Patents

Literature

1906 results about "Carding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carding is a mechanical process that disentangles, cleans and intermixes fibres to produce a continuous web or sliver suitable for subsequent processing. This is achieved by passing the fibers between differentially moving surfaces covered with card clothing. It breaks up locks and unorganised clumps of fibre and then aligns the individual fibers to be parallel with each other. In preparing wool fibre for spinning, carding is the step that comes after teasing.

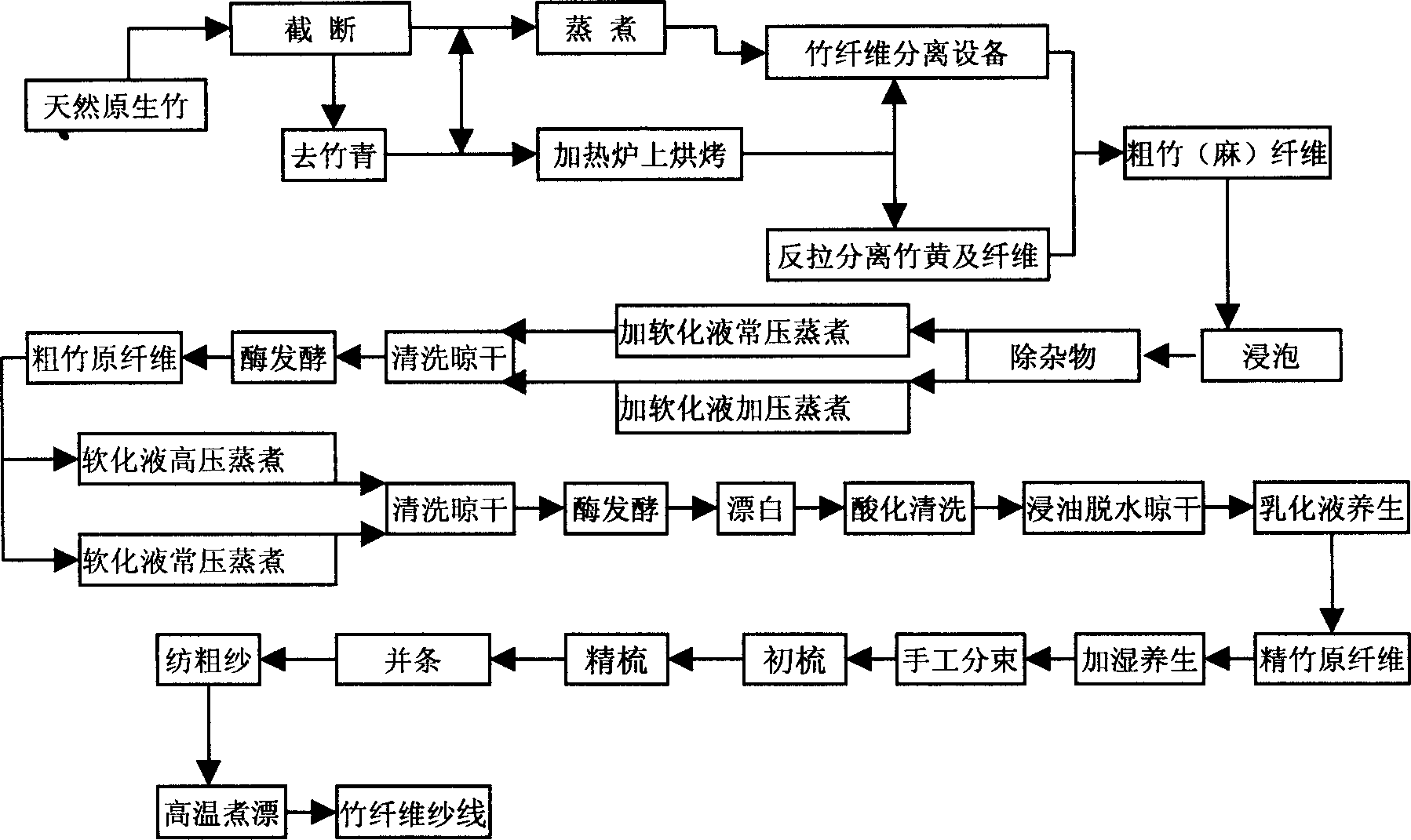

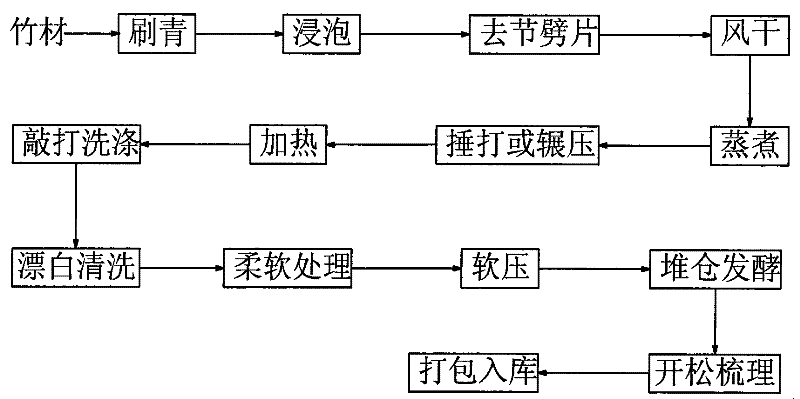

Method for making bamboo fiber

InactiveCN1621580ASolve the problem of excessive lignin contentHigh strengthWood working apparatusMechanical fibre separationCardingToughness

The present invention is preparation process of bamboo fiber, including coarse bamboo fiber, refined bamboo fiber and spinnable bamboo fiber. The coarse bamboo fiber is prepared through cutting bamboo, separating bamboo fiber, steaming inside the No. 1 softening liquid and enzyme fermentation; the refined bamboo fiber is prepared through steaming inside the No. 2 softening liquid, enzyme fermentation, rinsing and bleaching, acid treatment, and oil soaking and drying; and the spinnable bamboo fiber is prepared through emulsifying, initial carding, combing and drawing. The bamboo fiber has lignin content lower than 5 %, and has the features of being natural and green, high in strength, high toughness, high brightness and high elasticity.

