Patents

Literature

16152results about "Article feeders" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

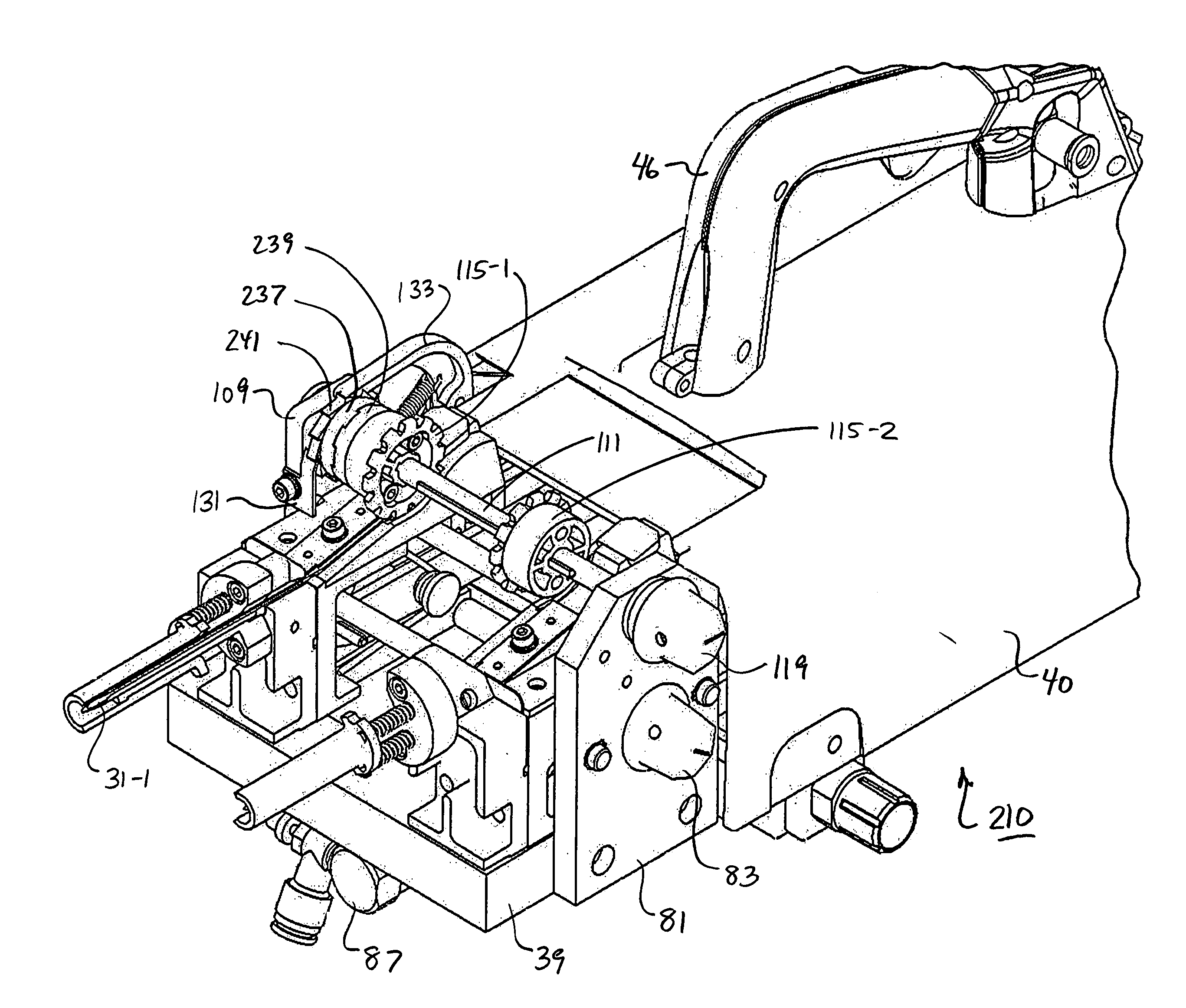

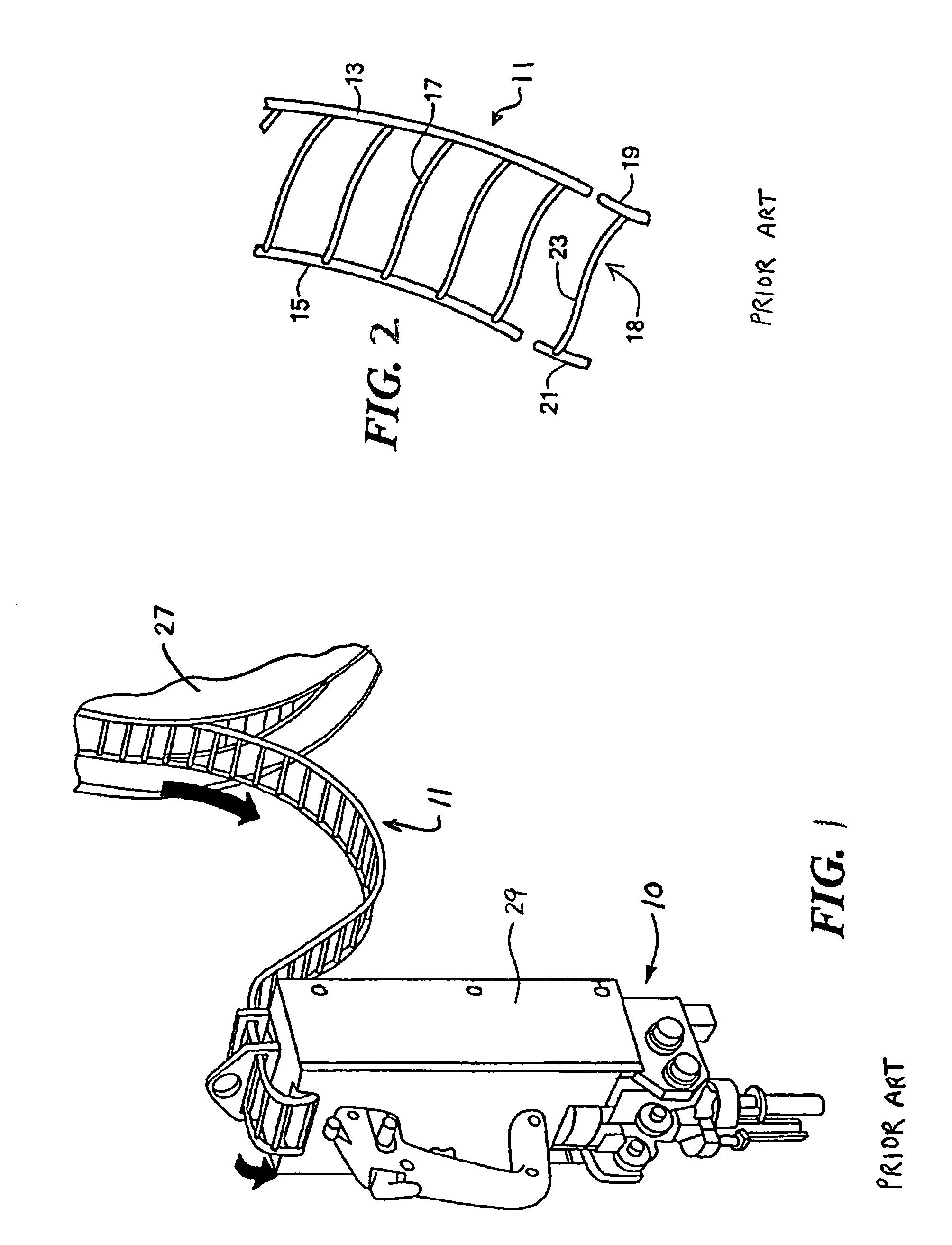

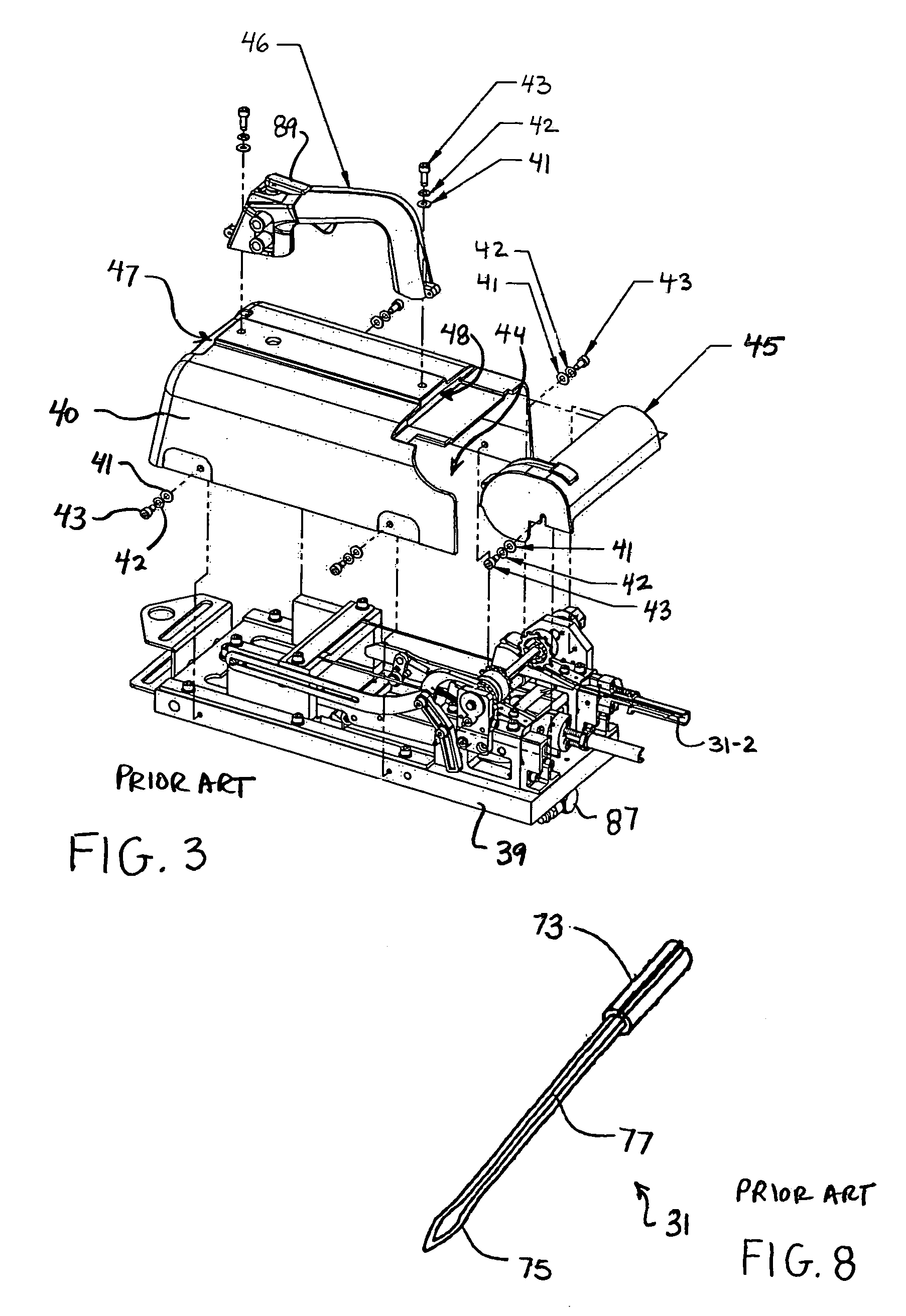

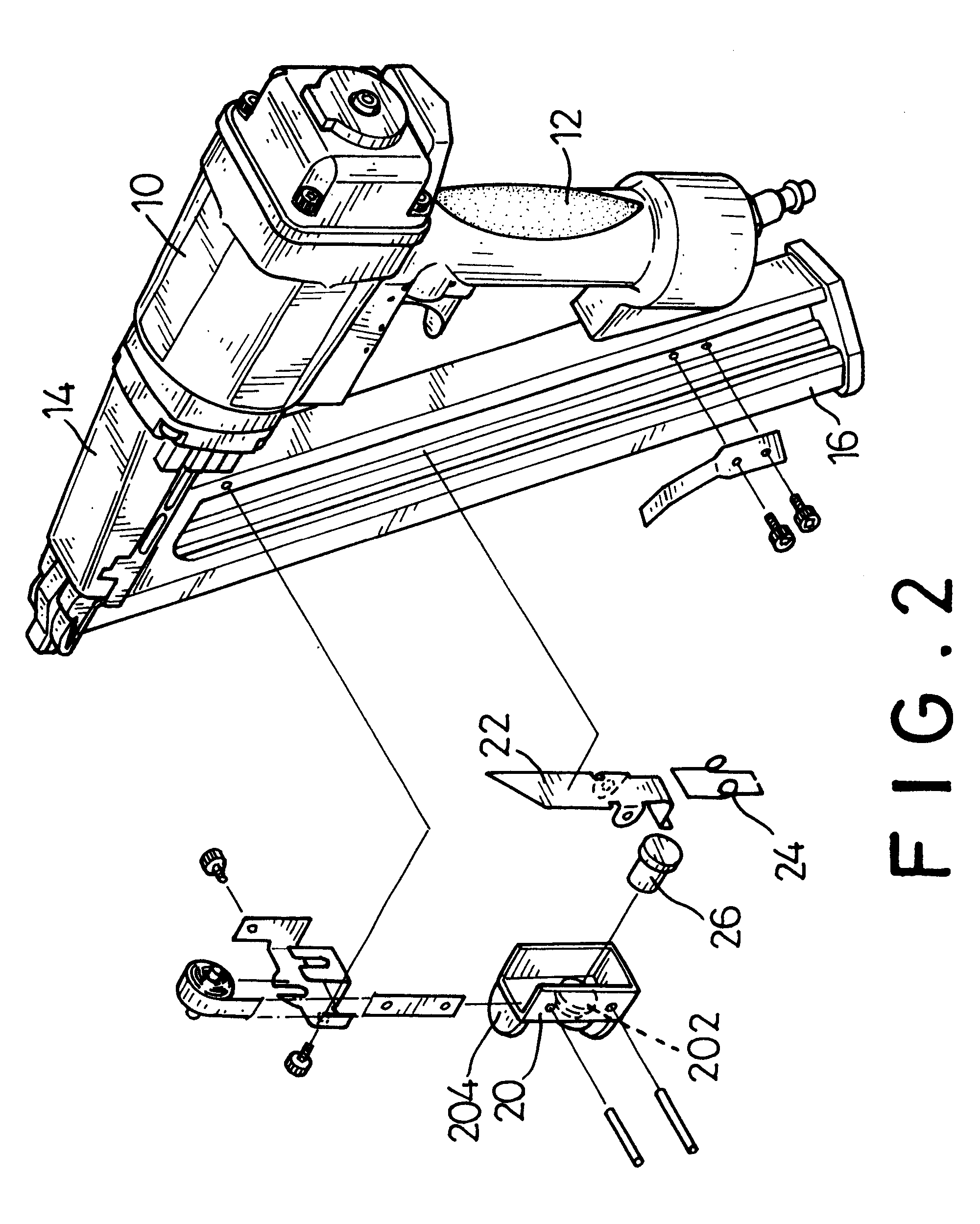

Device for dispensing plastic fasteners

ActiveUS7036680B1Easy to useReduce manufacturing costAffixing tagsCoin-freed apparatus detailsCross-linkEngineering

A device for dispensing an individual plastic fastener from a supply of fastener stock to couple together two or more objects. The supply of fastener stock includes a plurality of equidistantly spaced cross links which are coupled at one end to a continuous side rail. The fastener dispensing device includes a hollowed sharpened needle shaped to define a longitudinal bore and a feed mechanism for advancing the continuous side rail of the fastener stock into direct axial alignment behind the longitudinal bore of the hollowed needle. The feed mechanism includes a rotatably mounted feed shaft, a pair of feed wheels fixedly mounted on the feed shaft, each feed wheel comprising a plurality of sprockets which are sized and shaped to engage the supply of fastener stock, and first and second clutch wheels which are releasably matingly engageable with one another, the first clutch wheel being fixedly mounted on the feed shaft and the second clutch wheel being rotatably mounted on the feed shaft, each of the first and second clutch wheels including a plurality of ratchets. As a feature of the invention, the number of ratchets on each clutch wheel is at most equal to the number of sprockets on each feed wheel.

Owner:AVERY DENNISON CORP

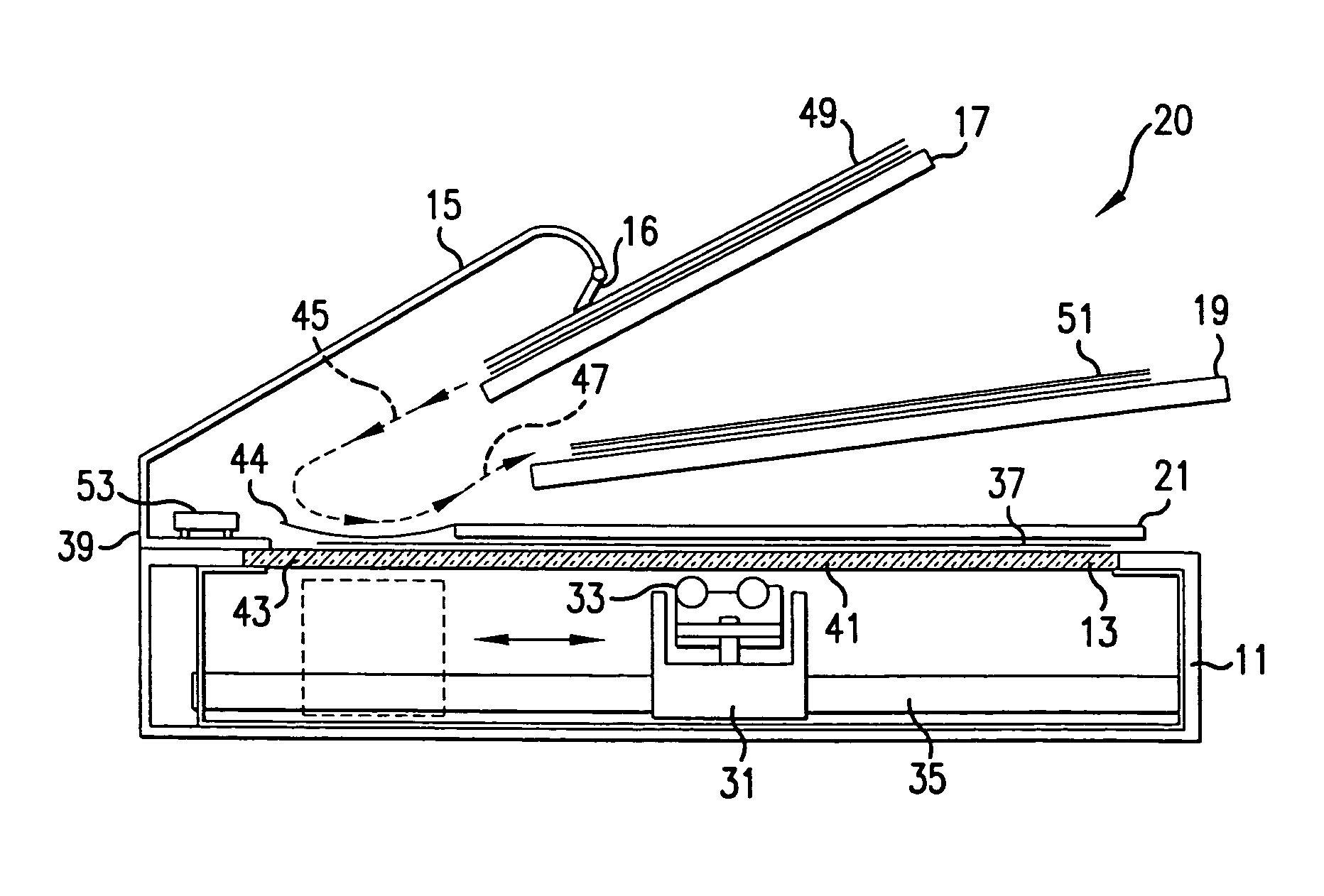

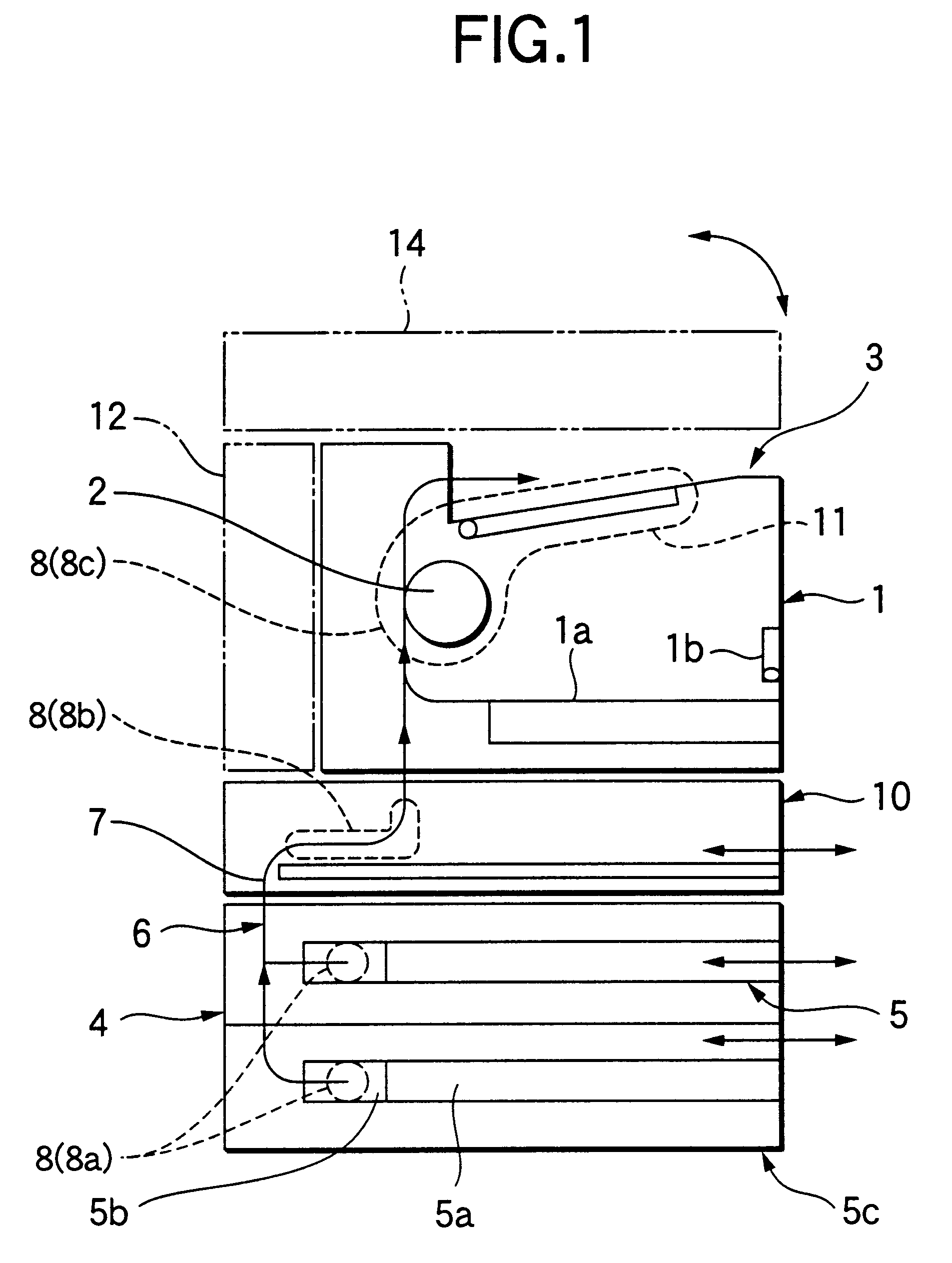

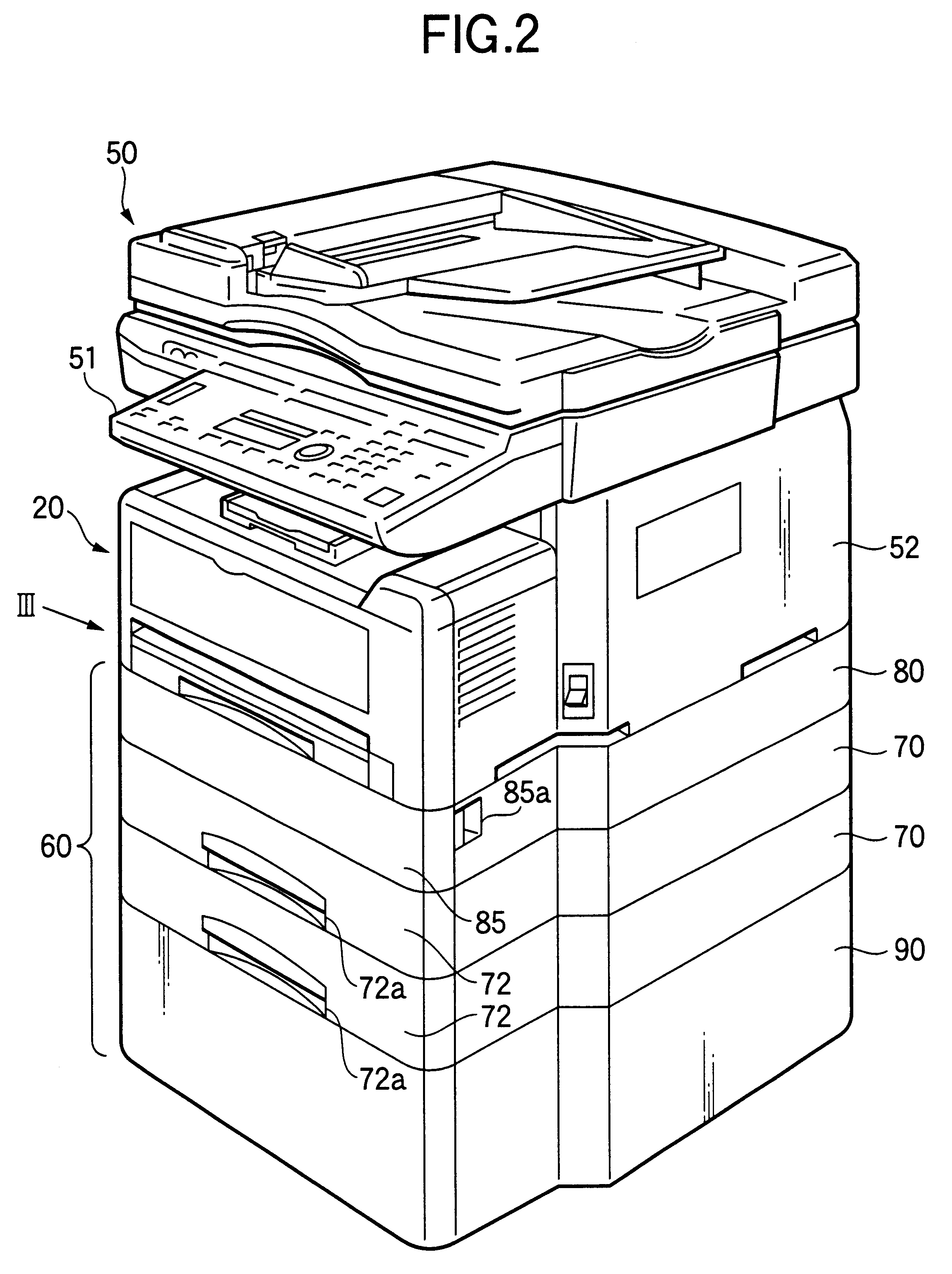

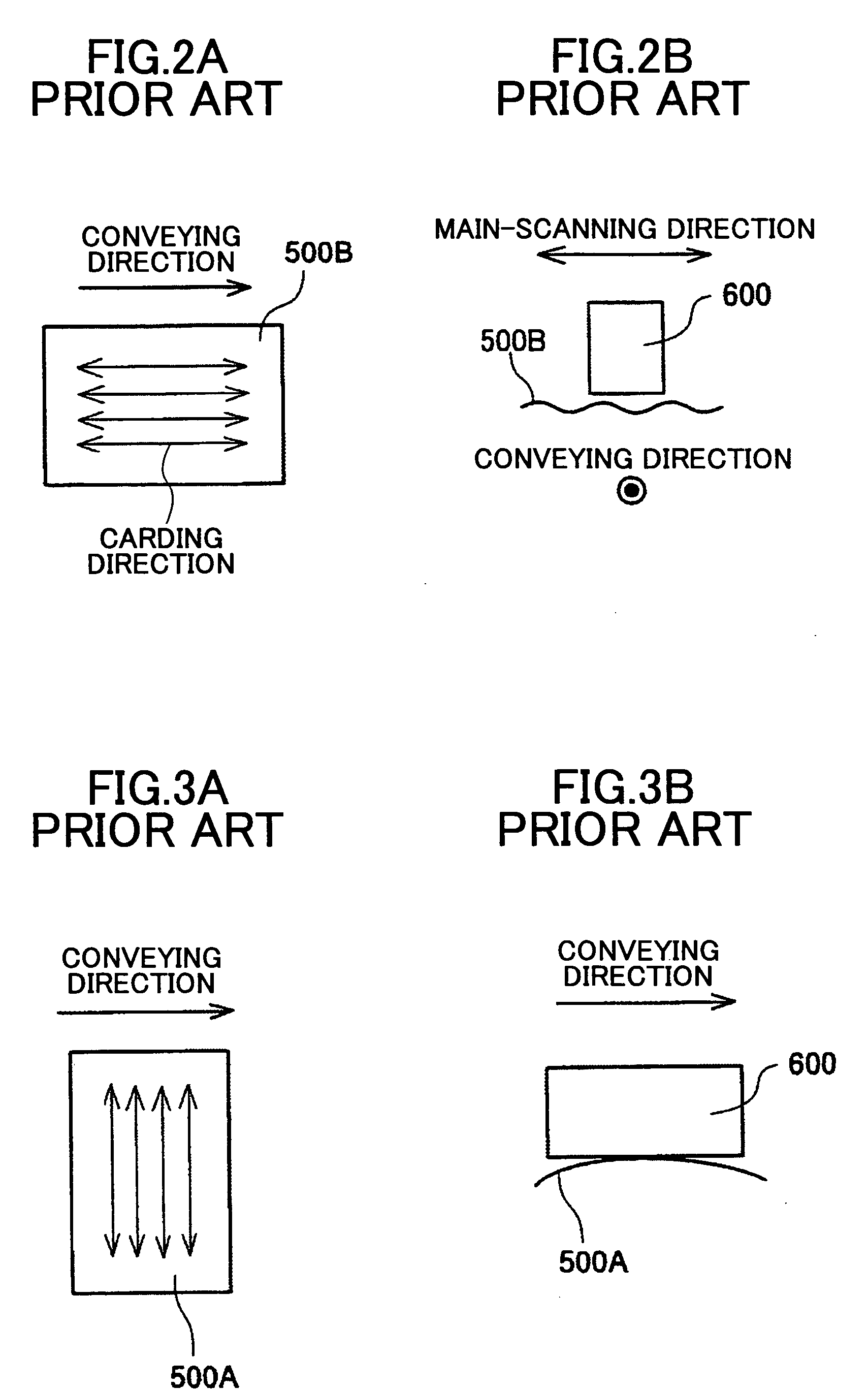

Image read device and copier

An image read device is provided, which conveys an original while performing reading of an image of the original at a read position on a transparent member by a read unit fixed, the image read device including: a moving unit that moves the transparent member back and forth in an original conveying direction; a control unit that conveys the original and moves the transparent member by using the moving unit while causing the reading of the image to be performed at the read position; and a determining unit that, when an event causing interruption of original conveyance occurs, stops the transparent member and determines whether a control of returning the transparent member to a home position is to be performed or not in accordance with a stopped position of the original in an original conveying path.

Owner:RICOH KK

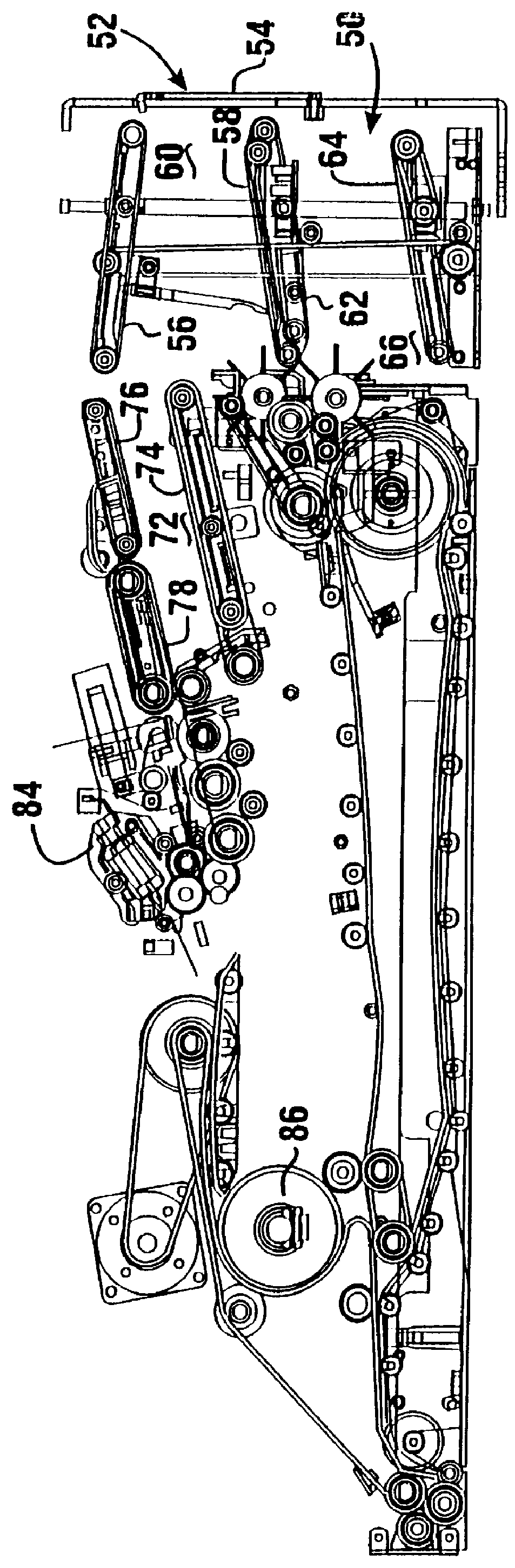

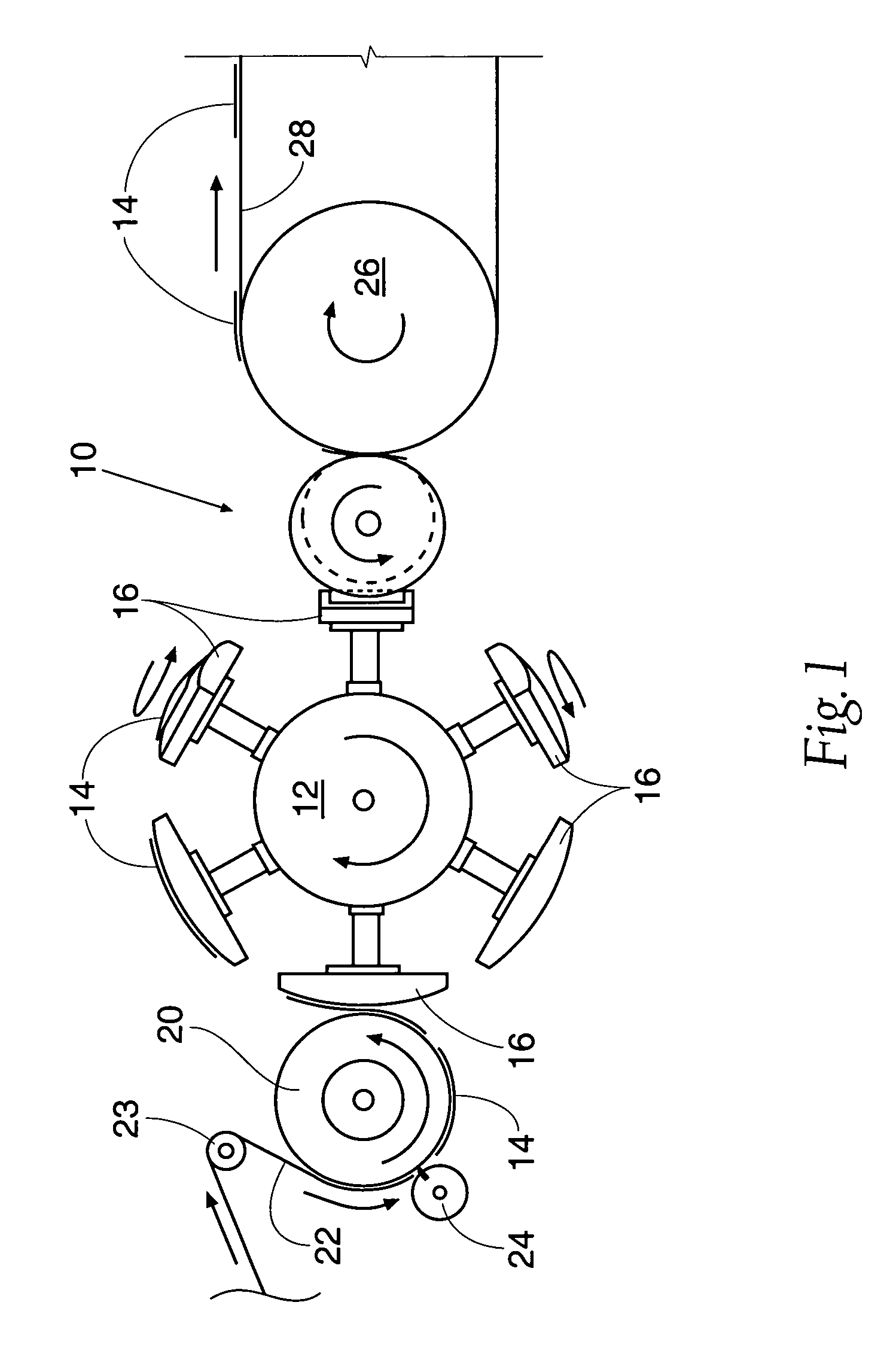

Sheet conveying device having multiple outputs

InactiveUS6612571B2Increase speedEfficient outputFunction indicatorsArticle feedersEngineeringServomotor

A sheet conveying device having multiple directional outputs with multiple registration options having no fixed registration wall for sequencing single sheets or two approximately identical sheets arriving in a two-up configuration, includes a first, second, third, and fourth pairs of rolls. The first pair of rolls and the second pair of rolls rotate about a first shaft, which is rotated by a first servomotor. The third pair of rolls rotate about a second shaft, which is rotated by a second servomotor, wherein the shaft is oriented at an angle approximately 90° relative to the first shaft. The fourth pair of rolls rotate about a third shaft oriented at an angle approximately 90° relative to the first shaft and approximately parallel to the second shaft, and a third servomotor operably connected to the third shaft rotates the third shaft.

