Patents

Literature

18504 results about "Leather belt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

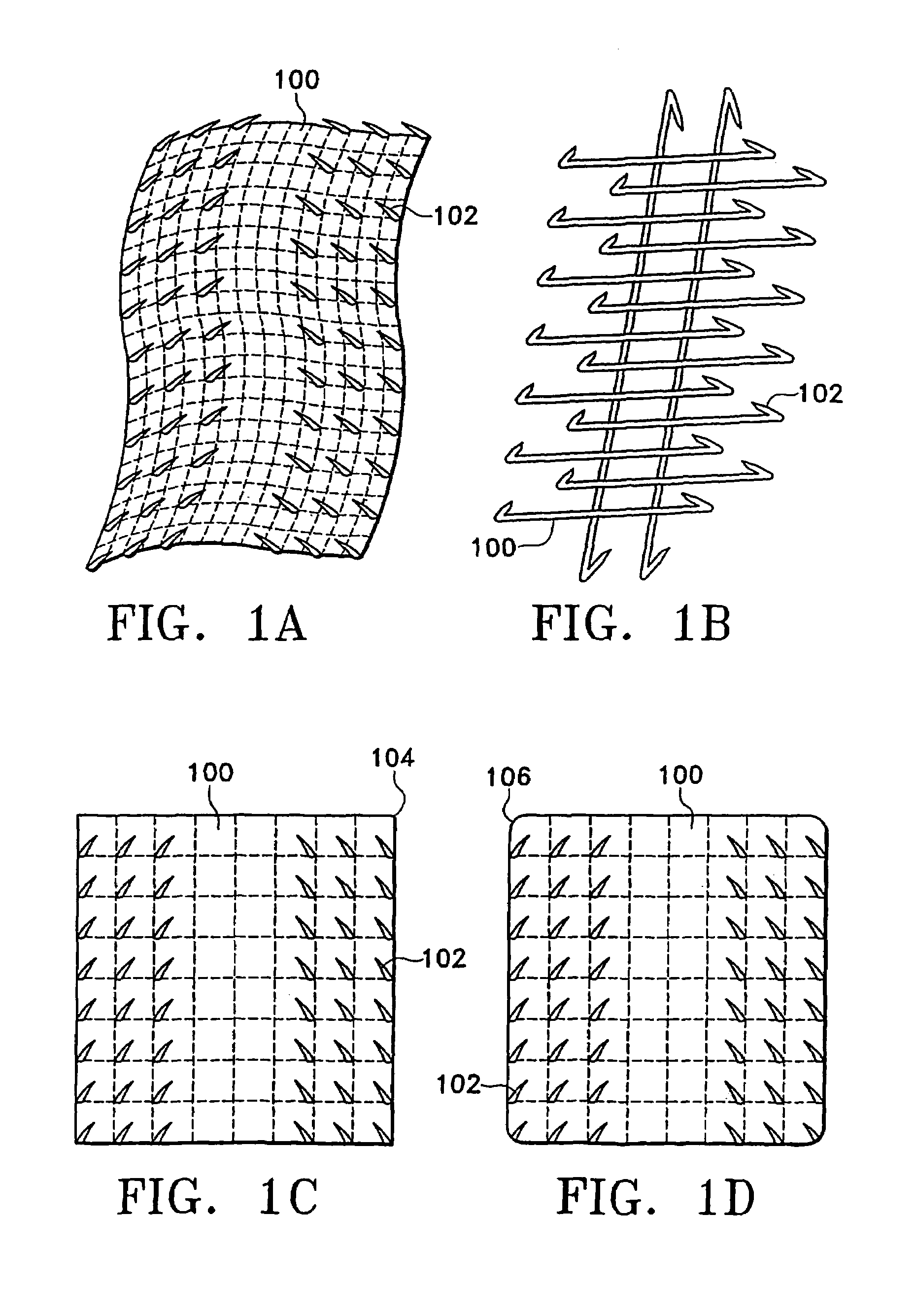

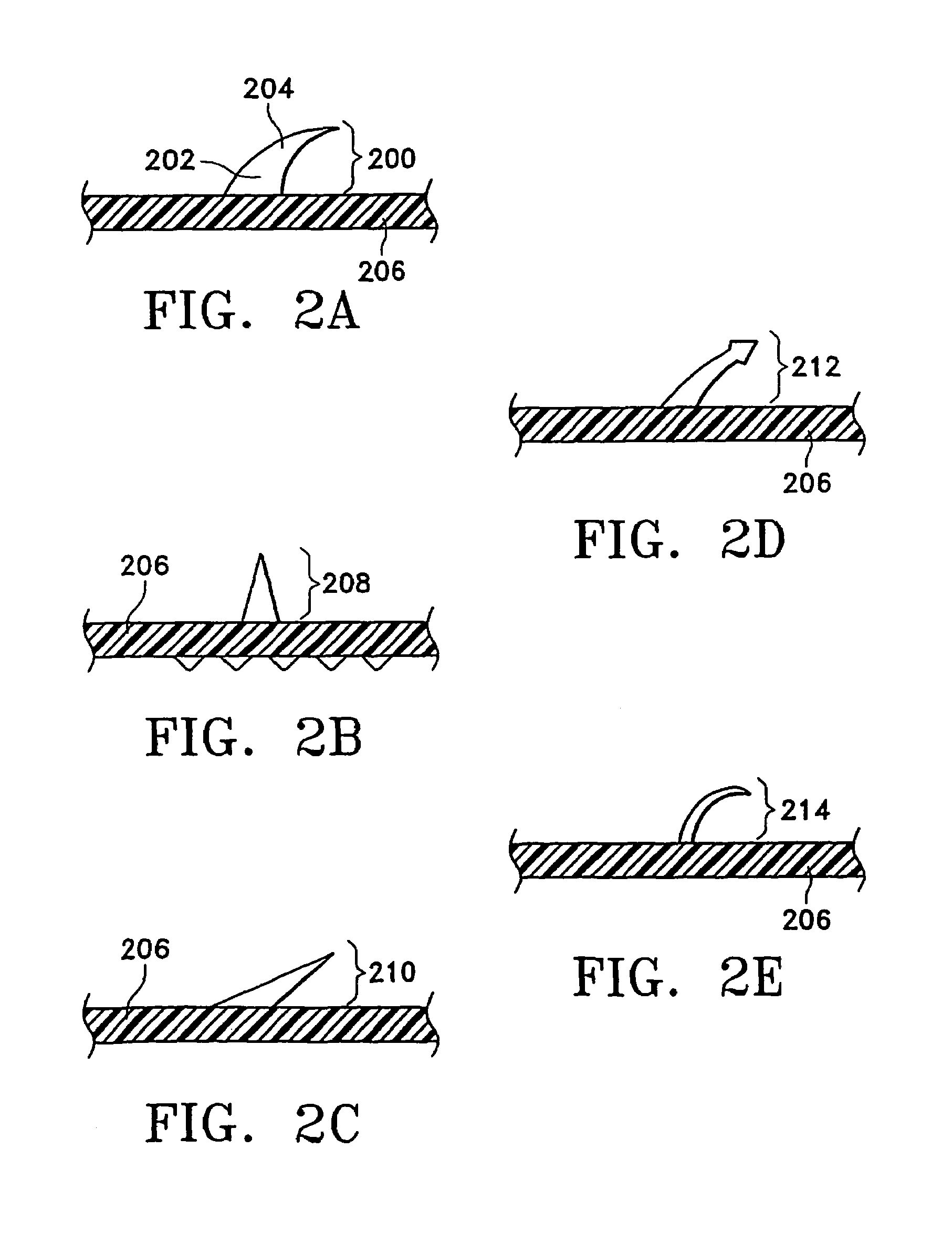

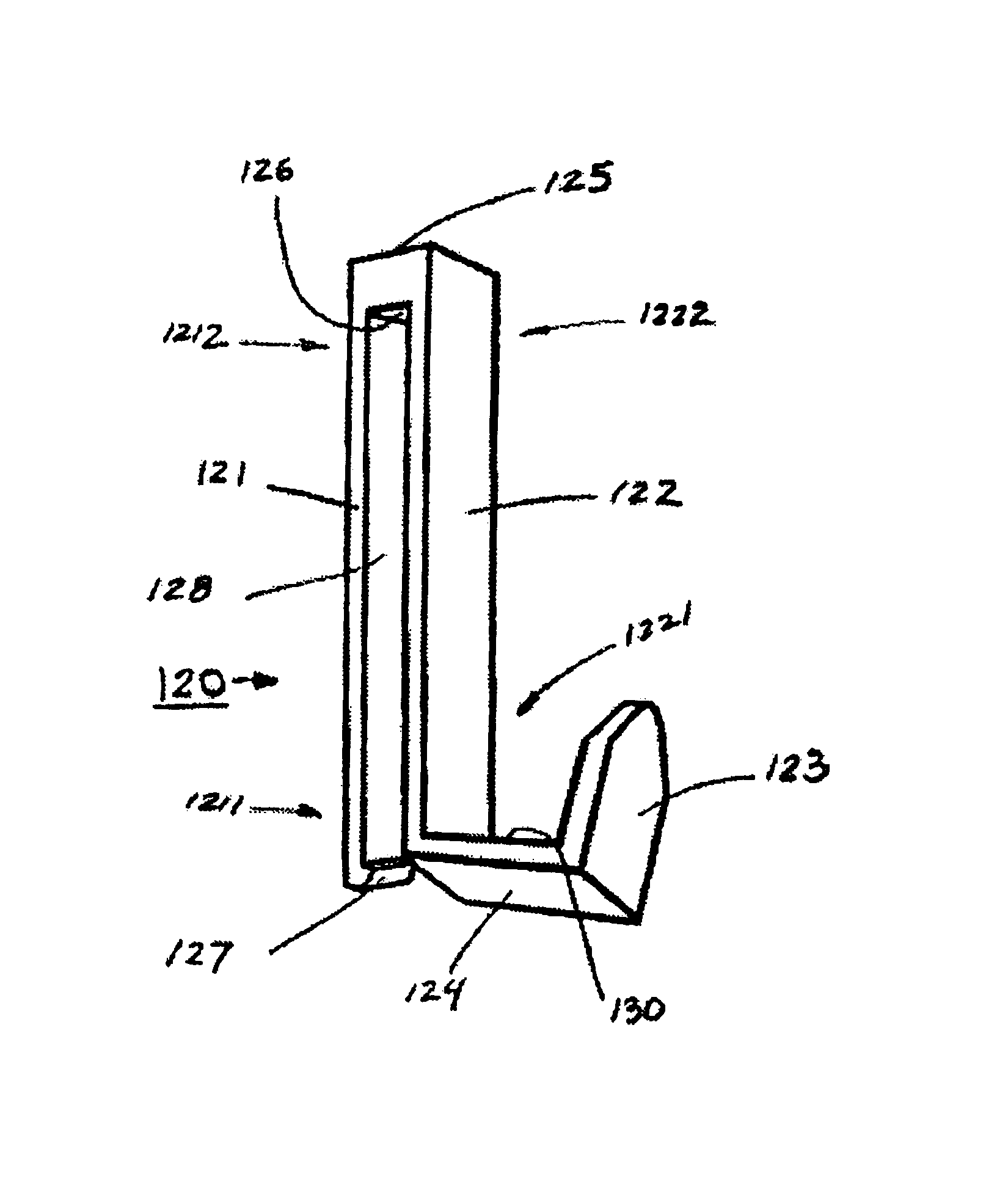

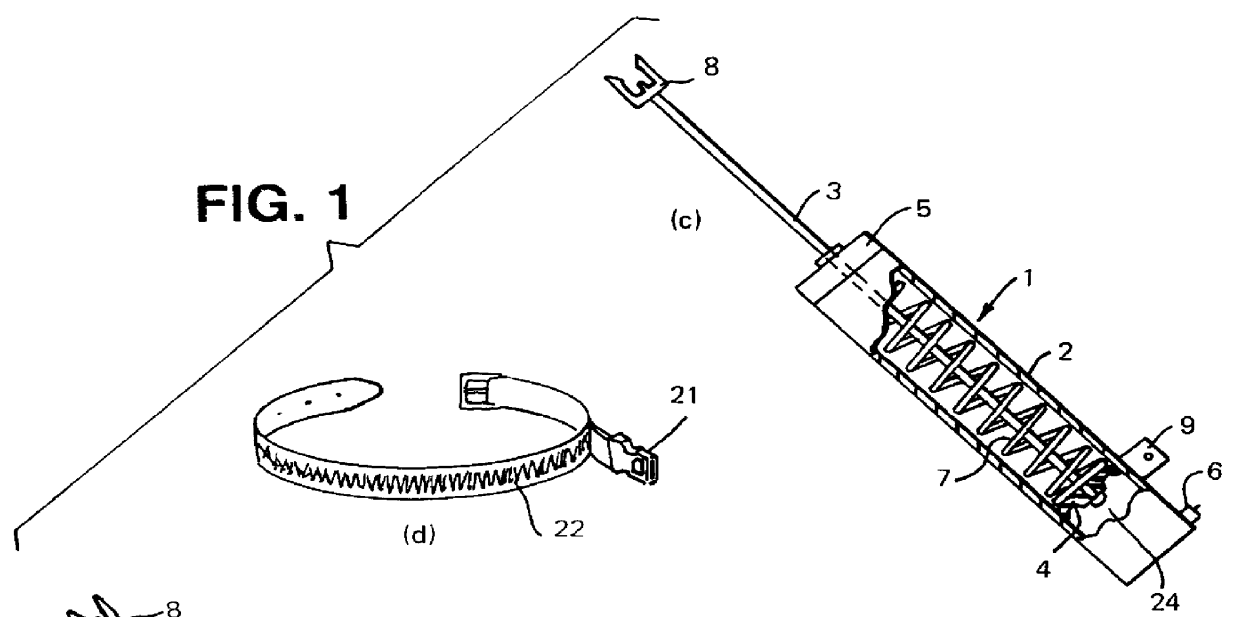

Remotely anchored tissue fixation device

InactiveUS7172615B2Degree of approximation necessaryVariable flexibilitySuture equipmentsCosmetic implantsWound healingBiomedical engineering

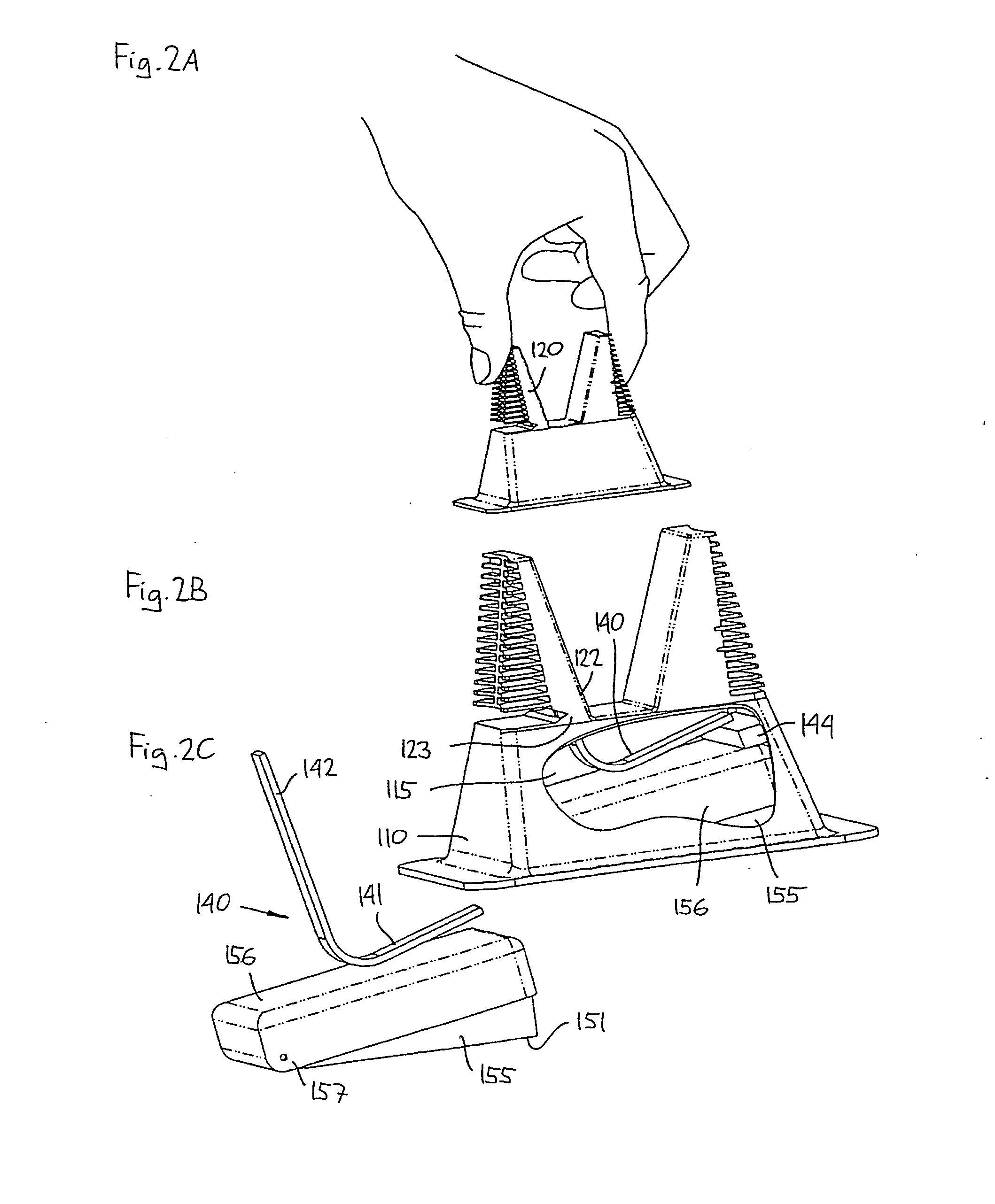

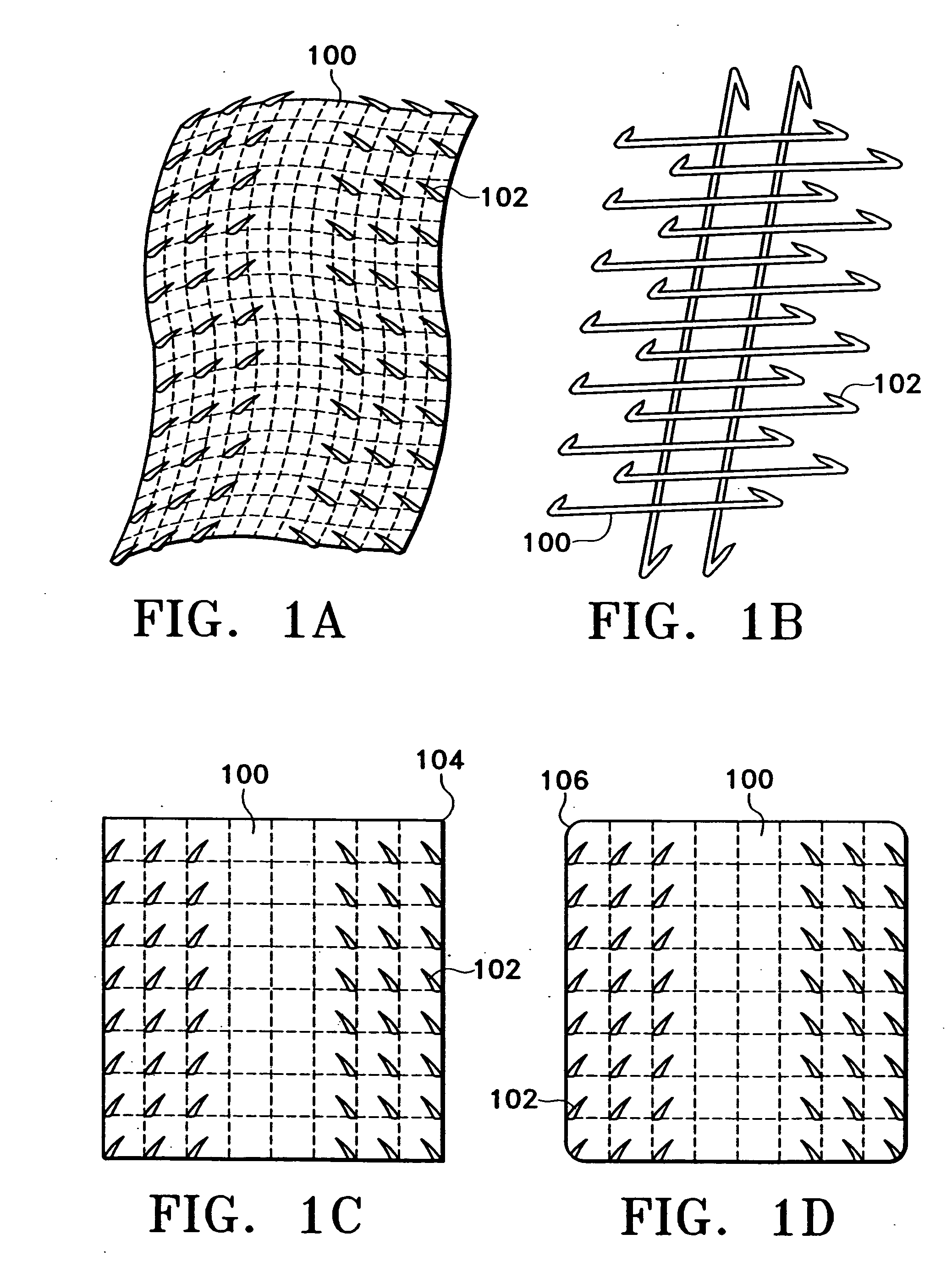

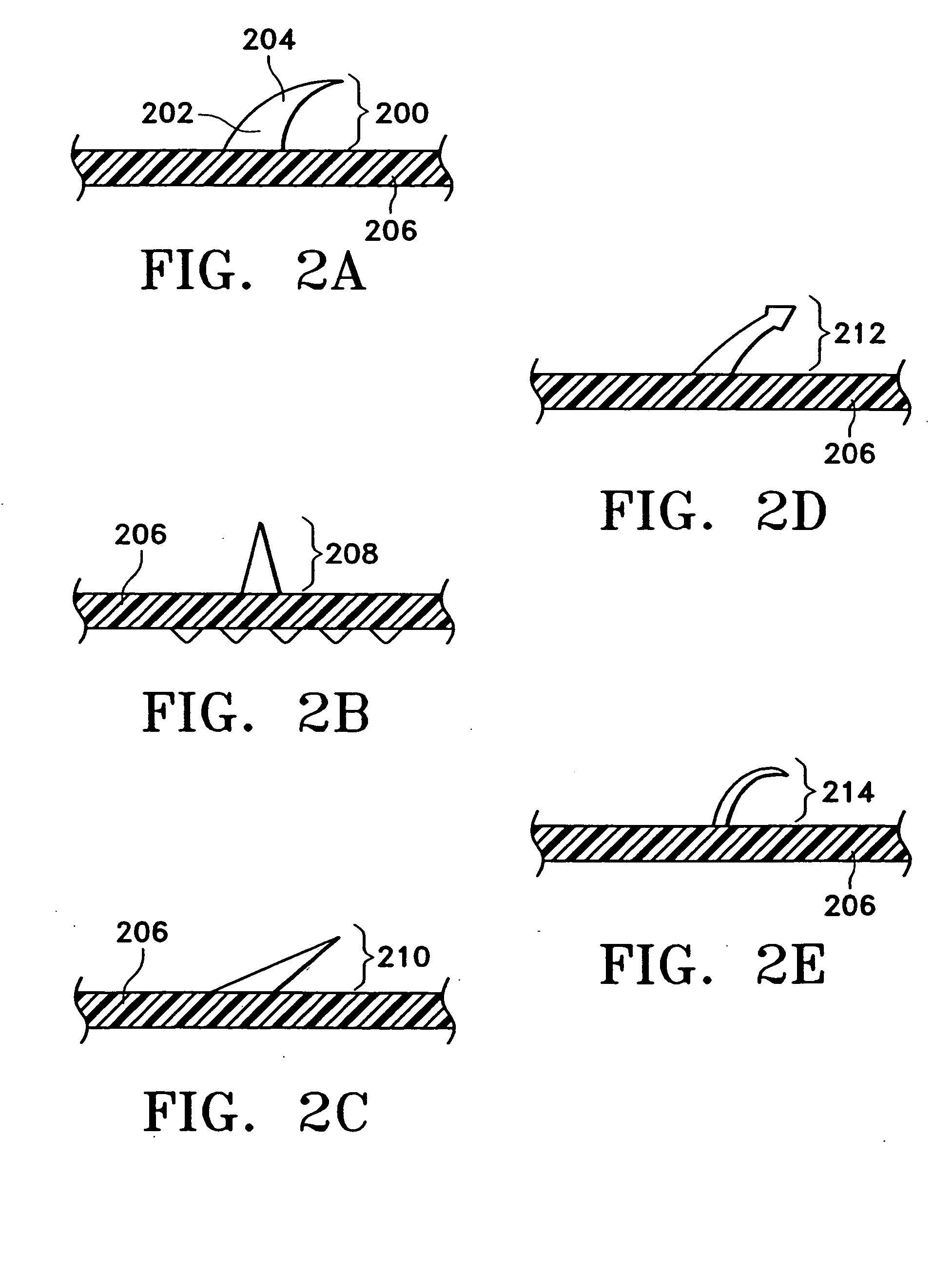

A tissue approximation device and processes for using the device, particularly in the mid-face region, are provided. The device is an implantable, biodegradable construct that has attachment points emanating from at least one supportive backing. The device also has a connecting member or leash which extends between the backing and an anchor which is attached to bone or soft tissue. Attachment to soft tissue is accomplished by a second backing having attachment points emanating from the backing and attachment to bone is accomplished by a post. The connecting member allows for repeated adjustments in length between the anchor and the backing in vivo or ex vivo until the desired amount of tissue approximation is achieved. The device improves the mechanical phase of wound healing and evenly distributes tension over the contact area between the device and tissue.

Owner:OXFORD FINANCE +2

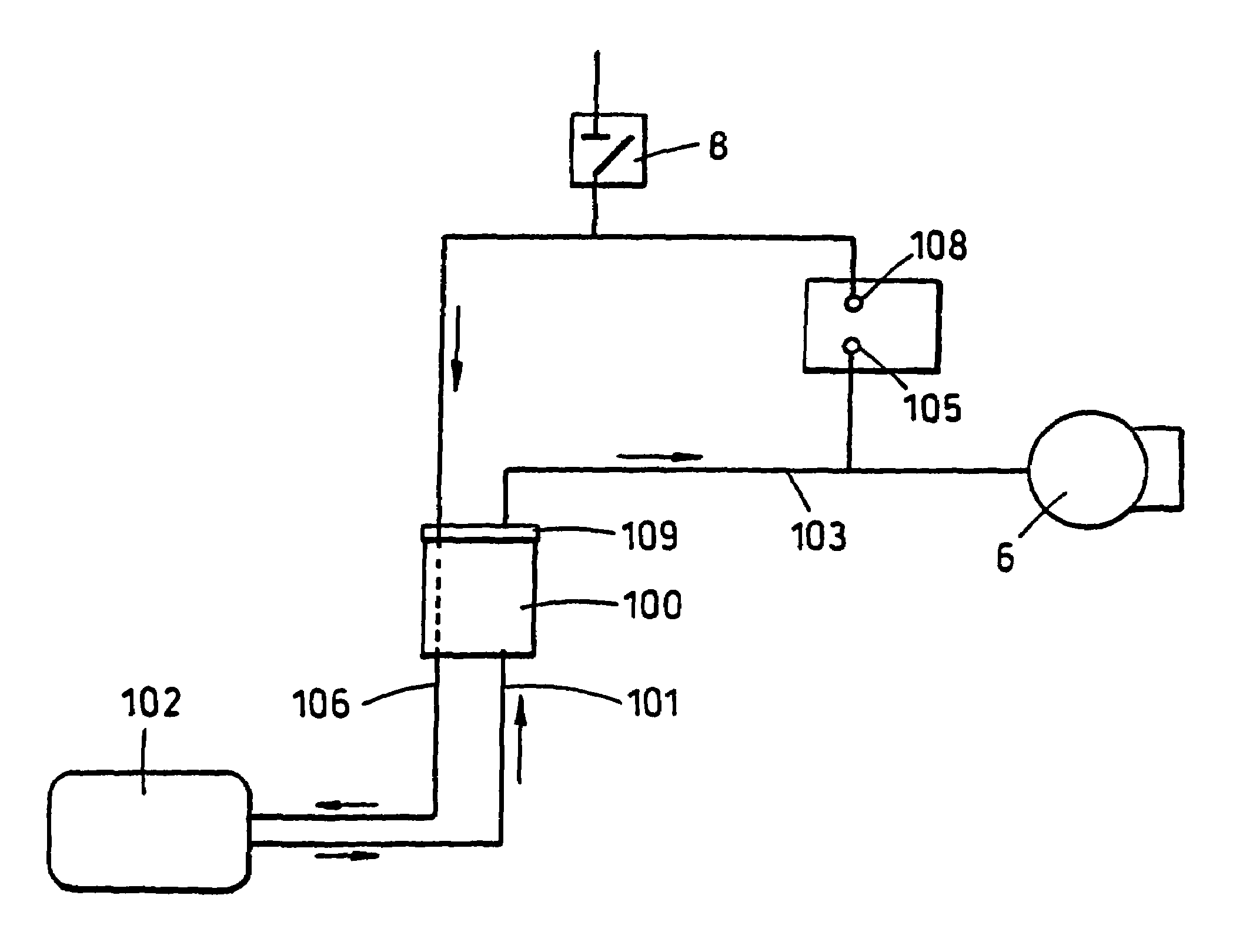

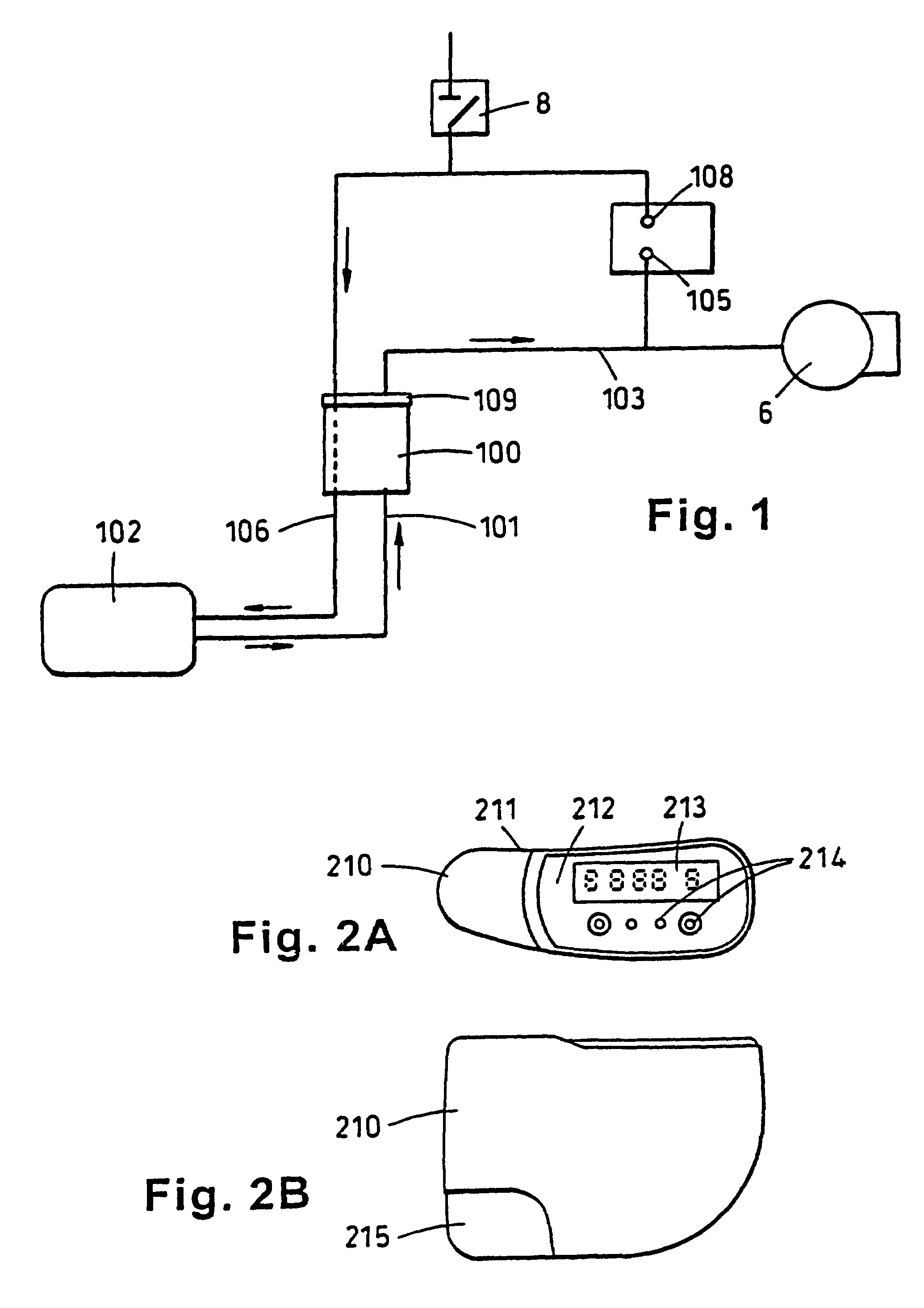

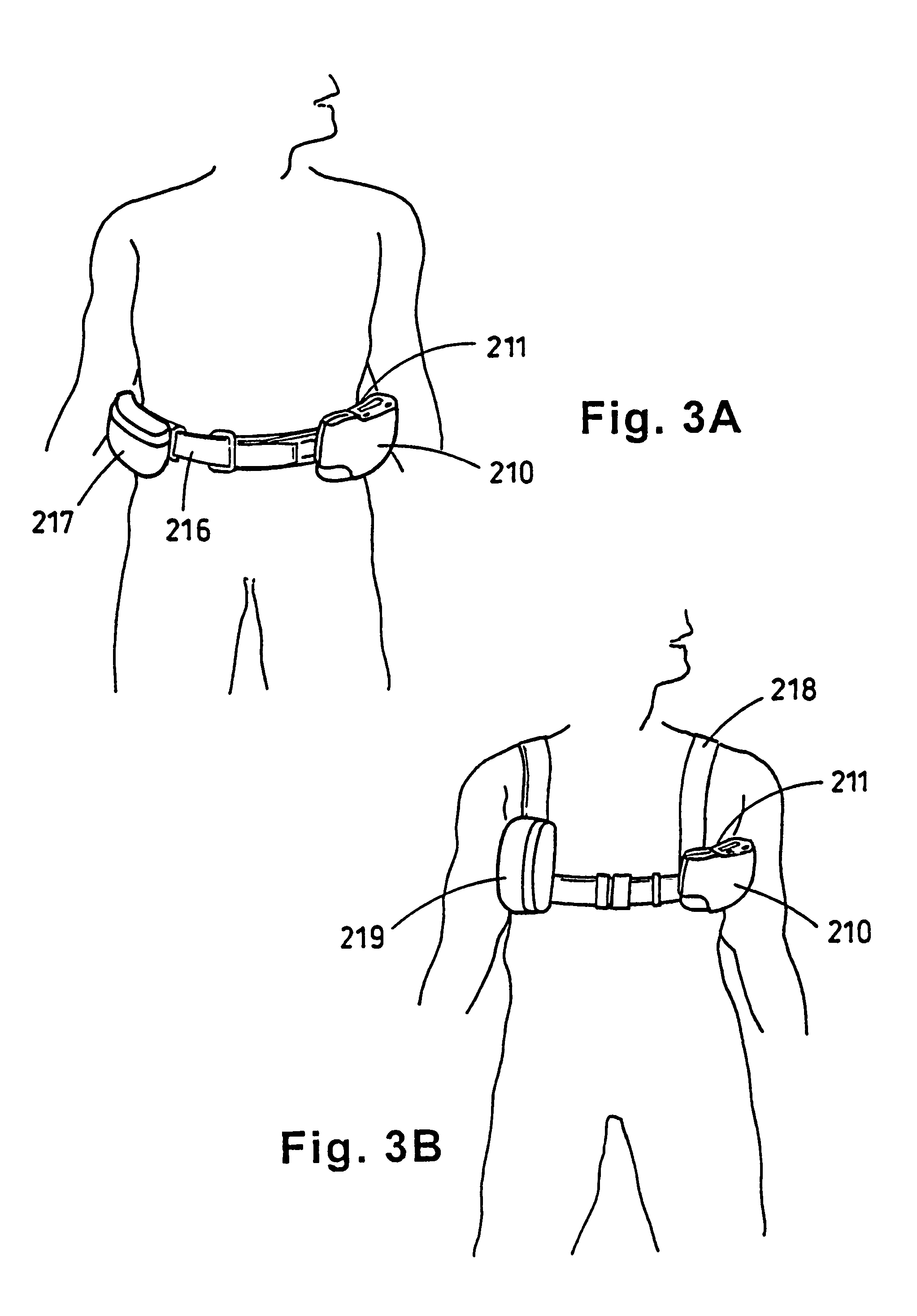

Portable wound treatment apparatus

A portable wound treatment apparatus, for stimulating the healing of superficial wounds, comprises a housing containing a suction pump and a canister for containing fluids drawn from the wound. The housing is supported on a harness or belt worn by the patient. The canister is connected to a porous wound dressing at the wound site via a plurality of tubes, a multi-lumen tube or a combination thereof. A rechargeable battery pack may be incorporated within the housing or externally thereto. The external battery pack may be shaped to balance the housing on the harness or belt. Pressure transducers are provided to monitor and report pressures at the wound site or internal to the canister. Monitored pressures may also be utilized to determine the filled state of the canister and, thereafter, either report this state to the operator or automatically discontinue suction from the wound, or both.

Owner:KCI LICENSING INC

Integrated package

InactiveUS20080009805A1Easy to handleEasy to useMedical devicesPressure infusionInterior spaceAdhesive

The present invention generally relates to skin-mountable devices. A device in accordance with the invention comprises a first skin-mountable unit having a mounting surface comprising adhesive means for adhering the unit to the skin of a subject, and a second handling unit releasably attached to the skin-mountable unit. The handling unit comprises an interior space at least partially accommodating the skin-mountable unit and has an opening through which the skin-mountable member can be moved when detached from the handling unit, the handling unit having a portion surrounding the opening. The device further comprises a seal member releasably attached to the circumferential portion, thereby providing a closed space for the skin-mountable unit. In this way a device is provided allowing for easy handling as a user can use the handling unit to grip and handle the combined device during operation thereof, just as the second unit can be designed and optimized for ease of use during manipulation of the skin-mountable unit.

