Patents

Literature

221results about "Fibre cleaning/opening by air draught arrangements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

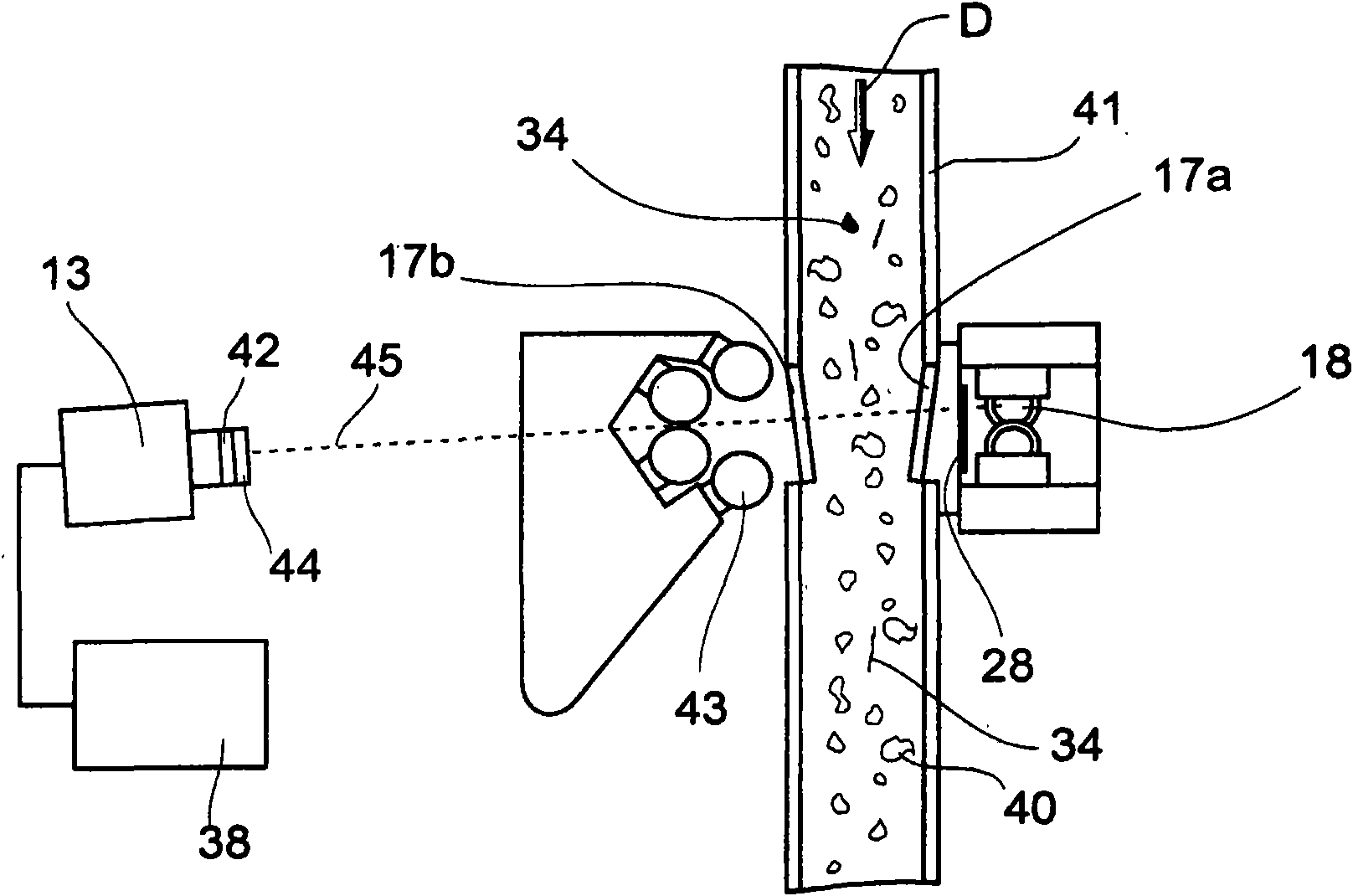

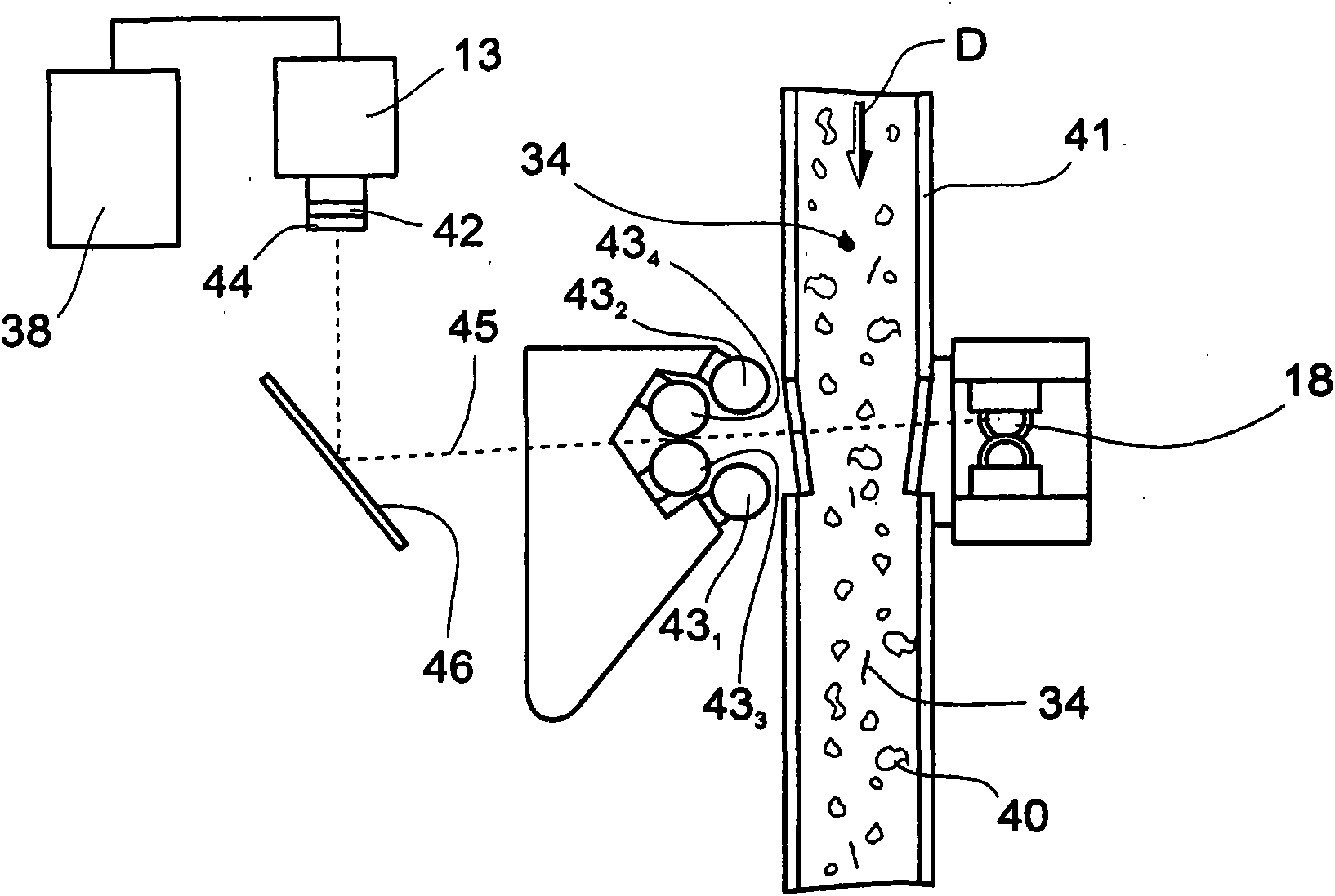

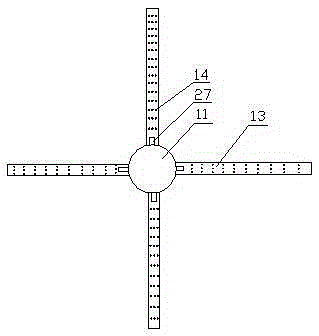

Method and device for online detection of foreign fiber in cotton

InactiveCN101629336AStrong discriminationLow costFibre cleaning/opening by air draught arrangementsFibre cleaning and opening machine combinationsFiberFrequency conversion

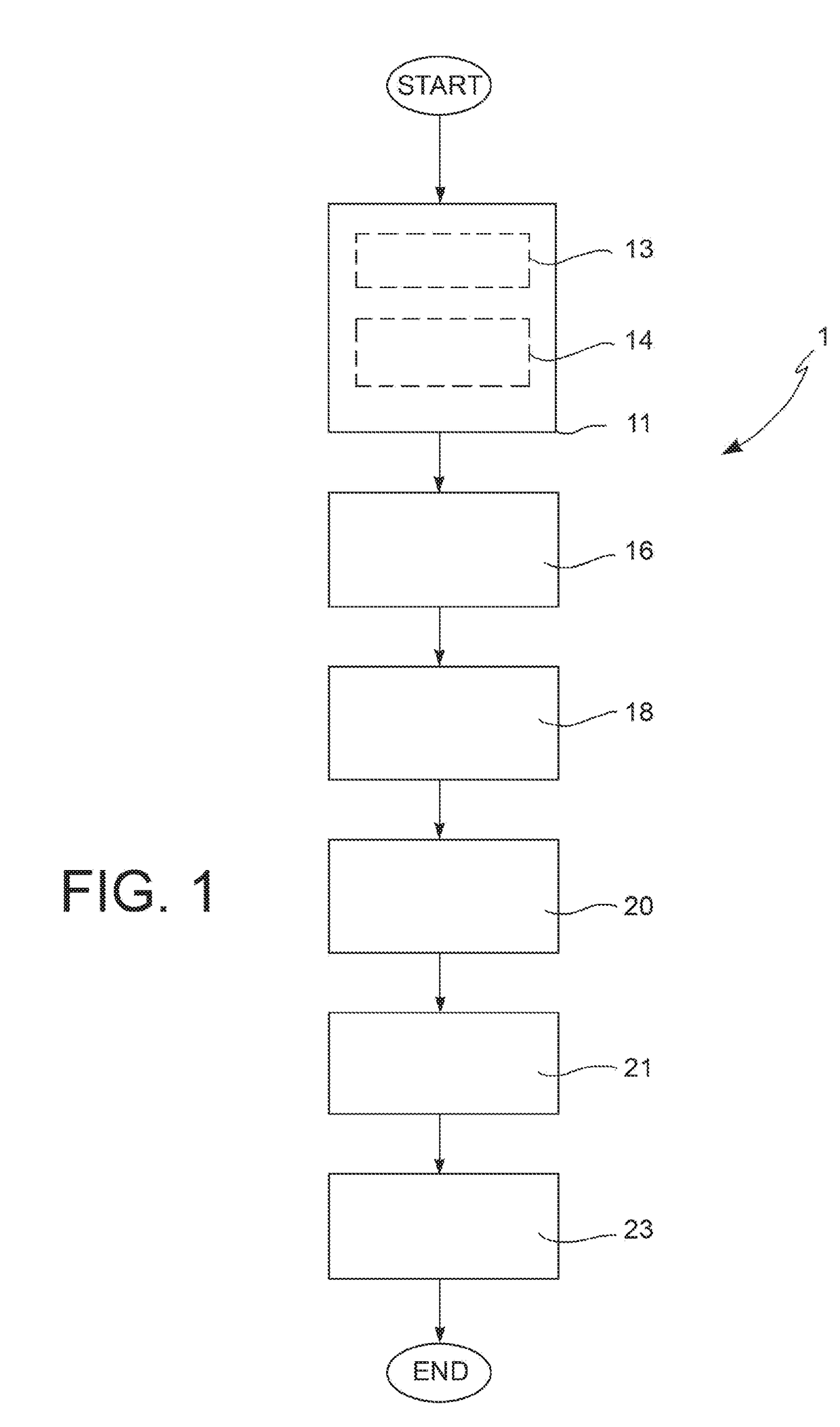

The invention provides a method and a device for online detection of foreign fiber in cotton. The device comprises a cotton opener, channels, windows, a CCD (Charge Coupled Device) camera, an illumination light source, a background plate, a nozzle array, a foreign fiber channel, a foreign fiber collecting unit, a computer, an electrical equipment cabinet, operating buttons, a frequency conversionfan and a cotton conveyance pipe. The method comprises the following steps: opening lint cotton; feeding the lint cotton into the detection area of the CCD camera through the channels; performing theillumination and CCD camera sampling in three steps, and further collecting the detection results of the three steps for identifying the foreign fiber; calculating the time for nozzles in the corresponding positions to the foreign fiber to open and close by combining the action delay time of each nozzle; controlling the corresponding nozzles to operate, so as to remove the foreign fiber; and meanwhile, outputting clean cotton with the foreign fiber being removed from the clean cotton output channel, wherein, by combining the performance parameters of the CCD camera, the cotton flow rate in the corresponding area of each nozzle can be calculated from the data obtained through infrared LED illumination and sampling, and the average cotton flow rate can be further calculated; and then, the cotton flow rate in the channels can be stabilized within a per-determined range by controlling the frequency conversion fan.

Owner:SHANGHAI ZHONGFANG BAODA TEXTILE INTELLIGENT INSTR +2

Cotton slitter with inward wind blowing function

ActiveCN103305969AEasy to dryCompact structureFibre cleaning/opening by air draught arrangementsFibre cleaning/opening by toothed membersNozzle

The invention discloses a cotton slitter with an inward wind blowing function. The cotton slitter comprises a rack box, a feed hopper, a discharging port, a beating roller and a blowpipe, wherein a working cavity is designed inside the rack box; the feed hopper and the discharging port are mounted on opposite surfaces of the rack box respectively and communicated with the working cavity; the bearing roller is mounted in the working cavity, and vertical round rods are distributed on the outer surface of the beating roller; the outer surface of the bearing roller adopts a framework and wire netting structure; the inside of the blowpipe is communicated with an air supply device, and the blowpipe is mounted on the axis of the bearing roller; an air nozzle facing the discharging port is designed on the blowpipe; the lower part of the beating roller is wrapped with a separation net for removing impurities. The cotton slitter has a simple structure, a smaller size, a drying function and a good cotton slitting effect.

