Patents

Literature

188results about How to "Improve water vapor permeability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

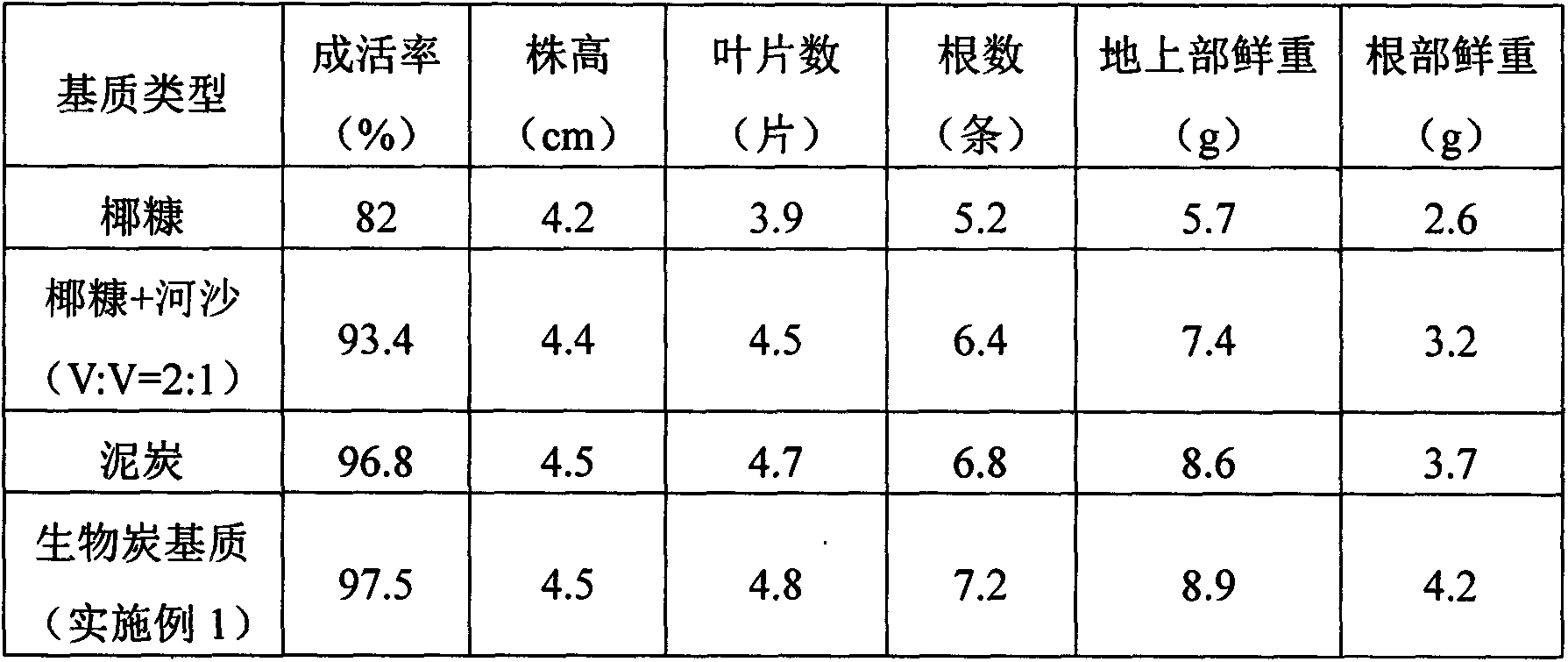

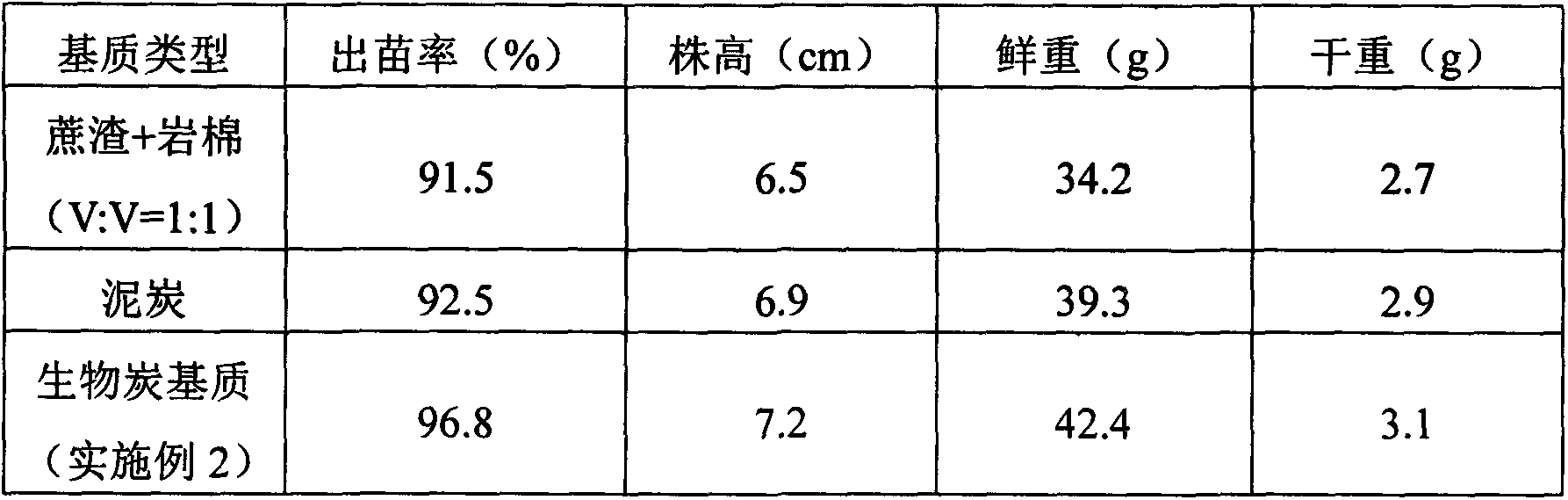

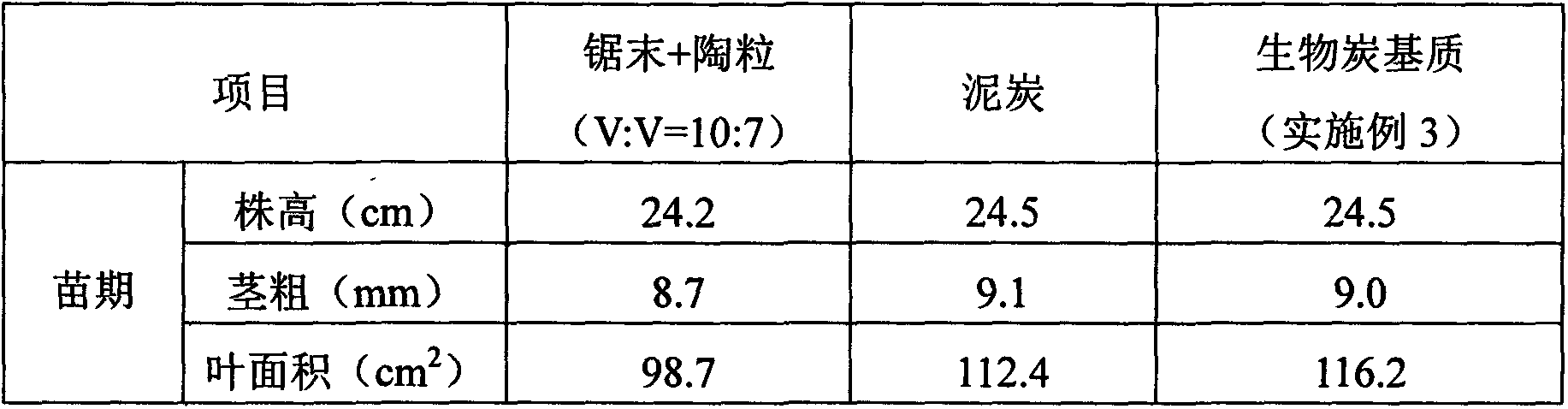

Charcoal based plant cultivation substrate and preparation method thereof

InactiveCN103435411AEnhanced ability to provide phosphorus and potassium fertilizersLight textureFertilizer mixturesPhosphatePotassium

The invention relates to a charcoal based plant cultivation substrate and a preparation method thereof, and belongs to the technical field of soilless culture. The invention adopts the specific scheme that: after being dried, biomass material is pyrolyzed to form charcoal particles under an anoxic and heating condition, potassium dihydrogen phosphate is used for neutralizing the alkalinity of the charcoal particles and filtering and drying are performed, and after a certain amount of inorganic fertilizer is added, the charcoal particles are fully mixed with inorganic filling material, organic filling material and organic fertilizer, namely the charcoal based plant cultivation substrate is obtained. The invention has the advantages that the physical chemical property is excellent, the nutrients are complete, the fertilizer efficiency is lasting, the moisture adjusting capability is strong, the cost is low, the ecological benefits are high, the suitability is strong, the application range is wide, and the charcoal based plant cultivation substrate is suitable for cultivation of various plants.

Owner:QIONGZHOU UNIVERSITY

Method for preparing organosilicon and nano-silicon dioxide modified acrylic resin soap-free emulsion

InactiveCN101735412AIncreased stability and solids contentImproves water resistance and adhesionSolventEmulsion

The invention relates to a method for preparing an organosilicon and nano-silicon dioxide modified acrylic resin soap-free emulsion. According to the method, a reactive emulsifier is used to replace a conventional emulsifier, and the method comprises the steps of: performing soap-free emulsion polymerization on acrylic ester monomers, (methyl) acrylic acid, vinyl silicone oil and alkoxy silane containing double bonds; and then adding ethyl orthosilicate for a sol-gel reaction to obtain the organosilicon and nano-silicon dioxide modified acrylic resin soap-free emulsion. The organosilicon and nano-silicon dioxide modified acrylic resin soap-free emulsion is suitable to be taken as a leather finishing agent. The method can completely eliminate the adverse effect of a small molecular emulsifier on an acrylic resin emulsion finishing agent, introduce good characteristics of organosilicon and nano-silicon dioxide into an acrylic resin, overcome the disadvantages of hot sticking and cold shortness, poor waterproof performance and poor solvent resistance and the like of the acrylic resin, and improve the mechanical property, adhesive force and wear resistance of the acrylic resin.

Owner:山西佳宇丰化工科技有限公司

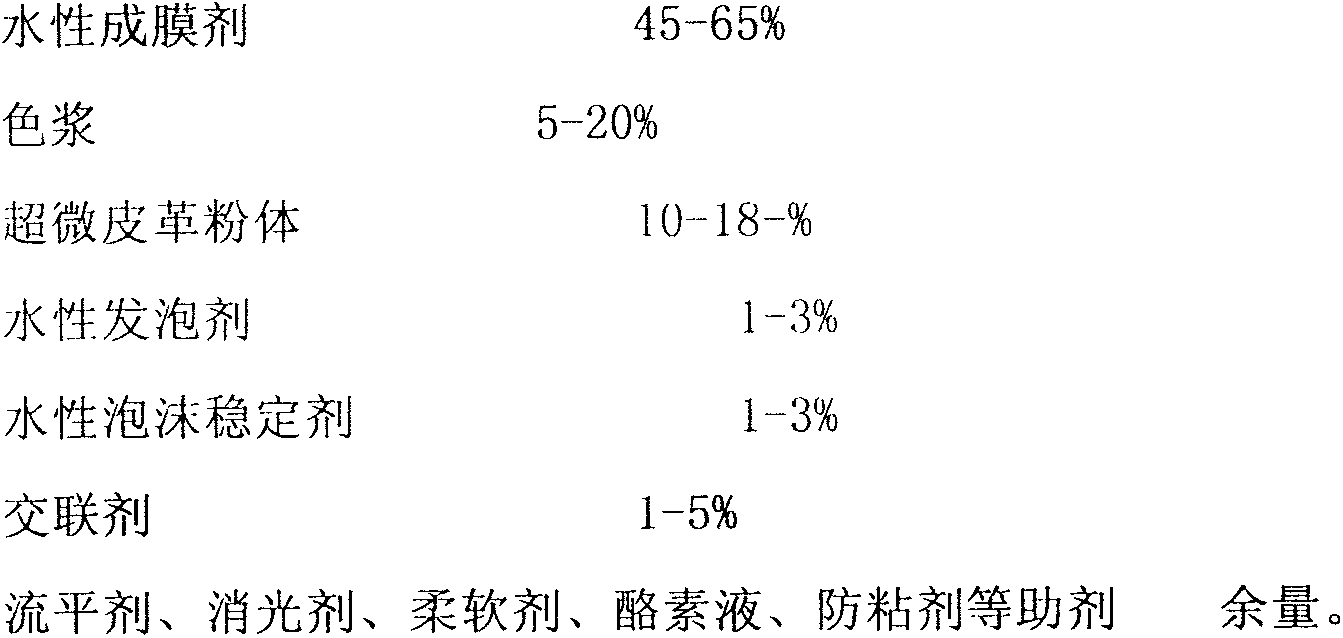

Clean production process for polyurethane synthetic leather base with ultramicro leather powder as filling material

