Patents

Literature

17442results about "Article separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

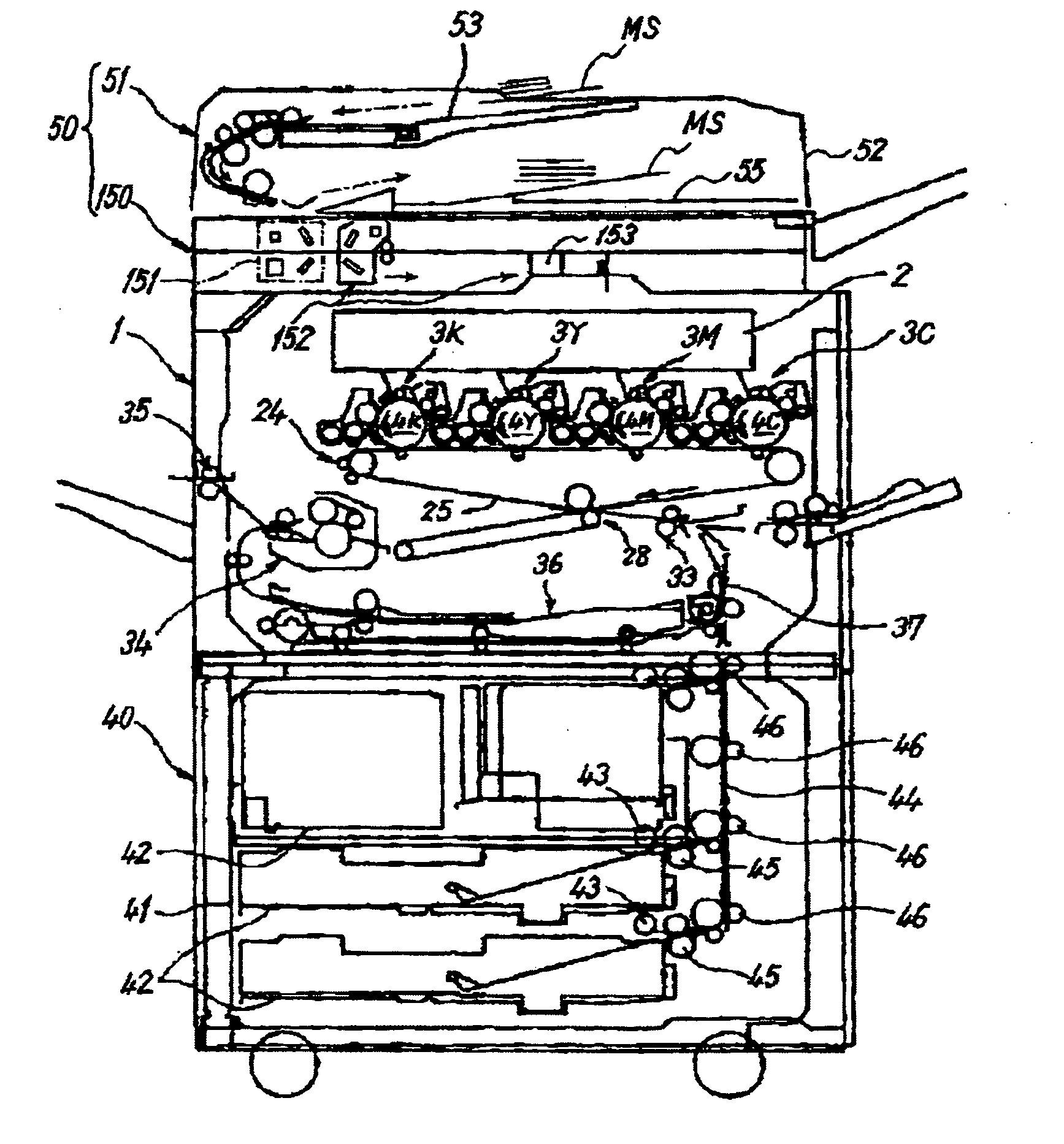

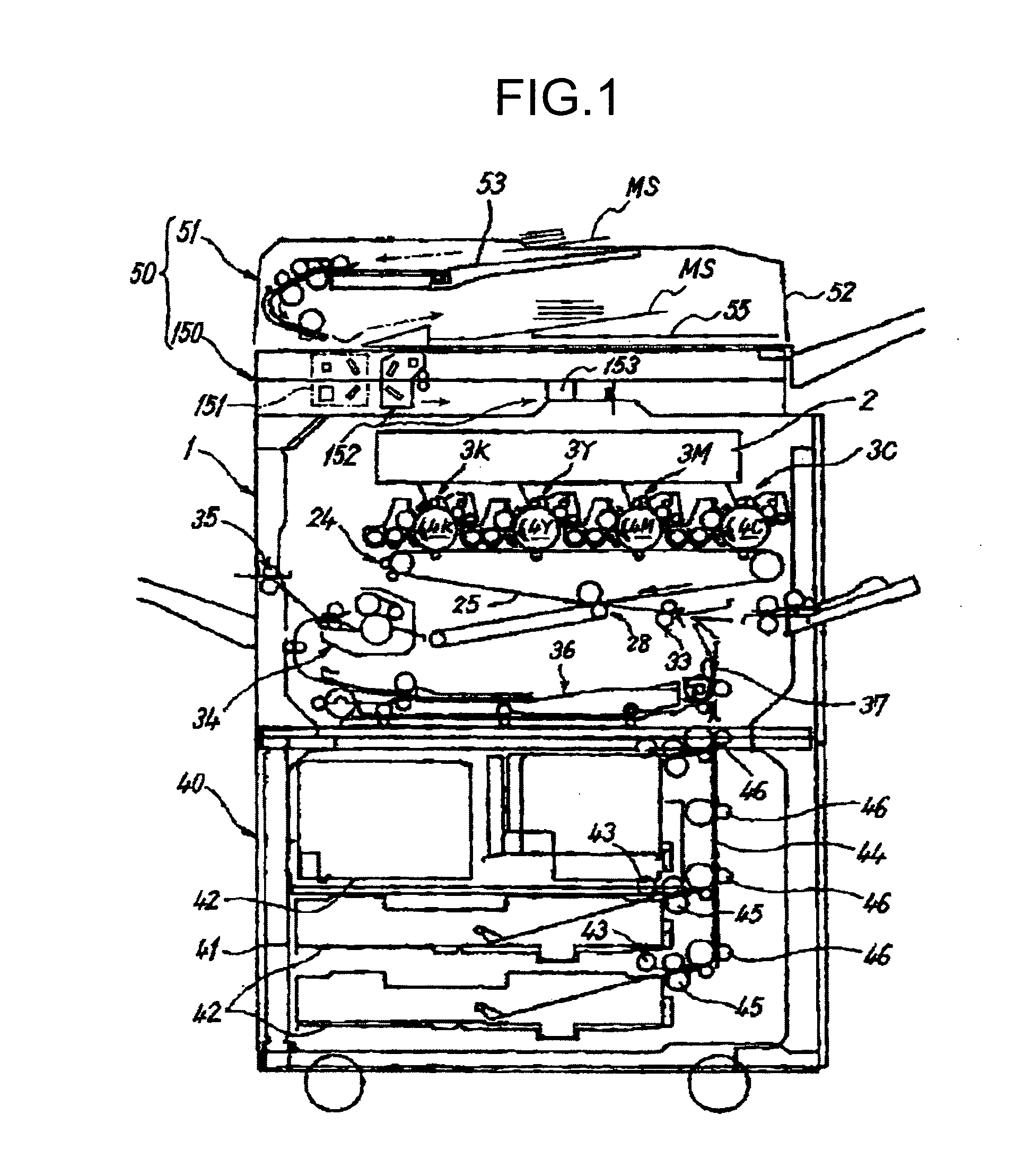

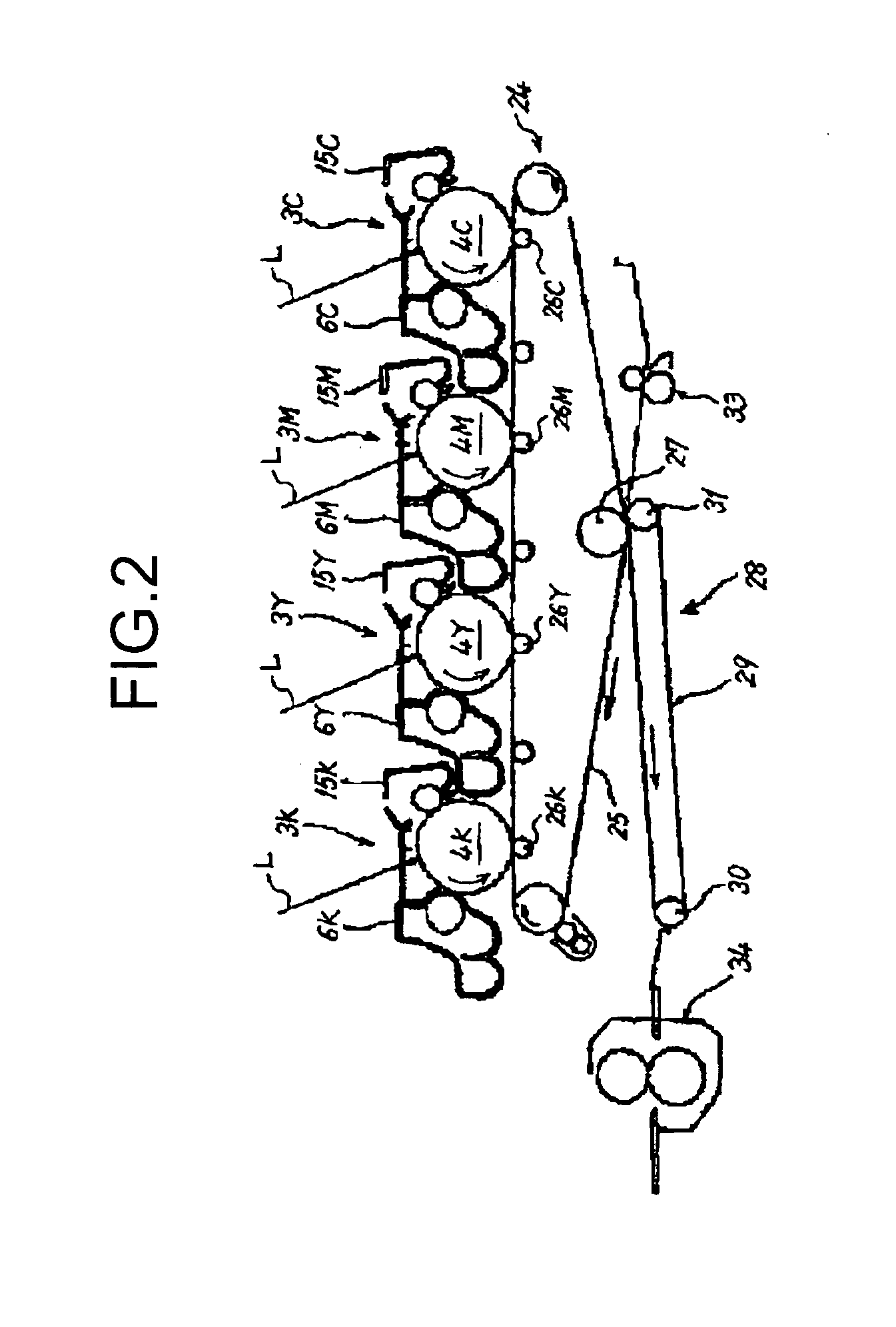

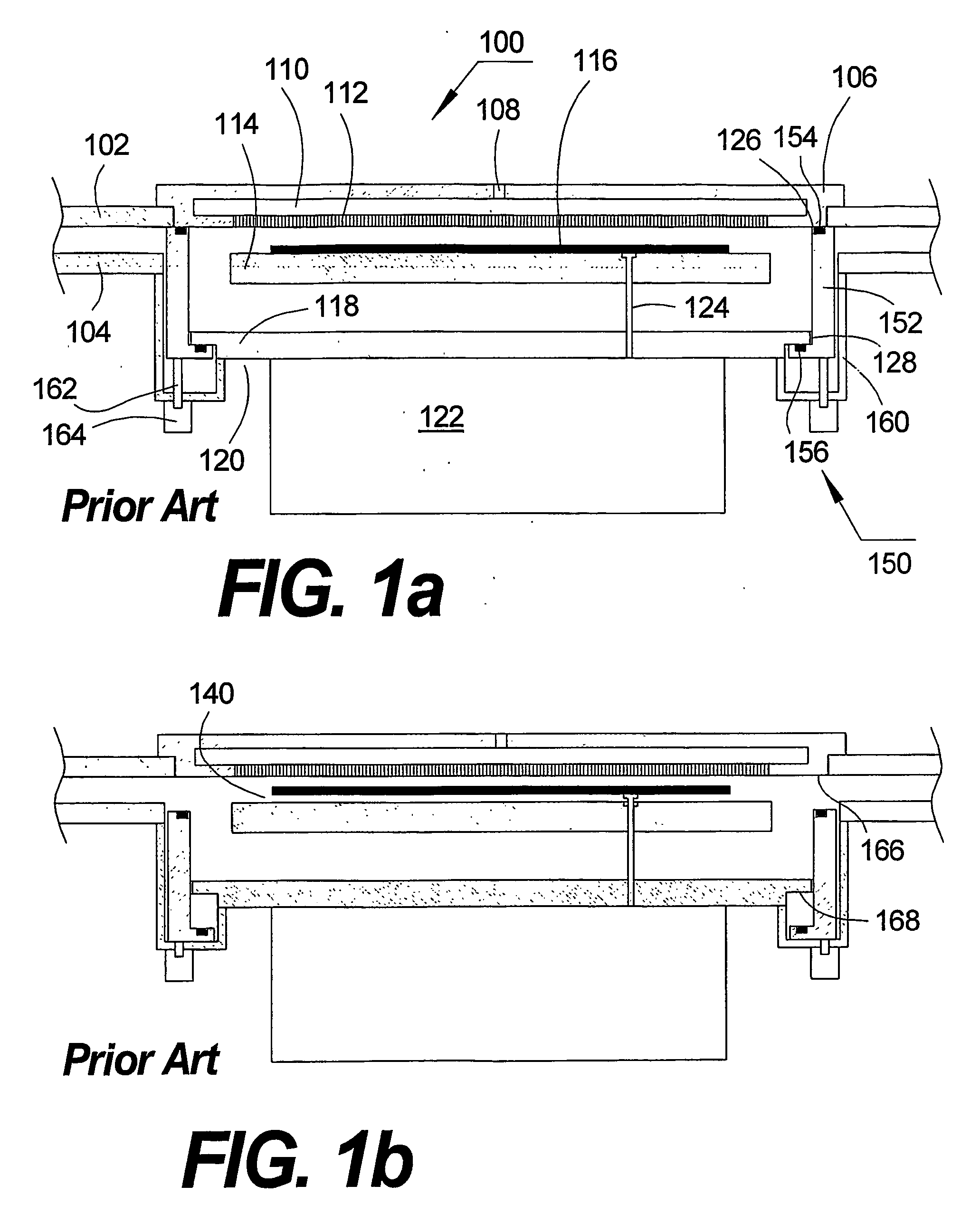

Image read device and copier

An image read device is provided, which conveys an original while performing reading of an image of the original at a read position on a transparent member by a read unit fixed, the image read device including: a moving unit that moves the transparent member back and forth in an original conveying direction; a control unit that conveys the original and moves the transparent member by using the moving unit while causing the reading of the image to be performed at the read position; and a determining unit that, when an event causing interruption of original conveyance occurs, stops the transparent member and determines whether a control of returning the transparent member to a home position is to be performed or not in accordance with a stopped position of the original in an original conveying path.

