Patents

Literature

696 results about "Water vapor permeability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water vapor permeability is a measure of the passage of water vapor through a membrane. It is the rate of water vapor transmission per unit area per unit of vapor pressure differential under test conditions. It is also known as water vapor transmission rate (WVTR) or moisture vapor transmission rate (MVTR).

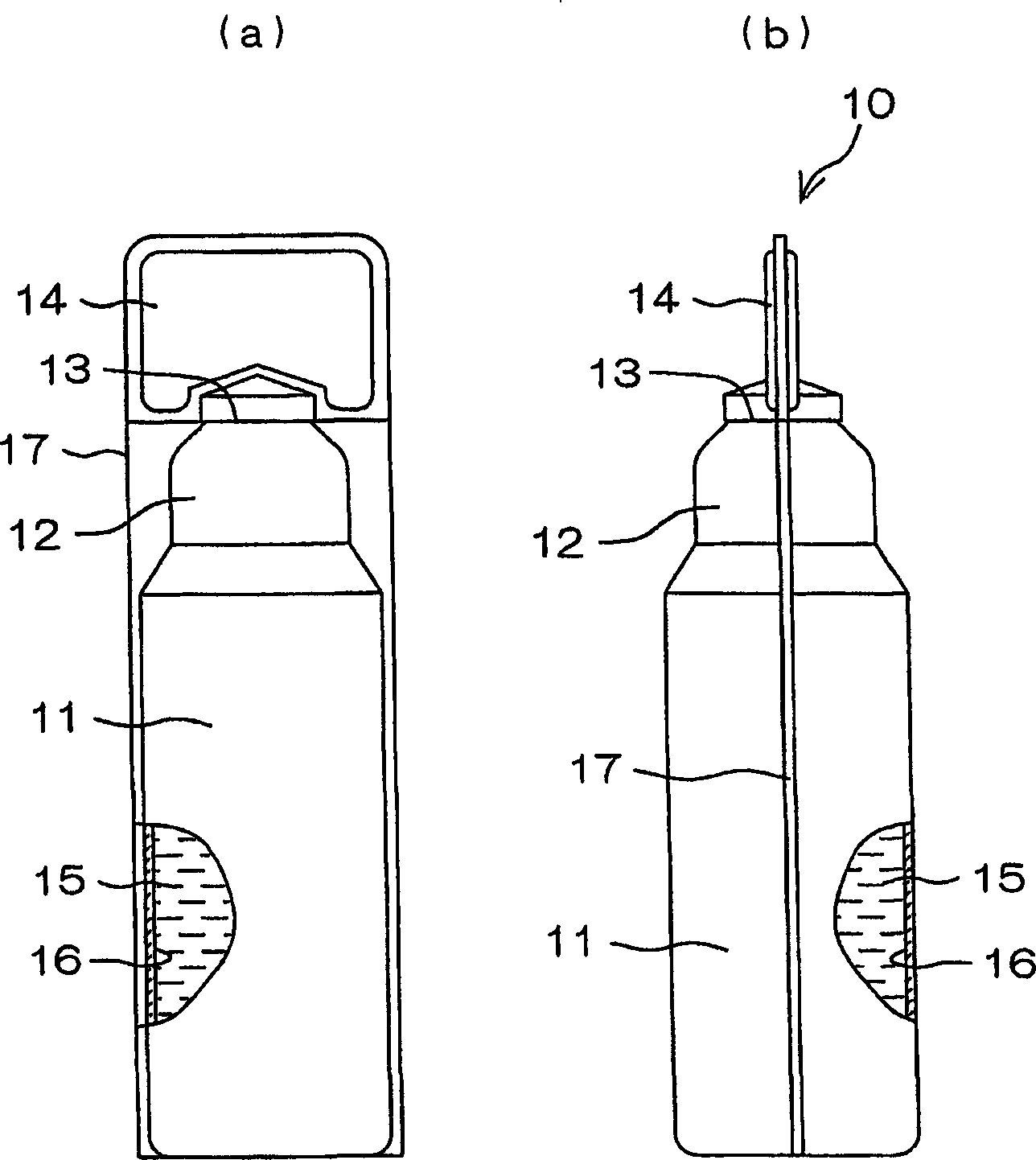

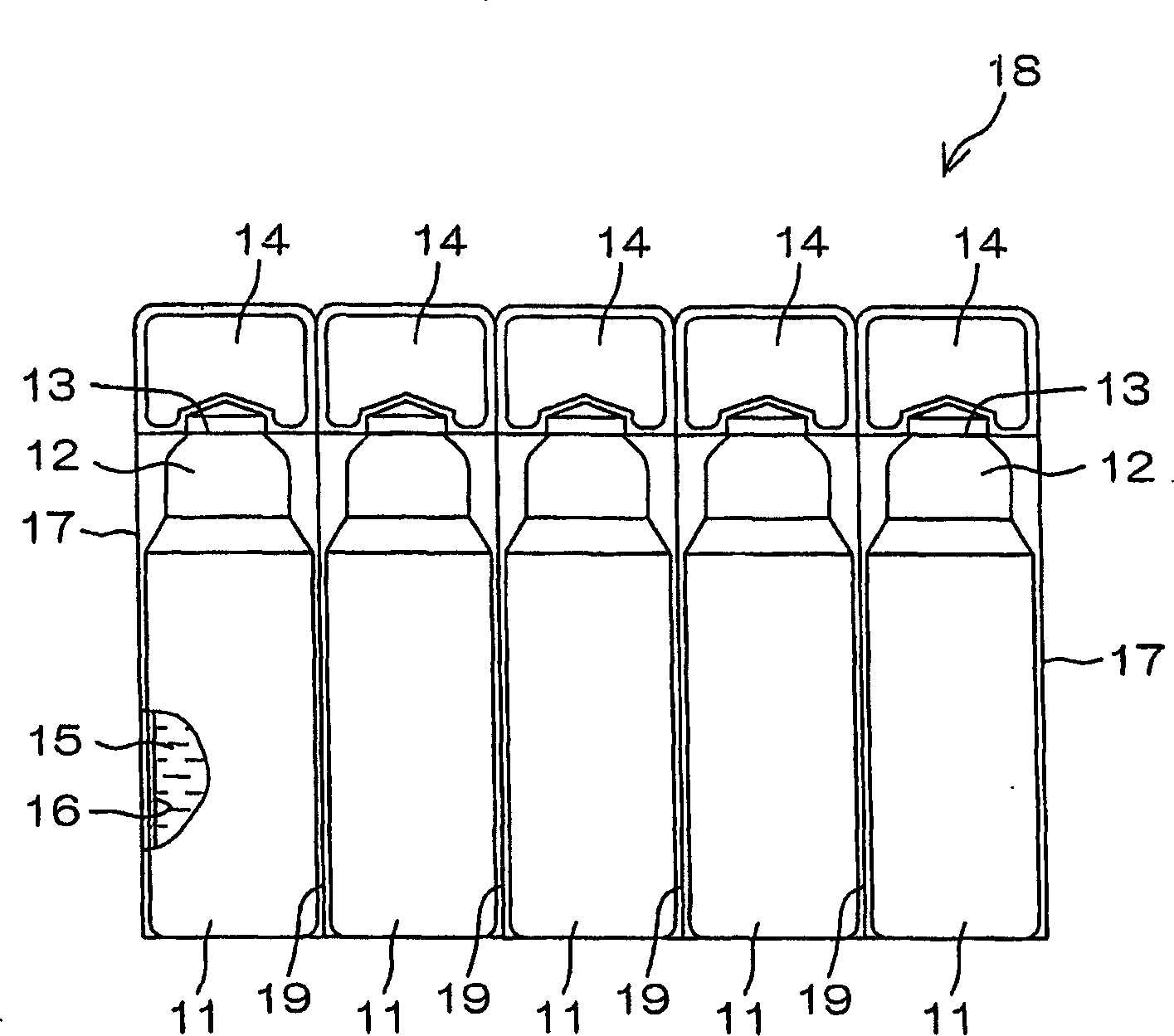

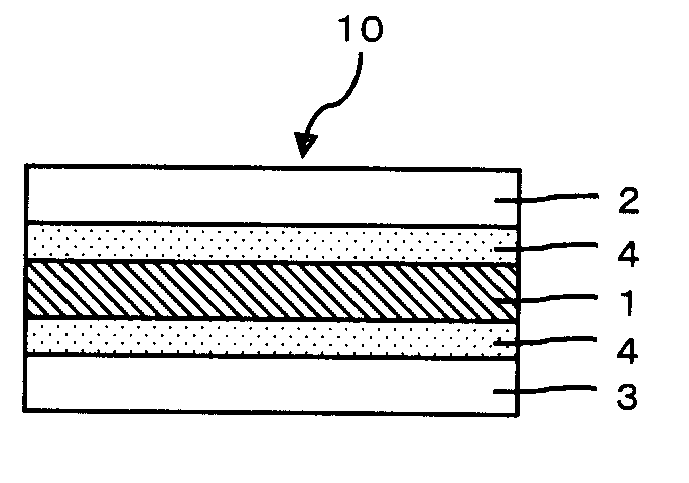

Drug solution filling plastic ampoule and production method therefor

The invention provides a plastic ampoule filled with medicinal liquid, which has the functions of blocking gas, water vapor and light and preventing drug penetration, absorption and adsorption, and a preparation method thereof. The plastic ampoule 10 for filling medicinal solution of the present invention comprises a container main body 11, a fused portion 13 closing its opening 12 and a holding portion 14 connected thereto for twisting. The ampoule 10 is formed using a parison having two or more layers, at least one of which is a material selected from the group consisting of gas transmission, water vapor transmission, light transmission, drug transmission and A functional layer that prevents at least one of drug absorption and adsorption properties. That is, the parison is extruded from a multi-layer blow mold, clamped by the lower parting die to form the main body part 11 of the container, and after filling the liquid medicine 15 therein, the opening part 12 is clamped by the upper parting die to form a fusion joint. Part 13 and holding part 14, thereby making the product of the present invention.

Owner:OTSUKA PHARM FAB INC

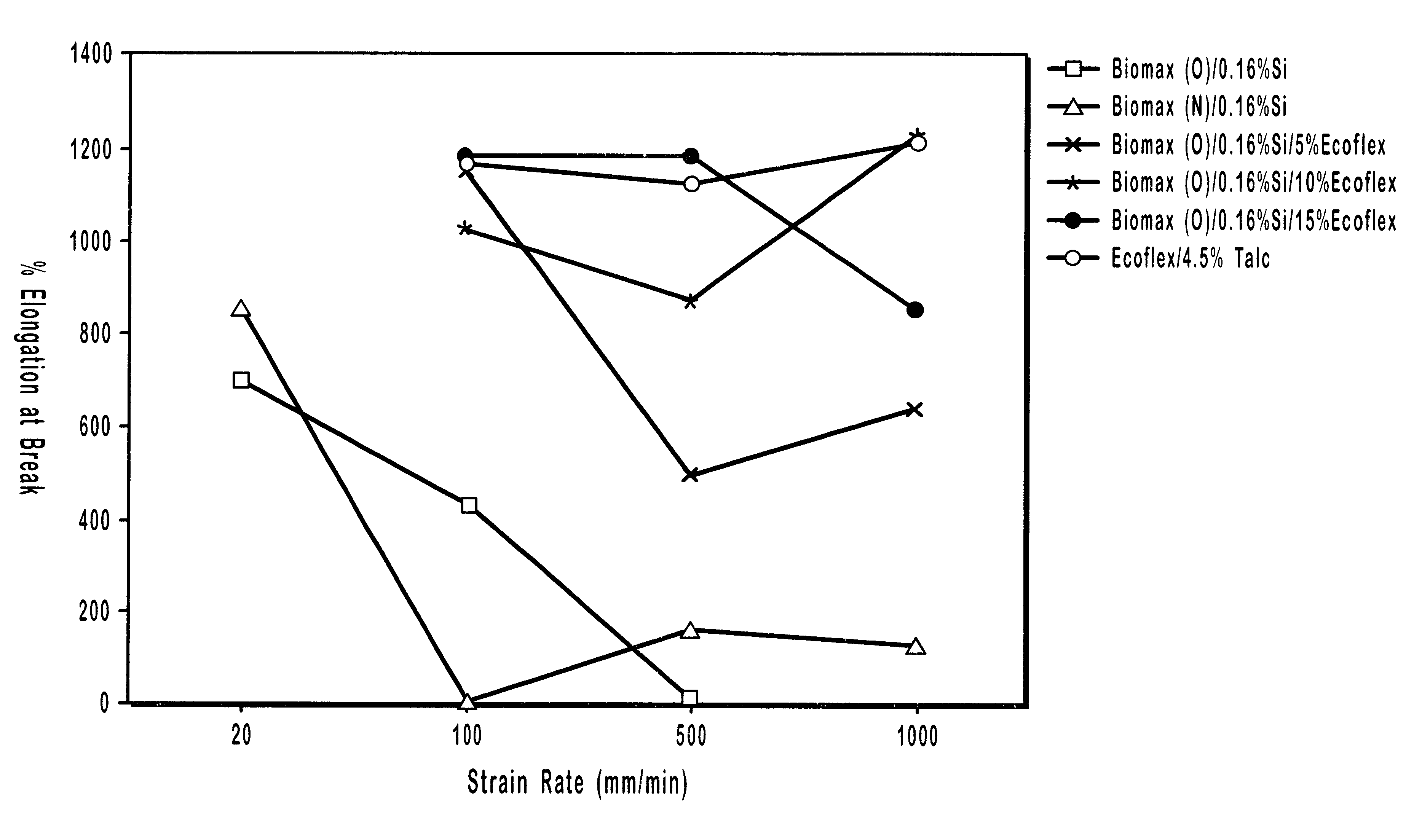

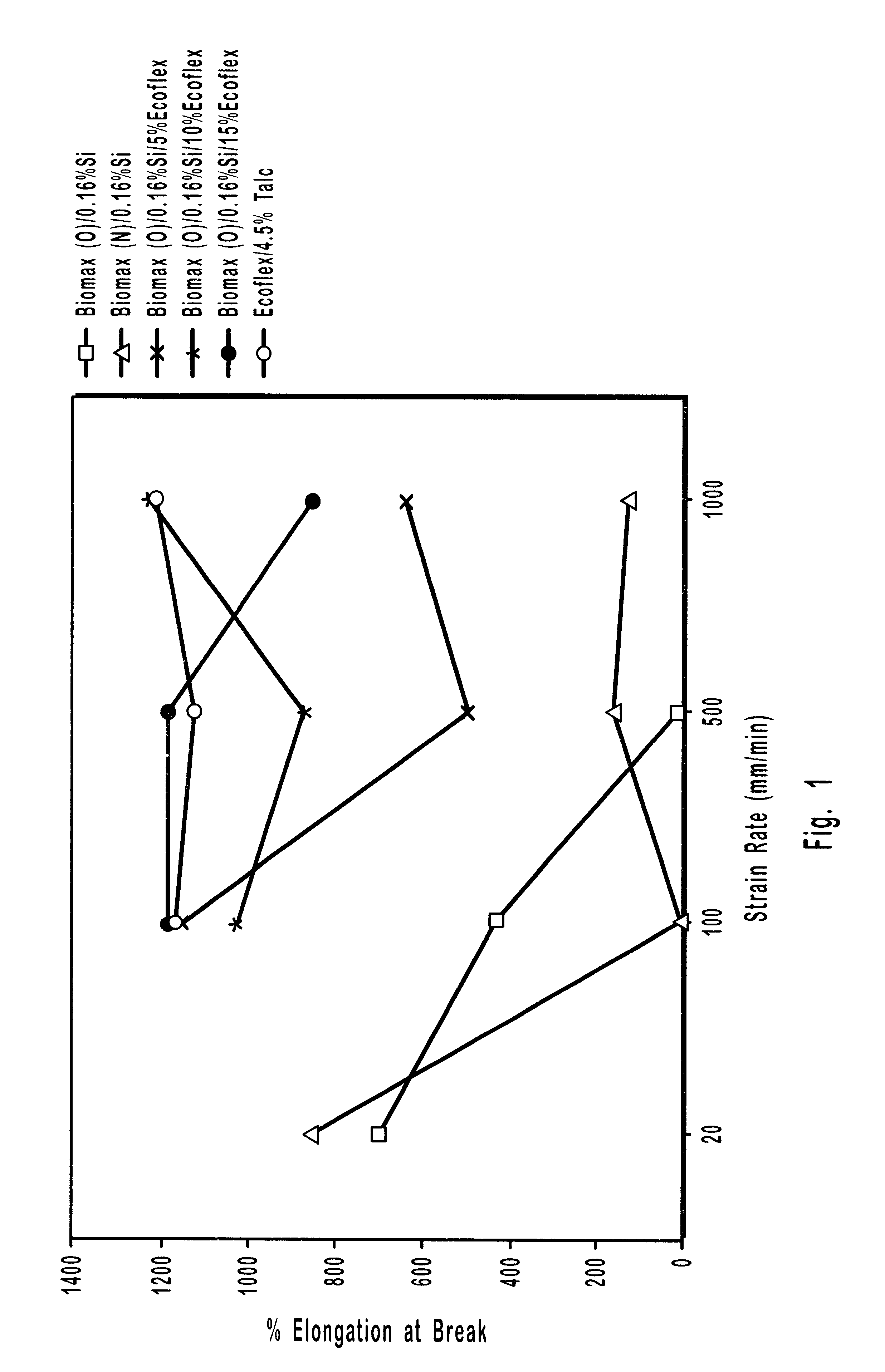

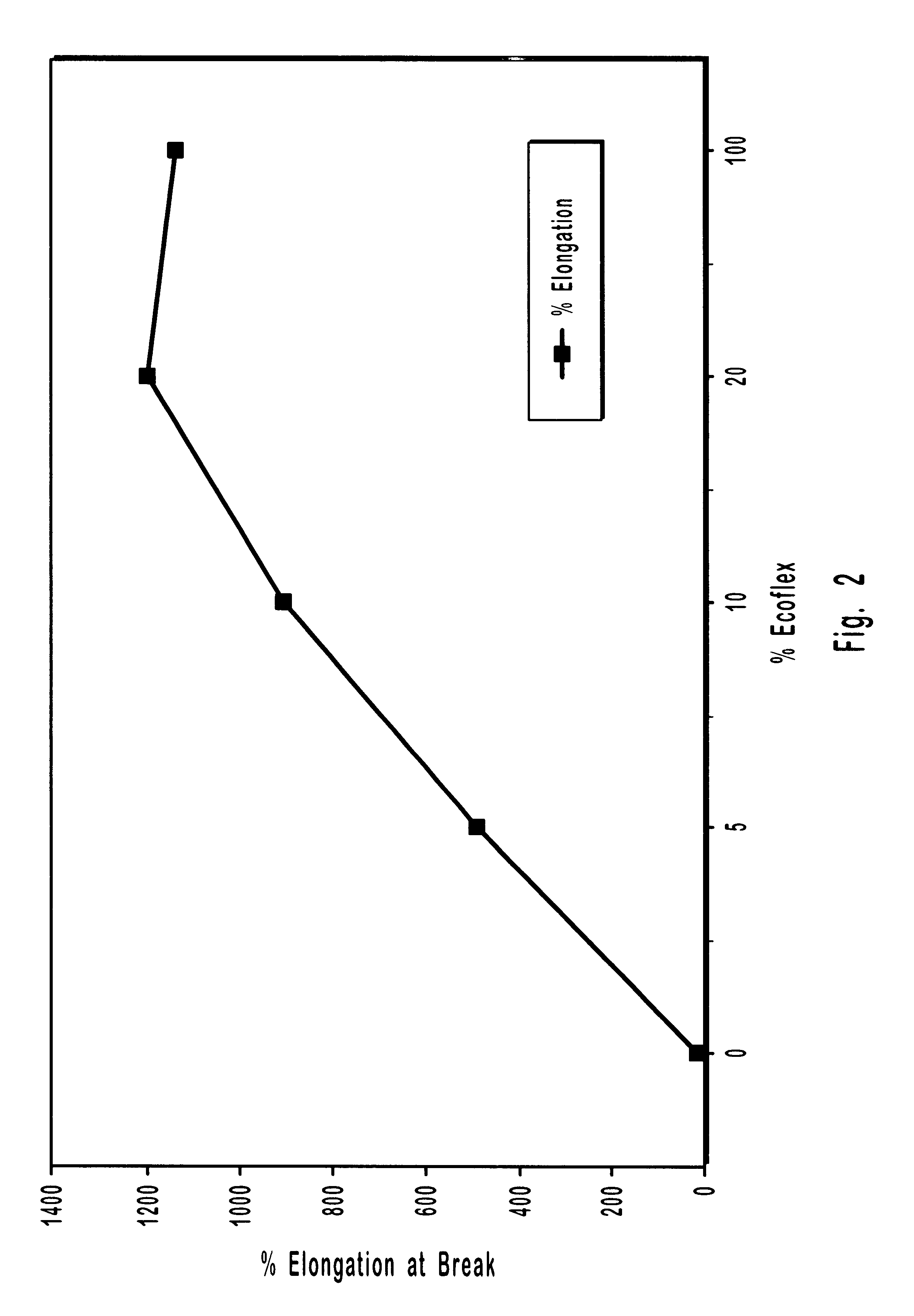

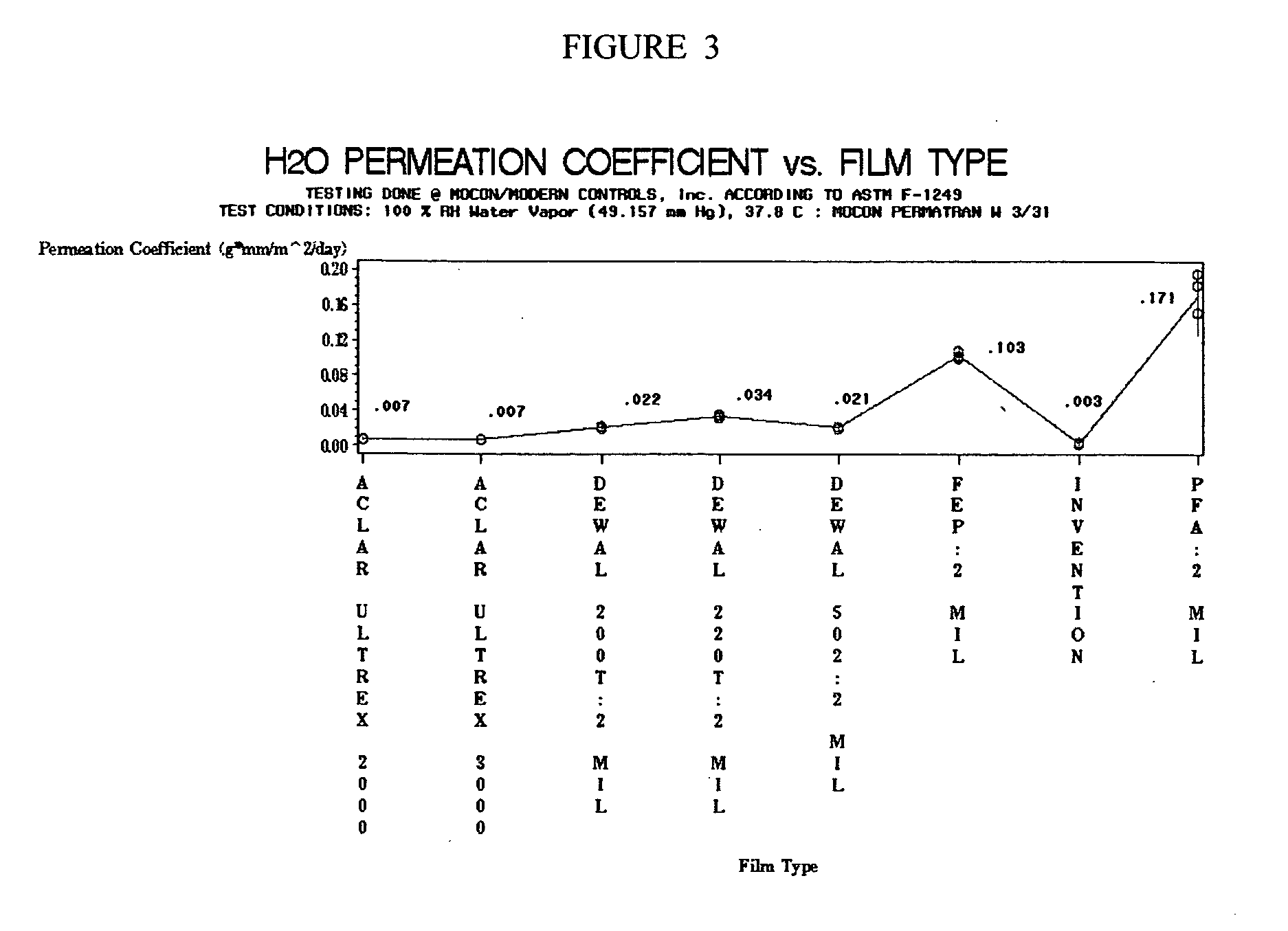

Biodegradable polymer films and sheets suitable for use as laminate coatings as well as wraps and other packaging materials

Biodegradable polymer blends suitable for laminate coatings, wraps and other packaging materials manufactured from at least one "hard" biopolymer and at least one "soft" biopolymer. "Hard" biopolymers tend to be more brittle and rigid and typically have a glass transition temperature greater than about 10° C. "Soft" biopolymers tend to be more flexible and pliable and typically have a glass transition temperature less than about 0° C. While hard and soft polymers each possess certain intrinsic benefits, certain blends of hard and soft polymers have been discovered which possess synergistic properties superior to those of either hard or soft polymers by themselves. Biodegradable polymers include polyesters, polyesteramides and thermoplastically processable starch. The polymer blends may optionally include an inorganic filler. Films and sheets made from the polymer blends may be textured so as to increase the bulk hand feel. Wraps will typically be manufactured so as to have good "dead-fold" properties so as to remain in a wrapped position and not spring back to an "unwrapped" and planar form. Laminate films will typically have good water vapor barrier properties as measured by the their Water Vapor Permeability Coefficient (WVPC).

