Continuous densification and efficient production line and technology of fiber-reinforced thermosetting plastic pipelines

A plastic pipe, fiber reinforced technology, applied in the direction of tubular items, other household appliances, household appliances, etc., can solve the problems of loose wires, stuck cables, reduced production efficiency, etc., and achieve high-efficiency production lines and processes, pressure resistance Good and efficient production results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

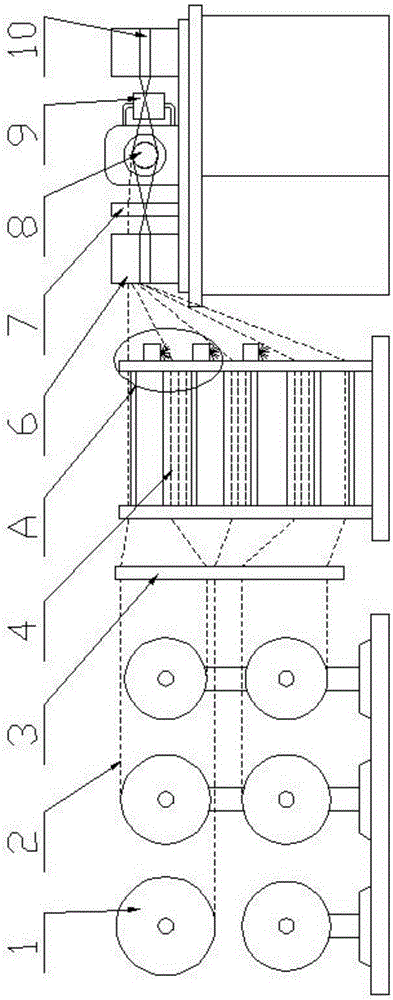

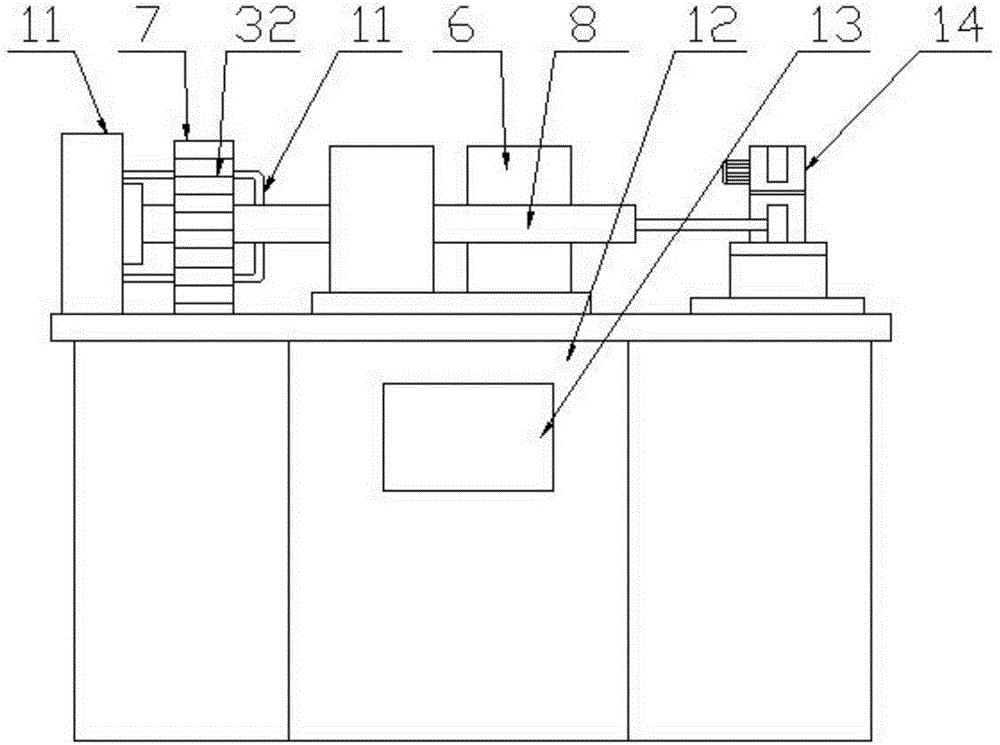

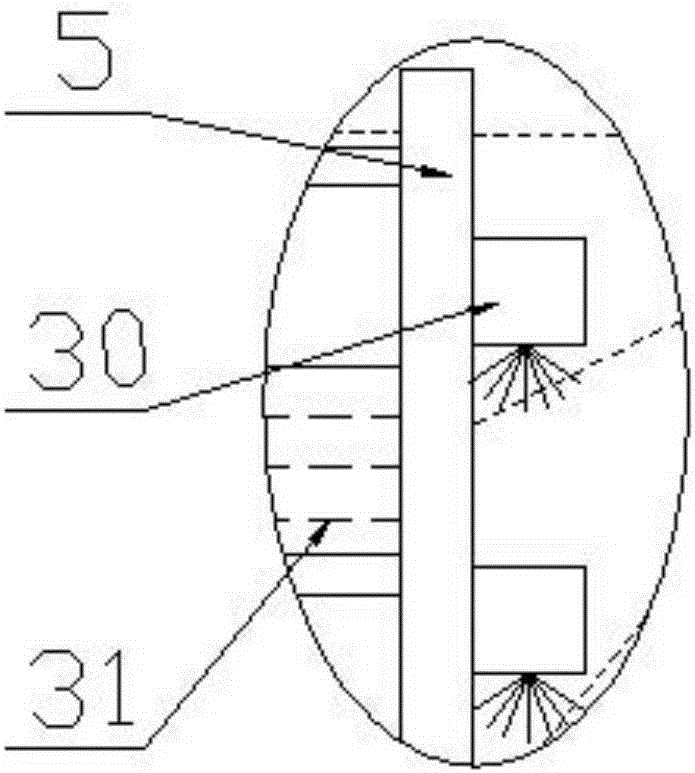

[0059] as attached figure 1 , 2 , Shown in 3, a kind of fiber-reinforced thermosetting plastic pipe continuous compacting, efficient production line of the present invention is to apply in the field of fiber-reinforced thermosetting plastic pipe production after the paper tube machine production line is improved, and the paper tube machine production line after the improvement is along the paper tube machine production line In the direction of tube movement, a strip frame 1, a first hollow partition 3, a gluing frame 5, an atomizing hair generator 30, a second hollow partition 7, and a spiral paper tube machine refitting device are provided in sequence. Wherein, the strip frame 1 is used to place the fiber strip 2 and the film strip 2 in rolls, the first hollow partition 3 and the second hollow partition 7 are provided with spacers 32, and the gluing frame 5 is a multi-layer frame body, the gluing rack 5 is provided with a dipping pool 4 filled with thermosetting resin and ad...

Embodiment 2

[0078] as attached Figure 8 , 9 , 10, embodiment two is the same as embodiment one, the difference is that the rubber scraping assembly includes a rubber scraping pair of rollers arranged above the dipping pool 4, and the rubber scraping rollers are arranged on the scraper frame 35, and the fiber strip 2 Passing through the middle of the squeegee roller, its structure includes a fixed roller 40 and a movable roller 39, a chute 37 is provided on the squeegee frame 35, and the roller shaft of the movable roller 39 slides in the chute 37 through a slider 38, The upper end of the slider 38 is provided with a limit screw 36, and the lower end is connected to the inner bottom wall of the chute 37 through a spring. The atomizing generator 30 is connected with the atomizing chamber 41, the atomizing chamber 41 is a sealed housing for containing the atomized liquid droplets, the atomizing chamber 41 is installed on the atomizing bracket 33, and the fiber strip 2 is set on the sealed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com