Patents

Literature

1173results about How to "Aging resistant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

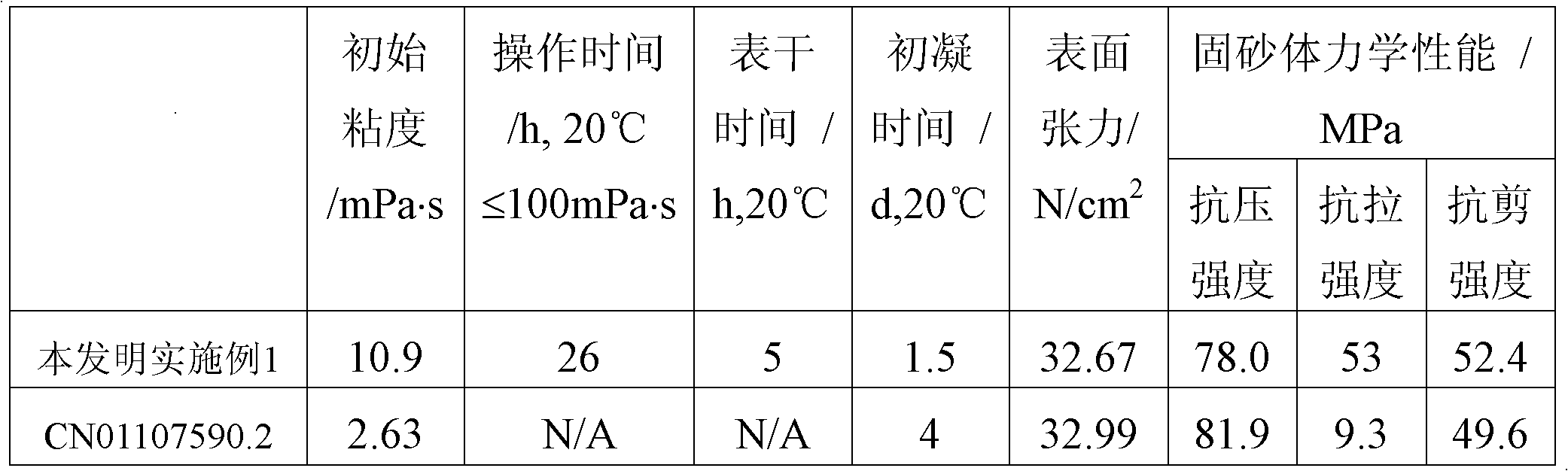

Spray polyurea high-performance waterproof paint and preparation method thereof

InactiveCN101818019AFast curingHigh strengthPolyurea/polyurethane coatingsDiluentUltimate tensile strength

The invention relates to a spray polyurea high-performance waterproof paint which is characterized by comprising component A and component B, wherein the component A comprises semi-prepolymer formed by the reaction between 70-35 parts of polyisocyanate and 30-50 parts of polyether glycol, and 0-15 parts of diluent based on parts by weight; the component B comprises 50-70 parts of amine-terminated polyether, 20-40 parts of amine chain extender and 5-10 parts of filler; and the volume ratio between the component A and the component B is 1:1. Compared with the common spray polyurea high-performance waterproof paint, the spray polyurea high-performance waterproof paint has higher tensile strength, elongation at break, tearing strength and other physical properties, and not only is applicable to waterproof projects of common building projects, basic facilities and the like, but also is especially suitable for high-difficulty waterproof projects of large basic facility construction such as a high speed railway, a subway, a tunnel, water conservancy project and the like.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +2

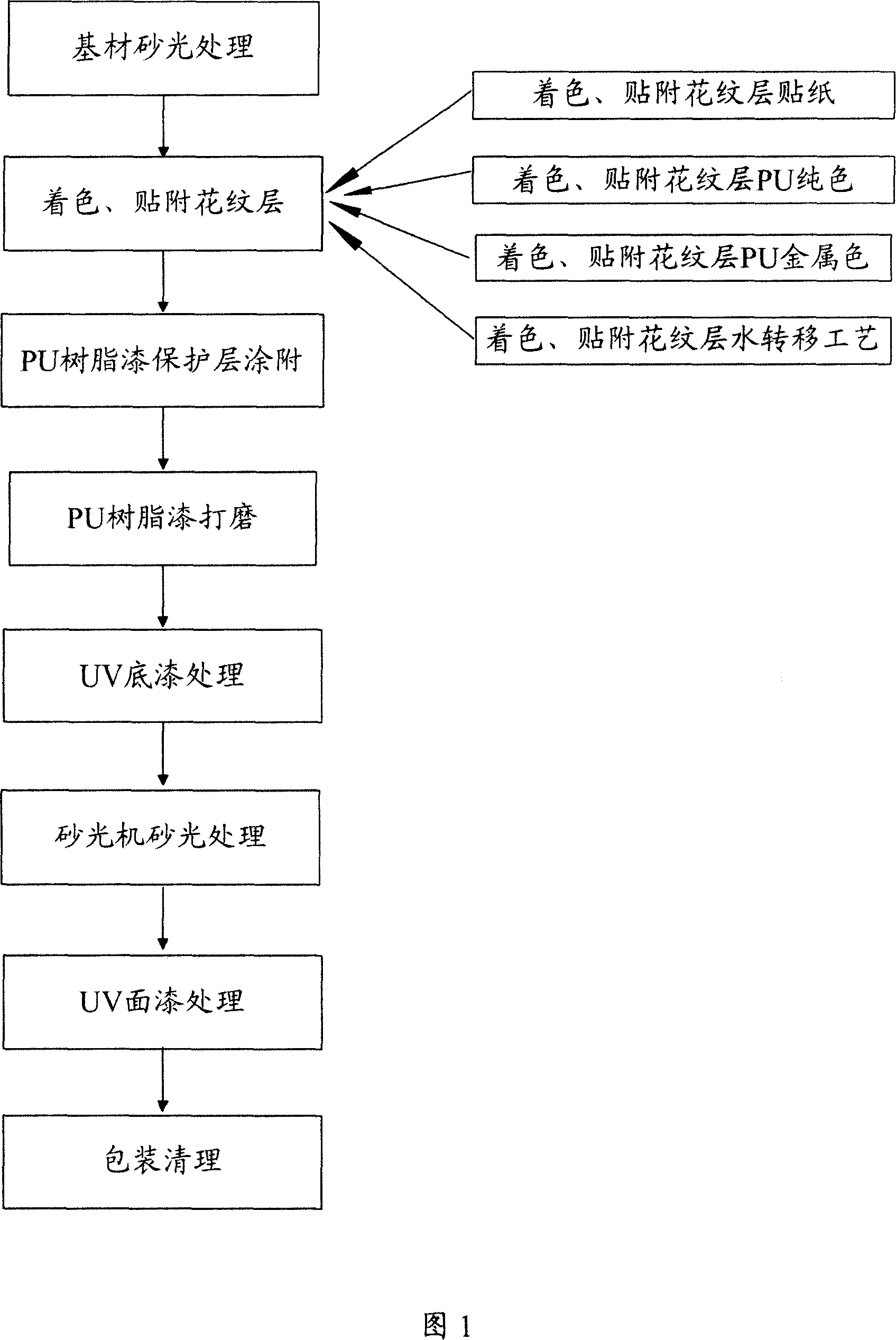

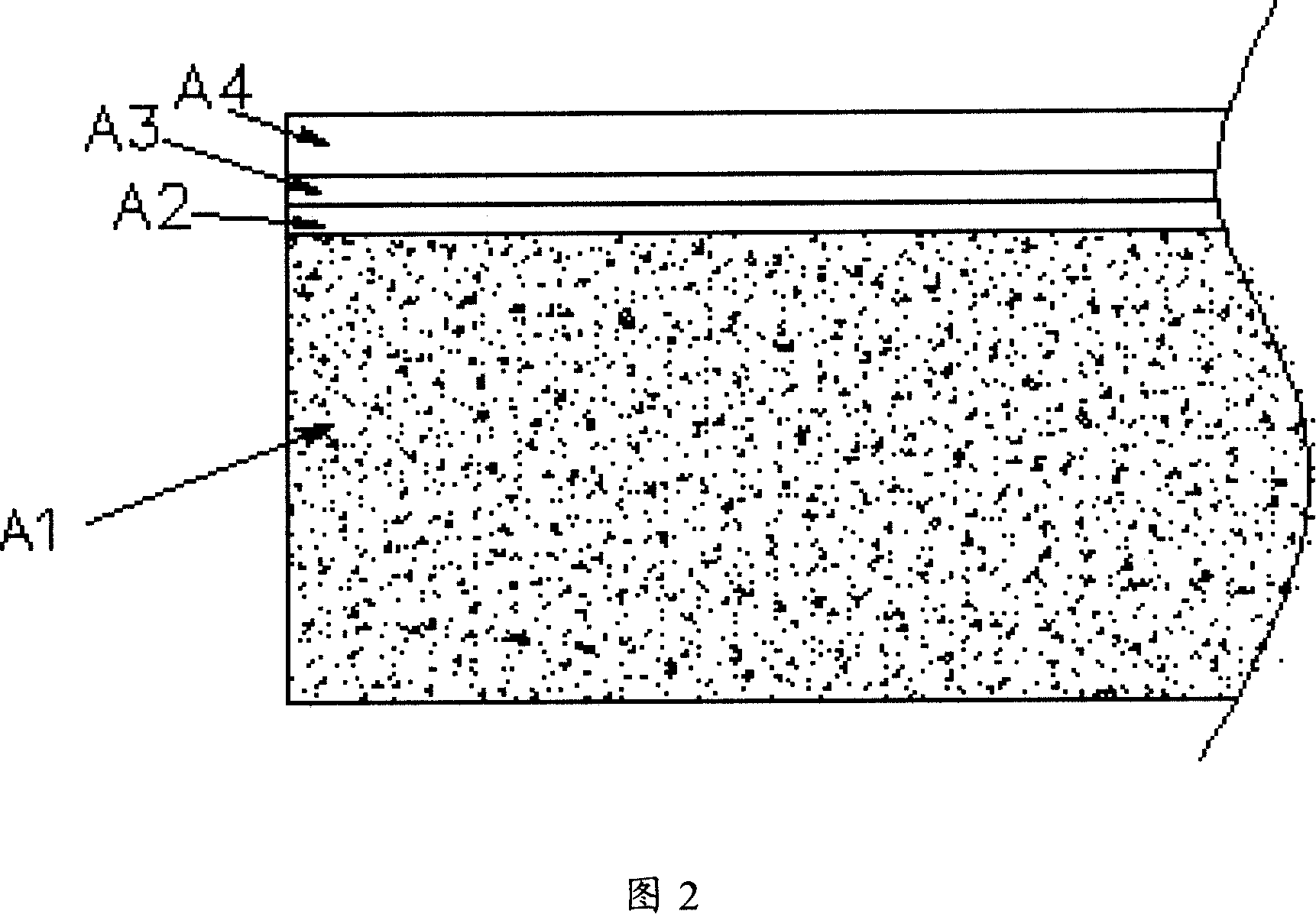

Decorative board processing method

ActiveCN101116987AFlexible color changeRich and gorgeous appearanceWood working apparatusLacquerMedium density fiberboard

The invention relates to a processing method of decoration boards. The decoration boards are processed by the substrate material surface and substrate material coloring and UV rays fixes the base lacquer and the surface lacquer by the forward drench-roll technology and the drench-spread technology. The substrate materials are particle board adhered with melamine fumiture surface paper on single or double faces or medium density fiberboard. The steps comprise 1) substrate material surface is processed; 2) substrate material surface is colored; 3) the base lacquer is fixed by UV rays; 4) the surface lacquer is fixed by UV rays. Prior to step 4), a step of polishing can also be comprised, i.e. large-scale polishing machine polishes the whole base lacquer after the fixing machine of UV rays fix completely. After the step 4), a step of cleaning package can also be added, that is, micro flaws can be removed that decoration boards with small bubbles or unapparent impurities are polished by dropping sand and package is checked. The decoration boards produced by the method has the advantages of wear resistance, environmental protection, rich and bright colors.

