Patents

Literature

74070results about "Conveyor parts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

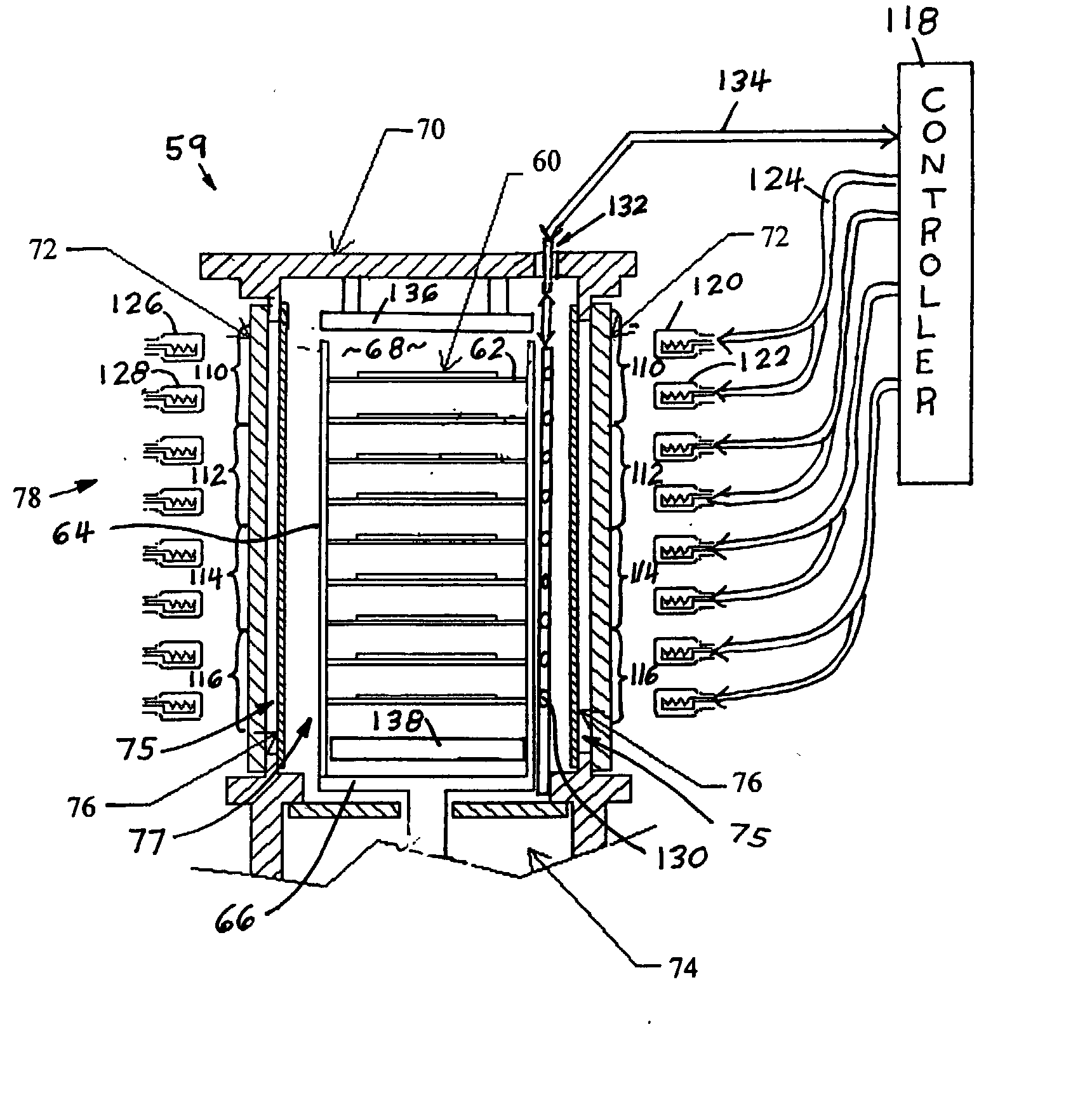

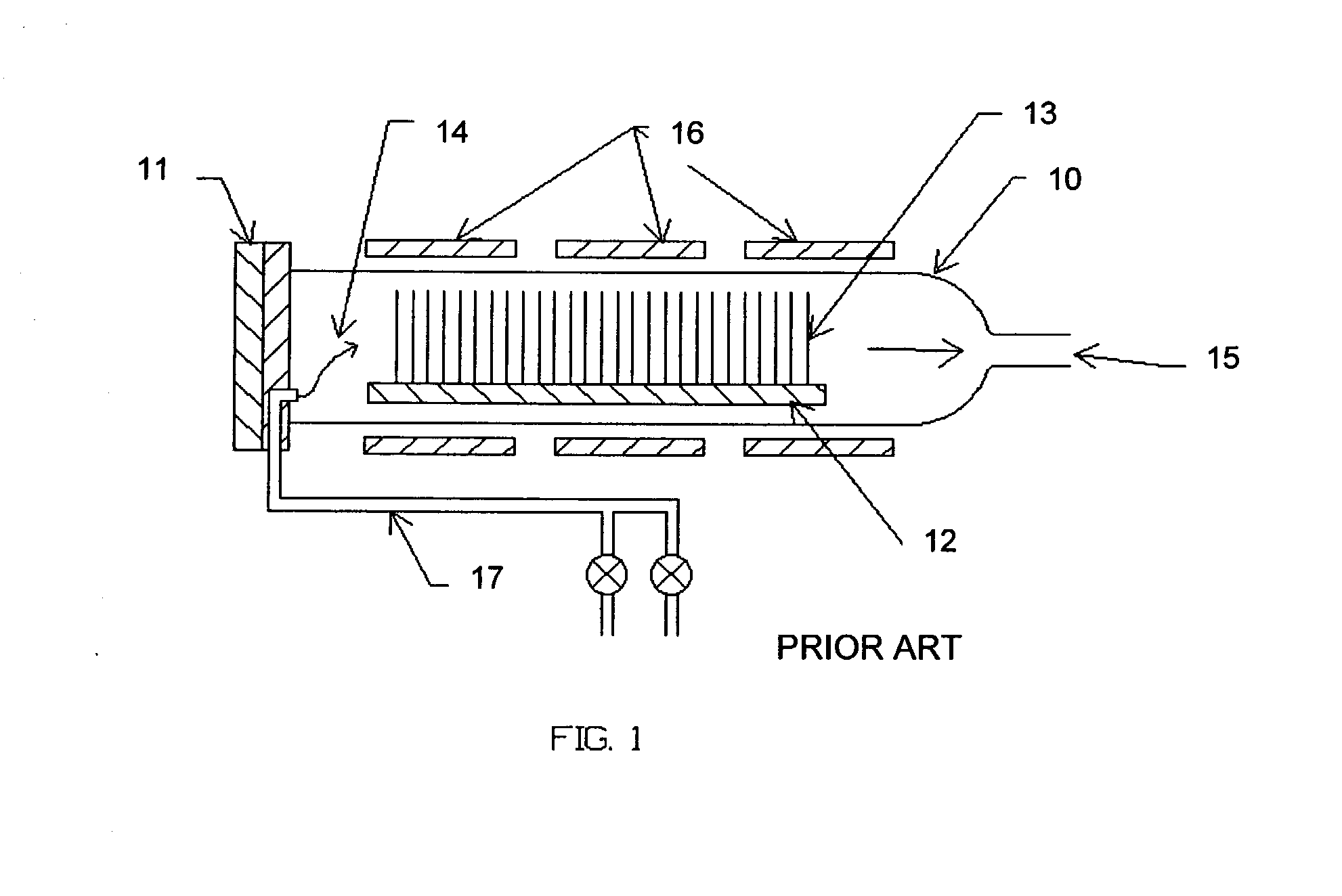

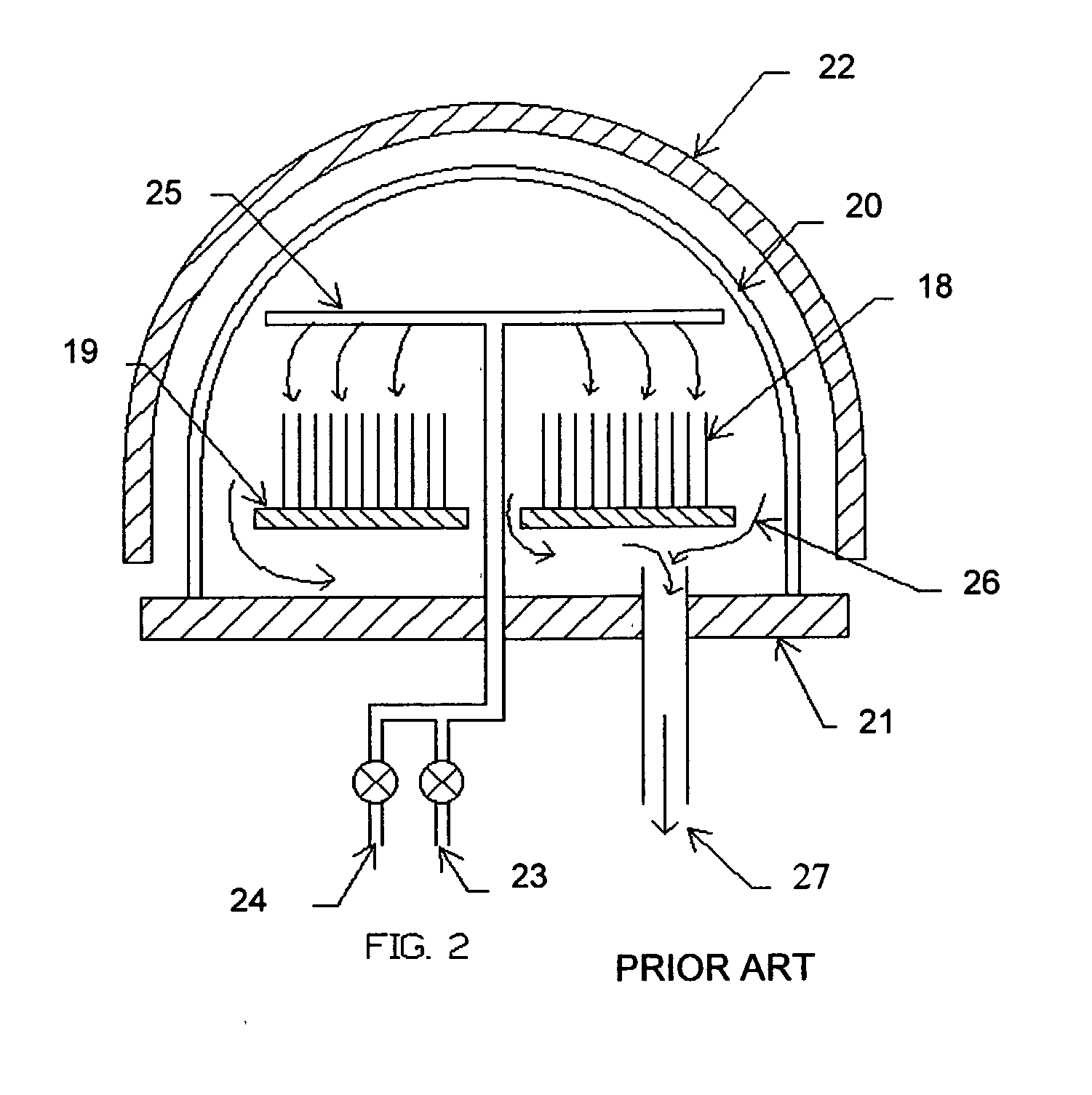

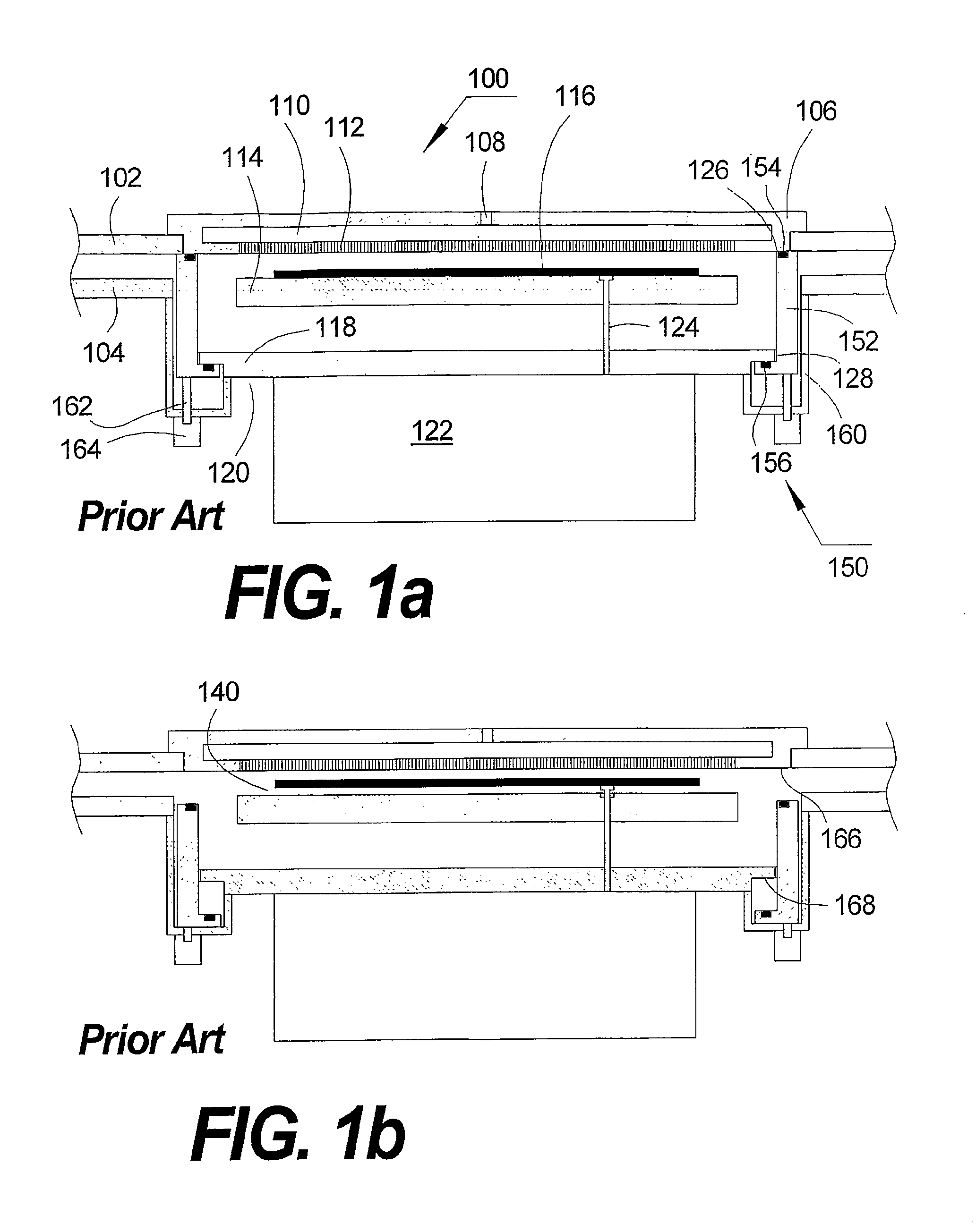

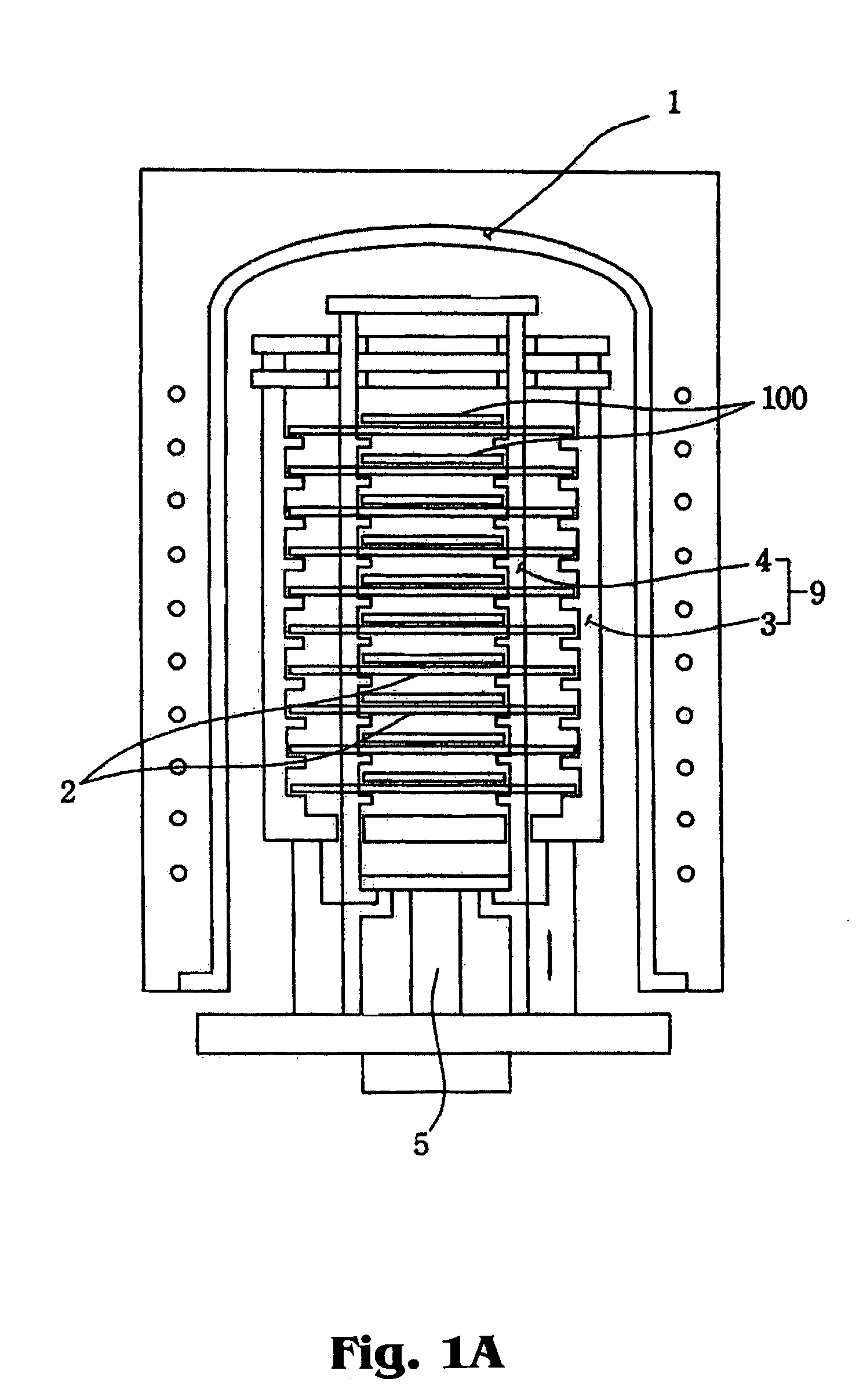

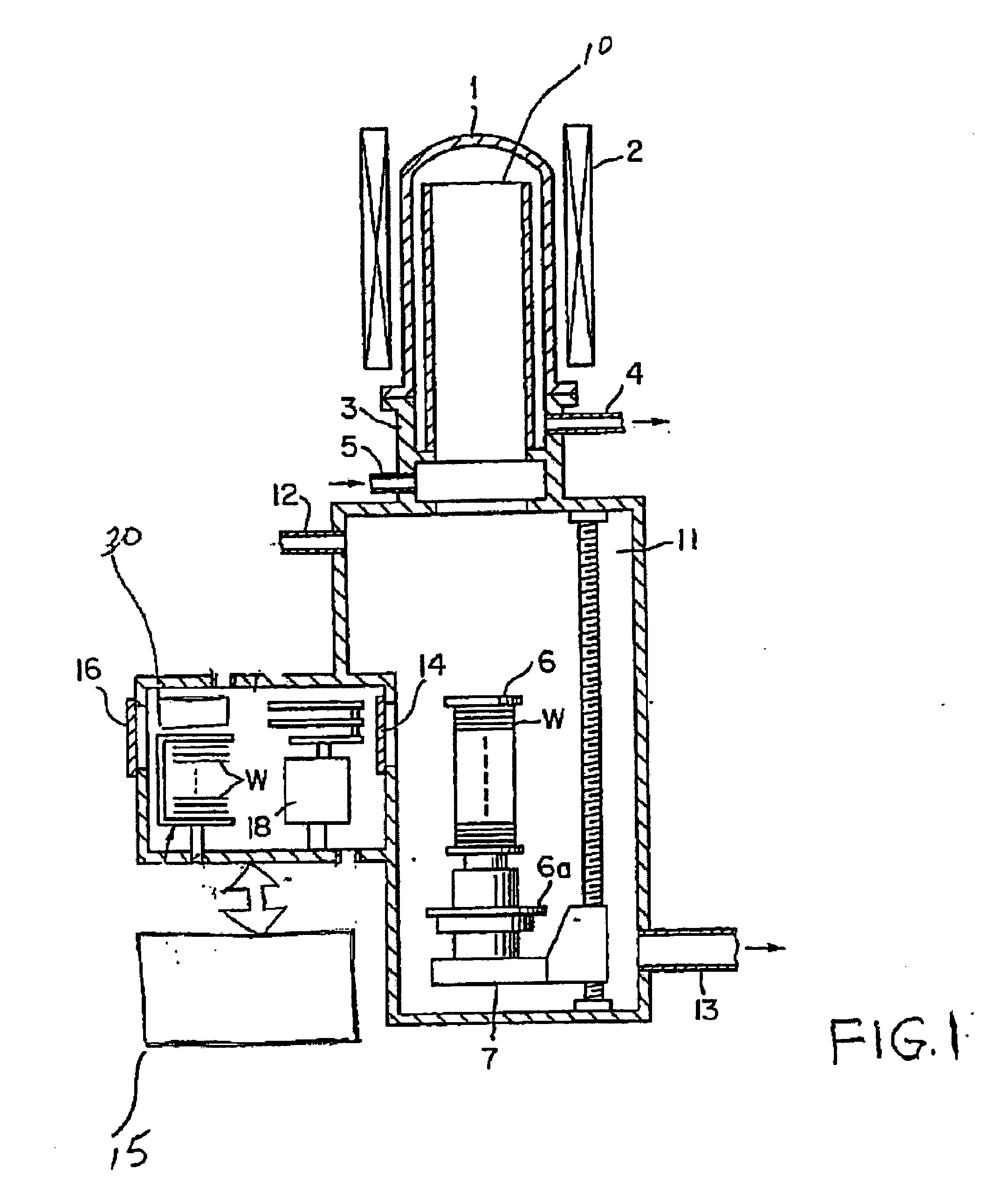

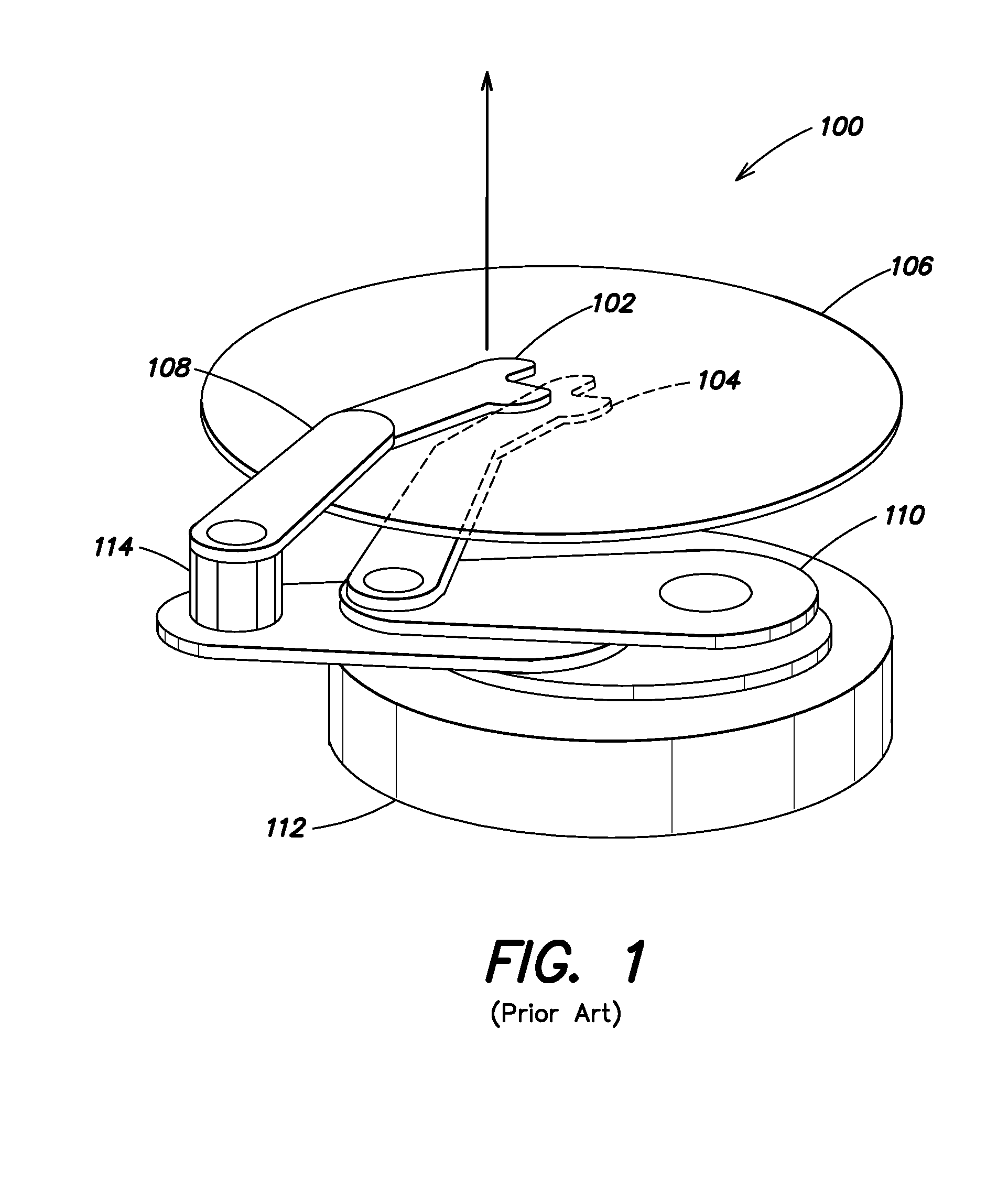

High rate deposition at low pressures in a small batch reactor

InactiveUS20030049372A1Increase ratingsRapid and uniform deposition of materialElectric discharge tubesSemiconductor/solid-state device manufacturingHigh rateSusceptor

A chemical vapor deposition reactor including a wafer boat with a vertical stack of horizontally oriented susceptors serving as thermal plates and each having pins extending upward for suspending a wafer between a pair of susceptors. Reactant gas injector and exhaust apparatus are positioned to concentrate a forceful supply of reactant gas across each wafer at a speed in excess of 10 cm / sec. The pressure is held in the range of 0.1 to 5,000 mTorr. The forceful gas flow avoids gas depletion effects, thinning the boundary layer and resulting in faster delivery of reactants to substrate surfaces, resulting in surface rate reaction limited operation. A plurality of individually controllable heaters are spaced vertically around the sides of the boat. Temperature sensors monitor the temperature along the boat height and provide input to a controller for adjusting the heater drive to optimize the temperature uniformity.

Owner:APPLIED MATERIALS INC

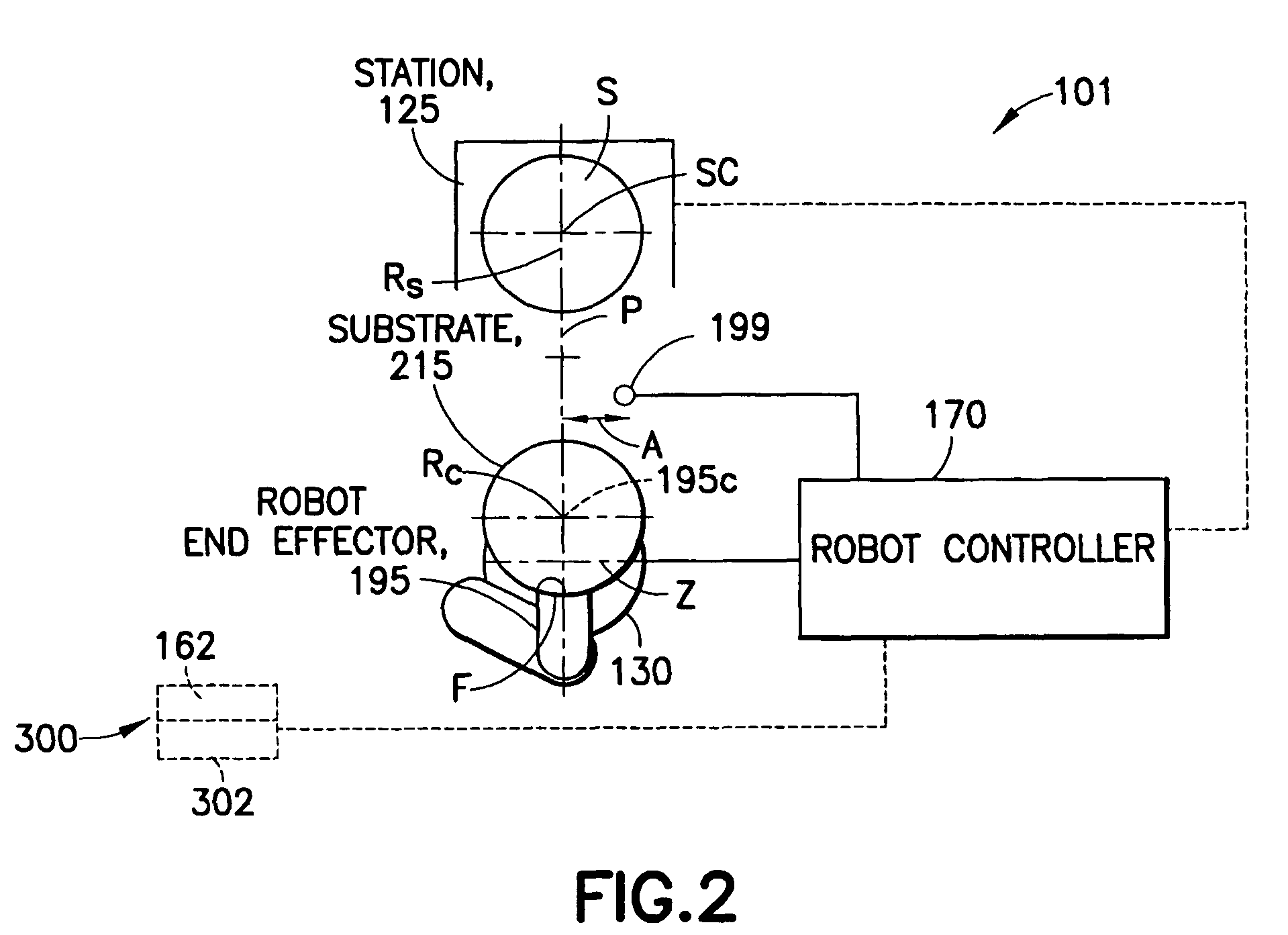

Process apparatus with on-the-fly workpiece centering

ActiveUS7925378B2Digital data processing detailsSemiconductor/solid-state device manufacturingEngineeringElectrical and Electronics engineering

A substrate processing apparatus having a transport apparatus, at least one sensor connected to the transport apparatus and a controller. The transport apparatus is adapted for transporting the substrate between processing stations of the processing apparatus. The sensor is capable of sensing the substrate transported by the transporting apparatus. The sensor is arranged for sending at least one signal in response to sensing the substrate. The controller is communicably connected to the sensor and arranged to determine alignment of the substrate in at least two directions, angled relative to each other, relative to a predetermined location. The controller is capable of determining alignment from the at least one signal identifying no more than two points on the substrate and independent of radial variances between substrates.

Owner:BOOKS AUTOMATION US LLC

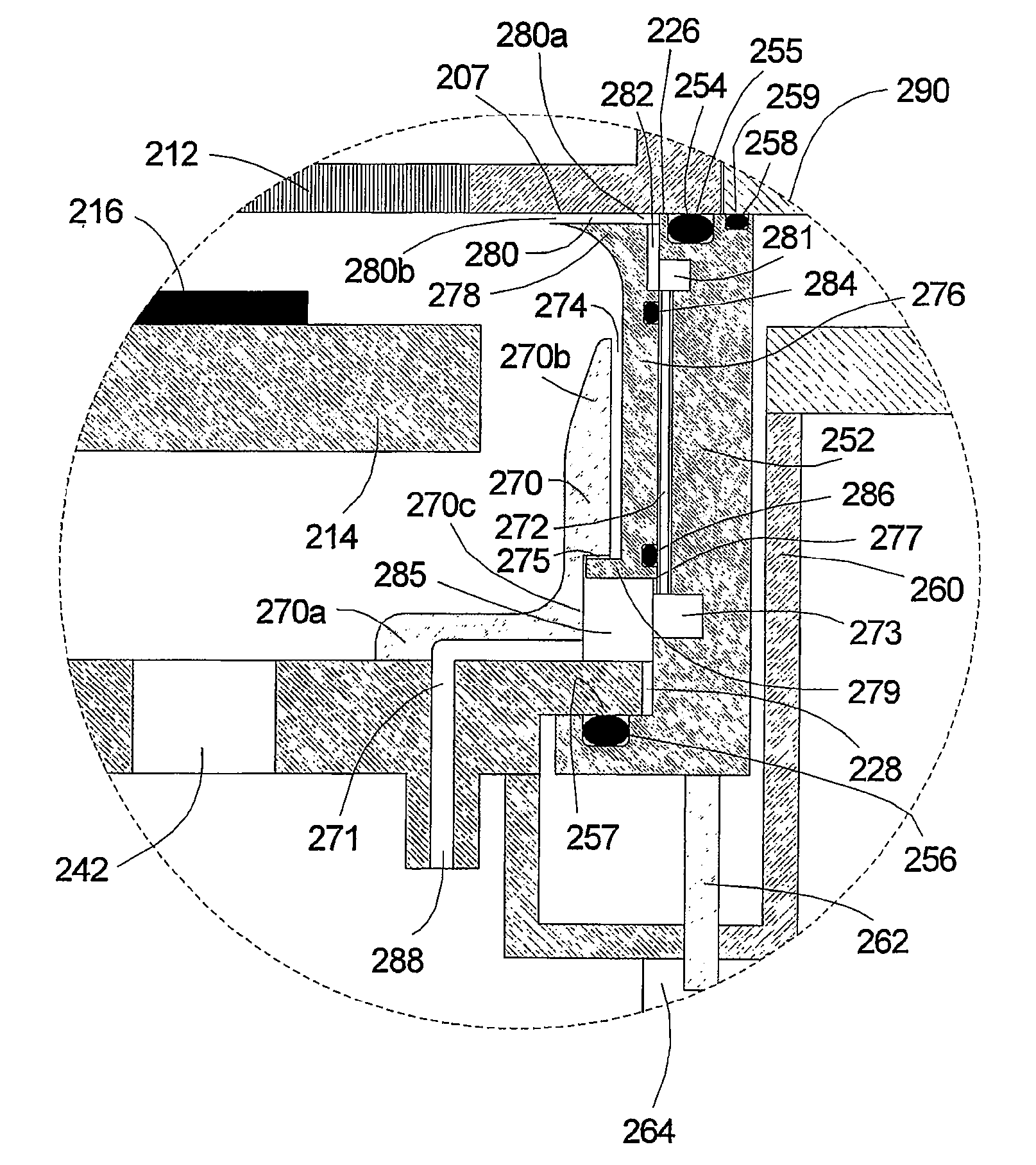

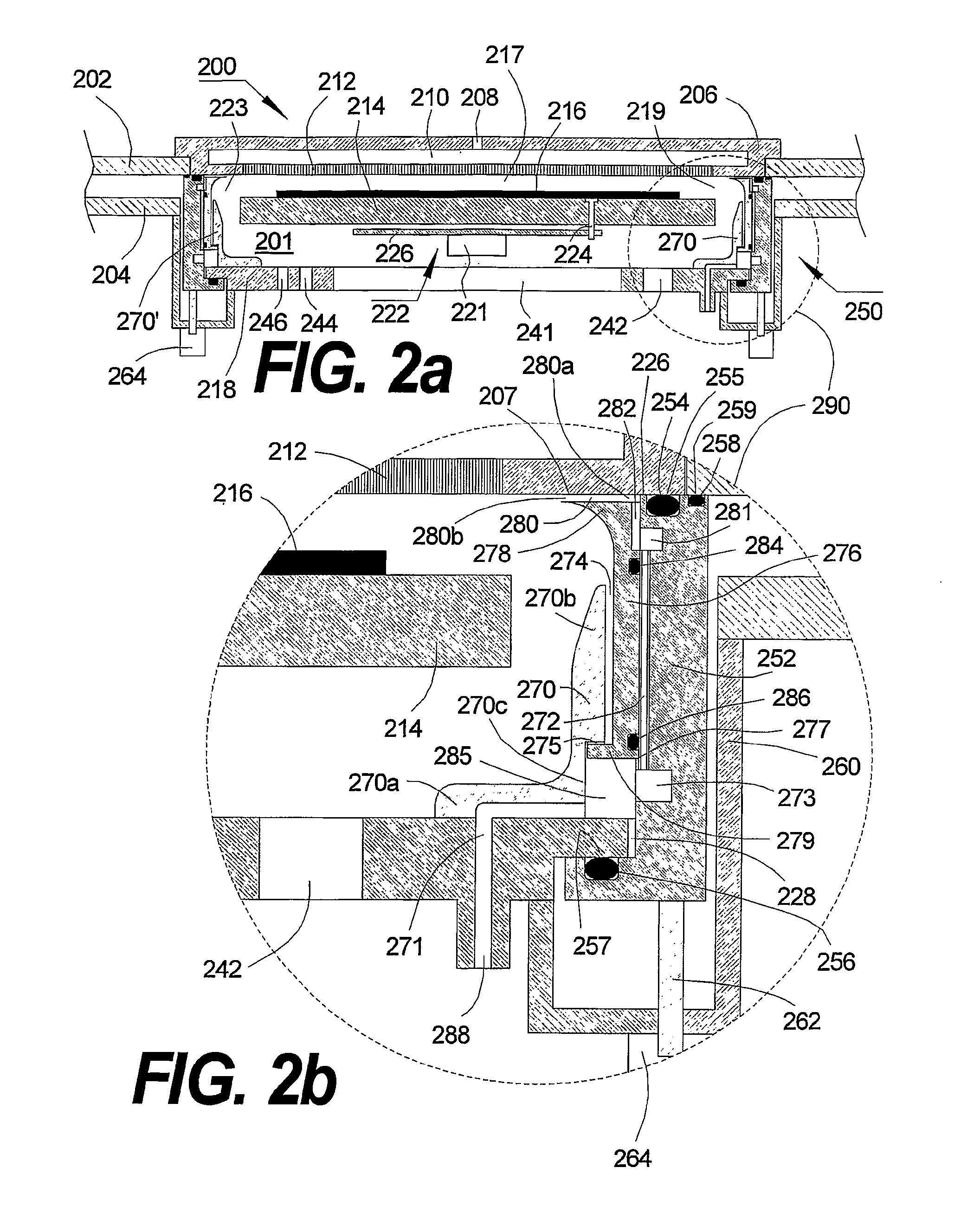

Perimeter partition-valve with protected seals and associated small size process chambers and multiple chamber systems

ActiveUS7682454B2Improve performanceSmall sizeVacuum evaporation coatingSputtering coatingModularityHandling system

