Patents

Literature

4538results about How to "Improve labor efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

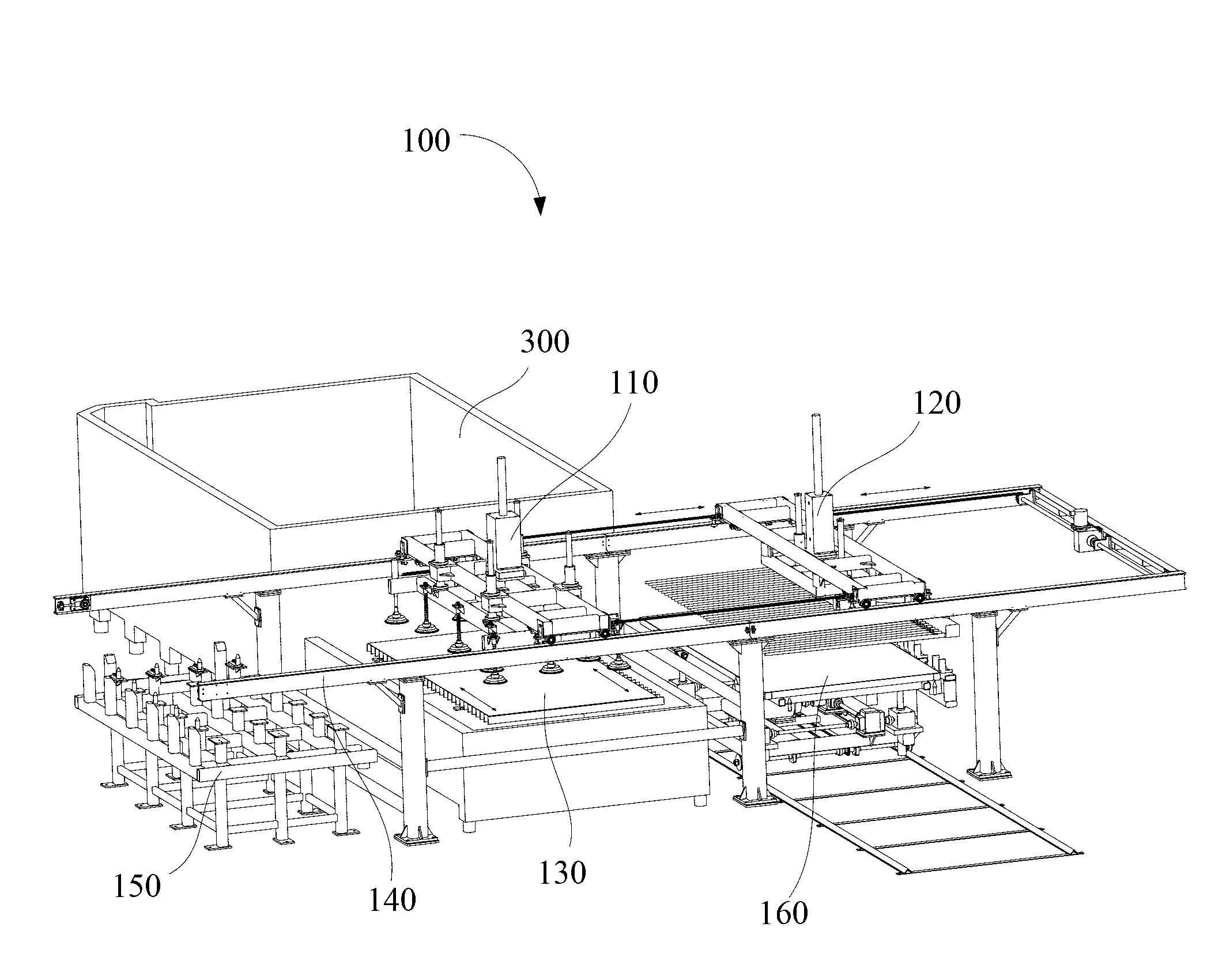

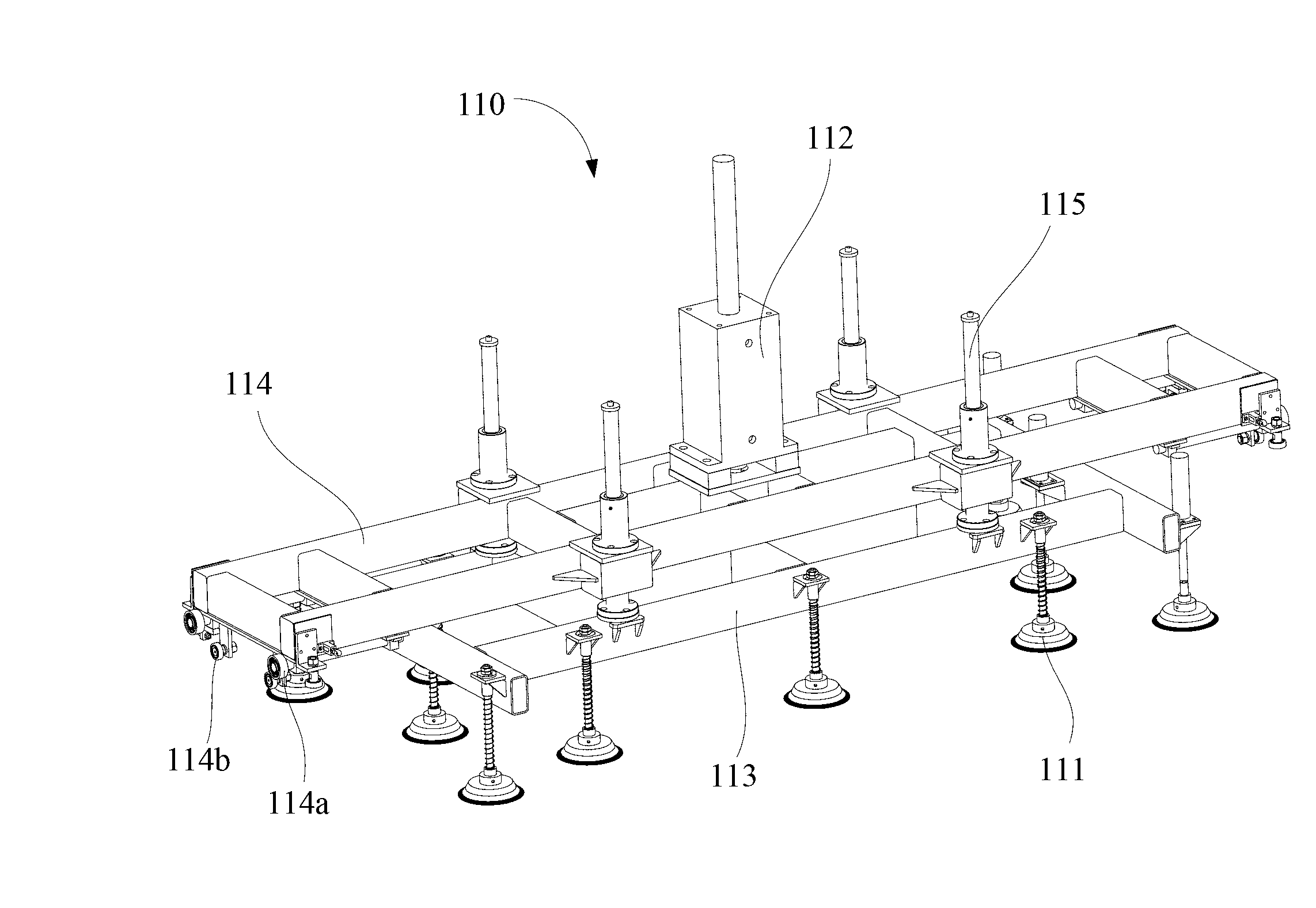

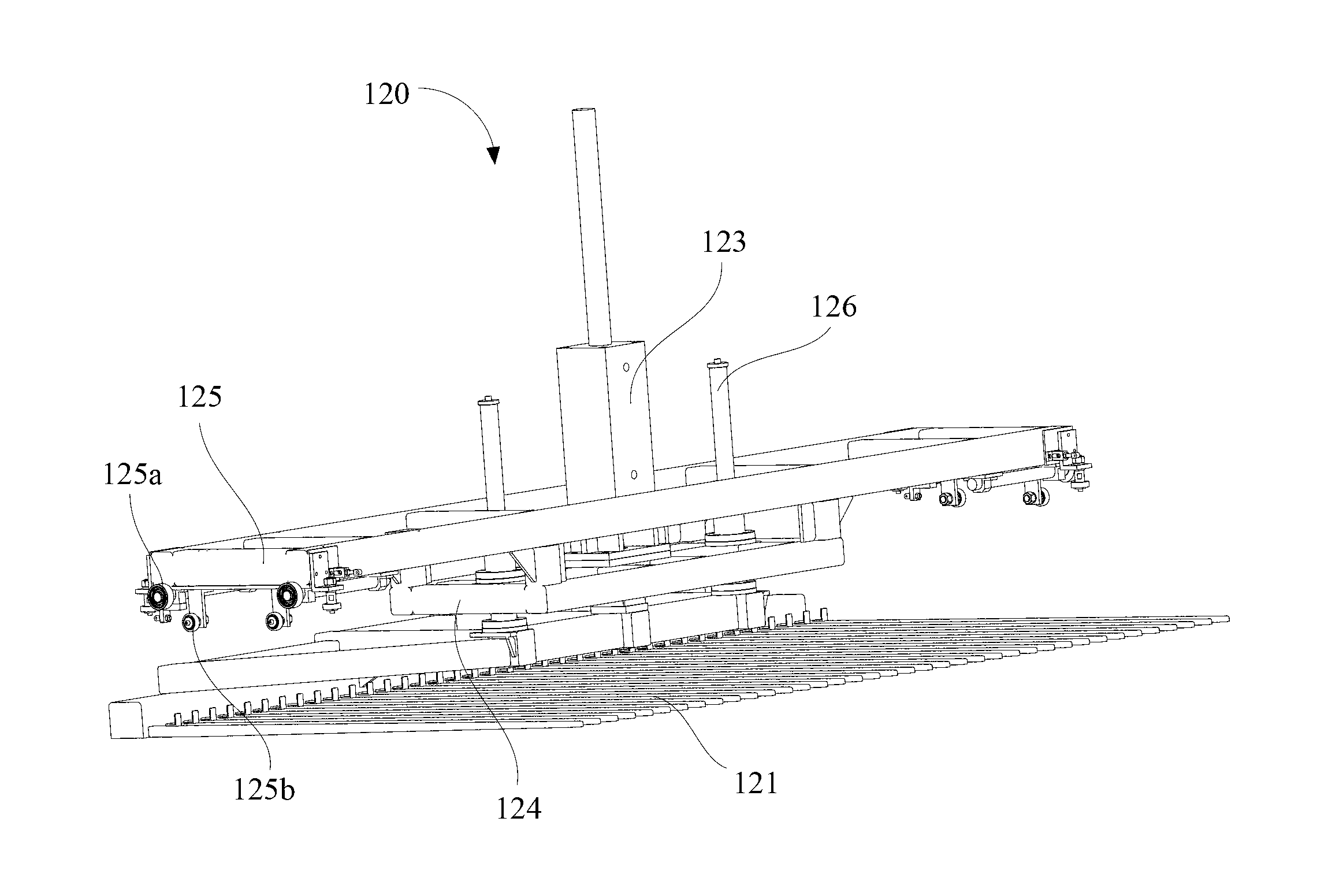

Laser cutter standalone automatic feeding and discharging device and laser cutter standalone automatic feeding and discharging method

ActiveCN103056532AReduce the burden onMake full use of the floor spaceLaser beam welding apparatusEngineeringMechanical engineering

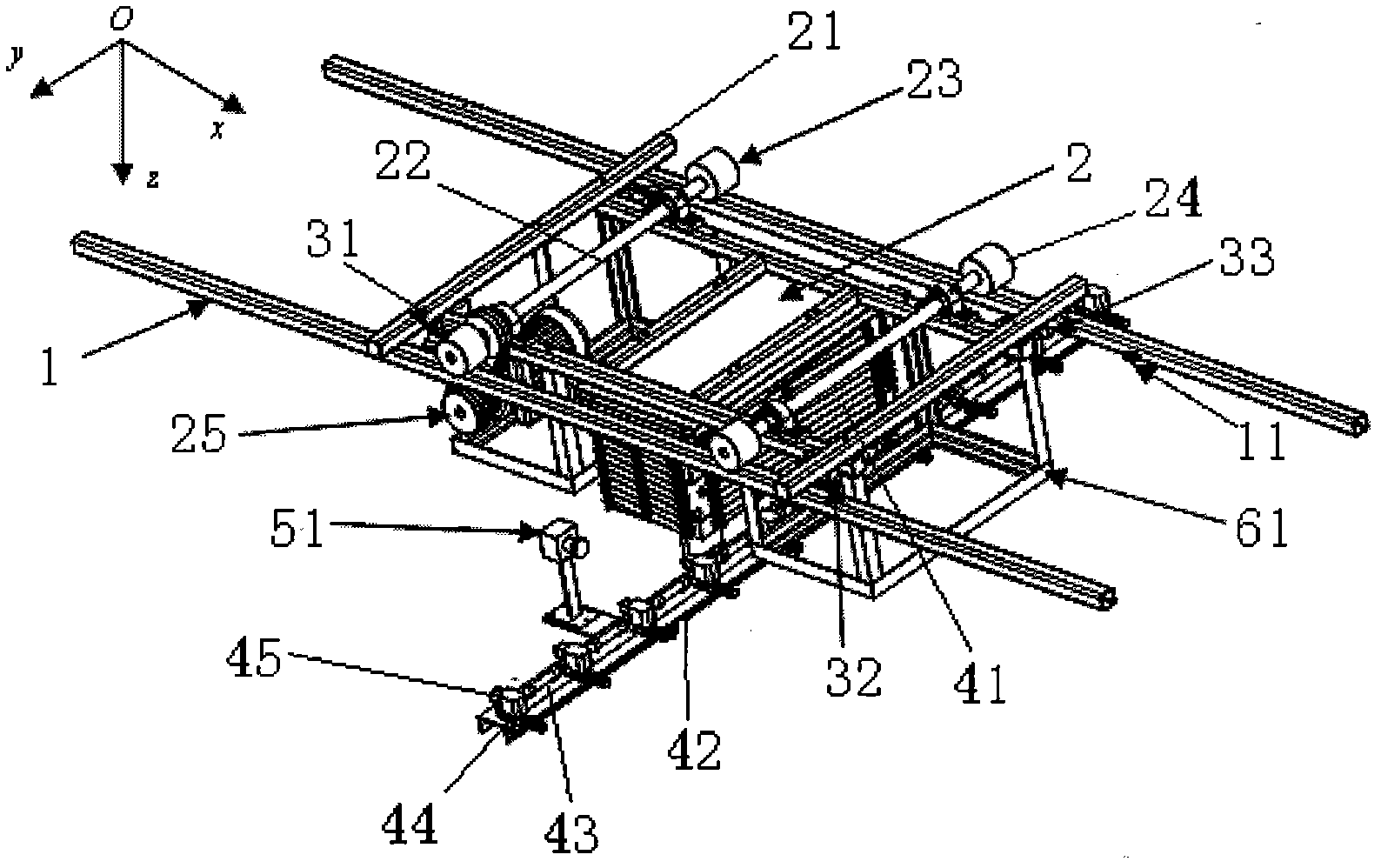

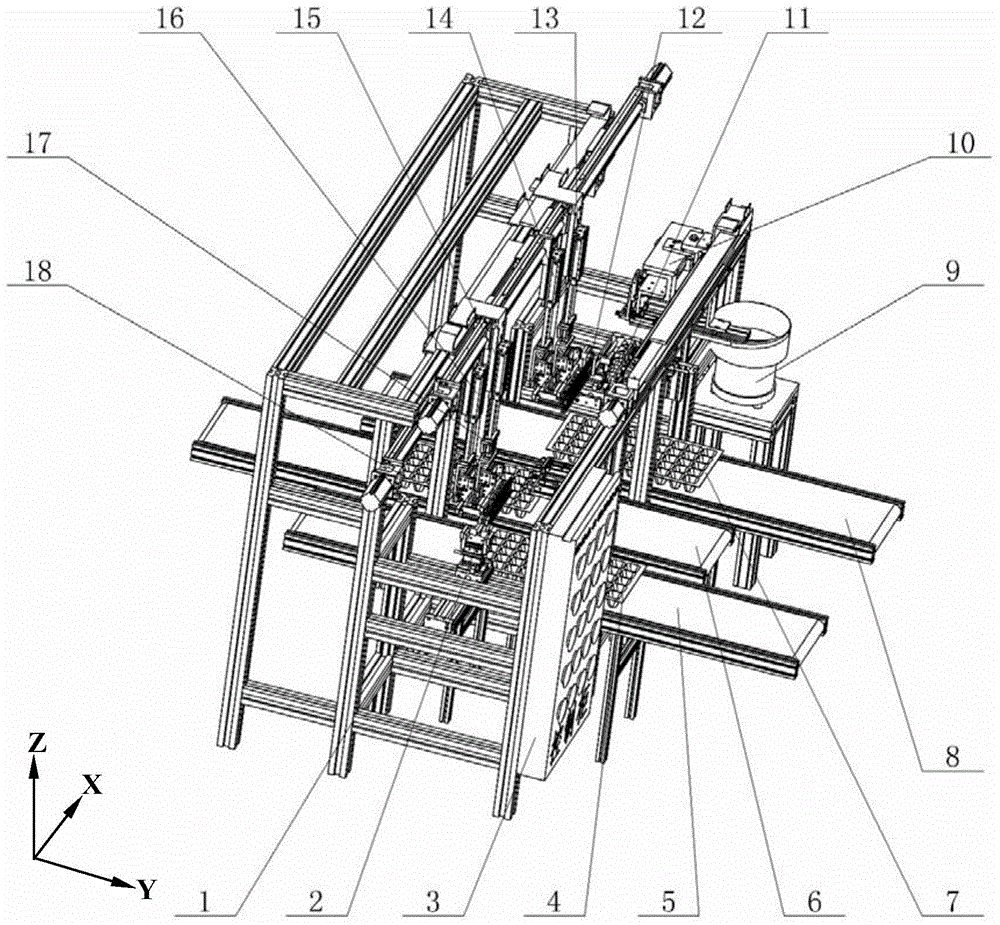

A laser cutter standalone automatic feeding and discharging device comprises a rack mechanism, a suction device, a forking device and a laser cutter workbench arranged below the rack mechanism. The suction device and the forking device are arranged on the rack mechanism, the suction device comprises multiple vacuum suckers and a first air cylinder, the multiple vacuum suckers generate vacuum through airways to realize adsorption of cutting workpieces, the forking device comprises multiple forking teeth through which the cutting workpieces are forked up and put down, the suction device and the forking device can move to be above the laser cutter workbench along the rack mechanism, and the suction device, the forking device and the laser cutter workbench are in vertical or horizontal arrangement. The laser cutter standalone automatic feeding and discharging device can realize a method for standalone automatic feeding and discharging by rationally choosing from the vertical arrangement mode and the horizontal arrangement mode; and by the vertical arrangement mode, a discharging portion can be demounted, and operations of automatic feeding can be realized independently. The invention further provides a laser cutter standalone automatic feeding and discharging method.

