Patents

Literature

383results about "Continuous processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

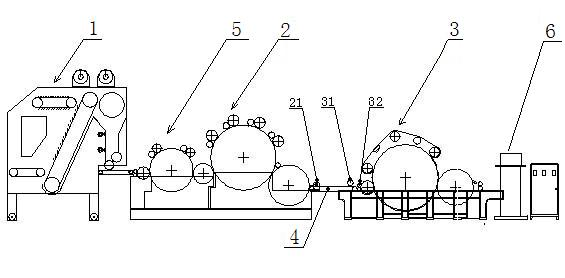

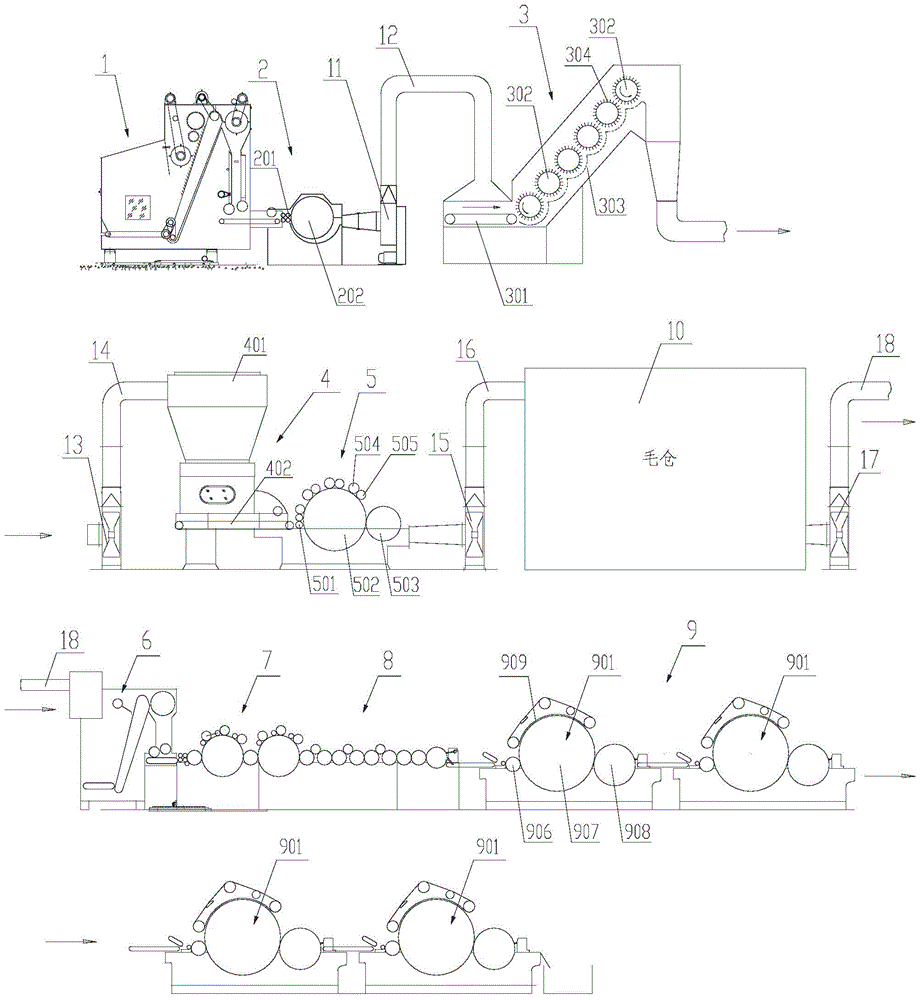

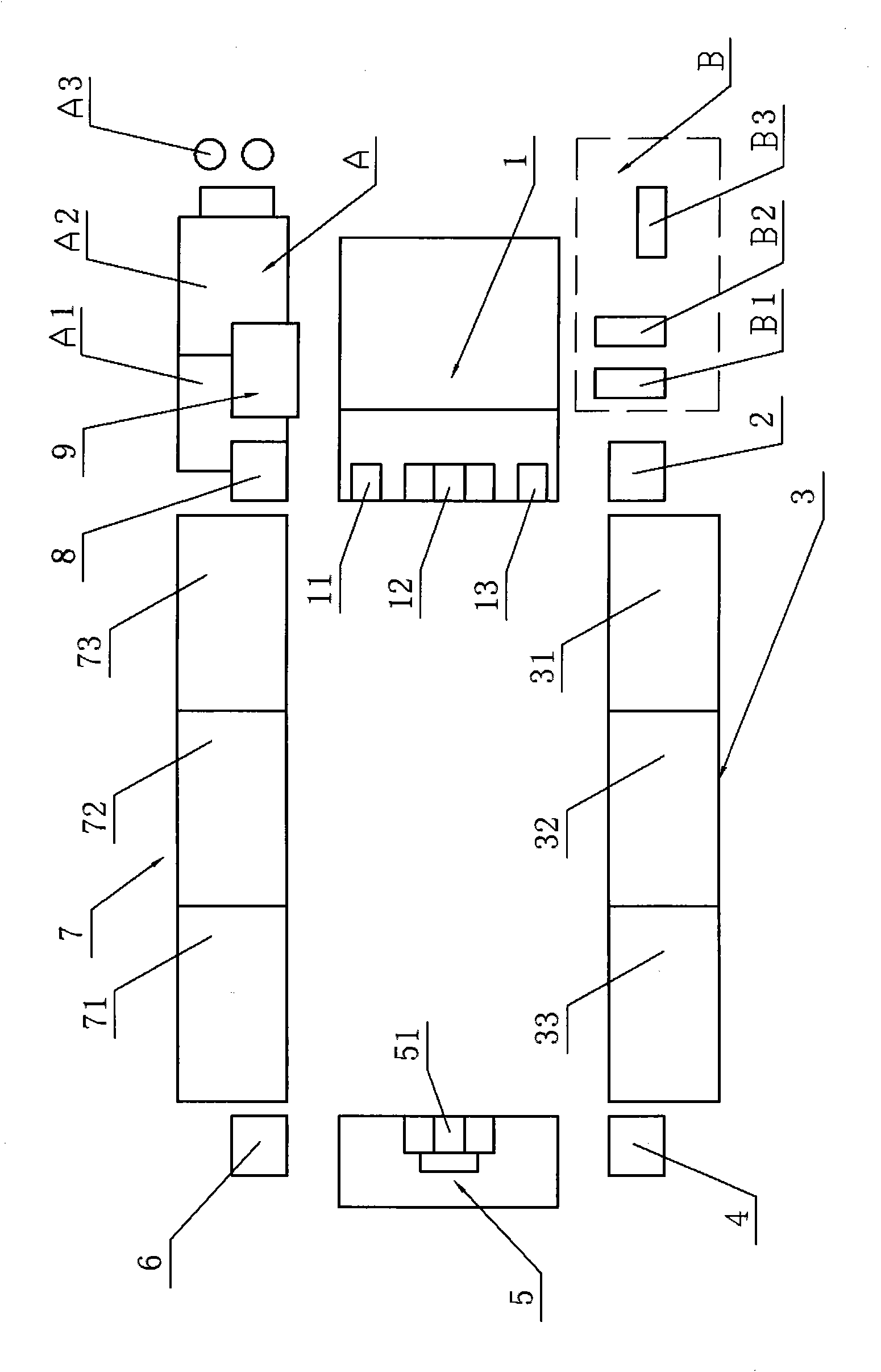

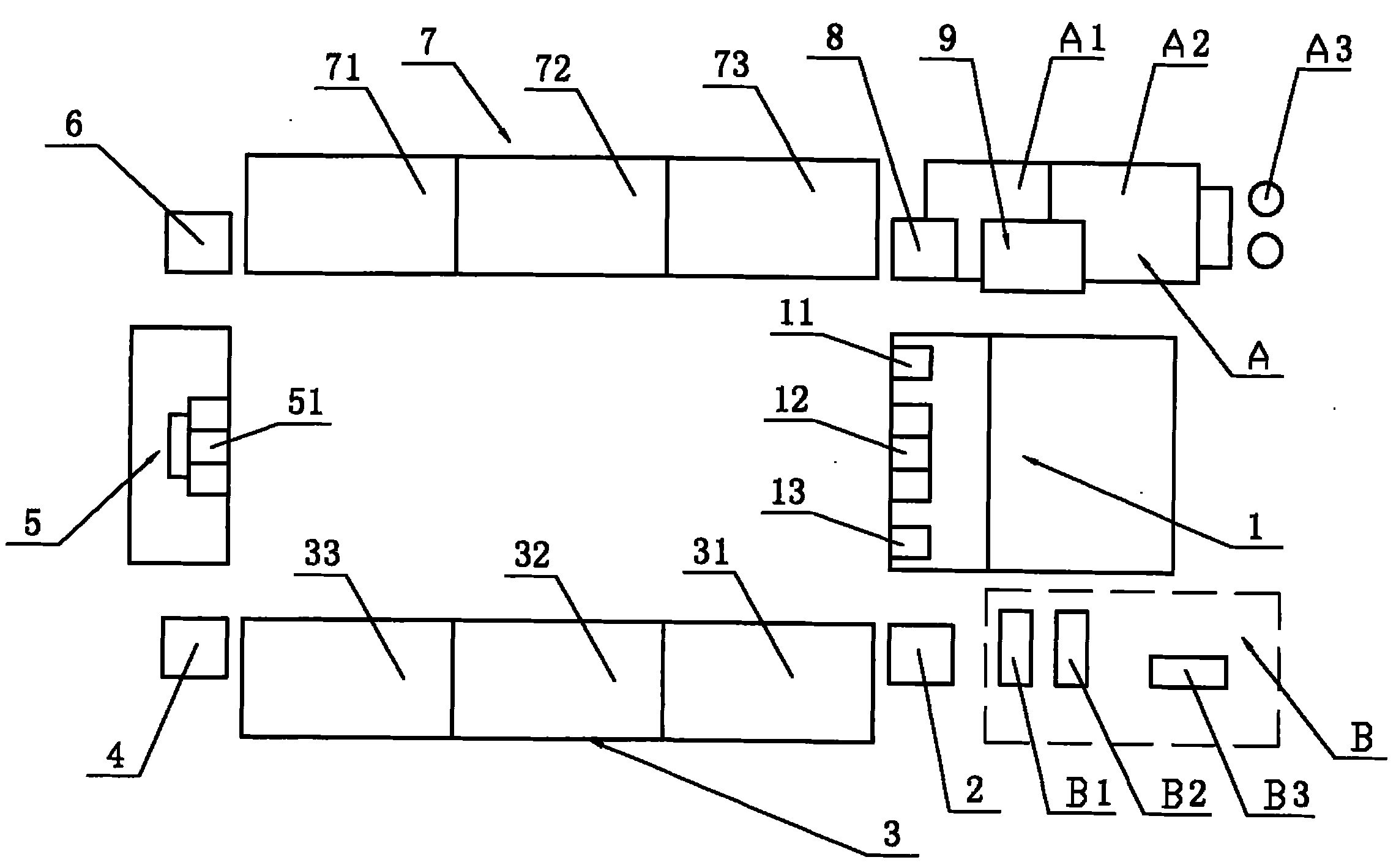

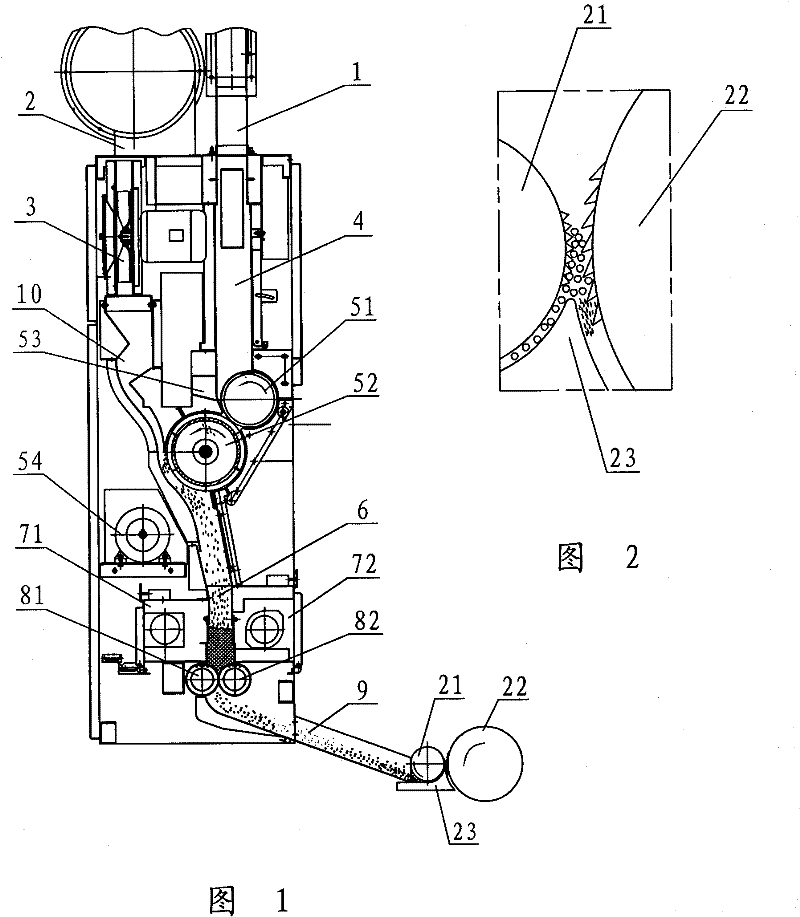

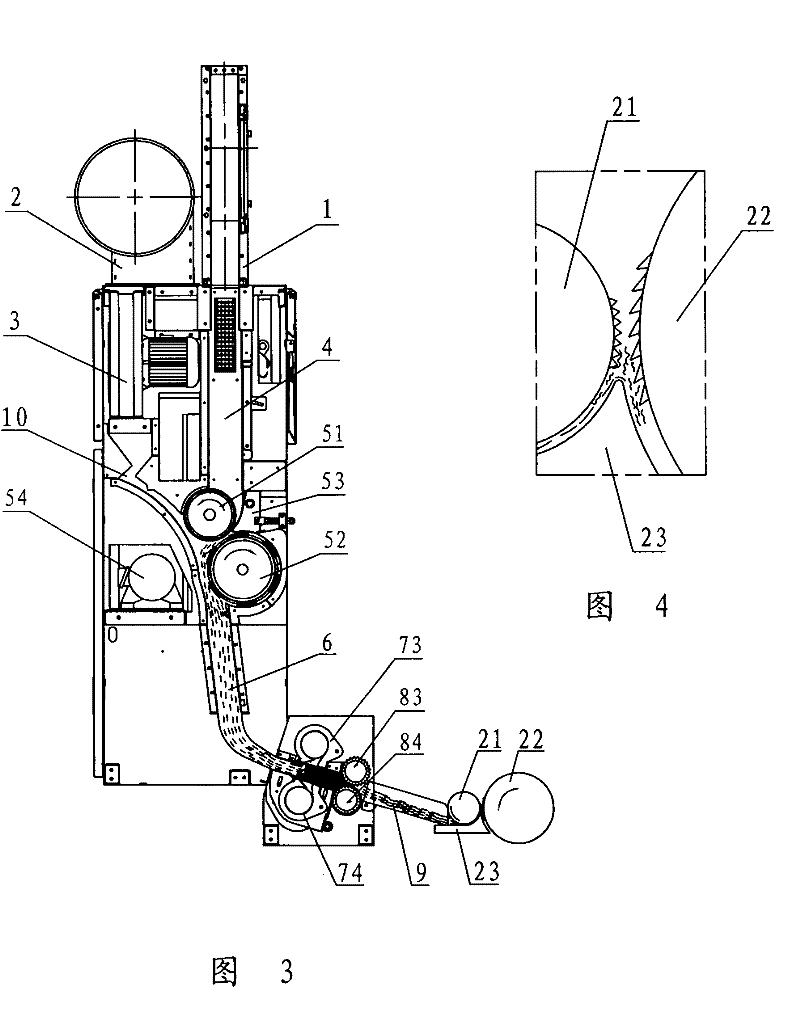

Processing Line of Bast Fiber

ActiveUS20120324677A1Improve fiber separation indexImprove biochemistry degumming uniformityMechanical impurity removalLubricating devicesCardingEngineering

A processing line of bast fiber is provided. The processing line is comprised of various devices for carding, cutting, degumming, high temperature washing, separating and water washing, softening, drying, batching and applying oil, permeating and reconditioning, stretching-breaking carding, and combing and sorting. The processing line of bast fiber can improve production efficiency, and improve the yield of long hemp fibers. Moreover, the produced fiber has stable quality and is convenient for post-processing.

Owner:WUHAN HEMP BIOLOGICAL TECH CO LTD +2

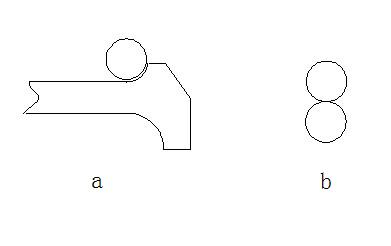

Combined roller top card

InactiveCN102505201AAvoid damageCarding evenlyContinuous processingCarding machinesCardingEngineering

The invention discloses a combined roller top card, which comprises a wool feeding hopper, an opening device, a wool carding device and a cotton carding device. The wool feeding hopper, the opening device, the wool carding device and the cotton carding device are connected in sequence to form a combine. An output portion of the wool carding device is a cutting and stripping device. The cotton carding device is provided with double feed rollers for feeding. The output portion of the wool carding device is connected with a feed portion of the cotton carding device through a feed curtain. A pressure roller is disposed on the feed curtain and close to the front of the double feed rollers of the cotton carding device. An output portion of the cotton carding device is a spinning coiler. The combined roller top card is modified from original cotton spinning and wool spinning equipment, and has the advantages that wool top carding is uniform, neps and impurities are few, fiber damage is reduced, and silver quality is improved, while a gap of semi-worsted product equipment is bridged.

Owner:WENSHANG RUYI TIANRONG TEXTILE

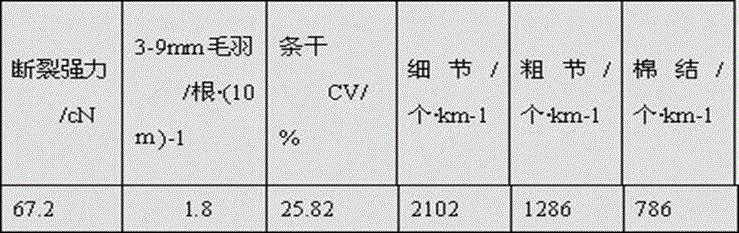

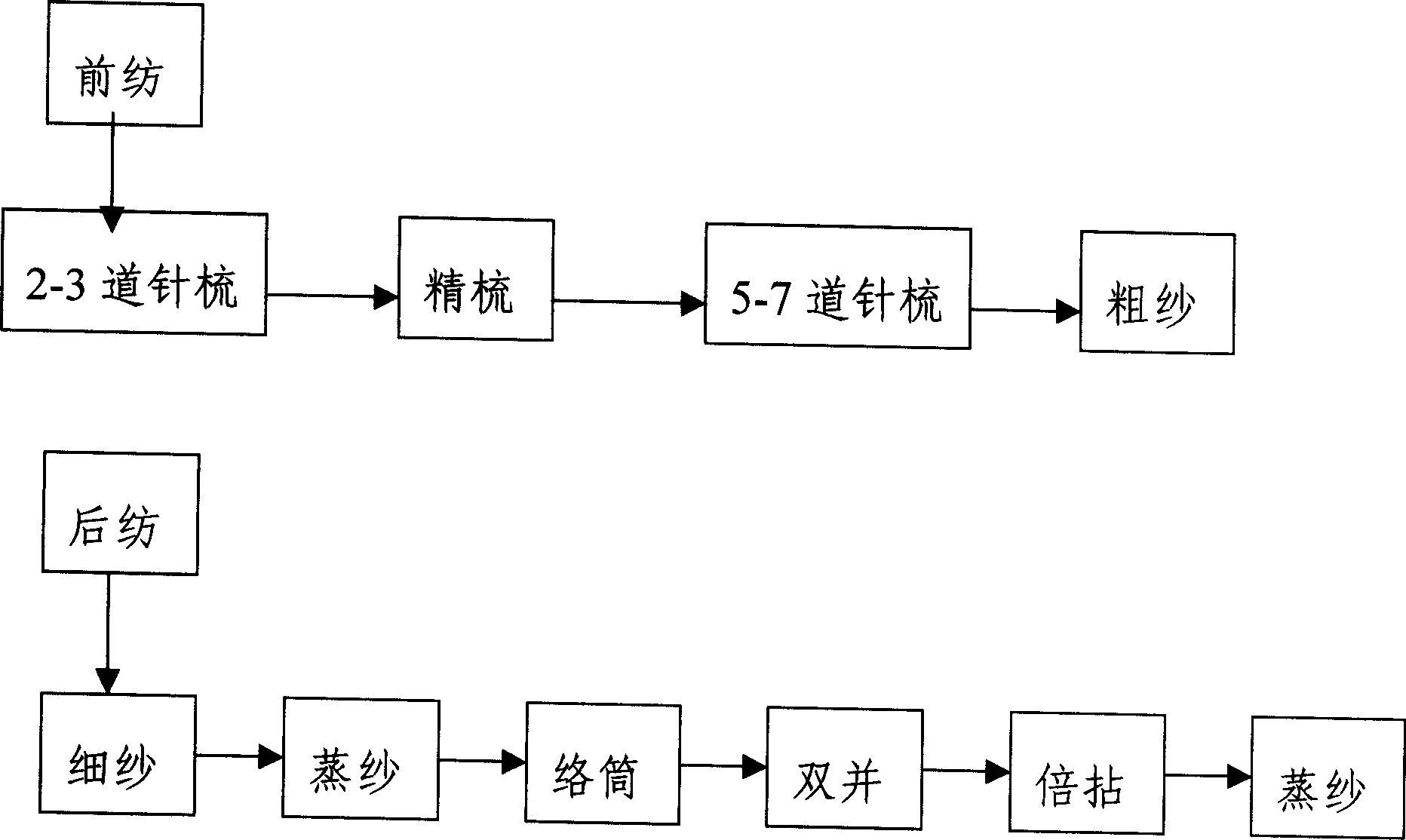

Ultra-high-count pure cotton combing yarn and spinning technology of ultra-high-count pure cotton combing yarn

ActiveCN103334190APromote maturityAmerican cotton has high strengthContinuous processingCombing machinesYarnFiber

The invention discloses ultra-high-count pure cotton combing yarn and a spinning technology of the ultra-high-count pure cotton combing yarn. Raw cotton comprises, by weight, 15%-25% of Egypt cotton, 25%-35% of American cotton and 40%-50% of Xinjiang long stapled cotton, wherein the Egypt cotton, the American cotton and the Xinjiang long stapled cotton are blended to spin 200S to 300S pure cotton yarn. The spinning technology includes the following steps that the first procedure of blowing-carding, the second procedure of combing, the third procedure of drawing, the fourth procedure of roving yarn, the fifth procedure of spun yarn and the sixth procedure of spooling. With the blending scheme, the raw cotton can integrate the advantages of high fineness and good maturity of the Egypt cotton, the advantages of high strength and non-existing abnormal fibers of the American cotton, the advantage of large length of the Xinjiang long stapled cotton and the like. The raw cotton reaches the requirements for the fiber length, the length CV value, the Micronaire value, the fineness, the strength and other performance indexes of raw cotton in producing ultra-high-count yarn. According to the spinning technology of the ultra-high-count pure cotton combing yarn, the ultra-high-count yarn can be produced under a large ration of roving yarn, the spinning efficiency is improved and meanwhile, quality of resultant yarn is ensured.