Owner:RICOH KK

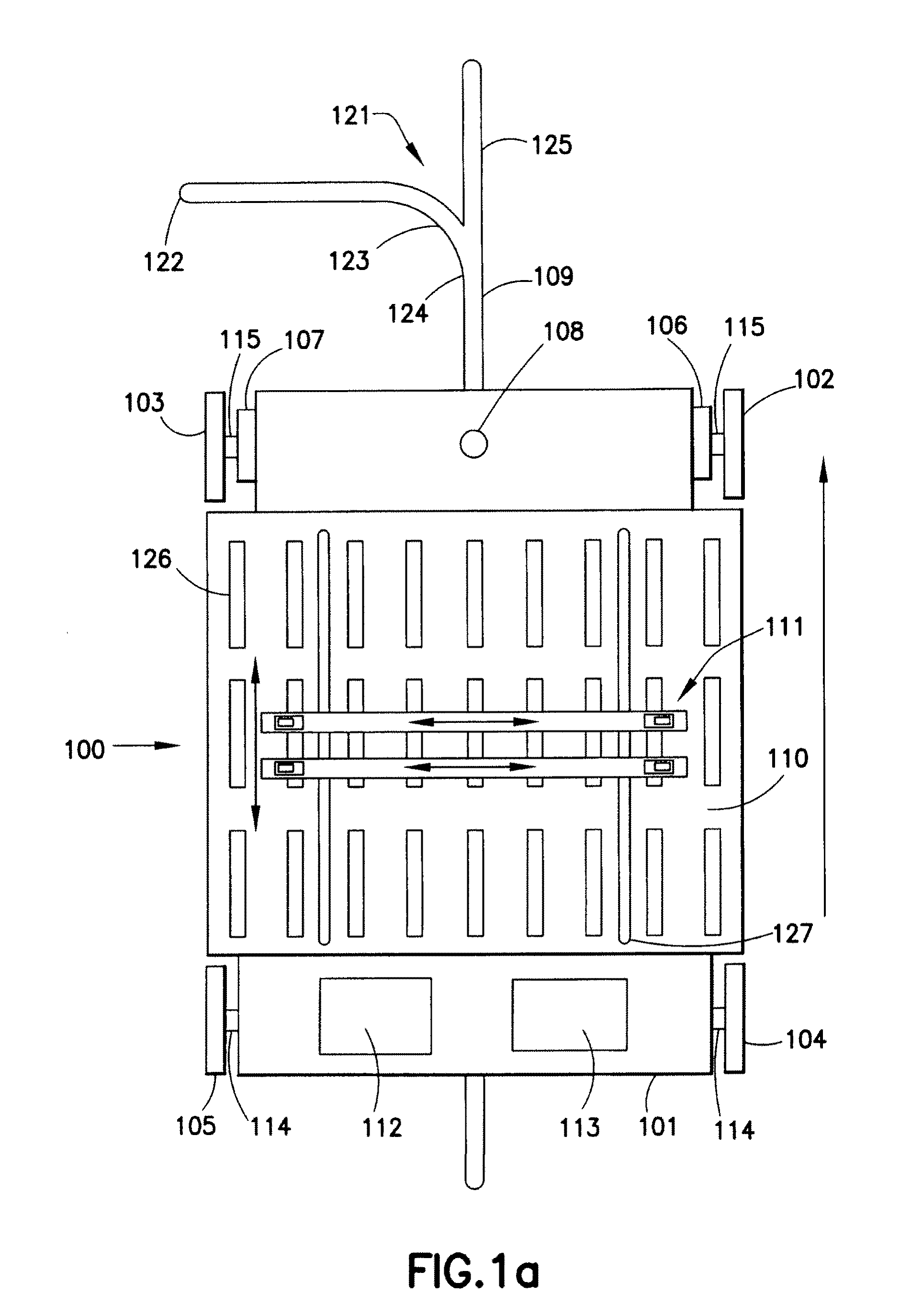

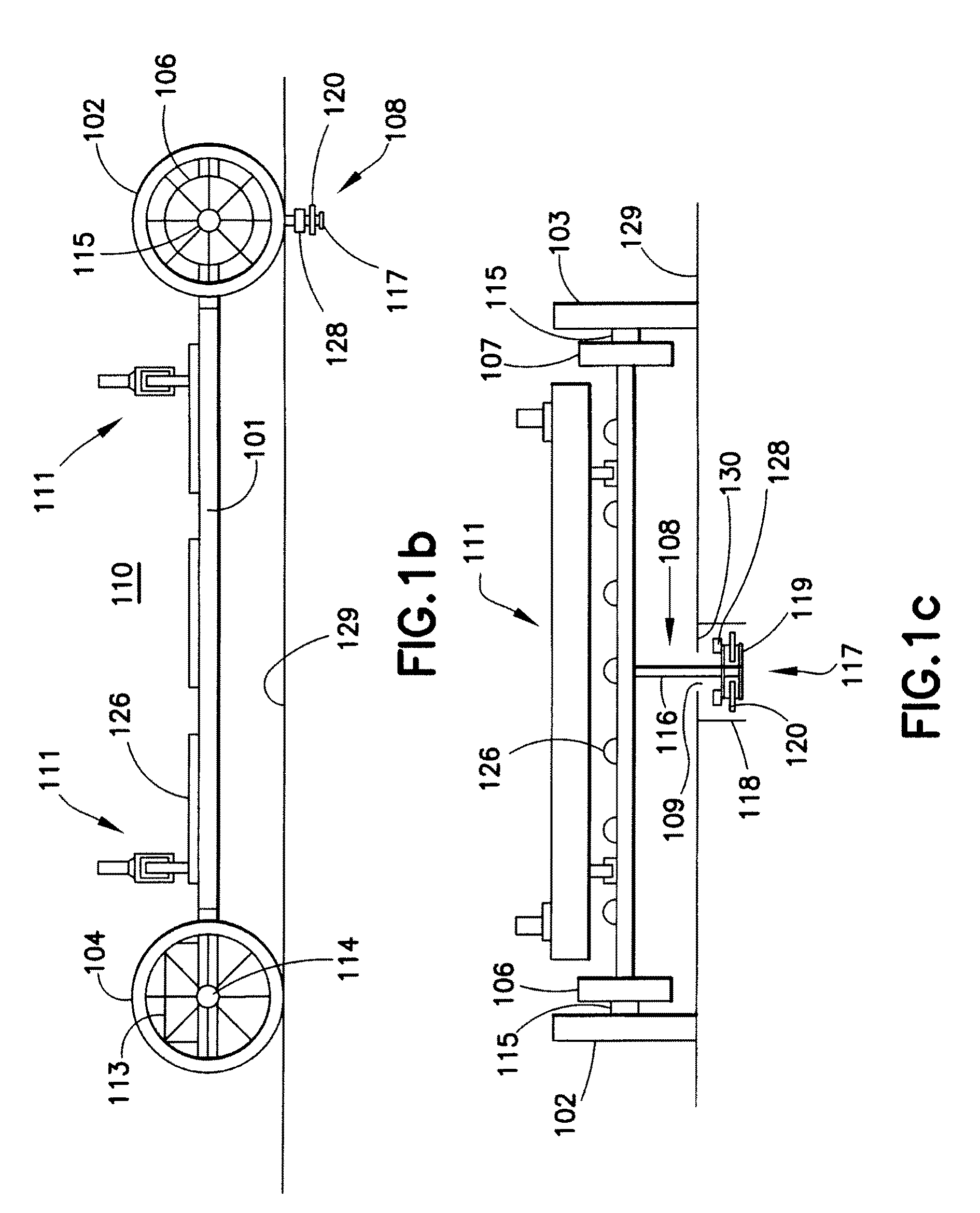

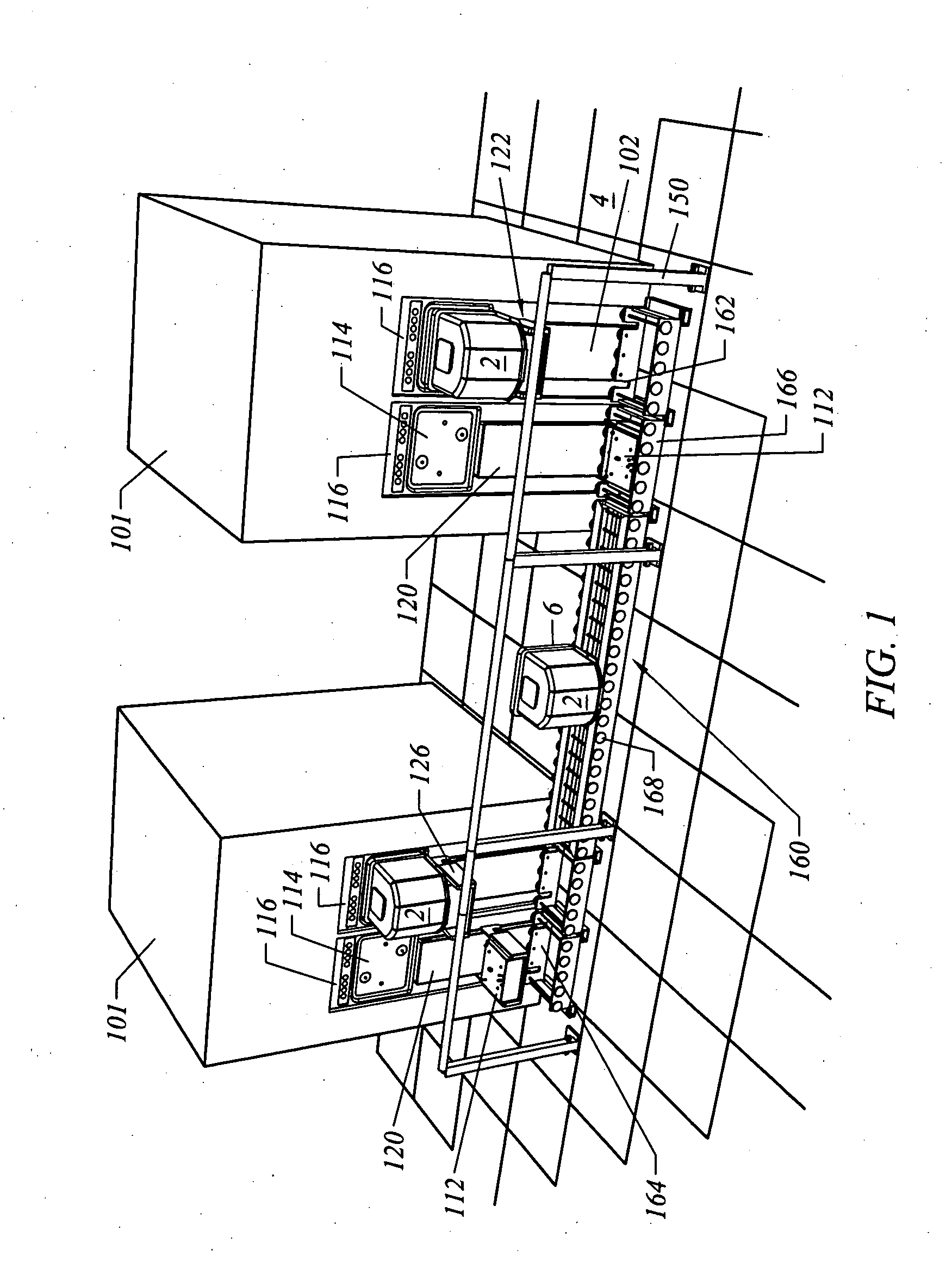

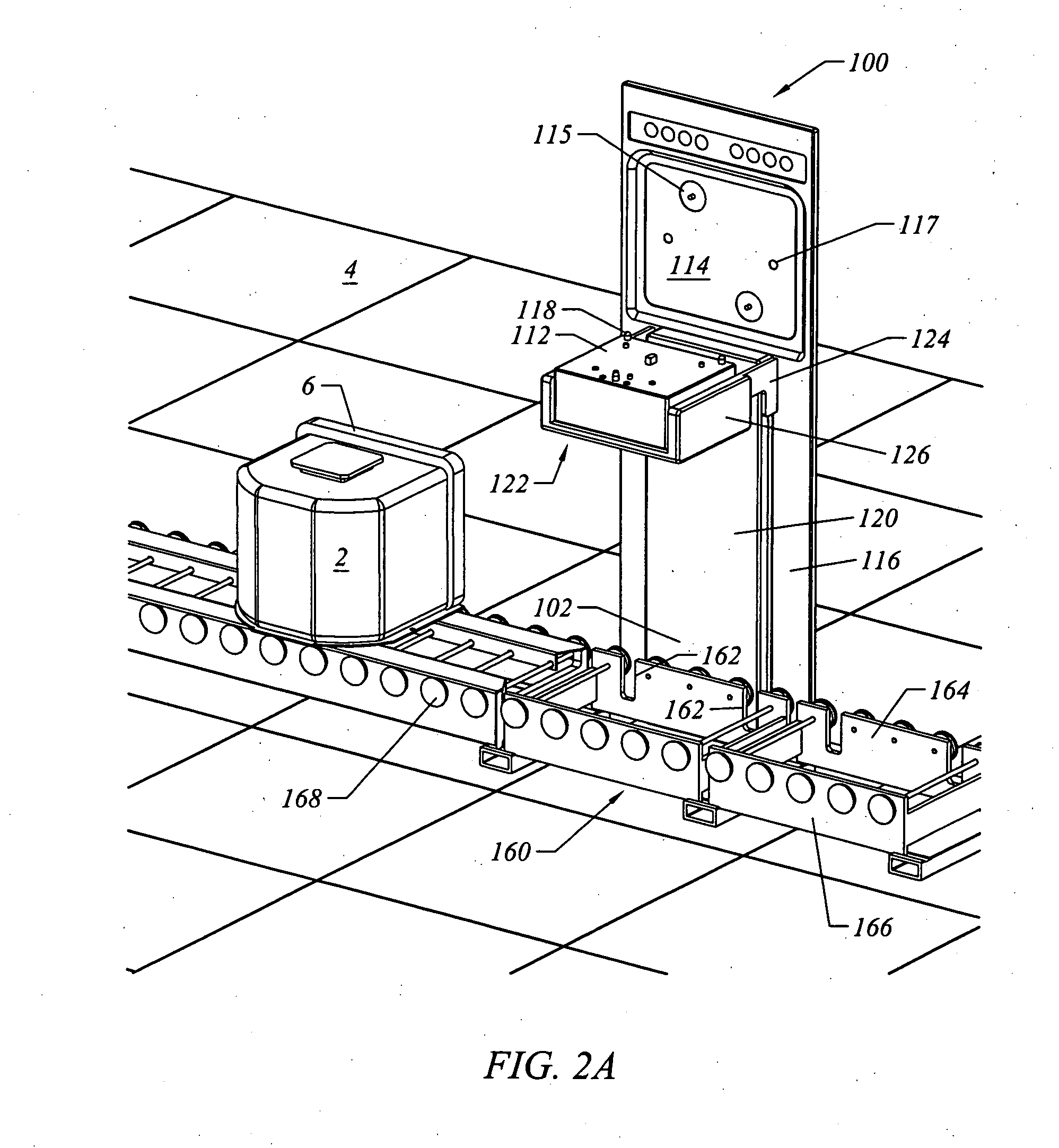

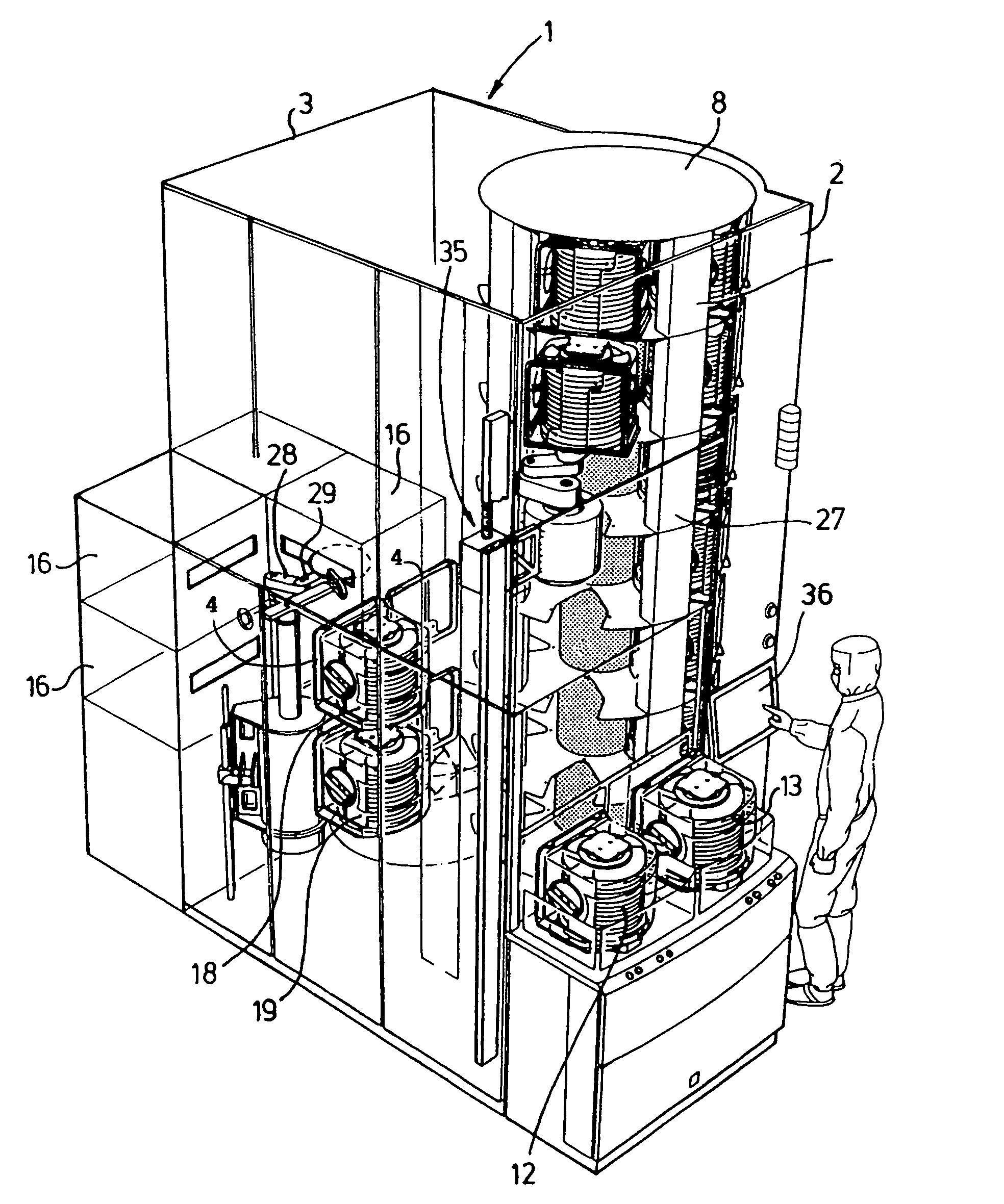

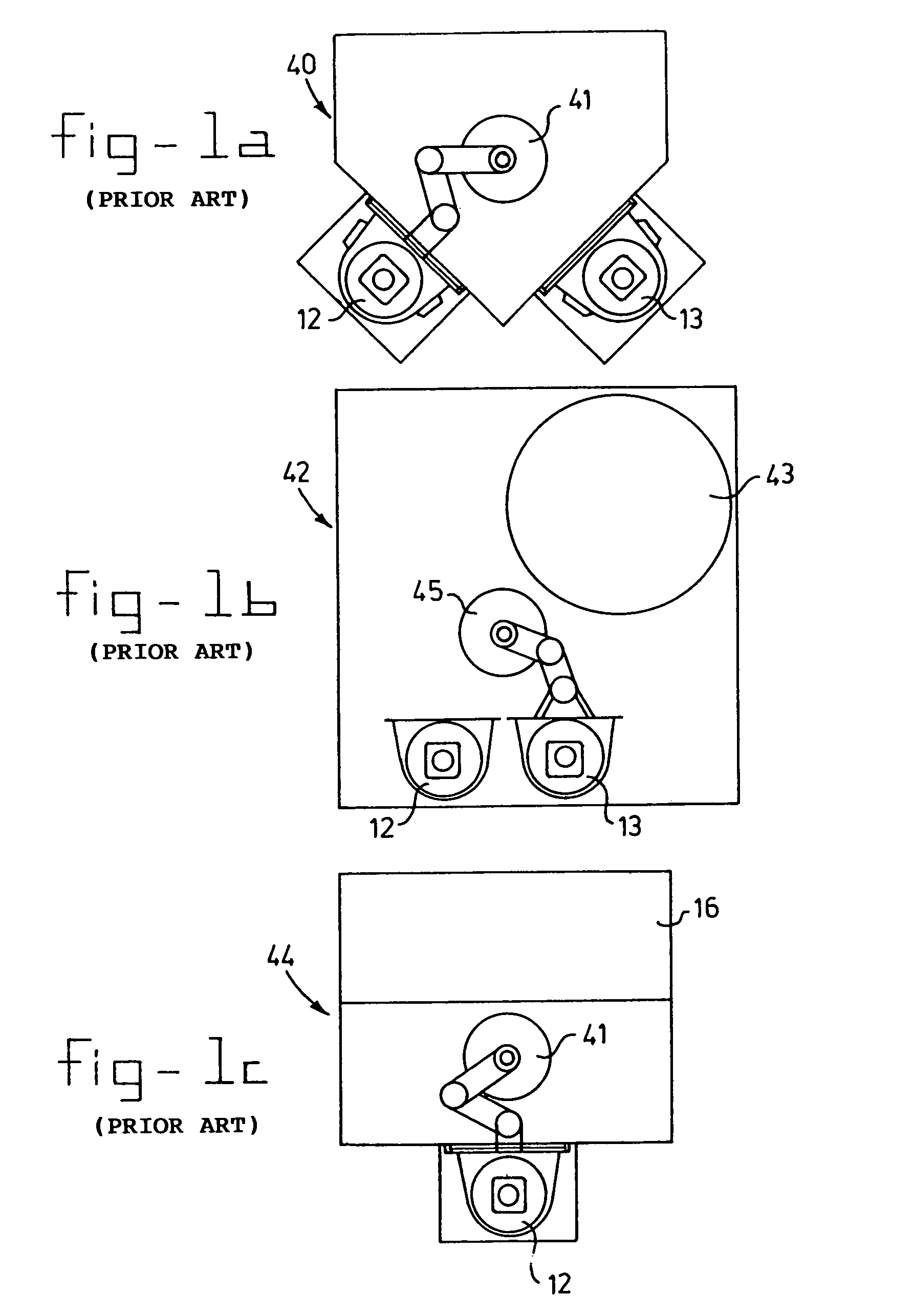

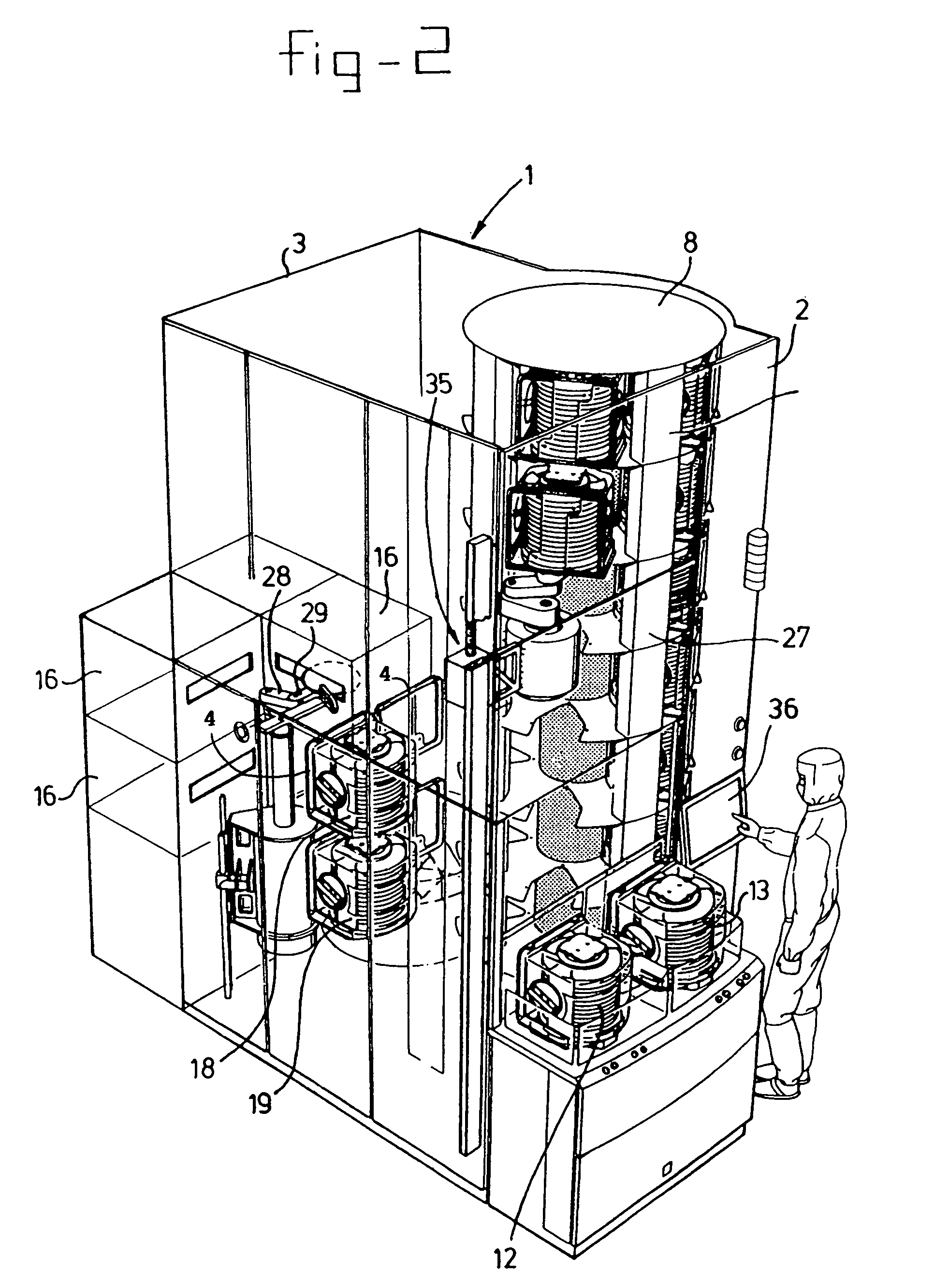

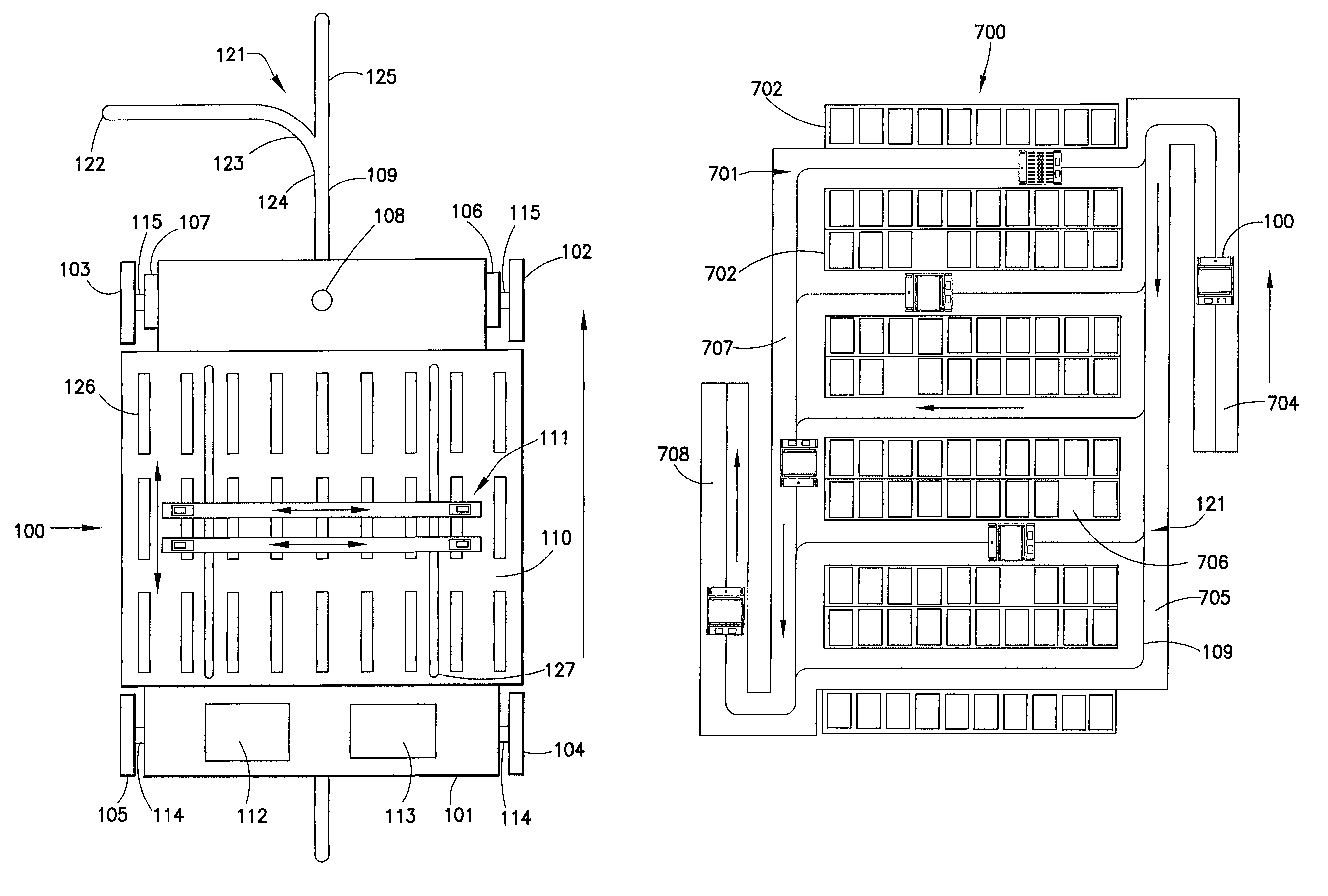

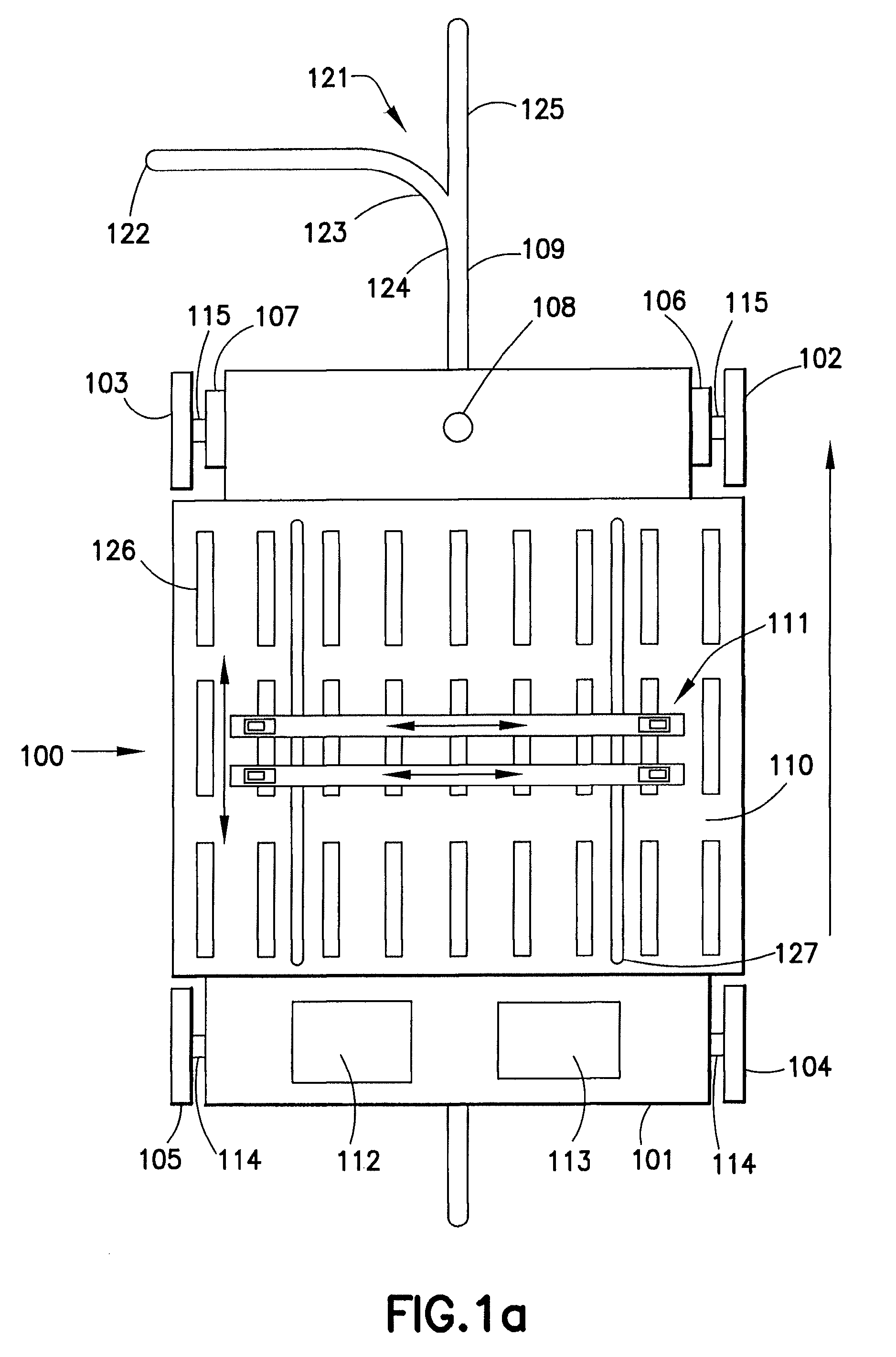

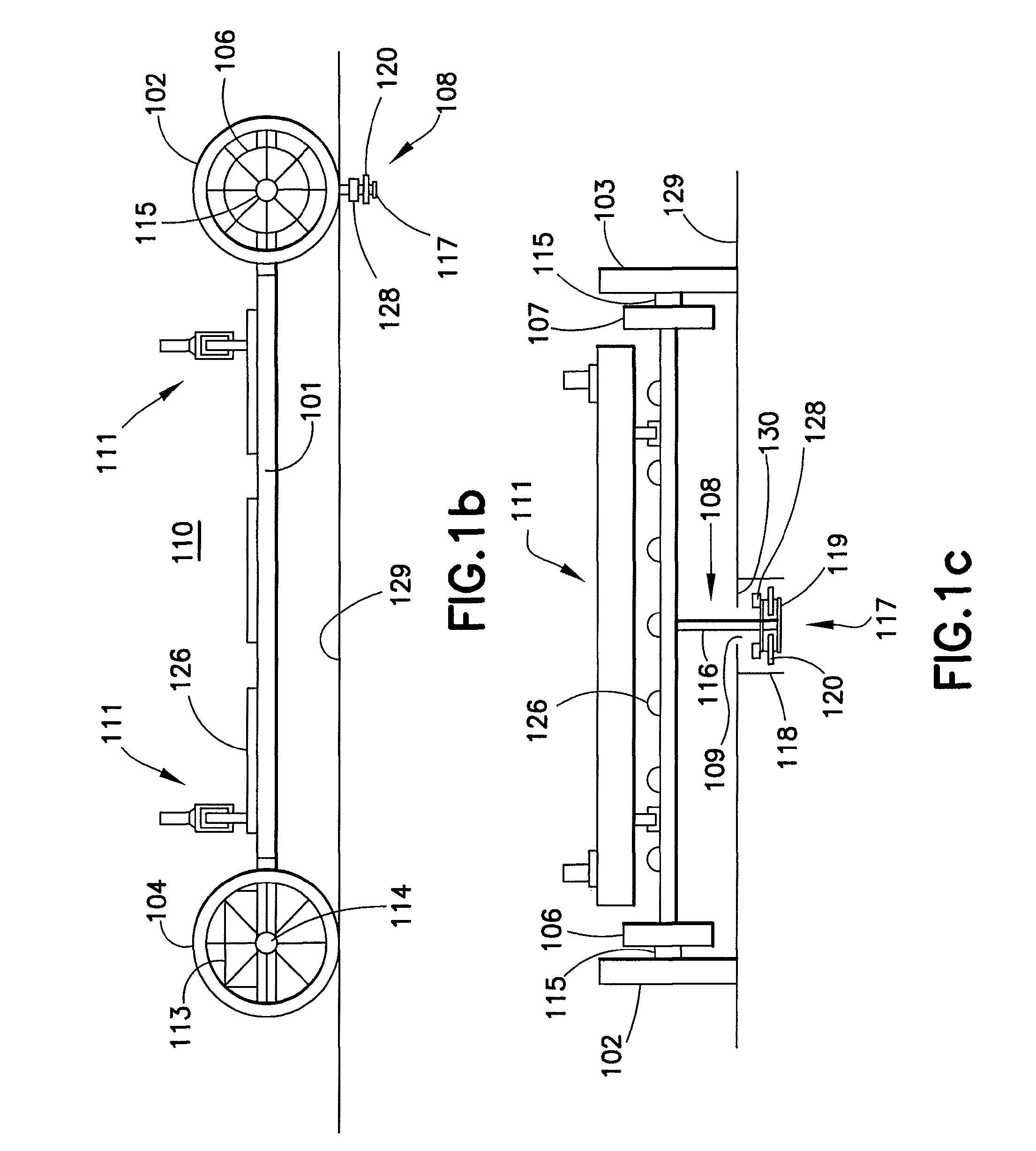

Materials-handling system using autonomous transfer and transport vehicles

ActiveUS20090074545A1High degree of automationEfficient automationDigital data processing detailsLoading/unloadingEngineeringHandling system

Methods and apparatus for selecting and combining packages in an outbound container by employing autonomous transfer and transport vehicles which move on a network of roadways to carry a plurality of individual cases each containing the same kind of product from a loading station and to a destination station where individual packages are combined in the outbound container. The travel of each vehicle through the roadway network is computer controlled, and each vehicle includes means for automatically loading and unloading packages from predetermined locations on the network.

Owner:SYMBOTIC LLC

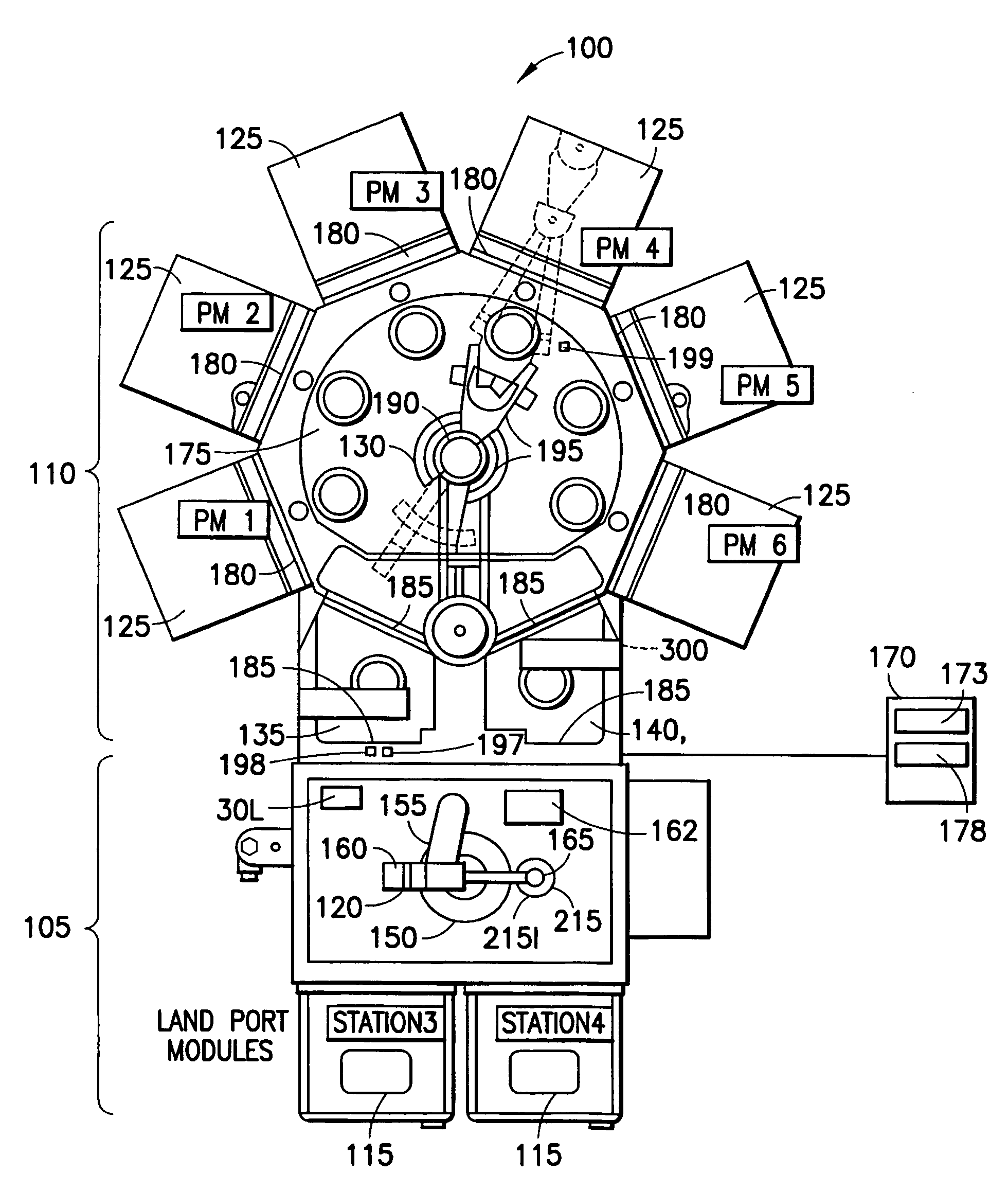

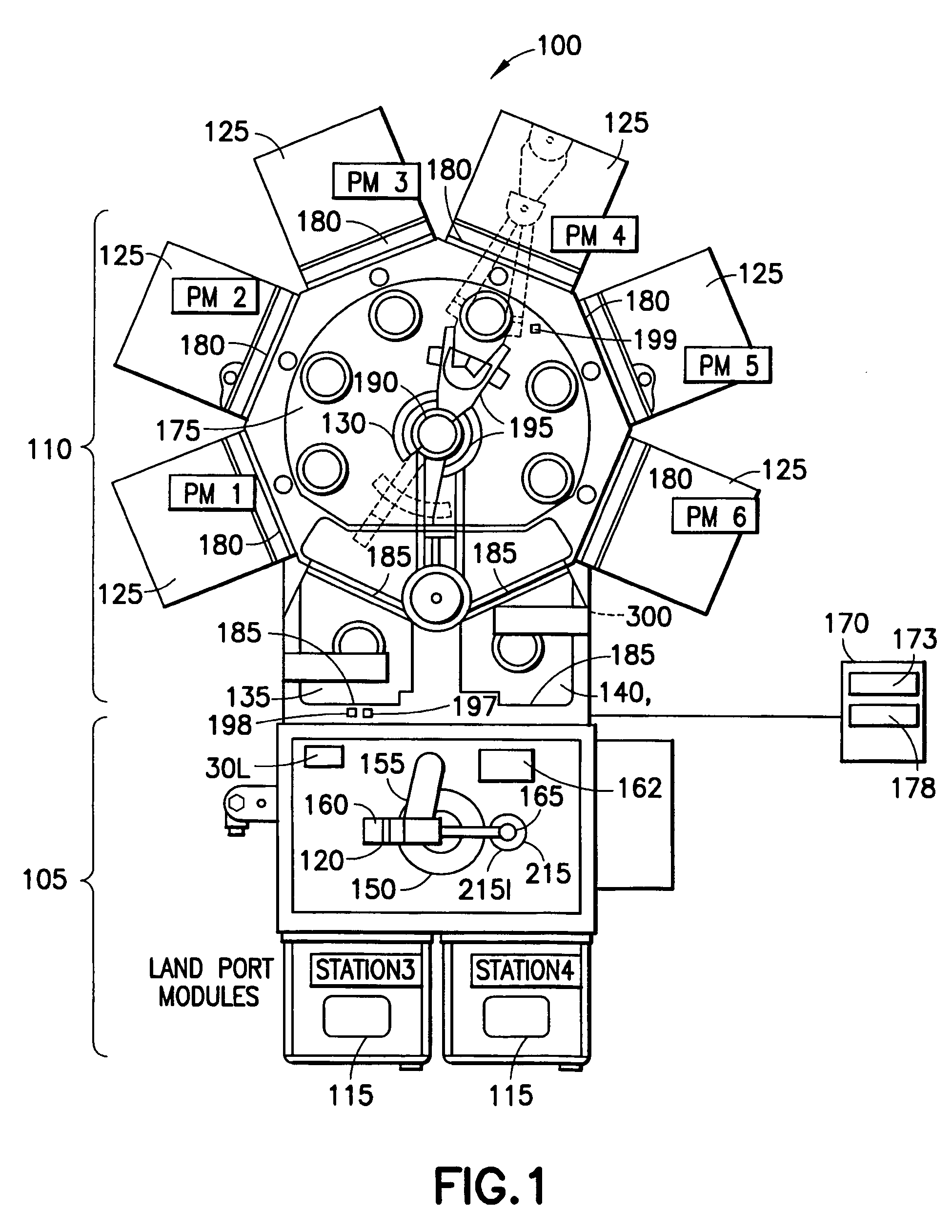

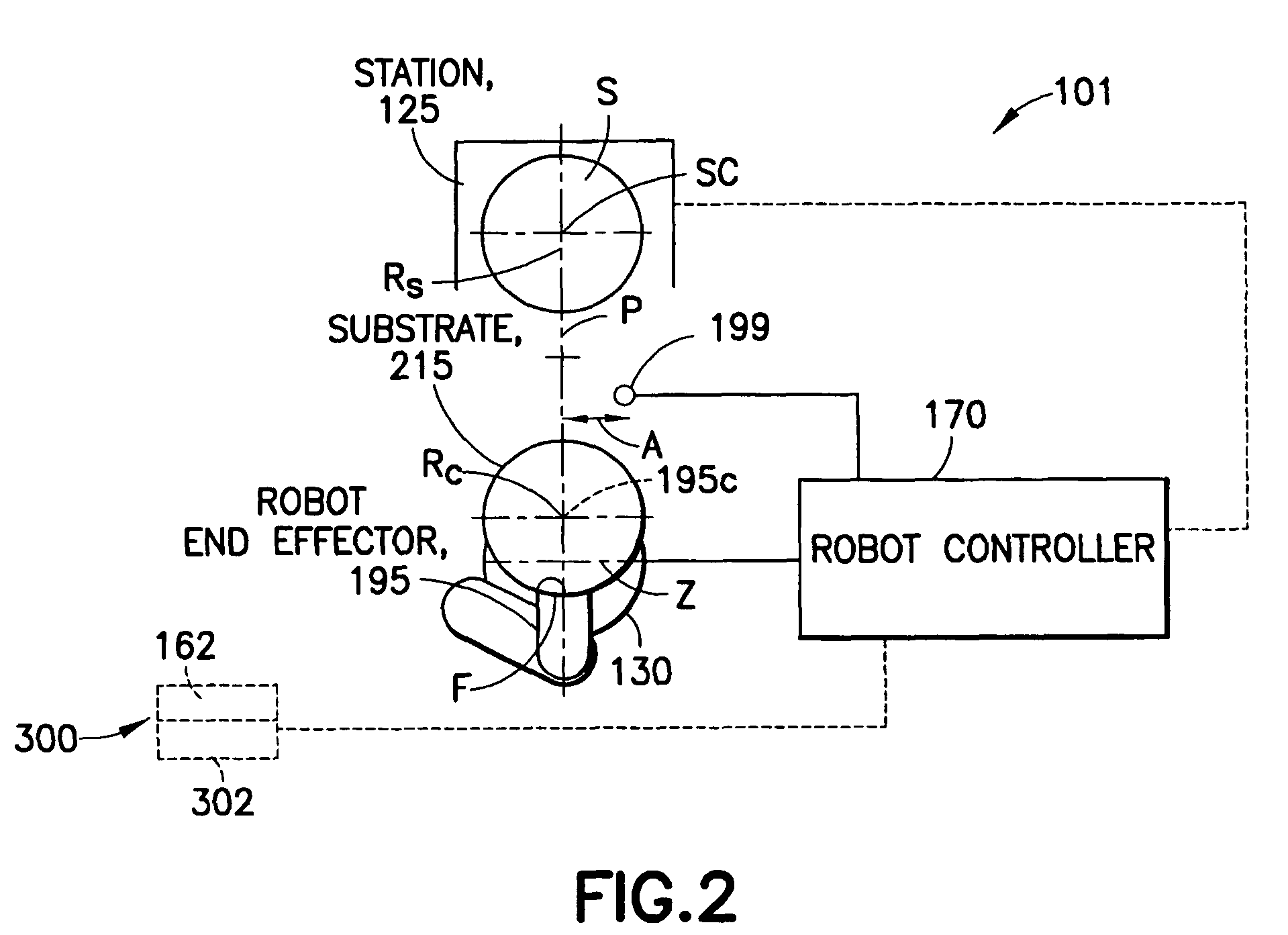

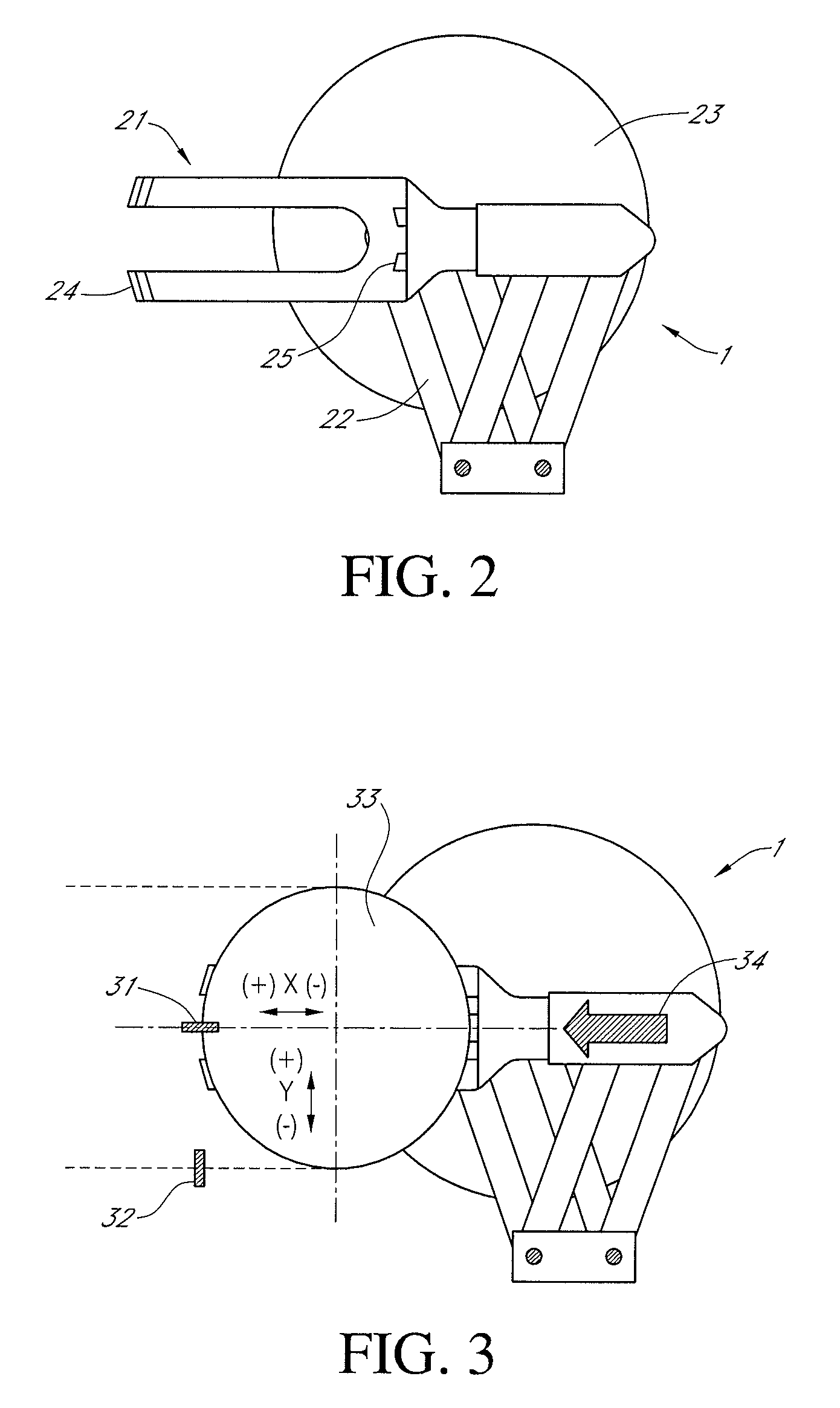

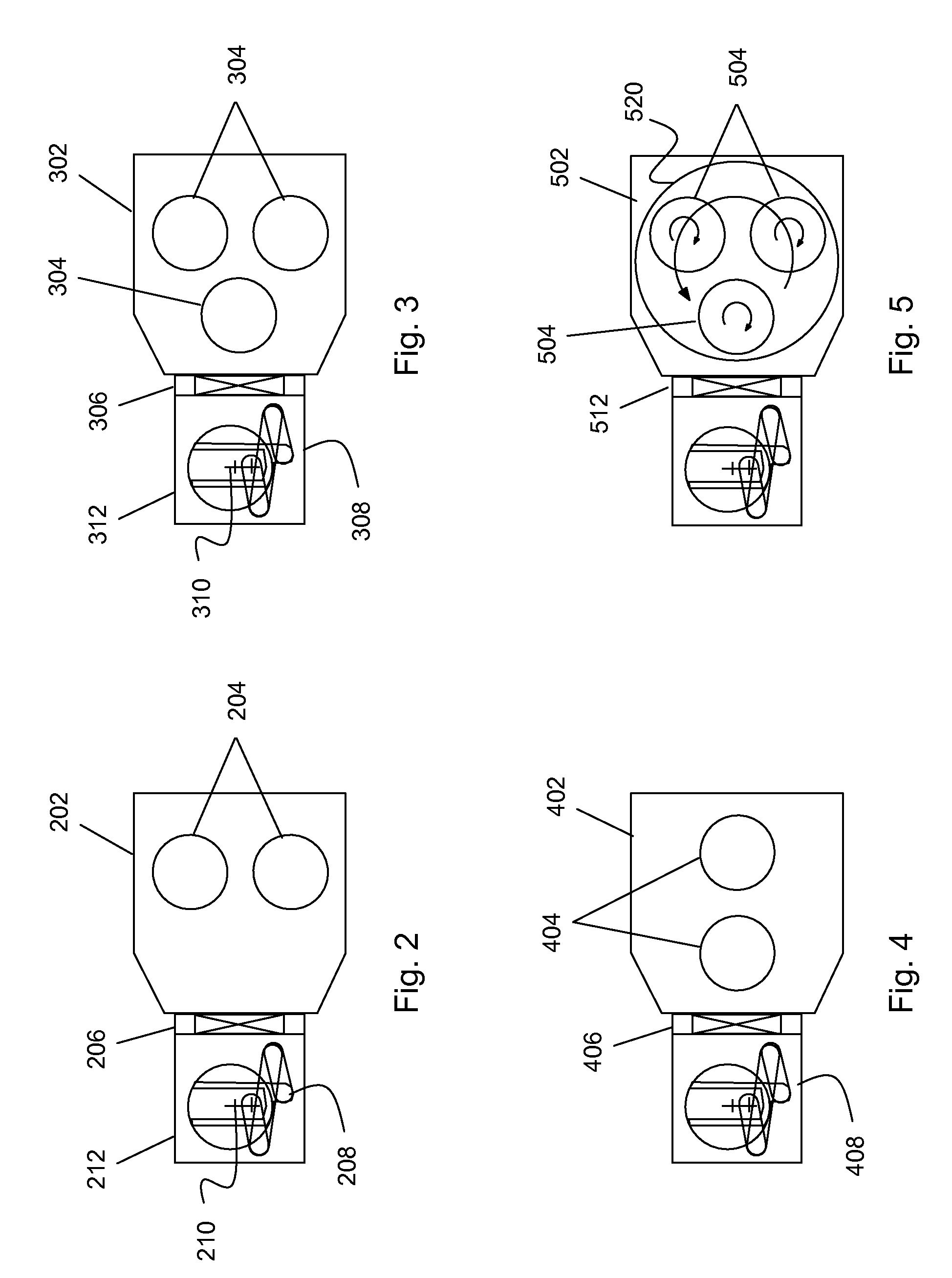

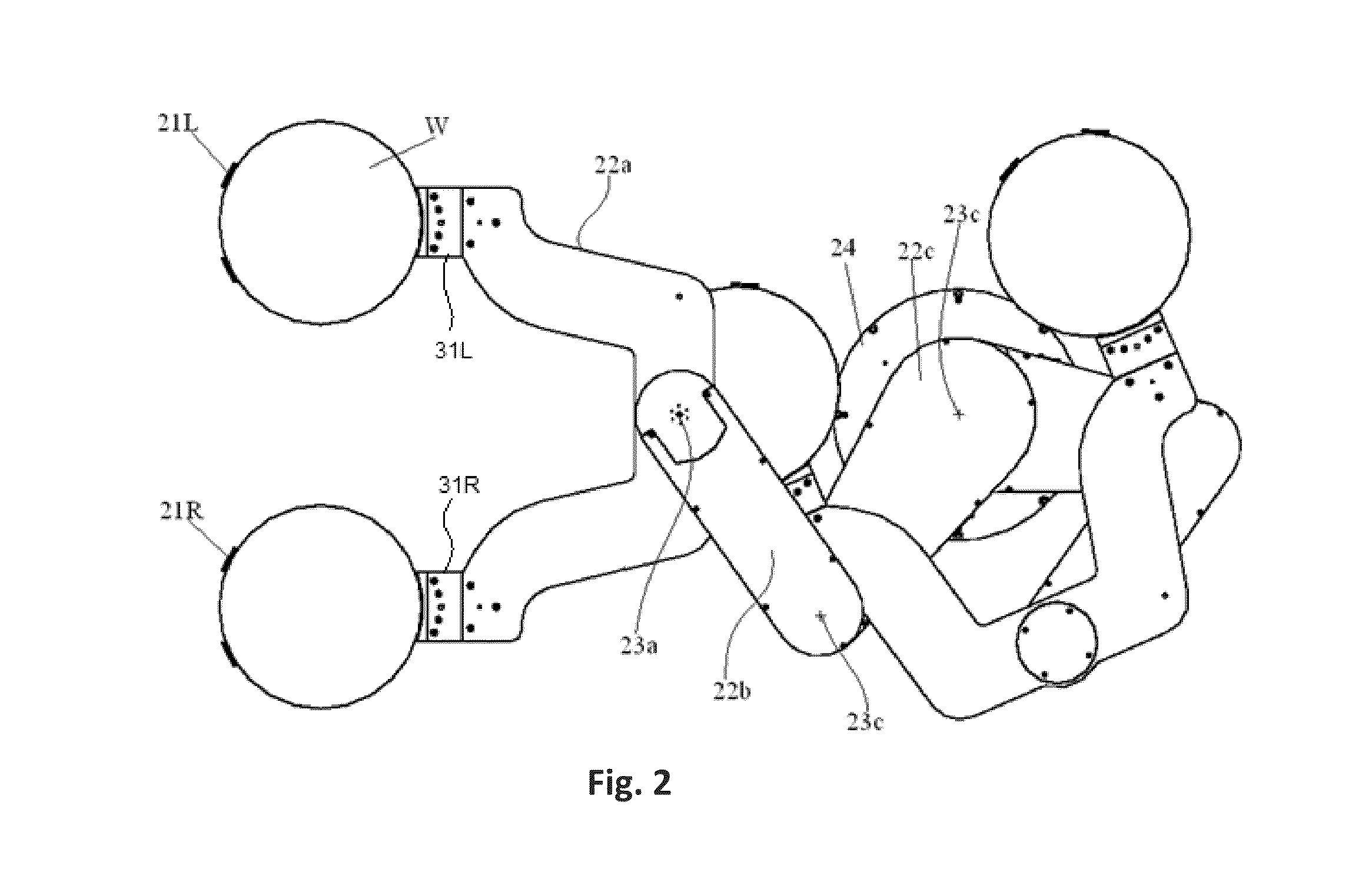

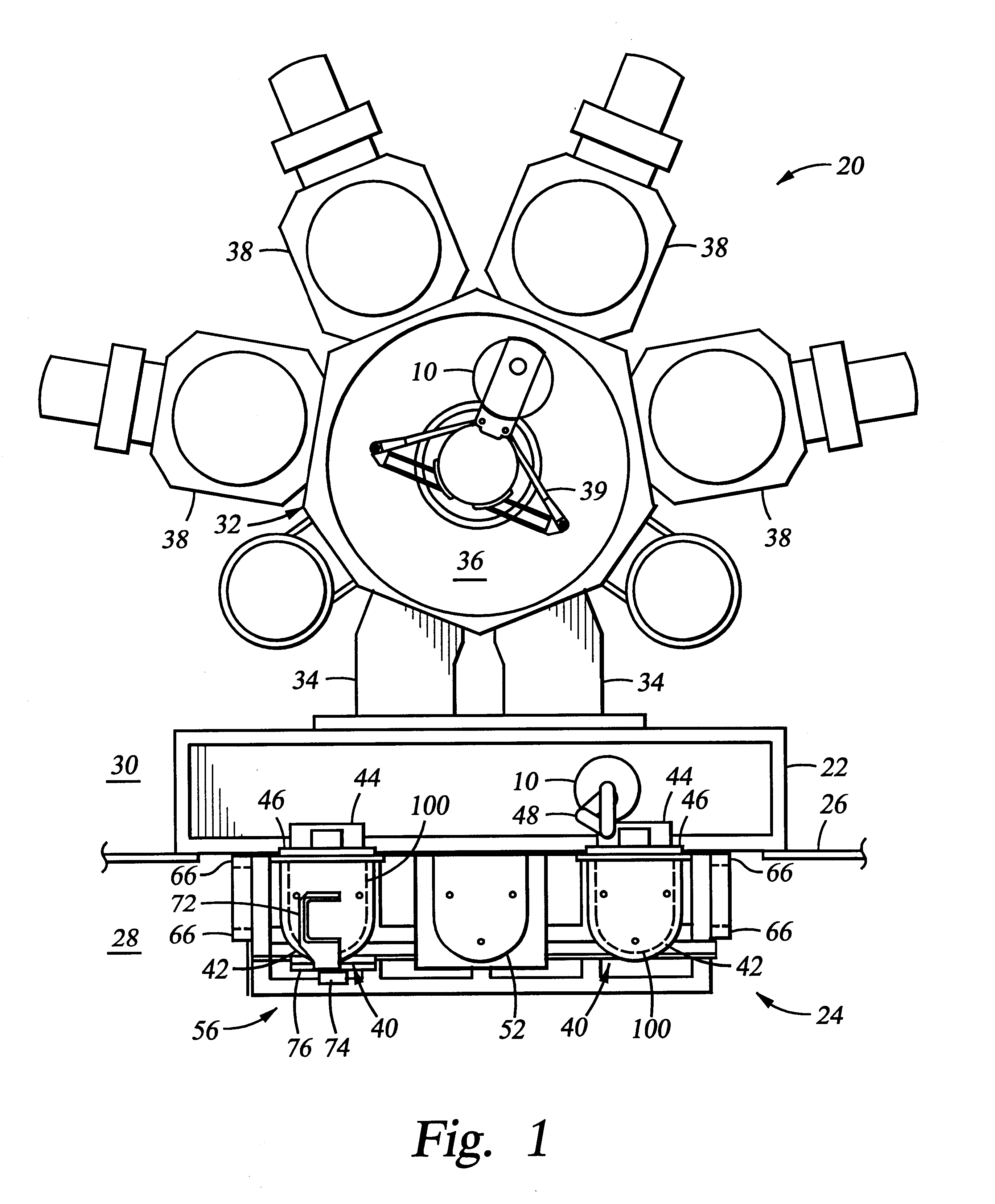

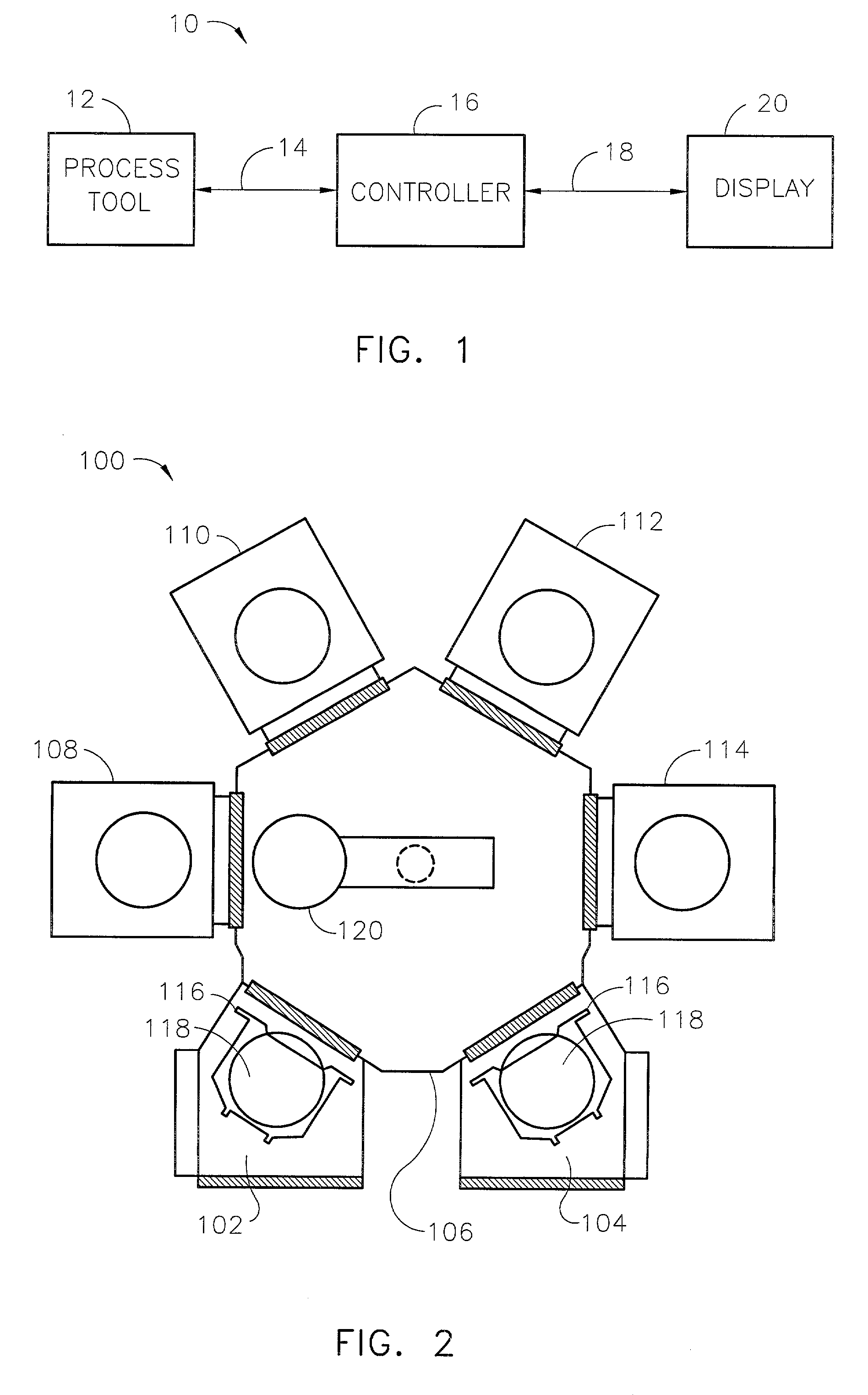

Process apparatus with on-the-fly workpiece centering

ActiveUS7925378B2Digital data processing detailsSemiconductor/solid-state device manufacturingEngineeringElectrical and Electronics engineering

A substrate processing apparatus having a transport apparatus, at least one sensor connected to the transport apparatus and a controller. The transport apparatus is adapted for transporting the substrate between processing stations of the processing apparatus. The sensor is capable of sensing the substrate transported by the transporting apparatus. The sensor is arranged for sending at least one signal in response to sensing the substrate. The controller is communicably connected to the sensor and arranged to determine alignment of the substrate in at least two directions, angled relative to each other, relative to a predetermined location. The controller is capable of determining alignment from the at least one signal identifying no more than two points on the substrate and independent of radial variances between substrates.

