Patents

Literature

900results about How to "Low temperature resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

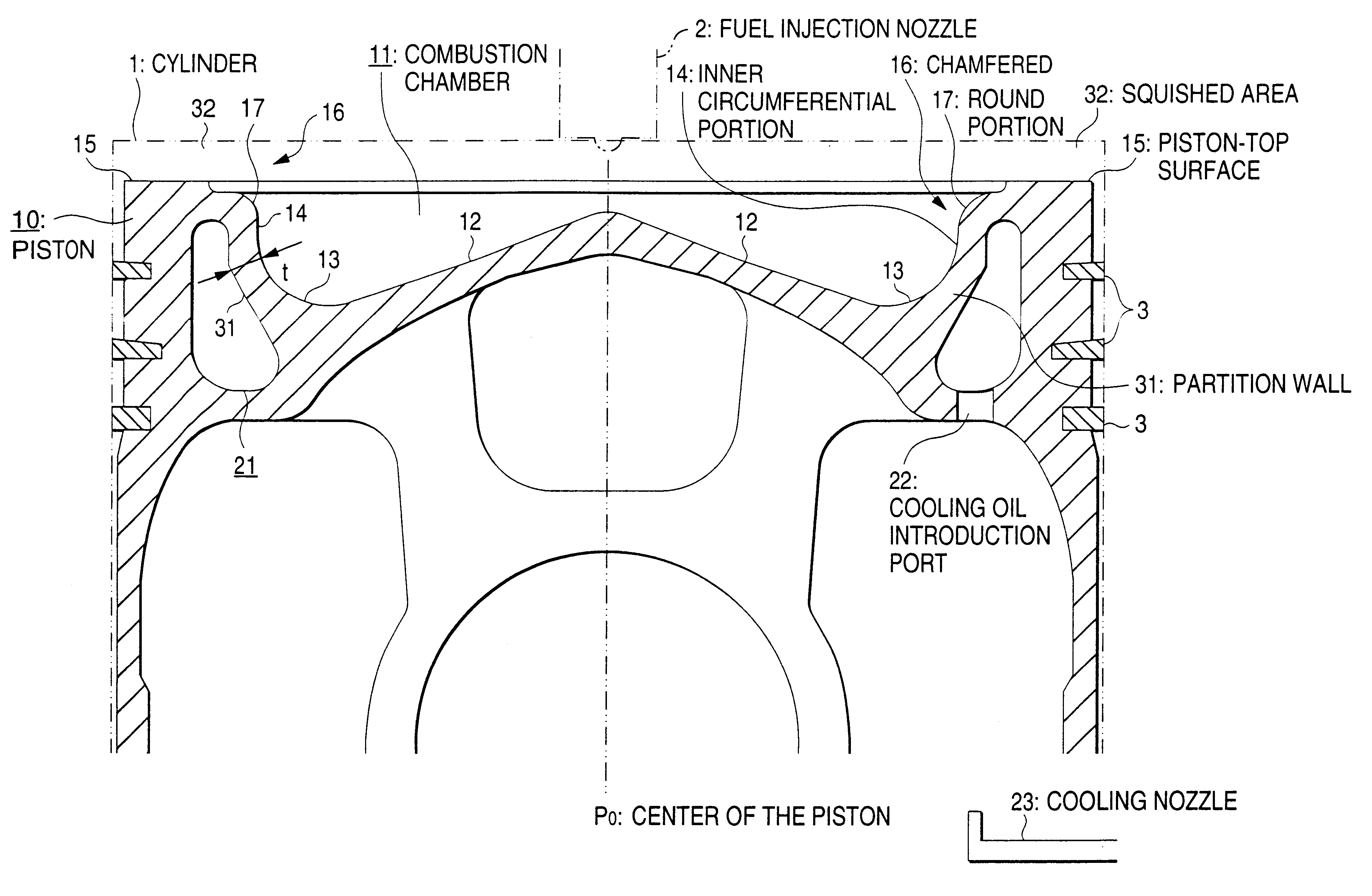

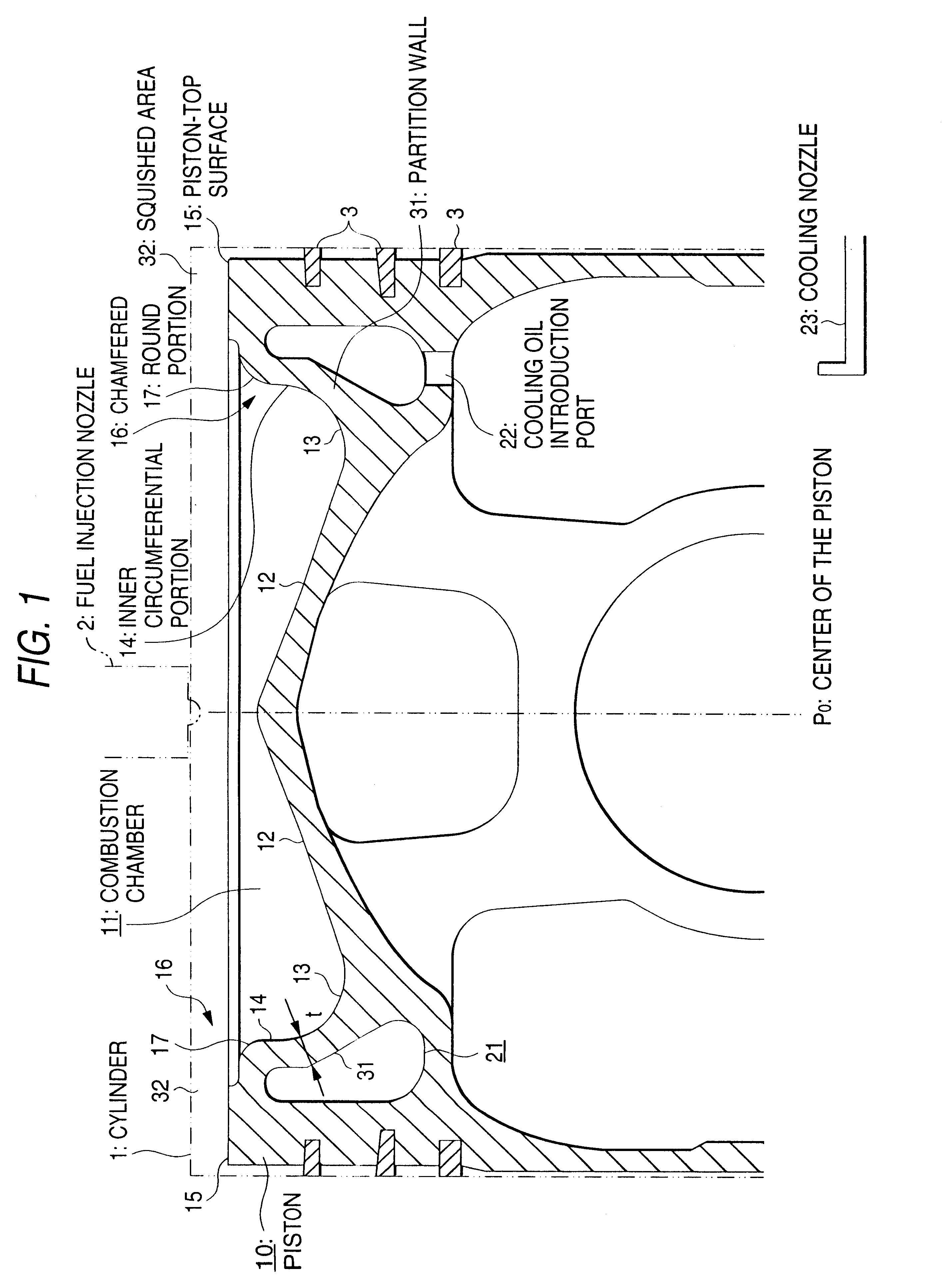

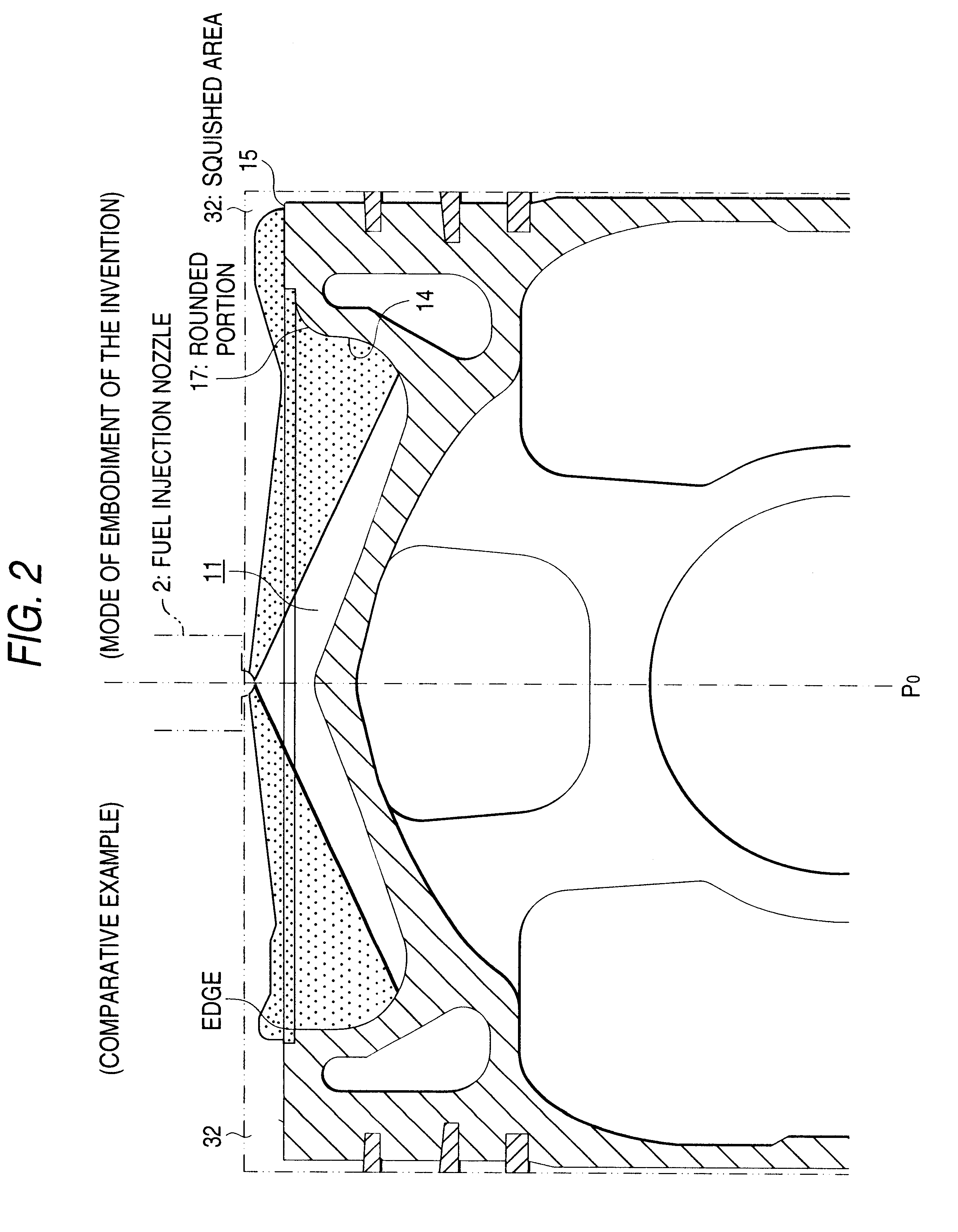

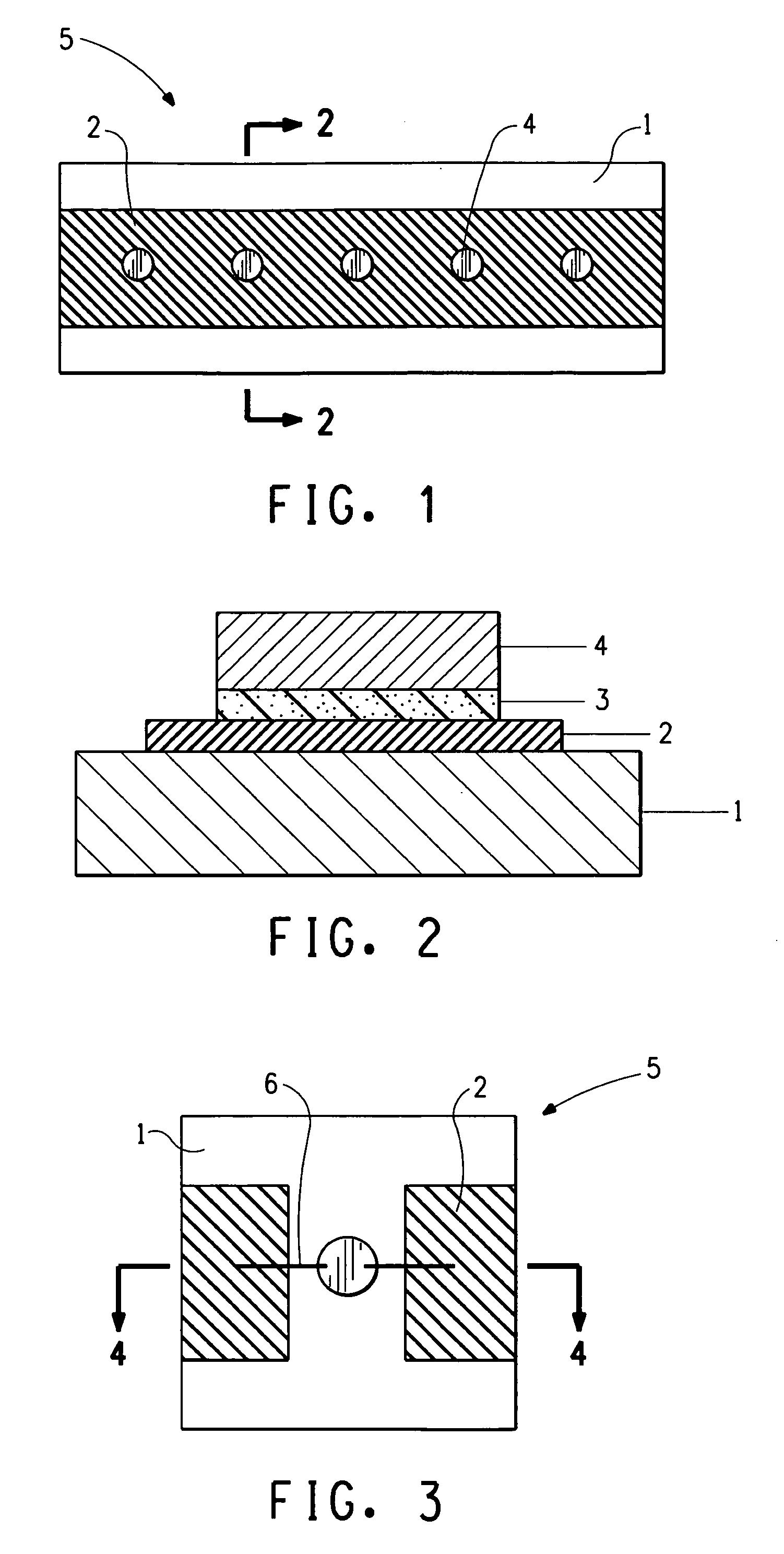

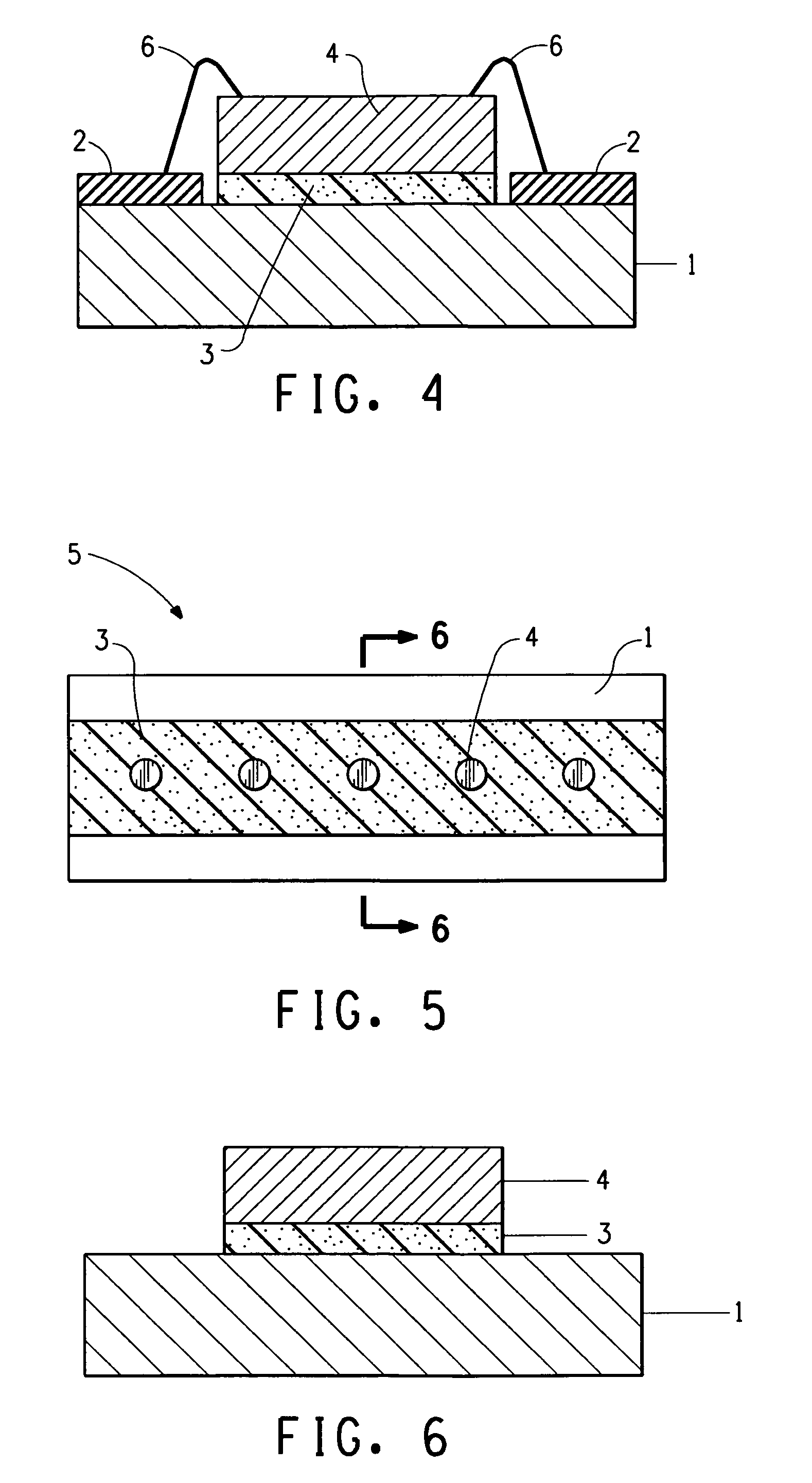

Piston for internal combustion engines

InactiveUS6314933B1Low temperature resistanceIncreased durabilityInternal combustion piston enginesAir coolingCombustion chamberReciprocating motion