Owner:SHENZHEN HANS MP LASER TECH CO LTD

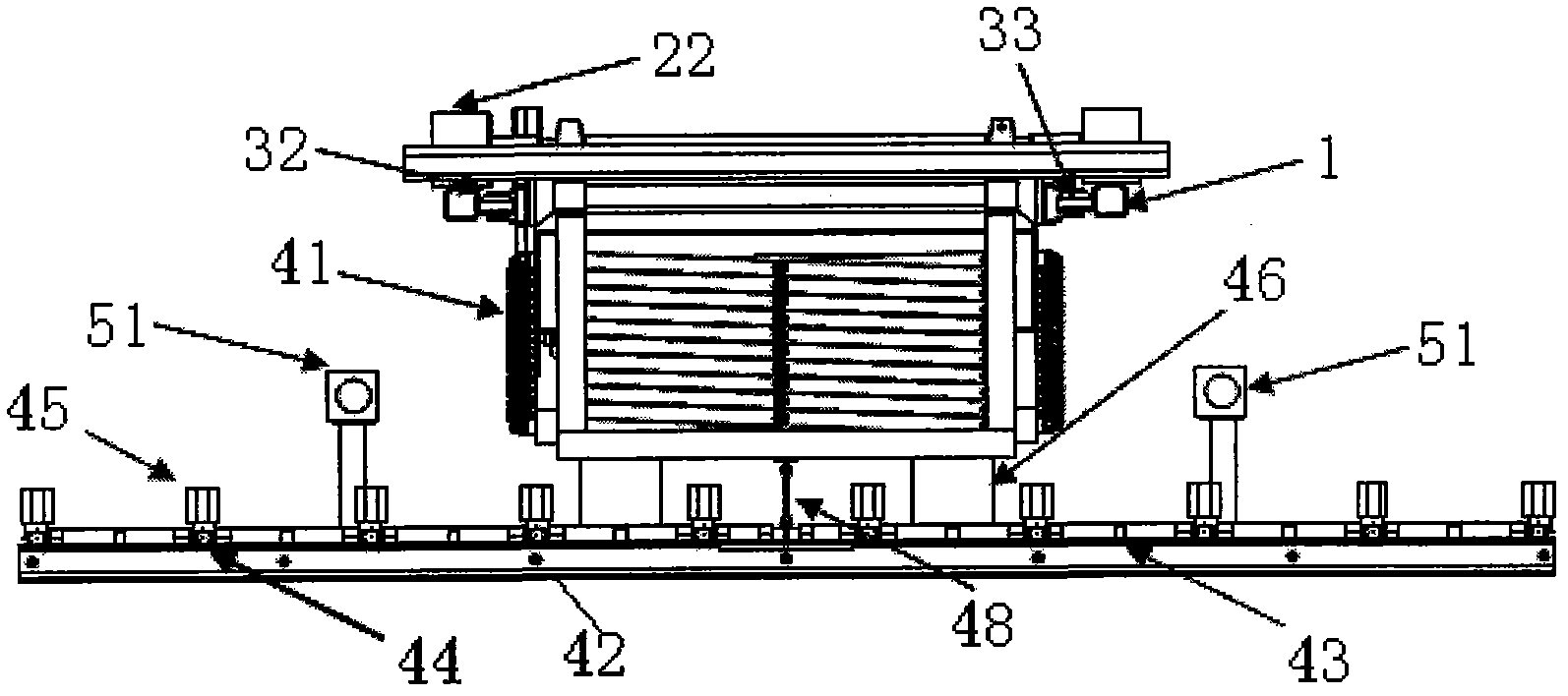

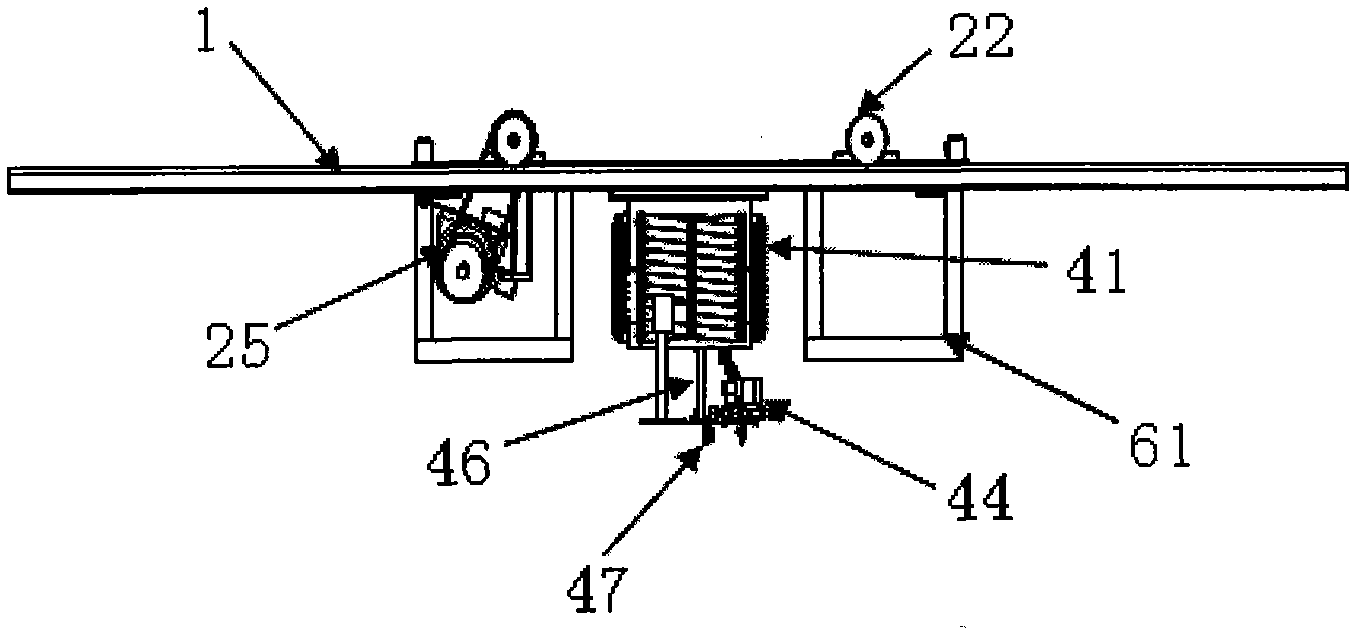

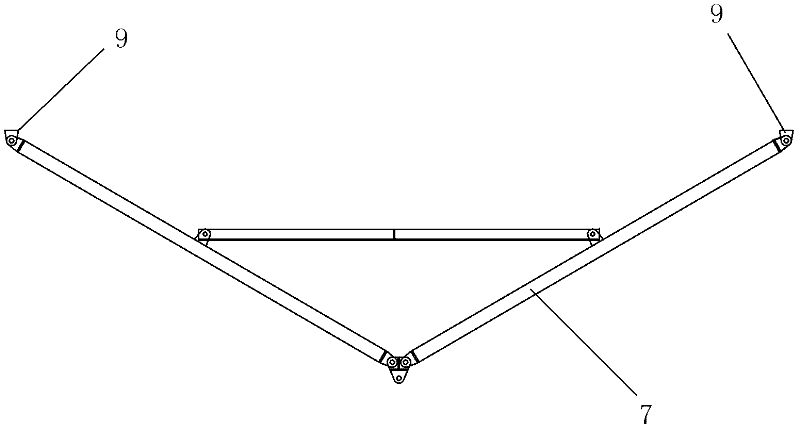

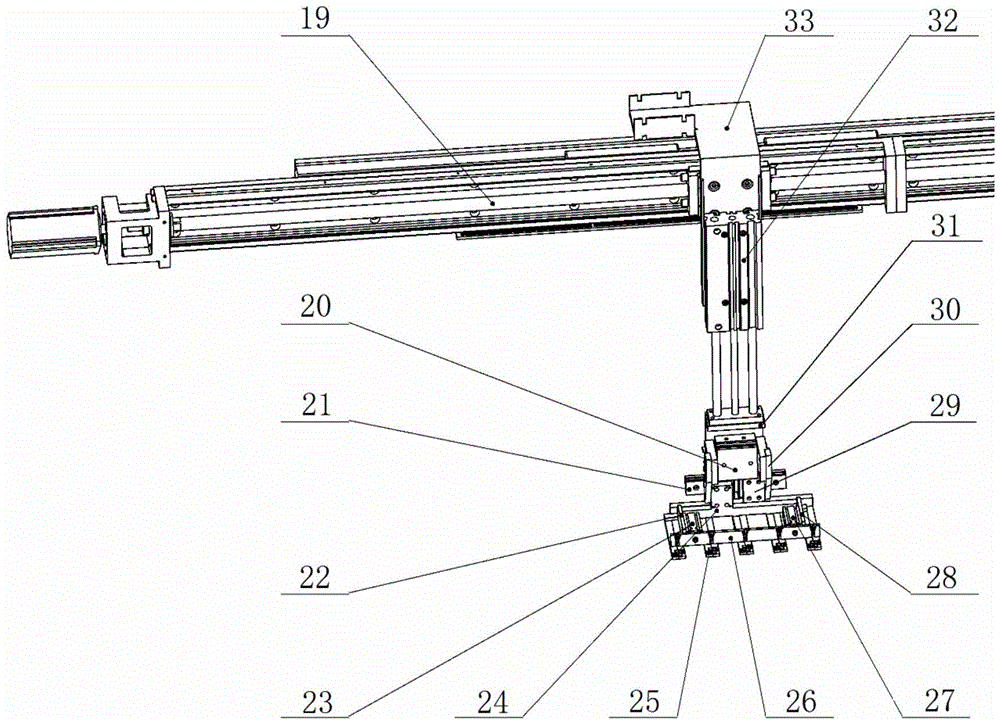

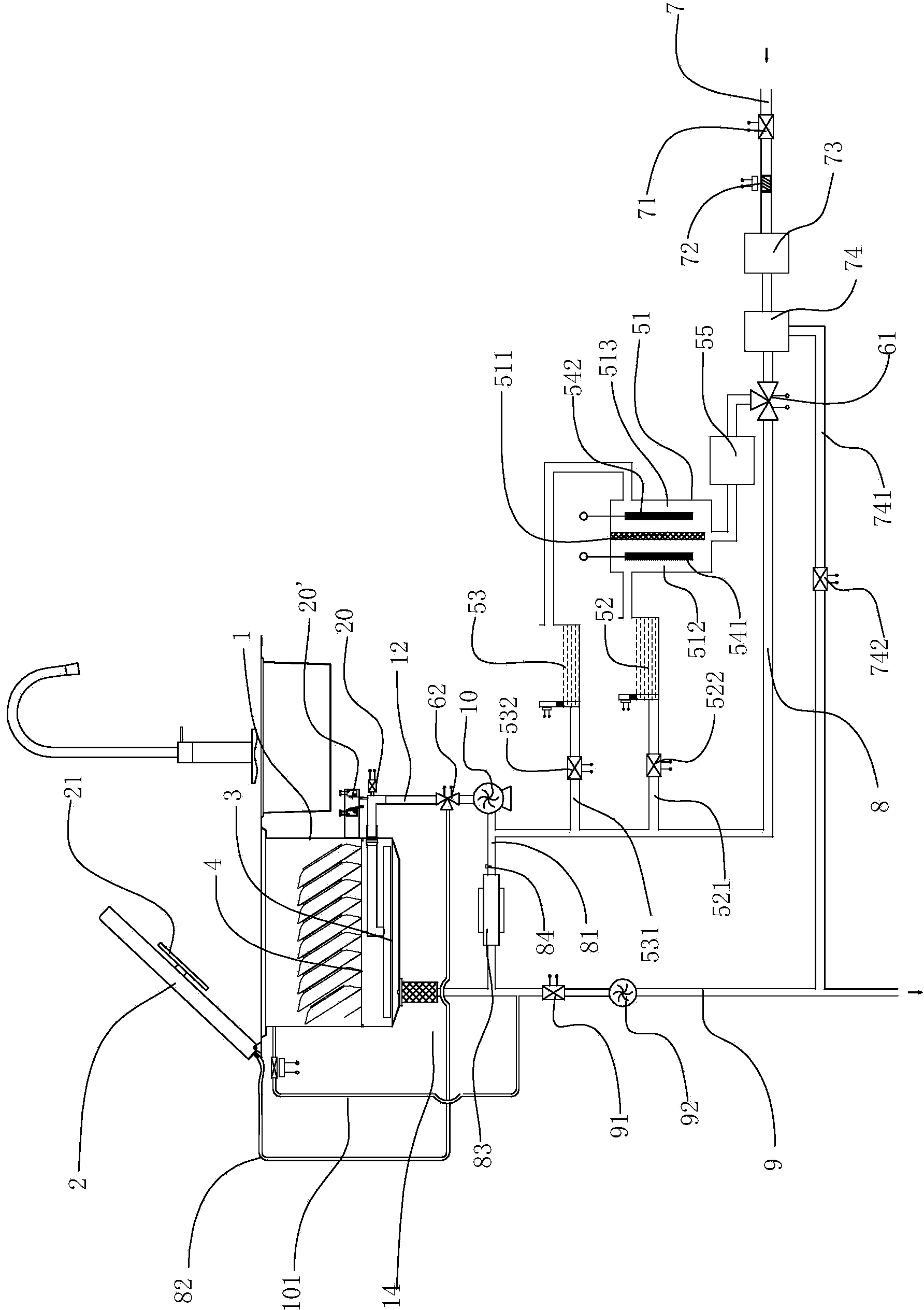

Greenhouse suspended self-propelled target-oriented sprayer system and operation method thereof

InactiveCN102017938AAvoid bodily harmImprove labor efficiencySpraying apparatusInsect catchers and killersSprayerEngineering

The invention relates to a greenhouse suspended self-propelled target-oriented sprayer system and an operation method thereof. The greenhouse suspended self-propelled target-oriented sprayer system is characterized by comprising a guide way, a self-propelled mobile platform, a hall sensor, a spraying manipulator device, a binocular vision system and a PLC (Programmable Logic Controller), wherein a plurality of magnetic positioning marks are preinstalled on the guide way; the self-propelled mobile platform is arranged on the guide way through a walking mechanism and provided with the hall sensor; the spraying manipulator device comprises a Z direction cross-shear hanger which is arranged on a rack; a spray rod is horizontally arranged below the hanger through a rotary positioning mechanism; a spray pipe is fixedly arranged on the spray rod; a plurality of spray heads are arranged on the spray pipe at intervals and independently controlled by electromagnetic valves; the hanger has the functions of extension and retraction; the binocular vision system comprises two CCD (Charge-Coupled Device) video cameras; the two CCD video cameras are fixedly installed on both ends of the spray rod respectively and connected with an upper computer in which control software is prearranged; and the PLC is electrically connected with the upper computer, the hall sensor, a frequency converter, a drive controller, the electromagnetic valves and the CCD video cameras respectively.

Owner:CHINA AGRI UNIV

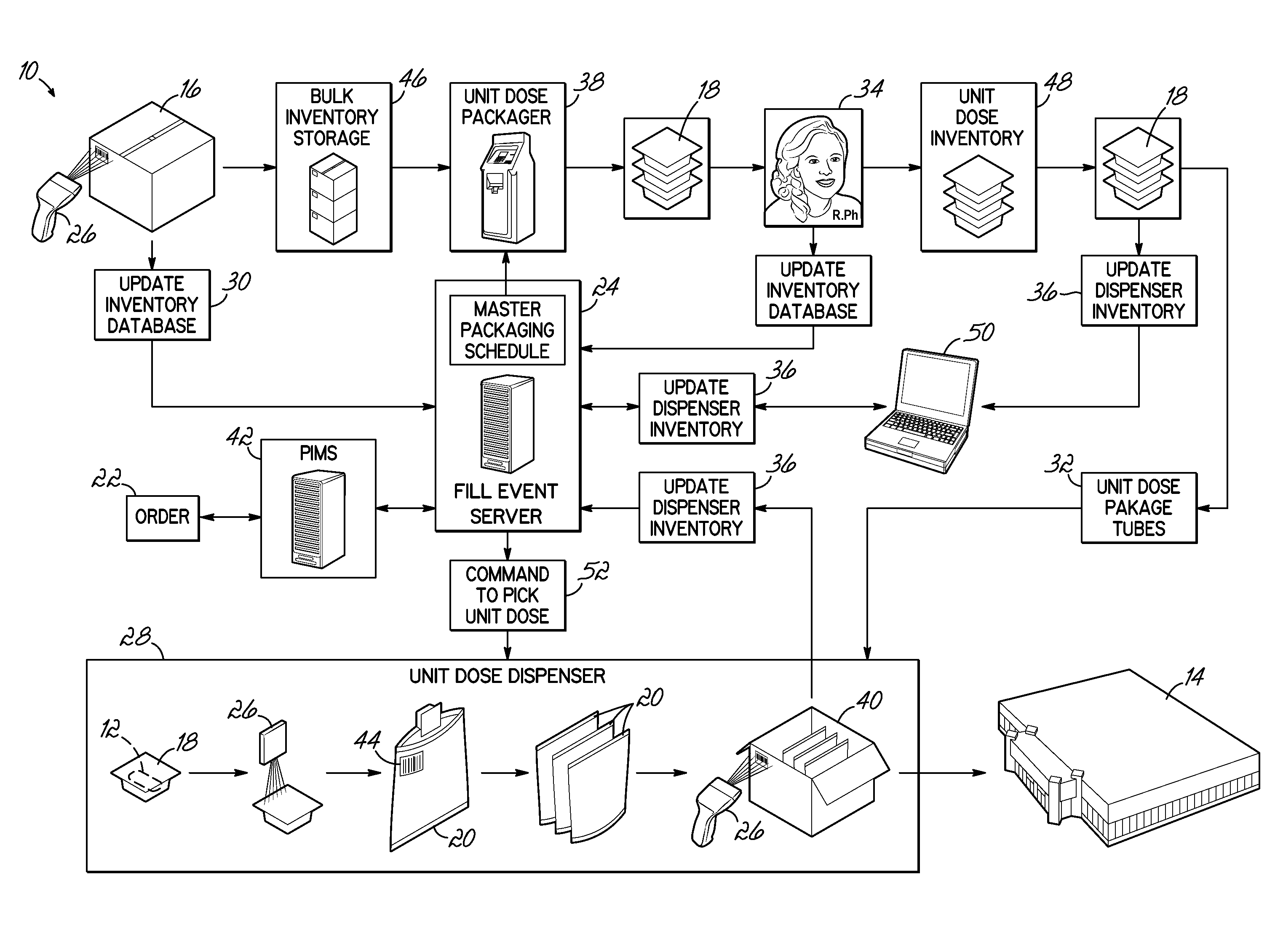

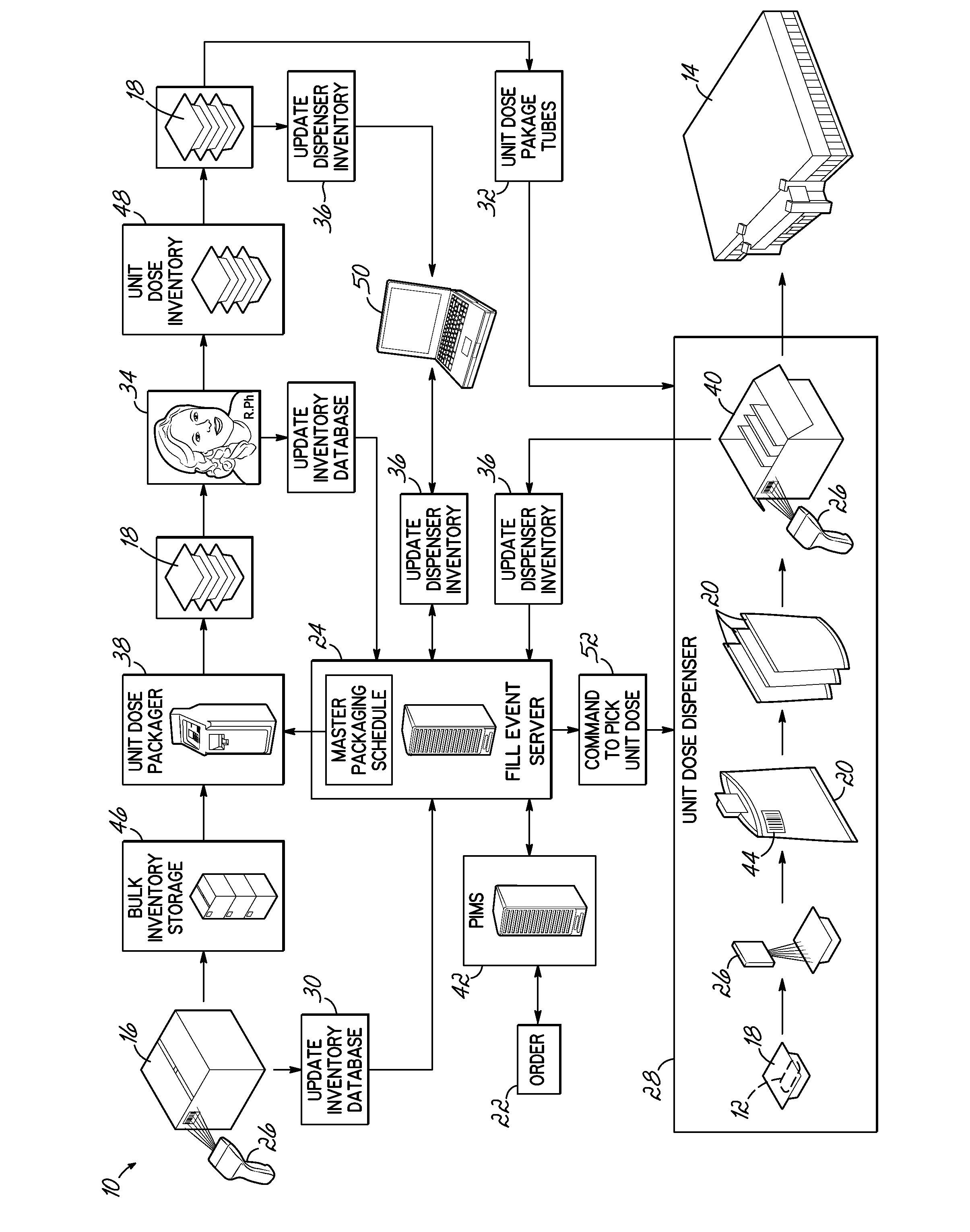

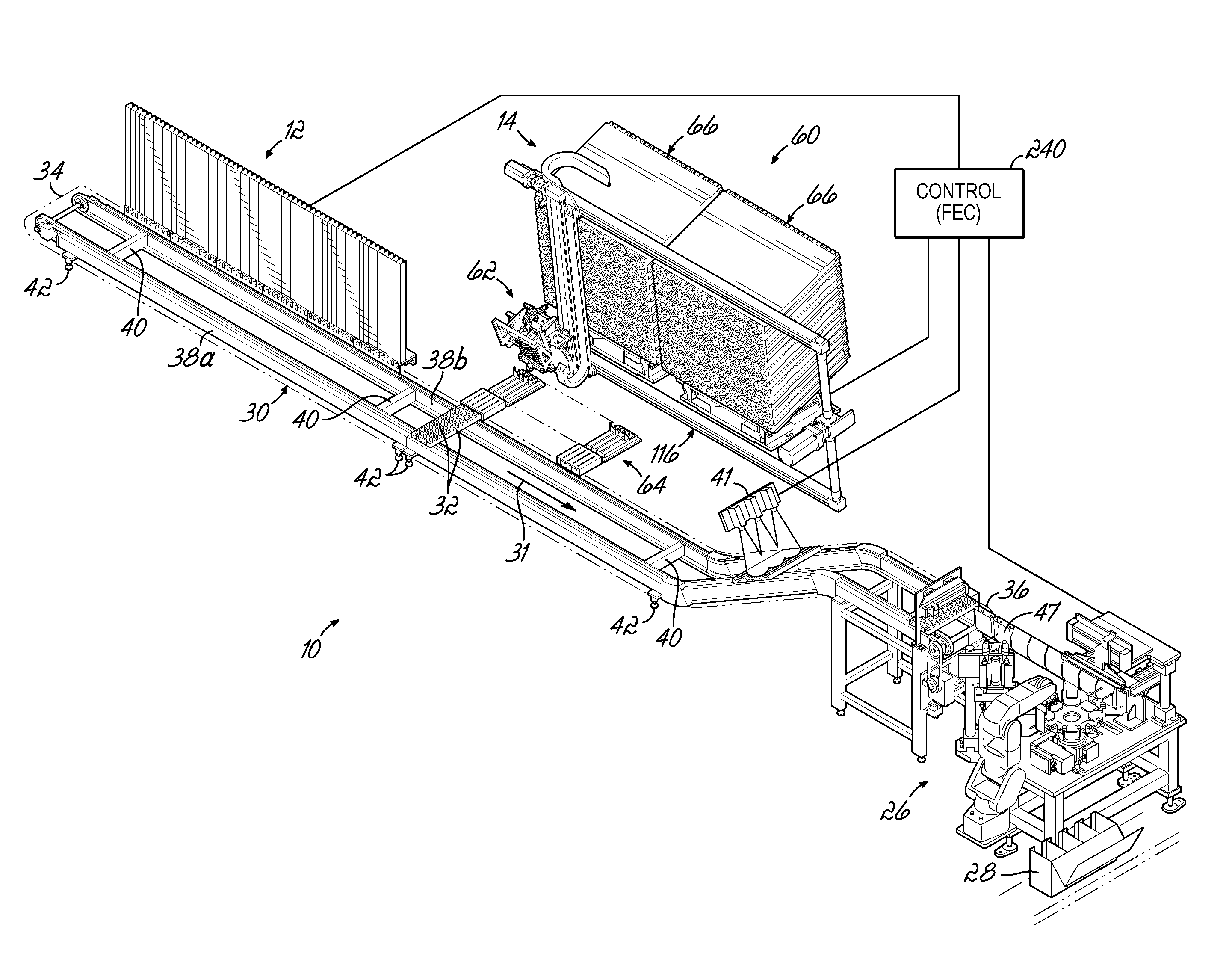

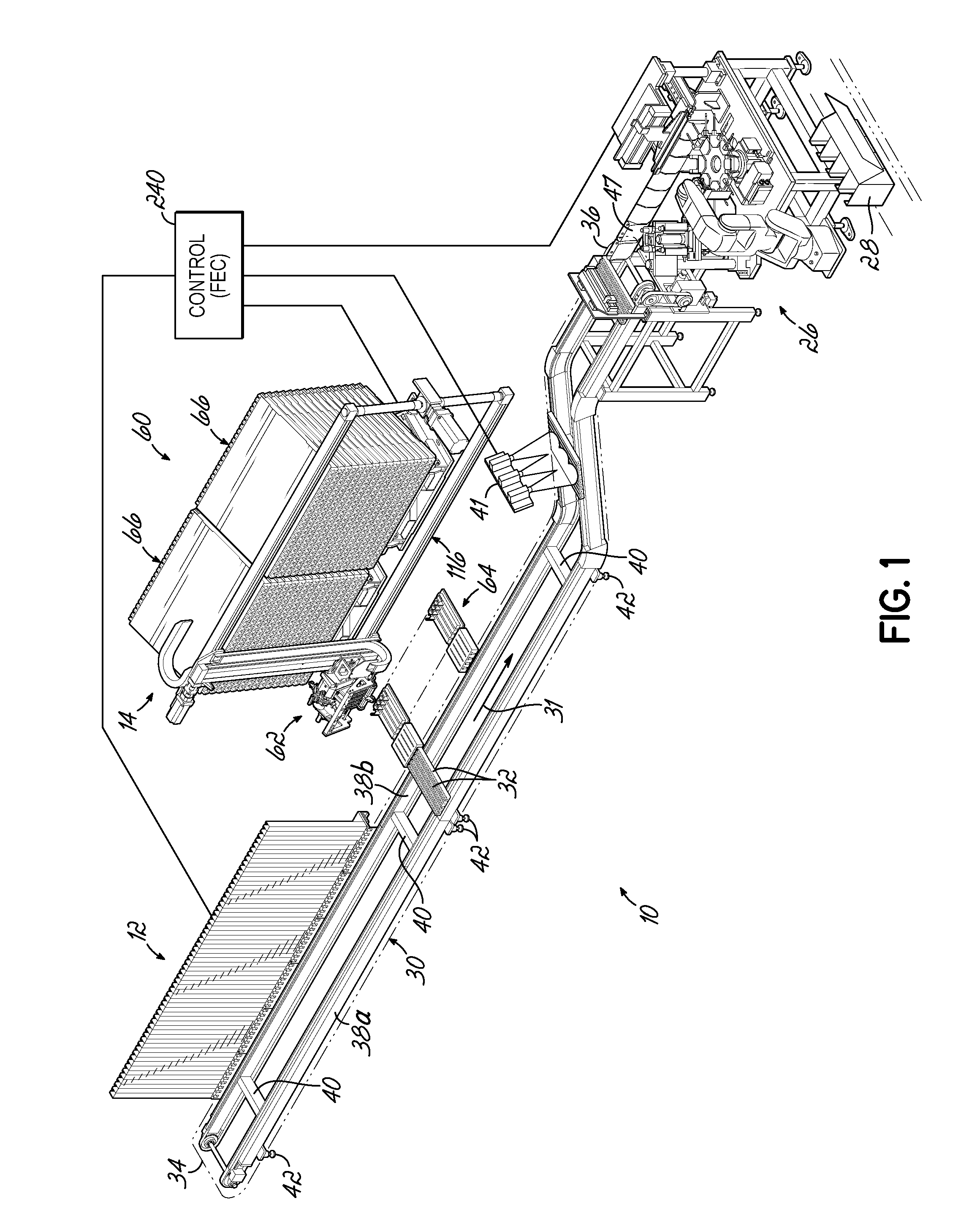

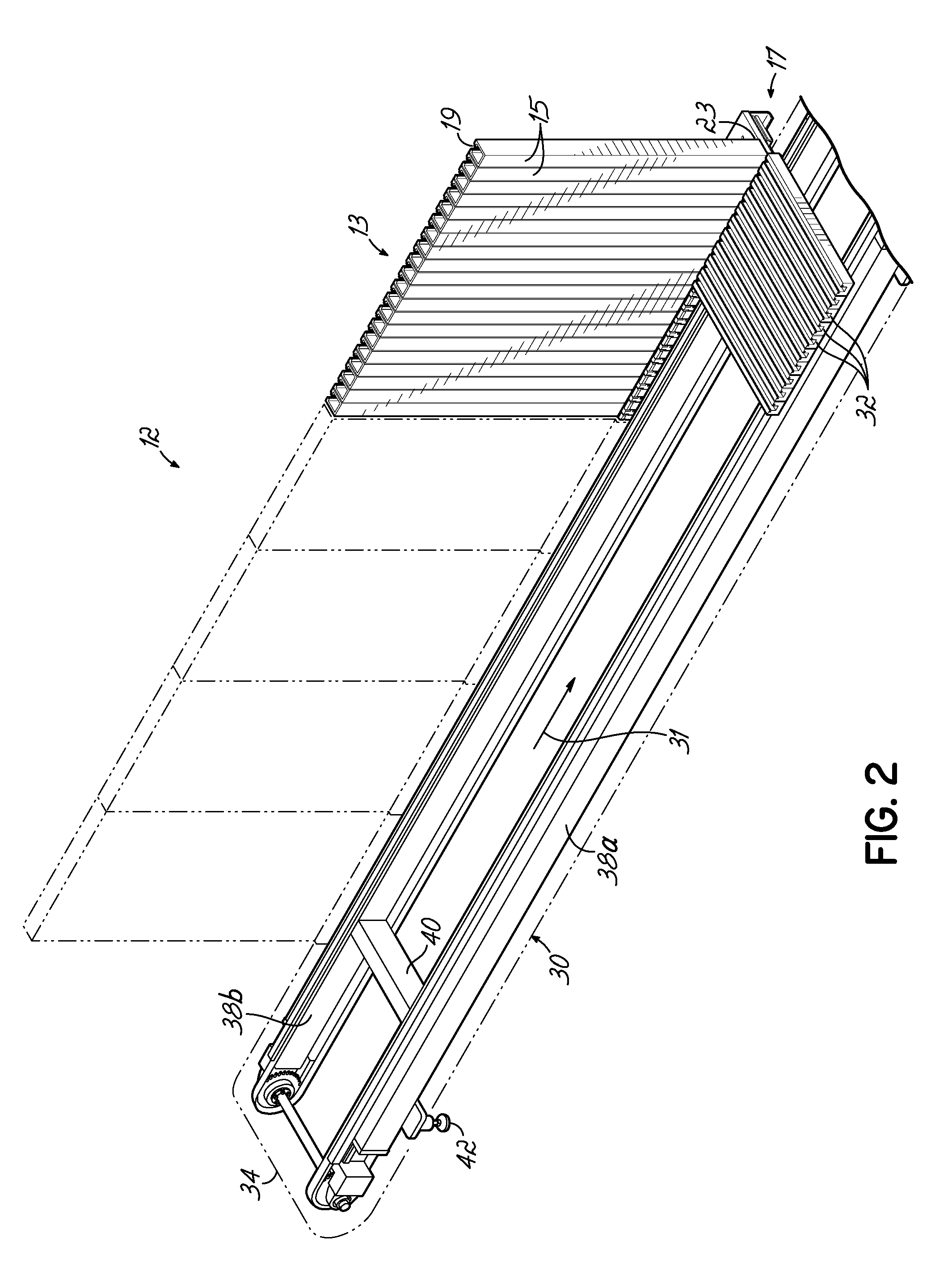

System and methodology for filling prescriptions

ActiveUS20100174552A1Automate processingSolve the real problemData processing applicationsDigital data processing detailsPhysical controlWork flow

An overall pharmacy system and methodology begins with bulk medications and supplements introduced into the work flow, individually packaged and assembled into med pass orders per patient and delivered to the long-term care (LTC) facility or other institution for patient consumption. The process according to one embodiment of this invention begins by converting bulk medications and supplements to packaged unit doses and ultimately individually packaged med pass bags for each patient on a 24-hour schedule. The various safeguards and measures built into this system increase patient safety eliminate waste and increase labor efficiency by reducing and / or minimizing the disposal of unused medications and supplements. The design of the overall system and its individual components allows for physical control of each unit dose package from start to finish without any unit dose package “free fall” in the system. This process is automated and does not rely upon manual sorting. The med pass bags are consolidated into the final shipping container and do not require manual sorting and packing.

