Patents

Literature

236results about How to "Reduce wet work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

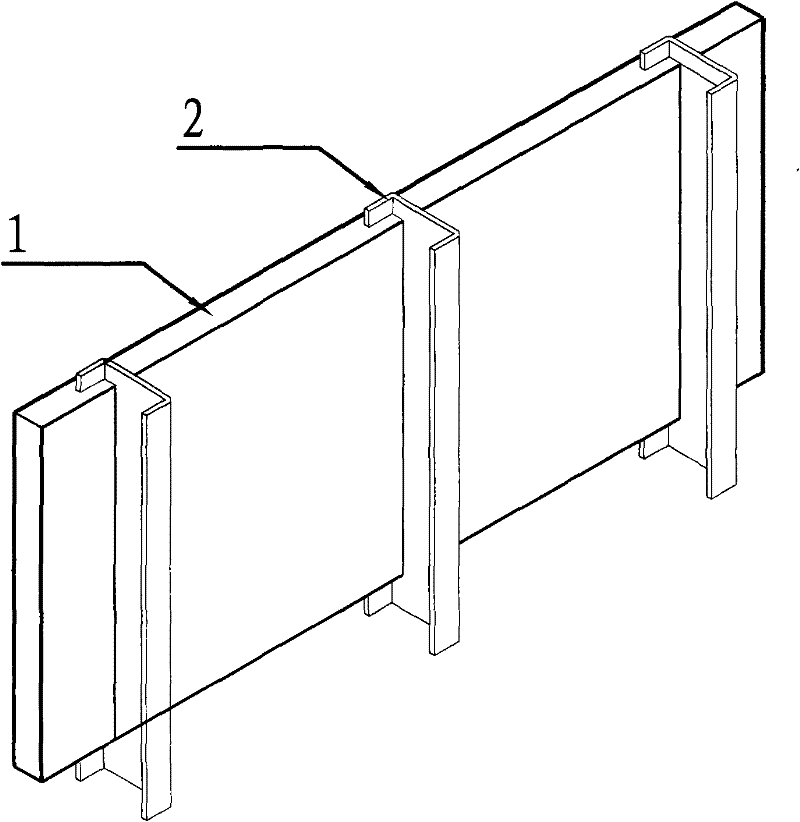

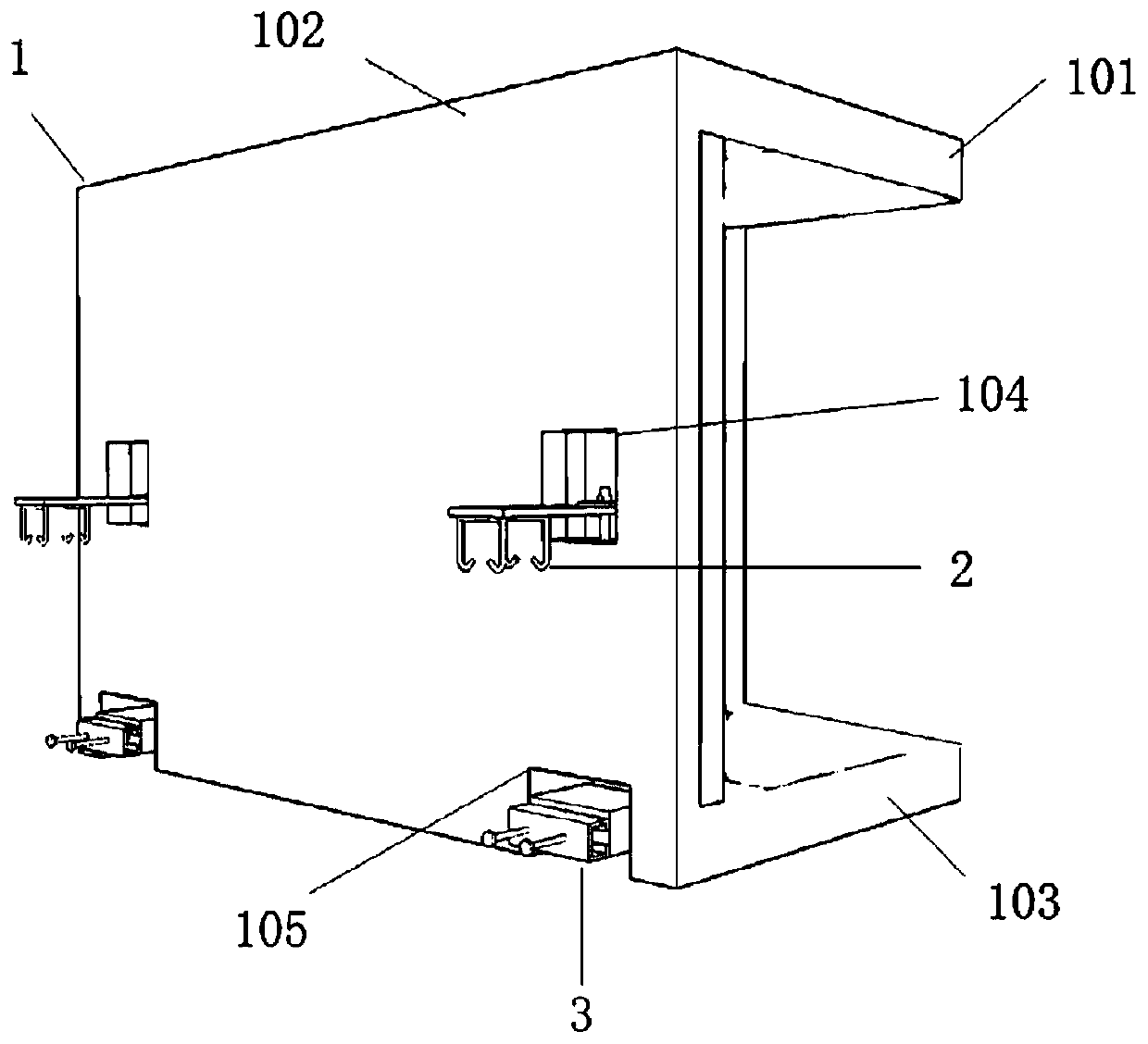

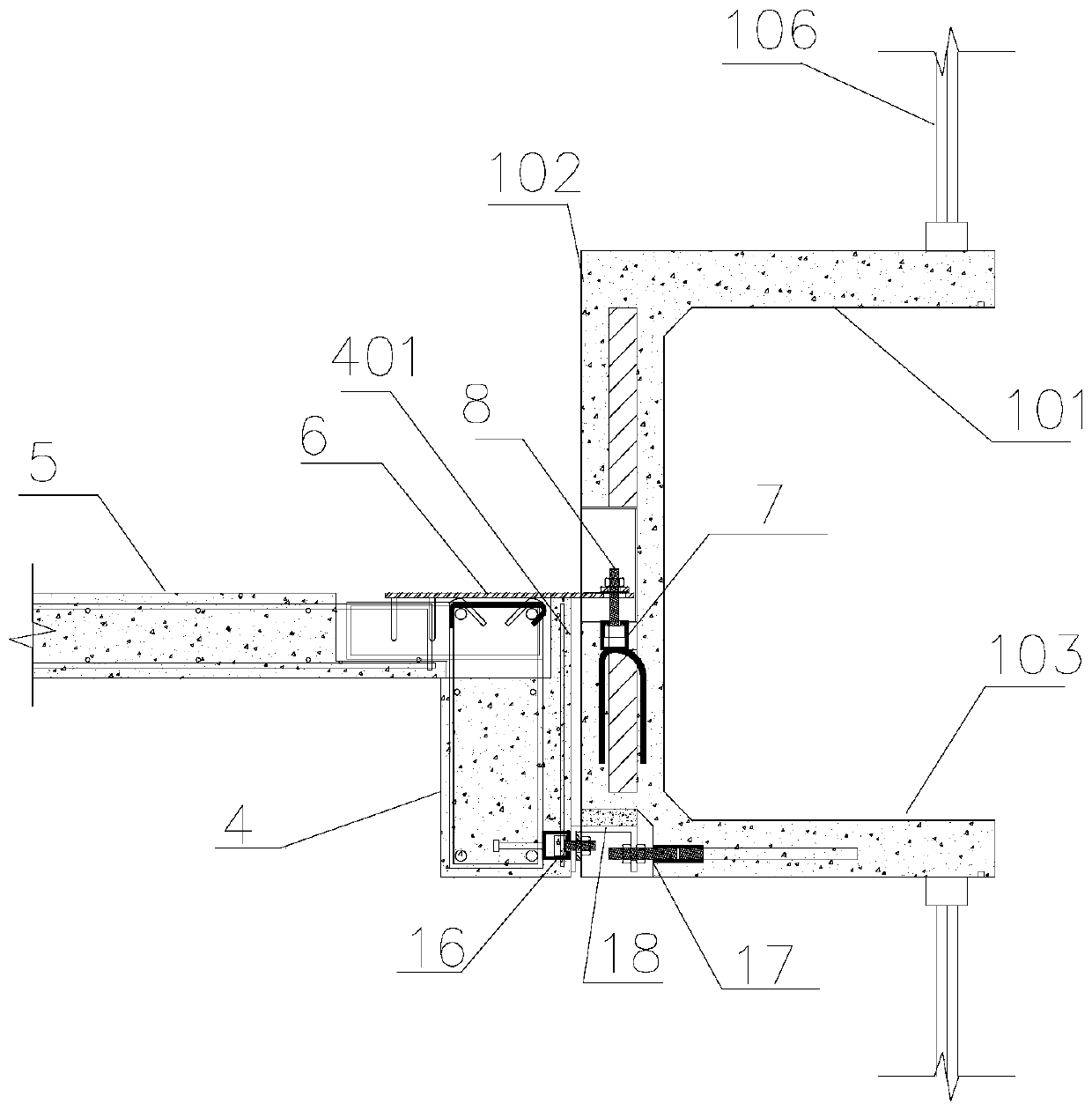

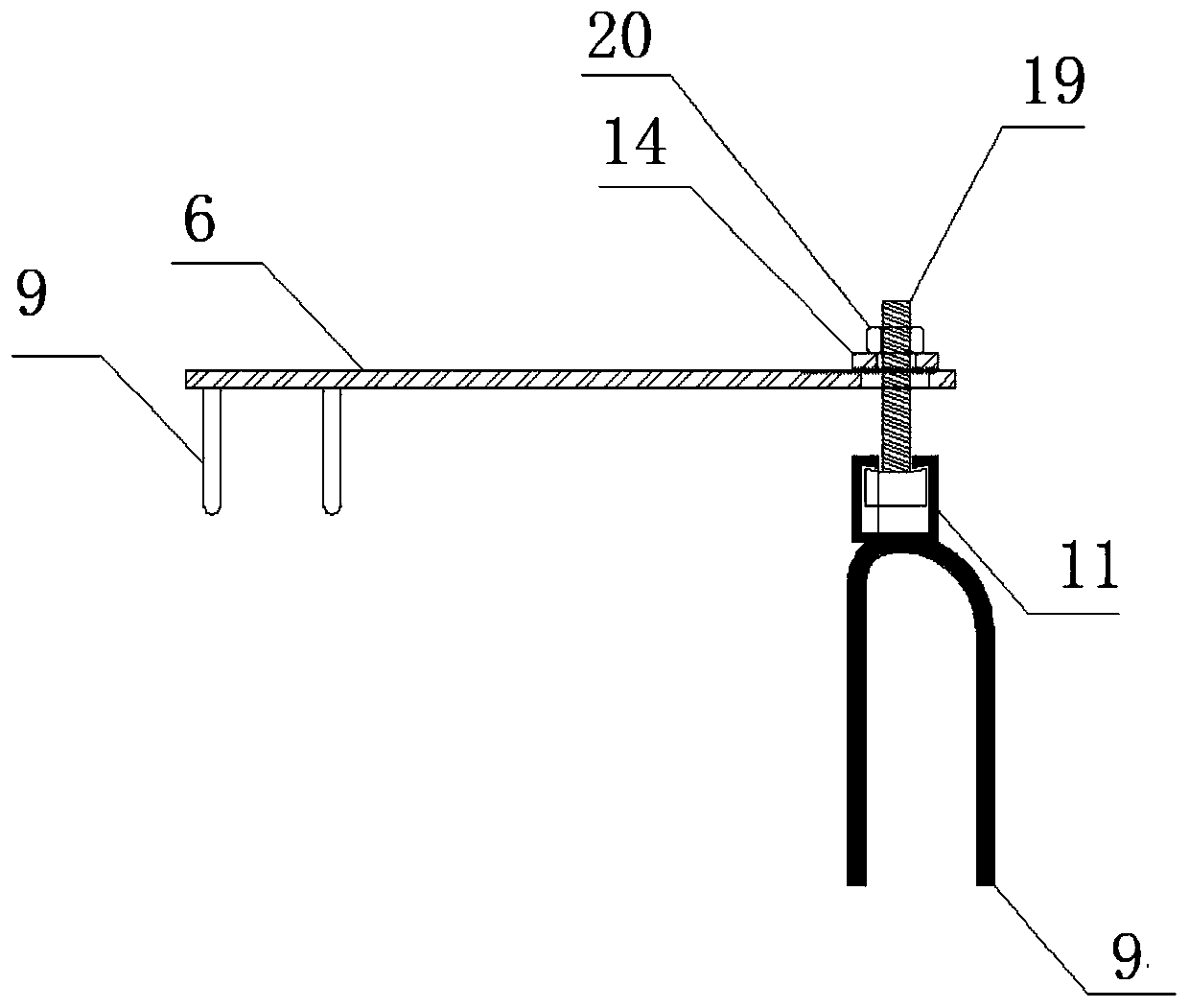

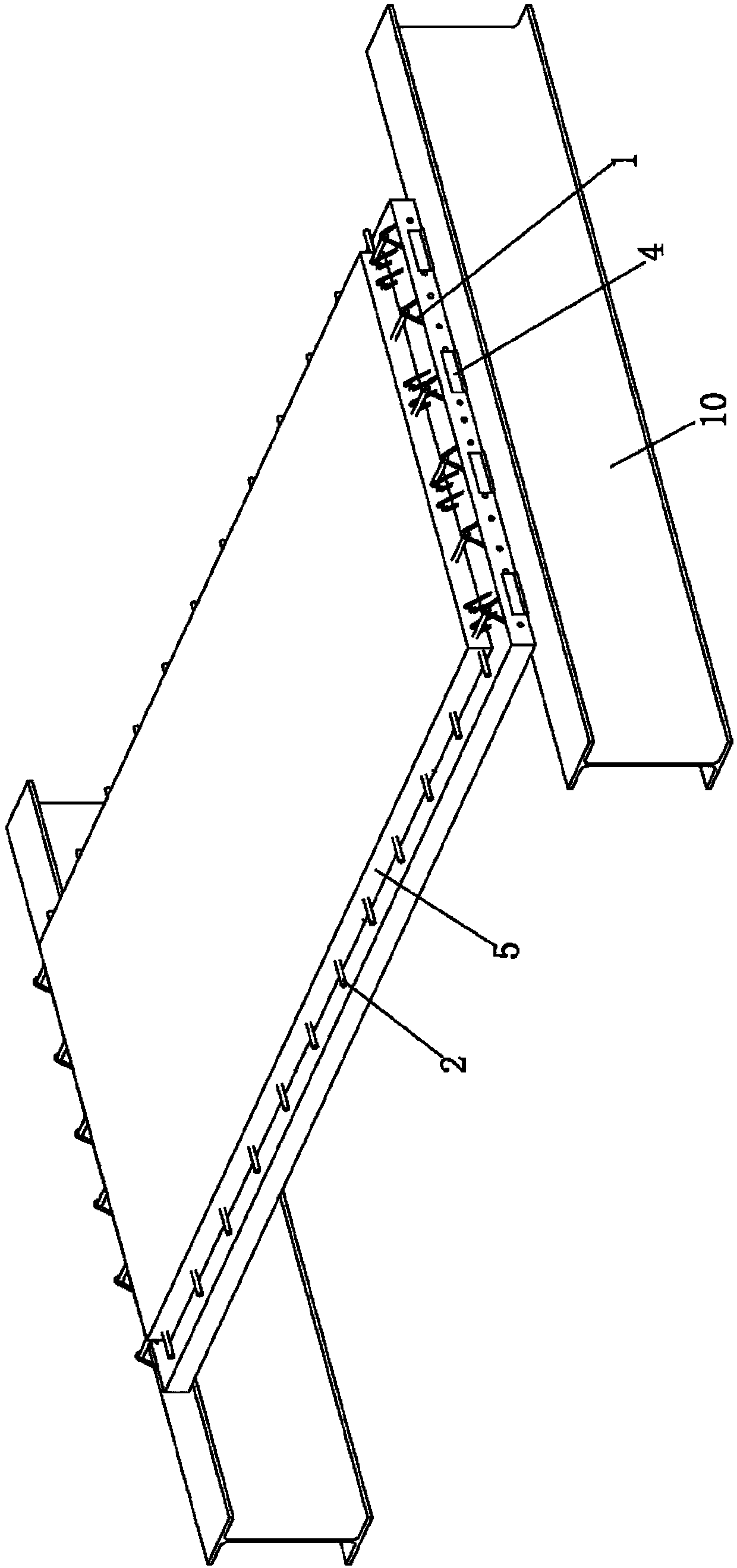

Assembly connecting structure and assembly connecting method of assembled concrete frame and shear wall combination

ActiveCN102808465ASplit location is reasonableEasy to manufactureWallsBuilding material handlingFloor slabRebar