Owner:傲丝生态(中国)有限公司

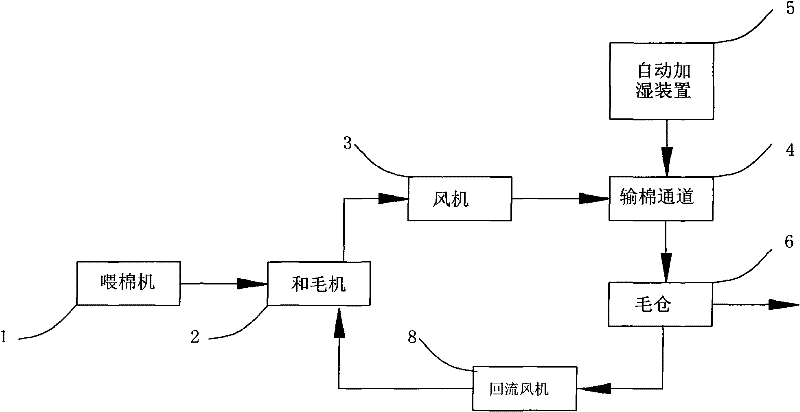

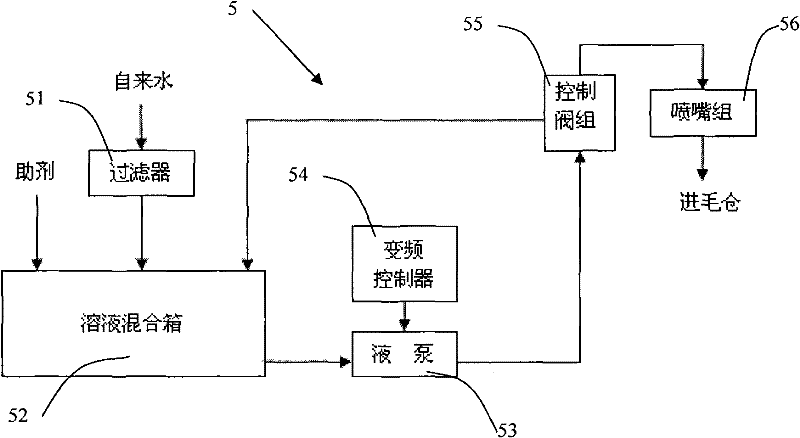

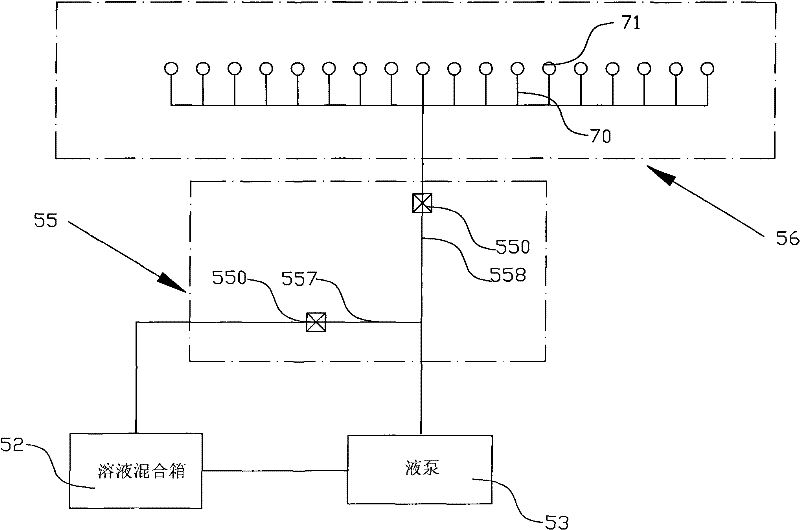

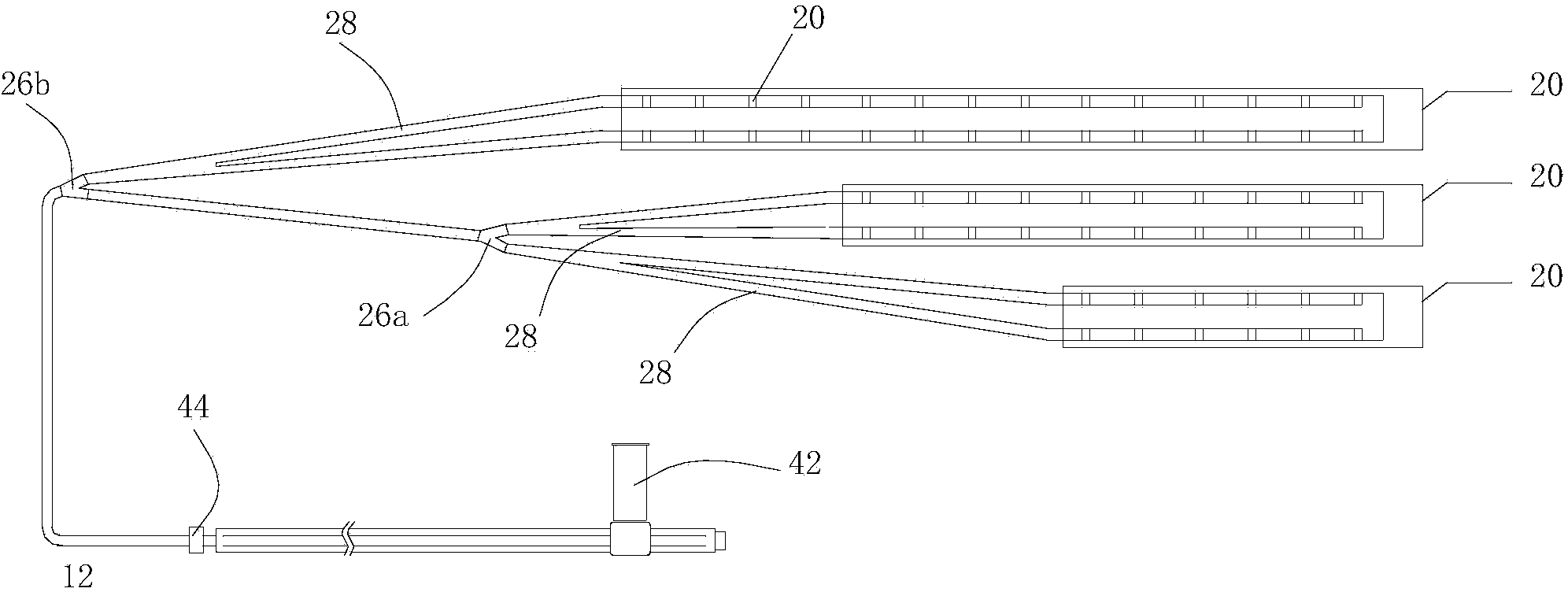

Fiber pretreatment device and method

InactiveCN102453982AReduce labor intensitySave spaceContinuous processingLiquid/gas/vapor removalYarnFiber

The invention discloses a fiber pretreatment device and method. The fiber pretreatment device comprises a cotton feeder, a wool mixer, a fan, a cotton conveying channel, an automatic humidification device and a wool bin which are connected in sequence by pipes; the automatic humidification device is connected with the cotton conveying channel; the fiber pretreatment device further comprises a reflow fan; the reflow fan is connected with the wool mixer and the wool bin through pipes; the wool bin is provided with an air blowing device; and the air blowing device is a ventilating pipe which is connected with an air blower. The method for humidifying manually for fiber pretreatment for a long time is changed, the working labor intensity is reduced, the defect of incontinuous production caused by manual humidification is overcome, and the reflow step, namely the secondary humidification step is adopted so that the fiber pretreatment can further meet the yarn spinning requirement and the fiber spinnability is improved.

Owner:上海第三十六棉纺针织服装厂有限公司

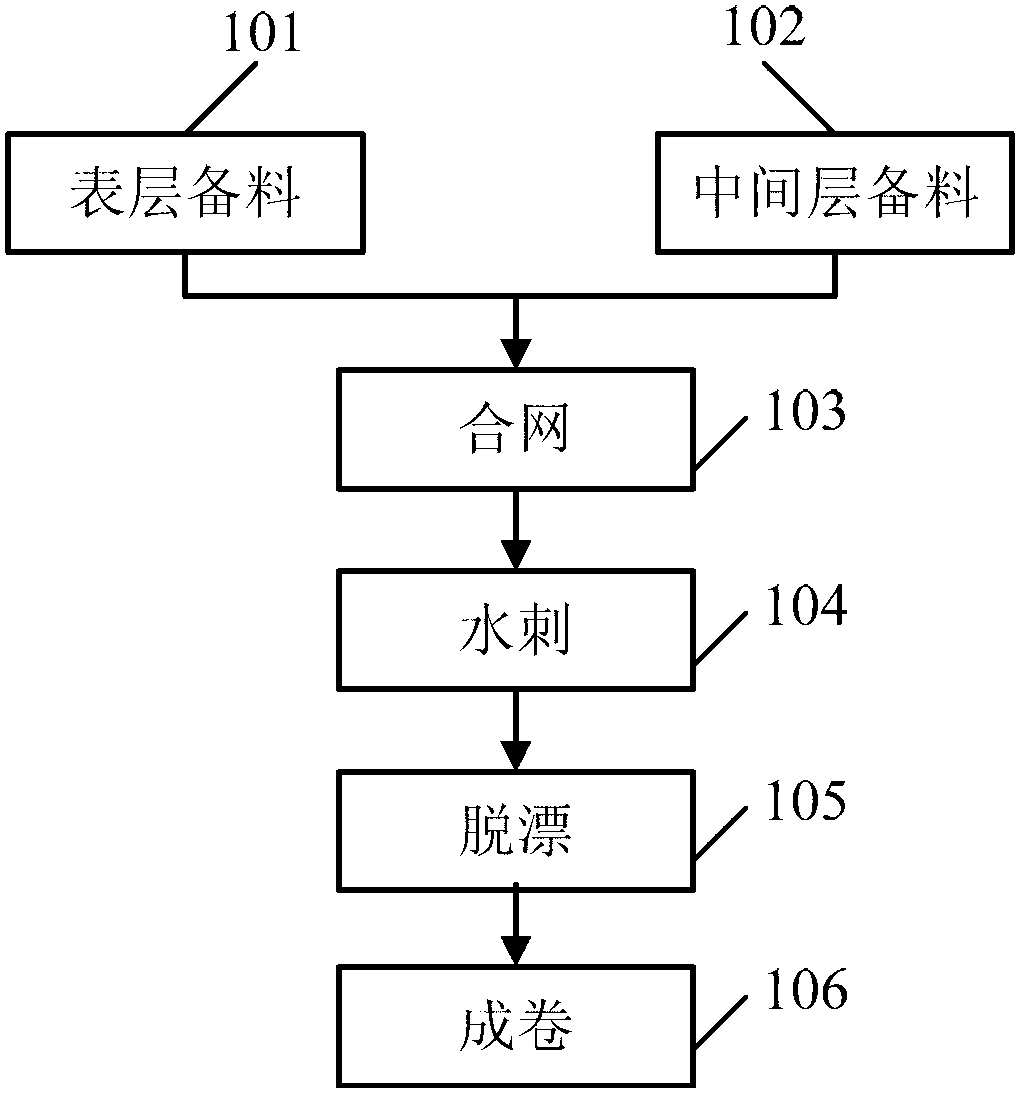

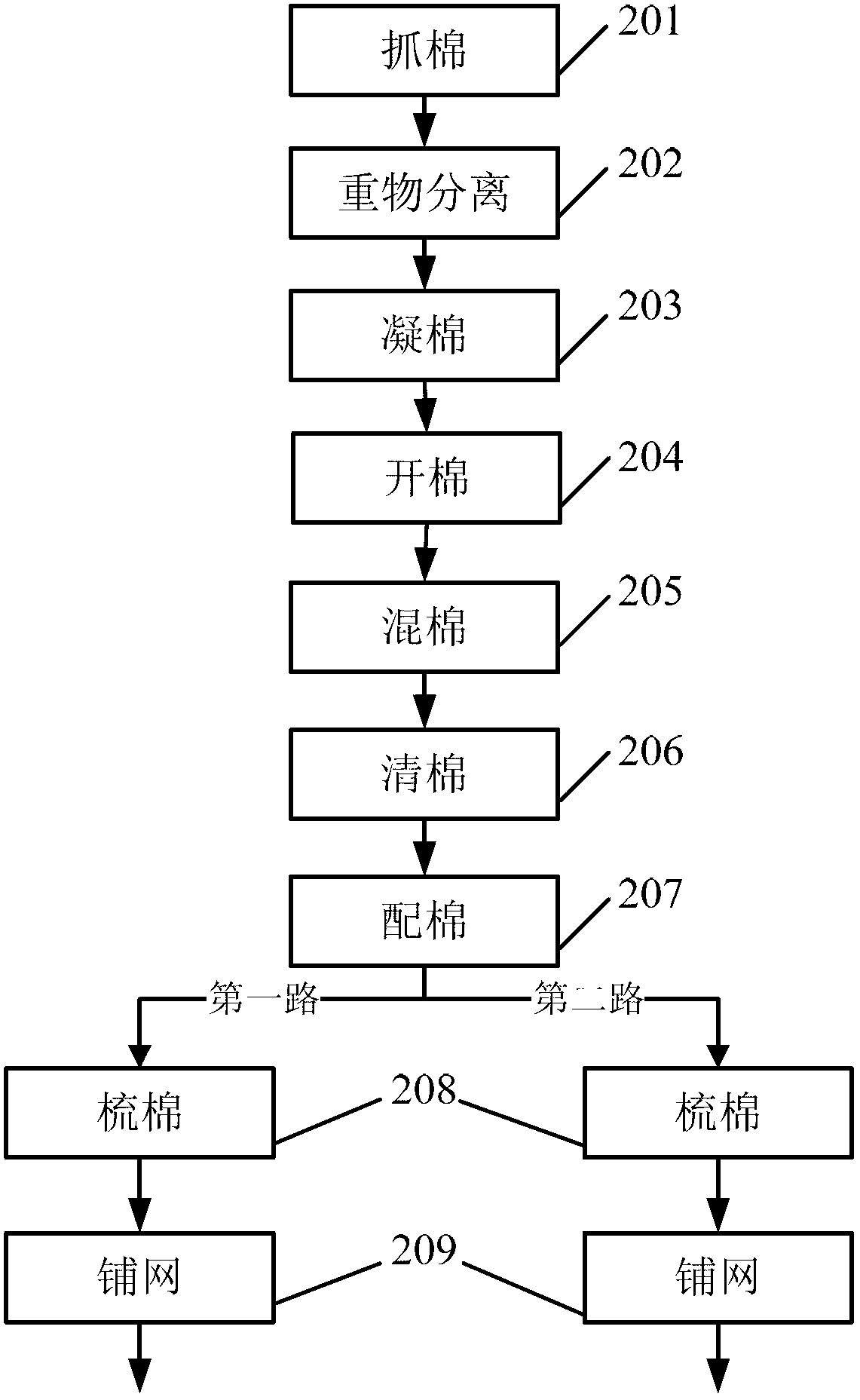

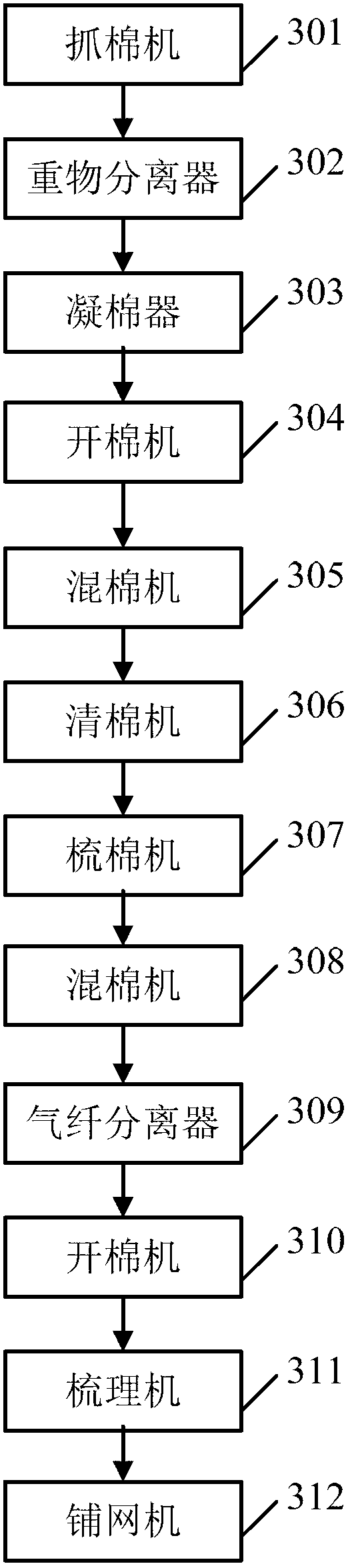

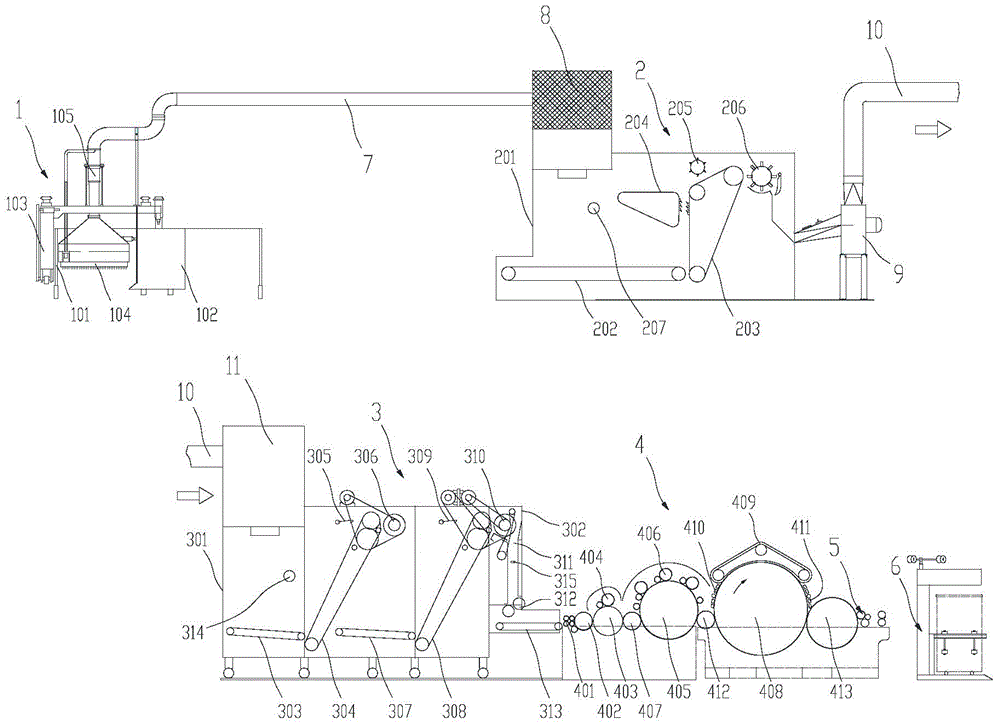

Manufacturing methods and devices of cotton fiber net and multilayer non-woven material

ActiveCN103074737AImprove fluencyIncrease production capacityContinuous processingNon-woven fabricsFiberPulp and paper industry

The invention relates to a manufacturing device of a cotton fiber net. The device comprises a cotton grasper, a weight separator, a condenser, openers, mixers, a cleaner, combers, a gas-fiber separator and a lapping machine. The manufacturing method of the cotton fiber net comprises cotton grasping; weight separation; condensation; opening; mixing; cleaning; combing; mixing; gas-fiber separation; opening; combing and paving. A manufacturing device of a multilayer non-woven material comprises the manufacturing device of the cotton fiber net. The manufacturing method of the multilayer non-woven material comprises the manufacturing method of the cotton fiber net. According to the manufacturing methods and the manufacturing devices of the cotton fiber net and the multilayer non-woven material provided by the invention, cottonseed hulls in the pure cotton material can be effectively removed through a cottonseed hull removing process, so that the subsequent production process is not affected. In addition, a combing process is further added to further comb the pure cotton material to obtain uniform cotton fiber nets, therefore, uniform non-woven material can be obtained.

Owner:WINNER MEDICAL (HUANGGANG) CO LTD +2

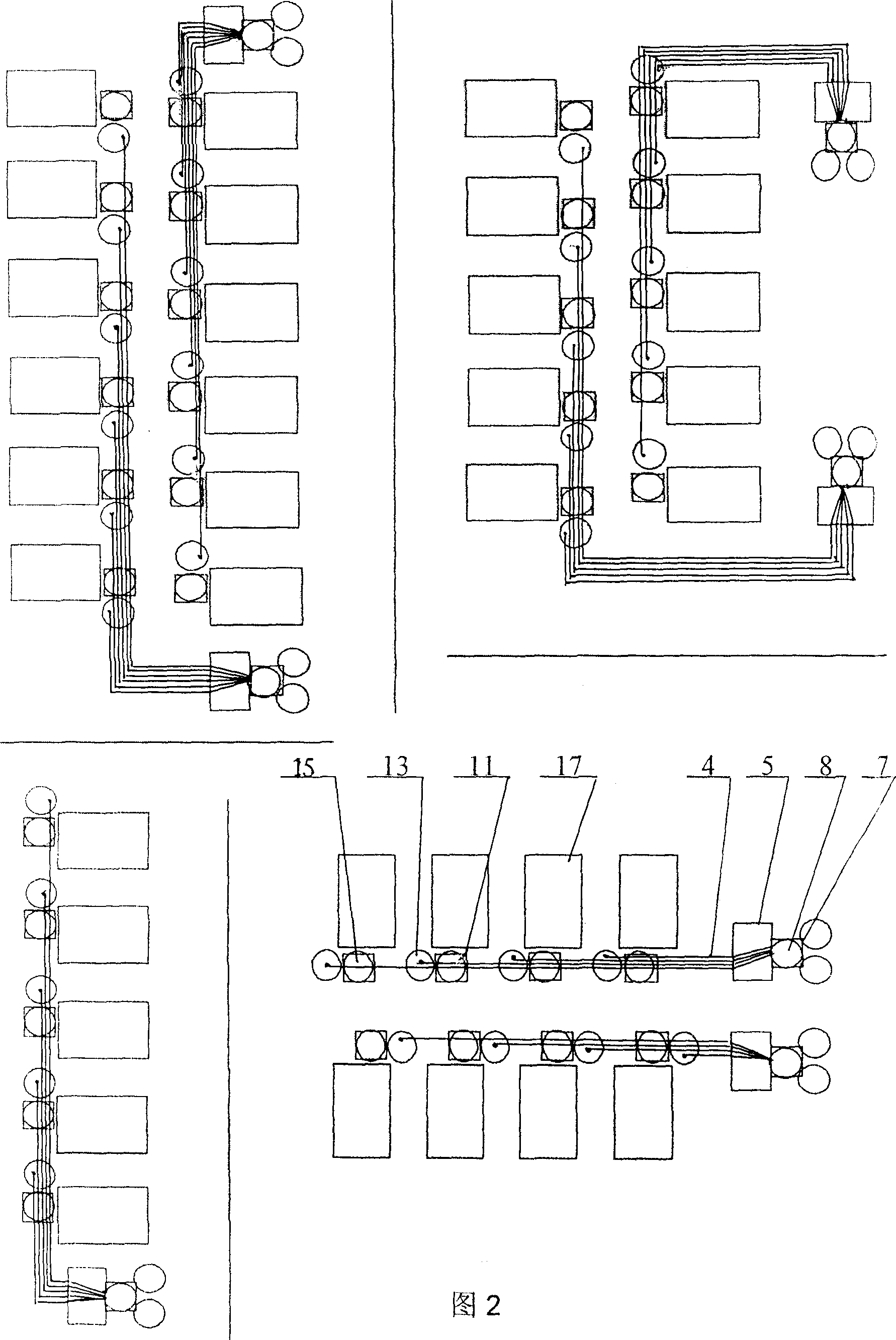

Method and device for combining carding, combing and drawing

InactiveCN1510183AImprove operational efficiencyEase of modern managementContinuous processingFibre feedersCardingCombing

An apparatus and method for combining the carding or combing step with drawing step is disclosed. Said apparatus is composed of planitary coiler head, overlapped cotton sliver diverting mechanism, dynamic cotton sliver storage, guide delivering unit, and running state monitor unit. Its advantage is automatic and continuous production.

Owner:倪远 +1

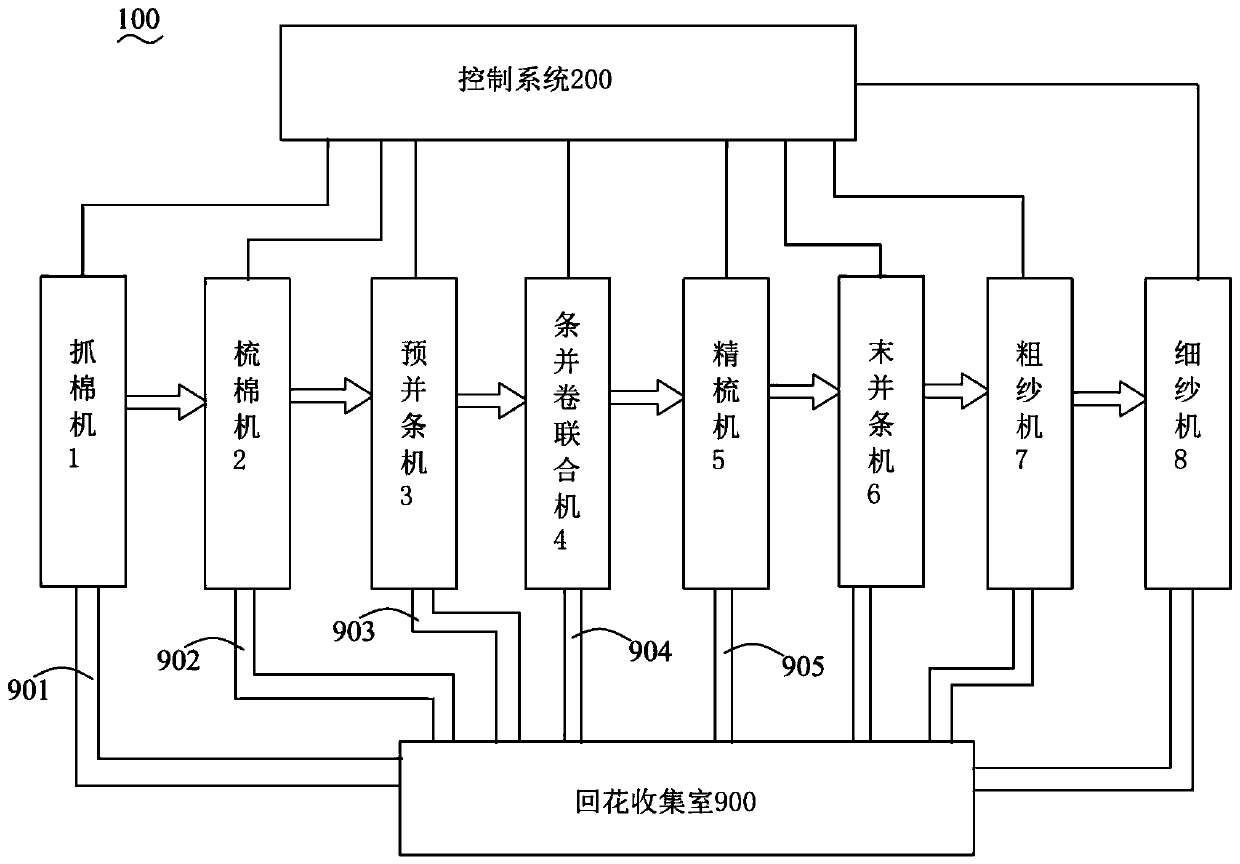

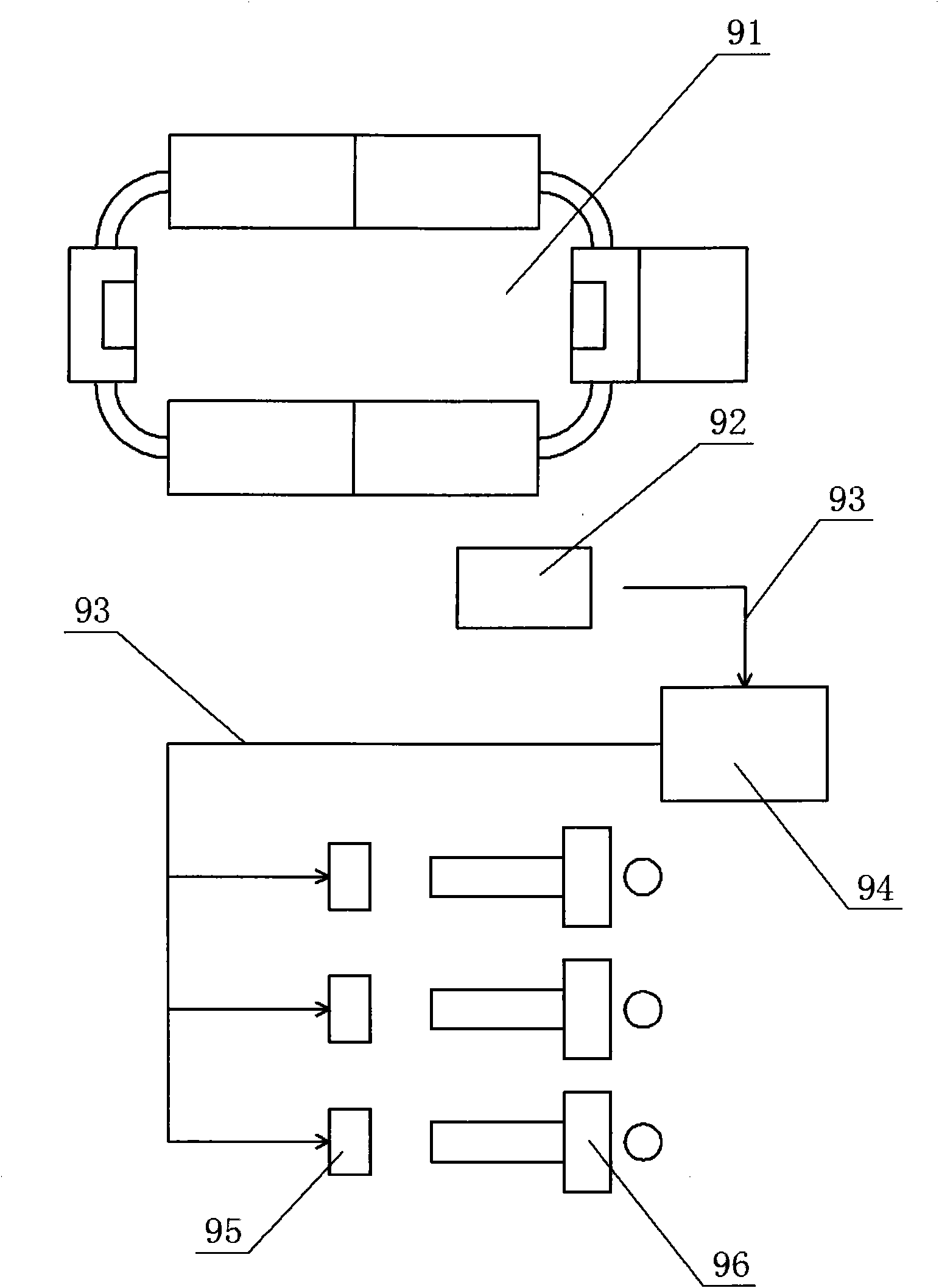

Whole-flow intelligent spinning production line

ActiveCN110331483AReduce labor intensityAvoid harmContinuous processingFibre feedersProduction lineLogistics management

The invention discloses a whole-flow intelligent spinning production line. A conveying system for connecting output sides of adjacent process work points and feeding sides of next processes is arranged among a bale plucker, a carding machine, a pre-drawing frame, a draw frame and lap machine, a combing machine, an end drawing machine, a roving frame and a spinning frame which are sequentially arranged; a control system in signal connection with the bale plucker, the carding machine, the pre-drawing frame, the draw frame and lap machine, the combing machine, the end drawing machine, the rovingframe, the spinning frame and a conveying system is arranged; the control system controls working states of the bale plucker, the carding machine, the pre-drawing frame, the draw frame and lap machine, the combing machine, the end drawing machine, the roving frame, the spinning frame and the conveying system to control normal operation of the whole-flow intelligent spinning production line. The whole-flow intelligent spinning production line realizes automation, continuity and intelligence of each process by use of the conveying system, the logistics cost is reduced, and unmanned management ofa spinning workshop is realized.