Owner:TIANJIN DAYIN BUILDING MATERIAL CO LTD

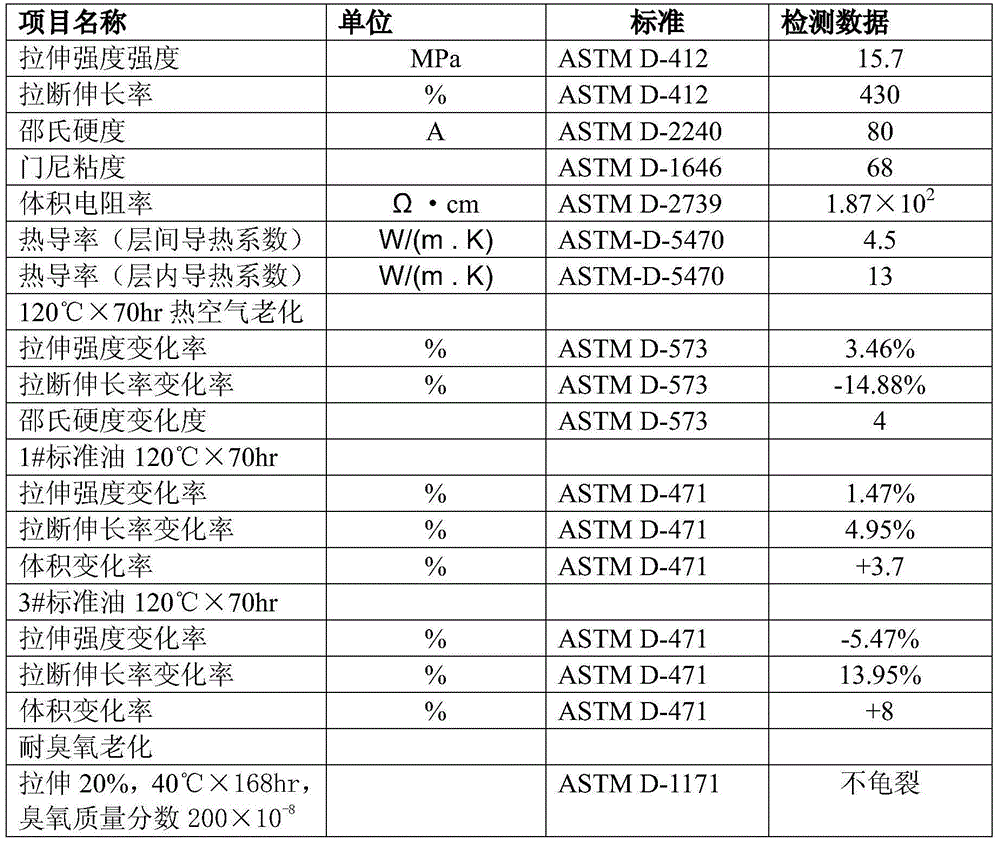

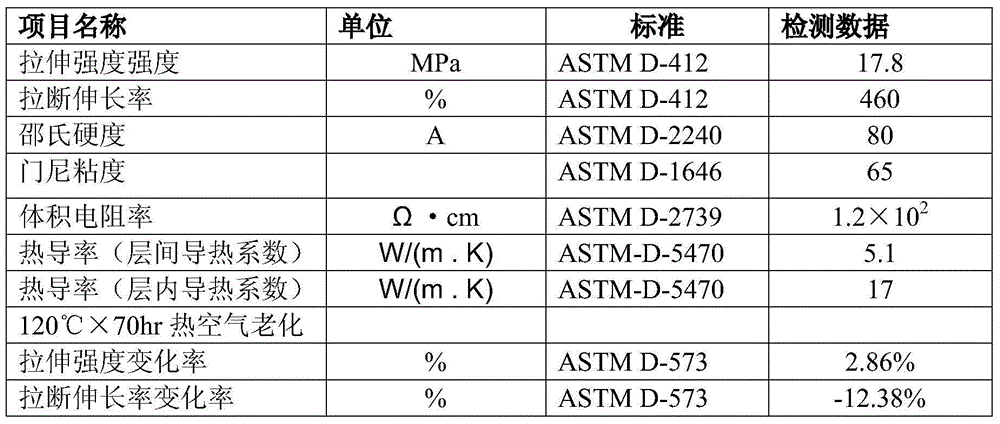

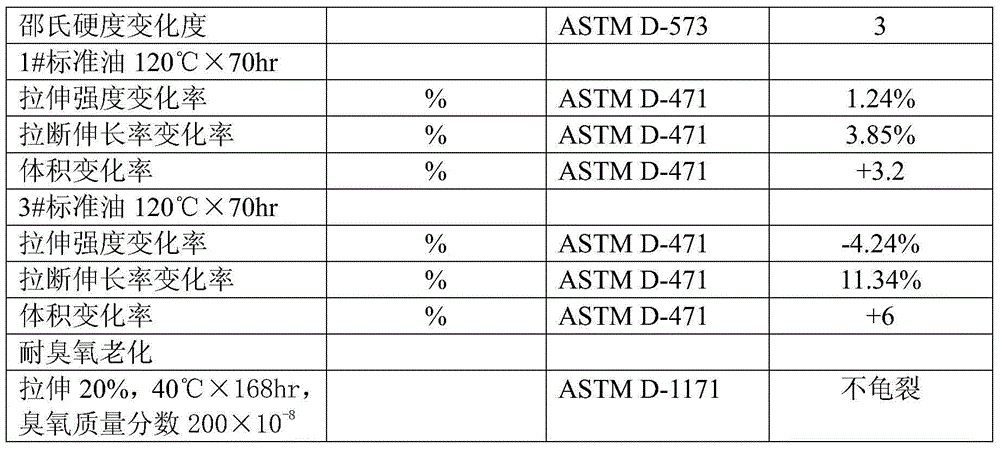

High-electrical conductivity high-thermal conductivity oil-resistant aging-resistant rubber material, and preparation method and applications thereof

ActiveCN104961983AExcellent electrical and thermal conductivityExcellent mechanical properties and oil resistancePetroleumConductive rubber

The invention relates to a high-electrical conductivity high-thermal conductivity oil-resistant aging-resistant rubber material. The high-electrical conductivity high-thermal conductivity oil-resistant aging-resistant rubber material is prepared from following ingredients, by weight, 50 to 100 parts of an electroconductive thermal conductive rubber master batch, 40 to 60 parts of an auxiliary rubber material, 30 to 50 parts of a reinforced material, 30 to 50 parts of a flexibilizer, 30 to 50 parts of a filling material, 8 to 10 parts of a stabilizing agent, 10 to 15 parts of a tackifier, 3 to 5 parts of a vulcanizing agent, and 2 to 3 parts of a vulcanizing assistant agent. The high-electrical conductivity high-thermal conductivity oil-resistant aging-resistant rubber material possesses excellent electrical conductivity and thermal conductivity; volume resistivity is as high as 102 omega.cm; heat conductivity coefficient is higher than 4W / (m.K); the high-electrical conductivity high-thermal conductivity oil-resistant aging-resistant rubber material can be applied to special fields such as petroleum, coal mine, and spaceflight; the high-electrical conductivity high-thermal conductivity oil-resistant aging-resistant rubber material possesses excellent mechanical properties, oil resistance, and air aging resistance, and can be used in oil medium or in outdoor environment.

