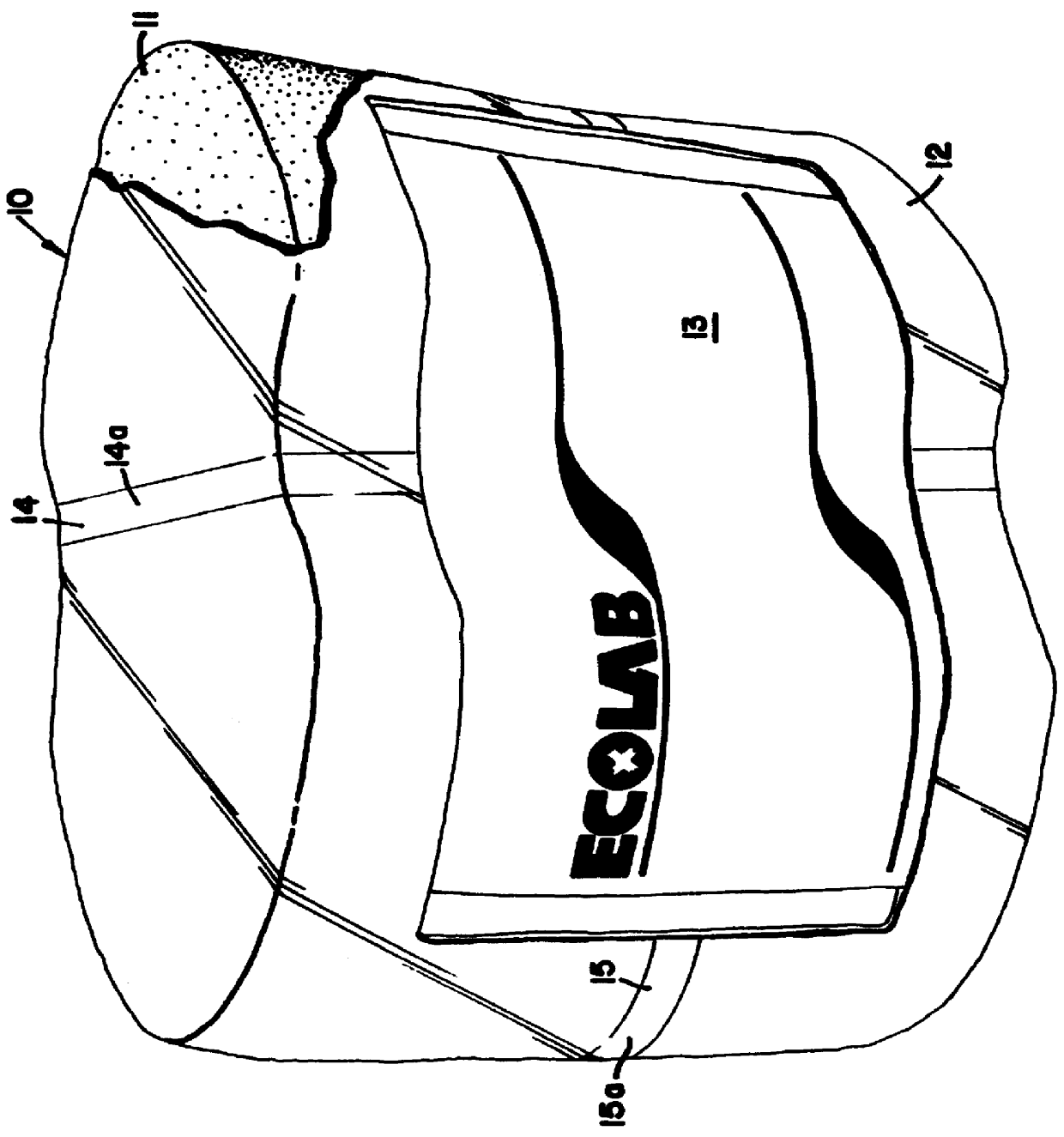

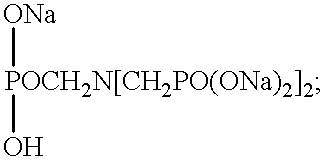

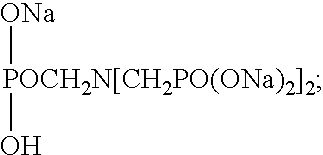

The dimensionally stable alkaline solid block warewashing detergent uses an E-form binder forming a solid comprising a sodium carbonate source of alkalinity, a sequestrant, a surfactant package and other optional material. The solid block is dimensionally stable and highly effective in removing soil from the surfaces of dishware in the institutional and industrial environment. The E-form hydrate comprises an organic phosphonate and a hydrated carbonate.

Owner:ECOLAB USA INC

Stable solid block metal protecting warewashing detergent composition

InactiveUS6156715AFit tightlyEasy to cleanInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsAlkalinityIndustrial setting

The dimensionally stable alkaline solid block warewashing detergent uses an E-form binder forming a solid comprising a sodium carbonate source of alkalinity, a metal corrosion protecting alkali metal silicate composition, a sequestrant, a surfactant package and other optional material. The solid block is dimensionally stable and highly effective in removing soil from the surfaces of dishware in the institutional and industrial environment. The E-form hydrate comprises an organic phosphonate and a hydrated carbonate.

Owner:ECOLAB USA INC

Alkaline detergent containing mixed organic and inorganic sequestrants resulting in improved soil removal

InactiveUS6150324ASoften waterImprove organic soil removal propertyInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsWater useAlkalinity

Solid block alkaline detergent compositions are disclosed comprising a source of alkalinity, and other detergent additives including sequestrants. The solid block detergents of the invention used a mixed inorganic and organic sequestrant composition that successfully softens service water used in manufacturing aqueous detergents from the composition, but also obtains substantially improved organic soil removal on dishware or flatware. The solid block detergents of the invention comprise large masses of the chemical ingredients having a weight of greater than about 500 grams in a solid block product format that is typically dispensed using a spray on water dispenser that creates an aqueous concentrate that is used in a washing machine.

Owner:ECOLAB USA INC

Stable solid block metal protecting warewashing detergent composition

InactiveUS6410495B1Easy to cleanImprove decontamination abilityInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsAlkalinityIndustrial setting

Owner:ECOLAB USA INC

Stable solid block detergent composition

InactiveUS6583094B1Easy to cleanImprove decontamination abilityInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsAlkalinityIndustrial setting

The dimensionally stable alkaline solid block warewashing detergent uses an E-form binder forming a solid comprising a sodium carbonate source of alkalinity, a sequestrant, a surfactant package and other optional material. The solid block is dimensionally stable and highly effective in removing soil from the surfaces of dishware in the institutional and industrial environment. The E-form hydrate comprises an organic phosphonate and a hydrated carbonate.

Owner:ECOLAB USA INC

Method for selectively combining multiple membranes for assembly into test strips

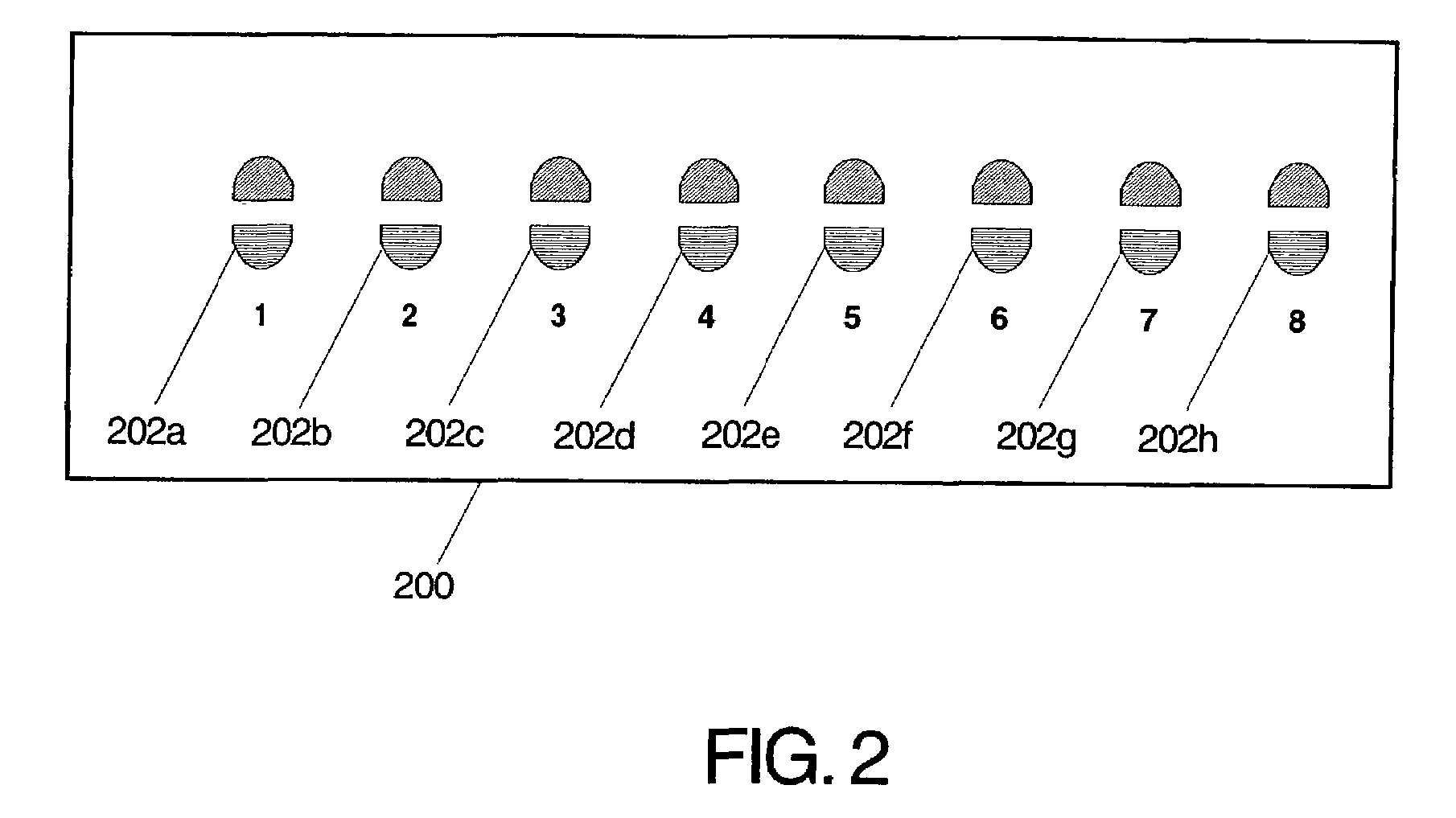

ActiveUS7129038B2Improve performanceReduce test strip lot rejectionBioreactor/fermenter combinationsBiological substance pretreatmentsCholesterolKetone

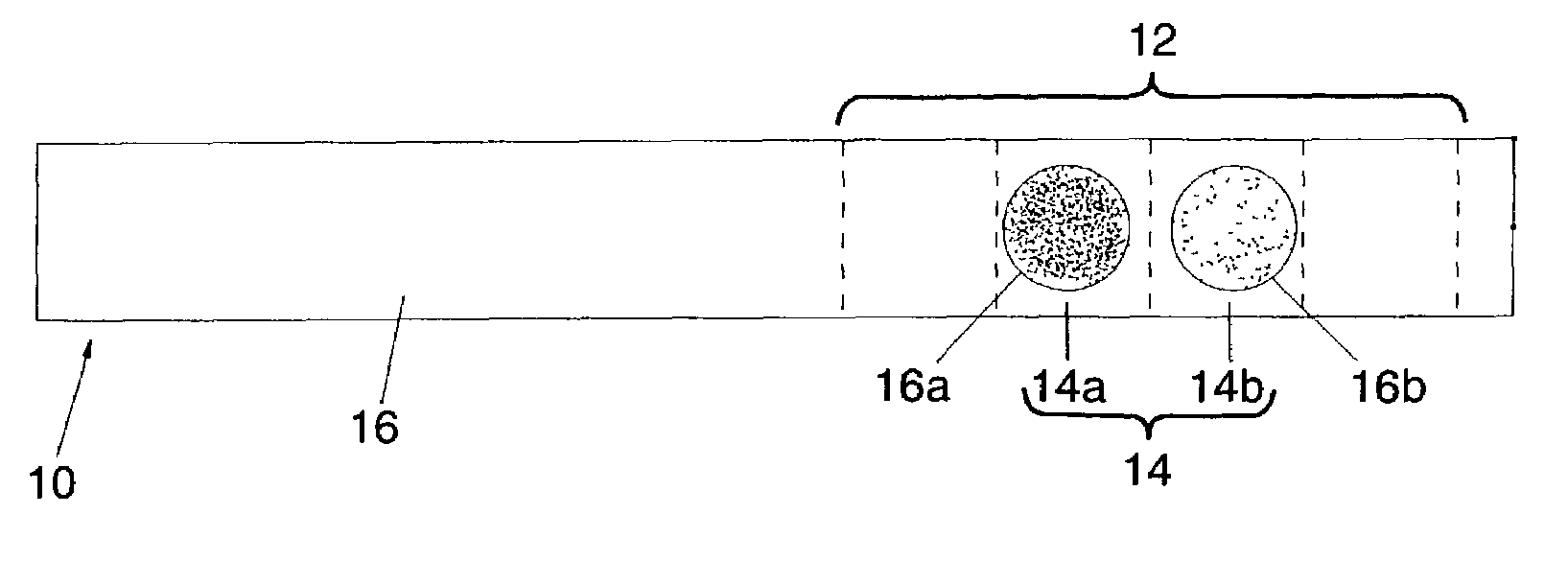

A method for selectively combining multiple membranes for assembly into test strips (such as visual blood glucose test strips with side-by-side membranes). The method includes first measuring a plurality of color parameters (e.g., L*, a* and b*color parameters) associated with membrane samples from at least two membrane lots. Next, response characteristics (e.g., blood glucose response levels) are simulated for a speculative test strip that includes, for purposes of the simulation, combined multiple membranes tentatively selected from the at least two membrane lots. The simulated response characteristics are based on the measured plurality of color parameters of the tentative selection of combined multiple membranes. Optionally, the simulated response characteristics can also be based on simulated color parameters of the tentative selection of combined multiple membranes. Subsequently, assembly of the at least two membrane lots into a test strip with combined membranes is contingent on acceptable simulated response characteristics. Any suitable color parameters can be employed. The method can be used to selectively combine two or more membranes based on any number of color parameters. The assembled test strips can be used to measure glucose, cholesterol, proteins, ketones, phenylalanine or enzymes in blood, urine, saliva or other biological fluid, as well as sample fluid characteristics (e.g., pH and alkalinity).

Owner:LIFESCAN IP HLDG LLC

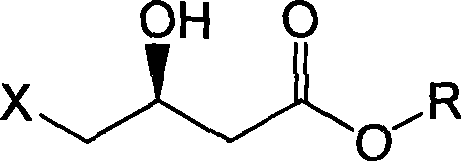

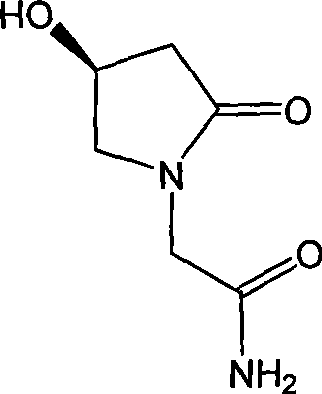

Preparation method for (S)-4-hydroxyl-2-oxo-1-pyrrolidine ethanamide

The present invention provides a preparation method of (S)-4-hydroxyl-2-oxo-1-pyrrolidine acetamide. The preparation method comprises: (S)-4-halogen-3-hydroxyl butyric ester as a raw material reacts under the conditions with polar solvent and alkalinity to prepare the crude product of (S)-4-hydroxyl-2-oxo-1-pyrrolidine acetamide; and the crude product is purified. The preparation method is characterized in that inorganic alkali is added for a plurality of times in the reaction process under the condition with alkalinity so as to control the pH value in the reaction to be less than or equal to 8.5. A large quantity of repeated tests are completed to determine that the optimum pH value of the reaction under the condition with alkalinity is less than or equal to 8.5, and the alkali is added in batches to strictly control the pH value of the whole reaction process, so that the alkali conditions required in the reaction can be satisfied and the reaction can be performed completely, and the target product (S)-oxiracetam is prevented from being damaged in the alkaline solution, thereby improving the yield rate of the target product (S)-oxiracetam and reducing the cost.

Owner:CHONGQING RUNZE PHARM CO LTD

Catalyzer used for low carbon alkane catalytic dehydrogenation and method of manufacturing propylene by paraffin hydrocarbons catalytic dehydrogenation with the same as catalyzer