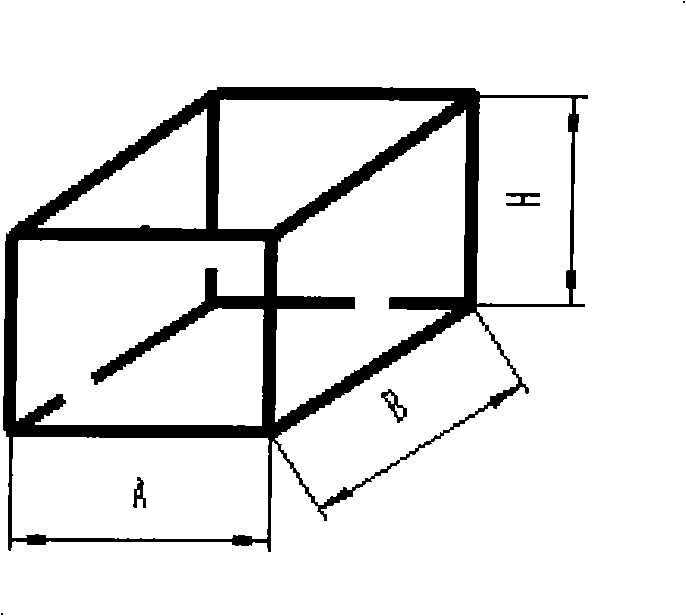

A piston for internal combustion engines, capable of being manufactured easily and improving the durability of a combustion chamber, moved reciprocatingly in a cylinder of an internal combustion engine, and provided in a top surface thereof with a combustion chamber formed by recessing the same top surface, and in an outer circumferential wall of the combustion chamber with a cooling cavity the inner diameter of a lower portion of an inner circumferential surface of which is set smaller than that of an upper portion thereof, wherein a cross-sectionally angular portion defined by an upper edge portion, at which the combustion chamber is opened in the interior of a cylinder, of an inner circumferential surface of the combustion chamber and a piston-top surface is chamfered greatly in conformity with the cross-sectional shape of the upper portion of the inner circumferential surface of the cooling cavity to such an extent that the thickness of an upper portion of an inner circumferential wall of the cooling cavity does not greatly vary.

Owner:KOMATSU LTD

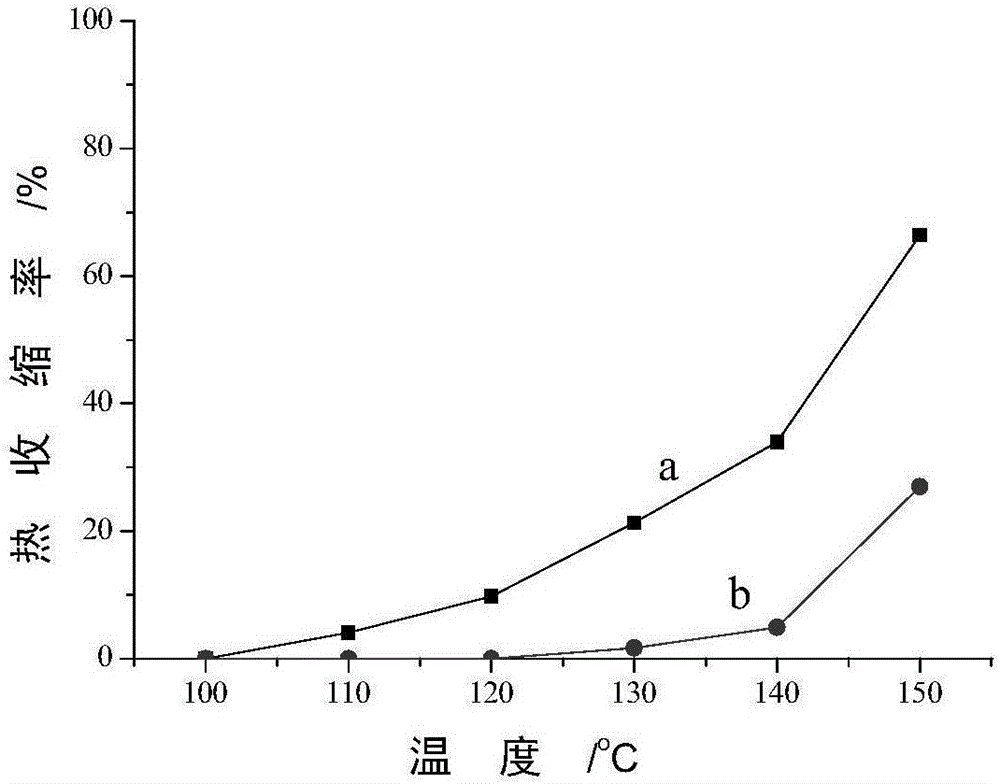

Trilaminar co-extrusion thermal contraction resin film, manufacturing method and application method thereof

InactiveCN101318392AReduce pollutionReduce packaging costsWrappers shrinkageSynthetic resin layered productsThermal contractionPuncturing

The invention discloses a three-layer coextrusion heat shrinkage resin film, a production method and an application method. The-three layer coextrusion heat shrinkage resin film is produced by taking PE(LDPE, HPPE, LLDPE, mPE), EVA, PP, PA and EVOH resins as the main materials which are matched with a functional master batch and adopting a production method of one-step huffing. The largest transverse and longitudinal shrinking rates of the product can reach 60 percent and 85 percent; the largest shrinking force of the product can reach 2.0N / cm. The shrinking rate and the shrinking force of the product can be controlled and adjusted by controlling various technical parameters to lead a package to be firm and endurable. The packaged objects are pertinently led to reach the anti-rust, anti static, illumination-resistance, anti-aging, anti-puncturing, anti-low-temperature, anti-isolation, anti-bacteria and anti-degradation effects and the like by adjusting the material composition and mixture ratio of each layer. The three-layer coextrusion heat shrinkage resin film is used for replacing the traditional paper box wrappage to reduce the packaging cost. The mechanical properties are good, the pertinence is strong, the materials are saved; when the three-layer coextrusion heat shrinkage resin film is used, the shrinking temperature is low, the power is saved and the packaging cost is saved, thus effectively reducing the production cost and having extremely high application value.

Owner:大连华诺塑胶科技有限公司

Laminating propylene/1-butene random copolymer composition and composite film using the same

InactiveUS6214447B1Good molding effectLow-temperature propertiesSynthetic resin layered productsDomestic articlesLow-density polyethyleneComposite film

A laminating propylene / 1-butene random copolymer composition comprising a propylene / 1-butene random copolymer and a low-density polyethylene in a specified proportion. With respect to the propylene / 1-butene random copolymer, the content of structural units derived from propylene, content of structural units derived from 1-butene, MFR, Mw / Mn and B-value as a parameter indicating the randomness of copolymer monomer chain distribution fall within specified ranges. With respect to the low-density polyethylene, the MFR and density fall within specified ranges. The invention also provides a composite film comprising a substrate film such as a crystalline polypropylene film and, laminated onto at least one side thereof, a resin layer of the above composition having a thickness of 2 to 200 mum. The above composition is excellent in laminate moldability and enables producing a composite film having excellent low-temperature sealing properties, blocking resistance and hot tack. The composite film is characterized by having excellent low-temperature sealing properties, blocking resistance, slip properties and hot tack.

Owner:MITSUI CHEM INC

Water-based environment-friendly finishing paint and preparation method thereof

InactiveCN101712833AGood anti-corrosion decoration effectHigh hardnessEpoxy resin coatingsWater basedEpoxy

The invention discloses a water-based environment-friendly finishing paint, which is prepared from the following compositions in part by weight: 20 to 70 parts of water borne acrylic resin solution of which the solid content is 30 to 80 percent and / or 20 to 70 parts of water borne epoxy resin solution of which the solid content is 30 to 80 percent, 4 to 10 parts of water borne amino resin solution of which the solid content is 60 to 98 percent; 1 to 5 parts of organic amine, 0.2 to 2 parts of wetting and leveling agent, 0.2 to 2 parts of thickener, 0.1 to 0.8 part of defoaming agent, 1 to 5 parts of adhesion promoter, 0.2 to 5 parts of catalyst, 10 to 30 parts of alcohol diluting solvent and / or 1 to 5 parts of nontoxic ether diluting solvent, and 20 to 50 parts of deionized water, wherein the catalyst is one or more of ammonias, alcohols and benzenesulfonic acids. The water-based environment-friendly finishing paint has the advantages of wide applicable range, high hardness, good flexibility, strong adhesion, good scratchproof performance, and environmental protection. Simultaneously, the invention also discloses a method for preparing the water-based environment-friendly finishing paint.

Owner:重庆亢石新材料科技有限公司

Highly wear-resistant elastomer sole material and preparation method thereof

The present invention discloses a highly wear-resistant elastomer sole material, which comprises the following raw materials: a SBS rubber elastomer, a softening plasticizer, a thermoplastic polyurethane elastomer, a polyolefin elastomer, ethylene propylene diene monomer, a polystyrene resin, a styrene-butadiene rubber, a filler, an antioxidant, a light stabilizer and a processing aid. The invention further discloses a preparation method of the highly wear-resistant elastomer sole material. According to the present invention, the formula of the highly wear-resistant elastomer sole material is reasonable, the thermoplastic elastomer SBS is adopted as the substrate, and the highly wear-resistant elastomer sole material has advantages of high elasticity, high wear resistance, low compression deformation, weather resistance, low temperature resistance, excellent mechanical property, extremely easy extrusion processing molding, and the like; and the preparation method has characteristics of simple process, easy achieving and high production efficiency, and can quickly produce the highly wear-resistant elastomer sole material product, and the product can be widely used in the fields of sports shoes and casual shoes.

Owner:DONGGUAN JISU PLASTIC TECH

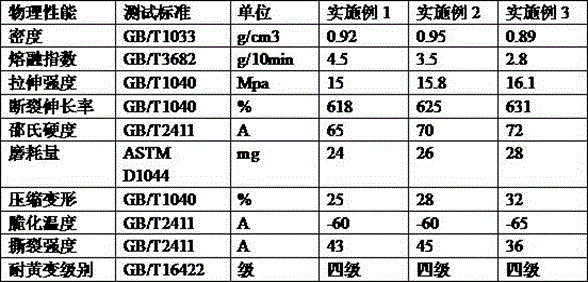

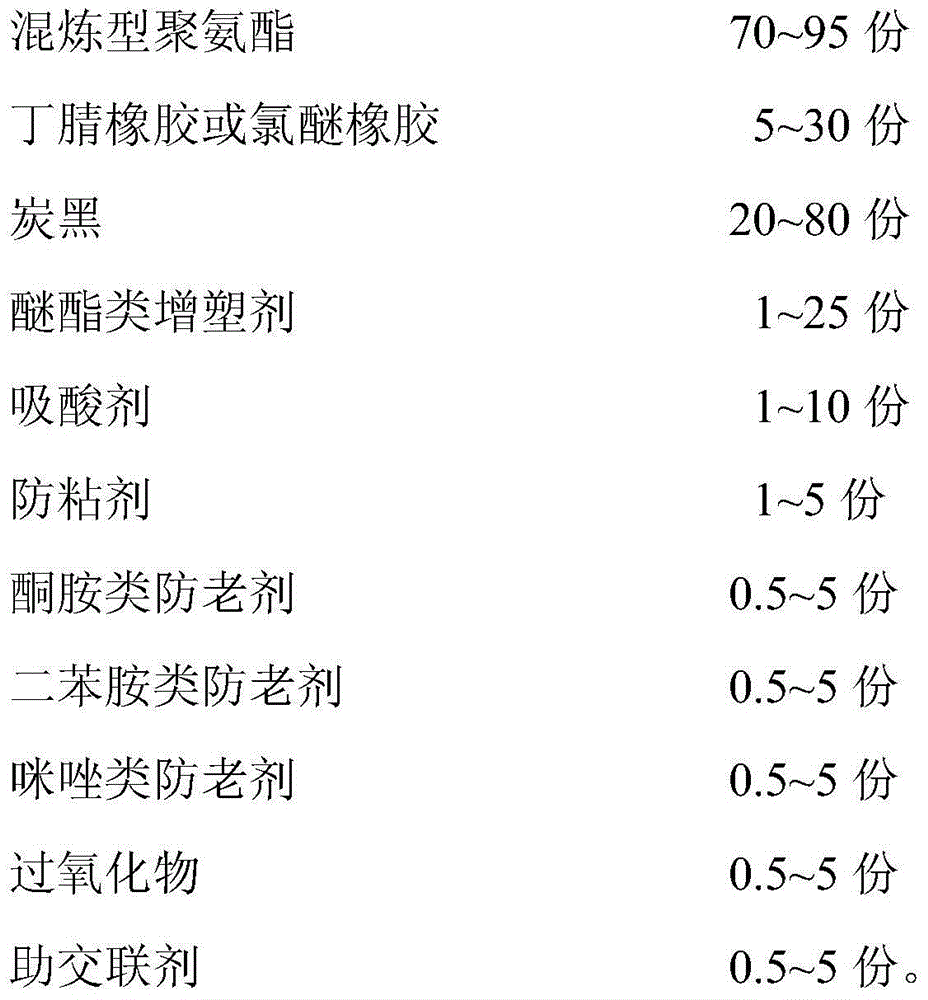

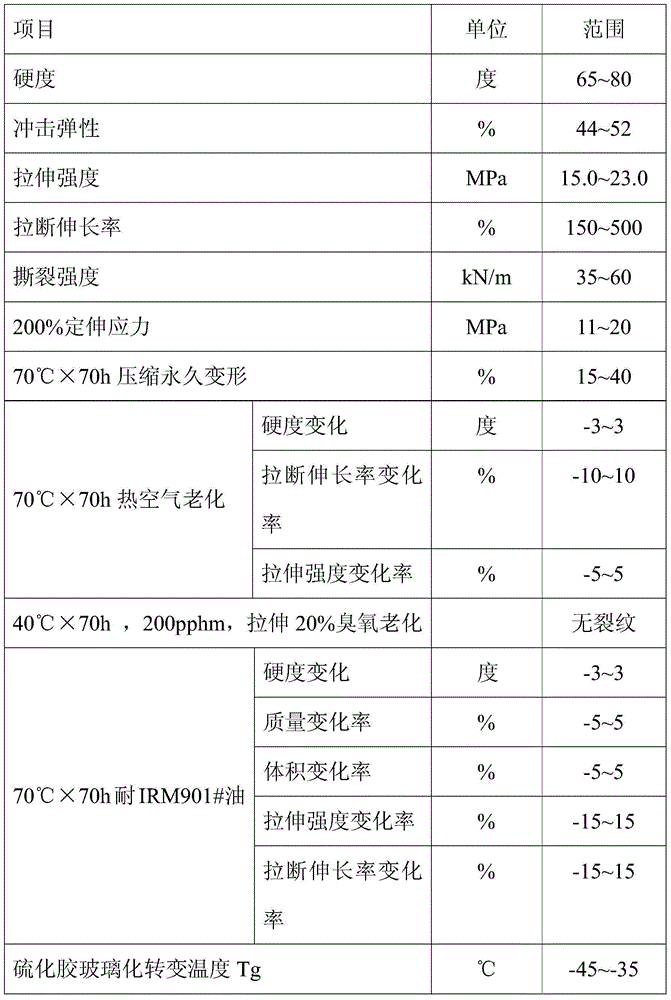

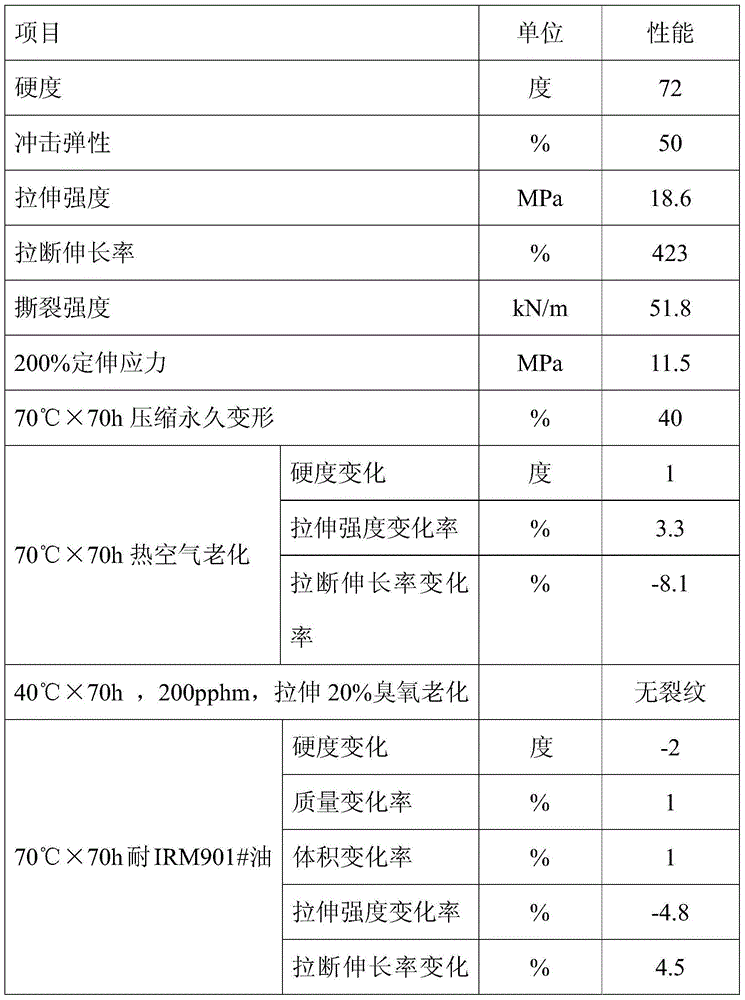

Oil-resistant low-temperature-resistant weather-proof rubber sealing material and preparation method and application thereof