InactiveCN103290701ARealize cleaner productionDevelop circular economySynthetic resin layered productsTextiles and paperWater basedFilling materials

The invention discloses a clean production process for a polyurethane synthetic leather base with ultramicro leather powder as a filling material. The process comprises the following steps: introducing air and water-based finishing slurry blended with ultramicro leather powder into a mixer according to a certain proportion and allowing a high-quality micro-foaming finishing agent to be formed under high-speed dispersion action of a stirring head; and coating the micro-foaming finishing agent and then drying and curing the micro-foaming finishing agent so as to prepare the synthetic leather base. The method provided by the invention has the advantages of simple preparation, easy control and the like, eliminates pollution of dimethyl formamide (DMF) produced in a wet production method for synthetic leather and reduces pollution of the industry of synthetic leather; and introduction of the natural ultramicro leather powder enables moisture and air permeability of polyurethane synthetic leather to be improved.

Owner:CHINA LEATHER & FOOTWEAR IND RES INST

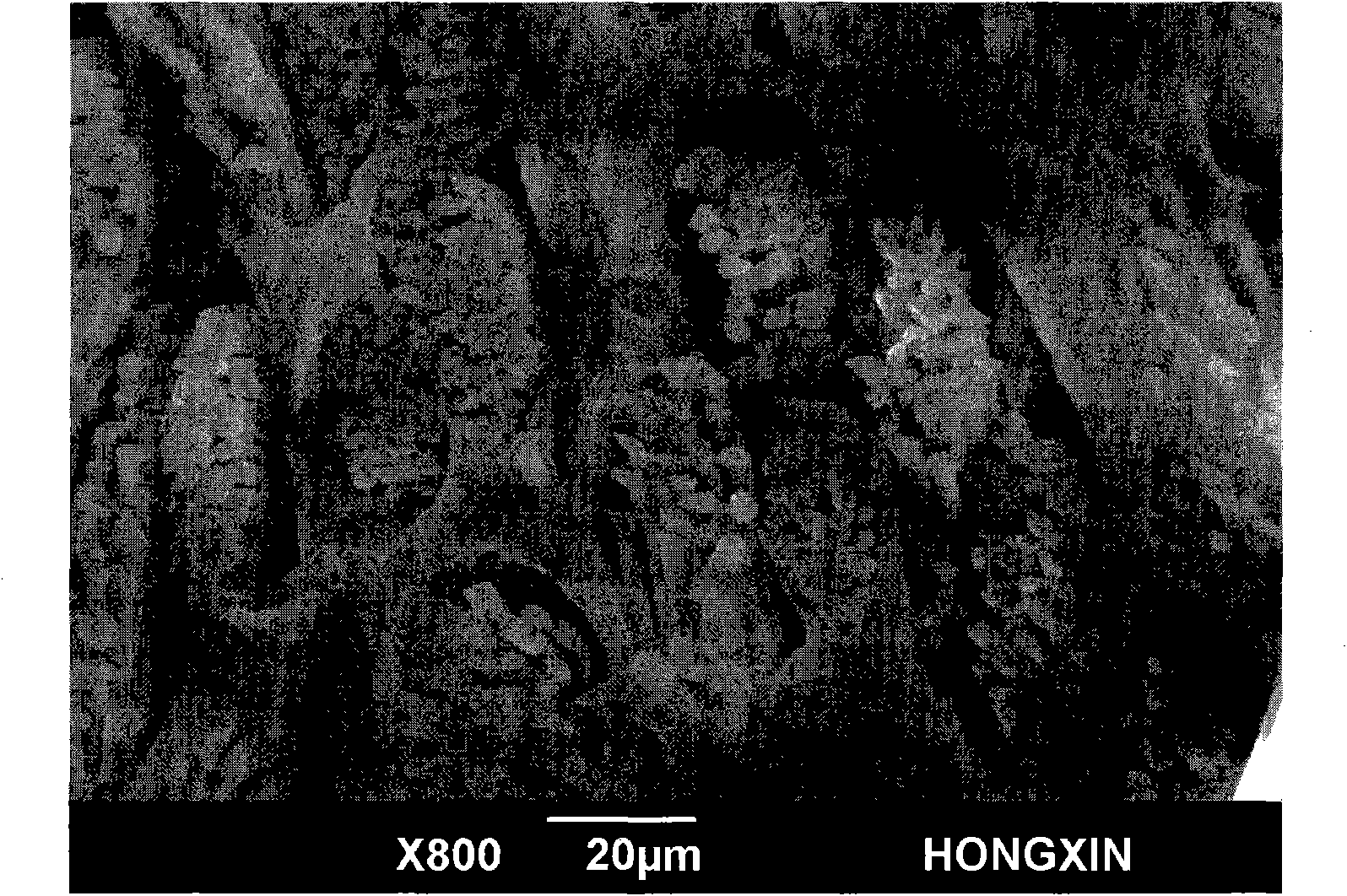

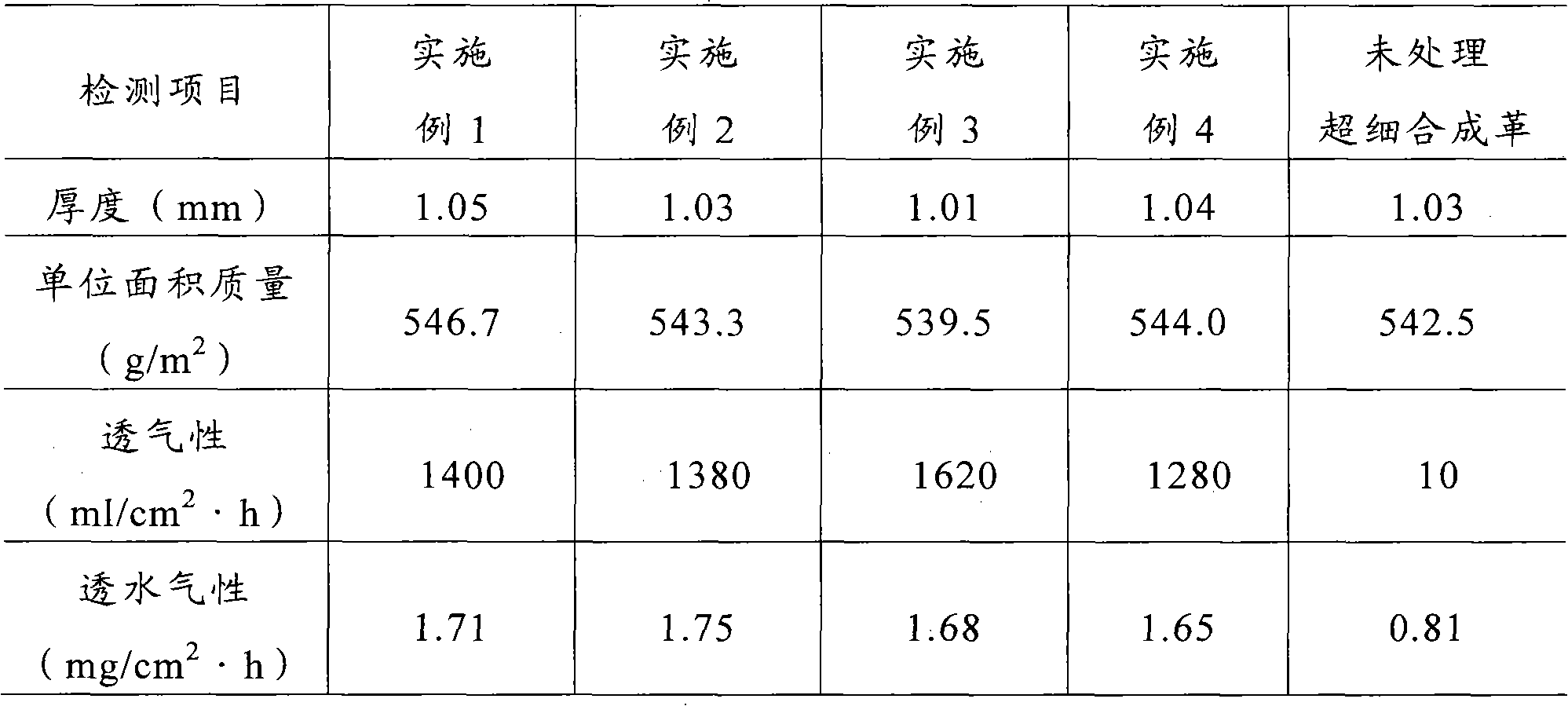

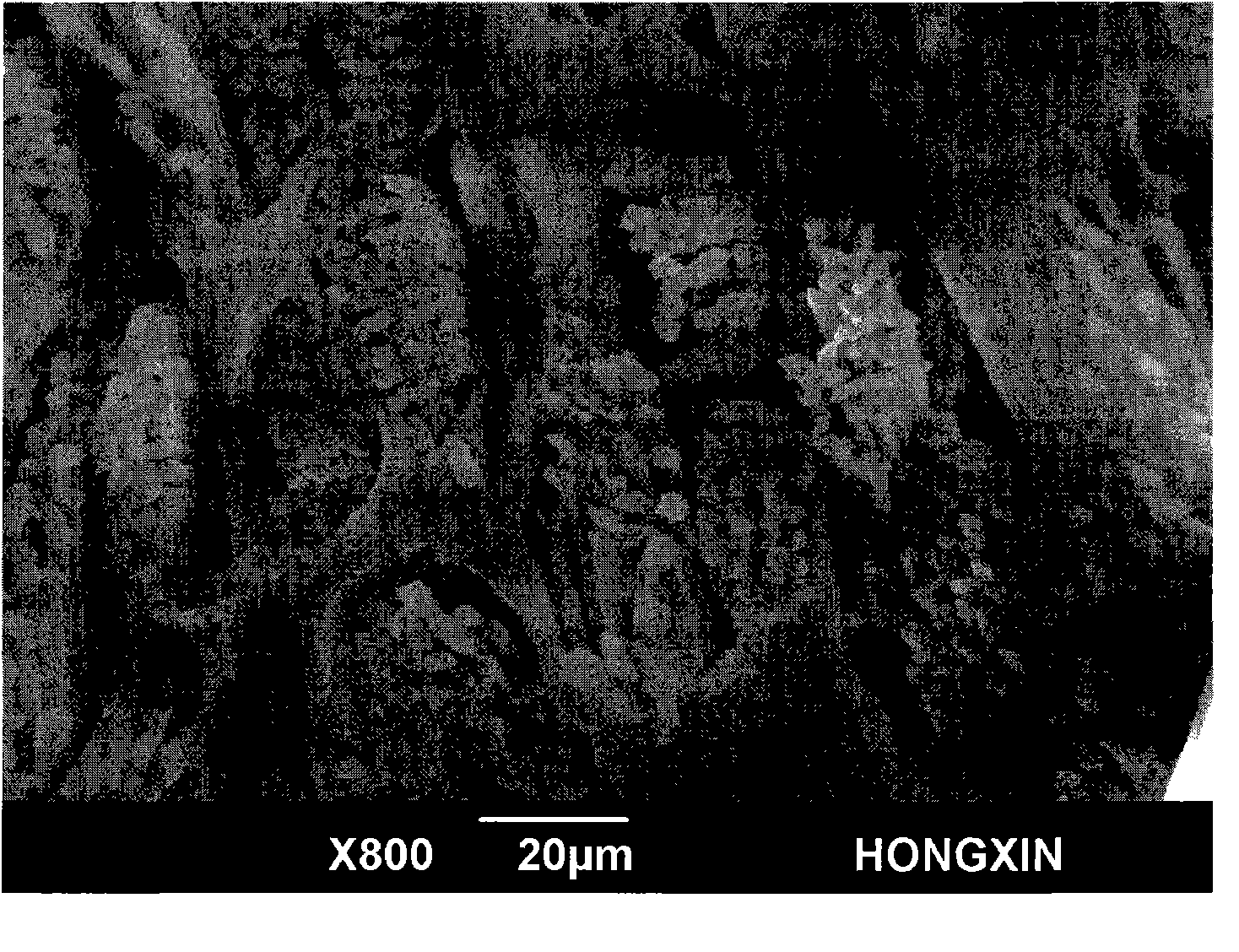

Method for improving hygienic performance of figured-island superfine fiber synthetic leather

