Vertical prestressing force opening mud jacking construction method and construction device

A technology of vertical prestressing and construction methods, which is applied in the direction of construction, building structure, and building material processing, etc., and can solve the problems of uncompacted tops of vertical prestressing tunnels, so as to save grouting pipe materials and construction costs , reduce artificial effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

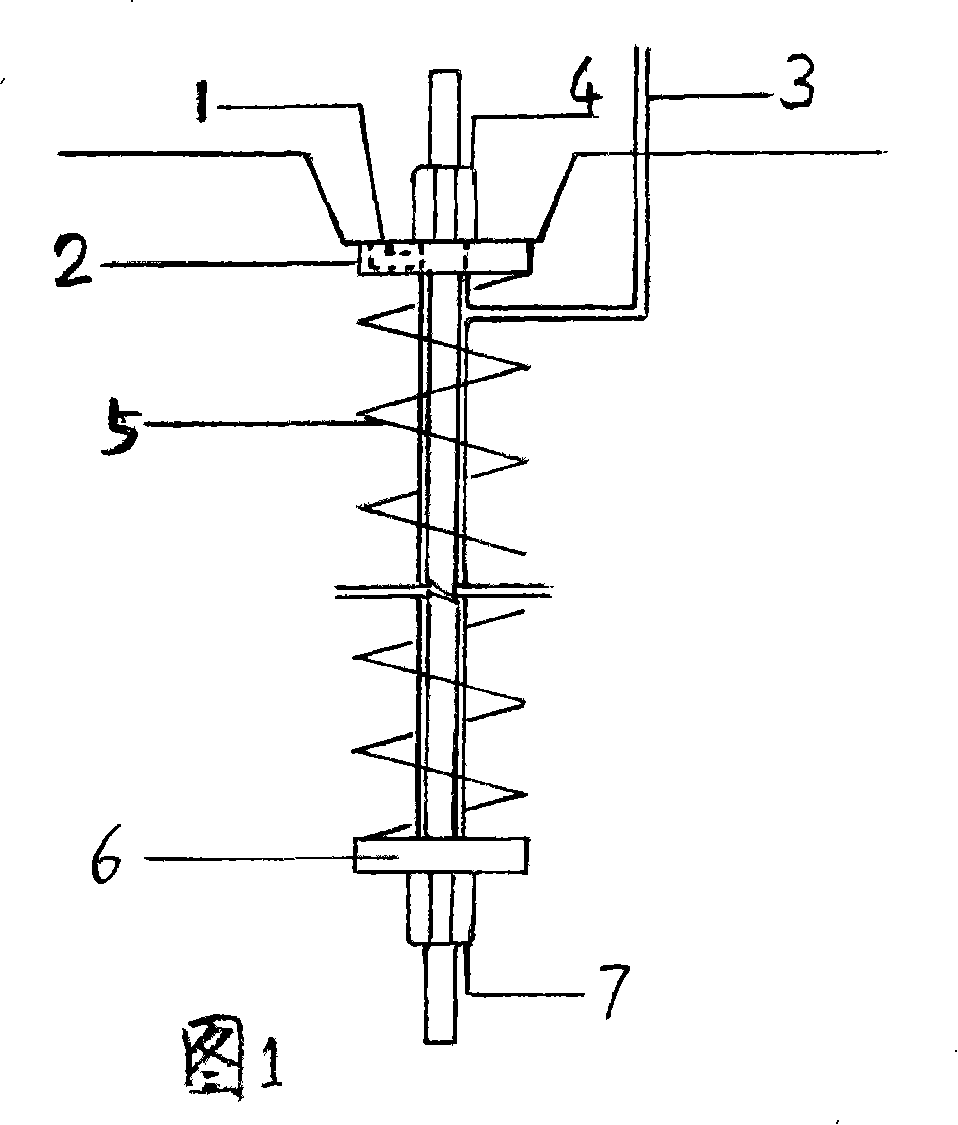

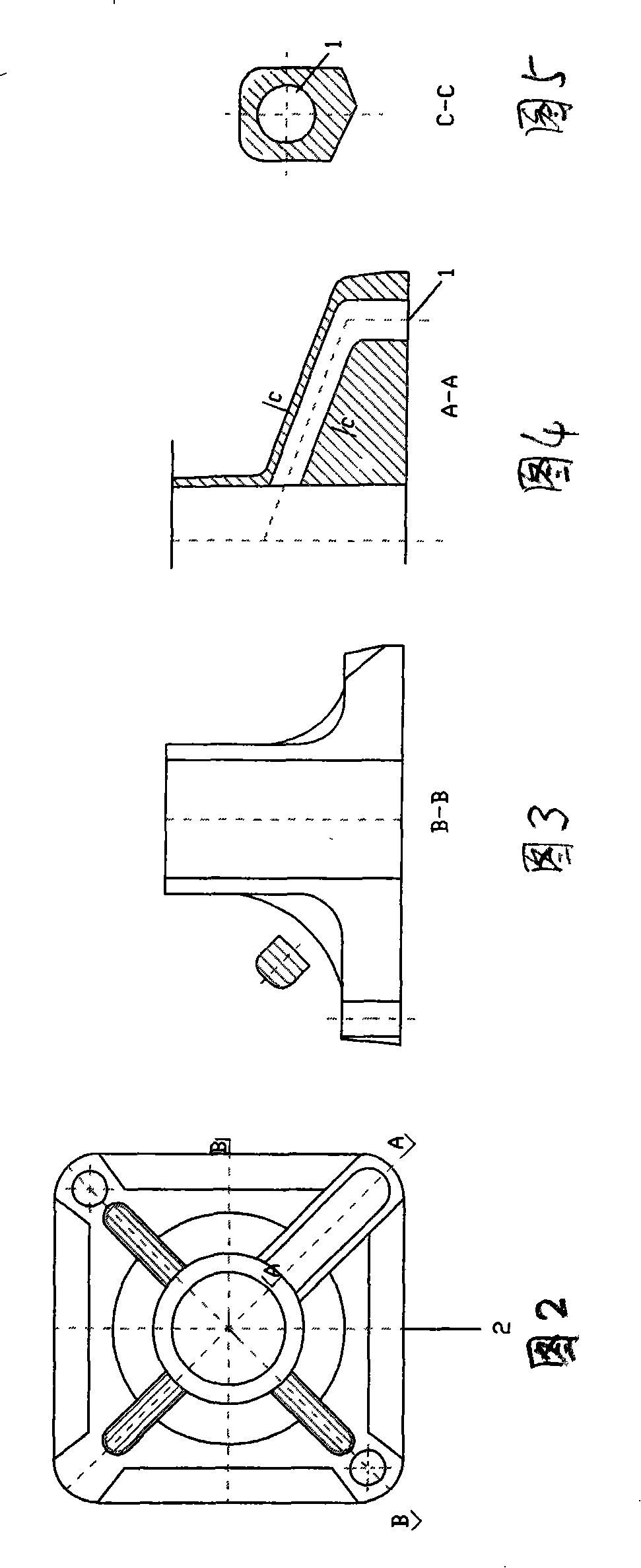

[0027] Compared with the traditional technology, the core of the present invention cancels the grouting pipe, and changes the anchor backing plate on the top into an iron casting, and directly sets a grouting hole on the iron casting. The steps of the grouting construction method for vertical prestressed channels of the present invention are as follows: for vertical prestressed pipelines, each channel is subjected to secondary grouting according to the procedure of gravity flow first, then low pressure and finally high pressure, and the grouting from top to bottom is adopted. Direction, specific steps; A. Gravity flow is the first choice for grouting for the first time, the time is 5 minutes, and low pressure control is adopted when the vent hole is vented, the pressure is controlled at 0.1MPa, and the time is controlled at 3 minutes; B. The exhaust pipe is blocked, and the second grouting is started, and the pressure is controlled at 0.3MPa until the slurry is full; C. Finally...

Embodiment 2