Owner:BIO TEC BIOLOGISCHE NATURVERPACKUNGEN

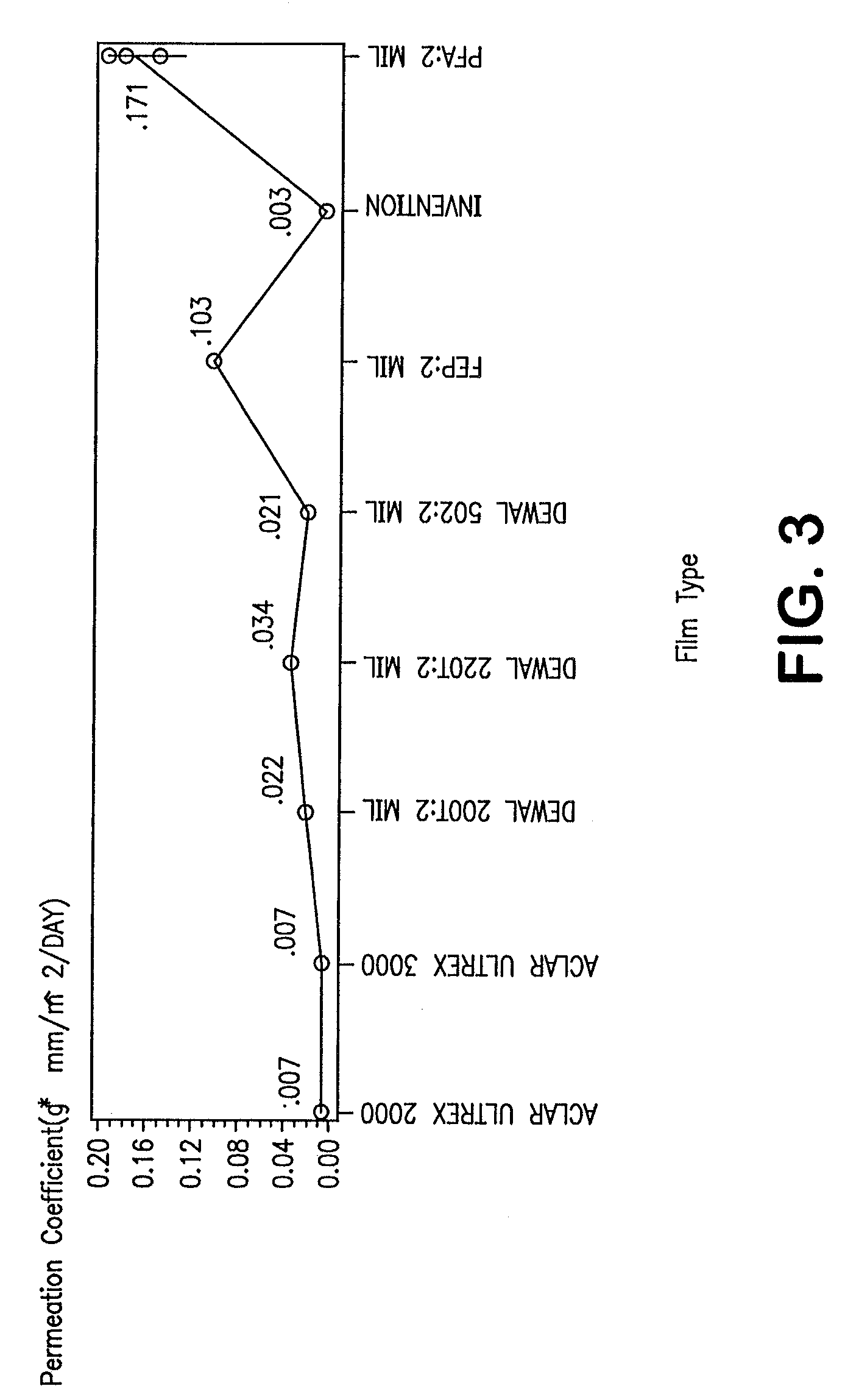

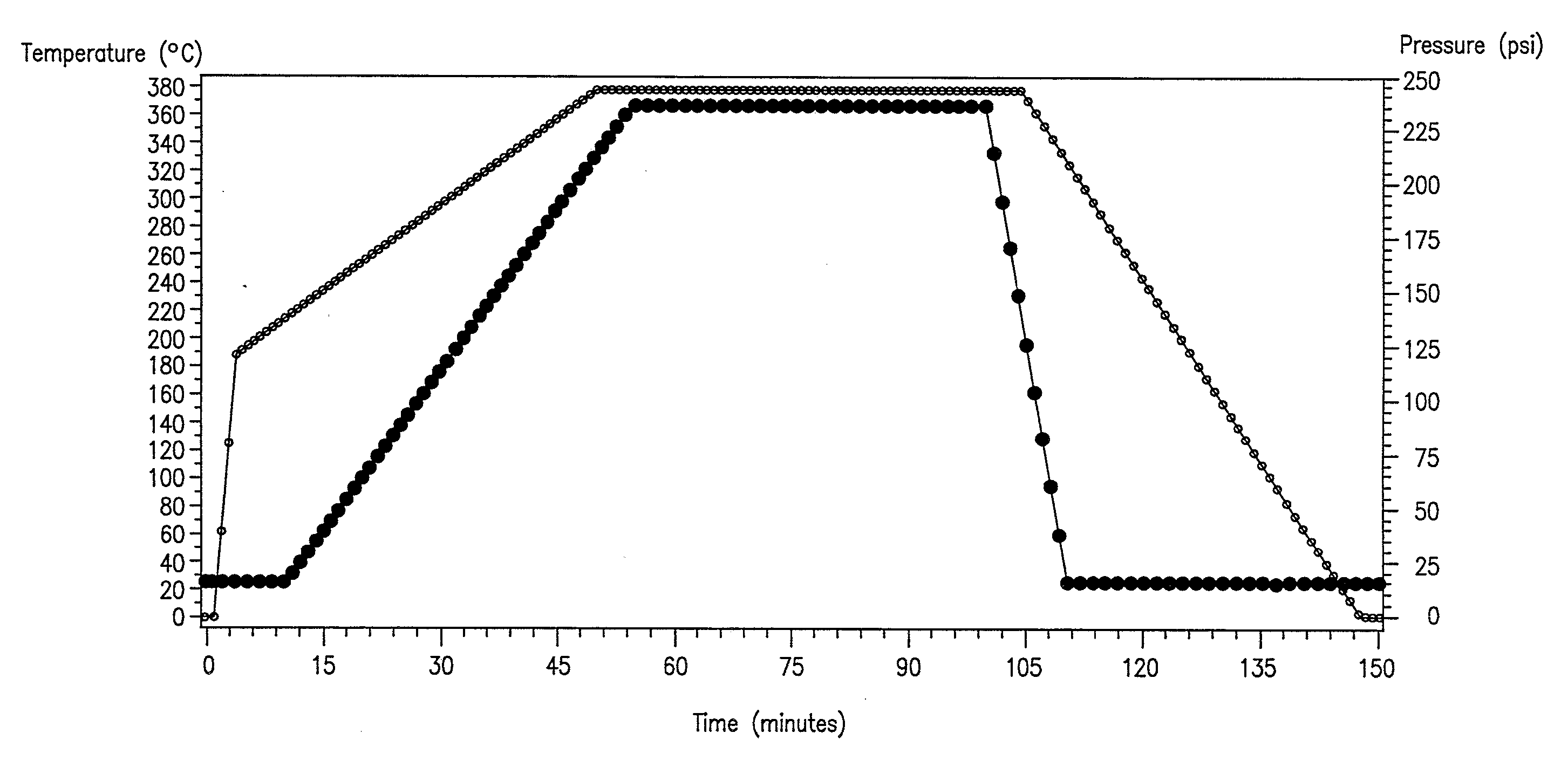

Fluoropolymer barrier material

InactiveUS7521010B2Improve barrier propertiesImprove permeabilitySynthetic resin layered productsCeramic shaping apparatusPolymer scienceWater vapor permeability

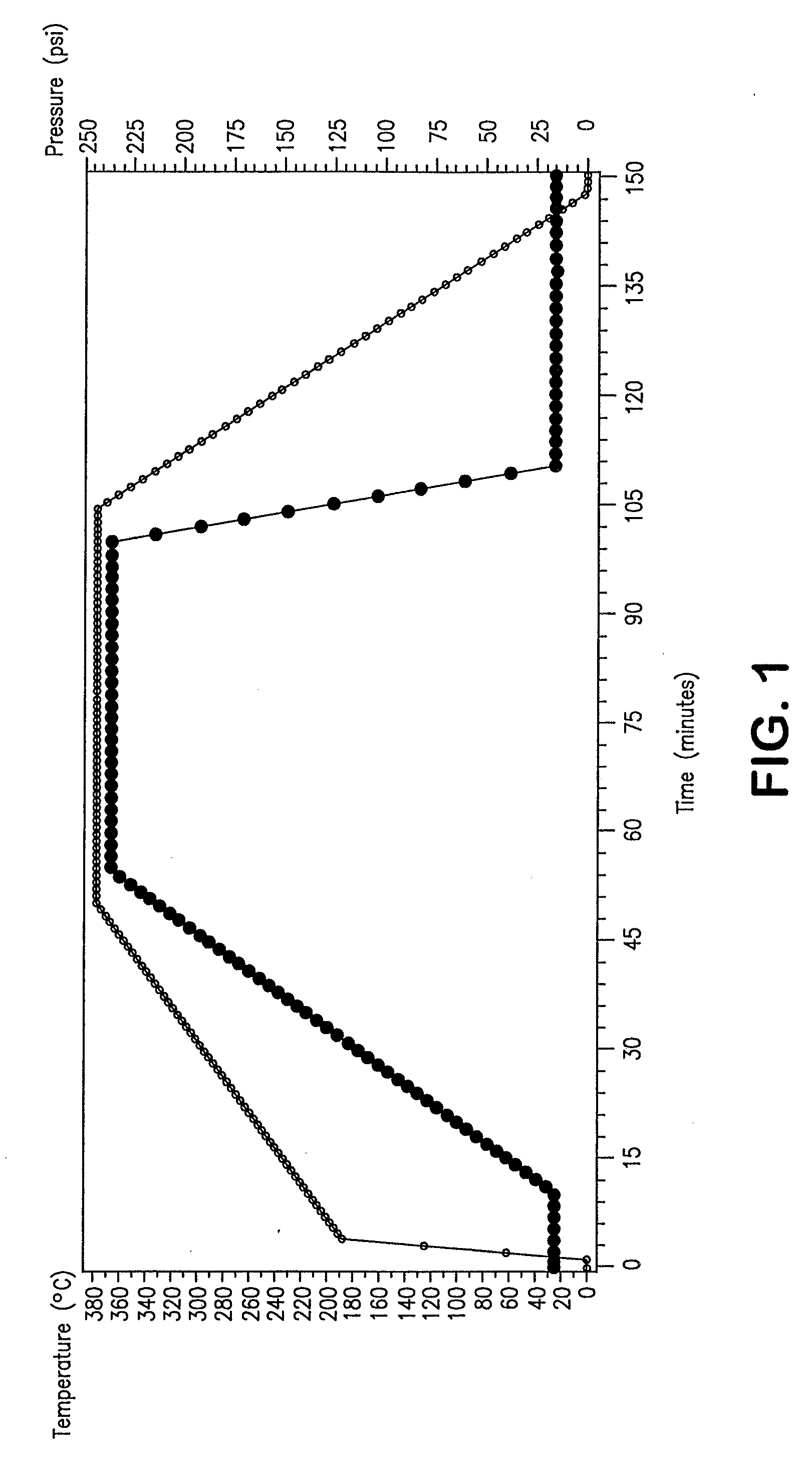

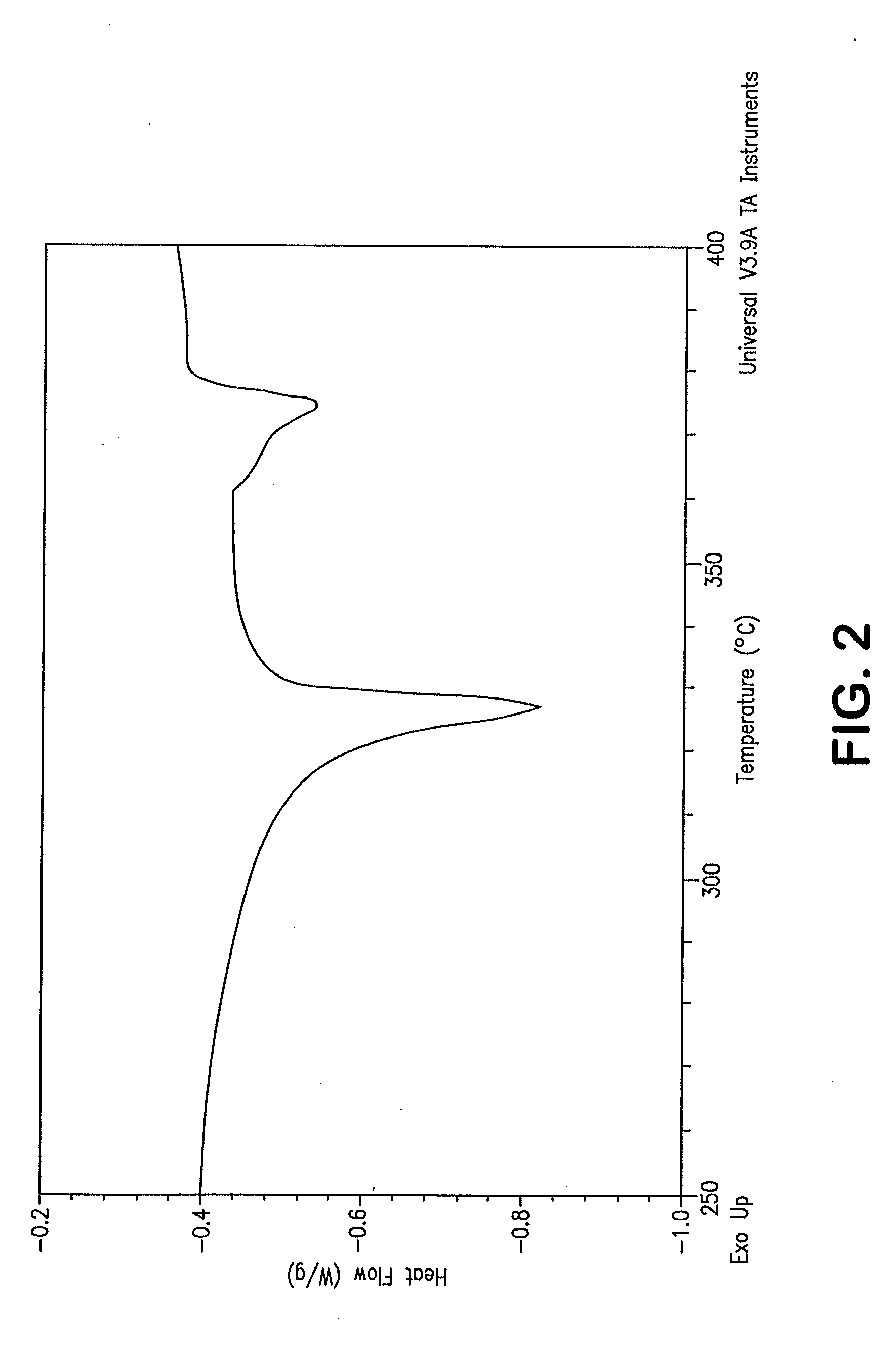

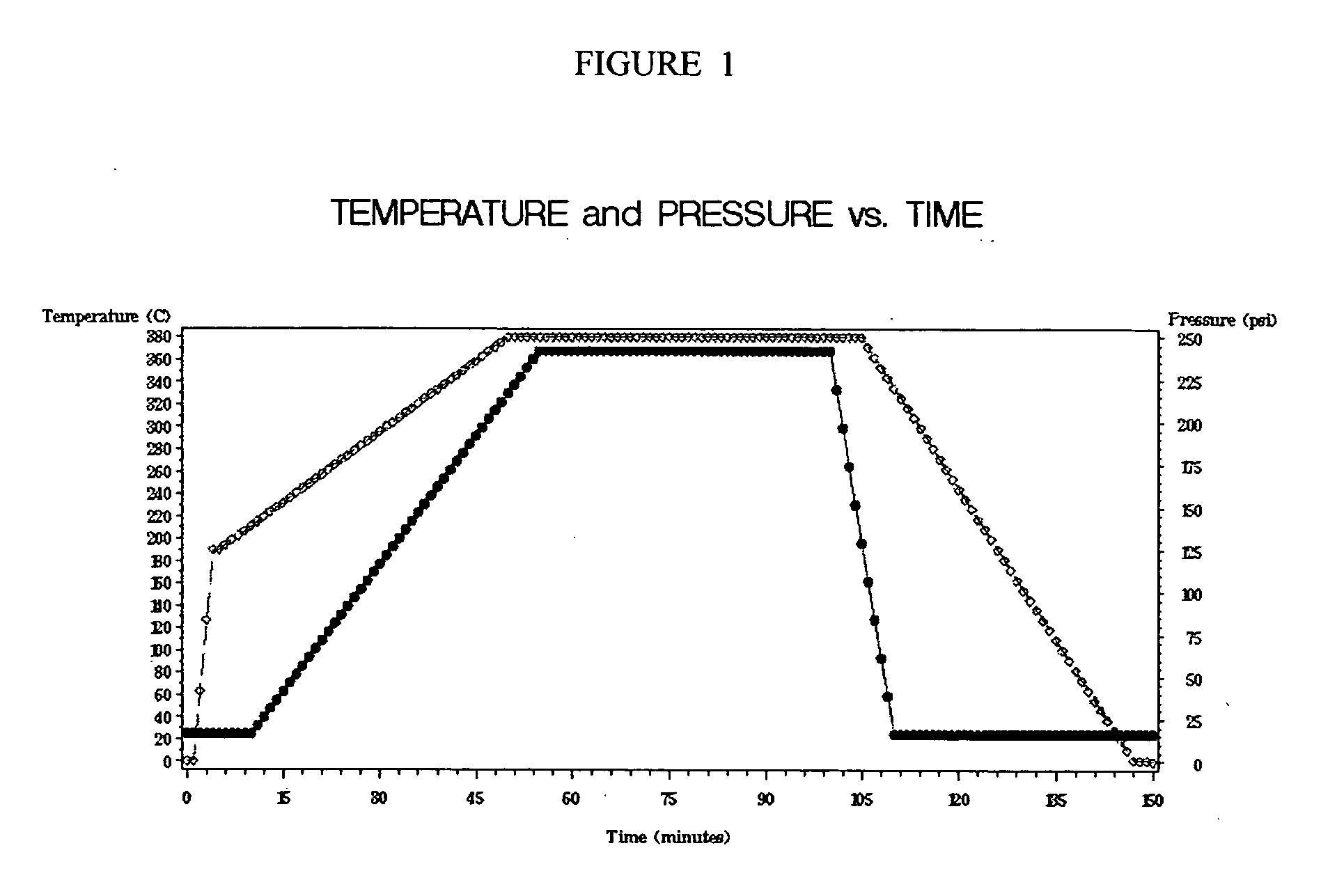

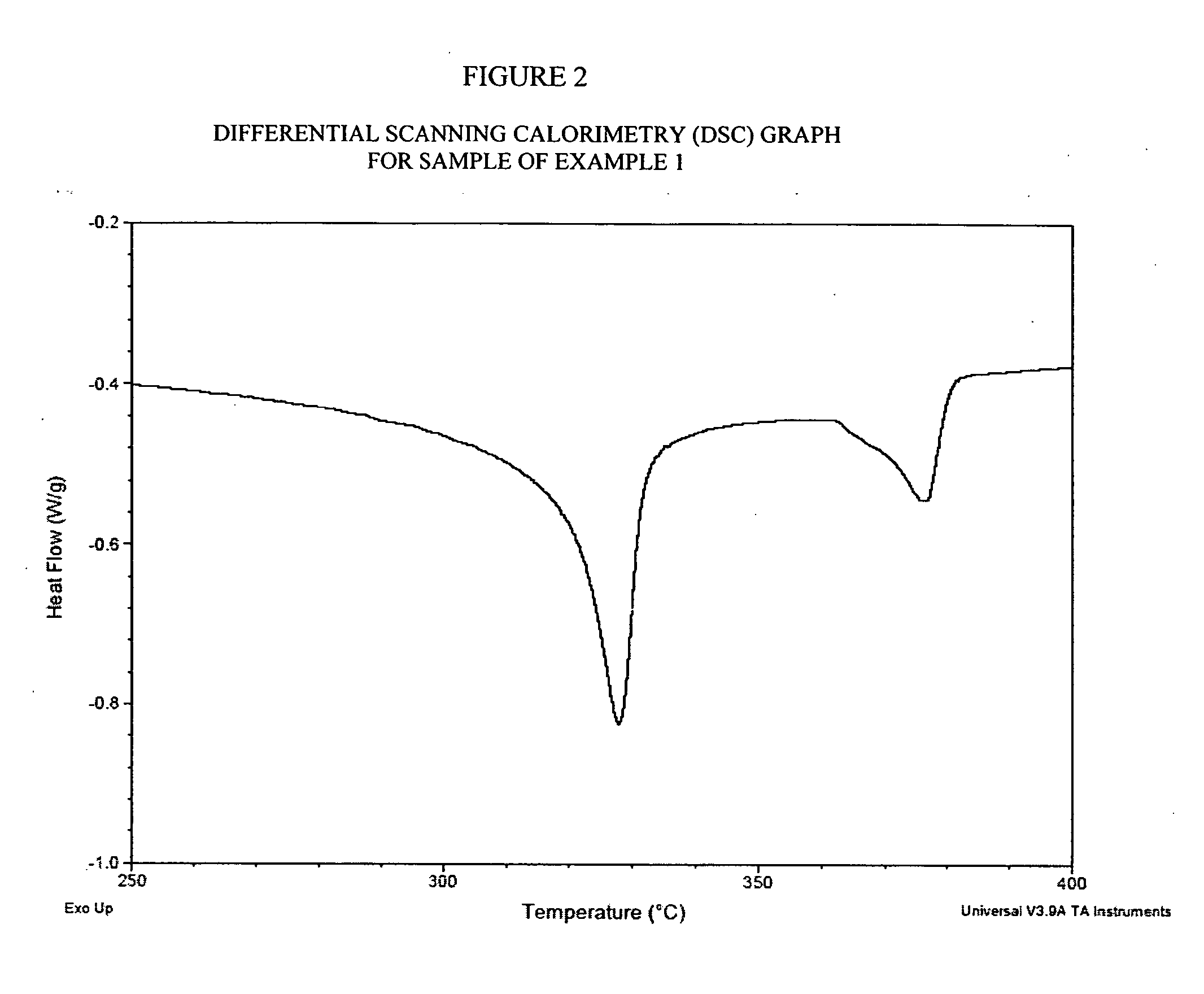

A novel densified fluoropolymer article is described which has a water vapor permeation of about 0.015 g-mm / m2 / day or less, and preferably has a matrix tensile strength of at least 10,000 psi in two orthogonal directions. The articles are made by compressing expanded porous PTFE at pressures, temperatures and times which result in elimination of the pores, and subsequent stretching above the crystalline melt temperature.

Owner:WL GORE & ASSOC INC

Polymer coated web with good water vapor permeability

InactiveUS20050014431A1Easy to printReduce chanceSynthetic resin layered productsWoven fabricsCelluloseParticulates

A composite material which is suitable as a wall covering comprises a substrate layer that is permeable to water vapor, such as a nonwoven web material made from cellulose and synthetic fibers, and that is coated, preferably extrusion coated, with a plastics material. In one embodiment the plastics material comprises an olefin polymer, olefin copolymer or blend of olefin (co)polymer and a particulate filler, e.g. calcium carbonate or a mixture thereof with titanium dioxide. In another embodiment the plastics material is a microporous breathable polymer film or a monolithic breathable polymer film.