InactiveCN101956333AImprove water vapor permeabilityImprove breathabilityFibre treatmentWater vapor permeabilityWater soluble

The invention provides a method for improving hygienic performance of figured-island superfine fiber synthetic leather, which is characterized by comprising the following steps of: a) treating base cloth of the superfine fiber synthetic leather through collagen and making the collagen fixedly crosslinked to superfine fibers in the superfine fiber synthetic leather; b) penetrating and adsorbing a hydrophilic material in the superfine fiber synthetic leather treated by the collagen; and c) performing finishing treatment on the superfine fiber synthetic leather which is penetrated with the hydrophilic material. By treating the base cloth of the superfine fiber synthetic leather through the collagen and the hydrophilic material, because the collagen and the hydrophilic material have a plurality of hydrophilic groups, the hydrophilcity of the treated superfine fiber surface is equivalent to that of collagen fibers of natural leather, the water vapor permeability and water absorbing capacity of the synthetic leather are improved, and finally a coating with micropores is formed on the surface of the synthetic leather after the finishing treatment on the synthetic leather by using water-soluble polyurethane so as to integrally improve the water vapor permeability and air permeability of the synthetic leather.

Owner:XIAMEN HONGXIN MICROFIBER MATERIALS +2

Anti-flaming antisepsis leather coating and preparation method thereof

InactiveCN105925099AImprove water resistancePrevent penetrationFireproof paintsAntifouling/underwater paintsDecabromodiphenyl etherTriterpenoid saponin

The invention discloses an anti-flaming antisepsis leather coating which is composed of, by weight, 2-3 parts of hydrous zinc borate, 1-1.5 parts of linoleic acid calcium soap, 0.1-0.2 part of triterpenoid saponin, 0.7-1 part of calcium naphthenate, 1.7-2 parts of polyvinylpyrrolidone, 0.8-1 part of polyacrylamide, 1.6-2 parts of stannous chloride, 0.1-0.13 part of triethanolamine, 190-200 parts of methyl methacrylate, 3-4 parts of lauryl sodium sulfate, 0.1-0.2 part of urotropine, 0.2-0.3 part of ammonium persulfate, 6-7 parts of a 20%-25% formaldehyde solution, 16-20 parts of zinc acetate, 4-7 parts of silver nitrate, 1-2 part of decabromodiphenyl ether and 0.4-1 part of sodium lauryl sulfate. The anti-flaming antisepsis leather coating has a good antibacterial property and excellent moisture permeability and water resistance. Leather coated with the obtained emulsion is good in antibacterial property and excellent in hygiene property.

Owner:CHUZHOU VOCATIONAL & TECHN COLLEGE

Preparation technology of ving/polymer/modified montmorillonoid nano composite tanoing agent

InactiveCN1556225AImprove performanceMeet the requirements of shrinkage temperatureTanning treatmentMontmorilloniteMoisture permeability

A process for preparing the nano-class composite tanning agent includes using ammonium hexadecane bromide to modify Na-base montmorillonite, using vinyl monomer (acrylic acid, acrylonitrile, or ethyl acrylate) to prepare vinyl polymer, and combounding them together by solution stripping-adsorption method. Its advantages are high effect on raising the shrinking temp of sheep leather to 76 deg.C and increasing leather thickness, and high air and moisture permeability of leather.

Owner:SHAANXI UNIV OF SCI & TECH

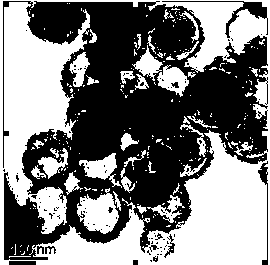

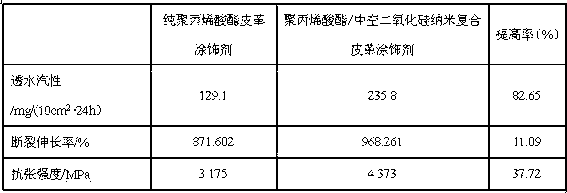

Preparation method of polyacrylic ester/hollow silicon dioxide nanometer composite leather finishing agent

InactiveCN102704273AImprove mechanical propertiesHigh tensile strengthFibre treatmentPigment treatment with macromolecular organic compoundsExtensibilityWater vapor

The invention relates to a preparation method of a polyacrylic ester / hollow silicon dioxide nanometer composite leather finishing agent. The polyacrylic ester is a kind of film forming matters most extensively applied in the leather finishing material, the polyacrylic ester has excellent optical stability, chemical resistance, extensibility and good cohesiveness, while the polyacrylic ester forms a layer of dense thin film on the leather surface to severely block the passage through which the water vapor emitted by a human body disperses to outside, so that the sanitary performance of a leather product is greatly affected. According to the invention, polystyrene microspheres are used as a template to prepare hollow silicon dioxide nanometer particles, and the hollow silicon dioxide nanometer particles are mixed with the polyacrylic ester to prepare the polyacrylic ester / hollow silicon dioxide nanometer composite leather finishing agent. Compared with the pure polyacrylic ester leather finishing agent, the composite leather finishing agent prepared by the preparation method has the advantages that the water vapor permeability is improved by 82.6%, the tensile strength is increased by 37.72% and the elongation at break is increased by 11.09%.

Owner:SHAANXI UNIV OF SCI & TECH

Method for producing aqueous polyurethane synthetic leather for costume by using physically-foamed pore forming coating technology

InactiveCN102425069AImprove hygieneQuality improvementSynthetic resin layered productsTextiles and paperWater vapor permeabilitySolvent based

The invention relates to a method for producing aqueous polyurethane synthetic leather for costume by using a physically-foamed pore forming coating technology. According to the present invention, a physically-foamed polyurethane coating dry film transferring process replaces the original solvent-based polyurethane wet coagulation coating process, such that the problems of pollution and residue of the DMF solvent are solved; with adopting the aqueous polyurethane dry film transferring process to replace the solvent-based polyurethane dry film transferring process, the solvent pollution problem during the production process is eliminated; the synthetic leather for the costume is washed in hot water, the pore forming agent is lixiviated by the hot water, such that the penetrating pores are formed in the aqueous polyurethane coating of the synthetic leather, the water vapor permeability and the air permeability of the synthetic leather for the costume are improved, and the synthetic leather with the good-sanitary property is obtained; with the method, the DMF solvent recovery apparatus and the DMF solvent recovery process are saved, the production cost is reduced, and the technical process is simplified; when the conventional physical properties and the conventional mechanical properties are met, the water vapor permeability of the synthetic leather for the costume is more than or equal to 1.6 mg / cm<2>.h, and the air permeability of the synthetic leather for the costume is more than or equal to 2500 ml / cm<2>.h.