Owner:青岛科凯达橡塑有限公司

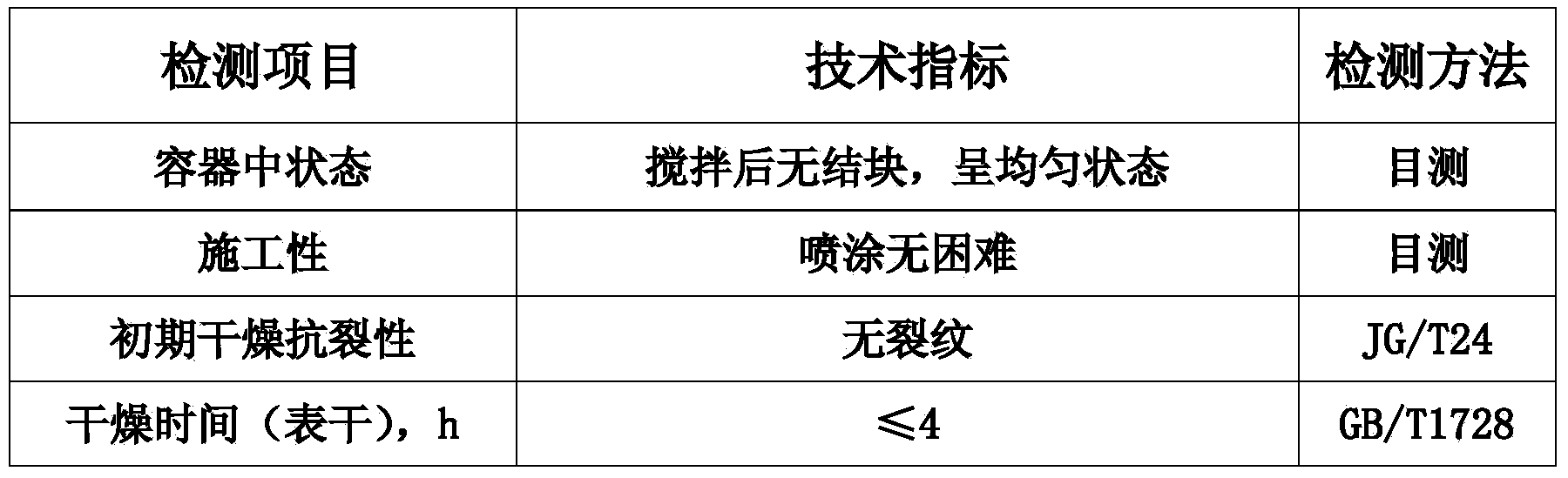

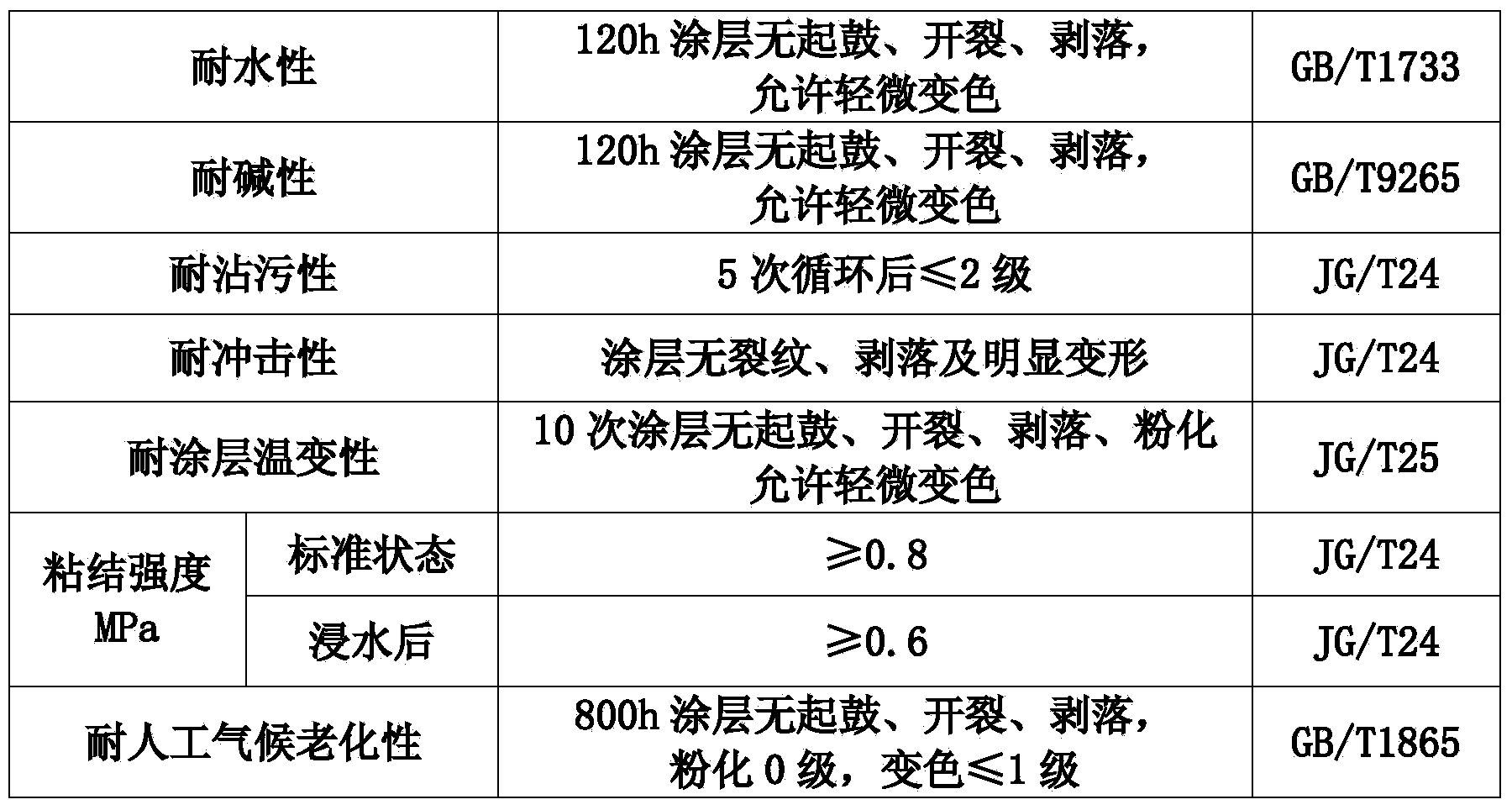

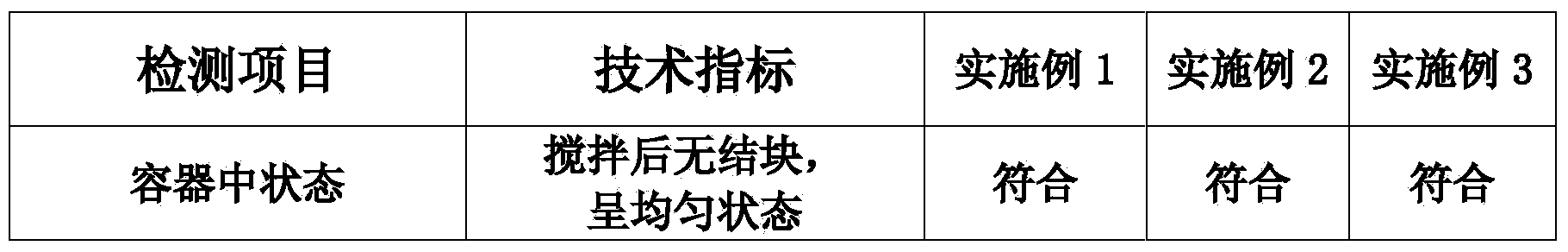

Heat preserving really stone paint and preparation method thereof

The invention discloses a heat preserving really stone paint and a preparation method thereof. The heat preserving really stone paint is prepared from the following components in parts by weight: 150-200 parts of a silicone acrylic emulsion, 450-500 parts of natural colored sand, 150-200 parts of hollow glass beads, 5-8 parts of hydroxyethyl cellulose, 200-250 parts of tap water and 35-50 parts of an auxiliary. By combining the silicone acrylic emulsion, the natural colored sand and the hollow glass beads, the heat preserving really stone paint disclosed by the invention has stabilities such as excellent weather resistance, tarnish resistance, temperature change resistance and ageing resistance and heat preserving performance as well as color diversification. In addition, the preparation method disclosed by the invention does not need grinding. Only dispersion is needed to prepare a product paint, so that the paint is simple in production process.

Owner:ZHANG ZHOU SAN PAINTS

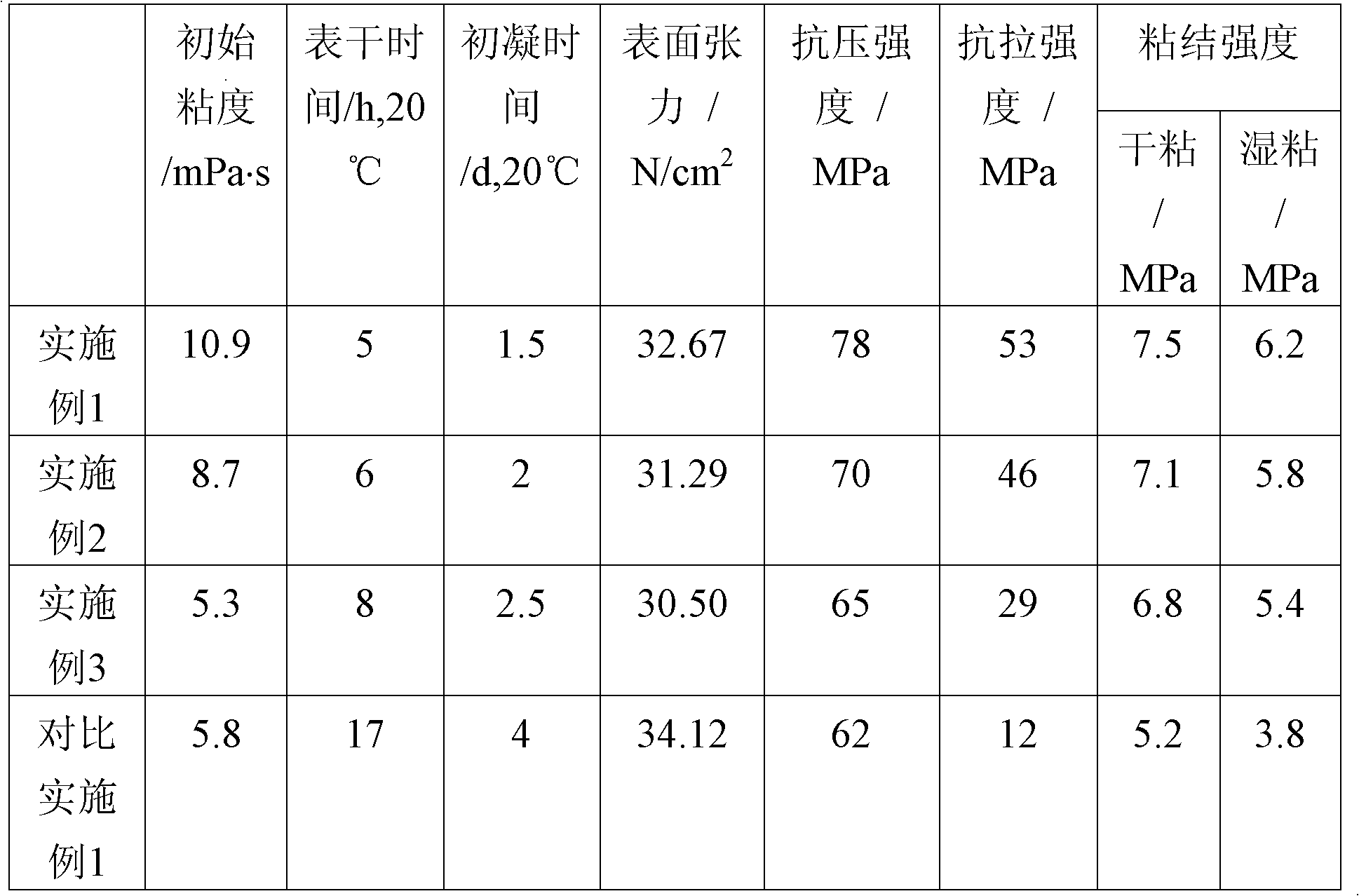

Inorganic composite heat insulation material and preparation method thereof

ActiveCN102093030ADecreased volumetric water absorptionStable physical and chemical propertiesFiberCellulose

The invention relates to an inorganic composite heat insulation material, which is prepared from the following raw materials in part by weight: 100 parts of common silicate cement, 10 to 30 parts of quick hardening sulfate aluminum cement, 10 to 30 parts of gypsum powder, 10 to 40 parts of admixture, 20 to 40 parts of mineral fiber, 150 to 200 parts of vitrified micro bubbles, 4 to 8 parts of re-dispersible latex powder, 2 to 4 parts of cellulose ether, 0.1 to 0.3 part of starch ether, 0.2 to 1.0 part of water reducing agent, 0.2 to 0.6 part of retarder, 1 to 3 parts of early strength agent, 0.5 to 3 parts of water repellent, and 0.02 to 0.06 part of air entraining agent. The raw materials are mixed uniformly to prepare dry powder, and the dry powder and water are mixed in a weight ratio of 1: (0.8-1.2) and stirred to form slurry for use. The inorganic composite heat insulation material has good workability, quick strength development, high construction efficiency, good adhesive property, low drying shrinkage, heat insulation, hydrophobic property, fire resistance and durability.

Owner:辽宁际洲环保节能建材有限公司

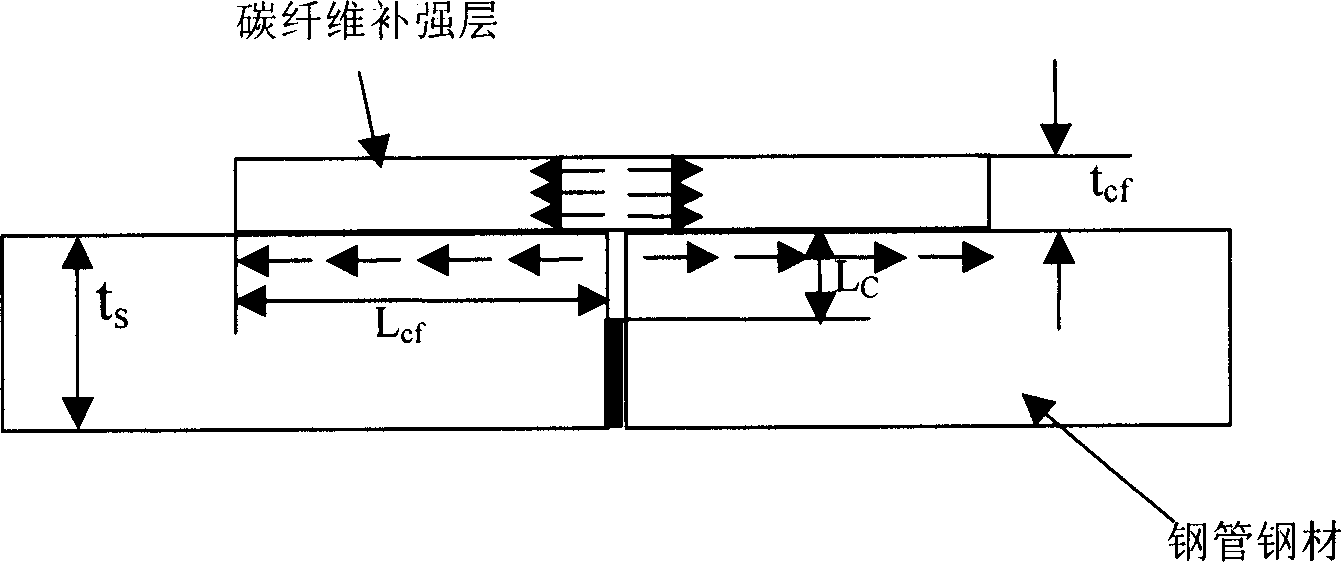

Carbon-fibre composite material for repairing and reinforcing weld seam defect and its method

A method for repairing and reinforcing the defect on the welded seam of pipeline by use of composite carbon fiber material features several layers of wet carbon fiber sheet are tightly wound around and adhered onto said weld seam in various directions. It is possible to use the repairing resin and perform anticorrosion treatment on the external surface of carbon fiber layer.

Owner:BEIJING SAFETECH PIPELINE

Method for manufacturing aluminium alloy sheet for automobile fuel tank

ActiveCN104294113AStable mechanical propertiesPrecise dimensional tolerancesFuel tankEconomic benefits

The invention provides a method for manufacturing an aluminium alloy sheet for an automobile fuel tank. The method comprises the steps of batching, smelting, refining, grain refining, degassing, filtering, casting, saw-cutting, milling, homogenized heating, hot-rolling, cold-rolling, cleaning, low-temperature stabilized annealing, transverse shearing, edge straightening, board cutting, inspecting and the like. The aluminium alloy sheet for the automobile fuel tank has the advantages of stable mechanical property, precise dimensional tolerance, finish surface and the like. Compared with the present plastic fuel tank, the automobile fuel tank manufactured by the aluminium alloy sheet produced by the method has the advantages of high strength, sun exposure resistance, aging resistance, breakage prevention, environmental protection and the like, and also has the advantages of corrosion resistance, rusting avoidance, light weight, good economic benefits within the product life cycle, high material reutilization ratio and the like in comparison with a copper fuel tank.

Owner:DALISHEN ALUMINUM

Two-component high-penetrability epoxy resin waterproof reinforcing coating, and preparation method and application thereof

InactiveCN102433057AEfficient activationImprove permeabilityEpoxy resin coatingsEpoxyTemperature resistance

The invention belongs to the engineering field of materials and discloses a two-component high-penetrability epoxy resin waterproof reinforcing coating, and a preparation method and application thereof. The coating consists of a main ingredient A solution and a main ingredient B solution. The main ingredient A solution contains epoxy resin, activated thinner, carbonyl compound, plasticizer and polyoxyethylene surfactant. The main ingredient B solution contains polyamine, intermediate activating agent, silane coupling agent and accelerating agent. The coating disclosed by the invention can be directly coated, the curing time is short, the penetrability is good, the coating can infiltrate into a treated surface, pretreatment and a protection layer are not required, the dual effects of waterprevention and reinforcing can be taken, the adhesive force is more excellent, the toughness is good, the requirement on the performance of waterproof coatings can be satisfied, the coating additionally has the characteristics of corrosion resistance, high temperature resistance, aging resistance and the like, and the defects of long curing time, insufficient toughness, poor penetrability and thelike of the existing like products are overcome.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Light heat preservation silicon and calcium compound plate

InactiveCN102888900APromote environmental protectionNo side effectsCeramic shaping apparatusHeat proofingEnvironmental resistanceSide effect

The invention discloses a light heat preservation silicon and calcium compound plate, which consists of an outer layer structure and an inner layer structure. The plate is manufactured by waste coal ash generated by local rich coal mine resources and crop stalks, so that waste is recovered, and the plate is beneficial to environment friendliness. The plate takes inorganic substances such as powder quartz, quartz sand, sanding powder and the like as main raw materials, has the advantages of high strength, aging resistance, ultraviolet resistance, water resistance, fire prevention, heat preservation and the like, is widely applied, does not have toxic or side effect and is pollution-free.