Owner:BOOKS AUTOMATION US LLC

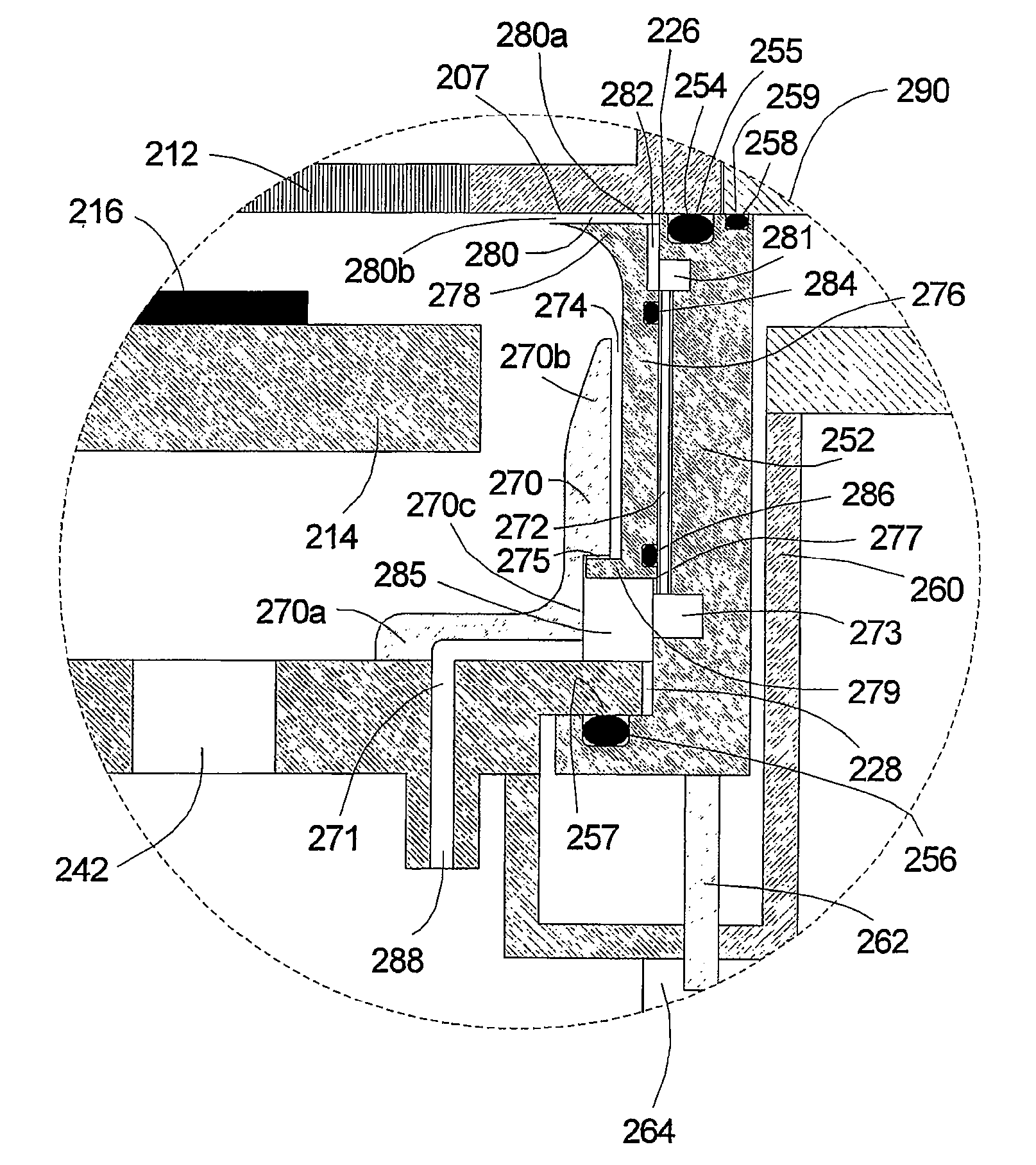

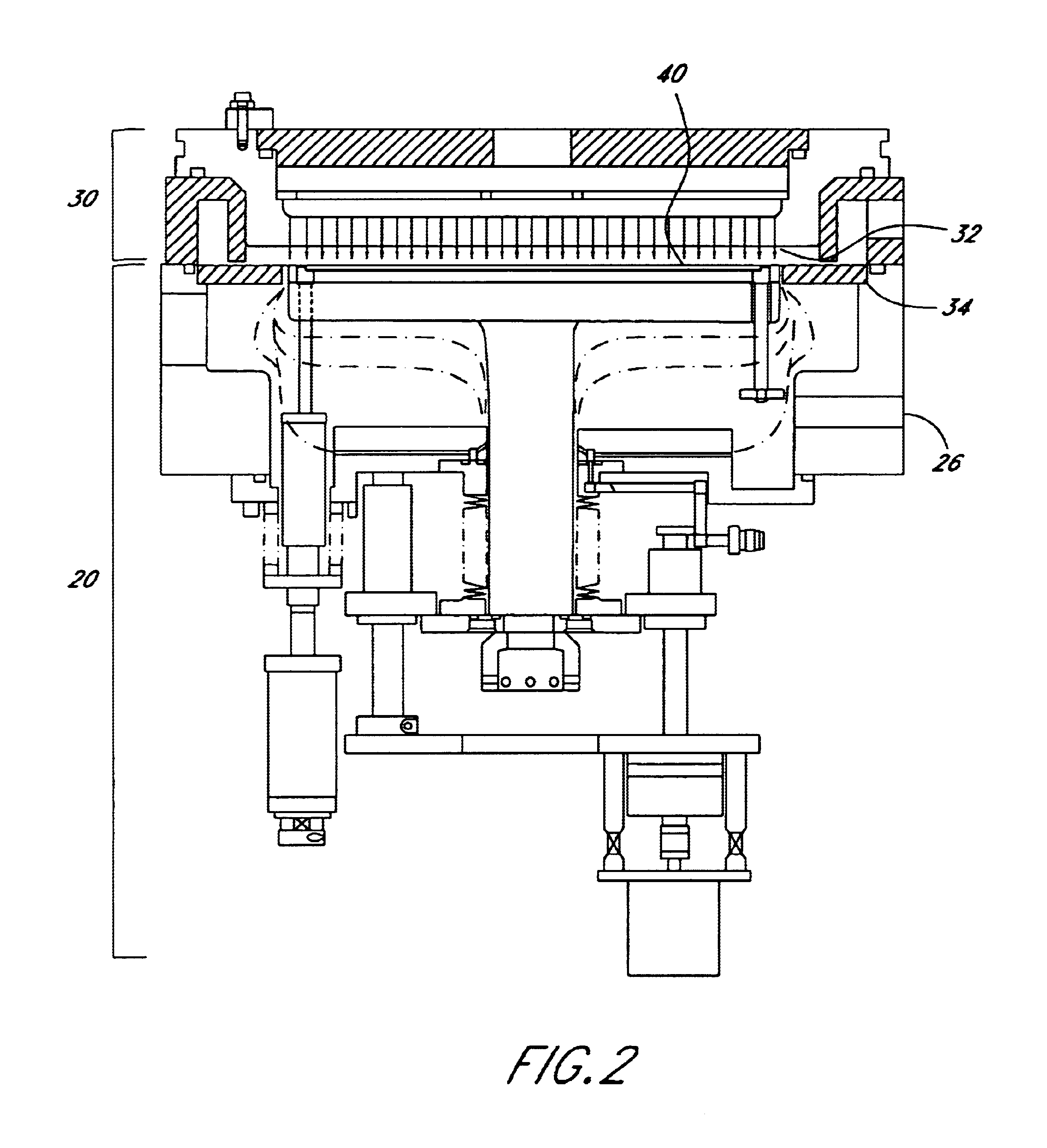

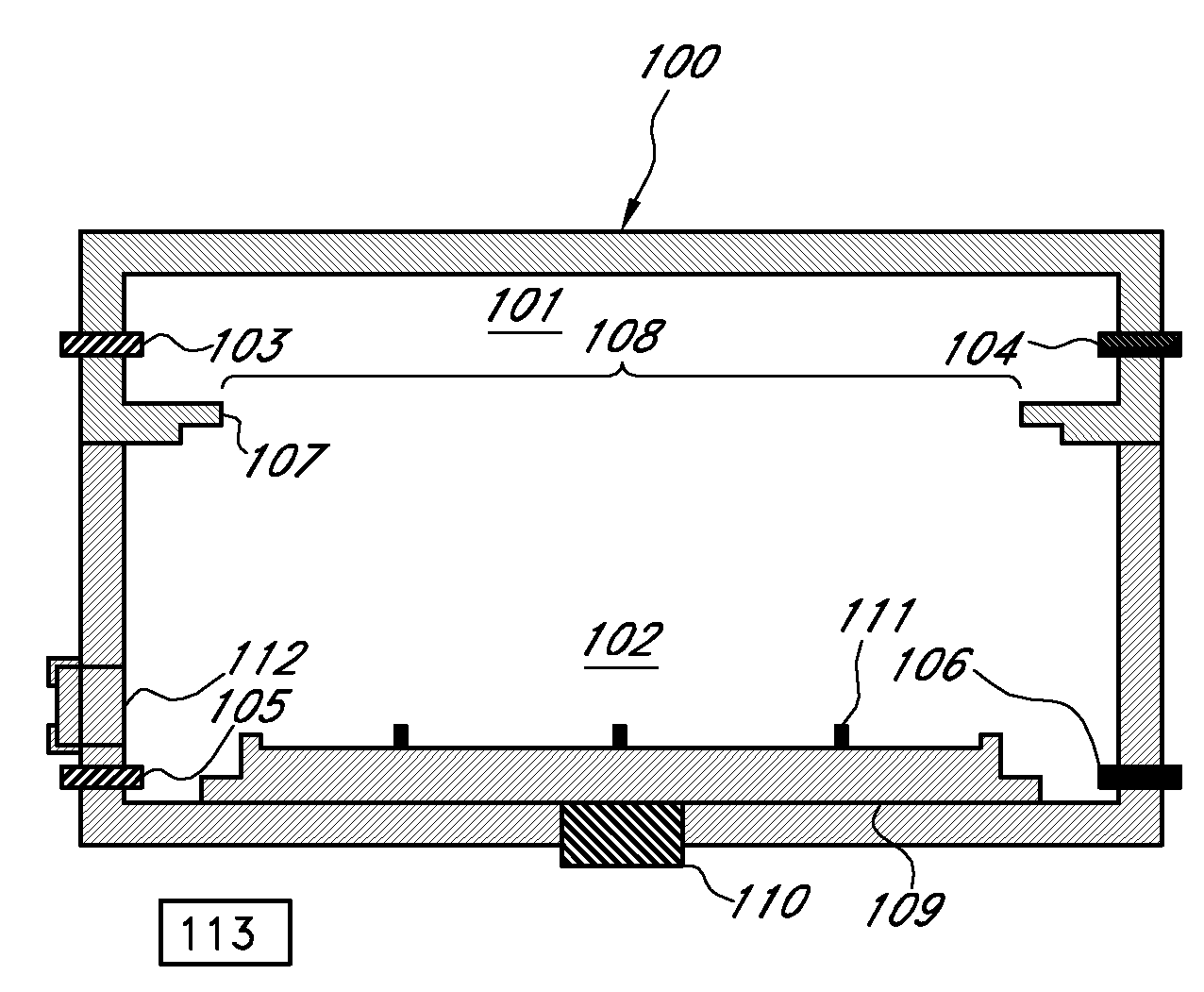

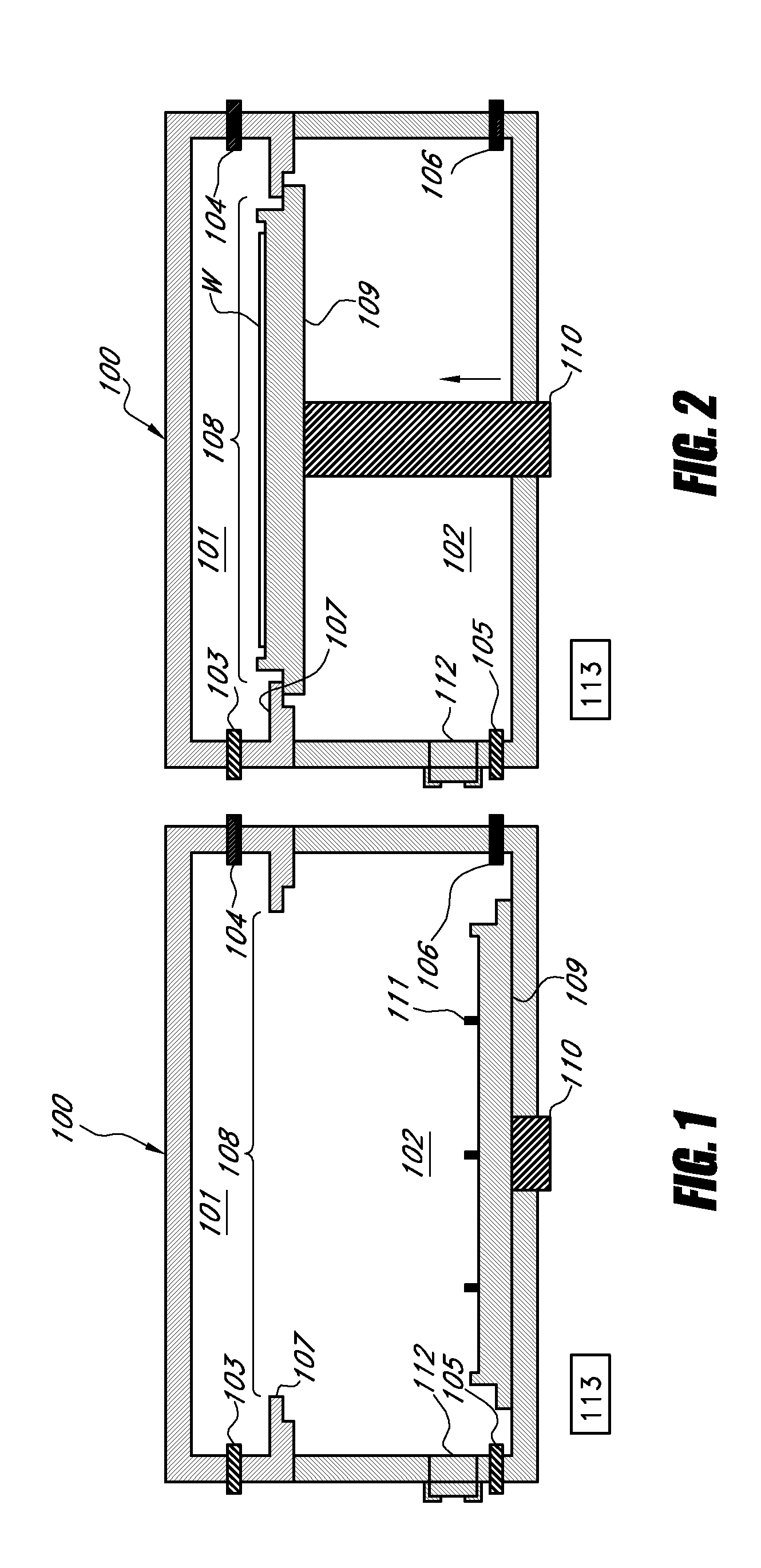

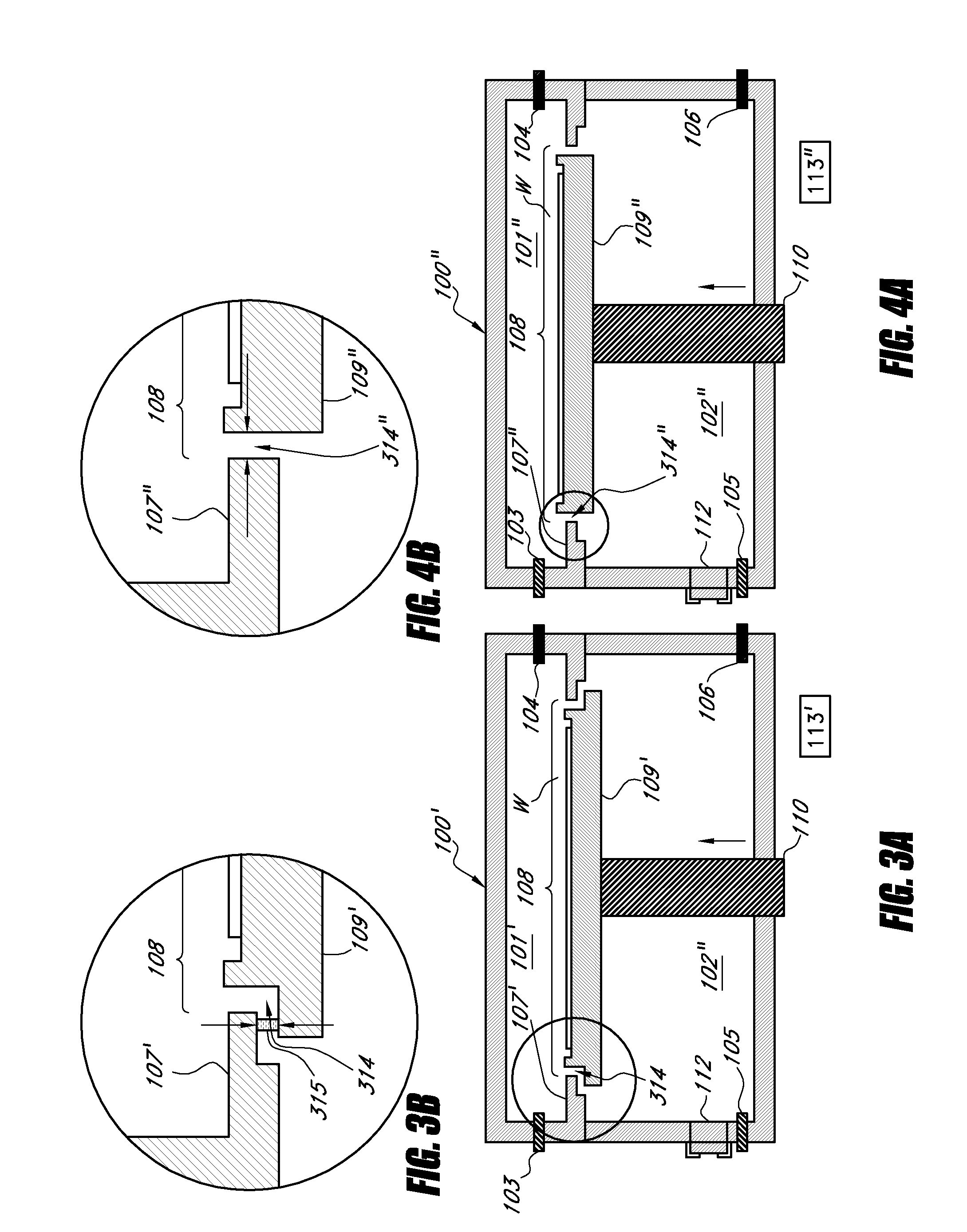

Perimeter partition-valve with protected seals and associated small size process chambers and multiple chamber systems

ActiveUS7682454B2Improve performanceSmall sizeVacuum evaporation coatingSputtering coatingModularityHandling system

