Patents

Literature

192 results about "Mortar" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

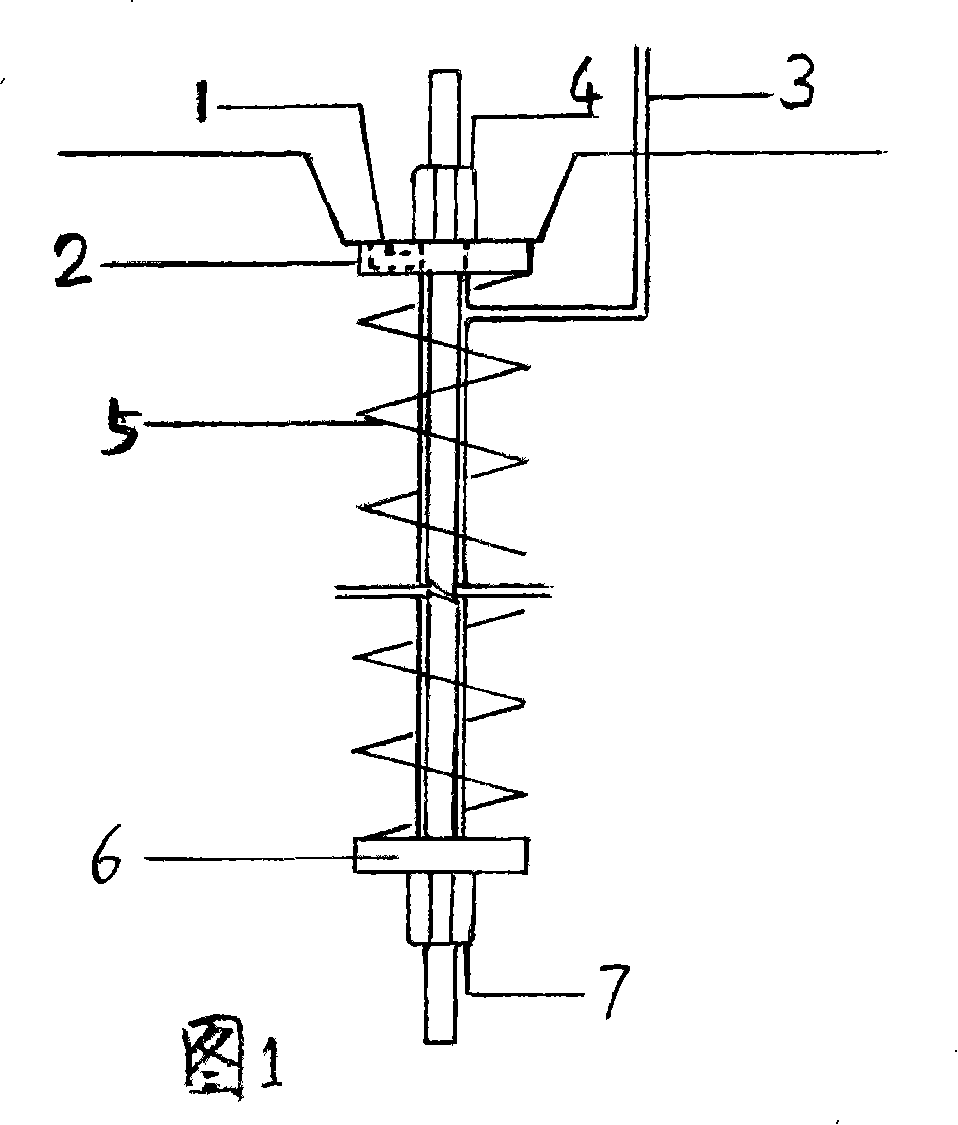

A mortar is usually a simple, lightweight, man portable, muzzle-loaded weapon, consisting of a smooth-bore metal tube fixed to a base plate (to spread out the recoil) with a lightweight bipod mount and a sight. They launch explosive shells (technically called bombs) in high-arcing ballistic trajectories. Mortars are typically used as indirect fire weapons for close fire support with a variety of ammunition.

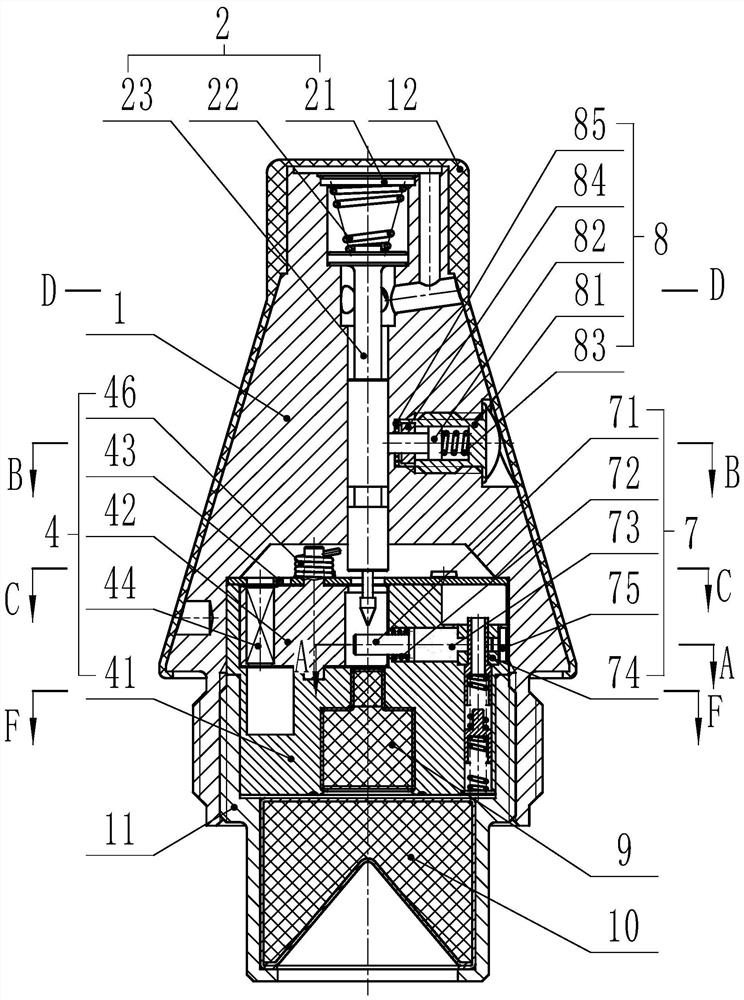

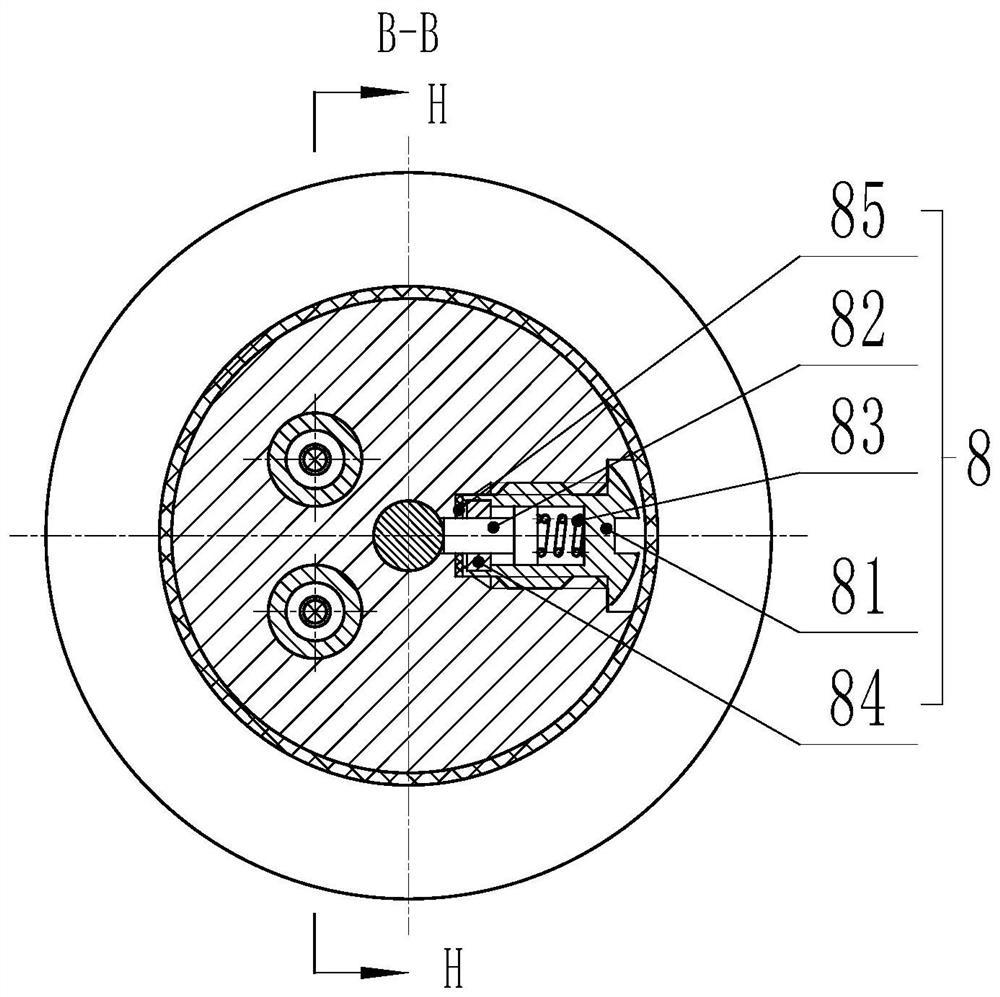

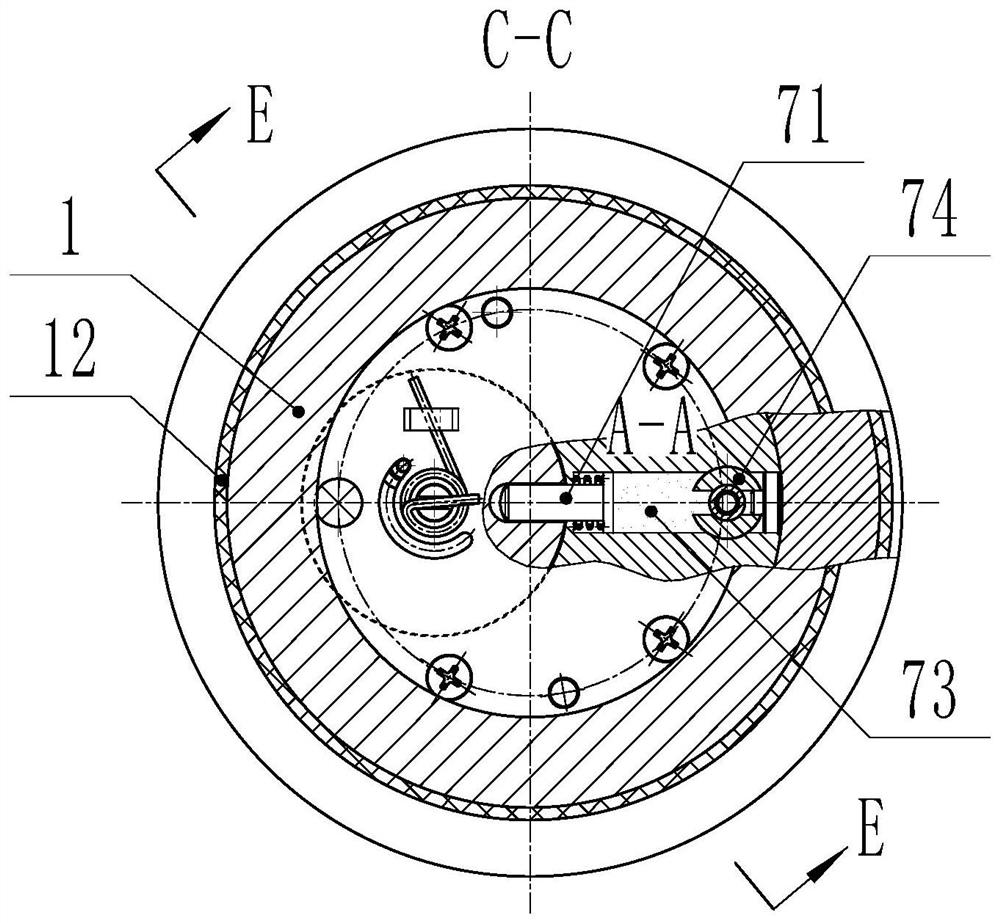

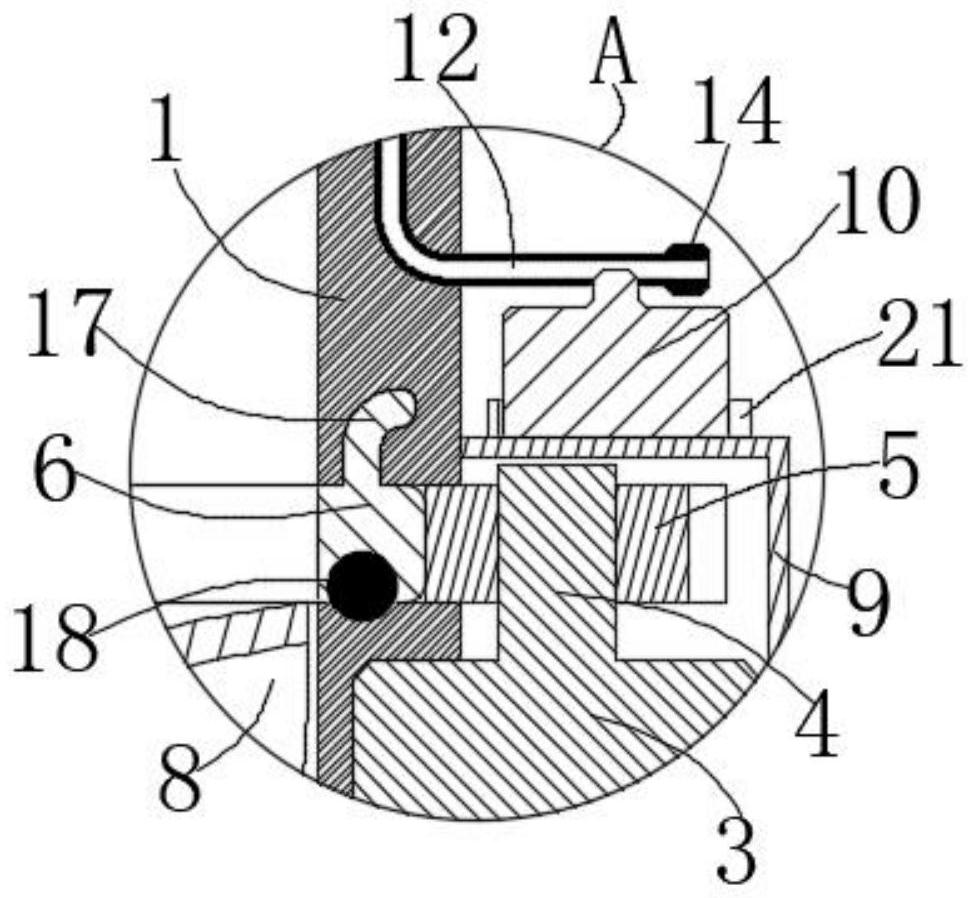

Mortar shell bullet mechanical trigger fuse with penetration time self-adaptive function

The invention discloses a mortar shell bullet mechanical trigger fuse with a penetration time self-adaptive function. The mortar shell bullet mechanical trigger fuse comprises a body, a pneumatic insurance mechanism / trigger ignition mechanism, an inertia ignition mechanism, an explosive-proof mechanism, a recoil insurance mechanism, an anti-recovery mechanism of the recoil insurance mechanism, a delay arming mechanism, a setting mechanism, a detonating tube, a booster tube and a bottom screw. Two insurances of the fuse respectively depend on an inner ballistic environment and an outer ballistic environment during launching to be released, and the two insurances of an explosive-proof piece are both in an insurance state at a filling stage and before getting out of a gun muzzle, so that thesafety is good. A fault insurance characteristic is possessed, in case that the recoil insurance mechanism is accidentally relieved, the fuse can be automatically switched into a fault insurance state, and safety in a credible service processing environment is guaranteed; a booster tube adopts an energy-gathered charging structure, so that the detonating capacity is high; the fuse has the characteristics of redundant ignition and redundant fire insulation, is high in reliability, and can ensure the treatment safety of unexploded ammunition explosives; and the fuse is simple in structure, is easy to process and low in cost.

Owner:NANJING UNIV OF SCI & TECH

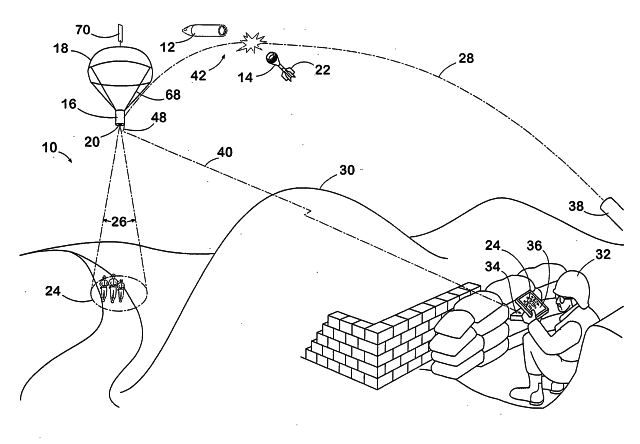

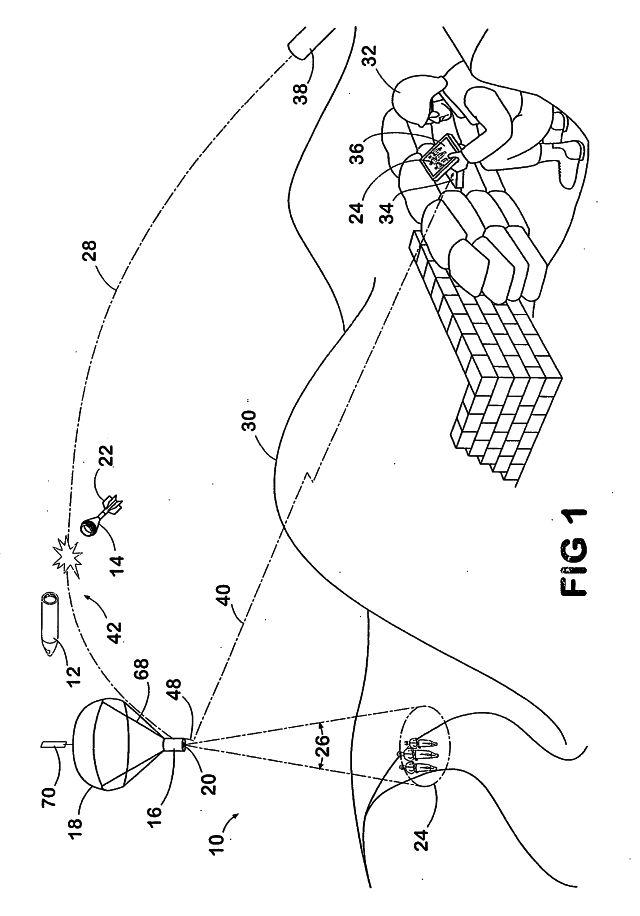

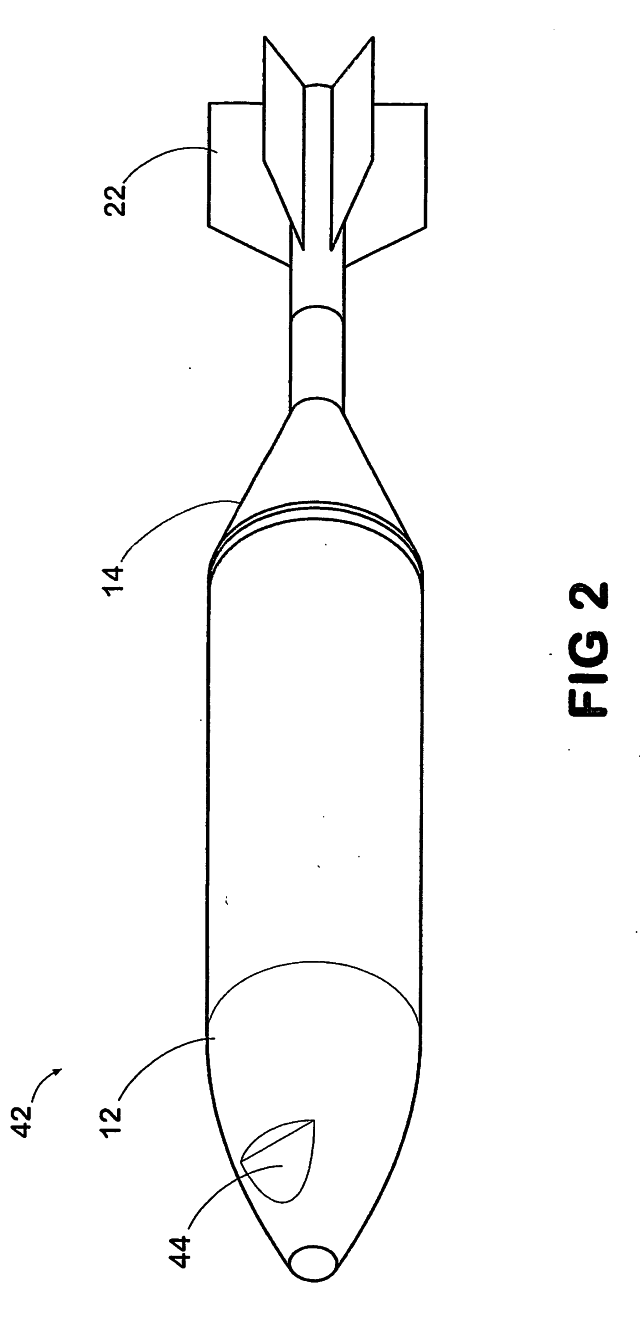

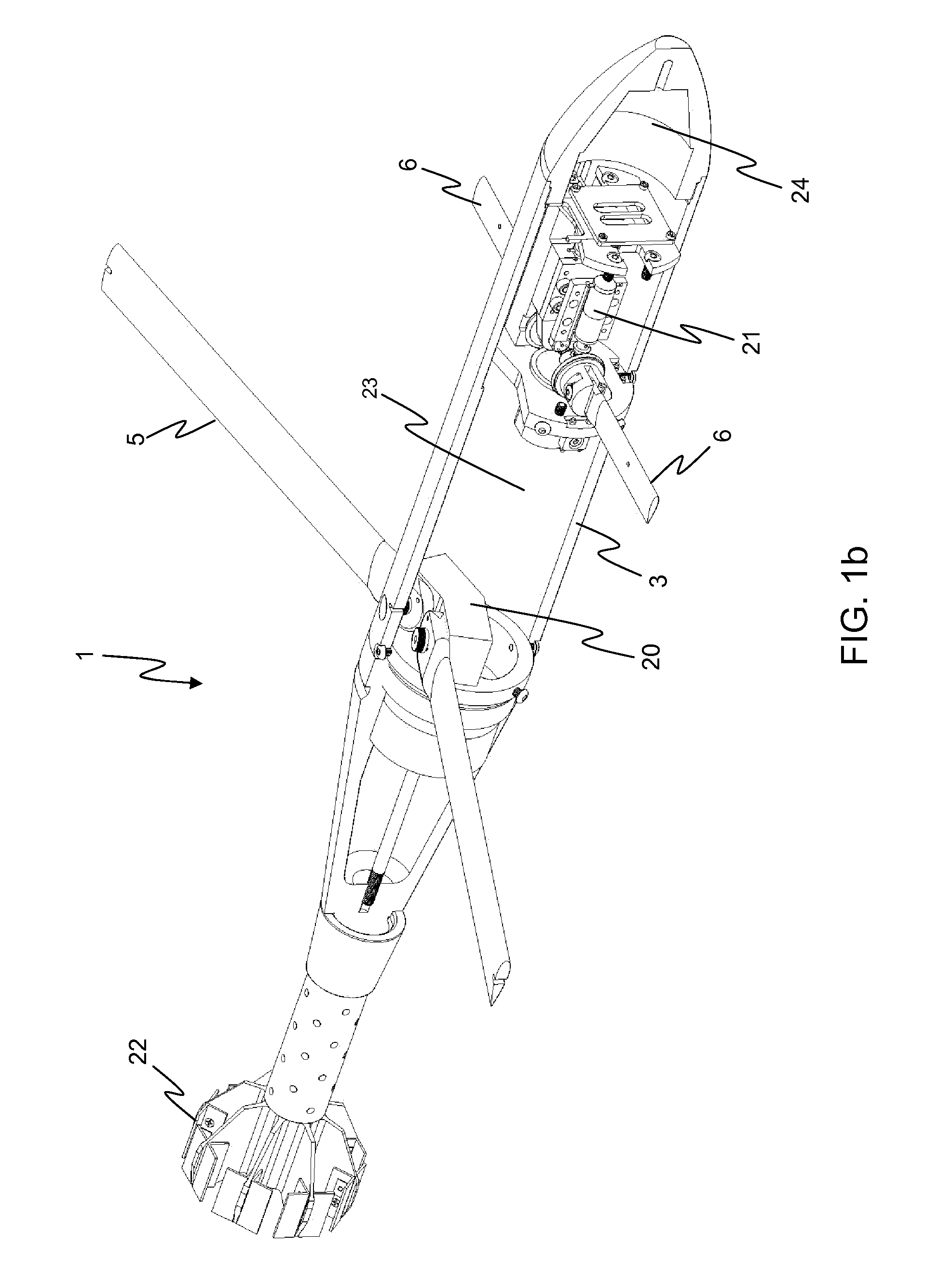

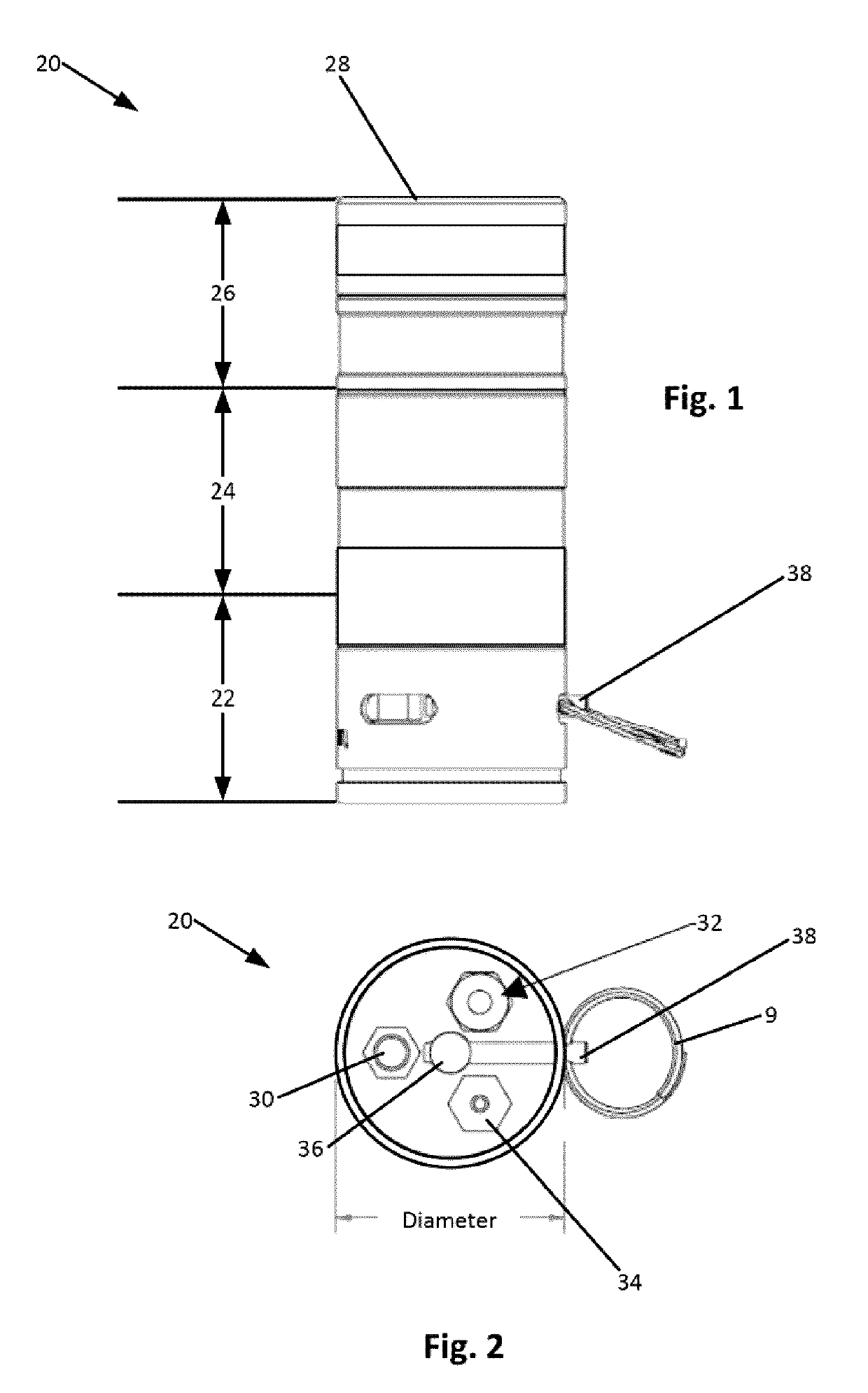

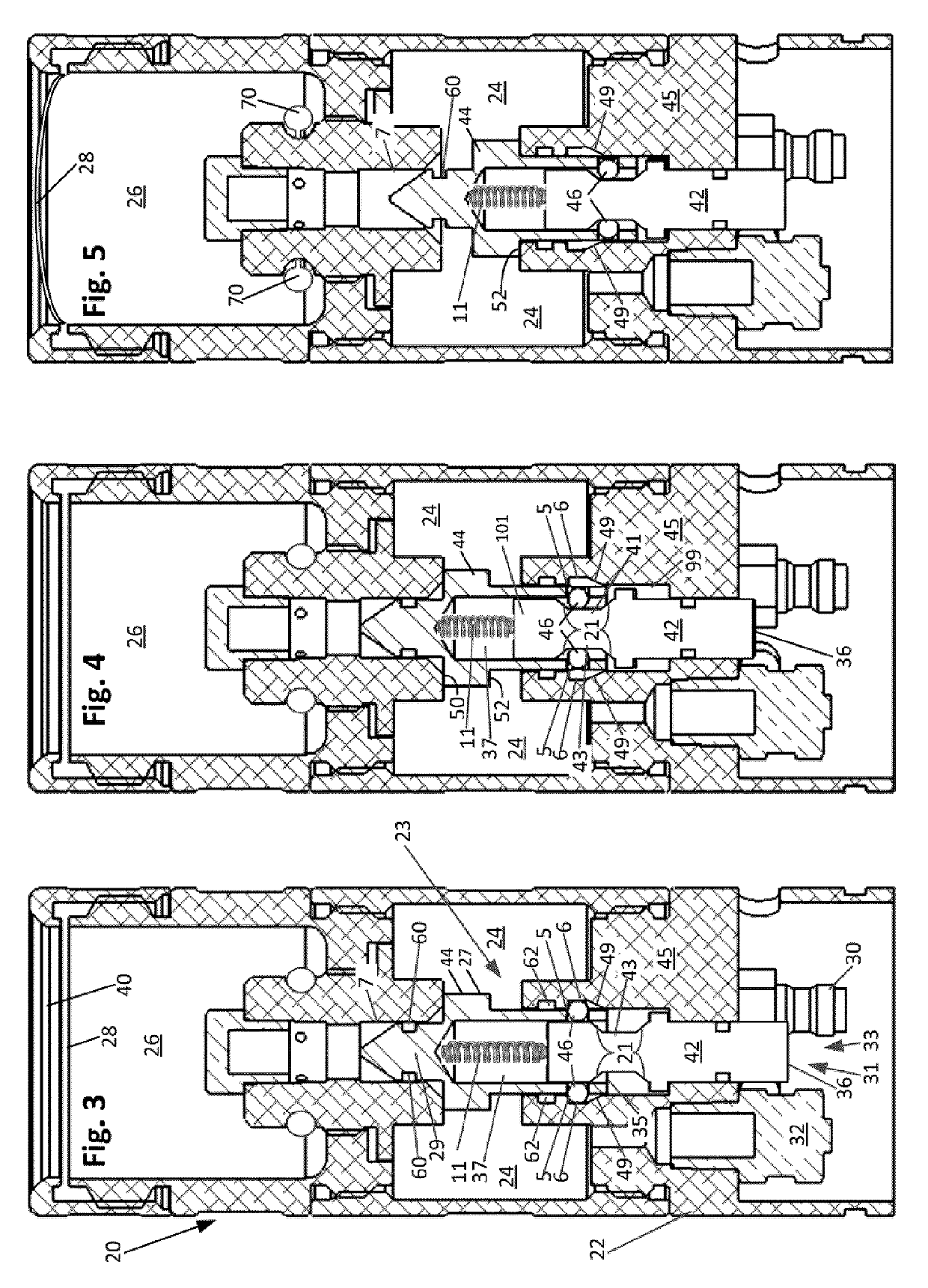

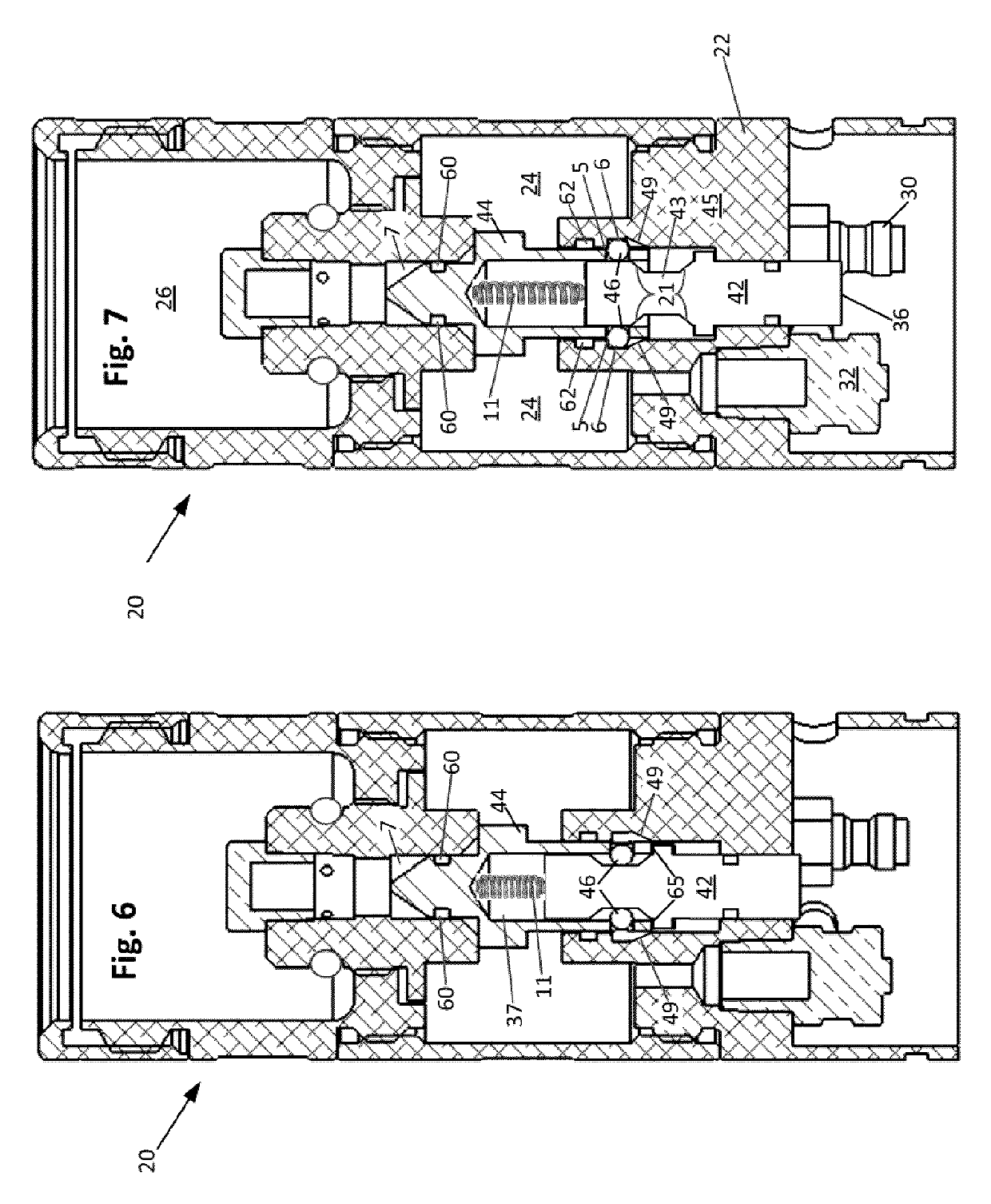

Projectile and System for Providing Air-to-Surface Reconnaissance

InactiveUS20080276821A1Improve position estimationFacilitate the parachute being deployedAmmunition projectilesTraining ammunitionRadio receptionRadio receiver

An aerial reconnaissance projectile, such as a mortar, is launched for viewing a battlefield scene. A reconnaissance section is released from the projectile and conveys back pictures of the battlefield scene taken by a camera and transmitted by radio to a ground position for viewing on a video screen. The reconnaissance section; may have an inertia measurement unit for determining its position over the battlefield scene. The projectile containing the reconnaissance equipment may be a convention mortar round or a rocket projectile. This aerial reconnaissance projectile is capable of carrying sensors for chemical, biological or nuclear activity on the surface area being traversed or intercepting radio signals from the ground and conveying this information by radio to a ground position with a radio receiver.