Owner:临沂鑫润建铜业有限公司

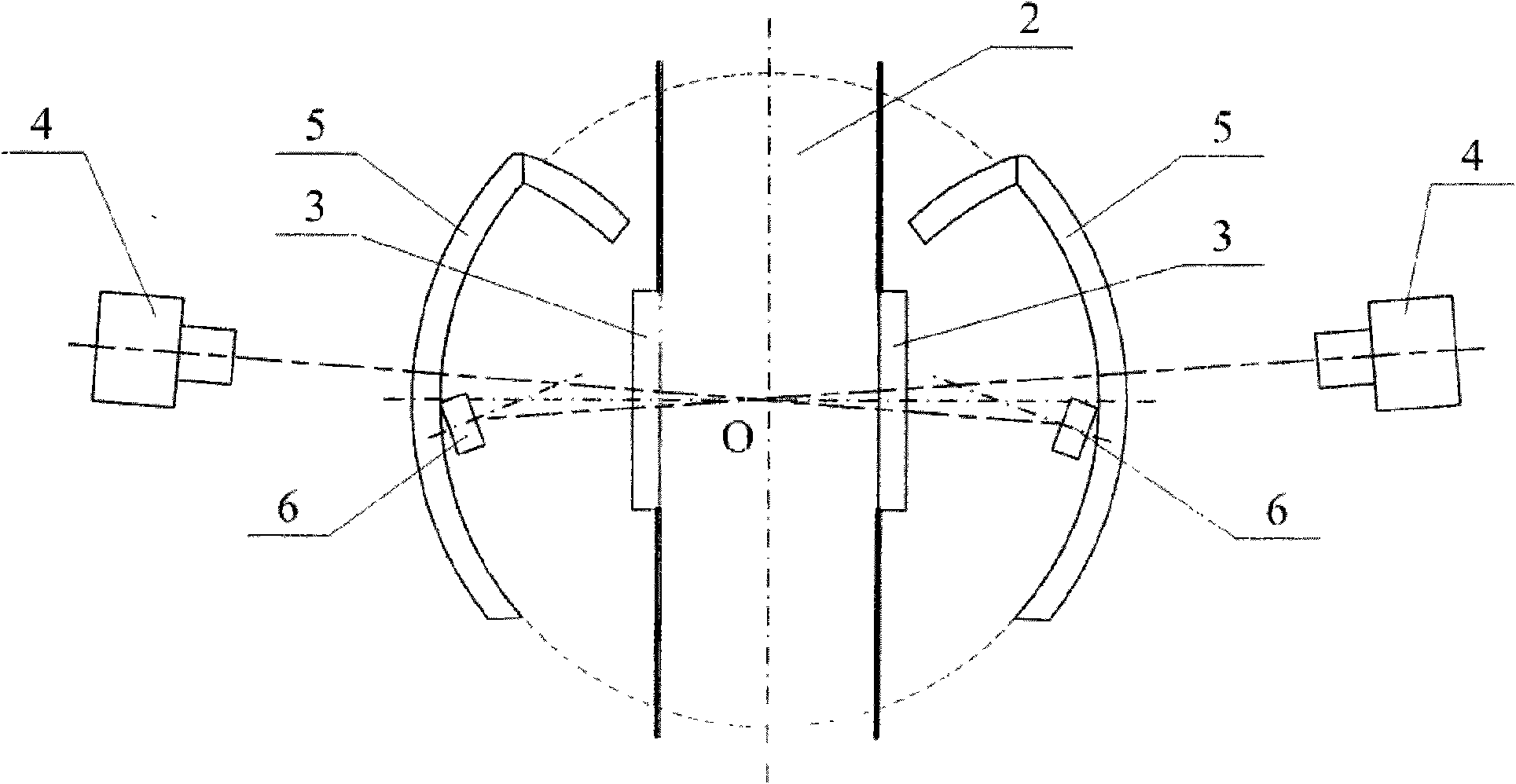

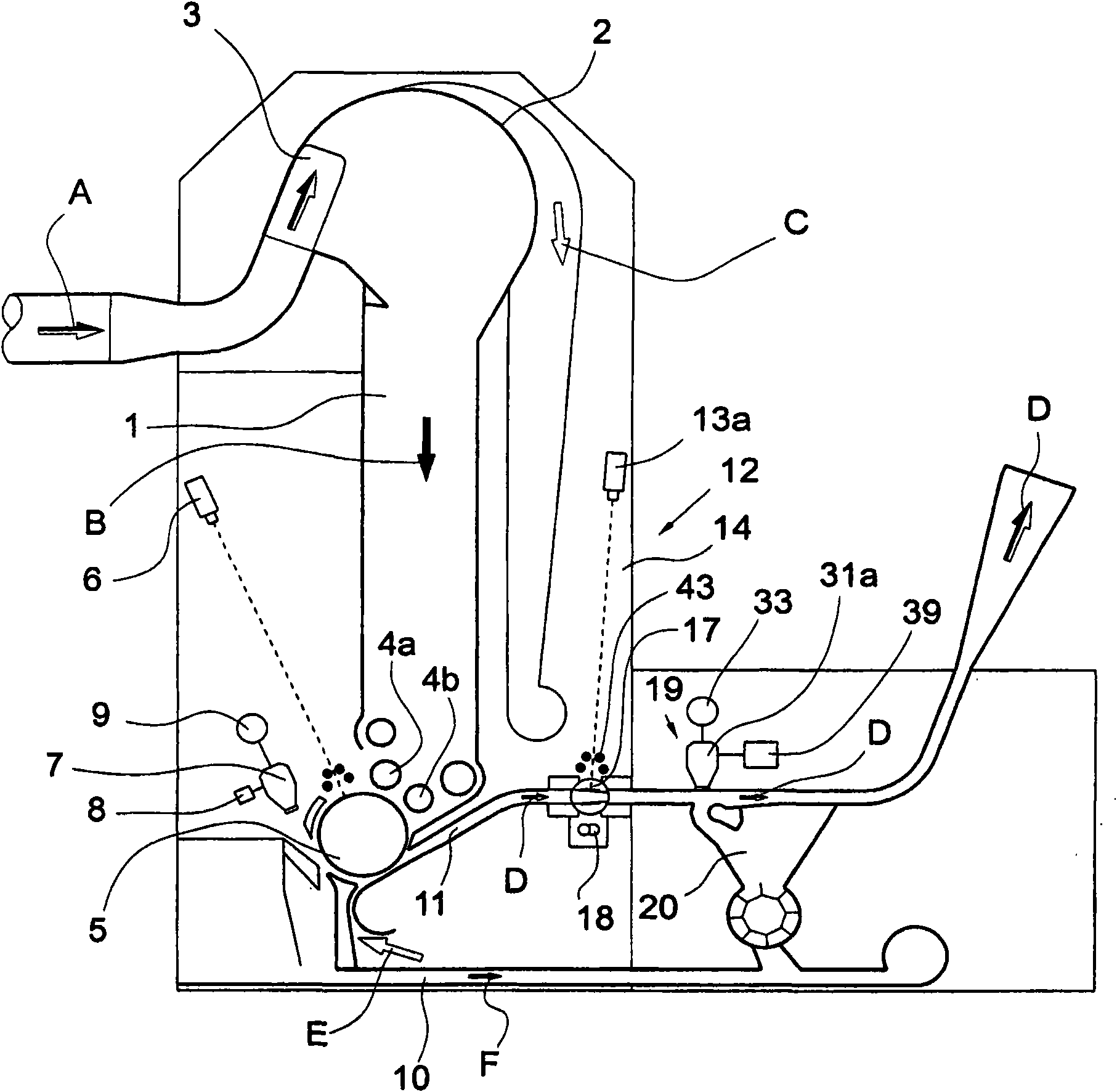

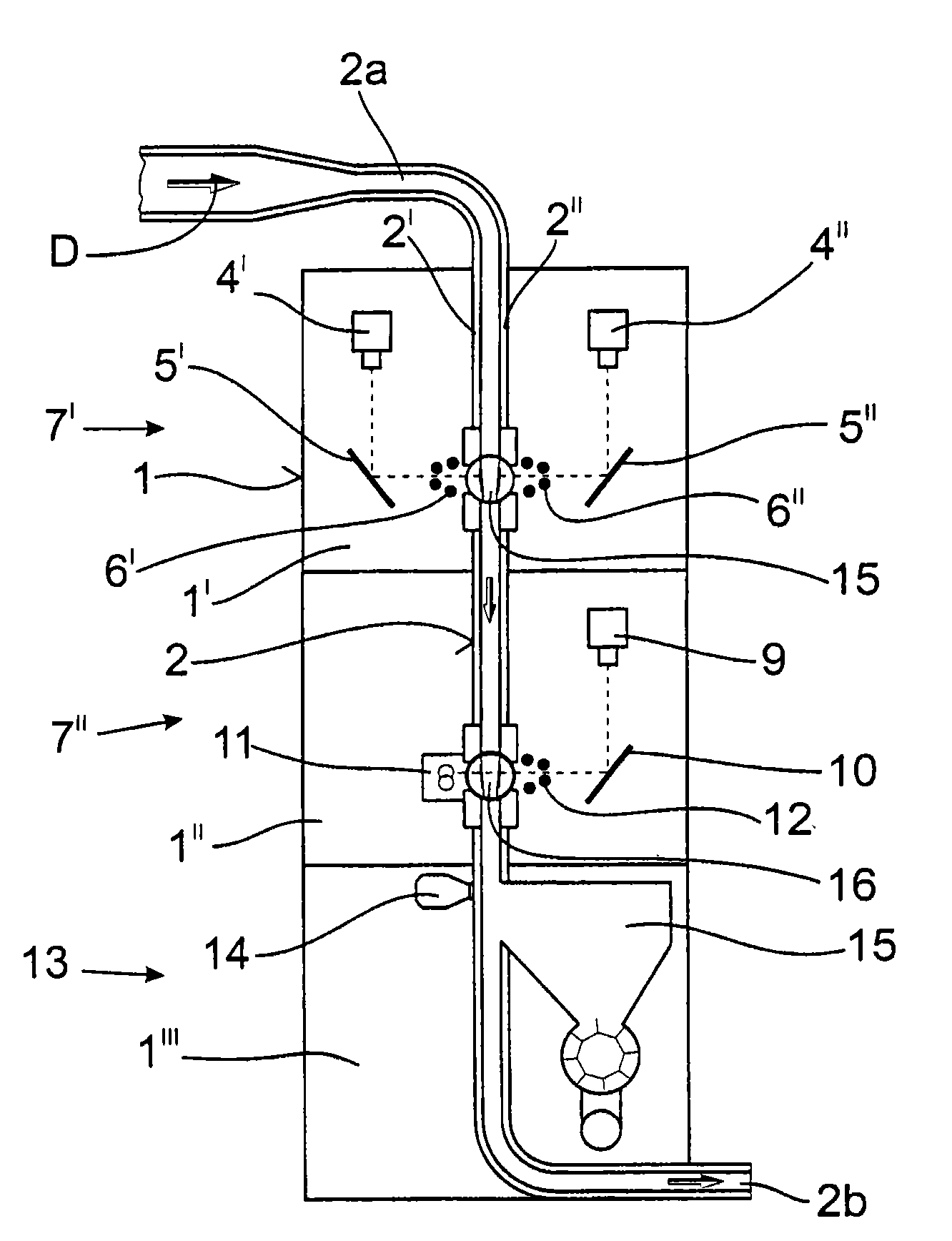

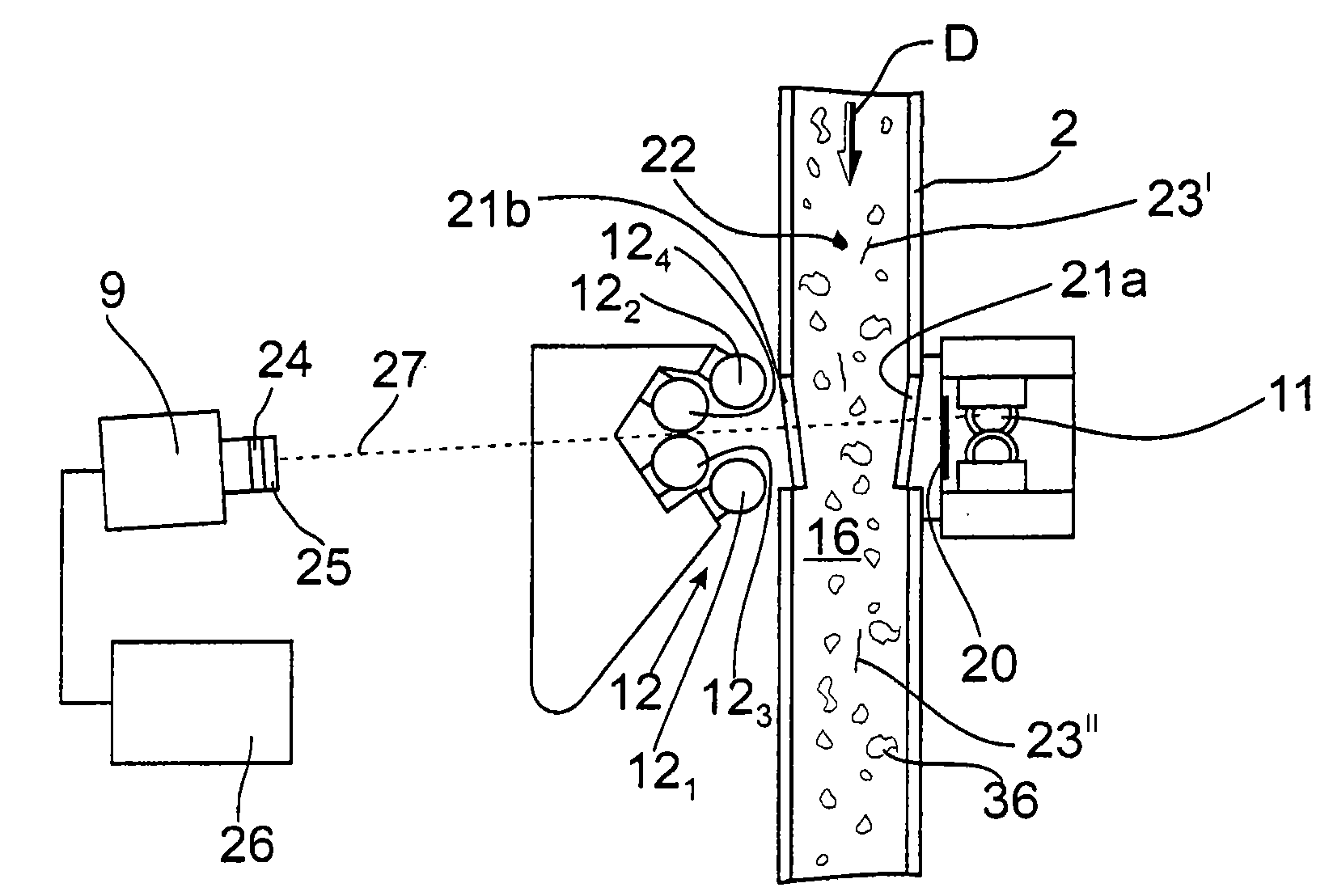

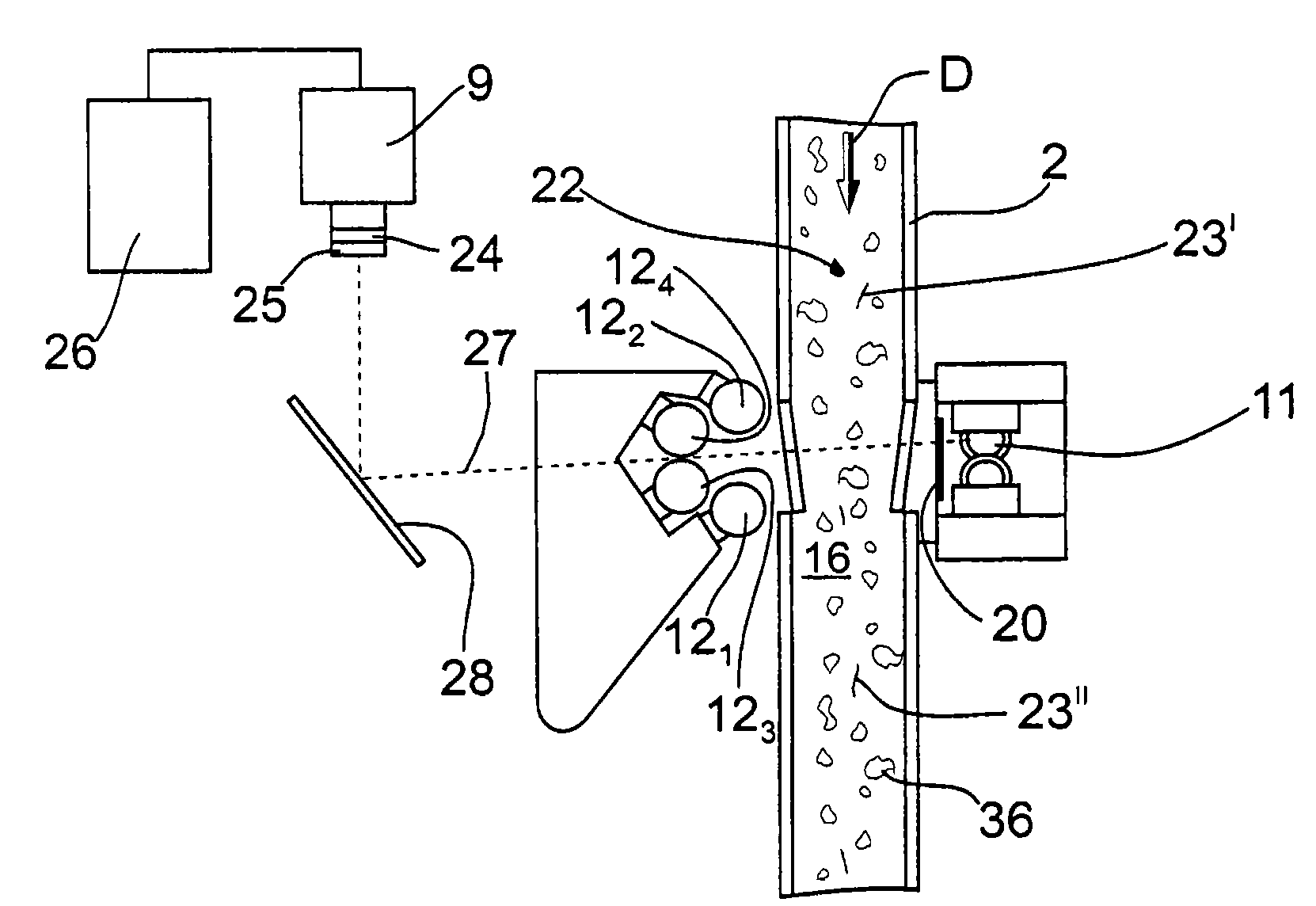

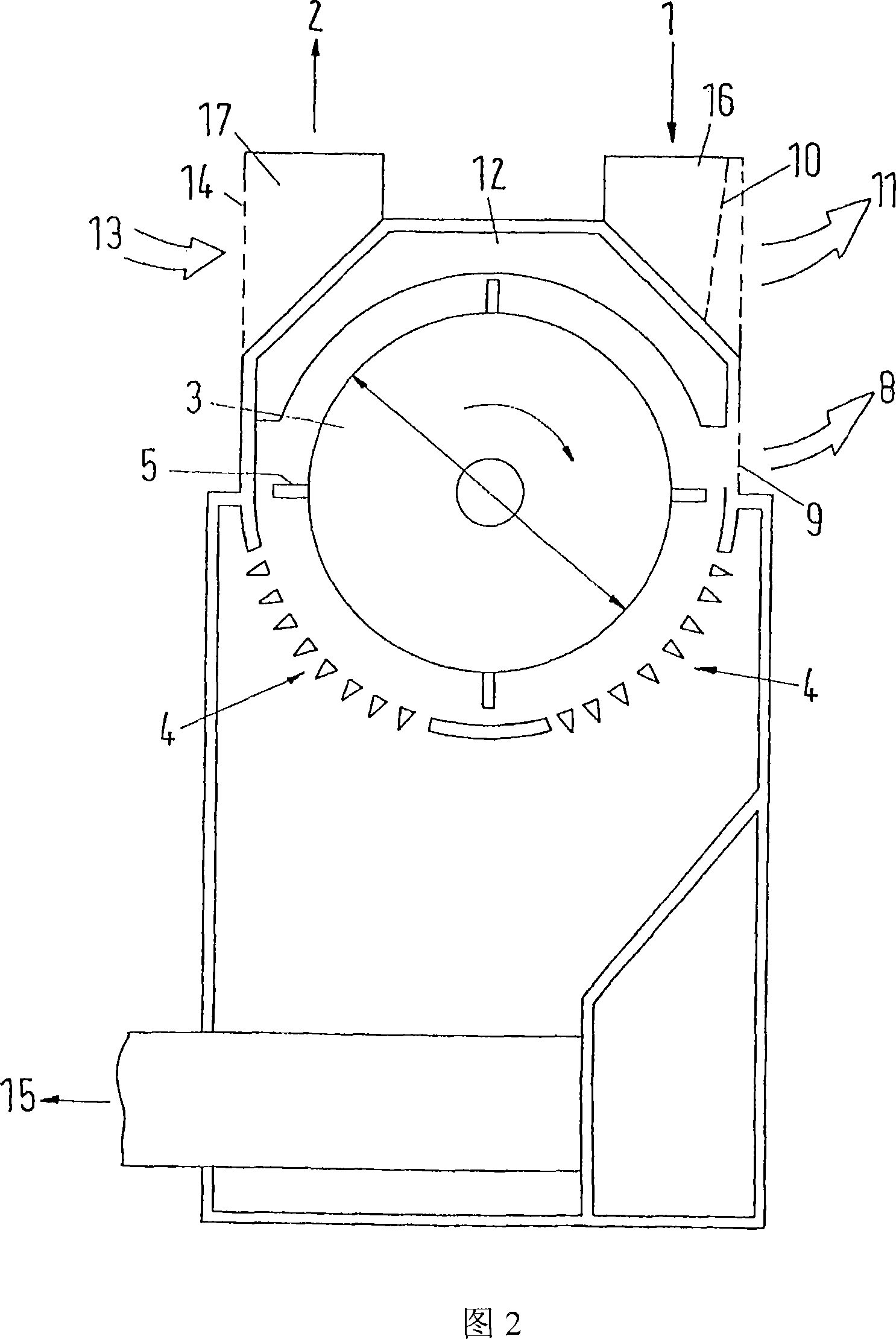

Apparatus for detection of foreign matter in plastic material in spinning room preparation, ginning or the like installation

ActiveCN101619537ASave installation spaceMomentary loss of clarityFibre cleaning/opening by air draught arrangementsSafety devices for fibre treatmentForeign matterFiber

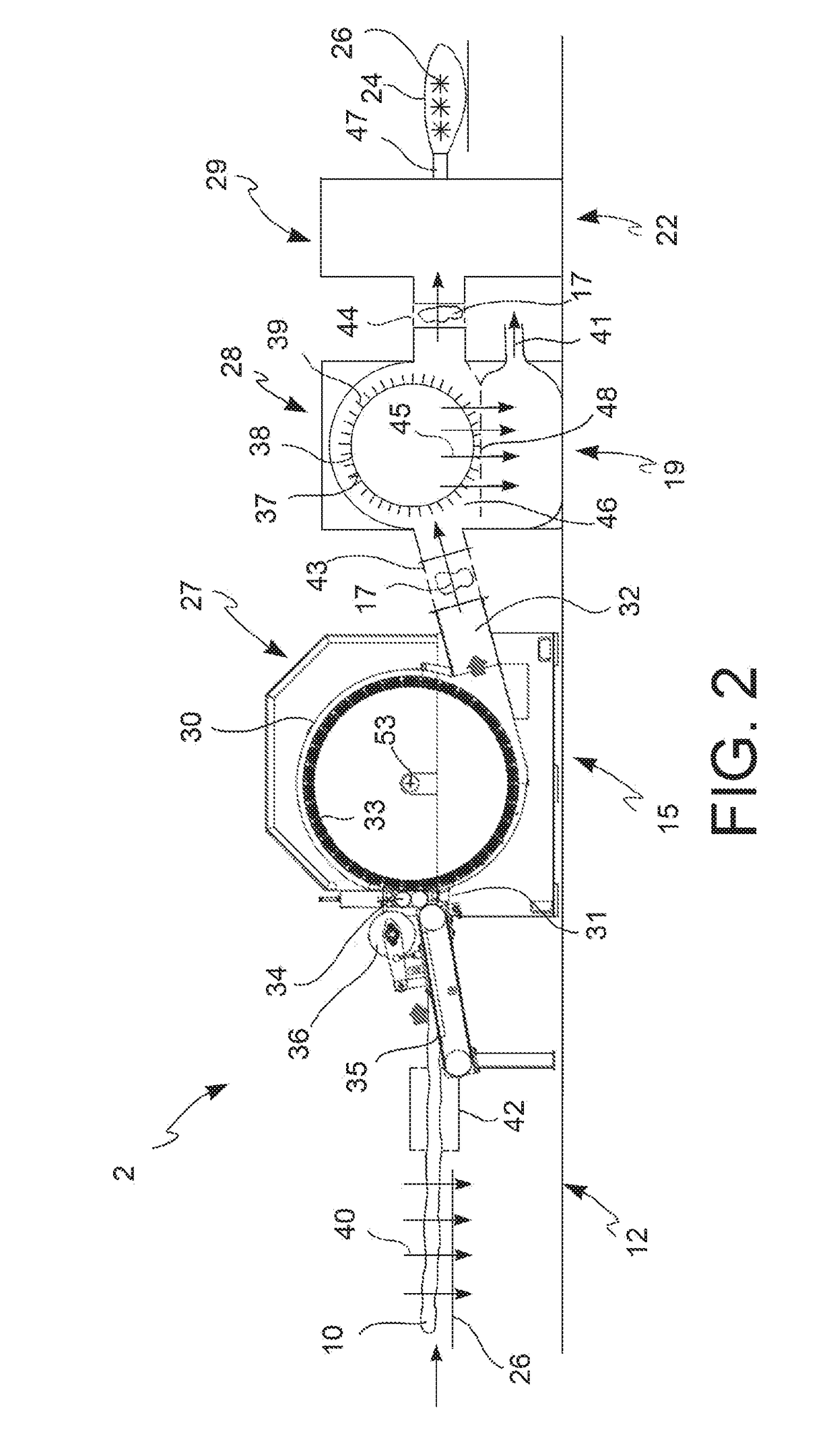

The present invention relates to an apparatus in a spinning room preparation, ginning or the like installation for detection of foreign objects of plastics material, such as polypropylene, weaving plastic, plastic sheet and the like, in or between a stream of fibre material, especially cotton. In the apparatus, the foreign objects in or between the stream of fibre material are arranged to be penetrated by a polarised light source cooperating with a detector, preferably a camera, weak color and / or transparent foreign objects are penetrated, and the light from another light source is applied on the stream of the fibre material. For effectively detecting the white and / or transparent plastic material sheets by a simple structure, the foreign objects in or between the stream of the fibre material are arranged to be illuminated by an ultraviolet light source or reflected light, and the ultraviolet light source cooperates with the detector, wherein the detector is capable of detecting the penetrated and illuminated foreign objects and separating them from the fibre material.

Owner:TRUETZSCHLER GRP SE

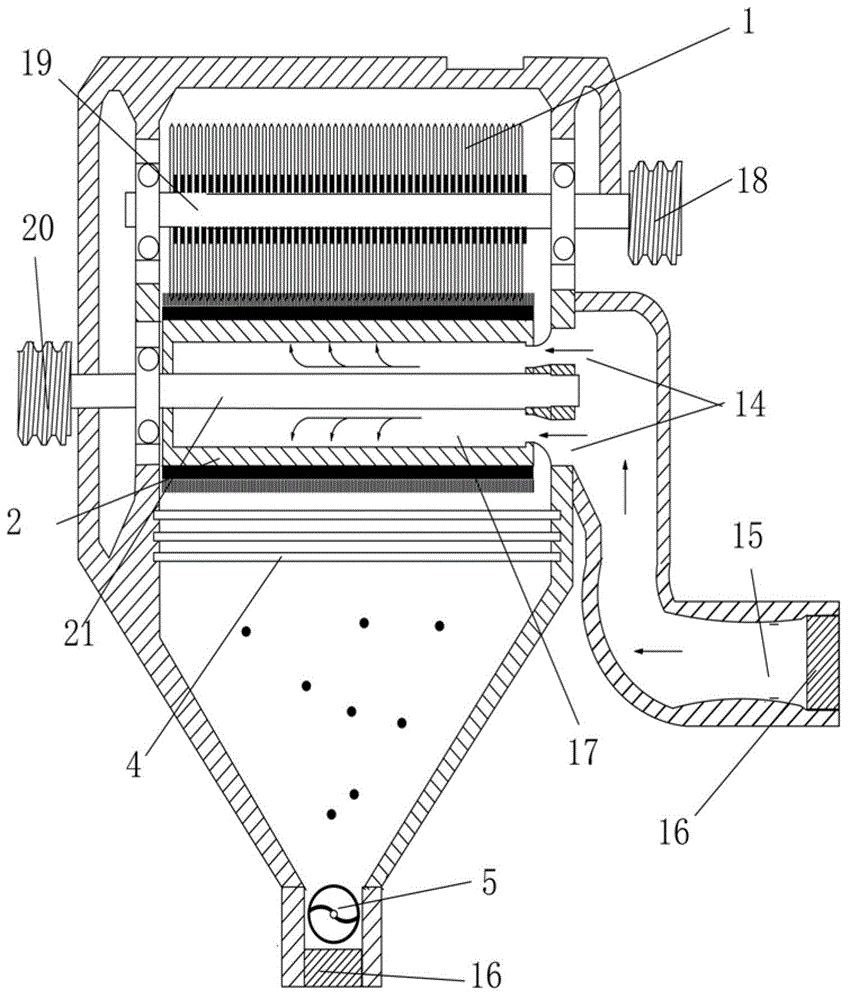

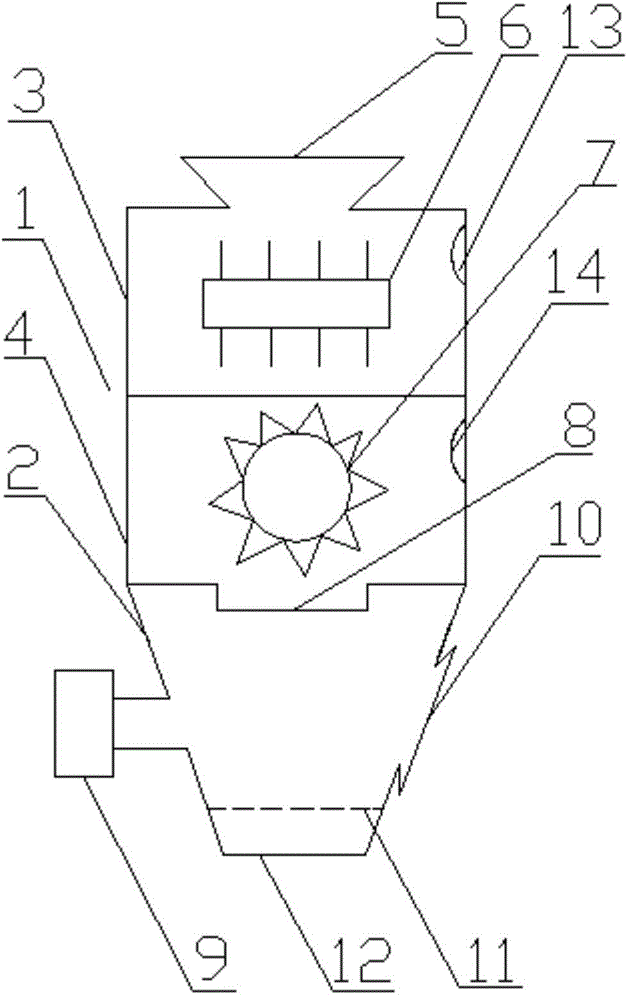

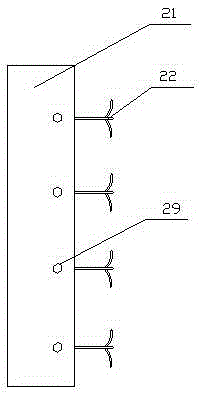

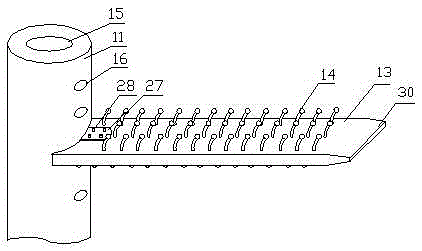

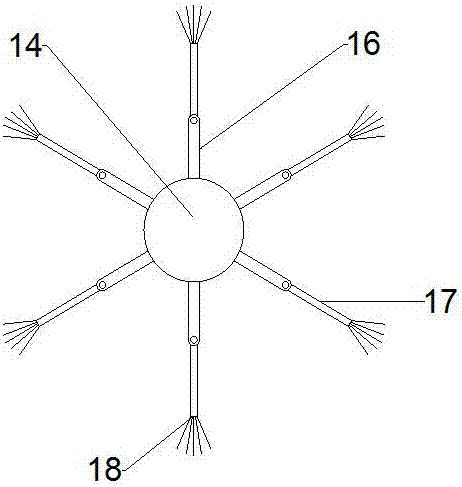

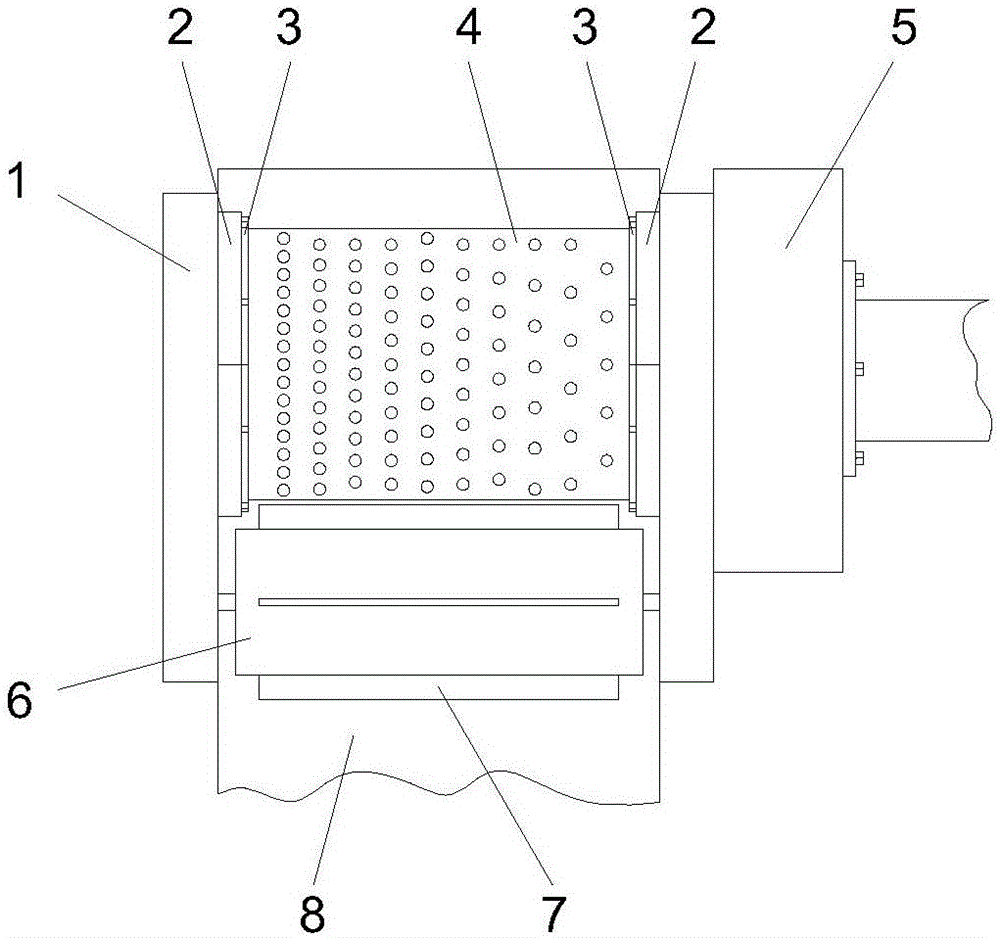

Back-suction-preventing high-efficiency embossing machine

InactiveCN103147134ASolve complexitySolve the cumbersomeFibre cleaning/opening by air draught arrangementsVegetable fibre separation from seedsFiberAir volume

The invention discloses a back-suction-preventing high-efficiency embossing machine. An air inlet (14) and an air quantity regulating device (16) are arranged on one end or two ends of a brush roll (2) of the embossing machine, and air outlets (11) among brush strips or cotton brushing plates are formed in the circumference of the roller of the brush roll (2); an impurity-removing combination comprises an impurity-removing lattice bar grid (4) and a lower impurity-removing stranding cage or an impurity-suction port (5), and is located on the outer side of the brush roll. According to the back-suction-preventing high-efficiency embossing machine disclosed by the invention, by means of changing the structure of the traditional roller, the roller under high-speed rotation not only has an air conveying function and an inertial centrifugal force, but also is free from a self back suction phenomenon, so that fibers and impurities locate at different positions of an air flow layer under the action of centrifugal force due to differences in self weight and connecting force, and are forced to be separated under the coordination of the impurity-removing combination, and moreover, the fibers can be prevented from being overflowed. Alternatively, by means of changing the traditional cotton supporting plate into the impurity-removing combination, the purpose of separating the fibers and the impurities can also be achieved by changing the air inlet position of the brush roll under the attraction of a proper quantity of air.