Owner:SUNDEW TECH

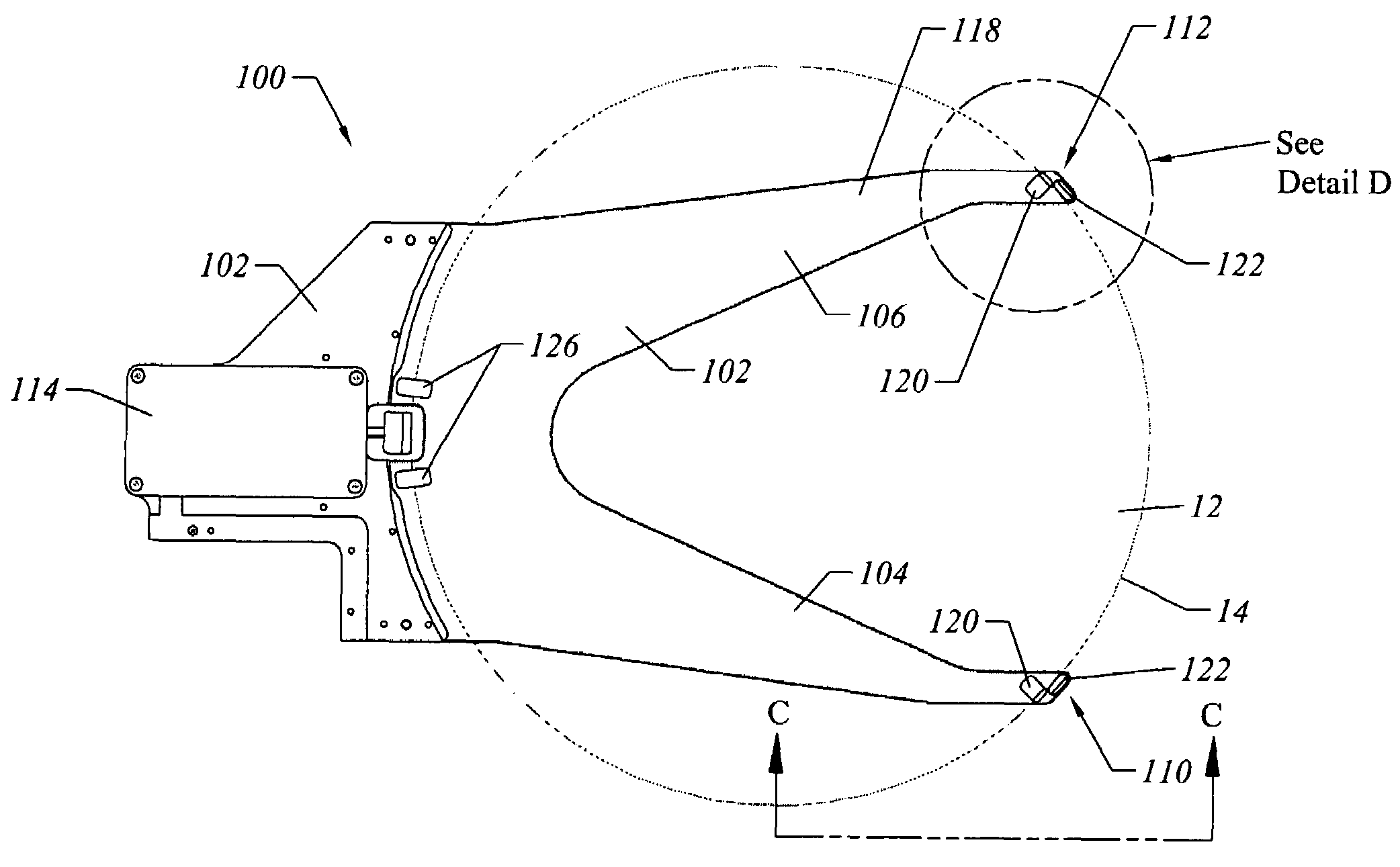

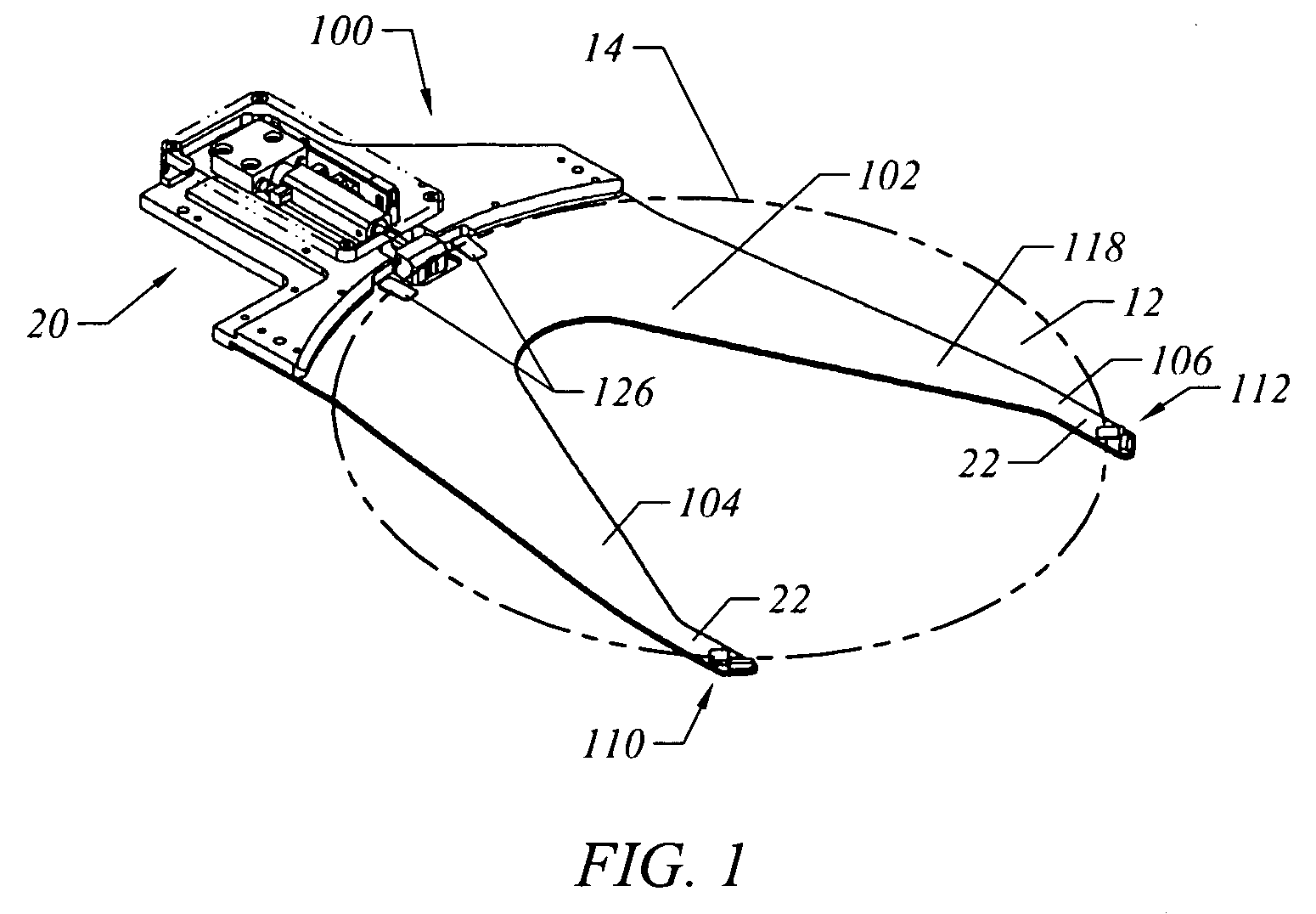

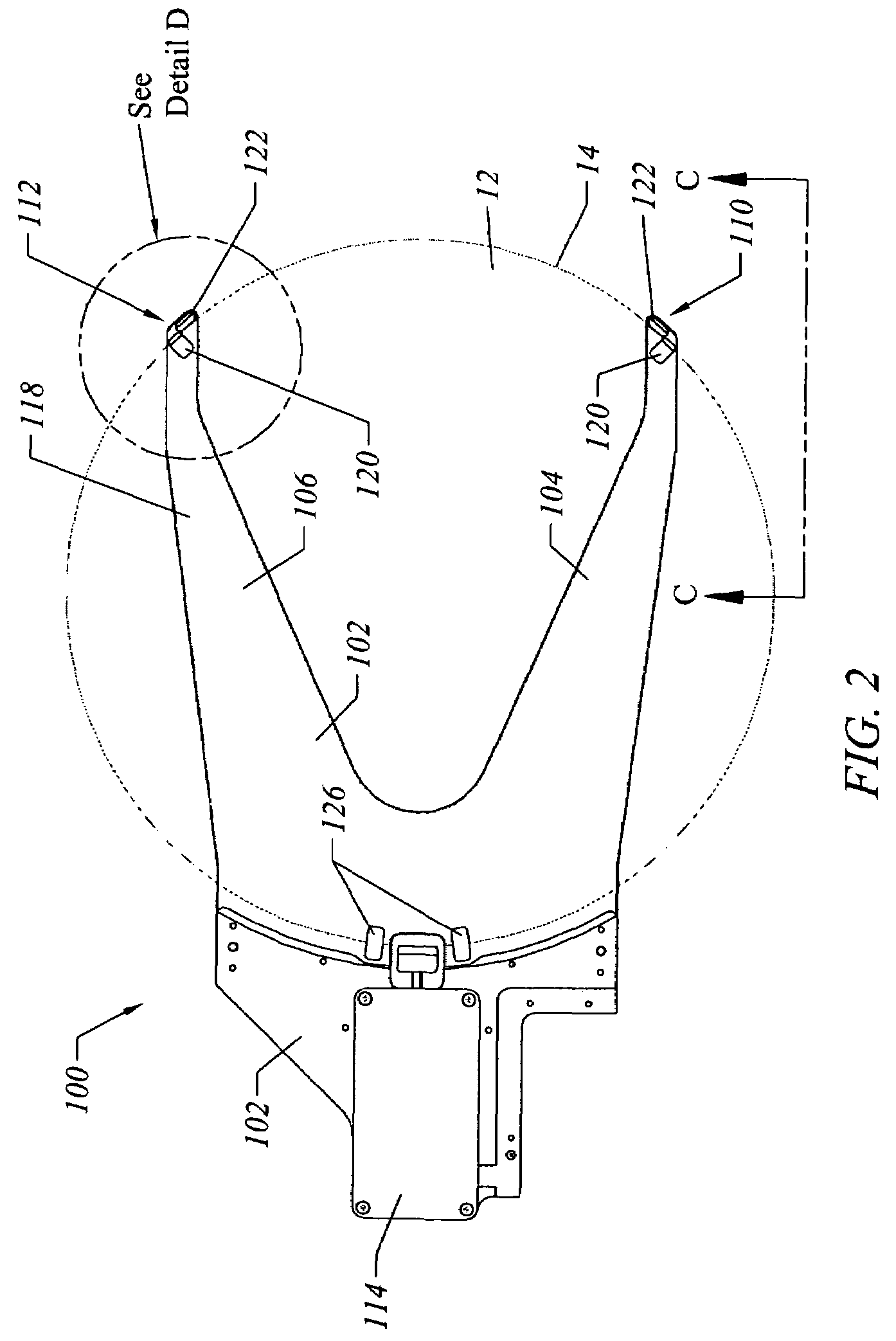

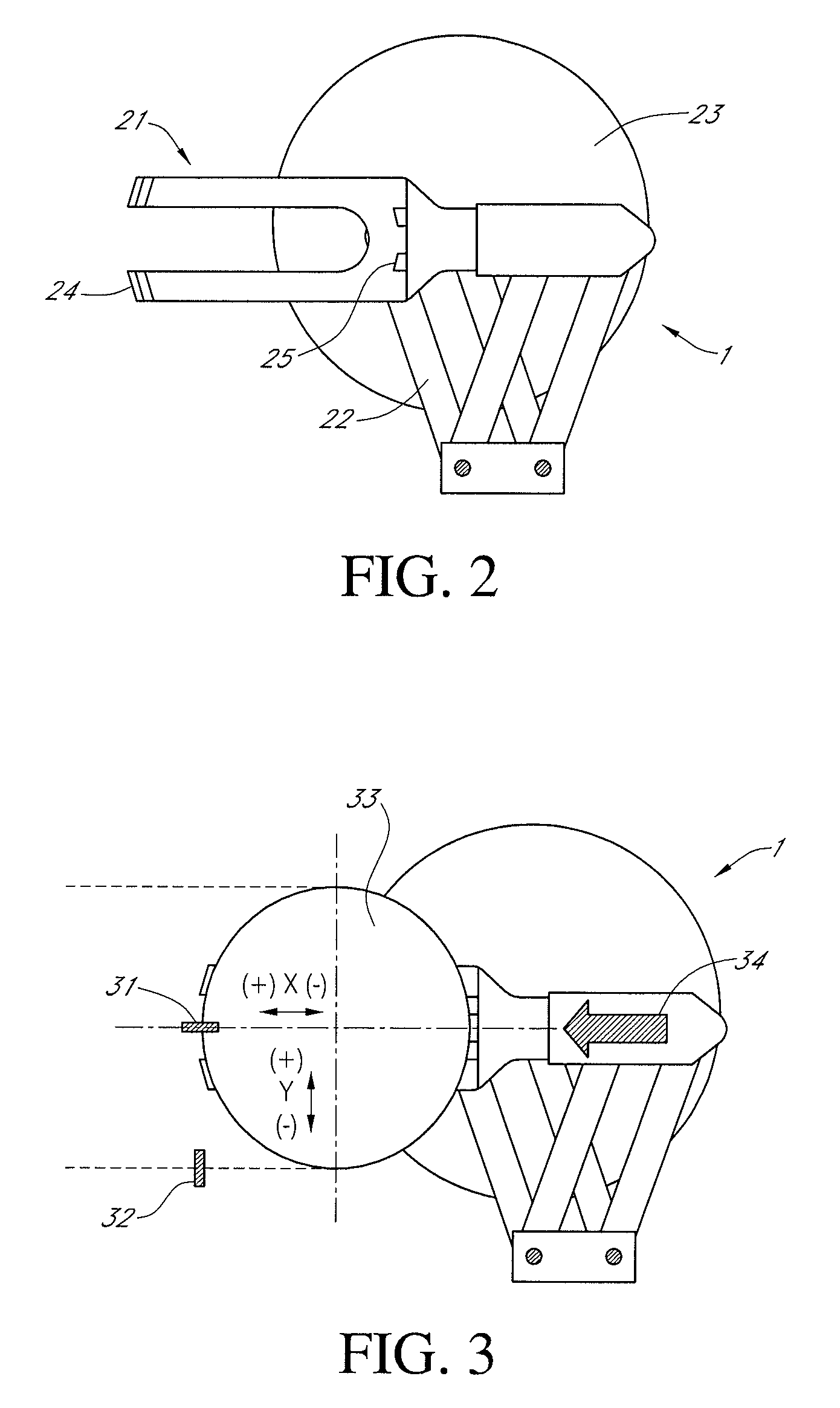

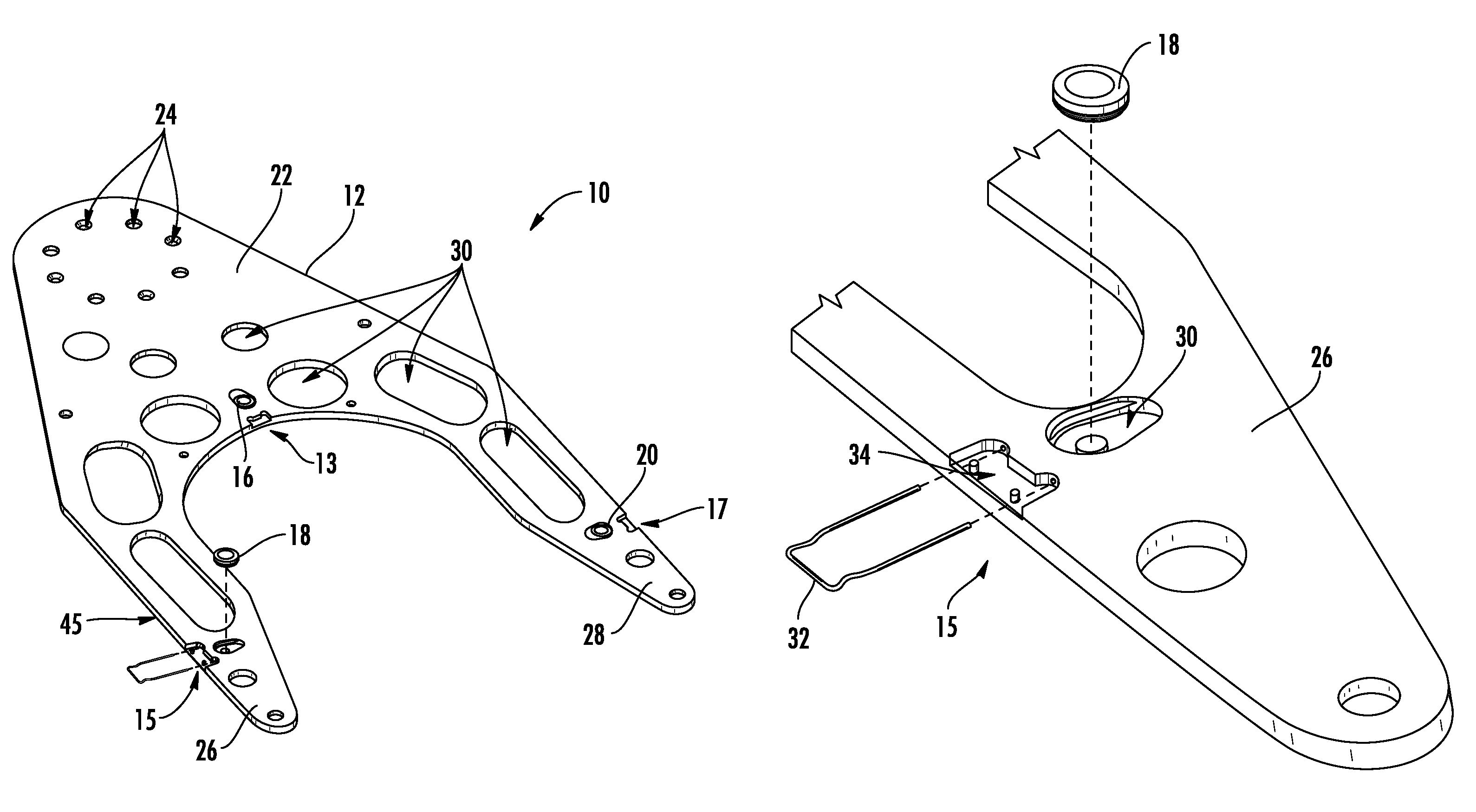

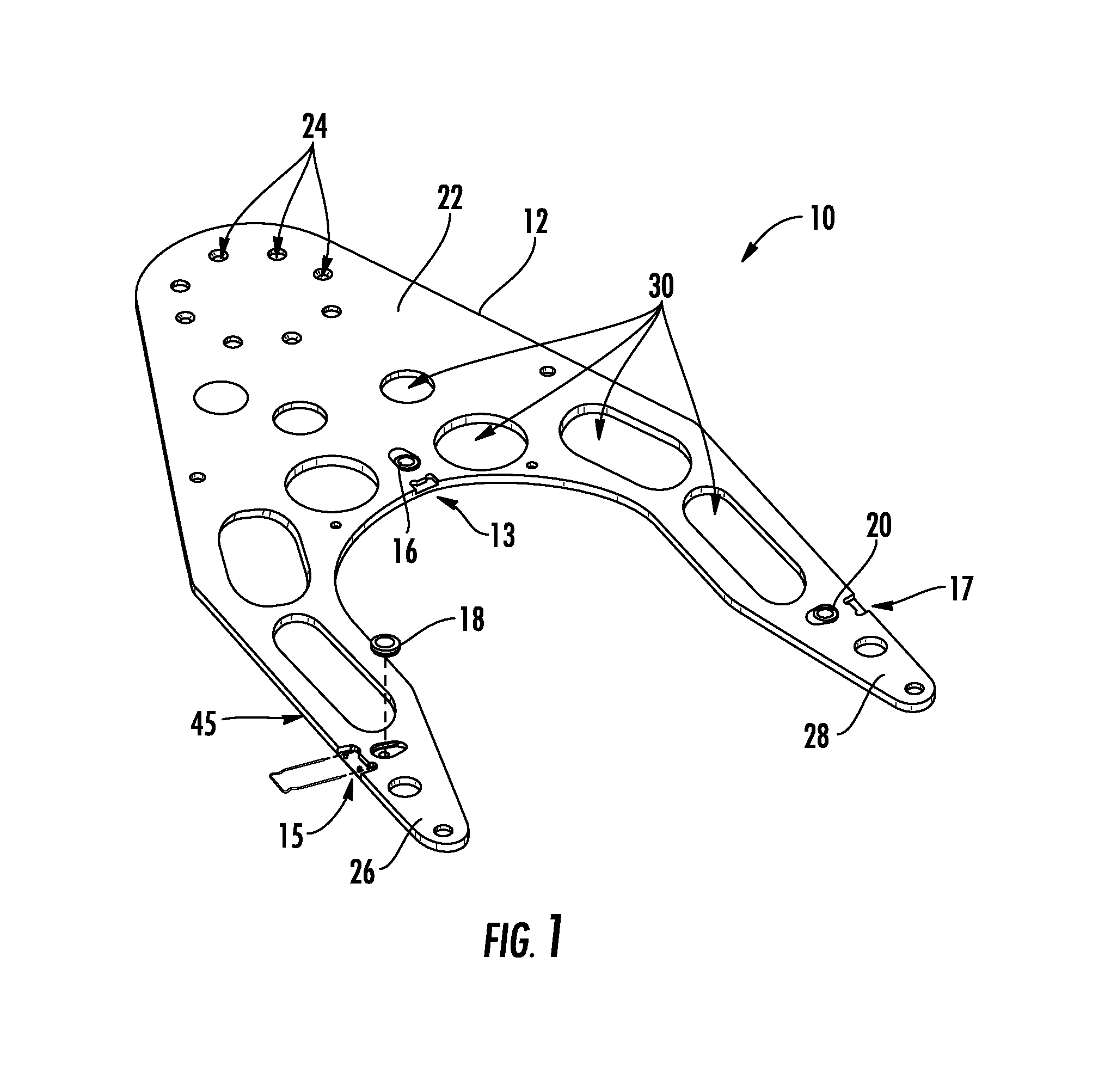

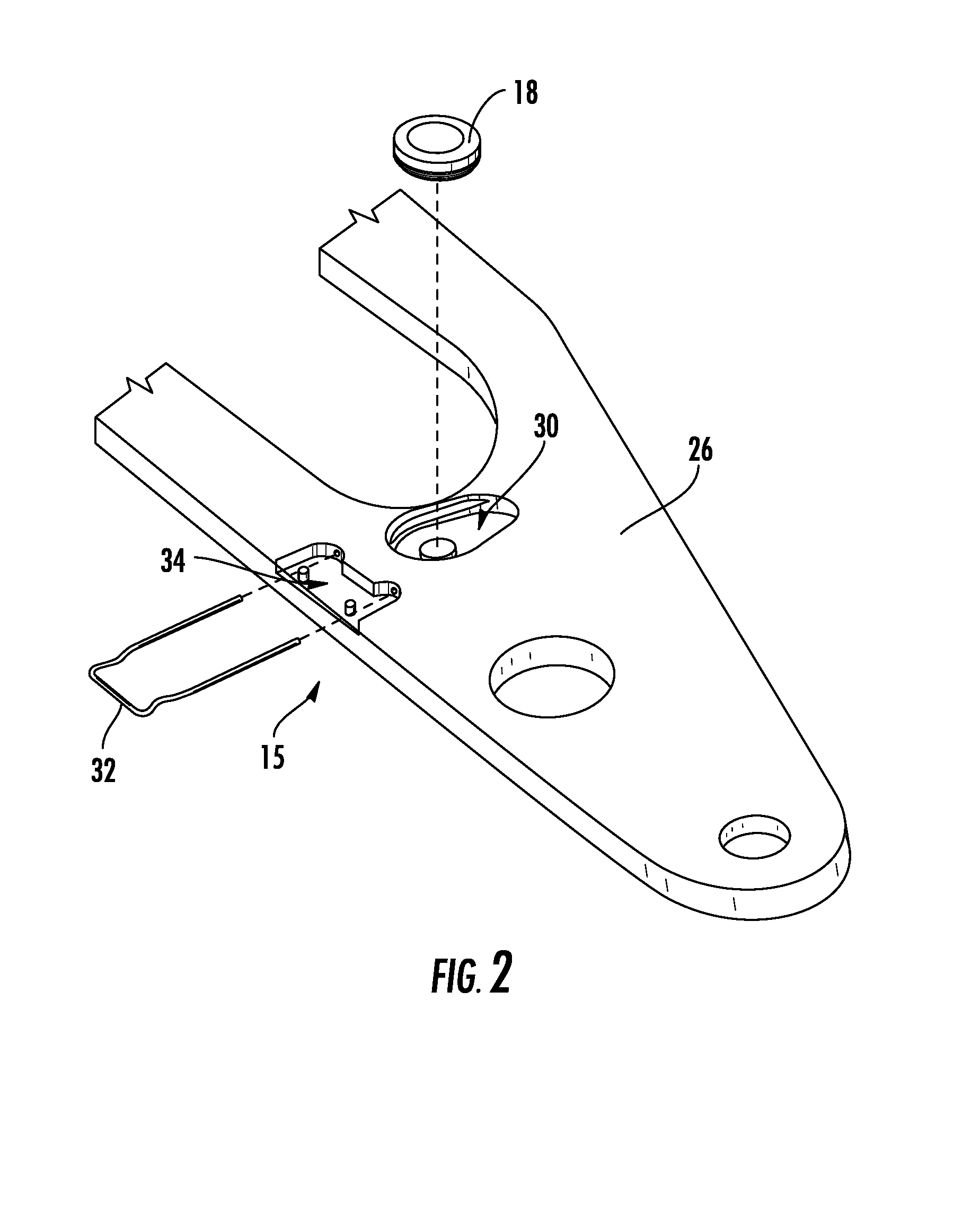

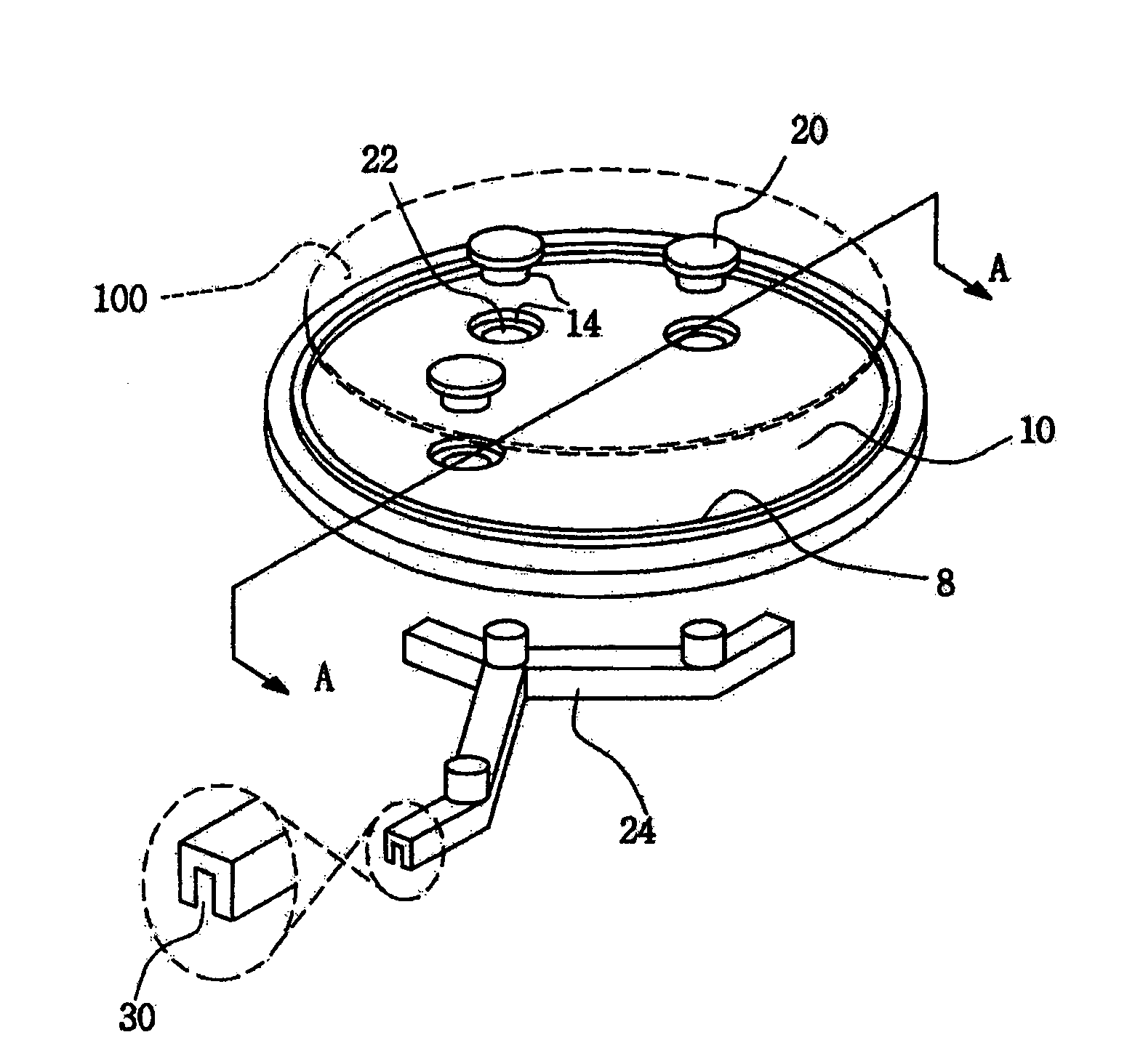

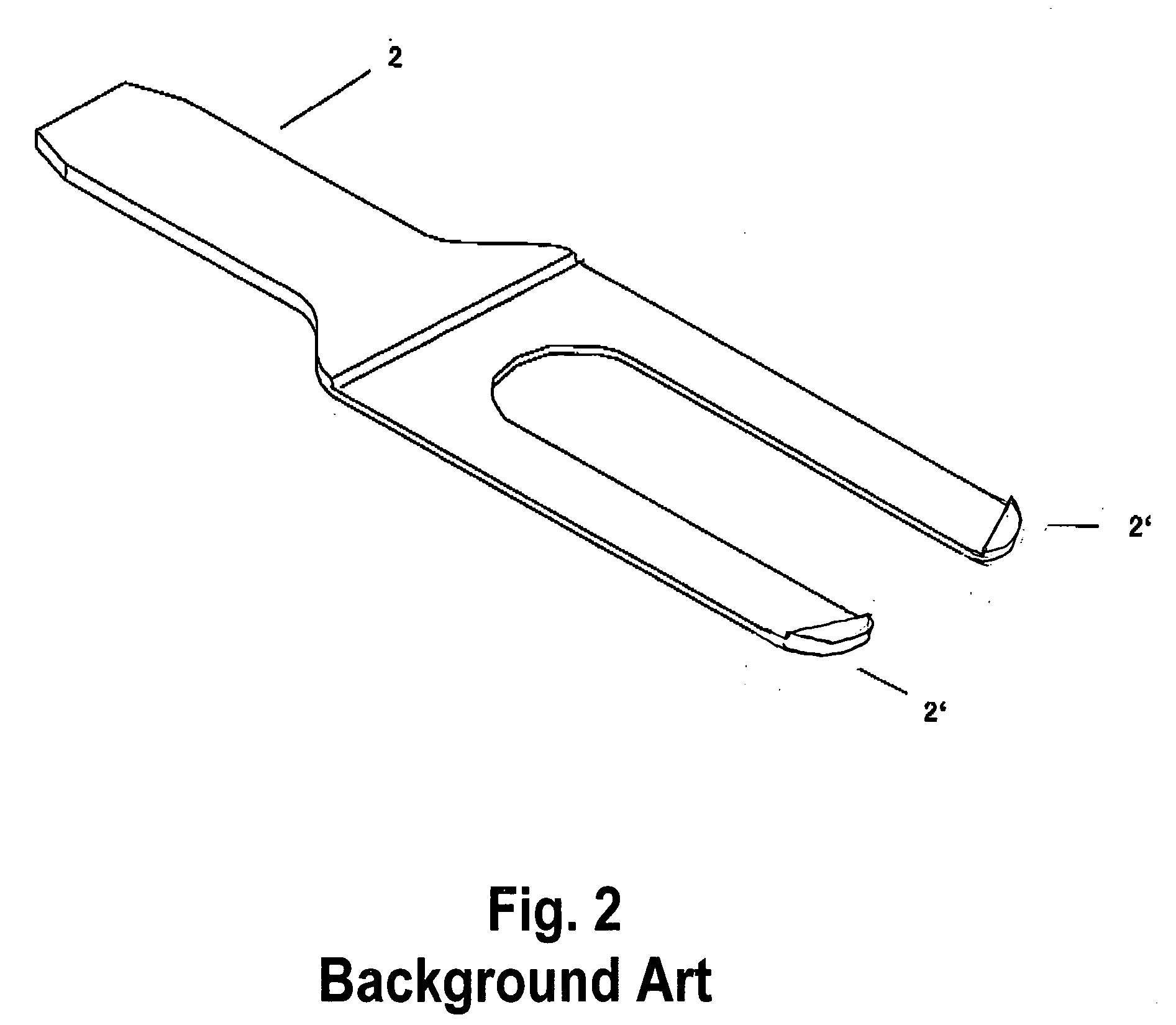

Active edge grip rest pad

ActiveUS7290813B2Precise and repeatable placementLow profileSemiconductor/solid-state device manufacturingLifting devicesActive edgeEngineering

The present invention comprises a distal rest pad for supporting a portion of a wafer seated on an end effector. In one embodiment, the rest pad includes a bottom support pad and an edge stop. Each element is mounted separately to the distal end of a support plate. The bottom support pad includes an inclined surface that transitions to a substantially horizontal surface at its distal end. The edge stop has a substantially vertical wafer contact surface that the peripheral edge of a wafer eventually contacts as the wafer is urged towards the distal rest pad. In another embodiment, the bottom support pad comprises an inclined surface. In yet another embodiment, the distal rest pad comprises a single structure. This distal rest pad includes a backstop portion and a bottom support separated by a particle collection groove. The bottom support may include an inclined lead-in surface that transitions into a flat contact surface or only comprise an inclined lead-in surface.

Owner:BOOKS AUTOMATION US LLC

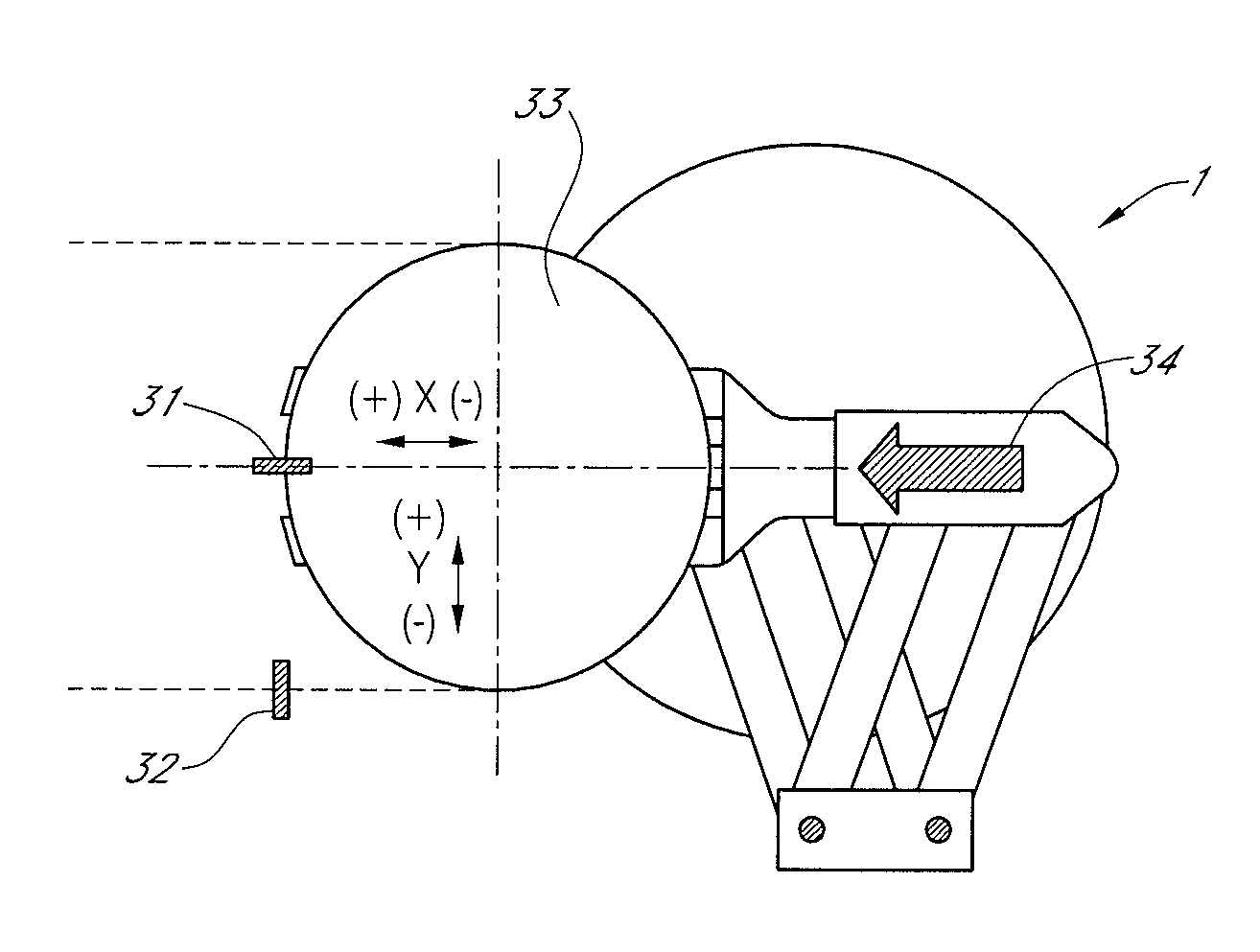

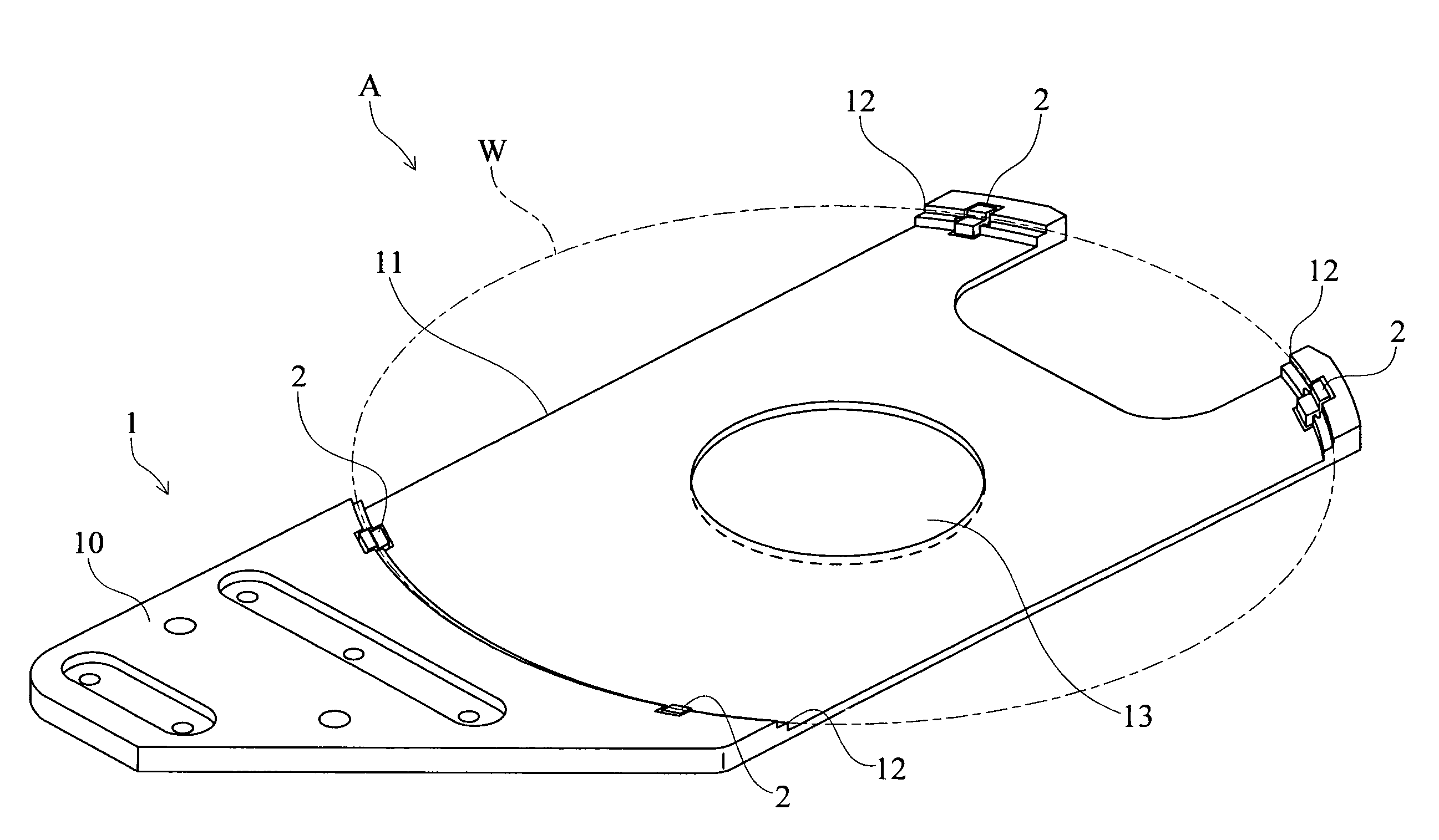

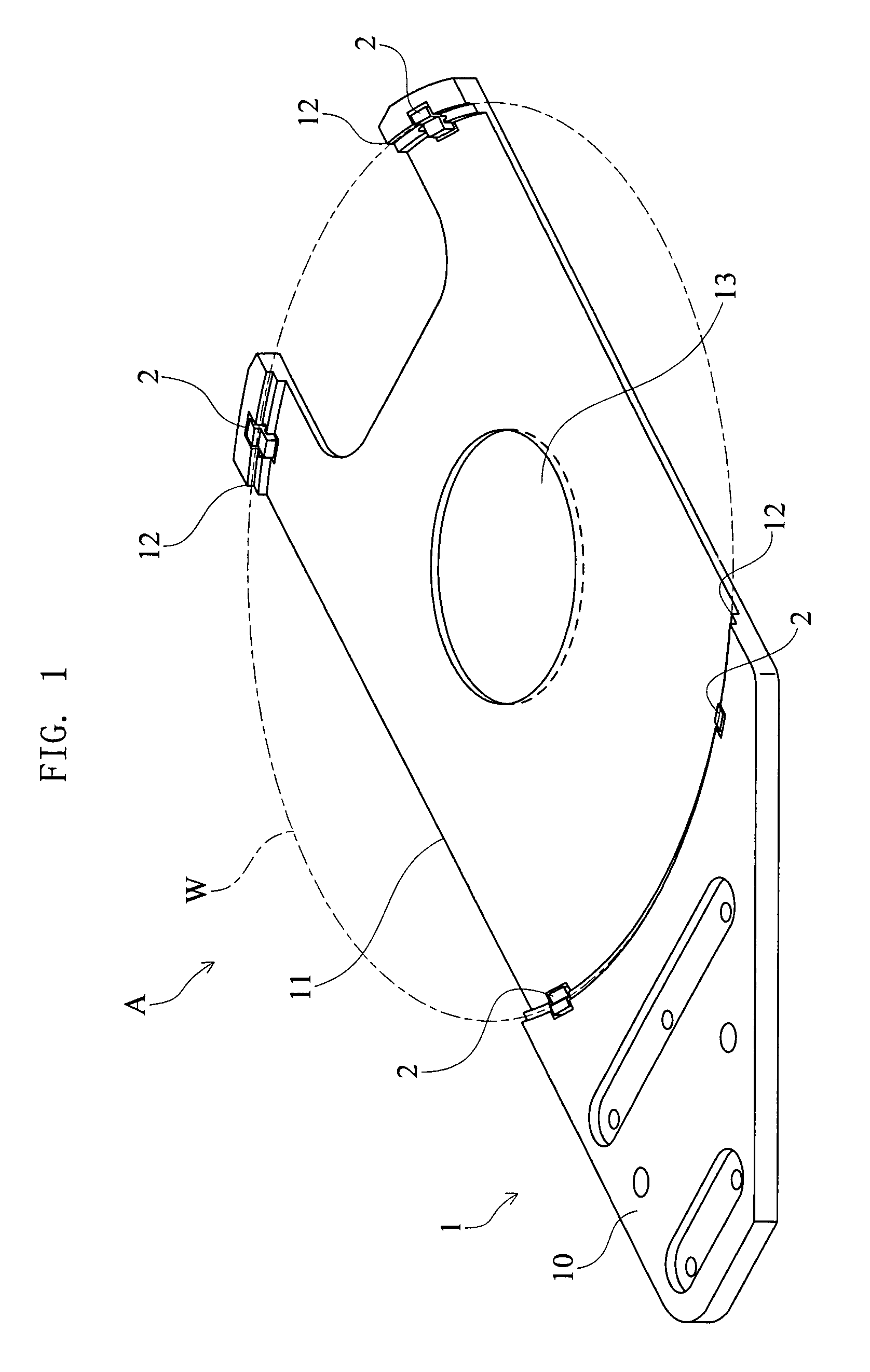

Wafer processing apparatus with wafer alignment device

ActiveUS7963736B2Increase speedProgramme controlSemiconductor/solid-state device manufacturingEngineeringSemiconductor

A semiconductor-processing apparatus includes: a wafer handling chamber; a wafer processing chamber; a wafer handling device; a first photosensor disposed in the wafer handling chamber in front of the wafer processing chamber at a position where the wafer partially blocks light received by the first photosensor at a ready-to-load position and substantially entirely blocks light received by the first photosensor when the wafer moves from the ready-to-load position toward the wafer processing chamber in the x-axis direction; and a second photosensor disposed in the wafer handling chamber in front of the wafer processing chamber at a position where the wafer does not block light received by the second photosensor at the ready-to-load position and partially blocks light received by the second photosensor when the wafer moves from the ready-to-load position toward the wafer processing chamber in the x-axis direction.

