Patents

Literature

306results about How to "Clean working environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Volatile rust preventive oil

InactiveCN102719302AInhibit corrosion and rustClean working environmentAdditivesGas phaseAntioxidant

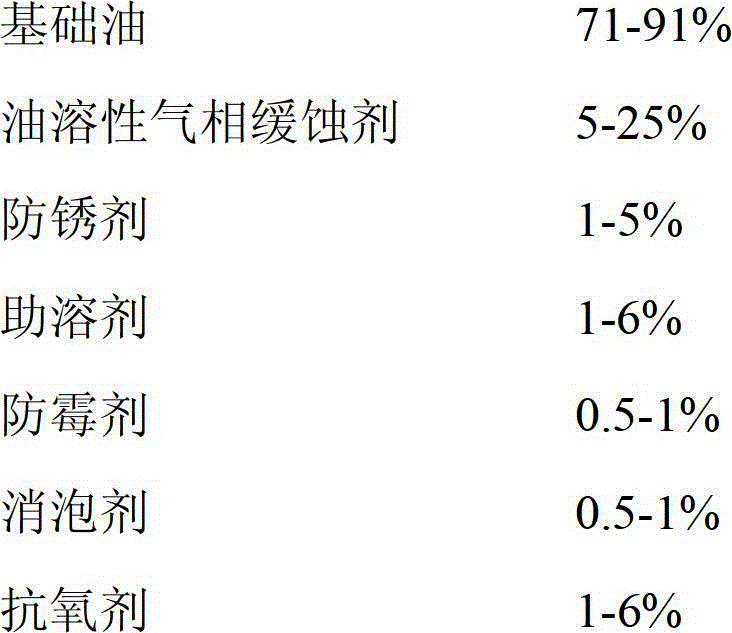

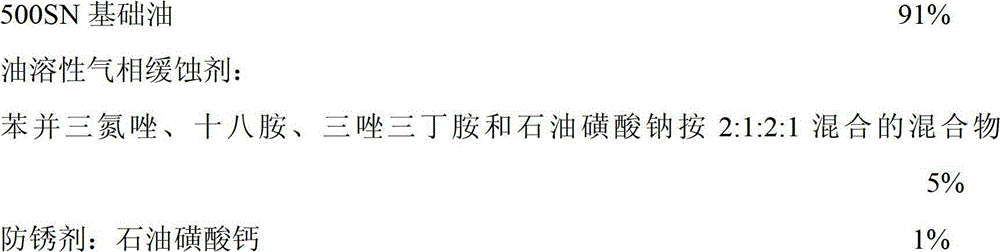

The invention discloses volatile rust preventive oil which comprises, by weight, 71-91% of base oil, 5-25% of an oil soluble volatile corrosion inhibitor, 1-5% of an antirusting agent, 1-6% of a cosolvent, 0.5-1% of a mildew-proof agent, 0.5-1% of an antifoaming agent and 1-6% of antioxidant, wherein the base oil is one of 500SN 46# machine oil, 32# machine oil, 600SN 150# machine oil and 100# machine oil; and the oil soluble volatile corrosion inhibitor is a mixture of four kinds of 2-heptadecenyl-imidalidine, octadecylamine, triazole tributylamine, dicyclohexylamine carbonate, dicyclohexylaminenitrite, benzotriazole, tert-butyl chromate, nephthenic soap, petroleum sodium sulfonate, sorbitan monooleate and stearic acid; and the antioxidant is sulfurphosphorousbutyloctyl zinc salt. The volatile rust preventive oil has good volatile rust preventive and corrosion resistant performances, metal which cannot be coated with rust preventive oil can achieve rust preventive protection, the operation is simple, and the cost is low.

Owner:上海福岛新材料科技有限公司

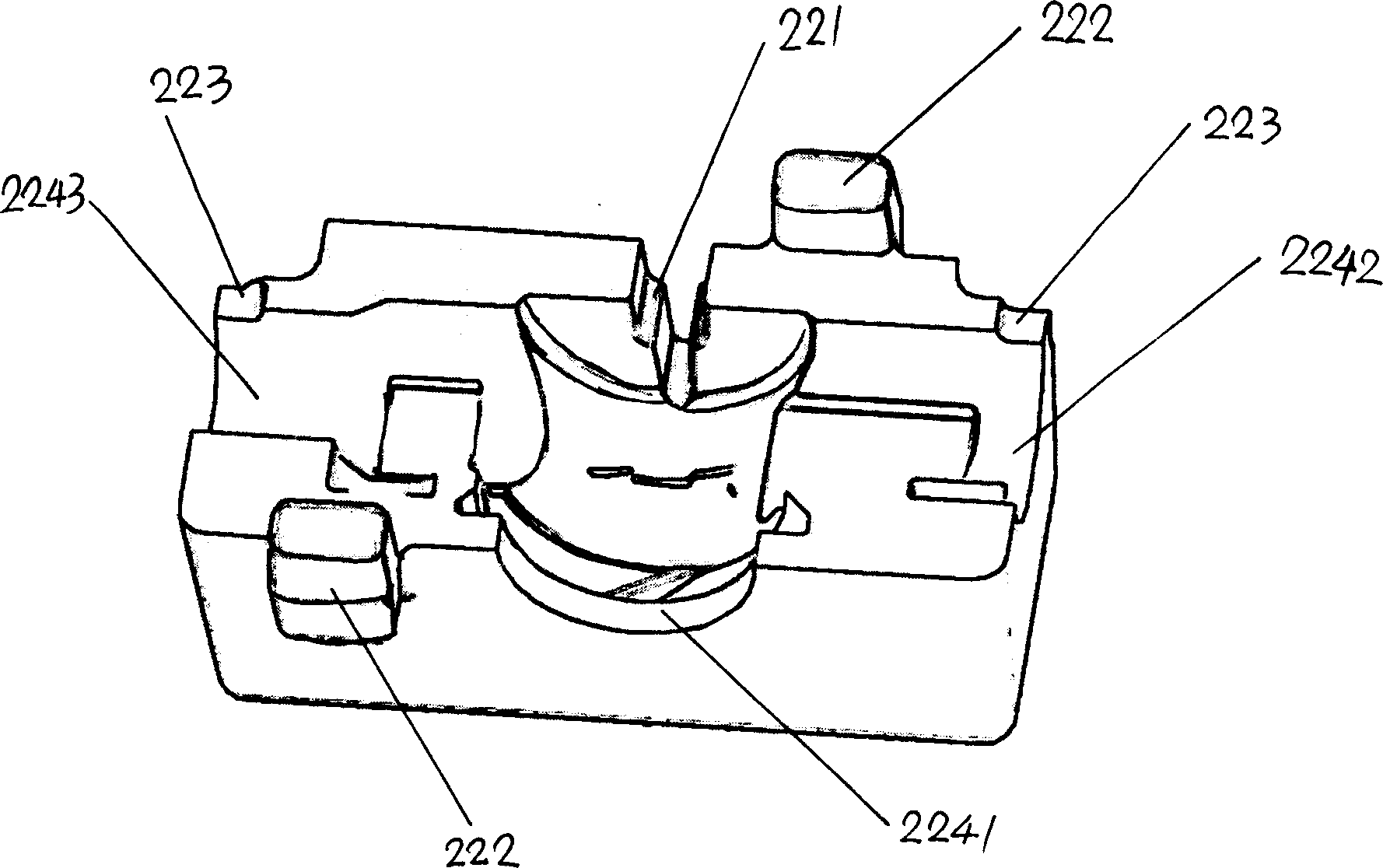

Metal mold type gravity casting die for cast of tin bronze, and casting method

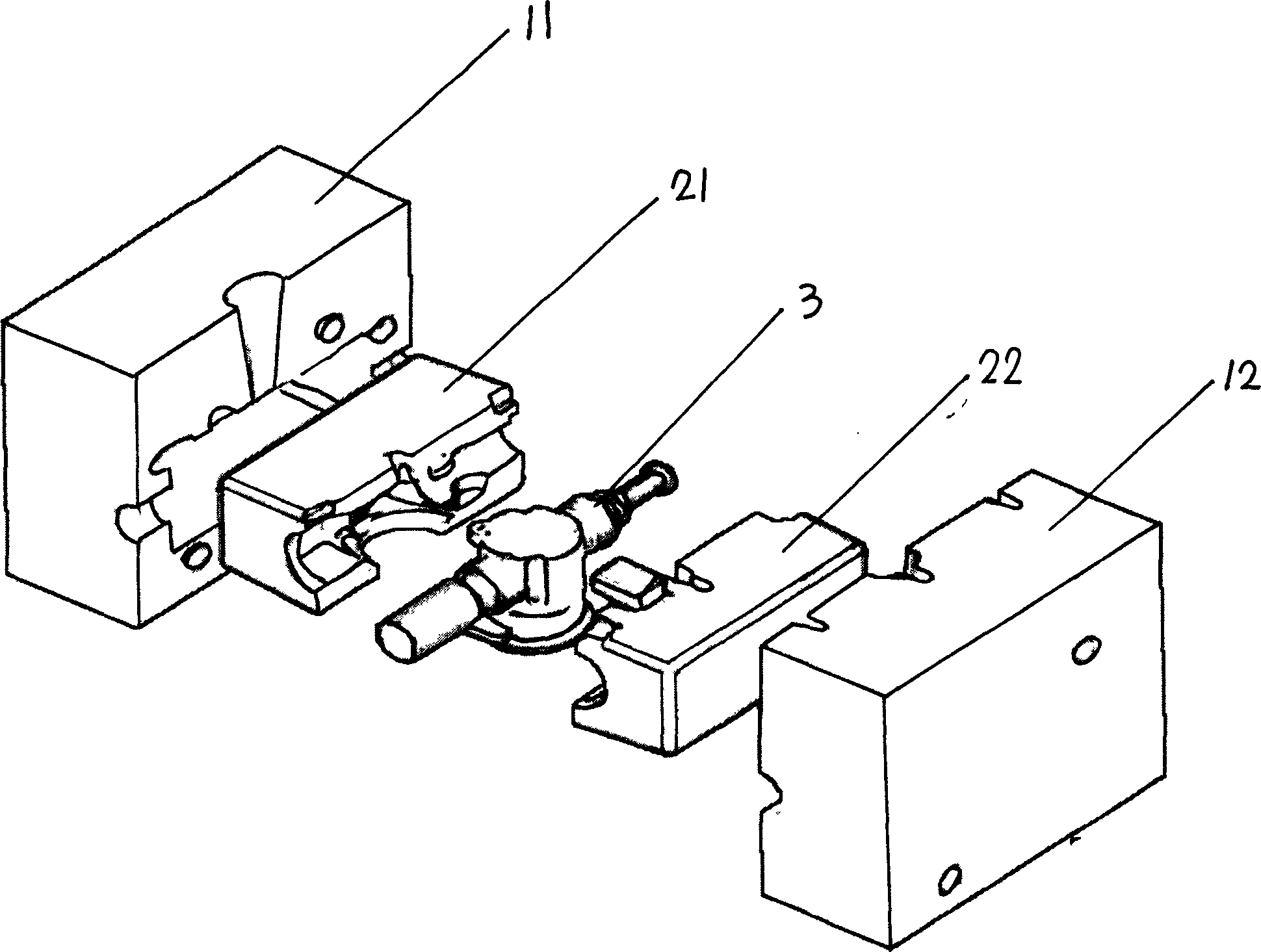

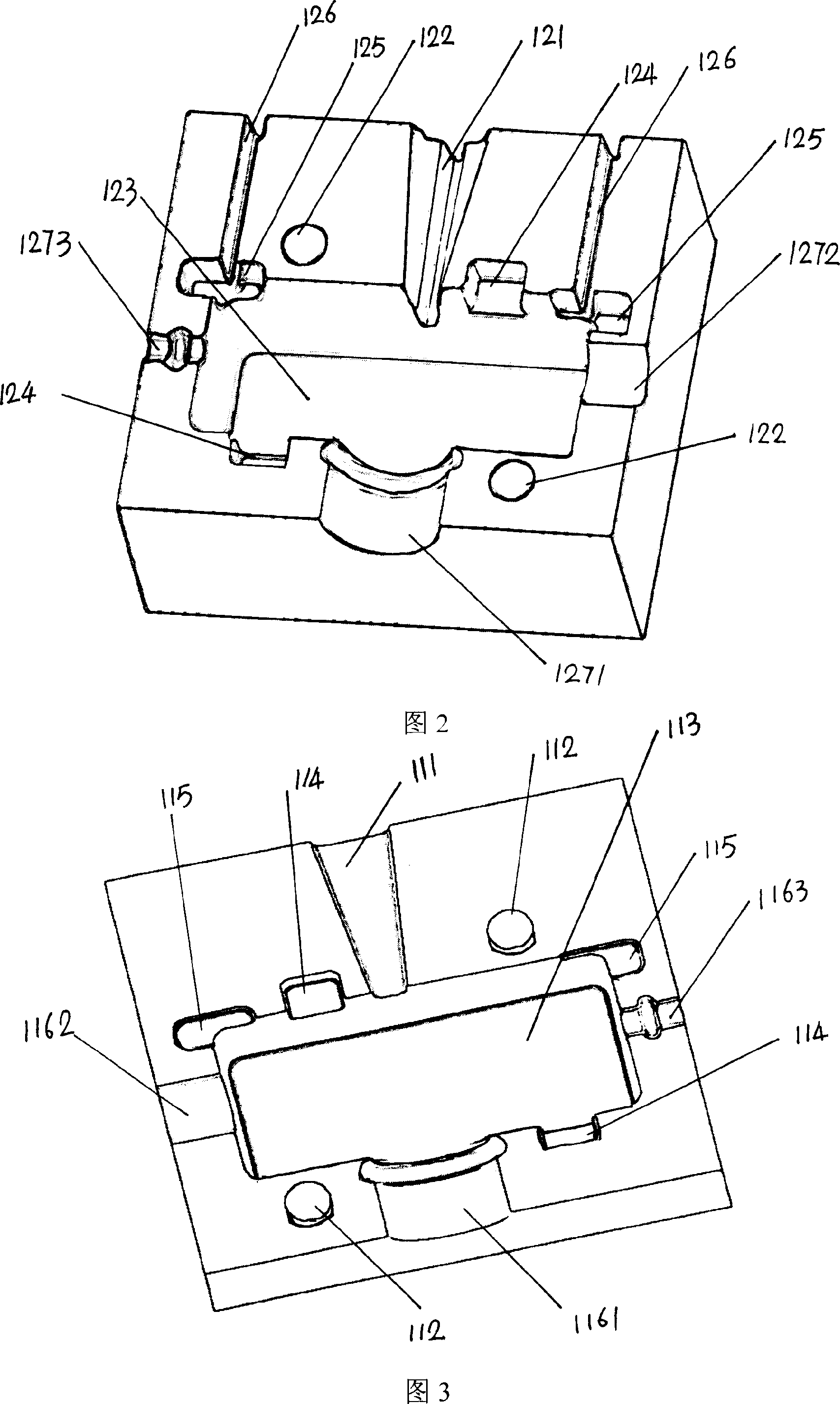

InactiveCN1915559ASolve the problem that is not suitable for gravity casting of metal moldResolve integrityMolten metal supplying equipmentsFoundry mouldsMetal moldTin bronze

A gravitationally casting metal mould set for casting the tin-bronze workpiece is composed of a metal mould consisting of upper and lower moulds, external sand core consisting of upper and lower cores and inlaid in the recess of metal mould, and internal sand core. Its casting method includes such steps as assembling the mould set, pouring molten tin-bronze, and cooling.