Owner:XEROX CORP

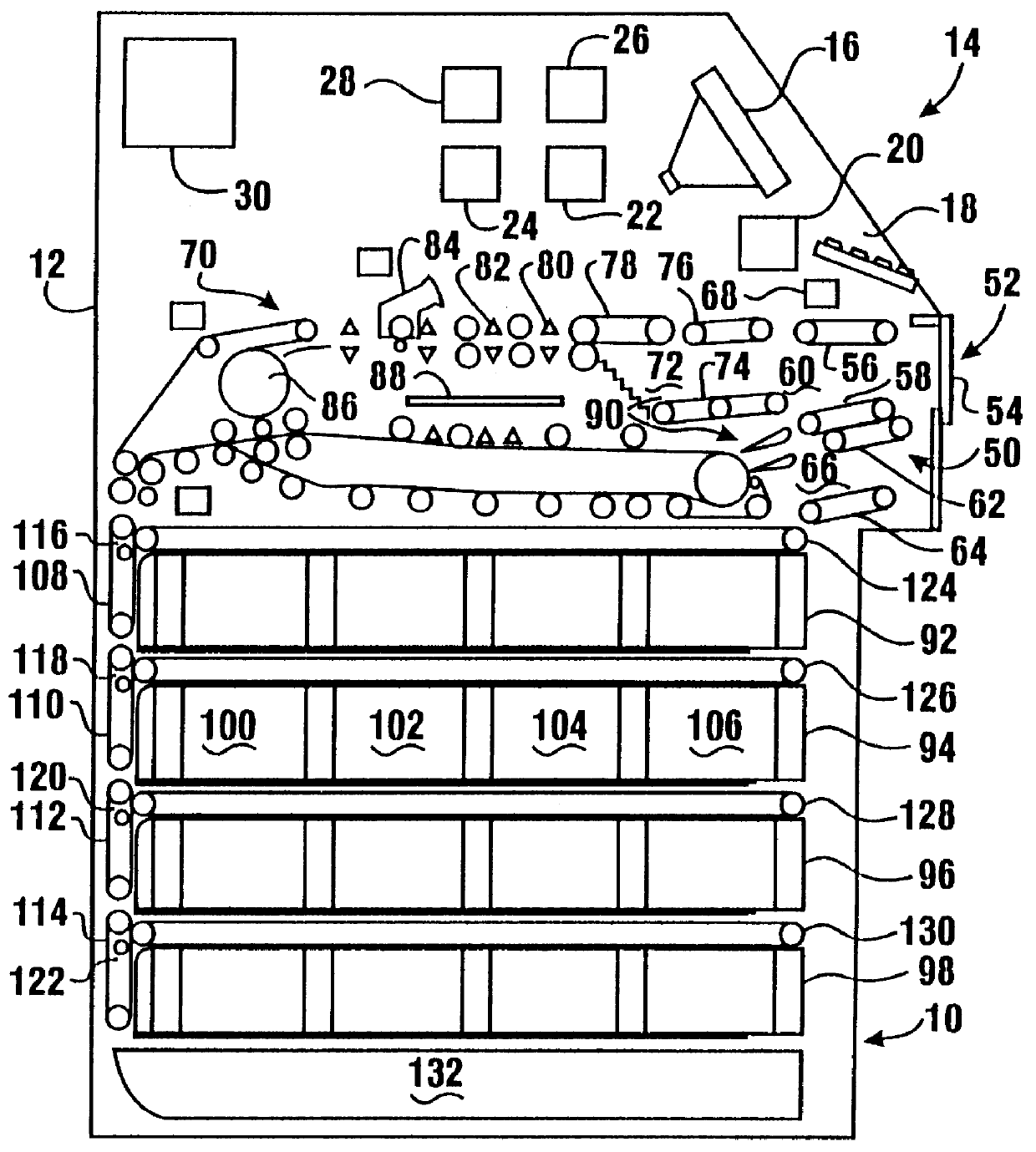

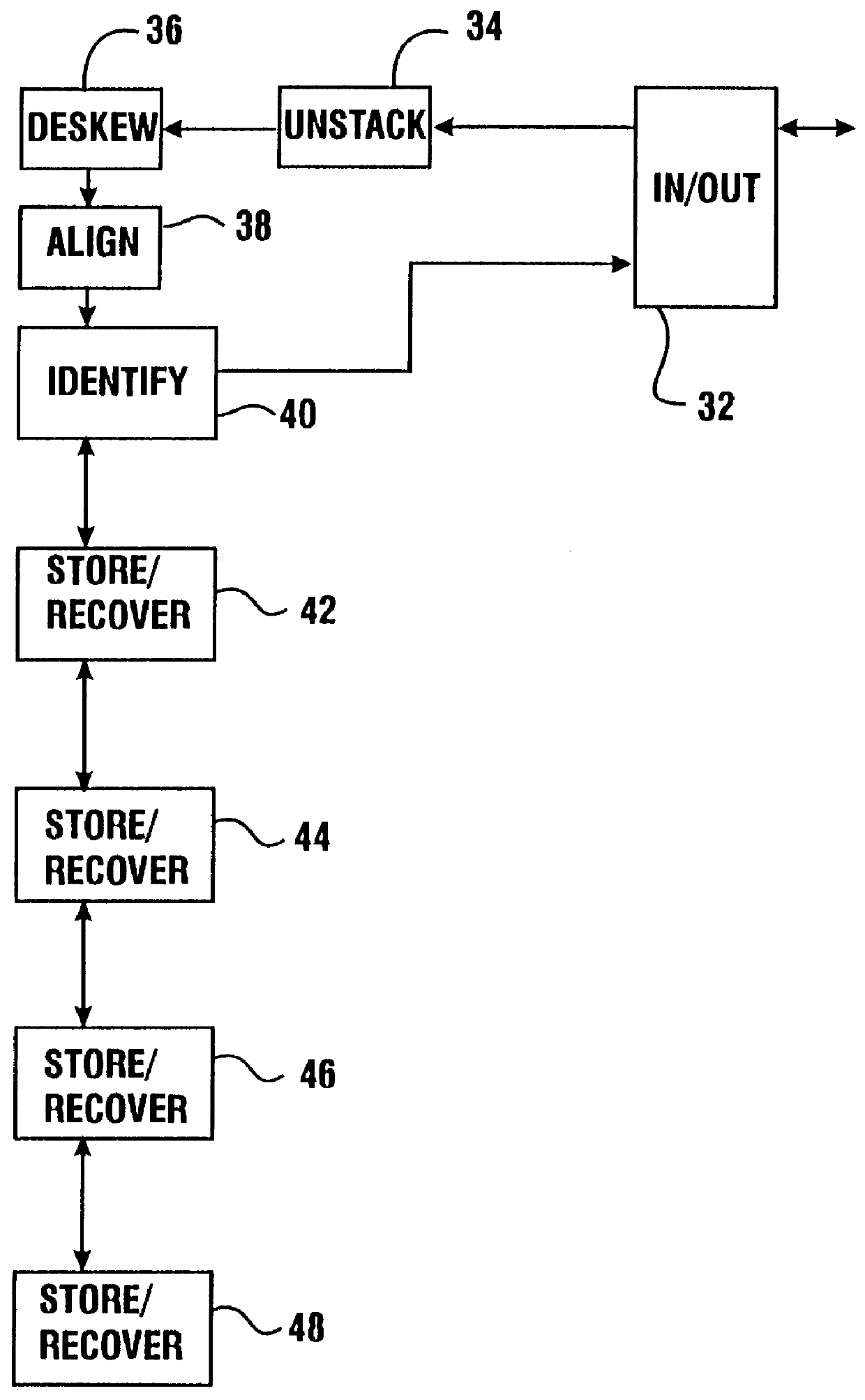

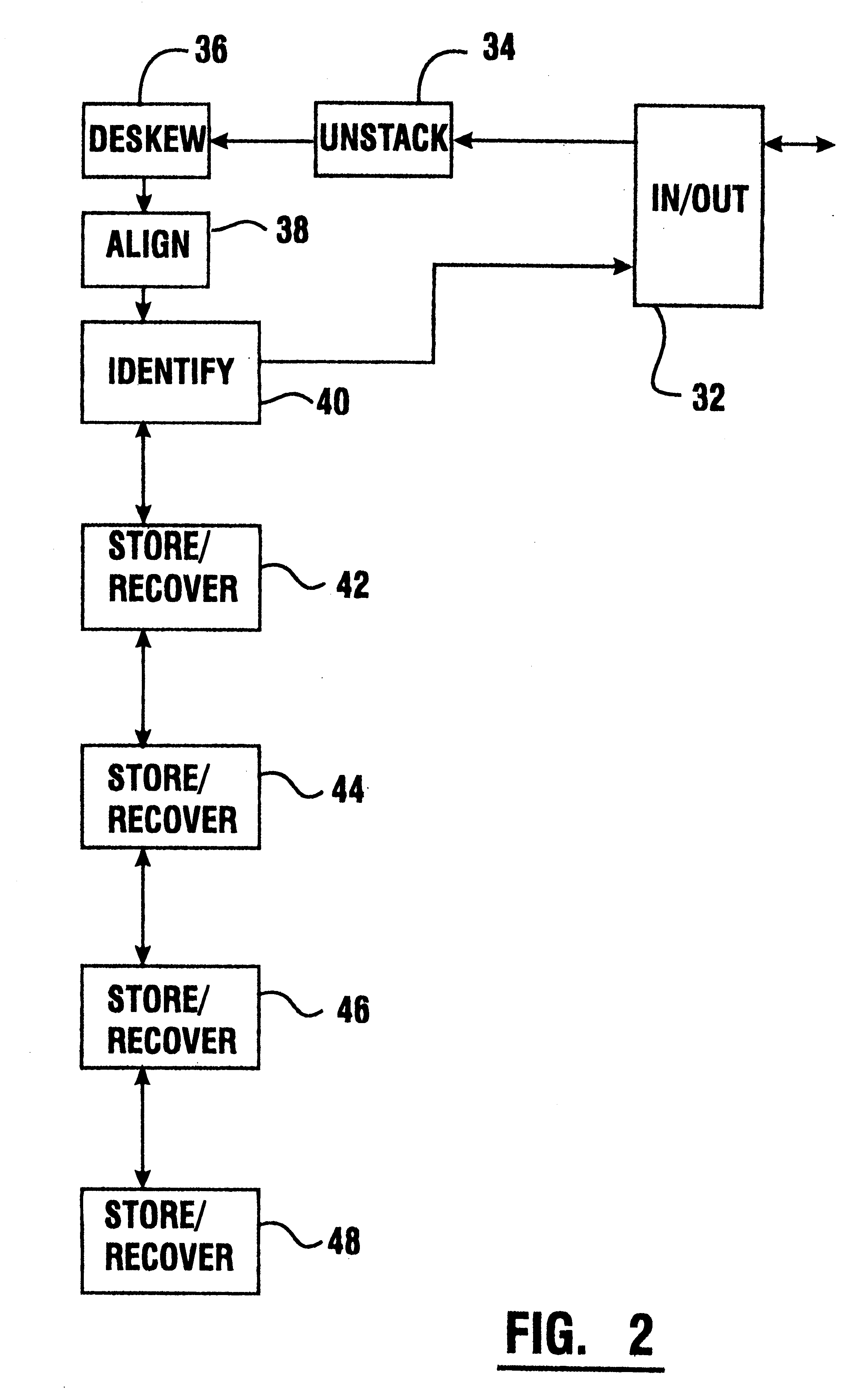

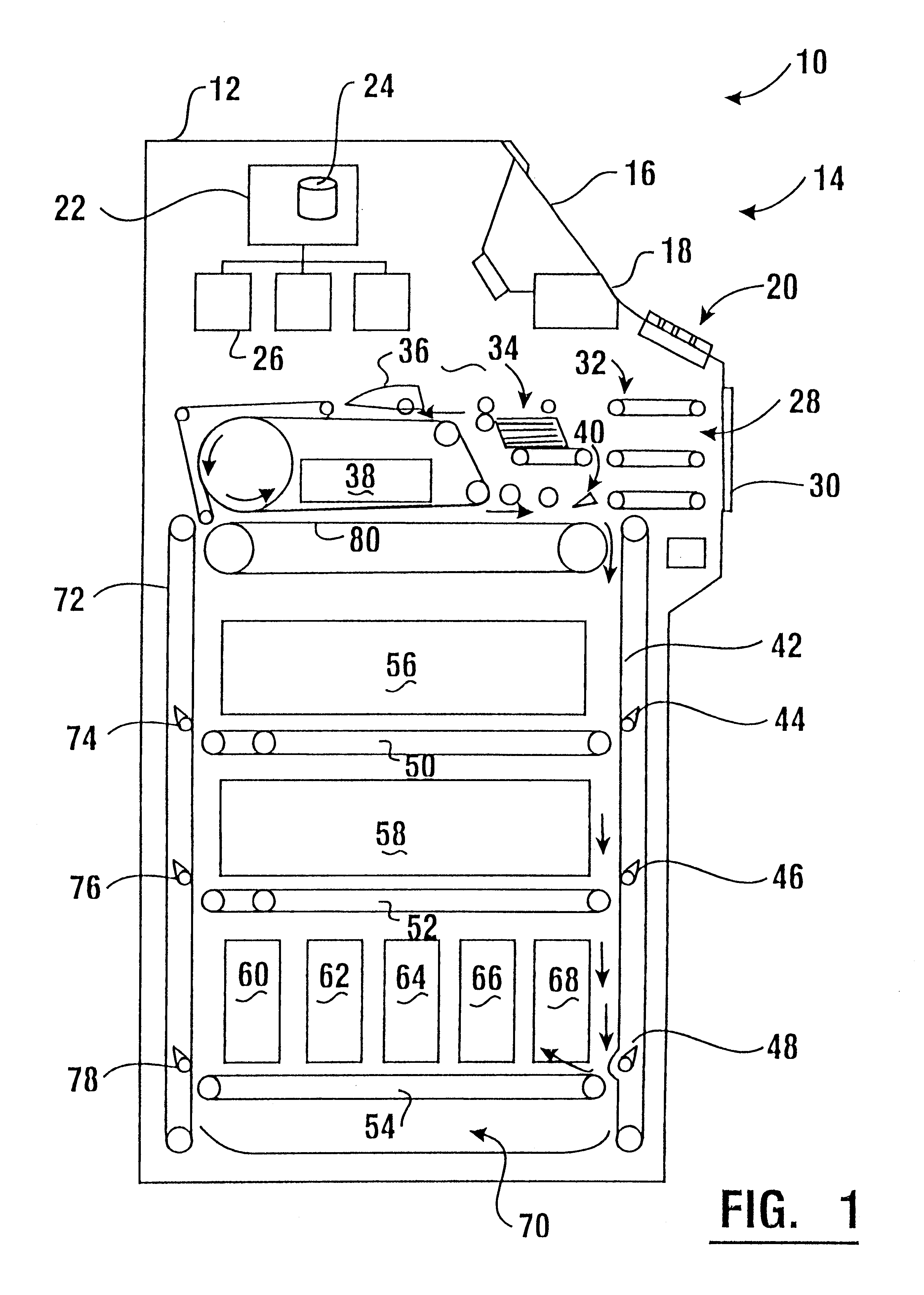

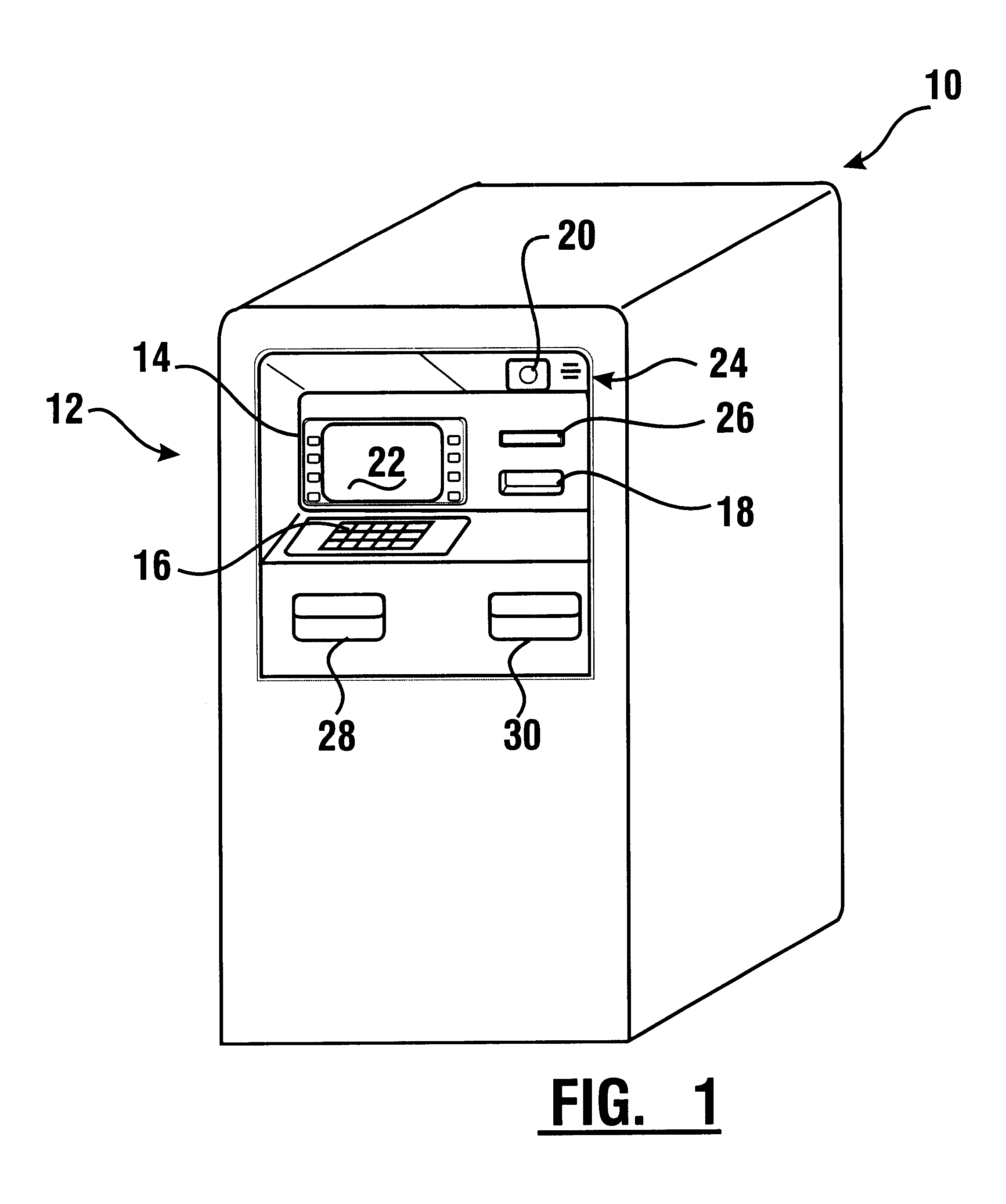

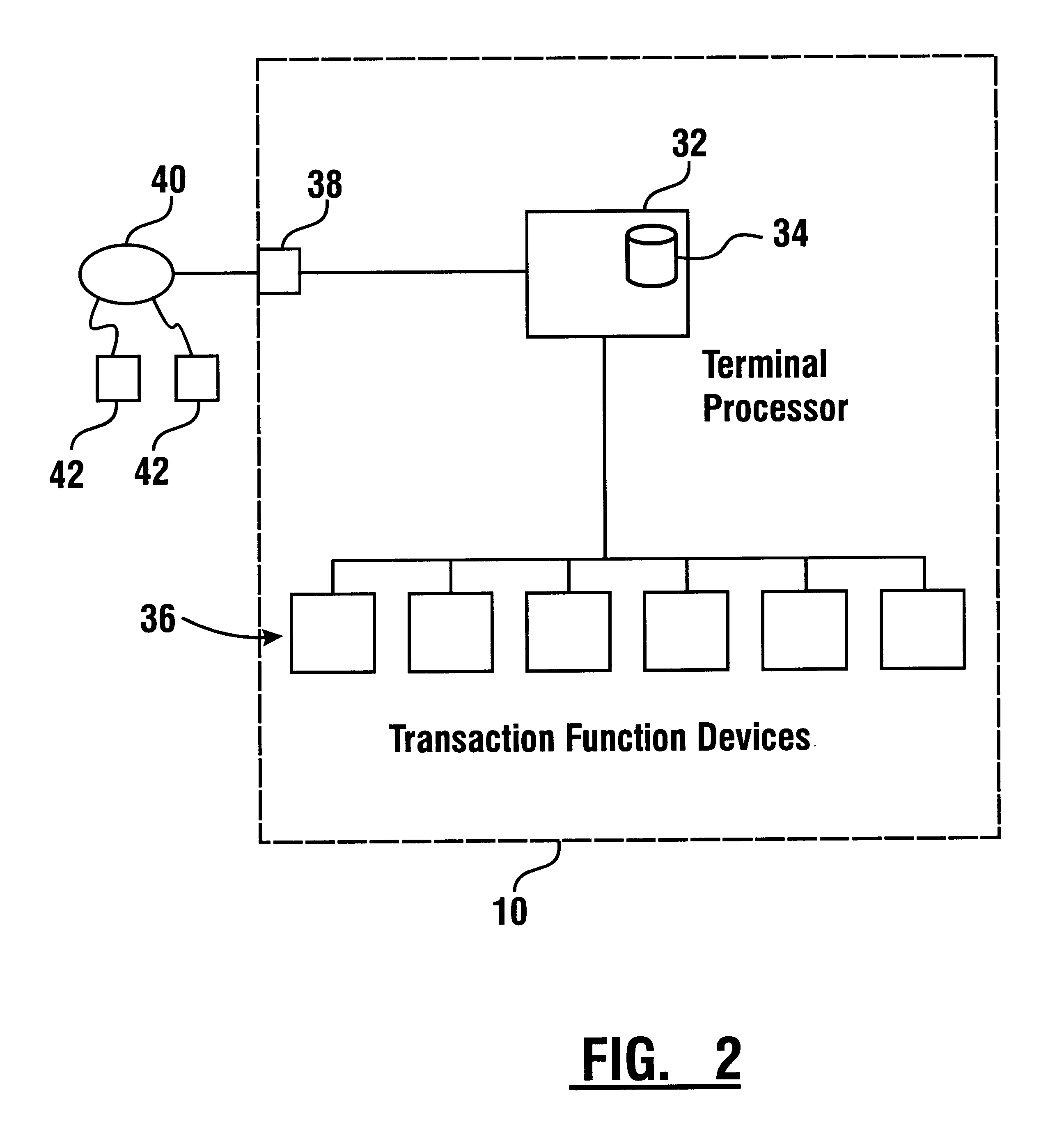

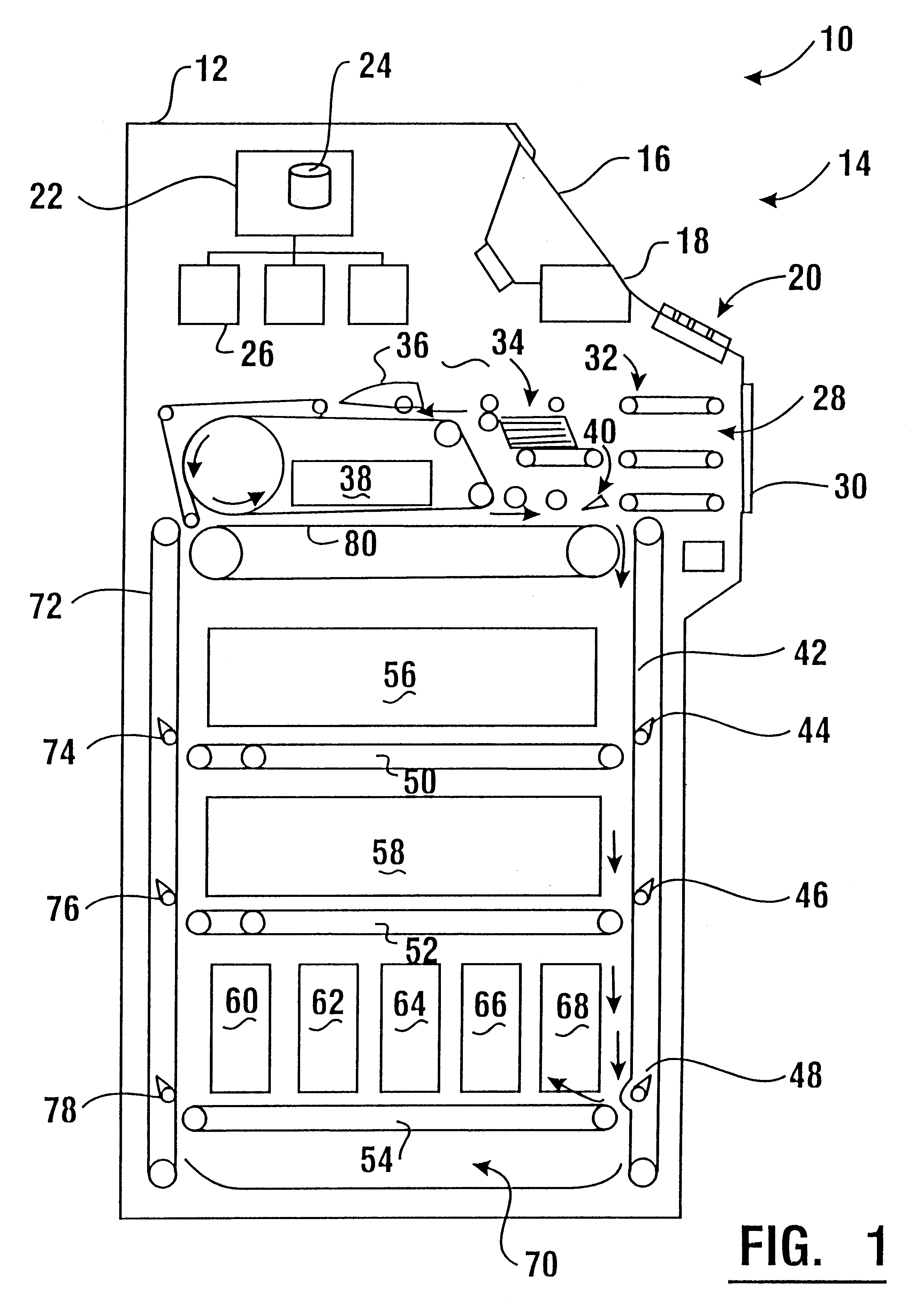

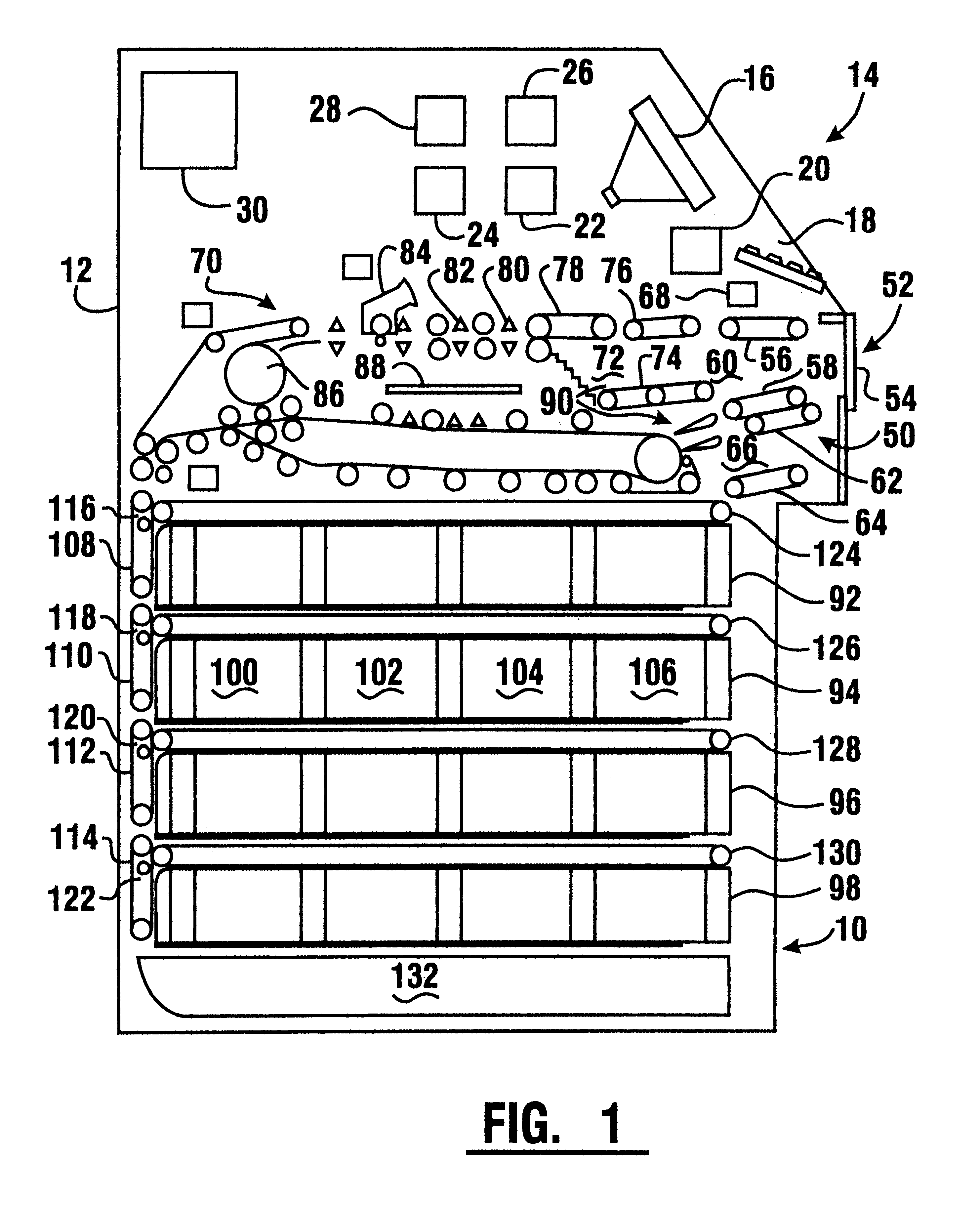

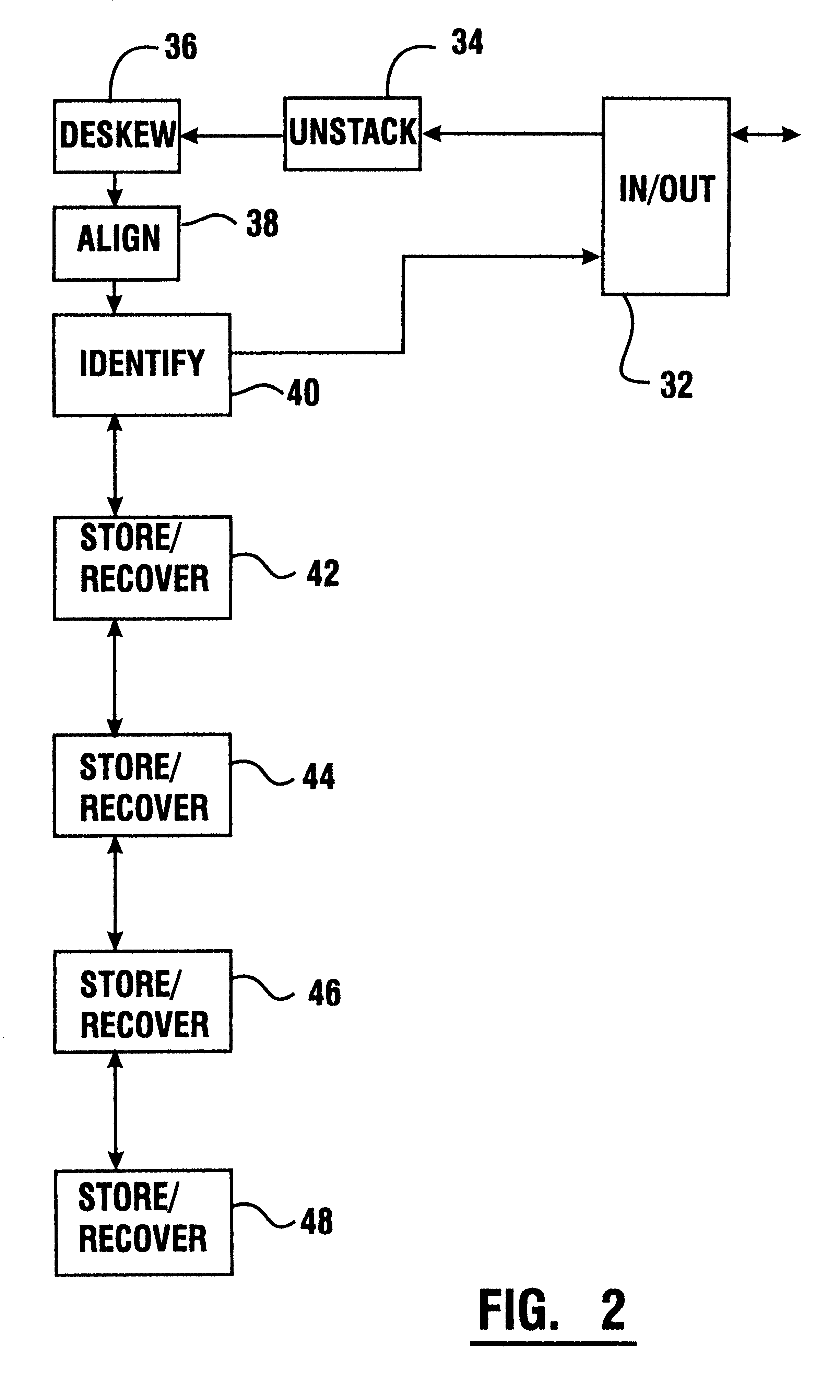

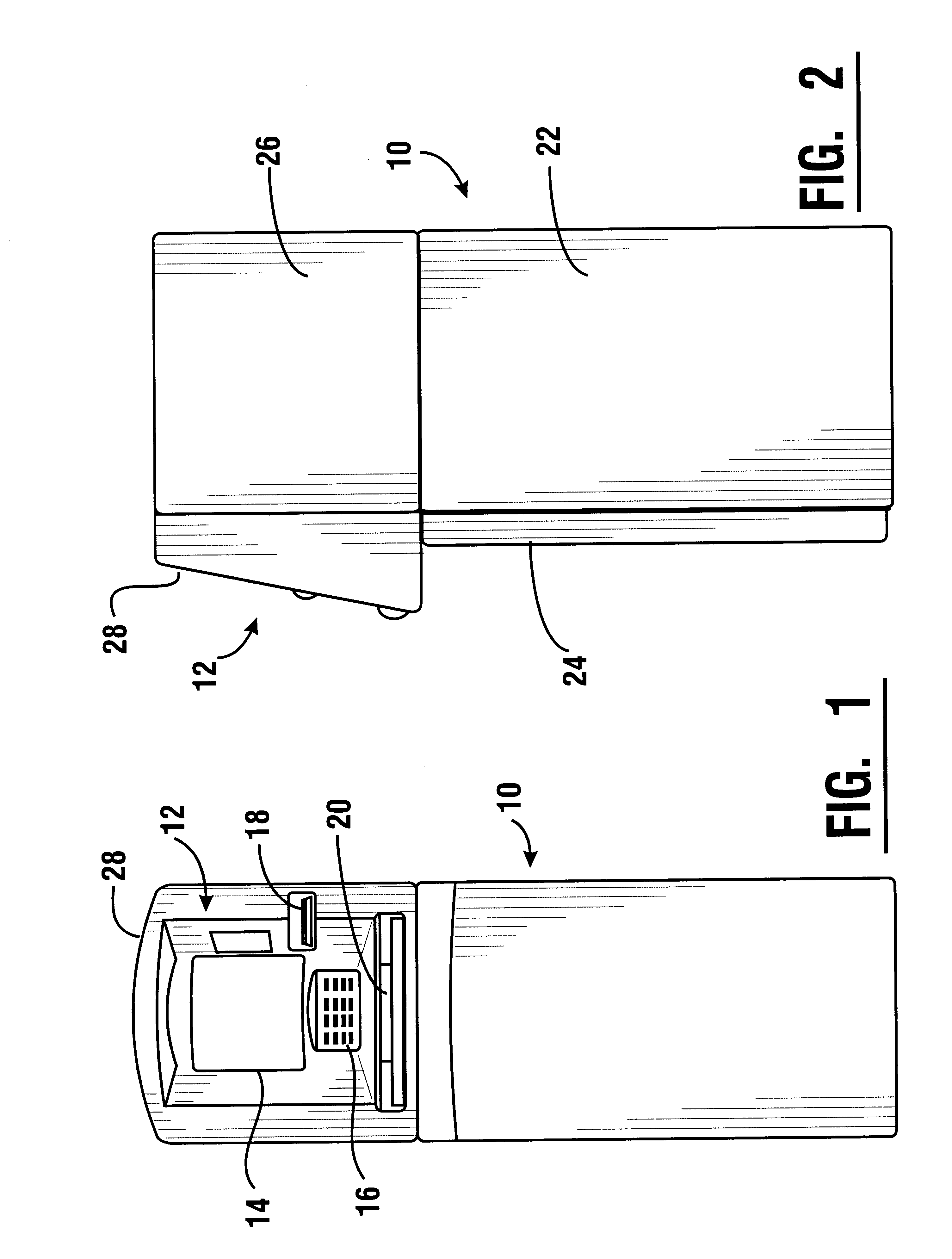

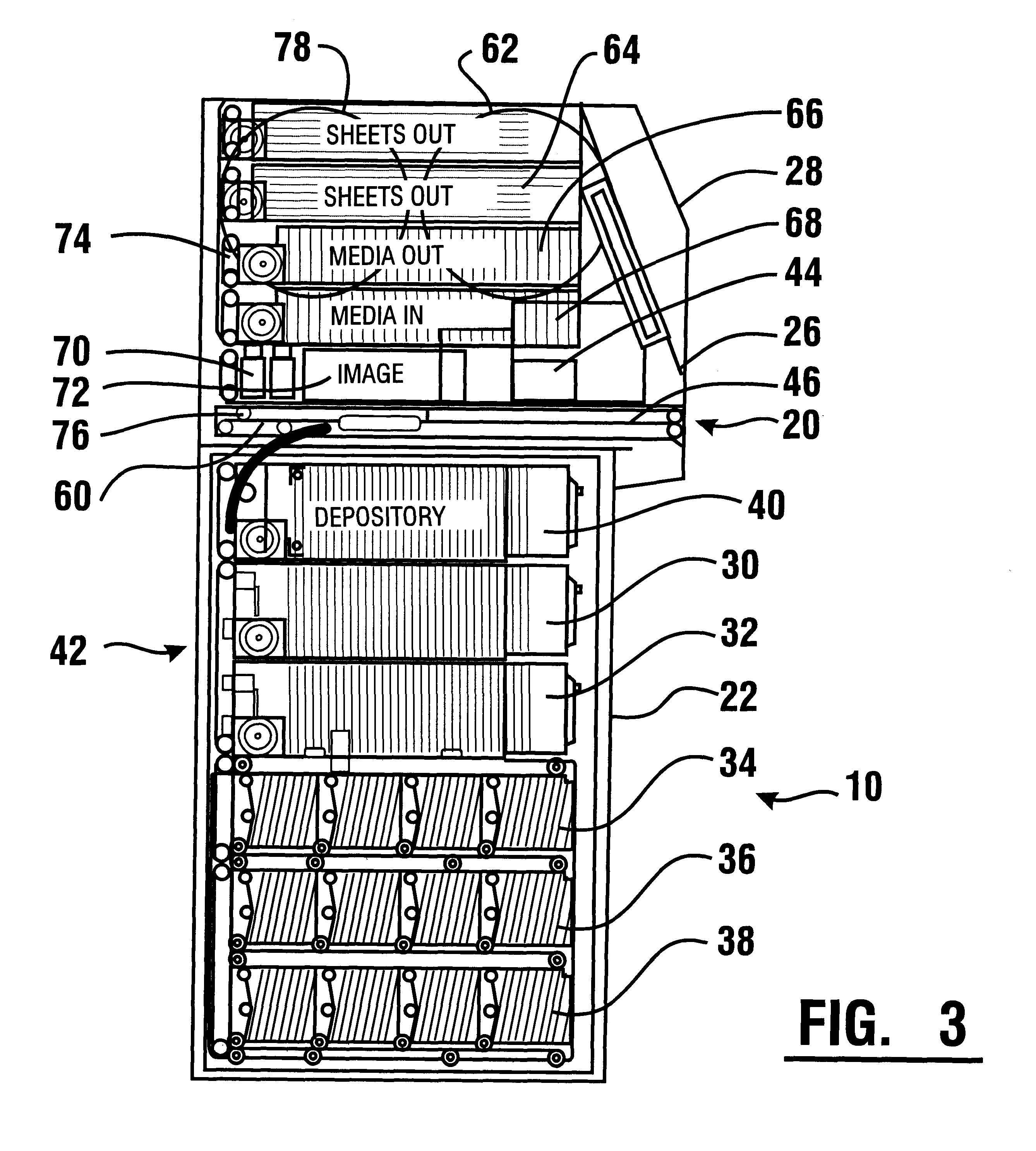

Automated banking machine with self auditing capabilities and system

InactiveUS6109522AEasy to operateRisk minimizationPayment architectureSpecial data processing applicationsMachine selectionDocumentation

An automated banking machine (10) identifies and stores in storage areas documents such as currency bills deposited by a user. The machine selectively recovers such documents from storage areas and dispenses them. The machine includes a central transport (70) wherein documents deposited in a stack are unstacked, oriented and identified. Such documents are then routed to storage areas in canisters (92, 94, 96, 98). Documents in the storage areas are selectively picked therefrom and delivered to a user through an input / output area (50) of the machine. Each canister includes a memory (626) which holds information concerning the number and type of documents housed in the canister as well as other information concerning the hardware and software resident on the canister. The memory also includes data representative of individuals responsible for loading and transporting the canister. The machine conducts self-auditing activities to verify that the documents held in the storage areas correspond to the information stored in memory and indicate discrepancies.