Owner:武汉裕大华纺织服装集团有限公司

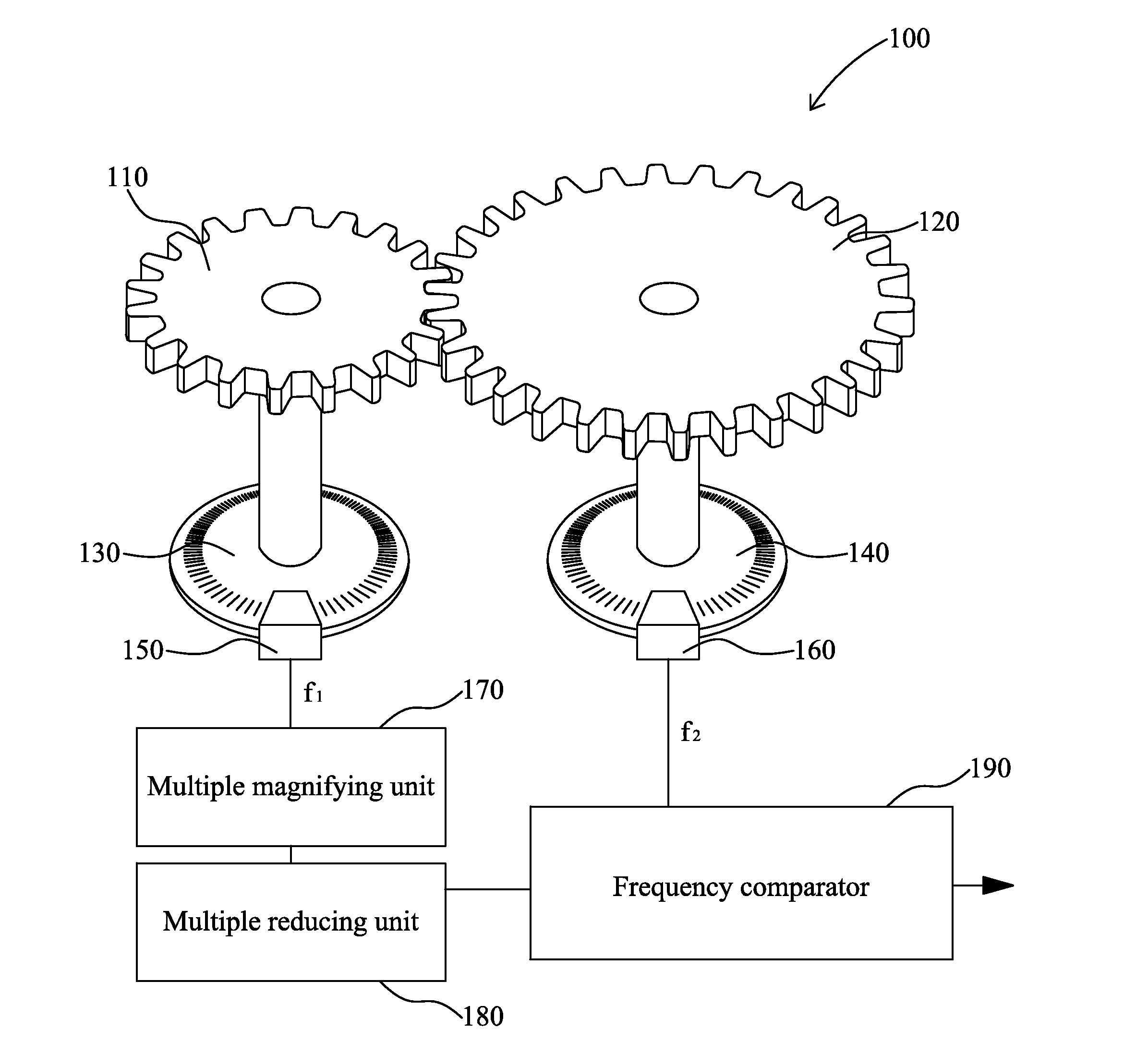

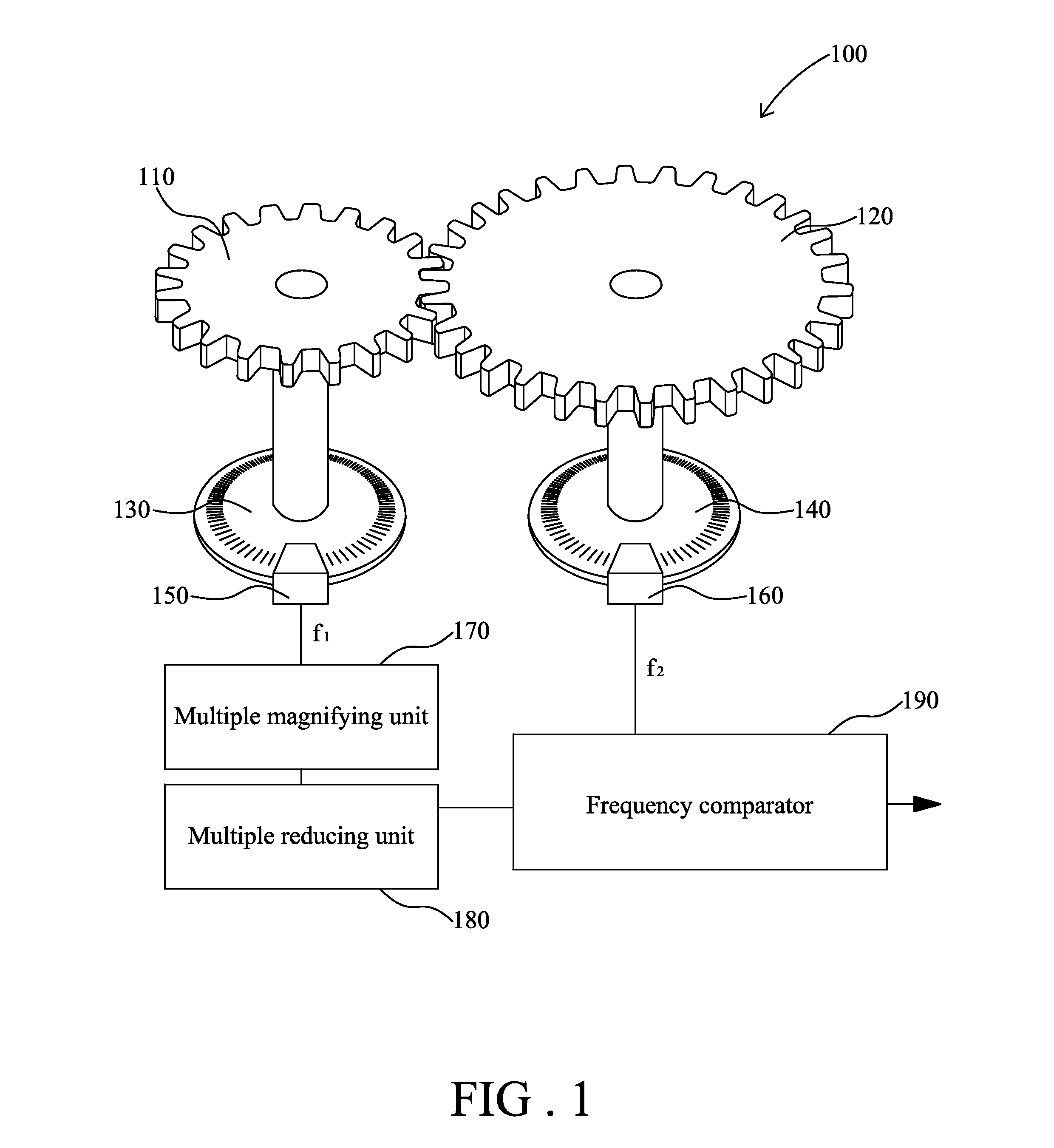

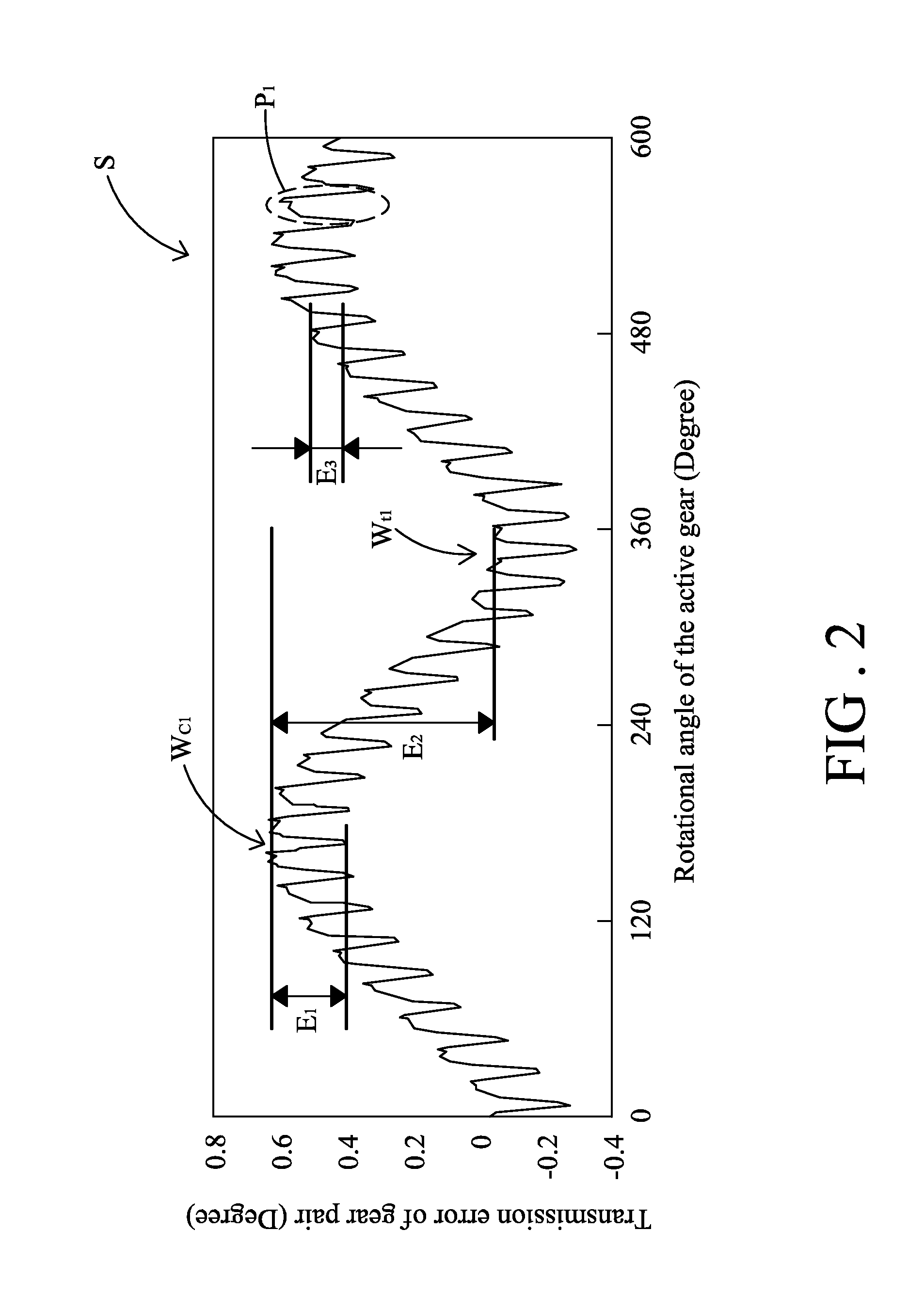

Method for determining the precision of gears

InactiveUS20140088891A1Less susceptible to noiseThe solution cannot be accurately determinedVibration measurement in solidsMachine part testingAlgorithmPitch error

A method for determining the precision of gears includes steps of providing a gear pair; performing a single flank test for the gear pair, to generate a testing signal graph; decomposing the testing signal graph into a plurality of intrinsic-mode-function graphs; selecting a first function graph and a second function graph from the intrinsic-mode-function graphs; measuring the amplitude of vibration of the first function graph, to get a profile error of gear; combining the first and second function graphs to form a graph of function combination; calculating an adjacent pitch error and an accumulated pitch error by means of the graph of function combination; and defining the gear precision for one of the gear pair according to the profile error of gear, the adjacent pitch error and the accumulated pitch error.