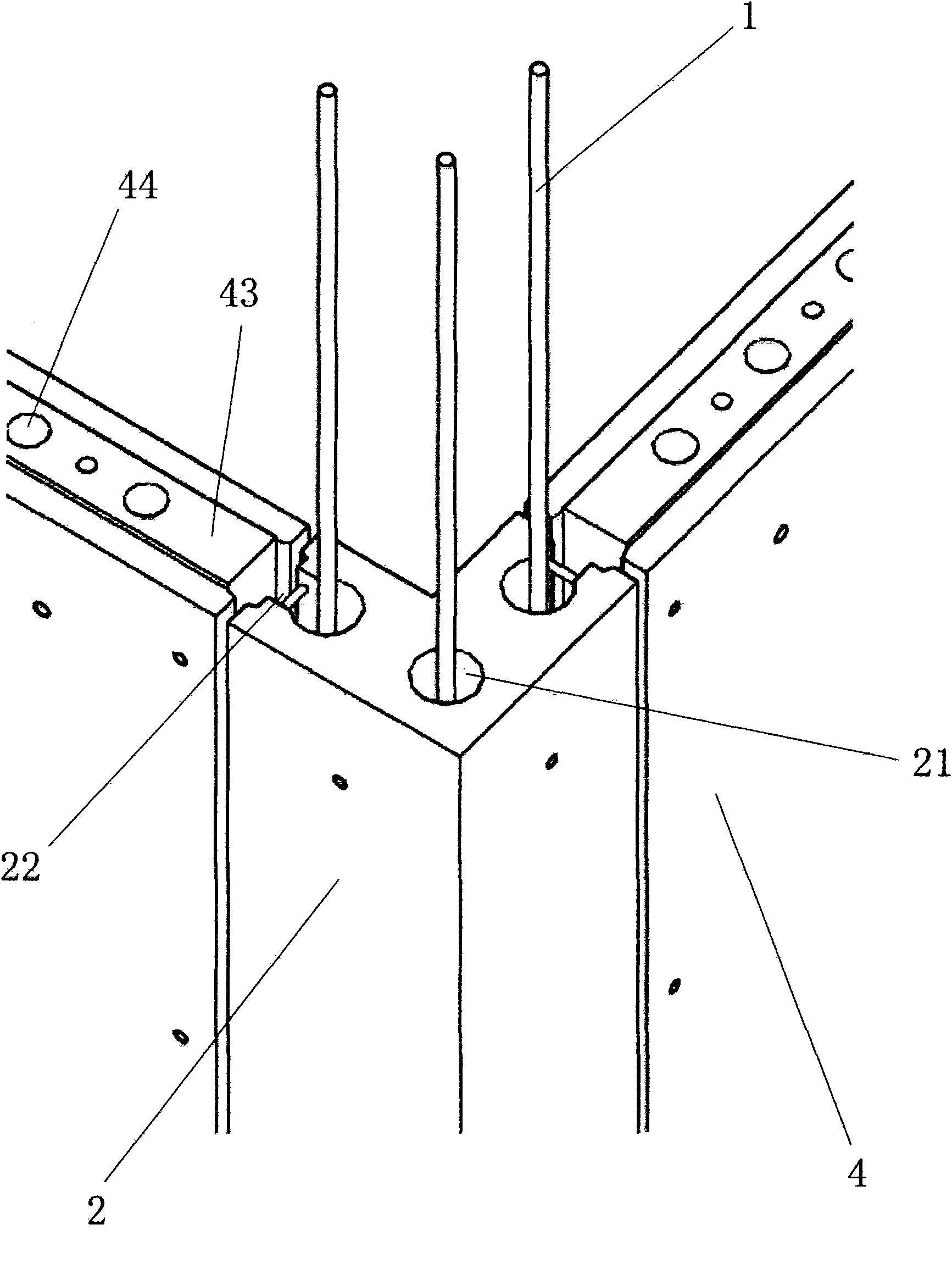

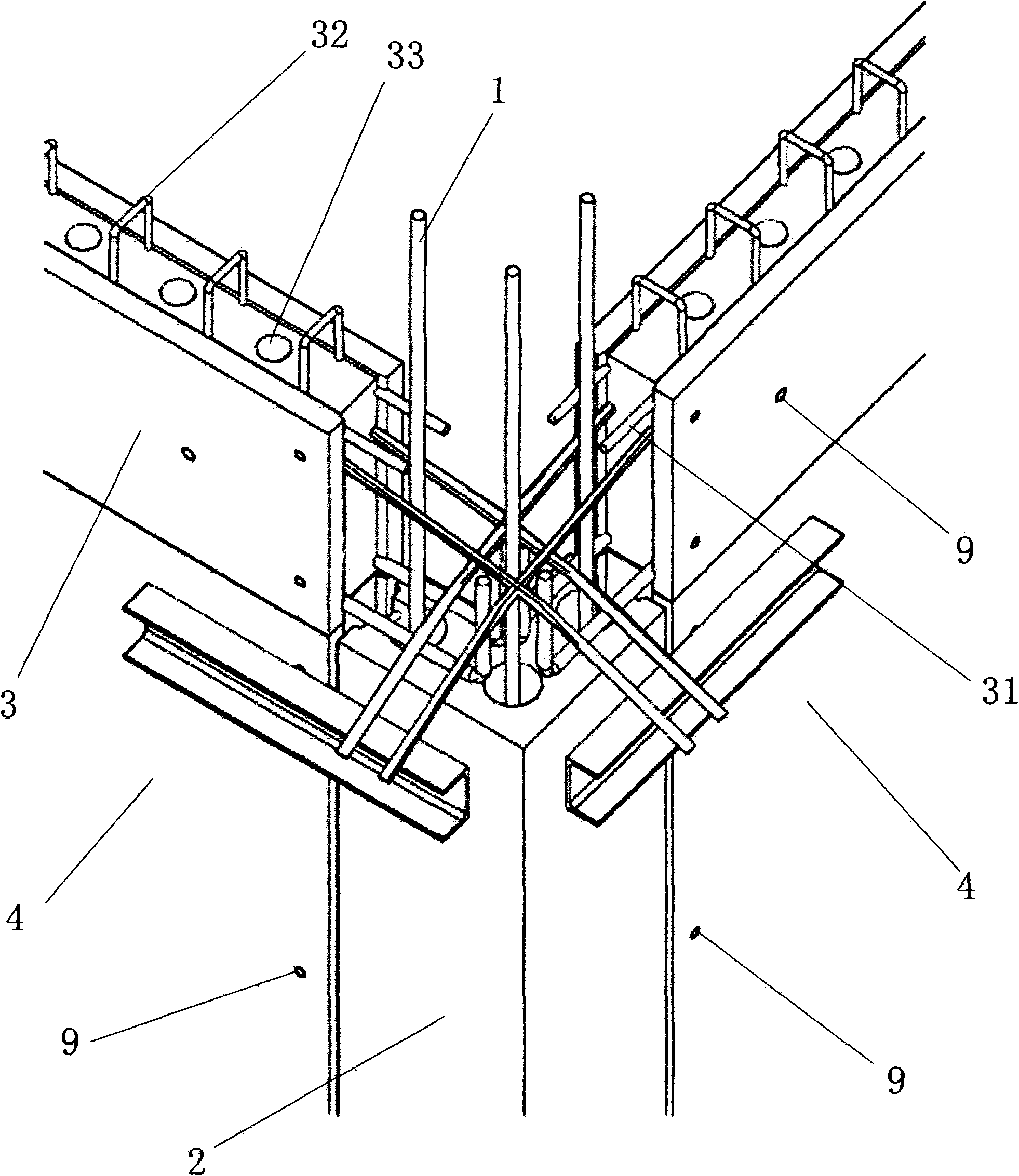

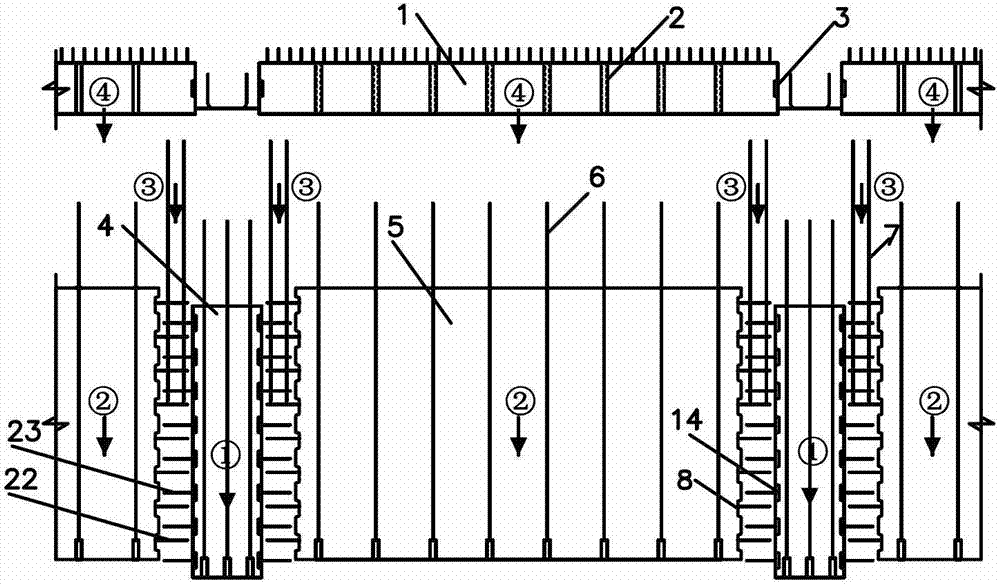

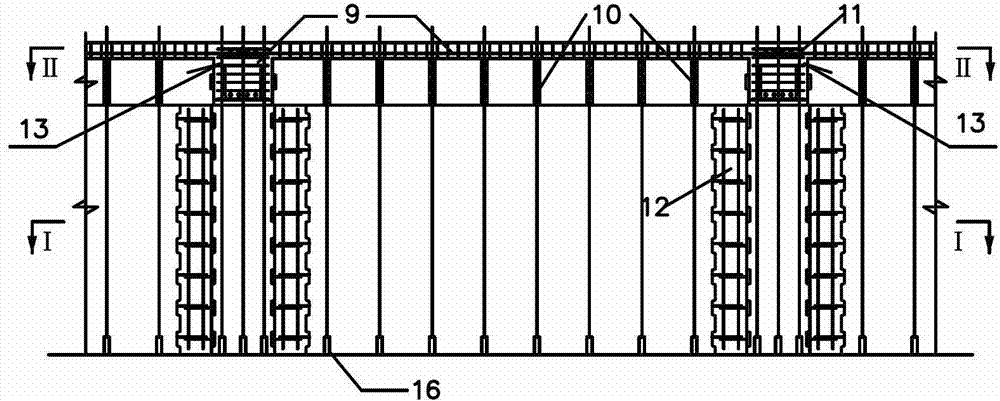

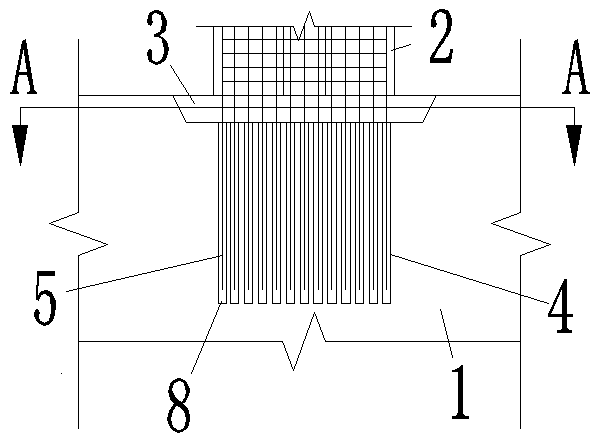

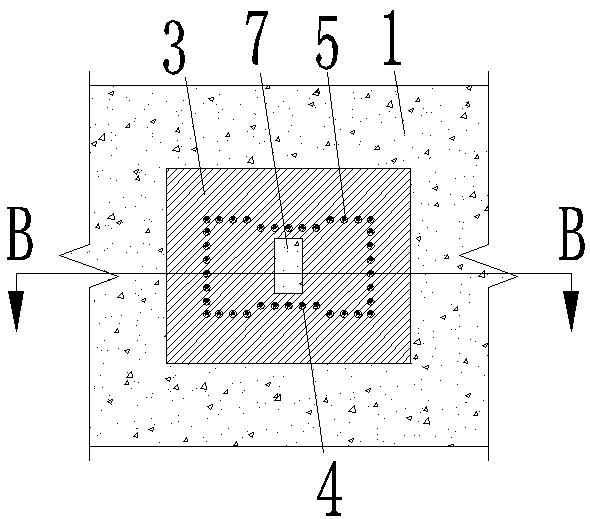

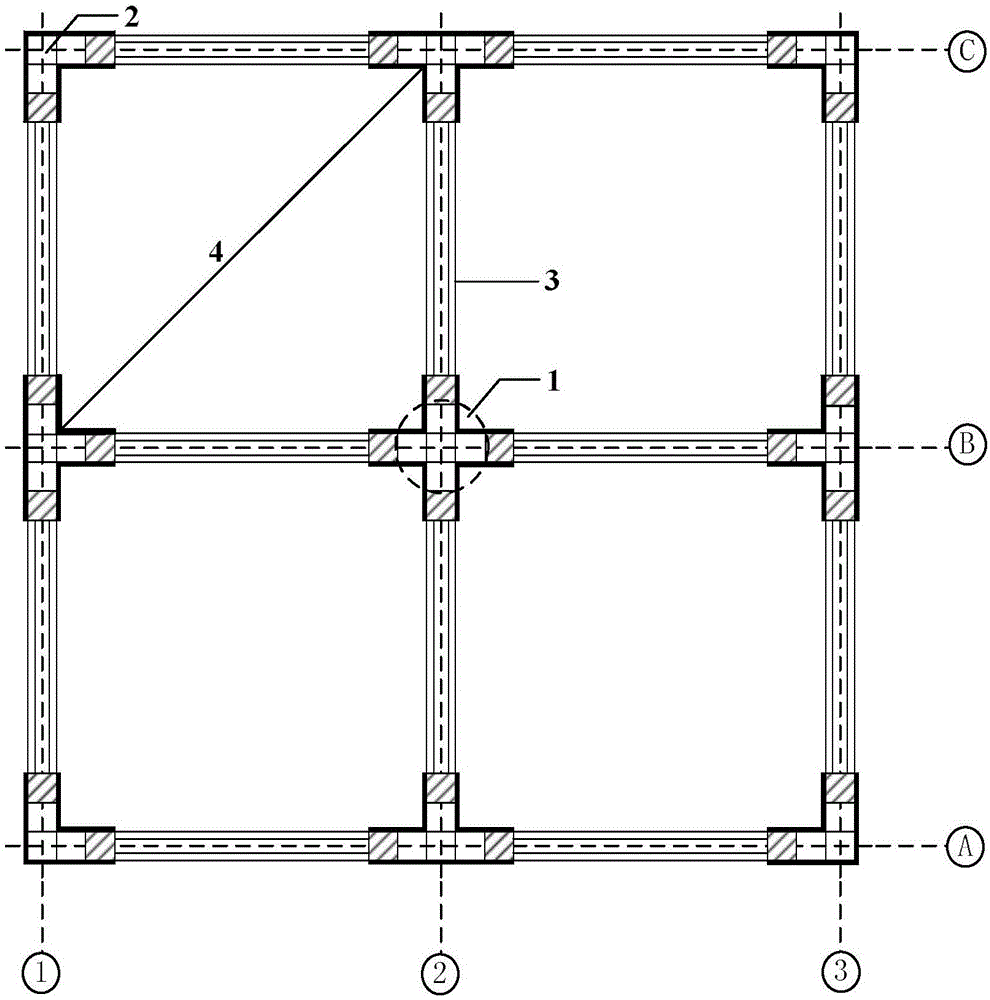

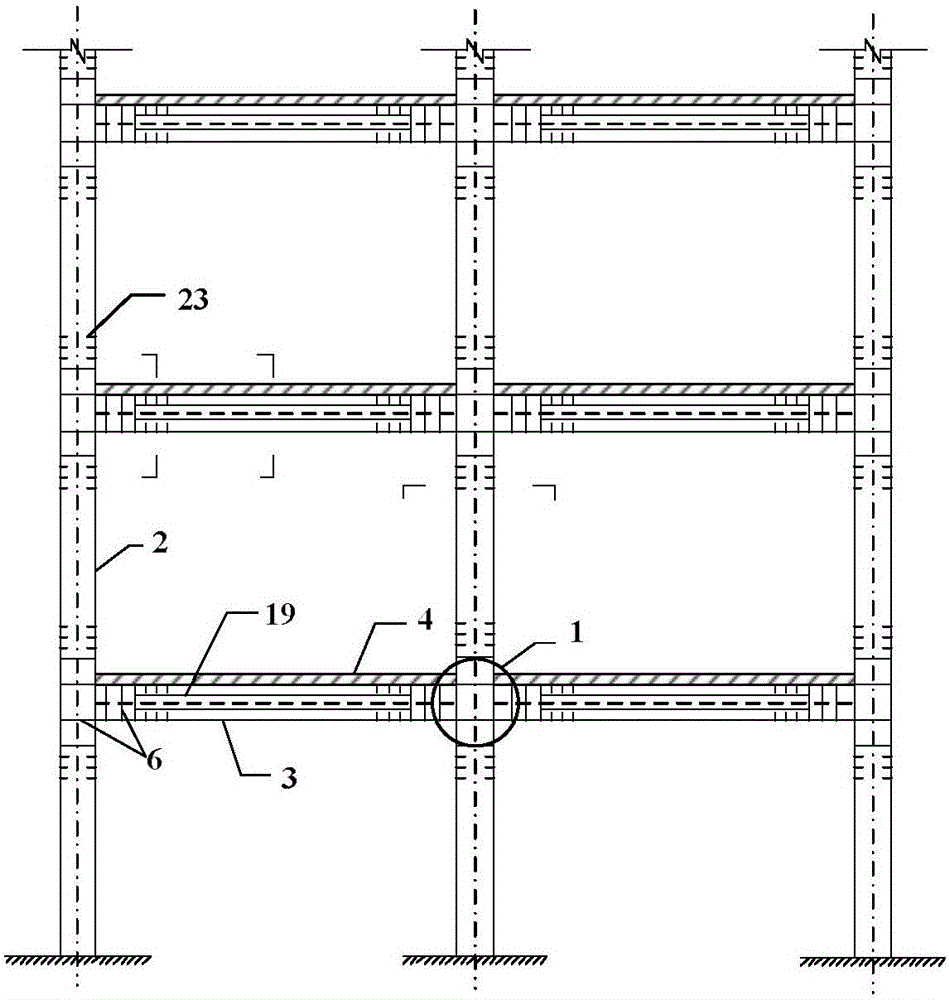

The invention relates to the field of assembled concrete structures, in particular to an assembly connecting structure and an assembly connecting method of an assembled concrete frame and shear wall combination. A cast-in-place strip is disposed between precast columns and precast shear walls to connect column-wall embedded rebars. Vertical through holes are reserved in a precast node-precast beam integrated component to achieve communicated connection of vertical rebars for the upper and lower columns and the upper and lower shear walls. Embedded steel sleeves at the lower ends of the precast columns and the precast shear walls are mutually embedded with projecting rebar segments extending up out of the lower columns and the lower walls, and are integrated with the lower columns and the lower walls through cast mortar. The projecting straight rebars at the upper ends of the precast columns and the precast walls penetrate through the through holes reserved in the precast node-precast beam integrated component and protrude a floor slab, and the precast columns and the precast nodes are firmly integrated with the precast shear walls precast beams by cast mortar. Wet operations such as in-place casting of concrete are reduced to the maximum extent, building quality is improved, construction period is shortened, and energy conservation and emission reduction are achieved.

Owner:SHENYANG JIANZHU UNIVERSITY

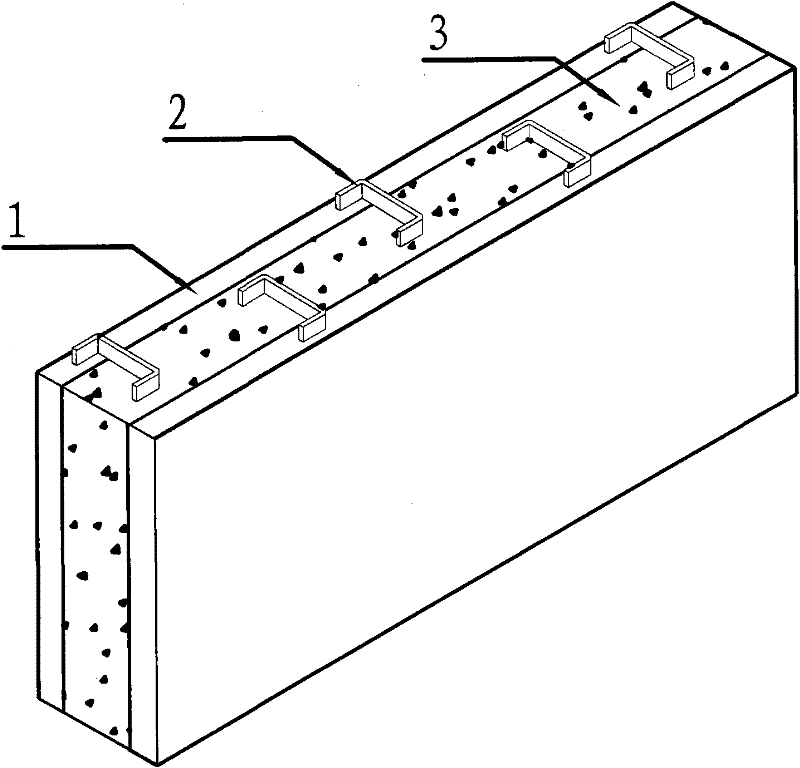

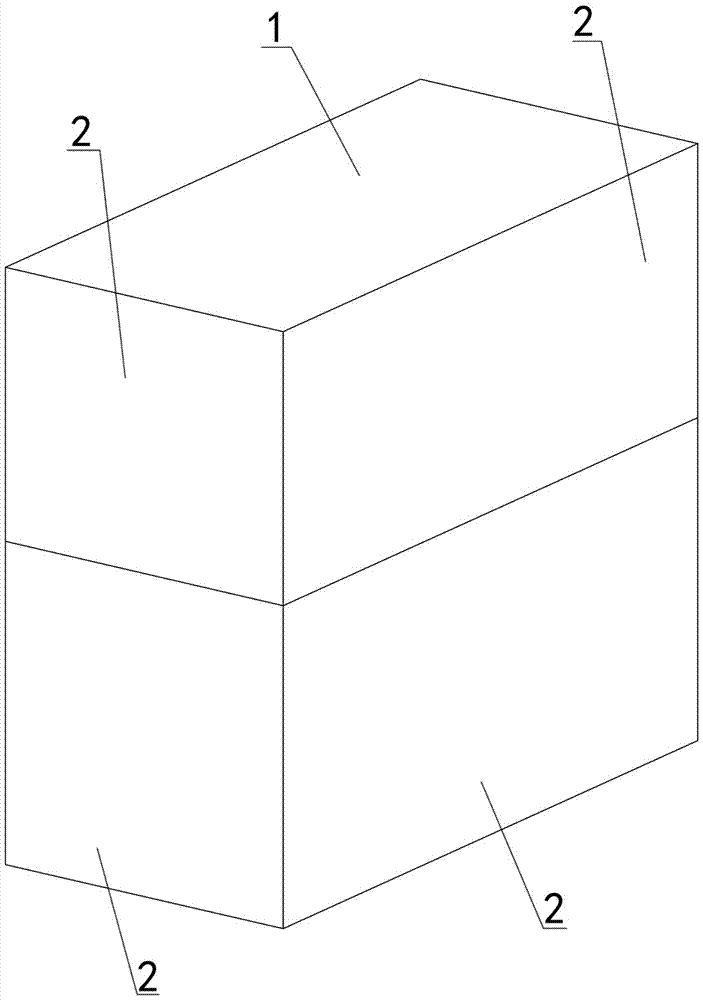

Full-fabricated assembly overall reinforced concrete house and building method thereof

InactiveCN101806095ASmall sizeNo secondary plastering requiredBuilding material handlingFloor slabReinforced concrete

The invention discloses a full-fabricated assembly overall reinforced concrete house which comprises a plurality of column ribs arranged at intervals and respectively and fixedly connected with a foundation, a plurality of column bodies prefabricated in a modularized way, a plurality of wall bodies prefabricated in the modularized way, and a floor slab prefabricated in the modularized way. The invention aims to overcome the defects of the prior art, and improve the full-fabricated assembly overall reinforced concrete house which has simple structure, is convenient to install, saves building materials, is quick to build, and has good overall safety performance. Another purpose of the invention is to provide a method for building the house.