Owner:SHANGHAI TIANSHEN COPPER GRP CO LTD

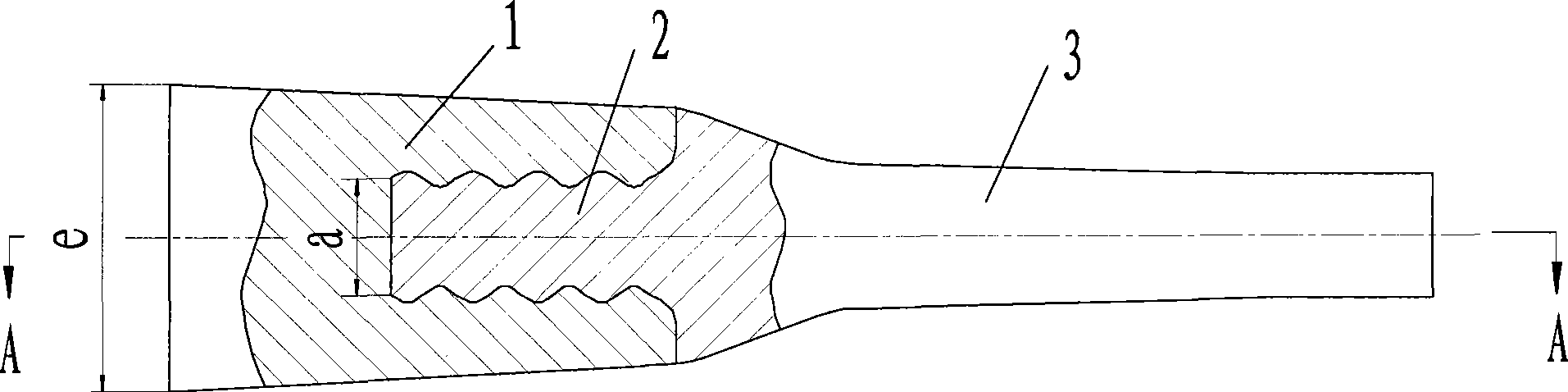

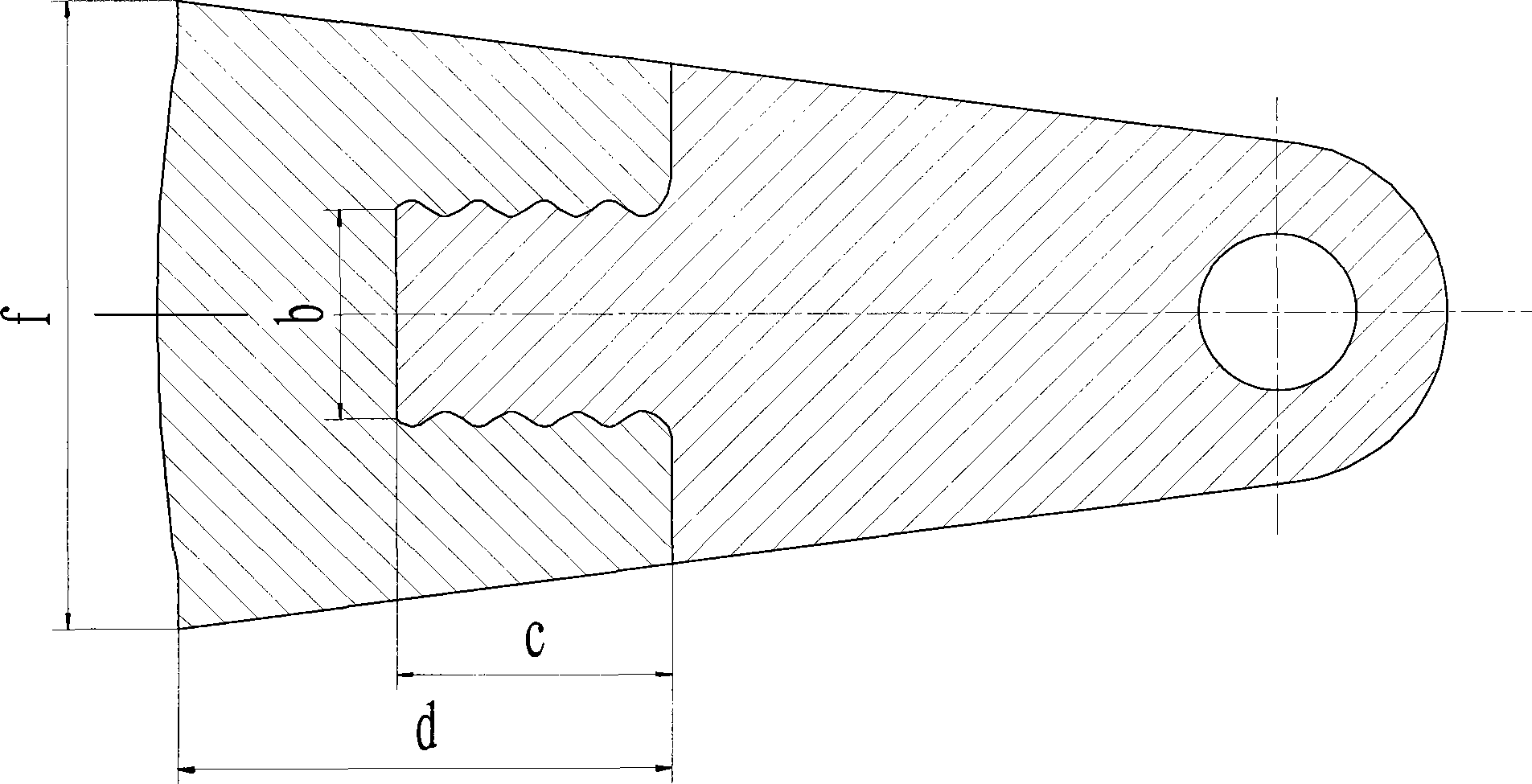

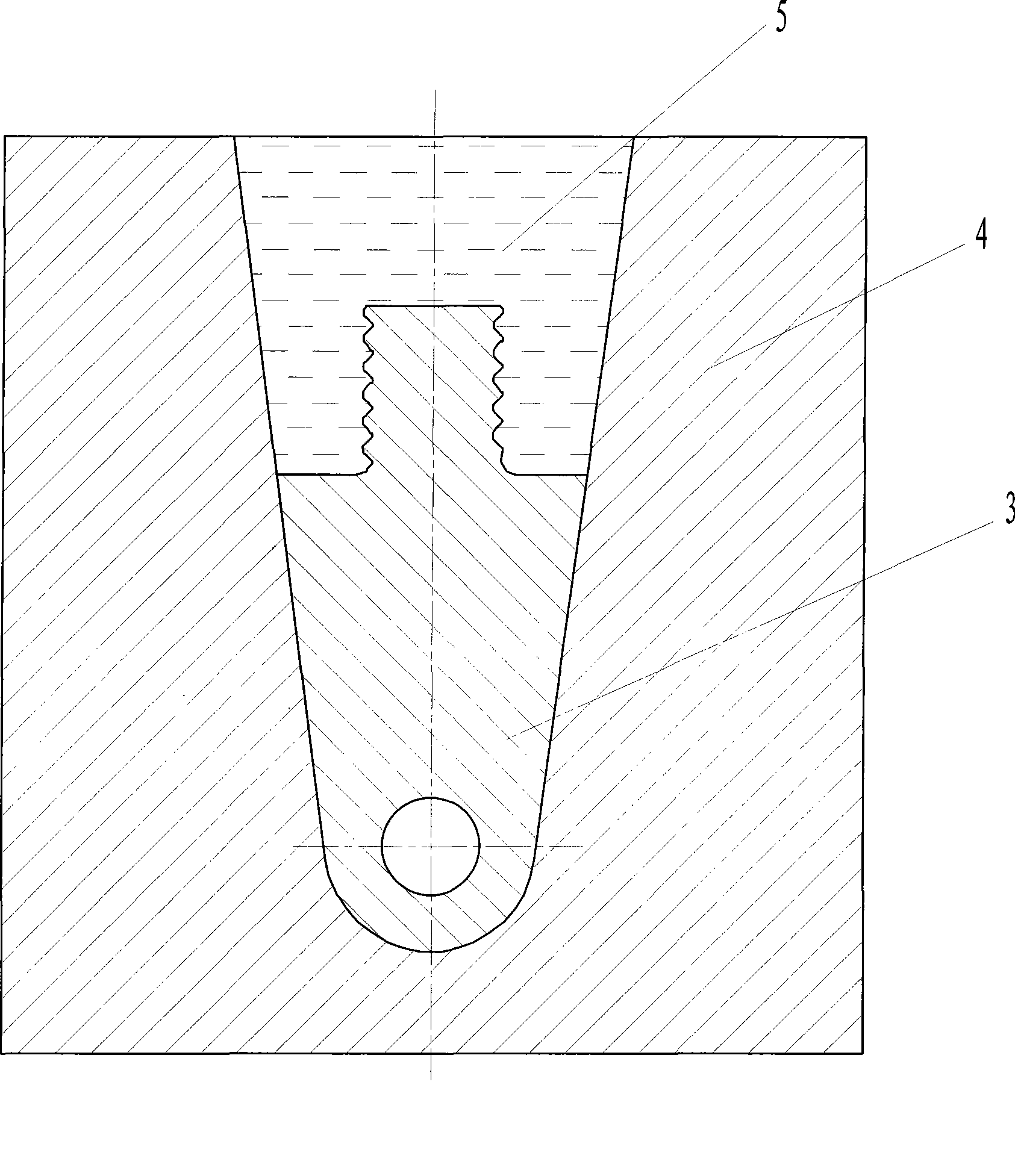

Bimetal composite hammer manufacture method and hammer handler precasting products

The invention relates to a method for preparing a double-metal composite hammer, which comprises the following steps: coating a thermal treatment protective paint on a hammer handle prefabricated member (3), and heating the hammer handle prefabricated member to be between 300 and 800 DEG C; coating casting paint on the surface of a cavity of a metal die (4), and preheating the metal die to be between 120 and 300 DEG C; putting the hammer handle prefabricated member into the cavity of the metal die, and pouring abrasion-resistant alloy melt (5) into the cavity of the metal die at a temperature of between 15 and 80 DEG C higher than a phase line temperature of the abrasion-resistant alloy melt; and within 10 seconds after pouring, pressurizing the hammer handle prefabricated member at 50 to 150MPa, keeping the pressure, and then taking out the hammer. Impact toughness of the hammer handle prefabricated member is more than or equal to 5 to 20 J / cm<2>, hardness is 25 to 40HRC, and the hammer handle prefabricated member is processed and shaped. The length of a connecting handle of the hammer handle prefabricated member is 1 / 4 to 4 / 5 of the length of the hammer head (1), and the thickness and the width of the connecting handle are 1 / 3 to 1 / 2 of the thickness and the width of the hammer respectively; and the surface of the connecting handle is provided with an annular groove. The method solves the problem that an embedded double-metal composite hammer is easy to fall off and a double-liquid double-metal composite hammer is easy to mix double liquids so as to reduce service performance.

Owner:BEIJING JIAOTONG UNIV +1

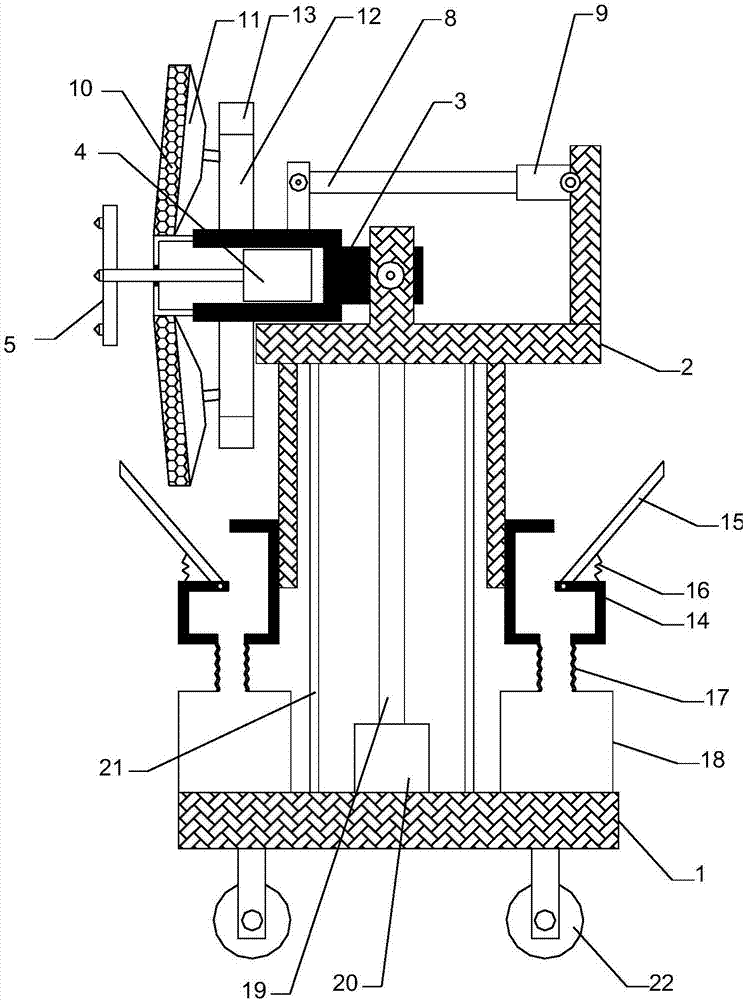

Wall scraping device with slag collecting function

InactiveCN107344309AAvoid random driftProtect healthBuilding repairsPlane surface grinding machinesDrive shaftSlag

The invention discloses a wall skin scraping device with the function of collecting debris, which comprises a moving plate, a first driving motor and a second driving motor; the moving plate is rotatably connected with a turret, and the turret is nested with a first drive Motor, the first driving motor is fixedly connected with the turret; the first driving motor is connected to a scraping wheel through a drive shaft; a grinding wheel is arranged on the rear side of the scraping wheel. The present invention is provided with a scraping wheel and a grinding wheel to scrape the wall and the ceiling, the scraping is thorough, and has a good scraping effect; the invention is provided with a turret, so that the device can scrape the ceiling operation, scraping efficiency is high, and manpower is saved; the present invention is equipped with a dust and slag collection device, which collects dust and slag efficiently and intensively during the operation process, avoids random dust floating, keeps the working environment clean and protects operators health.

Owner:吴佳慧

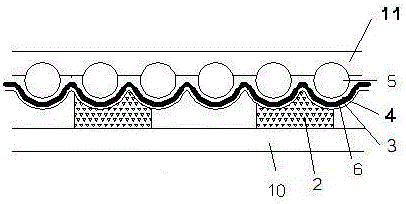

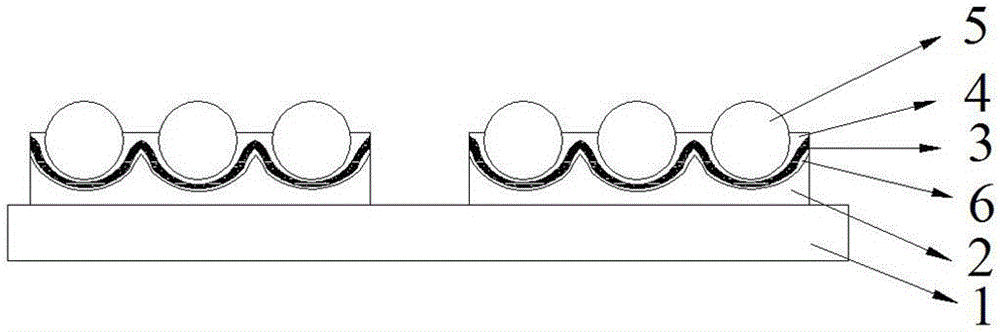

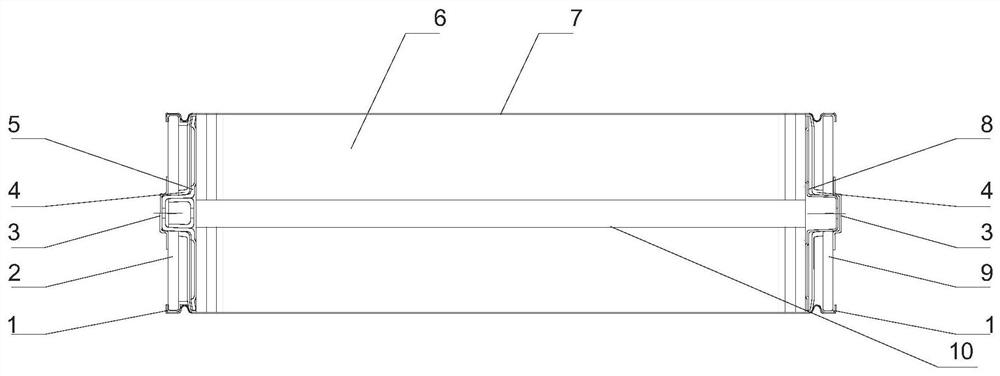

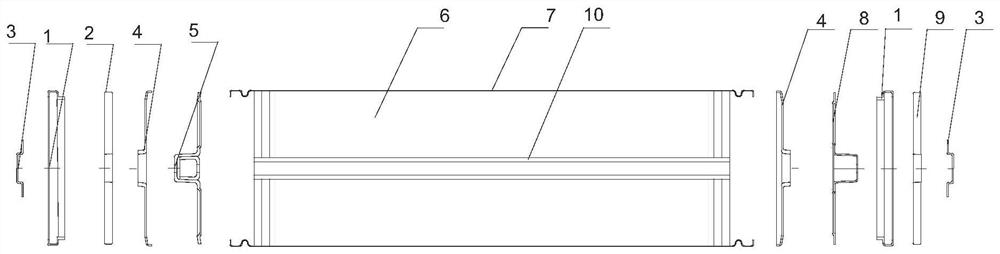

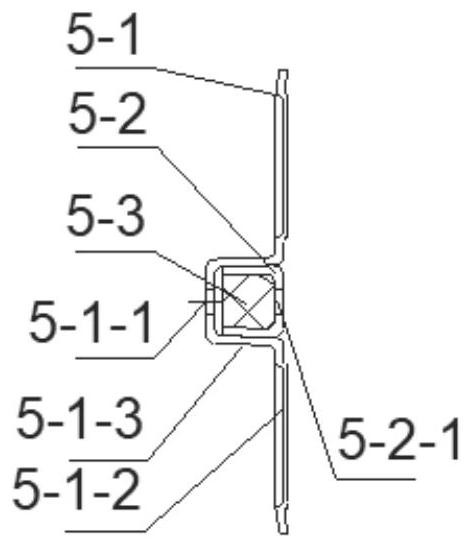

Continuous densification and efficient production line and technology of fiber-reinforced thermosetting plastic pipelines

ActiveCN105216340AEfficient productionContinuous compaction productivityTubular articlesProduction linePlastic pipework

The invention provides a continuous densification and efficient production line and technology of fiber-reinforced thermosetting plastic pipelines, and belongs to the field of fiber-reinforced thermosetting plastic pipeline manufacturing. After being innovatively improved, a paper tube machine production line is applied to the production field of the fiber-reinforced thermosetting plastic pipelines, the improved paper tube machine production line is sequentially provided with strip frames, a coating device, a curing agent applying device, hollow partition plates and a spiral paper tube machine refit device in the paper tube moving direction. Cylindrical dies transversely arranged above a rack are improved on the basis of an existing spiral paper tube machine, pressure perpendicular to the die direction and thrusting force parallel to the die direction are exerted on film strips wrapping the dies and impregnated and pre-cured fiber strips through a conveying belt, layer-by-layer densification and continuous efficient production are achieved, and the production efficiency is greatly improved. The produced pipelines have the beneficial effects of resisting pressure, being good in impact resistance and rigidity, resisting to corrosion and the like.

Owner:SHANDONG BOYUAN COMPOSITE MATERIALS TECH CO LTD

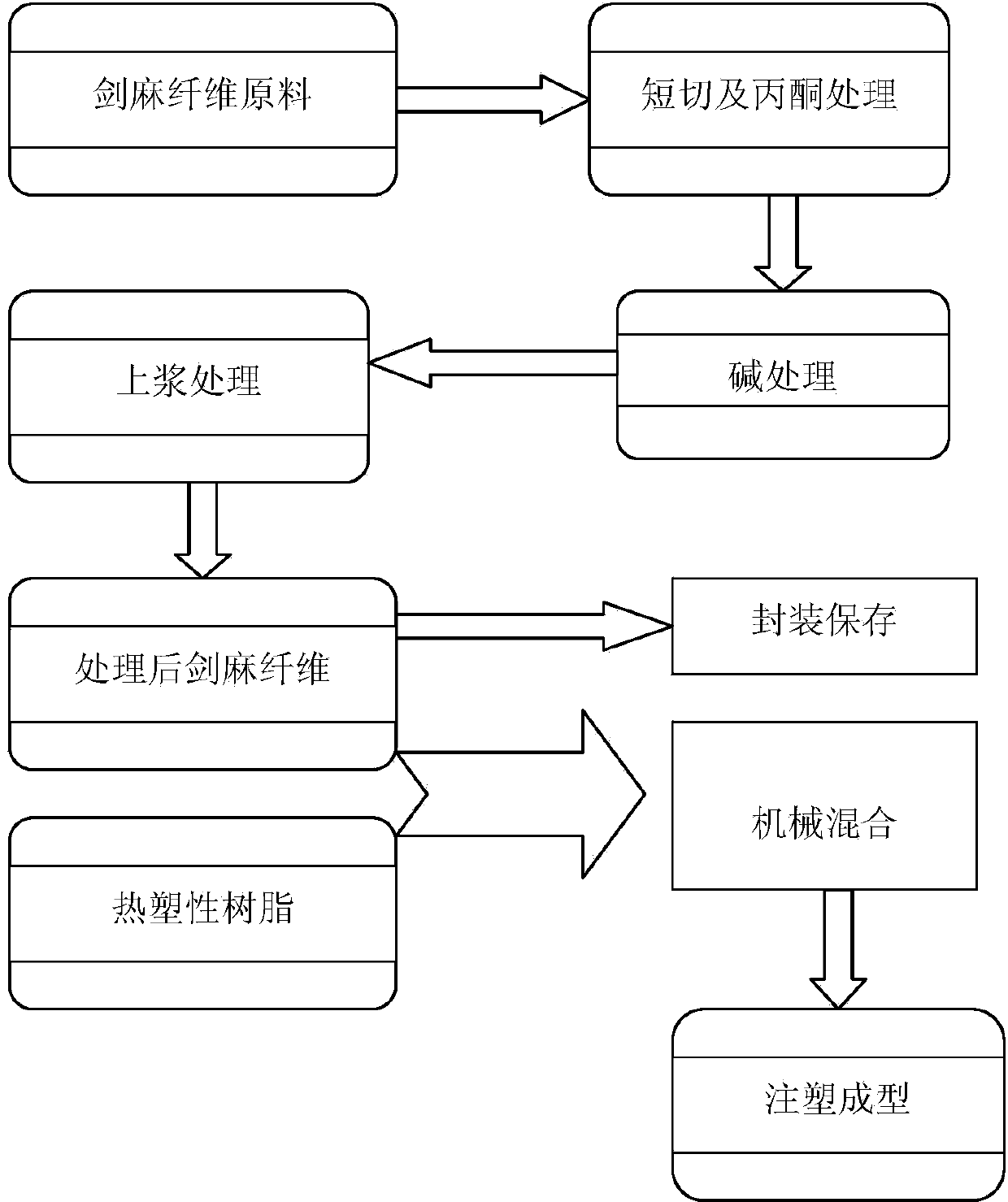

Preparation method of sisal fiber surface sizing agent and sisal fiber composite material

The invention discloses a preparation method of a sisal fiber surface sizing agent and a sisal fiber composite material. The sisal fiber surface sizing agent is water-based emulsion prepared from a modified resin film forming agent (1-60wt%), a coupling agent (0.5-8wt%), a levelling agent (0-1wt%), a wetting agent (0-8wt%), a surface active agent (0.5-8wt%), water and the like according to a phase inversion emulsification method, sisal fibers are treated by the sizing agent and then are mixed with a certain amount of resin, and one-step injection moulding is carried out by adopting an injection moulding machine, so that the sisal fiber composite material is obtained. The sisal fiber surface sizing agent well improves compatibility of the sisal fibers and matrix resin, and tensile strength of the sisal fiber composite material is effectively increased. The preparation method of the sisal fiber composite material is simple, cost is saved, fiber content is easy to control, the problem that compatibility of the sisal fibers and matrix is poor can be well solved, and the preparation method of the sisal fiber composite material can be applied to industrialization production.