Owner:DIEBOLD NIXDORF

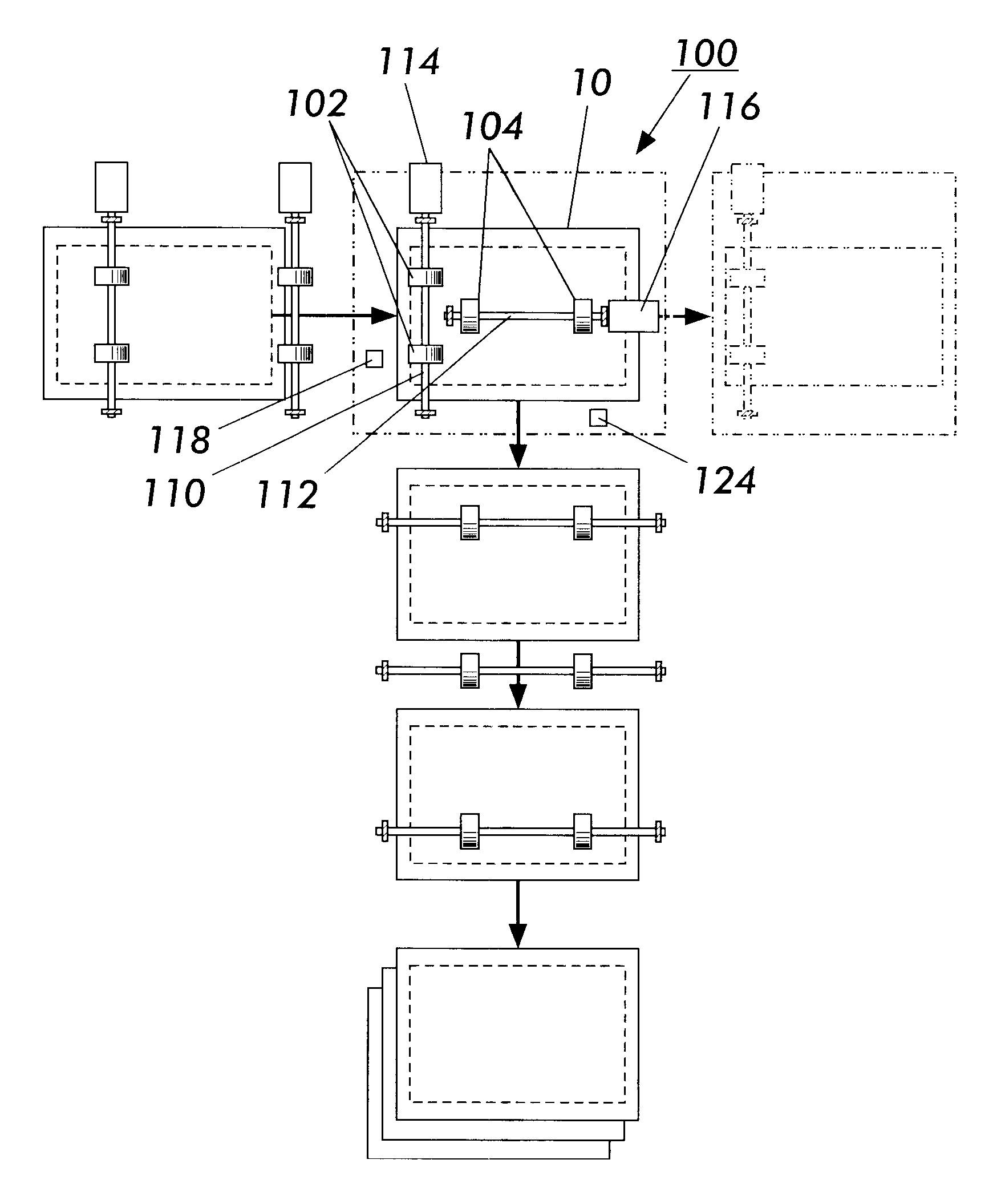

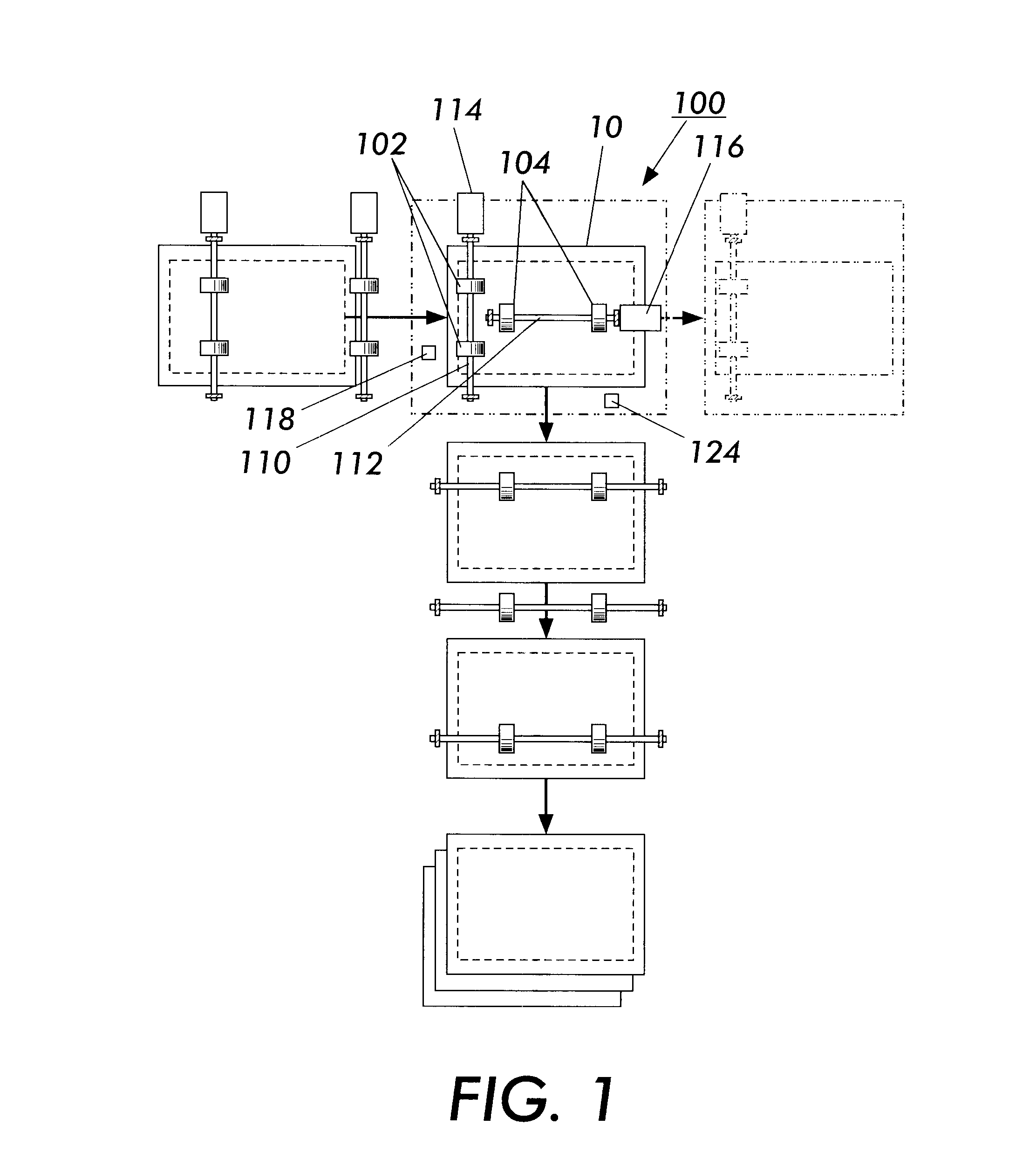

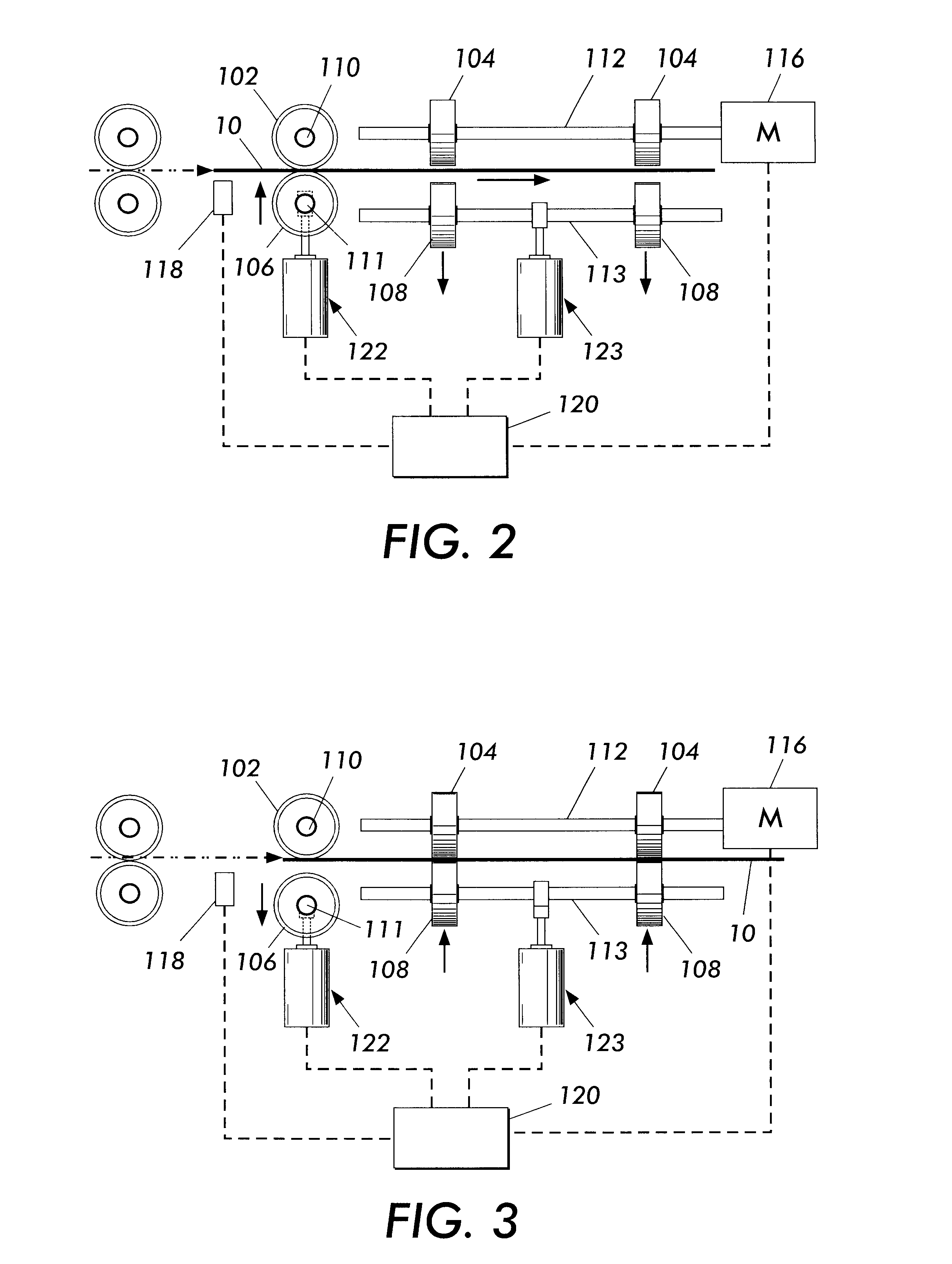

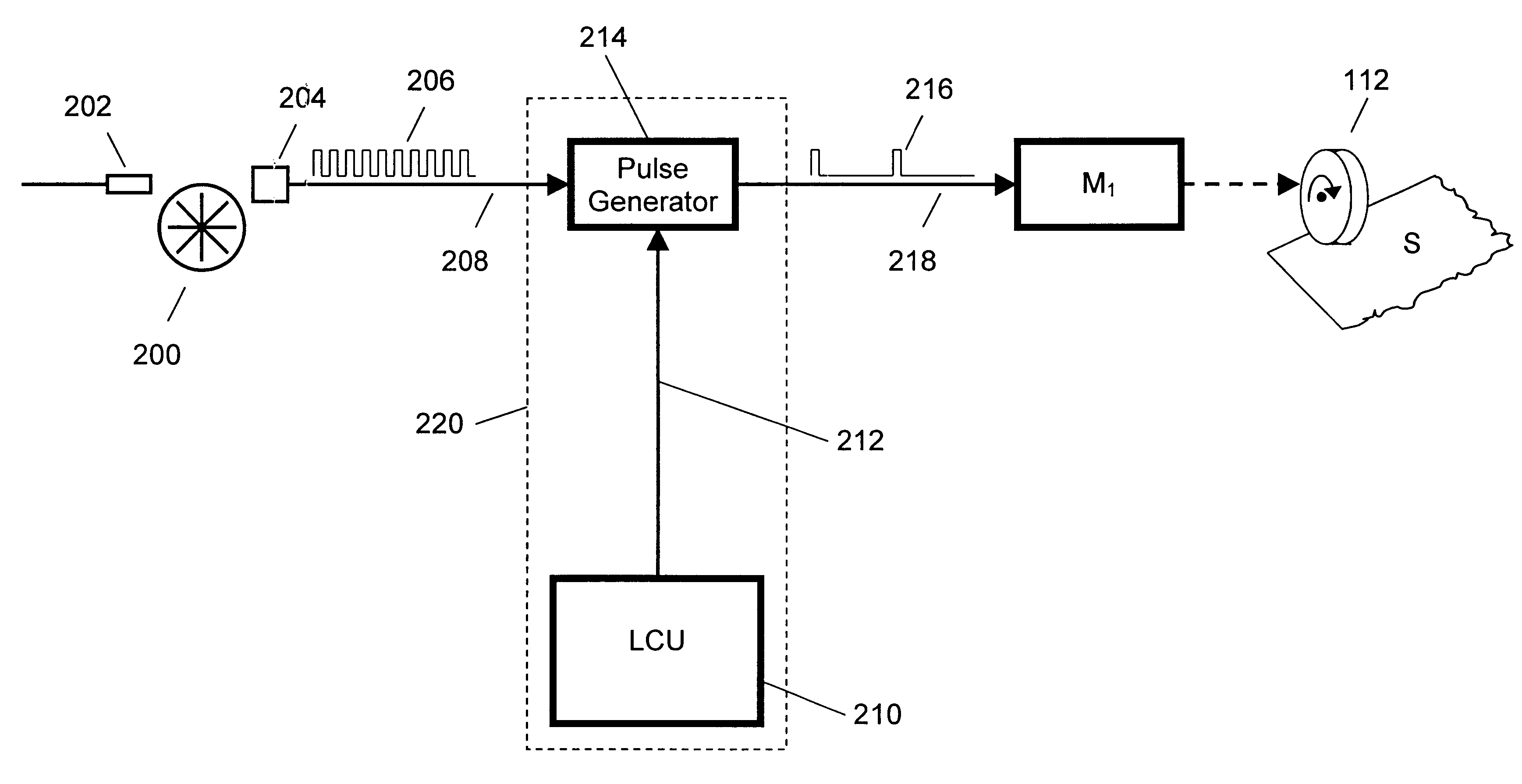

System and method for improved registration performance

InactiveUS6641134B1Precise positioningRegistering devicesElectrographic process apparatusMotor driveDelayed time

An apparatus and method for advancing a receiver into registered relationship with a moving image-bearing member. A motor is provided that is responsive to motor drive pulses. A drive member engages the receiver, and a drive coupling connects the drive member and the motor. An encoder generates encoder pulses that correspond with movement of the image-bearing member. A pulse generator generates motor drive pulses in response to the encoder pulses to accelerate the receiver to a speed approximately equal to the speed of the image-bearing member speed. A timer determines an amount of delay time between detection of the receiver by an in-track sensor and the beginning of a subsequent movement of the motor. A delay mechanism delays the acceleration of the receiver to the image-bearing member speed by the amount of delay time.

Owner:EASTMAN KODAK CO +1

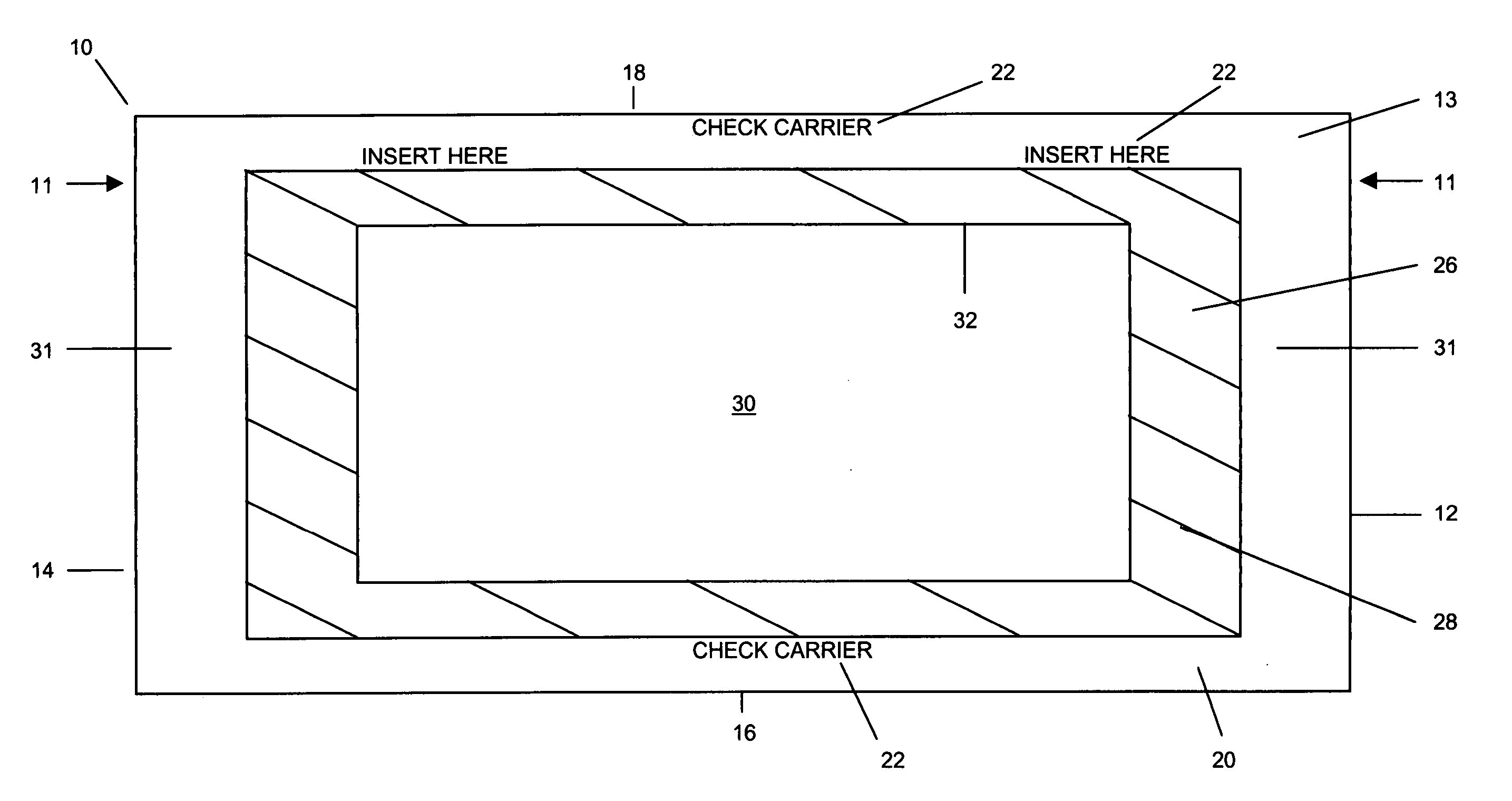

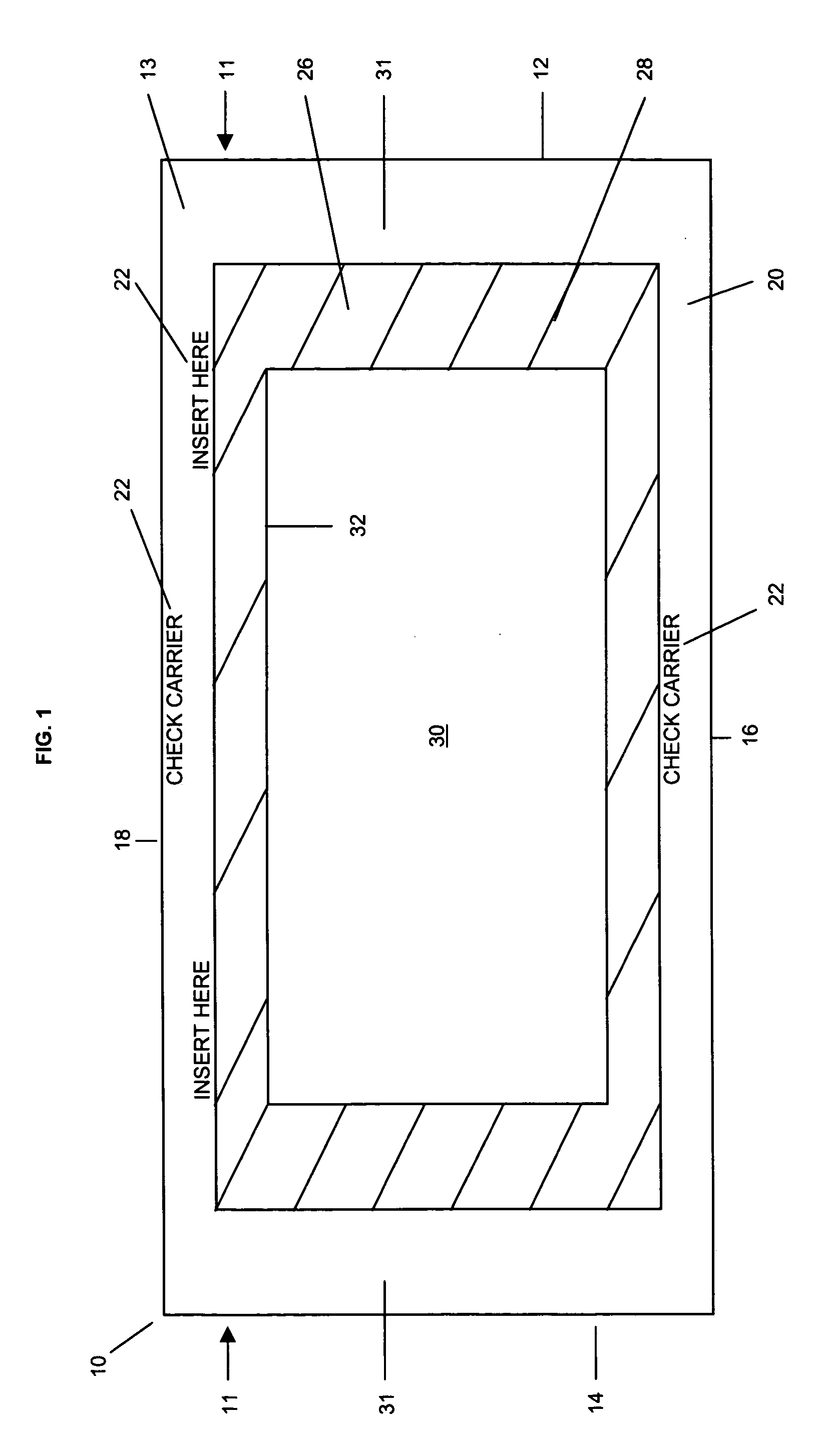

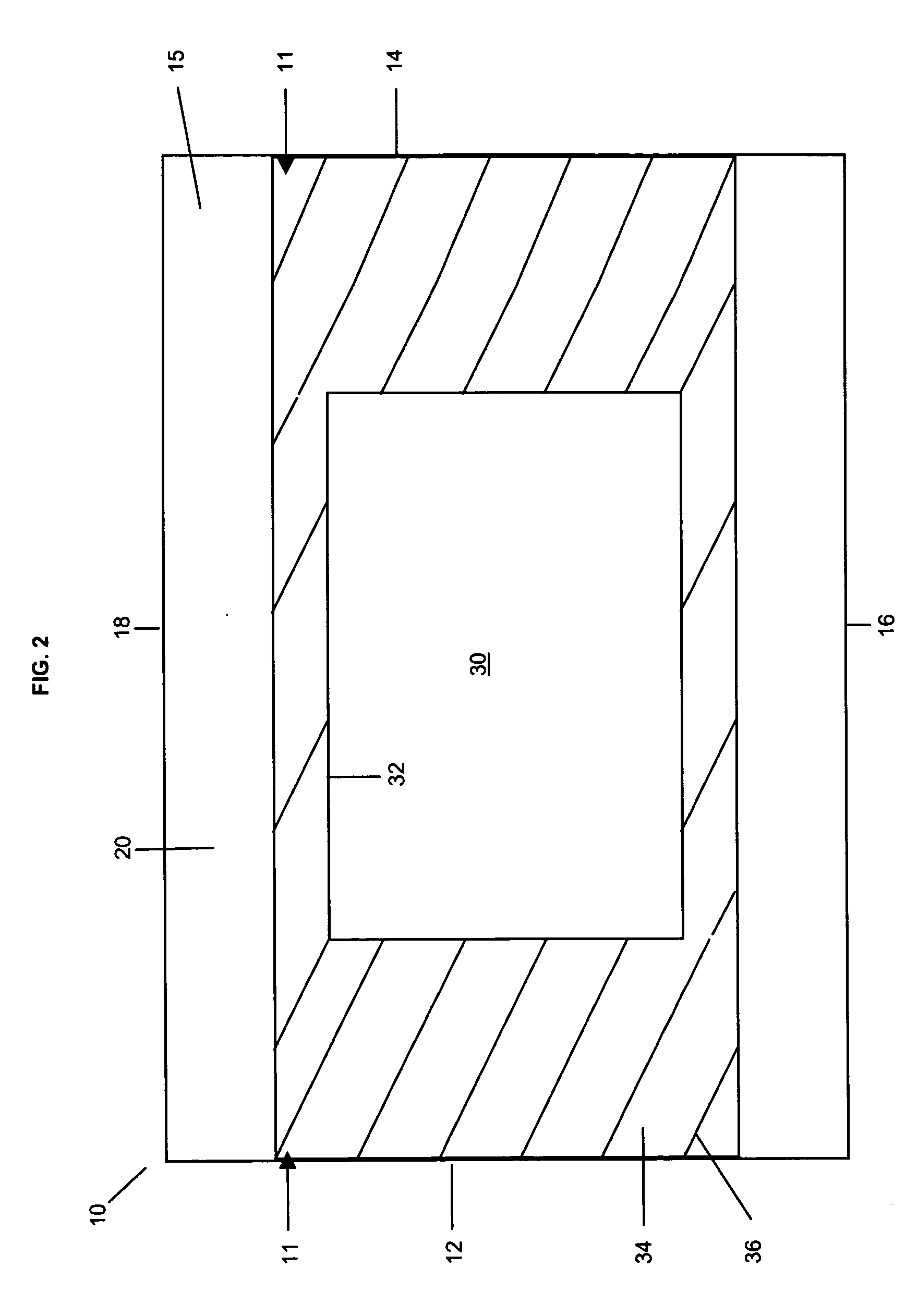

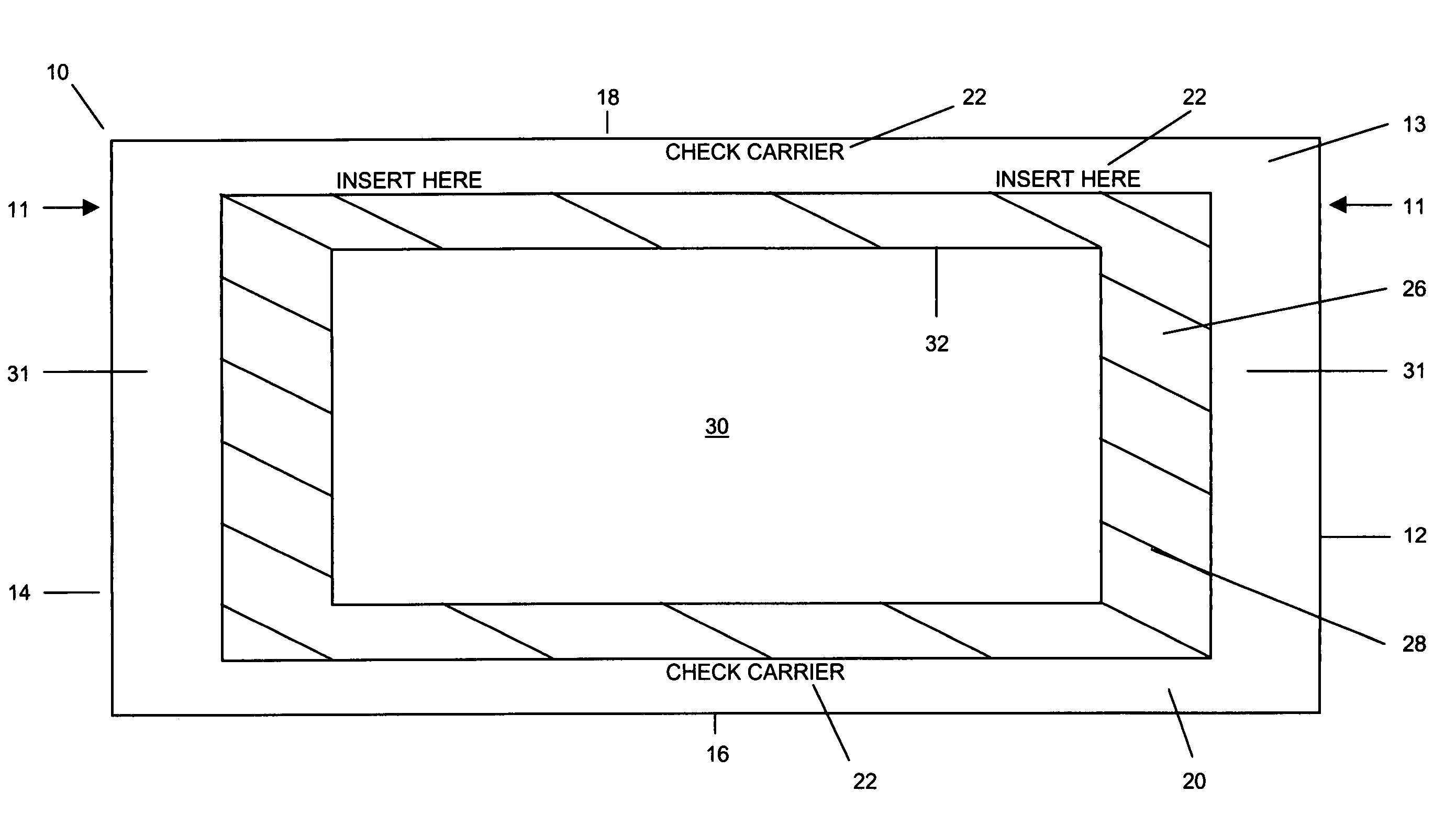

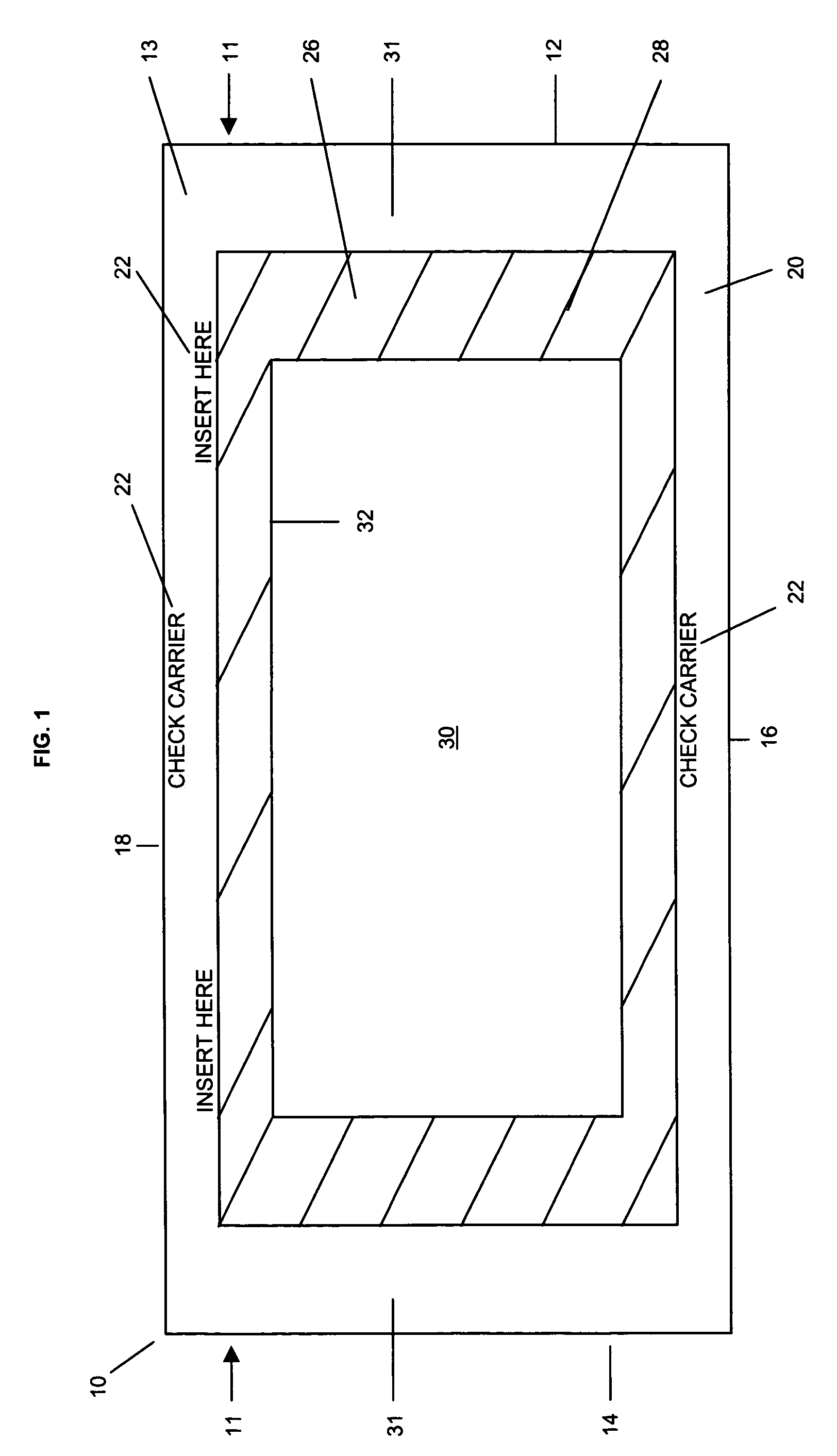

Document carrier and system for use therewith

The construction of the present invention is suitable for use as a document carrier and is particularly adapted for the transporting of negotiable instruments such as checks and other items that are used to transfer funds, credits or the like through automated processing equipment such as readers, scanners, copiers and the like. The assembly of the present invention includes an internal pocket that is created through the use of a pair of translucent sheets affixed about an opening created in a standard format sheet, such as a sheet having a dimension of 8½″ by 11″.

Owner:REYNDERS LISA A +1

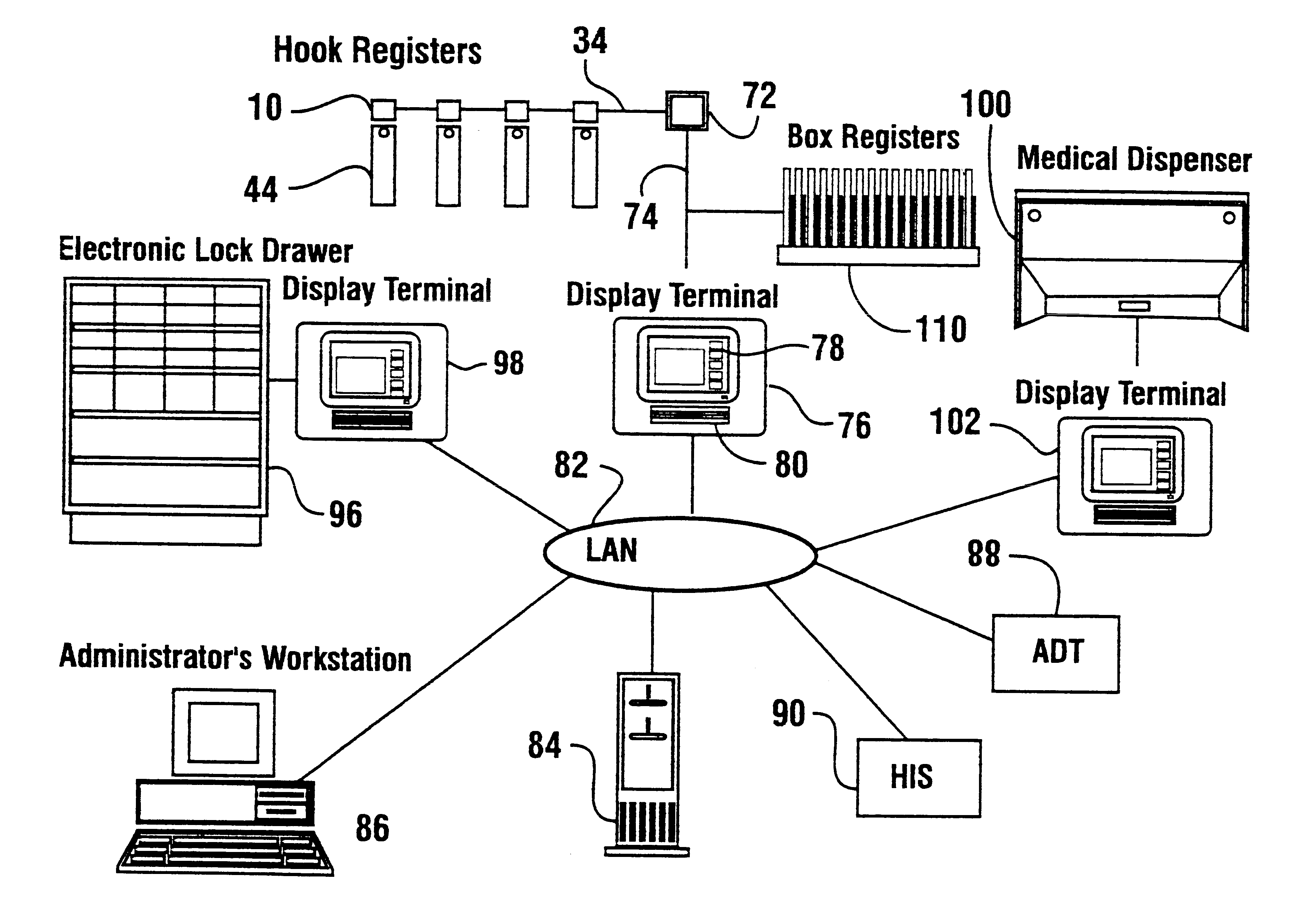

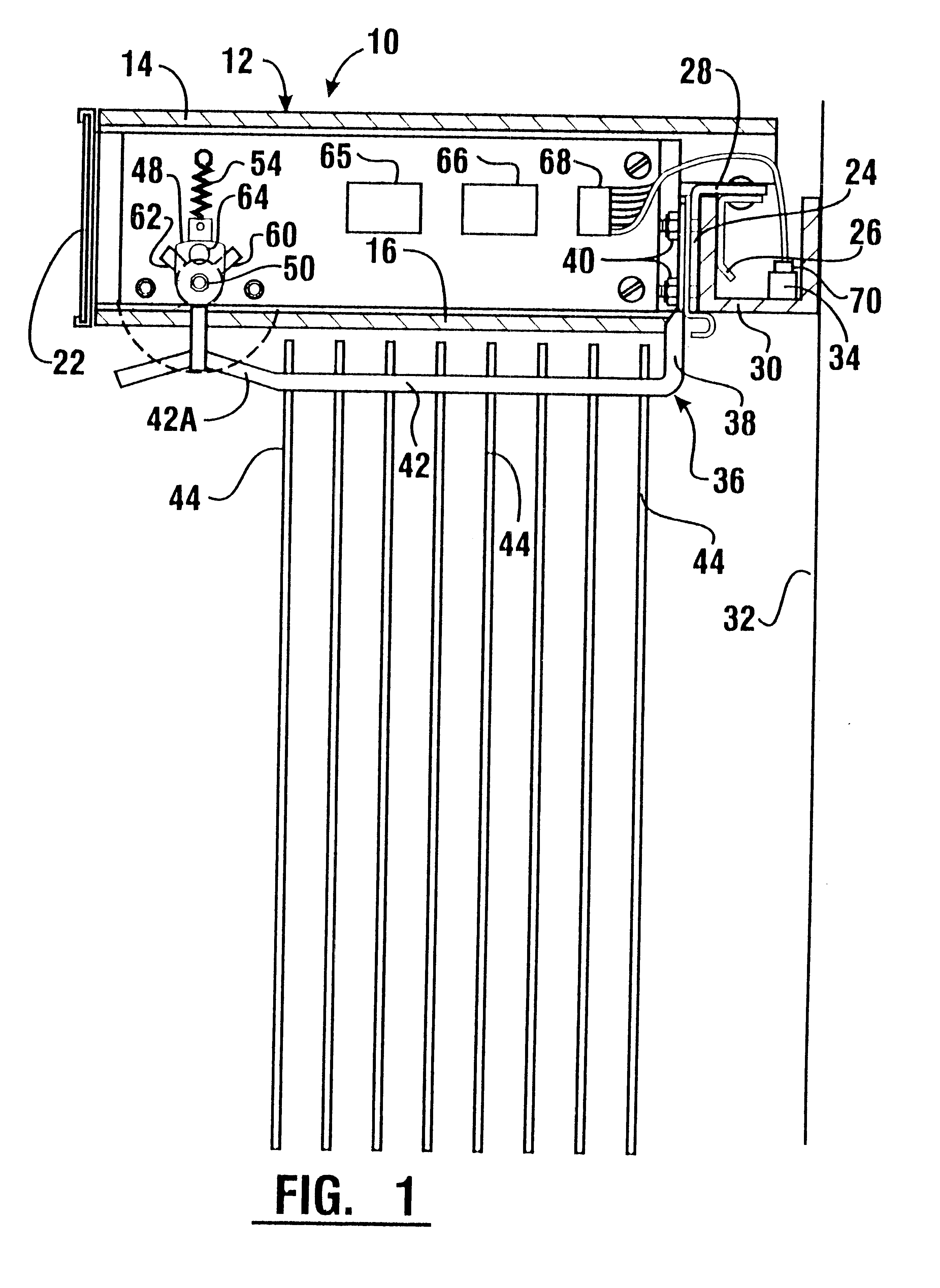

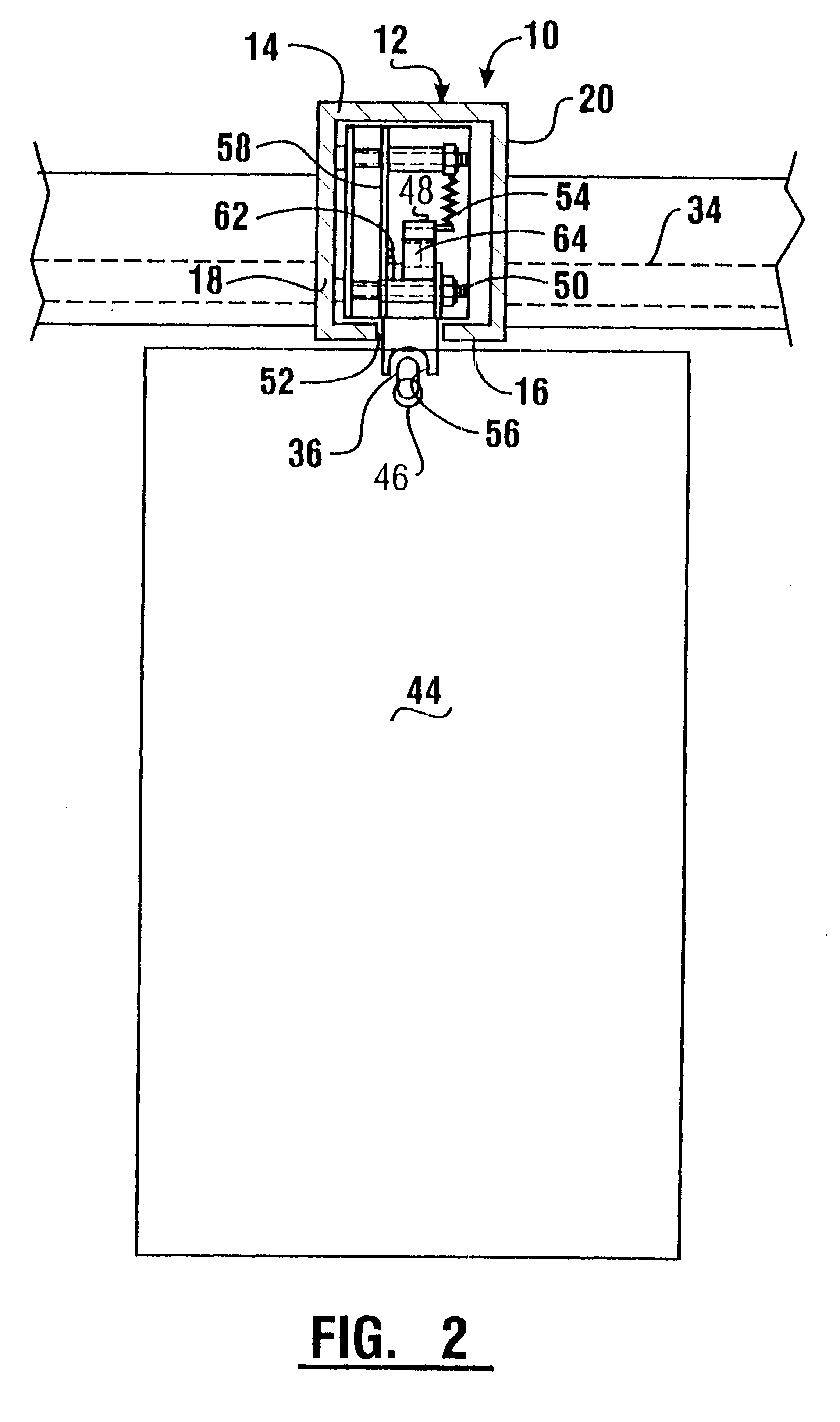

Medical item dispensing system

A system for monitoring and dispensing medical items includes a plurality of hook registers (10). Each of the hook registers includes sensors (48, 60, 62, 64) sensing the removal or addition of a medical item to the storage location on the hook register. Each hook register has a microprocessor (66) connected to the sensor which stores a count of the items added or removed from the location. The microprocessor also includes location identifying information specifically associated with the particular hook register. The microprocessor is periodically polled by a controller (72) which reads and stores the count and location identifying information from each of the hook registers. The controller information is periodically read by a data terminal (76) which is connected through a local area network (82) to a remote computer (84) having a processor and data store. A user of the data terminal is enabled to specify a patient for whom medical items will be used when the items are removed from the hook registers or other storage locations. In addition, the system also monitors inventories of items and levels of usage by users. The system also monitors and controls the dispense of other medical items from box registers (110) as well as controls the dispense of items from secure storage locations such as electronic lock drawers (96) and medicine dispensers (100).