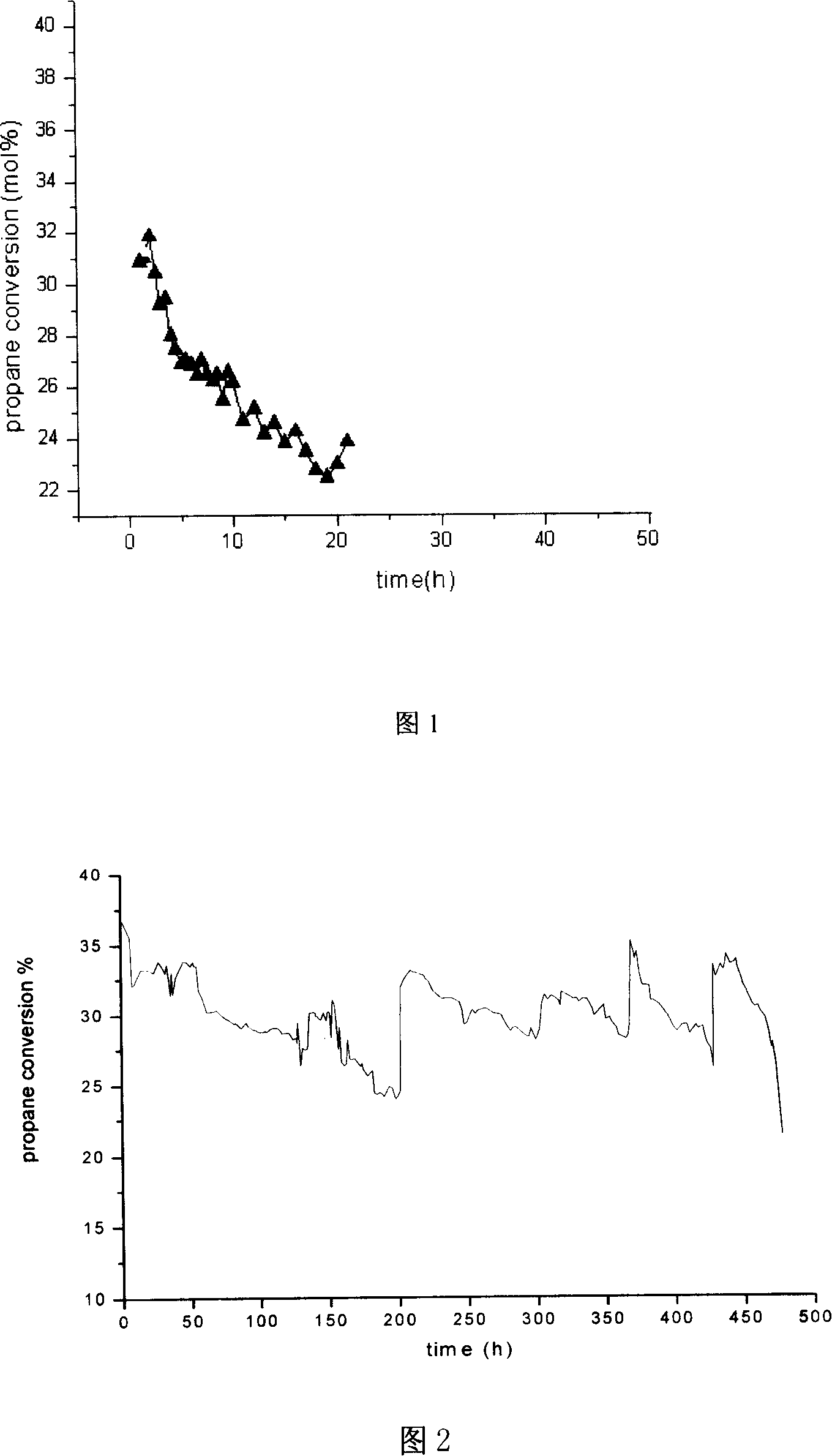

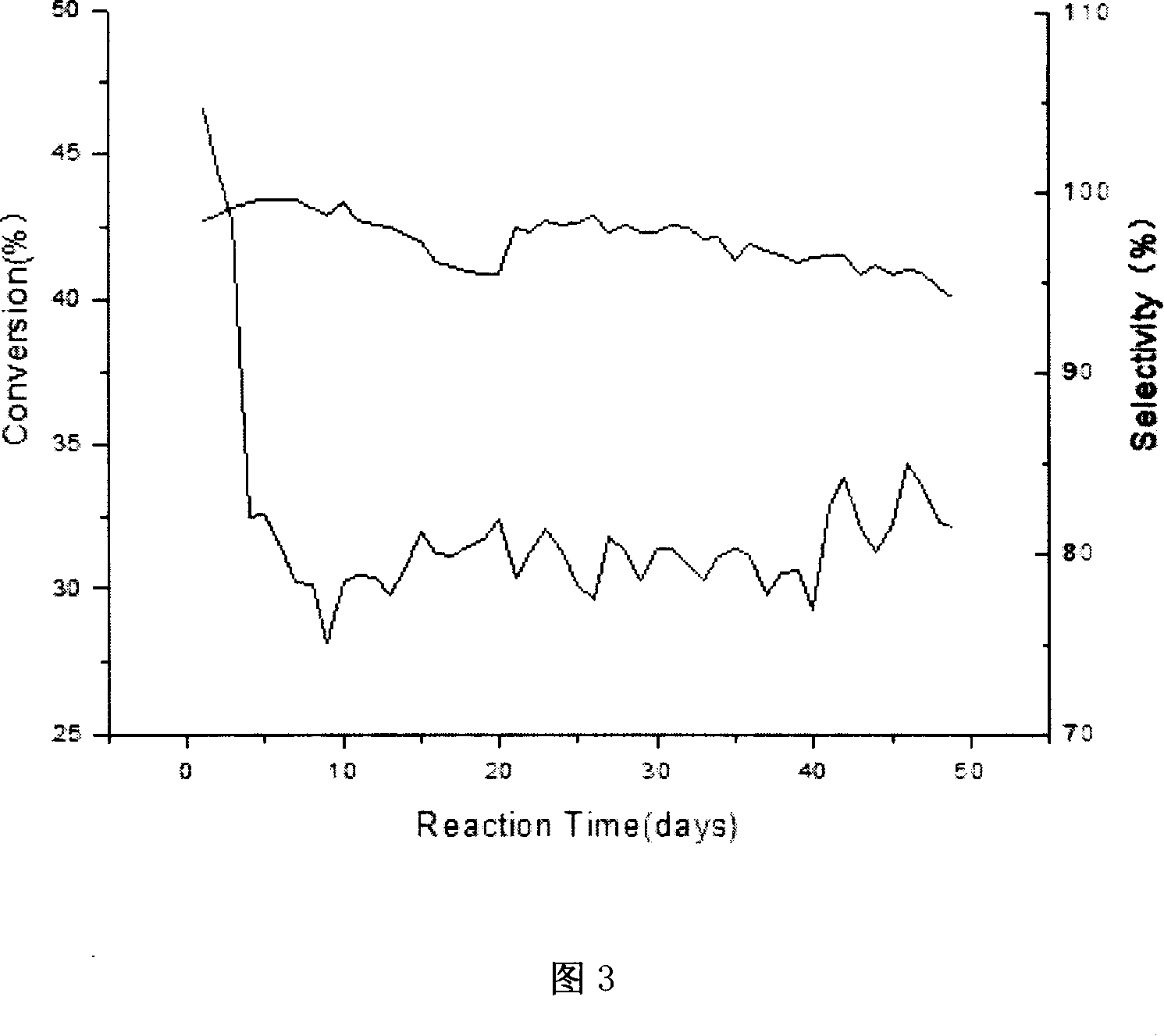

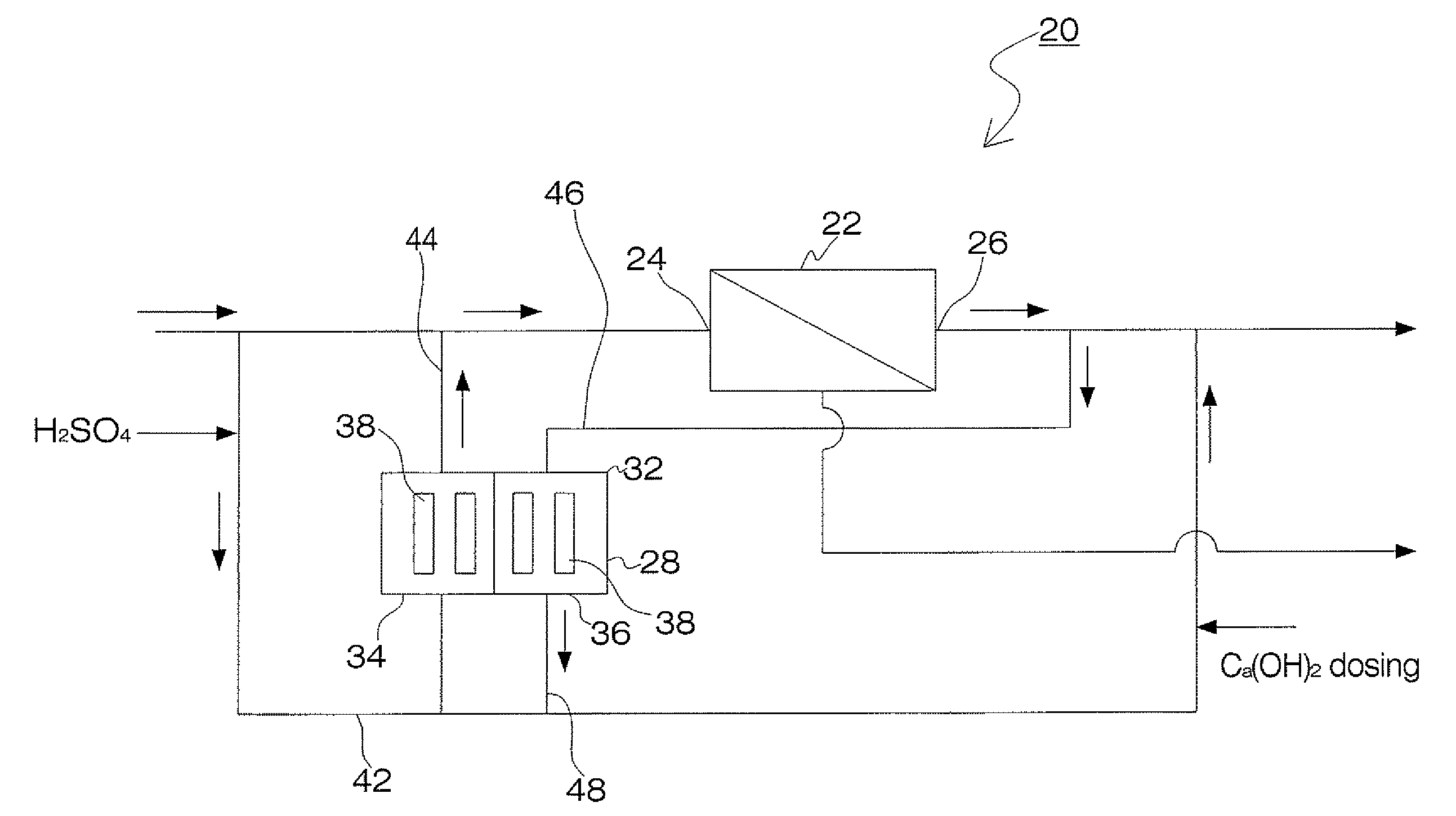

InactiveCN101108362AReactiveMitigation of heightened demandMolecular sieve catalystsHydrocarbonsAlkaneReaction temperature

The invention relates to a catalyst used for catalyzing and dehydrogenation of low-carbon alkane and the method of producing propylene by alkane catalyzing and dehydrogenation with the catalyst. The former catalyst used for catalyzing and dehydrogenation of low-carbon alkane, each molecule of the hydrocarbon has about 2 to 8 carbon atom, which is characterized in that: the catalyst makes a molecular sieve the carrier, the Pt family metal is loaded on the carrier as the active component, makes the IVA family metal element and alkalinity metal element as additional agent and high temperature standing inorganic oxide as connection agent; when the catalyst is used in producing propylene by alkane catalyzing and dehydrogenation, the reaction temperature is 500 to 700 DEG C., the pressure is 0 to 0.2Mpa, the quality air speed is 2 to 5h to 1, the regenerating temperature of the catalyst is 500 to 700 DEG C., the air speed is 100 to 1000h to 1, the pressure is 0 to 1.0MPa. With adopting the invention, the reaction of producing propylene by alkane catalyzing and dehydrogenation is good, the average transforming rate is 30 per cent, the selectivity above 95 per cent can keep for 50 days.

Owner:SINOPEC JINLING PETROCHEMICAL CO LTD

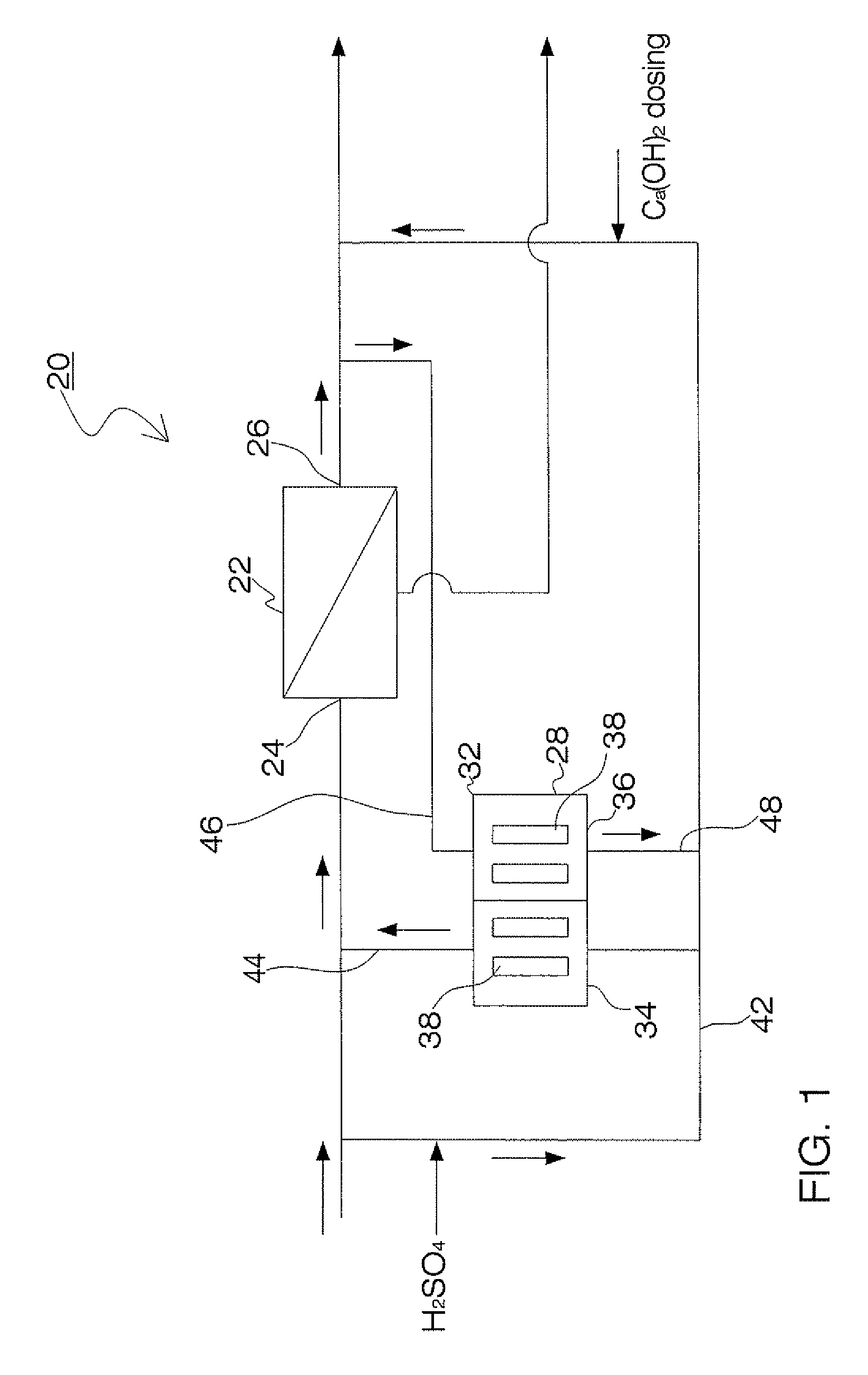

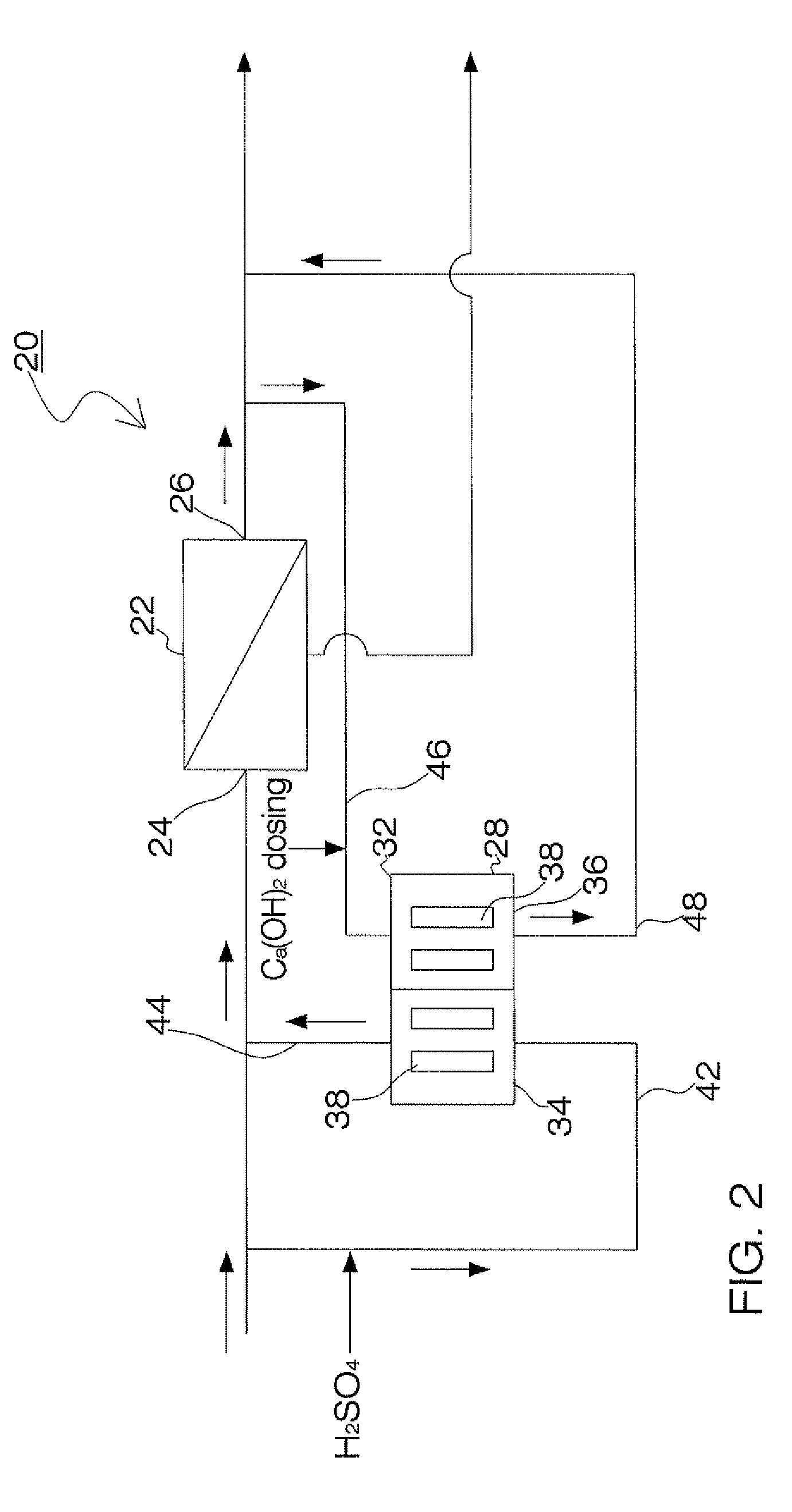

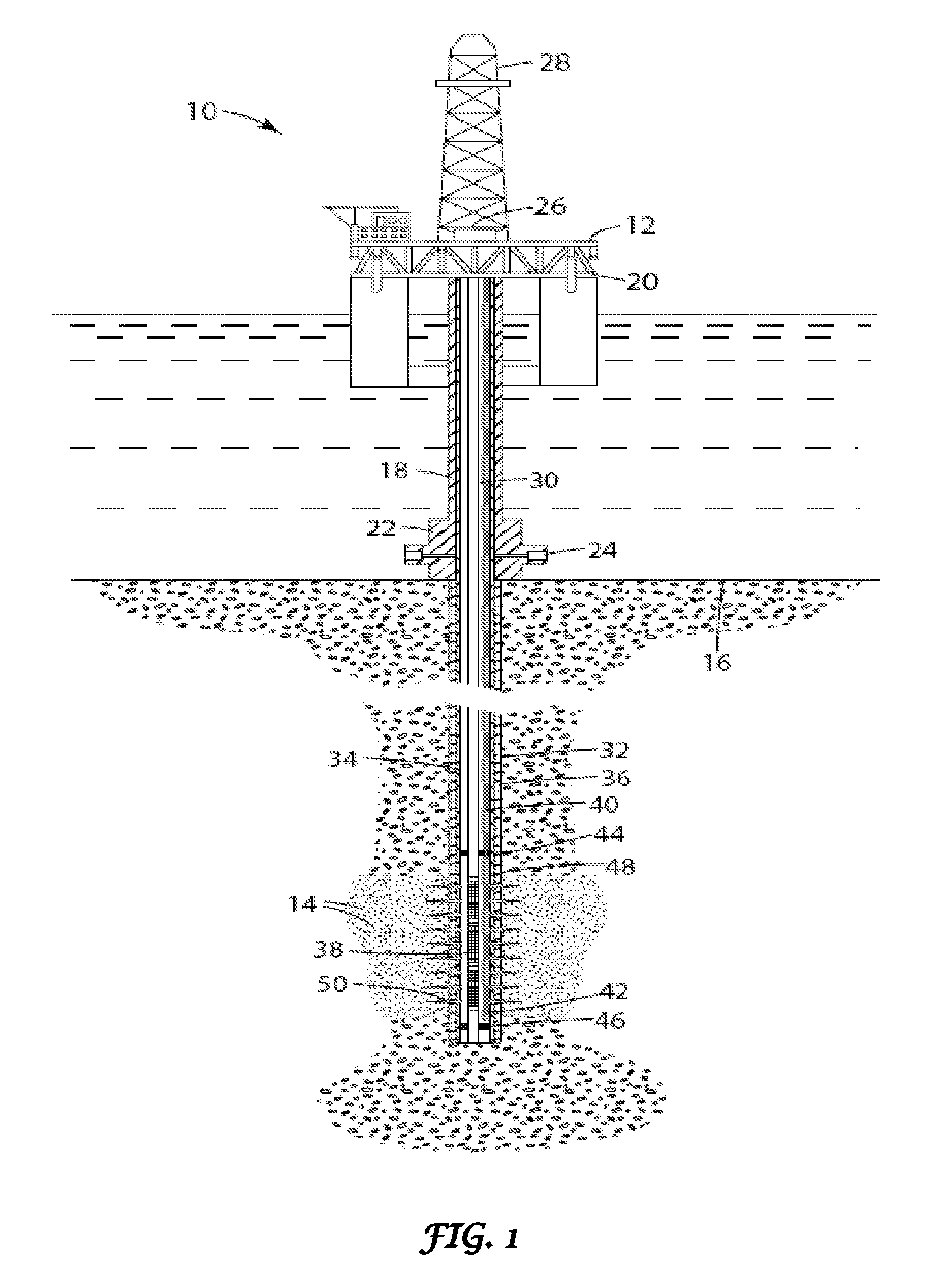

System and method for using carbon dioxide sequestered from seawater in the remineralization of process water

ActiveUS7771599B1Reduce scaleReduce inorganicLiquid degasificationGeneral water supply conservationSaline waterAlkalinity

Disclosed is an improved method for the remineralization of process water in a desalination system. The method sequesters carbon dioxide gas (CO2) from seawater or concentrate (brine) of desalination process via a gas transfer membrane. The sequestered carbon dioxide gas (CO2) is thereafter used in the production of soluble calcium bicarbonate (Ca(HCO3)2). The calcium bicarbonate (Ca(HCO3)2) adds hardness and alkalinity to the resulting process water.