Owner:NAT CENT UNIV

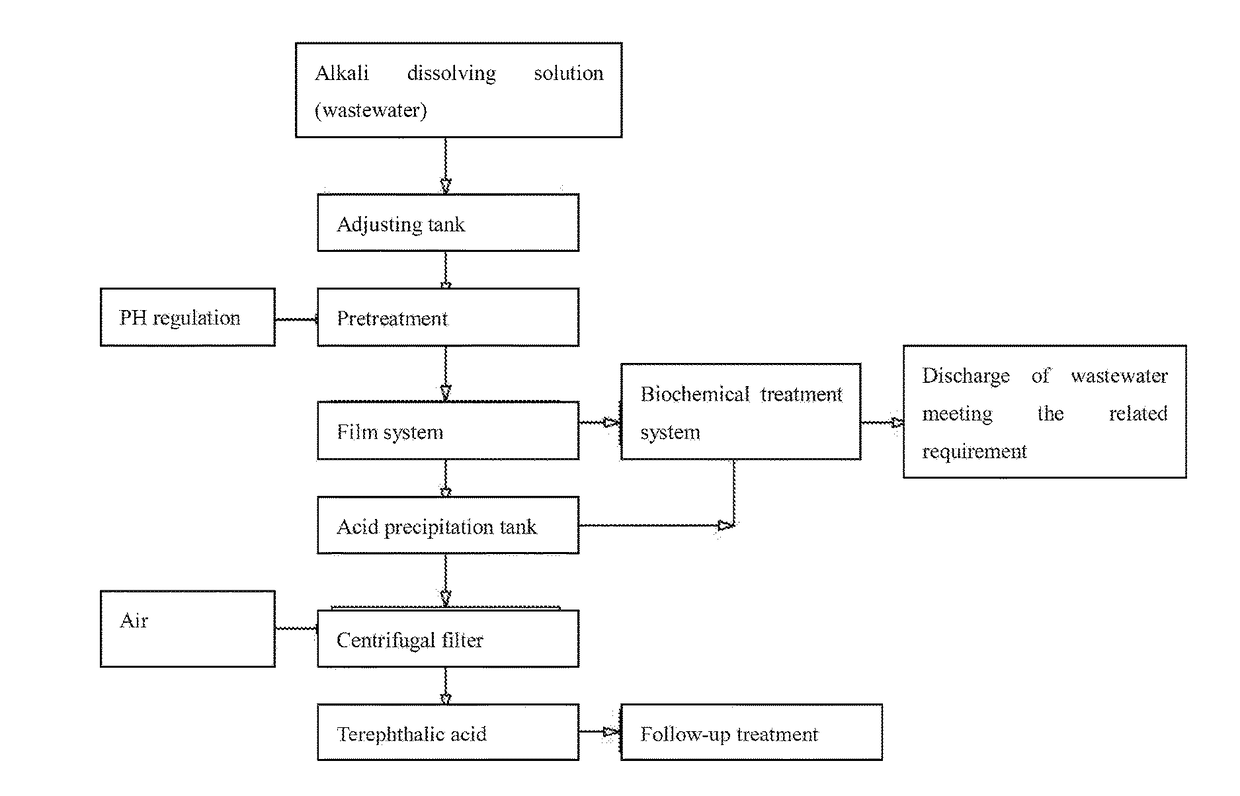

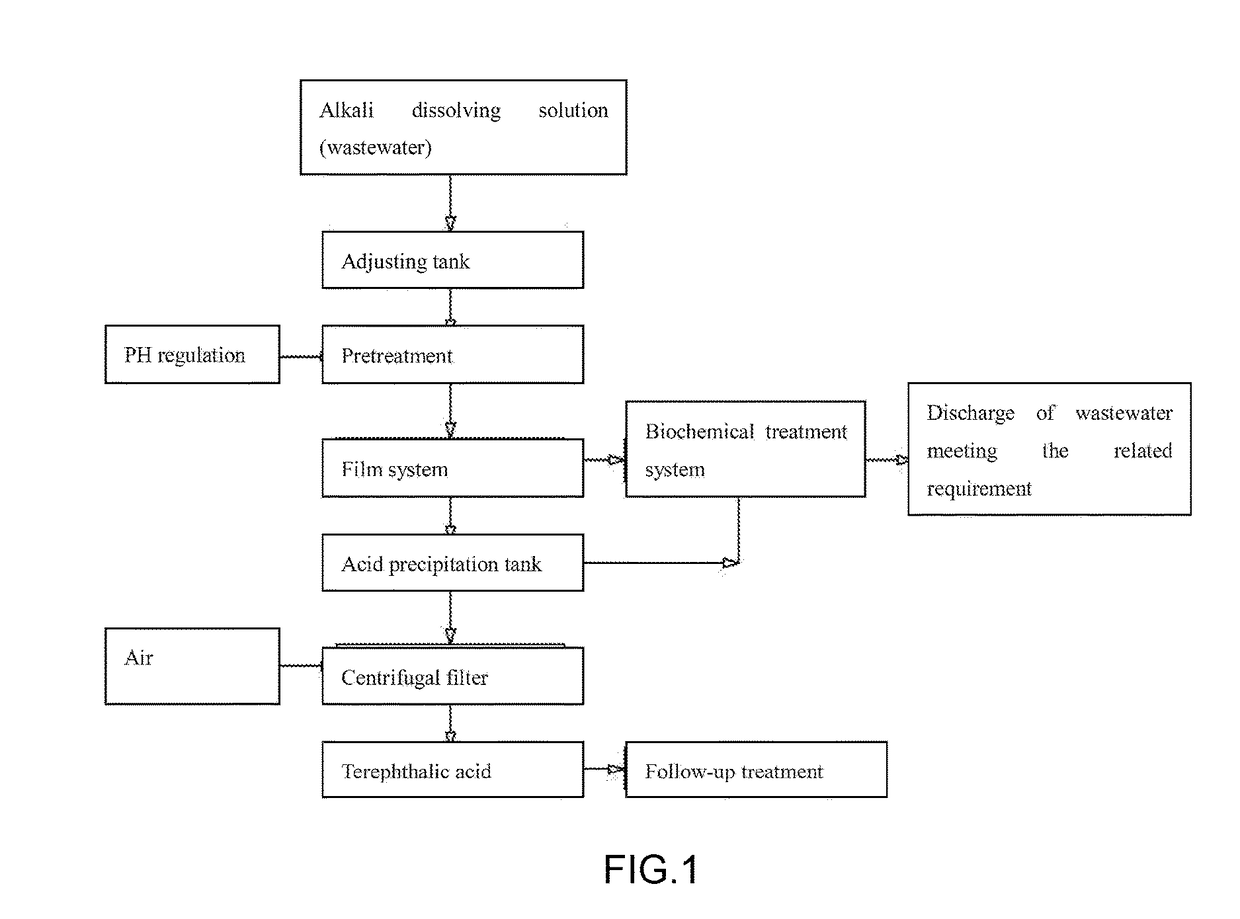

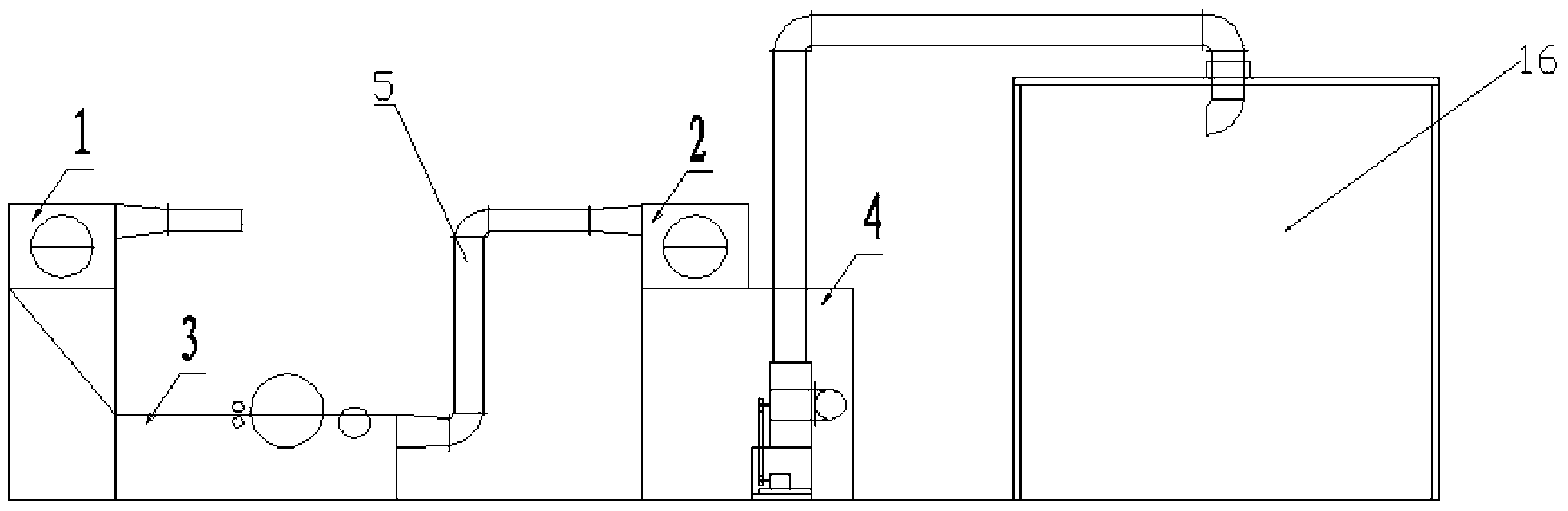

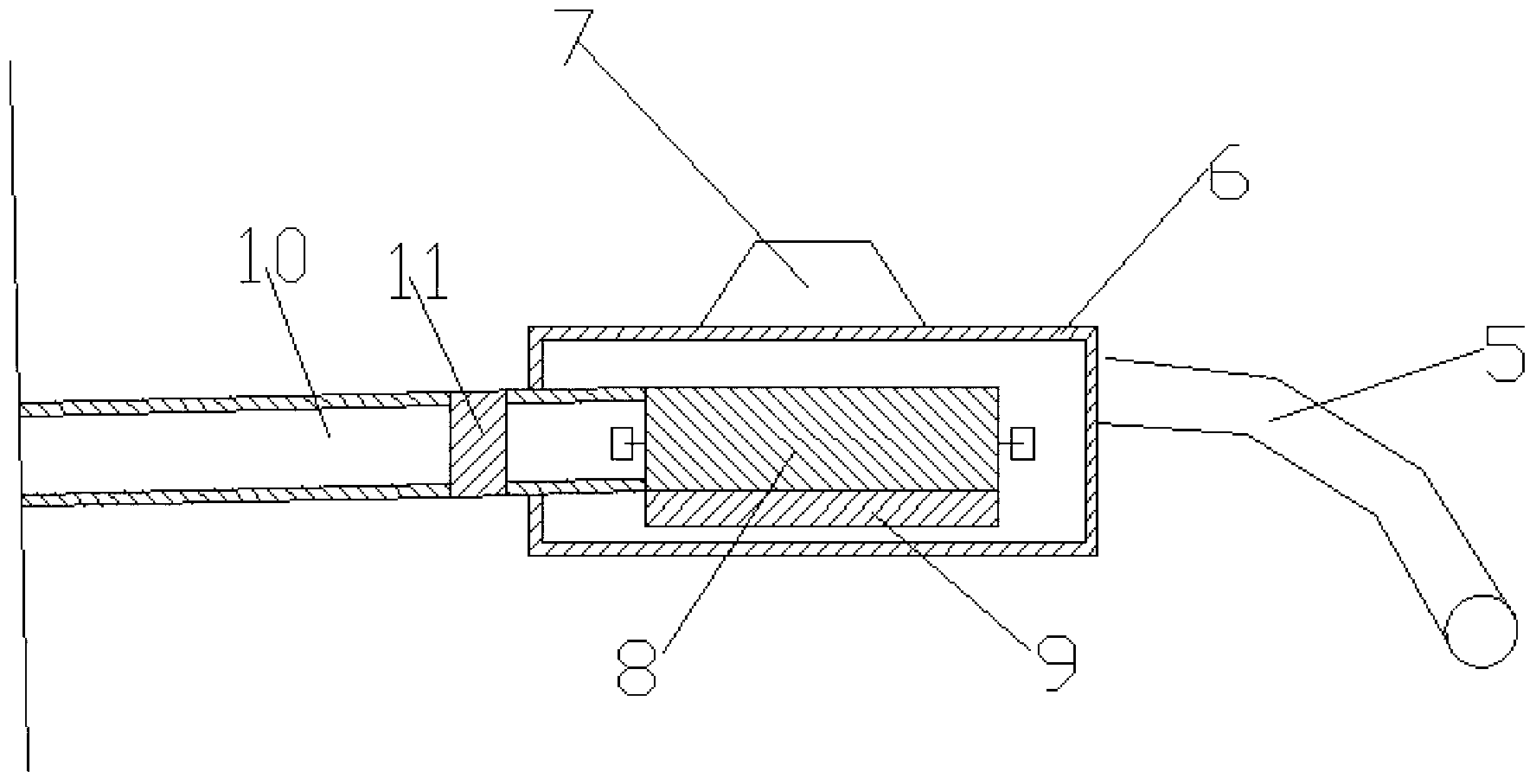

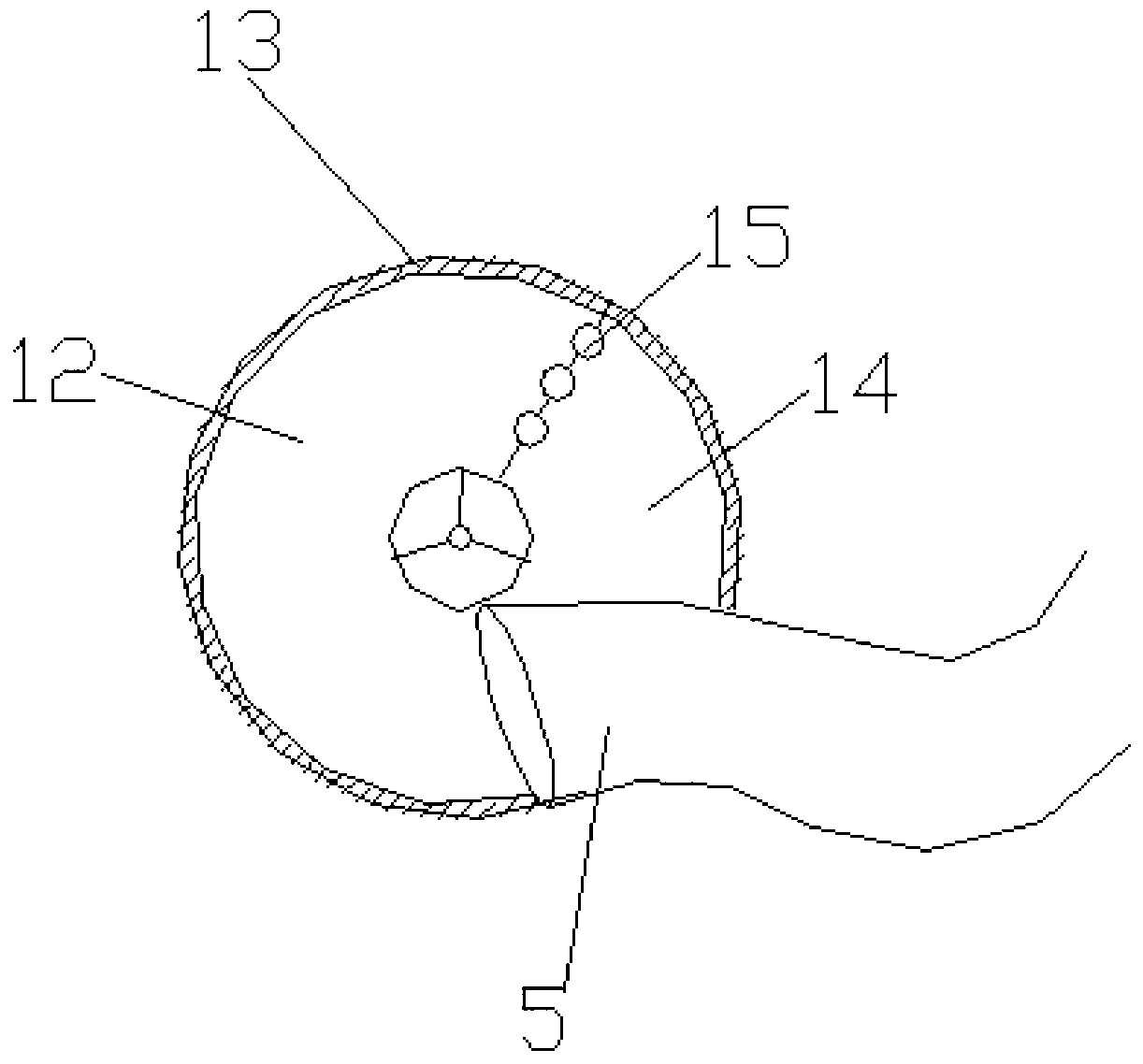

Technology for Recovery, Regeneration and Reuse of Soluble Textiles

InactiveUS20180002837A1Ensures spinnabilityEnsure wear performanceProductsReagentsTextile fiberDissolution

The invention discloses a technology for recovery, regeneration and reuse of soluble textiles. The technology comprises the steps of: the dissolution-controlled soluble polyester fibres are processed into soluble apparel accessories through conventional weaving, dyeing, finishing and tailoring or injection molding; the apparels or the soluble apparel accessories are dissolved under a certain condition, on one hand, the dissolving solution is filtered and solutes are recovered to obtain a high purity of terephthalic acid and ethylene glycol, which are reused to the polymerization of the soluble polyester, and the slices of the soluble polyester are obtained to be re-spun into the soluble fibres for reuse; on the other hand, the incompact and undissolved textiles are treated into an incompact fibre aggregation with good qualities by processes including disinfection, decolourization or redyeing, which are processed into high-quality textile fibres for reuse after drying or softly carding.

Owner:YU YANPING +3

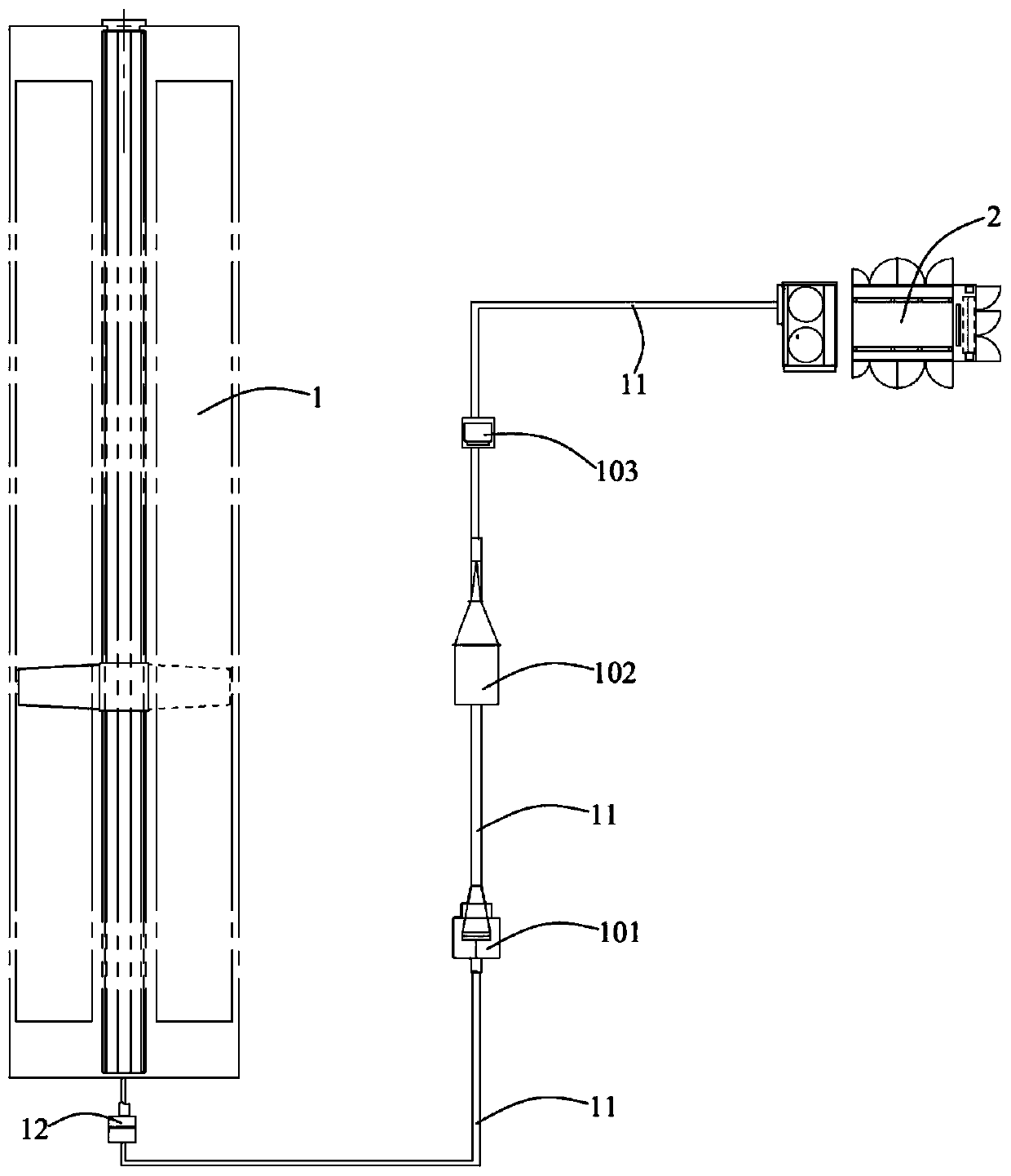

Blending and opening device

ActiveCN103290536AReduce labor intensityPass smoothlyLubricating devicesContinuous processingState of artFiber bundle

The invention relates to the technical field of wool top processing equipment, in particular to a blending and opening device which comprises a first automatic sucking device, a second automatic sucking device, an opener, an automatic oil filling tank and a plurality of delivery pipes. The blending and opening device has the advantages that fibers can be directly sucked into the opener from the ground by the aid of the first automatic sucking device without being manually placed into the opener, accordingly, the efficiency is high, the labor intensity of workers is low, fibers which are processed by the opener can be automatically sucked into the automatic oil filling tank by the aid of the second automatic sucking device, both the first automatic sucking device and the second automatic sucking device have impurity removal functions, and the quality of later-period finished products is greatly improved; manual blending in the prior art can be replaced by the automatic oil filling tank, so that the labor intensity of the workers is greatly reduced, a uniform blending effect is realized, cohesive force of fiber bundles is increased, the fibers can smoothly pass a carding device, a spinning device and the like advantageously, and twisting, end breaking and the like are reduced.

Owner:浙江中鼎纺织股份有限公司

Cotton blending device and cotton blending method

ActiveCN104178854AQuality improvementImprove stabilityFibre mixingContinuous processingFiberEngineering

The invention discloses a cotton blending device and a cotton blending method. The cotton blending device comprises a cotton picker and at least one cotton blending box. Each of the cotton mixing boxes is provided with a cotton spreading area and a cotton picking area arranged at the tail end of the cotton spreading area. The top of the cotton spreading area is provided with cotton inlets. The cotton picker is communicated with the cotton mixing boxes; cotton delivery pipes penetrate the cotton spreading area and pass the cotton inlets; an openable damper is mounted at each cotton inlet; a cotton conveying mechanism in the same direction as the arrangement direction of the cotton inlets is disposed at the bottom of the cotton spreading area. A cotton picking mechanism is disposed in the cotton picking area; an insert plate which can move up and down is disposed between the cotton spreading area and the cotton picking area. According the cotton blending method, an operating mode: laying prior to pick-feeding, laying with no pick-feeding and pick-feeding with no laying is adopted; all cotton fibers in a production batch are blended in all dimensions, blending uniformity quality is far superior to the effect of traditional cotton blending equipment.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +2

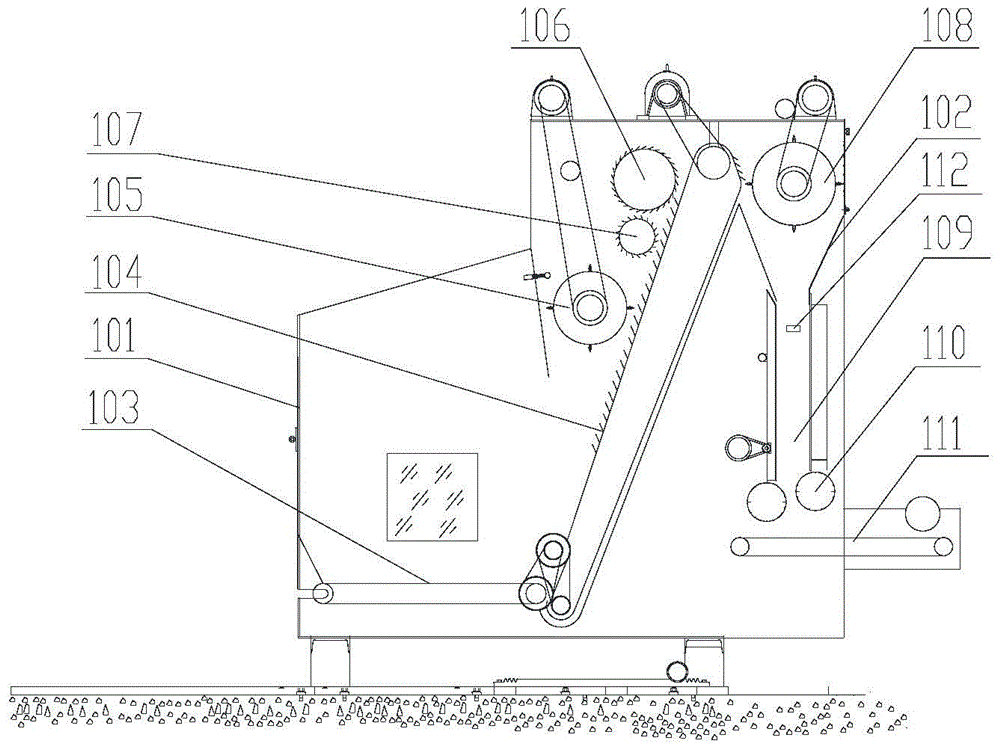

Sheep wool opening and carding complete equipment

ActiveCN105088427AOpen smoothlyInto the uniformFibre cleaning/opening by toothed membersContinuous processingEngineeringSheep wool

The invention belongs to the field of textile machines and particularly discloses sheep wool opening and carding complete equipment. The sheep wool opening and carding complete equipment comprises a first feeding mechanism, a first opening mechanism, a first coarse wood and impurity removal mechanism and a first carding mechanism which are sequentially connected from front to rear. A second feeding mechanism, a second opening mechanism, a third opening mechanism, a wool combination mechanism, a second carding mechanism and a wool bin are sequentially arranged in front of the first feeding mechanism in succession. By means of the design, primary opening, coarse wood and impurity removal and carding processes are conducted on sheep wool before sheep wool enters the first feeding mechanism, it is further guaranteed that sheep wool is evener when entering the first carding mechanism, and follow-up opening, coarse wood and impurity removal and carding effects are improved beneficially.