Owner:ASM JAPAN

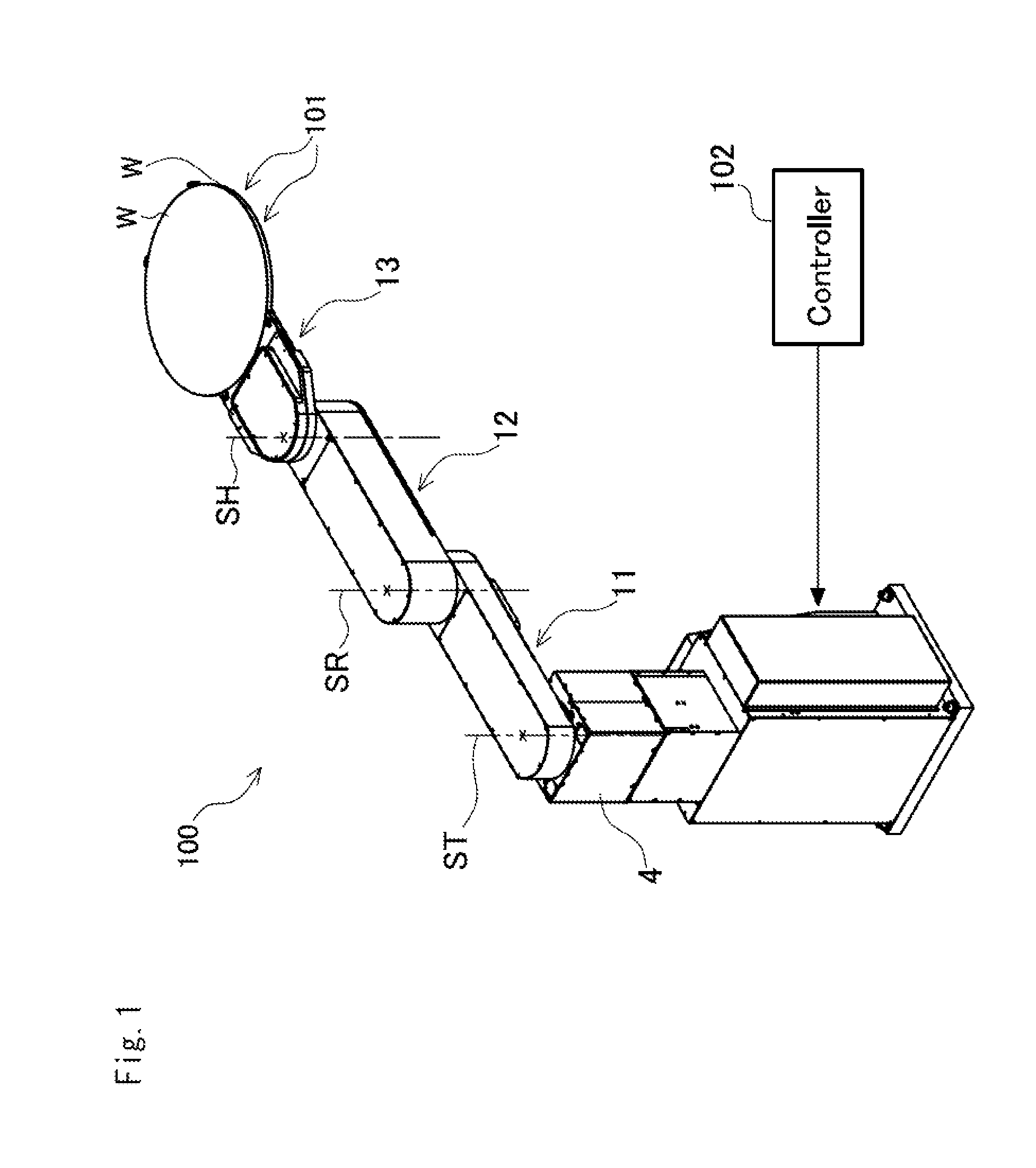

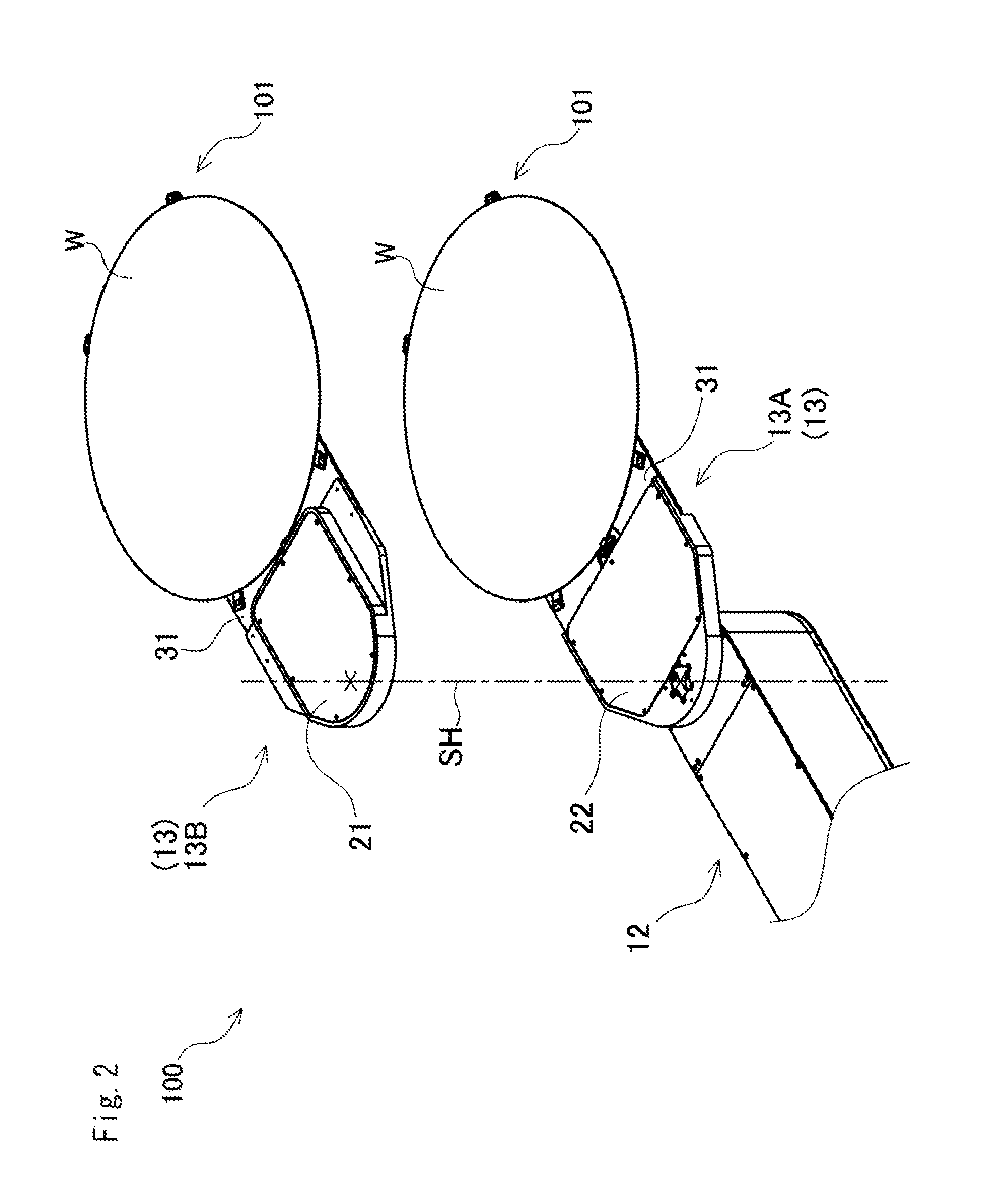

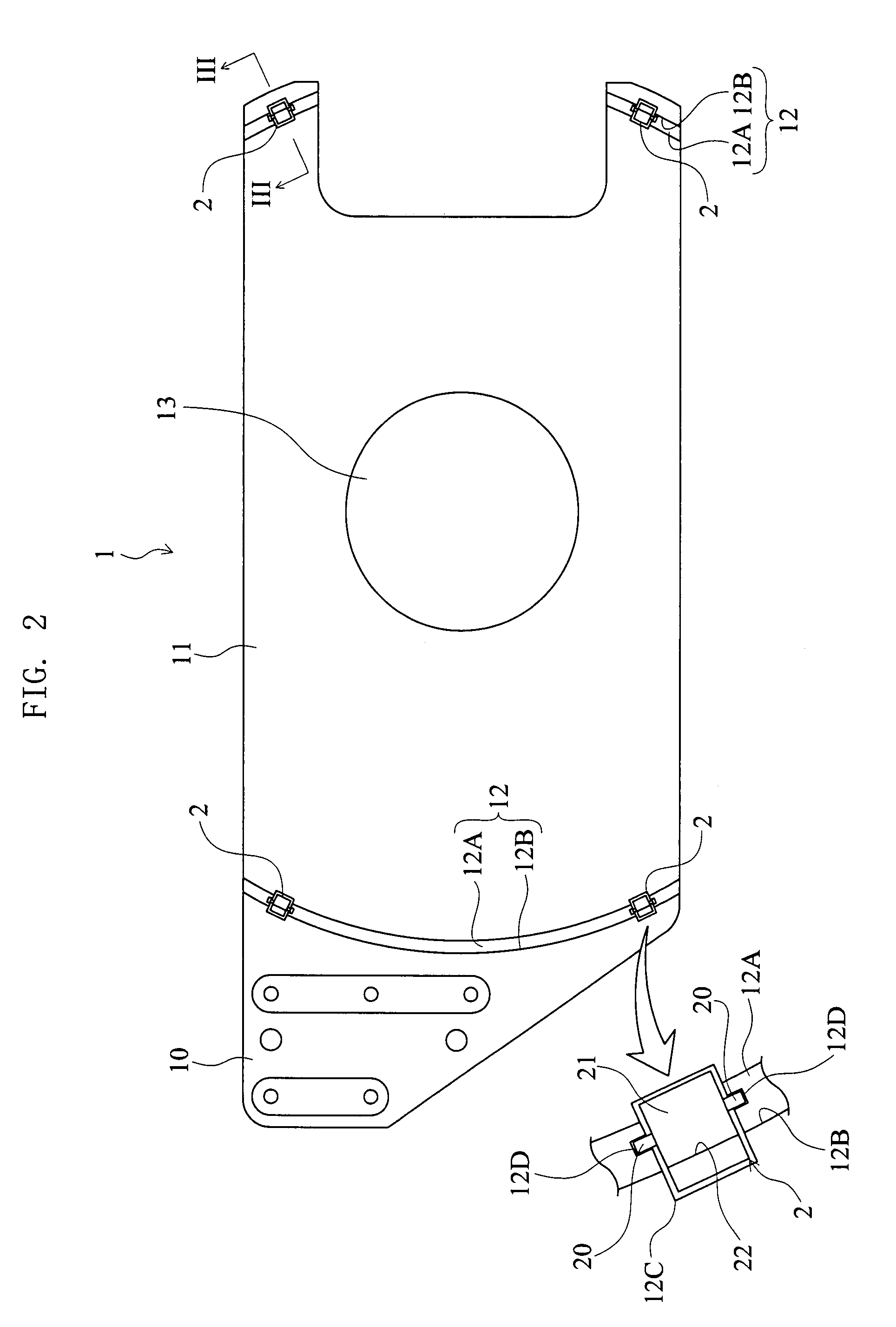

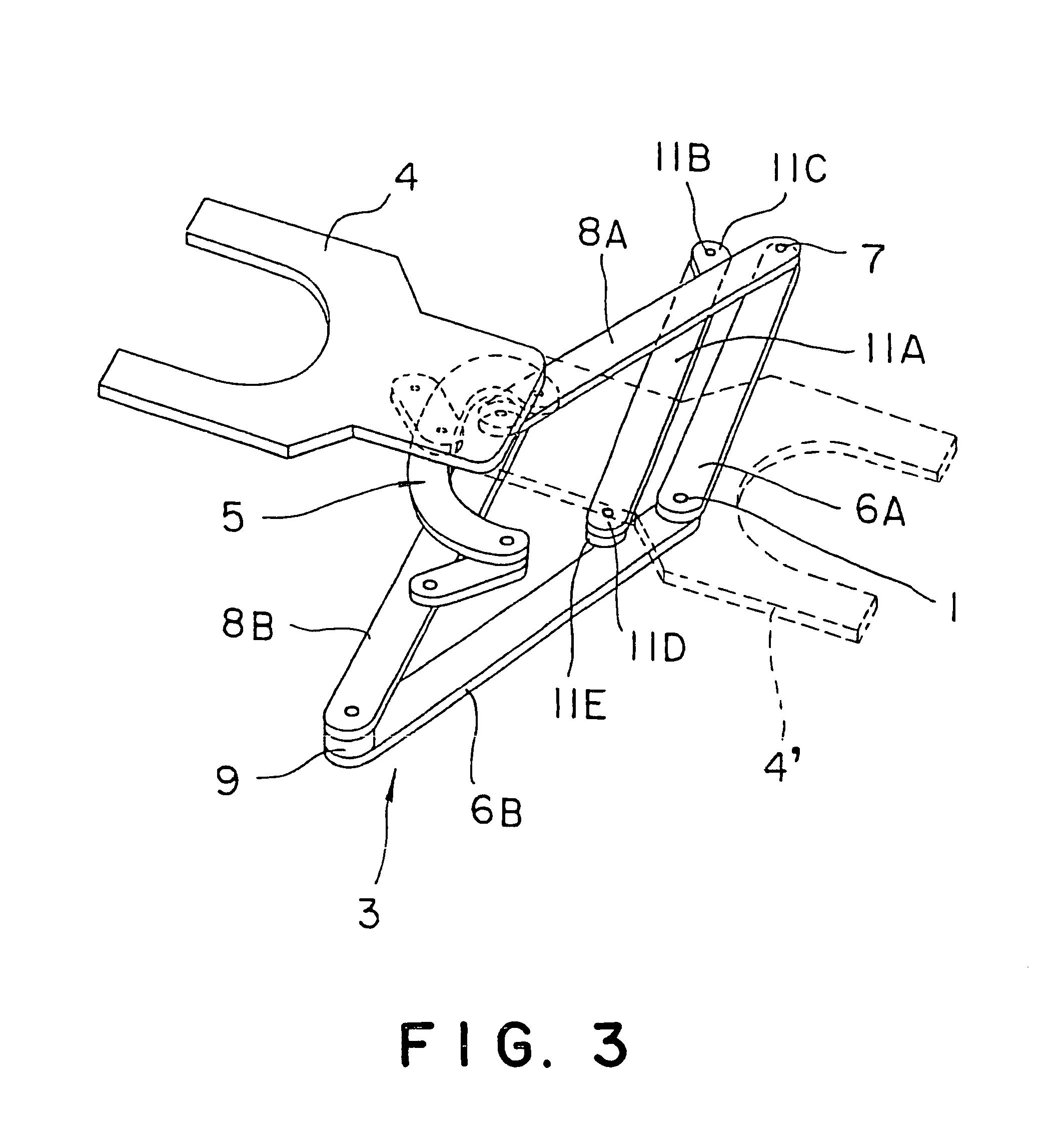

Clamping device and workpiece conveying robot

InactiveUS8764085B2High positionalImprove retentionGripping headsSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

Owner:SINFONIA TECHNOLOGY CO LTD

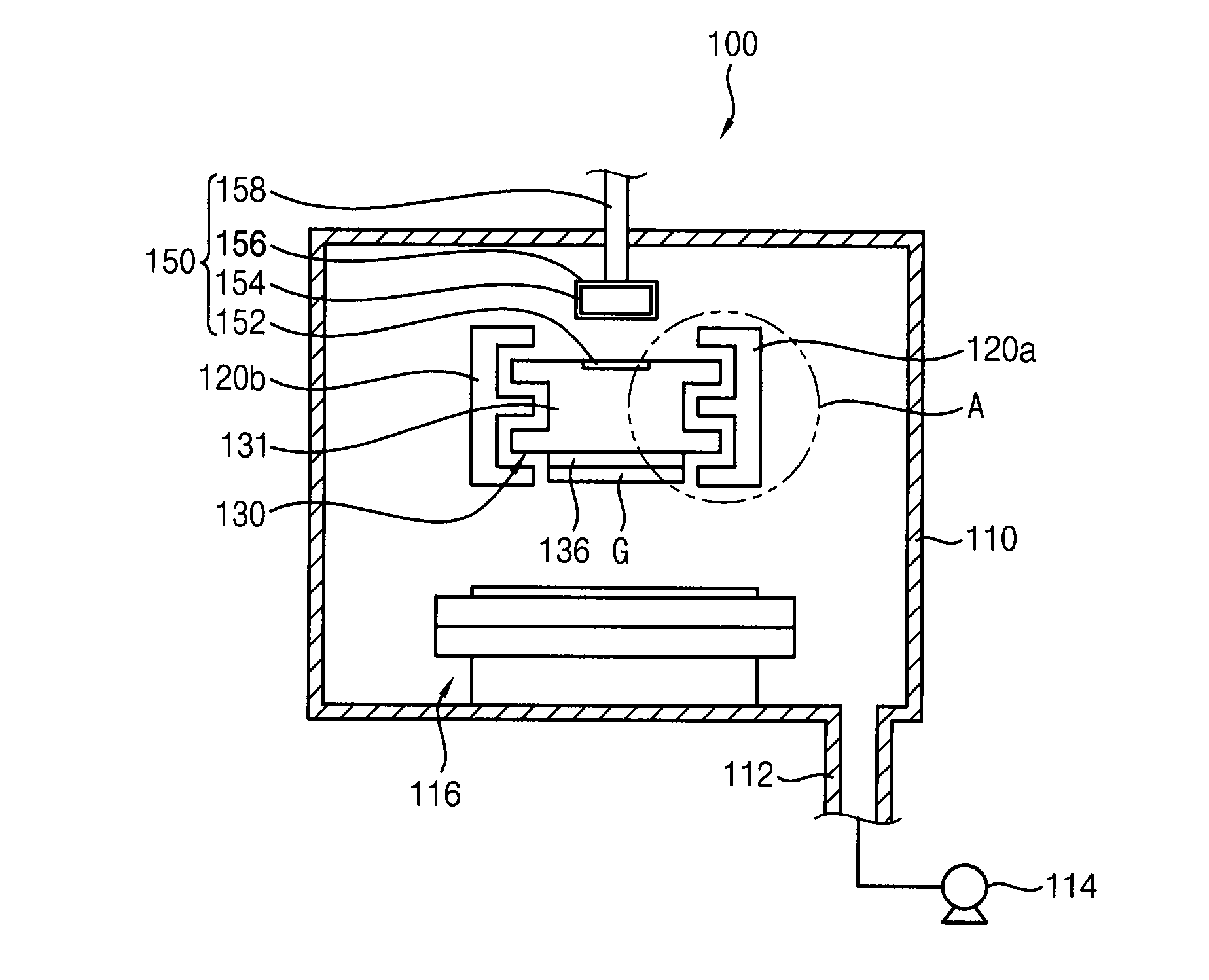

Semiconductor processing system

InactiveUS20070107845A1Easy to mergeSemiconductor/solid-state device manufacturingCharge manipulationAtmospheric pressureIntermediate structure

A semiconductor processing system includes an intermediate structure disposed between an atmospheric pressure entrance transfer chamber and a vacuum common transfer chamber. The intermediate structure includes a transfer passage for a target substrate to pass therein. The transfer passage includes a first buffer chamber a middle transfer chamber and a second buffer chamber detachably connected. An additional processing apparatus is detachably connected to the middle transfer chamber. The intermediate structure is selectively arranged in first or second state. In the first state, the additional processing apparatus performs a vacuum process, while the first buffer chamber is a load-lock chamber. In the second state, the additional processing apparatus performs an atmospheric pressure process, while the second buffer chamber is a load-lock chamber.

Owner:ISHIZAWA SHIGERU +6

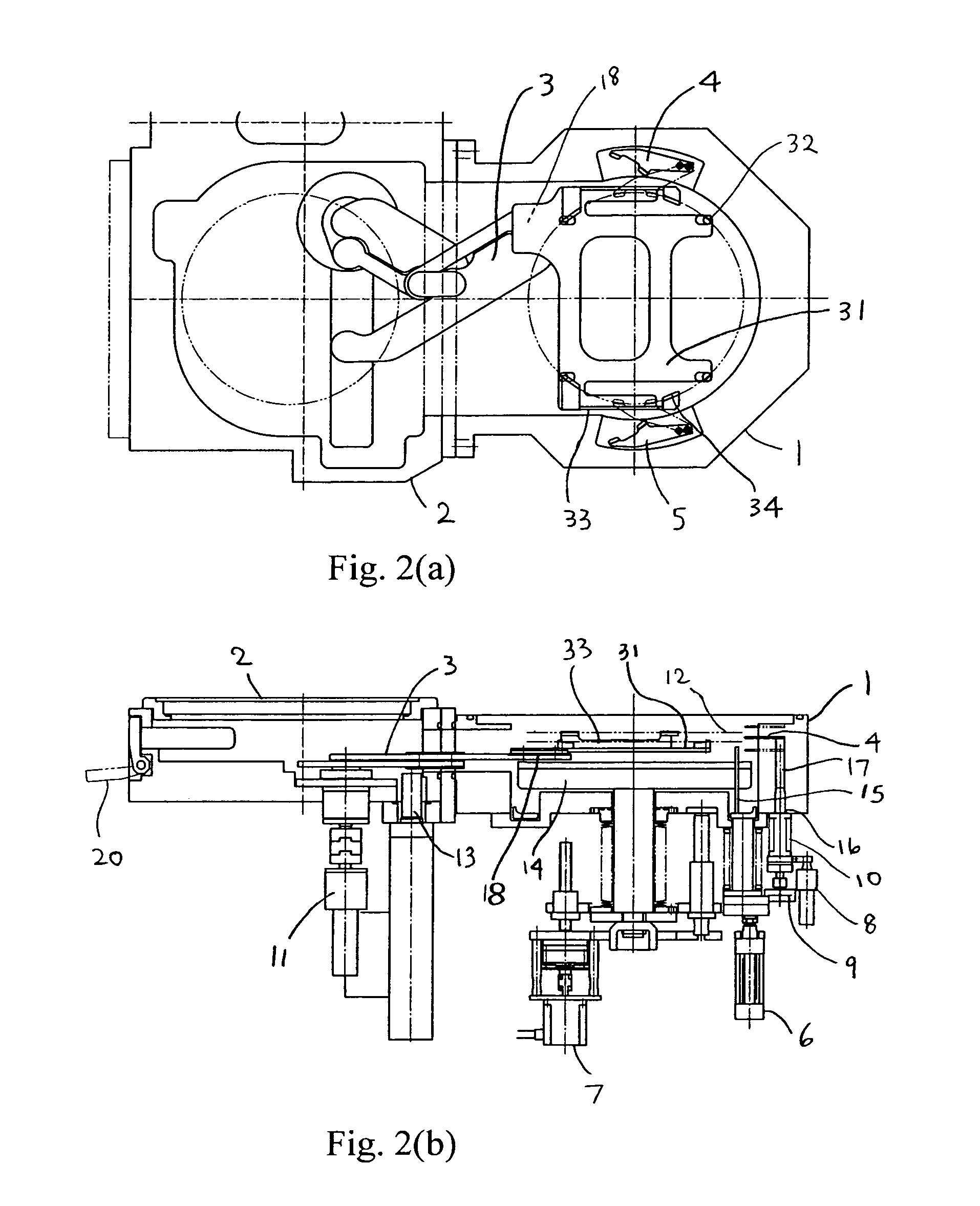

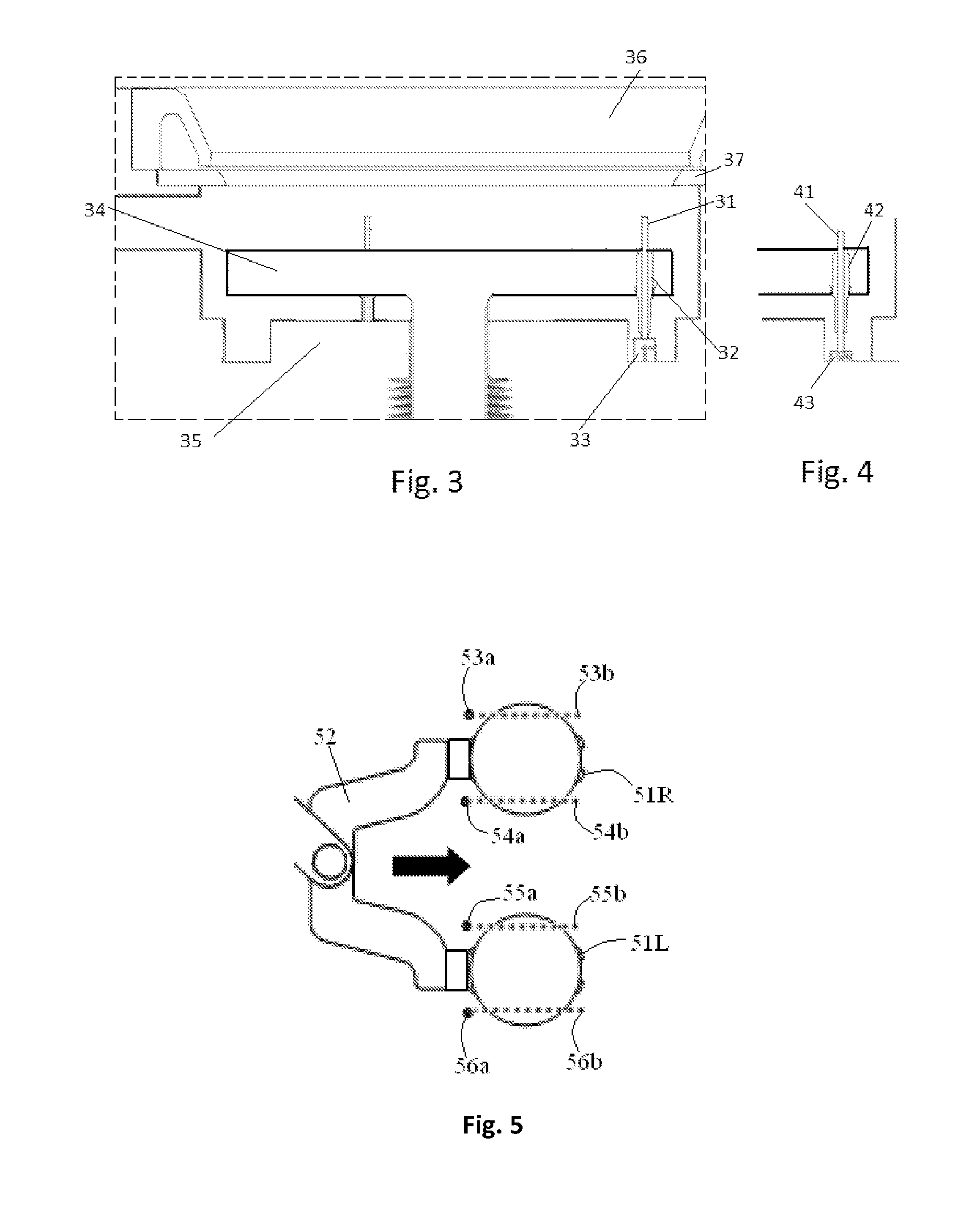

Semiconductor processing apparatus comprising chamber partitioned into reaction and transfer sections

InactiveUS6899507B2Reduce adhesionImprove efficiencySemiconductor/solid-state device manufacturingCharge manipulationEngineeringSemiconductor

Semiconductor processing equipment that has increased efficiency, throughput, and stability, as well as reduced operating cost, footprint, and faceprint is provided. Other than during deposition, the atmosphere of both the reaction chamber and the transfer chamber are evacuated using the transfer chamber exhaust port, which is located below the surface of the semiconductor wafer. This configuration prevents particles generated during wafer transfer or during deposition from adhering to the surface of the semiconductor wafer. Additionally, by introducing a purge gas into the transfer chamber during deposition, and by using an insulation separating plate 34, the atmospheres of the transfer and reaction chambers can be effectively isolated from each other, thereby preventing deposition on the walls and components of the transfer chamber. Finally, the configuration described herein permits a wafer buffer mechanism to be used with the semiconductor processing equipment, thereby further increasing throughput and efficiency.

Owner:ASM JAPAN

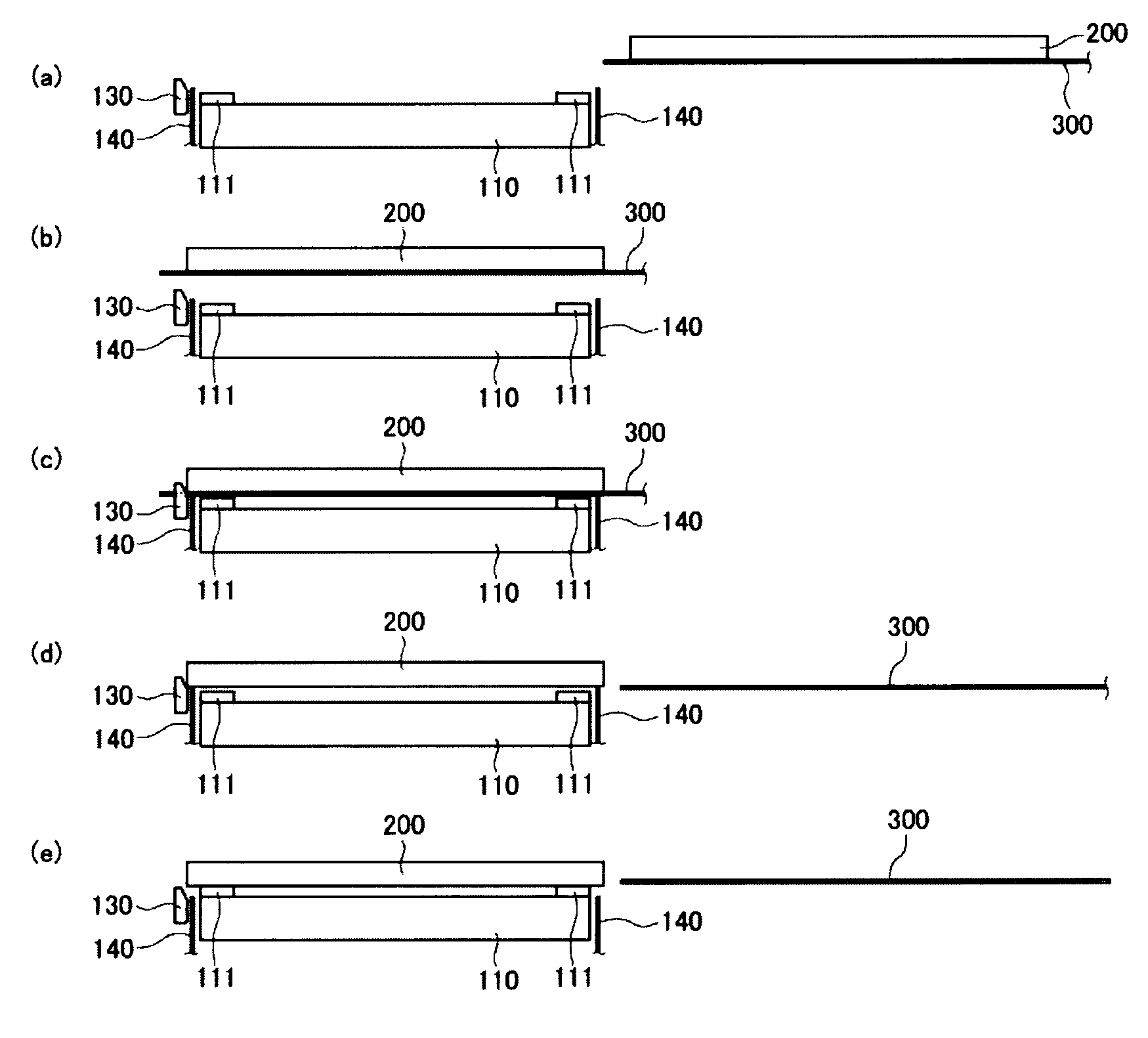

Substrate transfer device and substrate processing system

InactiveUS20130180448A1Suppress position deviationHigh positioning accuracyLiquid surface applicatorsSemiconductor/solid-state device manufacturingRoom temperatureProcessing element

A substrate transfer device includes a pick which has positioning pins to position a substrate and holds a positioned substrate; a drive unit which drives the pick such that the substrate is loaded / unloaded to / from a vacuum processing unit by using a pick; and a transfer control unit which controls a transfer operation of the substrate using the pick. The transfer control unit obtains in advance information on a reference position of the substrate at room temperature when the substrate is loaded into the vacuum processing unit, calculates a positional deviation from the reference position of the substrate when the substrate is loaded into the vacuum processing unit in actual processing, and controls a drive unit such that the substrate is loaded into the vacuum processing unit by correcting the positional deviation.

Owner:TOKYO ELECTRON LTD

Spring retained end effector contact pad

ActiveUS8864202B1Reduce dispersionSecure attachmentGripping headsSemiconductor/solid-state device manufacturingContact padActuator

An end effector is disclosed for use in substrate processing. The end effector includes a effector body portion, a contact pad pocket formed in the end effector body, a spring retaining pocket formed in the end effector body adjacent the contact pad pocket and extending to an edge of the end effector body, and a pair of through-holes extending from the spring retaining pocket to the contact pad pocket. The end effector can include a contact pad seated within the contact pad pocket, the contact pad having at least one retaining channel formed therein, and a retaining spring having a pair of retaining arms extending from the retaining spring pocket through the through-holes and into the contact pad pocket. The retaining arms may extend at least partially into the at least one retaining channel of the contact pad and may thereby restrict movement of the contact pad.

Owner:VARIAN SEMICON EQUIP ASSOC INC

Work holding mechanism

ActiveUS7748760B2Improve shipping speedVacuum operationGripping headsSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

Owner:DAIHEN CORP

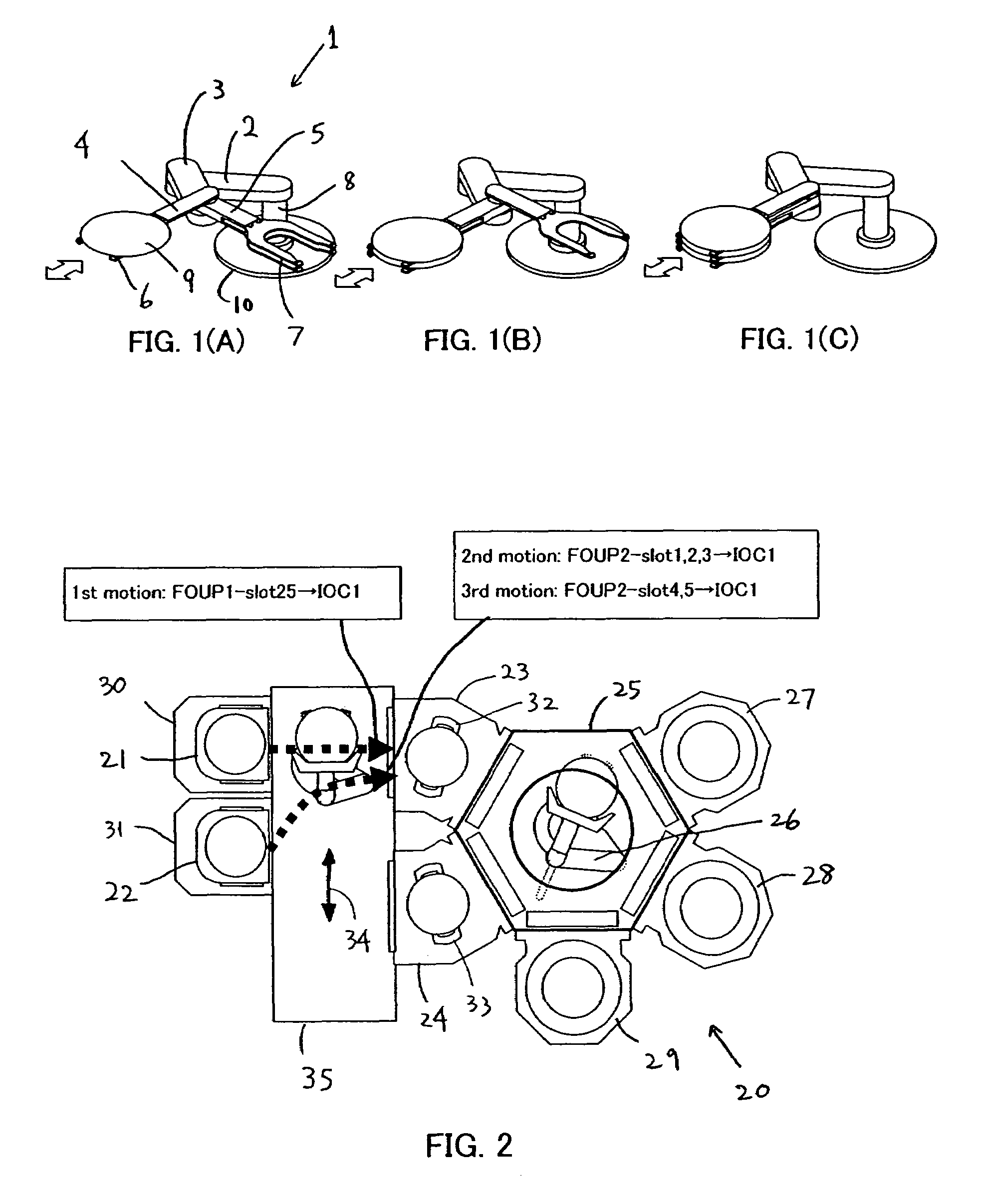

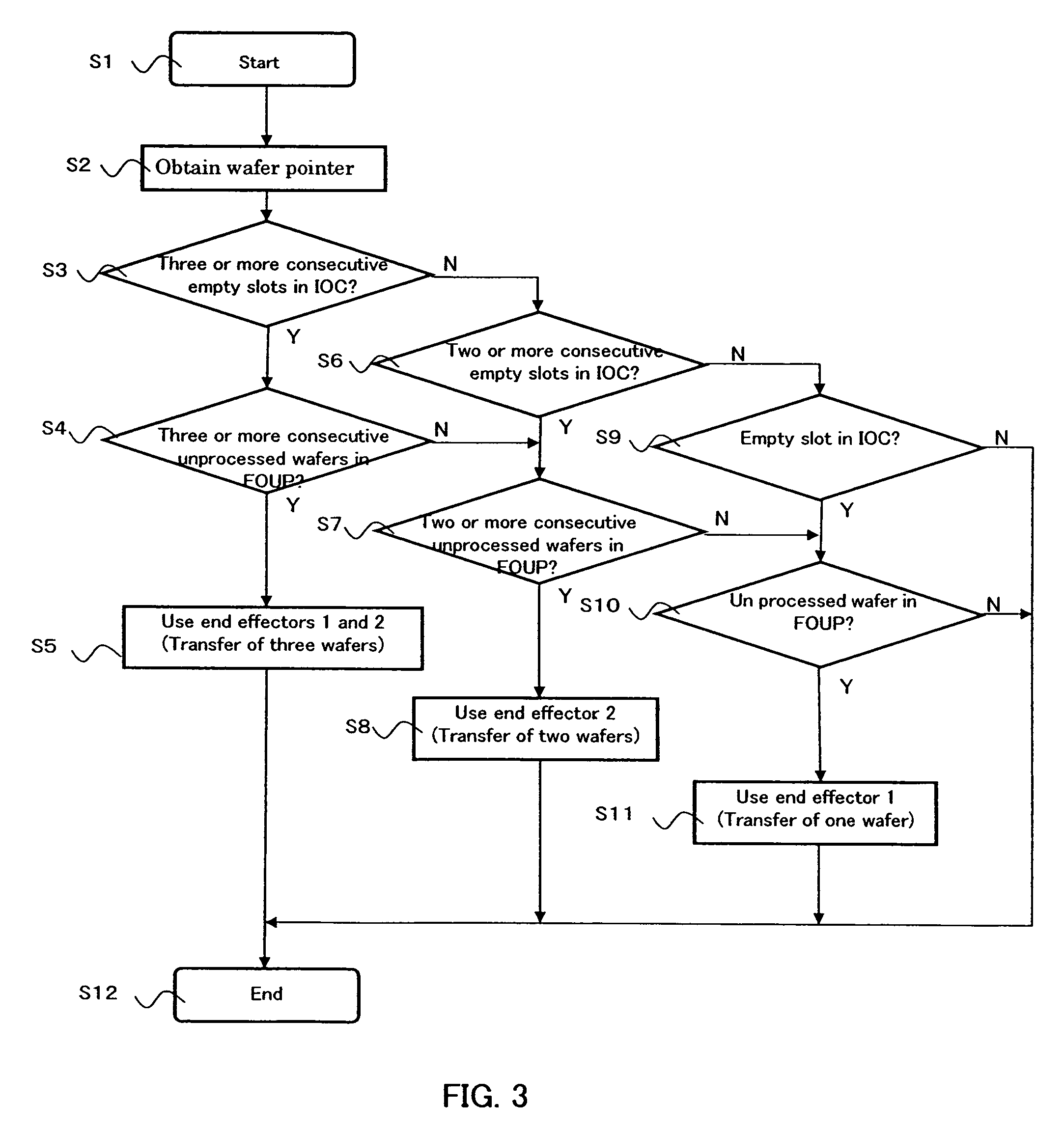

Semiconductor substrate transfer apparatus and semiconductor substrate processing apparatus equipped with the same

A semiconductor substrate transfer apparatus for transferring semiconductor substrates from a first container to a second container, includes: multiple end effectors; at least one robot arm with which the multiple end effectors are independently rotatably joined; and a controller storing software including instructions to judge which end effector or end effectors in the multiple end effectors are to be selected based on a distribution status of substrates stored in the first and second containers and to rotate the selected end effector(s) for unloading a substrate or substrates from the first container and loading the substrate or substrates to the second container.

Owner:ASM JAPAN

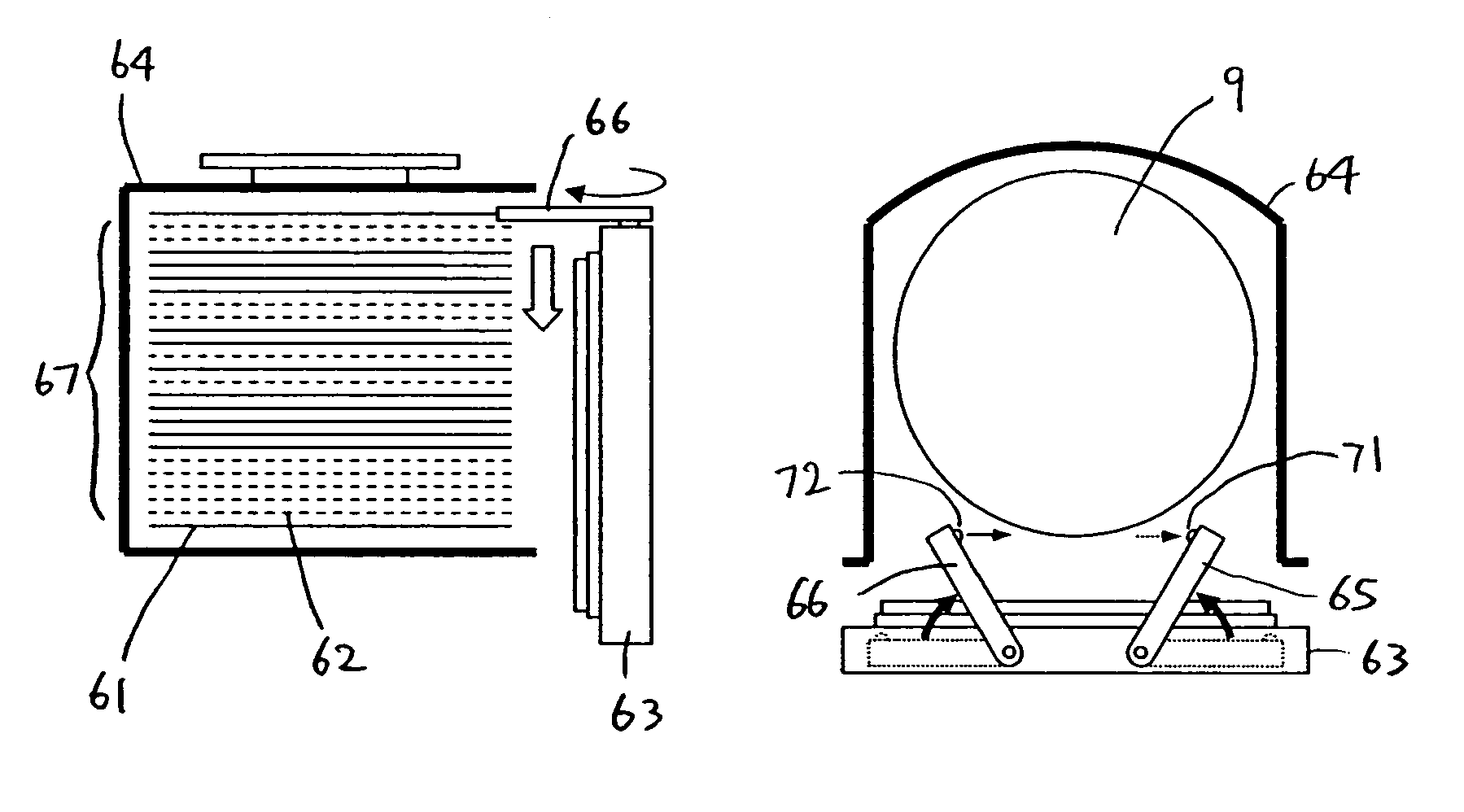

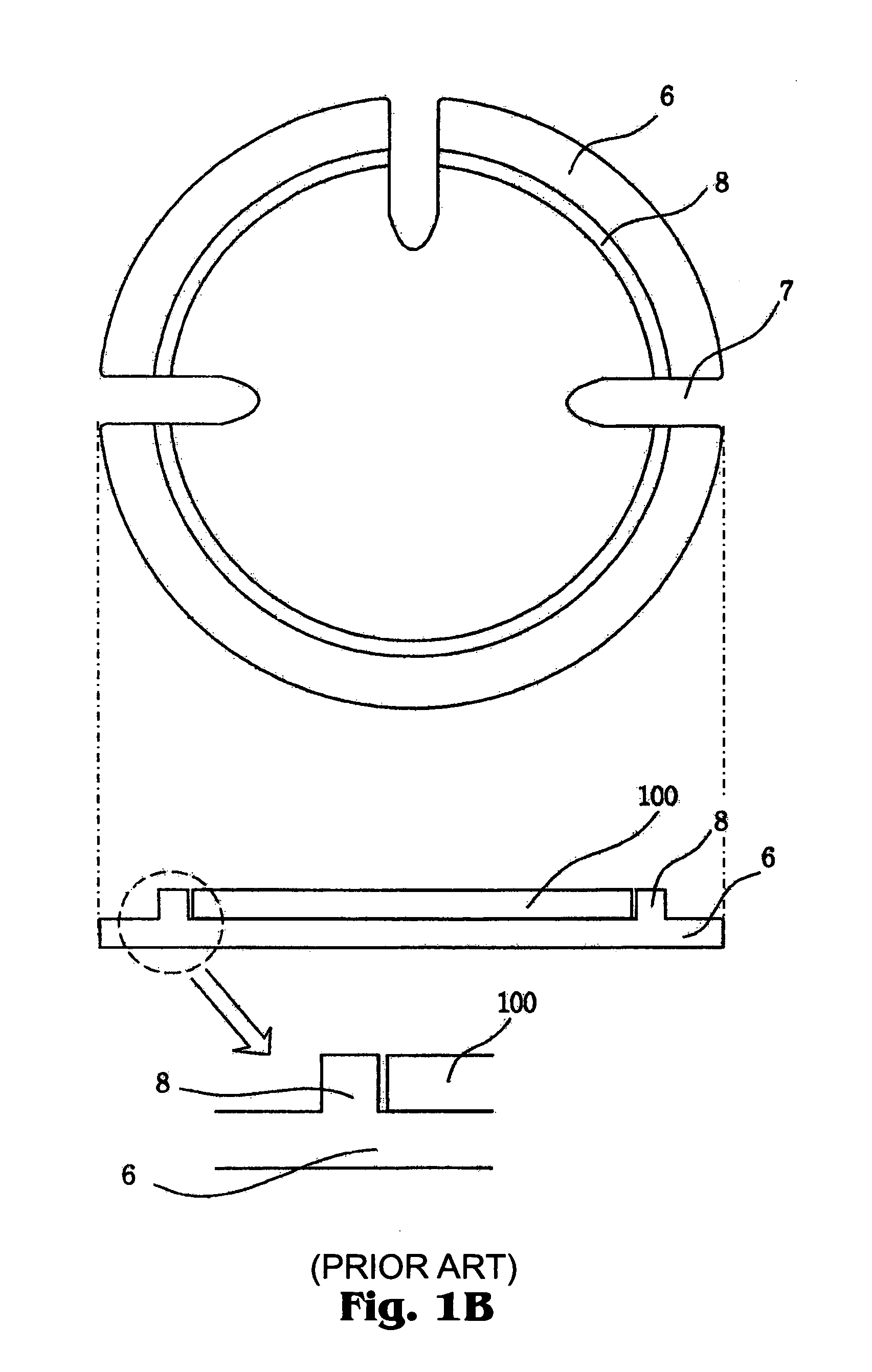

Semiconductor manufacturing system and wafer holder for semiconductor manufacturing system

InactiveUS7207763B2Improves yield and productivitySemiconductor/solid-state device manufacturingPlatesWaferingEngineering

A semiconductor manufacturing system and wafer holder for a semiconductor manufacturing system which prevents a semiconductor wafer from being exposed to a process reaction and which includes a reaction tube for providing a sealed process space and a dual boat and which prevents the backside deposition by the wafer holder. The wafer holder includes a holder body to hide the backside of the semiconductor wafer during a process in the reaction tube and a wafer lifter having a portion that can be disengaged from and coupled to the holder body so that a lower portion of the semiconductor wafer is supported by the dual boat and so that the semiconductor wafer can be lifted up from the wafer body when the semiconductor wafer is loaded and unloaded. A separation boundary between the holder body and the wafer lifter includes a gas inflow interception surface to hinder reaction gas from flowing through the separation boundary.