Owner:DOOSAN HEAVY IND & CONSTR CO LTD

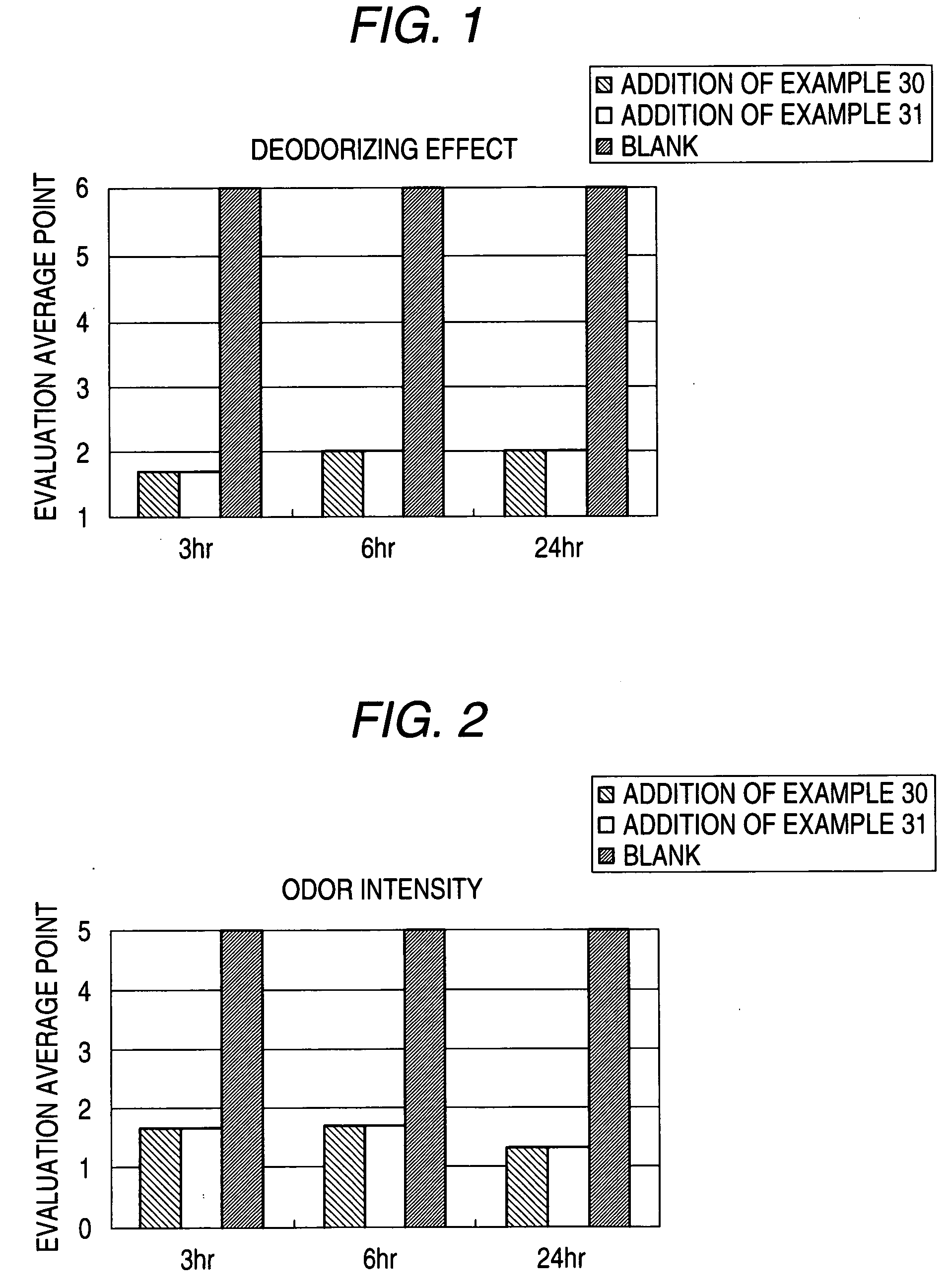

Deodorant composition

InactiveUS20060165622A1Easy to deodorizeSimple processCosmetic preparationsHair cosmeticsAlkalinityActive component

It is intended to provide a novel deodorant composition which is excellent in the deodorizing effect, is capable of affording a deodorant composition by a convenient method, and shows no decrease in the deodorizing performance even after a long period of time, once the deodorant being prepared. Specifically, there is provided a deodorant composition containing, as the active component, a colored compound obtainable by reacting a polyphenol in a solvent showing alkalinity in the coexistence of an oxygen molecule at a reaction pH value of 6.5 or more. As a substitute for a polyphenol, use can be made of a plant extract containing a polyphenol but containing substantially no amino acid. It is also possible to further employ an amino acid. Furthermore, use can be made of a plant extract and / or a plant body containing a polyphenol and an amino acid.

Owner:TAKASAGO INTERNATIONAL CORPORATION

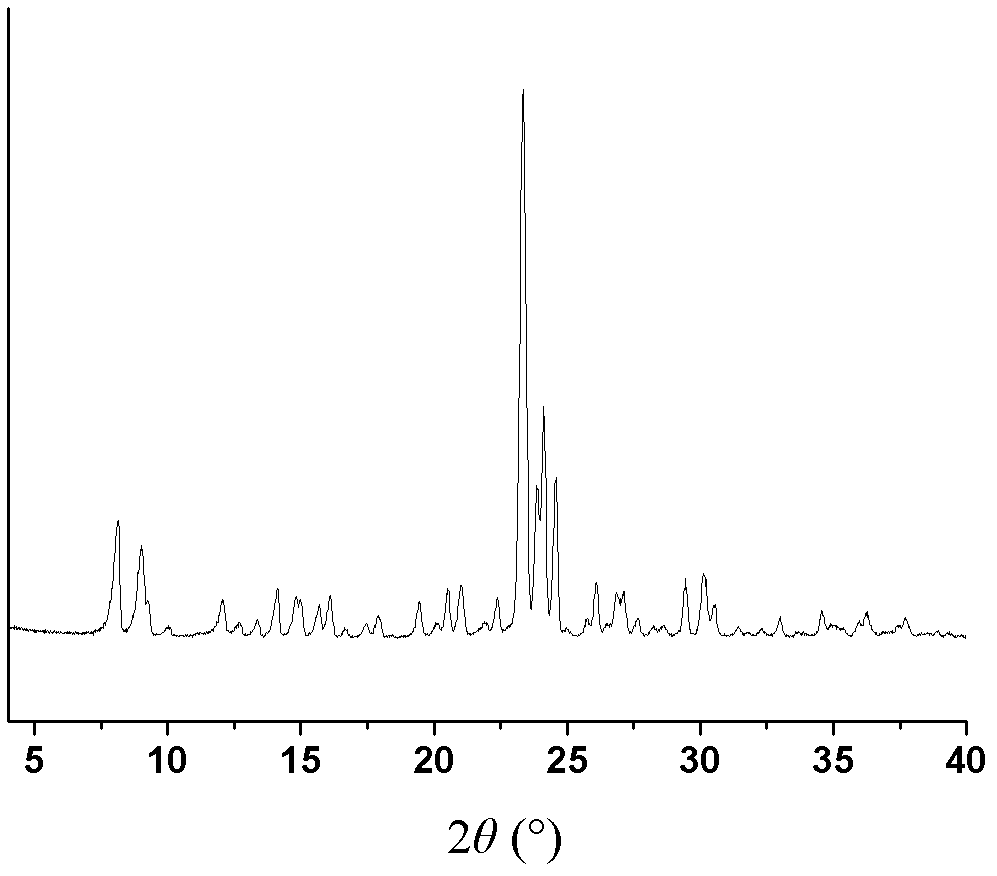

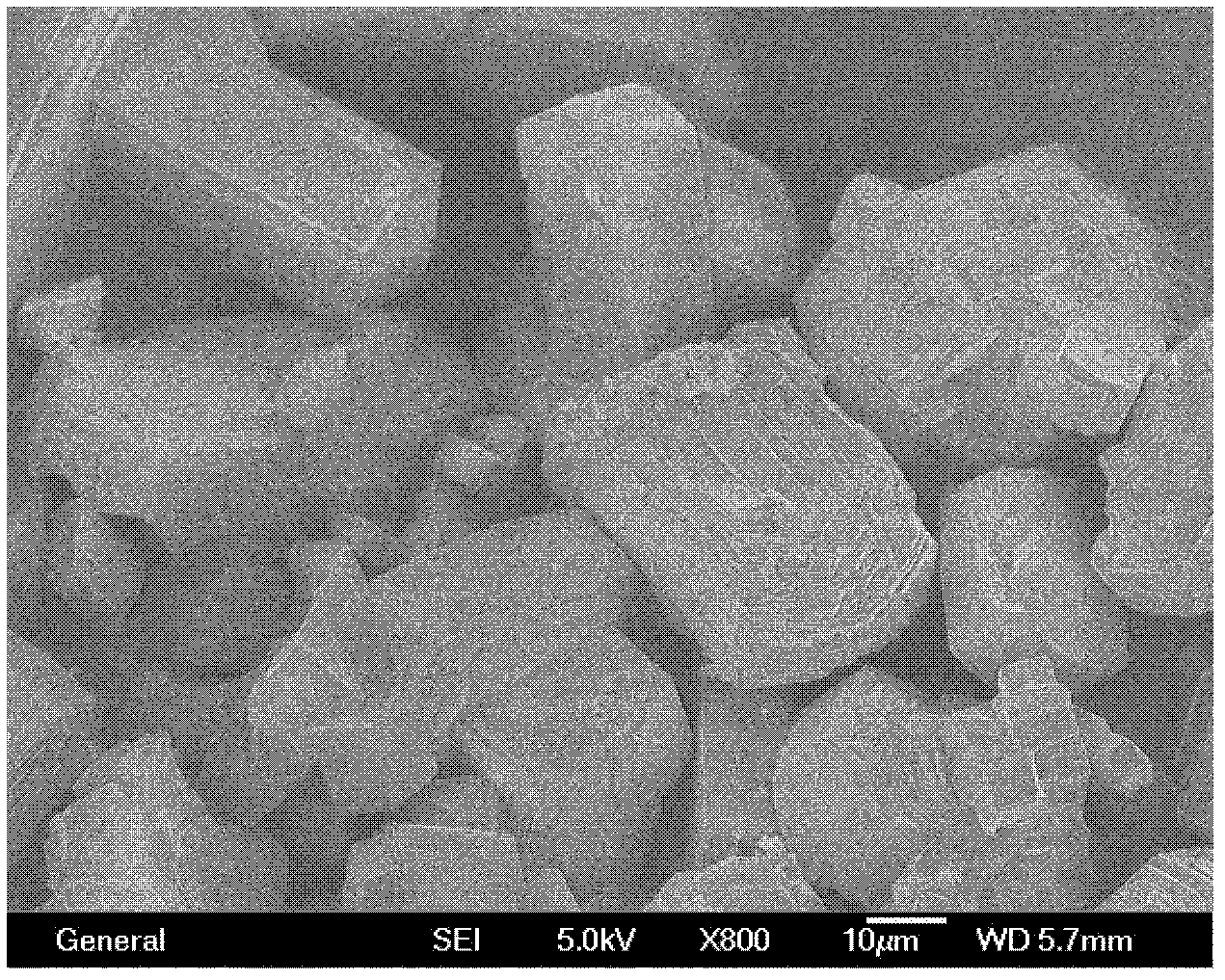

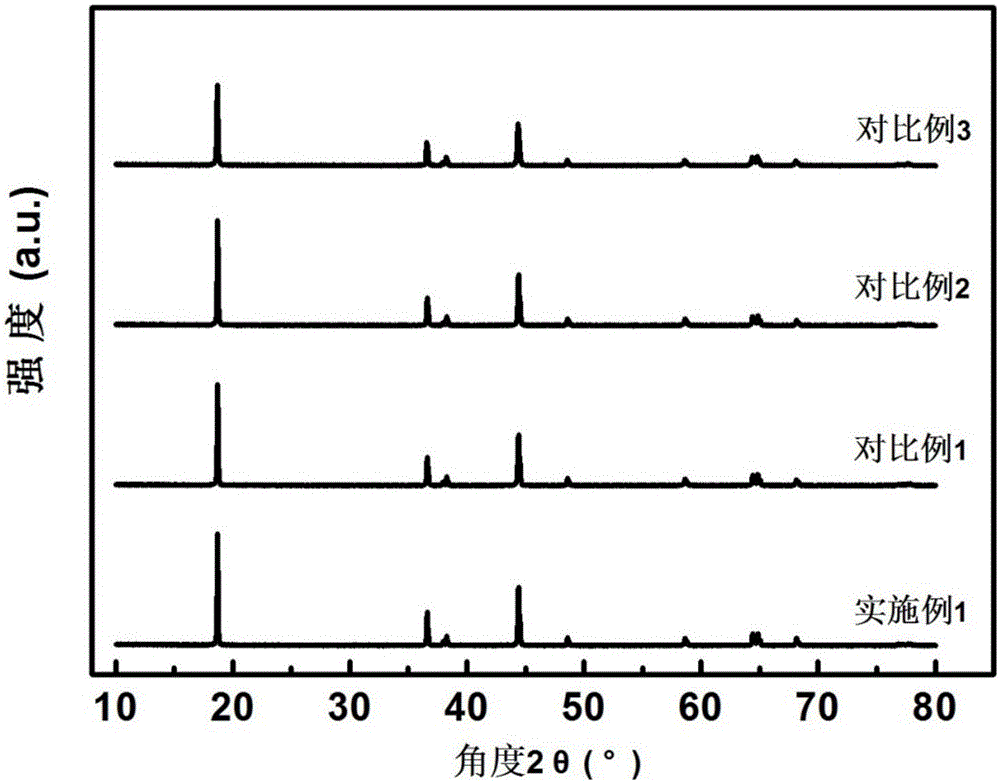

Method for synthesizing molecular sieve under solvent-free condition through grinding solid phase raw materials

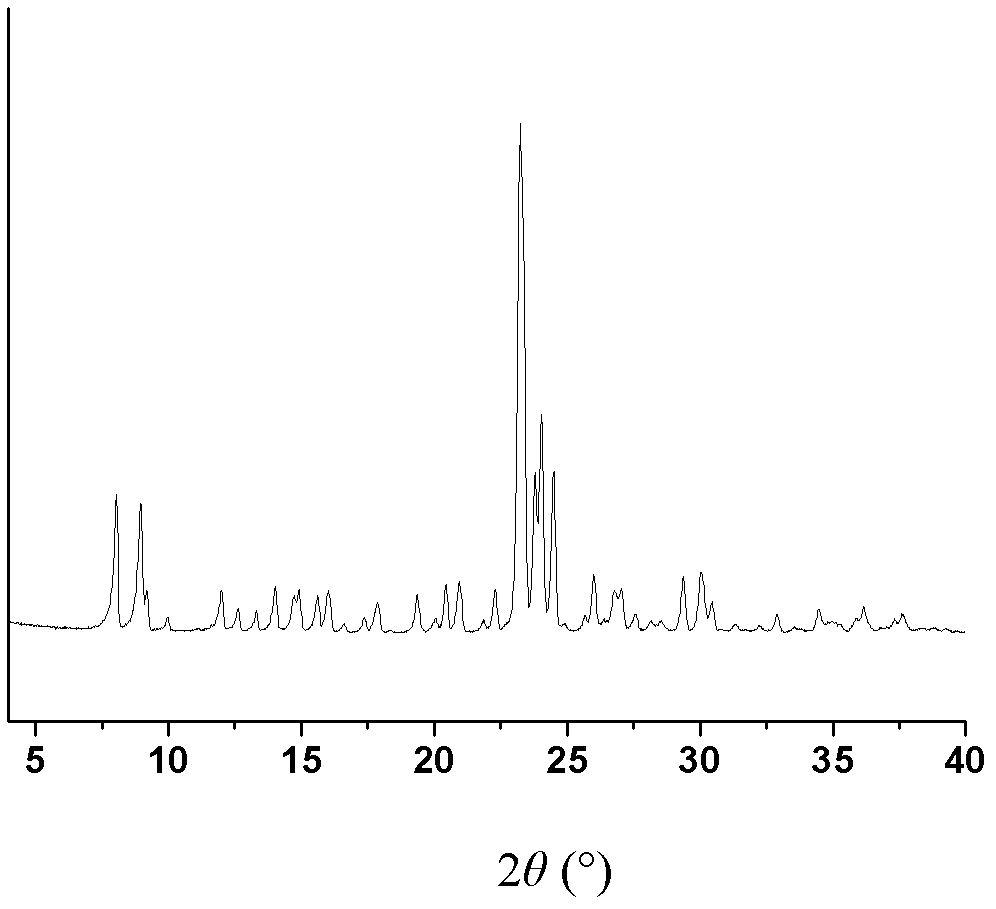

ActiveCN102627287AHigh crystallinityThe synthesis steps are simplePentasil aluminosilicate zeoliteSolvent freeSolvent

The invention relates to a method for preparing a molecular sieve, aiming to provide a method for synthesizing a molecular sieve under a solvent-free condition through grinding solid phase raw materials. The method comprises the following steps of: grinding and mixing the pre-weighed solid raw materials which include silicon sources, metal atom sources, an organic template agent, and an alkalinity regulator, putting the grinded material into a reactor, and performing a crystallization reaction for 1-8 days at a temperature ranged from 80 DEG C to 180 DEG C; and drying for over 12 hours at a temperature of 80 DEG C after washing the reaction product thoroughly by using deionized water to obtain a final product. A ZSM-5 molecular sieve, a Beta molecular sieve, a ZSM-39 molecular sieve, and a SOD molecular sieve, which have a good crystallinity and a controllable silicon-aluminum ratio, can be prepared through the method provided by the invention. The synthetic route only involves a mixture of the raw materials without a use of any solvents, which simplifies the synthetic process compared to the traditional method, improves the yield rate and the single reactor utilization rate greatly, reduces the production cost greatly, saves energy and reduces emission, and has a wide industrial application prospect.

Owner:淮安六元环新材料有限公司

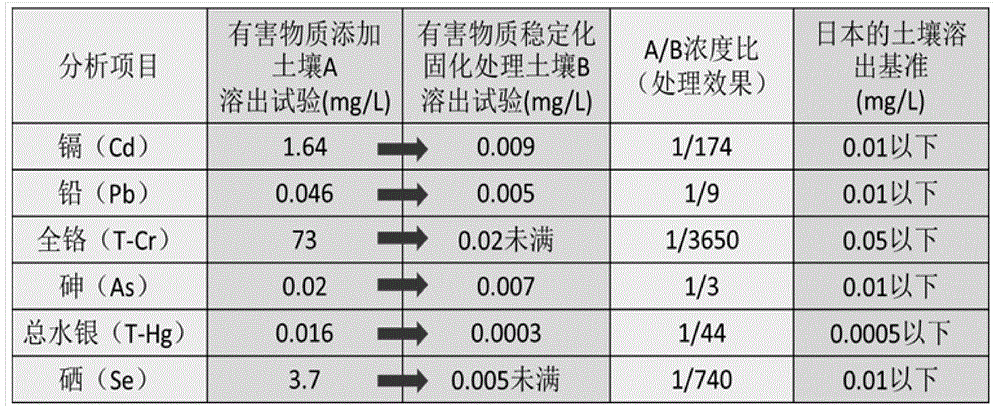

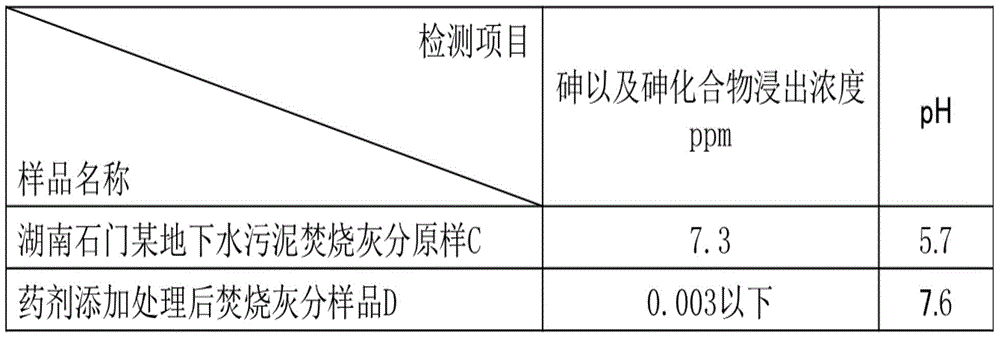

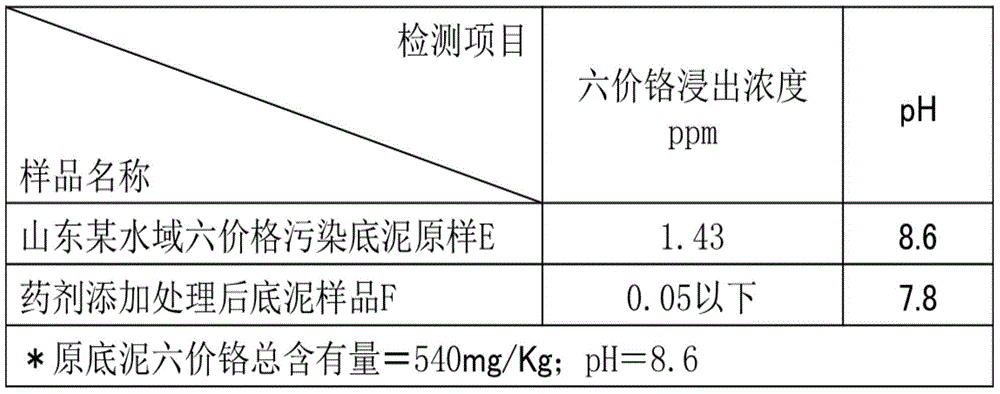

Stabilized curing agent for heavy metal contaminated soil or solid waste treatment and treatment method

ActiveCN104312591AAchieve adsorptionRealize functionContaminated soil reclamationBuilding constructionsTreatment effectDissolution

The invention discloses a stabilized curing agent for heavy metal contaminated soil or solid waste treatment and a treatment method. The stabilized curing agent comprises the following components in parts by weight: 5 to 10 parts of a magnesium-based compound, 1 to 5 parts of a sulfur-based compound and 1 to 3 parts of an activated silicon-based compound. The treatment method comprises the following steps of sampling inspection, experimental determination of adding proportion, mixing, backfill maintenance, sealing up for safekeeping and the like. The stabilized curing agent disclosed by the invention has an efficient long-term stabilizing effect on various heavy metals such as arsenic, mercury, hexavalent chromium, lead, cadmium, nickel, tin and cyanide, the repeated acid and alkali leaching experiments prove that the stabilized and cured harmful heavy metals cannot be dissolved out again, and the defects that in the traditional technology, the treatment effect and treatment agents are greatly affected by the environment, the long-term efficacy of harmless stabilization is poor, the medicament adding amount is difficult to control and the re-dissolution of harmful heavy metals is easily caused by the high alkalinity of cement solidification and the like are overcome.