ActiveCN104086980AGood oil resistanceImprove low temperature resistanceOther chemical processesPolymer scienceGlass transition

The invention belongs to the technical field of high molecular material, and discloses an oil-resistant low-temperature-resistant weather-proof rubber sealing material and a preparation method thereof. The rubber sealing material is prepared by taking millable polyurethane as a main material, adopting a small amount of nitrile rubber or epichloro-hydrin rubber, cooperatively adding a reinforcing agent, a plasticizer, an anti-sticking agent, a mold-release agent, an acid absorbing agent, a ketoamine anti-aging agent, a diphenylamine anti-aging agent, an imidazole anti-aging agent, a peroxide, an auxiliary cross-linking agent and other auxiliary materials, and mixing through an open mill or an internal mixer. A sealing product prepared by the rubber sealing material has better balance between low-temperature resistance and oil resistance, enables the glass transition temperature Tg to reach -40 DEG C or less, has excellent weather aging resistance performance, also has good comprehensive performance, and is long in service life.

Owner:GUANGZHOU MECHANICAL ENG RES INST

Aqueous environment-friendly packaging steel drum paint and preparation method thereof

InactiveCN101735703AGood anti-corrosion decoration effectHigh hardnessAnti-corrosive paintsEpoxy resin coatingsEpoxyAcrylic resin

The invention relates to an aqueous environment-friendly packaging steel drum paint, which is prepared by mixing the following compositions in part by weight: 20 to 70 parts of aqueous solution of acrylic resin with a solid content of 30 to 80 percent and / or aqueous solution of epoxy resin with the solid content of 30 to 80 percent, 4 to 10 parts of aqueous solution of amino resin with the solid content of 60 to 98 percent, 1 to 5 parts of organic amine, 1 to 50 parts of filling materials with the granularity of more than 2,000 meshes, 0.5 to 10 parts of color paste, 0.2 to 2 parts of wetting levelling agent, 0.2 to 2 parts of thickening agent, 0.1 to 0.8 part of antifoaming agent, 1 to 5 parts of adhesive force accelerant, 0.2 to 5 parts of catalyst, 0 to 30 parts of alcohol diluting solvent and / or 0 to 5 parts of non-toxic ether diluting solvent, and 20 to 50 parts of deionized water. The aqueous environment-friendly packaging steel drum paint has the advantages of wide application range, high rigidity, good flexibility, strong adhesive force and good anti-scraping and anti-collision properties and environmental protection; and meanwhile, the invention discloses a preparation method for the aqueous environment-friendly packaging steel drum paint.

