Preparation method of polyacrylic ester/hollow silicon dioxide nanometer composite leather finishing agent

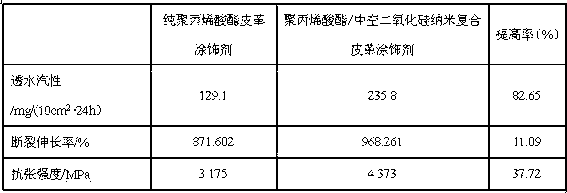

A technology of leather finishing agent and polyacrylate, which is applied in dyeing polymer organic compound treatment, textile and papermaking, fiber treatment, etc. It can solve the problem of no significant effect on the hygienic performance of leather finishing agent, and achieve the improvement of tensile strength and water permeability. The effect of improving the steam property and improving the mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Preparation of polystyrene microspheres:

[0023] Add 1.5 g of polyvinylpyrrolidone and 0.38 g of azobisisobutylamidine hydrochloride into a three-necked flask filled with 100 g of distilled water, and stir to form a uniform and transparent solution. Add 3.0 g of styrene to the above solution, stir for 30 min, deoxygenate with argon atmosphere for 1 h, raise the temperature to 70° C., and keep the reaction for 24 h. After the reaction, a uniform and stable polystyrene microsphere emulsion is obtained.

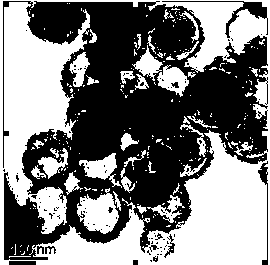

[0024] (2) Preparation of hollow silica nanoparticles:

[0025] Take 30g of polystyrene microsphere emulsion, adjust its pH to 4.12, add 1.33g of tetraethyl orthosilicate, and keep warm at 50°C for 24h. It was centrifuged with a high-speed rotary centrifuge, and the lower precipitate was washed three times with distilled water and absolute ethanol in turn to obtain core-shell polystyrene / silicon dioxide composite microspheres, which were then dispersed in tetrahydr...

Embodiment 2

[0029] (1) Preparation of polystyrene microspheres:

[0030] Add 0.5 g of cetyltrimethylammonium bromide and 0.39 g of azobisisobutylcyanide into a three-necked flask filled with 100 g of distilled water, and stir to form a uniform and transparent solution. Add 4.0 g of styrene to the above solution, stir for 30 min, deoxygenate in an argon atmosphere for 1 h, raise the temperature to 85°C, and keep the reaction for 23 h. After the reaction, a uniform and stable polystyrene microsphere emulsion is obtained.

[0031] (2) Preparation of hollow silica nanoparticles:

[0032] Take 37g of polystyrene microsphere emulsion, adjust its pH to 4.0, add 1.0g of vinyltriethoxysilane, and keep warm at 50°C for 25h. It was centrifuged with a high-speed rotary centrifuge, and the lower sediment was washed three times with distilled water and absolute ethanol in turn to obtain core-shell polystyrene / silicon dioxide composite microspheres, which were then dispersed in acetone and heated at 4...

Embodiment 3

[0036] (1) Preparation of polystyrene microspheres:

[0037] Add 2.5 g of dodecyltrimethylammonium bromide and 0.41 g of ammonium persulfate into a three-necked flask filled with 100 g of distilled water, and stir to form a uniform and transparent solution. Add 2.0 g of styrene to the above solution, stir for 30 min, deoxygenate with argon atmosphere for 1 h, raise the temperature to 80° C., and keep the reaction for 25 h. After the reaction, a uniform and stable polystyrene microsphere emulsion is obtained.

[0038] (2) Preparation of hollow silica nanoparticles:

[0039] Take 60g of polystyrene microsphere emulsion, adjust its pH to 6.0, add 1.4g of methyltriethoxysilane, and keep the reaction at 50°C for 20h. It was centrifuged with a high-speed rotary centrifuge, and the lower sediment was washed three times with distilled water and absolute ethanol in turn to obtain core-shell polystyrene / silicon dioxide composite microspheres, which were then dispersed in chloroform. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com