Owner:GUIZHOU MEIRUITE ENVIRONMENTAL PROTECTION TECH

Alkaline land soil repair agent

InactiveCN101417286AReduce alkalinityImprove biological activityContaminated soil reclamationOrganic fertilisersNatural organic matterAlkali soil

The invention relates to a restoration agent for saline-alkali land soil, which consists of free gypsum dehydration, nature organic substance, microbial fertilizer and inorganic nutrient with weight ratio of 60-70:25-35:1-4:3-6; the content of dihydrate calcium sulfate in the free gypsum dehydration is over 80 percent; the nature organic substance consists of weathered coal and grass carbon with weight ratio of 1.0:0.93; the content of effective bacteria in the microbial fertilizer is 2.0 hundred millions / g; and the inorganic nutrient consists of urea, ordinary superphosphate and potassium chloride with weight ratio of 1.0:2.42:075. The restoration agent can utilize calcium ions in the free gypsum dehydration for replacing sodium ions in the soil so as to lower the alkalinity in the soil and provide calcium and sulfur elements for crops, while the nature organic substance can lower and regulate the slat content and the alkalinity in the soil. In addition, the nature organic substance, the microbial fertilizer and the inorganic nutrient can supply large amount of nutrient elements such as nitrogen, phosphorus, potassium and the like to the crop for normal growth, thereby being capable of improving the yield of the crop.

Owner:TIANJIN INST OF AGRI RESOURCES & ENVIRONMENTAL

Manufacturing method of oxidative water to be employed for sterilization

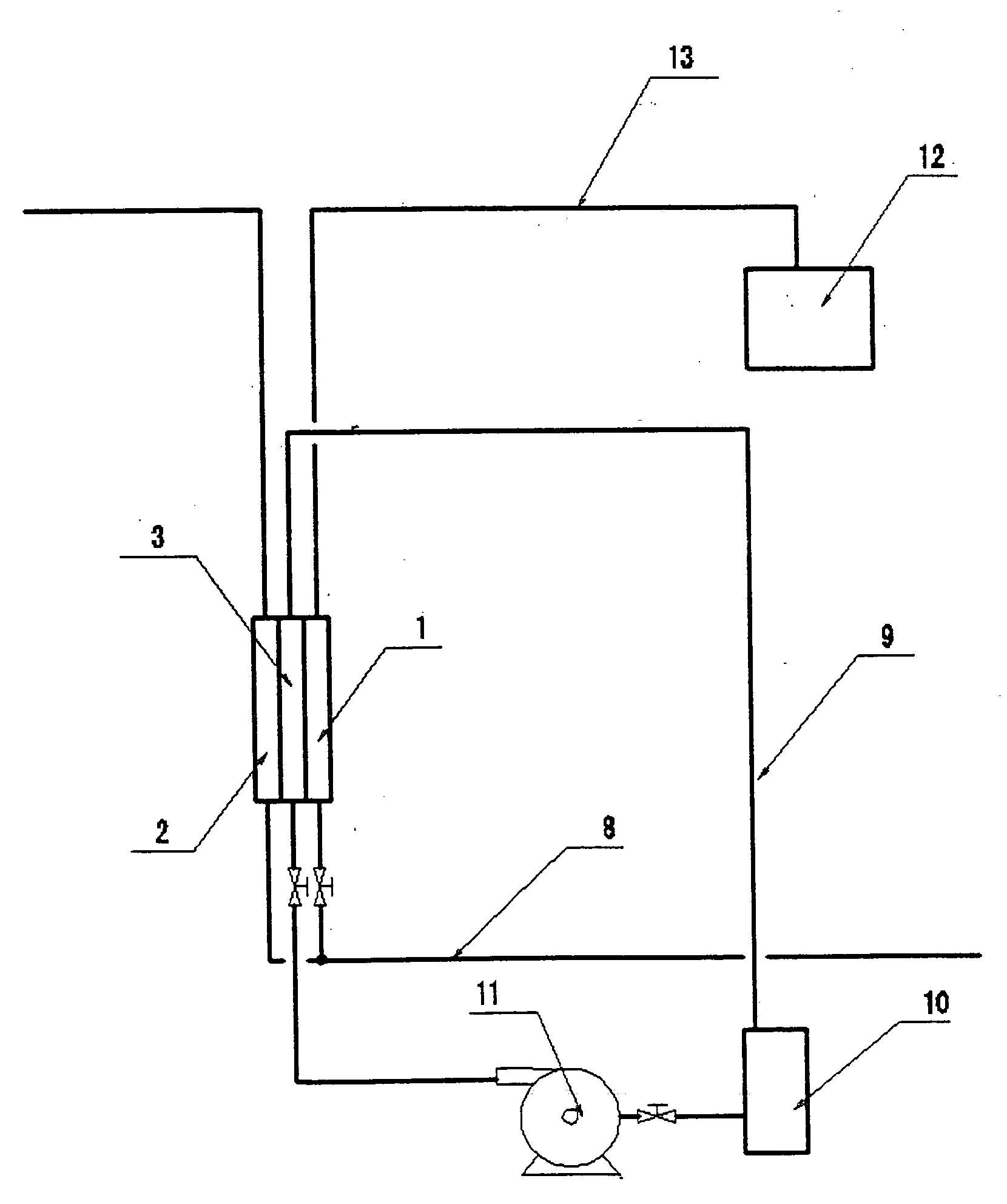

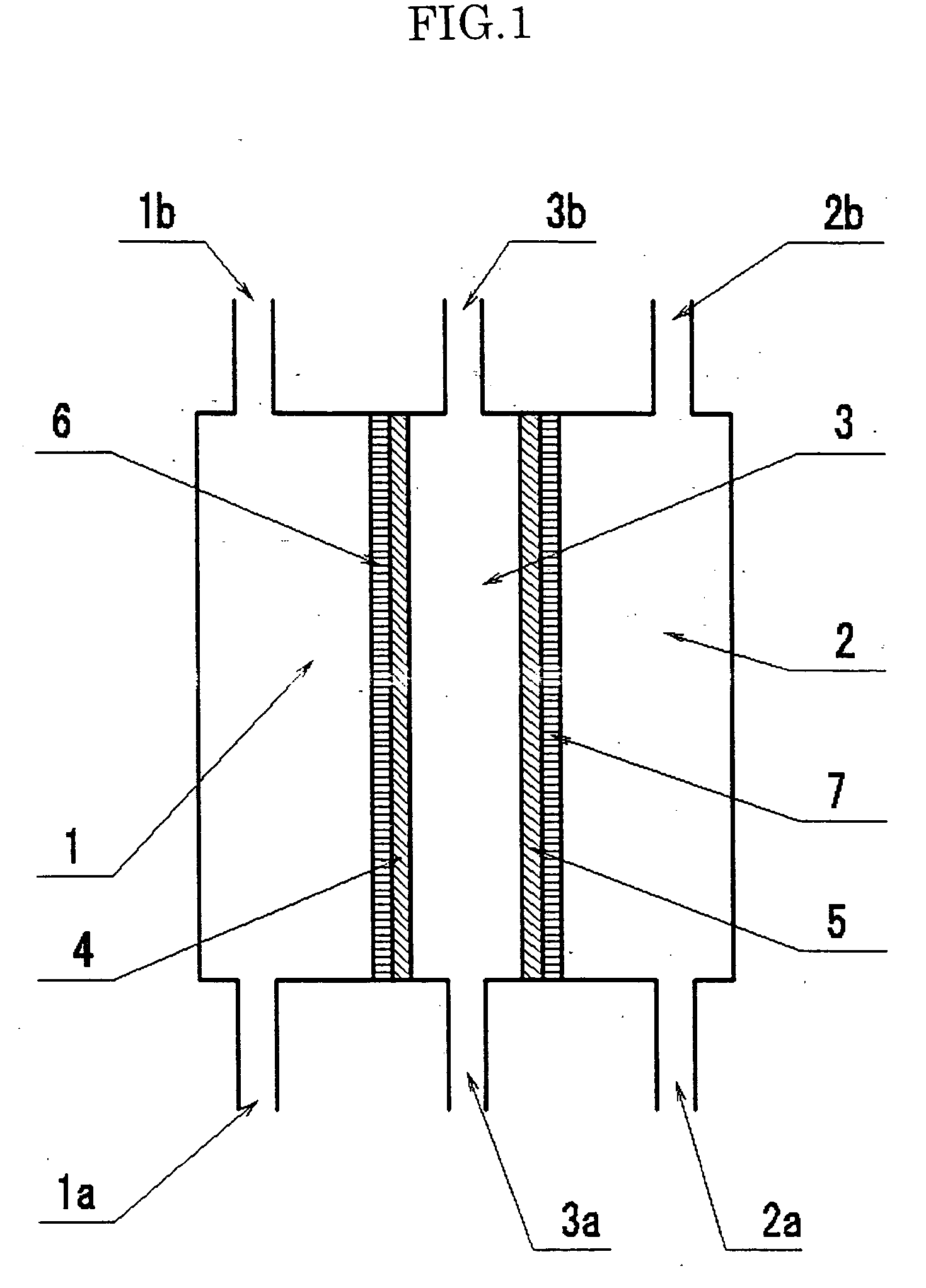

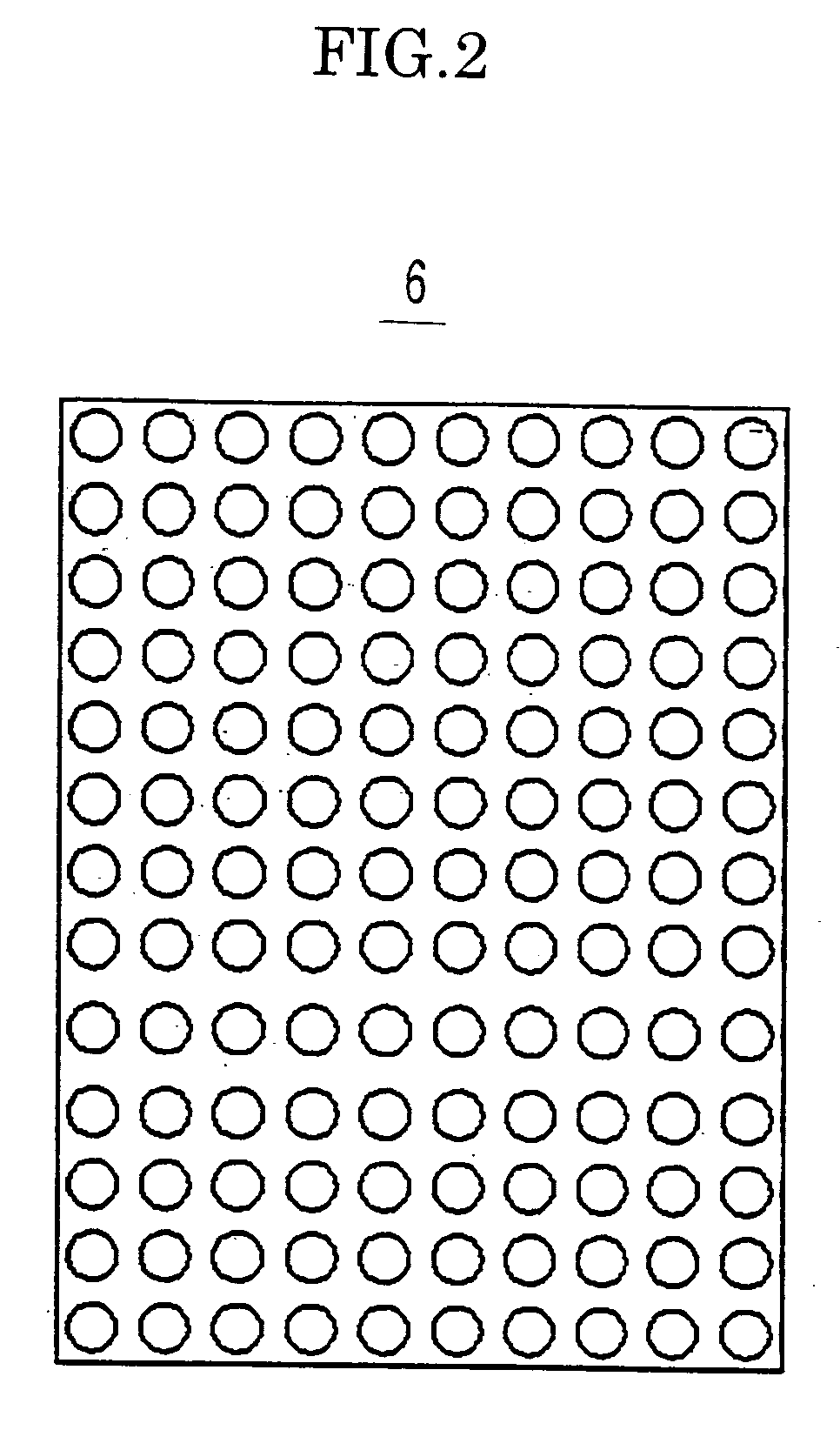

ActiveUS20060169575A1Increase powerElectrolysis componentsLiquid separation by electricityAlkalinityElectrolysis

This invention provides the oxidative mixed water with pH around 7.4 ranging from the weak acidity to weak alkalinity, high power of killing microorganisms, and high power of healing wound by electrolysis using the three-compartment cell composed of an anode compartment, a cathode compartment, and a middle compartment between the anode compartment and the cathode compartment. Mixing anode water with cathode water produced using the three-compartment device forms the oxidative mixed water.

Owner:TECH CORPORATION CO LTD

Producing method of clean steel

The invention discloses a producing method of clean steel, which can further enhance the cleanliness and comprise the following steps of: pretreating with molten iron for desulfurizing until [S] is not more than 0.010%; then delivering to a converter for smelting; dephosphorizing and controlling sulfur; controlling finished molten iron in the converter to be with [P] of not more than 0.0080% and [S] not more than 0.010%; adding a ladle slag modifying agent to ladles in a steel tapping process for regulating and modifying the ladle slag, wherein after treating, in the molten iron, [P] is not more than 0.0060% to 0.0080%, [S] is not more than 0.0080% and roughing slag quantity is not more than 0.5%; controlling refined finished slag components in LF (Low Frequency) refining, wherein soft argon blowing time of the molten iron is not less than 5 minutes after LF refining, and the composition is qualified when [S] is not more than 0.0020%; carrying out VD (Vacuum Degassing) refining to ensure that [H] is not more than 1.5ppm; and continuously casting, wherein a double-layer high-alkalinity covering agent is adopted as a middle ladle, a seal ring and a long water gap are additionally arranged for argon-blowing protective casting, which is carried out at constant speed, and overheat delta T of the molten iron ranged from 15 DEG C to 30 DEG C. Under the condition that the producing cost is not increased basically, the cleanliness of the clean steel is further enhanced by the control of each procedure junction point, and the clean steel comprises the following components by weight percent: S not more than 20ppm, P not more than 100ppm, TO not more than18ppm, H smaller than 2.0ppm, N not more than 35ppm, and A, B, C and D types of impurities not more than 0.5 grade.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

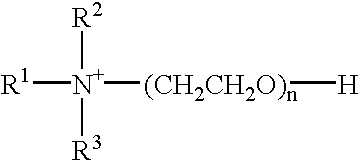

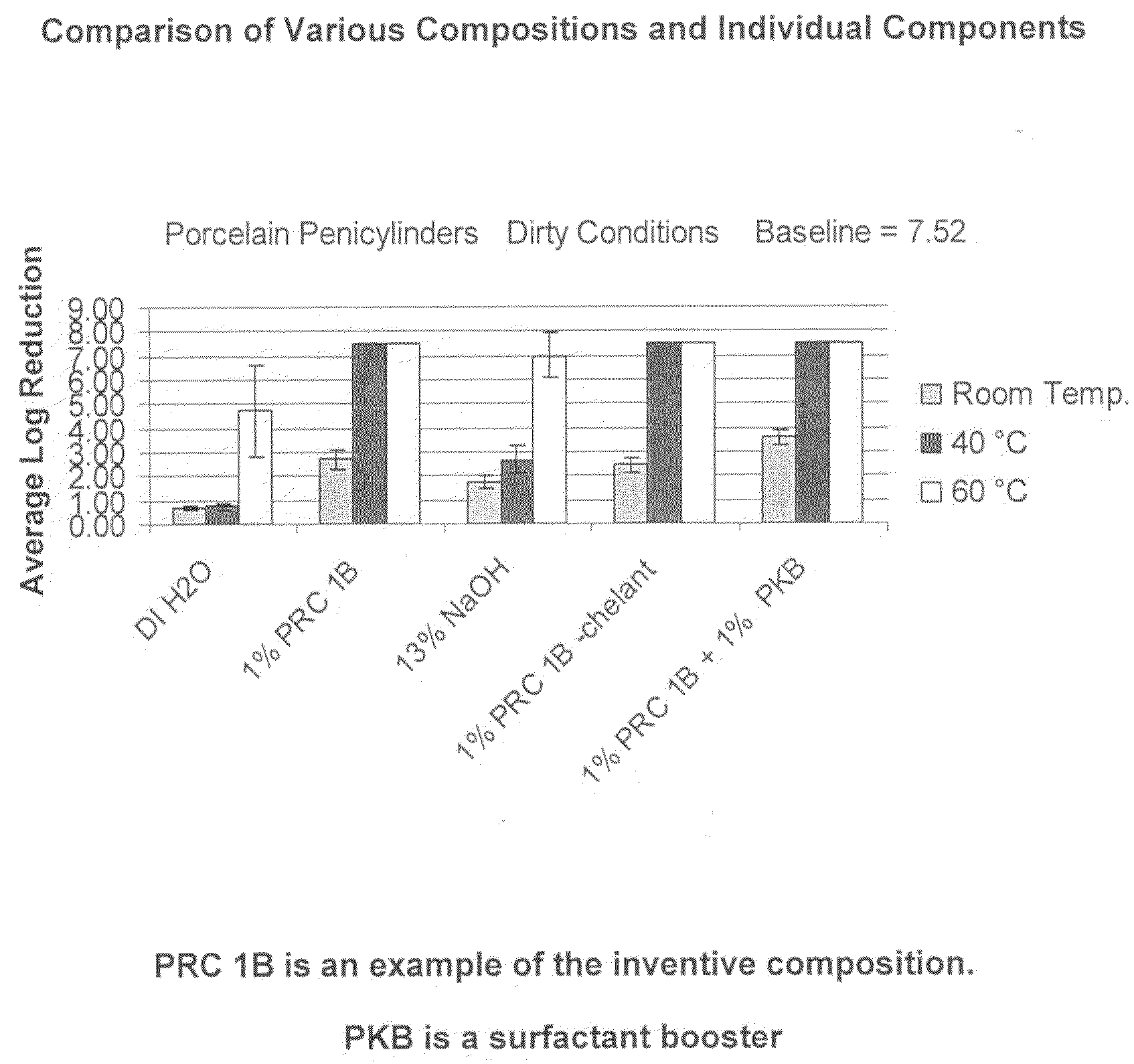

Antimicrobial hard surface cleaner comprising an ethoxylated quaternary ammonium surfactant

InactiveUS6605584B2No adverse effects on filming/streaking performanceGood removal effectInorganic/elemental detergent compounding agentsCationic surface-active compoundsWater dispersibleAmmonium compounds

The invention provides a, non- or minimized streaking / filming antimicrobial formulation, the cleaner containing:a. an akoxylated quaternary ammonium surfactant, present in a cleaning-effective amount;b. an alkoxylated short chain nonionic surfactant, also present in a cleaning-effective amount;c. alkanolamine as an alkalinity source, present in an amount effective to enhance soil removal in said cleaner;d. a quaternary ammonium compound in an amount present for antimicrobial efficacy;e. at least one water-soluble or dispersible organic solvent having a vapor pressure of at least 0.001 mm Hg at 25° C., said at least one organic solvent present in a solubilizing-or dispersion-effective amount; andf. the remainder, water.