Owner:重庆亢石新材料科技有限公司

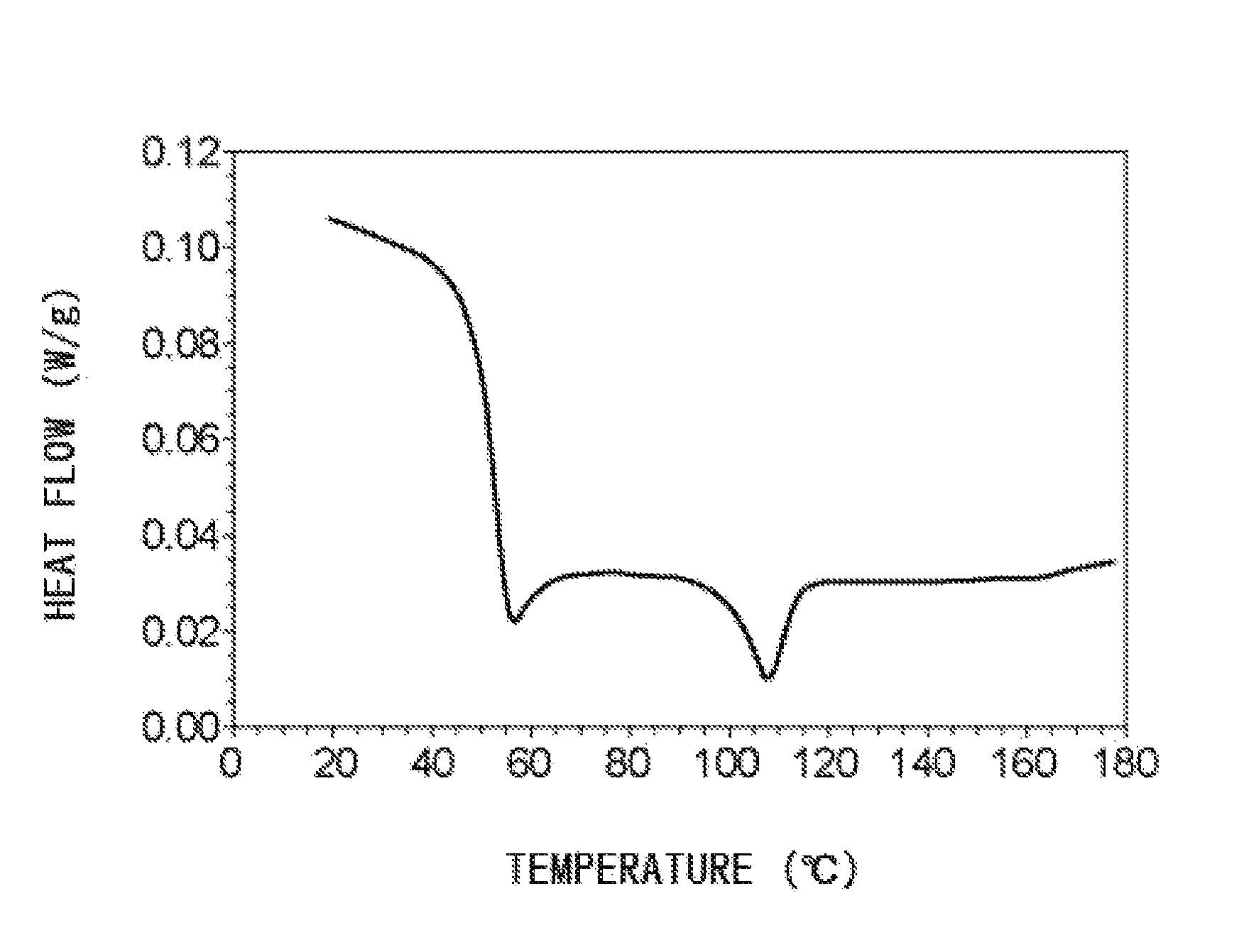

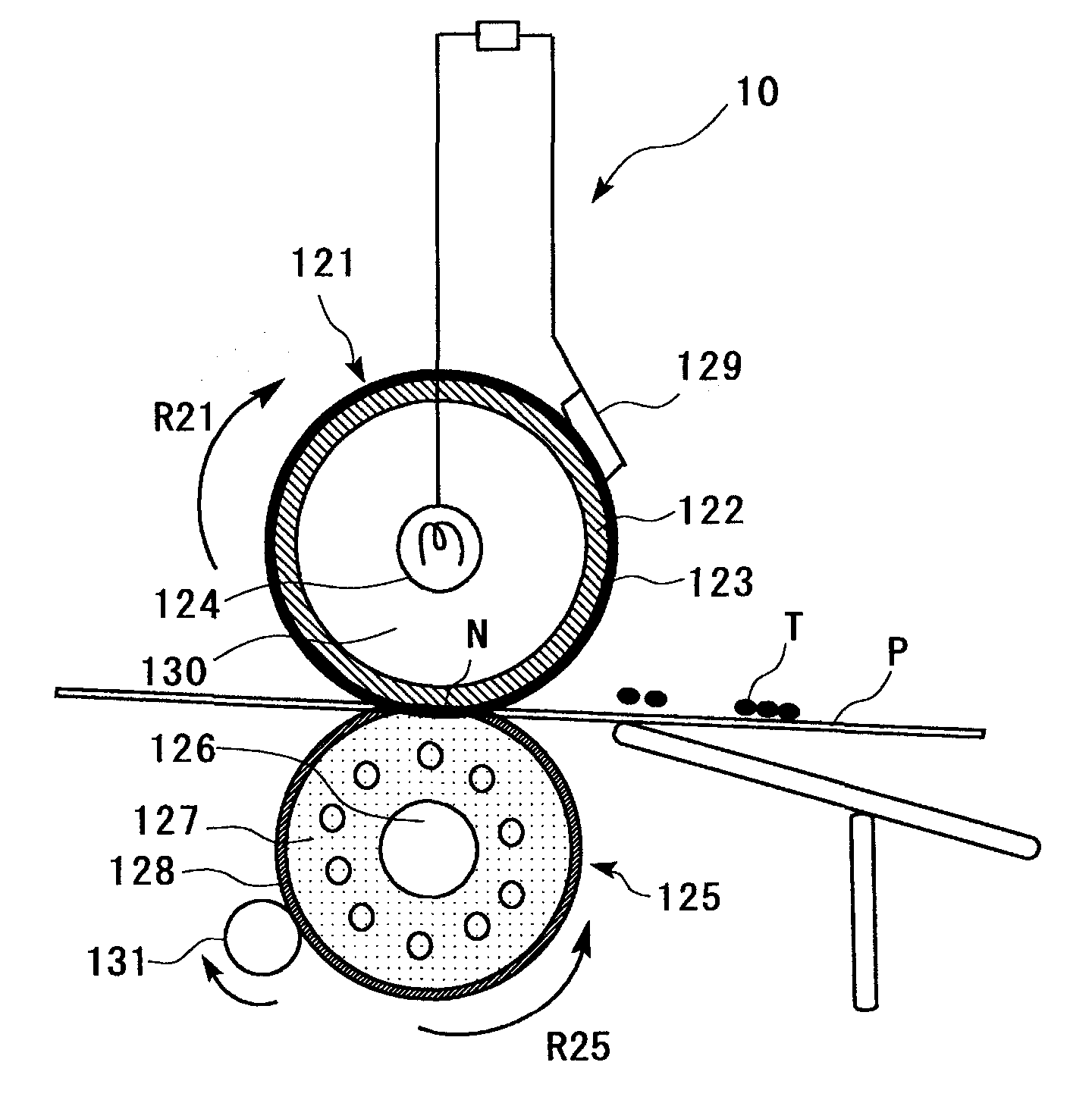

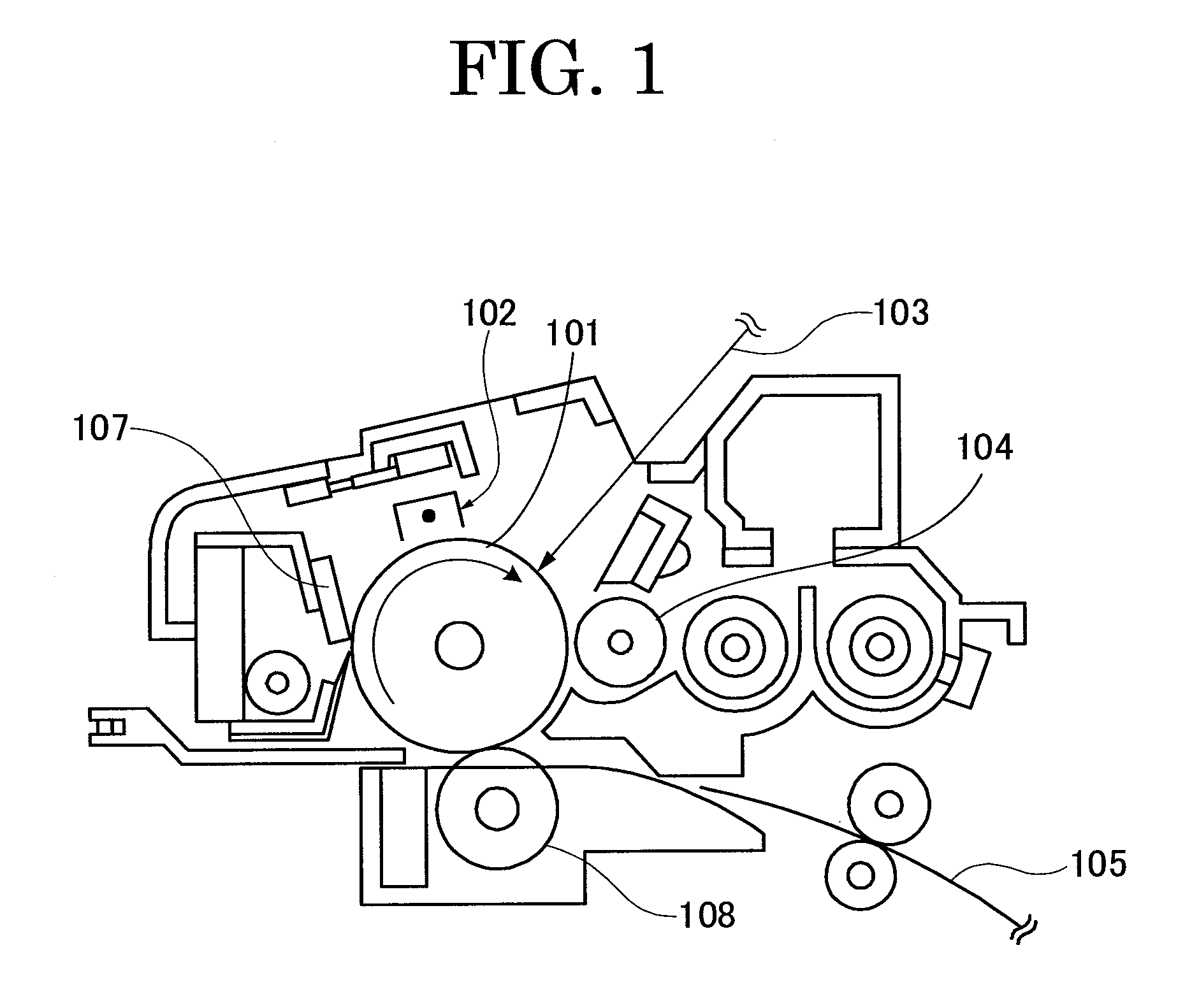

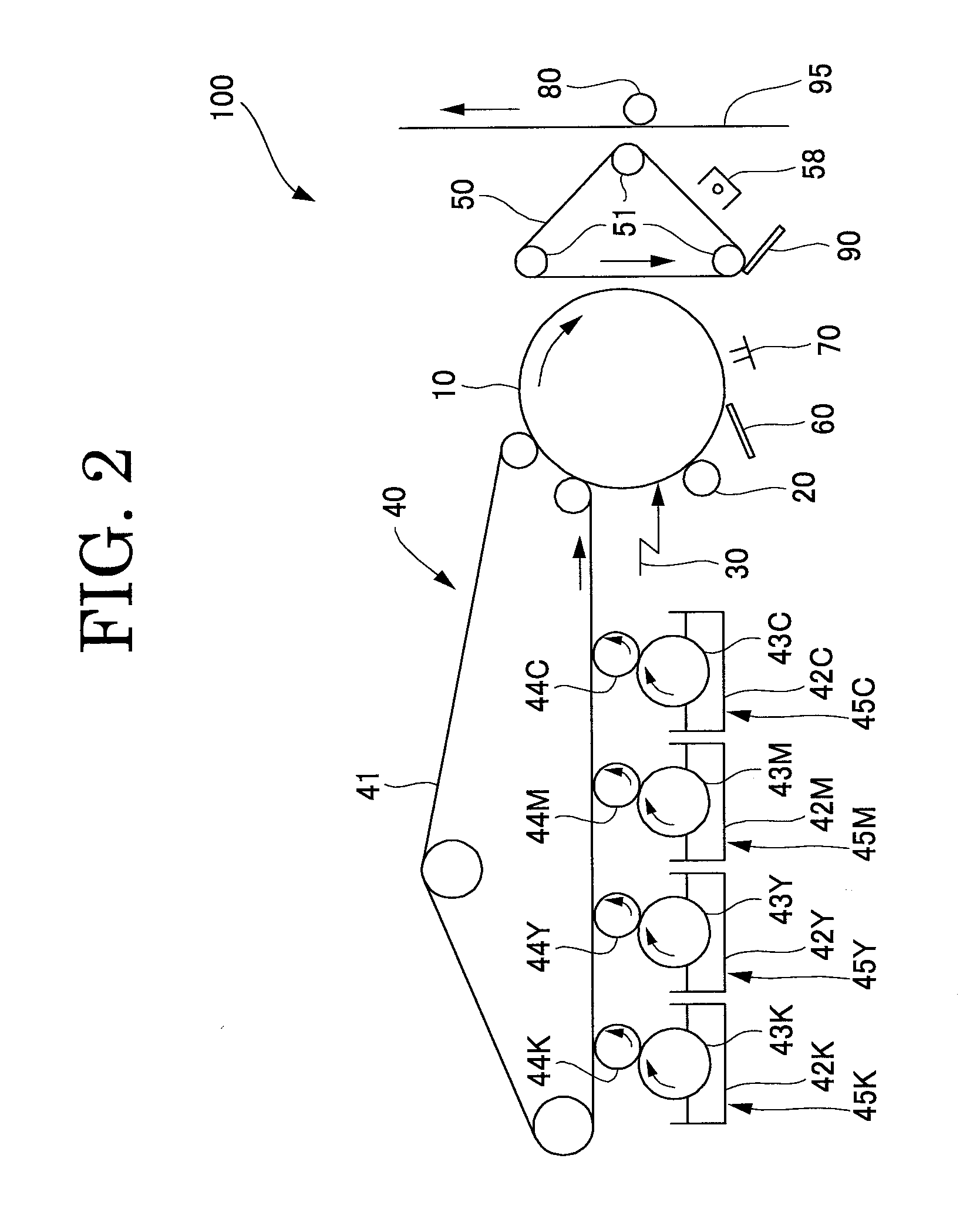

Toner

ActiveUS9097998B2Improve stabilityExcellent low temperature fixabilityDevelopersHeat flowEngineering

A toner is provided which is superior in the long-term storage stability and has high low-temperature fixing properties. In a DSC curve as measured with a differential scanning calorimeter, the toner has a glass transition temperature of not less than 50° C. and not more than 60° C.; and the toner has, in regard to a resin composition contained therein, a difference of not less than 0.060 W / g in heat flow between a point on the curve at a temperature of 40° C. and a baseline in the range exceeding the glass transition temperature; and in viscoelastic characteristics measured at a frequency of 6.28 rad / sec, the toner has a storage elastic modulus (G′40) at a temperature of 40° C. of not less than 7.0×108 Pa and not more than 2.0×109 Pa, and a storage elastic modulus (G′70) at a temperature of 70° C. of not less than 1.0×105 Pa and not more than 1.0×107 Pa.

Owner:CANON KK

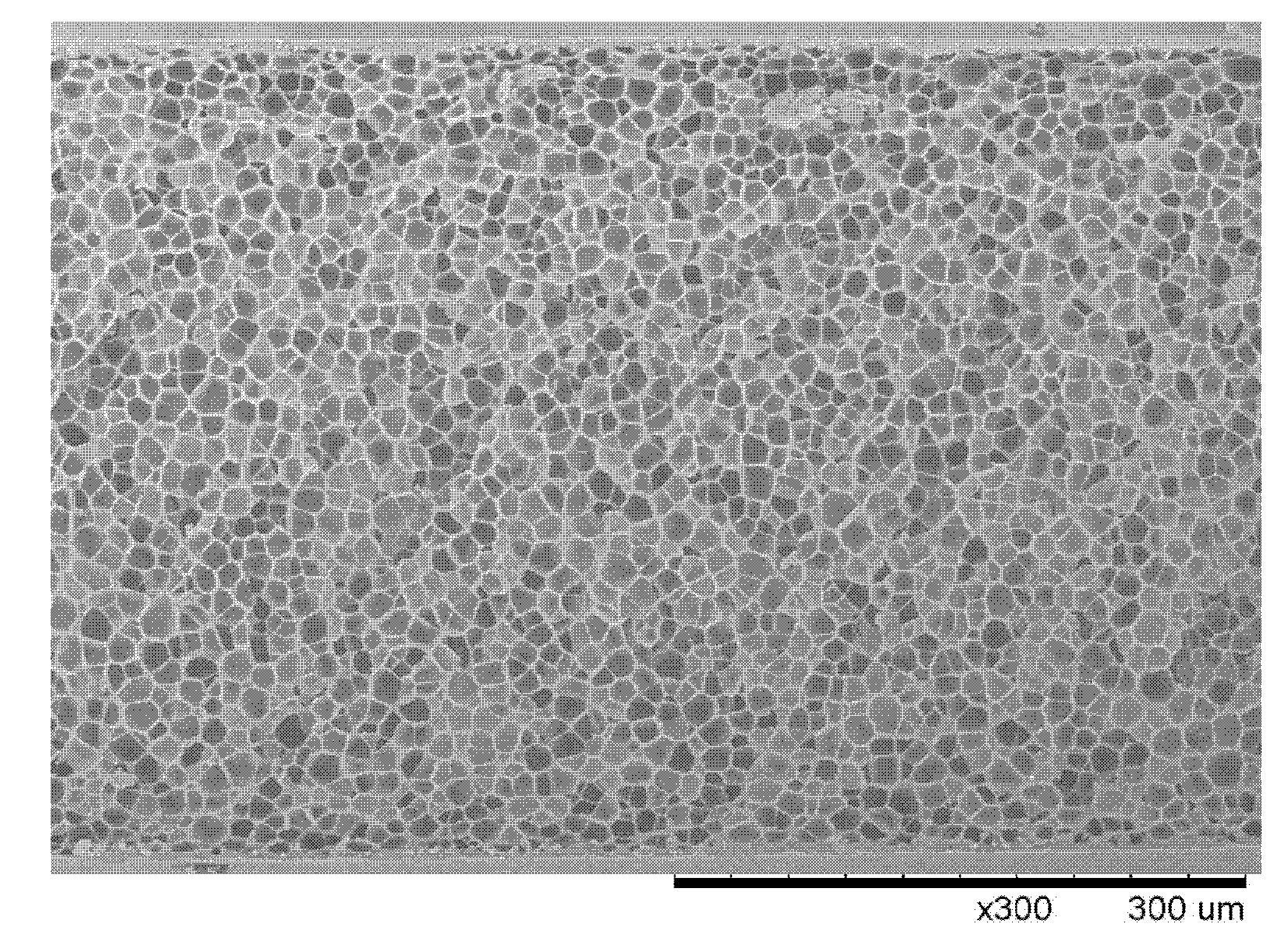

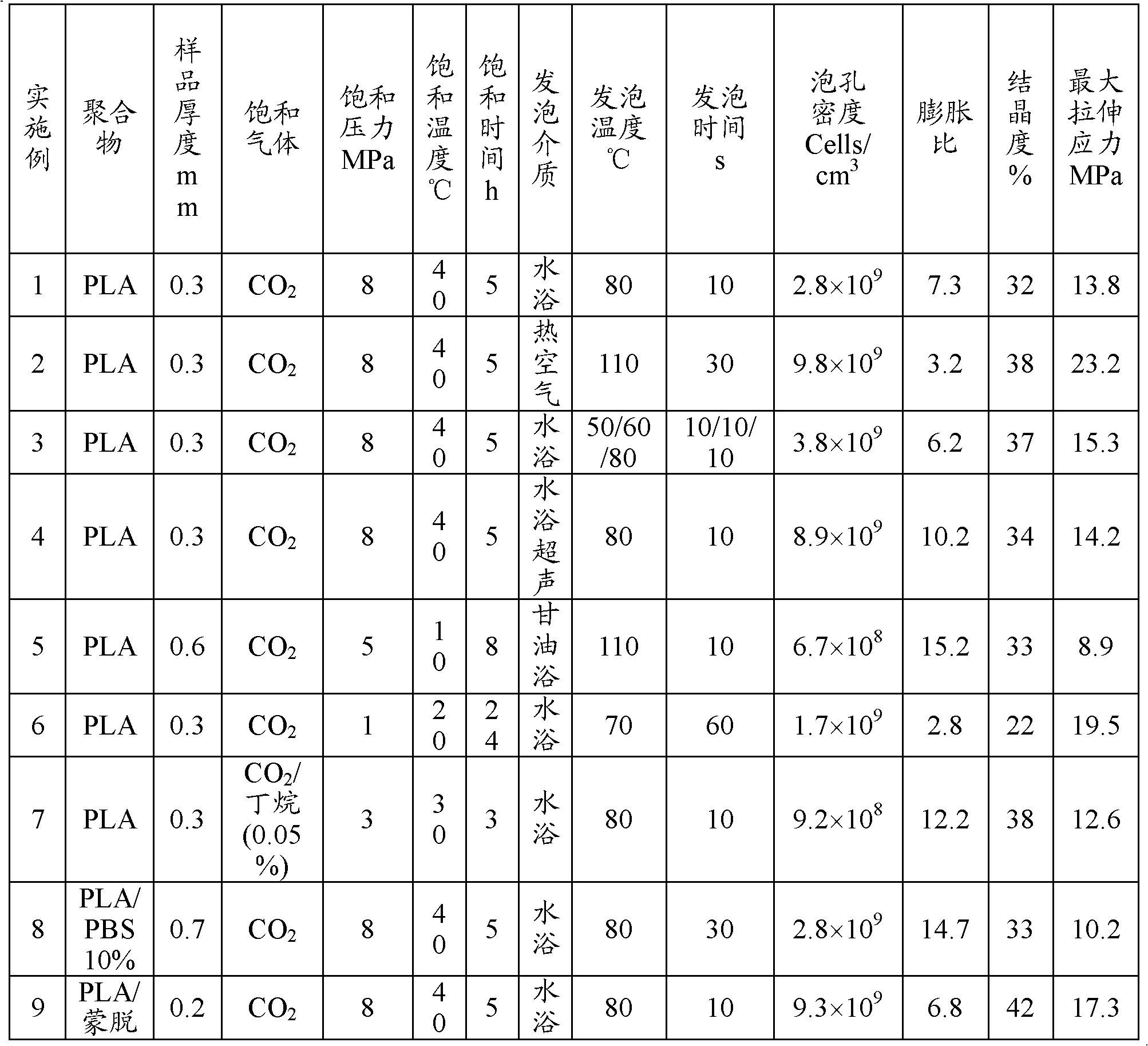

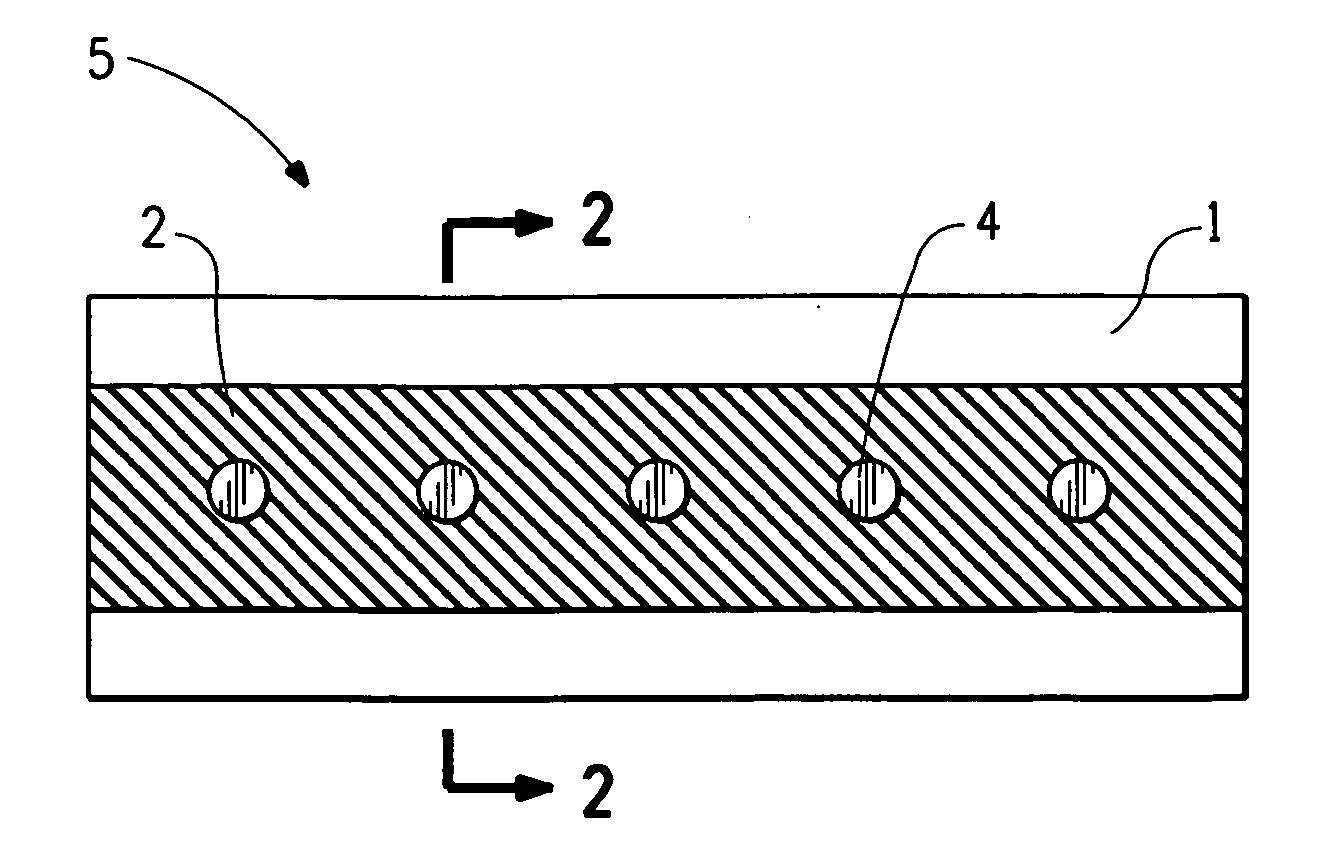

Preparation method of biodegradable polymer foamed sheet product

The invention discloses a preparation method of a biodegradable polymer foamed sheet product, comprising the following steps of: putting a polymer sheet into high-pressure fluid with the pressure of 0.5-10MPa to saturate the polymer sheet; then putting the saturated polymer sheet into a hot medium with the temperature of 40-140 DEG C for foaming for 2-300 seconds to obtain a polymer foamed sheet; and forming the polymer foamed sheet by heat treatment to obtain the biodegradable polymer foamed sheet product, wherein the polymer sheet is made of polylactic acid or the blend of polylactic acid and a polymer with an ester group or ether bond, and the thickness of the sheet is 0.1-2.0mm. The process disclosed by the invention is simple to operate, easy to control and favorable for industrial implementation, and the product has the advantages of bright and clean surface, light weight, uniform closed pore structure with the pore size of 5-50 micrometers, high tensile modulus and strength, excellent temperature tolerance and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Elecrically conductive adhesive

ActiveUS20090186219A1Increase heatHigh strengthConductive materialSolid-state devicesSolventSilicone resin

Disclosed is an electrically conductive adhesive that includes an electrically conductive powder, a heat-curable silicone resin, and a solvent.

Owner:DU PONT CHINA LTD

Soluble salt element for high-pressure casting

InactiveCN101073819AImprove flexural strengthImprove toughnessFoundry mouldsFoundry coresSolubilityAlloy

The invention is concerned with water-solubility salt core for high-pressure molding made of metal halides and ceramic whisker. The quality ratio of metal halides and ceramic whisker is 90 to 99:1 to 10, and the optimization is 91 to 98:2 to 9. The water-solubility salt core for high-pressure molding (press molding, extrusion molding) bases on the light alloy hardware with complicated inner cavity with equal or over 17 Mpa bending strength and the collapsibility time is less then a hour, the contract ratio of bulk is less than 12.30 percent and the moisture absorption is less than 0.05 percent. The bending strength of salt core is high and the capability for high temperature and absorption of moisture is well with low contract ratio and low cost to press molding or extrusion molding of light alloy hardware with complicated inner cavity.