Owner:AHLSTROM WINDSOR LOCKS LLC

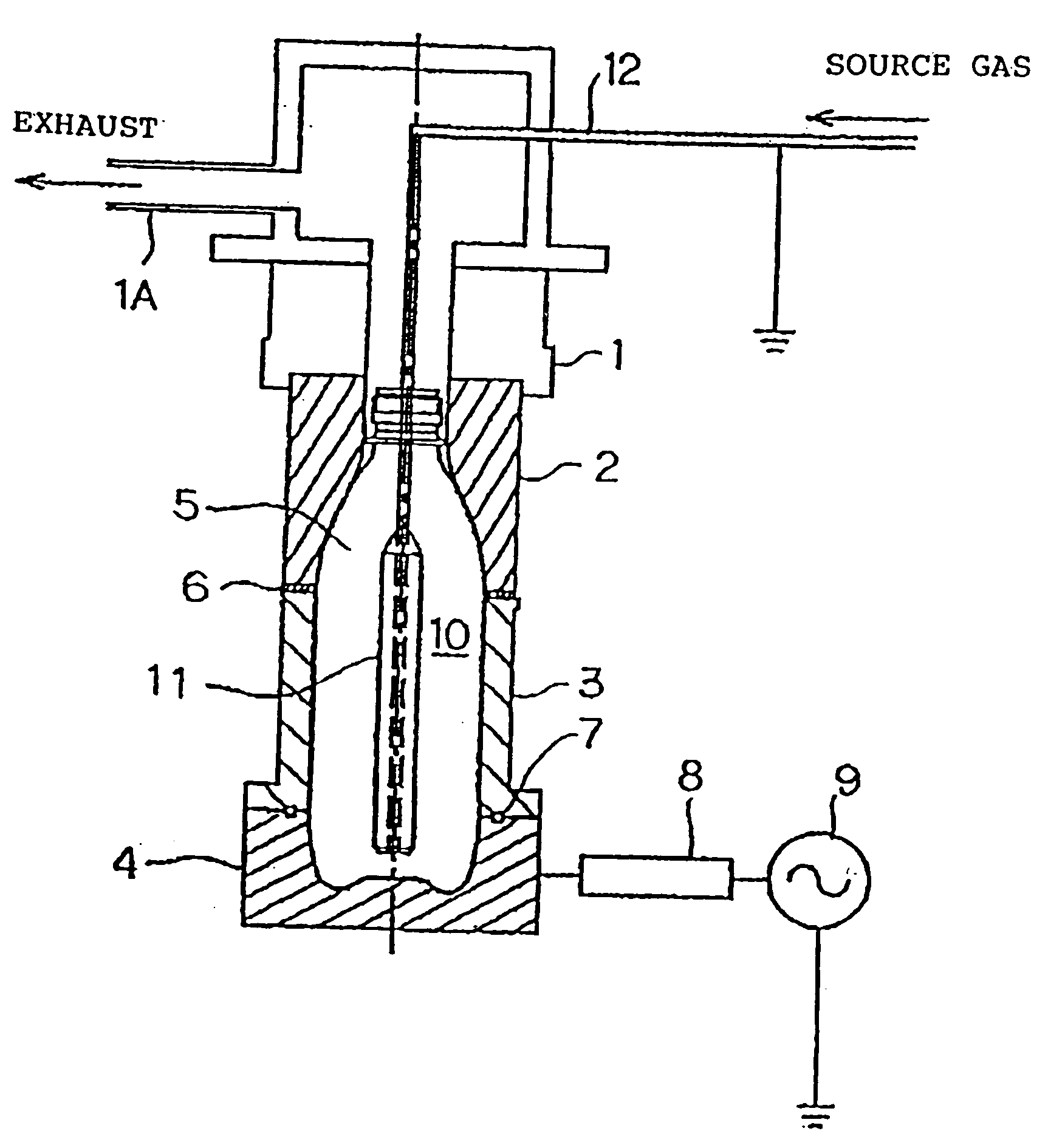

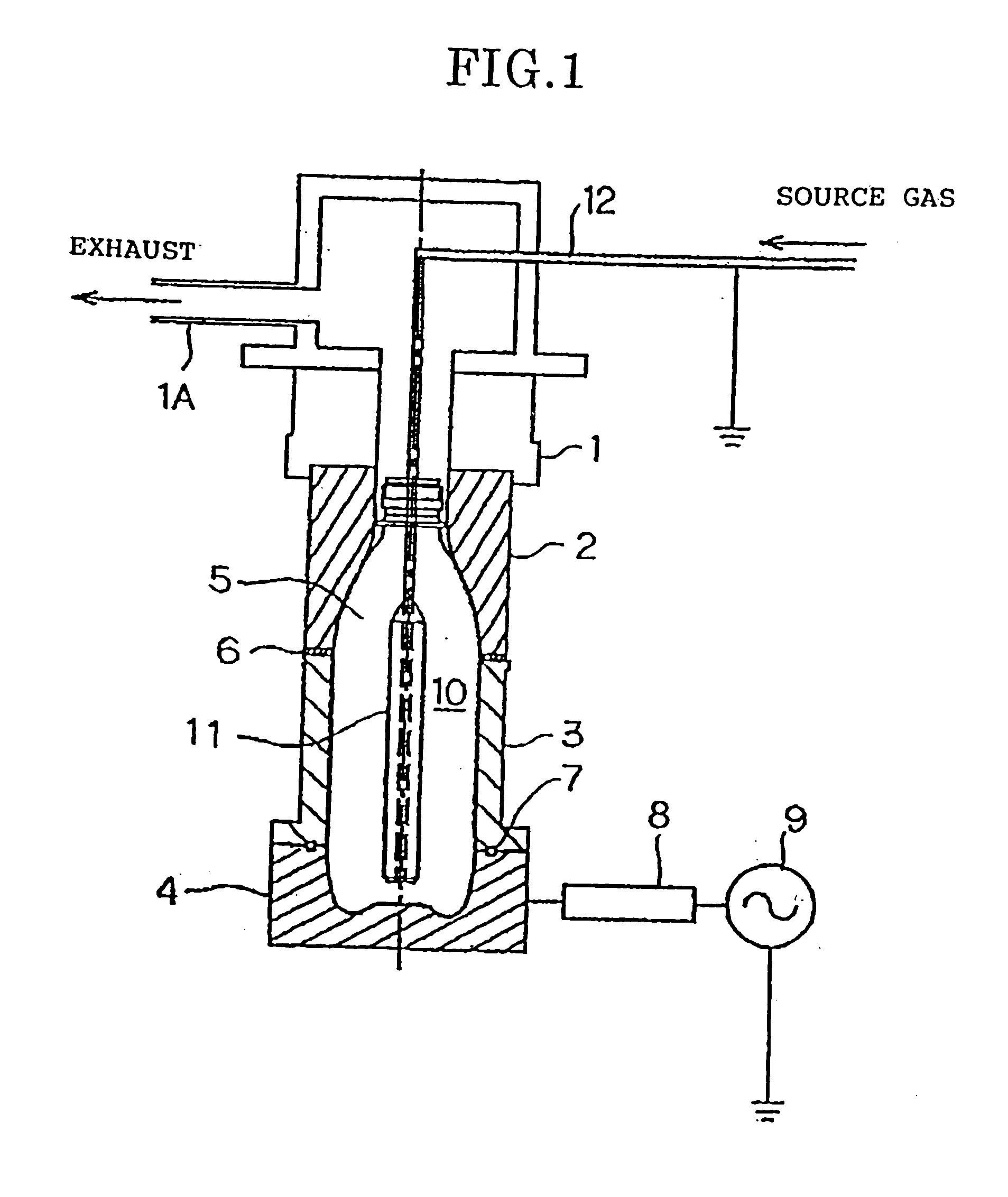

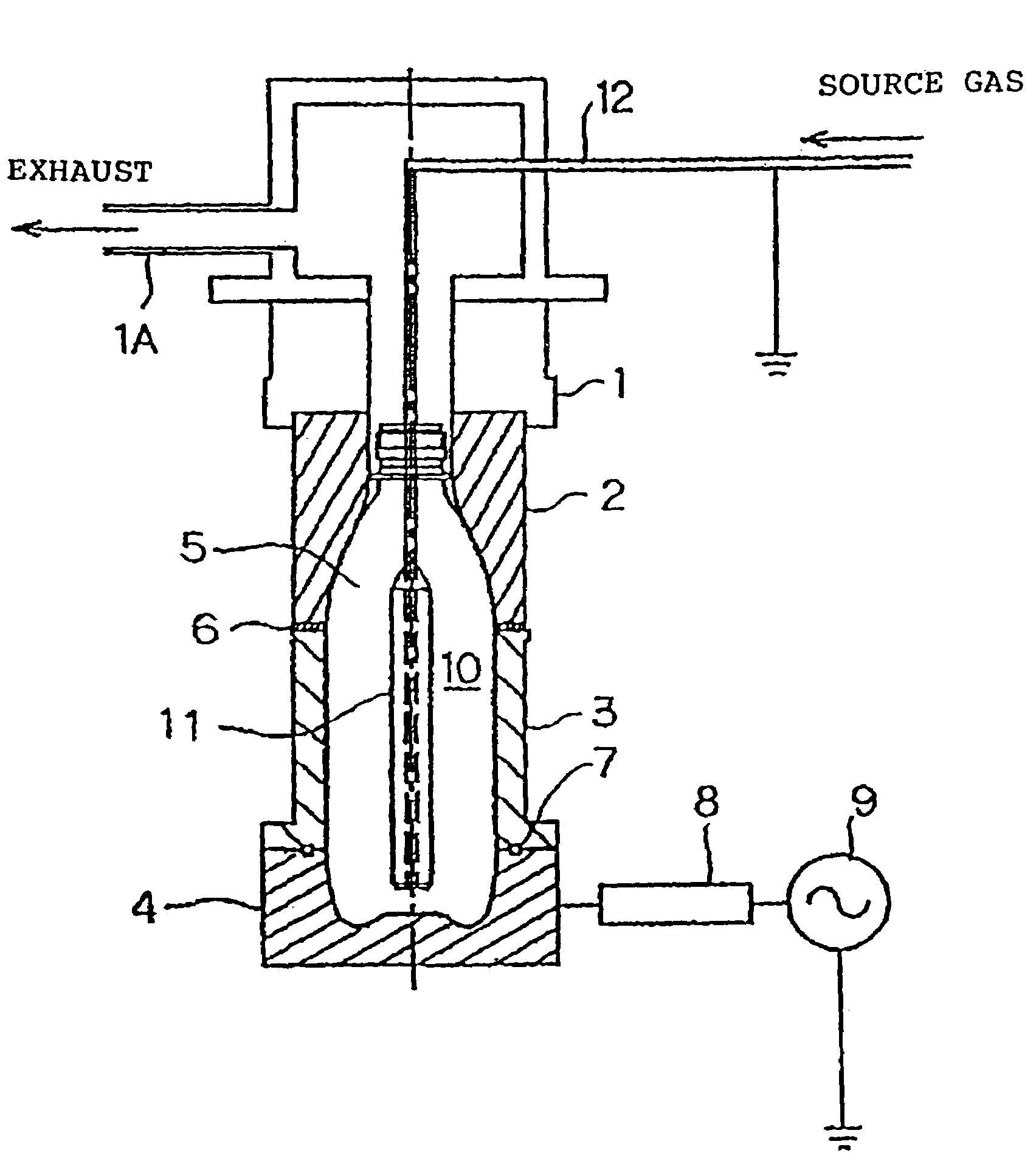

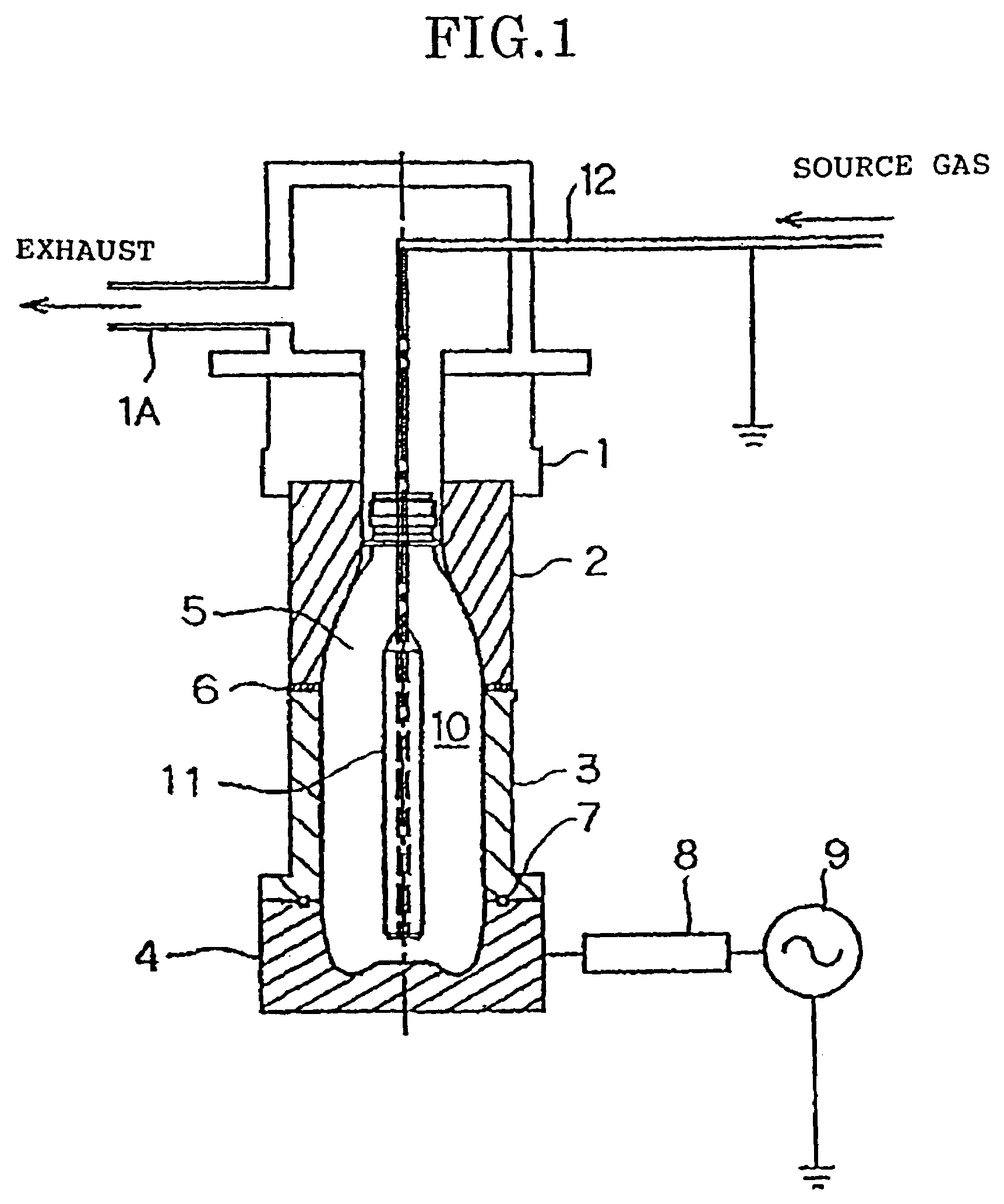

Plastic container for liquid medicine

InactiveUS20040050744A1Avoid concentration changesMaintain good propertiesBottlesSynthetic resin layered productsDiamond-like carbonWater vapor permeability

A plastic container for liquid medicine, which, concerning the effective components of liquid medicine, is capable of prevention of deterioration in quality due to mixing of oxygen and water vapor, prevention of variation in concentration due to water volatilization and moisture absorption, etc. A plastic container for liquid medicine, which is a plastic container internally coated with DLC (diamond-like carbon) film wherein water vapor permeability is 0-0.006 g / container / day and oxygen permeability is 0-0.011 ml / container / day, such properties being obtained by optimizing the three conditions, composition, density and film thickness of the DLC film.