Owner:SUNDEW TECH

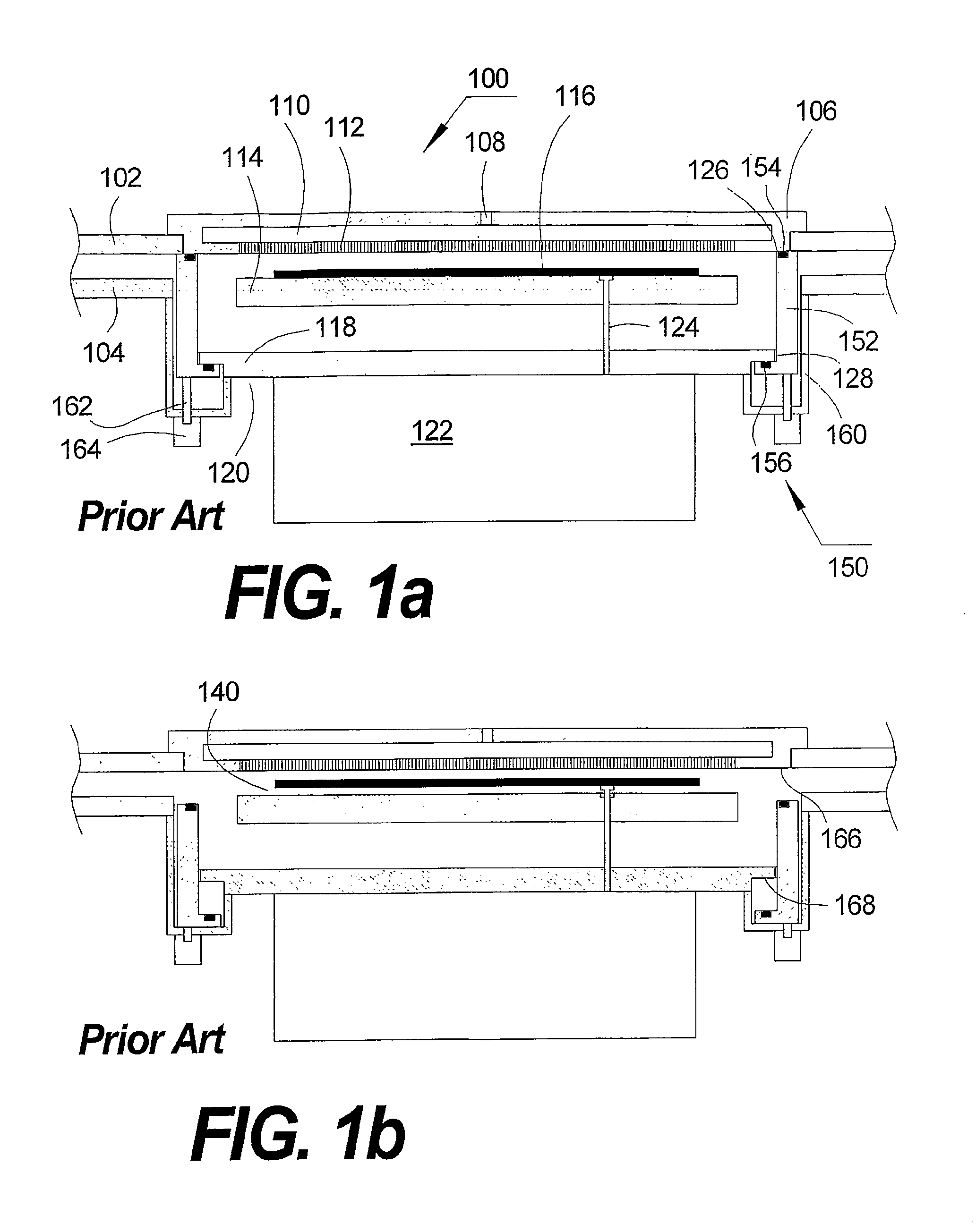

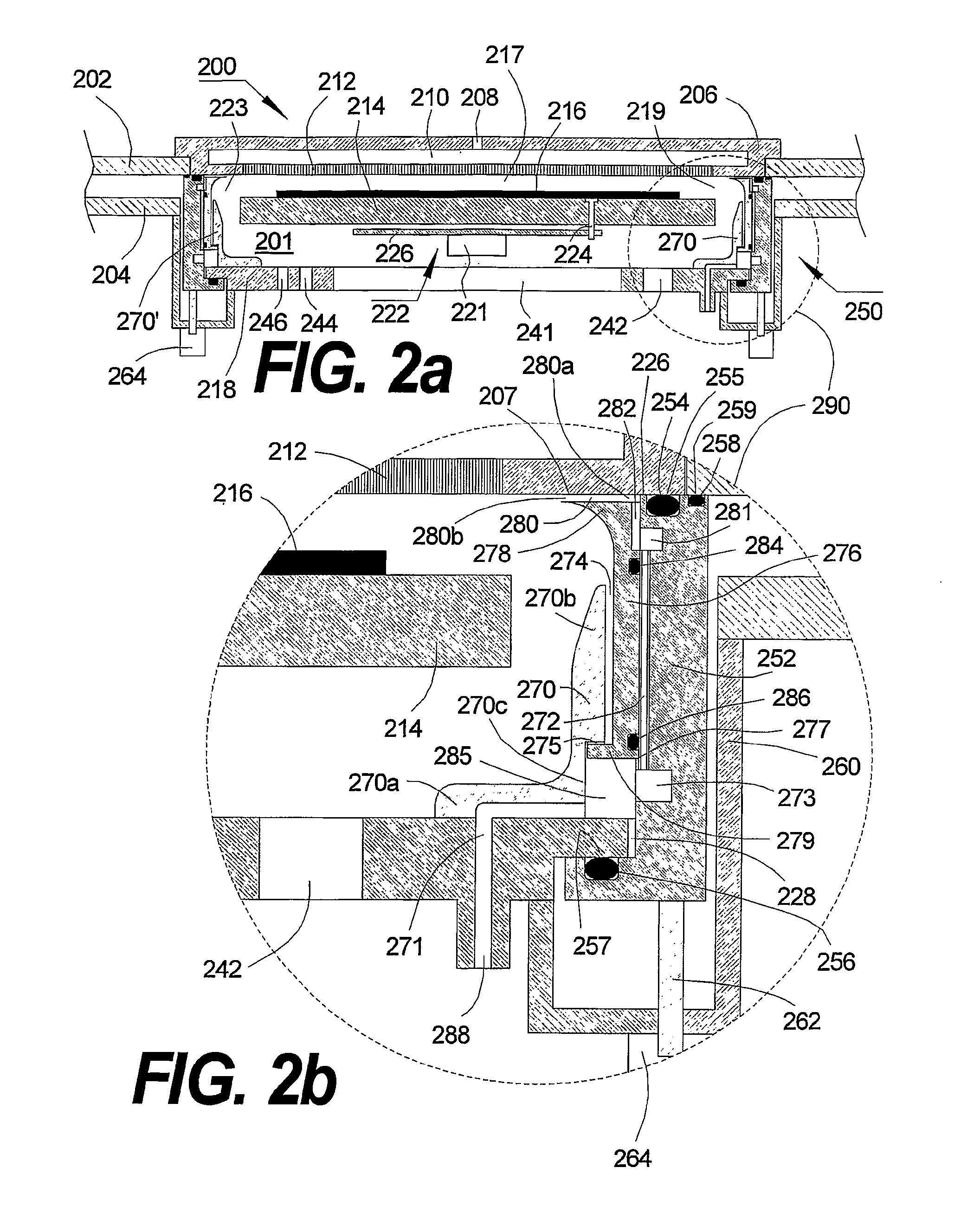

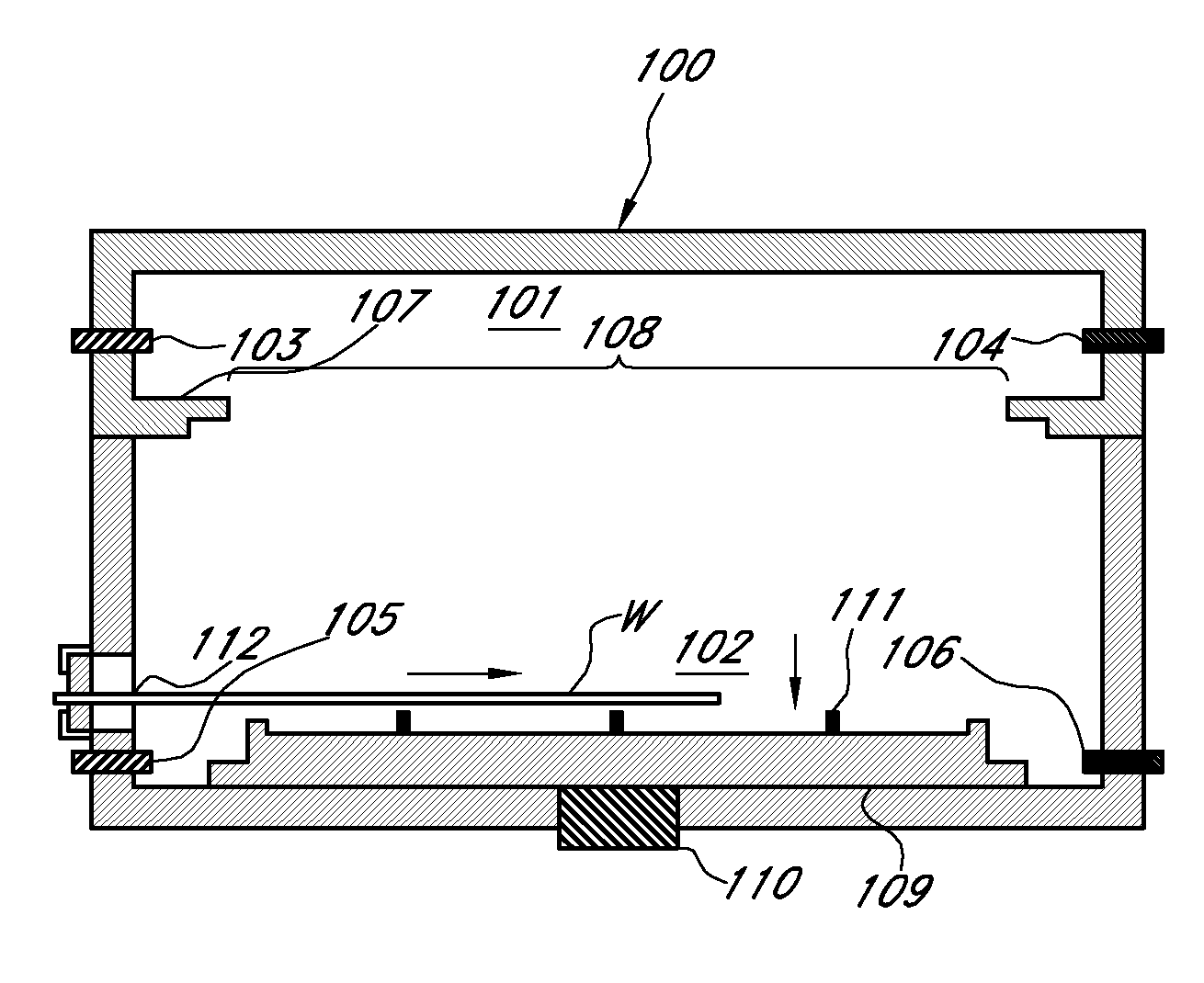

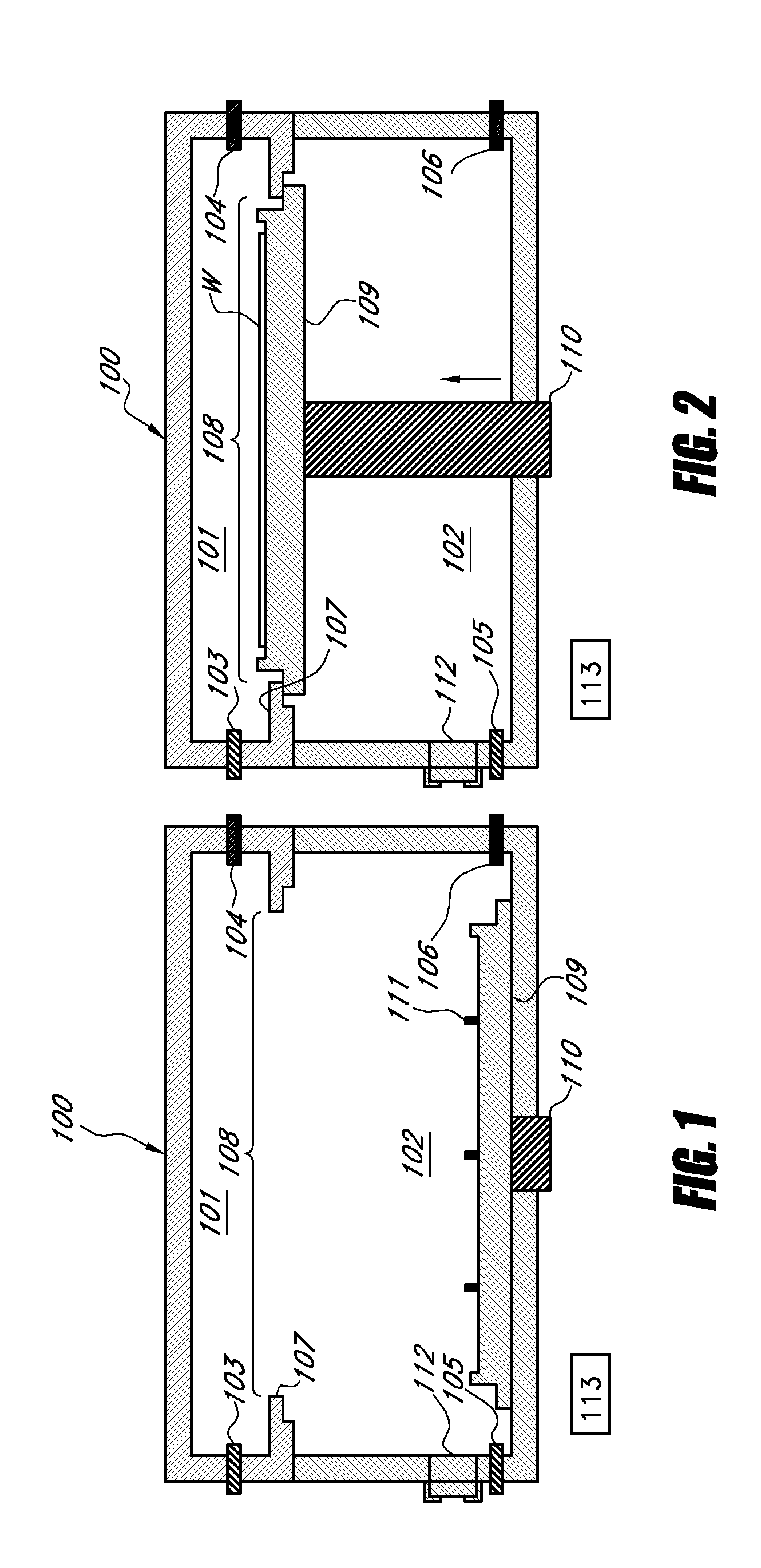

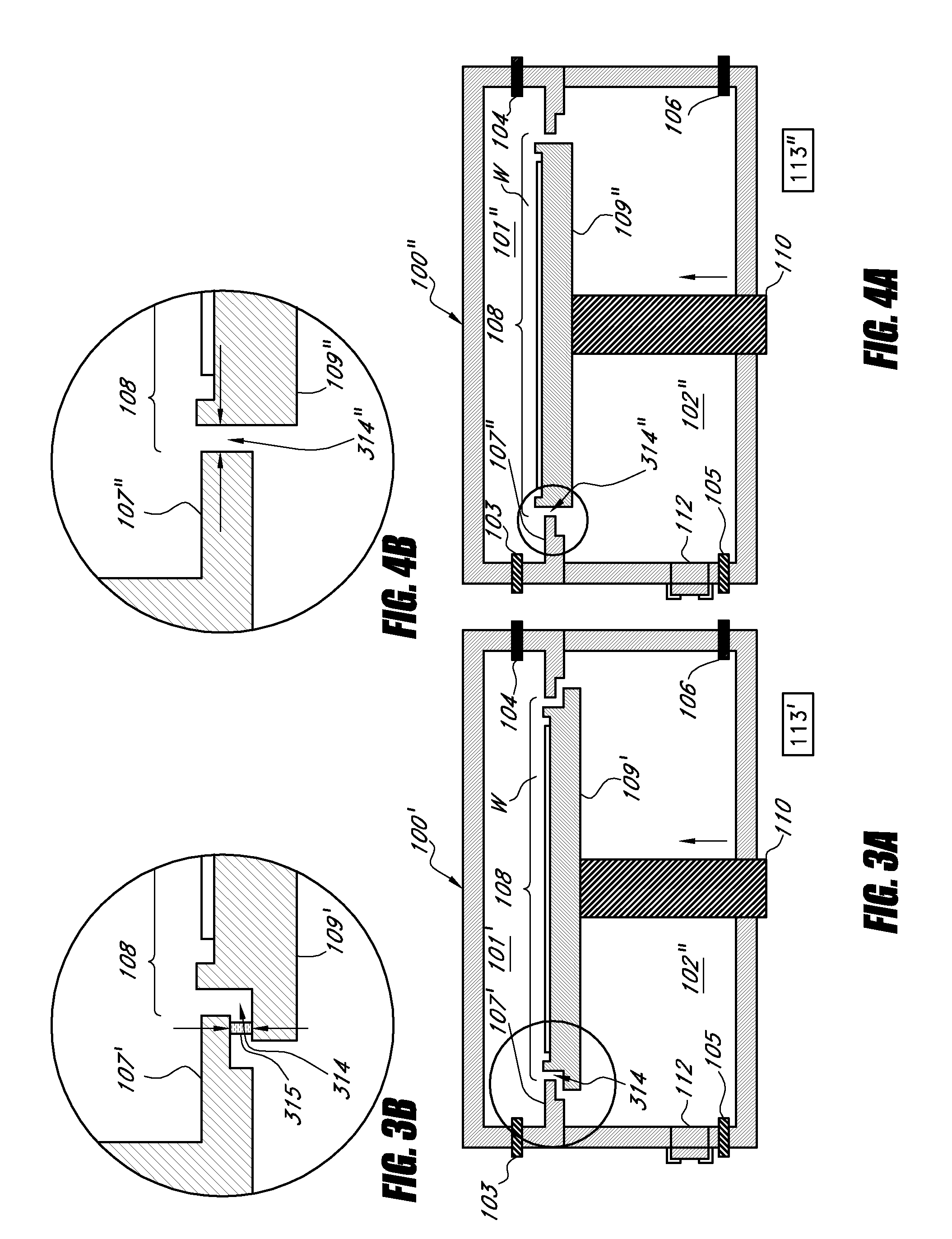

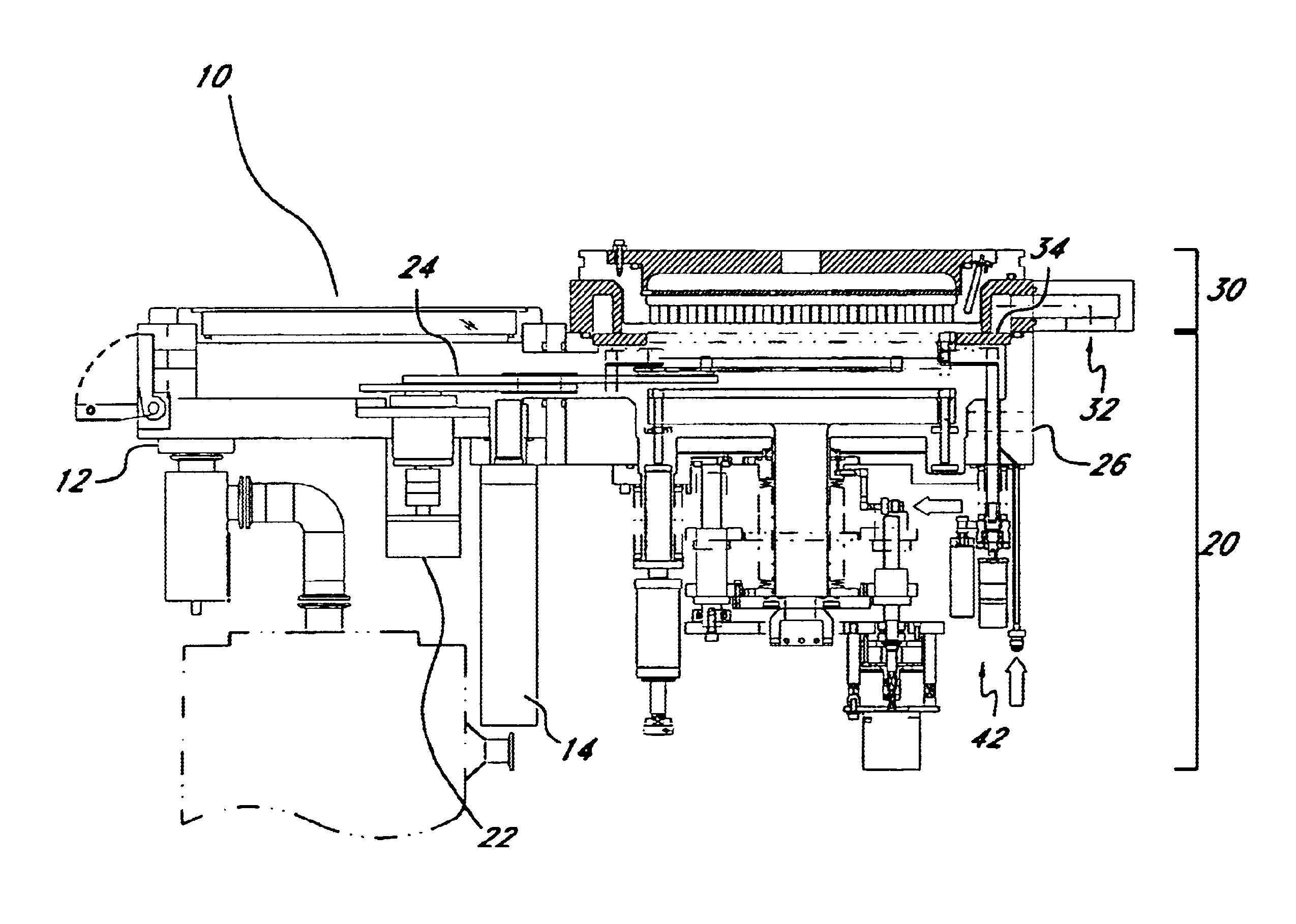

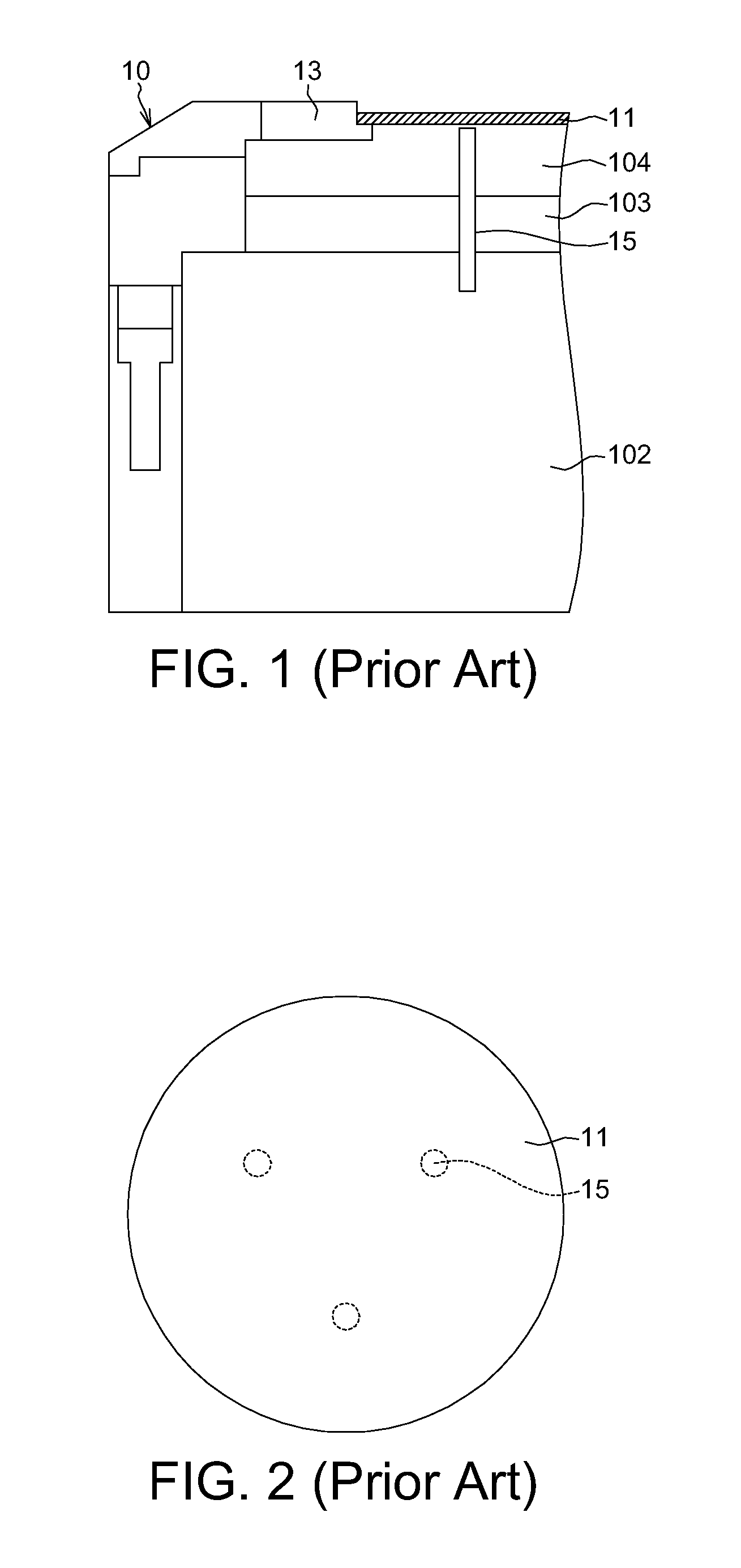

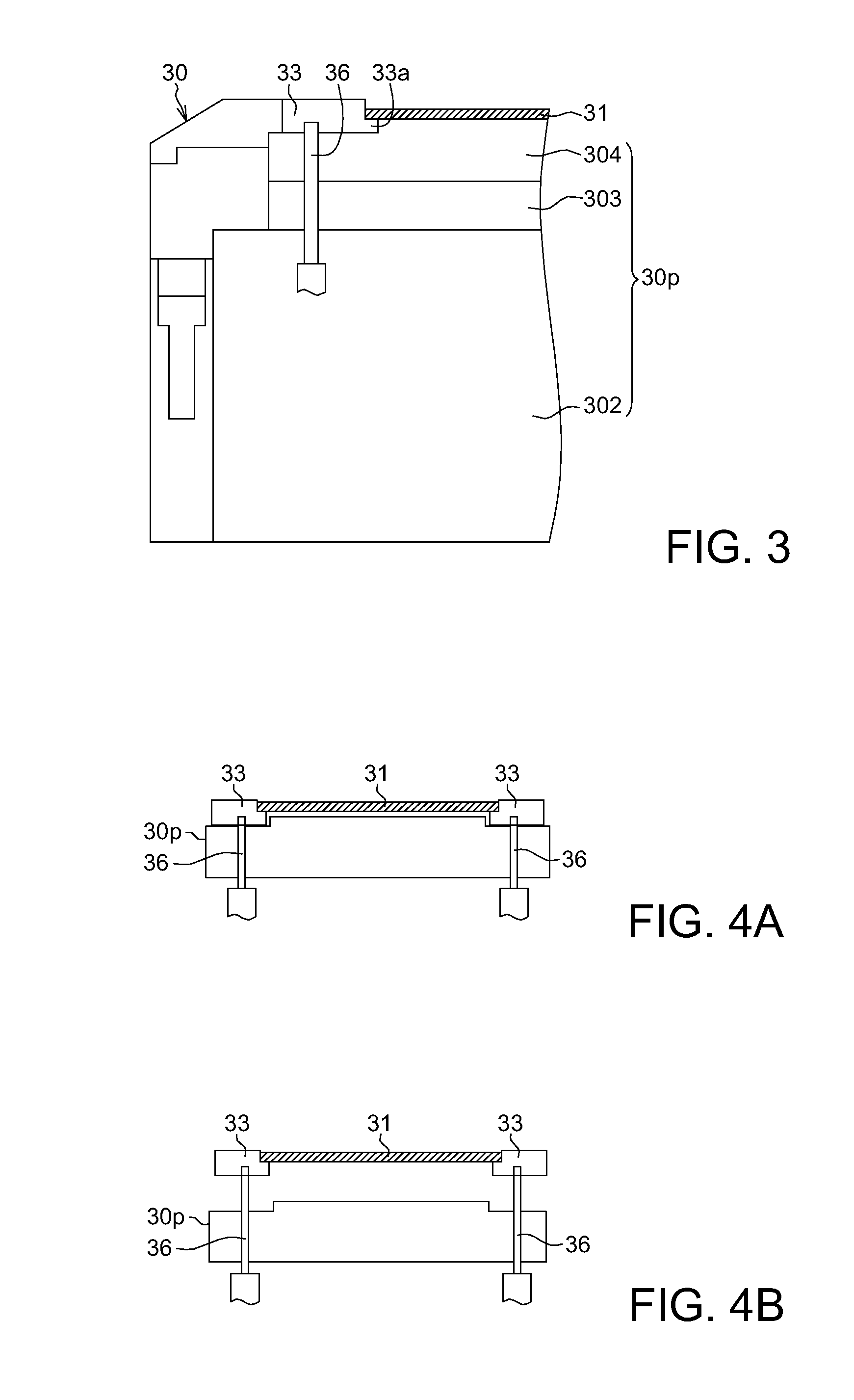

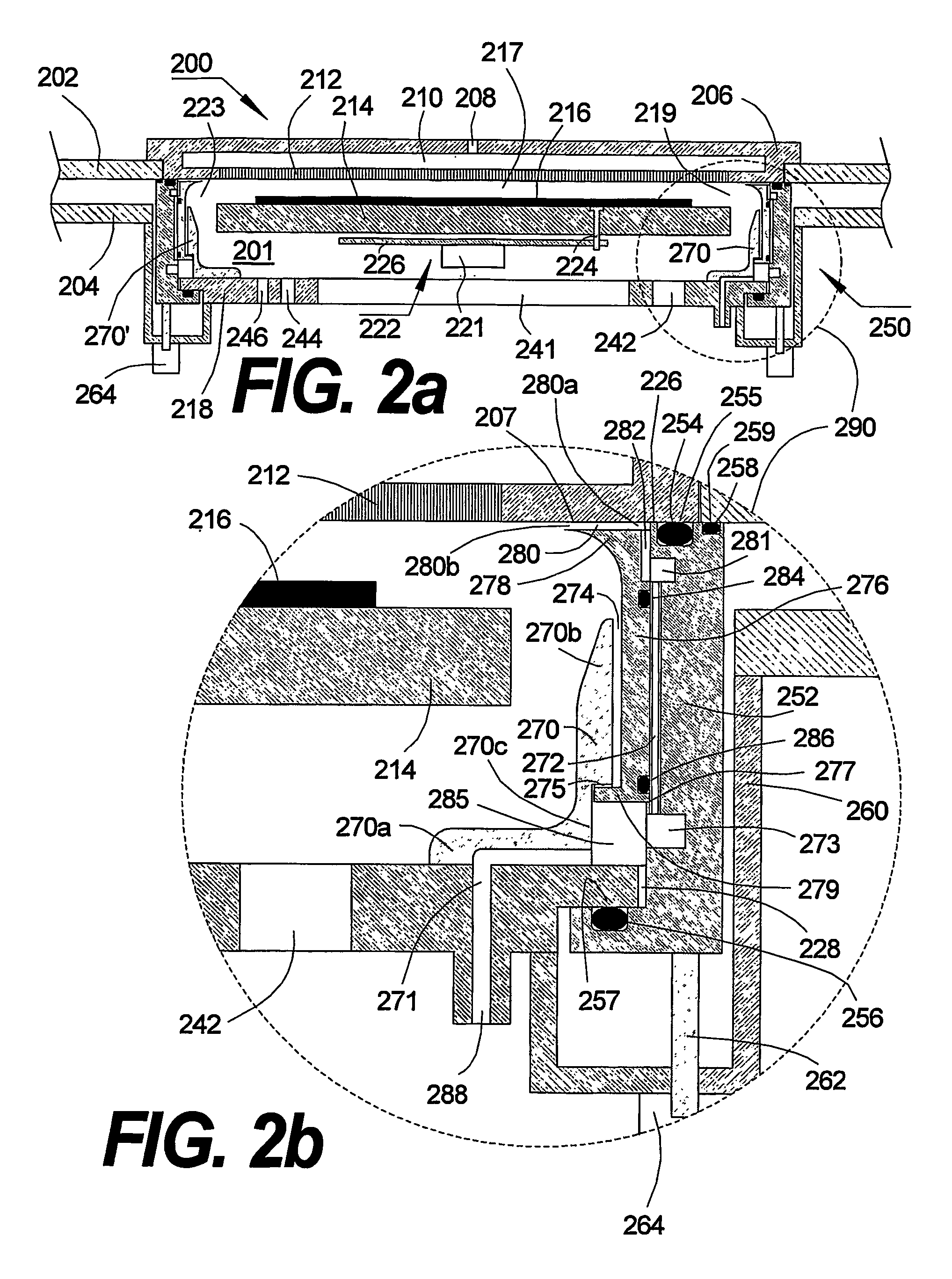

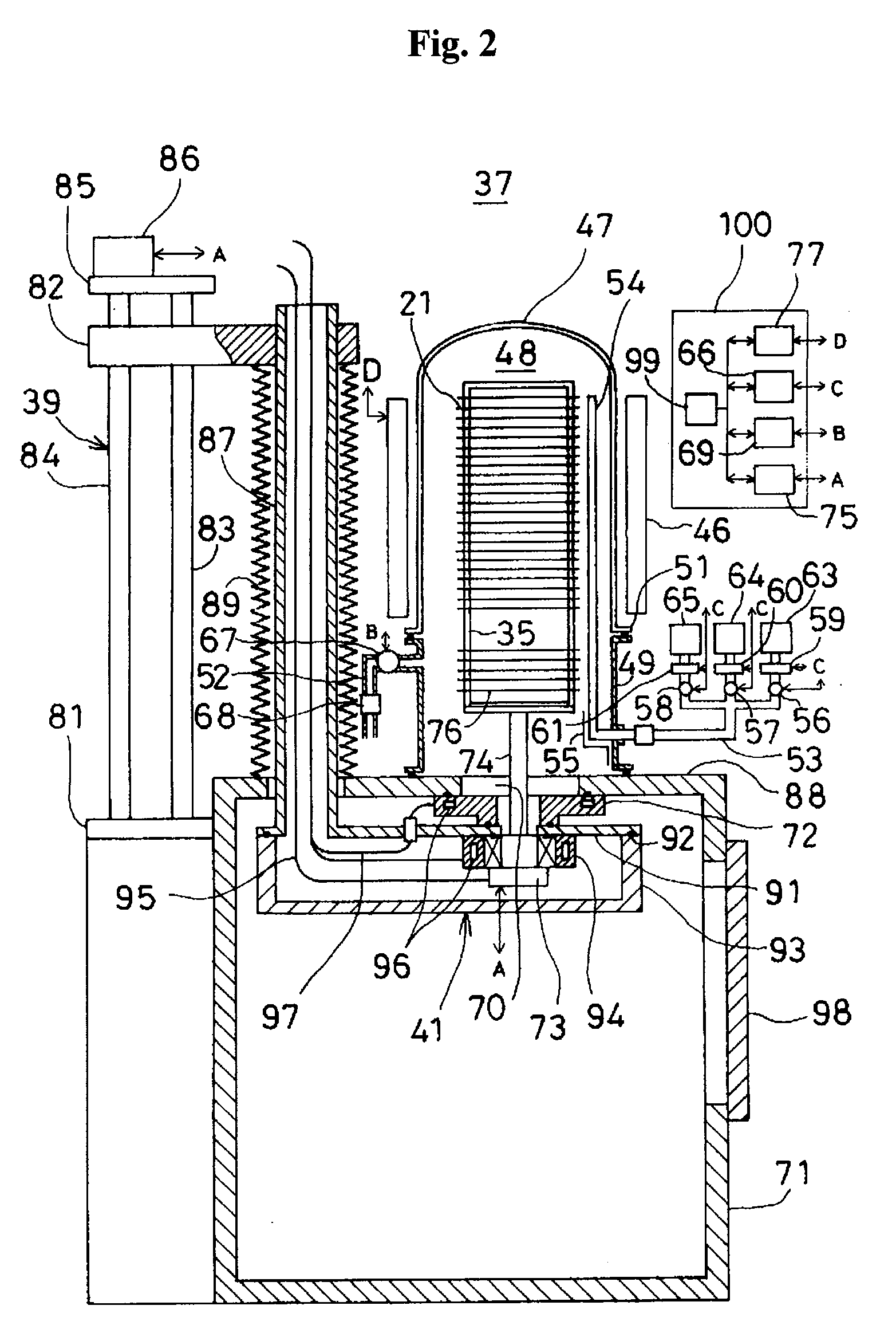

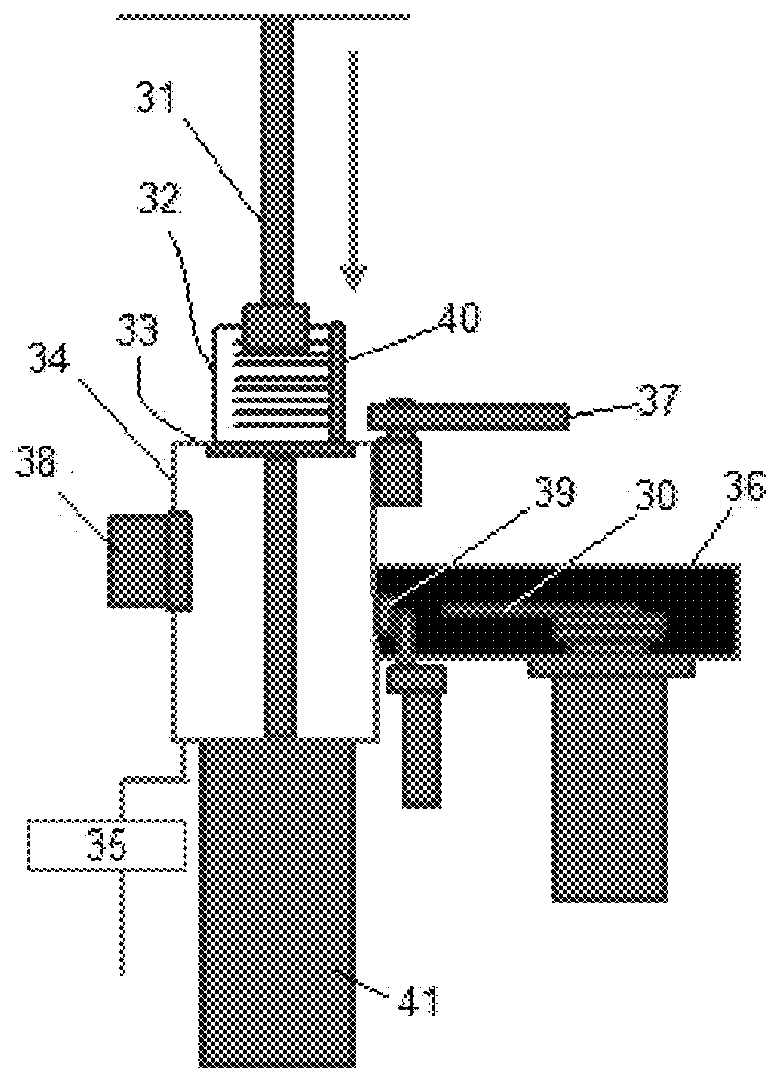

Method and apparatus for minimizing contamination in semiconductor processing chamber

ActiveUS8287648B2Liquid surface applicatorsSemiconductor/solid-state device manufacturingPositive pressureControl system

A semiconductor processing apparatus includes a reaction chamber, a loading chamber, a movable support, a drive mechanism, and a control system. The reaction chamber includes a baseplate. The baseplate includes an opening. The movable support is configured to hold a workpiece. The drive mechanism is configured to move a workpiece held on the support towards the opening of the baseplate into a processing position. The control system is configured to create a positive pressure gradient between the reaction chamber and the loading chamber while the workpiece support is in motion. Purge gases flow from the reaction chamber into the loading chamber while the workpiece support is in motion. The control system is configured to create a negative pressure gradient between the reaction chamber and the loading chamber while the workpiece is being processed. Purge gases can flow from the loading chamber into the reaction chamber while the workpiece support is in the processing position, unless the reaction chamber is sealed from the loading chamber in the processing position.

Owner:ASM IP HLDG BV

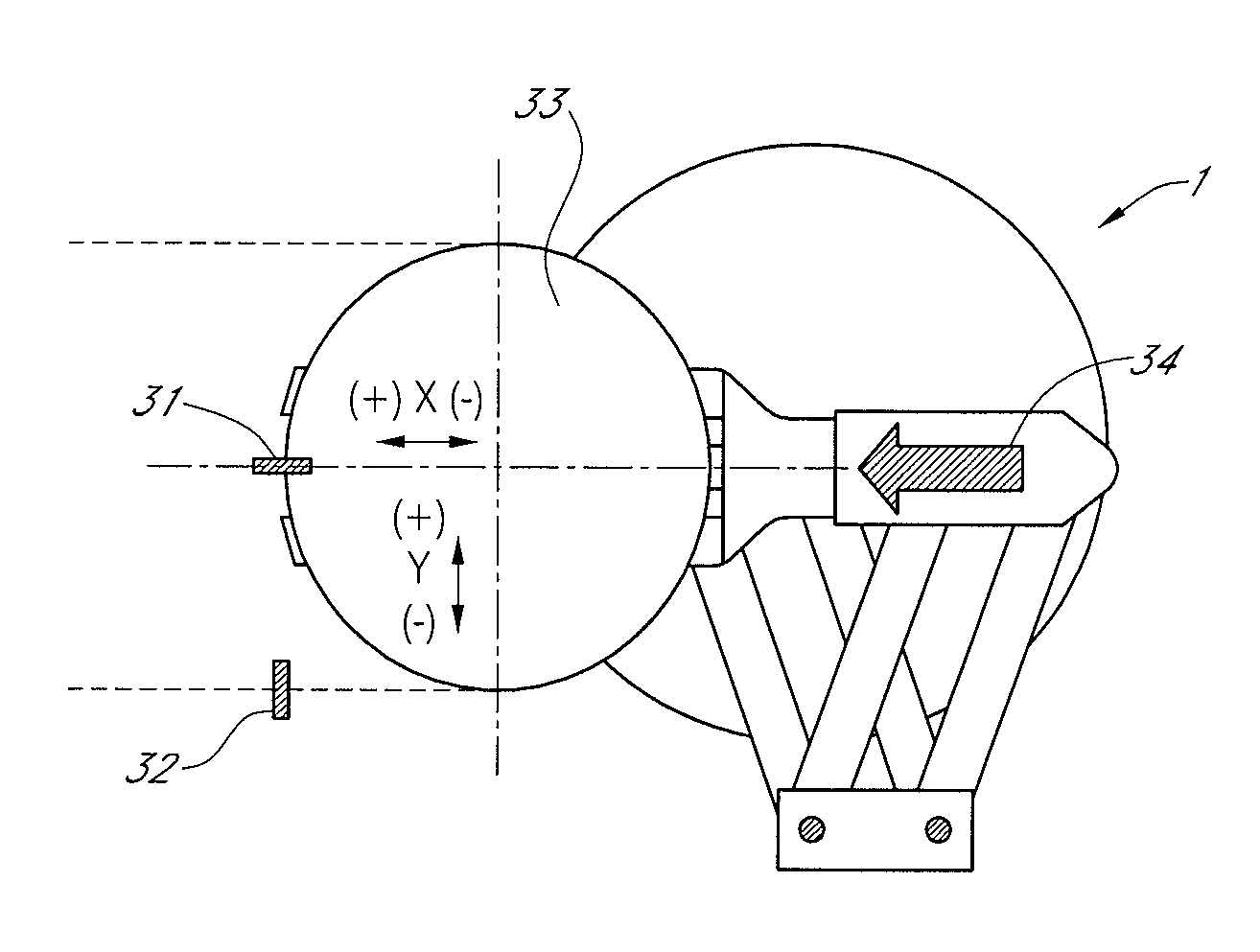

Wafer processing apparatus with wafer alignment device

ActiveUS7963736B2Increase speedProgramme controlSemiconductor/solid-state device manufacturingEngineeringSemiconductor

A semiconductor-processing apparatus includes: a wafer handling chamber; a wafer processing chamber; a wafer handling device; a first photosensor disposed in the wafer handling chamber in front of the wafer processing chamber at a position where the wafer partially blocks light received by the first photosensor at a ready-to-load position and substantially entirely blocks light received by the first photosensor when the wafer moves from the ready-to-load position toward the wafer processing chamber in the x-axis direction; and a second photosensor disposed in the wafer handling chamber in front of the wafer processing chamber at a position where the wafer does not block light received by the second photosensor at the ready-to-load position and partially blocks light received by the second photosensor when the wafer moves from the ready-to-load position toward the wafer processing chamber in the x-axis direction.