Owner:临安力源竹纤维技术开发有限公司

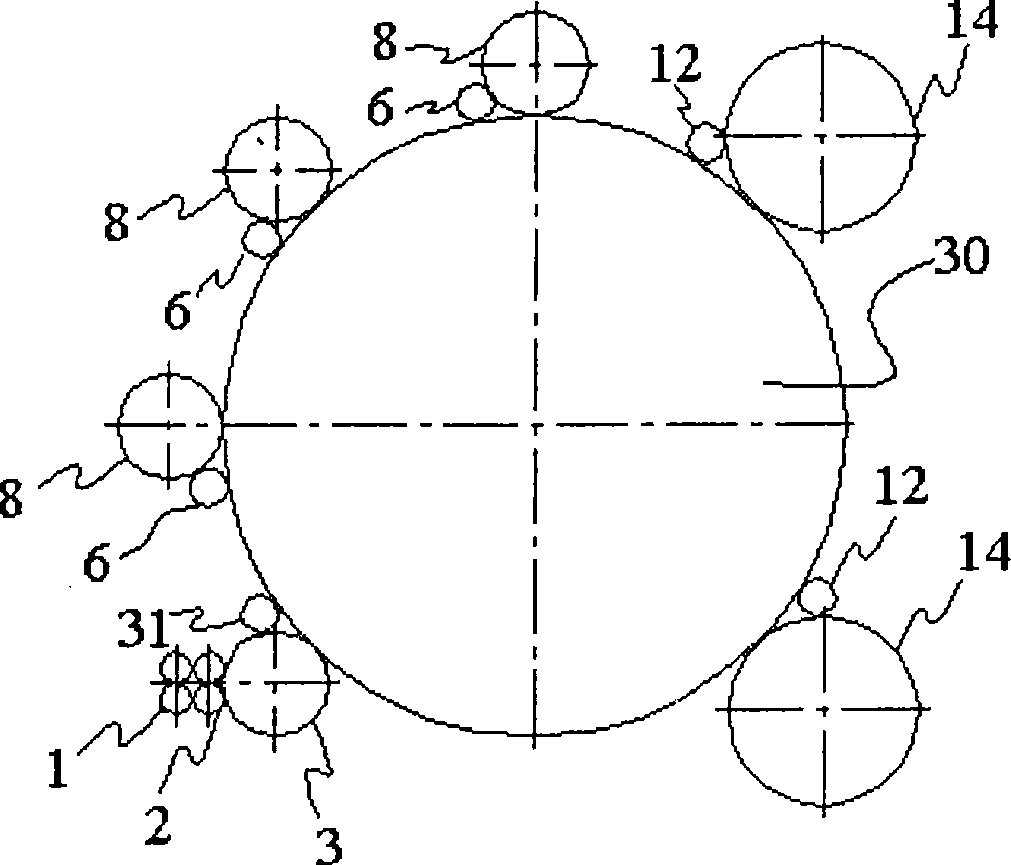

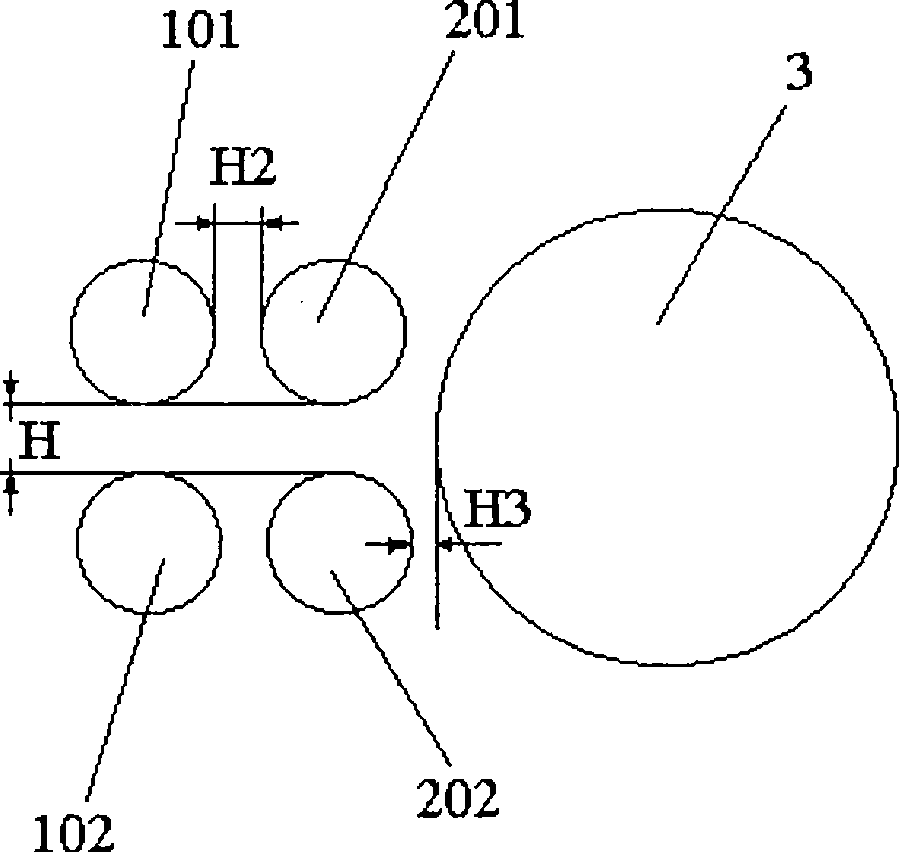

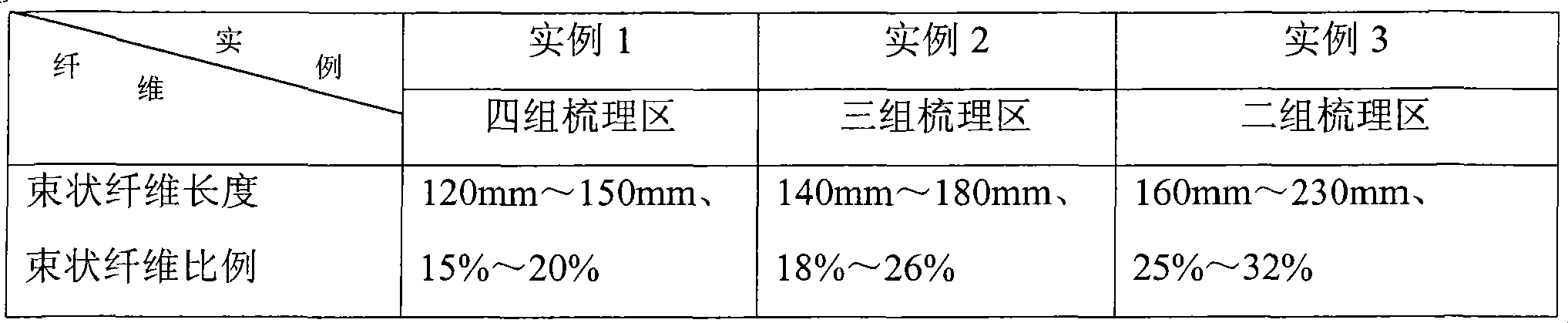

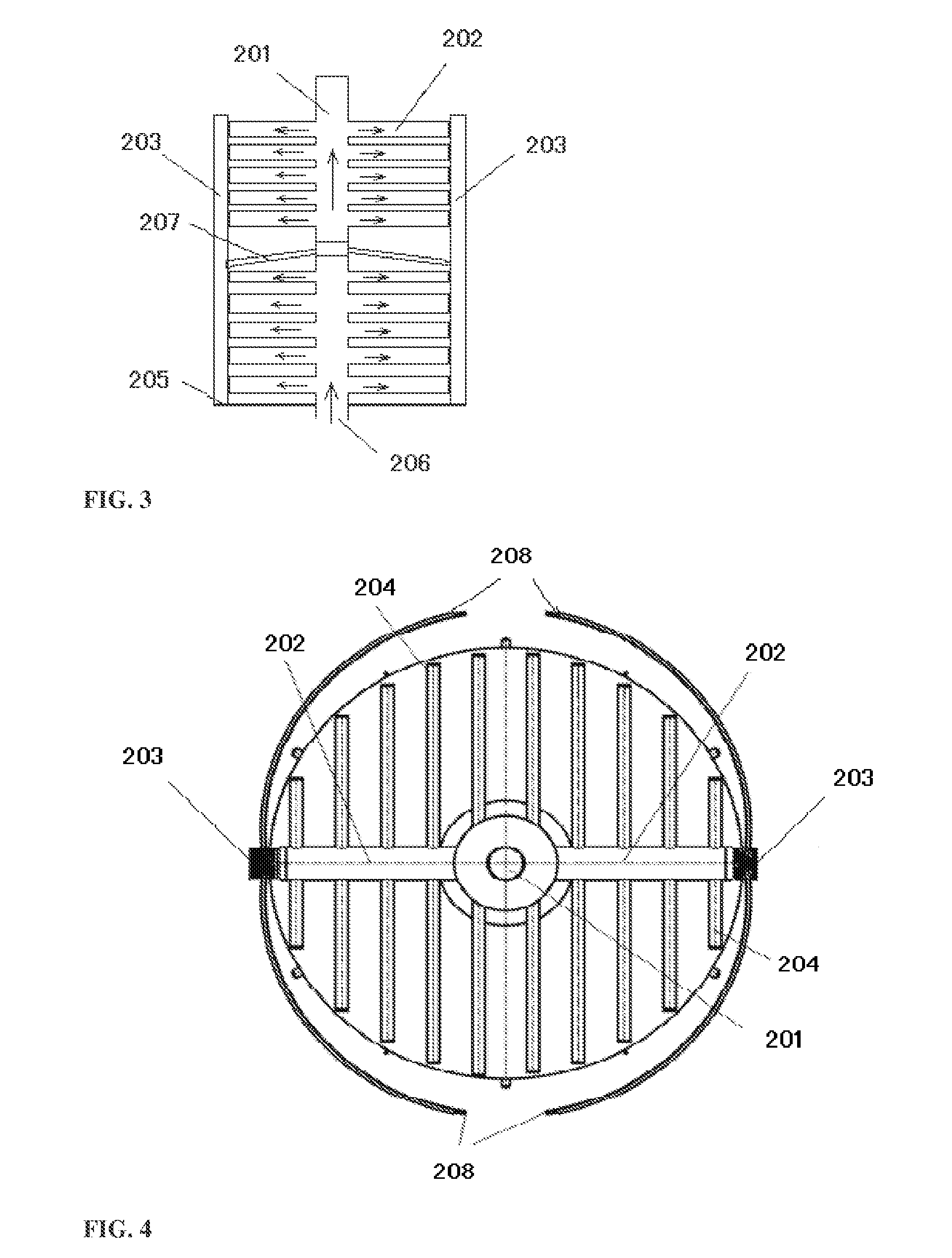

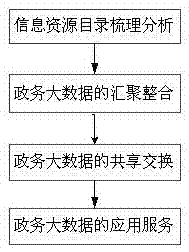

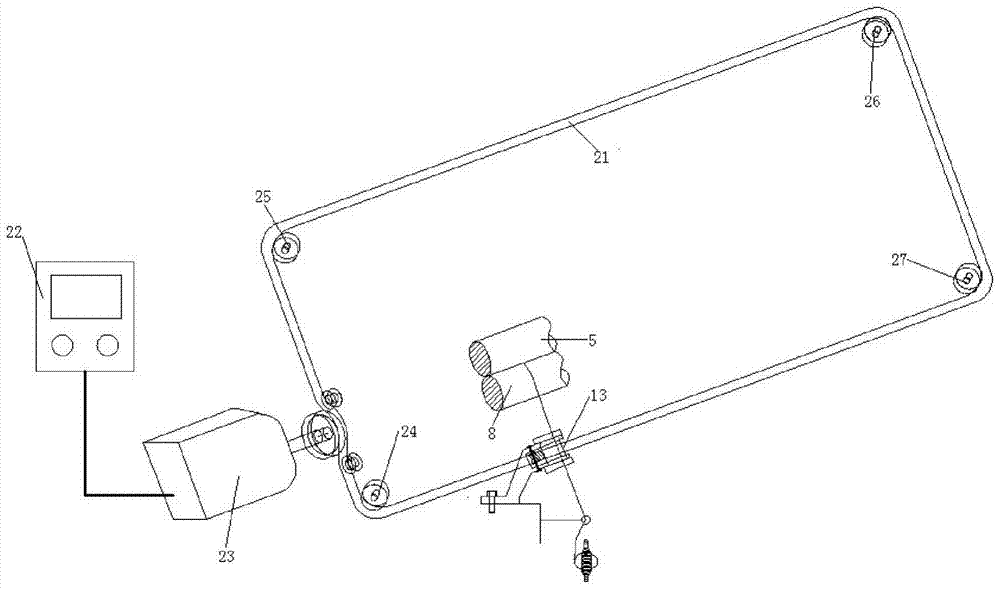

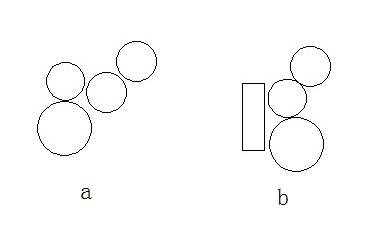

Feeding and carding system for hackling machine

InactiveCN100510211CAvoid damageMeet the characteristic requirementsCarding machinesGlass fiberCarding

The invention discloses a feeding and carding system of card clothing, characterized in that two to four pairs of carding region and two stripping regions are set on cylinder; the distance between principal up-down rollers is 10-70mm; the distance between secondary up-down rollers is 10-70mm, the distance between principal feeding roller and secondary feeding roller is 20-100mm, and the distance between principal feeding roller and thorny roller is 10-80mm. the invention is provided with smaller damage for fiber. Especially aiming to the carding for flax fiber, glass fiber, there is smaller tearing and rupturing to fiber. It can card cutting fiber with the length of 120mm-250mm. There is no influence to indexes such as drawing, bending of the fiber forming felt produced after prepared technology and so on and the product can satisfy the special demand of decoration material in special automobile. It is especially applied in carding for compound fiber, nature flax fiber, bamboo fiber, and glass fiber so on.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

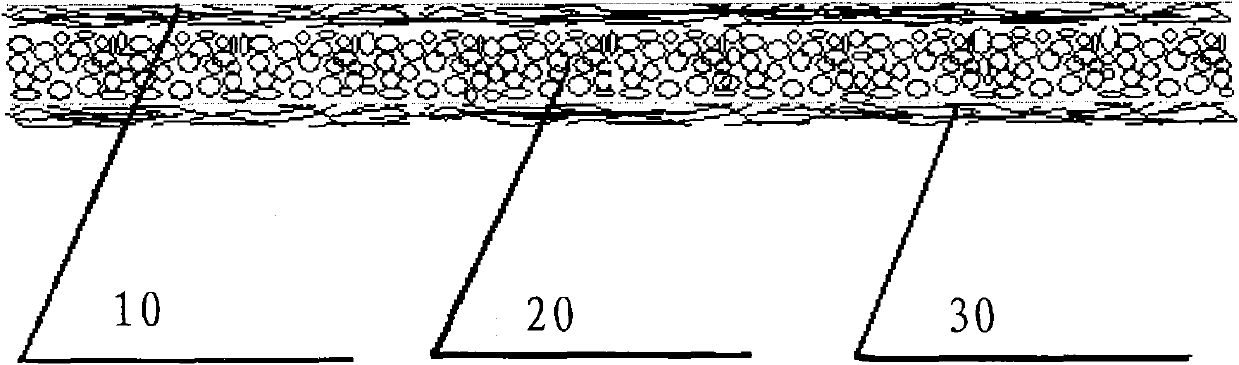

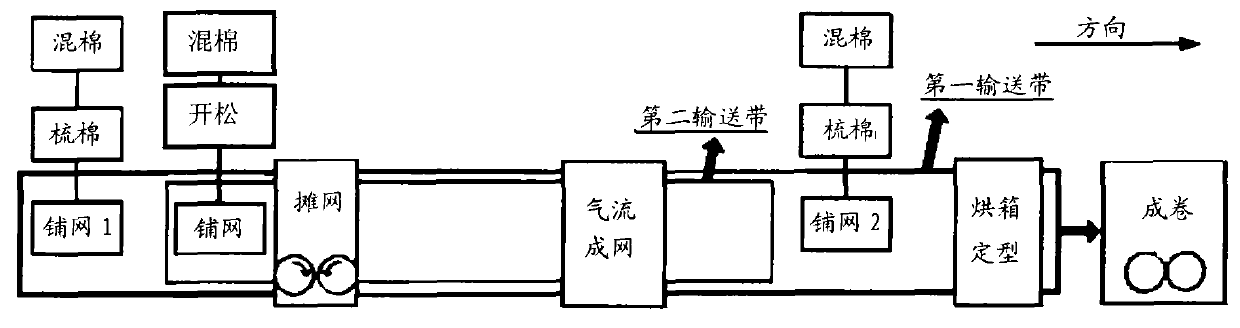

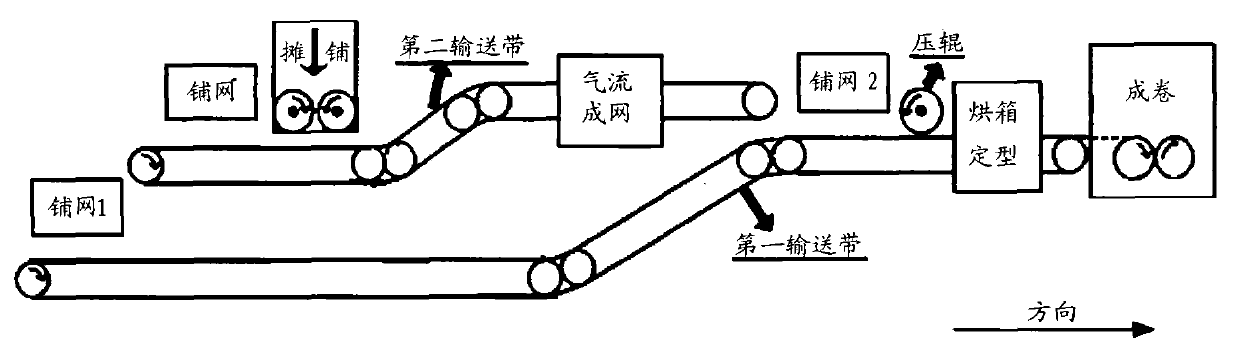

Three-layer sandwiched composite eiderdown flake and manufacturing method thereof

InactiveCN101787619AKeep the advantagesSolve the shortageNon-woven fabricsAdhesivesCardingPlant fibre

The invention relates to a three-layer sandwiched composite eiderdown flake and a manufacturing method thereof. The three-layer sandwiched composite eiderdown flake comprises a lower flake, a middle flake and an upper flake; the upper flake comprises animal and plant fibers and low-melting fibers; the middle flake comprises eiderdown fibers, animal and plant fibers and low-melting fibers; the lower flake comprises animal and plant fibers and low-melting fibers; and the upper flake, the middle flake and the lower flake are thermally fused together. The manufacturing method comprises the following steps: manufacturing the lower flake by using the animal and plant fibers and the low-melting fibers by cotton blending, cotton carding and lapping; manufacturing the middle flake by cotton blending, opening and lapping of the animal and plant fibers and the low-melting fibers, paving of the eiderdown fibers and air laying, and paving the middle flake above the lower flake; manufacturing the upper flake by using the animal and plant fibers and the low-melting fibers by cotton blending, cotton carding and lapping, and paving the lower flake above the middle flake; and thermally fusing the lower flake, the middle flake and the upper flake together.

Owner:杭州飞利弘羽绒寝具有限公司

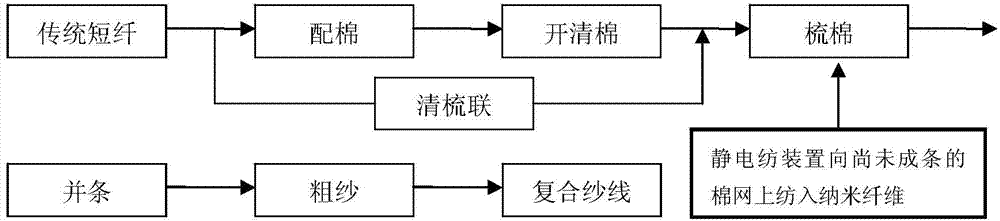

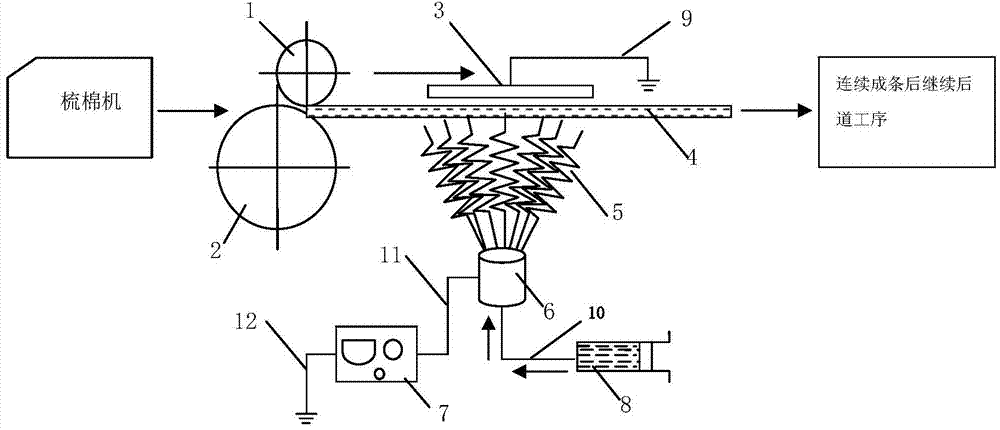

Method for preparing nano-fiber blending composite yarn

The invention relates to a method for preparing nano-fiber blending composite yarn. The method comprises the steps that (1) a functional high-molecular polymer is dissolved in a corresponding solvent to obtain an even electrostatic spinning solution; (2) traditional spinning, including cotton carding, is carried out on short fibers; (3) electrostatic spinning is carried out on the electrostatic spinning solution by means of a TAYLOR cone multi-spray-head electrostatic spinning machine, wherein spinning jet flows are directly sprayed upwards onto fleece which is about to become sliver and formed in the cotton carding process, then fleece containing nano-fibers is obtained, the fleece containing the nano-fibers enters the next yarn forming process directly after becoming the sliver, and finally the nano-fiber blending composite yarn is obtained. The preparing method is simple. The nano-fiber blending composite yarn prepared through the combination of the electrostatic spinning technique and the traditional spinning technique is functional to a certain degree, belongs to nano-textile in the true sense, and is capable of improving the additional value of a product.

Owner:DONGHUA UNIV

Processing Line of Bast Fiber

ActiveUS20120324677A1Improve fiber separation indexImprove biochemistry degumming uniformityMechanical impurity removalLubricating devicesCardingEngineering

A processing line of bast fiber is provided. The processing line is comprised of various devices for carding, cutting, degumming, high temperature washing, separating and water washing, softening, drying, batching and applying oil, permeating and reconditioning, stretching-breaking carding, and combing and sorting. The processing line of bast fiber can improve production efficiency, and improve the yield of long hemp fibers. Moreover, the produced fiber has stable quality and is convenient for post-processing.

Owner:WUHAN HEMP BIOLOGICAL TECH CO LTD +2

Method of processing semi-worsted flax blended yarn

The present invention involves a processing method of semi-worsted flax blended yarn, and it belongs to flax blended yarn technical field. The counts of the semi-worsted flax blended yarn is 30-85 Nm / 2D, the raw materials consists of flax 10-60 and other fiber 40-90; degelatinizing, dyeing and preserving flax, pretreating other fiber, then putting together wool, blowing cotton, carding and drawing, then prespinning and shirting, last the products are prepared after cheese winding, twisting and double twisting processes. The invention combines the 'straight' of flax fiber and the 'softness' of other fibers effectively; the prepared semi-worsted flax blended yarn has many advantages of good textile strands and less granulite, it is suitable for the face fabric of thin summer inner wear and coat.

Owner:山东恒泰纺织有限公司

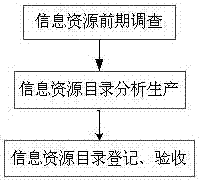

Method of constructing big data platform of government affairs

The invention, which belongs to the data processing technology, discloses a method for constructing a big data platform of government affairs. The method comprises; step one, carrying out an information resource catalog carding analysis: to be specific, carrying out information carding and a relevance analysis of information to form an information resource directory and information demanding and sharing; step two, carrying out government affair big data collection and integration; to be specific, according to the information resource directory, carrying out collection and integration of data resources to form a government affair big data set; step three, carrying out sharing and exchanging of government affair big data; to be specific, carrying out exchanging and sharing between government affair big data; and step four, carrying out an application service of the government affair big data; to be specific, building an application model, digging effective information, and pushing the effective information on needs. The method has the following advantages: government affair data can be dug, analyzed, integrated, and applied effectively and thus integration of electronic information and geographic information technologies can be realized, so that promotion and application of the smart city concept can be realized.