Owner:GEORGIA TECH RES CORP

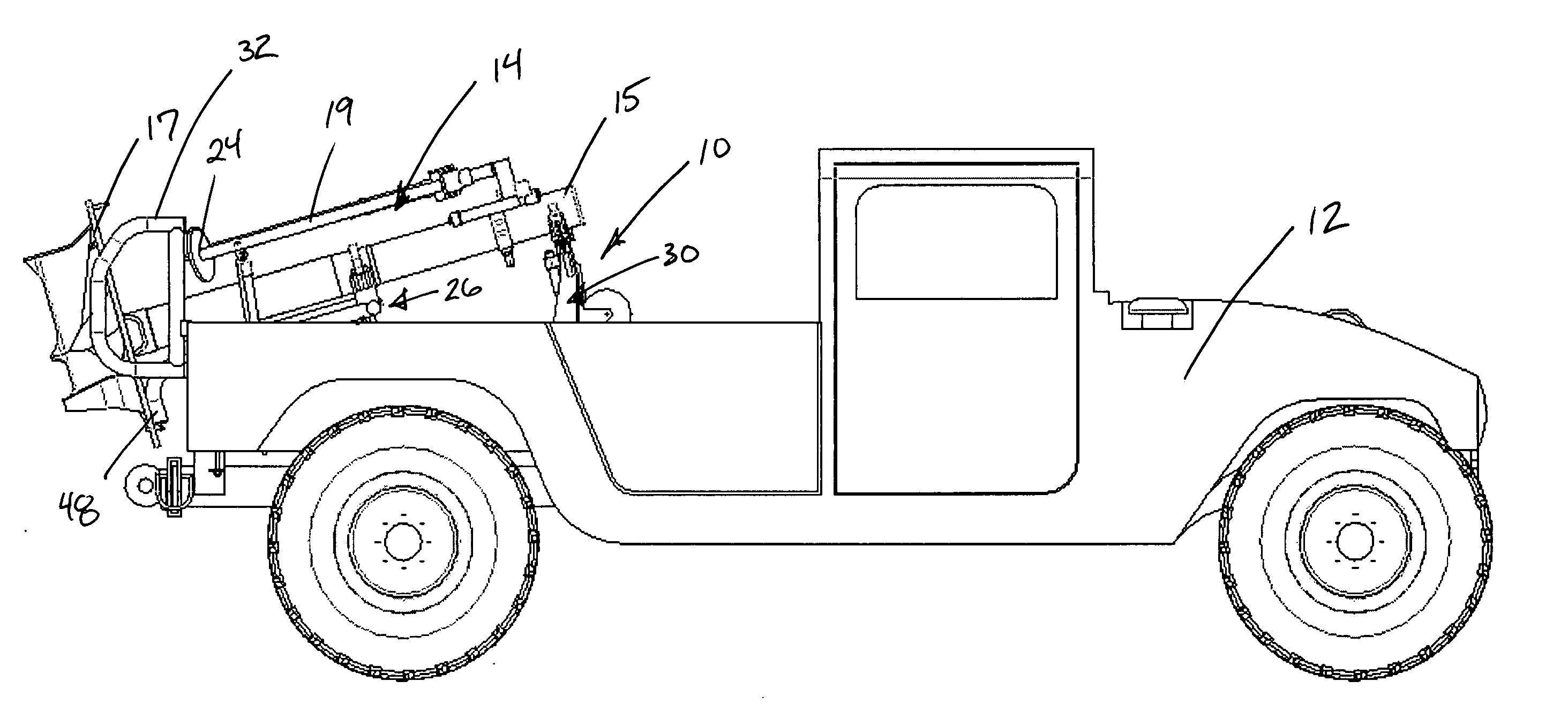

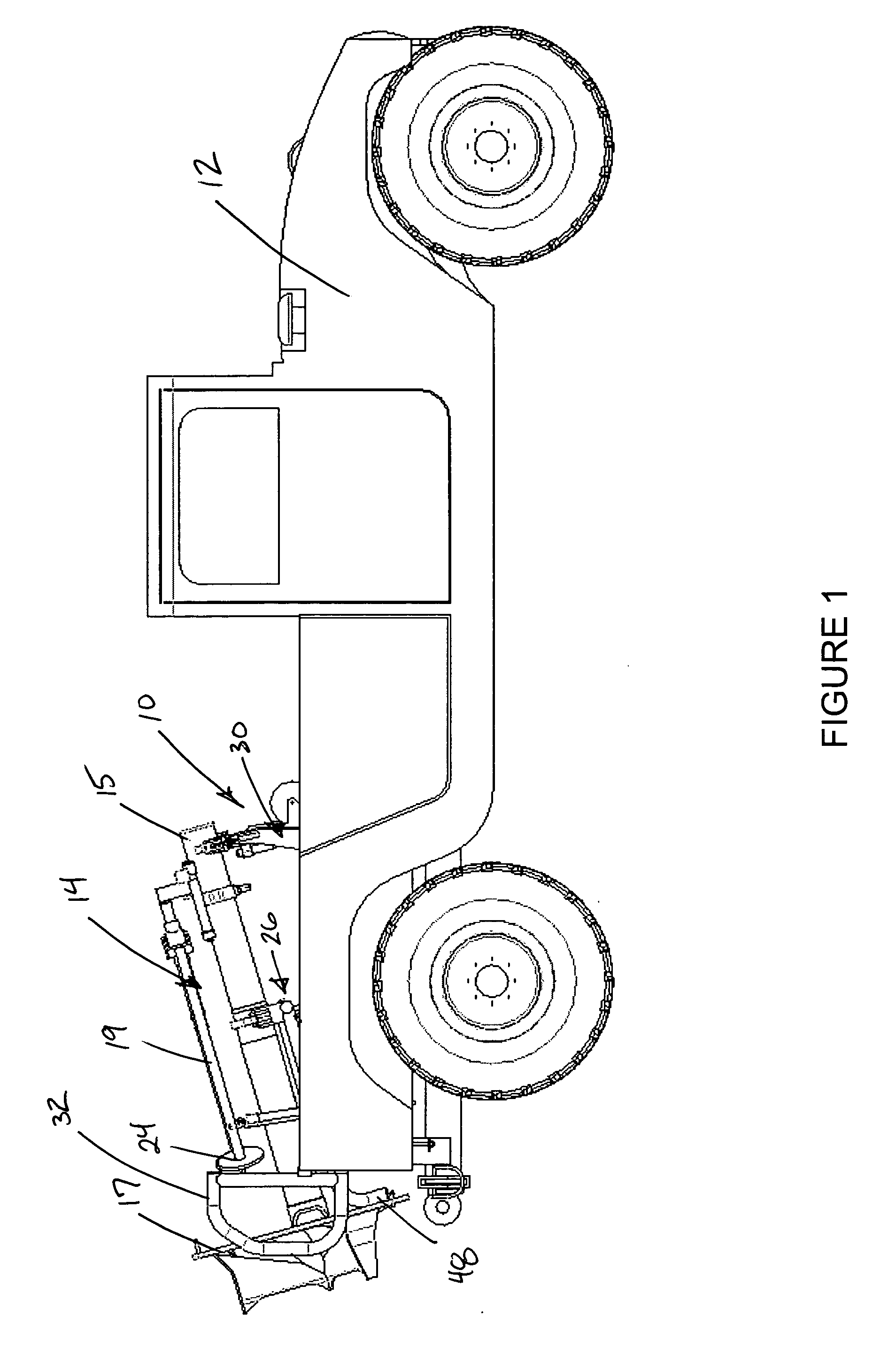

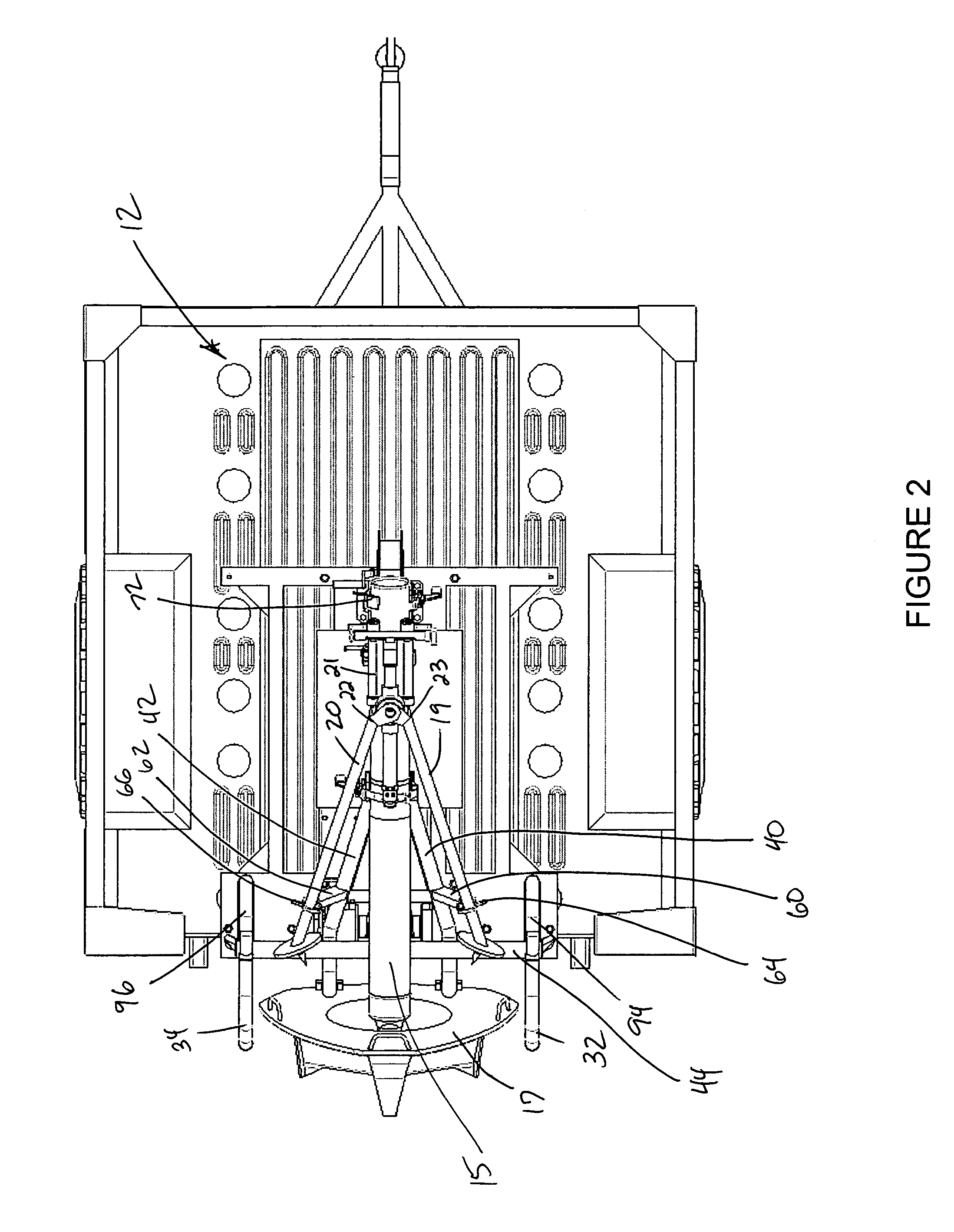

Mortar deployment and storage system

InactiveUS20050241468A1Avoid relative motionHand carts with one axisRefuse vehiclesBraced frameEngineering

A system for stowing and deploying a mortar from a transport vehicle employs a hoist mechanism, a support frame, a pair of guide arms and a barrel-support strut attached to a transport vehicle. The support frame is adapted to be temporarily engaged with the mortar barrel, the base plate and the pair of stabilizer arms of the mortar to prevent relative motion between them during stowing and deployment. The hoist mechanism has a lift arm that pivots between a retracted and a deployed position. One end of the lift arm is hook shaped for detachable engagement with the support frame. A pair of guide arms extend in spaced parallel relation from the rear of the vehicle and serve to guide a trajectory of the mortar as it is being stowed or lowered to the ground.

Owner:BAE SYSTEMS LAND & ARMAMENTS LP

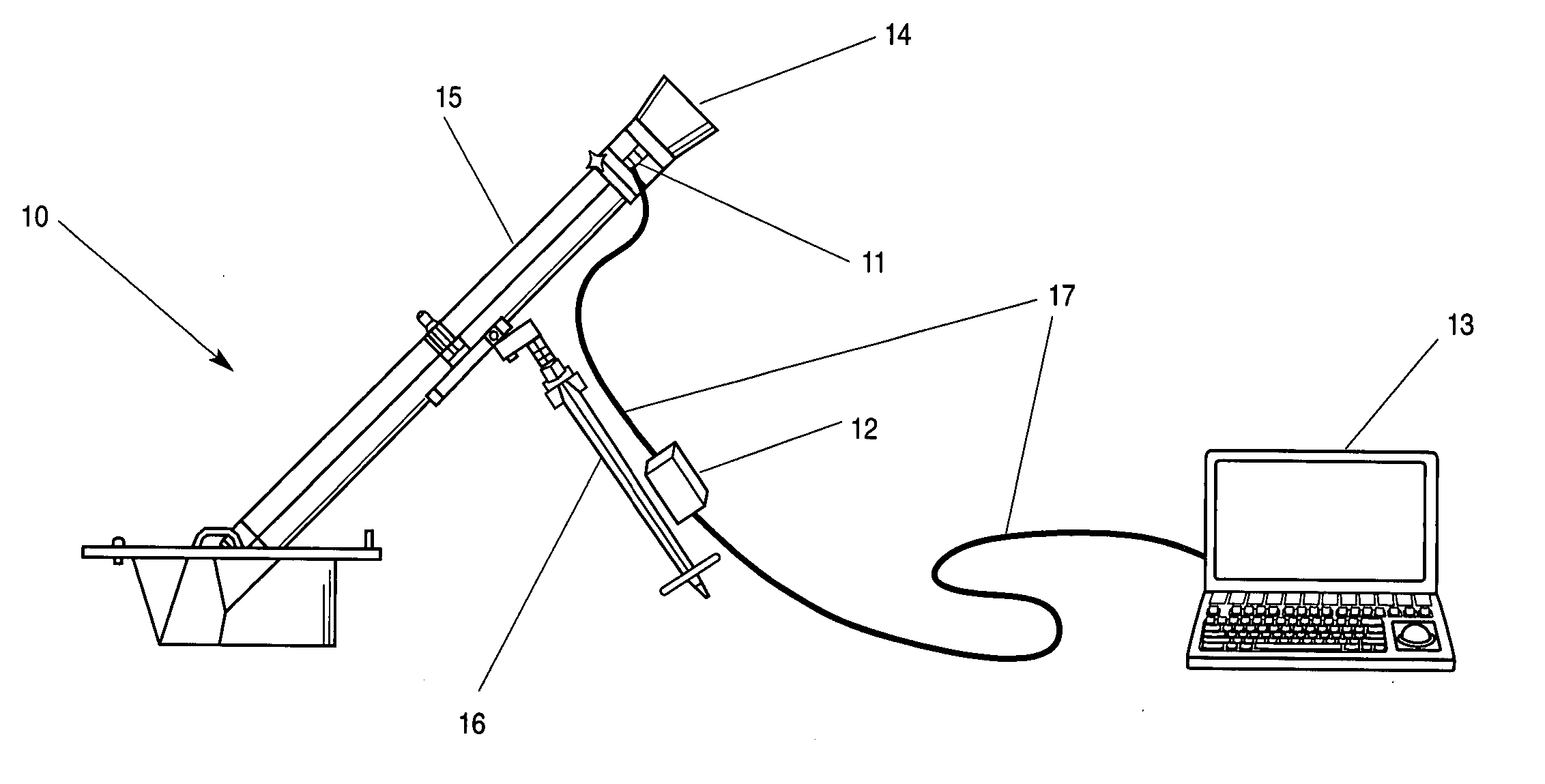

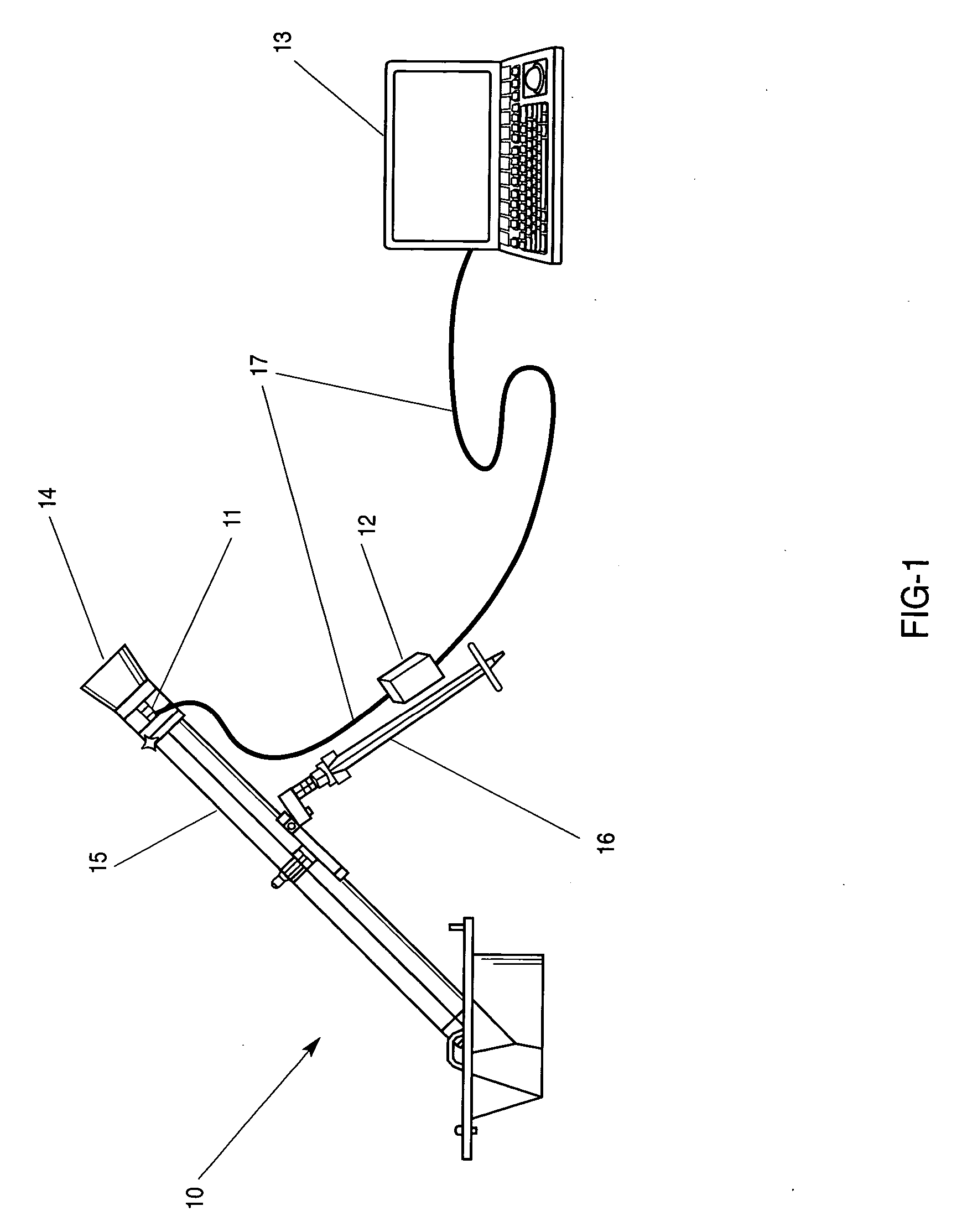

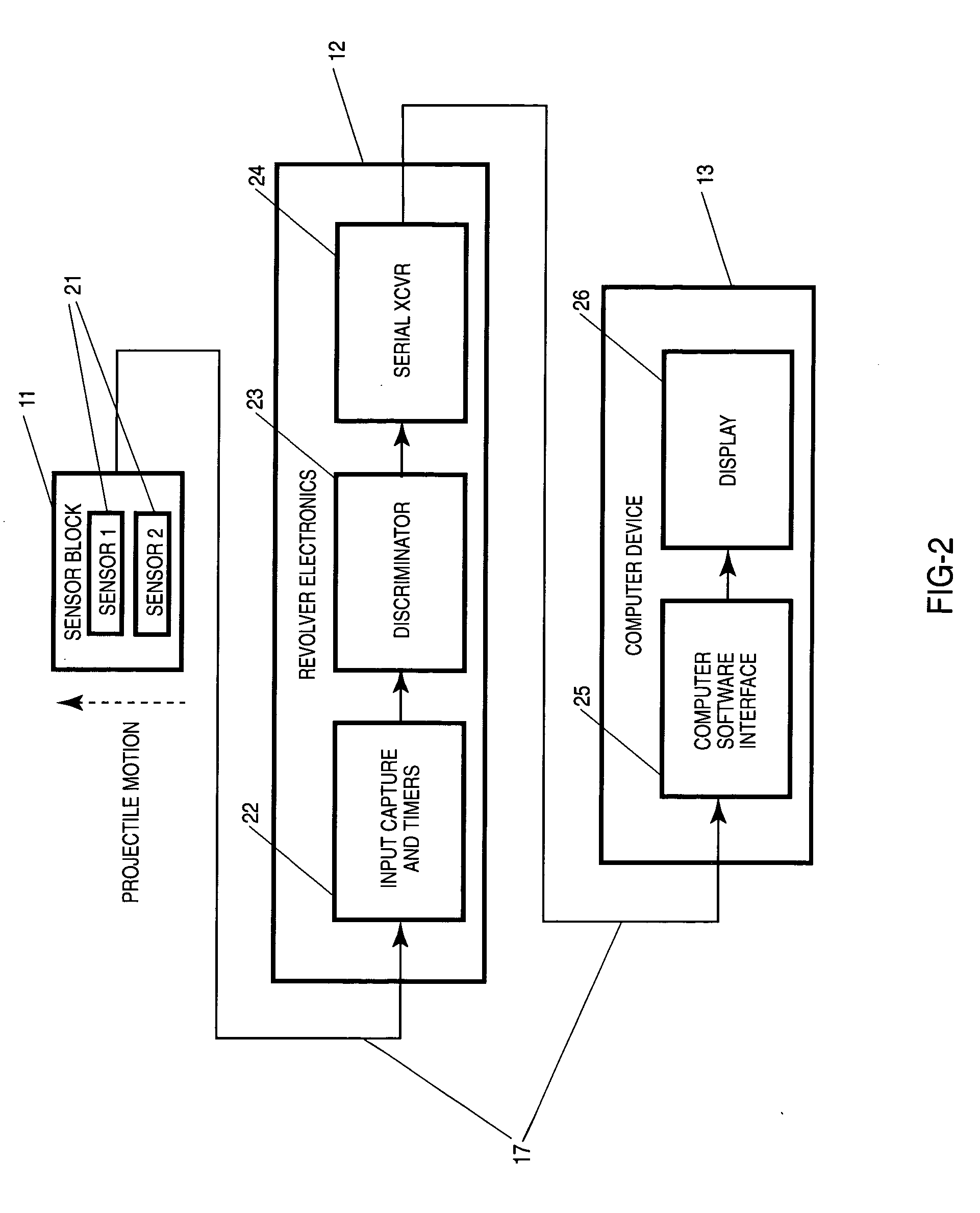

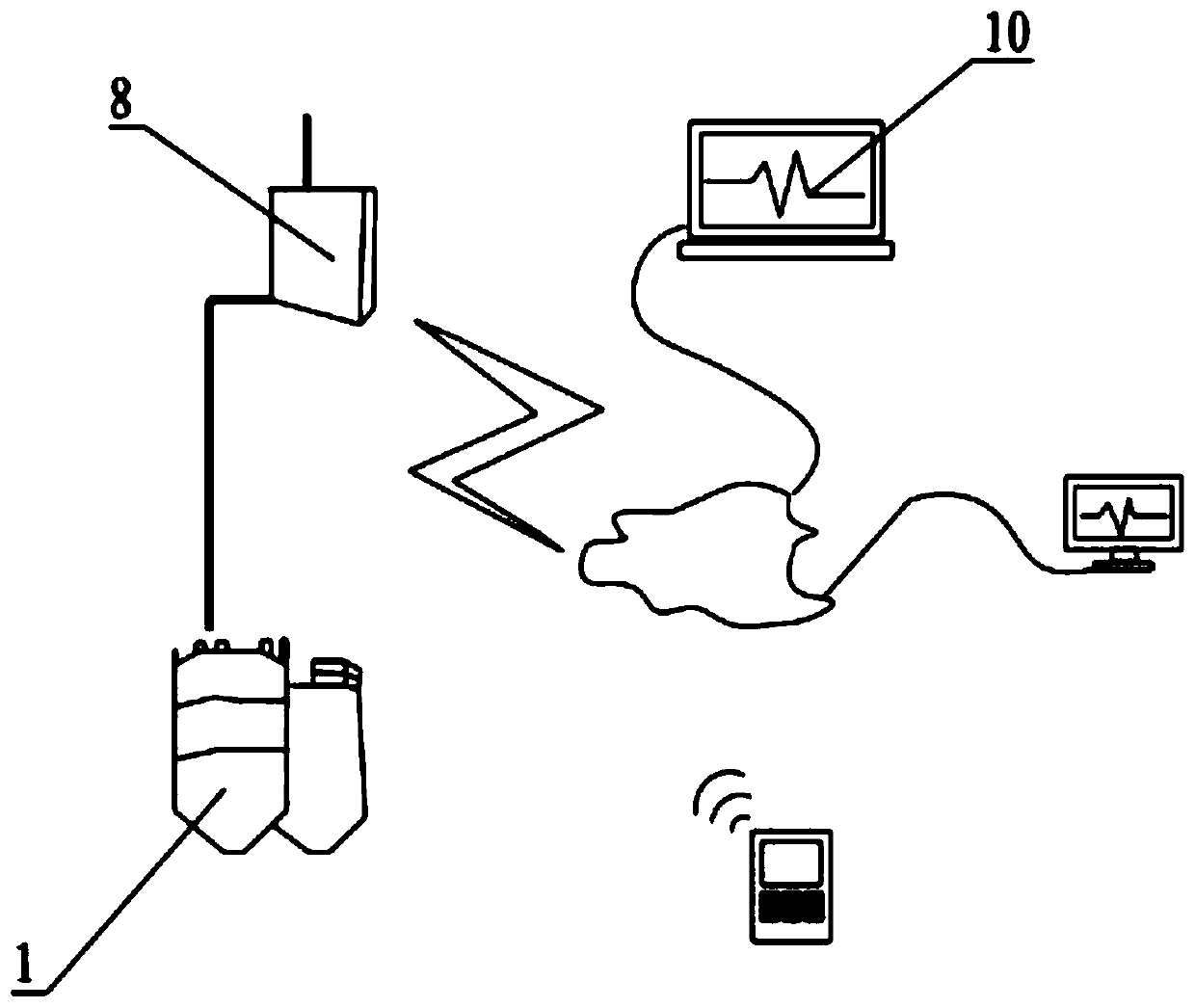

Digital signal processing back biased hall effect muzzle velocity measurement system

InactiveUS20060156804A1Simple installation designReduce power consumptionLinear/angular speed measurementMuzzle attachmentDigital signal processingMortar

A system for precisely measuring muzzle exit velocity of a “muzzle loaded” mortar projectile fired from a mortar tube using two back-biased Hall effect sensors for projectile gas ring channel detection. The system includes a back-biased Hall effect sensor block, a digital resolver electronic circuit and a computer software interface. The back-biased Hall effect sensors are located in a calibrated sensor block attached to a mortar tube. As the projectile metal casing passes a face of the sensors, the sensors trigger and release, providing two electronic pulses. The pulse edges are captured in the resolver electronics, containing a discriminator circuit for filtering all input pulses to distinguish between a projectile loading event and a projectile firing event. Once a valid firing event is detected, an output of precision timers is presented serially to a computer where it is processed and displayed by a computer software interface.

Owner:HONEYWELL INT INC

Large Gauge Pneumatic Launcher

A large gauge pneumatic launcher is disclosed to contain an innovative valve and valve chassis that enables said launcher to safely operate at compressed air pressures of 200-1000 psi, and launch large caliber paintball, Non-Lethal Weapon or other projectiles. The invention may be attached to an existing “host” paintball marker as an under-barrel second weapon. The valve and valve assembly may be fitted for use as a stand alone launching platform such as a pneumatic mortar, cannon or other system powered by compressed gas.