[0030] The steps of the grouting construction method for the vertical prestressed channel of the present invention are as follows: for the vertical prestressed pipeline, each channel is subjected to secondary grouting according to the procedure of gravity flow first, then low pressure and finally high pressure, and the method from top to bottom is adopted. Grouting direction, specific steps; A. Gravity flow is the preferred method for the first grouting, the time is 5.2 minutes, low pressure control is adopted when the vent hole is vented, the pressure is controlled at 0.12MPa, and the time is controlled at 3.2 minutes; B. 1. Block up the exhaust pipe, start the second grouting, and control the pressure at 0.31MPa until the slurry is full; C. Finally, erect the exhaust pipe so that its height is higher than that of the bellows.

[0031] The construction equipment of the vertical prestressed tunnel grouting construction method of the present invention: the construction equipment...

Embodiment 3

[0034] The steps of the grouting construction method for the vertical prestressed channel of the present invention are as follows: for the vertical prestressed pipeline, each channel is subjected to secondary grouting according to the procedure of gravity flow first, then low pressure and finally high pressure, and the method from top to bottom is adopted. Grouting direction, specific steps; A. Gravity flow is the preferred method for the first grouting, the time is 5.3 minutes, low pressure control is adopted when the vent hole is vented, the pressure is controlled at 0.13MPa, and the time is controlled at 3.3 minutes; B. 1. Block up the exhaust pipe, start the second grouting, and control the pressure at 0.32MPa until the slurry is full; C. Finally, erect the exhaust pipe so that its height is higher than that of the bellows.

[0035] The construction equipment of the vertical prestressed tunnel grouting construction method of the present invention: the construction equipment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com