Owner:星际空间(天津)科技发展有限公司

Fire retardant cotton nonwoven fabrics and manufacture method thereof

InactiveCN101307528AImprove flame retardant performanceGood anti-melting effectHeating/cooling textile fabricsNon-woven fabricsCardingPolymer science

The invention discloses an flame retardant non-woven cotton fabric, comprising anti-fcell flame retardant fiber and washing / washing composite hot melting short fiber, wherein, the weight percentage of the anti-fcell flame retardant fiber is between 70 and 90 percent, the balance is the washing / washing composite hot melting short fiber; the two fibers are stuck into an integrated whole by the hot wind heating and / or are penetrated together by prickling fibers to combine into the non-woven fabric. The method for producing the non-woven cotton fabric comprises the processes of mixing, opening, carding, mesh placing, moulding processing, etc. The moulding processing method has the needle point method and the through-air method. The flame retardant non-woven cotton fabric adopts the prescription of mainly taking the anti-fcell flame retardant fiber and solves the problems of the flammability of the terylene, dropping of the fusion and the flammability of the viscose. The washing / washing composite hot melting short fiber is added to increase the caking coefficient so that the fibers are conglutinated evenly. The unique processing flow ensures that the inflaming retarding non-woven cotton fabric has high tension intensity and anti-breakage intensity as well as certain elasticity and bulkiness.

Owner:DONGGUAN LIANYING NONWOVEN TECH

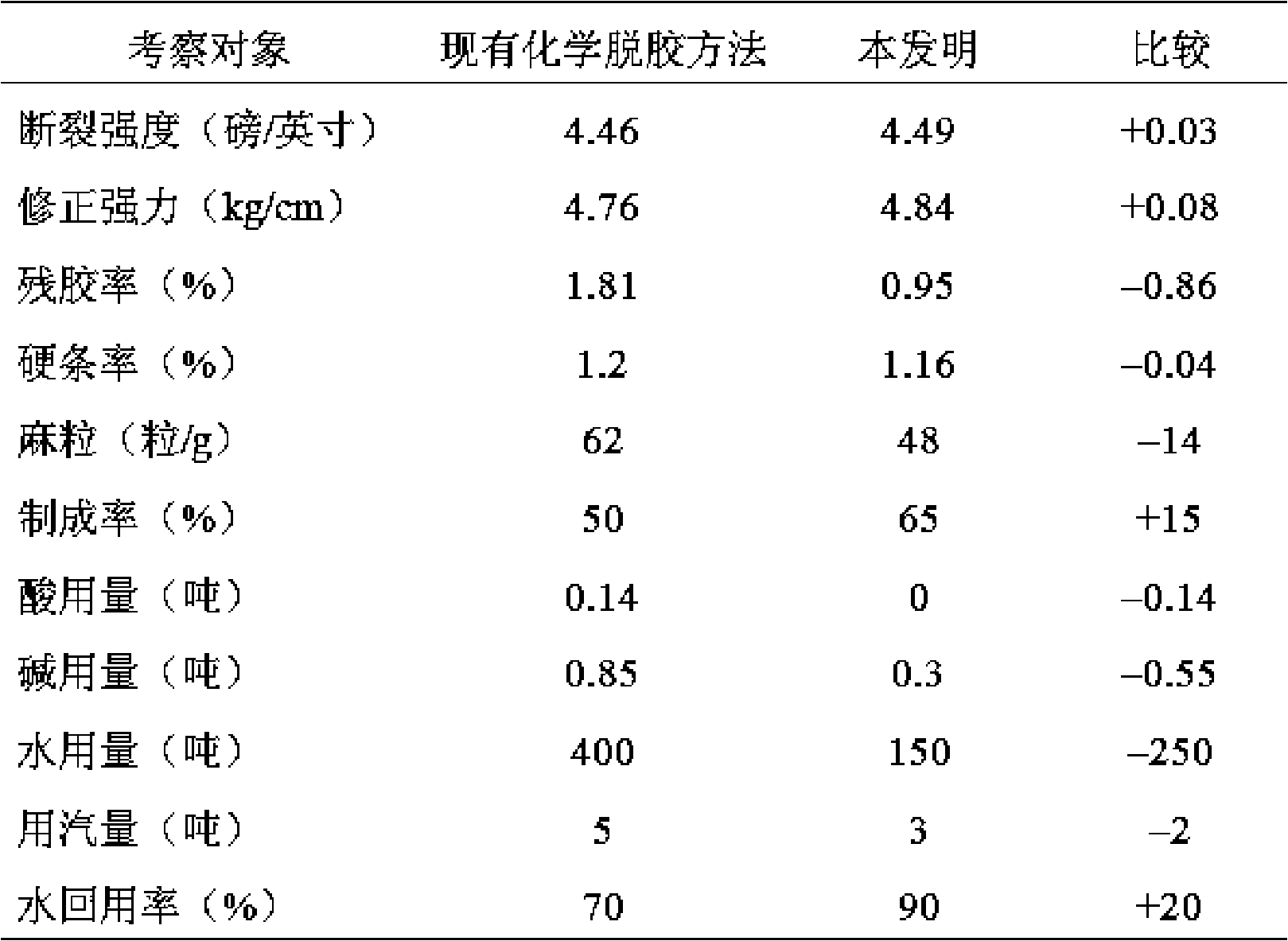

Manufacturing method of ramie based on sectioned circulation

ActiveCN101624727AGet rid of dependenceReduce dosageMechanical treatmentBacteriological rettingChemical treatmentCarding

The invention discloses a manufacturing method of ramie based on sectioned circulation, belonging to the manufacturing method of textile fibre and solving the problems that the prior method has a large quantity of waste water, serious pollution and high cost. The method comprises following steps: pretreatment of primary ramie, chemical treatment, biological treatment and post treatment; the pretreatment improves the degree of looseness of the primary ramie through beating, ultrasound or extraction; the biological treatment degrades pectin, hemicellulose and others impurities through bio-enzyme or microbial fermentation; the chemical treatment further degrades residual pectin and others impurities through alkali boil-off; the post treatment obtains refined dry ramie by beating, whitening, water scrubbing, dehydration, oil feeding, drying, carding and baking. The quality of the product meets the requirements of first-class GB / T 20793-2006, the degumming yield rate is improved by 15%, the water consumption is reduced by at least 60%, the method is free from using acid, the alkali charge is reduced by 65%; water, the alkali and the bio-enzyme used in each step are recyclable; the byproducts can be recycled in time, the sewage quantity is small and the pollution level is low.

Owner:HUAZHONG UNIV OF SCI & TECH

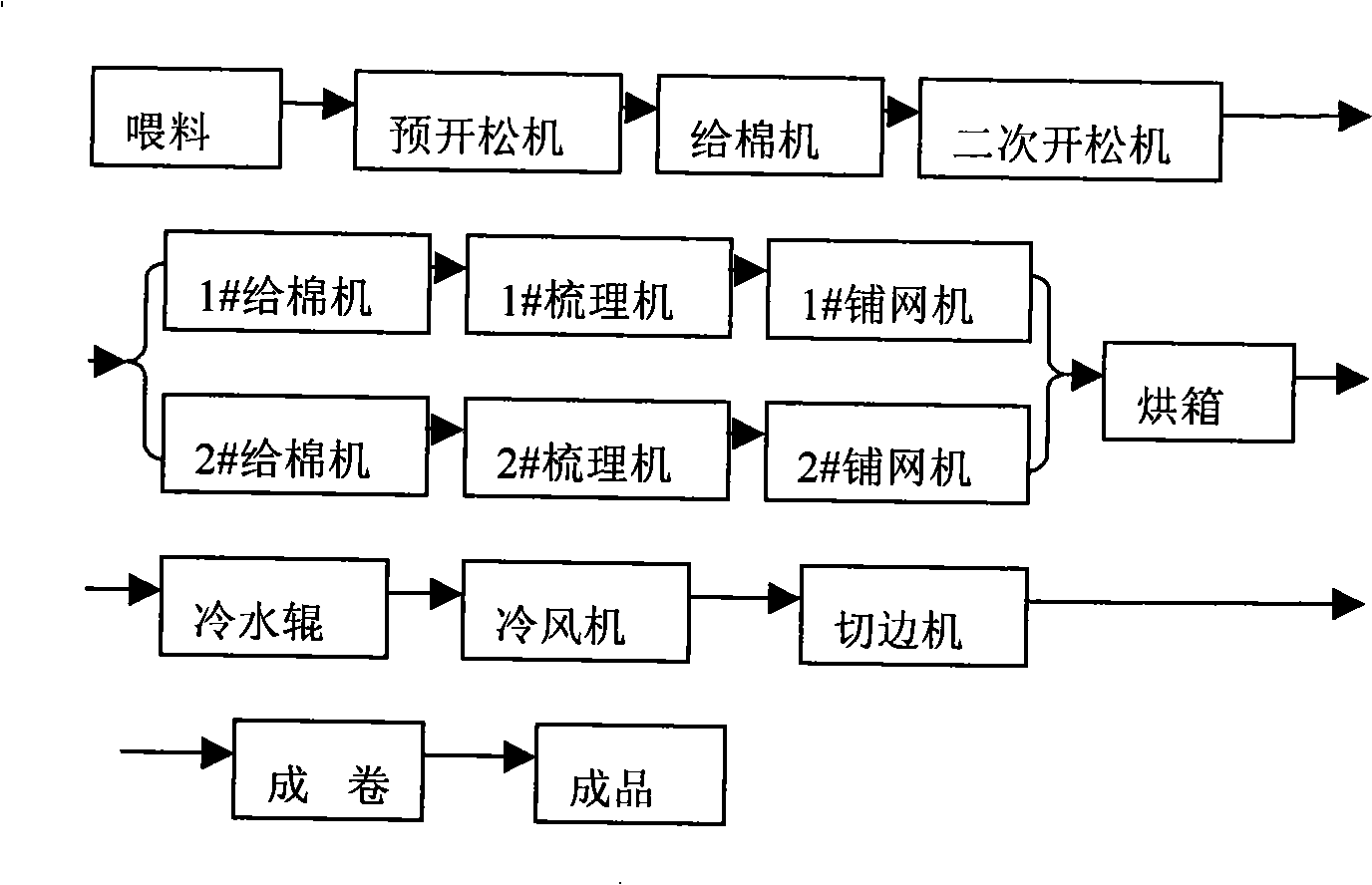

Green totally degradable warming material and producing method thereof

InactiveCN101509175AHigh strengthImprove stabilityHollow filament manufactureFilament/thread formingCardingKapok fiber

A green completely-degradable warm-keeping material and a production method thereof are disclosed, the weight percent of components thereof are: 40-60 parts of kapok fiber, 10-40 parts of polylactic bi-component fiber and 15-40 parts of polylactic hollow fiber; the material is formed by pre-needling at first and then the procedures of hot-melt shaping, cooling, winding, etc. after a fluffy three-dimensional netlike structure fiber net is formed by cotton plucking, cotton mixing, weighting, opening, mechanical carding and disordering. The inventive warm-keeping material employs the completely-degradable raw materials and has no pollution in the entire production process, the product has multiple functions of excellent strength, fluffiness, warm keeping, bacteriostasis and the like, which belongs to green environmentally-friendly products.

Owner:JIAXING UNIV

High-temperature resisting flame-retarding composite polysulfonamide fiber yarns and manufacturing method

Provided are high-temperature resisting flame-retarding composite polysulfonamide fiber yarns and a manufacturing method. The manufacturing method is used for providing high-quality yarns for high-temperature resisting flame-retarding fabrics. The technical scheme is that the yarns are 16.7*2 tex yarns formed by spinning raw materials including polysulfonamide fibers 50-70%, flame-retarding mucilage glue 28-48% and conductive fibers 1-2%, wherein the conductive fibers are carbon fibers. Proportions of various raw materials are prepared reasonably, a best proportion is obtained through multiple technological optimization, related technological parameters are further controlled in the processes including opening and picking, cotton carding, drawing, roving, spinning, plying and the like according to the characteristics of the raw materials so as to enable various fibers in products to be distributed evenly, the requirements of high-temperature resistance and flame retarding are met, the yarns are detected according to the SJ / T11090-96 standard, and density of electric charge caused by friction of the fabrics manufactured by the yarns reaches to the standards of first-grade products.