Owner:DIEBOLD NIXDORF

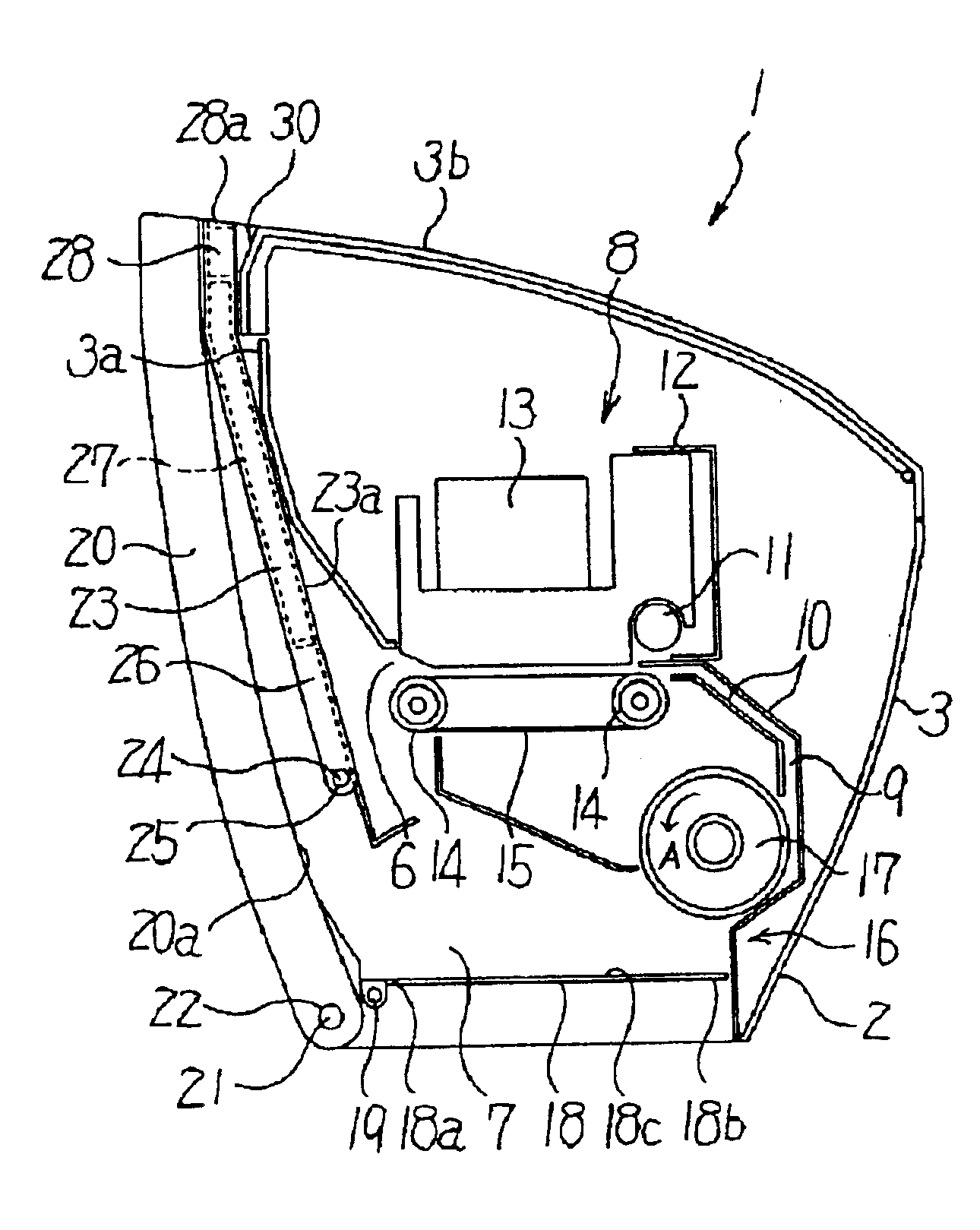

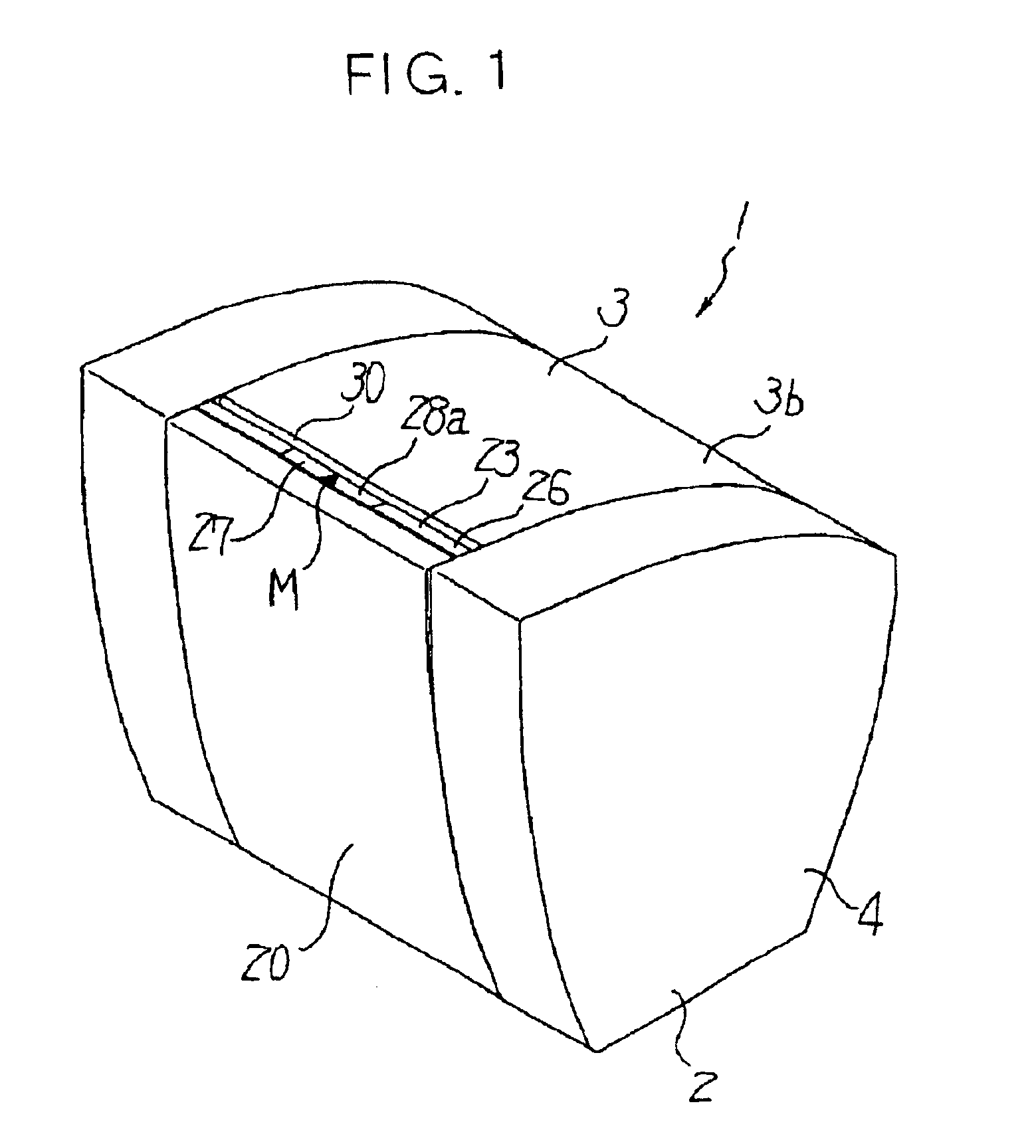

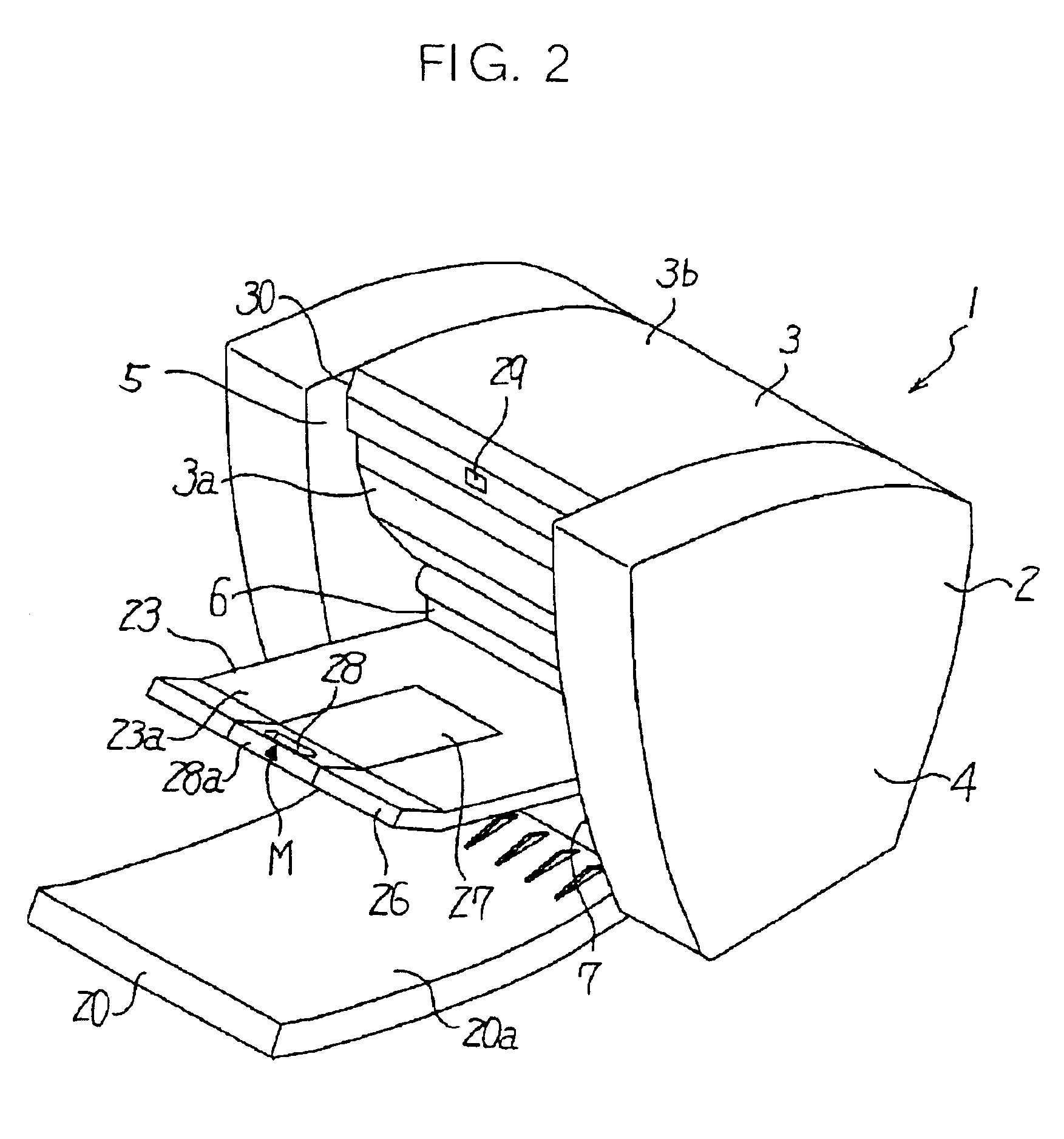

Printer

InactiveUS6848685B2Save spaceAvoid enteringPile receiversOther printing apparatusComputer printingEngineering

Owner:RICOH KK

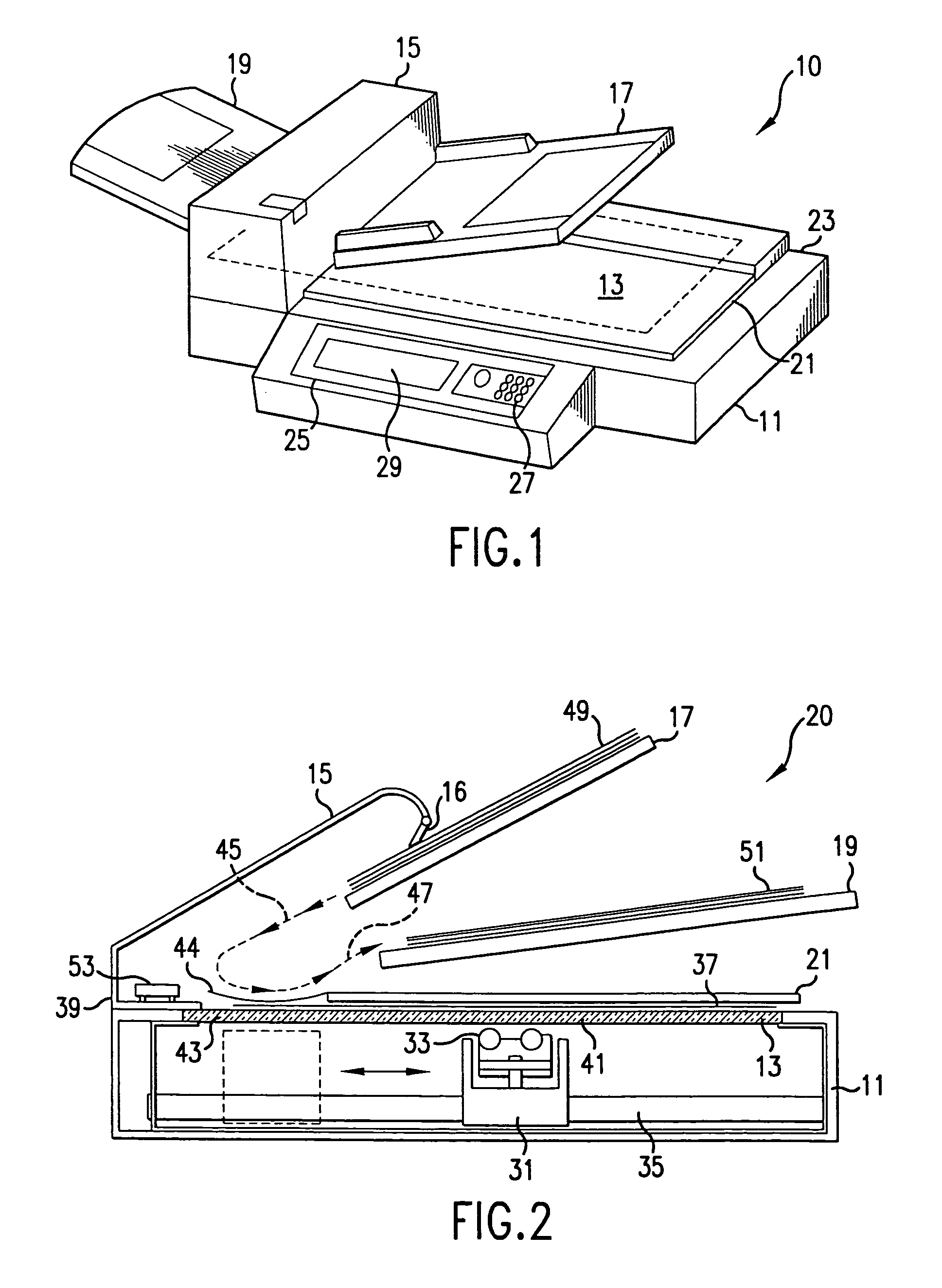

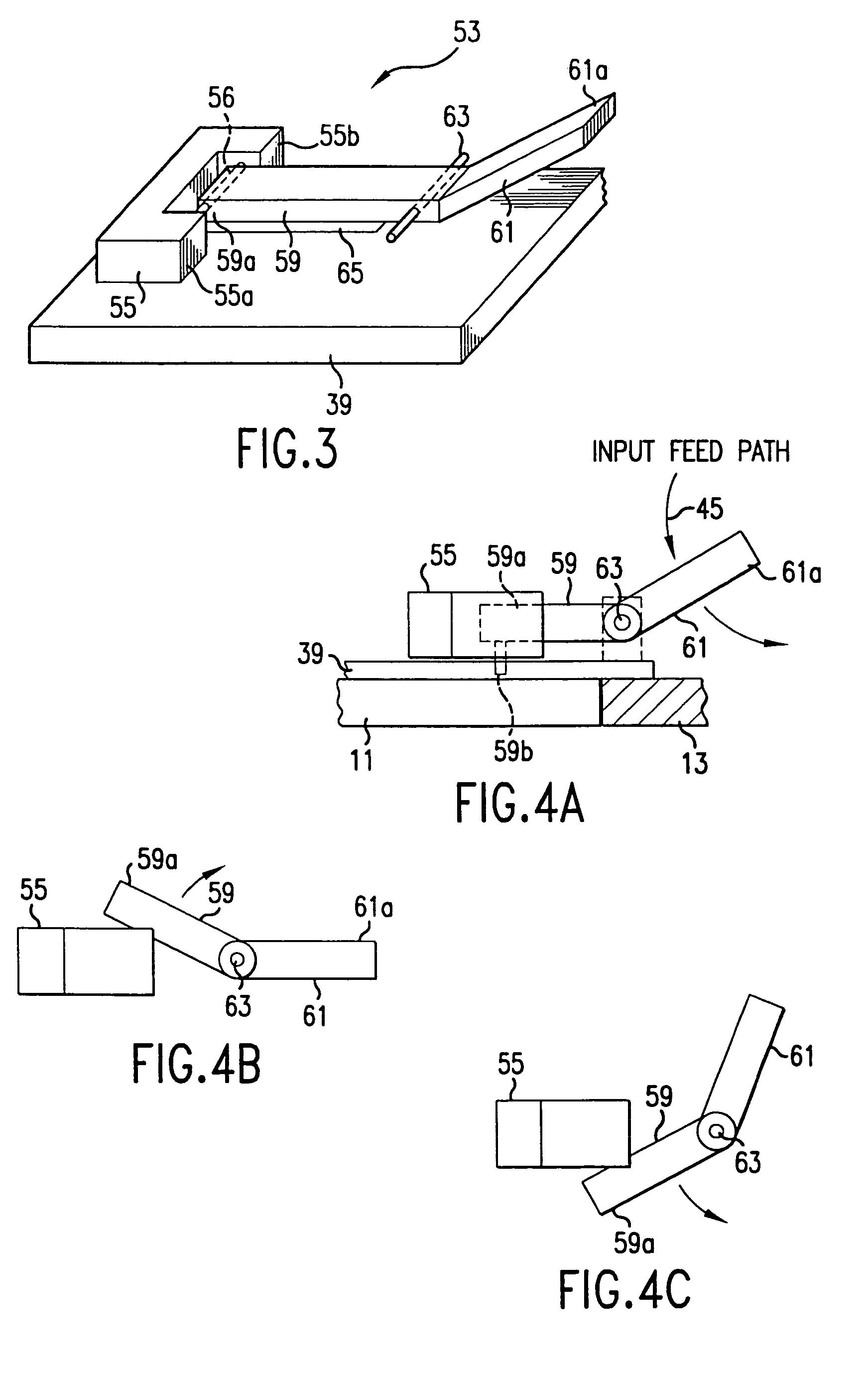

Single automatic document feeder sensor for media leading edge and top cover being opened detection

InactiveUS7139108B2Low costReduce the numberSolid-state devicesMaterial analysis by optical meansLeading edgeSingle plate

A single plate flatbed scanner utilizing a single sensor to detect both opening of a lid covering the plate and the leading edge of an automatically fed document. The flatbed scanner includes a contact glass plate defining a flatbed scanning area where a document to be scanned may be manually positioned. An automatic document feeder (ADF) scan window where ADF-fed documents are scanned is defined within the flatbed scanning area. An image sensor is maintained at a fixed position in the ADF scan window while scanning ADF-fed documents. To scan a manually fed document, the image sensor moves under the flatbed scanning area so as to scan an image of the document. Since the ADF scan window and the flatbed scanning area both are defined in the same area of the contact glass plate, a document inadvertently left on the contact glass blocks the ADF scan window and prevents the scanning of an ADF fed document. A single sensor is utilized to detect the opening of the ADF which uncovers the contact glass to allow manual placement of a document. Detecting the opening of the glass plate cover is used to determine whether or not a document has been left on the glass plate after scanning. The same sensor is also utilized to detect the leading edge of an ADF fed document to initiate the scanning process at the precise time the document reaches the ADF scan window.