Owner:MITSUBISHI SHOJI PLASTICS

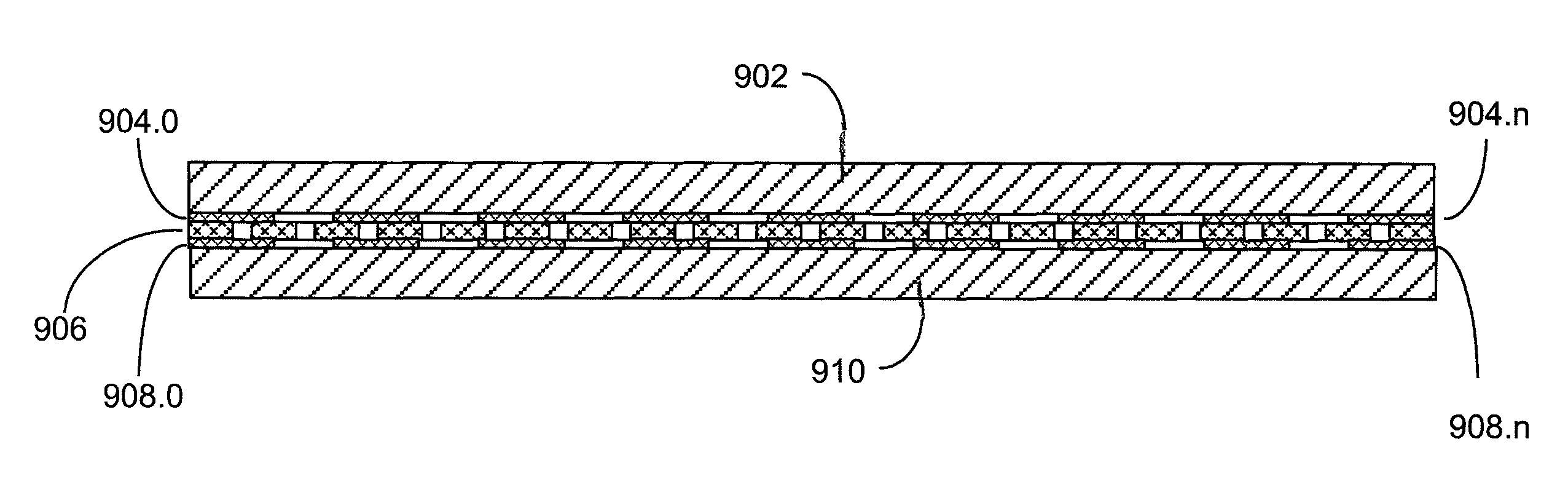

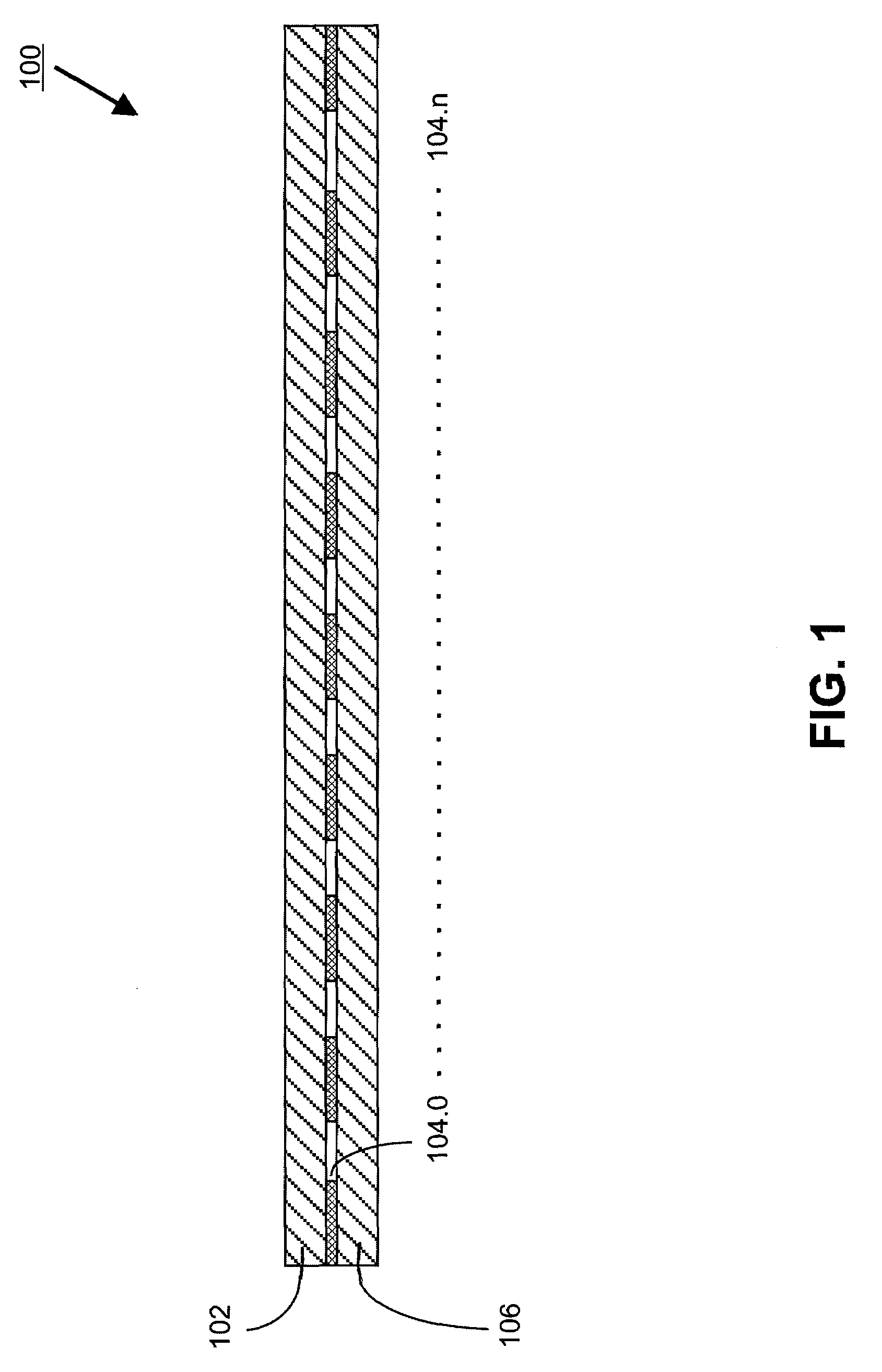

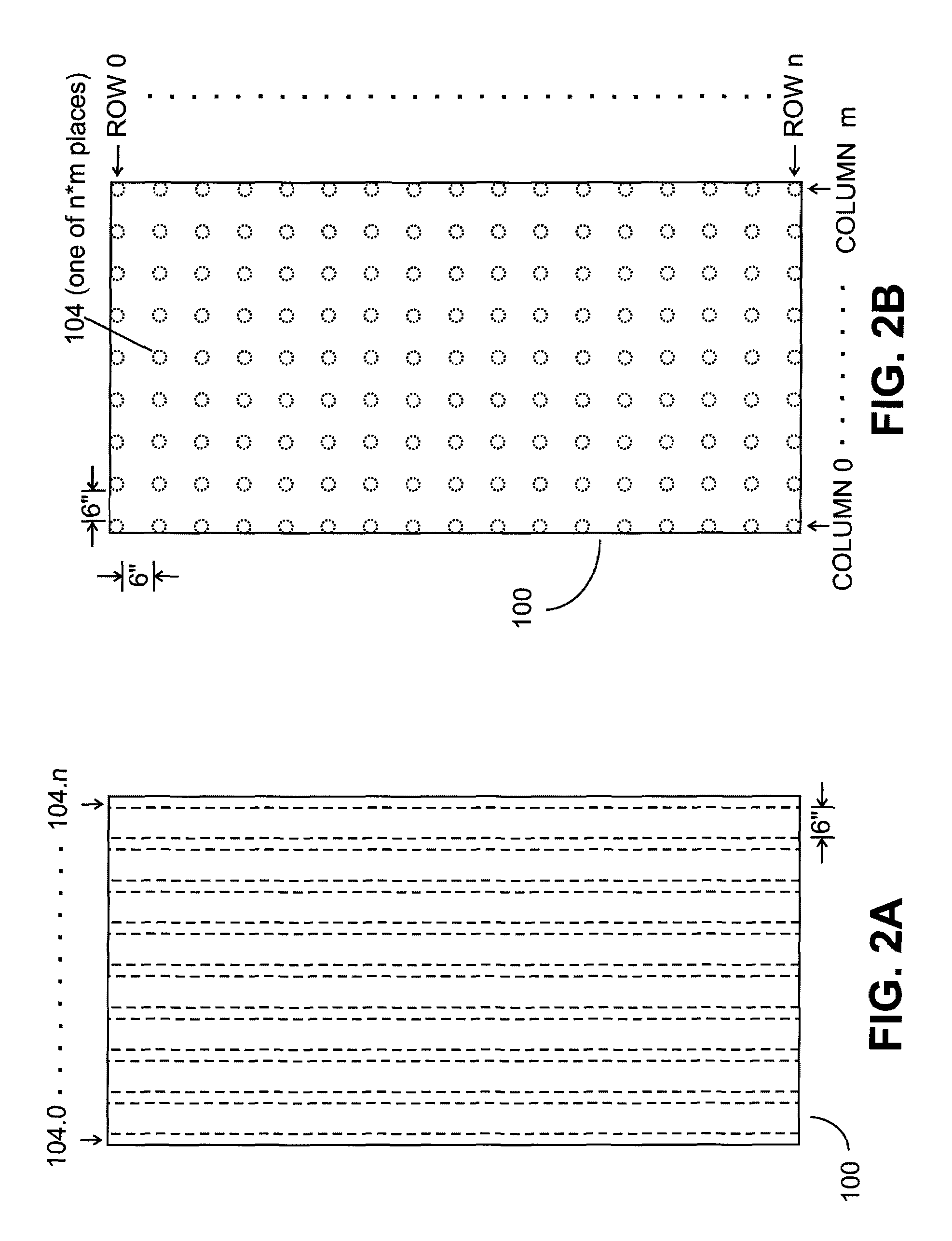

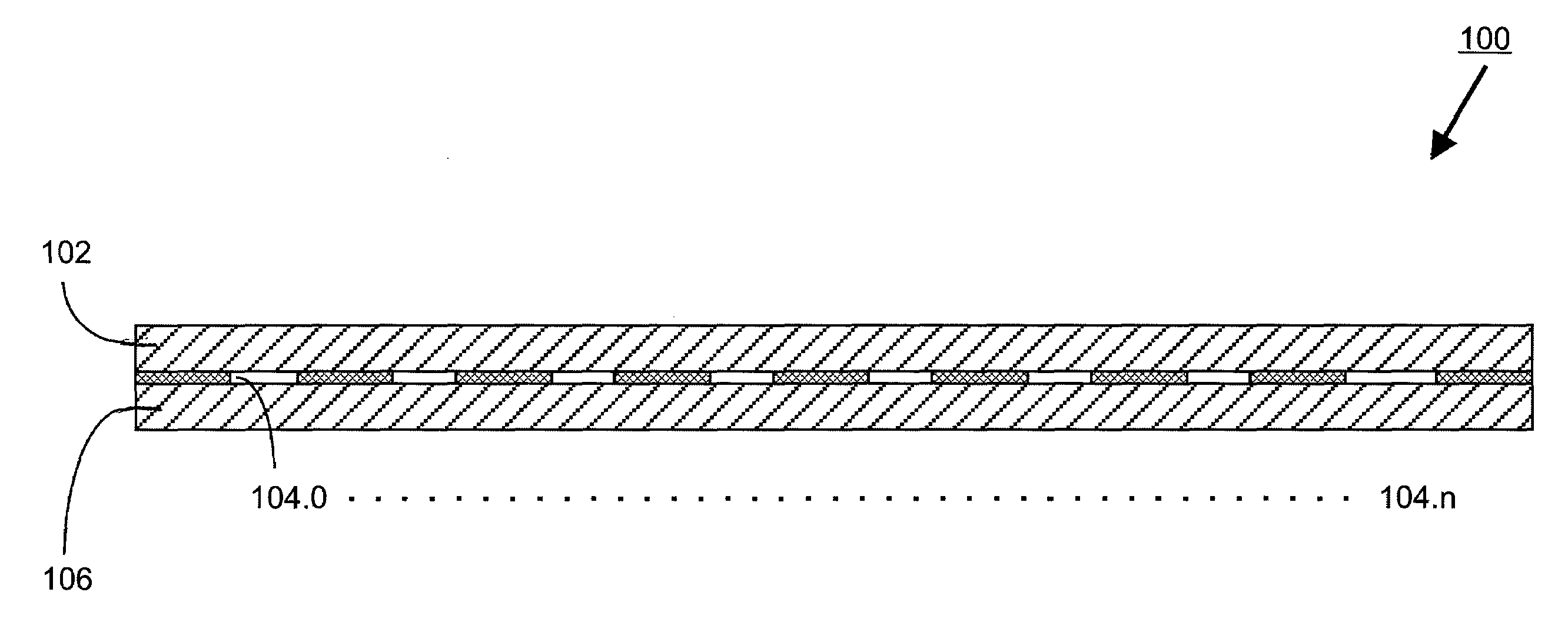

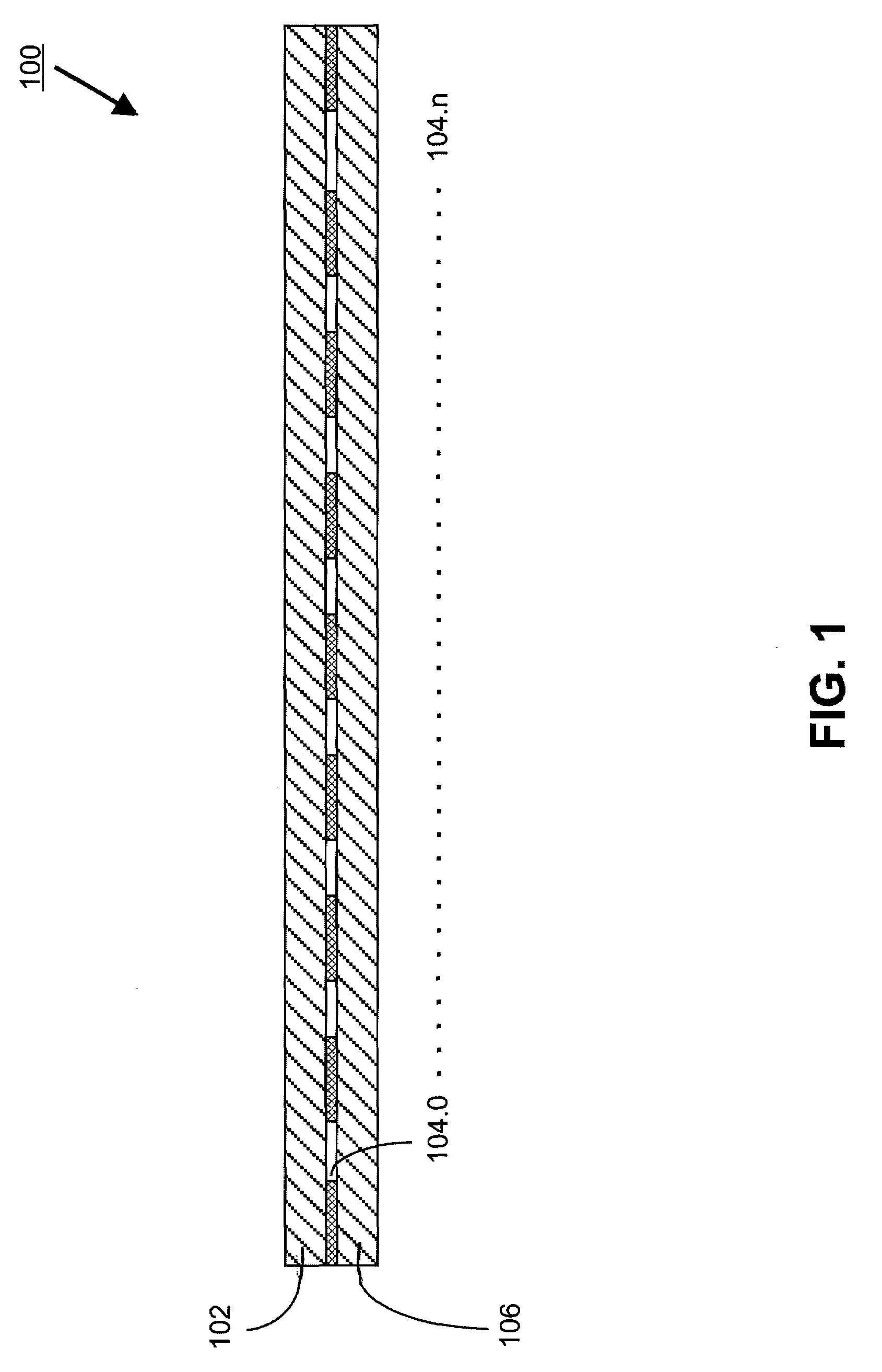

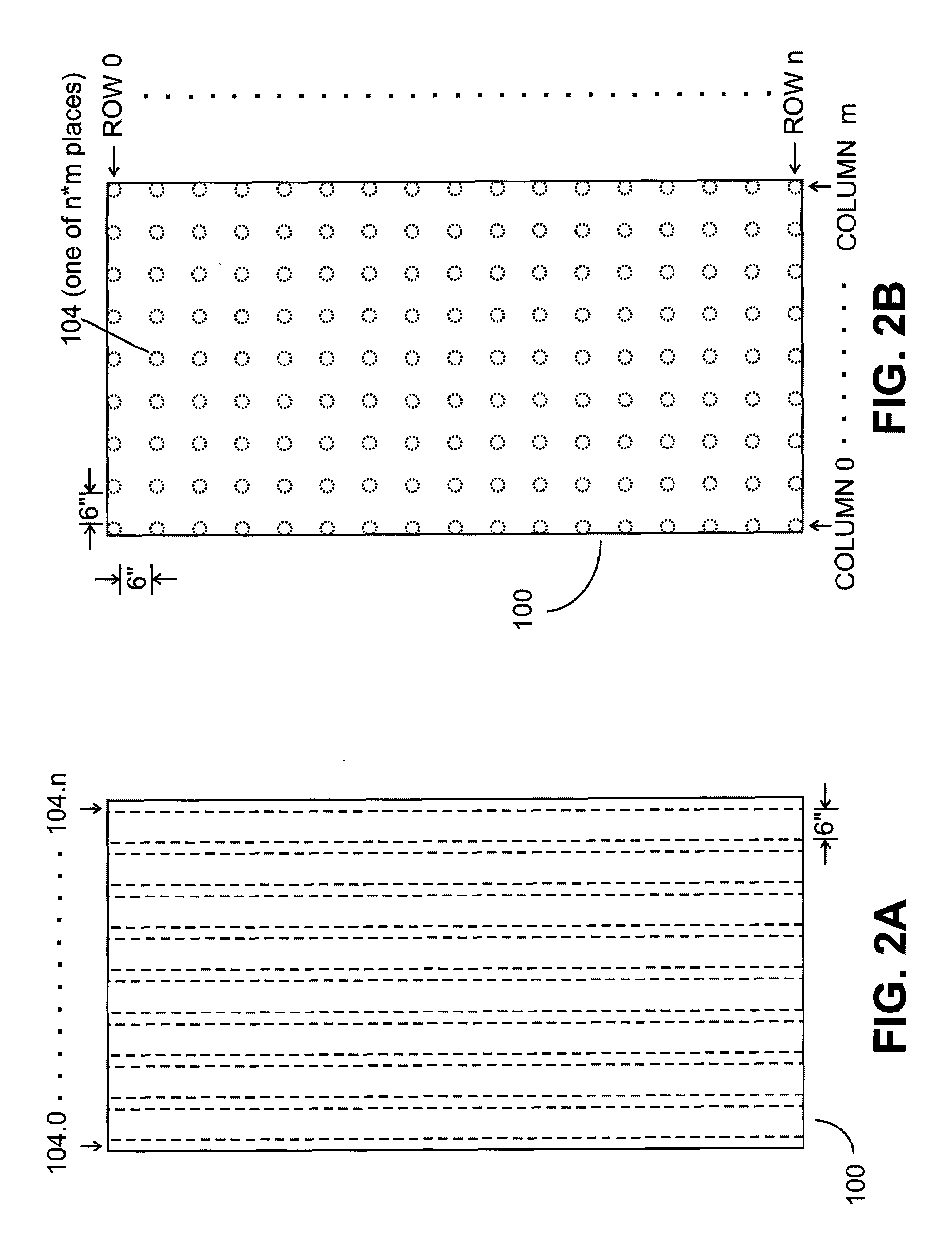

Acoustical sound proofing material with controlled water-vapor permeability and methods for manufacturing same

ActiveUS7883763B2Reduce sound transmissionImprove abilitiesCeilingsWallsWater vapor permeabilityMoisture

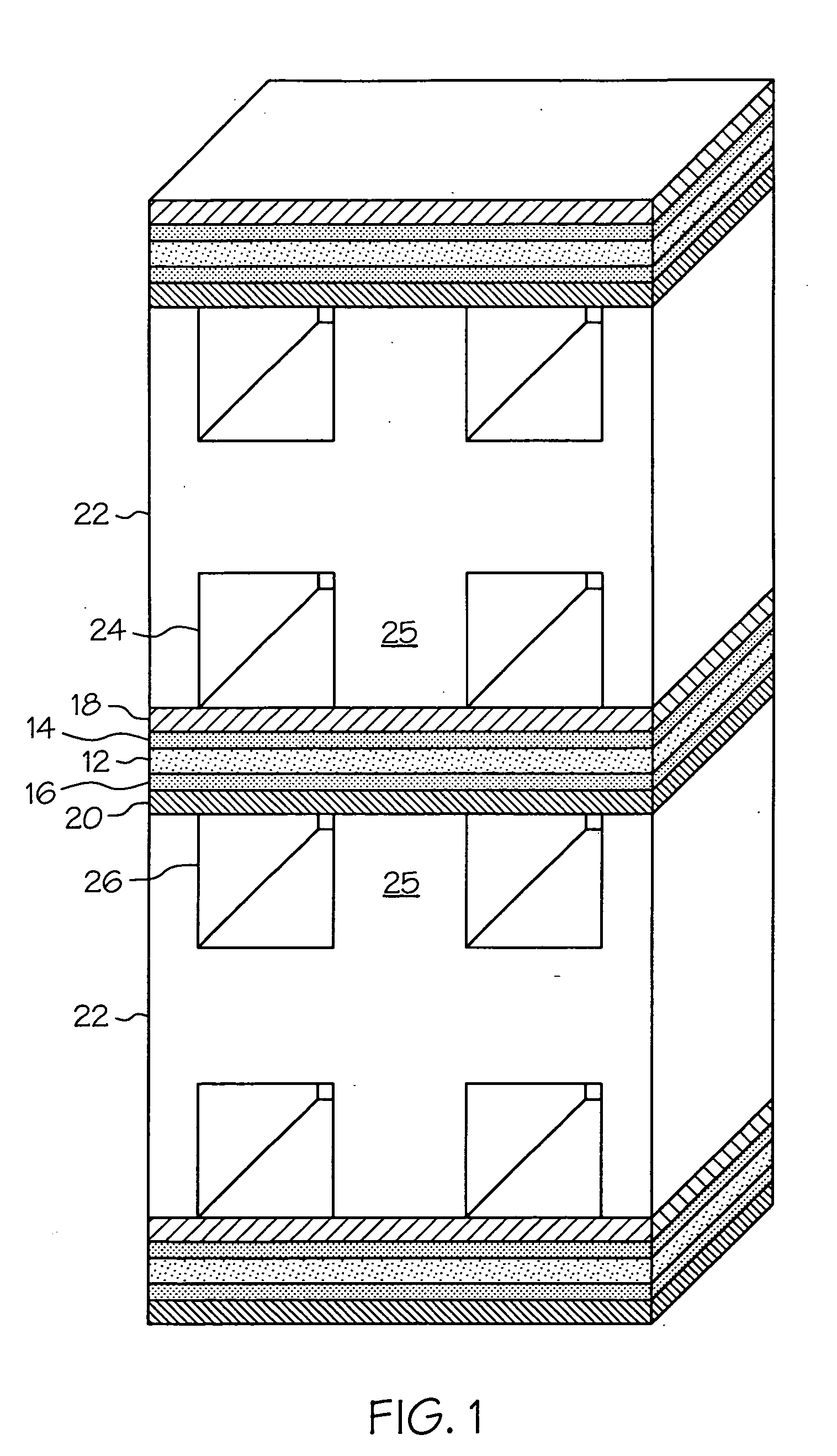

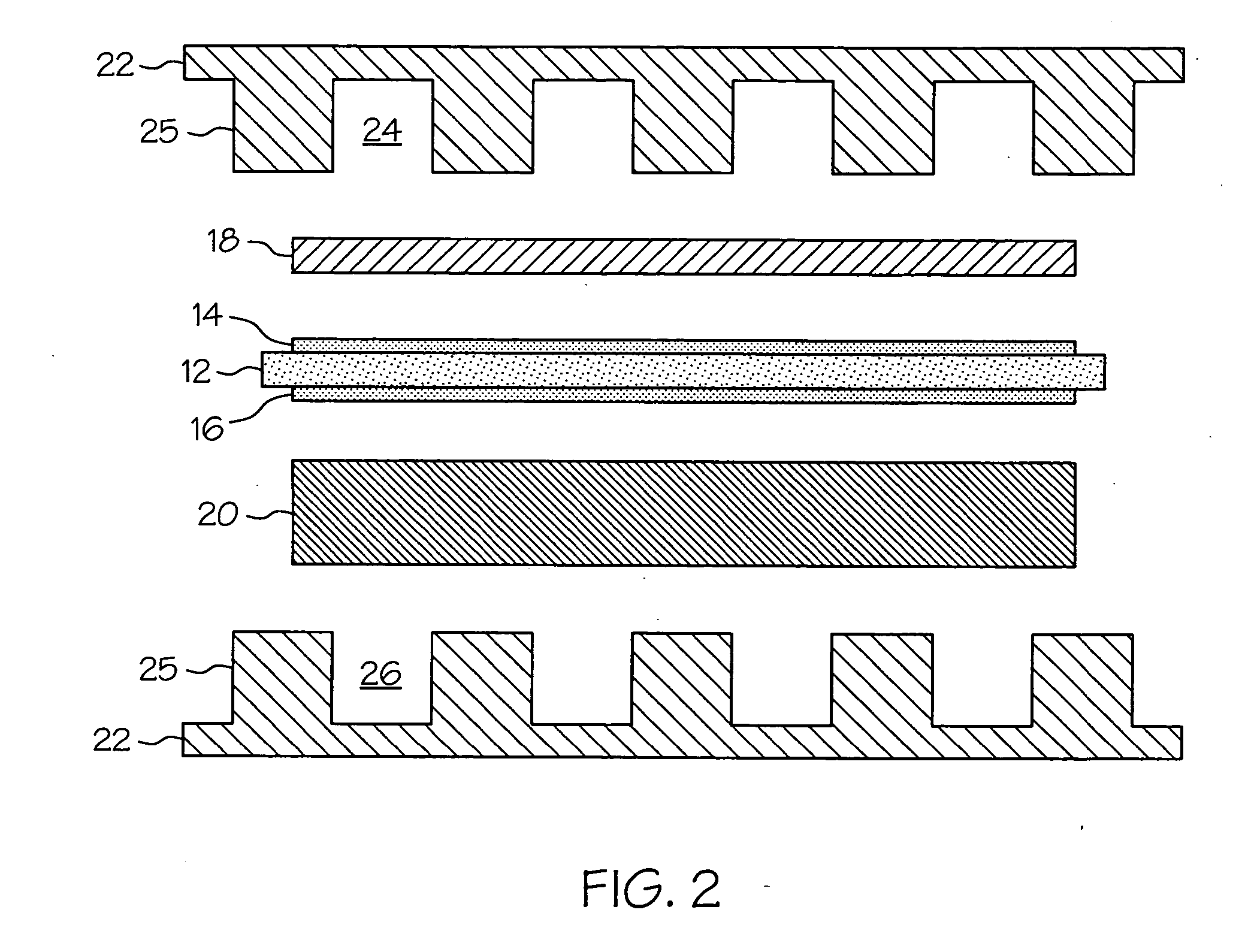

A laminated structure appropriate for use in constructing walls, floors, ceilings or doors, has a selected area and in one embodiment comprises two external layers of one or more materials such as, but not limited to, gypsum, at least one internal constraining layer having less than said selected area, and two or more internal layers of a viscoelastic glue separated by said at least one internal constraining layer, wherein each of said layers of viscoelastic glue is patterned to cover a selected percentage, but not all, of said area of said laminated structure thereby to allow moisture to pass through said structure.

Owner:SERIOUS MATERIALS +1

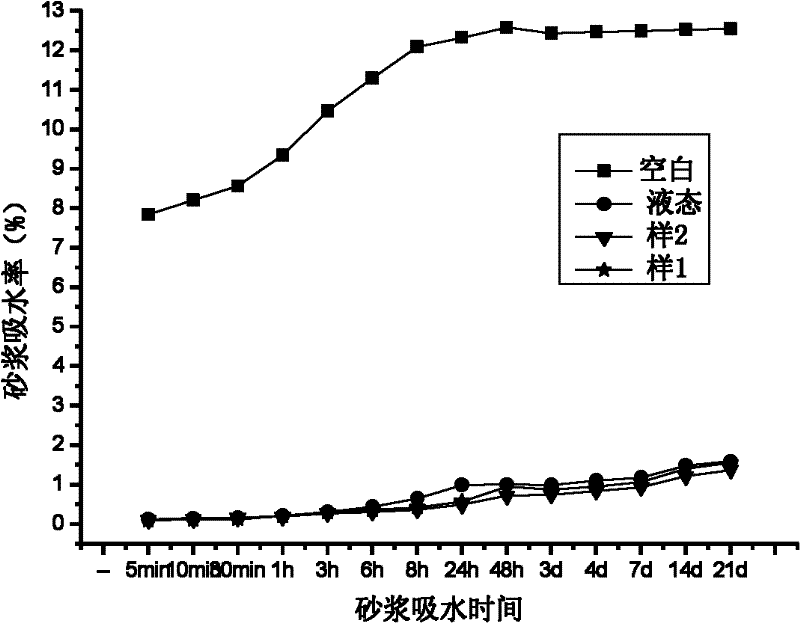

Preparation method of organic silicon microcapsule powder waterproof agent

InactiveCN102226072AGood dispersionImprove water resistanceOther chemical processesMicroballoon preparationSolvent freePolymer solution

The invention belongs to the fields of waterproofing of buildings and solid powdering and relates to a preparation method of an organic silicon microcapsule powder waterproof agent. The preparation method comprises the following steps: preparing water-soluble high polymer wall material into a water solution; mixing a superfine inorganic mineral filler with an organic silicon high-efficient waterproof agent according to a certain proportion for forming homogeneous dispersion; adding a polymer solution and other auxiliaries into the dispersion and dispersing for forming a homogeneous, stable and dry dispersion liquid; performing spray-drying on the uniform and stable dispersion liquid for getting organic silicon waterproof agent microcapsule powder with a certain fineness; and collecting a product, sealing and preserving. The adopted water-soluble polymer film-forming wall material, the inorganic filler and the organic silicon high-efficient waterproof core material have good performances and have no adverse effects on the performances of basic materials, the adopted equipment is easy to operate and the prepared organic silicon powder is white; the organic silicon microcapsule powder waterproof agent has excellent water repellency and water vapor permeability; the organic silicon microcapsule powder waterproof agent can be re-dispersed and has excellent workability with water; and the solvent-free design is healthy and environmentally-friendly.

Owner:TONGJI UNIV

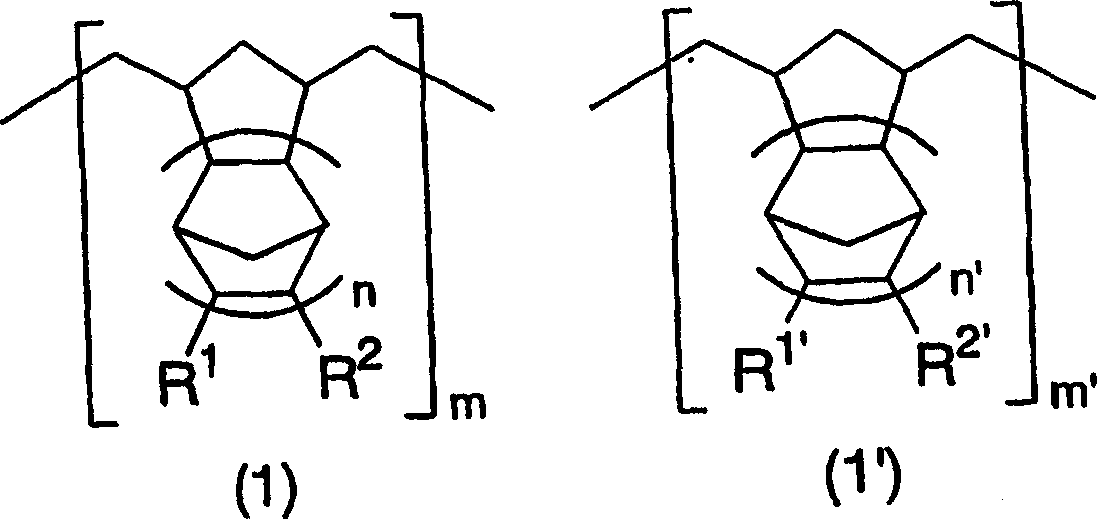

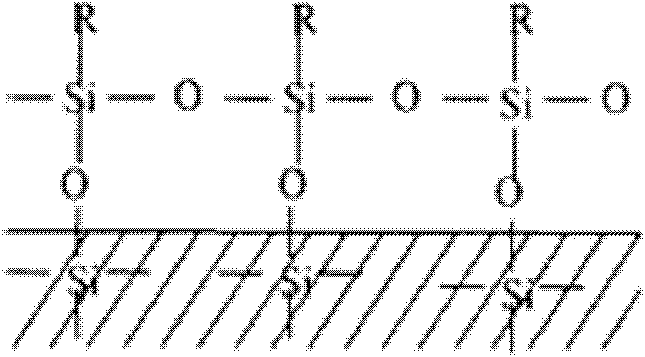

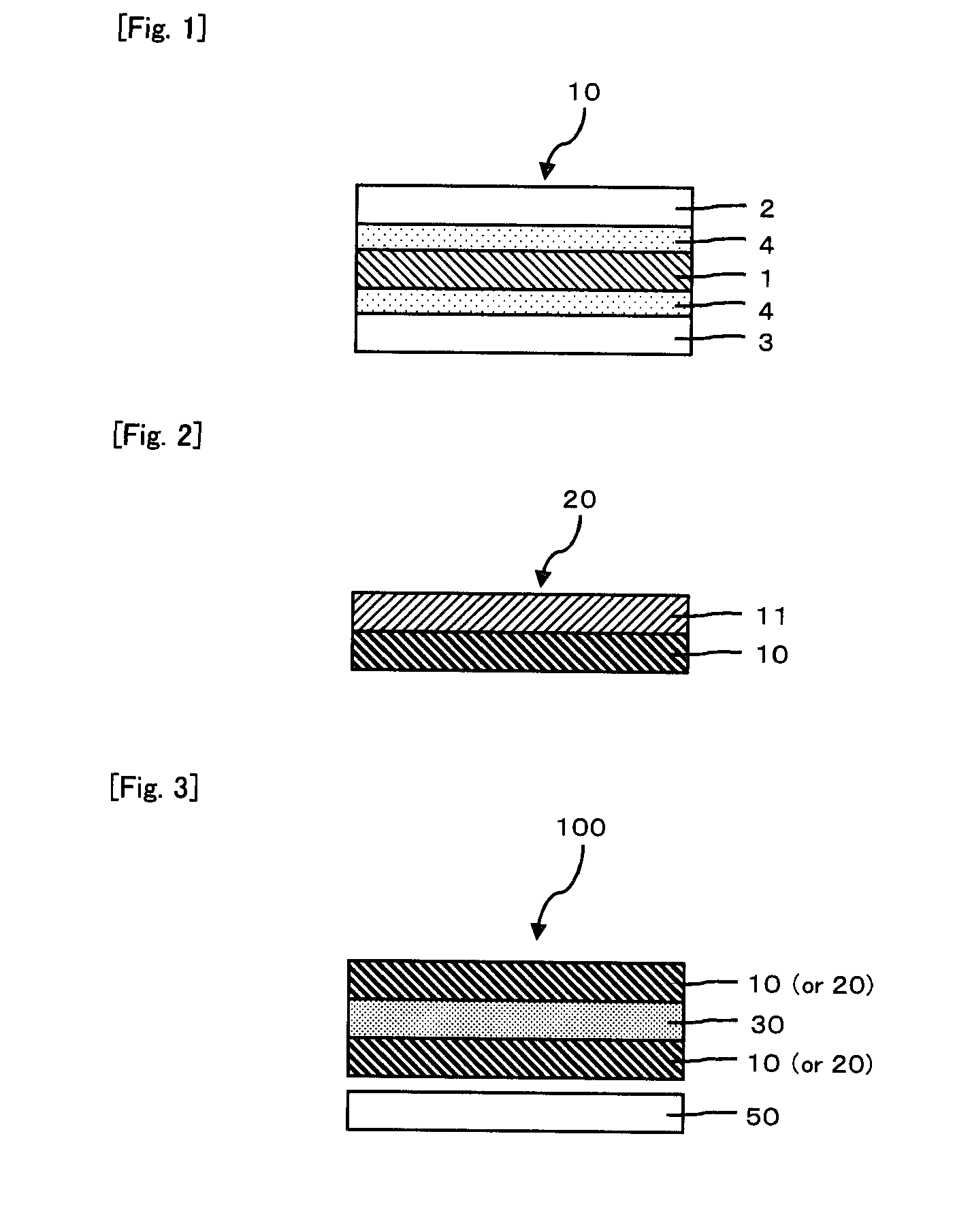

Hydrogenated block copolymer having alkoxysilyl group and use therefor

InactiveUS20130244367A1High glass transition temperatureImprove heat resistanceNon-fibrous pulp additionAluminium compoundsHigh humidityPolymer science