Owner:TERASEMICON CO LTD

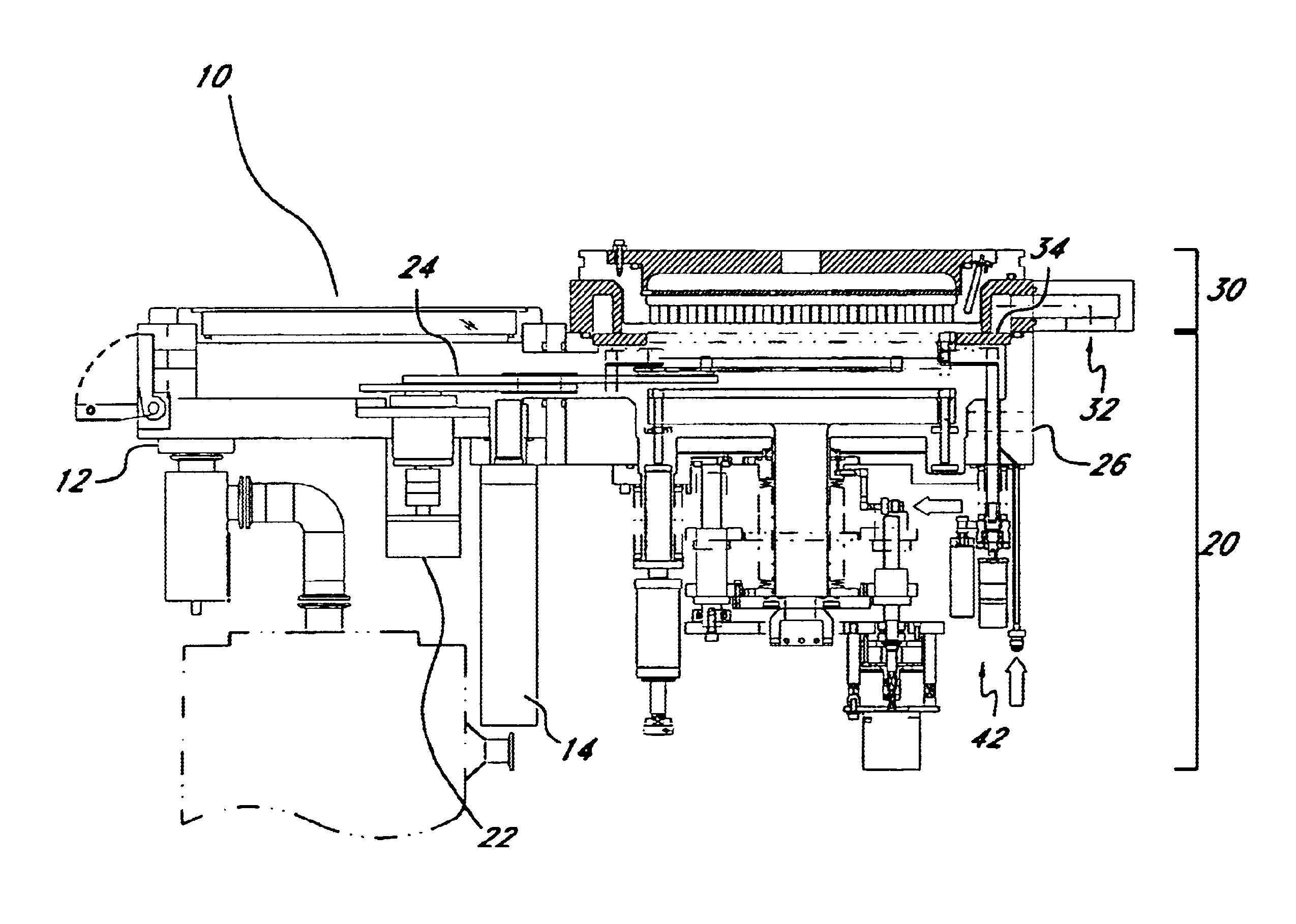

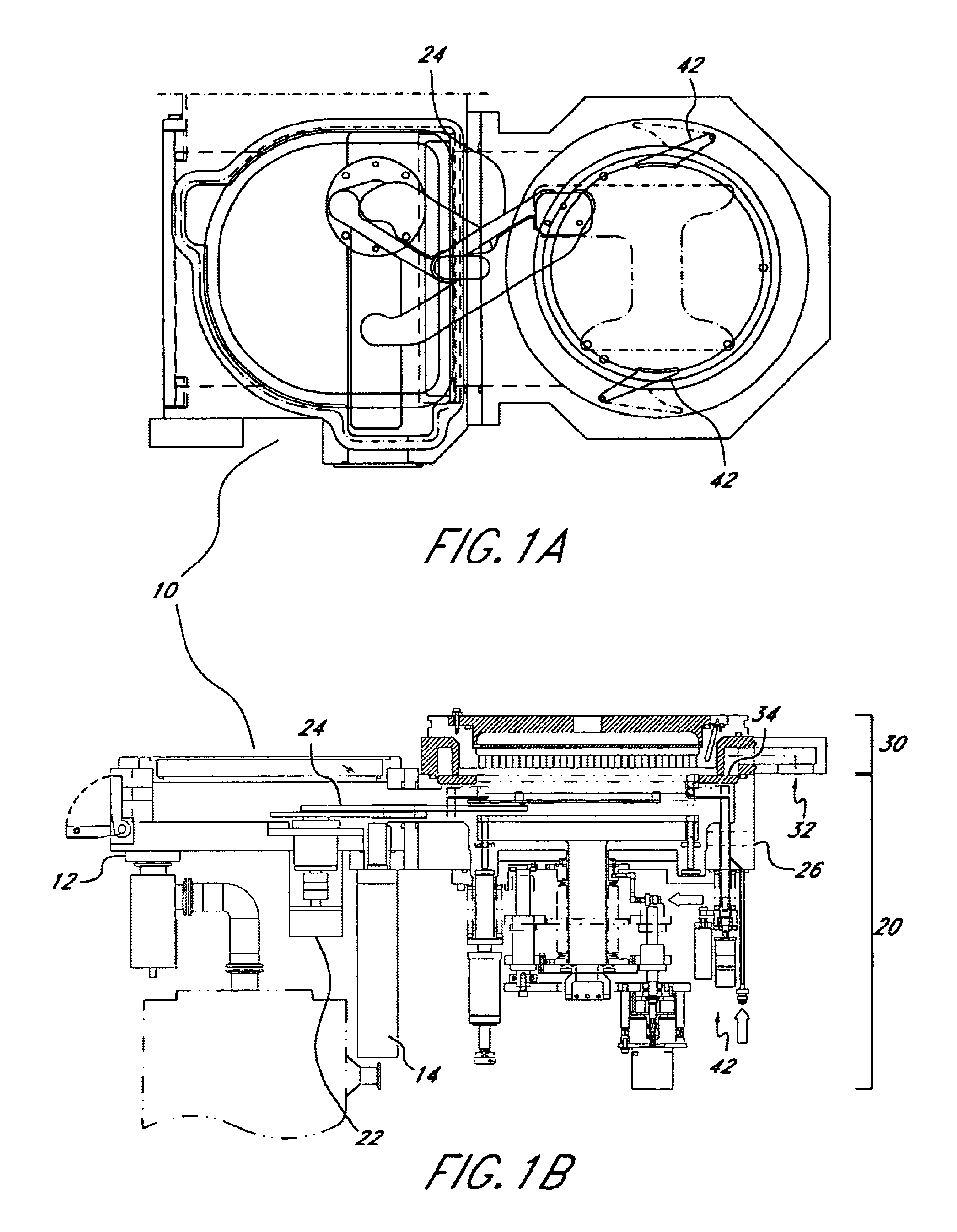

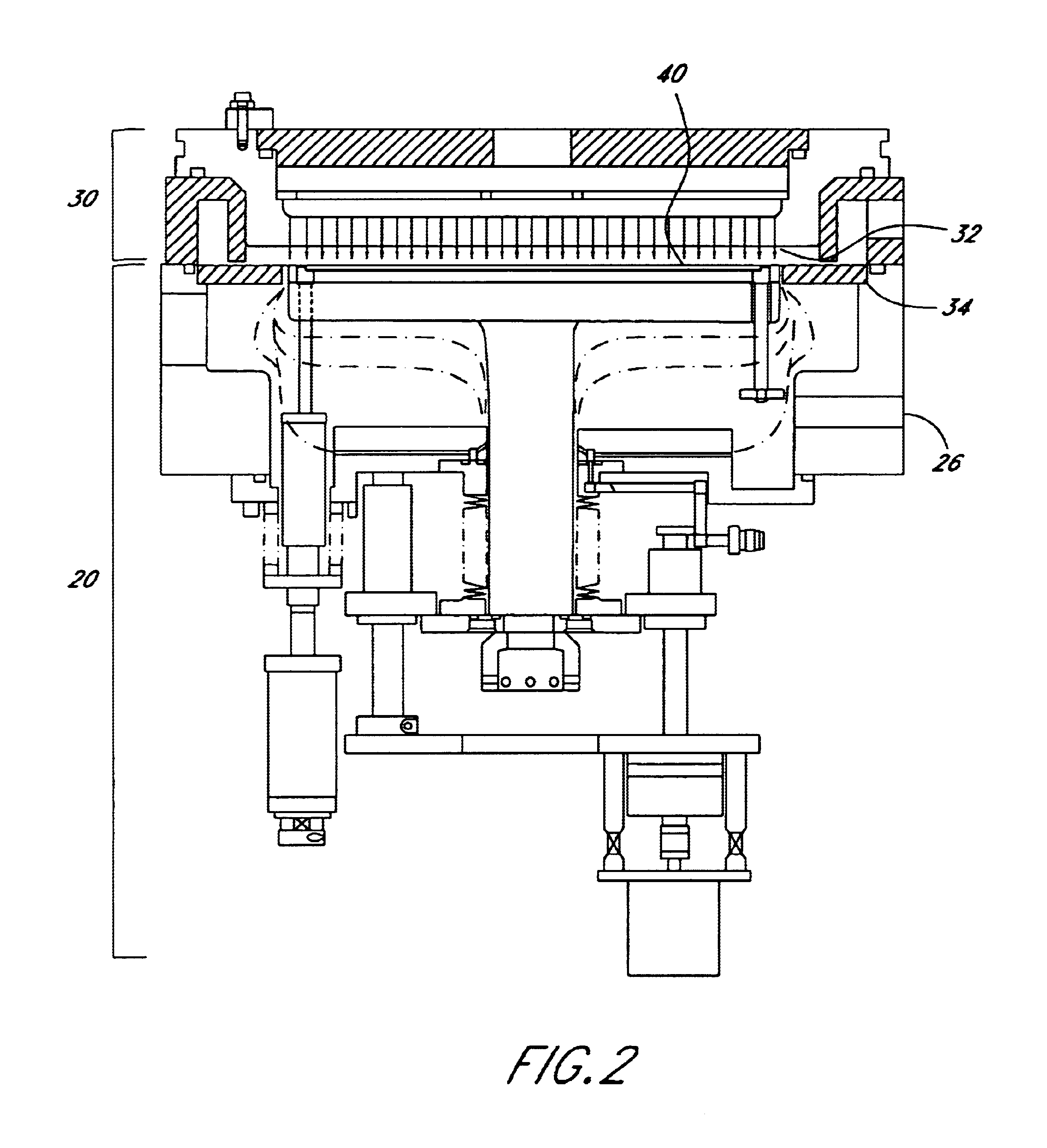

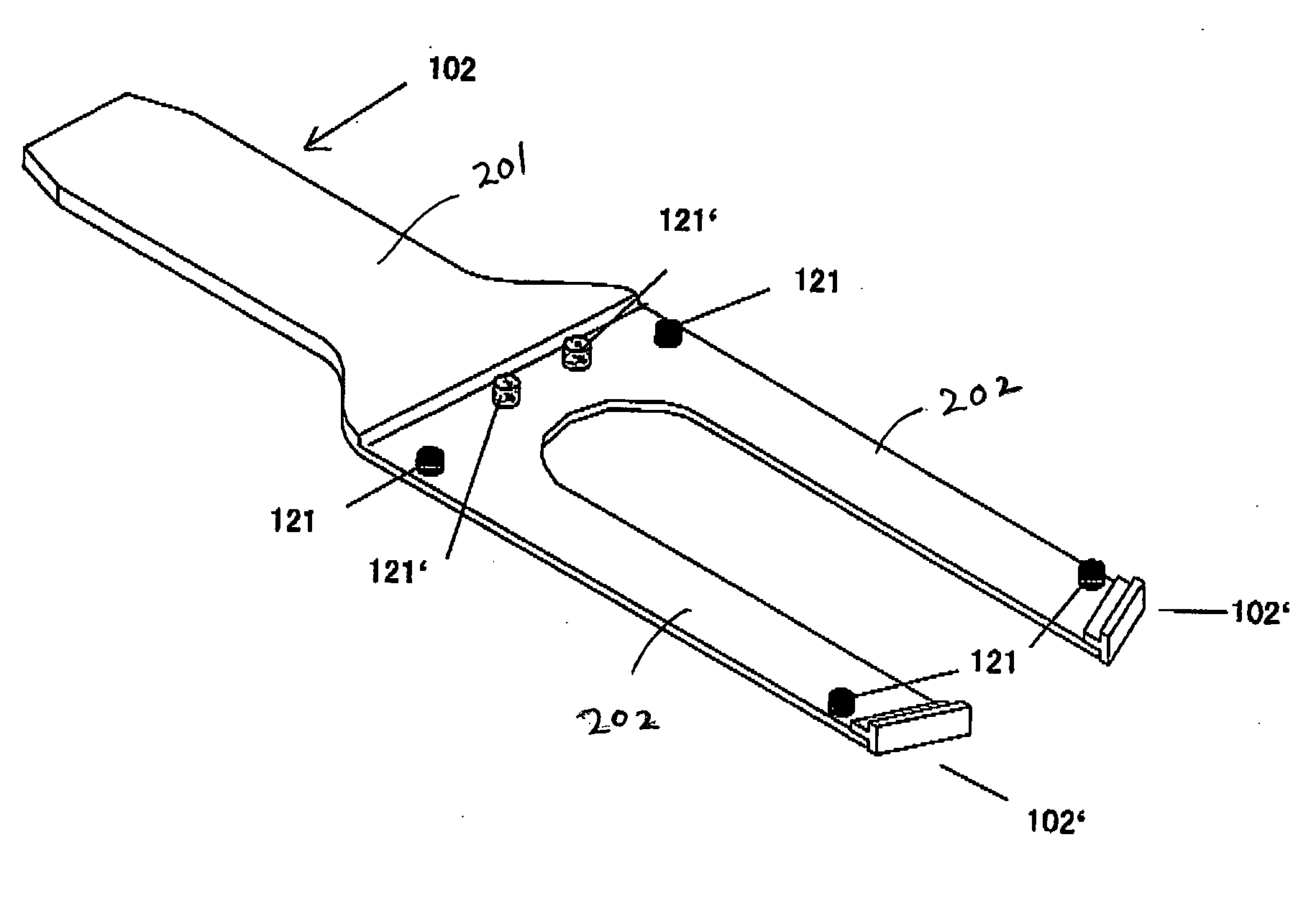

Substrate-processing apparatus with buffer mechanism and substrate-transferring apparatus

ActiveUS7690881B2Low costSmall footprintPliersSemiconductor/solid-state device manufacturingEngineeringActuator

A substrate transfer apparatus for loading and unloading substrates in a reaction chamber, includes: an arm having a distal end which is laterally movable in a straight line direction; and end-effectors for loading and unloading substrates in a reaction chamber, which include a lower end-effector and an upper end-effector. One of the lower end-effector or the upper end-effector is movably coupled to the arm at a distal end of the arm, and the other end-effector is fixed to the movably coupled end-effector. The fixed end-effector is fixed to the movably coupled end-effector.

Owner:ASM JAPAN

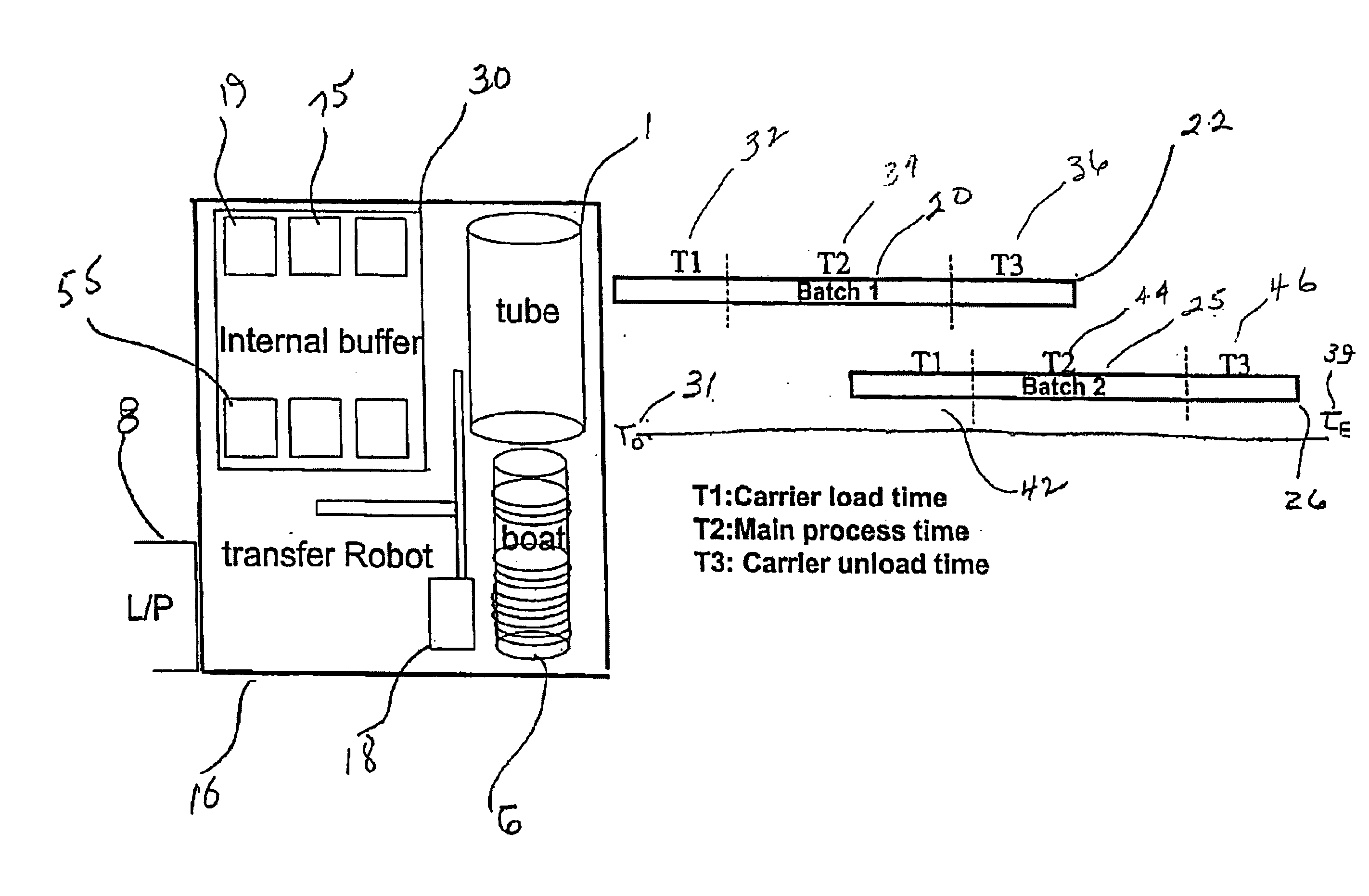

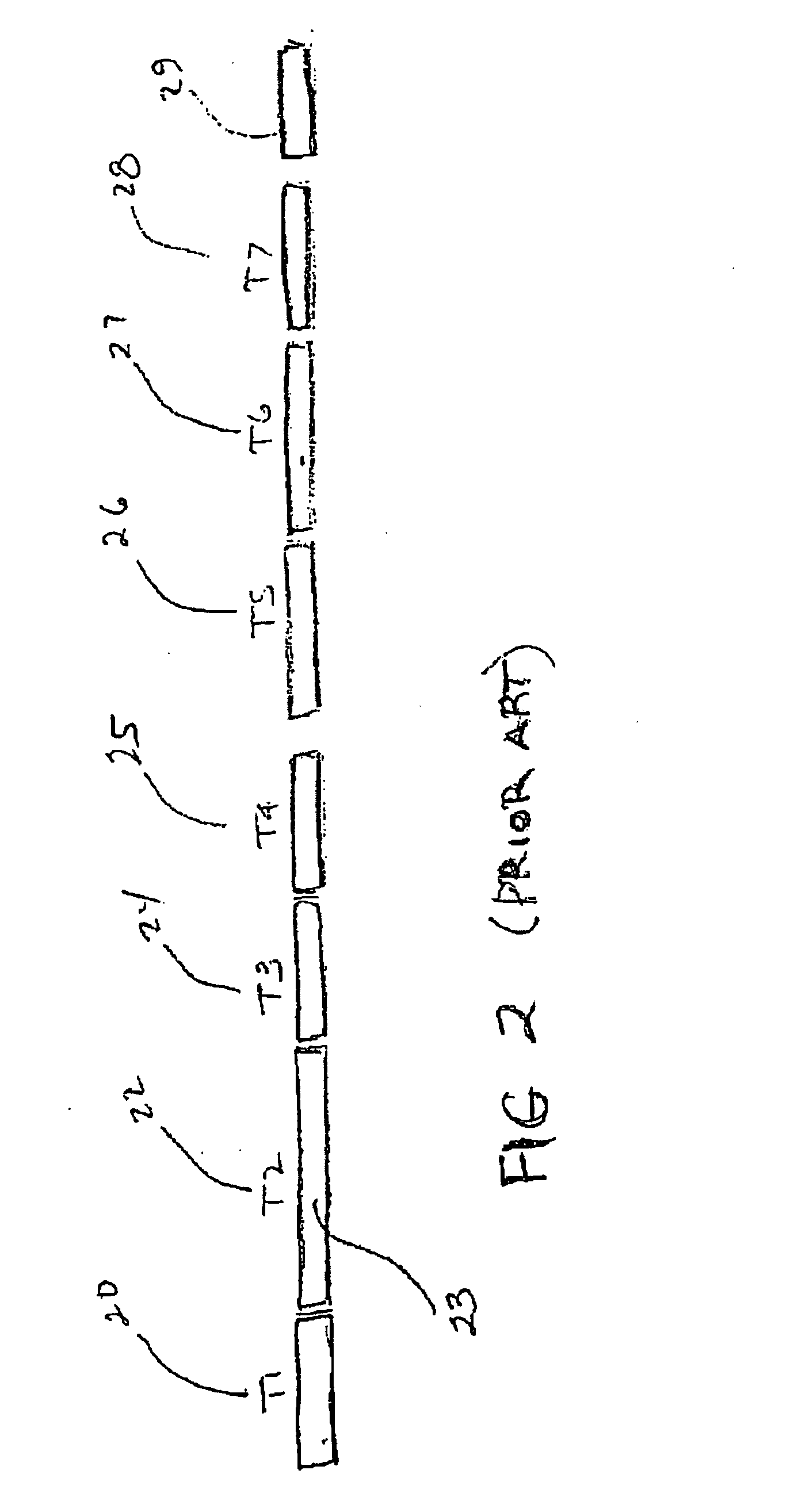

Intelligent full automation controlled flow for a semiconductor furnace tool

InactiveUS20050187647A1Reduce idle timeSemiconductor/solid-state device manufacturingSpecial data processing applicationsControl flowAutomatic control

The present invention relates to an apparatus and method for processing the flow of semiconductor wafers through a furnace tool having a front-opening unified pod (FOUP) material handling system. The invention provides for an automated control flow to realize greater efficiency and assure process quality. In one aspect of the invention the wafer batch completing its operation is discharged simultaneous with the charging of the next batch. Essentially the operation takes place by overlapping processing operations. An embodiment of the invention includes a process comprising the steps of: providing a first batch of semiconductor material, and loading the first batch into a carrier which transports the first batch into a semiconductor manufacturing process, and while the first batch undergoes the process, forming a second batch of semiconductor material, and pausing a second batch process operation until the first batch completes processing, to reduce the idle time of said process.

Owner:TAIWAN SEMICON MFG CO LTD

Wafer transfer mechanism

InactiveUS20060113806A1Easy to useEasy transferSemiconductor/solid-state device manufacturingCharge manipulationEngineeringTransfer mechanism

A transfer mechanism for transferring a workpiece includes an arm member including a tip projection provided at a tip end thereof for contacting a periphery of the workpiece and restricting movement of the workpiece. The arm member further includes multiple supporting projections protruding from a top surface thereof for contacting and supporting a back side of the workpiece.

Owner:ASM JAPAN

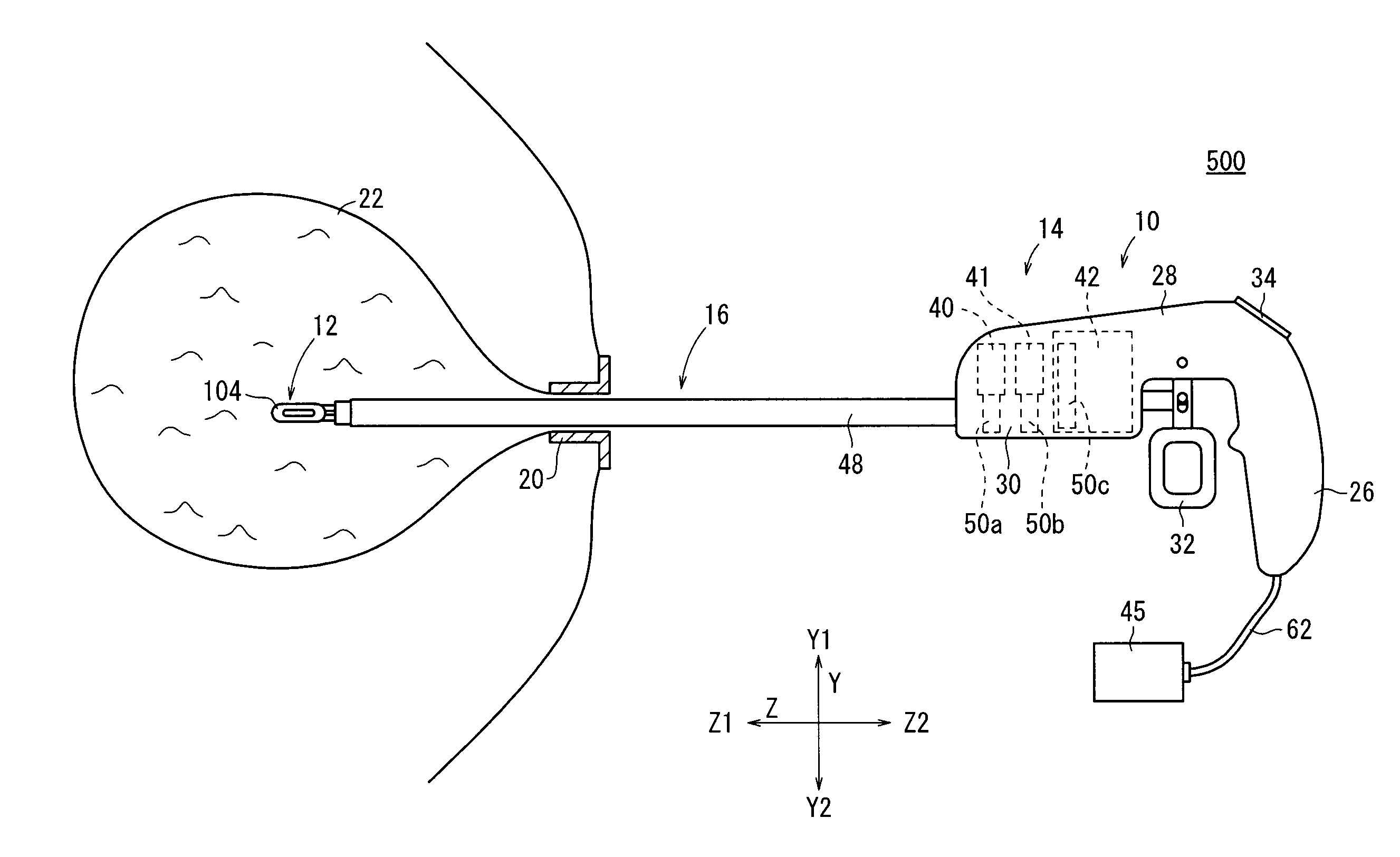

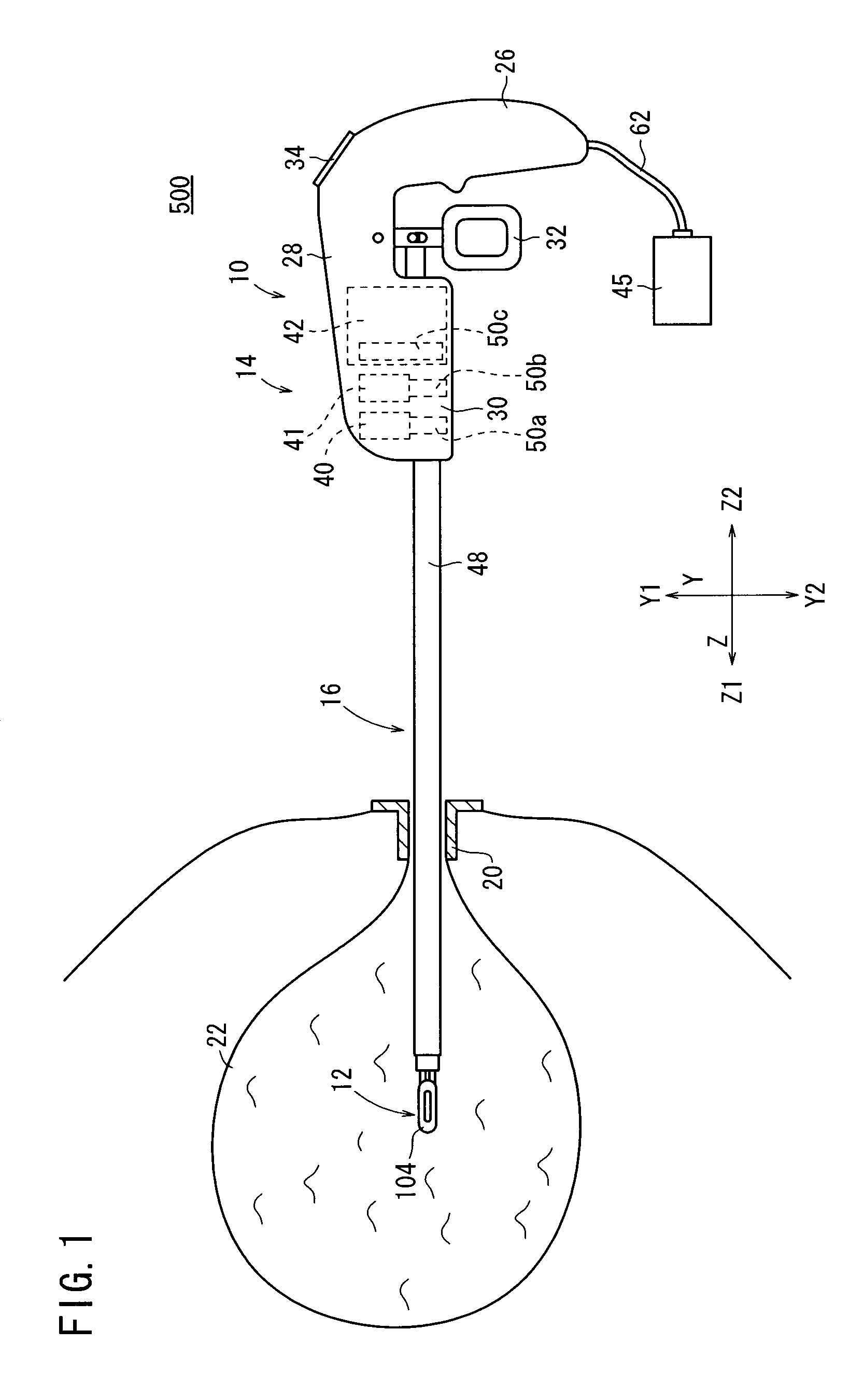

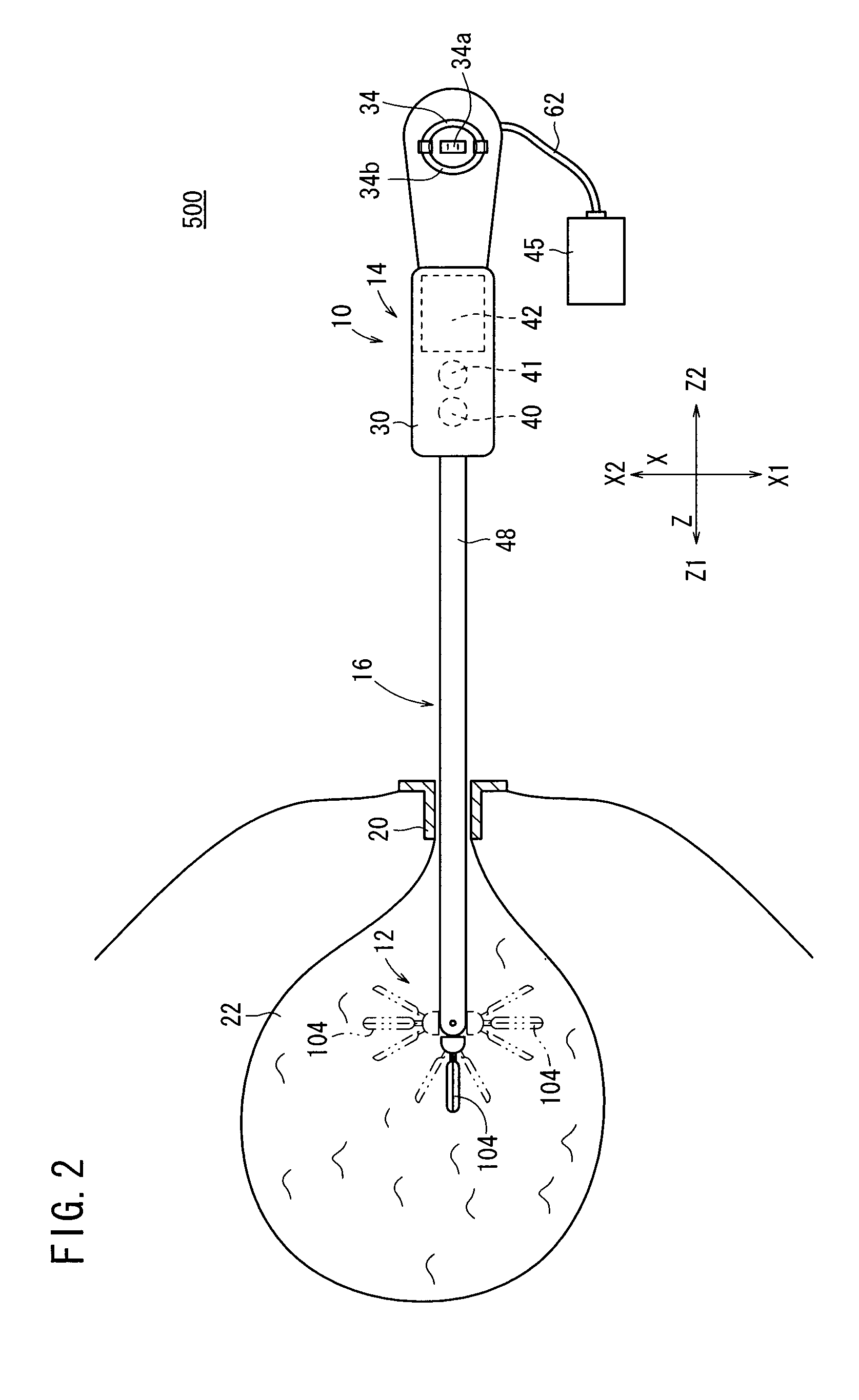

Manipulator system and manipulator control method

InactiveUS20090110533A1Increase freedomAdjustable effectDiagnosticsSemiconductor/solid-state device manufacturingWork unitActuator

A manipulator has an operating unit including a trigger lever, a distal end working unit including an end effector and a yaw axis and a roll axis for changing the direction of the end effector, and a connector shaft interconnecting the operating unit and the distal end working unit. The operating unit includes an actuator block housing therein motors for actuating the yaw axis and the roll axis and a gripper operational quantity corrector for mechanically transmitting an operational action of the trigger lever to actuate the end effector. A controller calculates an interference amount caused on the end effector by the attitude angles of the yaw axis and the roll axis. The gripper operational quantity corrector is controlled by the controller to extend or retract a push rod, for correcting the operational quantity of the operational action of the trigger lever to compensate for the interference amount.