Owner:NOVO NORDISK AS

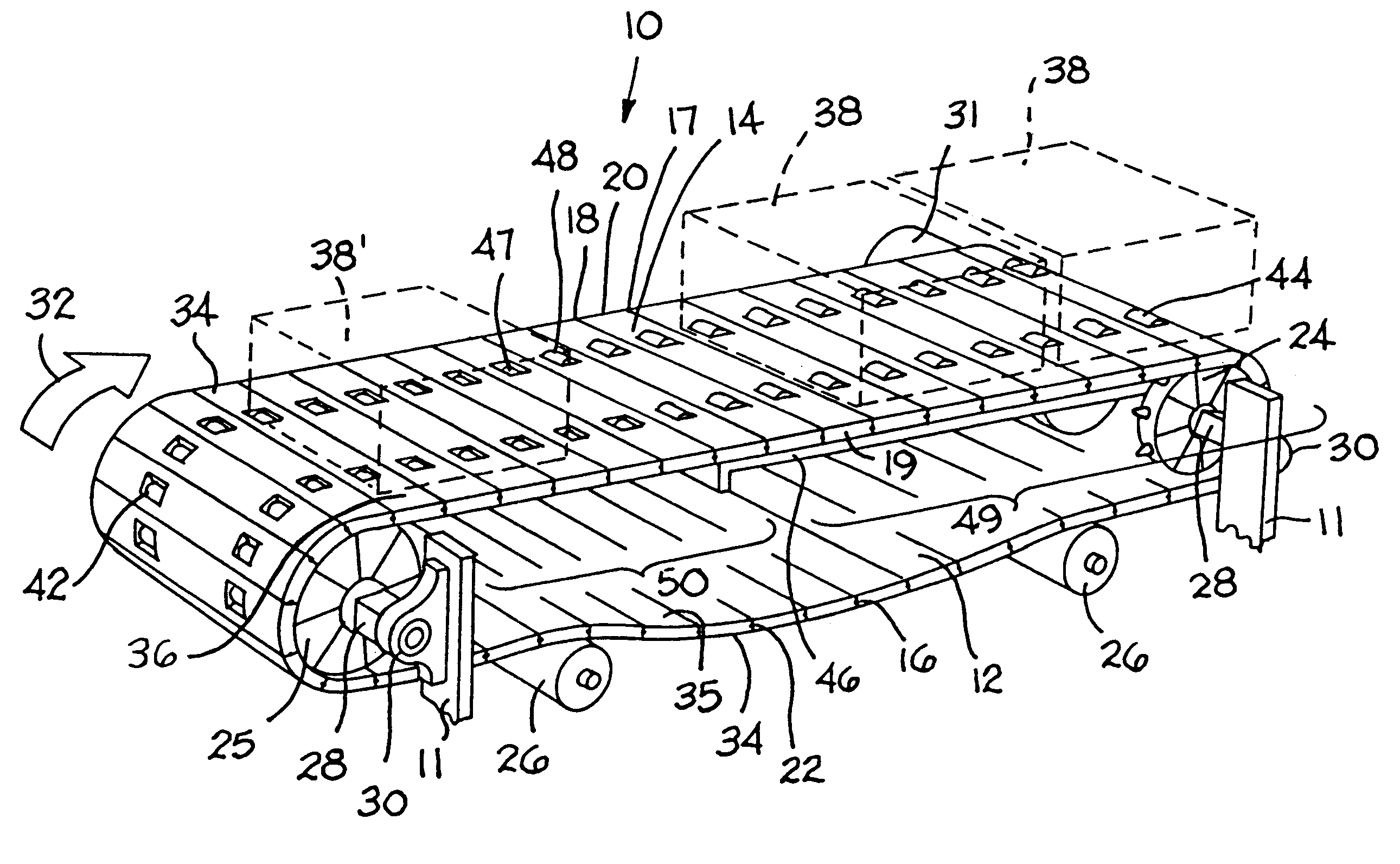

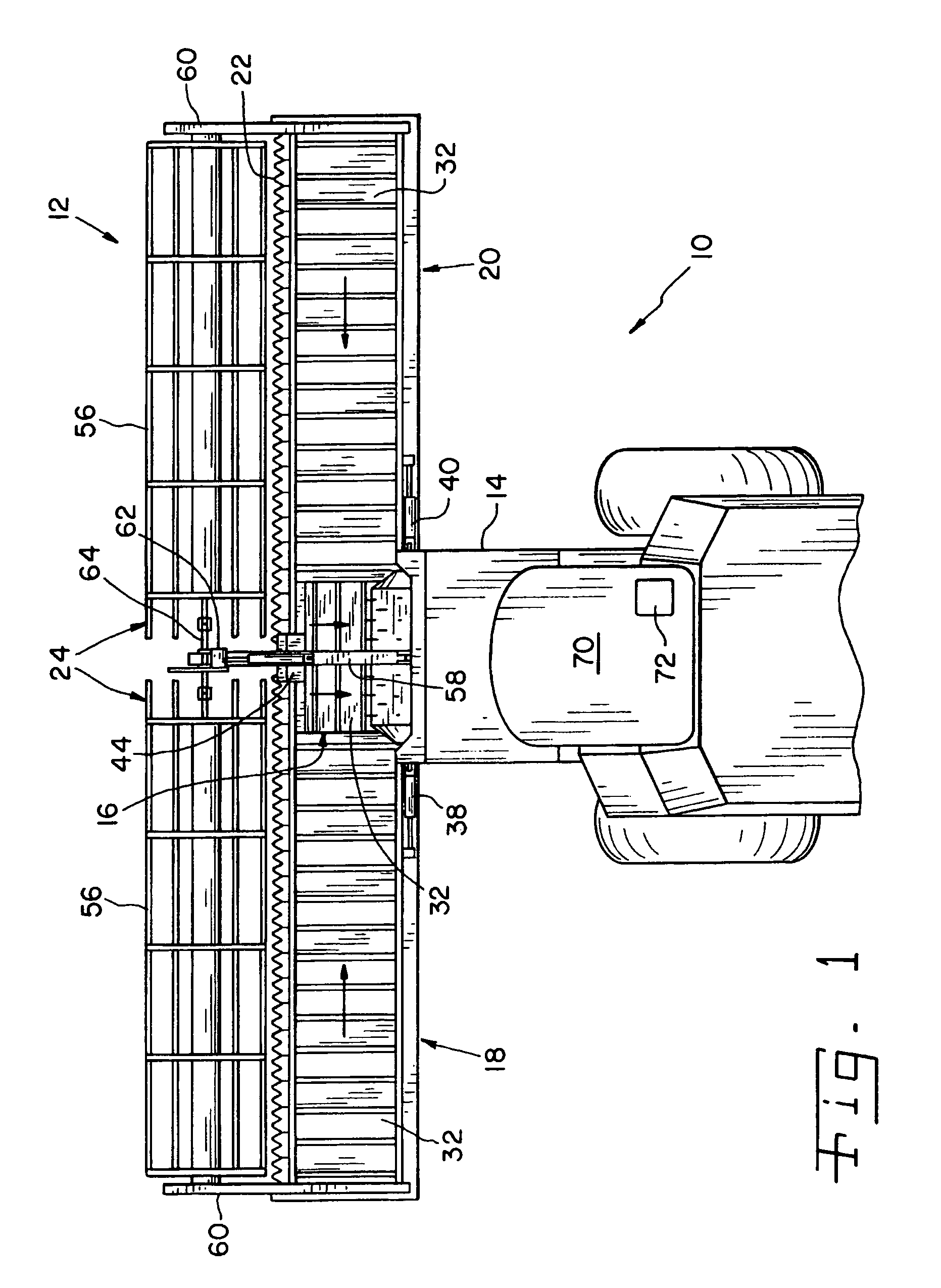

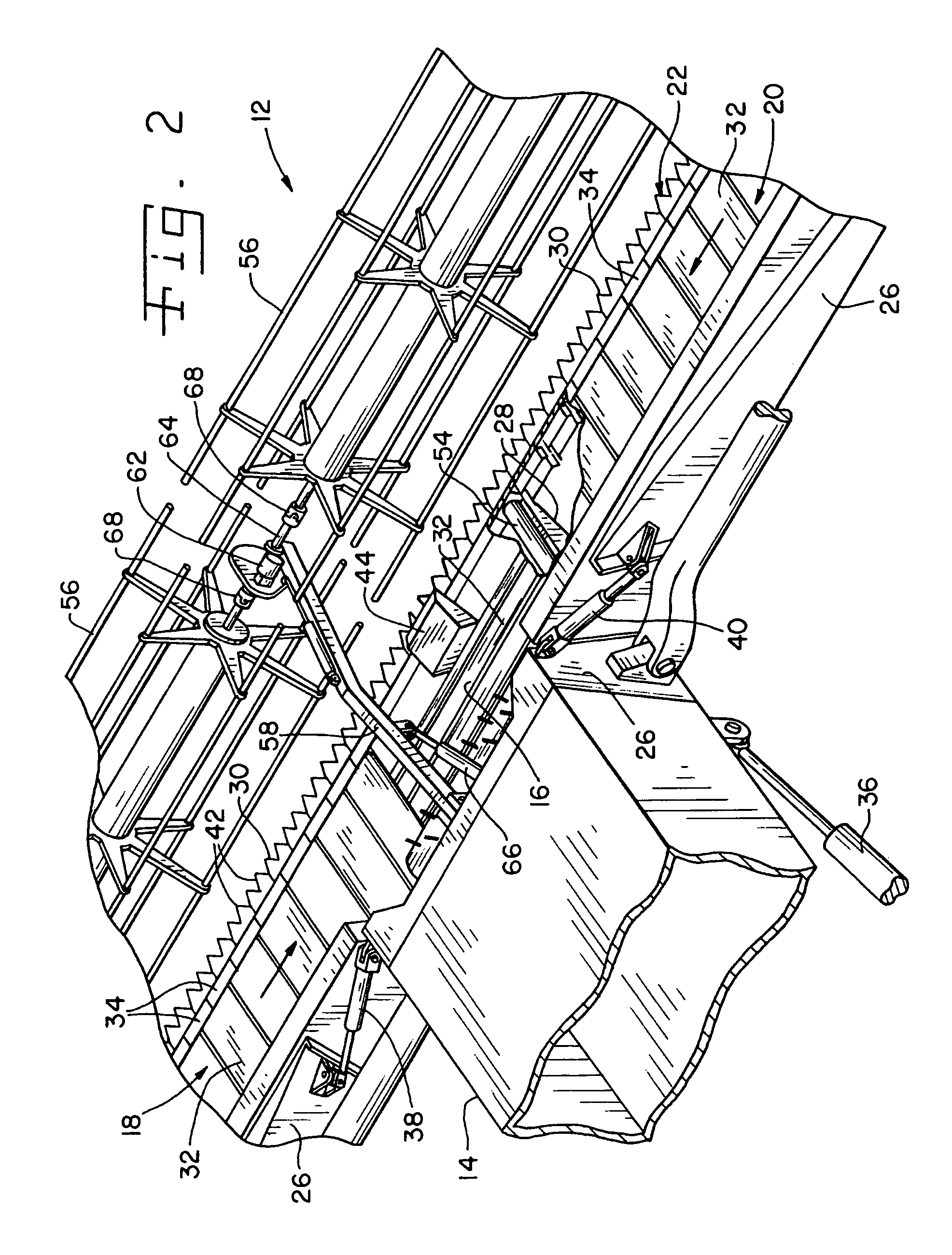

Changing the characteristics of an article-conveying belt surface on a running conveyor

A belt conveyor whose article-conveying characteristics can be changed as the belt is running. The conveyor belt includes a plurality of movable assemblies supporting an article-supporting element and an adjustable element. The adjustable element coacts with an adjustment control element supported in the conveyor frame as the belt is running. The coaction causes the adjustable element to move the article-supporting element to provide a different article-conveying characteristic to articles supported at the conveying surface of the belt in zones defined by the adjustment control elements.

Owner:THE LAITRAM CORP

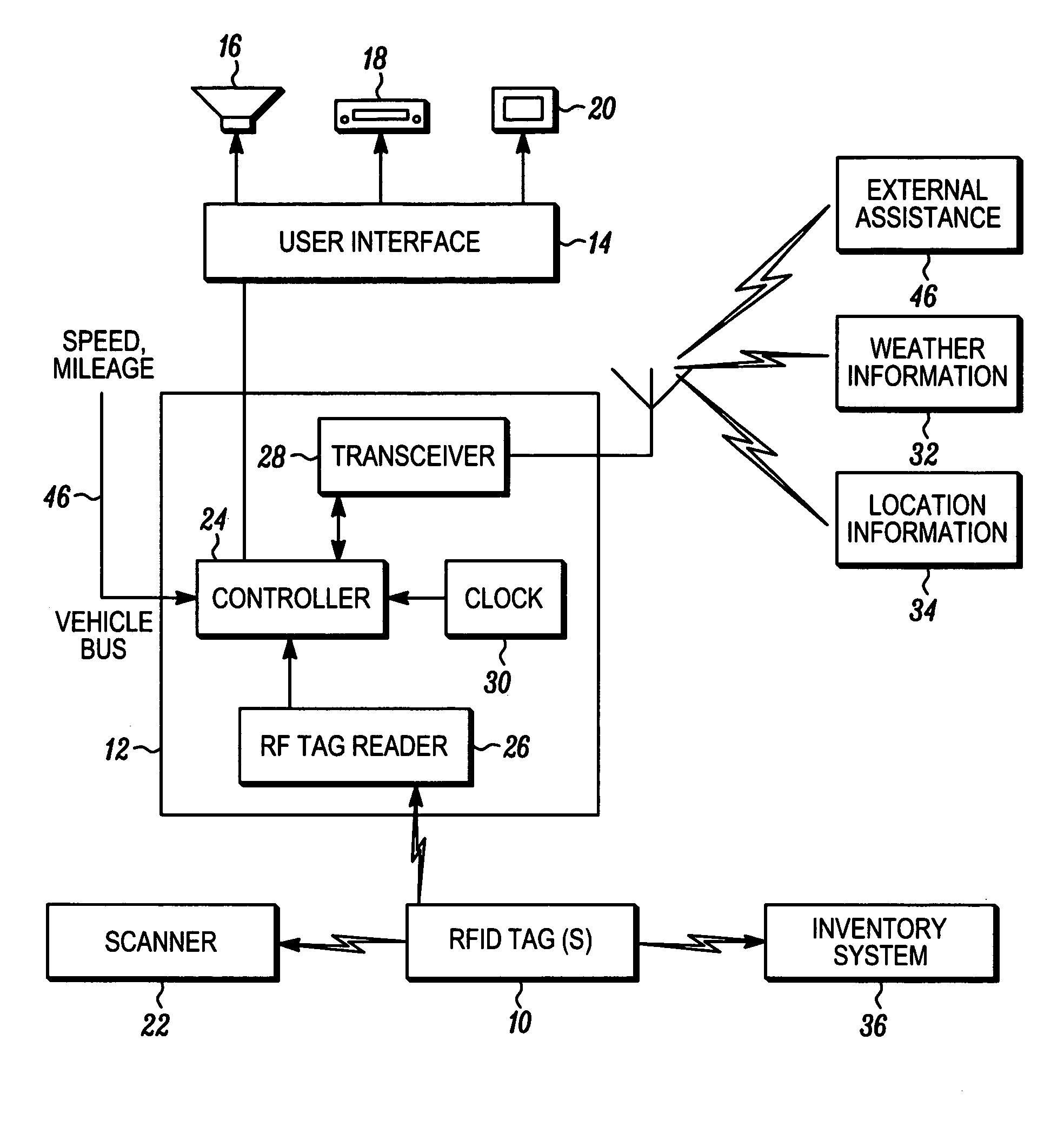

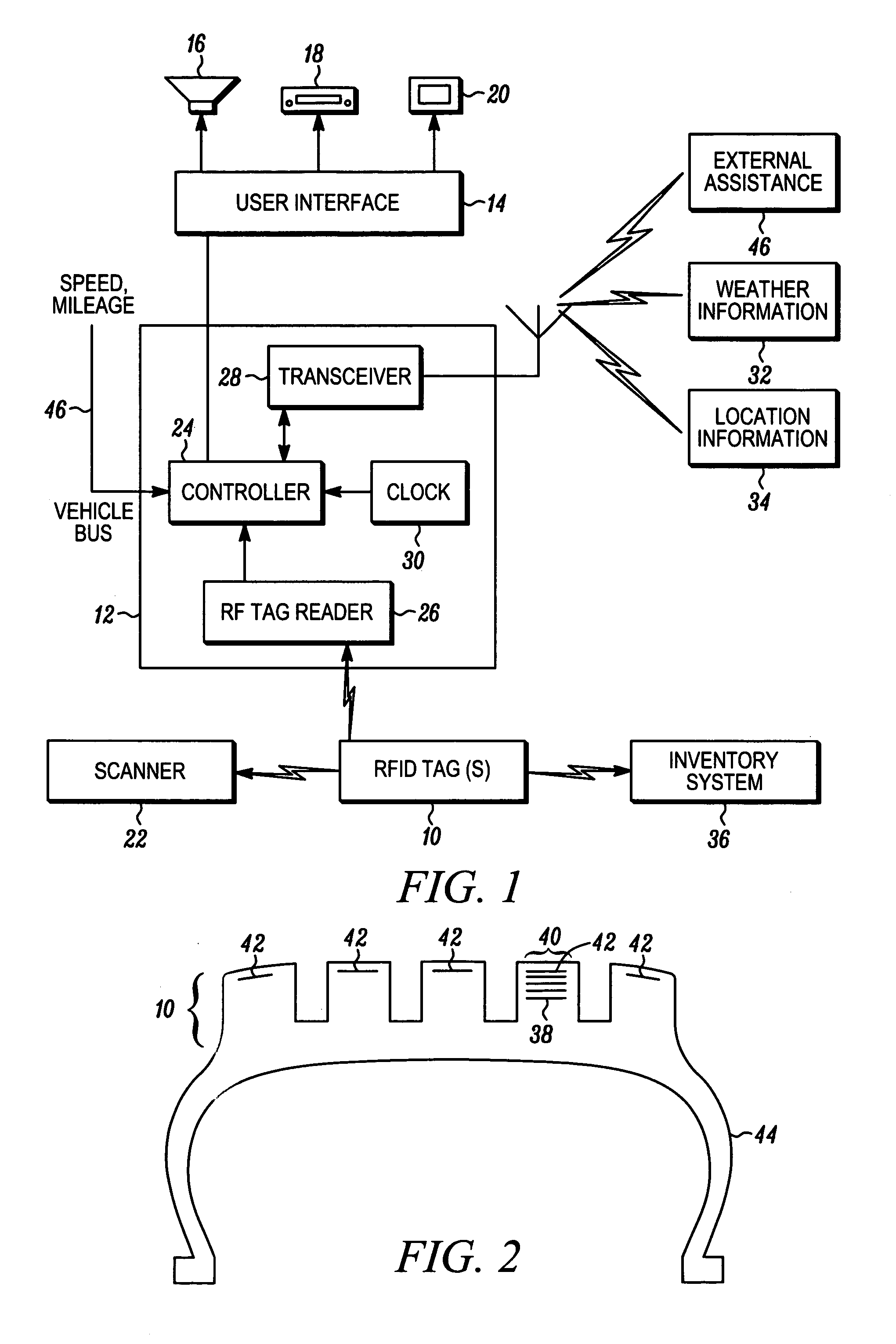

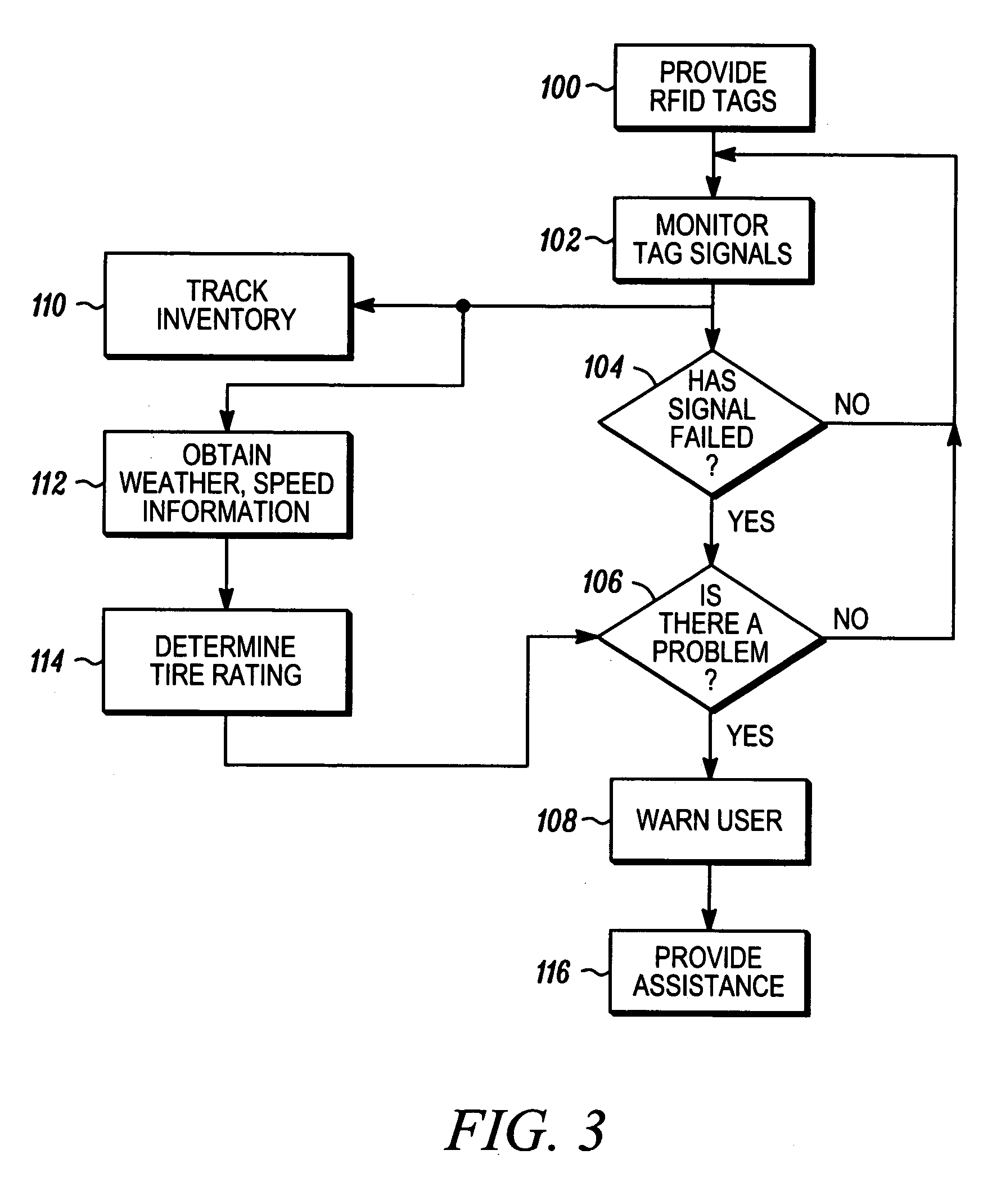

Tire tread wear sensor system

A system and method for monitoring belt wear or tread wear of a tire includes at least one radio frequency identification (RFID) tag with unique identification embedded in the belt or tread of the tire at one or more wear points. An RF tag reader periodically monitoring signals from the at least one RFID tag. If the RF tag reader fails to obtain any signals from the at least one RFID tag, indicating a destroyed RFID tag, the user can be warned about a wear problem of that belt or tire. RFID tags can be distributed at different depths of the tire(s), or across the tread at the same depth, of the tire(s) to determine different wear problems. The same RFID tag can also be used for inventory tracking purposes.

Owner:CONTINENTAL AUTOMOTIVE SYST INC

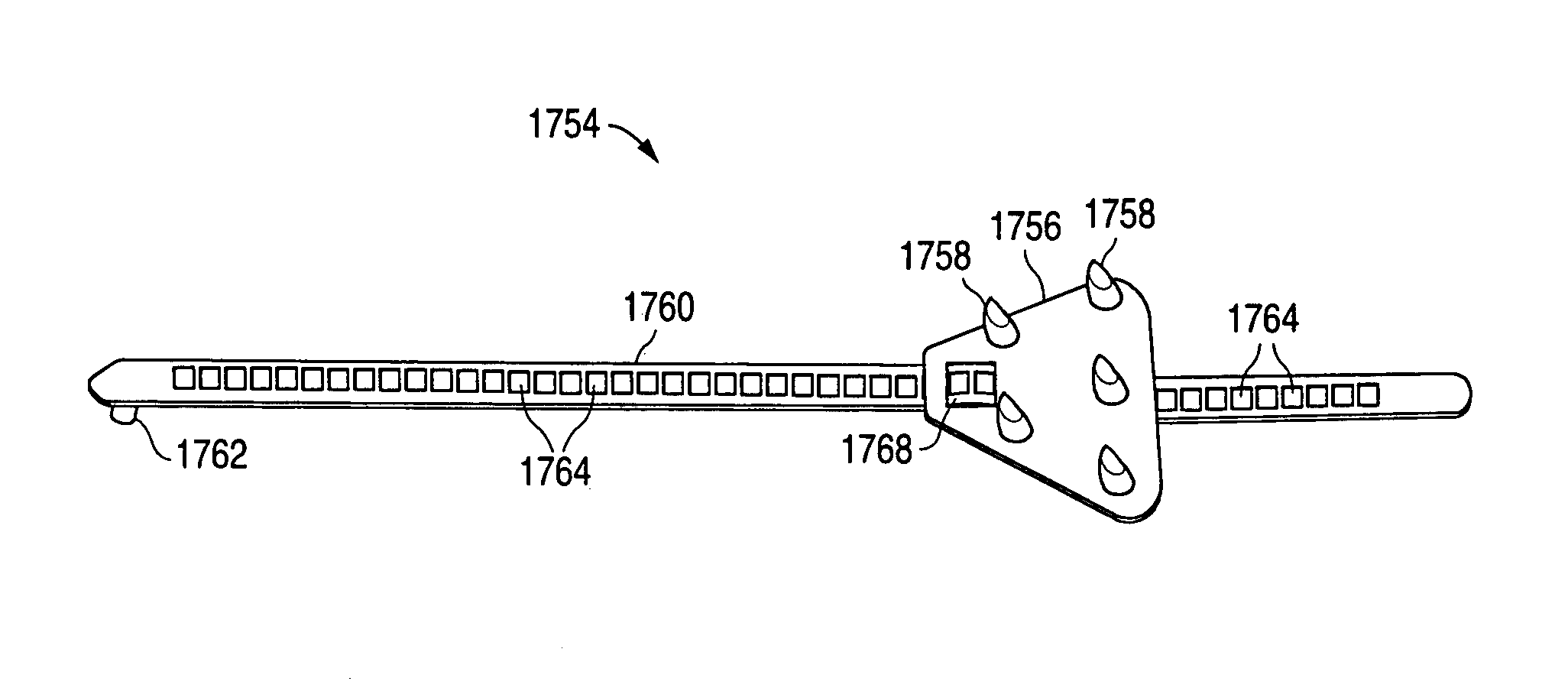

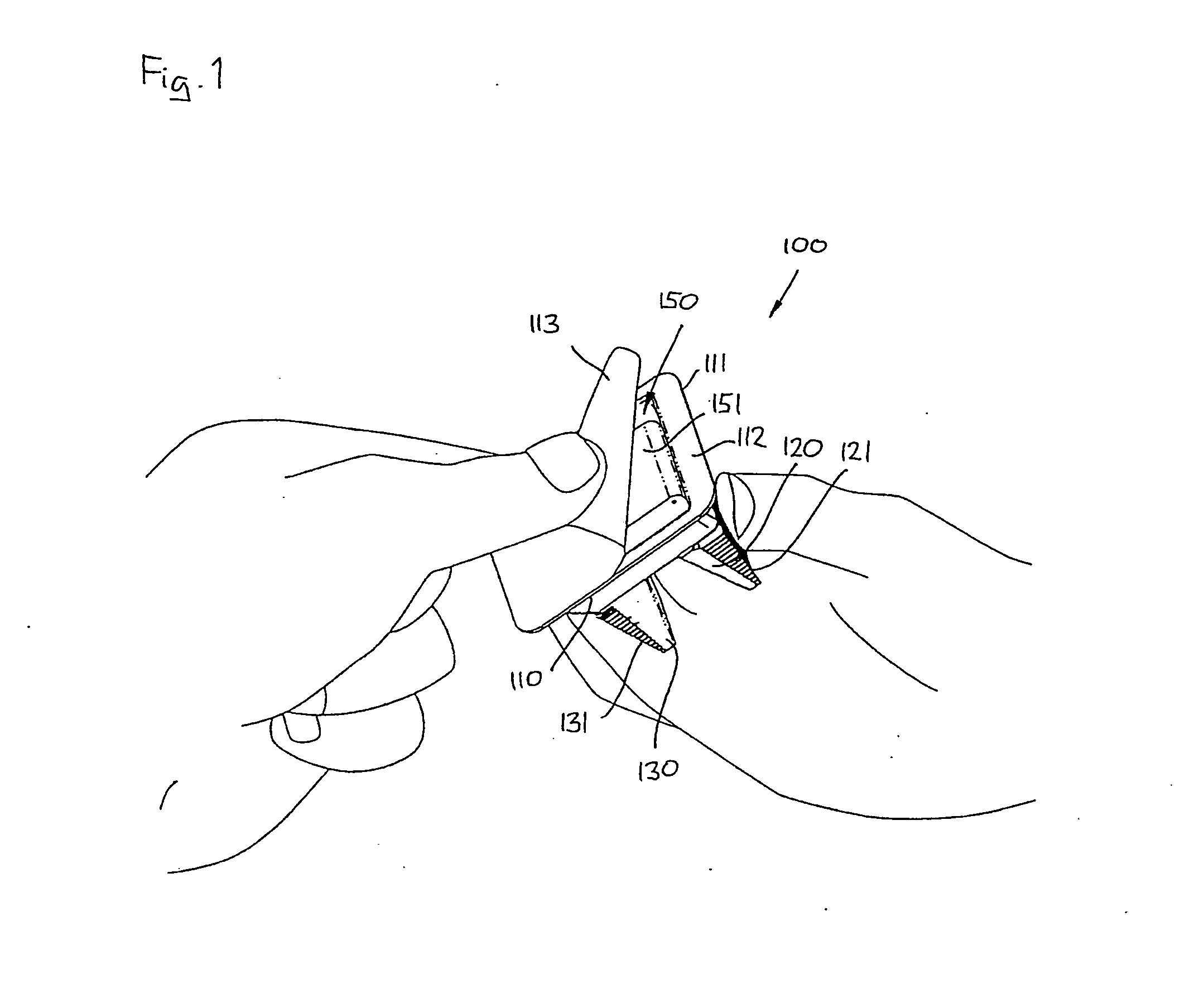

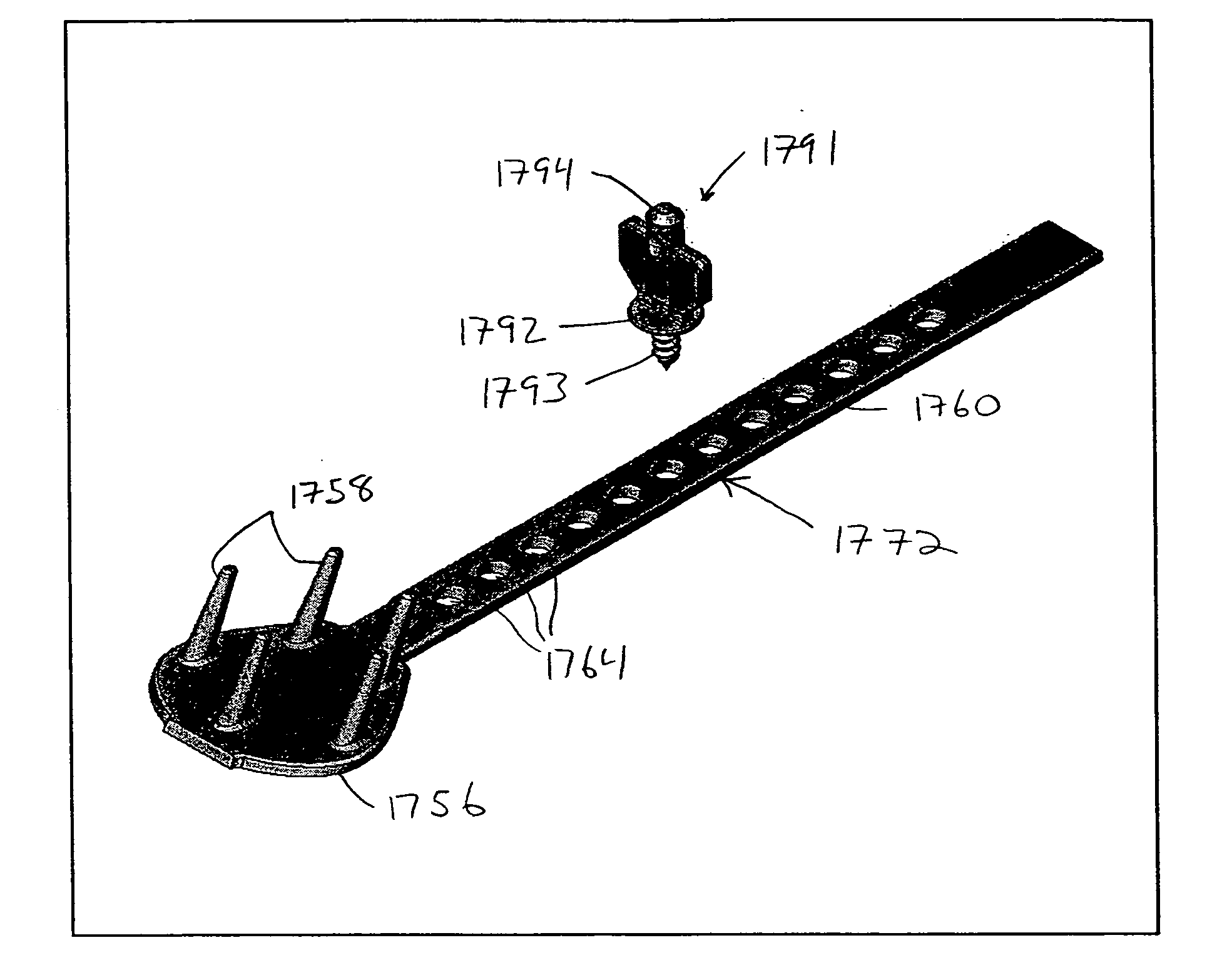

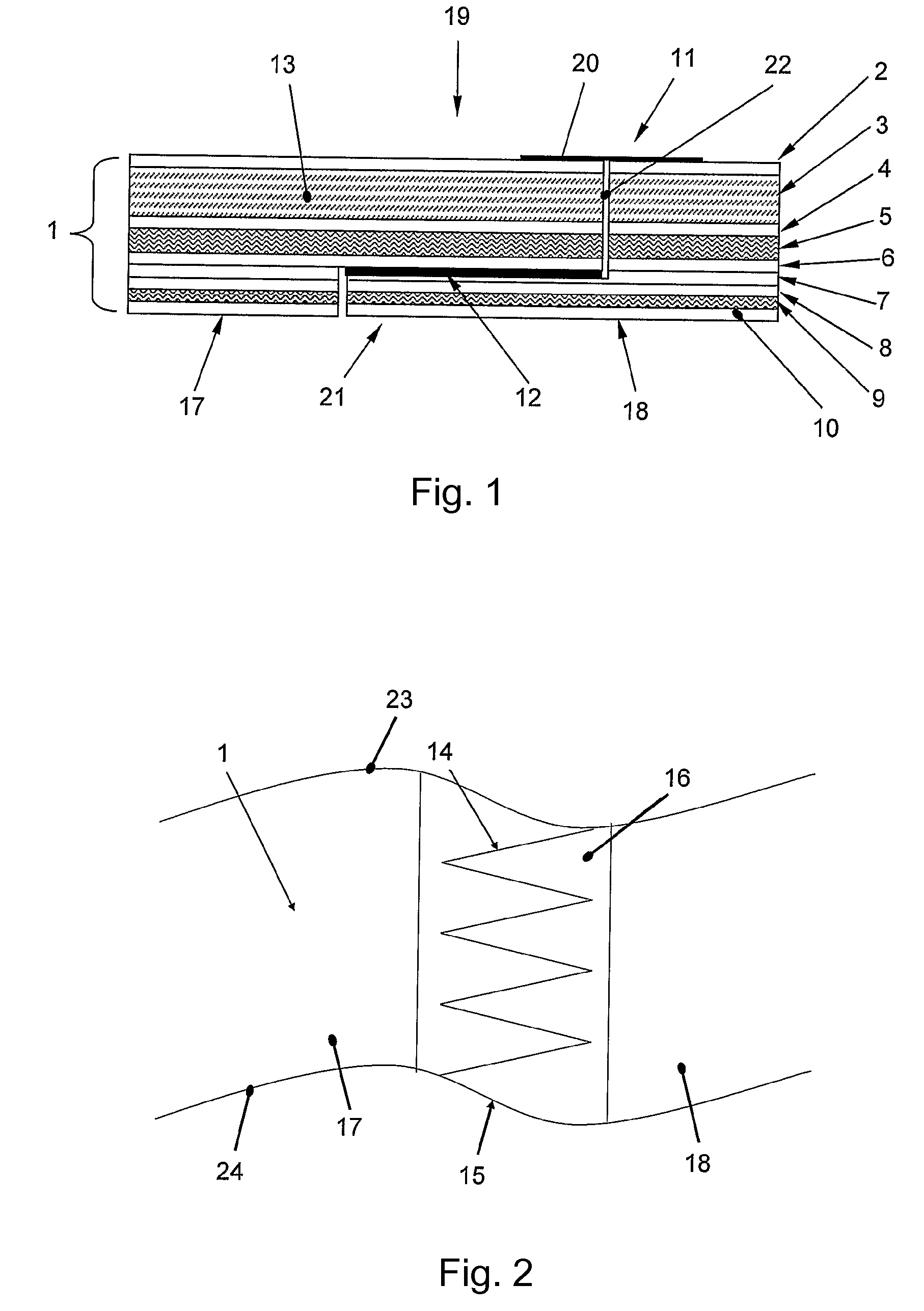

Remotely anchored tissue fixation device and method

A tissue approximation device and method, particularly in the mid-face region, are provided. The device is an implantable, biodegradable construct that has attachment points emanating from a supportive backing. The device also has an extension member or leash which extends from the backing which is configured to receive a tissue or bone attachment device at one of a plurality of selectable locations along the elongated member, for example via engagement holes extending in a line away from the backing. Once tissue is engaged with the attachment points, the extension member is pulled until the tissue is approximated in the desired position. Then the appropriate extension member hole(s) are selected to attach the extension member to supportive tissue or bone (for example temporal fascia) for permanent tissue approximation.