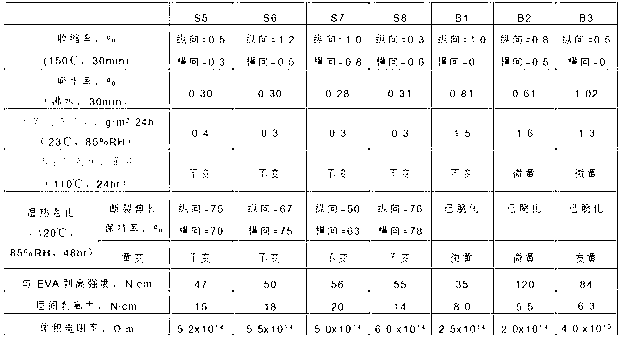

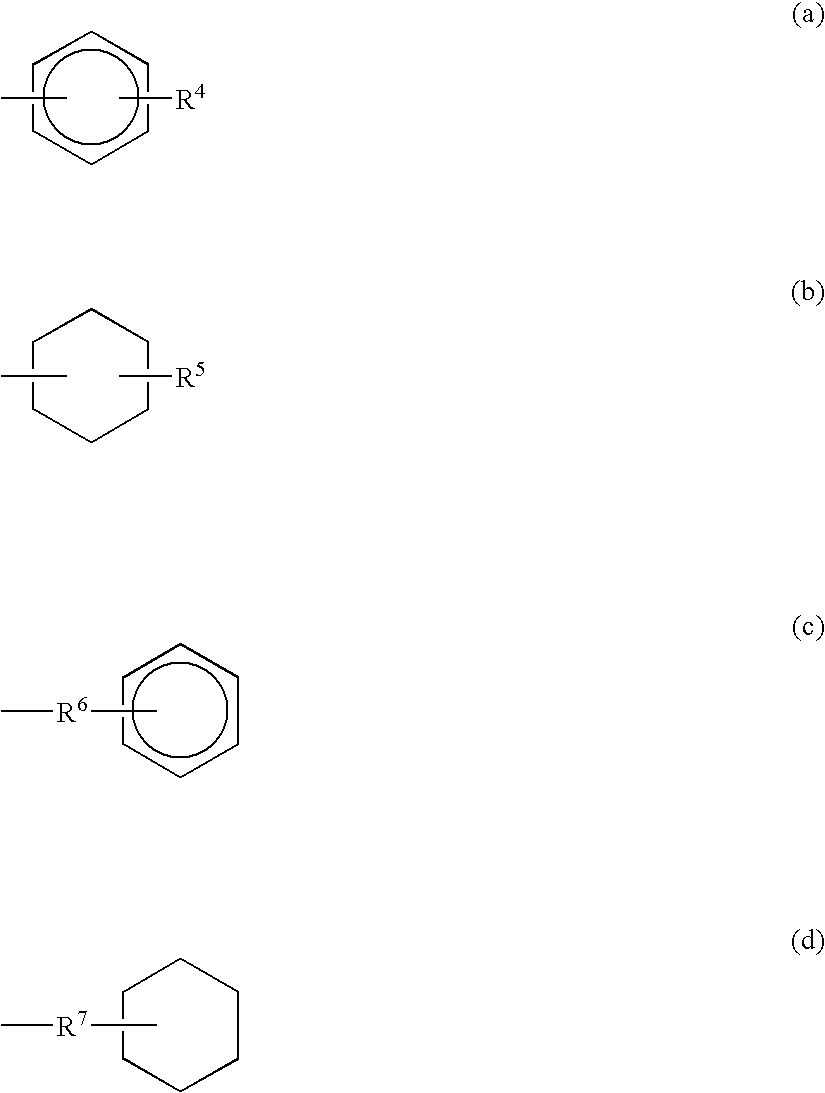

Provided are: an alkoysilyl group-containing hydrogenated block copolymer produced by introducing an alkoxysilyl group into a hydrogenated block copolymer that is obtained by hydrogenating 90% or more of unsaturated bonds of a block copolymer that includes at least two polymer blocks [A] and at least one polymer block [B], the polymer block [A] including a repeating unit derived from an aromatic vinyl compound as a main component, the polymer block [B] including a repeating unit derived from a linear conjugated diene compound as a main component, and a ratio (wA:wB) of a weight fraction wA of the polymer block [A] in the block copolymer to a weight fraction wB of the polymer block [B] in the block copolymer being 20:80 to 60:40; a method for producing the same; a solar cell element encapsulating material; a sheet, a laminated sheet; a multilayer sheet; and a method for encapsulating a solar cell element. The alkoxysilyl group-containing hydrogenated block copolymer exhibits low hygroscopicity, a low water vapor permeability, transparency, weatherability, and flexibility, maintains excellent adhesion to glass even when exposed to a high-temperature / high-humidity environment for a long time, and can encapsulate a solar cell element without applying a special waterproof treatment.

Owner:ZEON CORP

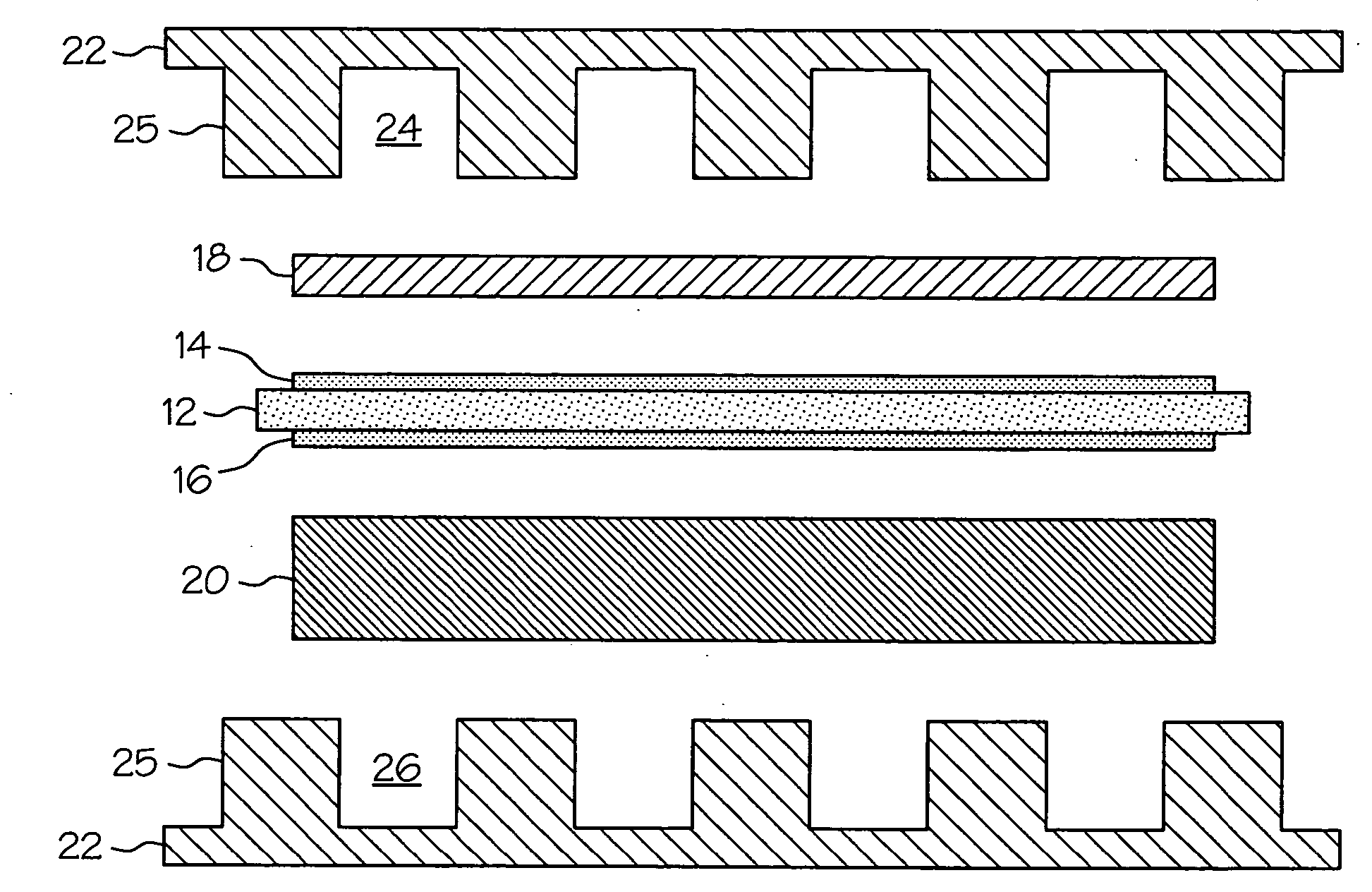

Laminate composite material

InactiveUS6602809B1Avoid Sealing ProblemsHigh permeance (WVTR)Synthetic resin layered productsGauze-woven fabricsParticulatesWater vapor

A laminate composite material comprises a layer of an open weave supporting fabric having a layer of breathable resin adhered thereto by an extruded layer of a thermoplastic resin blended with a high temperature volatile particulate. The resultant composite material is substantially impervious to air and water and permeable to water vapor and having a water vapor transmission rate exceeding one (1) perm of water vapor.

Owner:BERRY PLASTICS CORP

Proton exchange membrane fuel cell

A fuel cell system with a proton exchange membrane. There is a cathode catalyst layer overlying the first face of the proton exchange membrane, and a cathode diffusion layer overlying the cathode catalyst layer. There is an anode catalyst layer overlying the second face of the proton exchange membrane, and an anode diffusion layer overlying the anode catalyst layer. The cathode diffusion layer has a water vapor permeance of less than about 3×10−4 g / (Pa s m2) at 80° C. and 1 atmosphere. The invention also relates to cathode diffusion layers for fuel cell systems.

Owner:GM GLOBAL TECH OPERATIONS LLC

Thermoplastic food casing

A porous food casing consisting essentially of a film of food grade thermoplastic having a plurality of interconnected interstices therein. The interstices are defined by a porosity modifier selected from the group consisting of soybean oil, peanut oil, corn oil, glycerin, polyethylene glycol, monolaurate, mineral oil, polyoxyethylene, sorbitan monostearate, sorbitan monooleate and glycerol monooleate. The interstices are in a range of approximately 0.002 to 1 micron and the casing has a water vapor permeability in a range of about 1 to 1500 gms / m2 / min.

Owner:YEN WILLIAM W

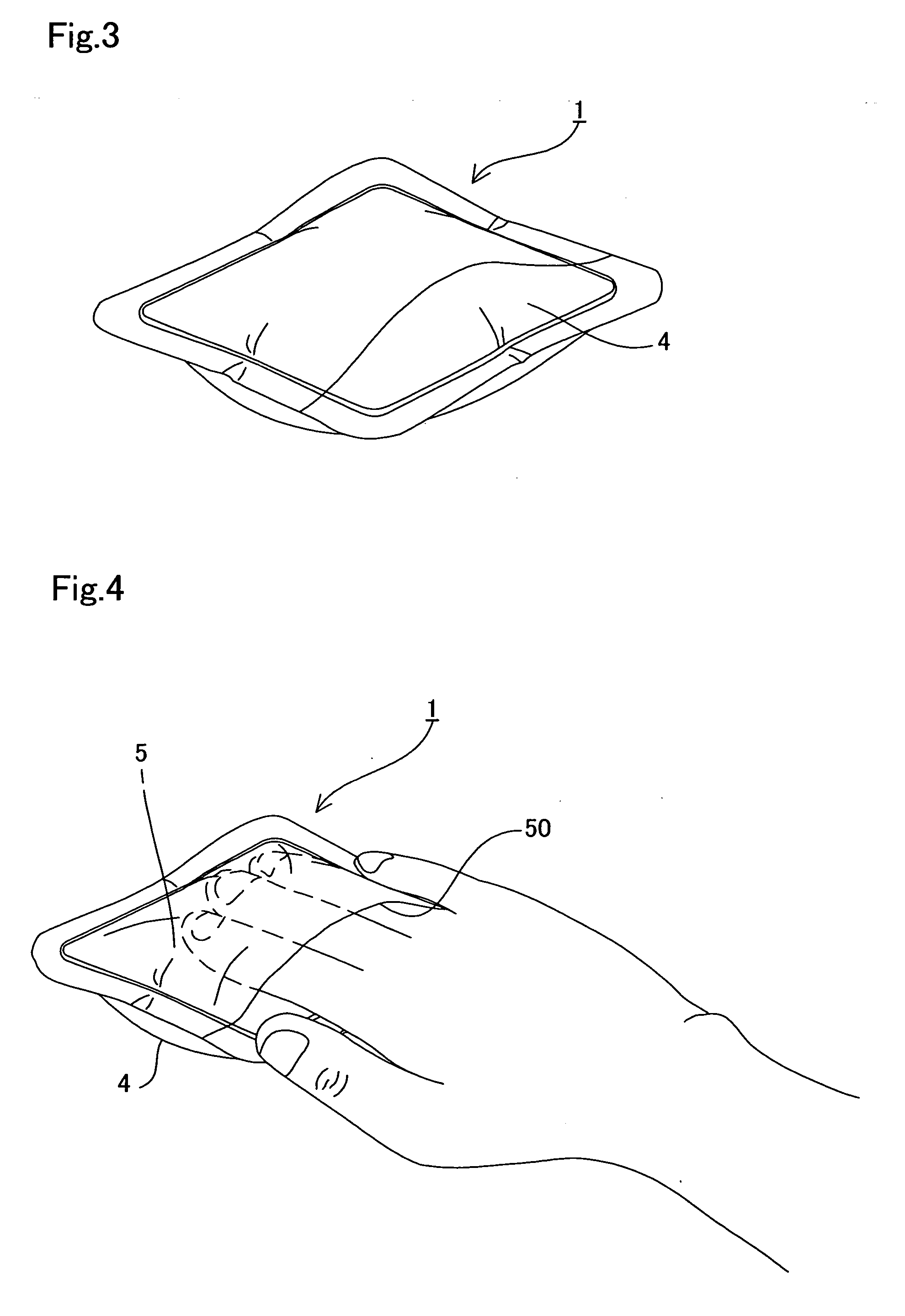

Warming tool

ActiveUS20060276863A1Good precisionTherapeutic coolingTherapeutic heatingWater vapor permeabilityWater vapor

A warming article having a heat generating main body (4). The heat generating main body (4) is composed of a heat generating element (2) having water vapor generating capability and an air permeable holder (3) for holding the heat generating element (2). The heat generating main body (4) is configured to expand with heat generation of the heat generating element (2). The amount of water vapor generated from the warming article is preferably 1.0 to 100 mg / (cm2·10 min). The holder (3) preferably has a water vapor permeability of 1.5 to 10 kg / (m2·24 hr). The heat generating element (2) is preferably a sheet molded by papermaking and containing an oxidizable metal, a moisture-retaining agent, and a fibrous material.

Owner:KAO CORP

Gas-barrier laminate

ActiveUS20070059541A1Good printabilityHigh industrial valueSynthetic resin layered productsCoatingsPolyesterVitrification

A gas-barrier laminate comprises a plastic substrate (A), an inorganic thin film (B) formed on at least one surface of the plastic substrate (A), and a polyester-based resin layer (C) formed by applying a coating material containing a polyester-based resin on a surface of the inorganic thin film (B), wherein the polyester-based resin has a glass transition temperature of 50 to 70° C., a molecular weight of 1500 to 15000 and a hydroxyl value of 10 to 60 mg KOH / g, and the gas-barrier laminate has an oxygen permeability of not more than 5 cc / m2 / day / atm and a water vapor permeability of not more than 5 g / m2 / day. The gas-barrier laminate of the present invention is excellent in printability (in particular, gradation printability), is free from deterioration in gas-barrier property, namely is excellent in gas-barrier property, even after providing a printed layer thereon, and further exhibits an excellent adhesion between the plastic substrate (A) and the inorganic thin film (B) even after being subjected to retort treatments.