Owner:KK TOSHIBA

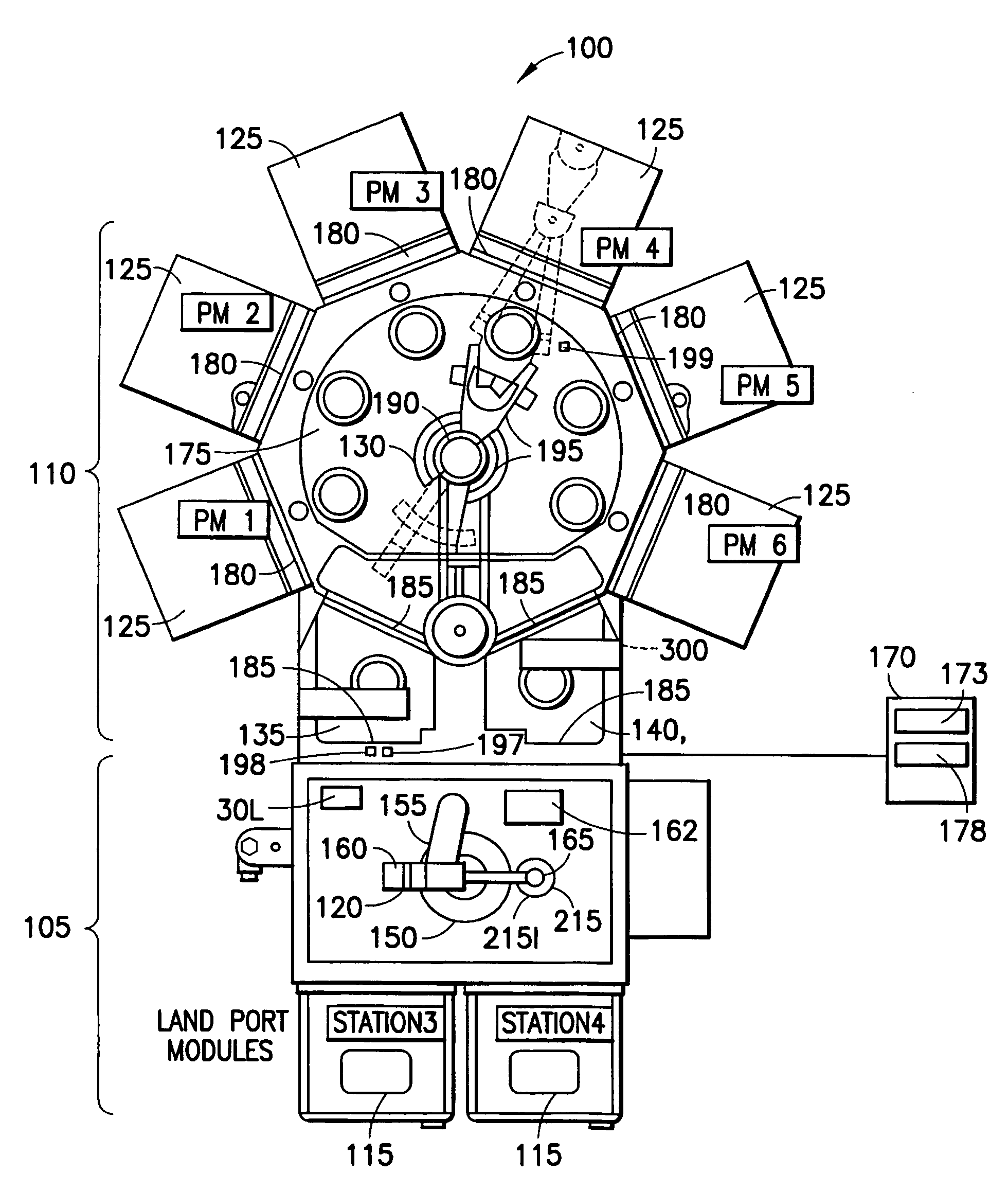

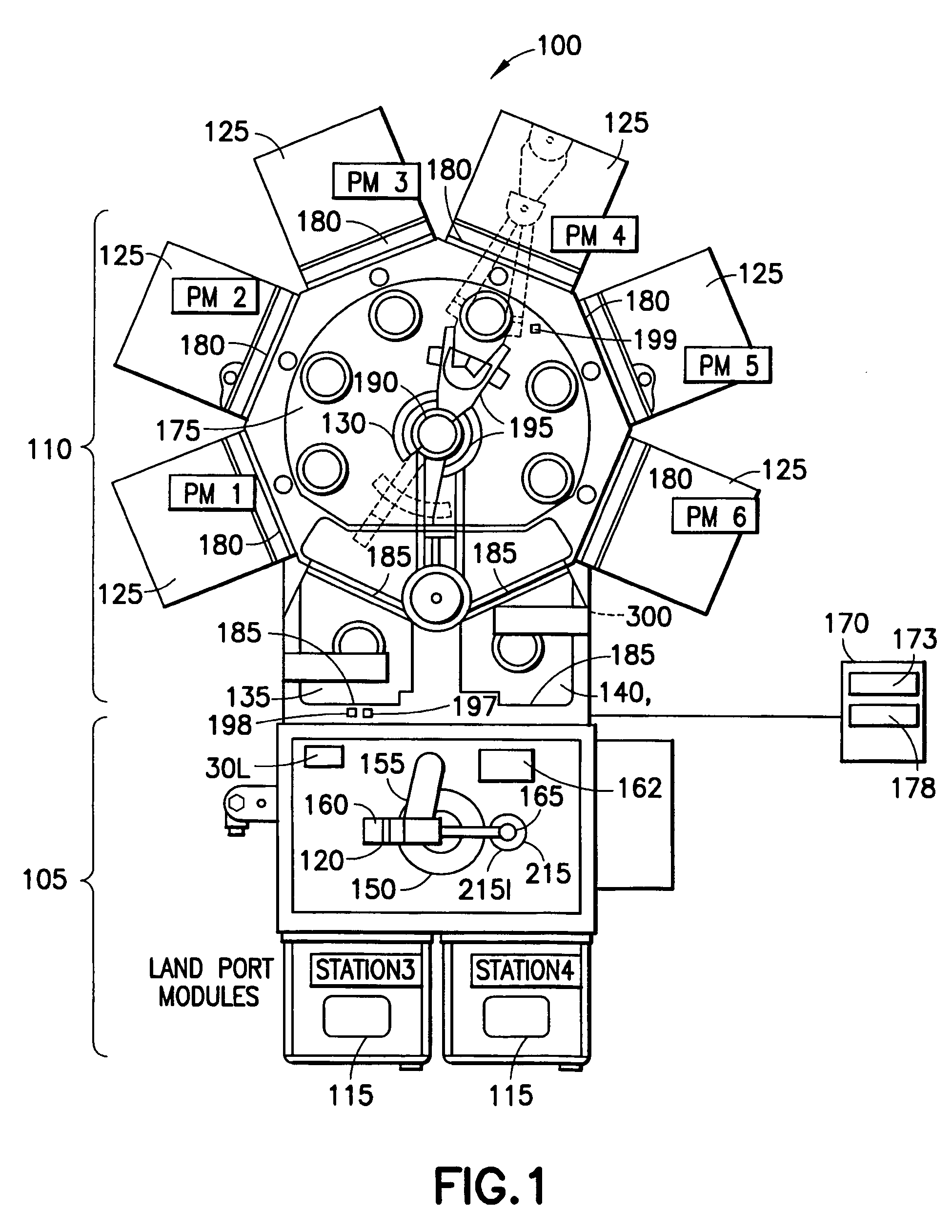

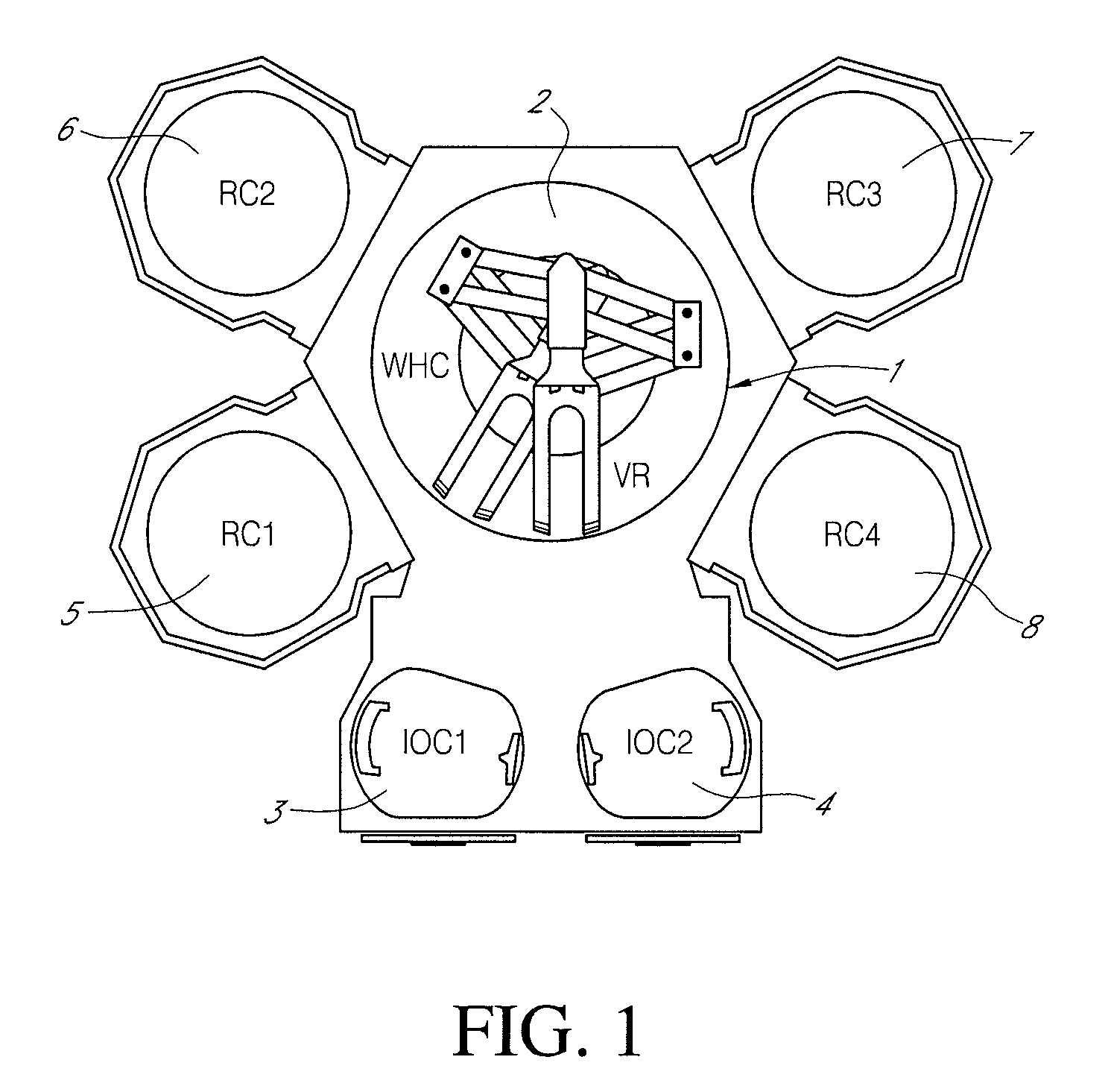

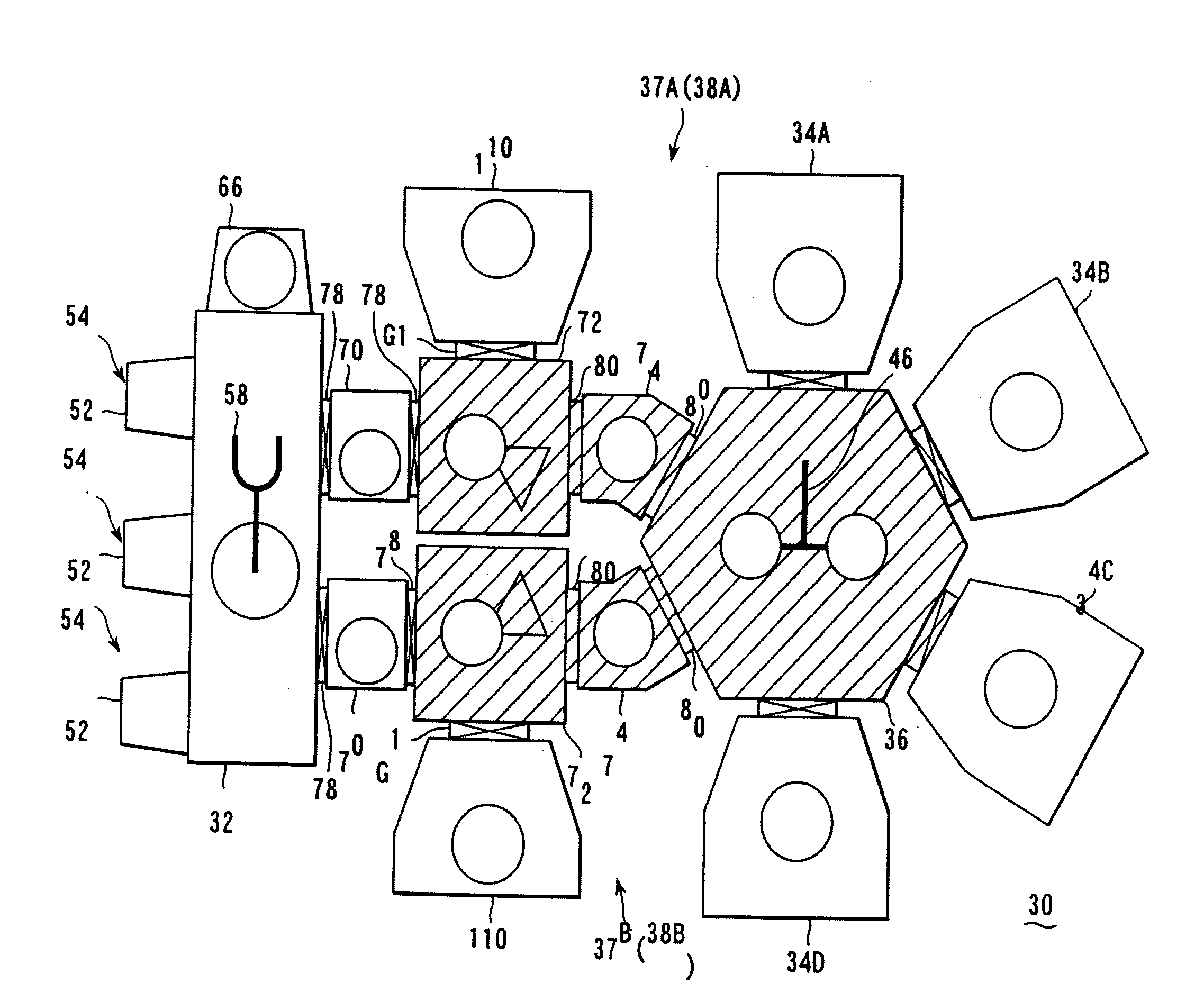

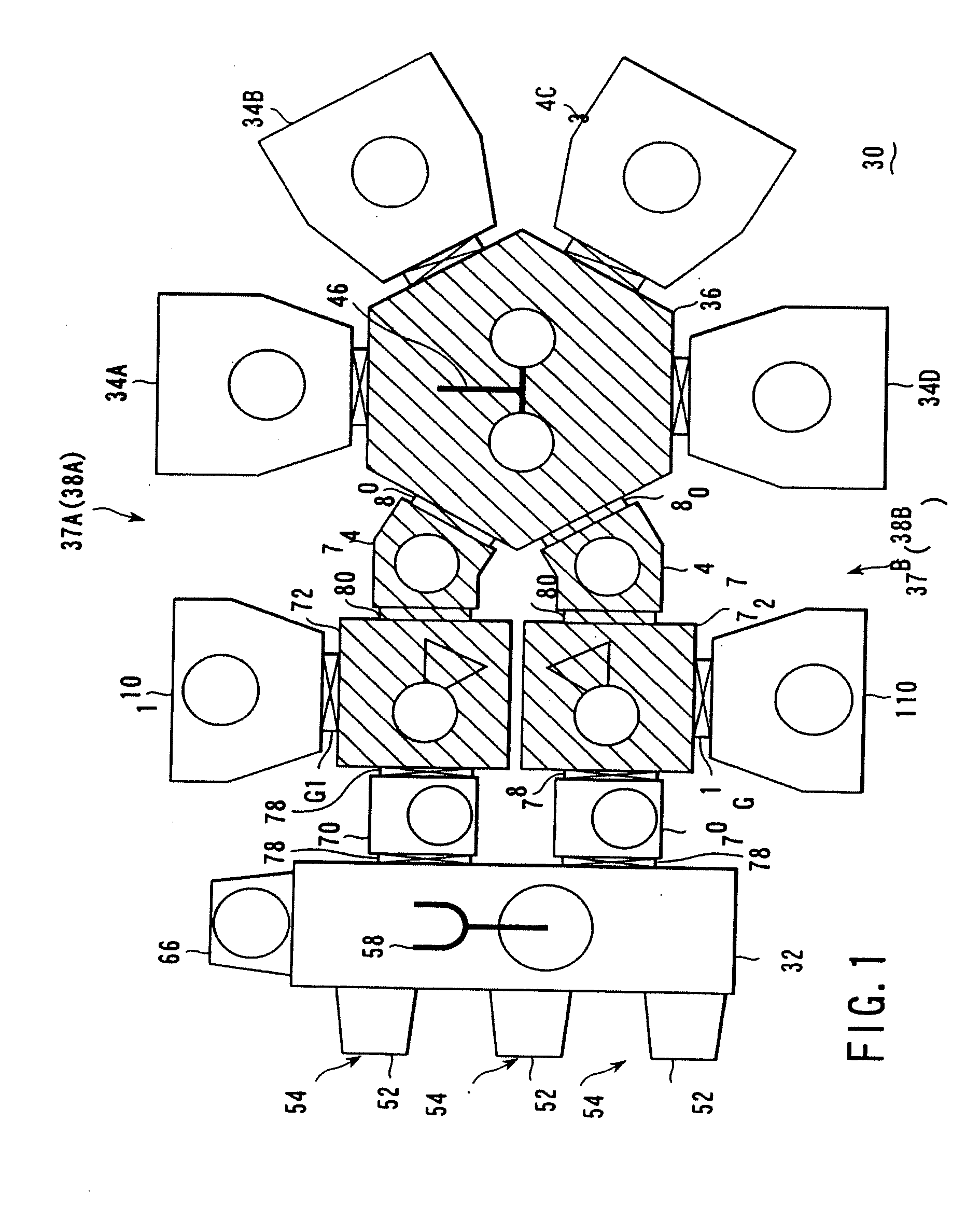

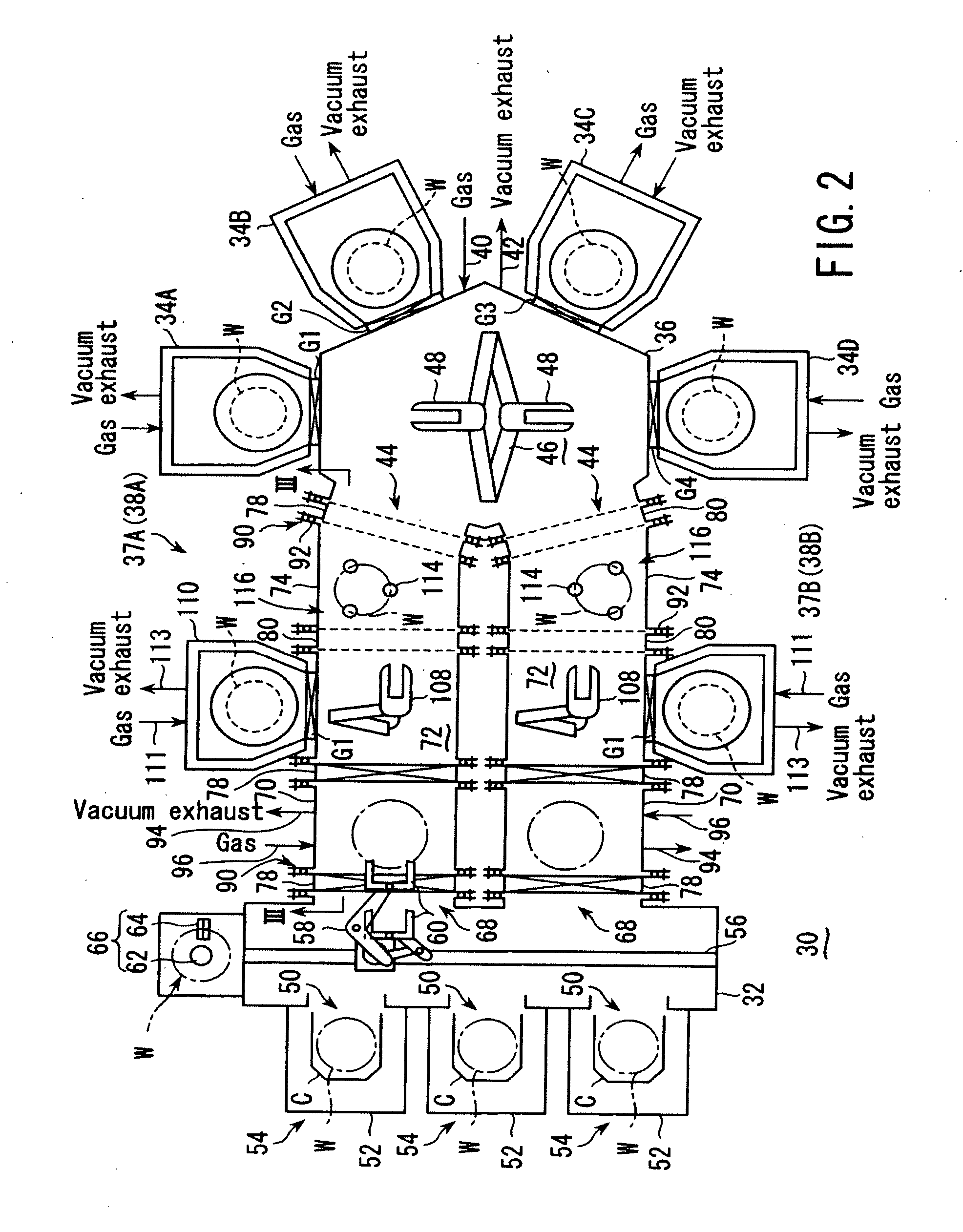

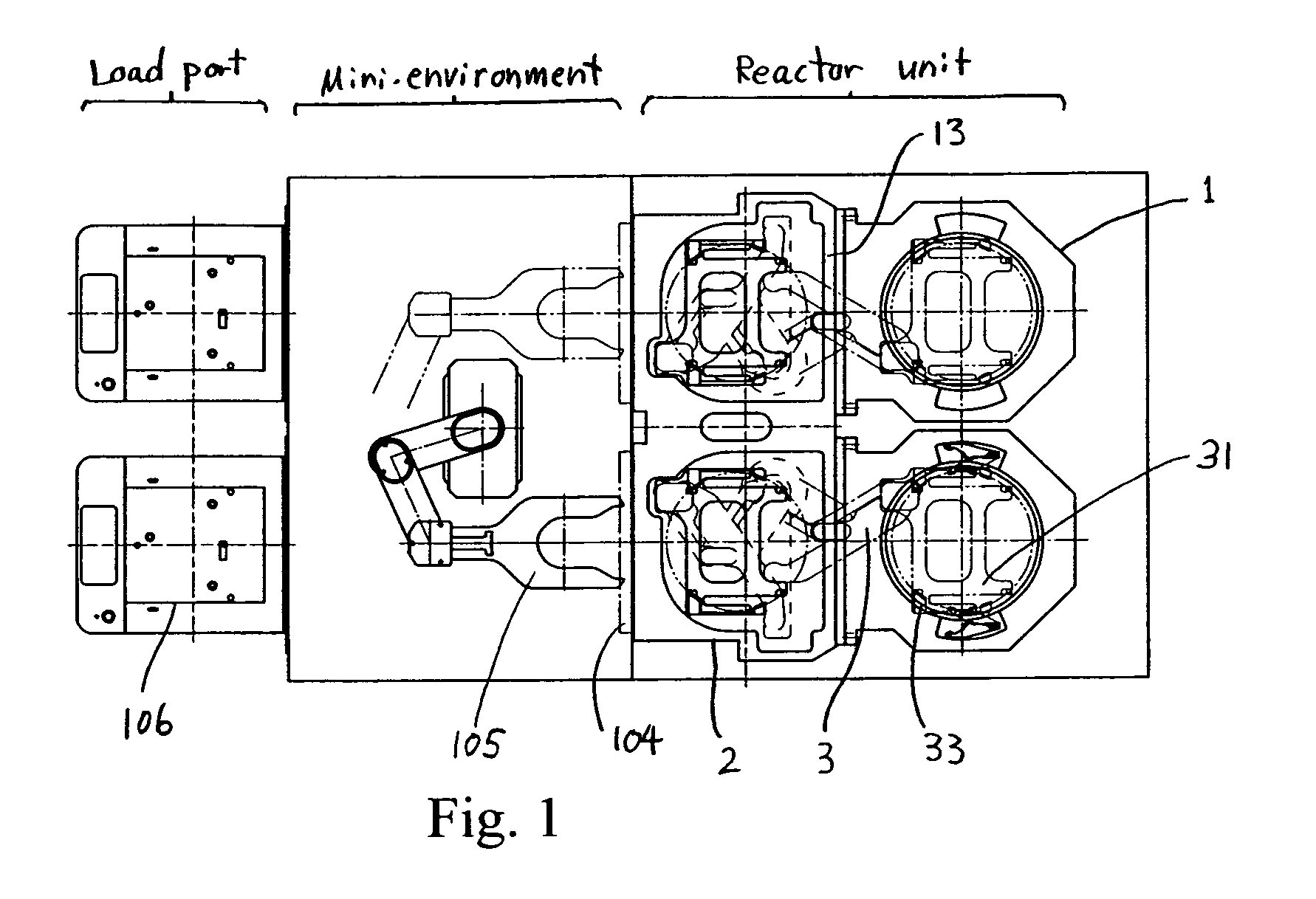

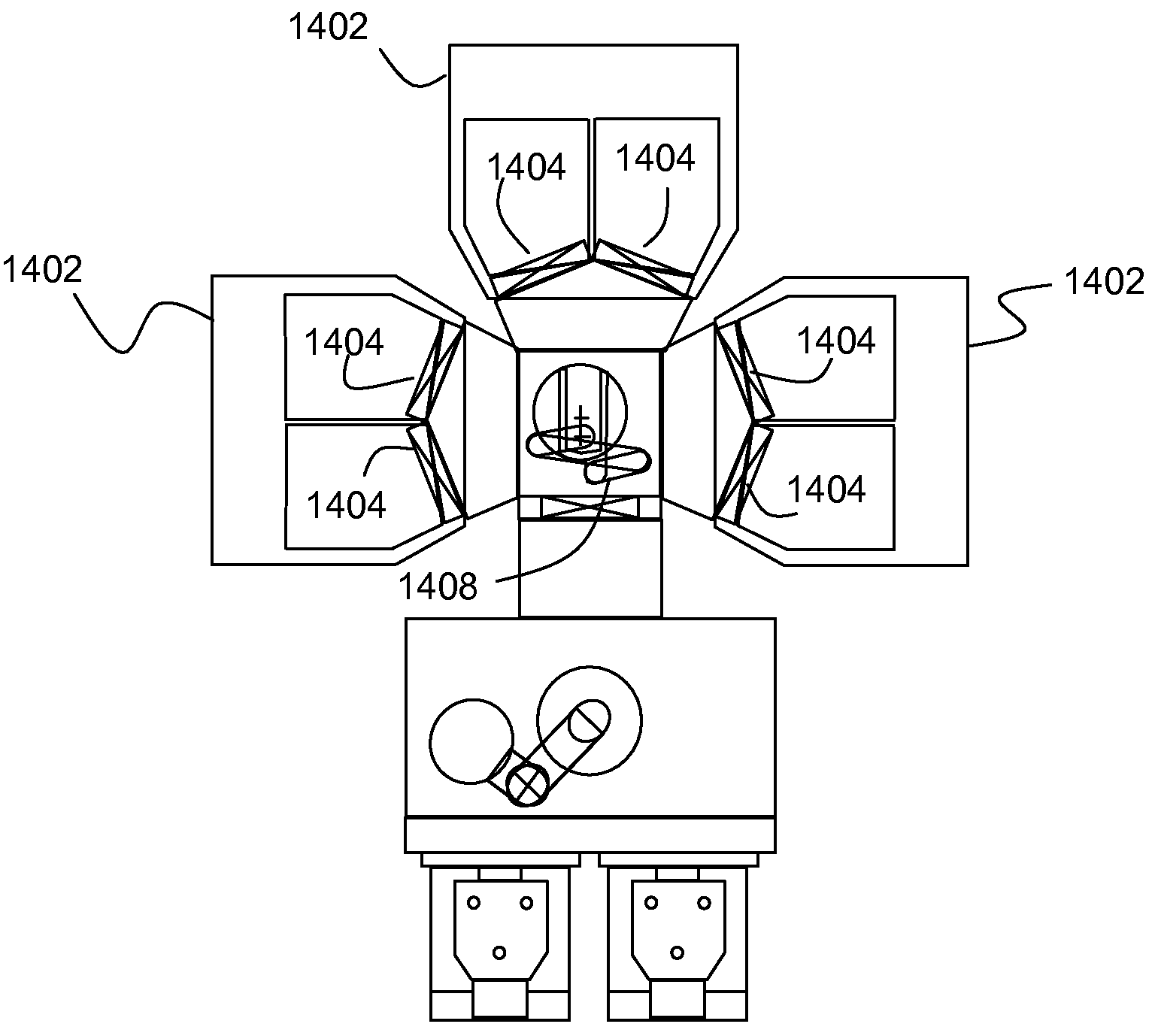

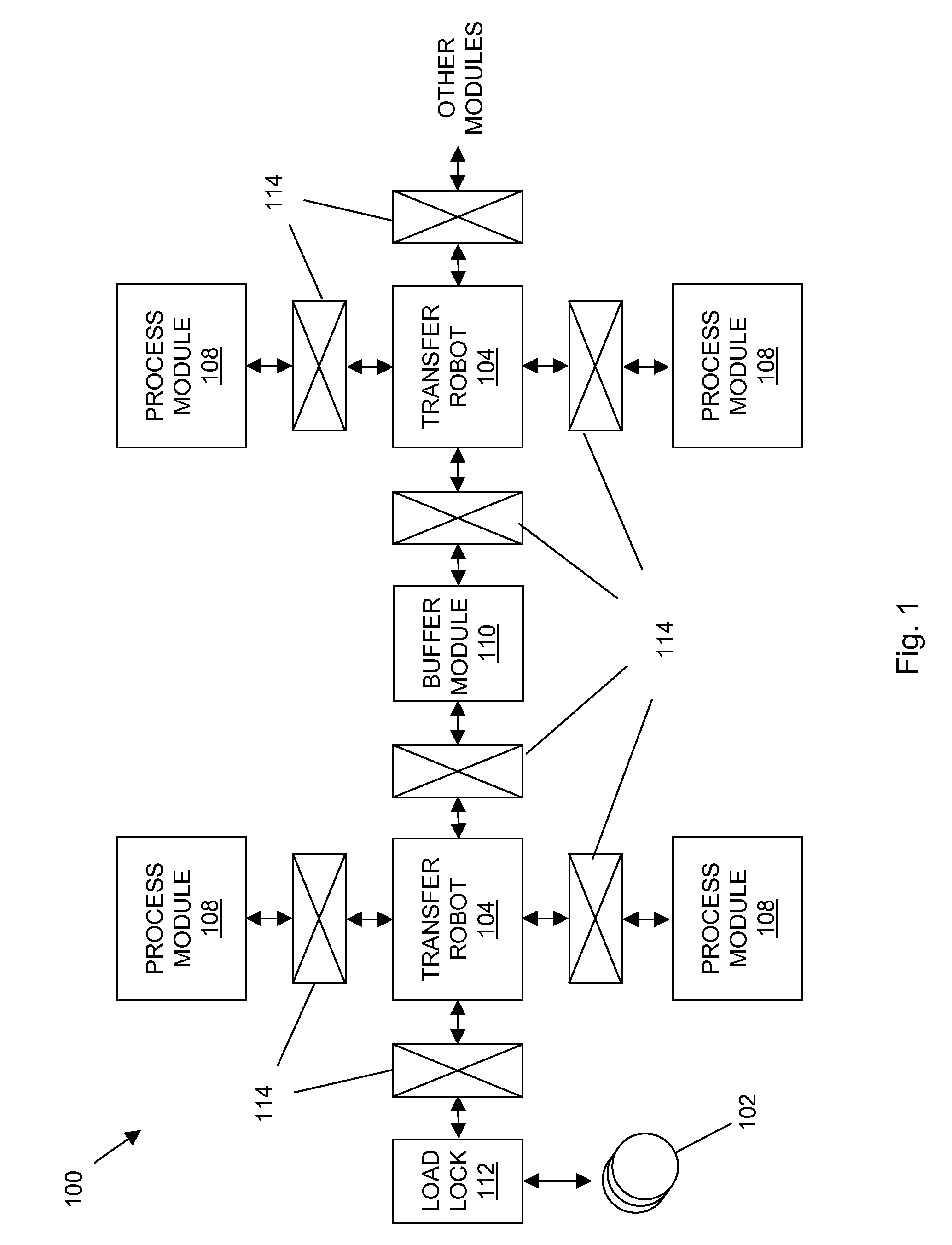

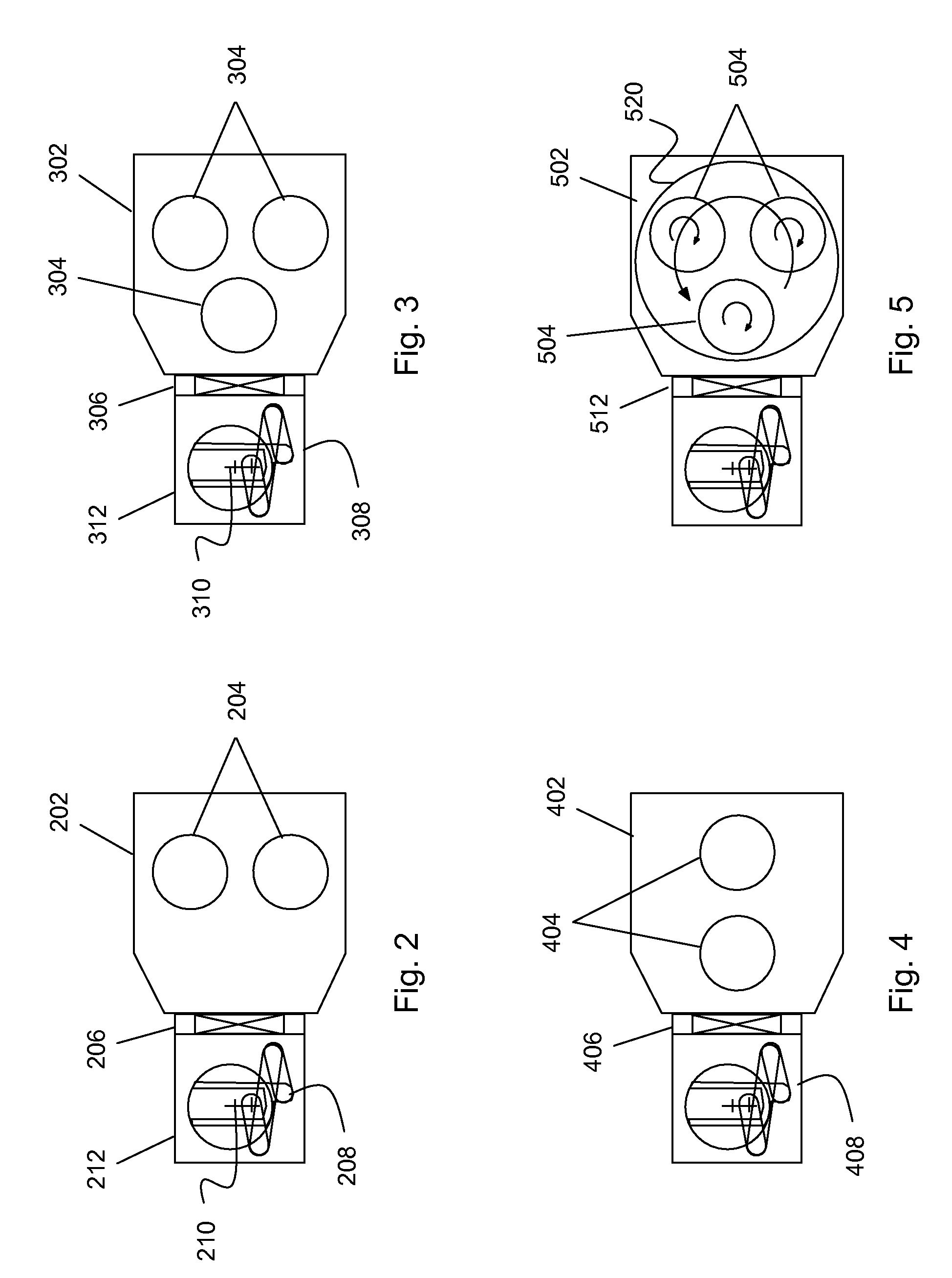

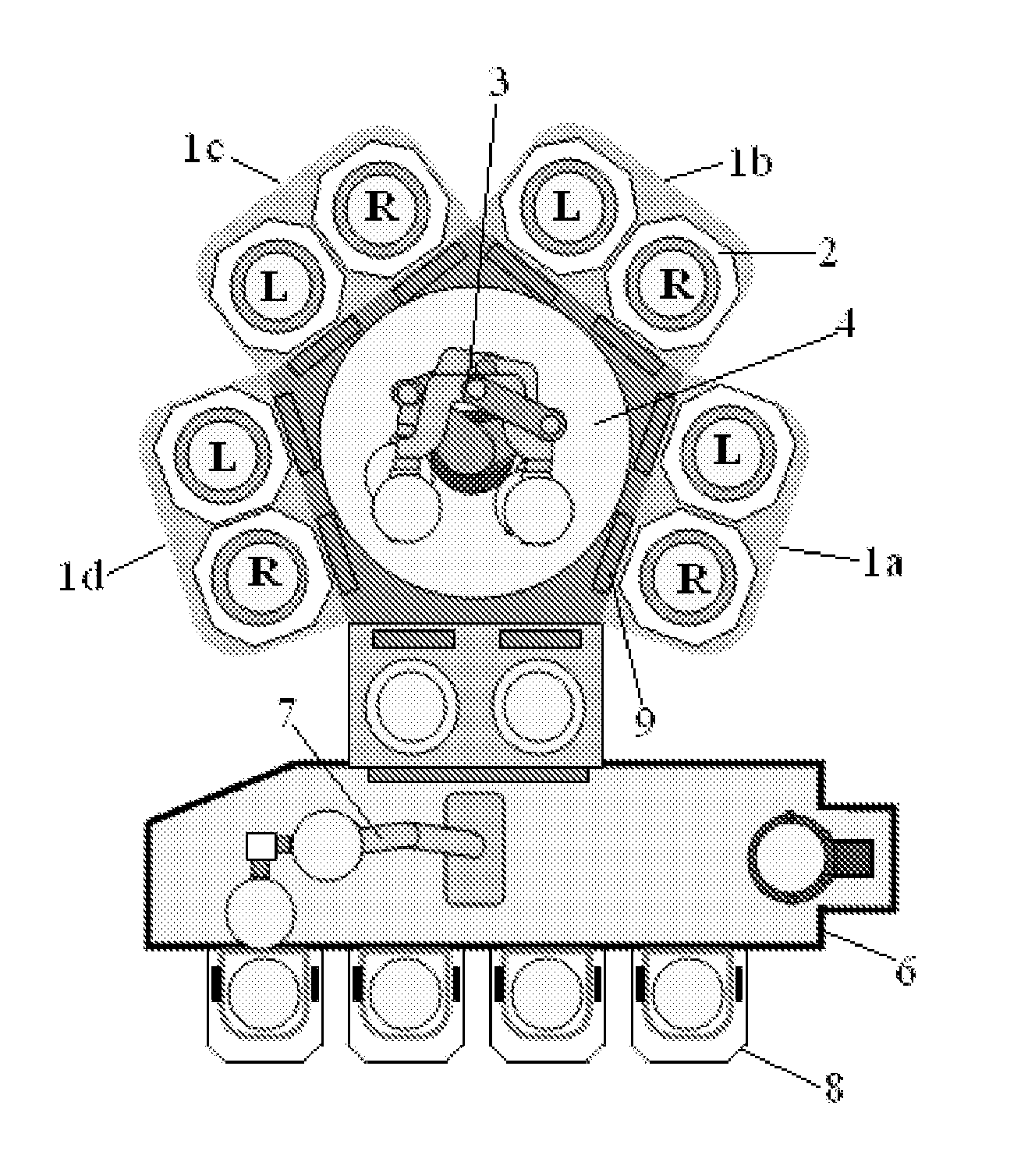

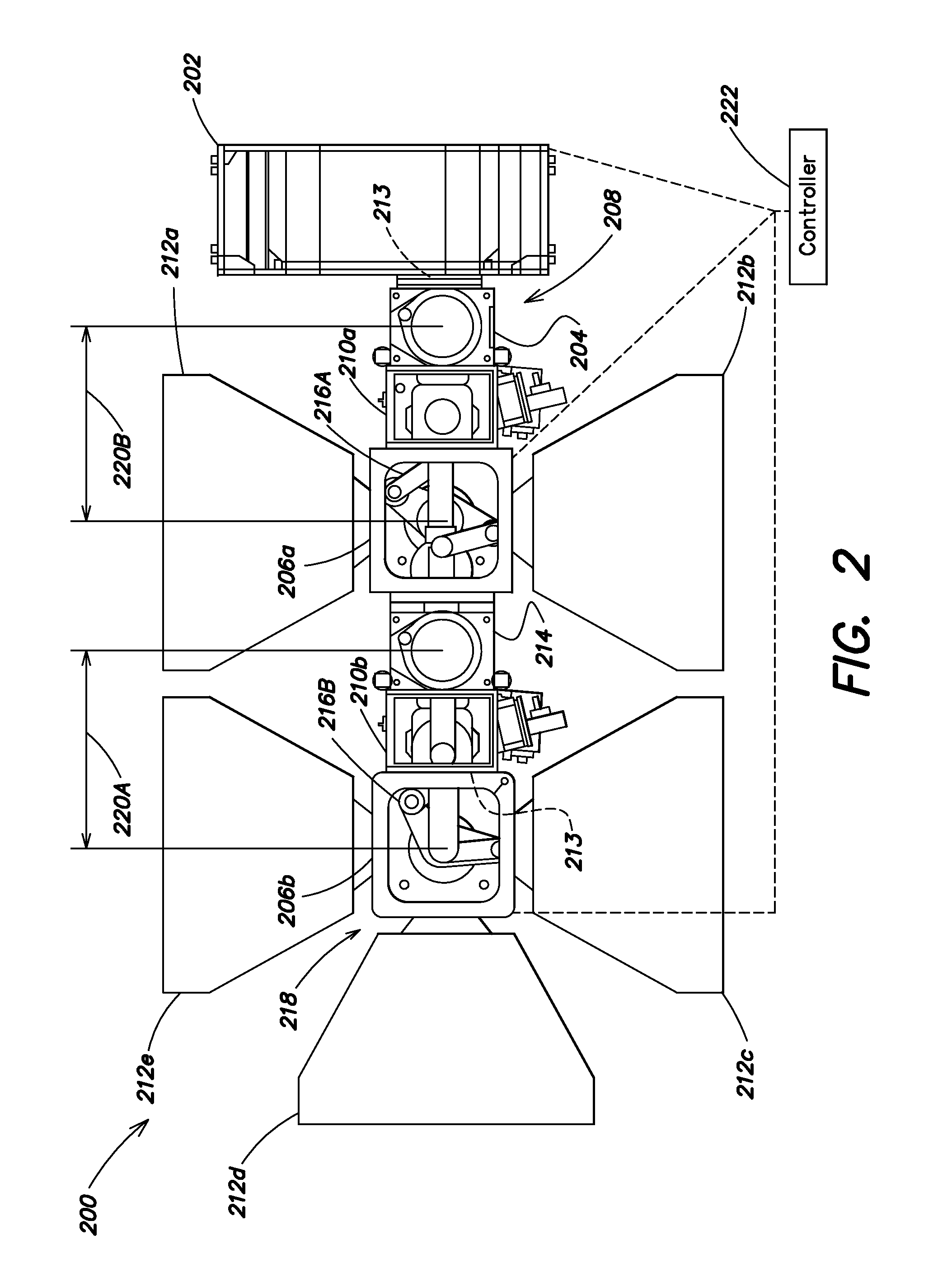

Semiconductor manufacturing process modules

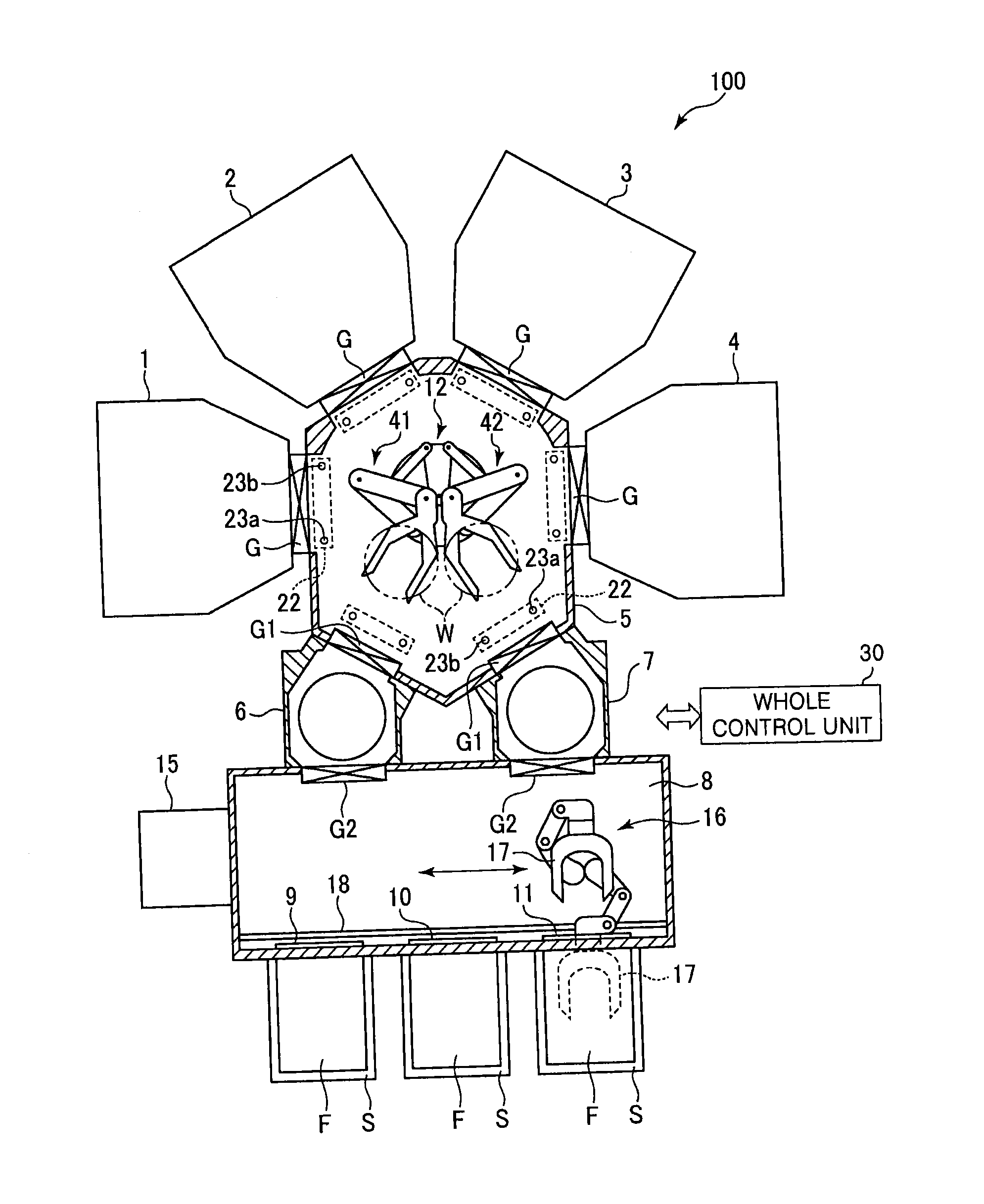

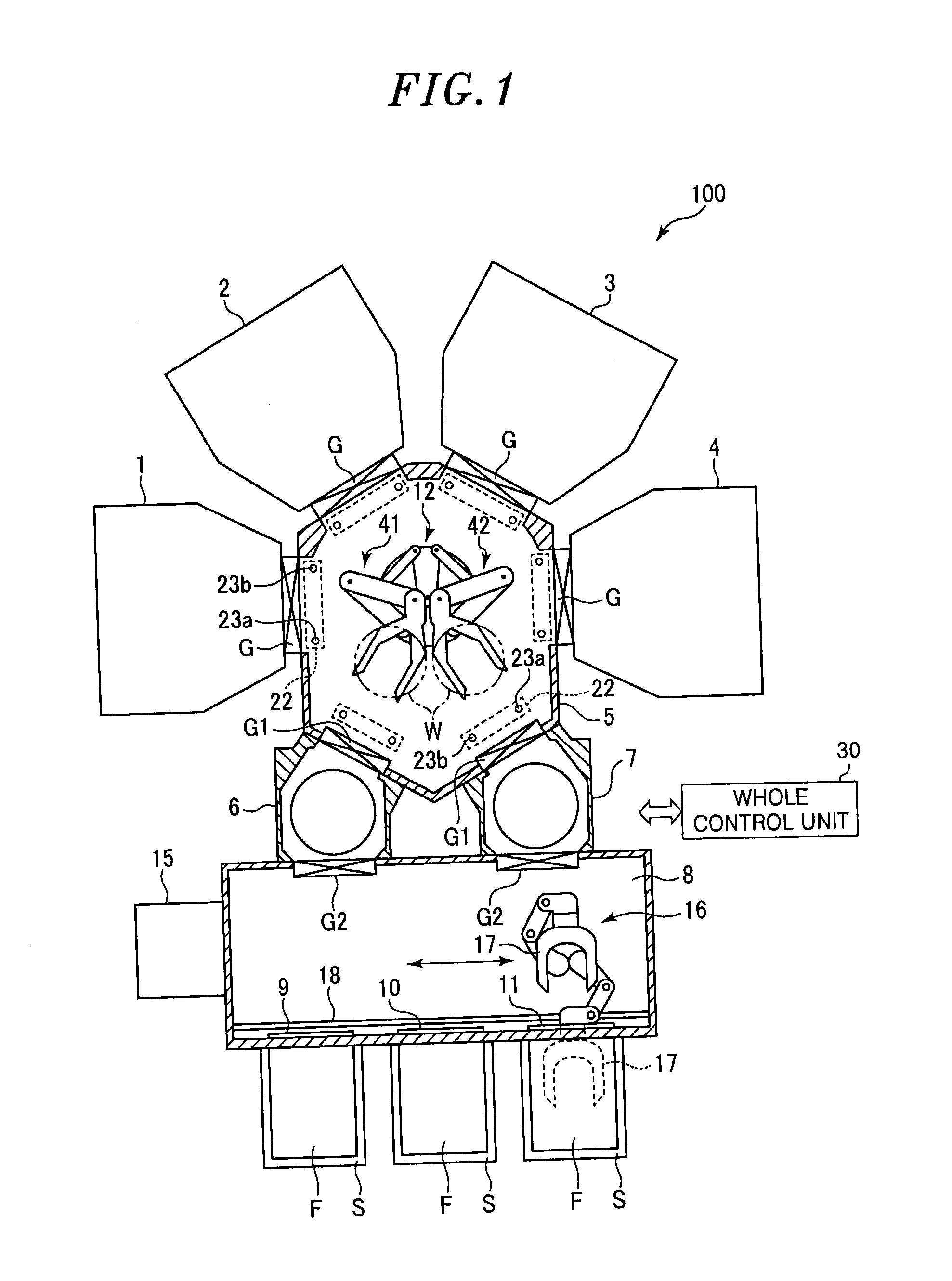

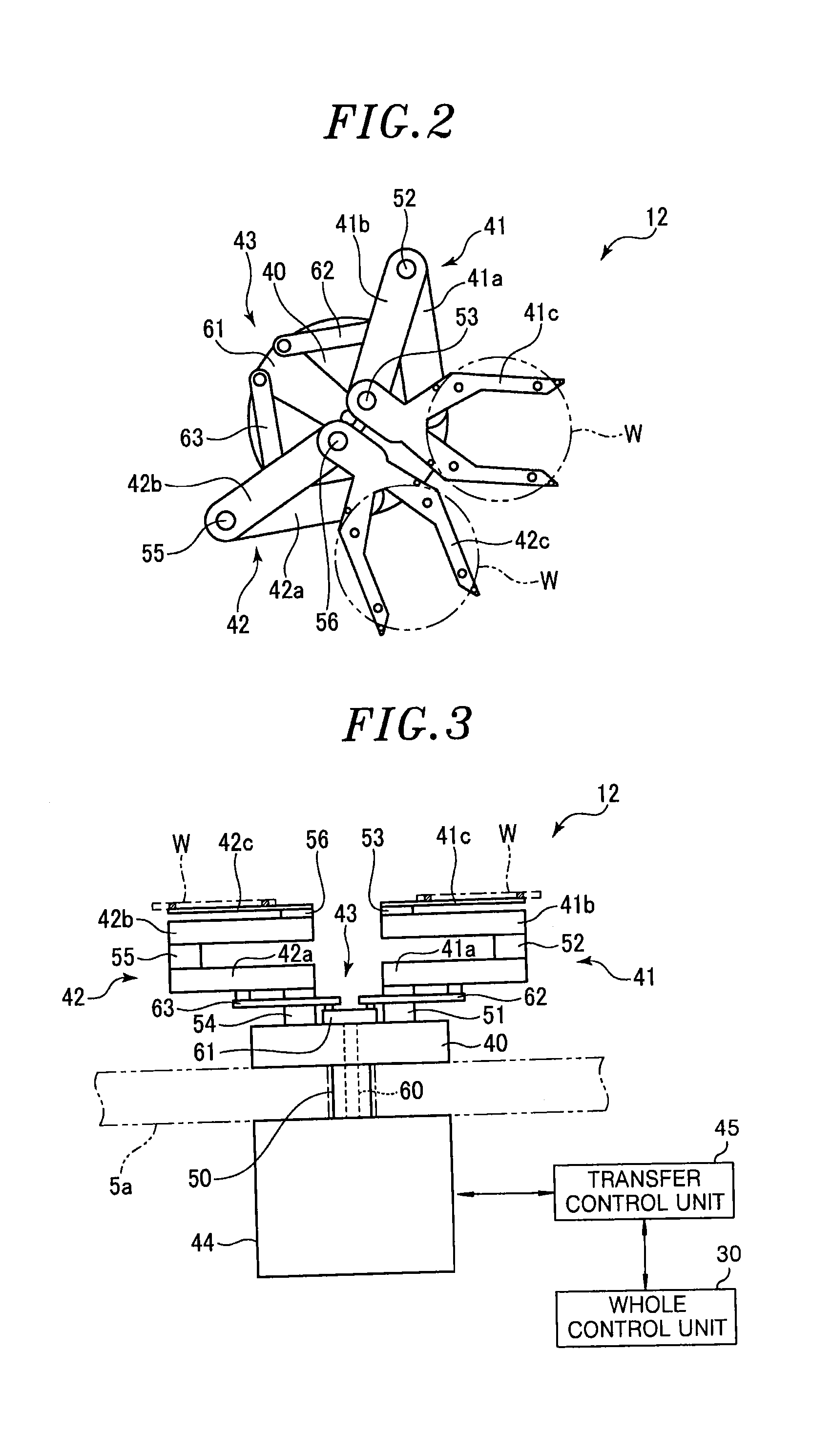

ActiveUS20080124197A1Balance processing loadSemiconductor/solid-state device manufacturingConveyor partsProcess moduleSemiconductor

Owner:BOOKS AUTOMATION US LLC

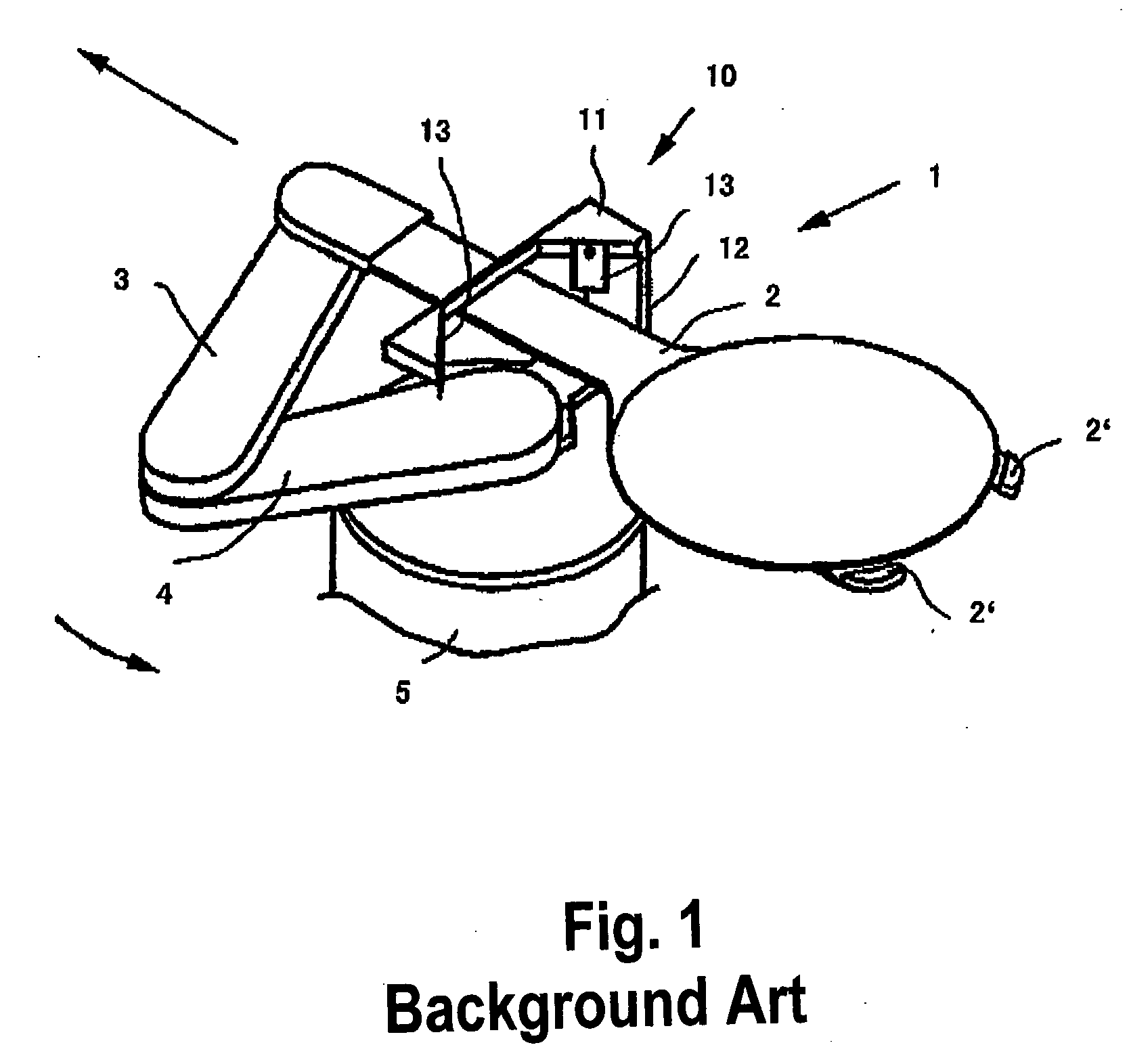

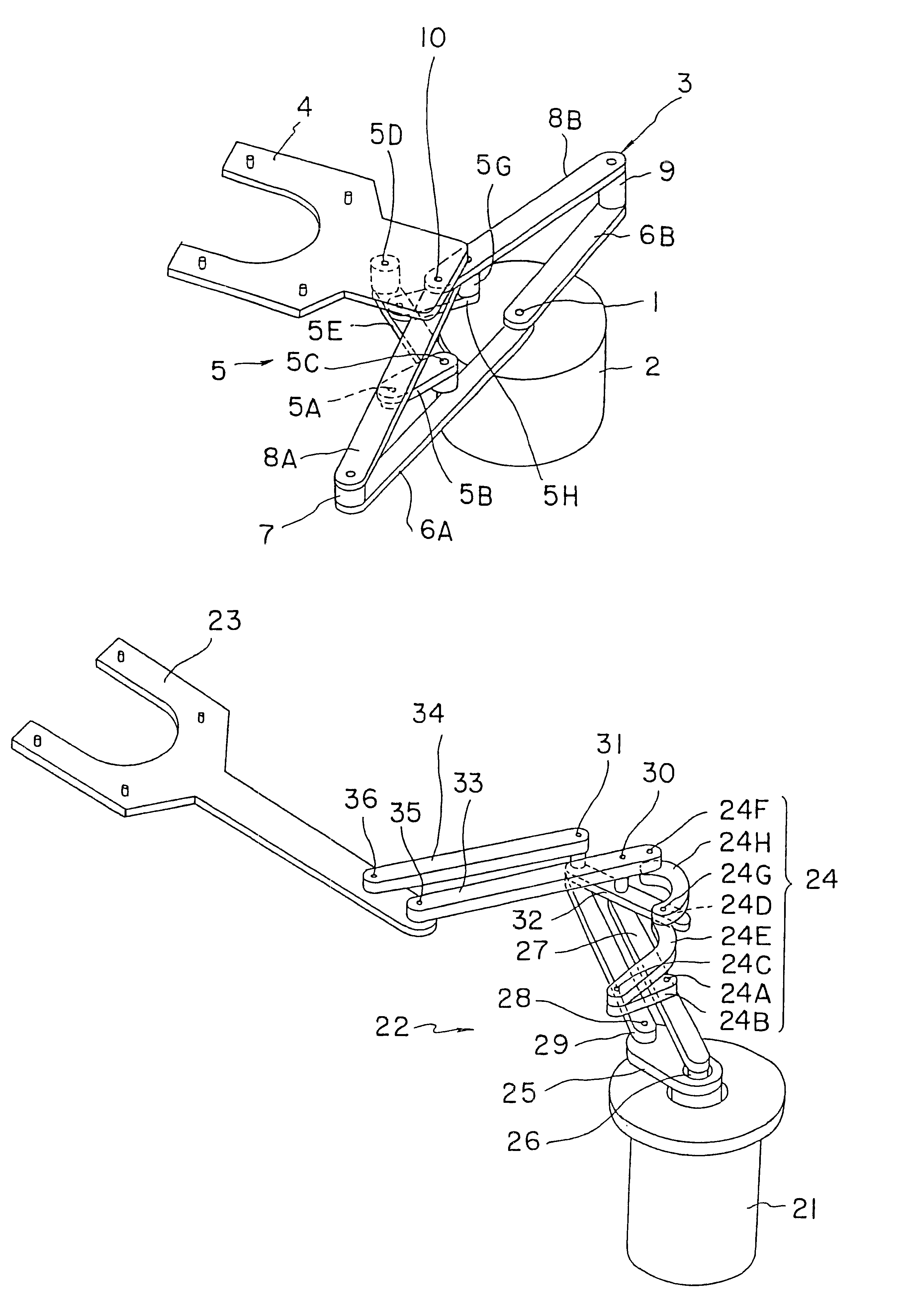

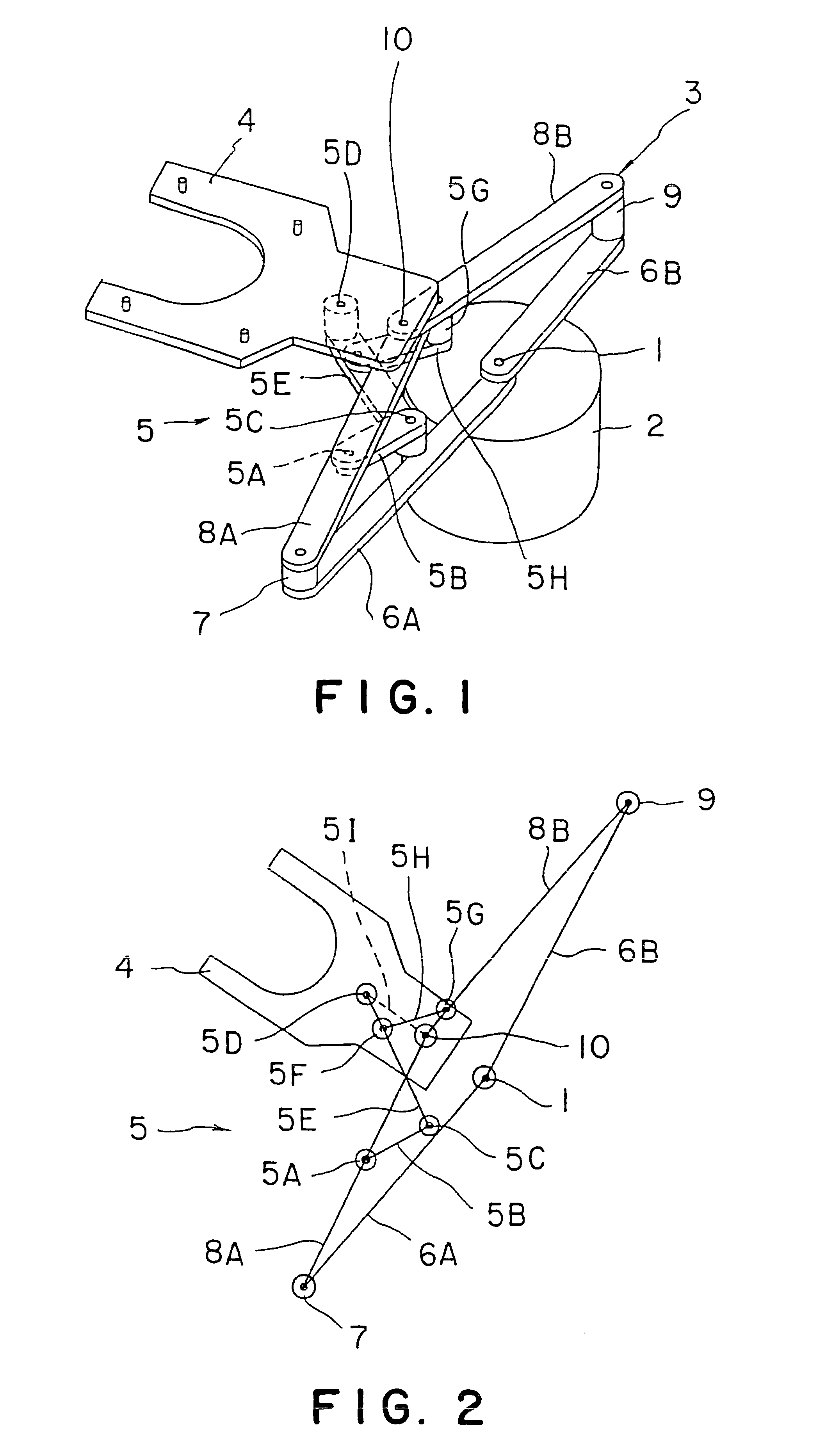

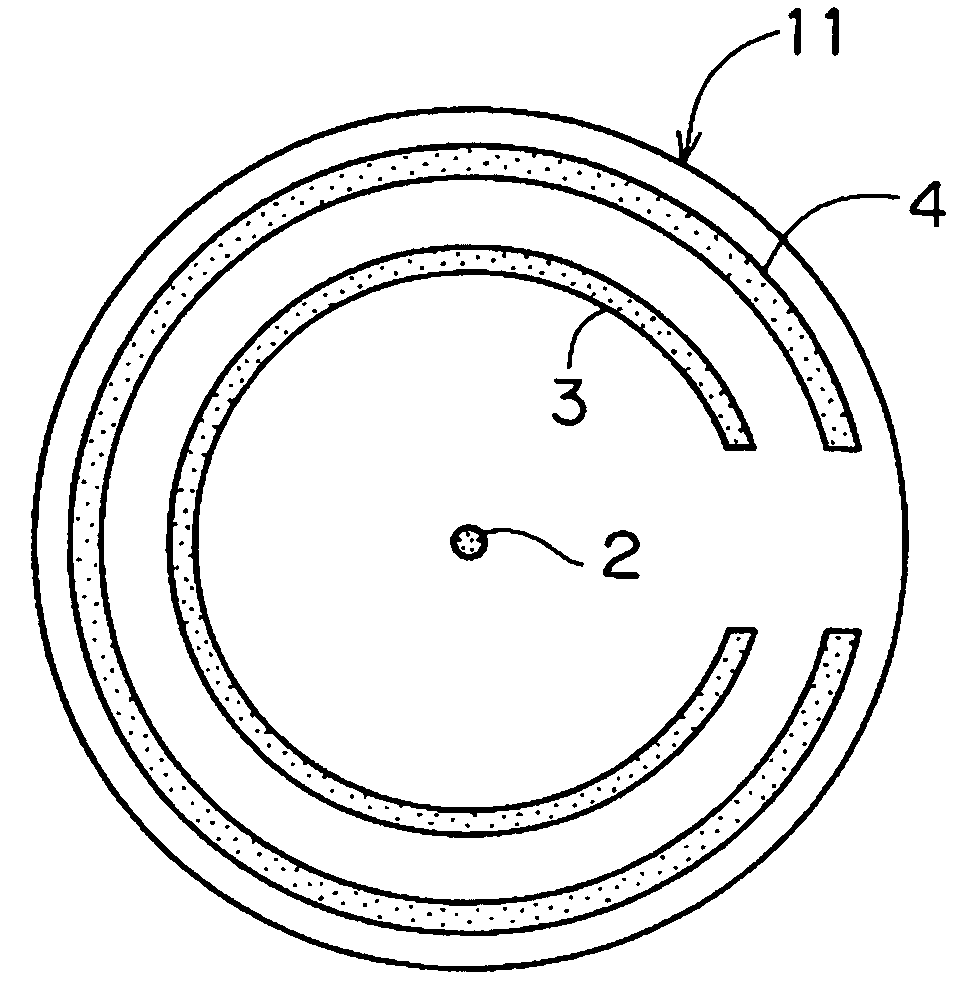

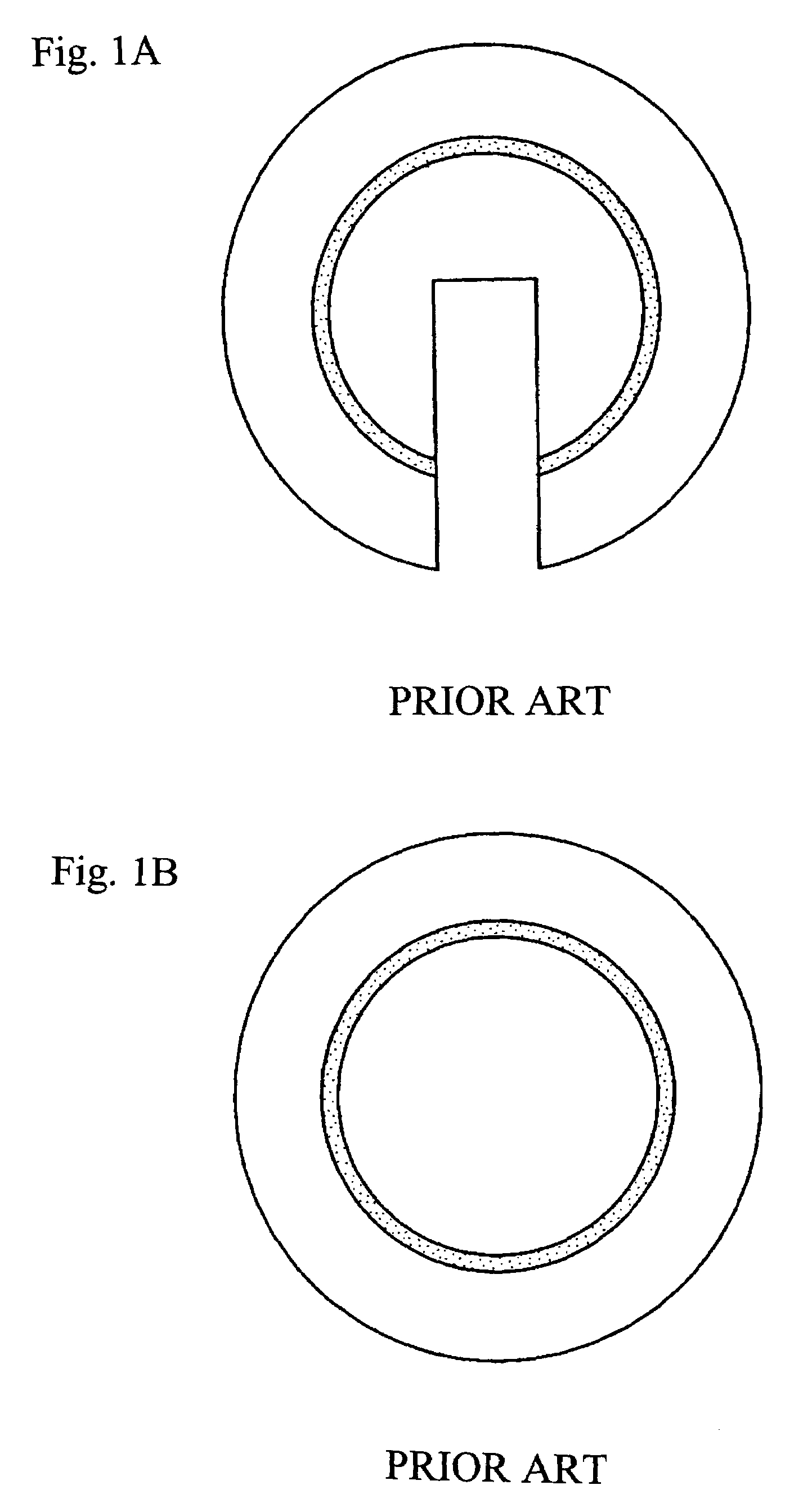

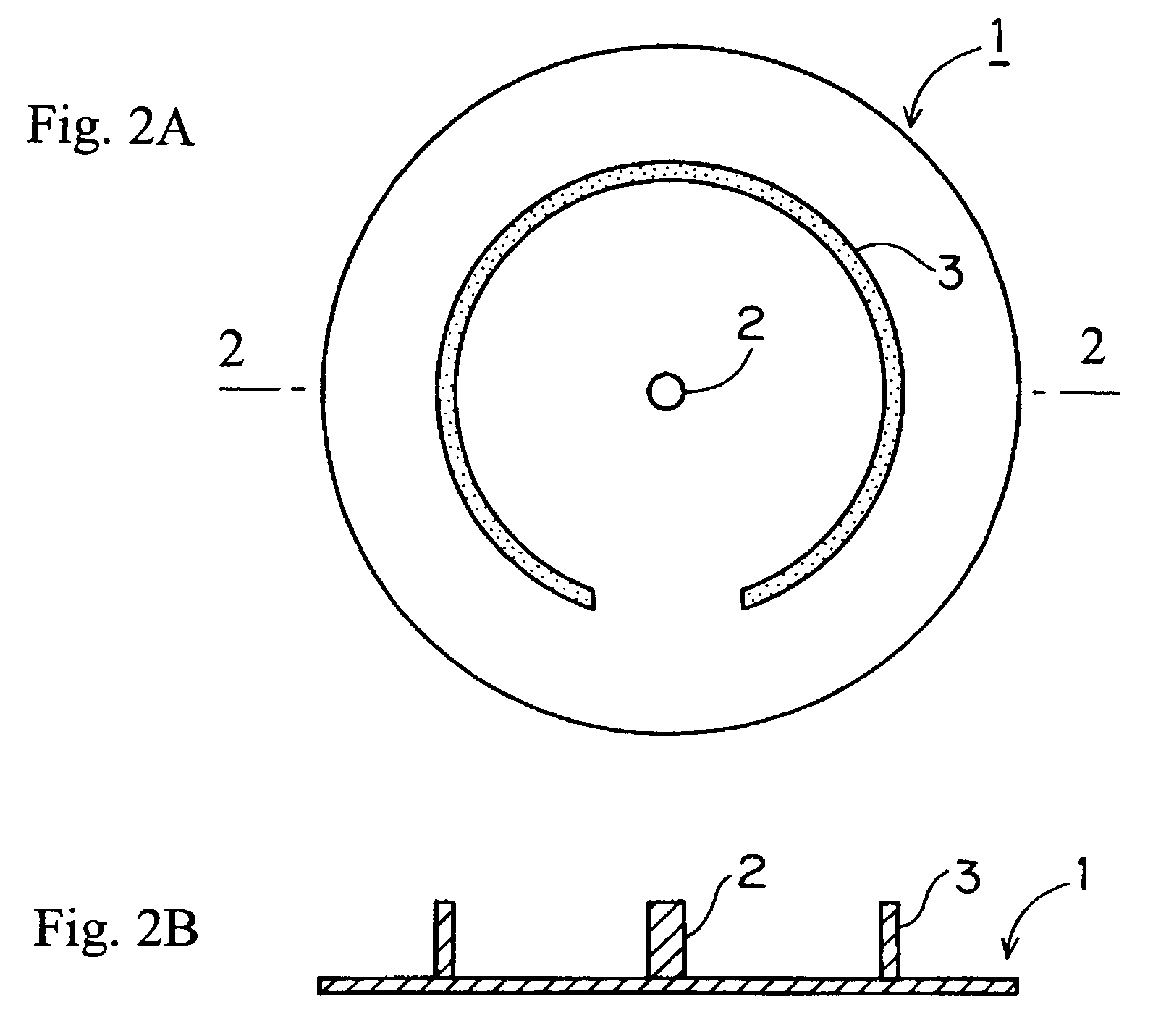

Conveyor system

InactiveUS6450757B1Increase resistanceAccurately and surely carrying a workpieceProgramme-controlled manipulatorMechanical apparatusMostly TrueHeat resistance

In most cases, a hot, corrosive atmosphere is created in, for example, a semiconductor wafer processing chamber. When an arm including belts, such as steel belts, is moved into such a semiconductor wafer processing chamber, the belts are exposed to the hot, corrosive atmosphere. Belts, such as steel belts, have limited heat resistance and corrosion resistance and the hot, corrosive atmosphere in the processing chamber shortens the life of the belts. A carrying device of the present invention has a frog leg type arm (3) and a wafer holder (4) connected to the frog leg type arm (3). The wafer holder (4) is pivotally connected to front end parts of a first front arm (8A) and a second front arm (8B) by coaxial joints (10). The wafer holder (4) is linked to the first front arm (8A) and the second front arm (8B) by a posture maintaining linkage (5) including two antiparallel linkages capable of controlling the turning of the wafer holder (4) relative to the first and the second front arms (8A, 8B).