Owner:THE CLOROX CO

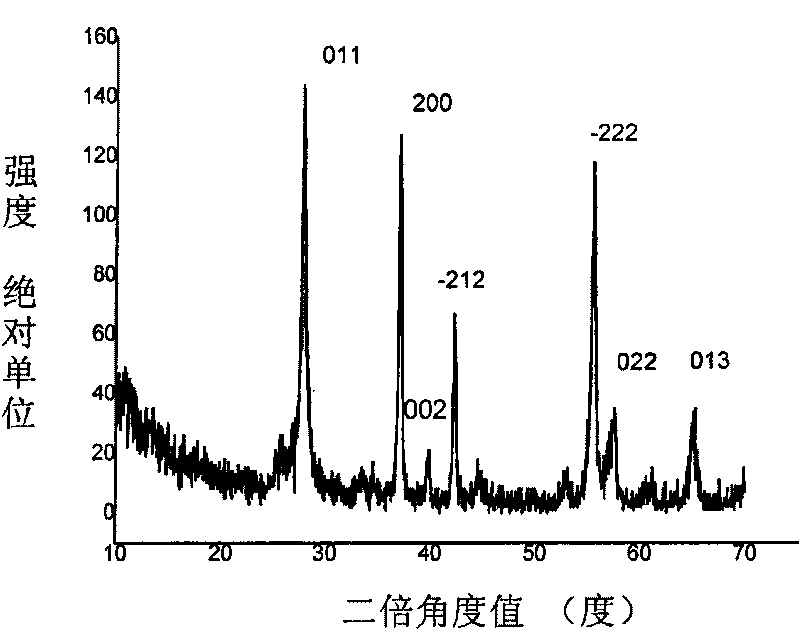

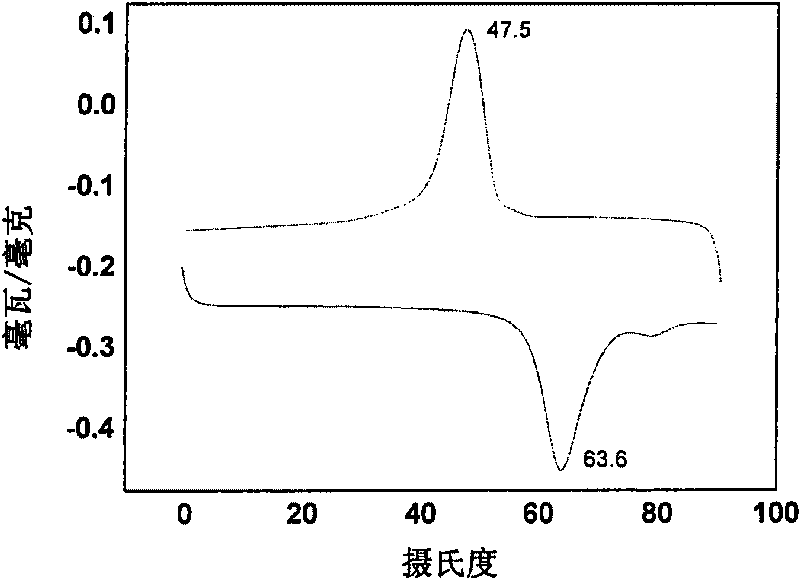

Method of preparing intelligent energy-saving vanadium dioxide by hydrothermal method

InactiveCN101700909ALow costRaw materials are cheap and easy to getChemical industryVanadium oxidesVanadium dioxideAlkalinity

The invention relates to a method of preparing vanadium dioxide by hydrothermal method. The method comprises the following steps: adding oxidant, reducing agent or acidity and alkalinity adjusting agent in a hydrothermal kettle containing proper amount of aqueous solution of the source of vanadium, then placing the hydrothermal kettle in a 40-300 DEG C of oven to perform heat preservation for 30 minutes to 5 days, and centrifuging to collect vanadium dioxide after the reaction is completely finished. The preparation method provided by the invention has simple process, low cost and high yield, the mass production can be realized and the purity of the obtained intelligent energy-saving vanadium dioxide nano-powder is high. Vanadium dioxide doped powder can further be obtained by adding proper amount of compound containing tungsten, molybdenum, manganese, chromium or titanium in the aqueous solution of the source of vanadium to realize wider industrial applications. The control of different appearances of vanadium dioxide nano-powder can be realized by controlling the categories of the source of vanadium and the dosage of oxidant, reducing agent or acidity and alkalinity adjusting agent.

Owner:UNIV OF SCI & TECH OF CHINA

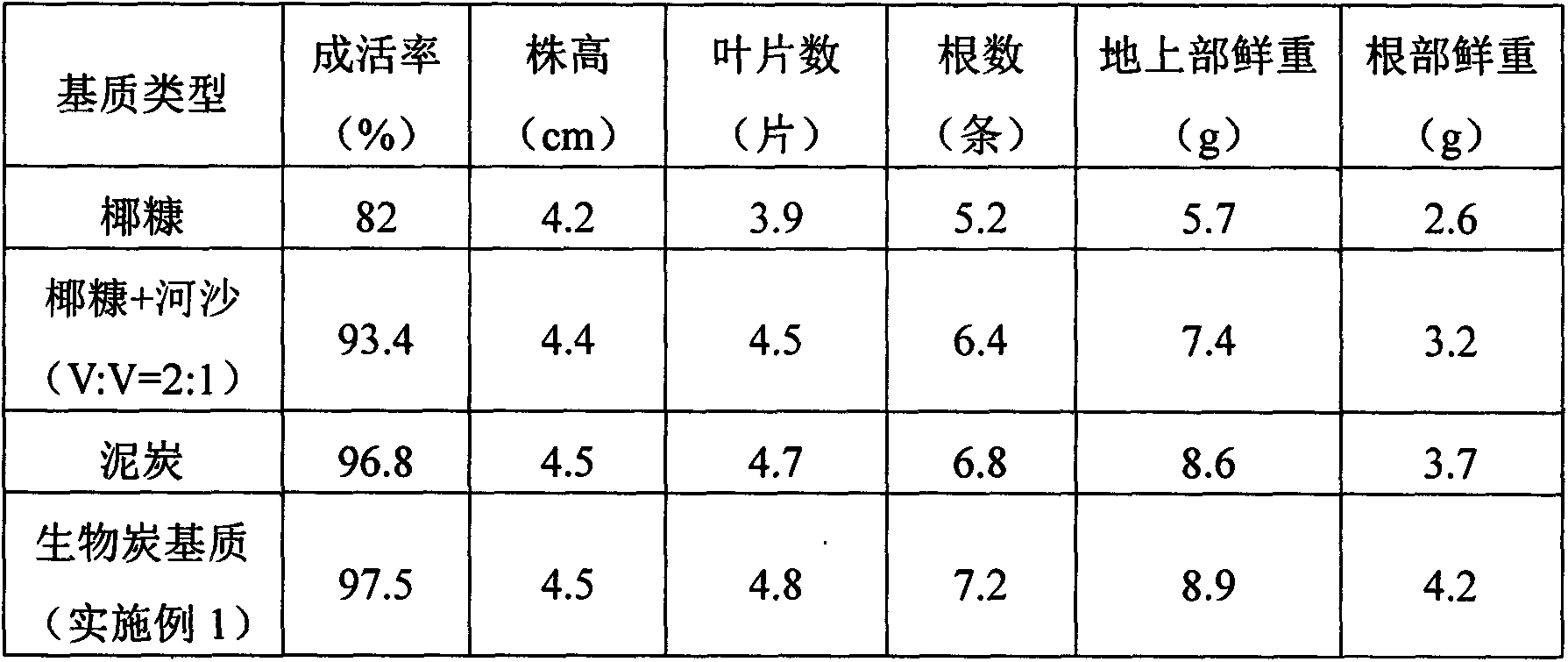

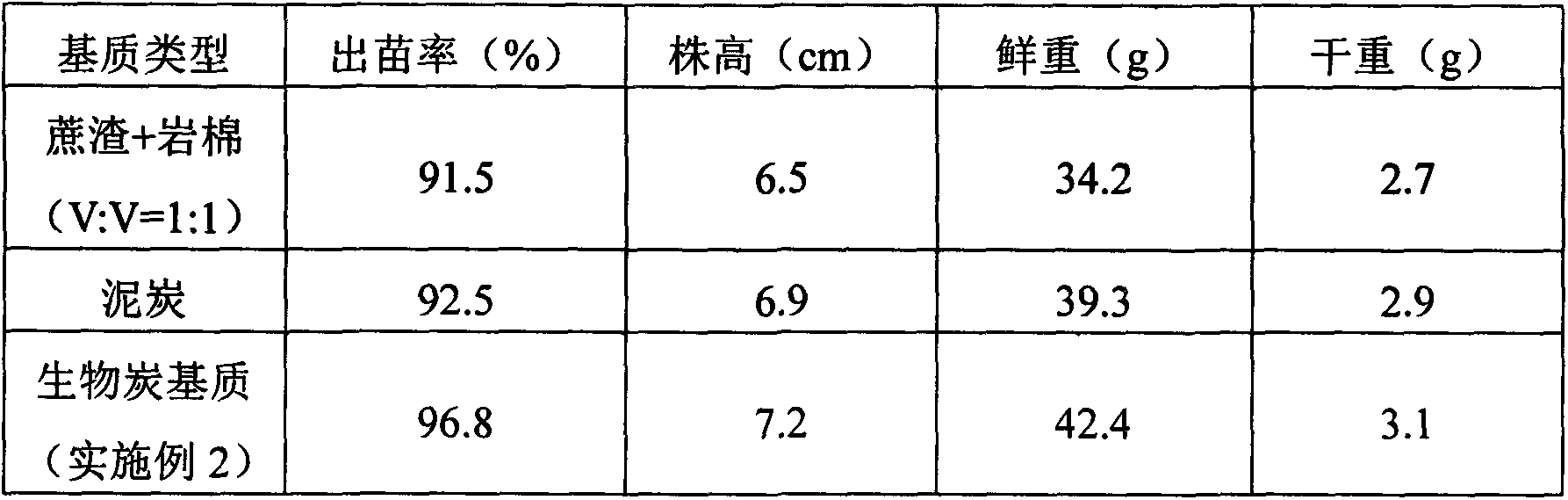

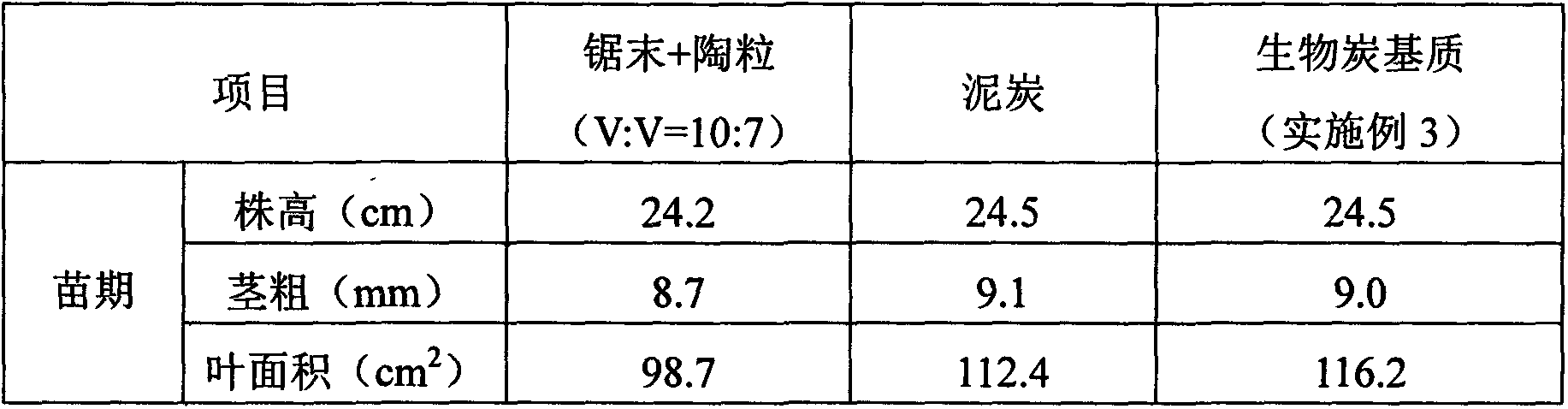

Charcoal based plant cultivation substrate and preparation method thereof

InactiveCN103435411AEnhanced ability to provide phosphorus and potassium fertilizersLight textureFertilizer mixturesPhosphatePotassium

The invention relates to a charcoal based plant cultivation substrate and a preparation method thereof, and belongs to the technical field of soilless culture. The invention adopts the specific scheme that: after being dried, biomass material is pyrolyzed to form charcoal particles under an anoxic and heating condition, potassium dihydrogen phosphate is used for neutralizing the alkalinity of the charcoal particles and filtering and drying are performed, and after a certain amount of inorganic fertilizer is added, the charcoal particles are fully mixed with inorganic filling material, organic filling material and organic fertilizer, namely the charcoal based plant cultivation substrate is obtained. The invention has the advantages that the physical chemical property is excellent, the nutrients are complete, the fertilizer efficiency is lasting, the moisture adjusting capability is strong, the cost is low, the ecological benefits are high, the suitability is strong, the application range is wide, and the charcoal based plant cultivation substrate is suitable for cultivation of various plants.

Owner:QIONGZHOU UNIVERSITY

High-efficiency plugging oil-base drilling fluid and preparation method thereof

ActiveCN103045210AEffective blockingPrevent penetrationDrilling compositionAlkalinityDifferential pressure

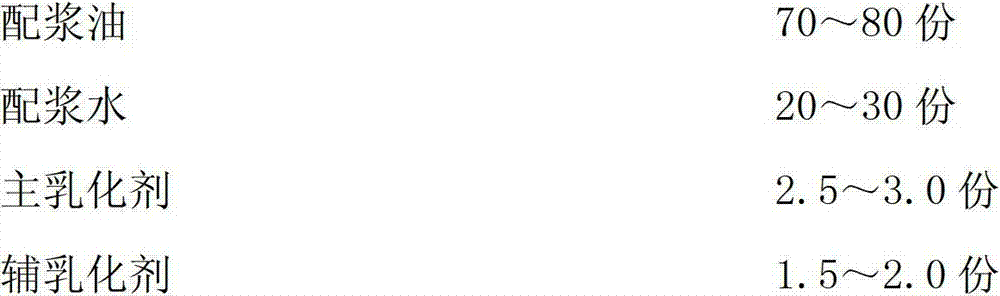

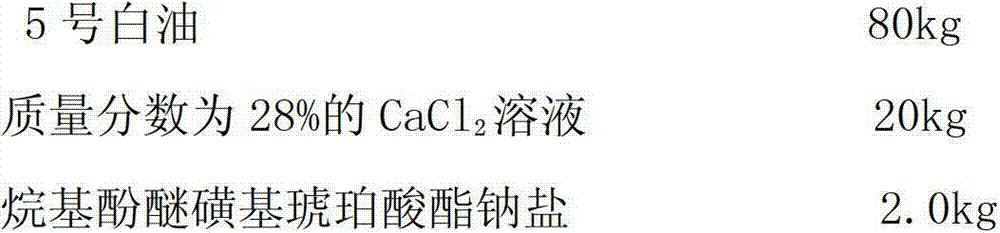

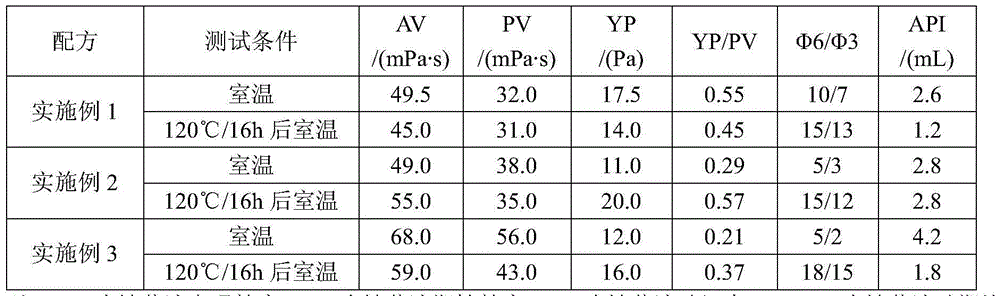

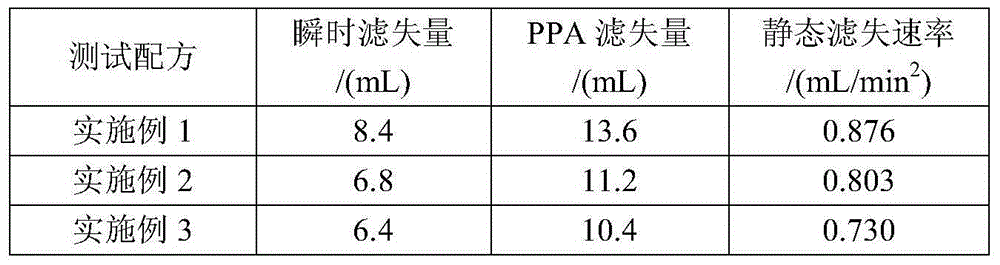

The invention discloses a high-efficiency plugging oil-base drilling fluid and a preparation method thereof. The drilling fluid is prepared from the following raw materials in parts by mass: 70-80 parts of slurrying oil, 20-30 parts of slurrying water, 2.5-3.0 parts of main emulsifier, 1.5-2.0 parts of auxiliary emulsifier, 2.0-2.5 parts of wetting agent, 2.0-2.5 parts of flow pattern regulator, 2.5-3.0 parts of fluid loss agent, 1.5-2.0 parts of alkalinity regulator, 0.5-0.8 part of extracting agent and 7-9 parts of plugging material. A weighting material is added so that the density of the drilling fluid reaches 1.45-1.56 g / cm<3>. By utilizing the well-drilling positive differential pressure, the high-efficiency plugging oil-base drilling fluid quickly implements bridging, filling and filming to plug the formation fractures on the well wall surface and near the well wall, effectively prevents the drilling fluid and filtrate thereof from permeating into microfractures, enhances the bearing capacity of the formation, has favorable plugging effect, and is beneficial to the stability of the well wall.

Owner:CHINA PETROLEUM & CHEM CORP +1

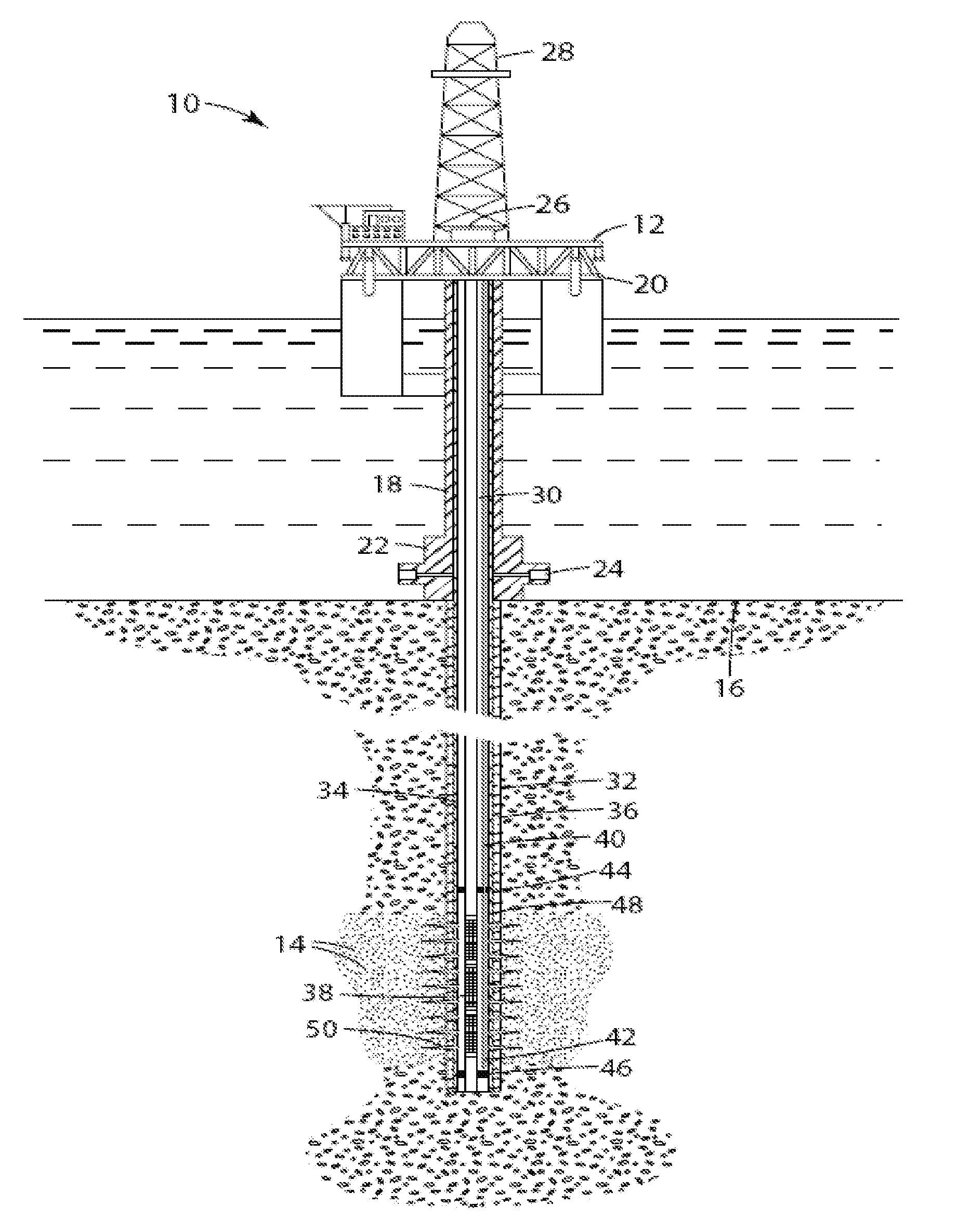

Water-based drilling fluid of shale gas horizontal well reinforced well wall and application thereof

ActiveCN104694092AImprove stabilityGood dispersionDrilling compositionBorehole/well accessoriesMicro nanoWater based

The invention relates to a water-based drilling fluid of a shale gas horizontal well reinforced well wall and an application thereof. The water-based drilling fluid comprises, by weight, 100 parts of water, 0-5 parts of clay, 0.5-3 parts of micro-nano particle blocking agents, 0.5-3 parts of chemical blocking agents, 0.1-2 parts of tackifier, 1-5 parts offiltrate reducer, 0.05-2 parts of encapsulating inhibiting agents, 0.1-3 parts of polyamine inhibiting agents, 1-5 parts of lubricant, 0.1-1 part of alkalinity regulator, 2-25 parts of inorganic salt, and 0-200 parts of weighting agents. The micro-nano particle blocking agents and the chemical blocking agents in the water-based drilling fluid of the shale gas horizontal well reinforced well wall have the effect of reinforcing the well wall in a cooperative mode, can effectively block micropore seams of shale to hinder pressure transmission, can further obviously improve the membrane efficiency of the shale, and facilitates the balance anti-collapse function of chemical activity.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

Production method for reducing and fining the high-carbon chromium bearing steel D-type impurity

ActiveCN1621538AGood workmanshipMeet production needsProcess efficiency improvementElectric furnaceAlkalinityHigh carbon

The production process with reduced and fined type-D inclusion in high-carbon chromium bearing steel features the four-step metallurgical process including initial smelting of steel liquid in electric furnace, refining in bottom blowing Ar LF ladle furnace, deairing in VD vacuum furnace, and die casting or continuous casting. By means of the comprehensive deoxidation process including pre-deoxidation of aluminum deposition of the steel from electric furnace, deoxidation with Fe-Si powder diffusion slag in LF site and vacuum carbon deoxidation in VD site; and the new refining process including high alkalinity slag desulfurization in LF site, adoption of low alkalinity slag in the VD site and reducing free CaO inside slag, the present invention reaches the aims of reducing and fining type-D inclusion.

