Charcoal based plant cultivation substrate and preparation method thereof

A technology of cultivation substrate and biochar, which is applied in the direction of fertilizer mixture, fertilization device, application, etc., can solve the problems that no effective cultivation substrate has been found, and achieve the effect of excellent physical and chemical properties, complete nutrients and strong adjustment ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

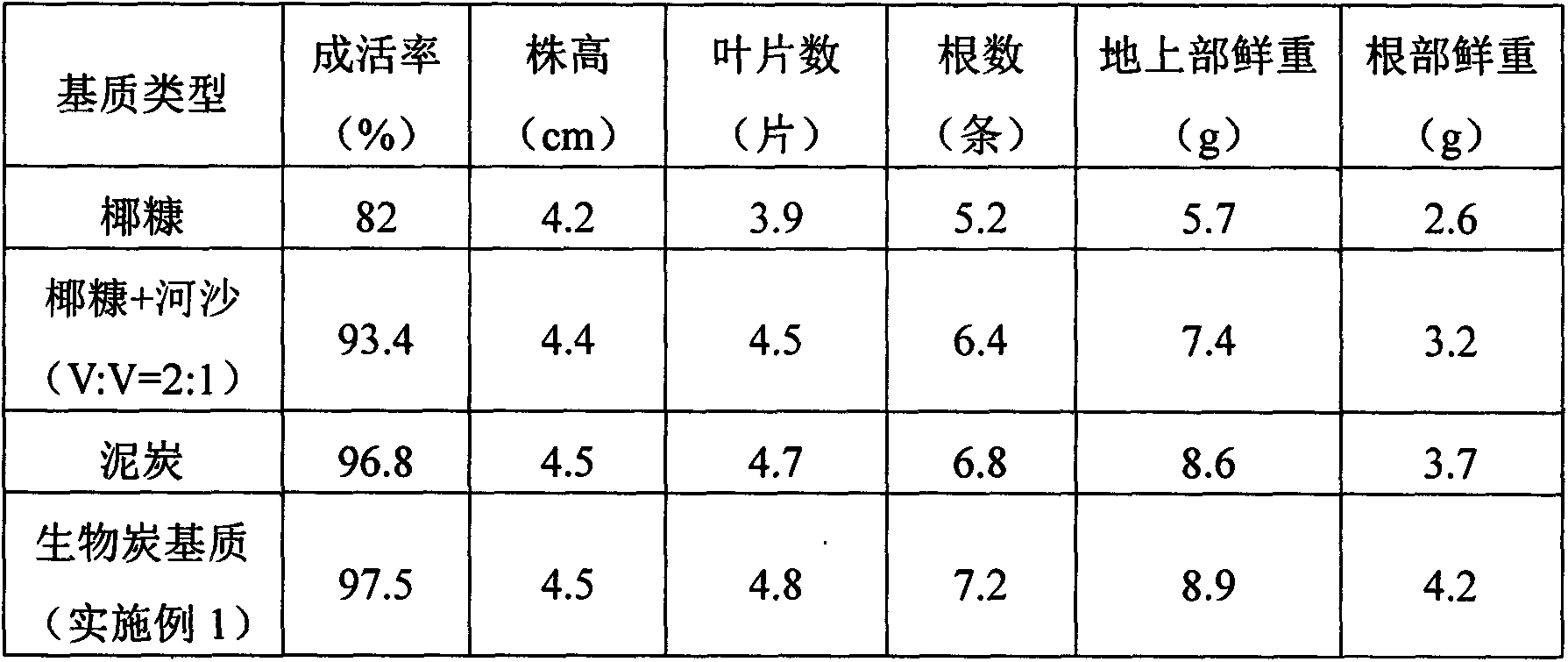

Embodiment 1

[0018] The dried sawdust is crushed into particles with a diameter of less than 2mm, and then pyrolyzed under the condition of anoxic and 300°C for 3h to form wood pellet biochar; the wood pellet biochar is added to 1% potassium dihydrogen phosphate solution, and stirred for 2h until Filter after the pH value of the solution is stable; wash the filtered biochar particles twice with clear water, the pH value of the washing liquid is about 6.5, filter, and dry; calculate by volume 10 parts of sawdust biochar particles, 5 parts of river sand, 2 parts of coconut peat and 0.5 part of decomposed chicken manure are fully mixed.