Owner:ASM JAPAN

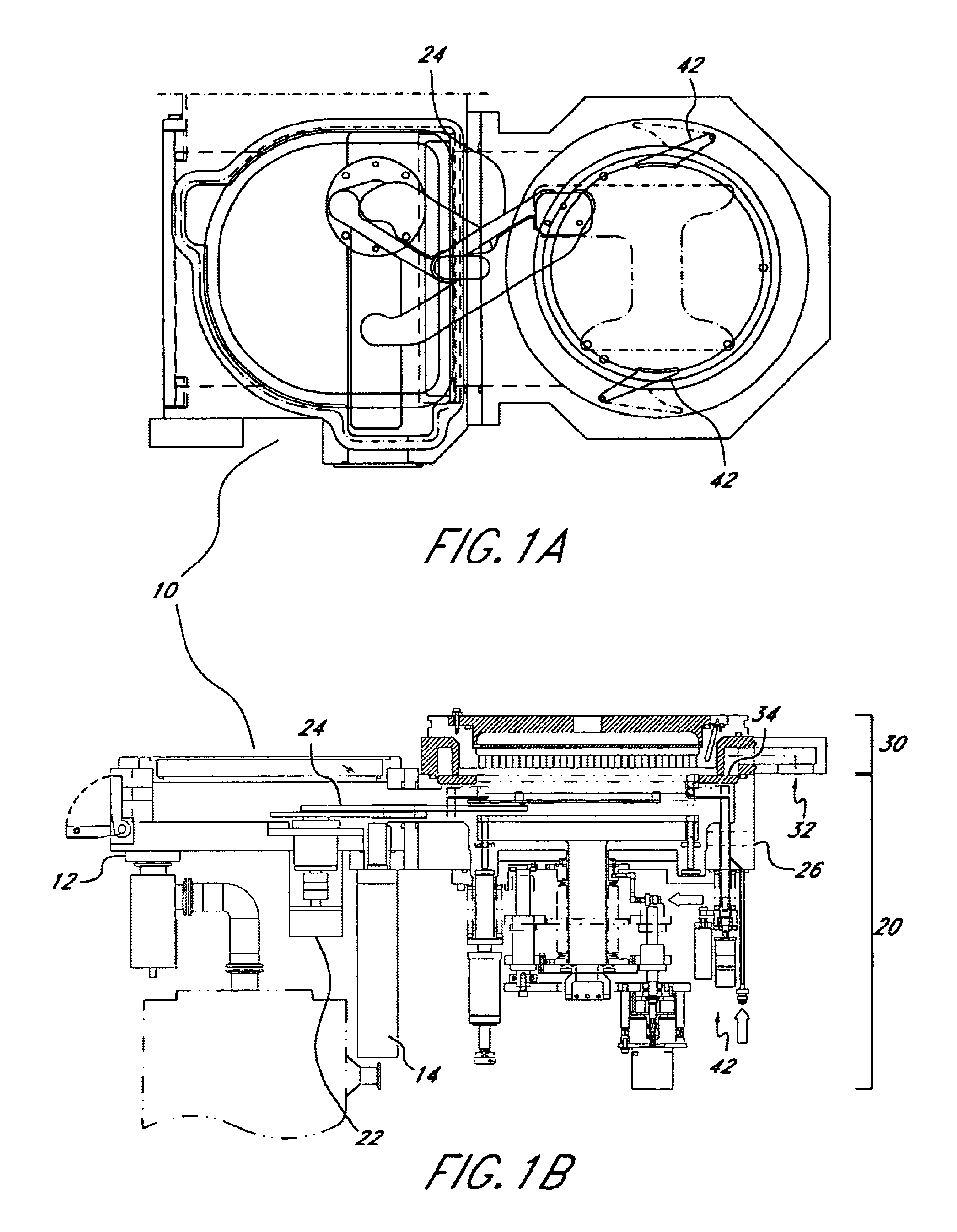

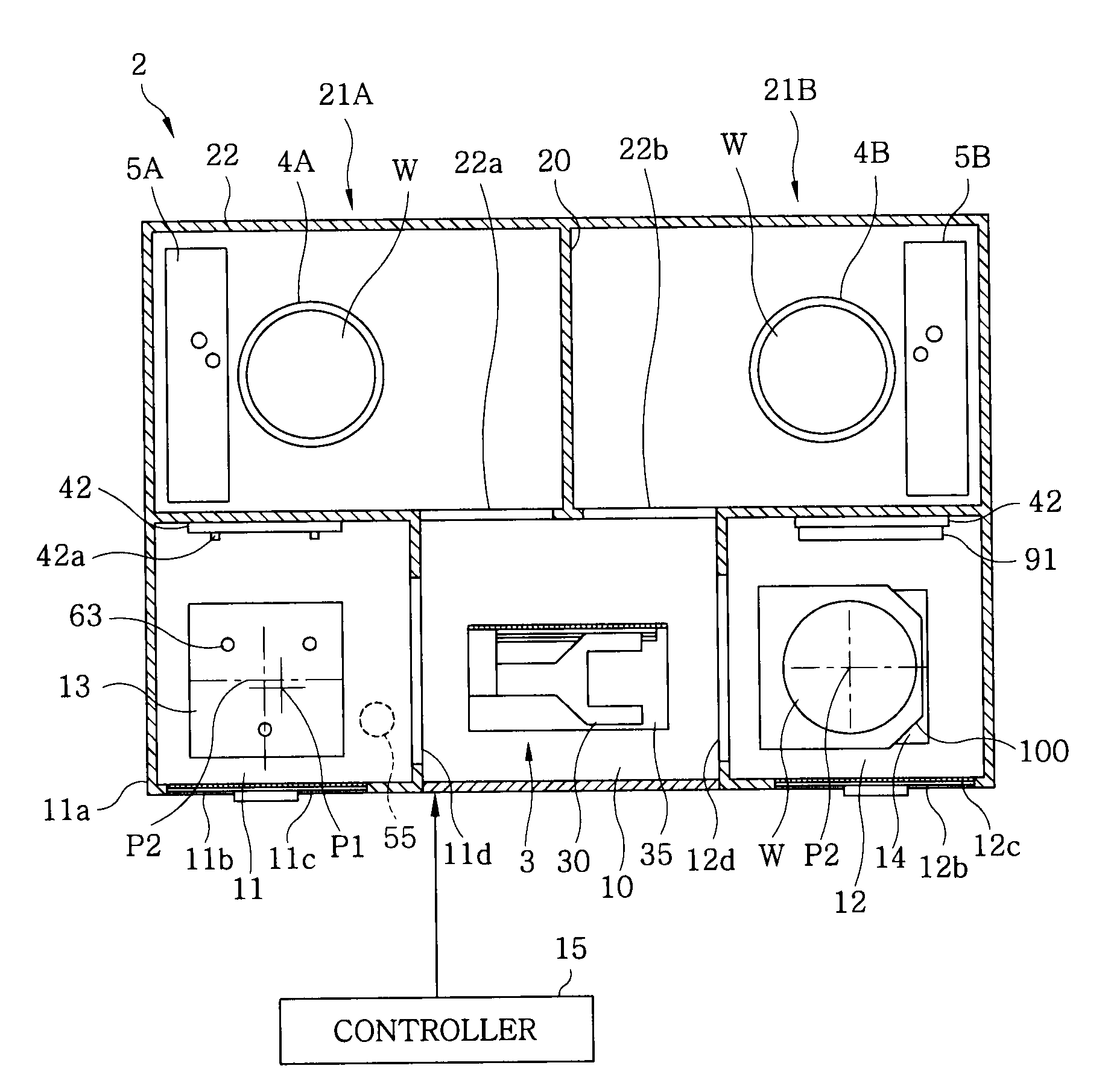

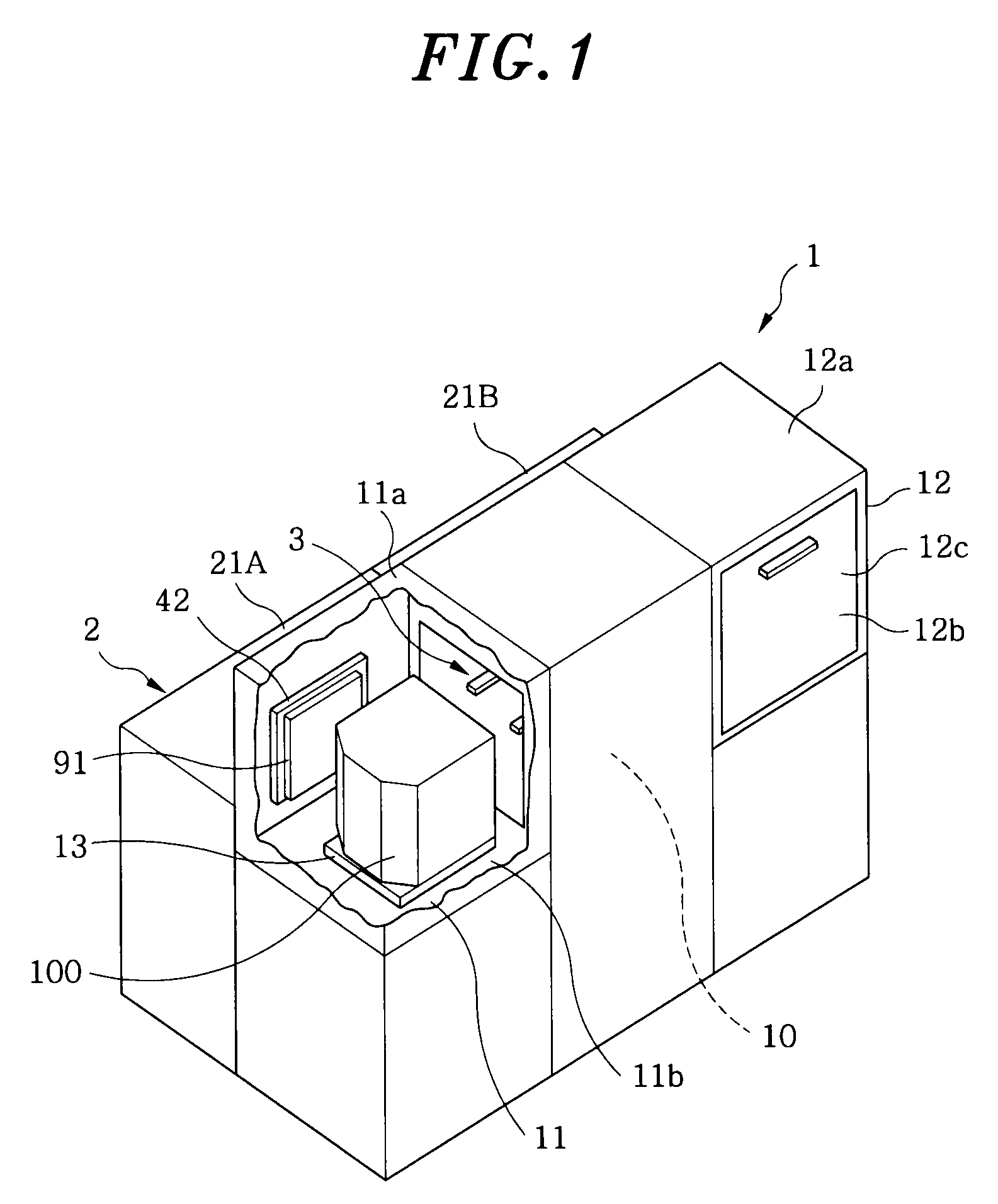

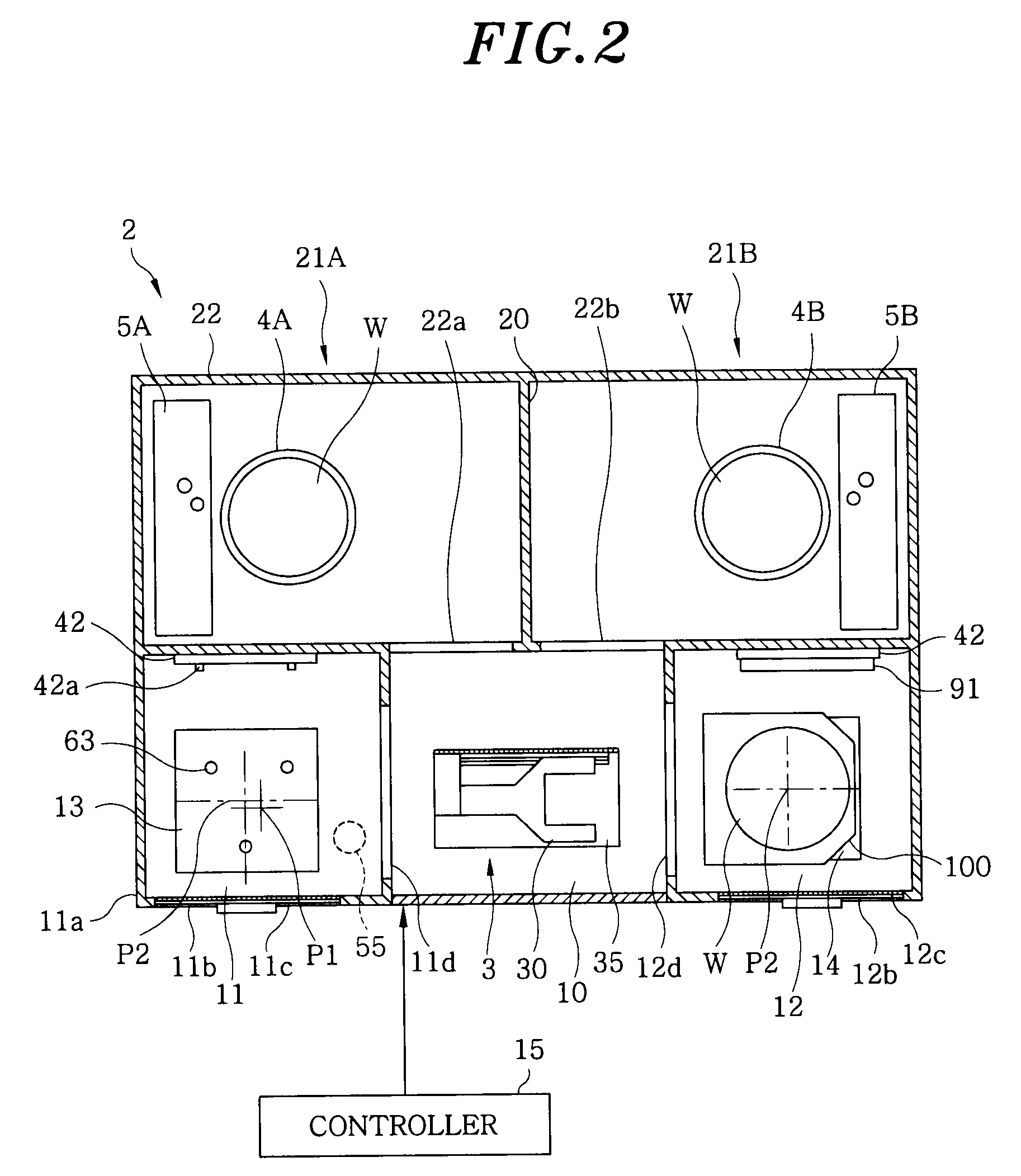

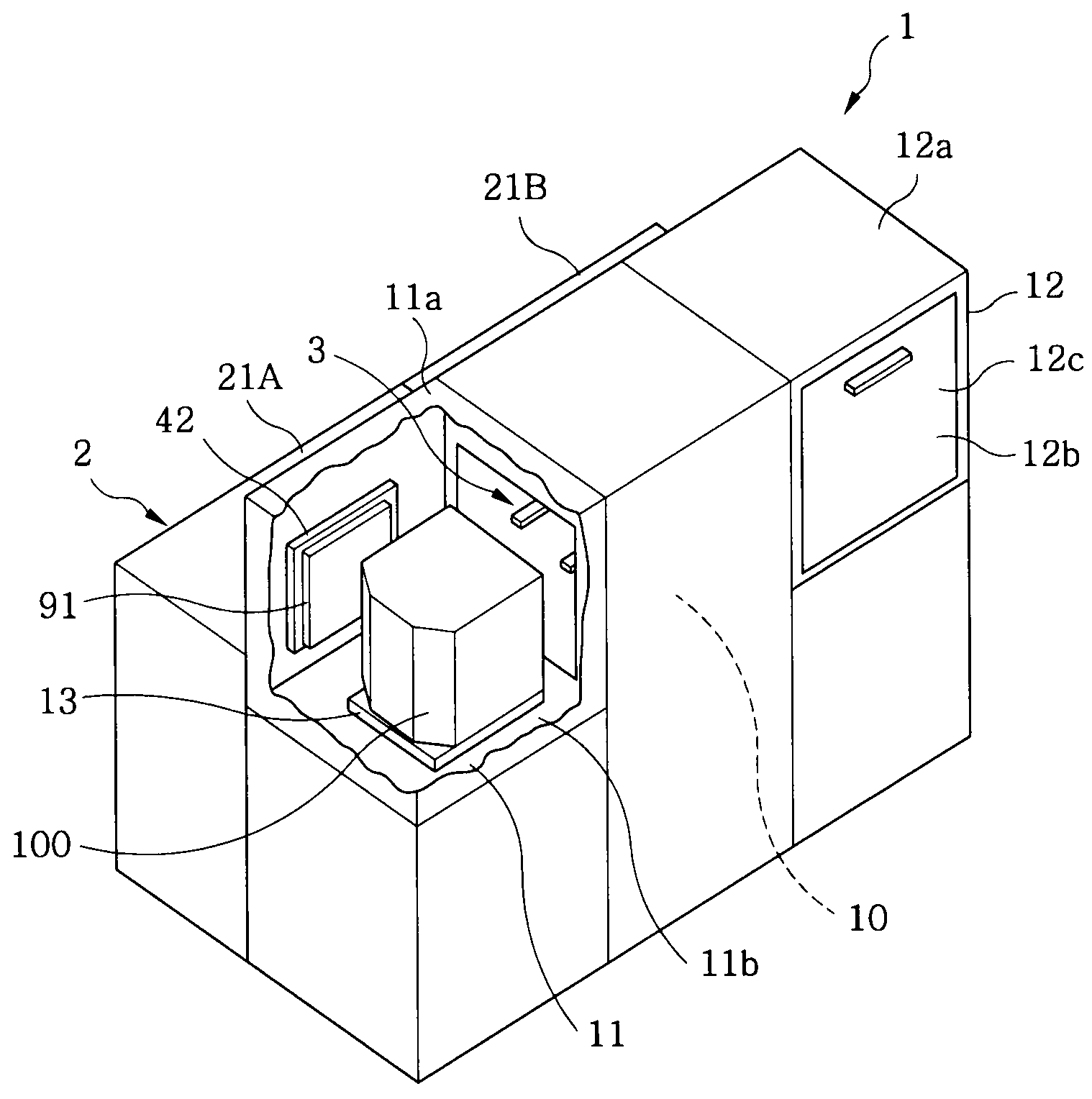

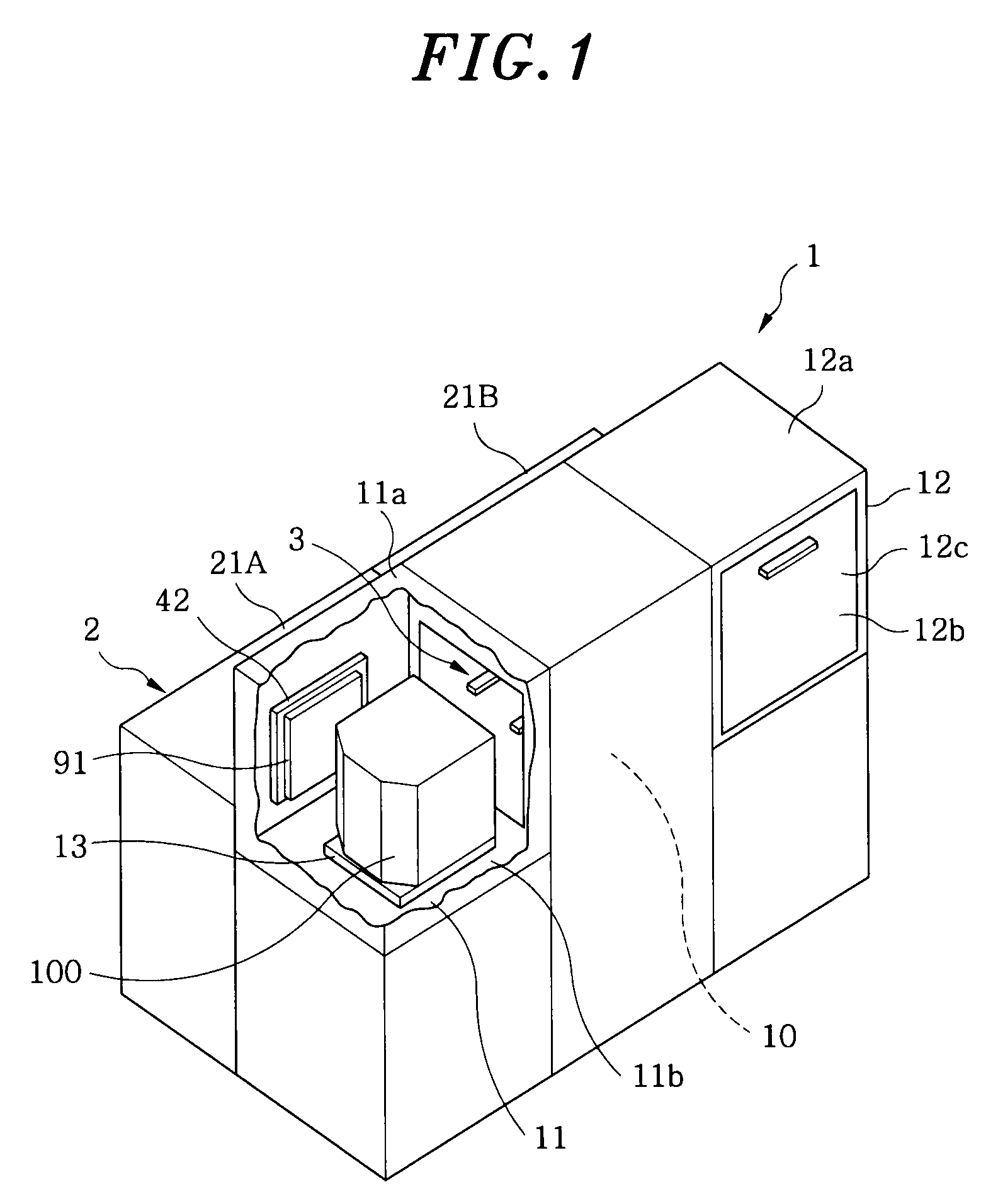

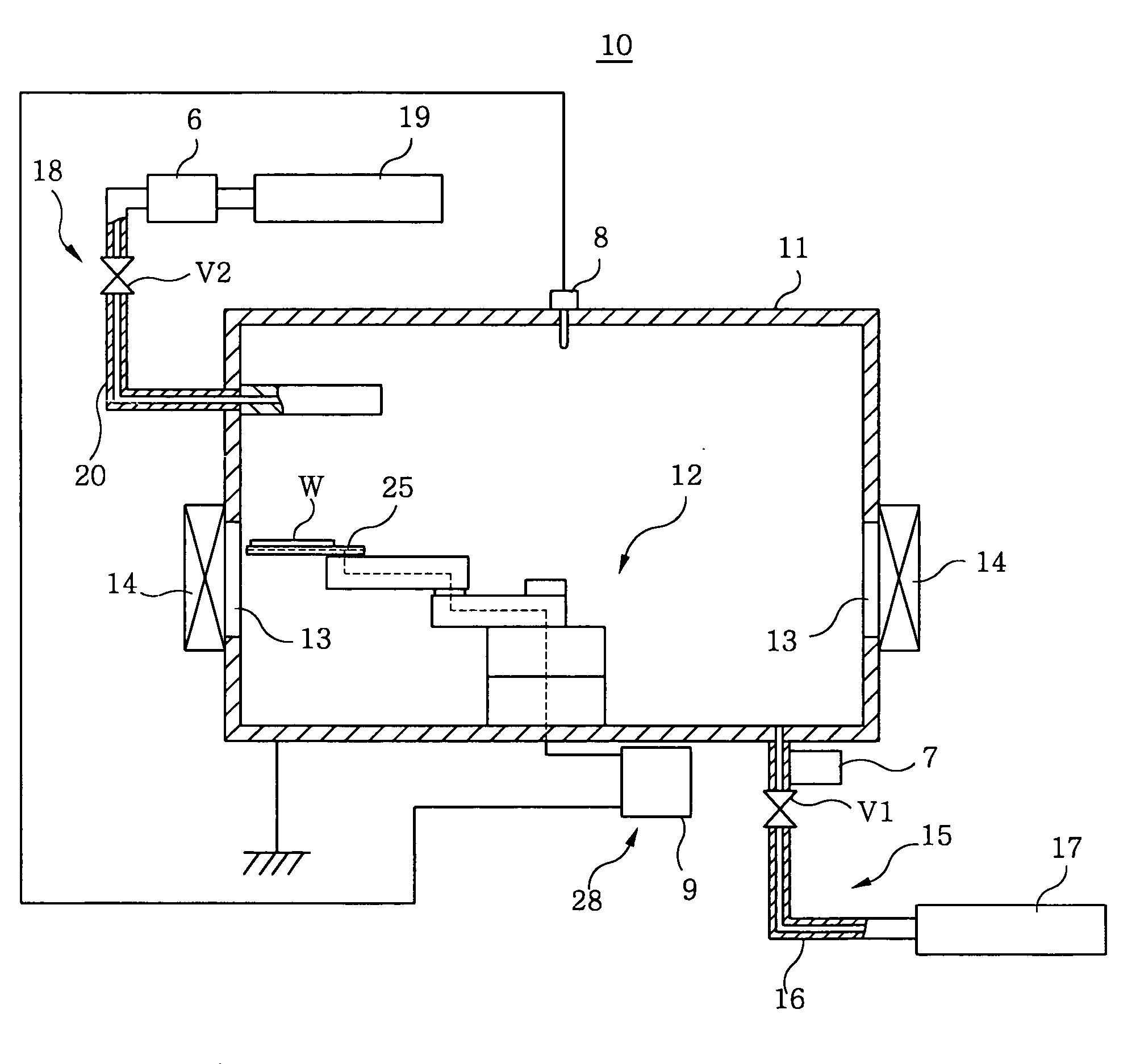

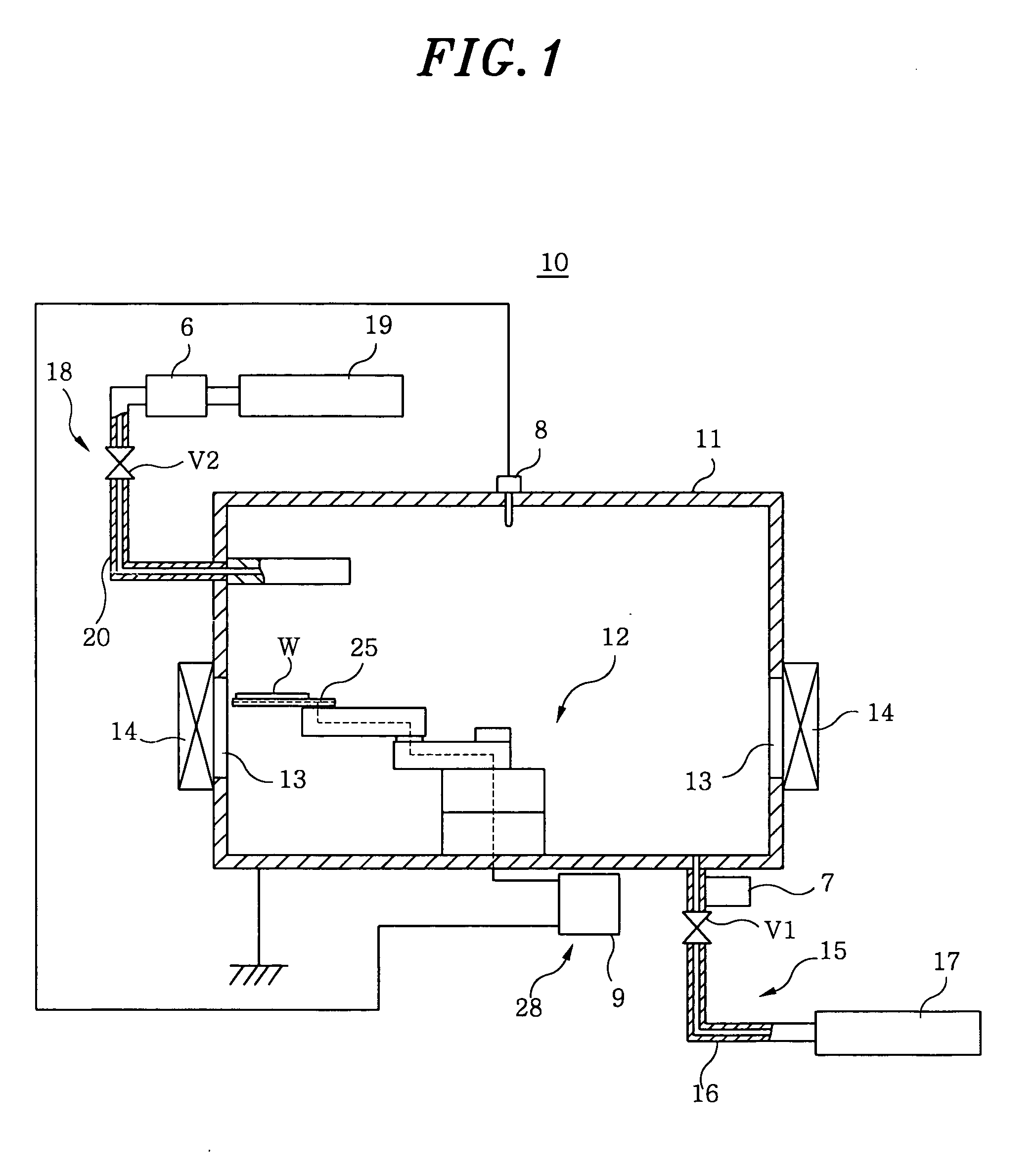

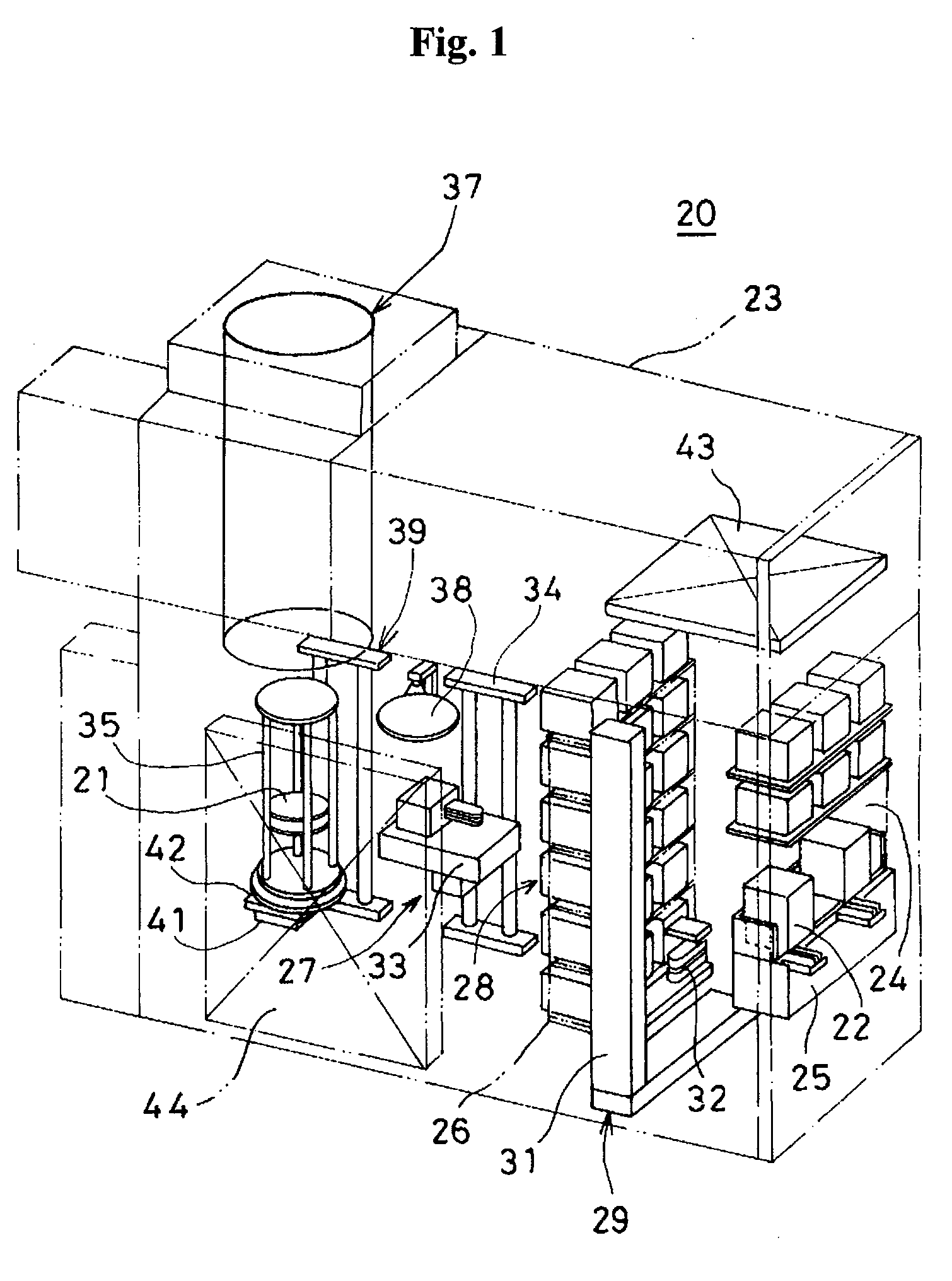

Semiconductor processing apparatus comprising chamber partitioned into reaction and transfer sections

InactiveUS6899507B2Reduce adhesionImprove efficiencySemiconductor/solid-state device manufacturingCharge manipulationEngineeringSemiconductor

Semiconductor processing equipment that has increased efficiency, throughput, and stability, as well as reduced operating cost, footprint, and faceprint is provided. Other than during deposition, the atmosphere of both the reaction chamber and the transfer chamber are evacuated using the transfer chamber exhaust port, which is located below the surface of the semiconductor wafer. This configuration prevents particles generated during wafer transfer or during deposition from adhering to the surface of the semiconductor wafer. Additionally, by introducing a purge gas into the transfer chamber during deposition, and by using an insulation separating plate 34, the atmospheres of the transfer and reaction chambers can be effectively isolated from each other, thereby preventing deposition on the walls and components of the transfer chamber. Finally, the configuration described herein permits a wafer buffer mechanism to be used with the semiconductor processing equipment, thereby further increasing throughput and efficiency.

Owner:ASM JAPAN

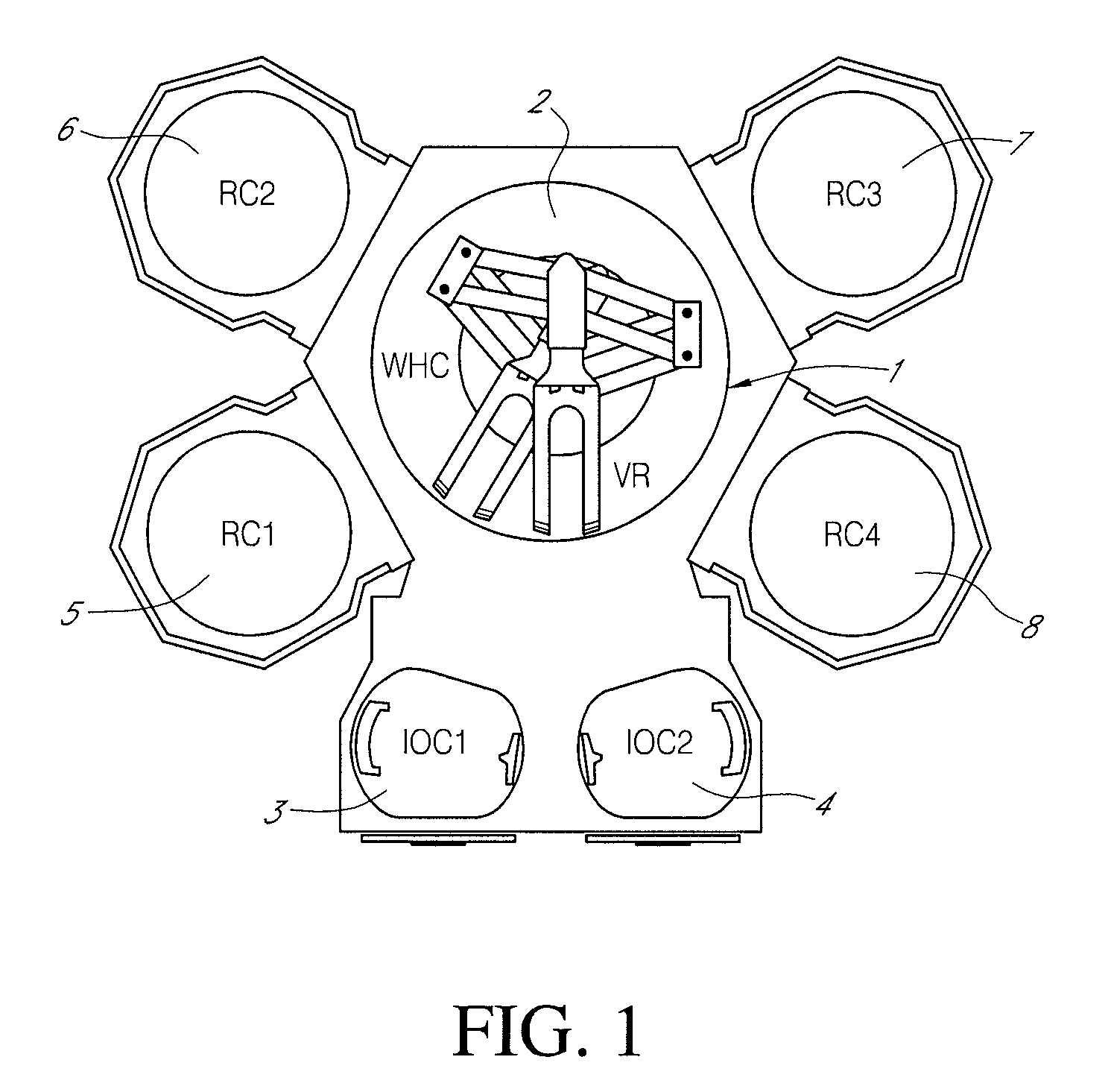

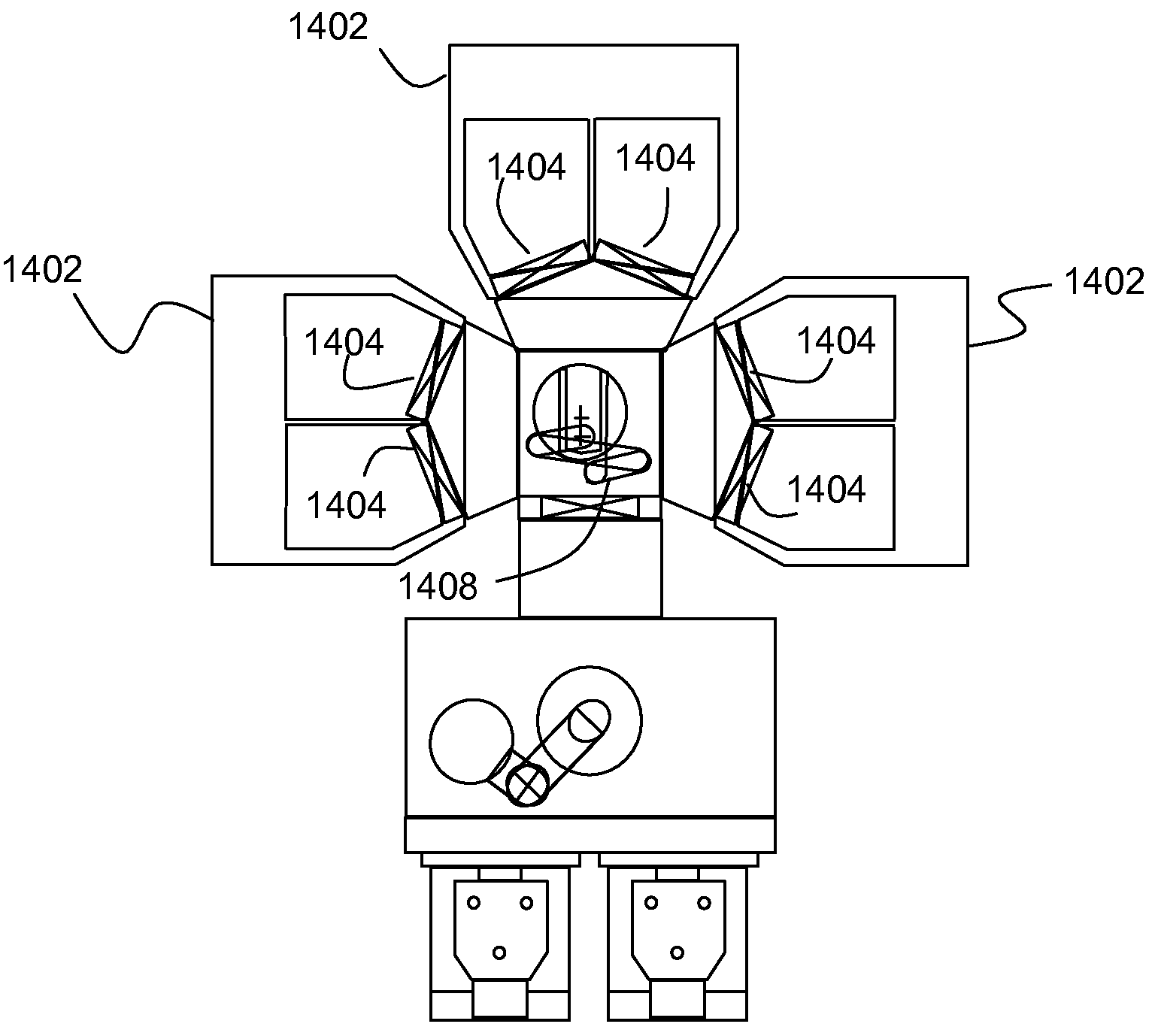

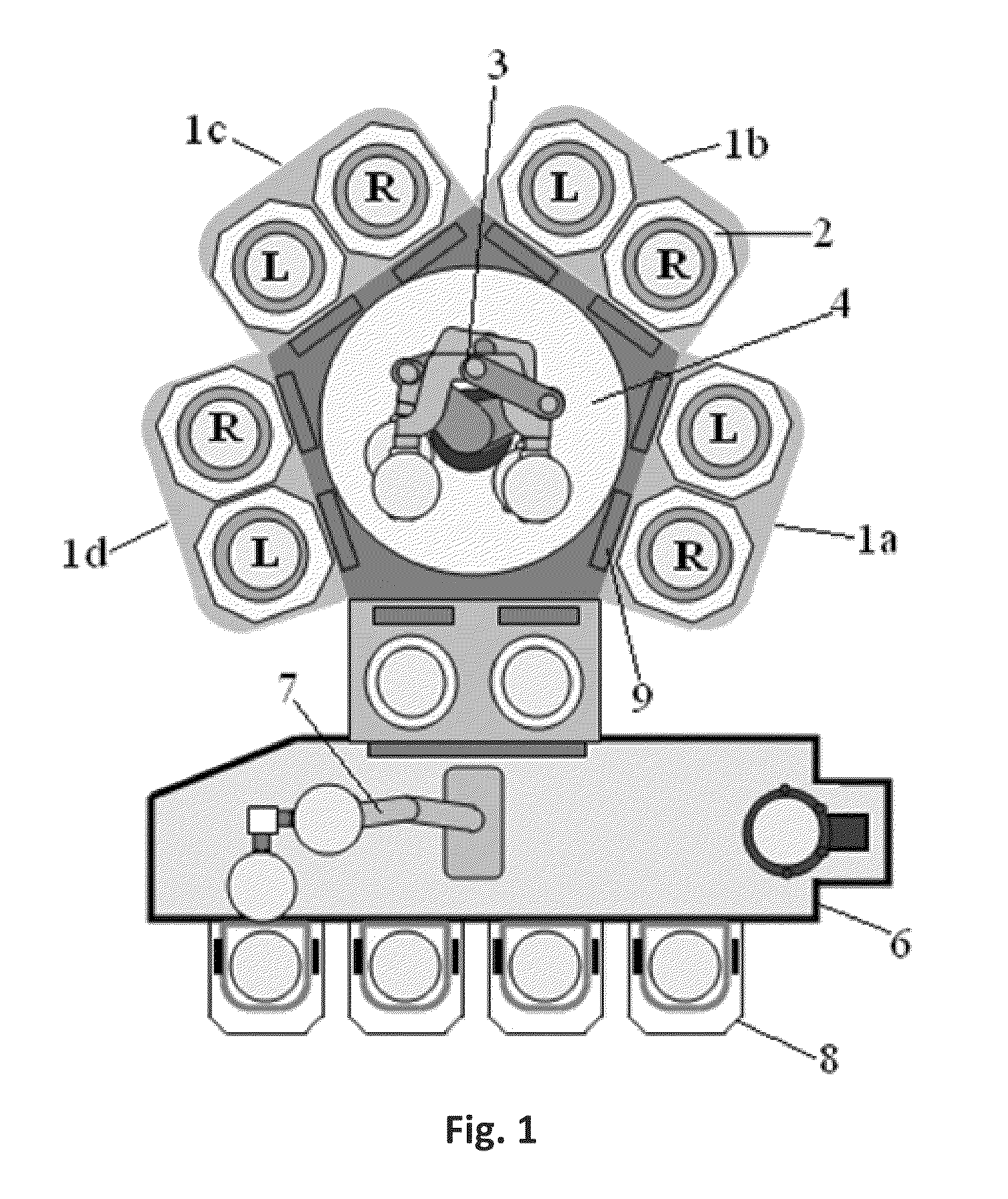

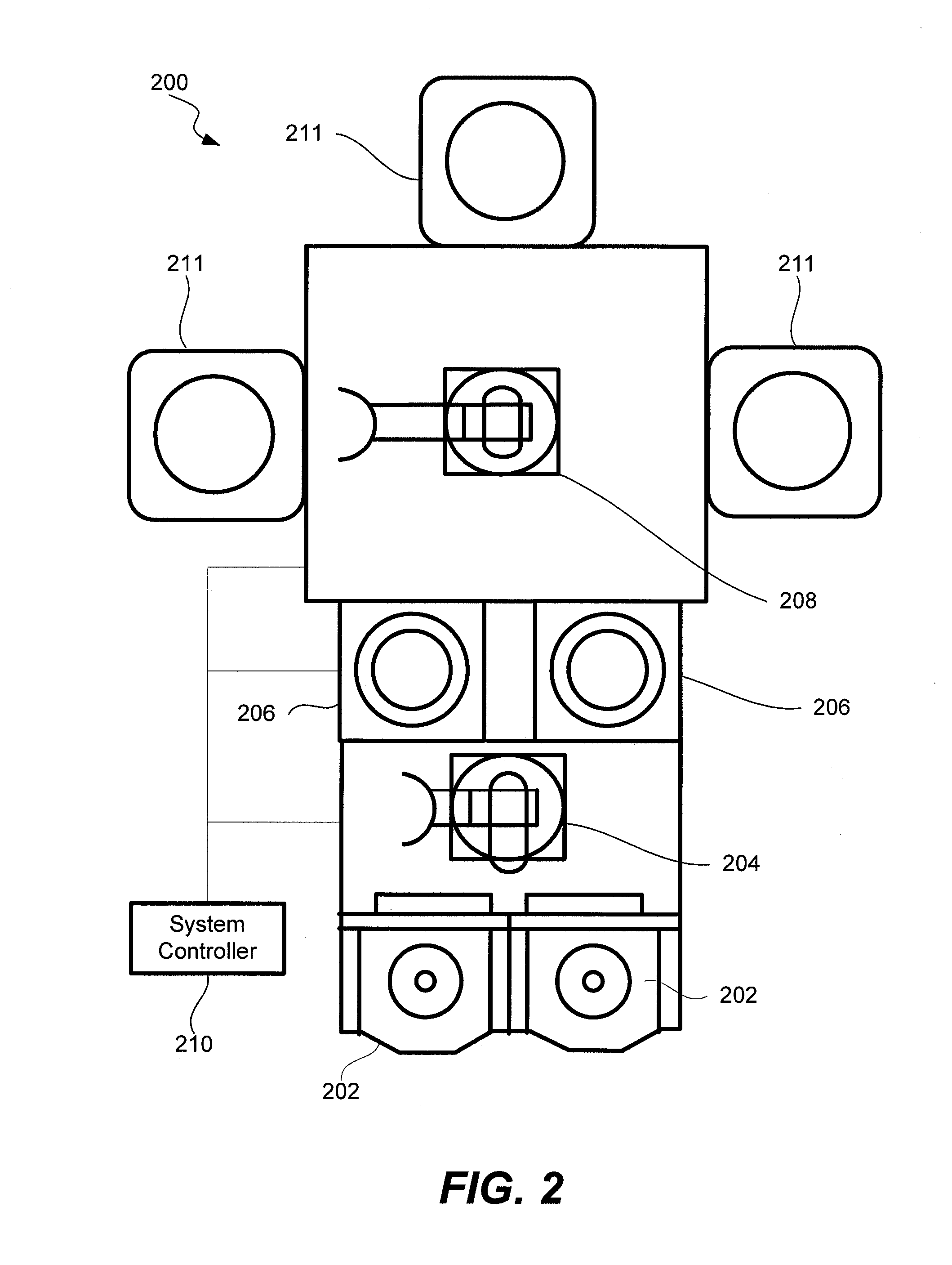

Semiconductor manufacturing process modules

ActiveUS20080124197A1Balance processing loadSemiconductor/solid-state device manufacturingConveyor partsProcess moduleSemiconductor

Owner:BOOKS AUTOMATION US LLC

Anti-Slip End Effector For Transporting Workpiece Using Van Der Waals Force

ActiveUS20150287626A1Prevent slippingImprove shipping speedSemiconductor/solid-state device manufacturingLifting devicesRobotic armEngineering

An anti-slip end effector for transporting a workpiece, configured to be attached to a robotic arm, includes: a workpiece-supporting area for placing a workpiece thereon for transportation; and at least one anti-slip protrusion disposed in the workpiece-supporting area for supporting a backside of the workpiece, said anti-slip protrusion having a top face capable of contacting and adhering to the backside of the workpiece by van der Waals force and capable of pivoting on a pivot axis, said pivot axis being disposed away from a center of the top face as viewed from above.

Owner:ASM IP HLDG BV

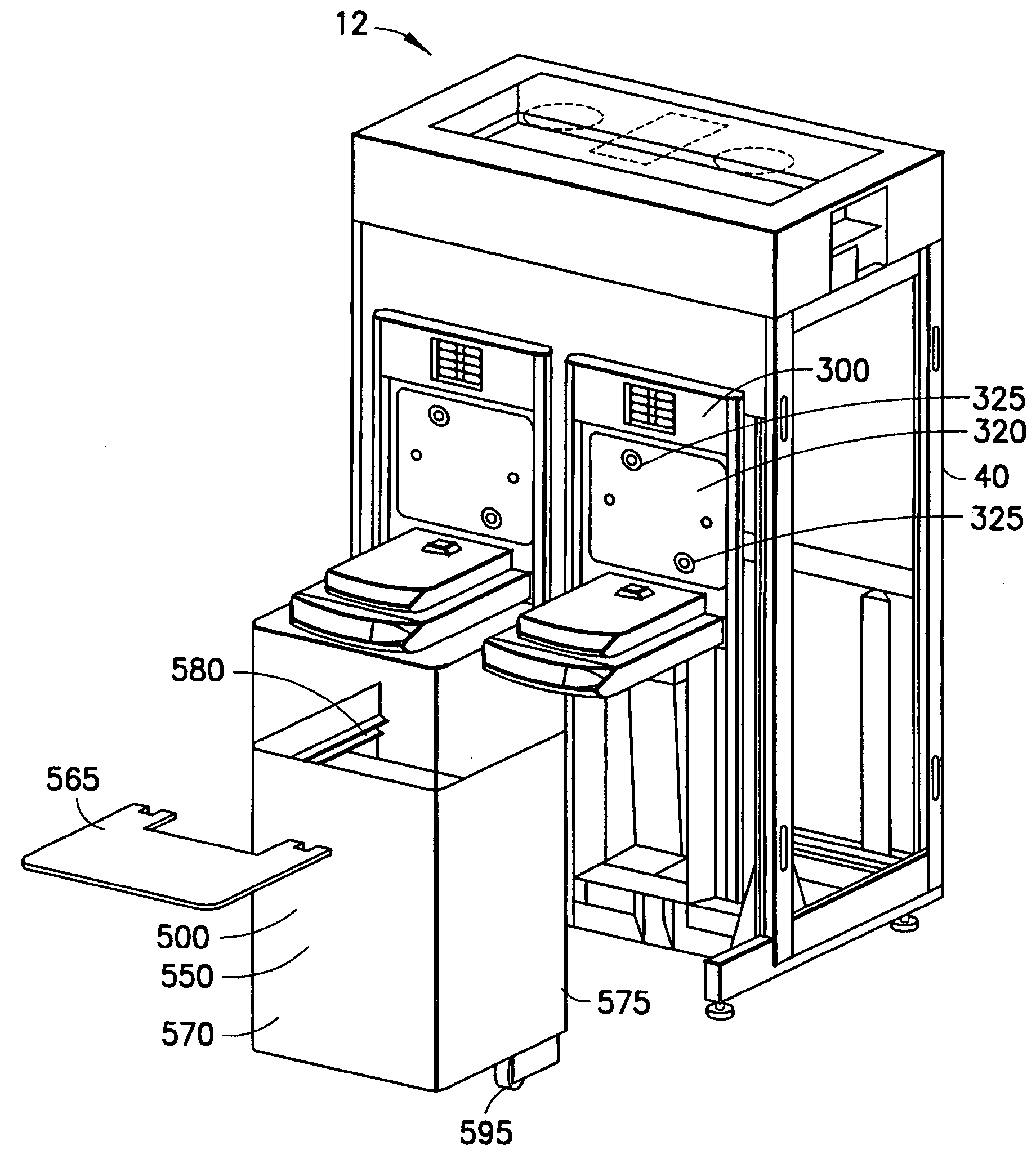

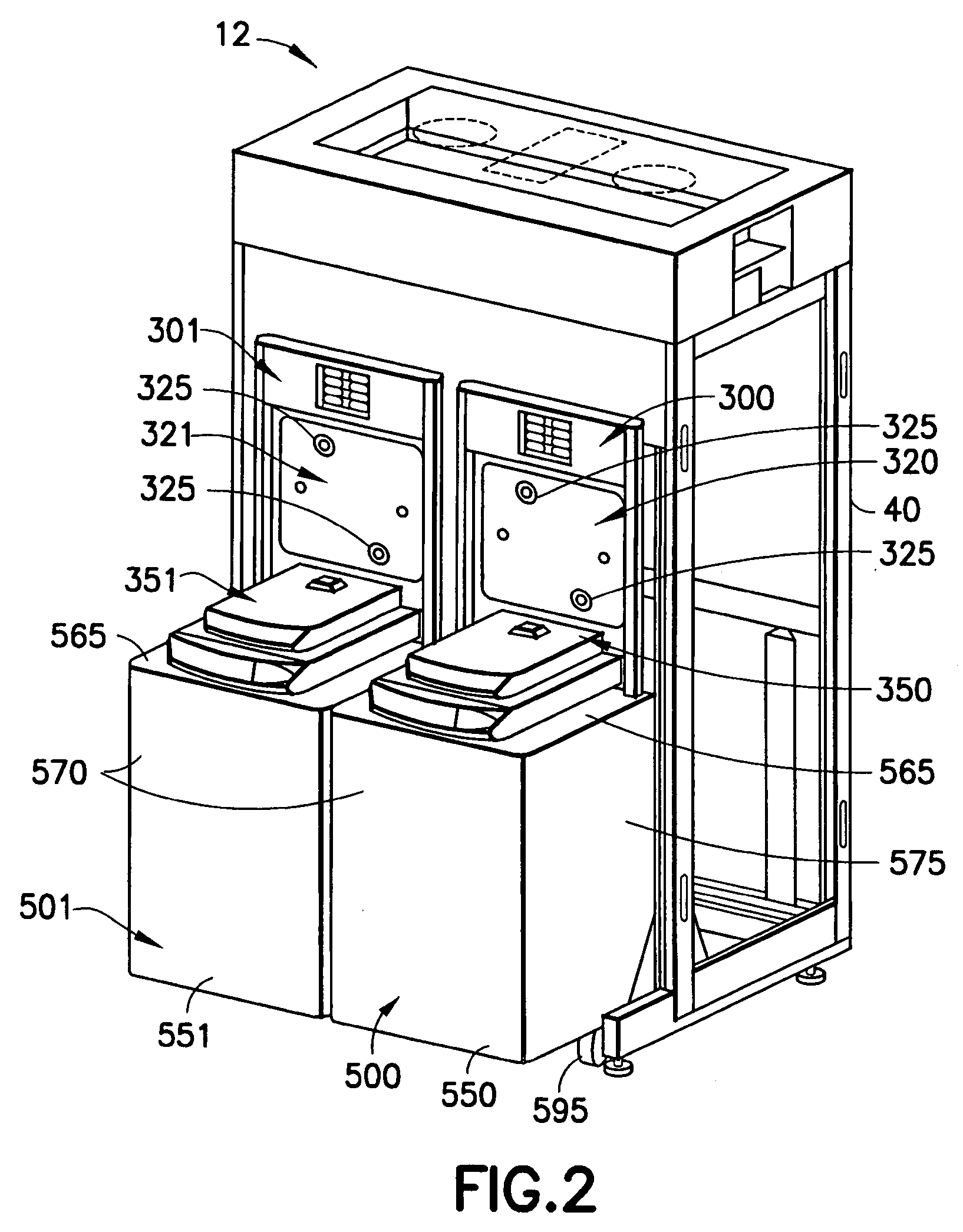

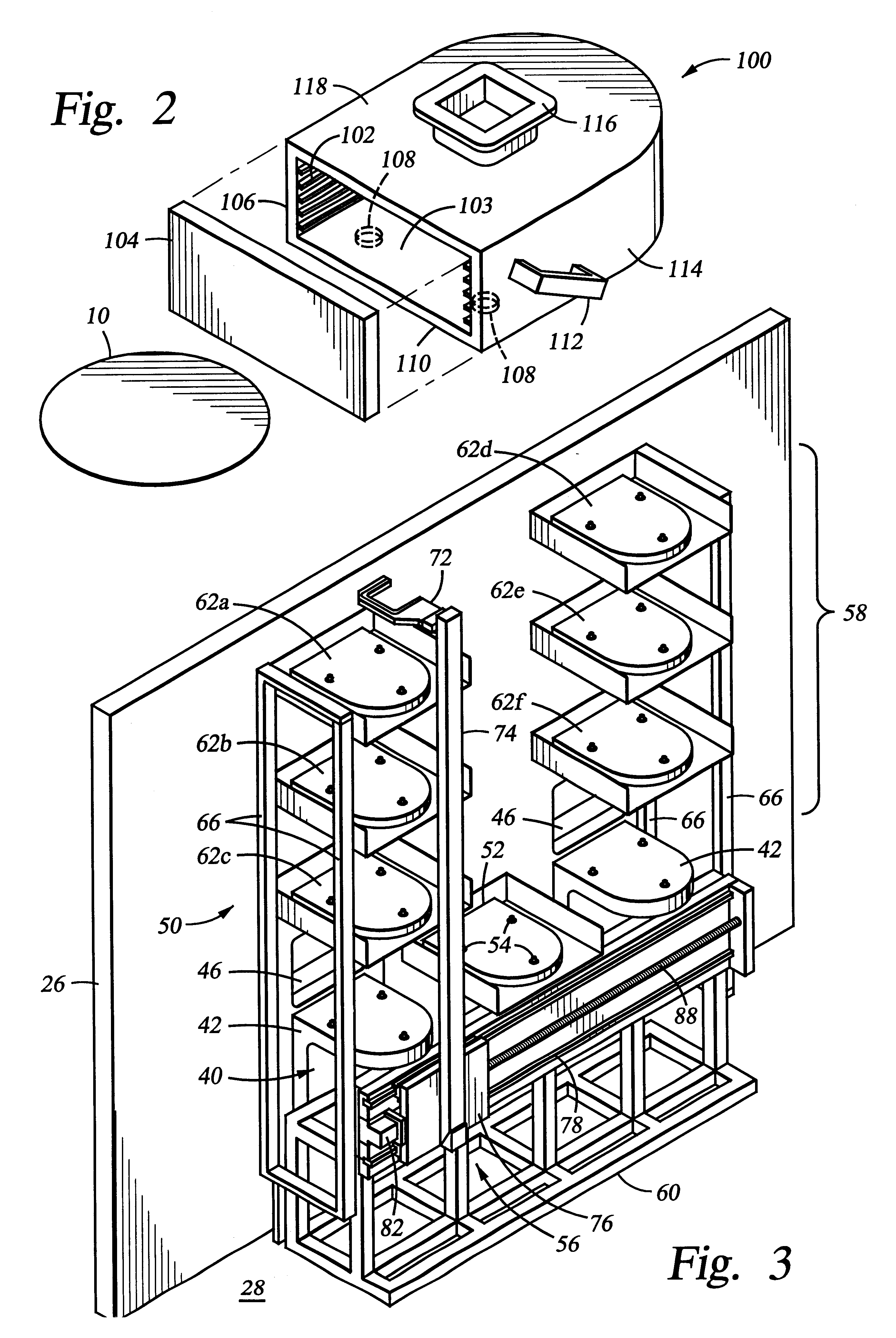

Equipment storage for substrate processing apparatus

A substrate processing apparatus has a frame and a load port connected to the frame and adapted to mate a substrate transport container to the frame. The apparatus has transportable storage that is adapted to be removably connected to the frame and fit beneath the load port. The storage may be an enclosure housing electrical, mechanical, or electromechanical devices of the substrate processing apparatus.