Owner:宝武特种冶金有限公司

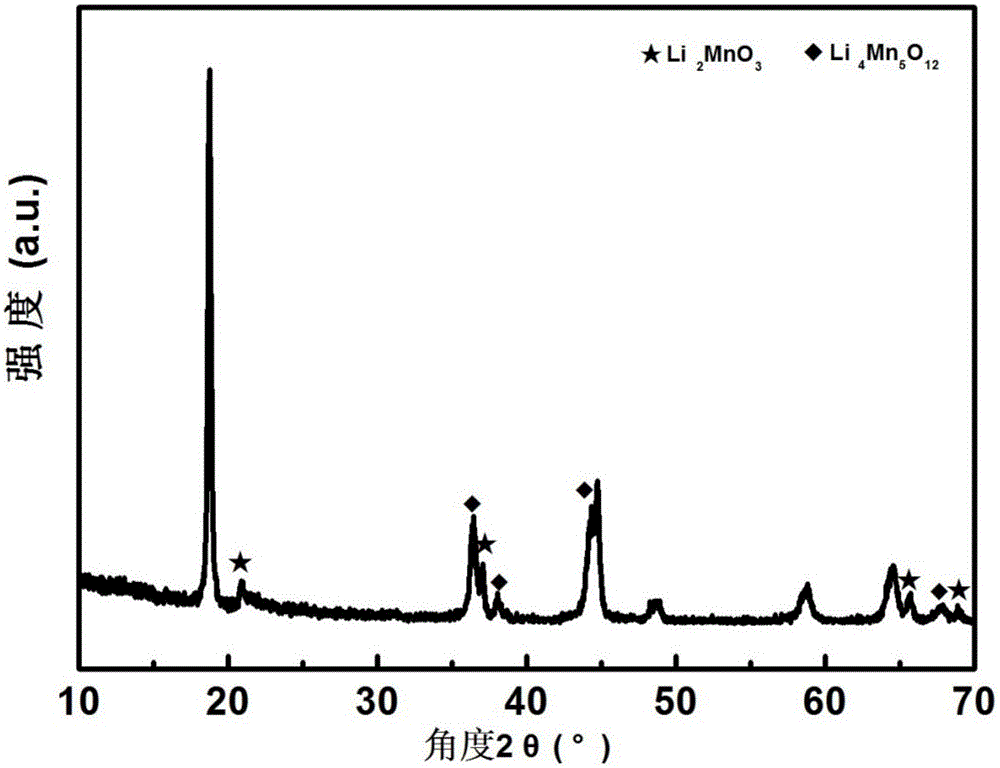

High-nickel multi-element positive electrode material for lithium secondary battery, and preparation method thereof

ActiveCN105070896AEasy to processImprove discharge specific capacityCell electrodesSecondary cellsPhosphateLithium-ion battery

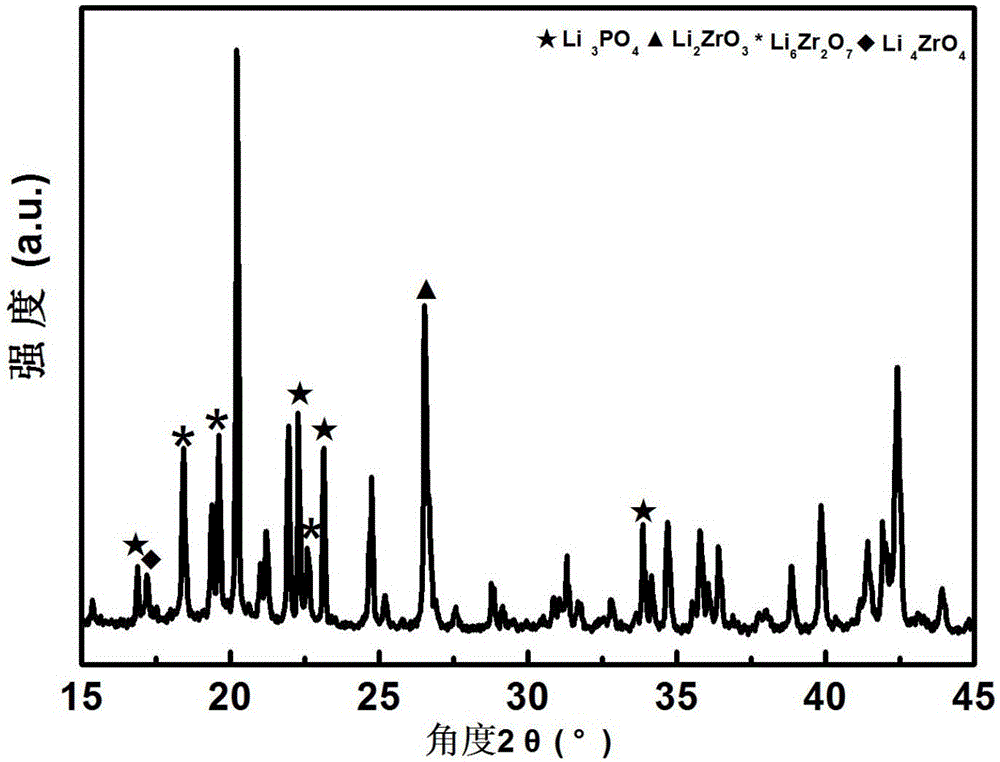

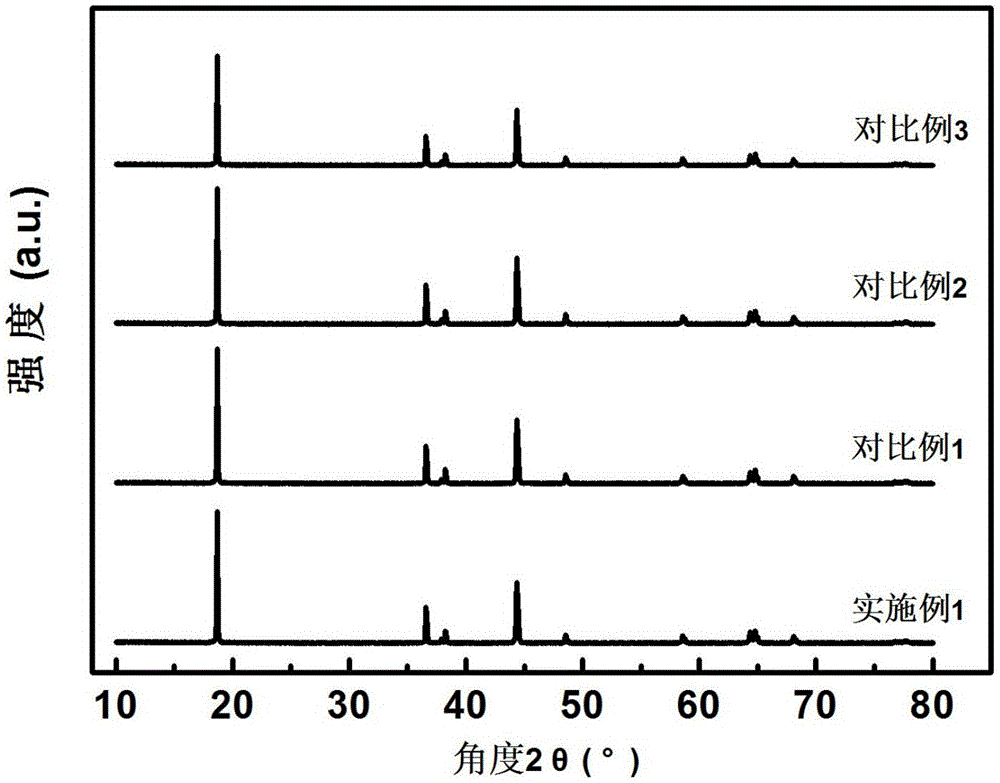

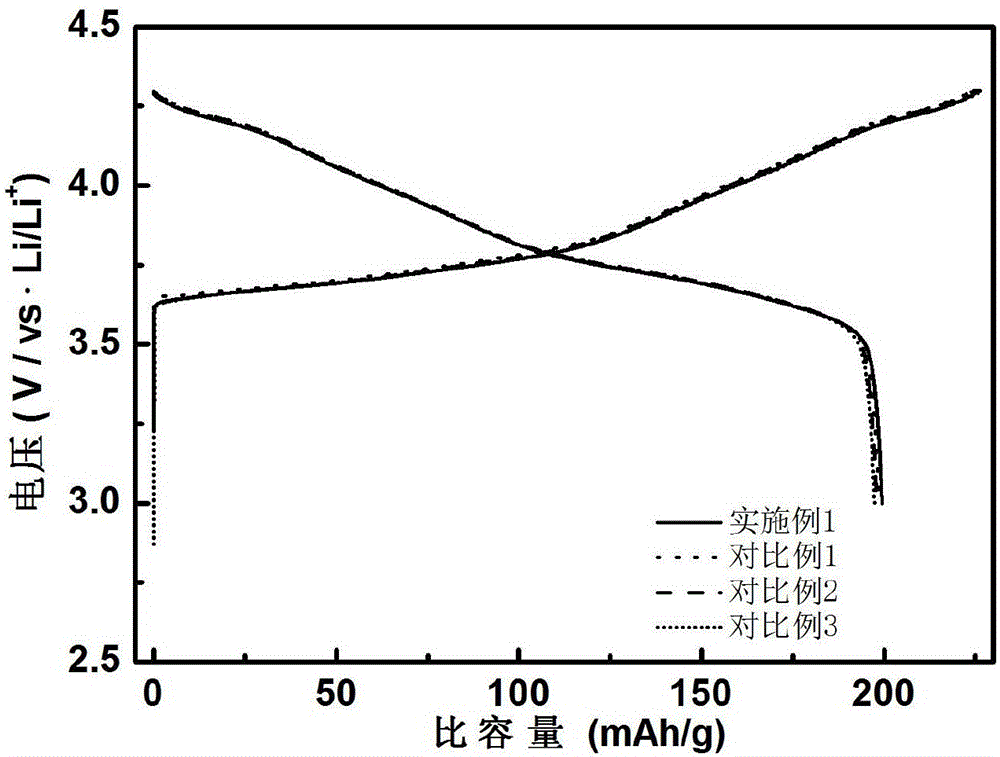

A high-nickel multi-element positive electrode material for a lithium secondary battery comprises a base material and a composite cladding layer outside the base material, the general formula of the base material is LiaNi1-x-yCoxMyO2, wherein M is at least one of Mn and Al, a, x and y respectively represent the molar ratios of Li, Co and M in the base material, a is not smaller than 1 and not greater than 1.2, 1-x-y is not smaller than 0.6 and not greater than 1, x is greater than 0 and not greater than 0.4, and y is not smaller than 0 and not greater than 0.4; and the composite cladding layer is a mixture containing lithium phosphorus oxide and at least one of lithium zirconium / lithium titanium / lithium aluminum oxides. A preparation method of the positive electrode material comprises the following steps: preparing the base material; adding a metallic Zr / Ti / Al-containing compound, and carrying out high temperature heat treatment to obtain a lithium zirconium / lithium titanium / lithium aluminum oxide coated base layer; and adding phosphate, and carrying out low temperature heat treatment to obtain the high-nickel multi-element positive electrode material for the lithium secondary battery. The high-nickel multi-element positive electrode material has the advantages of low alkalinity, small gas swelling degree, good processability and good electrochemical performances.

Owner:HUNAN SHANSHAN NEW ENERGY CO LTD

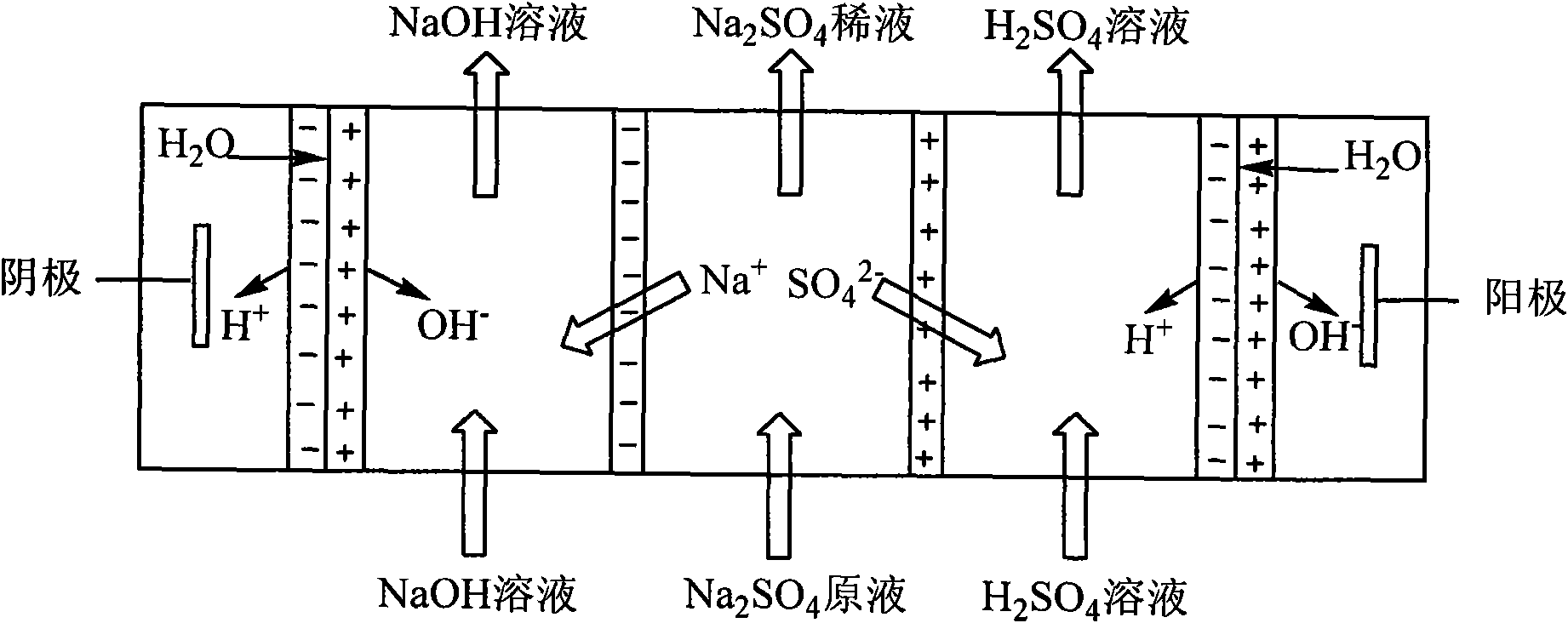

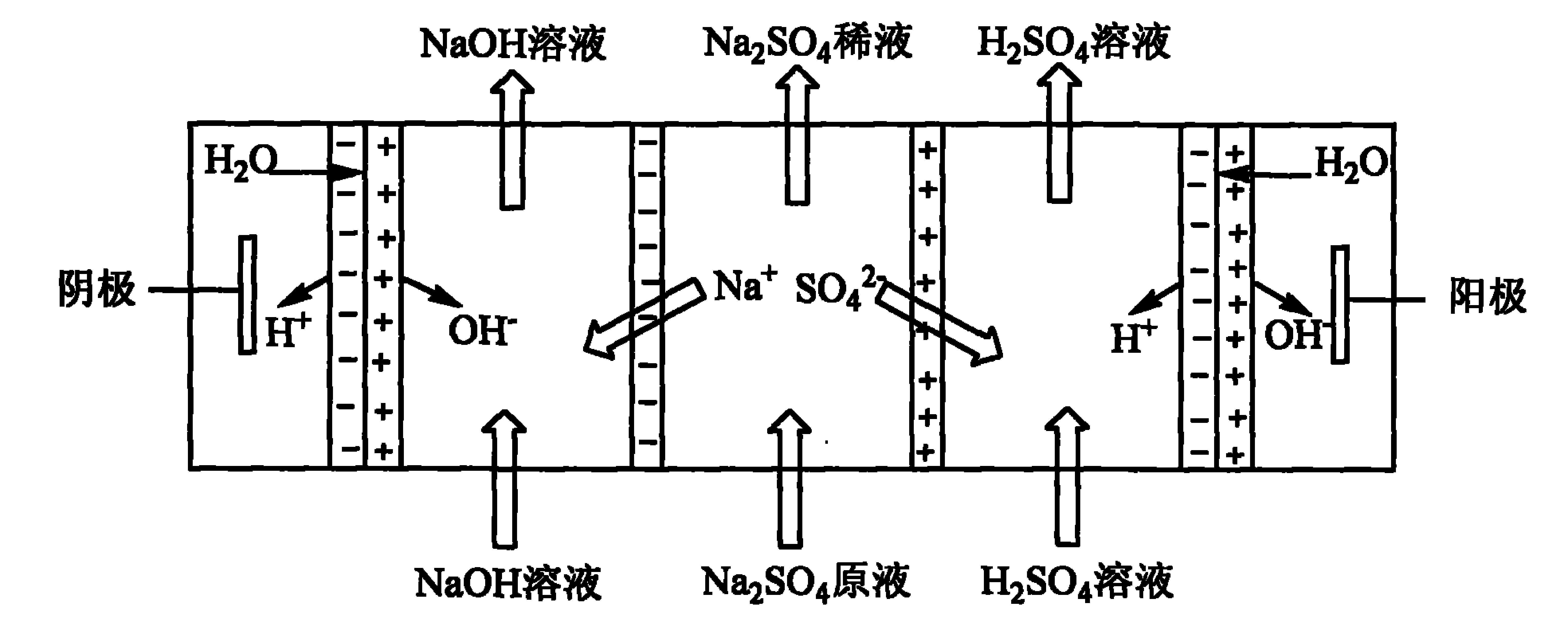

Reproduction method for sodium-base flue gas desulfurization liquid

InactiveCN102335553ALow costElectrolysis componentsDispersed particle separationElectrolysisResource utilization

The invention relates to a reproduction method for sodium-base flue gas desulfurization liquid, which is characterized in that the flue gas desulfurization liquid containing sodium sulphite and sodium bisulfite is oxidized to a solution containing sodium sulfate, the solution containing sodium sulfate is electrolyzed to a sodium hydroxide solution and a sulfuric acid solution by using bipolar membrane electrodialysis. According to the invention, the electrolytic conversion rate of sodium sulfate can reach more than 90%, the obtained sodium hydroxide solution can be used as absorption liquid for a flue gas desulfurization tower, the sulfuric acid by-product is produced simultaneously. By-product sulfuric acid can be used as sulfuric acid for treating high hardness and high alkalinity. The reproduction method for sodium-base flue gas desulfurization liquid is capable of achieving the purposes of strong brine zero-draining, comprehensive resource utilization and cost reduction.