Owner:BAODING CHINATEX YIMIAN TEXTILE

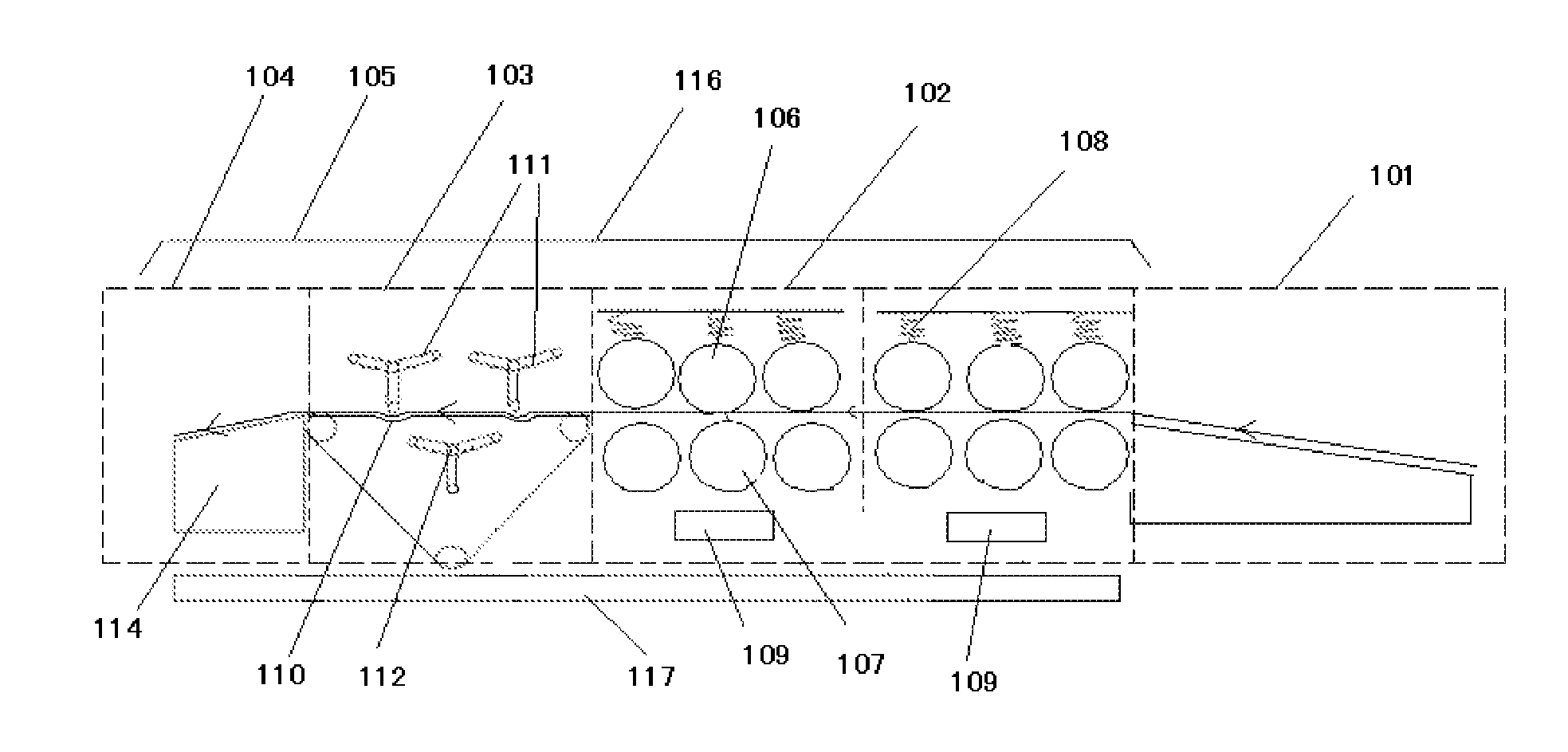

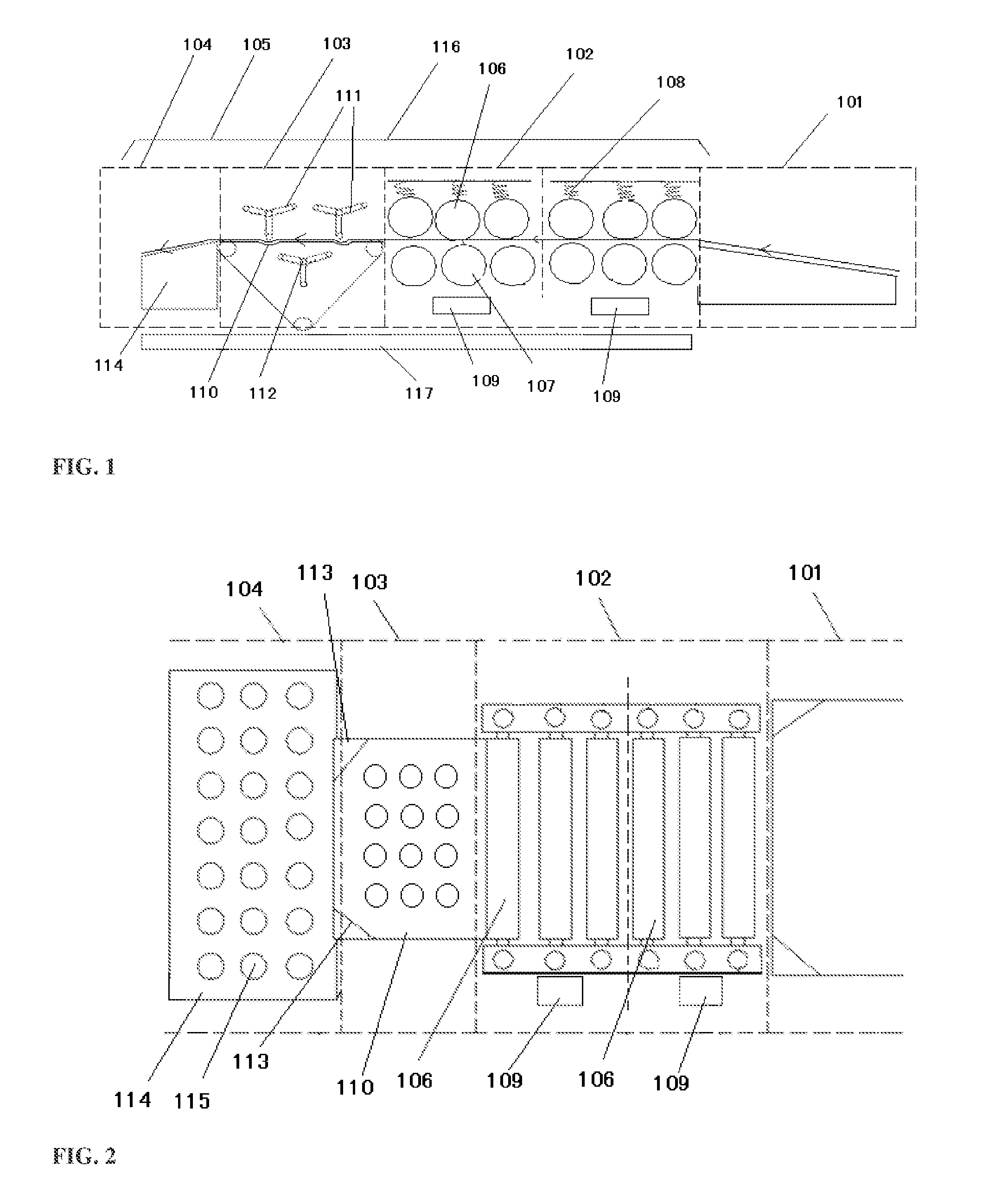

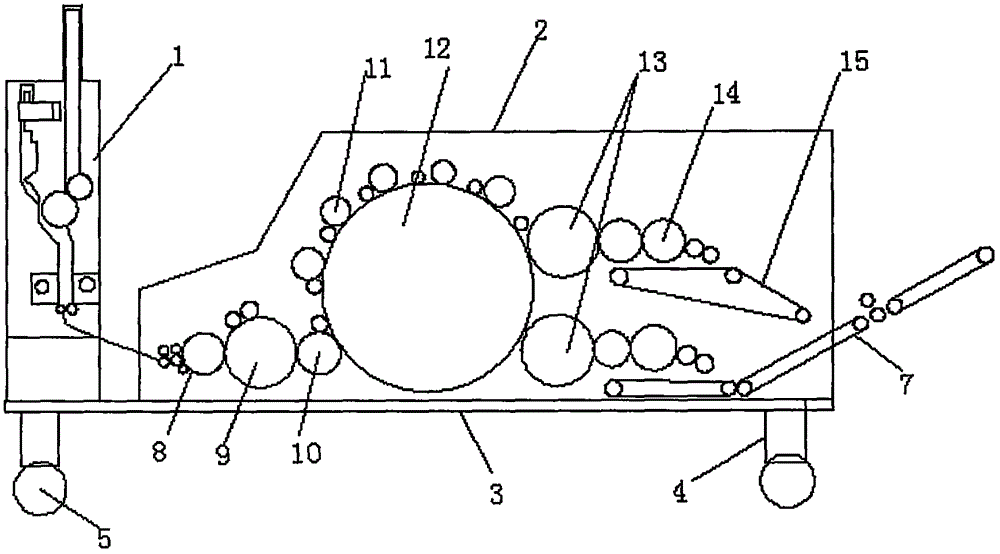

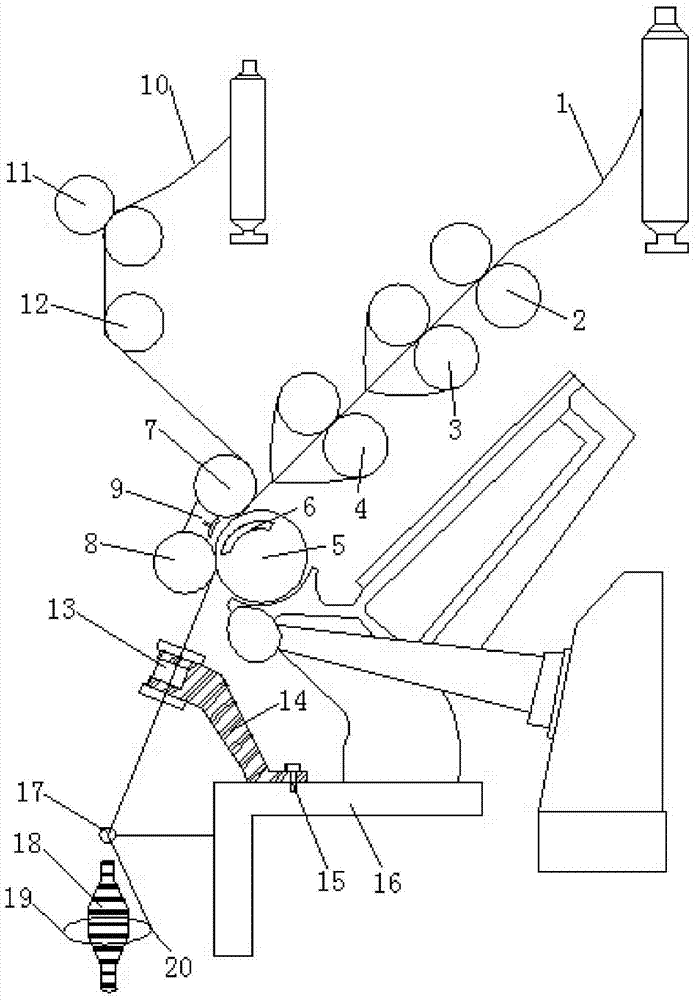

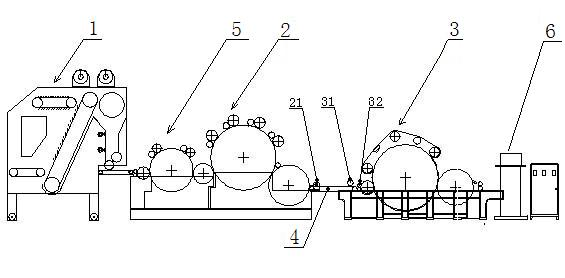

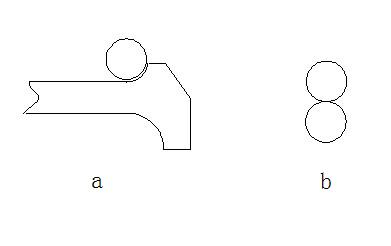

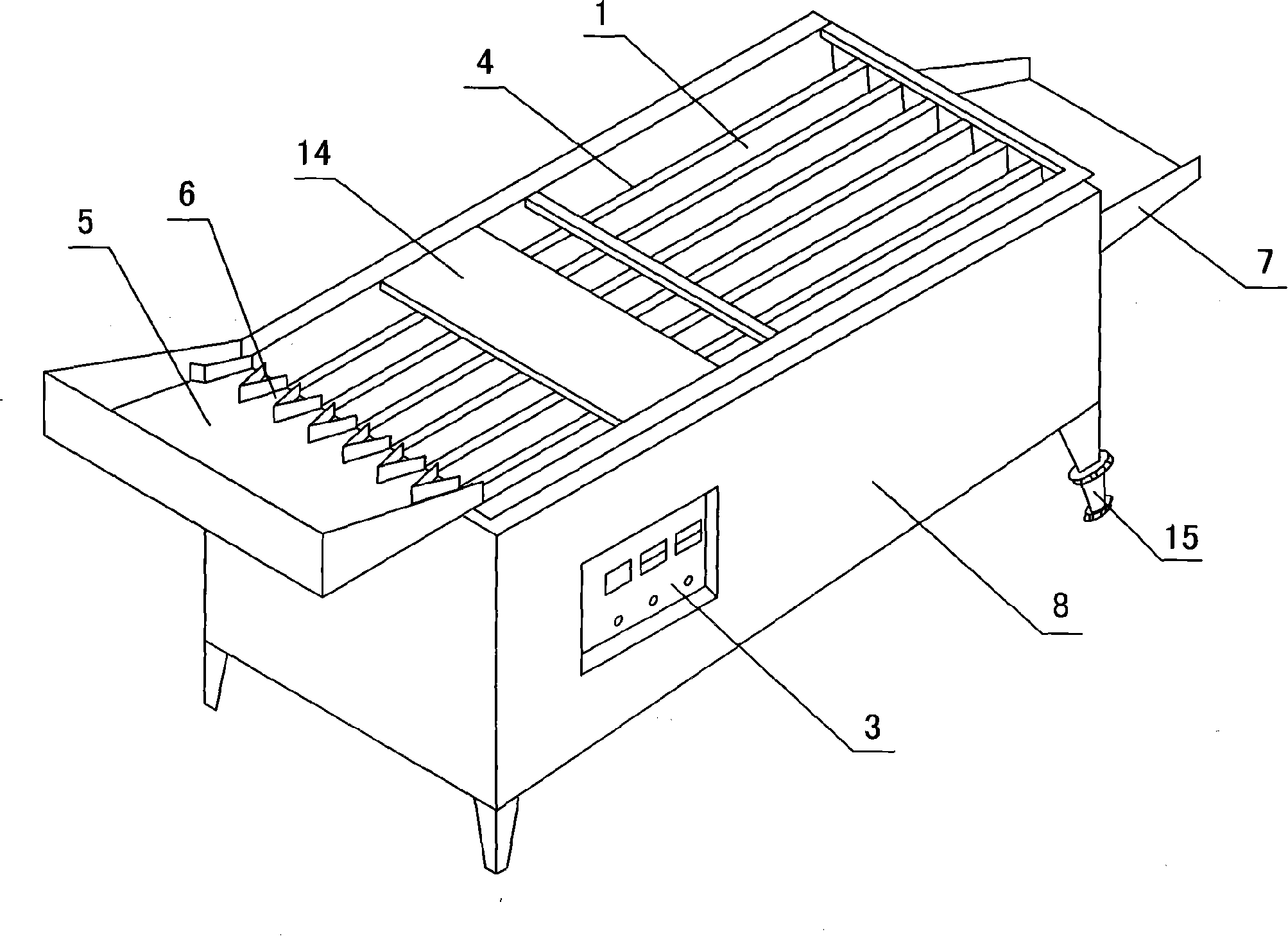

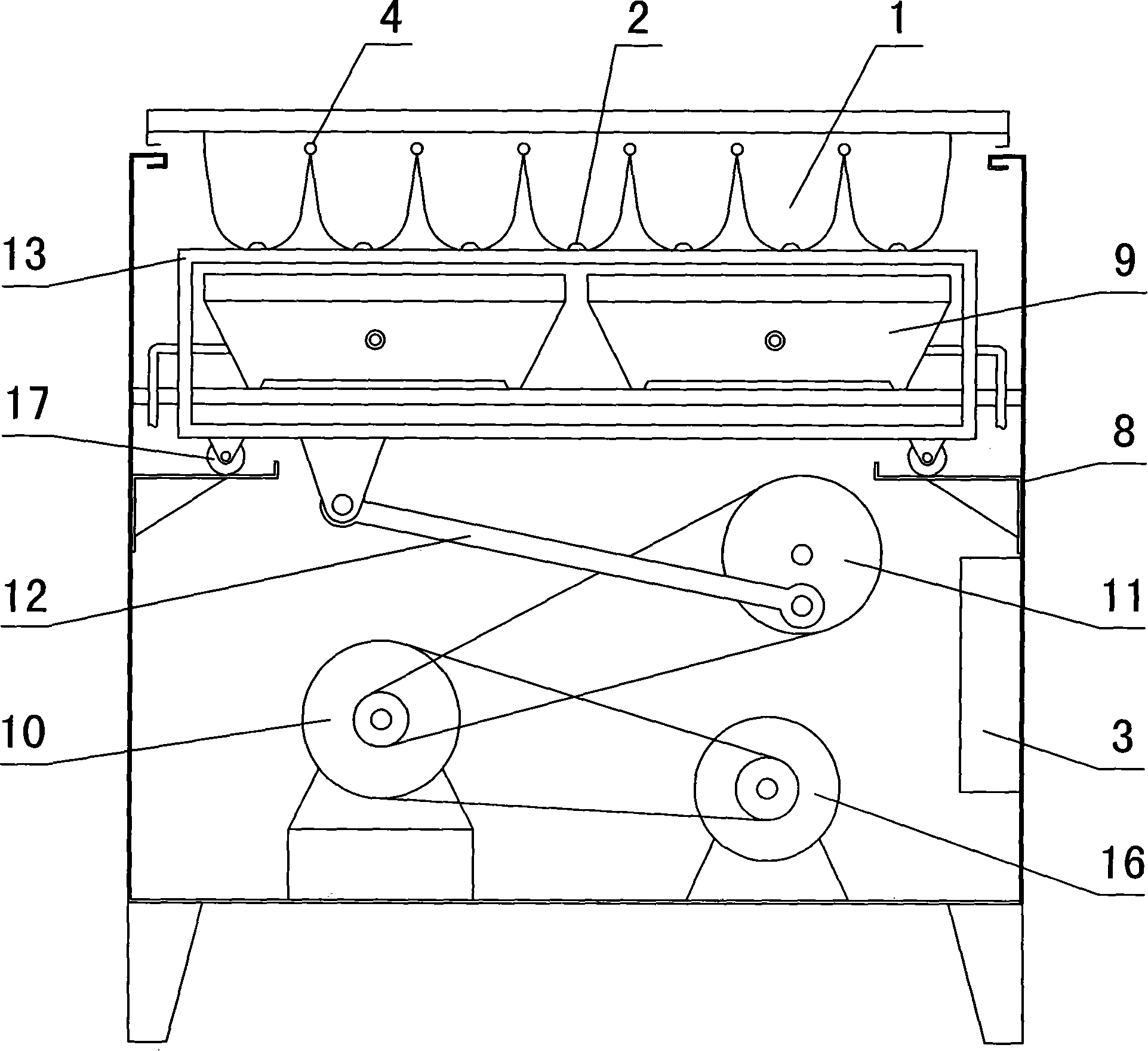

Carding machine equipment for textile fibers

The invention discloses carding machine equipment for textile fibers. The equipment comprises a feeding case, a casing, a machine base, supporting legs, a pre-carding mechanism, a main carding mechanism, double-doffer stripping-carding rollers, a conveying curtain mechanism and a discharging conveying belt, wherein the feeding case and the casing are arranged on the machine base, the supporting legs are arranged below the machine base, and a feeding conveying belt mechanism is arranged above the feeding case. The equipment is simple in structure and convenient to operate; the feeding case and the casing are arranged above the machine base, the pre-carding mechanism, the main carding mechanism, the double-doffer stripping-carding rollers, the conveying curtain mechanism and the discharging conveying belt are arranged in the casing sequentially, small impurities left in the equipment after pre-carding, main carding and processing by the double-doffer stripping-carding rollers and backing-off rollers are cleared, matched cotton composition fibers are sufficiently mild in a single-fiber state, uniform cotton slivers are prepared, requirements of the later process are met, and the practicability is high.