Owner:BOOKS AUTOMATION US LLC

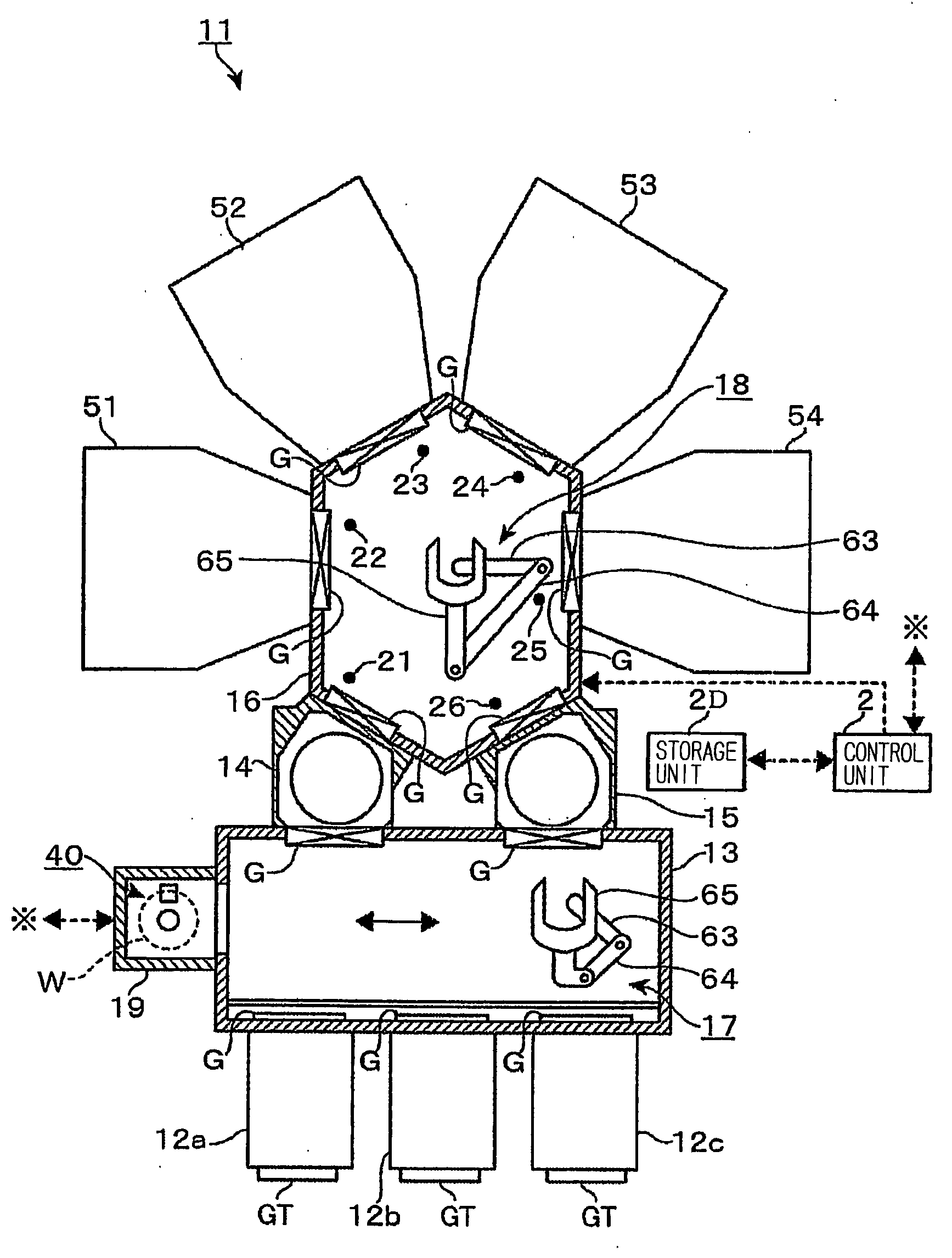

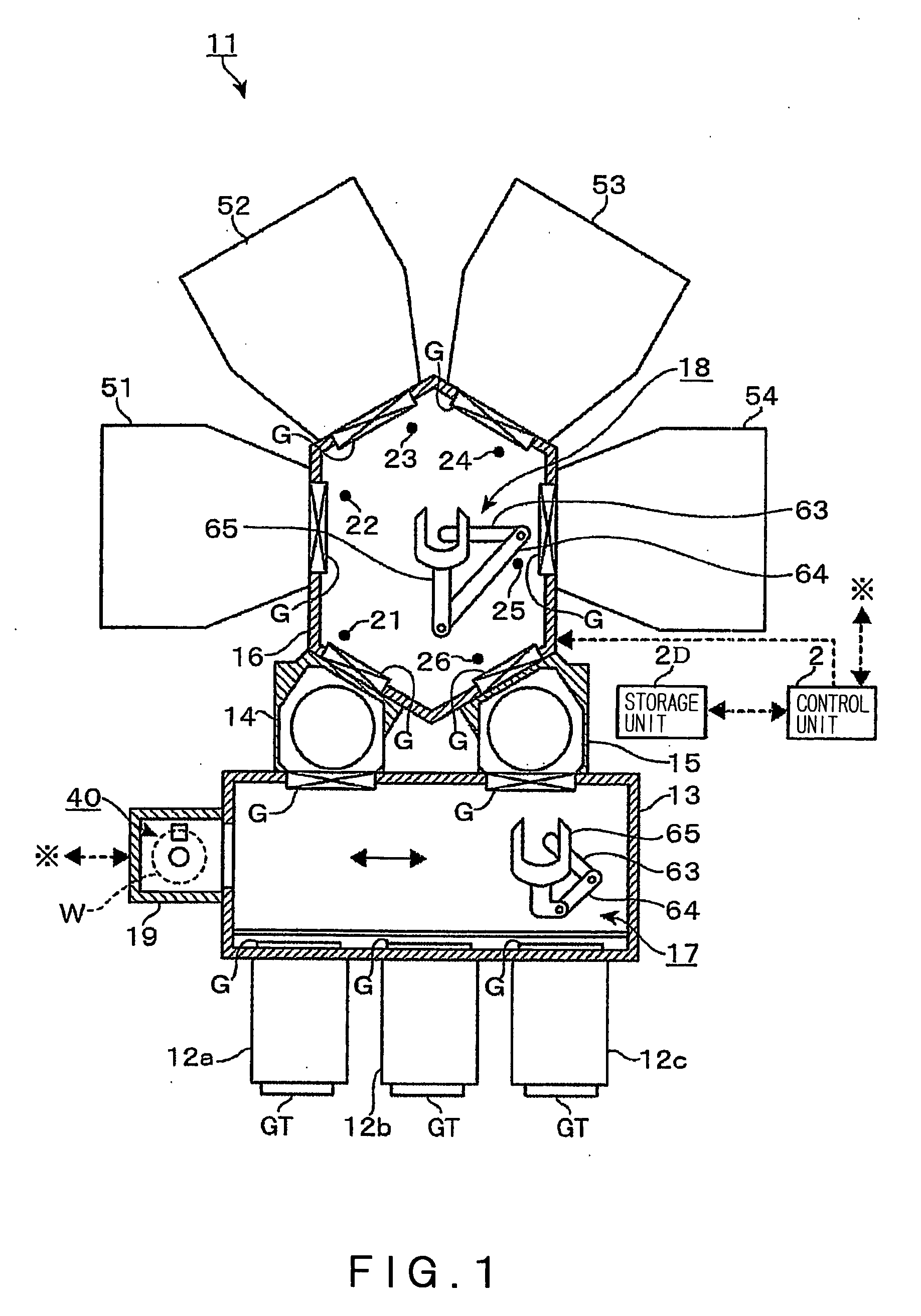

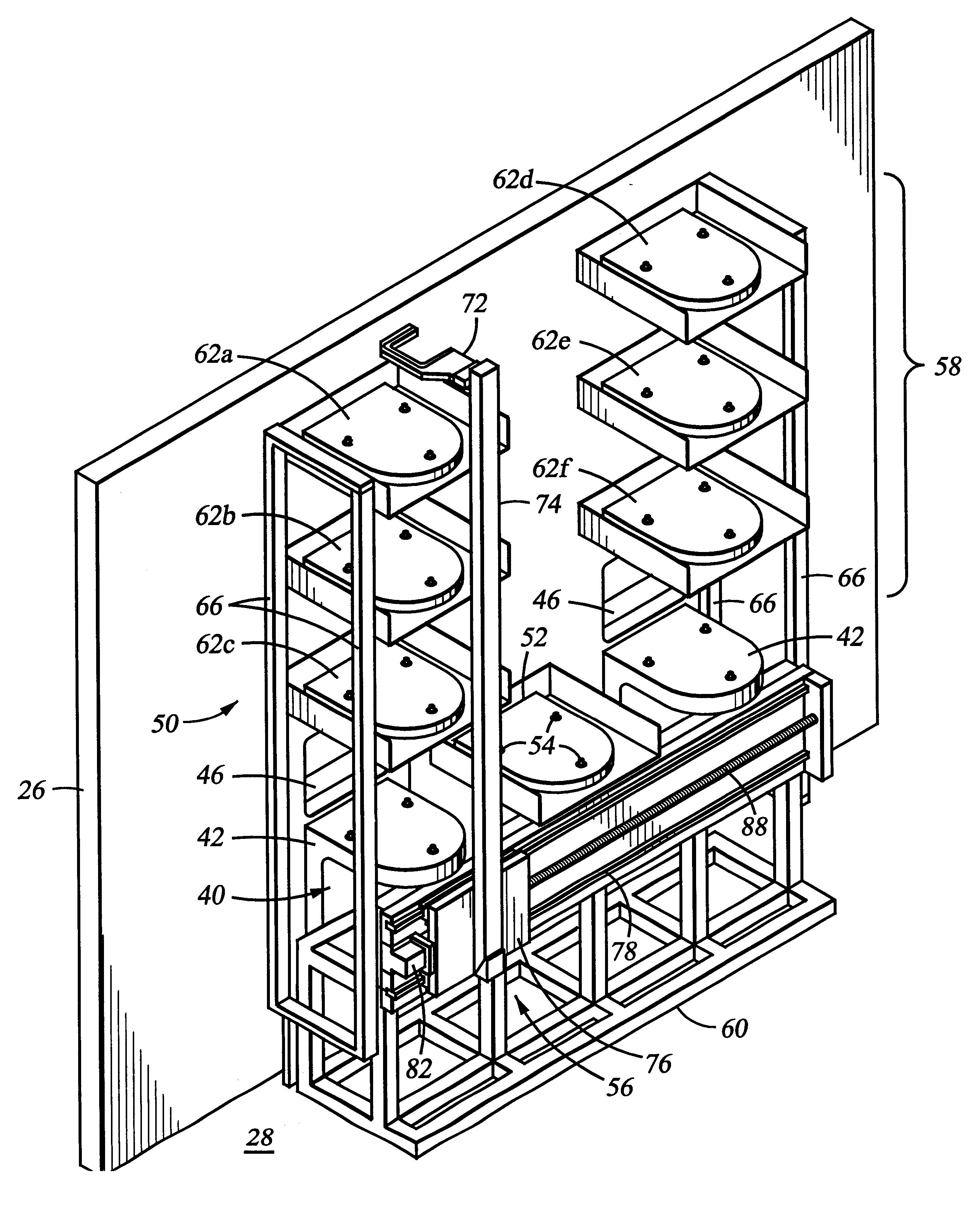

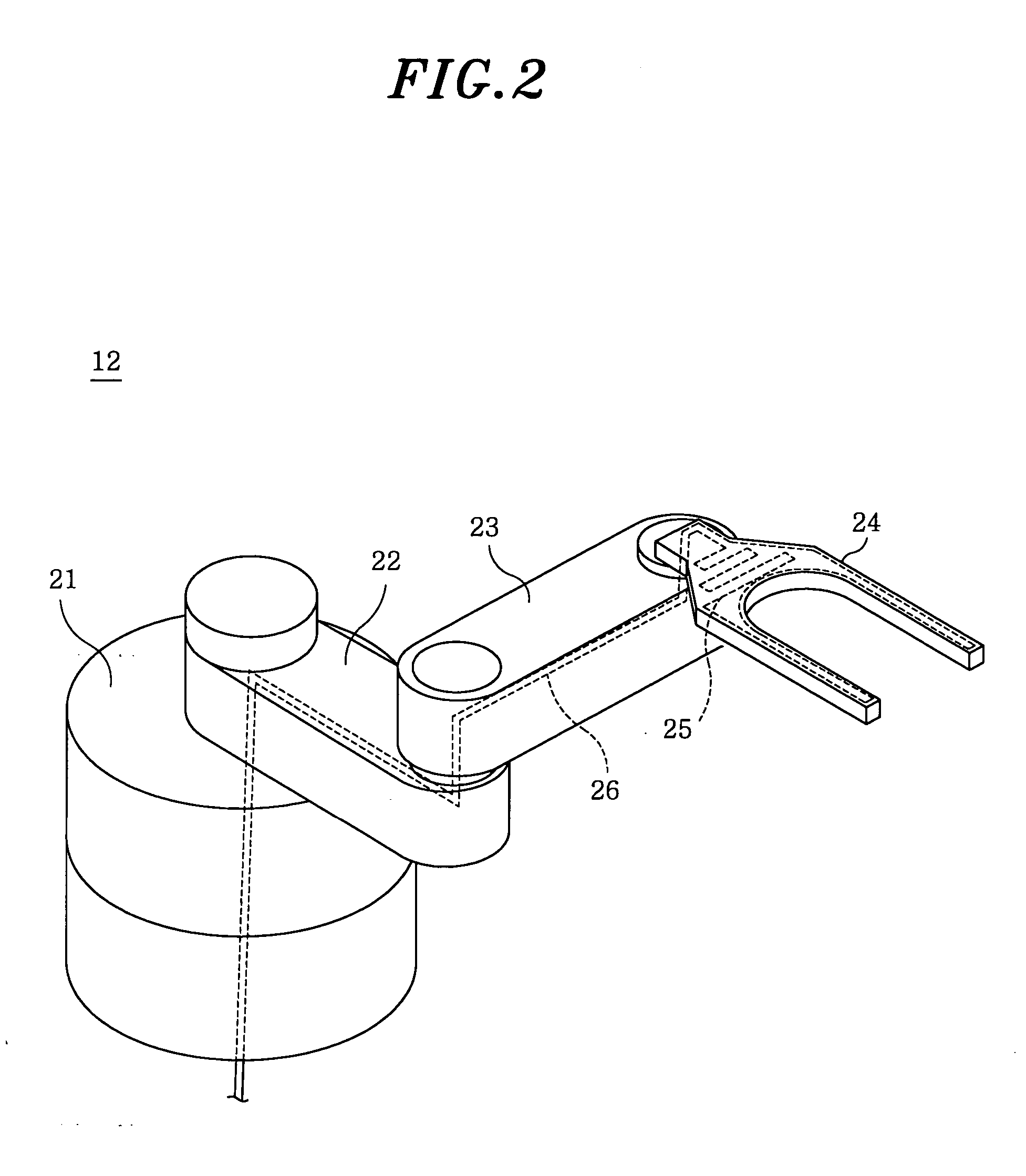

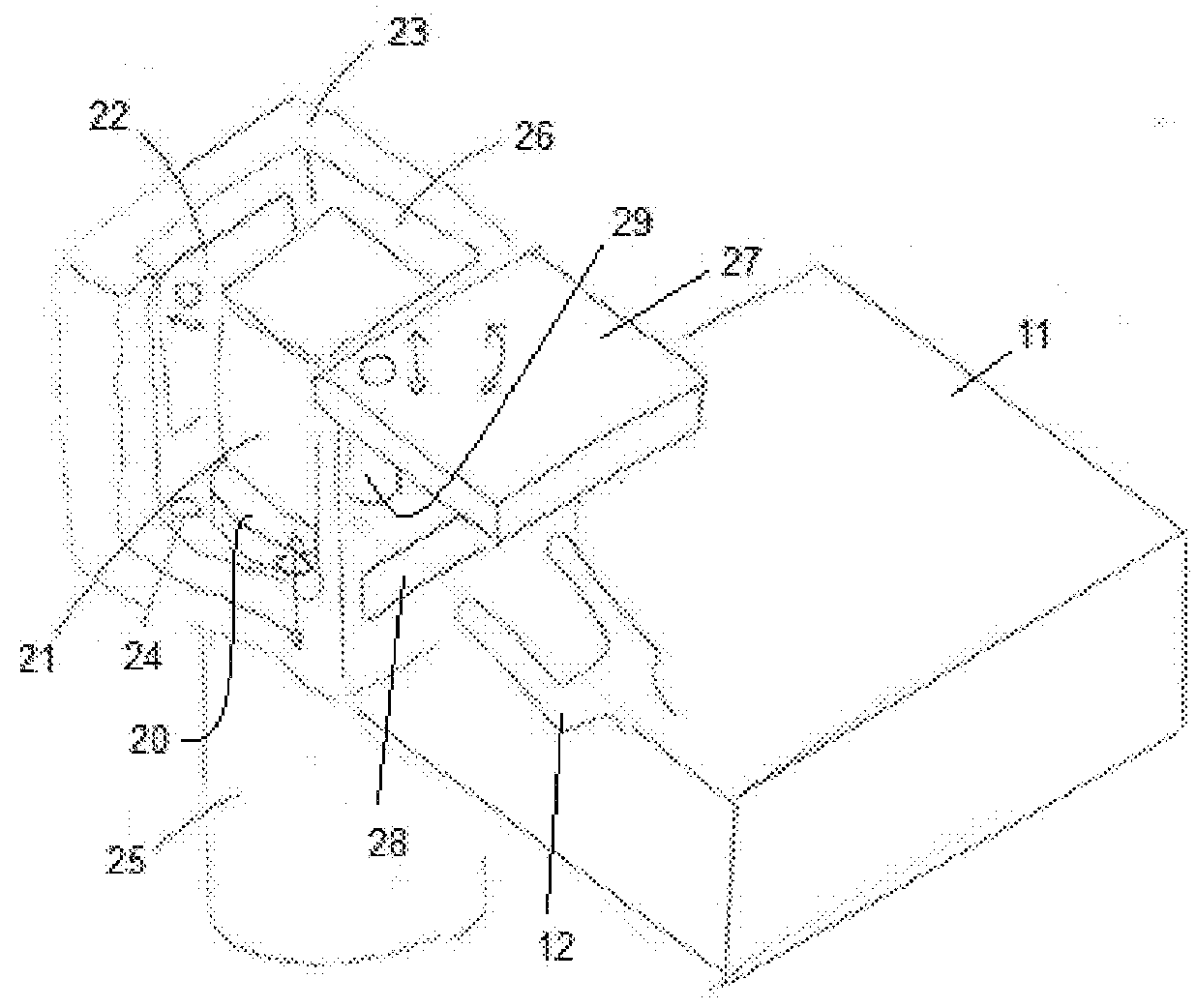

FOUP opening/closing device and probe apparatus

ActiveUS8267633B2Assure great degree of freedomEfficient comprehensive utilizationSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingControl signalFOUP

A FOUP opening / closing device includes a housing containing a mounting table for mounting the FOUP thereon, an FOUP loading opening, and a delivery opening. The device further includes a rotator for rotating the mounting table, a door opening / closing unit to open or close the door of the FOUP and keep the door open, a mover for moving the FOUP and the door opening / closing unit in a reciprocating manner, to allow the FOUP and the door opening / closing unit to be connected to or separated from each other, and a controller to output control signals for moving the FOUP and the door opening / closing unit via operation of the mover to mount the door of the FOUP to the door opening / closing unit, separating the door from the FOUP, moving the FOUP and the door opening / closing unit away from each other, and rotating the mounting table to make the FOUP face the delivery opening.

Owner:TOKYO ELECTRON LTD

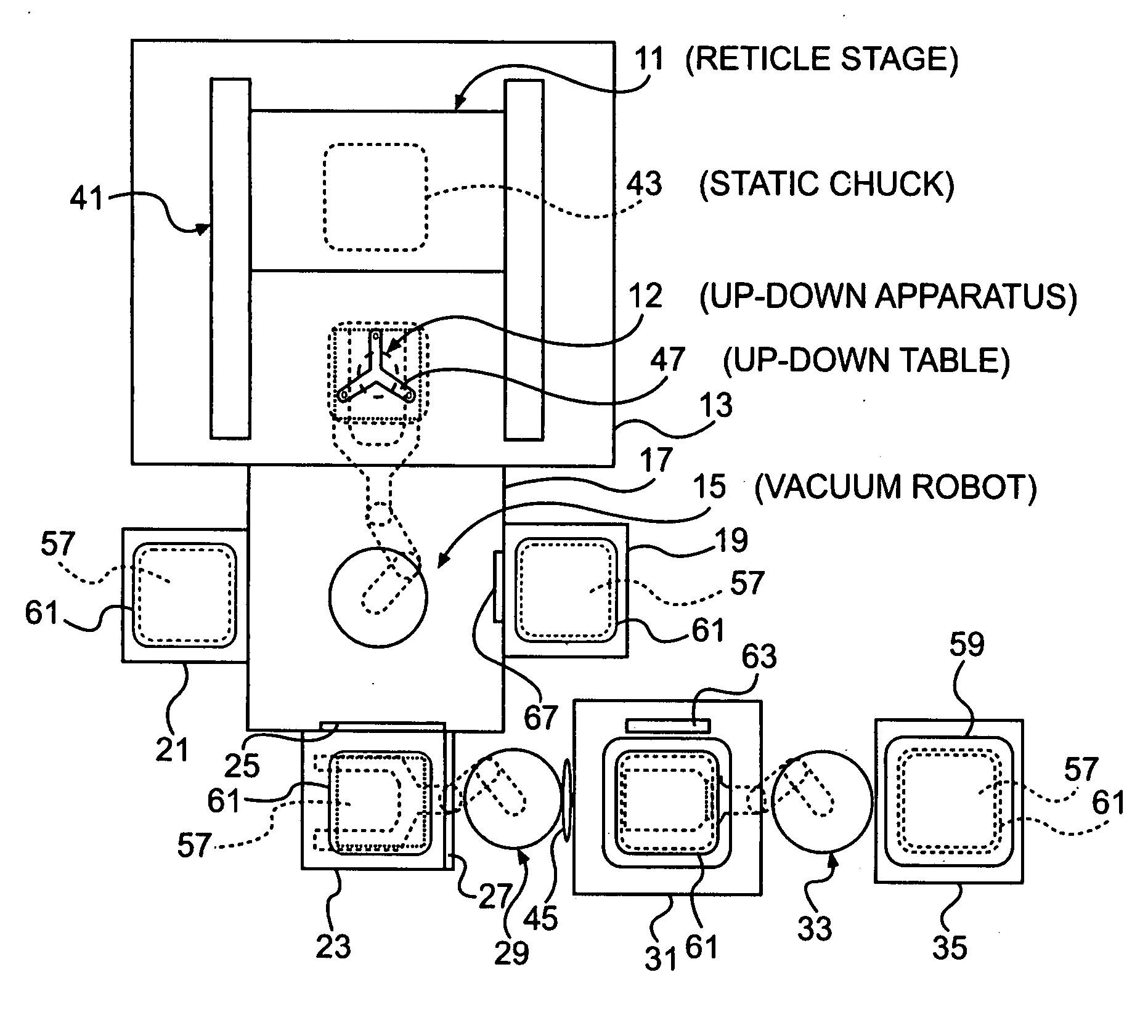

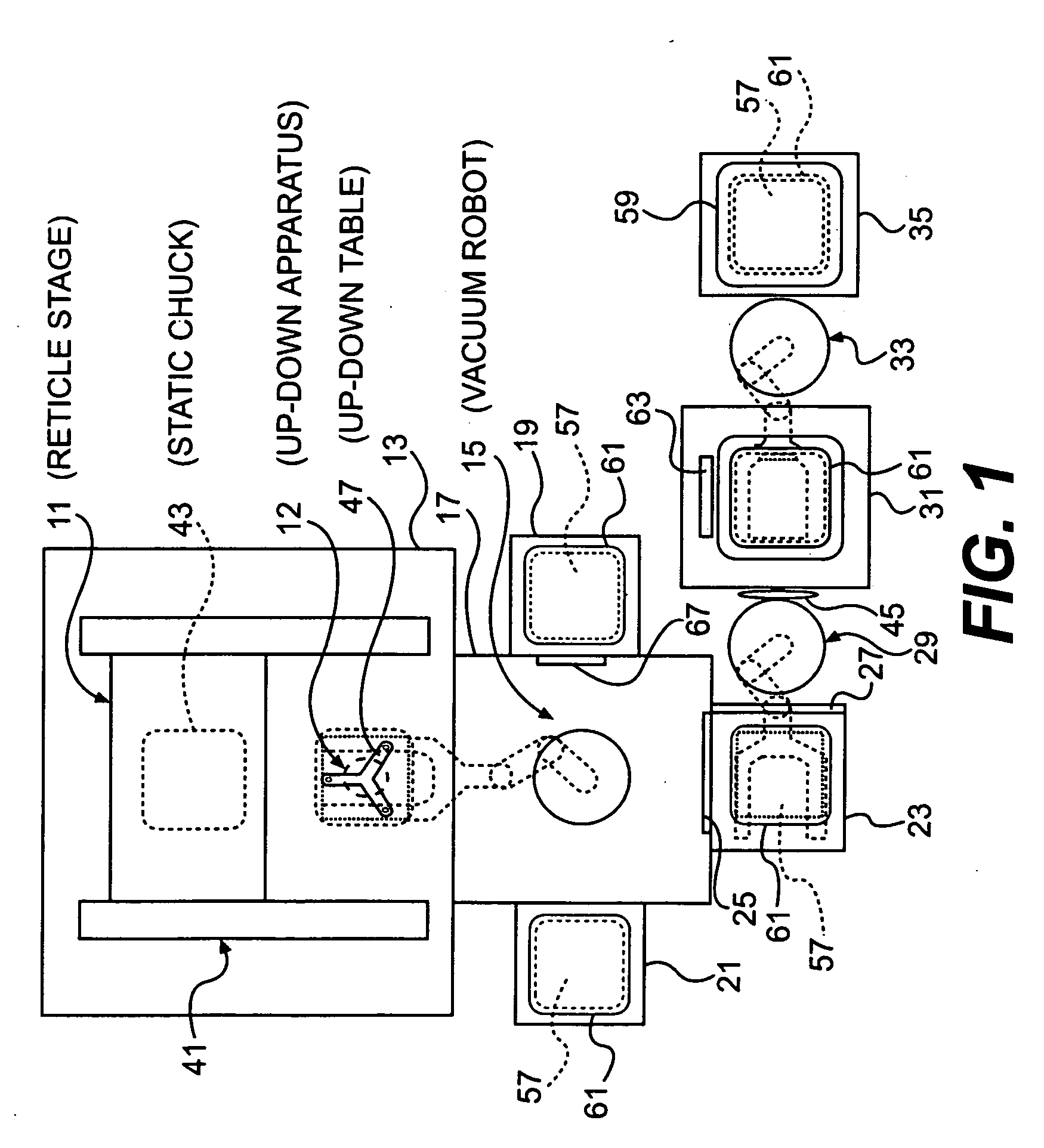

Substrate conveyor apparatus, substrate conveyance method and exposure apparatus

ActiveUS20060291982A1Improve reliabilityStrong adhesionPhotomechanical apparatusSemiconductor/solid-state device manufacturingEngineeringReticle

The present invention pertains to a substrate conveyor apparatus that carries a substrate such as a reticle, a substrate conveyance method and an exposure apparatus, with the object of reliably adhering a substrate to the lower surface of a chuck. The present invention is characterized by having a movable stage that can move in the horizontal direction and that is equipped with a chuck having an adhesion surface that faces down for adhering a substrate, an up-down means equipped with an up-down table that is positionable in a position below the substrate and within the movement range of the movable stage, and a conveyance means equipped with a conveyor arm that carries the substrate to the up-down means.

Owner:NIKON CORP

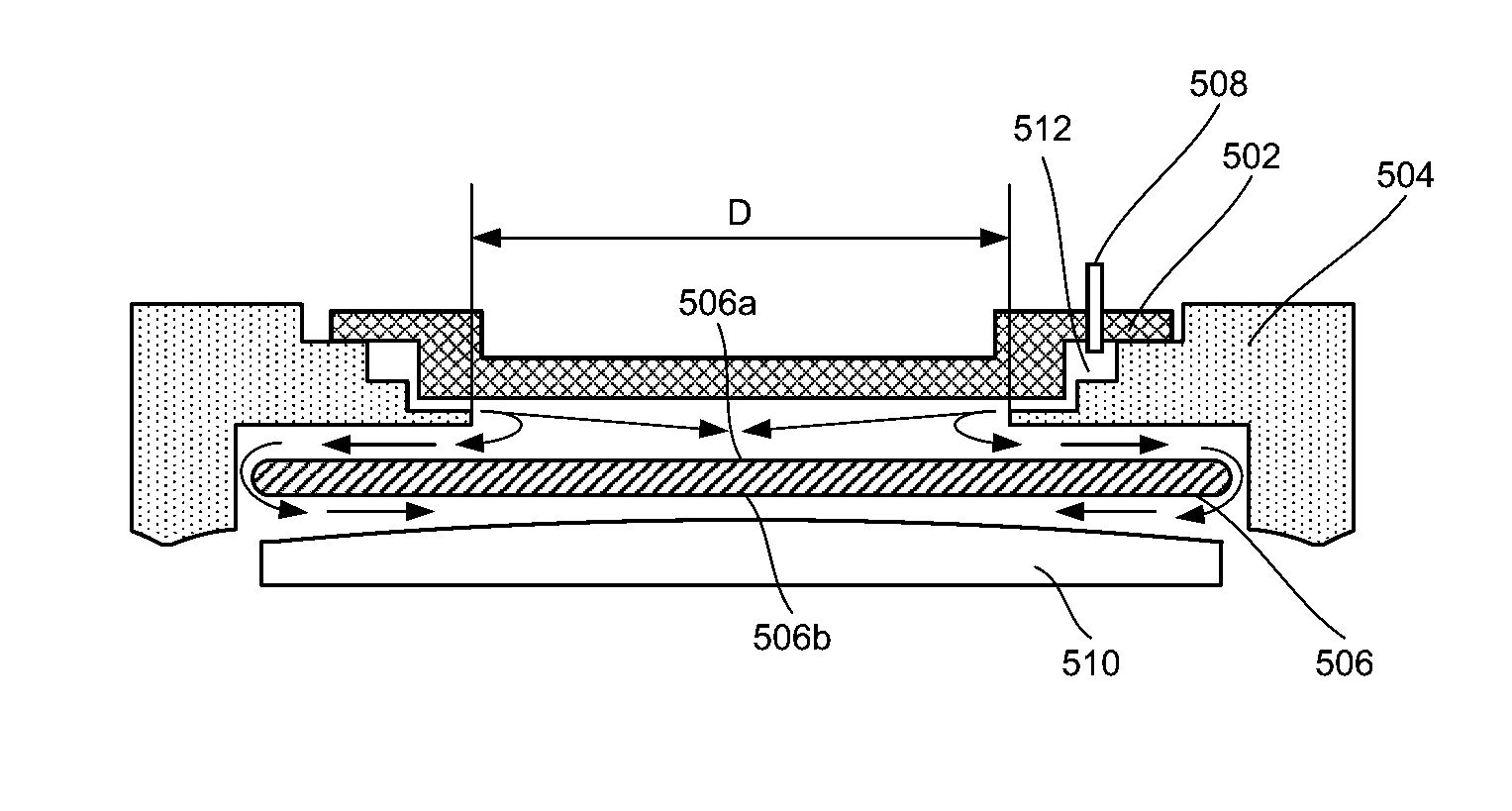

Method and apparatus for minimizing contamination in semiconductor processing chamber

ActiveUS20100202860A1Maintain gapCreate sealLiquid surface applicatorsSemiconductor/solid-state device manufacturingPositive pressureControl system

A semiconductor processing apparatus includes a reaction chamber, a loading chamber, a movable support, a drive mechanism, and a control system. The reaction chamber includes a baseplate. The baseplate includes an opening. The movable support is configured to hold a workpiece. The drive mechanism is configured to move a workpiece held on the support towards the opening of the baseplate into a processing position. The control system is configured to create a positive pressure gradient between the reaction chamber and the loading chamber while the workpiece support is in motion. Purge gases flow from the reaction chamber into the loading chamber while the workpiece support is in motion. The control system is configured to create a negative pressure gradient between the reaction chamber and the loading chamber while the workpiece is being processed. Purge gases can flow from the loading chamber into the reaction chamber while the workpiece support is in the processing position, unless the reaction chamber is sealed from the loading chamber in the processing position.

Owner:ASM IP HLDG BV

Wafer processing chamber and method for transferring wafer in the same

InactiveUS20150010381A1Improve propertiesArcing issue could be effectively preventedElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

A wafer processing chamber and a method for transferring wafer in the same are provided to prevent the arcing issue. In the embodiments, a wafer is positioned on the focus ring, and a lifting apparatus is provided outside the wafer such as corresponding to the focus ring. The lifting apparatus of the embodiment could be positioned below or above the focus ring. The wafer and the focus ring are lifted together by the lifting apparatus, and transferred together by a transferring unit.

Owner:UNITED MICROELECTRONICS CORP

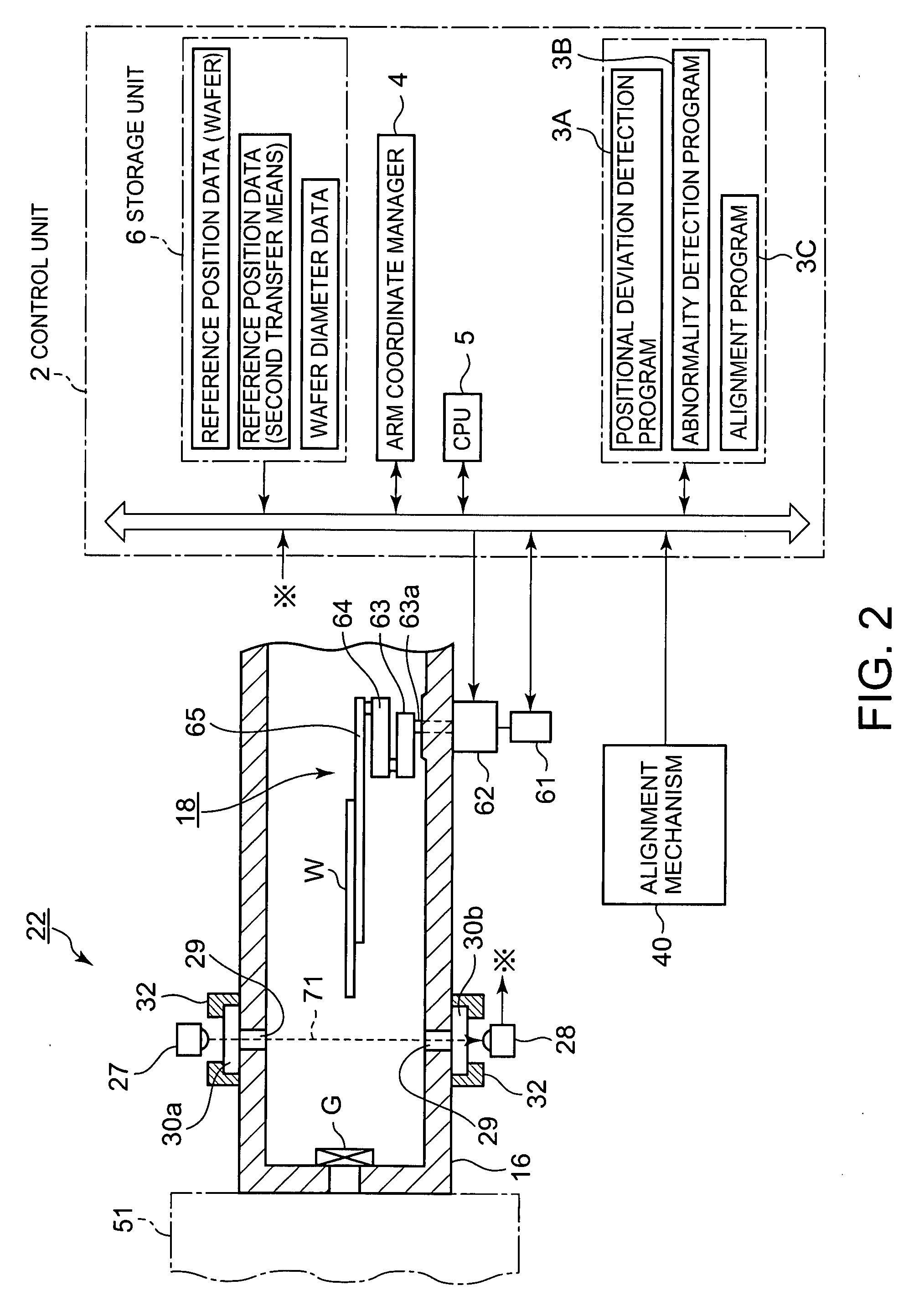

Wafer transfer apparatus, wafer transfer method and storage medium

ActiveUS20090053023A1Low costOptimize layoutDigital data processing detailsSemiconductor/solid-state device manufacturingEngineeringLight emission

One sensor constituted of a light emission element and a light-receiving element is provided in a path through which a wafer is transferred. The sensor is positioned so that the wafer passes through an area between the light emission element and the light-receiving element. Coordinates of the center of the wafer are calculated based on encoder values obtained when the wafer starts passing through the sensor and when the wafer completes passing through the sensor, position data of wafer transfer means corresponding to the encoder value, and the diameter of the wafer; and thereby the amount of positional deviation of the center of the wafer from a reference position is calculated.

Owner:TOKYO ELECTRON LTD

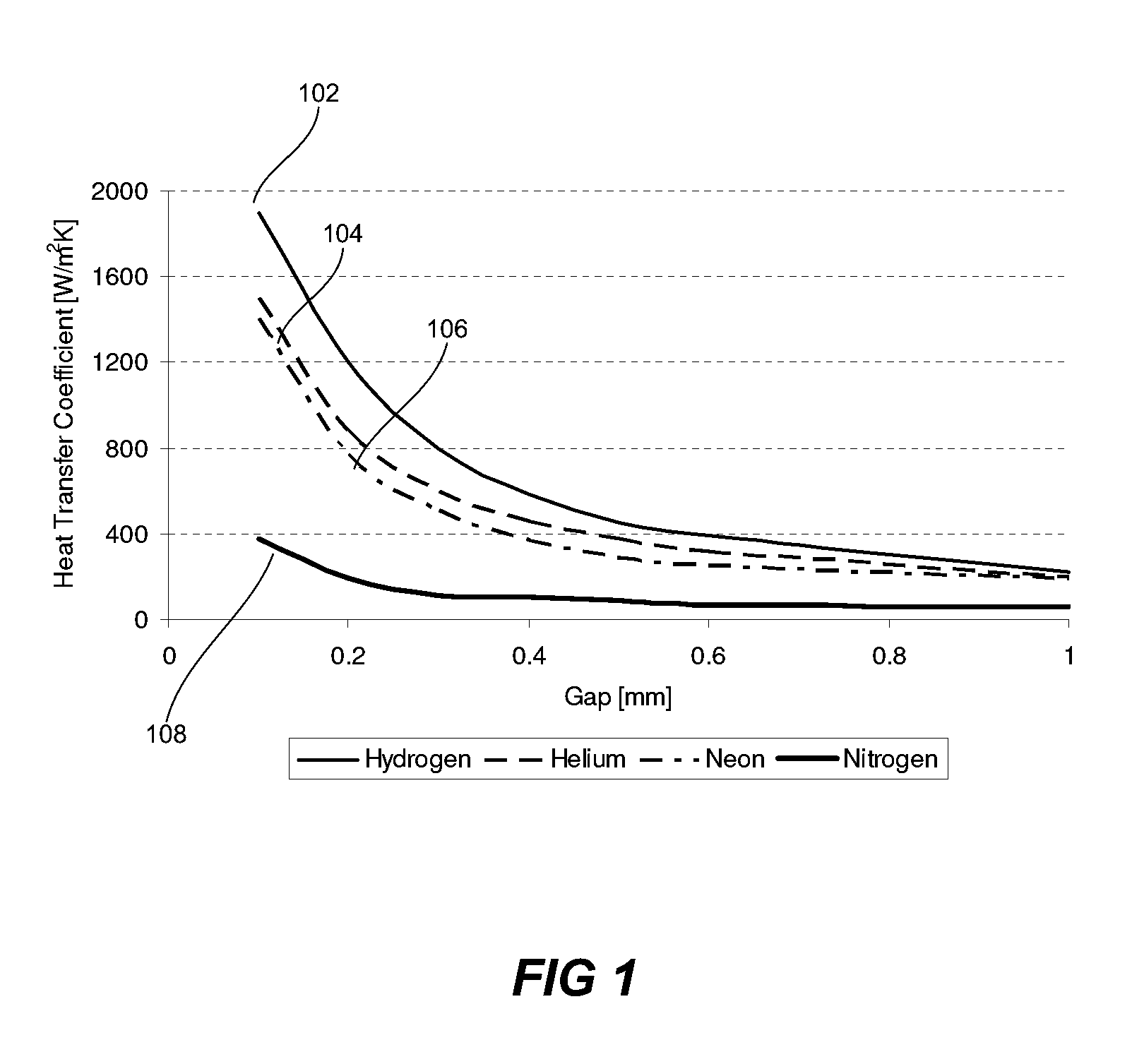

Minimum contact area wafer clamping with gas flow for rapid wafer cooling

ActiveUS8033771B1Reduce CooldownSemiconductor/solid-state device manufacturingConveyor partsNitrogenEngineering

Apparatuses and methods for cooling and transferring wafers from low pressure environment to high pressure environment are provided. An apparatus may include a cooling pedestal and a set of supports for holding the wafer above the cooling pedestal. The average gap between the wafer and the cooling pedestal may be no greater than about 0.010 inches. Venting gases may be used to increase the pressure inside the apparatus during the transfer. In certain embodiment, venting gases comprise nitrogen.

Owner:NOVELLUS SYSTEMS

Foup opening/closing device and probe apparatus

ActiveUS20100040441A1Efficient space utilizationThe degree of freedom becomes largerSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingControl signalEngineering

A FOUP opening / closing device includes a housing containing a mounting table for mounting the FOUP thereon, an FOUP loading opening, and a delivery opening. The device further includes a rotator for rotating the mounting table, a door opening / closing unit to open or close the door of the FOUP and keep the door open, a mover for moving the FOUP and the door opening / closing unit in a reciprocating manner, to allow the FOUP and the door opening / closing unit to be connected to or separated from each other, and a controller to output control signals for moving the FOUP and the door opening / closing unit via operation of the mover to mount the door of the FOUP to the door opening / closing unit, separating the door from the FOUP, moving the FOUP and the door opening / closing unit away from each other, and rotating the mounting table to make the FOUP face the delivery opening.

Owner:TOKYO ELECTRON LTD

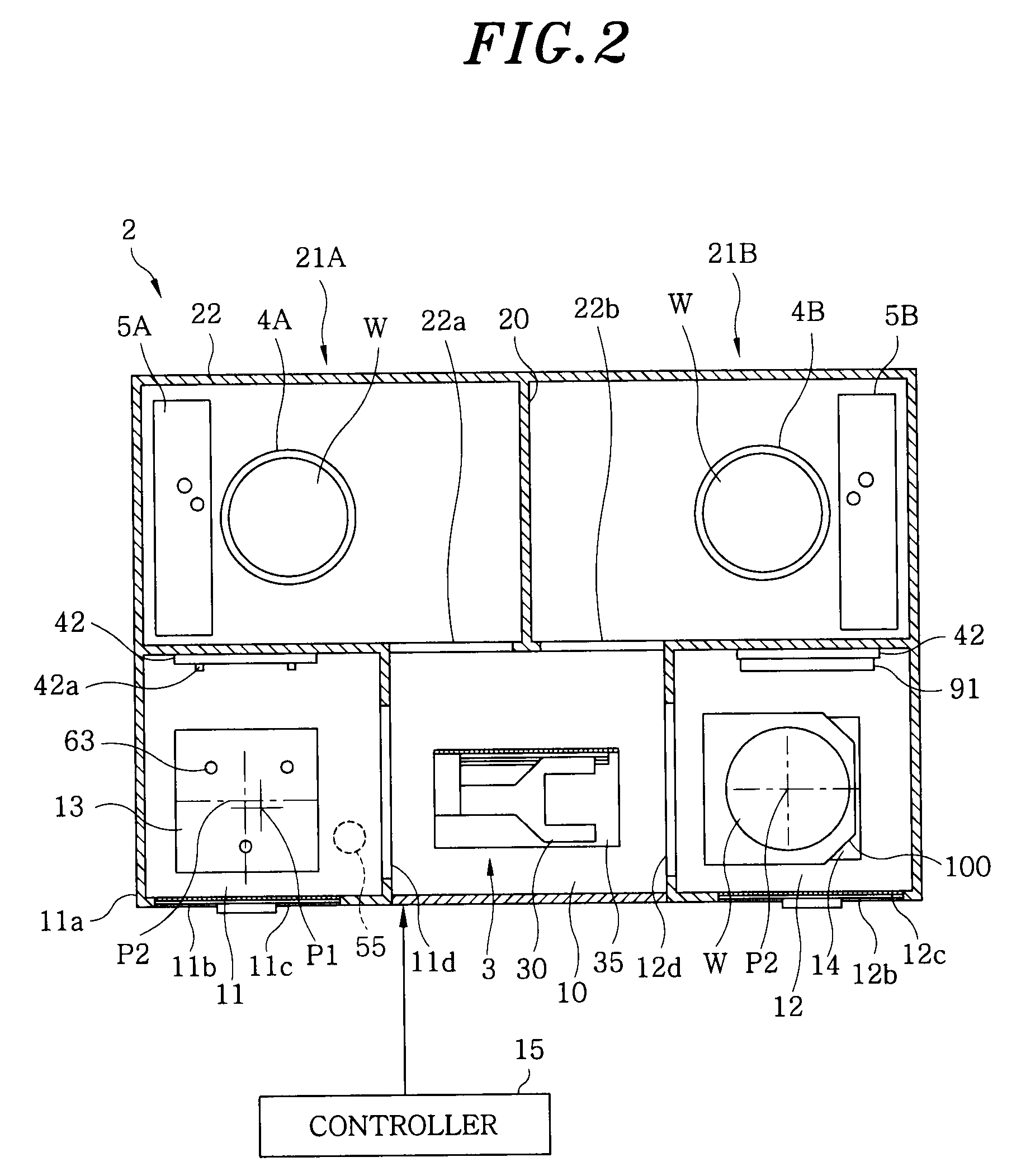

Apparatus for storing and moving a cassette

InactiveUS6283692B1Semiconductor/solid-state device manufacturingCharge manipulationDocking stationMagnetic tape

A cassette stocker includes a plurality of cassette storage shelves positioned adjacent a cleanroom wall above a cassette docking station, and a cassette mover to carry a cassette between the shelves and the docking station. An interstation transfer apparatus includes an overhead support beam and a transfer arm adapted to carry a cassette between processing stations.