Owner:李通

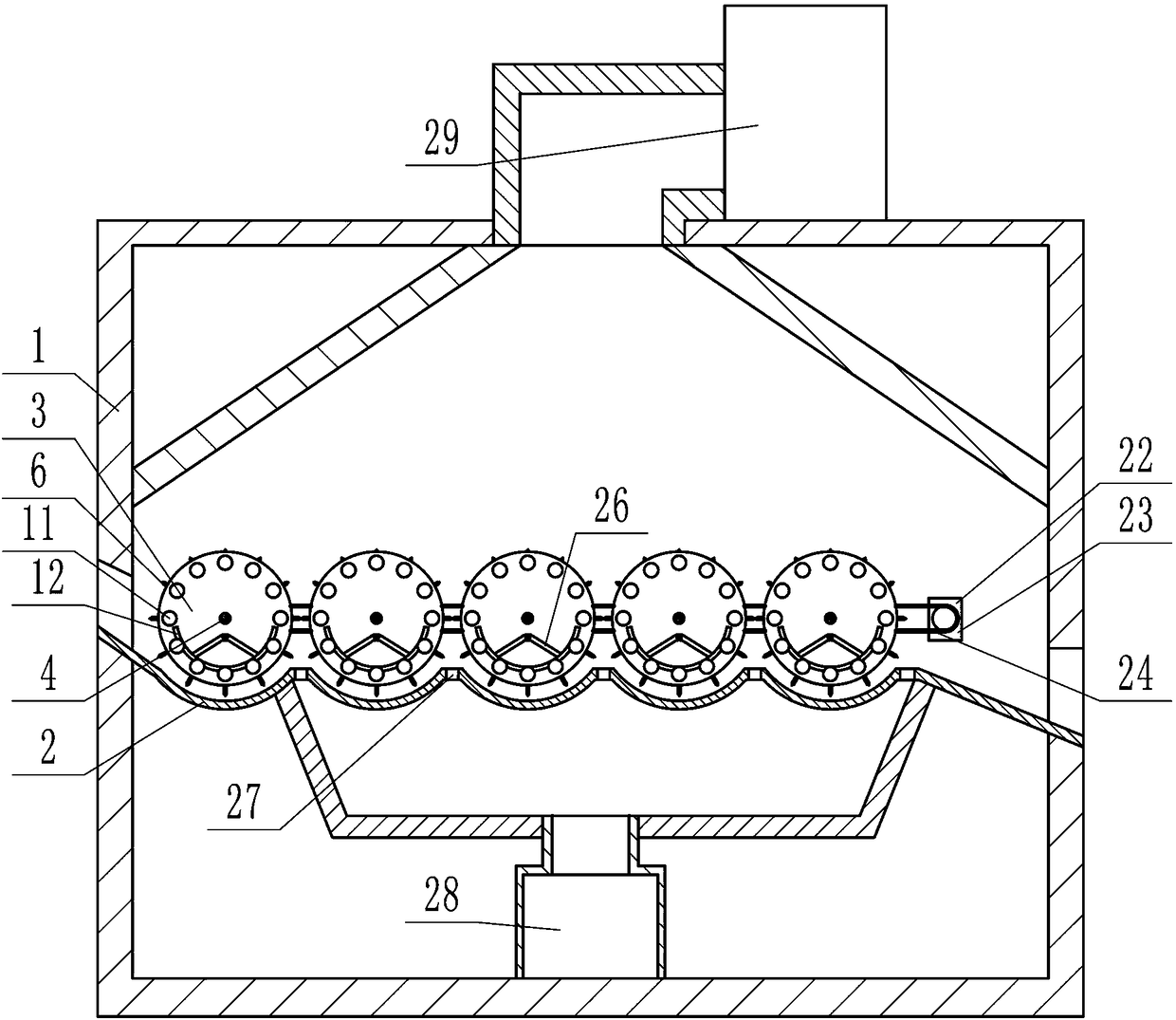

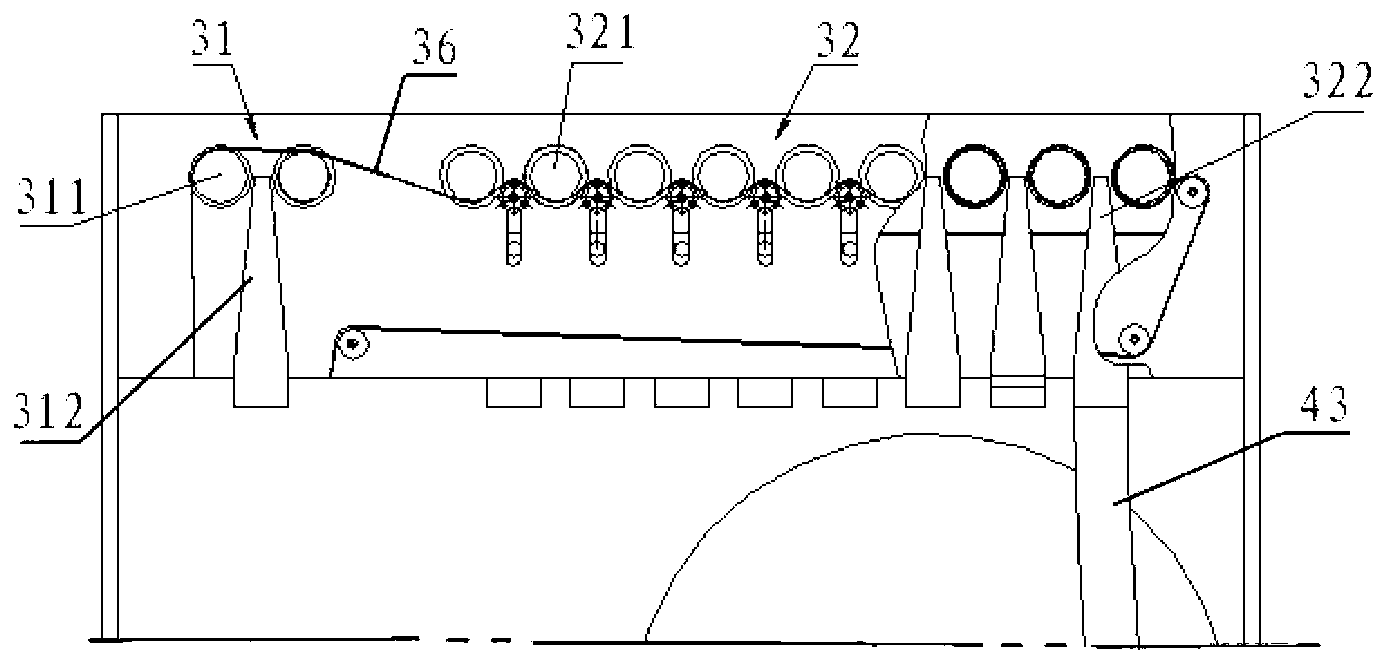

Blowing foreign fiber machine with function of spreading

ActiveCN108547014ANovel ideaIngenious structureFibre cleaning/opening by air draught arrangementsFibre cleaning/opening by toothed membersFiberEdge surface

The invention relates to a blowing foreign fiber machine with a function of spreading, and effectively solves the problem that the small foreign fiber cleaning of an existing foreign fiber cleaning machine is not complete. According to the technical scheme, the blowing foreign fiber machine comprises a box body, wherein the box body is internally provided with a plurality of rotatable first cylinders, the first cylinders are horizontally arranged along forward and backward directions, the first cylinders are internally fixedly provided with cams, a plurality of sets of stirring rods are circumferentially uniformly distributed on the first cylinders, the rotation of the first cylinders makes the stirring rods move along the radial directions of the first cylinders under the squeezing actionof the outer edge surface of the cams, same sides of each set of stirring rods are provided with two pull rods, each stirring rod is provided with a blocking rod, each pull rod is provided with a clamping groove, the outer side of each pull rod is provided with a blocking plate, front and back end faces of each first cylinder are respectively provided with an arc-shaped protruding block, the rotation of the first cylinders drives the blocking plates to contact with the protruding blocks, it is achieved that the pull rods drive the stirring rods to move toward the outer side under the squeezing action of the arc-shaped protruding locks, and the stirring rods are provided with compression springs capable of making the positions of the center faces on the front and back directions of the first cylinders reset. The blowing foreign fiber machine with the function of spreading has the advantages that the conception is novel, the structure is ingenious, and the practicability is high.

Owner:桐乡市常新农机专业合作社

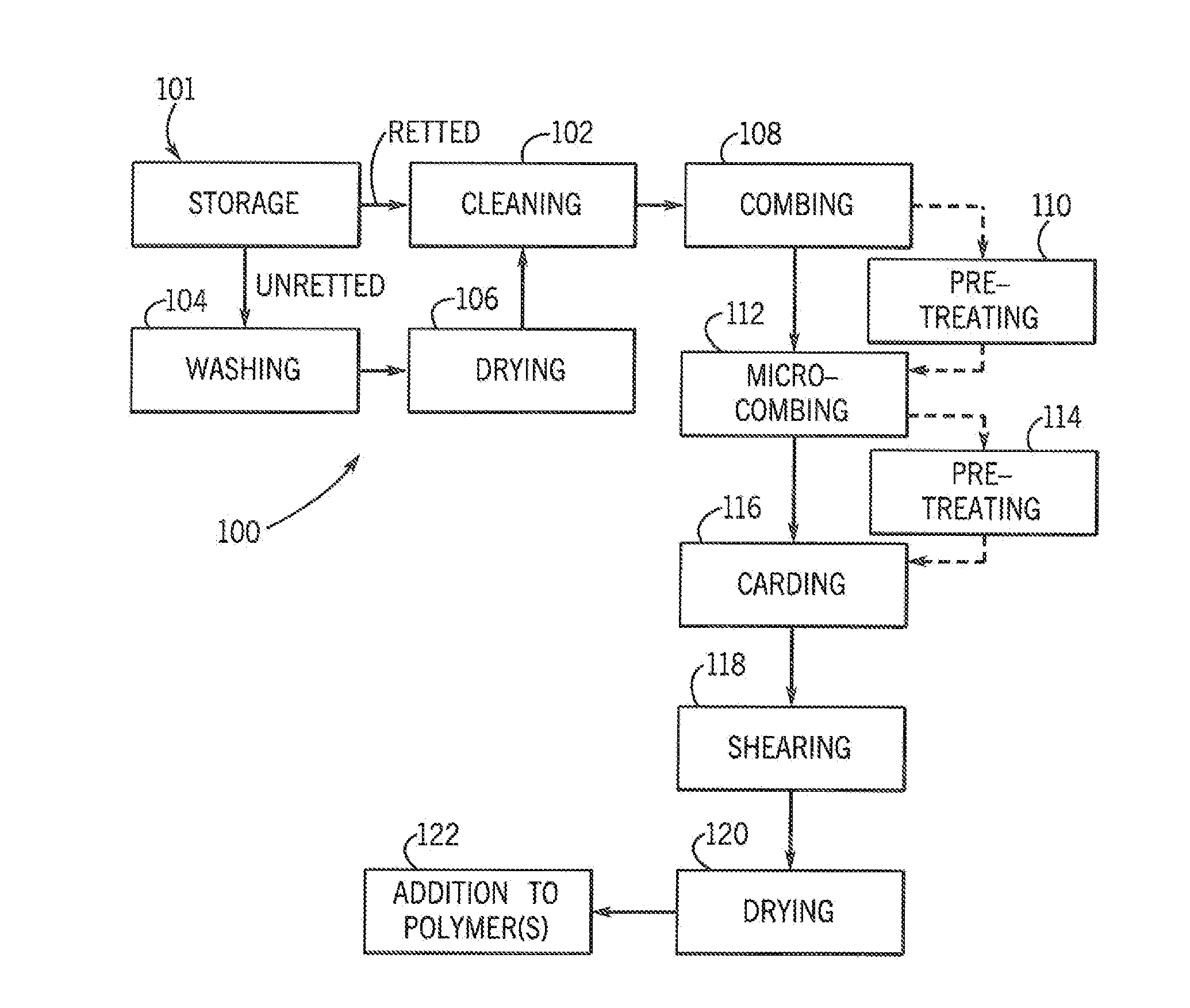

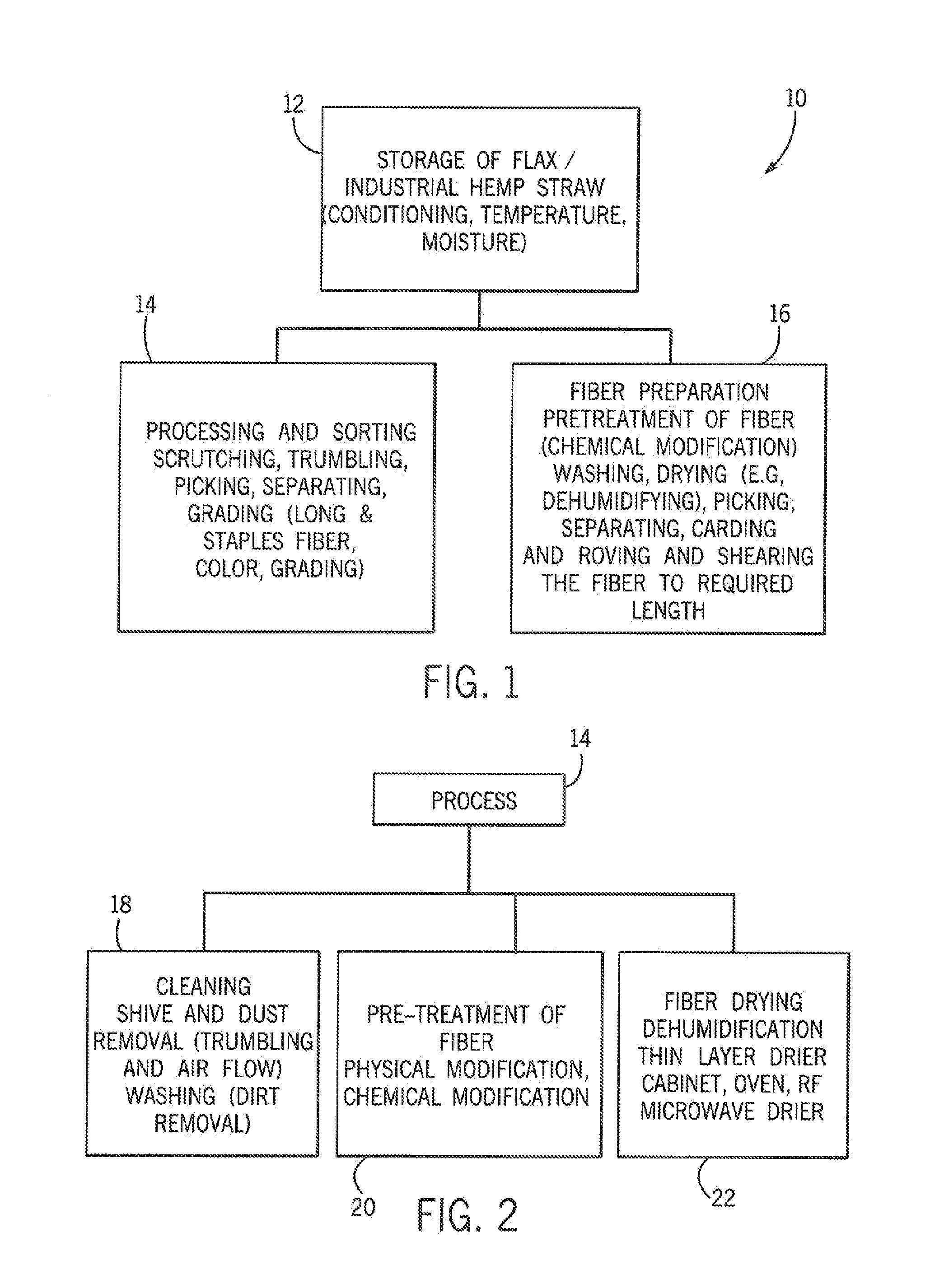

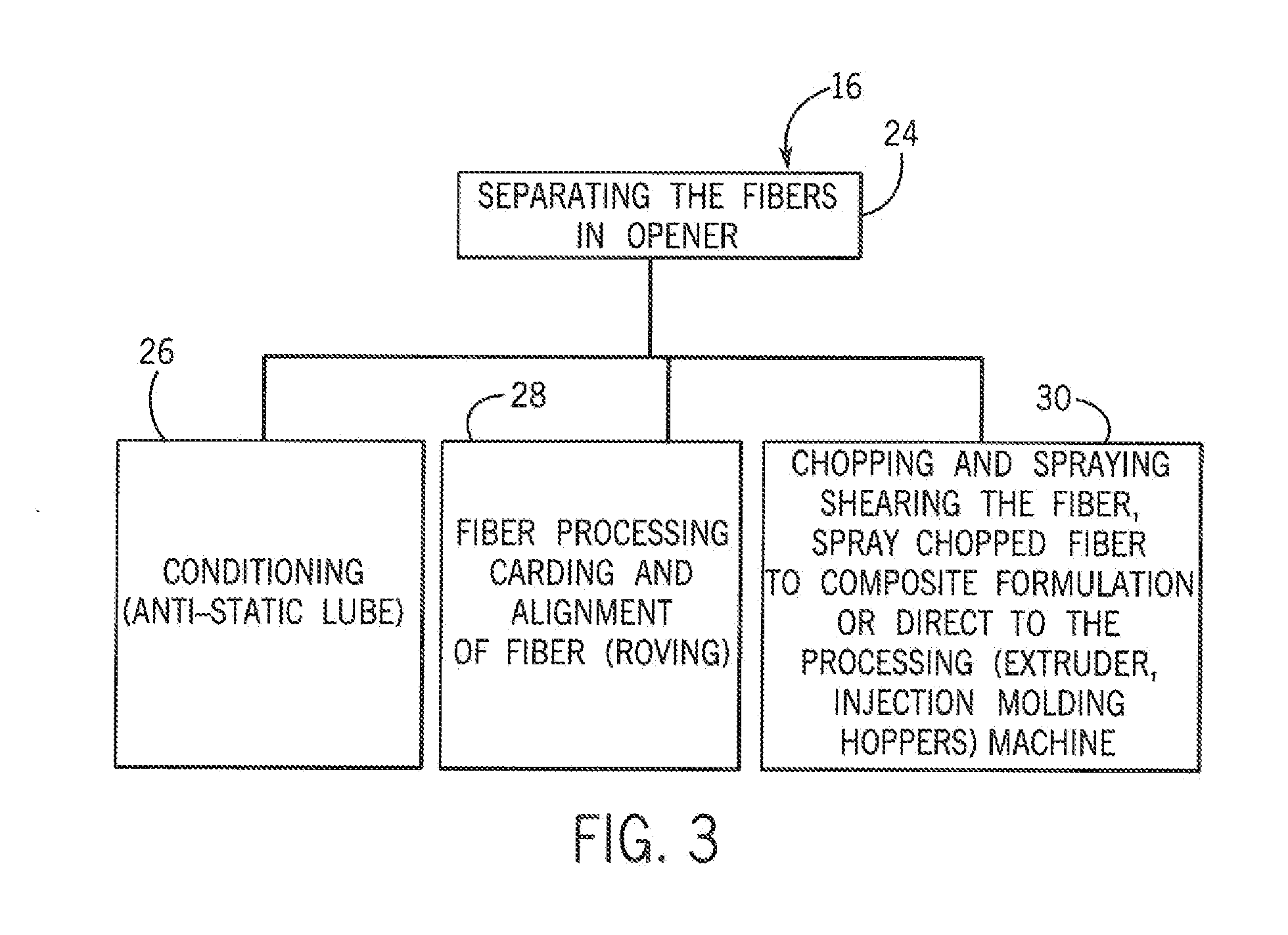

Method To Process Oilseed Flax Fiber For Use In Biocomposite Materials

ActiveUS20150166745A1Retention strengthOptimizationMechanical impurity removalFibre cleaning/opening by air draught arrangementsFlax fiberSISAL

A method and system for the production of fibers for use in biocomposites is provided that includes the ability to use both retted and unretted straw, that keeps the molecular structure of the fibers intact by subjecting the fibers to minimal stress, that maximizes the fiber's aspect ratio, that maximizes the strength of the fibers, and that minimizes time and energy inputs, along with maintaining the fibers in good condition for bonding to the polymer(s) used with the fibers to form the biocomposite material. This consequently increases the functionality of the biocomposites produced (i.e. reinforcement, sound absorption, light weight, heat capacity, etc.), increasing their marketability. Additionally, as the disclosed method does not damage the fibers, oilseed flax straw, as well as all types of fibrous materials (i.e. fiber flax, banana, jute, industrial hemp, sisal, coir) etc., can be processed in bio composite materials.