Owner:REMEDI TECH HLDG

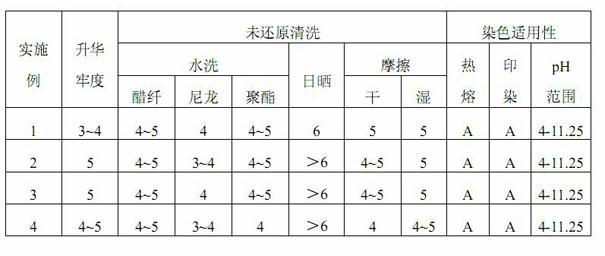

Alkali-resistant disperse dye complex

The invention discloses an alkali-resistant disperse dye complex, and relates to disperse blue BR-based alkali-resistant disperse dye complexes suitable for dyeing in a wide pH range. The complex comprises (1) alkali-resistant disperse dye blue complex, or (2) alkali-resistant disperse dye blue complex, or (3) alkali-resistant disperse dye black complex. The disperse dye complex of the invention has good dispersibility, dyeing stability and good reproducibility, and can effectively avoid the problems of stains, flaws, chromatic aberration and the like caused by dirt such as slurry, oil stain,wax and the like on fibers; and the pH value has wide range during use, dyeing can be performed in the pH range of 4.0 to 11.25, the dyed fabrics have full hue, and the dyed fabrics with predominant color fastness performance such as washing fatness, daylight fastness and the like can be obtained without reduction clearing.

Owner:HANGZHOU JIHUA JIANGDONG CHEMICAL CO LTD

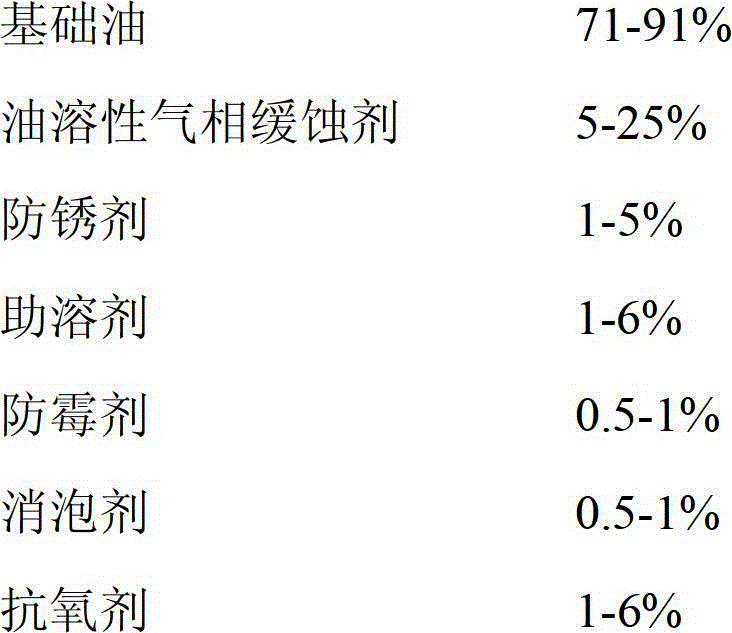

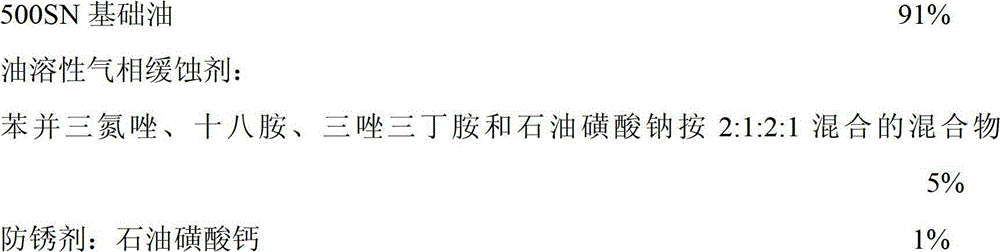

Volatile rust preventive oil

InactiveCN102719302AInhibit corrosion and rustClean working environmentAdditivesGas phaseAntioxidant

The invention discloses volatile rust preventive oil which comprises, by weight, 71-91% of base oil, 5-25% of an oil soluble volatile corrosion inhibitor, 1-5% of an antirusting agent, 1-6% of a cosolvent, 0.5-1% of a mildew-proof agent, 0.5-1% of an antifoaming agent and 1-6% of antioxidant, wherein the base oil is one of 500SN 46# machine oil, 32# machine oil, 600SN 150# machine oil and 100# machine oil; and the oil soluble volatile corrosion inhibitor is a mixture of four kinds of 2-heptadecenyl-imidalidine, octadecylamine, triazole tributylamine, dicyclohexylamine carbonate, dicyclohexylaminenitrite, benzotriazole, tert-butyl chromate, nephthenic soap, petroleum sodium sulfonate, sorbitan monooleate and stearic acid; and the antioxidant is sulfurphosphorousbutyloctyl zinc salt. The volatile rust preventive oil has good volatile rust preventive and corrosion resistant performances, metal which cannot be coated with rust preventive oil can achieve rust preventive protection, the operation is simple, and the cost is low.

Owner:上海福岛新材料科技有限公司

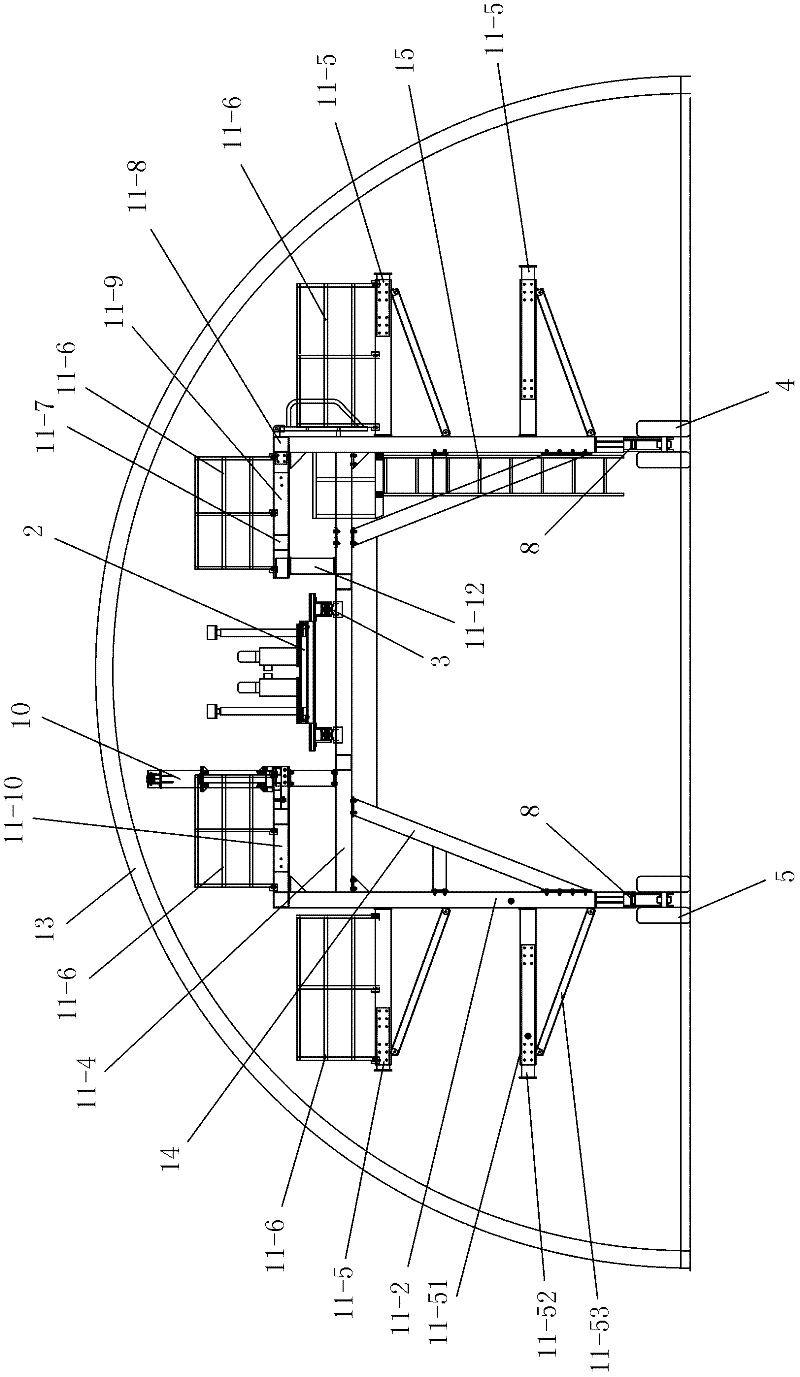

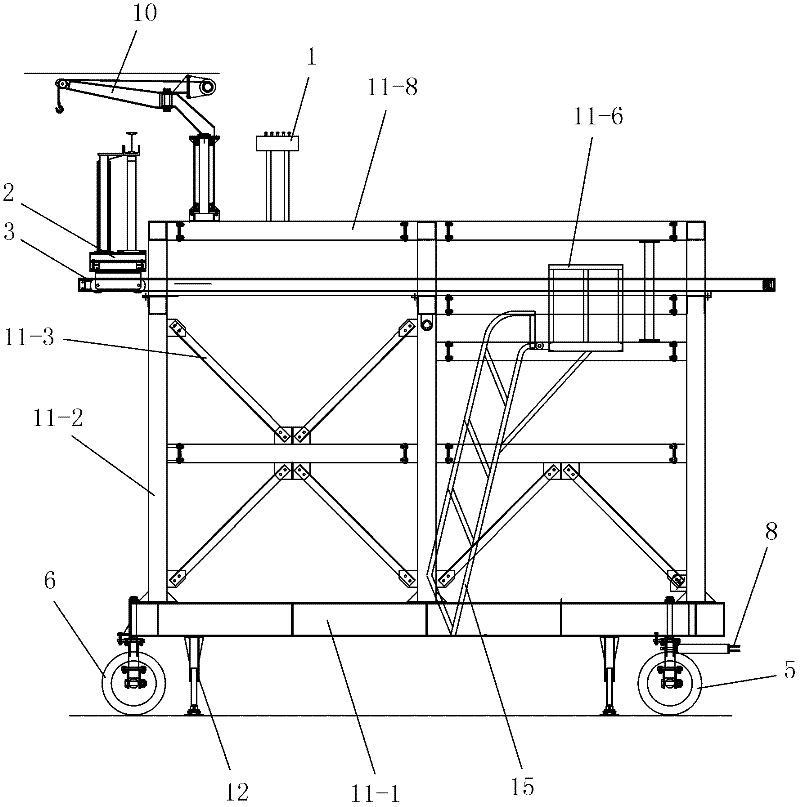

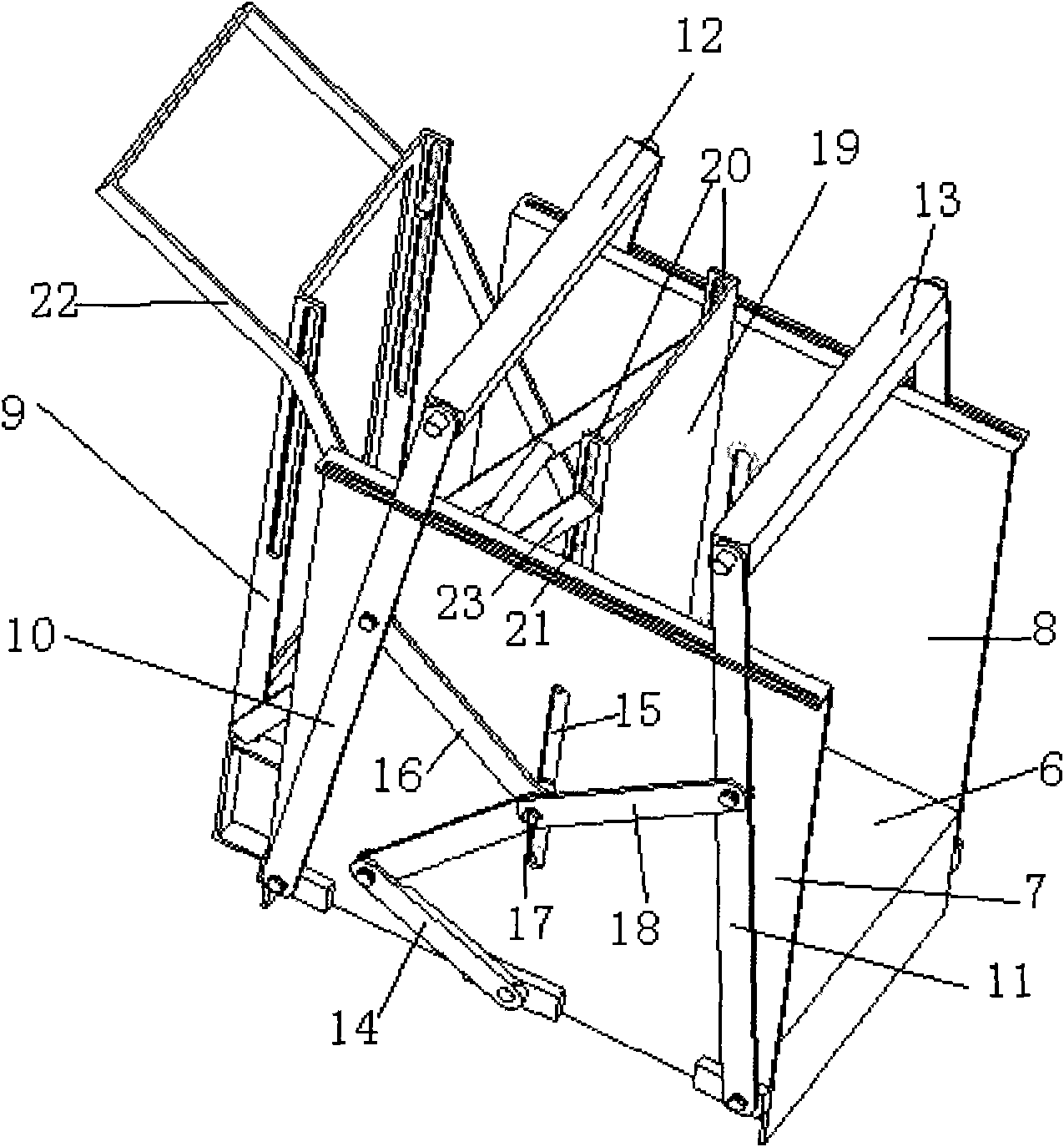

Tunnel arch installation vehicle

ActiveCN102287209ASimple structureReasonable designUnderground chambersTunnel liningWork performanceEngineering

The invention discloses a tunnel arch center installation operation vehicle. The tunnel arch center installation operation vehicle comprises a machine frame, a travelling mechanism, a traction mechanism, an arch center lifting device for lifting tunnel arch centers which are arranged on the rear part of the machine frame and are needed to be installed one by one, and an arch center transferring mechanism for transferring the arch centers which are lifted by the arch center lifting device one by one through alignment and adjustment; the arch center transferring mechanism comprises a translating trolley which can move forward and backward on the upper part of the machine frame, a lifting mechanism for stably lifting the tunnel arch centers, and a left and right movement mechanism for driving the lifting mechanism to synchronously move left and right; and the translating trolley, the left and right movement mechanism, and the lifting mechanism align and adjust the tunnel arch centers front and back, right and left and up and down respectively. The tunnel arch center installation operation vehicle has a reasonable design, is convenient to assemble, and easy and convenient to operate, safe and reliable in working performance, and good in a using effect, and can solve the problems of large working difficulty in movement and accurate positioning of steel arch centers after lifting during the installation of the conventional steel arch centers, low installation efficiency, large labor intensity and the like.

Owner:CHINA RAILWAY FIRST GRP CO LTD

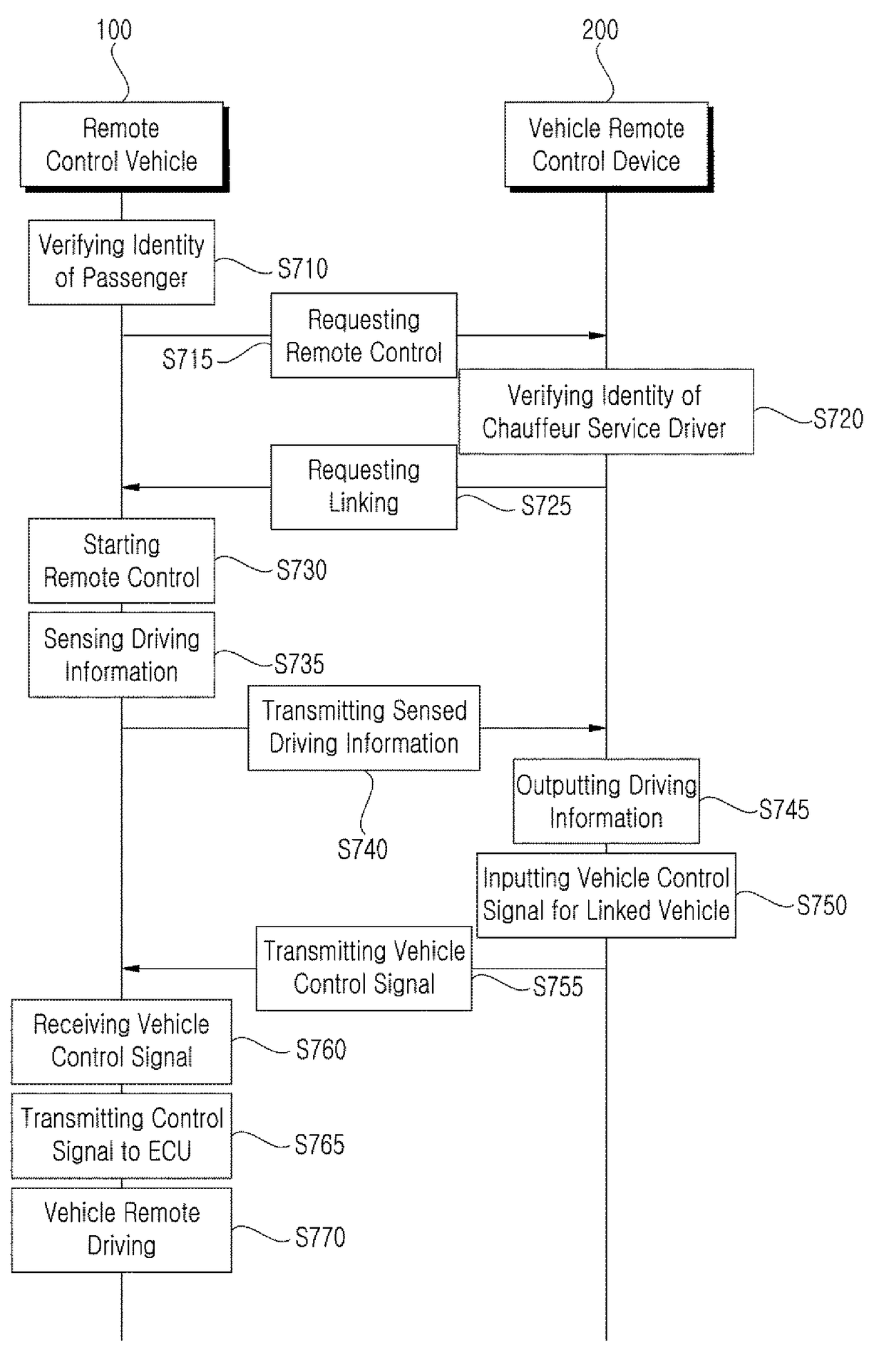

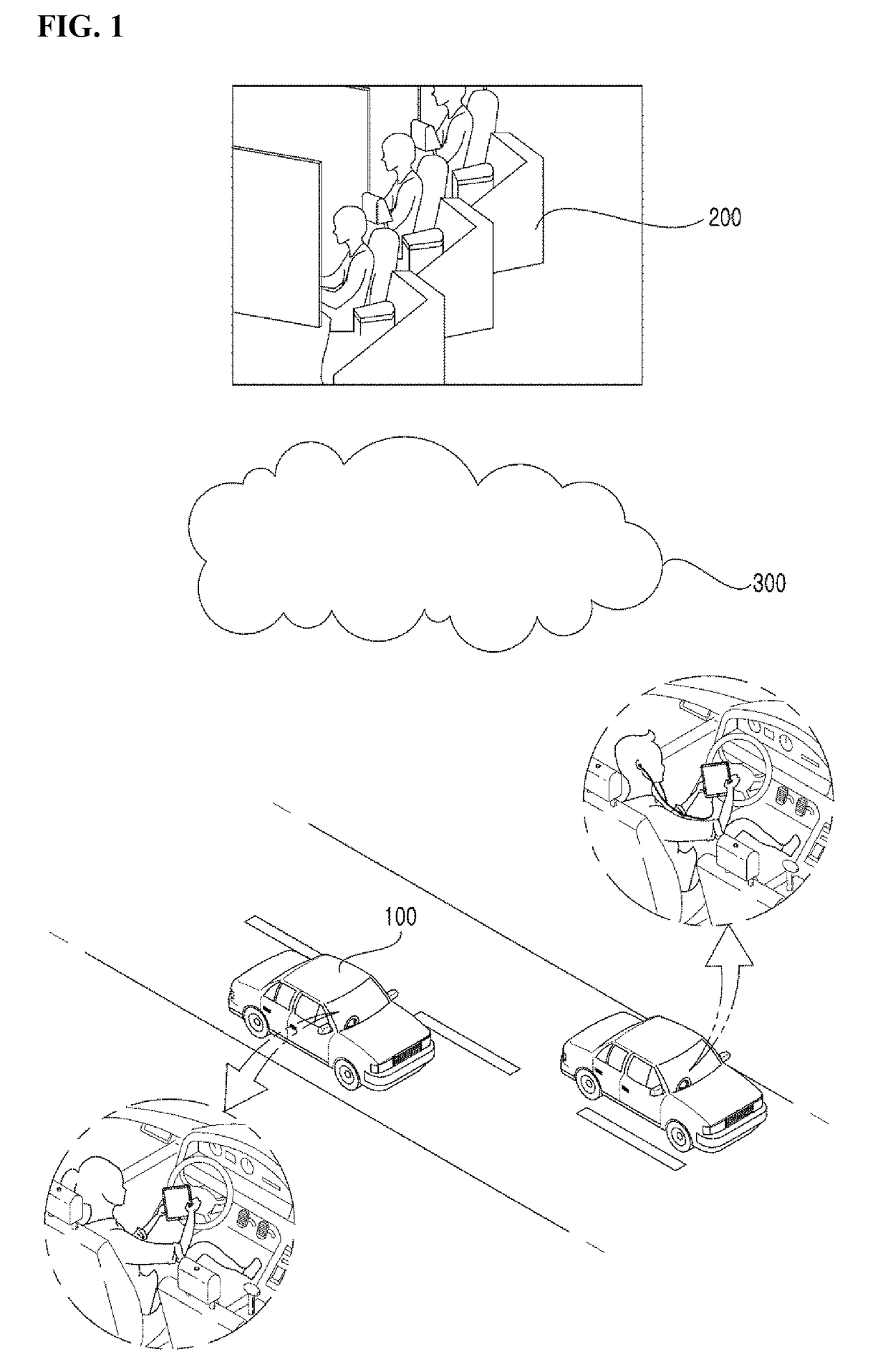

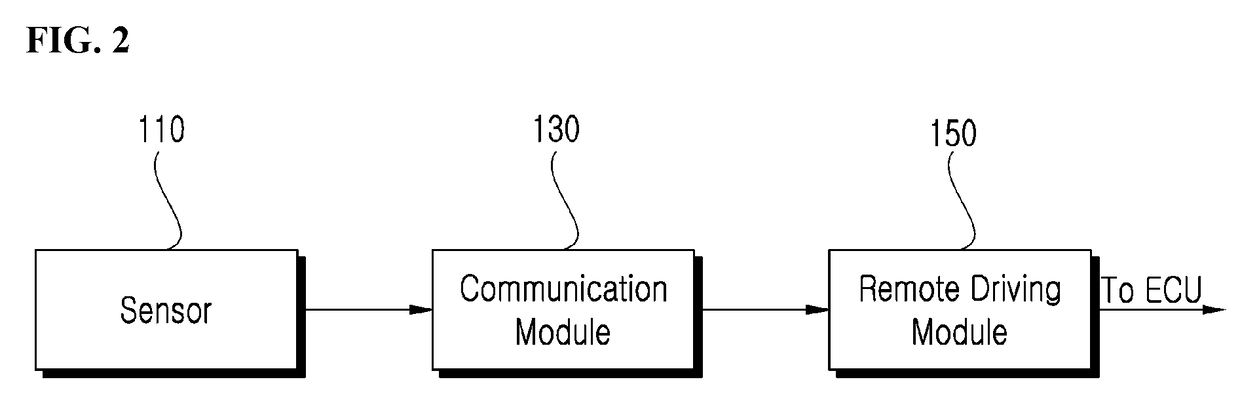

Apparatus and method for vehicle remote controlling and remote driving system

InactiveUS20180074490A1Many timesEfficient use ofTicket-issuing apparatusRegistering/indicating working of vehiclesSteering angleControl signal

Disclosed is a vehicle remote control device and system, and a method for remote driving. The vehicle remote control system includes a remote driving vehicle transmitting driving information including images of a front, a rear, and sides, and path information of a vehicle, and vehicle condition information including a vehicle speed, an steering angle, front and rear pressure, a body tilt, an engine condition to a remote control platform, and receiving an ECU (Engine Control Unit) control signal from the remote control platform, thereby remotely running according to the control signal; and a vehicle remote control platform receiving the driving information from the remote driving vehicle, and remotely controlling the vehicle drive according to the received information.