Owner:EASTERN LIAONING UNIV

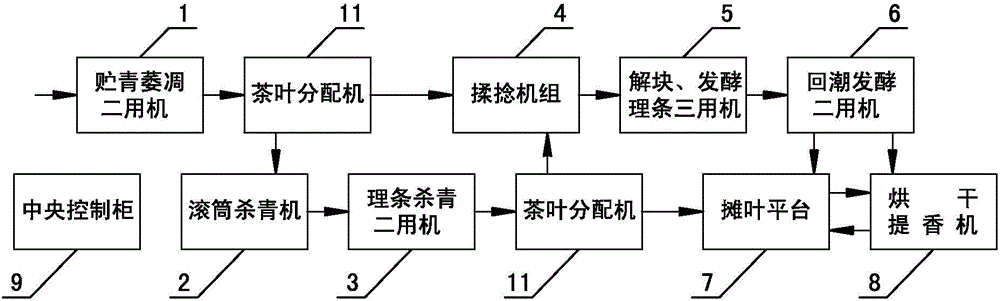

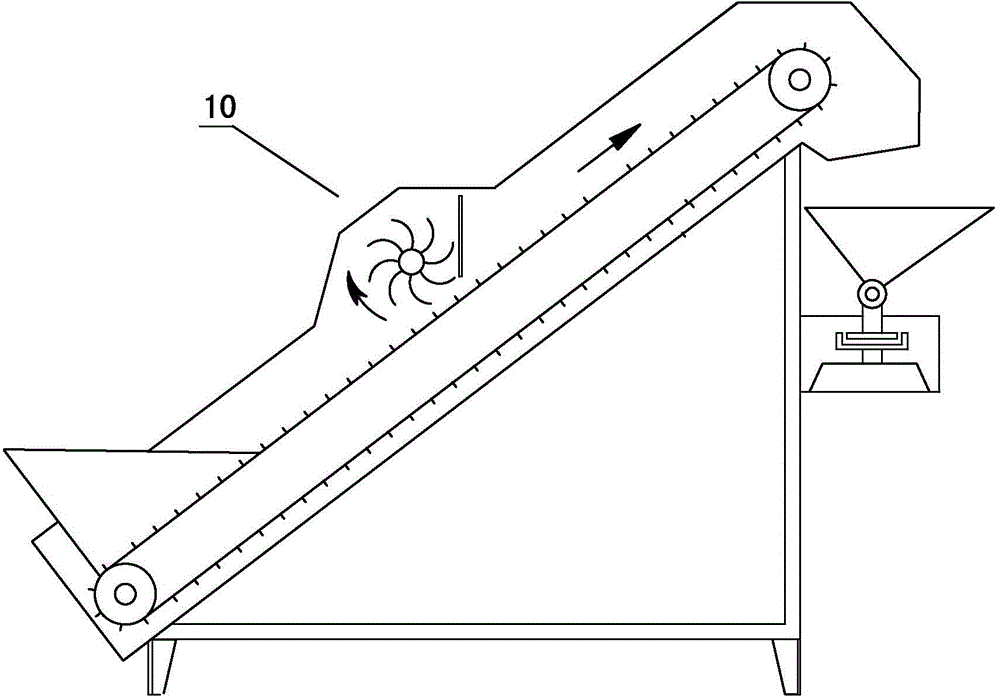

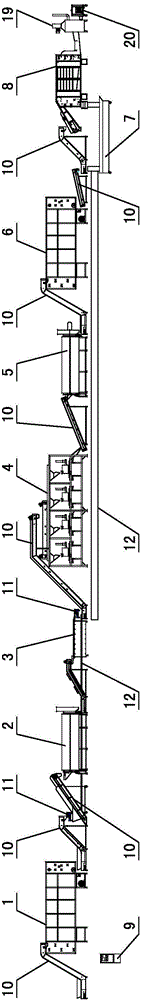

Continuous production line based on processing of black tea, green tea, yellow tea and white tea, and method thereof

ActiveCN104814170AReduce equipmentImprove versatilityPre-extraction tea treatmentCooking & bakingProduction line

The present invention discloses a continuous production line based on the processing of black tea, green tea, yellow tea and white tea and a method thereof. The continuous production line includes tea leaf frying devices, tea leaf transporting devices connected between the tea leaf frying devices, a green leaf storage and withering double function machine connected with a rotary drum enzyme deactivating machine and a tea leaf rolling assembling unit through a tea leaf dispenser, a carding and enzyme deactivating double function machine connected with the rotary drum enzyme deactivating machine and connected with the tea leaf rolling assembling unit and a tea leaf spreading platform through the tea leaf dispenser, a deblocking, fermenting and carding triple function machine connected with the tea leaf rolling assembling unit, a moisture regaining and fermenting double function machine connected to the deblocking, fermenting and carding triple function machine, and connected with the tea leaf spreading platform and a baking and fragrance improving machine. The continuous production line effectively solves the problem that the current tea leaf production line and tea leaf processing technology can only process a single tea variety, but cannot meet the requirement of tea leaf processing of many varieties of tea leaves of tea farmers, has high device versatility and good product quality, and is of high practical value.

Owner:浙江丰凯机械股份有限公司

Active sericin silk non-woven water jetting cloth process

InactiveCN1800473AReduce denaturationRetain nutritionNon-woven fabricsCardingPulp and paper industry

The invention discloses a method for producing silk water-needle non-woven cloth with active sericin protein, which comprises removing impurity, opening picking and carding, and water-needling; using penetrate hot air drying method in 40-58Deg. C or the method of covering cloth on the water-needle drying roller to dry the silk water-needle cloth; coiling, and cutting it into needed size to attain active sericin protein silk water-needle non-woven cloth. Said invention has the characters of light and flexibility, with less property change and kept nutrition of sericin protein. It can apply the basic material of silk face pack, sanitary towel (pad), and wound paste, etc.

Owner:刘杰

Low-twist, high-strength and little-fuzz yarn production method and yarn

The invention discloses a low-twist, high-strength and little-fuzz yarn production method and yarn. The method includes the opening picking process, the cotton carding process, the fine carding process, the drawing process, the roving process and the yarn spinning process. A larger-diameter and narrow-groove negative pressure hollow roller and a corresponding air draft assembly are adopted for the method, and therefore generated fuzz can be effectively reduced; under the condition that a mechanical friction twist device is adopted in the yarn spinning segment to reduce the twist coefficient by 15-30%, the single yarn strength is kept unchanged, polyester filament yarn serves as core silk so that the kind adaptability of the yarn can be effectively improved, the yarn strength is enhanced, the rotating direction of the twist device is opposite to that of a spindle, the twist stopping effect can occur, the width of a twisting triangular area is increased, the wrapping effect of core yarn is favorable for being improved, and a foundation is laid for developing fabric with good soft comfort. The low-twist, high-strength and little-fuzz yarn is produced with the method. Under the condition that the designed twist coefficient is reduced by 16-28%, compared with a normal designed twist coefficient, the strength is improved by 3-5%, resultant yarn is 3mm or longer, and the harmful fuzz is reduced by 80-95% compared with harmful fuzz in ring spun yarn.

Owner:WUJIANG JINGYI SPECIAL FIBER

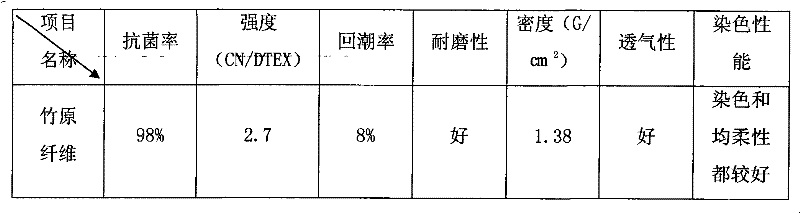

Solvent method for biologically preparing bamboo fiber

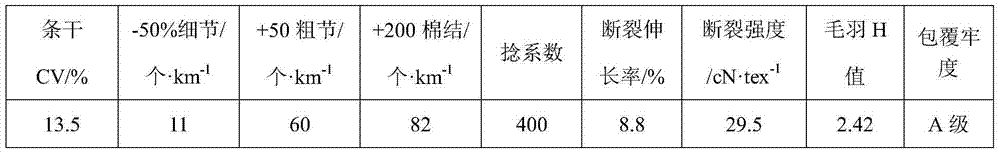

ActiveCN101538743BHigh antibacterial rateHigh strengthWood working apparatusMechanical fibre separationCardingBlack liquor

The invention provides a technology for preparing bamboo fiber by 1, 4-butanediol in a solvent method, which comprises the steps of preparing bamboo into bamboo filaments; soaking the bamboo filaments in the solvent and heating to remove lignin, hemicellulose and other impurities on the surface of the cellulose; preparing into coarse bamboo fibre; beating the coarse bamboo fibre, washing with water simultaneously, and then spin-drying through a centrifuge; bleaching and cleaning; conducting mellowing to the bamboo fiber; soft-impressing the bamboo fiber; stowing fermentation and curing, and finally obtaining the bamboo fiber with spinnability after opening and carding. The solvent adopted by the invention has high boiling point and stable chemical property and can be recycled; the whole technological process does not generate black liquor and seriously pollute the environment, and belongs to clean techniques; the obtained natural bamboo fiber has the remarkable advantages of moisture absorption, quick dry, coolness, comfort, antibacterium, deodorization and the like; and the method has low cost and good economic benefit and environmental protection benefit.

Owner:FUJIAN HAIBOSI CHMEICAL TECH

Combined roller top card

InactiveCN102505201AAvoid damageCarding evenlyContinuous processingCarding machinesCardingEngineering

The invention discloses a combined roller top card, which comprises a wool feeding hopper, an opening device, a wool carding device and a cotton carding device. The wool feeding hopper, the opening device, the wool carding device and the cotton carding device are connected in sequence to form a combine. An output portion of the wool carding device is a cutting and stripping device. The cotton carding device is provided with double feed rollers for feeding. The output portion of the wool carding device is connected with a feed portion of the cotton carding device through a feed curtain. A pressure roller is disposed on the feed curtain and close to the front of the double feed rollers of the cotton carding device. An output portion of the cotton carding device is a spinning coiler. The combined roller top card is modified from original cotton spinning and wool spinning equipment, and has the advantages that wool top carding is uniform, neps and impurities are few, fiber damage is reduced, and silver quality is improved, while a gap of semi-worsted product equipment is bridged.

Owner:WENSHANG RUYI TIANRONG TEXTILE

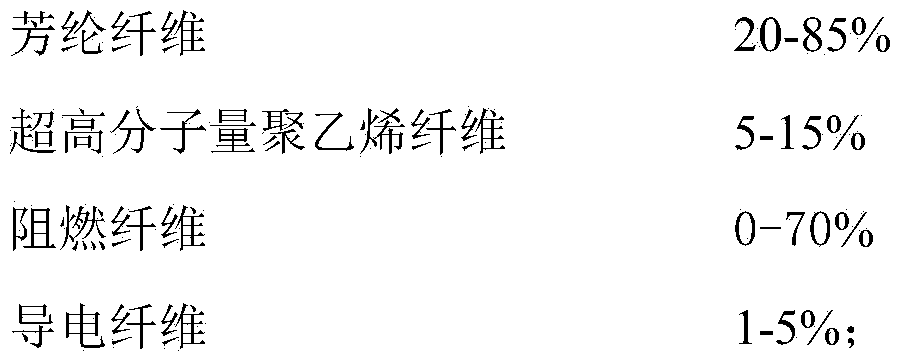

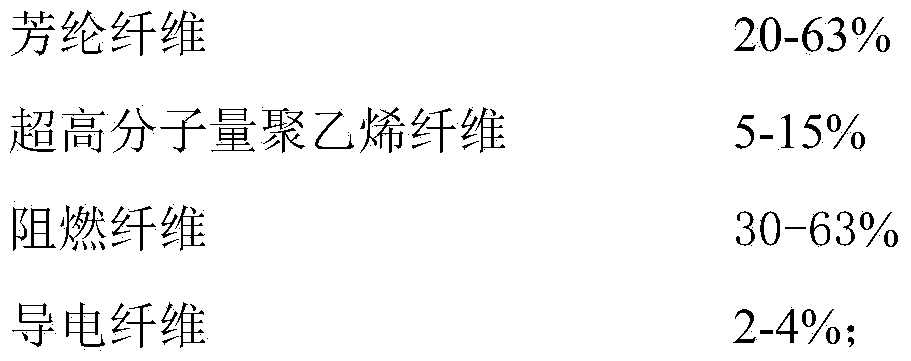

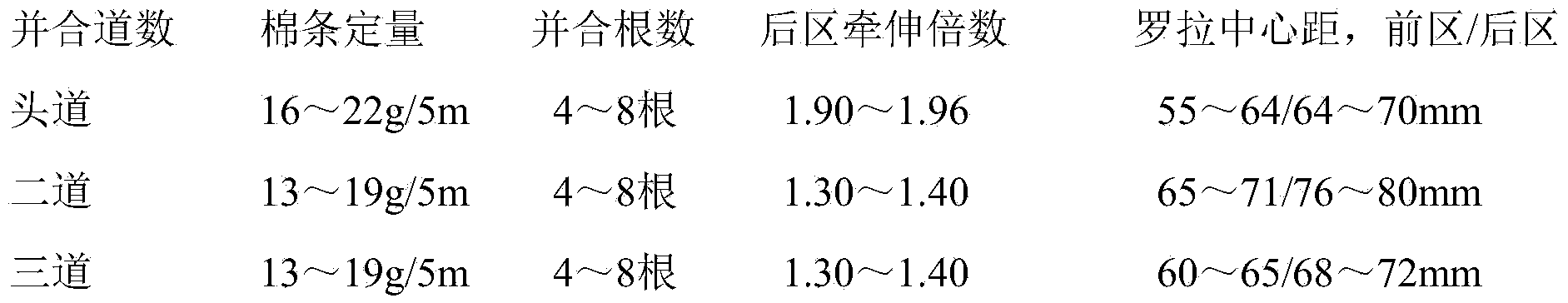

Aramid fiber and ultra-high molecular weight polyethylene blended yarn and production method thereof

The invention discloses an aramid fiber and ultra-high molecular weight polyethylene blended yarn and a production method thereof. The aramid fiber and ultra-high molecular weight polyethylene blended yarn comprises the following components in percentage by weight: 20-85% of aramid fiber, 5-15% of ultra-high molecular weight polyethylene fiber, 0-70% of fire resistant fiber and 1-5% of conductive fiber. The production method comprises the following steps of blending conductive fibers with a certain proportion, and pretreating raw materials before spinning, adding an antistatic agent, and standing for at least 8 hours to preform curing treatment. Technological conditions of each process are strictly controlled in a processing process, and temperature and relative humidity of cotton carding, drawing, roving and spinning processes are controlled, so the problem of serious static of the aramid fiber and the ultra-high molecular weight polyethylene during spinning can be solved well, strong rigidity of the aramid fiber is overcome, and the quality of the yarn is ensured.