Owner:WARNOCK GREGORY LEE

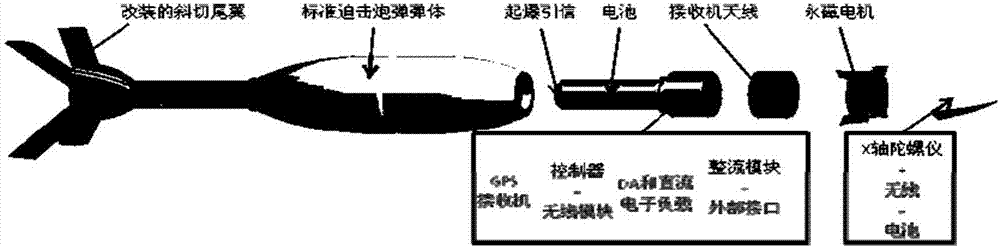

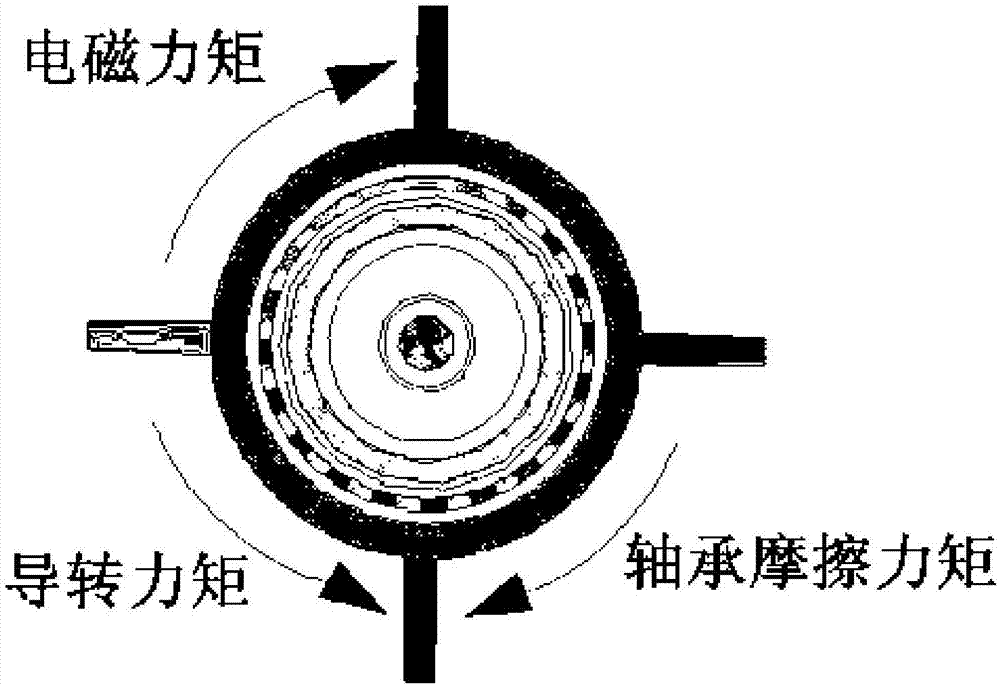

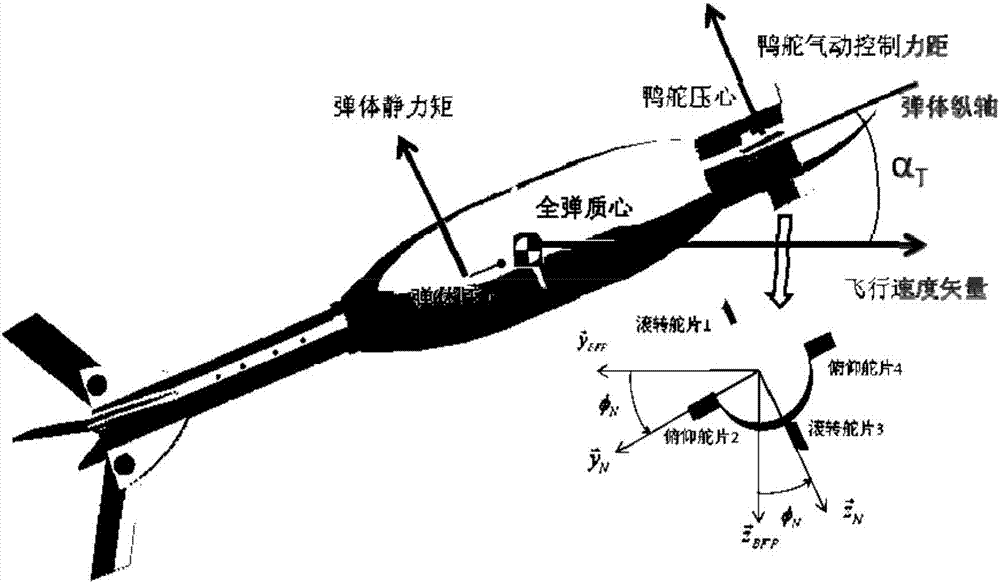

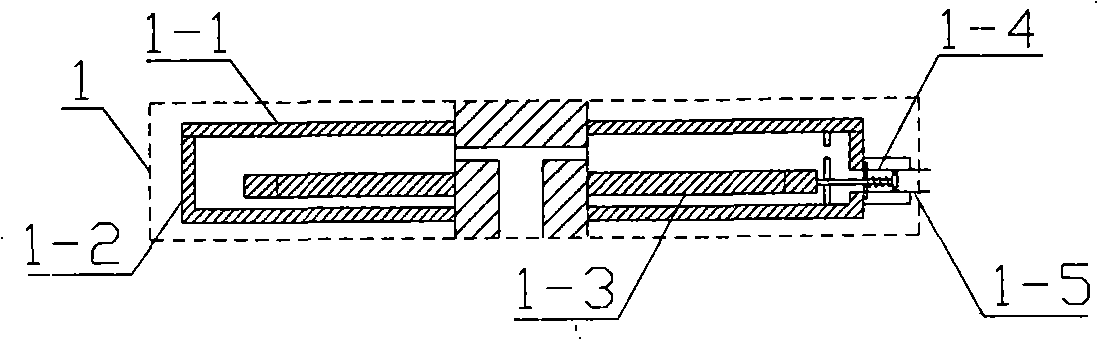

Control system arranged on projectile body

The invention discloses a control system arranged on a projectile body. The control system comprises a fixed wing canard rudder and a control assembly as a permanent magnet motor and a controller used for controlling the permanent magnet motor, wherein the control assembly is arranged at a control cabin on the front part of the projectile body; the permanent magnet motor comprises a rotor, a stator and a bearing; the stator is fixedly arranged on a longitudinal shaft of the projectile body; the rotor is arranged at the periphery of the stator; the rotor and the stator are connected through the bearing; the controller is arranged in the control cabin, and is connected with the longitudinal shaft through a control circuit; the fixed wing canard rudder is arranged on the outer wall of the rotor, and comprises two pairs of rudder plates with a fixed rudder angle; one pair of rudder plates is reverse in deflecting direction, and is used for providing external pneumatic angular moment needed for reverse rotation of the canard rudder; and the other pair of the rudder plates is the same in deflecting direction, and is used for providing pneumatic-control moment vector of posture adjustment of the projectile body. The control system arranged on the projectile body is arranged, so that cost and the size of the control cabinet of a mortar projectile can be greatly reduced, and a cost-benefit ratio is greatly increased.

Owner:BEIJING AEROSPACE AUTOMATIC CONTROL RES INST

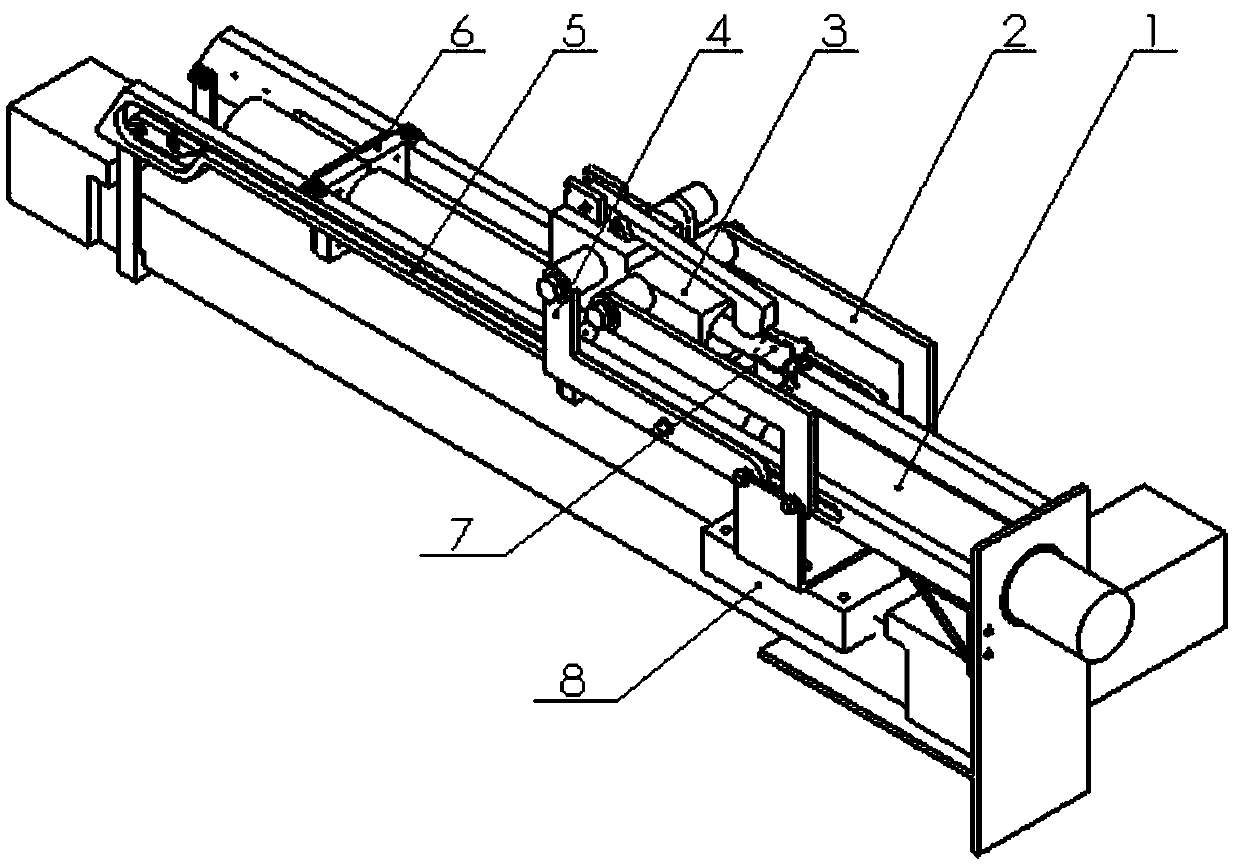

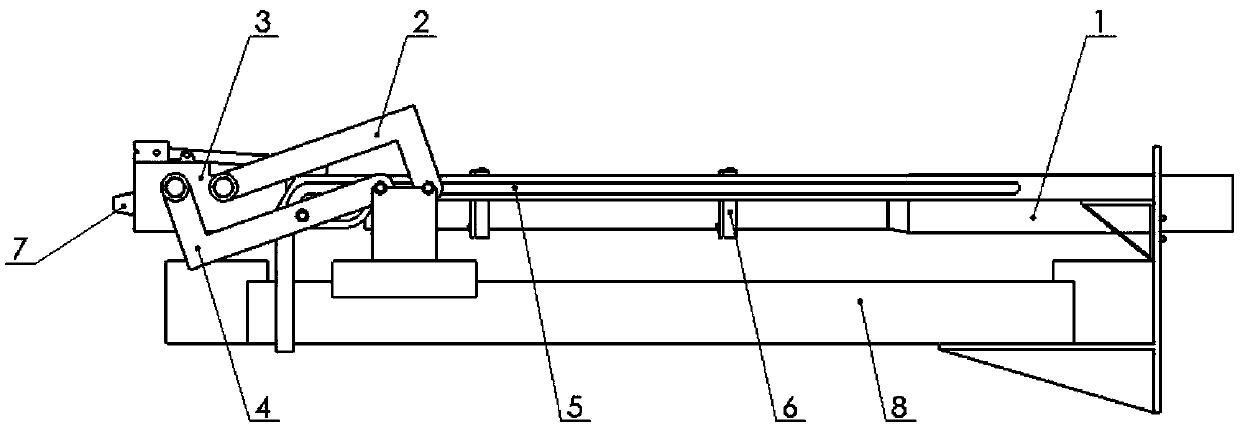

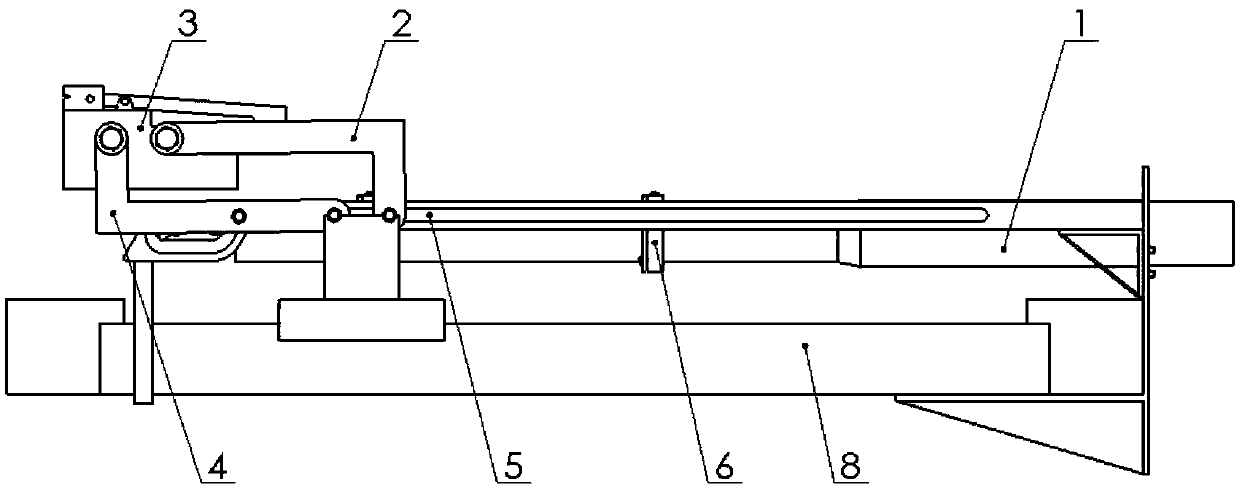

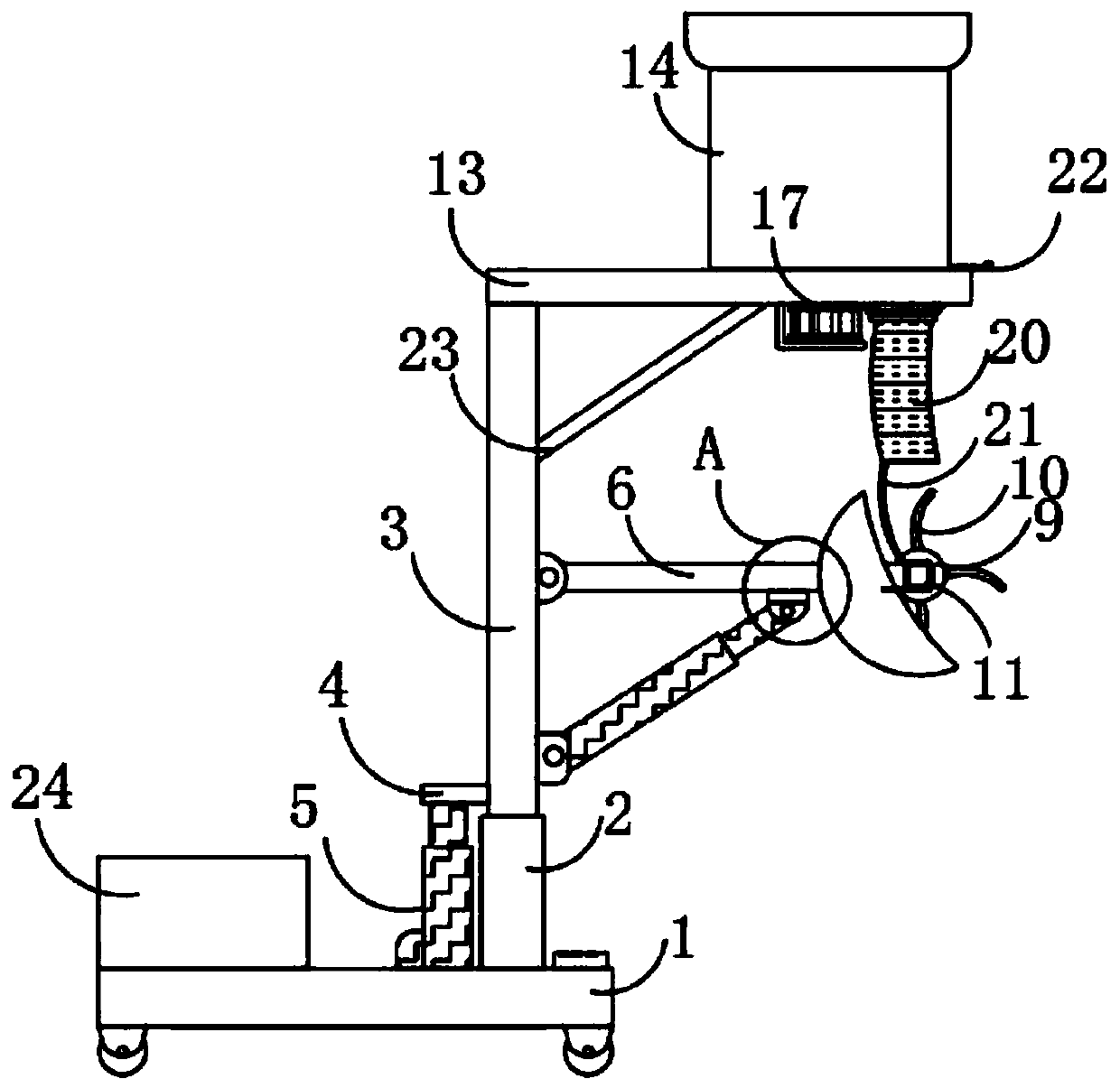

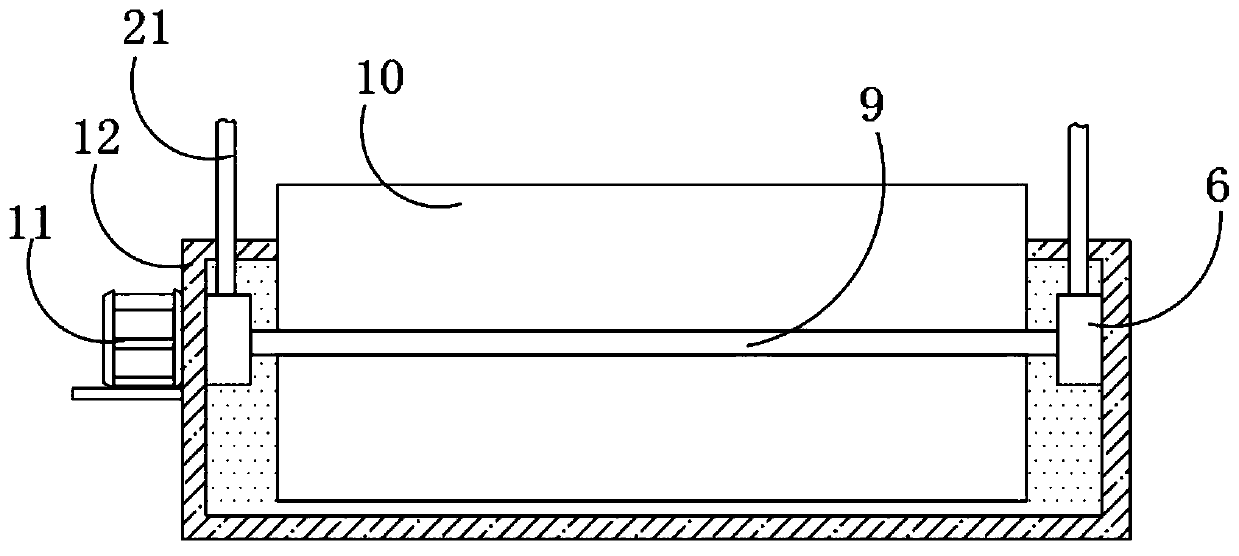

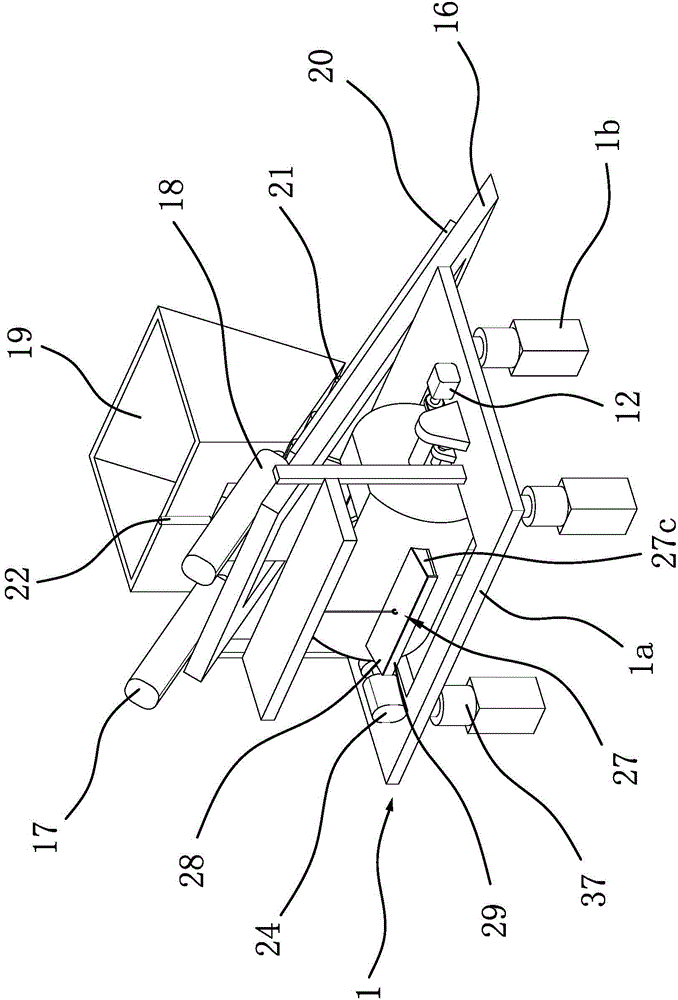

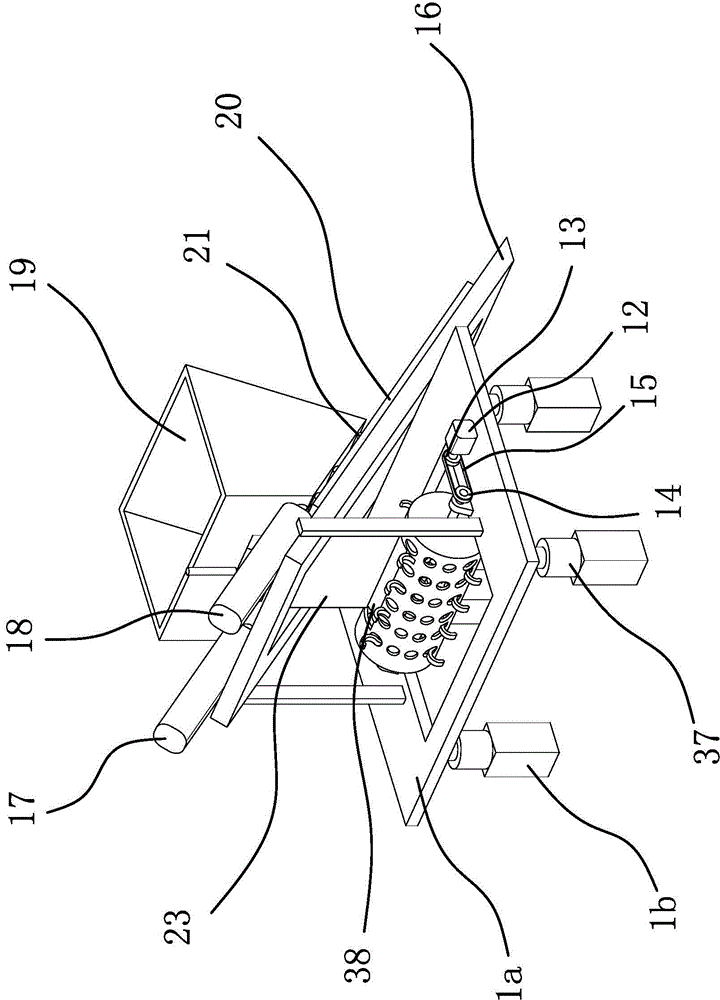

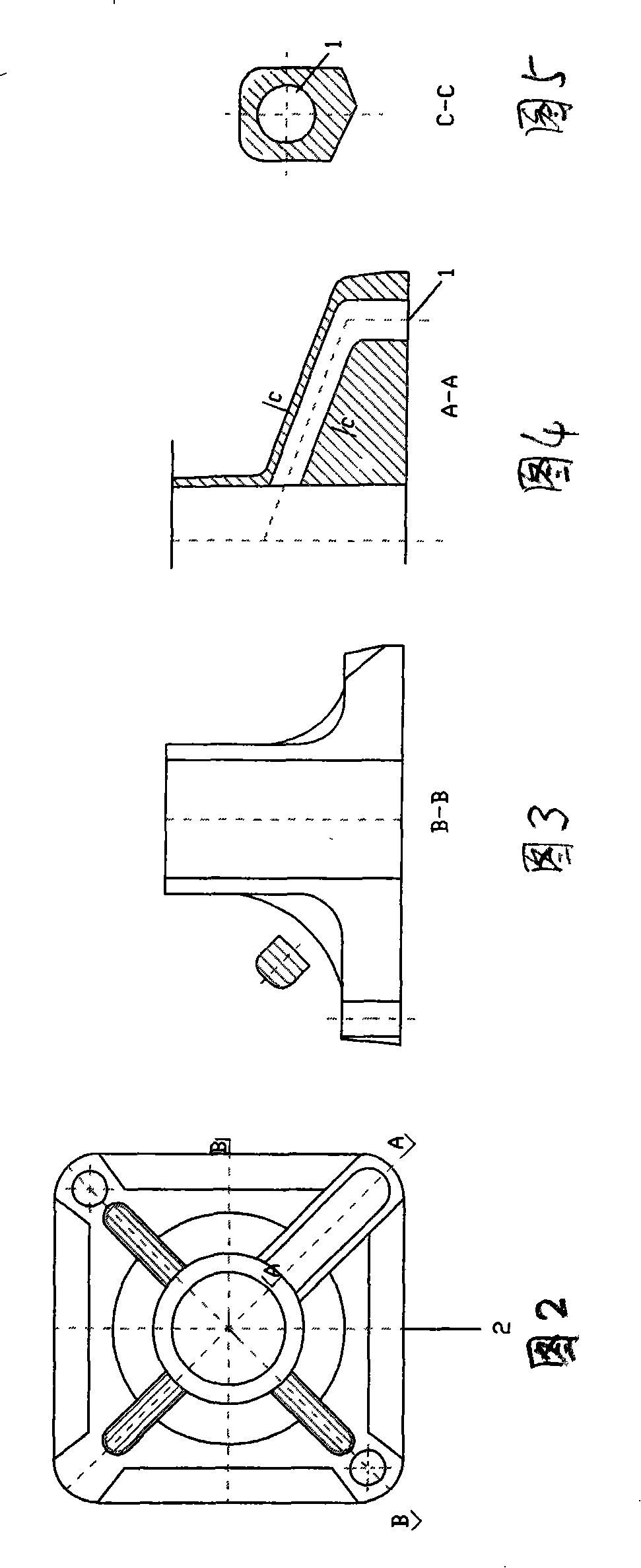

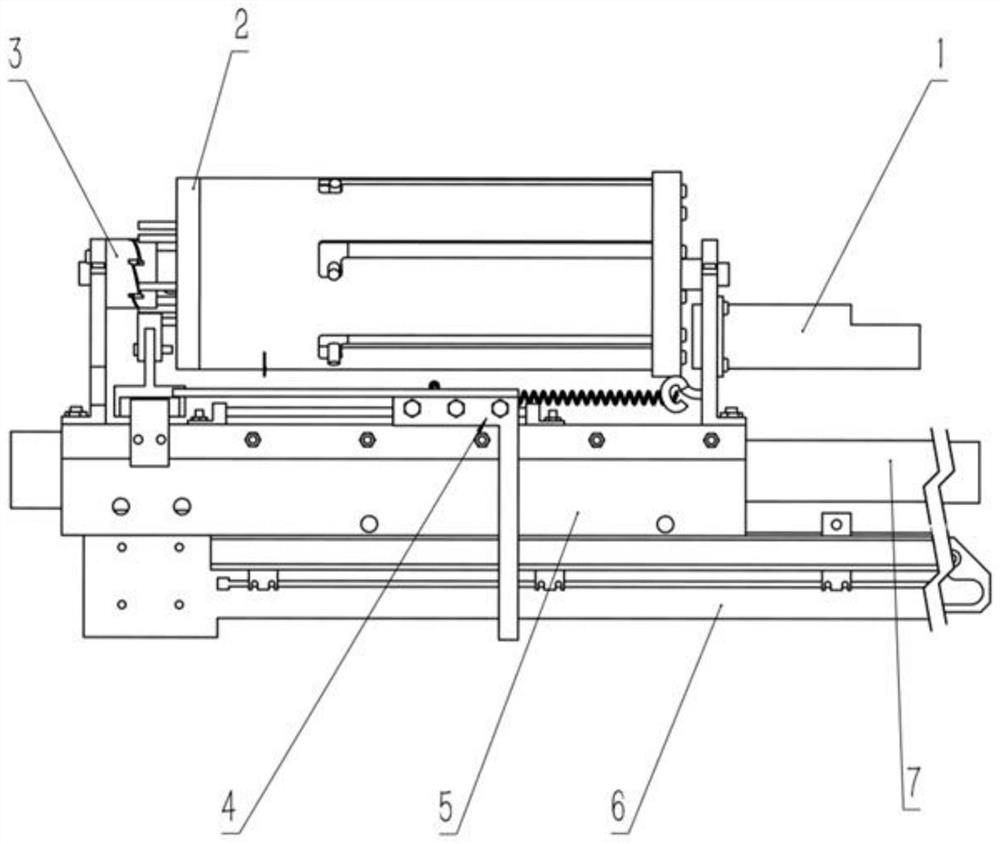

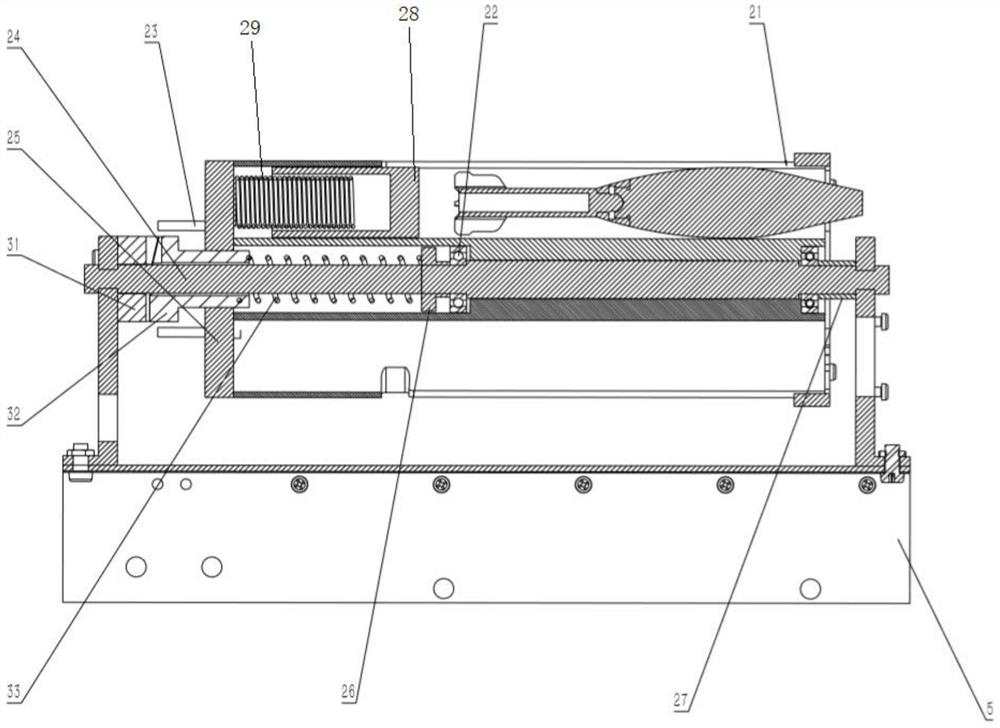

Mine thrower automatic front loading device and loading method thereof

The invention discloses a mine thrower automatic front loading device and a loading method thereof. The mine thrower automatic front loading device is used for achieving automatic loading of mine thrower shells and comprises a driven arm, a shell supporting device, a driving arm, a guide rail and a power system. The shell supporting device is used for clamping shells. The power system is used fordriving the front driven arm to move on the guide rail, and therefore the shell supporting device is driven to convey shells to a muzzle, and a curved trough on the guide rail is used for controllinga swing arm to complete loading. By means of the mine thrower automatic front loading device, mine thrower loading automation can be achieved, reliability is high, stability is good, manpower is saved, shells are supplied rapidly, the device can be used for replacing manual loading, the fighting efficiency is improved, and the hurt to personnel can be reduced.

