Full-fabricated assembly overall reinforced concrete house and building method thereof

A reinforced concrete and prefabricated assembly technology, applied in building construction, construction, building materials processing and other directions, can solve the problems of difficulty in guaranteeing the quality of cast-in-place parts, insufficient waterproof and sound insulation performance, and large differences in quality levels, and achieves pouring The operation is convenient and fast, the concrete surface is smooth and smooth, and the connection operation is convenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with accompanying drawing description and specific embodiment:

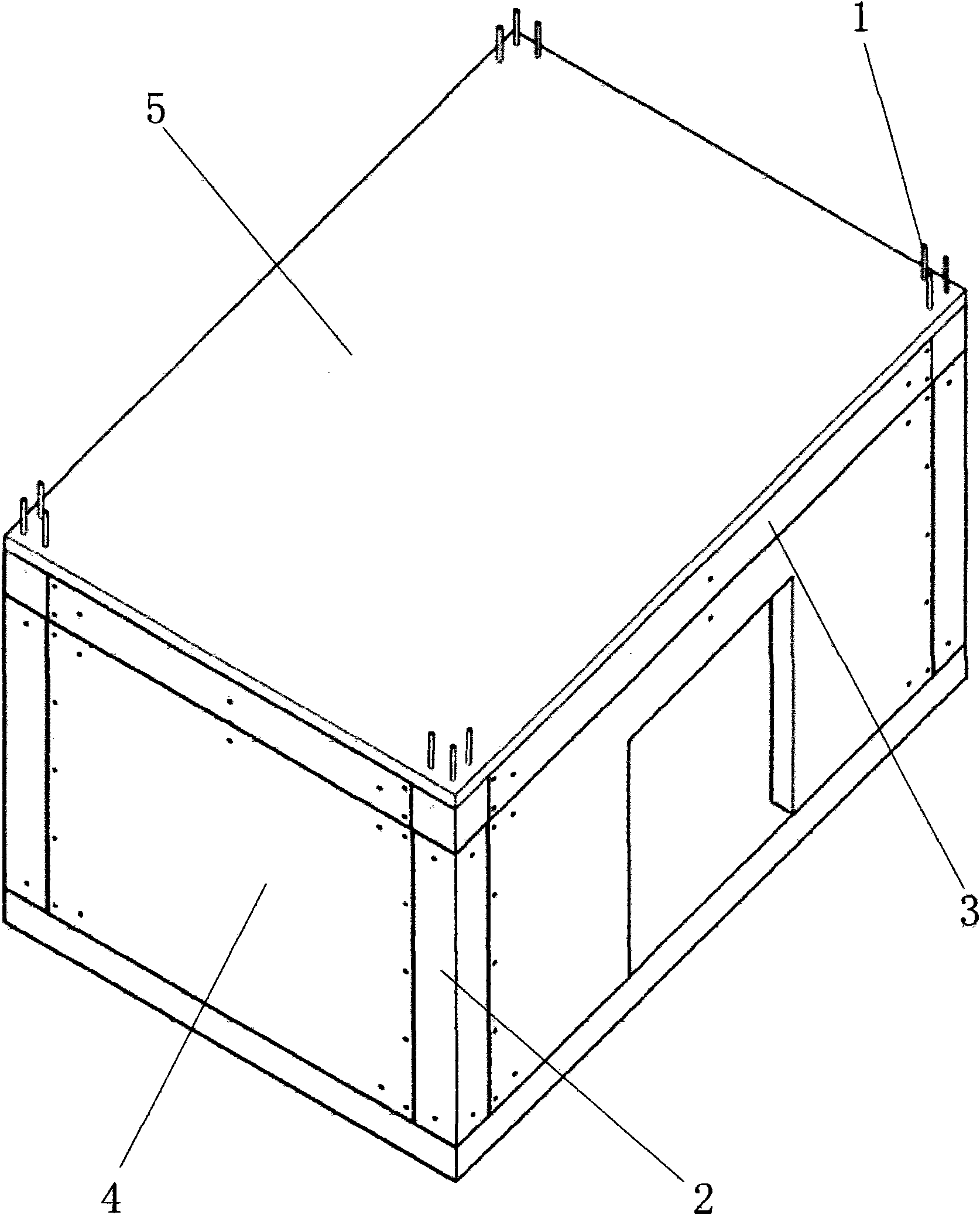

[0053] like Figures 1 to 10 A fully prefabricated monolithic reinforced concrete house shown, which includes:

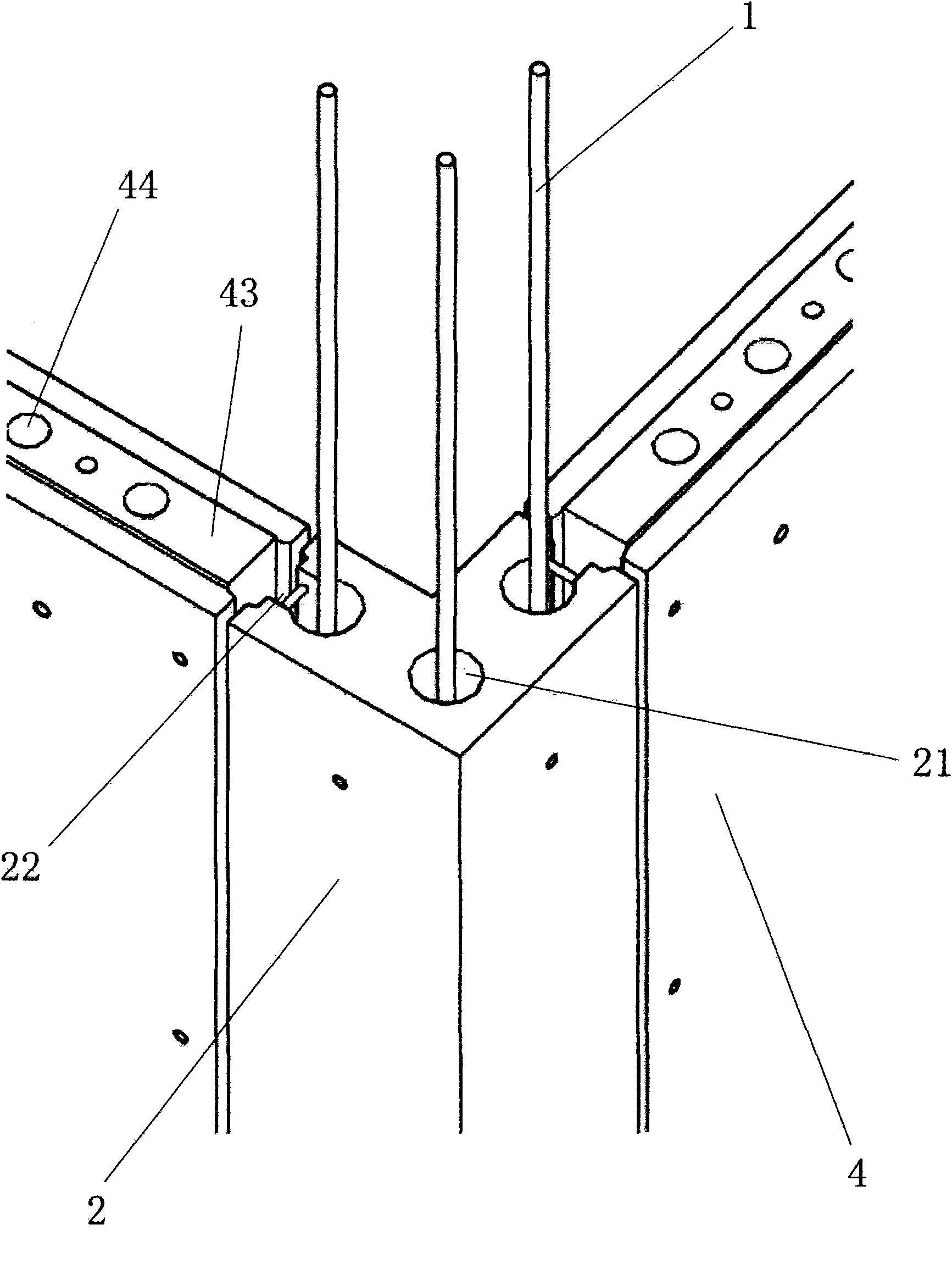

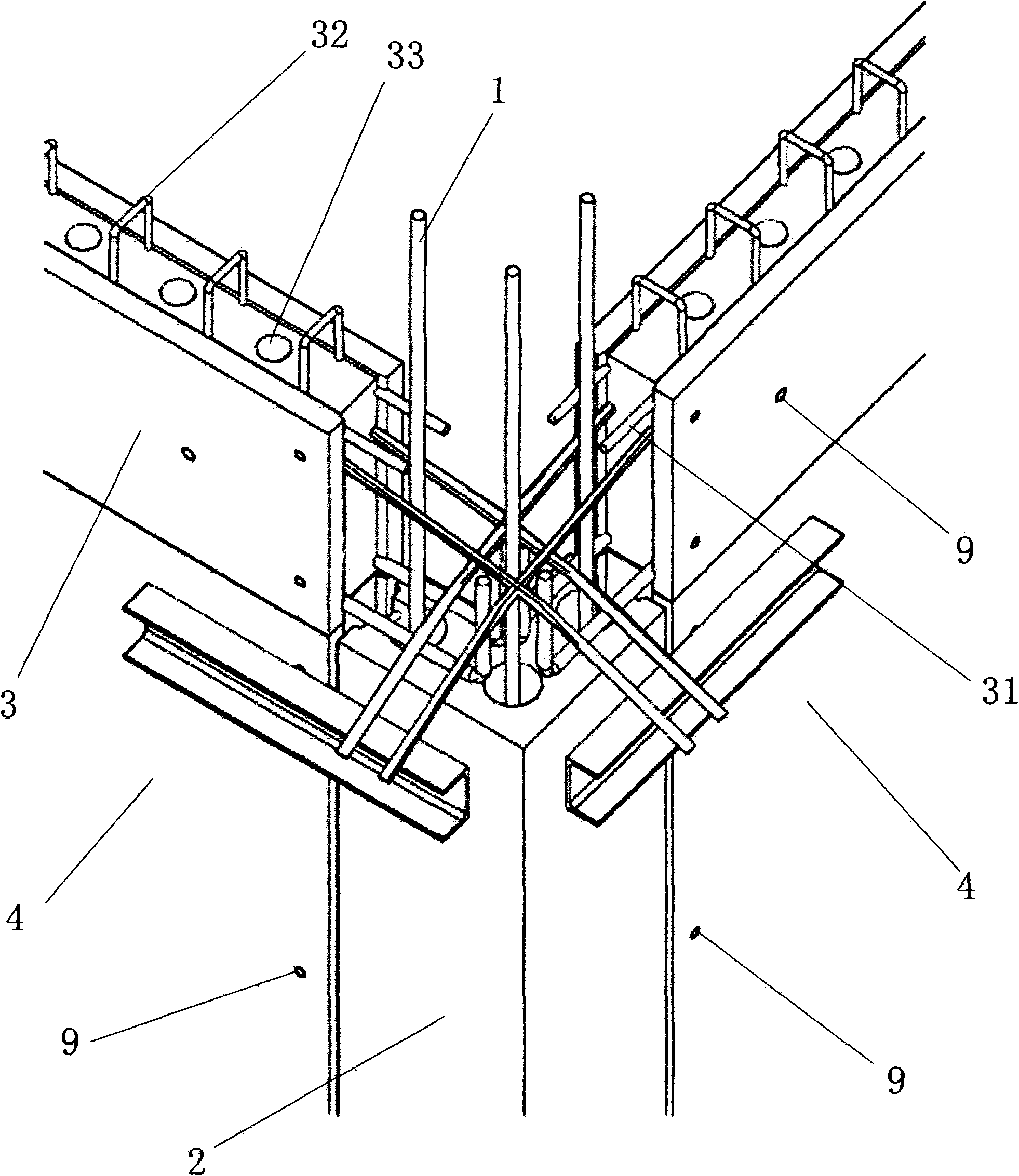

[0054] A plurality of column ribs 1 arranged at intervals and respectively fixedly connected to the foundation;

[0055] A plurality of modular prefabricated columns 2 are provided with through holes 21 for accommodating column ribs 1, and connection positions 22 are provided on the columns 2. The column body 2 is set on the column inserting bar 1 and can combine the column body 2 and the column inserting bar 1 into a whole by pouring concrete into the through hole 21;

[0056] A plurality of modular prefabricated walls 4 are provided with reserved connecting steel bars 41 on the walls 4, and the reserved connecting steel bars 41 are arranged on the connecting positions 22 of the columns 2 and inserted with the columns 1 fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com