Owner:青岛东佳纺机(集团)有限公司 +1

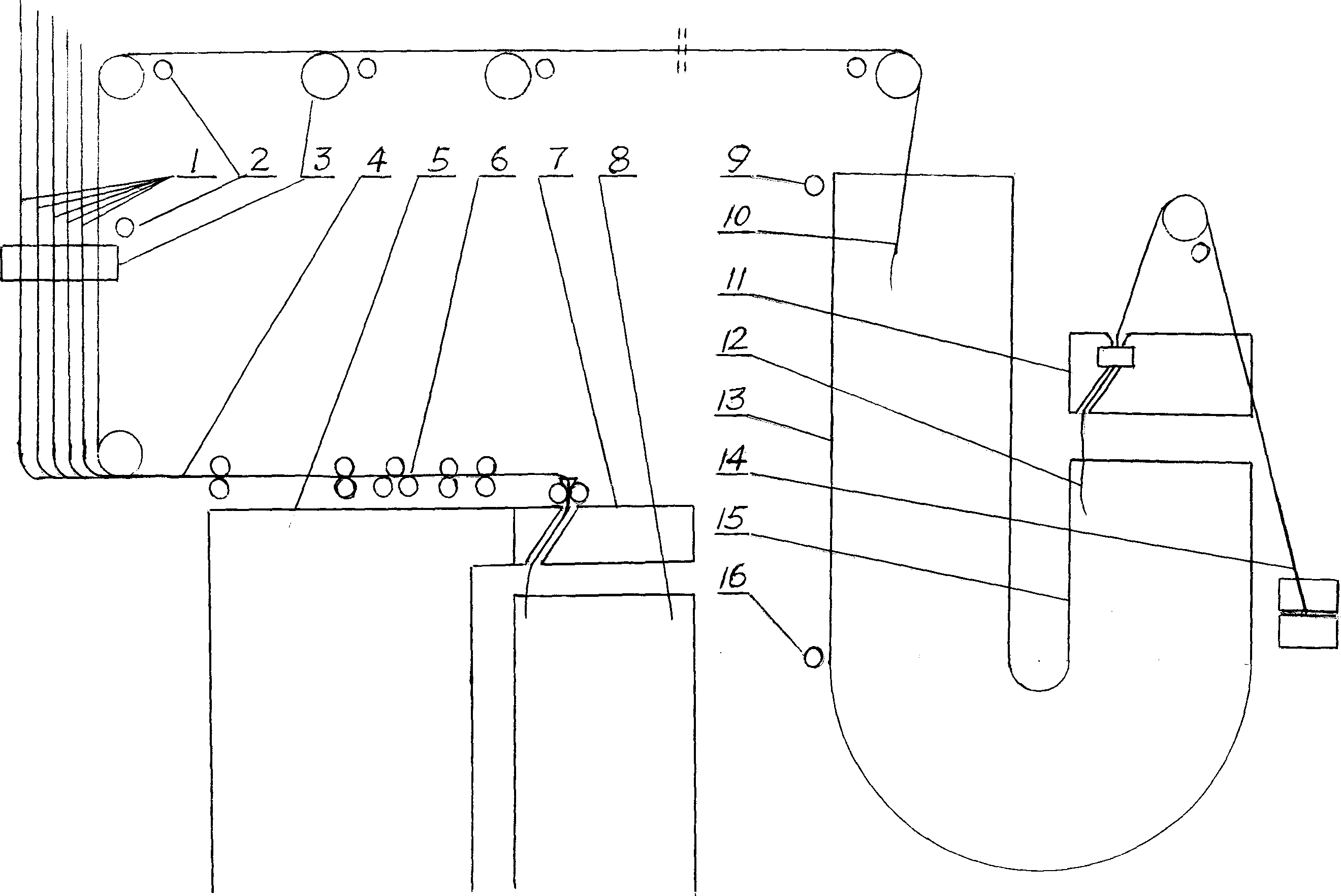

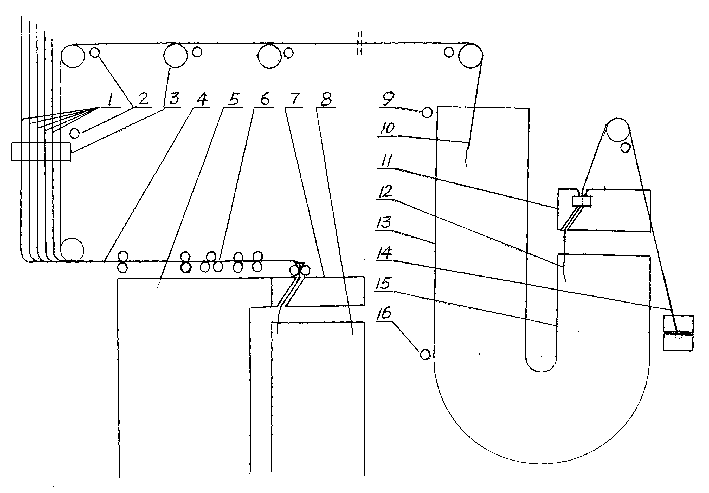

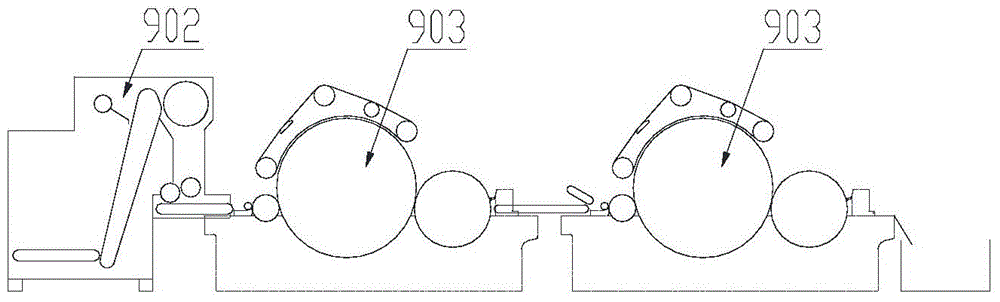

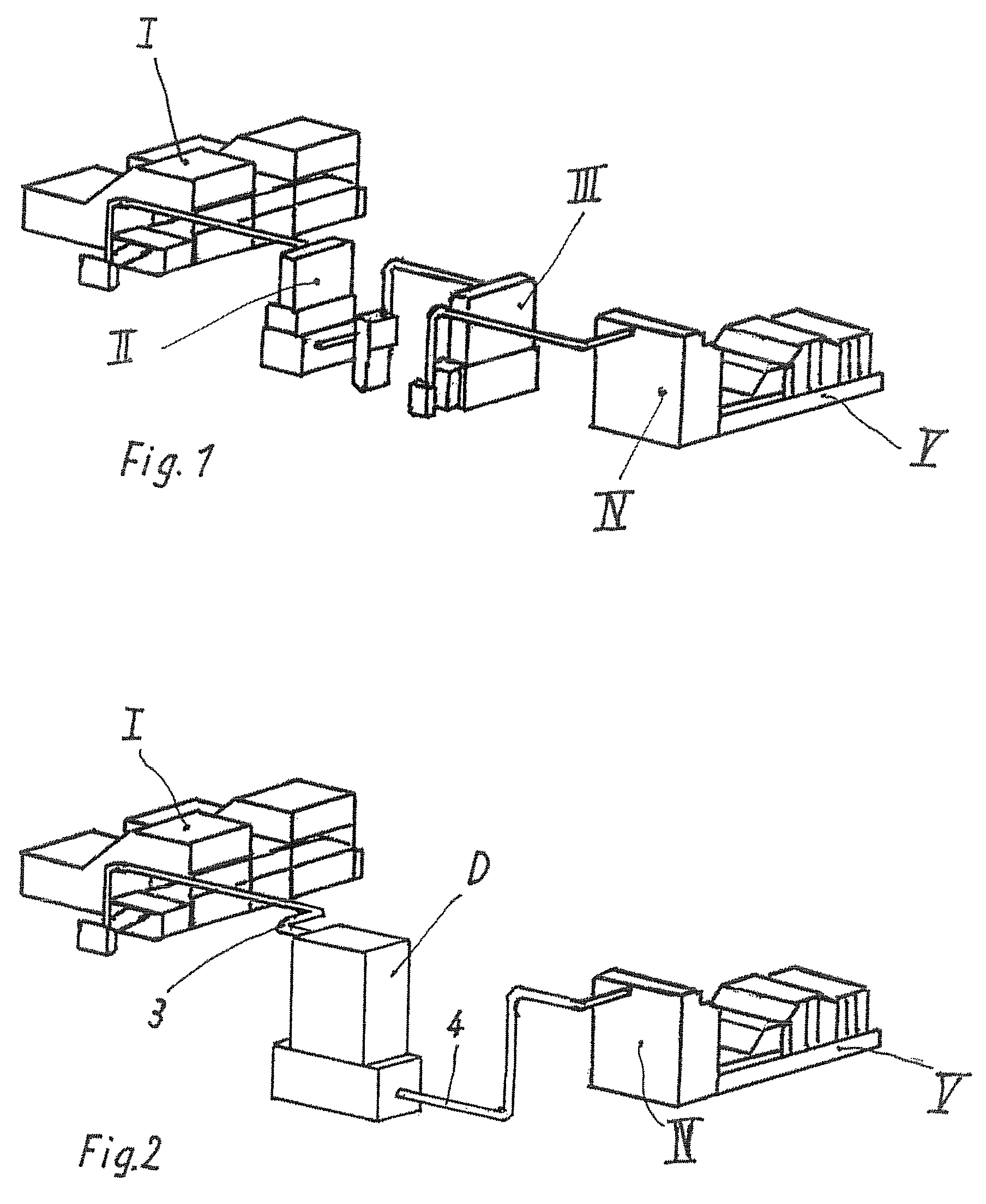

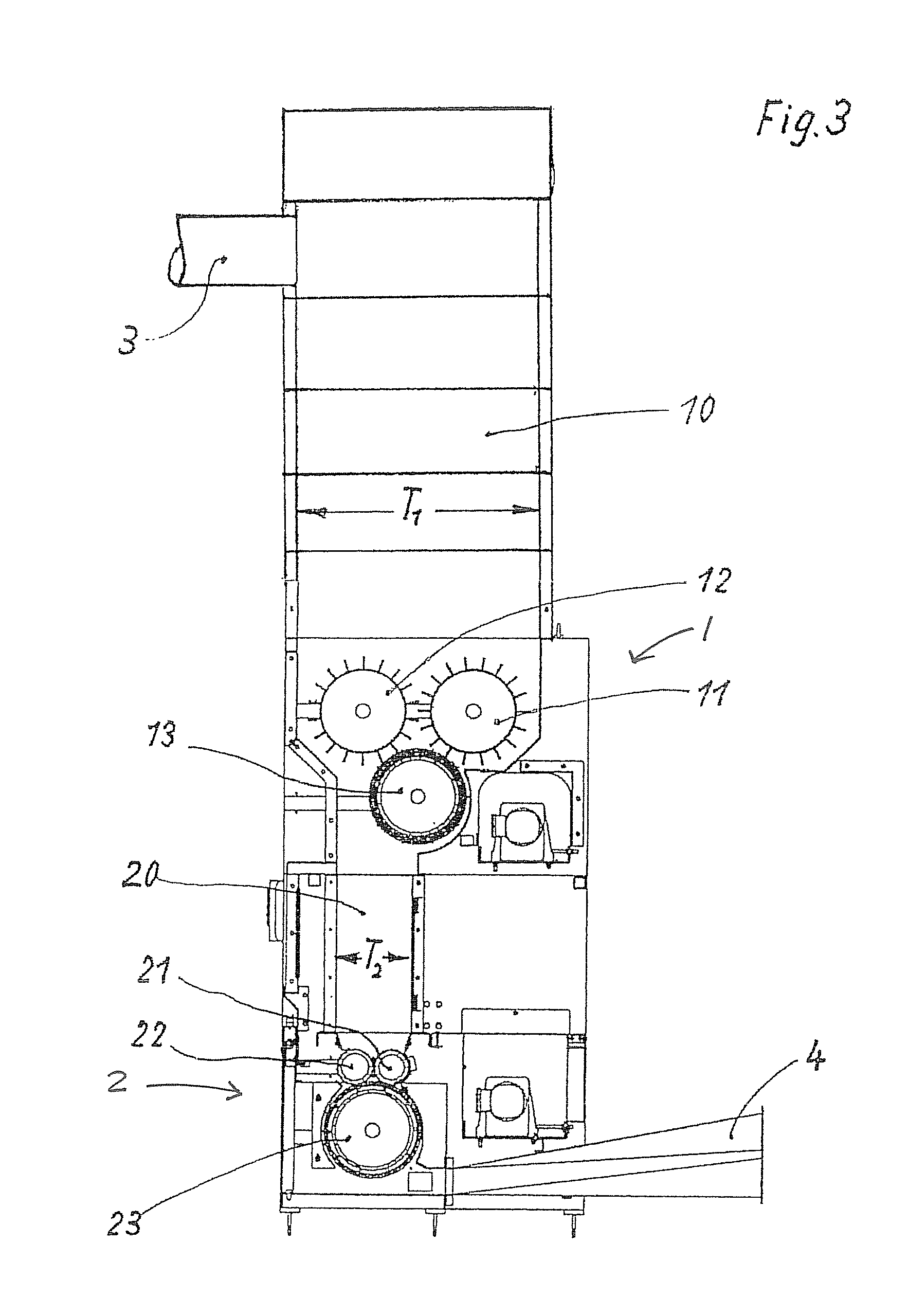

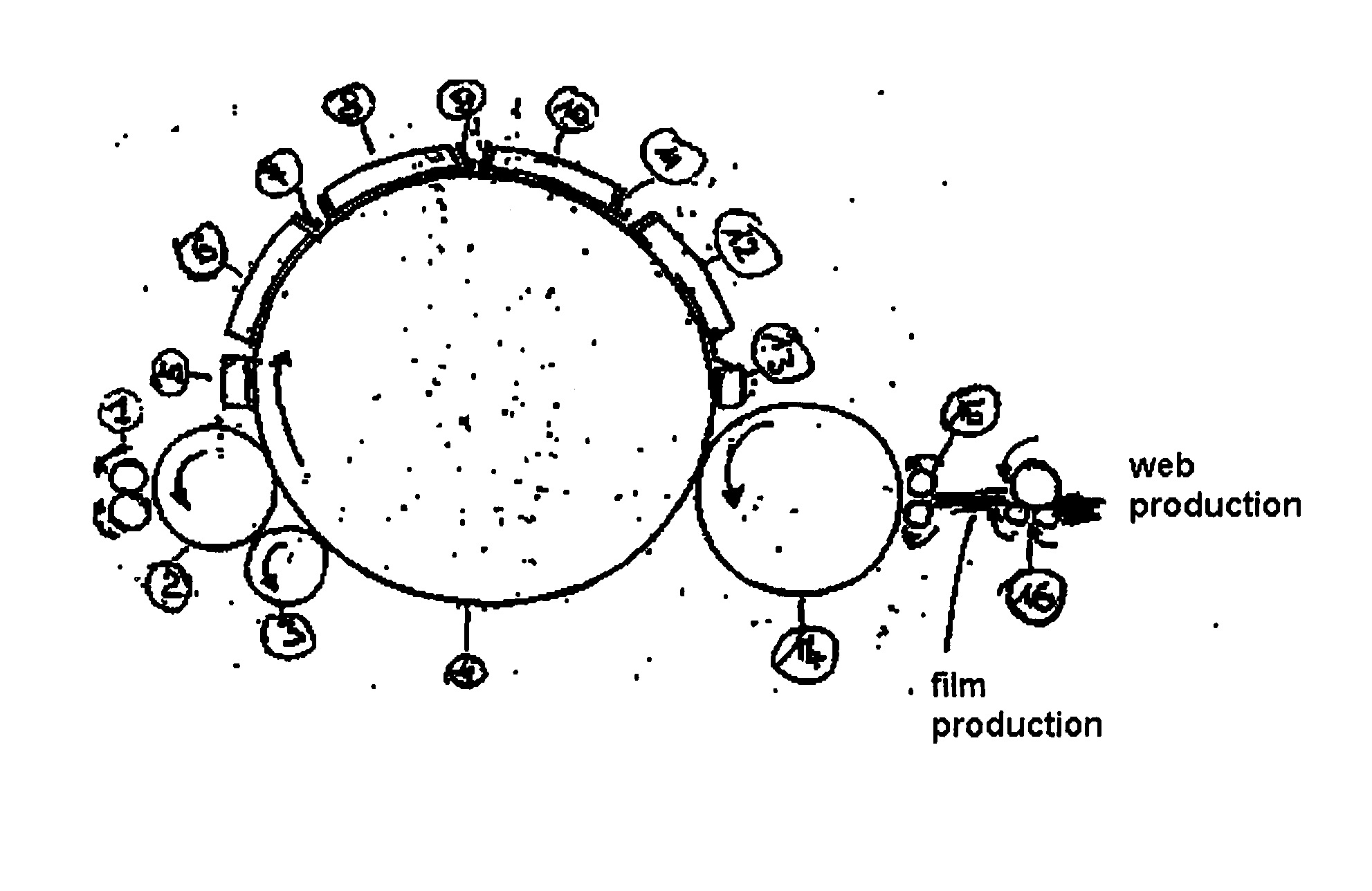

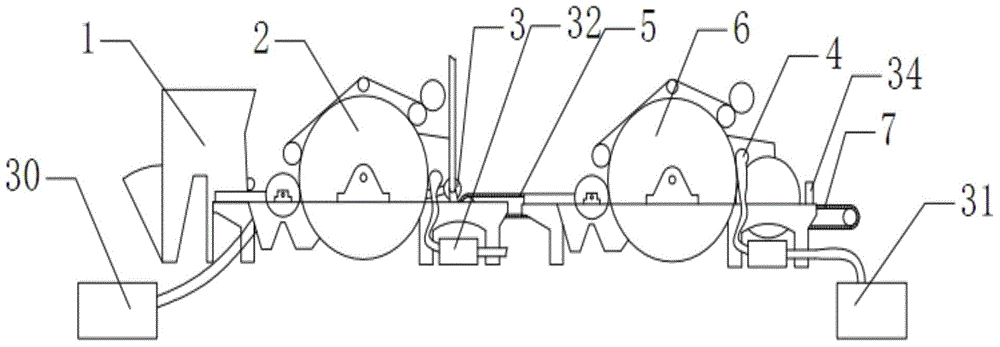

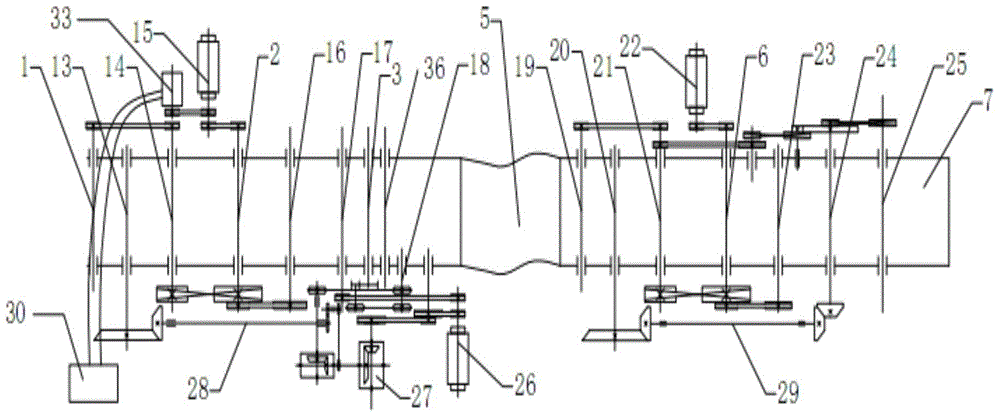

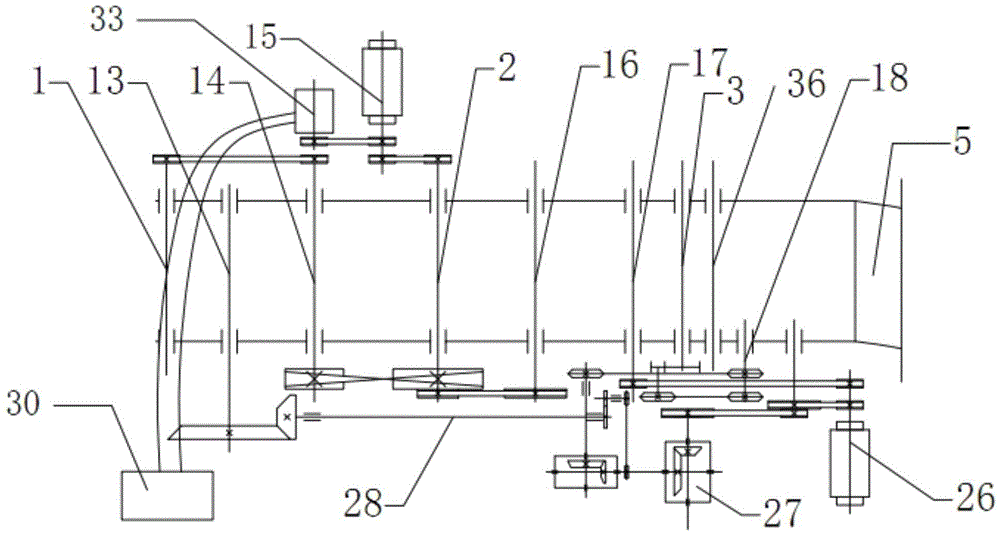

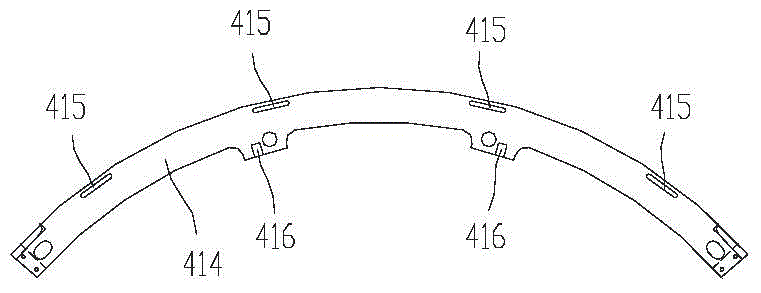

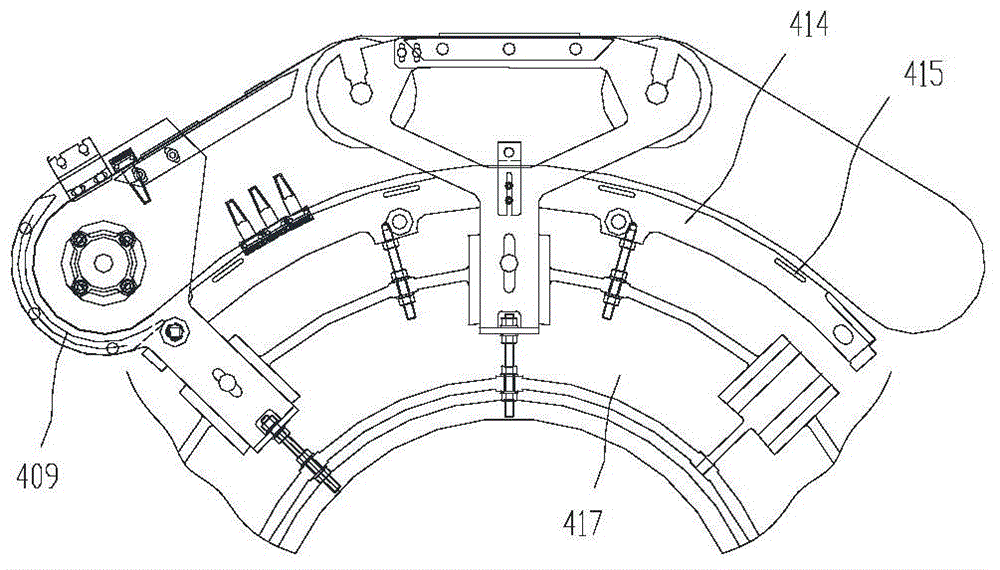

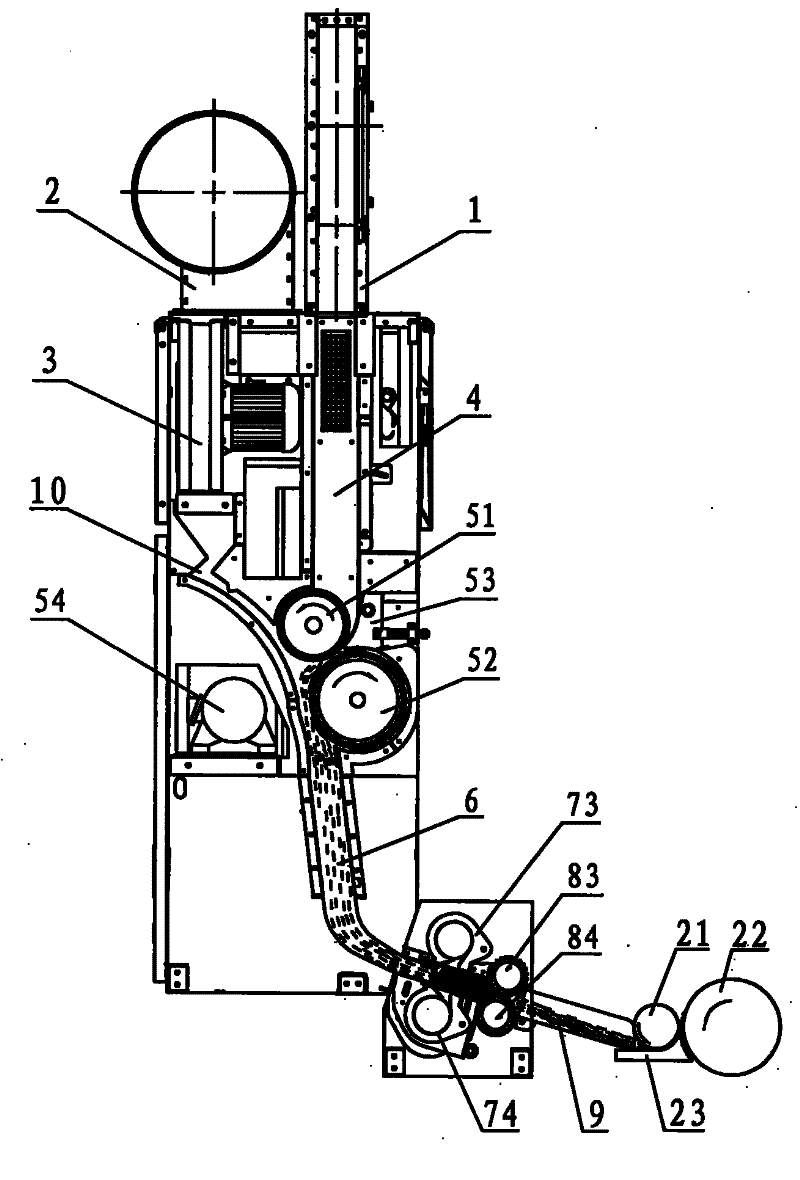

Automatic circular combined hackling machine for hackling and forming strip for flax and combined hackling method thereof

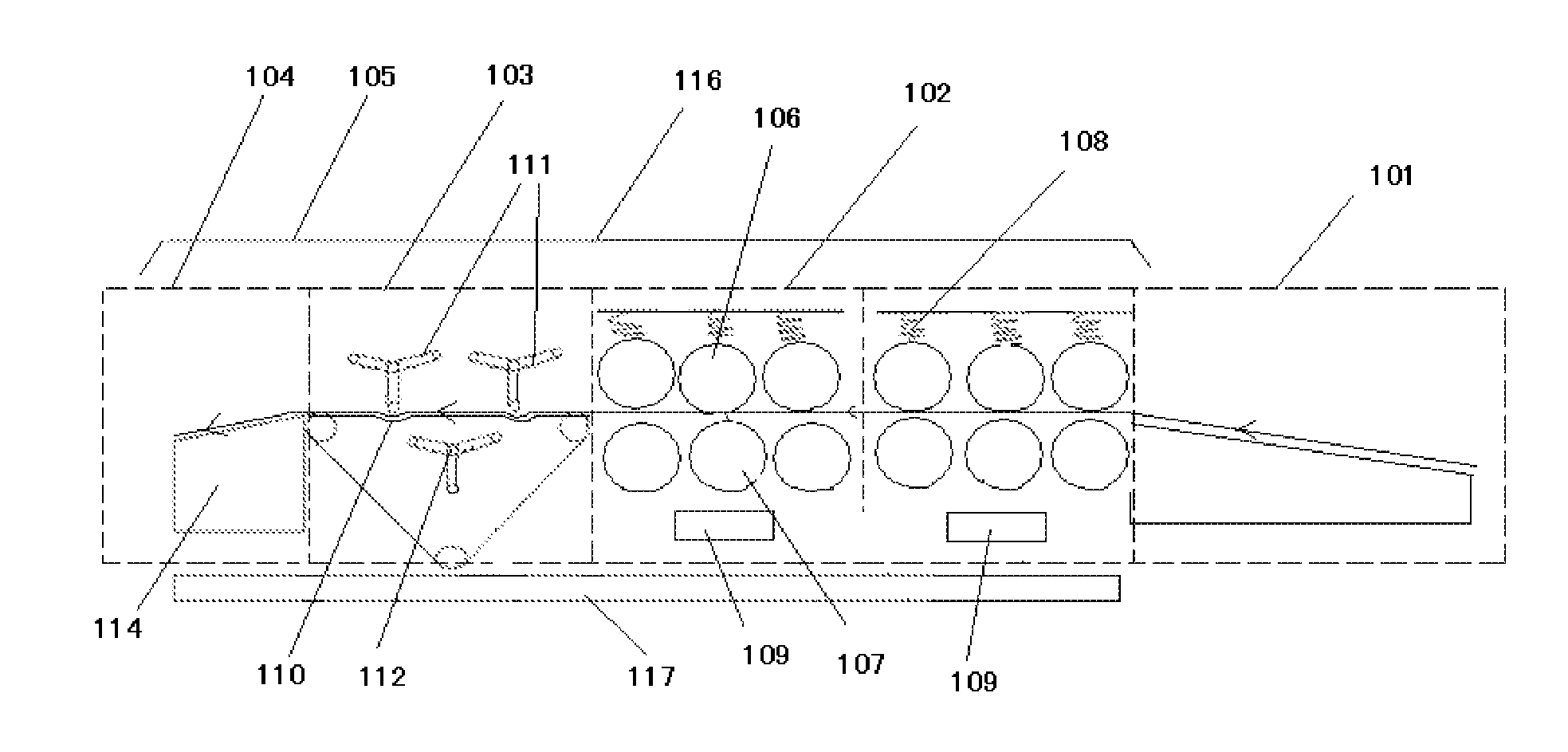

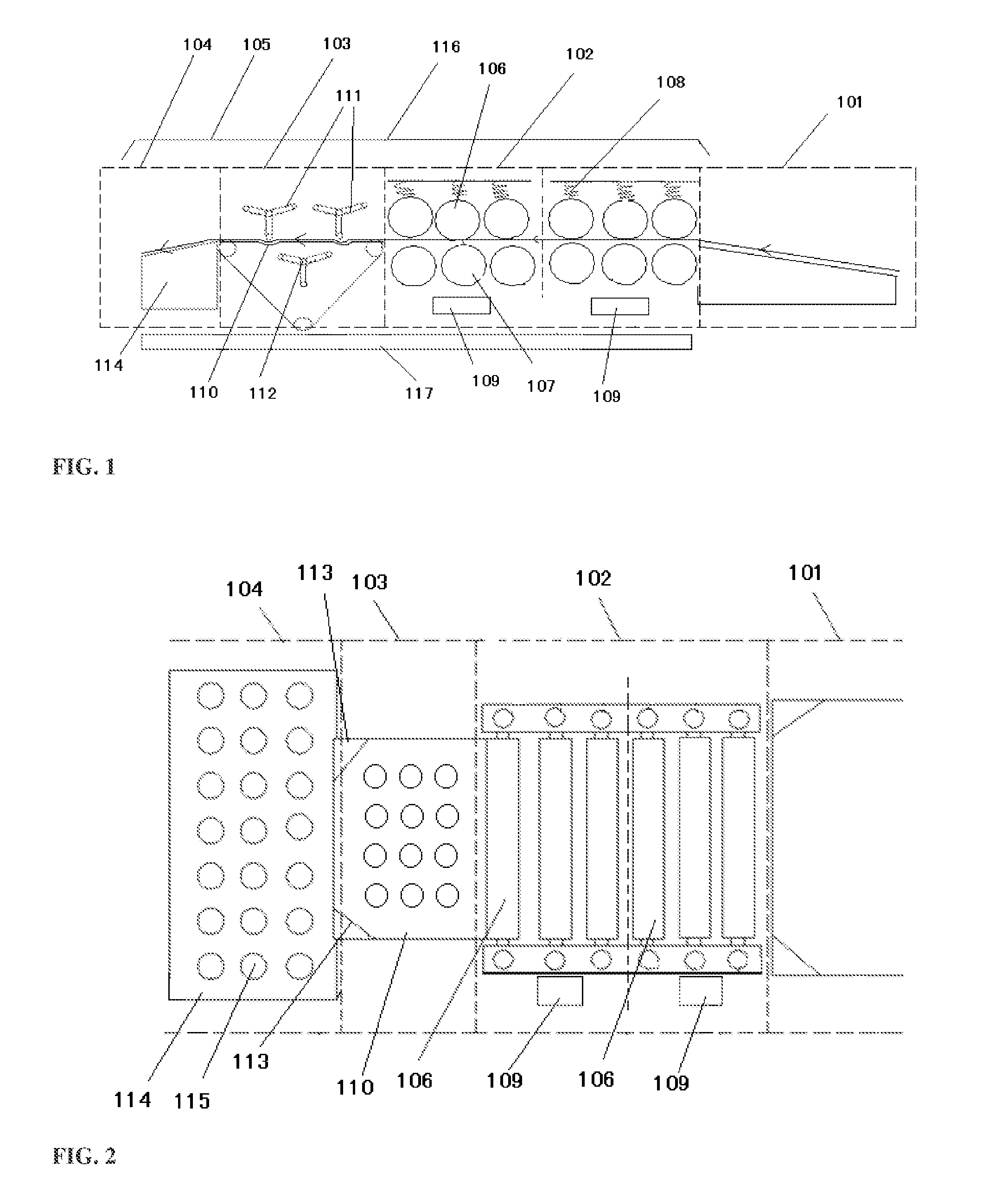

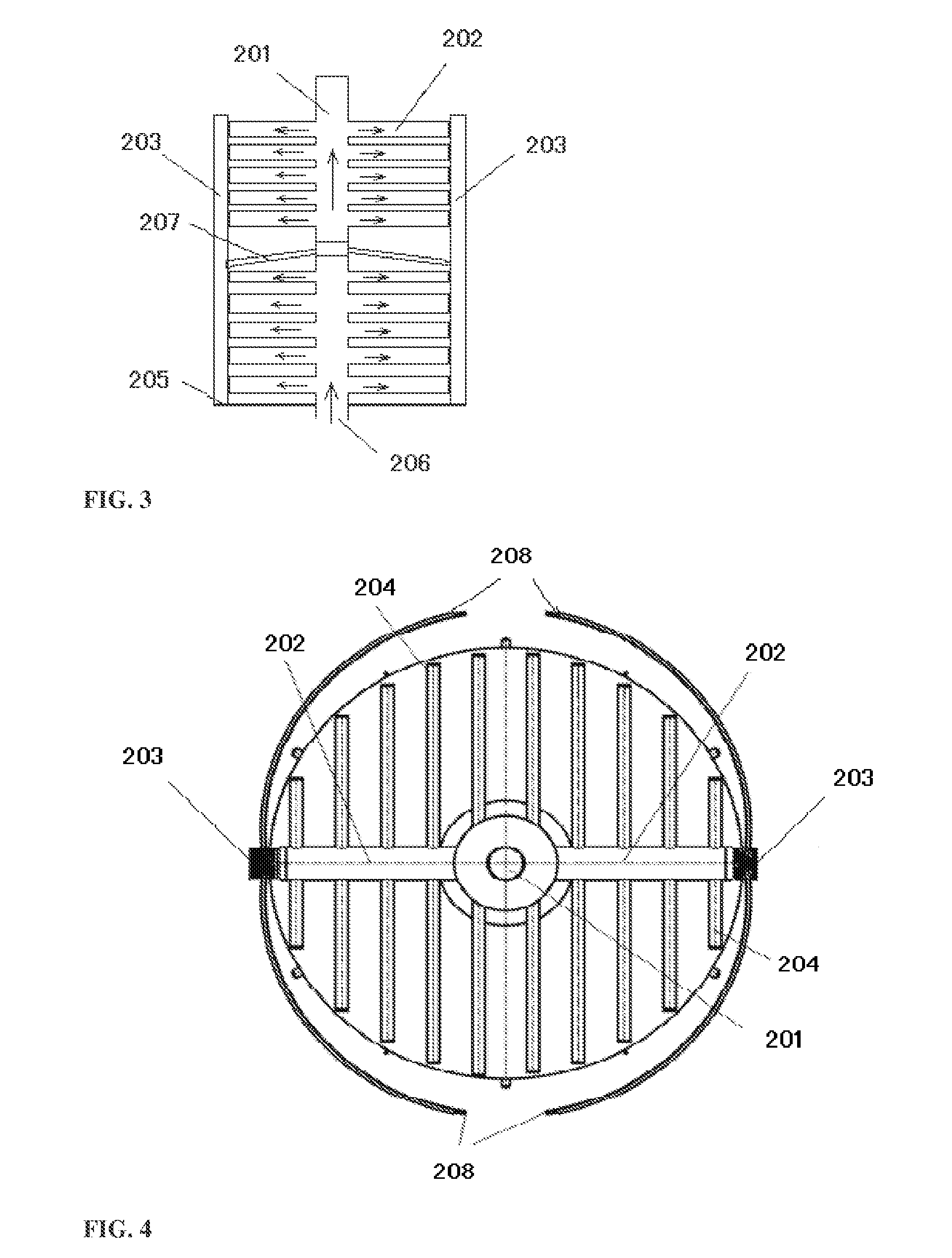

ActiveCN101845689AShort processReduce the number of employeesContinuous processingCarding machinesProduction lineCarding

The invention provides an automatic circular combined hackling machine for hackling and for forming strip for flax and a combined hackling method thereof. The combined hackling machine comprises an annular carding production line, a striping forming production line and a connecting device, wherein the annular carding production line is used for processing scutched flax into carded flax, the strip forming production line is used for making the carded flax into flax strips, and the connecting device is arranged between the annular carding production line and the strip forming production line to connect the annular carding production line and the strip forming production line. An advanced control technology adopted in the invention can combine a flax-hackling step with a strip forming step at present, thereby shortening the process flow, cancelling a non-value-added intermediate link, reducing number of employees greatly, reducing the labor intensity, improving the production efficiency, reducing the production cost and solving problems of large number of employee, high labor intensity, low production efficiency, high production cost and the like of equipment in China flax spinning industry.