Owner:MITSUBISHI CHEM CORP

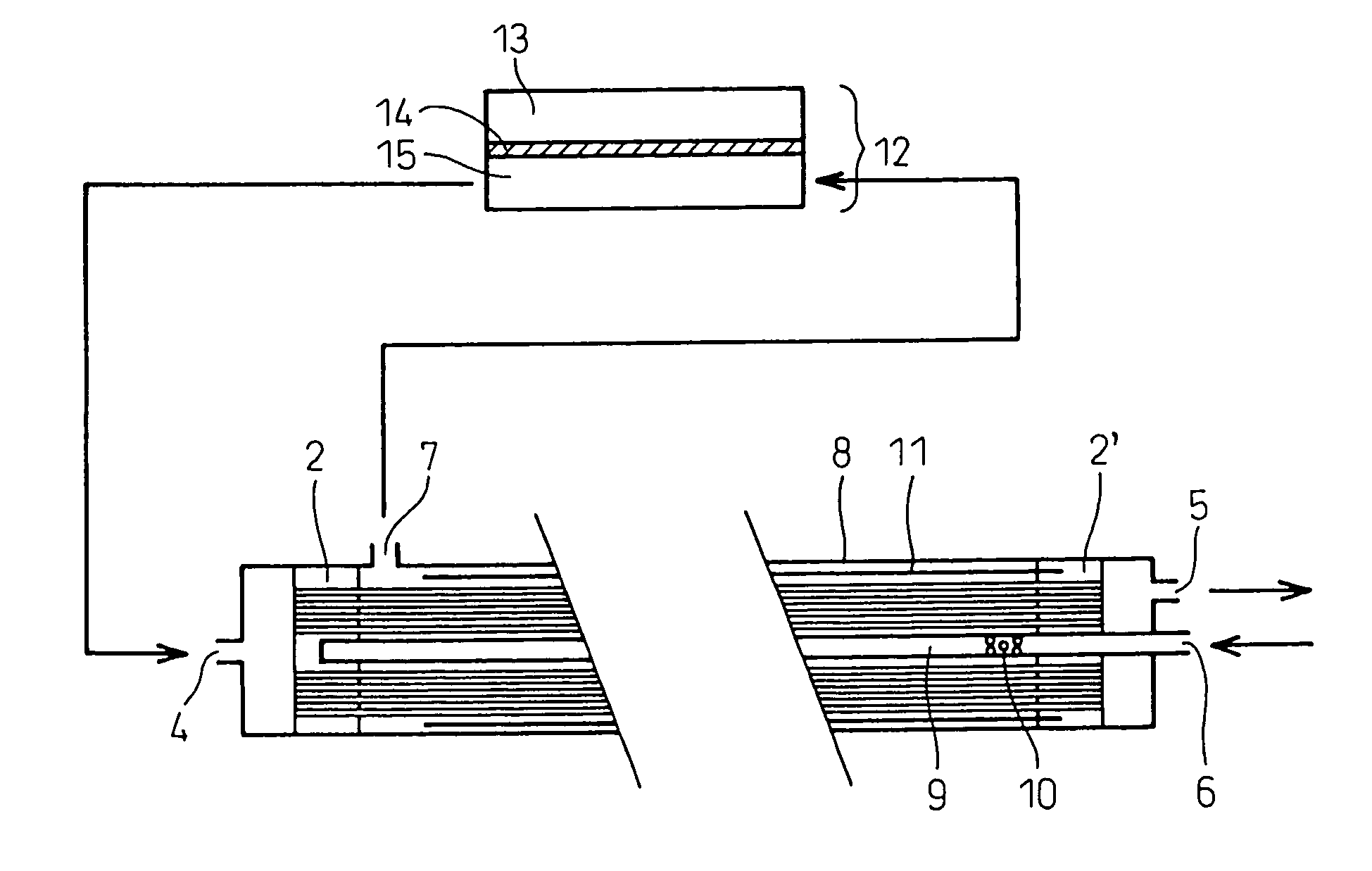

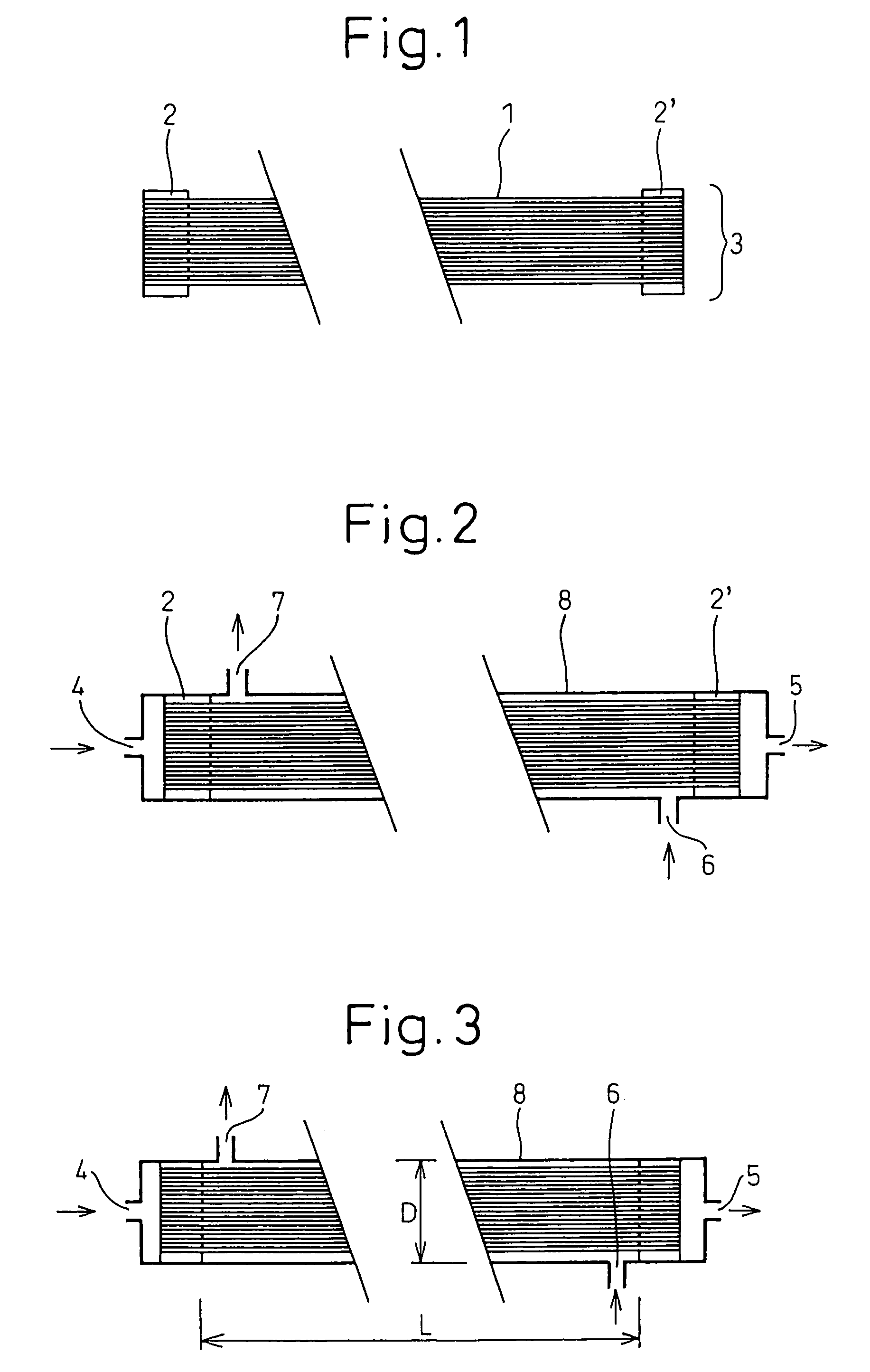

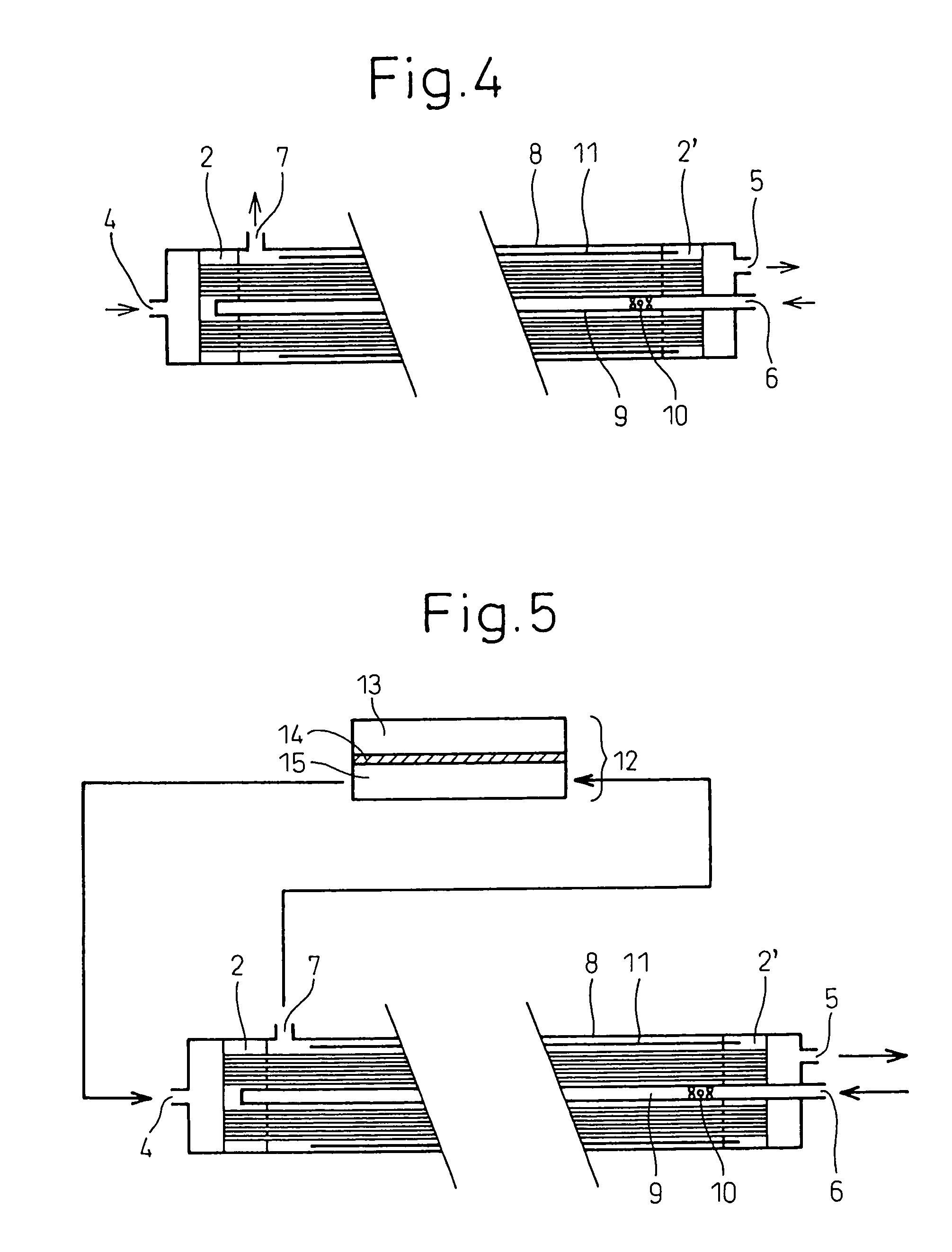

Fuel cell-use humidifier

An object of the present invention is to provide a humidifying apparatus capable of improving the humidification efficiency while lowering the pressure loss of gas even when a low-pressure gas is used, and is suitably usable for fuel cells. The present invention relates to a humidifying apparatus for fuel cells, fabricated by loading a hollow fiber membrane element into a container such that the space communicating with the hollow side of the hollow fiber membranes is isolated from the space communicating with the outer side of the hollow fiber membranes, wherein (a) the inner diameter of the hollow fiber membrane is larger than 400 μm, (b) the water vapor permeation rate (P′H2O) of the hollow fiber membranes is 0.5×10−3 cm3 (STP) / cm2·sec·cm Hg or more, (c) the ratio (P′H2O / P′O2) of the water vapor permeation rate to the oxygen gas permeation rate of the hollow fiber membranes is 10 or more, and (d) the elongation at tensile break of the hollow fiber membranes after hot water treatment in hot water at 100° C. for 50 hours is 80% or more of that before the hot water treatment; particularly, the present invention relates to a humidifying apparatus for fuel cells where, if the effective length of the hollow fiber membrane element is L and the inner diameter of the container into which the hollow fiber membrane element is loaded is D, L / D is 1.8 or more.

Owner:UBE IND LTD

Acoustical sound proofing material with controlled water-vapor permeability and methods for manufacturing same

ActiveUS20080251198A1Dissipating soundDissipating vibrationCeilingsWallsWater vapor permeabilityEngineering

A laminated structure appropriate for use in constructing walls, floors, ceilings or doors, has a selected area and in one embodiment comprises two external layers of one or more materials such as, but not limited to, gypsum, at least one internal constraining layer having less than said selected area, and two or more internal layers of a viscoelastic glue separated by said at least one internal constraining layer, wherein each of said layers of viscoelastic glue is patterned to cover a selected percentage, but not all, of said area of said laminated structure thereby to allow moisture to pass through said structure.

Owner:SERIOUS MATERIALS +1

Fluoropolymer Barrier Material

ActiveUS20080061472A1Improve barrier propertiesImprove permeabilitySynthetic resin layered productsCeramic shaping apparatusPolymer scienceWater vapor permeability

A novel densified fluoropolymer article is described which has a water vapor permeation of about 0.015 g-mm / m2 / day or less, and preferably has a matrix tensile strength of at least 10,000 psi in two orthogonal directions. The articles are made by compressing expanded porous PTFE at pressures, temperatures and times which result in elimination of the pores, and subsequent stretching above the crystalline melt temperature.

Owner:WL GORE & ASSOC INC

Multilayer breathable microporous film with reinforced impermeability to liquids and production method

InactiveUS20040170852A1Drawback can be obviatedReduce in quantitySynthetic resin layered productsThin material handlingPolymer sciencePolyolefin

The invention concerns a process for producing a polyolefin film having a combination of properties, specifically water vapor permeability and demonstrating reinforced liquid impermeability, said process comprising the steps of: coextrusion from a die of polyolefinic polymers and / or copolymers mixtures one of which at least contains inorganic fillers forming a precursor film; stretching of the precursor film to form a breathable multilayer film, which is characterized in that said precursor film is a base multilayer film having at least two contiguous layers of same composition, having at the structure "B"-"B", optionally associated to at least one layer having a different composition from the two contiguous layers "B"-"B", and having a specific characteristic.

Owner:GUSTAFSON BO

Fluoropolymer barrier material

InactiveUS20050238872A1Improve barrier propertiesImprove permeabilitySynthetic resin layered productsRecord information storagePolymer scienceWater vapor permeability

A novel densified fluoropolymer article is described which has a water vapor permeation of about 0.015 g-mm / m2 / day or less, and preferably has a matrix tensile strength of at least 10,000 psi in two orthogonal directions. The articles are made by compressing expanded porous PTFE at pressures, temperatures and times which result in elimination of the pores, and subsequent stretching above the crystalline melt temperature.

Owner:WL GORE & ASSOC INC

Method for preparing polyester film for solar cell backsheet film

ActiveCN101967272AHigh crystallinityImproved crystal configurationPhotovoltaic energy generationSemiconductor devicesSolar cellFatty acid

The invention discloses a method for preparing a polyester film for a solar cell backsheet film, which is characterized by comprising the following steps of: mixing 200 to 400 mass parts of binary acid, 80 to 160 mass parts of dihydric alcohol, 0.01 to 0.5 mass part of highly-branched polyatomic alcohol, an esterification catalyst for synthesis of polyester, a polycondensation catalyst and a stabilizing agent and carrying out an esterification reaction; adding 0. 1 to 1.0 mass part of high-grade polyenoic fatty acid or alcohol, continuously esterifying, filtering materials and pressing into a polycondensation kettle for a pre-polycondensation reaction so as to prepare modified polyester resin slices; mixing the modified polyester resin slices and master batch polyester slices according to a mass ratio of 100:5-30; and drying, melting, filtering, extruding, cooling a cast piece, biaxially drawing, performing molding treatment and the like so as to prepare the polyester film for the solar cell backsheet film. The film product has excellent mechanical and electrical performances, heat and humidity resistance, dimensional stability, flame retardant property and water vapor permeability resistance.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

Polarizing plate, method for production thereof, optical film, and image display device

InactiveUS20090040611A1Increased durabilityLess likely to cause knicksPolarising elementsOptical articlesTectorial membraneWater vapor

There are provided a polarizing plate that has excellent durability including both humidity resistance and heat resistance and is less likely to cause knick defects, and a method for production thereof. The polarizing plate includes: a polarizer including an iodine-containing polyvinyl alcohol resin and containing zinc; protective films each having a water-vapor permeability of 150 g / m2 per 24 hours or less in an atmosphere at 40° C. and 90% RH; and an adhesive including a polyvinyl alcohol resin, a crosslinking agent and a colloidal metal compound with an average particle size of 1 to 100 nm, wherein the protective films are bonded to both side of the polarizer with the adhesive interposed between the protective layer and the polarizer.