Owner:ZHONGSHAN FAST LIVING PREFABTED HOUSING

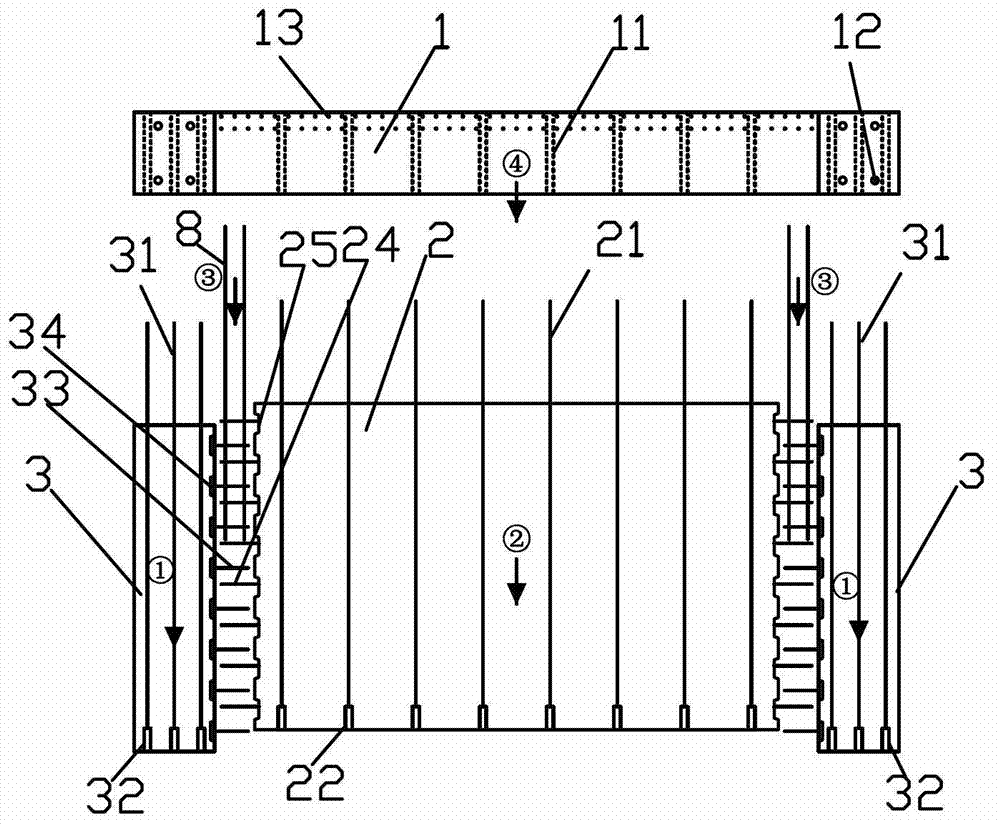

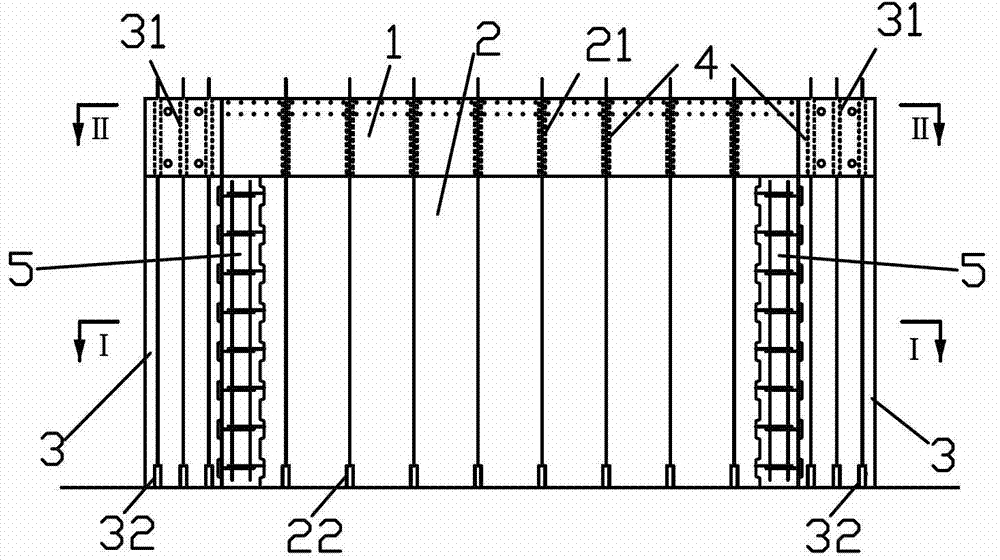

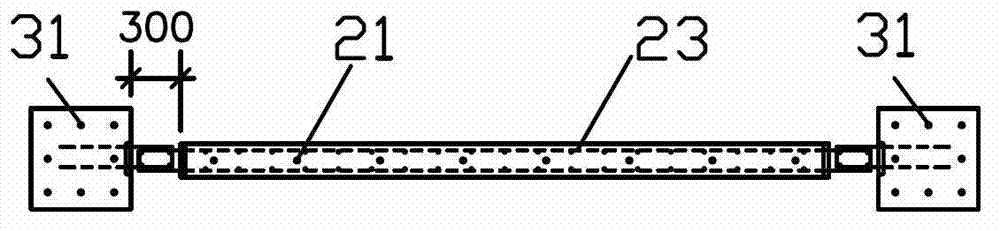

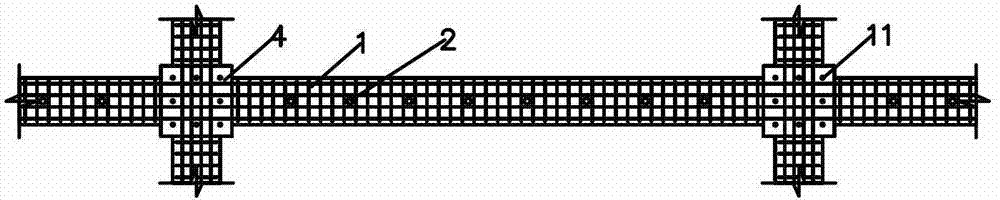

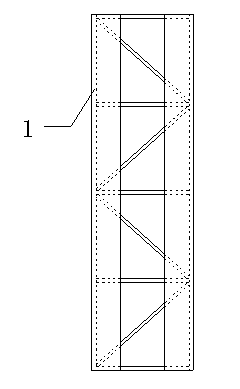

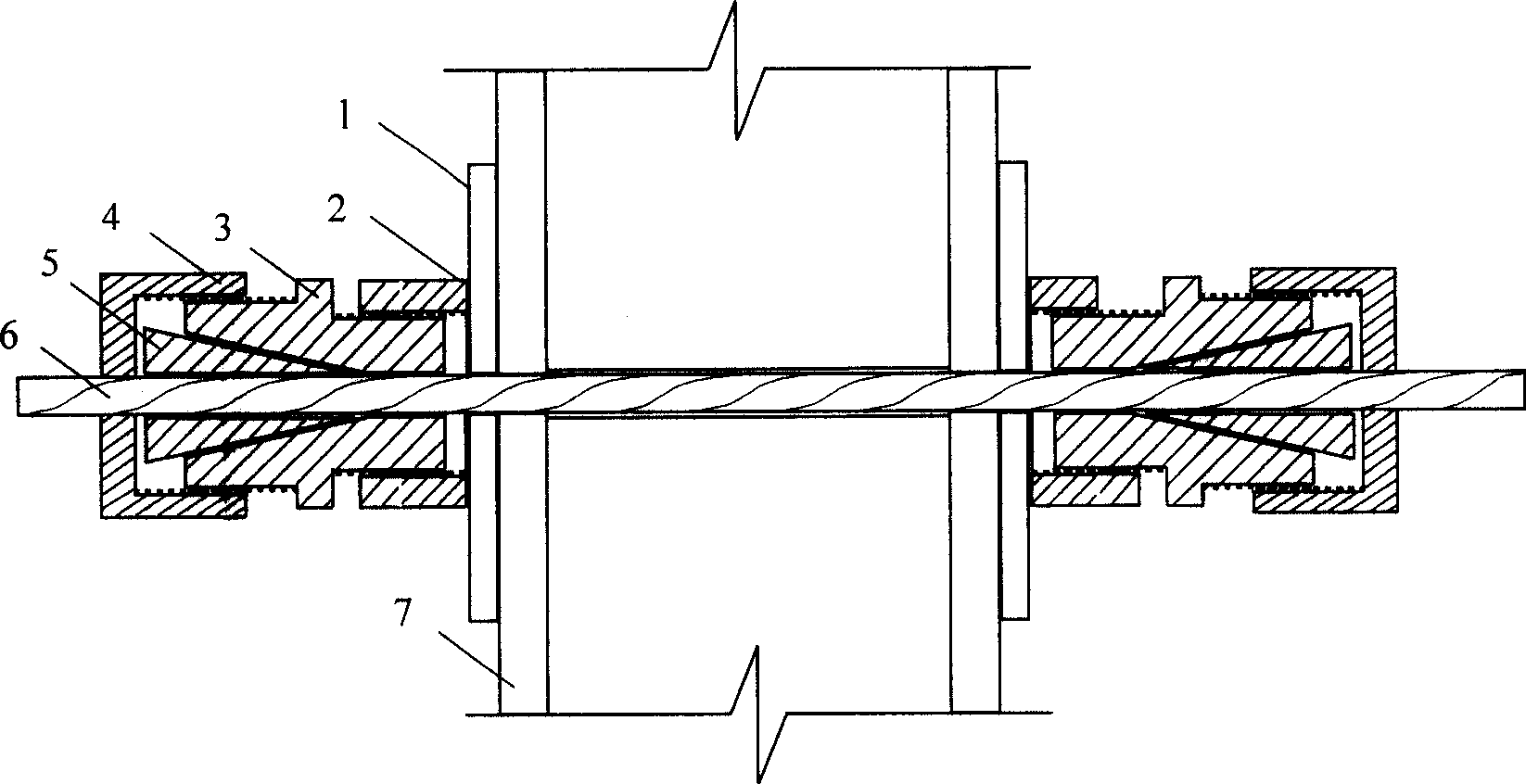

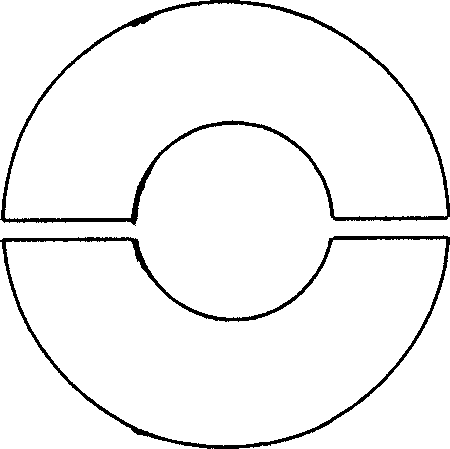

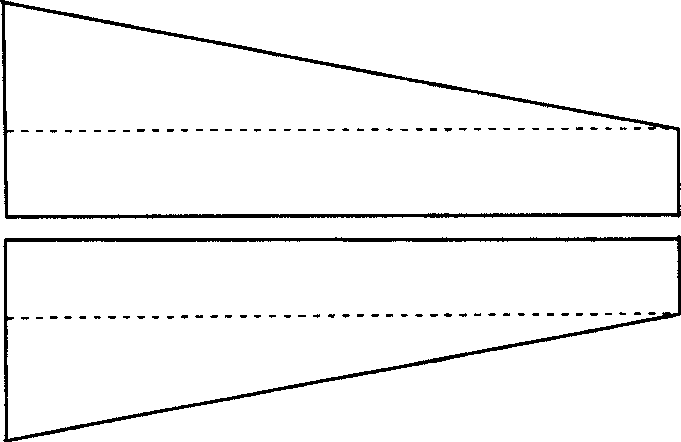

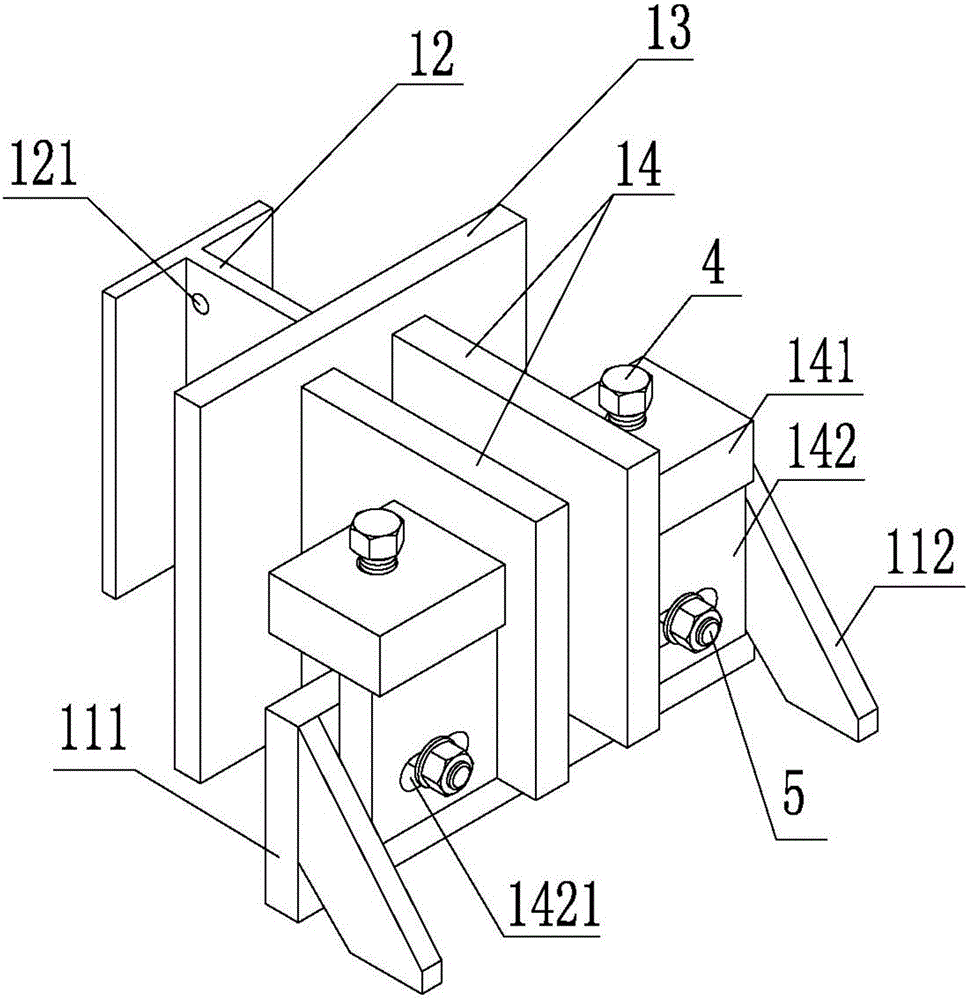

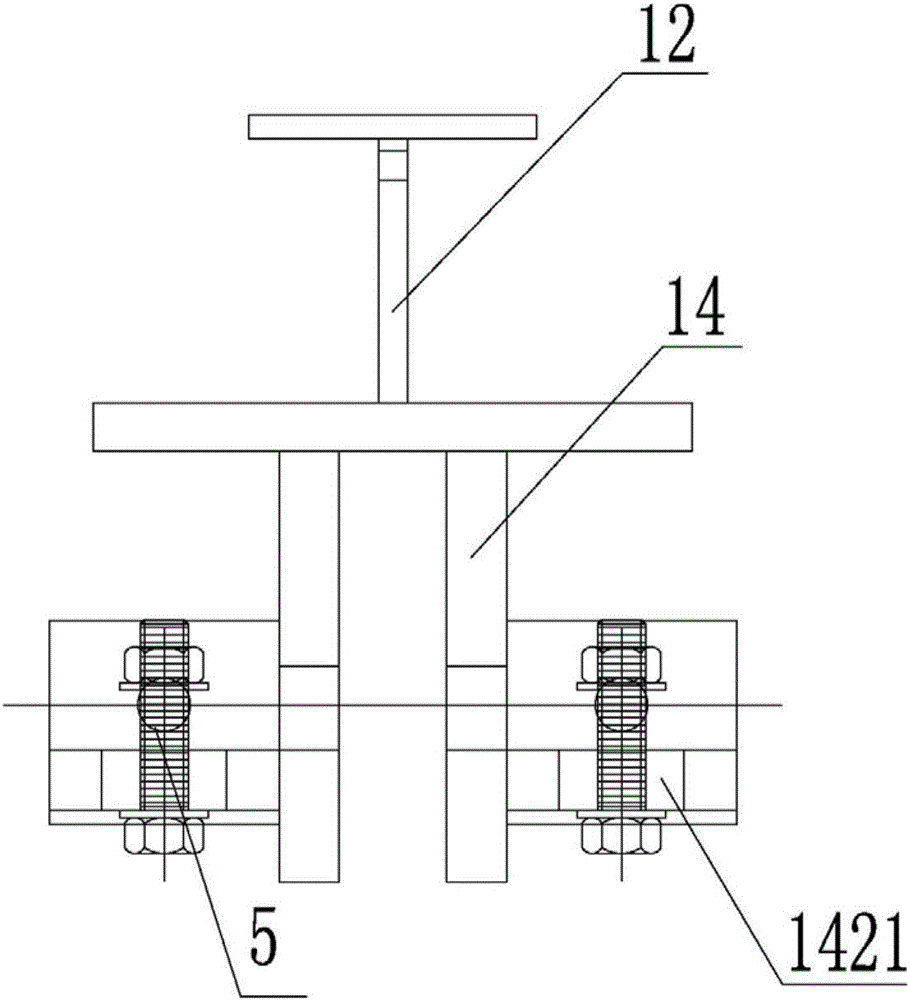

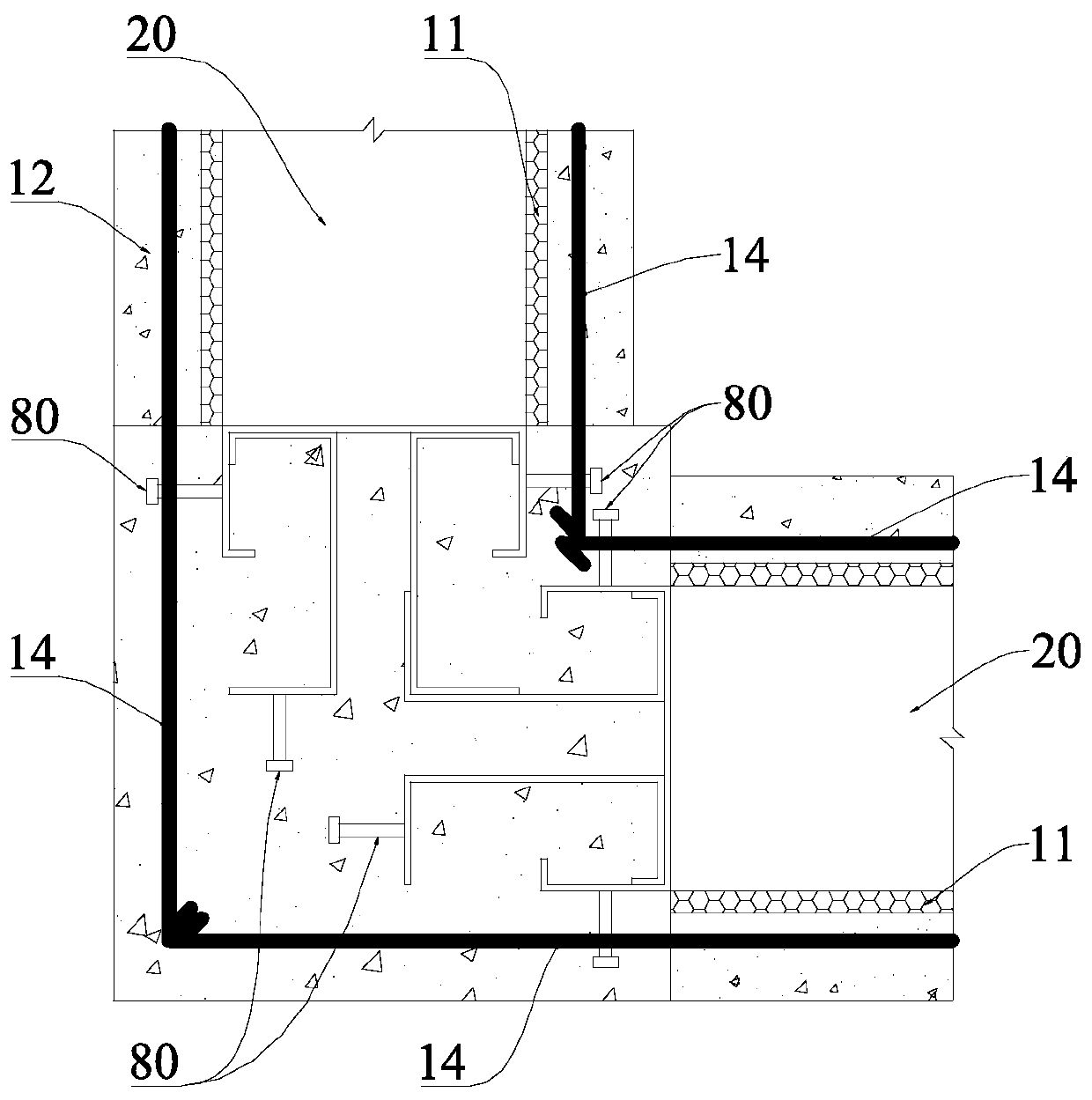

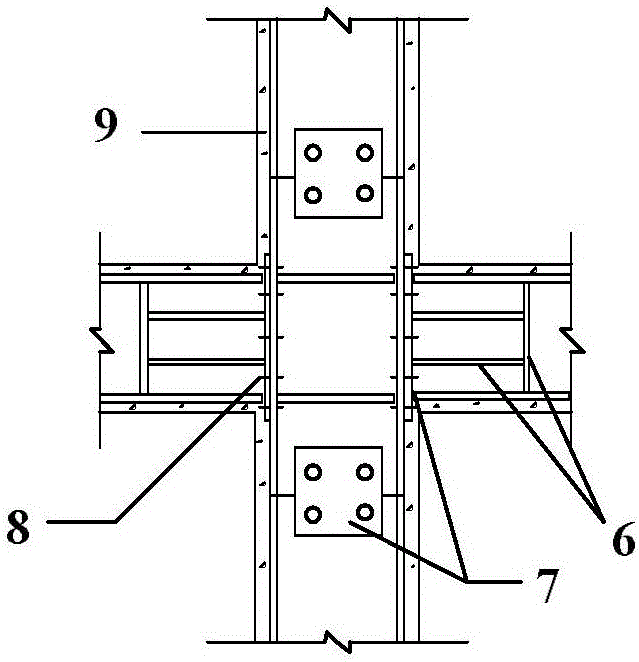

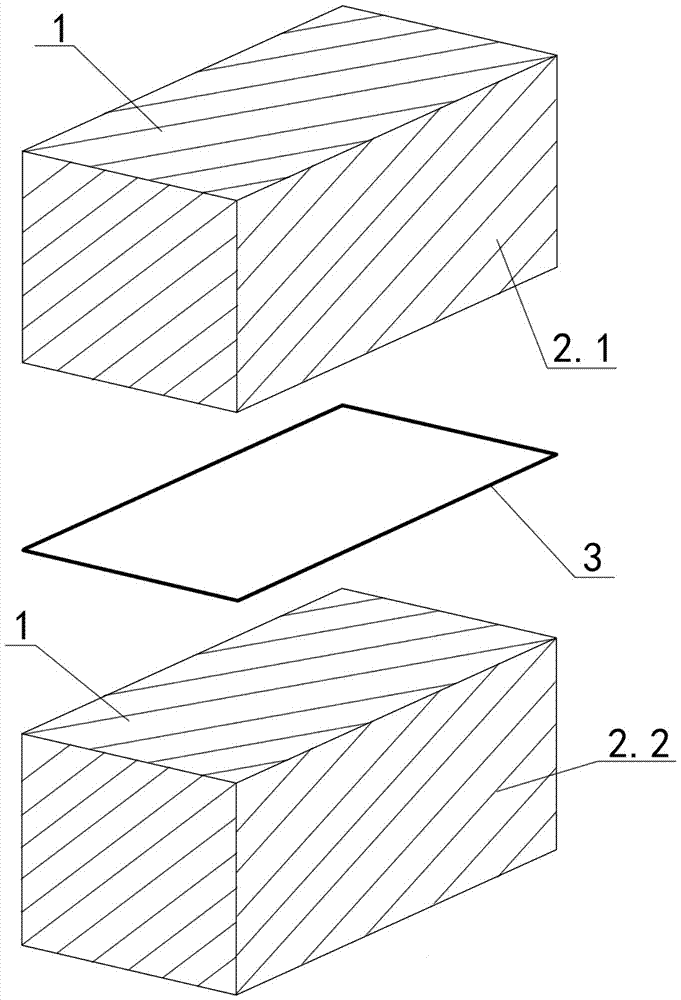

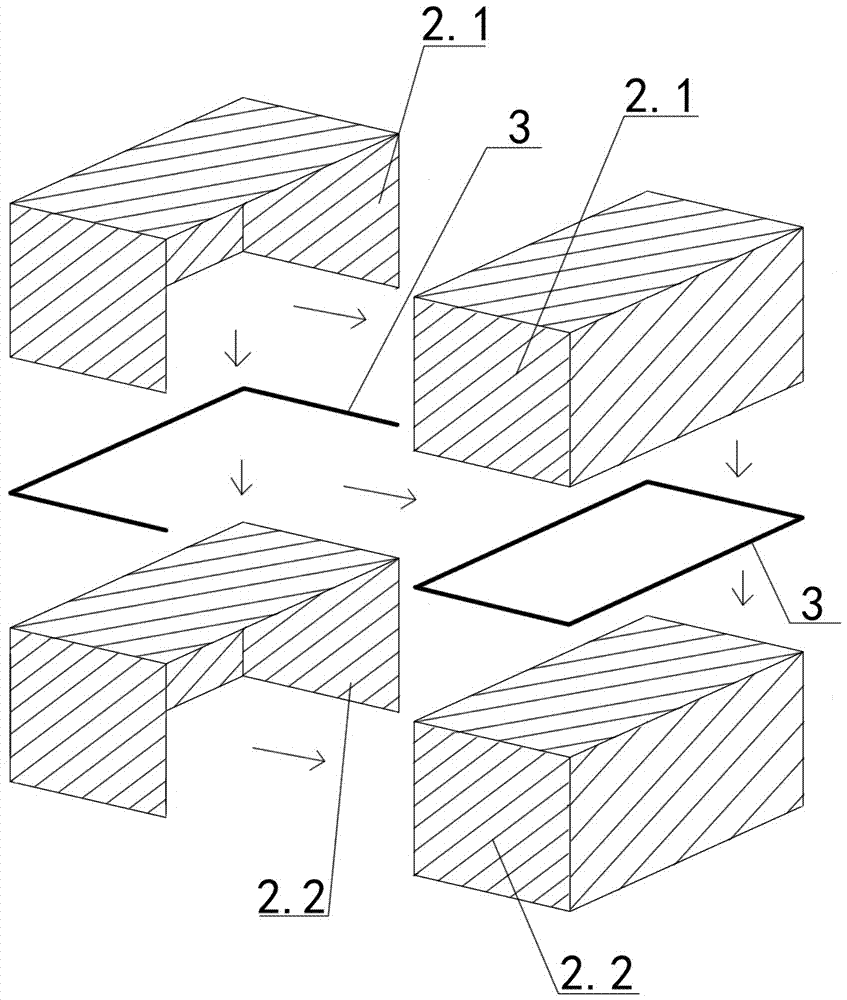

Splitting and assembling structure and assembling connecting method of assembled type concrete frame-shear wall

ActiveCN102900168ASplit location is reasonableEasy to manufactureWallsBuilding material handlingSteel barEngineering

The invention relates to the field of concrete structures, in particular to a splitting and assembling structure and an assembling connecting method of an assembled type concrete frame-shear wall. The splitting and assembling structure comprises prefabricated pillars, prefabricated beams, prefabricated shear walls and cast-in-situ joints, wherein sleeves are embedded at the lower ends of the prefabricated pillars, mutually embedded with protruding reinforcing steel bar sections which extend from the upper ends of lower layer pillars and are integrally connected with the lower layer pillars by filling mortar; longitudinal prefabricated beam reinforcing steel bars extend into a joint core area to be anchored or connected with side beam ribs in a mechanical manner; a cast-in-situ zone is arranged between the prefabricated pillars and the prefabricated shear walls so as to carry out the connection of the embedded ribs of the pillars and the walls; and the embedded reinforcing steel bar sleeves at the lower ends of the prefabricated shear walls are mutually embedded with protruding reinforcing steel bar sections which extend upwards from the walls at the lower layer and are integrally connected with the walls at the lower layer by filling the mortar. The through connection of the vertical reinforcing steel bars of the share walls at the upper and lower layers is realized by filling the mortar into the through holes and the sleeves at the upper ends of the prefabricated shear walls and the prefabricated beams, so that the key problem that the vertical reinforcing steel bars of the share walls are hard to be continuous because of the isolation of the prefabricated beams is solved.

Owner:SHENYANG JIANZHU UNIVERSITY

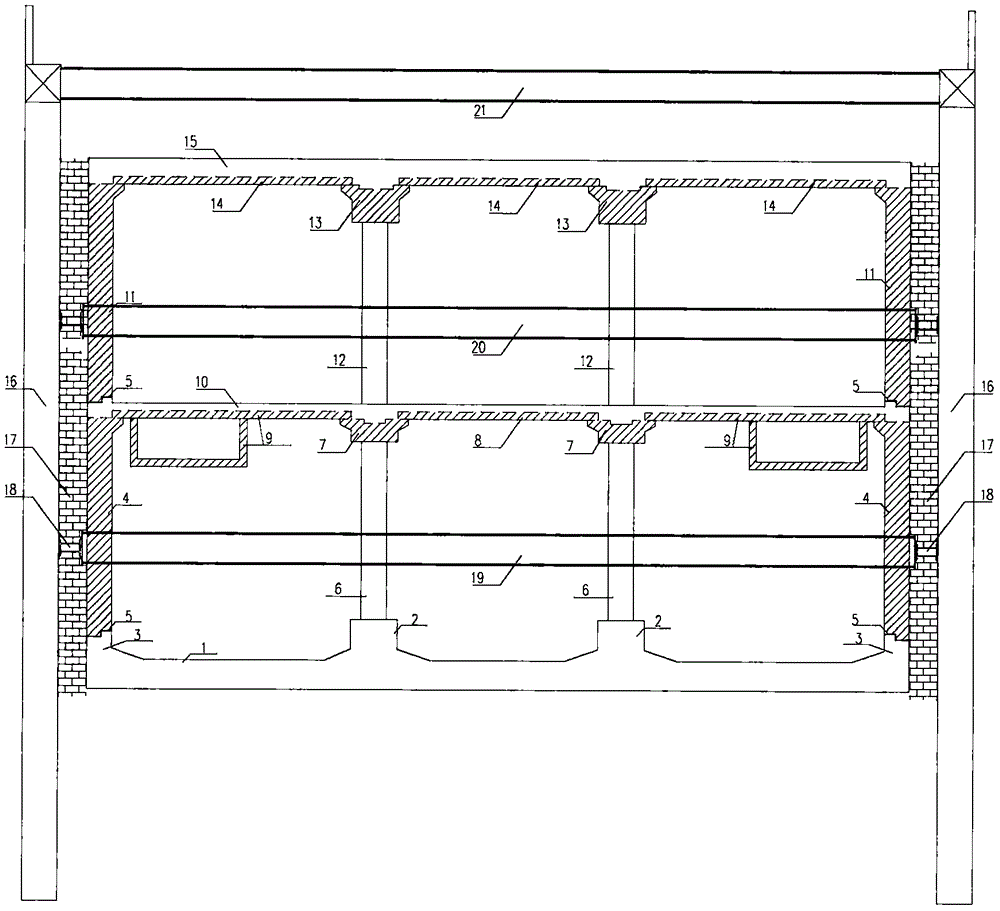

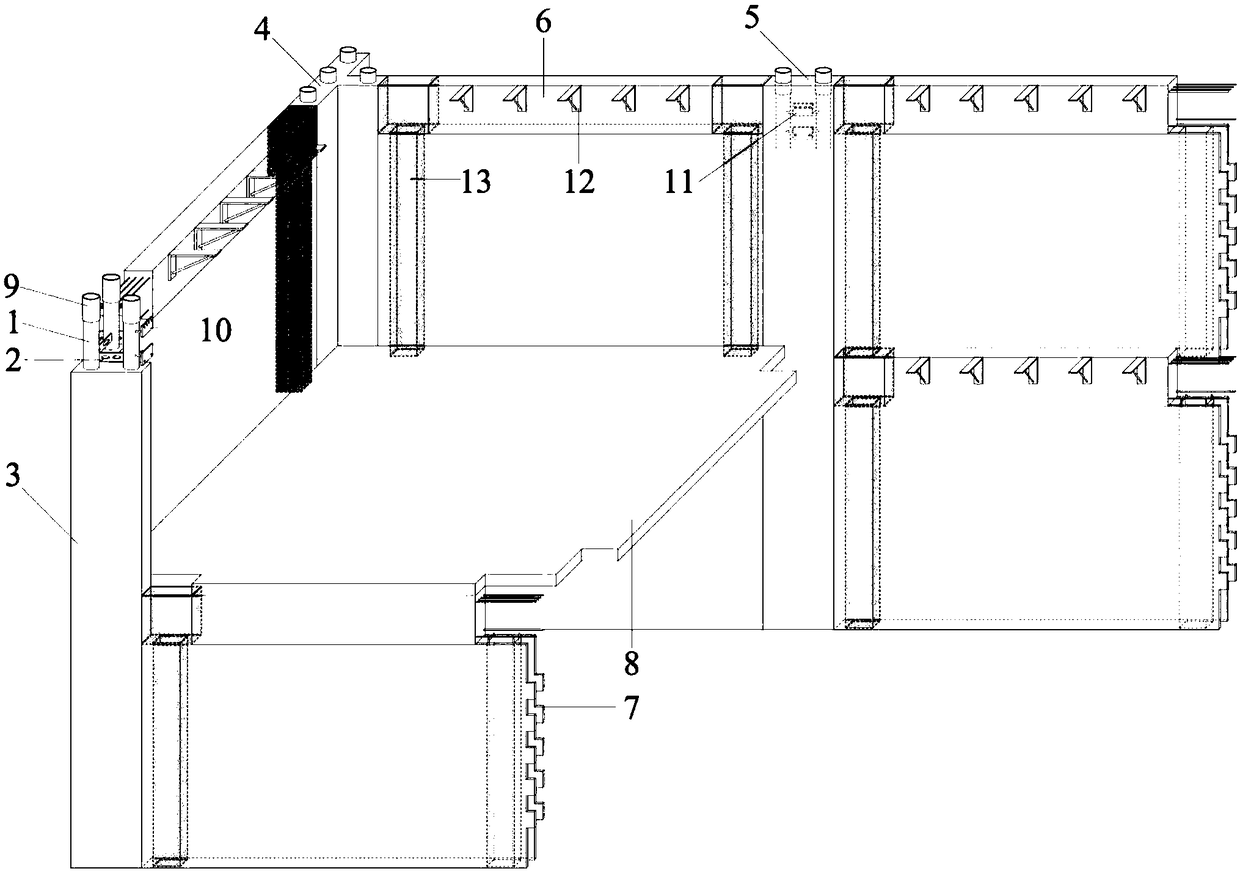

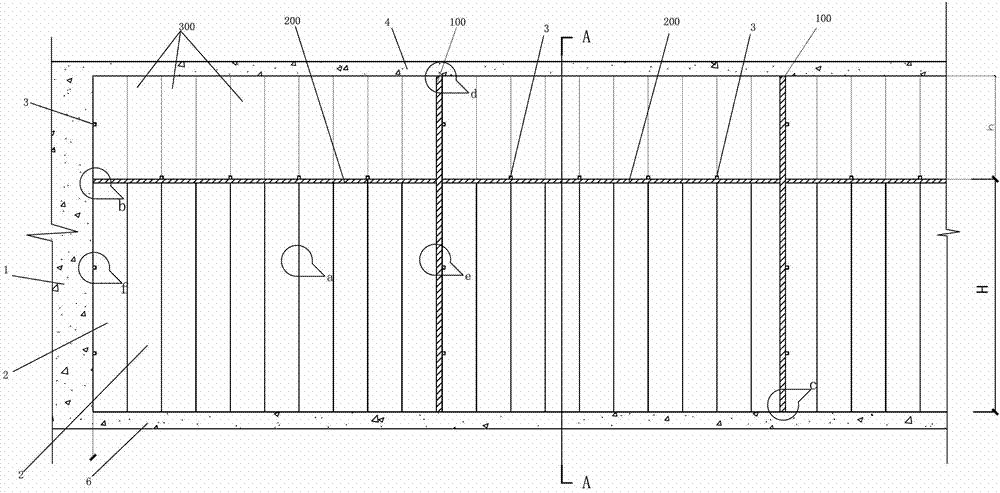

Construction method for open excavation assembly monolithic structure subway station using pile-strut bracing system

ActiveCN106223360AReduce the impactReduce the burden onArtificial islandsExcavationsEnvironment effectArchitectural engineering

The invention discloses a construction method for an open excavation assembly monolithic structure subway station using a pile-strut bracing system. The demand for labor force and the using requirement for on-site building circulating materials in traditional subway station construction can be lowered to the utmost extent, and wet construction work at the construction site can be greatly reduced. Flying dust and noise pollution at the construction site are reduced, and burdens to the surrounding traffic environment are reduced as well. The influence on the surrounding environment of the construction site is lowered. The novel component bracing system is adopted at the construction site, and therefore the degree of mechanization in the construction process is improved, and the demand for labor force by engineering is lowered. Moreover, the integral construction quality of associated works can be improved obviously by the adoption of plenty of prefabricated parts.

Owner:CHINA RAILWAY SIXTH GROUP +1

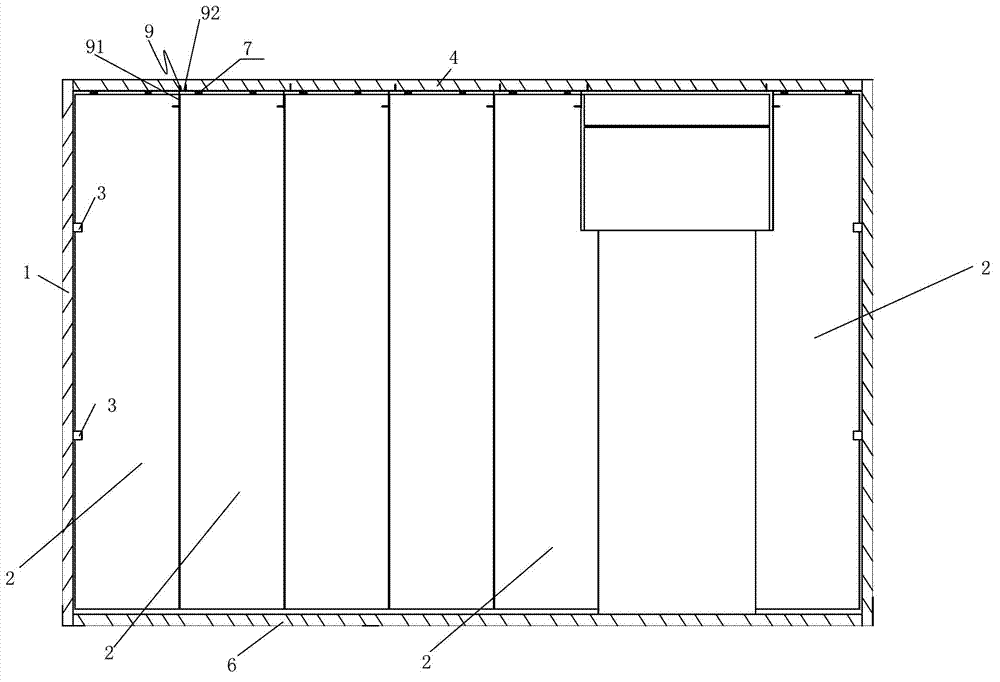

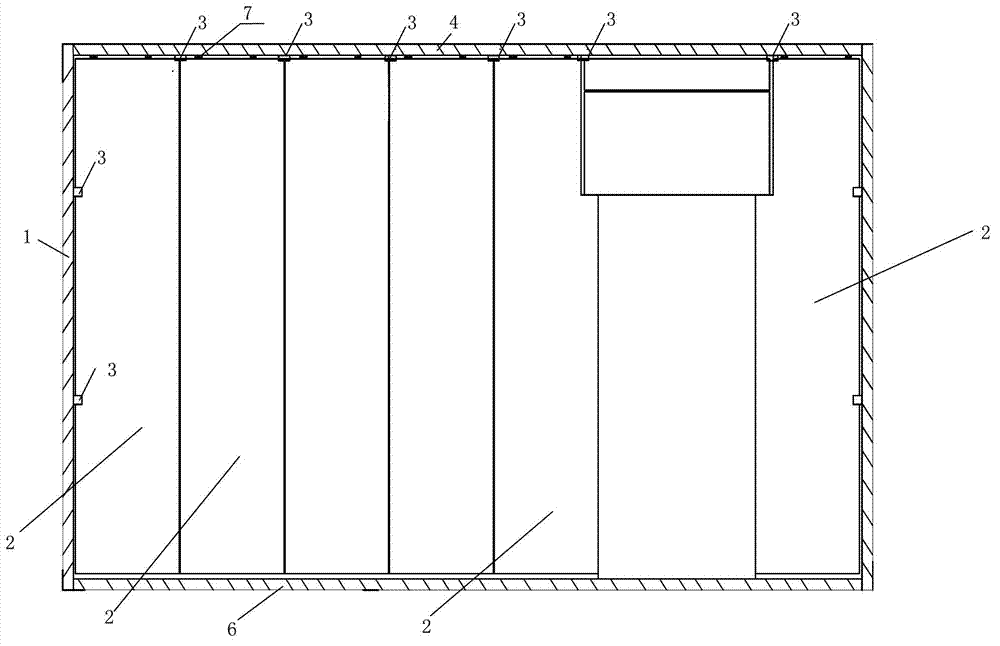

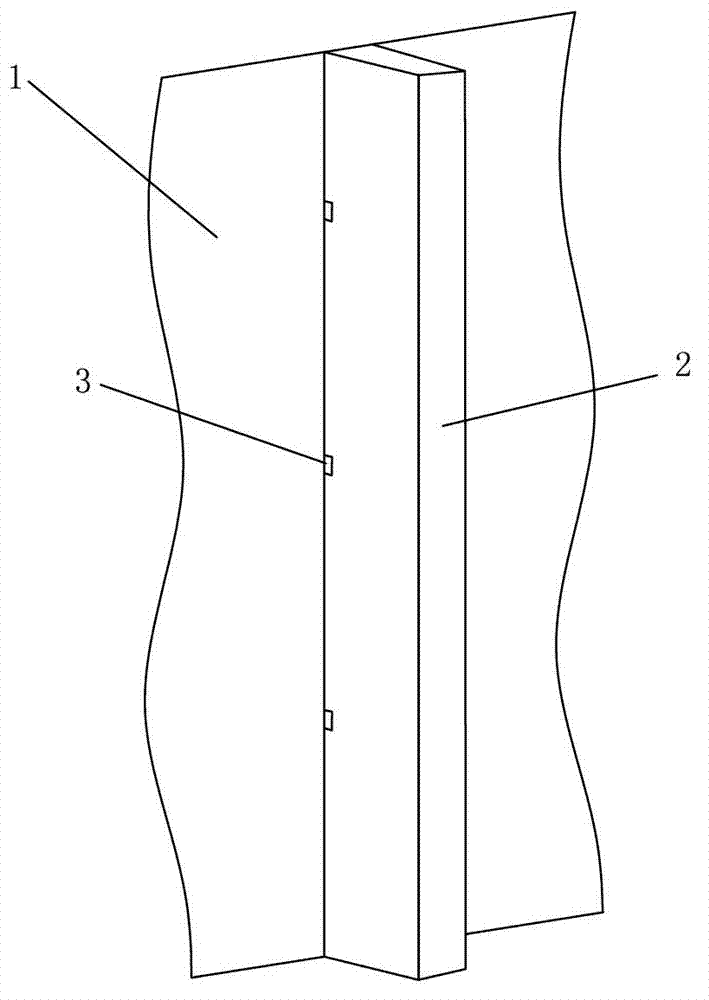

Installation technology of inner separation wall body

InactiveCN102777041ARapid positioningGuaranteed flatnessWallsBuilding material handlingStructural engineeringEngineering