Owner:常州金德纺机科技有限公司

Preparation method for light non-glue cotton

ActiveCN103173930AGuarantee and outstanding performanceIncrease productivityContinuous processingNon-woven fabricsCardingGram

The invention relates to a preparation method for light non-glue cotton. The preparation method sequentially comprises the steps of material selection, opening, cotton carding, oven drying and forming and packing. In the step of cotton carding, feed quantity is controlled according to product gram weight requirements. The speed of a hairy transmission chain is 6m / min to 20m / min. The reverse combing frequency is 10 times per minute to 25 times per minute and fiber is formed by combing for once. The combed fiber is directly laid in a net through a passing bridge and enters an oven to be dried. The temperature is 160 DEG C to 180 DEG C and drying time in the oven is 10 seconds to 25 seconds. The non-glue cotton produced through the method can guarantee and highlight excellent performance of the non-glue cotton. Net cotton does not need to be overlapped for a plurality of layers in the process of production, the cotton can be formed by combing for once, production efficiency is improved, cost is saved based on a prior foundation and the produced non-glue cotton is free of quality problems of uneven thickness such as connector gaps and lap head overlap and is high in quality.

Owner:DANYANG YUSHENG TEXTILE NEW MATERIAL

Technique for spinning blended yarns containing ultralow-ratio antistatic conductive polyester fibers

A technique for spinning blended yarns containing ultralow-ratio antistatic conductive polyester fibers belongs to the technical field of textile industry and includes blowing, carding, drawing, rough spinning, fine spinning and spooling procedures. The antistatic conductive polyester fibers are made into card slivers by the blowing, carding and drawing procedures, and each antistatic conductive polyester cotton roll is quantitated into 400-420g / m. In the carding procedure, the card silvers are mixed with pure cotton which is subjected to blowing, blended yarn card slivers containing conductive polyester fibers are spun, the blended yarns containing ultralow-ratio antistatic conductive polyester fibers are produced by double drawing procedures, the rough spinning procedure, the fine spinning procedure and the spooling procedure, and the mass of the antistatic conductive polyester fibers account for 0.5-1.0% of total mass. By using the technique, the problems that the cotton spinning flow is short, semi-finished products are high in quantification, and blended yarns with an ultralow ratio are hard to spin are solved, the blended yarns containing 1% ultralow-ratio antistatic conductive polyester fibers are produced, the requirement of customers on quality is met, and cost is reduced and economic benefit is created for enterprises.

Owner:ZHEJIANG LONGYUAN TEXTILE

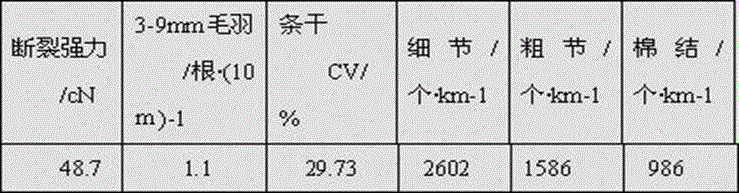

Method for producing blend yarn by ring spinning of kapok cotton

Owner:SHANGHAI RISOO TECH TEXTILE

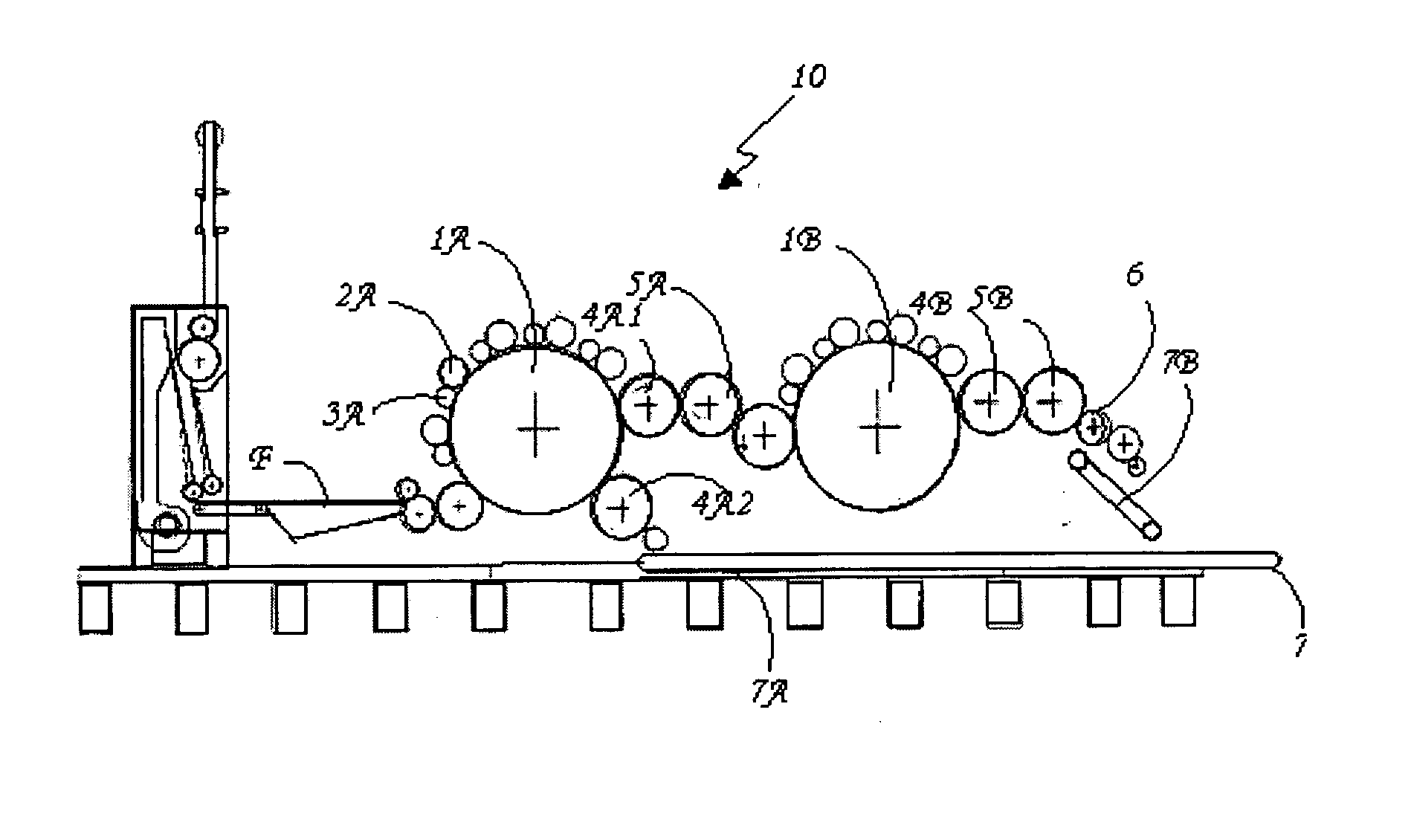

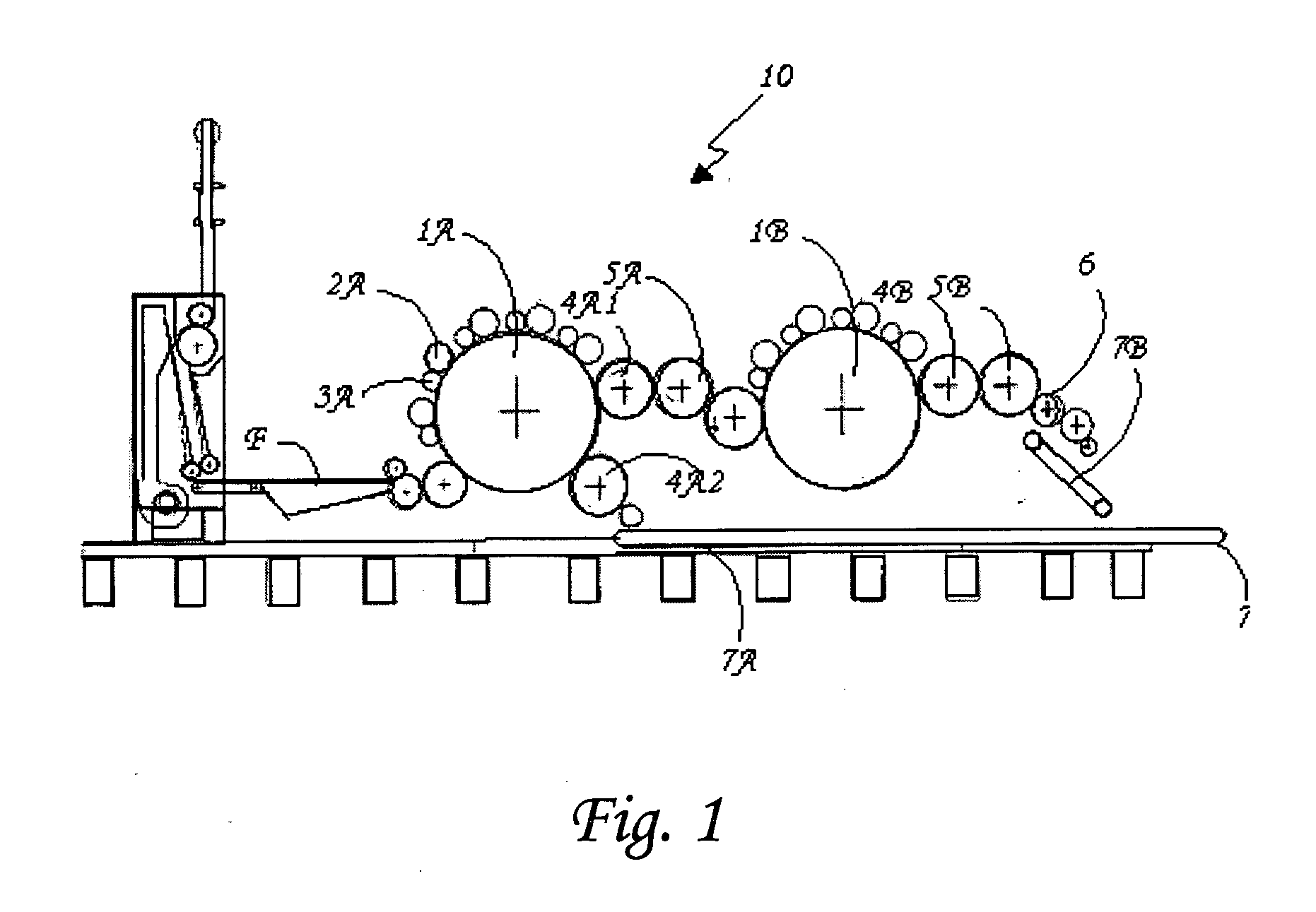

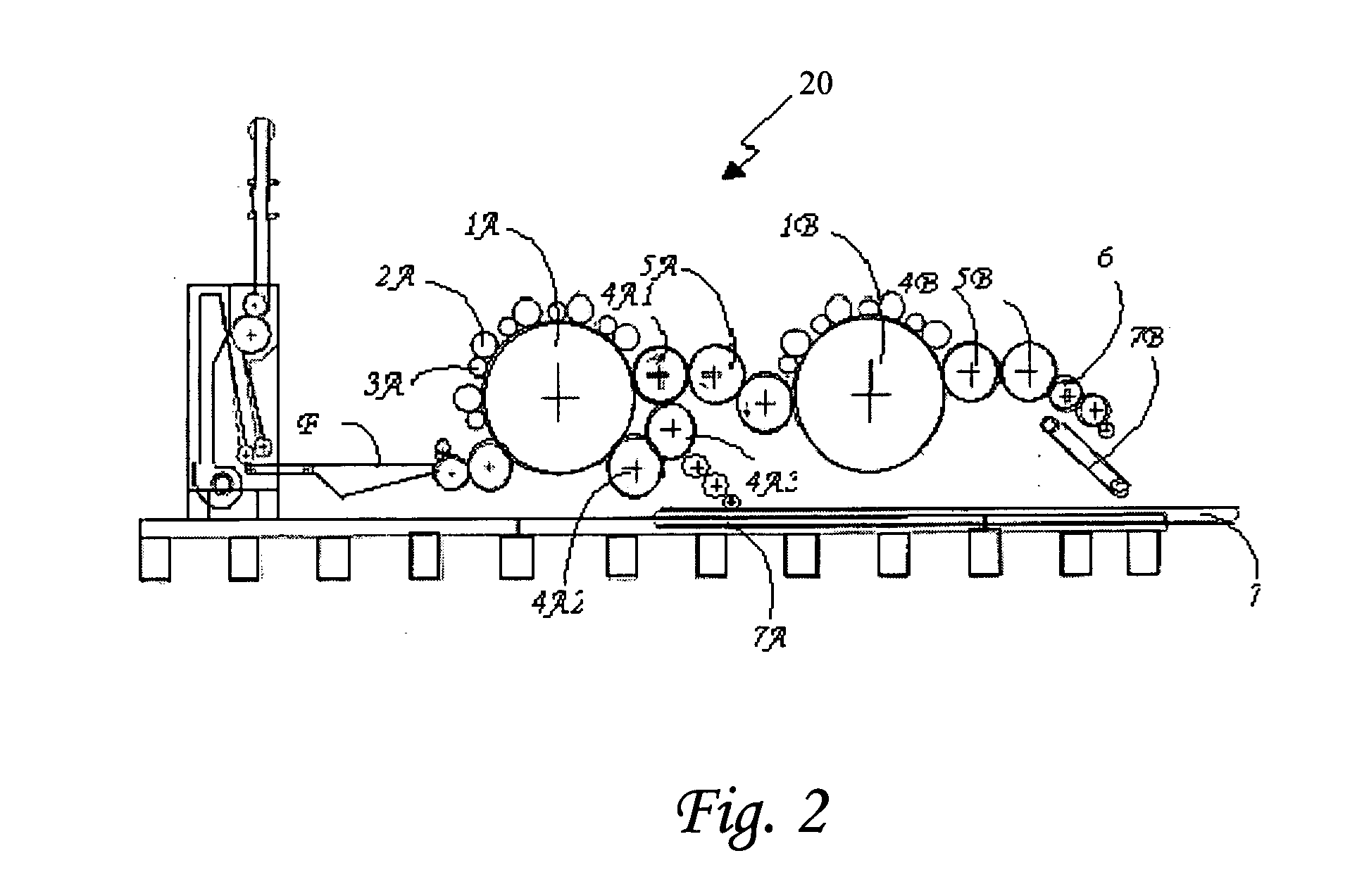

Machine for making a non-woven fibrous web

InactiveUS20060026801A1Maintaining fiber densityImprove productivityContinuous processingCarding machinesProduction rateMechanical engineering

The present invention provides a novel carding machine for preparing a continuous non-woven fibrous web. This machine is comprised of a succession of carding cylinders including a first carding cylinder and subsequently a final carding cylinder; said cylinders are in communication with one or more carding rolls—doffers and / or randomizing rolls arranged in juxtaposition and rotate wherein their axes horizontal; at least one feeding inlet unit in communication with said first carding cylinder; and at least one product outlet in communication with said last carding cylinder, wherein one or more product outlets commenced form said carding succession, previous to said final carding cylinder, The present invention also provides for a cost effective method for maintaining fiber density on the carding cylinder while increasing production rate of the machine through the discharge of a certain amount of fully opened fibers from the cylinder.

Owner:PINTO AKIVA

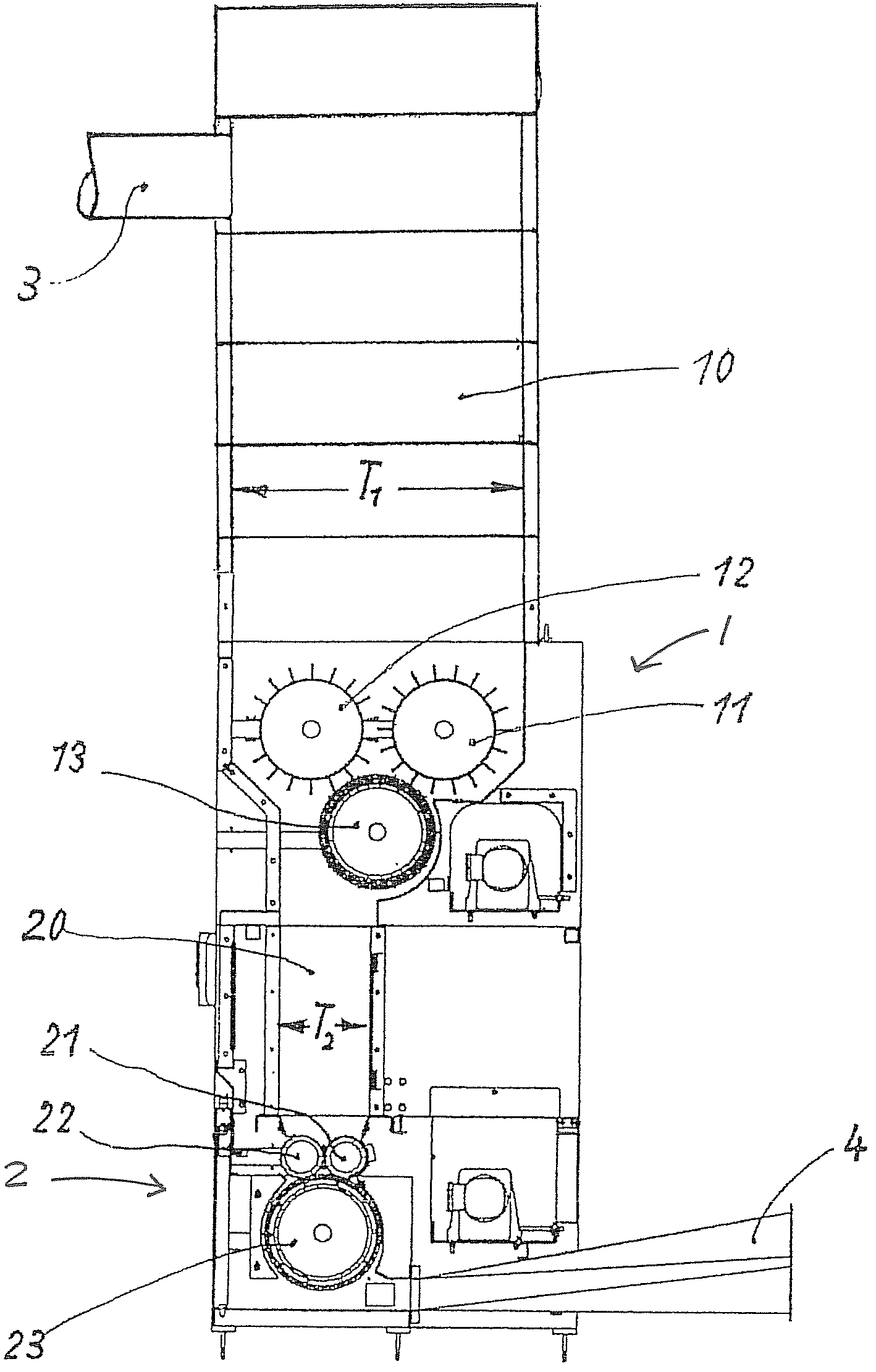

Procedure and system for opening and proportioning synthetic material

ActiveUS7752715B2Avoid Level FluctuationsDensity of fiber uniformFibre cleaning and opening machine combinationsFibre cleaning/opening by toothed membersFiberSynthetic materials

A method and a device for opening and dosing fiber feeds the fiber material via a feeding shaft of an opening device. The fiber material is processed in a first opening step of a dosing opener and is fed without an interconnecting pneumatic means to the feeding shaft of a second opening step. A large-volume feeding shaft has been placed before the first opening device from which the fiber material is delivered to a feeding shaft with a considerably smaller volume that delivers the fiber material to a second opening device. Both opening devices and their associated feeding shafts are placed on top of one other.