Owner:CNH IND CANADA

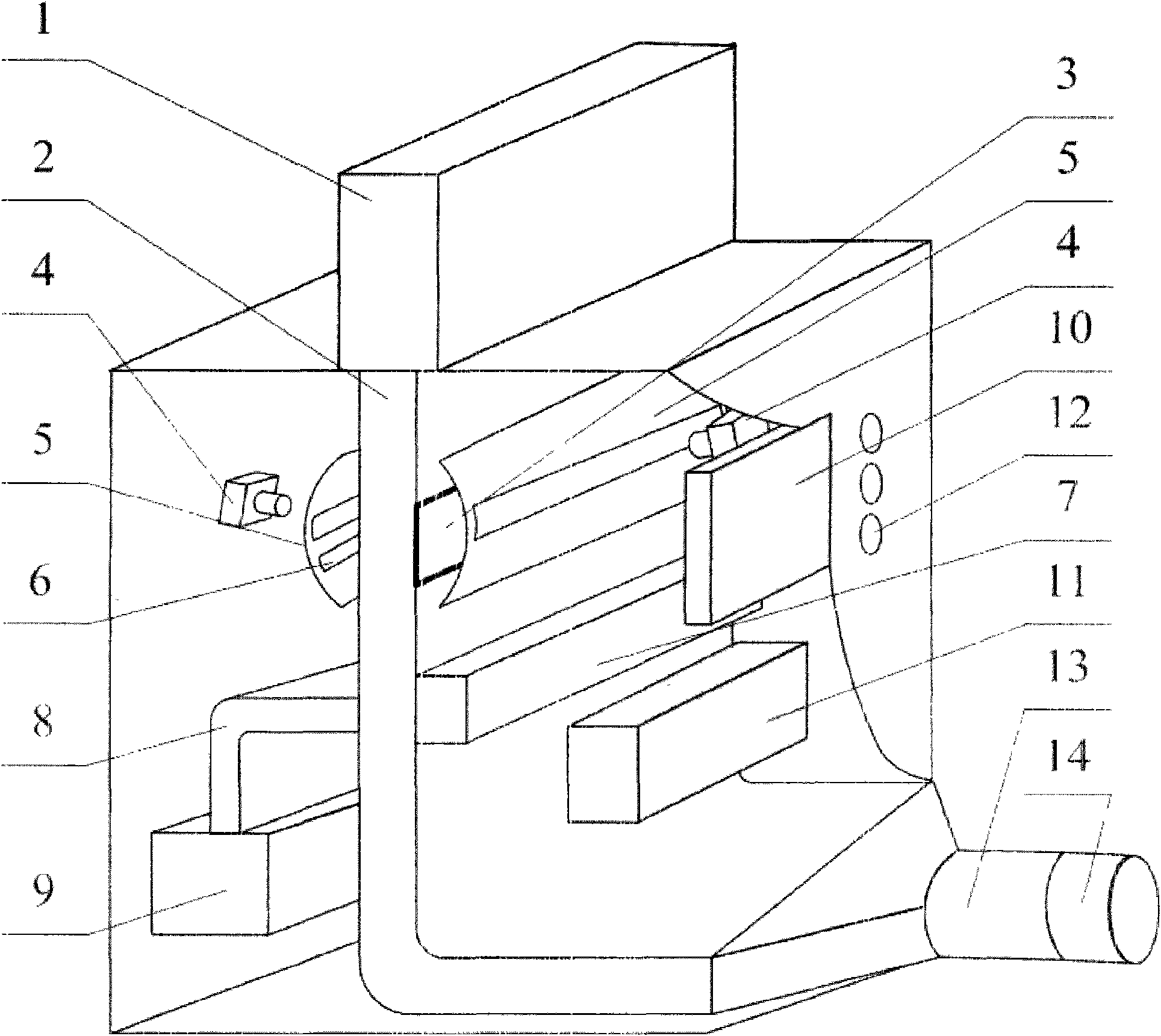

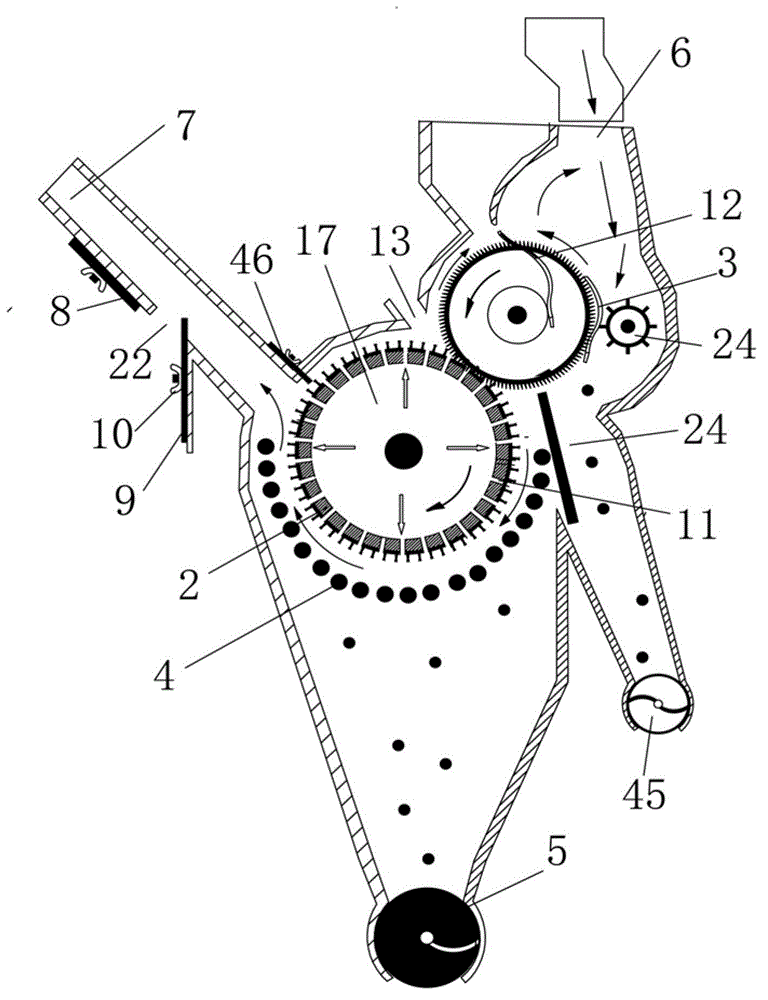

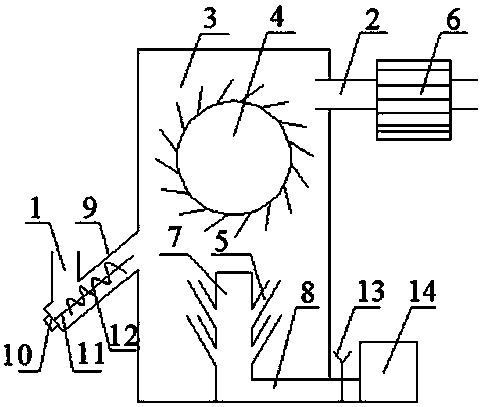

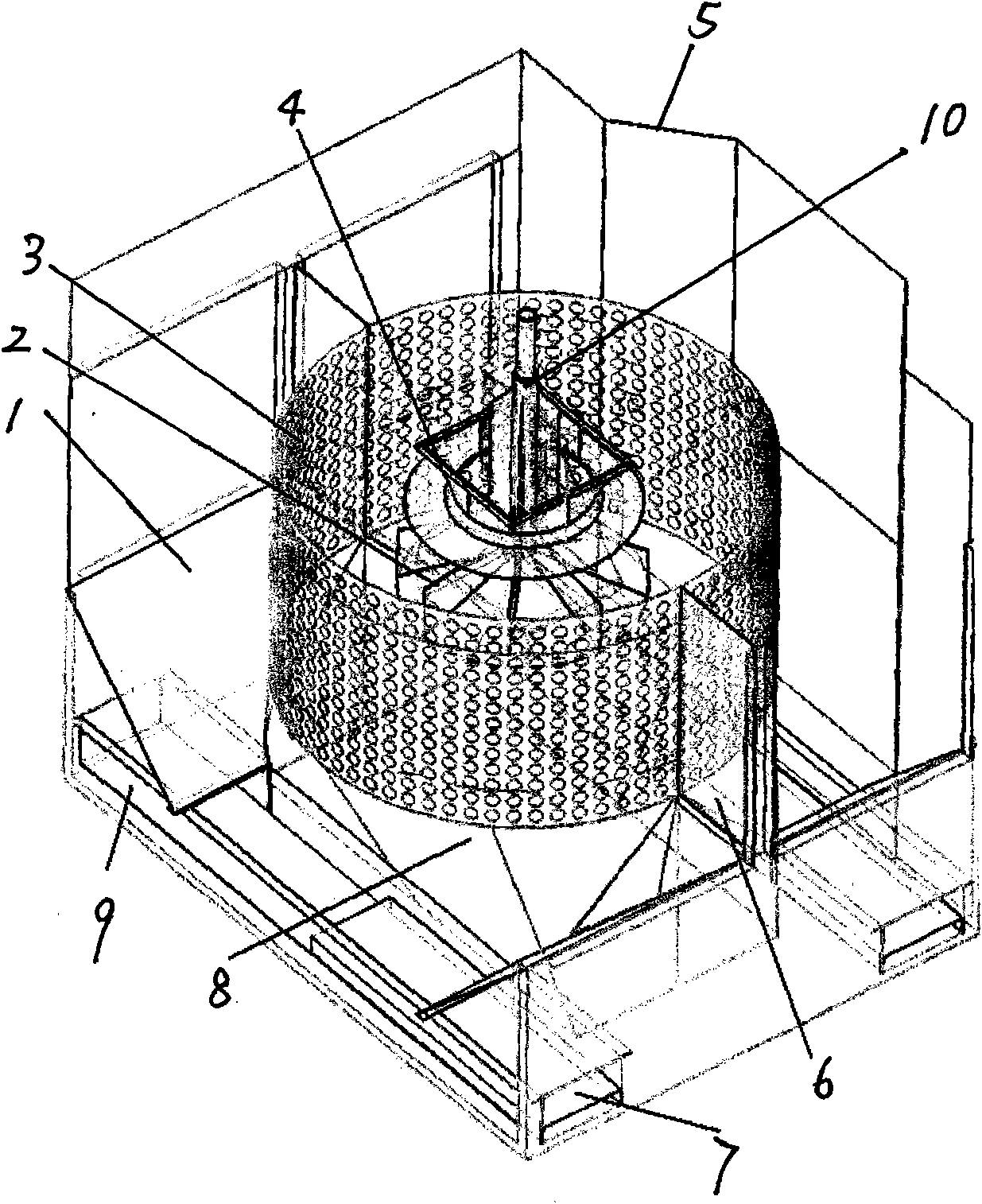

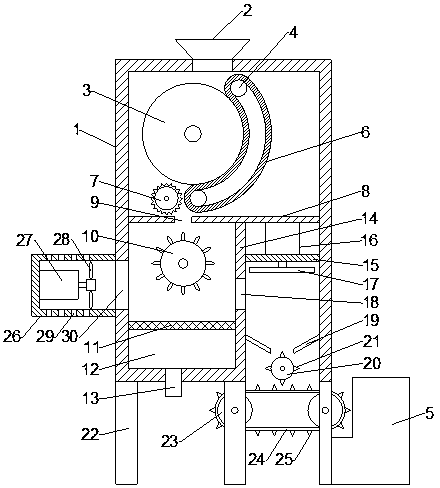

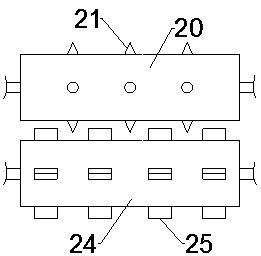

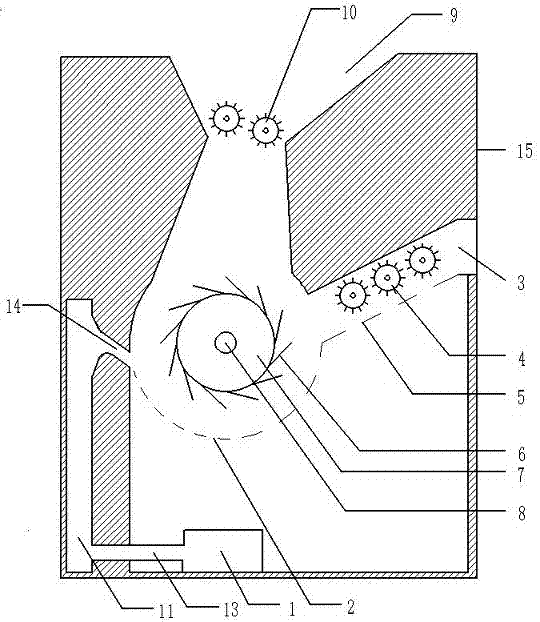

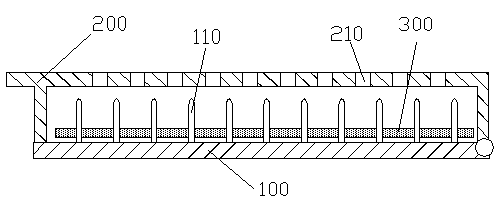

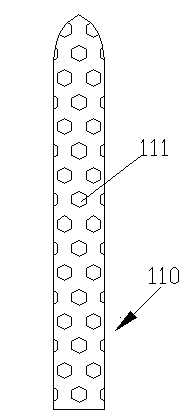

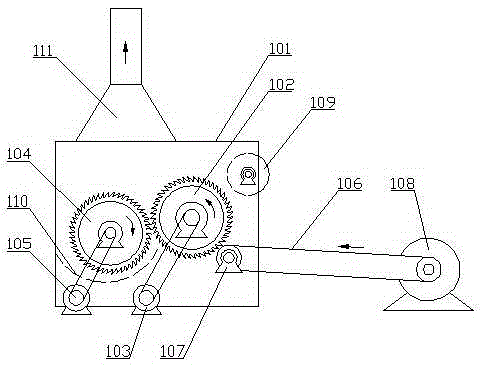

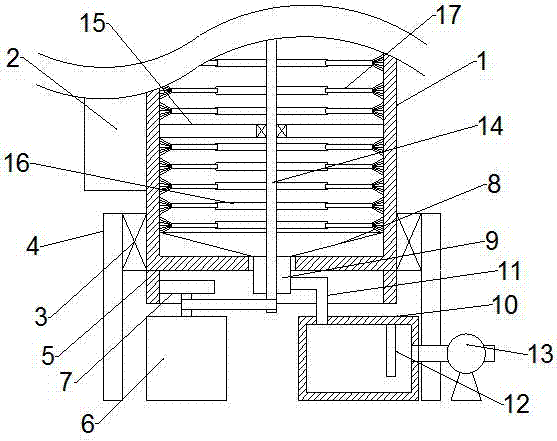

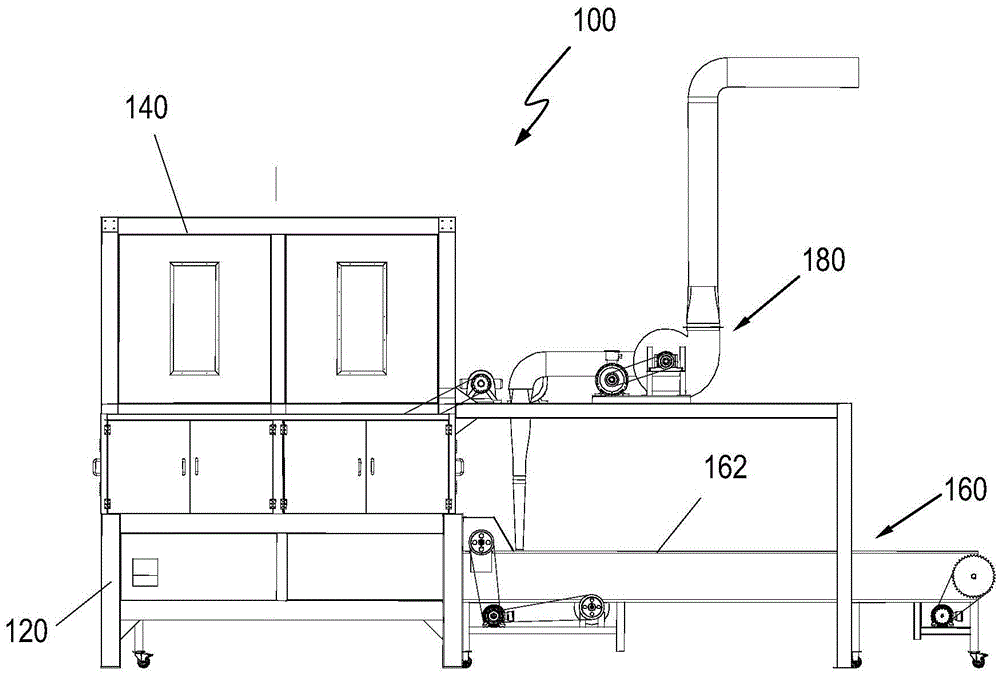

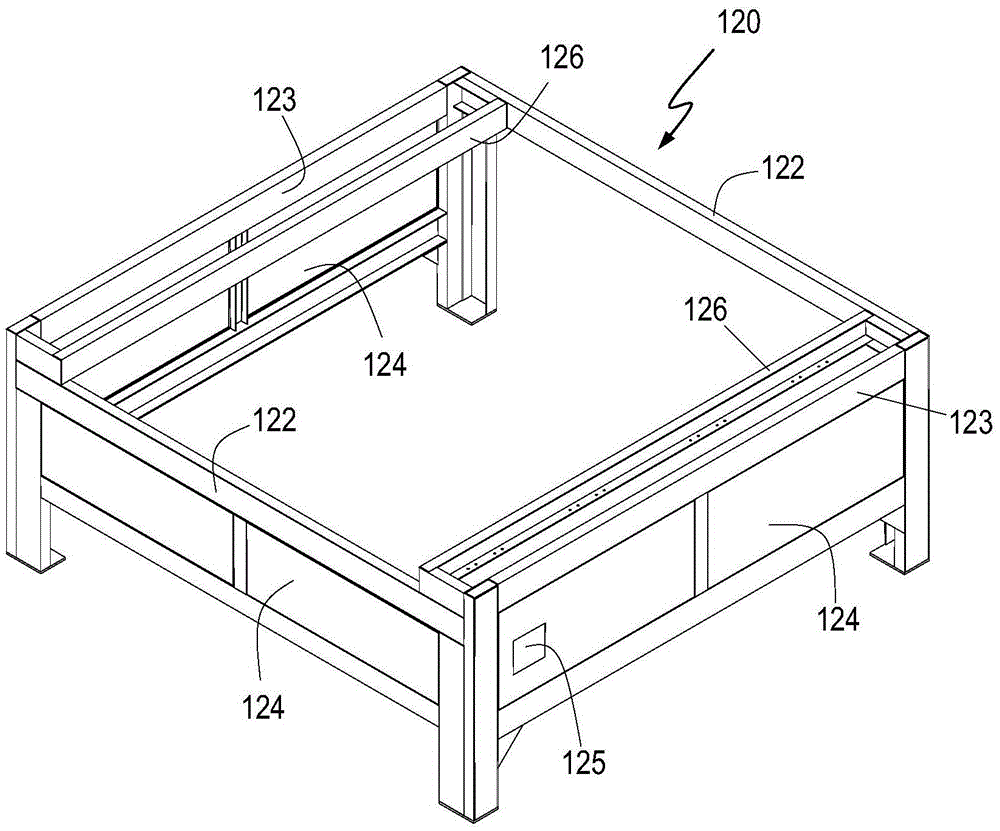

Seed-cotton foreign fiber cleaning machine

ActiveCN102191589AEasy to cleanImprove cleaning efficiencyFibre cleaning/opening by air draught arrangementsFibre cleaning and opening machine combinationsFiberEngineering

The invention relates to a combined-type seed-cotton foreign fiber cleaning machine which is characterized by comprising a tank body which is internally provided with a winding and cleaning device, a hook-pull purification cleaning device, a boiling and opening device and a wind power cleaning device, wherein the winding and cleaning device comprises two pattern feeding rollers; two groups of winding rollers are arranged under the two pattern feeding rollers; a regulating plate is arranged at a passageway dividing place of the two groups of winding rollers; the hook-pull purification cleaning device comprises at least one rack roller, one auger and one doffing roller, wherein the auger is arranged under the rack roller; the doffing roller is arranged slantwise under the rack roller; the boiling and opening device comprises a row of opening rollers; an air bellows which is connected with a fan is arranged under the opening rollers; a plurality of seam-type blast nozzles are arranged on the tops of the air bellows; each seam-type blast nozzle is arranged between any two adjacent opening rollers; and the wind power cleaning device comprises a gettering cover which is connected with the fan. The seed-cotton foreign fiber cleaning machine has a good seed-cotton cleaning effect and high cleaning efficiency and can be widely applied to cotton processing factories for cleaning various foreign fibers in seed cotton.

Owner:北京智棉科技有限公司

Scutcher

InactiveCN103526339AImprove adaptabilitySimple structureFibre cleaning/opening by air draught arrangementsFibre cleaning/opening machinesFiberGranularity

The invention relates to equipment in the technical field of scutchers, in particular to a scutcher. The scutcher comprises a scutching bin, a cotton inlet formed in the lateral wall of the scotching bin and a beater arranged in the scotching bin, and is characterized in that an air passage in the vertical direction is arranged at the bottom inside the scutching bin, is externally connected with an air supply device through a transverse pipe and is provided with an air spraying head, and the air spraying head inclines upwards at an angle. After the structure is adopted, cotton fibers fed by a feeding mechanism into the scutching bin are jacked up through the air sprayed by the air spraying head, the heavier cotton fibers will fall on the bottom of the scutching bin, the structure is simple, and realization is convenient. The granularity of separated-out impurities can be controlled by controlling the flow amount of the air inside the transverse pipe, the quality of products has larger controllability, and the adaptability of the products on the market is improved.

Owner:WUJIANG KESHIDA TEXTILE

Apparatus in a spinning room preparation, ginning or the like installation for detection of foreign matter in fibre material

ActiveCN101634103ANo transient loss of claritySave installation spaceFibre cleaning/opening by air draught arrangementsSafety devices for fibre treatmentFiberForeign matter

Owner:TRUETZSCHLER GRP SE

Airflow scutching impurity removal device

ActiveCN101962825AReduce the short fiber rateCotton feeding speed is fastFibre cleaning/opening by air draught arrangementsCotton fibreEngineering

The invention relates to an airflow scutching impurity removal device, belonging to the technical field of cotton spinning equipment. The airflow scutching impurity removal device is composed of a dust collection guide plate, an airflow nozzle, a dust filter cage, a cotton delivery airflow channel, an enclosure, an airflow pulse baffle, a dust collection outlet curtain board, a dust collection funnel, a dust collection pipe and a motor transmission shaft and is characterized in that the dust filter cage is arranged in the enclosure; in the dust filter cage, the motor transmission shaft is connected with the cotton delivery airflow channel and the airflow nozzle; the outer part of the dust filter cage is connected with the dust collection funnel; the airflow pulse baffle is fixed on the outer side of the dust filter cage; the dust collection guide plate is connected with the dust collection pipe; and the dust collection pipe is connected with the dust collection outlet curtain board. When the above scheme is adopted, the invention has the advantages and the beneficial effects of cleaning impurities in cotton fibre and lowering lower pile rate, has high cotton transmission speed and good quality and is automated.

Owner:YANCHENG KINGDA TEXTILE MACHINERY MFG

Cotton cleaning machine

InactiveCN105019061AEfficient removalThe opening process is sufficientFibre cleaning/opening by air draught arrangementsFibre cleaning/opening by toothed membersFiberPulp and paper industry

The invention provides a cotton cleaning machine, comprising a cotton loosening device and an impurity removing device, wherein the cotton loosening device comprises a first cotton loosening chamber and a second cotton loosening chamber, a feed port is formed in the top of the first cotton loosening chamber, a needle licker-in is arranged inside the first cotton loosening chamber, the second cotton loosening chamber is arranged at the bottom of the first cotton loosening chamber, a breaking roller is arranged inside the second cotton loosening chamber, an outlet is formed in the bottom of the second cotton loosening chamber and communicated with the impurity removing device, the left side of the impurity removing device is connected with a draught fan, a discharge port is formed in the right side of the impurity removing device, and a filter screen and a sundry box are sequentially arranged at the bottom of the impurity removing device from top to bottom. The cotton cleaning machine has the advantages that after being primarily loosened through the needle licker-in in the first cotton loosening chamber, cotton bales enter the second cotton loosening chamber to be secondarily loosened through the breaking roller, and therefore the cotton loosening process is more sufficient; moreover, impurities are removed through air flow, impurities mixed in cotton fibers are effectively removed, and therefore cotton bundles suitable for spinning are obtained.