Owner:HEWLETT PACKARD DEV CO LP

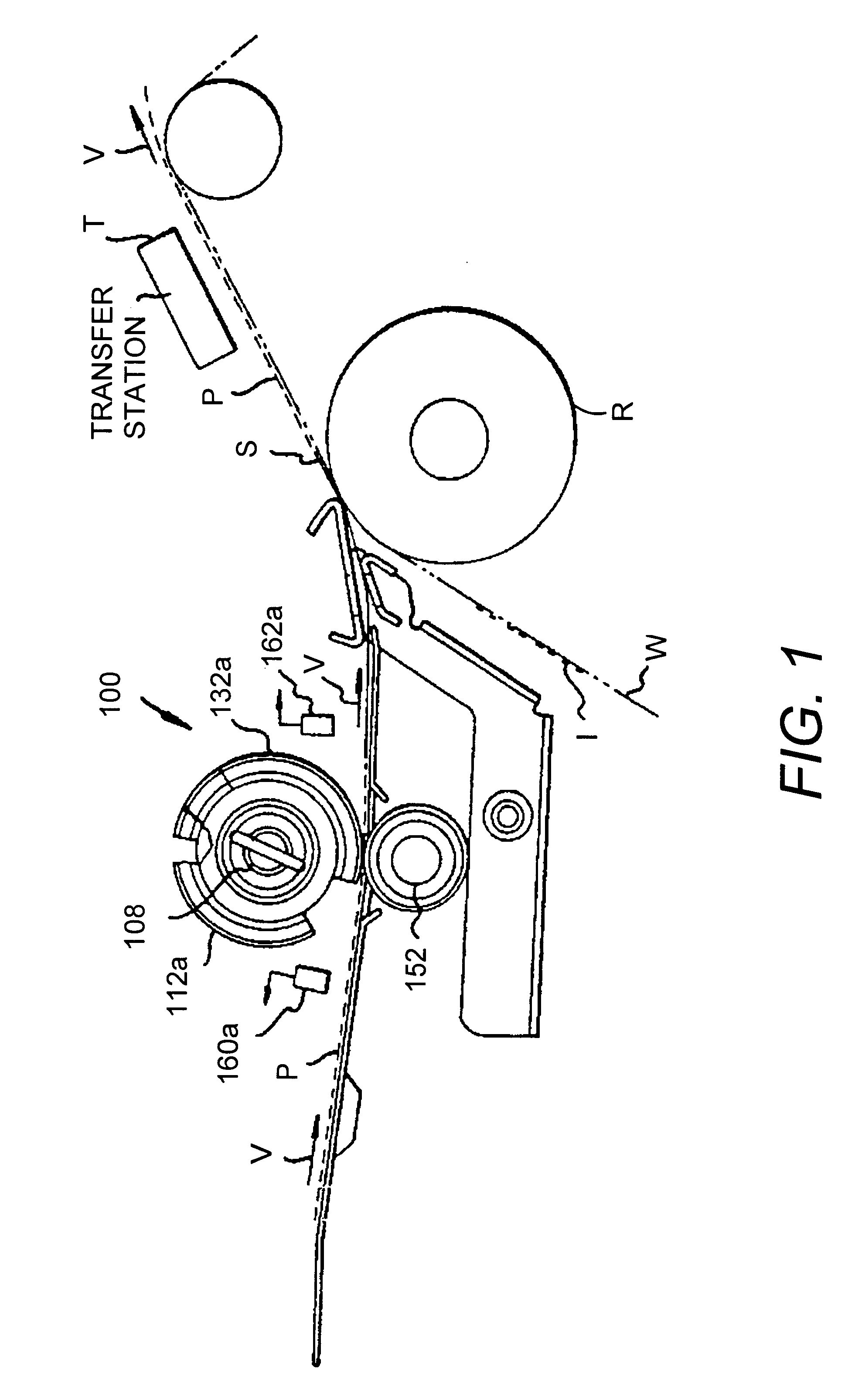

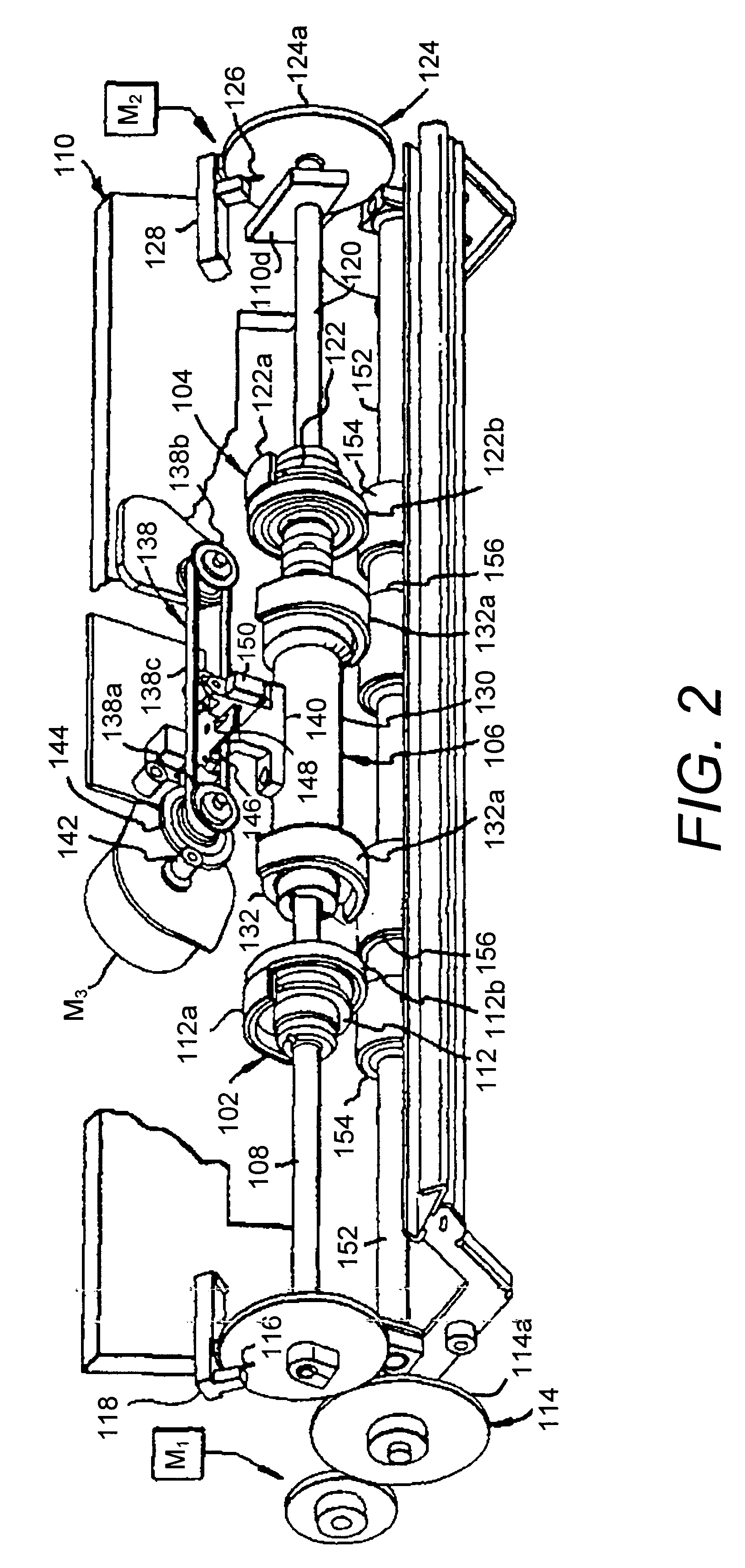

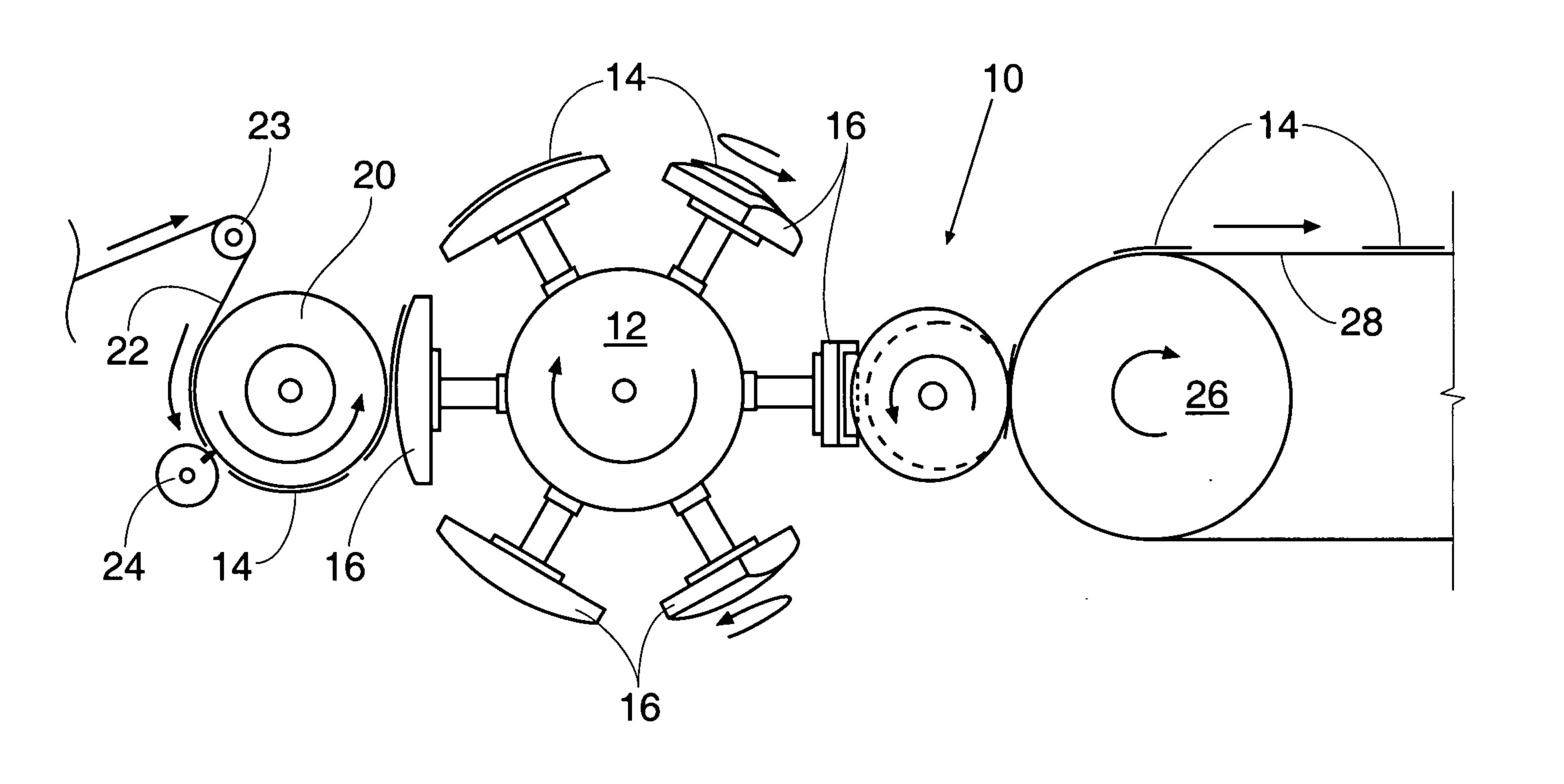

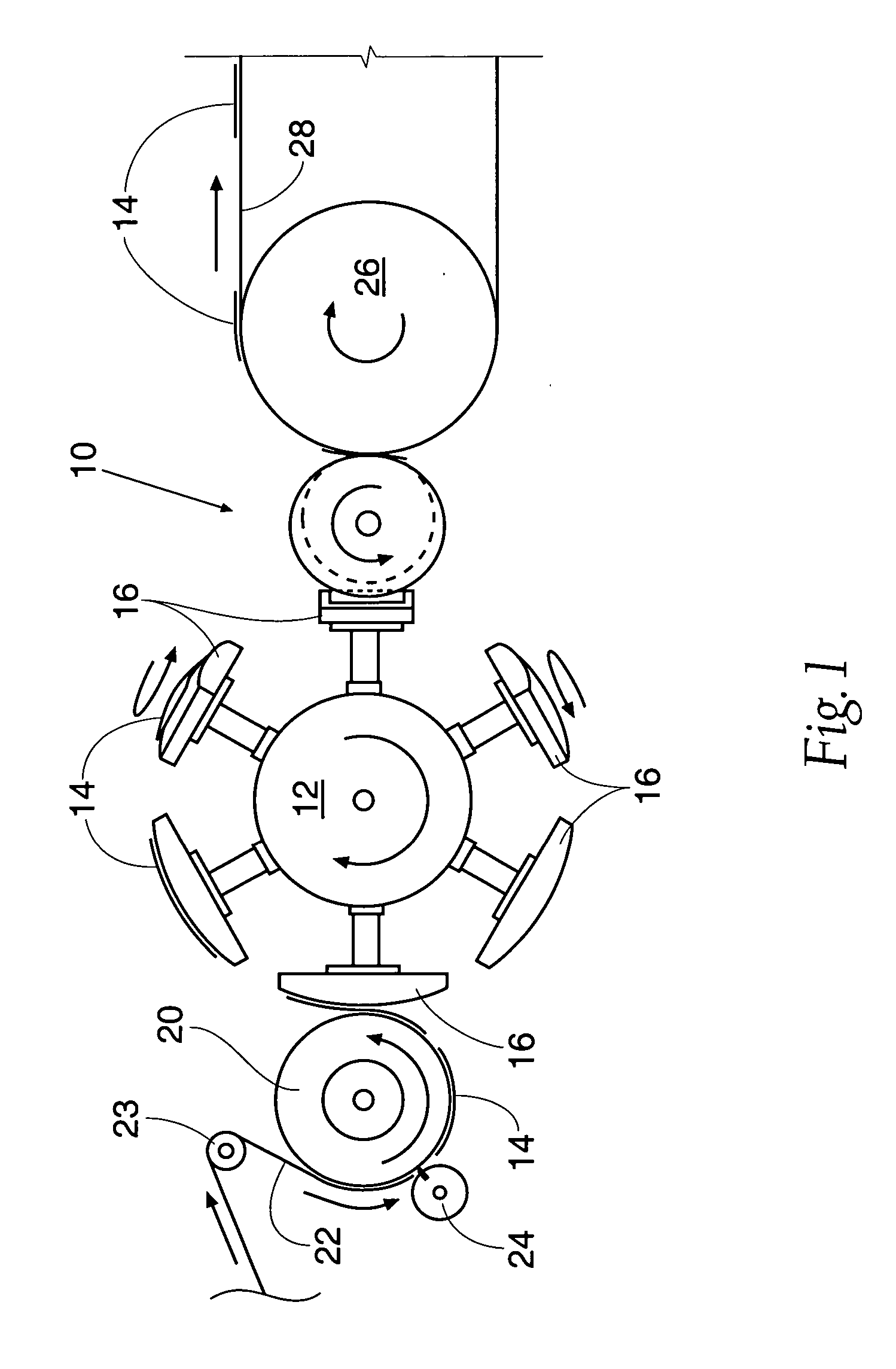

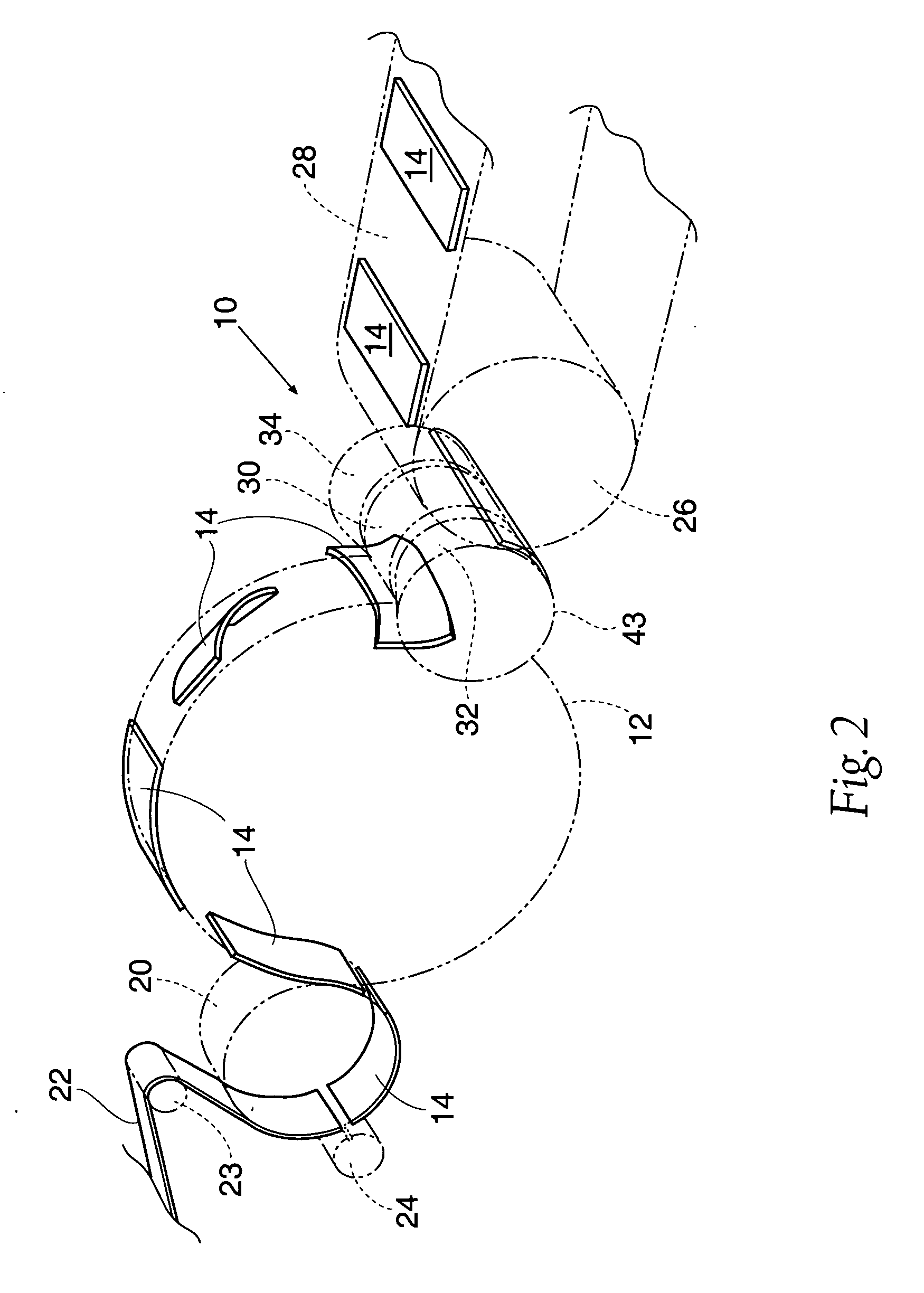

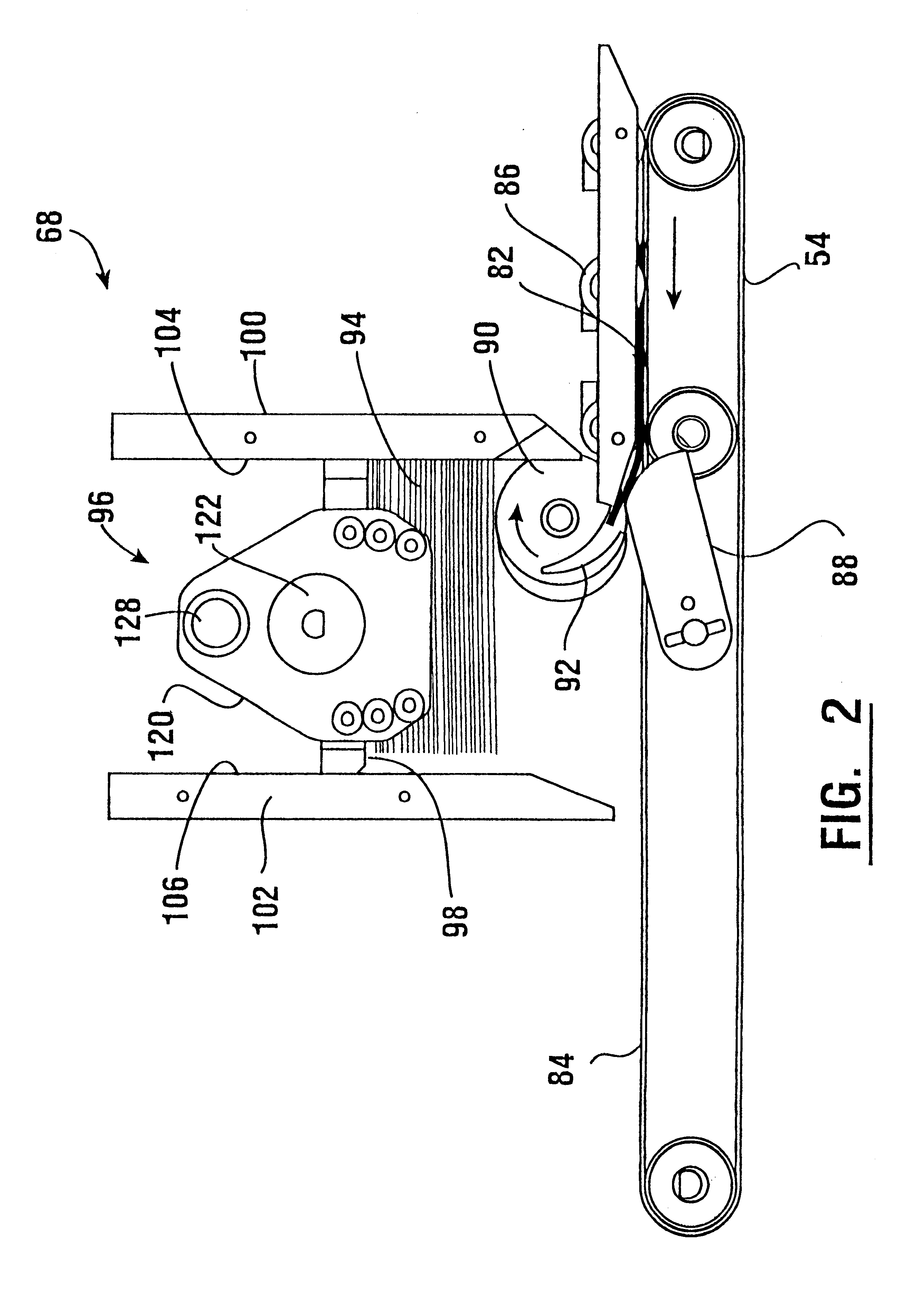

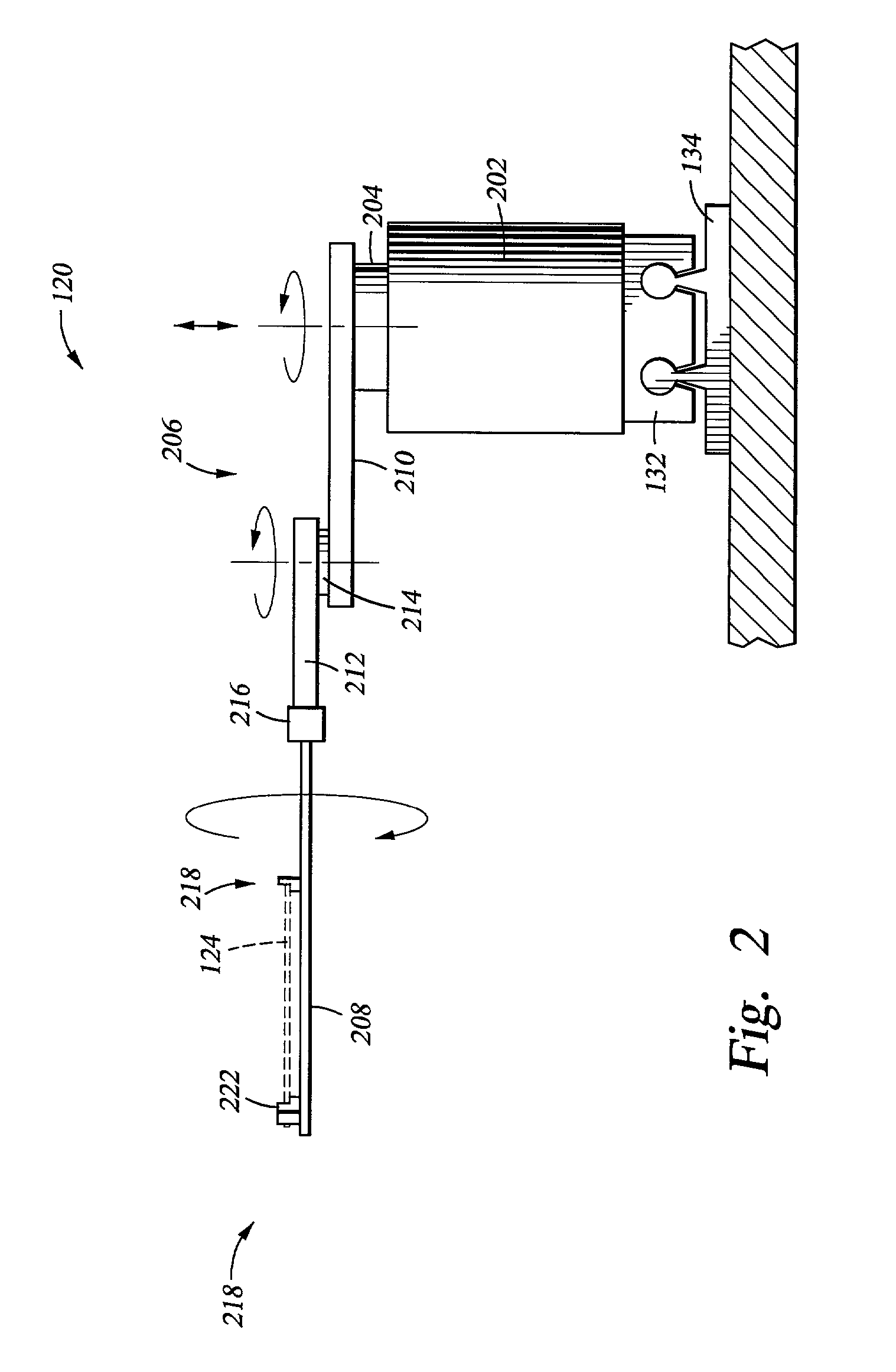

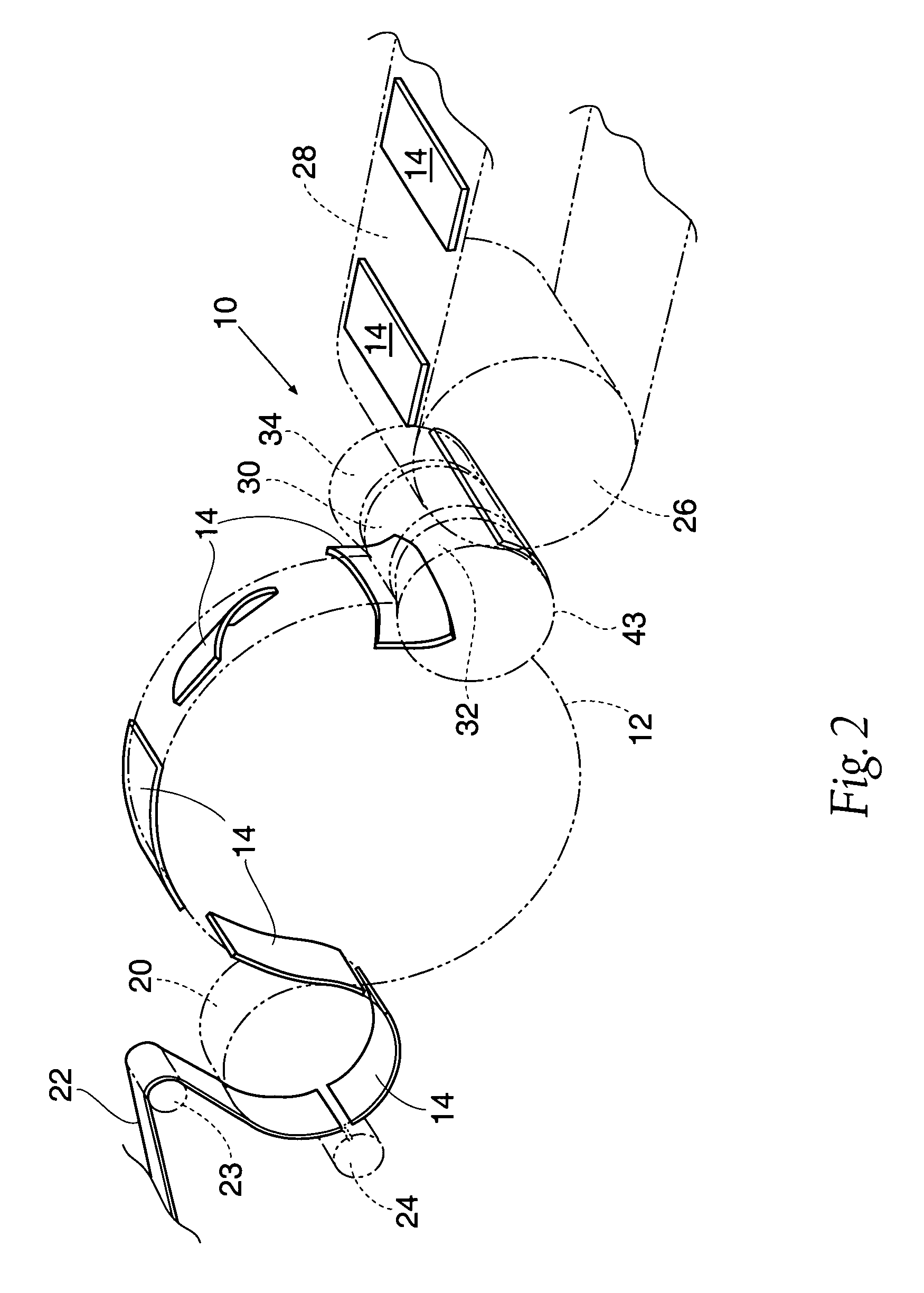

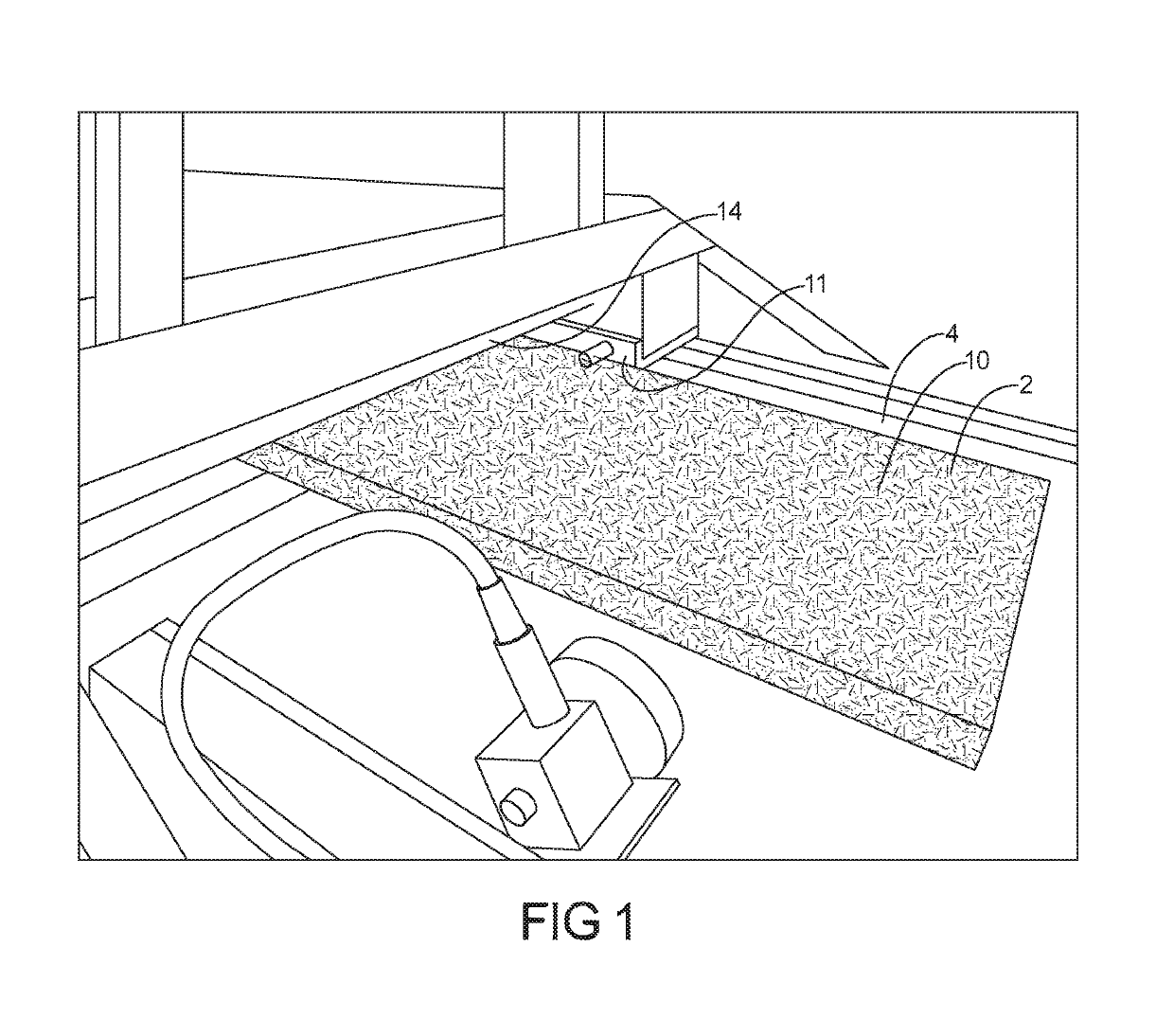

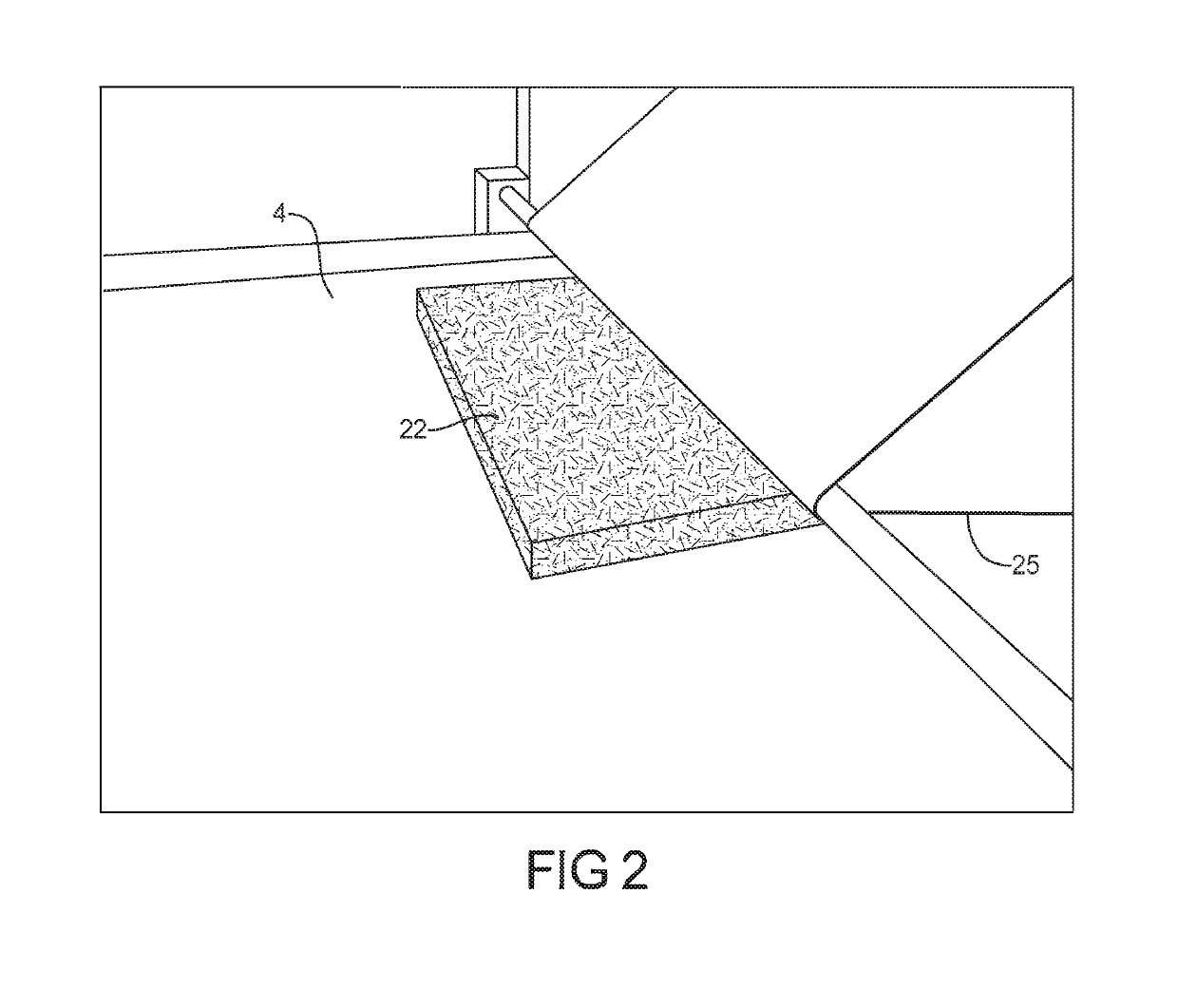

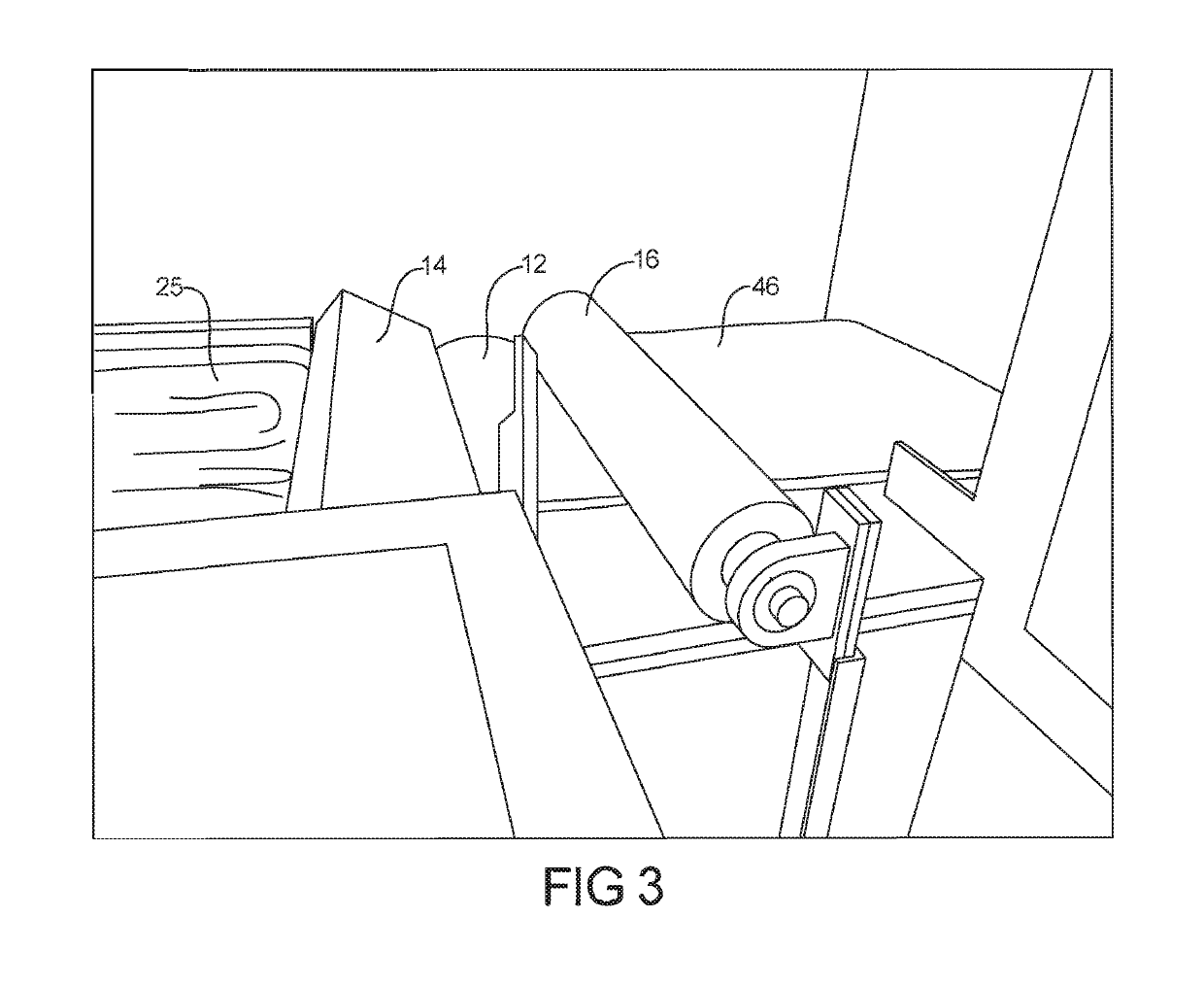

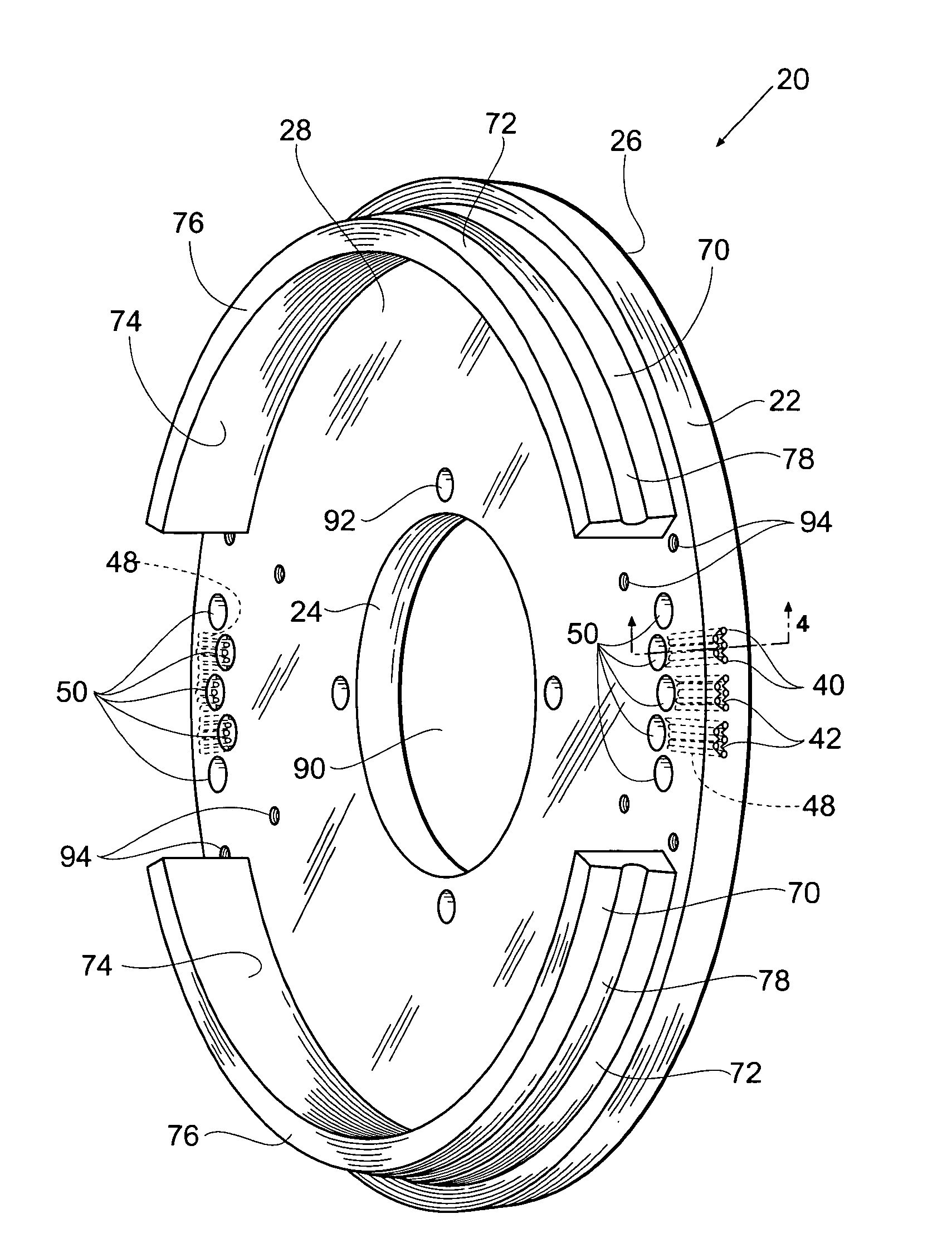

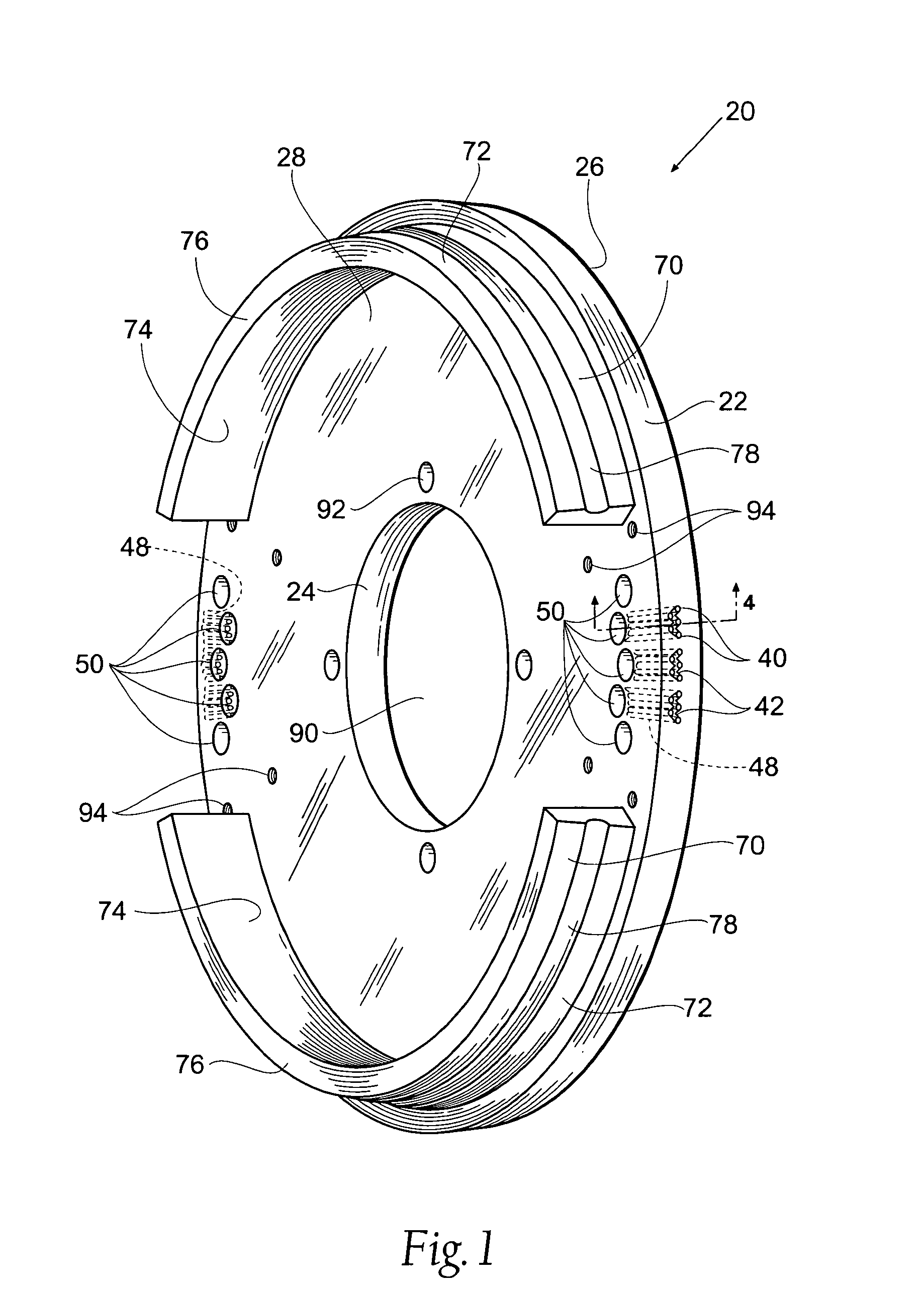

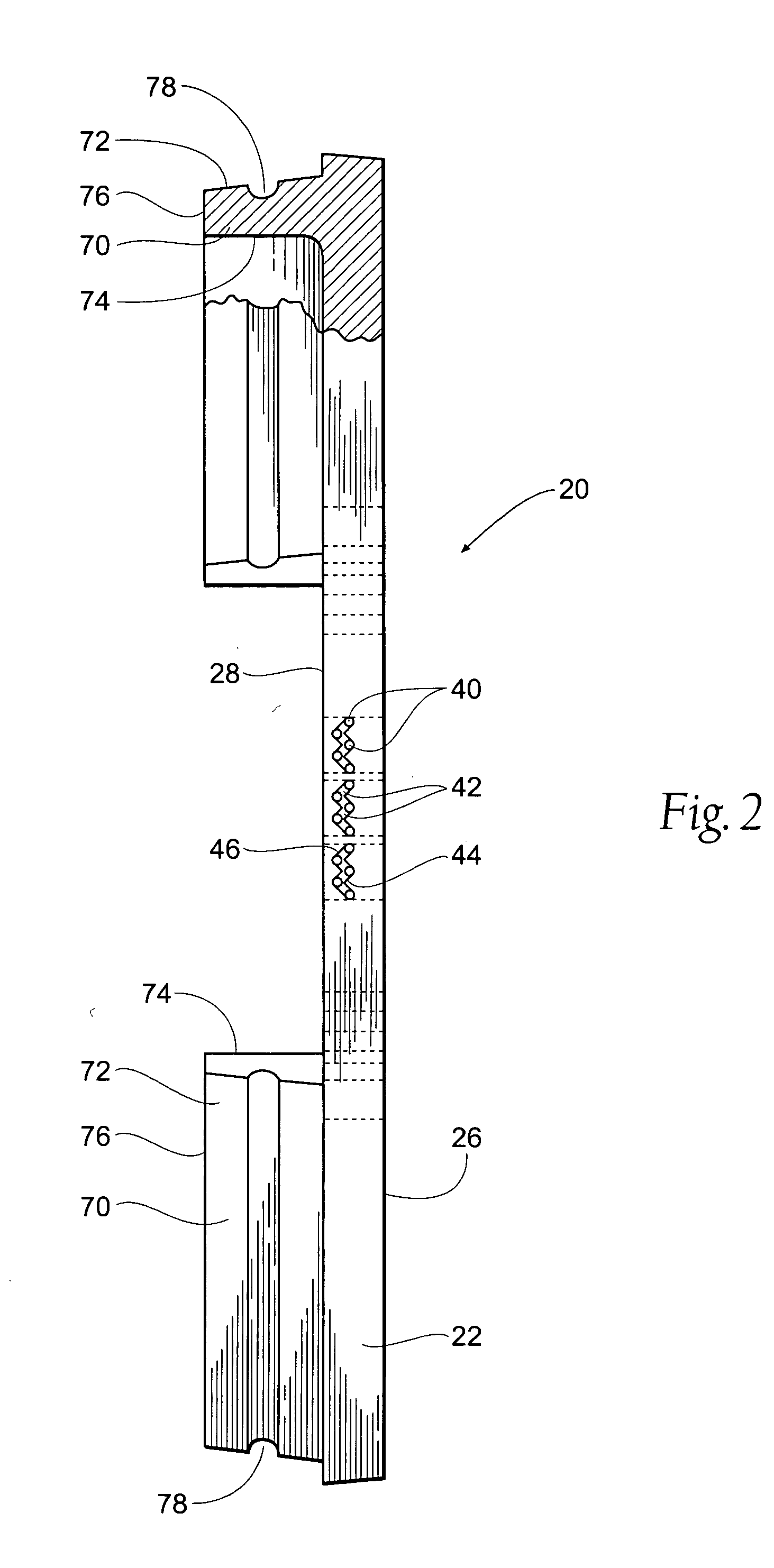

Article transfer and placement apparatus

ActiveUS20070074953A1Reduce the amount requiredEasy transferAbsorbent padsArticle feedersEngineeringElectrical and Electronics engineering

An apparatus for transferring articles such as absorbent cores or disposable diaper chassis components from a rotary mechanism, such as a pad turner, to a linear mechanism, such as a conveyor, for further processing. The invention provides a device for picking an article from the outside of a toroidal surface, thence extending transversely under tension the article to be transferred so that at the point of deposition the article is held flat and at full length. Further, the invention allows for apparatus to match the velocity of both the first and second transfer points, even if these velocities are not the same. The device is of particular benefit where an article to be transferred is subject to internally biasing elastic forces.

Owner:CURT G JOA

Document carrier and system for use therewith

Owner:REYNDERS LISA A +1

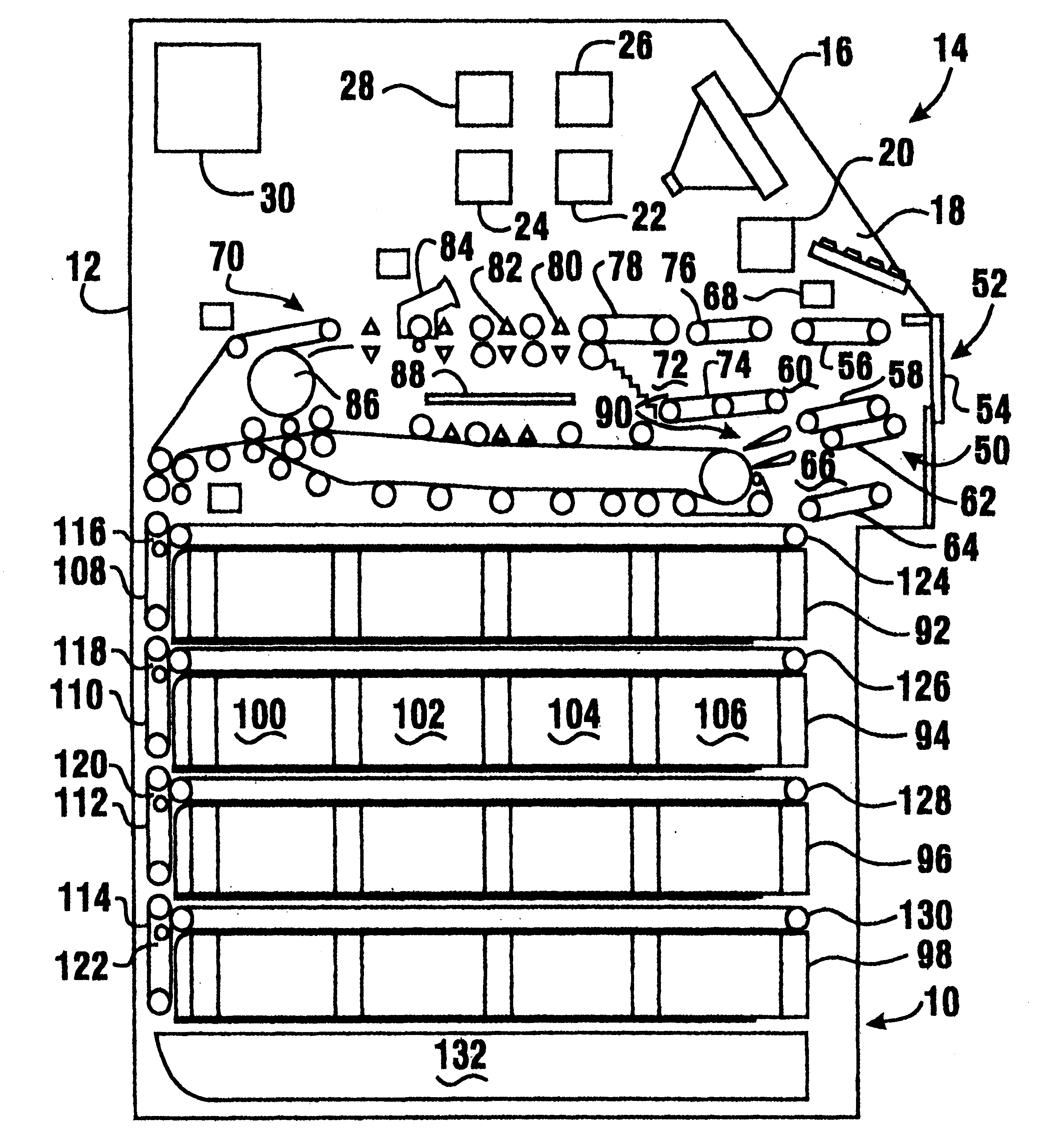

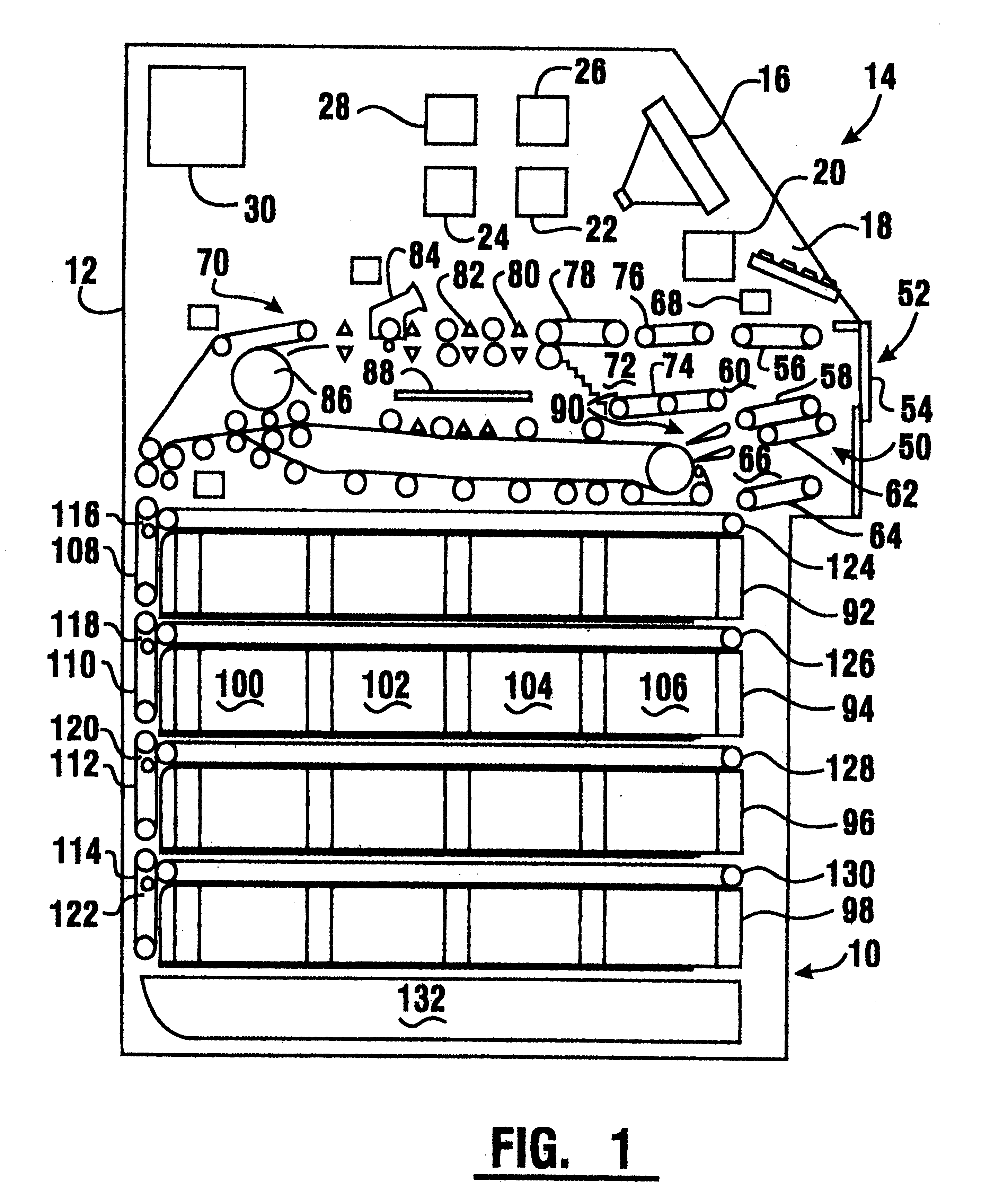

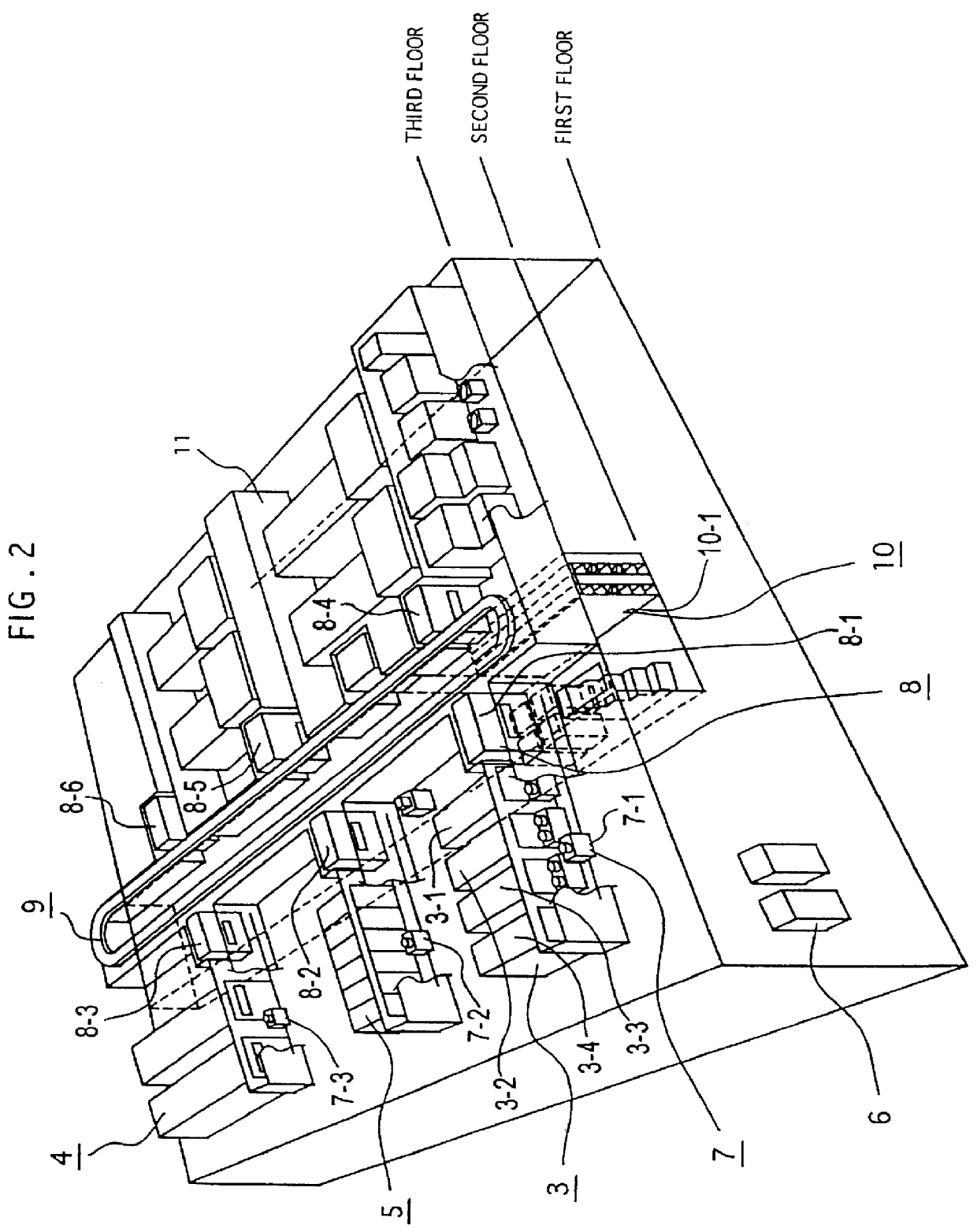

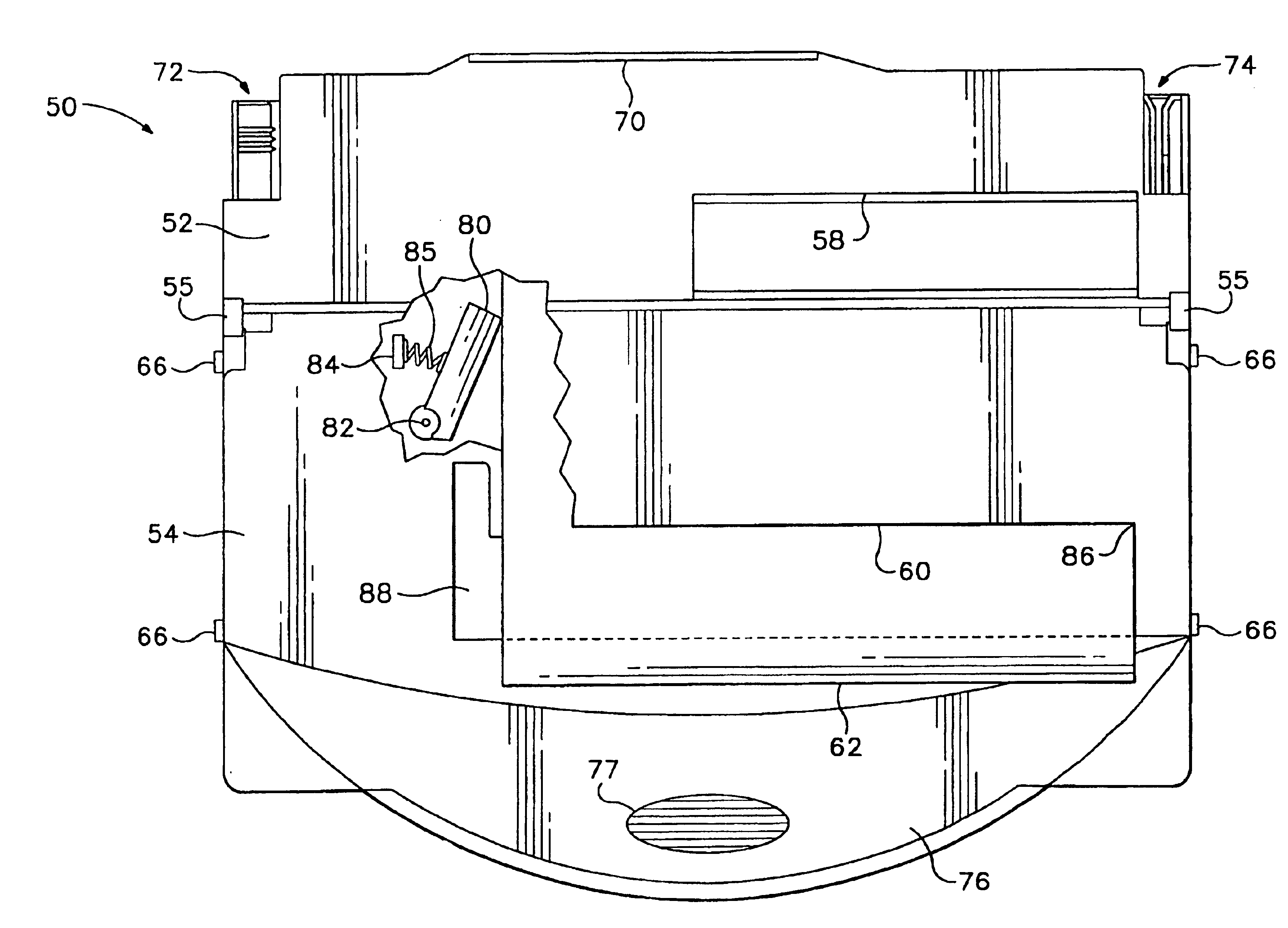

Currency recycling automated banking machine

InactiveUS6290070B1Easy to operateFacilitate rapid operation of machinePayment architectureSortingMachine selectionDocumentation

An automated banking machine (10) identifies and stores documents such as currency bills deposited by a user. The machine then selectively recovers such documents from storage and dispenses them to other users. The machine includes a central transport (70) wherein documents deposited in a stack are unstacked, oriented and identified. Such documents are then routed to storage areas in recycling canisters (92, 94, 96, 98). When a user subsequently requests a dispense, documents stored in the storage areas are selectively picked therefrom and delivered to the user through an input / output area (50) of the machine.