Owner:COAPT SYST INC

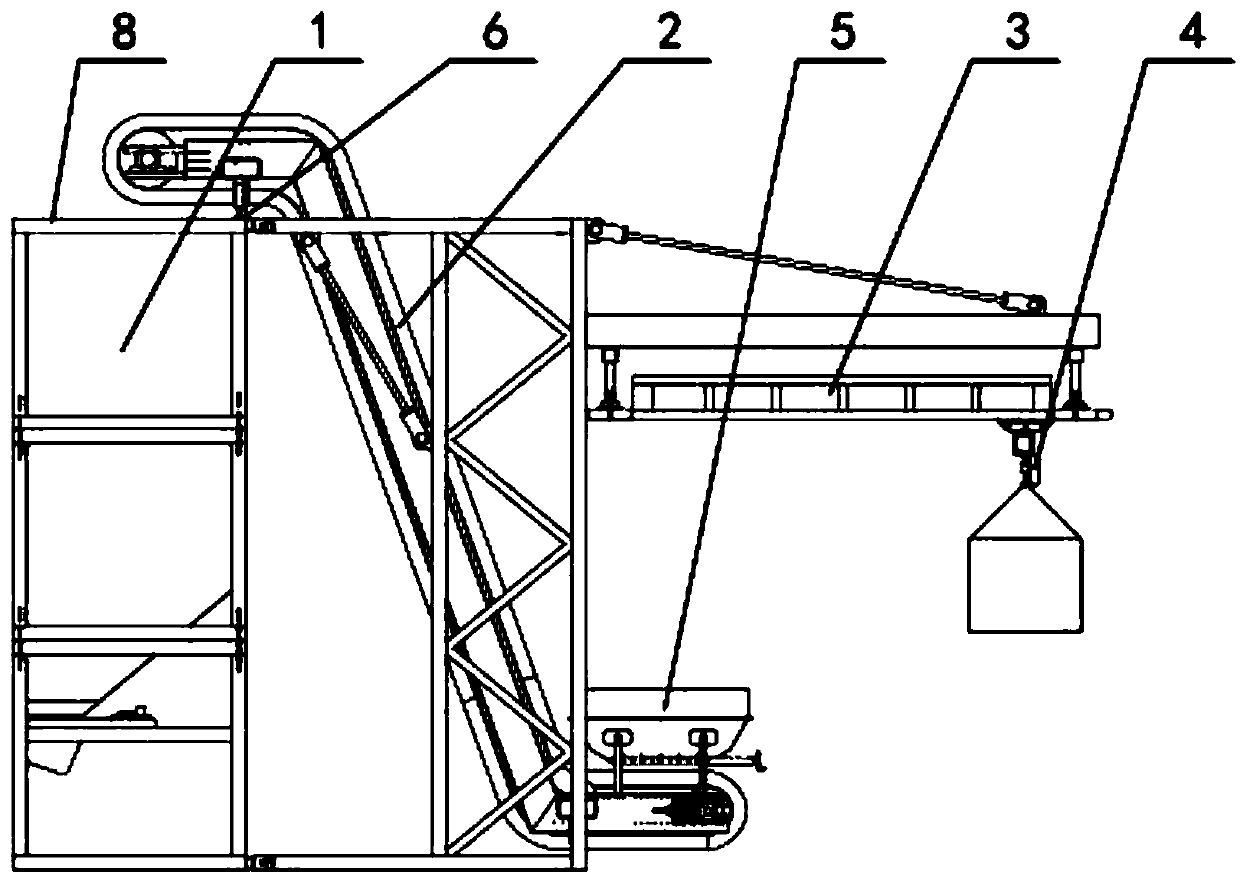

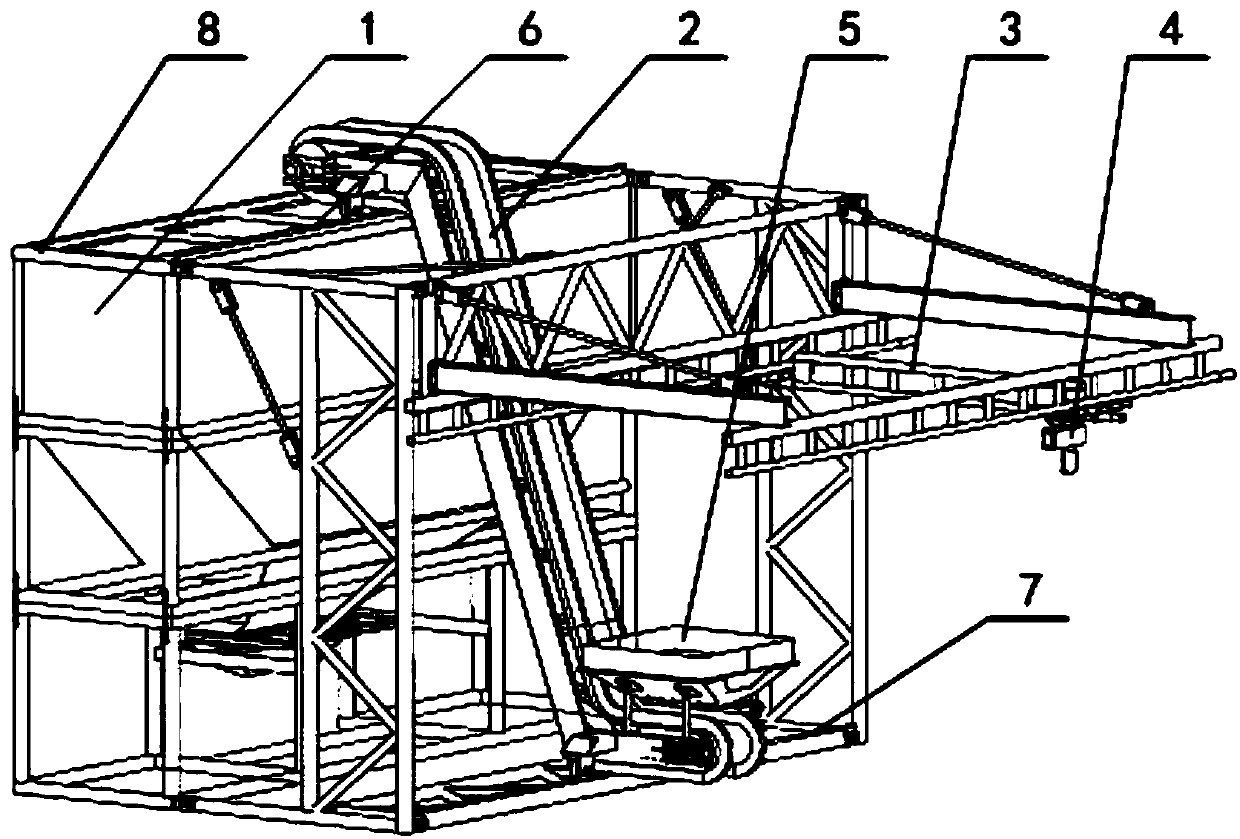

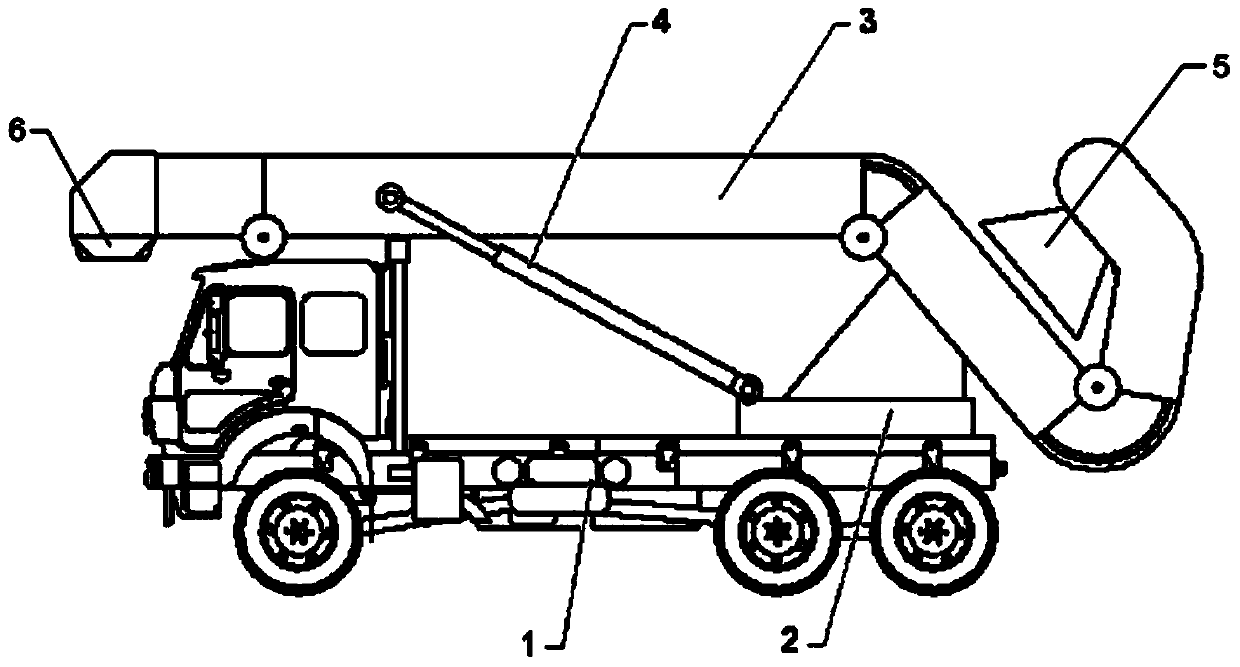

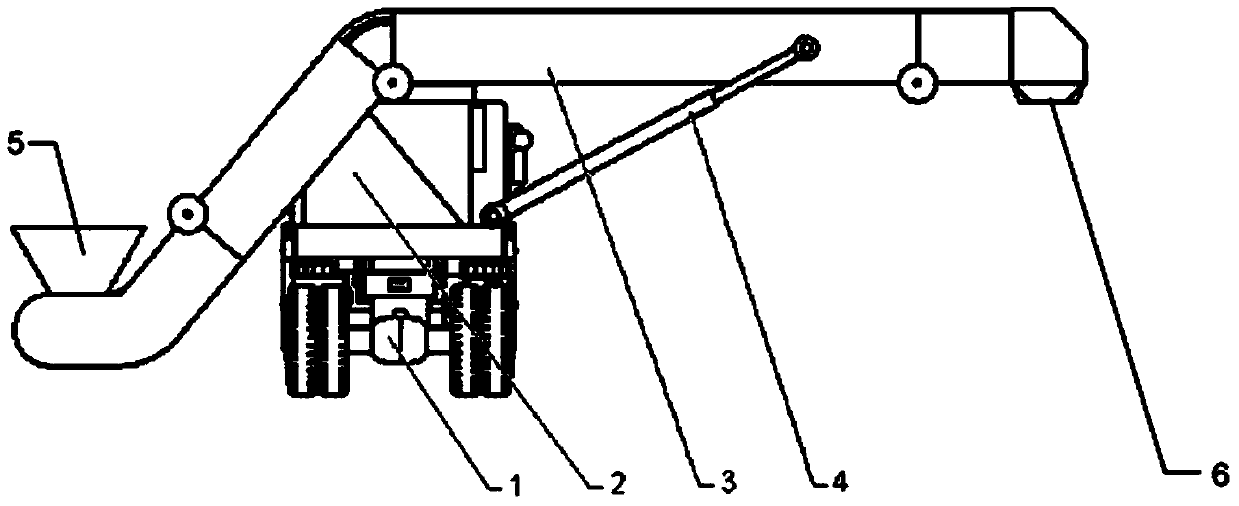

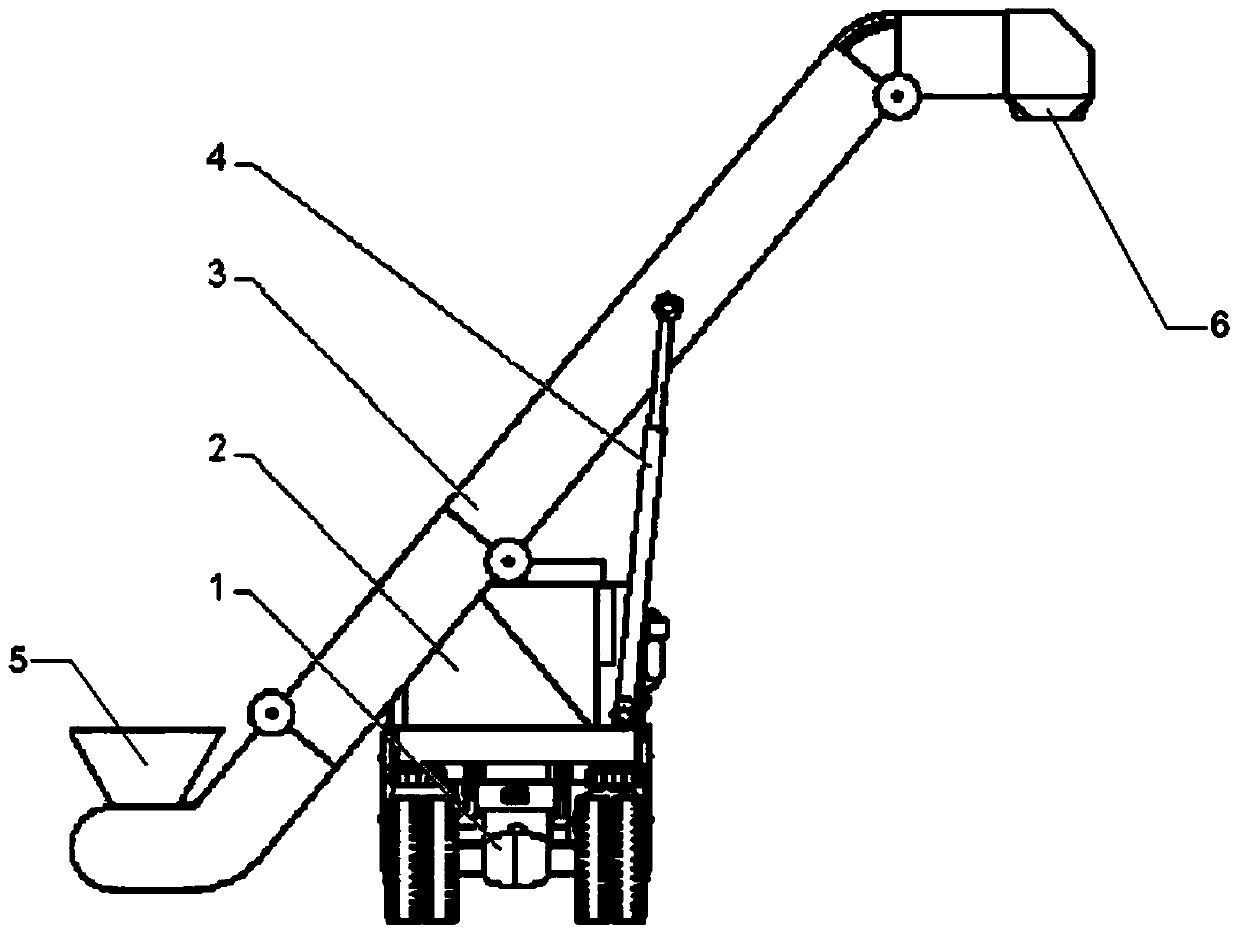

Material hoisting and transportation device

PendingCN107902427ASave on high costsEliminate potential safety hazardsStorage devicesEngineeringOrbit

The invention relates to the oil gas industry, particularly to a material hoisting and transportation device utilized in oil and gas field fracturing operation. The material hoisting and transportation device is characterized in that a material storage tank is mounted on the left of a frame body; an upper orbit is mounted at the upper part of the frame body; a lower orbit is mounted at the right end of the lower part of the frame body; a belt conveying device is mounted on the upper orbit and the lower orbit; a feeding hopper is mounted at the bottom of the belt conveying device; a hoisting device is mounted at the right end of the upper part of the frame body; the hoisting device is mounted in an operation orbit; a hook is mounted on the hoisting device; during operation, the belt conveying device can longitudinally move on the upper orbit and the lower orbit; and during operation, the hoisting device can longitudinally and transversely move in a horizontal plane. The material hoisting and transportation device has a one-key locating function, and automatic operation and locating of the belt conveying device and the hoisting device can be achieved through the function.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

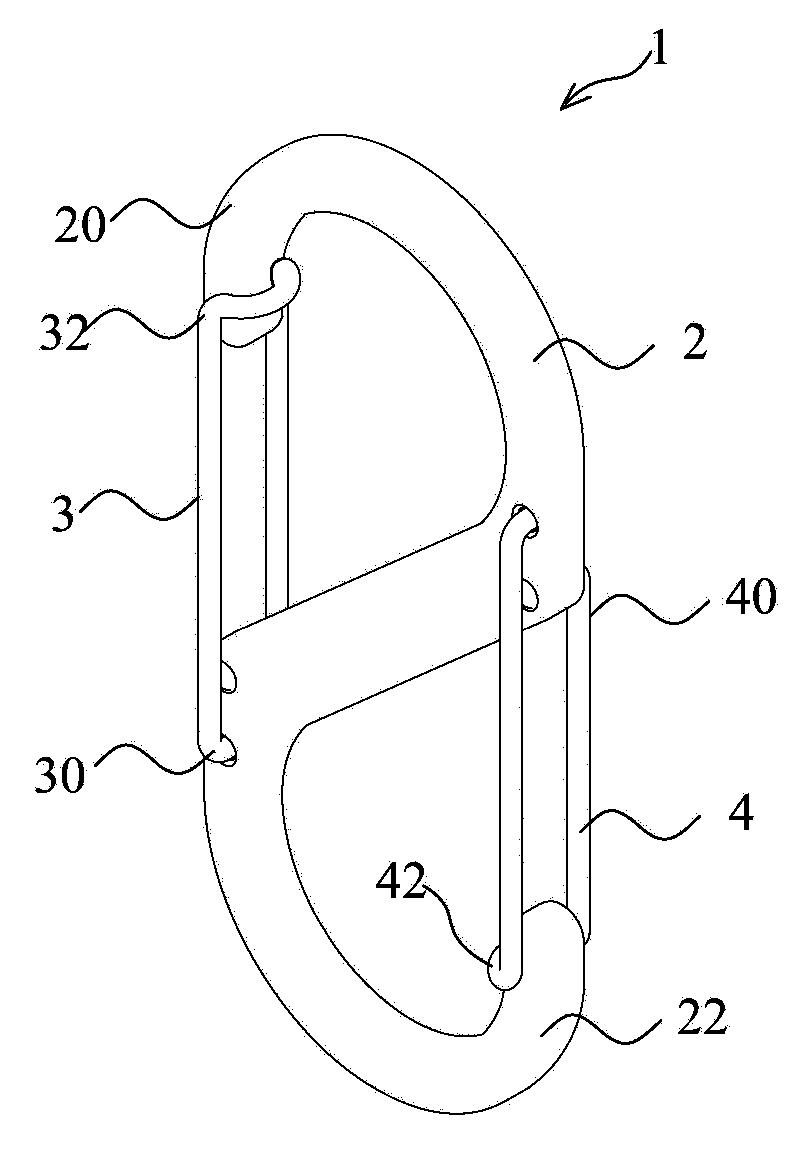

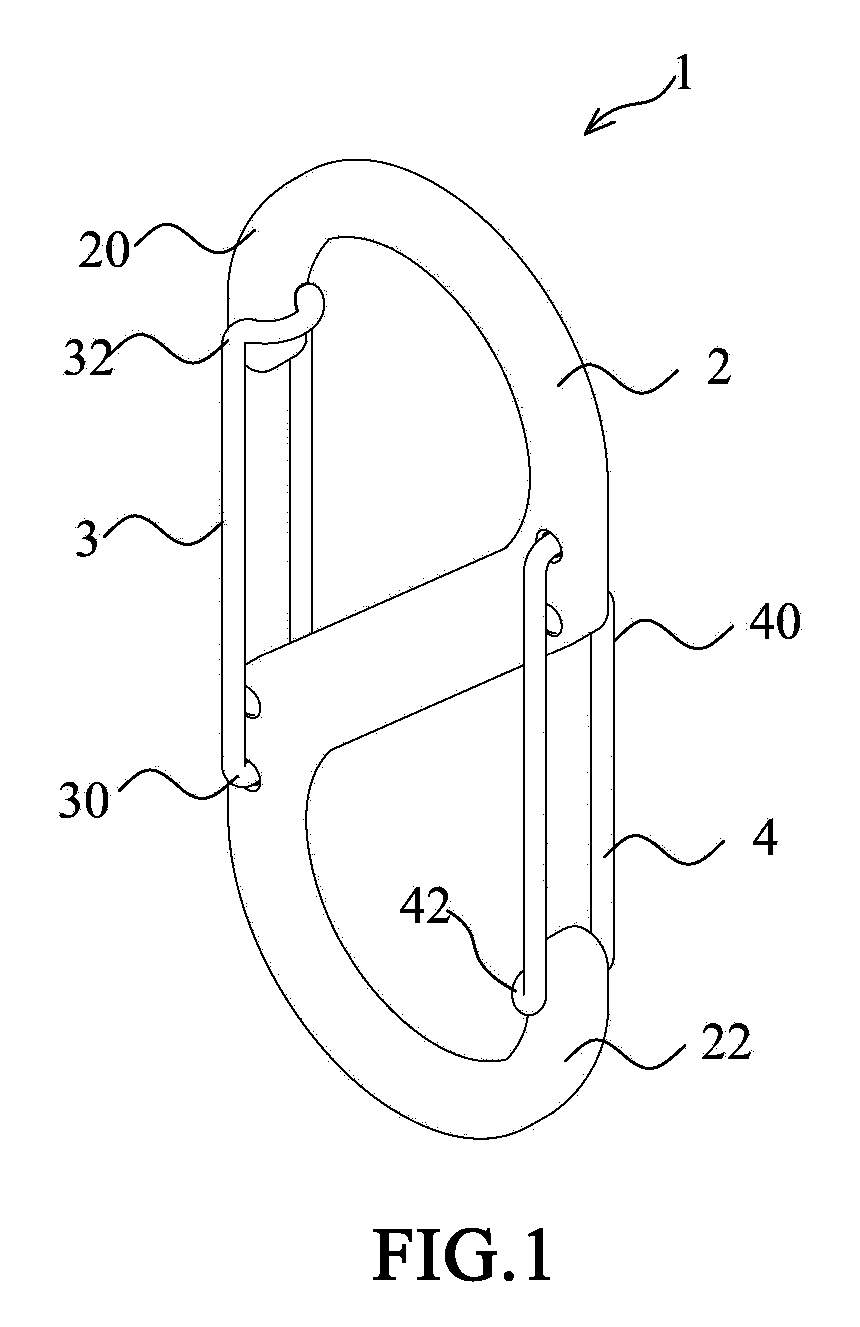

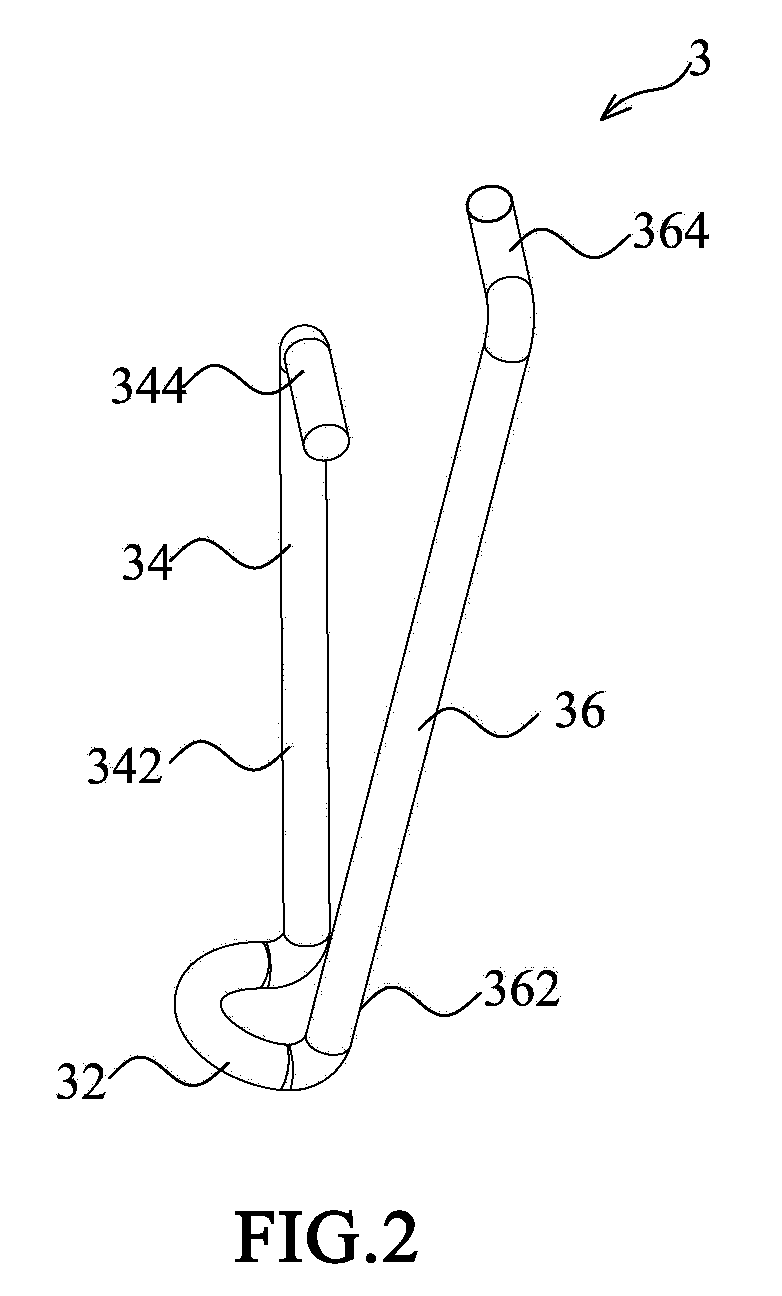

Hook

InactiveUS20090000086A1Conveniently and firmly hungEasy to carryHook fastenersEye fastenersEngineeringStructural engineering

The present invention relates to a hook, characterized in comprising: a S-shaped body (2) having hook-bills (20, 22) respectively at two ends; and, two self-locking members (3, 4) for locking said two hook-bills (20, 22), one end of each self-locking member (3, 4) is positioned on the said S-shaped body (2), and the other end of each self-locking member (3, 4) is locked on the corresponding hook-bill (20, 22) so that the two hook-bills (20, 22) are locked by said self-locking members (3, 4). The present invention brings forward a hook which can be conveniently hung to different objects such as a belt, the band of a schoolbag or other bands, or a metal pole, and can also keep desired rigidity and elasticity at the same time.

Owner:BING LIANG

Turnable multi-directional conveyer

InactiveCN104176522AImprove passabilityGaza with continuityLoading/unloadingIndustrial engineeringBelt conveyor

The invention relates to a turnable multi-directional conveyer which comprises a support seat, a belt conveyor and a lifting device, wherein the belt conveyor comprises a supporting section and a lifting section; one end of the supporting section is connected with one end of the lifting section; the supporting section is fixedly arranged on the support seat; the lifting device is used for controlling the ascending and descending of the lifting section; one end of the lifting device is fixedly connected onto the support seat, and the other end of the lifting device is fixedly connected onto the lifting section. According to the invention, the conveying is carried out through the belt conveyor, great convenience and quickness are achieved, the passing property is strong, and the characteristic of continuous sand adding is achieved, and the working efficiency is improved; the ascending and descending of the belt conveyor are realized through the lifting device, so that the turnable multi-directional conveyer can adapt to sand storage containers with different heights, and the ascending and descending amplitude is large. The turnable multi-directional conveyer further has the characteristics of simplicity in operation, low manual labor cost and high safety.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

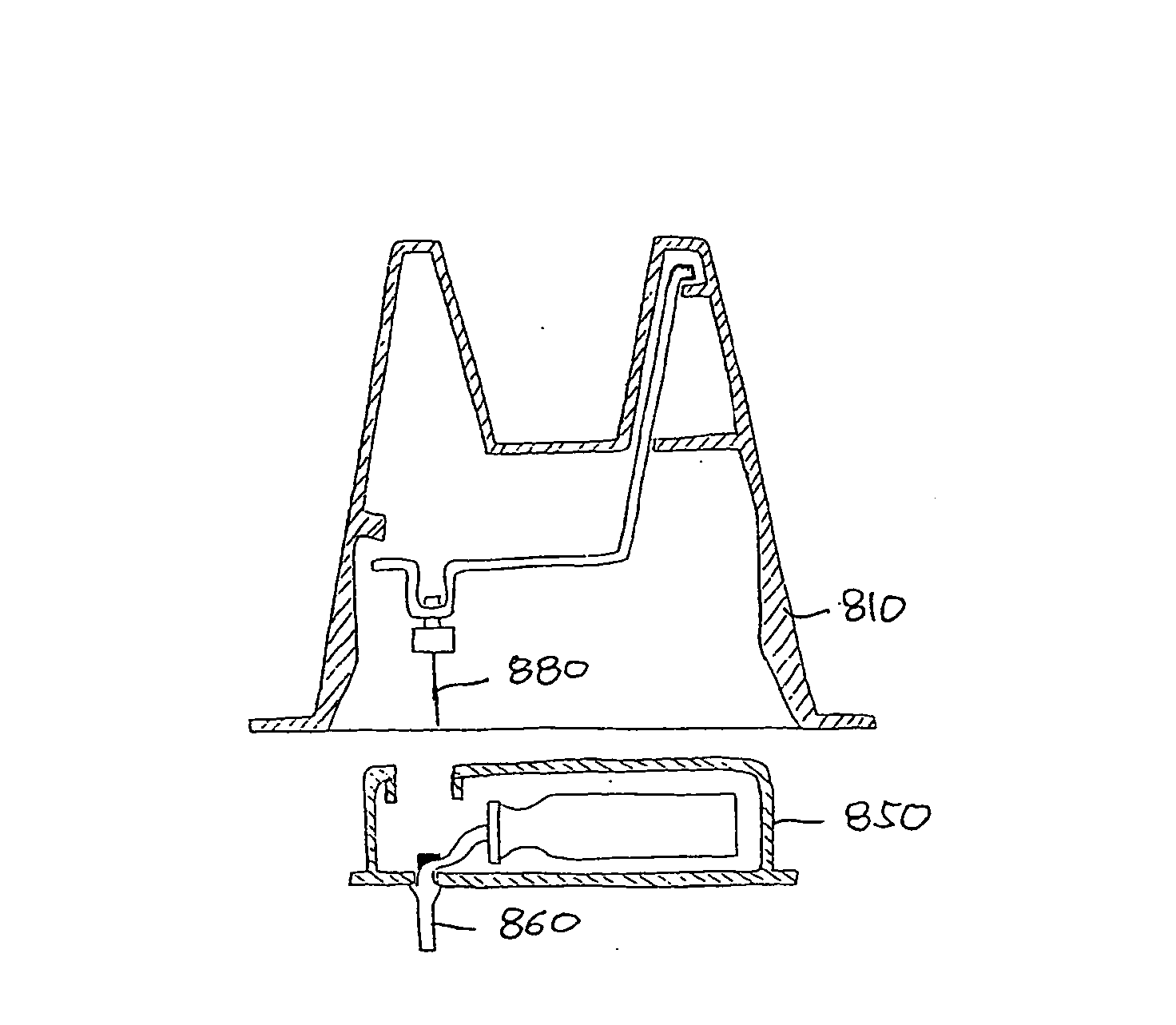

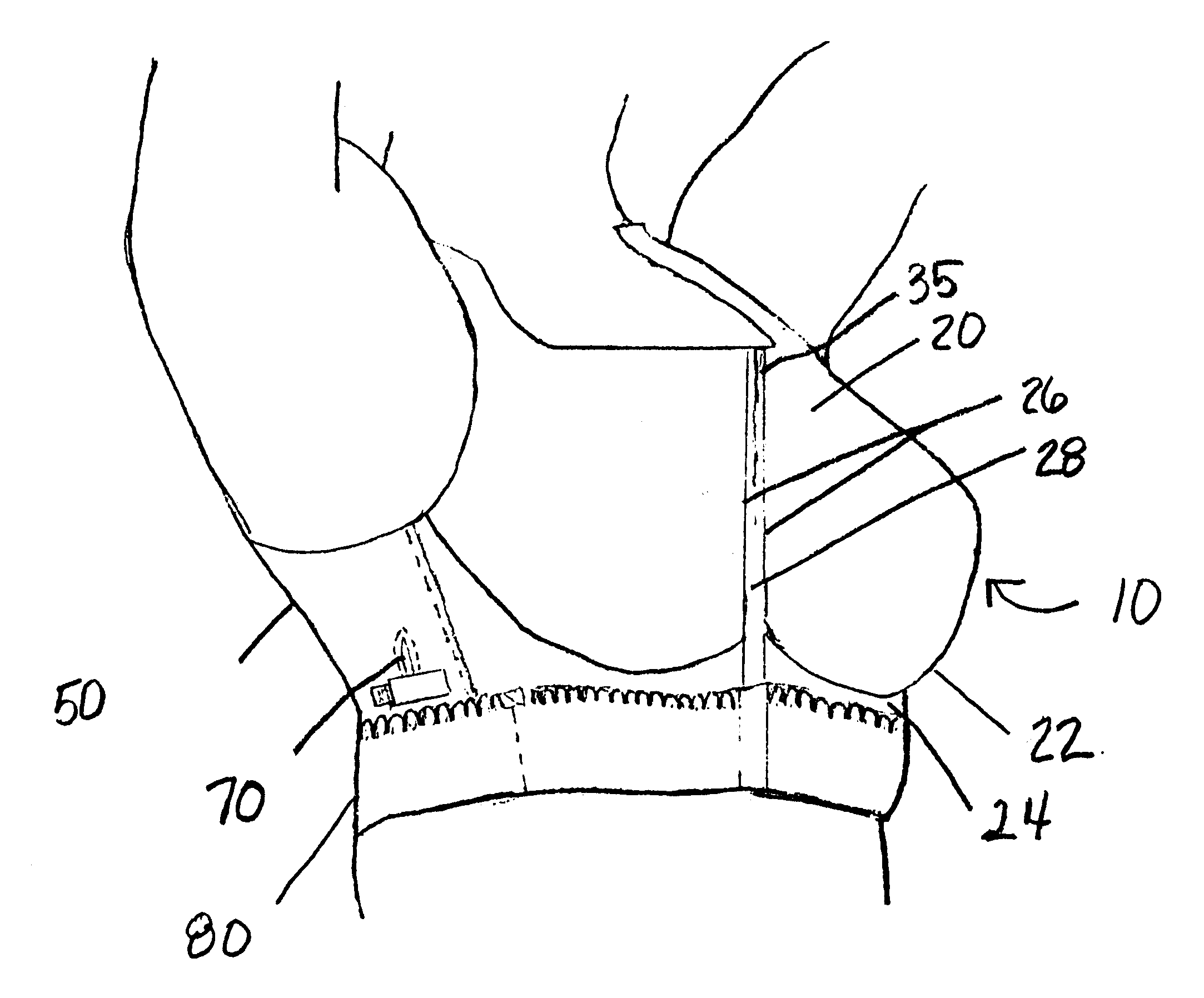

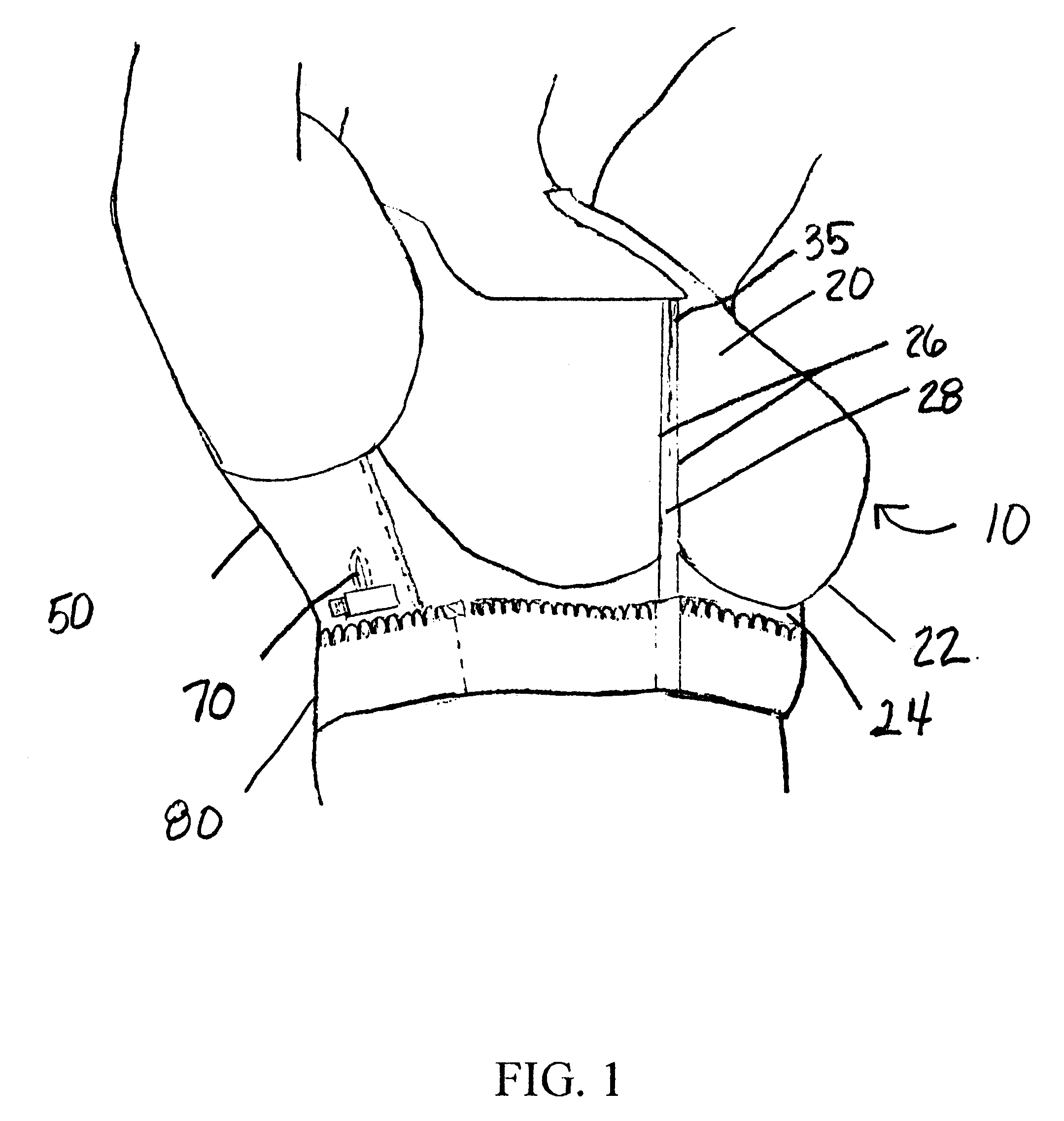

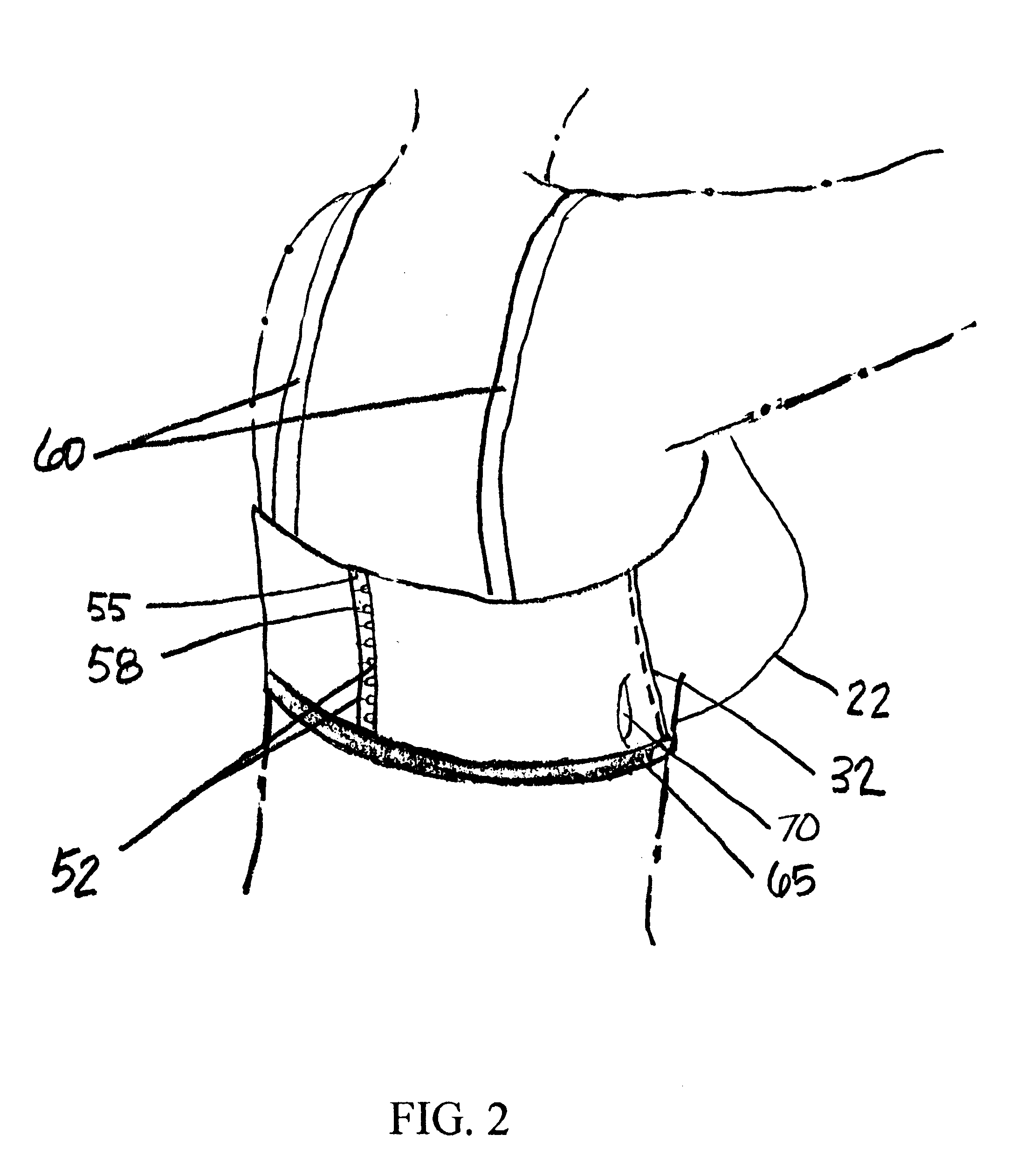

Surgical recovery brassiere

The present invention, in the preferred embodiment, is a surgery recovery brassiere which resolves many of the problems faced by women who have undergone breast surgery and particularly, mastectomy. The present invention comprises front panels, prosthesis panels, rear panels, torso band, straps, drain tube apertures and fluid collection storage pouch.More specifically, two front panels each comprise a cup portion and a conforming portion. The prosthesis panels are attached to the rear facing of the cup portion of the front panel to form enclosed pockets to hold one or two prosthesis. Each of the two rear panels are joined at one end to the front panels and extend to meet the opposing rear panel at a back closure. The free end of each of the front panels meet to form a front closure. Straps extend from the top of the front panel to the top of the adjacent rear panel. The torso band extends around the lower edge of the surgery recovery brassiere to form an almost continuous strip of material along the lower edge of the front and rear panels.The surgery recovery brassiere further accommodates post-operative surgical drainage systems composed of one or more drain tubes and associated fluid collection bulbs. The position of drainage tube apertures, generally located proximate to the joint between the front and rear panels, allow drainage tubes to protrude from the chest wall, through the apertures and into the collection storage pouch. Tab closures allow the wearer to secure the drainage tubes within the aperture to further reduce movement of the tubes and disturbance of the drainage system. The storage pouch provides pockets with elastic top entry so that collection bulbs are within easy, convenient reach for emptying lymphatic fluids and other waste materials. The upper edge of the storage pouch releasably attaches to the torso band with a hook-and-loop fastener system.