Owner:IPLAB INC

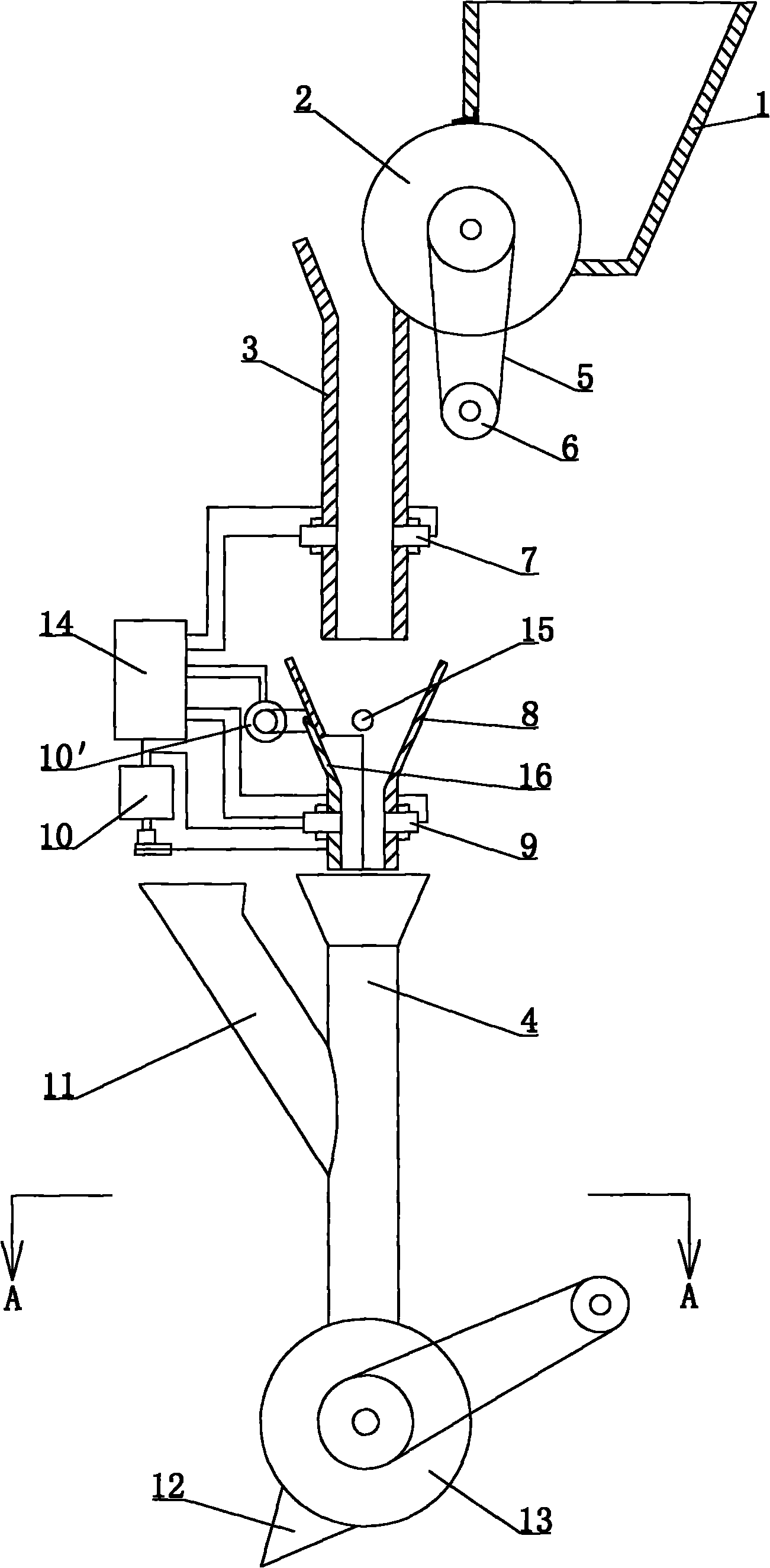

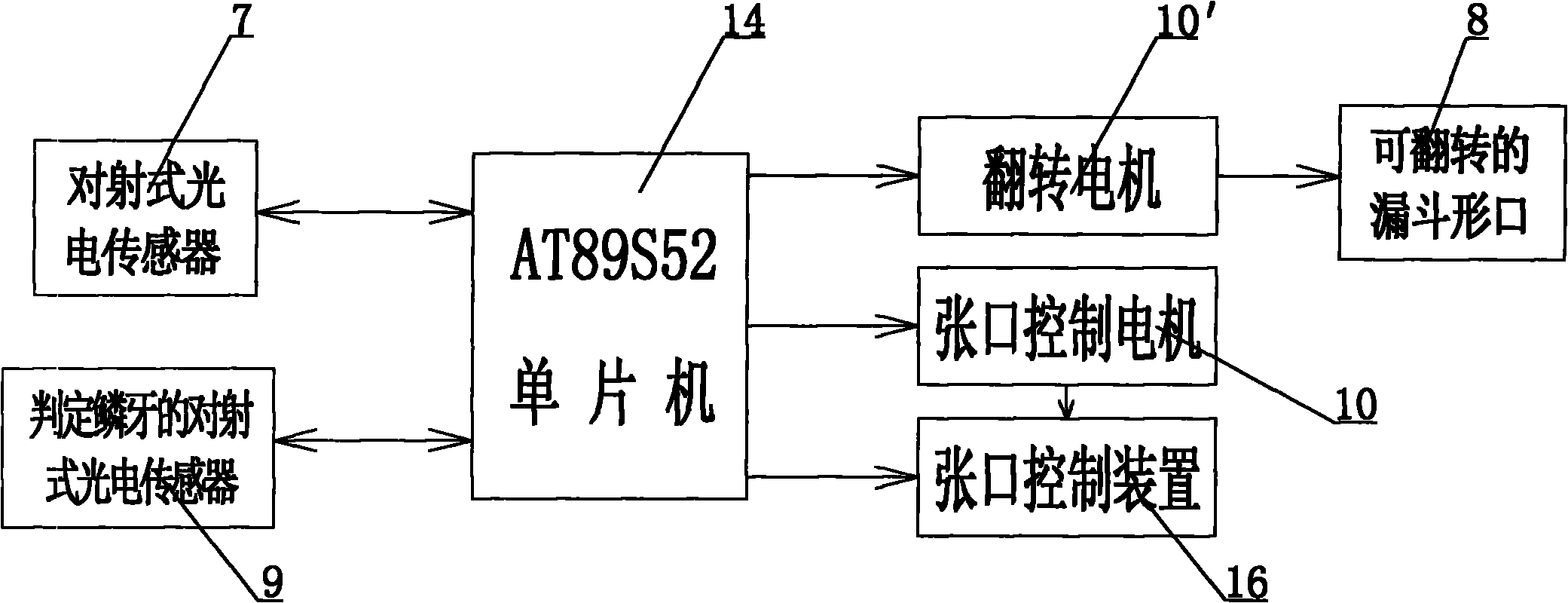

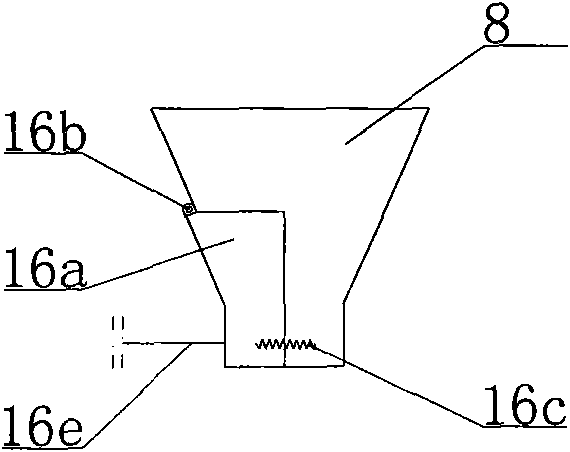

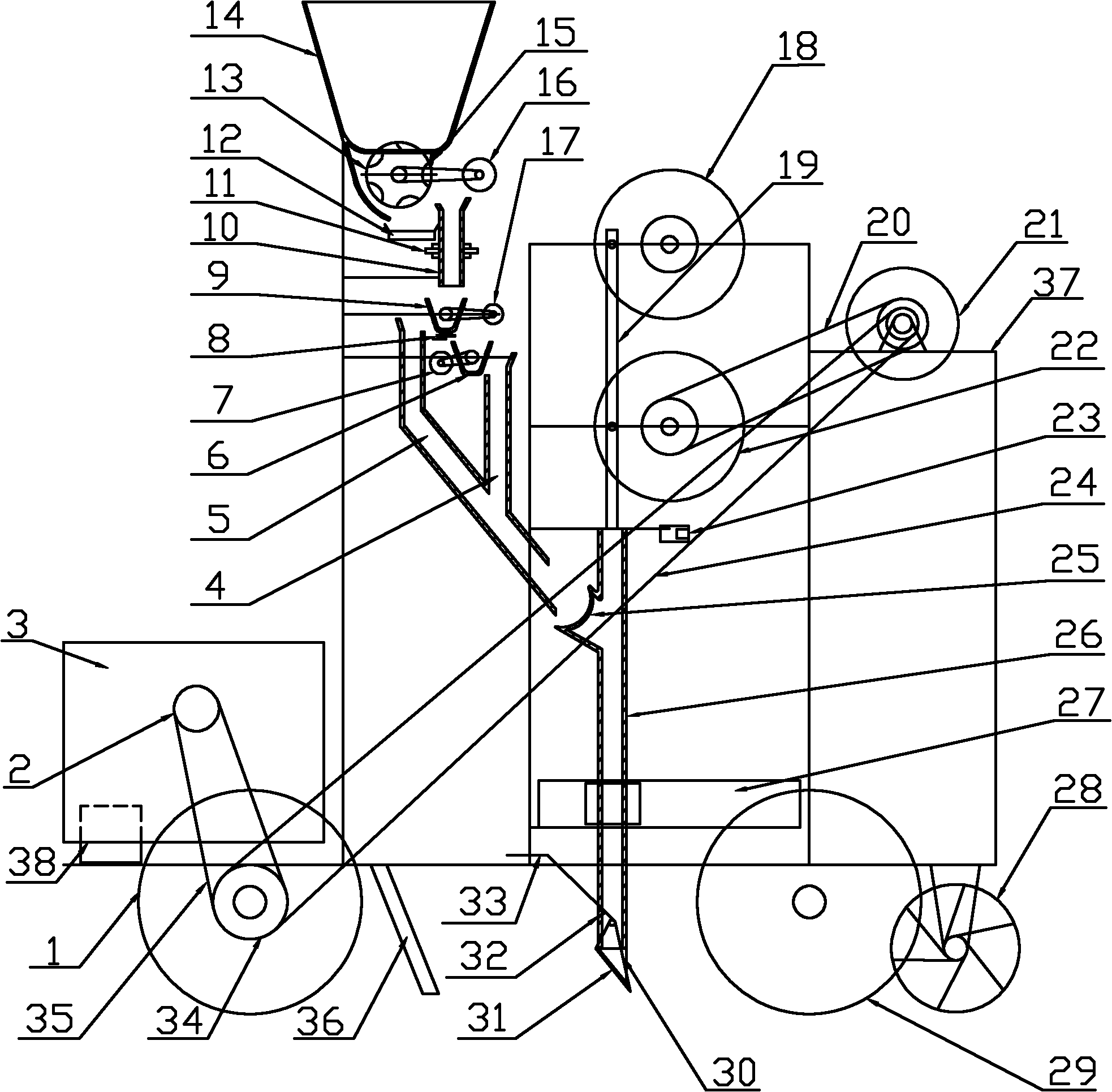

Sowing device capable of identifying bulbil direction of garlic cloves

The invention discloses a sowing device capable of identifying the bulbil direction of garlic cloves, which comprises a garlic seed box (1), a garlic clove fetcher (2), a garlic seed conveyer (3) and a garlic seed-sowing tube (4). The sowing device capable of identifying the bulbil direction of garlic cloves is characterized in that the middle of the garlic seed conveyer (3) is provided with an opposed photoelectric sensor (7) for detecting whether a single garlic clove passes by in a limited time, a lower opening of the garlic seed conveyer (3) is in butt joint with a turnable hopper-shaped opening (8), an opposed photoelectric sensor (9) for judging bulbil is arranged at the bottom opening part of the turnable hopper-shaped opening (8), and a furrowing blade (12) is arranged at the bottom end of the garlic seed-sowing tube (4) and provided with soil-covering wheels (13) at both sides of a seed-sowing opening. By combining a mechanical mode and a photoelectric sensing and detecting technology, the device identifies and controls the bulbil direction to directly sow, thereby lightening the labor intensity, improving the labor efficiency and the upward bulbil accuracy of garlic cloves and achieving high degree of automation.

Owner:高迟

Pharmaceutical dispensing system and associated method

InactiveUS20100176145A1Improve securityEliminate wasteSmall article dispensingDrug and medicationsLong-term careDrug dispensing

A dispensing system and associated method provides a turnkey solution for dispensing pharmaceutical products such as solid medications and nutritional supplements to be taken orally in health care settings, including but not limited to long term care (LTC) and assisted living settings.

Owner:REMEDI TECH HLDG

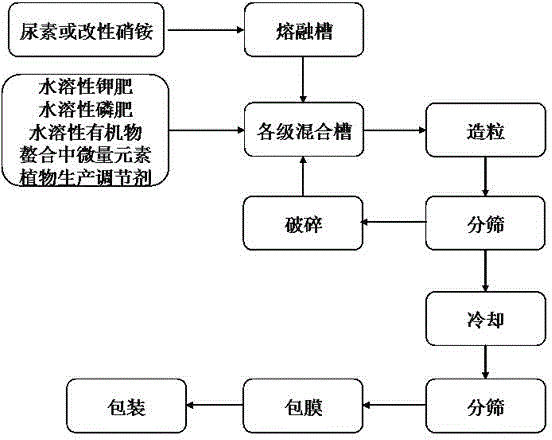

Water-soluble high-concentration organic-inorganic compound fertilizer for trickle and sprinkling irrigation and preparation method thereof

InactiveCN104446968AImprove solubilityRealize integrationCalcareous fertilisersMagnesium fertilisersHigh concentrationSolubility

The invention relates to a water-soluble high-concentration organic-inorganic compound fertilizer for trickle and sprinkling irrigation and a preparation method thereof, belongs to the technical field of integration of water and fertilizer and high concentration organic-inorganic compound fertilizers. The fertilizer comprises the following components in percentage by weight: 35-70% of urea or 40-70% of modified nitramine, 5-40% of water-soluble phosphatic fertilizer, 0-35% of water-soluble potassic fertilizer, 20-40% of water-soluble organic matters, 0.05-0.1% of a water-soluble fertilizer synergist, 0.1-10% of water-soluble chelating medium trace elements and 0.1-10% of a plant growth adjustor. Nitrogen, phosphorus and potassium account for 30-50% of the prepared water-soluble high-concentration organic-inorganic compound fertilizer for trickle and sprinkling irrigation and the organic matters account for 15-25% of the prepared water-soluble high-concentration organic-inorganic compound fertilizer for trickle and sprinkling irrigation. The water-soluble high-concentration organic-inorganic compound fertilizer is good in solubility, can be matched with trickle and sprinkling irrigation equipment and achieves integration of water and fertilizer; the utilization ratios of nitrogen, phosphorus and potassium and trace elements are high, and the fertilizer has the advantages of improving the soil environment, adjusting crop growth, enhancing stress resistance of the crop, and improving the quality of crops.

Owner:HUBEI SANNING CHEM

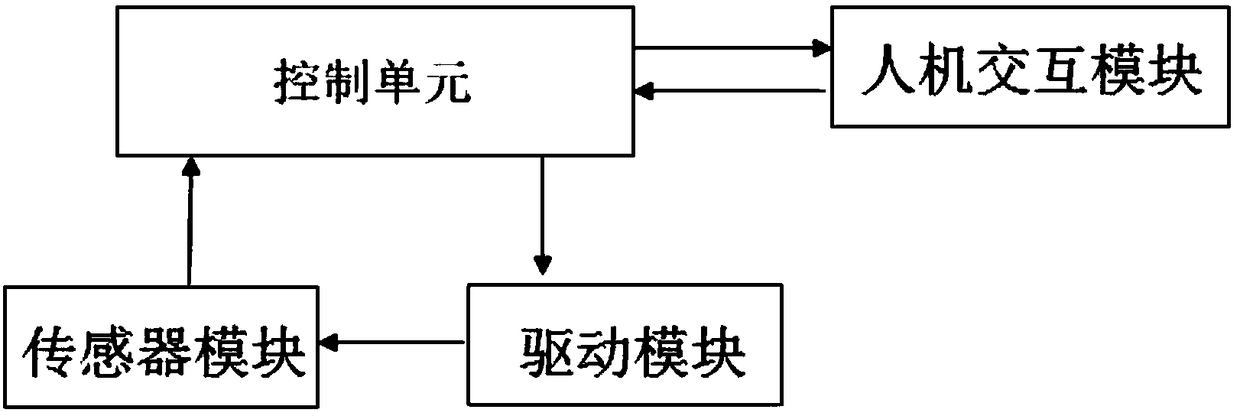

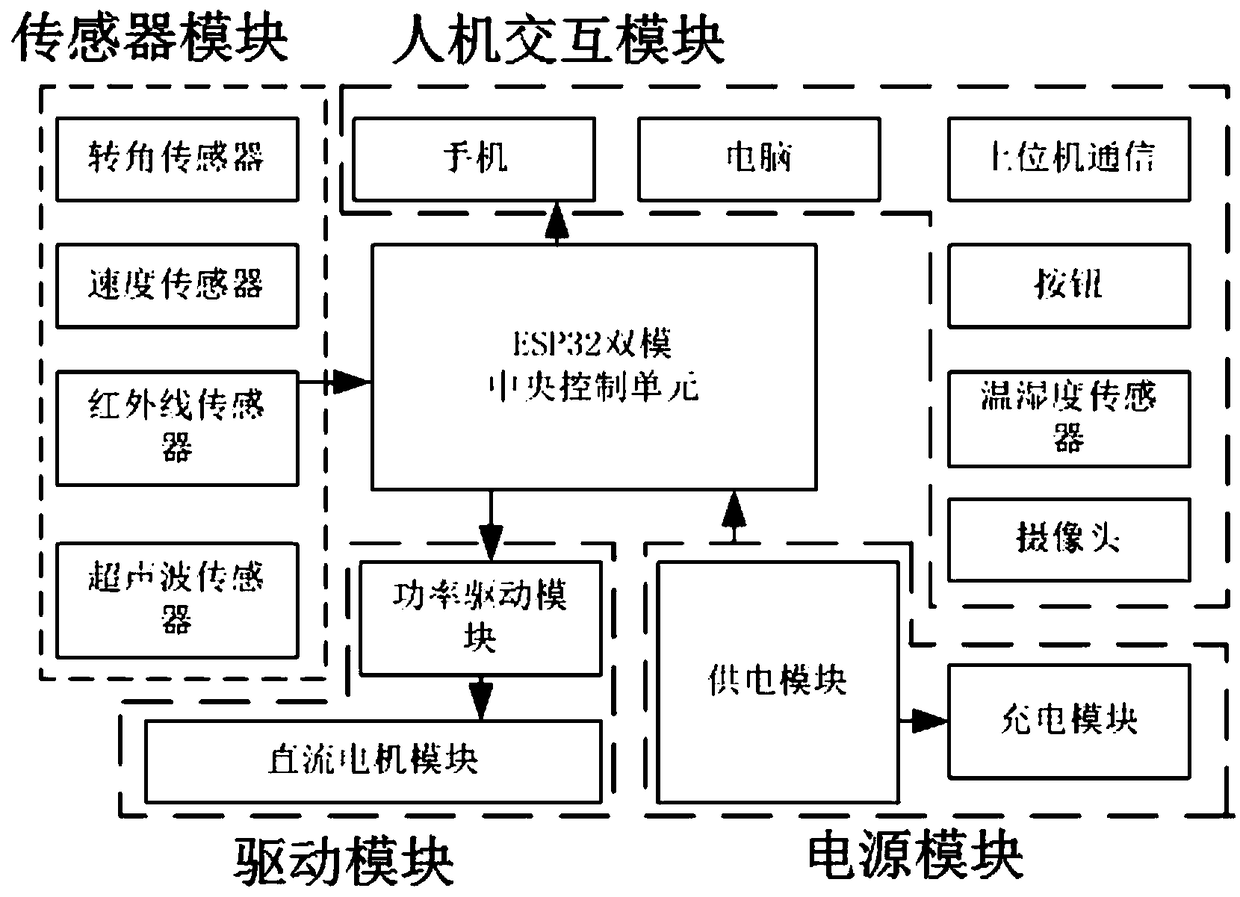

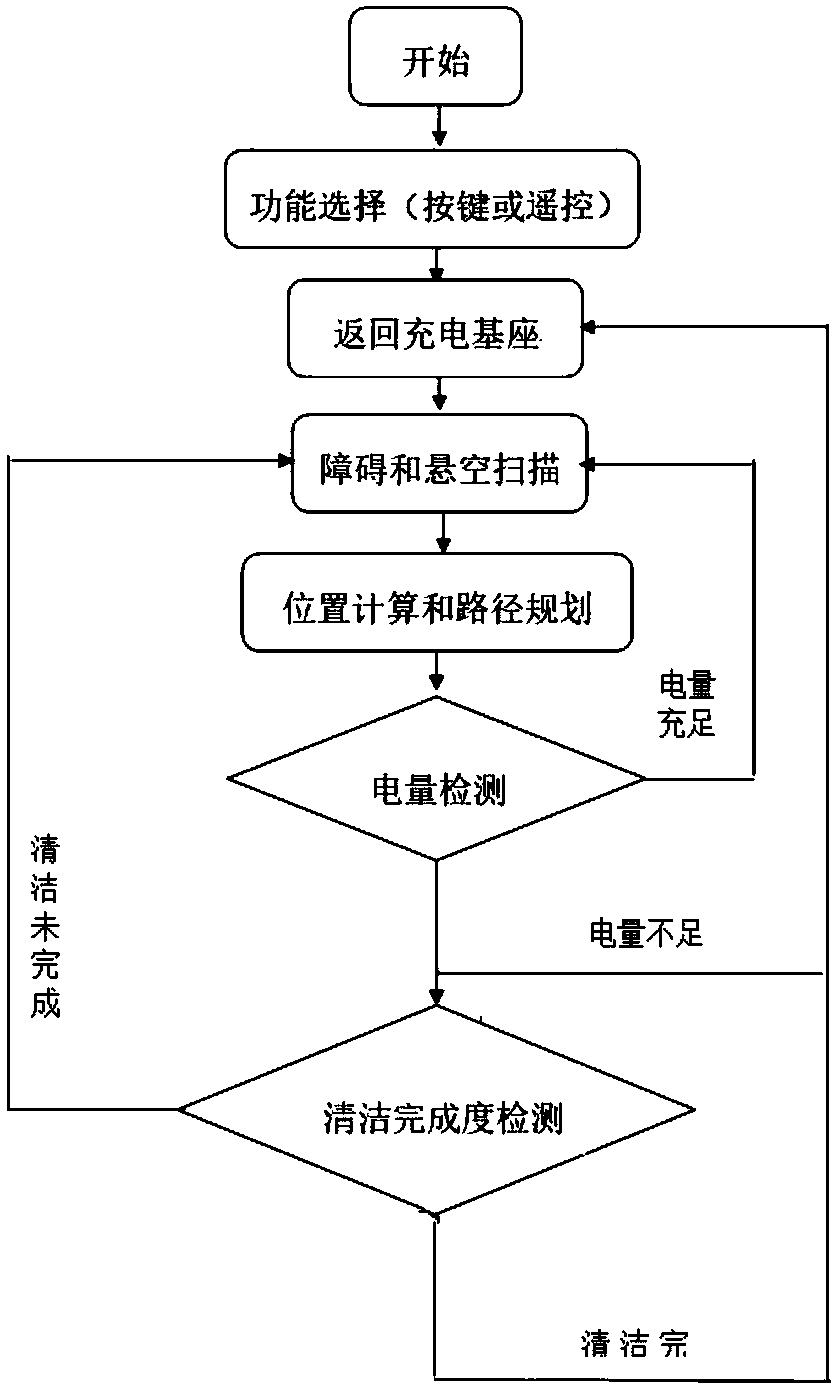

Intelligent cleaning robot and path planning method thereof

ActiveCN109144067AAchieve maximum coverageAchieving cleanlinessPosition/course control in two dimensionsVehiclesReal time analysisRemote control

The invention discloses an intelligent cleaning robot and a path planning method thereof. A sensor module is used for analyzing and feeding back real-time cleaning environment information; an accuratepositioning module is used for acquiring the position of the current intelligent cleaning robot on the environment map which is established through a geometric-topological hybrid map technology, andthe environment map and the real-time position are combined, the optimal sweeping path is planned by using an advanced path planning algorithm, and the data is uploaded to a cloud platform for realizing the real-time analysis, recording, and control; a driving module is used for driving the intelligent cleaning robot to run according to the planned optimal path and carrying out cleaning operation;a man-machine interaction module can be used for displaying the working state and performance of the intelligent cleaning robot by combining the temperature and humidity sensor with the camera, and the remote control and reservation functions of the intelligent cleaning robot can be completed through wifi / Bluetooth technology. According to the invention, the labor intensity is reduced, the laborefficiency is improved, and the robot is suitable for hotels, libraries, office places and public families.