Owner:APPLIED MATERIALS INC

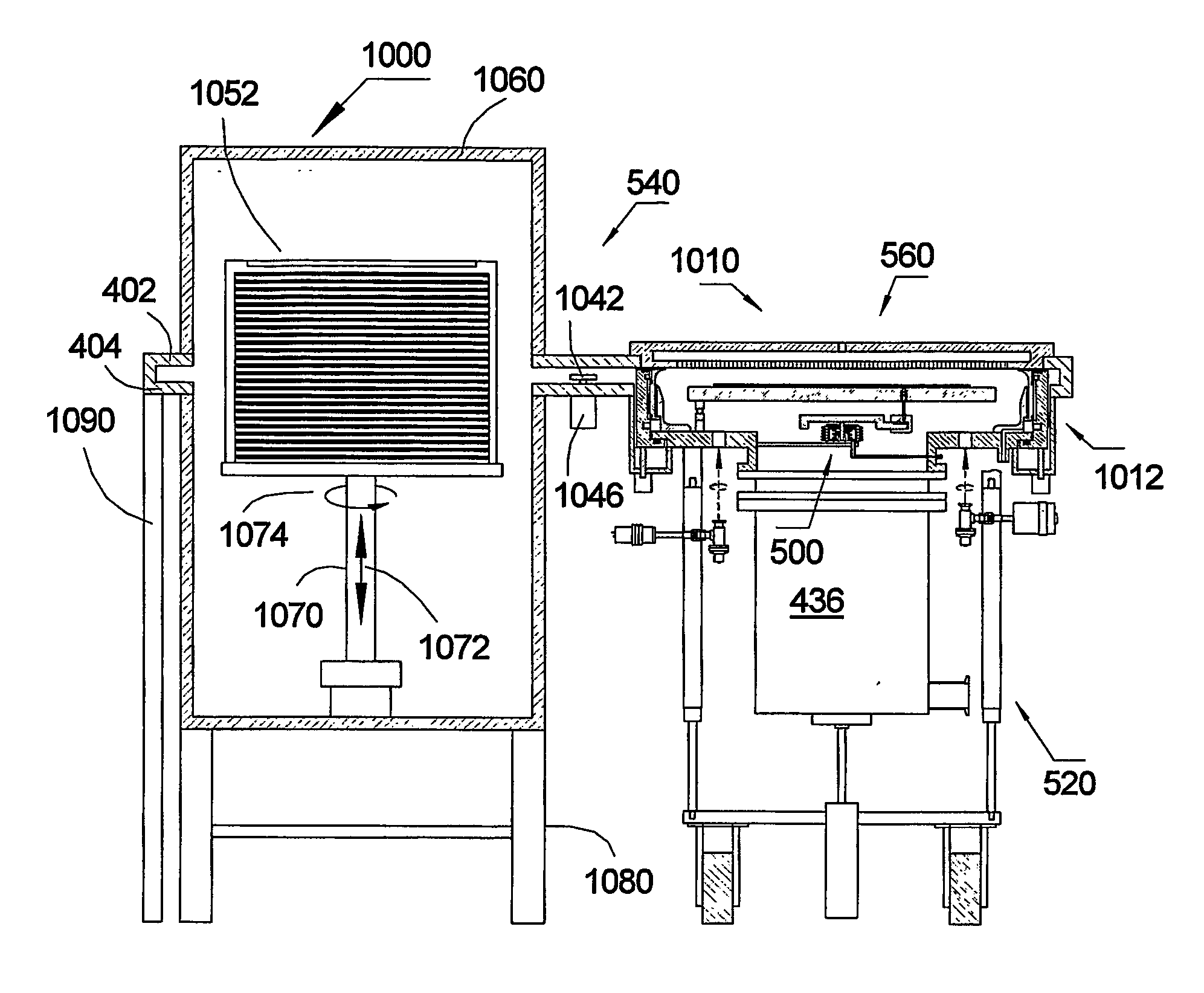

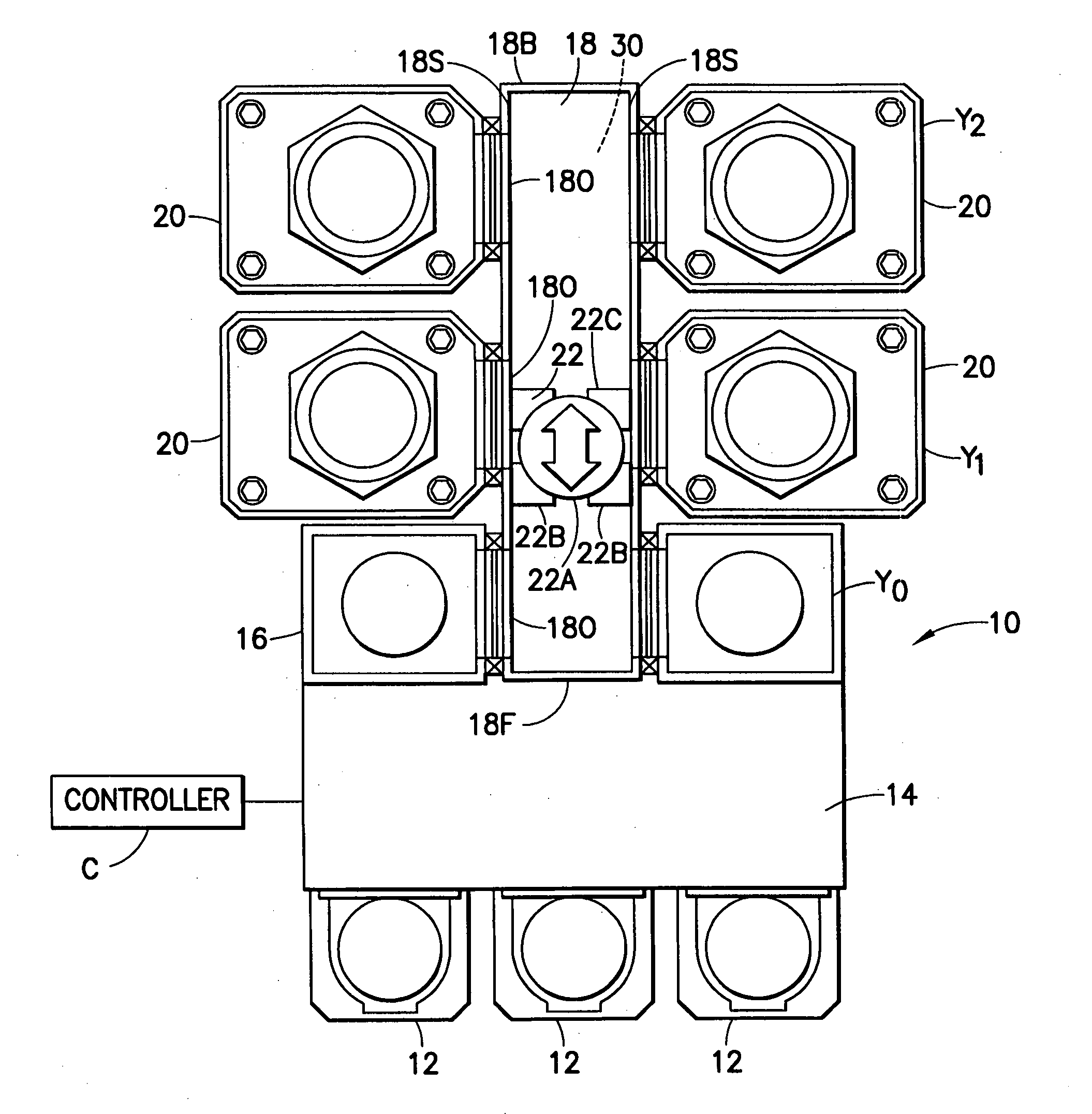

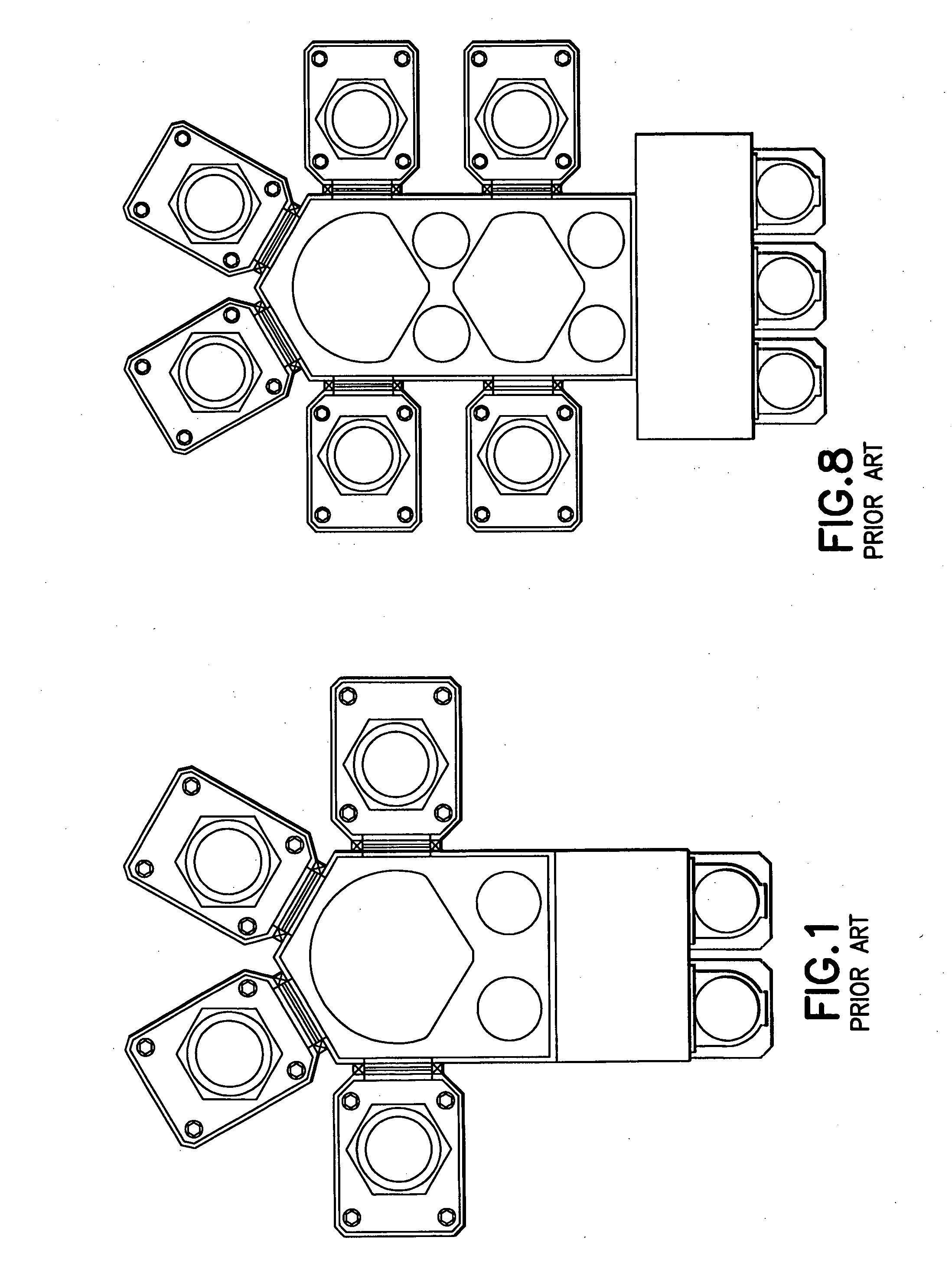

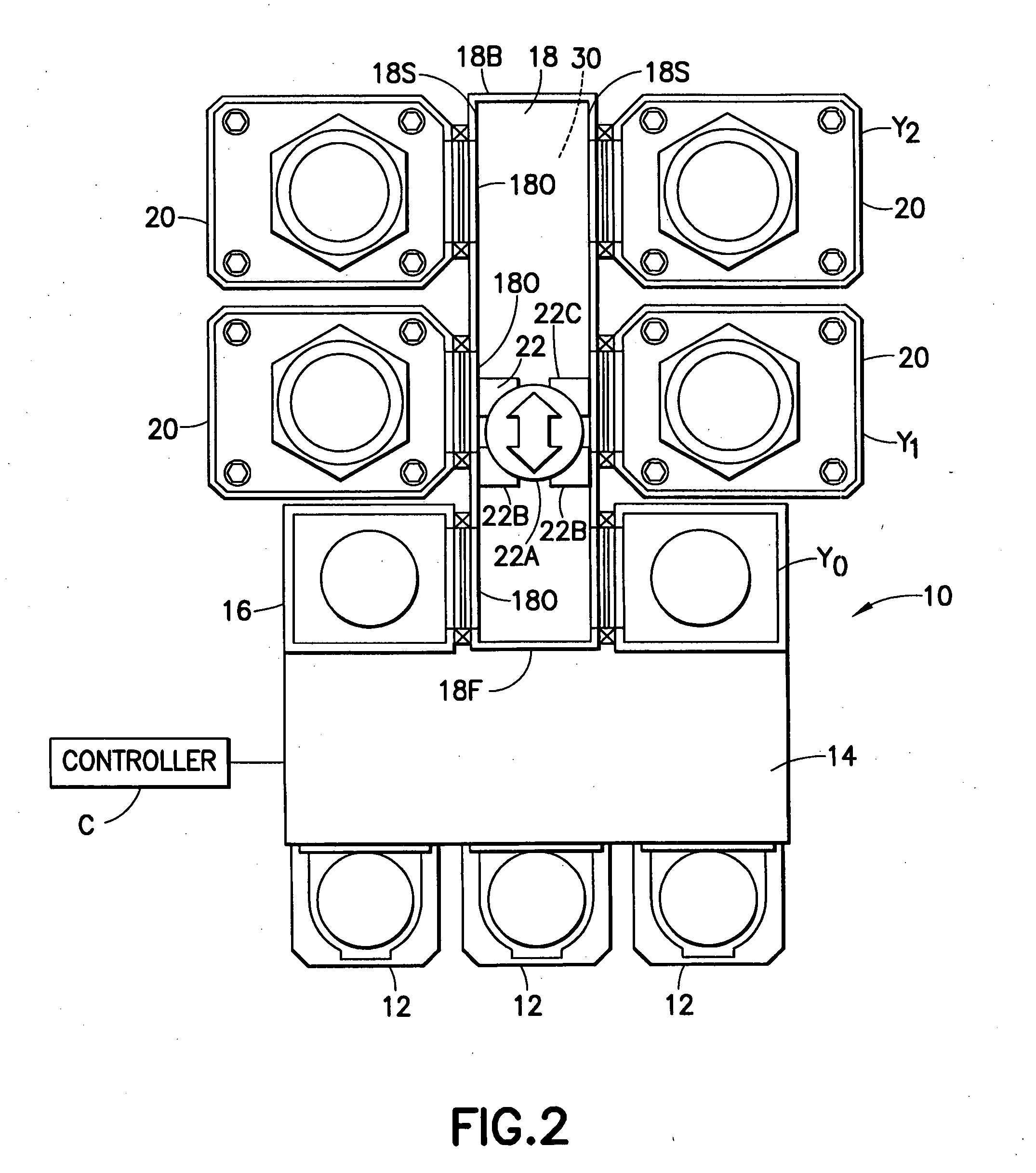

Perimeter partition-valve with protected seals and associated small size process chambers and multiple chamber systems

ActiveUS20070051312A1Improve securityImprove performanceVacuum evaporation coatingSemiconductor/solid-state device manufacturingModularityHandling system

A seal-protected perimeter partition valve apparatus (450) defines a vacuum and pressure sealed space (401) within a larger space (540) confining a substrate processing chamber with optimized geometry, minimized footprint and 360° substrate accessibility. A compact perimeter partitioned assembly (520) with seal protected perimeter partition valve (450) and internally contained substrate placement member (480) further provides processing system modularity and substantially minimized system footprint.

Owner:SUNDEW TECH

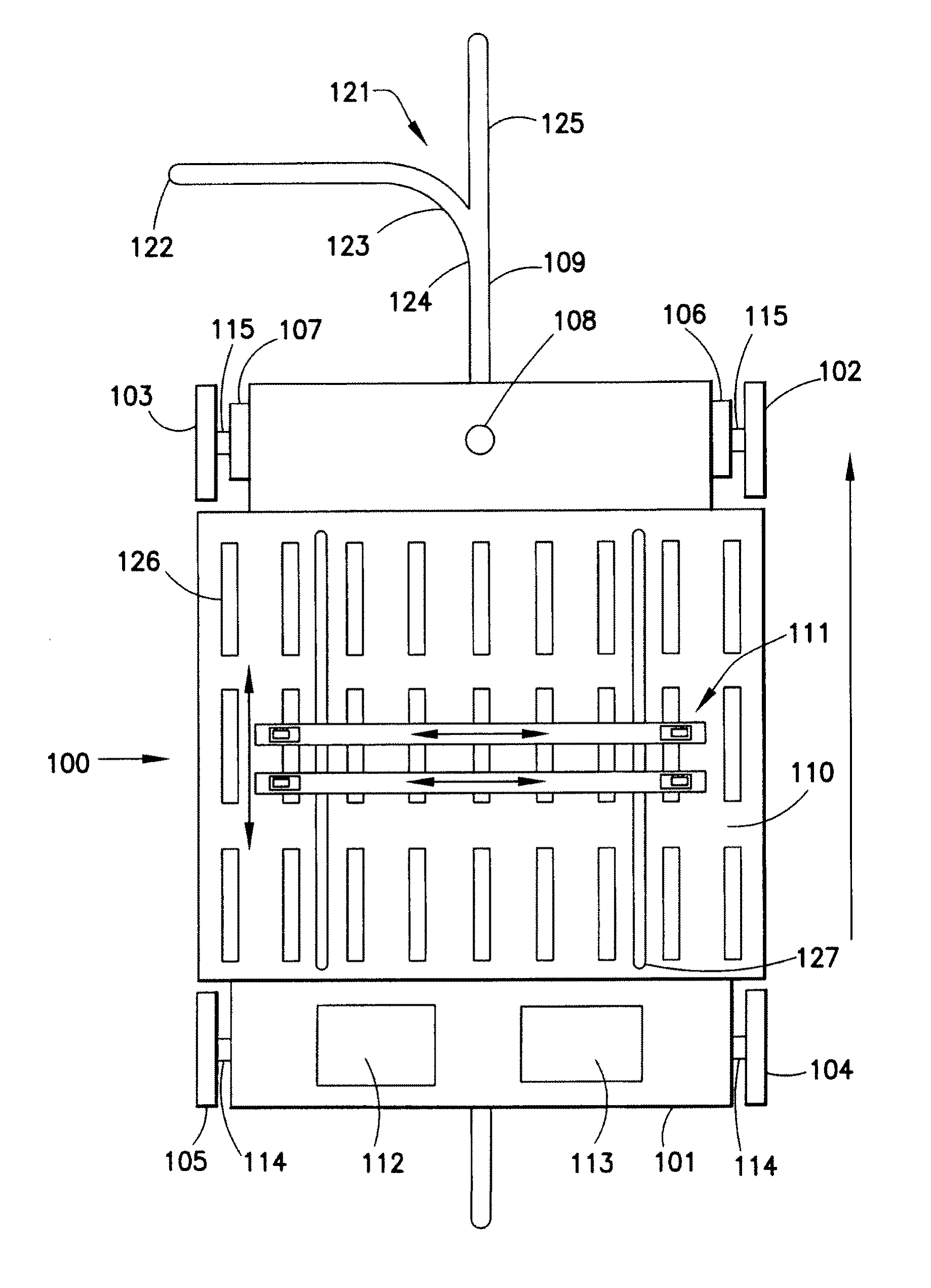

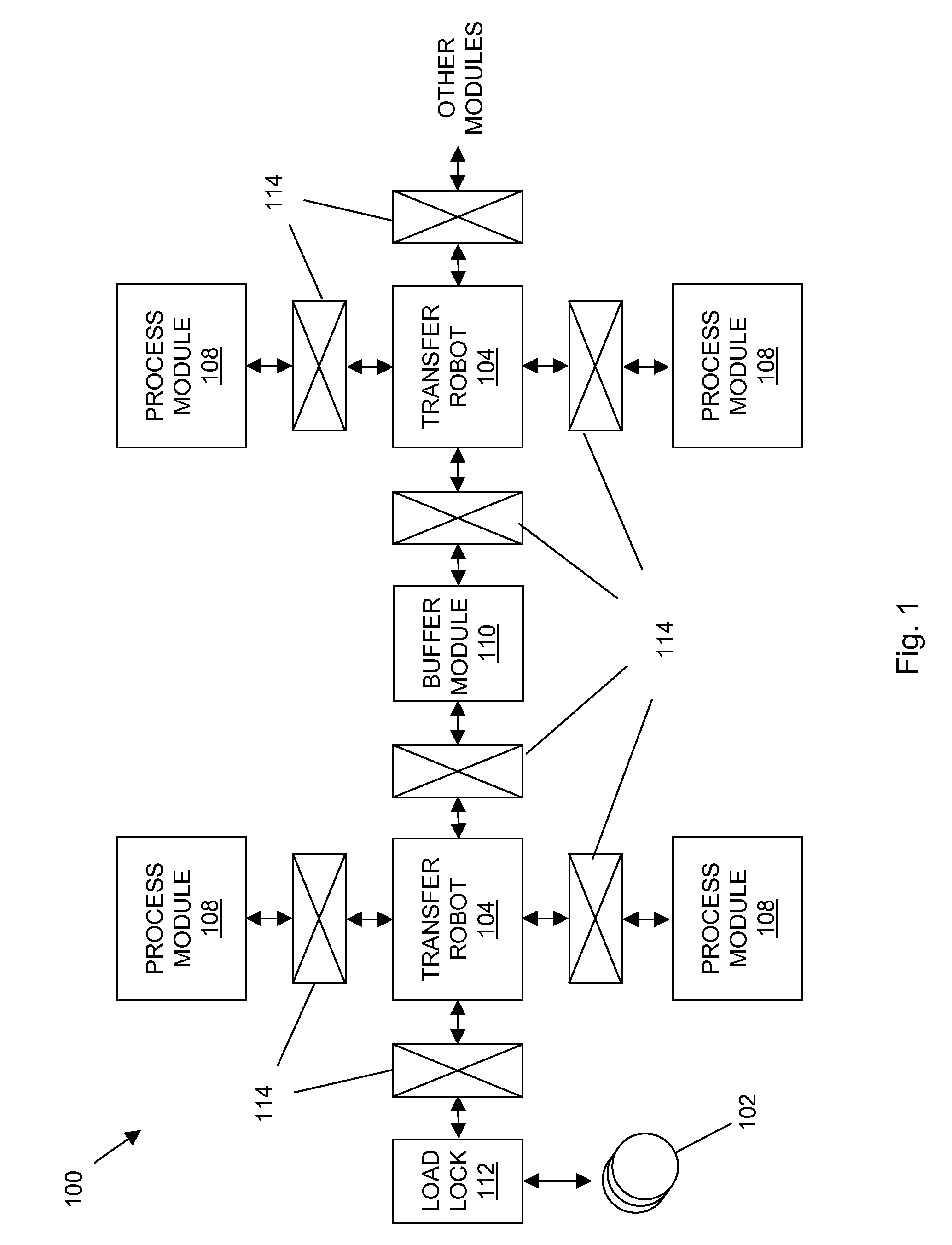

Substrate processing apparatus

Substrate processing apparatus having a chamber, a generally linear array of process modules, a substrate transport, and a drive system. The chamber is capable of being isolated from the outside atmosphere. Each process module of the array is communicably connected to the chamber to allow a substrate to be transferred between the chamber and process module. The substrate transport is located in and is movably supported from the chamber. The transport is capable of moving along a linear path defined by the chamber for transporting the substrate between process modules. The drive system is connected to the chamber for driving and moving the transport along the linear path. The chamber comprises a selectable number of chamber modules serially abutted to defined the chamber. Each module has an integral portion of the drive system.

Owner:BOOKS AUTOMATION US LLC

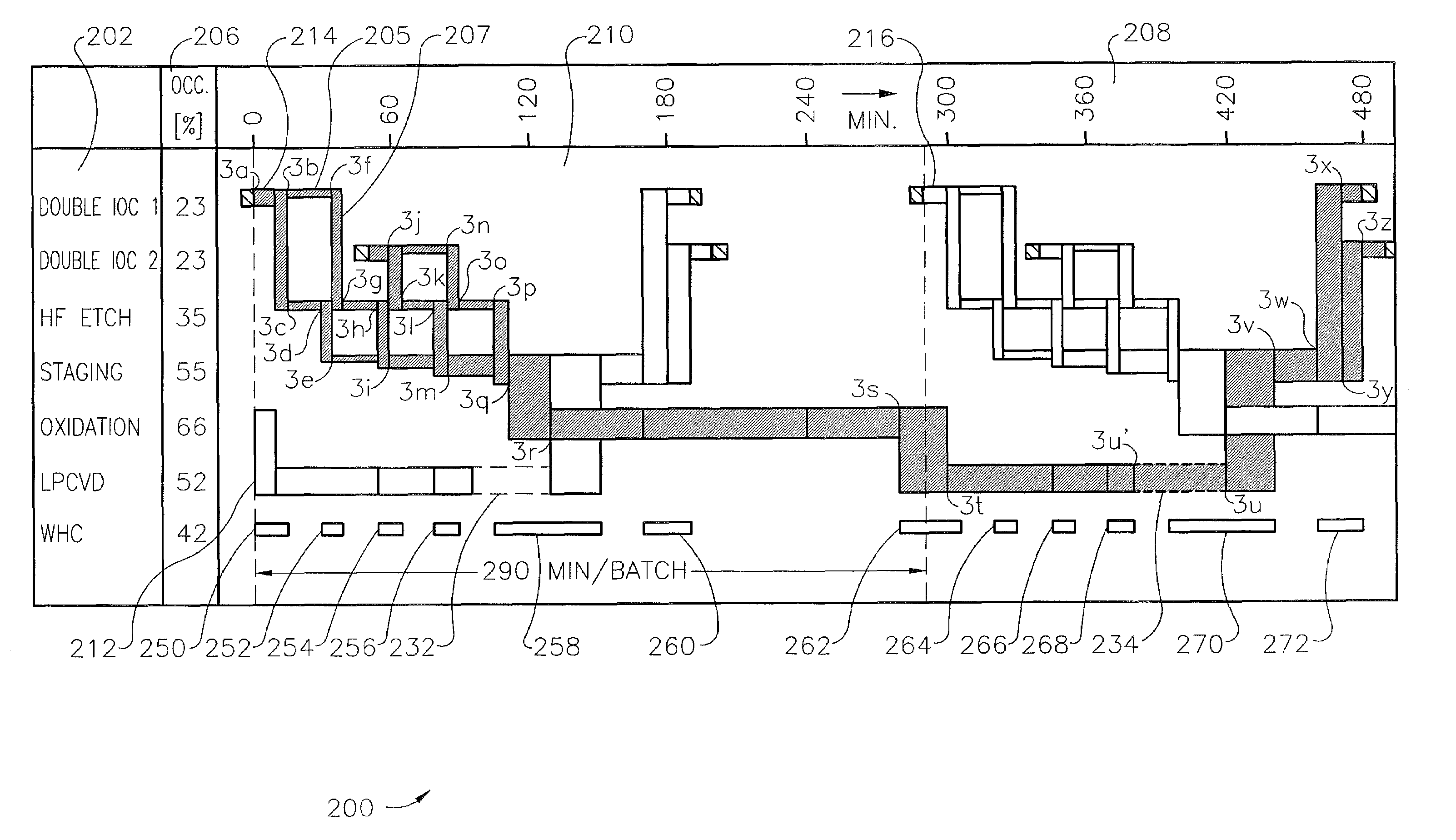

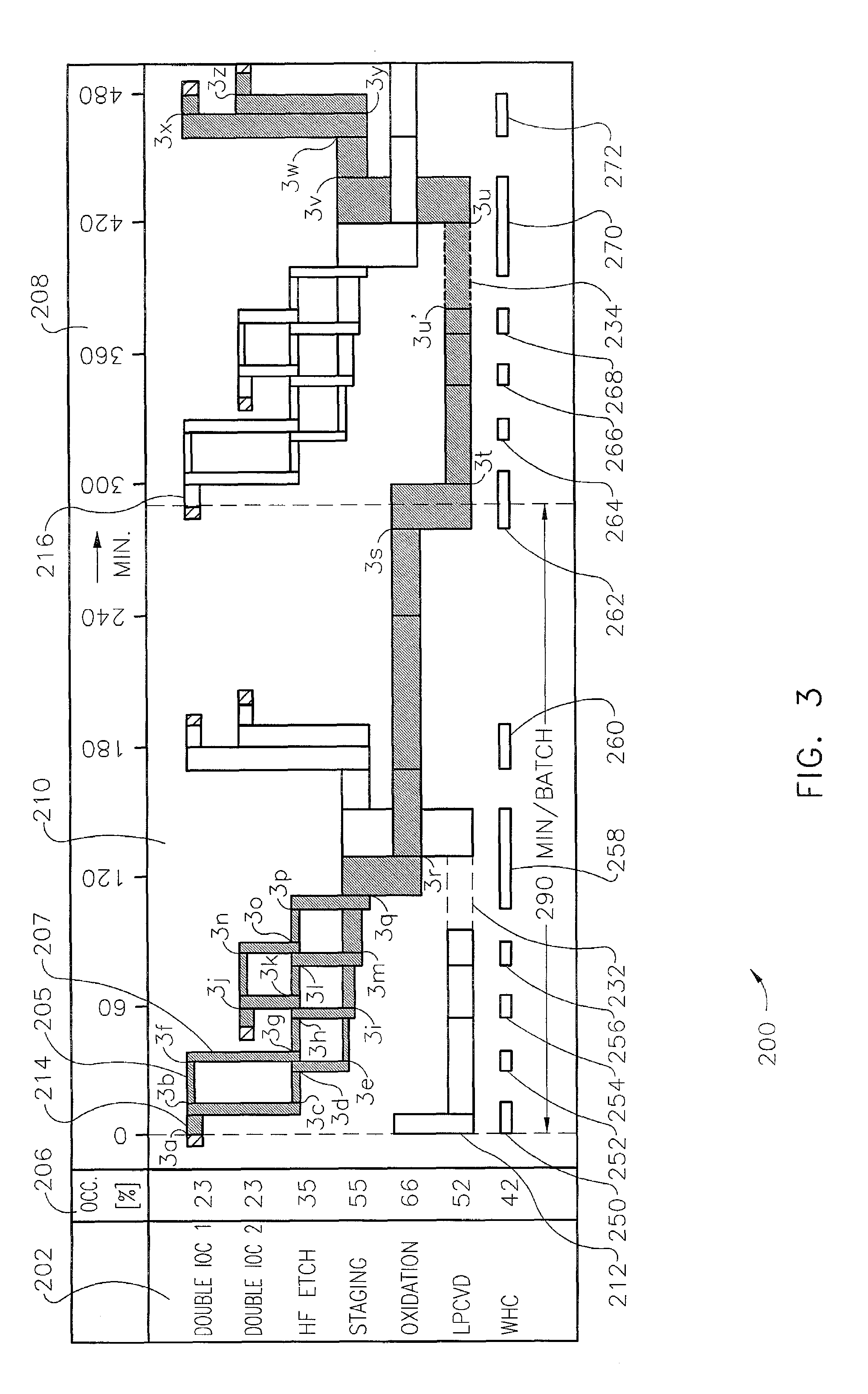

Graphical representation of a wafer processing process

A method for graphically representing the progress of wafers being processed in a plurality of process stations is disclosed. In one step, the start of a process performed on the wafers in one of the plurality of process stations is determined. Then, the generation of a first line segment parallel to a first axis is initiated. Next, the end of the process in one of the plurality of process stations is determined. Then the generation of the first line segment parallel to the first axis is terminated. The start of a transfer of the wafers from one of the plurality of process stations to another one of the plurality of process stations is detected in a next step. Then, the formation of a second line segment connected with the first line segment and substantially perpendicular to the first axis is initiated. The completion of the transfer of the wafers is then determined and the formation of the second line segment perpendicular to the first axis is terminated. The process is then repeated for each process station until the wafers have been processed through all the process stations.

Owner:ASM INTERNATIONAL

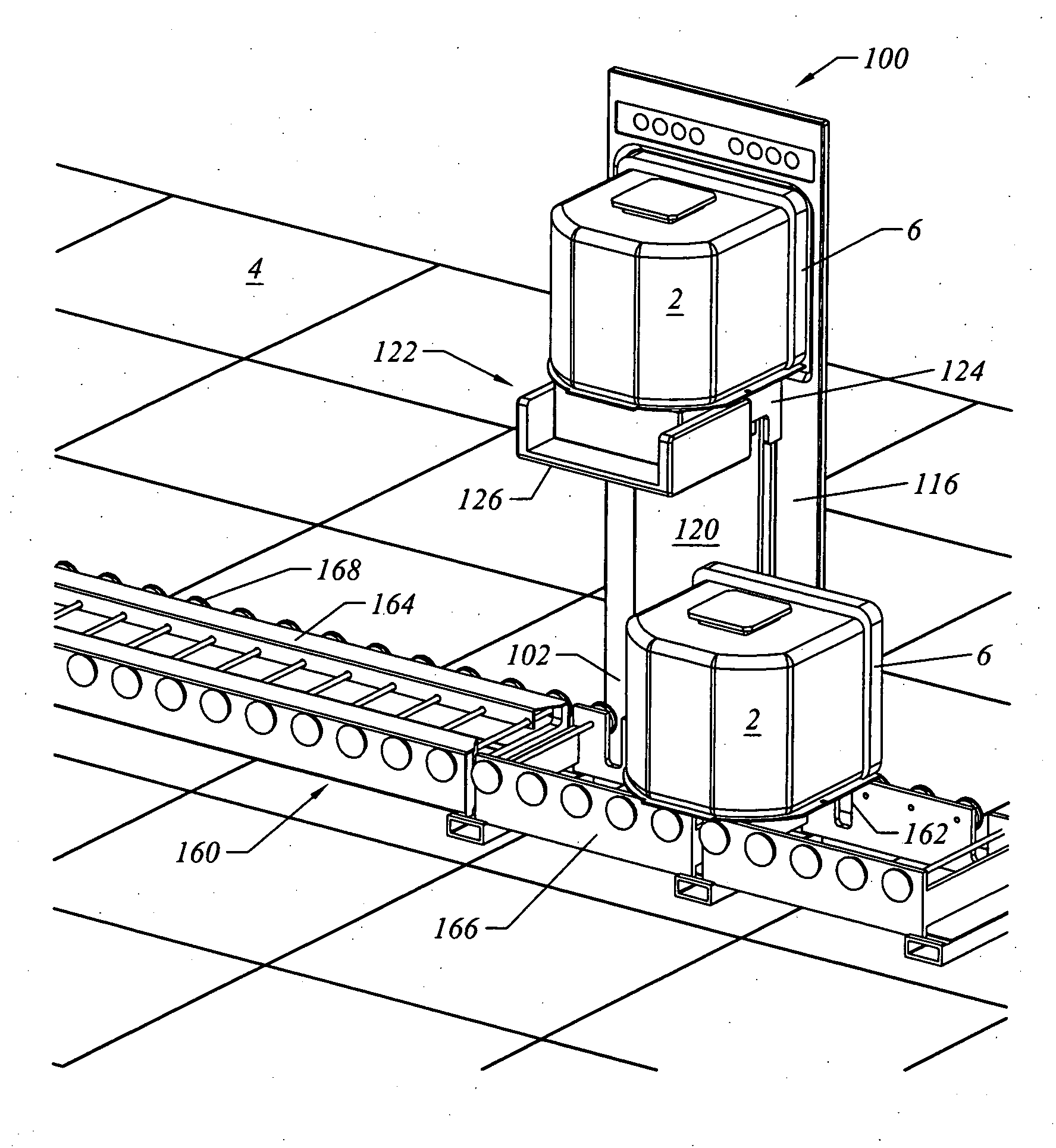

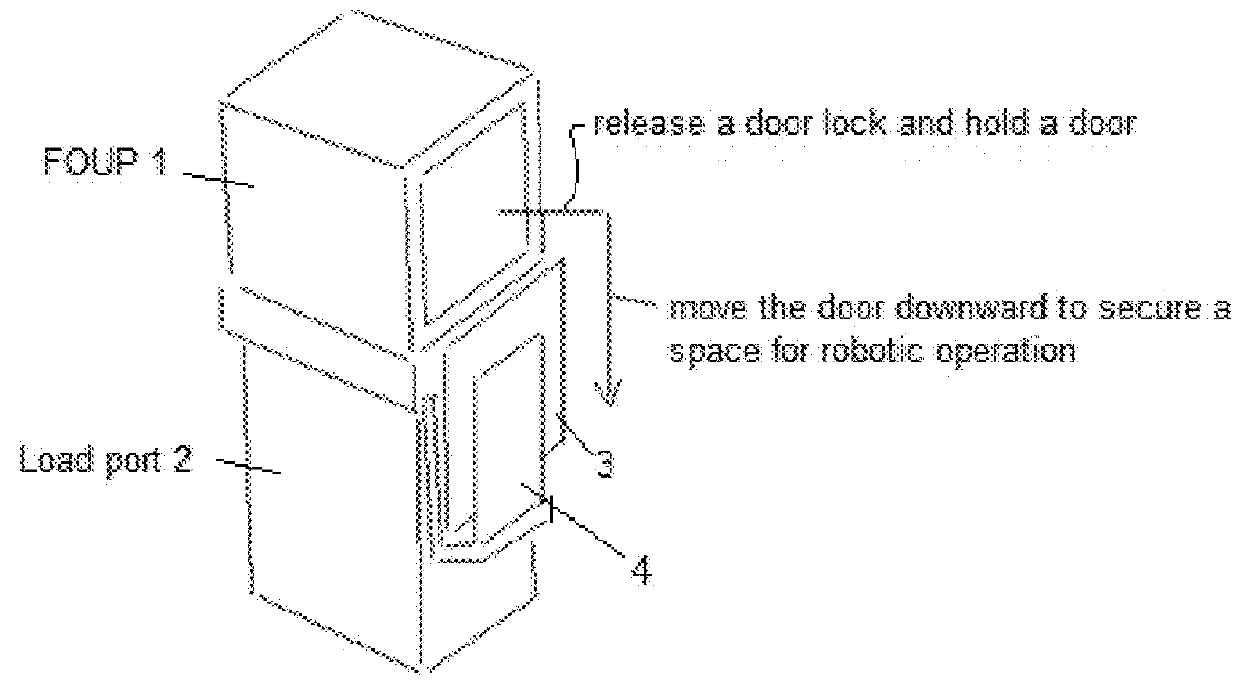

Direct tool loading

InactiveUS20060188360A1Effective movementConveyor—reducing the number of times the container is handledSemiconductor/solid-state device manufacturingStorage devicesTransport systemEngineering

The present invention comprises a load port for providing access to an article that is stored in a container having a container door removably coupled to a container shell. The load port preferably loads / unloads a container directly from a container transport system. In one embodiment, the load port includes a plate having an opening, a container support plate, a drive assembly for moving the support plate vertically and a shroud to partially enclose the opening. The shroud, which may be affixed to the mounting plate, has an open top and bottom. The shroud contains a mechanism for retaining the container shell at a controllable height. During operation, a container is raised from the transport system into the shroud until the container shell is retained by the mechanism. After the container shell is uncoupled from the container door, the container support plate is lowered until the article is accessible through the opening. The container shell remains located at the controllable height. The container shell, in combination with the shroud, creates a mini-environment isolating the article from ambient conditions in the fabrication facility.