Owner:SUZHOU WANAN NEW ENVIRONMENTAL PROTECTION BUILDING MATERIAL

Method for preparing polytetrafluoroethylene spatial structure building film material

The invention relates to a producing method of a teflon spatial structure membrane comprising following steps: fiberglass cloth low temperature genapping treatment, fiberglass cloth bottom layer dipping treatment, structure layer dipping treatment, surface layer dipping treatment and sintering treatment. Low temperature high speed genapping, multitime coating low-temperature treatment, and once hyperthermia flash sintering effectively reduce tensile strength descending caused by high-sintering treatment. Since fiberglass cloth is used as backing material, dipping treatment is not needed to be performed on the fiberglass yarn, the procedure is simplified to facilitate the production thereof, and shortcomings in prior art are overcome which are modified fiberglass yarn weaving difficulty and intensity and plasticity descending caused by multitime sintering. The teflon spatial structure membrane produced by using the invented method has a bottom layer, a structure layer and a surface layer, is provided with high pulling-against intensity, high tearing-against intensity, anti-aging property, good flexibility, good light-admitting quality and a long service life, and can be used widely in air stations, gymnasiums, exhibition halls, large-scale factory buildings and factory building warehouses.

Owner:JIANGSU VEIK TECH & MATERIALS CO LTD

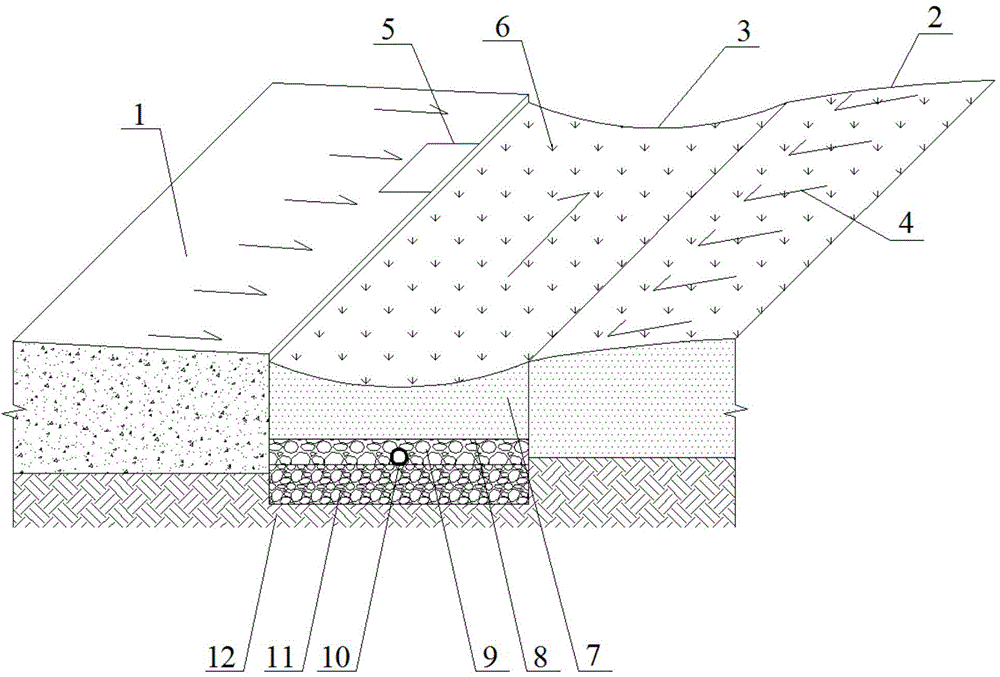

Ecological grass planting trench for cities with rich water resource

ActiveCN104313974AEasy to handleControl non-point source pollutionPaving gutters/kerbsSustainable biological treatmentVegetationRainfall runoff

The invention provides an ecological grass planting trench for cities with rich water resource, which is arranged on one side of a sidewalk road. The ecological grass planting trench sequentially comprises a vegetation layer, a planting soil layer, a building block brick layer, a water permeating and discharging pipe and a gravel layer from top to bottom. The ecological grass planting trench is arranged on one side of the sidewall road and used for collecting rainfall running water on the sidewall road, the pollutants in the running water can be reduced, and a purpose for locally purifying the running water and controlling the pollution of the running water can be achieved; the ecological grass planting trench is arranged between the sidewall road and a green land, so that not only is the landscape not influenced, but also convenience in construction can be realized; the rainfall running water is stopped in the gravel layer and gradually and slowly permeated, finally the water content of the soil of the green land is replenished, the rainfall running water can be completely absorbed and purified, and the water for irrigating the green land can be reduced; the lower end of the water permeating and discharging pipe is connected with a rainy water opening or a rainy water well, the other end of the water permeating and discharging pipe is closed, so that the collected rainfall running water on the sidewalk road can be collected into the rainy water opening or the rainy water well, and a purpose for reducing the rainfall running water and postponing the flood peak can be achieved.

Owner:SHANGHAI JIAO TONG UNIV

Low-cost environment-friendly water glass wood adhesive and preparation method thereof

ActiveCN102863906ARich sourcesLow priceNon-macromolecular adhesive additivesMacromolecular adhesive additivesEmulsionAdhesive

The invention discloses a low-cost environment-friendly water glass wood adhesive which comprises components of 100 parts of water glass with the mass percentage of 30-60%, 10-30 parts of a water-soluble polymer, 90-270 parts of deionized water, 10-50 parts of a high polymer emulsion, 1-5 parts of advanced fatty acid salt and 2-10 parts of an inorganic solidifying agent. Simultaneously, the invention further discloses a preparation method of the water glass wood adhesive. The preparation method includes heating the deionized water, slowly adding the deionized water to the water-soluble polymer, stirring the mixture to obtain a solution, adding the water glass to the solution, evenly stirring the solution to perform an aging reaction, adding the high polymer emulsion and the advanced fatty acid salt after the aging, and preserving heat after stirring at the temperature of 40-80 DEG C; and then cooling the mixture to the temperature of 30-60 DEG C, adding the inorganic solidifying agent, and evenly mixing the mixture to obtain the low-cost environment-friendly water glass wood adhesive. The water glass wood adhesive is stable in performance, simple and easy in preparation process and widely applicable to industrialization production.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

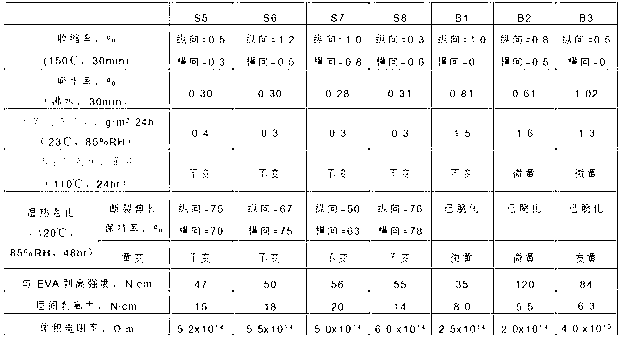

Modified polypropylene resin composition and solar energy rear panel made of the same

ActiveCN103066141AImprove low temperature impact resistanceAging resistantPhotovoltaic energy generationSemiconductor devicesSurface layerWater vapor permeability

The invention discloses a solar energy rear panel and a preparation method of the solar energy rear panel. The solar energy rear panel comprises an inner surface layer, a core layer and an outer surface layer from inside to outside. By a mass rate, the inner surface layer is 10%-20%, the core layer is 20%-40%, and the outer surface layer is 40%-60%. The inner surface layer and the outer surface layer are made of polyamide resin, fillings and additive, and the core layer is made of the modified polypropylene resin composition. The modified polypropylene resin composition comprises the following components: 100 parts of polypropylene resin, 5-50 parts of graft polyethylene, 0-2.5 parts of additive and 0-100 parts of fillings. Meanwhile, the invention discloses the novel modified polypropylene resin composition used for the solar energy rear panel. Due to the novel modified polypropylene resin composition, a final product obtained has good low temperature resistance and impact resistance, meanwhile anti-aging performance and especially has performance of humidity resistance and resistance to aging. The solar energy rear panel prepared by the novel modified polypropylene resin composition is better than other rear panels in terms of water absorption, water vapor permeability, and interlaminar peeling and has excellent electrical insulating property. A shrinking rate, hot air aging and insulation property required by the solar energy rear panel are met, and the novel modified polypropylene resin composition can be used for solar energy battery components manufacturing .

Owner:SUZHOU DUCHAMPS ADVANCED MATERIALS CO LTD

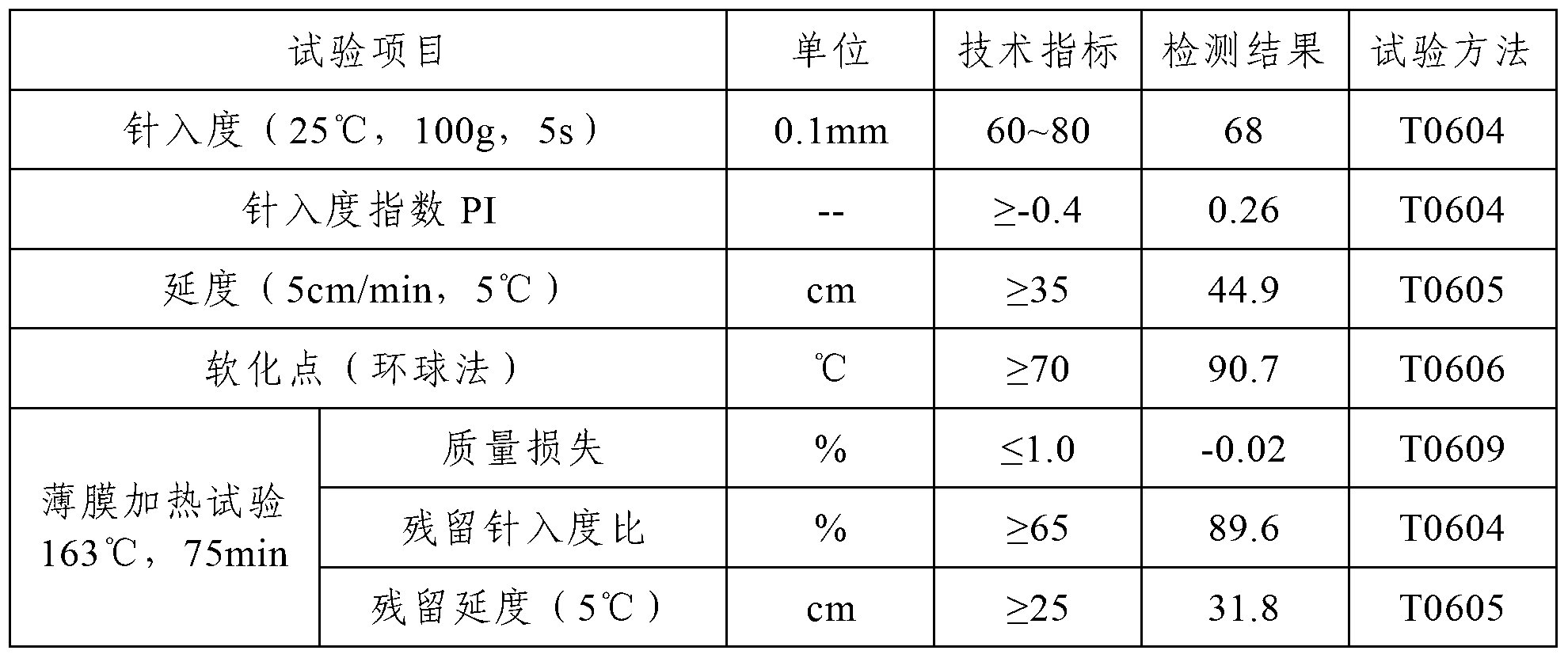

Irradiation crosslinking low-smoke halogen-free flame-retardant polyolefin cable material for photovoltaic cables

The invention provides an irradiation crosslinking low-smoke halogen-free flame-retardant polyolefin cable material for photovoltaic cables. The cable material is prepared from the following raw materials in parts by weight: 40-50 parts of polyethylene (PE), 30-40 parts of polyvinyl chloride resin, 20-30 parts of CSM2305, 10-12 parts of ethylene-acrylate copolymer, 10-15 parts of epichlorohydrin rubber T3100, 5-10 parts of epoxidized soybean oil, 2-3 parts of carbonyl iron powder, 10-12 parts of high abrasion carbon black N330, 5-10 parts of light calcium carbonate, 1-2 parts of zinc oxide, 5-10 parts of wollastonite powder, 4-5 parts of vermiculite, 1-2 parts of polytetrafluoroethylene micro powder, 1-2 parts of graphite, 1-2 parts of nano boron carbide, 2-3 parts of ferric oxide, 0.1-0.2 part of UV-O, 0.1-0.2 part of UV-53, 0.1-0.2 part of flame retardant TBC, 10-12 parts of aluminium hypophosphite, 5-8 parts of decabromodiphenyl ether, 8-10 parts of dioctyl terephthalate, 6-8 parts of trioctyl trimellitate, 8-10 parts of triethyl citrate, 1-2 parts of calcium stearate, 0.2-0.4 part of stearic acid, 0.1-0.2 part of oxidized polyethlene wax, 0.2-0.3 part of ethylene bis stearamide, 0.1-0.2 part of DCP, and 12-15 parts of modified filler. The cable material has the characteristics of high flame retardance, high ultraviolet resistance and high ageing resistance, and meanwhile, has a good mechanical property, and is environment-friendly.