Owner:CHECC DATA CO LTD +1

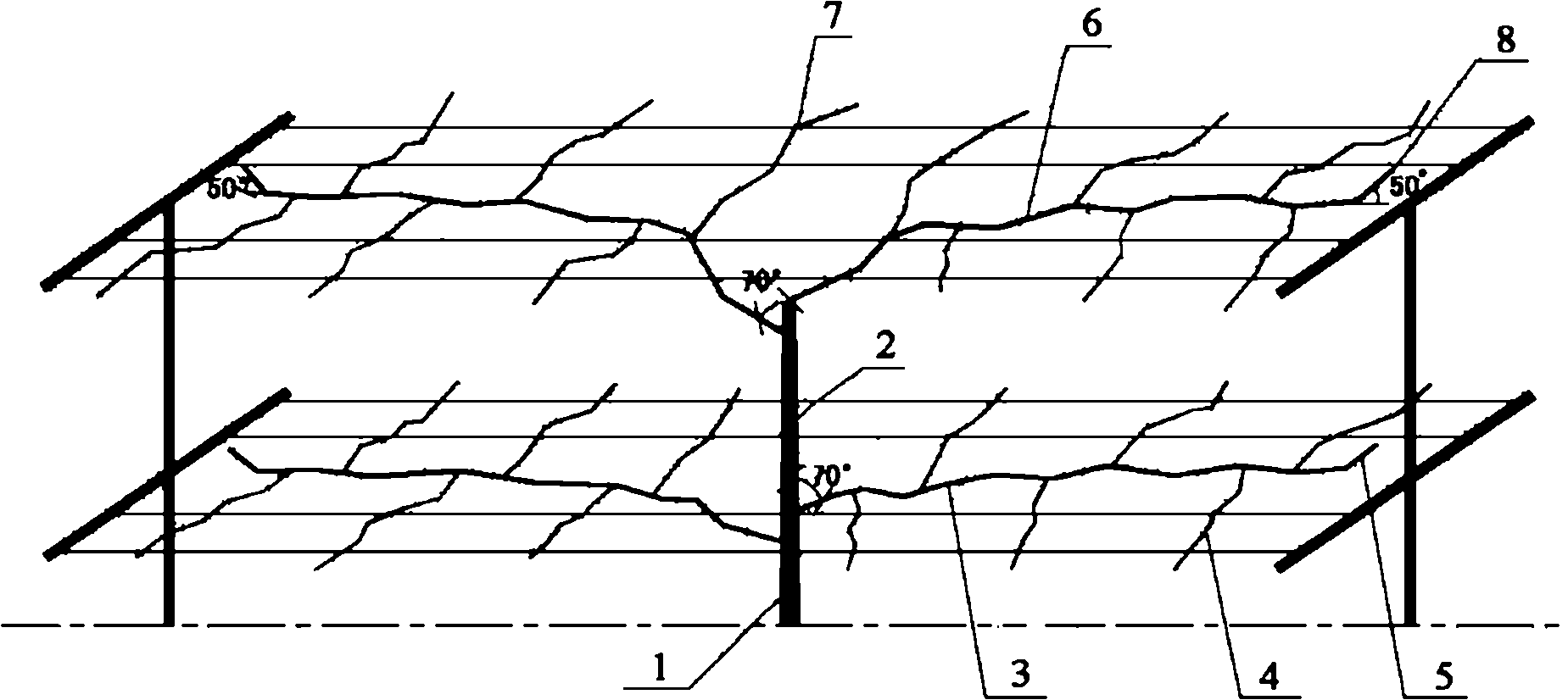

Shaping and trimming method of crowns of pear trees

The invention relates to a shaping and trimming method of crowns of pear trees. The crowns are trimmed into a structure of two layers of main branches, wherein each layer of main branches comprises two main branches facing south and north, and lateral branches are left at two sides of the main branches in the horizontal direction. The shaping and trimming method has the advantages of facilitating flower bud differentiation, increasing effective photosynthetic accumulation, enhancing wind resistance, and obviously improving the commodity quality of fruit of a single-layer planar pergola shaping method; moreover, the shaping of the crowns is quick; the cultivation of crown structure can be completed to enter the early fruit period 3 years after the planting in general; the yield of a single plant can be controlled to be 6-10kg, and increases year by year; meanwhile, trimmed crowns do not contain sub-main branches; the trimming method is simple, and is easy to master; the work space of the flower and fruit management of a pear orchard can be controlled; labor and force are saved; the labor efficiency is improved; and the management cost of the orchard is reduced; in addition, the method is suitable for a flat land or a gentle slope landform undulation, and is particularly suitable for a gentle slope with the landform undulation or a slope land with the slope of less than 15 DEG.

Owner:YANGZHOU UNIV +1

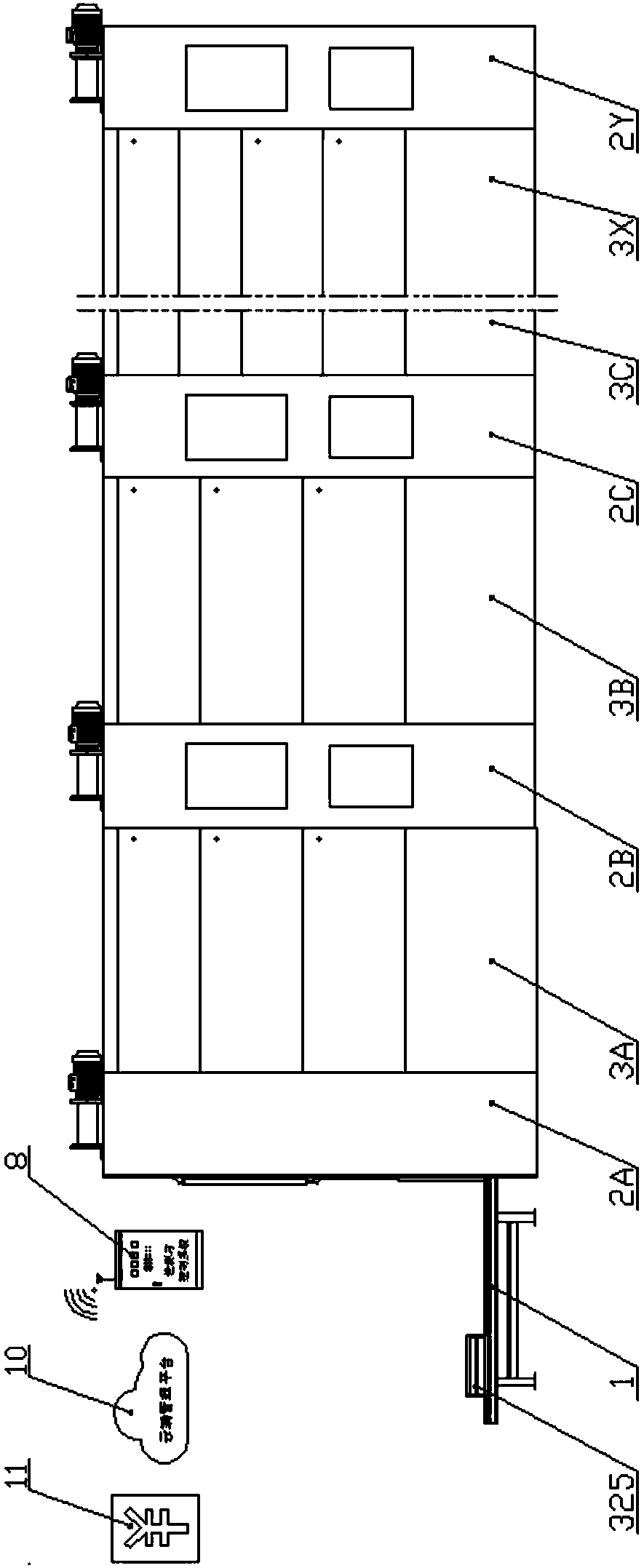

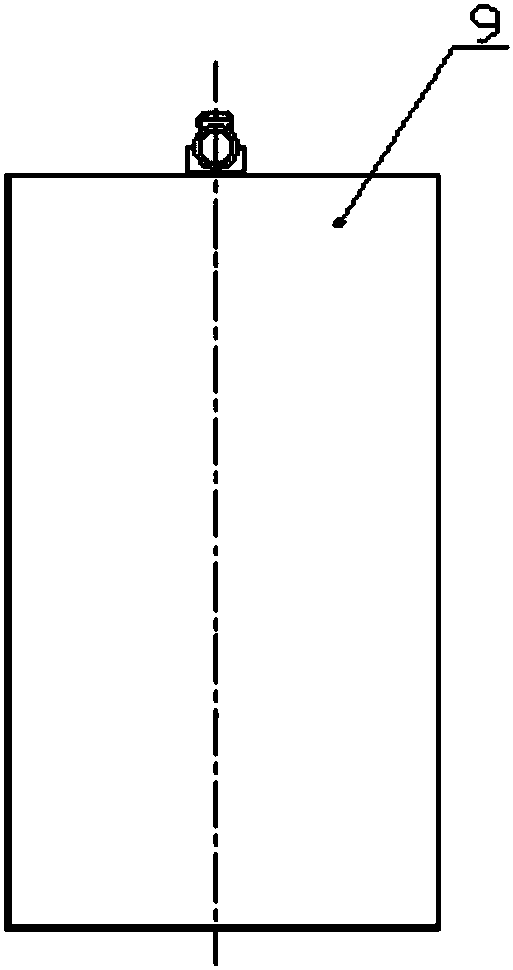

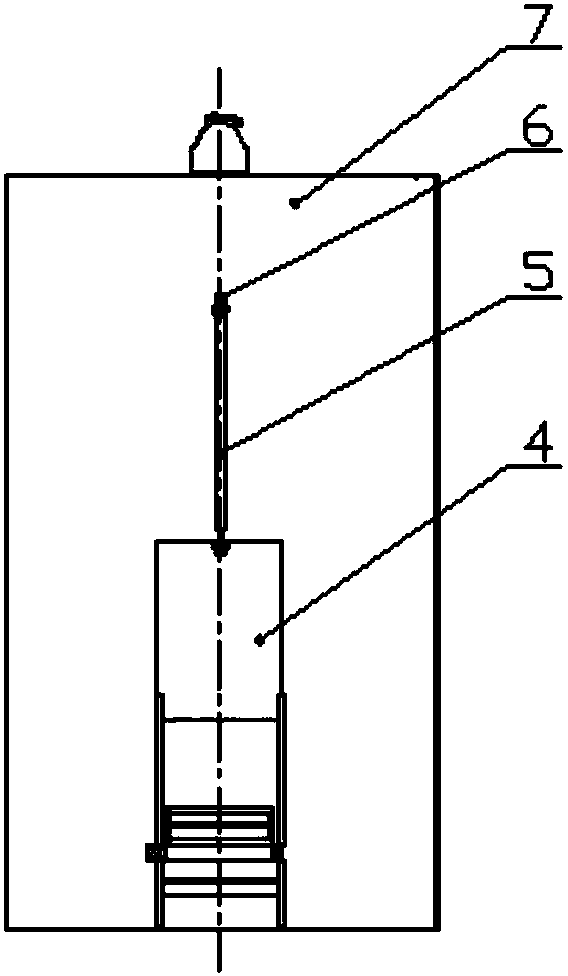

Caterpillar vending machine and automatic vending method

ActiveCN107945378AImprove adaptabilityReduce manual laborAcutation objectsCoin-freed apparatus detailsPayment systemIndustrial engineering

The invention provides a caterpillar vending machine. The caterpillar vending machine comprises a goods replenishing unit, m transshipment units, n container units, a detection control unit, a cloud side management platform and a payment system; the goods replenishing unit, the transshipment units and the container units are connected in sequence, and the integrated caterpillar vending machine isformed, wherein m and n are both natural numbers except 0, when n=1, m=1, and when n>1, m=n+1; regarding the m transshipment units and the n container units, when n>1 and m=n+1, the transshipment units and the container units are connected in an alternated and arranged mode, and the last unit is the transshipment unit; when n=1 and m=1, the transshipment units and the container units are of an integrated structure. The caterpillar vending machine solves the problem of a traditional vending machine that manual work is relied on to replenish goods, goods replenishing is troublesome, time and labor are wasted, and the adaptability of vended commodities are poor.

Owner:HUNAN SCIENTOP AUTOMATIC EQUIP SHARES +1

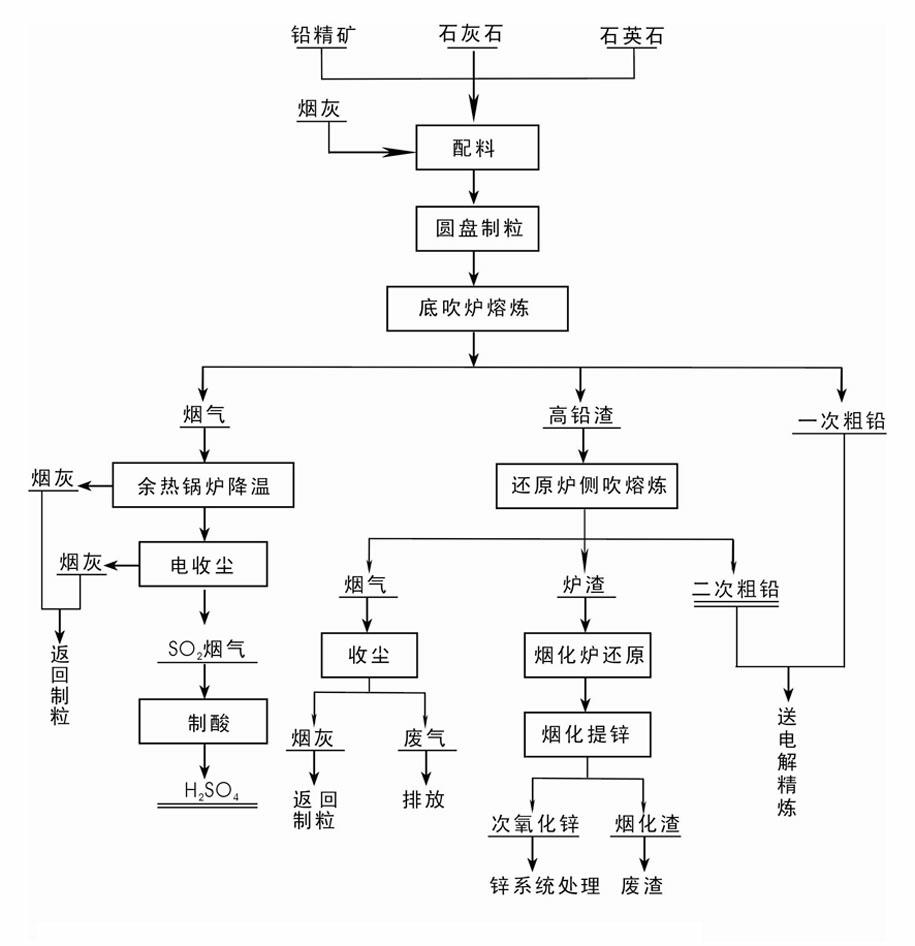

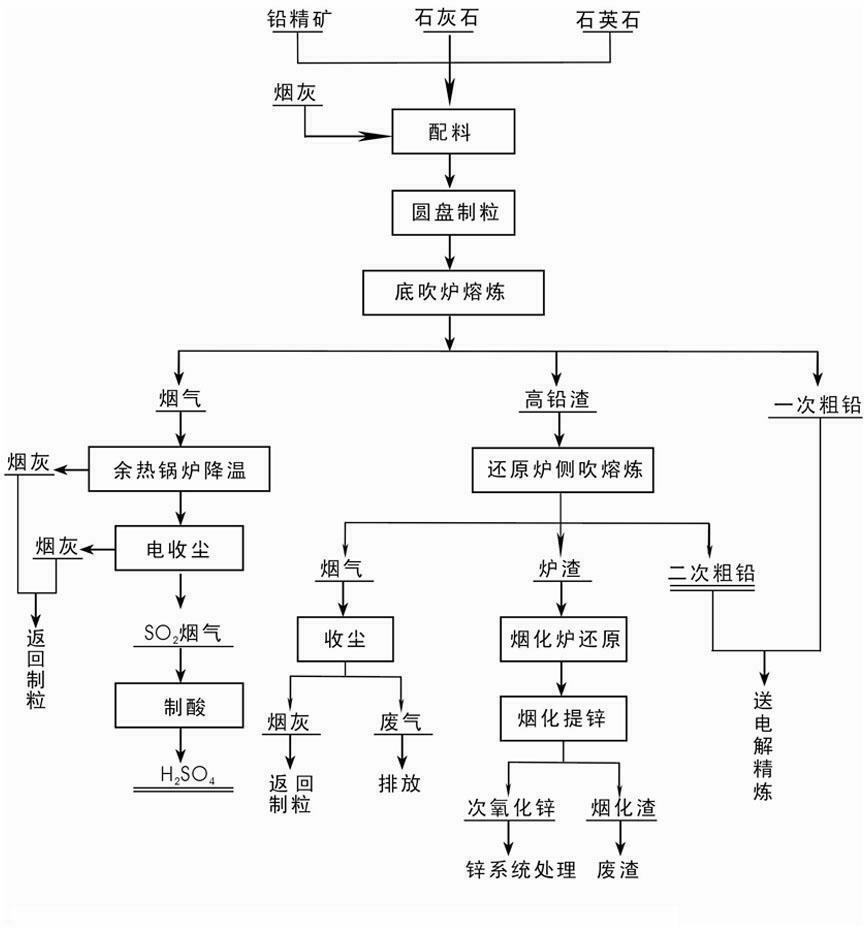

Oxygen bottom-blowing smelting and liquid-state high-lead slag side-blowing direct reduction process

InactiveCN102634674AEasy to separateShort and easy smelting processProcess efficiency improvementSlagOxygen

The invention relates to an oxygen bottom-blowing smelting and liquid-state high-lead slag side-blowing direct reduction process, belonging to the technical field of metallurgy. The process mainly comprises the steps of: directly injecting liquid-state high-lead slag melt subjected to oxidization smelting by a bottom oxygen blowing smelting furnace into a reduction furnace, and directly reducing liquid-state high-lead slag into secondary lead bullion through side blowing in the reduction furnace by adopting crushed coal as fuel; and after high-sulfur smoke produced by the bottom oxygen blowing smelting furnace is subjected to waste heat recovery by a first waste heat boiler and dust collection by an electric dust collector, and delivering the high-sulfur smoke to a sulfuric acid workshop for acid making. According to the process disclosed by the invention, a blast furnace, a slag casting machine and corresponding auxiliary facilities are omitted, the advantages of little investment and high automation level are achieved, and the industrial production of low pollution and low-carbon and economy is realized.