Owner:HUAZHONG UNIV OF SCI & TECH

Flame retardant polyurethane composite material and preparation method thereof

The invention relates to a flame retardant polyurethane composite material and a preparation method thereof. The traditional flame retardant polyurethane foamed material has a poor use effect. The flame retardant polyurethane composite material provided by the invention is a mixed system comprising 70-99wt% of flame retardant polyurethane and 1-30% of blending type fire retardant, wherein the blending type fire retardant is one or more than one of ammonium polyphosphate, melamine, melamine cyanurate acid, polysiloxane, graphine, a carbon nano tube and kaolin, the fire retardant polyurethane is a random copolymer consisting of a polycarbonate unit, a polyether and an isocyanate unit. The preparation method of the flame retardant polyurethane composite material comprises the following steps of: firstly, preparing fire retardant polyalcohol; then, mixing the fire retardant polyalcohol and the blending type fire retardant into a mixed system; and then adding polyisocyanates into the mixed system and reacting to finally obtain the flame retardant polyurethane composite material. The flame retardant polyurethane composite material prepared by using the preparation method disclosed by the invention has the advantages of excellent fire retardance, low-fogging performance and low-gas-releasing performance.

Owner:JIANGSU ZHONGKE JINLONG CHEM

Reinforced toughening flame-proof polyolefin resin composition and its preparation method

The invention discloses a flame-proof polyolefin resin component and preparing method in the resin flame resistant modifying domain, which comprises the following parts: a. 9-20% bromine fire retardant with decabran diphenyl ethane or octabromobium ether and heat-stability hexabromide cyclododecane with weight rate at 2: 1-1: 2, b. 3-8% synergic fire retardant with antimony trioxide, c. 3-12% melt resistant melt drip agent with one or more of organic montmorillonite, kaolin and clay.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Method for preparing polyurethane-polyurea coated fertilizer

InactiveCN101747123ARegular structureHigh strengthFertiliser formsFertilizer mixturesPolyolAtmospheric pressure

The invention relates to a method for preparing polyurethane-polyurea coated fertilizer, comprising the following steps: dehydrating polyether polyol to obtain dehydrated polyether polyol, adding polyisocyanate to the dehydrated polyether according to the molar ratio of NCO to OH of 2-5, heating the temperature of the mixture of the dehydrated polyether and the polyisocyanate to 70-90 DEG C, making the mixture of the dehydrated polyether and the polyisocyanate react until the mass of NCO being 5-9 percent of the mass of the product of reaction, defoaming the product of reaction in vacuum to obtain -NCO-ended polyurethane prepolymer, filling fertilizer in a spray dryer, heating the fertilizer to 60 DEG C, mixing the polyurethane prepolymer with amine chain extender according to the mass ratio of 7-8:1 to obtain spraying liquid by controlling the fan frequency at 45 Hz, the nozzle atomization air pressure at 0.7-1.2 MPa, the inlet air temperature at 20-80 DEG C and the spray rate at 0.4-0.6 Kg / h, spraying the spraying liquid whose mass is 7-10 percent of the mass of the fertilizer on to the fertilizer, and curing the coating film to obtain the polyurethane-polyurea coated fertilizer.

Owner:晋盾防护(山西)科技有限公司 +1

High-temperature-resistant and low-peel-strength acrylate pressure-sensitive adhesive and preparation method thereof

ActiveCN106520032ASmall peeling forceLow temperature resistanceEster polymer adhesivesFunctional monomerSolvent

The invention discloses a high-temperature-resistant and low-peel-strength acrylate pressure-sensitive adhesive. The pressure-sensitive adhesive is prepared from raw materials in parts by weight as follows: 50-90 parts of soft acrylate monomers, 5-25 parts of hard acrylate monomers, 0.5-15 parts of reactive functional monomers, 0.2-10 parts of high-temperature-resistant active monomers, 0.2-3 parts of an initiator, 0.5-5 parts of a curing agent and 60-200 parts of a solvent. All the monomers and part of the initiator are dissolved in the solvent firstly, the total concentration of the monomers is controlled to be not lower than 60wt%, and then the material is heated for a reflux reaction for 3-6 h; then the rest of the initiator is dropwise added to reaction liquid, a reaction is carried out for 0.5-2 h after adding dropwise is completed, and then the obtained product is diluted and reacts step by step; and the obtained material and the curing agent are evenly mixed, so that the high-temperature-resistant and low-peel-strength acrylate pressure-sensitive adhesive is obtained. The pressure-sensitive adhesive can still stick a stuck object at the relatively high use temperature, and an adhesive layer is free of residues and traces after being peeled.

Owner:ANHUI MINGXUN NEW MATERIAL TECH

Electric-insulation epoxy resin castable for outdoor mutual inductor

ActiveCN103709608AExcellent physical and chemical propertiesHeat resistantPlastic/resin/waxes insulatorsPolymer scienceFirming agent

The invention relates to an electric-insulation epoxy resin castable for an outdoor mutual inductor. The epoxy resin castable comprises the following materials by weight percent: 21-26% of resin, 45-55% of filling, 15-25% of a curing agent and 2-6% of other auxiliary agents, wherein the resin is formed by mixing organic silicon modified epoxy resin, phenolic aldehyde epoxy resin, brominated epoxy resin and bisphenol F-type epoxy resin; the filling is silane-processed silica powder; the curing agent is modified methylhexahydrophthalic anhydride; the other auxiliary agents include a curing catalyst, a plasticizer, a reactive diluent, a silane coupling agent, a coloring agent and an antioxidant. The electric-insulation epoxy resin castable has excellent physical and chemical properties and has the performance of heat resistance, low temperature resistance, ultraviolet irradiation resistance, ageing resistance and the like. The electric-insulation epoxy resin castable is applicable to the electric insulation of the outdoor mutual inductor and other electrical equipment.

Owner:JIANGXI TENGDE IND

Polyurethane, modified asphalt and mixture material containing same and pavement structure

InactiveUS20180312437A1High strengthExtended service lifeIn situ pavingsBuilding insulationsHydrogenPolyol

A polyurethane is obtained by continuously reacting a polyurethane prepolymer in an asphalt or asphalt mixture material system under high temperature. The prepolymer is prepared by: adding a polymerization inhibitor, catalyst and isocyanate component in a reaction container, adding a polyol to the reactor while stirring at room temperature under nitrogen, increasing the temperature to 50-80° C., and maintaining the temperature to react for 0.5-6 hours. A polyurethane modified asphalt, a mixture material containing the polyurethane and a polyurethane modified asphalt pavement structure can be prepared. The synthesis condition of the polyurethane is mild, and a secondary reaction with the air and an active hydrogen component in the asphalt can occur during maintenance and formation to further increase the strength of a mixture material. The standard Marshall stability at 60° C. meets the petroleum asphalt requirement, such that a service life of the asphalt pavement can be increased.

Owner:ZHONGLU HI TECH (BEIJING) HIGHWAY TECHNOLOGY CO LTD +1

Heat-conducting and wave-absorbing rubber material and preparation method thereof

InactiveCN106751910AHigh temperature resistantLow temperature resistanceHeat-exchange elementsCross-linkRubber material

The invention discloses a heat-conducting and wave-absorbing rubber material and a preparation method thereof. The heat-conducting and wave-absorbing rubber material is prepared from the following substances in parts by weight: 100 parts of a rubber matrix, 50-600 parts of heat-conducting powder, 50-400 parts of wave-absorbing powder, 0-2 parts of a release agent and 0.5-2 parts of a cross-linking agent. The heat-conducting and wave-absorbing rubber material has the properties of high temperature resistance, low temperature resistance, high voltage resistance, ozone aging resistance, radiation resistance, weather resistance, physiologically inert property, high permeability and solvent resistance, and especially has outstanding high temperature resistance, so that the possibility is provided for preparation of the heat-conducting and wave-absorbing material; the heat-conducting and wave-absorbing rubber material can be directly applied between a heat dissipation room and a metal housing, and heat energy can be effectively exported; and meanwhile, the heat-conducting and wave-absorbing rubber material has electromagnetic shielding and electromagnetic noise wave absorbing properties, so that a good solving scheme is provided for electronic communication products in heat conduction and electromagnetic shielding.

Owner:DALIAN DONGSHIN MICROWAVE TECH

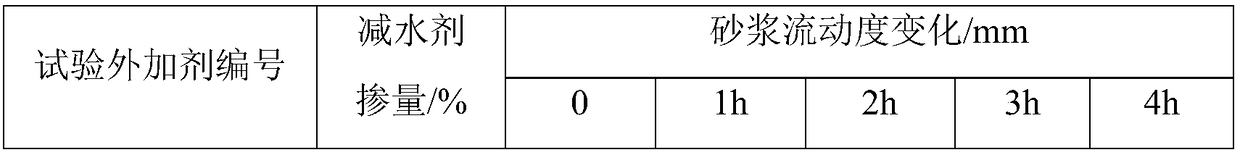

Highly adaptive ultralong-slow release slump-retaining agent and normal and low temperature preparation method thereof

The invention discloses a highly adaptive ultralong-slow release slump-retaining agent and a normal and low temperature preparation method thereof. Mainly, polyether macromonomer, unsaturated carboxylic acid monomer, unsaturated carboxylic ester monomer, unsaturated phosphate ester monomer, unsaturated amide monomer, oxidant, reducing agent, chain transfer agent and deionized water carry out freeradical polymerization by aqueous solution at the temperature of 5-25 DEG C, after sodium hydroxide solution is then added to regulate pH value, water is then replenished, and thereby the slump-retaining agent is prepared. The preparation method does not need a heat source, reaction is carried out under normal and low temperatures, equipment is simple, the operability is high, the production efficiency is high, the prepared slump-retaining agent has ultralong slow release capability, slump can be retained for a long time, the adaptability is high, and the performance is excellent.

Owner:SICHUAN TONGZHOU CHEM TECH

High-strength cold hardiness cable sheath rubber and technique of preparing the same thereof

ActiveCN101173067AImprove mechanical propertiesExtended service lifeInsulated cablesInsulated conductorsHigh intensityEngineering

The invention provides a high strength and non freezing cable cover rubber and a preparation process thereof, aiming at the disadvantages of the prior art and the market requirement. The M300 stress at elongation of the high strength and non freezing cable cover rubber is 6.5 to 7.0N / mm<2>, the breaking elongation is 400 to 500 percent, the tensile strength is 12.5 to 13.8 N per mm<2>, permanent set after breaking is 30 to 50 percent, the T-shaped tearing strength is 6.5 to 7.5 N / mm, and after aging by the heat air of 75 DEG C*240 hours, the tensile strength retention rate is not less than 90 percent, and the breaking elongation retention rate is not less than 80 percent. The non freezing property for the finished product cable prepared by adopting the cover rubber of the invention can pass the extremely low temperature impact and extremely low temperature bending test regulated in the UL44 standard, and the flame retardant property can pass a bundling burning test. Compared with the prior art, the cover rubber of the invention not only has higher mechanical property than the common rubber, but also has the advantages of low temperature and medium prevention. So the service life of the cable is prolonged under the condition of low temperature and having oil.

Owner:SHANGHAI MINING CABLE FACTORY

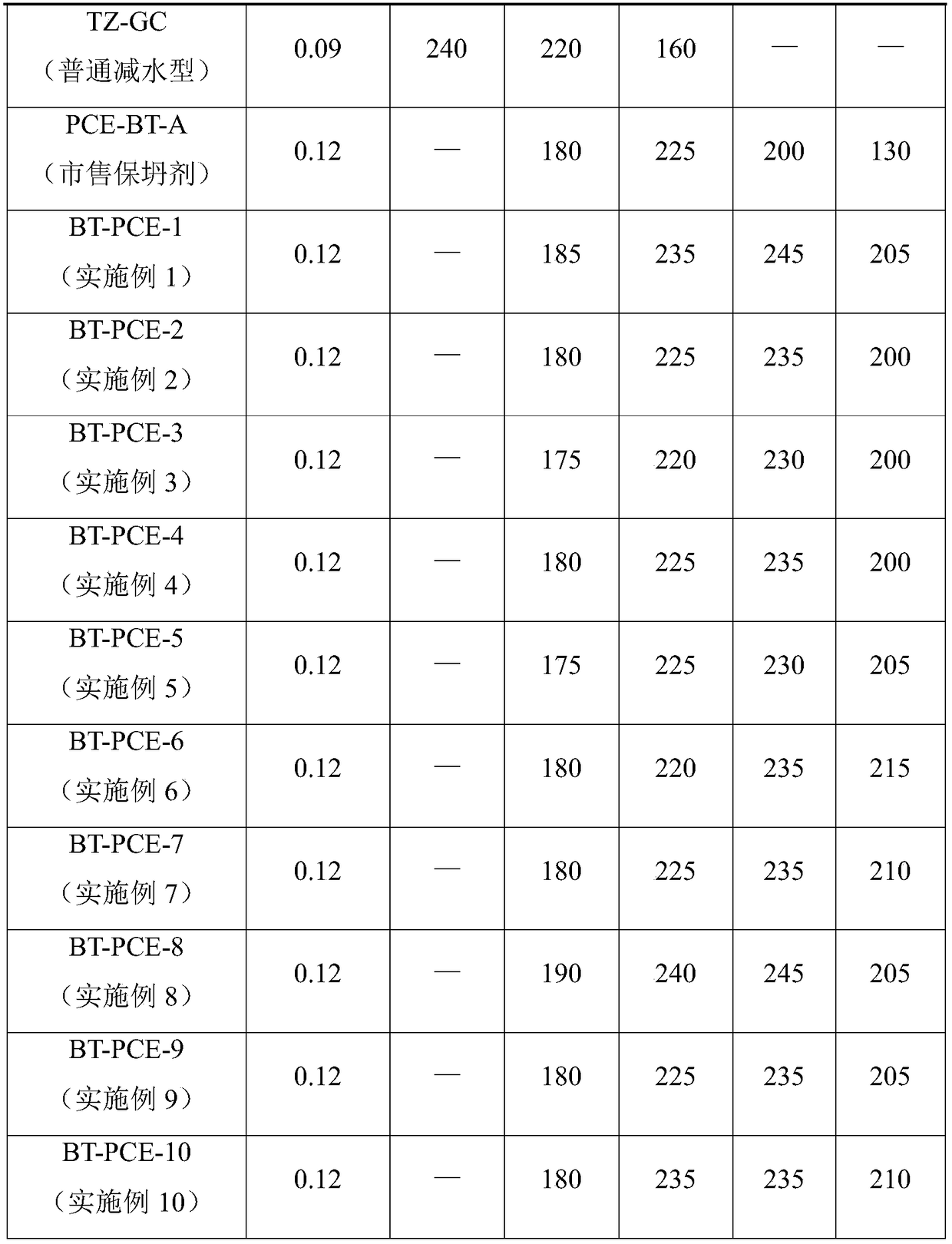

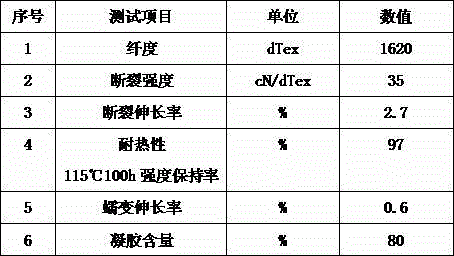

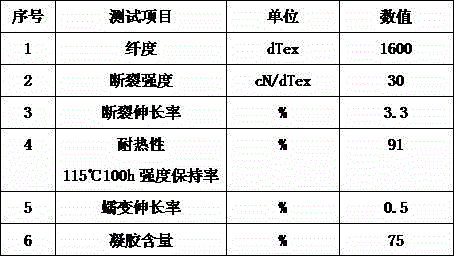

Heat-resisting creep-resisting ultra-high molecular weight polyethylene constant-strength fiber and preparation method thereof

InactiveCN104695038AHeat resistantHeat resistance and creep resistance haveMonocomponent polyolefin artificial filamentArtifical filament manufactureFiberCross-link

The invention discloses a heat-resisting creep-resisting ultra-high molecular weight polyethylene constant-strength fiber. The fiber comprises ultra-high molecular weight polyethylene powder, graphene, a cross-linking agent, a curing agent, an initiator and an anti-oxidant. The preparation method comprises the following steps: swelling the ultra-high molecular weight polyethylene powder by a solvent so as to form pores; then adding a composite modifying agent wetted by the cross-linking agent, the curing agent, the initiator, the anti-oxidant, the graphene and the solvent together; penetrating the composite modifying agent evenly into the ultra-high molecular weight polyethylene powder pores, and mixing evenly; and finally, carrying out irradiation crosslinking to obtain the heat-resisting creep-resisting ultra-high molecular weight polyethylene constant-strength fiber. The heat-resisting creep-resisting ultra-high molecular weight polyethylene constant-strength fiber has the comprehensive performances of heat resistance, creep resistance, abrasion resistance, impact resistance, self lubrication, corrosion resistance, low temperature resistance, hygiene, no toxicity, difficulty in adhesion and water absorption and relatively low density, is wide in applicability, and is long in service life.

Owner:JIANGSU SHENTAI SCI & TECH DEV

Toner and developer, toner container, process cartridge, image forming apparatus, and image forming method using the same

ActiveUS20080090165A1Excellent low temperature fixabilityMaintaining heat-resistant storage propertyDevelopersCross-linkAcetic acid

To provide a toner containing an ethyl acetate-soluble polyester component and an ethyl acetate-insoluble polyester component, wherein the toner is granulated in an aqueous medium, the ethyl acetate-insoluble polyester component is obtained by elongating and / or cross-linking a modified polyester resin during granulating and / or after granulating, the modified polyester resin is produced by condensation polymerization of an acid component and at least one type of diol compound selected from aliphatic diol and alicyclic diol in the presence of a catalyst, and the mass average molecular weight of the modified polyester resin is 10,000 to 100,000.