Owner:NANJING UNIV OF SCI & TECH

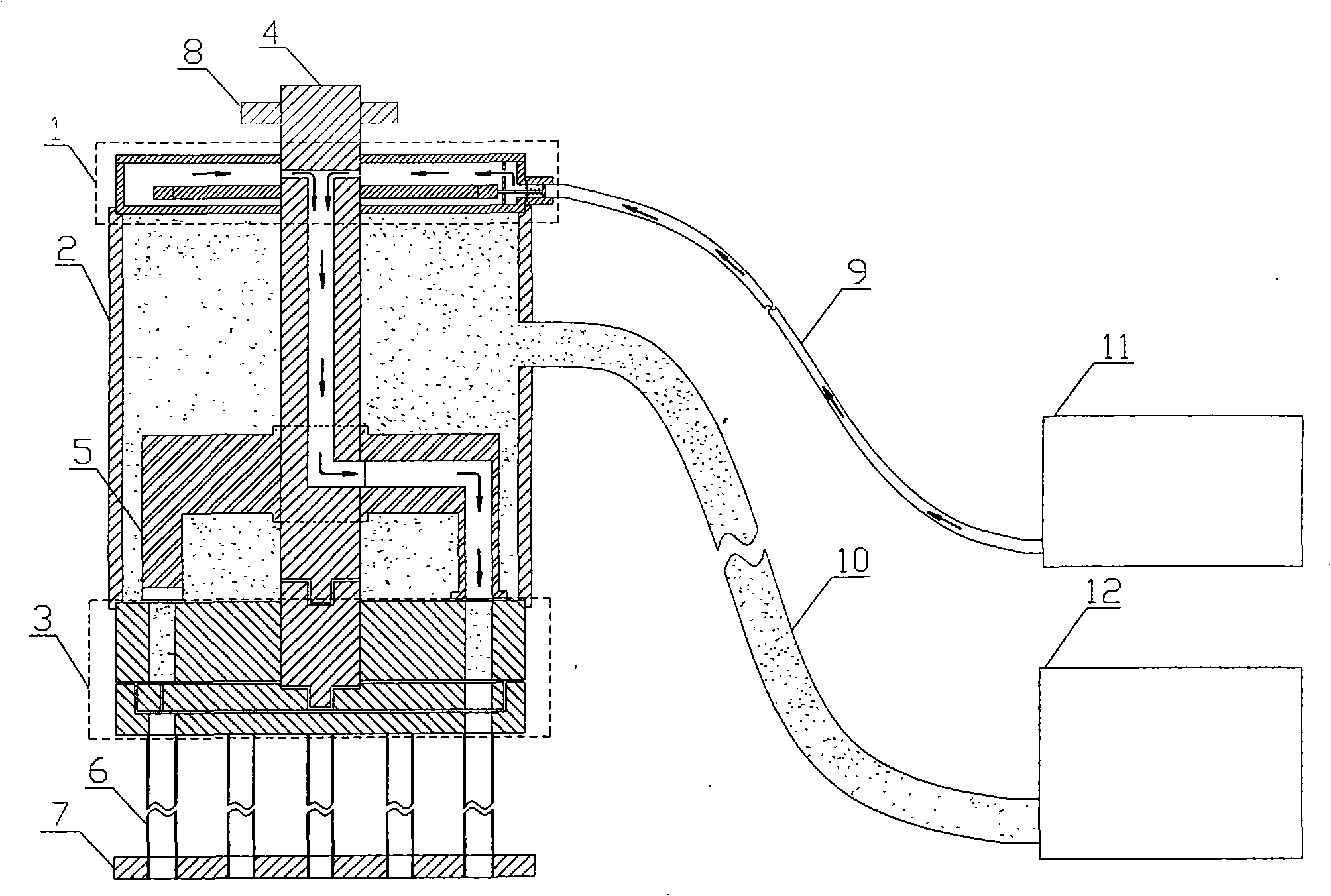

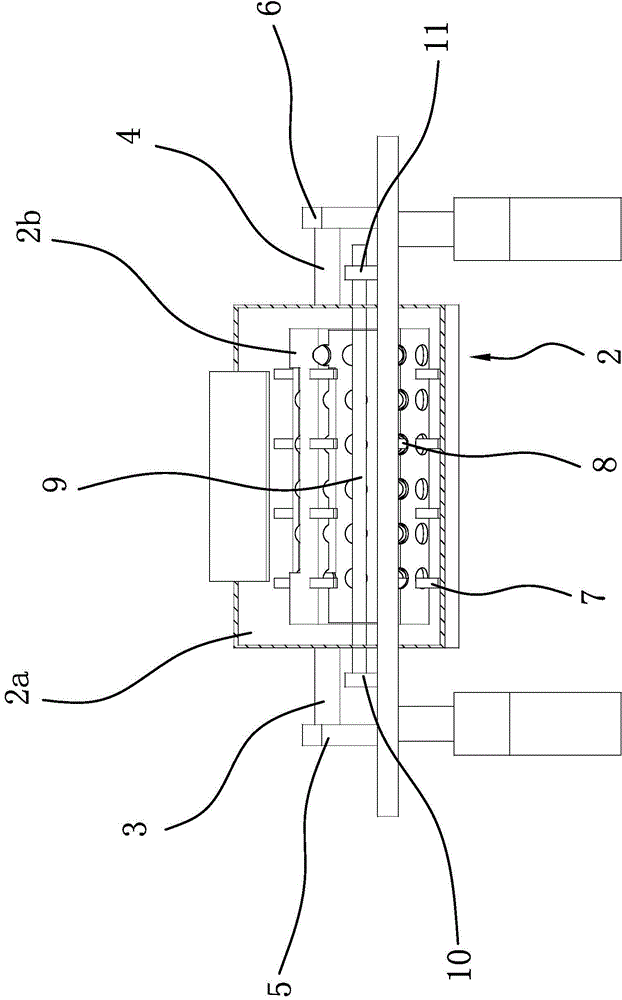

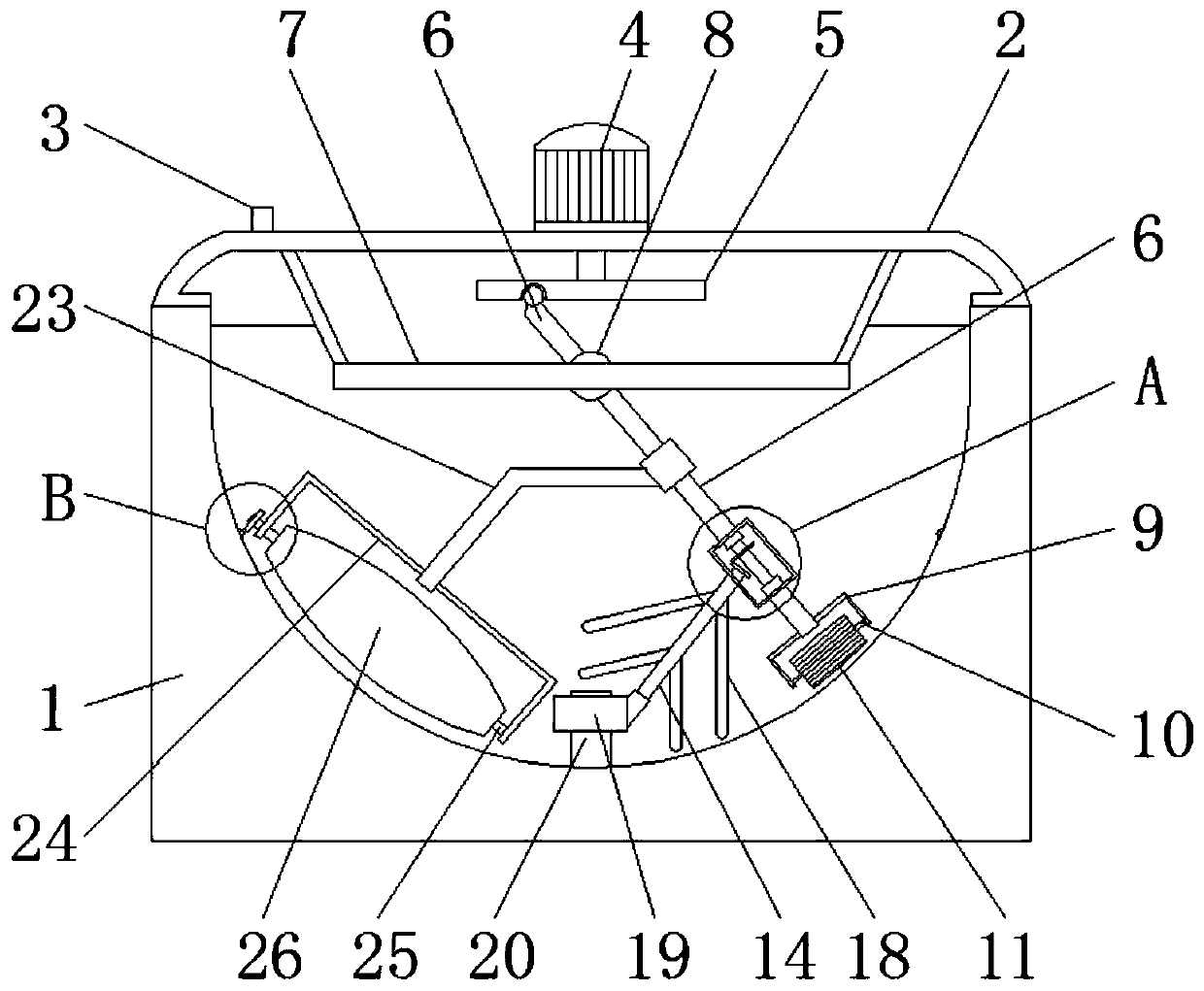

Automatic mortar spraying device for coating mortar for wall surface

InactiveCN101575904ASpray evenlyThickness controllable and adjustableBuilding constructionsSpray nozzleMortar

The invention relates to an automatic mortar spraying device for coating mortar for a wall surface, which utilizes compressed air to uniformly spraying mortar to building surface. The main structure comprises a high-pressure air chamber 1, a mortar box 2, a mortar separation disc composite member 3, a central rotation shaft 4, a mortar pressing and air spraying integrated head 5, a mortar spraying pipe 6, a mortar spraying head 7 and a drive wheel 8. When the central rotation shaft rotates, a multiple-point atmolysis cam, the mortar pressing and air spraying integrated head and a mortar control disc synchronously rotate. When an air spraying nozzle and a mortar through hole aim at a mortar separation hole of the multiple-hole mortar separation disc, air inlet holding valves are turned on at the same time, high-pressure air fast goes into the air inlet holding valves and presses the mortar in the mortar separation hole out, and the mortar reaches the mortar spraying head along a spraying pipe and is sprayed out. The invention utilizes controllable high pressure airflow to uniformly spray mortar with quantified volume to the building surface, the spraying of the mortar is uniform, the adsorption effect of the wall face is good, the thickness of the mortar is controllable and adjustable, and the invention can realize fully automated operation by combining with an automated bearing platform.

Owner:朱登仁

Spraying direction gradual-change type mortar spraying device

InactiveCN110748129AAvoid wastingImprove cleanupBuilding constructionsHydraulic cylinderSpiral blade

The invention provides a spraying direction gradual-change type mortar spraying device and relates to the technical field of construction decoration machinery. The spraying direction gradual-change type mortar spraying device comprises a base, the front and rear two sides of the top of the base are both provided with column tubes, the tops of the column tubes are connected with extension-type vertical rods in an inserted manner, a bottom plate is connected between the two vertical rods, the position, at the top of the base, located below the bottom plate is provided with a hydraulic cylinder,and an extension-type shaft at the top of the hydraulic cylinder is connected with the bottom of the bottom plate. According to the spraying direction gradual-change type mortar spraying device, a hood tube shields other portions of blades, so that the blades can only throw mortar to a wall, waste and increasing of extra cleaning work caused by the mortar being thrown to the other portions are avoided, a rubber guide pipe can guide the mortar to the blades precisely, the waste is further reduced, reducing of the cost is facilitated, a motor drives a spiral blade to rotate, the mortar can be mixed evenly, and the situation that vibration generated by working of the spraying direction gradual-change type mortar spraying device makes the mortar generate a segregation phenomenon to affect thecondensation degree is avoided.

Owner:湖州互融新材料科技有限公司

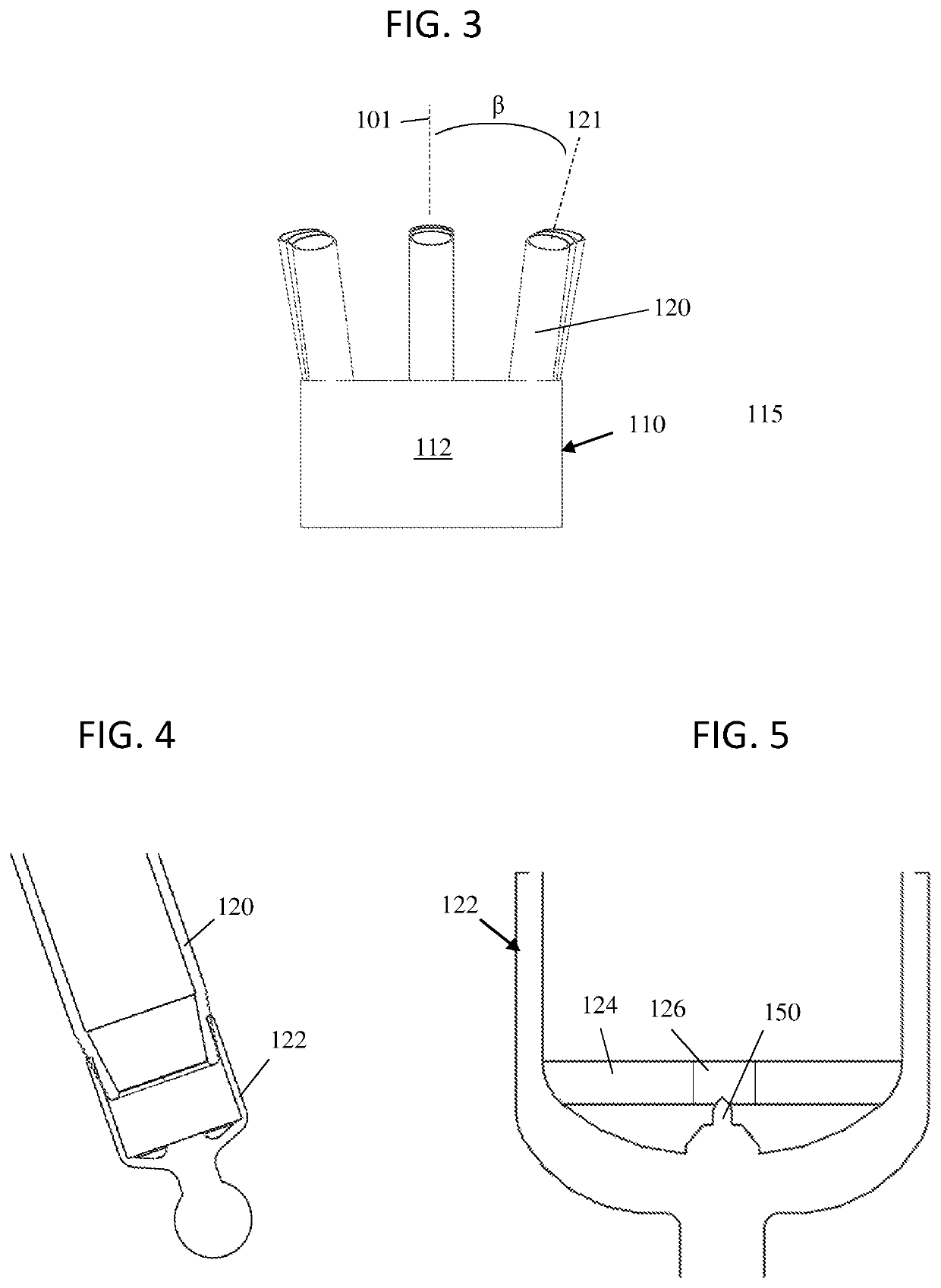

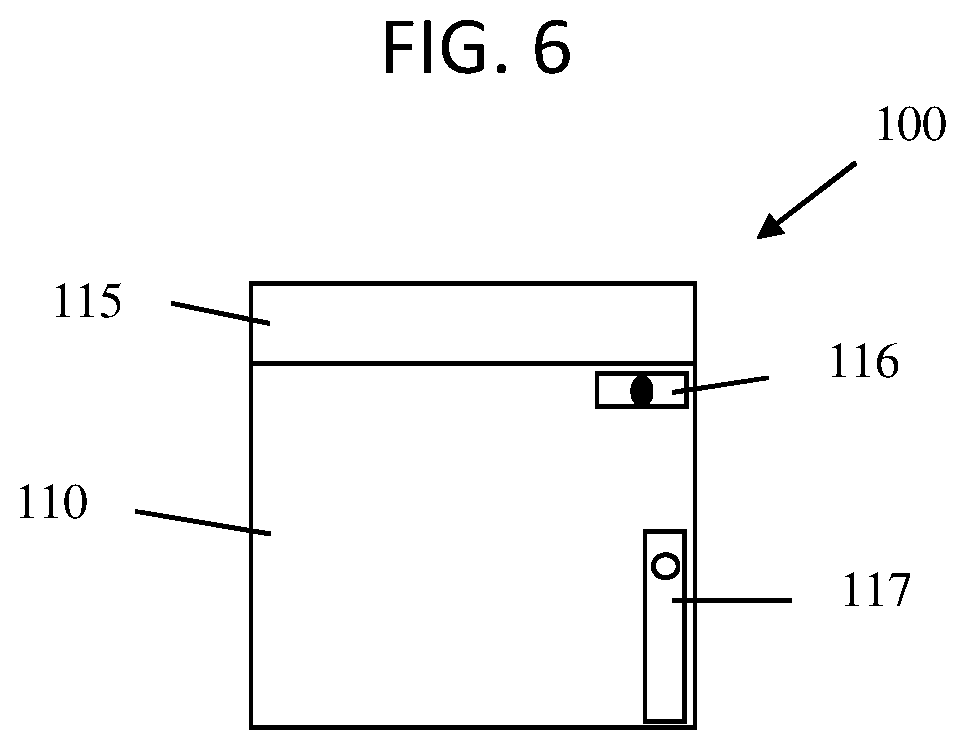

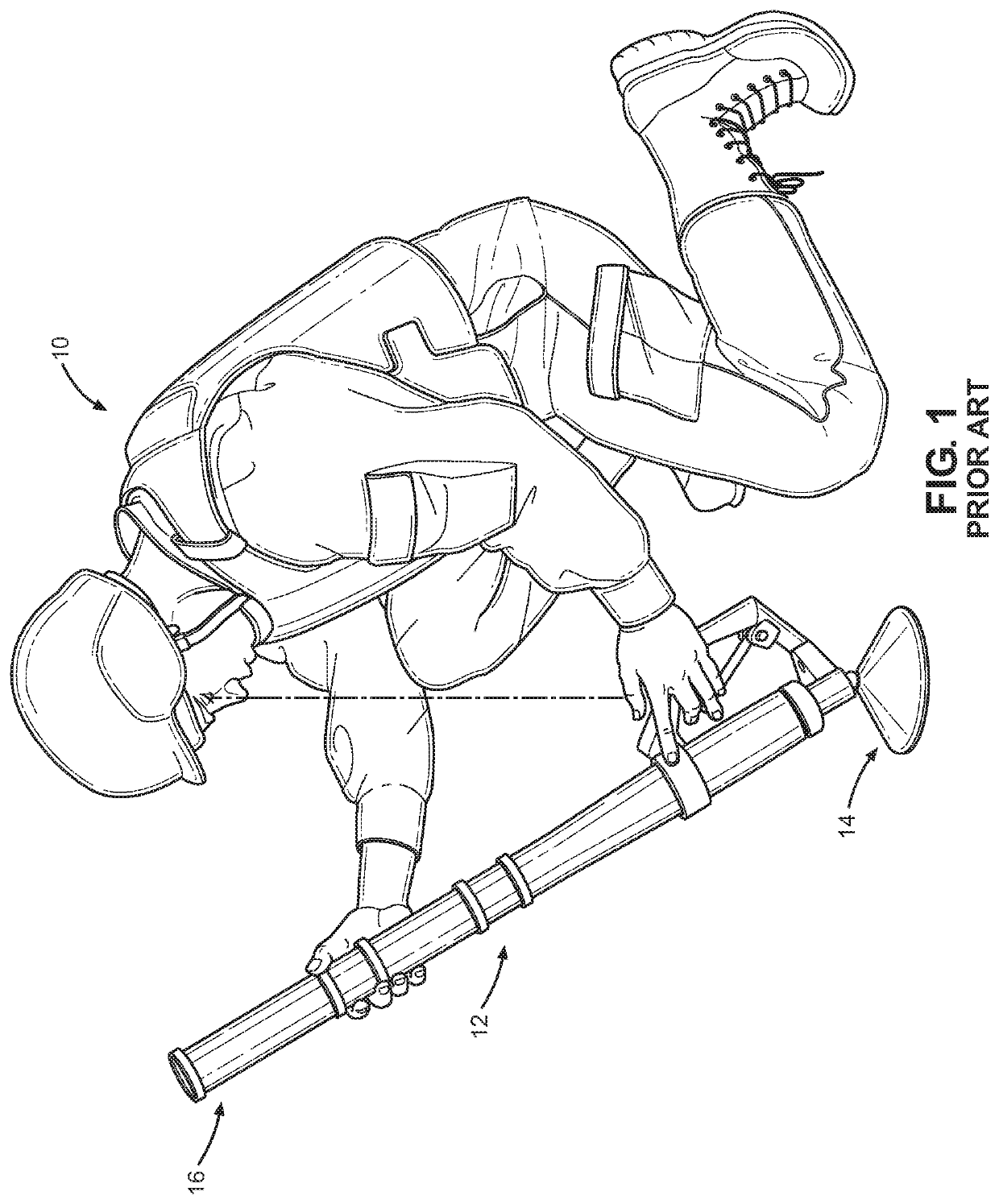

Multi-barrel mortar launcher and method

ActiveUS10551147B1Increase chances of survivalIncrease lethalityGun mountingsLaunching weaponsMortarEngineering

Owner:COMBAT WEAPONS DEV LLC

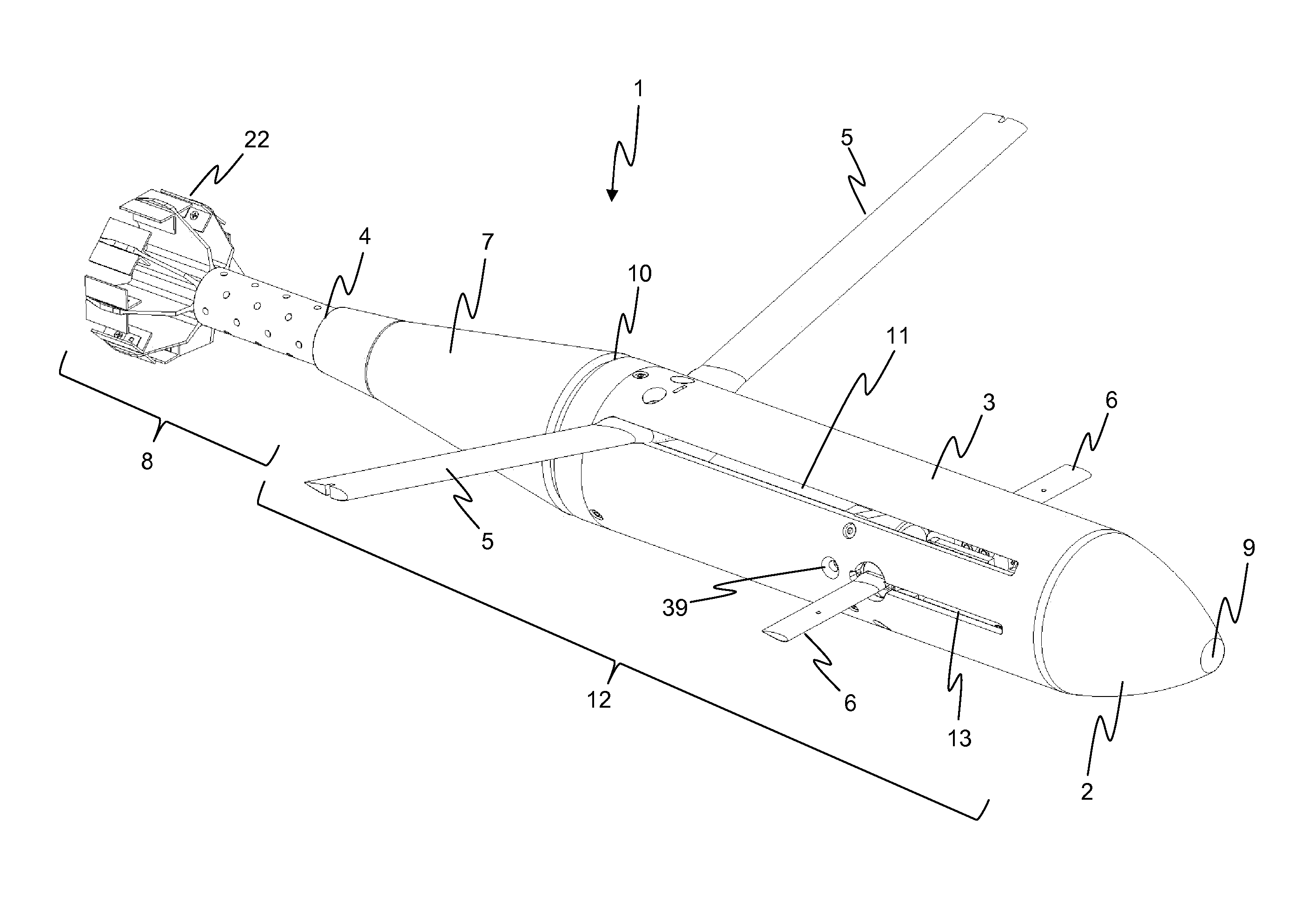

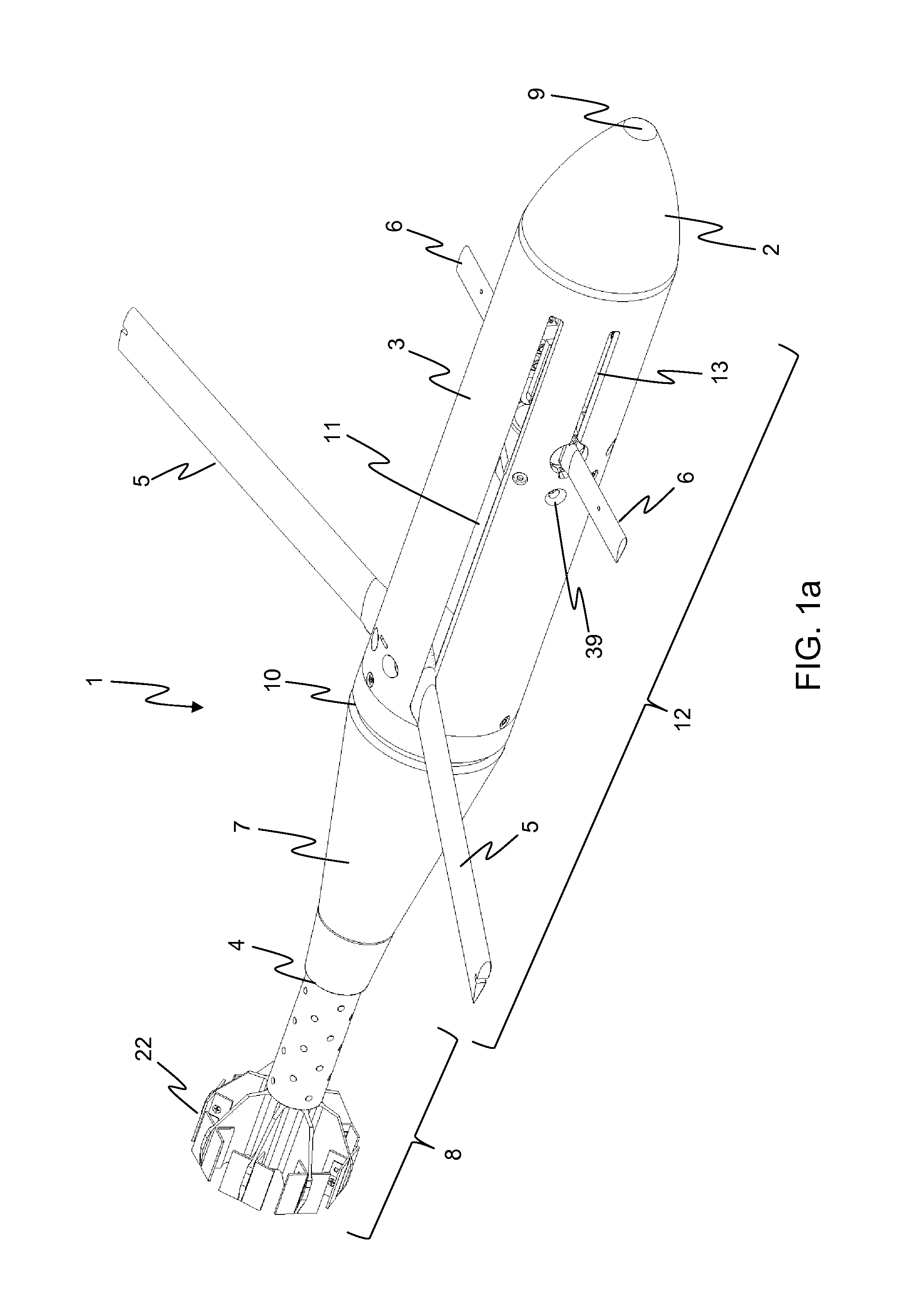

Methods for extended-range, enhanced-precision gun-fired rounds using g-hardened flow control systems

ActiveUS9395167B1Increase loadIncrease rangeAmmunition projectilesDirection controllersAccelerometerControl system

Methods involve using a guided munition (e.g., a mortar round or a grenade) that utilizes deployable flow effectors, activatable flow effectors and / or active flow control devices to extend the range and enhance the precision of traditional unguided munitions without increasing the charge needed for launch. Sensors such as accelerometers, magnetometers, IR sensors, rate gyros, and motor controller sensors feed signals into a controller which then actuates or deploys the flow effectors / flow control devices to achieve the enhanced characteristics.

Owner:ORBITAL RES

Cartridge for military training device, activation device for cartridge, cartridge kit, and related methods

Provided is a non-pyro cartridge for military training devices. The cartridge has a refillable compressed gas compartment fitted with a refill valve, which allows for quick reuse of the cartridge. The cartridge further has a blast compartment that receive a rush of compressed air from the gas compartment when the cartridge is triggered / detonated. Also provided is an activation device for the cartridge. The cartridge and activation device can generate physical and digital effects on the battlefield that safely and realistically simulate anti-tank weapon signatures, mortar weapon signatures, landmines signatures, improvised explosive device weapon signatures, artillery point of impact signatures, hand grenade signatures, weapon impact signatures on vehicles, weapon impact signatures on buildings, multiple types of battlefield effects, weapon signatures, impact signatures with a single device type.

Owner:MIL SIM FX INT INC

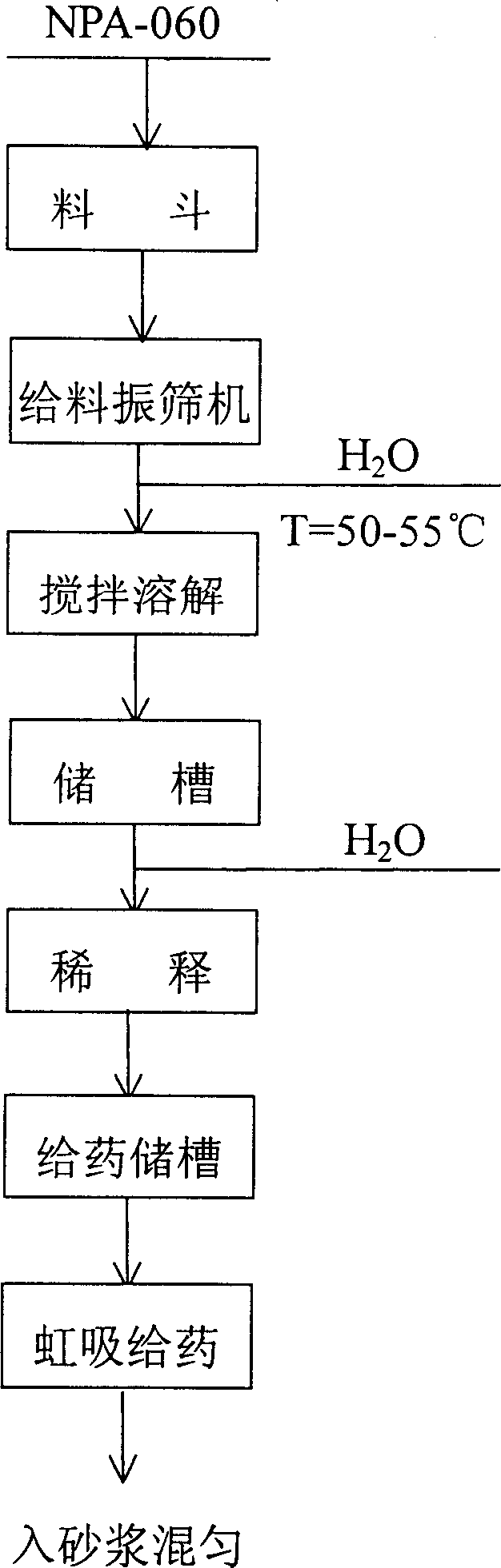

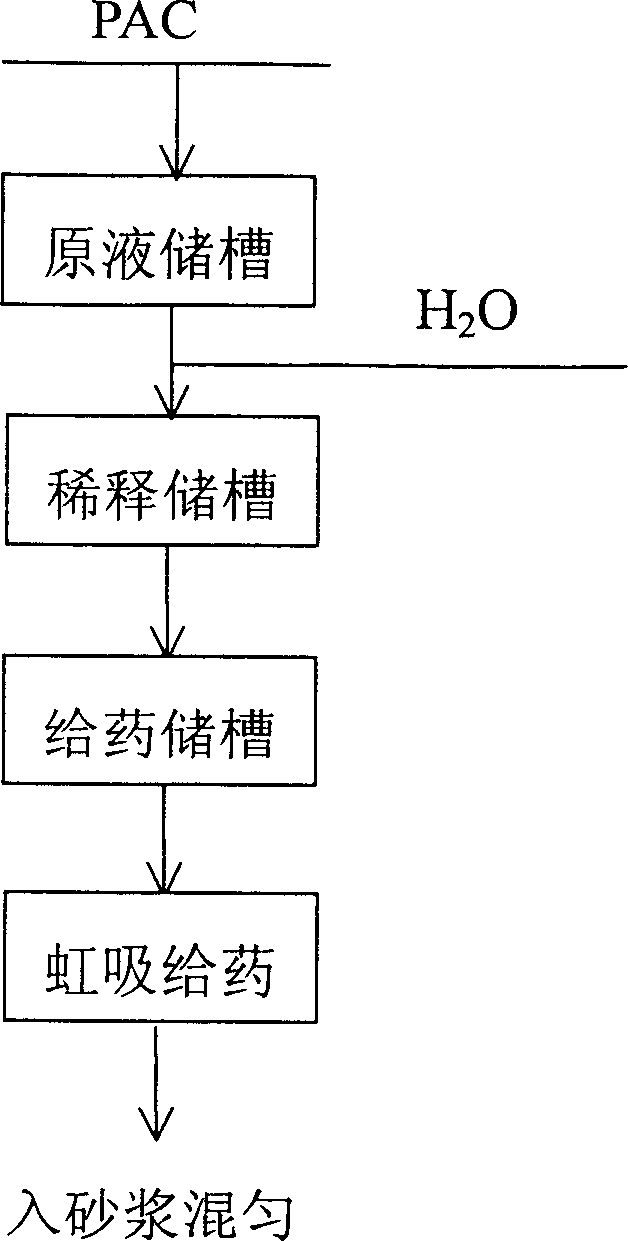

Full tail mortar quick concentrating technique in vertical sand cabin

InactiveCN1718285ARealize dynamic settlementAchieve continuous pulpingDifferential sedimentationWastewaterSlurry

Owner:CENT SOUTH UNIV

Unloading device of mortar mixer

InactiveCN104589514ARealize facing downPlay the role of drainageDischarging apparatusNozzleMaterials science

The invention provides an unloading device of a mortar mixer, belongs to the technical field of machines and aims to solve the problem that the mixed mortar cannot be automatically unloaded from the mixer in the prior art. The unloading device in the mortar mixer is characterized in that the mortar mixer comprises a rack and a mortar stirring cylinder, wherein the rack comprises a working plate and a support leg; the mortar stirring cylinder comprises a loading cylinder and an inner roller; a discharging hole is formed in the side wall of the loading cylinder; an unloading device is arranged in the discharging hole and comprises a rotation motor, a gear and a rack; the rotation motor is fixed on the working plate; the gear is fixed on the rotation motor; the rack and the gear are meshed with each other; the width of the rack is larger than that of the gear; the rack is arc-shaped and is concentric to the loading cylinder; a leakage nozzle for outflow of the mortar is formed in the discharging hole of the loading cylinder. The unloading device of the mortar mixer has the advantage that the mixed mortar can be automatically unloaded from the mixer.