Owner:TOKYO ELECTRON LTD

Glass substrate-holding tool and method for producing an EUV mask blank by employing the same

InactiveUS8967608B2InhibitionAccurate placementWorkpiece holdersVacuum evaporation coatingLithographic artistMaterials science

A glass substrate-holding tool employed during the production of a reflective mask blank for EUV lithography includes an electrostatic chuck and a mechanical chuck. A caught and held portion of a glass substrate caught and held by the electrostatic chuck, and pressed portions of the glass substrate pressed by the mechanical chuck are located outside a quality-guaranteed region on each of a film deposition surface and a rear surface of the glass substrate. The sum of a catching and holding force applied to the glass substrate by the electrostatic chuck and a holding force applied to the glass substrate by the mechanical chuck is at least 200 kgf. A pressing force per unit area applied to the glass substrate by the mechanical chuck is at most 25 kgf / mm2.

Owner:ASAHI GLASS CO LTD

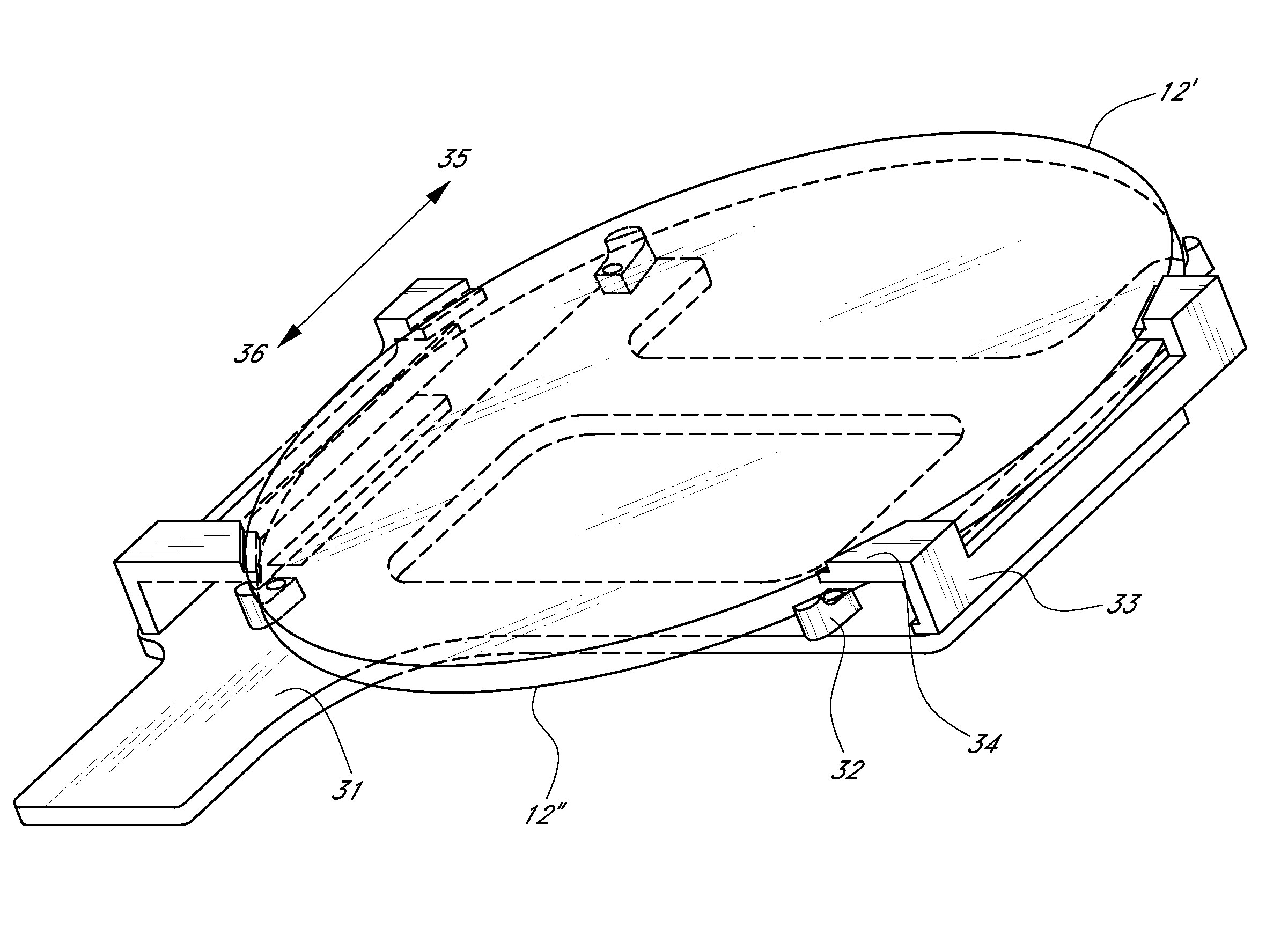

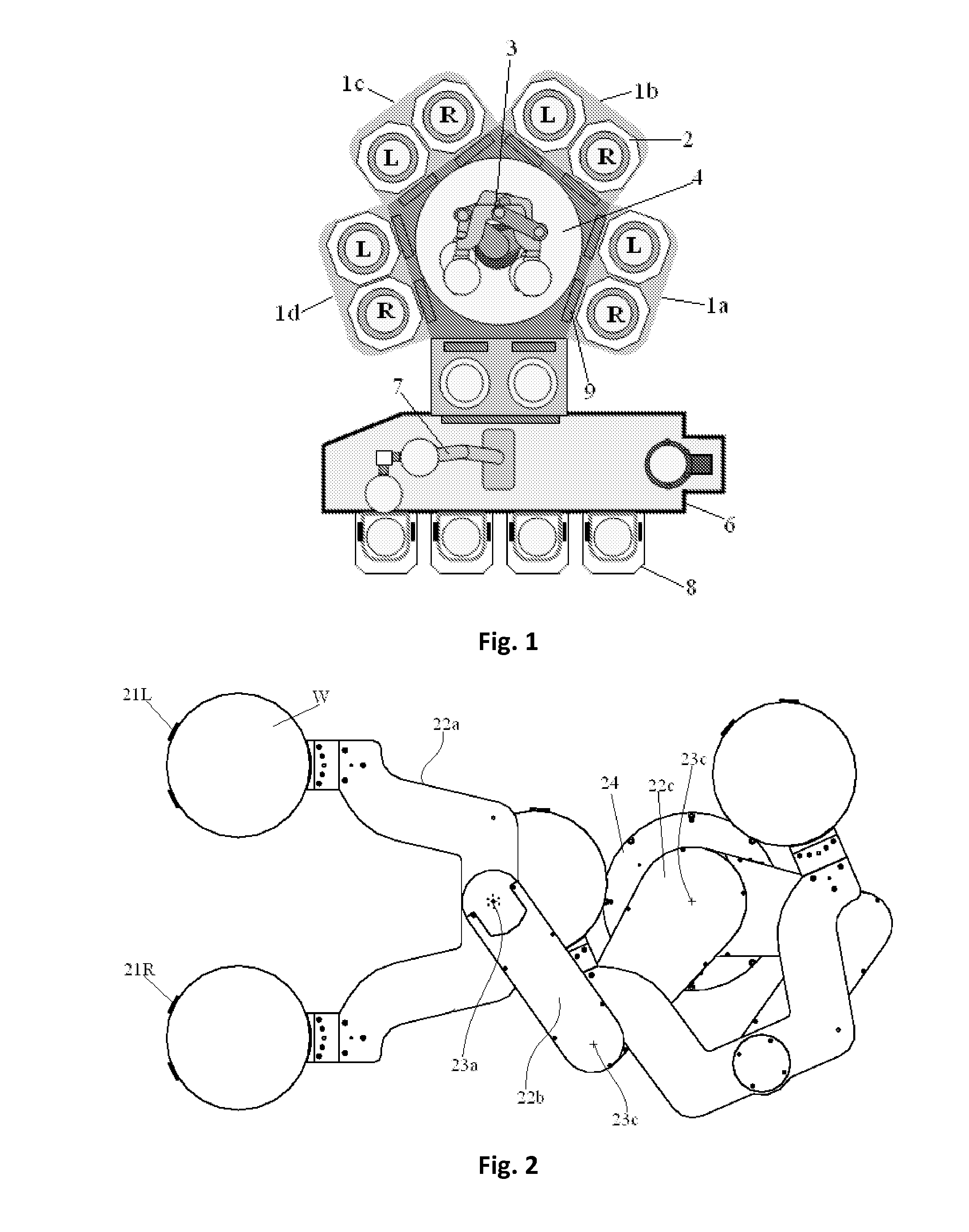

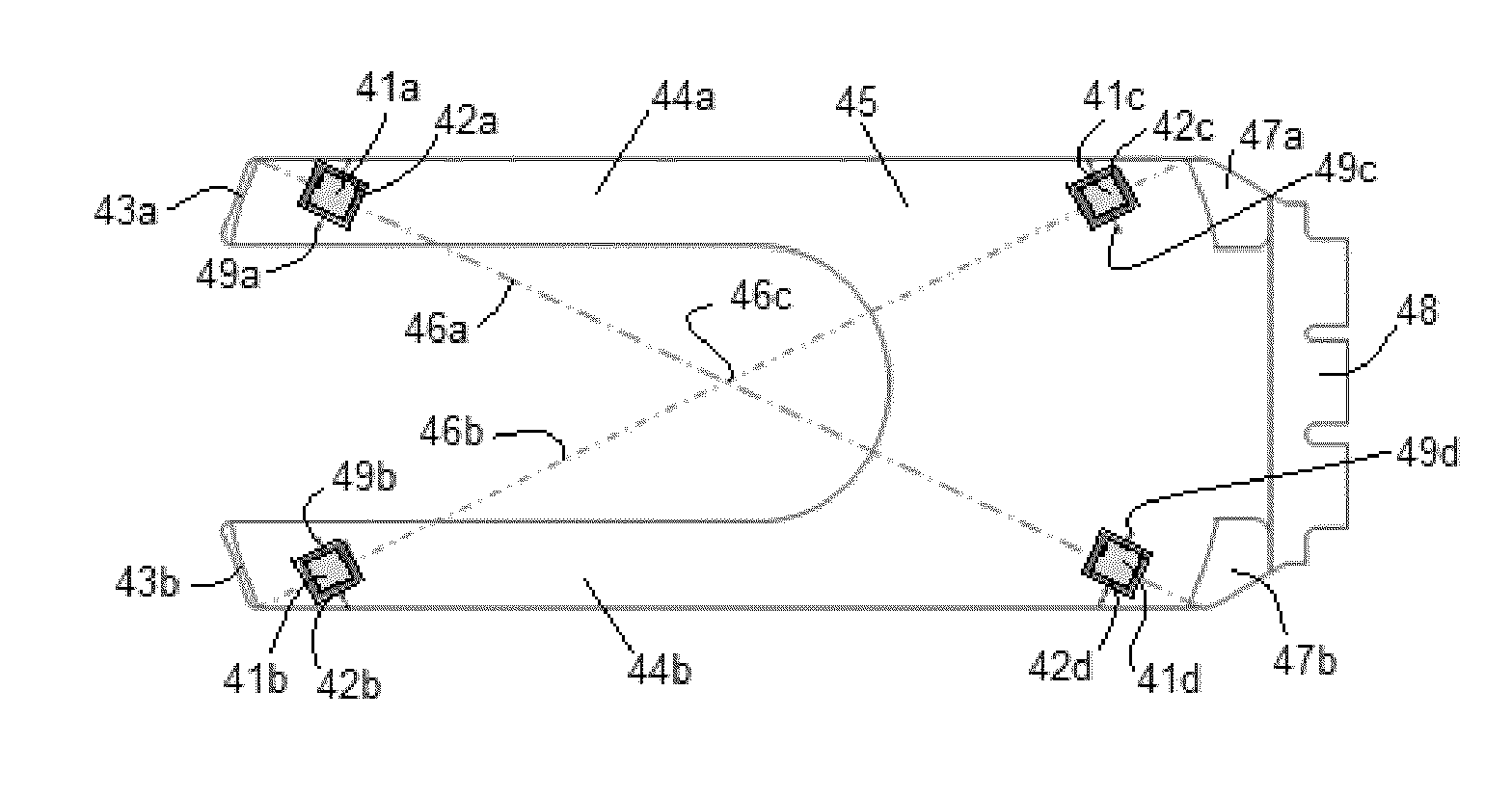

Method for Positioning Wafers in Multiple Wafer Transport

ActiveUS20120325148A1Liquid surface applicatorsSemiconductor/solid-state device manufacturingWaferingSusceptor

A method for positioning wafers in dual wafer transport, includes: simultaneously moving first and second wafers placed on first and second end-effectors to positions over lift pins protruding from first and second susceptors, respectively; and correcting the positions of the first and second wafers without moving any of the lift pins relative to the respective susceptors or without moving the lift pins relative to each other, wherein when the first and second wafers are moved to the respective positions, the distance between the first wafer and tips of the lift pins of the first susceptor is substantially smaller than the distance between the second wafer and tips of the lift pins of the second susceptor.