Owner:CHINA PETROLEUM & CHEM CORP

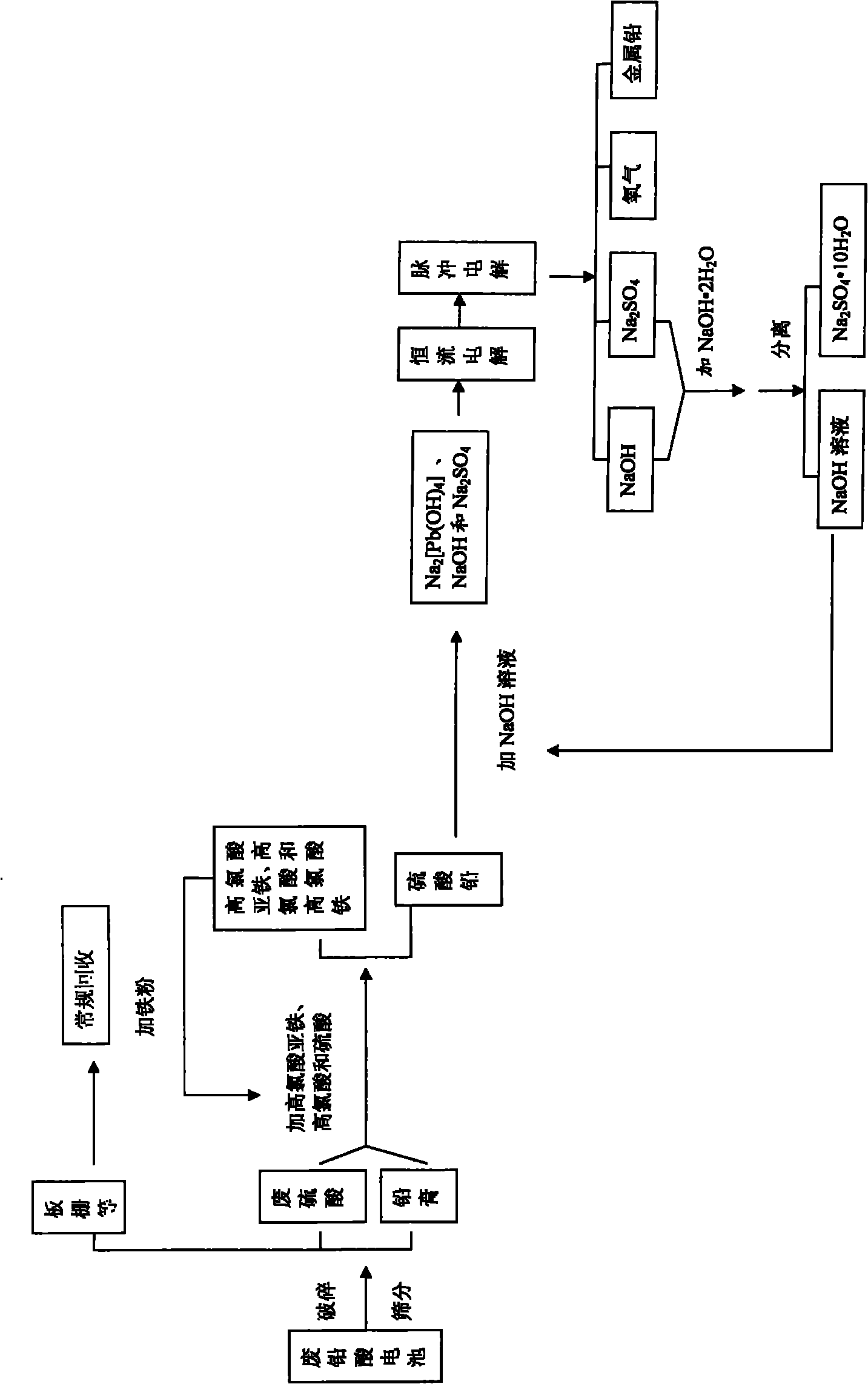

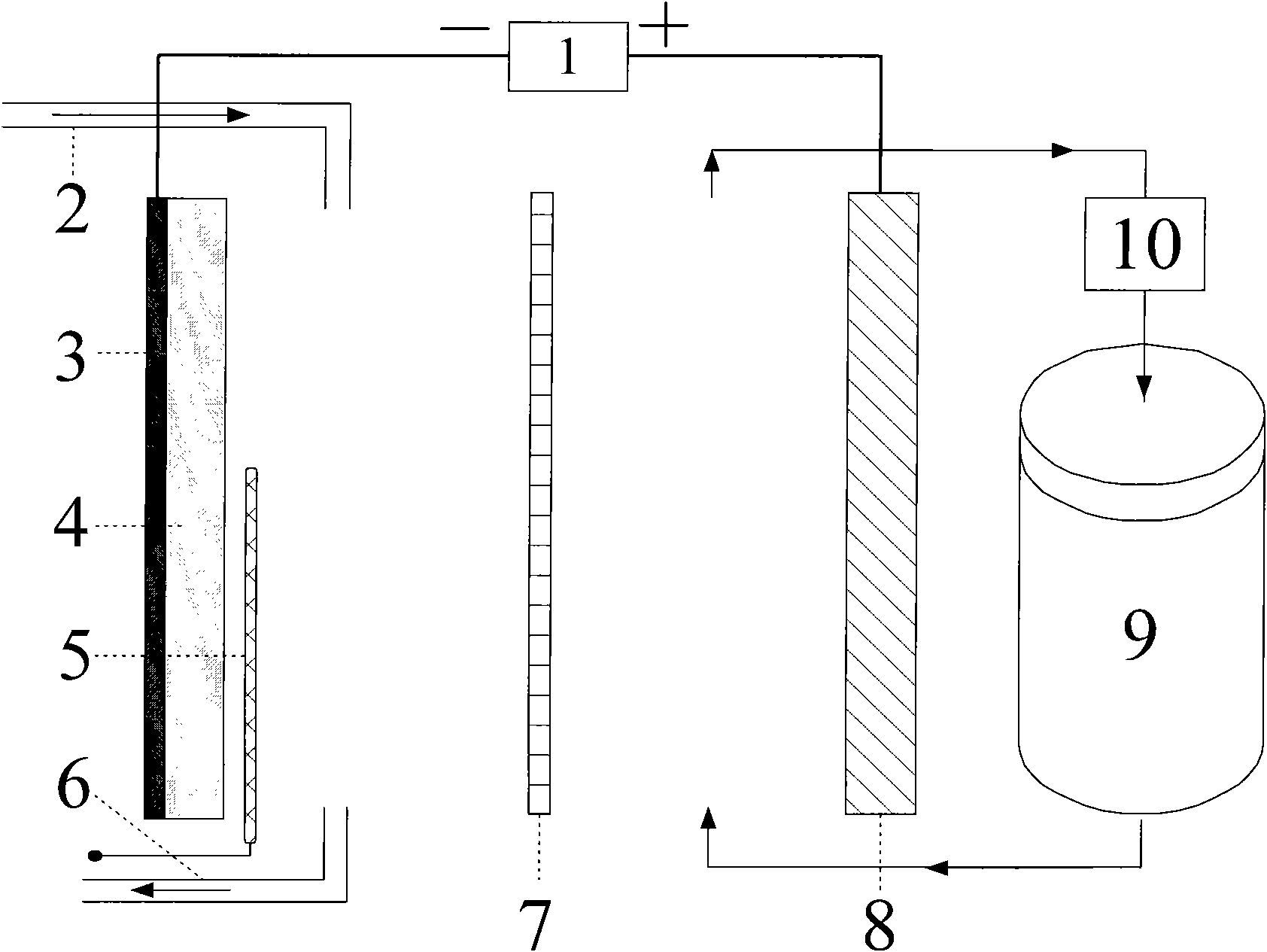

Method for recycling secondary lead by electrolyzing alkaline leaded solution

InactiveCN101956214AEfficient conversionReduce energy consumptionPhotography auxillary processesProcess efficiency improvementAlkalinityElectrolysis

The invention relates to a method for recycling secondary lead by electrolyzing an alkaline leaded solution. Leaded alkaline electrolyte is directly obtained by prepositive catalytic conversion and alkalinity desulfuration leaching processes; and then the leaded alkaline electrolyte is subjected to fractional electrolysis in an ion film electrolyser, thus directly obtaining the high-purity metal lead and byproducts of oxygen gas and sodium sulfate decahydrate. The method in the invention is a novel technology which has the advantages of energy conservation and large-scale industrialization application prospect.

Owner:BEIJING UNIV OF CHEM TECH

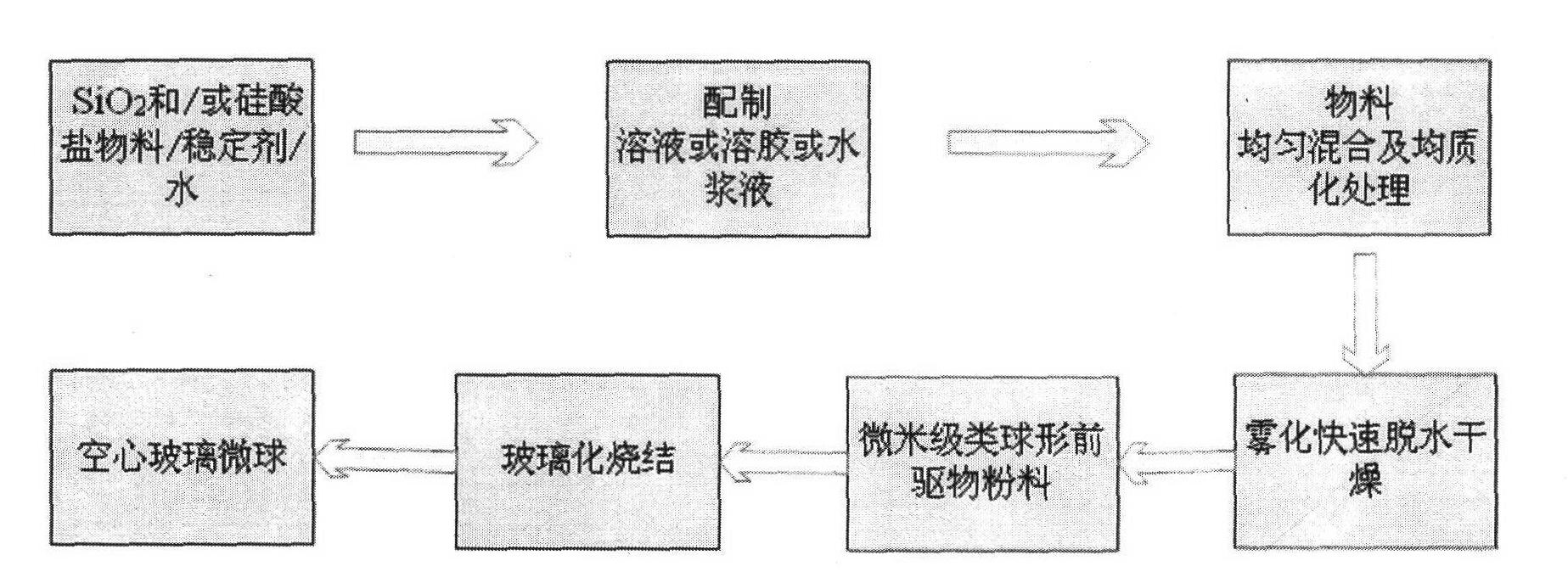

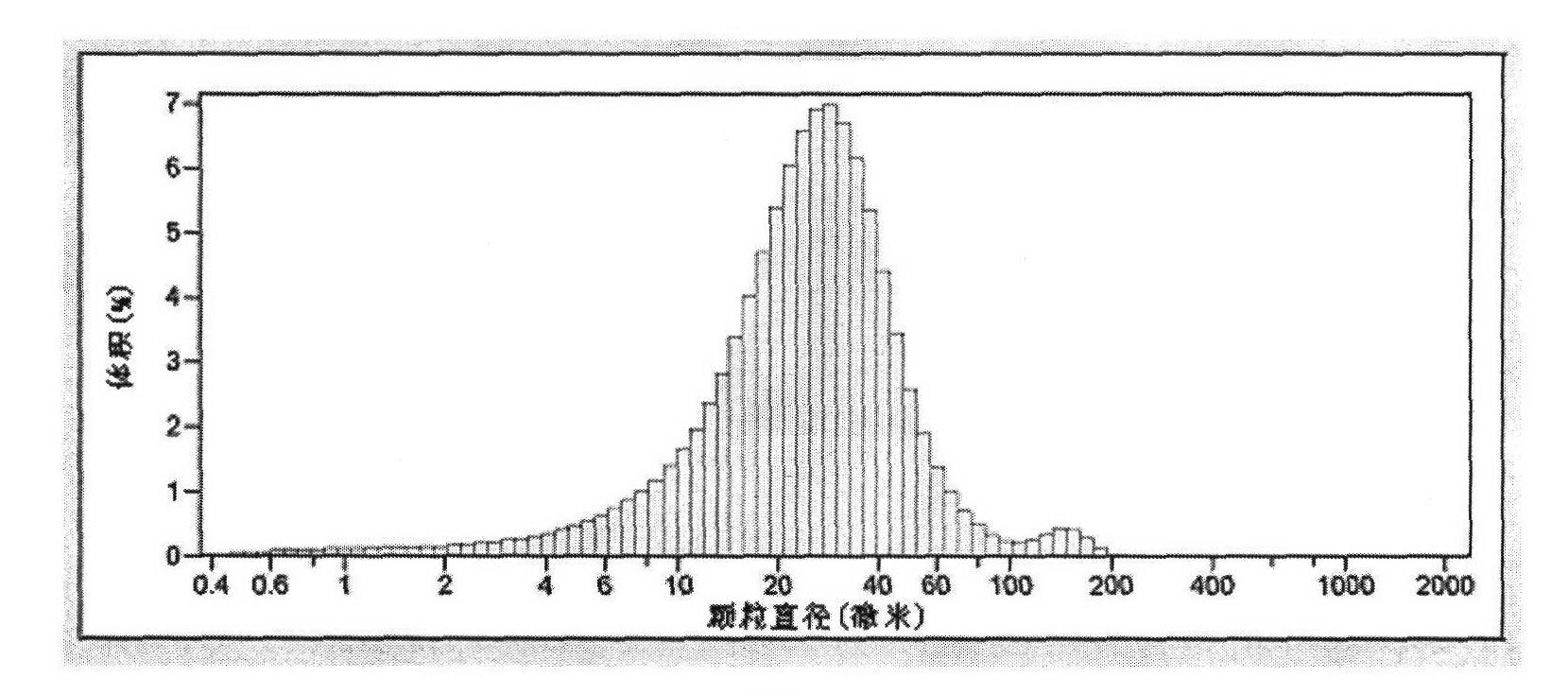

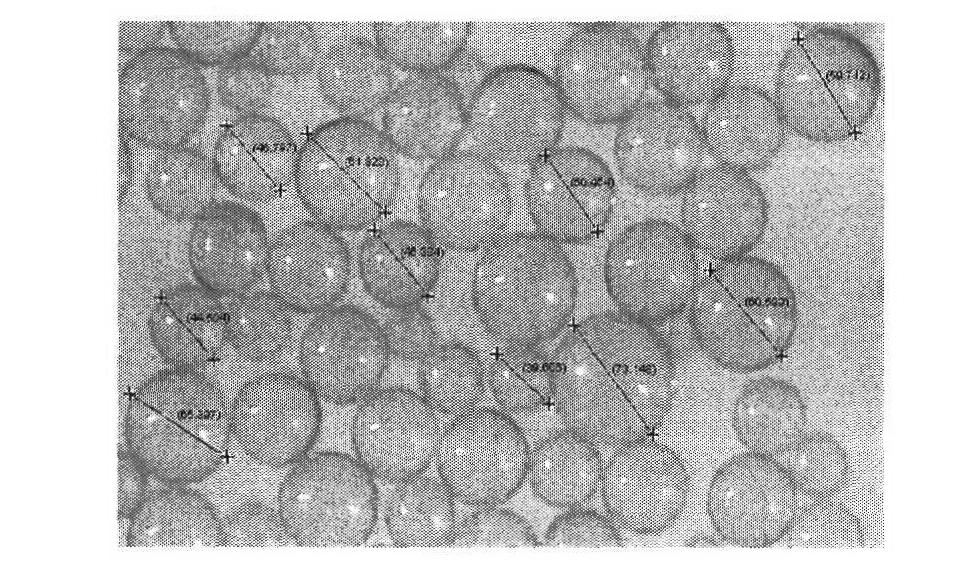

Soft chemical preparation method for hollow glass micro-balloon, prepared hollow glass micro-balloon and application thereof

ActiveCN102583973AHigh strengthHigh compressive strengthGlass shaping apparatusMicron scalePolymer science

The invention belongs to the technical field of a soft chemical method. According to the invention, the method is used for overcoming the defects that the traditional solid-phase glass powder method for preparing a hollow glass micro-balloon is high in energy consumption, long in technical process and difficult in controlling grain size distribution and the hollow glass micro-balloon prepared according to a liquid-phase atomizing method is high in alkalinity, easy to absorb water, high in strength and easy to break, and the like. A liquid material system is compounded through a chemical reaction; after the system is homogenized, the system is quickly atomized, dewatered and dried, thereby obtaining approximate spherical precursor powder with required grain size and corresponding distribution; and the powder is treated under high temperature at 600-1100 DEG C, thereby obtaining a micron-scale hollow glass micro-balloon with the volume floating rate being above 90%, the SiO2 content (weight) being 55-88%, the true density being 0.1-0.7g / cm<3> and the compression strength being 1-50MPa. The method is low in energy consumption, free from fusion and sintering, and high in yield. The prepared hollow glass micro-balloon is high in compression strength, light in weight, low-alkali, waterproof, excellent in fluidity and dispersibility, and suitable for various high-performance light compound materials.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Method for controlling the cross crack of blank angle of high nitrogen steel casting board containing vanadium

The invention discloses a transverse crack control method of high nitrogen steel continuous casting plate billet angle containing vanadium, the method can not only effectively eliminate transverse crack defect of the continuous casting billet surface and skin inferior angle, but also can eliminate the continuous casting billet surface longitudinal crack and surface transverse crack defect. The method synthetically applies following technique measures: presetting the mold cooling water amount, the wide face cooling water amount is 3000-30500 L / min, the narrow face cooling water amount is set to 360-365 L / min; improving casting pulling rate, the casting pulling rate is stabilized in 0.8-1.5 m / min, the vibration frequency is 140-210 Hz; after spruing the casting pulling rate, quickly putting casting powder into the mold, the alkalinity of the casting powder is 1.0-1.40, the melting point is 1100-1160 DEG C, when at 1300 DEG C, the viscosity is 0.10-0.40 Pa.s; reducing the second cool segment casting billet cooling water amount, and controlling the continuous casting ratio water amount in 0.55-0.60 L / kg by static or dynamic adjusting method.