Owner:石军朝 +11

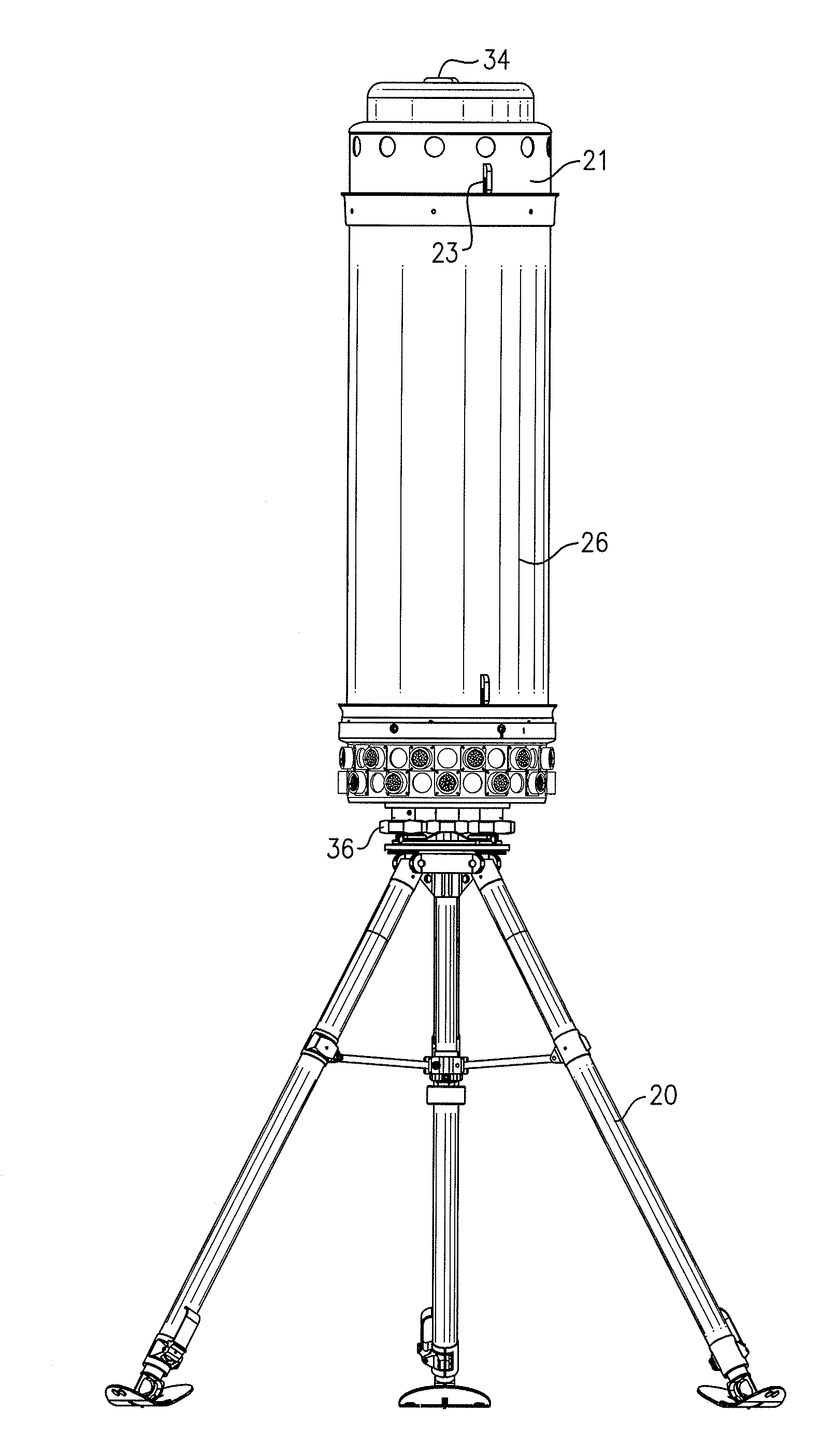

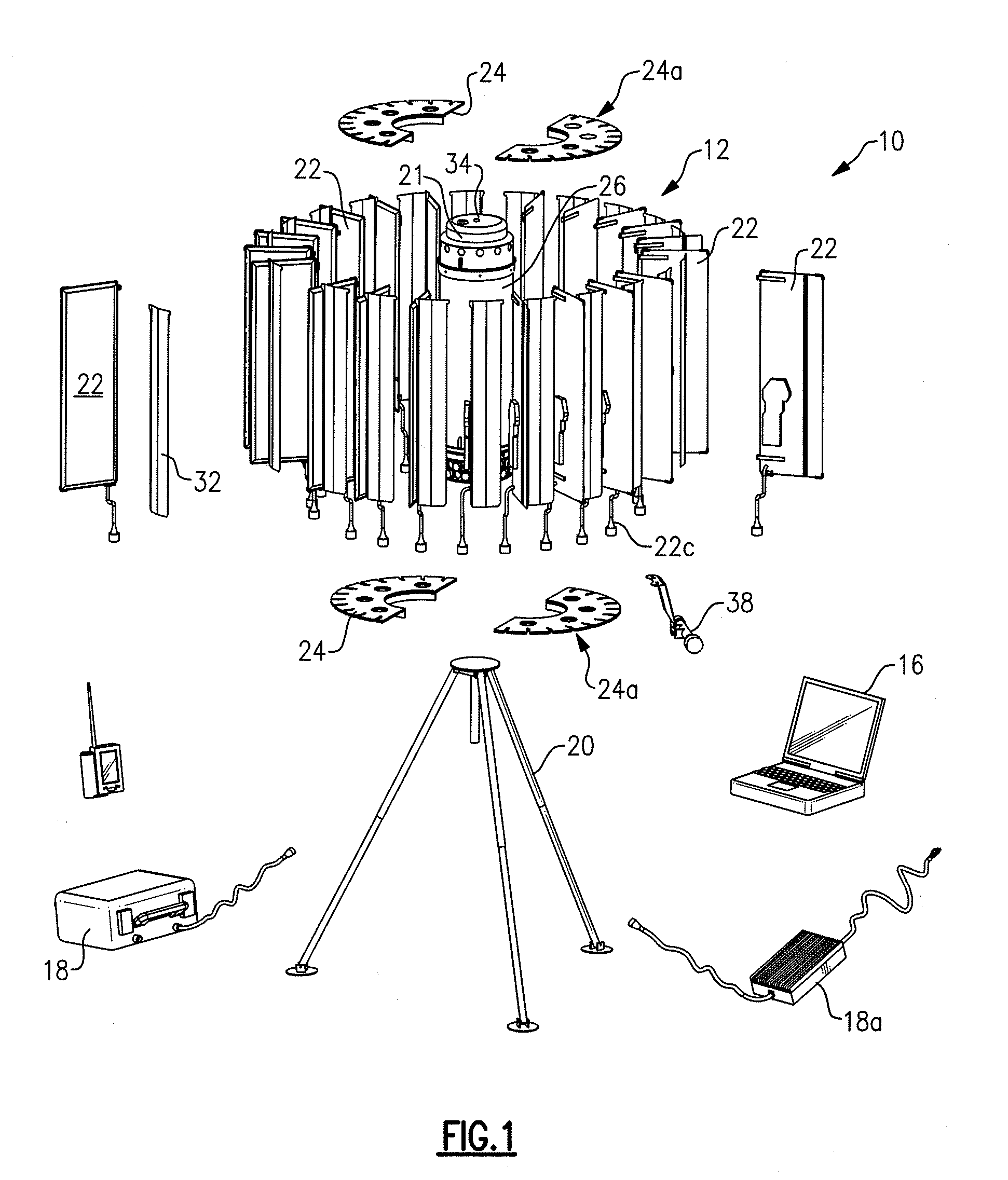

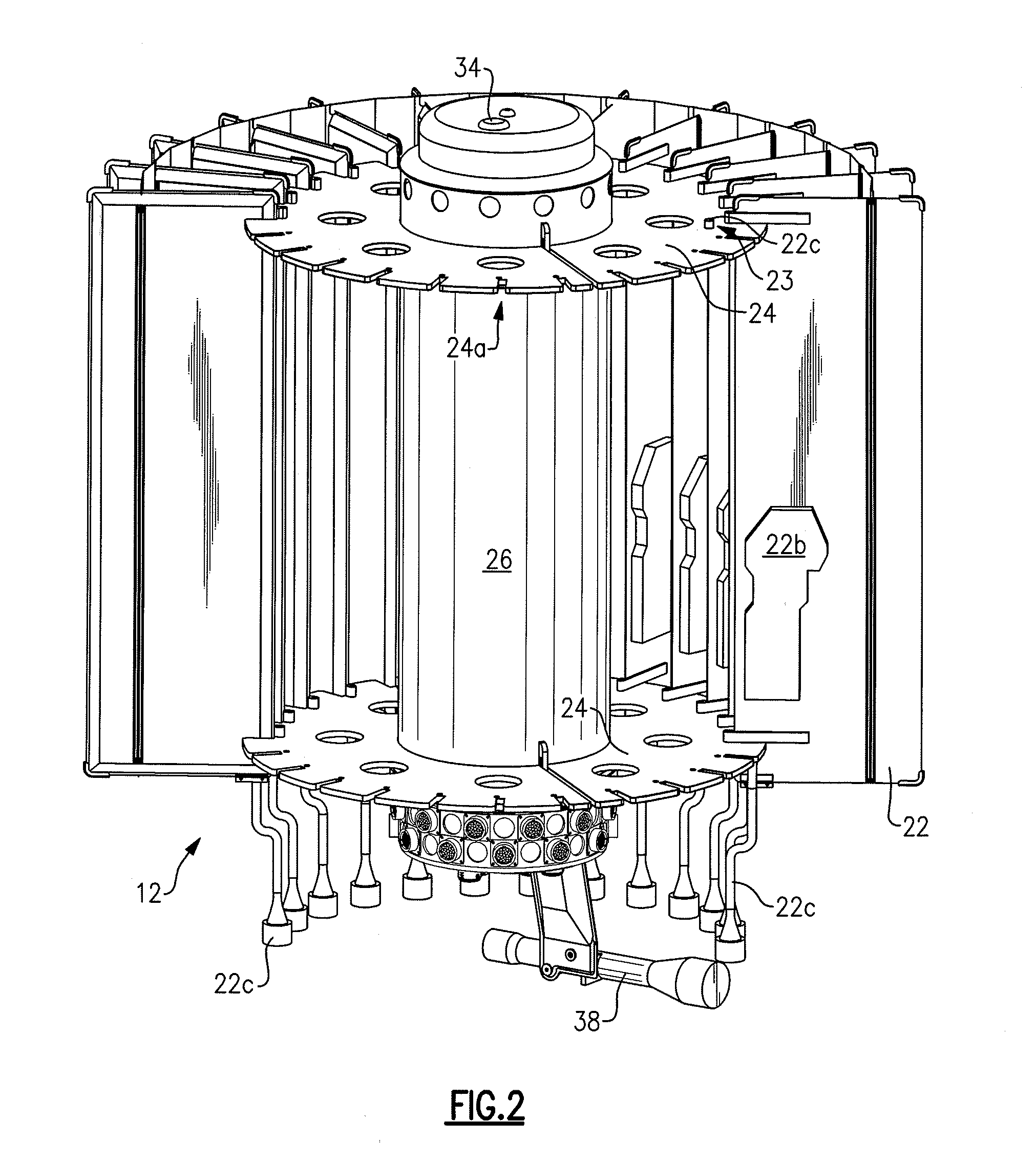

Man-Portable Counter Mortar Radar System

InactiveUS20100026552A1Carried and moved with easeCollapsable antennas meansAntenna arraysCountermeasureRadar systems

The present invention is a man-portable counter-mortar radar (MCMR) radar system that detects and tracks enemy mortar projectiles in flight and calculates their point of origin (launch point) to enable and direct countermeasures against the mortar and its personnel. In addition, MCMR may also perform air defense surveillance by detecting and tracking aircraft, helicopters, and ground vehicles. MCMR is a man-portable radar system that can be disassembled for transport, then quickly assembled in the field, and provides 360-degree coverage against an enemy mortar attack. MCMR comprises an antenna for radiating the radar pulses and for receiving the reflected target echoes, a transmitter that produces the radar pulses to be radiated from the antenna, a receiver-processor for performing measurements (range, azimuth and elevation) on the target echoes, associating multiple echoes to create target tracks, classifying the tracks as mortar projectiles, and calculating the probable location of the mortar weapon, and a control and display computer that permits the operation of the radar and the display and interpretation of the processed radar data.

Owner:SRC INC

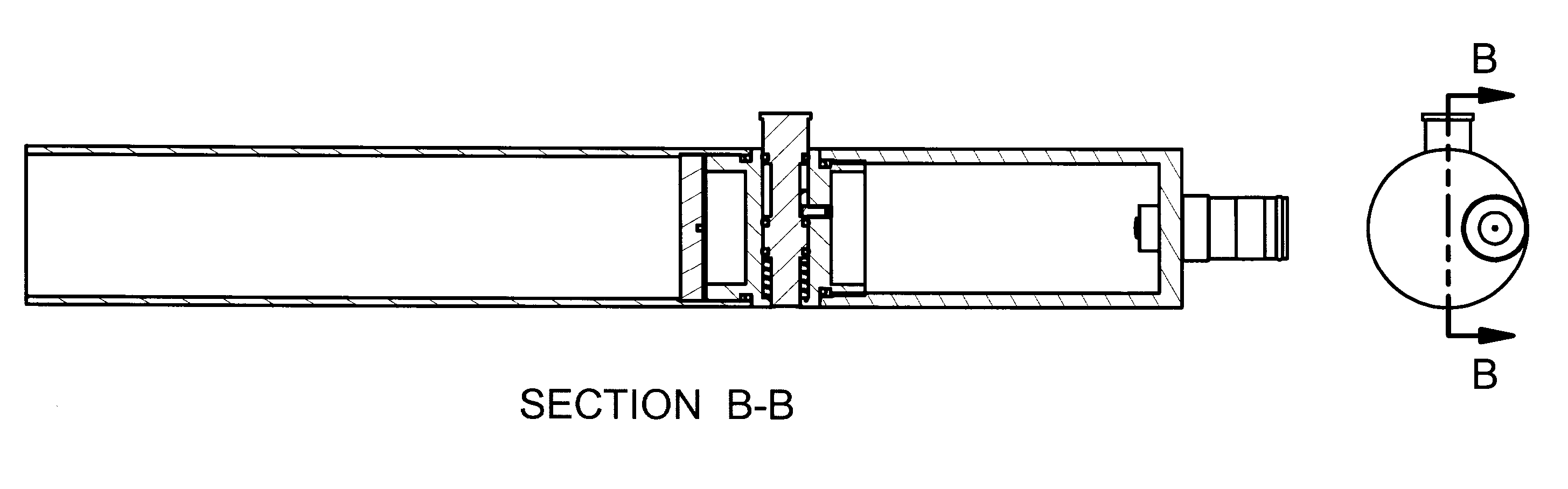

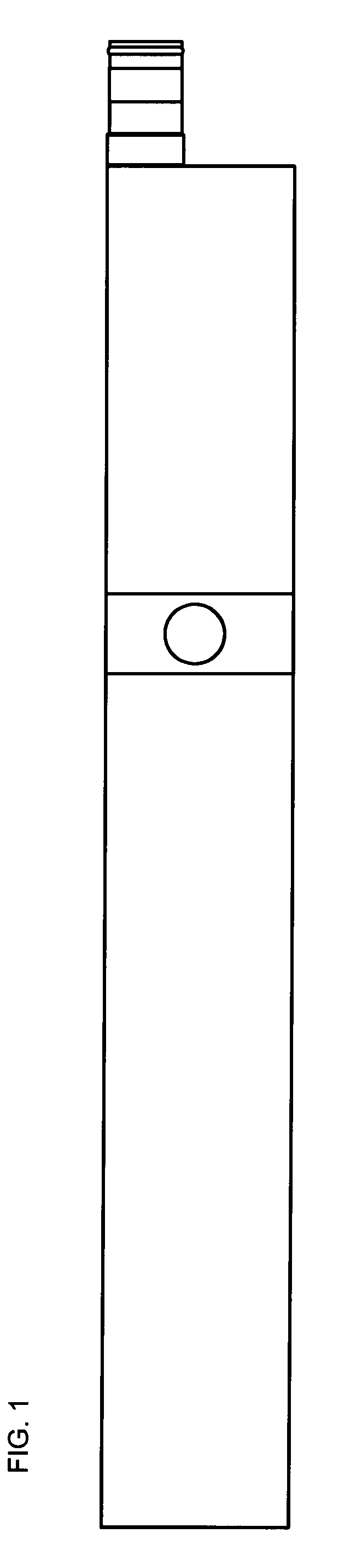

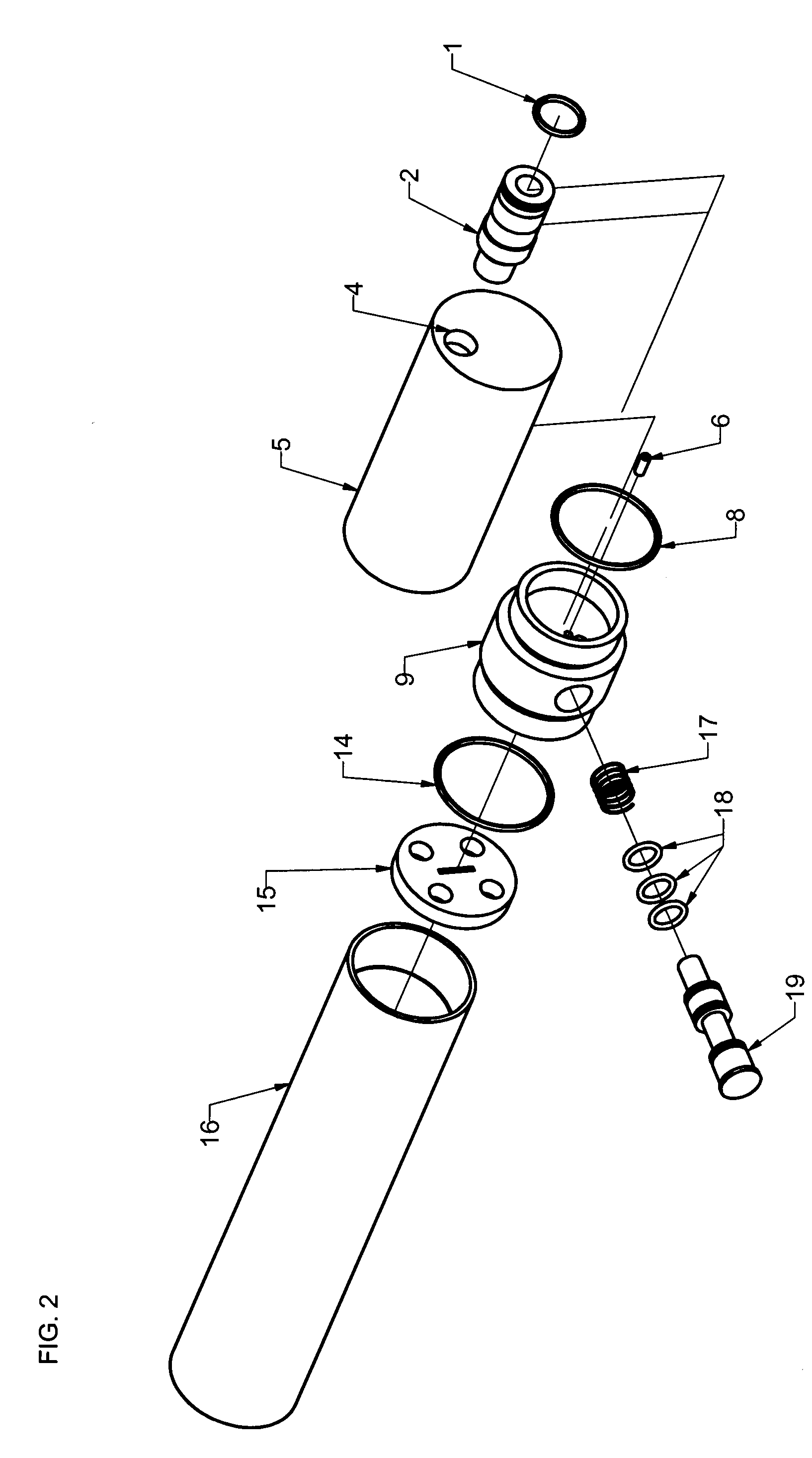

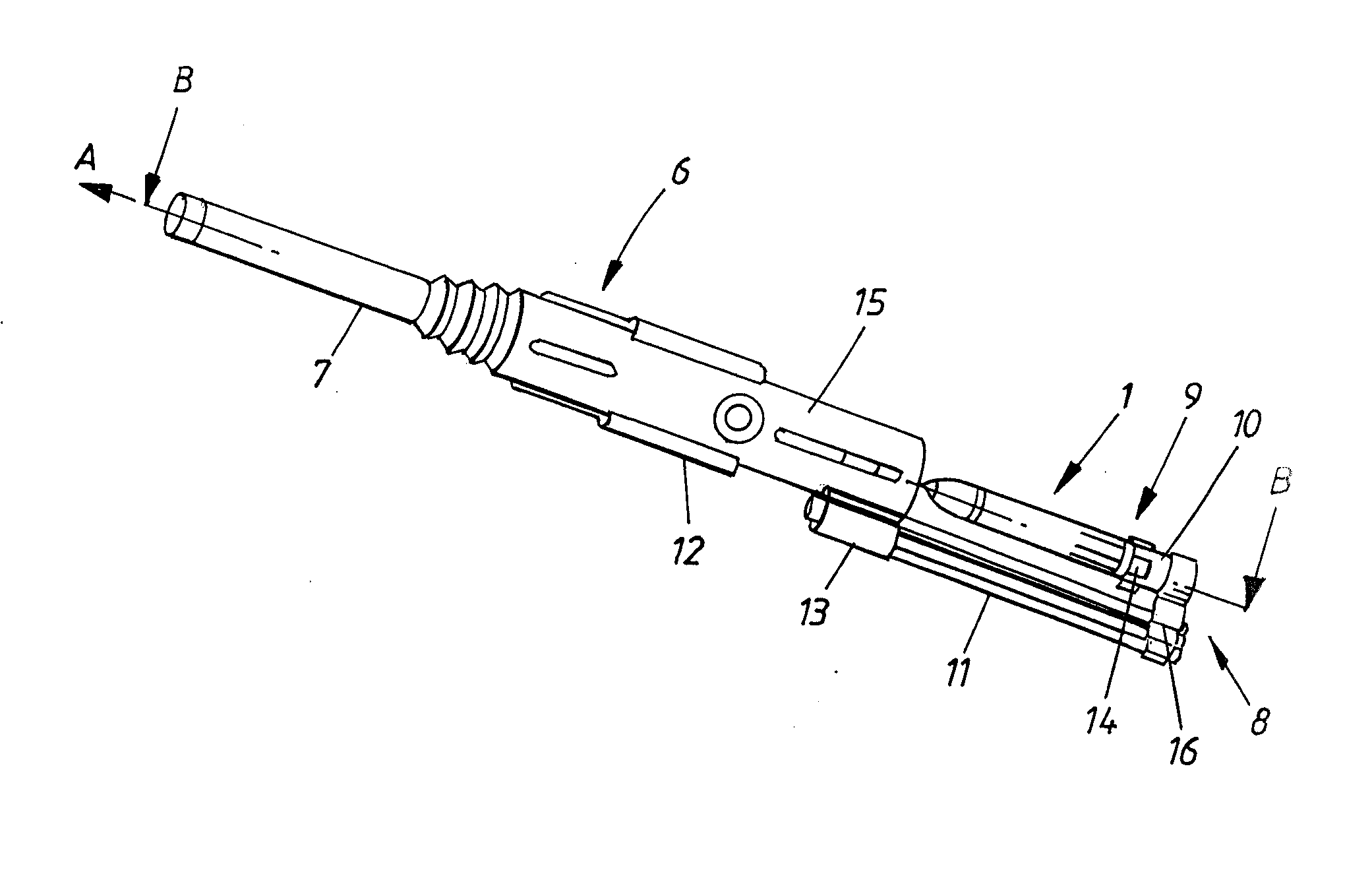

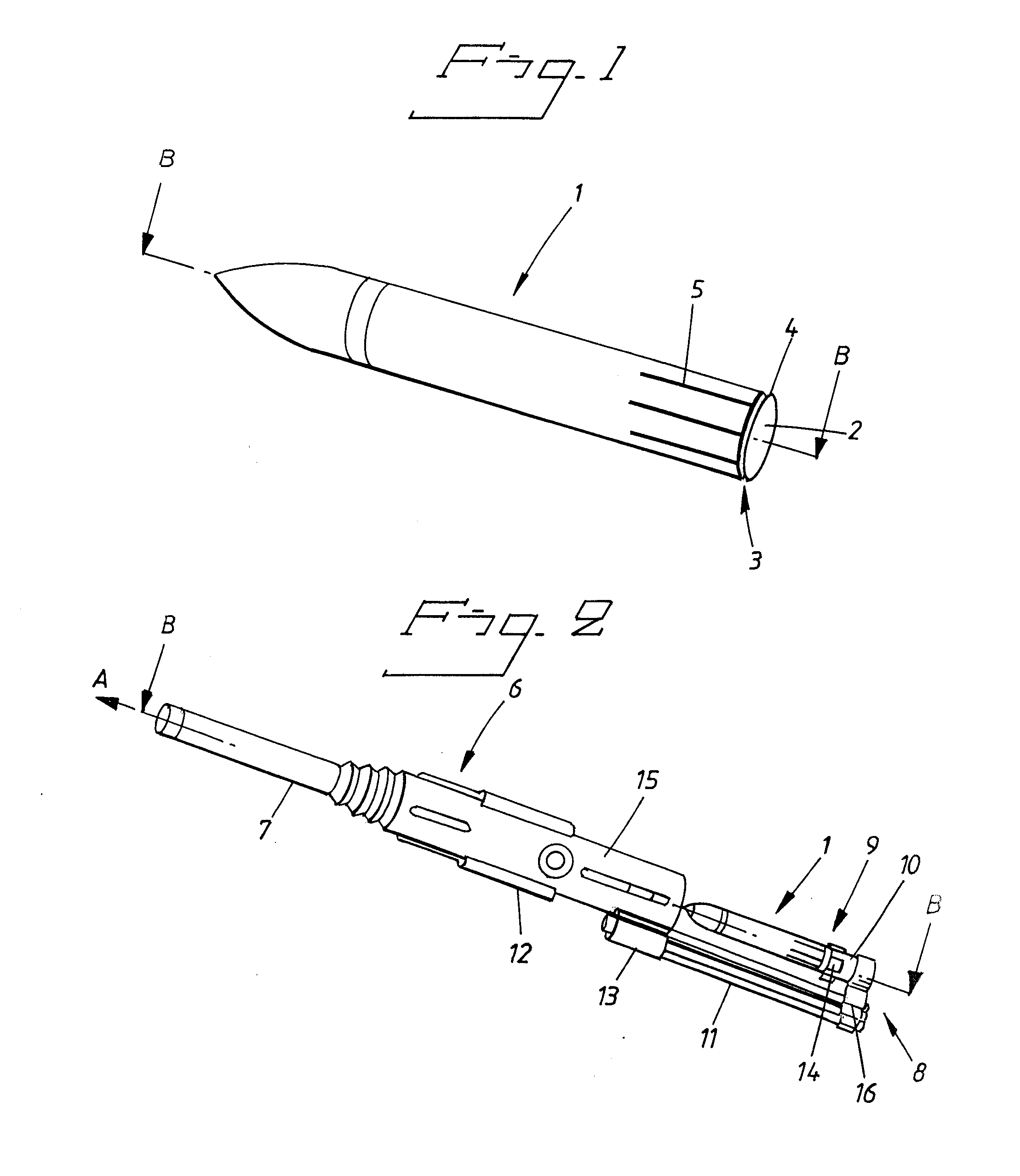

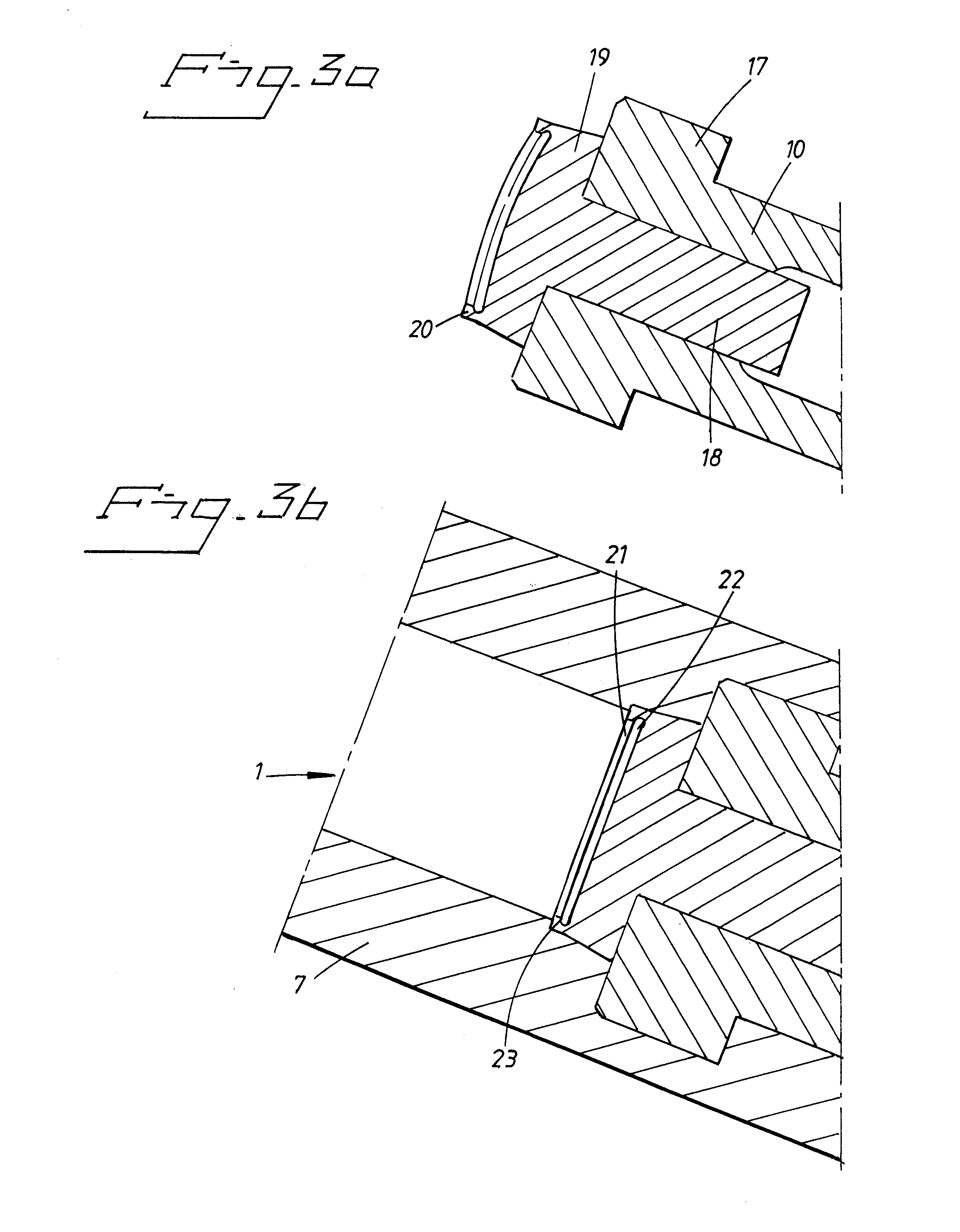

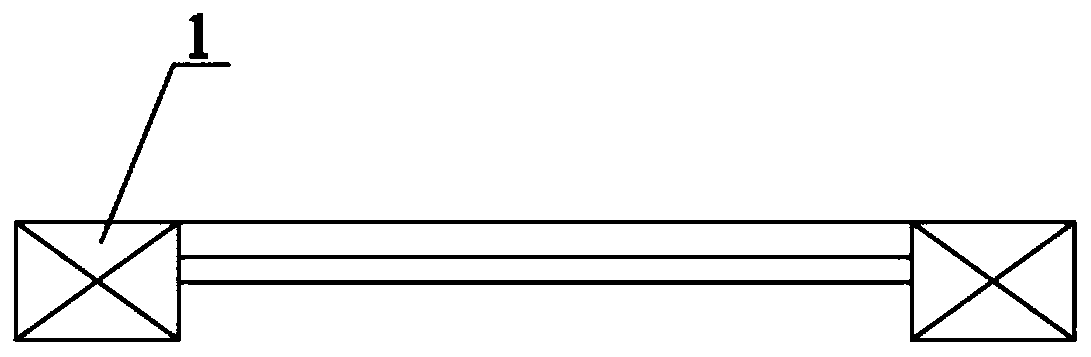

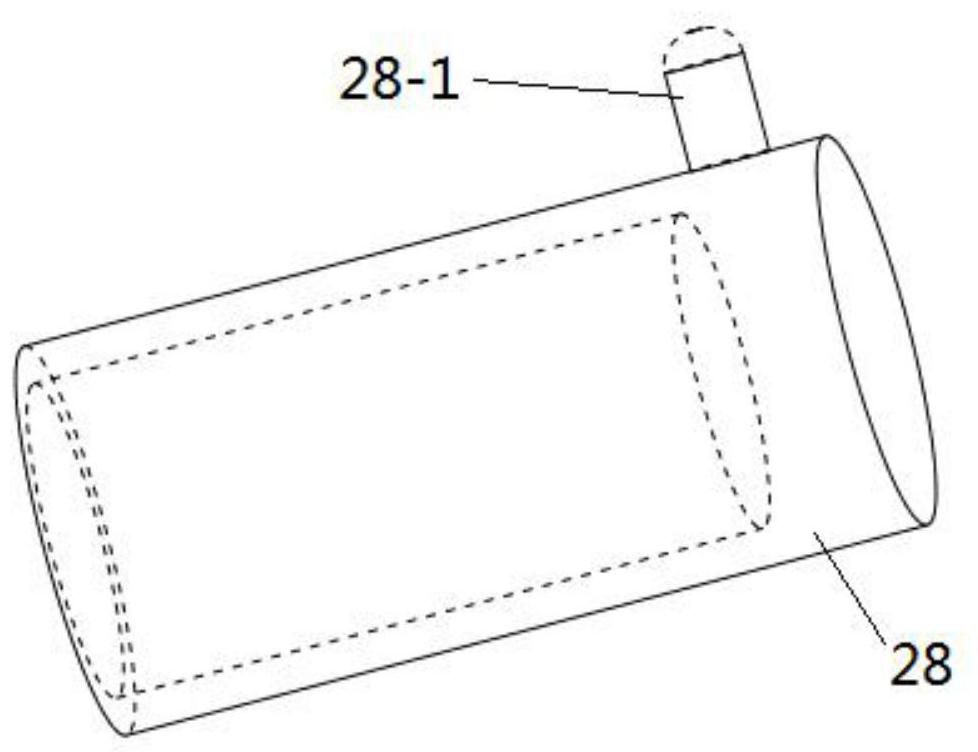

Shell designed for securing in a mortar and mortar designed for such a shell

ActiveUS20100300321A1Logistics system of the weapon is simplifiedAmmunition handling system becomes simpler, faster and less expensiveAmmunition projectilesRocket launchersMortarMechanical engineering

The invention relates to a shell (1) intended for firing from a weapon (6), preferably a mortar weapon (6), the shell (1) being designed for securing the shell (1) in a mortar weapon (6) in order thereby to prevent movement of the shell (1) when adjusting the angle of elevation of the weapon (6). According to the invention this is achieved in that the shell (1) comprises a locking part (19, 28, 37), the locking part (19, 28, 37) forming an integral part of the shell (1) and being designed so that the shell (1) after ramming home is locked to a corresponding securing part (19) in the mortar (6). The invention also relates to a mortar (6) intended for firing said shell (1), the mortar (6) being characterized in that the mortar (6) comprises a corresponding securing part (19) for locking the shell (1).