Owner:ASM JAPAN

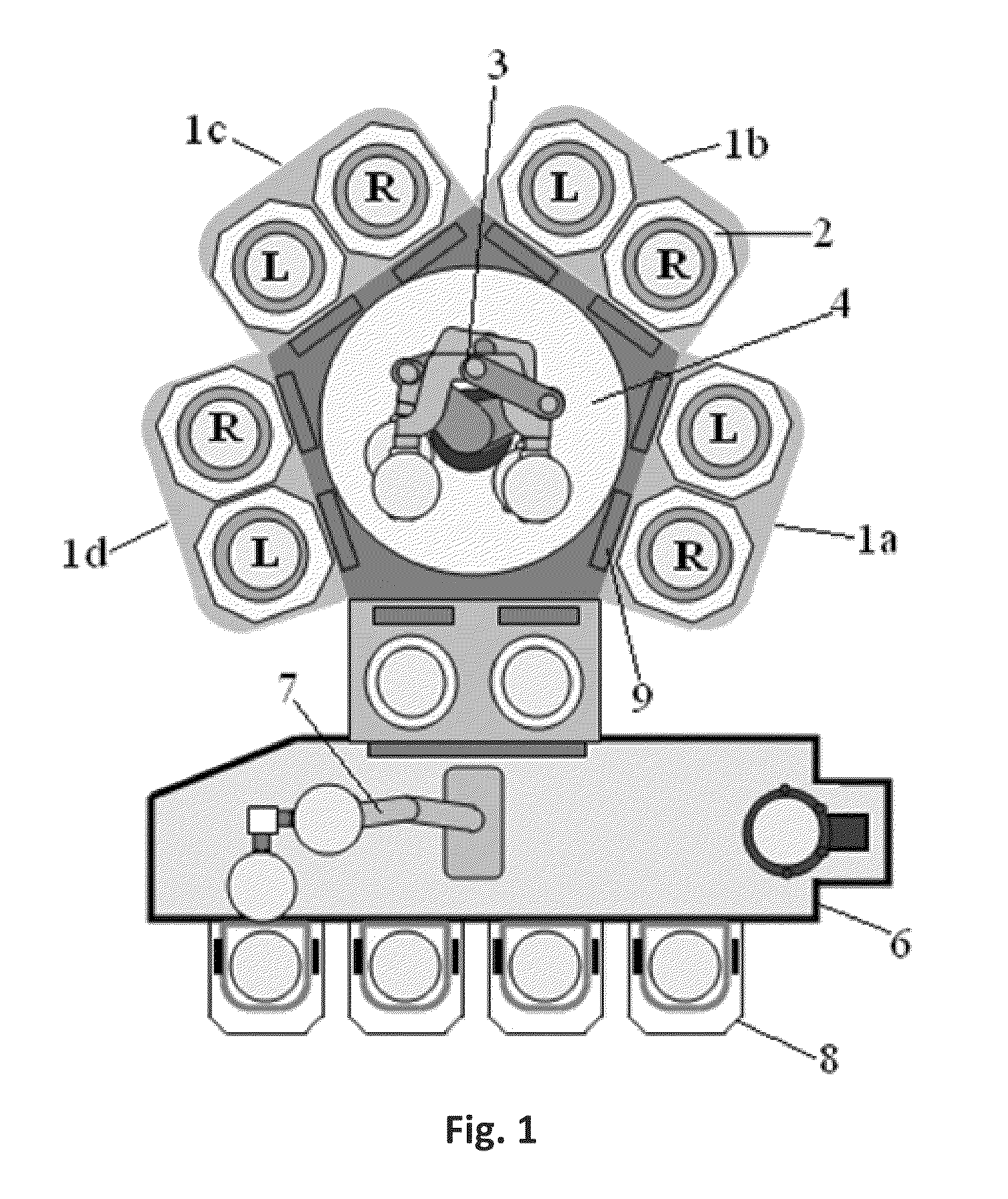

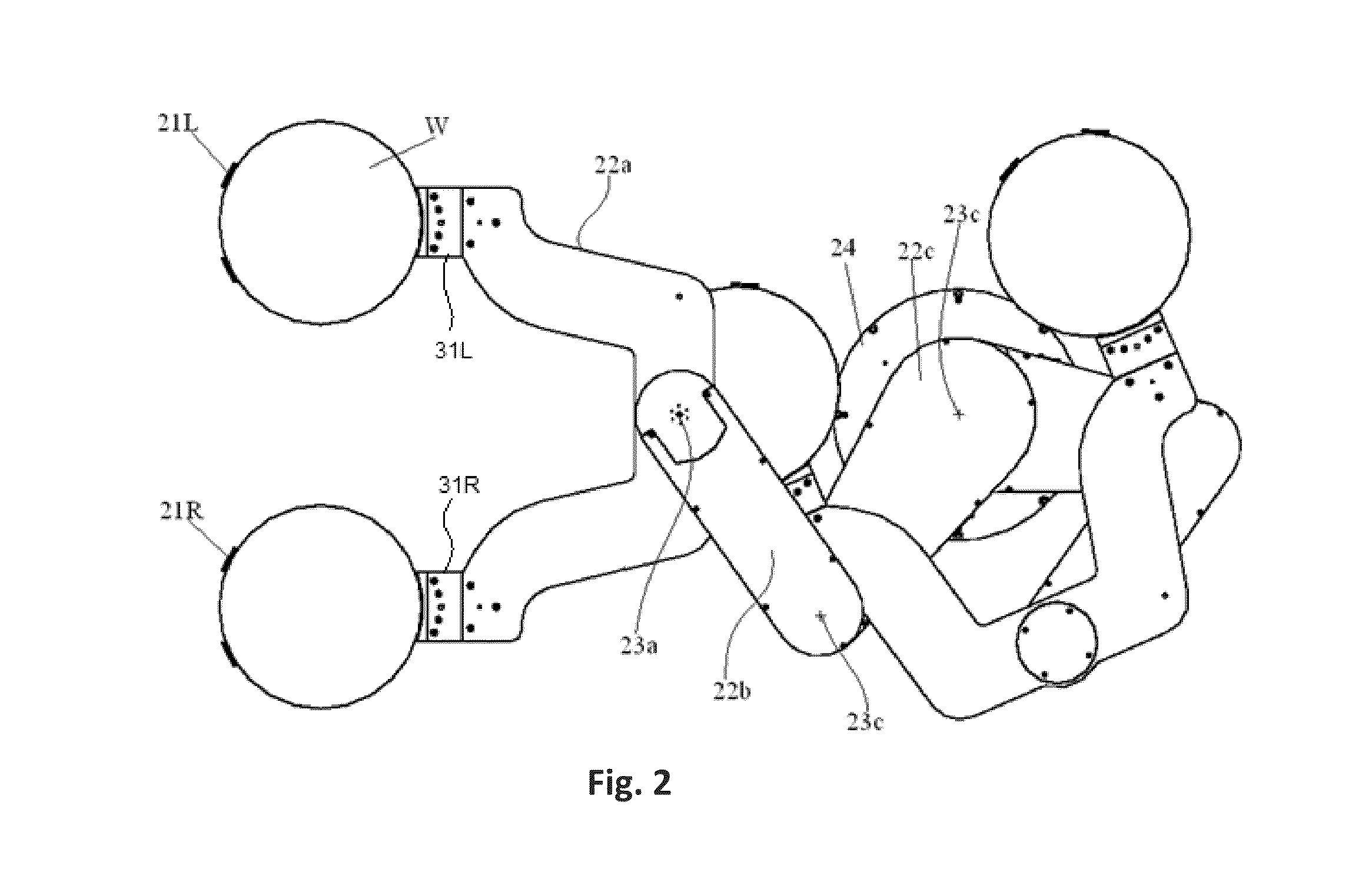

Methods and apparatus for extending the reach of a dual scara robot linkage

ActiveUS20080298945A1Avoid interferenceProgramme-controlled manipulatorMechanical apparatusEngineeringMechanical engineering

Methods and apparatus are provided for the use of a dual Selective Compliant Assembly Robot Arm (SCARA) robot. In some embodiments two SCARAs are provided, each including an elbow joint, wherein the two SCARAs are vertically stacked such that one SCARA is a first arm and the other SCARA is a second arm, and wherein the second arm is adapted to support a first substrate, and the first arm is adapted to extend to a full length when the second arm supports the first substrate, and wherein the first substrate supported by the second arm is coplanar with the elbow joint of the first arm, and the second arm is further adapted to move concurrently in parallel (and / or in a coordinated fashion) with the first arm a sufficient amount to avoid interference between the first substrate and the elbow joint of the first arm. Numerous other embodiments are provided.

Owner:APPLIED MATERIALS INC

Anti-Slip End Effector For Transporting Workpiece Using Van Der Waals Force

ActiveUS20150287626A1Prevent slippingImprove shipping speedSemiconductor/solid-state device manufacturingLifting devicesRobotic armEngineering

An anti-slip end effector for transporting a workpiece, configured to be attached to a robotic arm, includes: a workpiece-supporting area for placing a workpiece thereon for transportation; and at least one anti-slip protrusion disposed in the workpiece-supporting area for supporting a backside of the workpiece, said anti-slip protrusion having a top face capable of contacting and adhering to the backside of the workpiece by van der Waals force and capable of pivoting on a pivot axis, said pivot axis being disposed away from a center of the top face as viewed from above.

Owner:ASM IP HLDG BV

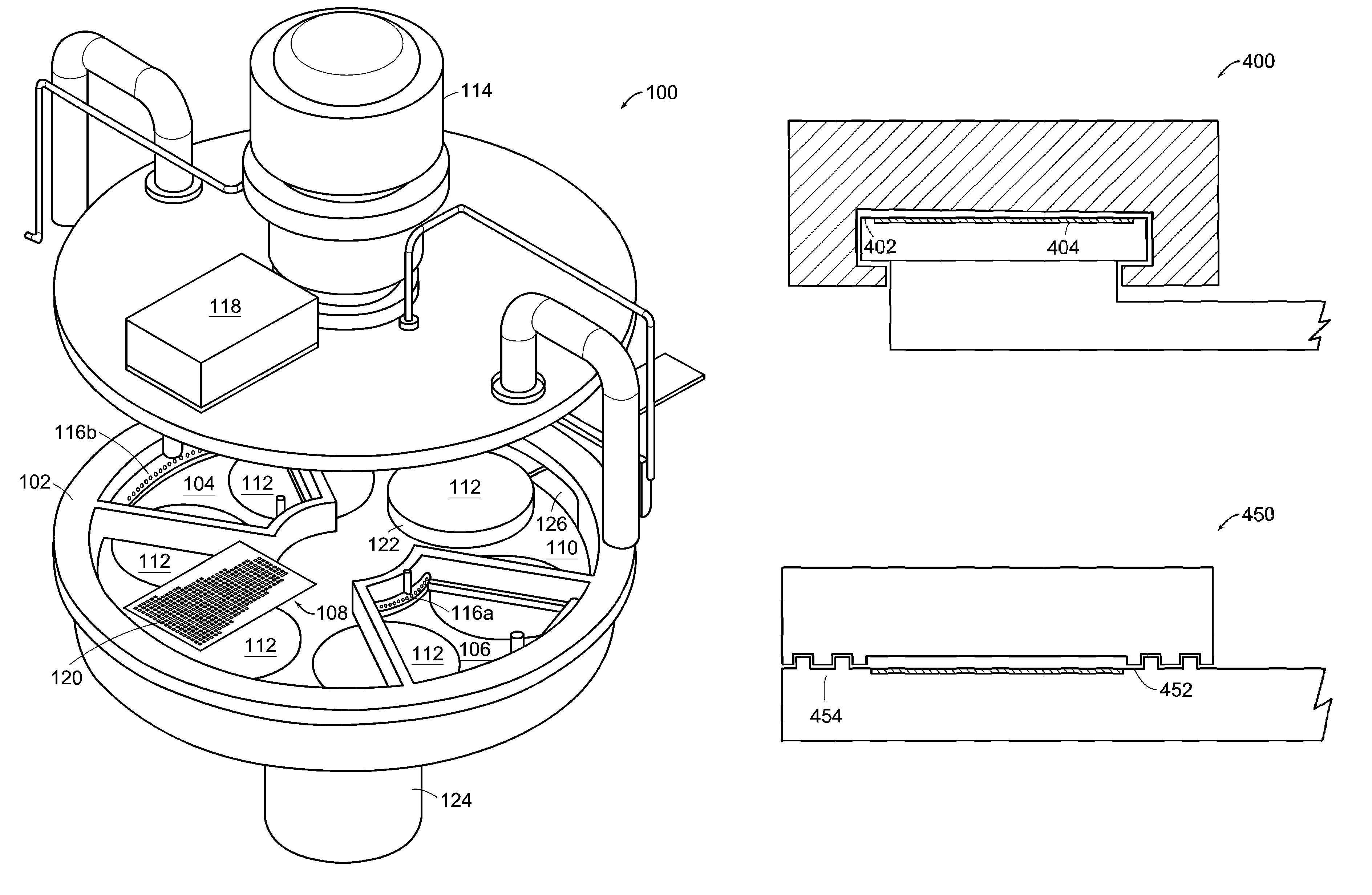

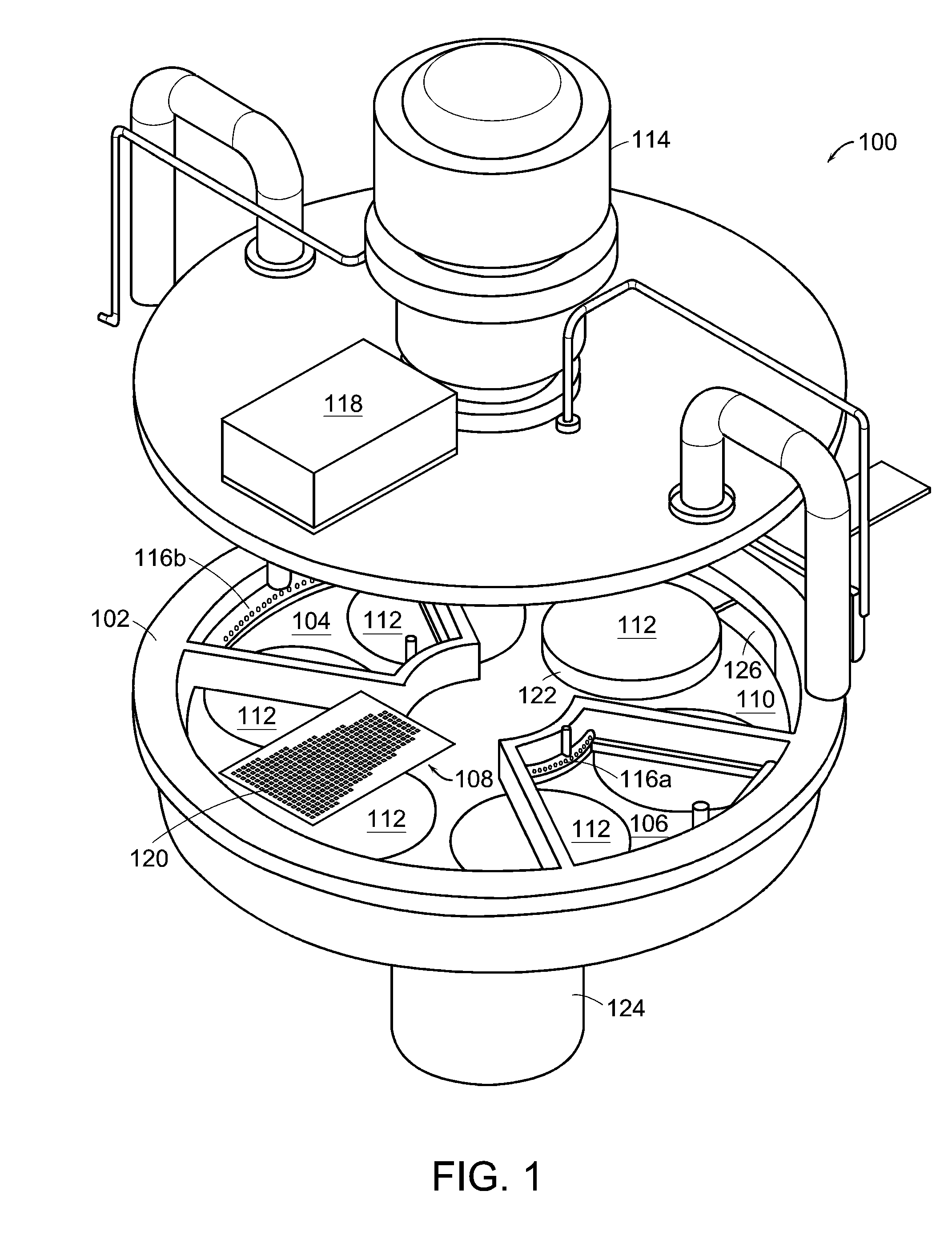

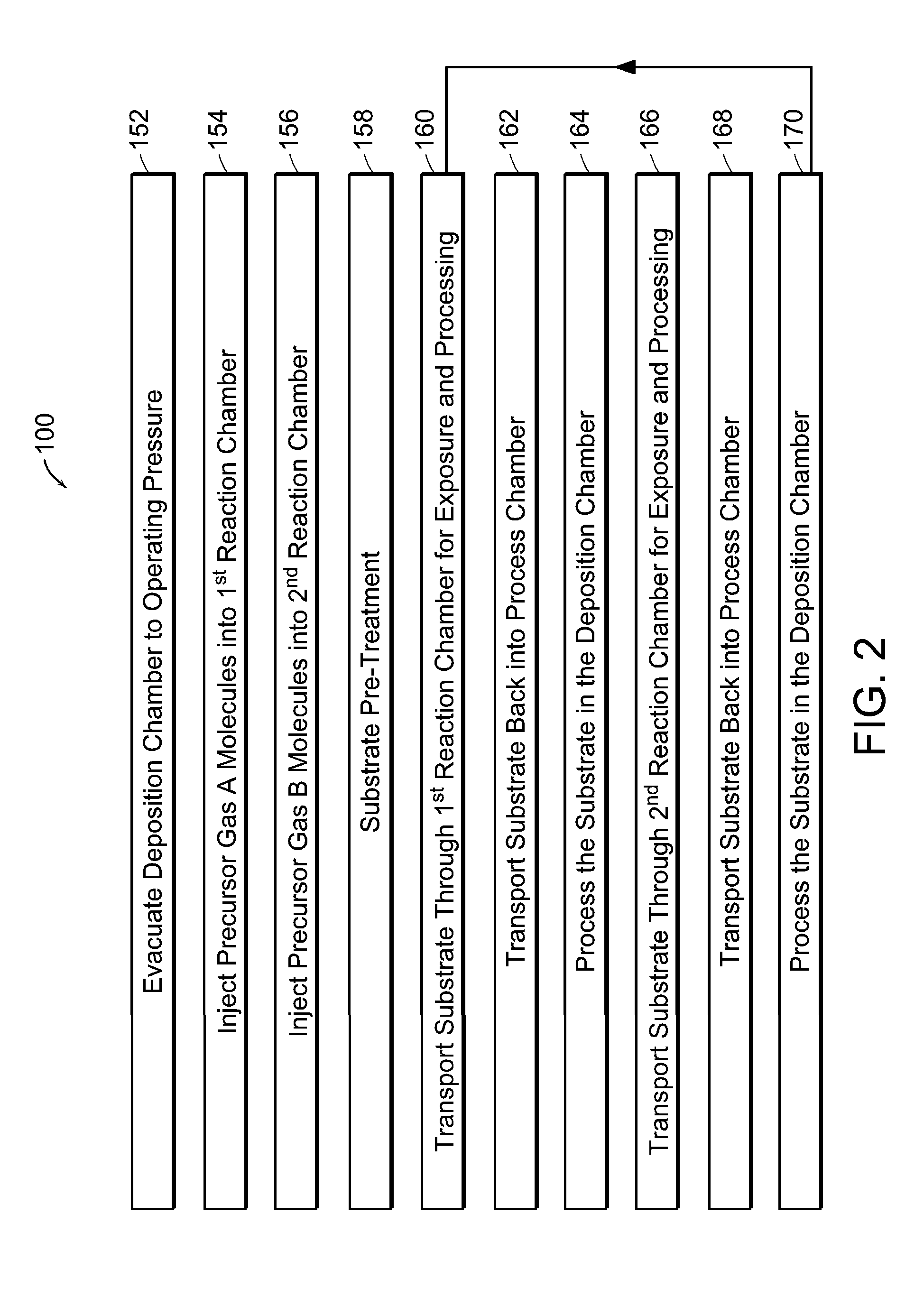

Continuous flow deposition system

An atomic layer deposition system is described that includes a deposition chamber. A first and second reaction chamber are positioned in the deposition chamber and contain a first and a second reactant species, respectively. A monolayer of the first reactant species is deposited on a substrate passing through the first reaction chamber. A monolayer of the second reactant species is deposited on a substrate passing through the second reaction chamber. A transport mechanism transports a substrate in a path through the first reaction chamber and through the second reaction chamber, thereby depositing a film on the substrate by atomic layer deposition. The shape of the first and the second reaction chambers are chosen to achieve a constant exposure of the substrate to reactant species when the transport mechanism transports the substrate in the path through the respective reaction chambers at the constant transport rate.

Owner:VEECON INSTR

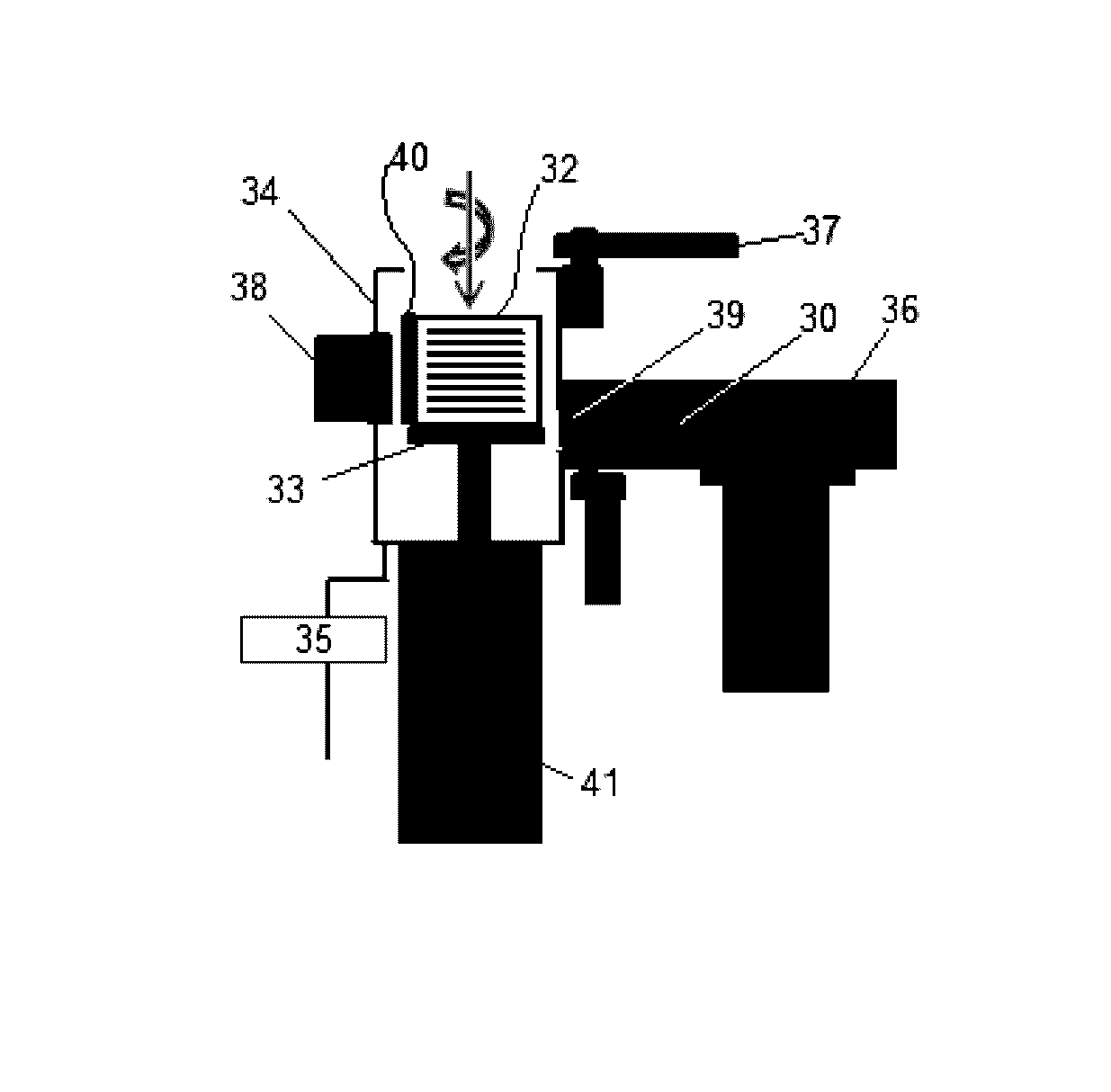

FOUP opening/closing device and probe apparatus

ActiveUS8267633B2Assure great degree of freedomEfficient comprehensive utilizationSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingControl signalFOUP

A FOUP opening / closing device includes a housing containing a mounting table for mounting the FOUP thereon, an FOUP loading opening, and a delivery opening. The device further includes a rotator for rotating the mounting table, a door opening / closing unit to open or close the door of the FOUP and keep the door open, a mover for moving the FOUP and the door opening / closing unit in a reciprocating manner, to allow the FOUP and the door opening / closing unit to be connected to or separated from each other, and a controller to output control signals for moving the FOUP and the door opening / closing unit via operation of the mover to mount the door of the FOUP to the door opening / closing unit, separating the door from the FOUP, moving the FOUP and the door opening / closing unit away from each other, and rotating the mounting table to make the FOUP face the delivery opening.