Owner:TIANJIN UNIV

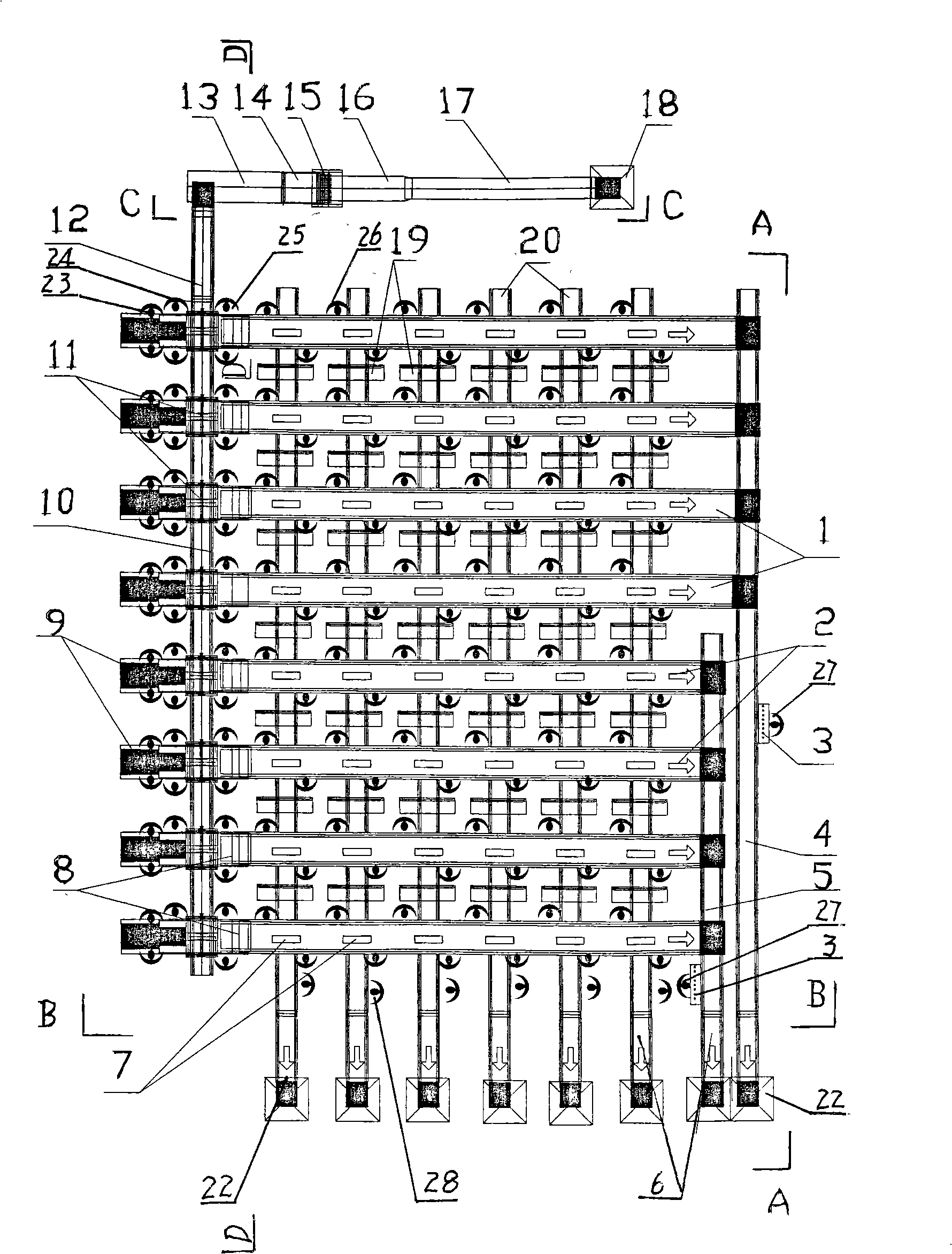

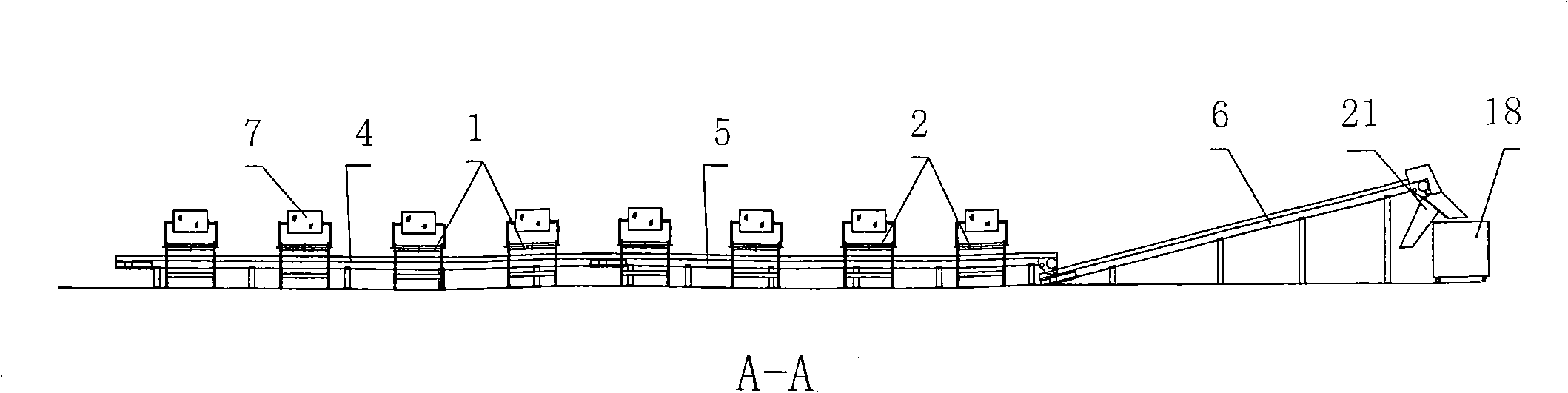

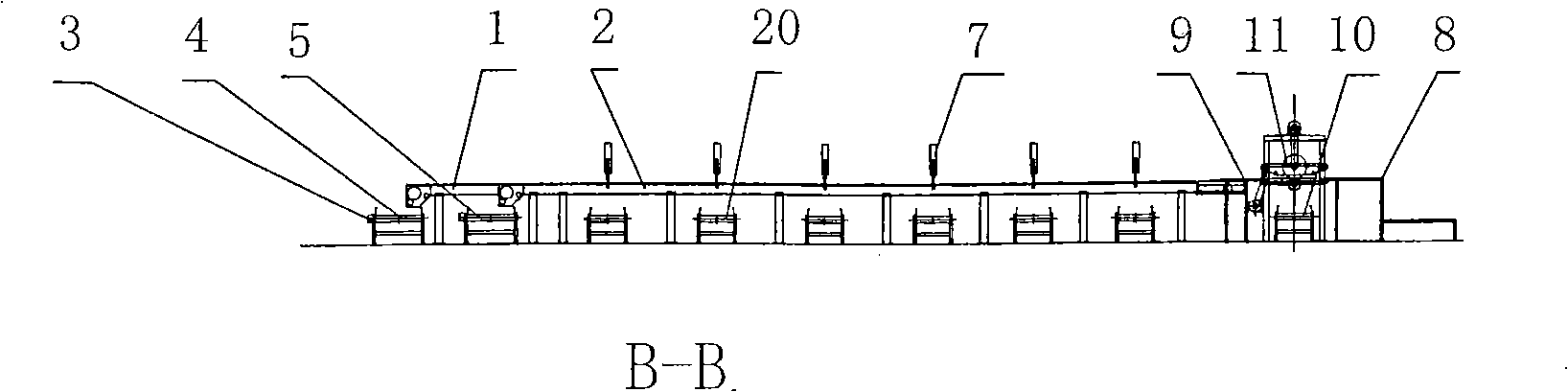

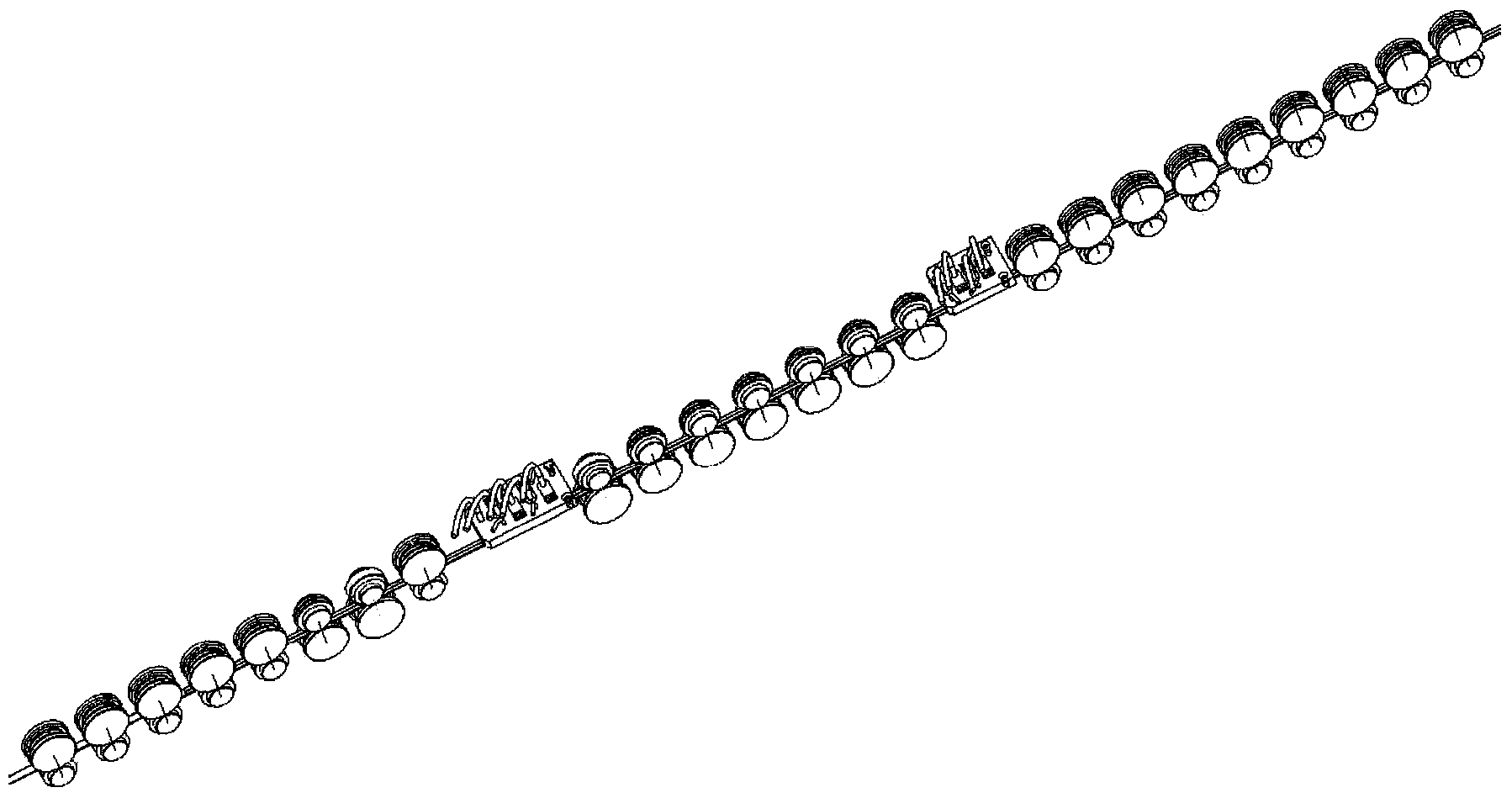

Grading technique for cutting cured leaf head and selecting slice on-line and device

InactiveCN101301109AEasy to replaceQuality improvementTobacco preparationSortingEngineeringControl switch

The present invention belongs to the tobacco leaf processing field for cigarette manufacture, in particular to an online chip selection grading technique for removing bundle head of raw tobacco, and the equipment thereof. Bundles of tobacco are put to a plurality of platform so as to be transferred to the machine for removing each bundle head, thereby, the bundle heads are separated from tobacco leaves, and then the bundle heads are tidied, disbanded, shaken, sieved and put into a bin; the tobacco leaves are shaken and put into selecting conveyer belt. The tobacco leaves are selected artificially comparing with a template in a template box. The selected tobacco leaves are conveyed into a bin through an output conveyer belt, while the remainder tobacco leaves are conveyed into a gathering bin through a gathering output conveyer belt. Person in a inspection bench can make corresponding treatments according to the condition of the tobacco leaves on the gathering output conveyer belt. The equipment comprises a platform for bearing bundles, a machine for removing bundle heads, conveyer belts, a bundle head processing unit, a platform for bearing leaves, a template box, bins, an inspection bench, and a control switch. The present invention has the advantages of good effect, reasonable technology, simple flow, compact equipment, reasonable arrangement, chip selection grading with high quality and high efficiency, and can be suitable for mass production.