Owner:BAE SYST BOFORS

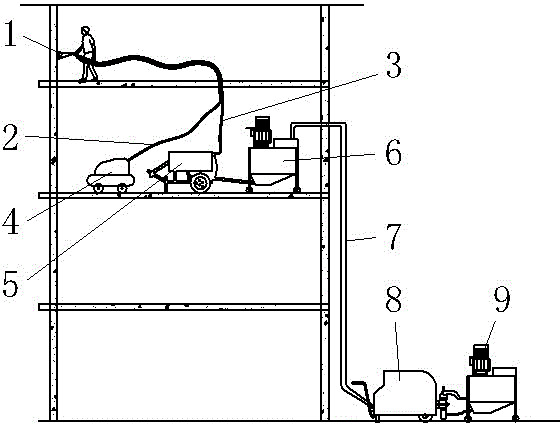

Mechanical spray plastering method and device

ActiveCN104420638AReduce investmentReduce construction costsBuilding constructionsMortarStructural engineering

The invention discloses a mechanical spray plastering method and a device. Mortar in an agitator is output to a spray gun through a mortar pump. When the mortar in the agitator is output to the spray gun through the mortar pump, an outlet end of the mortar pump is connected with a material absorber through a pipe, and an outlet of the material absorber is connected with a spray painting machine; and the spray painting machine is connected with the spray gun through a mortar spray painting pipe, and an air inlet of the spray gun is connected with an air compressor through an air pipe, so that the mortar in the agitator can be evenly sprayed to a constructed building wall surface through the spray gun when the mortar pump, the material absorber, the spray painting machine and the air compressor synchronously operate and work. The mechanical spray plastering method and the device have such advantages as simple production and mounting, low investment cost, convenience for use, reduction of construction cost, quickening of construction progress and good construction work quality.

Owner:CCFED THE FIRST CONSTR & ENG

Vertical prestressing force opening mud jacking construction method and construction device

The present invention discloses construction process and apparatus for extruding mortar to vertical prestressed hole canal. The twice mortar extruding process includes the following steps: 1. the first mortar extruding including the first gravitational flowing and the subsequent low pressure extruding after some mortar begins bursting out through the exhaust hole; 2. blocking the exhaust hole, and extruding mortar for the second time until reaching fullness; and 3. erecting the exhaust pipe for it to become higher than the corrugated pipe. The construction apparatus includes one upper anchoring back plate with mortar extruding hole canal. The present invention has the advantages of no jamming of mortar extruding hole, saving in mortar extruding pipe material, low cost, etc.

Owner:CHINA CONSTR SEVENTH ENG DIVISION CORP LTD +1

Mortar stirring device

PendingCN112109204AImprove stirring efficiencyAvoid cleaningHollow article cleaningCement mixing apparatusGear wheelElectric machinery

The invention discloses a mortar stirring device, and relates to the technical field of construction machines. The mortar stirring device comprises a stirring barrel, wherein installation seats are fixedly arranged at the bottoms of two sides of the stirring barrel; motors with upward output ends are installed in the installation seats; rotating shafts are fixedly connected to output ends of the two motors; two groups of gears are fixedly arranged at the outer sides of the two groups of rotating shafts; gear rings engaged with the two groups of gears at the same time are arranged at the positions, flush with the gears, in the stirring barrel; and a plurality of groups of fixing blocks are evenly and fixedly arranged at the inner sides of the gear rings. According to the invention, the gearrings located in the wall of the stirring barrel are driven by the two groups of gears to rotate, a plurality of groups of blades are fixedly arranged at the inner sides of the gear rings, and the plurality of groups of blades rotate at the edge in the stirring barrel, so that while being stirred, the mortar raw materials can be stirred and mixed at the central position of the stirring barrel through the plurality of groups of blades, so that the stirring efficiency is greatly increased.

Owner:浙江湖州长湖实业有限公司

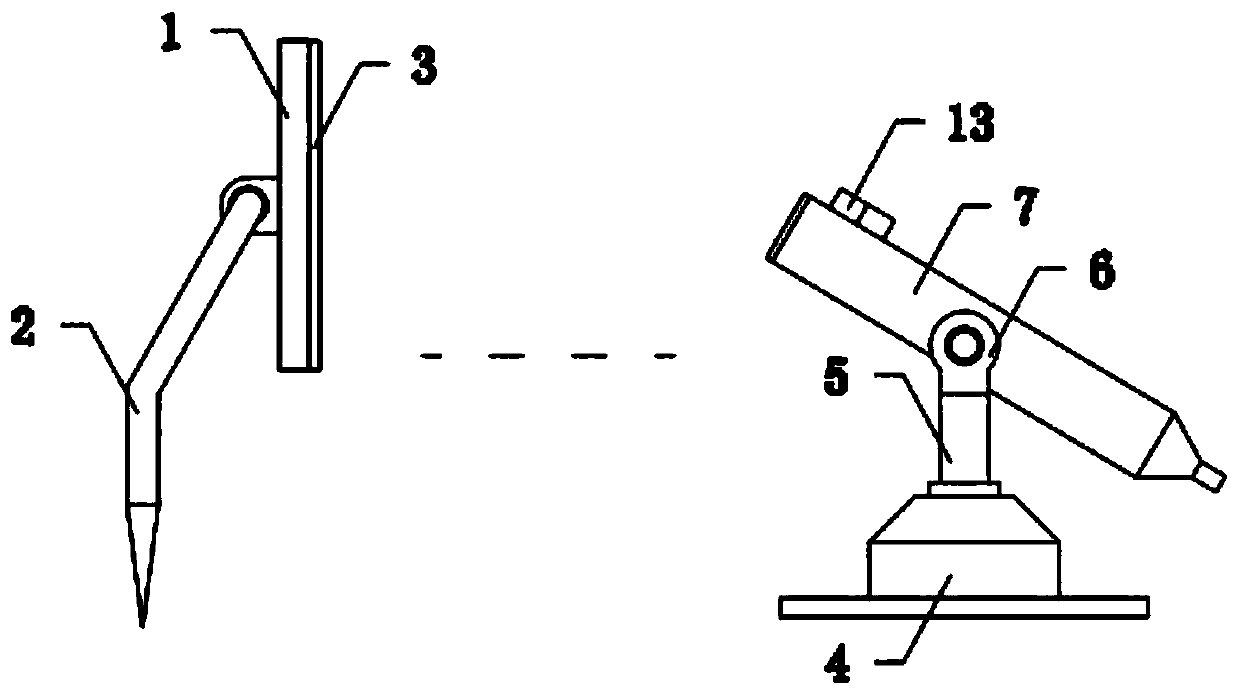

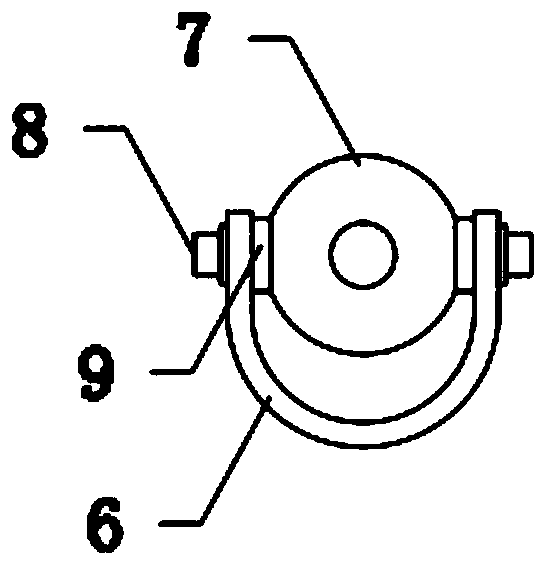

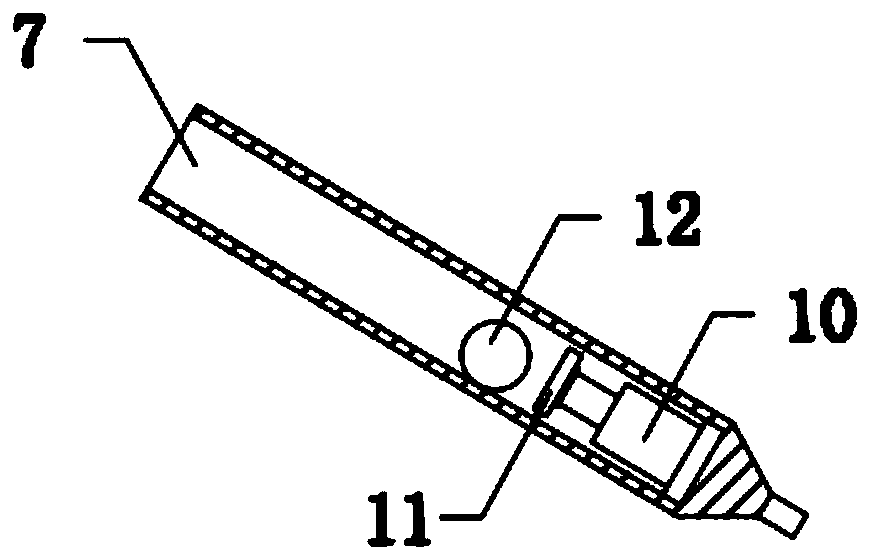

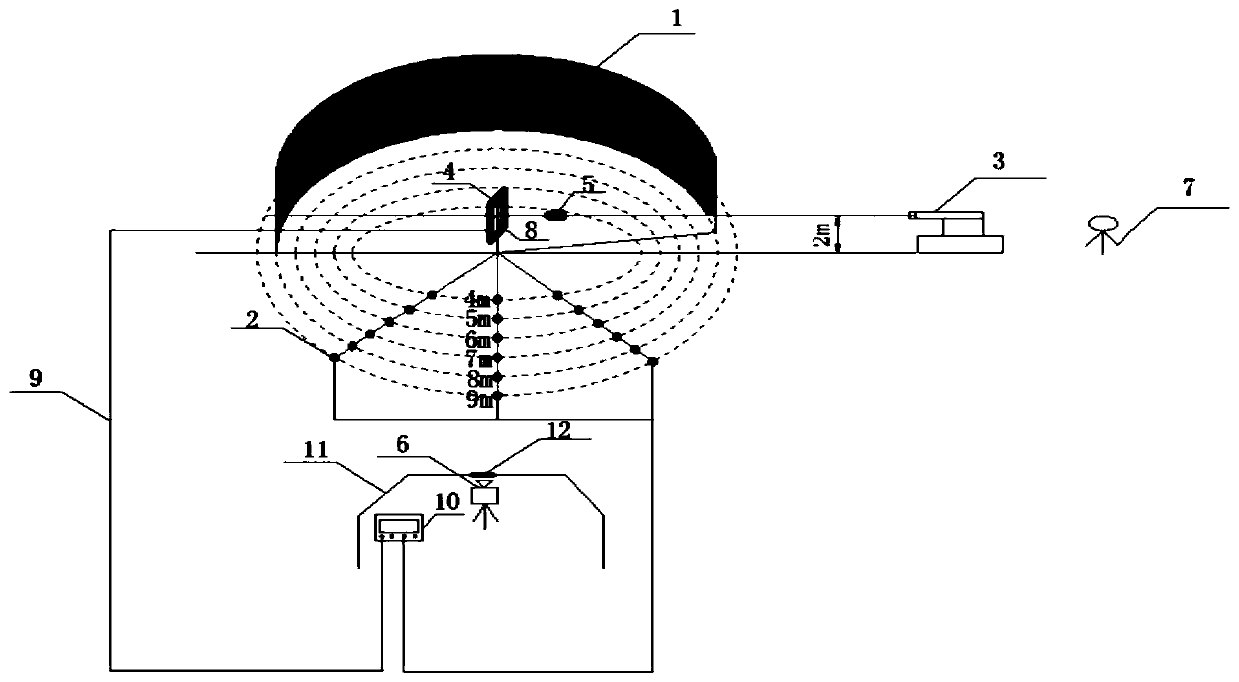

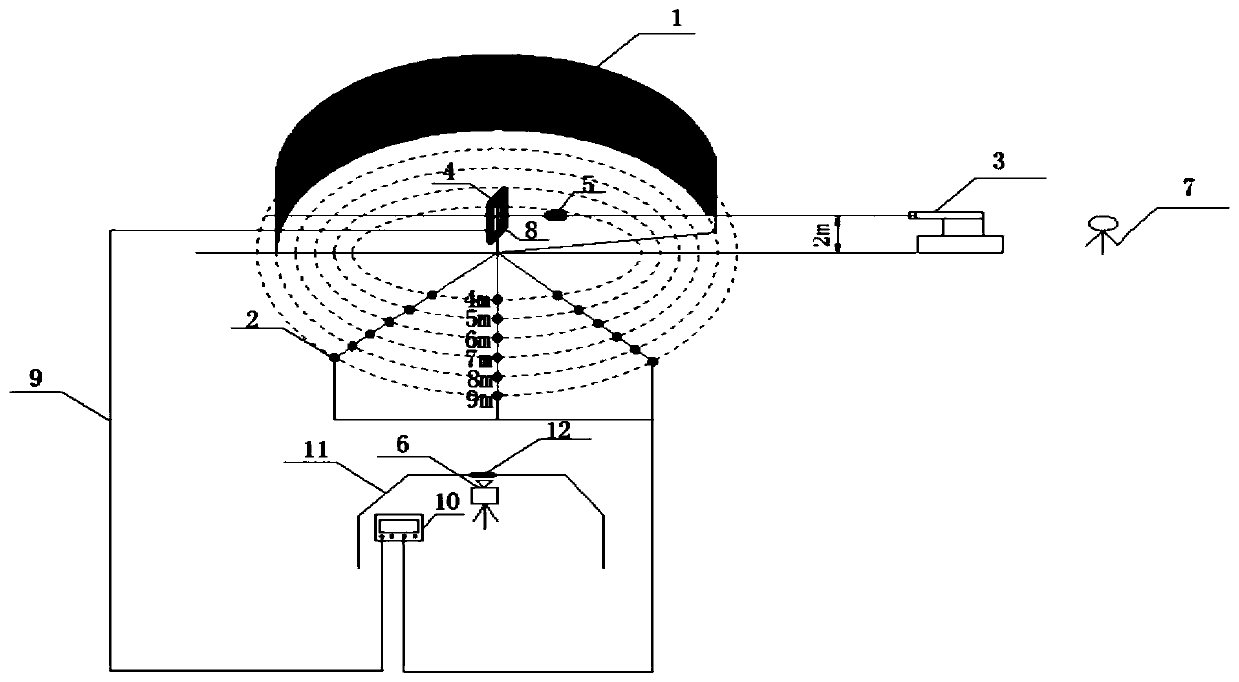

Mortar shooting training simulator

The invention belongs to the technical field of simulated training design, and particularly discloses a mortar shooting training simulator. The mortar shooting training simulator comprises a shootingtarget and a simulated launching device. The shooting target comprises a target board, two side walls of the target board are provided with an insertion column and a position sensing board respectively, and the position sensing board is located on the side, facing the simulated launching device, of the target board. By arranging the position sensing board, the position where a simulated projectileimpacts the target board can be sensed and detected, and the result can be quickly transmitted to a remote command terminal with high efficiency. Through the cooperation of a bearing base, a supporting shaft, a yoke and adjusting shafts, a launching tube can be rotated, the angle of the launching tube can be adjusted, and the physical strength of a user is saved. Through the cooperation of a windpower sensor and a distance sensor, the wind power at the use position and the distance between the target board and the launching tube can be detected, and then the launching angle of the launchingtube and the working stroke of a launching hydraulic cylinder can be conveniently set.

Owner:南京智能仿真技术研究院有限公司

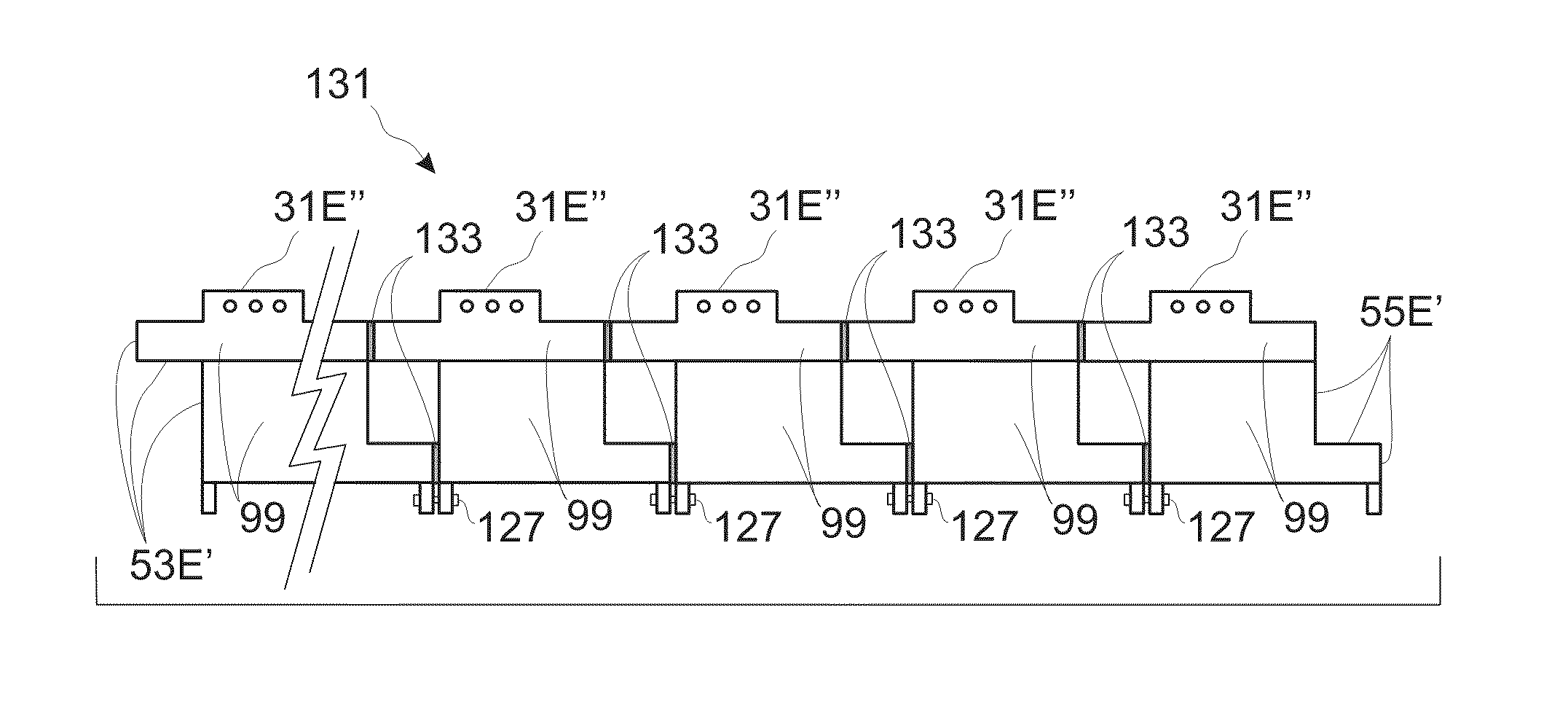

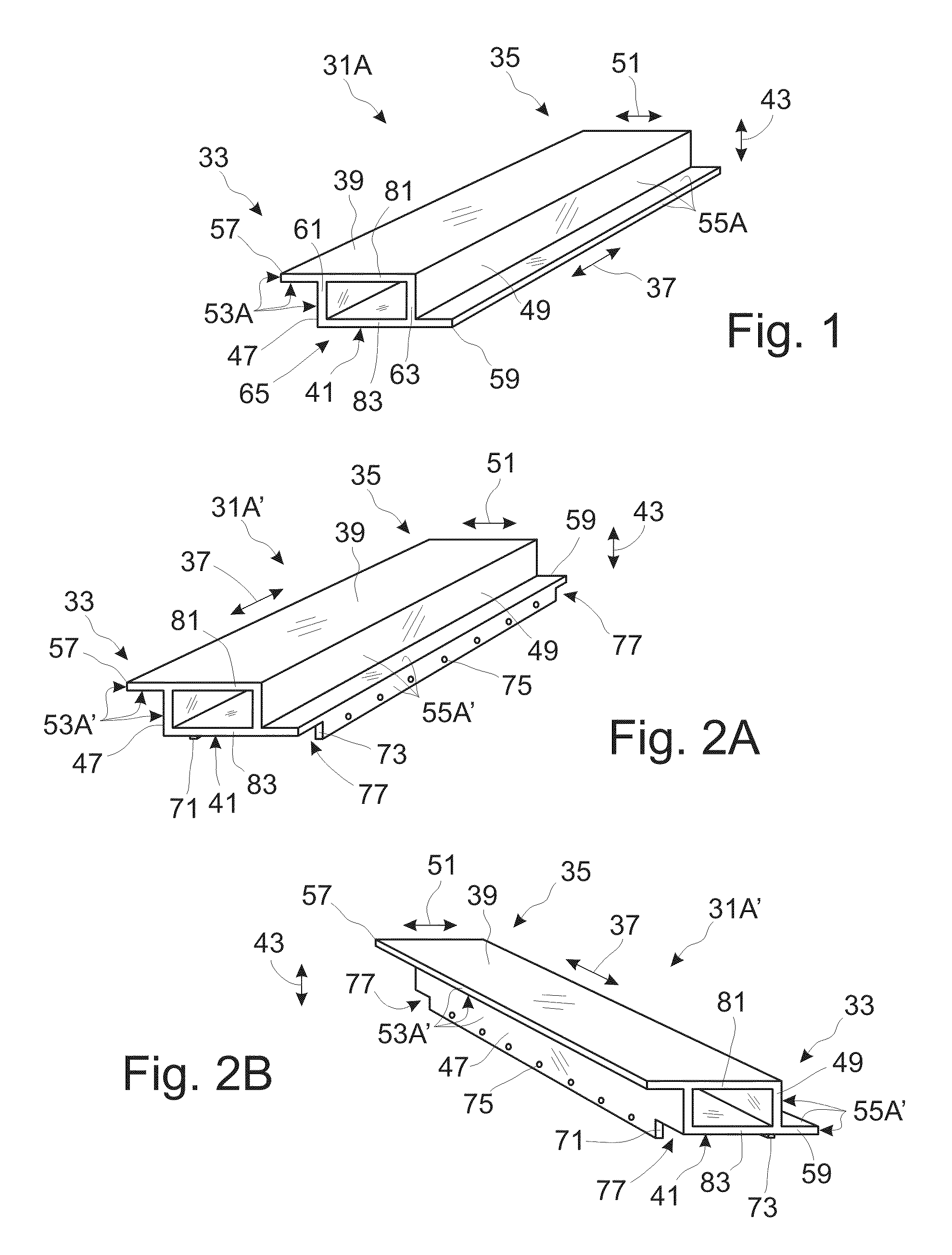

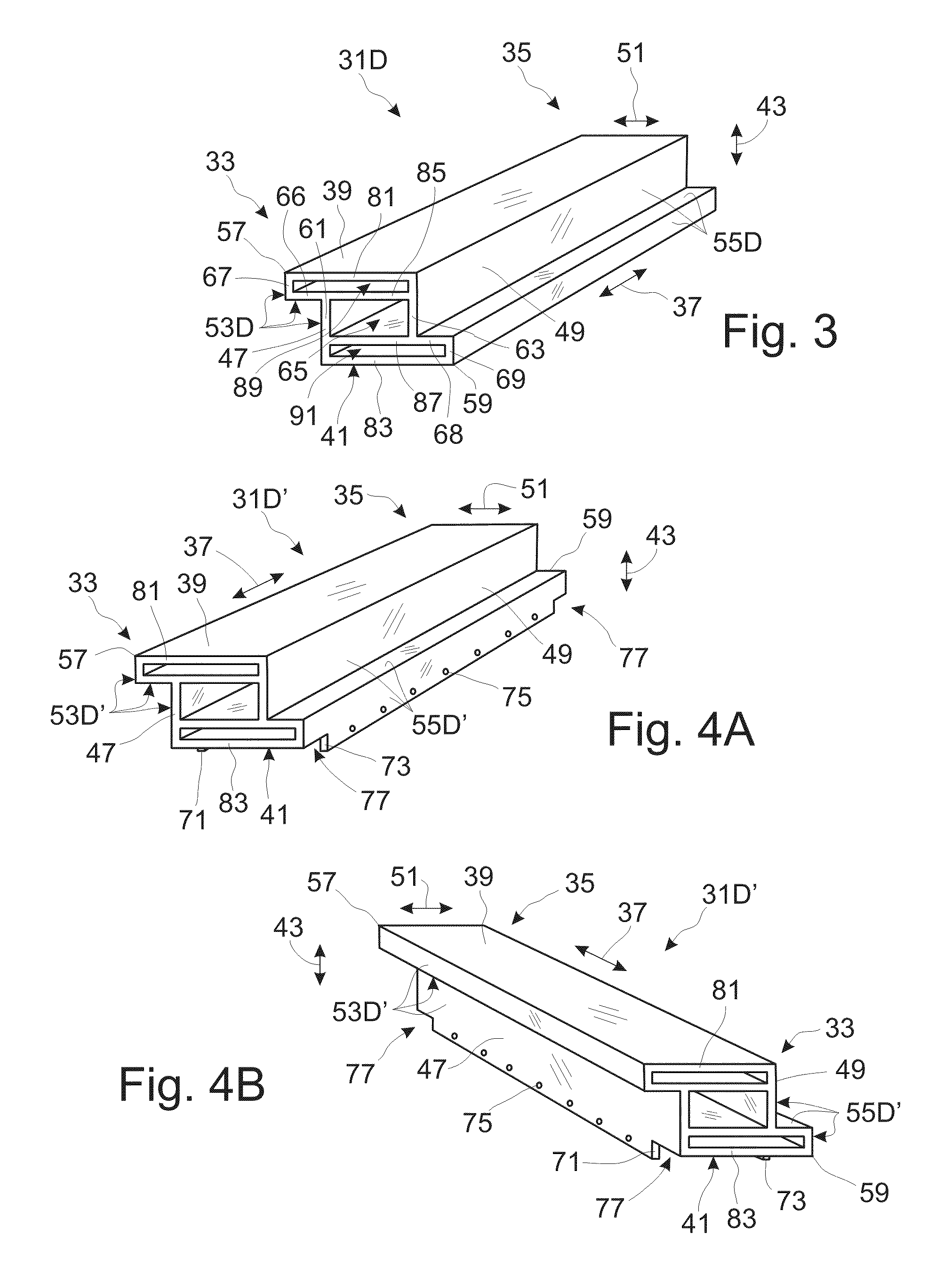

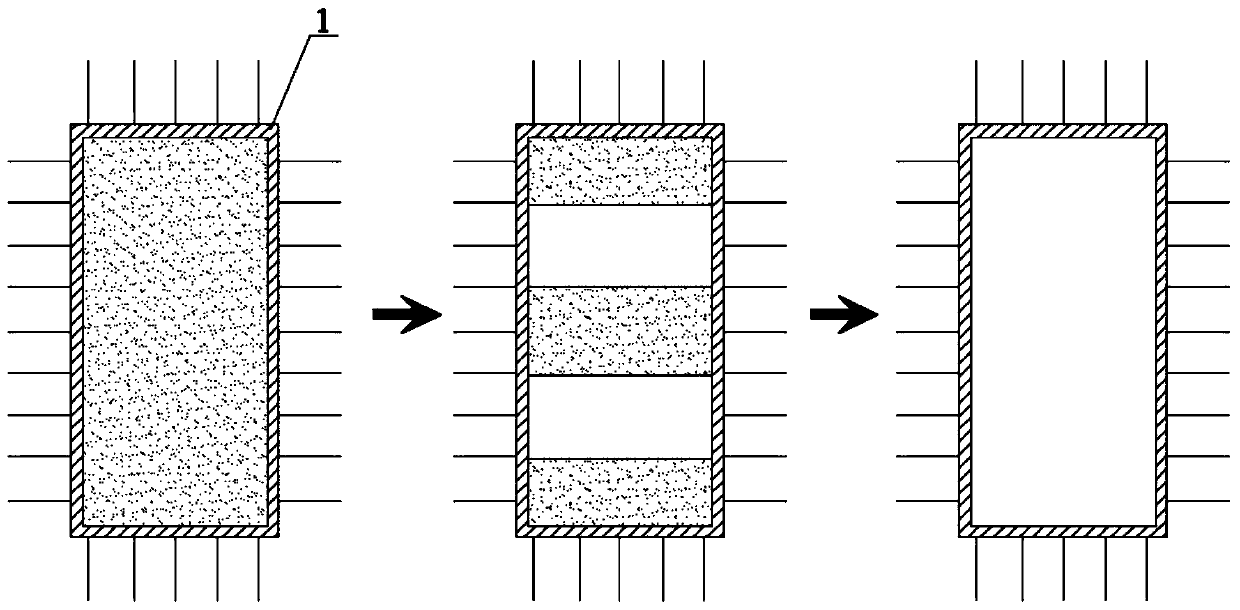

Armored building modules and panels—installation and removal

Panels and their modules, such as for walls and roofs, are disclosed that provide armored shelter for protecting people and equipment from ballistic projectiles and mortar attacks. Each module is made from multiple co-parallel plates arranged in a stack, spaced apart, and held together along their sides by side elements. This is done in such a way that, when assembled side-by-side or end-to-end into panels, adjacent modules overlap one another to prevent straight-through seams yet allow any damaged module to be removed and replaced without moving adjacent modules. Space within a module, between plates and sides, can contain energy absorbing material in a variety of shapes. Plates serve as structural flanges, and side elements comprise structural webs, to permit each module to function as a structural beam. With such designs, the modules and panels are easily and quickly inserted and / or removed individually by a sequence of simple manipulations.

Owner:KONTEK INDS

Boilogical teaching experiment display crushing and grinding integrated mortar capable of being rapidly disassembled and assembled

InactiveCN110961191AEasy to GrindEasy to operateGrain treatmentsTeaching apparatusElectric machineryMortar

The invention discloses a biological teaching experiment display crushing and grinding integrated mortar capable of being rapidly disassembled and assembled. The mortar comprises a mortar shell, a switch cover and a feeding hole, wherein an opening at a top end of the mortar shell is covered with a switch cover, crushing rods which are distributed in an inclined manner are mounted on an auxiliarytransmission rod, the two are in welded connection, a connecting rod is arranged in the mortar shell, the connecting rod is located below a supporting plate, a top end of the connecting rod is rotationally connected with a main transmission rod, a bottom end of the connecting rod is connected with a second frame, a second connecting shaft is installed on the second frame, the connecting rod and the second frame are rotationally connected, and a second grinding roller is fixedly connected with the second connecting shaft. The mortar has the advantages that in the same device, the grinding mechanism and a crushing mechanism are driven by the power of a motor to operate synchronously, the grinding and crushing dual-operation effect on objects is better, moreover, the whole device can be conveniently disassembled and assembled, and the mortar use is more convenient to use.