Owner:BROOKS DEBRA A

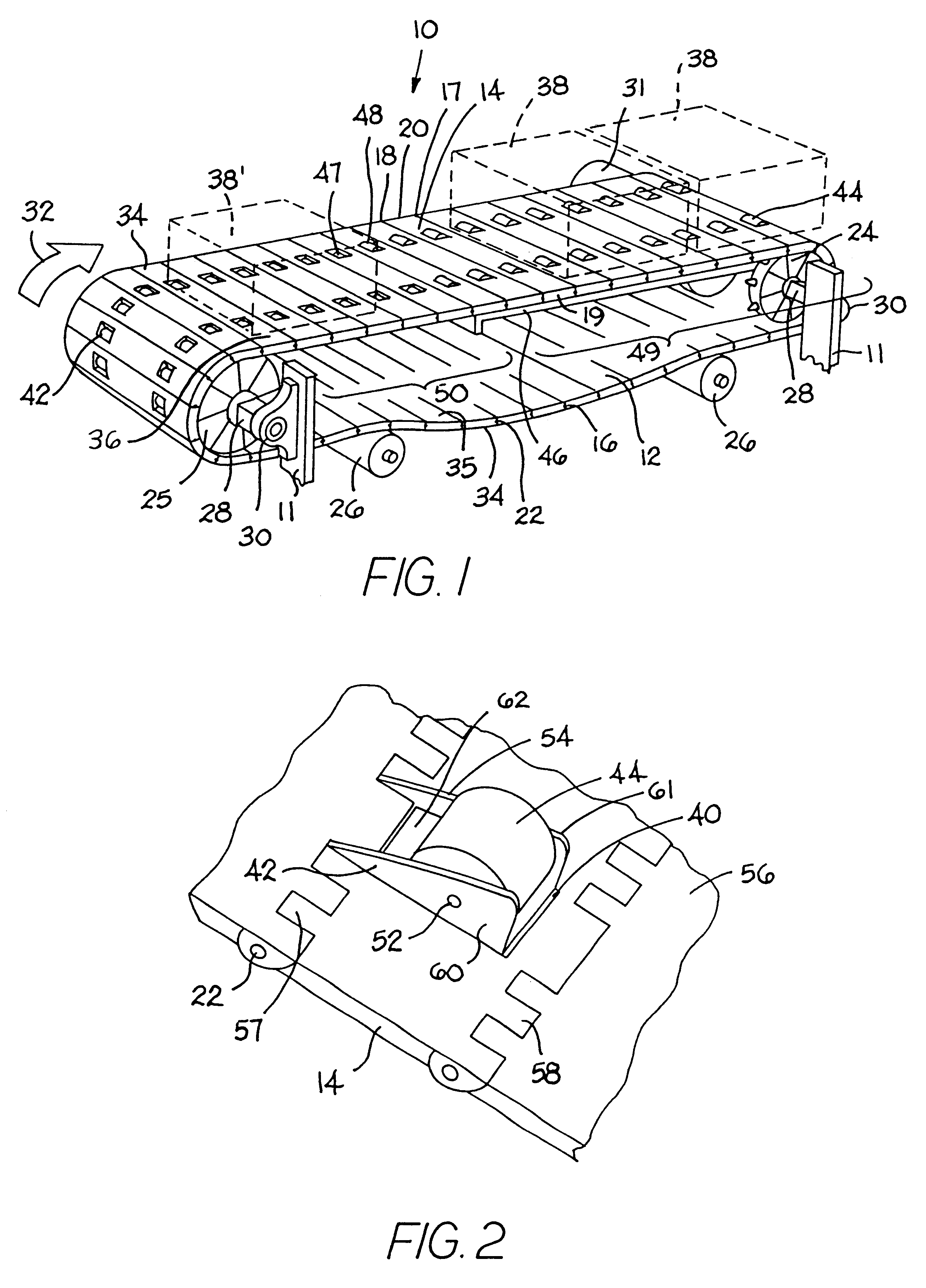

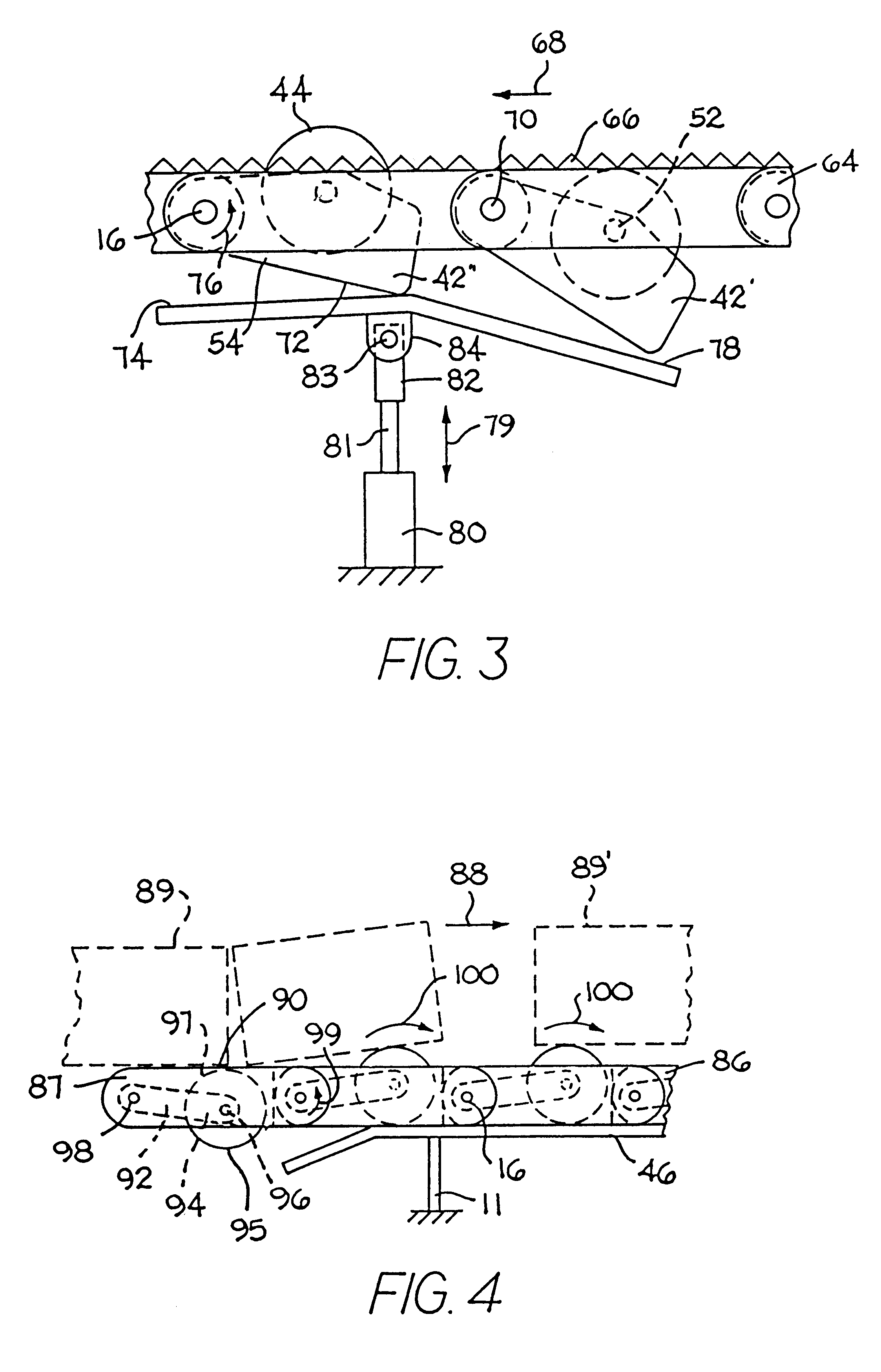

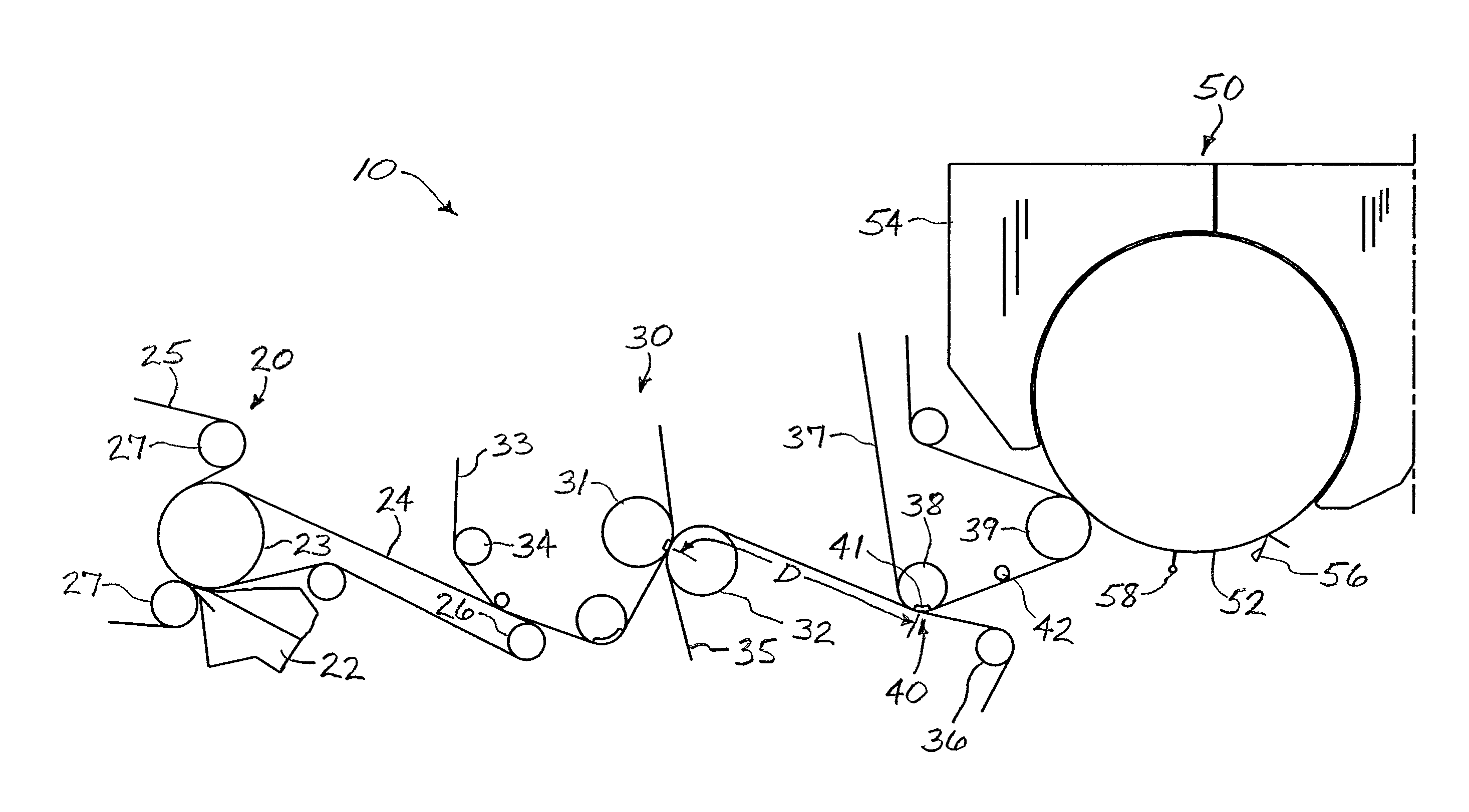

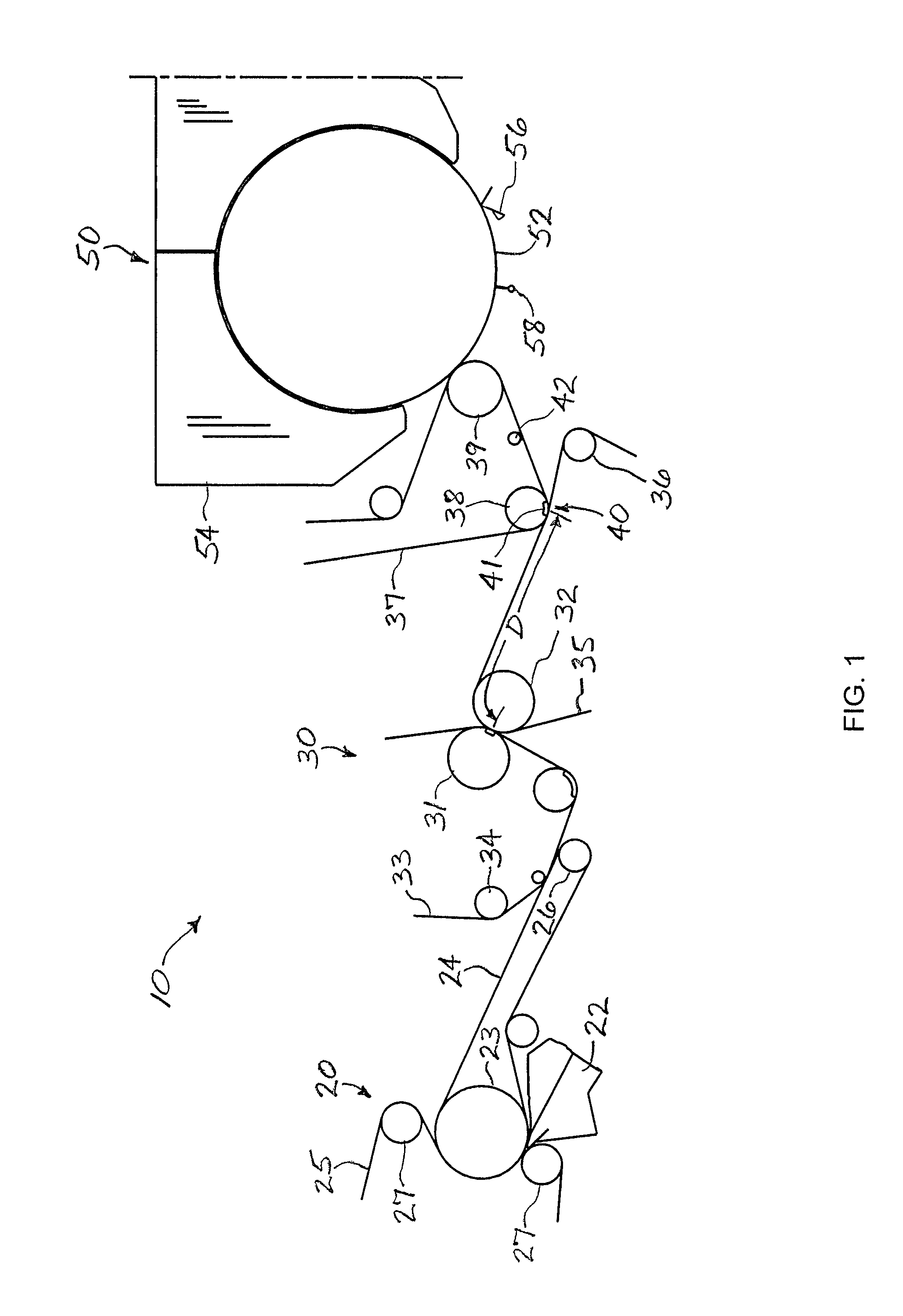

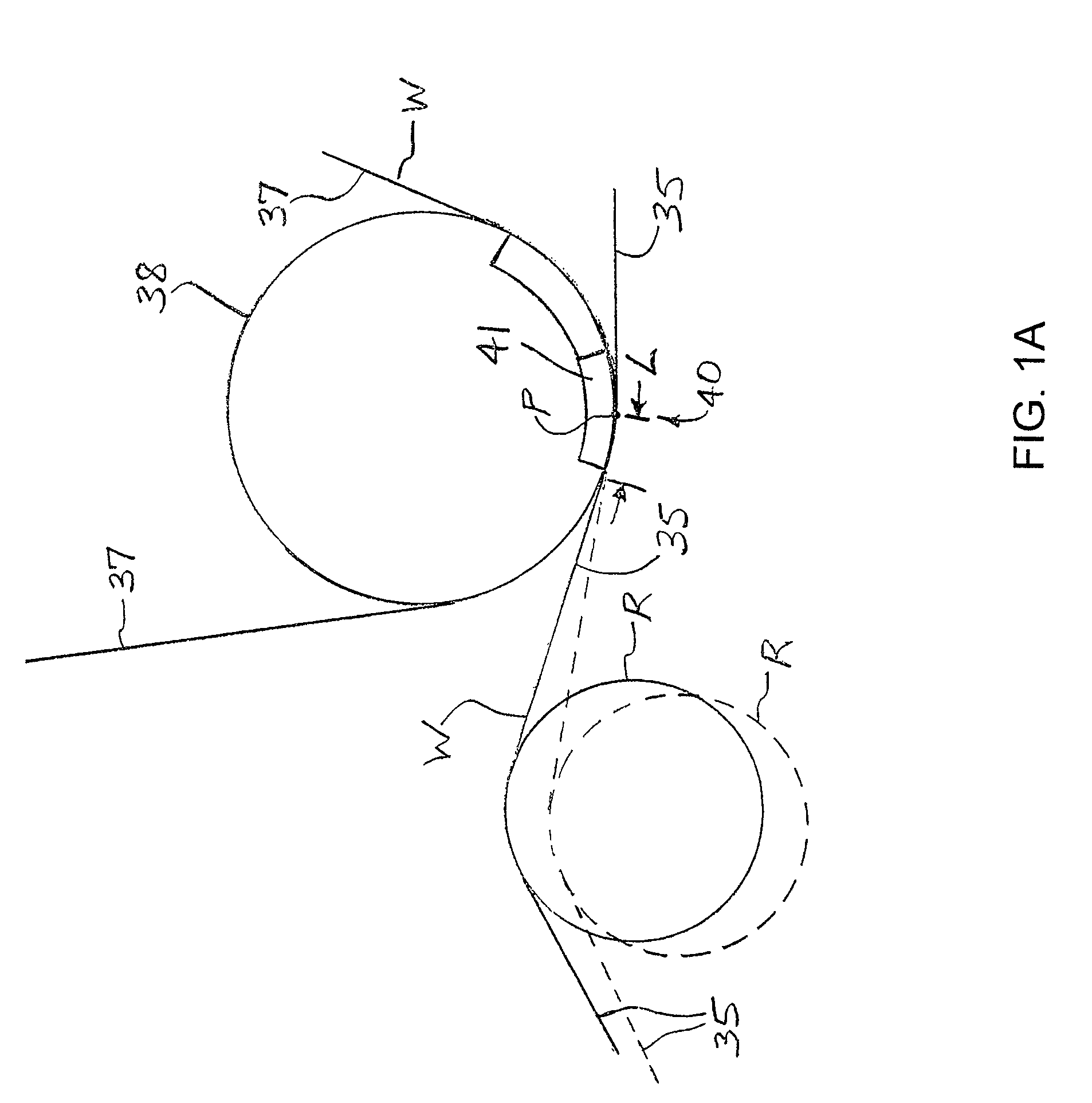

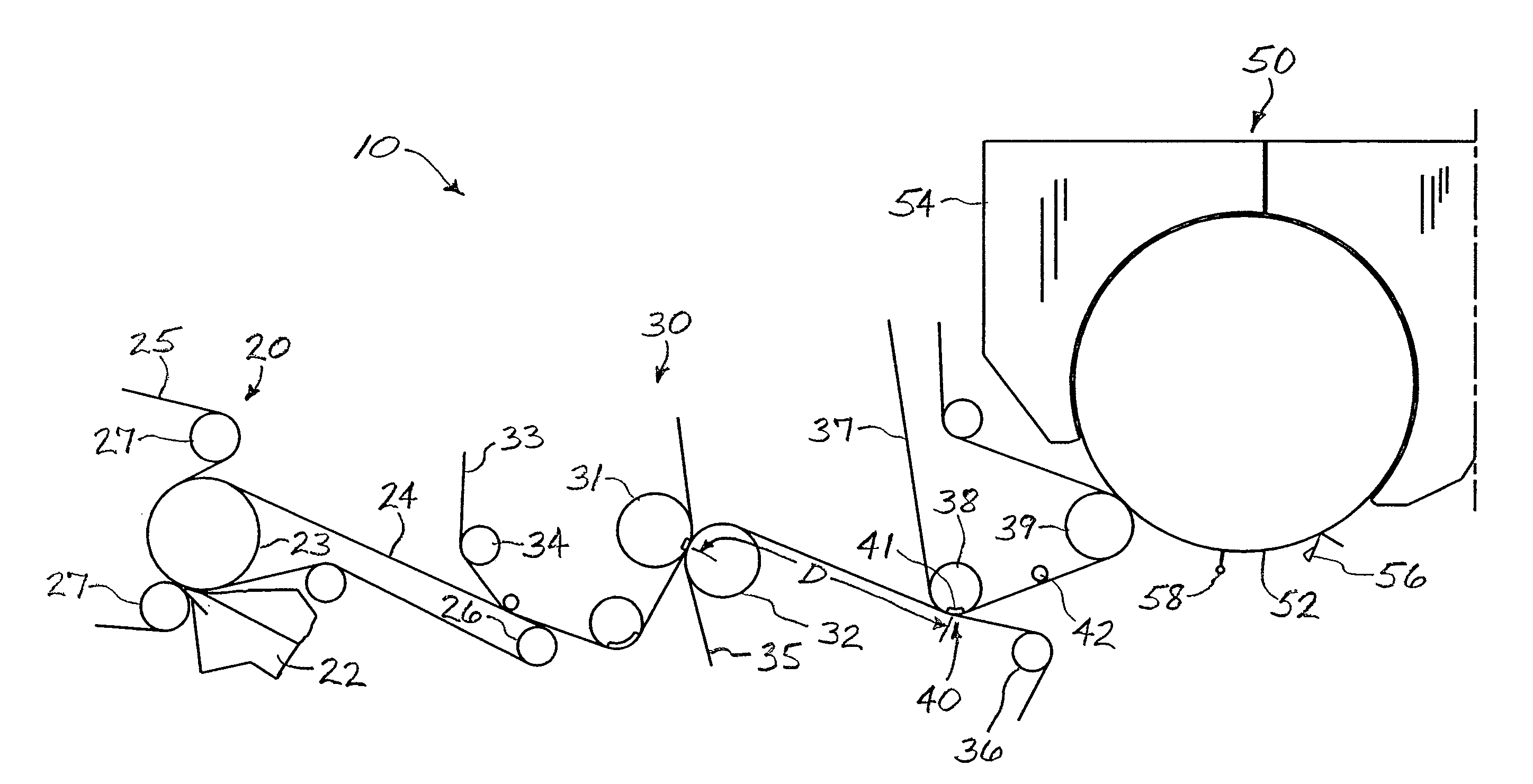

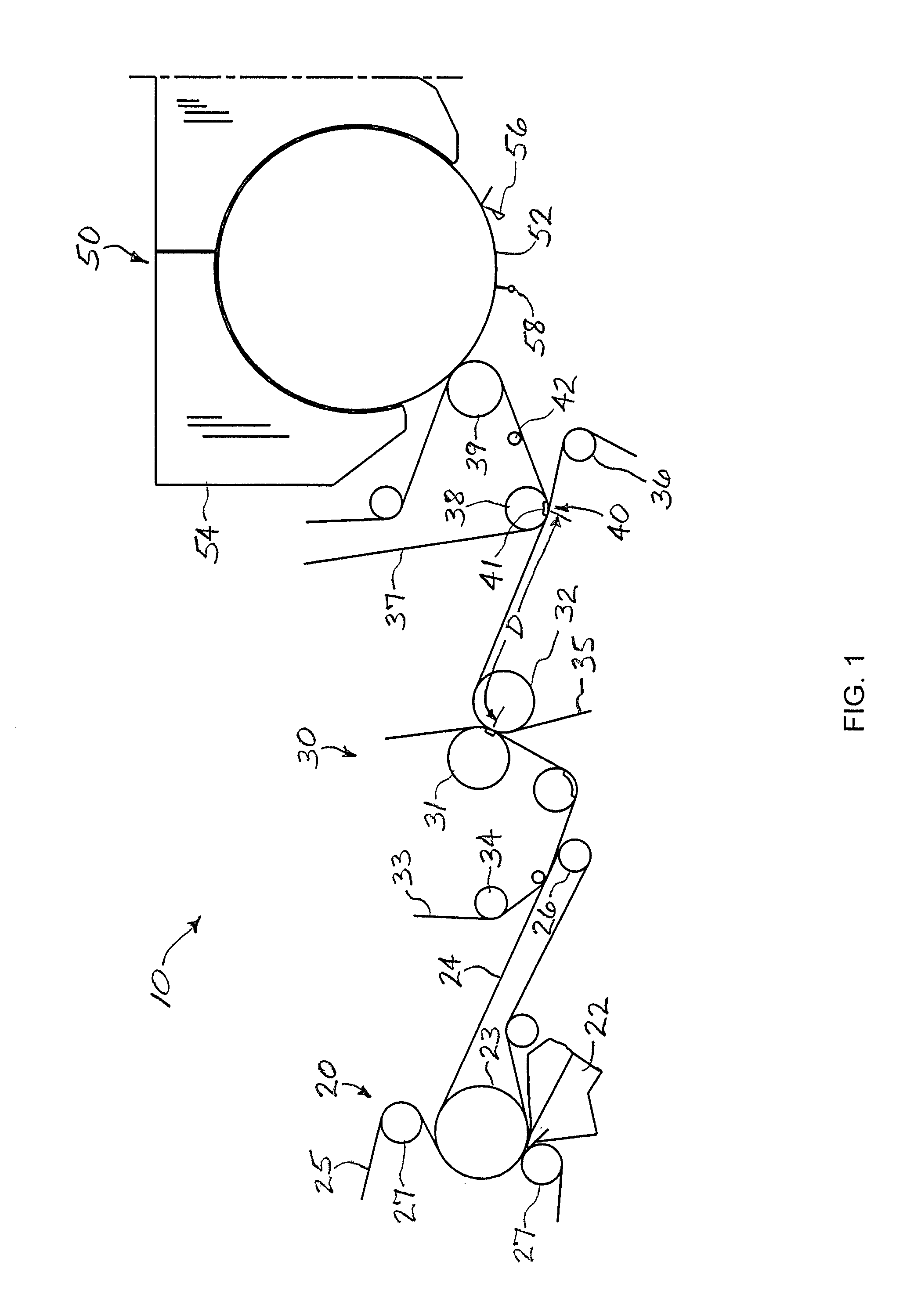

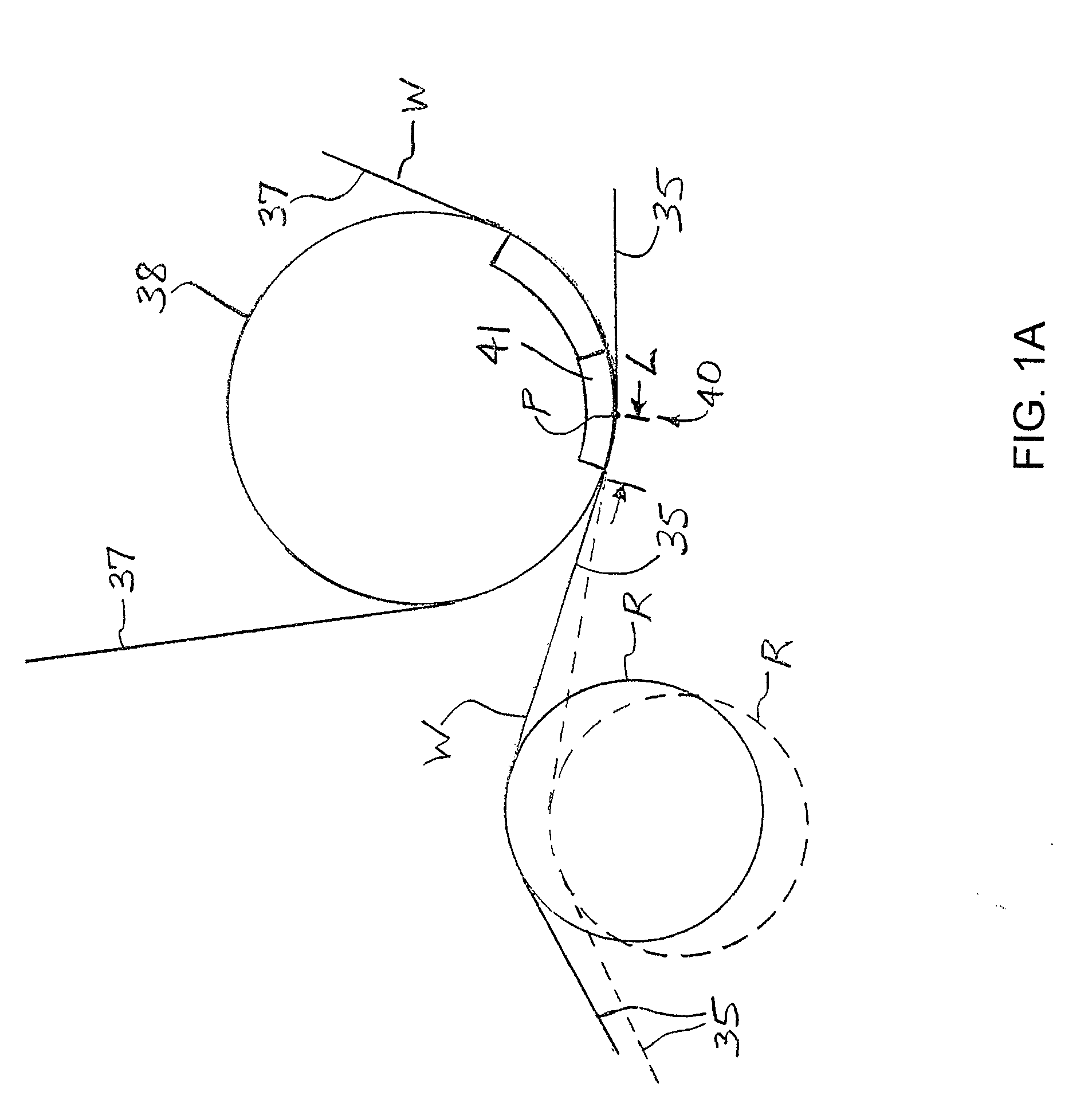

Papermaking machine employing an impermeable transfer belt, and associated methods

ActiveUS7811418B2Higher sheet caliperNon-fibrous pulp additionNatural cellulose pulp/paperLeather beltTransfer point

A papermaking machine for making paper includes a forming section, a press section, and a drying section. The paper web is pressed between two press members while enclosed between a press felt and a transfer belt having non-uniformly distributed microscopic depressions in its surface, the web following the transfer belt from the press to a transfer point at which the web is transferred via a suction transfer device onto a structuring fabric, the web then being dried on a drying cylinder. The transfer point is spaced a distance D from the press nip selected based on machine speed, a basis weight of the web, and the surface characteristics of the transfer belt, such that within the distance D a thin water film between the web and the transfer belt at least partially dissipates to allow the web to be separated from the transfer belt.

Owner:VALMET AB

Thermal treatment device

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

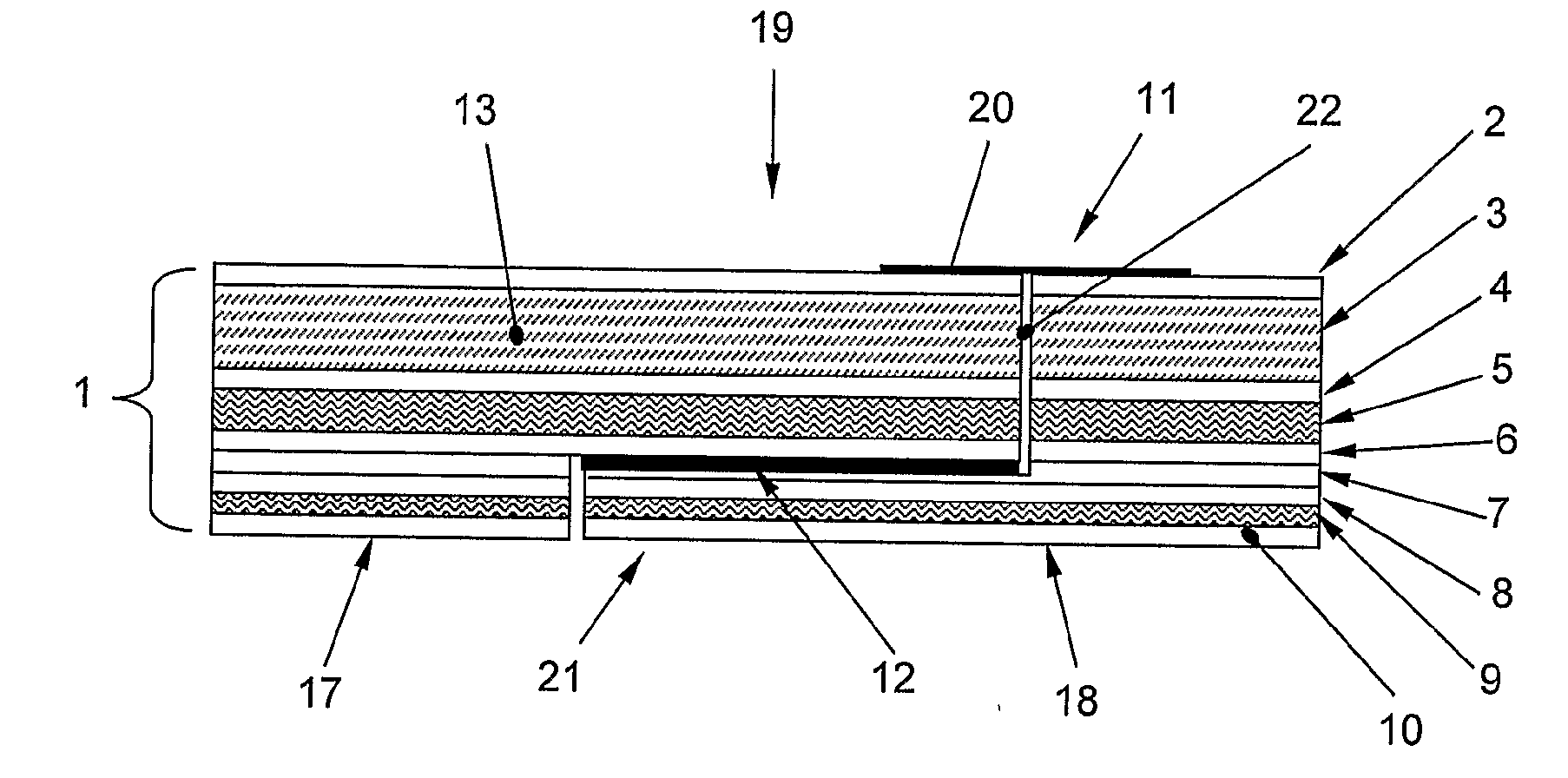

Multi-layered belt

InactiveUS20090098385A1Reliable and durable mechanical propertyReduce stress exertedConveyorsSynthetic resin layered productsEngineeringLeather belt

A multi-layered belt, in particular a continuous running and / or transport and / or processing belt, includes a traction layer and a functional layer that contains a gel. To reduce the stress placed on the transported goods, in particular persons, the gel is an unplasticized gel and the functional layer consist of a coating containing the interspersed gel. In addition, to a method for producing a belt of this type is provided, in which the gel is poured in a continuous method onto the traction layer and a mixer and delivery unit is guided back and forth in a reversible manner perpendicular to the displacement direction of the traction layer in such a way that a gel layer with a uniform thickness is applied to the traction layer. Furthermore, the use of said belt as a running belt for persons, in particular as a running belt for training and / or fitness equipment is described.

Owner:FORBO SIEGLING +1

Papermaking Machine Employing an Impermeable Transfer Belt, and Associated Methods

ActiveUS20080156450A1Improve wet strengthTransfer completelyNon-fibrous pulp additionNatural cellulose pulp/paperLeather beltTransfer point

A papermaking machine for making paper includes a forming section, a press section, and a drying section. The paper web is pressed between two press members while enclosed between a press felt and a transfer belt having non-uniformly distributed microscopic depressions in its surface, the web following the transfer belt from the press to a transfer point at which the web is transferred via a suction transfer device onto a structuring fabric, the web then being dried on a drying cylinder. The transfer point is spaced a distance D from the press nip selected based on machine speed, a basis weight of the web, and the surface characteristics of the transfer belt, such that within the distance D a thin water film between the web and the transfer belt at least partially dissipates to allow the web to be separated from the transfer belt.