Owner:PANZHIHUA IRON AND STEEL

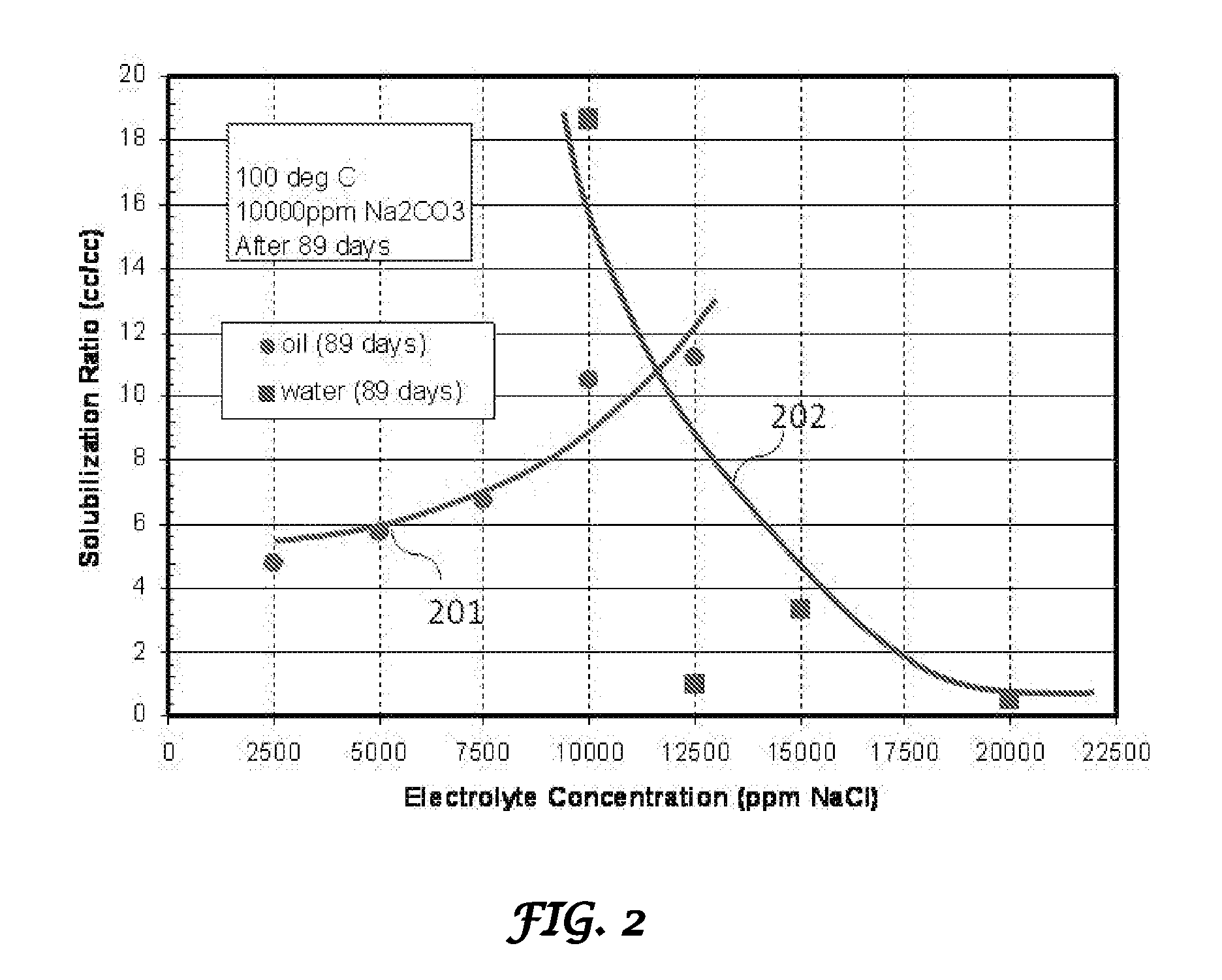

Compositions and methods for controlling the stability of ethersulfate surfactants at elevated temperatures

The present invention describes the method of making an ether sulfate surfactant solution hydrolytically stable by adding one or more alkalinity generating agents at levels greater than 0.05%. The surfactant solutions of the present invention have half-lives >8 months at 100° C. and find uses in EOR applications, environmental cleanups, detergent industry, and any other surfactant based high temperature applications.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

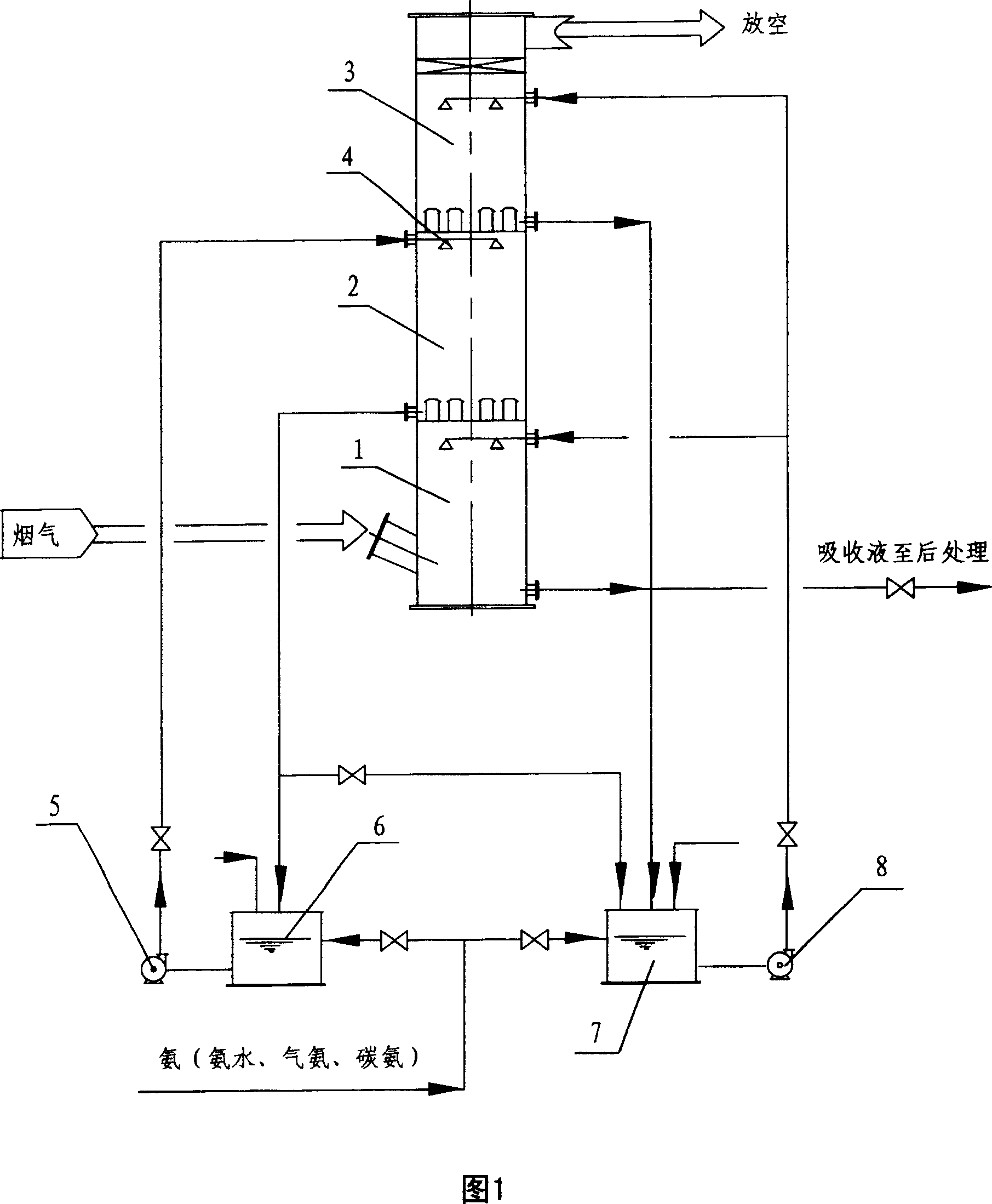

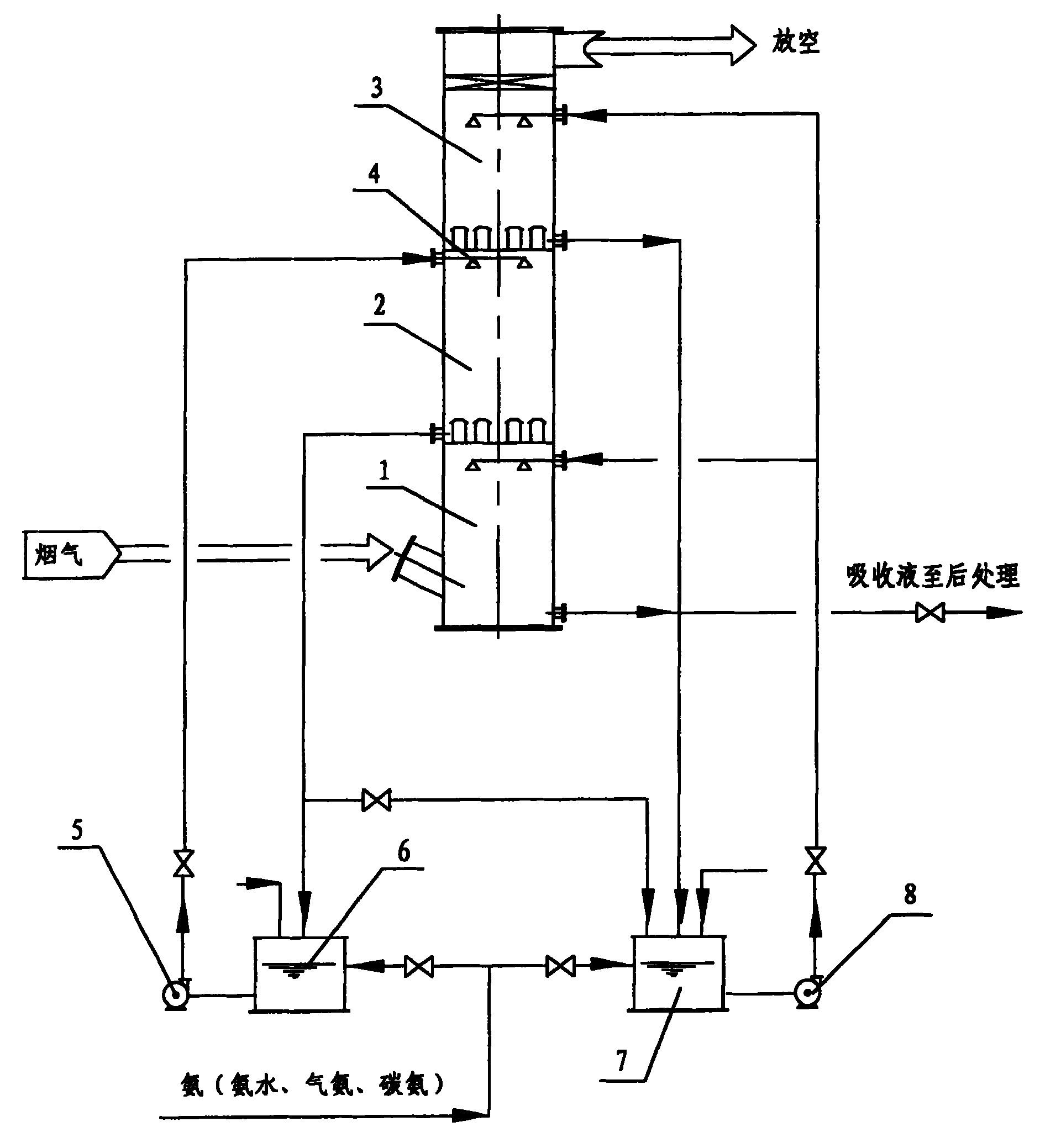

Method of separating and recovering sulfur dioxide in smoke using ammonia method

A process for separating and recovering SO2 from fume by ammonia method and use of an absorption tower with multiple function stages includes such steps as dusting and cooling by spraying the absorbing liquid A, master absorption by spraying the absorbing liquid B, frost and ammonia removal by spraying the absorbing liquid C, and exhausting clean fume.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

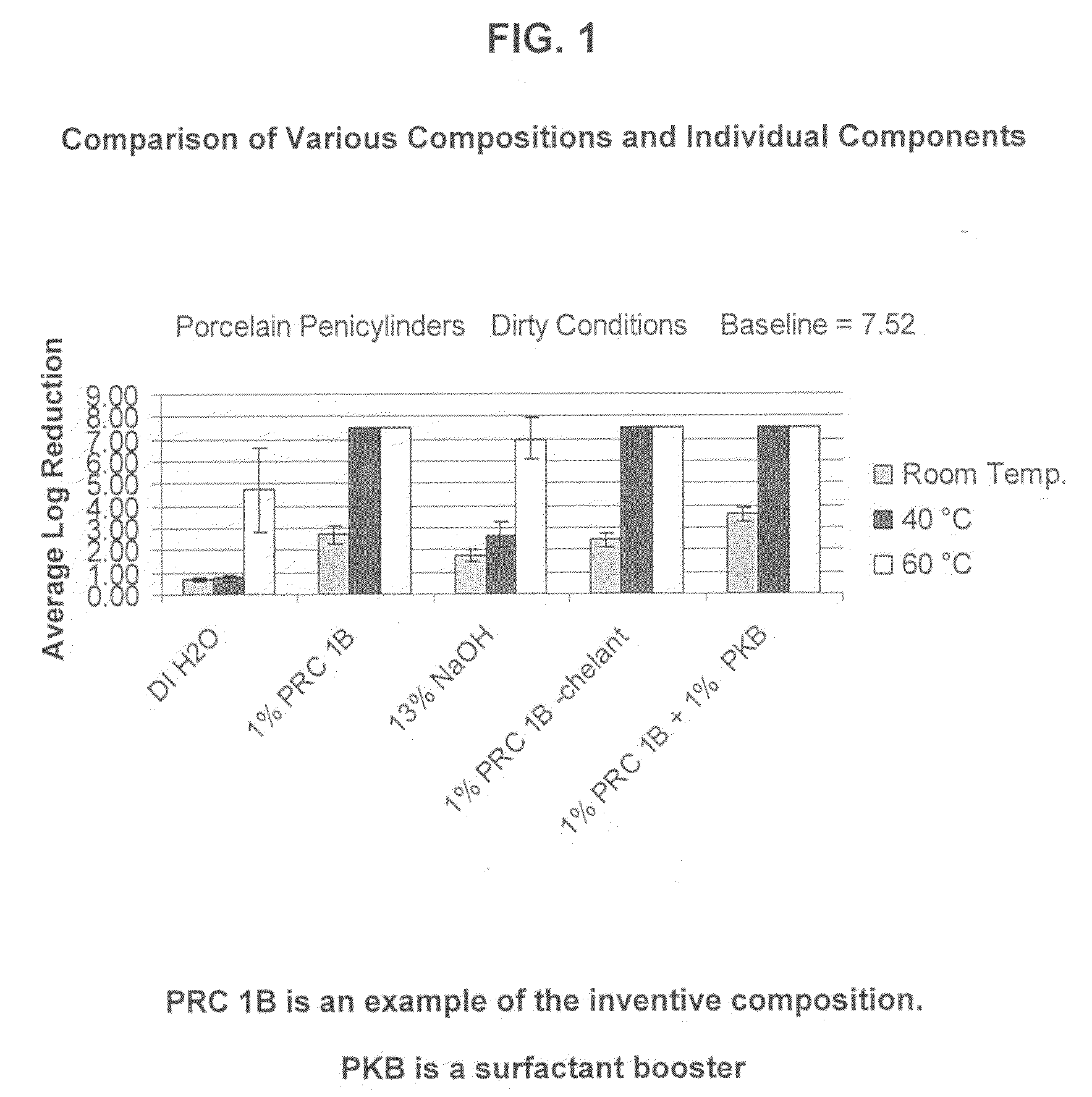

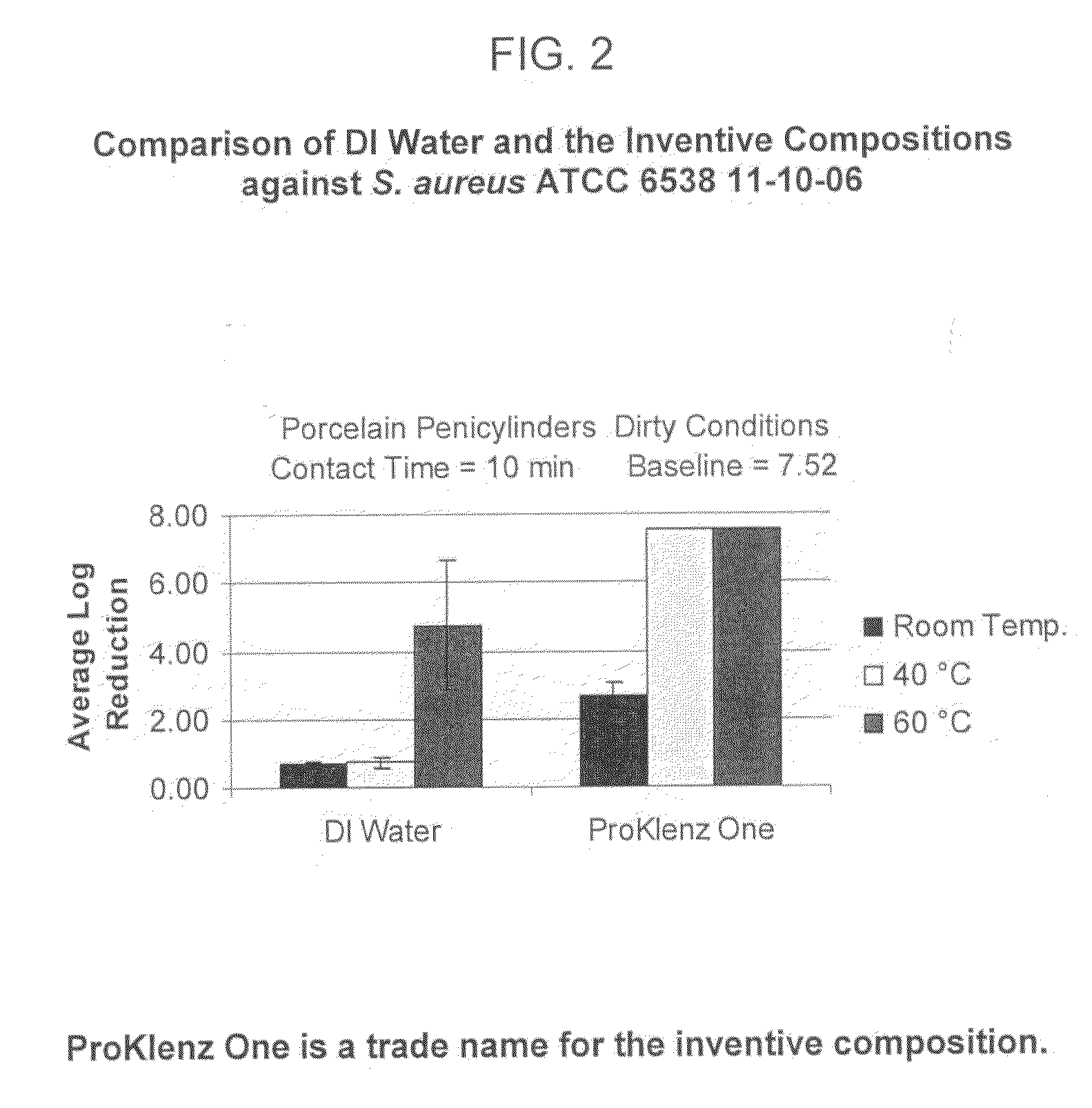

Biodegradable alkaline disinfectant cleaner with analyzable surfactant

ActiveUS20080221006A1Sure easyReduce downtimeOrganic detergent compounding agentsSurface-active detergent compositionsPersonal careAlkalinity

An aqueous, alkaline cleaning composition for use on hard-to-clean soils, encountered in pharmaceutical, personal care, food and cosmetic manufacturing, comprising a source of alkalinity, a biodegradable surfactant system further comprising one or more surfactants, one or more hydrotropes, and a UV-analyzable surfactant, and a biodegradable chelating agent. The composition offers unique advantages of stability over the expected shelf life, low-foaming property, phosphate-free and biodegradable components, and unexpectedly enhanced antimicrobial, including virucidal, activity in one cleaning composition. The UV-analyzable surfactant allows for validation of cleaning processes using known techniques for manufacturers who are required or desire to do so.

Owner:AMERICAN STERILIZER CO

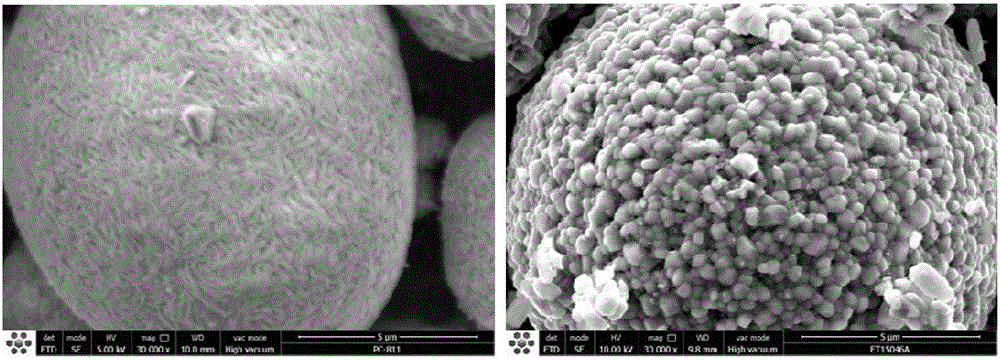

Polycrystal high-nickel positive electrode material used for lithium ion battery and preparation method for polycrystal high-nickel positive electrode material

InactiveCN105958062AExtended storage timeReduce lithiumCell electrodesSecondary cellsSodium-ion batteryLithium-ion battery

Disclosed is a polycrystal high-nickel positive electrode material used for a lithium ion battery. The polycrystal high-nickel positive electrode material comprises a base material with a layered structure and a coating layer which is arranged outside the base material and has a spinel structure; the general formula of the base material is LiNi<1-x-y>Co<x>M<y>O<2>, wherein M is at least one kind of Mn and Al; the coating layer is lithium manganese oxide; the mass percentage of the total impurity lithium on the surface of the base material is less than 0.085% based on the total mass percentage of the base material; the preparation method for the positive electrode material comprises the following steps of weighing Ni<1-x-y>Co<x>M<y>(OH)<2>, and mixing with a lithium source, then carrying out thermal treatment, cooling, crushing and sieving to obtain the base material; measuring the content of the residual impurity Li<2>CO<3> and LiOH on the surface of the base material, adding into the metal Mn compound according to the measurement result, and carrying out low-temperature thermal treatment in an oxygen atmosphere to obtain the polycrystal high-nickel positive electrode material used for the lithium ion battery. The polycrystal high-nickel positive electrode material provided by the invention has the advantages of low material alkalinity, low inflatable degree, excellent processing property and cycling performance, and the like.

Owner:HUNAN SHANSHAN NEW ENERGY CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com