Owner:TIANJIN JINGLONG TEXTILE RUBBER

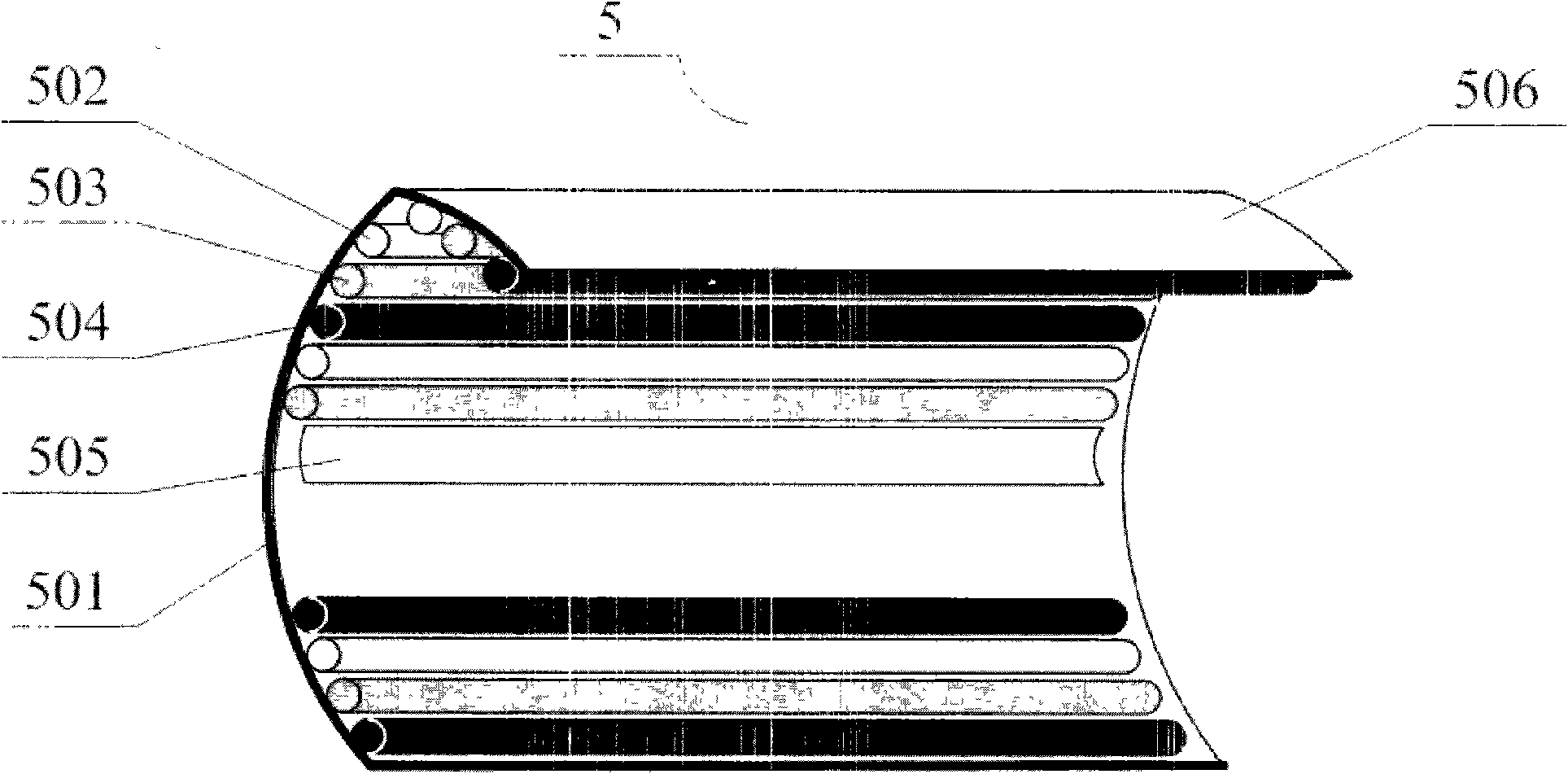

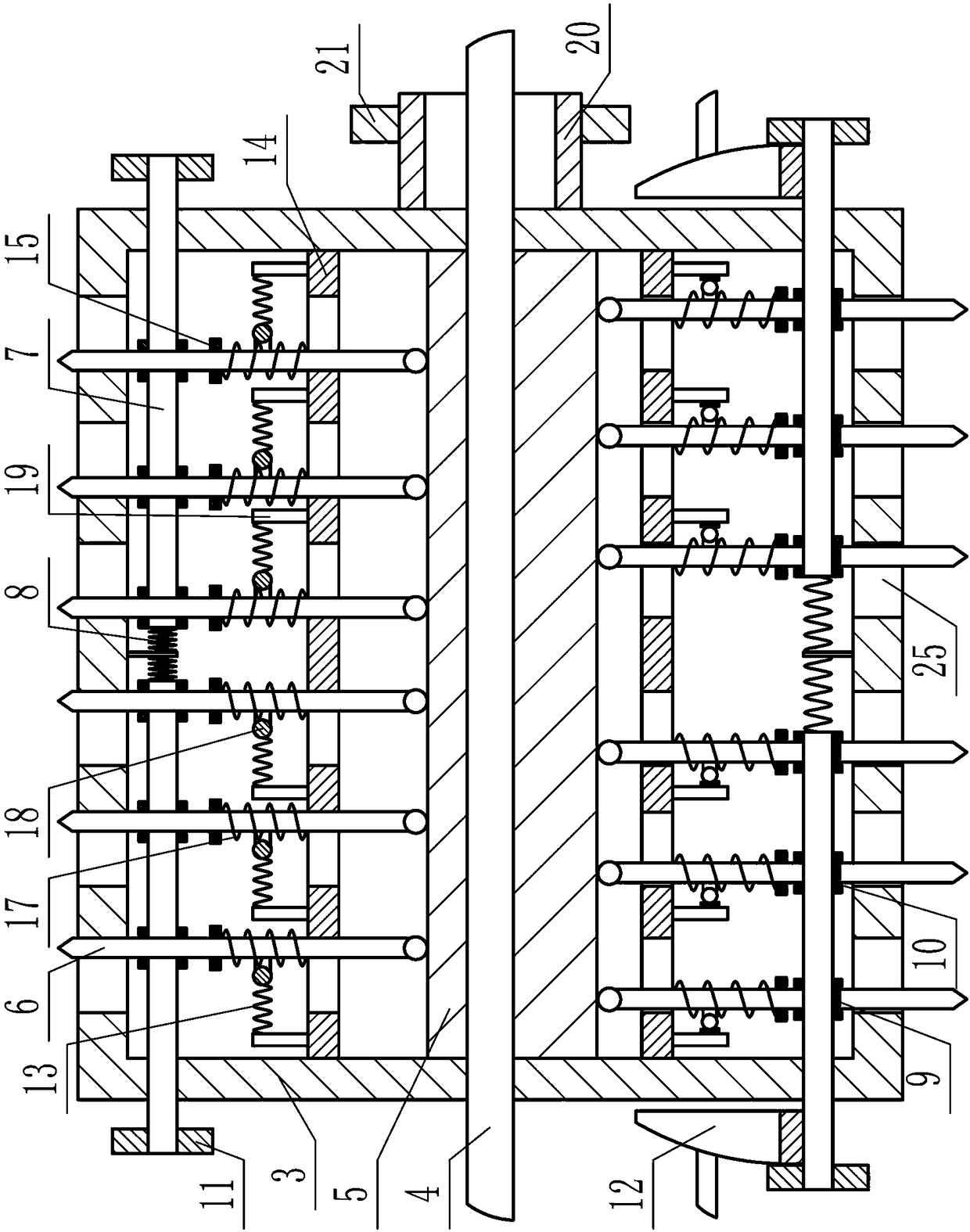

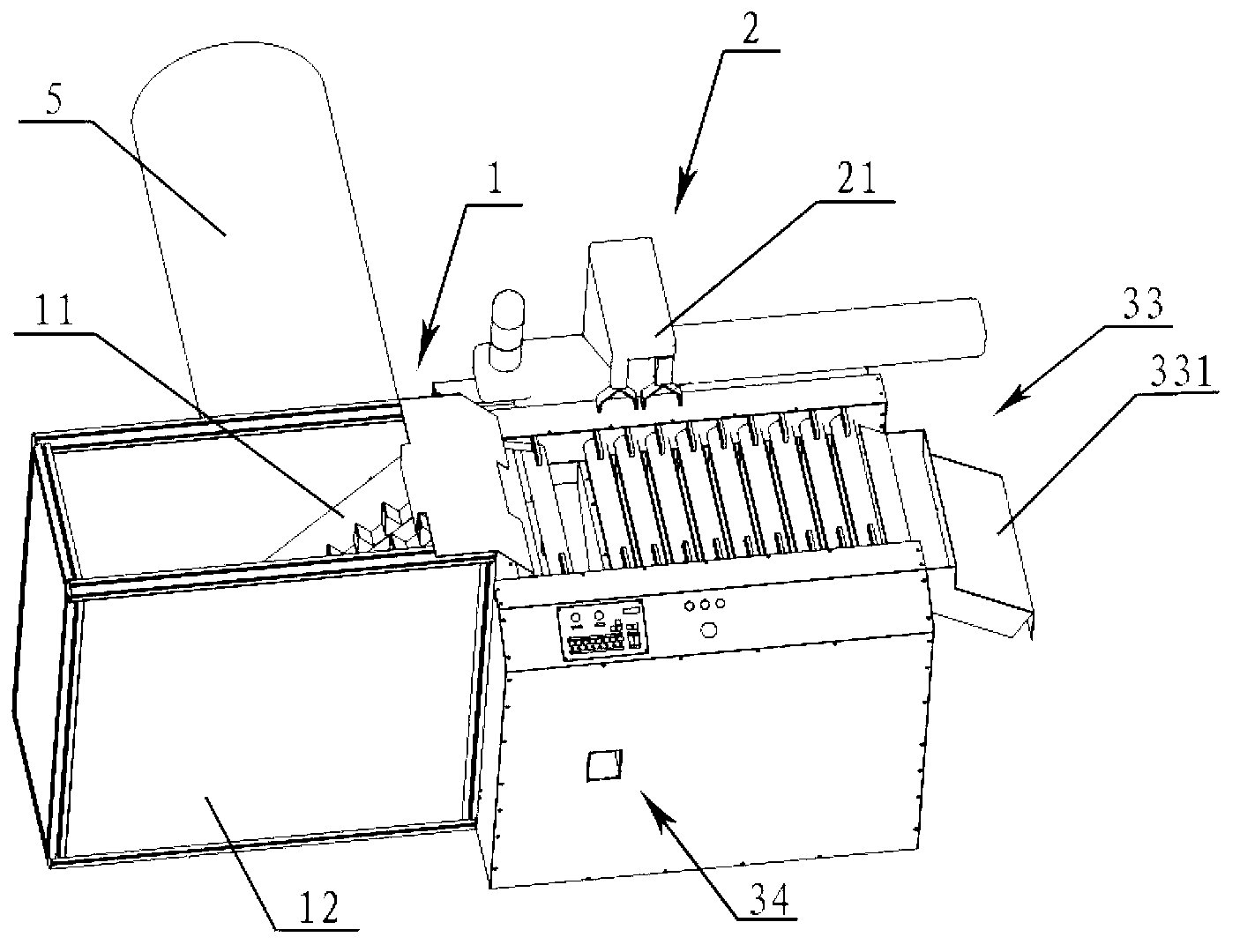

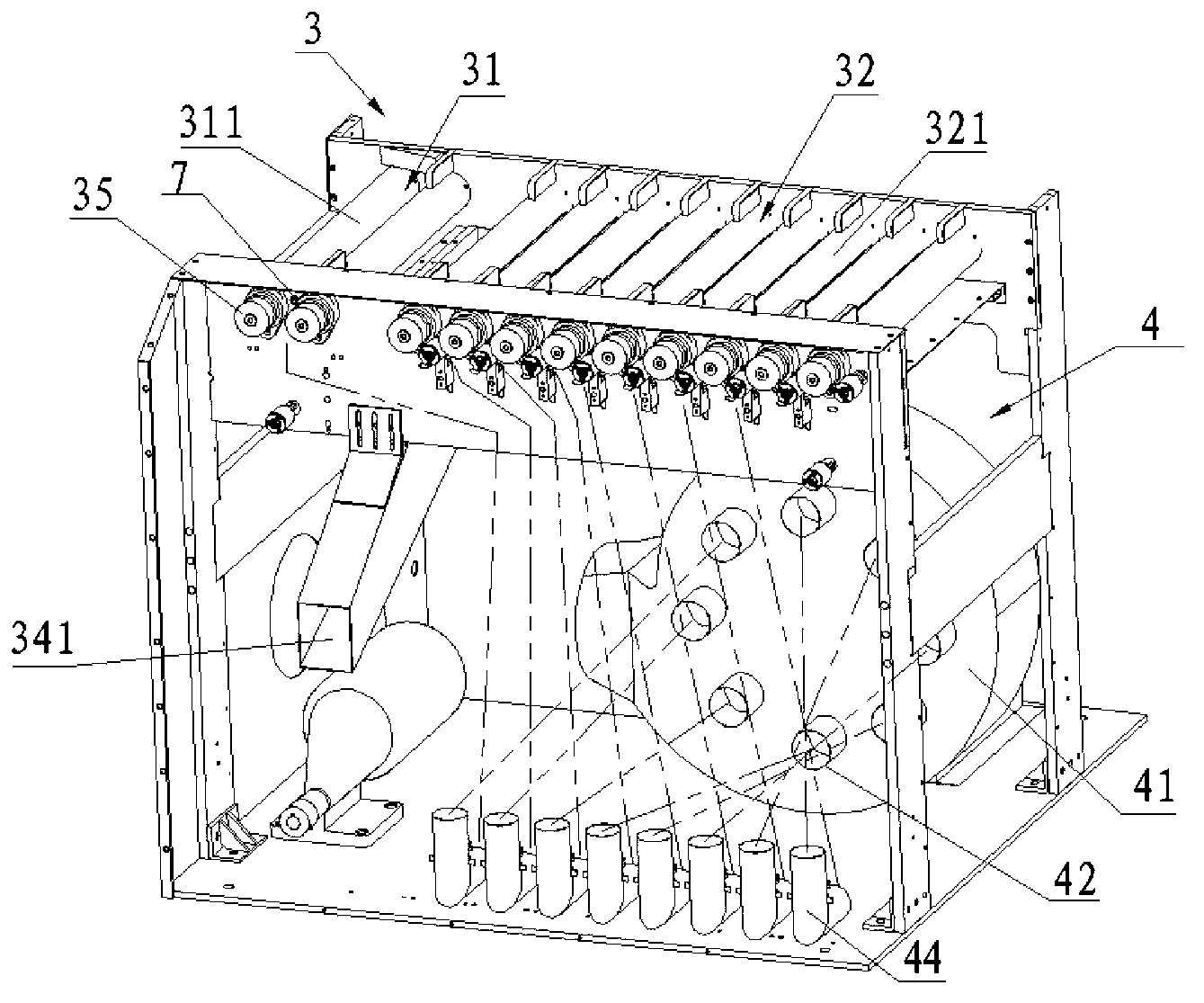

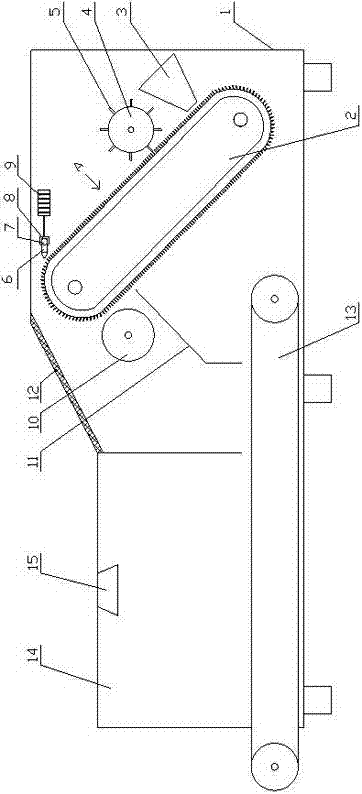

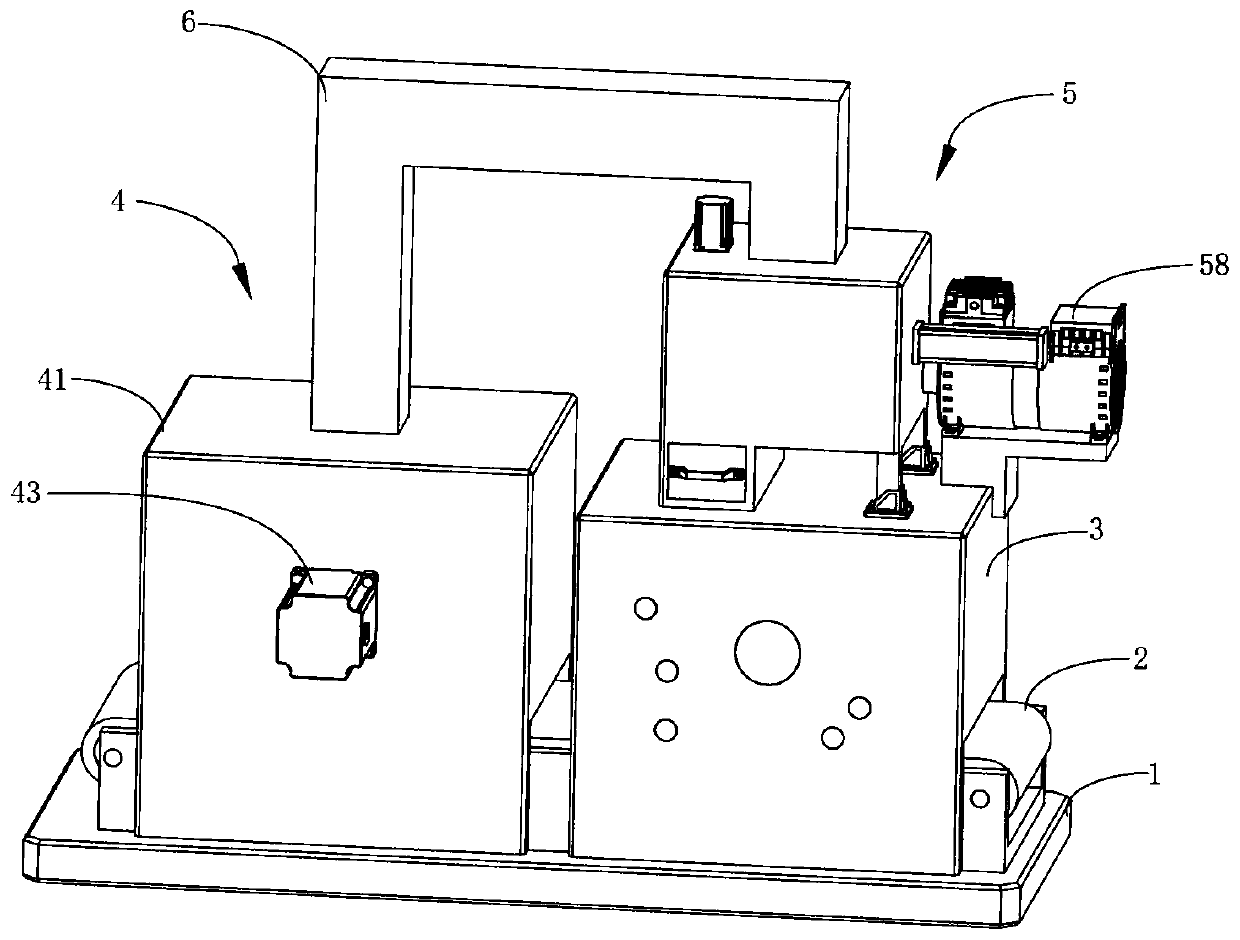

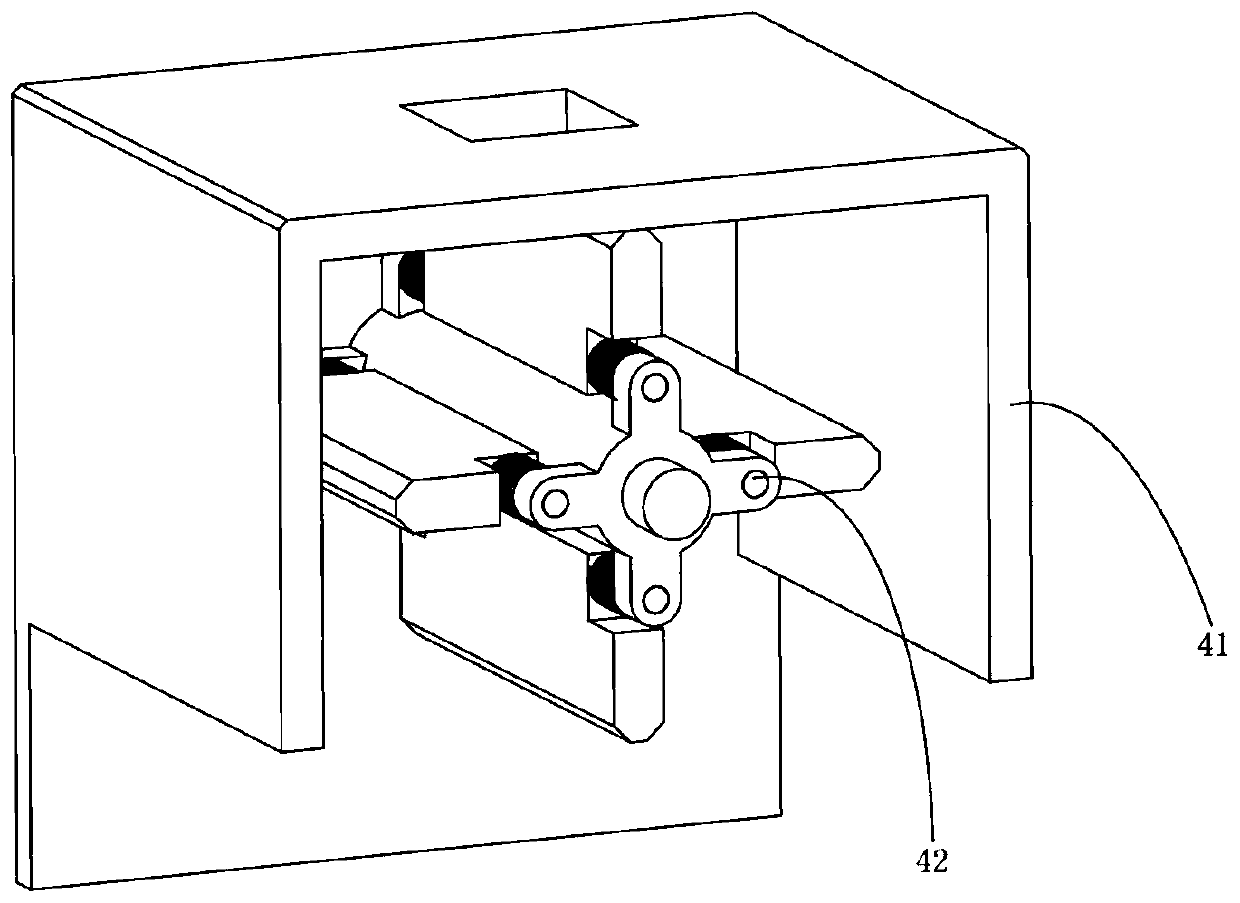

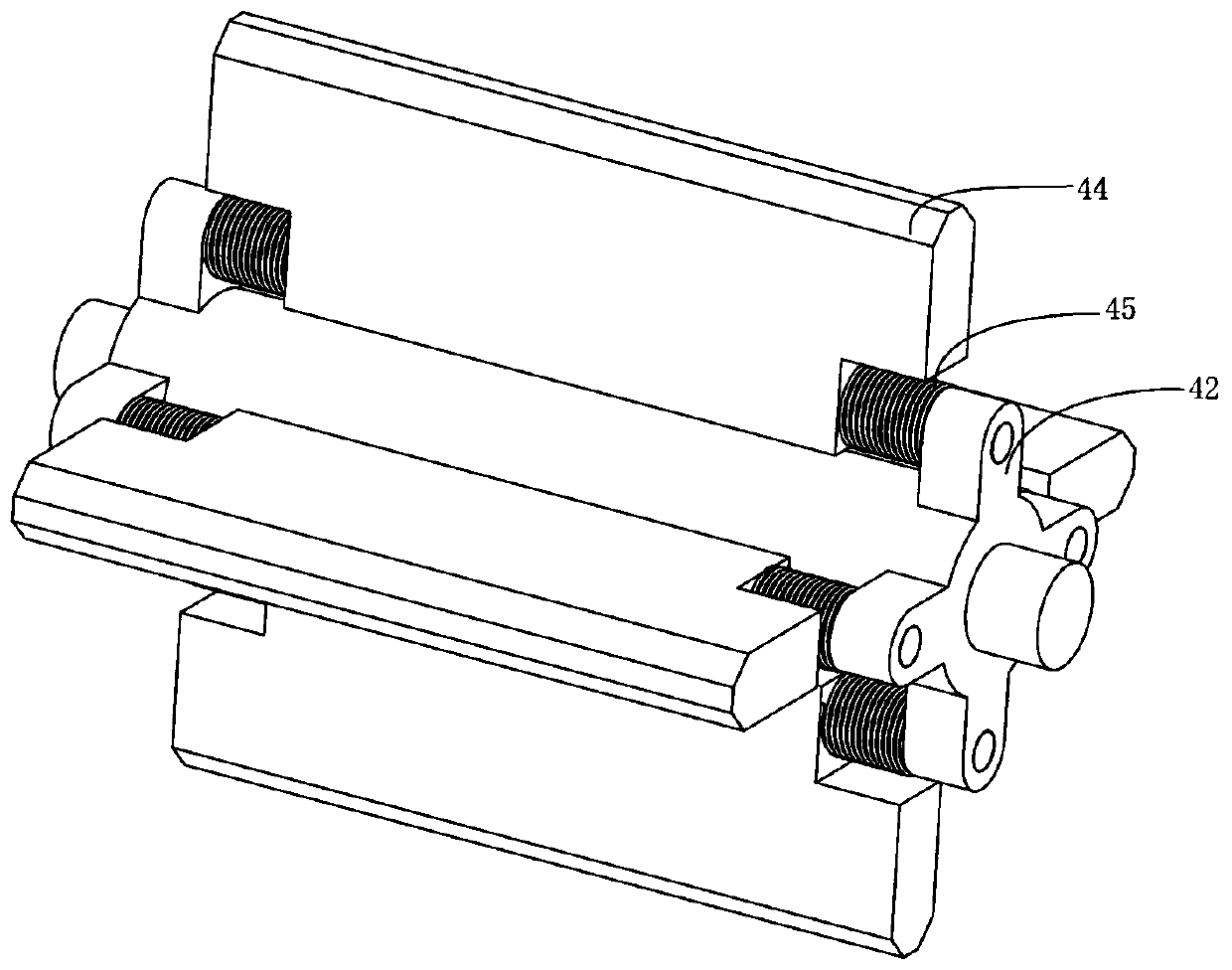

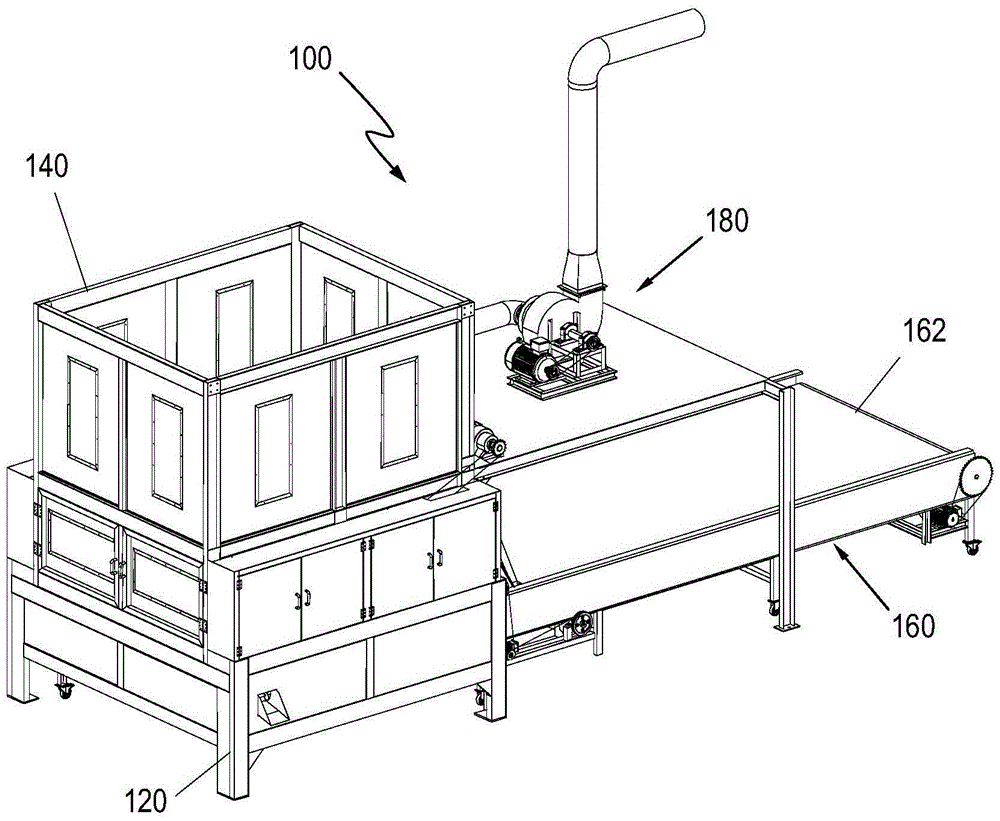

System for automatically cleaning tail yarns of roving bobbins

InactiveCN102704068AImprove the opening effectImplement automatic cleanupFibre cleaning/opening by air draught arrangementsYarnBobbin

The invention relates to a system for automatically cleaning tail yarns of roving bobbins. The system comprises a feeding device, a conveying device, an unwinding device, an opening device, a recovering device and a control system, wherein the feeding device is used for storing a plurality of roving bobbins of which large ends and small ends are respectively positioned in the same direction and which are wound with tail yarns and automatically conveying the roving bobbins to the unwinding device one by one; the unwinding device comprises a turnaround sliver cleaning mechanism, an unwinding mechanism, a successfully unwound roving bobbin collecting mechanism and an unsuccessfully unwound roving bobbin collecting mechanism; and the opening device is used for finding the ends of the tail yarns of the roving bobbins on the turnaround sliver cleaning mechanism and the unwinding mechanism and unwinding and opening the tail yarns. By matching the unwinding device, the opening device and the control system, the tail yarns of the roving bobbins are unwound and opened, the unwound roving bobbins are collected, or the roving bobbins which are not unwound or not completely unwound are collected, and the tail yarns are automatically cleaned in the whole process, so that a large amount of manpower is saved, and efficiency is improved.

Owner:CHANGDE TEXTILE MACHINERY

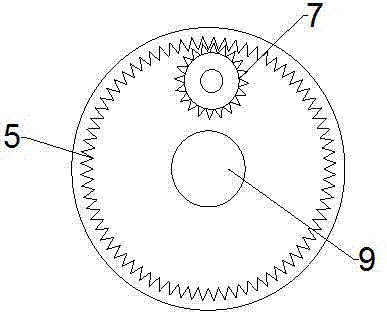

Impurity-removal automatic feeding device for carding machine

PendingCN109183205AEfficient removal of impuritiesSimple structureFibre cleaning/opening by air draught arrangementsFibre cleaning and opening machine combinationsDrive wheelEngineering

The invention discloses an impurity-removal automatic feeding device for a carding machine. The device includes an outer box, an inner box, supporting legs, a motor, a stirring shaft, a feeding port,a discharging port, a sliding baffle plate, a spring, a heating wire, an air distribution plate, an induced draft fan and a drying box, wherein the bottom of the outer box is provided with multiple supporting legs, the inner box is located inside the outer box, bottom plates of the inner and outer boxes are overlapped, the motor is arranged on the left side of the outer box, a rotating shaft of the motor penetrates through the outer box and is connected with a driving wheel, the stirring shaft is arranged inside the inner box, a left end of the stirring shaft penetrates through the inner box,the stirring shaft is connected with a driven wheel, the driven wheel and a driving wheel are engaged with each other, the inner box is further provided with the feeding port penetrating through the top of the outer box, the discharging port is arranged below the inner box, the sliding baffle plate is arranged at the discharging port, the spring is arranged between a right end of the sliding baffle plate and the outer box, the air distribution plate is further disposed above the inner box inside the outer box, the air distribution plate is provided with the heating wire, and an air inlet pipeis arranged at a top plate of the outer box above the heating wire.

Owner:湖州萌星服饰有限公司

High-pressure gas flow type soft fiber opener

ActiveCN102864525ANo windingNo damageFibre cleaning/opening by air draught arrangementsFiberSpray nozzle

The invention discloses a high-pressure gas flow type soft fiber opener which comprises a casing, wherein an obliquely-arranged needle plate conveying belt is arranged in the casing, a feeding hopper is arranged above a feeding end of the needle plate conveying belt, and a spreading roller is arranged above the needle plate conveying belt. Soft convex pieces are arranged on the surface of the spreading roller, the top end of each soft convex piece is close to the top end of the needle plate conveying belt, a high-pressure gas spraying nozzle is arranged at the position close to an arc-shaped discharging end of the needle plate conveying belt, and the gas spraying direction of the high-pressure gas spray nozzle is horizontally tangent to roots of needles at the discharging end of the needle plate conveying belt. The high-pressure gas spraying nozzle is arranged on a transverse rod, and one end of the transverse rod is connected with an eccentric wheel device which is connected with a moor. A cleaning brush is arranged below the discharging end of the needle plate conveying belt, a baffle is arranged below the cleaning brush, and screen cloth is arranged on the casing. A conveying belt is arranged below the baffle, one end of the conveying belt is arranged outside the casing, an atomizing chamber is arranged above the baffle, and an oil solution spraying nozzle is arranged at the top of the atomizing chamber. The high-pressure gas flow type soft fiber opener has the advantages that the structure is simple, a soft opening mode is adopted and fibers cannot be damaged.