Owner:SHANGHAI IBENA TEXTILE PROD

Tea-leaf automatically de-enzyming straightening out machine and de-enzyming straightening out method thereof

InactiveCN101199303ASolve the requestSolve labor intensityPre-extraction tea treatmentTemperature controlCarding

The invention discloses an automatic tea leaf green removing and tea carding machine and a green removing and tea carding method, the automatic tea leaf green removing and tea carding machine comprises a frame body, a reciprocating swinging type multi-slot pot arranged on the frame body and heating devices disposed under the multi-slot pot, the processes of tea leaf green removing and tea carding are combined into one and are continuously finished in the multi-slot pot, the cross section of the multi-slot pot is the U-shaped structure, and the bottom part thereof is provided with a protruding rib, a cover plate is arranged on a green removing area of the multi-slot pot, and a plurality of heating devices and temperature control devices with the temperature adapting to green removing and tea carding of tea leaves are arranged under the multi-slot pot. The invention effectively solves the problems that the current tea manufacturing machine can not stir-fry tea leaves evenly and has low degree of automation, the invention has advantages of high degree of automation, low technical requirements to production workers, low equipment investment and high production efficiency, and the processed tea leaves has the improved degree of quality from 0.5 to 1.5, so the invention deserves promotion and application.

Owner:苏和生

Face fabric containing ceiba fiber and producing technique thereof

InactiveCN101191268ABreathableMoisture-wickingWeft knittingWarp knittingAfter treatmentHigh humidity

The invention discloses a ceiba fabric containing ceiba fiber and a manufacturing technique thereof. The ceiba fabric containing ceiba fiber of the invention consists of the ceiba fiber and other fibers, wherein, content of the ceiba fiber is 20 percent to 100 percent, and content of other fibers is 0 percent to 80 percent; other fibers are mixture of one or a plurality of natural fibers and chemical fibers. The ceiba fabric of the invention is prepared after the following processing steps: pretreatment of raw materials; scutching; synchronous carding and slivering under the condition of high temperature and high humidity; combination of slivers; spinning; bleaching; weaving; after treatment; preparation of the ceiba fabric. The special technique of the invention is synchronous carding and slivering under the condition of high temperature of 80 to 120 DEG and high humidity and special comprehensive parameters under the condition of high temperature of 80 to 120 DEG and high humidity. The ceiba fiber fabric of the invention has the advantages of light weight, ventilation, wet permeability, heat preservation, mothproofing, mildew proofing and environmental protection.

Owner:晏国新 +2

Moisture-absorbing, sweat-releasing, washable and quick-drying shirt fabric and production method thereof

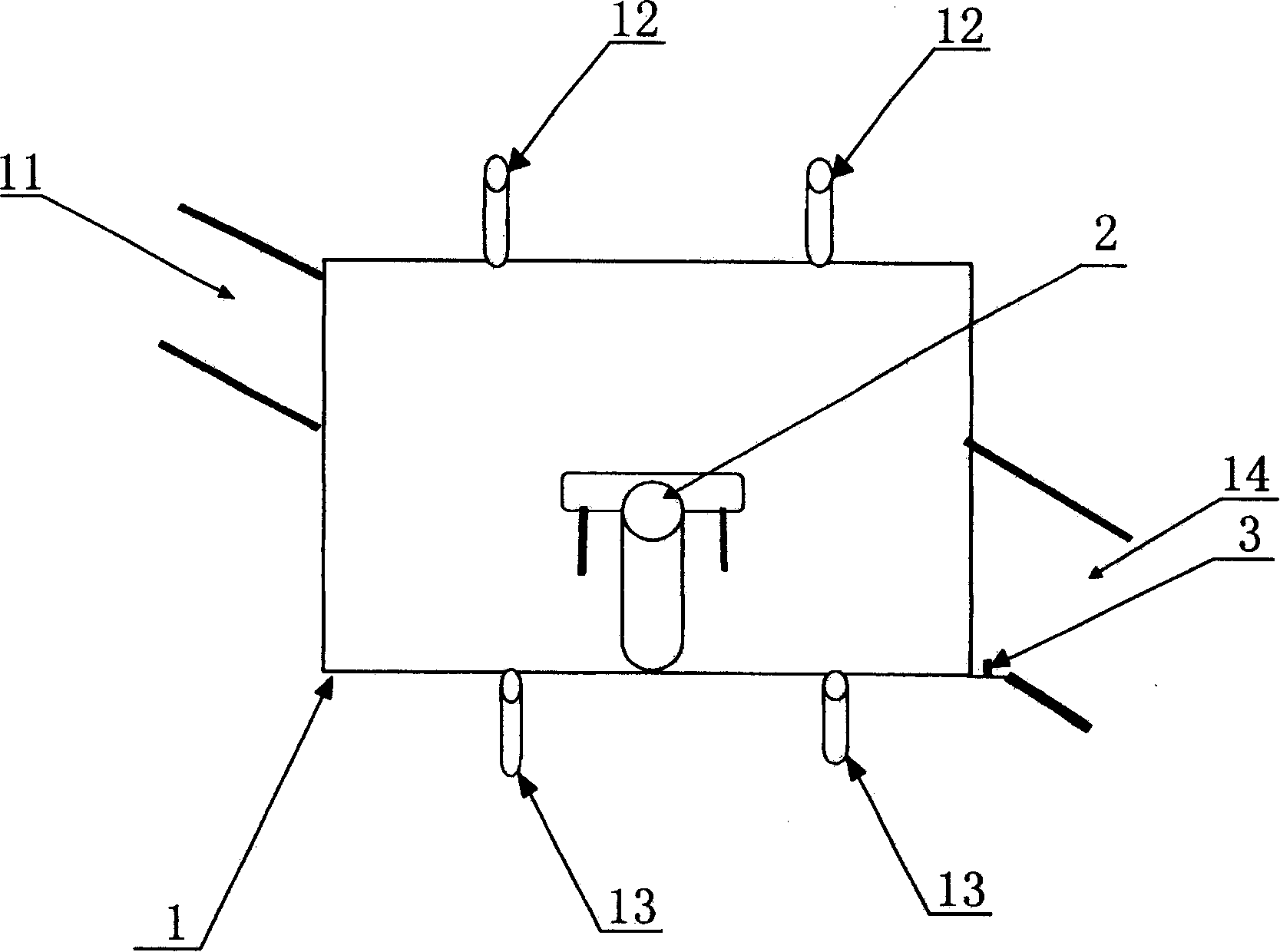

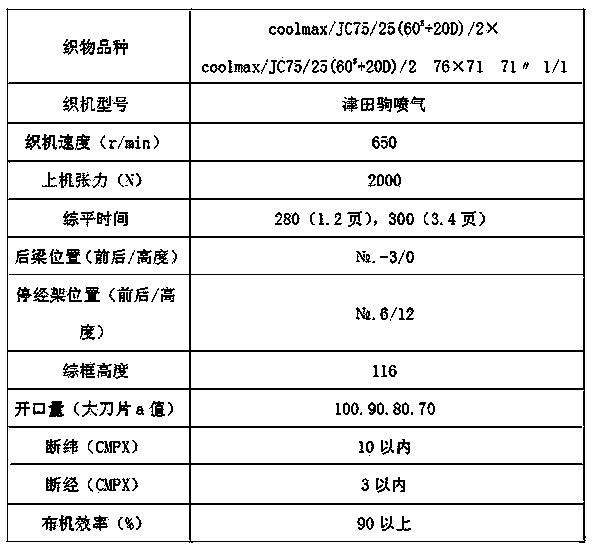

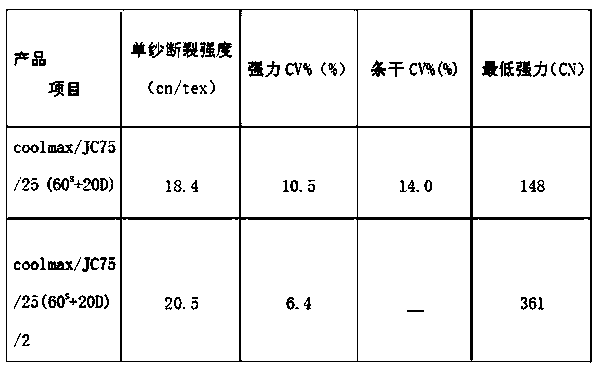

The invention provides moisture-absorbing, sweat-releasing, washable and quick-drying shirt fabric and a production method of the moisture-absorbing, sweat-releasing, washable and quick-drying shirt fabric and belongs to the technical field of textile. 75% of coolmax moisture-absorbing and sweat-releasing modified polyester fibers and 25% of cotton fibers are used as coated fibers, and 20D common polyester filament yarn is composed of covering yarn. Cotton opening and picking, cotton carding and pre-drawing are performed on the coolmax moisture-absorbing and sweat-releasing modified polyester fibers, and primary drawing, secondary drawing, roving, spinning, single yarn winding, yarn twisting and plied yarn winding are performed on the cotton fibers undergoing cotton opening and picking, cotton carding and combing to generate coolmax / JC75 / 25(60S+20D) single yarn and coolmax / JC75 / 25(60S+20D) / 2 plied yarn; the moisture-absorbing, sweat-releasing, washable and quick-drying shirt fabric is produced through beaming, slashing, denting, weaving and weave repairing. By means of reasonable scotching and cotton carding processes, two-time drawing mixing and appropriate slashing and weaving processes, the fabric has good moisture-absorbing, sweat-releasing, washable and quick-drying effects and good boney feel.

Owner:JIHUA 3542 TEXTILE CO LTD

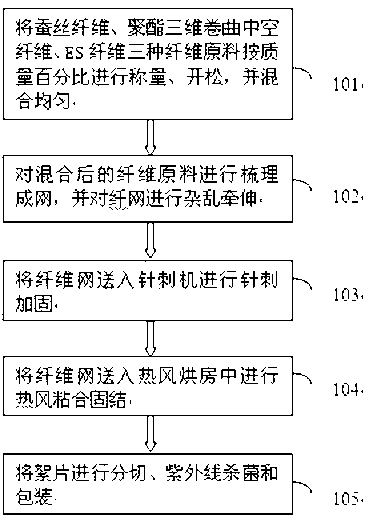

Preparation method of tailorable and washable silk floss flocculus

The invention provides a preparation method of a tailorable and washable silk floss flocculus, which comprises the following steps that 1), three raw fiber materials, namely a silk fiber, a polyester three-dimensional crimp hollow fiber and an ES (Ethylene-Propylene Side By Side) fiber are weighed according to mass percent, opened, and mixed uniformly, wherein the silk fiber is 55-80%, the polyester three-dimensional crimp hollow fiber is 10-35%, and the ES fiber is 5-20%; 2), the mixed raw fiber materials are subjected to carding and web forming, and a fiber web is subjected to disorder drafting; 3), the fiber web is fed into a needling machine for needling reinforcement; 4), the fiber web is fed into a hot air drying room for hot air bonding solidification; and 5), the flocculus is slit, subjected to ultraviolet sterilization and packed. The silk floss flocculus prepared by the method reserves the advantages of lightness, softness, comfortability, health care, heat preservation, breathability and the like of a silk product, and introduces the advantages of the polyester three-dimensional crimp hollow fiber, so that the heat preservation performance and the bulkiness are improved, and the production cost is lowered appropriately.

Owner:XINYUAN COCOON SILK GROUP

High temperature resistant alkaline water electrolytic cell barrier diaphragm and preparation thereof

InactiveCN101372752ASimple processEase of industrial implementationOrganic diaphragmsAlkaline waterCarding

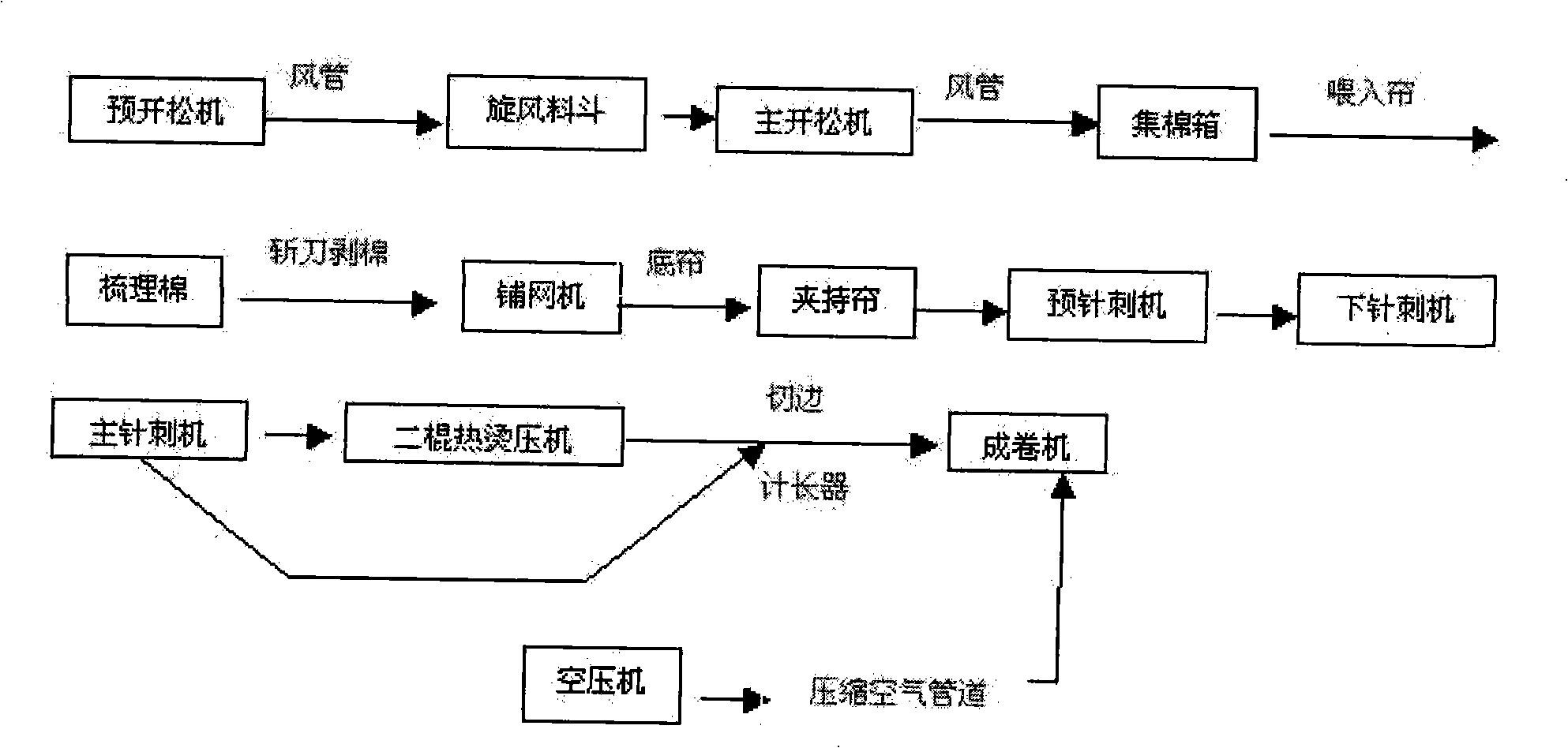

The invention provides a diaphragm for a high temperature resistance alkaline water electrolyser, which is a needle-punched non-woven polyphenyl thioether diaphragm. The method for preparing the diaphragm comprises the following steps: (1) fibrous material selecting: PPS fiber is selected to prepare non-woven base cloth; (2) web carding: the fibrous material is carded into a web by a carding machine by opening and mixing; (3) web lapping: a carded single-web is manufactured into a multi-layer fibrous web with required width and thickness by lapping the web by a lapping machine; (4) strengthening: reinforced materials of the lapped multi-layer fibrous web are fed into a needle machine to manufacture a non-woven cloth with certain strength by pre-needling and multiple main needling on front side and back side; (5) post-treatment: sulfonating treatment is carried out on the non-woven cloth in 90 to 98 percent of H2SO4, and then is treated by 30 percent of potassium hydroxide solution. The preparation method has the advantages of simple process, clearness and definitude, easy industrialized implementation, convenient operation and low cost; furthermore, the preparation method has easy process control so as to ensure stable performance of the product and stable quality.