Owner:DIEBOLD NIXDORF

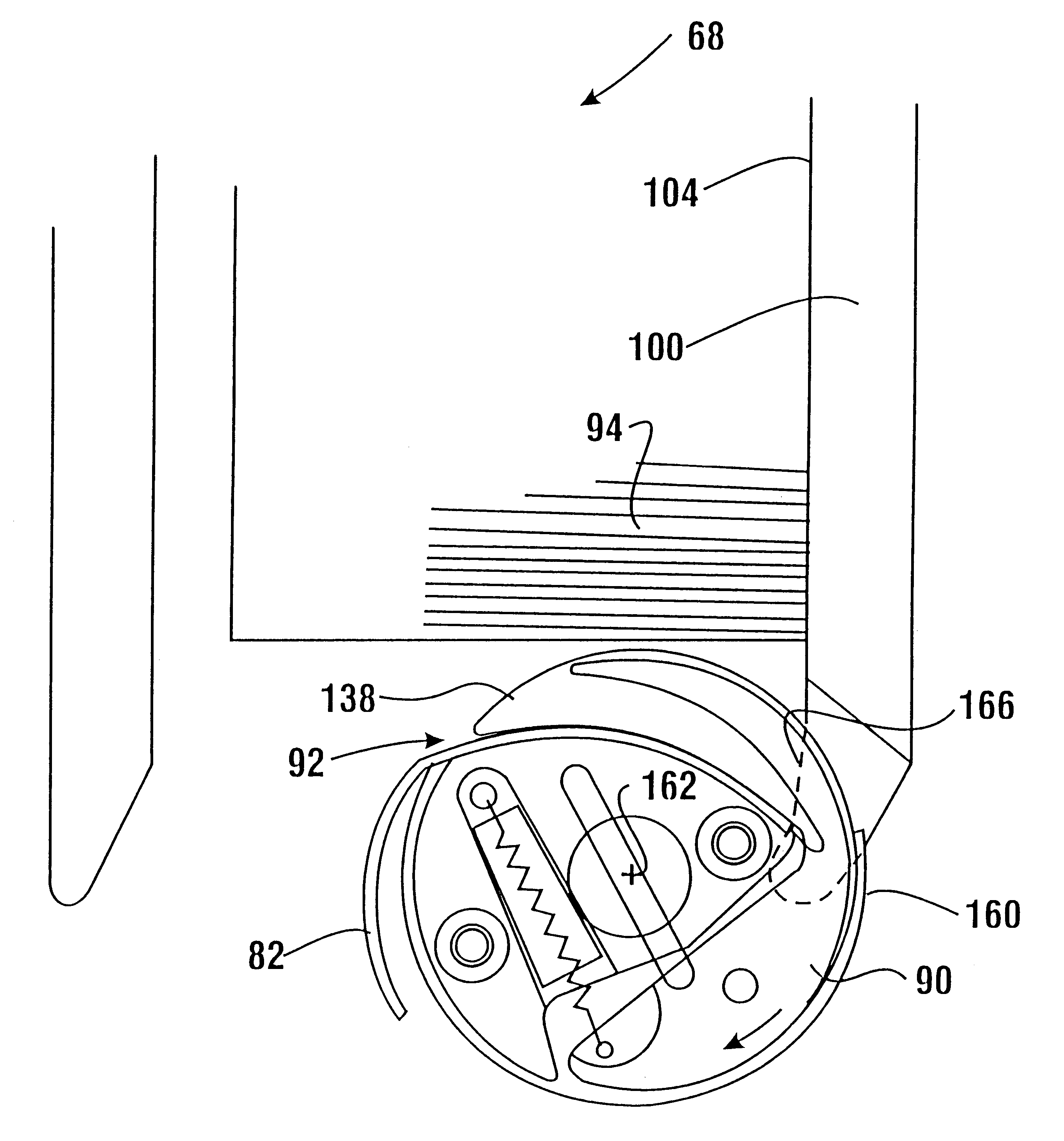

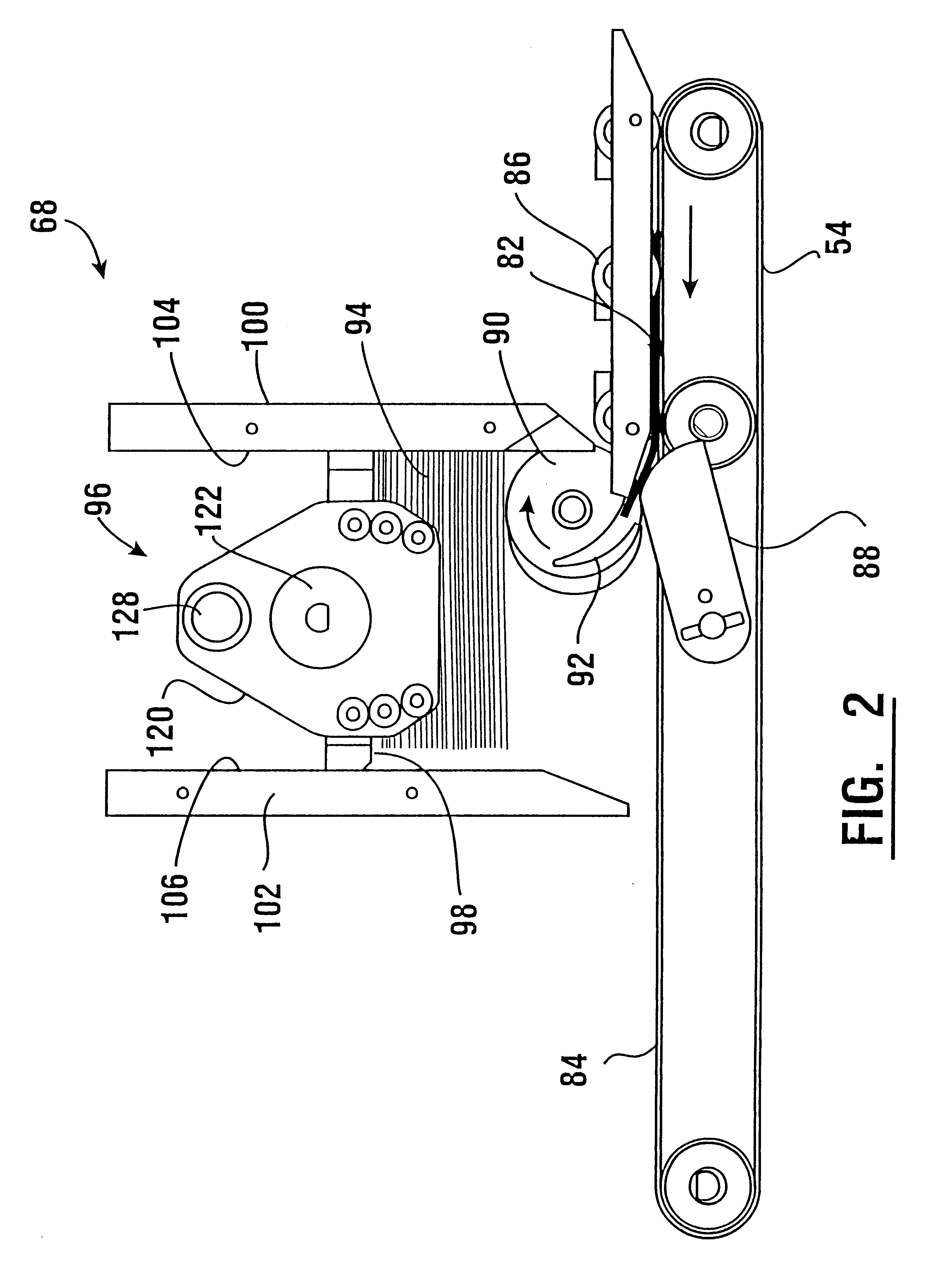

Currency recycling system and method for automated banking machine

InactiveUS6331000B1Stacks sheets reliablyIncrease speedCoin/currency accepting devicesPile receiversMechanical engineeringEngineering

A media storage system for an automated banking machine (10) includes a flipper member (90, 178) which is rotationally movable to engage sheets. A gripper member (138, 182) is movably mounted relative to the flipper member. The flipper member further includes an arcuately extending slot (92, 180). The sheet extending in the slot is held in fixed engagement with the flipper member by the gripper member. Rotation of the flipper member to a releasing position causes the sheet to be engaged with a stop surface (160, 188) as the gripper member moves to release the sheet. Sheets released by the flipper member are positioned in a stack (94, 184). The flexible flap (160) engages each sheet after it has been released by the flipper member to conform the sheet to the stack. In alternative embodiments a flipper member (178) includes a picker portion (202). Picker portion is selectively operated to remove sheets from the stack.

Owner:DIEBOLD NIXDORF

Method and apparatus for controlling semiconductor wafer fabrication equipment based on a remaining process time applicable to the processors

InactiveUS6134482ASemiconductor/solid-state device manufacturingCharge manipulationSemiconductor wafer fabricationSemiconductor

Semiconductor wafer fabrication equipment comprising a selecting device for selecting semiconductor wafers destined to a processor on the basis of a remaining process time applicable to that processor in the equipment, a transporting device for transporting the selected semiconductor wafers to the processor, another selecting device for selecting a processor or a storage device constituting a transport destination to which to transport processed semiconductor wafers, and another transporting device for transporting the semiconductor wafers to the destination processor or storage device in accordance with a transport control changeover code read from the processors and storage devices of the equipment.

Owner:MITSUBISHI ELECTRIC CORP

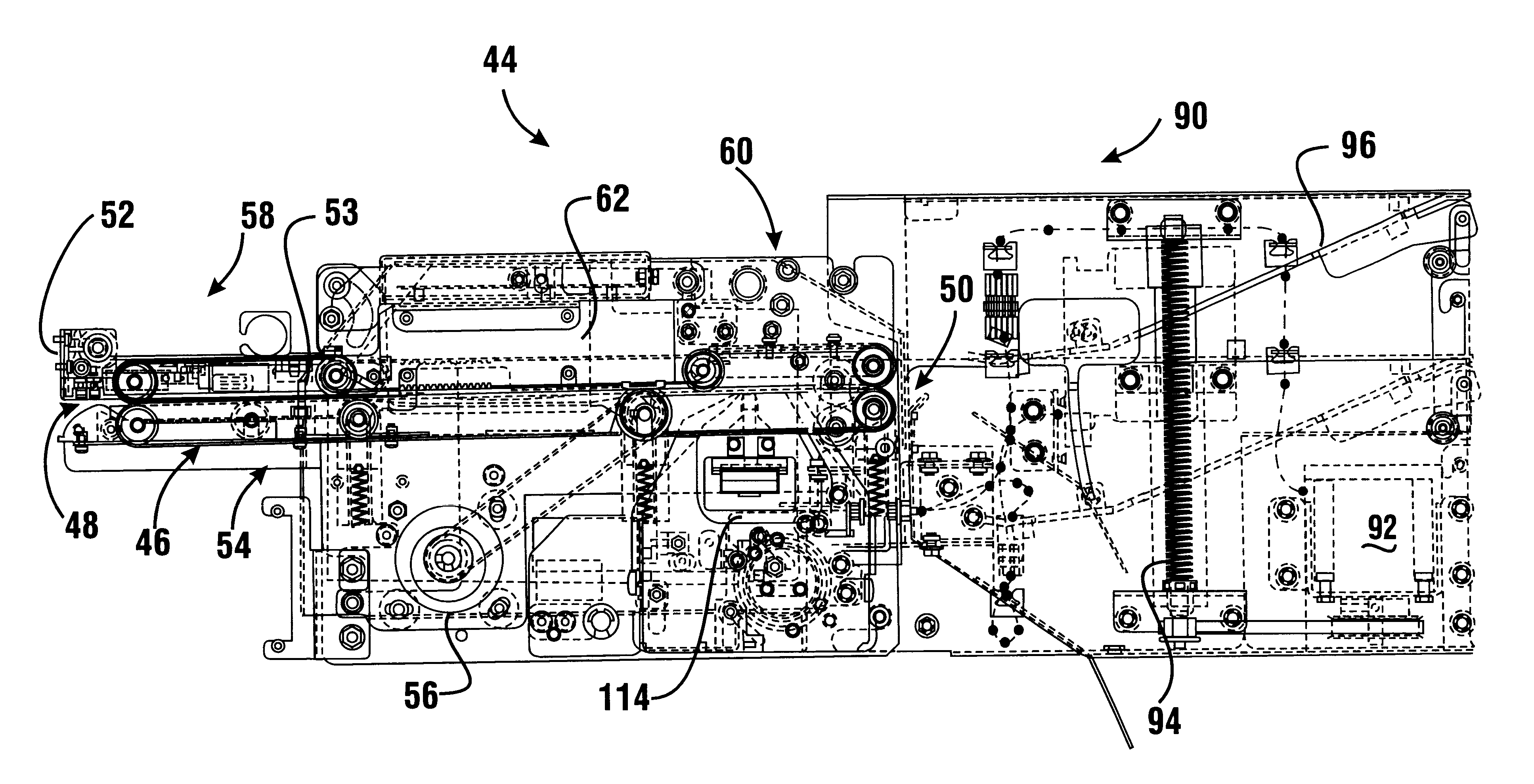

Deposit accepting and storage apparatus and method for automated banking machine

InactiveUS6474548B1Minimize the risk of damageReduce the possibilityComplete banking machinesRegistering devicesEngineeringInstrumentation

An automated banking machine (10) includes a deposit accepting apparatus (44) which is capable of accepting and authenticating instruments, as well as accepting envelopes deposited into the machine by a user. A transport section (46) is operative to engage and transport deposited items selectively from an inlet (48) to an outlet (50). A deposit holding module (90) includes compartments (98, 106) which are operative to hold different types of deposits. The machine operates to selectively move a compartment into communication with the outlet based on the particular type of item being deposited. The depository apparatus is further operative to acquire image and magnetic profile data from deposited instruments, to manipulate the image and profile data and to analyze and resolve characters in selected areas thereof. The data from deposited instruments is used for determining if a user is authorized to conduct certain requested transactions at the machine.

Owner:DIEBOLD NIXDORF

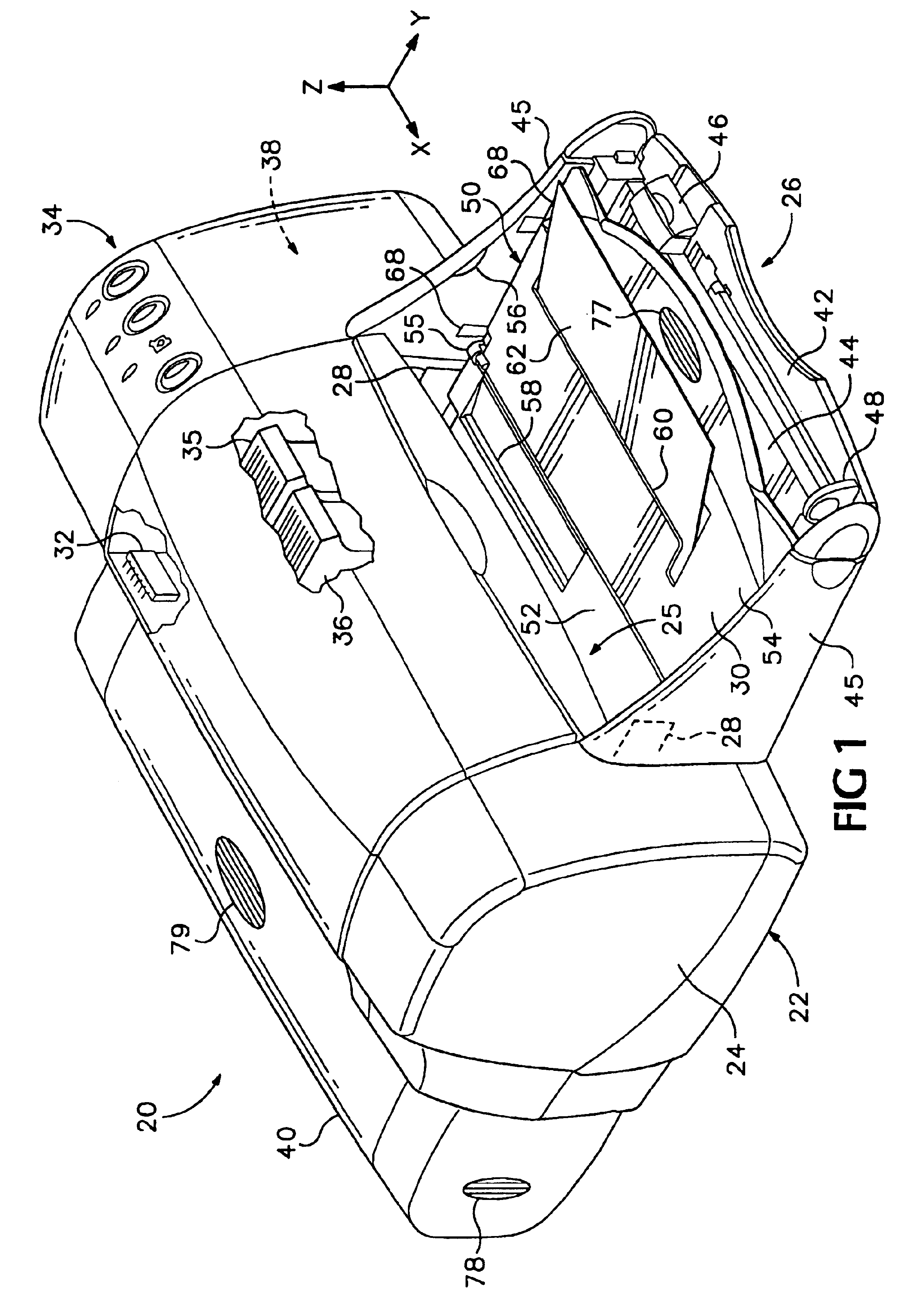

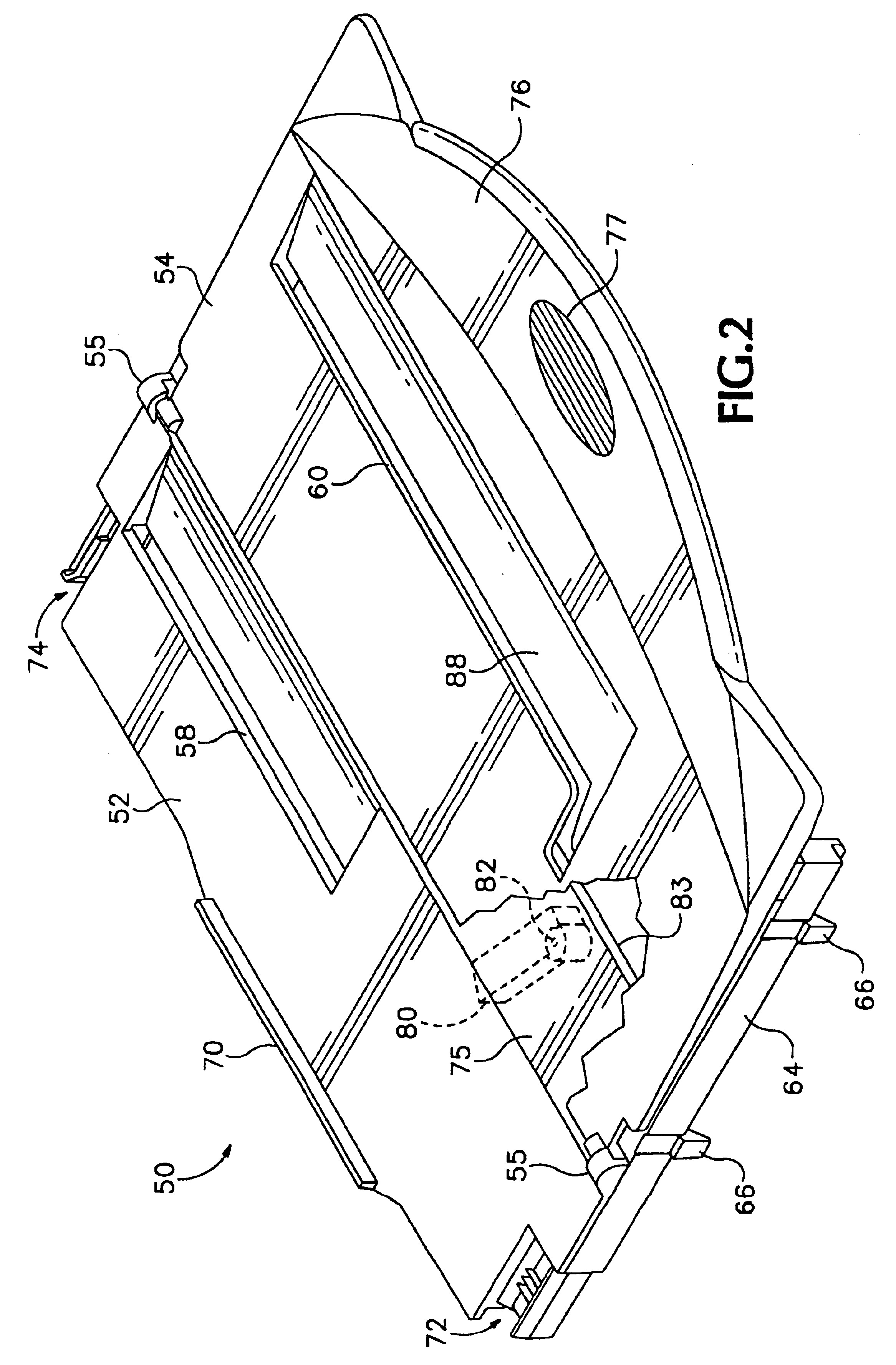

Greeting card feeder module for inkjet printing

InactiveUS6848844B2Easy to useClear imagingPrinting mechanismsRegistering devicesCard stockInk printer

A hardcopy printing mechanism and a greeting card feeder retrofit kit therefor, along with a retrofitting method are provided for printing images on a first-sized media, and on both surfaces a second-sized greeting card media without removing the first-sized media from its normal supply tray. The hardcopy device may be an electrophotographic or inkjet printer preferably equipped with a duplexer module which inverts media from a printed first surface to an opposing second surface for printing an image thereon. For a printer having an alignment surface, and a width adjuster to push the first-sized media against the alignment surface, the greeting card feeder includes a biasing member which pushes the card stock against the alignment surface. The retrofit kit includes a supply of pre-scored greeting card stock and a software program with a group of greeting card images for a consumer to select from to print store-bought quality greeting cards.

Owner:HEWLETT PACKARD DEV CO LP

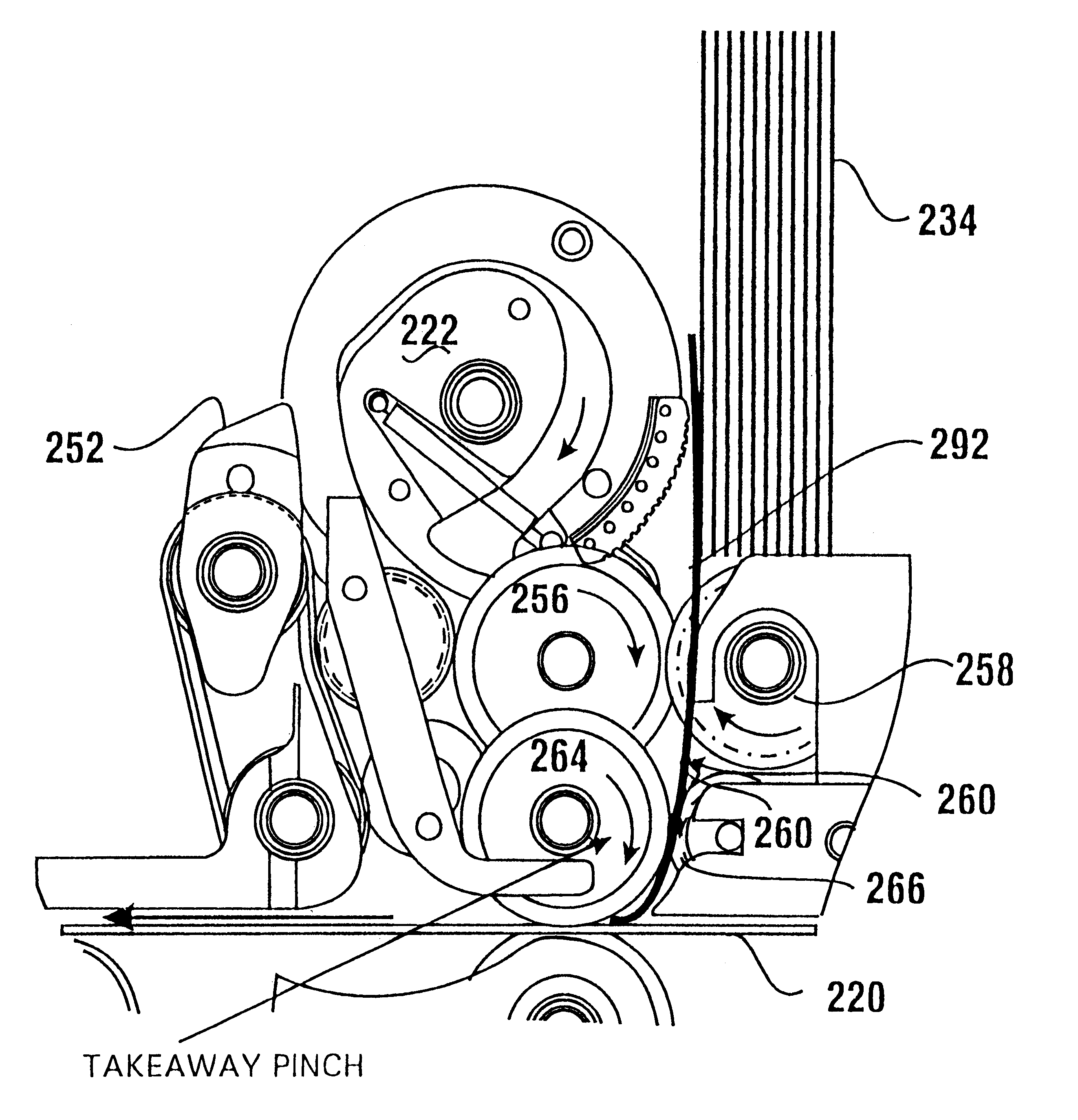

Media storage system for automated banking machine

InactiveUS6302393B1Increase speedStacks sheets reliablyCoin/currency accepting devicesPile receiversEngineeringMechanical engineering

A media storage system for an automated banking machine (10) includes a rotating flipper member (90, 178, 222) which is rotationally movable to engage sheets. A moveable gripper member (138, 182, 226) is movably mounted relative to the flipper member. The flipper member further includes an arcuately extending slot (92, 180, 232). A sheet extending in the slot is held in fixed engagement with the flipper member by the gripper member. Rotation of the flipper member to a releasing position causes the sheet to be engaged with a stop surface (160, 188, 284) as the gripper member moves to release the sheet. Sheets released by the flipper member are positioned in a stack (94, 184, 234). In alternative embodiments a flipper member (178, 222) includes a picker portion (202, 278). The picker portion is selectively operated to remove sheets from the stack for delivery to a user of the machine.

Owner:DIEBOLD NIXDORF

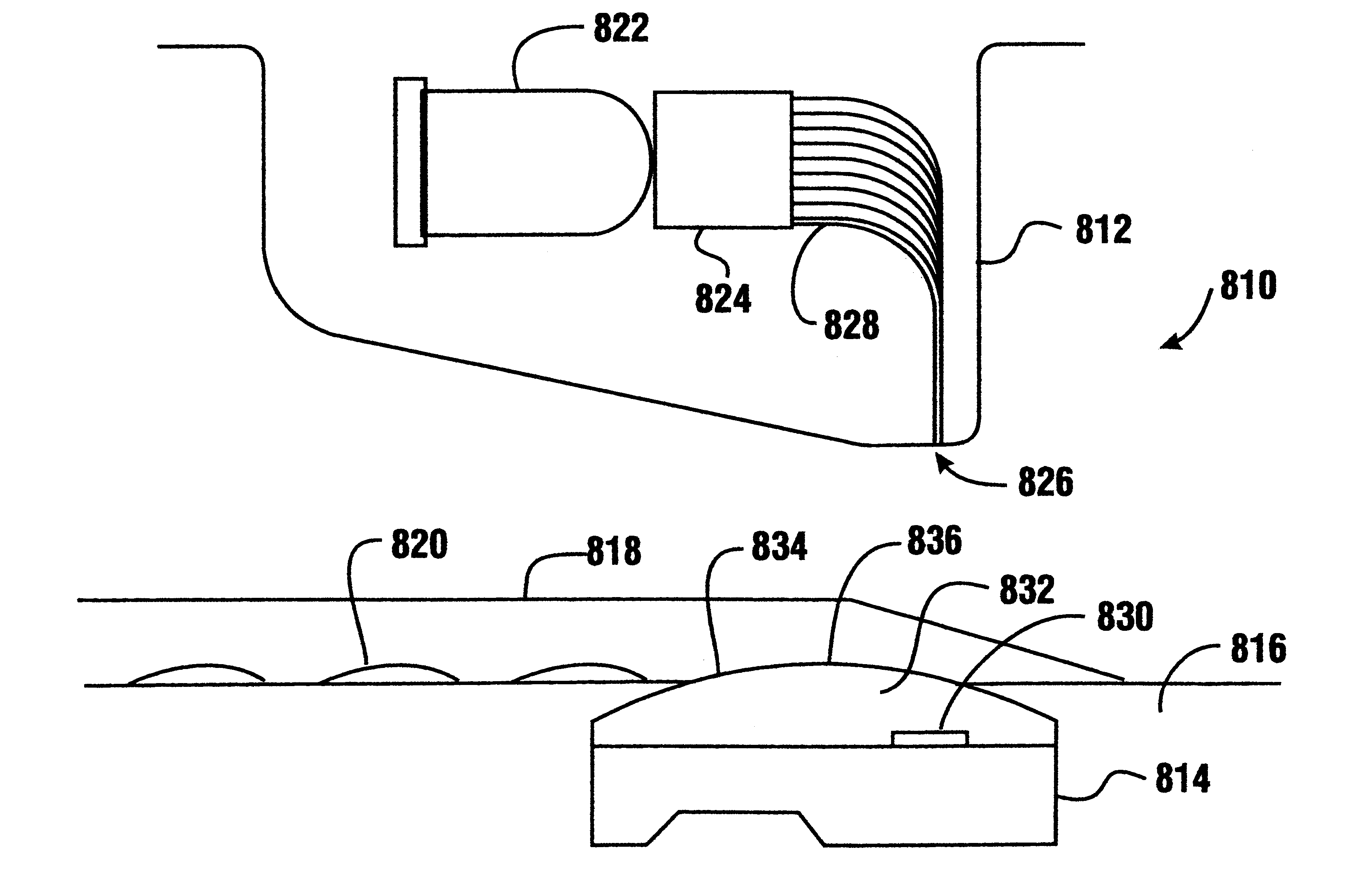

Document sensor for currency recycling automated banking machine

InactiveUS6241244B1Easy to operateFacilitate rapid operation of machinePaper-money testing devicesFunction indicatorsMachine selectionOptoelectronics

An automated banking machine (10) identifies and stores documents such as currency bills deposited by a user. The machine then selectively recovers such documents from storage areas and dispenses them to other users. The machine includes a sheet thickness detector (810) used for distinguishing single sheets from double sheets which pass through the machine. The thickness detector includes a radiation source (822). Radiation from the radiation source is directed by radiation guide (824) to a generally linear elongated radiation outlet (826) which extends transversely to the sheet path. A receiver (814) includes a radiation sensitive element (830) which is also transversely elongated relative to the sheet path. Sheets passing between the emitter and the receiver cause variations in the amount of radiation reaching the receiver. The transversely elongated surface of the sheet through which the transmission of radiation is sense enables accurately distinguishing single sheets from double sheets.

Owner:DIEBOLD NIXDORF

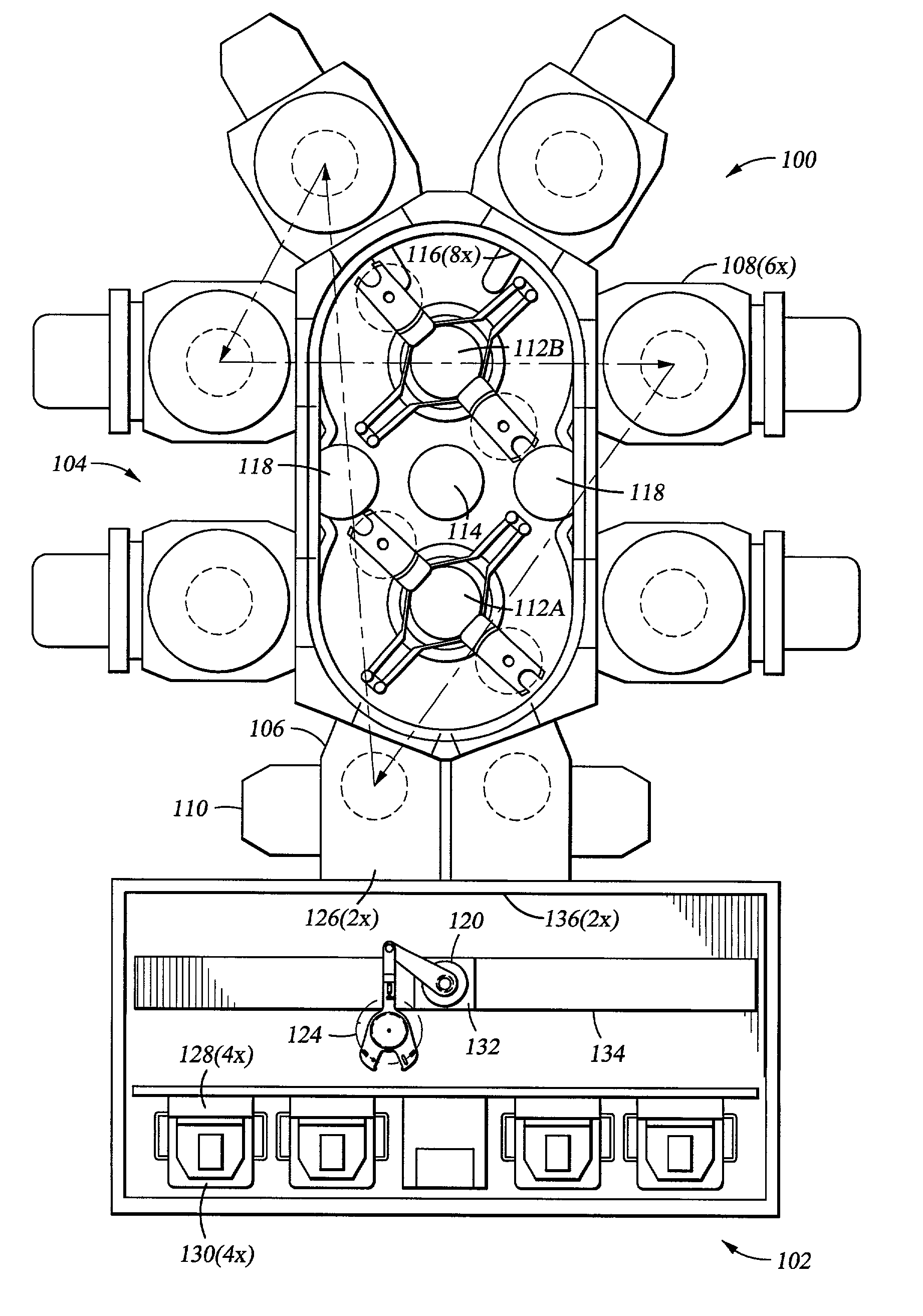

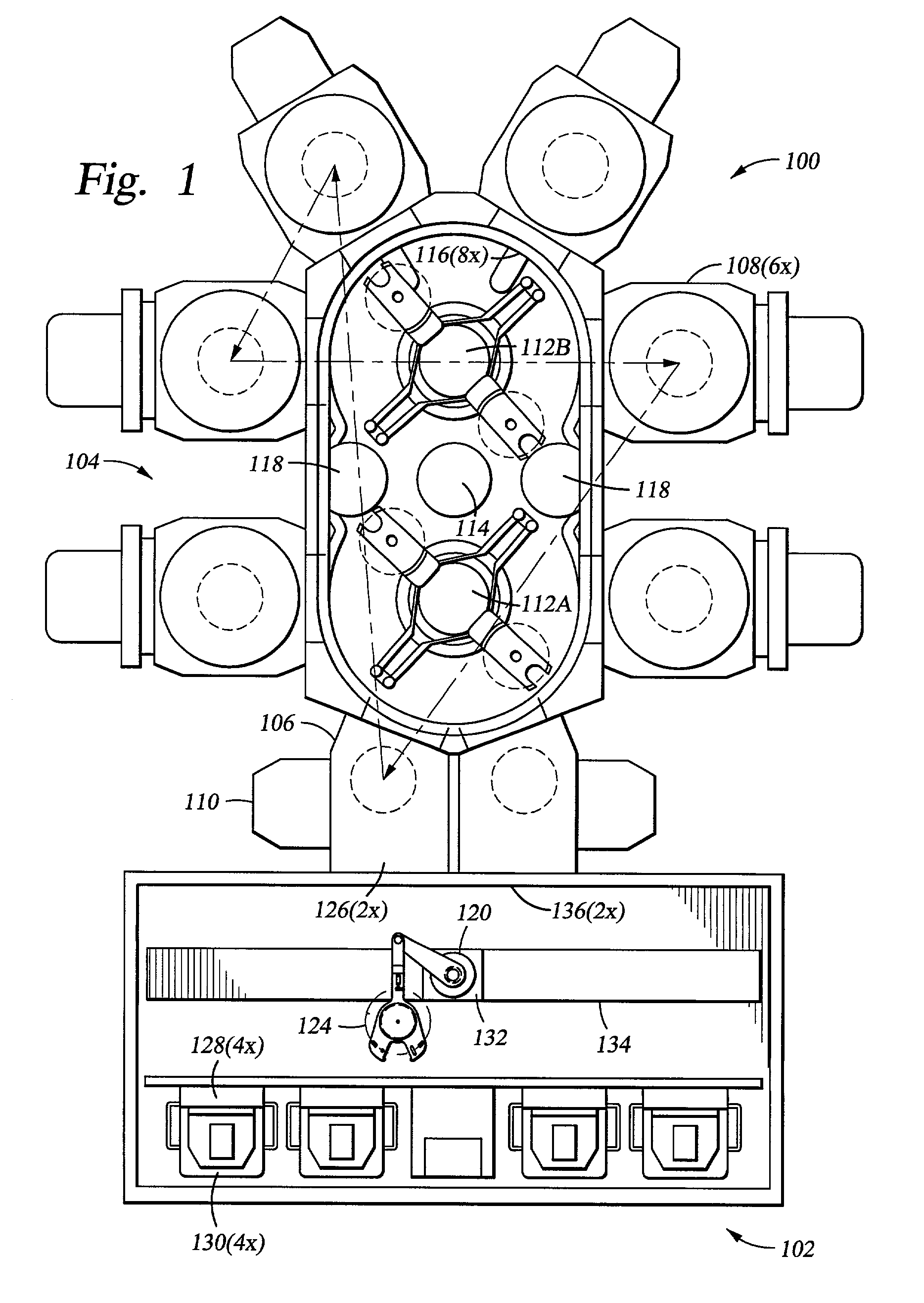

Method and apparatus for transferring a semiconductor substrate

InactiveUS20020192056A1Easy to understandProgramme-controlled manipulatorGripping headsEngineeringActuator

A method and apparatus for transferring a substrate is provided. In one embodiment, an apparatus for transferring a substrate includes at least one end effector. A disk is rotatably coupled to the end effector. The disk is adapted to rotate the substrate relative to the end effector. The end effector may additionally include a sensor coupled thereto. The sensor is adapted to detect an indicia of orientation of the substrate supported by the end effector. In another embodiment, a method for transferring a substrate includes rotating the substrate disposed on an end effector and detecting an indicia of orientation of the substrate.