Owner:NANJING XIAOZHUANG UNIV

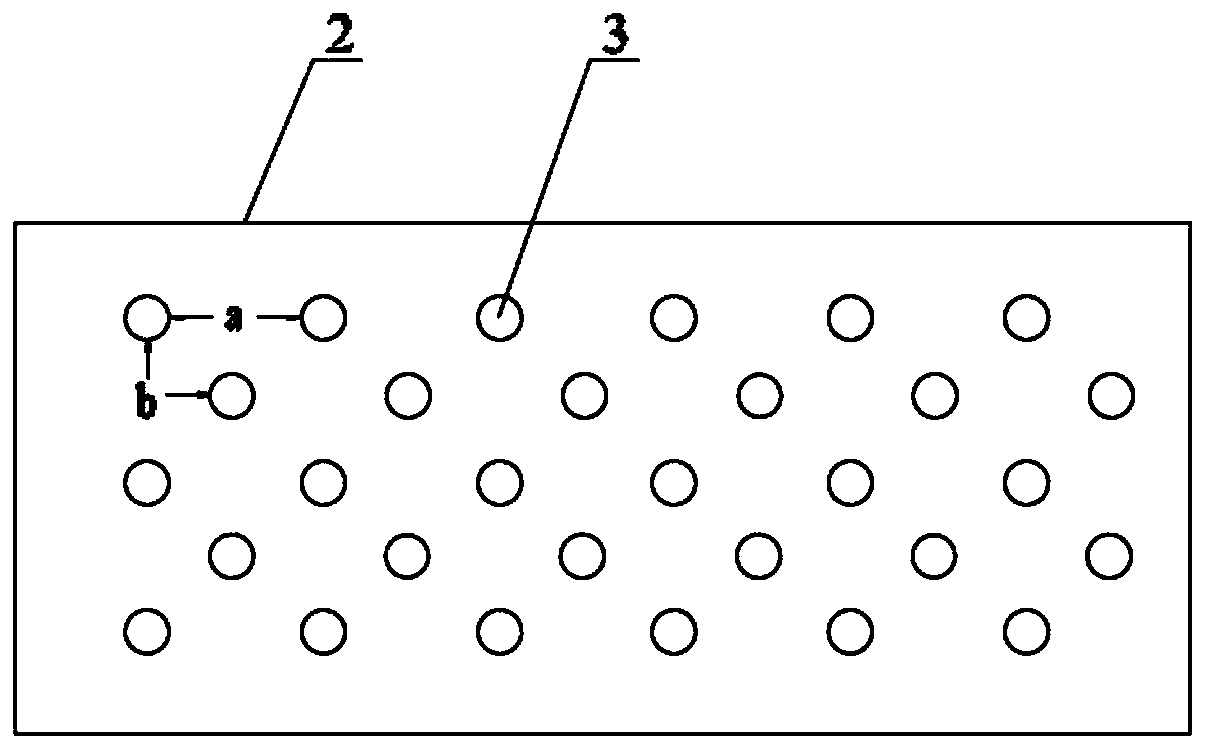

Dynamic detonation power field test system and test method for destruction detonation grenade

The embodiment of the invention provides a dynamic detonation power field test system and test method for a destruction detonation grenade, and belongs to the technical field of damage evaluation. Thedynamic detonation power field test system for the destruction detonation grenade involves a trigger target, a sector plate and a shock wave pressure detection device; the trigger target is arrangedopposite to a ballistic mortar, and the ballistic mortar is used for launching the destruction detonation grenade; the sector plate is arranged at one side of the trigger target and protrudes in a direction away from the trigger target, and fragments generated after the destruction detonation grenade detonates penetrate into the sector plate; and the shock wave pressure detection device is arranged at the other side of the trigger target and is used for detecting a pressure signal generated by a shock wave after the destruction detonation grenade detonates. According to the technical scheme, the distribution rules of the fragment power field and the shock wave power field of the destruction detonation grenade under the dynamic detonation state can be detected, and the distribution rules include the fragment scattering condition, the shock wave overpressure distribution condition and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

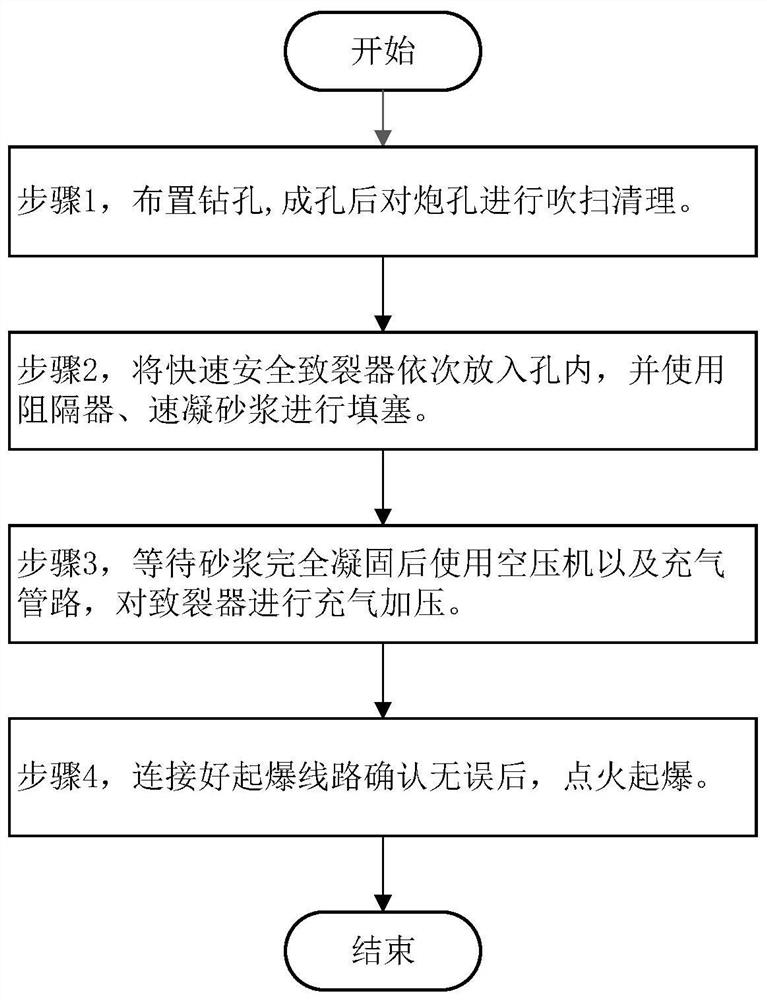

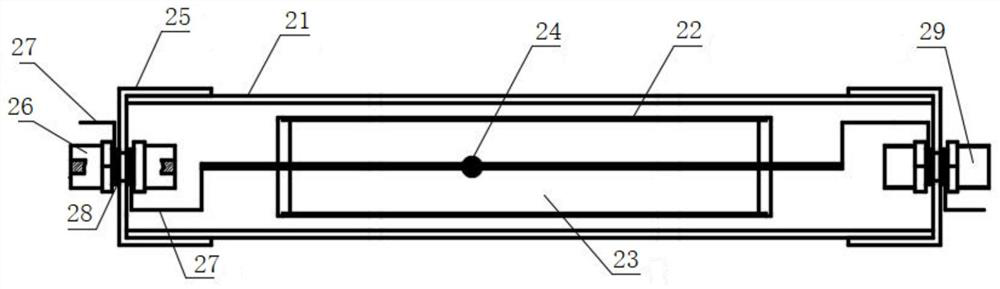

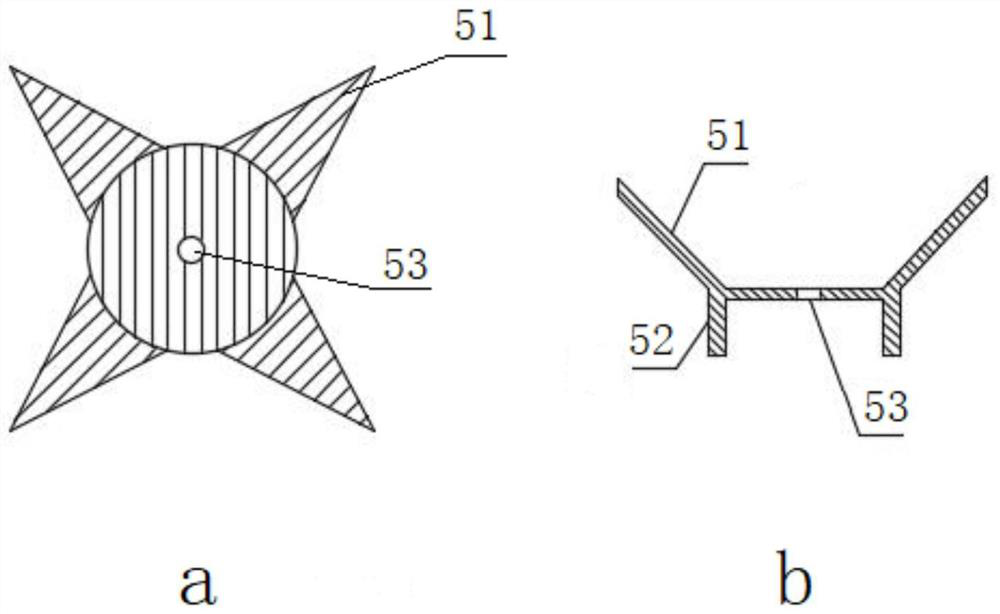

Blasting construction method for blasting equipment

PendingCN111692935AThe blasting implementation process is convenientStrong blasting controllabilityBlasting cartridgesBlastingDetonationArchitectural engineering

The invention discloses a blasting construction method for blasting equipment. The blasting construction method comprises the steps: firstly a hole net is arranged, a first row of holes is formed in the direction of a free face, the hole diameter is larger than 90 mm, the hole distance is 500-1000 mm, the row distance between a second row of holes and the first row of holes is 500-1000 mm, and inthe same way, after hole forming, purging clearing is conducted on the blast holes; then the blasting equipment is sequentially put into the holes, the blast holes are stuffed with barriers, the blasting equipment is sealed in the blast holes, and the exteriors of the barriers are stuffed with quick-setting mortar; after the mortar is solidified, the blasting equipment is inflated and pressurizedthrough an air compressor and an inflating pipeline, and a pressure value reaches the initiation pressure; and finally after connection of an initiation circuit is completed and confirmed, ignition detonation is conducted. According to the method provided by the invention, the blasting implementation process is convenient, blasting controllability is high, blasting vibration can be reduced, greatprotection effect on the construction ambient environment can also be achieved, and meanwhile the blasting effect is ensured.

Owner:马铭泽

Construction method for excavating shield receiving well in complex geology

InactiveCN110206550APrevent landslidesReduce the probability of landslidesBlastingShaft sinkingSurface layerUrban area

The invention discloses a construction method for excavating a shield receiving well in complex geology. The technologies of opening-locking ring beam construction, surface layer earth excavation, rock stratum blasting excavation, mortar anchor rod construction, steel structure grille construction, C20 early strength concrete spraying construction, and steel structure cross brace erecting are sequentially adopted, excavation construction of the shield receiving well can be conducted in a central urban area with the narrow construction environment; a carbon dioxide blasting technology is used for replacing explosive blasting, the adverse influences on central urban area buildings and construction safety and the adverse influence of pollution and the like on the surrounding environment are avoided; and stage-type construction is adopted, the second step to the seventh step in the construction method are repeated at each excavation stage, the side wall of the shield receiving well is anchored, supported, subjected to concrete pouring shaping and subjected to cross brace stable construction, the collapse risk of the side wall of the shield receiving well under the complex geological condition is reduced, geological sedimentation around the shield receiving well is avoided, the surrounding urban buildings of the shield receiving well are effectively protected, the construction method is easy to operate and high in safety, and the environment influence is small.

Owner:THE FOURTH ENGIENERING OF CHINA RAILWAY18 BUREAU GROUP +1

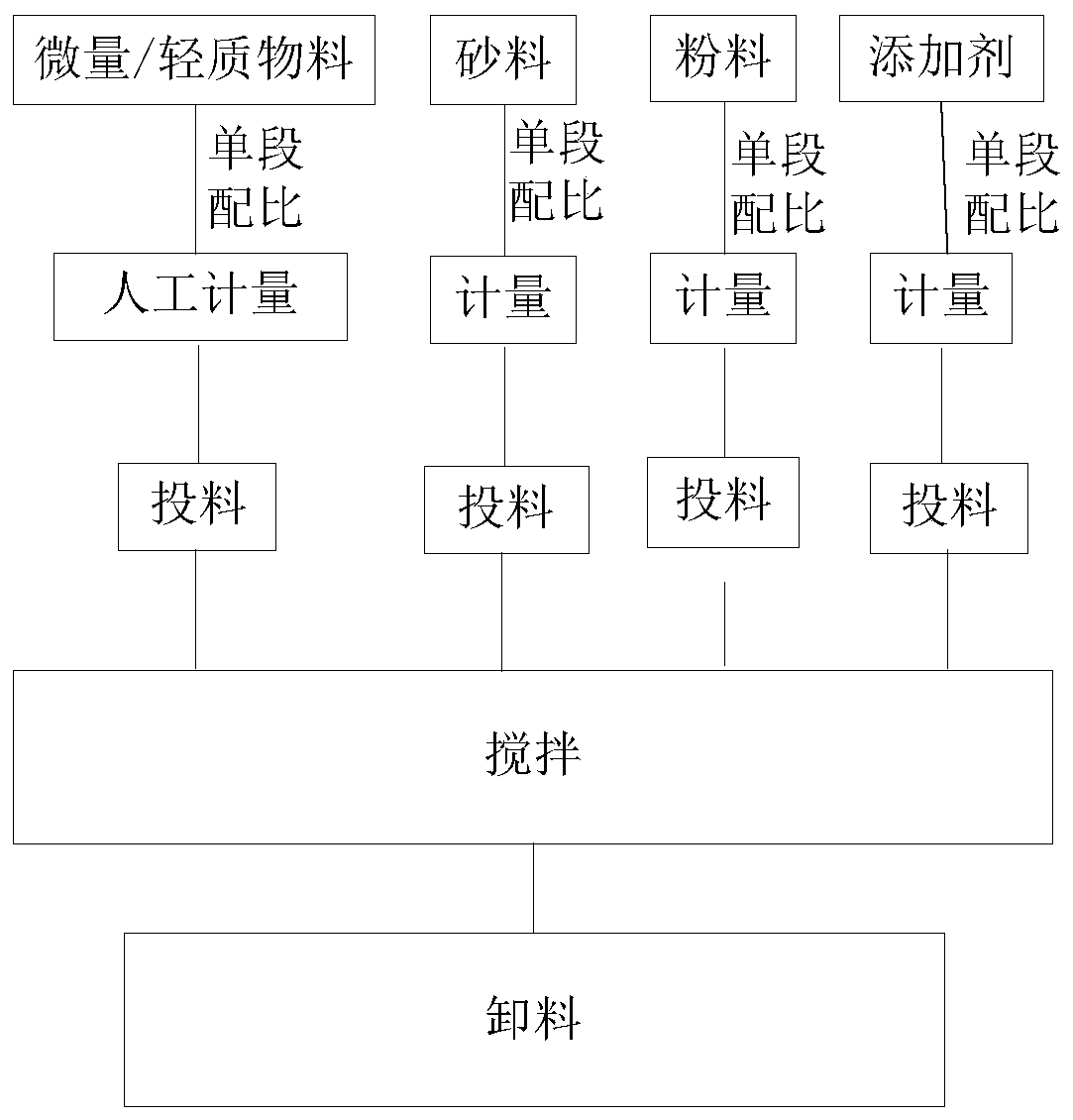

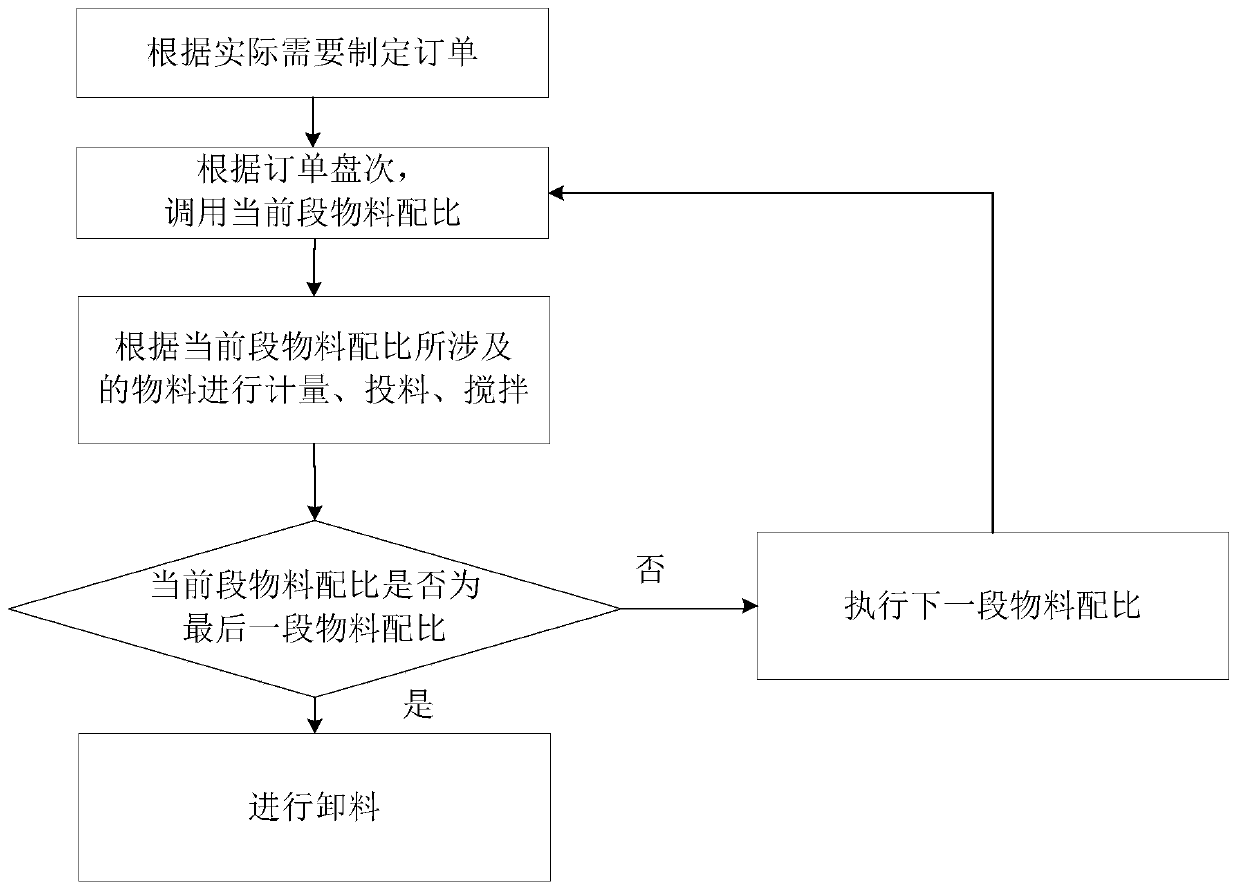

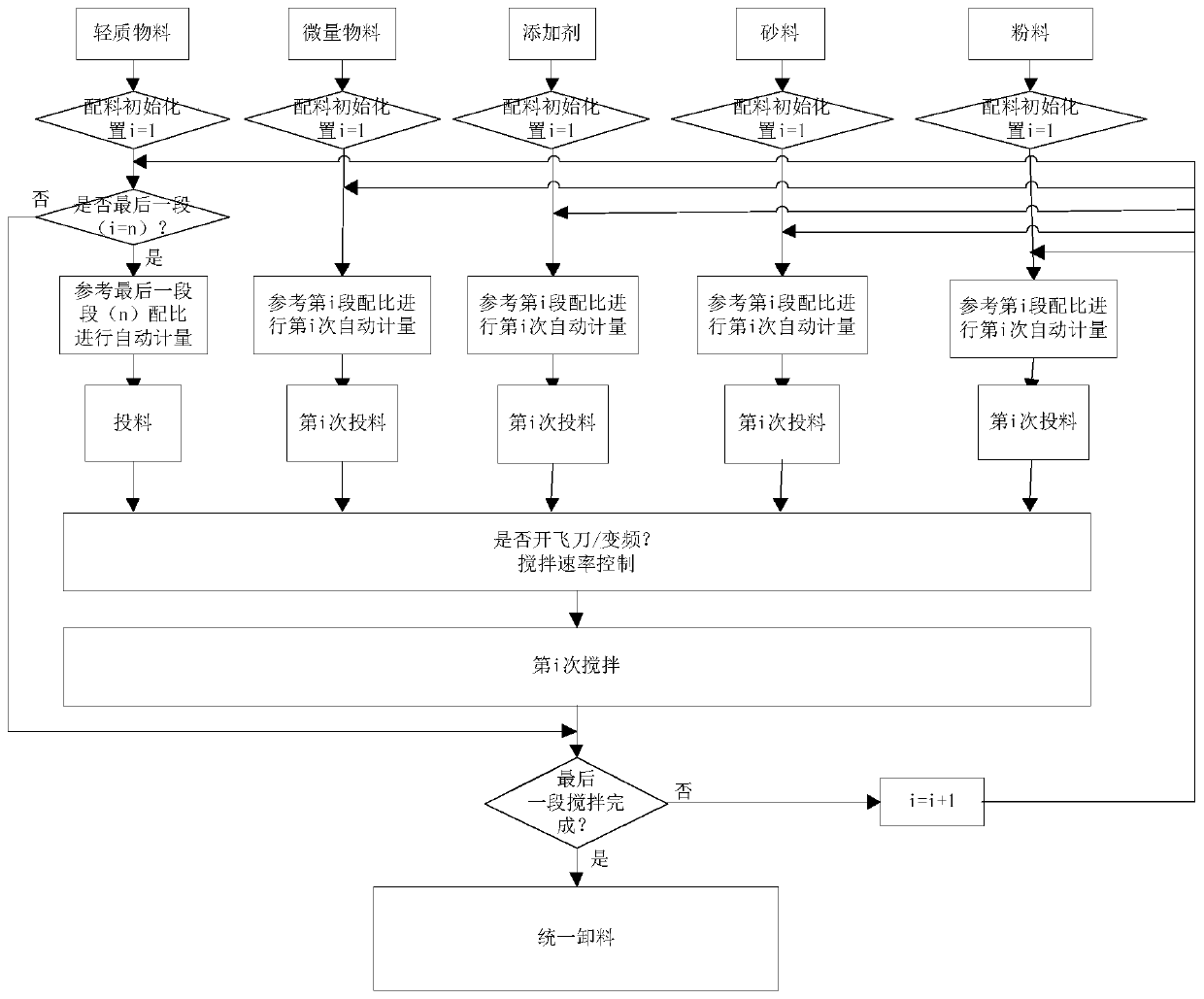

Mortar production control method and system

ActiveCN111168840AImprove product qualityFully consider material propertiesMixing operation control apparatusClay mixing apparatusControl mannerMortar

The invention discloses a mortar production control method. The method comprises the steps that a current-segment material ratio is called; according to the called current-segment material ratio, materials related to the current-segment material ratio are metered, fed and stirred; whether the current-segment material ratio is a last-segment material ratio or not is determined; and under the situation that it is determined that the current-segment material ratio is not the last-segment material ratio, a next-segment material ratio is executed, and otherwise, unloading is conducted. According tothe mortar production control method, a control mode of the multiple-segment material ratios can be provided so as to finely control equipment to complete production of special mortar, and the product quality of the produced special mortar is improved.