Owner:TIANJIN POLYTECHNIC UNIV

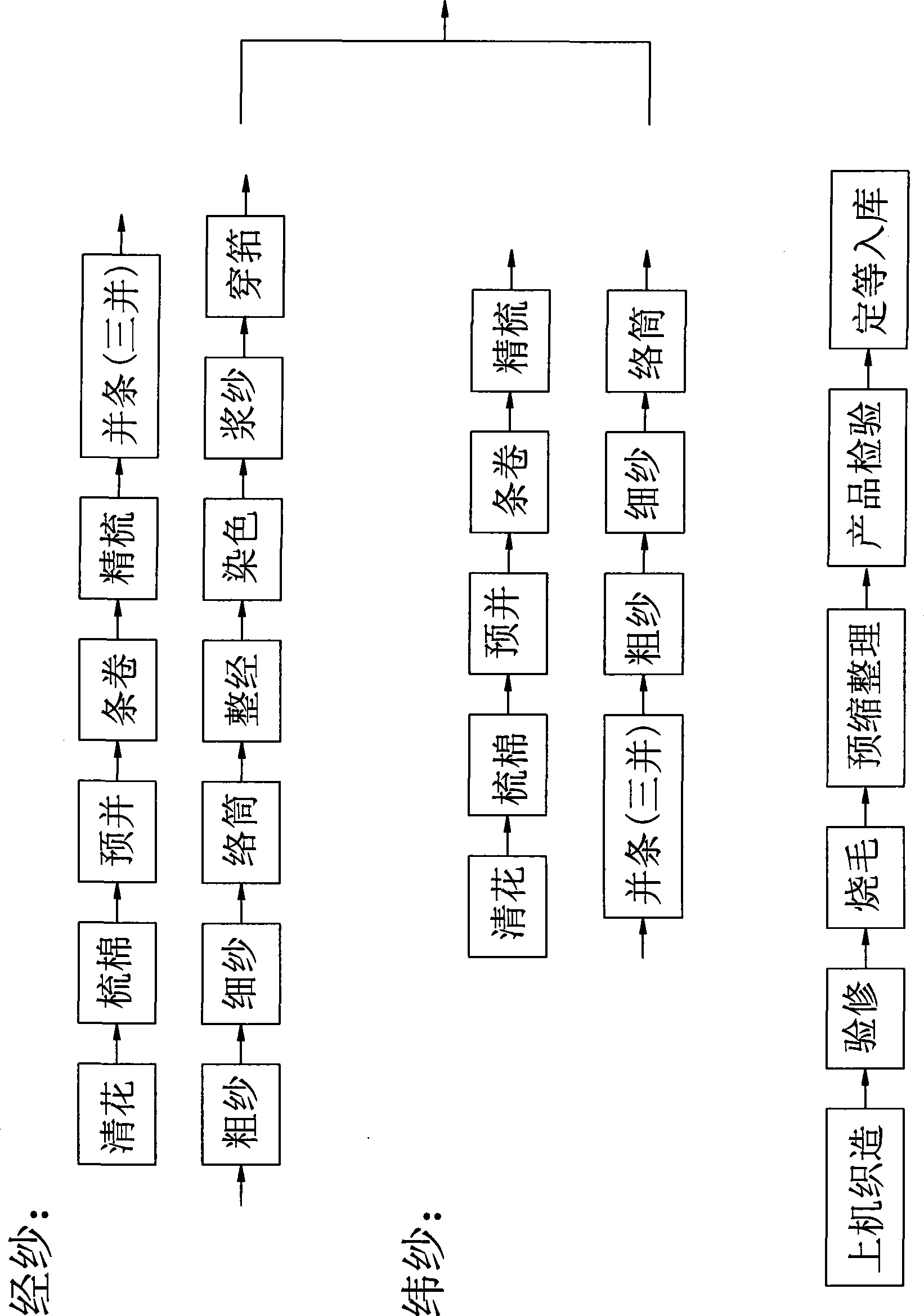

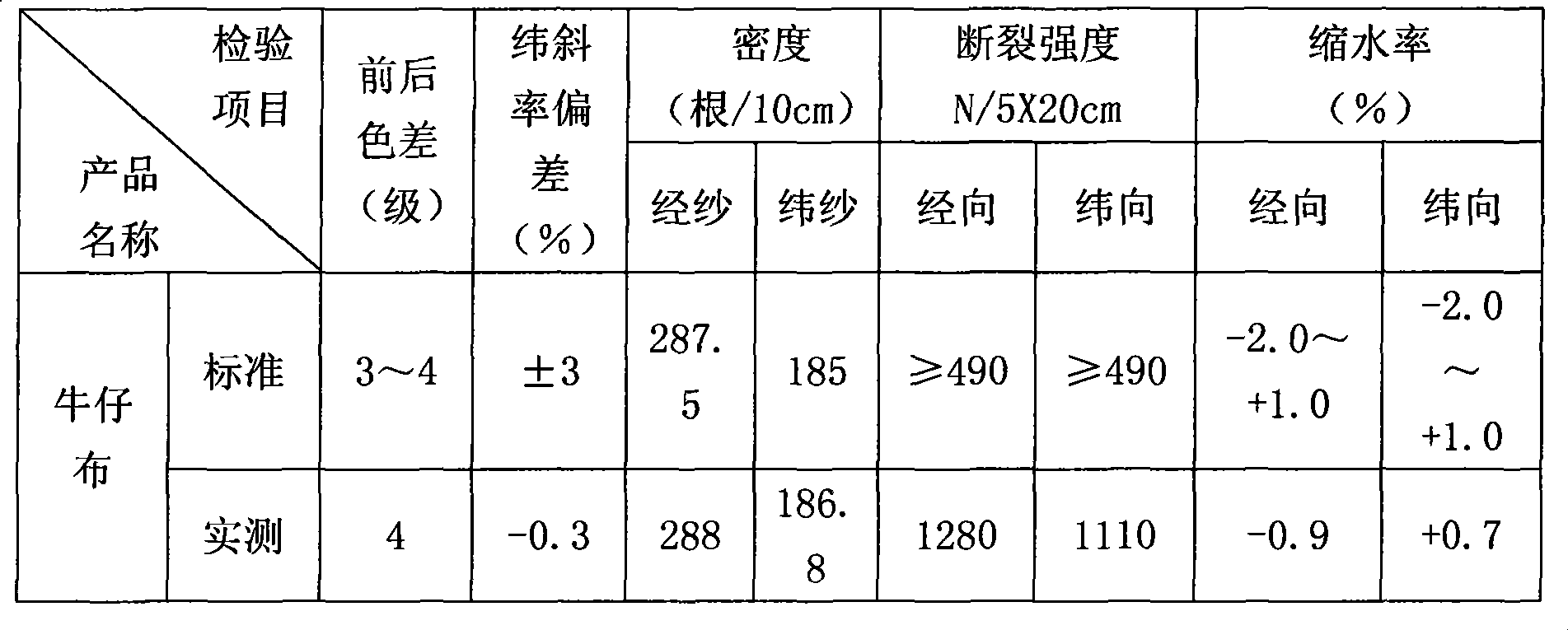

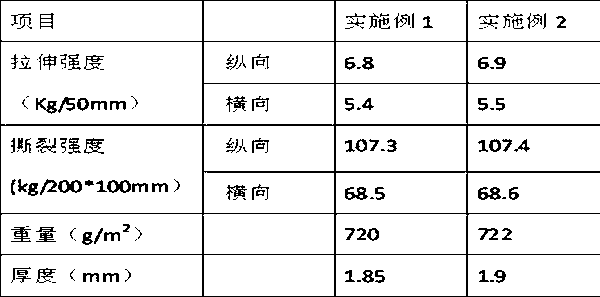

Viloft shengma smooth edge denim and production technology thereof

The invention relates to VILOFT sunn crotataria plain edge jean which comprises the following components by weight percentage: 20-40% of VILOFT fiber, 20-40% of sunn crotataria, 20-40% of one or multiple of cotton fiber, color cotton fiber, prolivon, cashmere, milk fiber, soybean fiber, tencel yarn, flax, silk, etc. In the picking process, the lap pressure is weighted, multi-combing and little beating, combing instead of beating are adopted, the speed of each beater is reduced, and the gauge of the beater and grid bars is enlarged. In the carding process, the lap is fully carded and the card sliver quota is increased; in the drawing process, the clockwise drawing process is adopted, the gauge is enlarged; the pressurizing quantity is improved and the vehicle speed is reduced, the combination process and the three blending combination process are adopted, and the first tension drawing multiple is grasped in a slightly large way; in the spinning process, large postzone roller gauge, small postzone draft multiple and small nip gauge are required, the vehicle speed is reduced, and the pressure is increased. The fabric of the jean has the advantages of environment protection, moderate elastic, soft texture, good luster and drapability, and obviously bamboo joint effect.

Owner:山东万泰创业投资有限公司

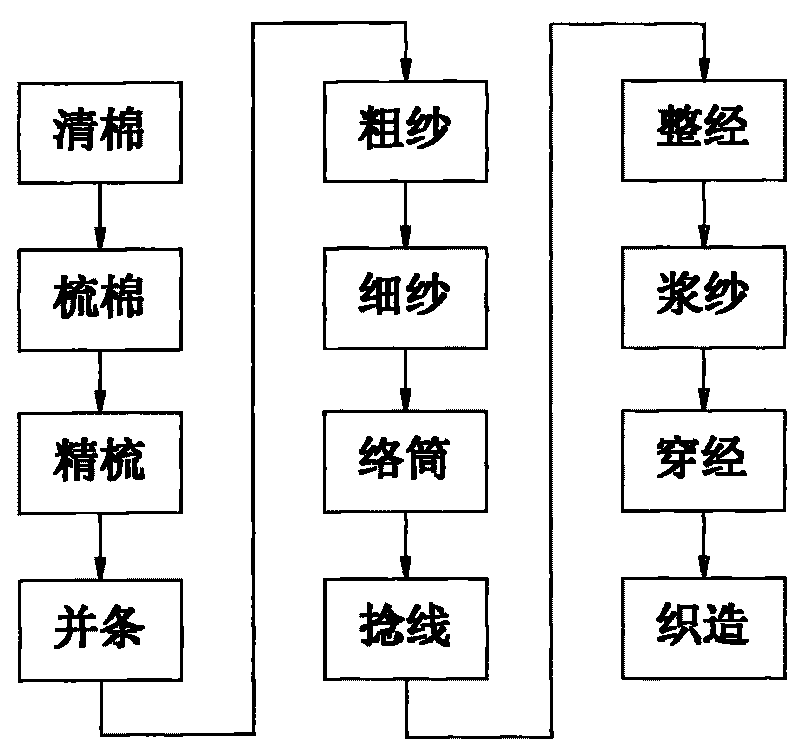

Method for producing towels by utilizing bamboo fiber and cotton fiber

InactiveCN101694037AImprove breathabilityInstant water absorptionWoven fabricsYarnCardingCotton fibre

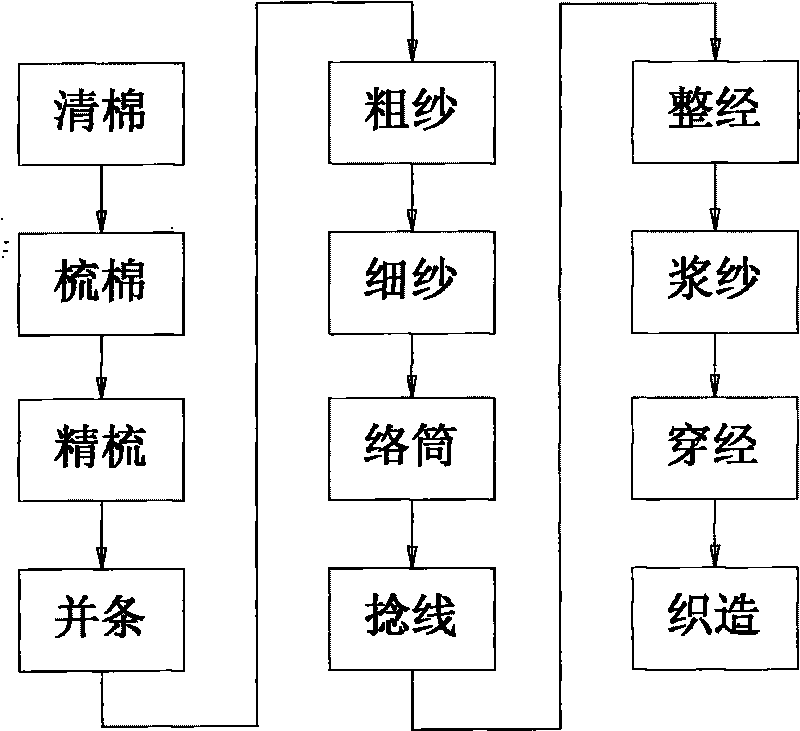

The invention relates to a method for producing towels by utilizing bamboo fiber and cotton fiber, comprising twelve steps such as cotton cleaning, cotton carding, combing, drawing, roving, spinning, winding, twisting, warping, sizing, passing, weaving, and the like, wherein in the fourth step, a finished cotton silver and the cotton silver of the cotton fiber are combined, a blending cotton silver is generated, and then the blending cotton silver is taken as the basis to implement the next steps, thereby leading the bamboo fiber and the cotton fiber to be mixed and taken as raw materials for weaving the towels; and the towels produced by the adopting the method have good air permeability, instant water absorption, strong wear resistance, good dyeing performance and other excellent performances.