Owner:HUNAN HUAXIN RAREANDPRECIOUS METALS TECH CO LTD

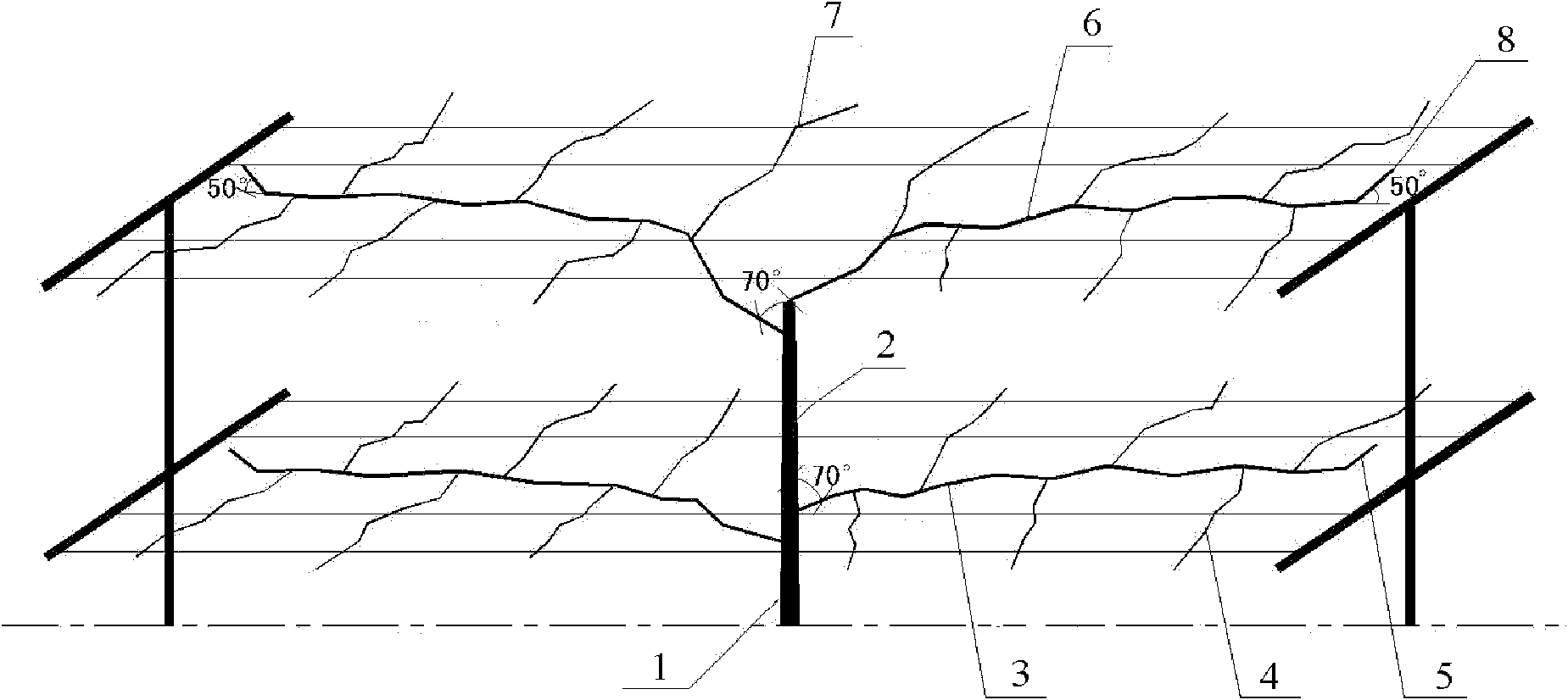

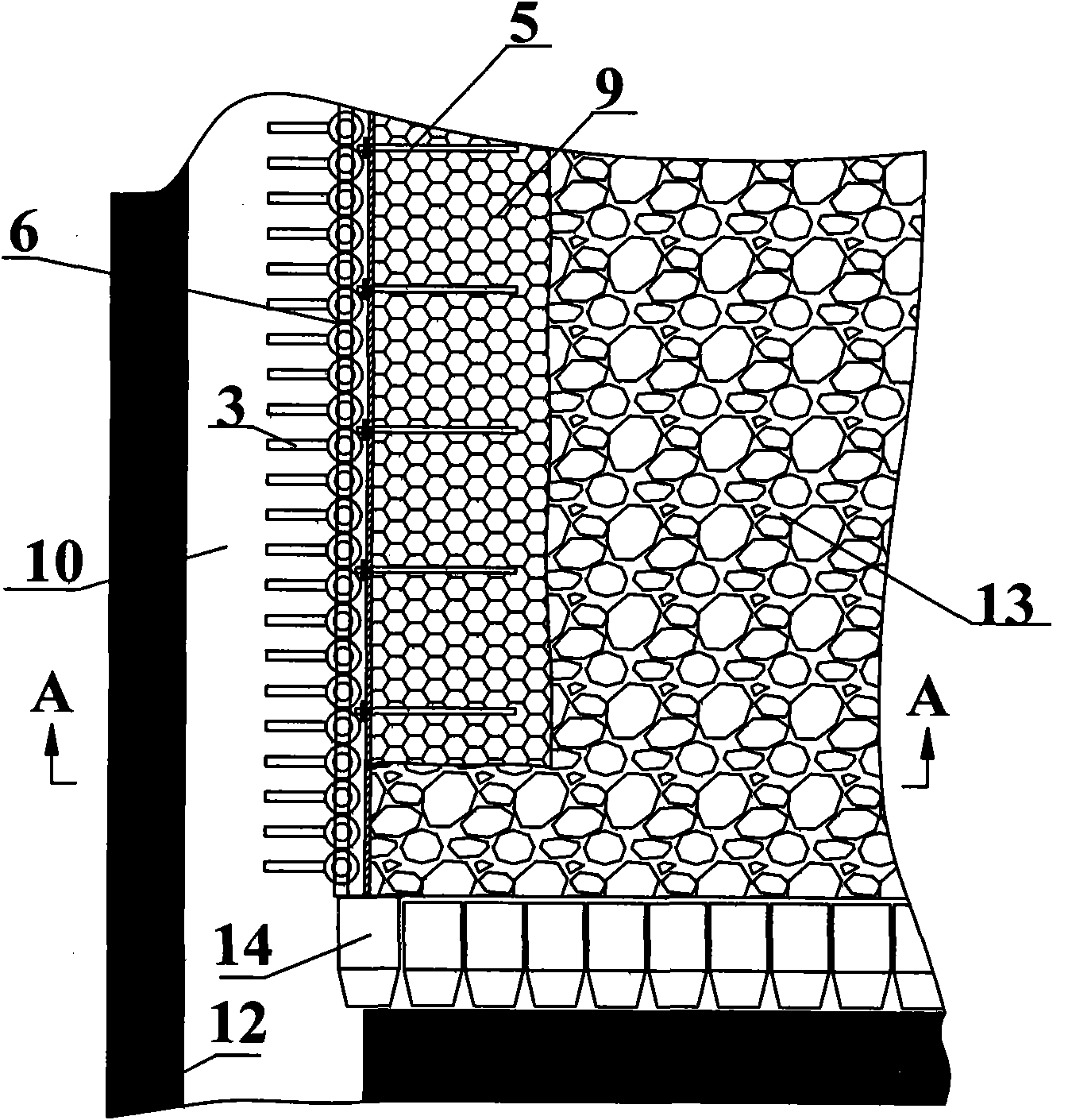

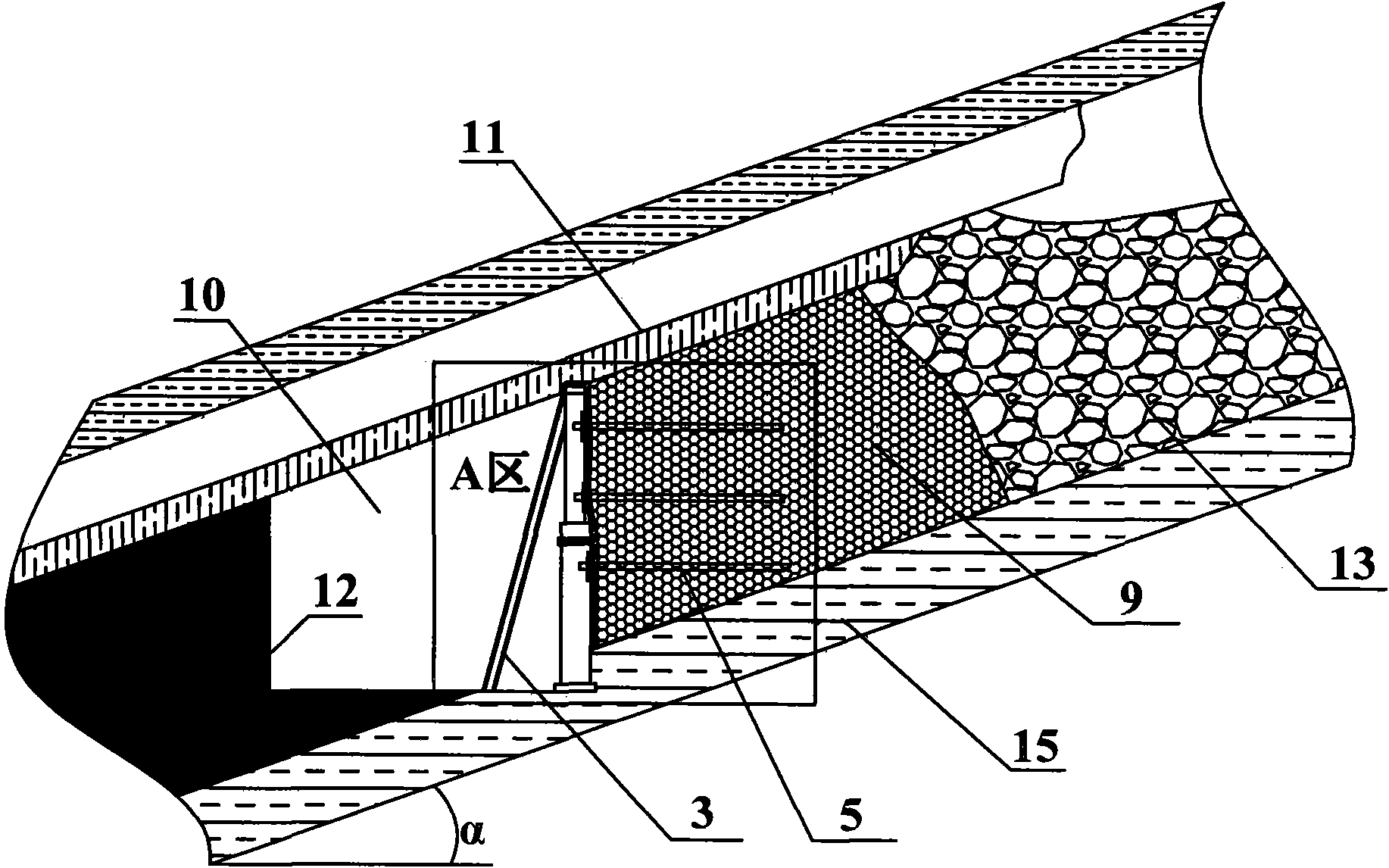

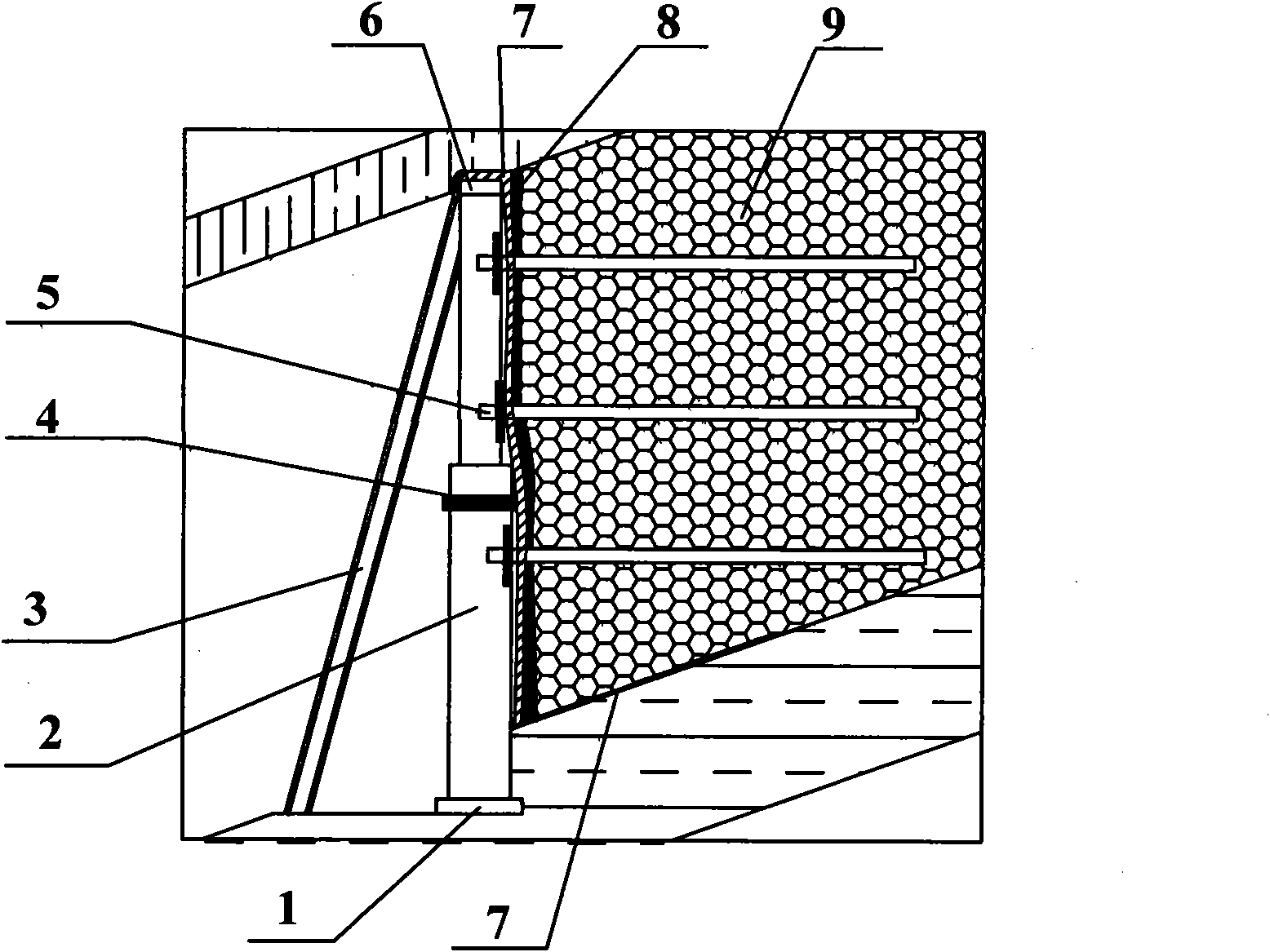

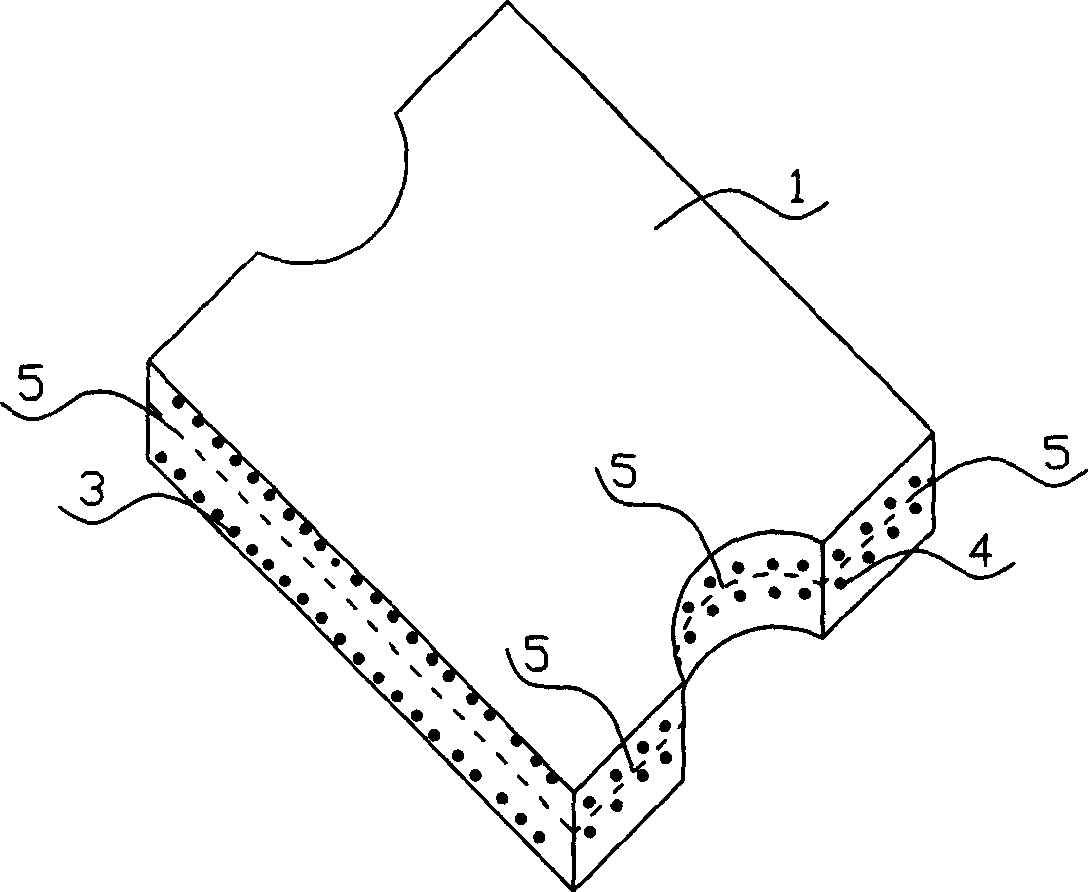

Building method of filled wall body for gob-side entry retaining of large-inclination coal seam

The invention relates to a building method of a filled wall body for gob-side entry retaining of a large-inclination coal seam, which comprises the following steps: erecting dense individual props on the entry retaining side on the rear part of a heading stope to retain roadway space on the rear part of the heading stope, erecting anti-tilting side supports along the dense individual props, laying reinforcing fabric and high-strength fiber cloth on the side of the dense individual props close to the gob, and building a structure used for intercepting waste rocks in the gob; and when the dropped waste rocks in the gob automatically slide along the large-inclination footwall to the waste rock blocking structure formed by the reinforcing fabric and the high-strength fiber cloth under the effect of the dead weight and pile up to a certain degree, grouting and cementing part of the dropped waste rocks near the entry retaining side for consolidation, thereby forming the filled wall body, and repeating the steps in sequence along with the advancement of the heading stope until the whole filled wall body for gob-side entry retaining. The invention has the advantages of simple method and high working efficiency, the filled wall body built in the method is of high strength and is also economical and practical, and the method is suitable for the building of the filled wall body for gob-side entry retaining under the high-inclination condition.

Owner:CHINA UNIV OF MINING & TECH

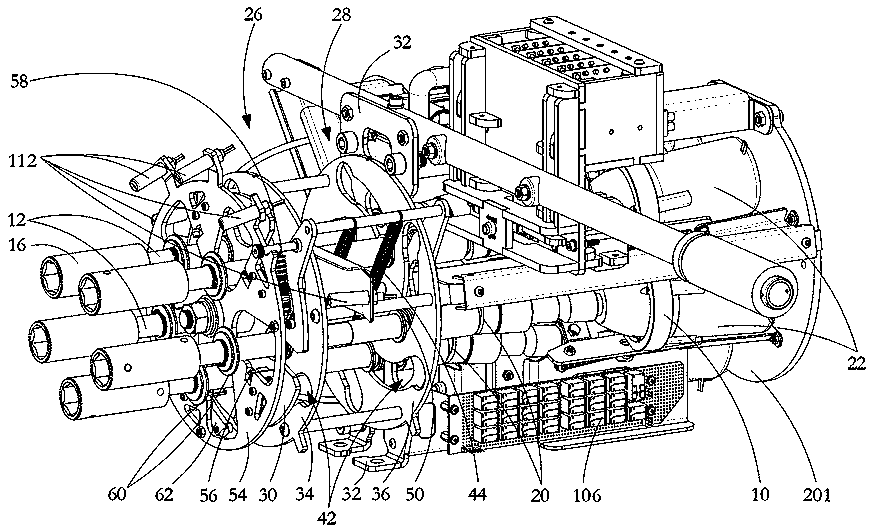

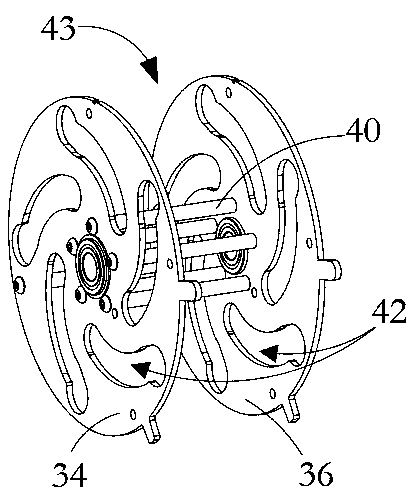

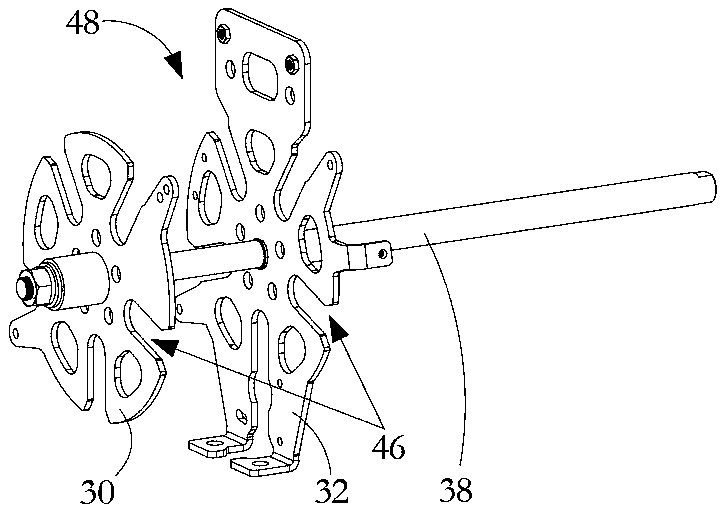

Apparatus and method for attaching / detaching circular arrayed fasteners

ActiveCN109454436AQuickly adjust spacingAppropriate volumeWheel mounting apparatusMetal working apparatusThreaded fastener

An apparatus and method for attaching / detaching a circular array of threaded fasteners are suitable for mounting a fastener of a wheel to a vehicle or removing a fastener of the wheel from the vehicle. The apparatus has a bracket and a set of parallel rotating shafts mounted on the bracket, the axes of the rotating shafts being distributed in a circular array, or equivalently described as that,the axes of the rotating shafts being equidistantly distributed on a cylindrical surface. These shafts can be rotated about respective axes, and one end of these shafts can be used to hold and rotatesome type of threaded fastener. The threaded fastener is configured to form a thread pair with another type of threaded fastener on the wheel mounting member for securing the wheel to the wheel mounting member. The apparatus has an adjustment mechanism capable of synchronously adjusting the positions of all the rotating shafts such that the diameter of the cylindrical surface of the axis of all the above-mentioned rotating shafts varies between the first diameter and the second diameter, thereby adjusting the size of the rotating shaft spacing.

Owner:文洪财

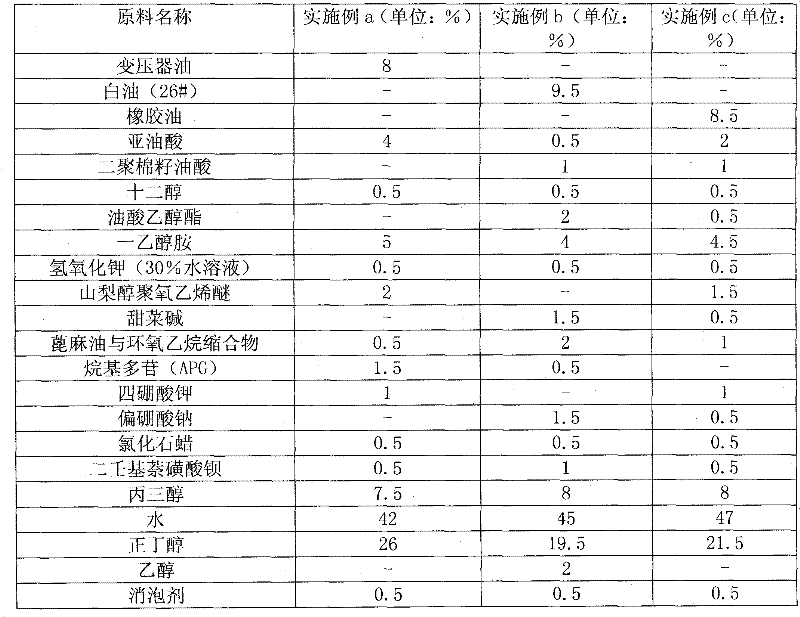

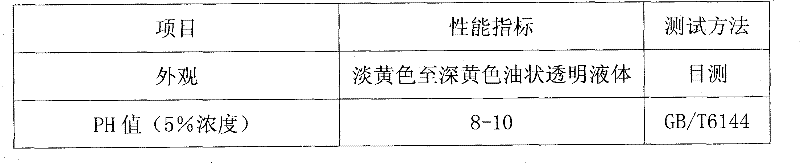

Heavy-duty metal processing cutting lubricant and preparation method thereof

The invention discloses a lubricant for heavy-load machining of metals and a preparation method thereof. The lubricant comprises mineral oil, component A, component B, component C, component D, component E and an antirust agent, and the sum weight percentage of the above-mentioned raw materials is 100%. The preparation method is as follows: adding mineral oil in a container capable of stirring and heating, allowing the temperature of the container to rise to 75 to 80 DEG C, adding component A and component B, allowing the temperature of the container to maintain 75 to 80 DEG C, allowing the mixture in the container to react for 30 min, adding component C and the antirust agent, carrying out insulation and an reaction for 30 min, adding component D, carrying out insulation and an reaction for 30 min, cooling the container to a temperature of 30 DEG C, adding component D, and carrying out filtering and packaging so as to obtain a finished product. The lubricant for heavy-load machining of metals provided in the invention costs little, is nonflammable and has excellent performance. The preparation method for the lubricant in the invention has the characteristics of low cost, simple operation and easiness in large scale popularization and application.

Owner:圣保路石油化工(天津)股份有限公司

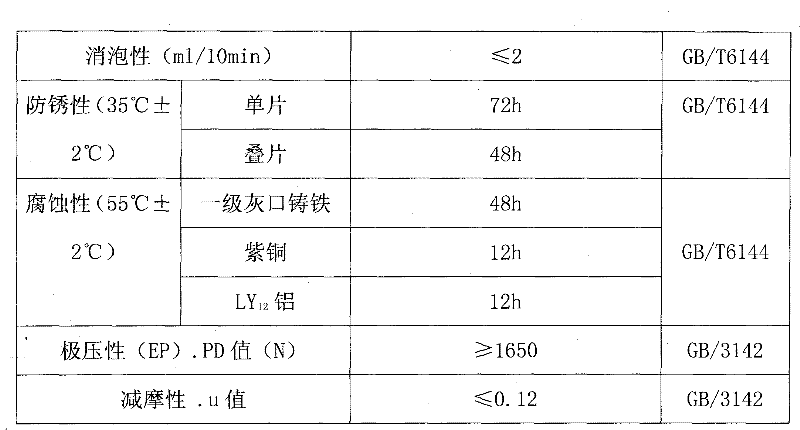

Garlic planter

ActiveCN102027822AImprove accuracySolve the orientation problemSowingConverting sensor outputSeederAgricultural engineering

The invention discloses a garlic planter belonging to the agricultural machinery and structurally comprising a stand, a soil casing mechanism, a soil hacking mechanism, a front wheel, a rear wheel, a seed box and a power speed shifting mechanism, wherein the power speed shifting mechanism comprises a power box, a power wheel, a chain wheel, a third chain and a speed shifting mechanism; the power wheel is connected with the power box, the bottom of the seed box is provided with a garlic flake taking mechanism, the lower part of the garlic flake taking mechanism is provided with an identifying and steering mechanism, the power speed shifting mechanism is connected with an inserting-planting mechanism, the lower part of the inserting-planting mechanism is provided with a holing mechanism, and the garlic flake taking mechanism, the identifying and steering mechanism, the power speed shifting mechanism and the inserting-planting mechanism are respectively connected with a controller arranged on the stand. The garlic planter has the characteristics of identifying and controlling the bulbil direction of the garlic flake, solving the problem of bulbil direction through inserting-planting after the garlic flake is planted, improving the accuracy rate of upturned bulbil point of the garlic flake and the accuracy rate of the upturned bulbil point of the garlic flake, and lowering the labor intensity.