Owner:徐州时代纺织有限公司

Metal and dust removing device for cotton

InactiveCN104099690AImprove removal efficiencySimple structureFibre cleaning/opening by air draught arrangementsFibre cleaning/opening by toothed membersEngineeringImpurity

The invention provides a metal and dust removing device for cotton. The metal and dust removing device comprises conveying rollers assembled in an vertical direction, a conveying belt is assembled between the two conveying rollers, a licker-in is assembled on the lateral side in the vertical direction of the conveying belt and comprises a shell, round-pipe-shaped licker-in pipes are uniformly distributed on the shell, the inside of each licker-in pipe is communicated with that of the shell, and the licker-in pipes are vertically fixed on the surface of the shell; a central shaft is assembled on the axis of the shell, magnetic rods entering inside the licker-in pipes are fixed on the central shaft, through holes are uniformly distributed on the surface of each licker-in pipe, an annular cavity is formed between the shell and the central shaft and connected with an air incoming end of a fan through a pipeline, and the shell and the central shaft are driven to synchronously rotate by a transmission device. The metal and dust removing device can remove metal and dust in the process of belt conveying and is simple in structure and high in overall impurity removing efficiency.

Owner:WUJIANG TEXTILE SCI & TECH CENT

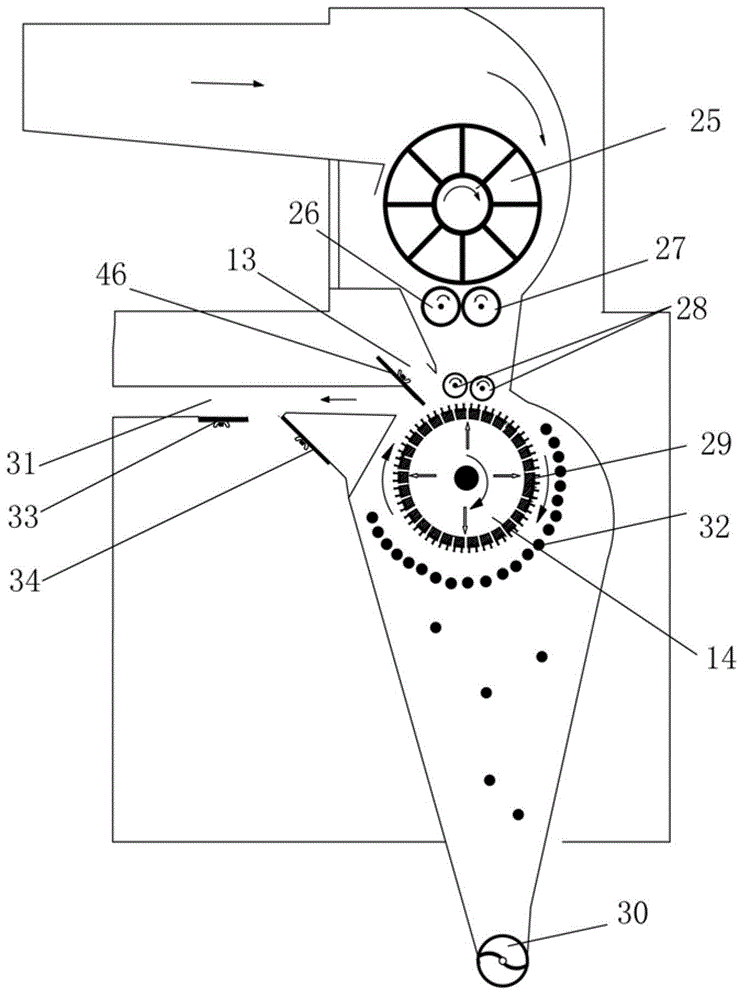

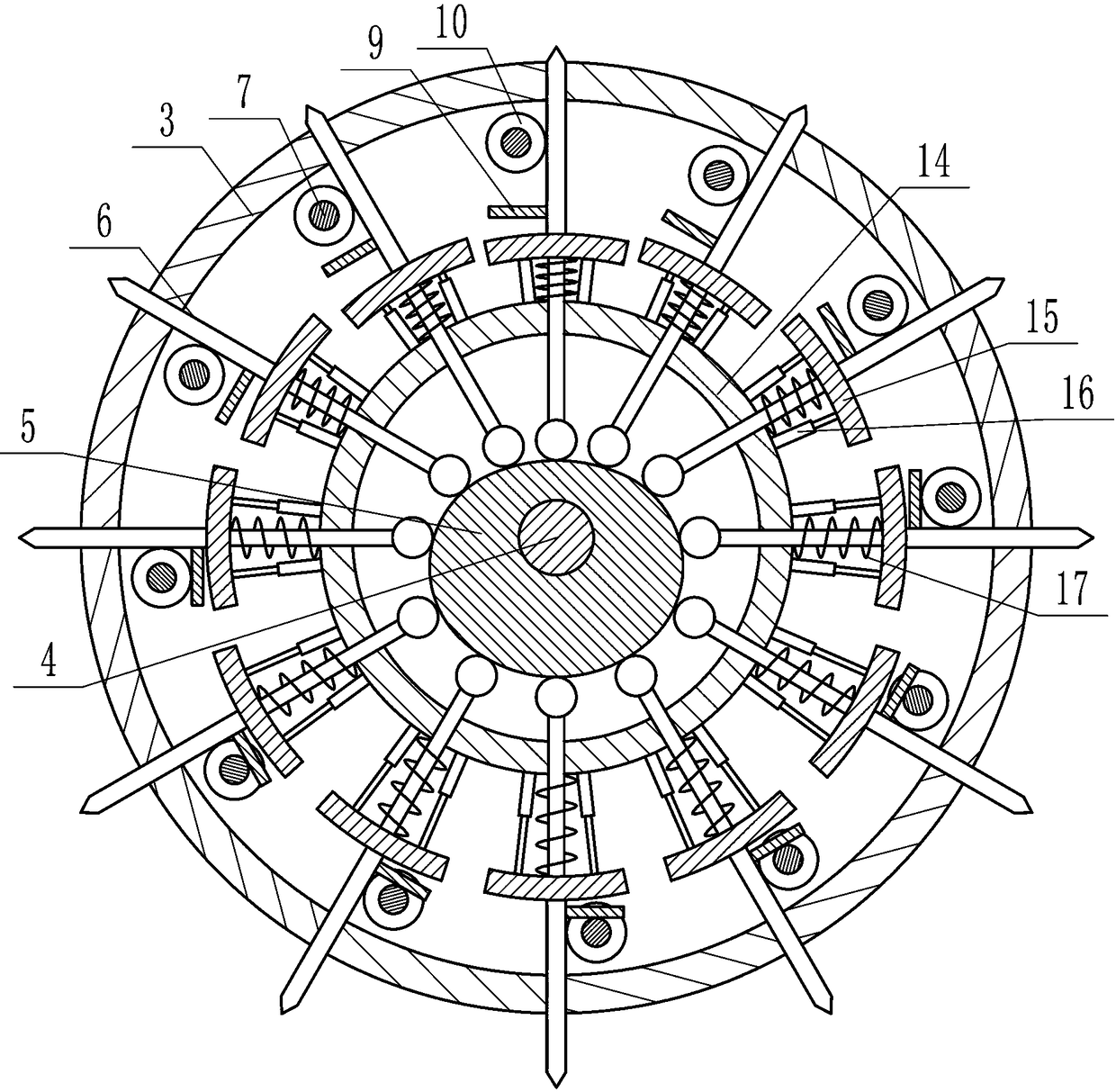

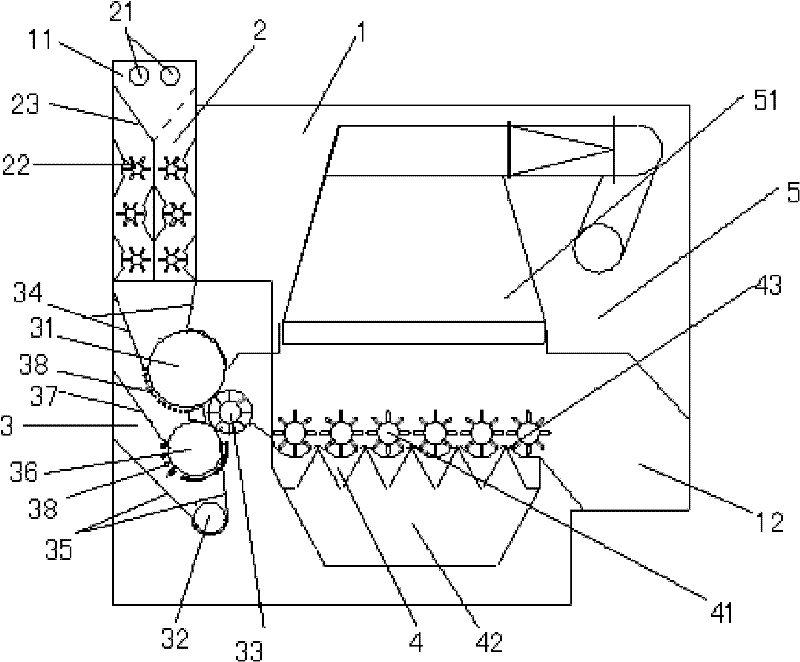

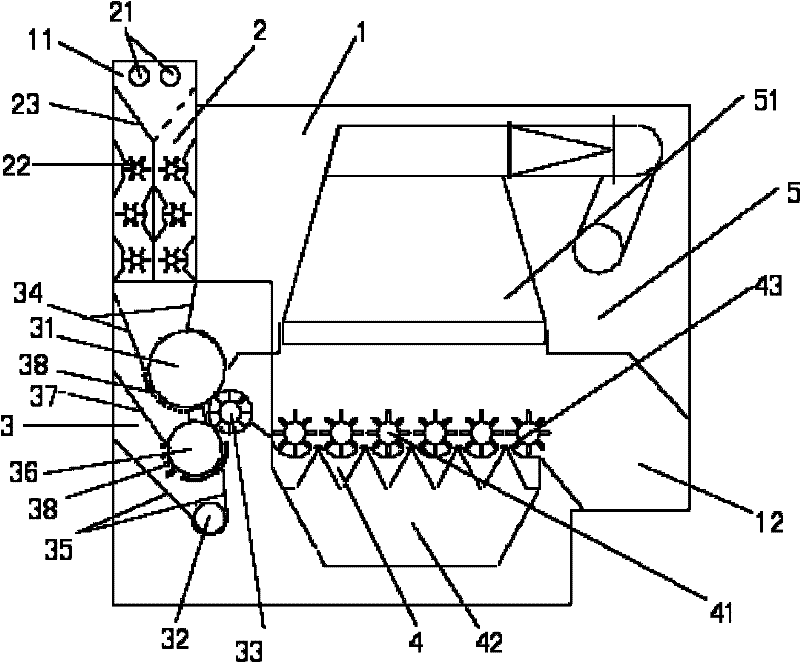

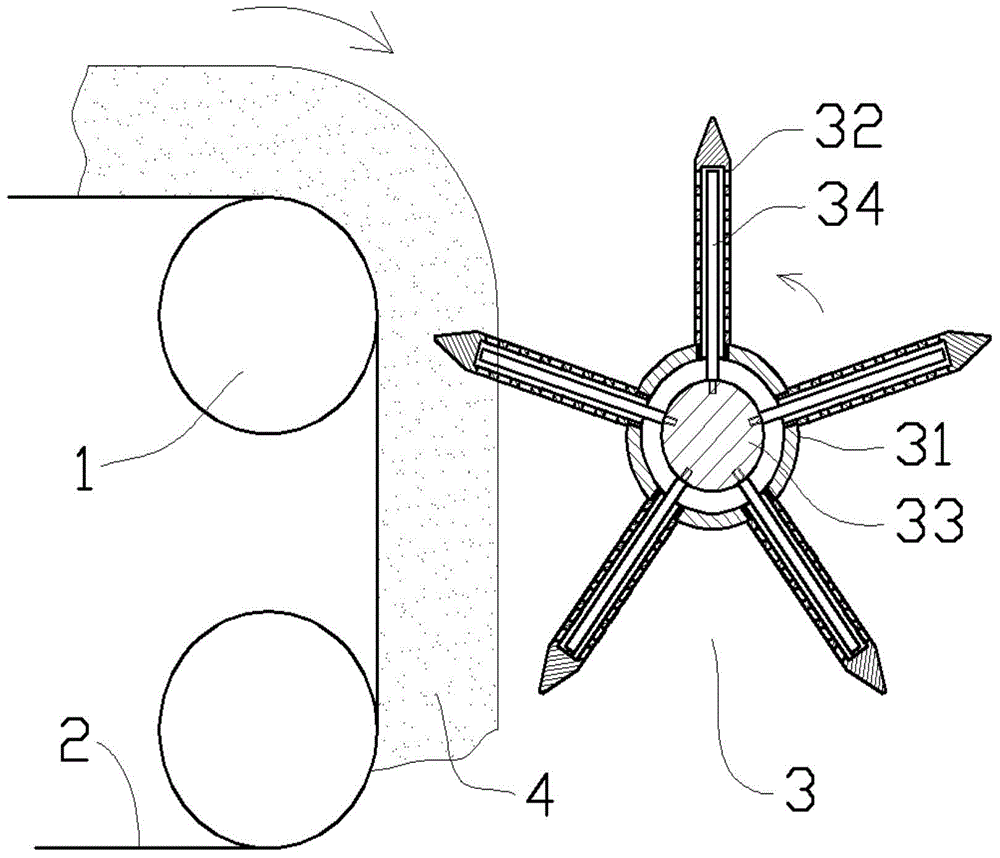

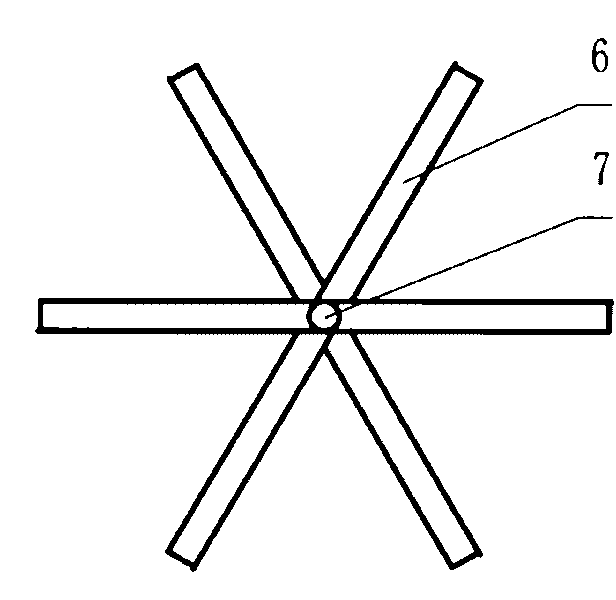

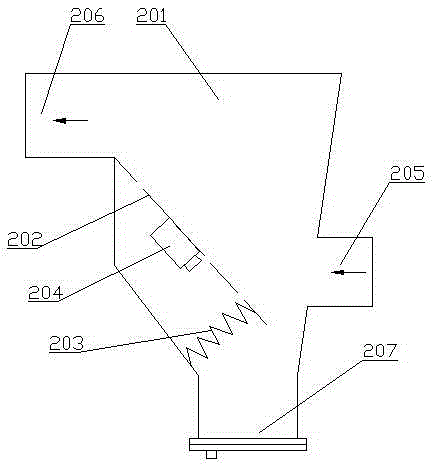

Seed cotton foreign fiber separating and opening machine

ActiveCN101760810AAvoid damageEasy to separateFibre cleaning/opening by air draught arrangementsFibre cleaning/opening machinesFiberStops device

The invention relates to a seed cotton foreign fiber separating and opening machine for separating and removing a foreign fiber in a machine picked seed cotton processing link. The machine comprises a machine shell, wherein the upper part of the machine shell is provided with a feed opening and a discharge opening, and the lower part is provided with an impurity discharge opening; a fluidizing chamber comprising an upper cavity and a lower cavity is arranged in the machine shell; the volume of the upper cavity of the fluidizing chamber is larger than that of the lower cavity of the fluidizing chamber; the lower part in the fluidizing chamber is provided with a shifting rod disperser; the shifting rod disperser comprises a shifting rod which is vertically arranged at the bottom of the fluidizing chamber and an opening plate which is arranged on the shifting rod; the lower part of the fluidizing chamber is provided with an air inlet, the air inlet is connected with a fan; a mesh partition plate is arranged at the upper part of the air inlet in the fluidizing chamber; and an air stopping device is arranged near the feed opening in the fluidizing chamber. The invention has simple structure, production cost saving and good effects of seed cotton opening and foreign fiber separation, and can effectively prevent the damage to the seed cotton fiber by mechanical force action.