Owner:福建可利得皮革纤维有限公司

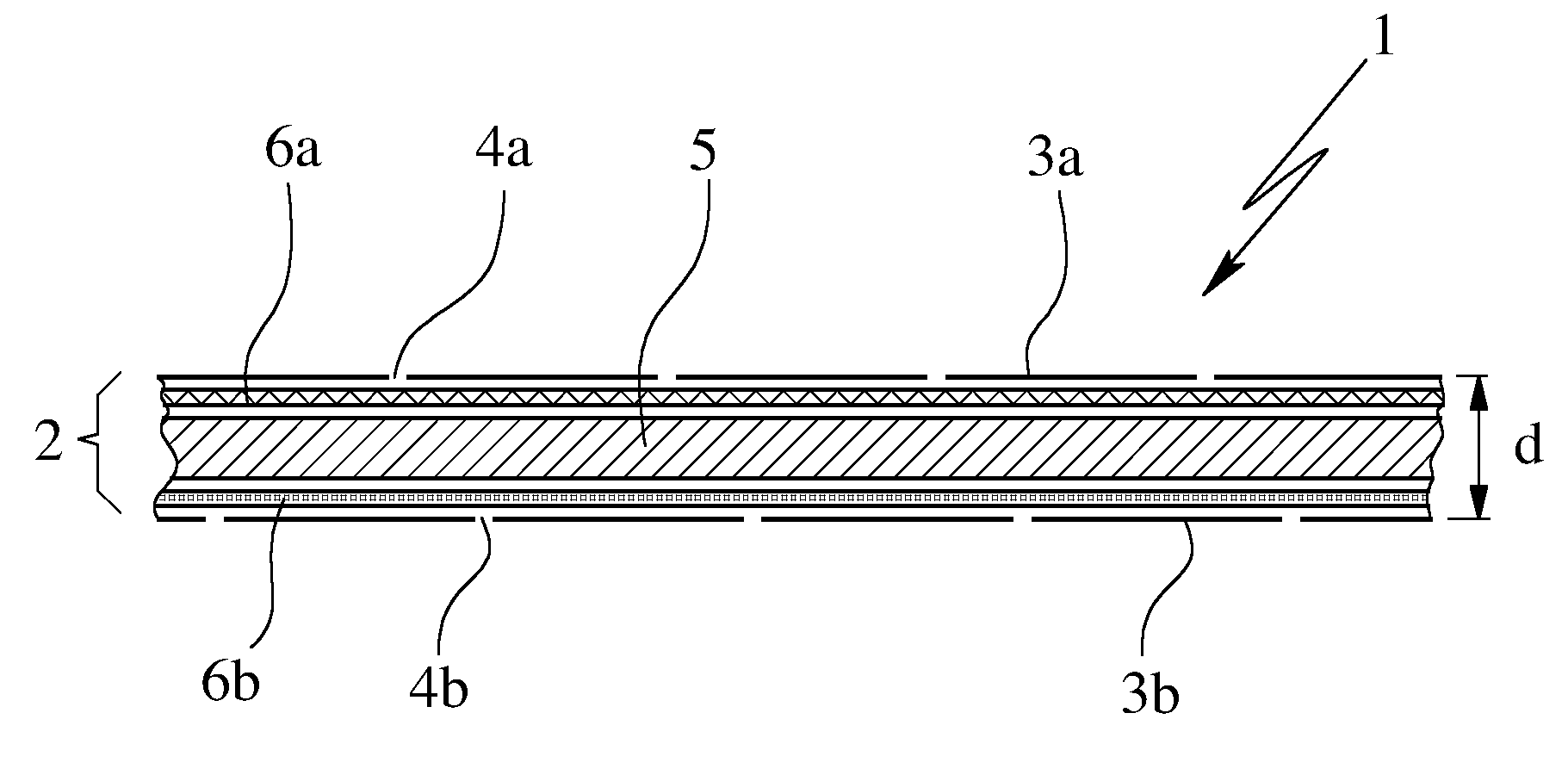

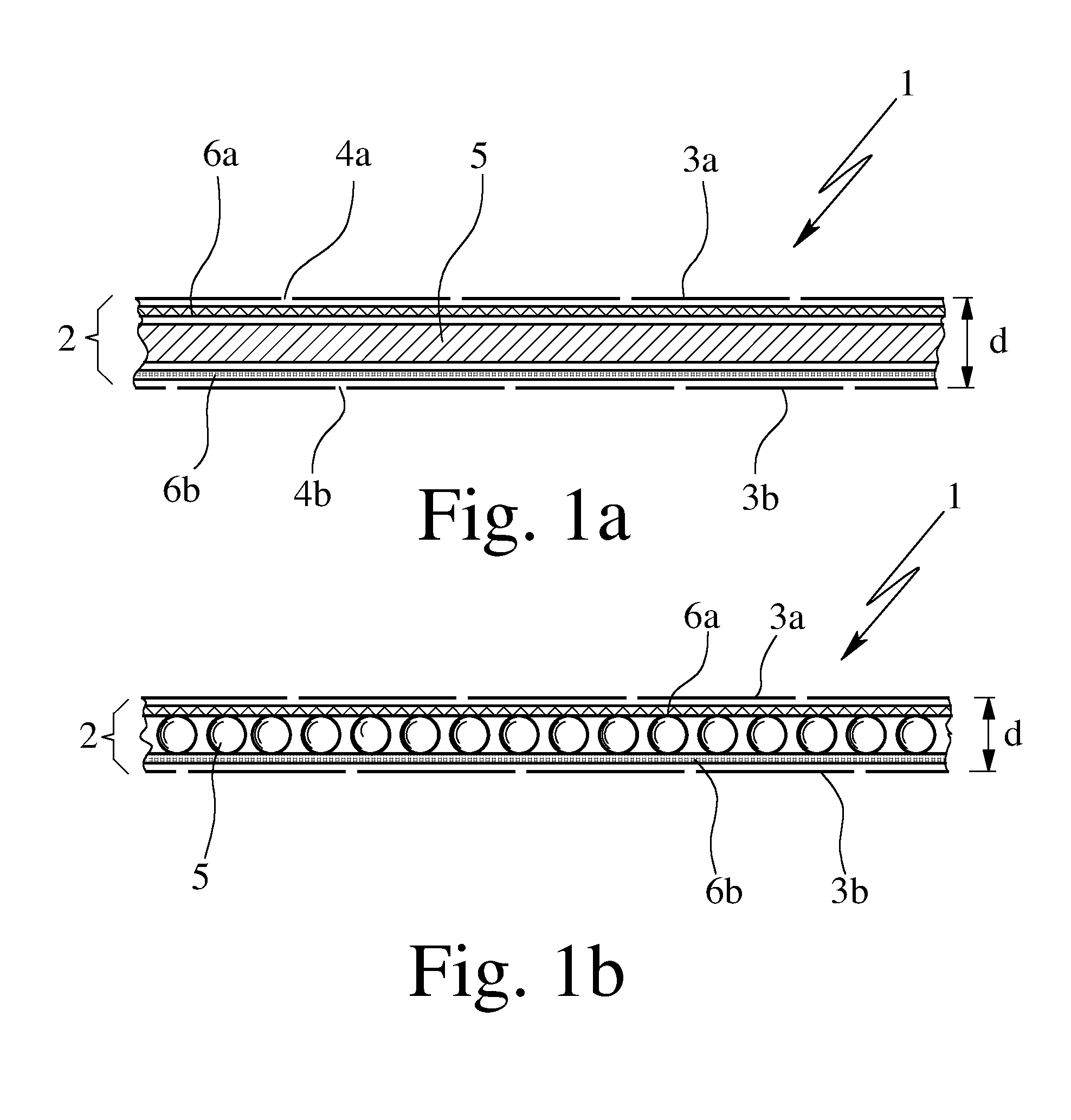

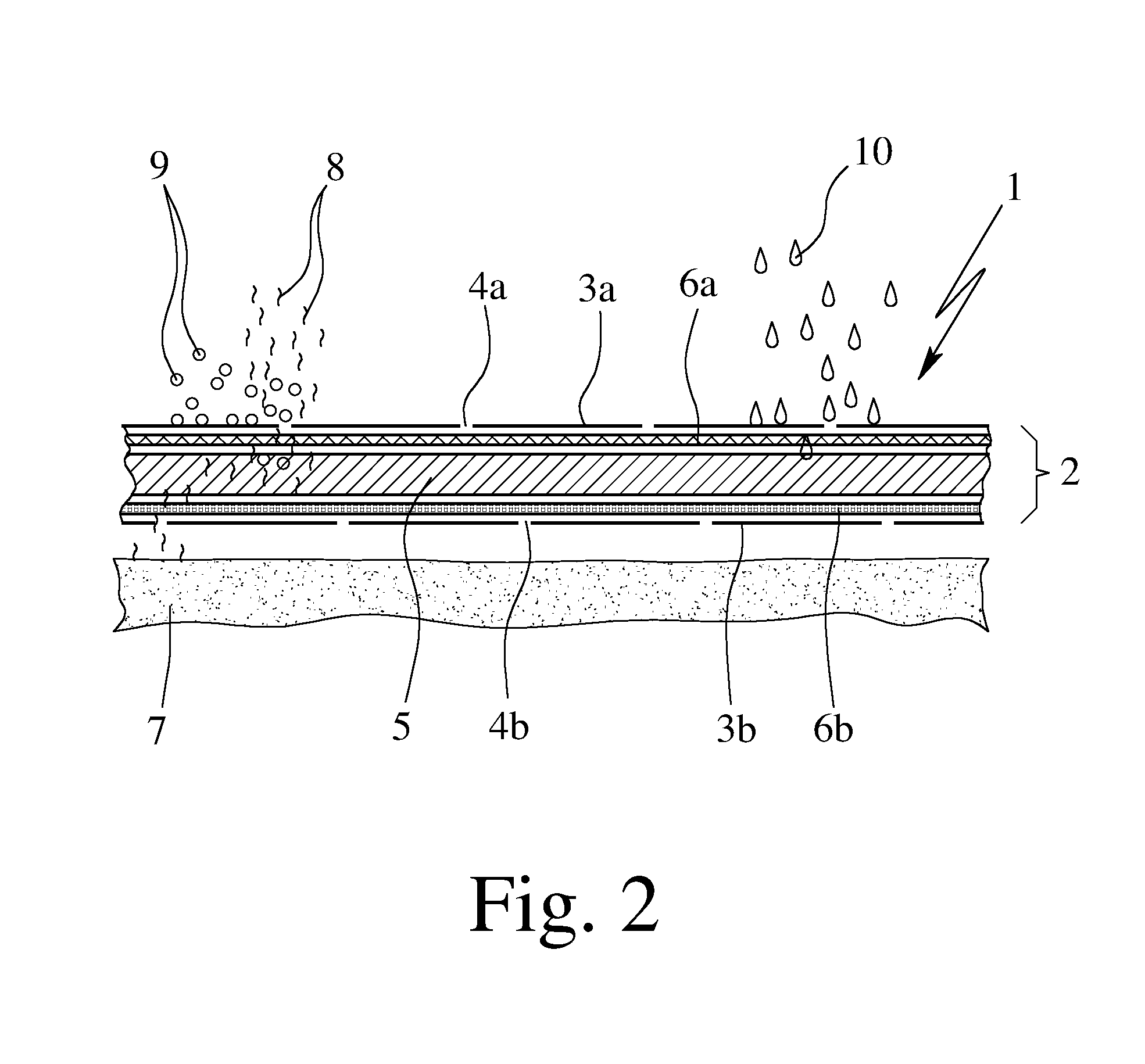

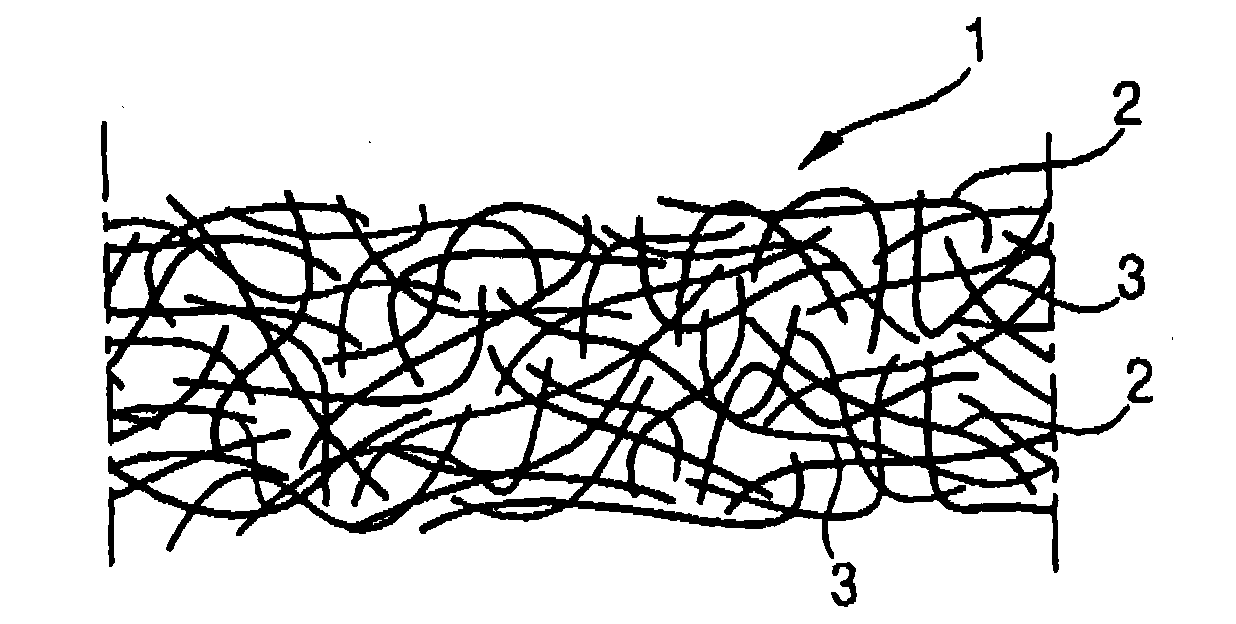

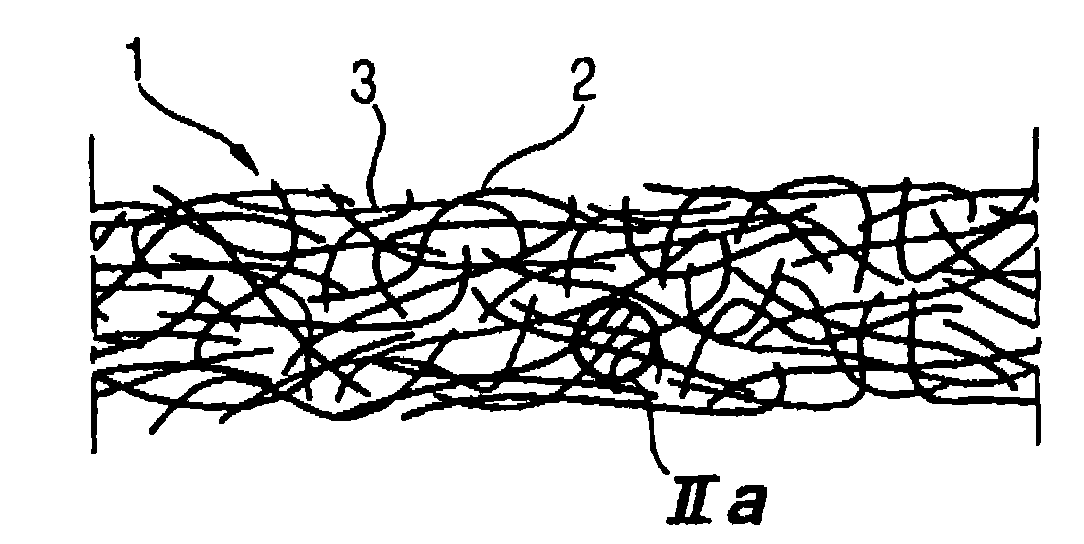

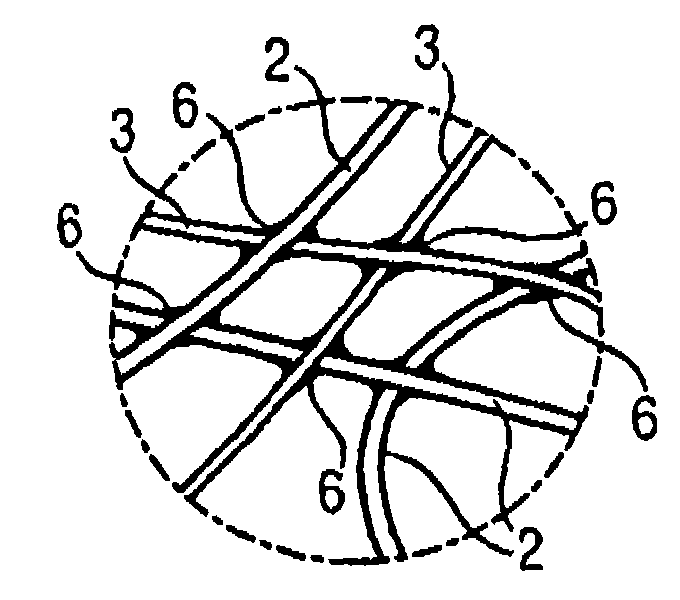

Adsorption filter material, especially a permeable barrier layer composite with an adsorbent, and the use thereof

ActiveUS20100313759A1Improve performanceHigh wearing comfortChemical protectionHeat protectionSorbentEngineering

The invention relates to an adsorption filter material with a multilayer construction, particularly with a permeable adsorptive barrier layer composite, preferably for ABC protective clothing, wherein the adsorption filter material has at least a first barrier layer having a plurality of openings and at least a second barrier layer having a plurality of openings, as well as an adsorption layer disposed between the first and second barrier layers, wherein the first and second barrier layers are disposed in such a manner, that the openings and the openings do not overlap and / or do not coincide. The adsorption filter material is very comfortable and, at the same time, offers excellent protection against chemical poisons.