Owner:云南新紫烟科技有限公司

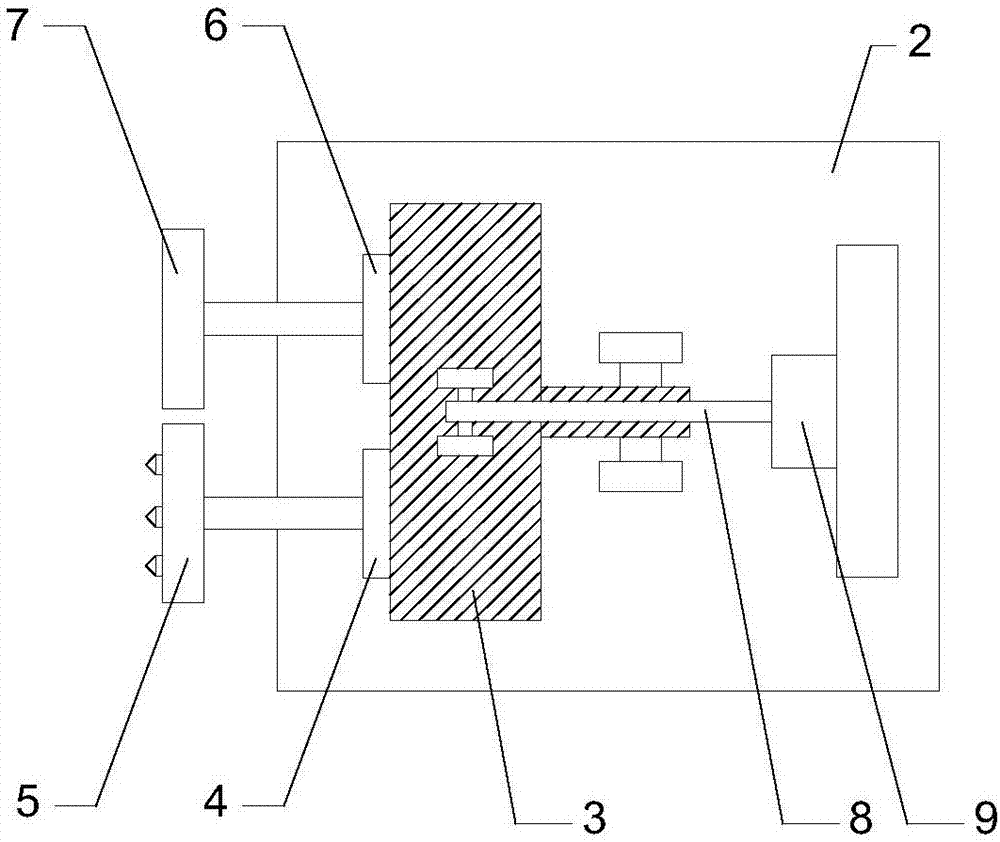

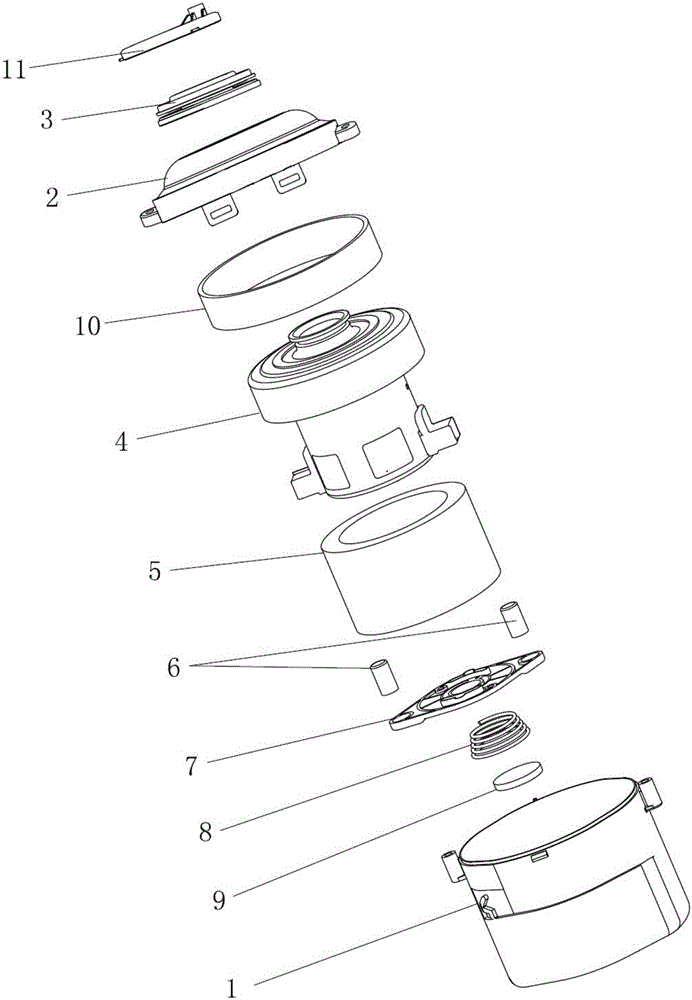

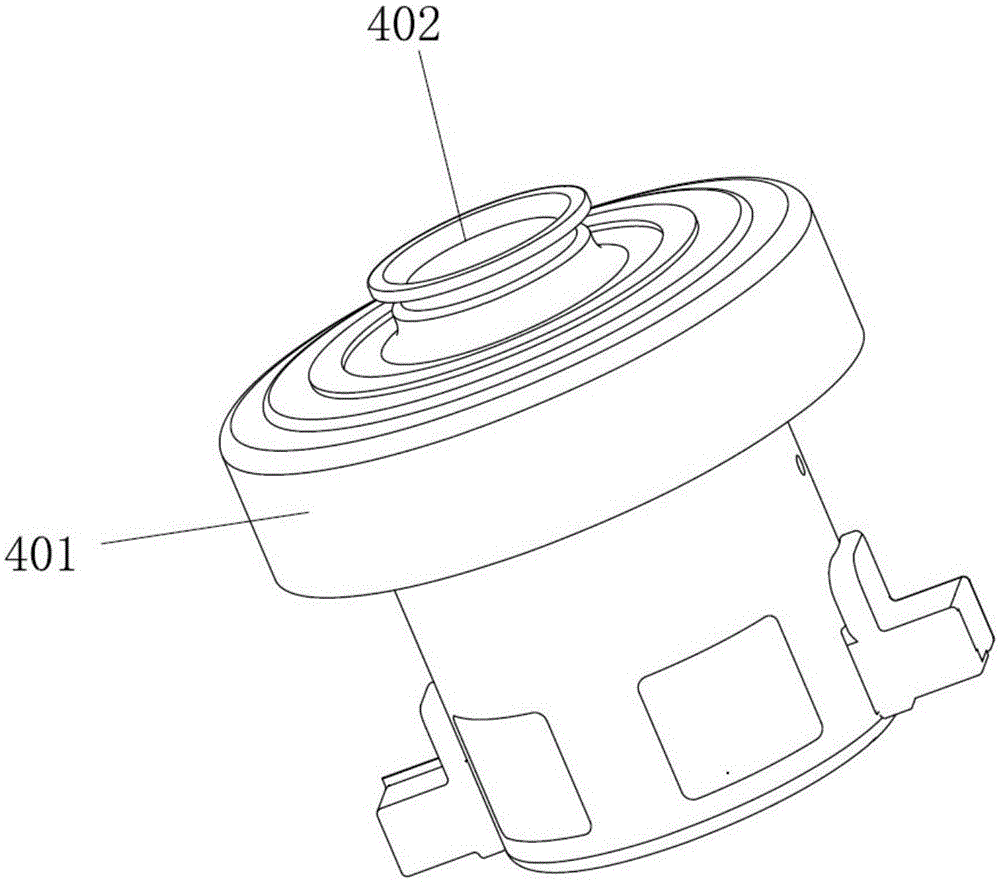

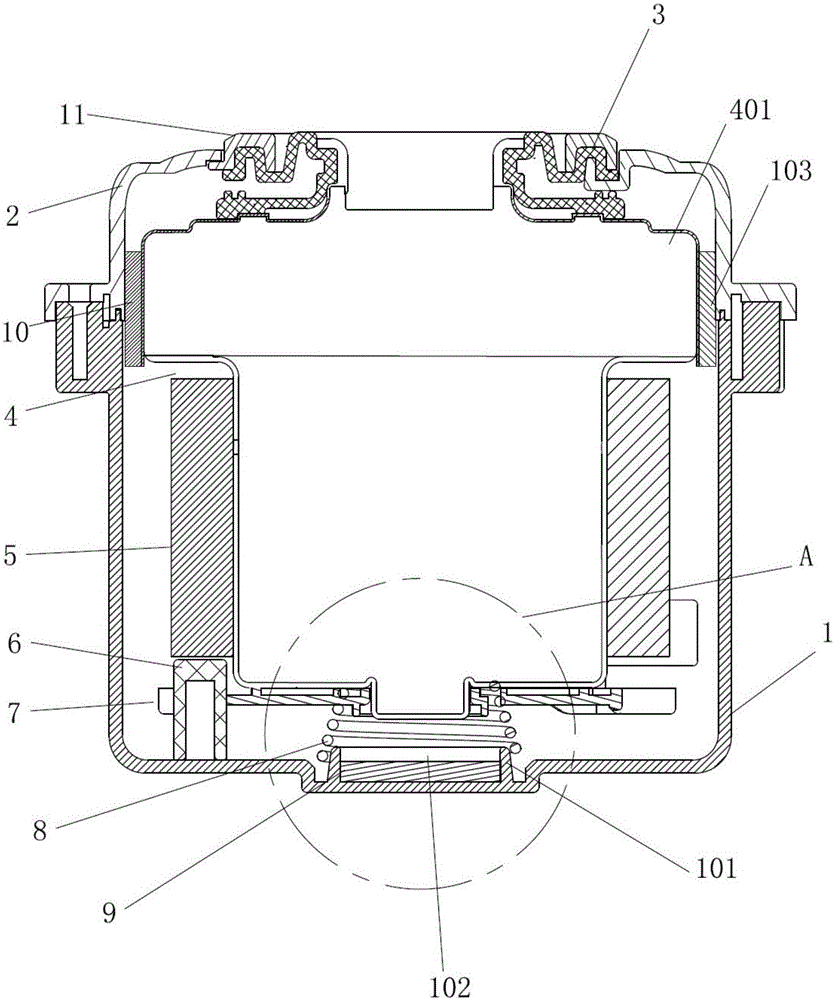

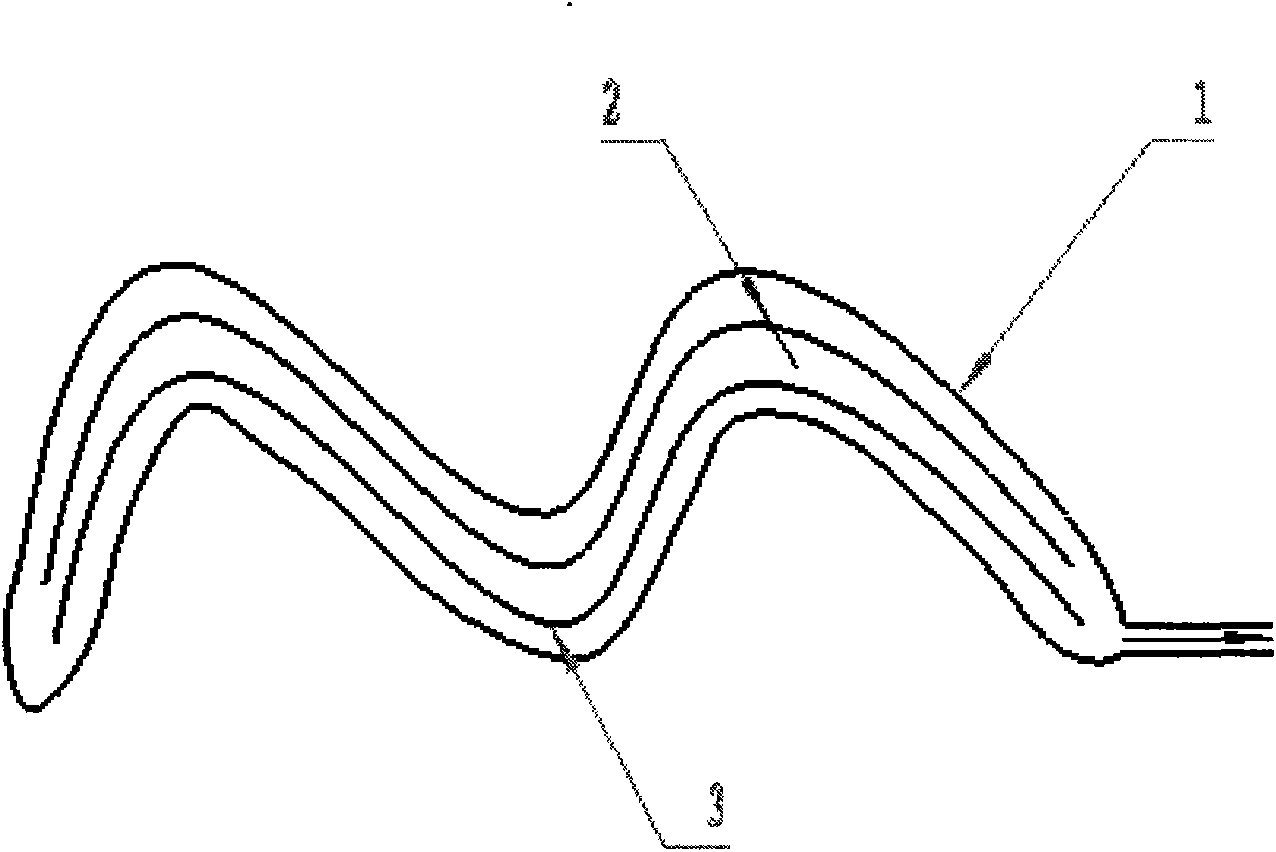

Suspension noise-reduction motor

ActiveCN105054867AReduce noiseClean working environmentSupports/enclosures/casingsElectric equipment installationMultiple bufferingThree-dimensional space

A suspension noise-reduction motor comprises a motor body, a motor housing, a seal ring and buffering components, wherein the motor housing at least partially contains the motor body, the seal ring is arranged on an air inlet of the motor body in a sleeving mode, and the buffering components are installed between the motor body and the motor housing. Due to the seal ring and the multiple buffering components, the motor body is allowed to move in a three-dimensional space, the seal ring comprises an upper shock absorption piece, a lower shock absorption piece and a connecting side wall which is connected with the upper shock absorption piece and the lower shock absorption piece and clamped on the air inlet of the motor body, an S-shaped bent mechanism is arranged on the upper shock absorption piece, and a press plate matched with a protrusion is arranged on the protrusion of the S-shaped bent mechanism so that the seal ring will not be sucked into the air inlet of the motor body. The motor body is suspended in the motor housing by means of the seal ring and the buffering components, and when the motor moves in any direction by means of an elastic mechanism, the seal ring and shock pads, a motor plastic part makes soft contact with the motor housing to achieve the effect of noise reduction.