Owner:RICOH KK

Alive sturgeon low-temperature anhydrous transportation technology

InactiveCN101138331AReduce size and weightReduce shipping costsClimate change adaptationPisciculture and aquariaAir transportTransport time

The present invention provides a low-temperature transportation technology without water of live sturgeon; the transported live sturgeons are not fed for 2 to 3 days and put into water with a temperature of 1 to 2 Celsius degrees for precooling for 10 to 15 minutes; and then the sturgeons are put into an insulation box in which a seal bag is laid; the air in the seal bag is extruded and the seal bag is tied tightly after oxygen is infused; after the insulation box is sealed, the sturgeons can be transported and the transportation time is less than or equal to 18 hours. Compared with the prior art, sturgeon is a sub-cold water fish which has a low temperature resistant nature and the method makes use of the nature to freeze the sturgeons for transportation without water; in this way, the volume and weight of fish transportation tools are greatly reduced and at the same time the transportation cost is reduced which is convenient for vehicle or aviation transportation. The transportation time can reach 18 to 20 hours and the survival rate in transportation can reach more than 99 percent.

Owner:AQUACULTURE INST OF GUIZHOU PROVINCE

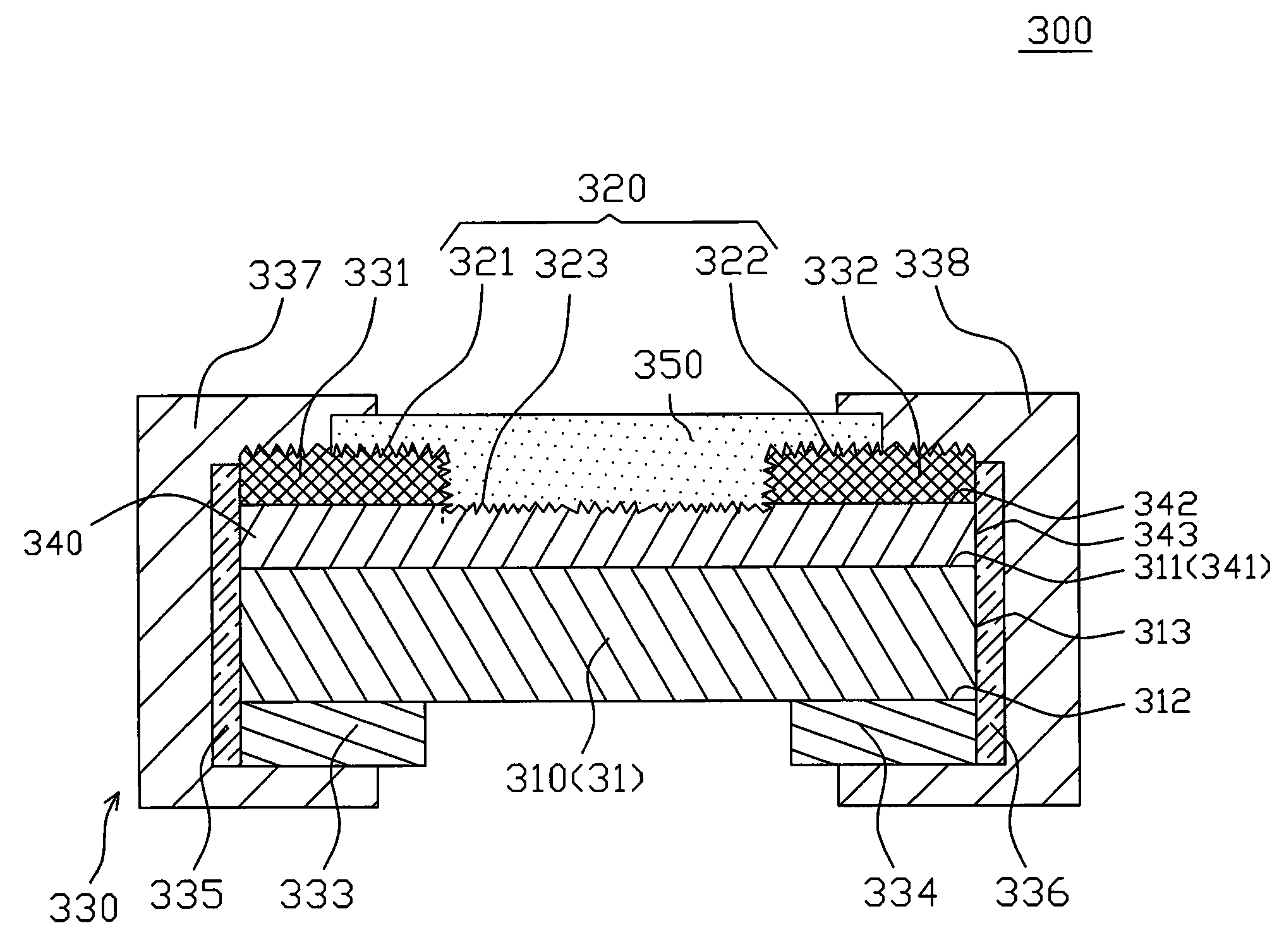

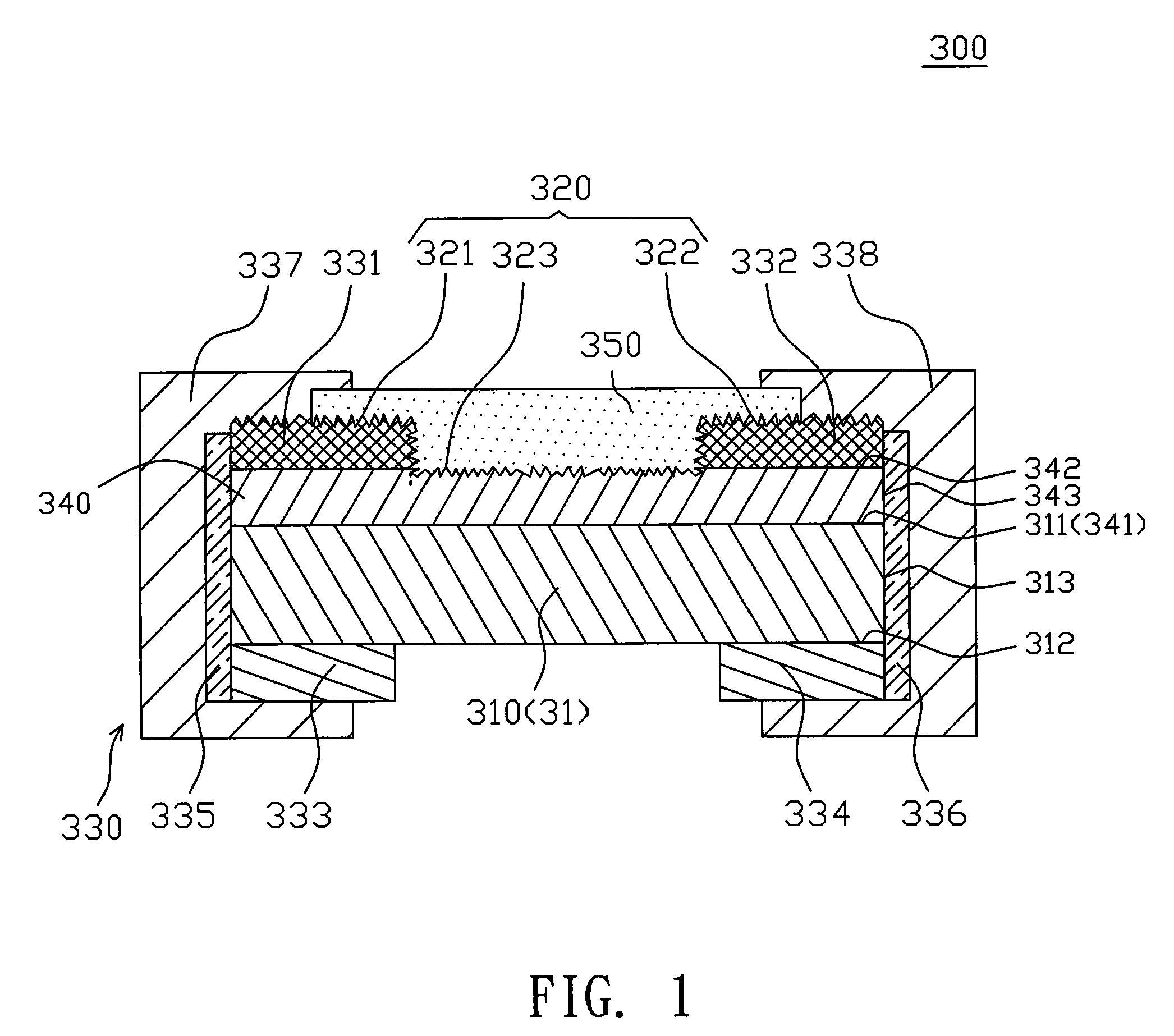

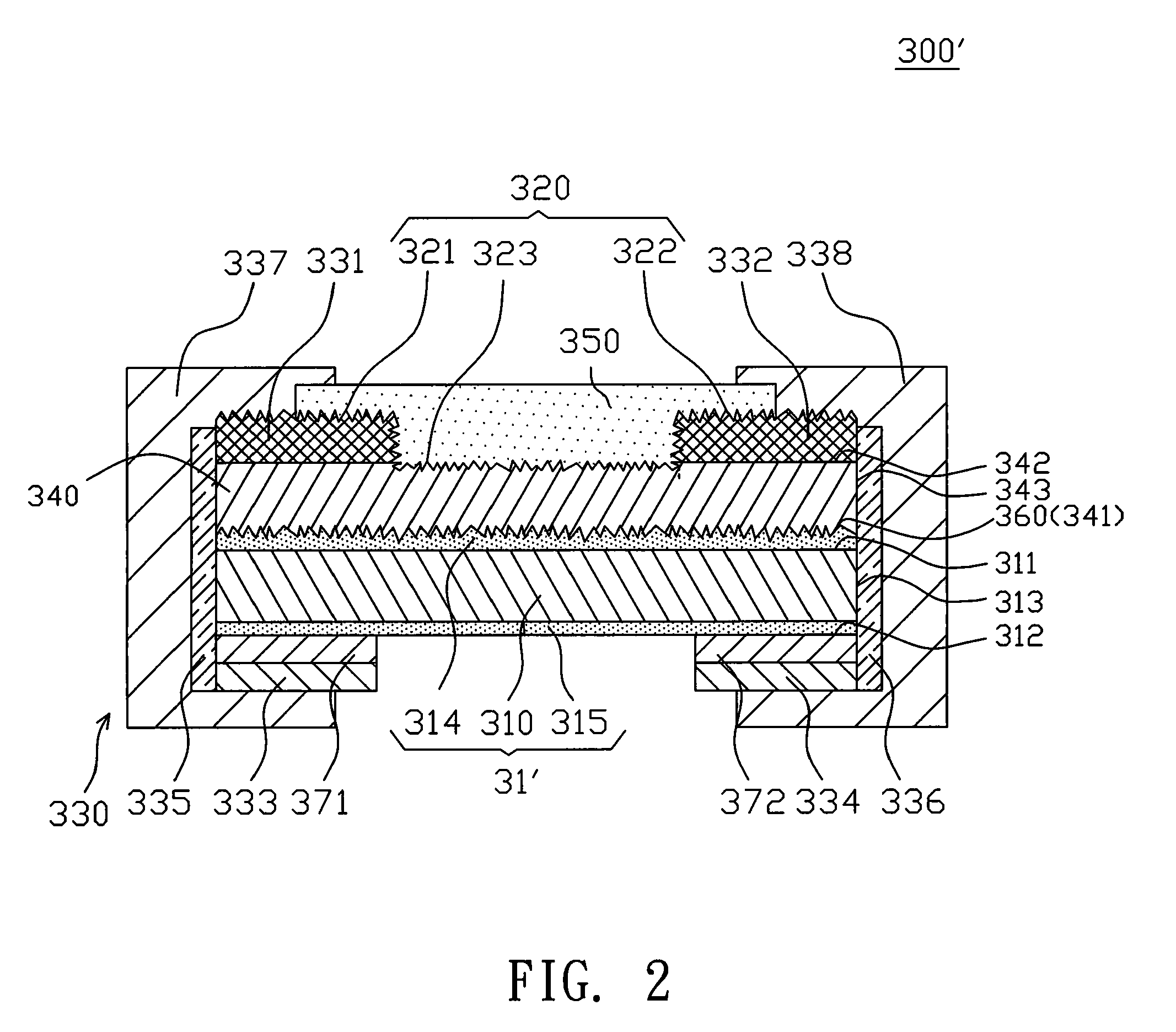

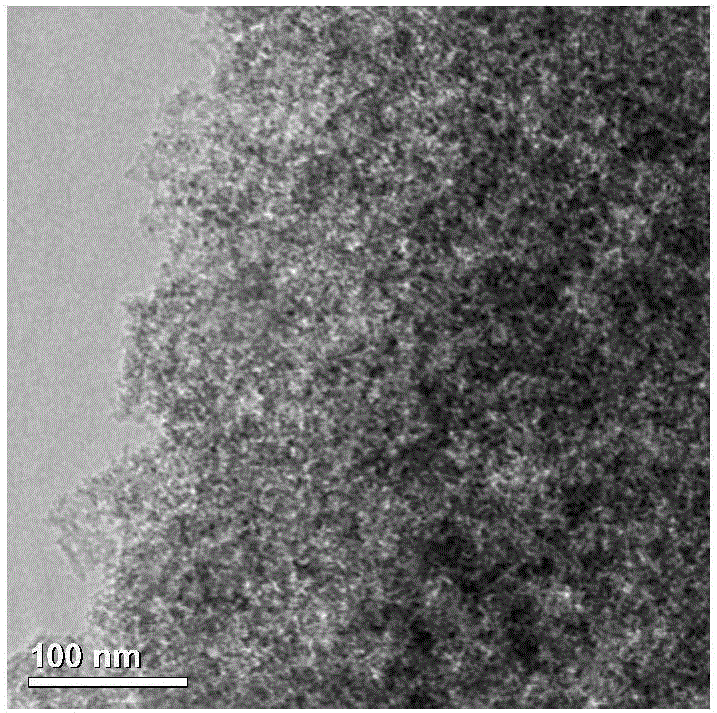

Resistive component and method of manufacturing the same

ActiveUS20100039211A1Improve stabilityAdhesionResistor chip manufactureEnvelope/housing resistor manufactureElectrical resistance and conductanceOptoelectronics

A resistive component suitable for detecting electric current in a circuit and a method of manufacturing the resistive component are provided. The resistive component includes a carrier, a resistive layer, an electrode unit, an upper oxide layer and a protective layer. The resistive layer comprises copper alloy and is disposed on the carrier. The electrode unit is electrically connected to the resistive layer. The upper oxide layer is disposed on a part of a surface of the resistive layer and includes oxides of the resistive layer. The protective layer covers at least a part of the upper oxide layer.

Owner:CYNTEC

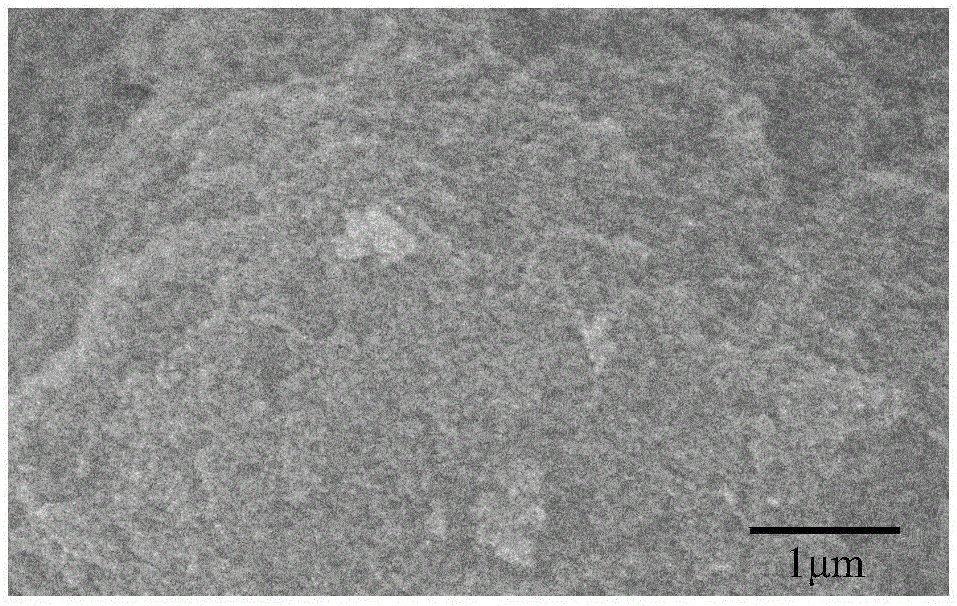

Ceramic diaphragm taking aerogel as powder body, and applications of ceramic diaphragm in lithium ion battery

InactiveCN106784558AHigh porosityLarge specific surface areaSecondary cellsCell component detailsPorosityMetallurgy

The invention provides a ceramic diaphragm taking aerogel as a powder body, and applications of the ceramic diaphragm in a lithium ion battery, relating to a lithium ion battery diaphragm. The ceramic diaphragm takes aerogel as the ceramic powder body which is coated on the diaphragm to form a ceramic diaphragm. The ceramic diaphragm taking aerogel as the powder body can be applied to batteries. The batteries include non-aqueous electrolyte secondary batteries and the like; each battery comprises an anode material, a cathode material and a ceramic diaphragm taking aerogel as a powder body, and the ceramic diaphragm taking aerogel as a powder body is arranged between the anode material and the cathode material. Aerogel is a lightweight nanometer mesoporous noncrystaline material formed by crosslinking of atom clusters, the porosity is up to 80%, the specific surface area is up to 800-1000m<2> / g, the aerogel has the characteristics of being excellent in transparency, extremely low heat conductivity, resistant to high temperature, low in density and the like. The ceramic diaphragm can be used as a highly safety diaphragm material of secondary batteries such as lithium ion batteries, and has excellent thermal stability and electrochemical performances.