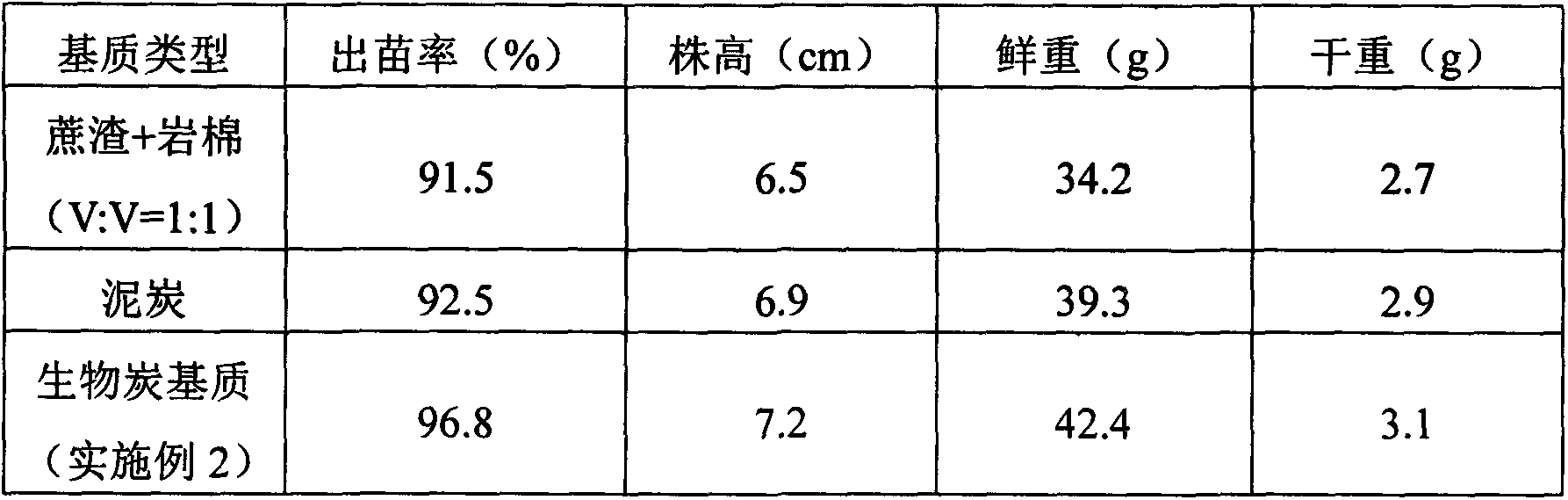

Embodiment 2

[0020] The rice straw is dried and crushed into particles with a diameter of less than 1mm, and then pyrolyzed for 2.5 hours under the condition of anoxic and 400°C to form rice straw granular biochar; the rice straw granular biochar is added to 0.2% potassium dihydrogen phosphate solution, Stir for 3h, filter until the pH value of the solution is stable; wash the filtered biochar particles once with clear water, the pH value of the washing solution is about 6, filter, and dry; calculate by mass 0.1% compound fertilizer ( N:P 2 o 5 : K 2 O=15%: 15%: 15%) is added to rice straw biochar particles, and 10 parts of rice straw biochar particles, 10 parts of rock wool, 2 parts of bagasse, and 1 part of commercial organic fertilizer are fully mixed by volume. .

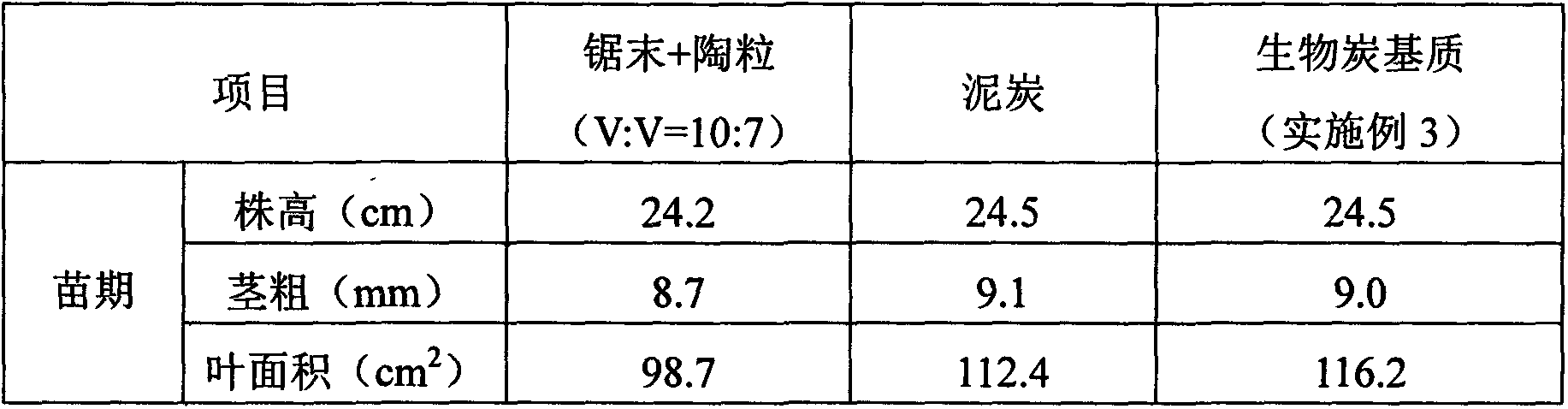

Embodiment 3

[0022] Peanut shells are dried and crushed into particles with a diameter of less than 3mm, and then pyrolyzed for 6 hours under anoxic conditions at 200°C to form peanut shell granular biochar; add peanut shell granular biochar to 5% potassium dihydrogen phosphate solution, and stir 1h, filter until the pH value of the solution is stable; wash the filtered biochar particles twice with clear water, the pH value of the washing solution is about 5.7, filter and dry; calculate by mass 0.2% chemical fertilizer (hydrogen phosphate A mixture of diammonium and potassium nitrate in a mass ratio of 2:1) was added to the peanut shell biochar particles, and 10 parts of peanut shell biochar particles, 7 parts of ceramsite, 3 parts of sawdust, and 0.8 parts of commercial organic fertilizer were fully mixed by volume. Instantly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com