Owner:KINGCLEAN ELECTRIC

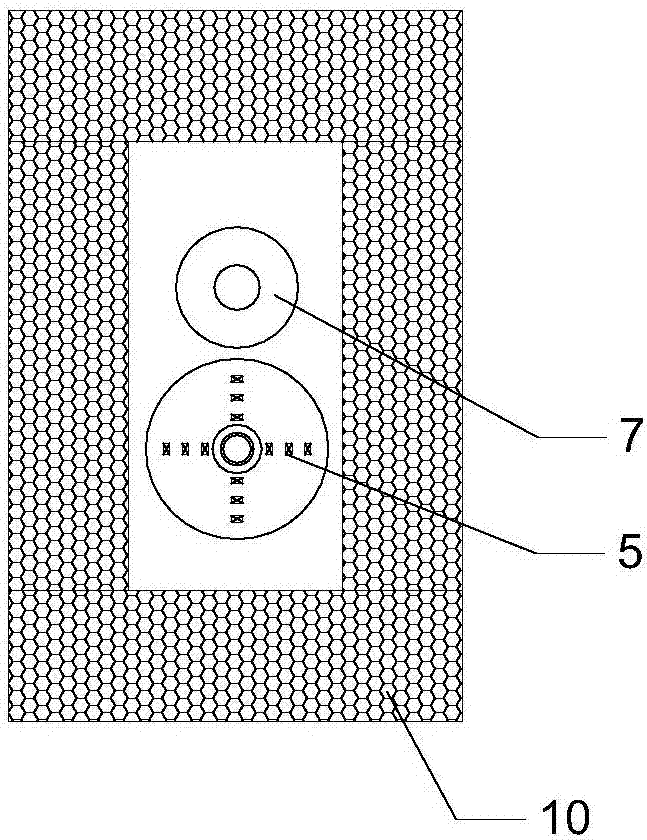

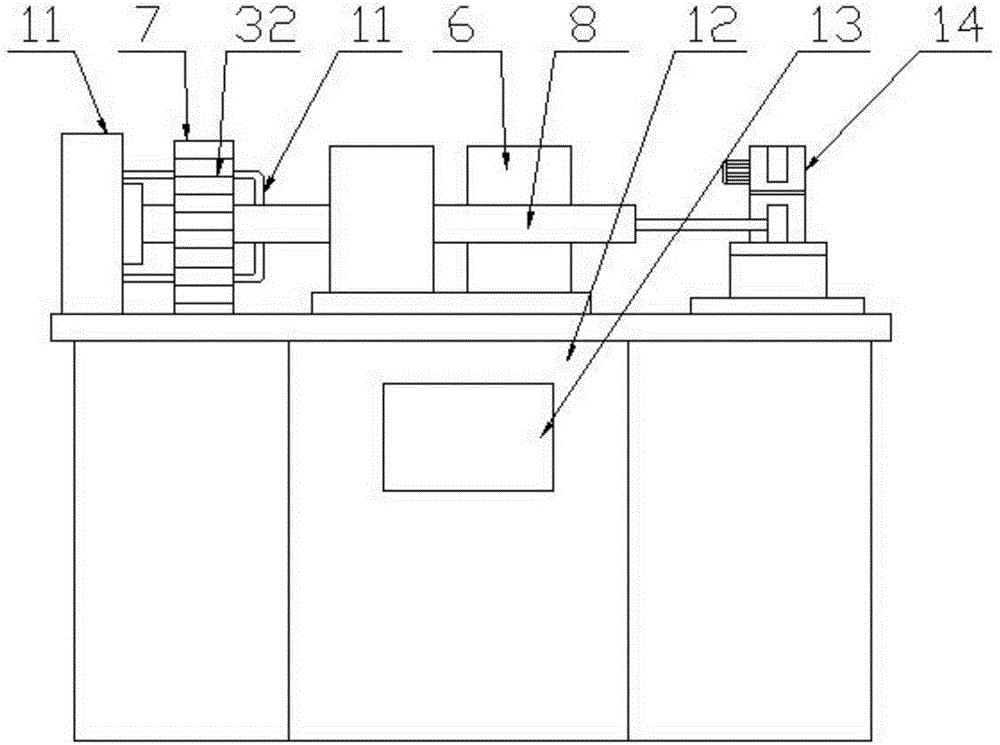

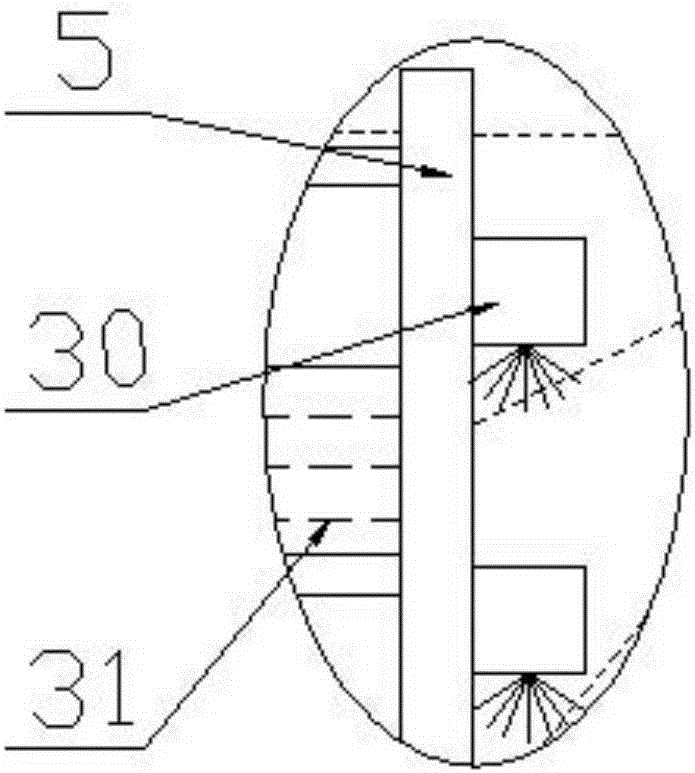

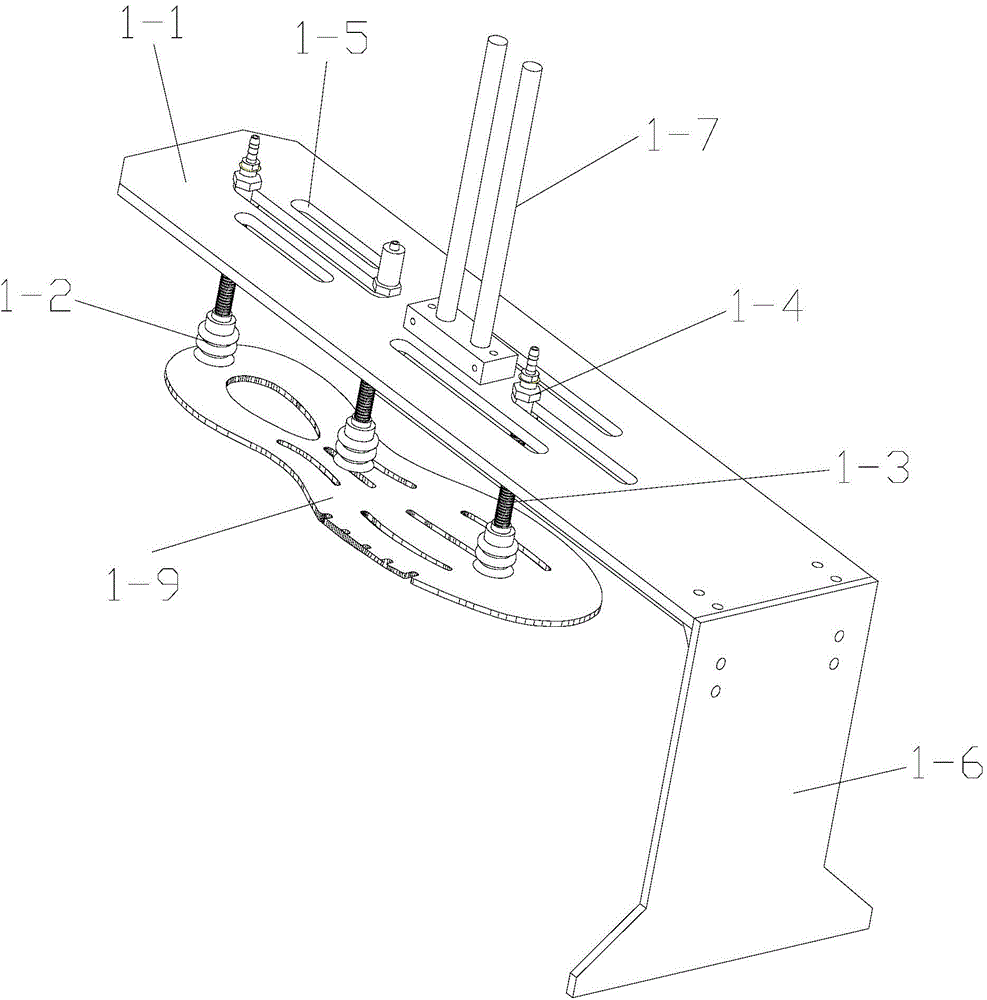

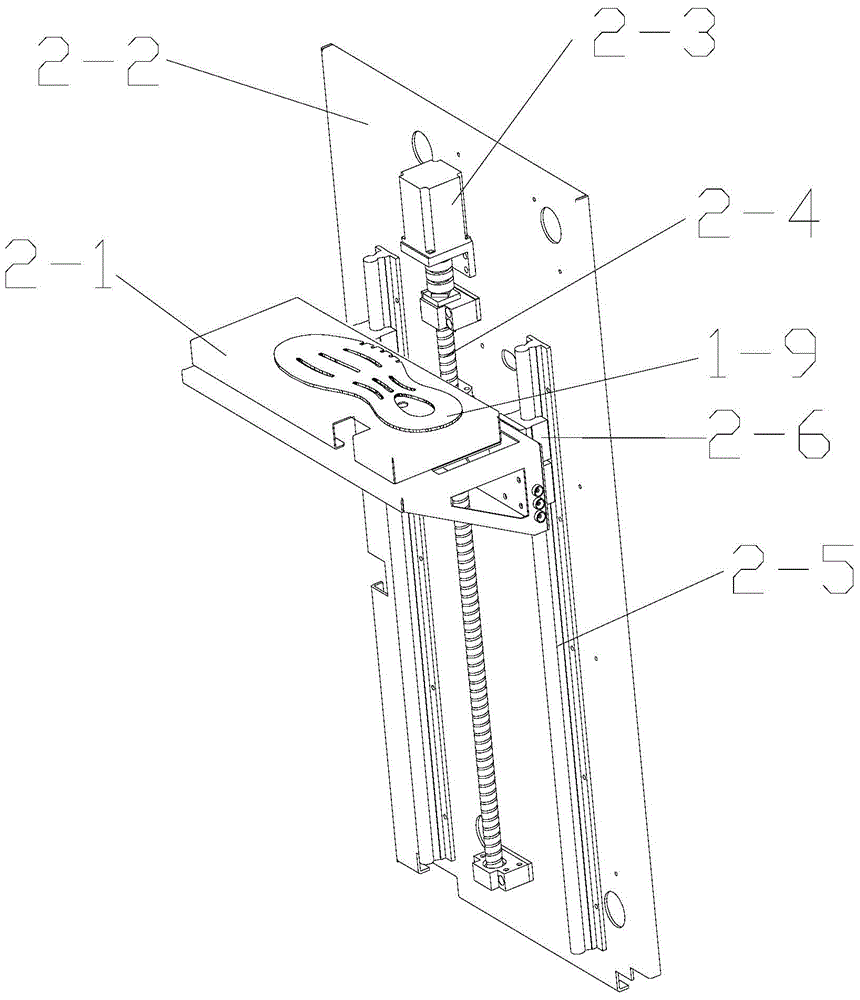

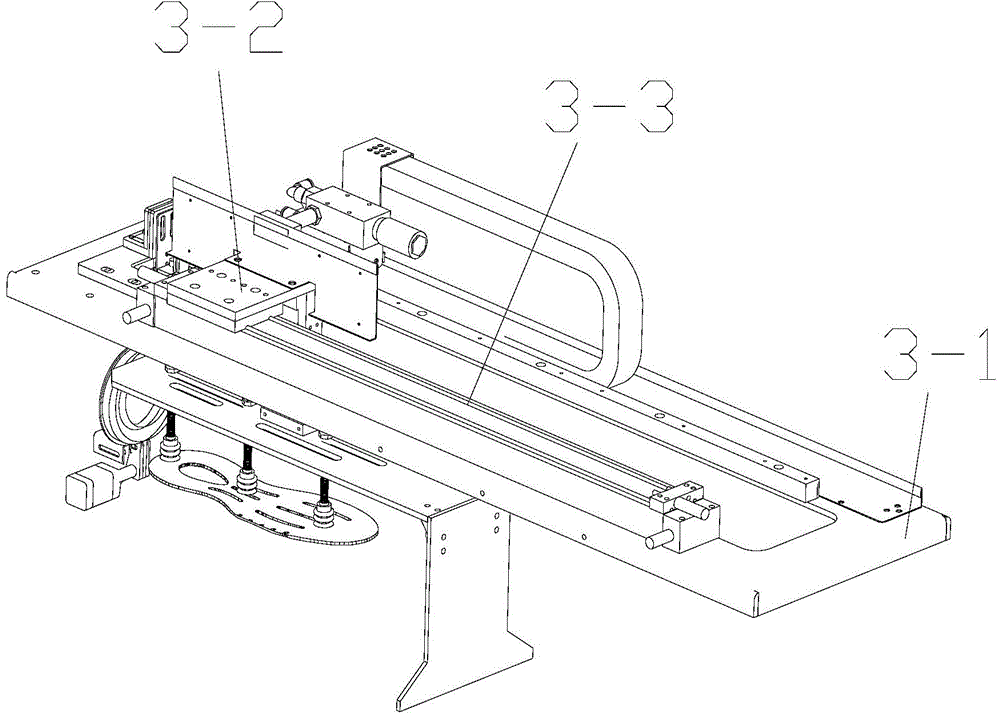

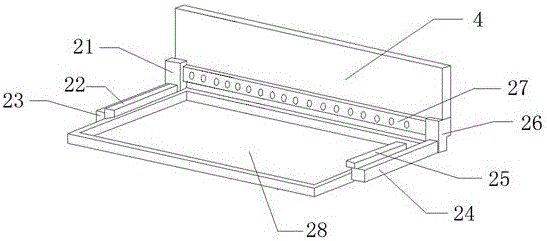

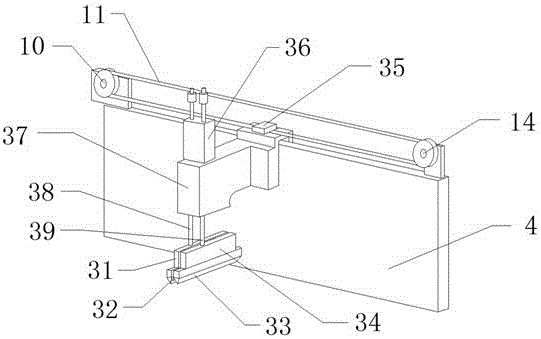

Double-station shoe sole laser cutting machine and method

ActiveCN104942450ASimple structureEasy to operateLaser beam welding apparatusLaser cuttingEngineering

The invention relates to a double-station shoe sole laser cutting machine, and belongs to the technical field of shoe sole machining machines. The double-station shoe sole laser cutting machine comprises a rack, a machining table, two groups of feeding mechanisms for feeding shoe soles to the machining table and a group of laser machining mechanisms for cutting the shoe soles on the machining table through a laser. The machining table comprises two cutting tables arranged side by side from left to right. The two cutting tables for holding the shoe soles move horizontally on the rack through a double-station horizontal movement mechanism from left to right. One group of feeding mechanisms is fixed to the left end of the rack, and the other group of feeding mechanisms is fixed to the right end of the rack. The laser machining mechanism is located between the groups of feeding mechanisms. The cutting table on the right side right faces the laser machining mechanisms when the cutting table on the left side right faces the feeding mechanisms on the left side. The cutting table on the left side right faces the laser machining mechanisms when the cutting table on the right side right faces the feeding mechanisms on the right side. The invention further relates to a double-station shoe sole laser cutting method. The double-station shoe sole laser cutting machine and method have the advantages of being simple in structure, automated in machining process and high in machining efficiency.

Owner:GUANGZHOU RUISU INTELLIGENT TECH CO LTD

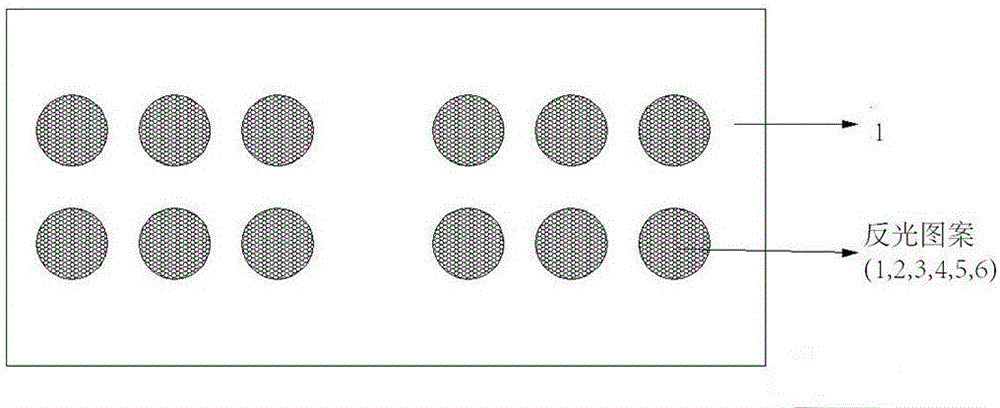

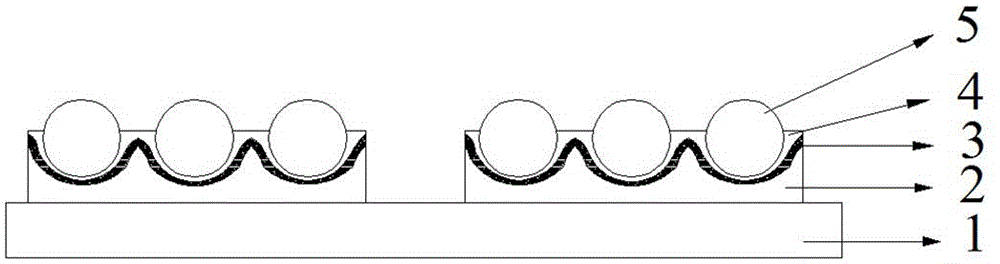

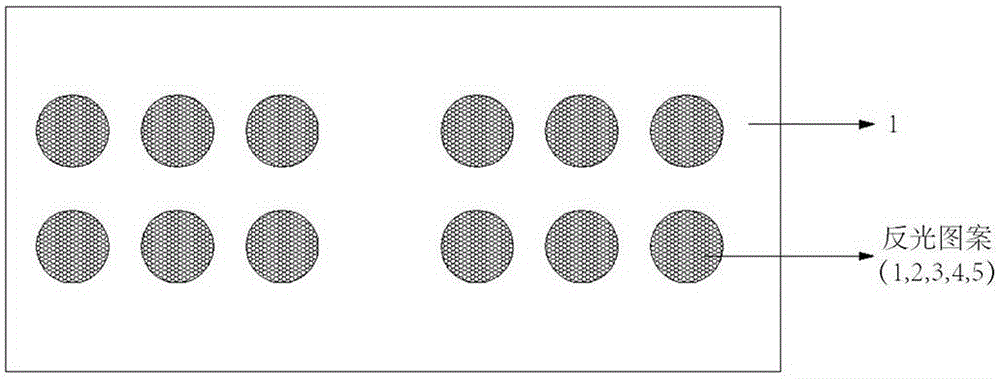

High-efficiency wide air-permeable fancy-type reflecting material and preparation method therefor

Owner:HANGZHOU CHINASTARS REFLECTIVE MATERIAL

Technological method for upwardly continuously casting, rolling, drawing and producing copper alloy tubes

The invention provides a technological method for upwardly and continuously casting, rolling, drawing and producing copper alloy tubes. The technological method comprises the following steps: melting copper alloy raw materials according to a content proportion; further homogenizing the contents of an undercurrent passing by a standing chamber; keeping the temperature of the undercurrent by a maintaining furnace; cooling the undercurrent by a crystallizer to enter a tractor; upwardly drawing and continuously casting copper alloy tube blanks; then rolling the copper alloy tube blanks by a rolling mill; and drawing finished products of copper alloy tubes by a drawing mill. The technological method simplifies a traditional technological process in a new once-forming technology and has little investment, small occupation of land, low energy consumption, high efficiency, high rolling yield, little pollution and low cost, thereby being an advanced technological method with a certain market competitiveness.

Owner:高玉树

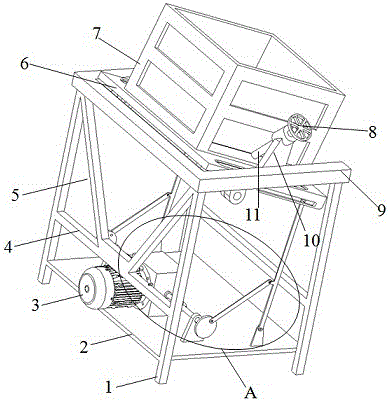

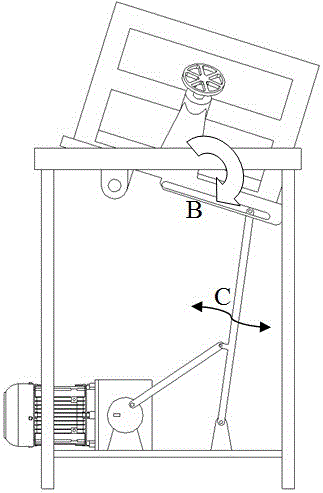

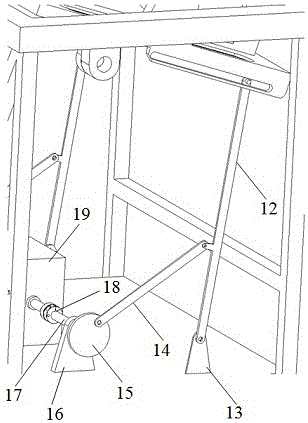

Coarse barium slag discharge overturning table based on crank-link mechanism

InactiveCN106115288ASimple and smart structural designMitigates negative effects of inertial loadsConveyorsBottle emptyingBarium saltSlag

The invention discloses a barium slag removal turning table based on a crank connecting rod mechanism. Before the device works, the crank disc rotates under the action of the turning motor, so that the connecting frame rod is located at one of the limit positions, and this position makes the connecting frame rod vertical On the level ground, so that the turning table is in a horizontal state, then the operator places the hopper on the turning table through the equipment, the operator turns the compression handwheel to make the locking screw press the side of the hopper, and then the turning motor starts, through the two-axis The reducer makes the crank disc rotate until the connecting frame rod is at another limit position. At this time, the turning table tilts, and the materials inside the hopper fall to the ground under the action of its own gravity to complete the unloading process of the barium salt firing hopper. The turning table Lifting equipment removes the material box when it is turned to the horizontal position again. The device can dump the materials in the material box at one time, and the amount of dust generated when the materials fall to the ground is small, which is conducive to maintaining a clean working environment and reducing the physical exertion of operators.

Owner:GUANGXI LIANZHUANG SCI & TECH CO LTD

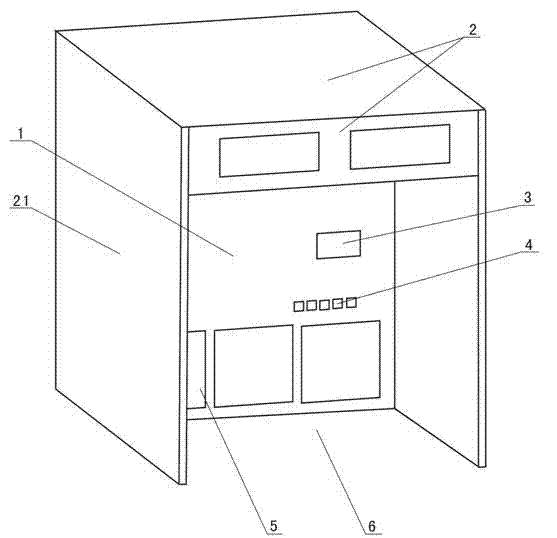

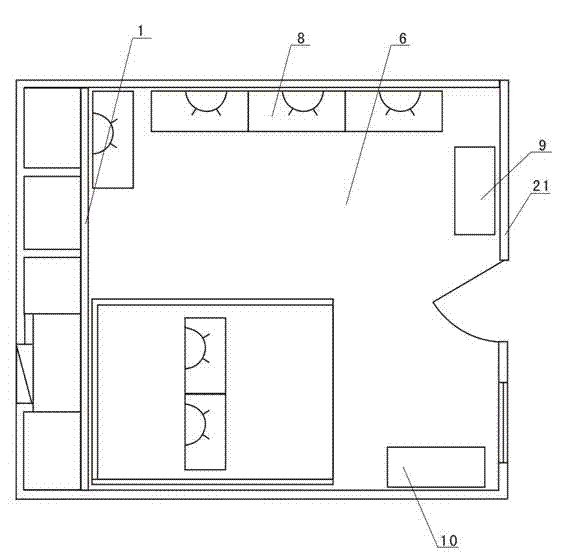

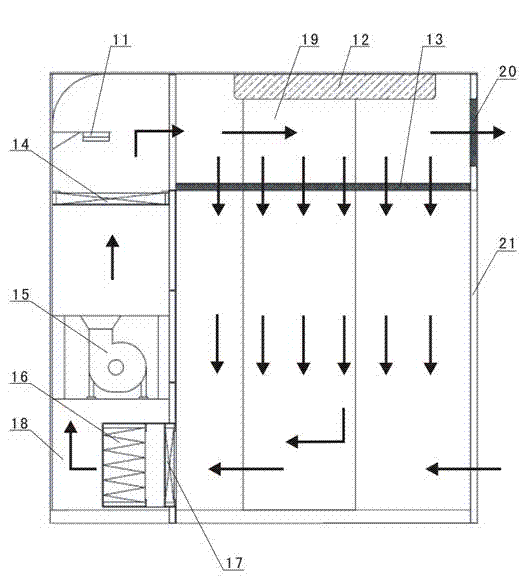

Digital intelligent integrated weighting chamber

ActiveCN102828627AImprove cleanlinessClean working environmentDispersed particle filtrationSpace heating and ventilation safety systemsExhaust valveFrequency conversion

The invention discloses a digital intelligent integrated weighting chamber which comprises a combined wall and an air processing system, wherein an operation space is arranged in the combined wall; in the air processing system, an inward air inlet is arranged on the lower part of the combined wall; a fresh air valve is mounted at the inward air inlet; an air return opening is arranged at the bottom of the operation space; an air inlet of a primary filter is communicated with the air return opening; air flues between the primary filter, a medium filter, a frequency conversion fan, a high-efficiency filter and a plenum chamber are connected in turn; the plenum chamber is arranged at the top of the operation space; a self-circulation flow-equalizing membrane is mounted at a self-circulation air outlet of the plenum chamber; an outer circulation flow-equalizing membrane is mounted at an outer circulation air outlet of the plenum chamber; an outward air outlet is arranged on the upper part of the combined wall; and an exhaust valve is mounted at the outward air outlet. According to the digital intelligent integrated weighting chamber, air is purified by multi-stage filters and the purified air is blown out at a constant speed by the self-circulation flow-equalizing membrane on the plenum chamber, and a high-cleanness working environment is formed in the operation space.

Owner:SICHUAN CHUANJING CLEAN TECH HLDG

Vacuum rush gum forming method of fiber-reinforced resin matrix compound material

The invention relates to a resin flowing compound material forming method which is aided by vacuum. A fiber-reinforced material is tailored and then paved in a mould cavity according to the design of layer quantity and structure of a product. Resin and firming agent are prepared into dipping glue solution which is evenly coated in the mould cavity and ensured to permeate the fiber-reinforced material. A mould is sent into a vacuum bag which is sealed and then vacuumized till a vacuum bag film closely clings to the surface of the reinforced material supported by the mould. A panel with elastic planes is used for expel foams and surplus glue solution in the vacuum bag to the edges outside the mould cavity. Then, in the conditions of normal temperature or heating and vacuum, the product gradually undergoes solidification and demoulding. The method can improve the mechanical properties and the surface quality of the compound material product, reduce the cost on production apparatuses and auxiliary materials and simplify the method operation.