Owner:XIAMEN UNIV

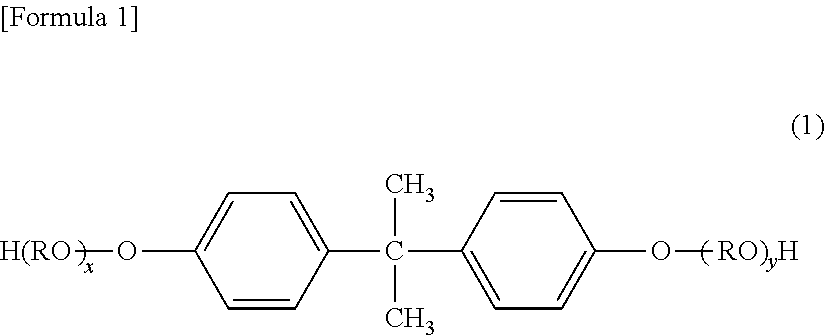

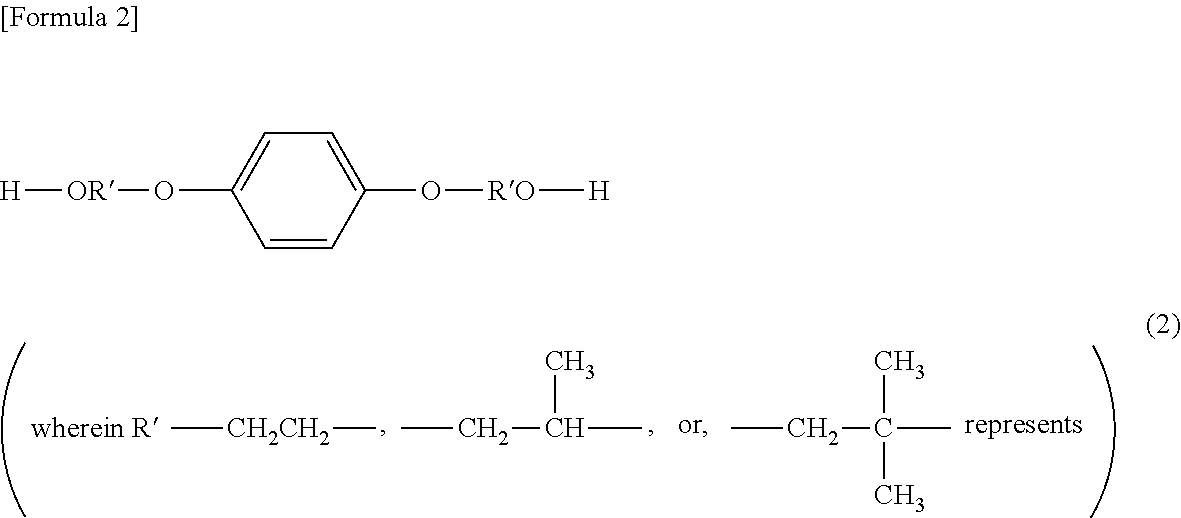

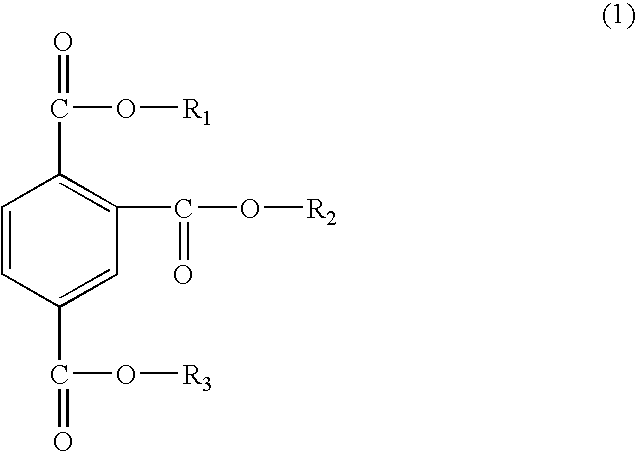

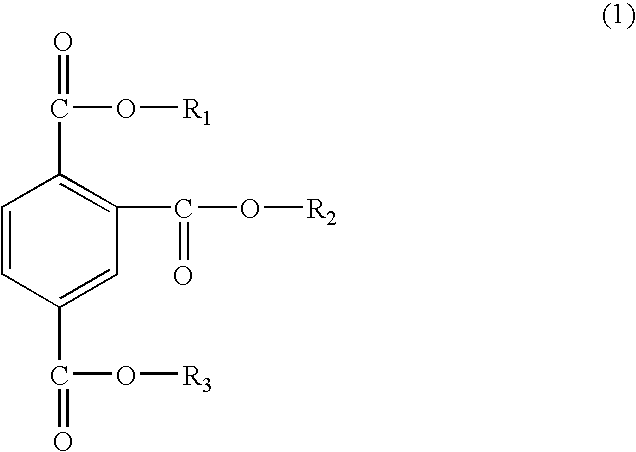

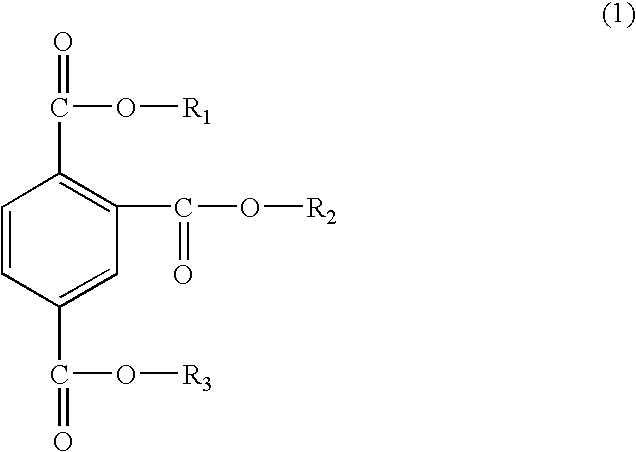

Vinyl chloride resin composition for powder molding, molded object obtained therefrom, laminate, vehicle interior material, and method for producing vinyl chloride resin composition for powder molding

InactiveUS20100272984A1Good fluidity of powderImprove heat aging resistanceSynthetic resin layered productsThin material handlingPlasticizerVinyl chloride

A vinyl chloride resin composition for powder molding of the present invention includes: 100 parts by mass of vinyl chloride resin particles made of vinyl chloride resin whose average degree of polymerization is 1500 or more, the vinyl chloride resin particles having an average particle size ranging from 50 to 500 μm; and 110 to 150 parts by mass of a particular trimellitate plasticizer. The vinyl chloride resin composition has excellent powder flowability and results in a molded object having excellent heat aging resistance and low-temperature resistance.

Owner:ZEON CORP

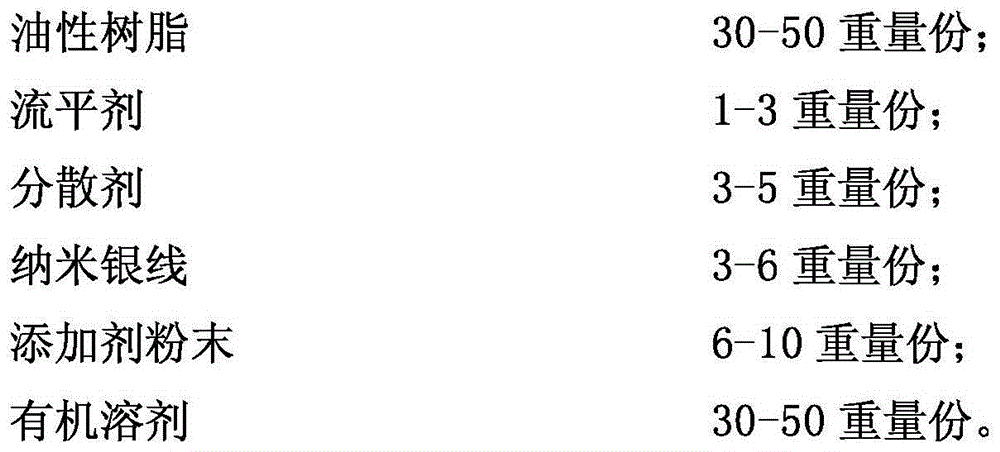

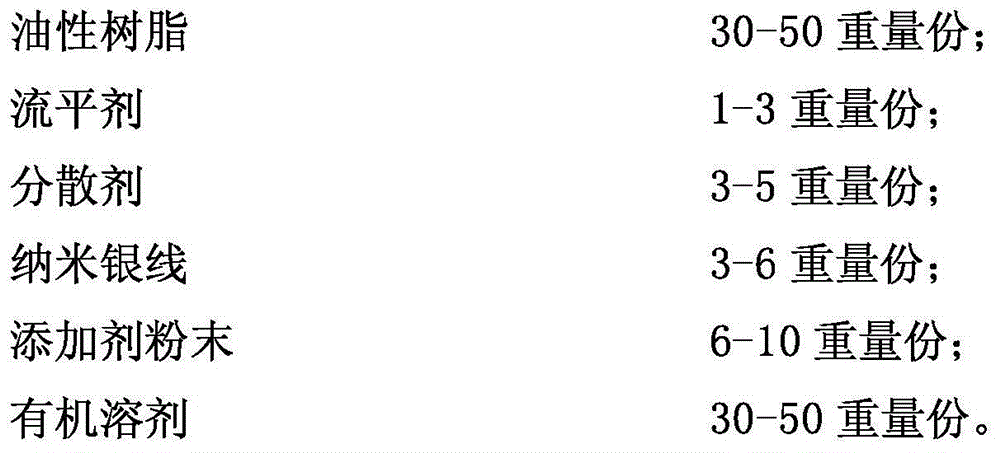

Heat-resistant flexible transparent conductive film and preparation method thereof

InactiveCN104464880AImprove conductivityImprove heat resistanceConductive layers on insulating-supportsNon-conductive material with dispersed conductive materialFiberCarbon fibers

The invention discloses a heat-resistant flexible transparent conductive film and a preparation method of the film. According to the film, the surface of PET is coated with coating, and then the film is prepared after being dried . According to the formula of the coating, the coating is composed of nanometer silver wires, oleoresin, additive powder, flatting agents and a proper quantity of organic solvents. The nanometer silver wires excellent in electrical conductivity and mixed additives composed of carbon fibers, nanometer limestone powder, nanometer palygorskite powder, nanometer aluminum oxide powder and propyl gallate are adopted for improving the electrical conductivity and the heat resistance of the film. The heat-resistant flexible transparent conductive film is low in cost and raw materials are easy to obtain.