Owner:温州市粤来电子加速器应用有限公司

Multicomponent phenolic resin fire-retardant paint composition

InactiveCN102153936AHigh bonding strengthAging resistantFireproof paintsEpoxy resin coatingsEpoxySolvent

The invention discloses a multicomponent phenolic resin fire-retardant paint composition. The paint composition comprises a component (A), a component (B) and a component (C), wherein the component (A) at least comprises one phenolic resin; the component (B) at least comprises an epoxide resin; the component (C) at least comprises a curing agent of the epoxide resin and the phenolic resin; the component (C) and the components (A) and (B) are stored separately; and the components (A), (B) and (C) are mixed, a crosslinking curing reaction is generated. The paint composition related to the invention does not contain solvents, such as an organic solvent, water and the like, or a dispersing agent, is paste suitable for various coating processes and can be used for fire-retardant coating of a steel structure, concrete and wood. A formed coating has the obvious characteristics of high bonding strength, ageing resistance and hydrocarbon fire resistance.

Owner:CHINESE PEOPLES ARMED POLICE FORCE ACAD

Wet paved/pre-paved polymer self-adhesive waterproofing rolled material and preparation method thereof

InactiveCN102454226AExtended service lifeWeather resistantUnderground chambersRoof covering using flexible materialsPolymer resinCompound (substance)

The invention provides a wet paved / pre-paved polymer self-adhesive waterproofing rolled material which comprises a modified asphalt self-adhesive layer. The modified bitumen self-adhesive layer contains petroleum asphalt, modifier, softener, tackifier and filler. The wet paved / pre-paved polymer self-adhesive waterproofing rolled material which is prepared from the by taking a polymer resin layer as a base has a long use life, stable chemical properties and excellent waterproof effect, wherein the modified asphalt self-adhesive layer is prepared through single side or double side adhering.

Owner:沈阳蓝光科技发展有限公司

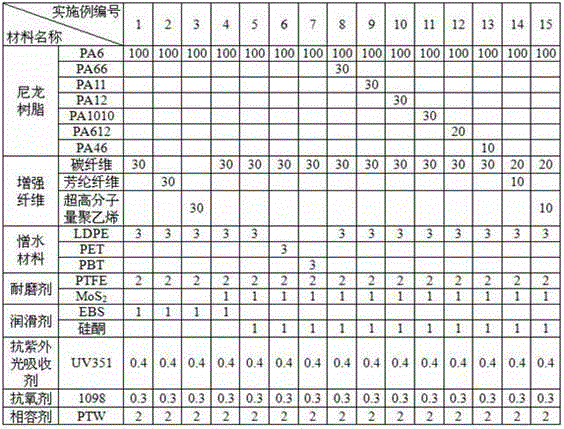

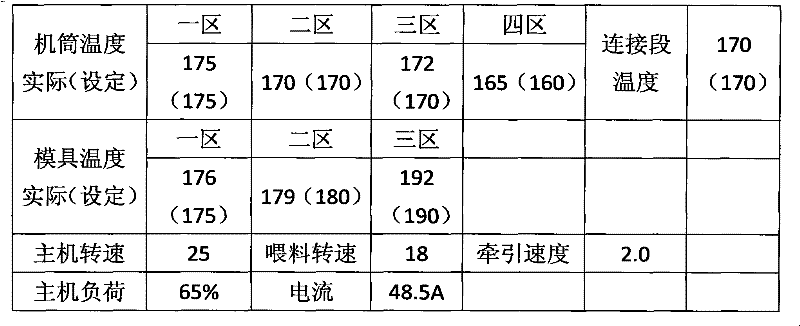

Wear-resistant self-lubricating nylon composite material, and preparation method and application thereof

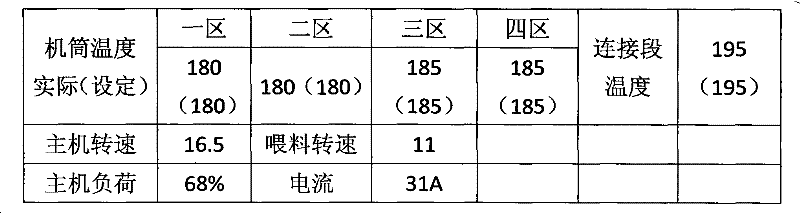

The invention relates to a wear-resistant self-lubricating nylon composite material, and a preparation method and application thereof. The nylon composite material is composed of a nylon resin, a reinforcing fiber, a hydrophobic material, an anti-wear agent, a lubricant, an ultraviolet-resistant light absorber, an antioxidant and a compatilizer. The preparation method comprises the following steps: mixing the nylon resin, hydrophobic material, anti-wear agent, lubricant, ultraviolet-resistant light absorption agent, antioxidant and compatilizer, adding into a charging hopper, continuously metering and feeding into a double screw extruder, feeding the reinforcing fiber into the double screw extruder through a side feed metering screw, merging with the main materials, sending into a compounding region for blending, cooling, granulating and drying. The nylon composite material prepared by the method has the characteristics of high strength, low hydroscopic property, wear resistance, moisture resistance, weather resistance, excellent self-lubricating and the like, has the advantages of favorable dimensional stability and long service life, and can be widely used in the fields of lubricating bearings, shaft sleeves, mechanical gears, mine support rollers and the like.

Owner:长沙五犇新材料科技有限公司

Anti-corrosion super-hydrophobic heat reflecting paint and preparation method thereof

ActiveCN105925073AImprove lotus leaf effectImprove hydrophobicityAnti-corrosive paintsReflecting/signal paintsNano sio2Water contact

The invention discloses an anti-corrosion super-hydrophobic heat reflecting paint and a preparation method thereof. The anti-corrosion super-hydrophobic heat reflecting paint is prepared from the following raw materials: modified nano TiO2, modified nano SiO2, micron TiO2 and / or SiO2, fluorocarbon resin, a solvent, a curing agent, a defoaming agent, a wetting dispersant and a flatting agent. After experiments, the heat reflecting rate of the obtained product reaches 90 percent or more, the water contact angle reaches 145 degrees or more, and the product can meet the requirements on a coating under outdoor severe environments.

Owner:SHANDONG UNIV OF SCI & TECH

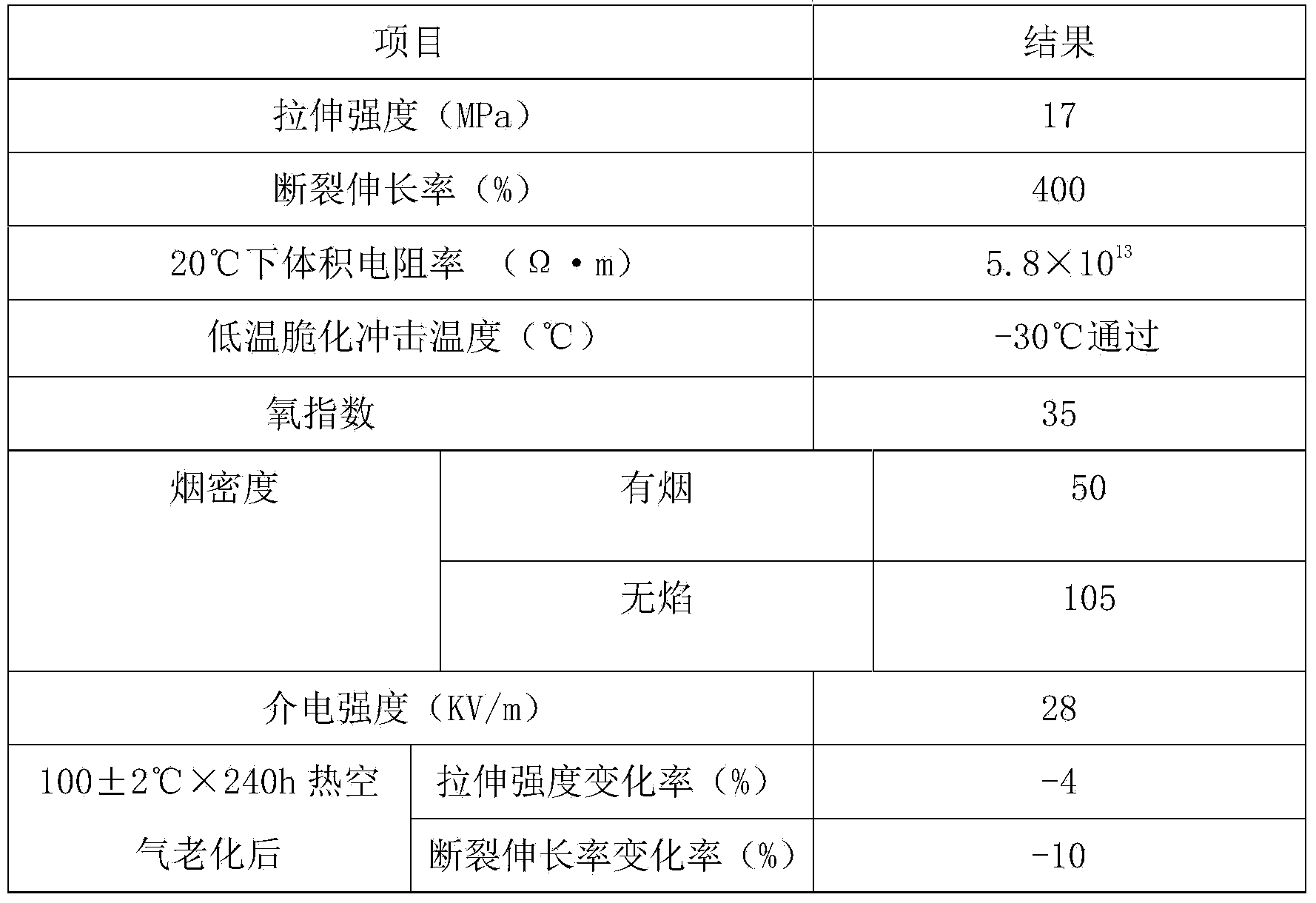

EVA/MLLDPE (ethylene-vinyl acetate/metallocene linear low-density polyethylene) component-type low-smoke halogen-free irradiation-crosslinked wire cable material, and preparation method and application thereof

InactiveCN104231409AImprove flame retardant performanceWith low smoke and non-toxicInsulated cablesInsulatorsLow-density polyethylenePolymer science

The invention discloses an EVA / MLLDPE (ethylene-vinyl acetate / metallocene linear low-density polyethylene) component-type low-smoke halogen-free irradiation-crosslinked wire cable material which is prepared from the following raw materials in parts by weight: 100 parts of EVA, 10-25 parts of MLLDPE, 80-130 parts of halogen-free flame retardant, 1.5-5.5 parts of coupling agent, 1.0-2.5 parts of crosslinking agent, 0.8-1.5 parts of antioxidant, 0.8-1.5 parts of ultraviolet absorbent, 5-10 parts of maleic anhydride graft compatilizer and 1.5-4.5 parts of lubricant. The invention also discloses a preparation method of the wire cable material and a low-smoke halogen-free irradiation-crosslinked wire cable prepared from the wire cable material. The low-smoke halogen-free irradiation-crosslinked wire cable material and wire cable are free of halogen elements, and have the characteristics of high flame retardancy, and low smoke and no toxicity during combustion. The MLLDPE and EVA are compounded to enhance the compatibility between the base and inorganic filler, and thus, the wire cable material has excellent mechanical properties. The wire cable material has the characteristics of high temperature resistance, aging resistance and the like. The preparation method of the wire cable material and wire cable is simple and easy to implement, and is suitable for industrial production.