Owner:中山建华墙体材料有限公司

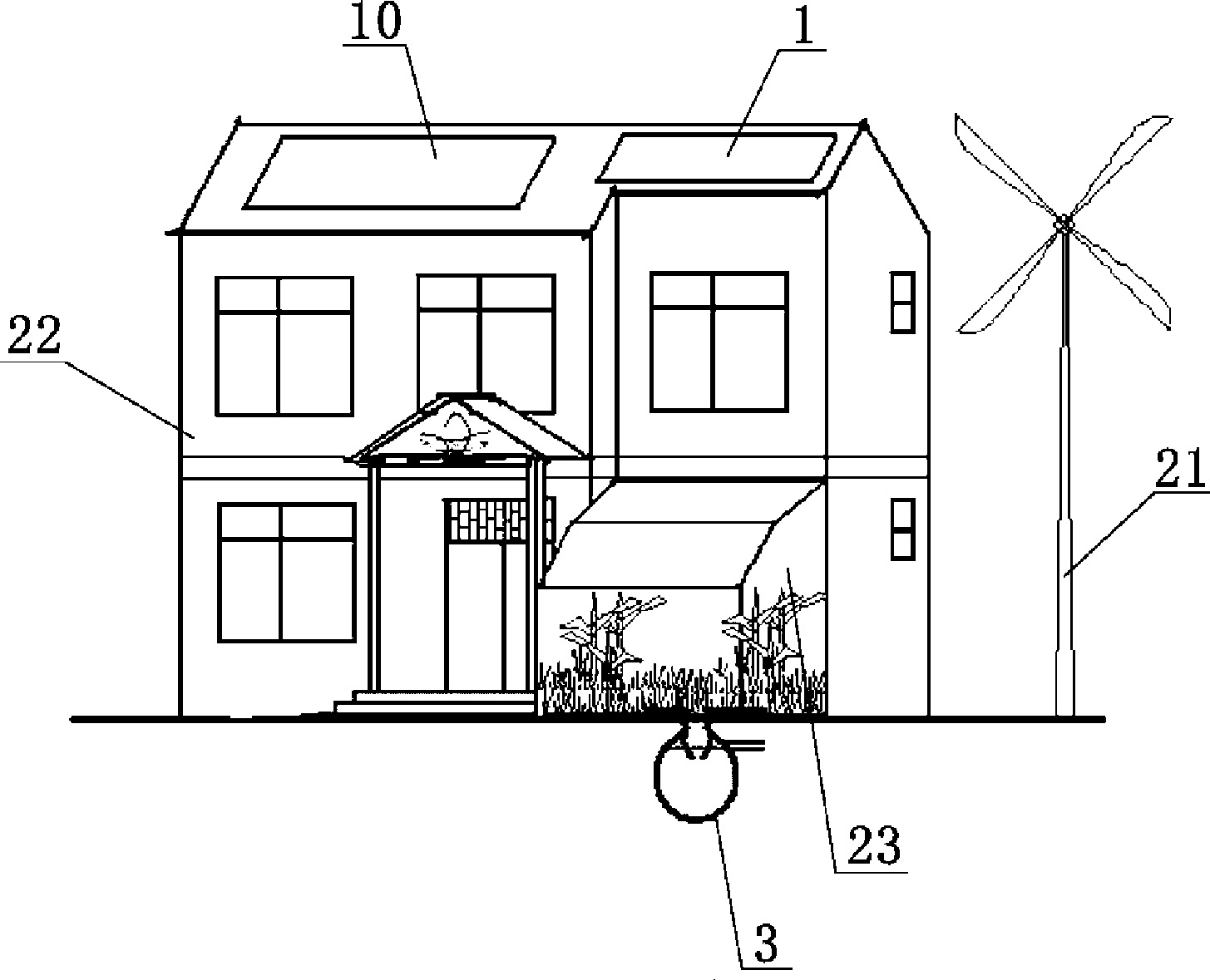

Green ecological zero energy consumption integration house

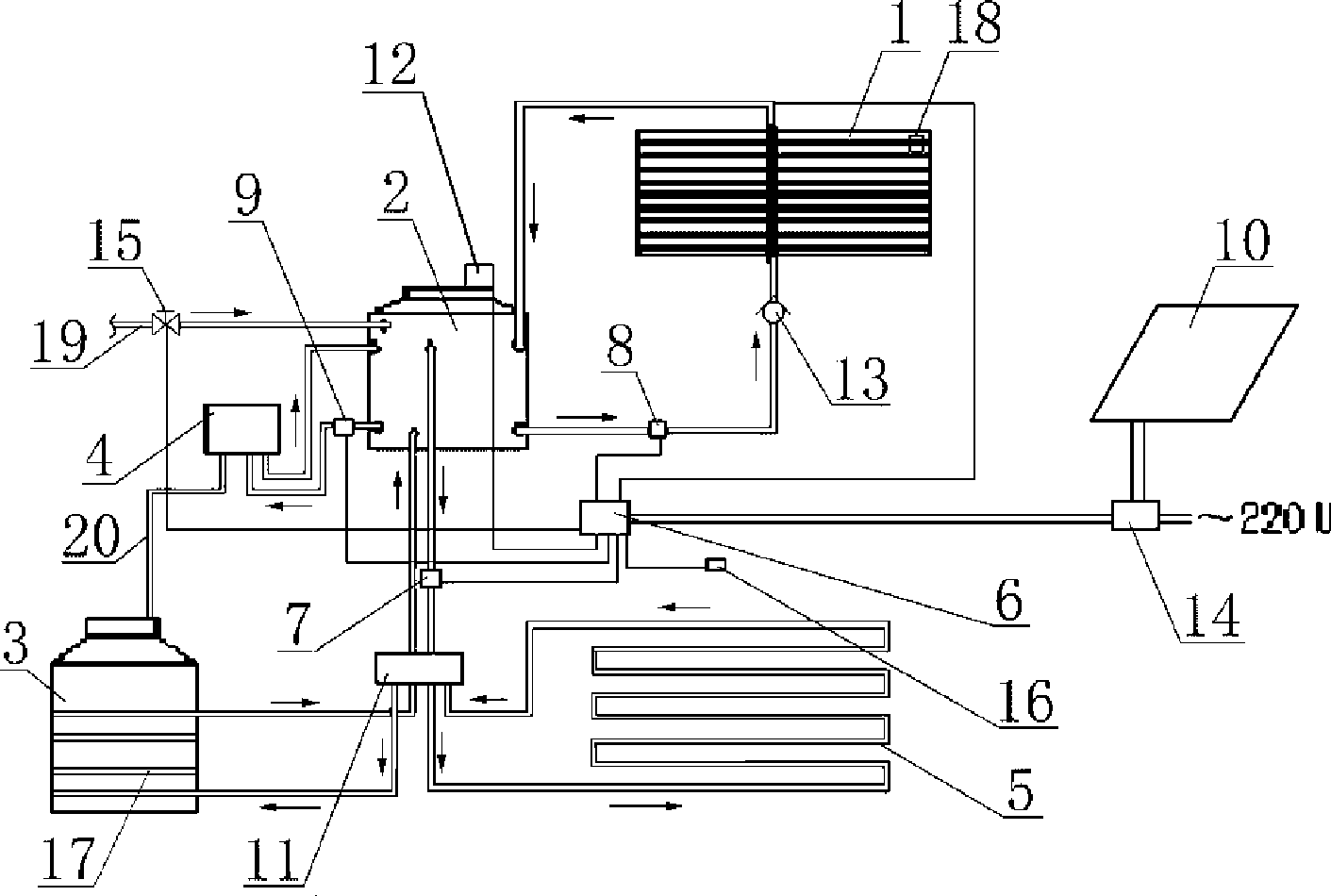

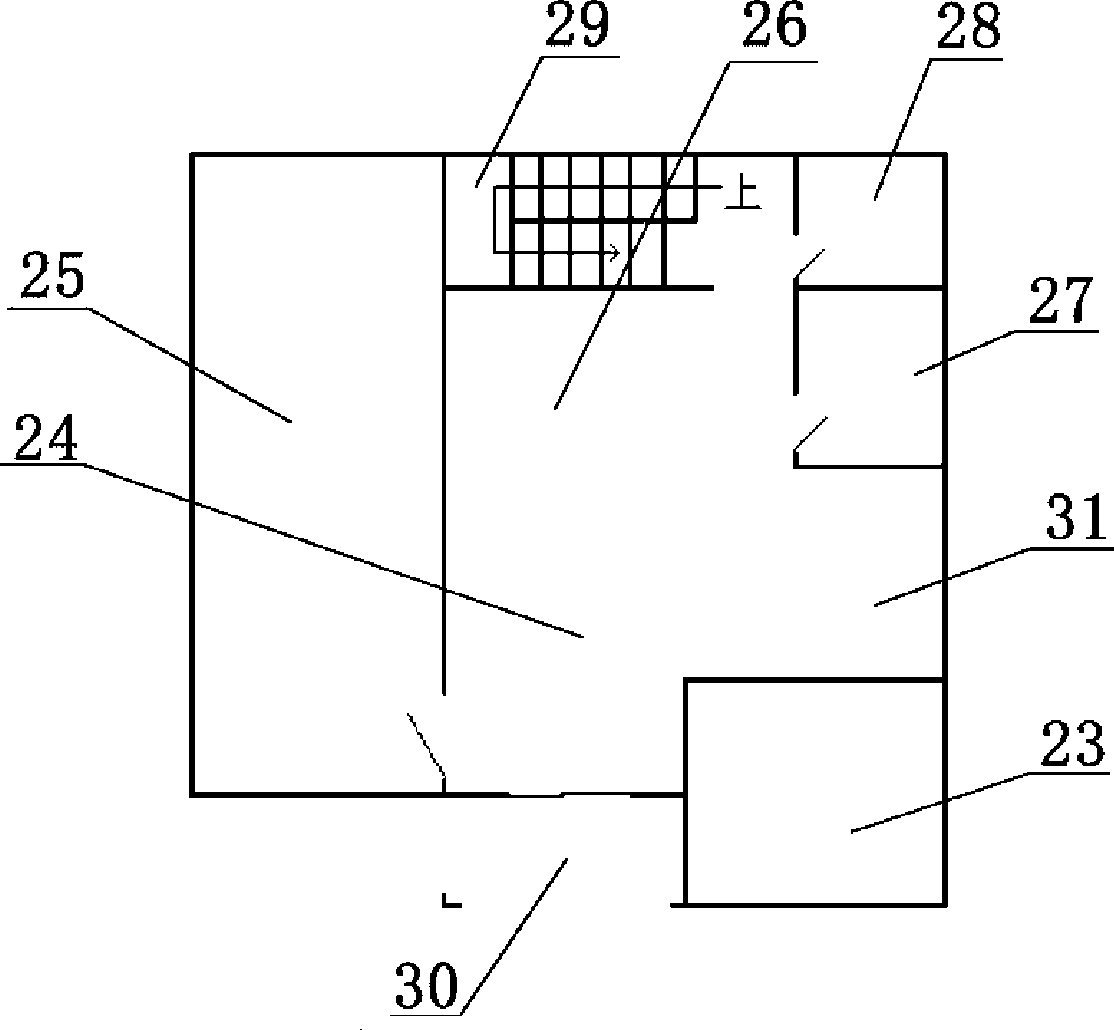

InactiveCN101457594AIncrease heatIncrease gas productionWallsSolar heat devicesLiving roomCollector device

The invention relates to a green ecological zero energy integrated building, a first floor of the building is provided with a living room, a bedroom, a dinning room, a kitchen, a toilet; a second floor of the building is provided with a bedroom and a toilet; a heat supply system is arranged inside the room, the building is connected with a heliogreenhouse on the ground and is connected with a methane tank under the ground. A solar thermal collector arranged at the top of the building is communicated with a temperature-holder box arranged inside the rooms of the building by a circulating pipe of the first line, the temperature-holder box is communicated with a water heating pipe of a gas-fuel heater by the circulating pipe, a gas line of the gas-fuel heater is communicated with the methane tank by a methane pipe. A hot water outlet of the temperature-holder box is respectively communicated with a PE-RT pipe and a heating pipe of the methane tank which is buried near the methane tank. A water tank temperature sensor, a room temperature sensor and a collector temperature sensor are connected with an intelligent controller. With the solar energy, bioenergy and wind energy complementing each other, the building has the characteristics of comfort, environmental protection, energy saving and zero-pollution.

Owner:赵民忠

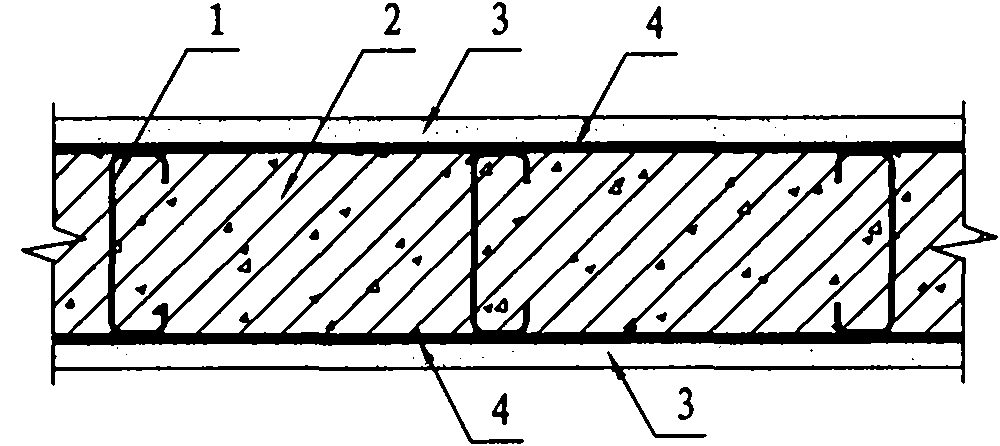

Integrally assembled steel-concrete superposed component and manufacturing method thereof

InactiveCN102477781AImprove labor productivityGuarantee the construction qualityWallsFloorsEngineeringBuilding construction

Owner:初明进

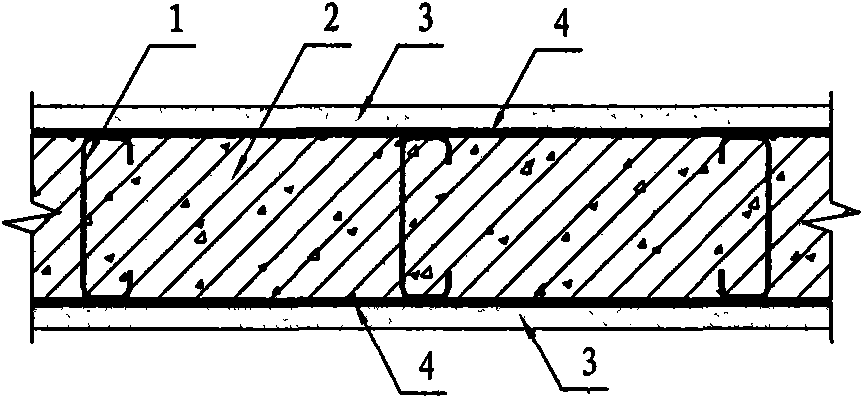

Light steel-concrete combination structure shear wall and manufacturing method thereof

InactiveCN102011442AImprove labor productivityGuarantee the construction qualityWallsRebarThin walled

The invention belongs to the field of civil engineering and discloses a light steel-concrete combination structure shear wall and a manufacturing method thereof. The light steel-concrete combination structure shear wall comprises a light-steel structure framework, reinforcing steel bars, cement boards and concrete, wherein the cement boards are used as permanent templates in a construction stage and as member protecting layers in a use stage; the light-steel structure framework is formed by connecting two or more than two cold-formed thin-walled steel or steel trusses together by using connecting pieces and has sufficient rigidity and bearing capacity in the construction stage; and the reinforcing steel bars are fixed on the light-steel structure framework, and a formed combination unit satisfies the stress requirements of the shear wall. The manufacturing method comprises the following steps of: fixing the reinforcing steel bars and the cement boards on both sides of the light-steel structure framework to form a space which satisfies the shape requirements of structural members; and then, pouring concrete. The shear wall can be used for various structural members, has the advantages of high durability and low cost and is suitable for industrial production.

Owner:初明进

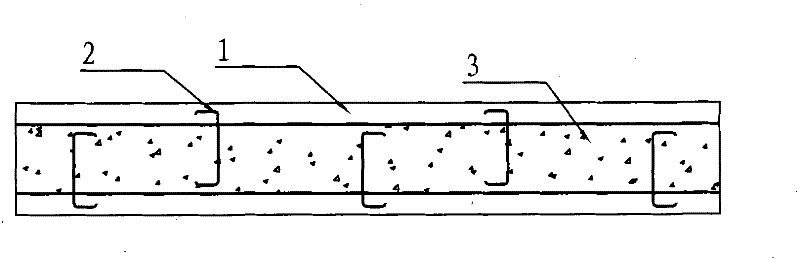

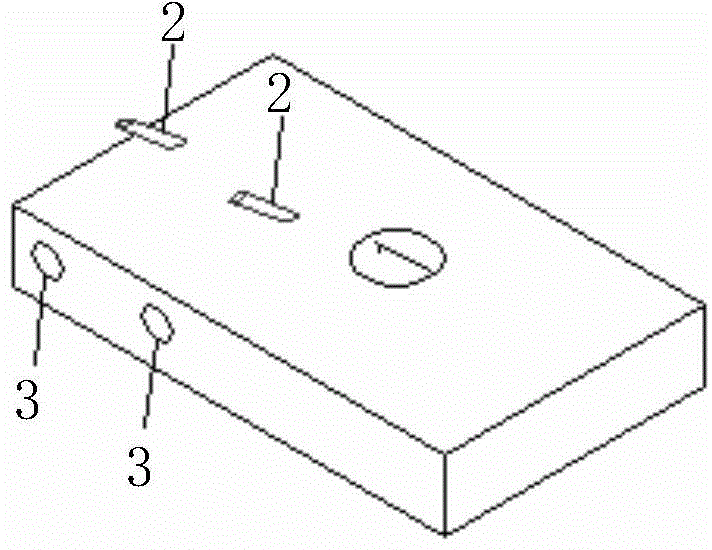

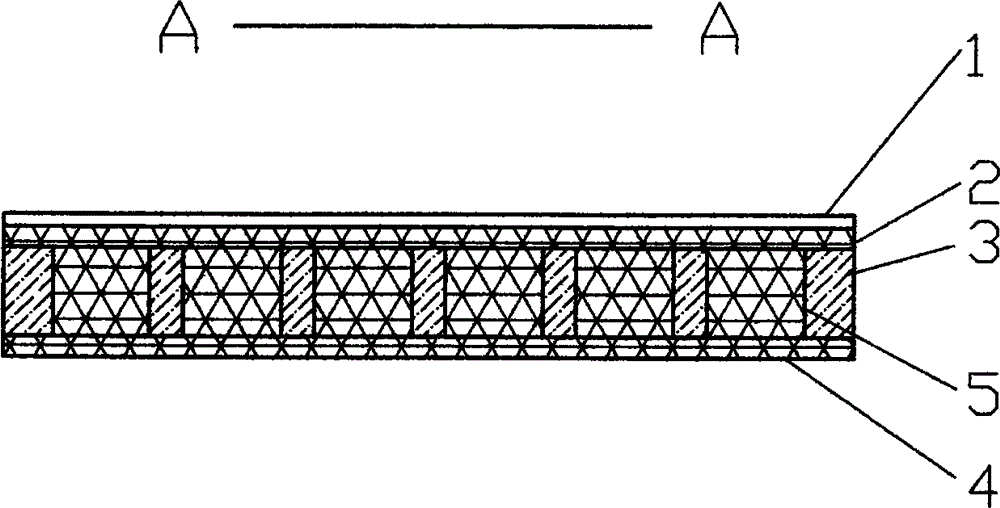

Compressed-steel sandwich combination wallboard

The invention discloses a compressed-steel sandwich combination wallboard comprising a lateral frame, compressed steel, a concrete or cement mortar face layer and core material, wherein the concrete or cement mortar face layer comprises an upper face layer and a lower face layer which are respectively connected with the lateral frame. The core material is arranged between the upper face layer and the lower face layer. The compressed steel is arranged in the combination wallboard and connected with the lateral frame or the concrete or cement mortar face layer. The compressed-steel sandwich combination wallboard integrates the characteristics of thin-wall compressed steel plate, such as good ductility and high strength, and the characteristics of lightweight core material, such as greenness and environmental protection. Due to the reasonable design of the cross section, the compressed-steel sandwich combination wallboard not only solves the problems of durability of steel products and the fire resistance of core materials and also fully uses the characteristics of each component. The compressed-steel sandwich combination wallboard not only can be used as the structure of the normal filling wallboard body, but also can be used as the shearing wall with high anti-seismic requirements, so that the compressed-steel sandwich combination wallboard is specially used as the shearing walls of high-rise buildings, filling walls of frame structures, outer walls of industrial workshops, and structures of other retaining wall.

Owner:JIANGSU SAITE STEEL STRUCTURE

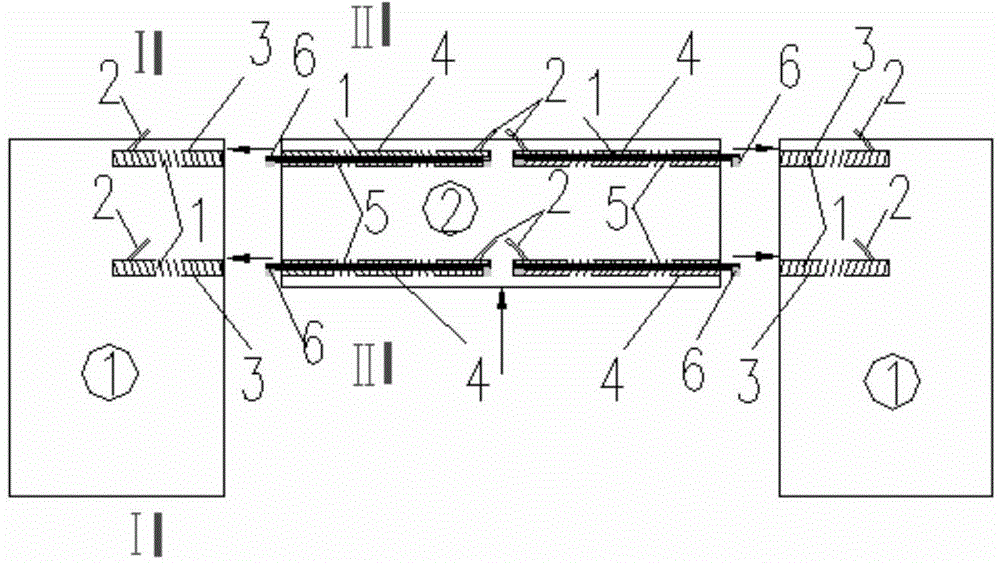

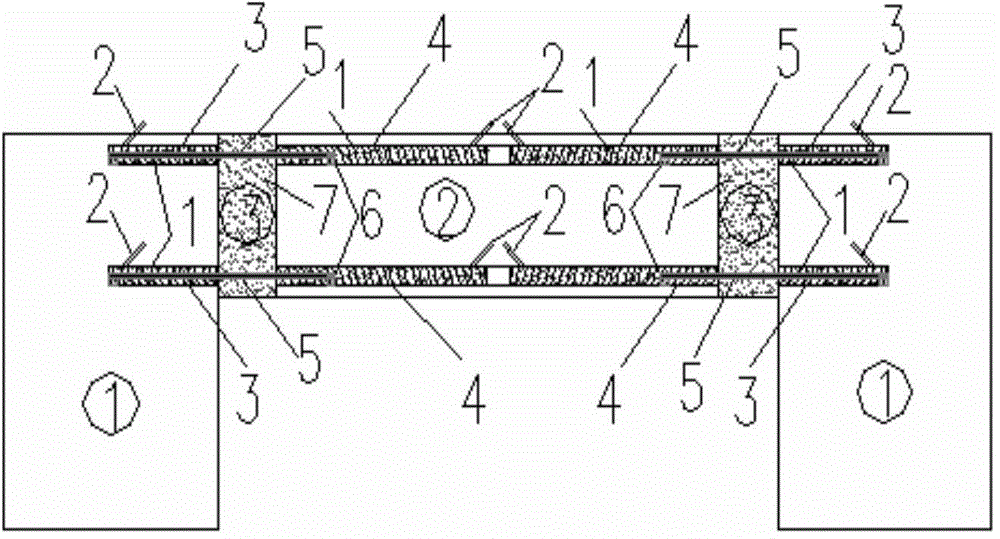

Assembly connection structure and method of coupling beams of shear walls of assembly concrete frame shear structure

The invention relates to the field of assembly concrete structures, in particular to an assembly connection structure and method of coupling beams of shear walls of an assembly concrete frame shear structure. Grouting seams and equivalent bars are arranged between prefabricated coupling beams and prefabricated shear walls or between the coupling beams of the shear walls with half-span coupling beams for beam-wall or beam-beam connection. Holes are reserved in the prefabricated coupling beams and the coupling beams of the prefabricated shear walls or the shear walls with half-span coupling beams, spiral stirrups are arranged surrounding the holes in advance, the equivalent bars penetrate through the preserved holes, the reserved horizontal holes and the grouting seams between the beams and walls or between the beams are filled by grouting minimum inflation mortar, therefore the prefabricated coupling beams, the prefabricated shear walls and the equivalent bars, or the coupling beams of the shear walls with half-span coupling beams and the equivalent bars can be firmly integrated, and connection of the prefabricated coupling beams and the coupling beams of the prefabricated shear walls or the shear walls with half-span coupling beams can be achieved. The assembly connection structure and method greatly reduce the project construction cost and reduce site concreting wet construction.