Owner:SHENZHEN OYA CARBON TECH +1

Cigarette box opening method and cigarette box envelope reclamation method

ActiveCN1789084AMeet the requirements of logistics automationMeet automation requirementsPackaging cigaretteEngineeringSmall footprint

Owner:CHINA TOBACCO SHANDONG IND

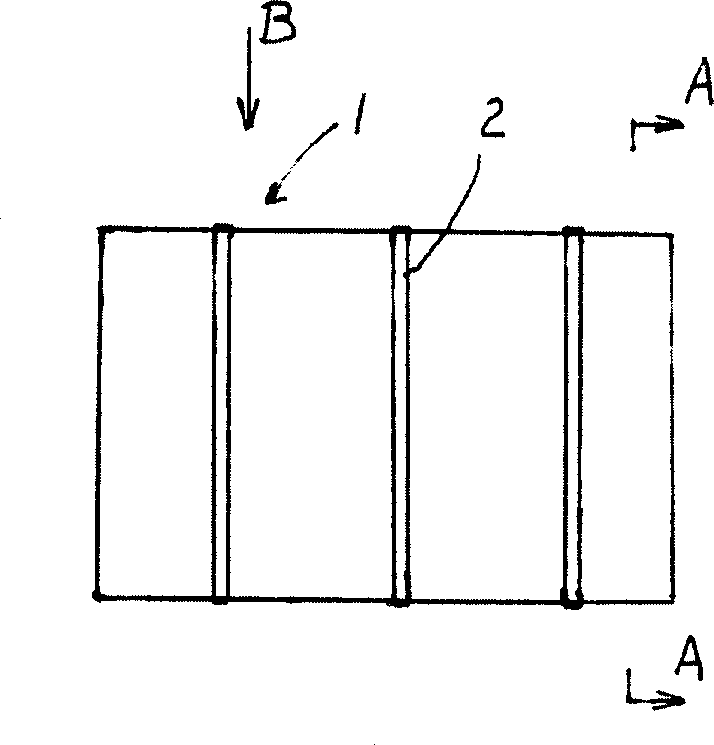

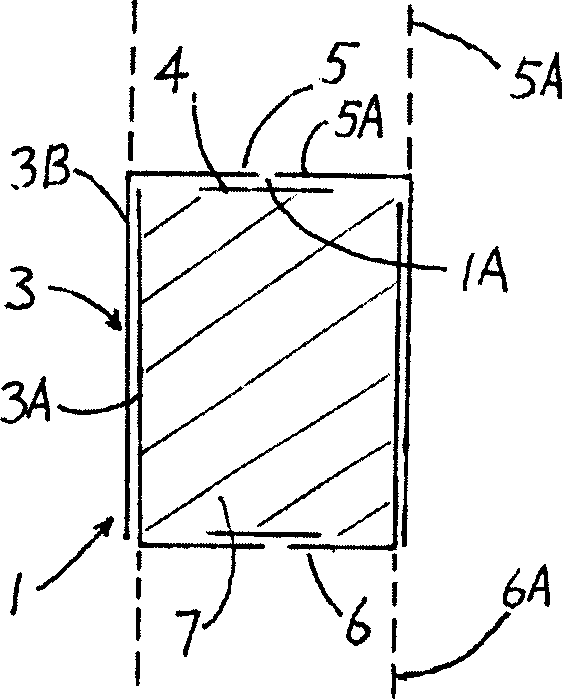

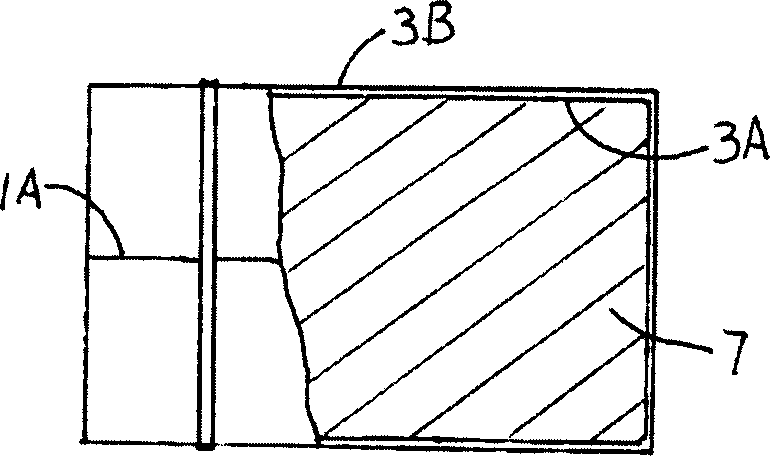

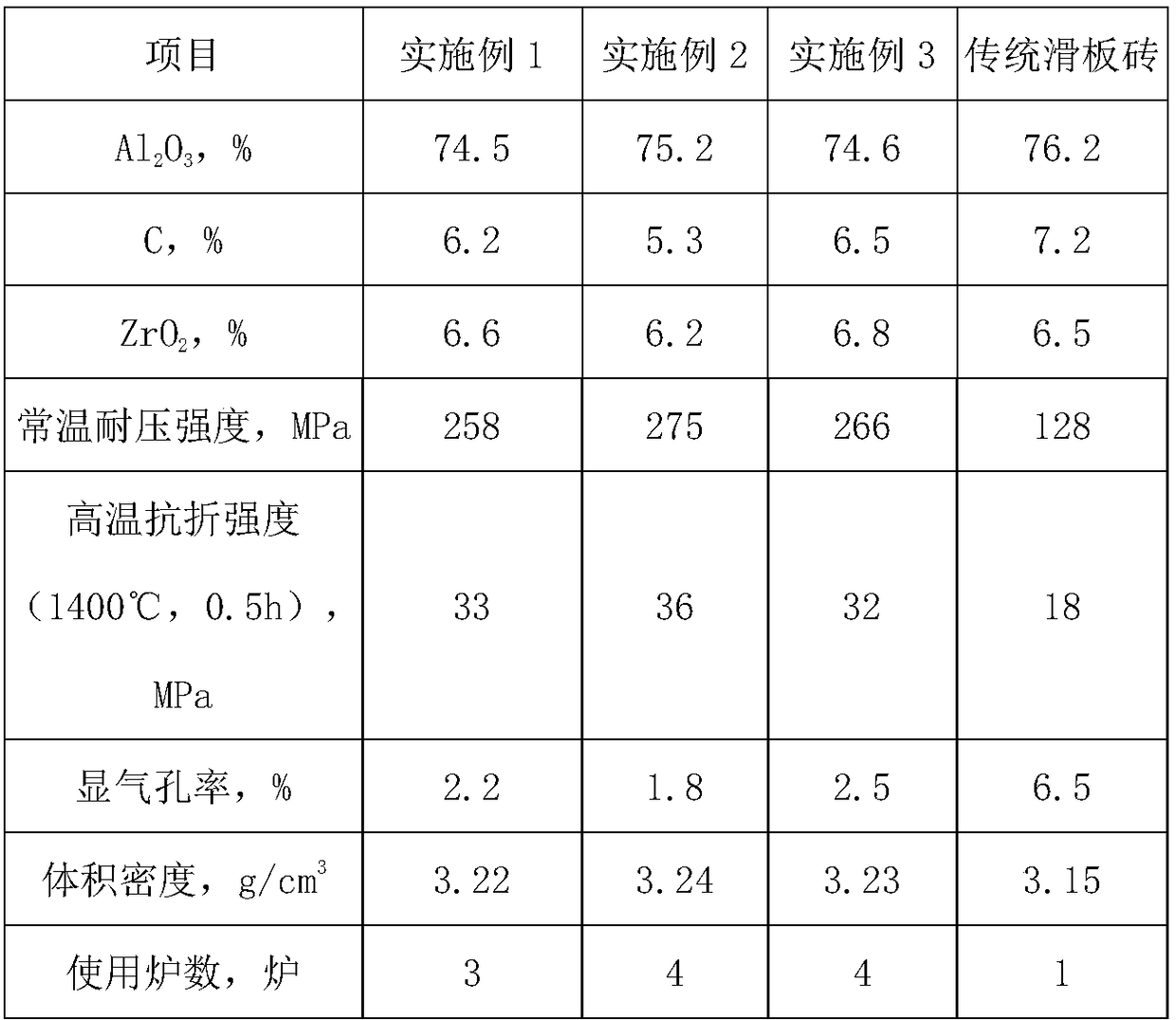

Sliding plate brick added with compound aluminium oxide micropowder and carbon source and preparation method thereof

The invention discloses a sliding plate brick added with compound aluminium oxide micropowder and a carbon source and a preparation method thereof and relates to the technical field of refractory materials. The sliding plate brick is prepared from the following raw materials and components in percentage by weight: 40-50% of platy corundum granule, 10-20% of fused zirconia corundum granule, 5-10% of platy corundum fine powder, 5-10% of fused zirconia corundum fine powder, 10-15% of compound aluminium oxide micropowder, 0.5-3% of flake graphite, 0.5-3% of carbon black, 0.5-5% of metal aluminiumpowder, 0.5-5% of metal silicon powder and 1-4% of special additive, and the sum of the percents is 100%; in addition, 4-6% of phenolic resin is added. The finished sliding plate brick is obtained bythe processes of crushing and mixing of raw materials, mixing and rolling, forming, heat treatment, firing, digestion and carbonization, finish processing, inspection and packaging and the like. The sliding plate brick added with the compound aluminium oxide micropowder and the carbon source has the beneficial effects that by changing for the adjustment of the aluminium oxide micropowder, the heatshock resistance, washout resistance and erosion resistance of the sliding plate brick are improved and the service life is prolonged.

Owner:瑞泰马钢新材料科技有限公司

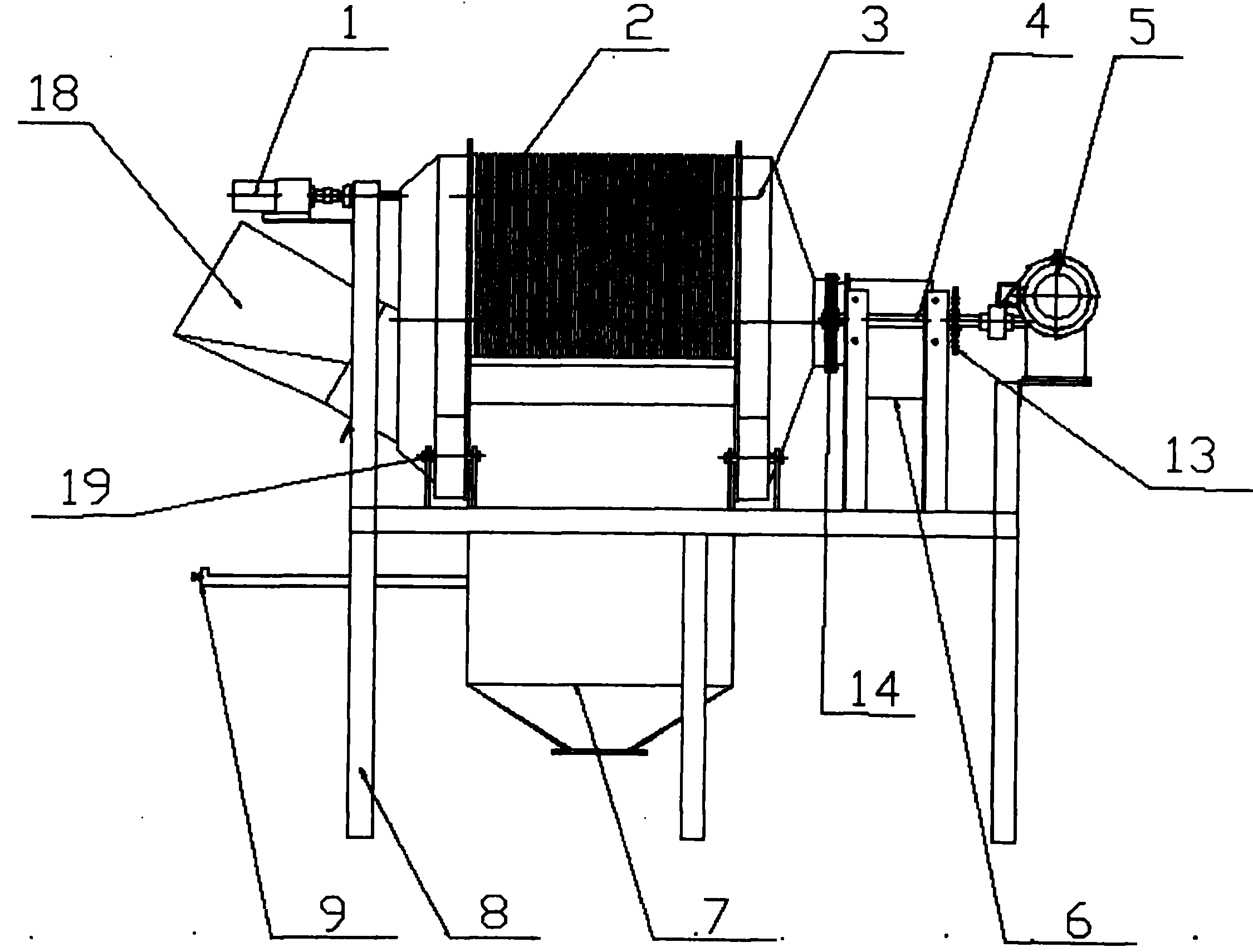

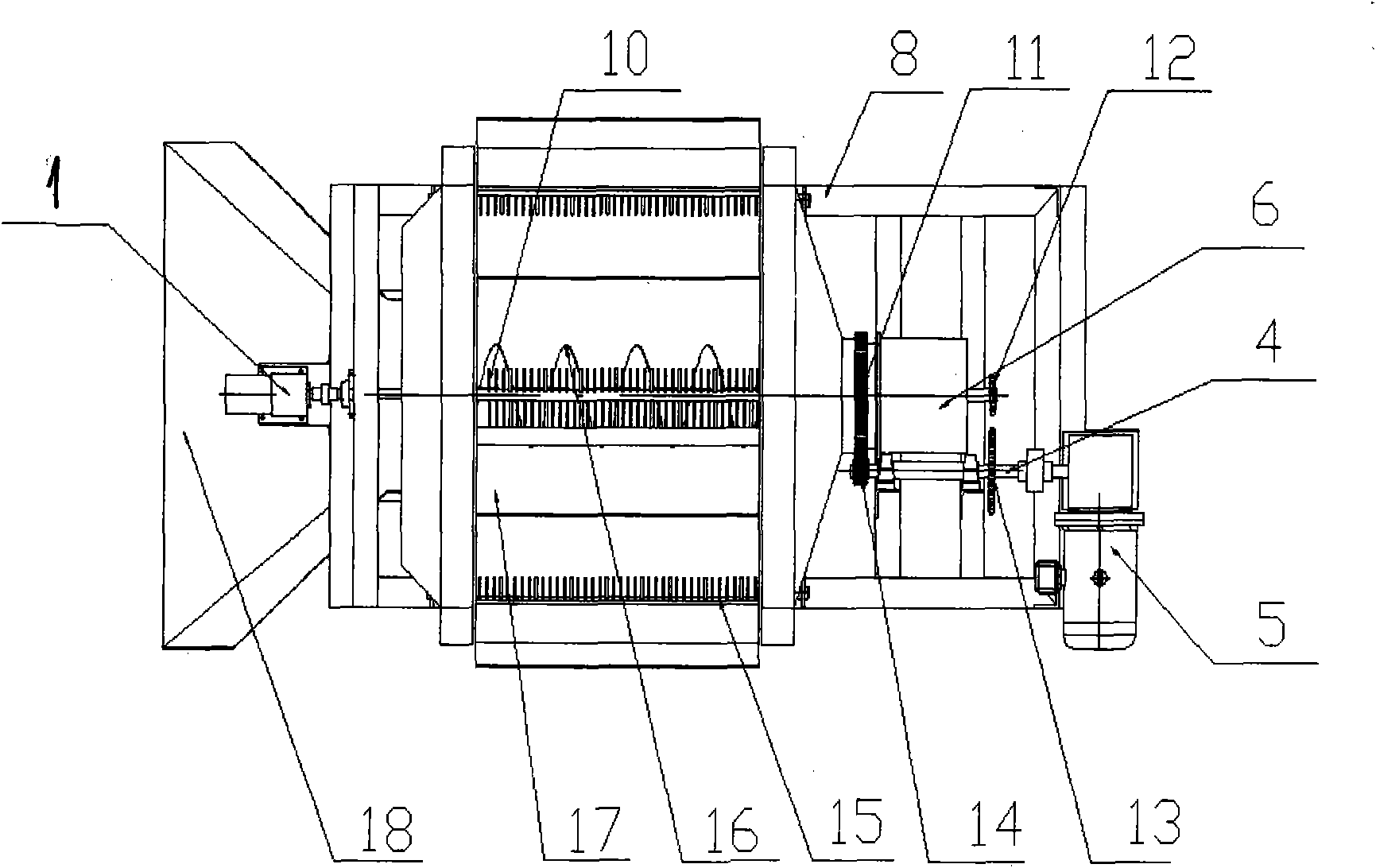

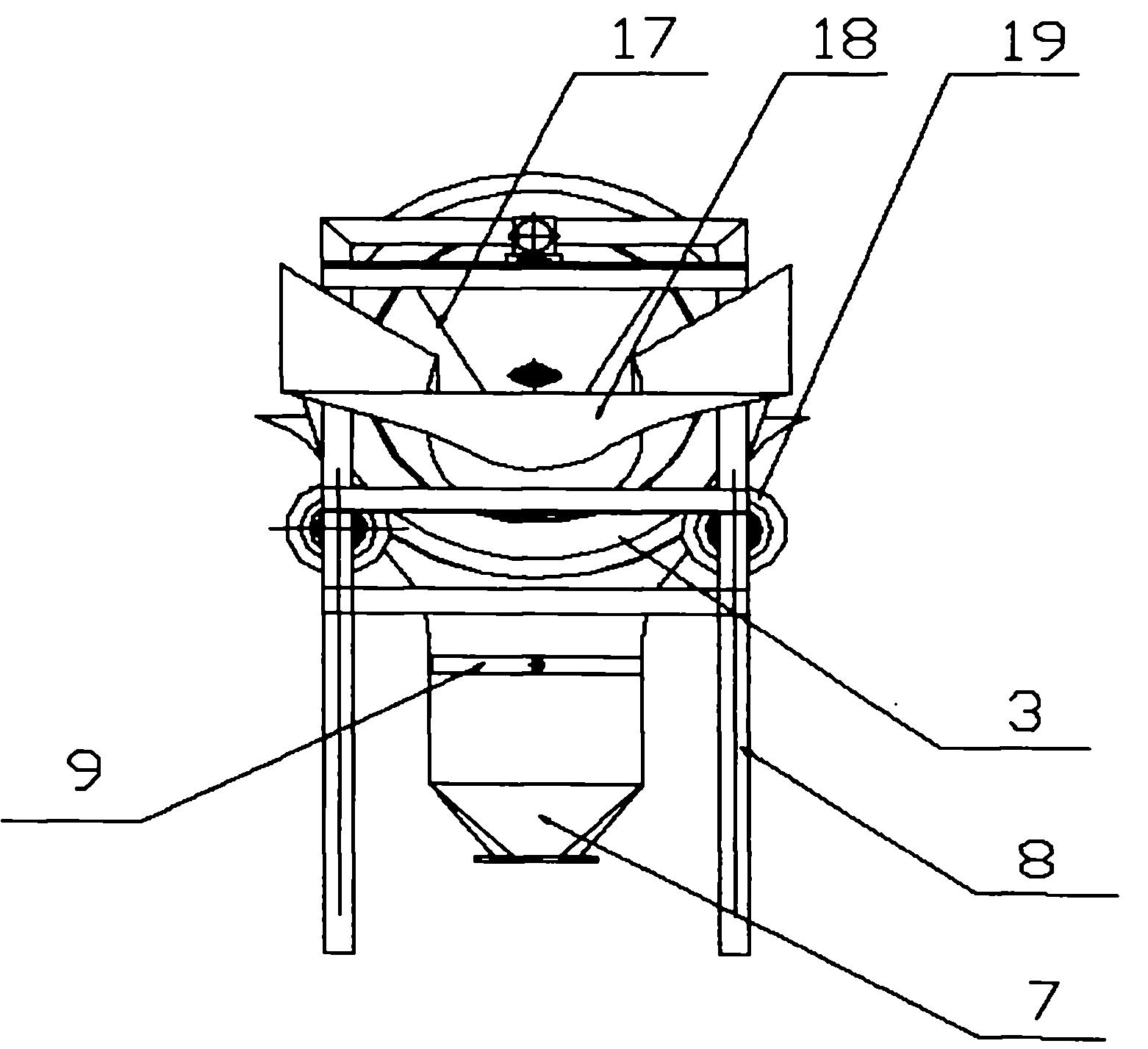

Kitchen garbage component sorting machine

InactiveCN102151680AConducive to the protection of healthImprove protectionSolid waste disposalWet separationGratingSprocket

The invention discloses a kitchen garbage component sorting machine which belongs to auxiliary garbage treatment equipment. A vice speed reduction motor, a feeding hoper, a cleaning brush roll, a spiral conveyer, a support roller, a solid screened material collection box, a liquid screened material collection box, a main shaft and a main motor are arranged on a frame assembly; a revolving drum is arranged on the support roller; a cylindrical grating with a baffle is arranged on the revolving drum and integrally contains the cleaning brush roll and the spiral conveyer; the vice speed reduction motor is connected with the cleaning brush roll; the main motor is connected with the main shaft; a driving sprocket and a driving gear are fixedly arranged on the main shaft; a driven sprocket is fixedly arranged on the spiral conveyer; a ring-shaped gear is fixedly arranged on the revolving drum; the driving sprocket is connected with the driven sprocket; the driving gear is meshed with the ring-shaped gear; and a drawer type oil-water separator is inserted on the liquid screened material collection box. The machine is simple and reasonable in structure, high in operation efficiency, good in sorting quality, less in failure, clean in operation environment and free of pollution.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Soil conditioning fertilizer and production method thereof

ActiveCN103274879AThe effect of increasing production is obviousImprove Yield BenefitsFertilizer mixturesHumic acidPhosphate

The invention discloses a soil conditioning fertilizer and relates to the technical field of agricultural fertilizer. The soil conditioning fertilizer is prepared from the following materials in weight parts: 50-100 parts of humic acid, 50-100 parts of dolomite dust, 5-10 parts of dilute sulphuric acid solution, 100-150 parts of monoammonium phosphate, 1-30 parts of urea, 300-350 parts of potassium chloride, and 5-10 parts of zinc sulfate. The experimental results of the field fertilizer efficiency demonstration of the soil conditioning fertilizer on various crops including field crops like crops, commercial crops like soybean and green pepper, as well as melons and fruits and vegetables like Chinese cabbage, grape and radish show that the yield is remarkably increased and the product quality is remarkably improved, the stress resistances like cold resistance, drought resistance, disease resistance and lodging resistance of the crops are remarkably improved, the tastes of the melon, the tomato, the Chinese cabbage, the green pepper, and the like are good, and therefore, the soil conditioning fertilizer is well received by the masses and is worthy of popularization and application.