Owner:BLUCHER GMBH

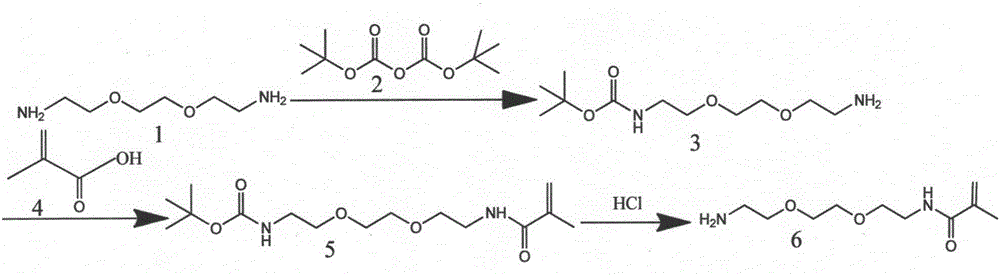

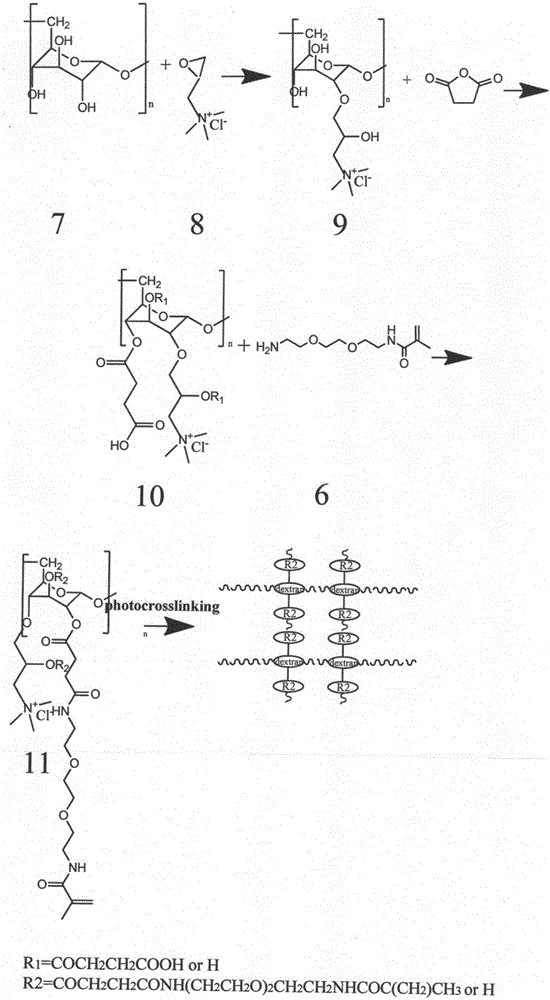

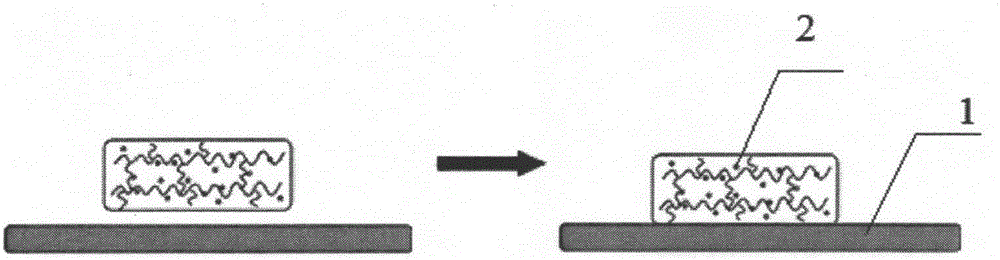

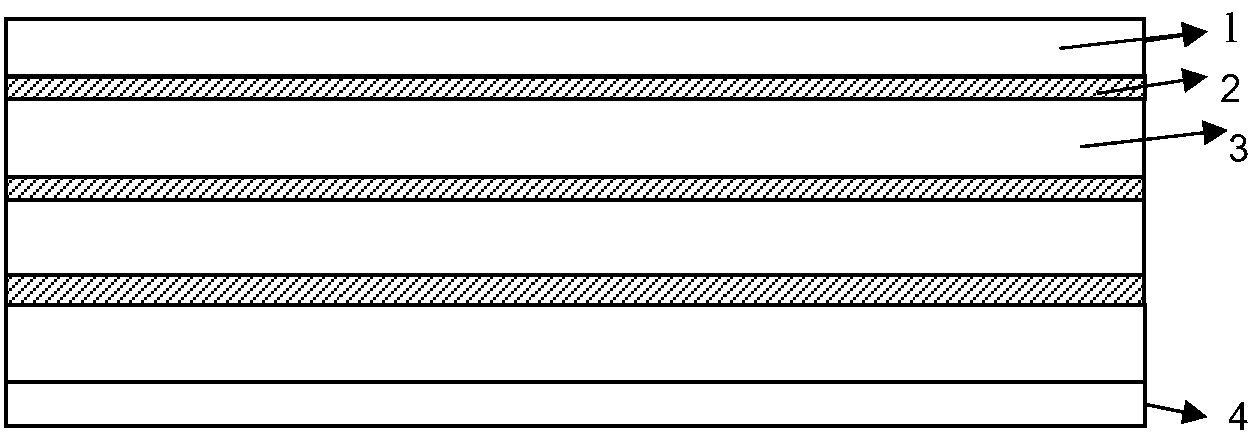

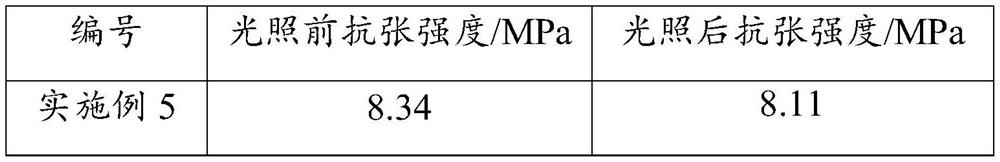

Glucan-based transparent hydrogel dressing and preparation method thereof

InactiveCN106039382AGood biocompatibilityBoosts Collagen ProductionOrganic compound preparationCarboxylic acid amides preparationGlucanDouble bond

The invention provides a glucan-based transparent hydrogel dressing and a preparation method thereof. The preparation method of the glucan-based transparent hydrogel dressing comprises the following steps: conducting a reaction between a glucan quaternary ammonium salt derivative and succinic anhydride; then promoting an obtained product to react with small molecules of amination, so that a macromonomer which contains illuminated cross-linking double bonds is obtained; mixing the macromonomer which contains illuminated cross-linking double bonds with an antibacterial agent and an initiating agent; conducting photo initiation so as to prepare a glucan-based transparent hydrogel; and combining the glucan-based transparent hydrogel with a polyurethane film by virtue of a bonding agent, so that the glucan-based transparent hydrogel dressing is prepared. The finished product (the glucan-based transparent hydrogel dressing) prepared by the invention not only can absorb a great amount of wound exudates so as to keep a wound surface wet, but also can avoid wound adhesion, so that the probability of wound infection is reduced and wound surface healing is promoted.

Owner:深圳市菩安科技有限公司

Method for producing high-performance suede superfine fiber synthetic leather for clothes

InactiveCN102444026AFull dispersionEnsure adequate lubricationBiochemical fibre treatmentDyeing processCross-linkDisperse dye

The invention discloses a method for producing high-performance suede superfine fiber synthetic leather for clothes. Superfine fiber synthetic leather base cloth is used as a base material; by adopting the technologies of combined hydrolysis of diethanol amine and multiple enzyme preparations, surface adsorption modification of hydrolyzed gelatin and cross-linking immobilization of glutaraldehyde, the water vapor permeability of the suede superfine fiber synthetic leather is improved; the superfine fibers are fully dispersed and lubricated by adopting a combined greasing technology of multiple greasing agents, so that the softness and the handfeel property of the suede superfine fiber synthetic leather are improved; by adopting a one-bath dyeing technology of a metal complex dye and a disperse dye in a ratio of 1:1 and a color fixing technology of a macromolecular color fixing agent, the luster and the dyeing fastness of the suede superfine fiber synthetic leather are improved; and byadopting a technology of combining mechanical raising and cutting, the 'writing effect' of the suede of the suede superfine fiber synthetic leather is improved, and the suede superfine fiber synthetic leather is endowed with good chamois appearance. Under the condition that the conventional physical and mechanical properties are met, the dry scraping fastness of the surface color of the produced suede superfine fiber synthetic leather is more than or equal to level 4, the wet scraping fastness of the surface color is more than or equal to level 3, and the water vapor permeability is more thanor equal to 1.5mg / cm<2>.h.

Owner:福建可利得皮革纤维有限公司

Organic Li-based bentonite-WPU (waterborne polyurethane) leather finishing agent and preparation method thereof

InactiveCN102251400AImprove surface microenvironmentImprove wettabilityFibre treatmentPigment treatment with organosilicon compoundsIn situ polymerizationWater vapor permeability

The invention discloses an organic Li-based bentonite-WPU (waterborne polyurethane) leather finishing agent and a preparation method thereof. The method comprises the following steps: firstly, carrying out organic modification on Li-based bentonite so as to prepare organic Li-based bentonite; and then, dispersing the organic Li-based bentonite into a WPU matrix in nano scale by using a latex commixing or in-situ polymerization method so as to obtain the organic Li-based bentonite-WPU leather finishing agent. In the invention, because quaternary ammonium salts, organic amines, a coupling agentand polyisocyanates are selected to carry out organic modification on Li-based bentonite, the surface microenvironment of a chain-connected silicate layer of the Li-based bentonite and the wetting action (on polymers) of the Li-based bentonite are improved, thereby enhancing the dispersibility of the Li-based bentonite in organic polymers and the compatibility of the Li-based bentonite and the organic polymers, and better facilitating the expression of nano effects; and because the Li-based bentonite with a two-dimensional nanostructure is introduced into the WPU matrix by using a latex commixing or in-situ polymerization method, therefore, due to the unique structure and properties of a nano-clay, while the transparency of a finishing material is not affected, the thermal stability, friction-resistant strength and water vapor permeability of the finishing material can be improved markedly, and the mechanical properties of the finishing material are also enhanced and toughened.