Owner:浙江筑工科技有限公司

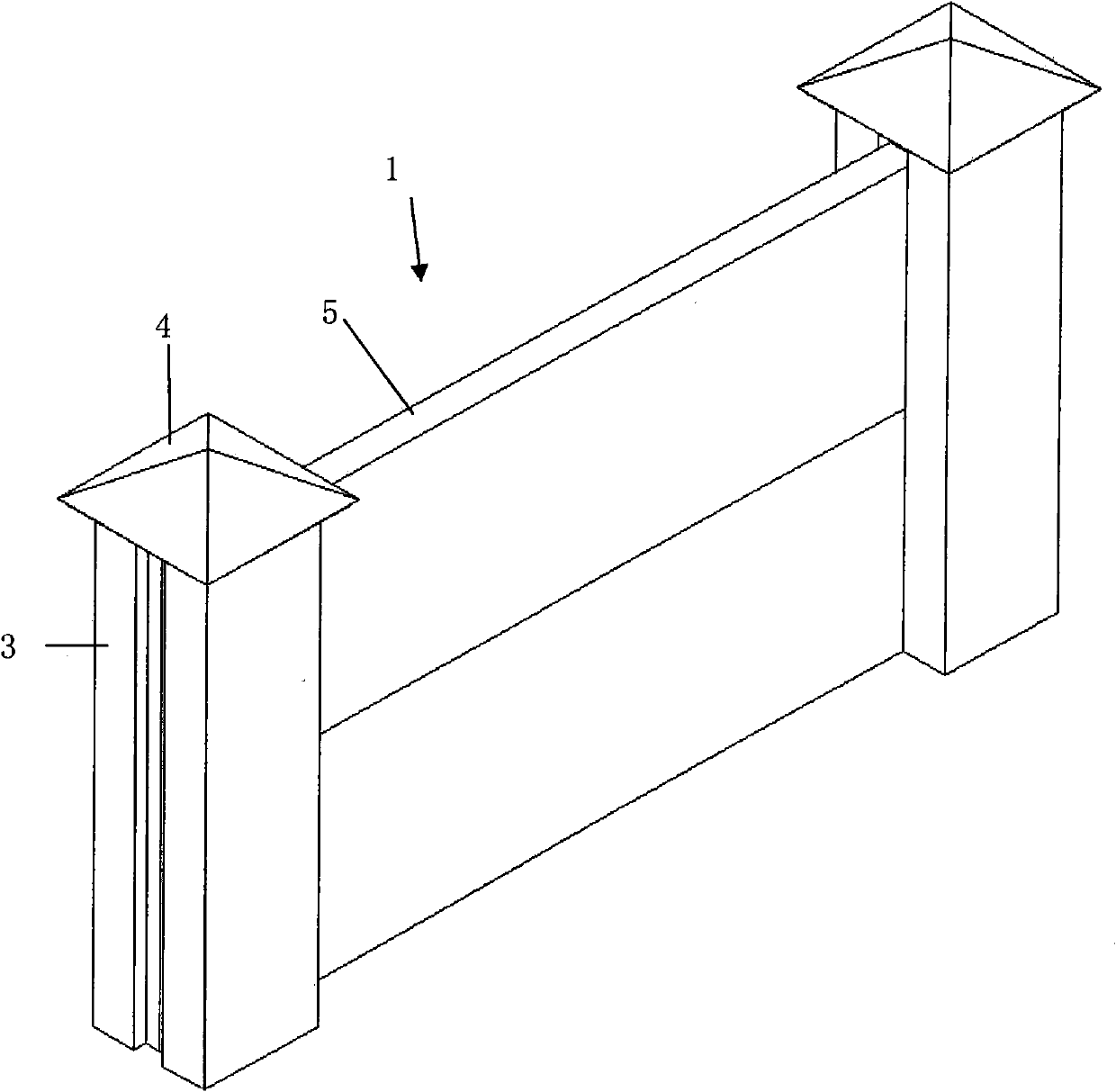

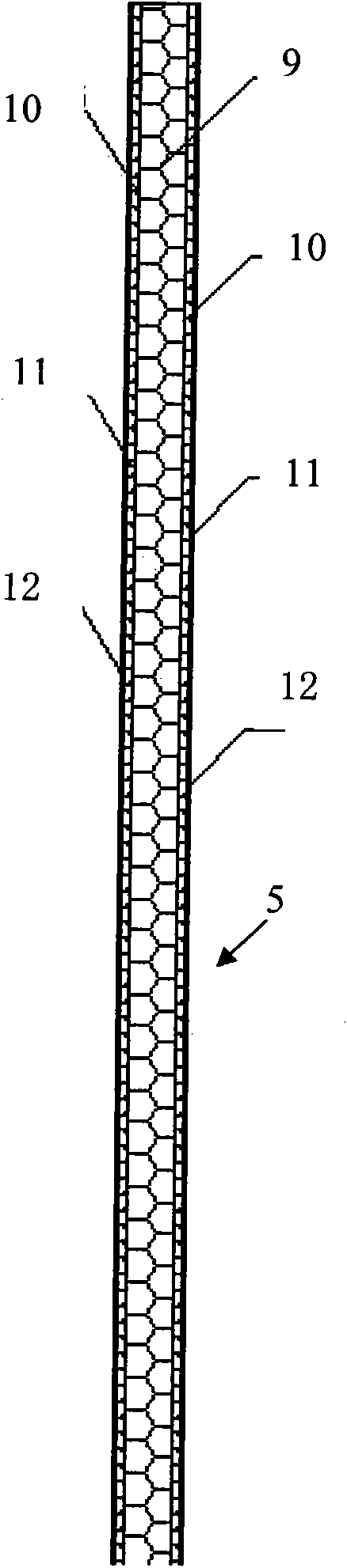

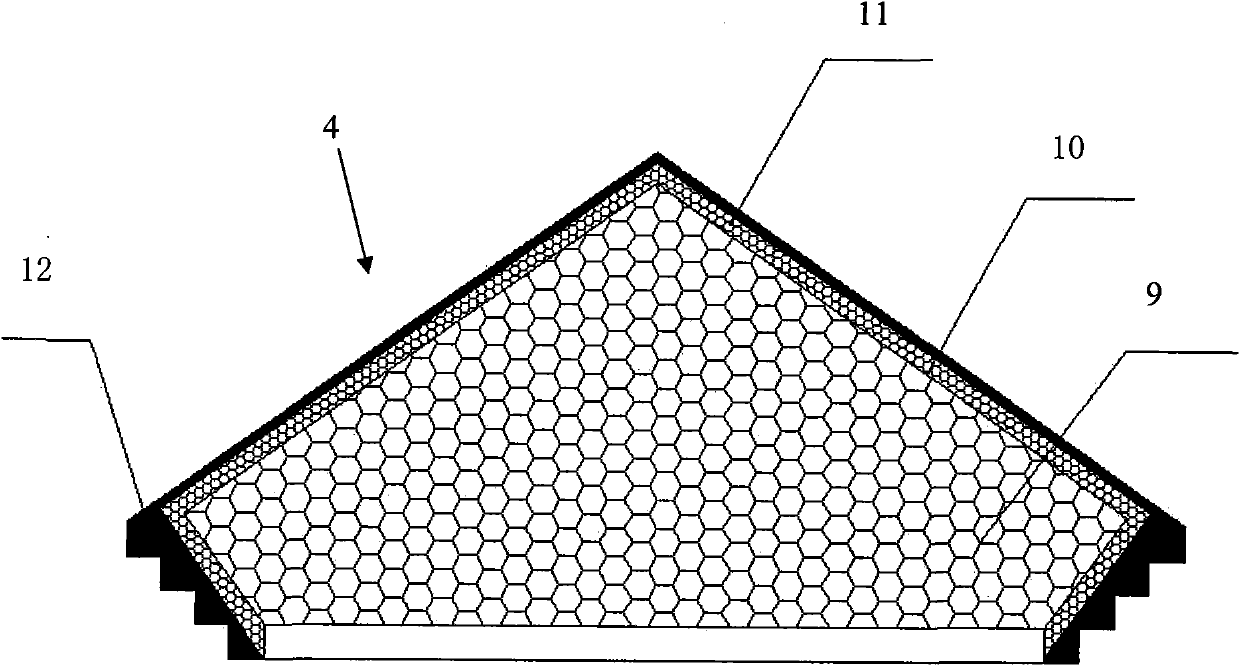

Fence structure

The invention relates to the technical field of building structures, particularly to a fence structure, wherein a central column is connected with two column bodies through a building adhesive or a connecting piece, each column body is a long cube comprising a polyphenyl board, a strengthening net, an adhesive layer or a finishing layer, and each column body is higher than a wallboard; a plane is arranged at one side of each column body, two projections are arranged at the other side, and a recess is arranged in the middle of the two projections; one side of the wallboard is inserted into a groove formed after the two column bodies are merged, the other side of the wallboard is inserted into the groove formed after the other two column bodies are merged, and the upper part of each column body is connected with a column cap. The novel combined fence provided by the invention can be industrially produced in large scales, can reduce field wet operation, has high construction speed, can be disassembled and assembled for many times and repeatedly used, greatly saves the cost, saves the manpower, reduces the construction difficulty, is economical and practical, saves the energy, reduces the emission, lowers the engineering cost, and facilitates the construction.

Owner:TIANJIN JINKE ZHIBO TECH DEV

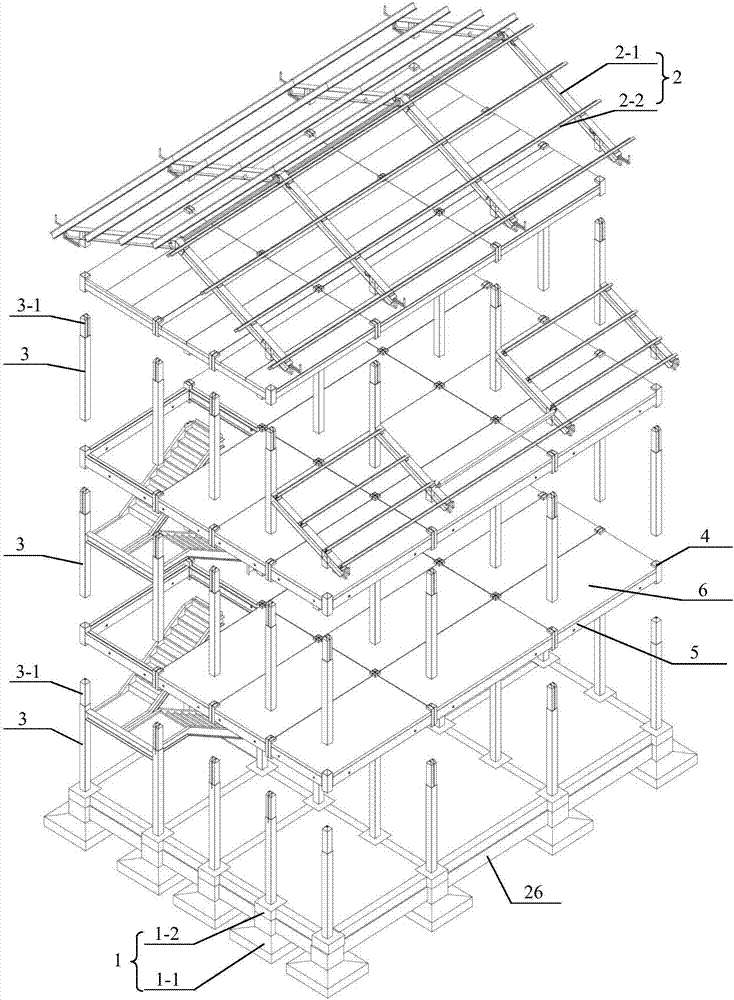

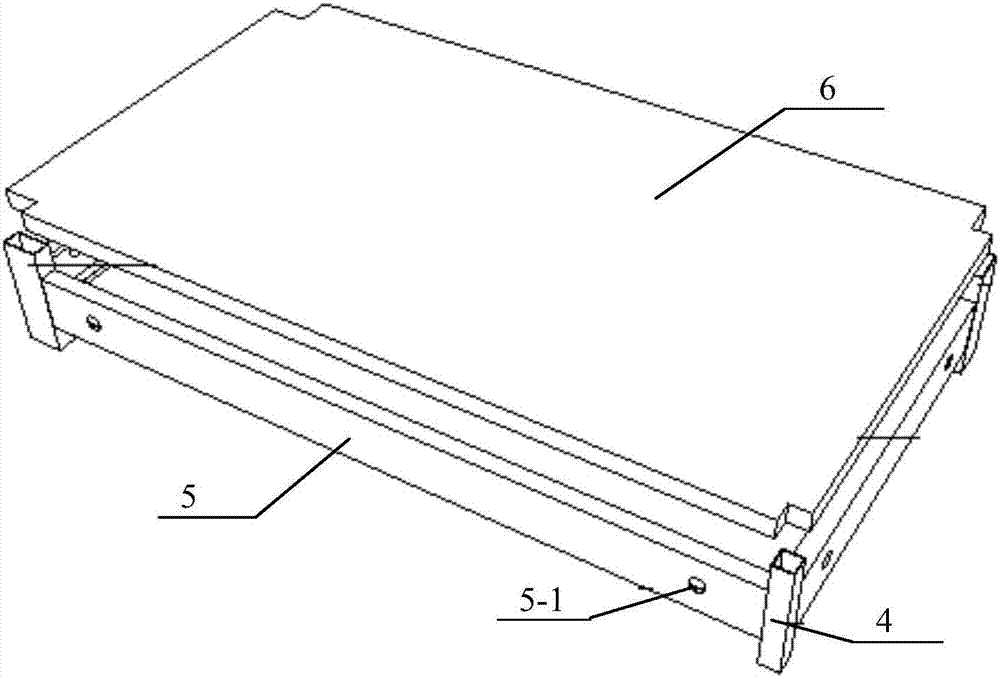

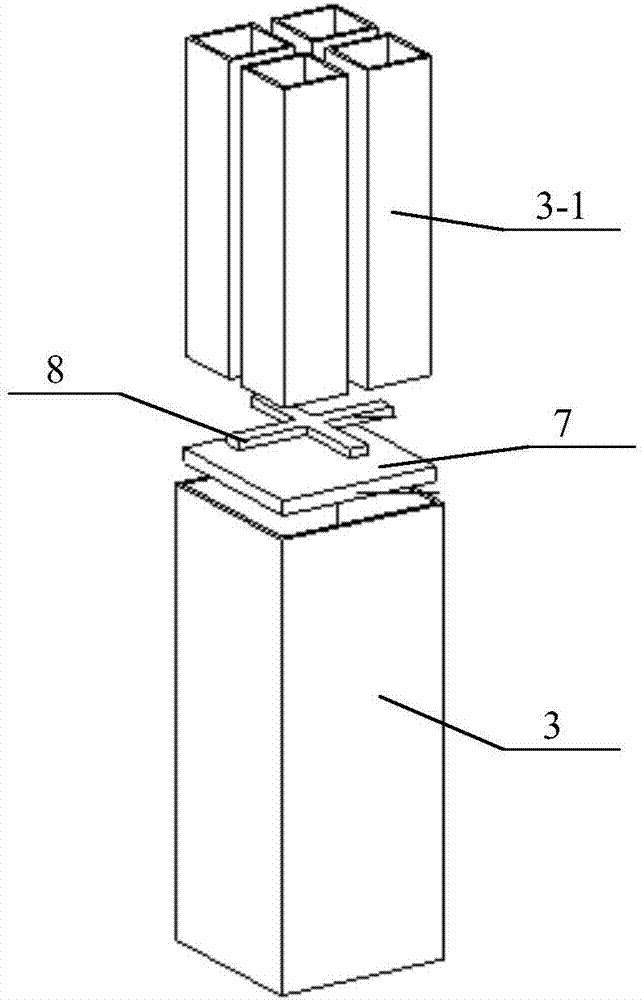

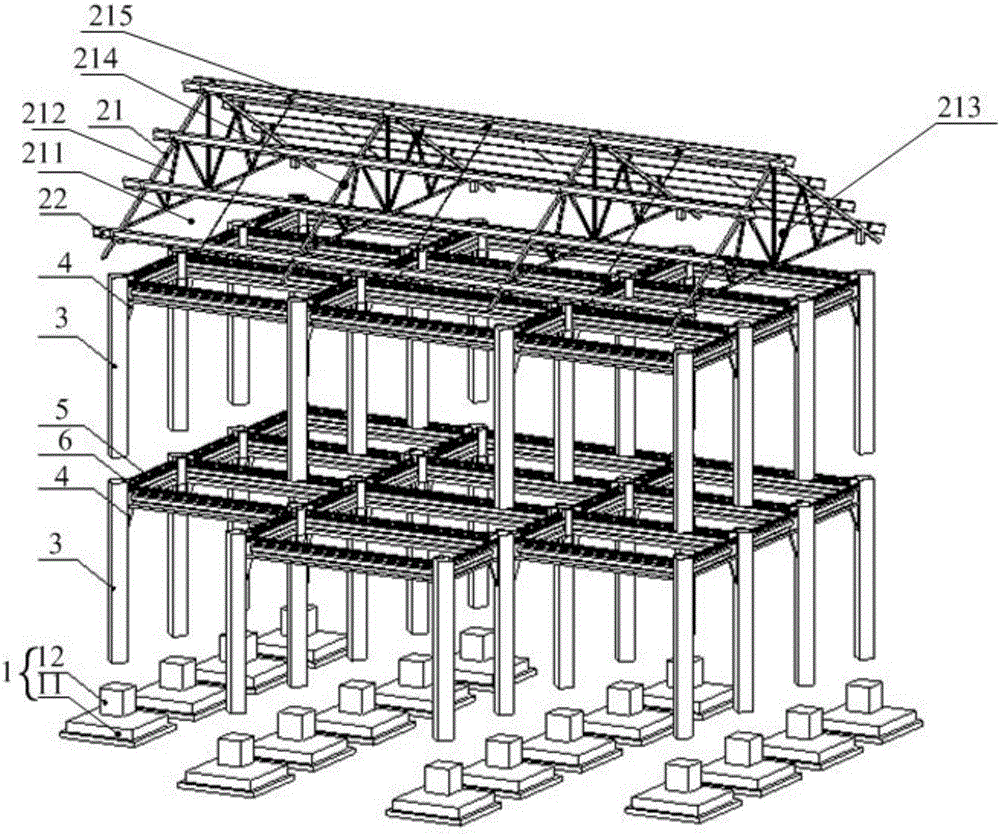

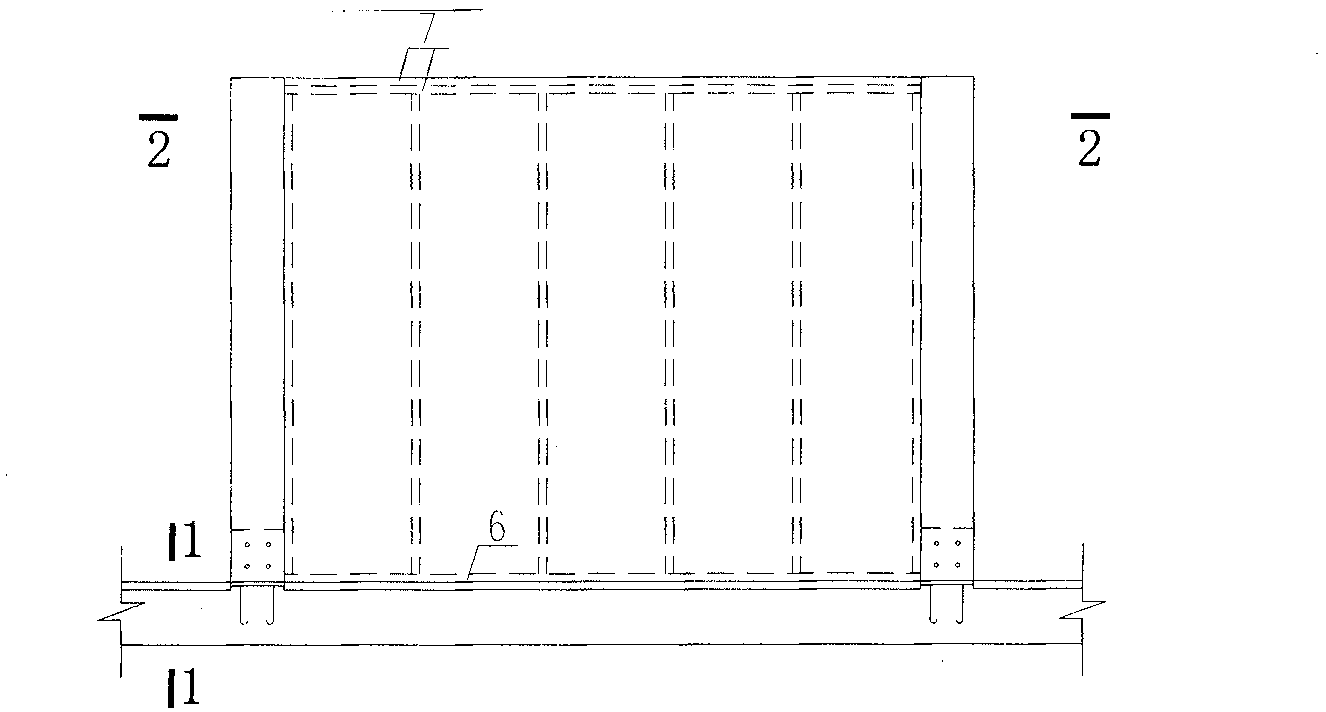

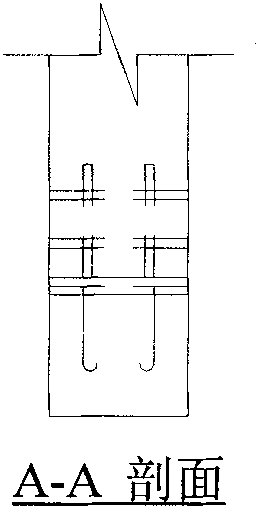

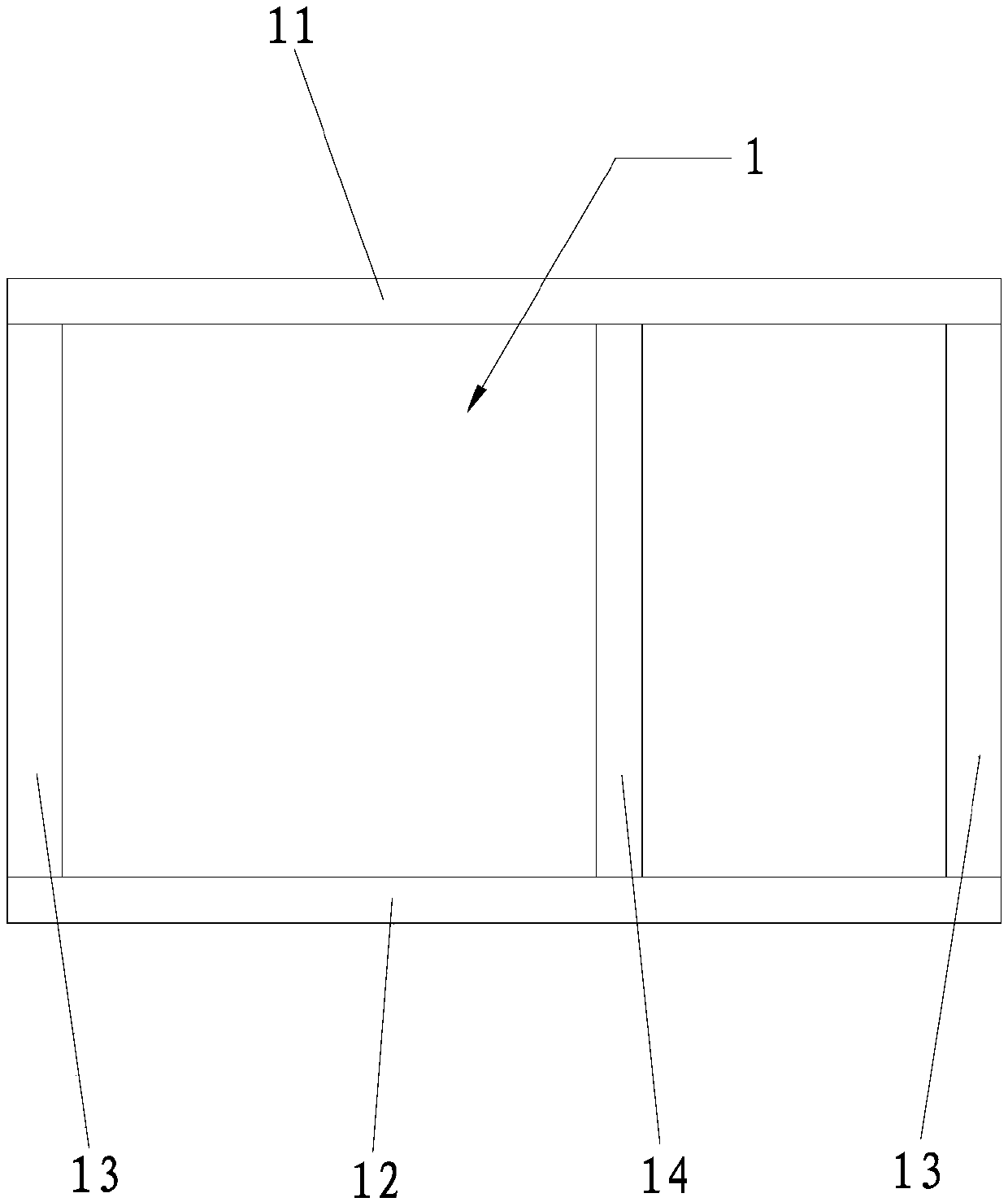

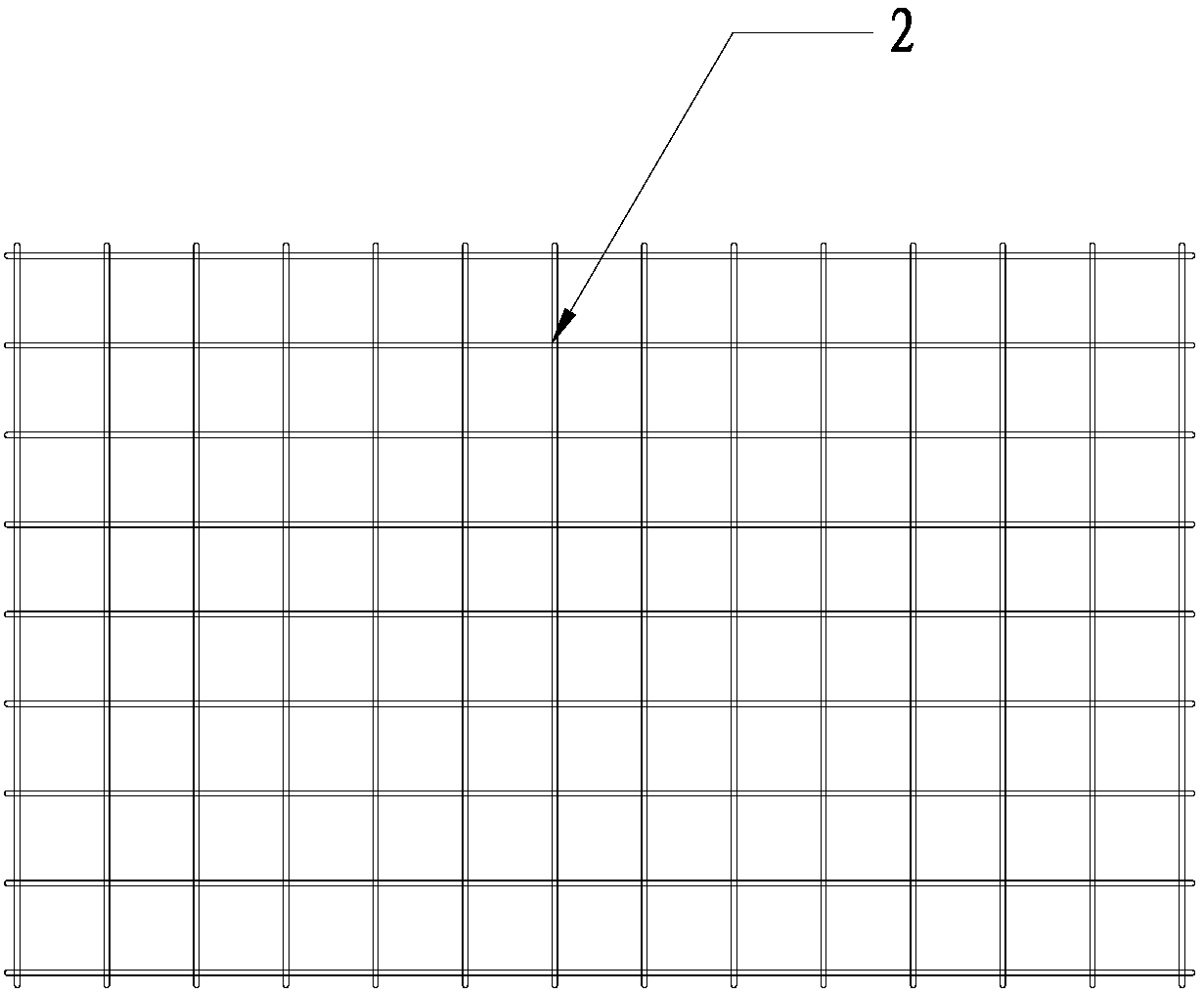

Prefabricated building main body structure

PendingCN107366356AReasonable connectionEasy to installBuilding constructionsFloor slabArchitectural engineering

The invention discloses a prefabricated building main body structure, and relates to the technical field of constructional engineering structures. The prefabricated building main body structure comprises an independent foundation; at least one layer of floor slabs is fixedly arranged above the independent foundation; a supporting structure is arranged under each layer of the floor slabs; a roof frame structure is fixedly arranged above the top layer of the floor slabs; the floor slabs comprise a plurality of combination beam plates; the supporting structure of each layer comprises a plurality of square pipe columns; tenon pipes connected with the combination beam plates in an inserting manner are arranged on the square pipe columns; a stairway is arranged between every two vertically adjacent layers of floor slabs; the combination beam plates comprise four-corner components; steel beams are fixedly connected between the adjacent four-corner components; the upper edges of the steel beams are spaced from the top ends of the four-corner components by a certain distance; concrete slabs are poured on the steel beams; reinforcement meshes are arranged in the concrete slabs; reserved pipeline holes are formed in the side surfaces of the steel beams; and the four-corner components are sleeves matched with the tenon pipes in an inserting manner. The beam and column connection is reasonable, the mounting is convenient and the flexural capacity is high.