Owner:NITTO DENKO CORP

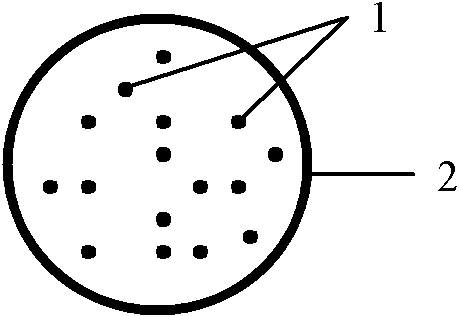

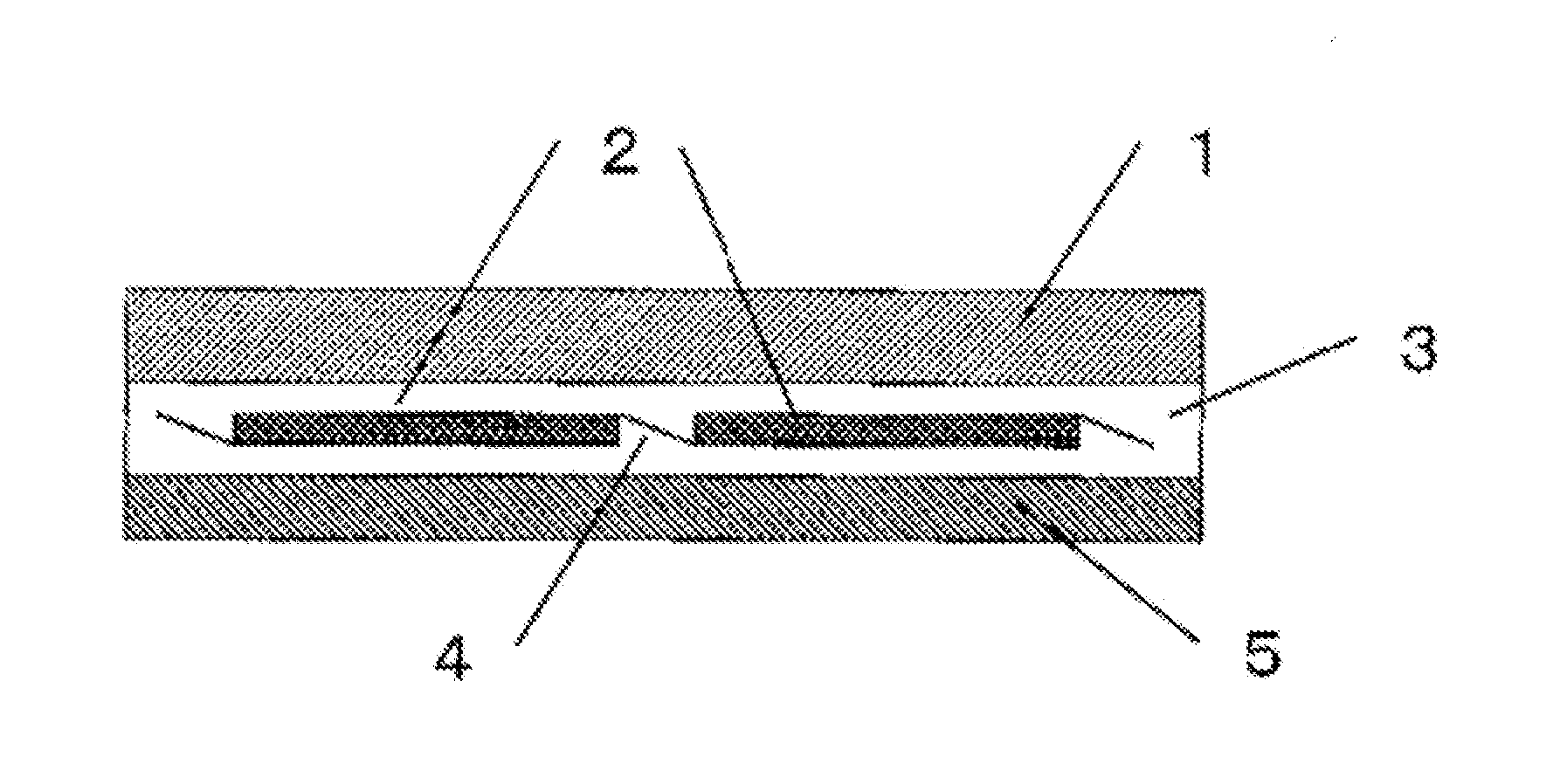

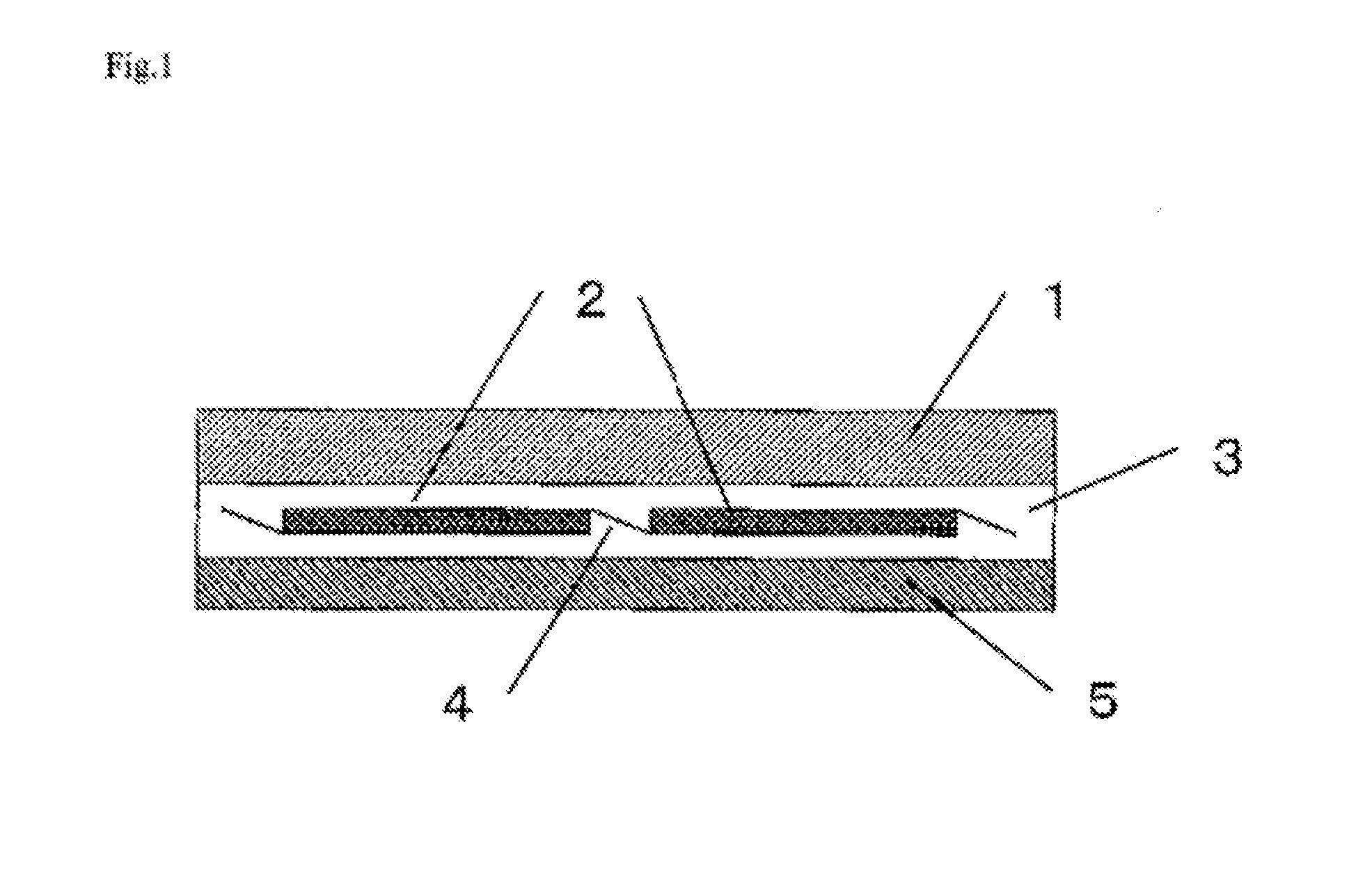

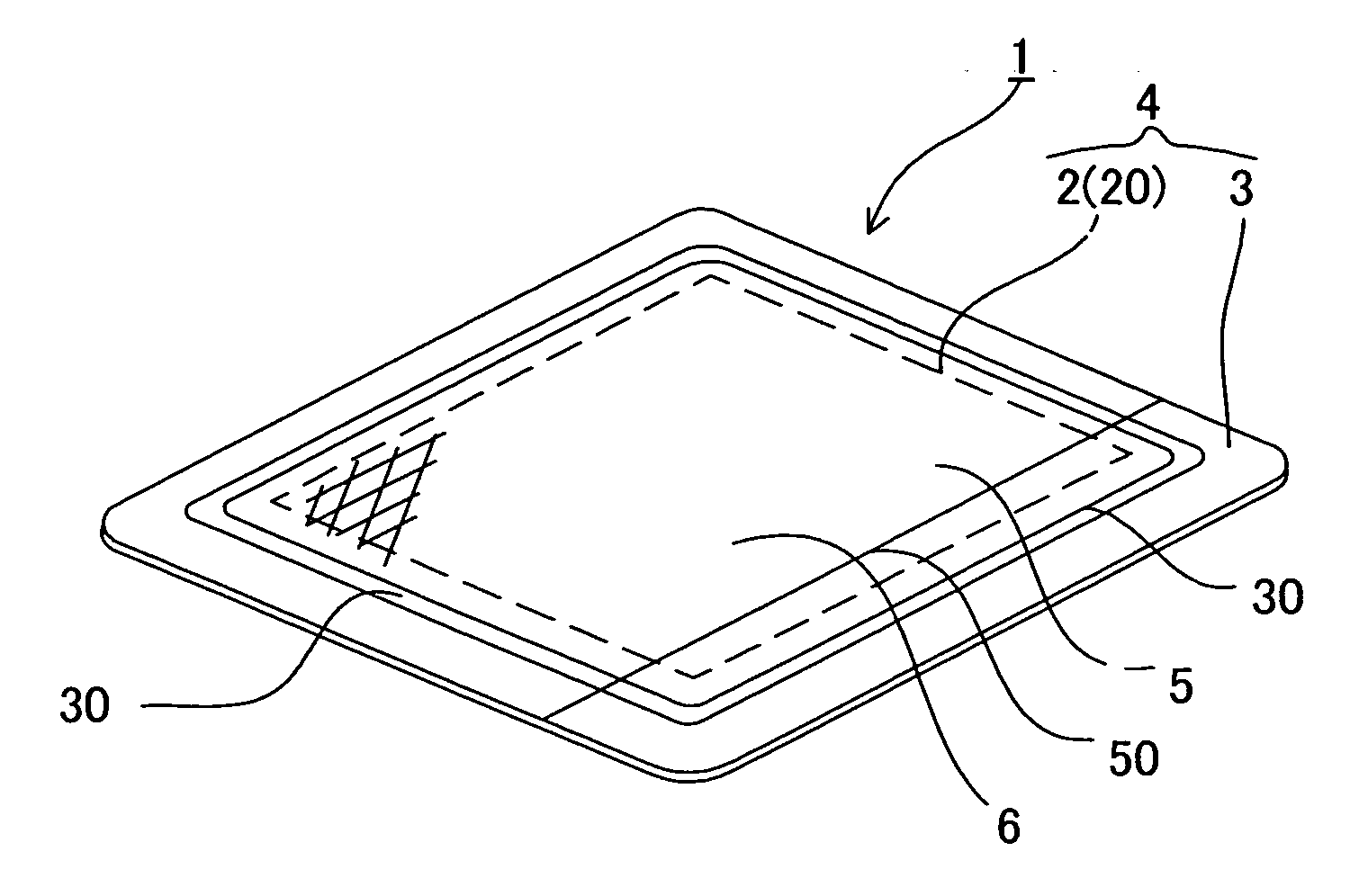

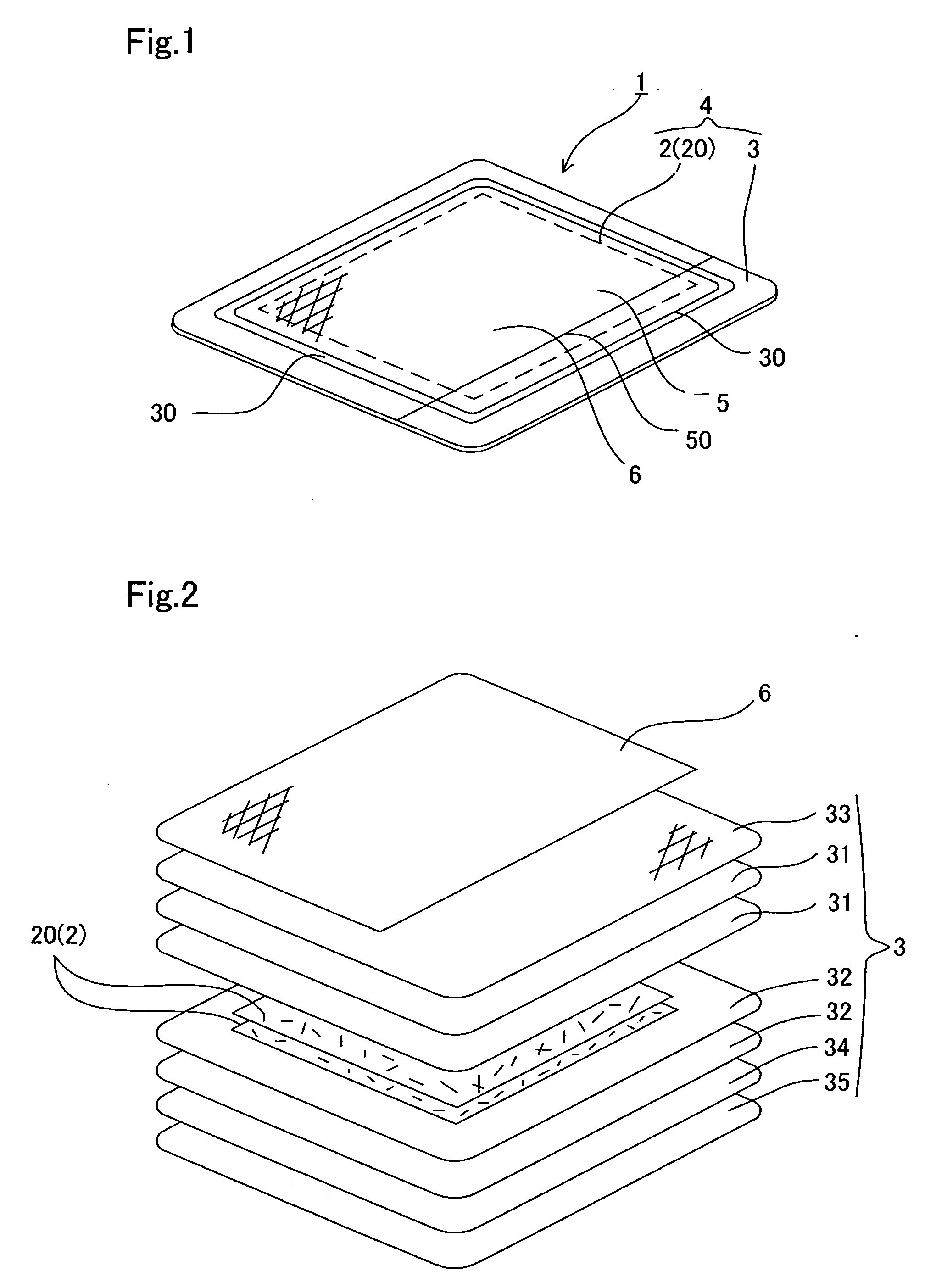

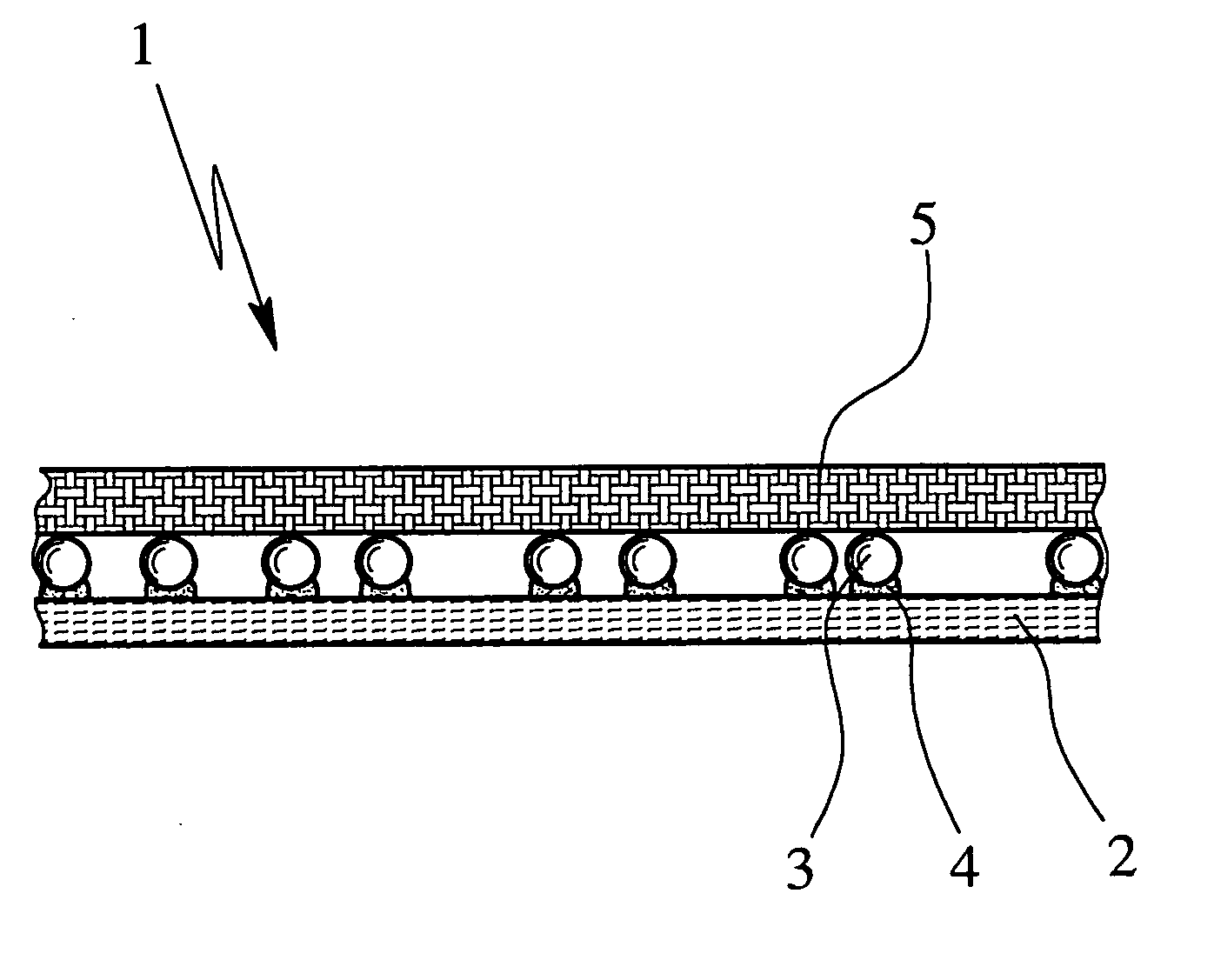

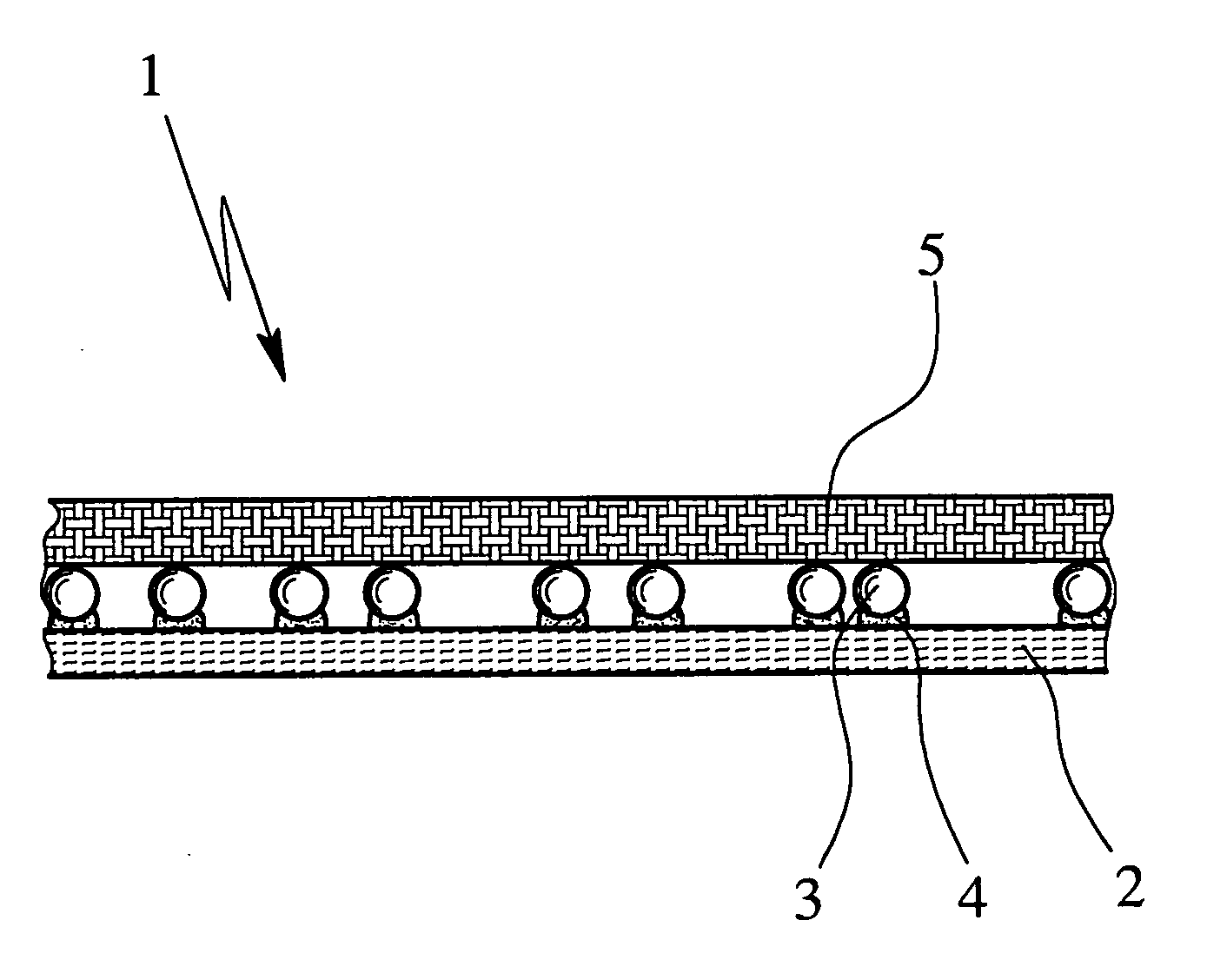

Functional textile material provided with microcapsules containing an active ingredient and use thereof

InactiveUS20070065658A1Reduce basis weightIncrease flexibilityMedical devicesDomestic netsAdhesiveWater vapor permeability

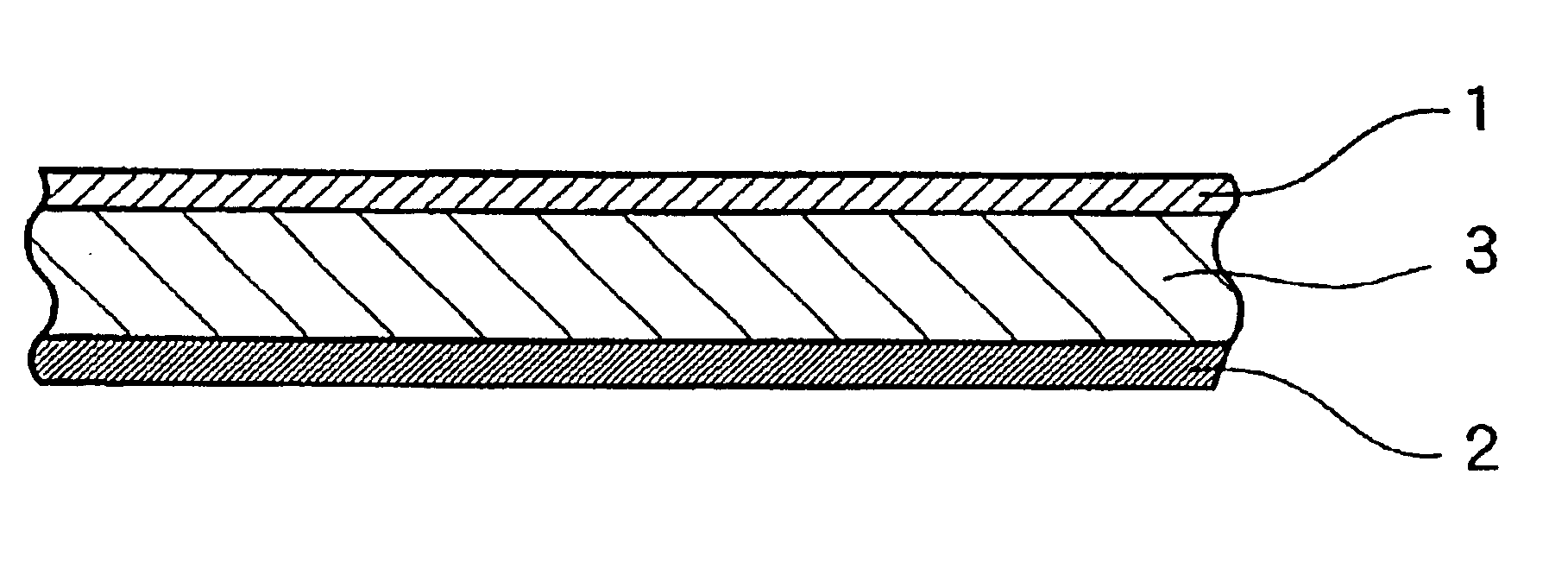

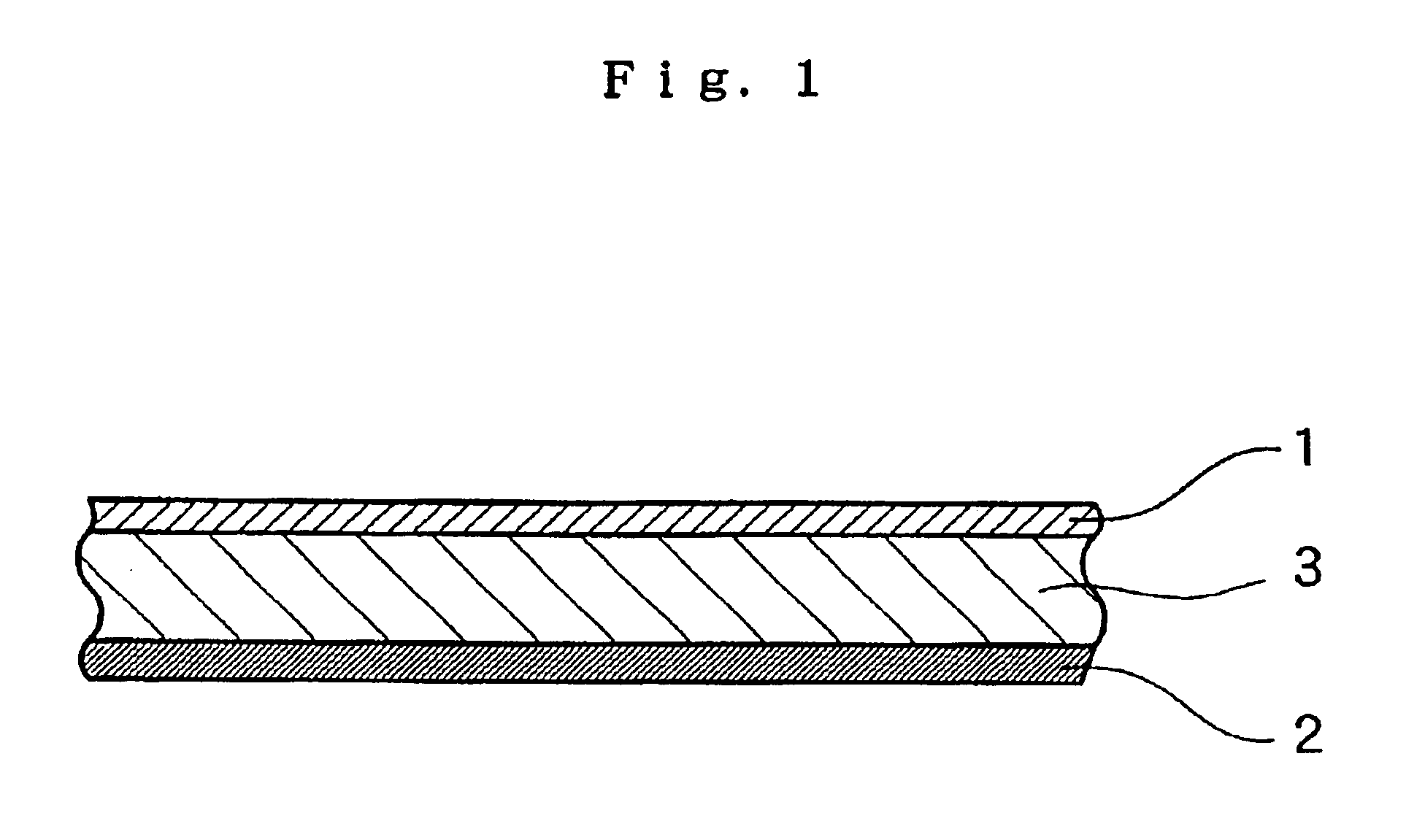

The subject of the invention is a functional textile material (1), wherein the functional textile material (1) comprises a textile backing (2) in the form of a two-dimensional textile formation, and the textile backing (2) is provided with microcapsules (3), which contain at least one active ingredient, and the microcapsules (3) are secured to the textile backing (2) by means of an adhesive (4) applied discontinuously to the textile backing (2). In this way, one obtains a functional textile material (1) with high air-permeability and high water vapor-permeability at reduced basis weight, which material can be used in particular for making functional clothing.

Owner:BLUCHER GMBH

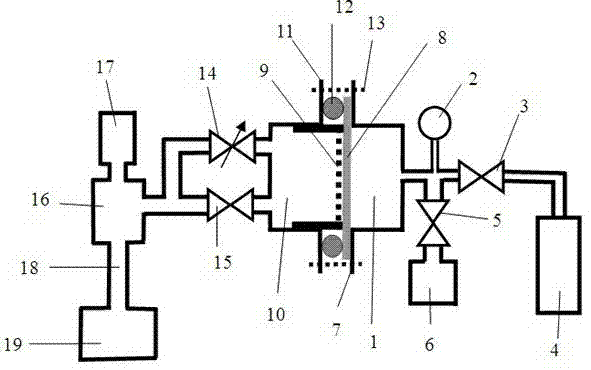

Measuring device and measuring method for measuring gas permeability of material

InactiveCN103115858AHigh measurement sensitivityIncreased permeability measurement sensitivityPermeability/surface area analysisMass spectrometry measurementThermodynamics

The invention discloses a measuring device and a measuring method for measuring gas permeability of a material. The measuring device comprises a gas chamber, a gas accumulation chamber and a high-vacuum chamber, wherein a film of the material to be measured or a thin sheet is installed between the gas chamber and the gas accumulation chamber; the gas chamber is connected with a gas source to be measured and a low-vacuum pump; the accumulation chamber is connected with the high-vacuum chamber through a needle valve; and the high-vacuum chamber is connected with a mass spectra gauge and a super-high-vacuum sucking system. By utilizing the device and the method, after a measured gas which permeates through the measured material is accumulated in the gas accumulation chamber to a relatively large gas quantity, part of the gas is sampled into the high-vacuum chamber to be subjected to mass-spectrometer measurement, so that the sensitivity in permeability measurement is improved; and the longer the accumulation time is, the higher the measurement sensitivity is, for example, the sensitivity in steam permeability measurement can reach the level of 10-7g / m<2>day grade.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

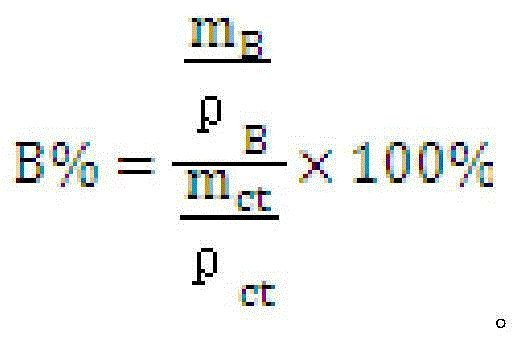

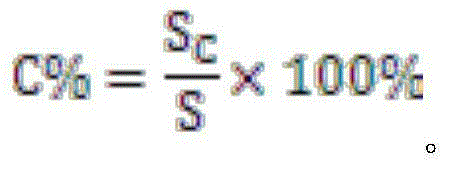

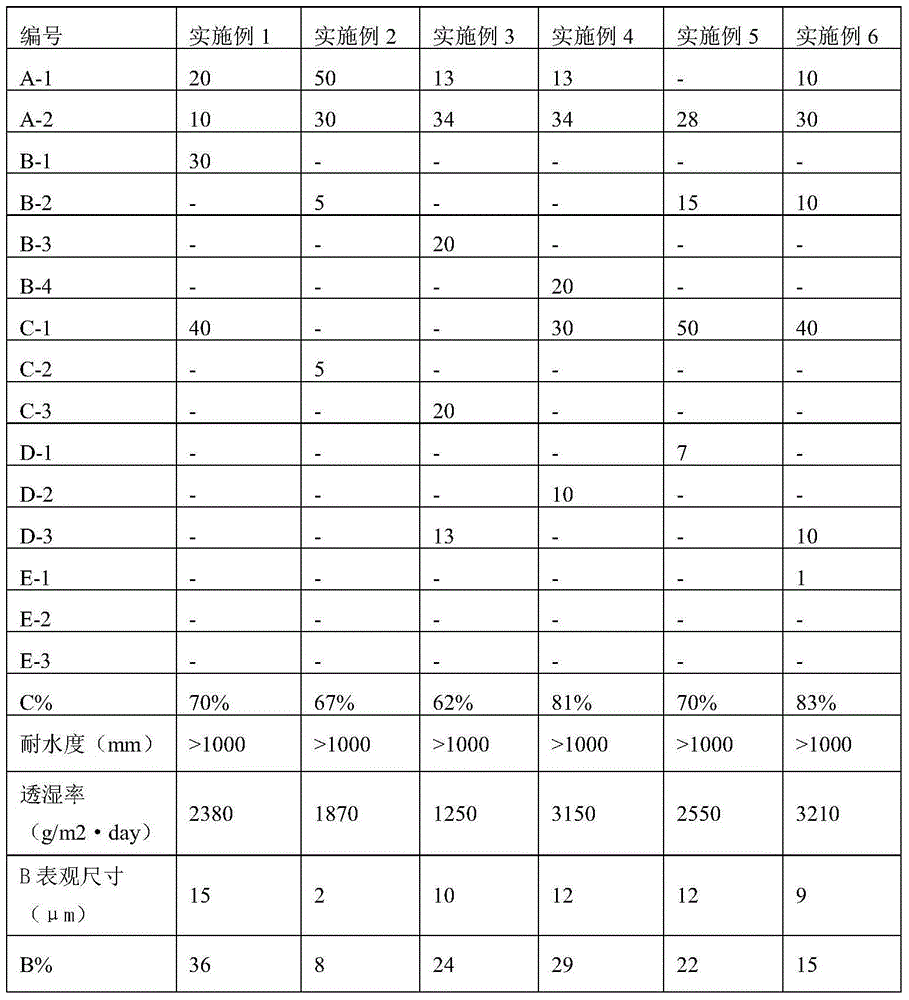

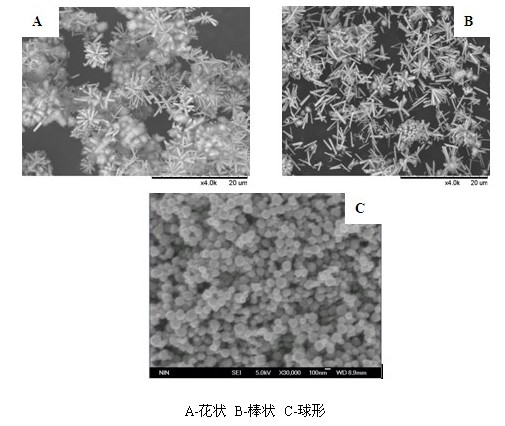

Resin composition for preparing micro-porous thin film and micro-porous thin film

The invention relates to a resin composition for preparing a micro-porous thin film and the prepared micro-porous thin film. The composition comprises the following components in parts by weight: 20-80 parts of polylactic resin A, 5-50 parts of a resin component B which is incompatible with polylactic acid and 5-50 parts of filler C, wherein the percentage by weight of the filler C which is fully in the phase B or partially in the phase B is as follows: C% is greater than (0.9*B%+10%) and B% is the volume percentage of B in the resin composition. The water vapor permeability of the micro-porous thin film prepared from the resin composition is higher than the water vapor permeability of a thin film where the filler is averagely distributed. The resin composition for preparing the micro-porous thin film provided by the invention can be used for preparing the micro-porous thin film and can be used in the field of hygienic products, building materials and the like.

Owner:TORAY IND INC

Polyacrylate/nanometer ZnO composite finishing agent and preparation method thereof

ActiveCN102304316ASolve the defect of "hot sticky and cold brittle"Improve water resistanceCoatingsLeather surface finishingPolymer sciencePOLYMER SUBSTANCE

The invention relates to a polyacrylate / nanometer ZnO composite finishing agent suitable for the base coating of clothing leathers, instep leathers and corrected leathers and a preparation method of the polyacrylate / nanometer ZnO composite finishing agent. The polyacrylate / nanometer ZnO composite finishing agent comprises the following raw materials by weight: 22wt%-28wt% of acrylic ester monomer, 2wt%-5wt% of emulsifying agent, 0.4 wt%-0.8 wt% of initiating agent, 0.2wt%-1.5 wt% of nanometer ZnO, 0.6 wt%- 5wt% of water-solubility high polymer materials, and the rest of deionized water. The preparation method comprises the following steps of: firstly, carrying out surface modification on the nanometer ZnO by adopting a water-solubility high molecular polymer, enabling the nanometer ZnO tobe uniformly dispersed in a water solution, then triggering the acrylic ester monomer to polymerize in site, and preparing the polyacrylate / nanometer ZnO composite finishing agent. Compared with the pure polyacrylate emulsion, the polyacrylate / nanometer ZnO composite finishing agent has the advantages that the water tolerance, the elongation at break, the air permeability and the water vapor permeability of a finished leather sample are all substantially increased.

Owner:SHAANXI UNIV OF SCI & TECH

Plastic container for liquid medicine and method of storing and recovering liquid medicine

InactiveUS7029752B2Reduced activityReduce concentrationBottlesSynthetic resin layered productsDiamond-like carbonWater vapor

A plastic container for liquid medicine, which, concerning the effective components of liquid medicine, is capable of prevention of deterioration in quality due to mixing of oxygen and water vapor, prevention of variation in concentration due to water volatilization and moisture absorption, etc. A plastic container for liquid medicine, which is a plastic container internally coated with DLC (diamond-like carbon) film wherein water vapor permeability is 0–0.006 g / container / day and oxygen permeability is 0–0.011 ml / container / day, such properties being obtained by optimizing the three conditions, composition, density and film thickness of the DLC film.