Owner:SICHUAN UNIV

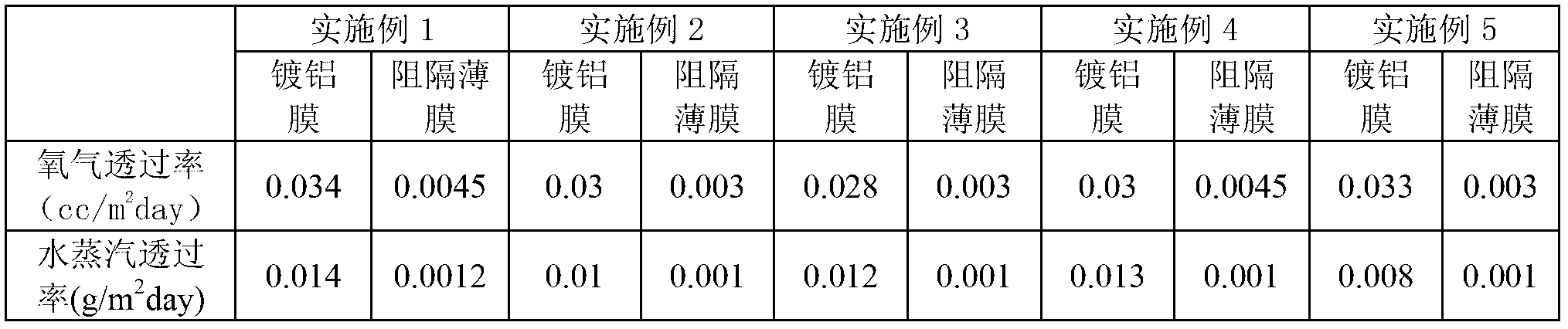

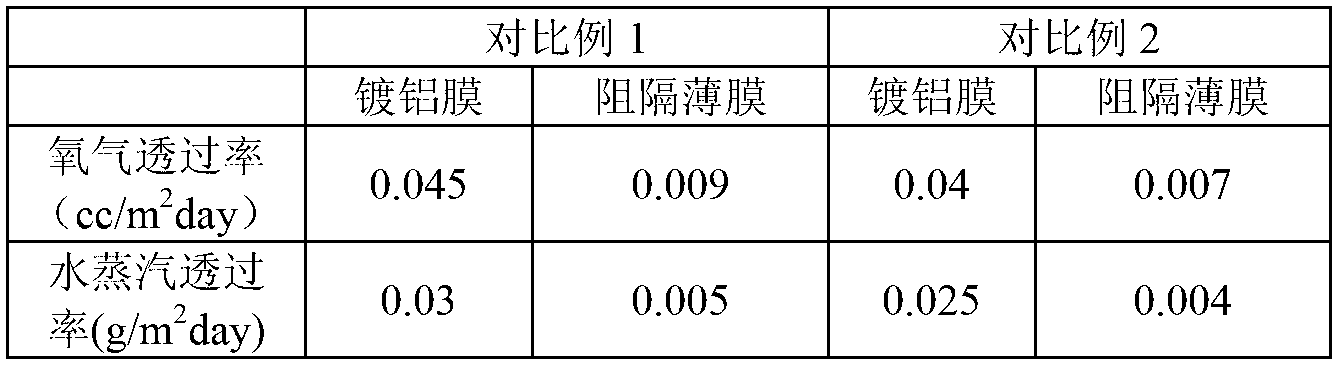

Barrier film and vacuum insulating board adopting same

ActiveCN103057212AHigh gas barrierHigh barrierVacuum evaporation coatingSputtering coatingPolyethylene terephthalateSurface layer

The invention provides a barrier film and a vacuum insulating board compounded by utilizing the barrier film. The barrier film is formed by adhering a surface layer, a gas barrier layer and a heat seal layer, wherein the gas barrier layer consists of at least one aluminum-plated polyethylene terephthalate (PET) film layer. The preparation process of the aluminum-plated PET film comprises the following of: (1) arranging a PET substrate film in an aluminum-plating chamber for performing vacuum aluminum plating, and forming an aluminum-plating layer on the surface of the PET substrate film; and (2) introducing nitrogen into the aluminum-plating chamber in stages after aluminum plating is ended, introducing the nitrogen until the nitrogen pressure is 800-1200pa at the first time, maintaining for 8-12 hours, introducing the nitrogen until the nitrogen pressure is 1300-1500pa, maintaining for at least 12 hours, and obtaining the aluminum-plated PET film. Compared with the conventional aluminum-plated film prepared by the prior art, the aluminum-plated film has the advantages that the overall barrier performance of the barrier film can be effectively improved, so that the requirements can be met in occasions with strict barrier performance requirement.

Owner:中亨新型材料科技有限公司

Method for producing multifunctional waterborne polyurethane superfine fiber decorative leather

InactiveCN103015219APurify the decorative spaceImprove breathabilityLamination ancillary operationsSynthetic resin layered productsMicrofiberSilver oxide

The invention relates to a method for producing multifunctional waterborne polyurethane superfine fiber decorative leather. According to the method, superfine fiber non-woven cloth is used as a base material, and the method comprises the following steps of: firstly, preparing mixed slurry containing the components of waterborne polyurethane, wood powder loaded with nano silver oxide and the like into superfine foam slurry by adopting a physical and mechanical stirring method; secondly, forming a functional coating on release paper by adopting a knife coating method, closely integrating the release paper with the base material, and drying, cooling and stripping to obtain superfine fiber non-woven cloth provided with the functional coating; and finally, performing various beautification processes on the superfine fiber non-woven cloth to obtain the multifunctional waterborne polyurethane superfine fiber decorative leather which has a variety of functions of decorating, purifying air, removing formaldehyde, deodorizing, sterilizing, adjusting moisture and the like and has a through microcellular structure. The multifunctional waterborne polyurethane superfine fiber decorative leather can be widely used in a variety of fields such as house wall decoration, hotel decoration, furniture soft package, automobile interior trim, jewelry package and the like.

Owner:福建可利得皮革纤维有限公司

Organic montmorillonite-aqueous polyurethane compound leather finishing agent and method for preparing same

InactiveCN101544820ARestricted free movementImprove mechanical propertiesEthylene diaminePolymer science

The invention discloses an organic montmorillonite-aqueous polyurethane compound leather finishing agent and a method for preparing the same. The method comprises the following steps: firstly using quaternary ammonium salt such as cetyl trimethyl ammonium chloride, octadecyl dihydroxyethyl methyl ammonium bromide and the like, organic amine such as ethylene diamine, octadecylamine and the like, or a silane coupler, polyisocyanate and the like to organically modify montmorillonite to prepare organic montmorillonite; and secondly, performing intercalation reaction of emulsion of a polyurethane resin finishing agent and the organic montmorillonite to obtain the finished product of the organic montmorillonite-aqueous polyurethane compound leather finishing agent. In the method, the quaternary ammonium salt, the organic amine, the silane coupler or the polyisocyanate are used for organically modifying the montmorillonite, so that the interlamellar spacing of the montmorillonite is increased, the micro environment among the lamellas is improved, the compatibility of the montmorillonite and the organic phase is improved, and the intercalation reaction of the polyurethane molecules and the montmorillonite is easily performed; moreover, due to the interlamellar compound of the organic montmorillonite on the polyurethane resin finishing agent, the mechanical property, the thermal resistant stability, the water resistance and the water vapor permeability of the finishing material are improved. When the leather finishing material is applied to leather finishing, the leather finishing material has the advantages of greatly improving the mechanical strength and thermal resistant stability of the coating and having active effects on water resistance, sanitary property and the like of the coating.

Owner:SICHUAN UNIV

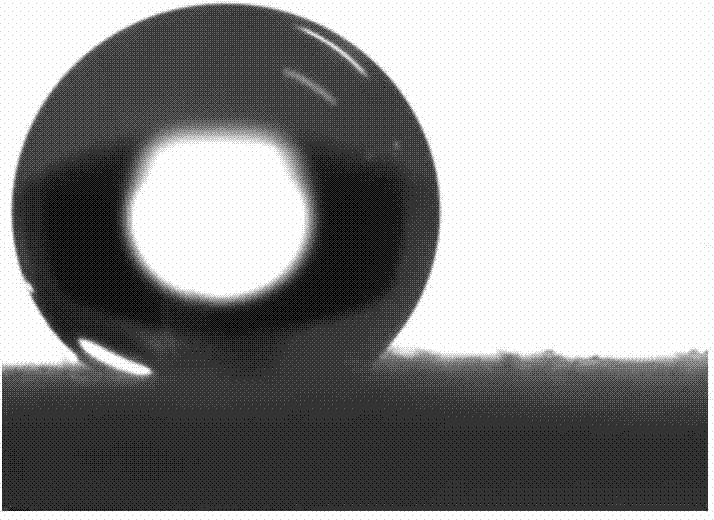

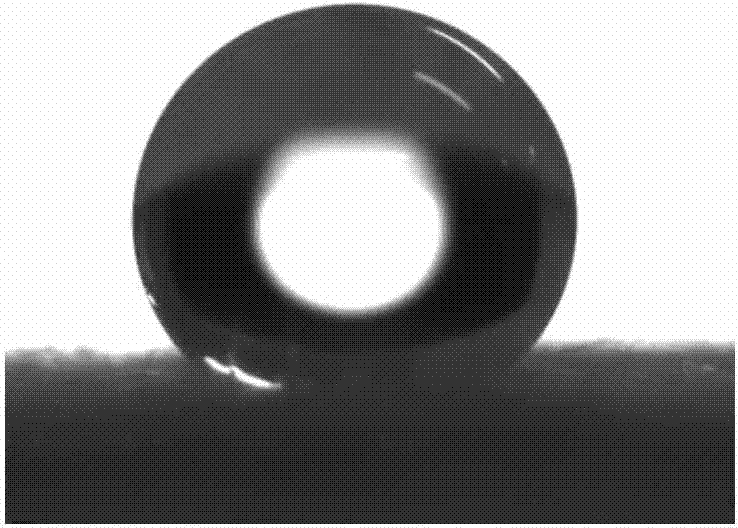

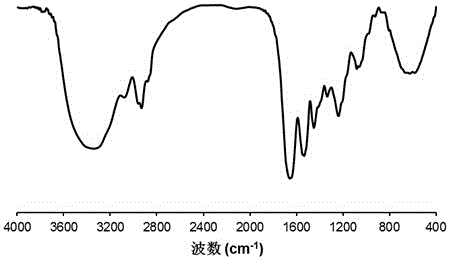

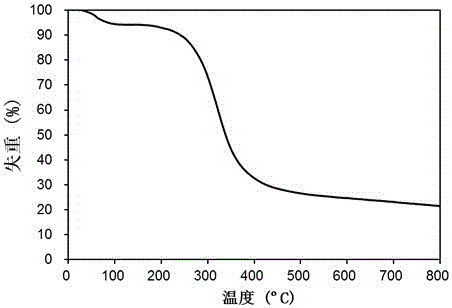

Preparation method of super-hydrophobic crosslinked polysiloxane-polysilsesquioxane nanosphere hybrid material

The invention discloses a preparation method of a super-hydrophobic cross linked polysiloxane-polysilsesquioxane nanosphere hybrid material. The super-hydrophobic crosslinked polysiloxane-polysilsesquioxane nanosphere hybrid material is obtained by carrying out in situ condensation reaction on a reactive group Si-OH in a crosslinked structure polysiloxane of low surface energy epoxy-containing side group and Si-OH on the surface of a polysilsesquioxane nanosphere, and the super-hydrophobic crosslinked polysiloxane-polysilsesquioxane nanosphere hybrid material is applicable to formation of a firm super-hydrophobicity film on the surface of multiple substrates of cotton fabric, polyester fabric, leather and the like.

Owner:SHAANXI UNIV OF SCI & TECH

Emulsion polymerization process for in-situ preparing nano SiO2/acrylate resin composite paint

InactiveCN1986582AImprove breathabilityImprove water vapor permeabilityCoatingsAging resistanceNano sio2

The present invention relates to emulsion polymerization process for in-situ preparing SiO2 / acrylate resin composite paint for leather. Acrylate resin is one filming matter widely used for leather. The present invention synthesizes SiO2 / acrylate resin composite paint for leather with ethyl silicate and acrylate monomer and through emulsion polymerization. The SiO2 / acrylate resin composite paint for leather is superior to traditional acrylate resin, and the coated leather has excellent ageing resistance, excellent hand feeling and raised sanitation performance.