Owner:TOKYO ELECTRON LTD

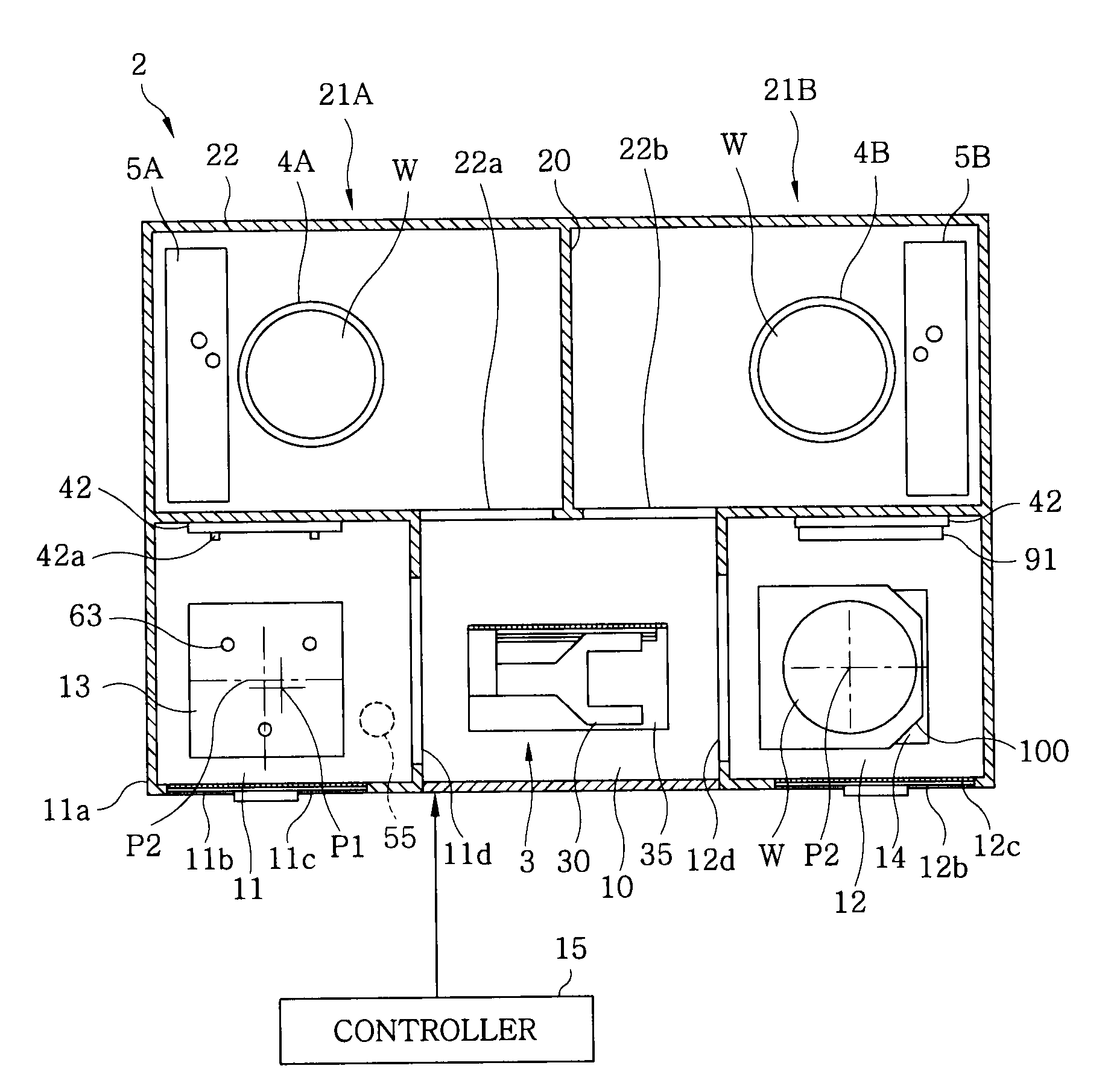

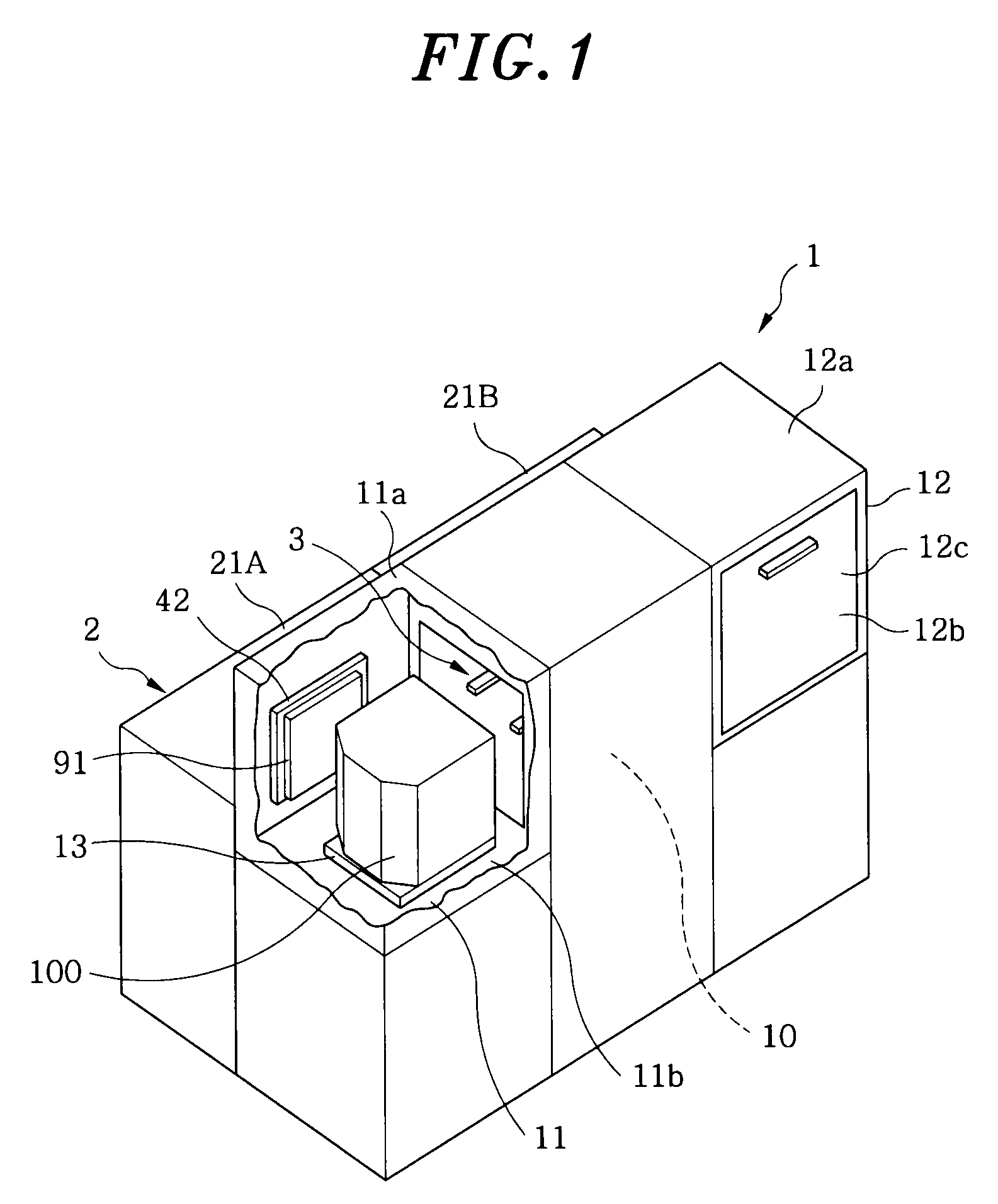

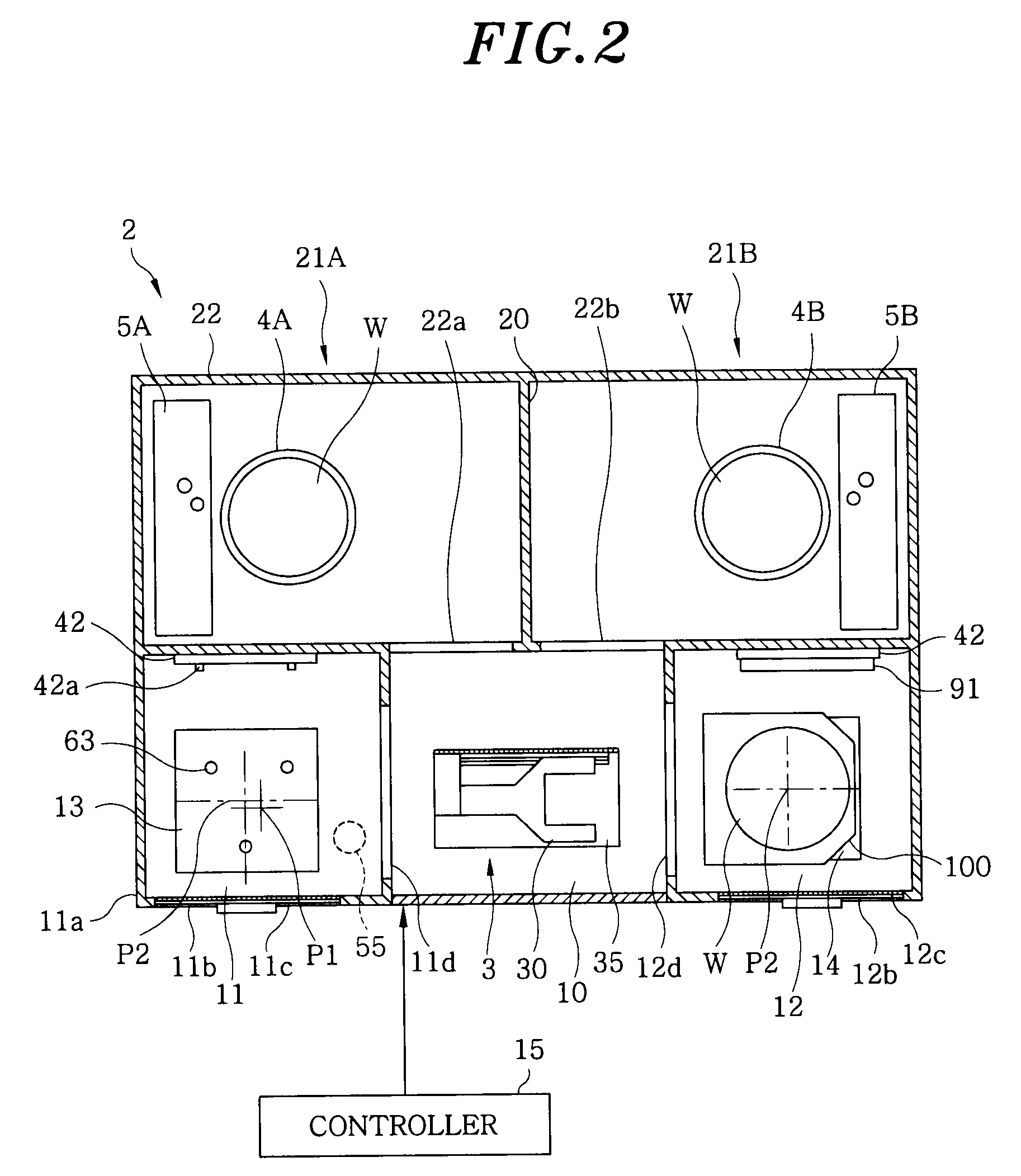

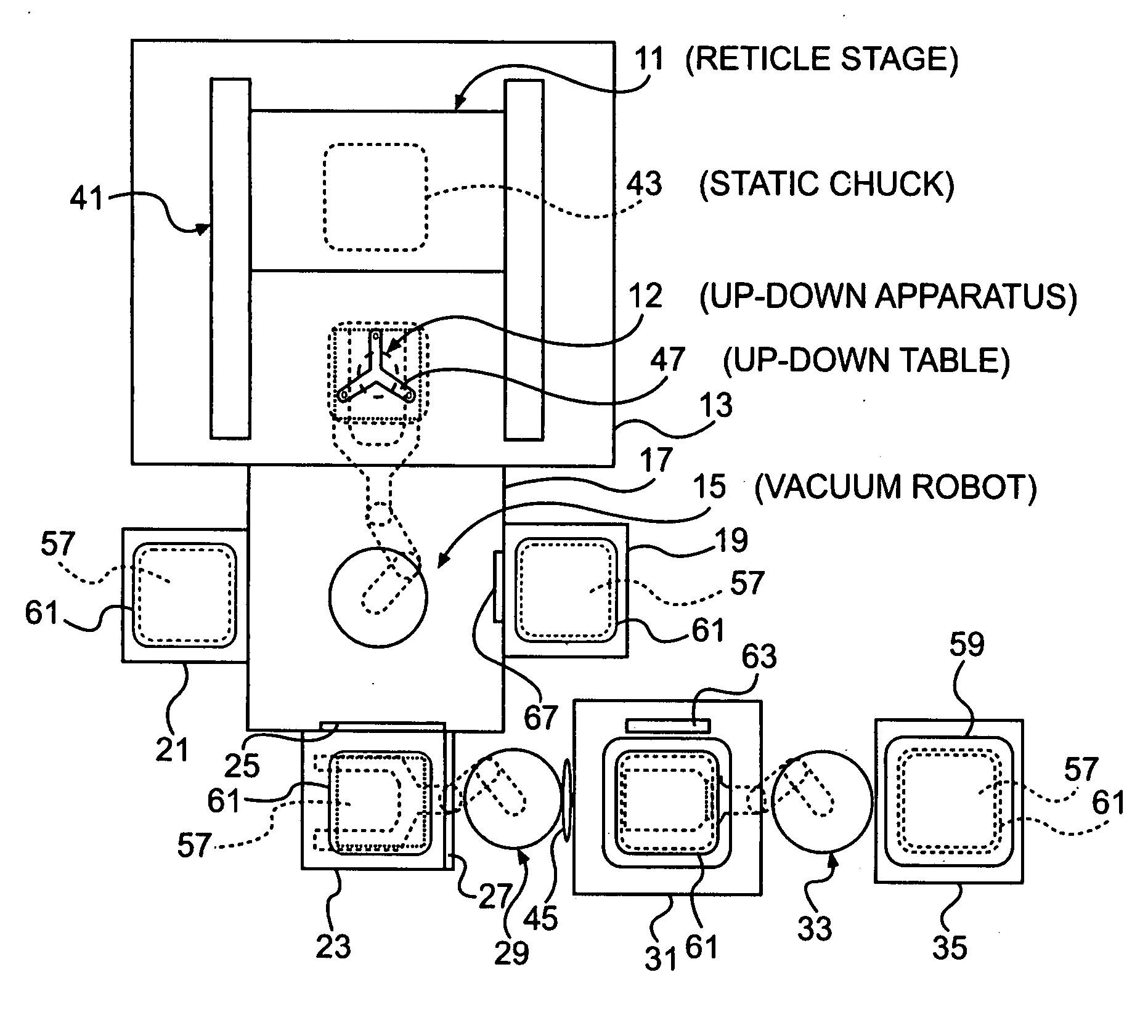

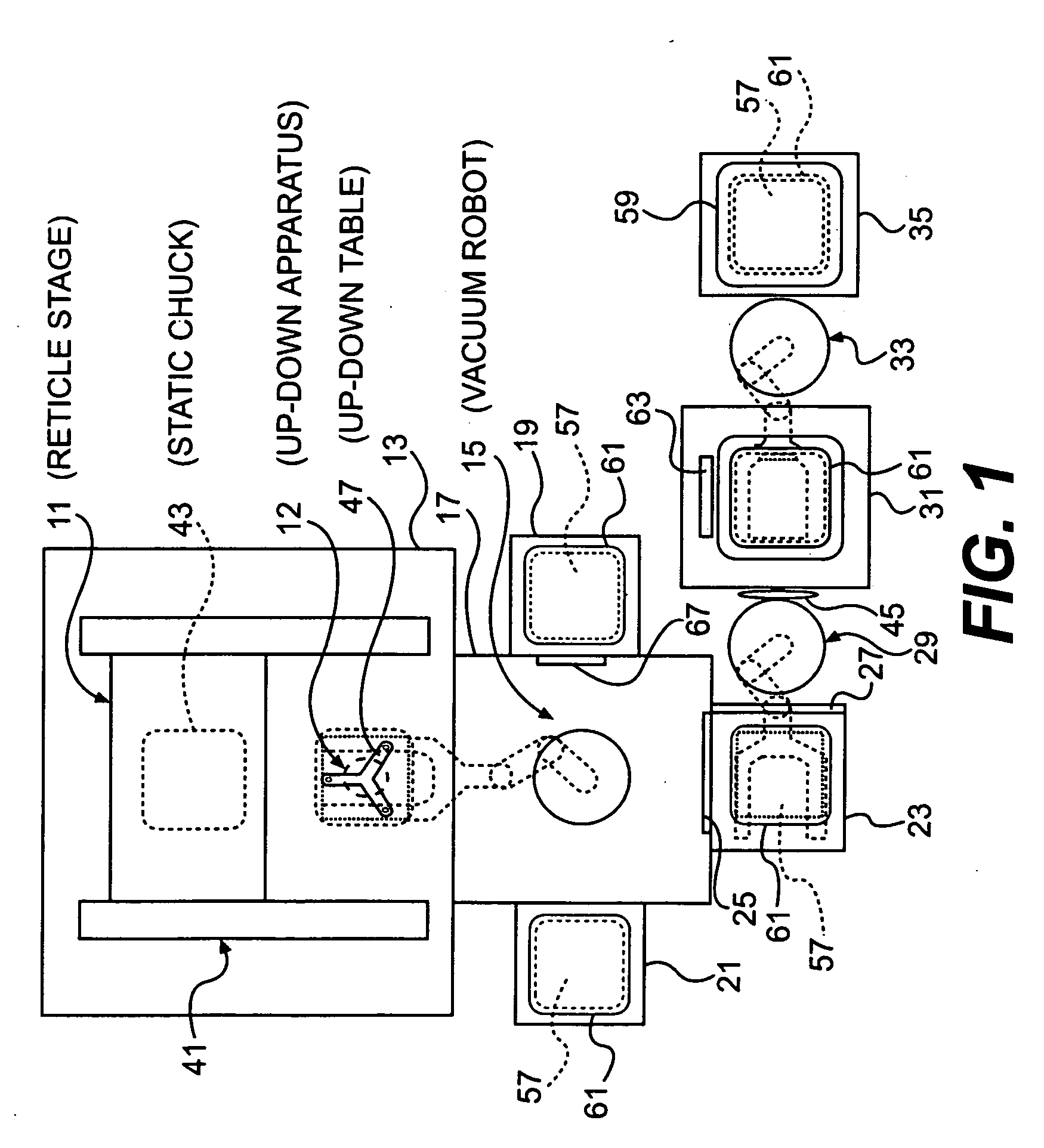

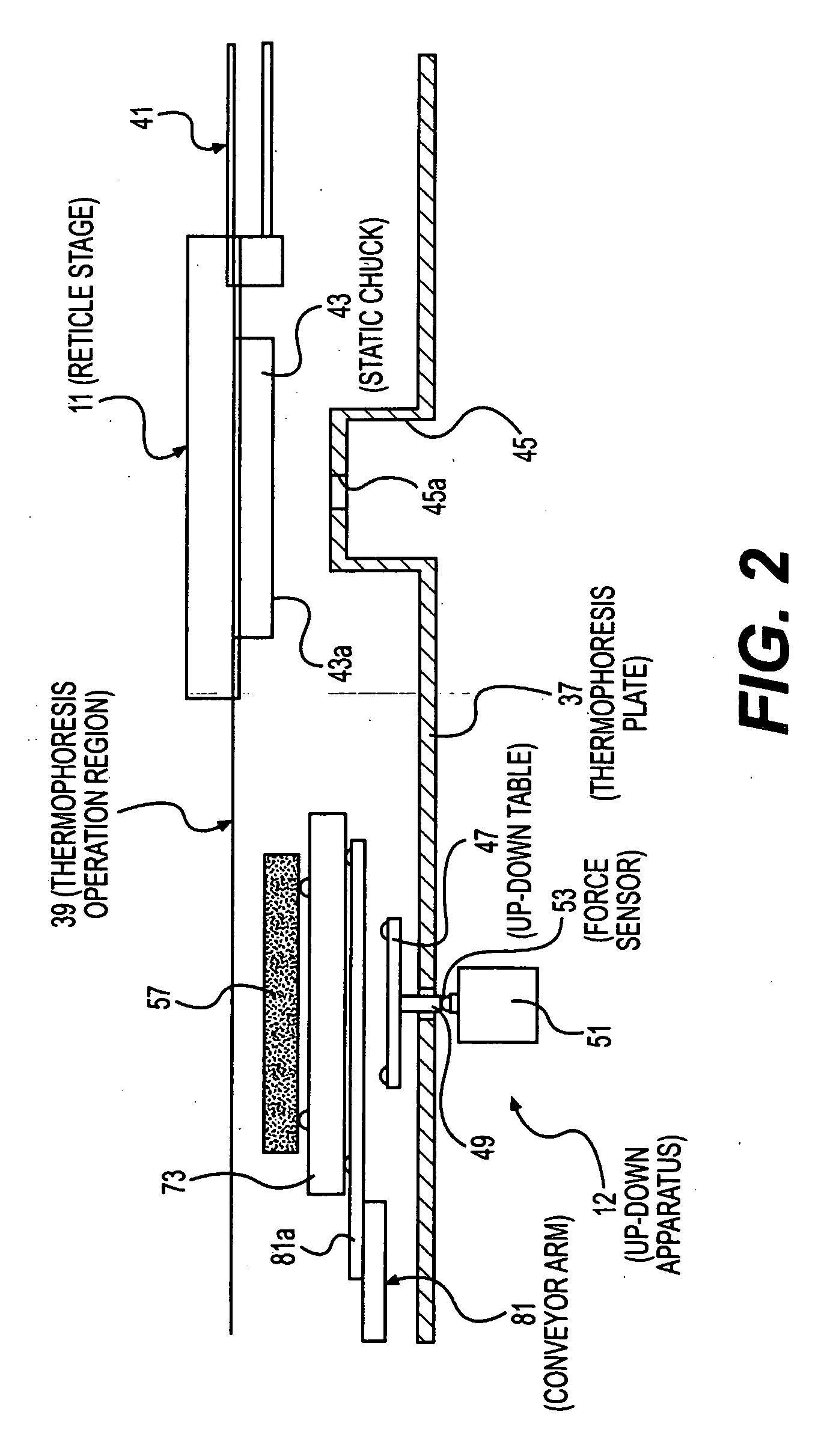

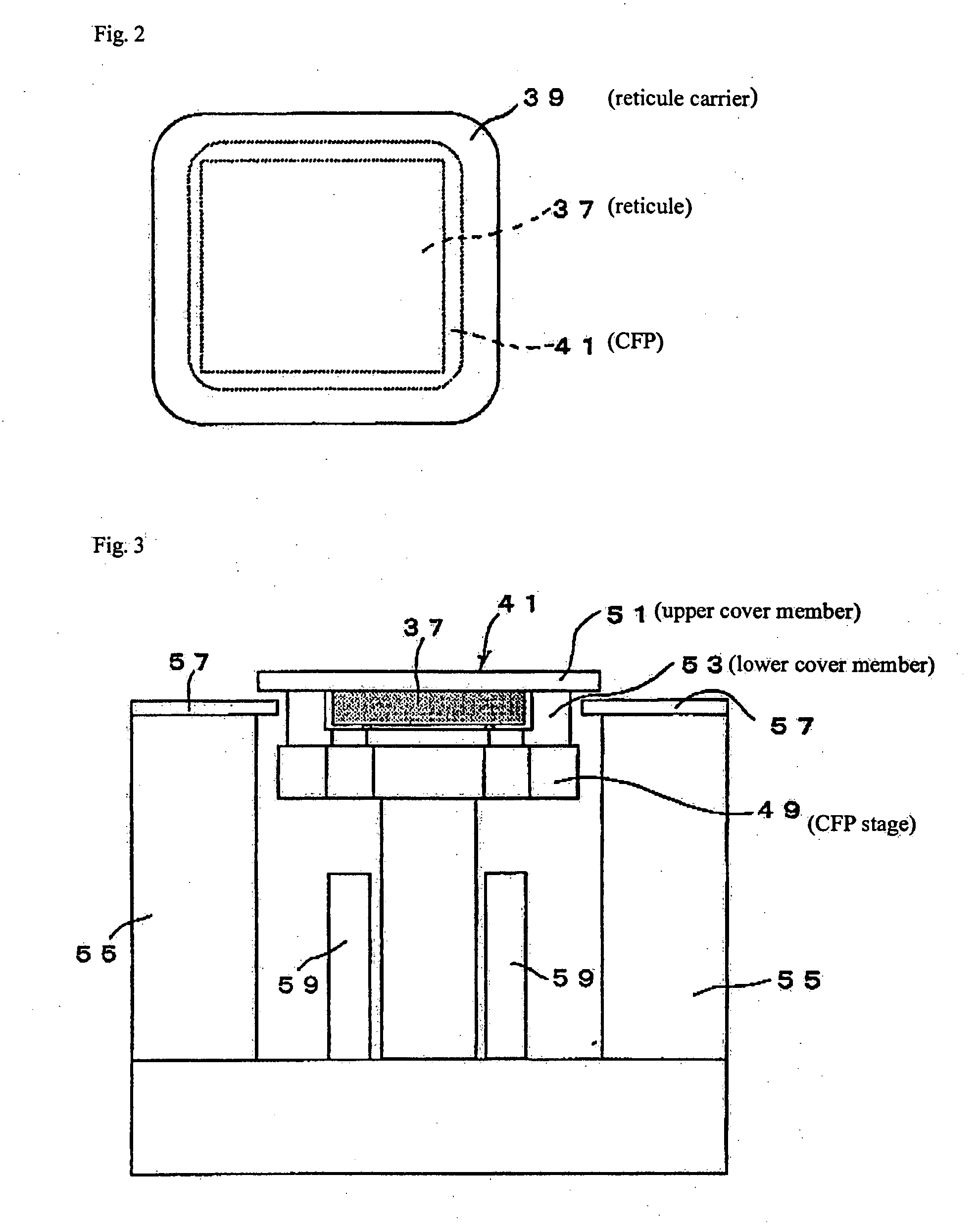

Substrate conveyor apparatus, substrate conveyance method and exposure apparatus

ActiveUS20060291982A1Improve reliabilityStrong adhesionPhotomechanical apparatusSemiconductor/solid-state device manufacturingEngineeringReticle

The present invention pertains to a substrate conveyor apparatus that carries a substrate such as a reticle, a substrate conveyance method and an exposure apparatus, with the object of reliably adhering a substrate to the lower surface of a chuck. The present invention is characterized by having a movable stage that can move in the horizontal direction and that is equipped with a chuck having an adhesion surface that faces down for adhering a substrate, an up-down means equipped with an up-down table that is positionable in a position below the substrate and within the movement range of the movable stage, and a conveyance means equipped with a conveyor arm that carries the substrate to the up-down means.

Owner:NIKON CORP

Substrate conveyor apparatus, substrate conveyance method and exposure apparatus

ActiveUS20060087638A1High yieldSmall contaminationNanoinformaticsSemiconductor/solid-state device manufacturingEngineering

Owner:NIKON CORP

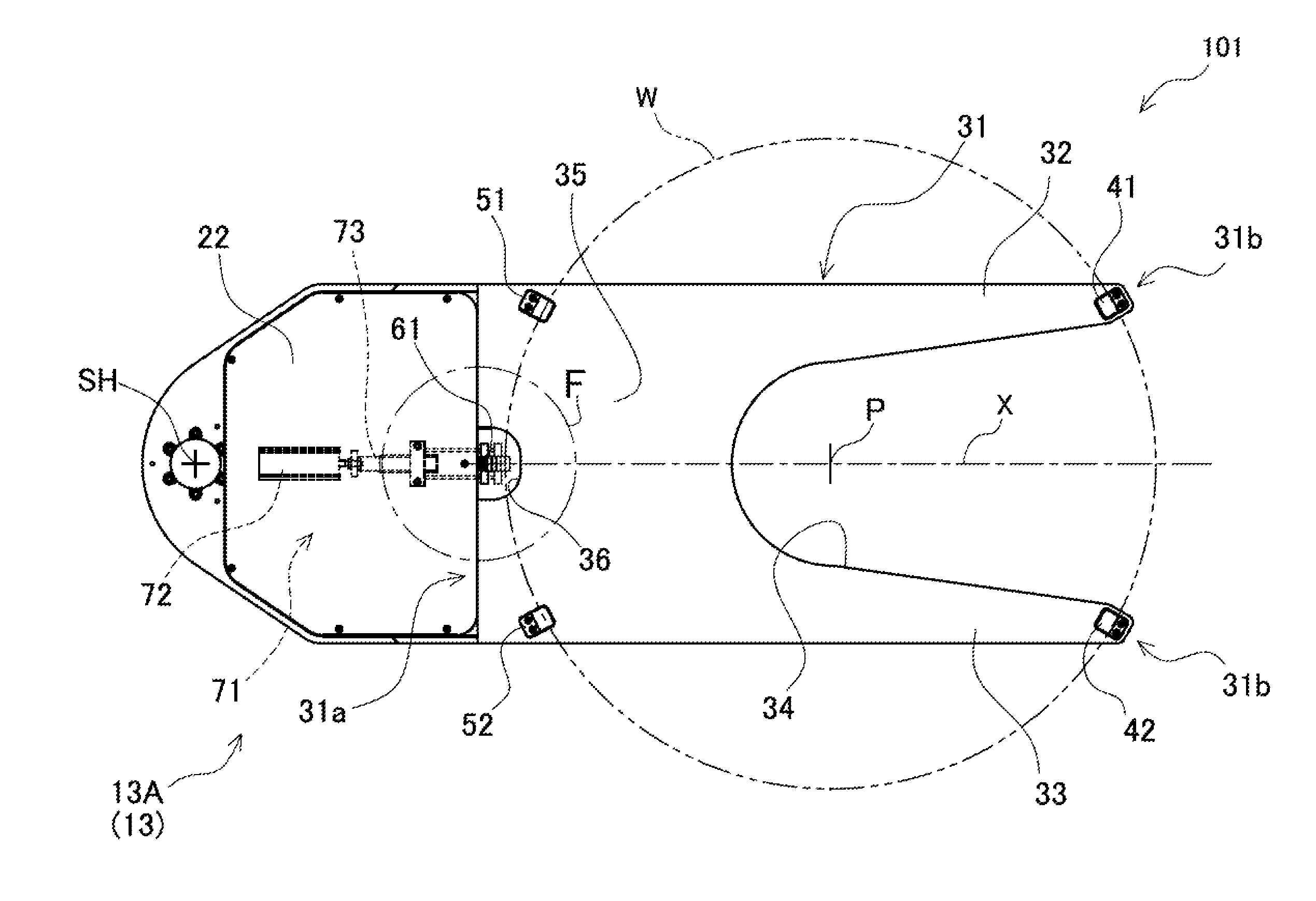

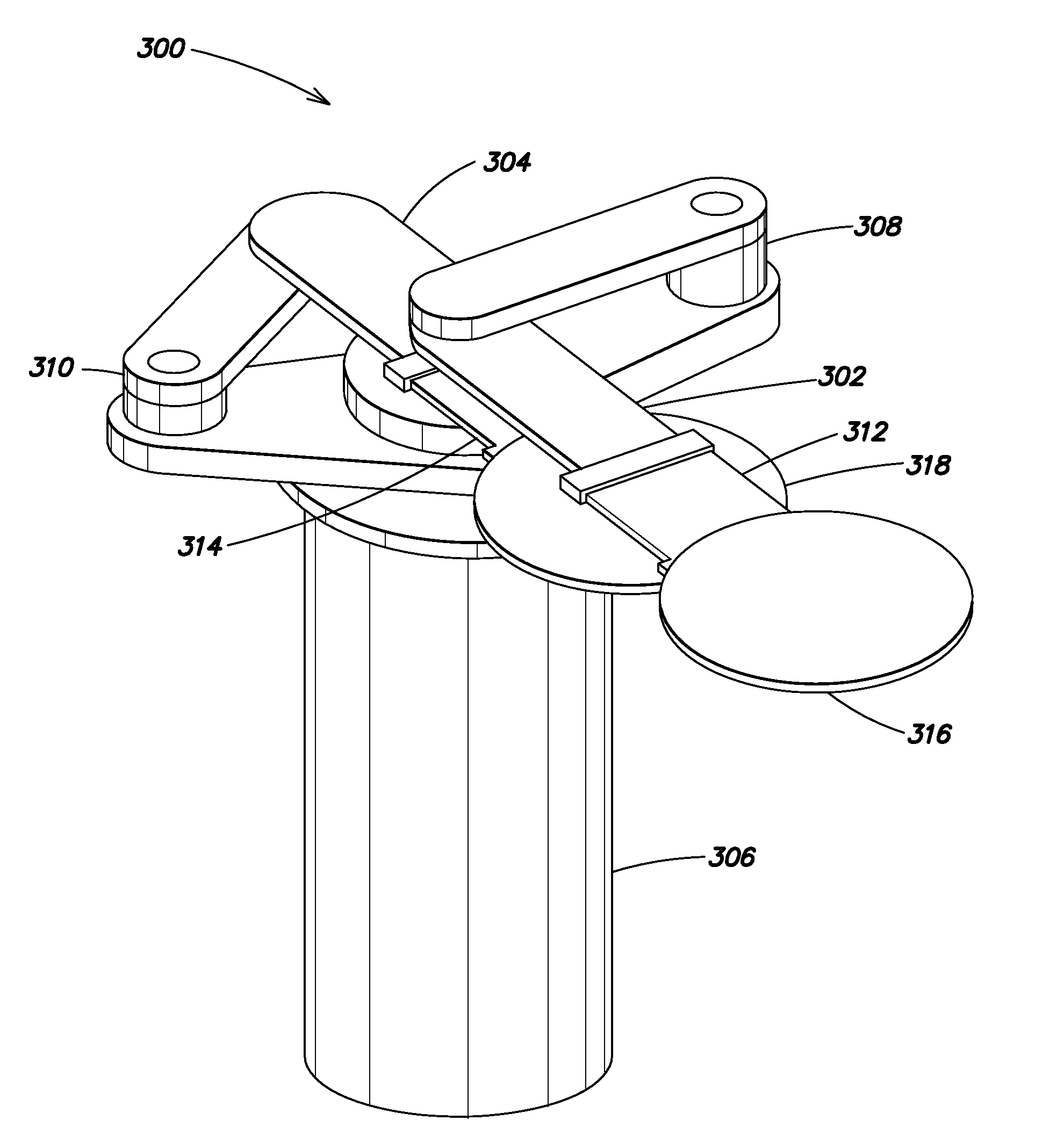

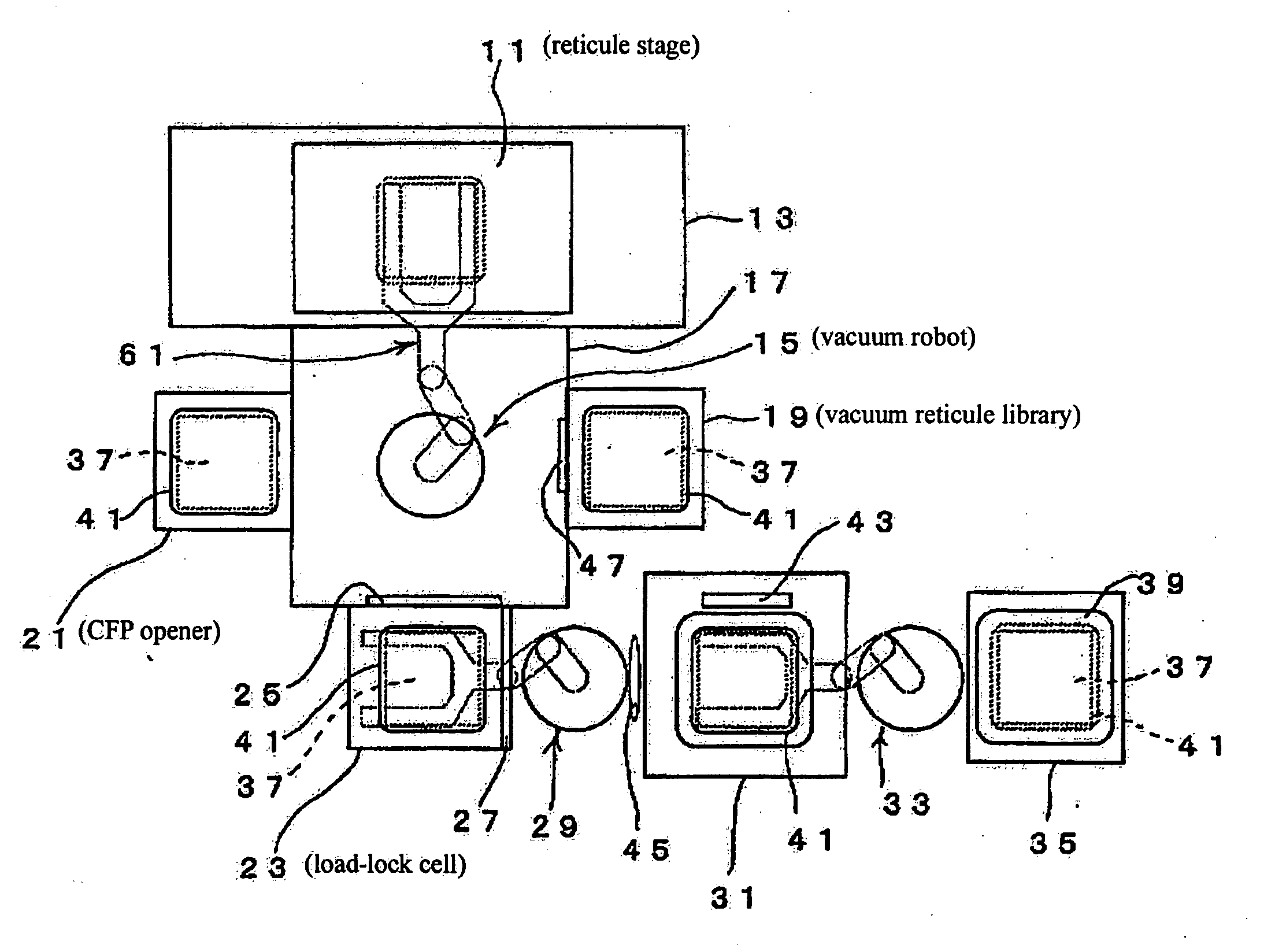

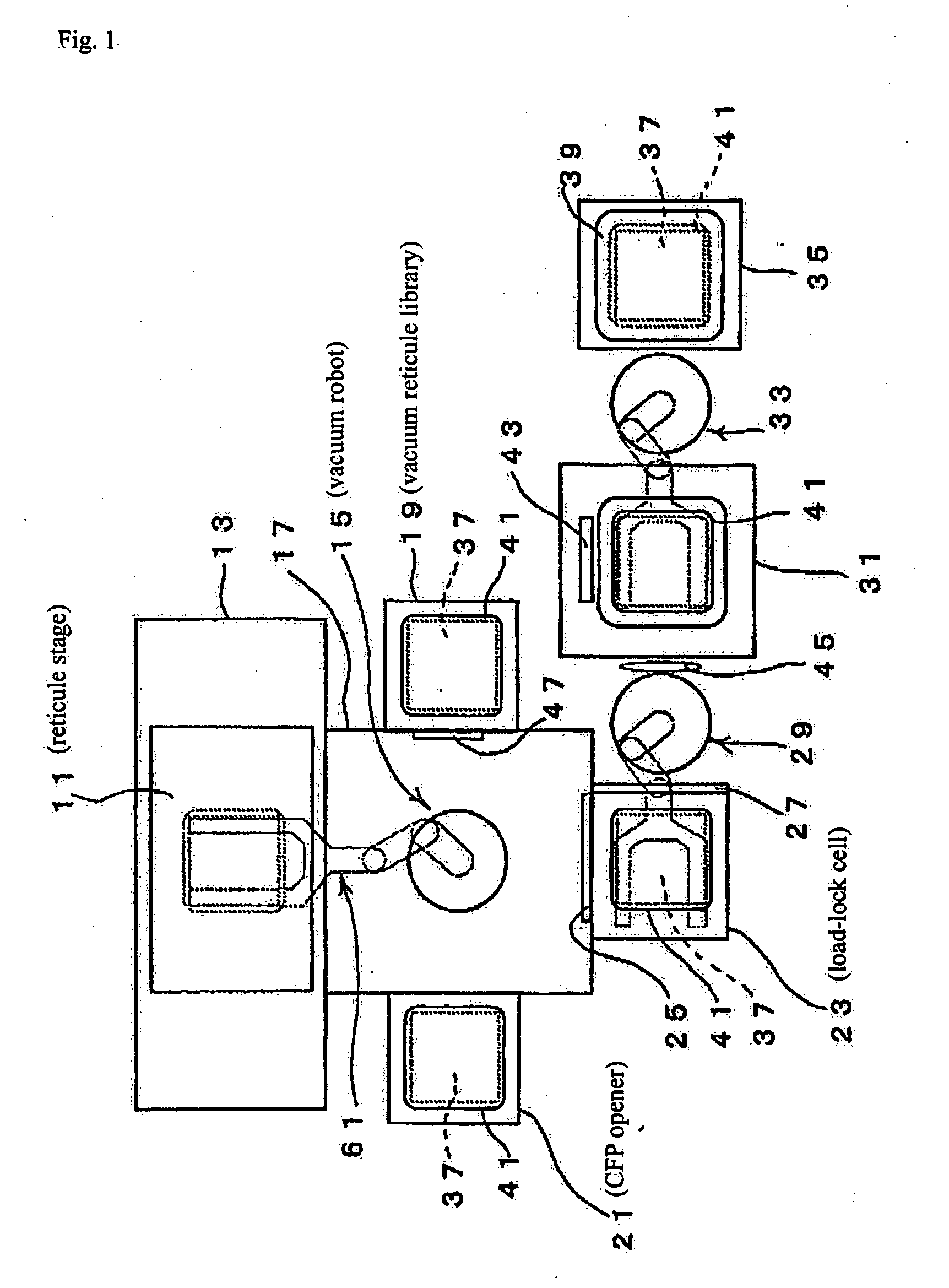

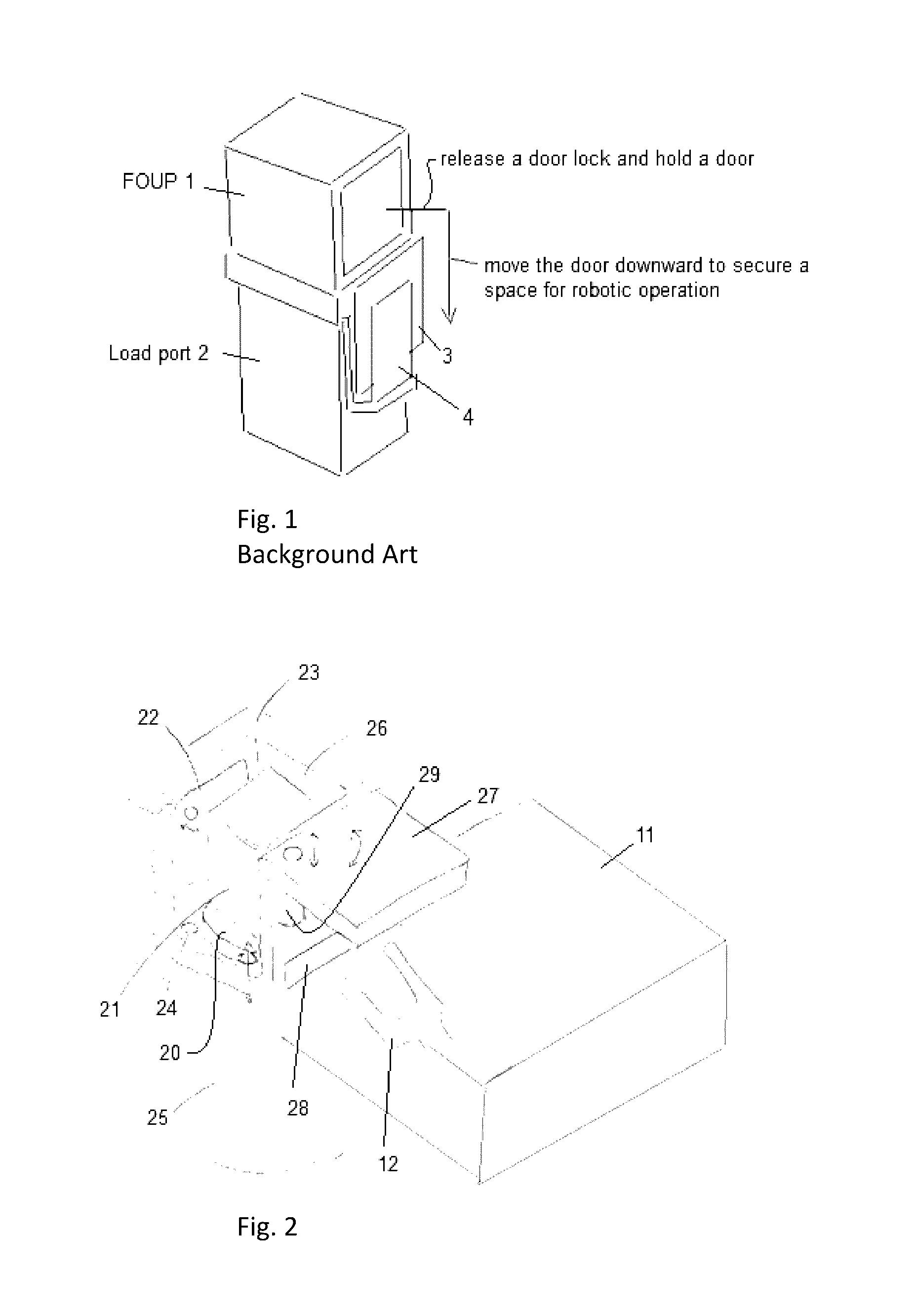

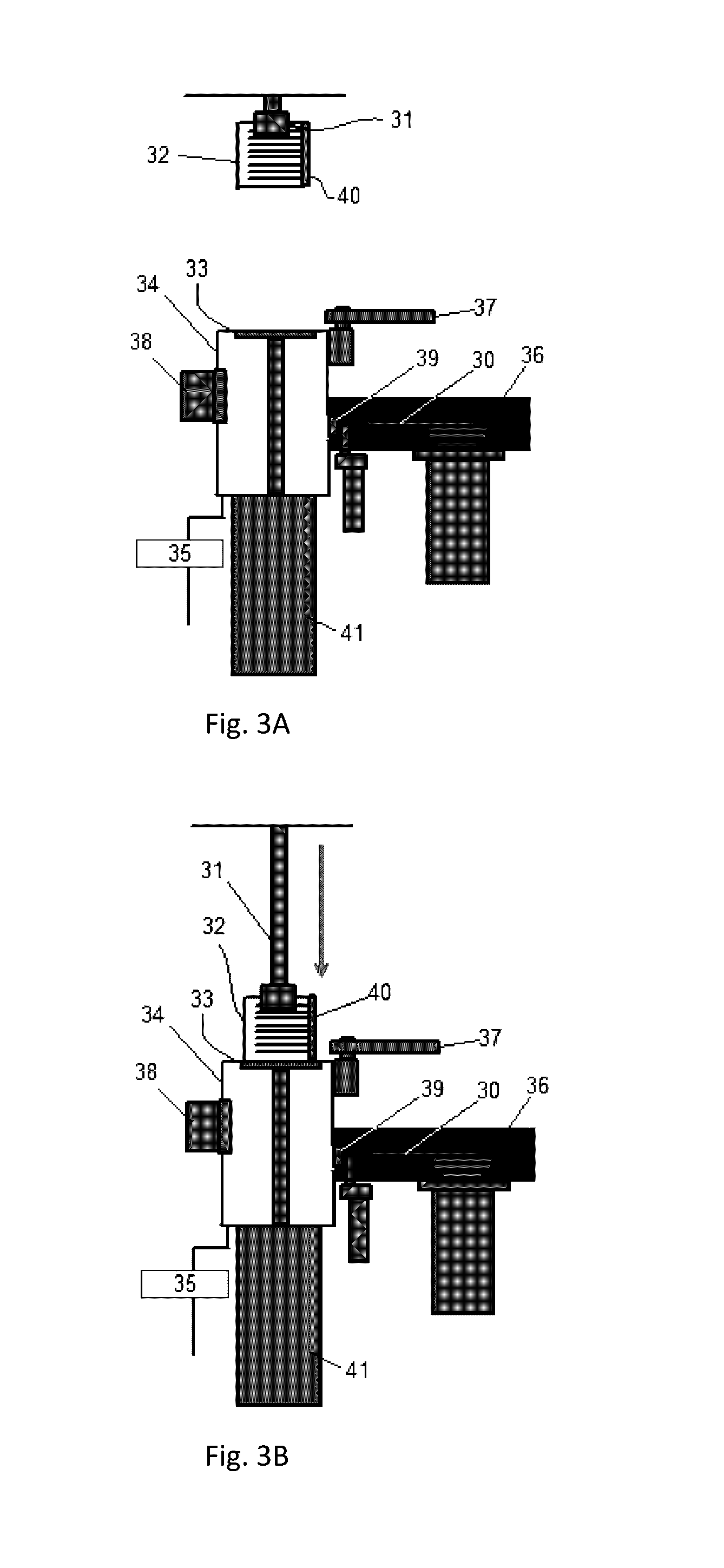

Apparatus and method for transporting wafers between wafer carrier and process tool under vacuum

ActiveUS9543180B2Efficient solutionReduce volumeSemiconductor/solid-state device manufacturingConveyor partsEngineeringElectrical and Electronics engineering

An integrated transport device for a wafer carrier includes: an evacuatable chamber for accommodating therein a wafer carrier having a front opening with a cover; a rotatable platform for placing the wafer carrier thereon in the chamber; and an opening / closing device for opening and closing the cover of the wafer carrier placed on the platform at a first position, wherein the platform rotates to set the wafer carrier at the first position and a second position for transporting a wafer to a wafer-handling chamber.

Owner:ASM IP HLDG BV

Heat treatment jig for semiconductor silicon substrate

ActiveUS7163393B2Charge supportsSemiconductor/solid-state device manufacturingDislocationHydrogen annealing

Owner:SUMITOMO MITSUBISHI SILICON CORP

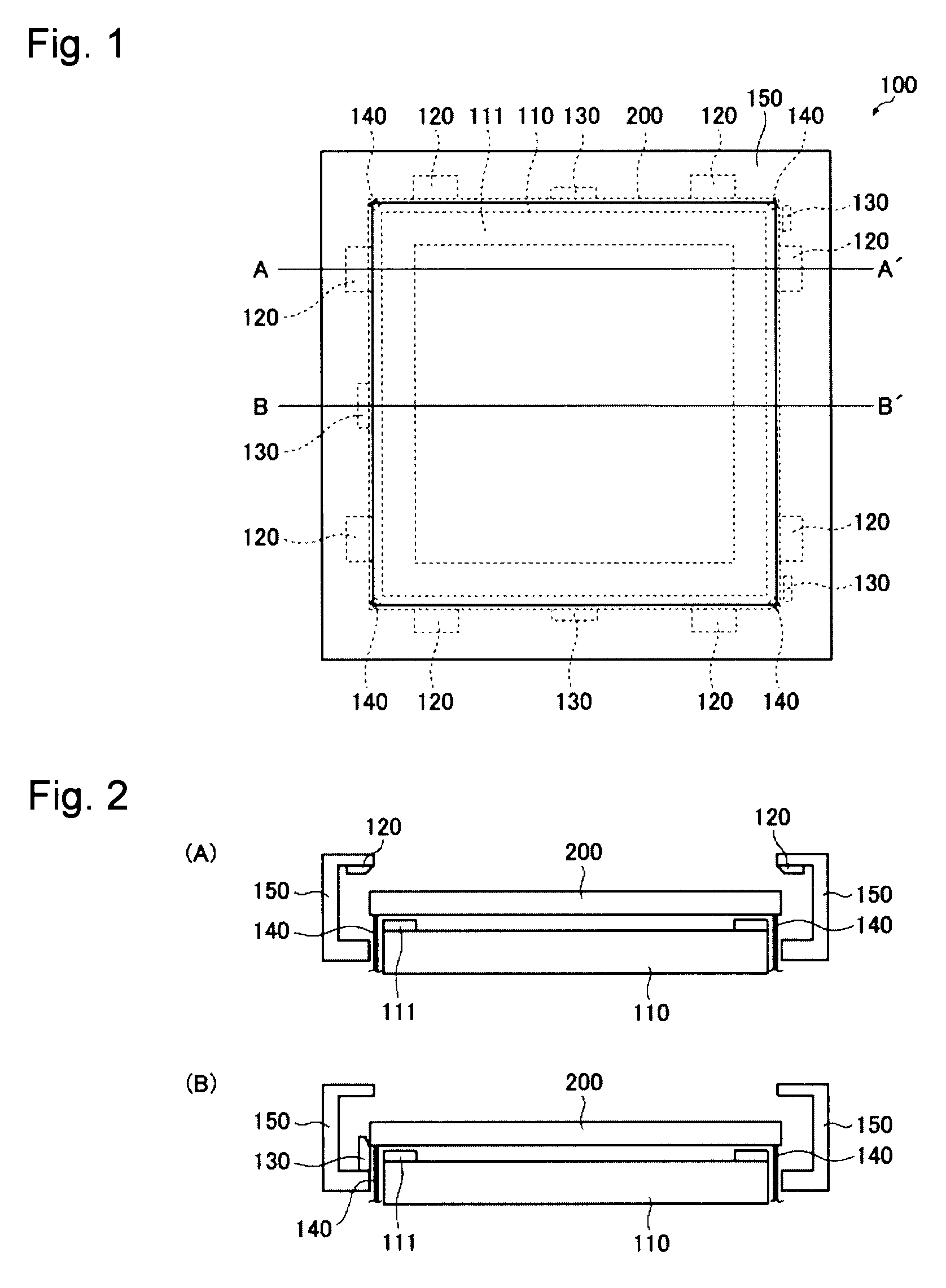

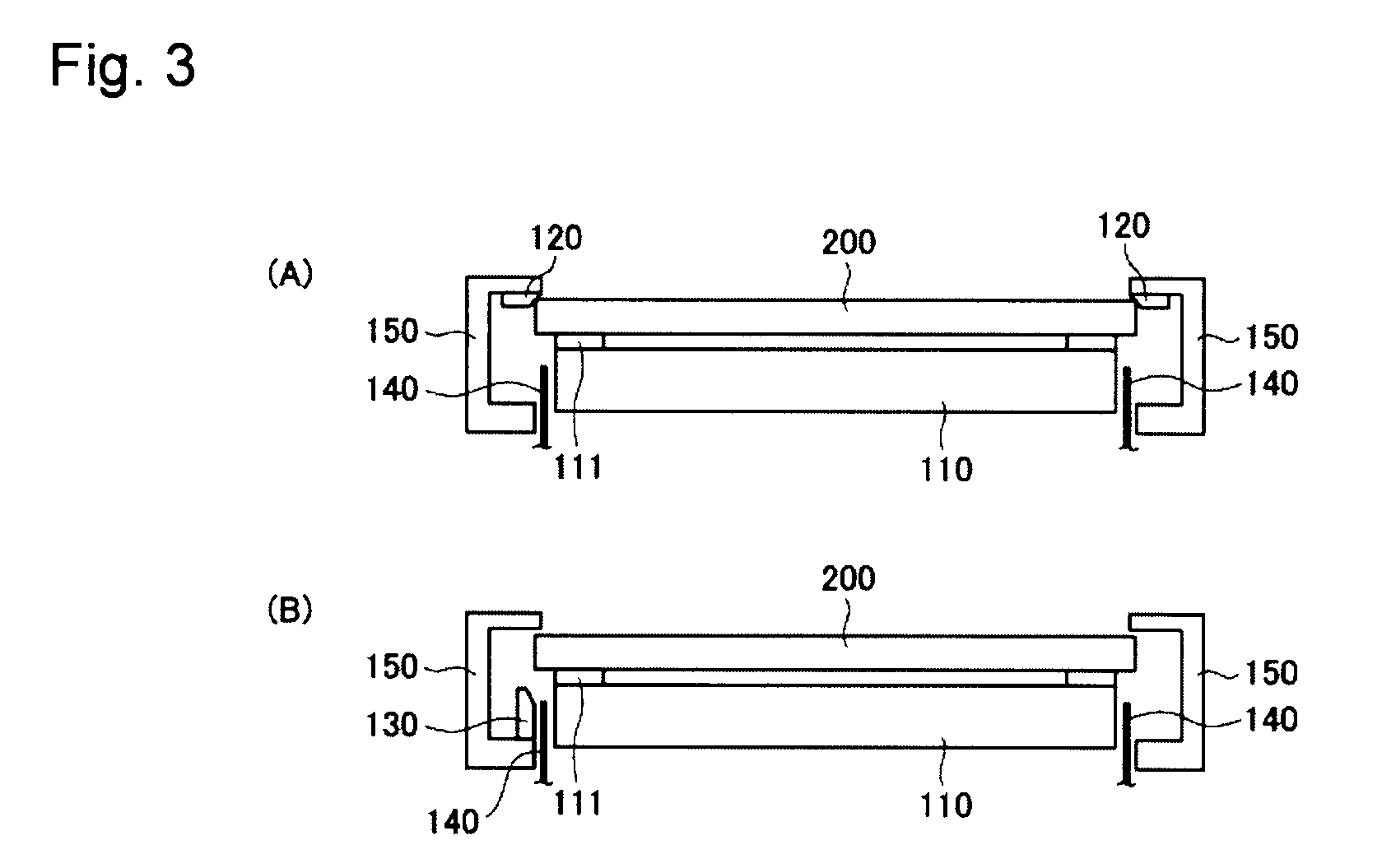

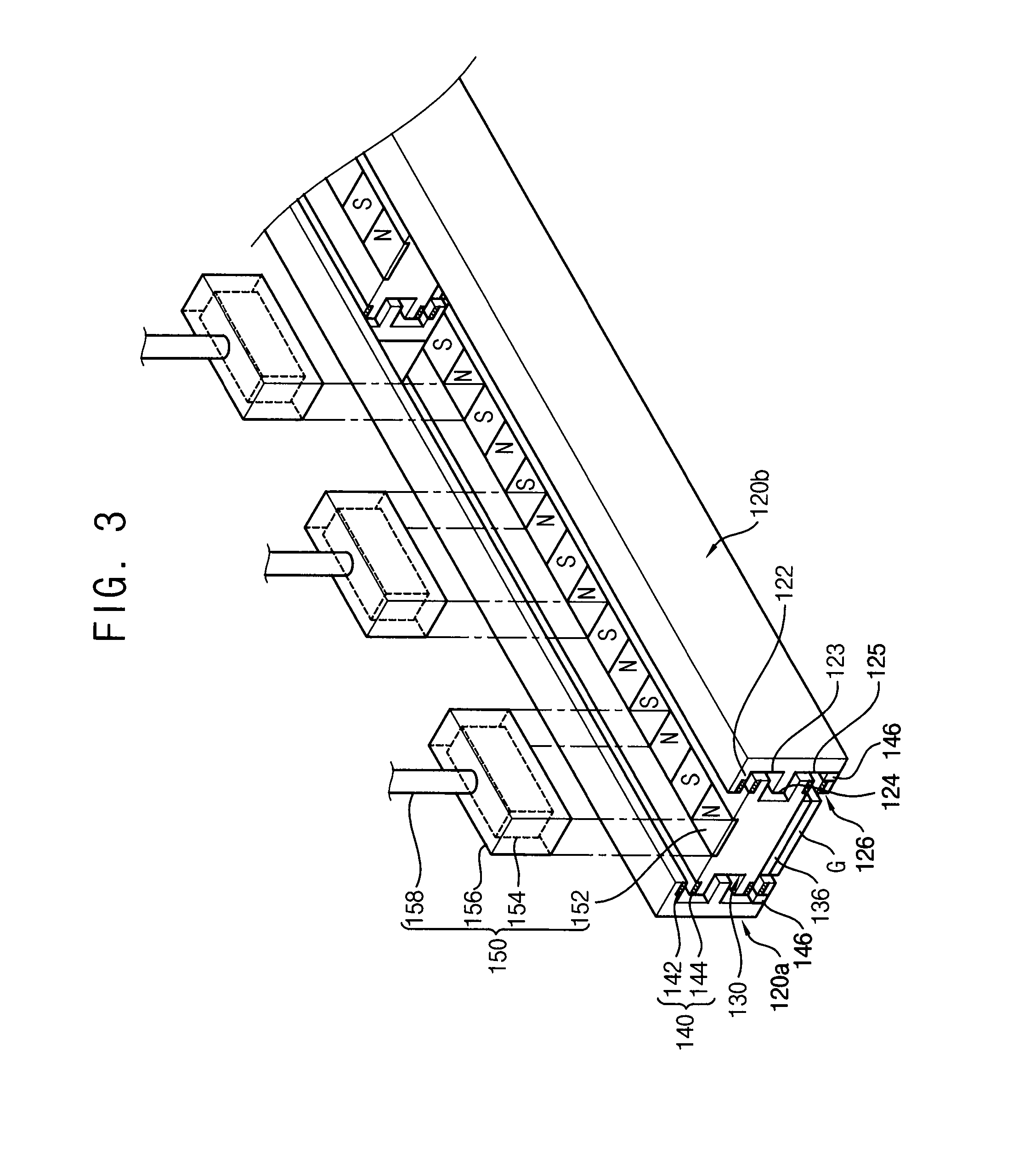

Substrate transfer apparatus and thin film deposition apparatus having the same

InactiveUS20150122180A1Accurately and sequentially transferringEfficient transferVacuum evaporation coatingSputtering coatingEngineering

A substrate transfer apparatus includes a guide rail, a carrier, a magnetic levitation unit, and a transferring unit. The guide rail is in a vacuum evacuable chamber. The carrier may carry a substrate and may be linearly movable along the guide rail. The magnetic levitation unit is configured to generate a magnetic levitation force between the guide rail and the carrier. The transferring unit is configured to generate a momentum for linearly transferring the carrier and includes a plurality of first transferring magnetic material members on an upper surface of the carrier, a plurality of second transferring magnetic material members over the carrier and spaced apart from the first transferring magnetic material members, and a plurality of containers in which the plurality of second transferring magnetic material members is respectively disposed.

Owner:SAMSUNG DISPLAY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com