Owner:VALMET AB

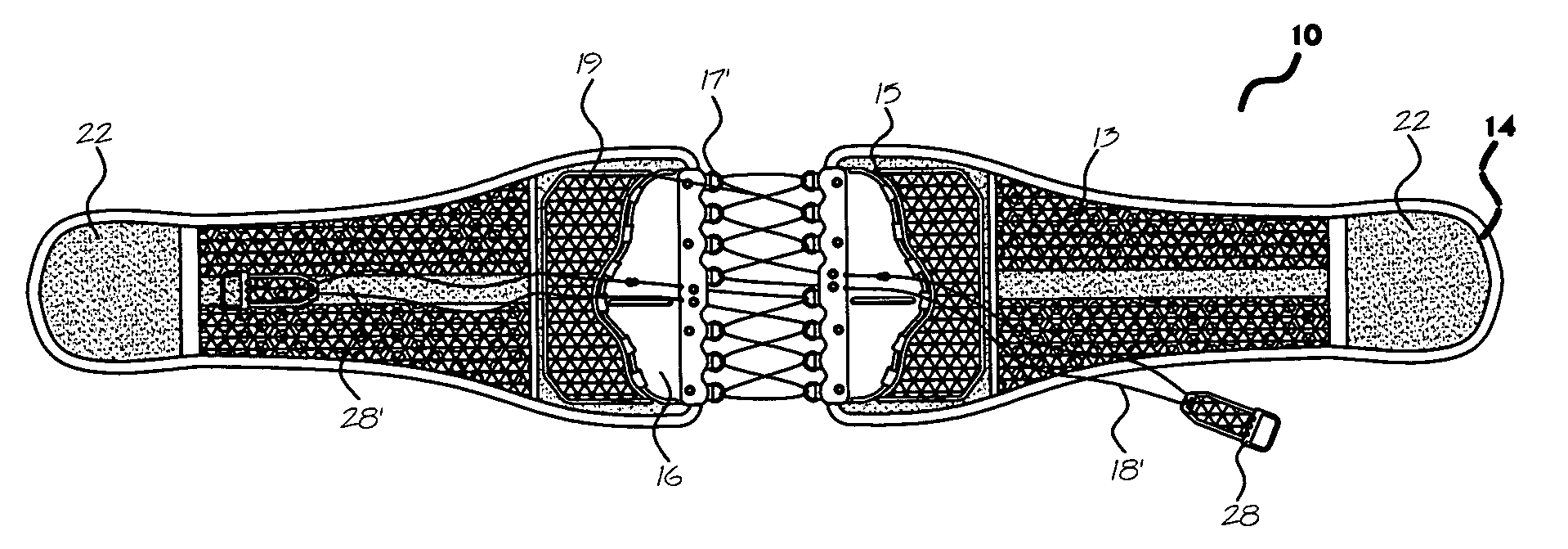

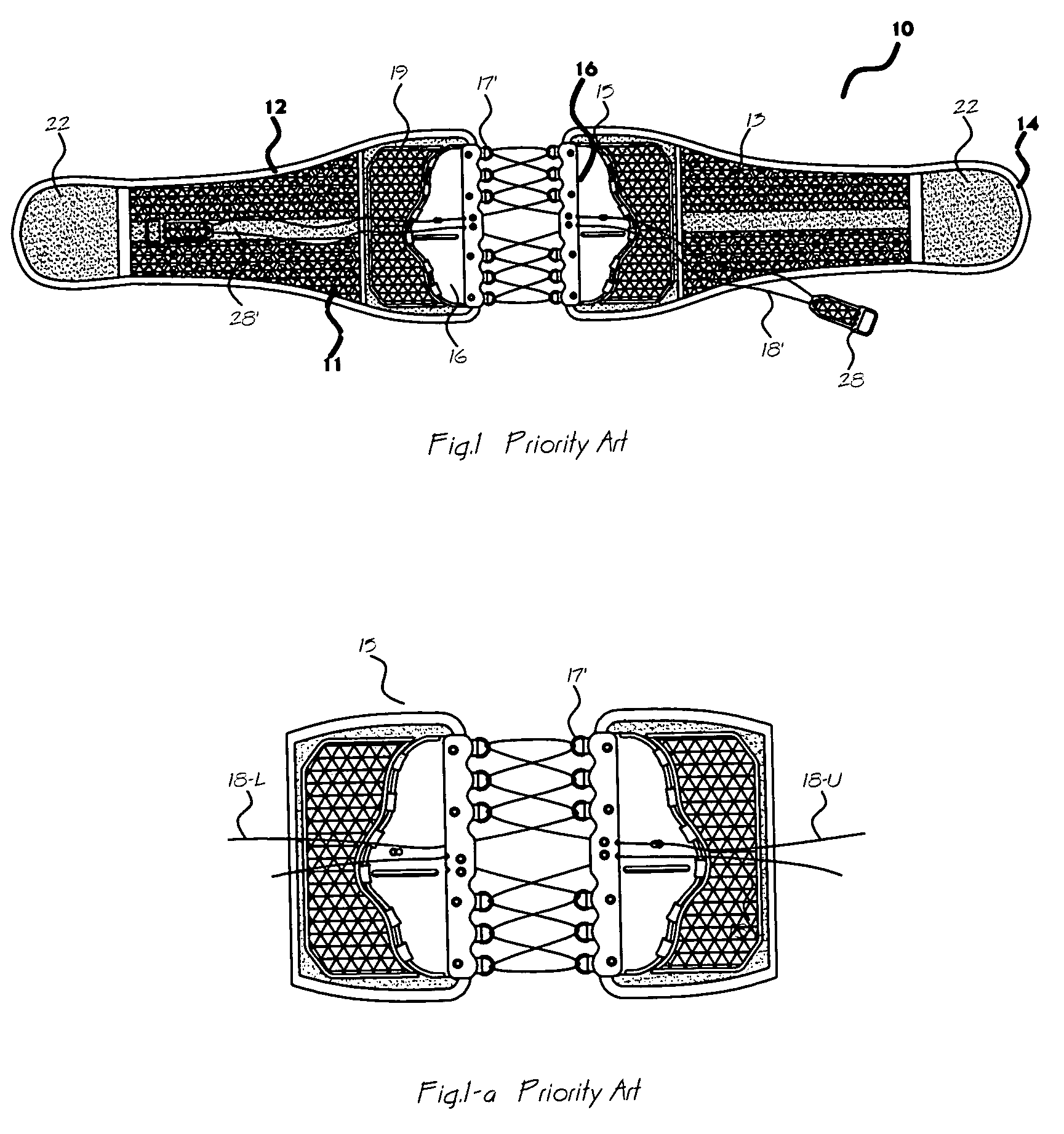

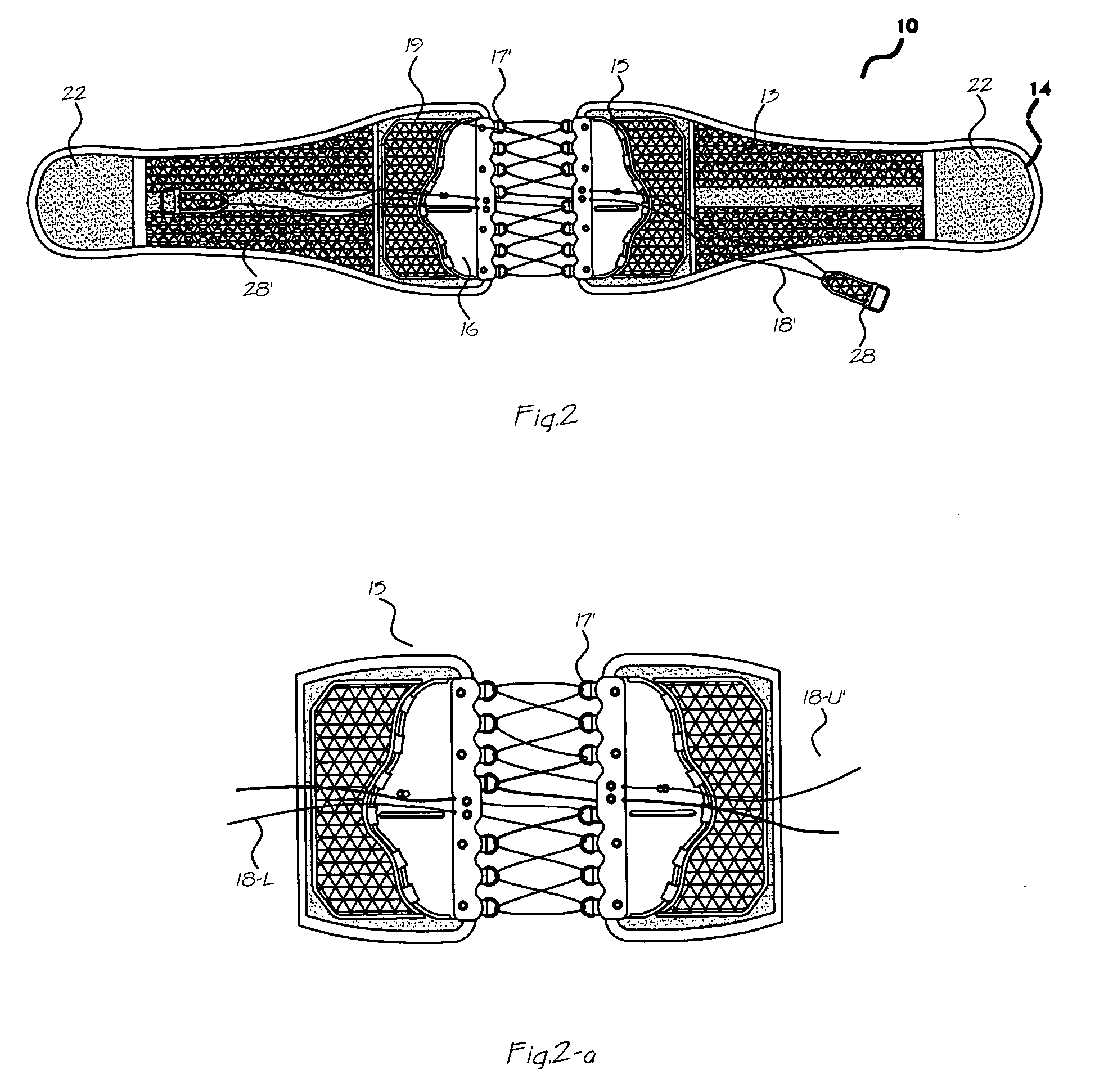

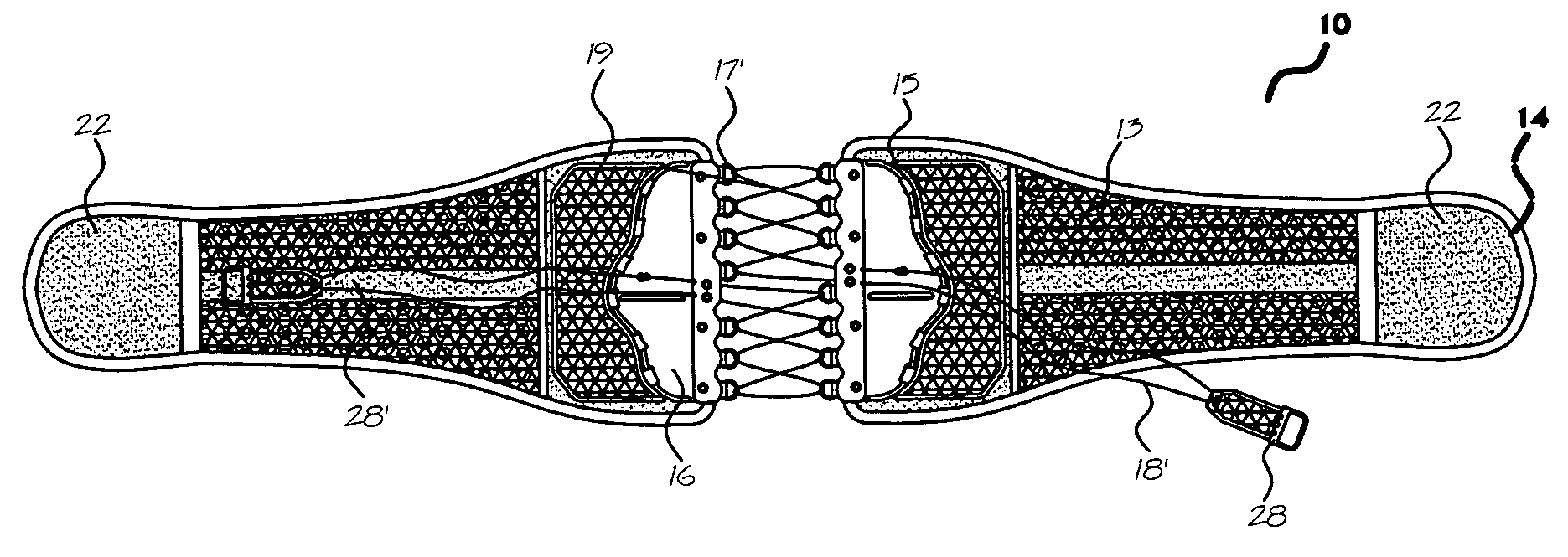

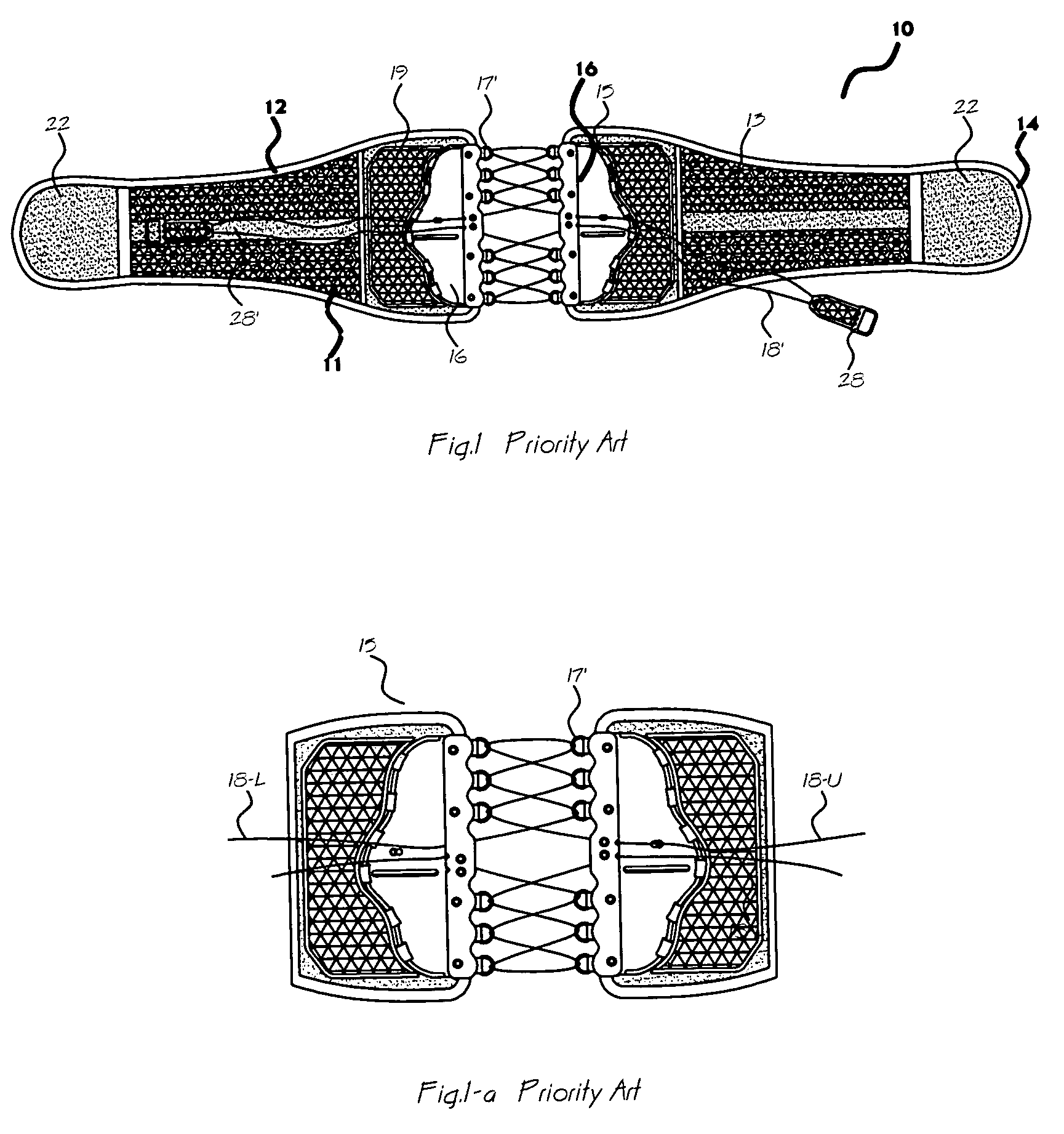

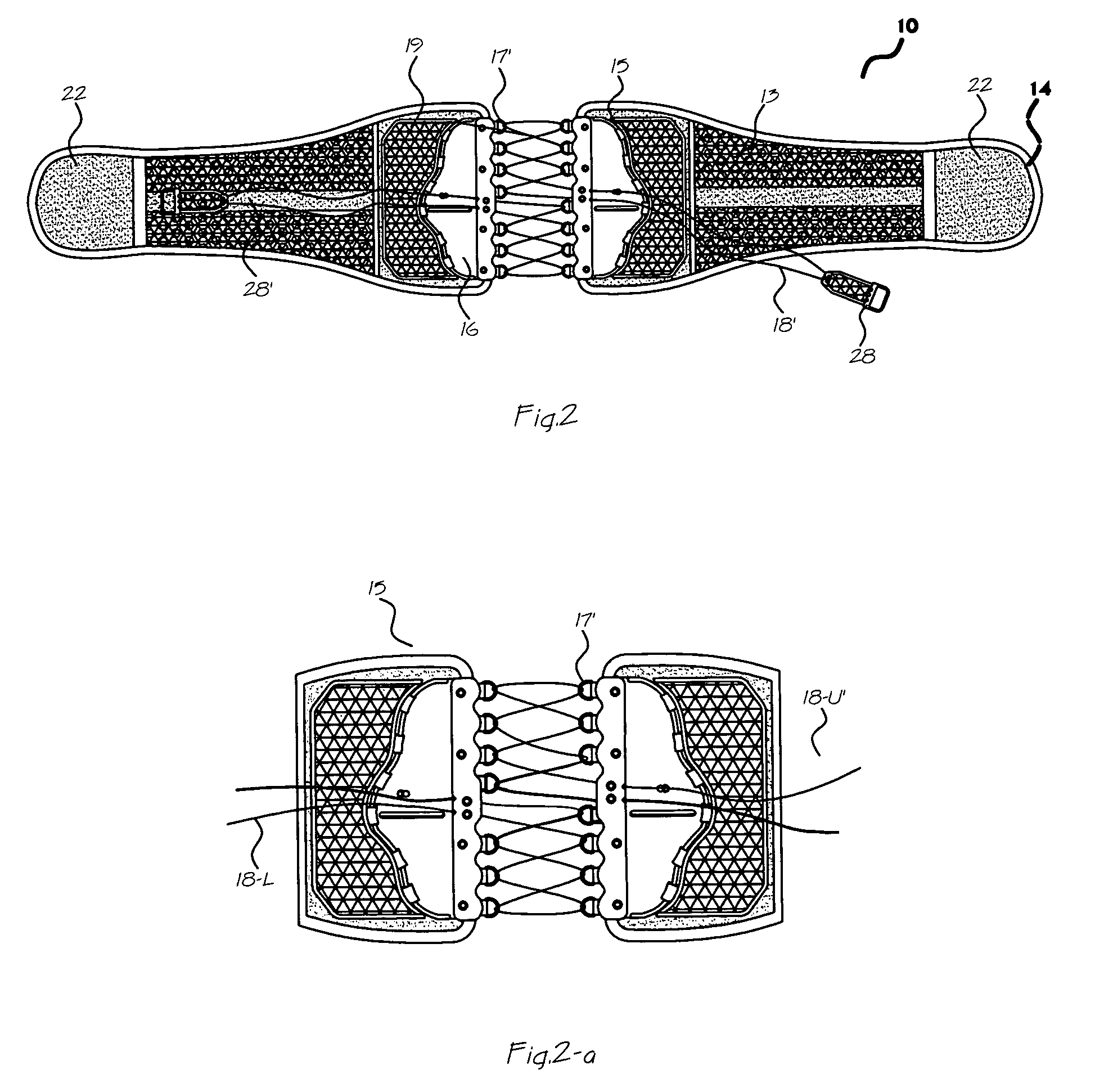

String arrangement of a separate back immobilizing, dynamically self-adjusting, customizing back support for a vertebra related patient

A string arrangement for a detachment type waist-protecting belt to hold the vertebra region of a vertebra related patient is provided. The string arrangement enables a separate fastening of the upper portion and lower portion of the belt to form a saddle like shape that fits the contour of the waist of an individual patient dynamically with or without the extra support of a frame. The waist-protecting belt can also be connected to a back supporting frame, which is comprised of two plastic plates, via two guiding nuts, fixed on the center of the exterior side of the inner-half of the rim of each solid plastic plate, guided through the two narrow and long holes found on the wider portions of the belt, and held in place by two wide head bolts which screw on to the nuts. Then the upper portion and lower portion of the frame is adjusted separately by the movement of the upper and lower portion of the belt.

Owner:LATHAM MARK ALAN

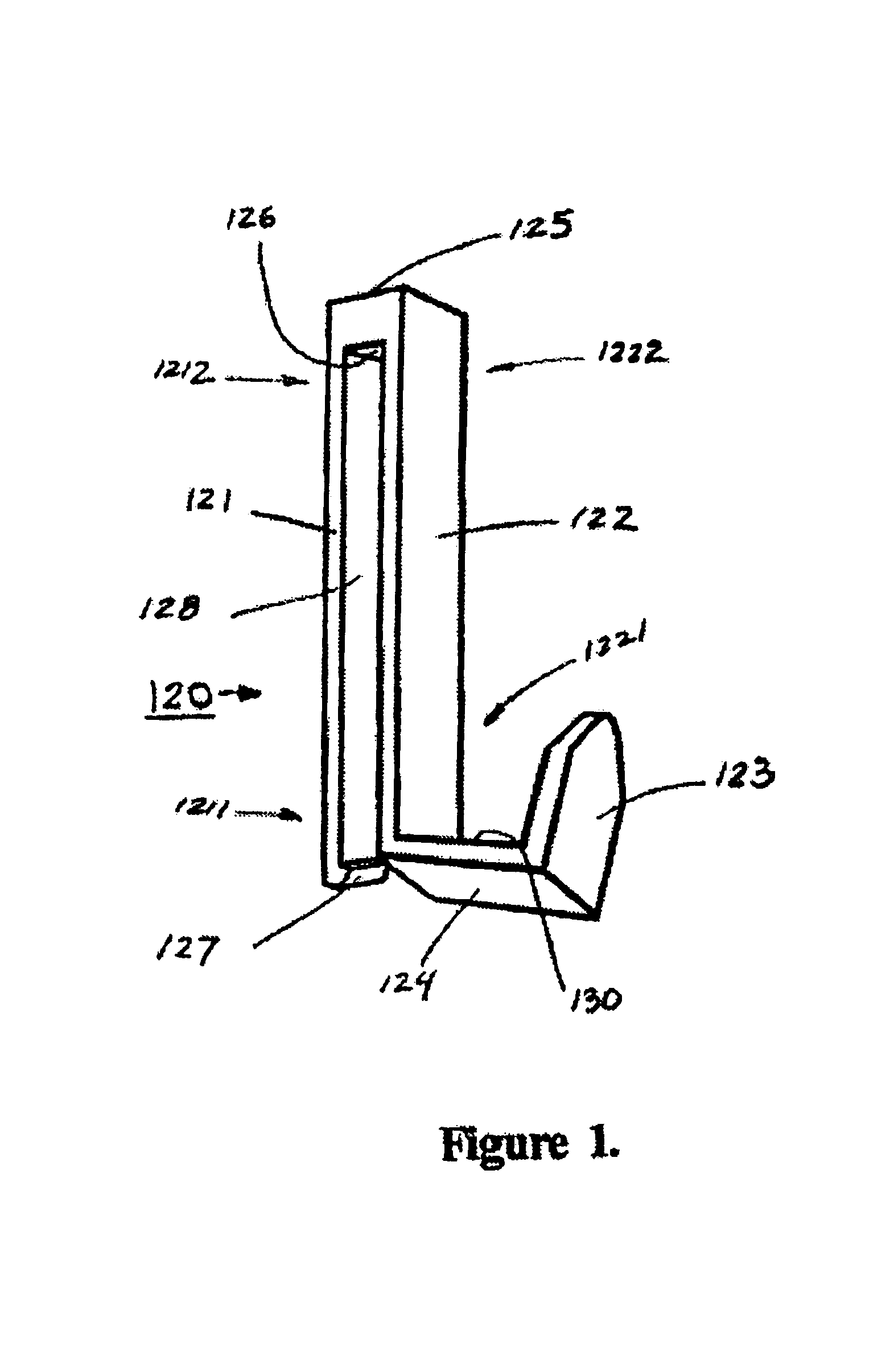

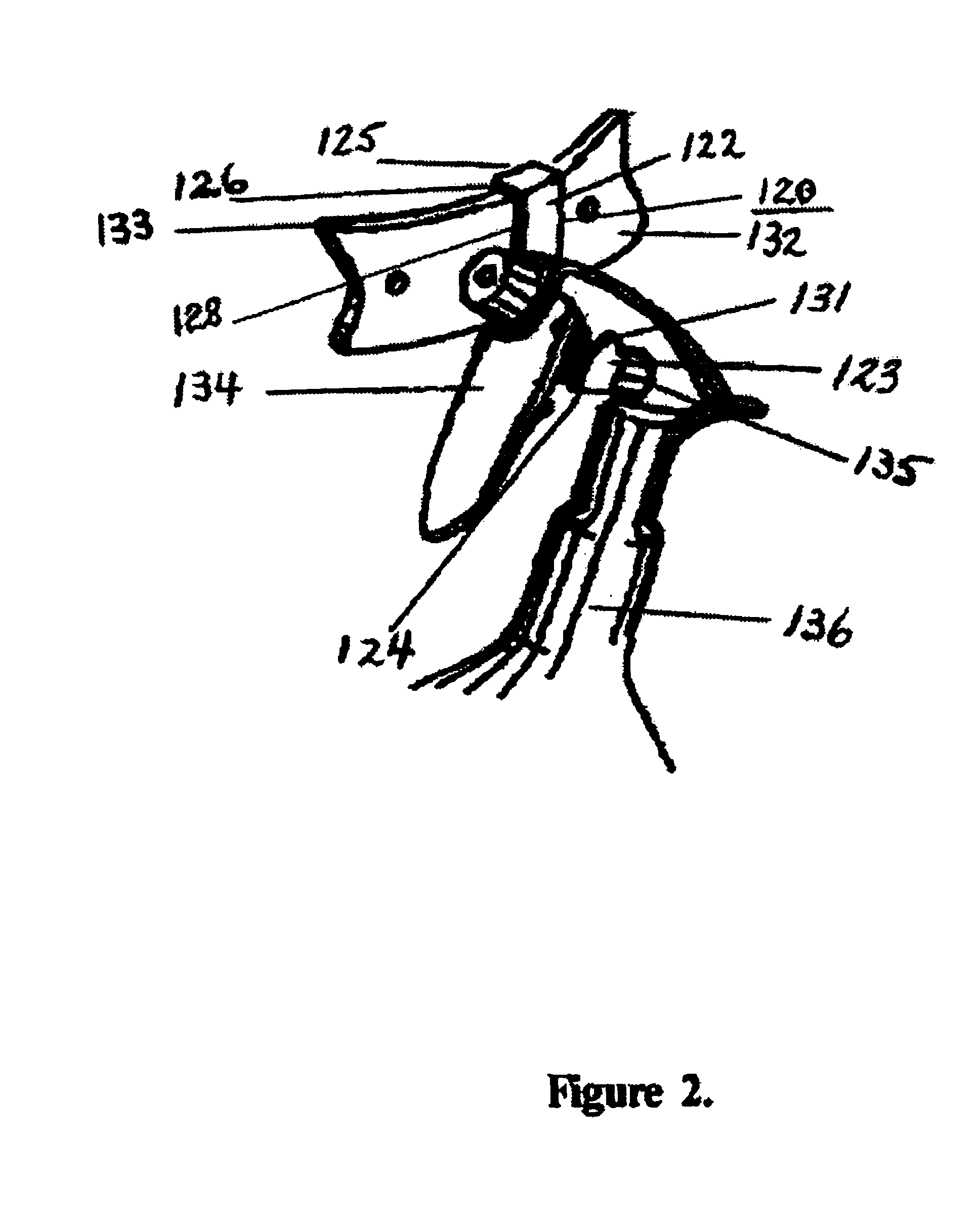

Spray applicator belt hook

A Spray Applicator Belt Hook for use in conjunction with spray applicator bottles. These bottles are usually of 500 mL or 1 L capacity; usually contain a chemical or liquid substance for use in cleaning, gardening or other duties whereby the belt hook allows the user to carry the spray bottle on their belt when not in use.

Owner:VERNON WOODS DONALD MICHAEL

String arrangement of a separate back immobilizing, dynamically self-adjusting, customizing back support for a vertebra related patient

InactiveUS7083585B2Superior and inferior variationSmall rib cageOrthopedic corsetsBraced frameEngineering

A string arrangement for a detachment type waist-protecting belt to hold the vertebra region of a vertebra related patient is provided. The string arrangement enables a separate fastening of the upper portion and lower portion of the belt to form a saddle like shape that fits the contour of the waist of an individual patient dynamically with or without the extra support of a frame. The waist-protecting belt can also be connected to a back supporting frame, which is comprised of two plastic plates, via two guiding nuts, fixed on the center of the exterior side of the inner-half of the rim of each solid plastic plate, guided through the two narrow and long holes found on the wider portions of the belt, and held in place by two wide head bolts which screw on to the nuts. Then the upper portion and lower portion of the frame is adjusted separately by the movement of the upper and lower portion of the belt.

Owner:LATHAM MARK ALAN

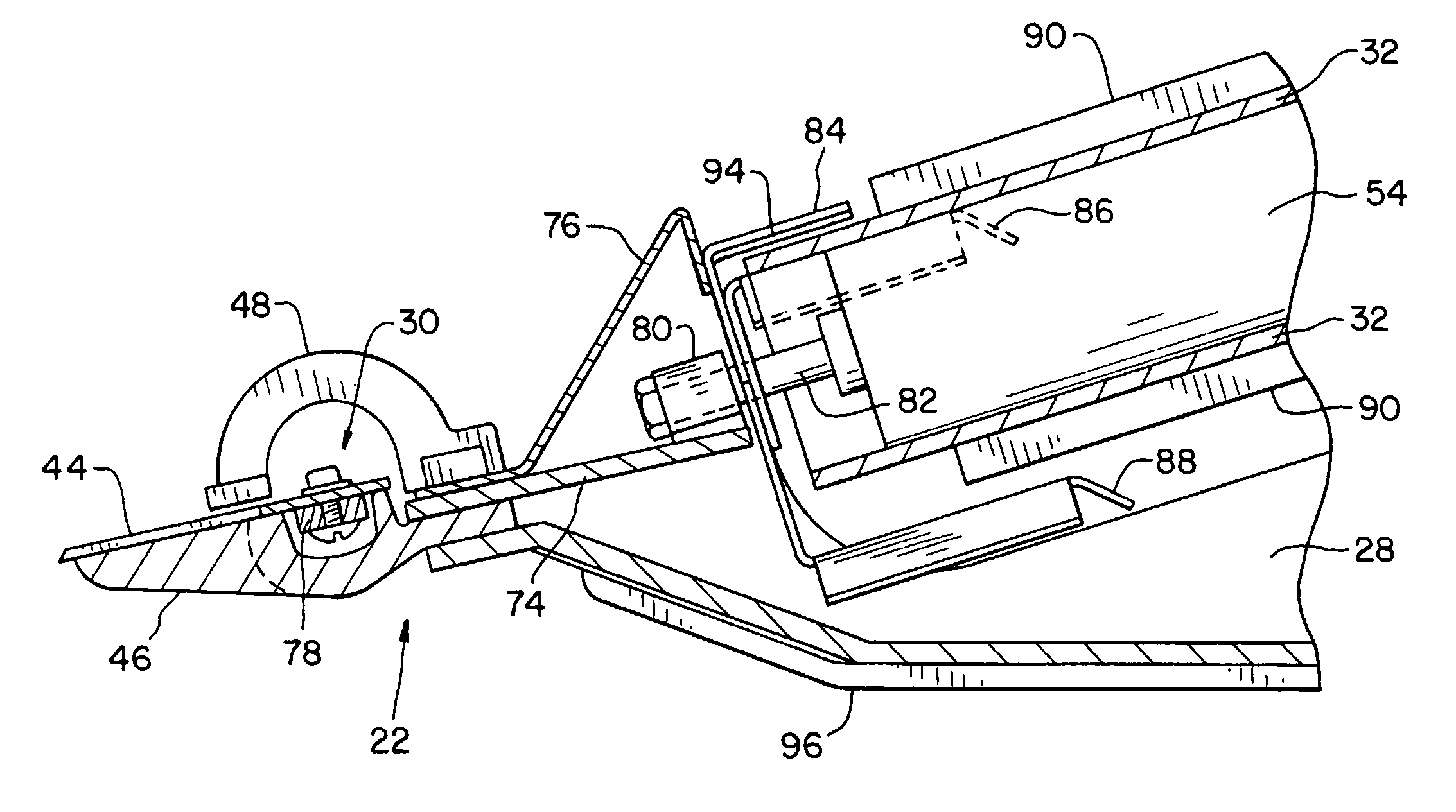

Sectionalized belt guide for draper belt in an agricultural harvesting machine

A cutting platform for use with an agricultural harvesting machine includes a plurality of platform sections, with each platform section including a leading edge. At least one platform section includes a cutterbar assembly movable in a localized manner in upwards and downwards directions, an endless belt, and a plurality of belt guides positioned partially above the endless belt adjacent the leading edge. The belt guides are movable relative to each other.

Owner:DEERE & CO

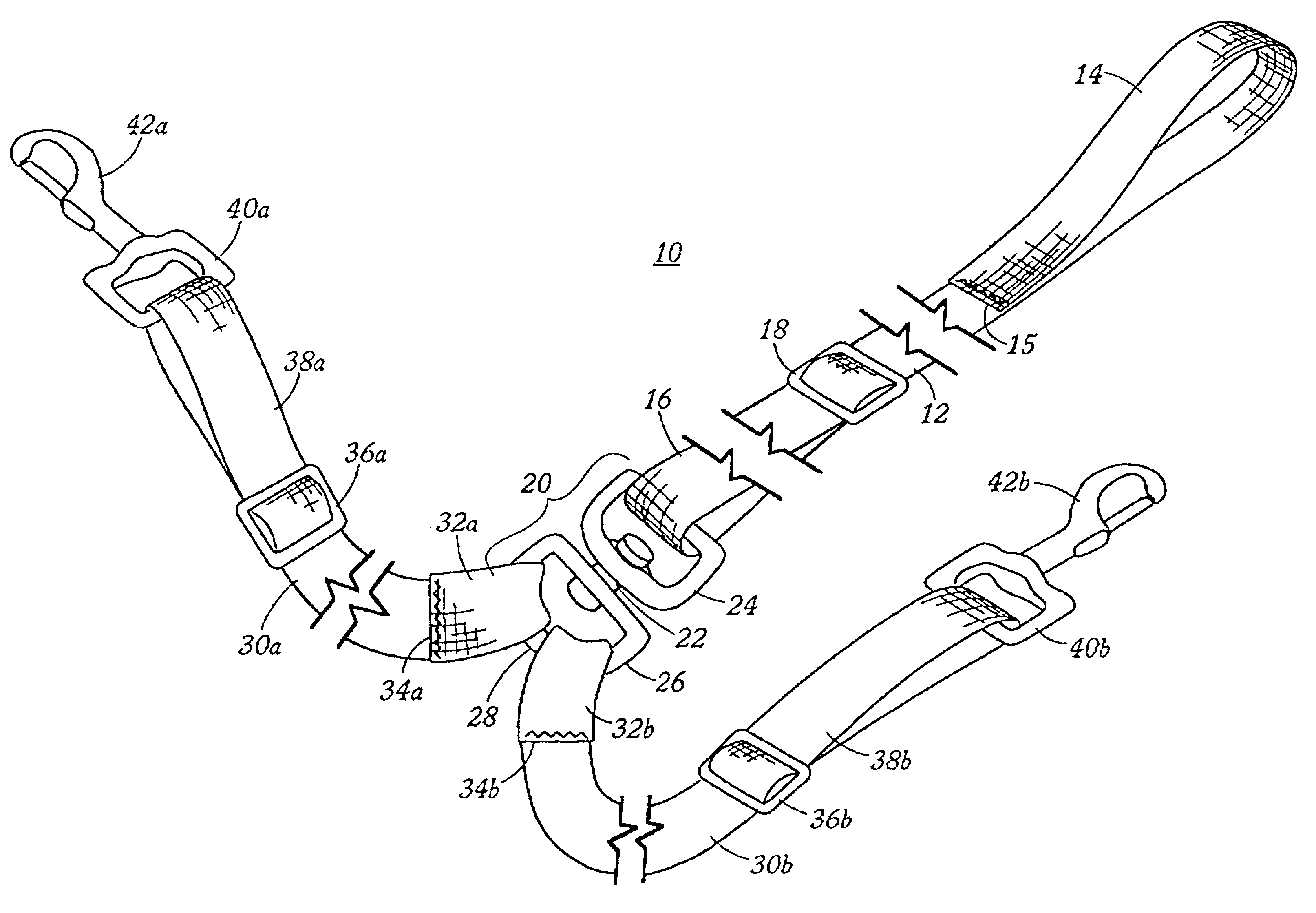

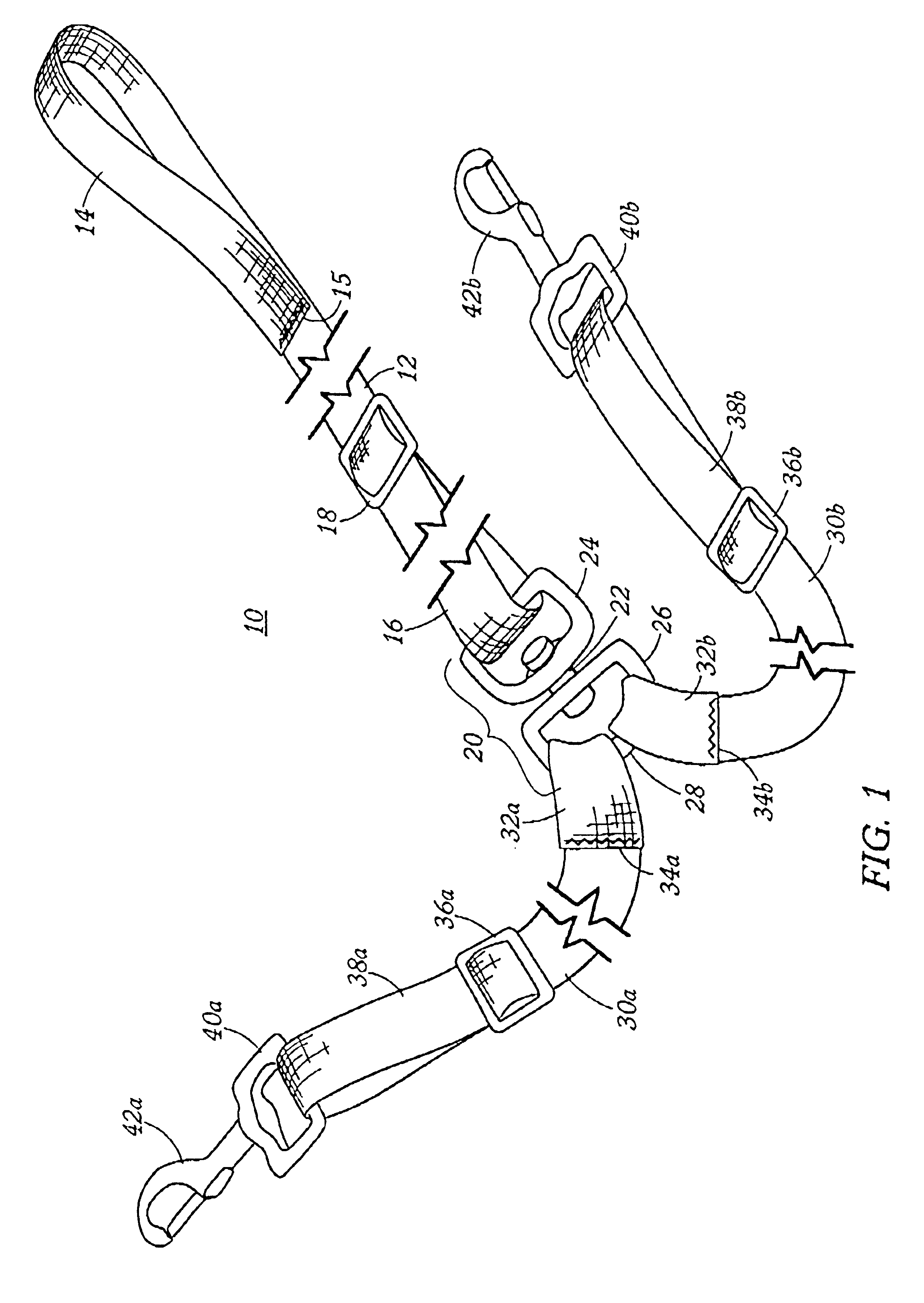

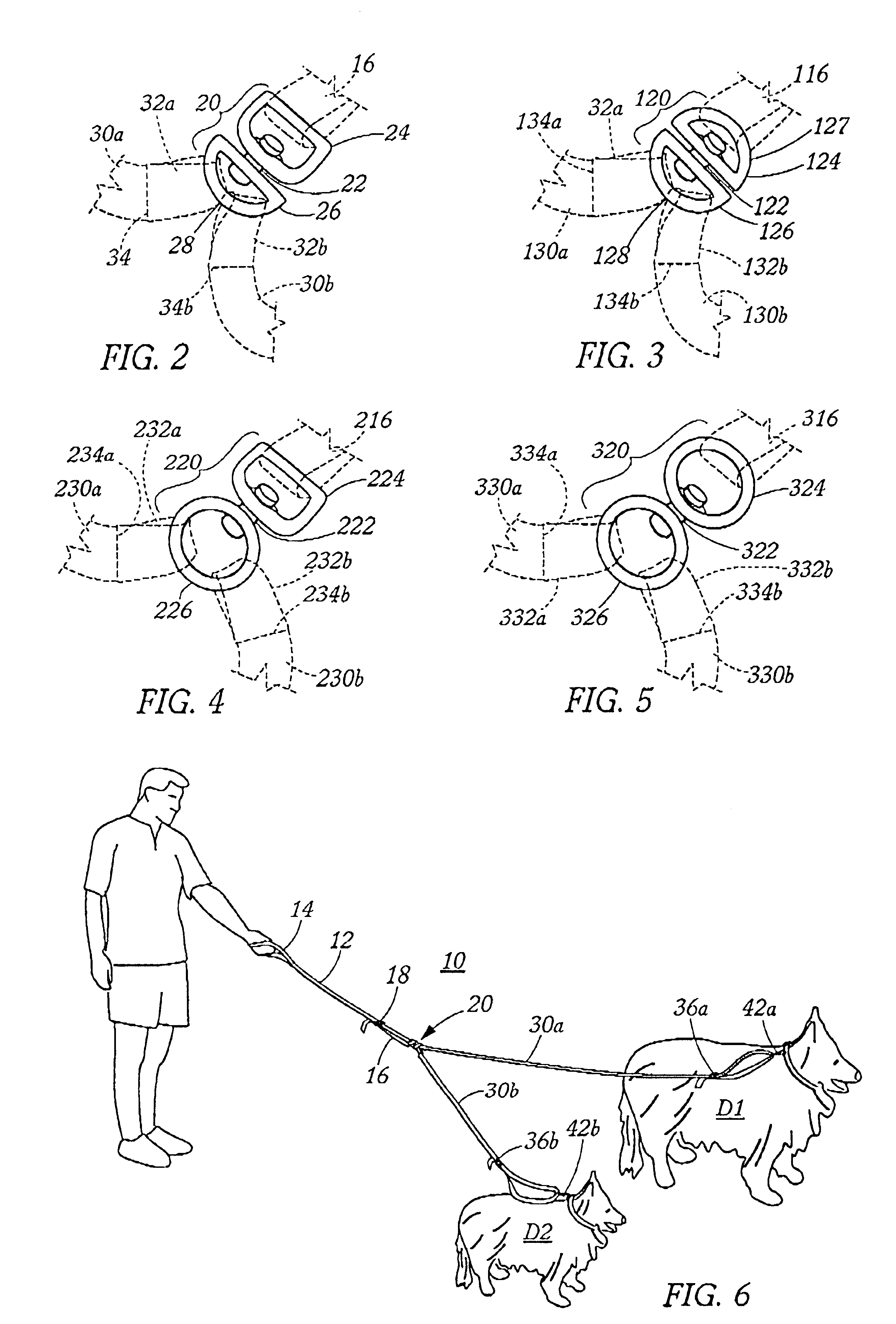

Multiple pet leash

A multiple pet leash includes an elongated handle portion having a loop at one end and a swivel at another end, which engages at least two pet tethers. Each of the tethers includes a swiveled, snap hook members located at the distal end for attaching the tether to a dog collar. The proximate end of each tether is permanently but slidably attached to a"D" shaped portion of the swivel, which helps avoid tangling of the tethers due to pets crossing paths. The length of the handle portion is adjustable to allow the handler adjustment of the handle portion The lengths of the pet tethers are adjustable, enabling pets of different sizes to walk around, over or under each other without requiring the handler to constantly disconnect, untangle and reconnect the leashes in order to resume orderly walking.

Owner:DOUBLE DOGGIE LLC

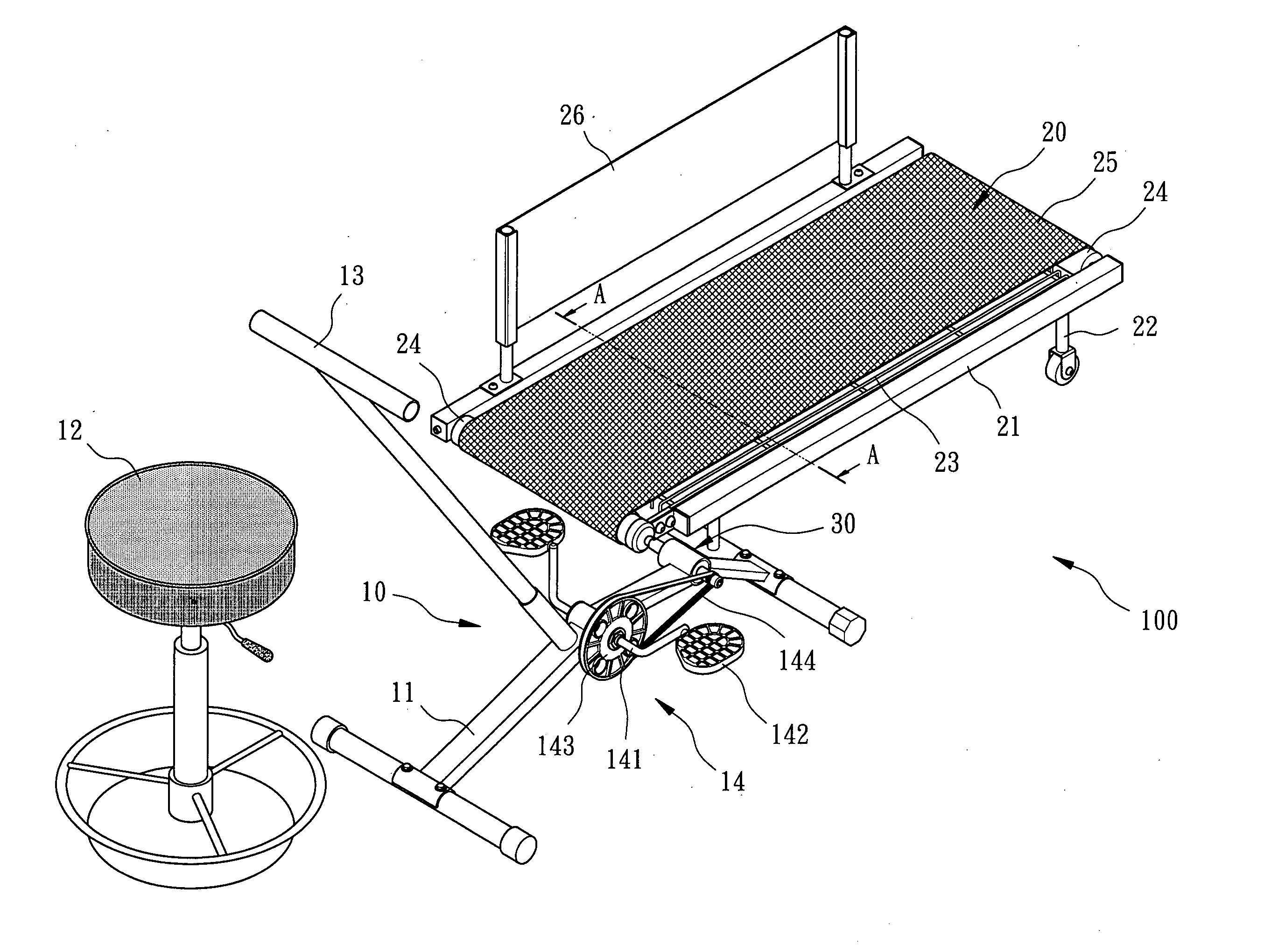

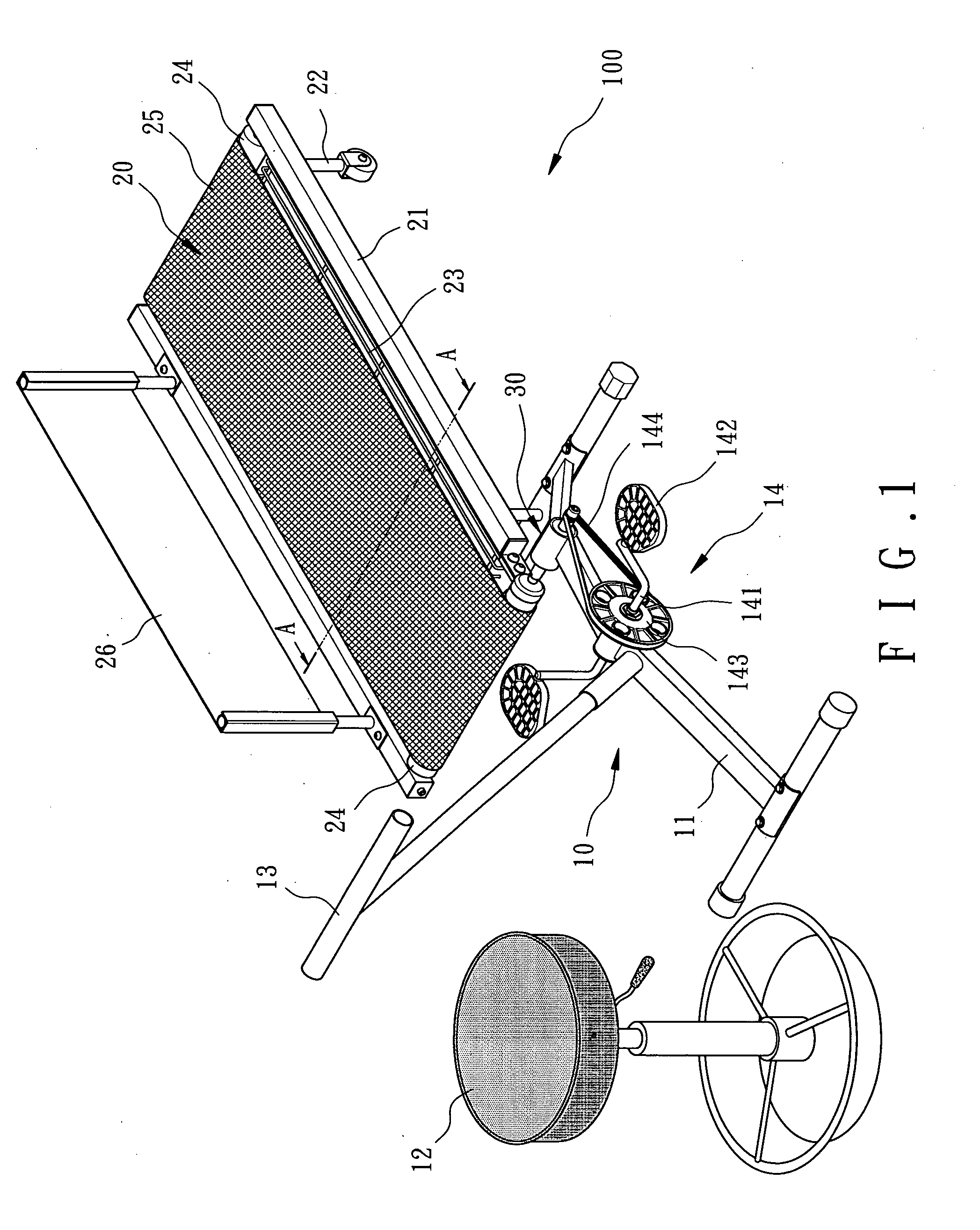

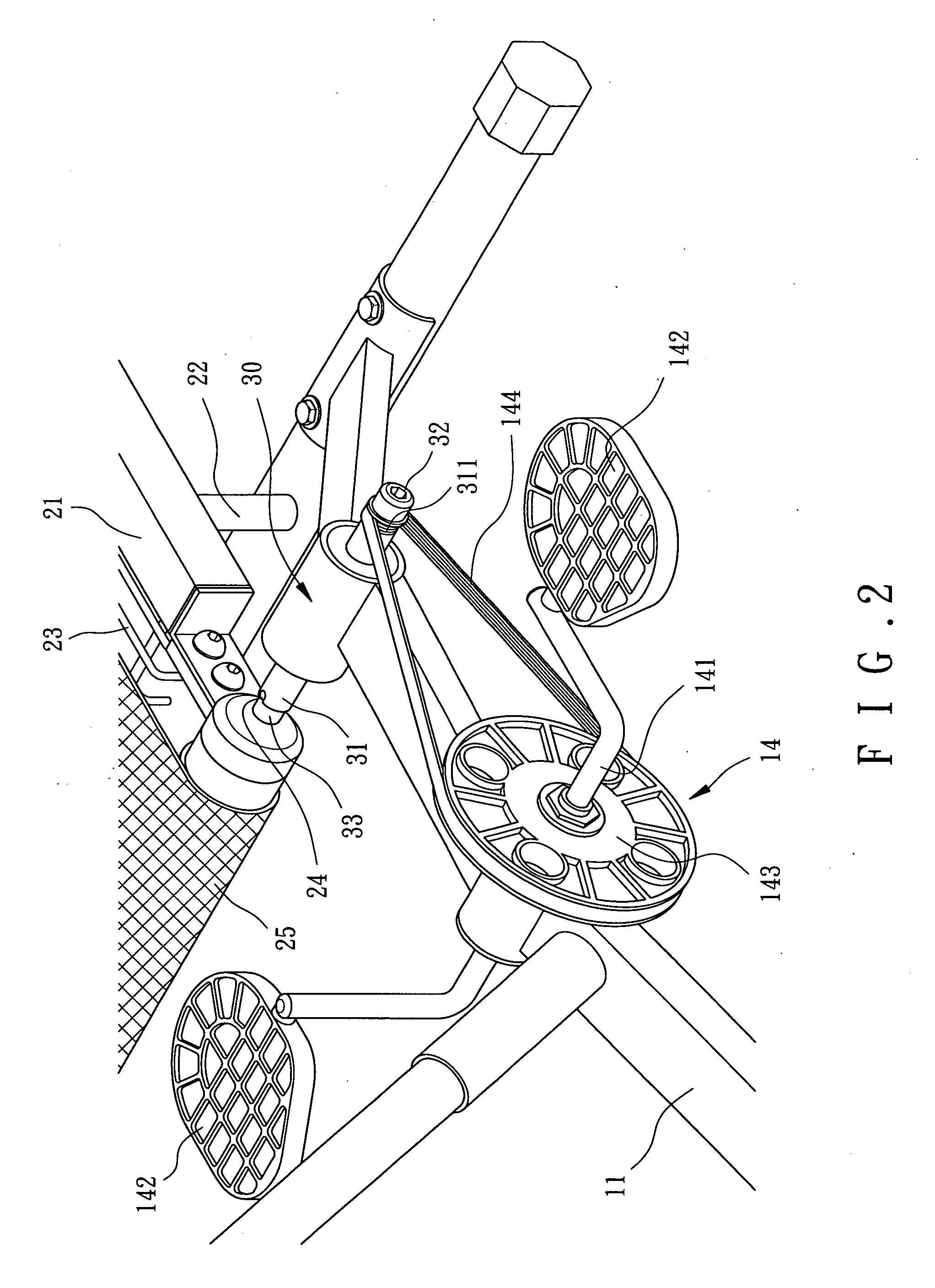

Pet treadmill

A pet treadmill includes a power source for outputting a drive power. An exercise platform is laterally connected to the power source. The exercise platform includes a longitudinally main from stably disposed on a supporting ground, multiple supports secured on a bottom of the main frame to make the main frame being separated from the supporting ground, a support platform mounted within the main frame for enhancing the structure of the main frame, two driven axles transversely and rotatably mounted to two opposite ends of the main frame, and an endless strap coiled the two driven axle and surround the support, wherein a corresponding one of the two driven axle is driven by the manual power source to operate the endless strap, on which the pet imitates a jog action.