Owner:SHAANXI UNIV OF SCI & TECH

Modification method for improving hygienic performance of superfine fiber synthetic leather base fabric through collagen

ActiveCN103382637AImproved water vapor permeabilityAchieve covalent modificationFibre typesPolymer scienceAcid hydrolysis

The invention relates to a modification method for improving hygienic performance of superfine fiber synthetic leather base fabric through collagen. The superfine fiber synthetic leather base fabric serves as a main body of synthetic leather, and water vapor can not be transferred effectively between fibers and the outside due to a few active groups on the base fabric. According to the modification method, gelatin is hydrolyzed to obtain the collagen; dry superfine fiber synthetic leather base fabric is processed with concentrated sulfuric acid to obtain the superfine fiber synthetic leather base fabric with the acid-hydrolysis modified surface; the extracted collagen is grafted to the processed base fabric for reaction to obtain target products. By the aid of the modification method, the active groups on the surface of the superfine fiber synthetic leather base fabric are effectively increased, covalent modification is performed on the surface of the superfine fiber synthetic leather base fabric through the collagen, the hygienic performance of the superfine fiber synthetic leather base fabric is improved through the collagen, resource utilization of the waste collagen is achieved, and meanwhile, the problem of the poor hygienic performance of the superfine fiber synthetic leather is solved.

Owner:SHAANXI UNIV OF SCI & TECH +1

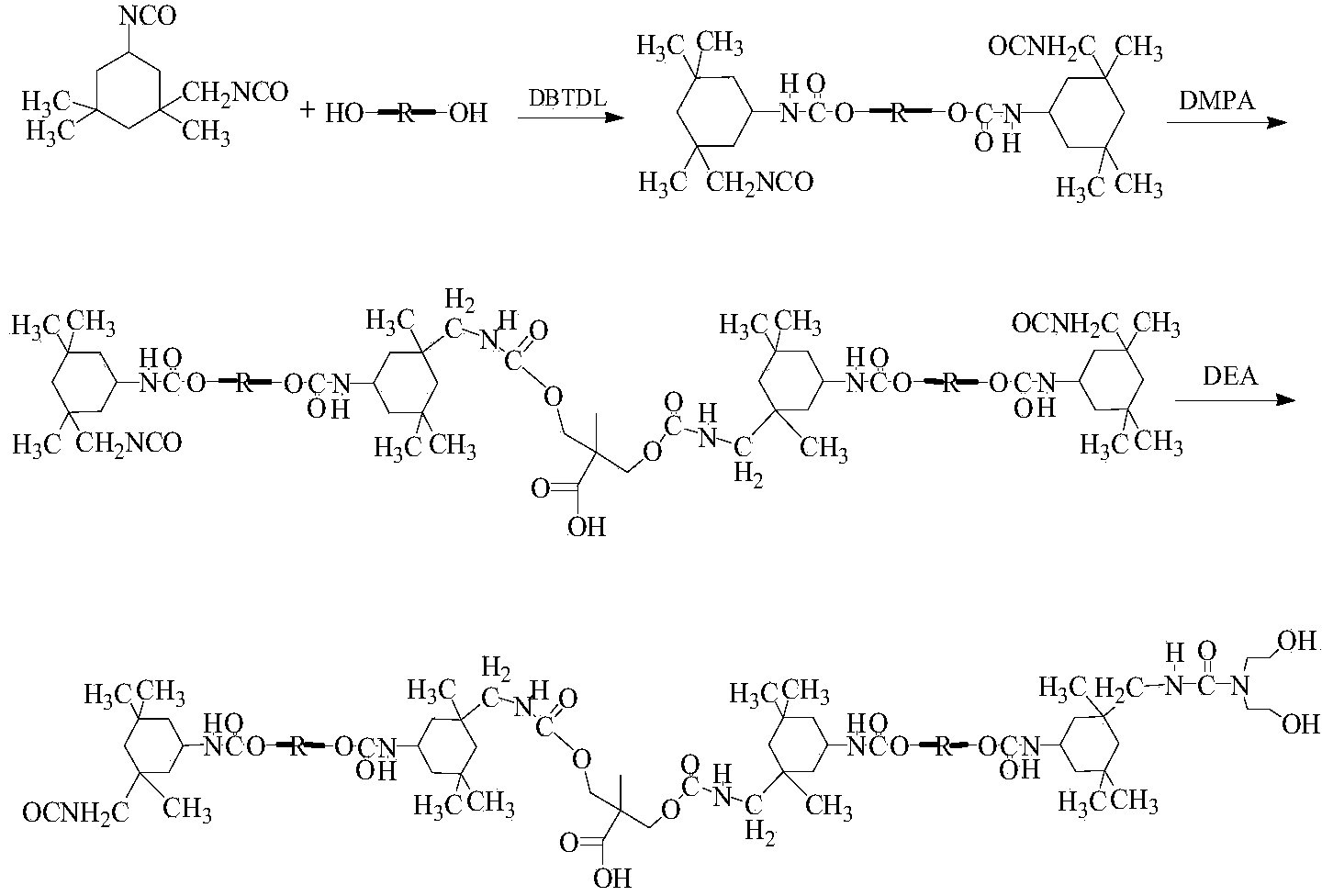

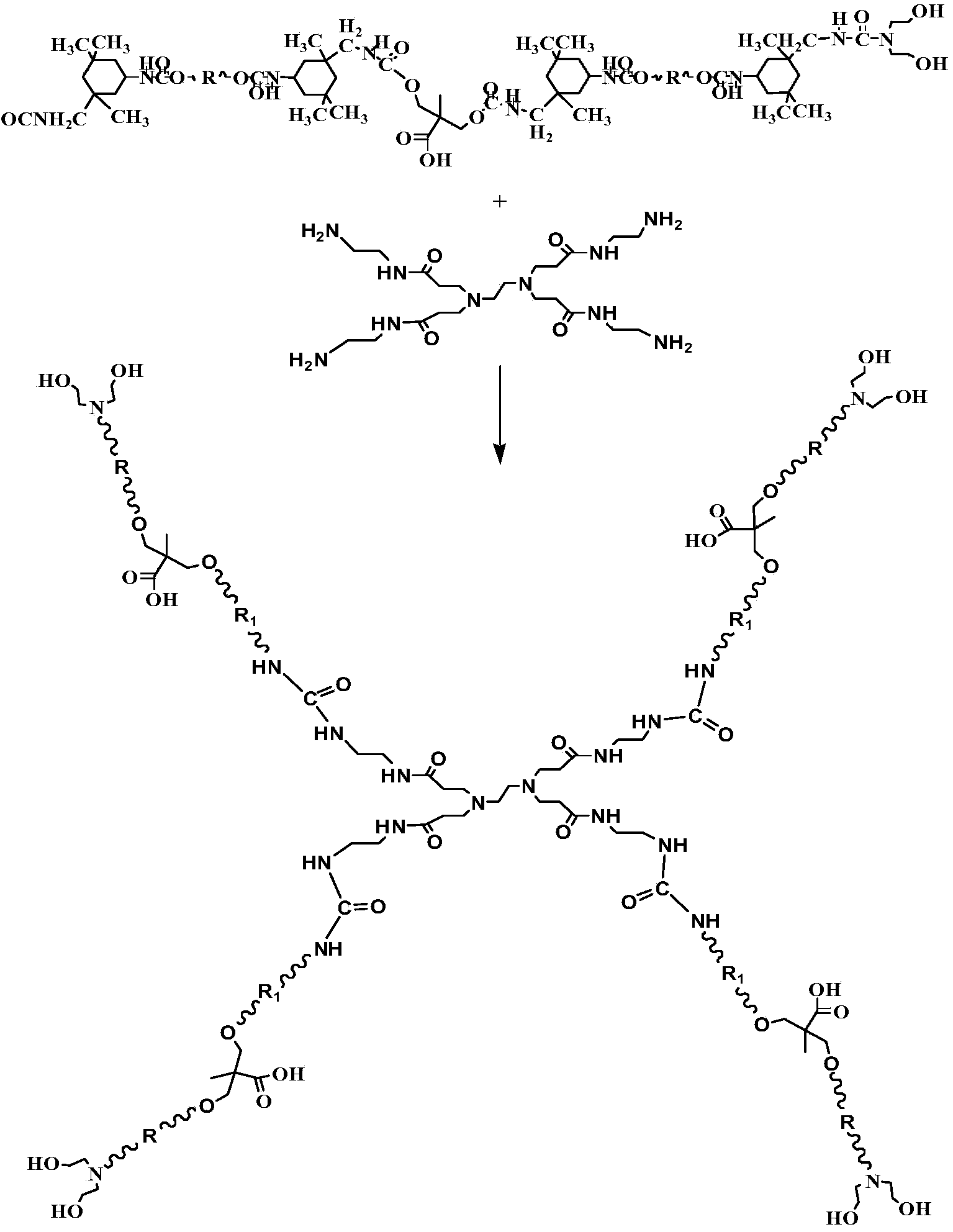

Preparation method of dentritic waterborne polyurethane

The invention discloses a preparation method of dentritic waterborne polyurethane, comprises the following steps: by using diisocyanate, polyol, dimethylolpropionic acid and diethanol amine as main raw materials, preparing single terminated polyurethane prepolymer, grafting the single terminated polyurethane prepolymer with the generational polyamide-amine 1GPAMAM dentritic polymers, and finally adding a neutralizer, forcibly dispersing in the water to obtain the dentritic waterborne polyurethane emulsion. The dentritic waterborne polyurethane has a high-branched dentritic structure, more structured molecular structure, controllable molecular weight, and is free from organic solvent; the water is used as the dispersion medium, so that the product is non-toxic, the use is safe, efficient and environmental friendly; the dentritic waterborne polyurethane is non-flammable, non-explosive and easy to store.

Owner:昇英新材料科技(常州)有限责任公司

Preparation of collagen base biological medical material

InactiveCN101264337AGood biocompatibilityGood blood compatibilitySurgeryAbsorbent padsFreeze-dryingFibril

The invention discloses a preparation method for collagen-based biomedical materials, which is characterized in that: fresh animal skin and / or tendon and / or sheet-beam are adopt to make collagen fiber dispersion liquid (gel) or freeze-dry the collagen fiber materials via the enzymatic method, then are immersedly treated for 20 to 60 minutes through ethanol alcohol solution with concentration of 35 to 65 percent with 8 to 12g / L 2- sulfonic acid under the temperature of 15 to 40 DEG C, and then are immersedly treated for 4 to 24 hours through solution with 1.0 to 5.5g / L N-hydroxy amber imide and 0.8 to 4.0g / L carbodiimide hydrochloride under the temperature of 15 to 40 DEG C; the collagen raw materials are cleaned and immersed for two times through ethanol with concentration of 80 to 95 percent, each time for 10 to 30 minutes, then are immersed and cleaned for one time through Na2HPO4 solution with concentration of 1.5 to 2.0 percent and NaCl solution with concentration of 5.5 to 6.5 percent respectively, the time is 30 to 60 minutes; then are immersed and cleaned for 2 times through distilled water immersion, each time for 10 to 30 minutes, the materials after being cleaned are freeze-dried, and the collagen-based biomedical materials are obtained.