Owner:北京善筑科技股份有限公司

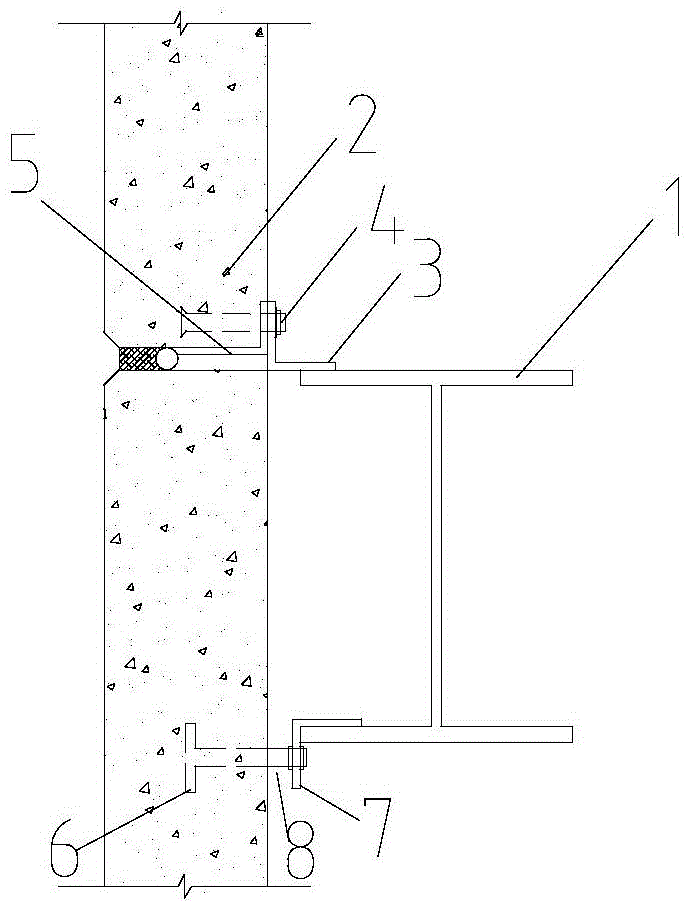

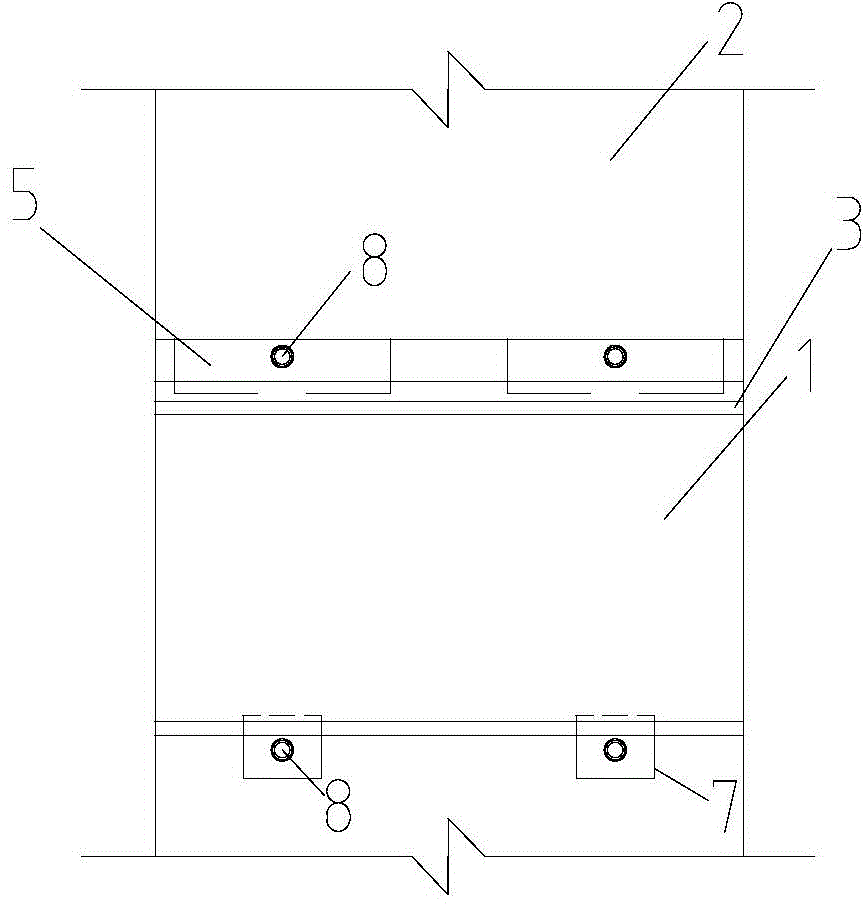

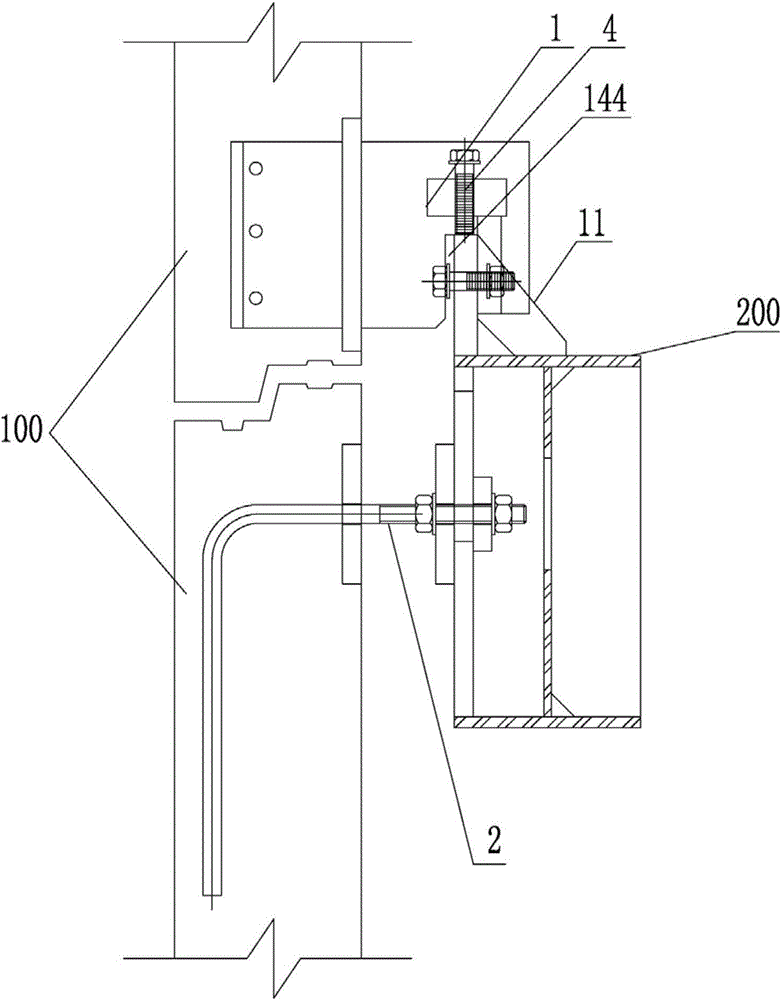

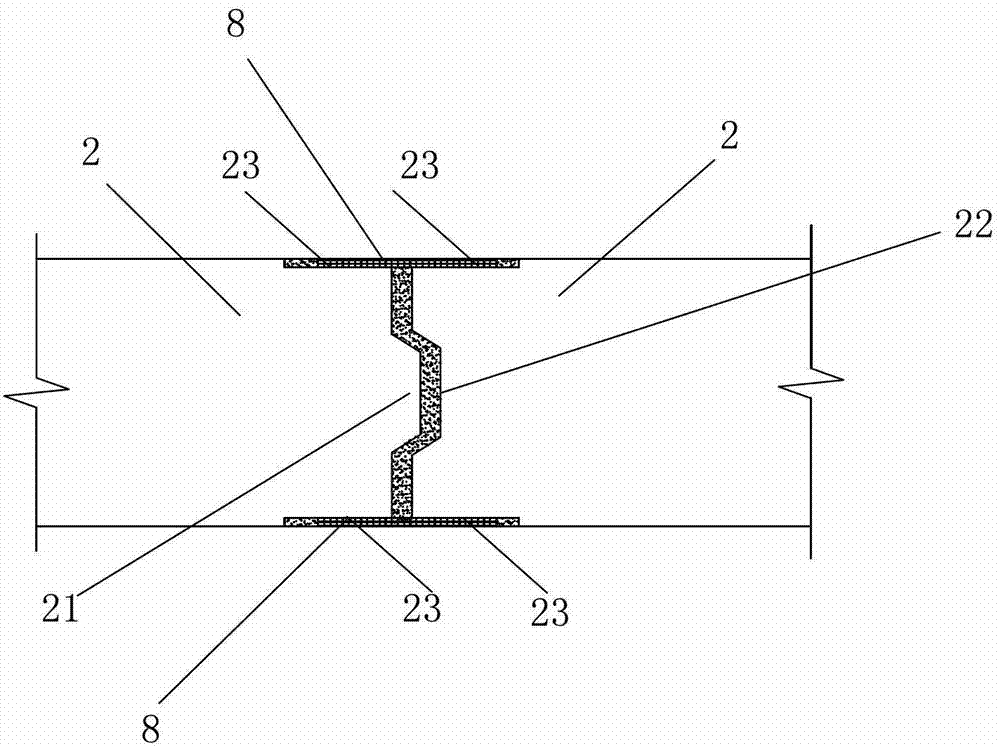

Connection structure of fabricated steel structure building enclosure outer wall and H-shaped steel beam

Disclosed is a connection structure of a fabricated steel structure building enclosure outer wall and an H-shaped steel beam. The connection structure of the fabricated steel structure building enclosure outer wall and the H-shaped steel beam is characterized in that the lower end of an outer wall board is fixedly connected with the top flange of the H-shaped steel beam by welding a steel angle on the top flange of the H-shaped steel beam, welding a support board on the reverse side of the steel angle, placing the lower edge of the outer wall board on the support board, and fixedly connecting the lower end of the outer wall board, the support board and the steel angle into a whole through high strength friction type bolts A embedded in the outer wall board, and the upper portion of the outer wall board is fixedly connected with the bottom flange of the H-shaped steel beam by welding a steel angle connection piece on the bottom flange of the H-shaped steel beam, fixedly connecting the upper portion of the outer wall board and the steel angle connection piece into a whole through a bolt B embedded in the outer wall board, arranging a steel cap at the end of the high strength friction type bolt B, placed in the outer wall board, and setting the distance between the other end of the high strength friction type bolt B, stretched out of the outer wall board, and the steel angle connection piece as 30mm. The connection structure of the fabricated steel structure building enclosure outer wall and the H-shaped steel beam has the advantages of being strong in shear resistance capacity, good in shock resistance performance, needless of a cold and hot bridge, and convenient and quick to install at site, enabling a wall body to move along with a steel frame and the like.

Owner:SHENYANG JIANZHU UNIVERSITY

Assembly type main structure of building

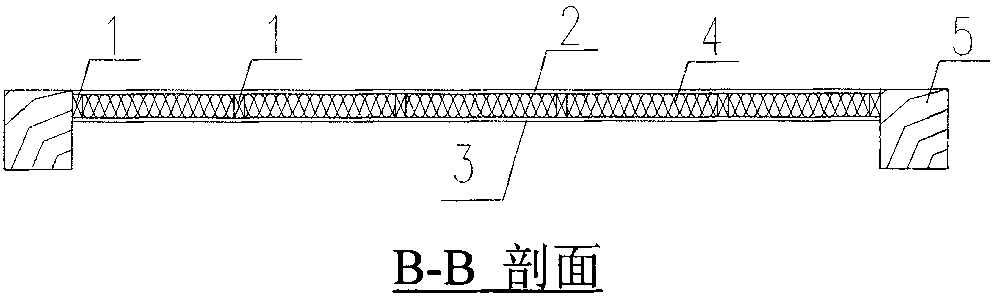

InactiveCN106759900AReasonable connectionEasy to installFloorsFoundation engineeringCold formedEngineering

The invention discloses an assembly type main structure of a building, and relates to the technical field of building engineering structures. The assembly type main structure of the building comprises isolated foundations, at least one layer of supporting beam group and at least one layer of cold-formed thin-walled steel composite beam plates are arranged on the isolated foundations, and a roof frame structure is arranged on the top supporting beam group, wherein each layer of supporting beam group comprises a plurality of square tubular columns, and the upper portion of each square tubular column is provided with a beam support; each cold-formed thin-walled steel composite beam plate comprises a lipped channel stiffened structural beam, a profiled steel sheet, a reinforcing mesh and a concrete plate, and the end of each lipped channel stiffened structural beam is provided with a sleeve; each lipped channel stiffened structural beam comprises a vertical plate, a first transverse plate and a second transverse plate, a vertical baffle is arranged above each first transverse plate, and stiffened structures are arranged on the first transverse plates, the second transverse plates, the vertical plates and the vertical baffles respectively. The assembly type main structure is reasonable in beam-column connection, convenient to install, high in flexural capacity and suitable for large-span commercial complex buildings.

Owner:北京善筑科技股份有限公司

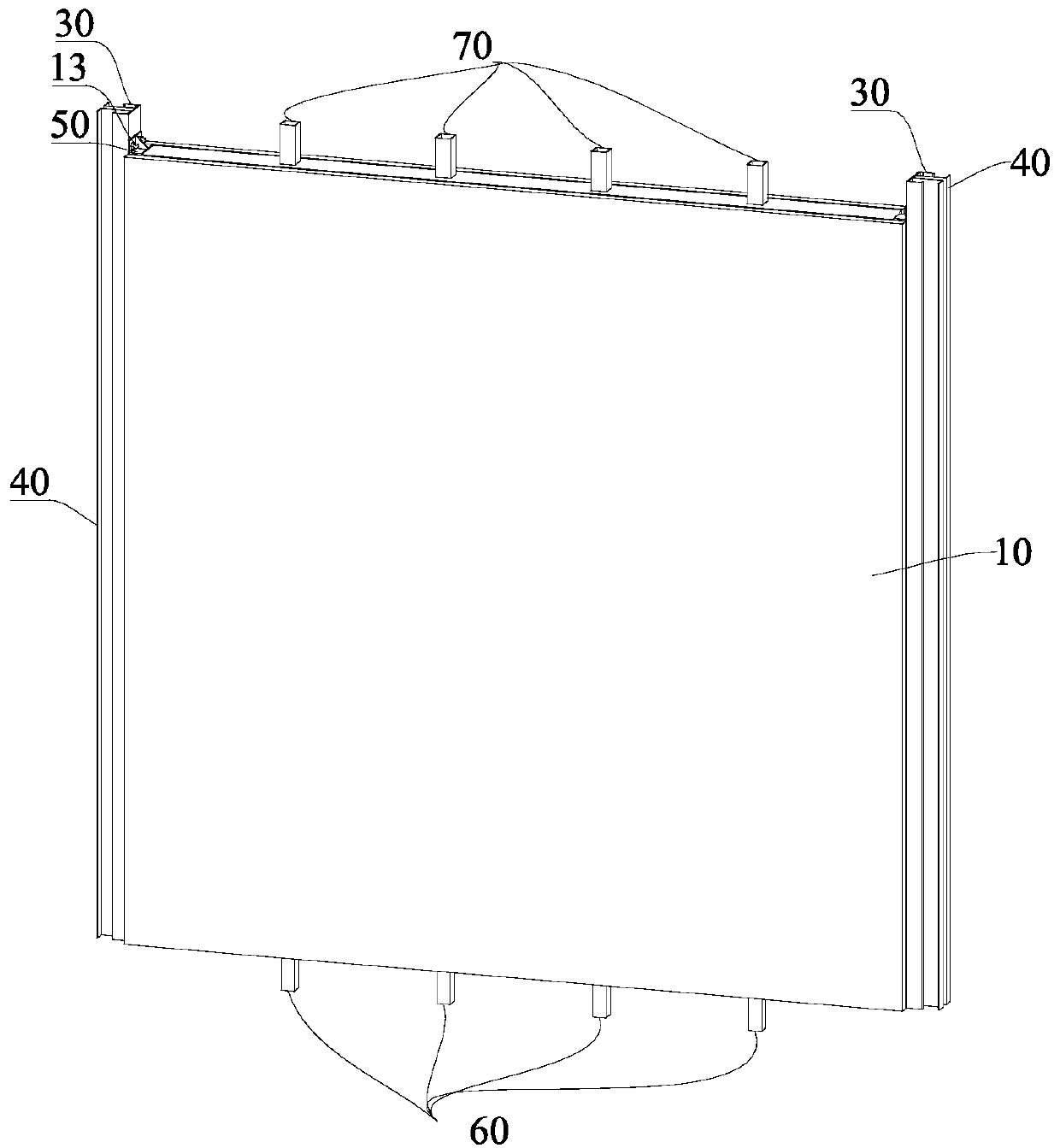

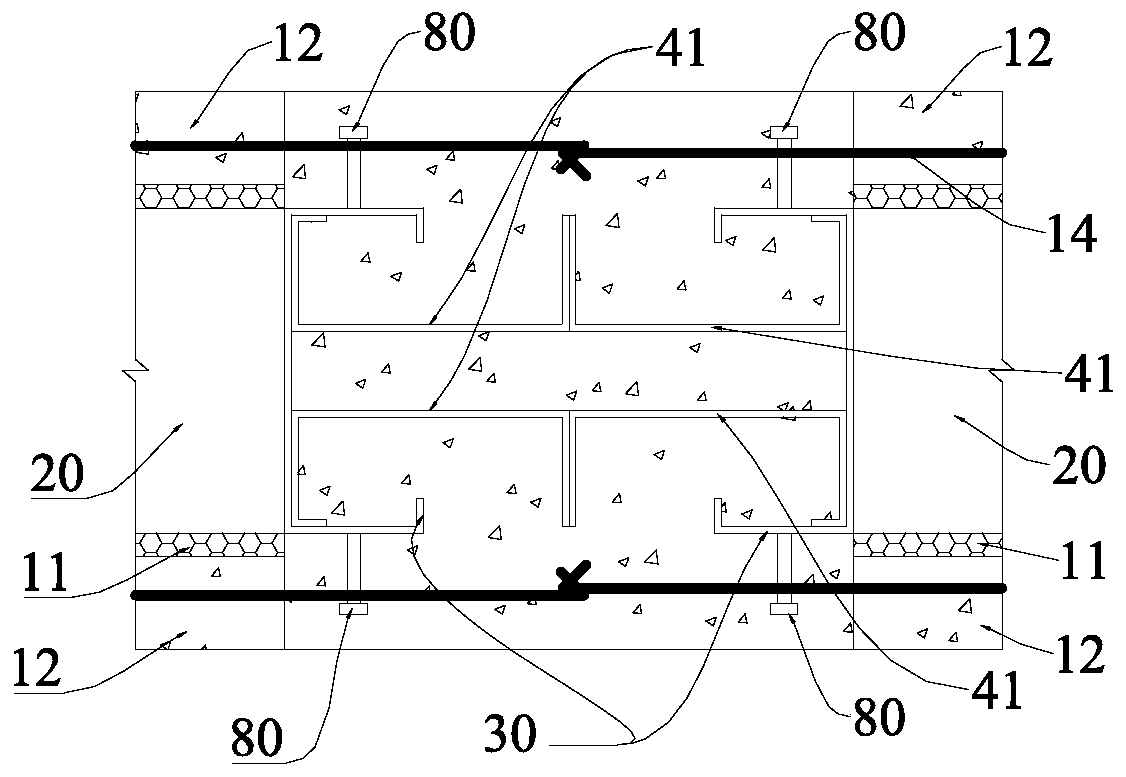

Large-template drawing steel stranded wire

InactiveCN101476390AImprove inner qualityReduce the amount of repairAuxillary members of forms/shuttering/falseworksMaterials scienceExtrusion

The invention relates to a large formwork oppositely-drawing steel strand, which has the main technical characteristic that a large formwork oppositely-drawing steel strand consists of a large formwork, an anchoring system and a steel strand, and is characterized in that the oppositely-drawing steel strand passes through the large formwork, and two ends of the steel strand are fixed and tightened by the anchoring system. The anchoring system comprises a liner plate, a tensioning sleeve, an anchor cylinder, an extrusion sleeve and a clamping piece, wherein the tensioning sleeve is fixed on the liner plate. After the large formwork is mounted and positioned, the oppositely-drawing steel strand with a jacket passes through the oppositely-drawing hole on the large formwork to fasten the anchoring system on one side of the large formwork on one end of the steel strand first and then fasten the anchoring system on the other side on the other end of the steel strand, and the steel strand is tightened and the anchoring system is screwed down. Compared with the prior oppositely-drawing bolts, the oppositely-drawing steel strand can reduce the oppositely-drawing aperture, reduce the repairing quantity and the impression defects on the concrete surface, and improve the repairing working efficiency.

Owner:DALIAN AERBIN GROUP

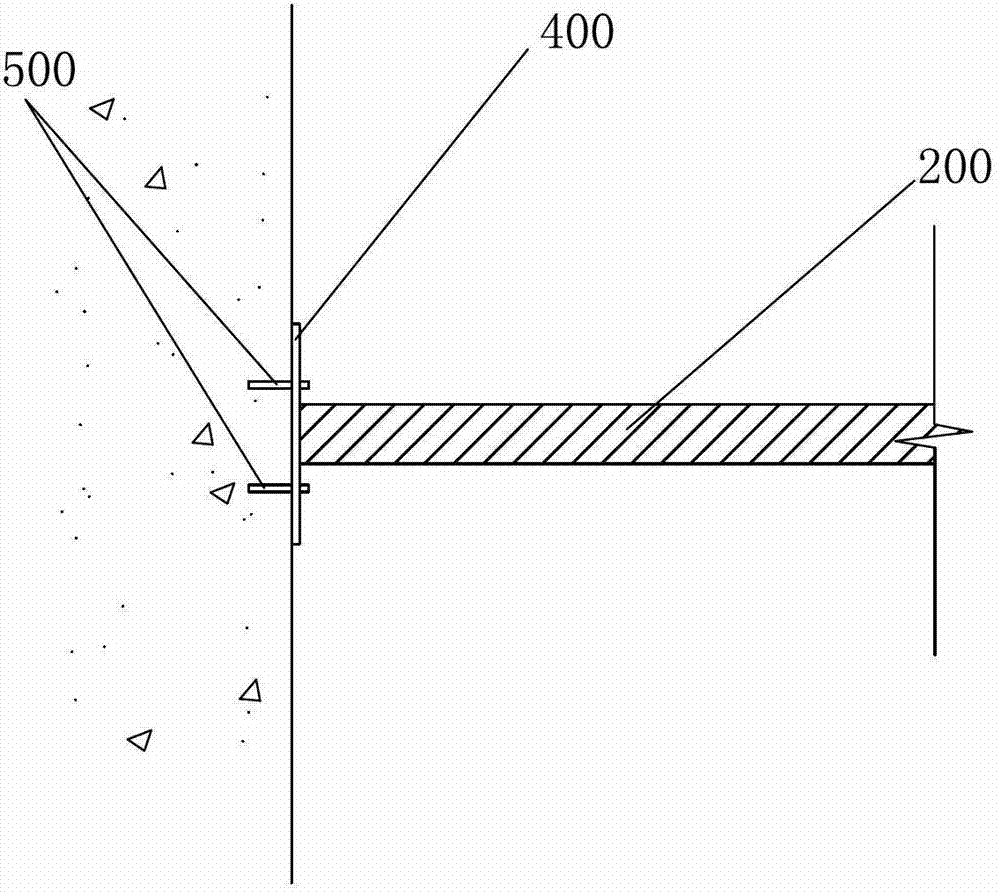

Connection joint of lower bearing prefabricated concrete external wall and steel beam

ActiveCN106284682AAvoid participating in structural overall calculationsImprove construction efficiencyBuilding constructionsPrecast concreteFlange

The invention relates to a connection joint of a lower bearing prefabricated concrete external wall and a steel beam. The connection joint comprises the prefabricated concrete external wall, the steel beam, a lower bearing joint and an upper connection joint body. The upper end of the lower bearing joint is embedded in the prefabricated concrete external wall, and the lower end of the lower bearing joint is welded to an upper flange of the steel beam. One end of the upper connection joint body is embedded in the prefabricated concrete external wall, and the other end of the upper connection joint body is anchored to the steel beam. According to the connection joint, the steel beam and a connection base are prefabricated in a factory, full-bolt splicing of the prefabricated concrete external wall and a steel structure is completed on site, the displacement, relative to a main structure, of the prefabricated concrete external wall can be completely released through the connection joint, and the situation that the wall participates in the overall structure calculation is avoided; and then joint seams of the wall face are subjected to waterproof treatment, fireproof treatment and the like. A large amount of welding work and wet work on site is reduced, the construction efficiency and quality of steel structure buildings are greatly improved, and safety and environment friendliness are achieved.

Owner:ZHEJIANG GREEN BUILDING INTEGRATION TECH CO LTD

Compound type decorating thermal insulation panel with cement polymer at double surfaces and preparation method thereof

InactiveCN104563428ANot affected by the weatherNice appearanceCovering/liningsWater-setting substance layered productEpoxyPolymer science

The invention relates to a compound type decorating thermal insulation panel with cement polymer at double surfaces and a preparation method thereof. The thermal insulation panel comprises a surface layer, a cover surface layer coated on the surface layer surface, a bottom layer connected with the surface layer through a connecting post, and a thermal insulating layer clamped between the surface layer and bottom panel layer. The surface layer is made of cement polymer composed of special cement, surface layer padding and acrylic elastic emulsion or epoxy resin emulsion, and the bottom layer is made of cement polymer composed of cement and bottom layer padding. The compound type decorating thermal insulation panel with the cement polymer at double surfaces is mechanically produced in a factory, the labor cost is saved, the appearance is beautiful, the size is uniform, and the quality is guaranteed; the construction is not influenced by weather; the surface of the thermal insulation panel bonded with the wall surface is cement polymer, and the problem of thermal insulation panel detachment from the wall surface due to the fact that the surface of the thermal insulation panel bonded with the wall surface is inconsistent with the interface of the wall surface in coefficients is avoided; crack is avoided, the outer surface is smooth and clean, and the service life is long.

Owner:四川安美达节能科技有限公司

Heat-preservation wall body of wood-frame shear wall

InactiveCN101929207AReduce wet workImprove construction efficiencyWallsClimate change adaptationMachining processSurface plate

The invention belongs to the technical field of structural engineering, and particularly relates to a heat-preservation wall body for a mixed structure of a wood frame and a wooden shear wall, and assembly technology. The assembled heat-preservation wall body consists of wall studs, a wood base structural slab, a gypsum board, heat-preservation cotton, a wood-frame pillar, a mudsill board and a top beam board, wherein a horizontal interval between every two adjacent wall studs is 400 to 600 millimeters, and the wall studs on both sides are connected with the wood-frame pillar through nails; the wood base structural slab covers the wall body, is connected with the wall studs, the top beam board and the mudsill board through the nails, and is flush with the outer side of the wood-frame pillar; the gypsum board is covered on the inner side of a wallboard and is connected with the wall studs through screws; and the heat-preservation cotton is filled between inner and outer cladding boards. Materials for the assembled wall body provided by the invention can improve the natural environment in the process of growth, have the advantages of low energy consumption in the machining process, regeneration and natural degradation after abandonment, and have the functions of quick construction, vibration prevention, energy conservation, heat preservation, heat insulation and the like; the heat-preservation wall body has the advantages of high industrial production degree, high production efficiency, less on-site wet operation, a plurality of operational surfaces and quick construction; and the materials, such as dimension stocks, connectors, plywood, laminated wood and the like can be localized to reduce the construction cost.