Owner:APPLIED MATERIALS INC

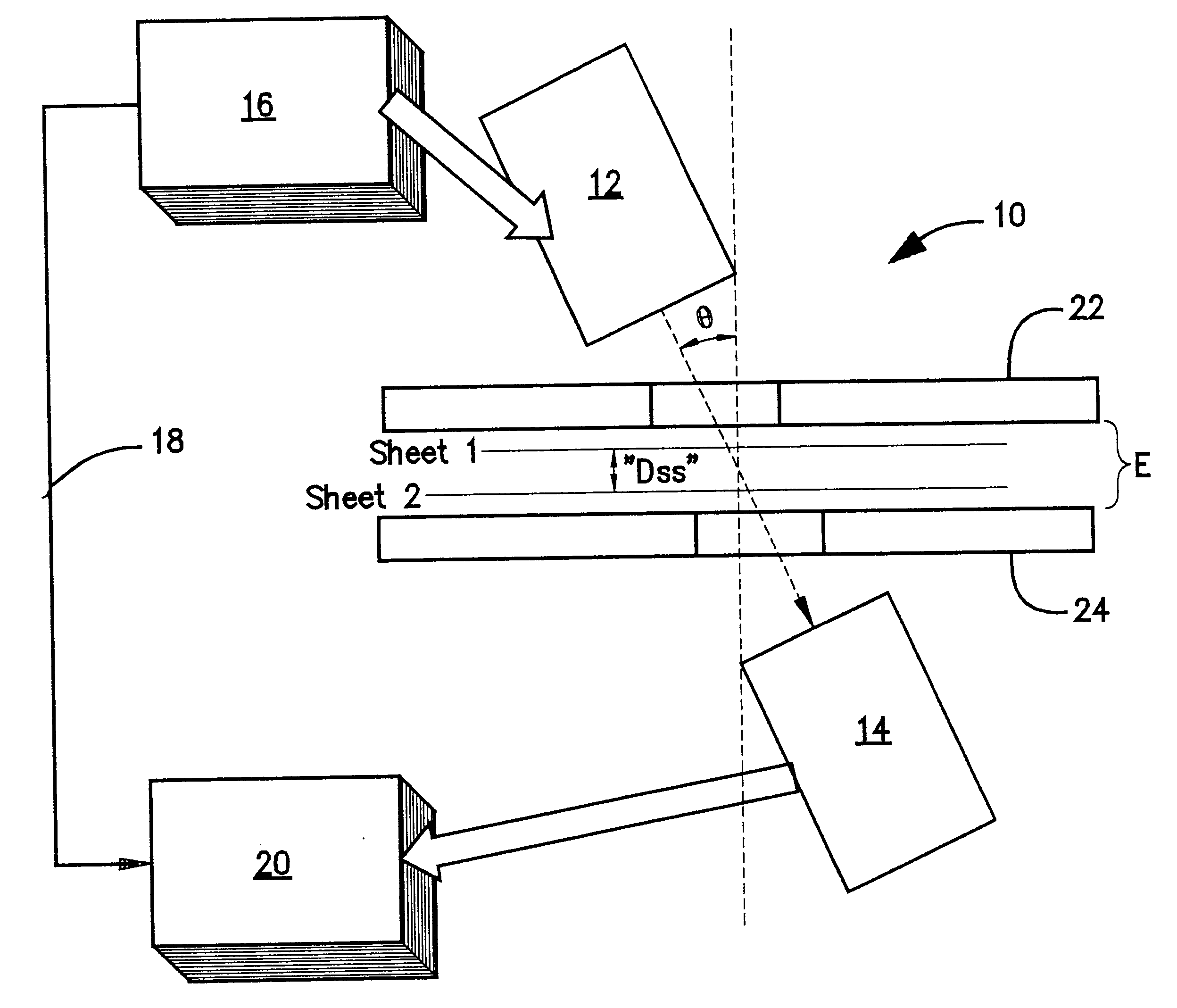

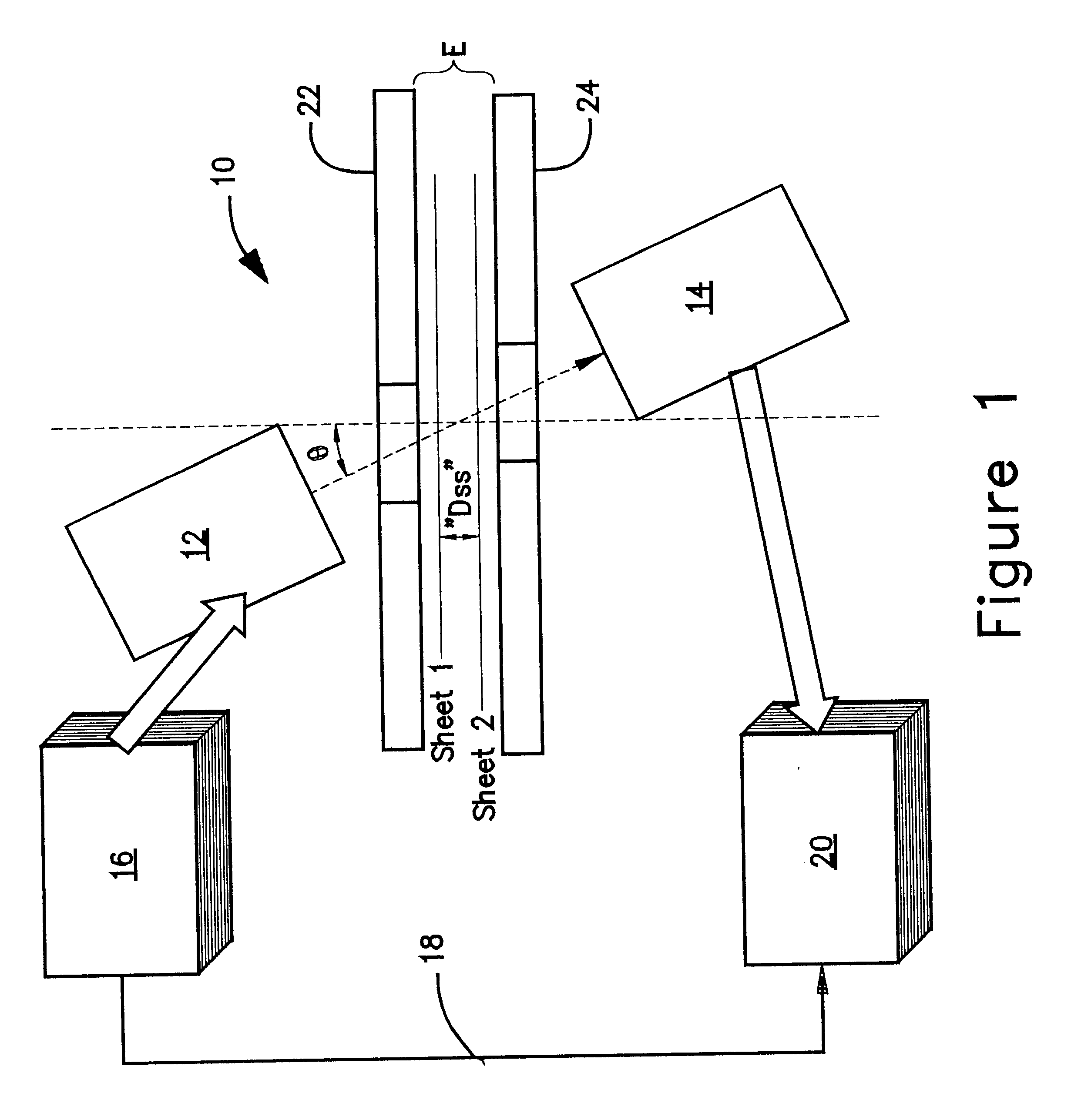

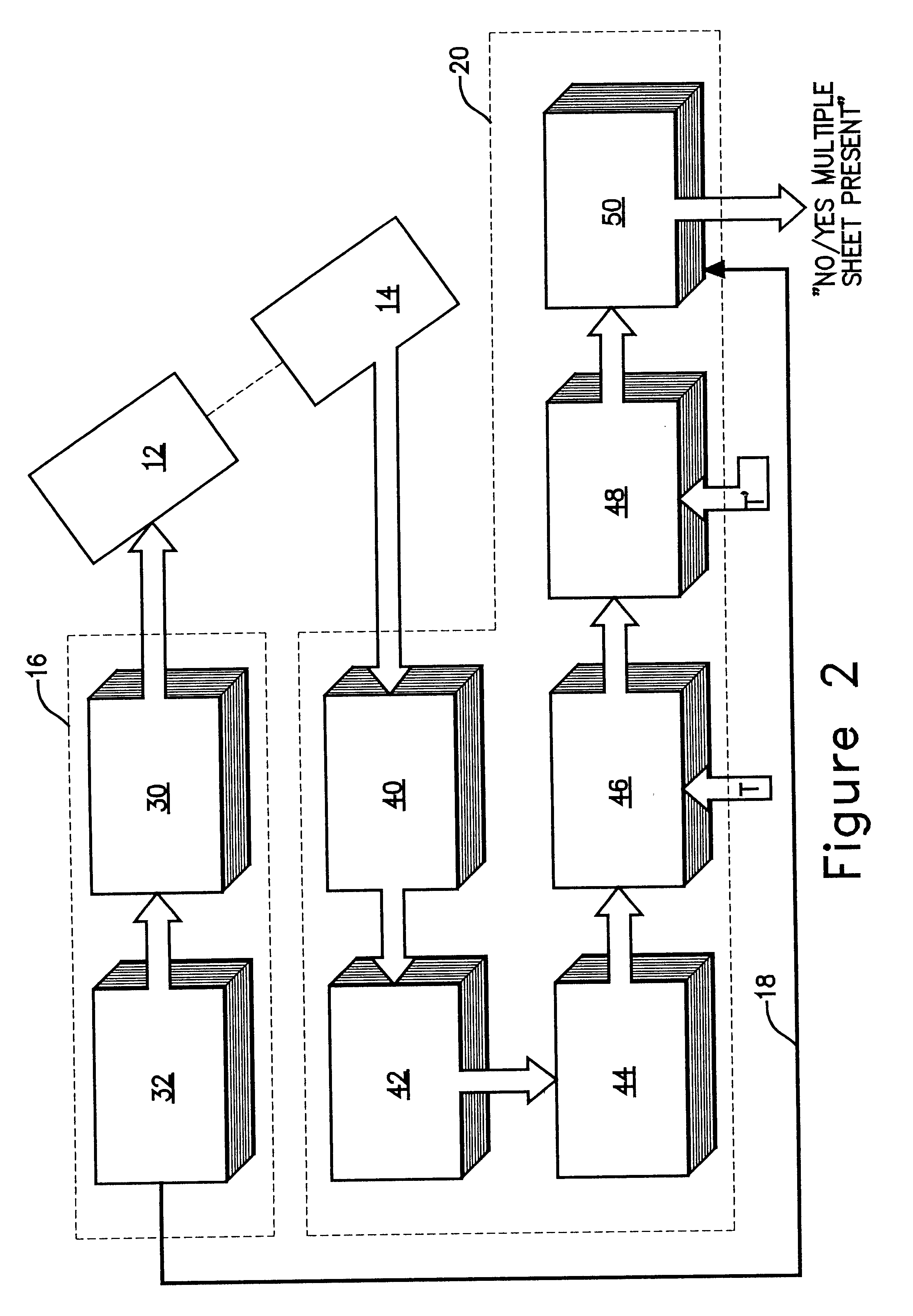

Method and apparatus for plural document detection

The presence of overlapped sheets on a paper transport is detected by employing such sheets as an acoustic interference filter. A beam of ultrasonic energy of appropriate frequency, angularly oriented to the planar transport path, will be attenuated to a much greater extent than the attenuation calculated based on the attenuation of a single sheet, as a result of destructive combining of wavefronts reflected from the facing surfaces of the overlapped sheets.

Owner:PATRIARCH PARTNERS AGENCY SERVICES +1

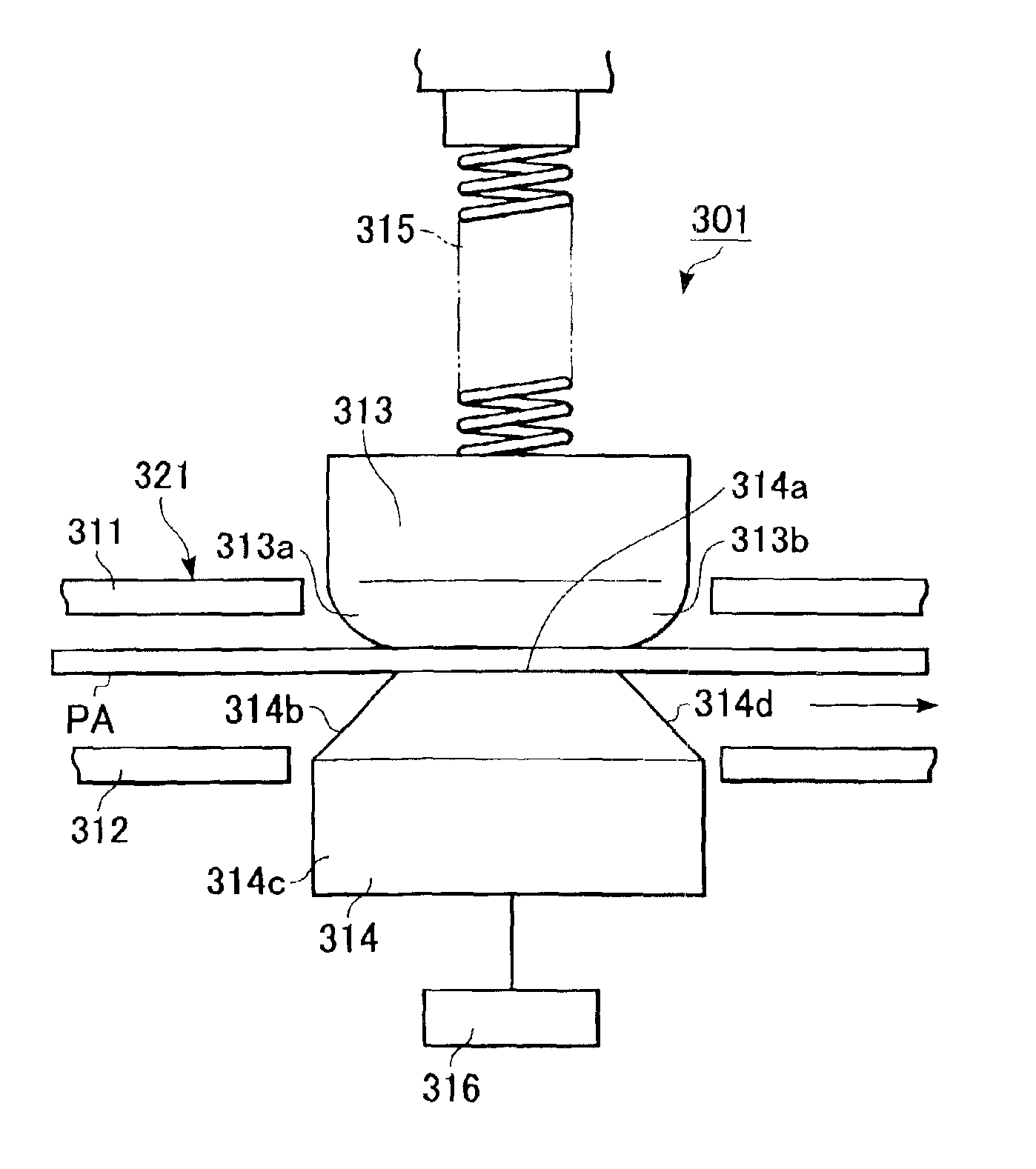

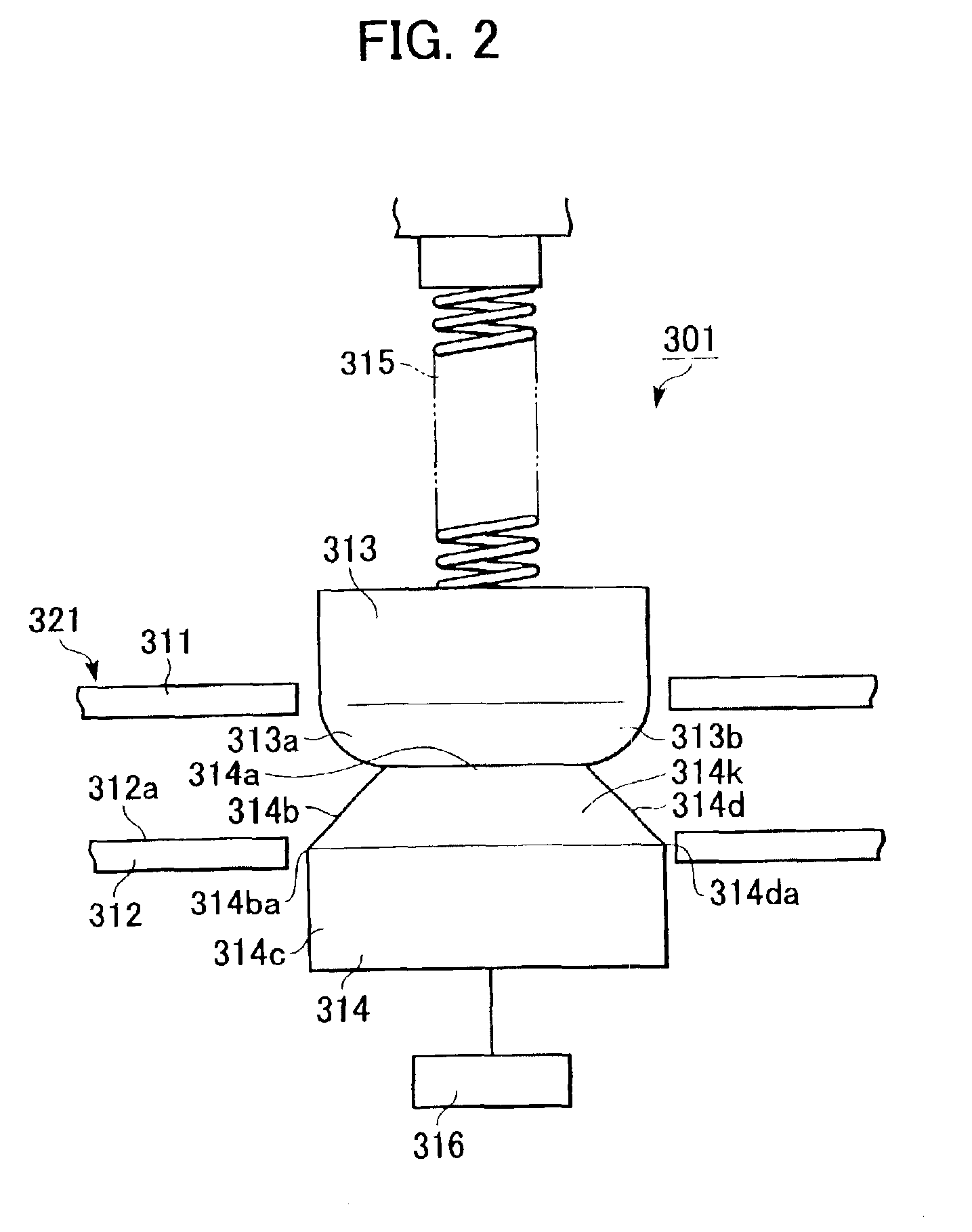

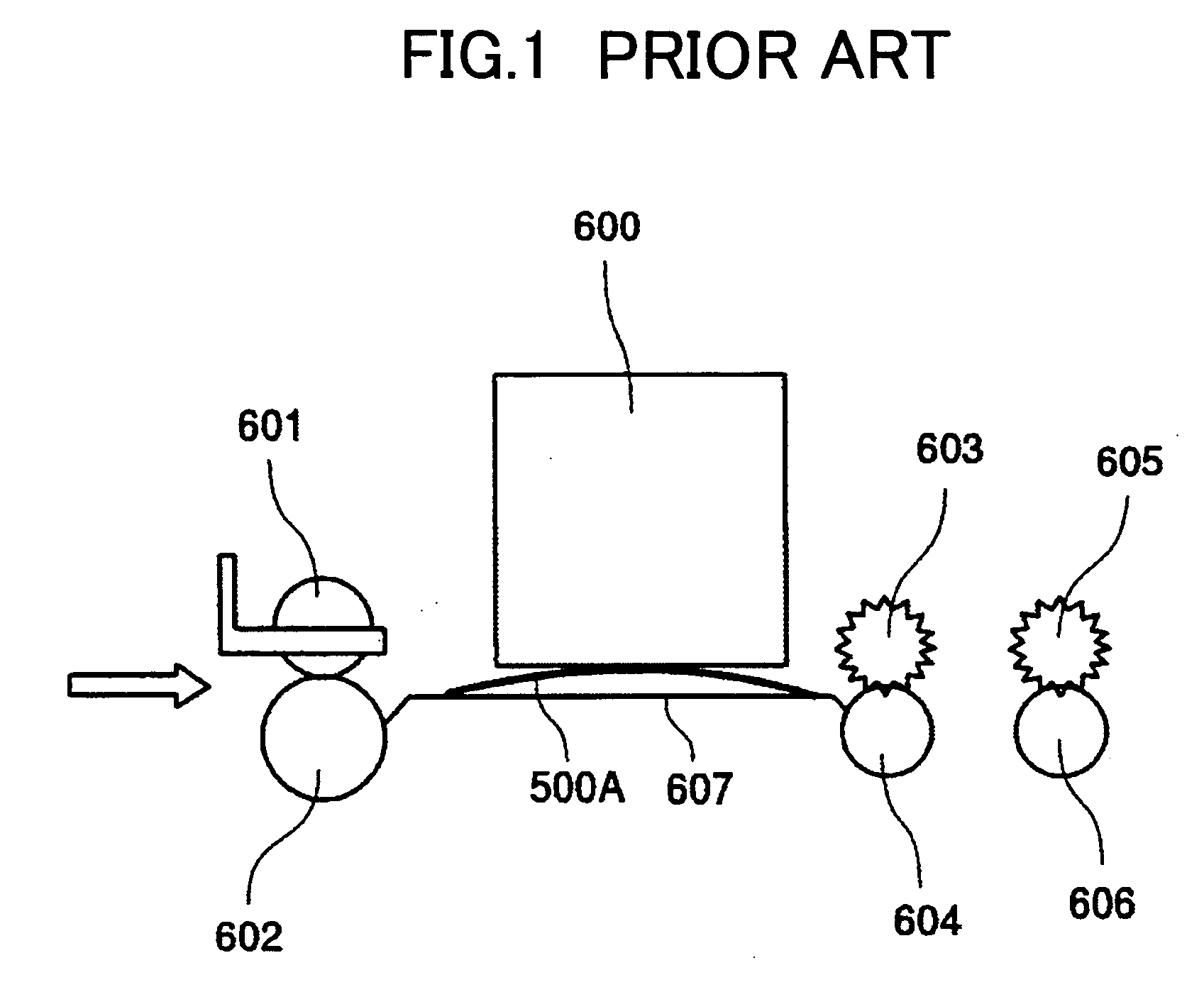

Sheet-thickness detector device and sheet-processing apparatus, image-forming apparatus having the same

A sheet-thickness detector device has a sheet guide with a sheet-guide surface for guiding a sheet between a magnetic field sensor and a magnetic guide element. The magnetic field sensor, having an approach-guide plane disposed upstream in a sheet conveying direction for guiding the sheet to a detection surface, comes into direct contact with the sheet. By the structure mentioned above, the thickness of a sheet is detected so as to determine sheet double feeding and the like without producing sheet jamming.

Owner:CANON KK

Article transfer and placement apparatus

An apparatus for transferring articles such as absorbent cores or disposable diaper chassis components from a rotary mechanism, such as a pad turner, to a linear mechanism, such as a conveyor, for further processing. The invention provides a device for picking an article from the outside of a toroidal surface, thence extending transversely under tension the article to be transferred so that at the point of deposition the article is held flat and at full length. Further, the invention allows for apparatus to match the velocity of both the first and second transfer points, even if these velocities are not the same. The device is of particular benefit where an article to be transferred is subject to internally biasing elastic forces.

Owner:CURT G JOA

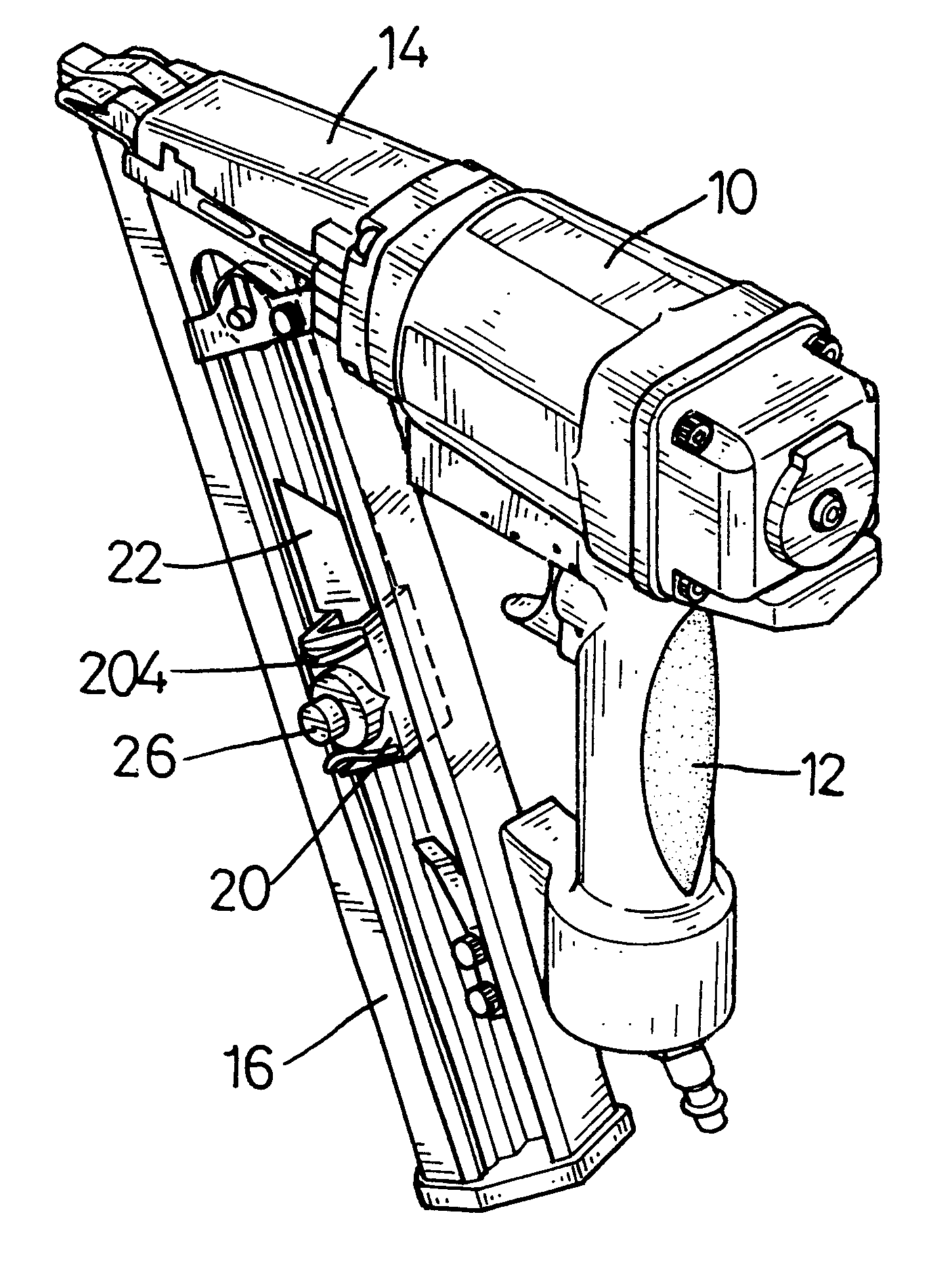

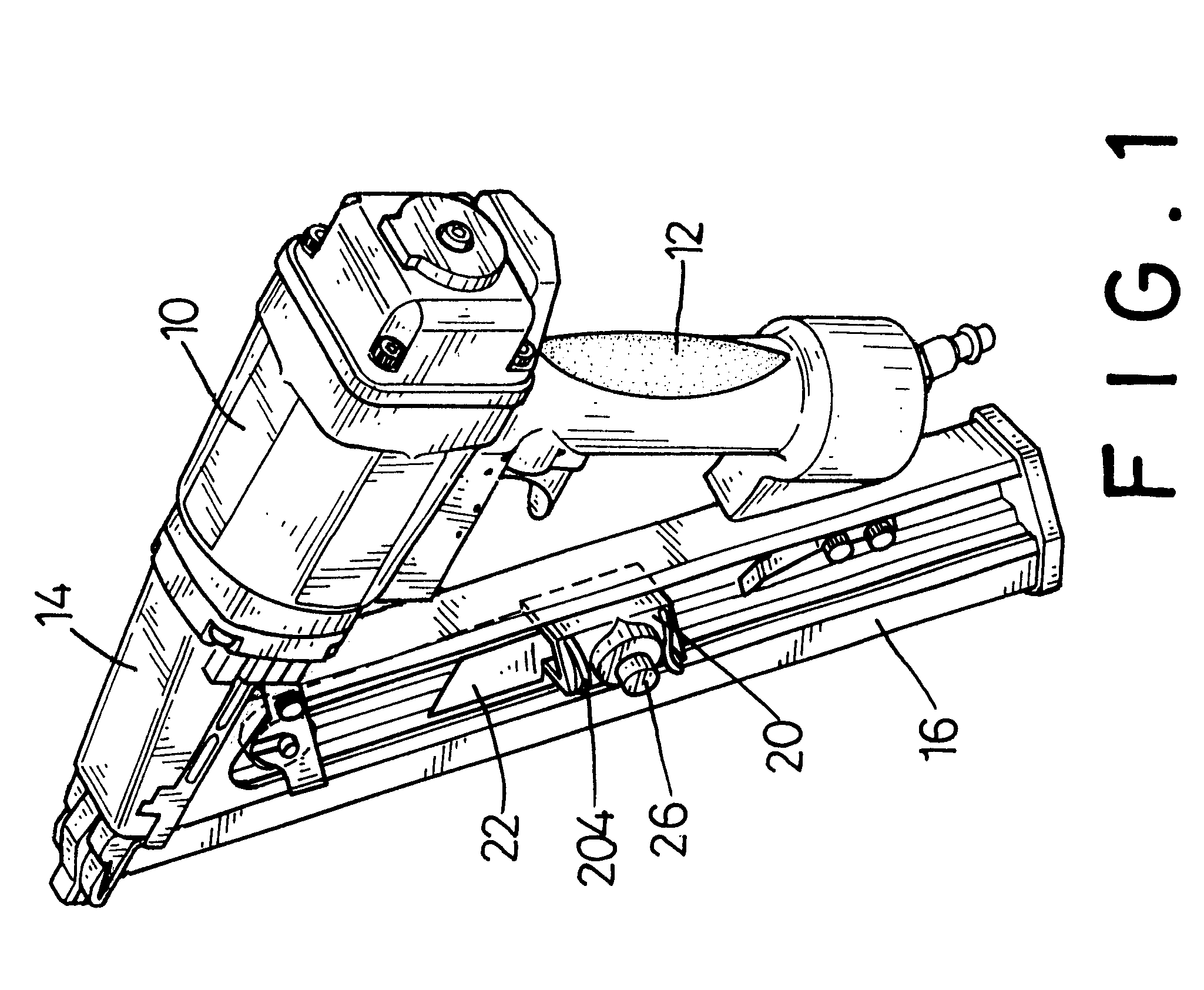

Quick-release device for a pneumatic nail gun magazine

A quick-release device for a pneumatic nail gun with a magazine has a base, a pusher plate, a spring and a button. The base has a through hole defined in the top of the base. The pusher plate has a first end that normally extends into the channel of the magazine and a second end. The spring abuts the second end of the pusher plate. The button is moveably mounted in the base and extends out from the through hole. The button abuts the second end of the pusher plate, such that the pusher plate can be pivoted by pressing the exposed button. The finger of the user does not extend into the device. Consequently, the operation of the quick-release device is simplified, and the finger of the user will not be injured during the process of clearing jammed nails.

Owner:REXON IND CORP LTD

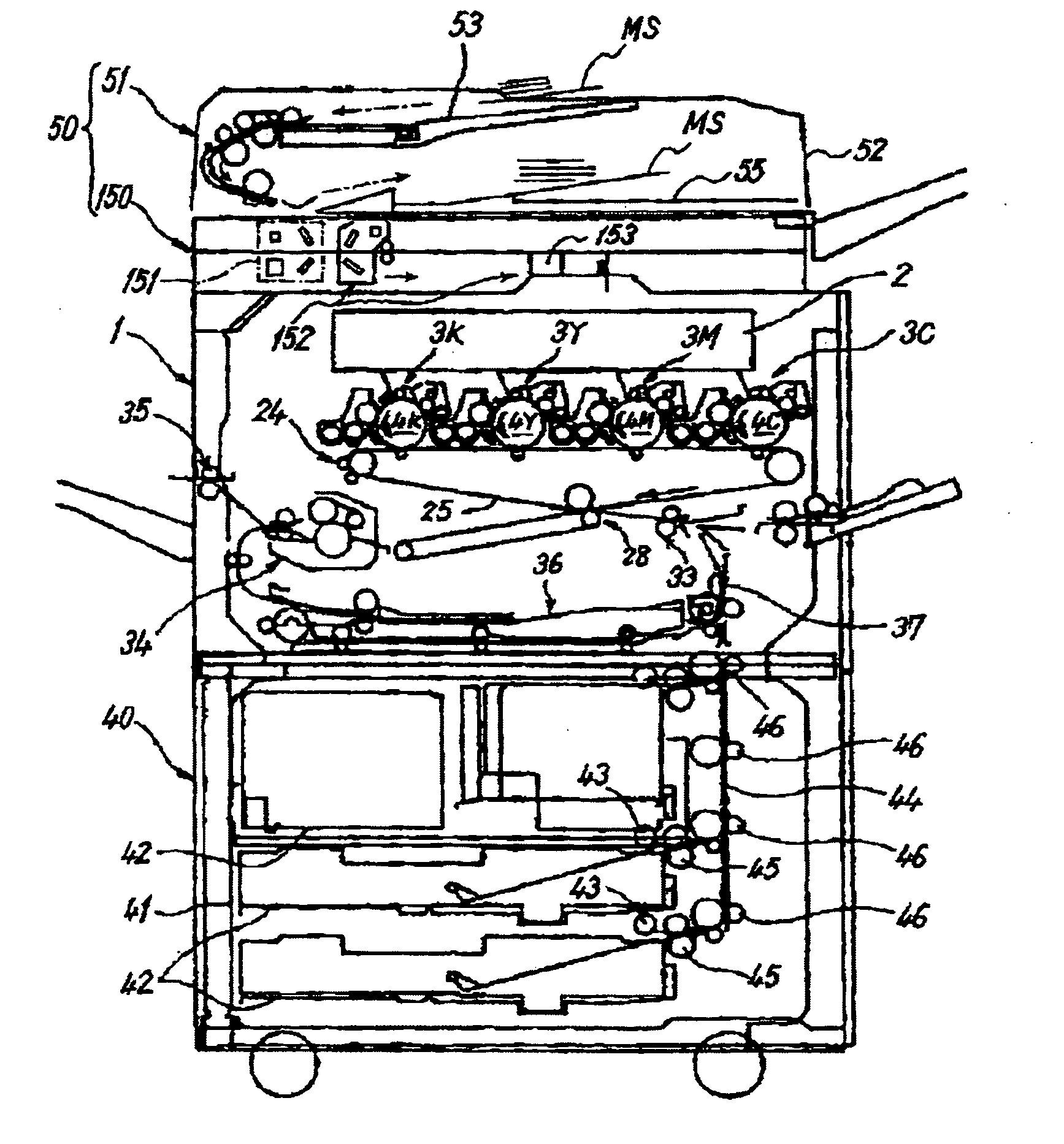

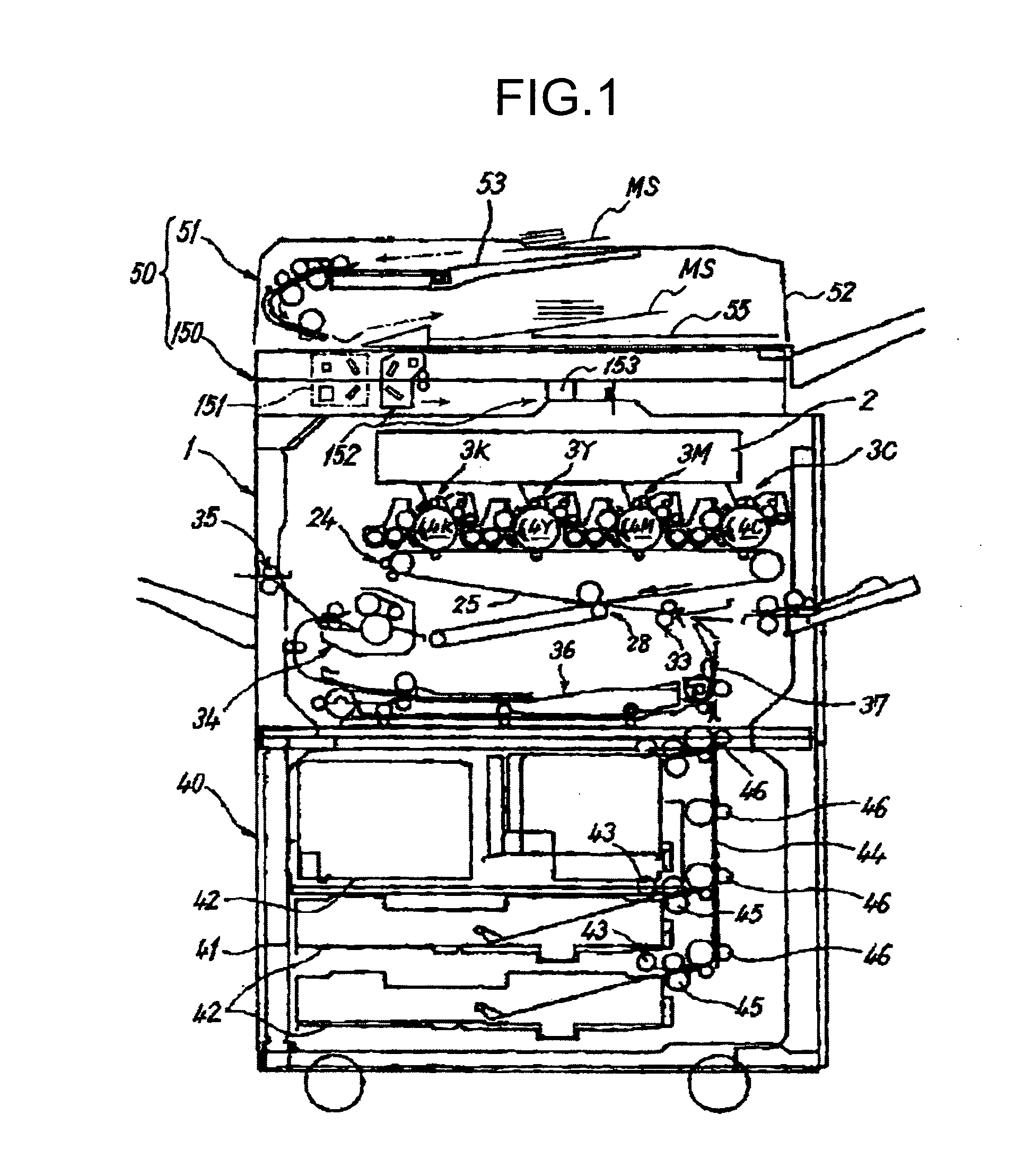

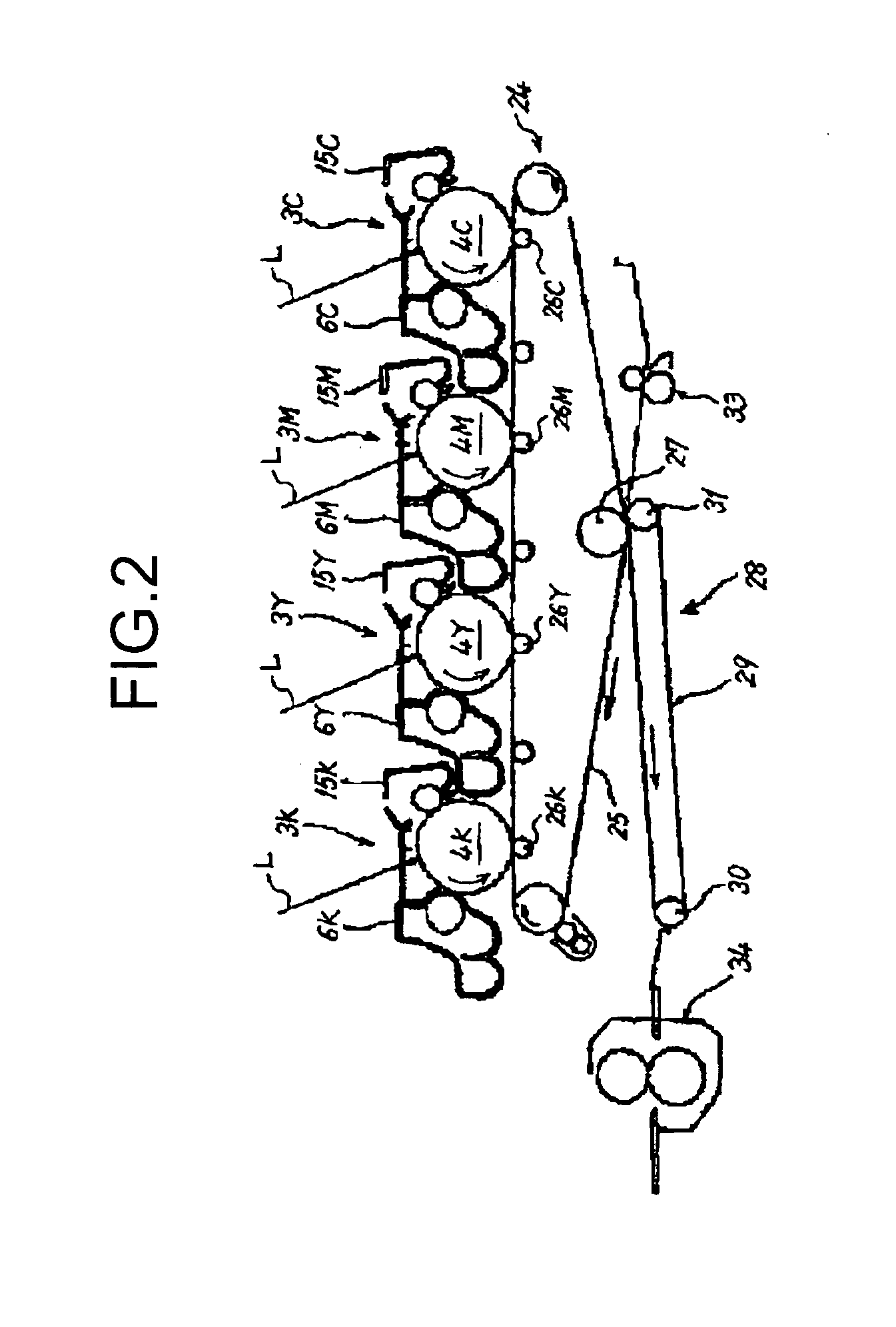

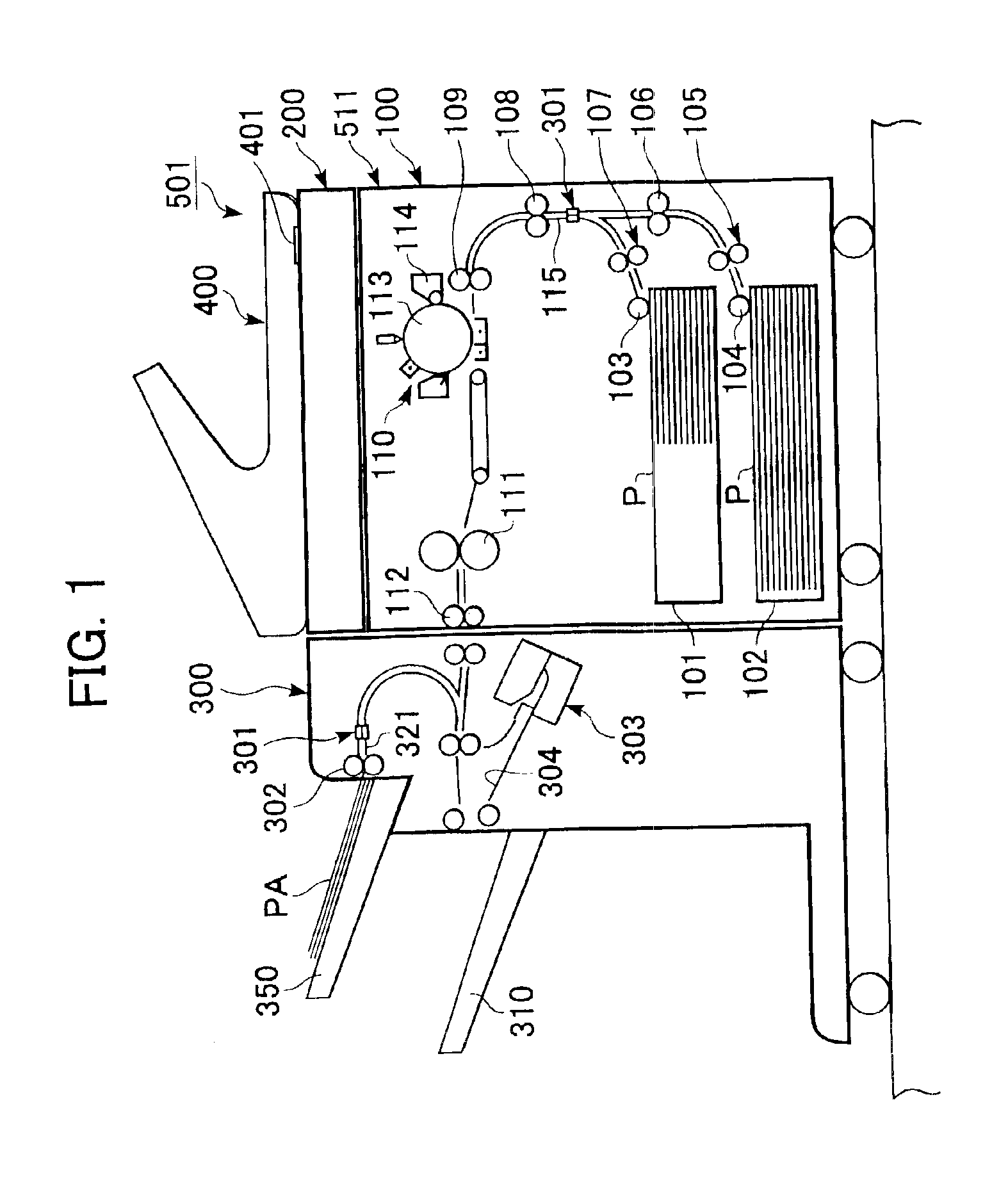

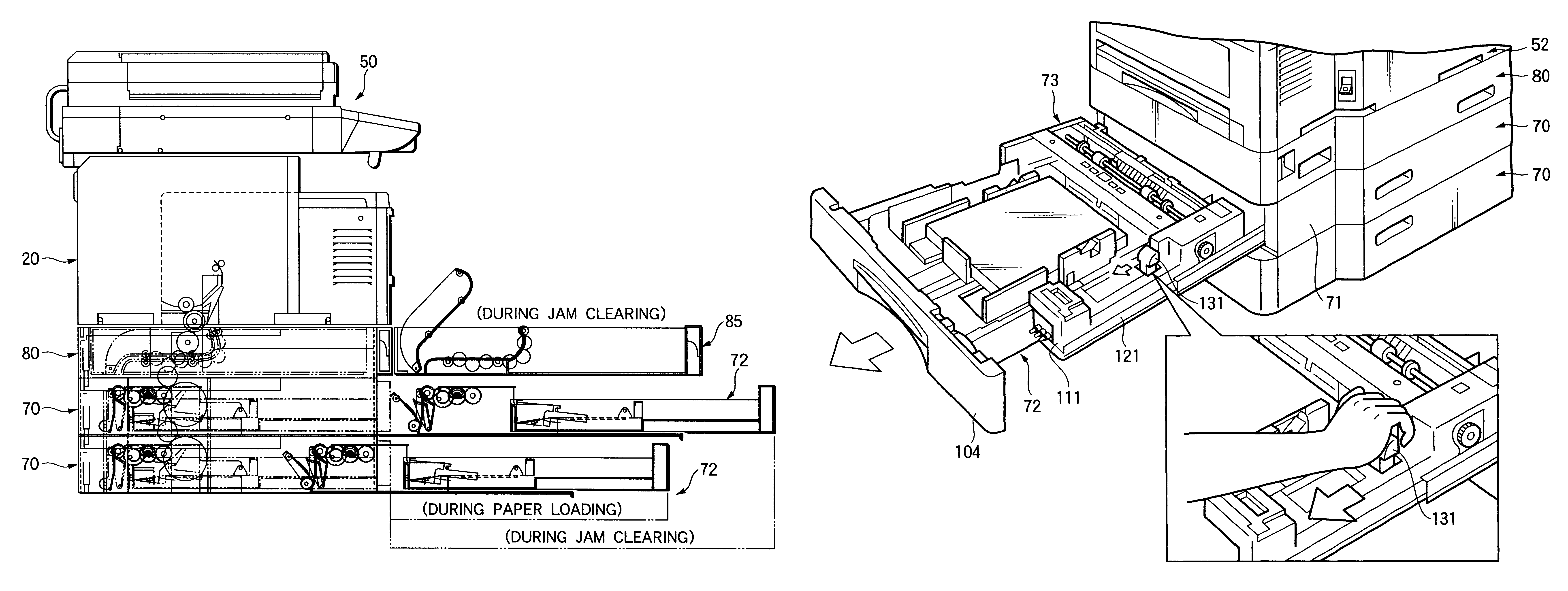

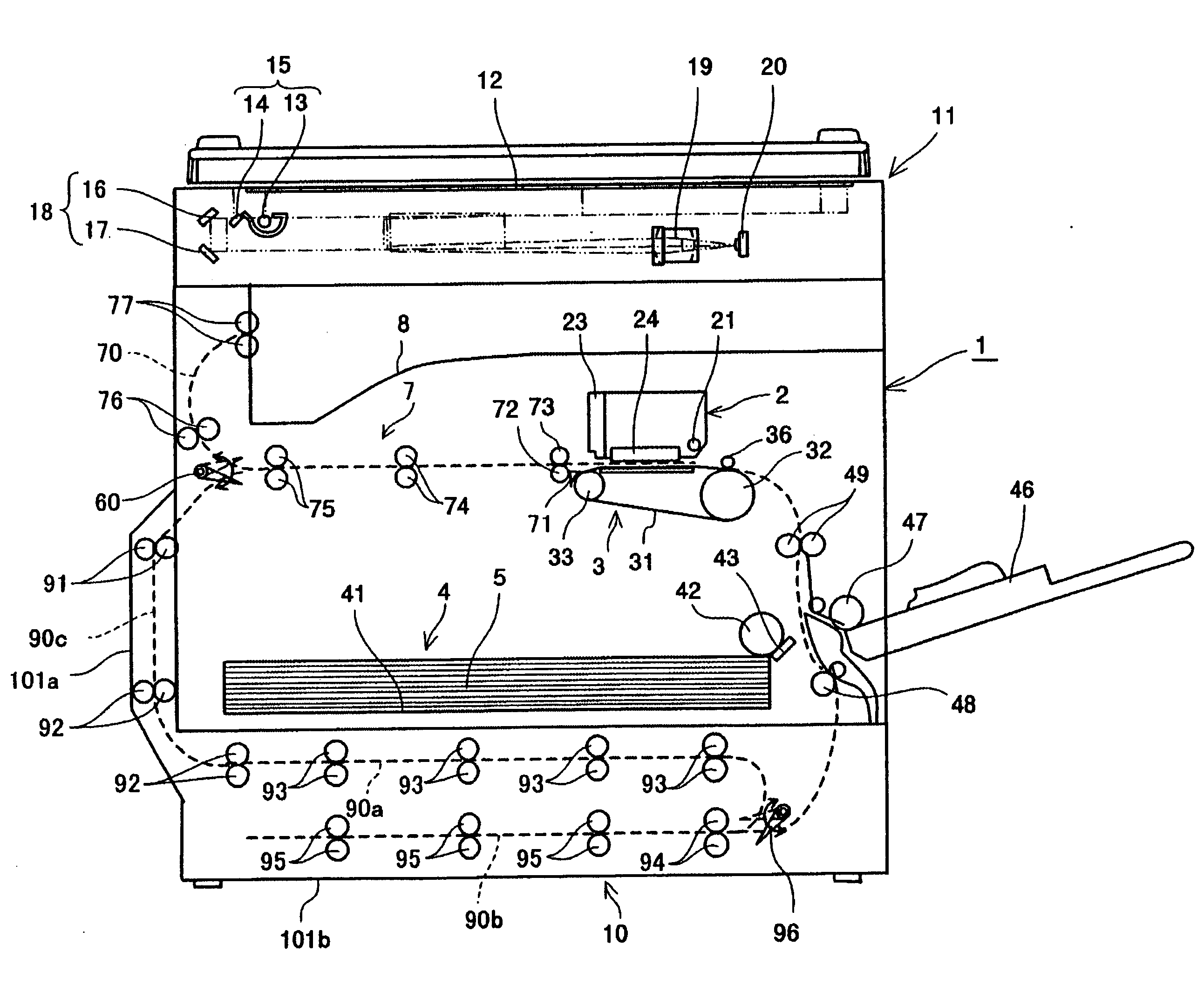

Image forming apparatus and sheet feeder

InactiveUS6674983B2Increase the areaEasy to disassembleElectrographic process apparatusArticle feedersImage formationMaterial supply