Owner:SHIHEZI UNIVERSITY

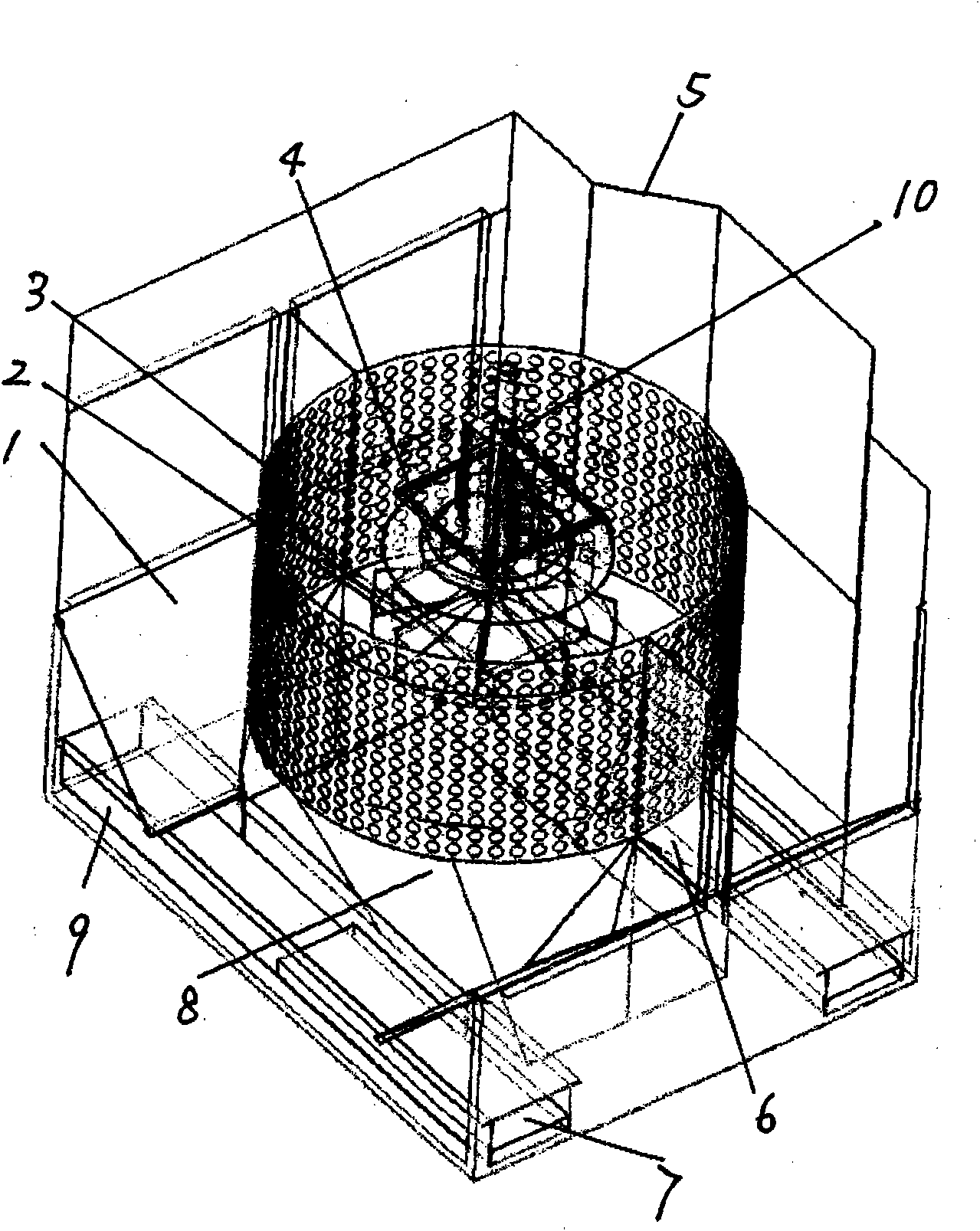

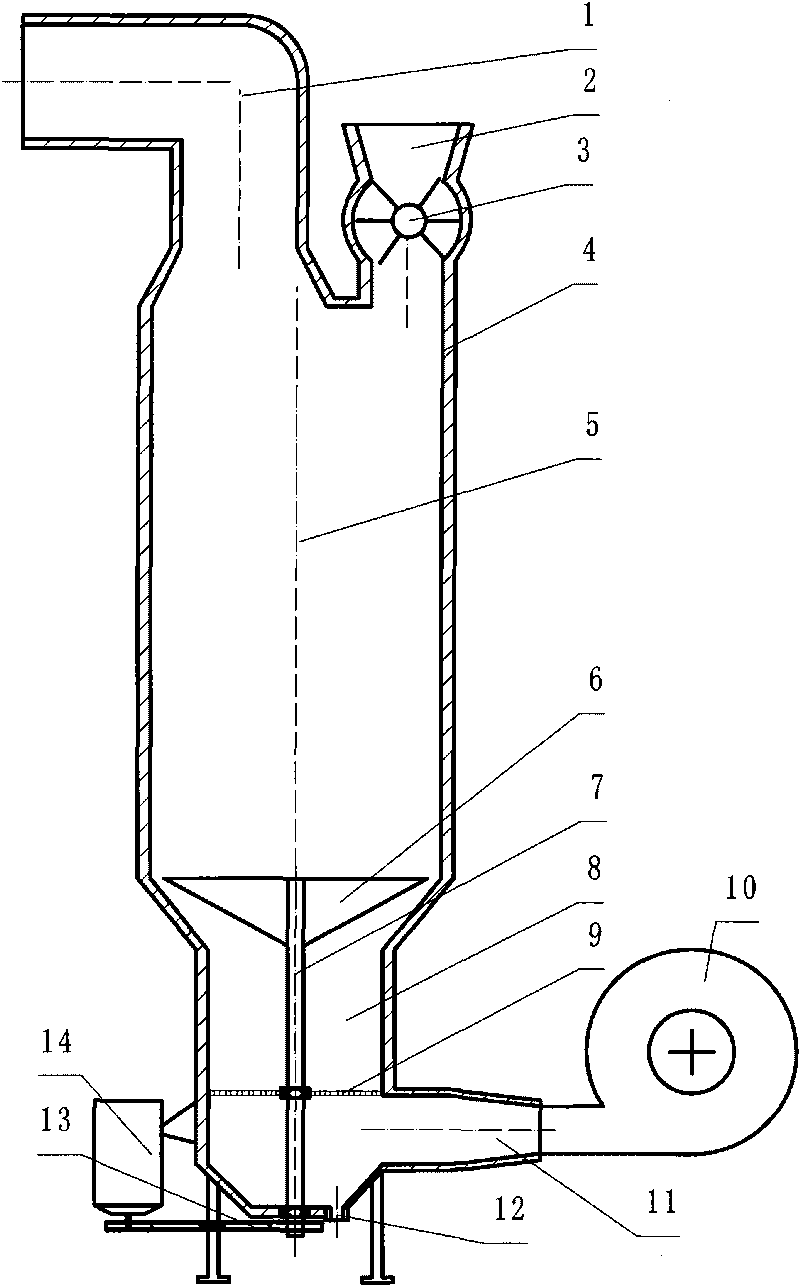

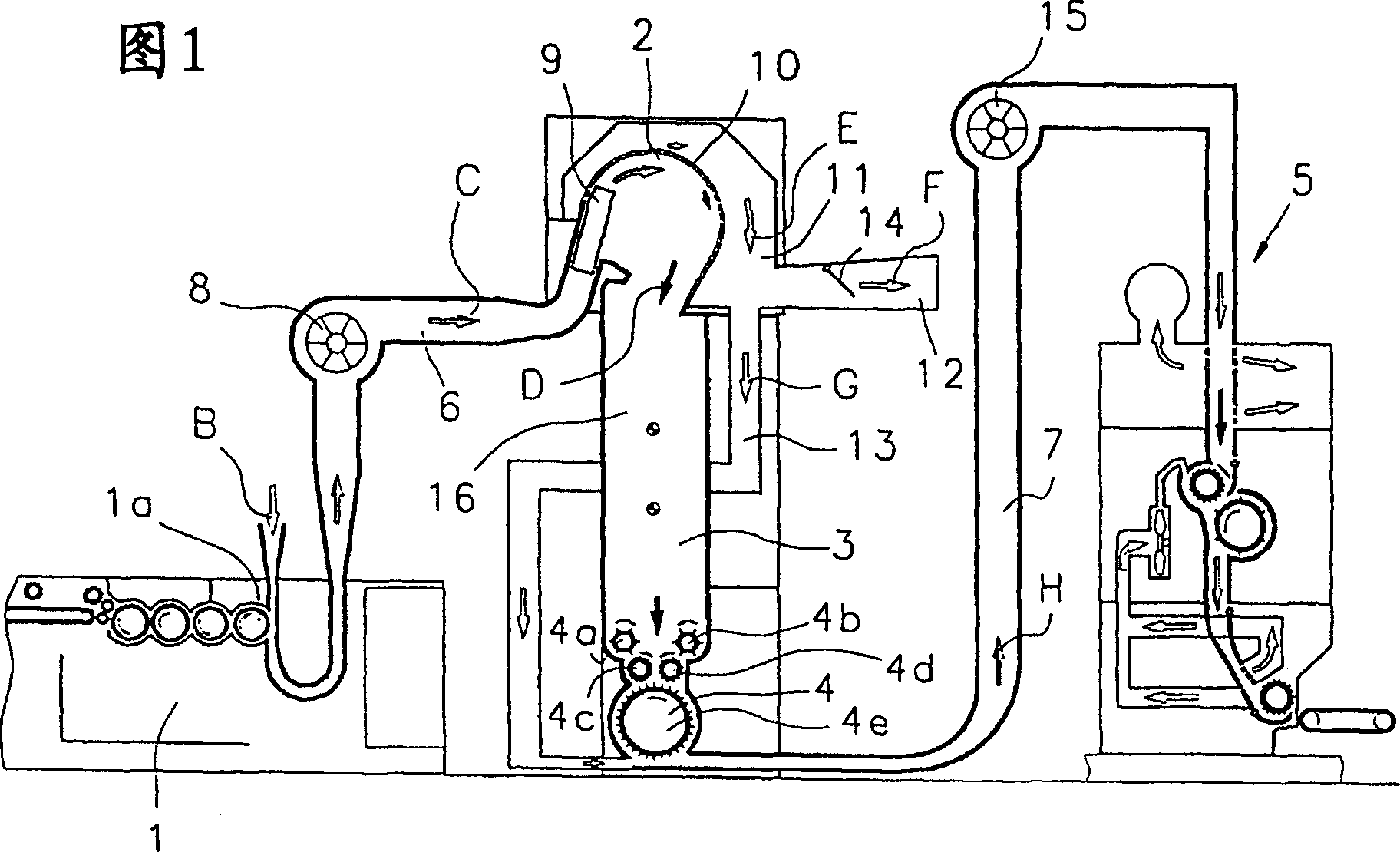

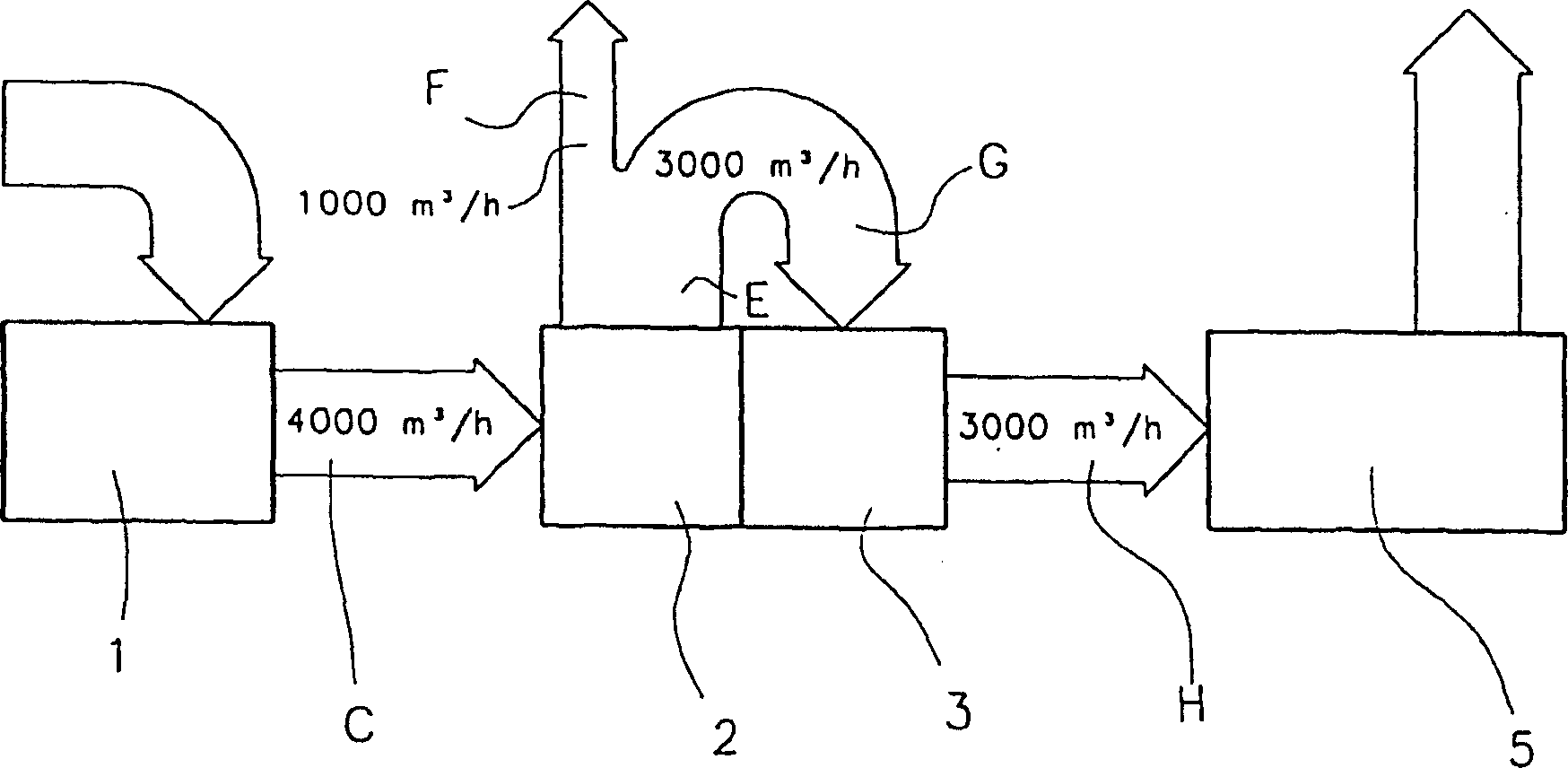

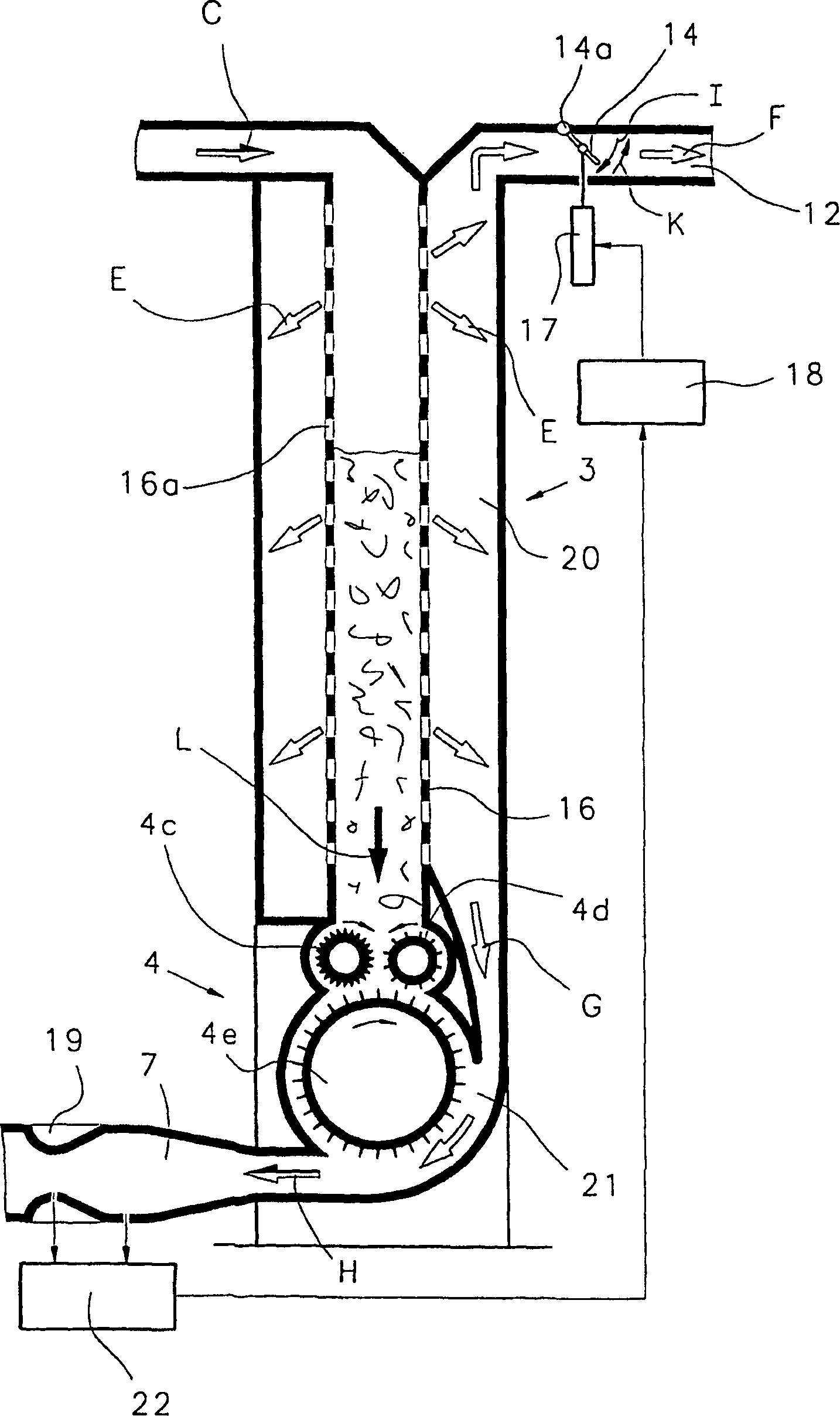

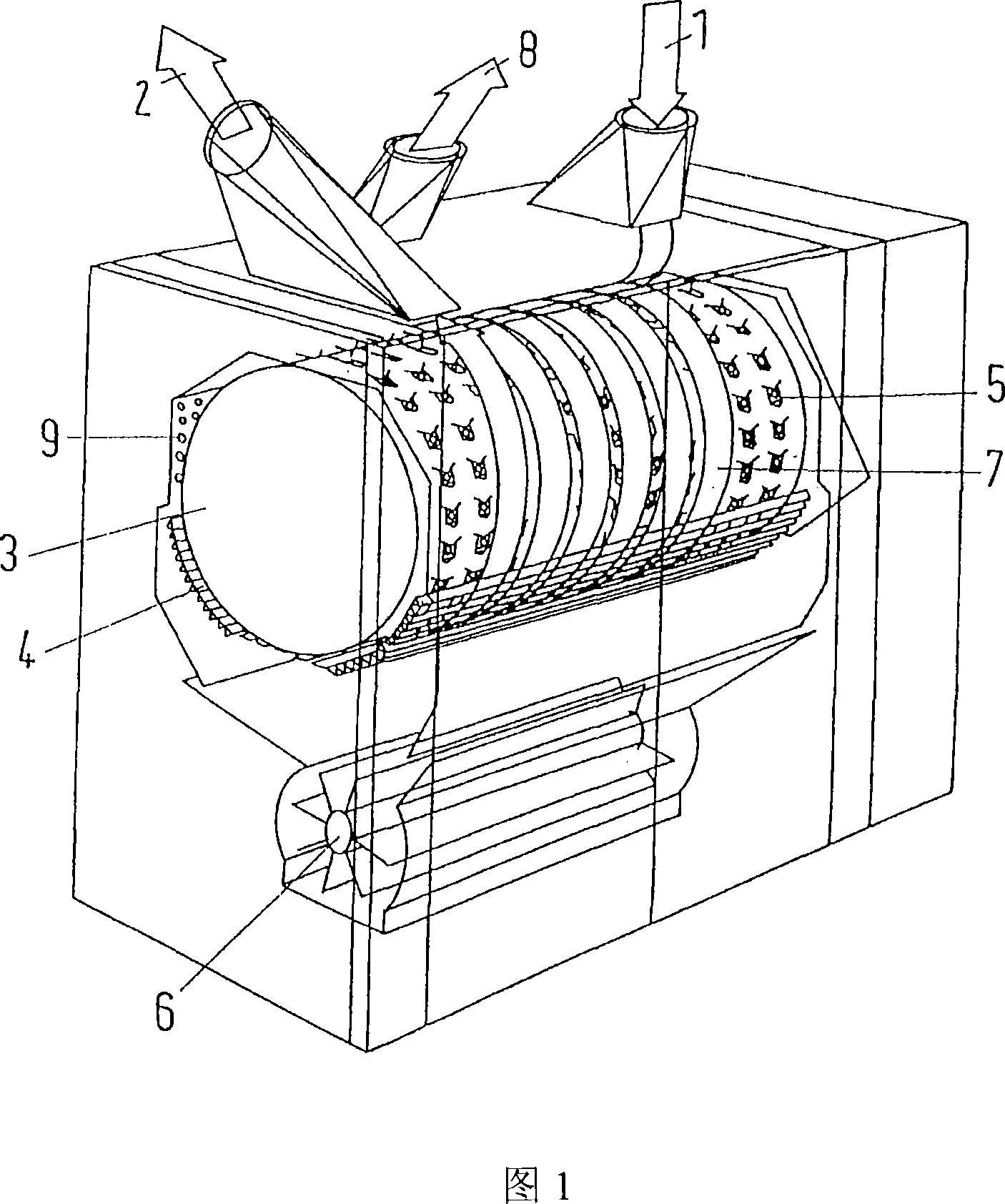

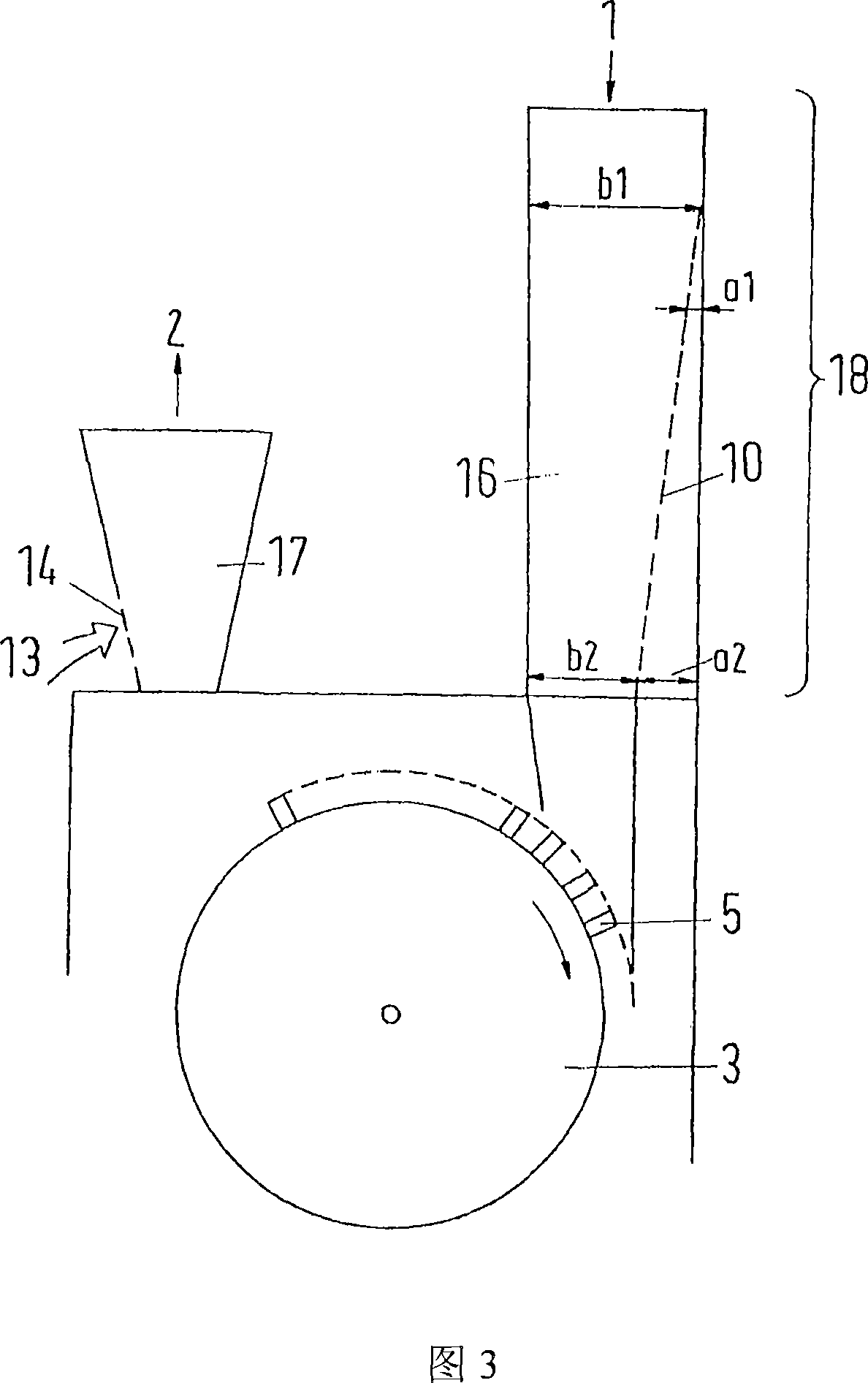

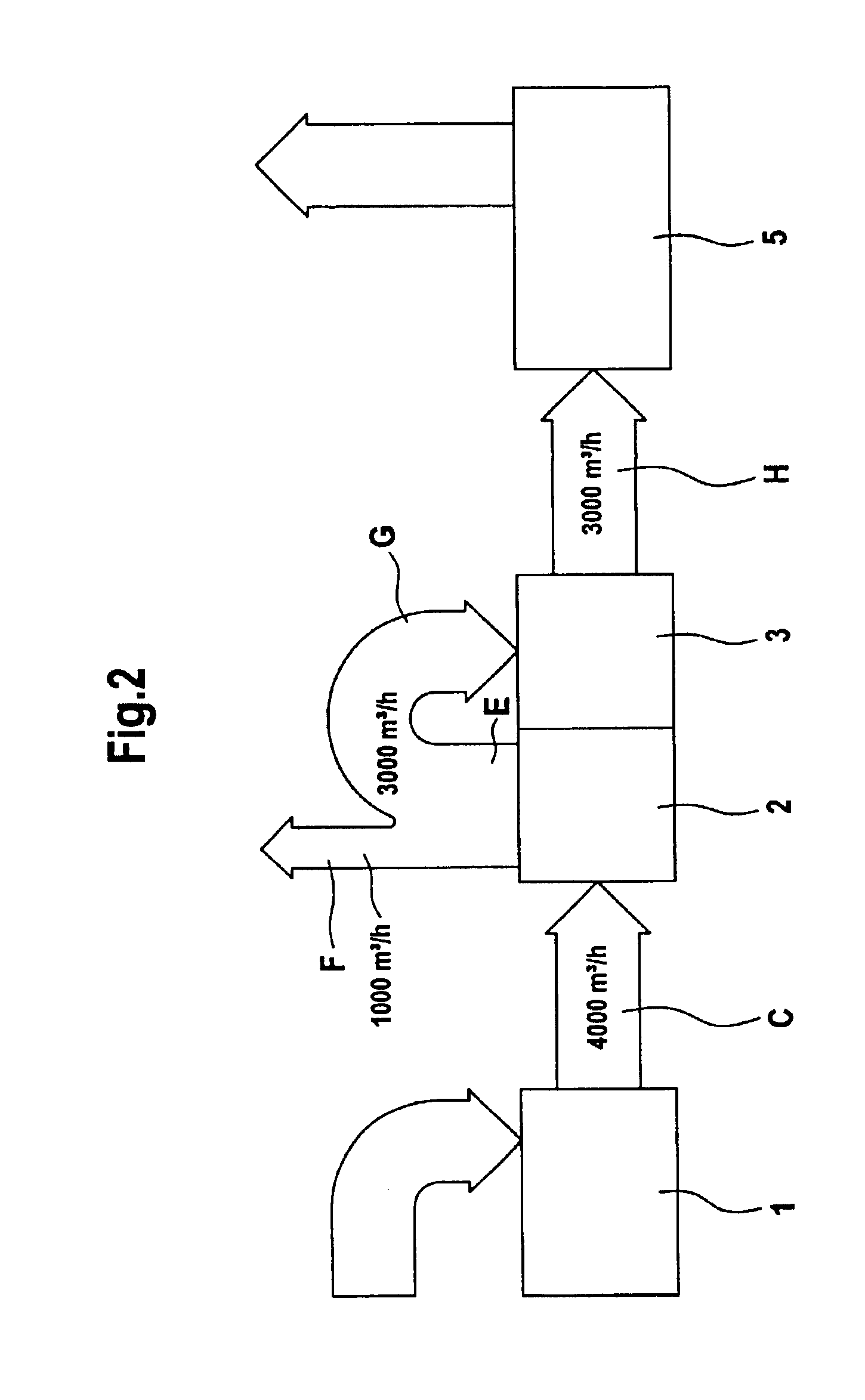

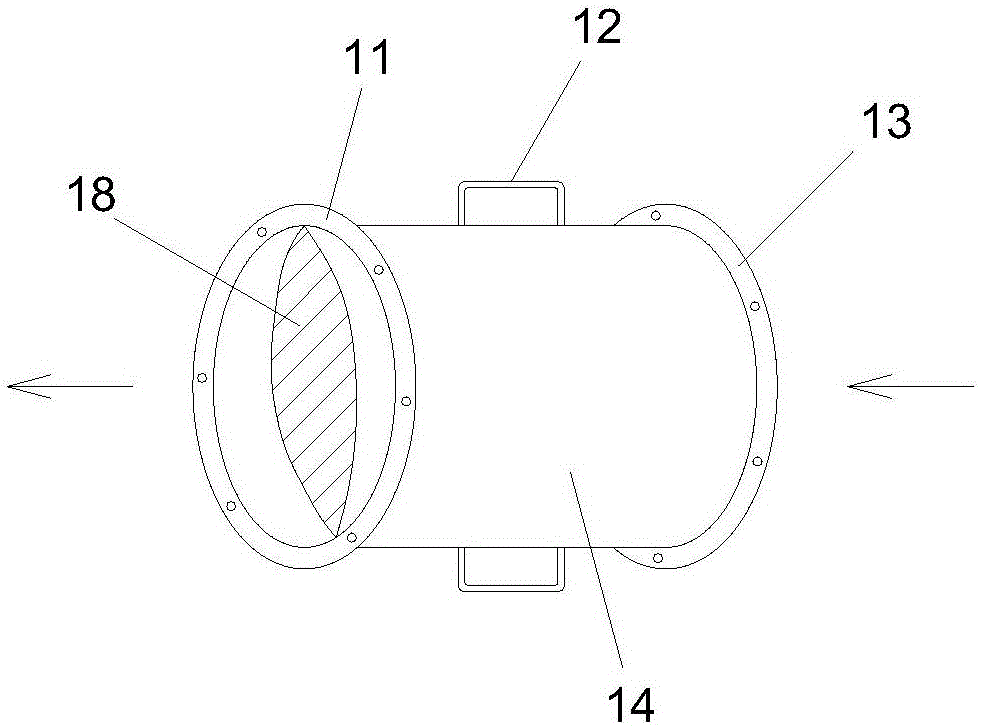

Apparatus for separating transporting air in fibrous material transportation

InactiveCN1448556AConstant sizeLow costFibre cleaning/opening by air draught arrangementsFibre cleaning/opening machinesFiberEngineering

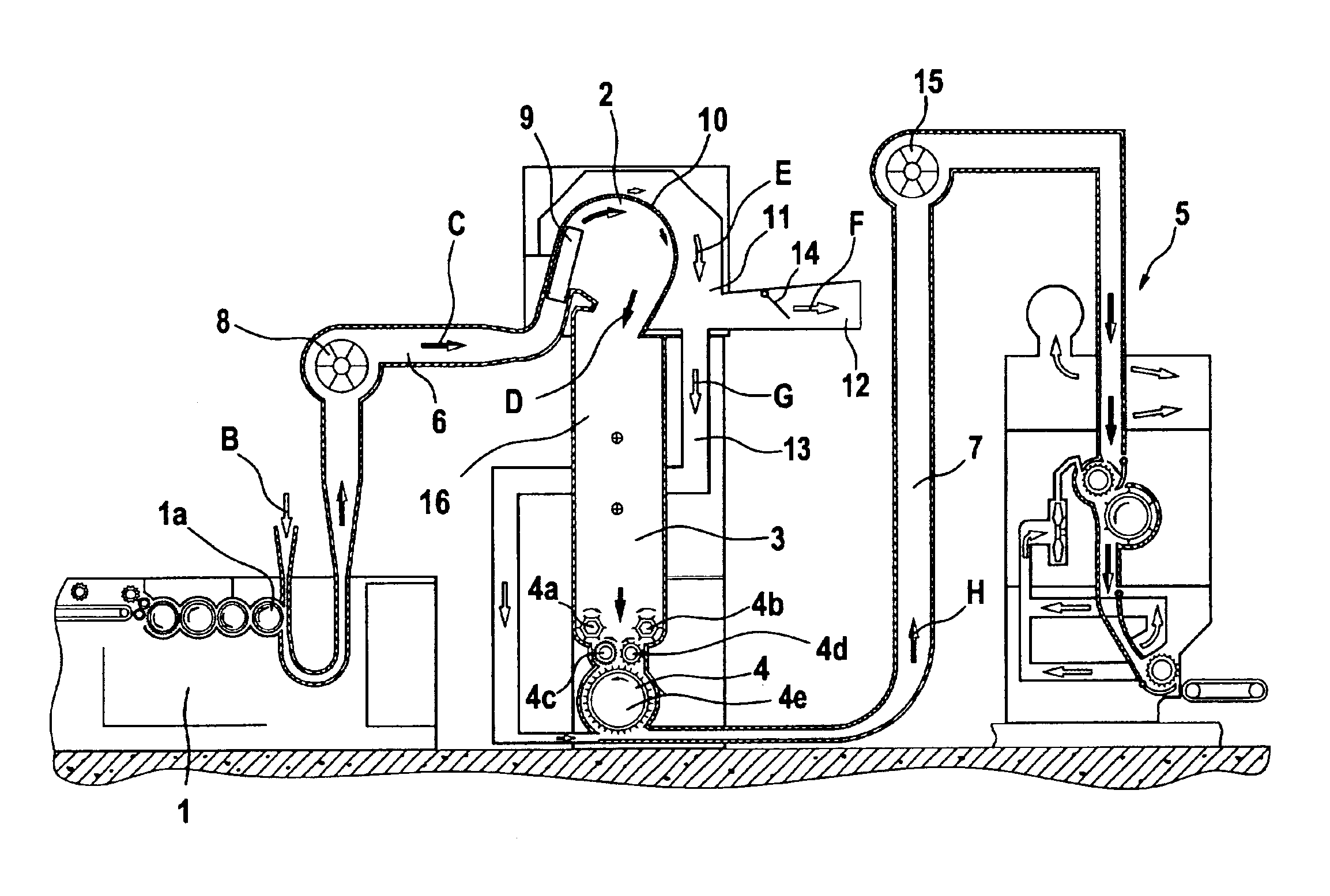

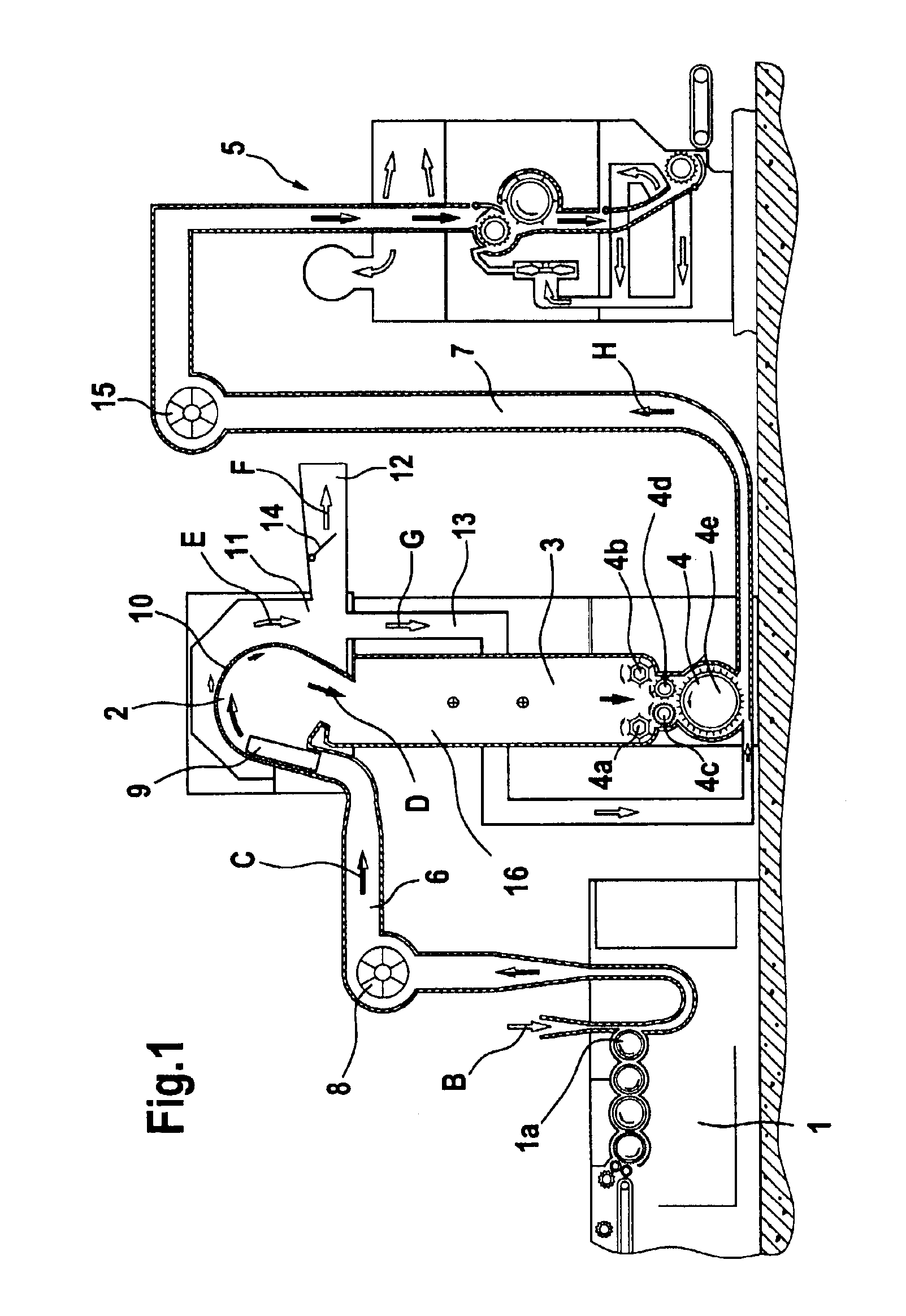

An arrangement used for filtering out conveying air when supplying fiber material, e.g. cotton and the like to a processing machine is provided. The arrangement has an essentially vertical filling chute for the fiber material, the chute having a device with pneumatic fiber feed at the upper intake opening, and a floccule-forming device at the lower exit opening including a system of draw-in rolls and a fast-rotating opening roll. The chute includes at least one air-permeable surface for separating the fiber material from the conveying air. An evacuating device evacuates the filtered out conveying air. An exhaust air device is coupled to the evacuating device and has an air stream regulator which is connected to a control and regulating device. The conveying air stream is guided along the opening roll, and a partial air stream of the filtered out conveying air is guided into the exhaust air device.