Owner:江苏南田工机有限公司

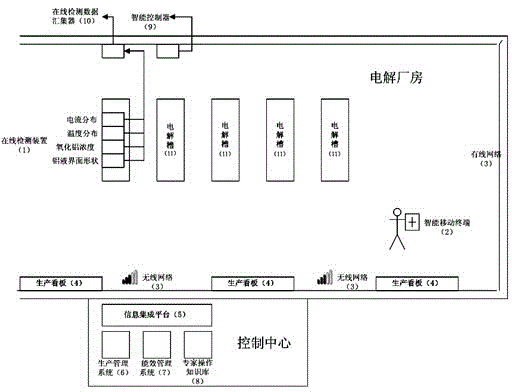

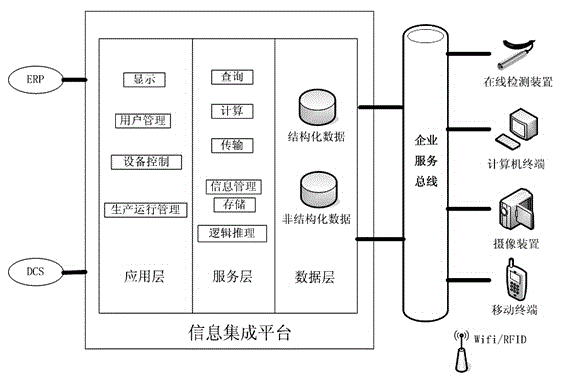

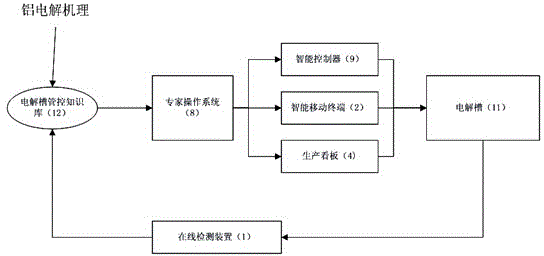

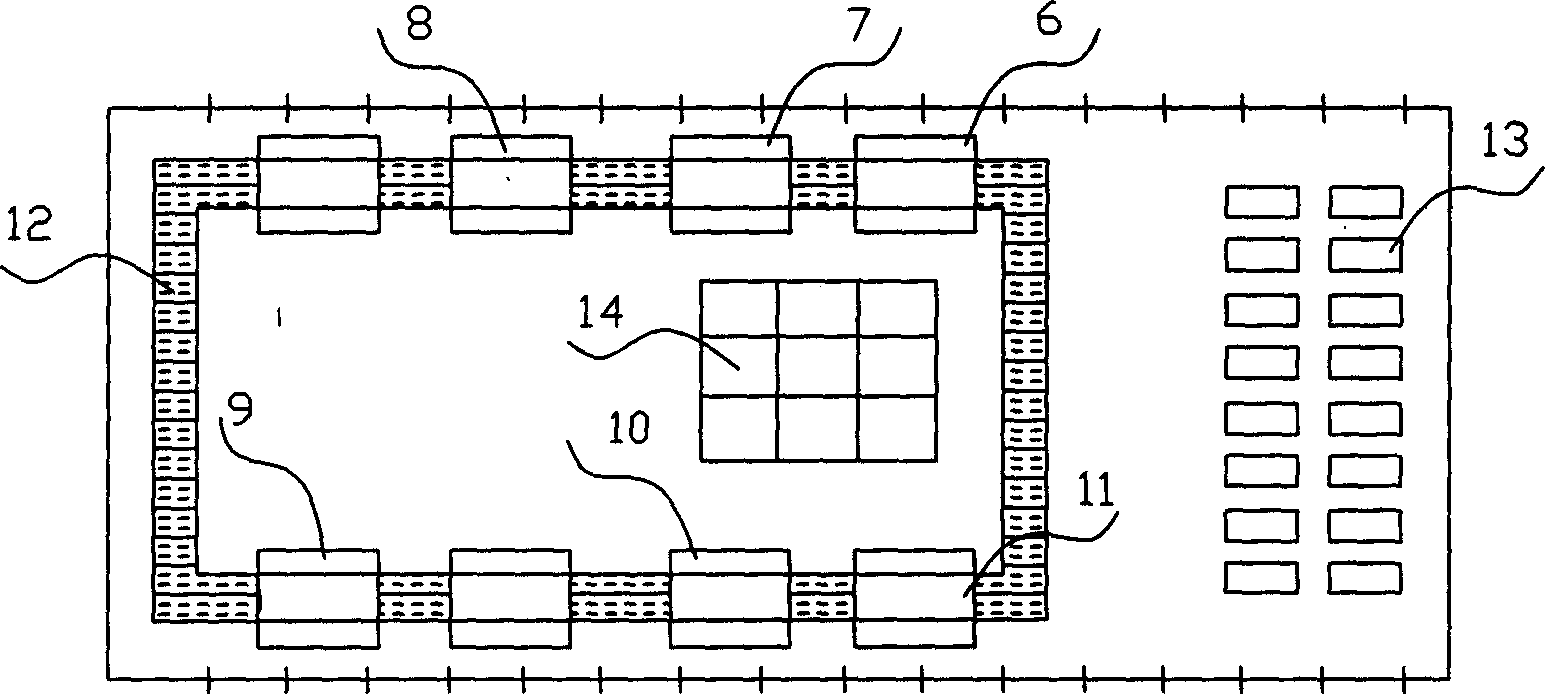

Aluminum electrolytic MES system based on accurate perception and intelligent decision

ActiveCN105467946ARealize precise perceptionReal-time detection of real-time production dataEnergy industryTotal factory controlManagement efficiencyInformation integration

The present invention discloses an aluminum electrolytic MES system based on an accurate perception and an intelligent decision. The system comprises an electrolytic tank online detection device (1) for detecting aluminum electrolytic real-time production data, an online detection data collection device (10) for collecting real-time production data, an intelligent mobile terminal (2) for obtaining the position information of an operator, a plant wireless or wired network (3), a production billboard (4) for information display, an information integration platform (5), a production management system (6) based on production process real-time data, an aluminum electrolytic process energy management system (7), an expert operation system (8) based on electrolytic tank (11) real-time production data, and an intelligent controller (9) for production control. According to the system, the degree of precision and the automation level of the aluminum electrolytic production management and control can be improved, the management efficiency is improved, and the influence on aluminum electrolytic production brought by personnel technology and management level differences can be reduced.

Owner:GUIYANG AL-MG DESIGN & RES INST

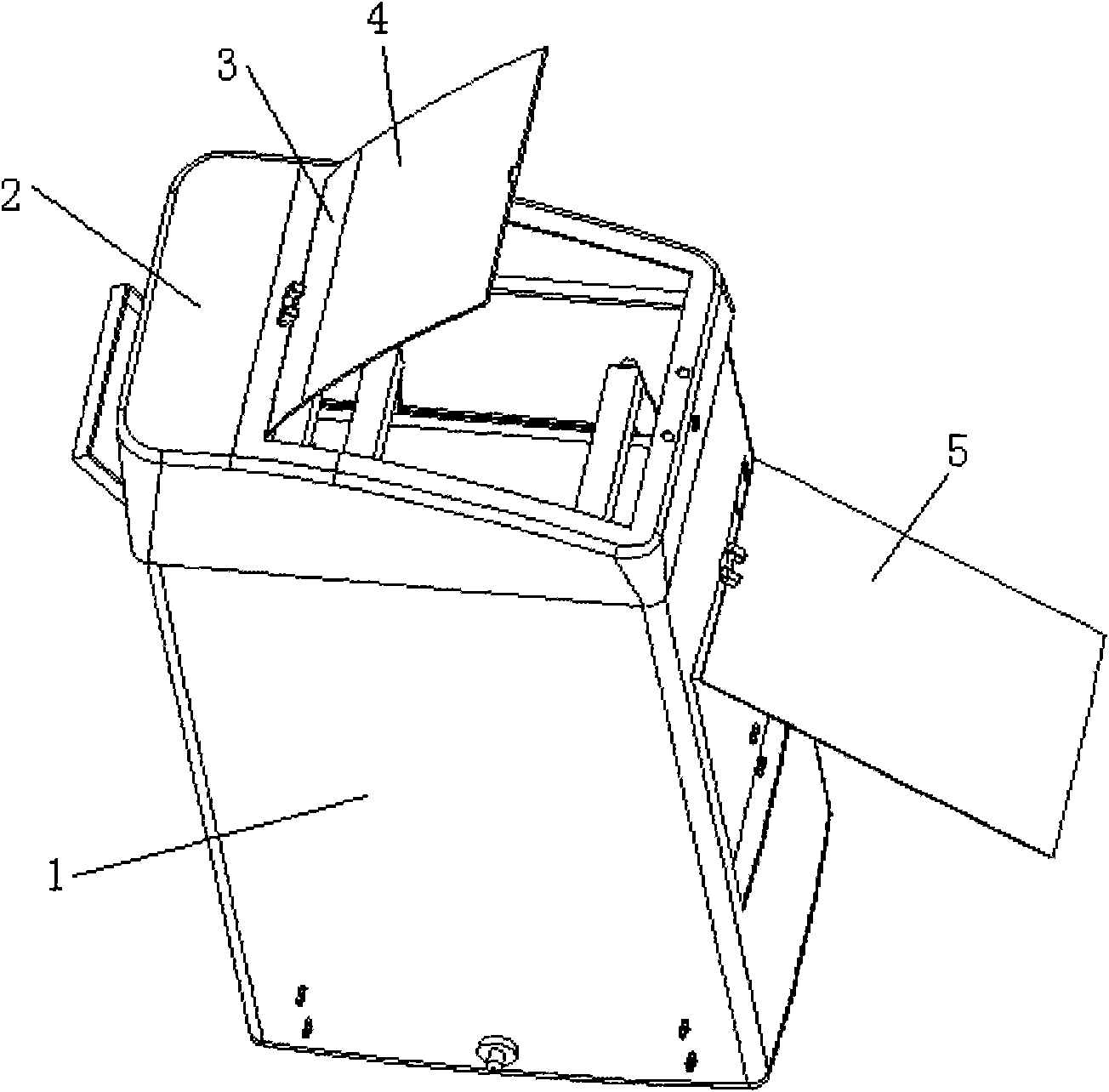

Multifunctional intelligent garbage bin

InactiveCN101580165AChange a single functionAvoid distributingRefuse receptaclesButt jointControl system

The invention discloses a multifunctional intelligent garbage bin which comprises a body, a cover installed at the upper end of the body, an upper garbage inlet arranged on the cover, and an upper cover installed on the upper garbage inlet, wherein the upper cover is formed by the hinge joint of a front cover plate and a rear cover plate, the front cover plate is hinged on the cover; the side wall of the body is provided with a side cover door, and a pull-in magnet is arranged at the butt joint part of the side cover door and the inner side of the body; the body is internally provided with a sealing mechanism, a bag-pushing mechanism and a bag changing mechanism, and the bottom of the body is provided with a sealing motor; the upper end of the cover is provided with an infrared sensor, and the front cover plate is provided with a contact sensor; a cover-opening motor, the sealing motor, a butt-joint heat-sealing device, the infrared sensor and the contact sensor are all connected with a control system, and the control system is arranged at the bottom of the body. The invention has artful structure, can realize the functions of automatic cover opening and cover closing, automatic bag-sealing and bag-pushing and automatic bag-changing, brings convenience to operation for cleaners, improves the labor efficiency of the cleaners, and guarantees the environmental health.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE +1

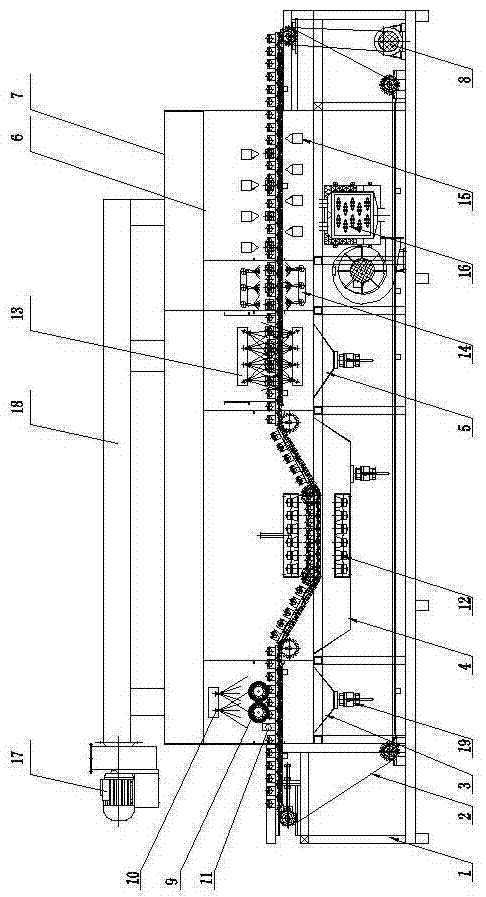

Cleaning machine for rack parts of automobile steering devices

ActiveCN105436111AImprove processing timeImprove labor efficiencyDrying gas arrangementsCleaning using toolsMegasonic cleaningSmall footprint

The invention relates to a cleaning machine for rack parts of automobile steering devices and belongs to the field of cleaning equipment for racks of the automobile steering devices. The cleaning machine is composed of a machine frame, a conveying chain, a spraying and scrubbing tank, an ultrasonic cleaning tank, a high-pressure spraying and cleaning tank, a drying room and an electric appliance control box. The spraying and scrubbing tank is arranged below one end of the conveying chain in a cleaning room. The ultrasonic cleaning tank is arranged at the portion, on one side of the spraying and scrubbing tank, of the machine frame. An ultrasonic vibration plate is arranged on the portion, corresponding to the conveying chain, of the ultrasonic cleaning tank and connected with an ultrasonic generator. The cleaning machine is small in occupied area and convenient to operate. Working efficiency is improved and is high, the cleanliness and cleanliness quality of rack workpieces are guaranteed, and the problems that a manual one-by-one scrubbing manner is adopted for existing steering device rack products, so that working efficiency is low, it is difficult to keep the same cleanliness quality, the labor intensity of workers is larger, and the industrial production requirements cannot be met are avoided. The cleaning machine is especially suitable for cleaning and use of rack products of the steering devices.

Owner:荆州恒隆汽车零部件制造有限公司

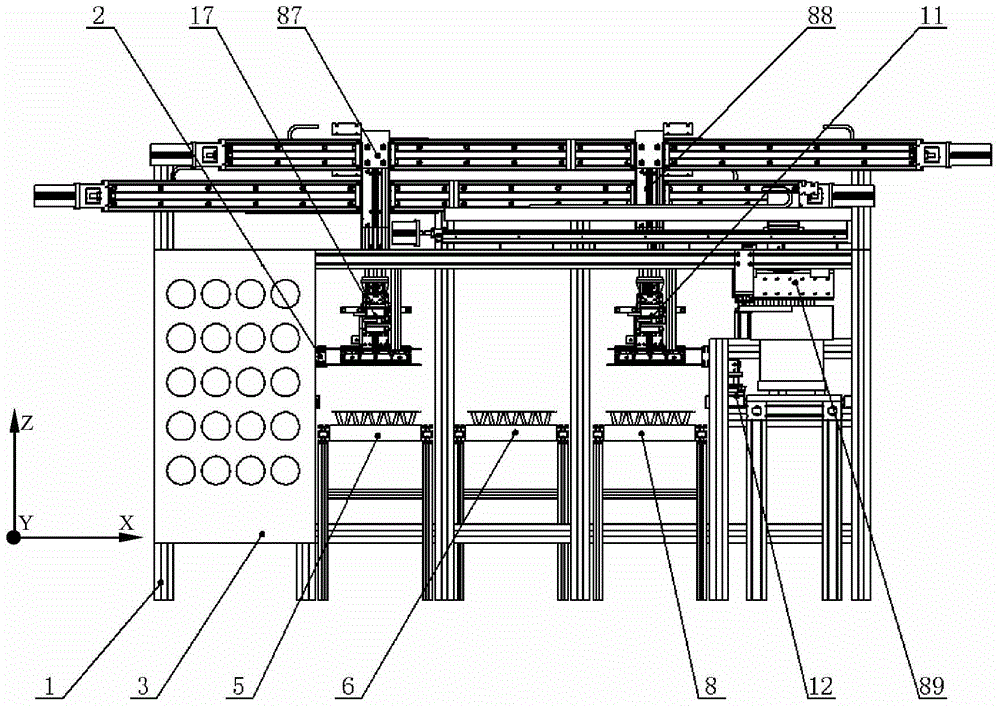

Automatic whole-row grafting device for grafted seedlings

The invention relates to the technical field of agricultural machinery, in particular to an automatic whole-row grafting device for grafted seedlings. The device comprises a rack (1), an electric control cabinet (3), a scion conveying mechanism I (5), a scion conveying mechanism II (8), a grafted seedling conveying mechanism (6), a scion clamping mechanism (87), a rootstock clamping mechanism (88), a scion seedling cutting mechanism (17), a rootstock seedling cutting mechanism (11), a scion seedling gathering mechanism (2), a rootstock seedling gathering mechanism (12) and an automatic whole-row grafting clamp conveying mechanism (89). According to the automatic whole-row grafting device for the grafted seedlings, plug seedling supply, whole-row seedling grabbing, seedling cutting, fixing and grafting of plug rootstock seedlings and plug scion seedlings are realized, and the whole operation process is automatically completed by a machine; the plug seedlings are rapidly grafted, the labor efficiency of grafting operation is improved, and the labor force is saved.

Owner:CHINA AGRI UNIV

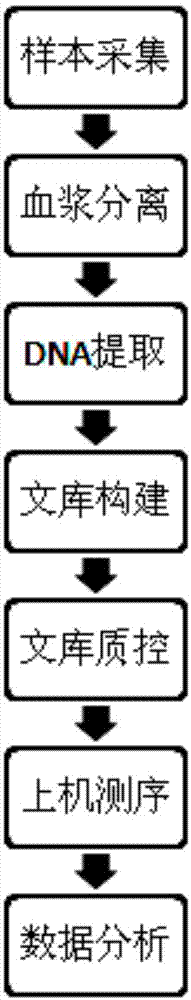

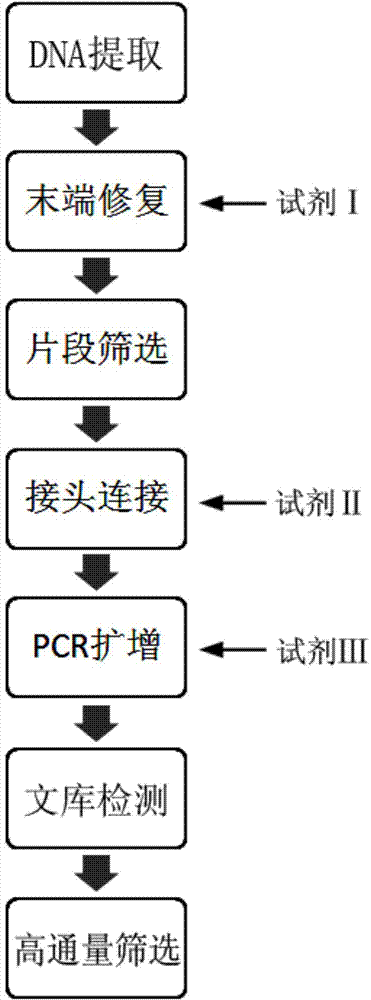

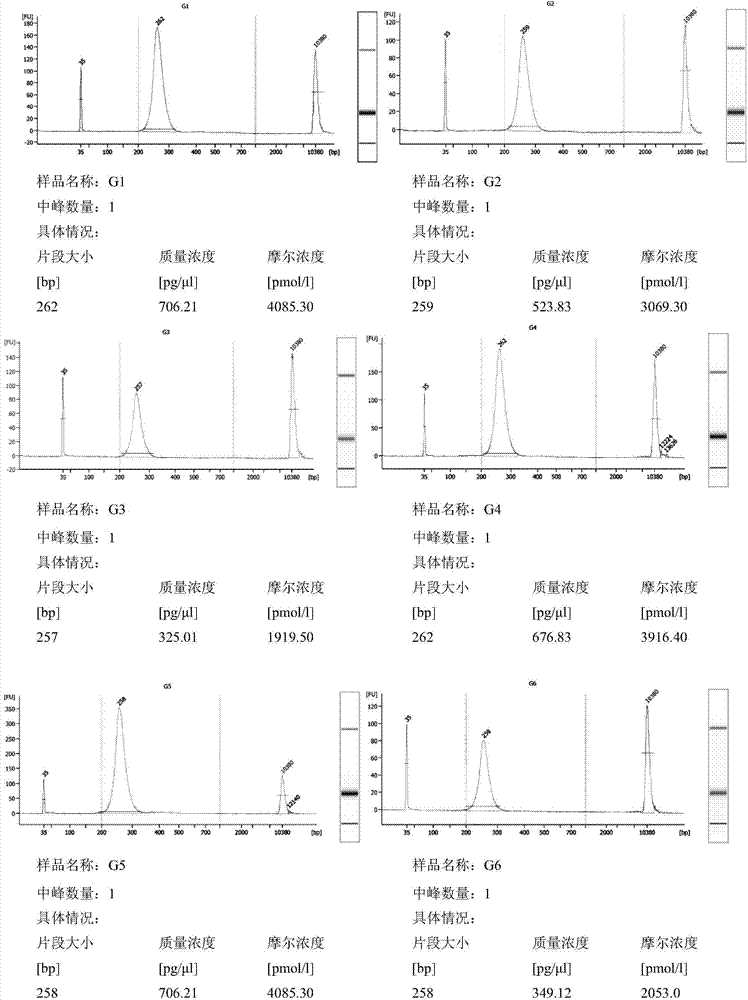

Establishment method for small fragmental DNA (Deoxyribose Nucleic Acid) library based on Ion ProtonTM sequencing platform and application of establishment method

ActiveCN103572378AReduce lossesReduce wasteNucleotide librariesMicrobiological testing/measurementIonDeoxyribose

The invention belongs to the field of gene sequencing, and discloses an establishment method for a small fragmental DNA (Deoxyribose Nucleic Acid) library based on an Ion ProtonTM sequencing platform, and a relevant solvent composition solution. The establishment method disclosed by the invention comprises the steps of DNA sample extraction, tail end repairing, fragment selection, joint connection, PCR (Polymerase Chain Reaction) amplification, library detection, high-throughput sequencing and the like, wherein a reagent I, a reagent II and a reagent III are respectively adopted in the steps of tail end repairing, joint connection and PCR amplification. The establishment method disclosed by the invention is precise and simple in step, simple to operate, small in reagent variety and low in cost, the loss and waste of the library are reduced, and the working efficiency is improved; in addition, the establishment method can be applied to noninvasive antenatal diagnosis on pregnant woman peripheral blood fetus chromosome aneuploid based on the Ion ProtonTM sequencing platform, the diagnosis result is high in accuracy rate and is safe and economic, and the birth rate of chromosome aneuploid fetuses can be effectively controlled.

Owner:BOAO BIOLOGICAL CO LTD

Cleaning machine with brine electrolysis device and cleaning method thereof

ActiveCN103801530AEasy to cleanImprove antivirusWashing processesSpecific water treatment objectivesAlkaline waterElectricity

The invention discloses a cleaning machine with a brine electrolysis device and a cleaning method thereof. The cleaning machine comprises a container. A water inlet is formed in the circumferential face of the container, a rotary gushing arm is arranged above the bottom face of the container, and the outer side of the water inlet is provided with a movable water inlet pipe which can be inserted in or stretch out of the water inlet and is communicated with the rotary gushing arm. The cleaning machine further comprises the brine electrolysis device. The water inlet pipe of the outside enters a first three-way electromagnetic valve, the other two ends of the first three-way electromagnetic valve are connected with a water channel and a circulating water pump of the brine electrolysis device respectively, and a water outlet of the circulating water pump is connected to a second three-way electromagnetic valve. A water outlet pipe of an acidic water tank and a water outlet pipe of an alkaline water tank are both communicated with the circulating water pump. The second end of the second three-way electromagnetic valve is connected to a movable water inlet pipe. According to the cleaning machine with the brine electrolysis device and the cleaning method thereof, electrolyzed alkaline water and acidic water are used for conducting circulation cleaning and sterilizing, and thus pollution of waste water to the environment is reduced; moreover, the design process is reasonable and compact, cleaning time is short, the quantity of electricity is greatly saved, and the efficiency of labor is improved.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