Owner:TEMAFA MASCHFAB

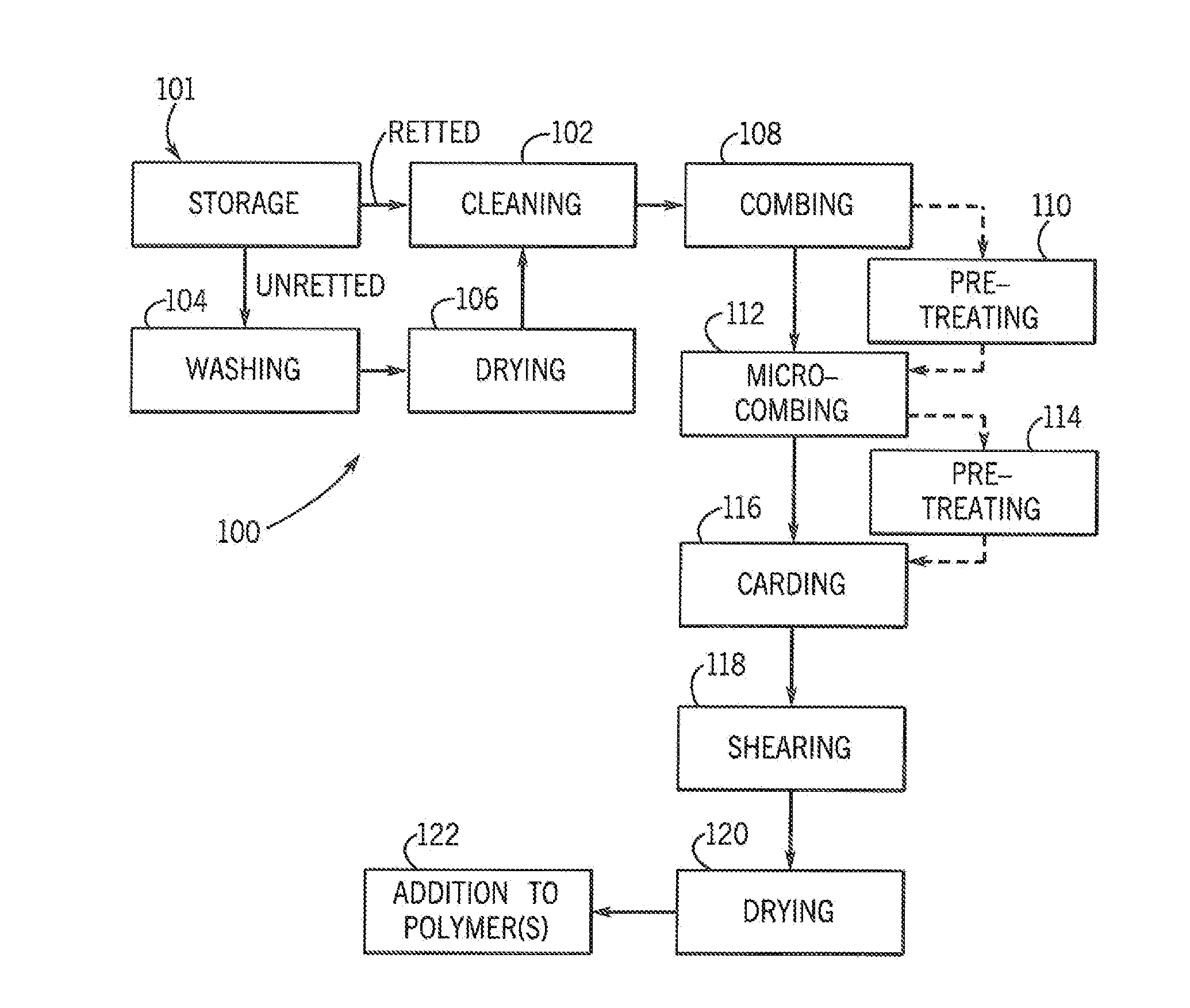

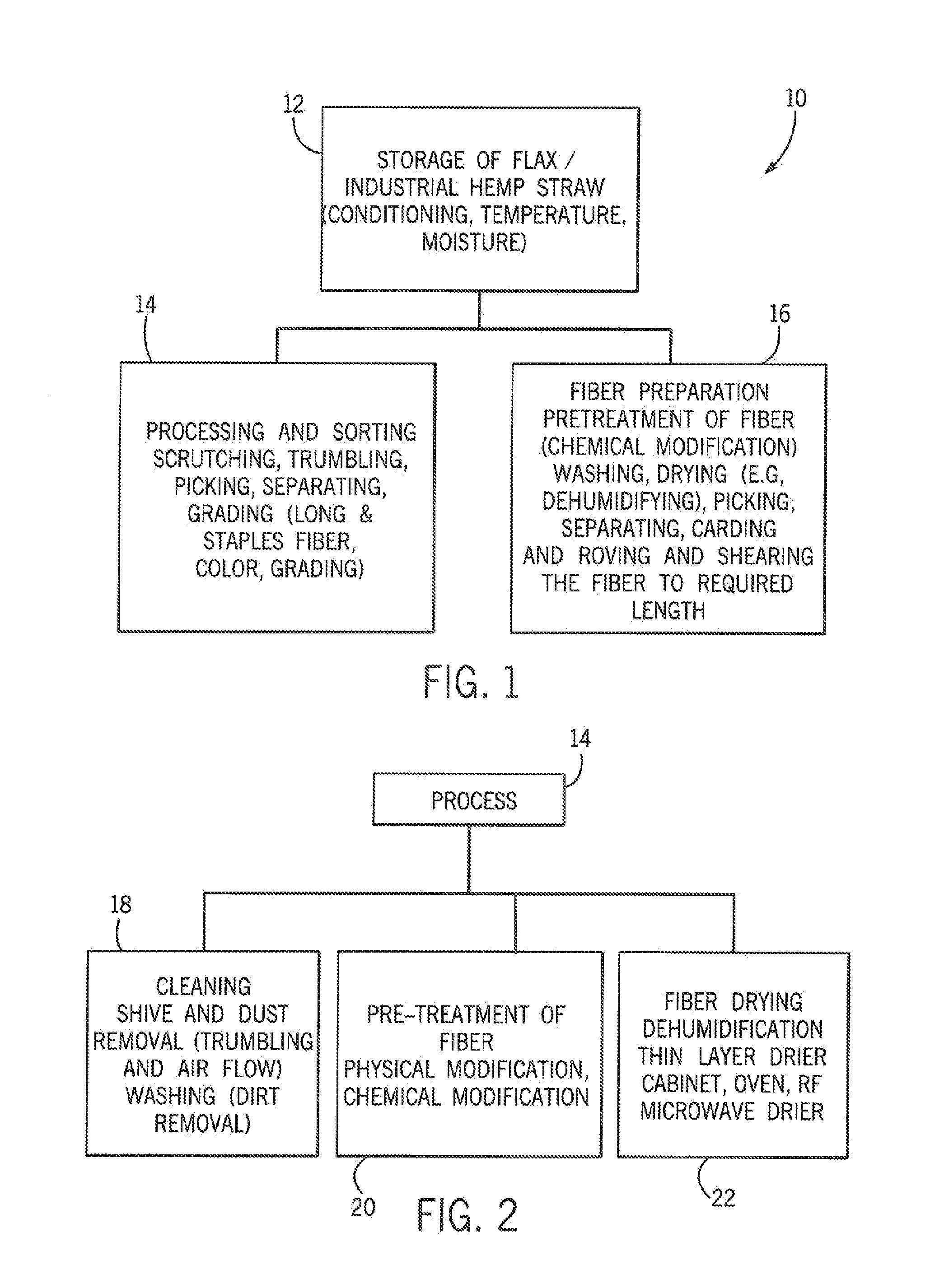

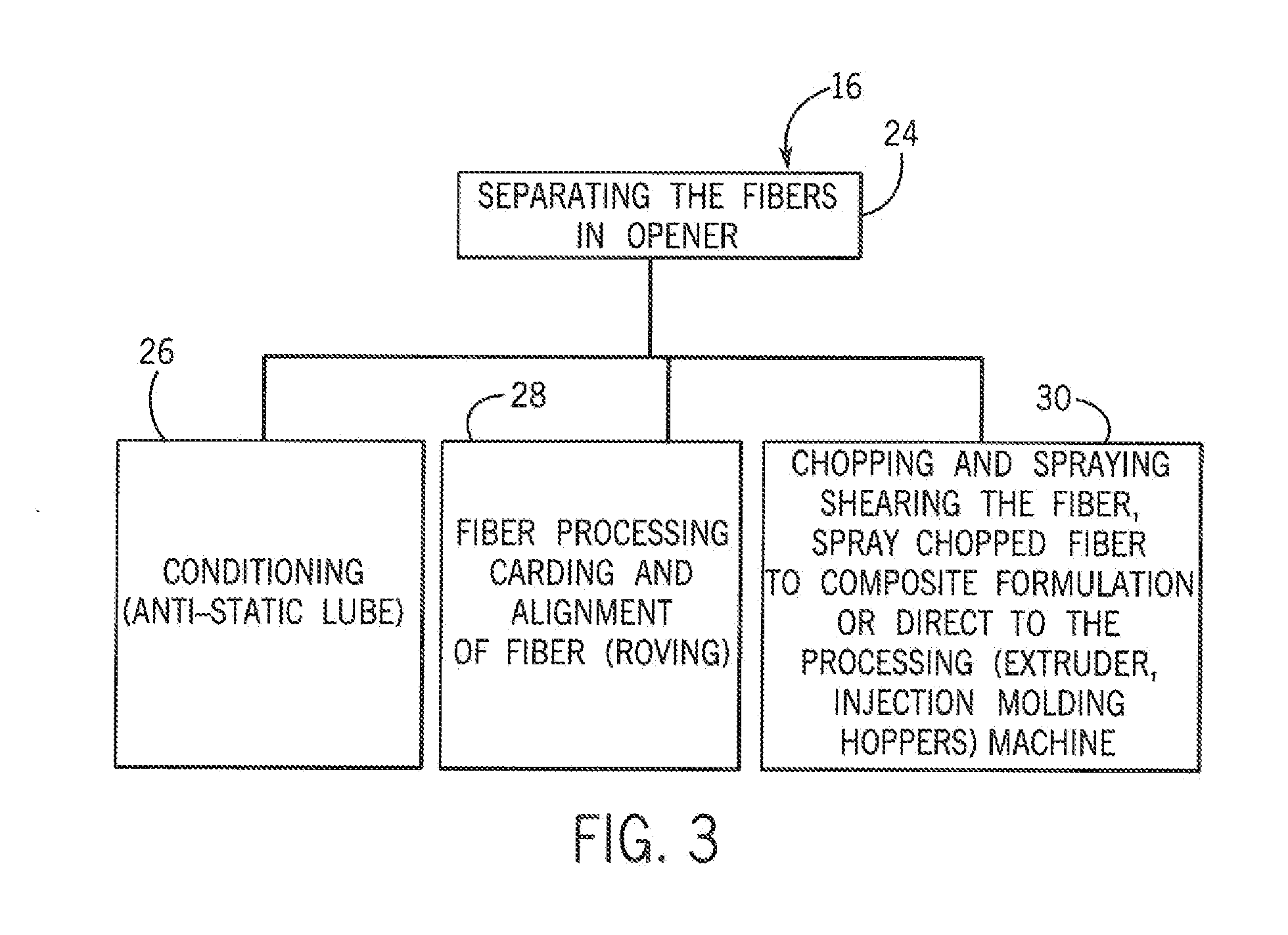

Method To Process Oilseed Flax Fiber For Use In Biocomposite Materials

ActiveUS20150166745A1Retention strengthOptimizationMechanical impurity removalFibre cleaning/opening by air draught arrangementsFlax fiberSISAL

A method and system for the production of fibers for use in biocomposites is provided that includes the ability to use both retted and unretted straw, that keeps the molecular structure of the fibers intact by subjecting the fibers to minimal stress, that maximizes the fiber's aspect ratio, that maximizes the strength of the fibers, and that minimizes time and energy inputs, along with maintaining the fibers in good condition for bonding to the polymer(s) used with the fibers to form the biocomposite material. This consequently increases the functionality of the biocomposites produced (i.e. reinforcement, sound absorption, light weight, heat capacity, etc.), increasing their marketability. Additionally, as the disclosed method does not damage the fibers, oilseed flax straw, as well as all types of fibrous materials (i.e. fiber flax, banana, jute, industrial hemp, sisal, coir) etc., can be processed in bio composite materials.

Owner:CNH IND CANADA

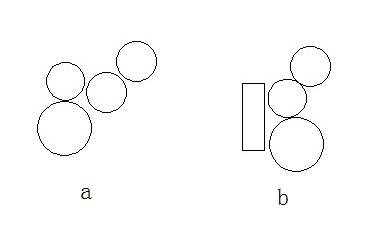

Cashmere carding combination machine

InactiveCN101205644AFibre cleaning and opening machine combinationsContinuous processingAssembly linePulp and paper industry

The invention is a cashmere separating joint machine which relates to a textile mechanical device used for cashmere carding process. The cashmere separating joint machine is composed of feeders, refining machines and carding machines. The invention is characterized in that: the cashmere separating joint machine adopts an sequential arrangement of a feeder, an open refining machine, a refining machine, a feeder, a refining machine, a feeder, a refining machine, a feeder, a refining machine, a carding machine and a carding machine, which are all combined in a way of assembly line. A blanking recovery hopper is arranged under each feeder, a blanking outlet is arranged at a feed port of each feeder, and a delivery device is arranged between the blanking recovery hopper and the blanking outlet. Each carding machine is provided with a blanking collecting hopper which allows the recovered crushed materials to be delivered to a blanking port to be feed into a feeder again. The cashmere separating joint machine is high in separating efficiency, suitable for large amount separation, applicable to various sorts of cashmere, low in damage to cashmere, and high in cashmere utilization rate.

Owner:孙贤功

Method for producing kapok scribbled by ring spinning

InactiveUS20070283676A1Effectively improve slivering of the resultant yarnsEffectively reduces the roller gaugeContinuous processingYarnBreaking strengthPolyester

The present invention discloses a method for producing kapok scribbled by ring spinning, in which the mixed raw materials of kapok fibers and other fibers are subjected to the processes of opening and scutching, carding, drawing, roving, spinning, etc., and a device of guiding cotton sliver is provided after a carding procedure, wherein the said spinning adopts a double-short-apron drafting mode, the said carding is performed twice, and the said drawing is performed twice. The blended yarns produced according to the inventive method have the superior technical indexes in terms of the single yarn breaking tenacity, single yarn elongation at break, etc. which are better than the industrial standard of cotton berber yarn. And the shell fabric produced from the product of the invention has the superior technical indexes in terms of the fabric heat retention, fabric moisture vapour transmission, fabric touching cold-warm feeling, fabric bulking intensity, fabric compressive elastic recovery ratio and fabric soft draping property, etc. which are better than those of the similar products such as the pure cotton and polyester cotton, etc.

Owner:SHANGHAI RISOO TECH TEXTILE

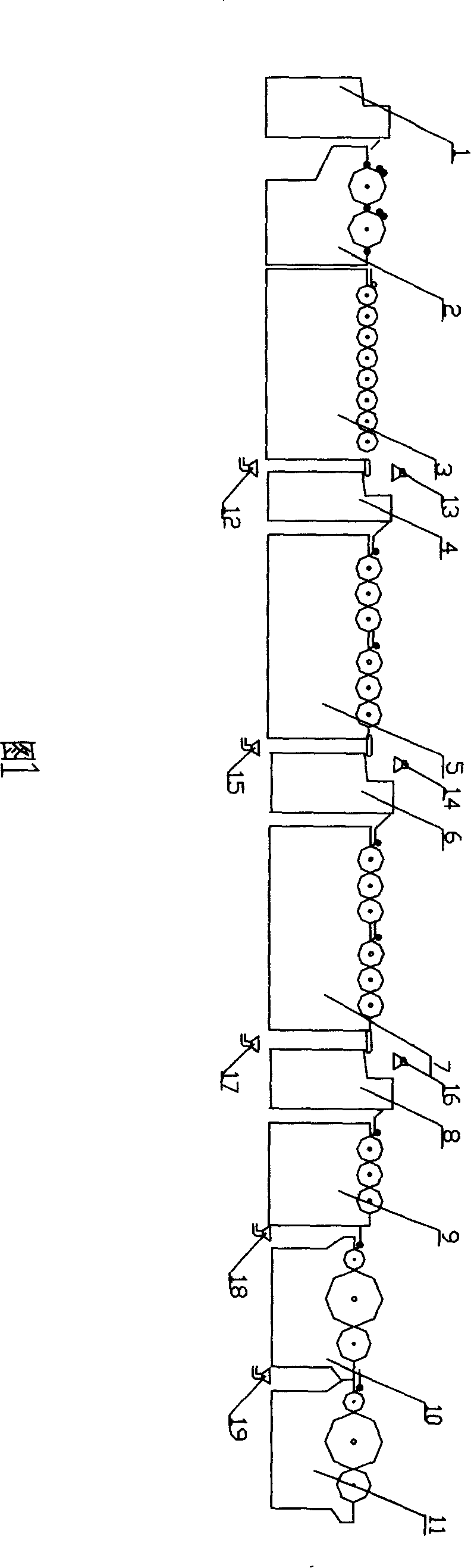

Superfine wool fiber spunyarn, and its spinning method

The invention relates to the super thin wool fiber thin yarn and the method of producing the yarn, the average diameter of the said super thin wool fiber is 11-12 micron, the number of the single yarn branch of the said super thin wool fiber thin yarn is 170-180 branch. According to the spinning process, the Gallo NSC newest producing line is choose to machine in the former yarn producing process, the low car speed and the light fix quantify are adopted, the to-and-fro extracting combing process is added; the coming strip of the roving keeps the 0.105garm / meter under highly the common roving machine ration. After the thin yarn and the joint stock double picking up of the back spinning process, there the together braising process. So, the thin yarn of the super thin wool fiber can be produced, the super thin wool fiber can used in the top grade cloth and other exactitude industry, the texture, the taste, the useful and the value can be improved more.

Owner:HENGYUANXIANG GRP

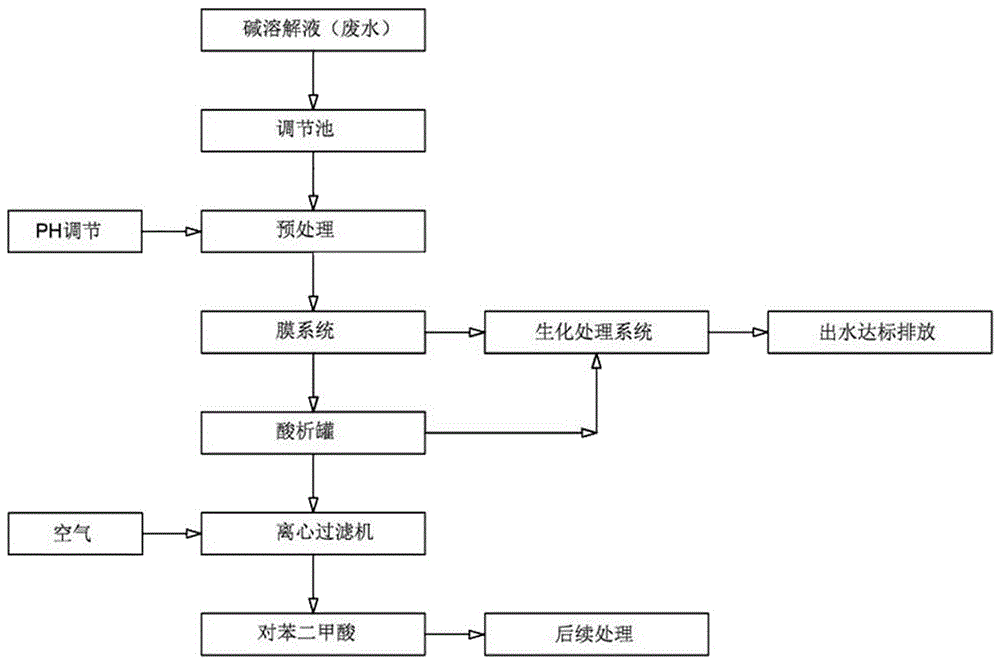

Soluble textile recovery, regeneration and recycle technology

InactiveCN106065085AGuaranteed spinnabilityGuaranteed rendering effectProductsReagentsSolubilityTextile fiber

The invention discloses a soluble textile recovery, regeneration and recycle technology. According to the technology, polyester-type solubility-controllable soluble fibers are woven through a conventional weaving method, the obtained fabric is dyed and finished and then is subjected to tailoring to obtain ready-made clothes or is subjected to injection molding processing to obtain a soluble cloth accessory, the ready-made clothes or the soluble cloth accessory is dissolved under a certain condition, the solution is filtered, the dissolved matters are recovered so that high purity terephthalic acid and glycol are obtained, the terephthalic acid and glycol are used for soluble polyester polymerization so that soluble polyester slices are obtained, the soluble polyester slices can be re-spun to form soluble fibers for recycle, a loose undissolved textile is disinfected, stripped or re-dyed to form a loose fiber polymer with good quality, the loose fiber polymer is dried and optionally, the dried fiber polymer is subjected to gentle carding so that high-quality textile fibers are obtained for recycle.

Owner:余燕平 +3

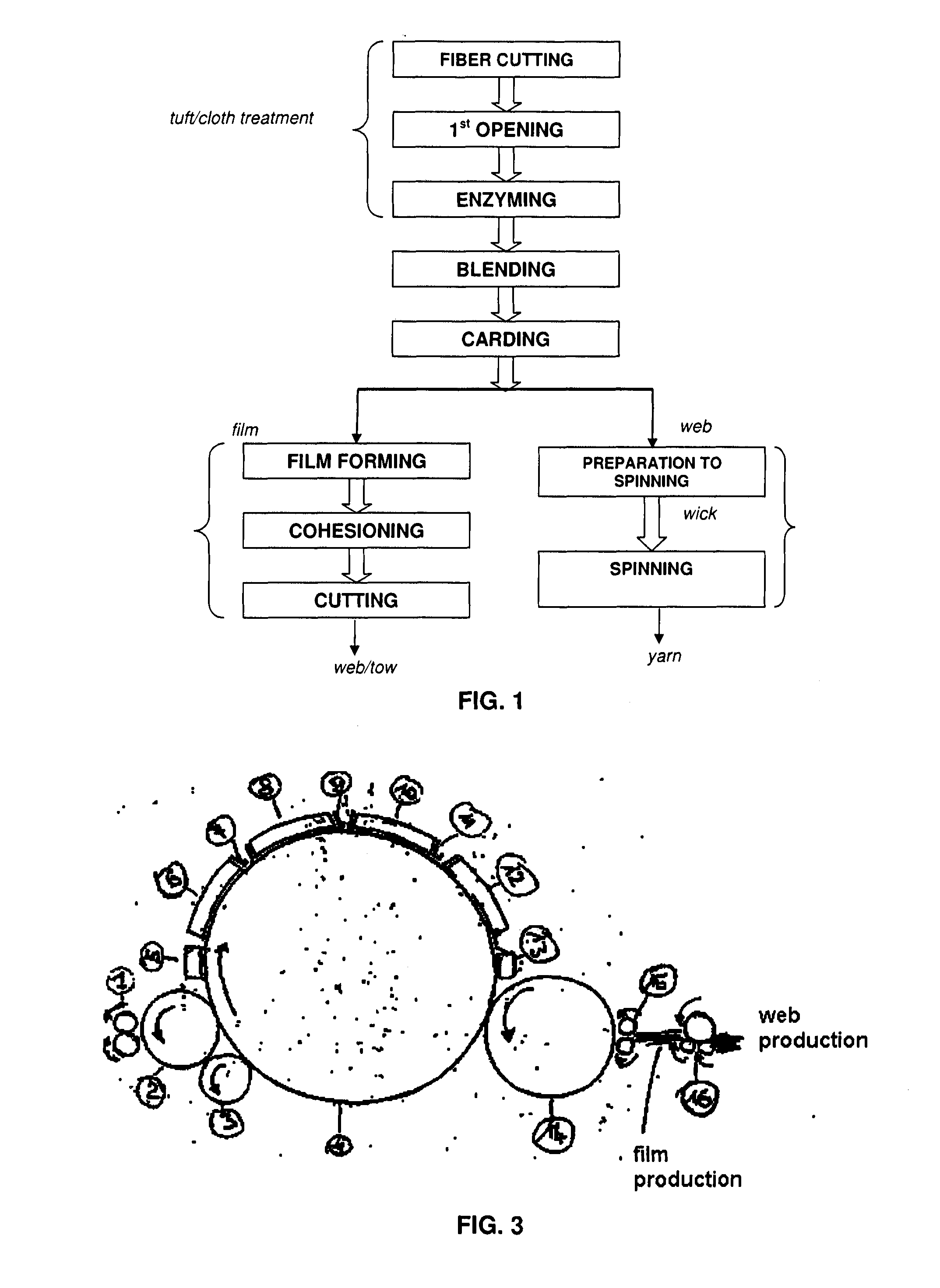

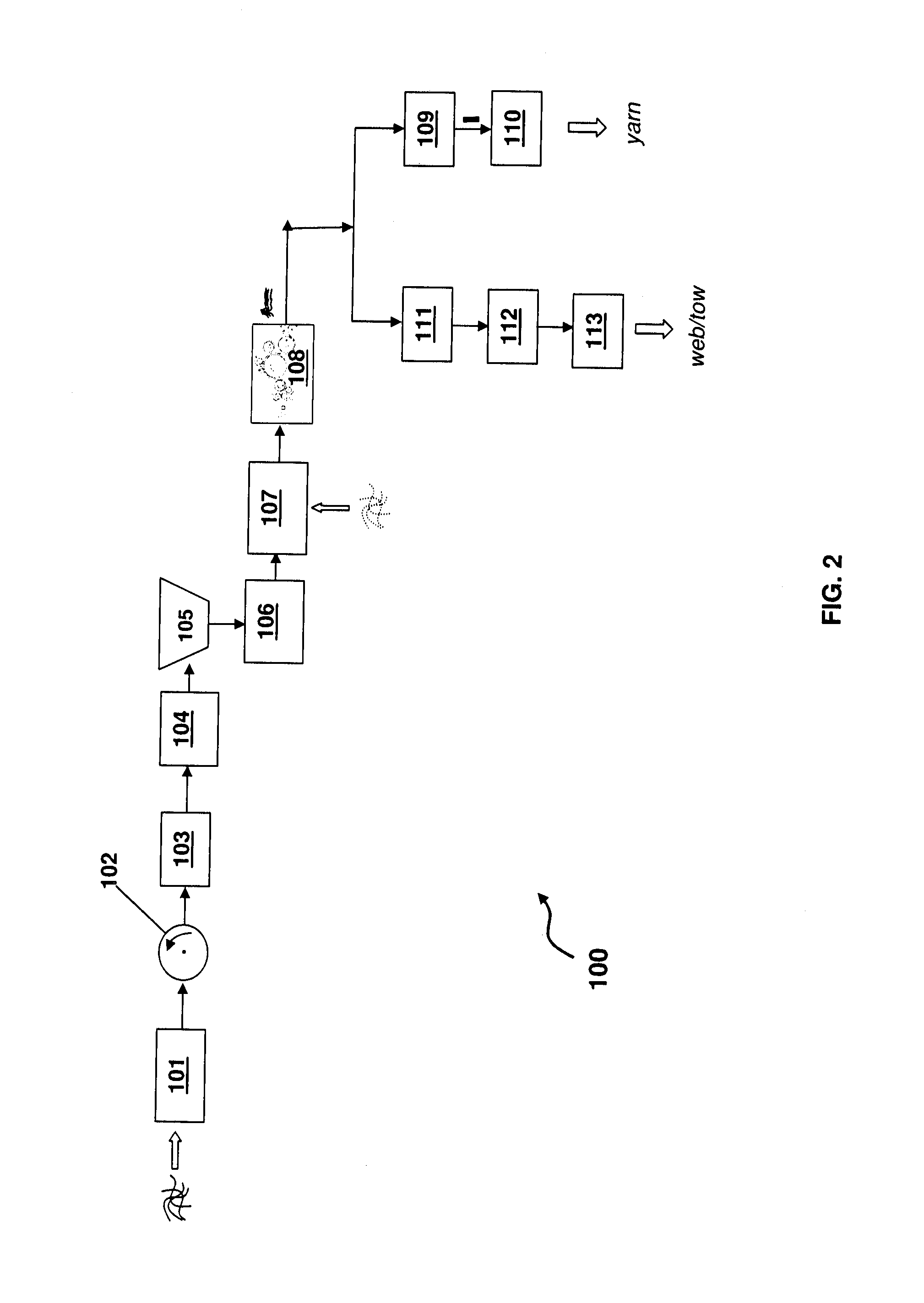

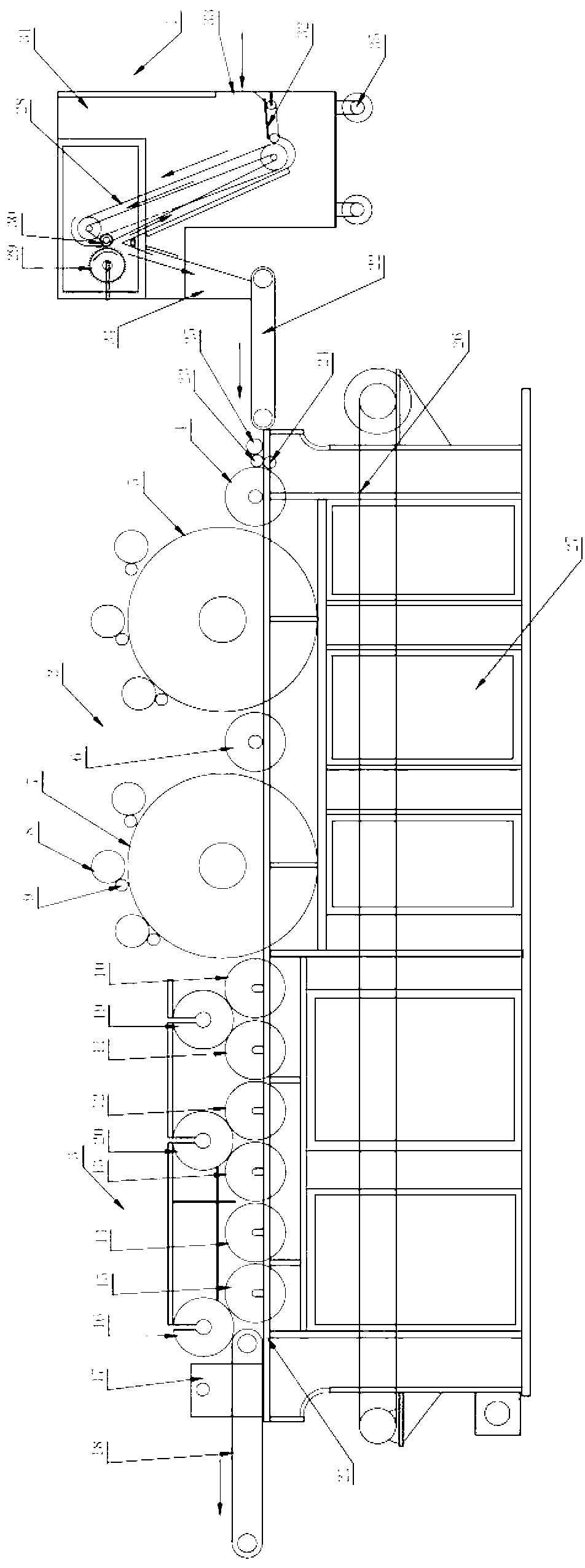

Method for the manufacturing of yarns from recycled carbon fibers

InactiveUS20140245577A1Good molding effectReduce wrinklesContinuous processingCarding machinesYarnCarbon fibers

A method for the manufacturing of textile products in the form of a yarn, web or tow starting from recycled carbon fibers in the form of tuft, cloth or the like, comprising the steps of: • (a) discontinuous cutting of the fibers to obtain dimensionally homogeneous fibers of selected length; • (b) enzyming of the fibers cut in step (a), wherein the latter are additioned with one or more substances; • (c) blending of the fibers treated in step (b) with auxiliary fibers; • (d) double carding of the blended fibers obtained in said step (c); and • (e) feeding a pair of wicks to a spinning machine.