Owner:TONGJI UNIV

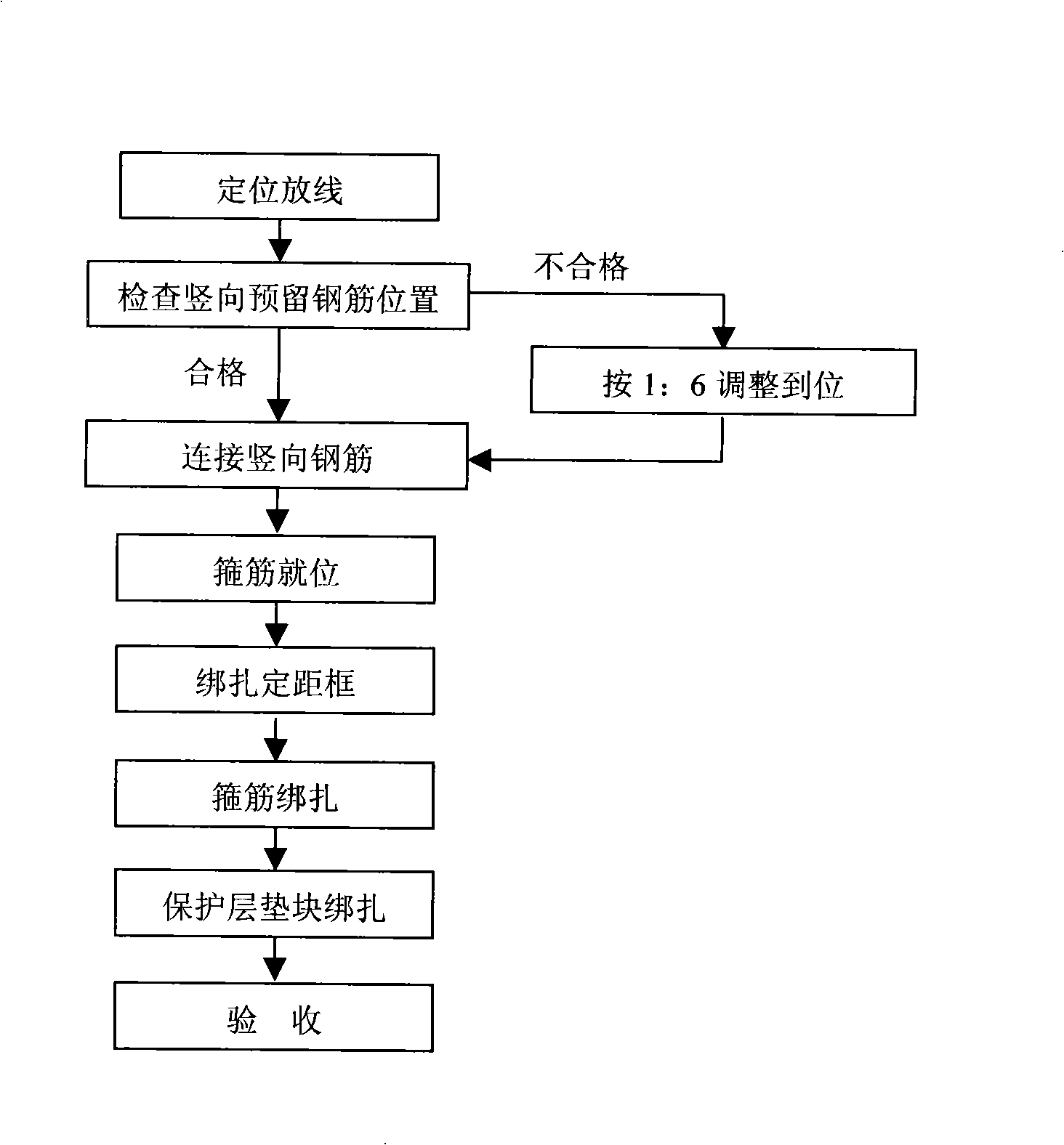

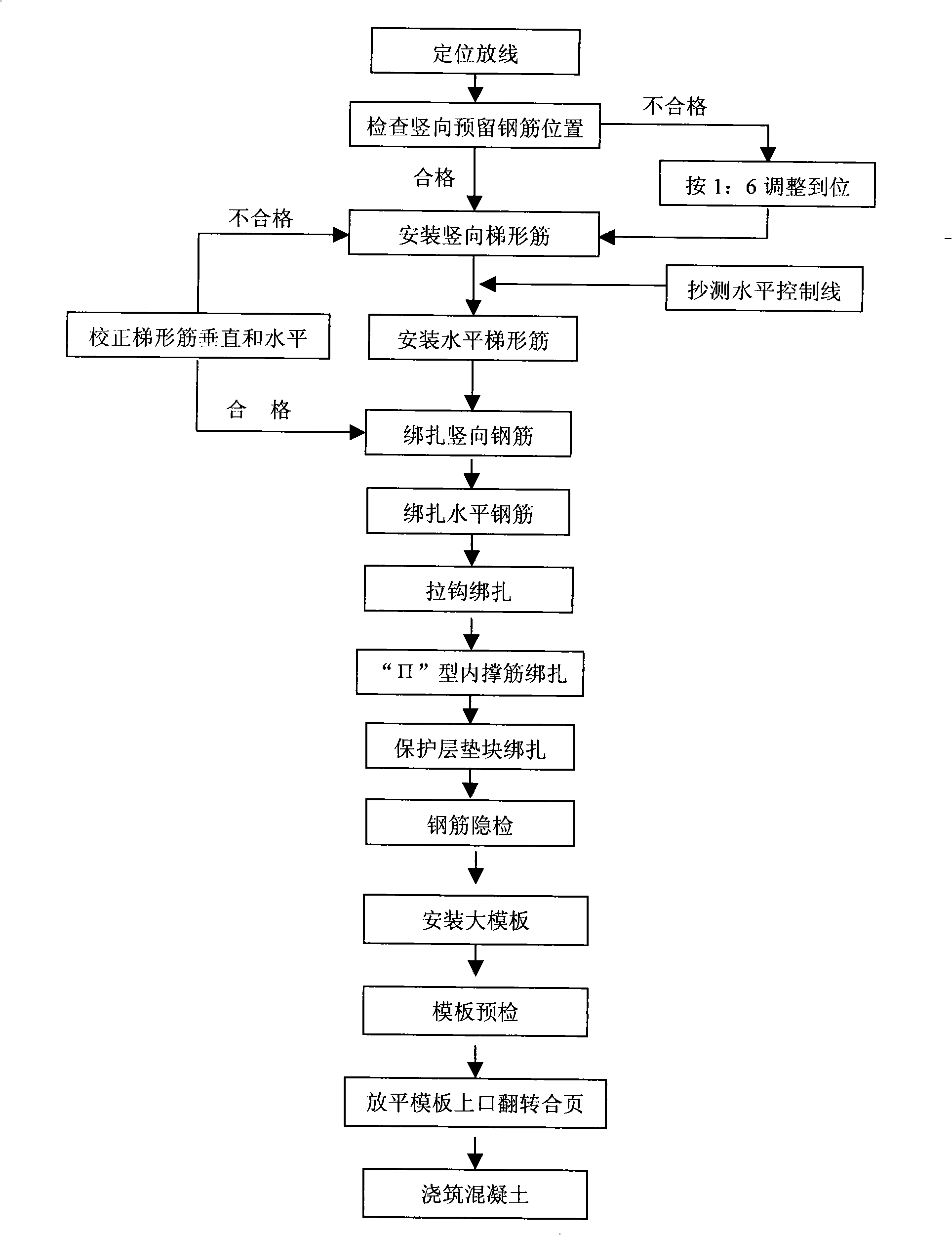

Method for binding high-layer shear force wall reinforcing steel bar

InactiveCN101353920AReduce the ratioImprove protectionBuilding reinforcementsReinforced concreteSteel bar

The invention discloses a steel bar bonding method of a shearing wall of a high-rise building, which relates to the technical filed of building engineering, in particular to the technical field of steel bar bonding in the construction of the shearing wall of the high-rise building. The method comprises ordinal steps of bonding a vertical ladder steel bar, bonding a horizontal ladder steel bar, bonding the vertical steel bars of a wall body and boding the horizontal steel bars of the wall body; the vertical ladder steel bar consists of two vertical steel bars and a plurality of horizontal steel bars; the horizontal ladder steel bar consists of two vertical steel bars and a plurality of horizontal steel bars; and the horizontal ladder steel bar is disassembled after concrete is poured. The method has easy operation and promotion, reduces the proportion of skillful workers, raises assembly speed, improves labor productivity, can effectively control the interval between the steel bars of walls and columns in reinforced concrete structure and the accuracy of the protective layer, and ensure the quality of assembly location of steel bar engineering.

Owner:JIANGSU JIANGDU CONSTR GRP

Modular fabricated composite wall, fabricated building structure system and construction method

ActiveCN110130527AImprove standardizationIncrease production capacityWallsHeat proofingCold formedStructure system

The invention provides a modular fabricated composite wall, and belongs to the technical field of buildings. The modular fabricated composite wall comprises a wall plate, two column bodies, a first beam body and a second beam body, and a frame used for mounting the wall plate in an embedding mode is defined by the first beam body and the two column bodies; first connecting parts used for being connected with another modular fabricated composite wall are arranged on the outer surfaces of the column bodies; the first connecting parts comprise two pieces of first cold forming sectional steel withopenings oppositely arranged, the first cold forming sectional steel is cold forming C-shaped sectional steel or cold forming U-shaped sectional steel, and a gap capable of accommodating the two pieces of the first cold forming sectional steel which are correspondingly perpendicularly to the first connecting parts is formed between the two pieces of the first cold forming sectional steel; and steel tubes are arranged on the outer sides of the first beam body and the second beam body, and used for being connected with other components. The invention further provides a fabricated building structure system and construction method. The modular fabricated composite wall, the fabricated building structure system and the construction method have the characteristics that the degree of modularization and standardization is high, and the connecting mode is simple and convenient.

Owner:河北比穆建筑科技有限公司

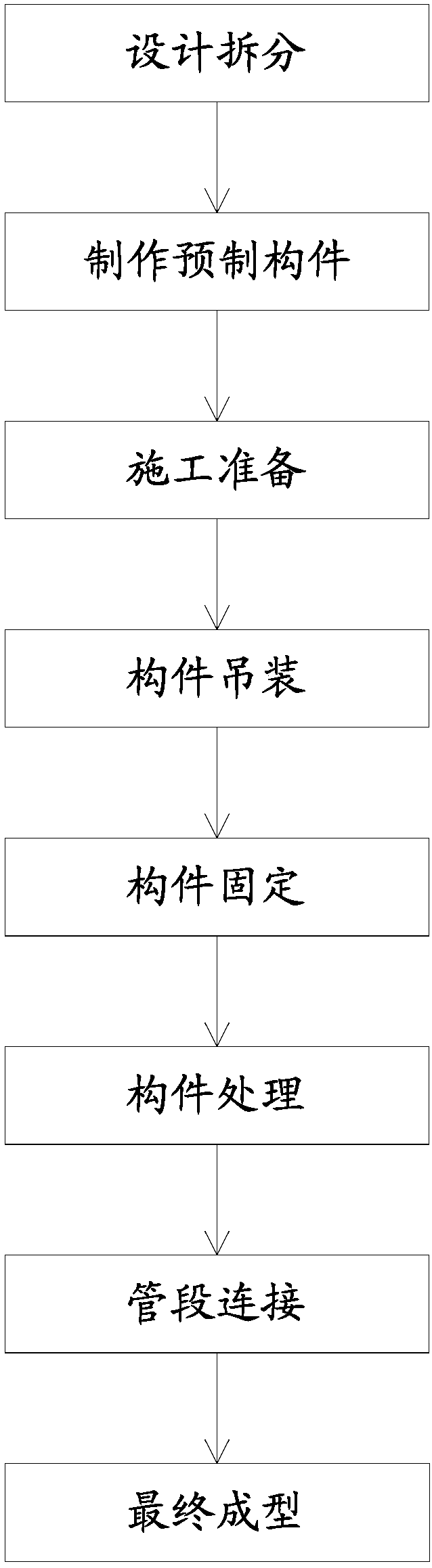

Manufacturing method for prefabricated slab assembly type comprehensive pipe rack

InactiveCN107653900AReduce manufacturing difficultyReduce the difficulty of transportationArtificial islandsCeramic shaping apparatusBuilding constructionManufacturing engineering

The invention is suitable for the field of building construction, and provides a manufacturing method for a prefabricated slab assembly type comprehensive pipe rack. The manufacturing method comprisesthe following steps of designing and dismounting, manufacturing of a prefabricated component, construction preparation, hoisting of components, fixing of components, processing of components, connecting of pipe sections and final forming. According to the manufacturing method provided by the invention, the comprehensive pipe rack is designed into a plurality of pipe sections, each pipe section isdismounted into a plurality of prefabricated slabs, each manufactured prefabricated slab is transported to a construction site, and each prefabricated slab and each pipe section are connected and subjected to waterproof treatment, so that the comprehensive pipe rack with stable up-to-standard quality is formed, and therefore, construction difficulties are reduced, and the construction period is shortened.

Owner:CHINA CONSTR SCI & TECH CO LTD

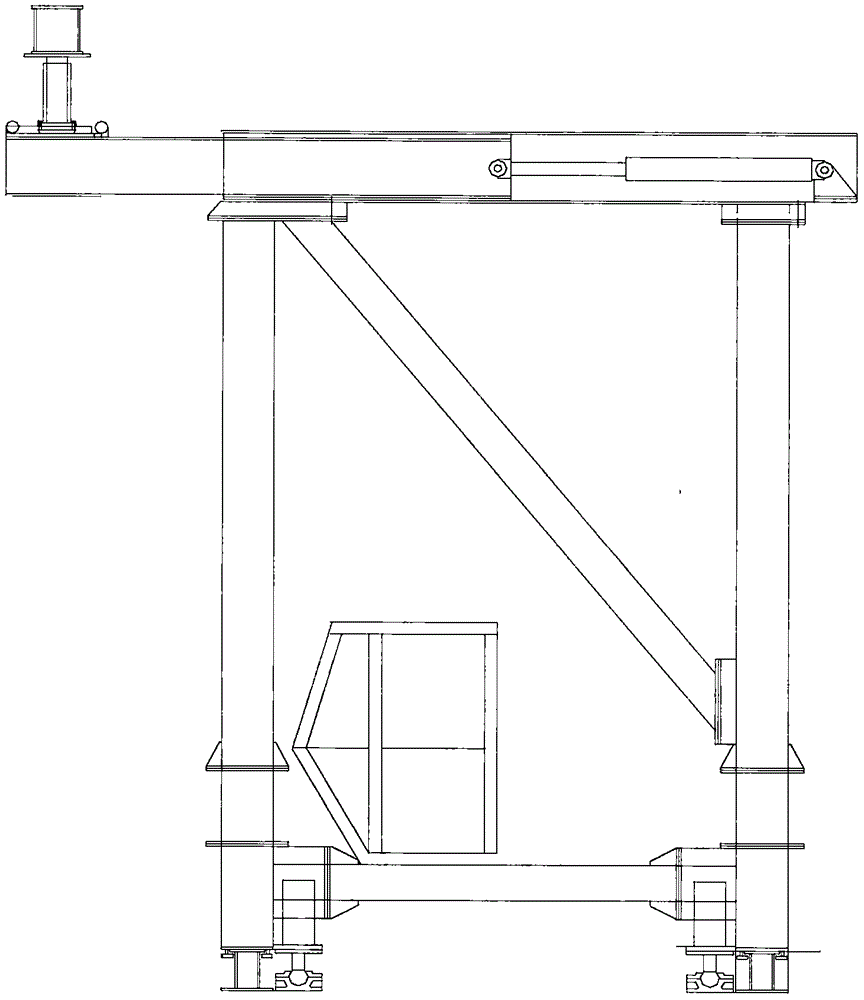

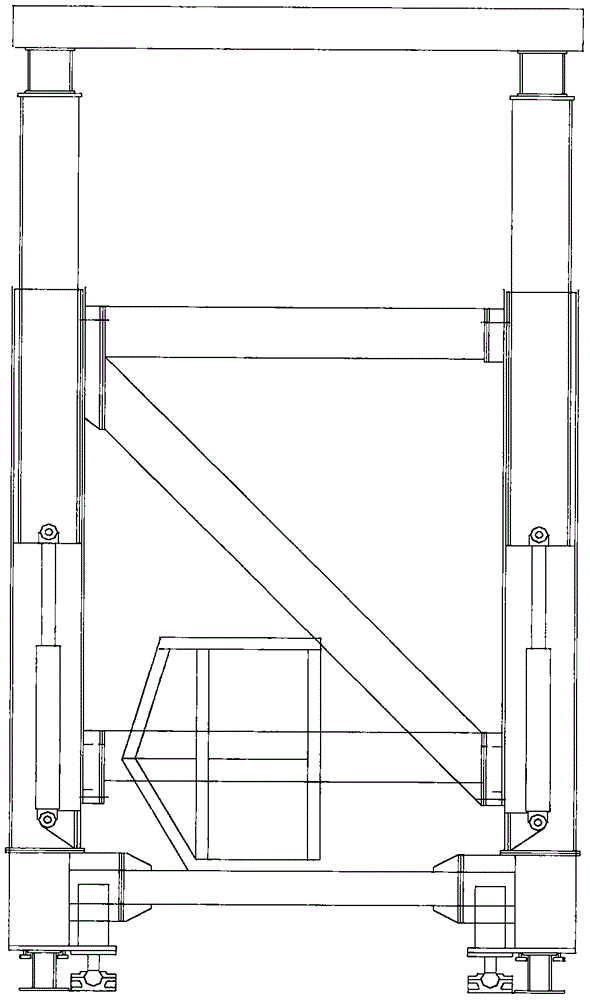

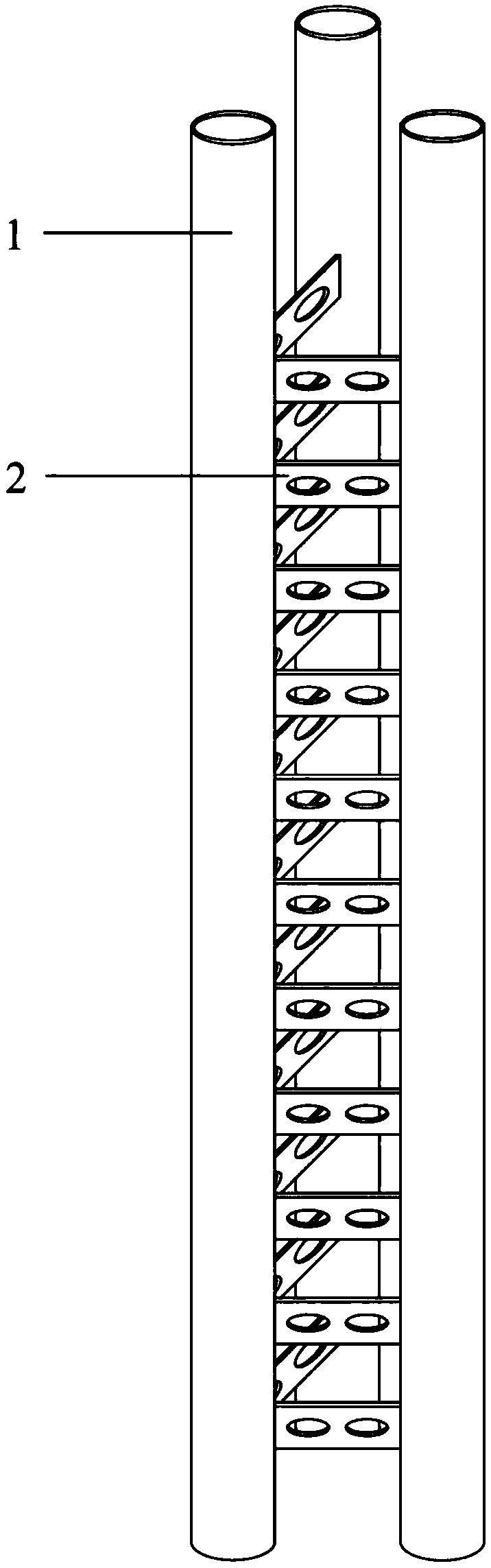

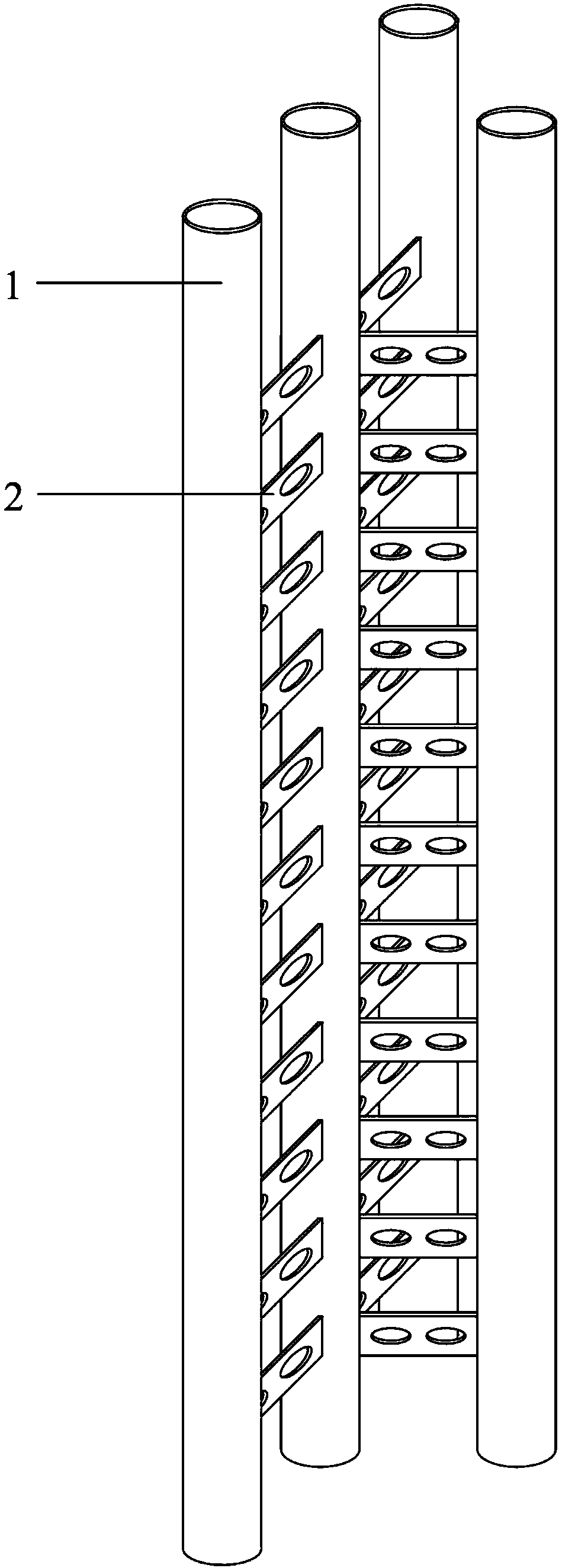

Assembled frame system with concrete filled steel tube branch limb combined special-shaped column and shock absorption wall

ActiveCN109372186AImprove seismic performanceFlexible layoutStrutsWallsEarthquake resistanceReinforced concrete

The invention discloses an assembled frame system with a concrete filled steel tube branch limb combined special-shaped column and a shock absorption wall and belongs to the field of building structure techniques and earthquake resistance and shock absorption of structures. The system primarily comprises a round concrete filled steel tube long column welded steel batten plate, and a prefabricatedcorner column, a prefabricated side column, a prefabricated middle column, a reinforced concrete beam, a steel plate wall, a prefabricated steel floorslab, a column-column connecting sleeve, a column-beam anchoring part, a middle column-beam anchoring part, a beam-plate connecting part, ECC post-cast strips and the like prepared by pouring concrete outside. Upper and lower concrete filled steel tubes are connected through the column-column connecting sleeve, and the column-beam anchoring part, the middle column-beam anchoring part and the round concrete filled steel tube long column are connected and prefabricated through dowels, so that the beam-column node connecting performance is enhanced. The ECC post-cast strips are arranged at two ends of the beam and the wall and are poured up anddown in a penetrating manner, so that the energy consumption ability and the anti-earthquake performance of the structural system are improved. The assembled frame system achieves the functions of hiding column edges and being attractive in building, a project is simple and rapid to construct, the construction efficiency is high, the nodes are connected stably and reliably, and the structural system is good in anti-earthquake performance.

Owner:BEIJING UNIV OF TECH

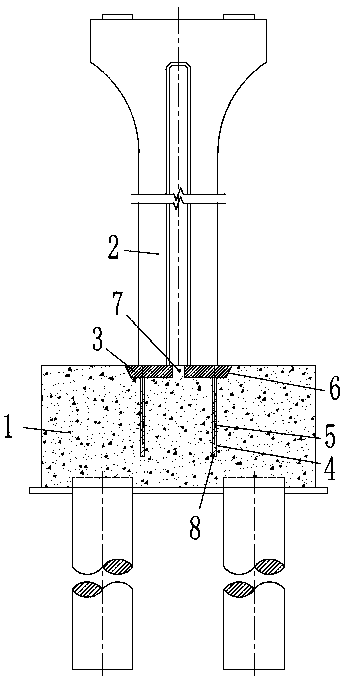

Prefabricated assembled pier column structure connected by inserting steel bars into corrugated pipes and construction method thereof

PendingCN110205921ASimple structureOn-site construction is fast and safeBridge structural detailsFoundation engineeringRebarColumn structure

The invention relates to a prefabricated assembled pier column structure connected by inserting steel bars into corrugated pipes. The prefabricated assembled pier column structure comprises a bearingplatform, wherein a groove is formed in the upper surface of the bearing platform, a supporting column used for supporting the bottom surface of the pier column is arranged inside the groove, a plurality of corrugated pipes are vertically embedded in the periphery of the supporting column inside the groove, a plurality of main steel bars at the bottom of the pier column are in one-to-one correspondence with the corrugated pipes and are inserted into the corrugated pipes, inner filling layers are arranged inside the corrugated pipes, and concrete filling layers are poured inside the groove. Theprefabricated assembled pier column structure connected by inserting steel bars into corrugated pipes is simple.

Owner:FUZHOU UNIV

Assembly type steel-concrete combined beam column frame structure system

ActiveCN106567458AImprove anti-corrosion and fire performanceSave materialBuilding constructionsConcrete beamsRebar

The invention discloses an assembly type steel-concrete combined beam column frame structure system. The assembly type steel-concrete combined beam column frame structure system comprises a steel joint, a steel-concrete combined column, a steel-concrete combined beam and a laminated slab. The steel joint comprises profile steel, a stiffening rib, a connection plate and a bolt, and a concrete protection layer is poured outside the steel joint. The steel-concrete combined column comprises a concrete column, a steel-concrete combined section, a short steel column, a rebar, a drilling device, a finish-rolled deformed bar and an anchoring nut. The steel-concrete combined beam comprises a concrete beam, a steel-concrete combined section, a short steel beam, a rebar, a drilling device, an anchoring device, a prestressed cable and a beam end connection plate. The laminated slab comprises a precast concrete slab and a cast-in-place layer. After the precast concrete slab is installed in place, the concrete cast-in-place layer is poured on the precast concrete slab. The assembly type steel-concrete combined beam column frame structure system combines the advantages of a cast-in-place concrete frame system and a steel structure frame system and has good mechanical performance, economic indicators and a very high prefabrication assembly rate which can reach 100%. Fast assembly construction is adopted, and the construction period is shortened effectively.

Owner:SHAOXING UNIVERSITY

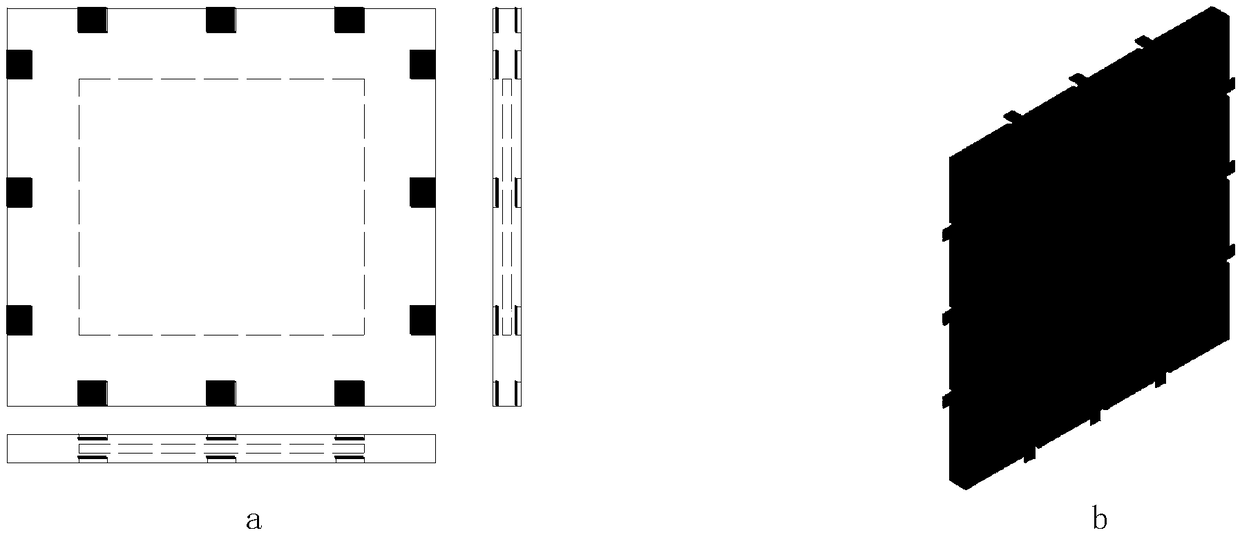

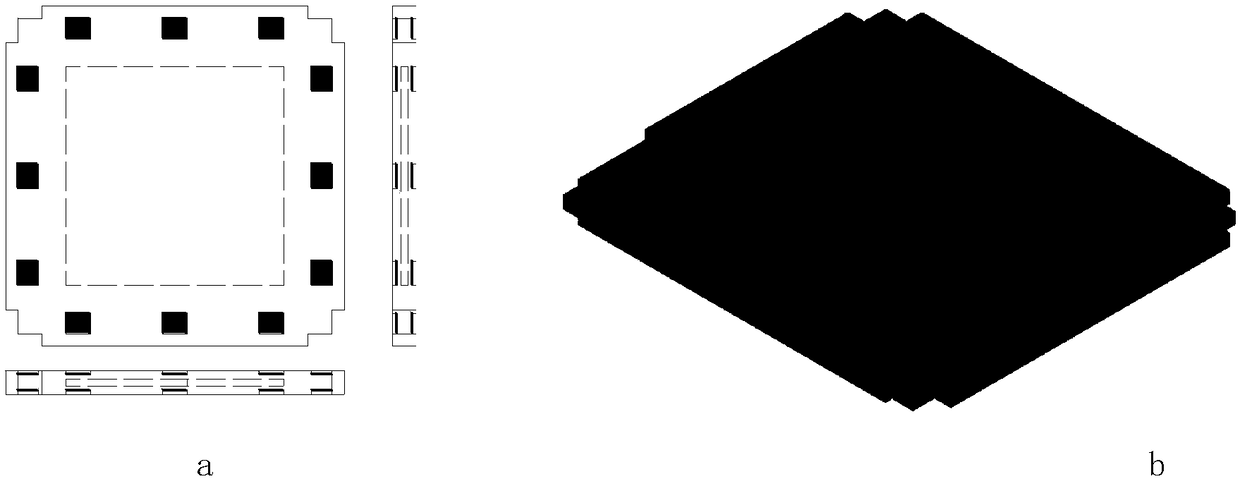

Novel energy dissipation bolt joints for low-rise fabricated wallboard structure

InactiveCN108360901AImprove ductilityGuaranteed energy consumptionProtective buildings/sheltersShock proofingFloor slabEngineering

The invention discloses novel energy dissipation bolt joints for a low-rise fabricated wallboard structure. The novel energy dissipation bolt joints for the low-rise fabricated wallboard structure comprise prefabricated wallboards, prefabricated floor slabs and prefabricated corner columns, and the prefabricated wallboards, the prefabricated floor slabs and the prefabricated corner columns are connected by the novel energy dissipation bolt joint for the low-rise fabricated wallboard structure. Grooves are formed at the edges of connection parts among the prefabricated wallboards, the prefabricated floor slabs and the prefabricated corner columns, and bolt holes are formed in the parts of the prefabricated wallboards, the prefabricated floor slabs and the prefabricated corner columns in thegrooves in a reserved mode. Arc-shaped connecting steel plates are arranged outside the grooves. Bolt holes are formed in the arc-shaped connecting steel plates. Adjacent elements are connected by means of bolt connection through the arc-shaped connecting steel plates and high-strength bolts. An energy dissipation joint with good ductility is provided, the arc-shaped connecting steel plates are selected as main energy dissipation parts, so that failure first occurs on the arc-shaped connecting steel plates, it is guaranteed that bolt connecting pieces and other parts are not damaged and surrounding concrete is not destroyed before the failure first occurs on the arc-shaped connecting steel plates, and the ductility, deformation performance and energy dissipation performance of the energydissipation bolt joints are guaranteed.