Owner:临沂草之美医药科技有限公司

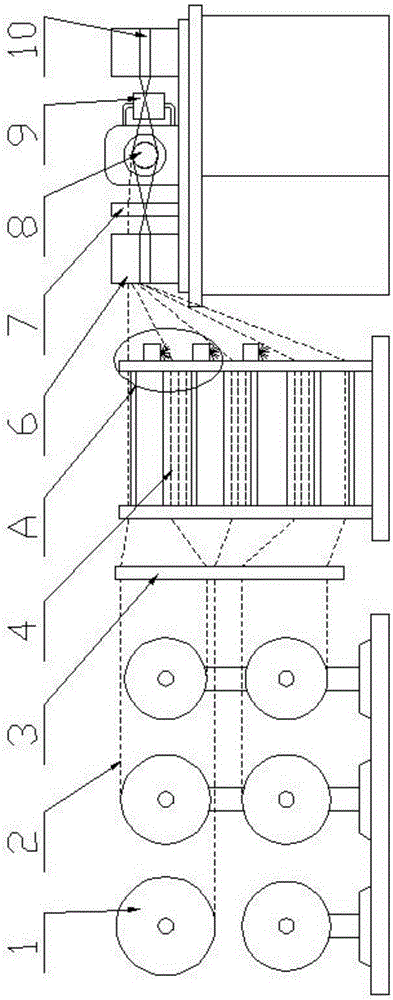

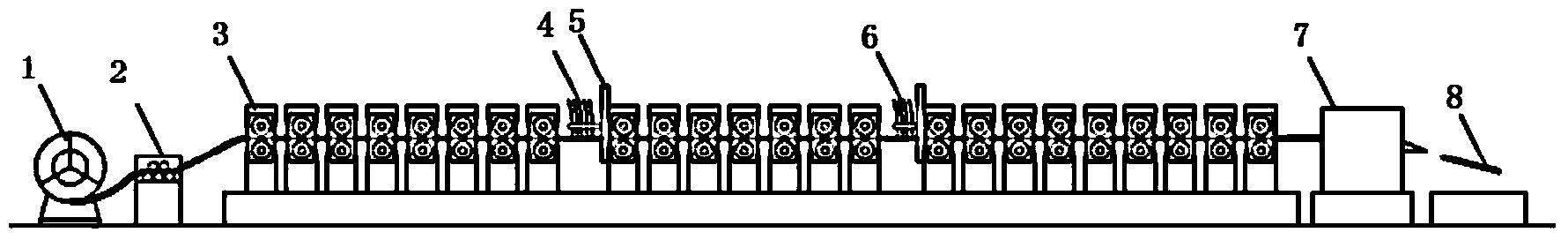

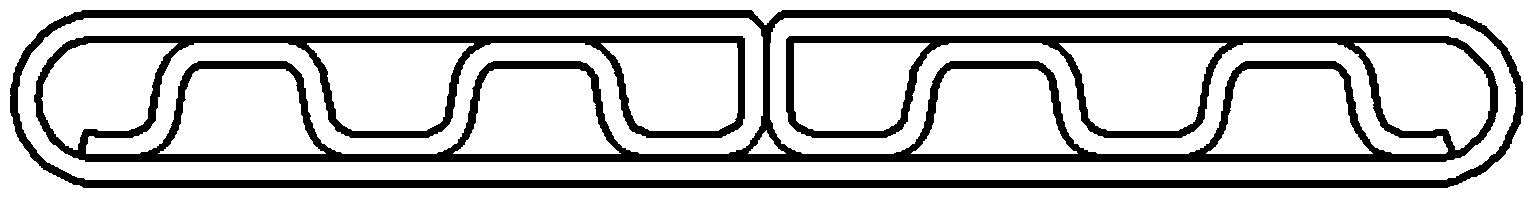

Roll bending forming device and forming method for ten-hole micro-channel flat tubes

ActiveCN103753162AImprove stress statusSolution to short lifeOther manufacturing equipments/toolsEngineeringWelding process

The invention discloses a roll bending forming device for ten-hole micro-channel flat tubes. The roll bending forming device comprises an uncoiling machine, a straightening machine and a roll bending forming unit which are sequentially arranged. The roll bending forming unit comprises an upper row of mill rolls, a lower row of mill rolls, a brazing flux coating device and a product straightening device, multi-pass roll bending forming roll pairs are sequentially configured to form the upper row of mill rolls and the lower row of mill rolls, the brazing flux coating device and the product straightening device are arranged among the roll bending forming roll pairs, gaps are reserved between the upper row of mill rolls and the lower row of mill rolls, and the shapes and the sizes of the gaps are matched with the shapes and the sizes of the ten-hole micro-channel flat tubes. The invention further discloses a forming method implemented by the forming device. The roll bending forming device and the forming method have the advantages that precision dies can be omitted, a series of problems caused during continuous extrusion can be solved, and the manufactured flat tubes are stable in quality; the extrusion speed normally ranges from 2 meters per minute to 3 meters per minute when ten-hole micro-channel flat tubes are manufactured in an extrusion mode, but the roll bending technological manufacturing speed is higher than 80 meters per minute, and the manufacturing efficiency can be improved by 20 times as compared with the traditional extrusion mode; additional welding techniques are omitted in roll bending forming procedures, and integral heat exchangers can be manufactured only by the aid of a brazing technique.

Owner:上海瀚兰通科技有限公司

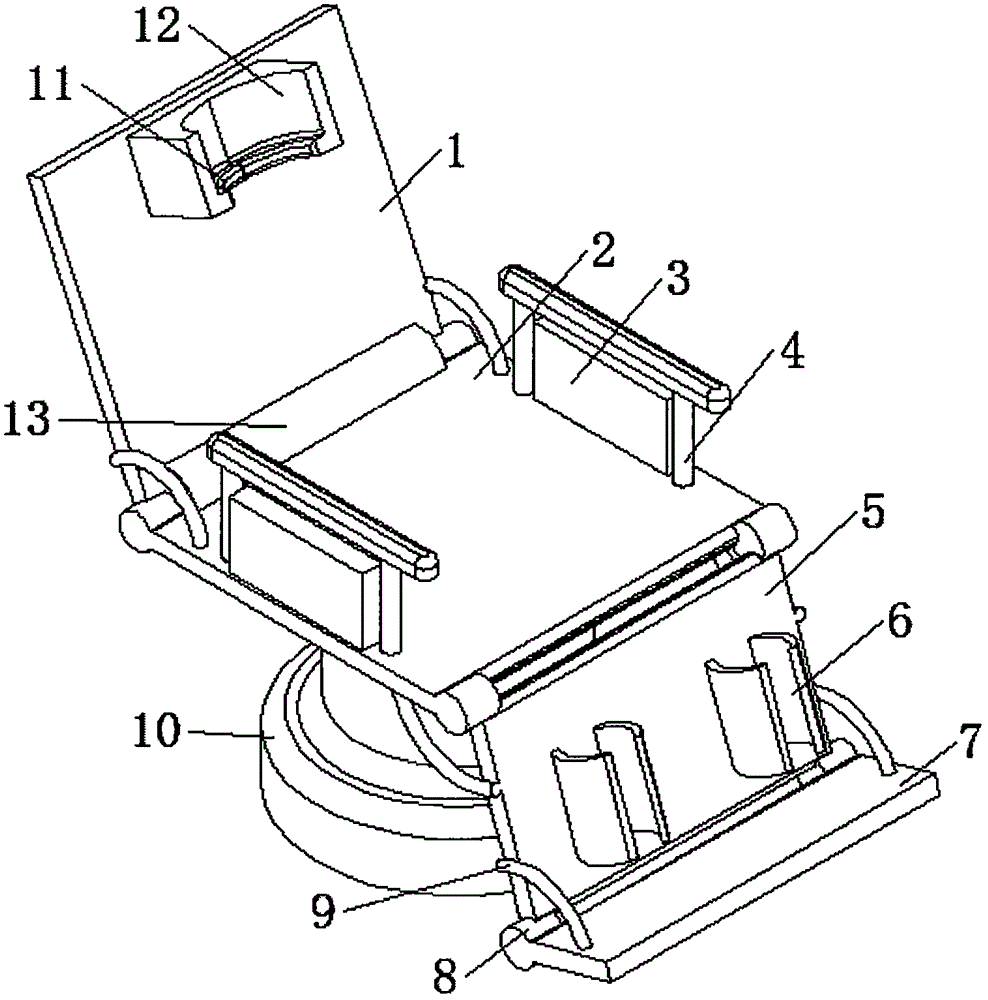

Intelligent nursing and rehabilitation chair device

InactiveCN105769503AConvenient angleSmall thermal inertiaOperating chairsChiropractic devicesEngineeringFully automatic

The invention discloses an intelligent nursing and rehabilitation chair device, which comprises a first back board, a second back board, a third back board and a footrest, the first back board is connected with the second back board through an angle adjustor and arc-shaped retractable rods, the second back board is connected with the third back board through an angle adjustor and arc-shaped retractable rods, the third back board is connected with the footrest through an angle adjustor and arc-shaped retractable rods, the bottom of the second back board is fixedly connected with a base, armrests are respectively added on both sides of the second back board, moreover, infrared radiation heaters are added under the armrests, the infrared radiation heaters are fixedly connected with the second back board, furthermore, the infrared radiation heaters are connected with a controller in the base through wires, leg massagers are added on the surface of the third back board, the leg massagers are connected with the controller through wires, and a pillow is fixedly mounted on the surface of the first back board. The novel intelligent nursing and rehabilitation chair device adopts fully automatic intelligent control, so that users can feel more comfortable.

Owner:管培兰

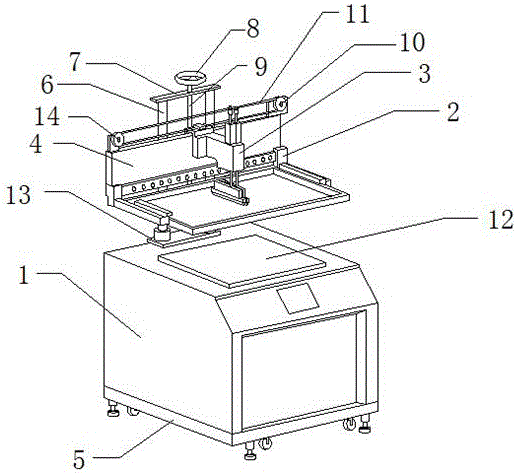

Automatic silk-screen printing device

The invention provides an automatic silk-screen printing device. The device comprises a movable clamping groove, a movable arm, a fixed arm, a fixed clamping groove, a right scraper, an ink nozzle, a nozzle groove, a bottom plate and universal wheels. The movable clamping groove is formed in the movable arm, the fixed clamping groove is formed in the mixed arm, and the problem that a screen clamping structure is not adjustable in range and accordingly the application range is small is solved by means of the design, and the purchase quantity of silk-screen equipment is reduced; the nozzle groove is formed in the lower end face of the right scraper, the ink nozzle is installed in the nozzle groove, the problem that existing silk-screen equipment wastes printing ink is solved due to the design, the work environment becomes clean, and waste of the printing ink is reduced; the universal wheels are installed on the lower end face of the bottom plate, the problem that the silk-screen equipment is difficult to carry is solved due to the design, labor intensity of workers is reduced, the silk-screen equipment can be quickly and conveniently carried by the workers, and work efficiency is improved. The automatic silk-screen printing device is simple, convenient to operate, simple in printing and platemaking, low in cost and high in adaptability.

Owner:中山市恒辉自动化科技有限公司

Quenching medium preparing method in production technique of suspension insulator ultralow temperature steel pins

ActiveCN103589831AEasy to cleanClean working environmentQuenching agentsAging resistanceWorking environment

The invention discloses a quenching medium preparing method in a production technique of suspension insulator ultralow temperature steel pins. The specific preparation is as follows: firstly, 25% of a PAG stock solution and 75% of running water are fully mixed; the concentration of PAG is regulated within 10-13%; then 5% of a W901 antirust agent, 0.5% of an XJ-103 defoaming agent, 1.5% of a G801 antiseptic bactericide and 3% of an RQ-322H surface active agent are added in the mixed liquid. Compared with the traditional PAG quenching liquid, the quenching medium used by the embodiment has the advantages of no oil, no smoke, no poison, more ageing resistance, clean working environment, low movement viscosity, easy workpiece cleaning and no accumulation of carbon, oil and mud on equipment; the cooling capacity different from that of the traditional quenching liquid can be obtained by assisting to regulate concentration, temperature and stirring degree; for the low-temperature products of the embodiment, more pertinence is achieved on the quenching technique.

Owner:DALIAN SAIRUI METAL PROD

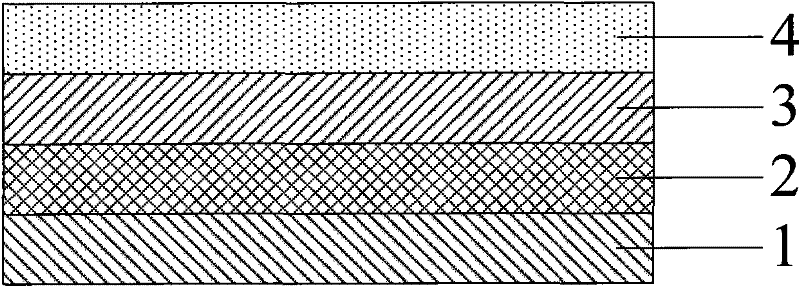

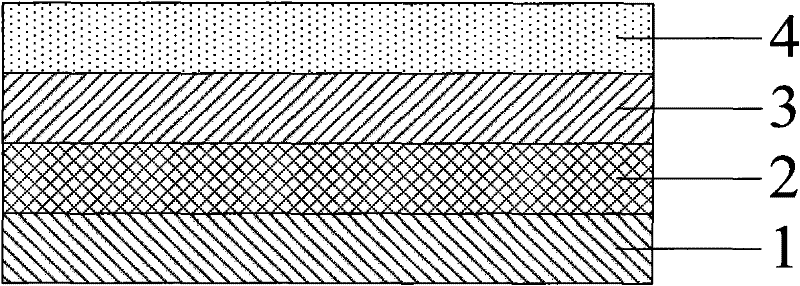

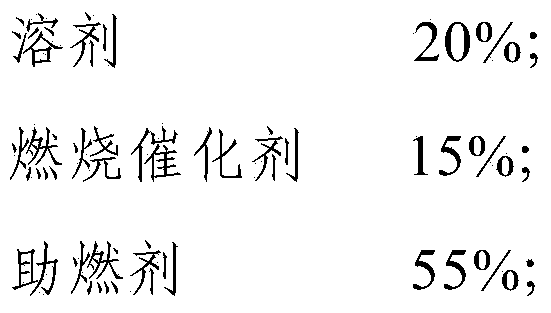

True metal wiredrawing composite board

InactiveCN102173135ALow costSimple preparation processGlass/slag layered productsMetal layered productsPolyvinyl chlorideOperating environment

The invention provides a true metal wiredrawing composite board which is characterized in that a substrate is made of toughened glass, a temperature-resisting double faced adhesive tape is adhered to the toughened glass, a composite membrane layer is covered on the temperature-resisting double faced adhesive tape, and the composite membrane layer is composed of polyethylene terephthalate (PET), an aluminium foil wiredrawing layer and polrvinyl chlorides (PVC). The true metal wiredrawing composite board provided by the invention has the advantages that the PET / aluminium foil wiredrawing layer / PVC composite membrane layer is compounded on the surface of the toughened glass through the temperature-resisting double faced adhesive tape, thus the effects of adornment, protection and beautification are achieved, and meanwhile, the manufacturing process is simple, and the operation is convenient; due to the beautiful colors, the obtained product is delicate, and appropriate for durability products; the board is good in abrasion resistance and stain resistance; and the step of painting is omitted, thus the operating environment is ensured to be neat and clean, the expenditures can be cut down, and the productivity can be improved. The true metal wiredrawing composite board can be applied to refrigerator panels through replacing stainless steel wiredrawing boards, thereby remarkably reducing the cost of materials.