Owner:ENEA AGENZIA NAT PER LE NUOVE TECH LENERGIA E LO SVILUPPO ECONOMICO SOSTENIBILE +1

Carding equipment of collagenous fibers

The invention discloses carding equipment of collagenous fibers. The carding equipment of the collagenous fibers is formed by a fur-feeding machine and a rough-fining integrated machine which are connected in series, wherein a rough carding portion of the integrated machine comprises an opening licker, a first large cylinder, a first transferring roller and a second large cylinder which are closely arranged in sequence. A working roller and a stripper roller are matched with the first large cylinder and the second large cylinder and are respectively arranged at the upper portion of the first large cylinder and the second large cylinder. A fining carding portion of the integrated machine comprises a first coarse-rejecting roller, a second transferring roller, a second coarse-rejecting roller, a third transferring roller, a third coarse-rejecting roller, a fourth transferring roller, a doffer, a chopper and a discharging curtain which are closely arranged in sequence. A cohesion roller which is tangent with the outer circles of the first coarse-rejecting roller and the second transferring roller is arranged on the upper portion of first coarse-rejecting roller and the second transferring roller, and a cohesion roller which is tangent with the outer circles of the the second coarse-rejecting roller and the third transferring roller is arranged on the upper portion of the second coarse-rejecting roller and the third transferring roller. The carding equipment of the collagenous fibers has the advantages of organically combining rough carding equipment and fining carding equipment into a whole, improving work efficiency, reducing waste of raw materials and equipment investment, and improving degree of automation.

Owner:JIANGYIN JUNHUA TEXTILE TECH

Duplex cashmere carding machine

InactiveCN104404660AIncrease profitReduce pollutionContinuous processingCarding machinesForeign matterElectric machinery

The invention discloses a duplex cashmere carding machine, which comprises a first cashmere carding machine, a second cashmere carding machine, a driving system, a dust removal system and an induced air main pipeline, wherein the head parts and the tail parts of the first cashmere carding machine and the second cashmere carding machine are sequentially connected, the first cashmere carding machine and the second cashmere carding machine respectively adopt a cover plate type cashmere carding machine, and rolling pipes are arranged at the back sides of a first cylinder and a first cashmere outlet pipe of the first cashmere carding machine. The duplex cashmere carding machine is characterized in that the two cover plate type cashmere carding machines are jointly used, and the rolling pipes are arranged at the back sides of the first cylinder and the first cashmere outlet pipe of the first cashmere carding machine, so long wools are conveyed to a first wool conveying curtain under the action of air flow, and the working efficiency is improved; by improving the driving system, a wool feeding machine and the two cashmere carding machines are driven by three motors to operate, the energy consumption is decreased, and the production efficiency is improved; by additionally arranging the dust removal system, the carded short wools, foreign matters and floating matters are uniformly recovered, the pollution by floating dust is reduced, the short wools can be recycled and reutilized, and the utilization rate of the wools is improved.

Owner:河北利意蒙羊绒制品有限公司

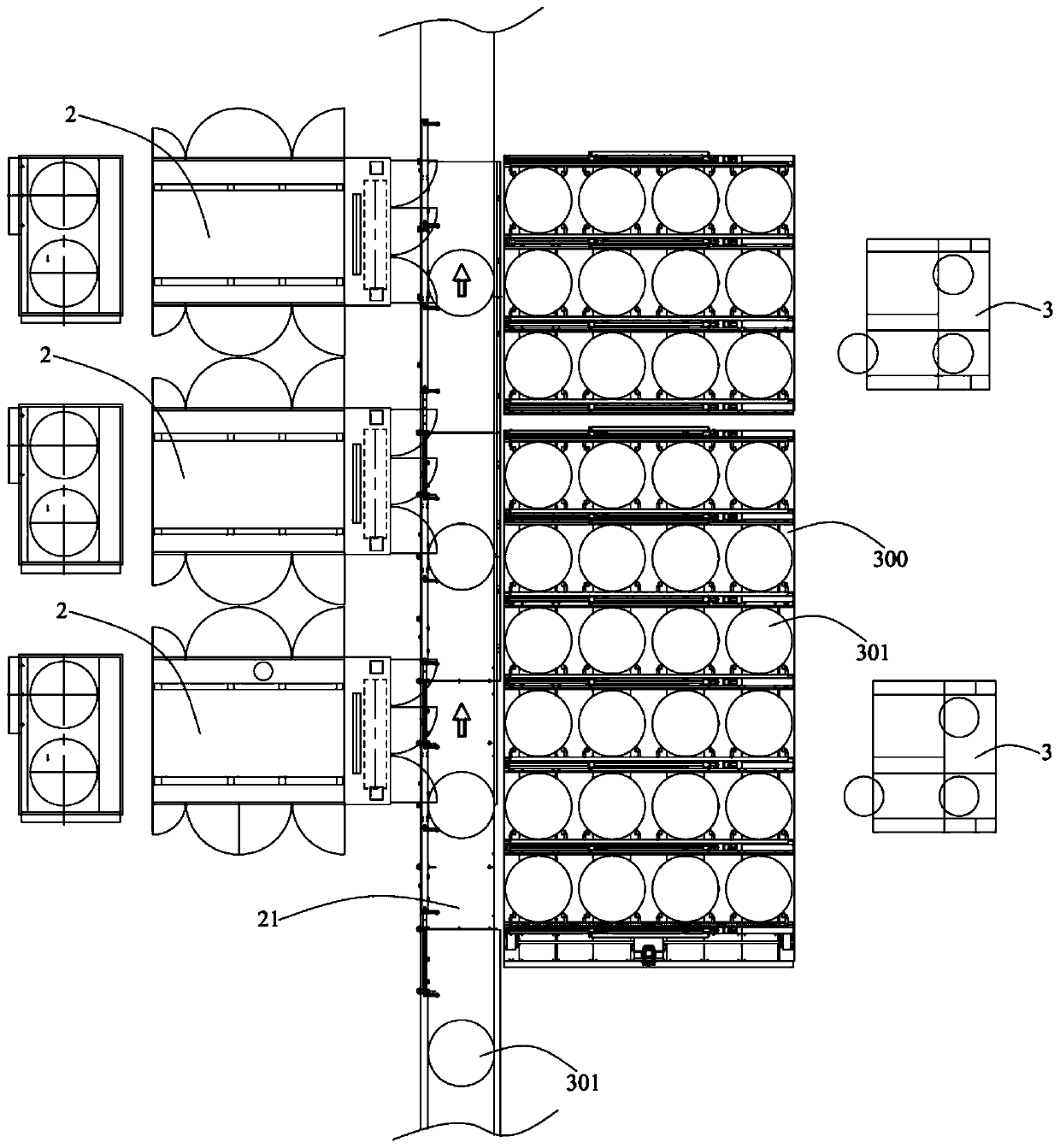

Automatic-feeding wool slivering machine complete equipment

ActiveCN105088428ASmooth feedingRealize continuous productionFibre mixingContinuous processingEngineeringMechanical engineering

The invention discloses automatic-feeding wool slivering machine complete equipment which comprises a wool balling mechanism, a wool mixing mechanism, a feeding mechanism, a carding mechanism, a stripping mechanism and a coiling mechanism. A first condenser is arranged on an inlet of the wool mixing mechanism. A first wool conveying pipeline is arranged between the wool balling mechanism and the first condenser. A wool mixing mechanism comprises a wool mixing box. A wool conveying curtain, a brad nail curtain, a wool pressing curtain, a wool homogenizing roller and a stripper beater are arranged inside the wool mixing box. The first condenser is located above the front portion of the wool conveying curtain. The brad nail curtain is located behind the wool conveying curtain. The wool pressing curtain is located in front of the brad nail curtain and above the rear portion of the wool conveying curtain. The wool homogenizing roller is located in front of the upper portion of the brad nail curtain. The stripper beater is located behind the upper portion of the brad nail curtain. A fan is connected to the rear portion of the wool mixing box. A second wool conveying pipeline is connected to the fan. A second condenser is arranged in an inlet of the feeding mechanism. The other end of the second wool conveying pipeline is connected with the condenser. The automatic-feeding wool slivering machine complete equipment is beneficial to achieving the continuous production process for wool slivering.

Owner:青岛东佳纺机(集团)有限公司

Degumming process of apocynum venetum fiber

The invention discloses a degumming process of an apocynum venetum fiber, which belongs to the field of spinning. The apocynum venetum fiber is prepared by boiling wild apocynum venetum straw with water, degumming, beating, dehydrating, drying, nourishing, loosening, carding and packaging. By adopting the process, the apocynum venetum fiber is good in degumming effect, the apocynum venetum fiber yield is high, 1 ton of apocynum venetum fiber can be prepared from 2-2.5 tons of apocynum venetum peel, the apocynum venetum fiber can be blended with cotton to produce high count yarn more than 40S, a fabric can be made into various home textiles, paints, socks, quilts, summer sleeping mats, pillows and the like, and has the unique functions of natural bacteriostasis and human body beneficial far infrared ray emission.

Owner:新疆优麻良品生物科技有限公司

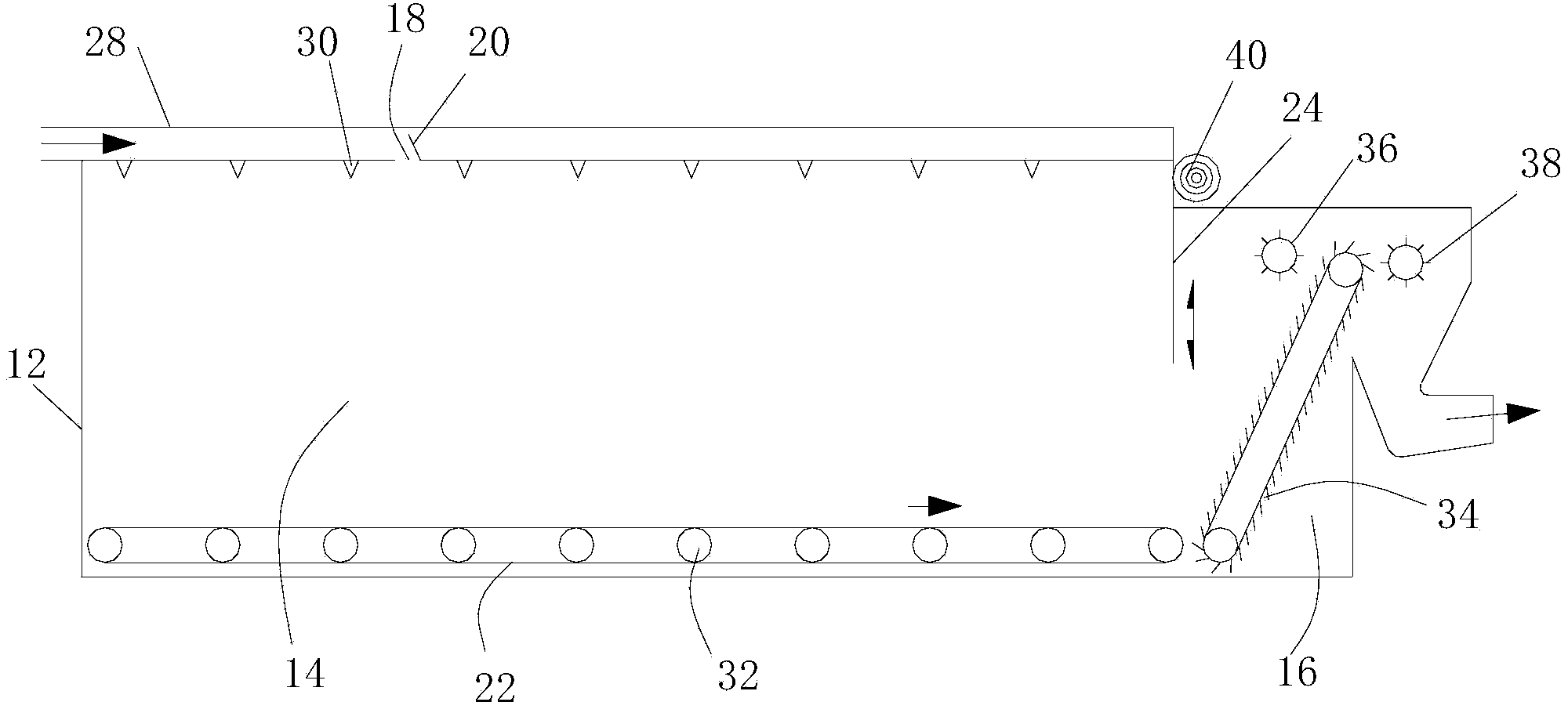

Fiber low-damage output device for continuous blowing-carding feeding hopper

InactiveCN101748517AImprove cohesionAvoid damageContinuous processingCarding machinesFiberEngineering

The invention relates to a fiber low-damage output device for a continuous blowing-carding feeding hopper. A dust absorption part and an output roller part are arranged between an L-shaped lower conveying channel and a dripping plate; an upper air return box and a lower air return box in the dust absorption part are vertically and symmetrically distributed along the bottom surface of the dripping plate; an upper output roller and a lower output roller in the output roller part have identical radial dimension and are vertically and symmetrically distributed along the bottom surface of the dripping plate; the dripping plate is arranged at an outlet of the output roller part; an included angle between the dripping plate and a horizontal plane is 10-25 degrees; and the lower conveying channel is connected with the output roller part through a circular arc curve. Because the conveying channel is changed from the prior vertical channel into the L-shaped channel with the circular arc curve, the prior output state of fibers can be changed; and the length direction of the output fibers is vertical to a feeding roller axis of a carding machine, so that the cohesive force of the fibers among rock cotton is improved, and the faultage is reduced, and the damage to the fibers is greatly reduced.

Owner:SAURER CHANGZHOU TEXTILE MACHINERY CO LTD

Sheared wool weaving method

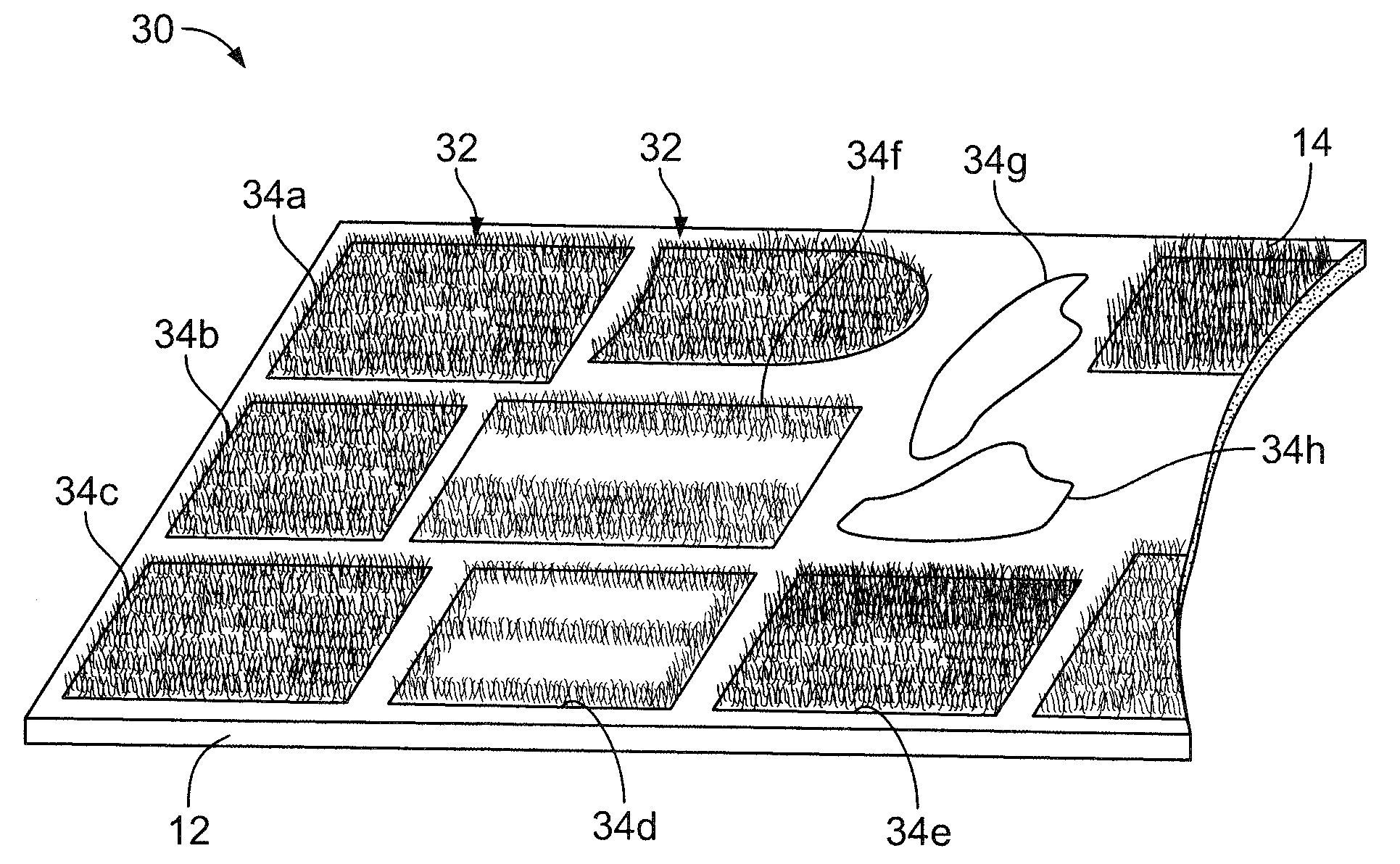

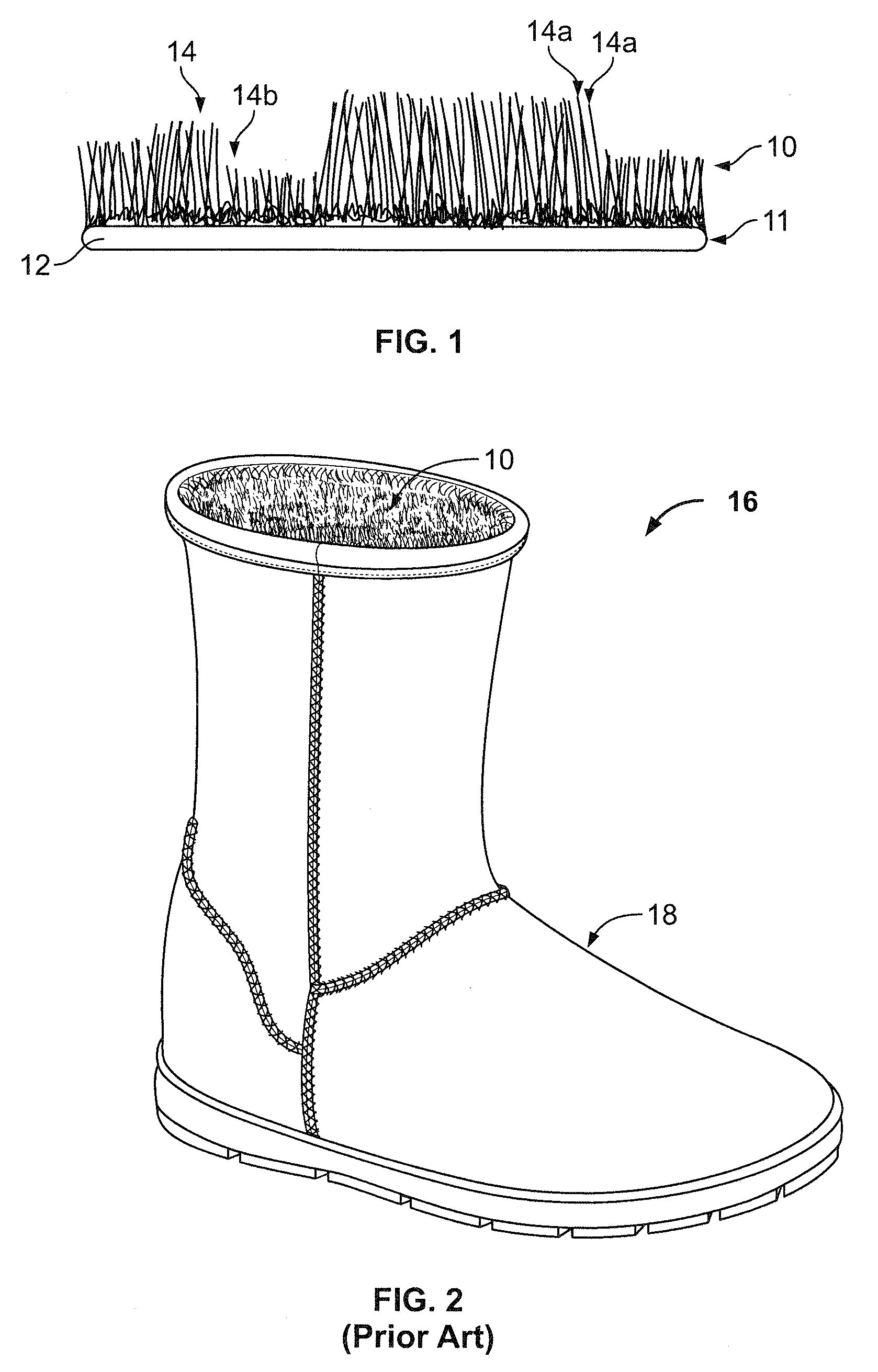

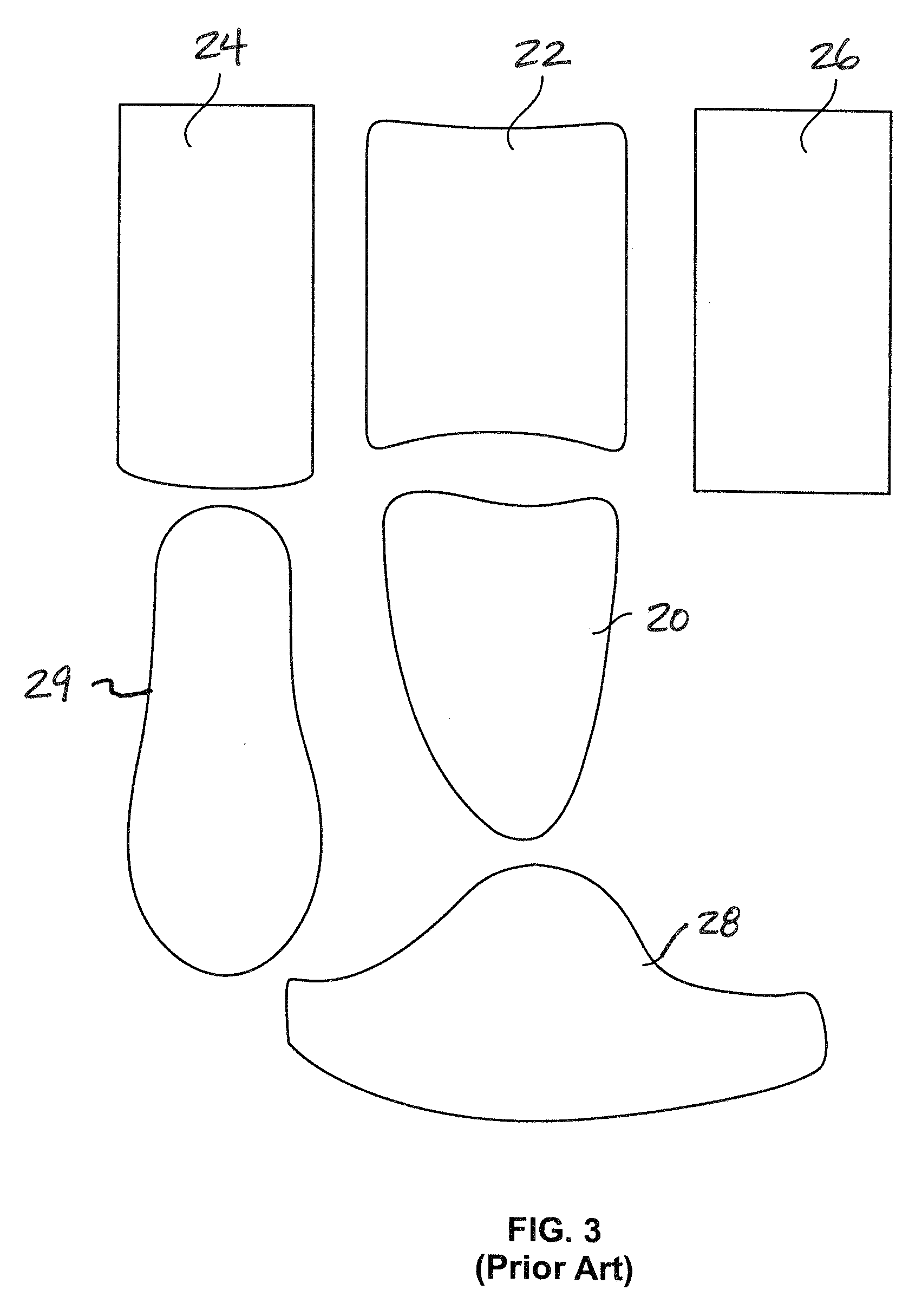

ActiveUS20130261785A1Improve production efficiencyReduce material wastePattern makingContinuous processingEngineeringMechanical engineering

A method of manufacturing an article of footwear includes providing a knitting machine having a processor programmed to cause the knitting machine to knit a wool pile fabric having a plurality of footwear components and simultaneously knitting wool fibers and a scrim to form the wool pile fabric including the footwear components.

Owner:DECKERS OUTDOOR CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com