An image forming apparatus and sheet feeder in which a recording-material transporting system is provided for transporting to an image forming section recording material supplied from a recording-material supplying section and for subsequently guiding the recording material to a recording-material discharging section. A portion of the transporting path is arranged on a rear side of the apparatus body located on an opposite side to the user operation side. At least either one of the recording-material supplying section and the recording-material transporting system is provided with a jam clearing section for allowing recording material jammed in the recording-material transporting system to be both accessed from and cleared on the user operation side without need to open any access panels on the side portions or rear portion of the apparatus body. As a result the apparatus may be located without reserving space for opening a side or rear access portion.

Owner:FUJIFILM BUSINESS INNOVATION CORP

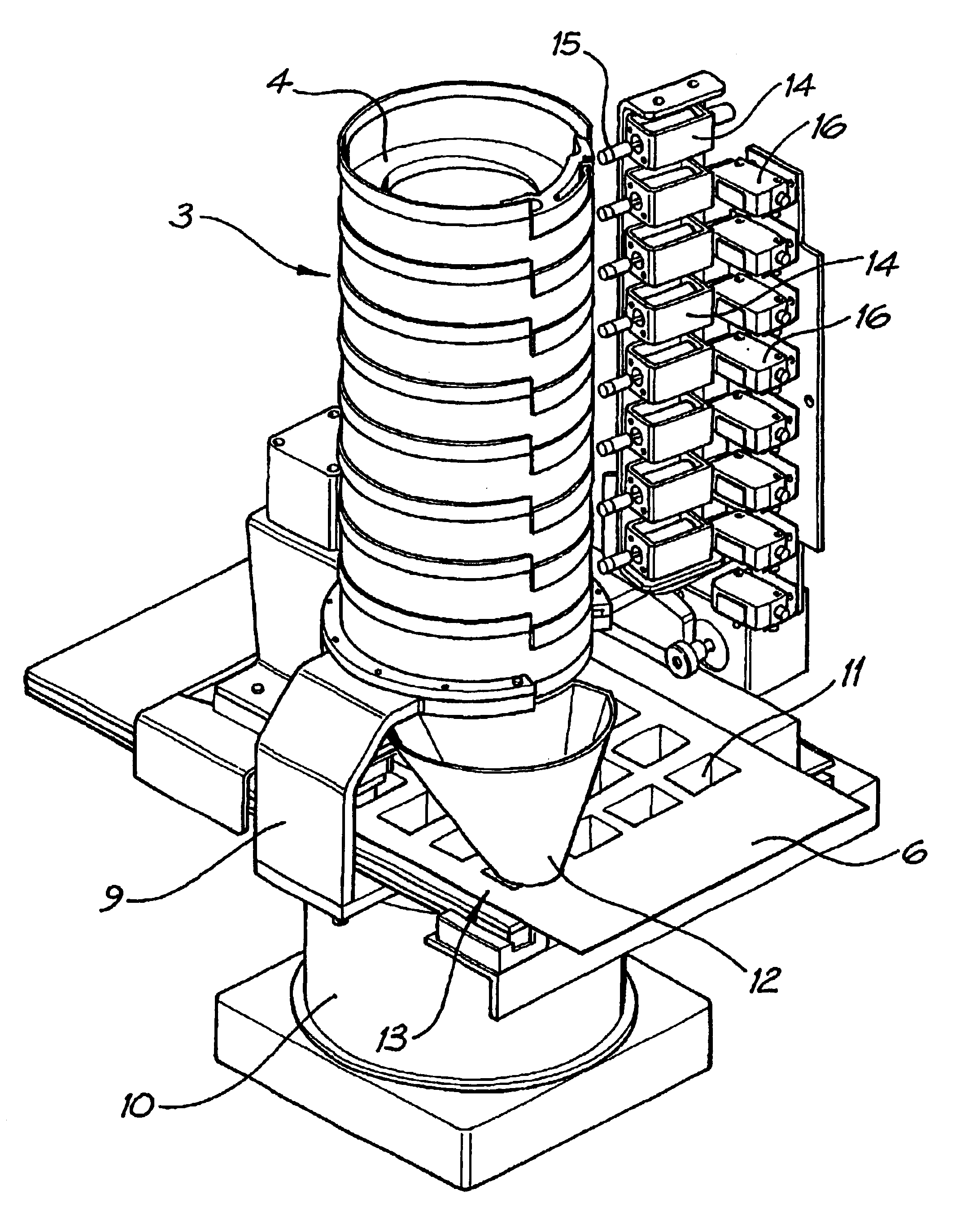

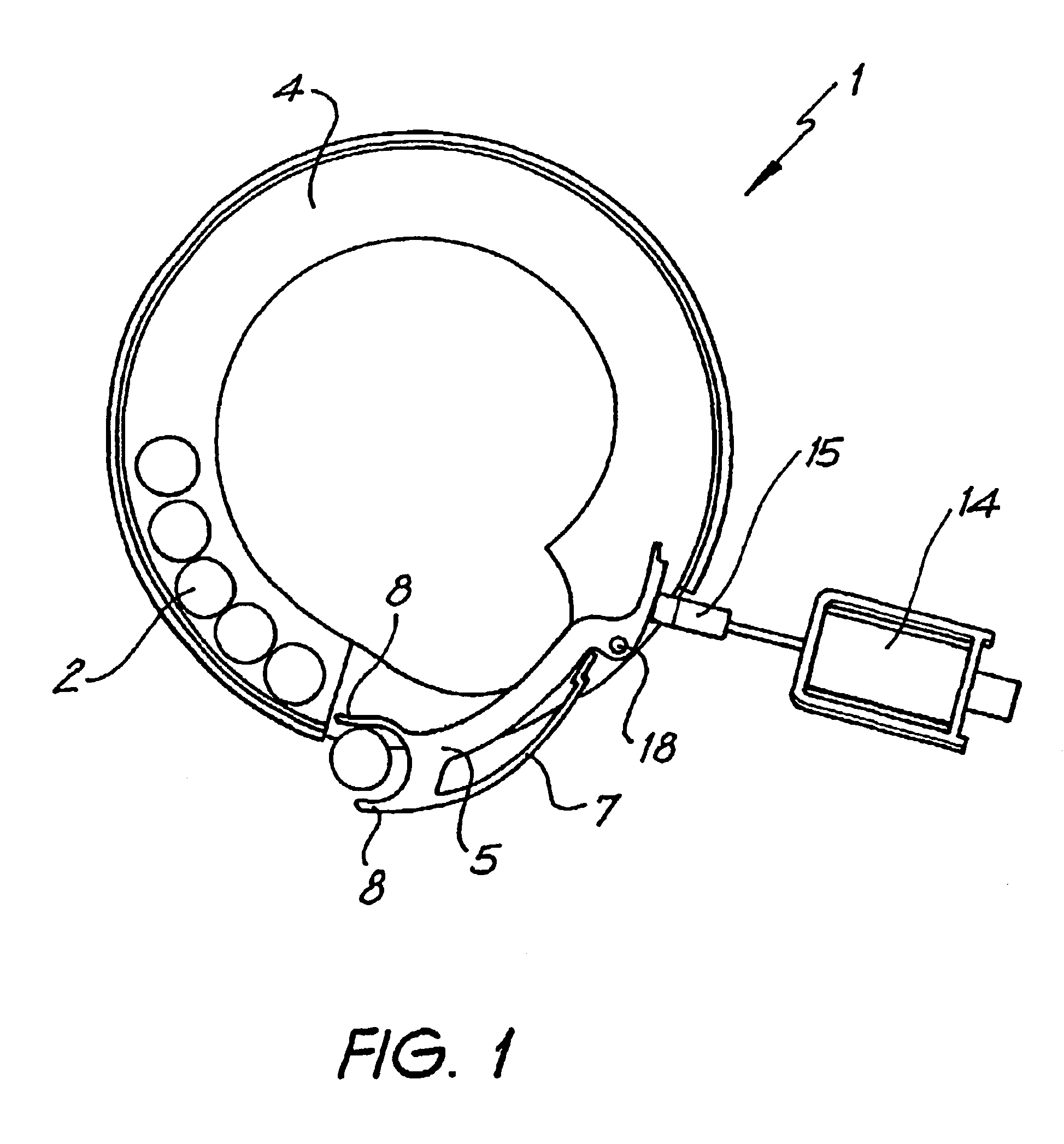

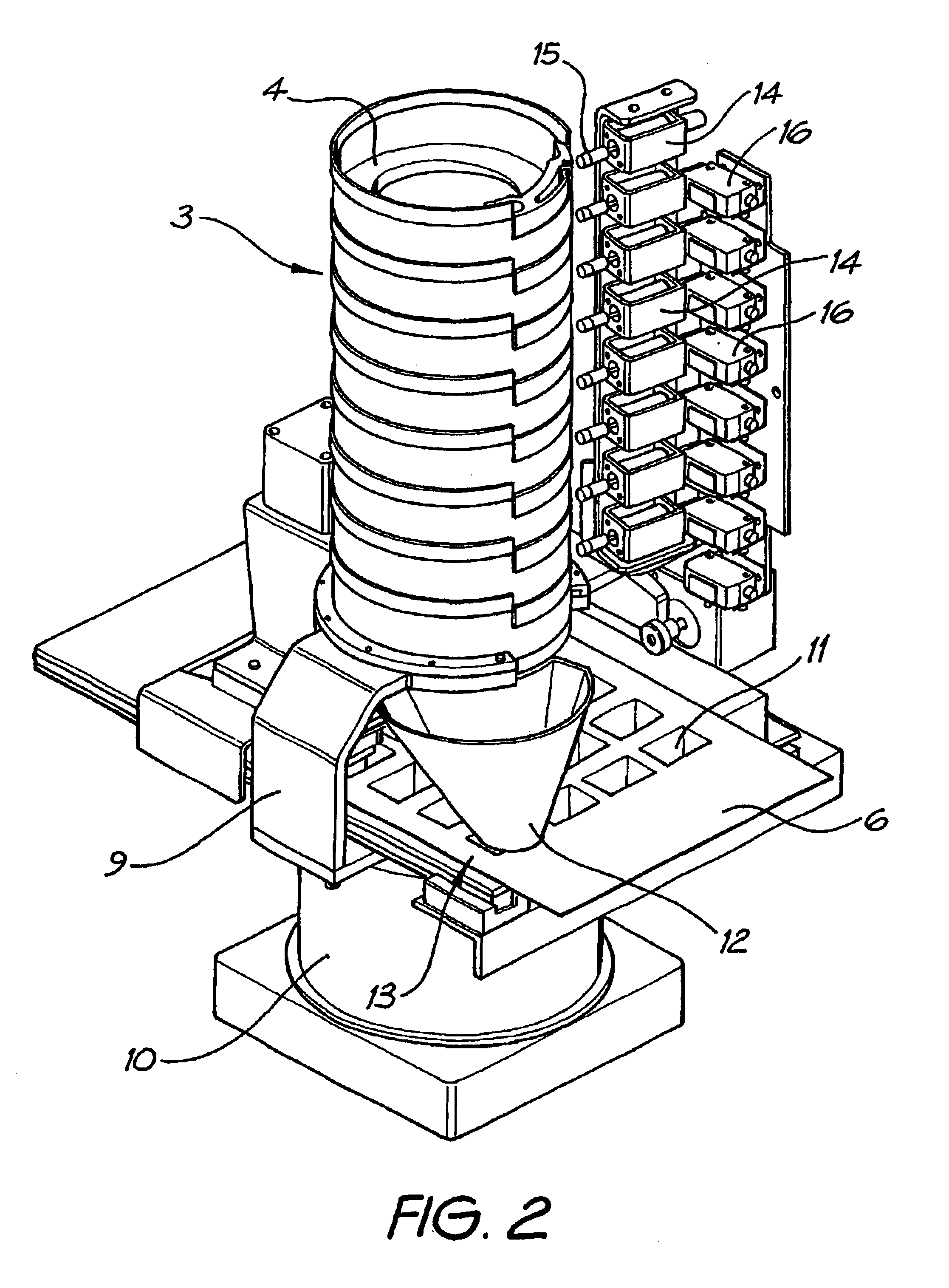

Medication dispenser

InactiveUS6805259B2Coin-freed apparatus detailsOral administration deviceMedication DispenserReciprocating motion

A medication tablet dispenser has an upright casing providing a tower which is subdivided by horizontal partitions into eight compartments which individually contain removable holders each containing a charge of tablets to be dispensed. The holders have framing portions which together provide a funnel opening downwardly into a cavity of a blister sheet. The casing is vibrated back and forth about its vertical axis through a small angle to cause tablets in the holders to progress towards an outlet leading into the funnel and having an associated ejector which discharges selected tablets into the funnel when required by a computer program. Conical vibration of the casing is prevented by a connection located on its vertical axis and held stationary by a fixed arm. The ejectors operate in response to slide-rods individually reciprocated by associated solenoids controlled by the computer program.

Owner:MANREX AUSTRALIA

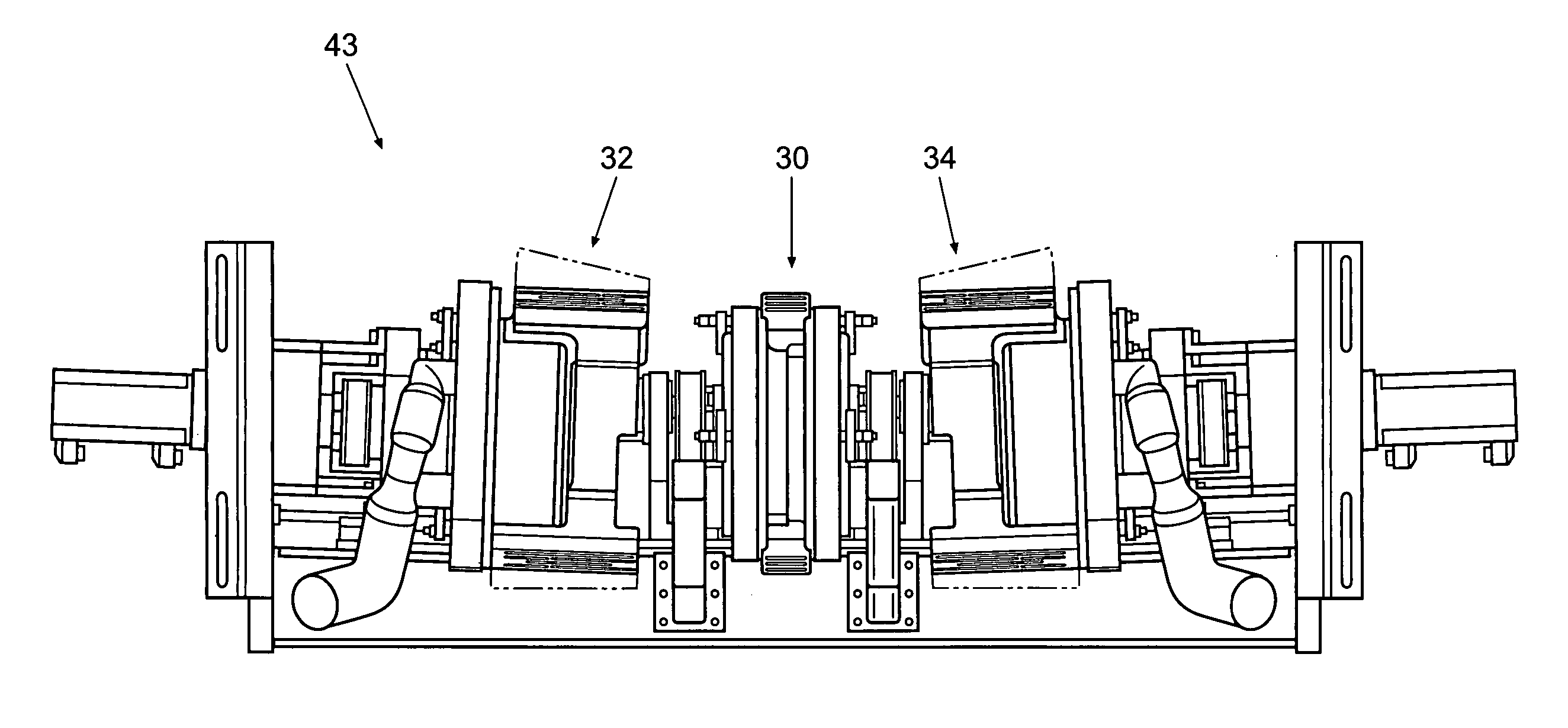

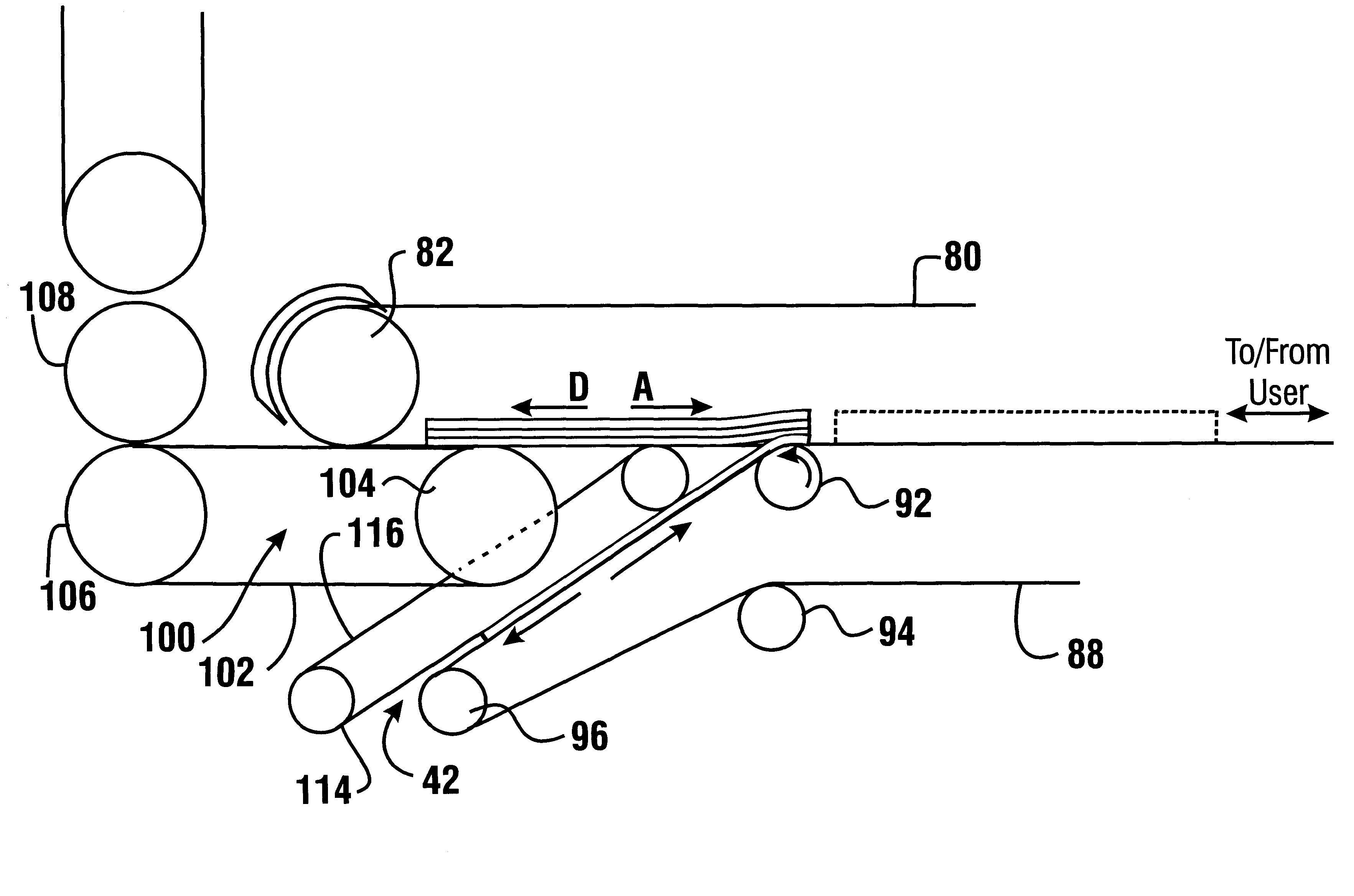

Automated banking machine with sheet directing apparatus

InactiveUS6273413B1Reduce physical sizeOptimizationComplete banking machinesCoin-freed apparatus detailsEngineeringControl circuit

An automated banking machine (10) includes a user interface (12) including an opening (20) for users to deliver and receive individual sheets and stacks of sheets to and from the machine. The machine includes a sheet handling mechanism therein including a first transport path (46) and a second transport path (42). Various devices for dispensing and receiving sheets (30, 32, 34, 36, 38, 40) are positioned adjacent to the second transport path and dispense and / or receive sheets therefrom. The second transport path meets the first transport path at an intersection (60). The machine includes control circuitry (44) which controls the dispensing and movement of sheets along the sheet paths in response to inputs by customers. A sheet directing apparatus (110) is positioned adjacent to the intersection (60). The sheet directing apparatus (110) is selectively operative as a stack of sheets moves through the intersection to either add a sheet to the stack or to separate a sheet from the stack.

Owner:DIEBOLD NIXDORF

Image forming apparatus

InactiveUS20050194730A1Improve convenienceIncrease speedOther printing apparatusArticle feedersImage formationEngineering

An inkjet recording apparatus provides an improved printing speed and improved convenience of use. A recording head discharges droplets of a recording liquid onto a paper so as to form an image on the paper. A belt conveyance mechanism has a belt onto which the paper is electrostatically attached. The paper attached onto the belt is conveyed in a direction perpendicular to a carding direction of the paper.

Owner:RICOH KK

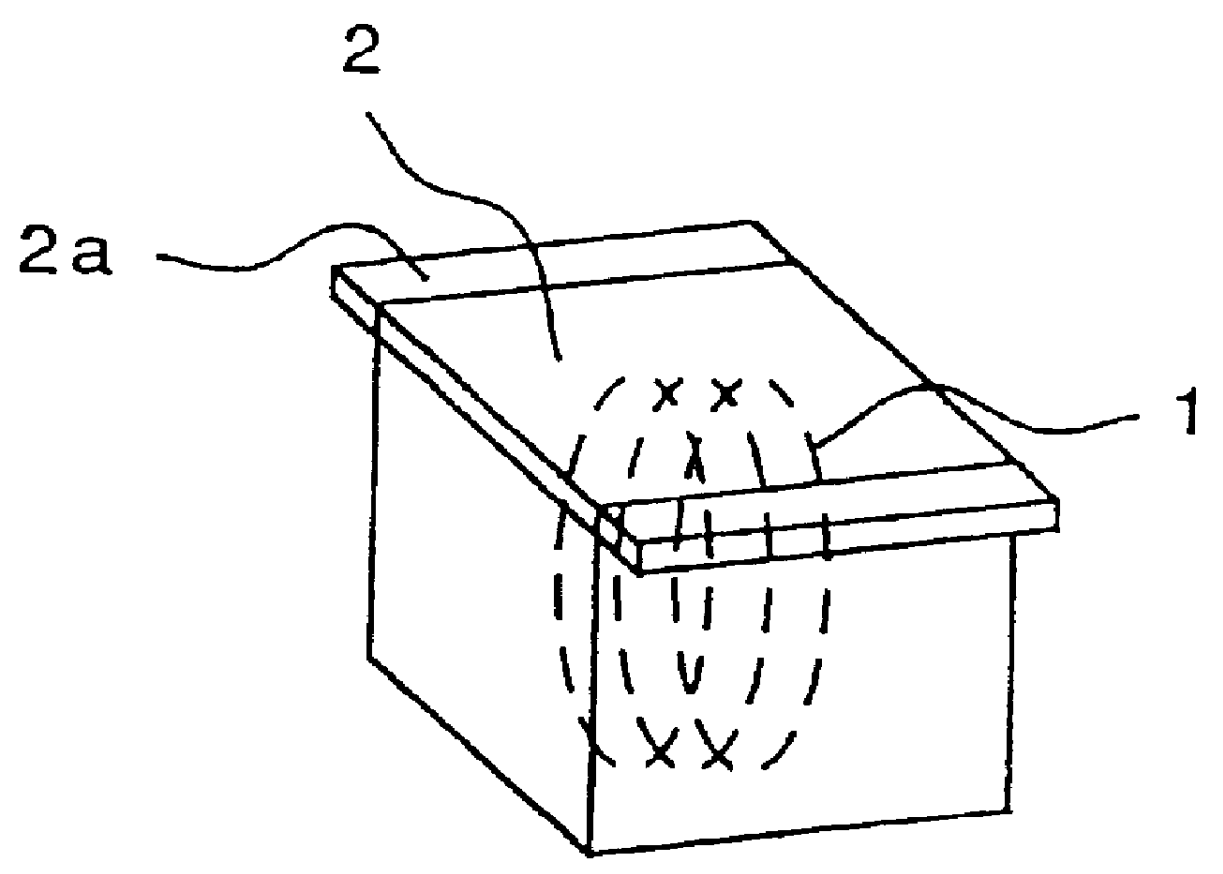

Repulpable container

A repulpable insulated container assembly having a container formed of paper such as corrugated cardboard or varying paper materials and defining an interior; and a repulpable insert placed within the interior of the container and formed of a first paper layer; and a paper fiber pad coupled to the first paper layer.

Owner:PRATT RETAIL SPECIALTIES LLC

Method and apparatus for securing stretchable film using vacuum

InactiveUS20050275148A1Improve gripImprove retentionLaminationLamination apparatusElectrical and Electronics engineering

Owner:CURT G JOA

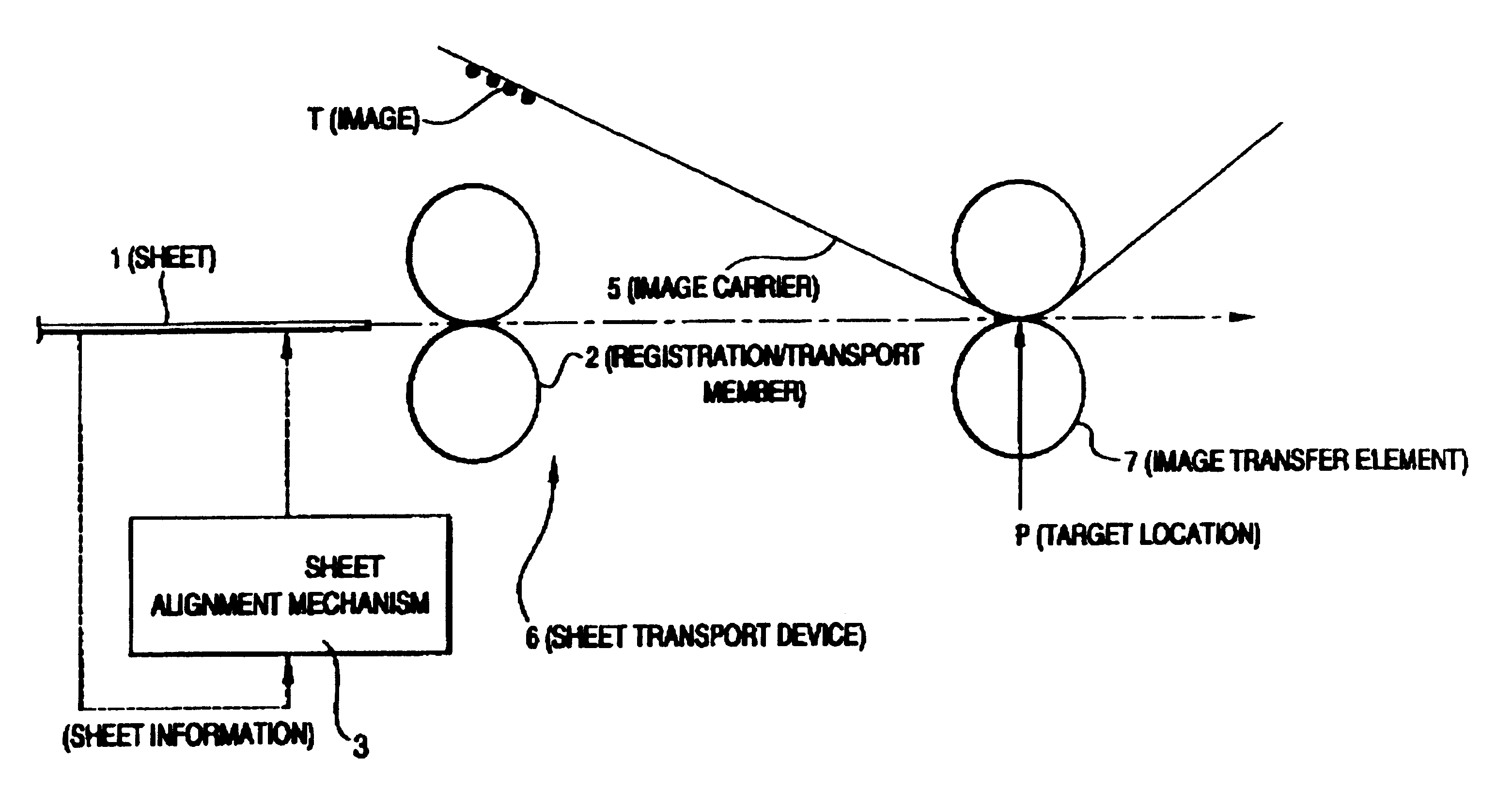

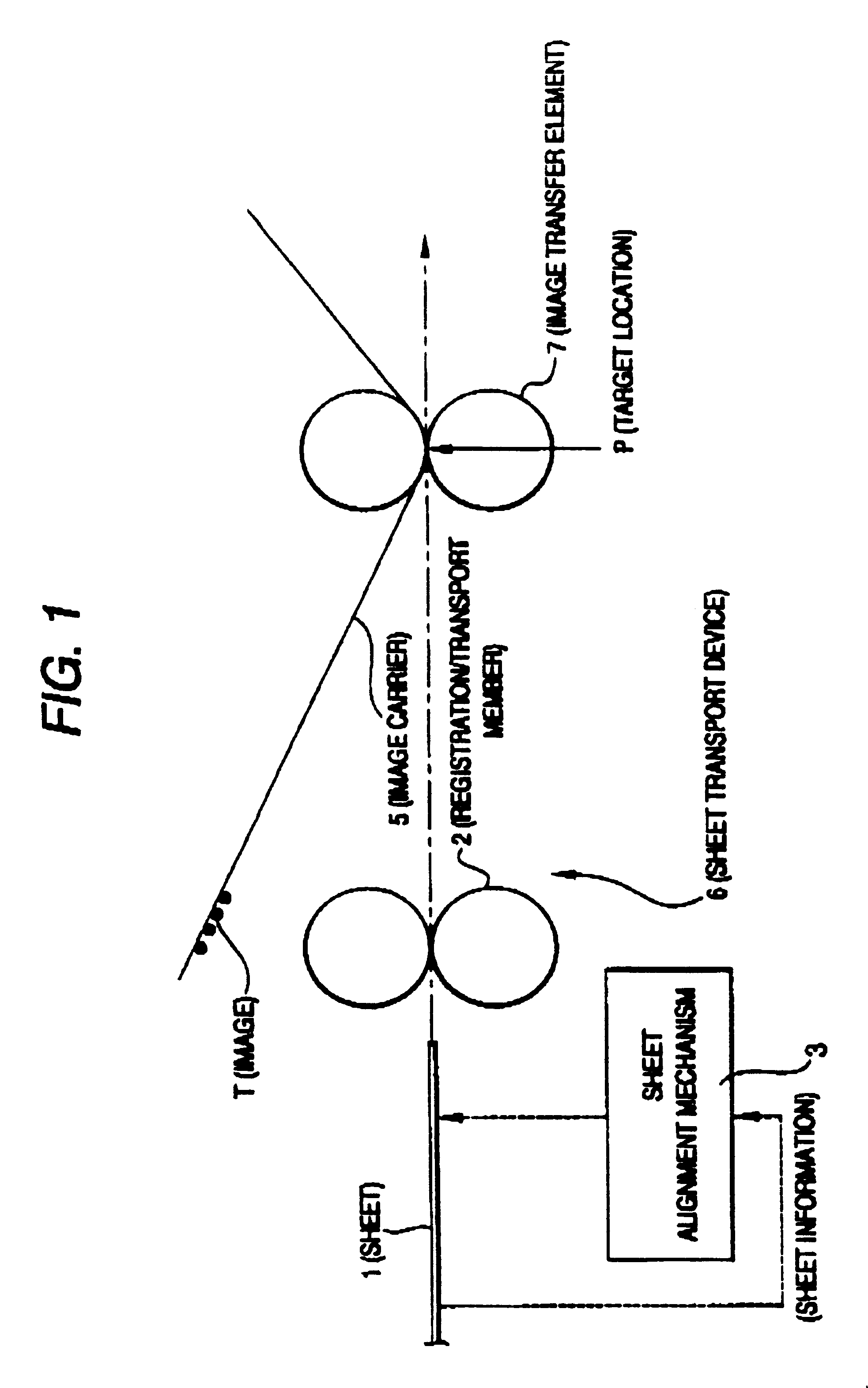

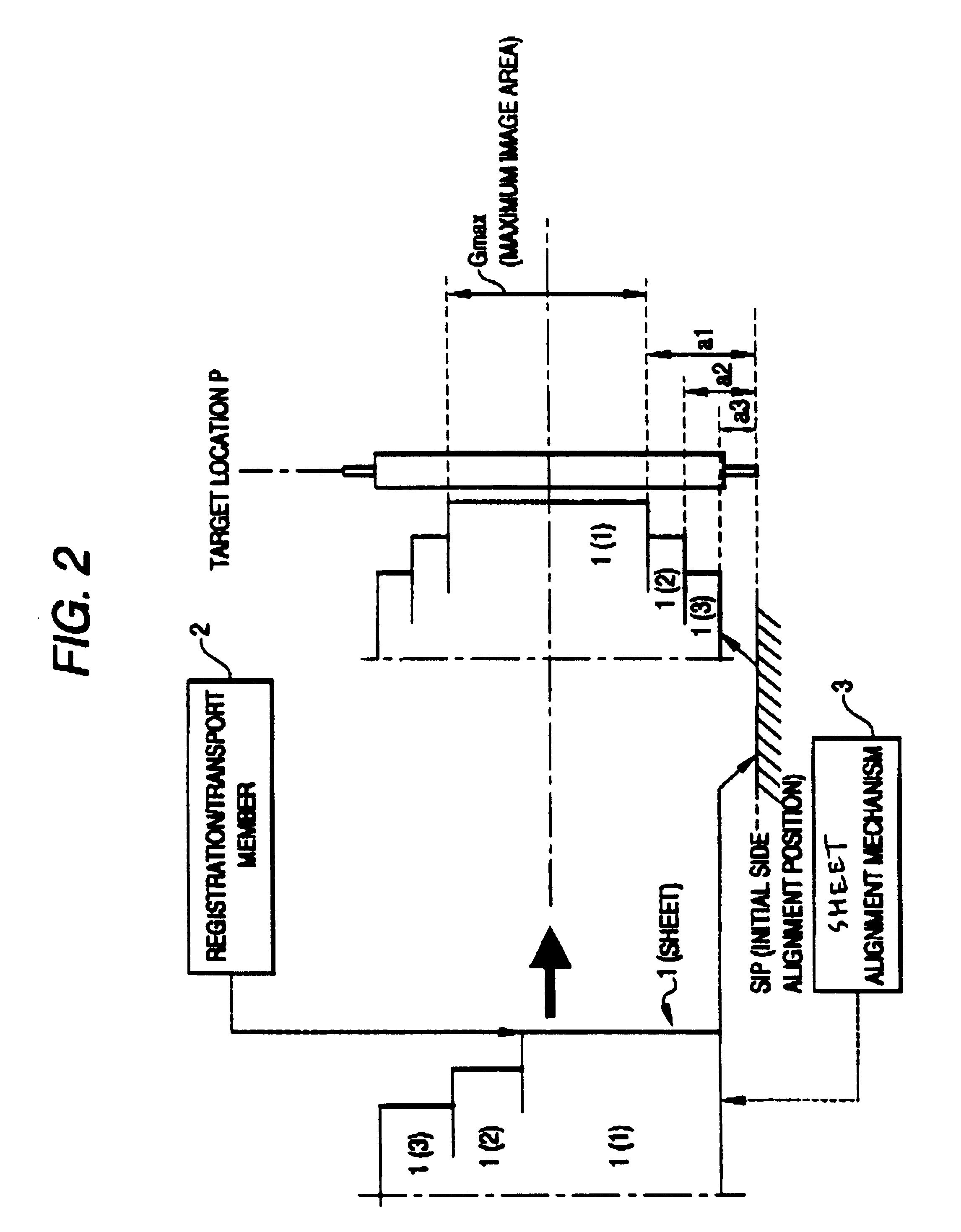

Sheet transport device and an image-forming apparatus employing the sheet transport device

InactiveUS6356735B1Registering devicesElectrographic process apparatusEngineeringMechanical engineering

To make it possible to transfer an image to an exact position even on a sheet of a maximum size having cutoff margins around a maximum image area of the image-forming module, the invention provides a sheet transport device (5) comprising a registration / transport member (2) provided in a sheet path upstream of a target location (P) for correctly positioning a sheet (1) in a sheet transport direction and transporting it toward the target location (P), and a sheet alignment mechanism (3) provided in the sheet path upstream of the target location (P) for moving the sheet (1) in a direction perpendicular to the sheet transport direction to align the sheet (1) to a reference position predefined for each set of sheet information. The invention also provides an image-forming apparatus incorporating the sheet transport device (5).

Owner:FUJIFILM BUSINESS INNOVATION CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com