Owner:GUANGDONG HUASHENG ELECTRICAL APPLIANCES CO LTD

A surface treatment process of wall decorative board

InactiveCN101531114AStrong adhesionWear-resistantDecorative surface effectsPretreated surfacesCalcium silicateCement board

The invention relates to a surface treatment process of wall decorative board, which takes one of the fiber-reinforced calcium silicate board, fiber cement board, fiberglass magnesium oxide board or the like as a substrate, firstly coats an UV coating on the surface of the substrate, and performs dust exhaustion and sanding to the cured surface; re-coating PU or UV white bottom; and then performs dust exhaustion and sanding to the surface; and then coats PU or UV glue again on the surface, uses low-temperature heat-transferring technology to transfer the pattern on the heat-transferring die to the surface; finally, coats a UV protective coating on the surface of the transferred pattern. This wall decorative board has high-grade, wear-resistance, anti-aging, non-susceptibility to contamination, good fire prevention and waterproof performance.

Owner:黄醒帆

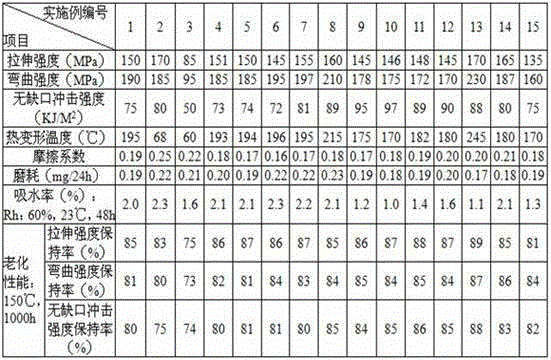

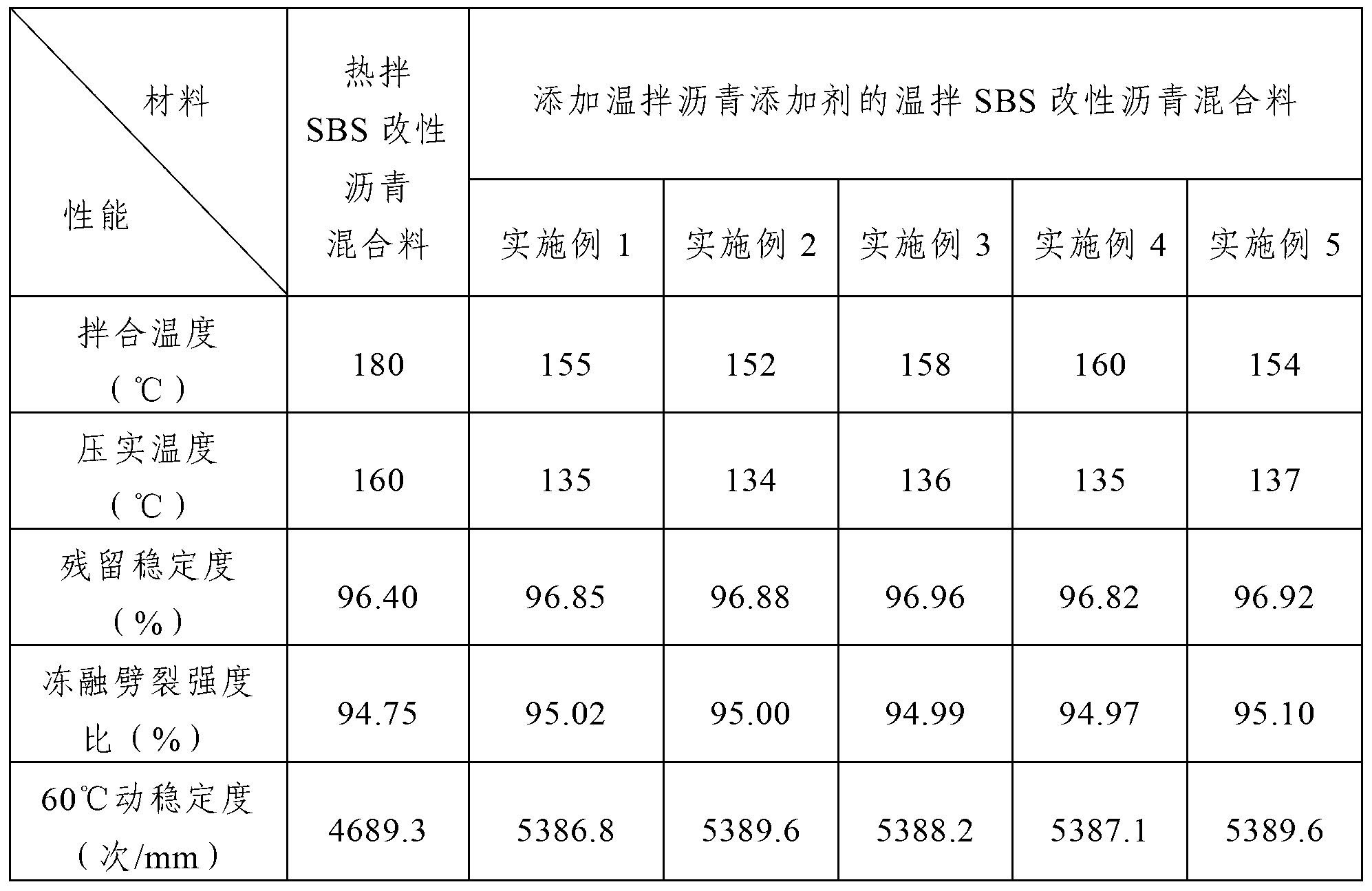

Warm mix asphalt additive and preparation method thereof

ActiveCN103242666AReduce high temperature viscosityReduce the temperatureClimate change adaptationBuilding insulationsChlorinated paraffinsBall mill

The invention provides a warm mix asphalt additive which is prepared from the following raw materials in parts by weight: 15-20 parts of polyethylene wax, 15-20 parts of chlorinated paraffin-70, 30-50 parts of kieselguhr, 1-3 parts of stearamide and 1-4 parts of solid anti-striping agent. The invention further provides a method for preparing the warm mix asphalt additive. The method comprises the following steps of: both grinding the polyethylene wax and stearamide into micro-powder, and subsequently putting the chlorinated paraffin-70, kieselguhr, the solid anti-striping agent and the grinded polyethylene wax and stearamide into a high-speed ball mill to be milled so as to obtain the warm mix asphalt additive. By utilizing the warm mix asphalt additive, the mixing and compressing temperature of an asphalt mixing material can be decreased by more than 20 DEG C on the premise that the property of the asphalt mixing material is not affected, so that the warm mix asphalt additive can be widely applied to asphalt mixing material construction in areas of different climates.

Owner:辽宁奥鹏交通科技集团股份有限公司

Scraping coating type polyurea elastomer corrosion-resistant and wear-resistant material and preparation method thereof

ActiveCN105802460AHigh mechanical strengthAnti-corrosion and wear-resistantAnti-corrosive paintsPolyurea/polyurethane coatingsElastomerEnd-group

The invention discloses a scraping coating type polyurea elastomer corrosion-resistant and wear-resistant material and a preparation method thereof. The scraping coating type polyurea elastomer corrosion-resistant and wear-resistant material is characterized by comprising an ingredient A and an ingredient B, wherein the ingredient A is prepolymers with NCO end groups obtained through the reaction between 30 to 40 mass percent of polyether polyol and 60 to 70 mass percent of polyisocyanates; the ingredient B is prepared from 30 to 40 mass percent polyaspartic acid ester, 60 to 70 mass percent of filling materials and a small number of auxiliary agents through high-speed dispersion grinding. In the use process, the prepared ingredient A and the prepared ingredient B are weighed according to the weight ratio of 1:4, and are then uniformly mixed; next, scraping coating construction is performed. The material has the characteristics of high mechanical intensity, corrosion resistance, wear resistance, good anti-seeping performance, aging resistance, proper reaction speed, no solvent, convenient construction and the like. The scraping coating type polyurea elastomer corrosion-resistant and wear-resistant material is particularly suitable for industrial and mining enterprise equipment and spare part anti-corrosion wear-resistant liners.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Modified urea-formaldehyde powder adhesive

InactiveCN1542074AReduce sizing costsHigh bonding strengthAldehyde/ketone condensation polymer adhesivesStrong acidsToughening

The modified urea-formaldehyde powder adhesive for adhering wood product mainly is prepared by using spray dried pure urea-formaldehyde powder or melamine-urea-formaldehyde powder as base material; composite curing agent comprising amine salt of strong acid, organic acid and maleic anhydride; fine water soluble vinyl resin powder, tanning extract and coconut shell powder as toughening, antiageing and free aldehyde absorbing additive; and certain amount of corn powder, gypsum powder and flour as stuffing, and through mixing. The modified urea-formaldehyde powder adhesive has the advantages of high strength, high toughness, ageing resistance, water resistance, chemical corrosion resistance and environment friendship.

Owner:SHANGHAI UNIV

Plastic boat production method

InactiveCN101380990AReduce weightImpact resistantNon-magnetic metal hullsPolytetramethylene terephthalateGlass fiber

The invention discloses a production method used for a plastic ship; the ship material of the plastic ship is polypropylene (PP) or flame retardant PP, modified PP, polycarbonate (PC), flame retardant PC, anti-aging ABS, PC / ABS alloy, PVC, PET, PBT, PPS, PA, glass fiber reinforced nylon and the like; the seat lining material on the plastic ship can be expandable polystyrene foam and the covering material thereof is PP; the quant head material is PP; the quant rod material is PP; the production method of the plastic ship has three types: mold forming method, cutting and welding forming method and injection molding method; the plastic ship has the advantages of light weight, anti-collision, anti-corrosion, anti-aging, convenient carrying and low production cost, and can be widely applied to the fields such as military affairs, succor, on-water motion, on-water game, and the like.

Owner:刘凤勇

Macromolecule composite metal healant and preparation and use method

The invention discloses a macromolecule composite metal healant containing two components which are separately prepared and are used together. The invention also discloses preparation and use methods of the macromolecule composite metal healant. The macromolecule composite metal healant has the following advantages: 1, the material after being cured has high strength and can be used for various mechanical reprocessing; 2, the macromolecule composite metal healant has high combination strength with metal and composite materials; the macromolecule composite metal healant has wide application range, and is suitable for repairing and reproducing various metal materials with defects; the macromolecule composite metal healant has the characteristics of resisting against abrasion, aging, high temperature, oil, weak acid-base media and the like; 5, no micromolecule is volatilized during the curing period, and the solid has no shrink. The preparation process disclosed by the invention is simple and easy to implement and is favorable for scale production.

Owner:CHENGDU YUEDING TECH

Two-layer co-extruding plastic drainage pipe and preparation method thereof

The invention relates to the plastic pipe field, in particular to a two-layer co-extruding plastic drainage pipe used outdoors. The drainage pipe contains an inner layer and an anti-aging outer layer, wherein the inner layer comprises the following components in parts by weight: 90-110 parts of polyvinyl chloride resin, 3.5-4.8 parts of composite stabilizer, 3-8 parts of impact modifier, 0.2-0.5 part of stearic acid, 0.2-0.6 part of calcium stearate, 0.3-0.6 part of AC foaming agent, 4-8 parts of foaming regulator ZB530, 5-40 parts of calcium carbonate, 0.4-1.0 part of polyethylene (PE) wax and 0.3-0.8 part of lead stearate. The outer layer of the drainage pipe is the anti-aging layer, thus the aging resistant problem can be solved. The inner layer adopts the foaming technology, thus the overall weight of the drainage pipe can be reduced, the impact resistance of the pipe can be increased, the pipe has the effect of sound insulation and the cost of the drainage pipe can be reduced. In addition, the invention also discloses a preparation method of the two-layer co-extruding plastic drainage pipe.