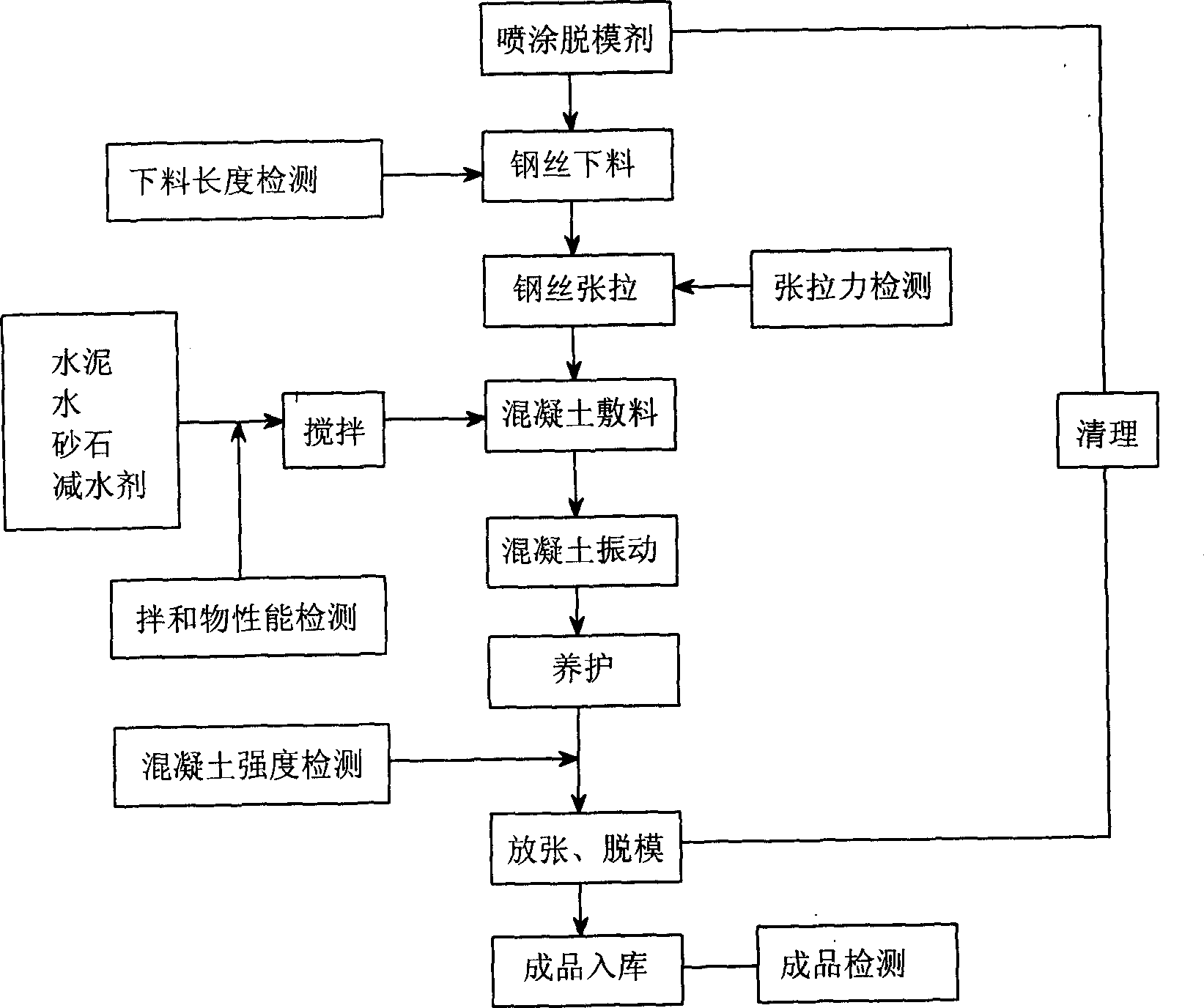

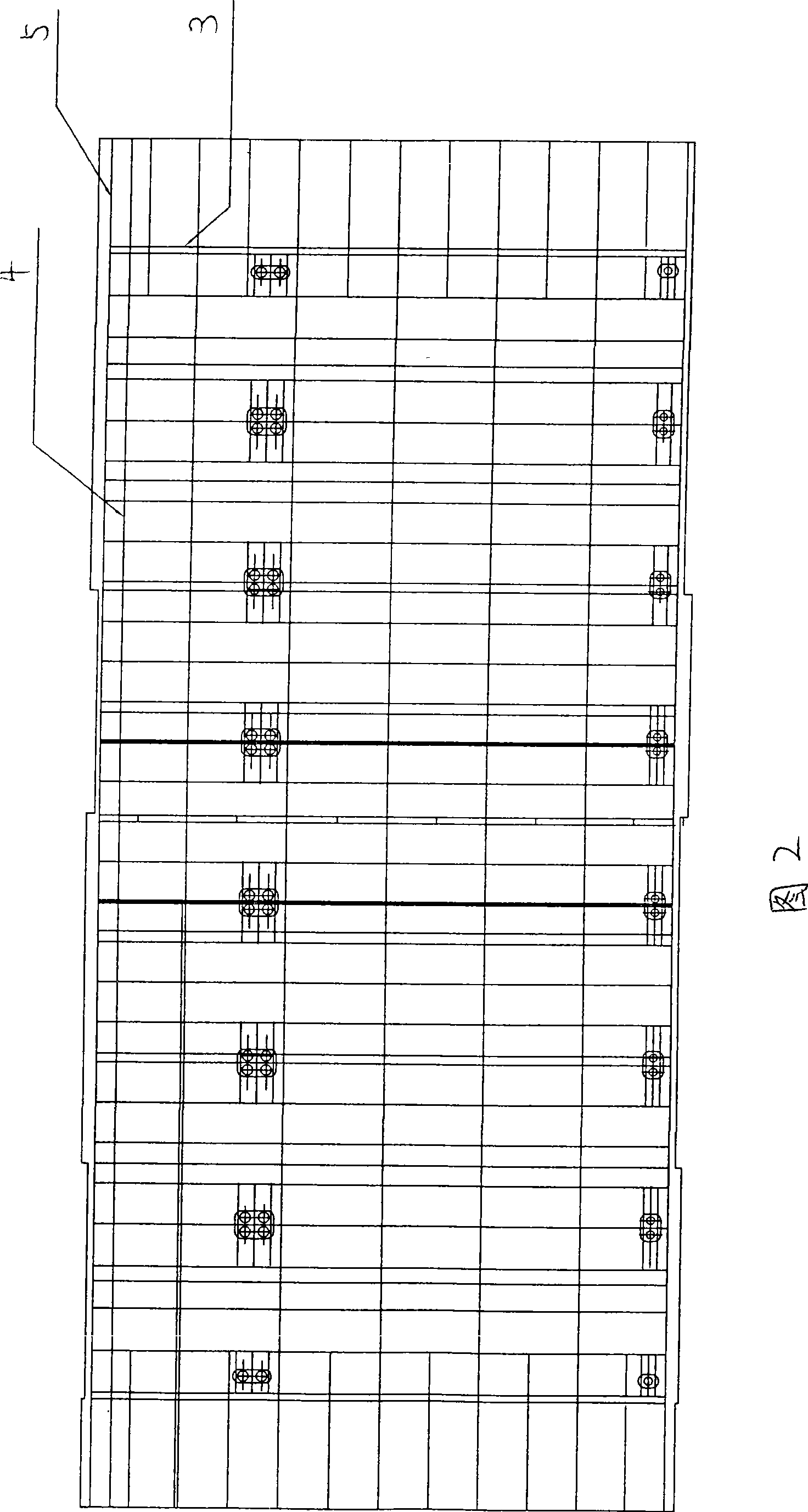

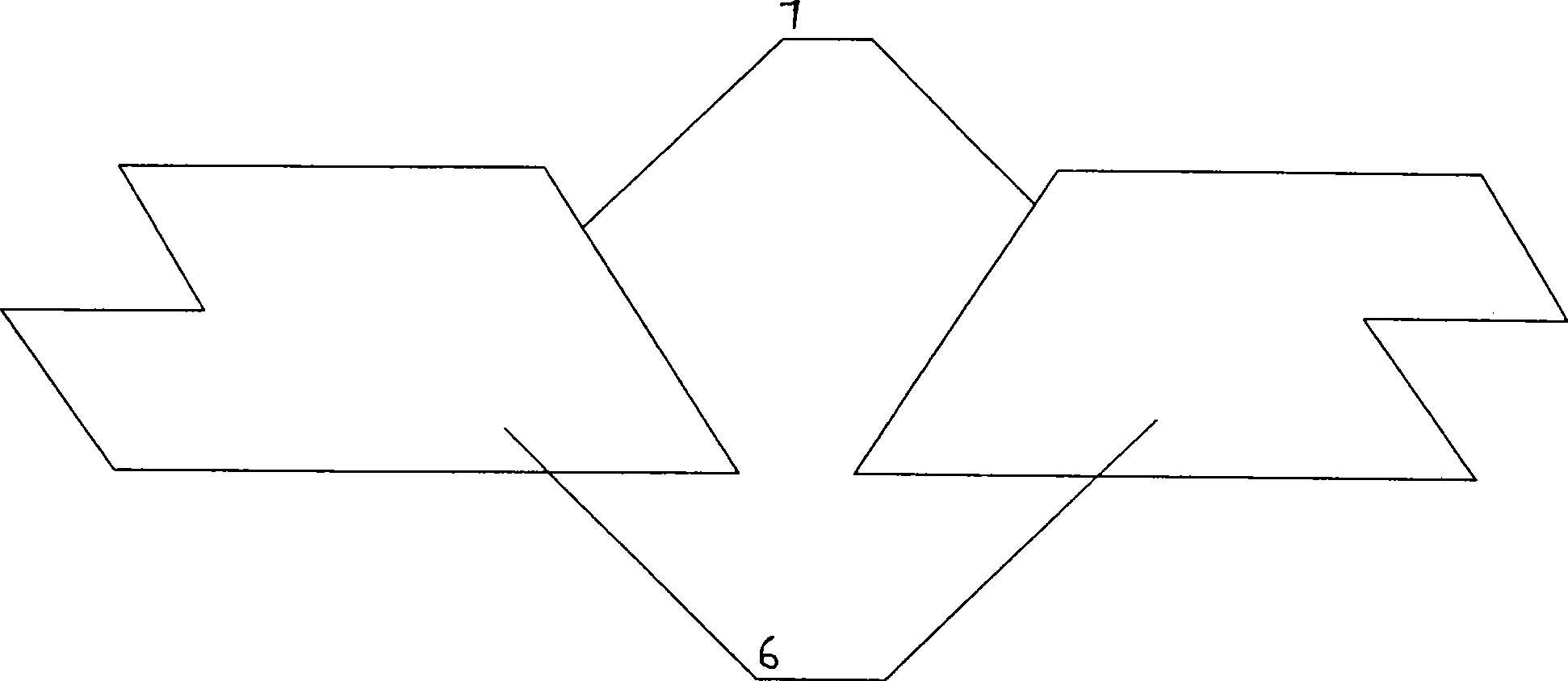

Bidirectional pretensioning method prestressed concrete railway board and assembly machine sets method production process

InactiveCN1865593AReduced creep warpageReduces the possibility of creep warpingBallastwayCeramic shaping plantsProduction linePre stress

The invention relates to a bidirectional pre-stress concrete track plate with significant electric property and lower producing cost, and relative production line. Wherein, the track plate is a cuboid, with several preset structures; there are at least two layers of steel wires inside the track plate along its length and width directions; the steel wires in said two directions do not contact each other; said pre-stress concrete track plate are tensioned along the length and width directions; the production method comprises: spraying demoulding agent, feeding material, tensioning, coating concrete, vibrating, maintaining, tensioning and demoulding. The invention can overcome the defects of present technique, with simple method, while it can be used to build high-speed railway.

Owner:欧阳炎

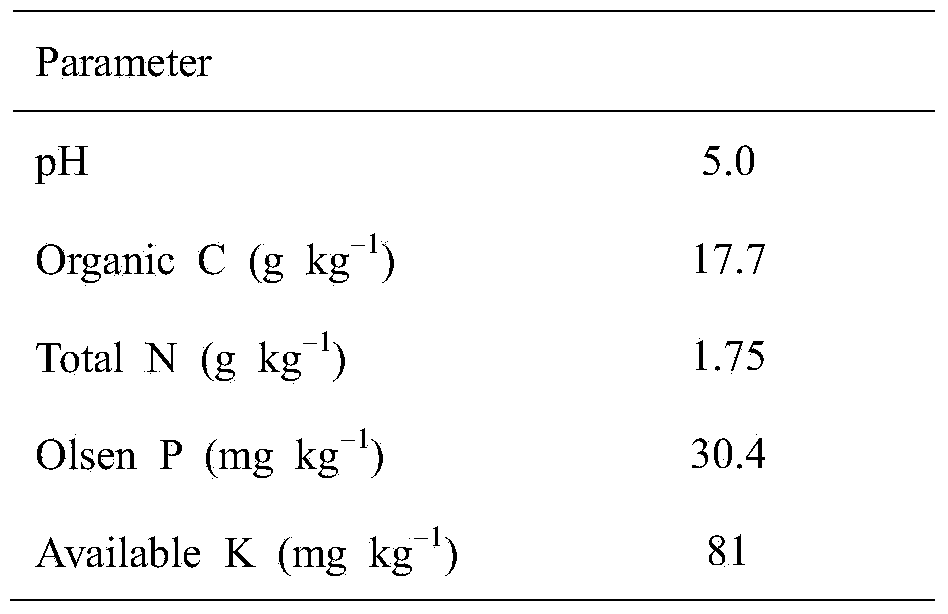

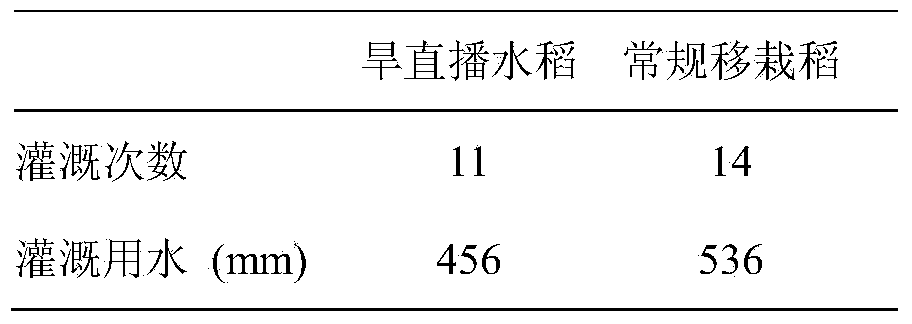

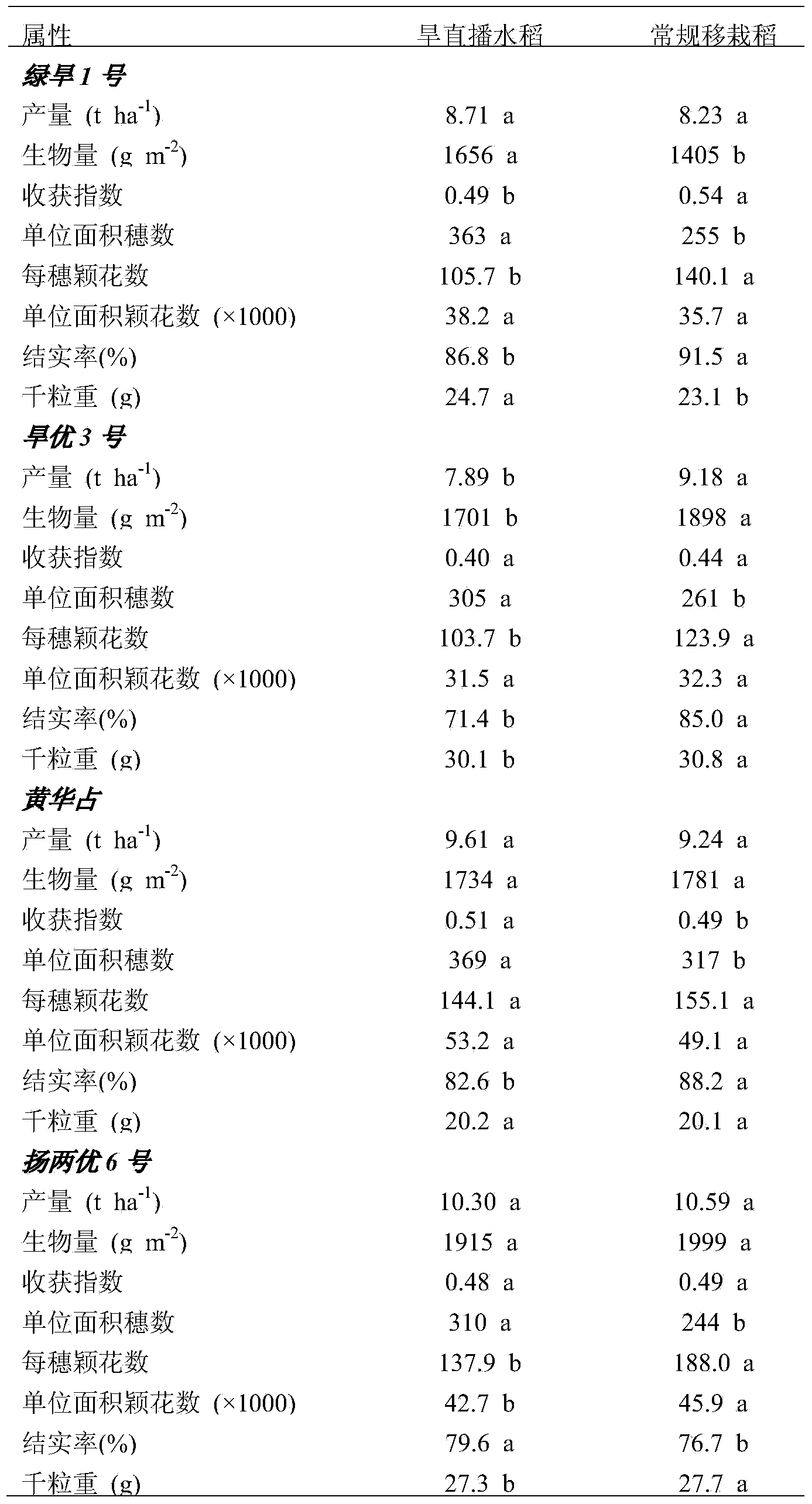

High-yield and high-efficiency cultivation technology for drily direct-seeding rice

The invention discloses a cultivation method for drily direct-seeding rice. The cultivation method comprises the following steps: A. dry soil preparation: drily ploughing and preparing the land, and raking the land thoroughly; B. application of fertilizer: during the whole growth period, the dosage of nitrogen phosphorus and potassium being 10-13 kg of N, 4-6 kg of P2O5 and 5-8 kg of K2O per mu (a unit of area, equal to 0.0667 hectares), wherein the nitrogen phosphorus and potassium in the base fertilizer is 40%, 100% and 50% of the planned dosage in the whole growth period; C. seed selection and coating: selecting high-yield large-panicle type or intermediate form type of rice seeds, utilizing a special dry cultivation seed coating agent to be mixed with the seeds; D. sowing: sowing the seeds in the last twenty days of April and the first ten days of June at a seed amount per mu of 1.5-4.0 kg; E. weed control: utilizing a weed control method of removing the weed, utilizing a herbicide and supplementing the rice seeds; F. water management: taking rainwater cultivation as a main manner from the seedling emergence period to a three-leaf and one-core period, and conducting flood irrigation from the three-leaf and one-core period to two weeks before harvesting; G. integrated control of diseases and pests. With adoption of the high-yield and high-efficiency cultivation technology for the drily direct-seeding rice, the average yield per mu is 608.7 kg, which is not lower than the conventional transplant planting pattern; furthermore, the moisture production efficiency and the grain nitrogen production efficiency are both obviously higher than that of the conventional transplant planting pattern.

Owner:HUAZHONG AGRI UNIV

Pholiota nameko culture method

InactiveCN102613006ATake full advantage of the mushrooming effectRaw materials are easy to getHorticultureFertilizer mixturesPholiotaMycelium

The invention relates to a pholiota nameko culture method, which comprises the steps of: culture material proportioning and preparation, sterilization, inoculation and bagging, mycelium culture, summer-crossing management and primordium inducement fruiting. The pholiota nameko culture materials comprise the following recipe and mixture ratios: 30 to 50 parts of corncobs, 30 to 50 parts of soft mixed hardwood sawdust, 10 to 20 parts of bran, 2 to 4 parts of corn starch, 0.5 to 1.5 parts of gypsum and 0.5 to 1.5 parts of lime. The culture raw materials adopt the corncobs and the soft mixed hardwood sawdust as major materials, a good basis is laid for the smooth implementation of the Natural Forest Protection Projects and the pholiota nameko planting in flat areas, planting trays are omitted, the culture cost can be saved by 15 percent, the culture process is simple and is easy to implement, the work efficiency is improved, the edge fruiting effect of the pholiota nameko bag type culture is improved by 30 percent through being compared with that of the disc type culture, the edge fruiting effect of the edible fungi is sufficiently utilized, the yield can be improved by more than 10 percent, and the high-quality fruiting rate is improved by more than 40 percent.

Owner:沈阳蕈丰食用菌科技有限公司

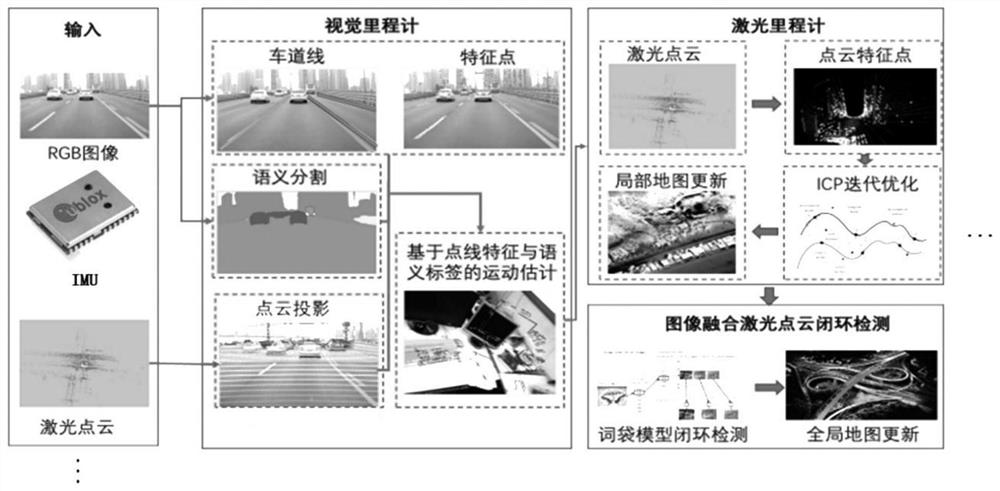

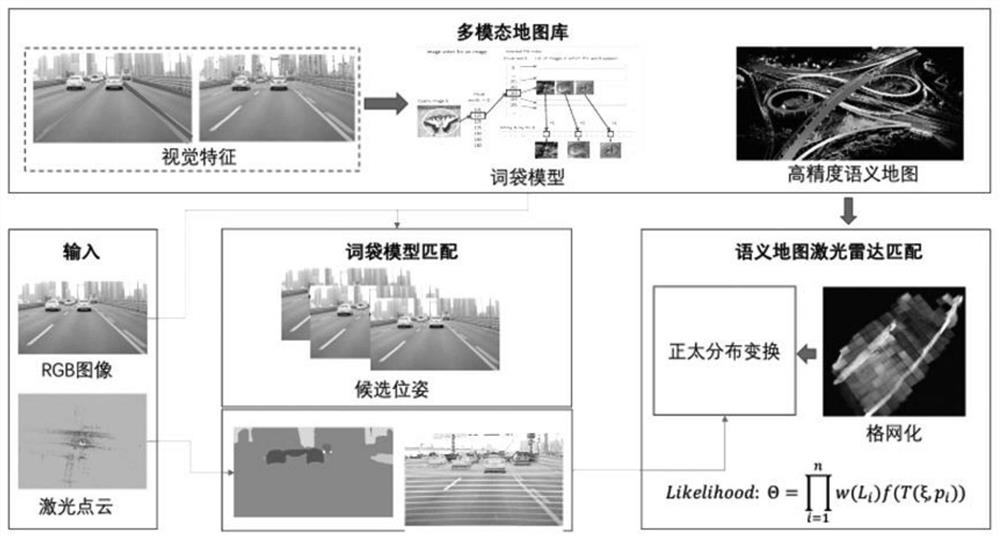

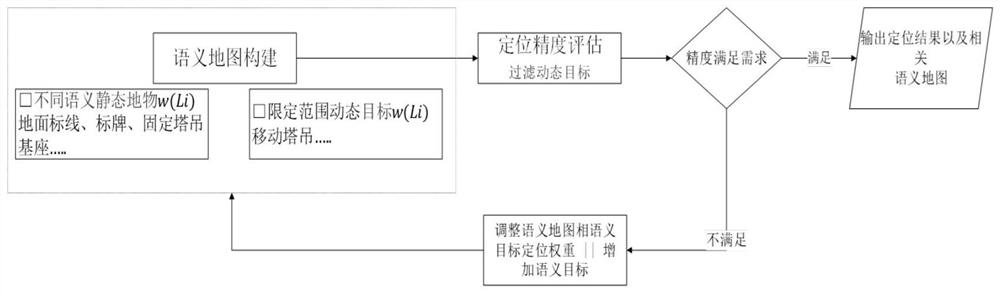

Semantic high-precision map construction and positioning method based on point-line feature fusion laser

PendingCN111652179APrecision editingAccurate removalCharacter and pattern recognitionGeographical information databasesPoint cloudGraph model

The invention discloses a semantic high-precision map construction method based on dot-line feature fusion laser, which comprises the following steps: 1) performing semantic segmentation and feature extraction on a visual image acquired by a camera to obtain a visual image containing semantic categories and dot-line features, and then obtaining a foreground and a background of a moving target; 2)projecting the laser three-dimensional point cloud acquired by the laser radar onto a visual image plane, fitting to obtain a depth map, and endowing the laser three-dimensional point cloud with semantic categories and dot line features; 3) performing super-pixel segmentation on the moving target, calculating the distance between super-pixel blocks, constructing a graph model, performing image segmentation, and accurately extracting the boundary of the moving target; and 4) removing the visual feature points and the laser three-dimensional points belonging to the moving target to construct a static high-precision semantic three-dimensional map. The invention further discloses athe positioning method of the semantic high-precision map constructed by adopting the method, and the mapping is more accurate and reliable by accurately removing the moving target.

Owner:DONGFENG AUTOMOBILE COMPANY

A hollow microsphere masonry dedicated thermal insulation mortar and a dedicated surface mortar

InactiveCN102690091AEliminate hot and cold bridgesEliminate hot and cold bridge phenomenonThermal insulationMicrosphere

A hollow microsphere masonry dedicated thermal insulation mortar and a dedicated surface mortar, especially a wall self-insulation system-matching hollow microsphere masonry dedicated thermal insulation mortar and a dedicated surface mortar, relate to a constuction energy-saving technology. The hollow microsphere masonry dedicated thermal insulation mortar comprises, by weight, 20-30% of special cement, 2-6% of coal ash, 20-35% of quartz sand, 5-8% of master batch, 35-45% of hollow microphere, and 3-6% of coarse whiting; and the hollow microsphere masonry dedicated surface mortar comprises, by weight, 28-40% of ordinary Portland cement, 3-6% of coal ash, 7-10% polymer, 40-55% of quartz sand, 10-16% of hollow microsphere, and 1-3% of coarse whiting. With a low heat conductivity coefficient, excellent thermal insulation effect, high compression strength, high bonding strength, low contractibility, environment-friendly and fire-proof properties and notable composite economic results, the wall self-insulation system-matching dedicated thermal insulation mortar and a dedicated surface mortar provided in the invention can be widely popularized and used in wall self-insulation system buildings.

Owner:HUBEI TIANQUAN NEW BUILDING MATERIALS

Hull section non-allowance healing accuracy control process

InactiveCN101439754AShorten the construction periodReduce the workload of positioning and trimmingVessel partsMarine engineering

The invention provides a process for controlling hull segmentation non-surplus seaming precision, which comprises the following steps: at the beginning of building, setting each segment of a hull to be in the reverse building state, building an inner bottom plank at the lower part and a bottom board at the upper part; lining out a structural line on the inner bottom plank and drawing surplus cutting lines at two ends thereof simultaneously, and getting 200 millimeters inwards from two ends of a seaming opening as a cross checking line; building the segments of the hull, and turning over the segments of the hull after selection; after turning over the segments of the hull, taking the inner bottom plank as a horizontal plane to adjust levels of four angles, and controlling the planeness of the inner bottom plank in certain range as required; assigning a length direction checking line in the rib direction of the seaming openings at two ends; and punching holes to make marks; lining out a surplus cutting line and a cutting checking line of a segmental annular seaming opening simultaneously; performing cutting, and machining dioxygen divided edges on the adjacent planks of the seaming opening; and after all the segmental cuttings, building a slipway to perform the seaming. Through the non-surplus precision control, the processes of seaming, cutting and secondary seaming are saved, the building cycle of the whole hull is greatly shortened, the labor efficiency is improved, and the enterprise benefit is increased.

Owner:JIANGDONG SHIPYARD CHINA NAT CHANGJIANG SHIPPING COOPERATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com