Owner:QIANHONG INDAL

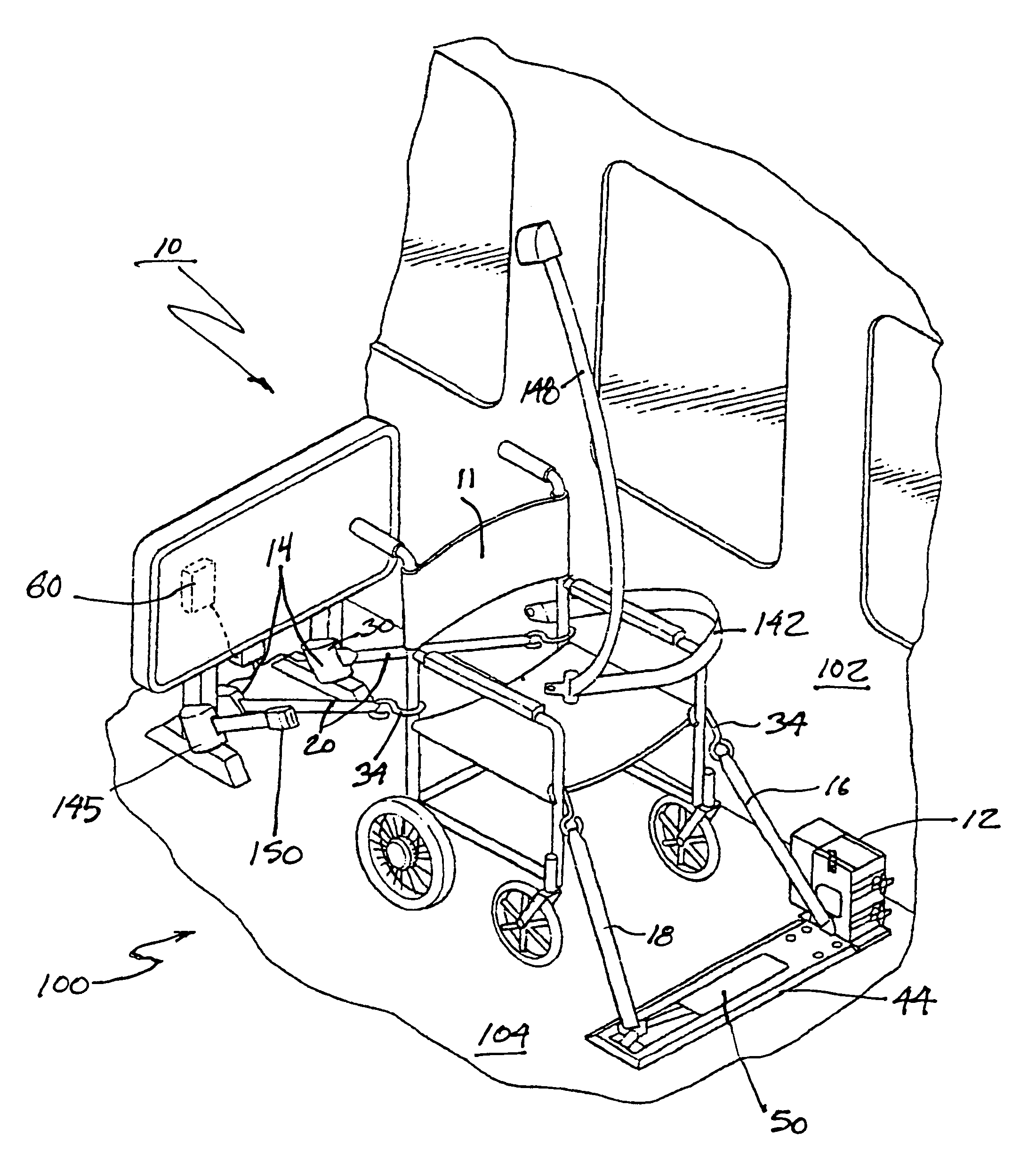

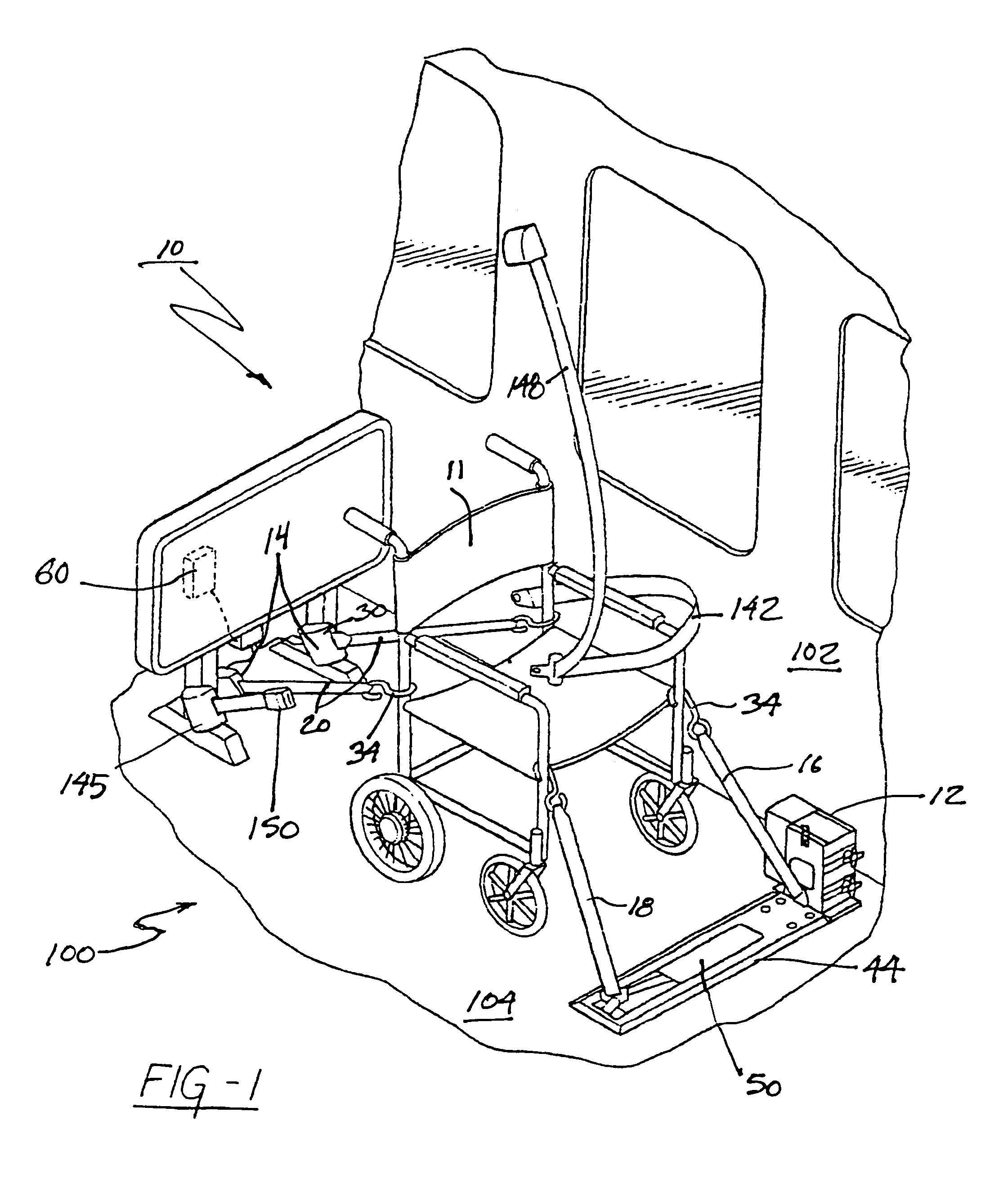

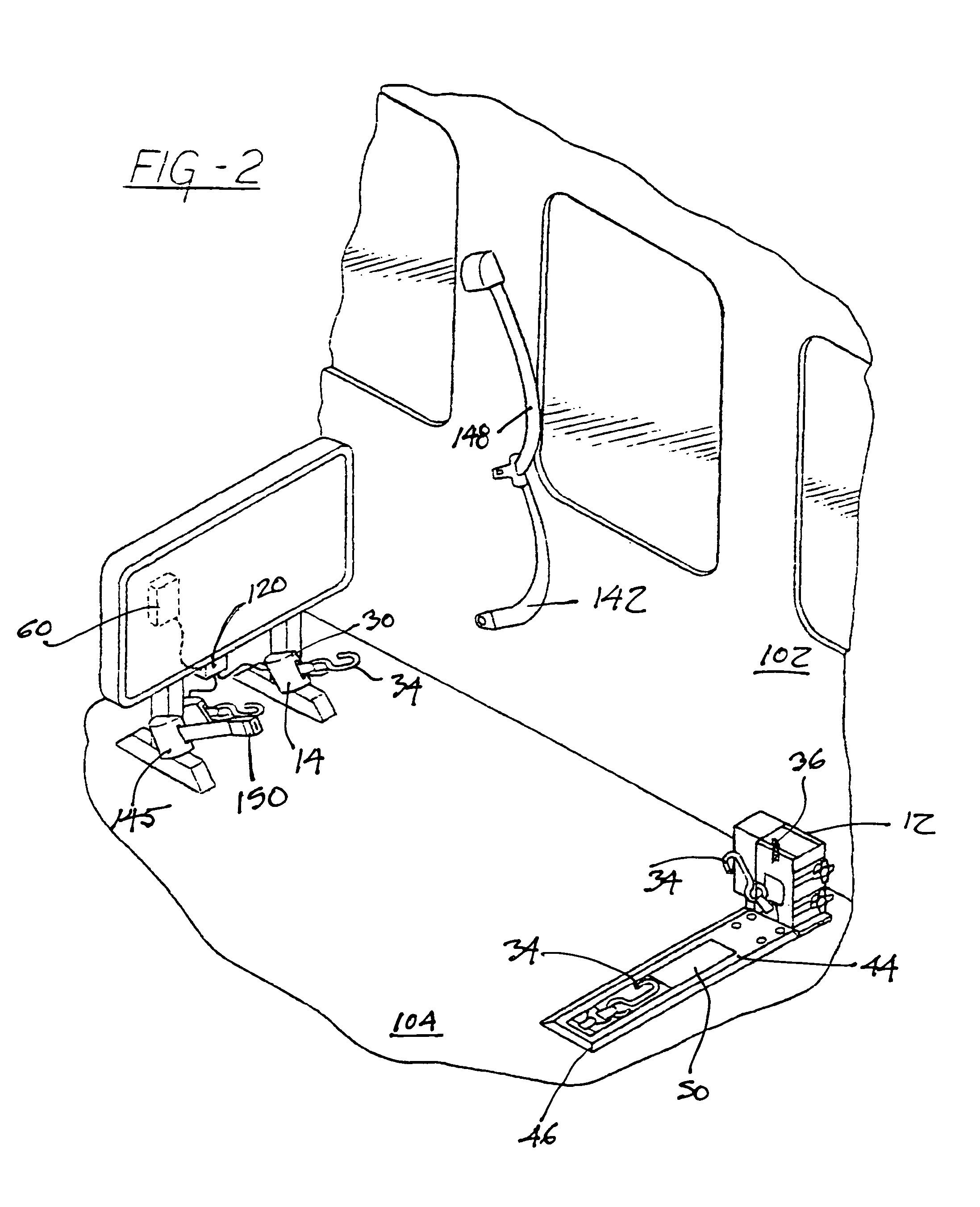

Electro mechanical webbed pre-tensioning wheelchair securement system

InactiveUS7040847B1Readily available for operationReadily moved awayItem transportation vehiclesWagons/vansWheelchairEmbedded system

The invention is a device for securing a wheelchair to a vehicle. The invention incorporates a pair of belts disposed near a wheelchair station in a vehicle, the belts being remotely operable between tension and release positions. When not in use, the belts are stowed in compartments beside and underneath the floor of the vehicle to eliminate potential obstacles. The rear of the wheelchair is secured to the vehicle using remotely lockable anchor elements which are also retractable when the wheelchair station is not in use.

Owner:SURE LOK INT

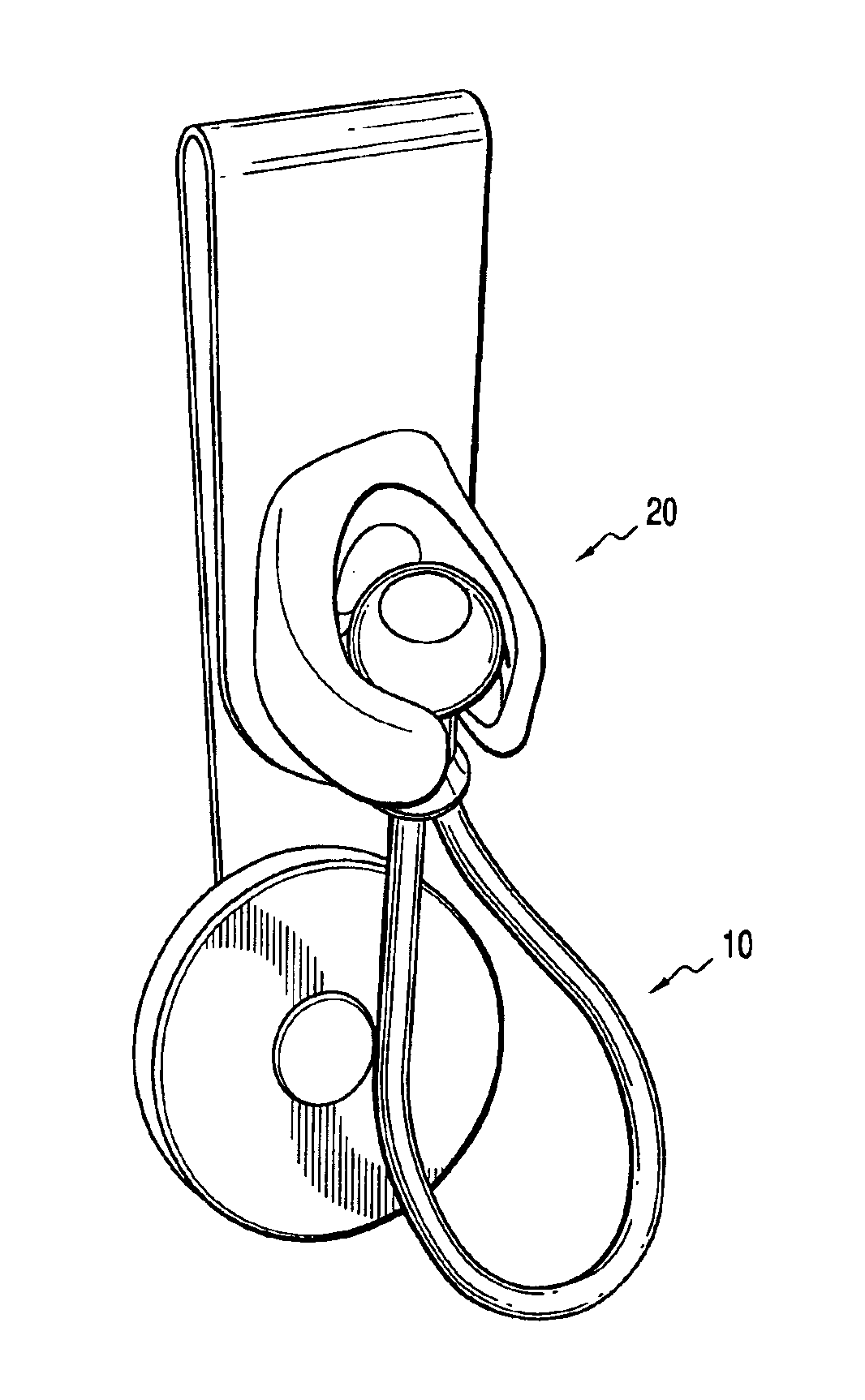

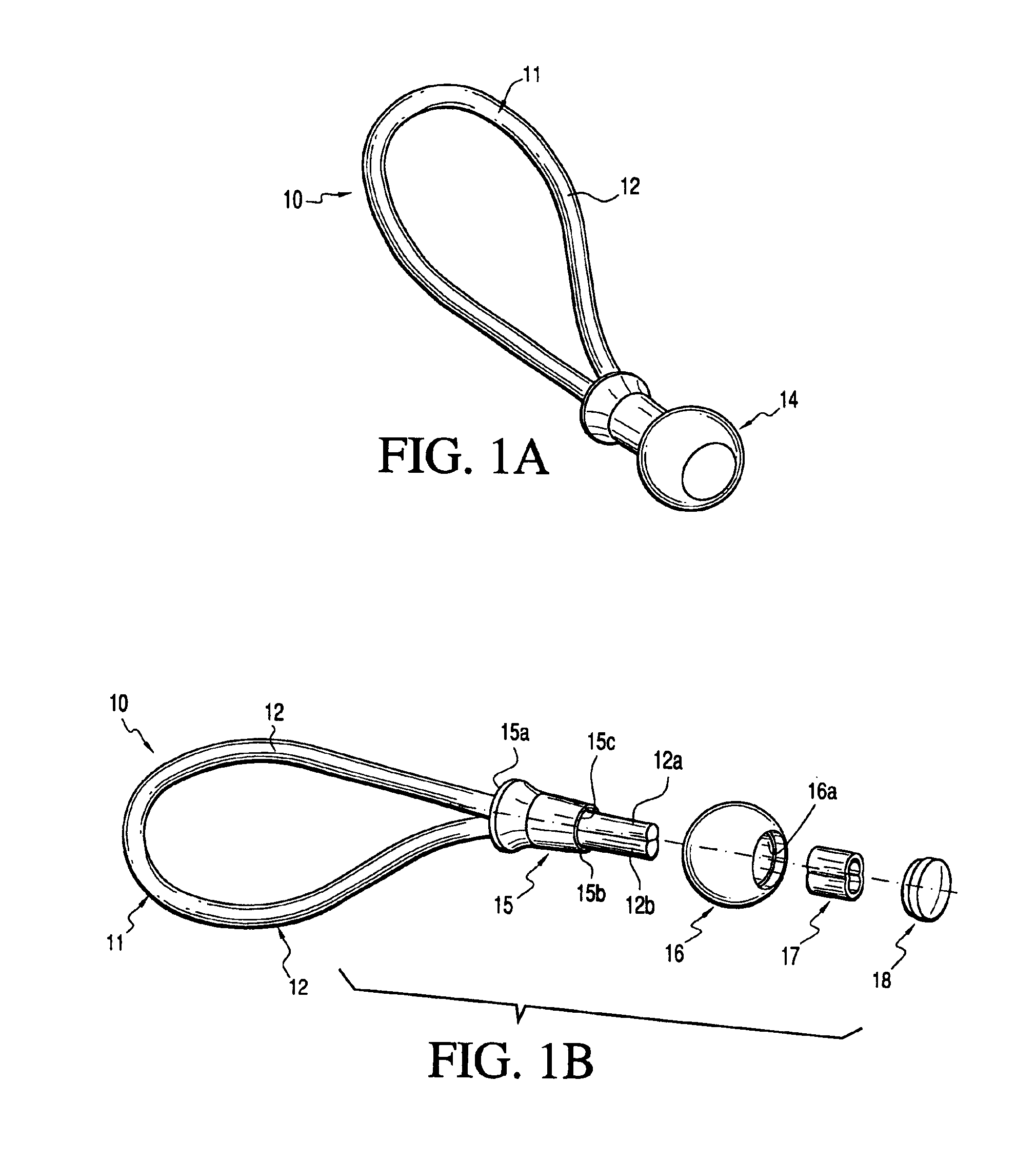

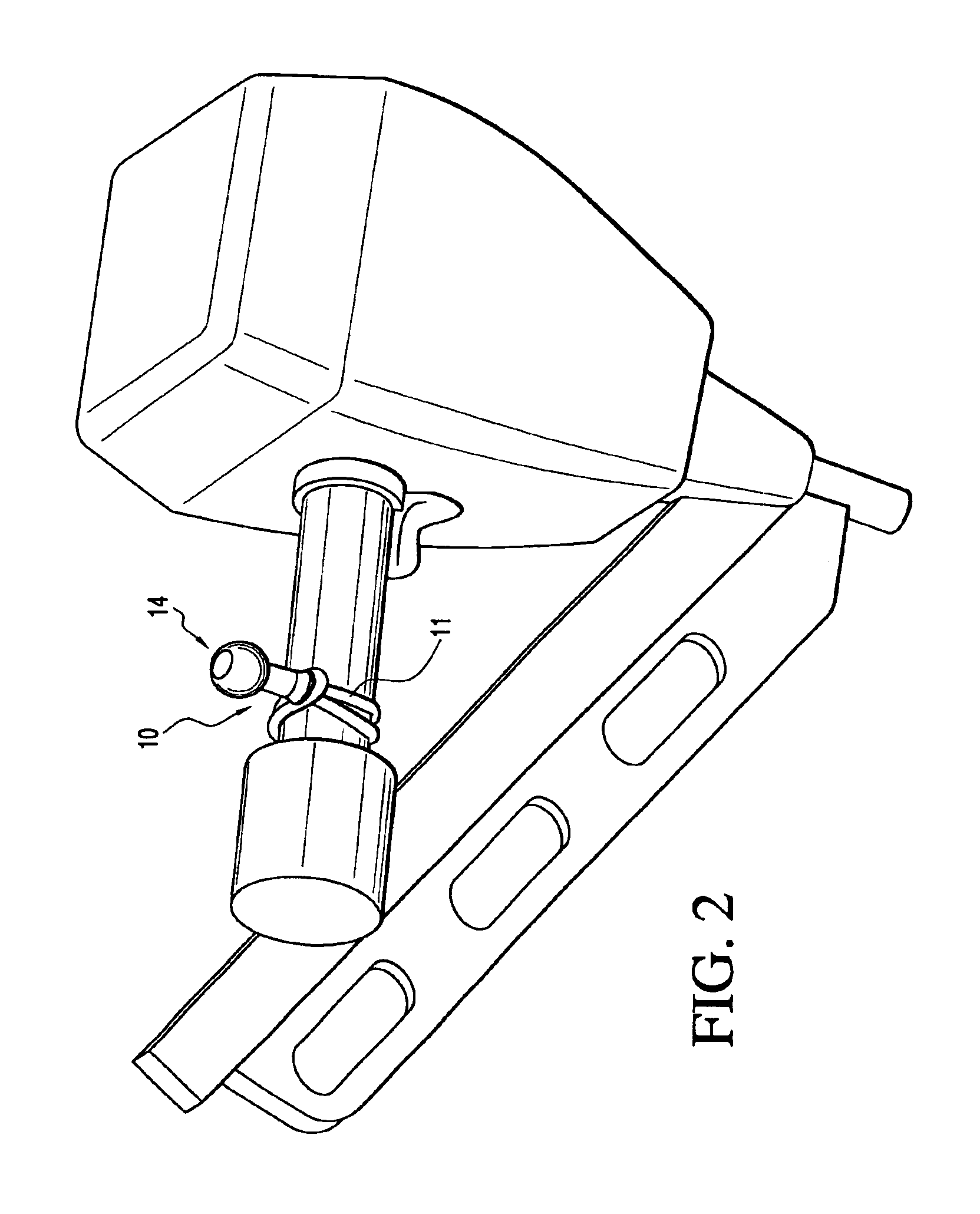

Universal tool holder

ActiveUS6880794B1Removably attachEasily and quickly introduced into retaining receiverSnap fastenersTravelling carriersDrillWall mount

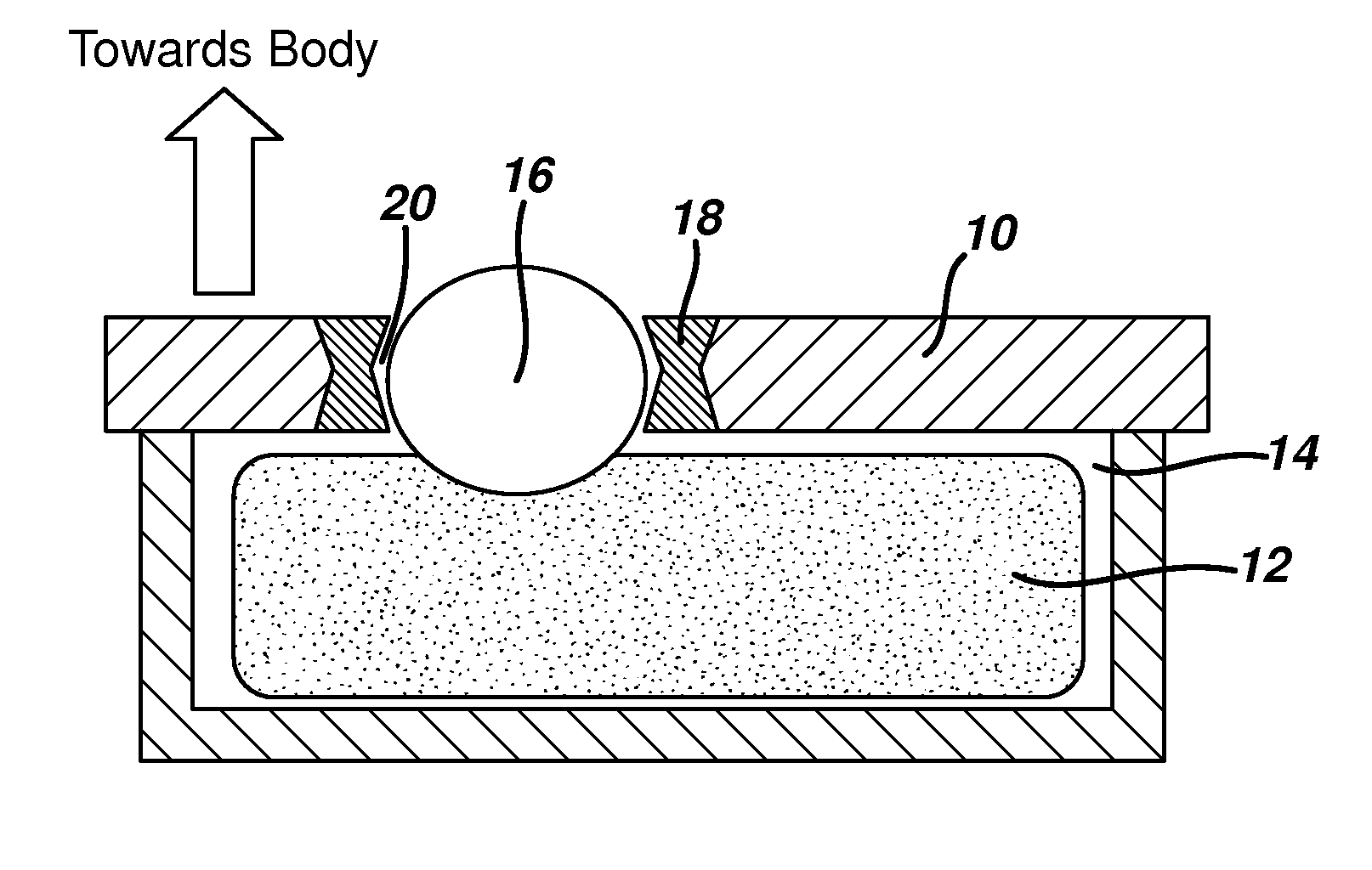

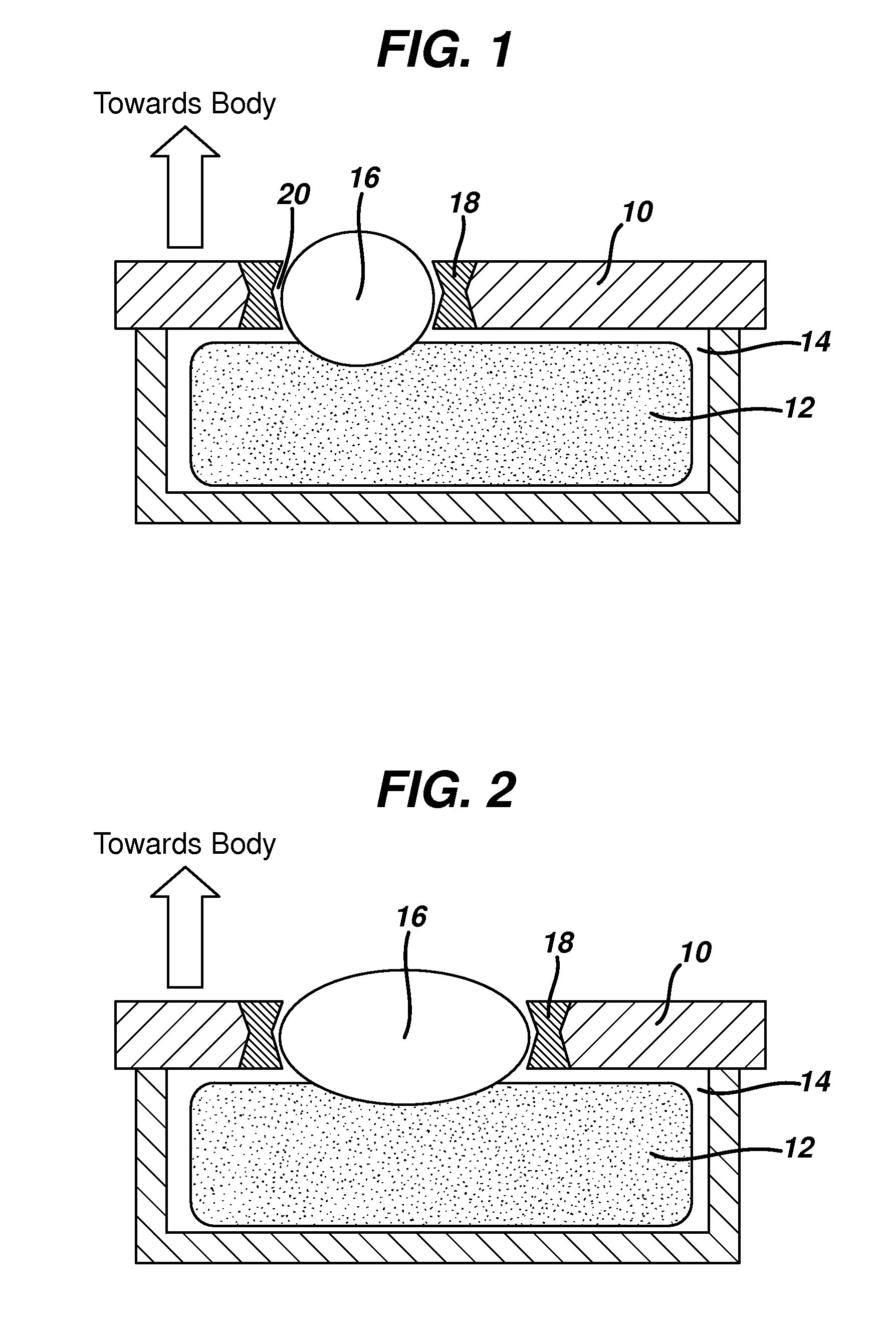

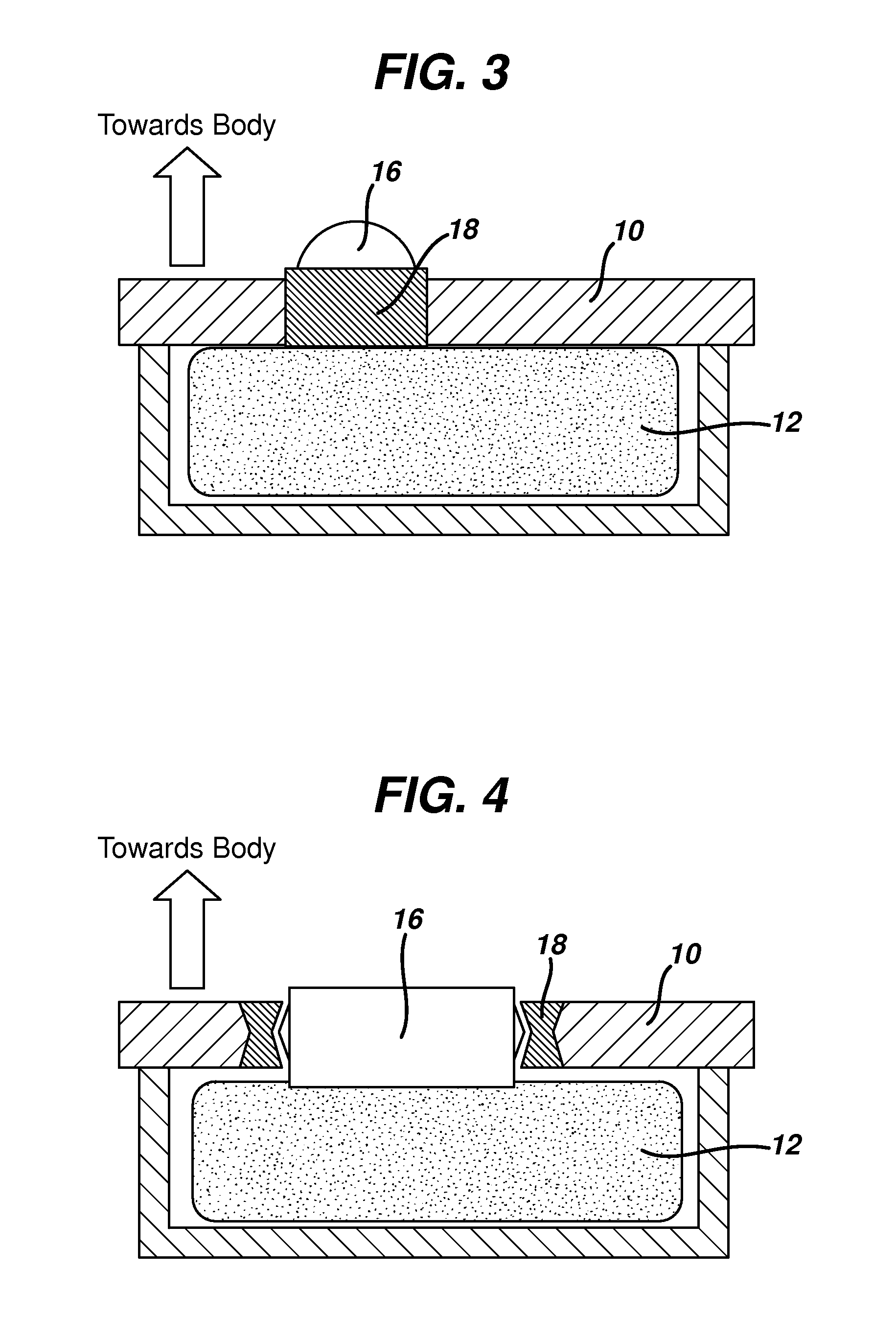

A universal tool holder for carrying a tool or other article, for example, a cordless drill, nail gun, hammer or shovel is provided comprising a stretchable cord that is formed into a looped end and adapted to be wrapped about the handle of a tool in such a manner that it tightly engages the tool, and a second end having a retainable object, such as a ball, that is configured to be safely and securely held within a retaining receiver. The retaining receiver is in the form of a socket-type receiver configured to correspond to the geometrical shape of the retainable object such it can removably secure the retainable object. The socket-shaped retaining receiver can be incorporated into a variety of articles usefull in carrying and storing tools, including a belt clip, a wall mounting implement or a ladder mounting implement. By integrating the retaining receiver into such a variety of articles, any tool carried by the universal tool holder can be removably secured to the retaining receiver, thereby enabling a user to suspend the tool from a belt clip, ladder or wall.