Owner:GUANGDONG LIANSU TECH INDAL

High-durability concrete shield system capable of rapid construction and preparation method thereof

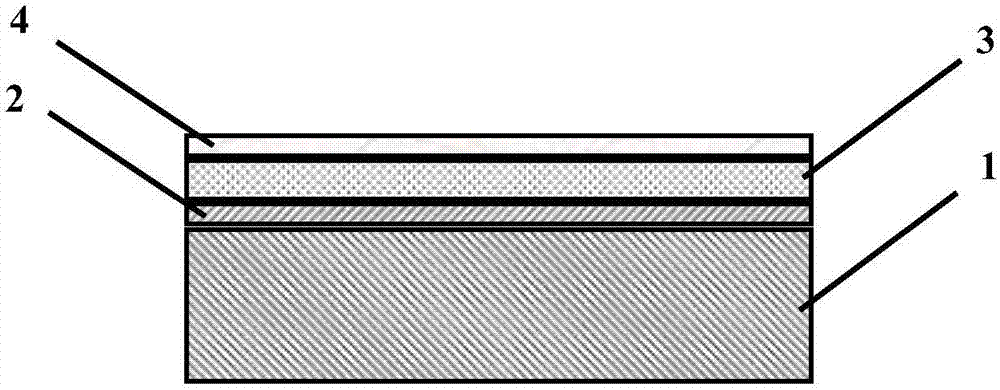

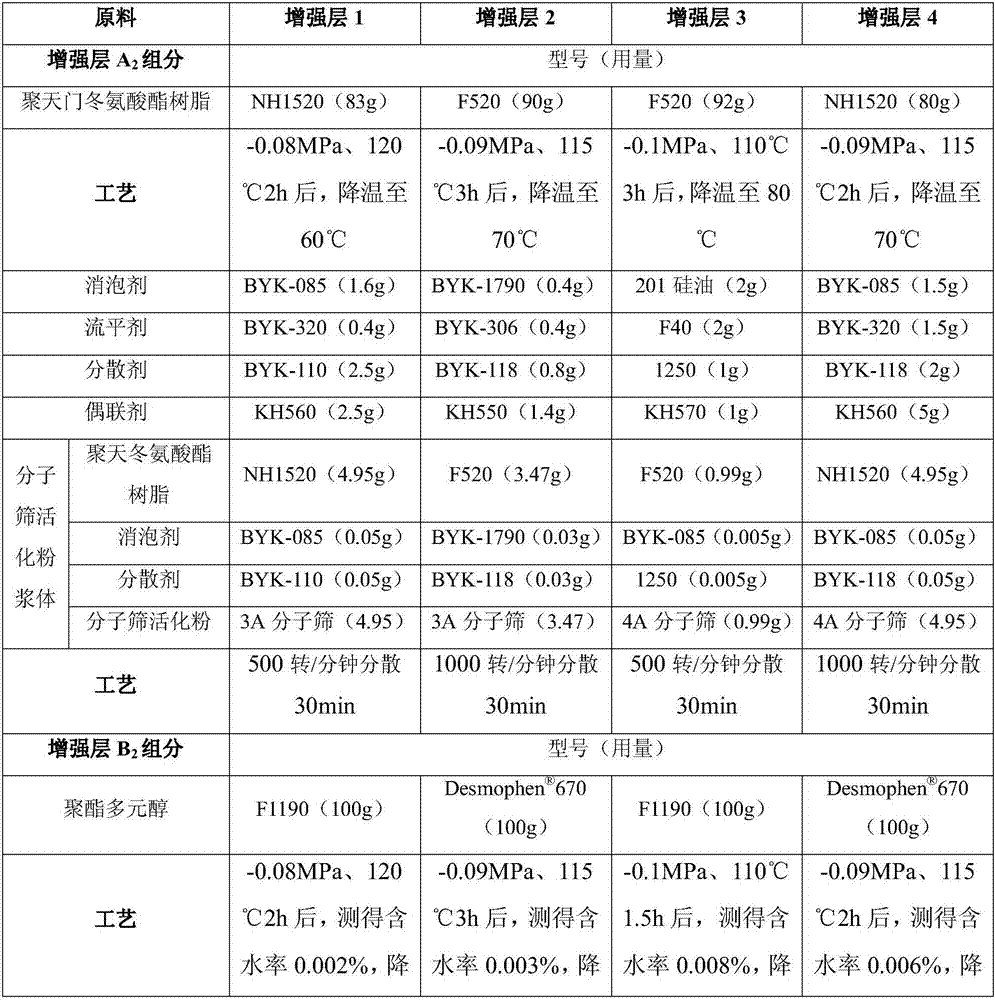

ActiveCN107337993AFast curing rateImprove adaptabilityPolyurea/polyurethane coatingsLow temperature curingEngineering

The invention discloses a high-durability concrete shield system capable of rapid construction and a preparation method thereof. The concrete shield system comprises a concrete base layer, a polyaspartate permeation primer layer, a polyaspartate elasticity enhancement layer and a fluorine-silicon-modified polyaspartate high-weather-resistance finish paint layer from bottom to top. Compared with the prior art, the system has the advantages of short construction cycle, high weather resistance and the like, can be constructed on a wet basal plane, can implement construction within one day and low-temperature curing, has the multiple functions of high mechanical strength, fatigue resistance, aging resistance, high elasticity, corrosion resistance and the like, and has the characteristics of simple construction, high safety and environment friendliness.

Owner:辽宁苏博特船牌制漆有限公司 +2

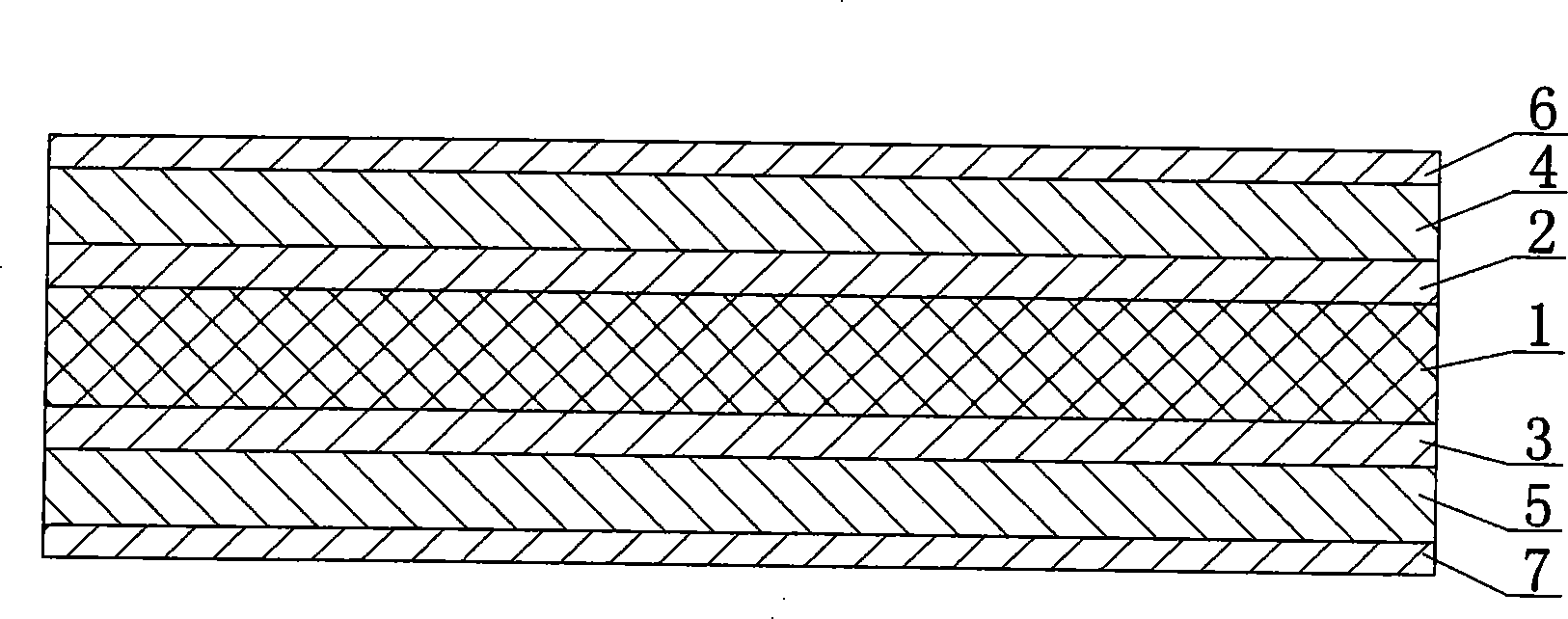

Knife-scrapping coating tent cloth and preparation process thereof

ActiveCN103317805AWaterproofAntifoulingNon-macromolecular adhesive additivesSynthetic resin layered productsUltravioletPolyvinyl chloride

The invention discloses knife-scrapping coating tent cloth. The knife-scrapping coating tent cloth sequentially comprises a basic cloth layer, an adhesion layer, a shading layer and a surface layer from inside to outside, wherein the adhesion layer is prepared from polyvinyl chloride paste resins, plasticizers, stabilizers, inorganic flame retardant and mould inhibitors; the shading layer is prepared from polyvinyl chloride of which the k value is 80, plasticizers, stabilizers, inorganic flame retardant, carbon black pigment color pastes, ultraviolet absorbent and mould inhibitors; the surface layer is prepared from polyvinyl chloride of which the k value is 85, plasticizers, acrylic ester, inorganic flame retardant and methylbenzene. The knife-scrapping coating tent cloth has the excellent performances of waterproofing, antifouling, inflame retardance, anti-aging and the like, is high in tearing resistant performance and extremely high in peeling strength, and has high self-cleaning and excellent uvioresistant functions. The knife-scrapping coating tent cloth is high in product performance and long in service life, and the requirement of clients is met.

