Resin composition for preparing micro-porous thin film and micro-porous thin film

A resin composition, microporous technology, applied in the field of microporous film, can solve the problem of low moisture permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

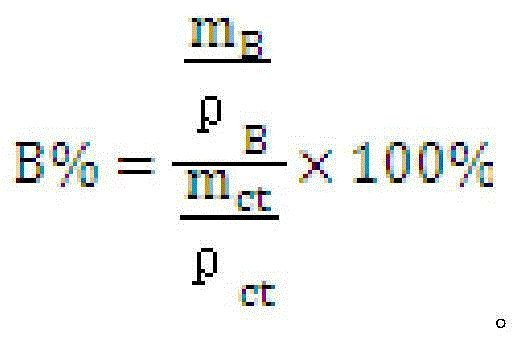

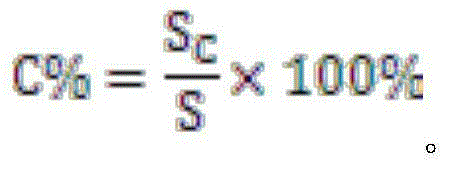

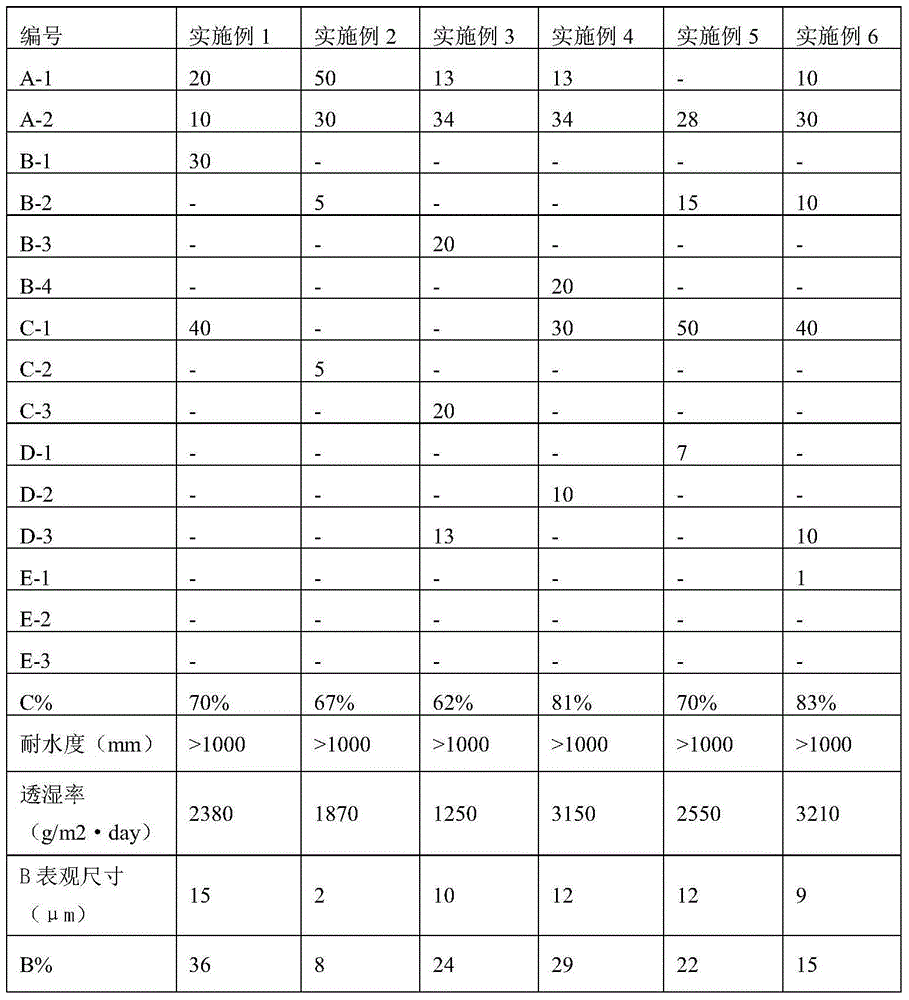

[0079] According to the proportion listed in Table 1, pelletize with a twin-screw extruder at an extrusion temperature of 160-220°C. Next, an original film with a thickness of 80 μm was prepared by blow molding with a single-screw extruder. The blow molding temperature is 180-200°C. Furthermore, at 85° C., the original film was biaxially stretched 3.5×3.5 times, and then various performance tests were performed on the obtained film, and the results are listed in Table 1.

[0080] Table 1 (unit: parts by weight)

[0081]

[0082] Table 1 (continued) (unit: parts by weight)

[0083]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| water resistance coefficient | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com