Owner:KAHN PETER P

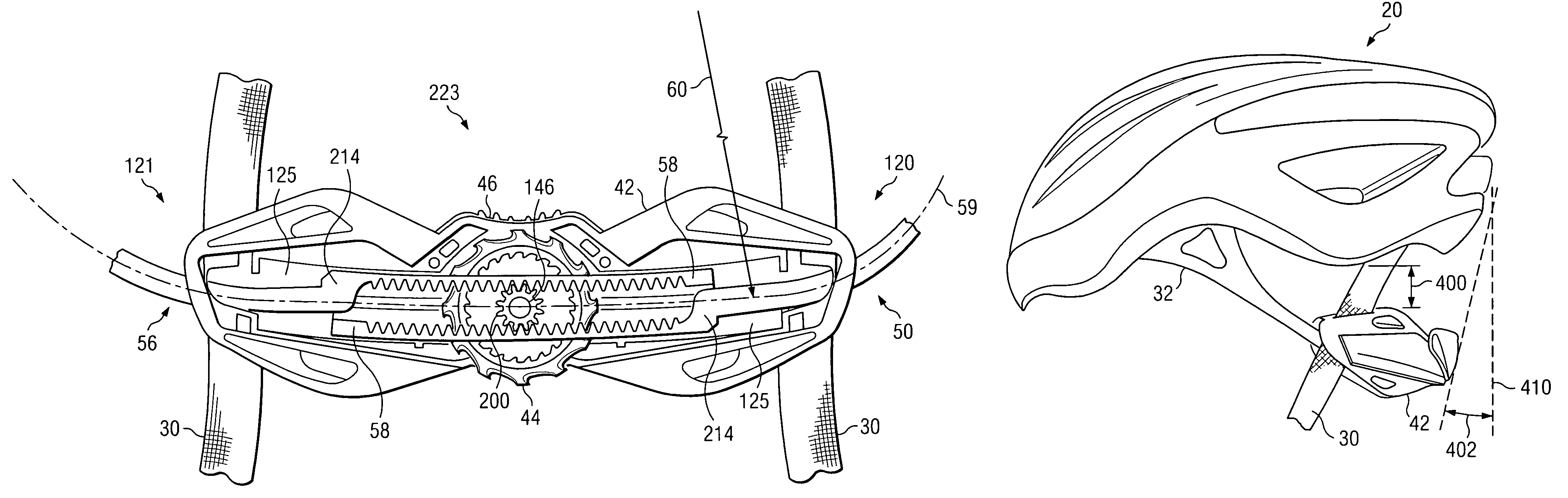

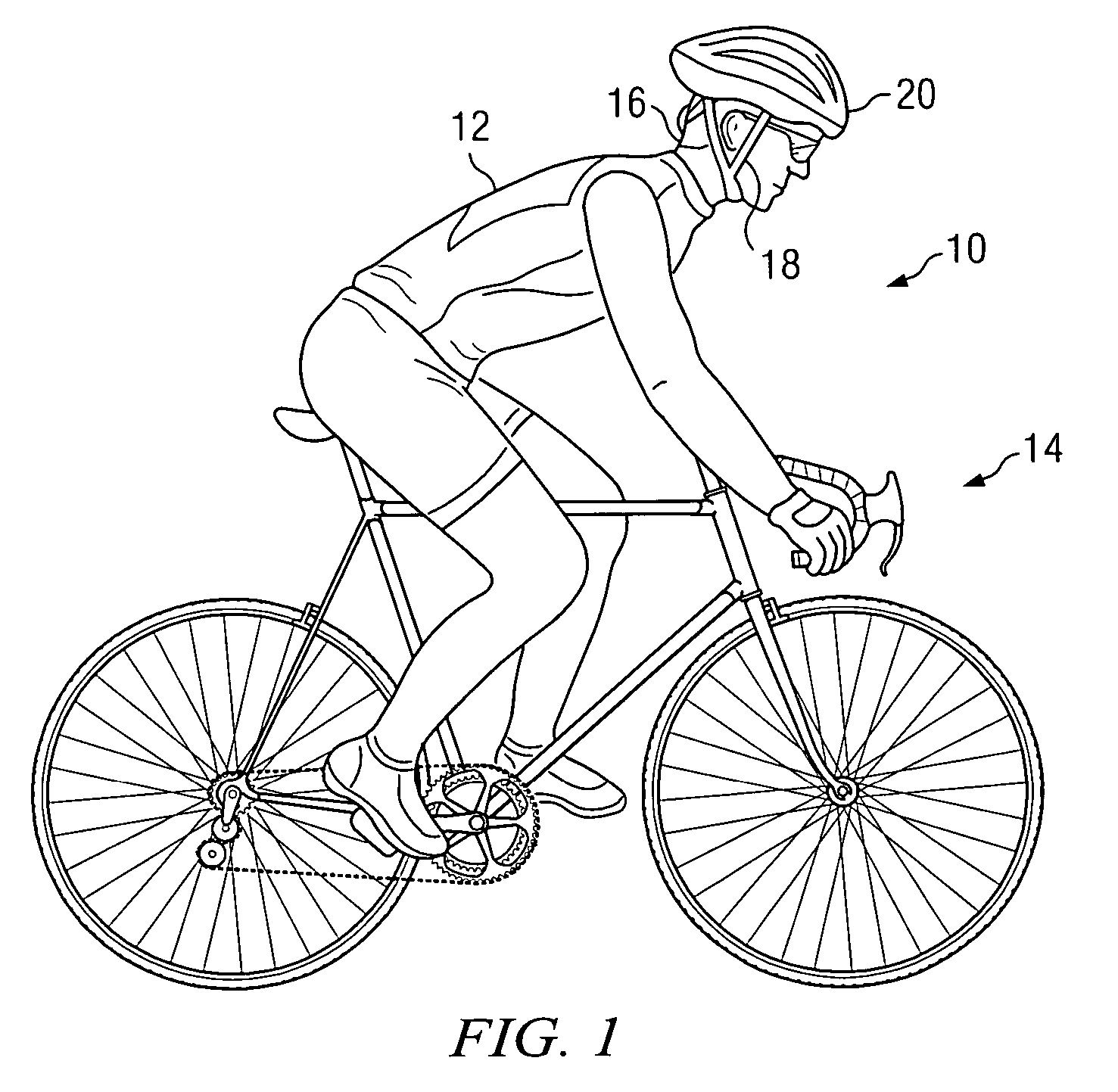

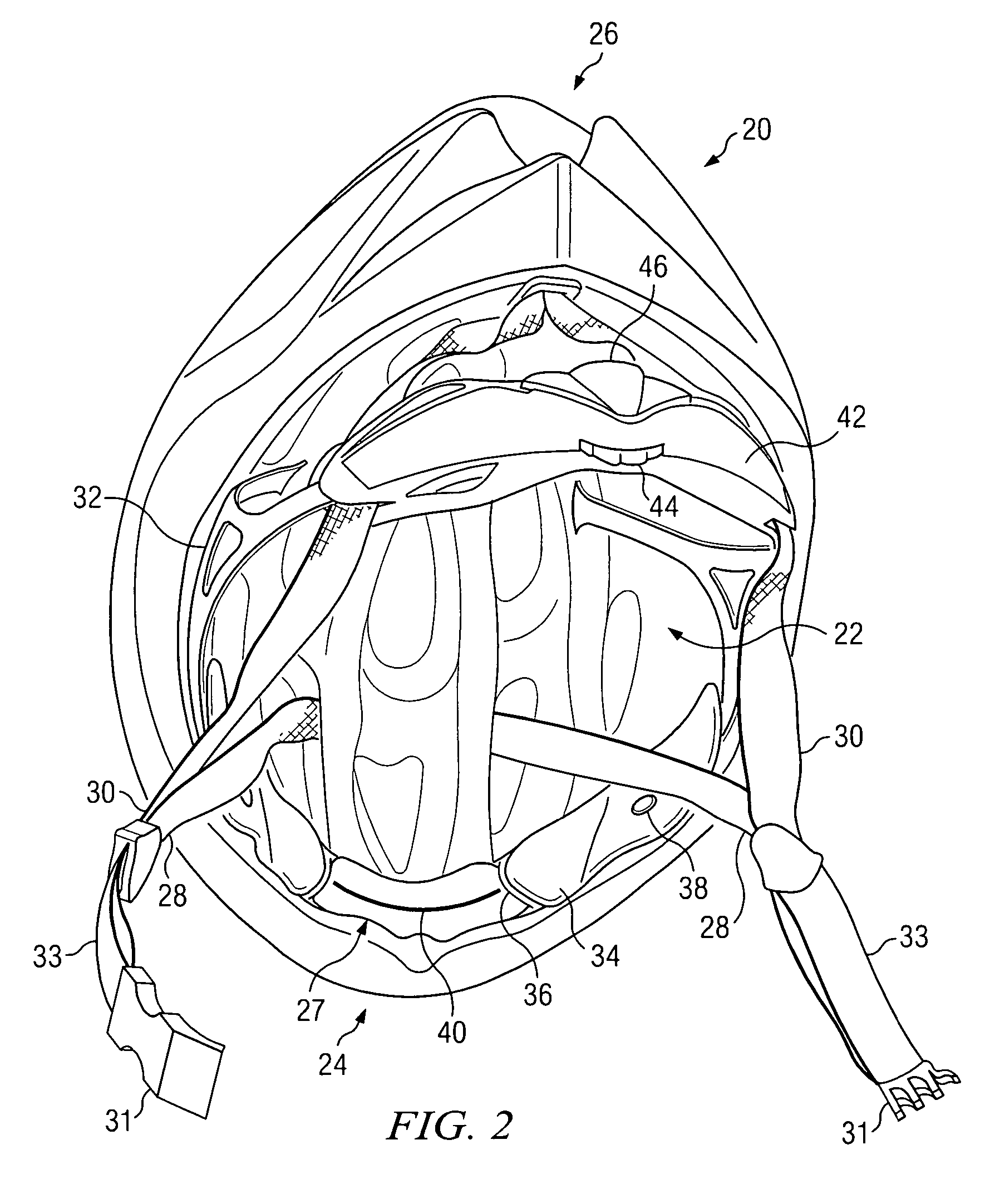

Head gear fitting system

ActiveUS7222374B2Quickly and conveniently tightening and looseningImprove comfortSnap fastenersClothes buttonsGear wheelEngineering

According to one embodiment of the invention, a fitting system for a helmet is provided. The fitting system includes a belt having supported racks coupled to a belt adjustment device. The belt adjustment device is operable to allow a user to tighten the belt, and release the belt at a single touch of a release actuator. The belt adjustment device and the racks are configured to hug the occiput of a user when the helmet is properly worn. The belt adjustment device is also operable to hold the rear straps of the helmet apart but is not attached to the helmet. The belt defines a collapsible button for securing a pad. The pad defines a substantially lateral compressed strip that is operable to urge the pad against the belt. The belt adjustment device and the belt are configured to allow rear straps of the helmet to approximately directly approach the chin of the user.

Owner:BELL SPORTS INC

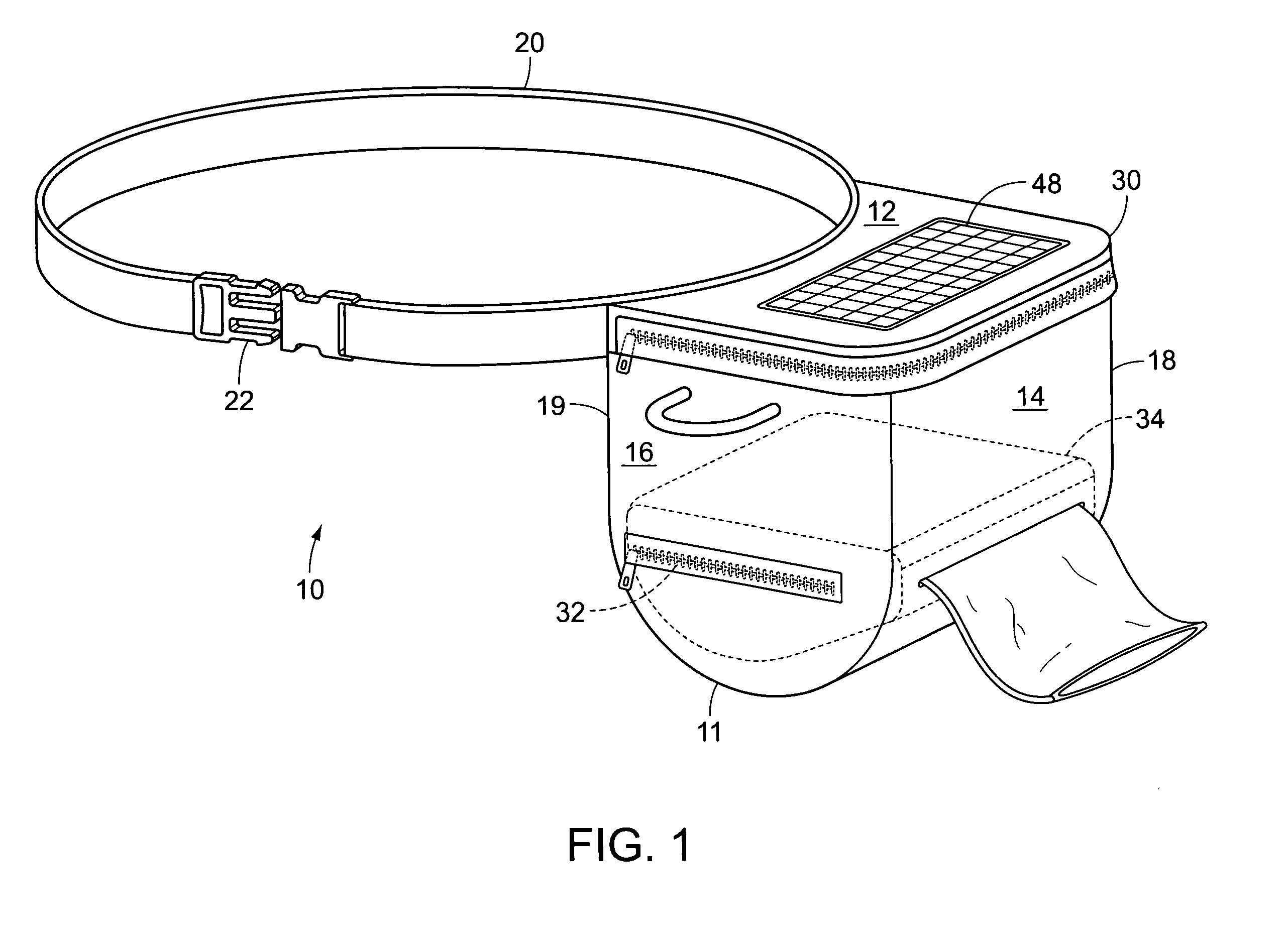

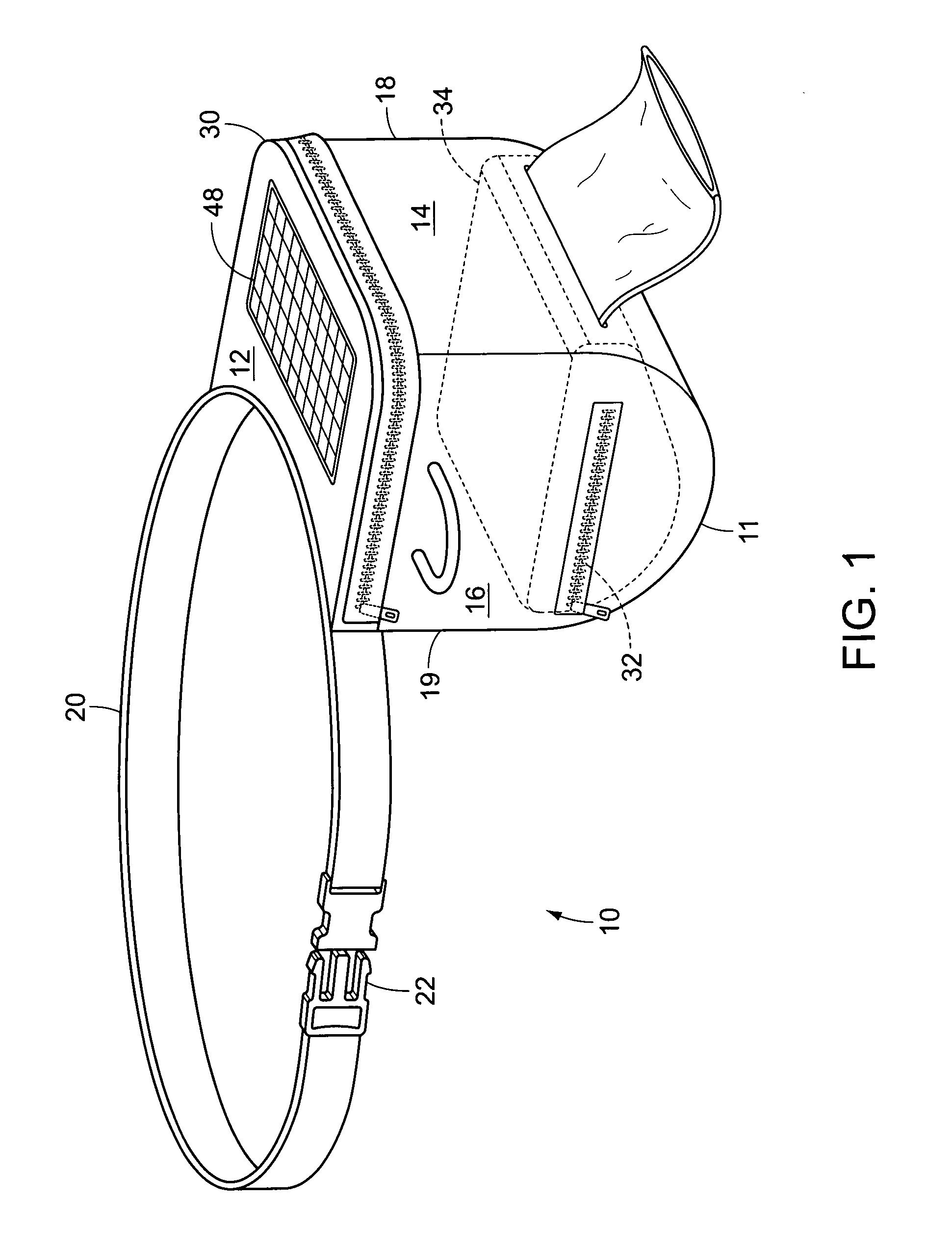

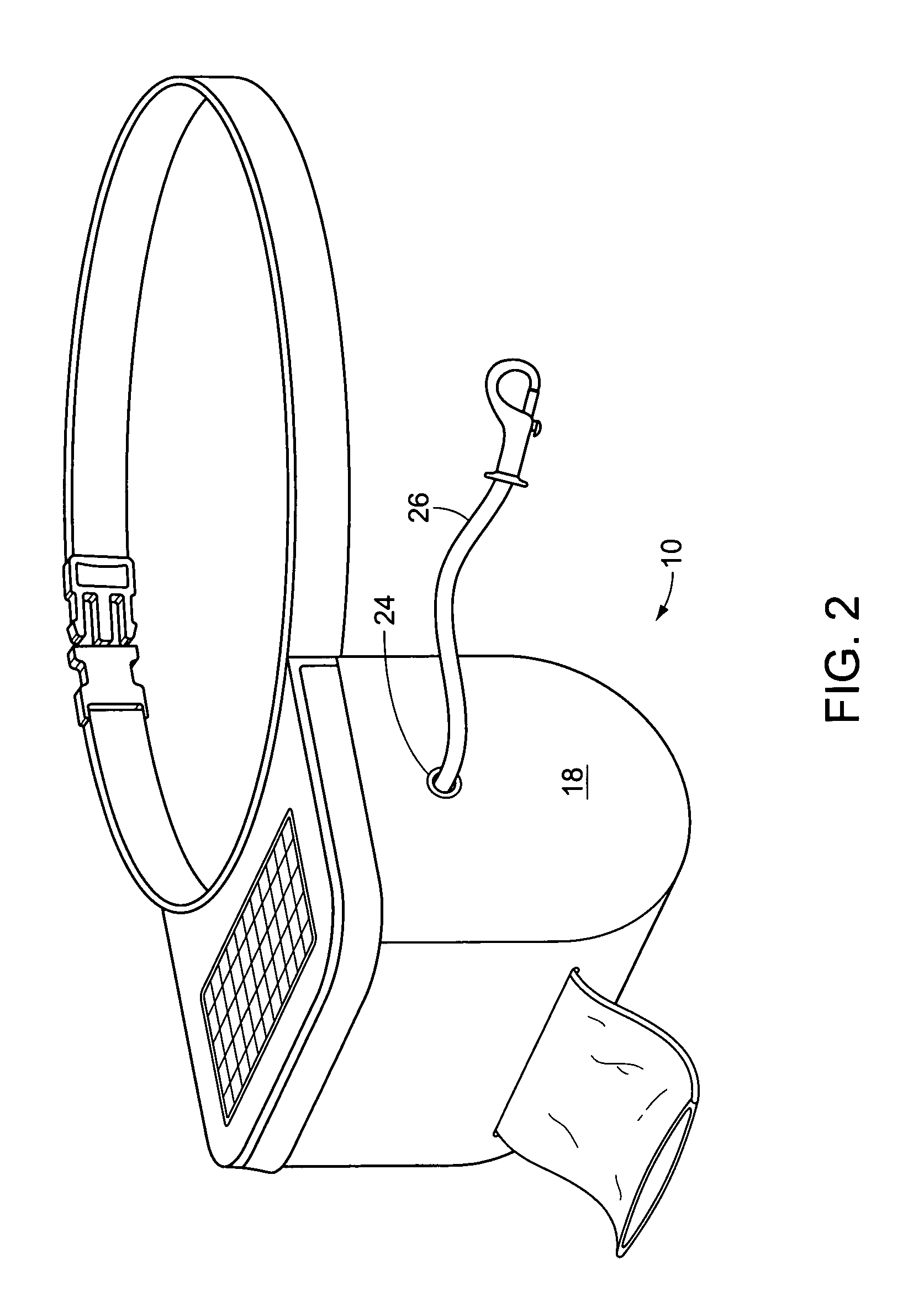

Organizer for taking dogs for walks

InactiveUS7073462B1Comfortably and securely worn by a userQuickly unzipOther apparatusTaming and training devicesPlastic bagLeather belt

An organizer for assisting a user when taking a dog for a walk. The organizer has an adjustable belt with an interlocking buckle and an attached pouch. The pouch has a top lid and front, left and right surfaces. The lid closes by means of a top zipper. A hook for tethering the dog is permanently affixed to the left surface. The user can insert a box of plastic bags in a bag compartment inside a side zipper in the left surface and dispense the bags through an elongated slot in the front surface to collect dog waste. Also, the pouch has separate compartments for a leash and other accessories. A solar energy panel is located on the lid and is in communication with a light-emitting diode. The diode can either be activated by opening the lid or via a switch mounted onto the right surface.

Owner:LAYMAN JEREMY

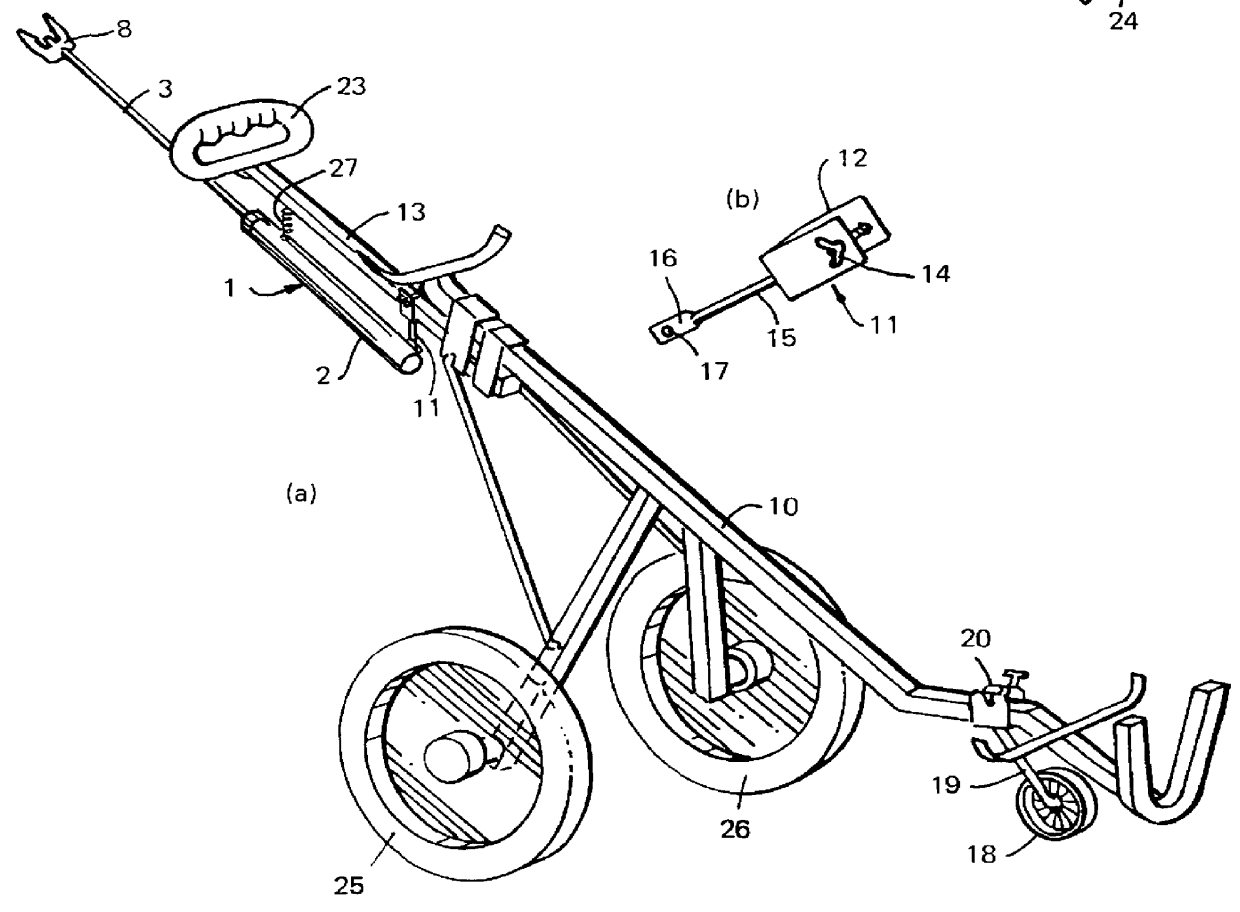

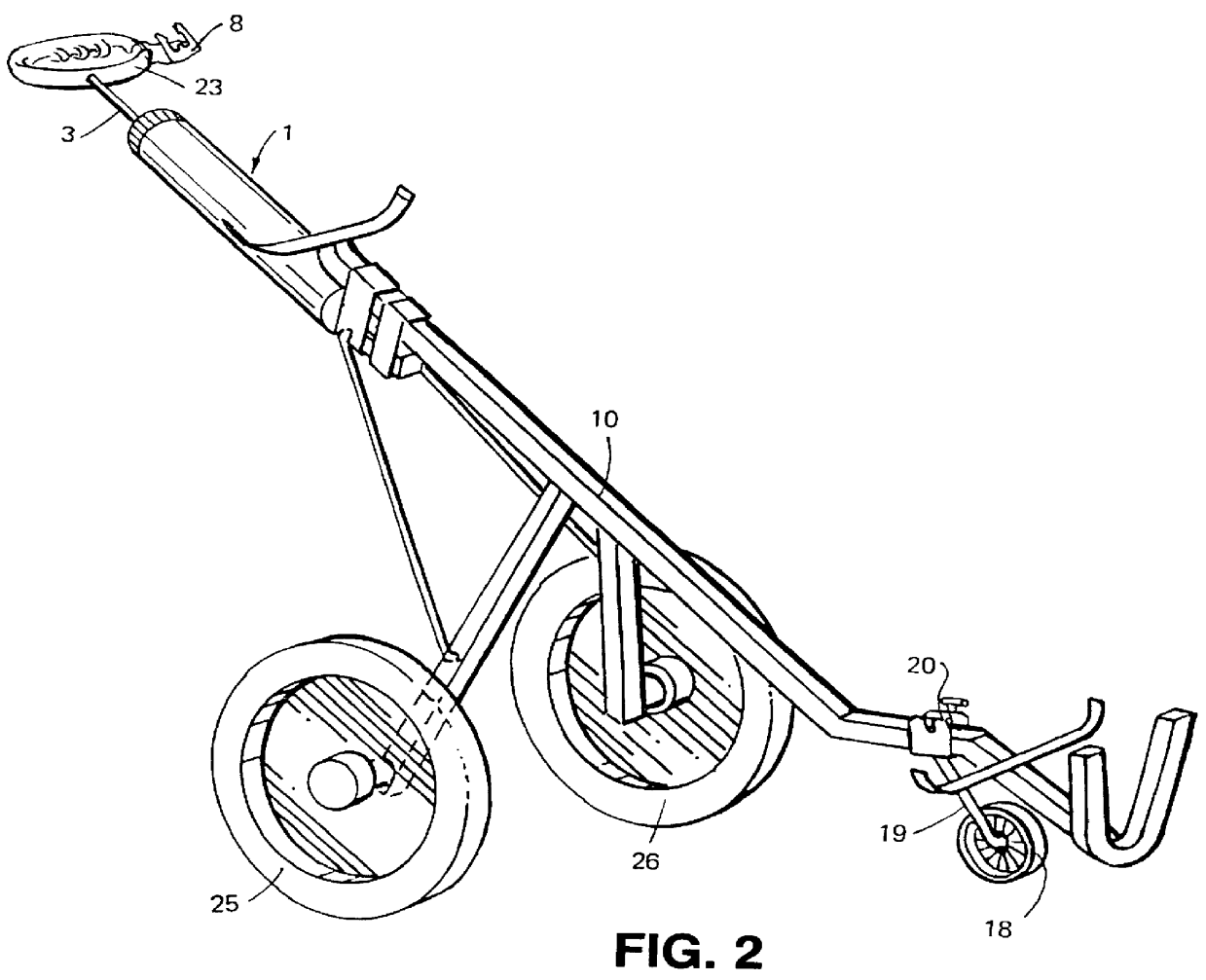

Towing device

InactiveUS6131917AReduce effortReduce necessityCarriage/perambulator with single axisUnderstructuresEngineeringHydraulic fluid

The invention relates to a towing device for a golf trolley comprising longitudinal resilient linkage means. The linkage comprises a spring, a damper for the resilient portion, the remainder of the linkage being rigid, and means at one end of the linkage for pivotal attachment of the linkage to the bag-carrying part of the trolley. The towing device may be incorporated in the handle of a trolley or may be an accessory attachable to the trolley. The damper may comprise a piston-and-cylinder type damper which may contain air or other gas or oil or other hydraulic fluid. Embodiments using telescopic cylinders are also described. The extent of pivotal movement of the towing device relative to the bag-carrying part of the trolley is restricted by a flexible link or spring. The device may be attached to a belt or other item of clothing on the trunk of a user, and the trolley may have an auxiliary wheel fitted to the bottom of the bag-carrying part. A mechanism for releasably securing the handle against pivotable or telescopic movement is also described.

Owner:WALSH PAUL

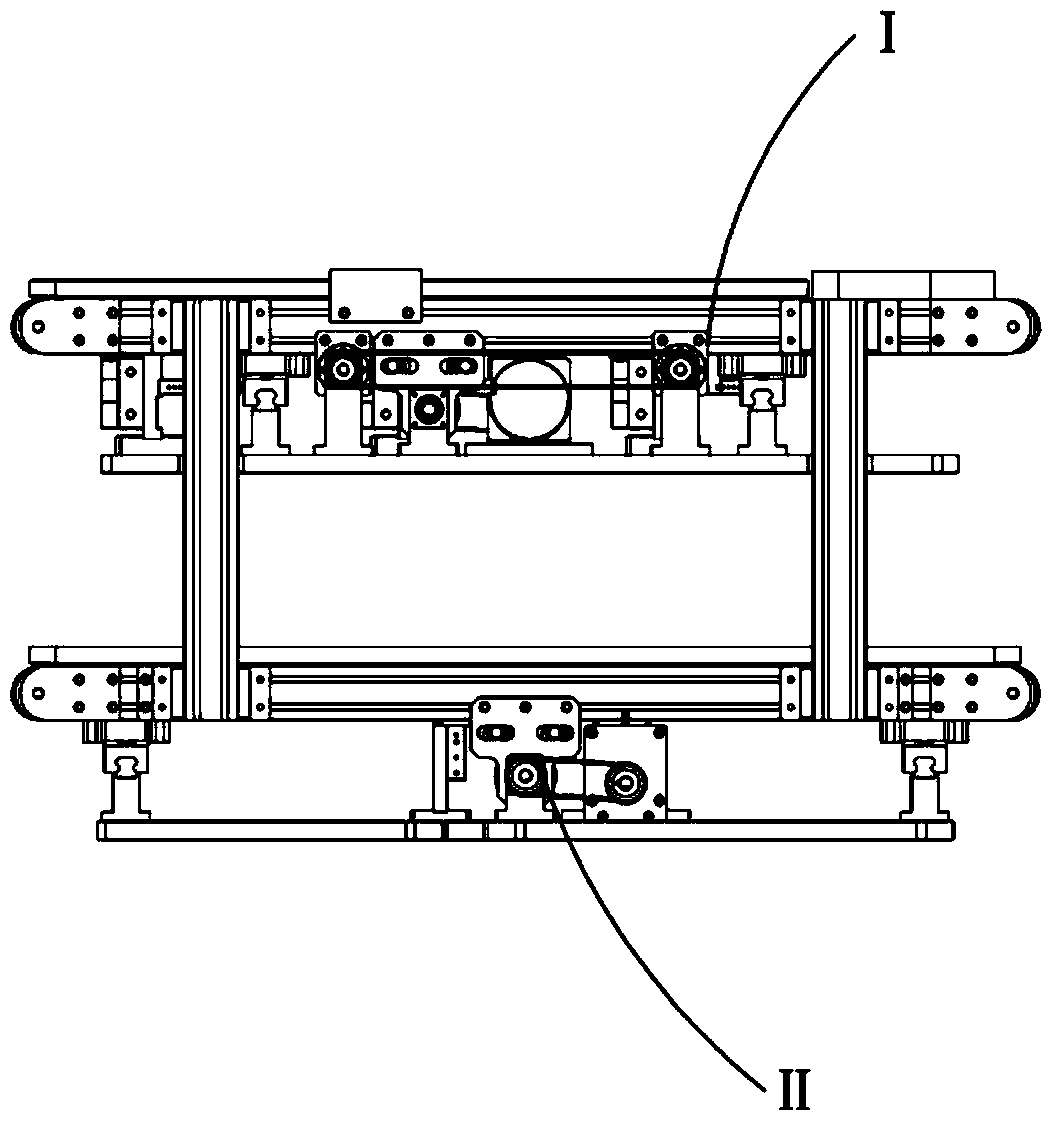

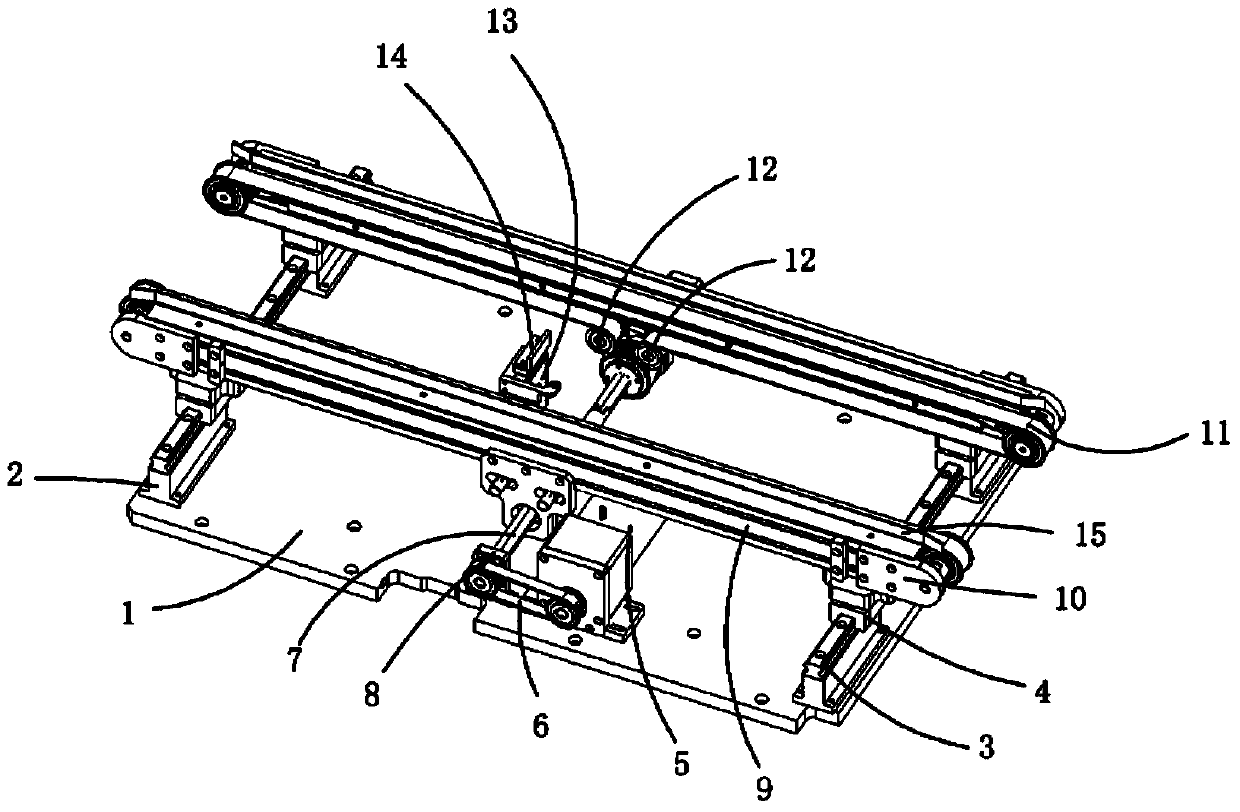

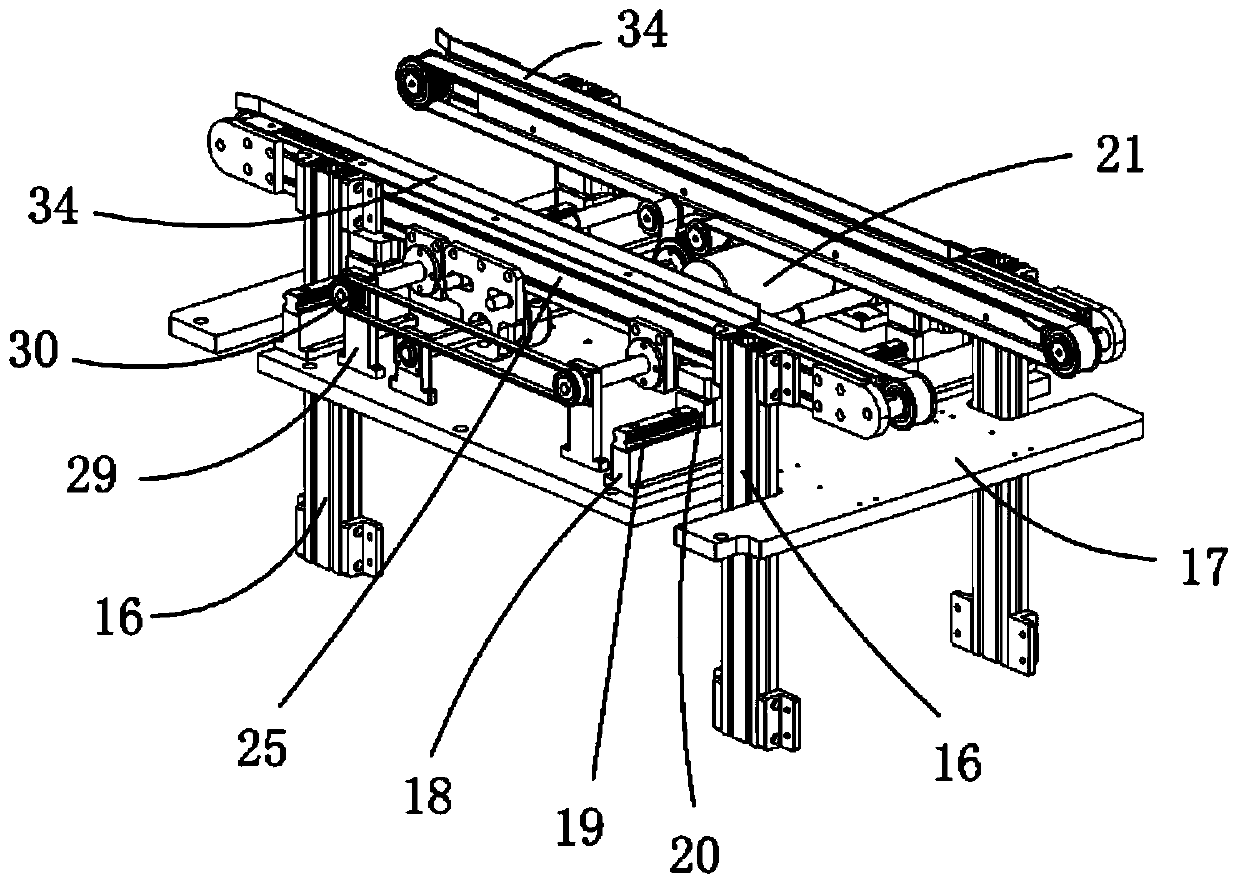

Double-layer assembly line with interval adjustable

ActiveCN103787025AAdjustable distanceGuaranteed uptimeConveyorsConveyor partsTransmission beltAssembly line

The invention relates to a double-layer assembly line with the interval adjustable. An upper layer adjustable assembly line of the double-layer assembly line with the interval adjustable is installed on a lower layer adjustable assembly line. When an adjusting screw rod is rotated, two upper belt mounting plates can move outwards or inwards simultaneously under the action of synchronizing wheels, meanwhile, under the action of four connecting frames, lower belt mounting plates can be driven to move outwards or inwards simultaneously under the action of lower sliders, thus, the distance between upper transmission belt wheels and lower transmission belt wheels can be adjusted simultaneously to adapt to carriers with various widths, three carrier lifting mechanisms and three carrier stopping mechanisms are installed on an upper plate of the upper layer adjustable assembly line, the carriers are jacked and positioned by the carrier lifting mechanisms after being stopped, and then each carrier can act in a corresponding station and flow to the next station after the action is completed; lifting air cylinders are installed on a lower plate of the lower layer adjustable assembly line, and stop dogs are connected to the lifting air cylinders. The double-layer assembly line with the interval adjustable is used for transporting product carriers, the carriers can stop in any position of the assembly line for machining, and thus the double-layer assembly line with the interval adjustable can adapt to different products.

