Heat preserving really stone paint and preparation method thereof

A technology of real stone paint and silicone acrylic emulsion, which is applied in the direction of coating, etc., can solve the problems of real stone paint insulation performance reduction, poor construction performance, poor water resistance, etc., achieve stain resistance and temperature change resistance, simple preparation method, and improve comprehensive performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

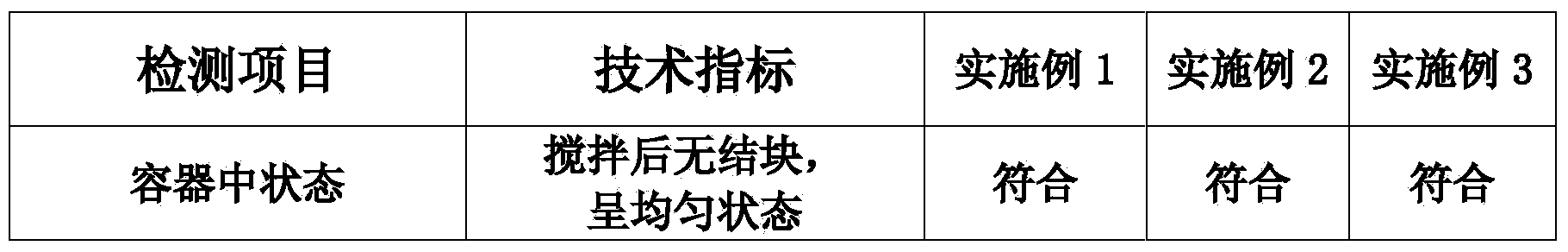

Embodiment 1

[0036] The thermal insulation real stone paint adopts the following components by weight: 200 parts by weight of tap water, 1 part by weight of preservative benzoic acid, 5 parts by weight of hydroxyethyl cellulose, 5 parts by weight of wetting and dispersing agent sodium polycarboxylate, antifreeze stabilizer propylene glycol 15 parts by weight, 8 parts by weight of film-forming agent polyvinyl alcohol, 150 parts by weight of silicon-acrylic emulsion, 450 parts by weight of natural colored sand, and 150 parts by weight of hollow glass microspheres.

[0037]Its preparation method comprises the following steps:

[0038] Put tap water and preservative into the paint tank, stir with a mixer at a speed of 1000 rpm, add hydroxyethyl cellulose while stirring, until the hydroxyethyl cellulose is fully swollen, the time is 25 minutes, and then add wetting Dispersant, antifreeze stabilizer, film-forming agent and stir at the same speed, then add silicone acrylic emulsion, natural color...

Embodiment 2

[0042] The thermal insulation real stone paint adopts the following components by weight: 220 parts by weight of tap water, 1.5 parts by weight of preservative sorbic acid, 7 parts by weight of hydroxyethyl cellulose, 6 parts by weight of wetting and dispersing agent polyoxyethylene, antifreeze stabilizer ethylene glycol 18 parts by weight of alcohol, 10 parts by weight of film-forming agent polyvinyl alcohol, 180 parts by weight of silicon acrylic emulsion, 480 parts by weight of natural colored sand, and 180 parts by weight of hollow glass microspheres.

[0043] The preparation method and construction method are basically the same as in Example 1, the difference is that in the preparation method, the rotation speed of the mixer is 1100 rpm, the swelling time of hydroxyethyl cellulose is 28 minutes, and the stirring time after adding the silicon-acrylic emulsion is 30 minutes.

Embodiment 3

[0045] The thermal insulation real stone paint adopts the following components by weight: 250 parts by weight of tap water, 2 parts by weight of preservative methyl paraben, 8 parts by weight of hydroxyethyl cellulose, and 7 parts by weight of wetting and dispersing agent nonylphenol polyoxyethylene ether , 25 parts by weight of antifreeze stabilizer propylene glycol, 12 parts by weight of film-forming agent sodium alginate, 200 parts by weight of silicon-acrylic emulsion, 500 parts by weight of natural colored sand, and 200 parts by weight of hollow glass microspheres.

[0046] The preparation method and construction method are basically the same as in Example 1, the difference is that in the preparation method, the rotation speed of the mixer is 1200 rpm, the swelling time of hydroxyethyl cellulose is 30 minutes, and the stirring time after adding the silicon-acrylic emulsion is 30 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com