Owner:SUZHOU SIDIKE NEW MATERIALS SCI & TECH

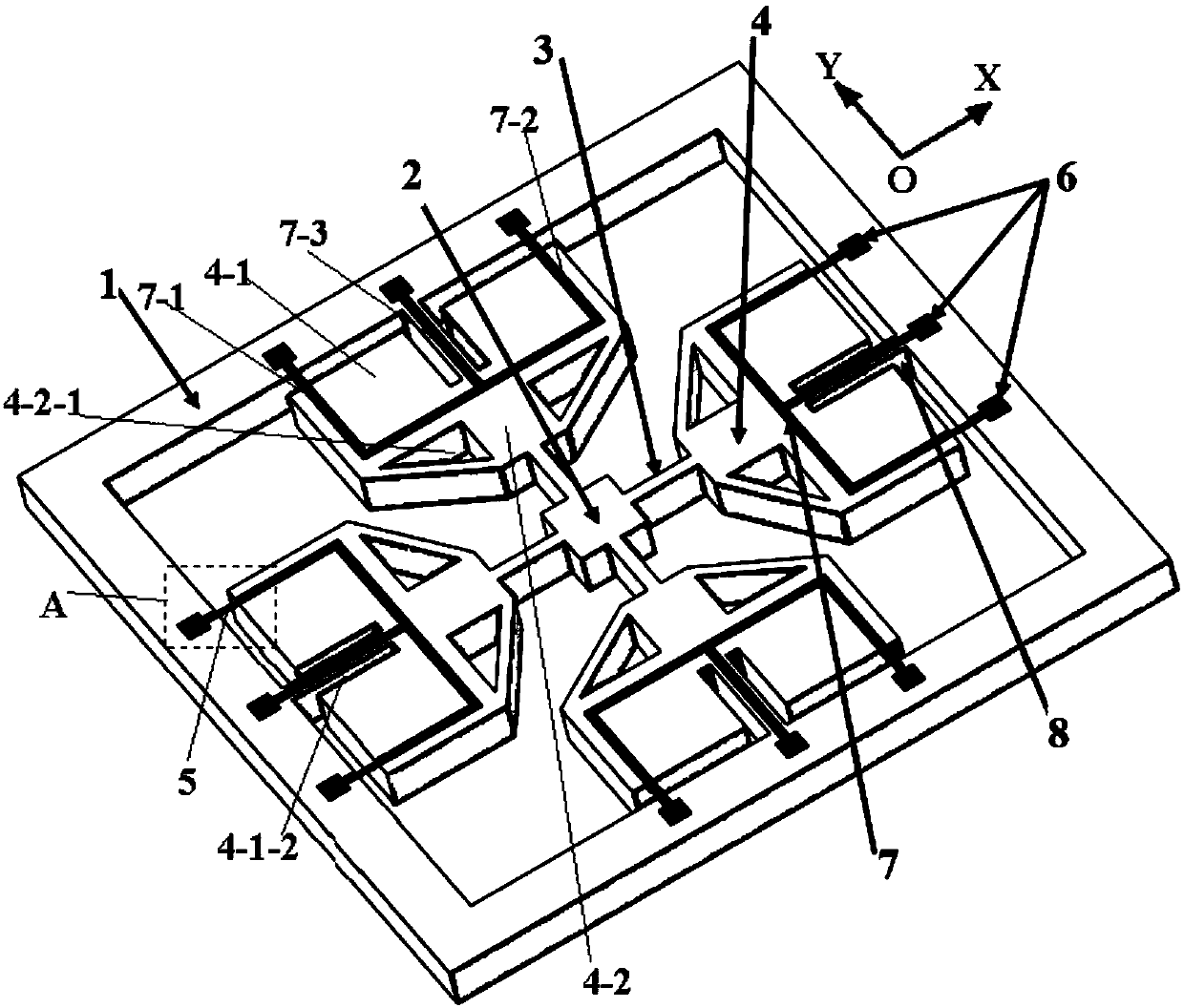

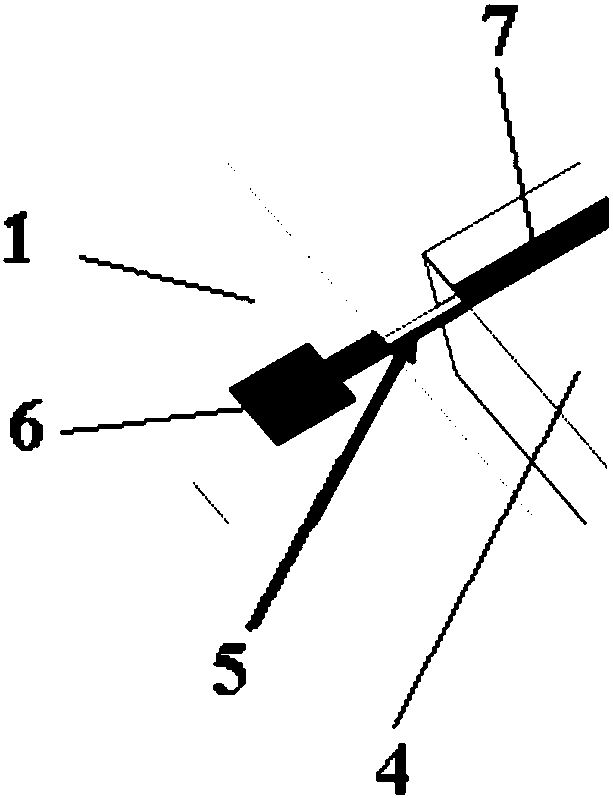

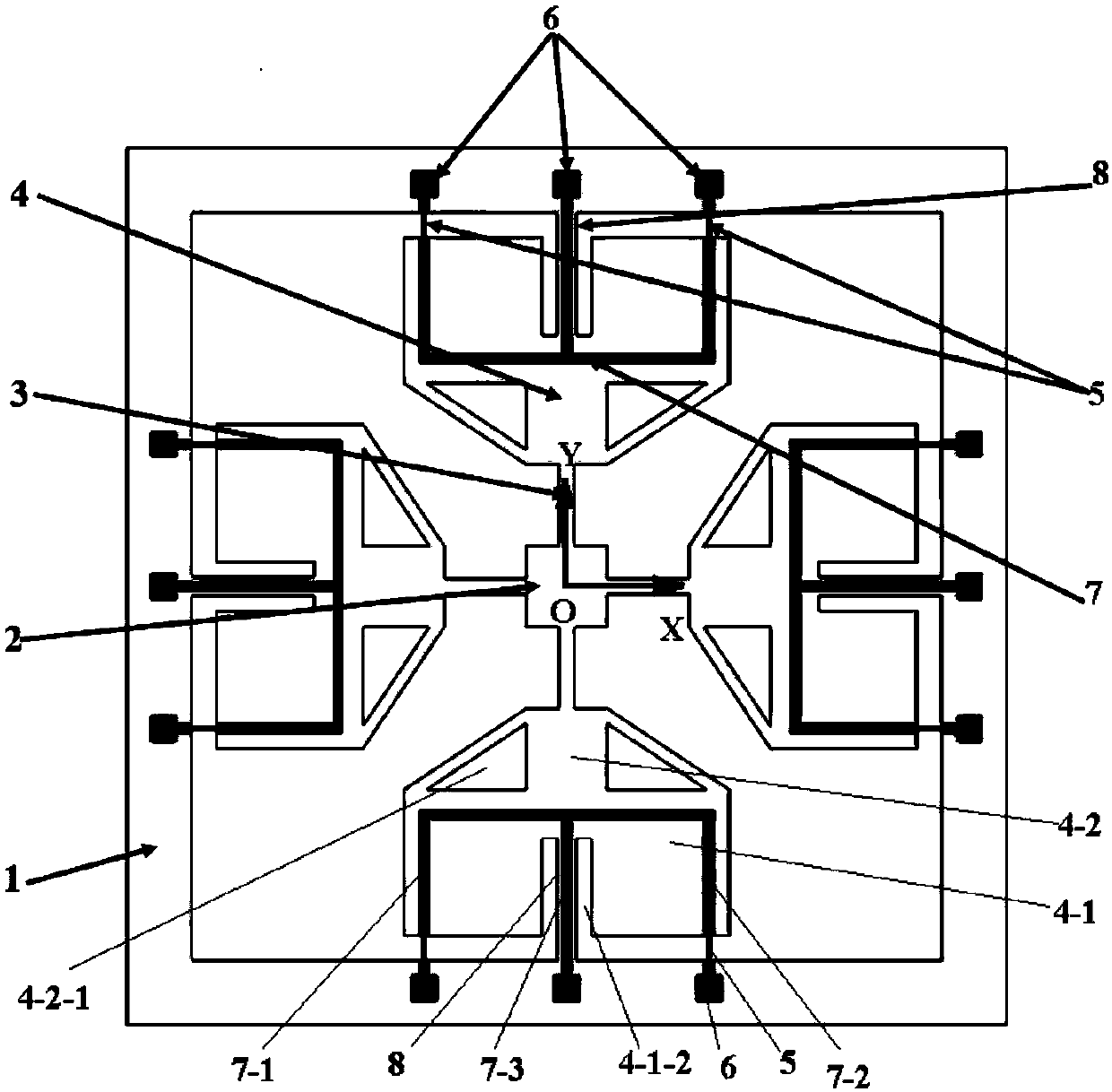

MEMS piezoresistance type two-axis acceleration sensor chip and preparing method thereof

ActiveCN107907710AIncreased sensitivity and resonant frequencyImprove performanceAcceleration measurement using interia forcesPressure sensitiveSemi open

The invention discloses an MEMS piezoresistance type two-axis acceleration sensor chip and a preparing method thereof. The MEMS piezoresistance type two-axis acceleration sensor chip comprises four sets of same sub-structures. The four sub-structures are uniformly distributed at the periphery of a fixed island. The fixed island is connected with a mass block through an inner supporting beam. The mass block is connected with an outer frame through an outer supporting beam. Sensitive beams are symmetrically distributed at two sides of the outer supporting beam. One end of the sensitive beam is connected with one end of the mass block, and the other end of the sensitive beam is connected with the outer frame. The two sub-structures which face each other relative to the fixed island form a set, thereby forming a whole working structure for measuring one acceleration direction, thereby respectively measuring the accelerations in an X-axis and a Y-axis. The two sensitive beams of each sub-structure are respectively provided with a pressure-sensitive resistor and are connected with a pad through metal leads, thereby forming a semi-open-ring Wheatstone full-bridge circuit. The sensor chipcan realize separated measurement of the accelerations below 200g in two axes. The natural frequency of the MEMS piezoresistance type two-axis acceleration sensor reaches above 20kHz, and the sensitivity is higher than 0.5mB / g / 3V. Furthermore the MEMS piezoresistance type two-axis acceleration sensor chip has relatively high resonant frequency and high sensitivity.

Owner:XI AN JIAOTONG UNIV

Wide-temperature high-efficiency catalyst for NOx removal by ammonia selective catalytic reduction ]and preparation method thereof

ActiveCN103877988AGood air source adaptabilityLow temperature resistanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsRare earthManganese oxide

The invention belongs to the technical field of catalysts and especially provides a wide-temperature high-efficiency NOx removal catalyst for ammonia selective catalytic reduction and a preparation method thereof. The catalyst consists of an active component, an auxiliary agent and a carrier. The weight of the active component accounts for 2%-10% of the weight of the catalyst, and the weight of the auxiliary agent accounts for 0.5%-7% of the weight of the catalyst. The active component is composed of a cupric oxide and / or a manganese oxide; the auxiliary agent is a mischmetal, a rare earth oxide or a transition metal oxide; and the carrier is Al2O3 or TiO2-Al2O3. The catalyst is particularly prepared by the steps of a drying operation and a roasting operation at a proper temperature. An NOx removal process at a wide temperature zone ranging from 100 DEG C to 400 DEG C can be achieved by the catalyst of the invention; meanwhile, the catalyst can be repeatedly used in normal after being washed and regenerated for several times in a nitrate tail gas denitration technology, and the catalytic intensity and the denitration performance are not decreased obviously. The catalyst of the invention is industrialized and has excellent industrial application prospect.

Owner:DALIAN CATALYTIC ENG TECH

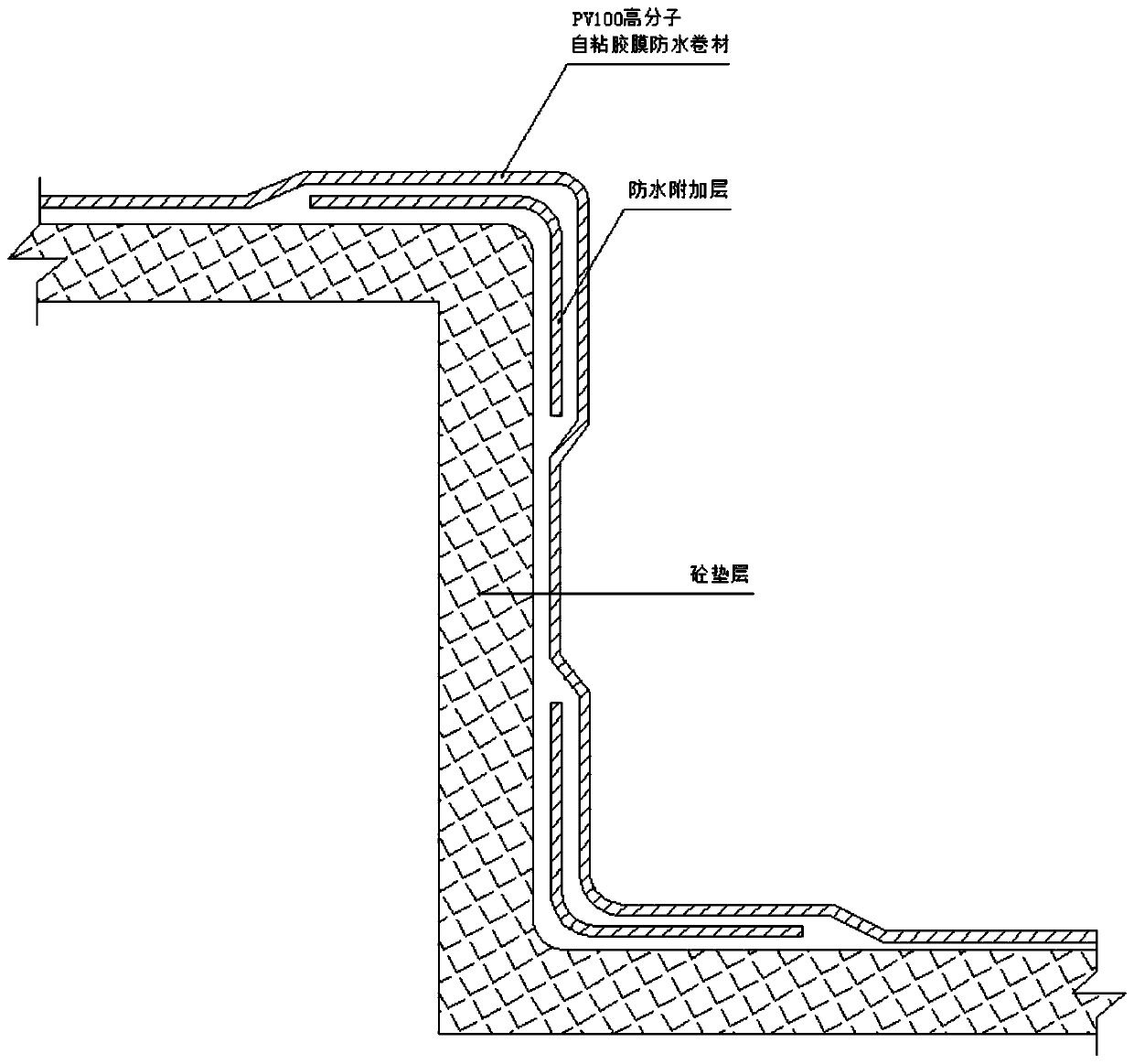

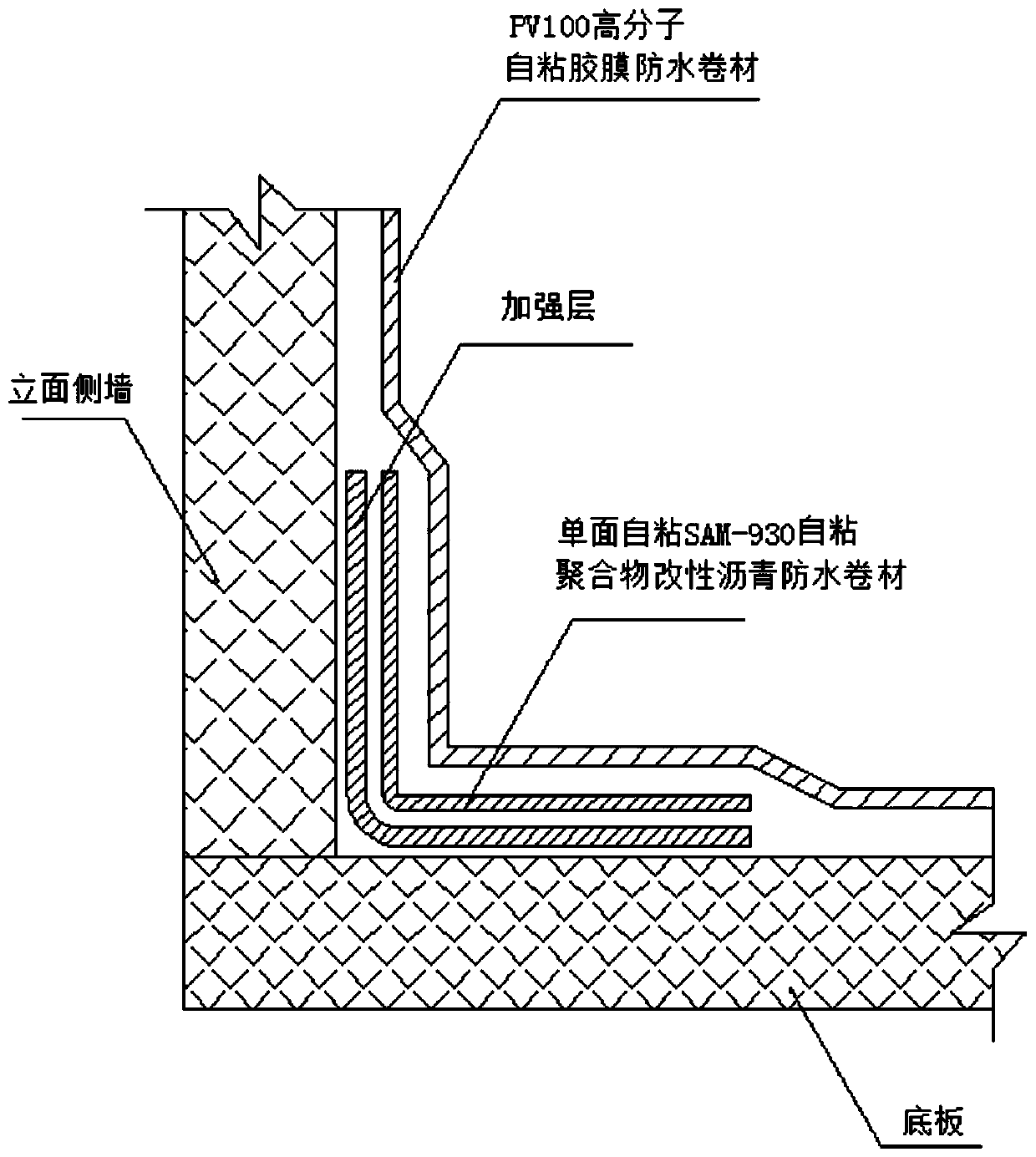

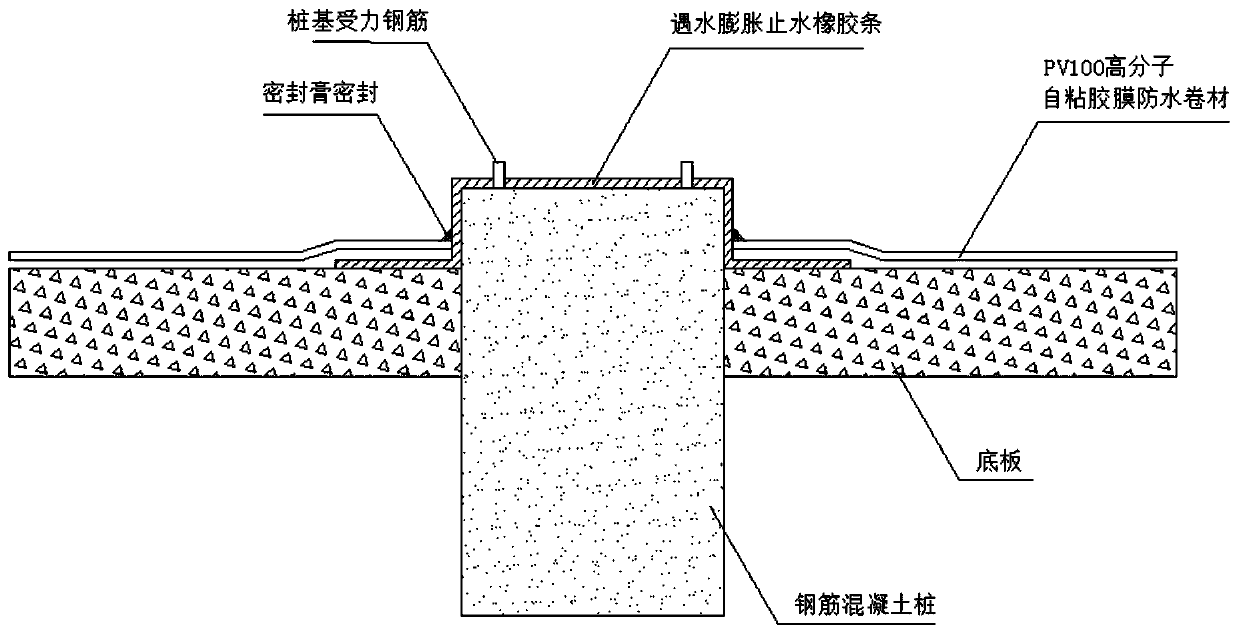

Waterproofing construction method for basement of building engineering

ActiveCN110607809AImprove waterproof performanceStrong toughnessProtective foundationGasketsBasementReinforced concrete

The invention discloses a waterproofing construction method for a basement of building engineering. The method comprises the following steps: S1, dust, sundries, oil stains and visible water on the surface of a base are cleared to make the surface flat and clean; S2, a control line for coil laying is released on the base, so as to accurately control the laying position and lap width of a coil andprevent dislocation, deflection and the like during coil laying; S3, on the basis of foundation treatment and elastic line positioning, construction of 1:2.5 waterproofing mortar is conducted on internal and external corners, the internal and external corners shall be round corners, and R of the arc of the internal and external corners is larger than or equal to 50. Waterproofing performance of inner reinforced concrete is strengthened by the PV100 waterproofing coil, and the PV100 waterproofing coil can form continuous and permanent full adhesion combination with poured concrete, so that water channeling is effectively prevented; the waterproofing coil is tightly adhered to the structure, cannot be affected by uneven settlement of the base, and construction of the next process can be directly performed without construction of a protective layer.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com