Owner:SICHUAN UNIV

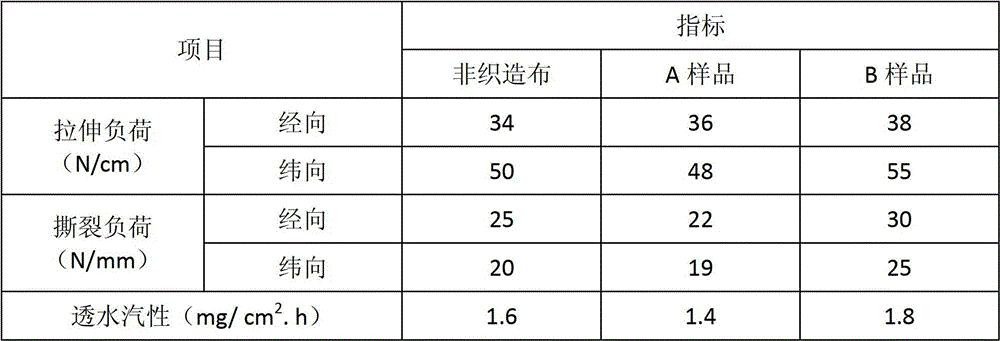

Production method for waterborne polyurethane synthetic leather wet process impregnated bass

The invention provides a production method for waterborne polyurethane synthetic leather wet process impregnated bass, comprising the following steps of: preparing impregnation liquid by using waterborne polyurethane, filler and water; preparing solidification liquid by mixing a demulsification cross-linking agent with water; saturating a non-woven fabric by the impregnation liquid through an impregnation groove, and extruding some impregnation liquid in the non-woven fabric by a pair of rollers; enabling the non-woven fabric with the impregnation liquid to pass through a solidification groove filled with a coagulating agent to form porous filler by the waterborne polyurethane coagulated by the coagulating agent and the filler, and filling the filler in the non-woven fabric; and washing by water, extruding water and drying to obtain the waterborne polyurethane synthetic leather wet process impregnated bass. The product produced by the invention has the extremely similar microcellular structure, and is better in physical and mechanical properties, water vapor penetration performance, and hand feel characteristic. According to the production method, the solvent pollution problem of DMF (dimethyl formamide) and the product safety problem caused by the residue of the DMF in the production of solvent type polyurethane wet process impregnated bass can be solved.

Owner:FUJIAN KELIDA SYNTHETIC FIBER

Aqueous polyurethane making method used for superfine fiber synthetic leather production

ActiveCN103981729AImprove the delivery effectImproved water vapor permeabilitySynthetic resin layered productsLaminationCross-linkPolyurethane adhesive

The invention relates to an aqueous polyurethane making method used for superfine fiber synthetic leather production. The method using a superfine fiber synthetic leather base cloth as a substrate comprises the following steps: knifing release paper with a surface layer slurry containing an aqueous polyurethane finishing agent, an aqueous color paste, nanometer silica, a wetting agent, a coupling agent and a cross-linking agent to form a surface layer, and drying; knifing the surface layer with a bonding slurry containing an aqueous polyurethane adhesive and the cross-linking agent, and applying to the superfine fiber synthetic leather base cloth; and drying, cooling, and peeling to obtain he superfine fiber synthetic leather with an aqueous polyurethane coating. The method solves the solvent pollution problem of superfine fiber synthetic leather production, and the peel strength, the surface color dry web fastness, the surface color wet rub fastness and the water permeability of the superfine fiber synthetic leather obtained in the invention are greater than 20(N / 20mm), greater than 4 grade, greater than 3.5 grade, and greater than 1.1(mg / cm<2>.h).

Owner:ANAN CHINA

Composite shoe sole, footwear constituted thereof and method for producing the same

The invention relates to a steam-permeable composite shoe sole (105) with an upper part (50), comprising at least one opening (31) extending through the depth of the composite shoe sole, a barrier unit (35) having an upper part that forms at least a section of the upper part (50) of the composite shoe sole (105) and having a steam-permeable barrier material (33) that is configured as a barrier to foreign matter penetrating the sole, said material obturating the at least one opening (31) in a steam-permeable manner. A reinforcing element (25) is associated with the barrier material (33) for mechanically reinforcing the composite shoe sole (105). Said element comprises at least one reinforcing web (37) that is disposed on at least one surface of the barrier material (33) and at least partially bridges the at least one opening (31). At least one outsole part (117) is arranged below the barrier unit (35).

Owner:W L GORE & ASSOC GMBH

Modified collagen fibers as well as preparation method and application thereof

ActiveCN112064346AWide variety of sourcesReduce material costsPolyurea/polyurethane coatingsAnimal fibresCollagen fibresFunctional composite

The invention relates to the technical field of functional composite materials, in particular to modified collagen fibers as well as a preparation method and application thereof. The preparation method of the modified collagen fibers comprises the following steps of mixing and reacting vegetable tannin and collagen fibers in a liquid environment with the pH value of 5-8, and performing washing anddrying treatment. According to the invention, by utilizing the structural characteristic that the vegetable tannin is rich in phenolic hydroxyl groups, the vegetable tannin can be combined with the collagen fibers by multiple modes such as multipoint hydrogen bonds, hydrophobic bonds and the like, so that vegetable tannin structures are combined in natural multi-level micro / nano structures of thecollagen fibers; and according to the collagen fibers combined with the vegetable tannin structures, due to the fact that a large number of phenolic hydroxyl structures exist in the vegetable tannin,the compatibility of the collagen fibers and water-based resin is improved, relatively strong hydrogen bond combination can be generated by the collagen fibers and polar groups in the water-based resin, the interface compatibility of the collagen fibers and the water-based resin is greatly improved, and the mechanical property, the water vapor permeability, the aging resistance, the flame retardant property and the like of the water-based resin are improved.

Owner:SICHUAN UNIV

Nuclear pore membrane composite medical dressing

InactiveCN1775301AGood mechanical strengthGood transparencyAbsorbent padsBandagesPressure sensitiveChemistry

The present invention relates to a nucleopore membrane composite type medical dressing. It includes basic membrane layer, said basic membrane layer is formed from single layer of nucleopore membrane or formed by superimposing several layers of nucleopore membranes, all the nucleopore membrane layers are successively up-down arranged according to the pore diameter from large to small, between membrane and membrane they are cohered together by means of pressure-sensitive adhesive, the pore diameter range of nucleopore membrane is 1-10 microns, its permeability range is 0.05%-50%, on one side of basic membrane layer directly-contacted with surface for wound a layer of skin friendly layer made up by selecting aquagel or silicon gel material is superimposed, on the side of basic membrane layer non-contacted with surface of wound a layer of reinforcing layer made up by using transparent porous semipermeable polymer material or non-woven fabric is superimposed.

Owner:长春吉原生物科技有限公司

Polyacrylate/nanometer ZnO composite leather finishing agent prepared by Pickering miniemulsion polymerization method and preparation method

ActiveCN108517024AImprove the shortcomings of poor stabilityImprove the defect of poor water resistance of film formationCoatingsLeather surface finishingPolymer scienceEmulsion polymerization

The invention relates to a polyacrylate / nanometer ZnO composite leather finishing agent prepared by a Pickering miniemulsion polymerization method and a preparation method. An acrylate monomer is usedas a main raw material, nanometer ZnO is used instead of a conventional surfactant, and meanwhile, a hydrophobic fluorinated monomer is introduced through the characteristic of droplet nucleation ofthe Pickering miniemulsion polymerization method to prepare polyacrylate / nanometer ZnO composite emulsion. The shortcomings, brought by the conventional surfactant, of polyacrylate emulsion are overcome, and meanwhile, the shortcoming of poor stability of emulsion prepared by a Pickering emulsion polymerization method is improved. When the leather finishing agent is applied to a leather finishingprocedure, the breathability, the moisture permeability, the hydrophobicity, the mechanical performance and the dry and wet rubbing fastness of a leather sample are all improved.

Owner:SHAANXI UNIV OF SCI & TECH

Self-emulsifying wet rubbing resistant leather top layer coating agent and preparation method thereof

ActiveCN103103765AExcellent abrasion resistanceImprove water vapor permeabilityFibre treatmentEpoxyAlcohol

The invention relates to a self-emulsifying wet rubbing resistant leather top layer coating agent and a preparation method of the self-emulsifying wet rubbing resistant leather top layer coating agent. The wet rubbing resistant leather top layer coating agent is formed by mixing the following raw materials: epoxy polysiloxane modified gelatin, solvent absolute ethyl alcohol and acetone, wherein the volume ratio of the absolute ethyl alcohol to the acetone is 3:7; and the proportion of the using amount of the epoxy polysiloxane modified gelatin to the solvent is 1g / ml. The structural formula of the epoxy polysiloxane modified gelatin is that FORMUAL, wherein n is an integer from 7 to 50. Compared with the prior art, the self-emulsifying wet rubbing resistant leather top layer coating agent is extremely high in wet rubbing resistance; and after being coated on leather, soft handfeel and high water steam permeation performance can be achieved.

Owner:QILU UNIV OF TECH

Method for producing two-layer transfer coating leather by aqueous polyurethane dry-method transfer coating process

InactiveCN102501442AImprove hygieneEliminate pollutionLamination ancillary operationsPolyureas/polyurethane adhesivesProduction lineSolvent based

The invention discloses a method for producing two-layer transfer coating leather by aqueous polyurethane dry-method transfer coating process. The method comprises the following steps of: firstly coating a bottom-closing foamed coating material on the surface of the split leather by use of a roll coating machine in leather production, and drying and then ironing by use of a drum-type ironing machine to form a bottom-closing foamed coating; then blade coating a top coating material and an adhesive coating material on release paper by use of a dry-method production line in synthetic leather production process; and finally, bonding the split leather with the bottom-closing foamed coating and the release paper with the adhesive coating, drying in a drying channel, cooling, separating, and transferring the coatings on the release paper onto the bottom-closing foamed coating, to obtain the two-layer transfer coating leather. The method produces the two-layer transfer coating leather by aqueous polyurethane dry-method transfer coating process and replaces the solvent-type polyurethane production system by the aqueous polyurethane production system, so as to eliminate pollution caused by solvents and solve the problem of MDF residues in the two-layer transfer coating leather. Besides, the method can enhance water permeability and vapor permeability of the coatings and improve health performance of the two-layer transfer coating leather final product.

Owner:SHAANXI UNIV OF SCI & TECH

Environment-friendly micro-nano foaming waterborne polyurethane synthetic leather and manufacturing method thereof

ActiveCN110195357AImprove breathabilityImprove water vapor permeabilityFurniture partsVehicle componentsMicro nanoCross-link

The invention relates to the technical field of synthetic leather production, in particular to environment-friendly micro-nano foaming waterborne polyurethane synthetic leather and a manufacturing method thereof. The method comprises the following steps of (1) adopting waterborne polyurethane as a raw material and a micro-nano bubble generator for foaming to obtain micro-nano foaming waterborne polyurethane A; (2) adding a filler, a coloring agent, a cross-linking agent and a thickener into the micro-nano foaming waterborne polyurethane A to obtain micro-nano foaming waterborne polyurethane slurry B; (3) coating a basic cloth with the micro-nano foaming waterborne polyurethane slurry B, and then placing the basic cloth in a drying box for drying to obtain micro-nano foamed waterborne polyurethane bass C; (4) performing post-finishing process of synthetic leather on the micro-nano foamed waterborne polyurethane bass C to obtain the environmentally-friendly micro-nano foamed waterborne polyurethane synthetic leather. The obtained environment-friendly micro-nano foaming waterborne polyurethane synthetic leather has excellent sanitary performance and environmental protection performance.

Owner:SHAANXI UNIV OF SCI & TECH

Feather keratin-based biopolymer external application material and preparation method thereof

ActiveCN105879101AGood flexibilityEliminate wound odorPharmaceutical delivery mechanismAbsorbent padsPlasticizerKeratin protein

The invention provides preparation of a feather keratin-based biopolymer external application material. The preparation method comprises the steps that feather keratin is dissolved into dispersion liquid to prepare a feather keratin solution; gelatin is dissolved into distilled water and then added into the feather keratin solution, and the solutions are mixed to be uniform under stirring at room temperature; a condensing agent is added, stirring is conducted, then a condensing auxiliary is added, the pH value of the system is regulated to be 5-7, and stirring is continuously conducted; a plasticizer is added, and reacting under stirring is conducted for a certain time; after reacting is finished, dialyzing is conducted with distilled water for 18-36 h under the dark condition, freeze drying is conducted, and then the biopolymer external application material is obtained. The biopolymer external application material is a spongy solid material, and a microporous sheet structure is arranged in the material; the good flexibility, adsorptivity, water-retaining property and vapor permeability are achieved. Antibacterial property and external releasing research shows that the material has the good bacteriostatic property and the quick releasing effect on micromolecular model drugs and is expected to be applied to the biomedicine field by serving as a quick sterilizing and inflammation diminishing external application material for acute wounds.

Owner:大有药业扬州有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com