Owner:黄学进

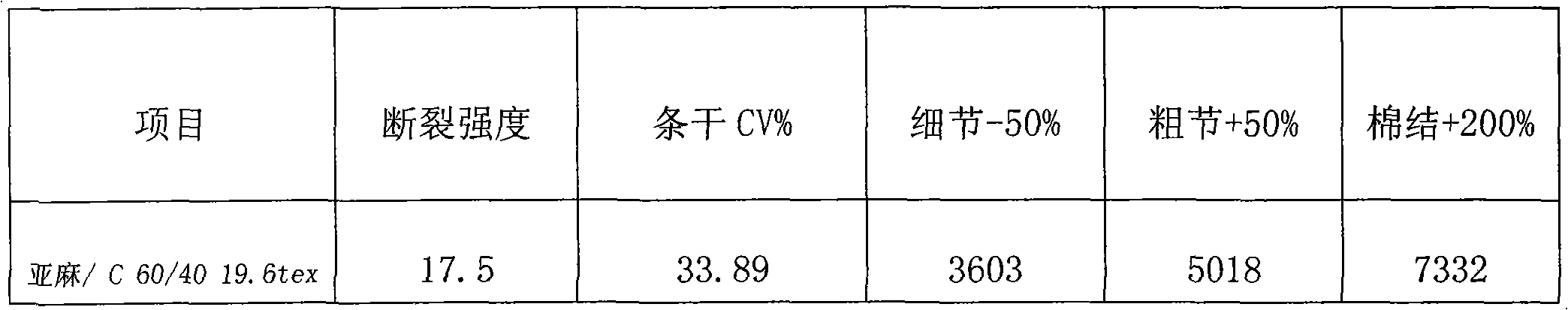

Blended yarn of flax fibers and cotton fibers and preparation process thereof

The invention discloses a blended yarn of selected flax fibers with superior count and cotton fibers and a preparation process thereof. The blended yarn consists of the flax fibers with superior count and the cotton fibers, wherein the flax fiber content accounts for 20 to 60 percent of the total weight of the blended yarn, and the cotton fiber content accounts for 40 to 80 percent of the total weight of the blended yarn. The preparation process comprises the following steps of: dividing the flax fibers with superior count and carded sliver or combed sliver into small heaps by proportioning; preparing uniform aqueous solution; and performing steps of fiber mixing, cleaning, cotton carding, drawing, roving and spinning to prepare the blended yarn of flax fibers and cotton fibers, wherein the relative humidity for the production environment of each step is 58 to 65 percent. The product produced by the invention can be made into various blended fabrics and thus provides a purely natural and comfortable textile product for the field of textile industry.

Owner:JIHUA 3542 TEXTILE CO LTD

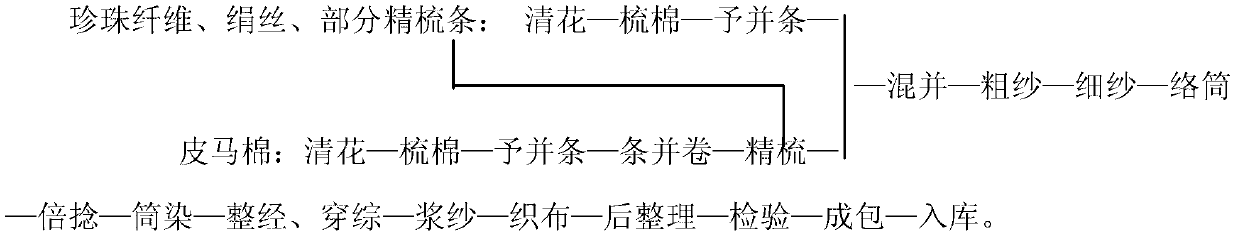

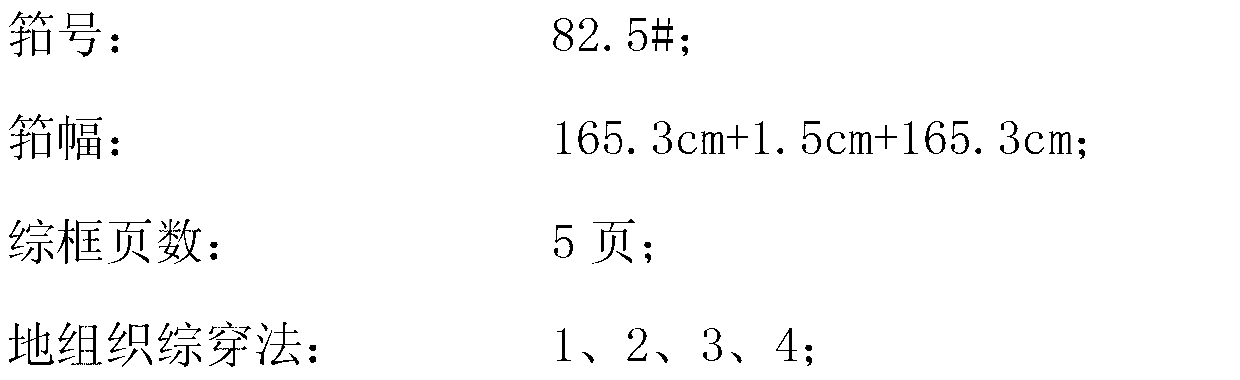

Pearl fiber shirt fabric and preparation method thereof

The invention provides a pearl fiber shirt fabric which has silky luster and is less in hairiness and anti-pilling. Warps and weft yarns of the pearl fiber shirt fabric are all 120 Ne two-fold yarns which are formed by compact spinning of 30% pearl fibers, 20% spun silks and 50% long stapled cottons. The invention further provides a preparation method of the pearl fiber shirt fabric. The preparation method of the pearl fiber shirt fabric includes the following steps: a, spinning; enabling part of combing long stapled cottons to be mixed with the spun silks and the pearl fibers and rolled in the process of opening picking, then drawing after cotton carding, mixing with other combing long stapled cottons and then through the processes of roving, fine spinning, spooling and two-for-one twisting; b, cheese dyeing; including the steps of cheese loosing, preprocessing, dyeing, hot washing, acid-washing, soaping, hot washing, cold washing, color fixing, softening, cylinder discharging, drying and cheese fastening, the preprocessing includes bleaching and enzyme treatment; c, weaving; including the steps of beaming, drafting, slashing and weaving; and d; post-processing, including the steps of desizing, softening, sizing and preshrinking.

Owner:JIANGSU YDTEX GRP LTD

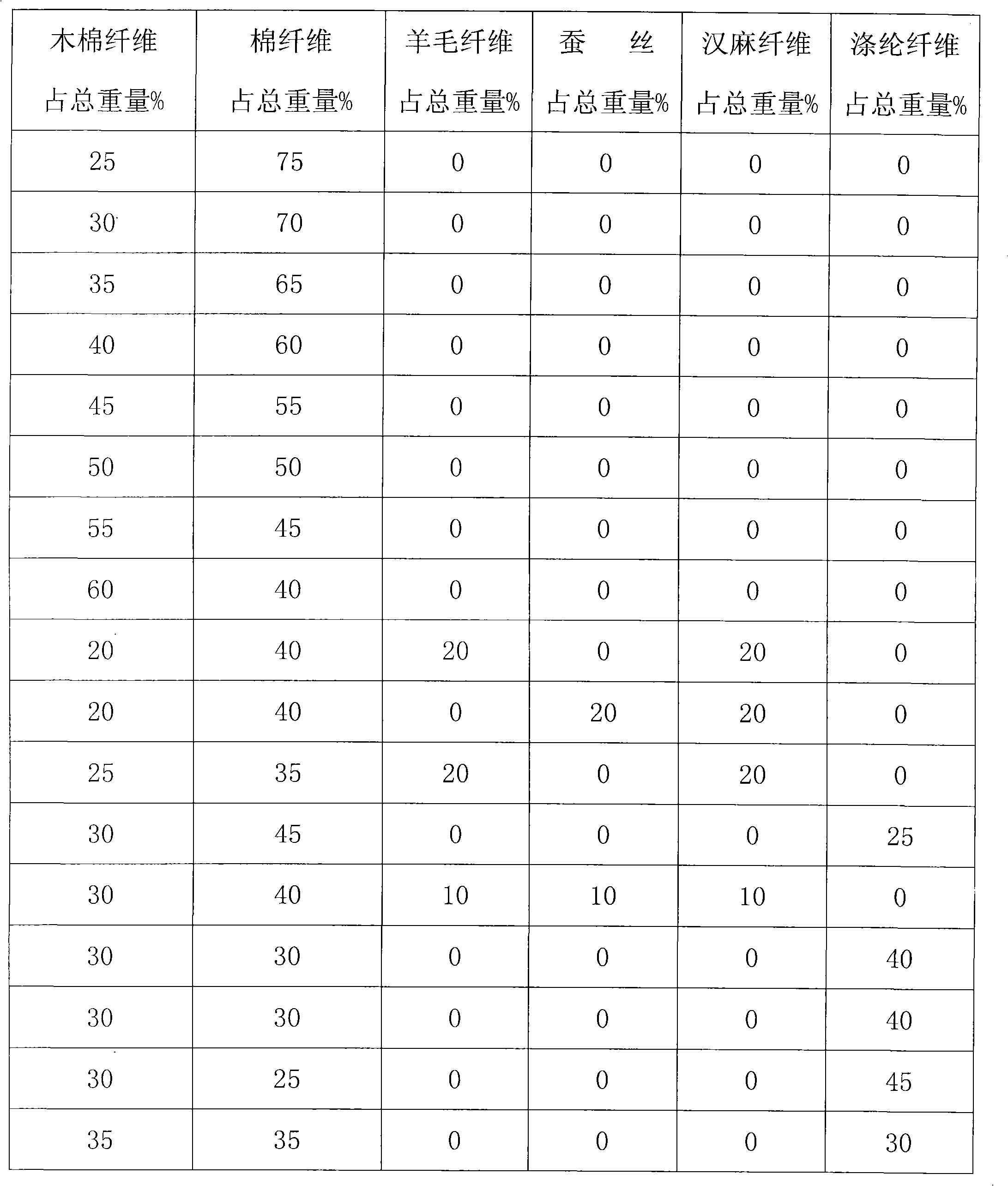

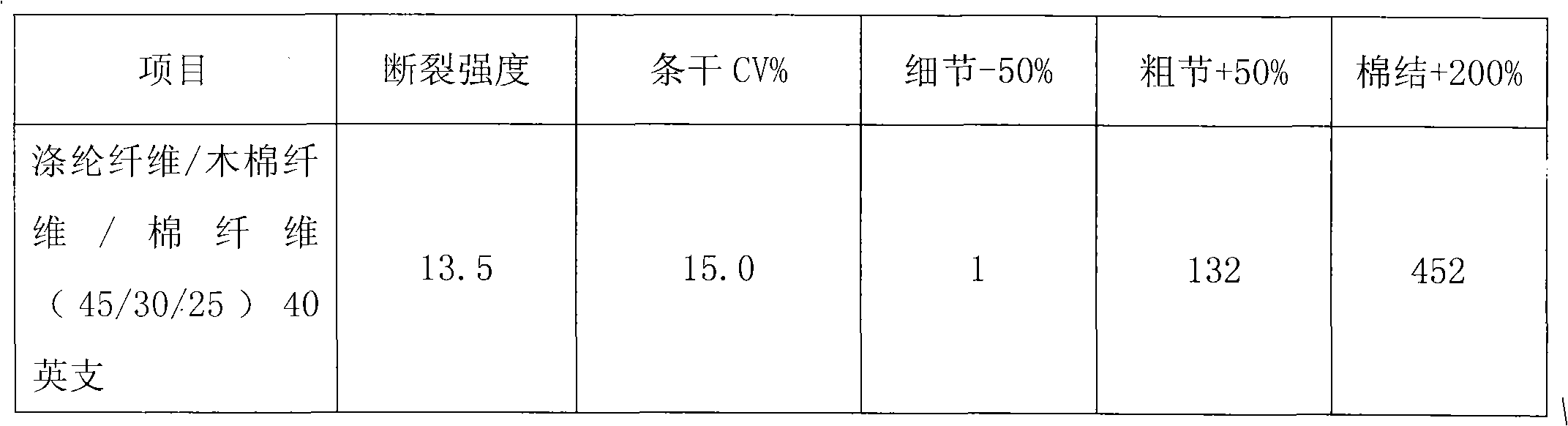

Process for manufacturing kapok fiber blended yarns

The invention discloses a process for manufacturing kapok fiber blended yarns, comprising the steps of selecting a plurality of kapok fibers, cotton fibers, wools, silks, hemp fibers and terylene fibers, wherein the content of the kapok fibers is 25-60% of the total blended yarns; the content of the cotton fibers, wools, silks, hemp fibers and terylene fibers is 40-75% of the total blended yarns; weighing the kapok fibers and other spinning fibers, dividing the fibers into small stacks, and obtaining multi-component blended yarns by mixing, blowing, cotton carding, drawing, roving and spinning, wherein the relative humidity of the production environment of each process is 60-65%; the products produced by the invention can be manufactured to be kinds of blended fabric materials; a fabric product which is pure natural, green, environment-friendly, soft and warming is increased in the spinning field.

Owner:JIHUA 3542 TEXTILE CO LTD

High-strength terylene microfiber needling fabric

ActiveCN103057219ALow costReduce water consumptionFibre typesTwo or more solvent application treatmentColour fastnessPolymer science

The invention relates to high-strength terylene microfiber needling fabric and belongs to the technical field of needling non-woven cloth. The high-strength terylene microfiber needling fabric is prepared by the following steps: performing non-woven double carding and double lapping on island type island short fiber to obtain double-layer cotton web; clamping base cloth which is obtained by using polyester filament yarn through a hydraulic loom in the middle of the double-layer cotton web; performing non-woven needling to obtain composite base cloth; starching; performing polyurethane (PU) resin impregnation; performing alkali reducing splitting; dyeing; drying; and performing double-sided sanding, wherein the polyester filament yarn is 68 to 75 D, the fineness of the island type island short fiber is 1 to 3 D, the island type island short fiber contains 37 islands and has the length of 38 to 51 mm, and the sea / island ratio is 30 / 70. The high-strength terylene microfiber needling fabric is low in dye cost and water consumption, uniform in dyeing, bright in color and luster, and high in color fastness and air permeability, enhances the stretching resistance, and takes both leather feeling and fluff feeling into consideration.

Owner:ZHEJIANG MEISHENG NEW MATERIALS CO LTD

Production process of high-elasticity non-woven three-dimensional cotton

The invention discloses a production process of high-elasticity non-woven three-dimensional cotton, comprising the following steps: mixing a low melting point hot melting viscose fiber and at least two fibers of other fibers in proportion; opening and scotching, and feeding cotton and carding and delivering to a vertical lapping forming machine to carry out vertical forming process. A fiber net is continuously folded and descends in a forming curtain at the action that a pendulum-type swinging folding mechanism swings left and right reciprocately, becomes continuous fiber net layers which are arranged in a vertical direction in a steerable channel, and finally forming the three-dimensional cotton which is arranged in a vertical direction through heat setting and cooling setting. The production process in the invention realizes production through a conventional non-woven heat setting machine at the condition of not adding any chemical adhesive, and sets the product thickness and density according to the process requirements; the process is simple, practical and efficient; any fiber can be used as the basic fiber of the material; the regenerated fiber also can be used for forming; and the material source is wide, is easy to obtain, and is relatively environment-friendly.

Owner:杭州缔星纤维科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com