Owner:MITSUBISHI SHOJI PLASTICS

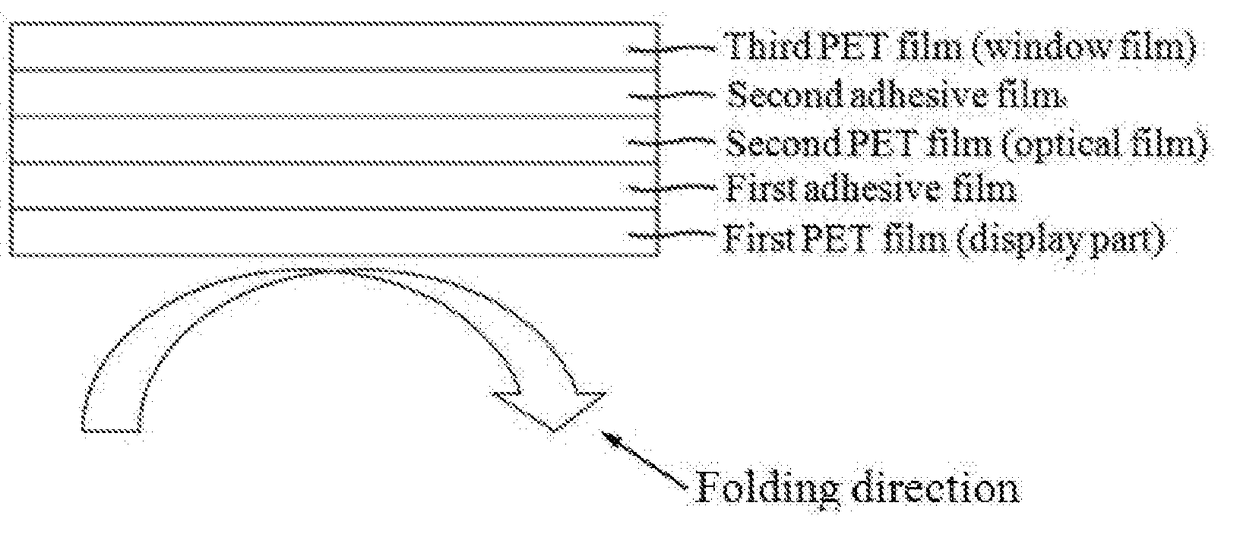

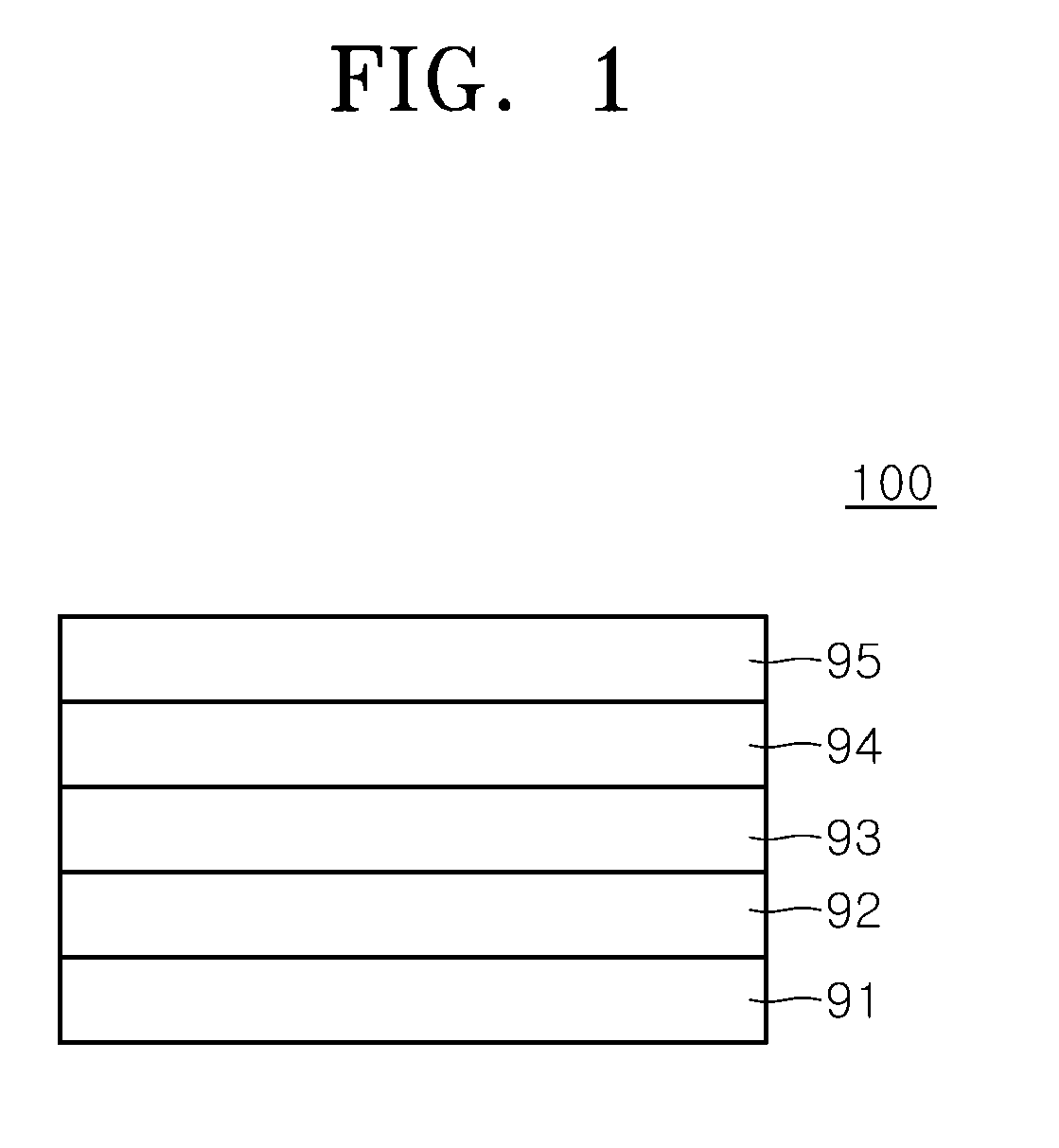

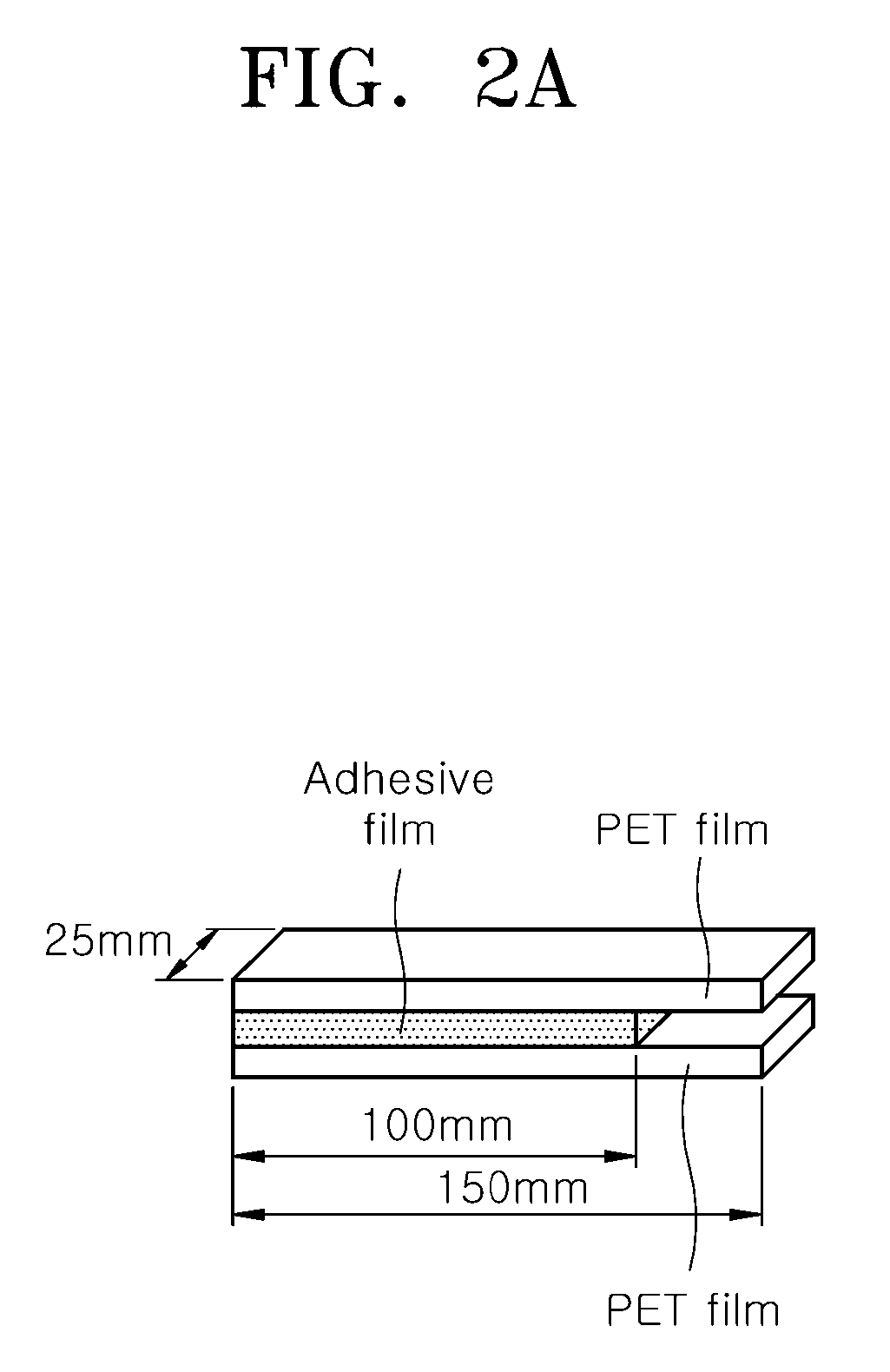

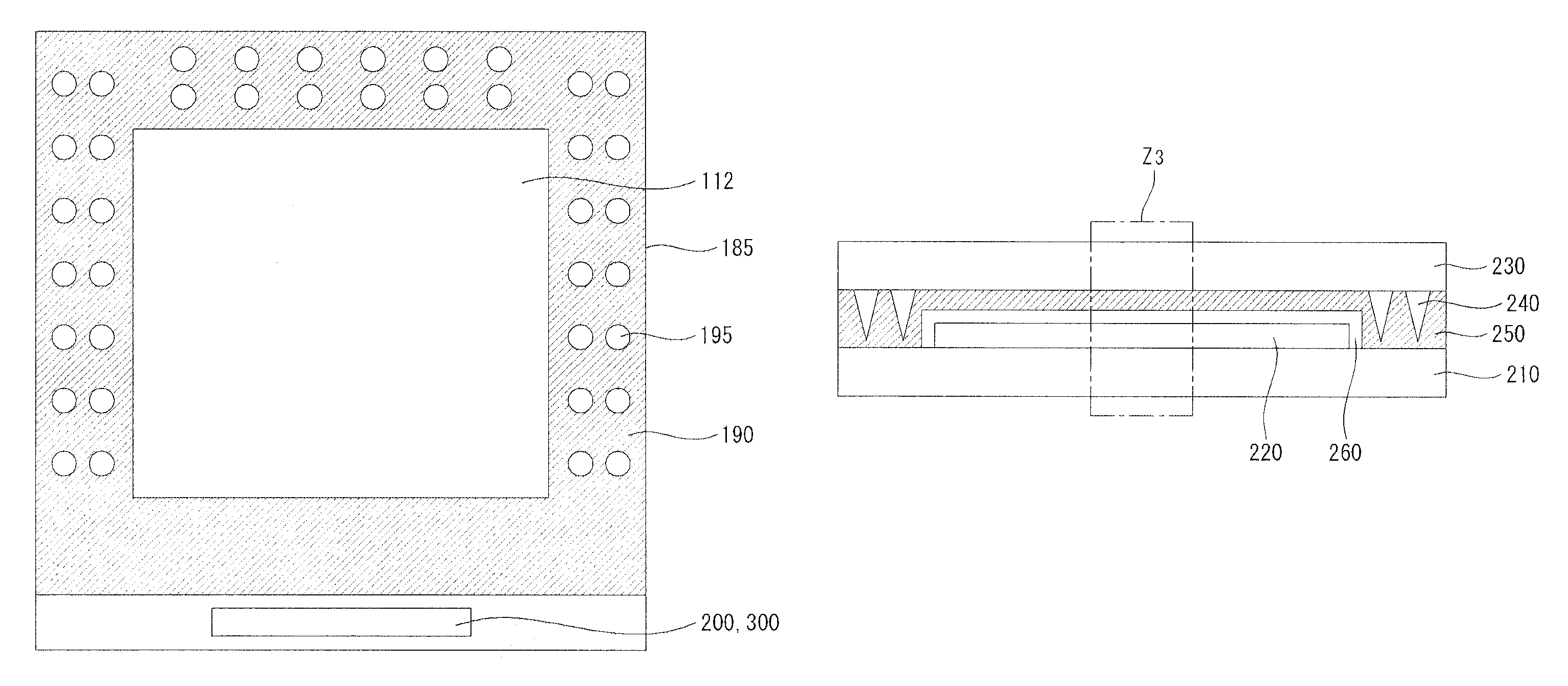

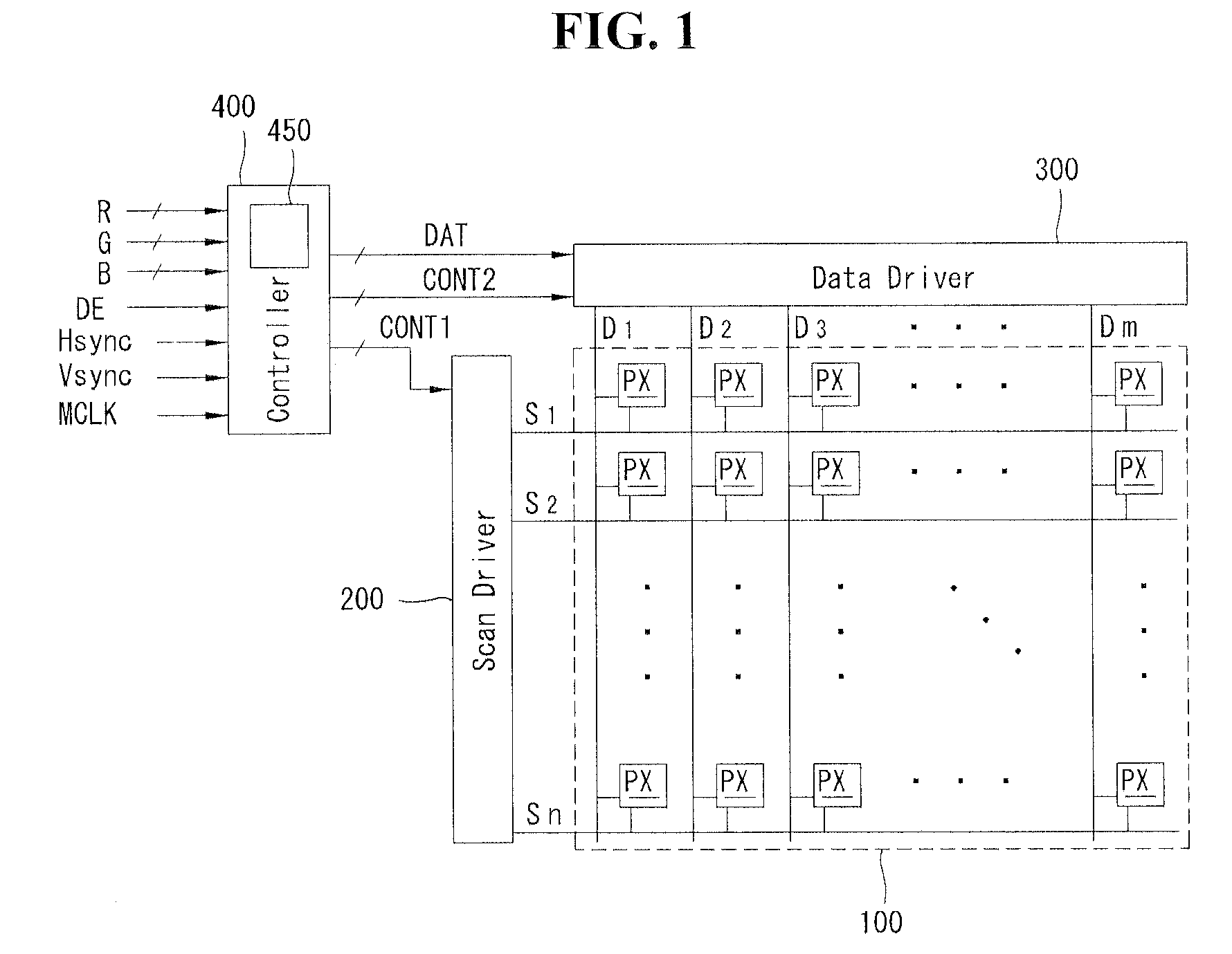

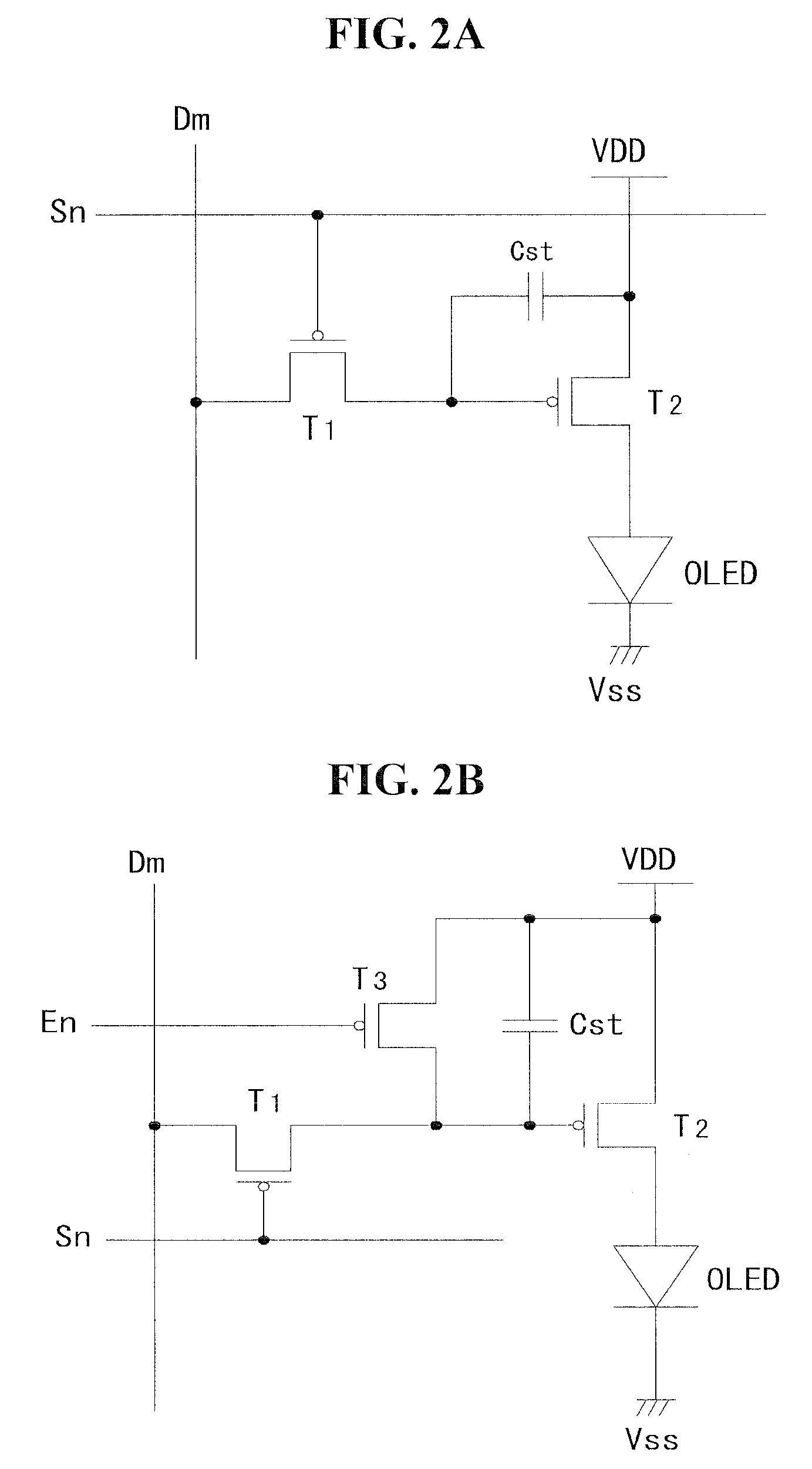

Flexible display apparatus

ActiveUS20170309867A1Reduced resilienceSynthetic resin layered productsSolid-state devicesWater vaporWater vapor permeability

Disclosed is a flexible display apparatus. The flexible display apparatus includes a display part, a first adhesive film, an optical film, a second adhesive film, and a window film sequentially stacked, and the second adhesive film has a water-vapor permeability of about 200 g / m2·24 hr or less, and the first adhesive film has a lower restoration force than the second adhesive film, as calculated by the Equation B set forth herein.

Owner:SAMSUNG ELECTRONICS CO LTD +1

Modified polypropylene resin composition and solar energy rear panel made of the same

ActiveCN103066141AImprove low temperature impact resistanceAging resistantPhotovoltaic energy generationSemiconductor devicesSurface layerWater vapor permeability

The invention discloses a solar energy rear panel and a preparation method of the solar energy rear panel. The solar energy rear panel comprises an inner surface layer, a core layer and an outer surface layer from inside to outside. By a mass rate, the inner surface layer is 10%-20%, the core layer is 20%-40%, and the outer surface layer is 40%-60%. The inner surface layer and the outer surface layer are made of polyamide resin, fillings and additive, and the core layer is made of the modified polypropylene resin composition. The modified polypropylene resin composition comprises the following components: 100 parts of polypropylene resin, 5-50 parts of graft polyethylene, 0-2.5 parts of additive and 0-100 parts of fillings. Meanwhile, the invention discloses the novel modified polypropylene resin composition used for the solar energy rear panel. Due to the novel modified polypropylene resin composition, a final product obtained has good low temperature resistance and impact resistance, meanwhile anti-aging performance and especially has performance of humidity resistance and resistance to aging. The solar energy rear panel prepared by the novel modified polypropylene resin composition is better than other rear panels in terms of water absorption, water vapor permeability, and interlaminar peeling and has excellent electrical insulating property. A shrinking rate, hot air aging and insulation property required by the solar energy rear panel are met, and the novel modified polypropylene resin composition can be used for solar energy battery components manufacturing .

Owner:SUZHOU DUCHAMPS ADVANCED MATERIALS CO LTD

Porous polypropylene film, process for producing the same, and absorbent article employing the film

InactiveUS6861132B2Improve breathabilityImprove textureOrganic chemistryFibre treatmentWater vapor permeabilityPolypropylene

Disclosed is a porous film made of a resin composition containing (I) (i) a propylene-ethylene copolymer or (ii) a polypropylene-based resin mixture containing a propylene-ethylene copolymer, each having an ethylene content of 3.0 to 7.0 wt. % and an MFR measured at 230° C. of 2.0 to 4.0 g / 10 min and (II) a β-crystal nucleating agent; the film having a porosity of 20 to 80%, a Gurley air permeability of 5,000 sec / 100 cc or lower as measured according to JIS P-8117, a water vapor permeability of 2,000 g / m2·24 h or higher as measured according to JIS Z-0208 and a water pressure resistance of 75 kPa or higher as measured according to JIS L-1092 using an aqueous surfactant solution; a process for producing the same; and an absorbent article employing the porous film as a backsheet.

Owner:NEW JAPAN CHEM CO

Organic light emitting device

ActiveUS7652424B2Increasing life-span and reliabilityDischarge tube luminescnet screensElectroluminescent light sourcesWater vapor permeabilityOrganic light emitting device

An organic light emitting device is disclosed. The organic light emitting device includes a first substrate, a display unit that is positioned on the first substrate and includes a plurality of subpixels, a second substrate facing the first substrate, a seal member attaching the first substrate to the second substrate, and at least one projection. The seal member substantially has a water vapor permeation rate of 100 g / m2 day to 103 g / m2 day. The projection is positioned at a location corresponding to a bezel area of at least one of the first and second substrates.

Owner:LG ELECTRONICS INC

Preparation method of high-density fine-denier double-surface double-layer PFY (Polyester Filament Yarn) fabric

The invention discloses a preparation method of high-density fine-denier double-surface double-layer PFY (Polyester Filament Yarn) fabric. The preparation method comprises the following steps of (1) raw material selecting; (2) space-variant compositing and sizing; (3) weaving; (4) dyeing and after-finishing. The high-density fine-denier double-surface double-layer PFY fabric which is generated by the preparation method has the characteristics that the fabric density is up to 120 / cm, the fineness is only 50 denier, the finest fiber is only 0.02 DPF, the fabric is woven by adopting a double-layer exterior and interior interconnection organization, the thinnest thickness can be lower than 100 g / m<2>, the fabric is fine and smooth in weaving, abundant pattern textures, color matching and check and pattern combination can be formed, the feeling is soft and comfortable, the recoverability is strong, the air permeability, the water vapor permeability and the anti-static performance of the fabric are good, and the fabric is ideal fabric for manufacturing sports wear, jackets and suits. The comprehensive running rate of a weaving machine is up to 95%, the cloth surface is smooth, and the product yield is ensured.

Owner:DANYANG DANQI YUYUE TEXTILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com