Owner:SUZHOU HESHENG NEW MATERIALS

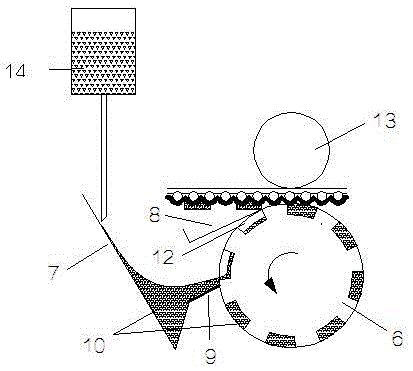

Wide air-permeable fancy-type reflecting material and preparation method therefor

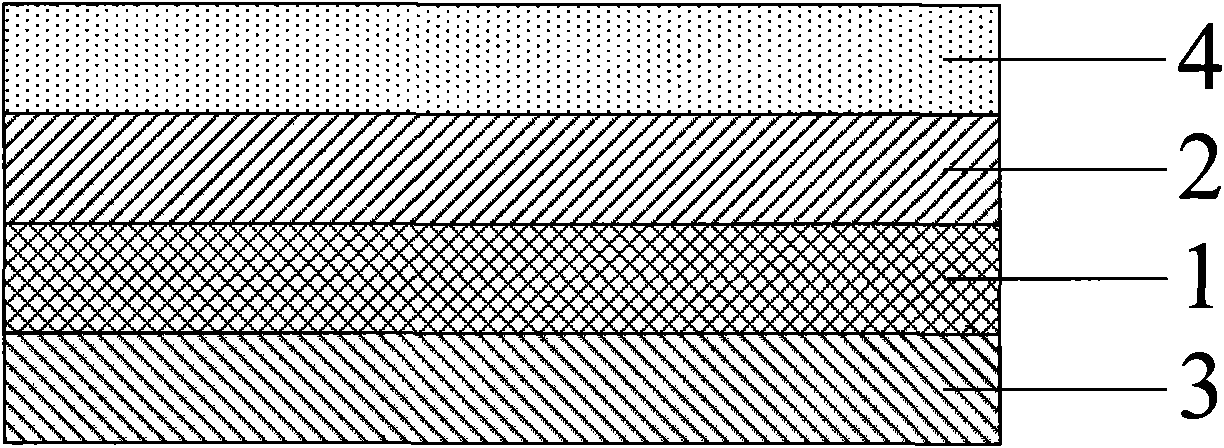

ActiveCN105301684AClear patternBreathableLamination ancillary operationsSynthetic resin layered productsHot-melt adhesiveCoating

Owner:HANGZHOU CHINASTARS REFLECTIVE MATERIAL

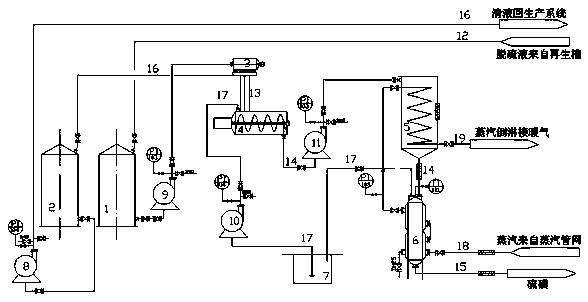

Technology and device for separating and melting sulfur

ActiveCN105502300ALess side effectsImprove desulfurization efficiencySulfur preparation/purificationChemical industryChemistry

The invention relates to a technology and device for separating and melting sulfur, and belongs to the technical field of separating and melting of chemical industry production. The technology in the technical scheme includes the steps that after a desulfurizing solution is subjected to regeneration and discharged out of a regeneration trough with sulfur foam, the desulfurizing solution and the sulfur foam are separated through a desulfurizing pressure filter, and separated clear liquid is directly fed to a system to be recycled through a desulfurizing pump; the separated sulfur foam is circularly stirred through a solution from a sulfur melting kettle to enter the sulfur melting kettle for sulfur melting, and a solution for sulfur melting and a solution for the production system are thoroughly separated. According to the technology and device, the content of solid matter of the clear liquid obtained after filtering of the desulfurizing pressure filter is lower than 60 ppm, stable production of the system is facilitated after the clear liquid is fed back to the production system, filtered-out sulfur paste is re-mixed to enter the sulfur melting kettle, energy consumption is saved, and compared with the traditional technology, energy consumption is reduced by 85% or above; the working environment is clean and free of pollution; the device is simple and convenient to install and maintain; the automatic degree of the system is high, the labor intensity is low, labor cost is saved, and continuous and stable operation of the system is facilitated.

Owner:HEBEI KAIYUE CHEM GROUP

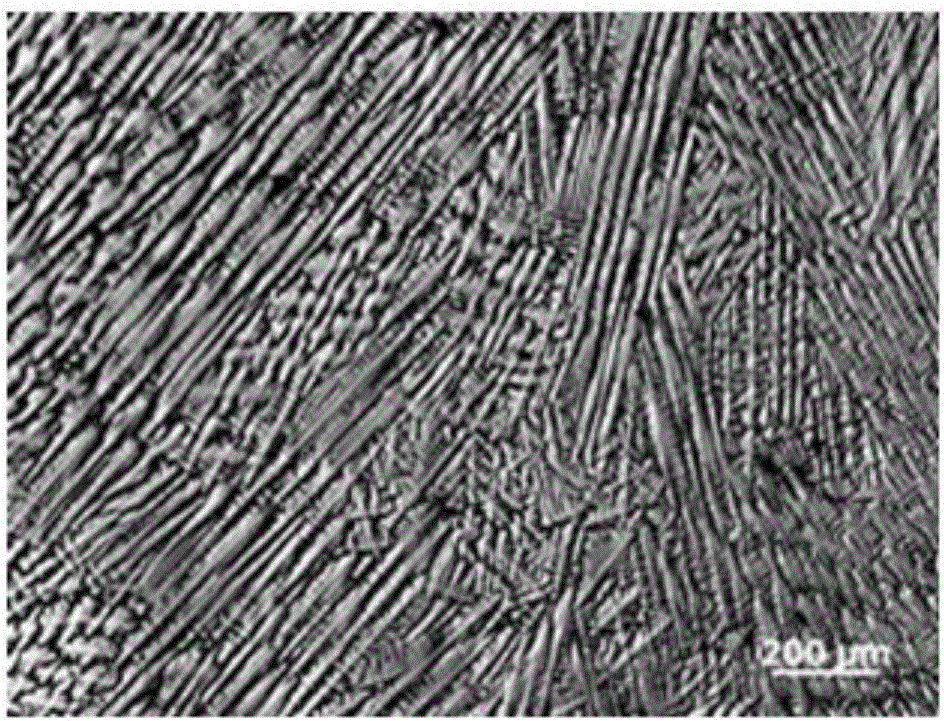

Method for preparing medium and low carbon chrome-silicon-manganese martensite cast steel with hardening surface layer

The invention relates to a method for preparing a medium and low carbon chrome-silicon-manganese martensite cast steel with a hardening surface layer. The cast steel comprises the following components (wt%): 0.26-0.4 of C, 0.95-1.3 of Si, 0.70-1.20 of Mn, 0.70-1.10 of Cr, less than 0.05 of impurities and the balance of Fe; then, the cast steel is prepared from the steps of smelting-casting-cleaning and polishing-thermal insulating at the temperature of 830 DEG C-860 DEGC for 550-600 seconds-quenching or incompletely quenching at constant temperature of 180-230 DEGC and thermal insulating for 120-240 seconds-thermal insulating for 180-300 seconds within the temperature range of 340-430 DEGC-quenching to the room temperature-heating the surface of a steel piece in a scanning mode through a cross flow tube-sheet type multimode continuous carbon dioxide laser; and the steel piece treated through the method disclosed by the invention keeps high strength and has certain plasticity and high surface hardness at the same time, moreover, a workpiece is kept not to deform, and the comprehensive mechanical property is obviously improved than a conventional technology.

Owner:夏雨

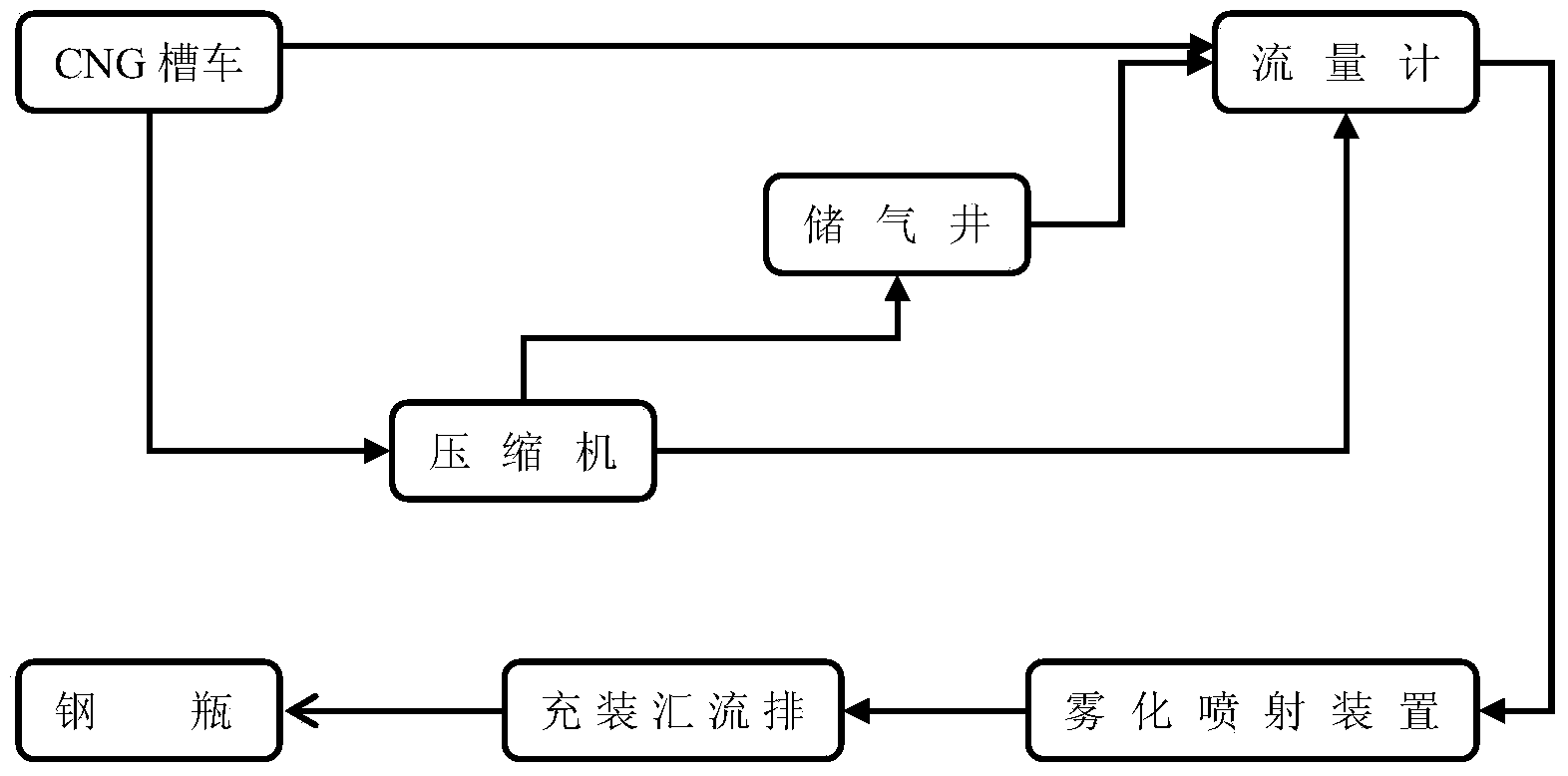

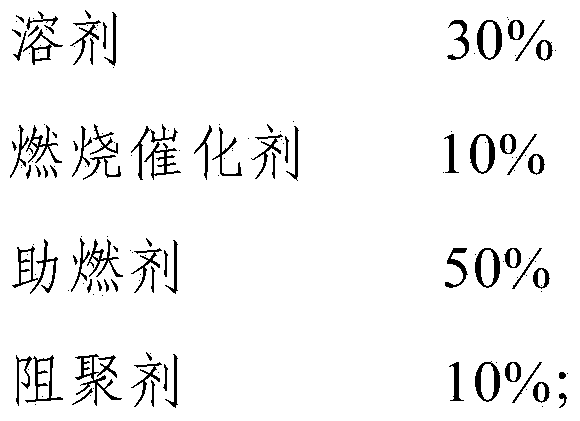

Natural gas combustion synergist, natural gas mixture containing same, and preparation method of natural gas mixture

ActiveCN103468339AReduce gas activation energySpeed up chemical reactionsGaseous fuelsIndustrial gasHigh energy

The invention provides a natural gas combustion synergist, comprising the following components in percentage by mass: 20 to 30% of solvent, 10 to 15% of combustion catalyst, 40 to 60% of combustion improver and 10 to 20% of polymerization inhibitor. The combustion synergist provided by the invention is mainly used for carrying out modification synergism to natural gas to improve the combustion speed and the combustion efficiency of the gas, improve the total effective energy, increase flame temperature and improve components of a combustion product, therefore, the natural gas can become a core product of high-energy industrial gas, and consequently, the technical effects of reducing the energy consumption, reducing the pollution, reducing production cost of a using department, improving the production efficiency and the like can be realized.

Owner:HEBEI RUIPU ENERGY CO LTD

Drawing-like stainless steel clad steel plate

InactiveCN101564920ASimple processEasy to operateSpecial ornamental structuresMetal layered productsSteel platesFingerprint

The invention provides a drawing-like stainless steel clad steel plate which comprises a steel plate and a compound coating covered and stuck to the steel plate. The compound coating comprises polyethylene terephthalate, a printing layer and polyvinyl chloride, a protective coating is covered and stuck to the compound coating, and a back coating is arranged at the back of the steel plate layer. The drawing-like stainless steel clad steel plate with the stuck compound coating can take the actions of decoration, protection and beatification, has better chemical resistance and fingerprint resistance as well as clean surface, is widely applied to industries, such as household electrical appliances, and the like and is particularly deep punched and stretched to be used for a ventilator cover as a special application.

Owner:SUZHOU HESHENG NEW MATERIALS

Cylindrical steel shell battery and manufacturing method thereof

PendingCN113809335AIncrease in sizeWeight increaseFinal product manufactureElectrode carriers/collectorsPower batteryElectrical battery

The invention relates to a cylindrical steel shell battery and a manufacturing method thereof, and belongs to the technical field of energy storage power batteries of new energy automobiles. The battery comprises a positive electrode cover plate, a positive electrode collector plate assembly, a full-tab roll core, a steel shell, a negative electrode collector plate assembly and a negative electrode cover plate, the negative electrode cover plate is located at the negative electrode end of the steel shell, the full-tab roll core welded with the positive electrode collector plate assembly and the negative electrode collector plate assembly is located in the steel shell, the positive electrode cover plate is located at the positive electrode end of the steel shell, the positive electrode collector plate assembly and the periphery of the positive electrode cover plate are sealed by laser welding, and the negative electrode collector plate assembly and the periphery of the negative electrode cover plate are sealed by laser welding. According to the invention, the large-current charge-discharge performance of the battery can be improved, battery accessories are simplified, the cost is reduced, the space of inactive substances in the battery is reduced, the volumetric specific energy and gravimetric specific energy of the battery are improved, a sealed formation process is realized, formation gas can be eliminated, the structure of formation equipment is simplified, and the environment control cost is reduced. The working environment is clean and pollution-free.

Owner:贵阳比耐新能源科技有限公司

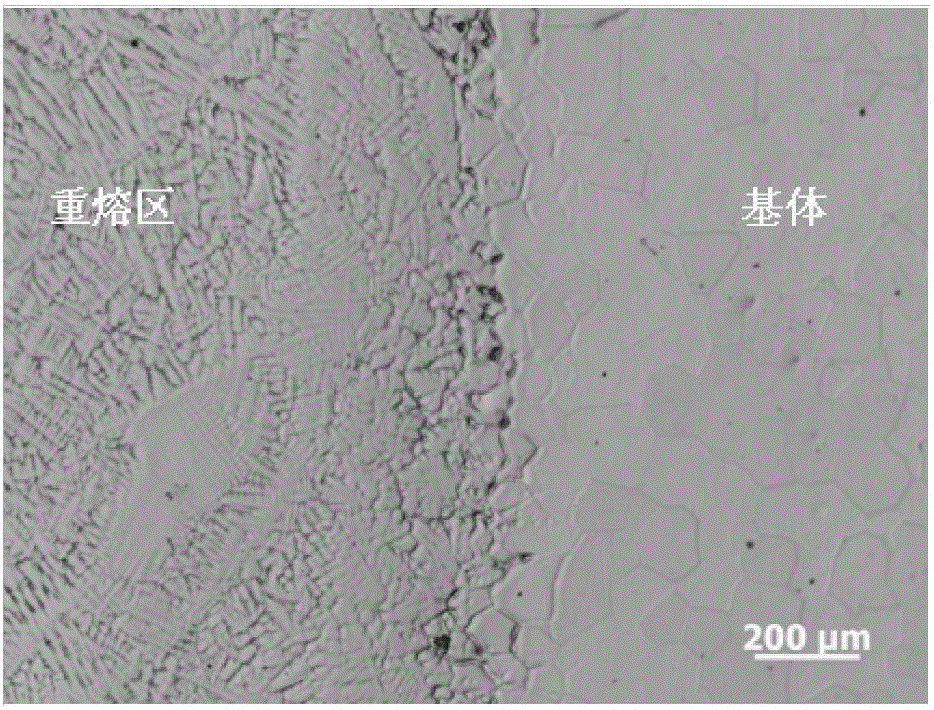

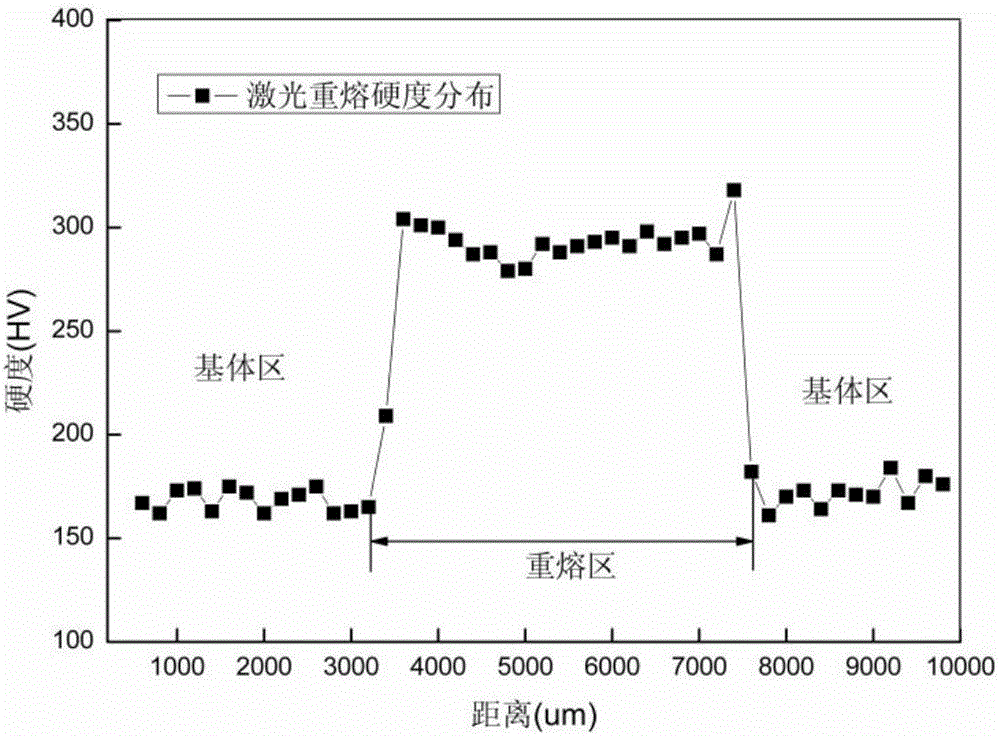

Method for surface modification of medical beta titanium alloy by laser remelting technology

ActiveCN105018925AProcessing speedImprove surface propertiesMetallic material coating processesHardnessMachining

The invention provides a method for surface modification of a medical beta titanium alloy by a laser remelting technology; the surface remelting treatment is performed for the medical beta titanium alloy through a semiconductor laser; and the laser remelting comprises process parameters of 350-500 W of laser power, 1-5 mm / s of scanning speed and 1 machining pass. The method prominently improves the surface hardness of the medical beta titanium alloy material; and the medical beta titanium alloy after the surface modification is smooth in surface, and can be applied to subsequent process flows without needing surface finishing.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com