Owner:SICHUAN UNIV

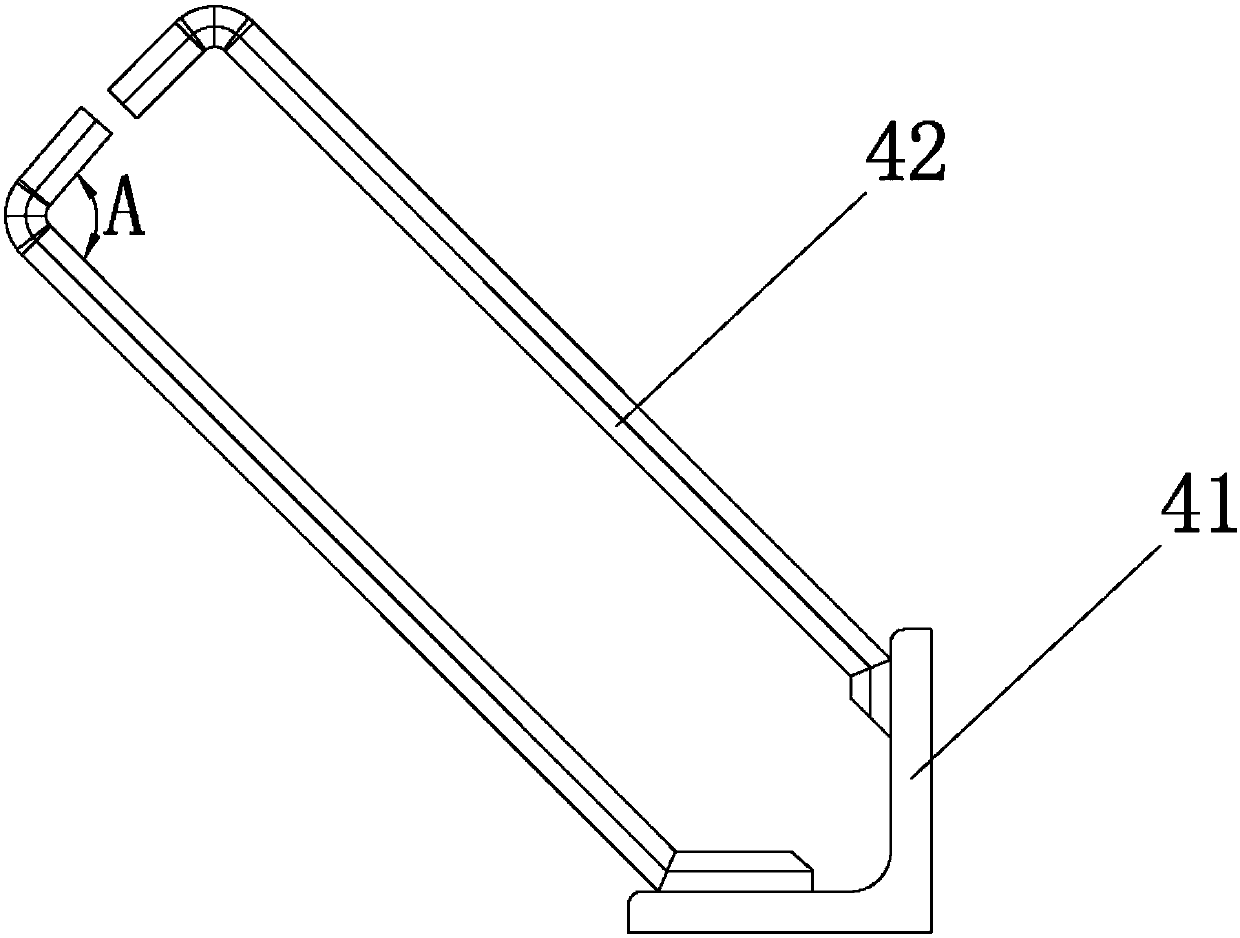

Connection structure for prefabricated integral bay window, and assembling method thereof

The invention provides a connection structure for a prefabricated integral bay window. The connection structure comprises a prefabricated integral bay window and a superposed beam and is characterizedin that the prefabricated integral bay window is integrally poured into a C-similar shape and comprises a top plate, a side wall and a bottom plate; the superposed beam comprises a prefabricated partand a cast-in-place part; the bottom surface of the bottom plate and the bottom surface of the prefabricated part are positioned on the same horizontal plane; the indoor side of the side wall is fixedly connected with the cast-in-place part through an upper connecting component; and the bottom plate is fixedly connected with the prefabricated part through a lower connecting component. When the connection structure for the prefabricated integral bay window in the scheme is produced and manufactured, no reinforcing steel bars extend out of the edge part of the prefabricated integral bay window,a production module is simple, demoulding efficiency is high, and a mould turnover frequency is improved. In a transportation stage, a loading rate can be improved; wet operations in an assembling field are few, form erection is avoided, field construction efficiency is improved, and construction cost is lowered; an error-tolerant rate of field assembling is high, the position of the prefabricated integral bay window can be regulated in field through ways, including gaskets, bolts, mortar, bed mortar and the like, and the connection structure disclosed by the invention is convenient for fieldinstallation and regulation.

Owner:CHINA MINGSHENG DRAWIN TECH INVESTMENT CO LTD

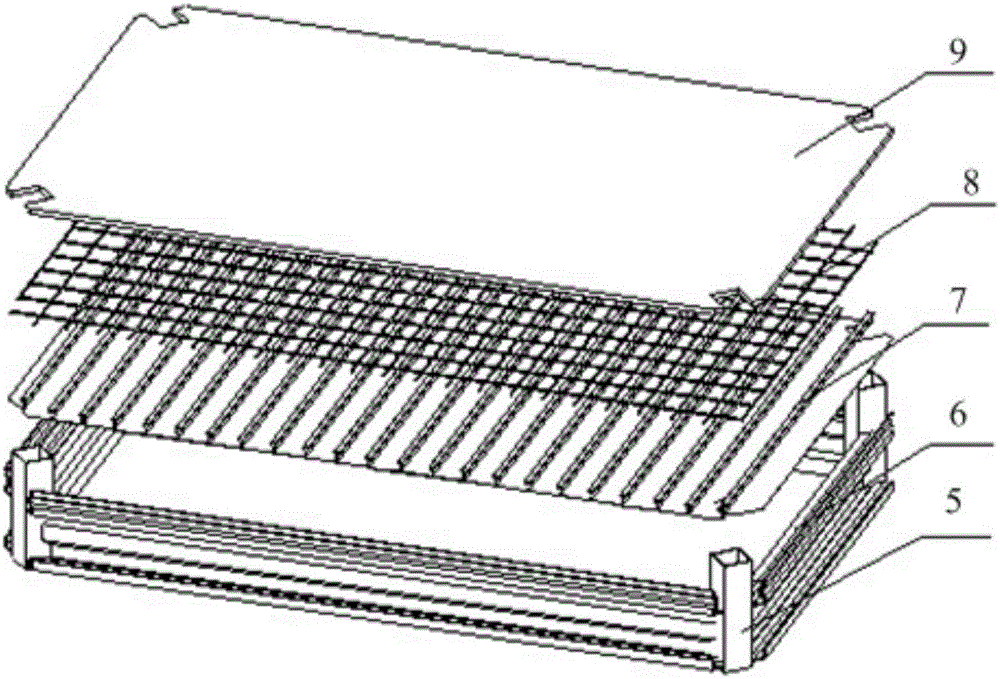

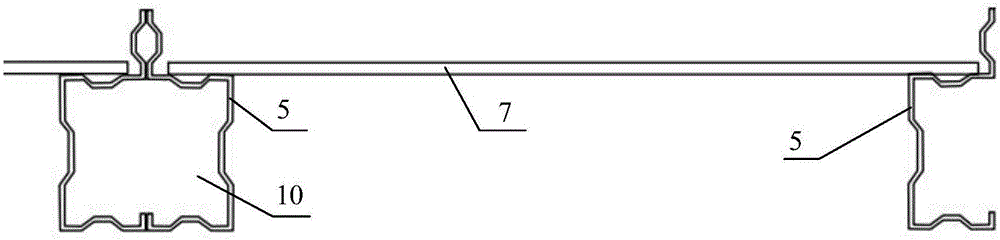

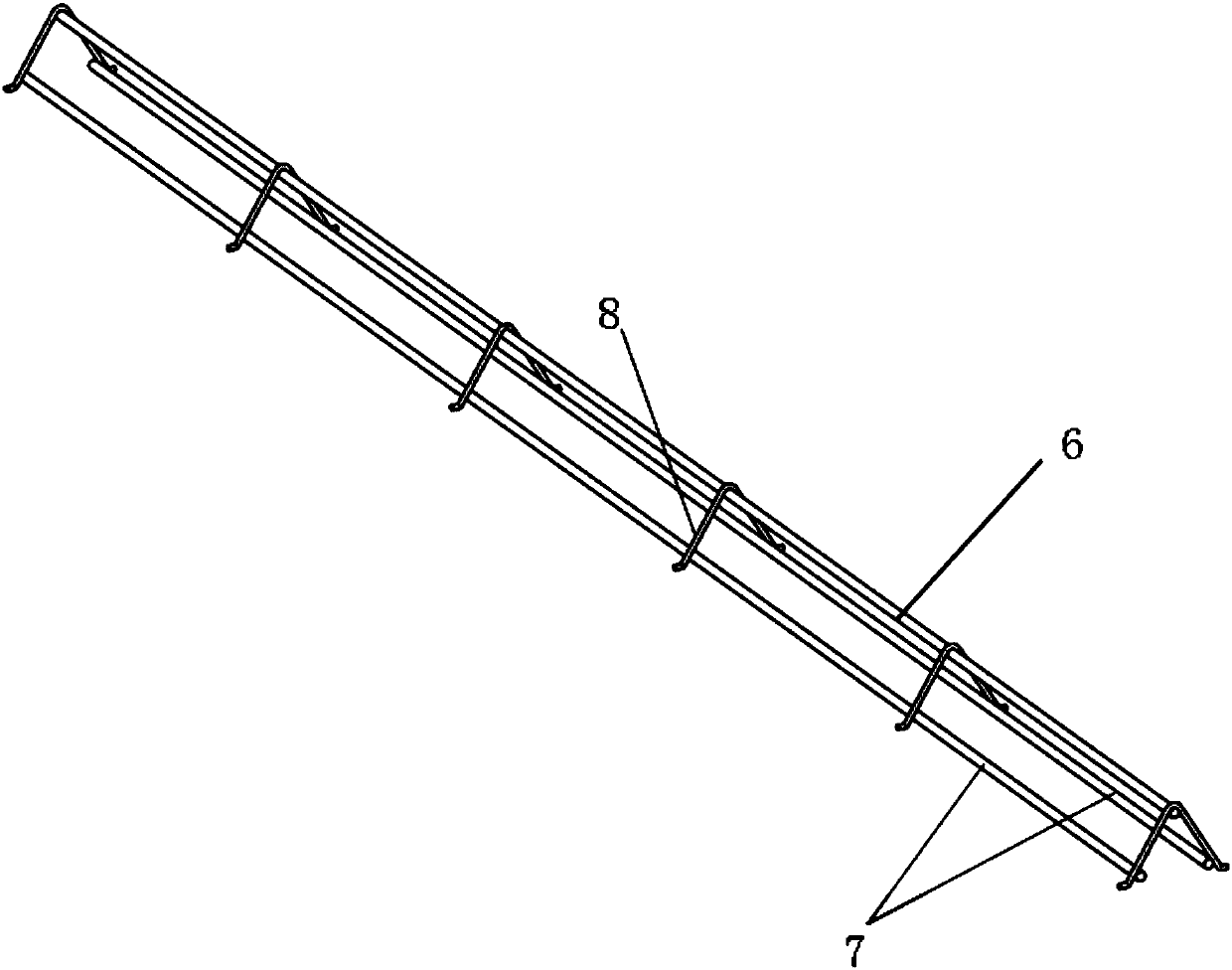

Full-prefabricated floor special for fabricated steel structure

The invention relates to a full-prefabricated floor special for a fabricated steel structure. The full-prefabricated floor is arranged on a steel beam and comprises a steel bar truss, surface bars, bottom bars, an embedded part and a prefabricated concrete layer. The steel bar truss comprises upper string steel bars, lower string steel bars and erecting bars. The upper string steel bars and the lower string steel bars are arranged in parallel and welded to the upper ends and the lower ends of the erecting bars correspondingly. The erecting bars are arranged at equal intervals, and the surfacebars and the upper string steel bars of the steel bar truss are bound together. The bottom bars and the lower string steel bars of the steel bar truss are bound together, and the steel bar truss, thesurface bars, the bottom bars and the embedded part are pre-embedded in the prefabricated concrete layer. The embedded part is connected with the steel beam. According to the full-prefabricated floor,through effective connection with a steel structure main body, the structural integrality and shock resistance are improved, meanwhile, only a joint laminated layer needs to be cast in situ, and thefabricated efficiency is greatly improved, so that the full-prefabricated floor can play a significant role in the fabricated steel structure field.

Owner:ZHEJIANG GREEN BUILDING INTEGRATION TECH CO LTD

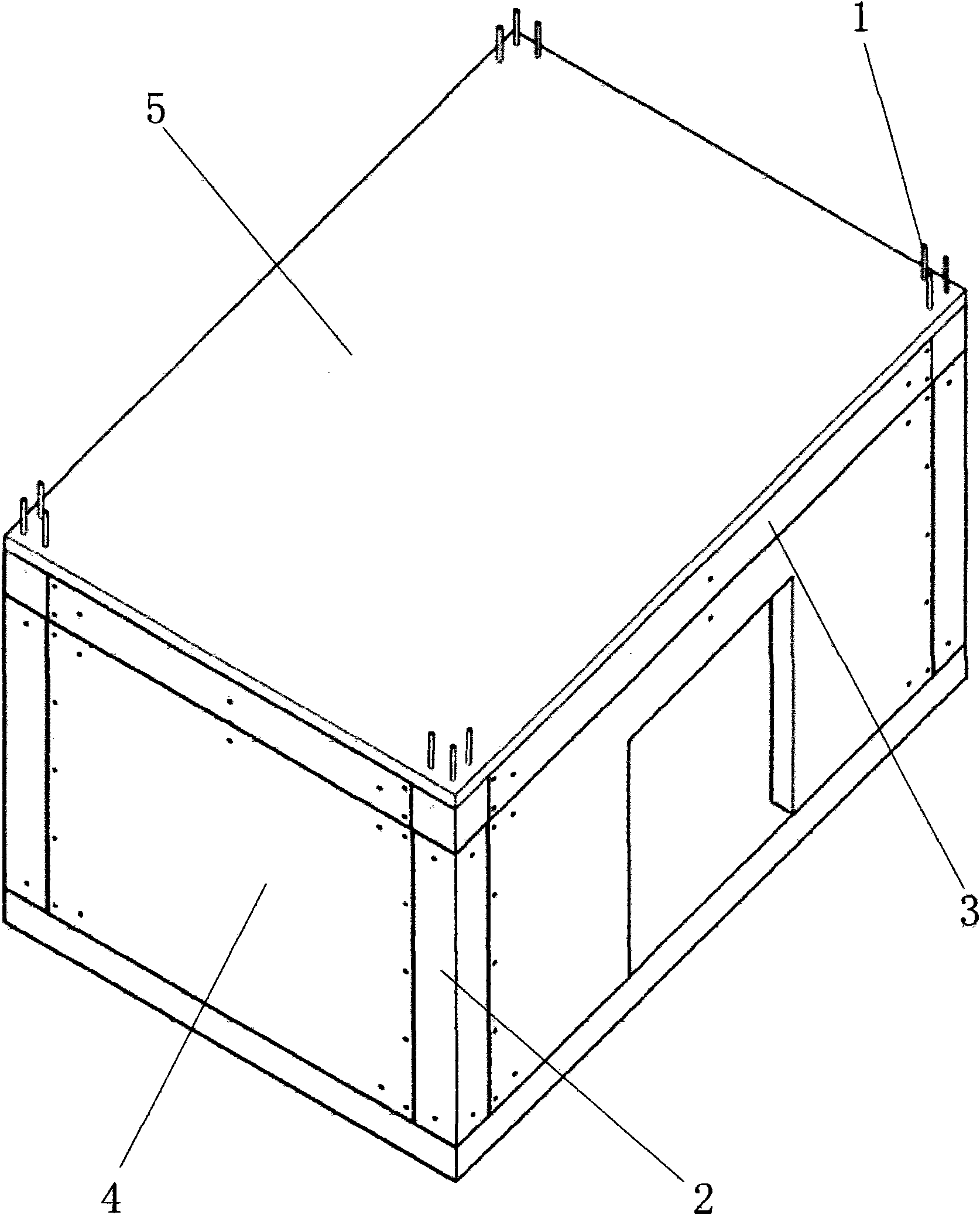

Assembled type steel frame concrete box type unit structure system and construction method thereof

ActiveCN107060104AFast constructionImprove the level of assemblyBuilding reinforcementsMortise and tenonSteel frame

The invention discloses an assembled type steel frame concrete box type unit structure system and a construction method thereof. The structure system comprises a foundation and an overground structure connected with the foundation; the overground structure comprises at least an upper-layer structure and a lower-layer structure which are vertically spliced through a steel frame; the steel frame is a groove-type horizontal steel frame which is preset on the spliced position of upper-layer and lower-layer wall face components and is embedded along the inner side of the bottom of the upper-layer wall face component in a through mode; a bottom vertical throwing rib of the upper-layer wall face component penetrates through the steel frame to be fastened through an upper flange plate sleeve; and a top vertical throwing rib of the lower-layer wall face component penetrates through the steel frame to be fastened through a lower flange plate sleeve. Box-type structure units of each layer of structure are connected into a whole in a mortise-tenon joint mode. The construction method of the structure system comprises the steps of designing and prefabricating of the box-type structure units, conveying of the box-type structure units to a site to be connected with a cast-in-situ part, connection between the box-type structure units, and the like. The assembly level of a building structure is improved, detachable connection is achieved, the construction speed is increased, and the wet construction on the site is reduced.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

Installation technology of connecting board type inner separation wall

InactiveCN102777042AImprove stabilityImprove labor efficiencyWallsBuilding material handlingStructural engineeringEngineering

The invention discloses an installation technology of a connecting board type inner separation wall. The installation technology comprises the following steps of: locating, despoiling, installing vertical metal supporting columns, installing horizontal metal supporting columns, installing wallboards in lower installation spaces and installing connecting boards with the height being lower than that of the wall boards in upper installation spaces. According to the installation technology disclosed by the invention, the space between beam boards and floor boards are separated into multiple lower installation spaces and multiple upper installation spaces through horizontal metal supporting beams and vertical metal supporting beams, the wall boards are arranged in the lower installation spaces, the connecting boards are arranged in the upper installation spaces, thus the labor efficiency is greatly increased, and the firm performance of a wall body is enhanced.

Owner:中山建华墙体材料有限公司

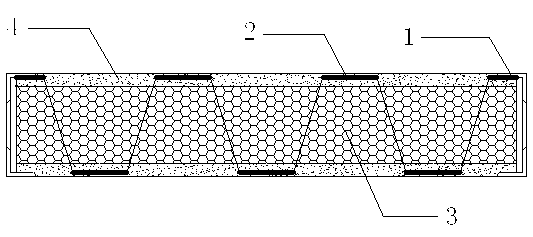

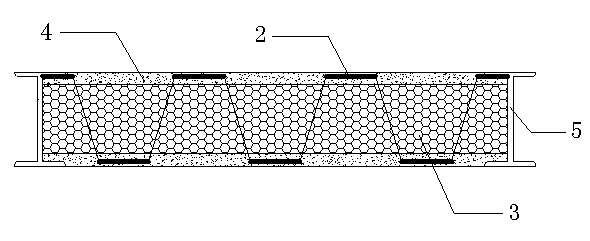

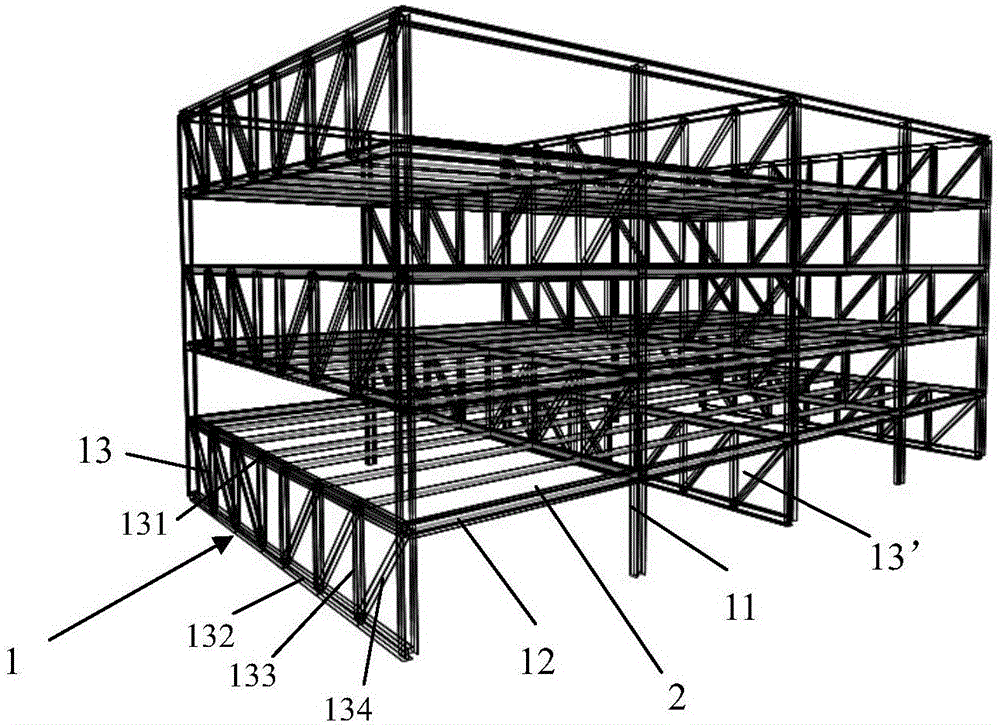

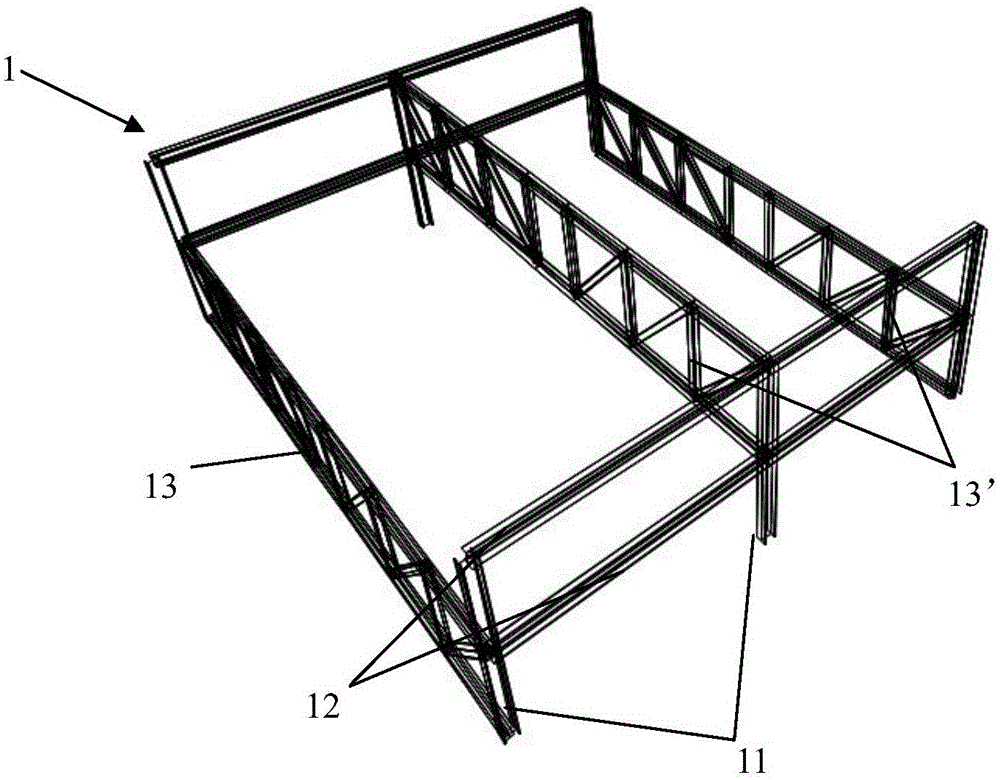

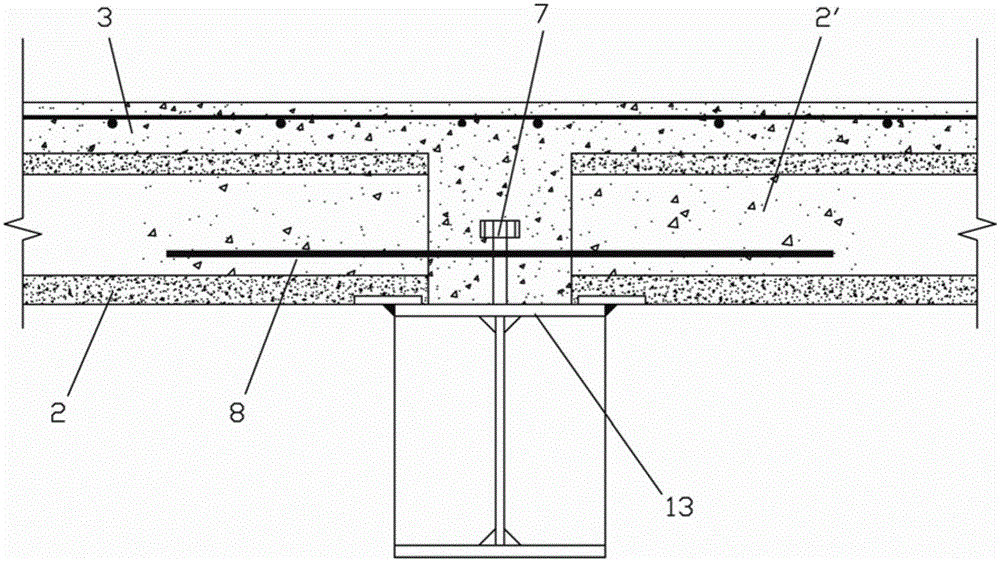

Large-span, secondary-beam-free and high-assembly industrialized steel structure system

A large-span, secondary-beam-free and high-assembly industrialized steel structure system comprises a staggered steel structure truss, a plurality of prefabricated large-span prestressed hollow slabs and concrete composite layer, wherein the staggered steel structure truss adopts a multilayer structure with at least double spans, and comprises framework columns, framework beams and plane trusses; the framework columns and the framework beams are vertically arranged at the periphery of the staggered steel structure truss to form a framework structure; the plane trusses are arranged in an upper-and-lower staggered manner in the height direction of the framework columns, and the plane trusses on the adjacent framework columns are arranged in an upper-and-lower staggered manner; the two ends of each plane truss are supported on the framework columns on the two sides; each plane truss is formed by connecting upper chords, lower chords, straight web members and diagonal web members; the prefabricated large-span prestressed hollow slabs are arranged on the staggered steel structure truss; one ends of the prestressed hollow slabs are supported on the upper chords of the plane trusses, and the other ends of the prestressed hollow slabs are supported on the lower chords of the adjacent plane trusses; the concrete composite layers are paved on the prefabricated large-span prestressed hollow slabs. The large-span, secondary-beam-free and high-assembly industrialized steel structure system is economical in steel consumption, standard in element production, convenient and fast to construct, and convenient for industrialized production.

Owner:ZHEJIANG GREEN BUILDING INTEGRATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com