Owner:湖南中联重科新材料科技有限公司 +1

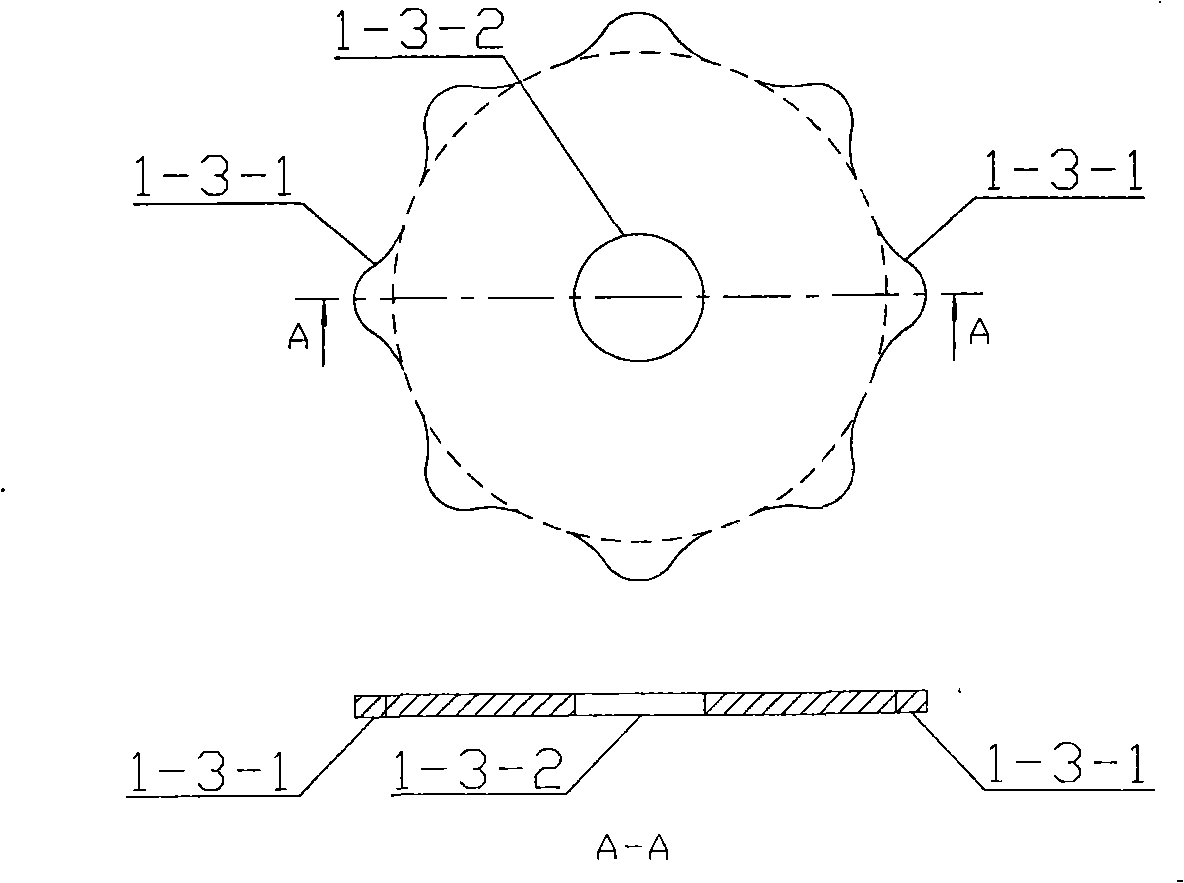

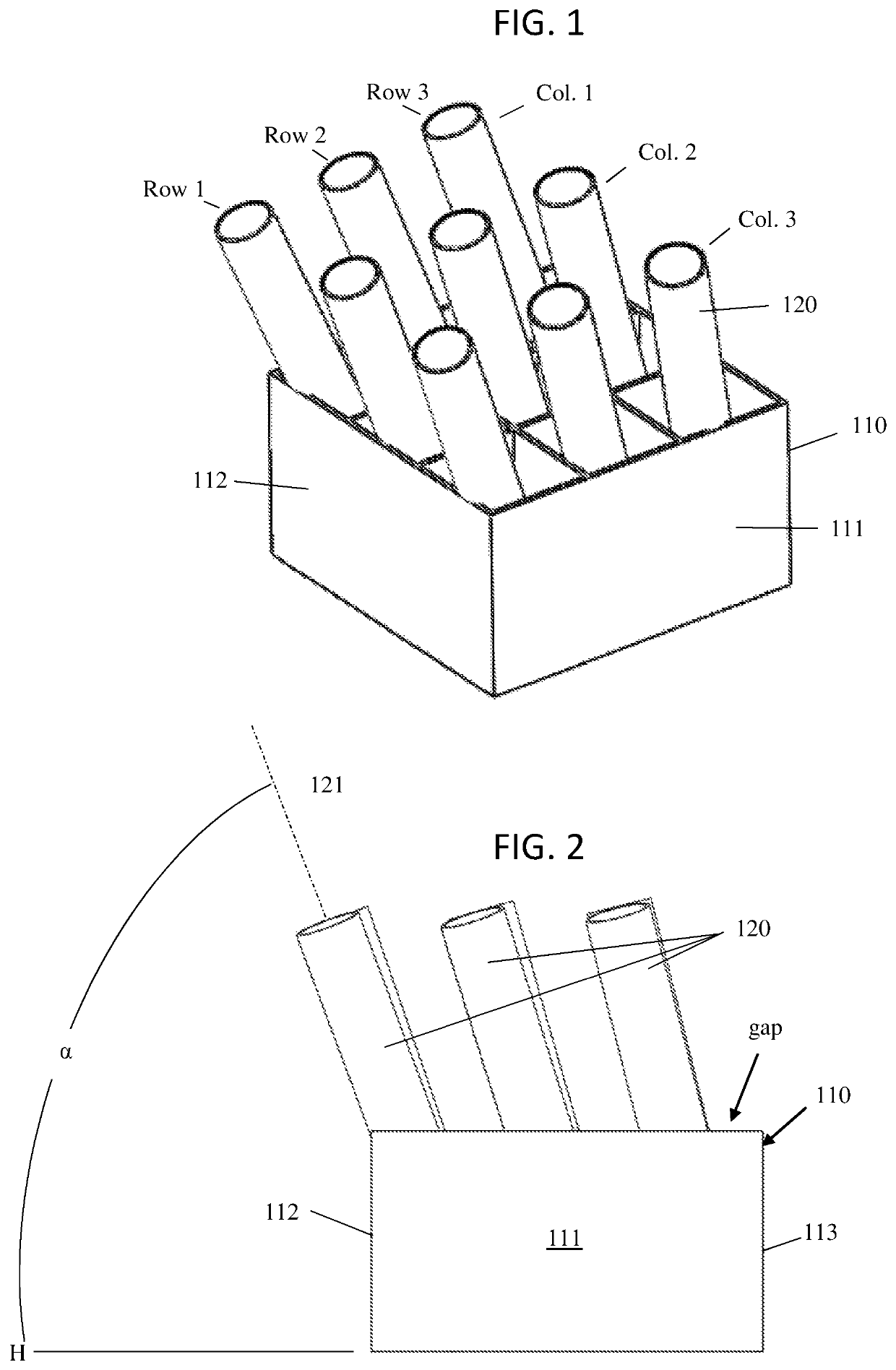

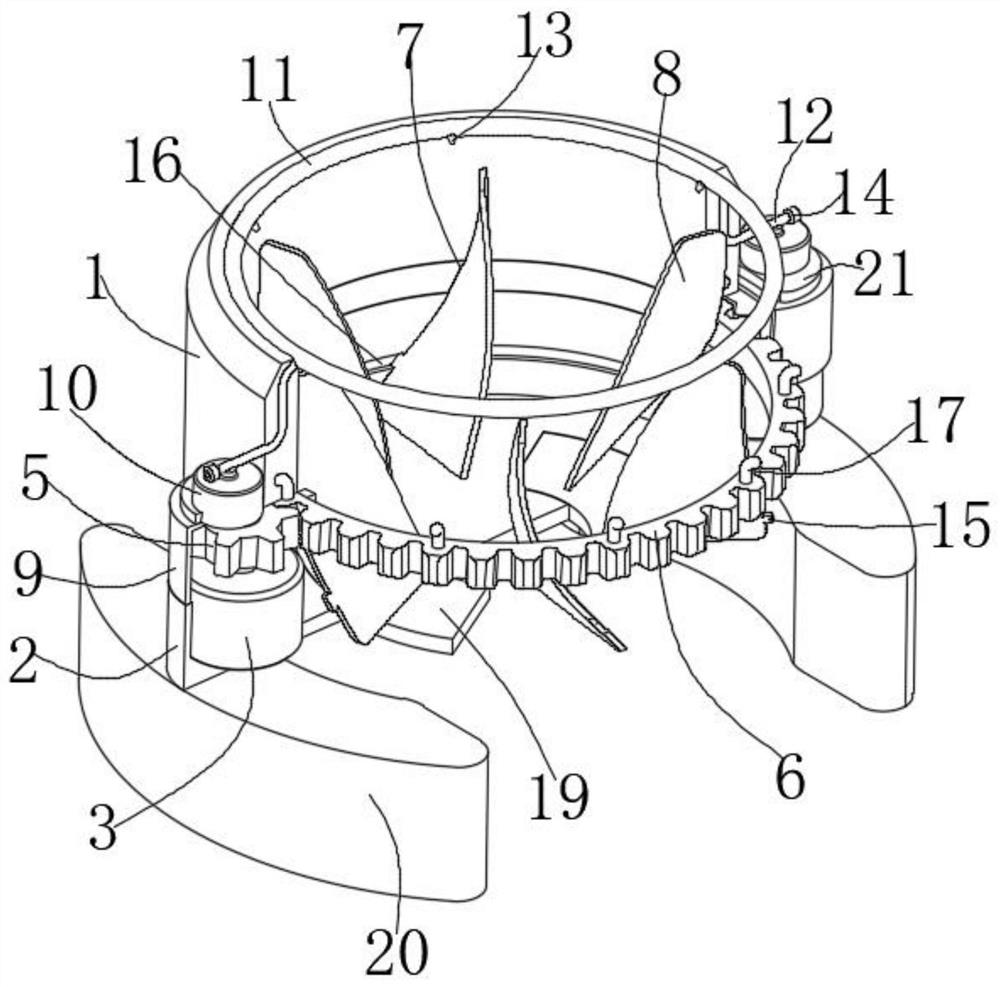

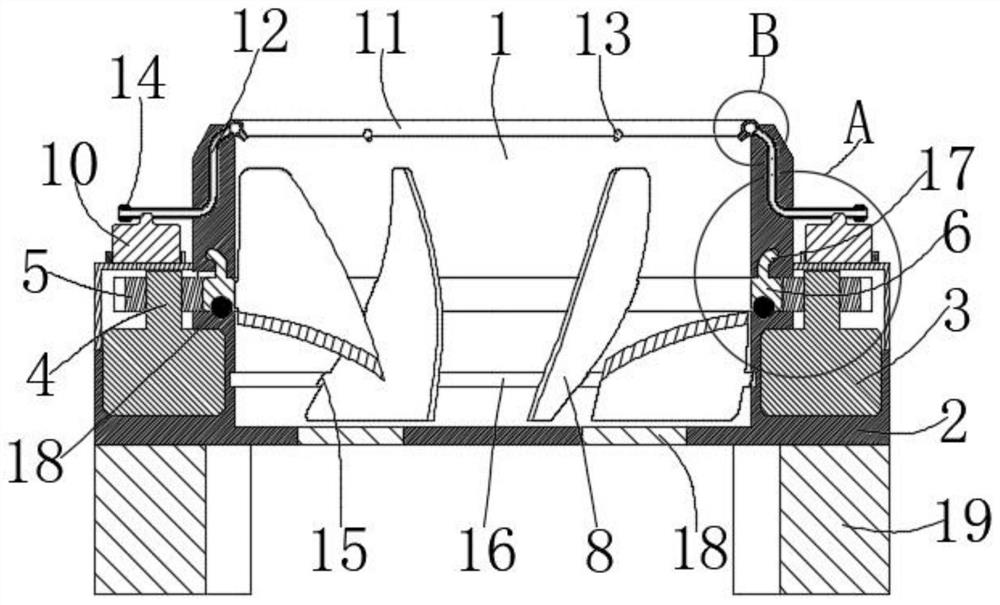

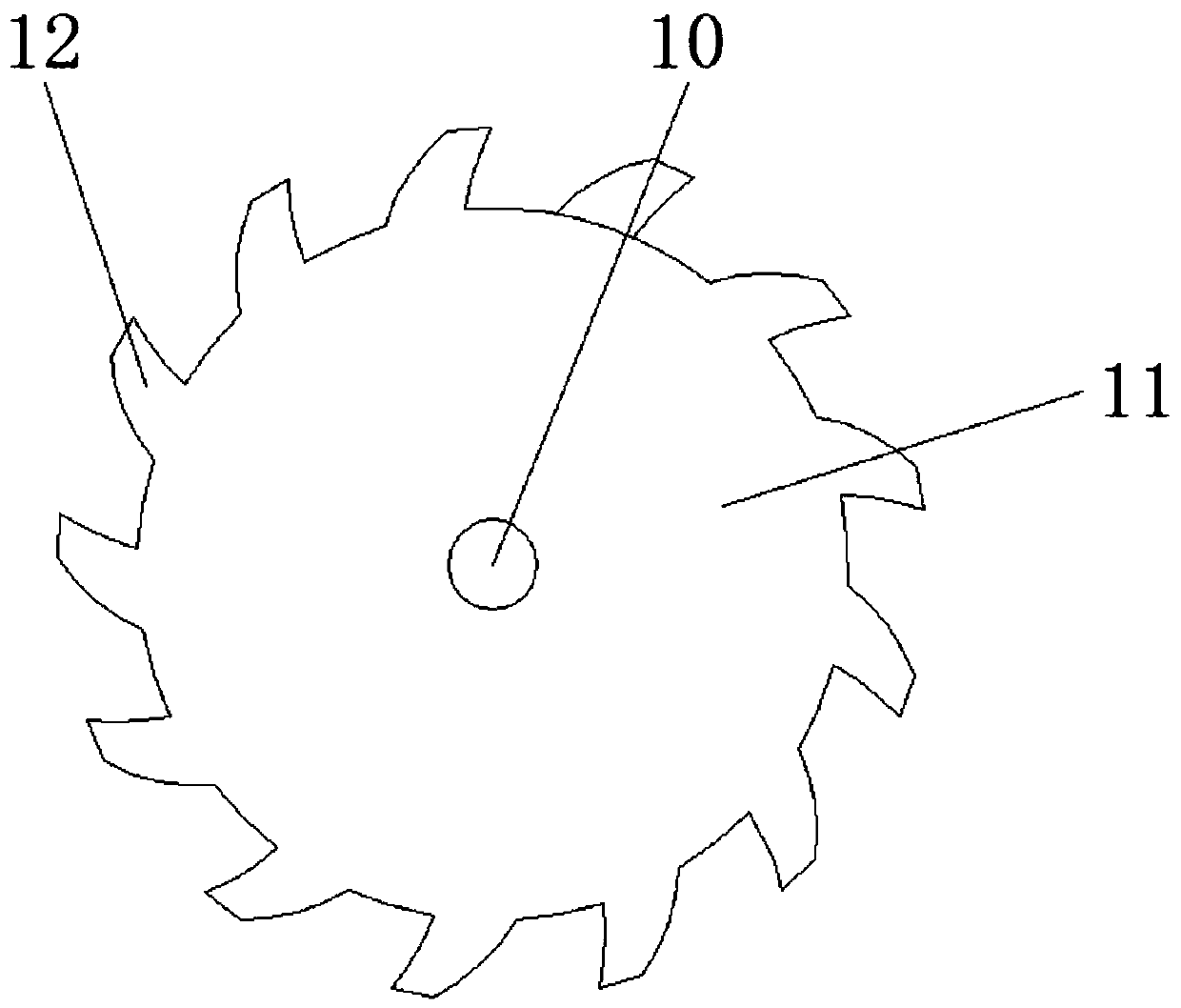

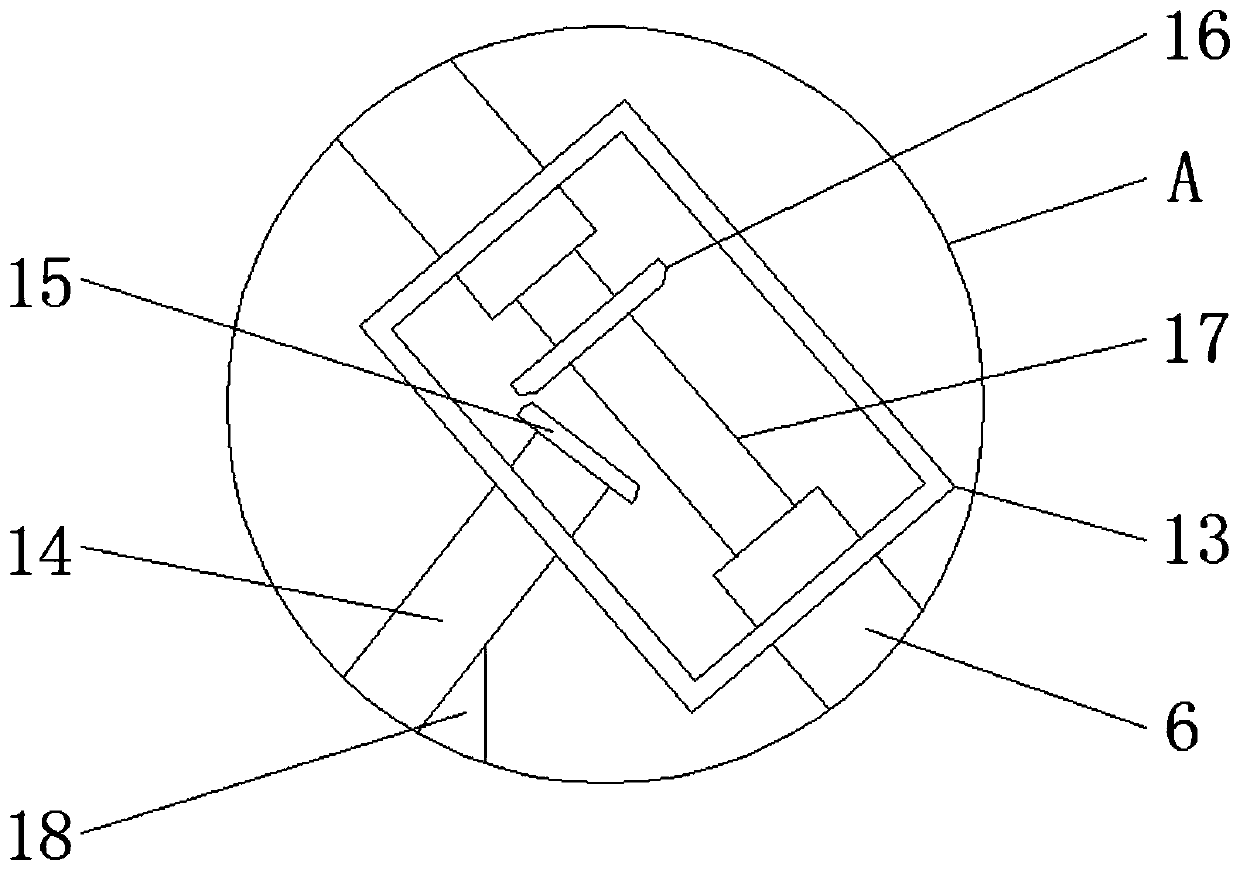

Rotary magazine with accurate ammunition shifting for mortar and ammunition shifting method of rotary magazine

ActiveCN111928727ARealize automatic fillingNo need for manual fillingAmmunition loadingMortarStructural engineering

The invention relates to a rotary magazine with accurate ammunition shifting for a mortar and an ammunition shifting method of the rotary magazine. The rotary magazine comprises an ammunition storagemechanism, an ammunition shifting mechanism, a positioning mechanism, a guide cylinder and a rack, wherein the ammunition storage mechanism is used for accommodating a mortar shell; the ammunition shifting mechanism is used for aligning one mortar shell loaded in the ammunition storage mechanism with the guide cylinder; and the positioning mechanism is used for limiting the angular size of each rotation of the ammunition storage mechanism. According to the rotary magazine with accurate ammunition shifting for the mortar and the ammunition shifting method of the rotary magazine, an automatic ammunition shifting process of filling in front of the mortar can be realized, the reliability is high, the stability is good, the manpower is saved, the ammunition shifting is rapid and the ammunitionshifting angle is accurate, the combat efficiency is improved, the automatic filling speed of the mortar is increased, the multi-shot continuous hitting can be carried out on enemies, and the battlefield survival capability of the mortar is remarkably improved.

Owner:NANJING UNIV OF SCI & TECH

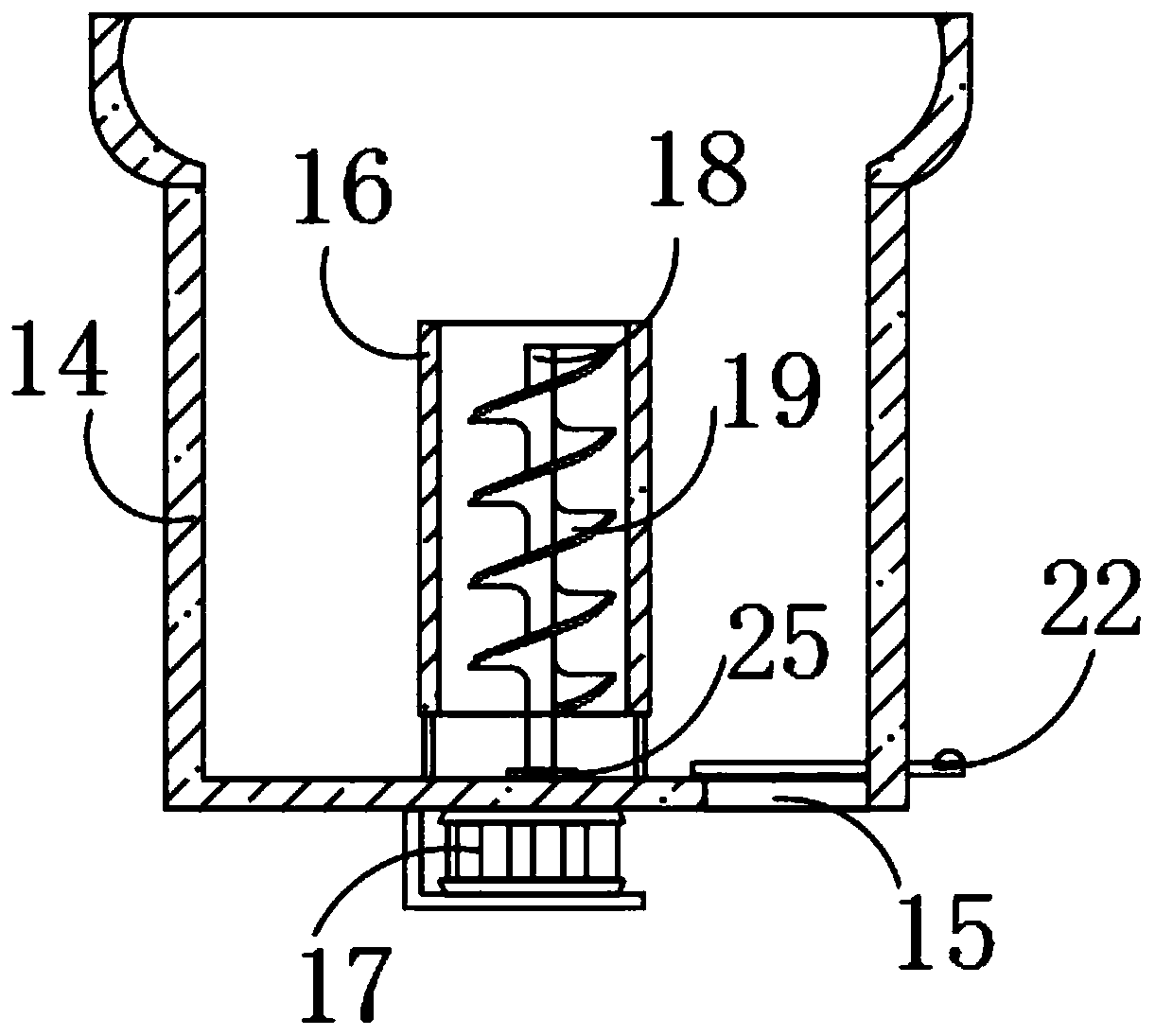

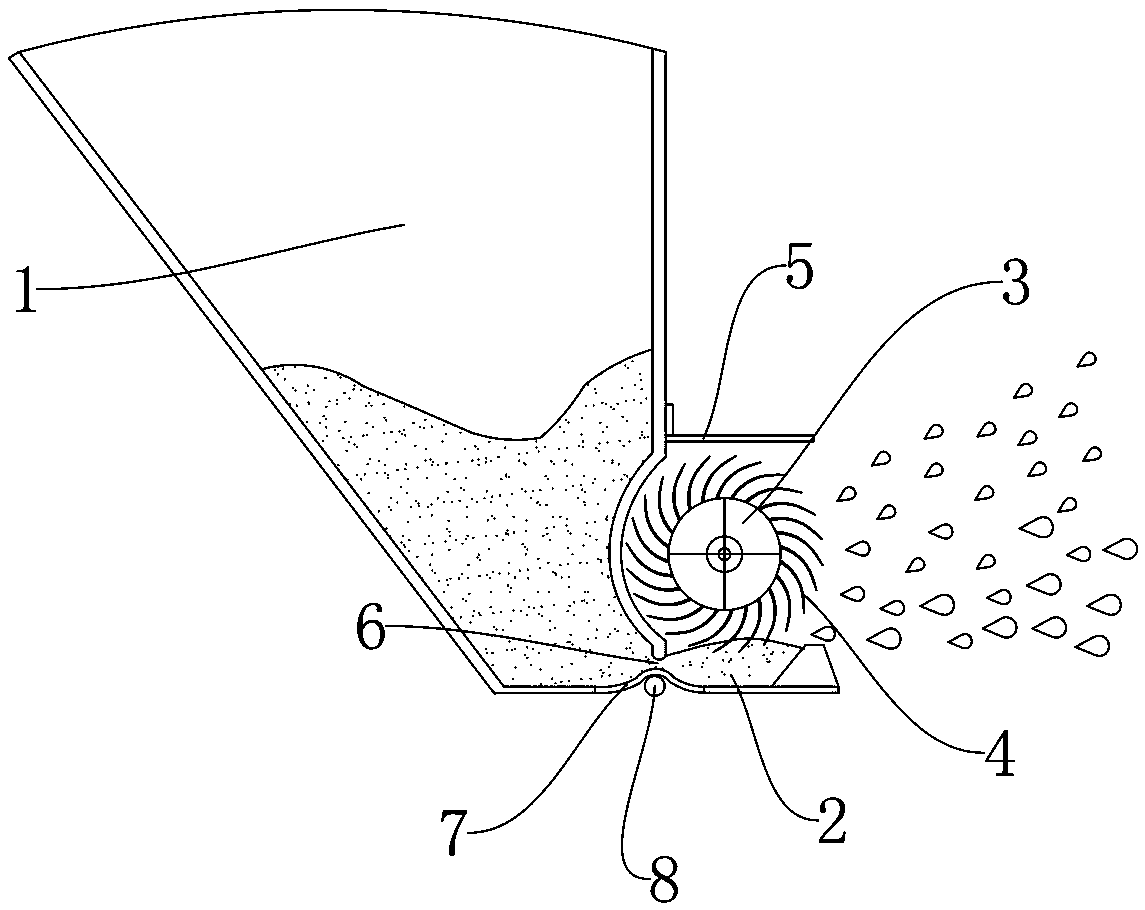

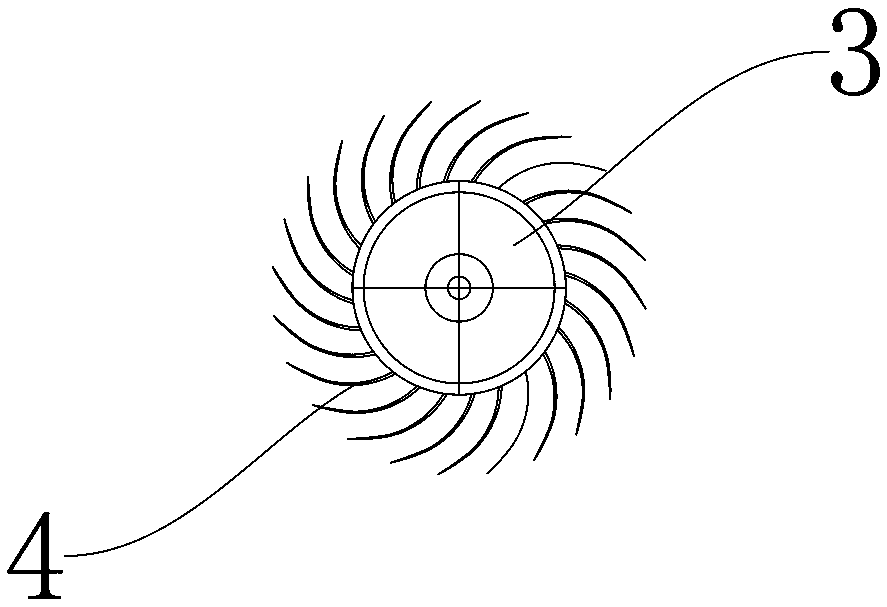

Fast mortar construction device

PendingCN111472523AShotcrete improves its efficiencyFlexible and fast sprayingBuilding constructionsArchitectural engineeringMortar

The invention relates to a fast mortar construction device so as to improve the construction efficiency and the construction quality of the mortar top. According to the technical scheme, the fast mortar construction device is characterized in that the device is provided with a material bin and a mortar pool which communicates with the lower portion of the material bin through a mortar dischargingcontrol valve; a mortar tossing mechanism which can toss out mortar in the mortar pool in a small particle mode is disposed above the mortar pool; the mortar tossing mechanism is provided with a mortar tossing roller which is horizontal and is parallel to the length direction of the mortar pool; a plurality of mortar tossing rods which are uniformly distributed are fixed to the roller wall of themortar tossing roller; and one ends of the mortar tossing rods are fixed to the mortar tossing roller, and the other ends of the mortar tossing rods are mortar tossing ends which can make contact withthe mortar in the mortar pool below the mortar tossing rods during rotation of the mortar tossing roller and can be driven by the mortar tossing roller to toss out the mortar in the mortar pool in asmall particle mode. The fast mortar construction device is applicable to the technical field of mortar construction devices.

Owner:POWERCHINA HUADONG ENG COPORATION LTD +1

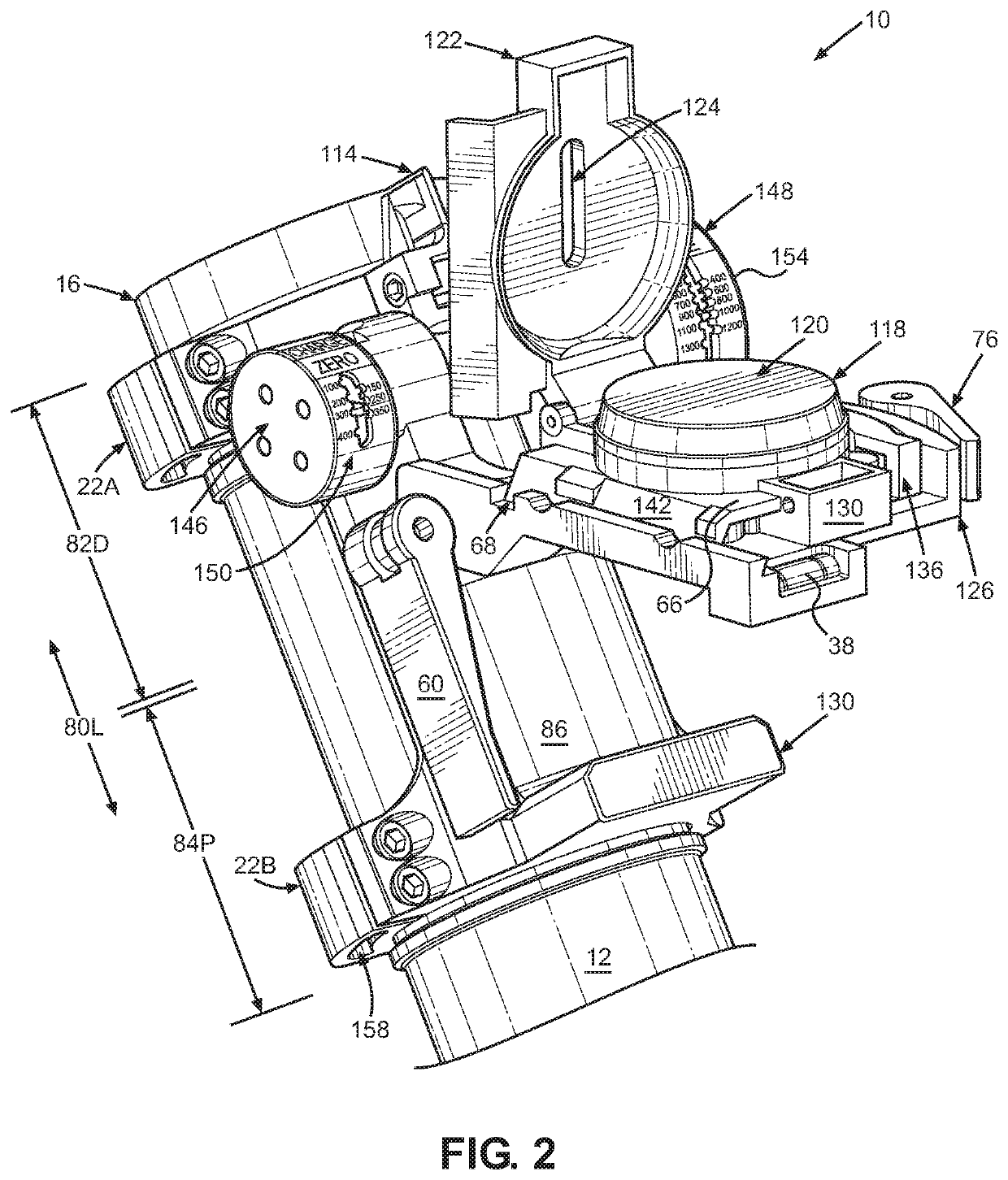

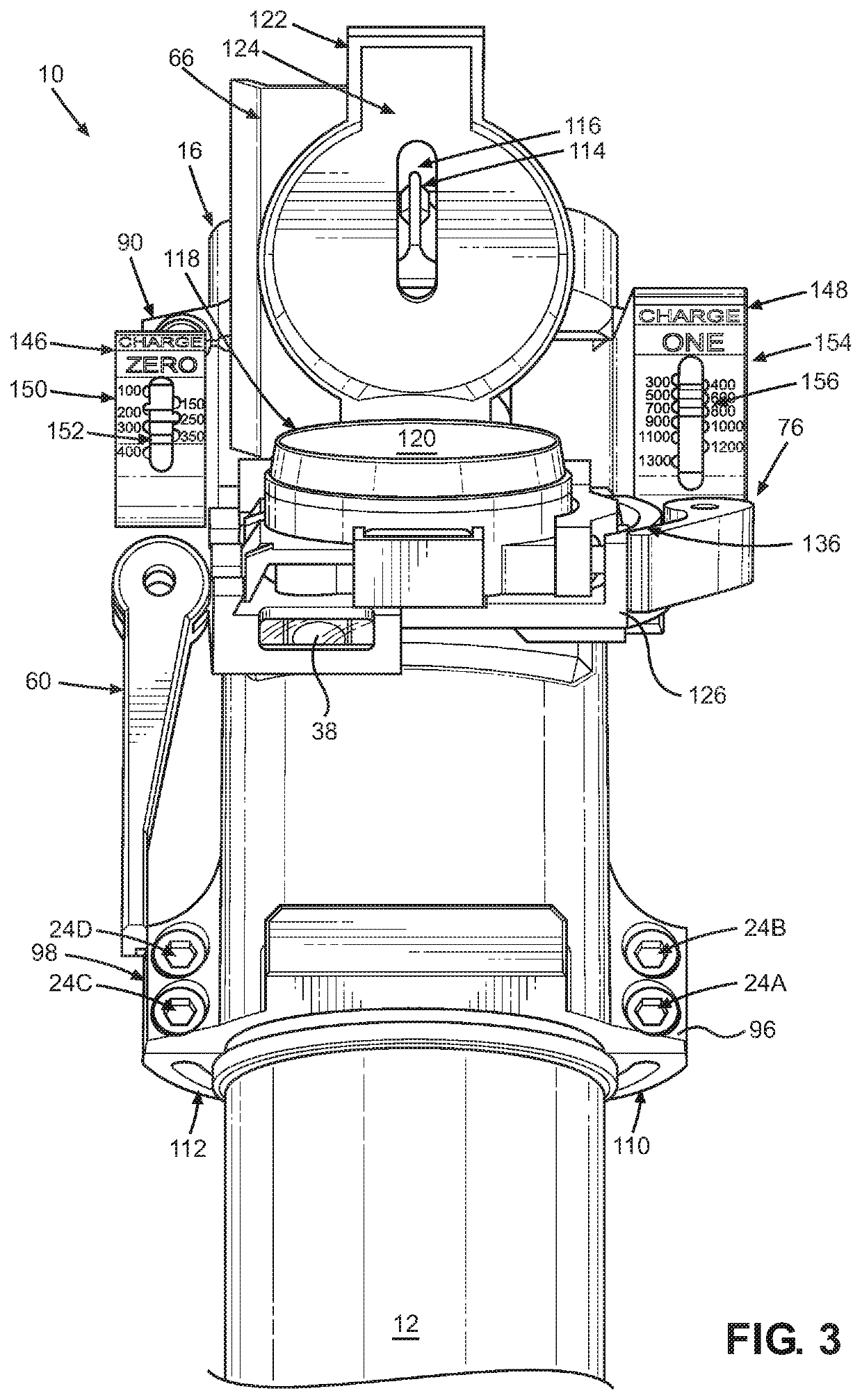

Sighting device for handheld mortar system

A sighting assembly for a mortar employed in handheld mode. The sighting assembly is attached to the discharge end of a mortar tube by a mounting collar. The collar includes first and second distance indicator dials that employ a pointer to indicate the distance a mortar projectile will travel at different mortar angles and charges. The sighting assembly further includes structure allowing a compass to be locked in a housing by a first cam lever. The entire housing pivots about a cam bolt attached to a second cam lever that can lock the housing in a position parallel to the ground at any angle the mortar is positioned. This will allow a measurement of azimuth to a target to be taken. The azimuth and distance measurements can be used to deliver a mortar projectile to the target while keeping the target in the mortarman's line of sight.

Owner:HARTMAN STEVEN T +1

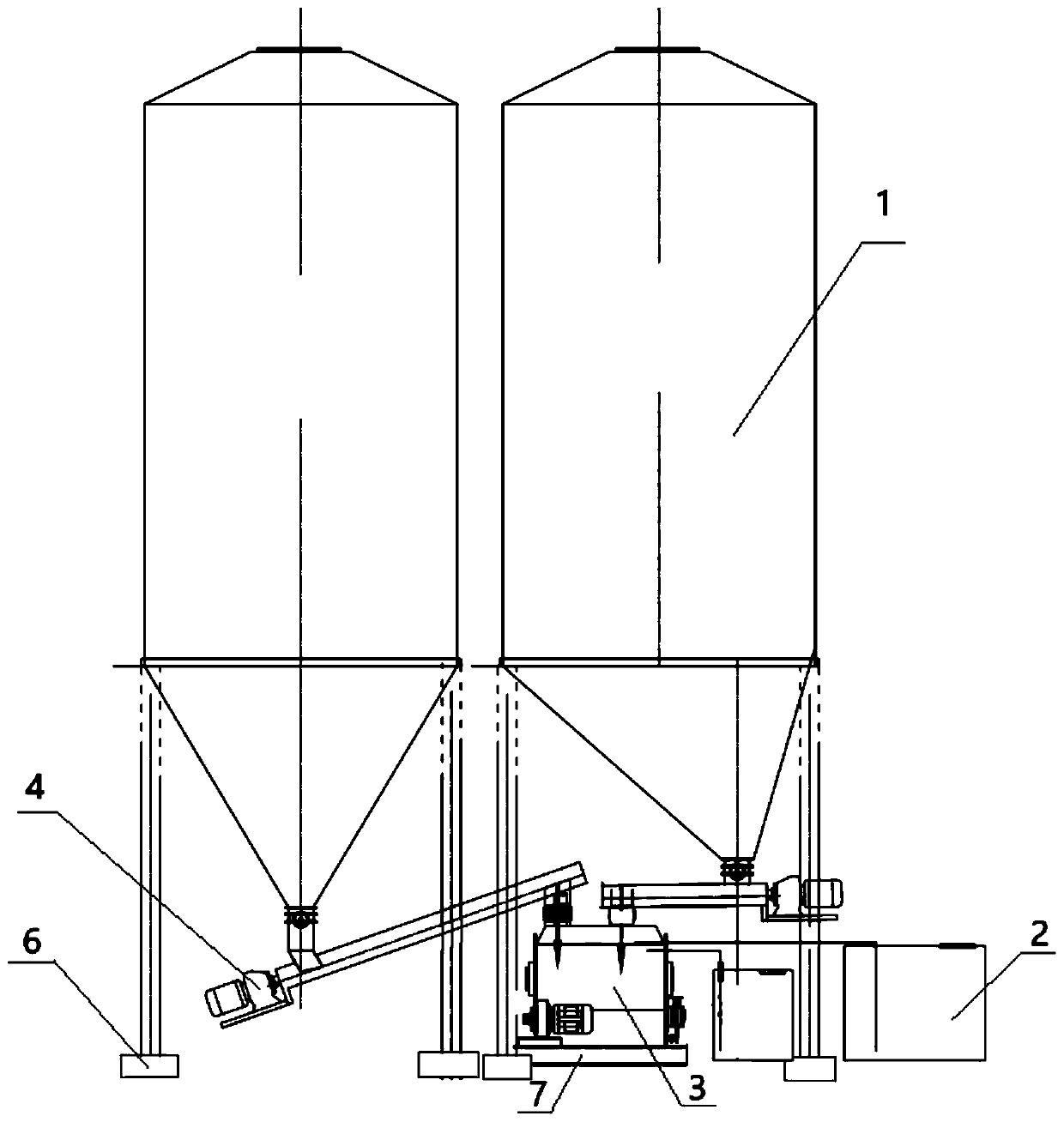

Remote control automatic mortar production system

PendingCN111186029AFast automatic production modeIncrease productivityIngredients weighing apparatusControl apparatusRemote controlControl engineering

The invention discloses a remote control automatic mortar production system. The remote control automatic mortar production system comprises at least one mortar production device and a remote controlcomponent. Each mortar production device comprises a plurality of storage tanks, a stirring device, a weight metering device and a controller, wherein each material storage tank is provided with a tank inlet and a tank outlet, each tank outlet is provided with a raw material valve, each material storage tank is provided with at least two support legs, and each support leg is provided with a gravity sensor; each stirring device is provided with a stirring cavity and a stirring assembly, the stirring cavities are provided with feeding ports and discharging ports which are communicated with the corresponding tank outlets, and discharging valves are arranged at the discharging ports; each weight metering device is located below the corresponding stirring device; the controllers are in communication connection with the gravity sensors and the weight metering devices and are electrically connected with power devices of the raw material valves, the discharging valves and the stirring assemblies; and the remote control component comprises signal transmitting device in communication connection with the controllers in a one-to-one corresponding manner, signal receiving devices in remote communication connection with the signal transmitting devices and a remote control terminal in communication connection with the signal receiving devices.

Owner:泰安启新建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com