Owner:MURATA MASCH LTD

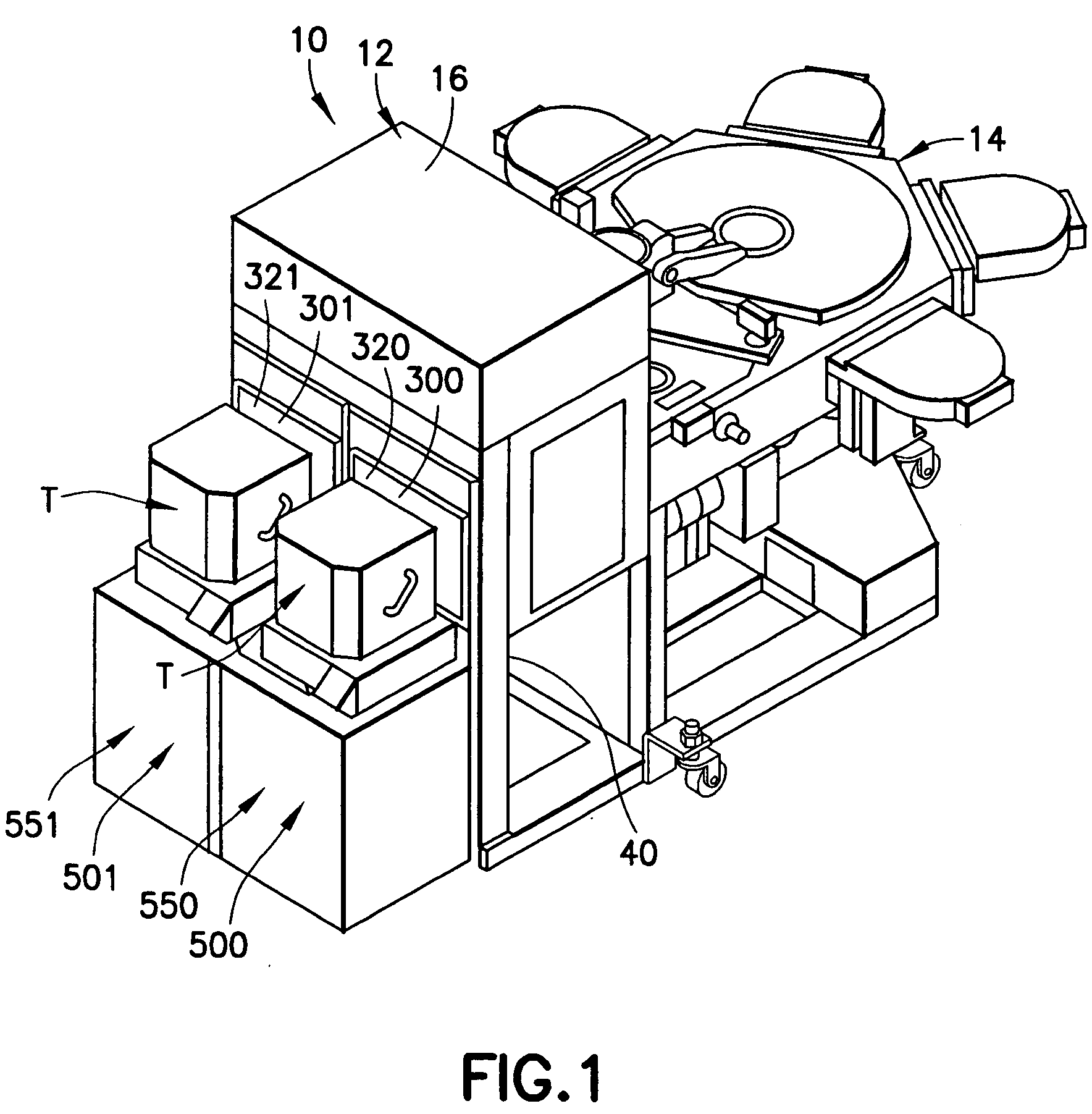

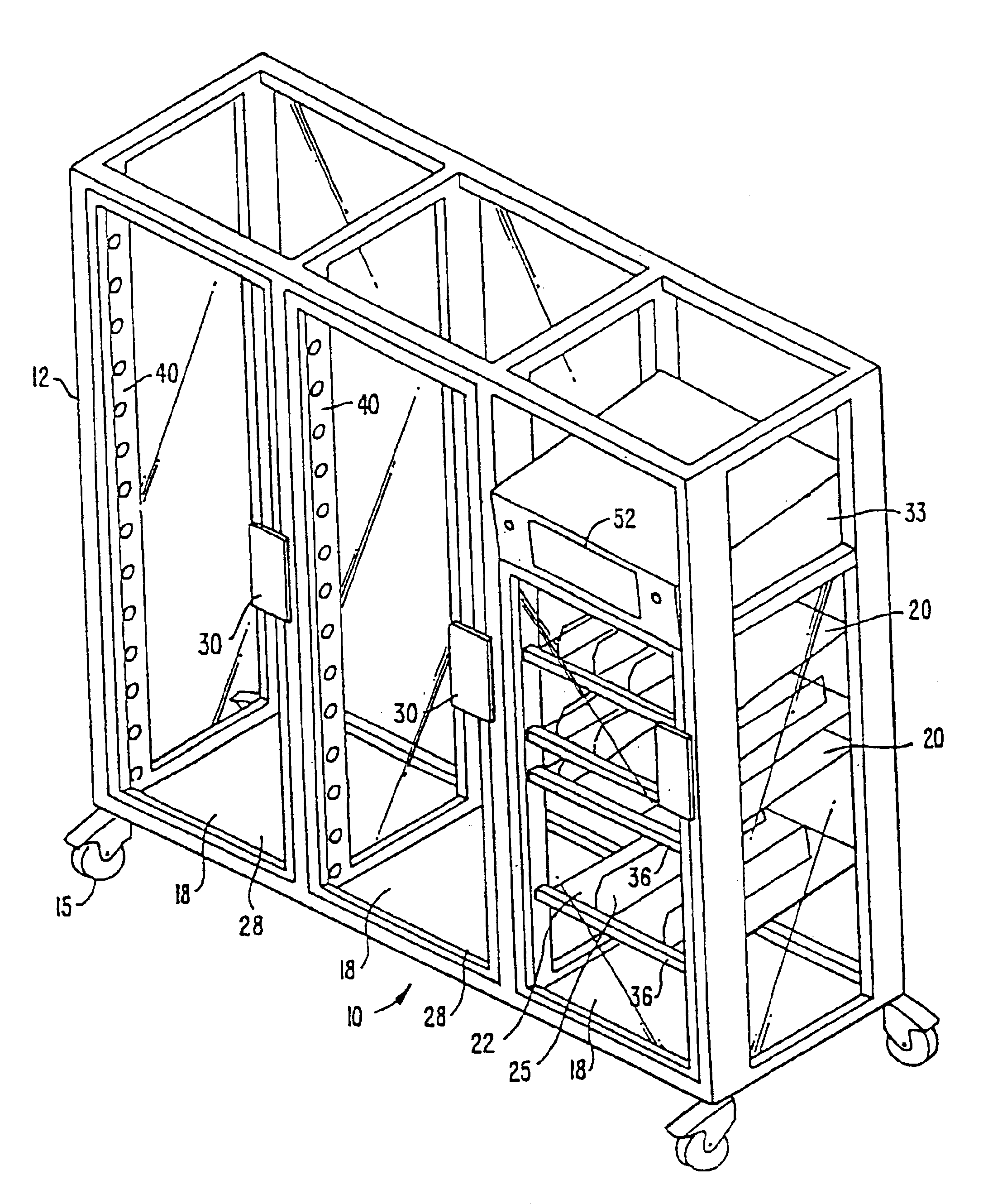

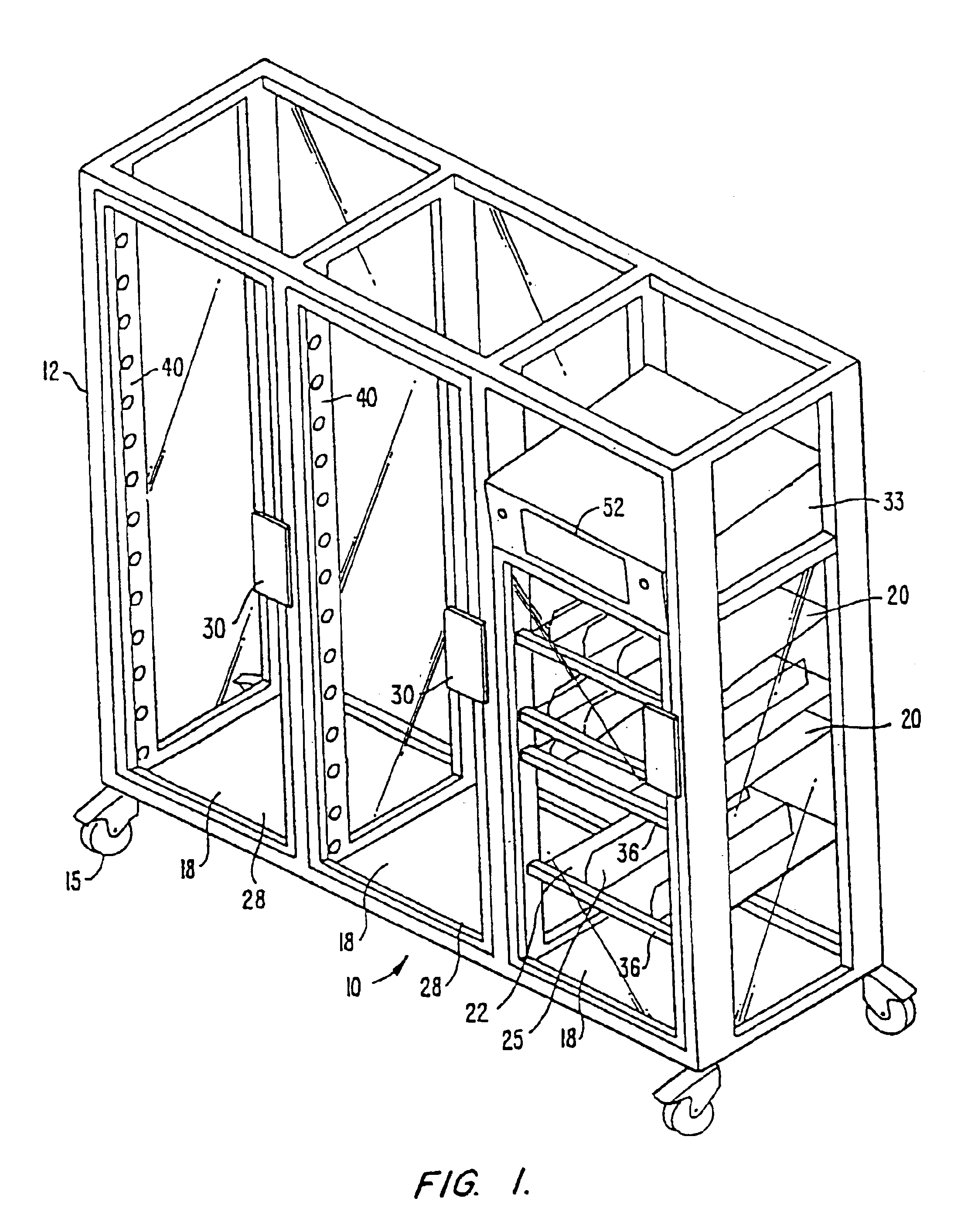

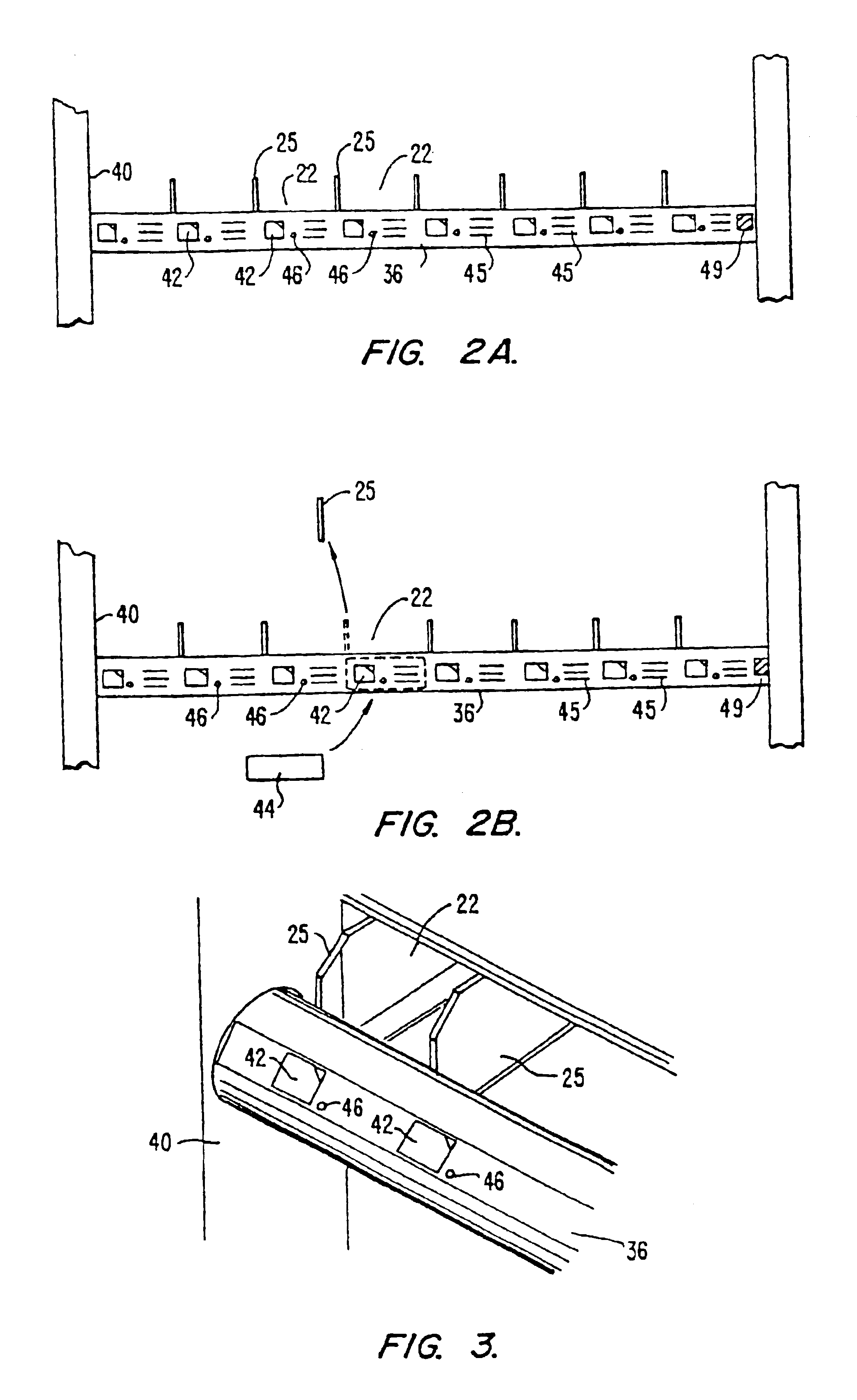

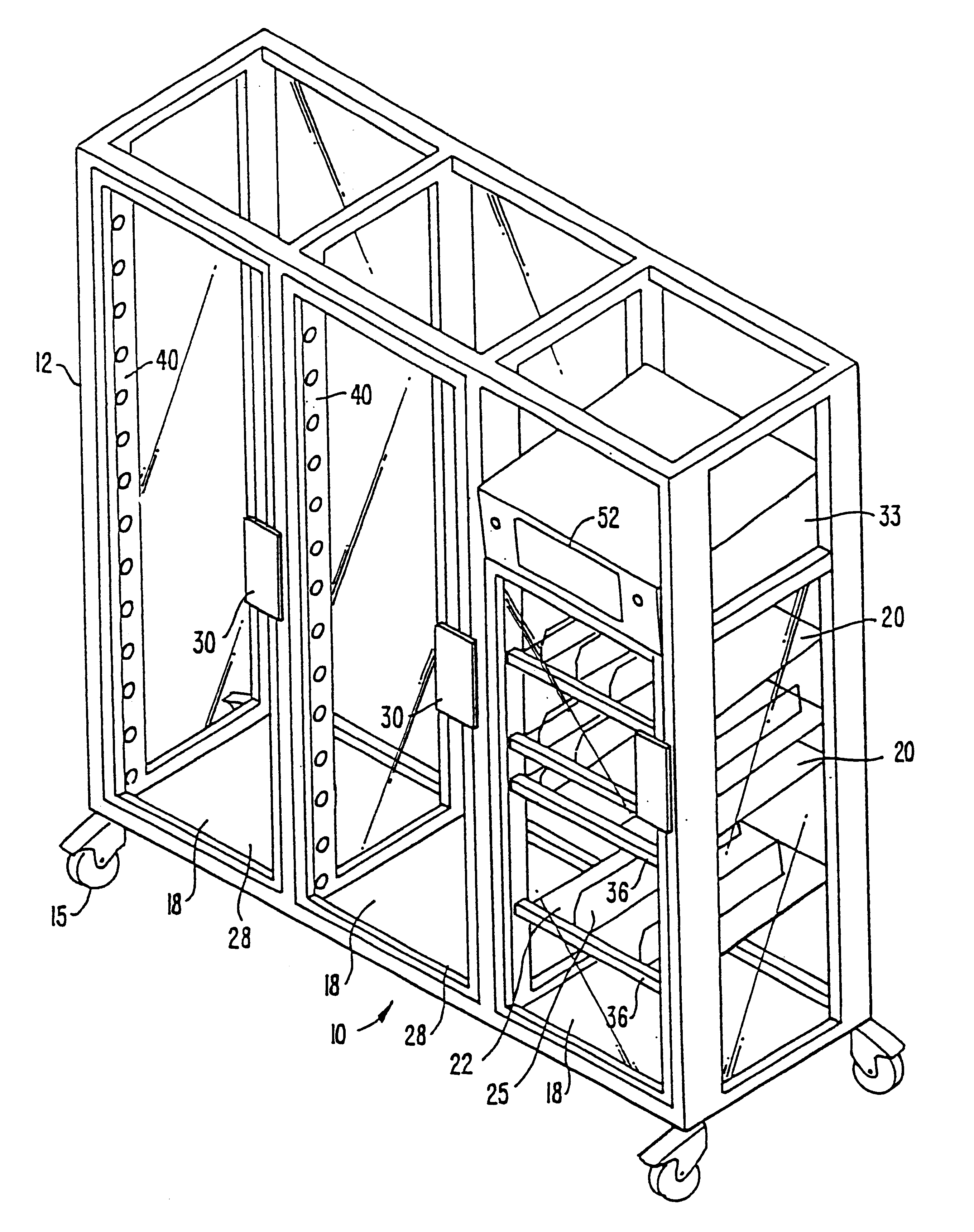

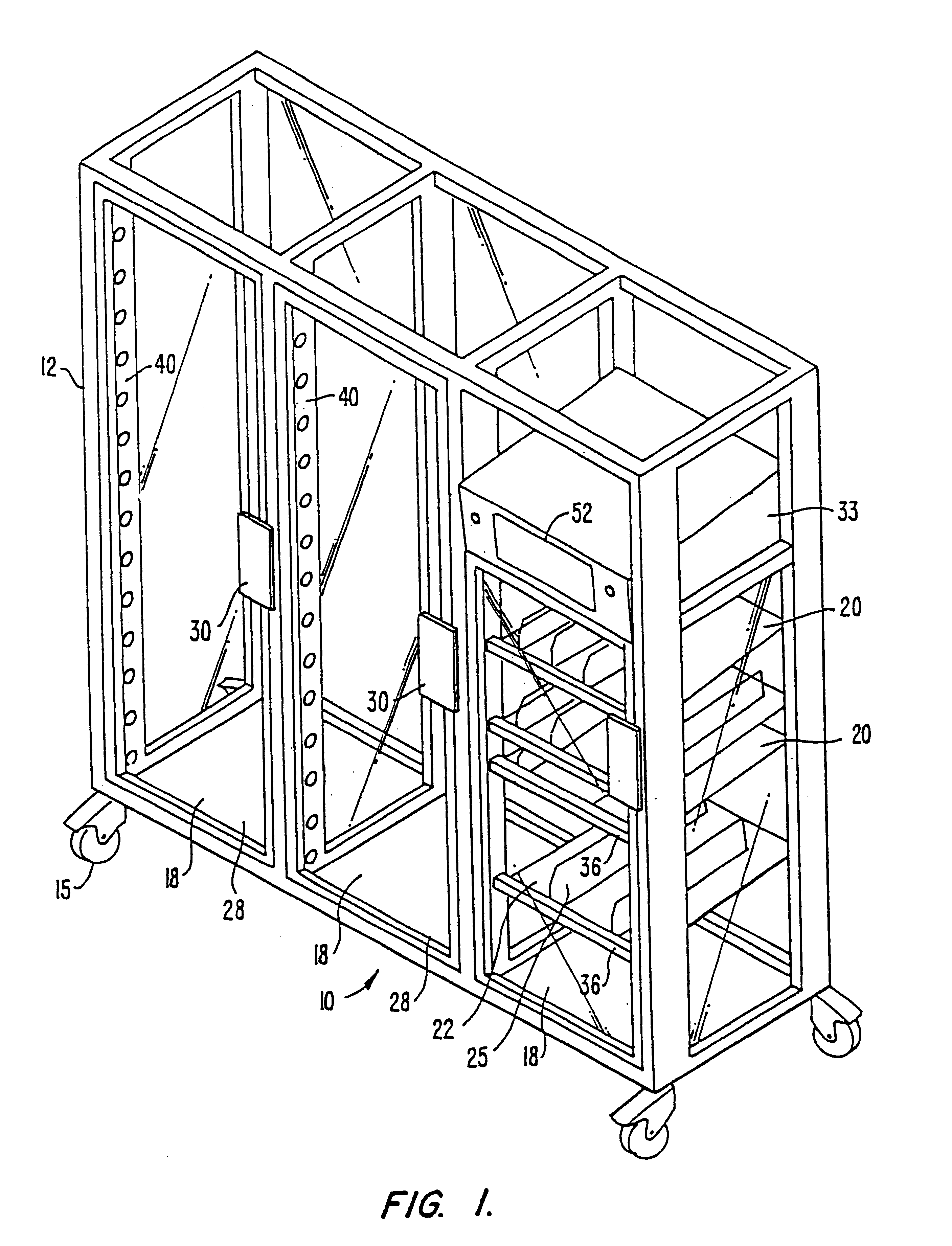

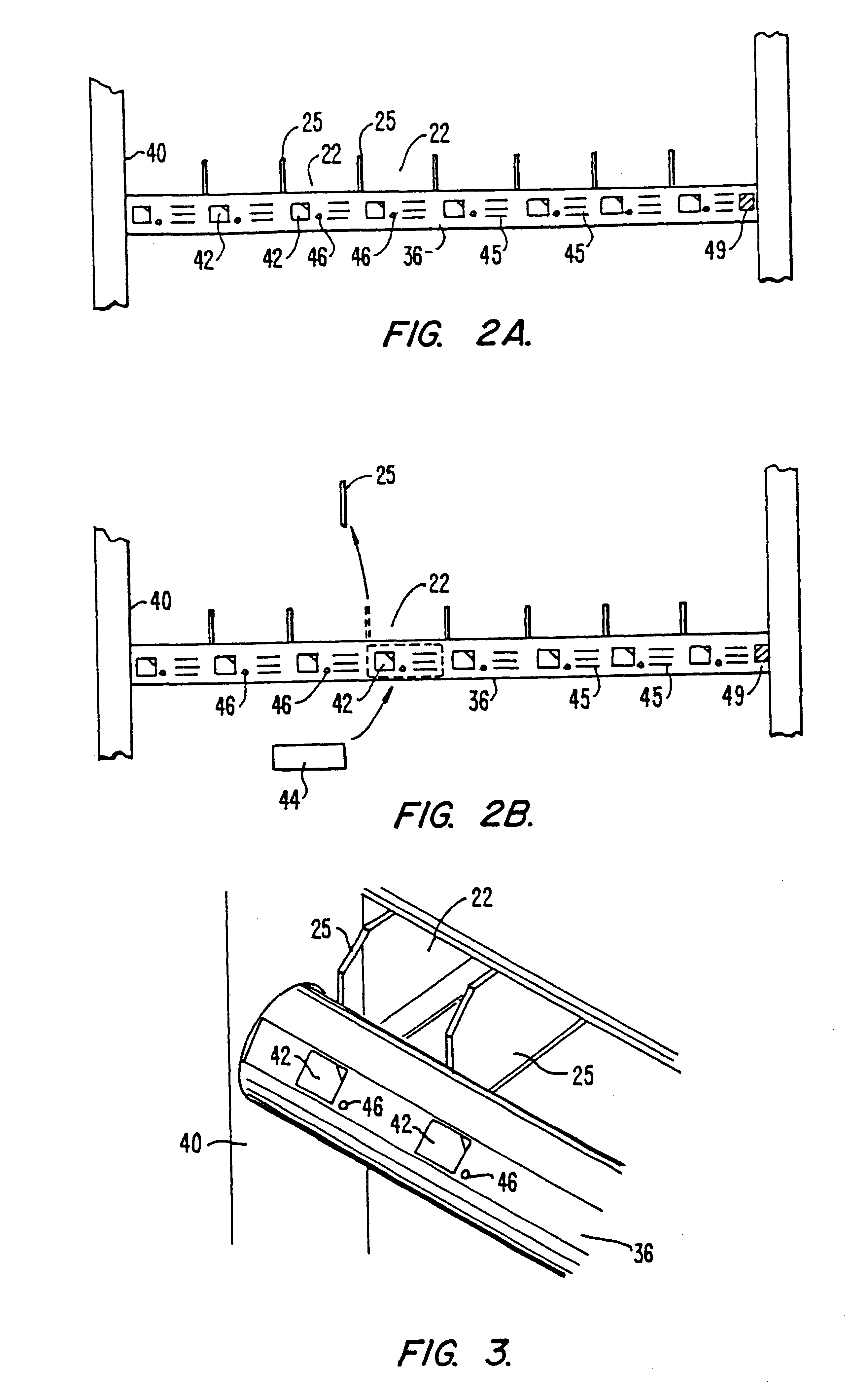

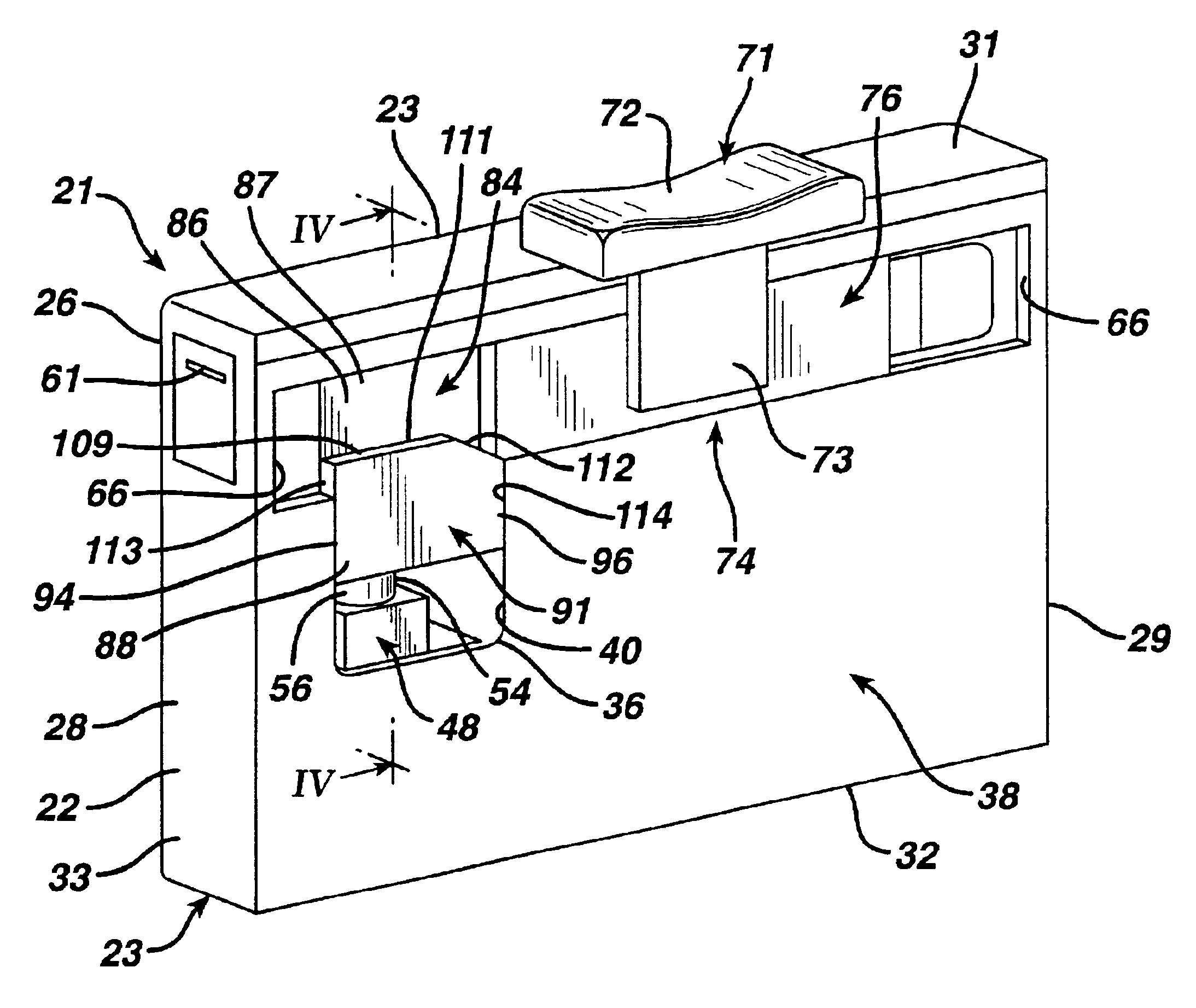

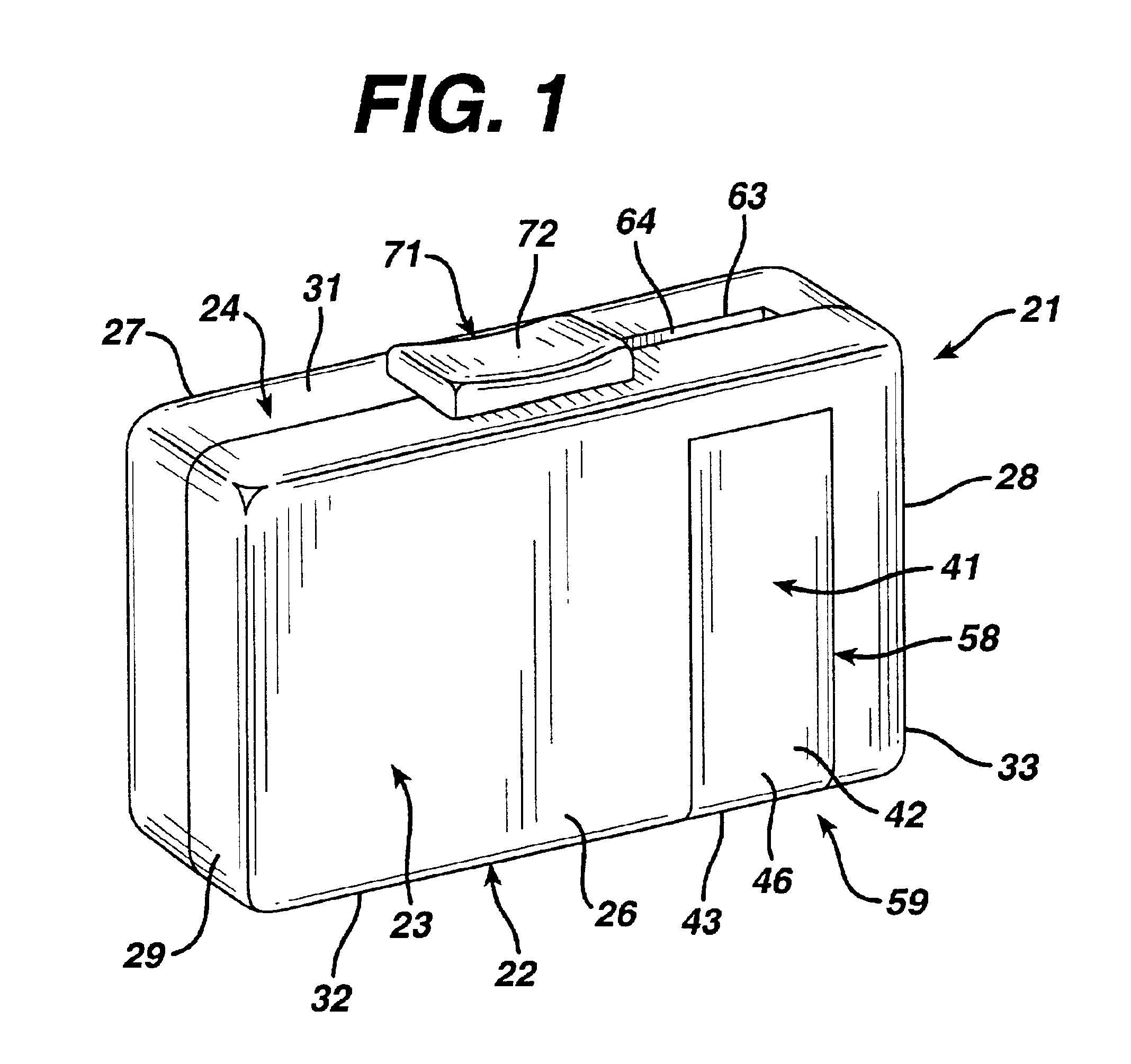

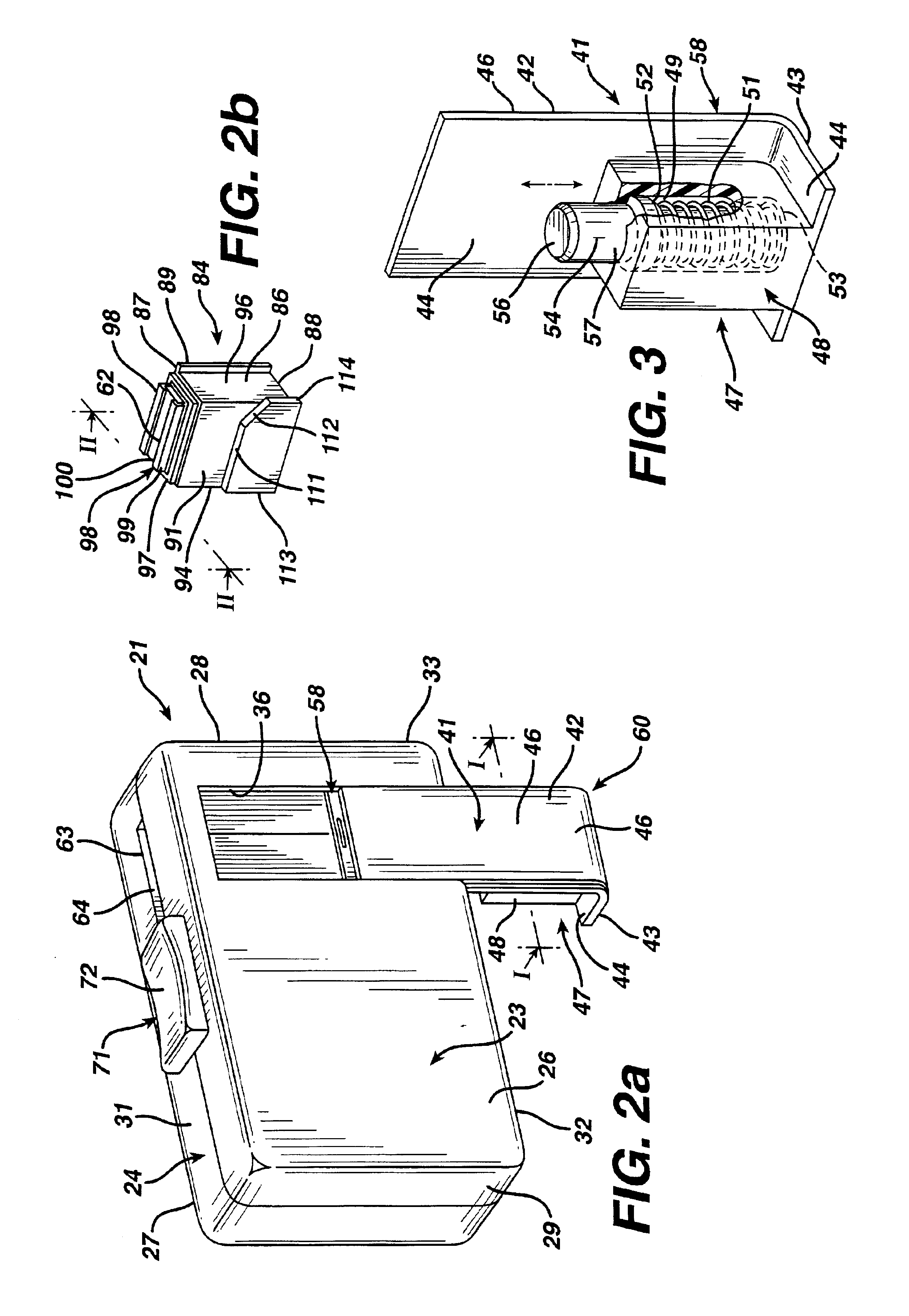

Methods and apparatus for dispensing items

The invention provides methods and apparatus for dispensing items from a dispensing unit. According to the invention, the dispensing unit comprises a plurality of locations in which the items are held, a processor in which records corresponding to the items on the unit are stored, and a plurality of item switches corresponding to the locations in which the items are held. The item switches are connected to the processor so that a user of the dispensing unit can input records of items removed from the unit into the processor. The apparatus described is particularly suited for dispensing medical supplies although the apparatus will be usable for other types of items as well. Preferred embodiments will include a plurality of visual indicators, typically in the form of light emitting diodes, corresponding to the locations in which the items are held. Upon selection of a desired item from a list of items held by the unit, the visual indicator corresponding to the item is actuated so that the user can locate the desired item quickly and conveniently with the help of the visual indicator.

Owner:OMNICELL

Methods and apparatus for dispensing items

The invention provides methods and apparatus for dispensing items from a dispensing unit. According to the invention, the dispensing unit comprises a plurality of locations in which the items are held, a processor in which records corresponding to the items on the unit are stored, and a plurality of item switches corresponding to the locations in which the items are held. The item switches are connected to the processor so that a user of the dispensing unit can input records of items removed from the unit into the processor. The apparatus described is particularly suited for dispensing medical supplies although the apparatus will be usable for other types of items as well. Preferred embodiments will include a plurality of visual indicators, typically in the form of light emitting diodes, corresponding to the locations in which the items are held. Upon selection of a desired item from a list of items held by the unit, the visual indicator corresponding to the item is actuated so that the user can locate the desired item quickly and conveniently with the help of the visual indicator.

Owner:OMNICELL

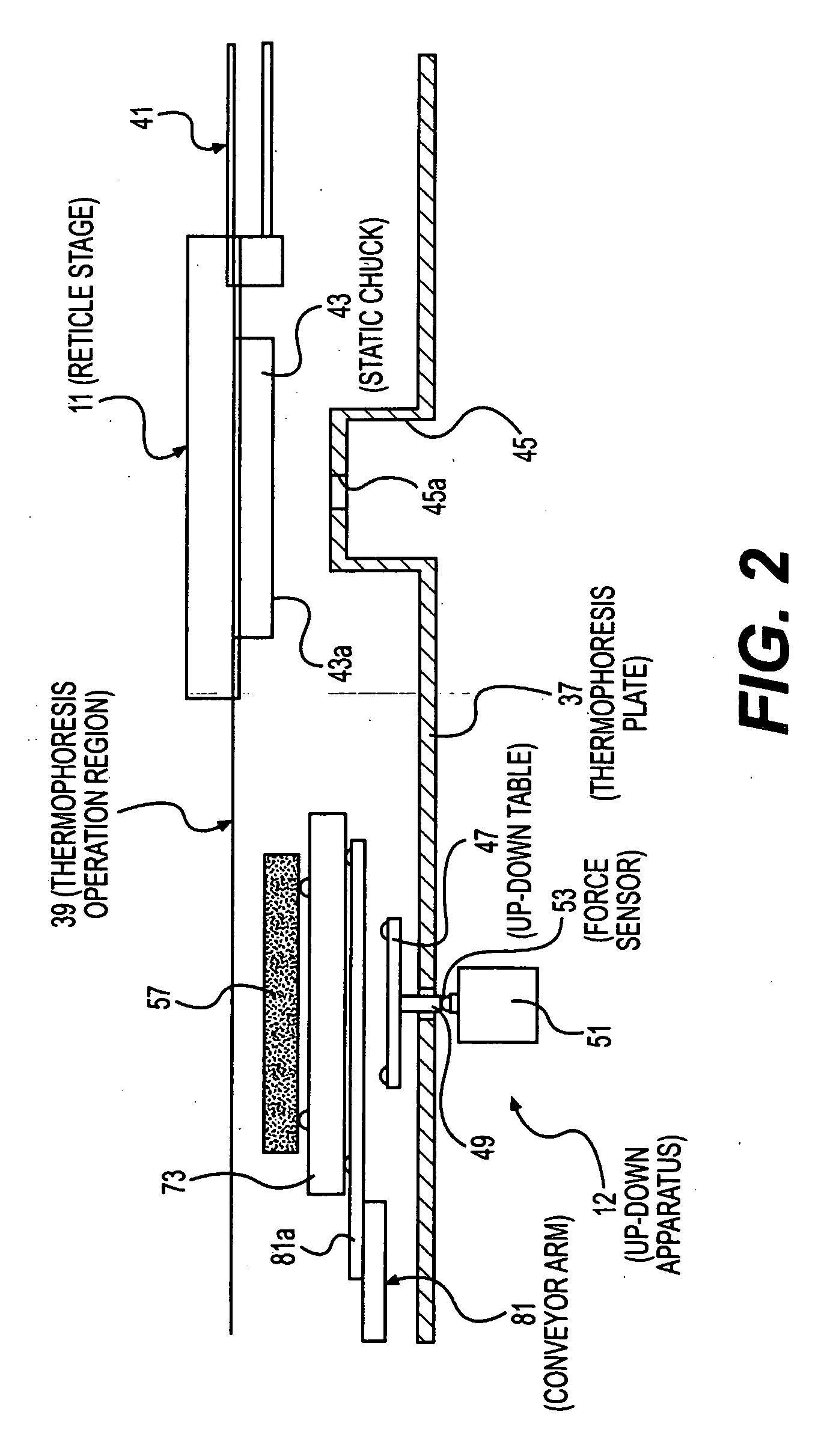

Substrate transfer mechanism and subtrate transfer apparatus including same, particle removal method for the subtrate transfer mechanism and apparatus, program for executing the method, and storage medium for storing the program

ActiveUS20050252455A1Reduce bond strengthDrying solid materials with heatSemiconductor/solid-state device manufacturingTemperature controlTransfer mechanism

A substrate transfer mechanism for transferring a substrate includes a mounting table on which the substrate is mounted; an arm member connected to the mounting table and moving it. The substrate transfer mechanism further includes a temperature control unit for controlling temperature of the mounting table, wherein the temperature control unit forms a temperature gradient in the mounting table. The temperature control unit includes a detector for detecting temperature in an environment or a chamber in which the substrate transfer mechanism is installed a heater for heating the mounting table and a controller for controlling an operation of the heater based on the temperature in the environment or the chamber detected by the detector.

Owner:TOKYO ELECTRON LTD

Substrate processing apparatus

ActiveUS20090116936A1Prevent slippingProcess safety and stabilityConveyorsSemiconductor/solid-state device manufacturingMechanical engineeringMaterials science

Provided is a substrate processing apparatus. The substrate processing apparatus includes a reaction tube, a substrate holder, a gas nozzle, a heating unit, a temperature detector, and an exhaust unit. The reaction tube accommodates and processes substrates. The substrate holder holds substrates stacked at predetermined intervals in the reaction tube. The gas nozzle is installed along a stacked direction of the substrates. The heating unit heats the substrates. The temperature detector is installed along the stacked direction of the substrates. The exhaust unit exhausts an inside atmosphere of the reaction tube. Each of the gas nozzle and the temperature detector includes first and second parts and is supported by a narrow tube supporting member including first and second supporting parts. The first supporting part makes contact with the first part. The second supporting part is parallel with the second part and supports the second part.

Owner:KOKUSA ELECTRIC CO LTD

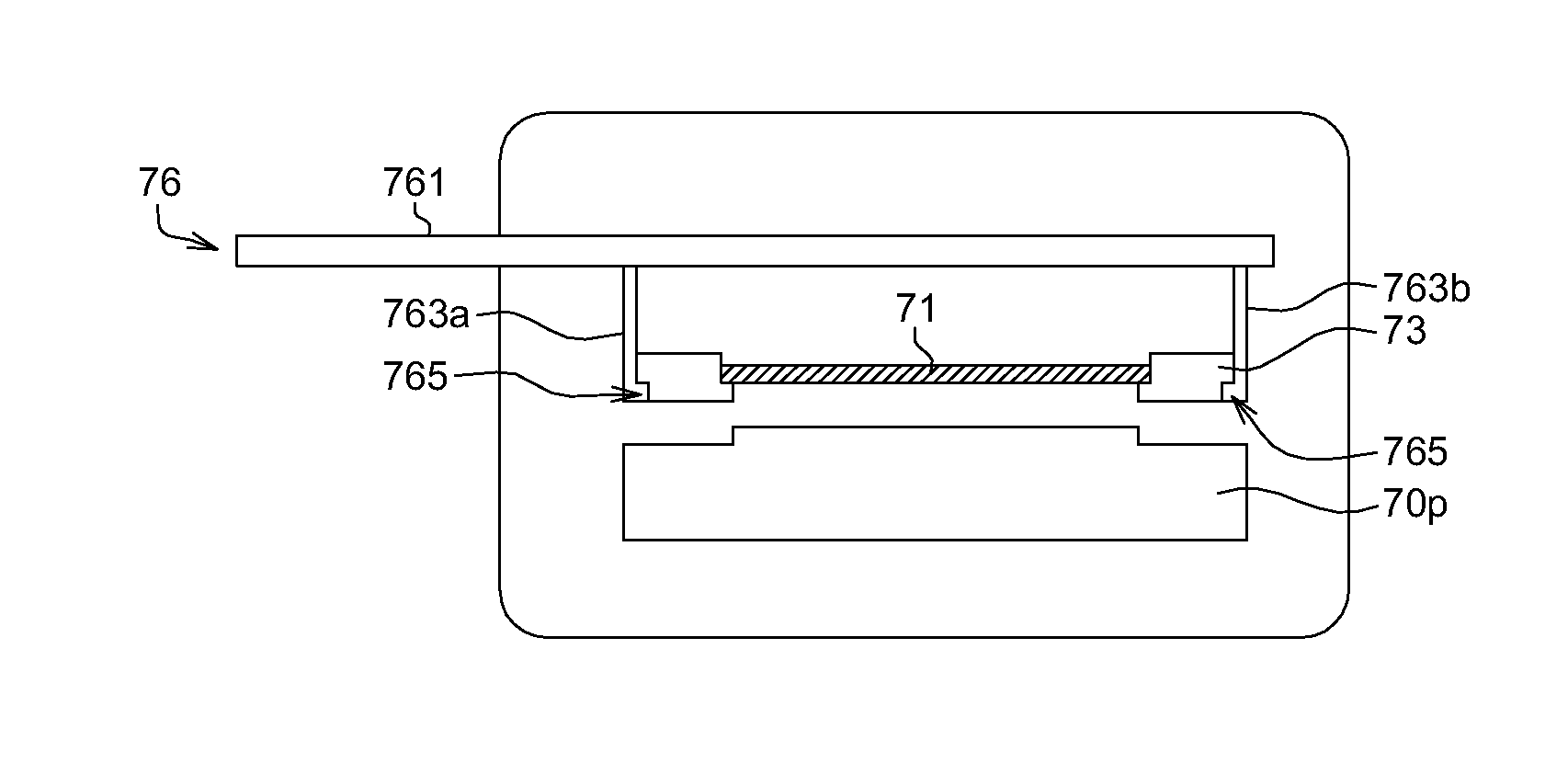

Apparatus And Method For Transporting Wafers Between Wafer Carrier And Process Tool Under Vacuum

ActiveUS20160035596A1Efficient solutionReduction in inner volumeSemiconductor/solid-state device manufacturingLoading/unloadingEngineeringElectrical and Electronics engineering

An integrated transport device for a wafer carrier includes: an evacuatable chamber for accommodating therein a wafer carrier having a front opening with a cover; a rotatable platform for placing the wafer carrier thereon in the chamber; and an opening / closing device for opening and closing the cover of the wafer carrier placed on the platform at a first position, wherein the platform rotates to set the wafer carrier at the first position and a second position for transporting a wafer to a wafer-handling chamber.

Owner:ASM IP HLDG BV

Test device with means for storing and dispensing diagnostic strips

The invention provides a substantially moisture-proof, air-tight apparatus for both dispensing a plurality of diagnostic test strips and testing a biological fluid dispensed onto the strip. One strip may be advanced for use in testing using a single, translational movement.

Owner:LIFESCAN IP HLDG LLC

Sorting/storage device for wafers and method for handling thereof

InactiveUS7077614B1Easy and less-expensive to produceReducing throughout capacitySemiconductor/solid-state device manufacturingCharge manipulationMeasurement stationBiomedical engineering

Sorting / storage device for wafers. A sorting device is provided in which at least two cassettes containing wafers may be present and the wafers are moved from one cassette to the other cassette or vice versa. If appropriate, a measuring station may be present in the sorting device. In the immediate vicinity of the sorting device, the cassettes are stored in a magazine which is designed for this purpose and the cassettes are moved using a handling device for cassettes.

Owner:ASM INTERNATIONAL

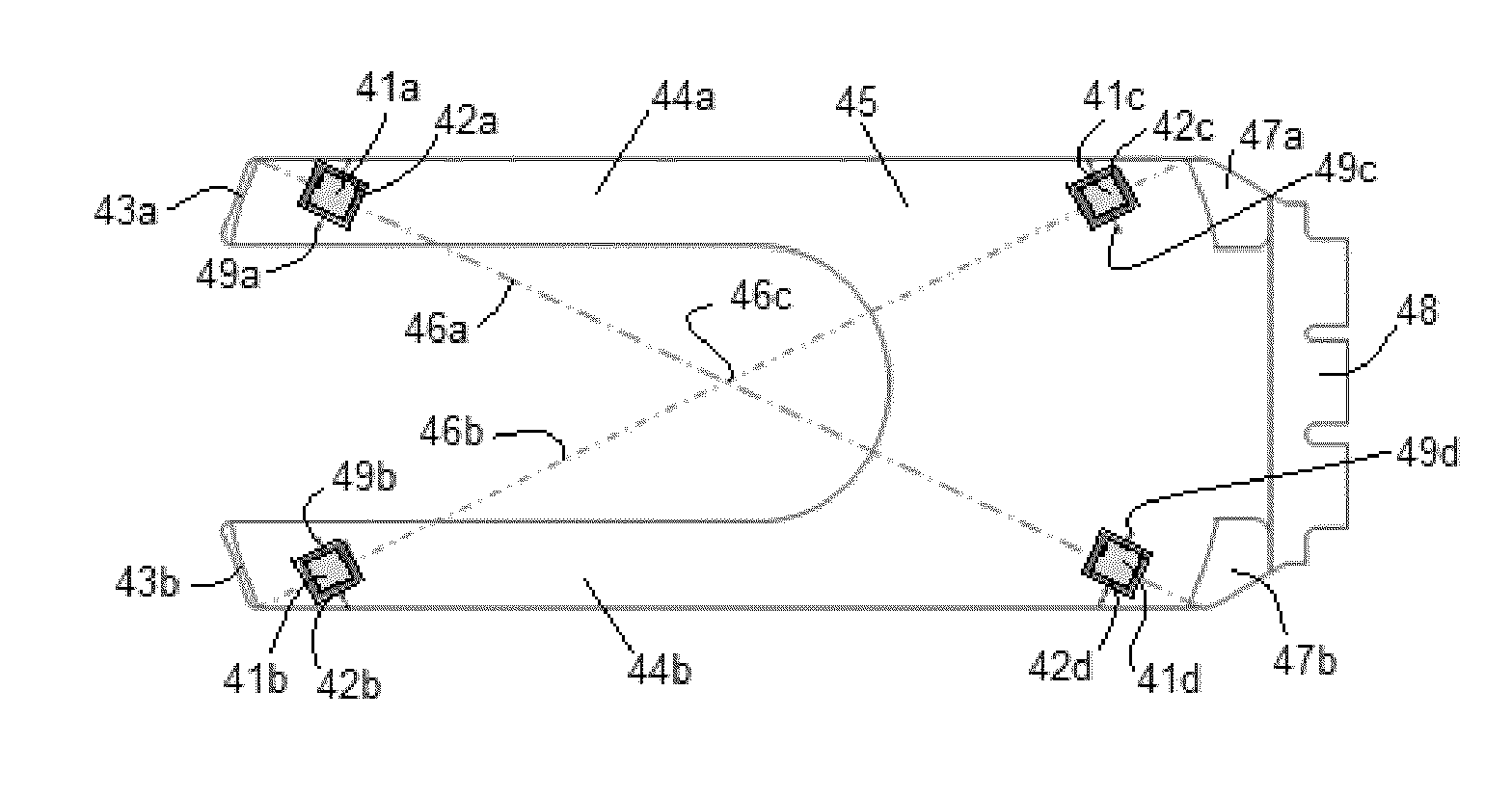

Materials-handling system using autonomous transfer and transport vehicles

ActiveUS7991505B2High degree of automationEfficient automationDigital data processing detailsLoading/unloadingEngineeringHandling system

Methods and apparatus for selecting and combining packages in an outbound container by employing autonomous transfer and transport vehicles which move on a network of roadways to carry a plurality of individual cases each containing the same kind of product from a loading station and to a destination station where individual packages are combined in the outbound container. The travel of each vehicle through the roadway network is computer controlled, and each vehicle includes means for automatically loading and unloading packages from predetermined locations on the network.

Owner:SYMBOTIC LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com