Owner:GUANGDONG UPAL DISPLAY TECH CO LTD

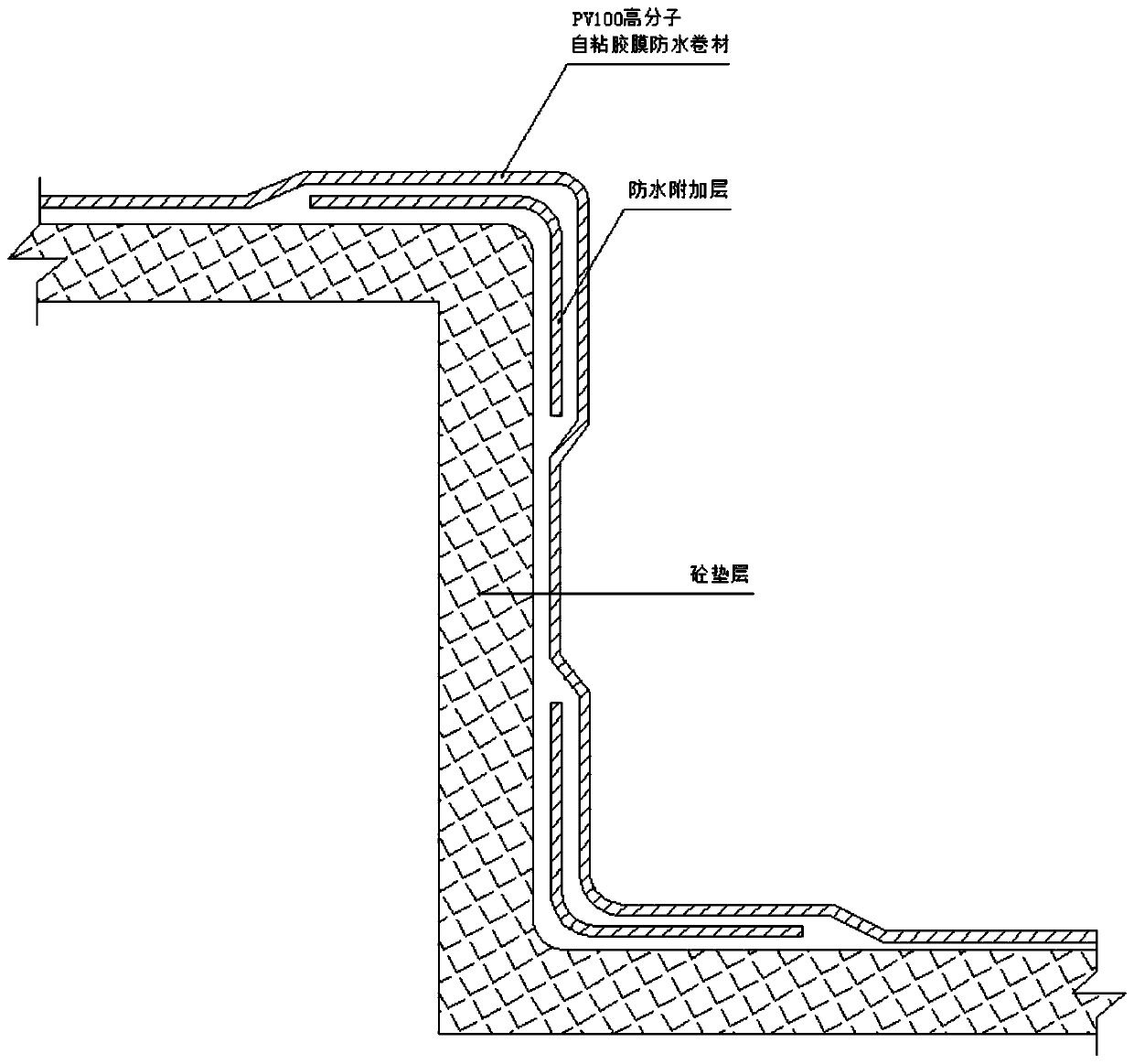

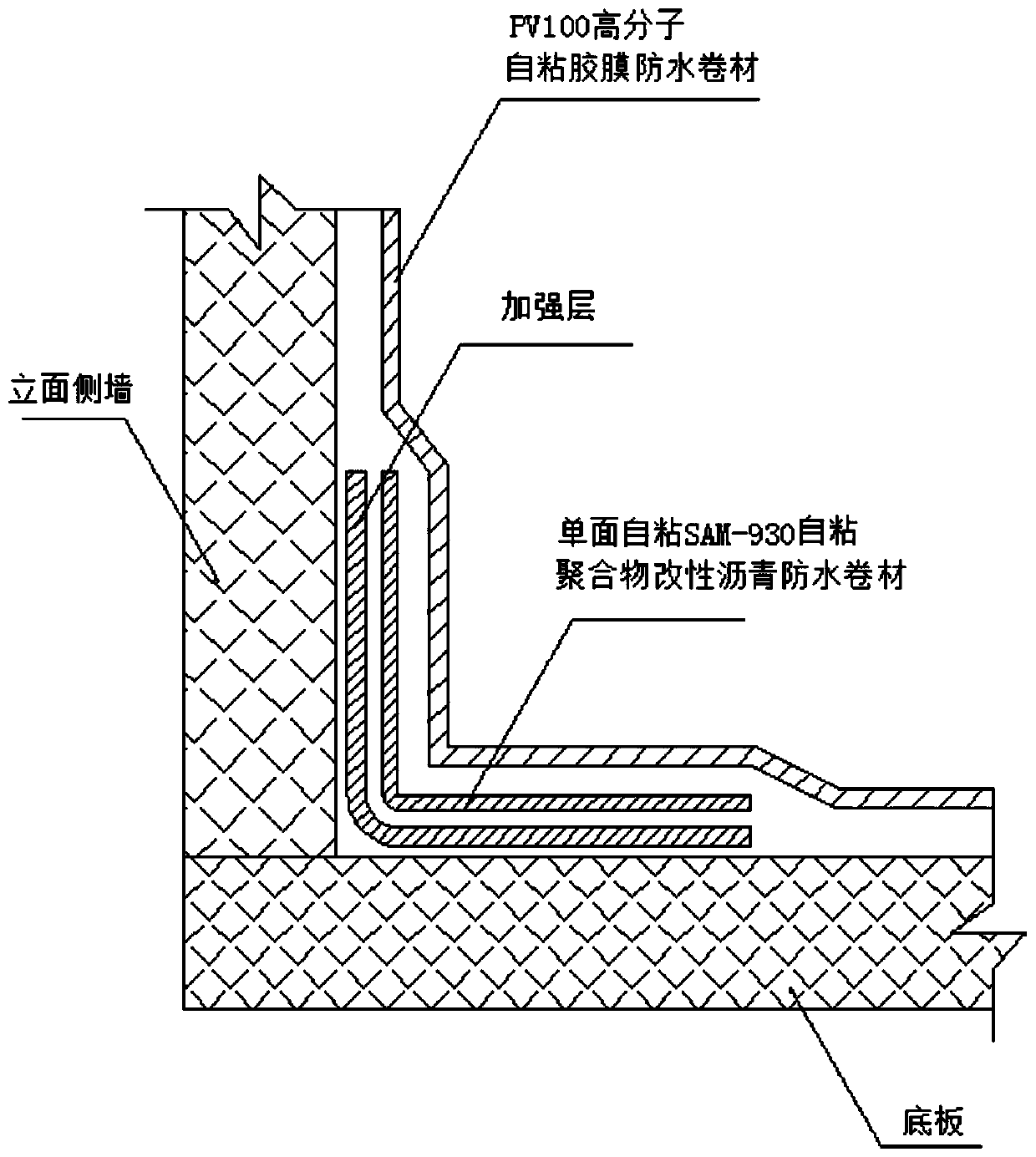

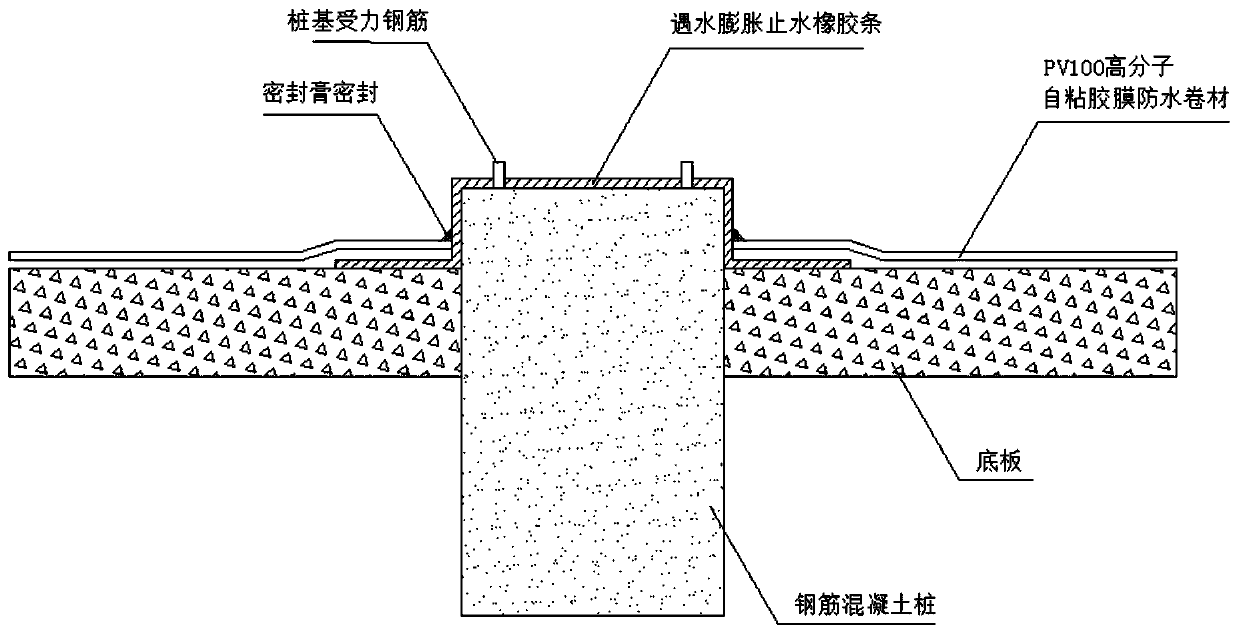

Waterproofing construction method for basement of building engineering

ActiveCN110607809AImprove waterproof performanceStrong toughnessProtective foundationGasketsBasementReinforced concrete

The invention discloses a waterproofing construction method for a basement of building engineering. The method comprises the following steps: S1, dust, sundries, oil stains and visible water on the surface of a base are cleared to make the surface flat and clean; S2, a control line for coil laying is released on the base, so as to accurately control the laying position and lap width of a coil andprevent dislocation, deflection and the like during coil laying; S3, on the basis of foundation treatment and elastic line positioning, construction of 1:2.5 waterproofing mortar is conducted on internal and external corners, the internal and external corners shall be round corners, and R of the arc of the internal and external corners is larger than or equal to 50. Waterproofing performance of inner reinforced concrete is strengthened by the PV100 waterproofing coil, and the PV100 waterproofing coil can form continuous and permanent full adhesion combination with poured concrete, so that water channeling is effectively prevented; the waterproofing coil is tightly adhered to the structure, cannot be affected by uneven settlement of the base, and construction of the next process can be directly performed without construction of a protective layer.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

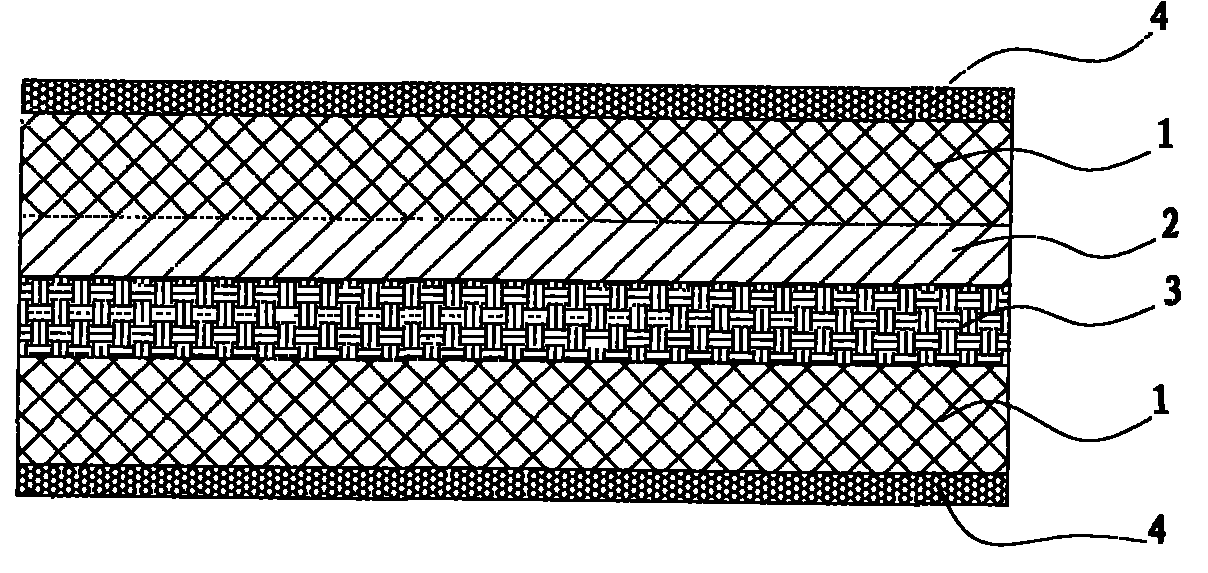

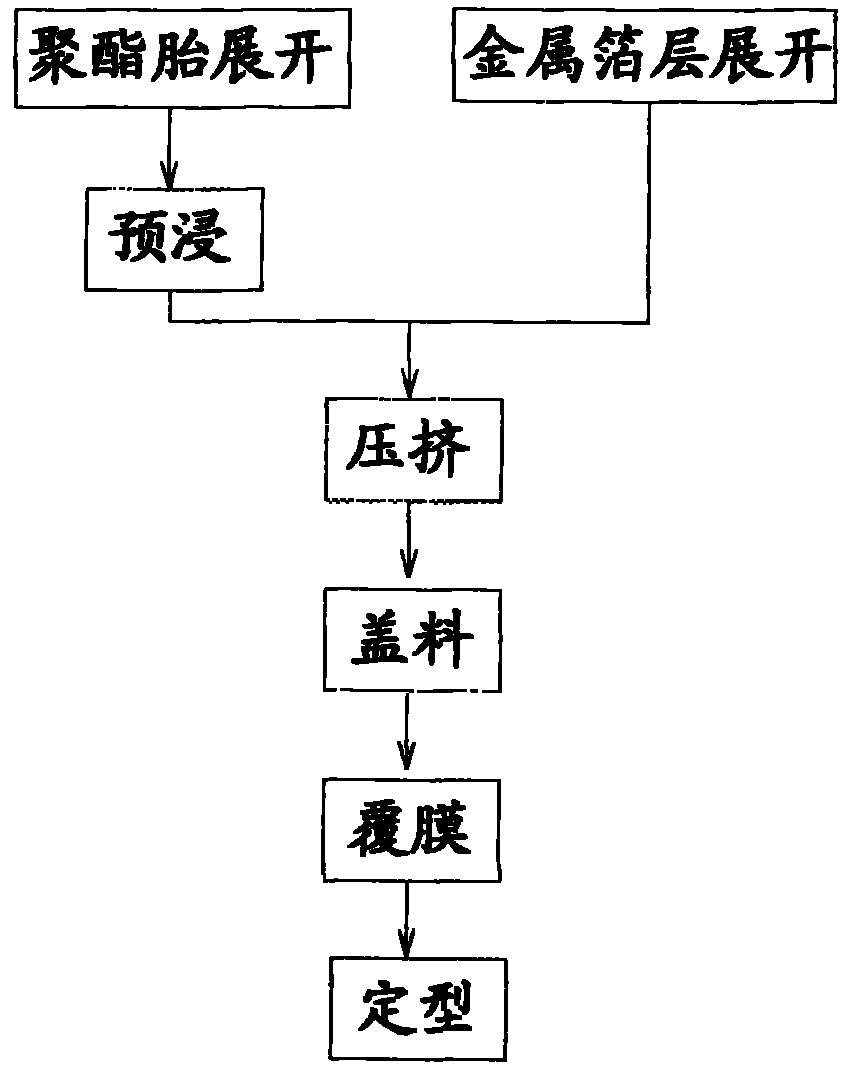

Root thorn-proof and waterproof coiled material and preparation technology

InactiveCN101818548APrevent penetrationDoes not affect growthLamination ancillary operationsRoof covering using flexible materialsPolyesterBituminous waterproofing

The invention provides a root thorn-proof and waterproof coiled material, which comprises a modified asphalt waterproof layer, a metal foil layer and a polyester tire, which are composited together. The polyester tire is presoaked by special modified asphalt. The root thorn-proof and waterproof coiled material is formed by the composite of the modified asphalt waterproof layer, the metal foil layer and the polyester tire, wherein the polyester tire is presoaked by the special modified asphalt, so that the root thorn-proof and waterproof coiled material has double functions of the water resistance and the penetration resistance of plant roots, can prevent from being penetrated by plant root hairs, and keeps the waterproof function for a long time.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com