Owner:BOZHON PRECISION IND TECH CO LTD

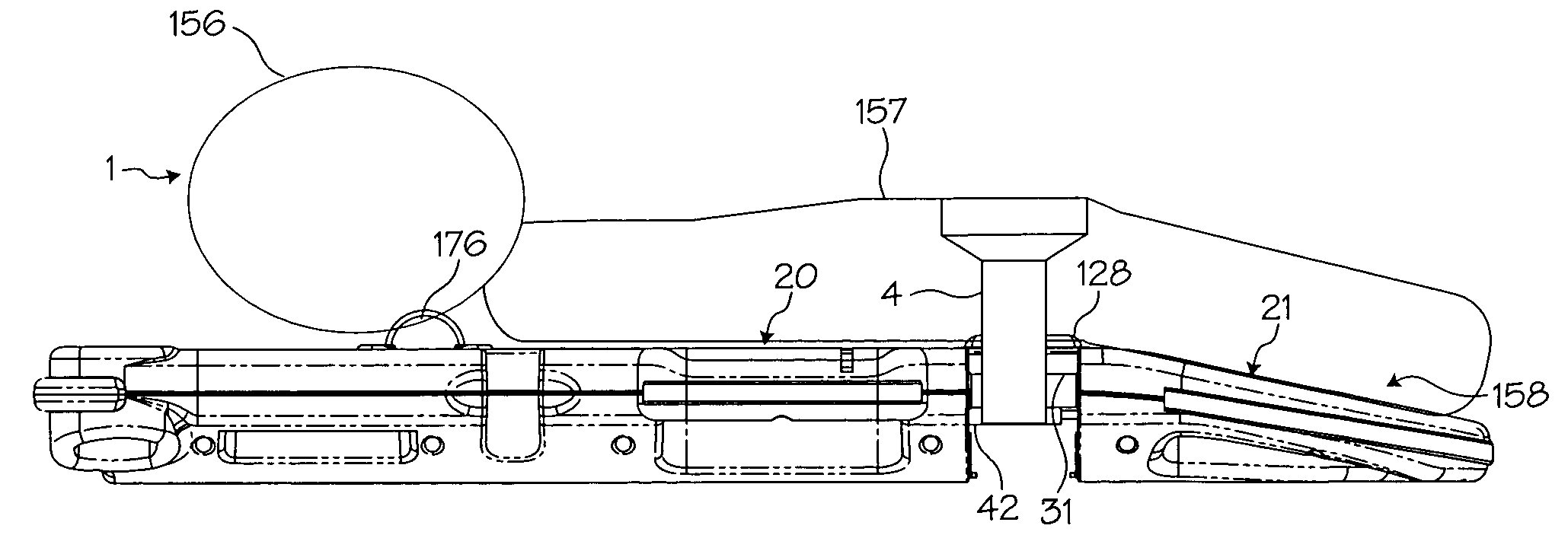

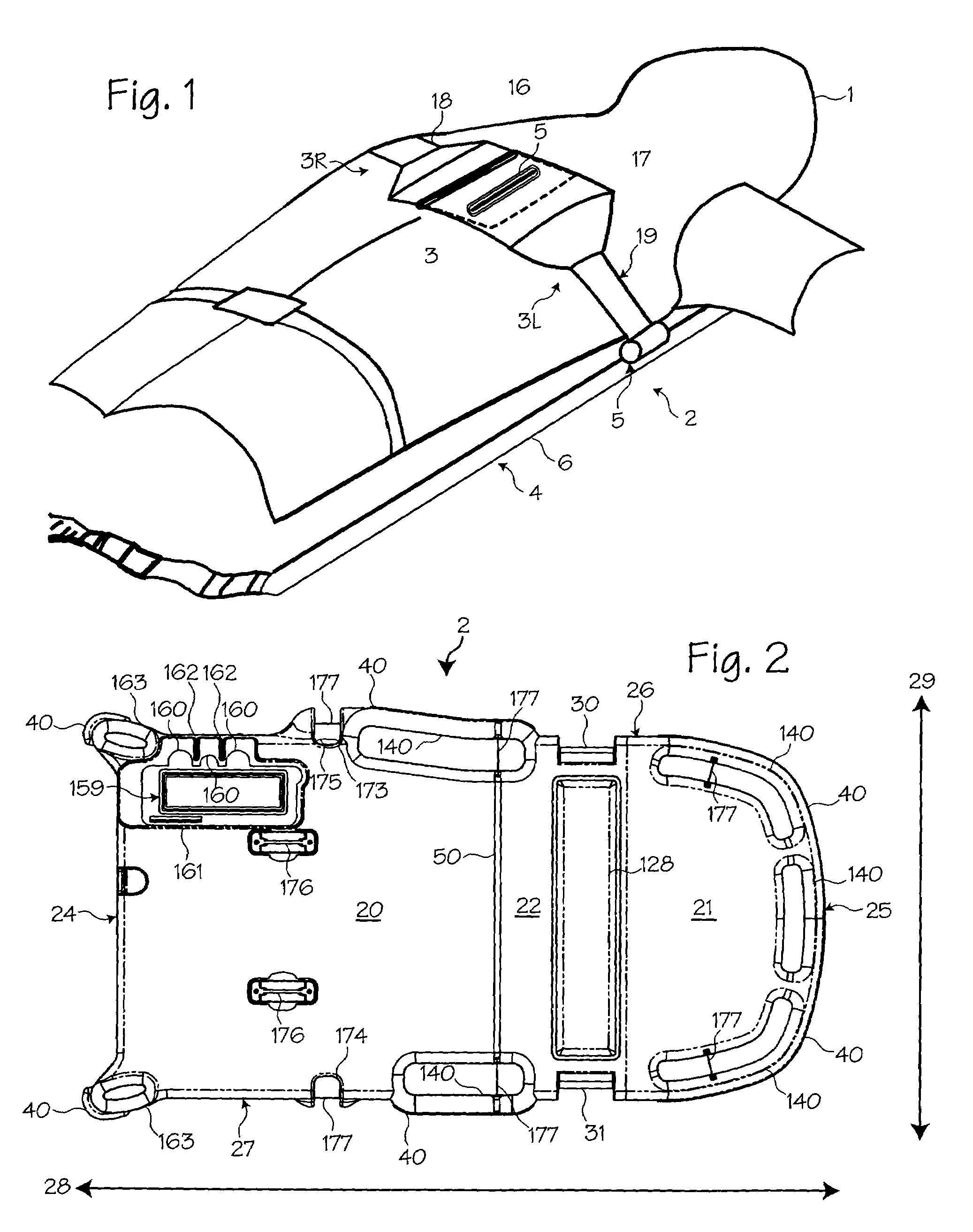

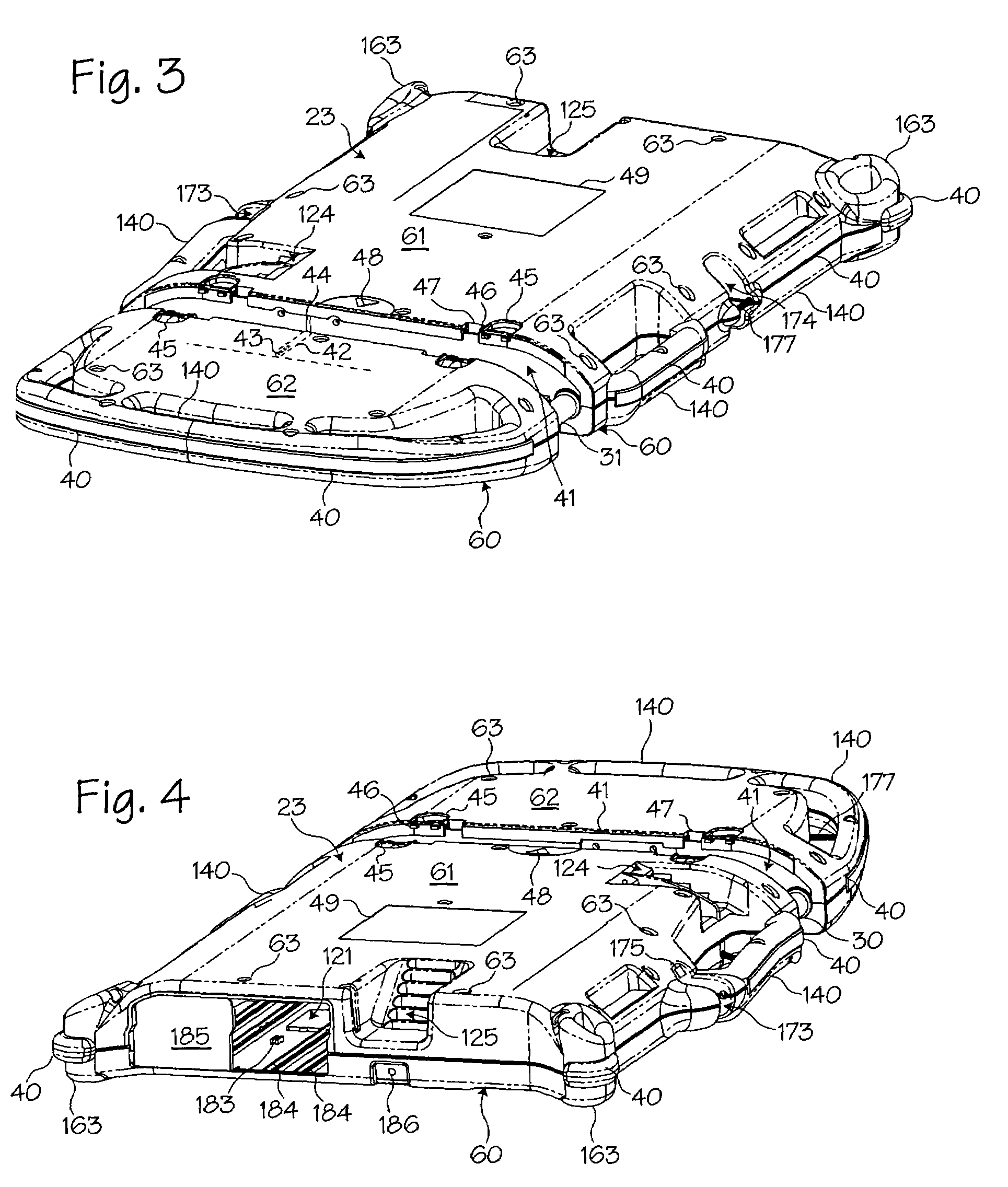

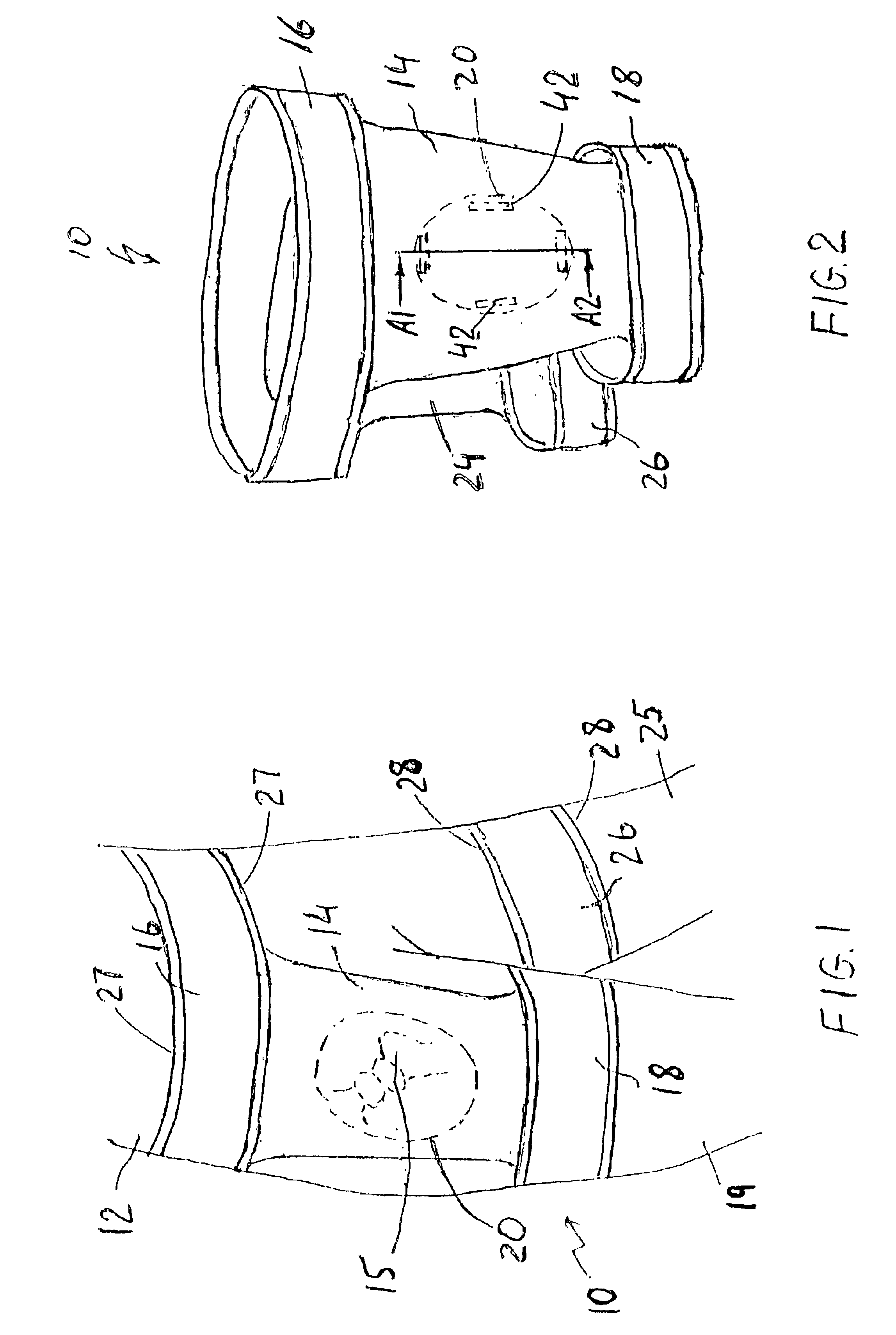

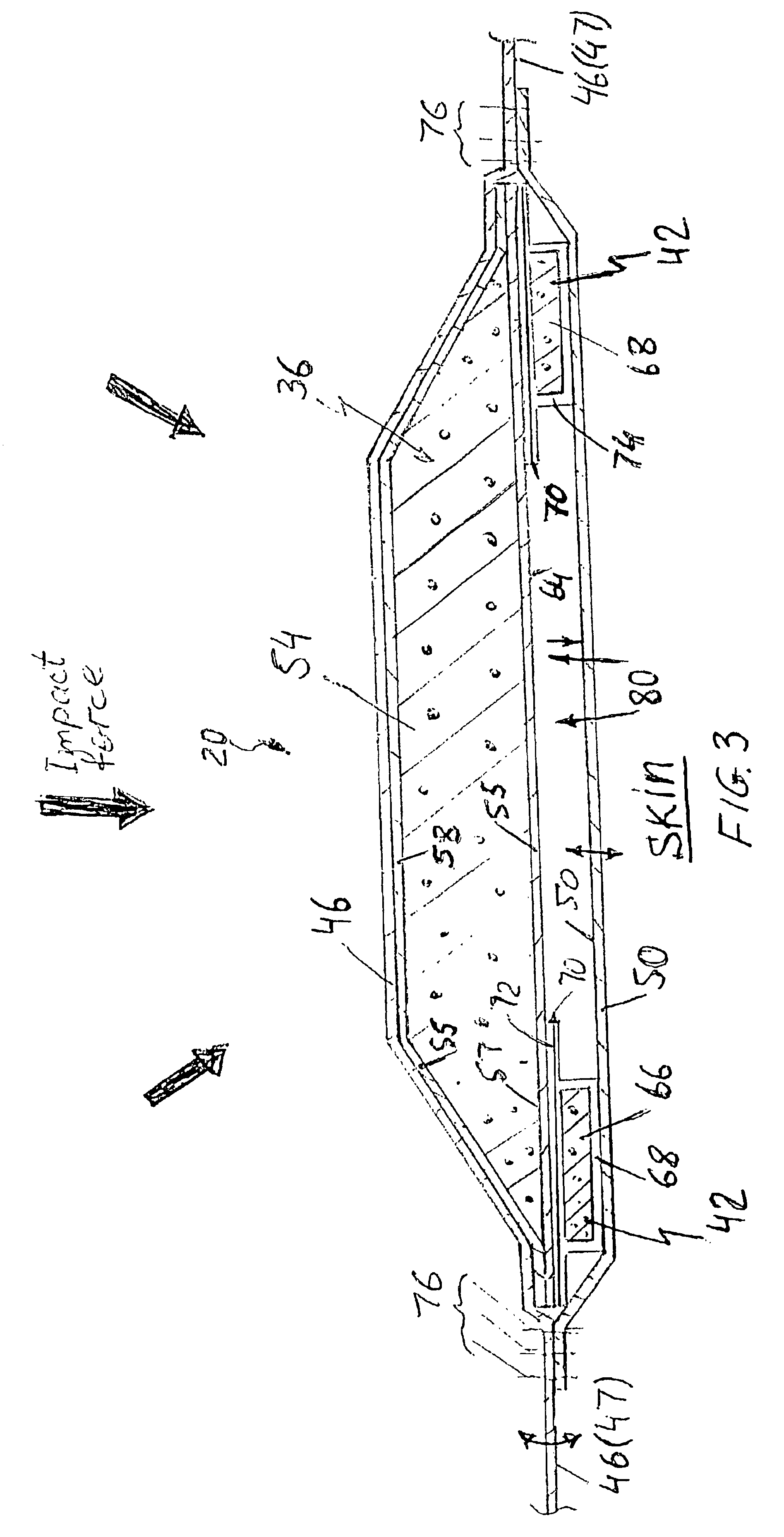

Lightweight electro-mechanical chest compression device

ActiveUS7347832B2Easy to changeLightweight materialElectrotherapySurgeryControl systemCompression device

A lightweight electro-mechanical chest compression device. The device is provided with a motor, a brake, a drive spool, a control system, and a metal channel beam to brace the device and guide a compression belt. The belt is provided in a belt cartridge that attaches to the channel beam. In use, the belt is secured around the patient and to the drive spool. The motor tightens the belt by turning the drive spool. The electro-mechanical chest compression device weighs less than 30 pounds when fully assembled with its power source.

Owner:ZOLL CIRCULATION

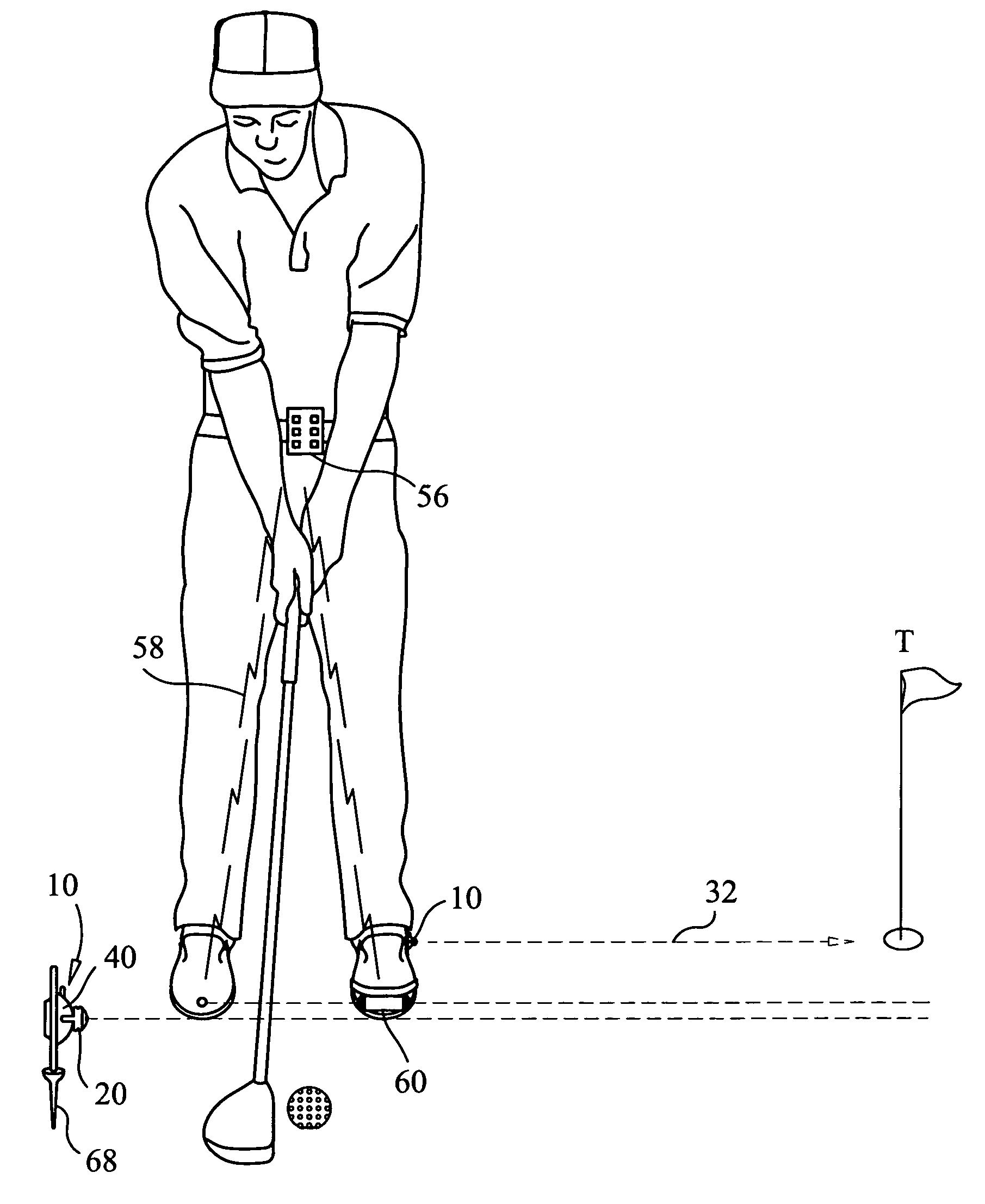

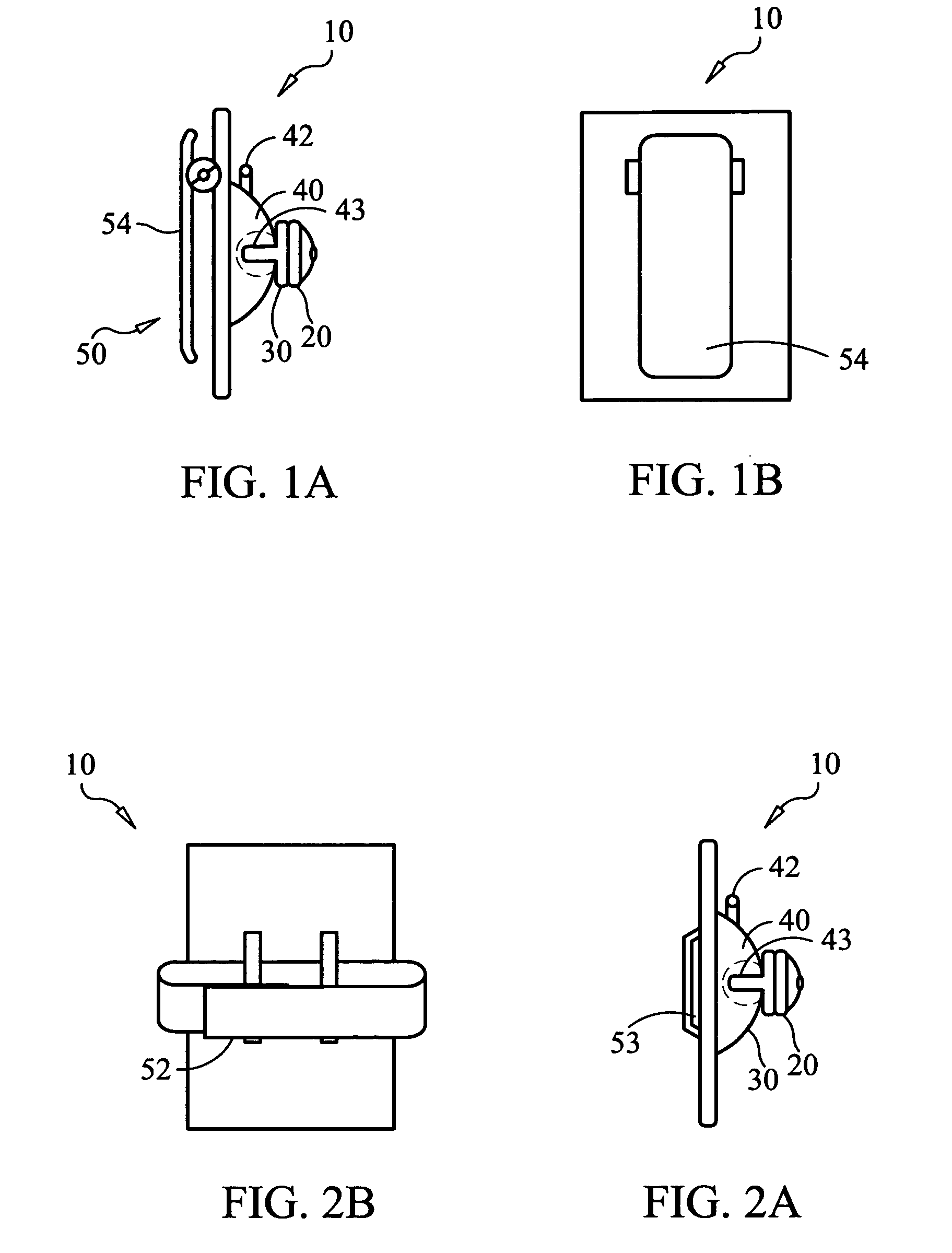

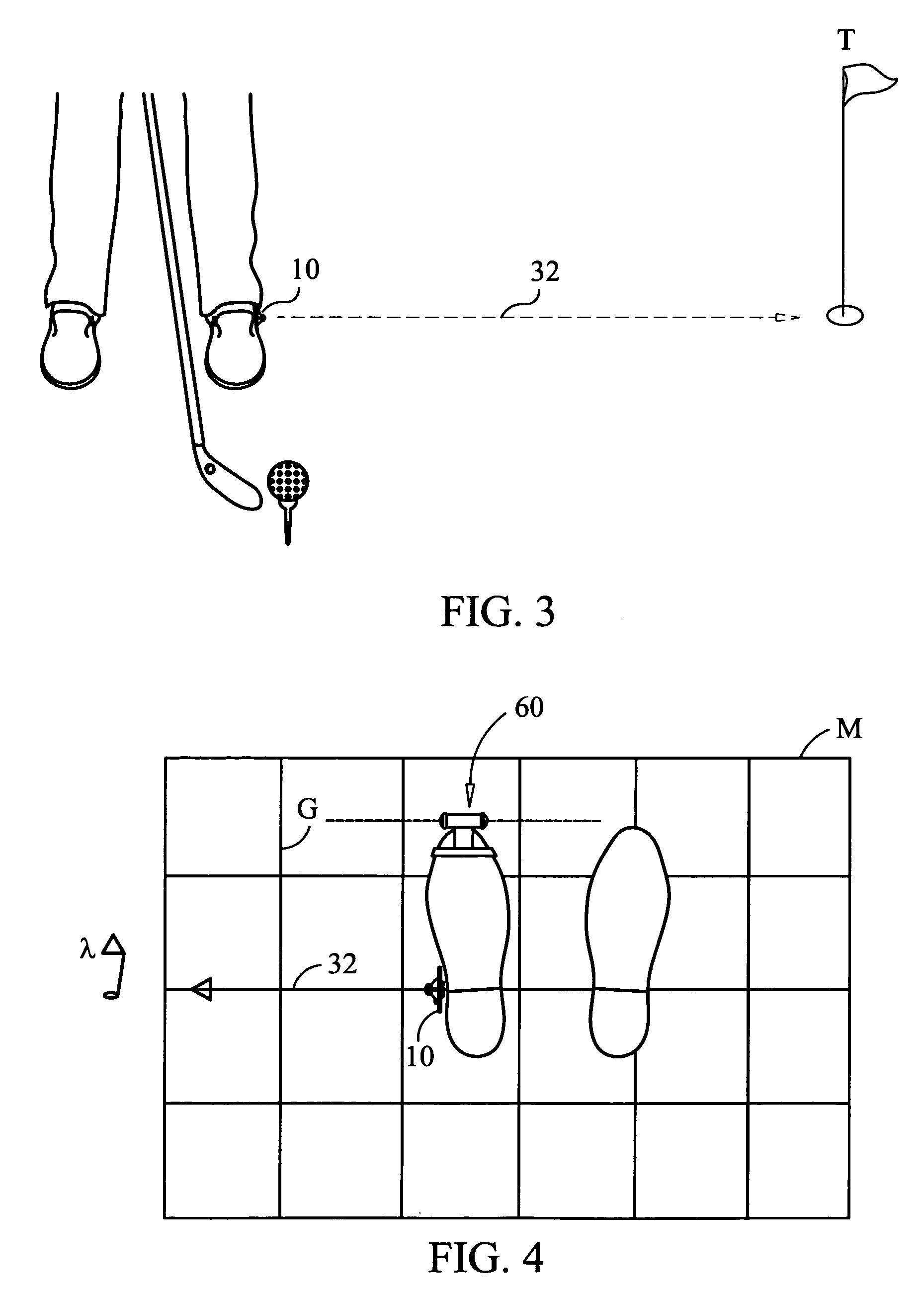

Body attached golf aim alignment device and method for use

A golf swing alignment device that includes a housing having a laser, which can be directed at a target such as a golf hole to enable the golfer to pre-position his or her body and feet prior to striking the ball. An affixing device for affixing the housing to a location on a golfer's body such as a VELCRO® strap or belt clip is also provided. The laser emits a signal that points toward an external reference for providing the golfer with a swing alignment reference separate from the golfer's body. One or more laser devices can be placed at various positions on the golfer's body or clothing such as the ankle, belt or cap. The golfer can activate one or more of the laser devices by use of a remote control unit that sends power and command signals to the one or more laser devices. The remote control unit can also modify the laser signal to produce, for example, intermittent bursts of laser light in order to better define the path to the target. A swiveling member is affixed to the housing of each laser device to allow the golfer to adjust the lasers such that visible light can be emitted in various planes and directions.

Owner:ROSSELLI MATTEO J

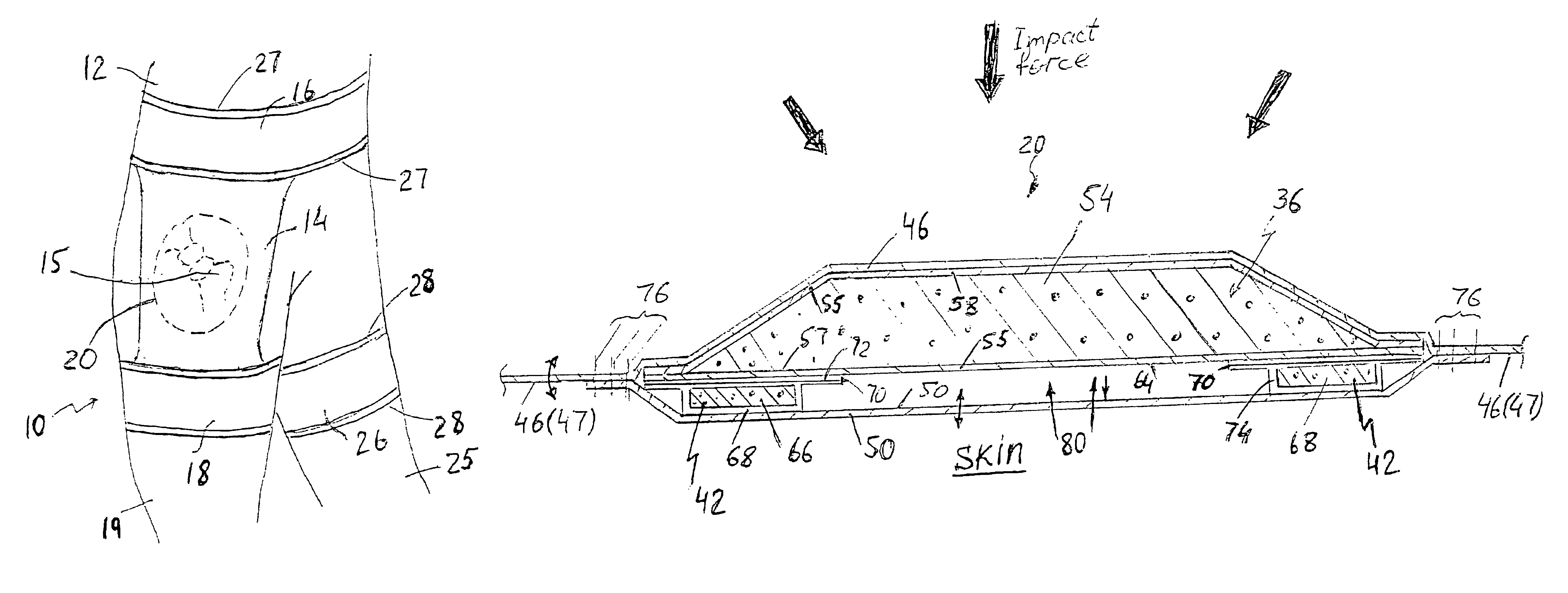

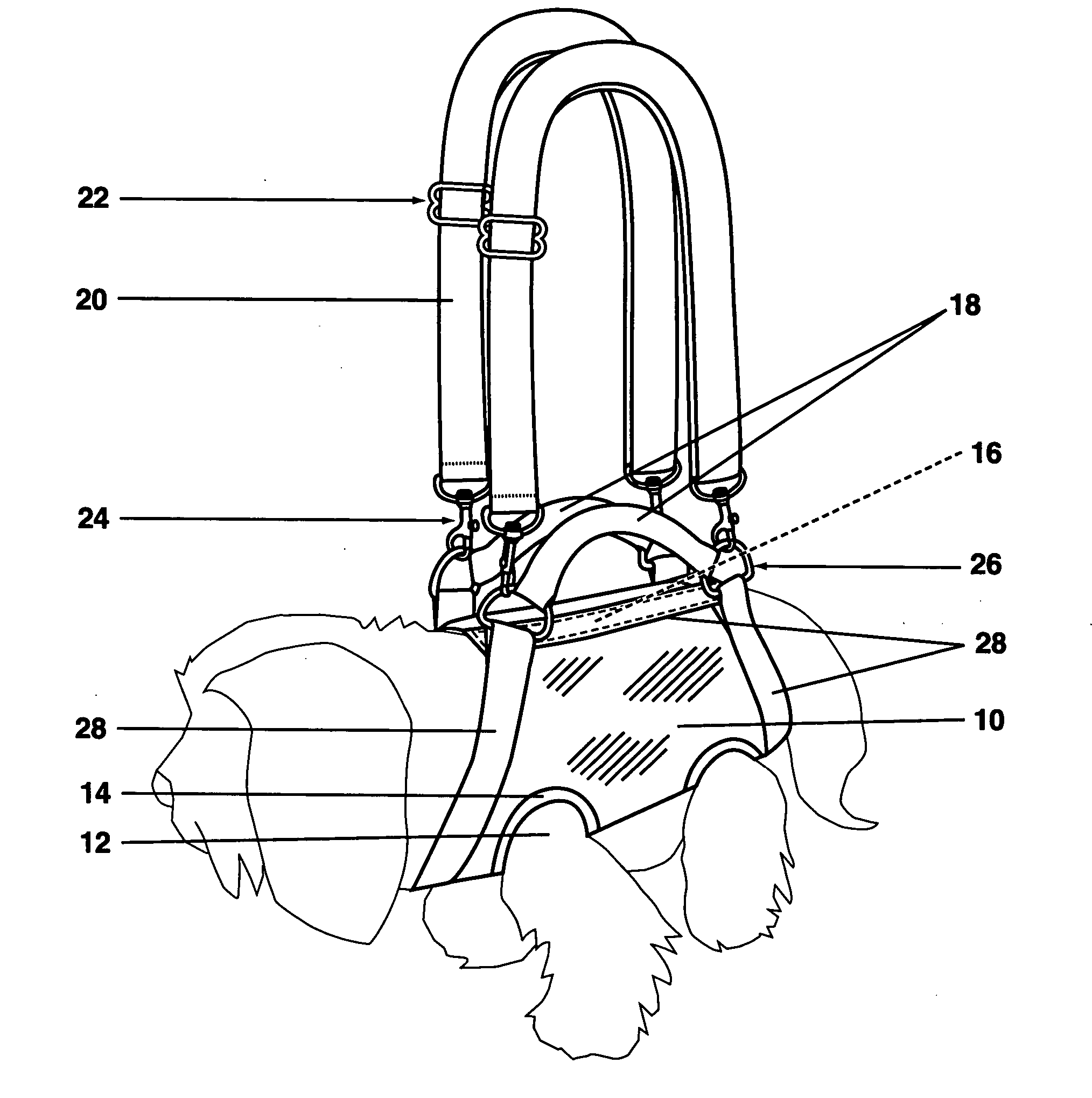

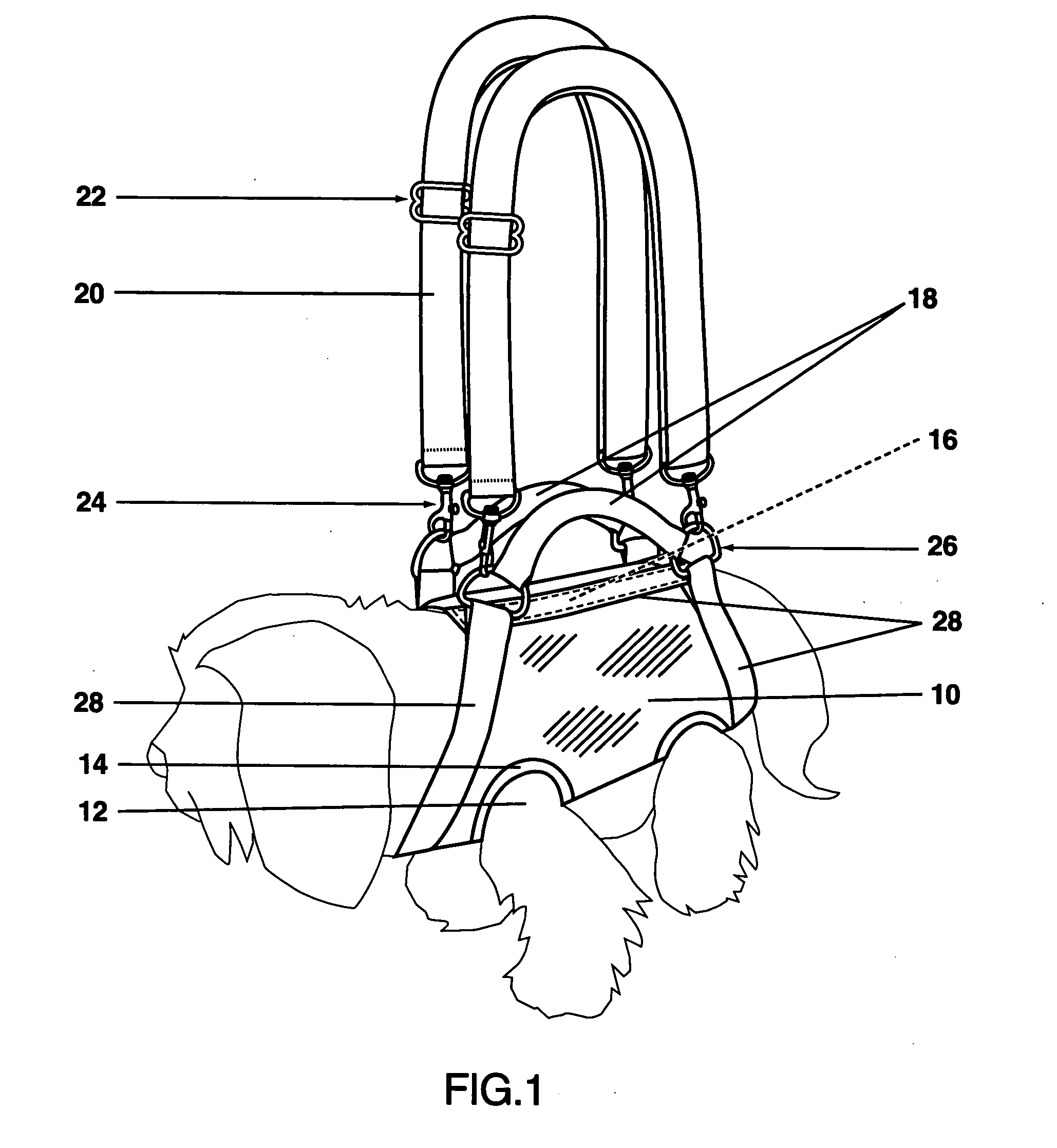

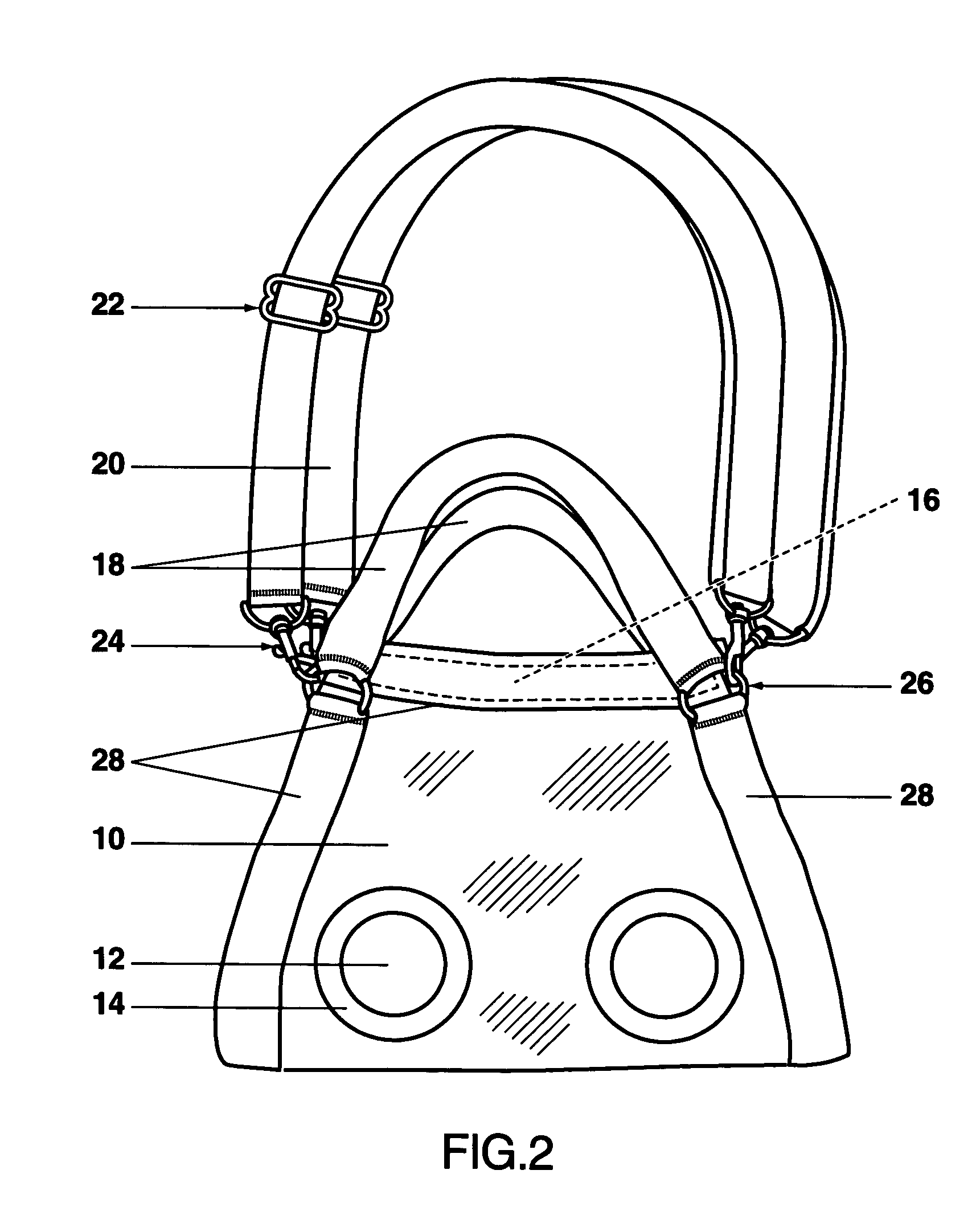

Hip protector system

Hip protector (10) worn primarily by the elderly, preventing / reducing hip fractures, resulting from a fall. The protector is made of all-soft materials using a matching pair of hip protective holsters (14 / 24) interconnected by a waist encircling belt (16) from which a pair of protective pad pouches (20) are suspended in the holsters over the user's hips and secured in place by leg encircling bands (18 / 26). The protective pouches include foam bodies (54) with underlying, intermediate, spacer elements (42) and a bottom cover (50), all in combination creating an enclosed, moisture-holding, air chamber (80). The protector is worn under clothing (under pants, bed clothes or swimming trunks, etc.), light weight, easily put on & removed, does not interfere in daily living (sleeping, usual body movements, restroom or bathing activities, etc.), and, when the user sweats, the surface of the user's skin under the hip protector is maintained dry using “one-way-moisture flow” material.

Owner:MELTS MICHAEL

Wearable horizontally oriented multi-positional pet carrier

A wearable, multi-positional apparatus and method for transporting an animal horizontally in an adjustable, body-conforming apparatus worn about the human torso. The carrier consists of a convex shaped main body panel bound at it perimeter by flexible, semi-rigid binding material. The body panel passes beneath and is drawn up around the animal that is secured under its hindquarters and beneath the chest area in front of the forelegs away from the esophageal area with the pet in a natural horizontal level orientation. The carrier provides for leg openings that are cushioned and mold around the animal's legs to produce a custom fit. The animal within the apparatus can be carried by hand via tote style handles, and has a multi-positional strap system that permits the carrier to be draped over the shoulder, around a person's waist, across the human chest, or converted to a leash.

Owner:SHERMAN SUZANNE E +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com