Owner:TRUETZSCHLER GMBH & CO KG

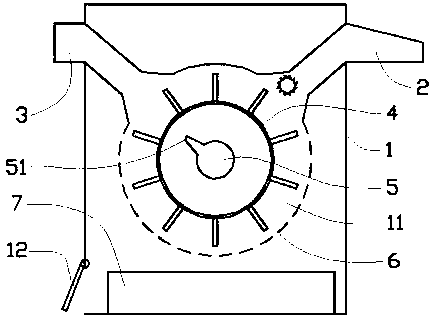

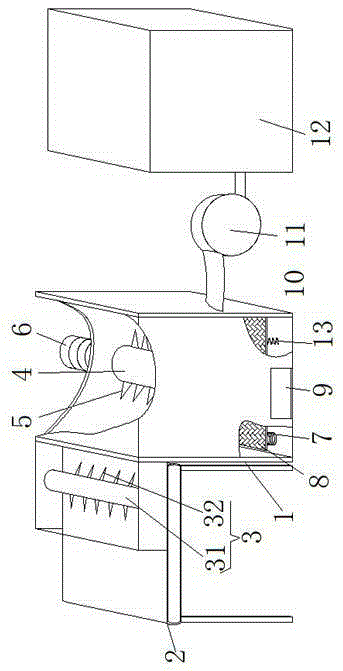

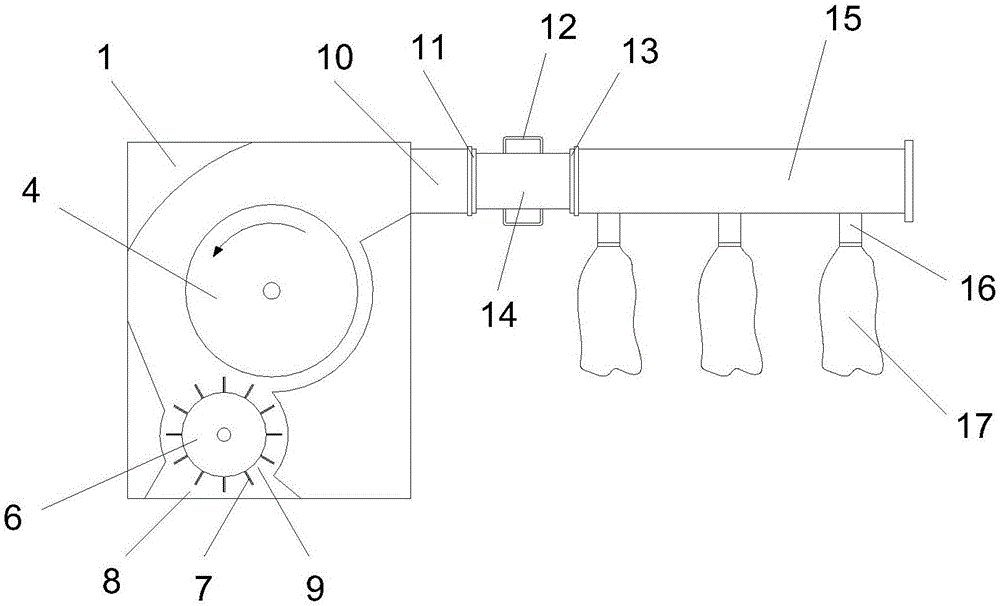

Self-cleaning scutcher

InactiveCN107460563AClean cotton easilyProcessing quickly and adequatelyFibre cleaning/opening by air draught arrangementsFibre cleaning/opening machinesPower unitBlow out

The invention discloses a self-cleaning scutcher and belongs to the field of textile machinery. The self-cleaning scutcher solves the problem of twining between a scutching stick and cotton. The self-cleaning scutcher comprises an inlet unit, a scutching wheel set, an outlet unit, a power unit and a scutcher housing (15), wherein the inlet unit comprises a feeding port (9); the outlet unit comprises an outlet channel (3) and a scutching baffle (2); the scutching wheel set comprises a central shaft (8) and the scutching stick (7) supported by the central shaft; the power unit comprises a fan (1), an air channel (11) and an air pipe (13) connected with the fan and the air channel, the air channel (11) is arranged in the wall of the scutcher housing (15) instead of the outlet unit, one end of the air pipe (13) is connected with the outlet of the fan (1), the other end of the air pipe (13) is connected with the air channel (11), and air is blown out of an air channel outlet (14) and towards blades (6) on the scutching stick (7).

Owner:余庆县鸿祥棉纺有限责任公司

Device for cleaning fiber wadding

InactiveCN101052759AInfluence takeoverAvoid damageFibre cleaning/opening by air draught arrangementsYarnFiberWadding

The invention relates to a cleansing device for fibre flocks, in particular, of cotton, with a horizontal roller, fitted with impact elements, with an inlet on the upper side at one end of the roller and an outlet at the other end for the feed stream. Transfer chambers defined by guide plates are placed at an angle to the roller axis between the inlet opening and the outlet opening for the feed stream rotating about the roller axis. The fibre flock stream can be compacted by provision of an air separation device before the inlet opening, which gives the cleansing device an improved cleansing with increased production.

Owner:MASCHINENFABRIK RIETER AG

Cotton batting re-fluff structure

InactiveCN103305970AReduce generationReturn to inflated stateFibre cleaning/opening by air draught arrangementsEngineeringHigh pressure

The invention provides a cotton batting re-fluff structure which comprises a processing baseplate, wherein a seal cover used for sealing the processing baseplate is hinged to one side of the processing baseplate, an atomization nozzle is arranged on the processing baseplate and communicated with an ultrasonic atomizer, the atomizing working substance of the ultrasonic atomizer is high voltage liquid gas which is arranged in a fluidsupply reservoir with a valve, the fluidsupply reservoir is connected with a compressor supplying the high voltage liquid gas, and a valve body is arranged on the seal cover or the processing baseplate. According to the cotton batting re-fluff structure provided by the invention, the ultrasonic atomizer is adopted to atomize the high voltage liquid gas discharging from the fluidsupply reservoir, after being atomized, the high voltage liquid gas is sprayed into the cotton batting from the position of the atomizing nozzle, after the valve body arranged on the seal cover is opened, the atomized high voltage liquid gas expands rapidly, and the cotton batting is opened and expanded.

Owner:WUJIANG XINHE WEAVING

Carding machine with dust removing function

ActiveCN110219158AFully raisedImprove dust removal effectFibre cleaning/opening by air draught arrangementsMechanical cleaningFiberHydraulic cylinder

The invention provides a carding machine with a dust removing function. The carding machine comprises a frame, a conveyor belt, a carding machine body, a dust raising mechanism, a dust removing mechanism and a square tube. A box in the dust raising mechanism is located above the conveyor belt, and a support frame is rotatably mounted in the dust raising box. A plurality of beating plates are rotatably mounted on the support frame. Torsional springs are arranged between two ends of each beating plate and the support frame. A dust removing box in the dust removing mechanism is located on a casing of the carding machine body, and is communicated with the dust raising box through the square tube. A dust filtering plate is movably mounted in the dust removing box through a hydraulic cylinder. Abrush is movably mounted in the dust removing box. A fan is communicated with the dust removing box. The support frame drives the beating plates to rotate to beat conveyed cotton, so that dust can befully raised to improve the dust removing effect; the brush moves up and down to recycle cotton fibers from the dust filtering plate, so that meshes of the dust filtering plate are prevented from blockage to avoid influences on the dust removing effect.

Owner:山东大和纺织科技股份有限公司

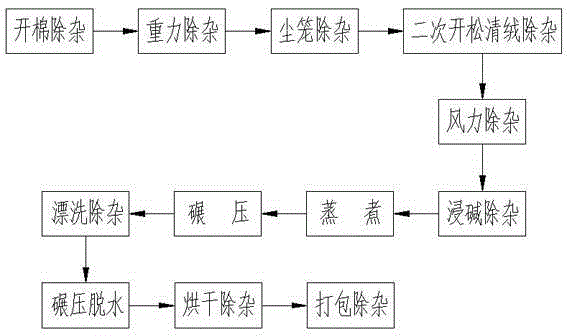

Cleaning system for refined cotton production

InactiveCN106544761AGuaranteed qualityFibre cleaning/opening by air draught arrangementsFibre cleaning/opening machinesFiberBlack liquor

The invention discloses a cleaning system for refined cotton production. Raw cotton linters are subjected to primary opening via an opening and cleaning device, the cotton linters subjected to the primary opening are cleaned via a gravity cleaning device, a dust cage cleaning device, a secondary opening, fiber-removing and cleaning device and a pneumatic cleaning device sequentially, the cleaned cotton linters are then charged into an alkali soaking cleaning device for alkali soaking, the alkali-soaked cotton linters are cooked via a rotary spherical digester to form cotton pulp, the cotton pulp is subjected to black liquor rolling and primary cleaning via a rolling device, the cotton pulp subjected to the primary cleaning is blanched and washed via a rinsing cleaning device, the washed pulp is then subjected to rolling dewatering and drying cleaning to form a finished product, and the finished product is packaged via a packaging cleaning device. The cleaning system for refined cotton production has the advantages that cleaning control is provided for each of the main steps of refined cotton production, such as opening, alkali soaking, rinsing, drying, and packaging, full-course systematic cleaning is provided, the impurities such as cotton seed hulls, sand, cotton dust and iron dust are removed thoroughly, and the product quality is effectively guaranteed.

Owner:HUBEI JINHANJIANG REFINED COTTON

Sliding rail type dust-free fiber wool opener

InactiveCN105386161AWon't tangleReduce the burden onFibre cleaning/opening by air draught arrangementsFibre cleaning and opening machine combinationsFiberEngineering

The invention discloses a sliding rail type dust-free fiber wool opener which comprises an auger conveyor and a housing. A feeding port is formed in the upper portion of the housing, a discharging port is formed in the lower portion of the housing, and the housing is internally divided into a coarse opening area and a collecting area. A second motor is arranged on one side of the feeding port and connected with a stirring shaft, a stirring paddle is arranged on the stirring shaft and provided with protruding circular wool opening balls, an air channel is formed in the stirring shaft, air outlet holes are formed in the side face of the stirring shaft, an impurity area is arranged below the coarse opening area, at least two sets of wool outlet holes in the vertical direction are formed in the side face of the coarse opening area, vertical rails are arranged on the side face of the collecting area, wool loosening blocks are connected to the rails, wool loosening hooks are arranged on the side faces of the wool loosening blocks and are in an anchor type, air nozzles facing inwards are arranged on the side face of the housing, a suction fan is arranged on the outer side of the discharging port, and a control box is arranged on the outer side of the housing. Materials produced through the sliding rail type dust-free fiber wool opener are fluffy, fine and soft, the burden of equipment is small, production efficiency is high, the phenomenon that many materials are wound on the inner wall of the wool opener can be avoided, and thus the service life is long.

Owner:盐城瑞德棉业有限公司

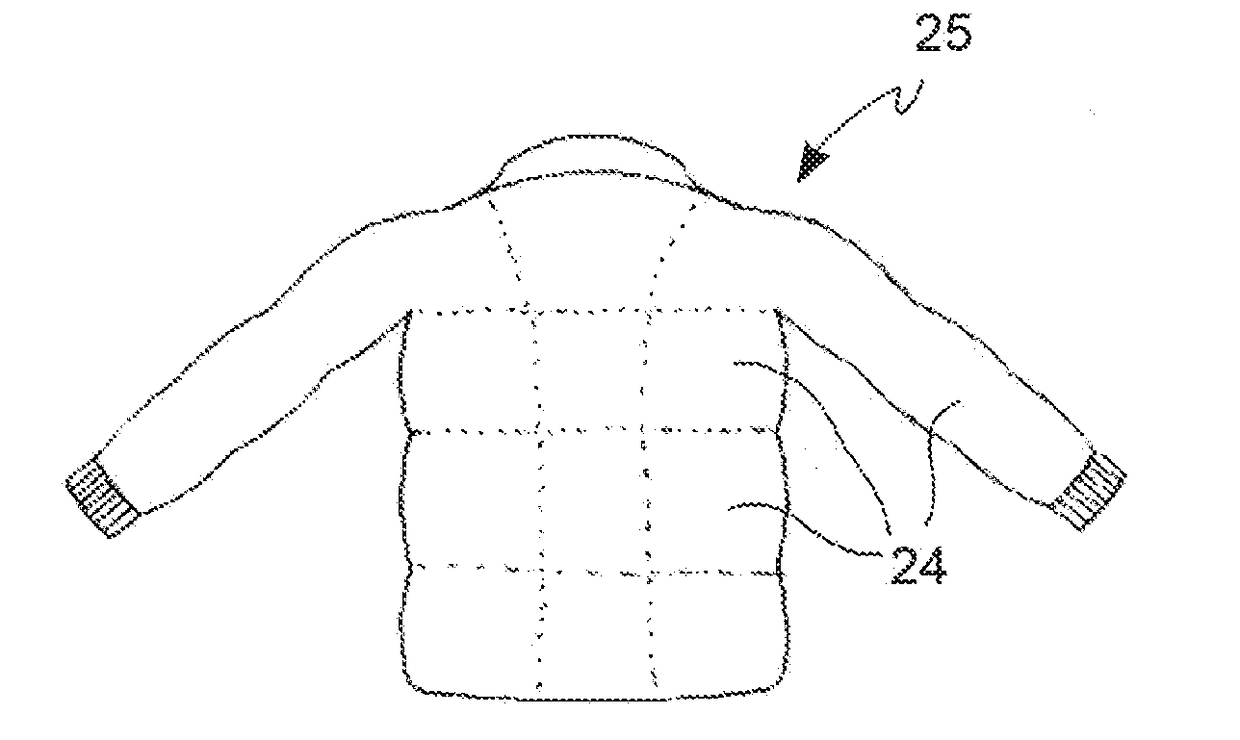

Method for filling a fillable portion of a garment to be padded and padded garment

ActiveUS20170211209A1Avoids property of thermalUpholstery manufactureGarment special featuresFiberEngineering

A method is for filling a fillable portion of a garment to be padded to obtain a padded garment, such as a garment or blanket. A cashmere fiber mass is fed towards a carding station. The cashmere fiber mass is mechanically opened and blended in the carding station by a carding machine to obtain a staple cashmere fiber. The staple cashmere fiber exiting from the carding station is fed towards a beating station. The staple cashmere fiber is cleaned in the beating station by cleaning air flow adapted to cross and inflate the staple cashmere fiber to remove residual impurities and dust from the staple cashmere fiber. The staple cashmere fiber exiting from the beating station is fed towards an injecting station and injected into the fillable portion by a pusher for introducing the staple cashmere fiber into the fillable portion to obtain the padded garment.

Owner:TRUST MONTI FONTI

Conveying air filtration system

InactiveUS6905528B2Weaken energyReduce processing costsCombination devicesFibre cleaning/opening by air draught arrangementsFiberAir filtration

An arrangement used for filtering out conveying air when supplying fiber material to a processing machine is provided. The arrangement has an essentially vertical filling chute for the fiber material, the chute having an upper intake opening and a lower exit opening, a device with pneumatic fiber feed at the upper intake opening, and a floccule-forming device at the lower exit opening including a system of draw-in rolls and a fast-rotating opening roll. The chute includes at least one air-permeable surface for separating the fiber material from the conveying air. An evacuating device evacuates the filtered out conveying air. An exhaust air device is coupled to the evacuating device and has an air stream regulator which is connected to a control and regulating device. The conveying air stream is guided along the opening roll, and a partial air stream of the filtered out conveying air is guided into the exhaust air device.

Owner:TRUETZSCHLER GMBH & CO KG

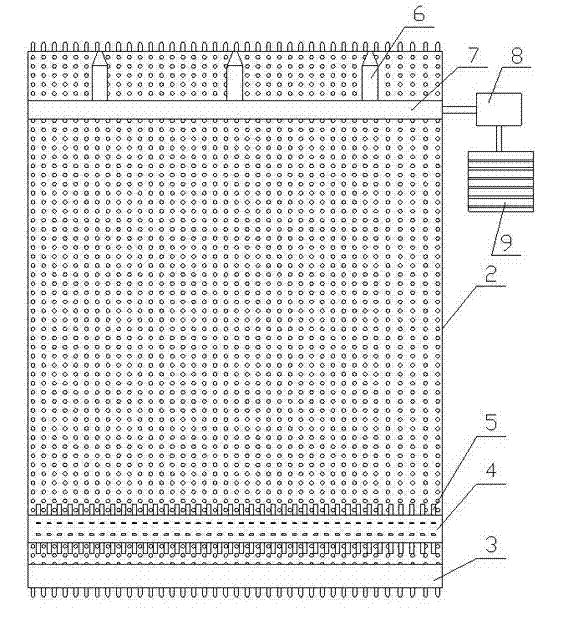

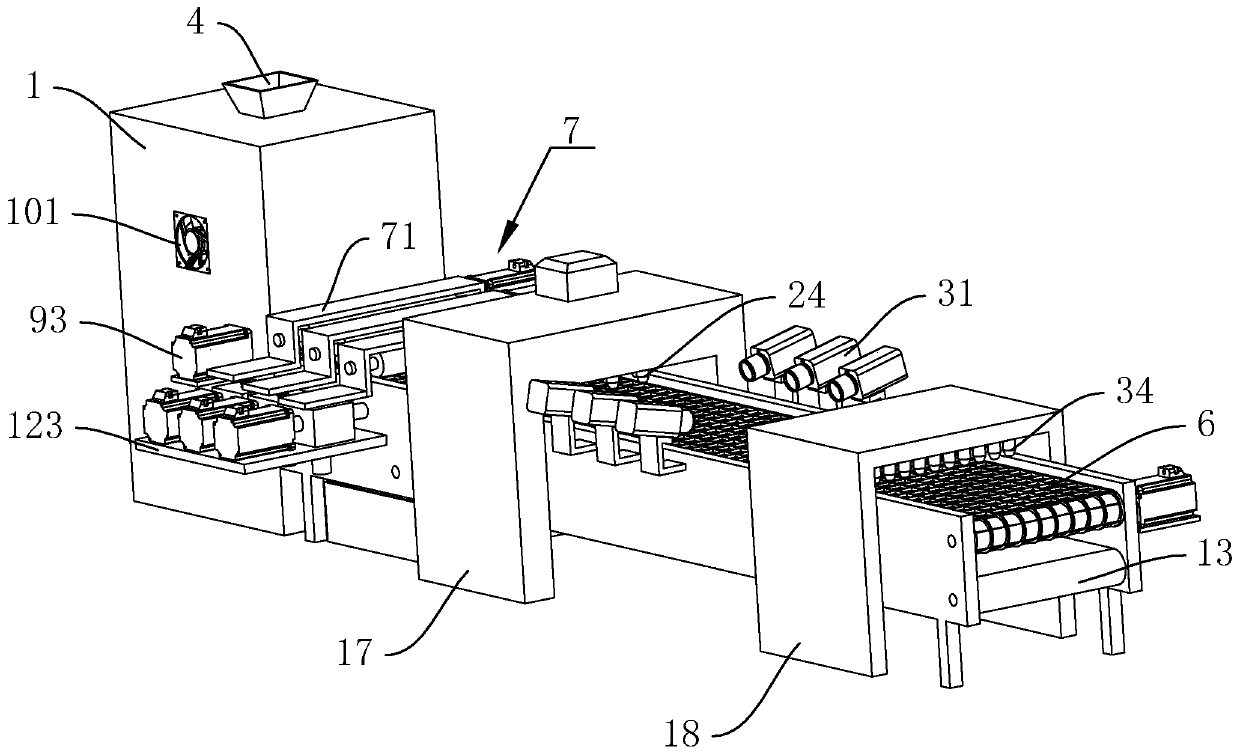

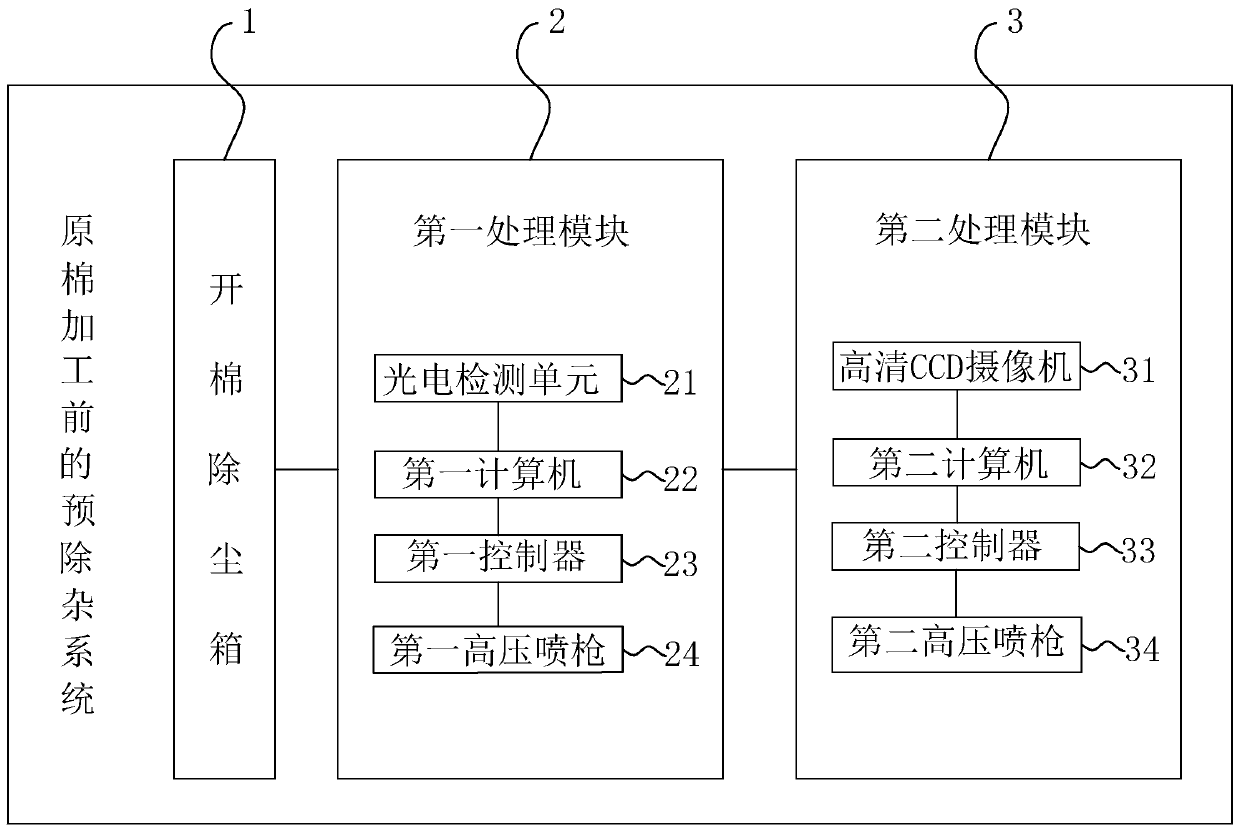

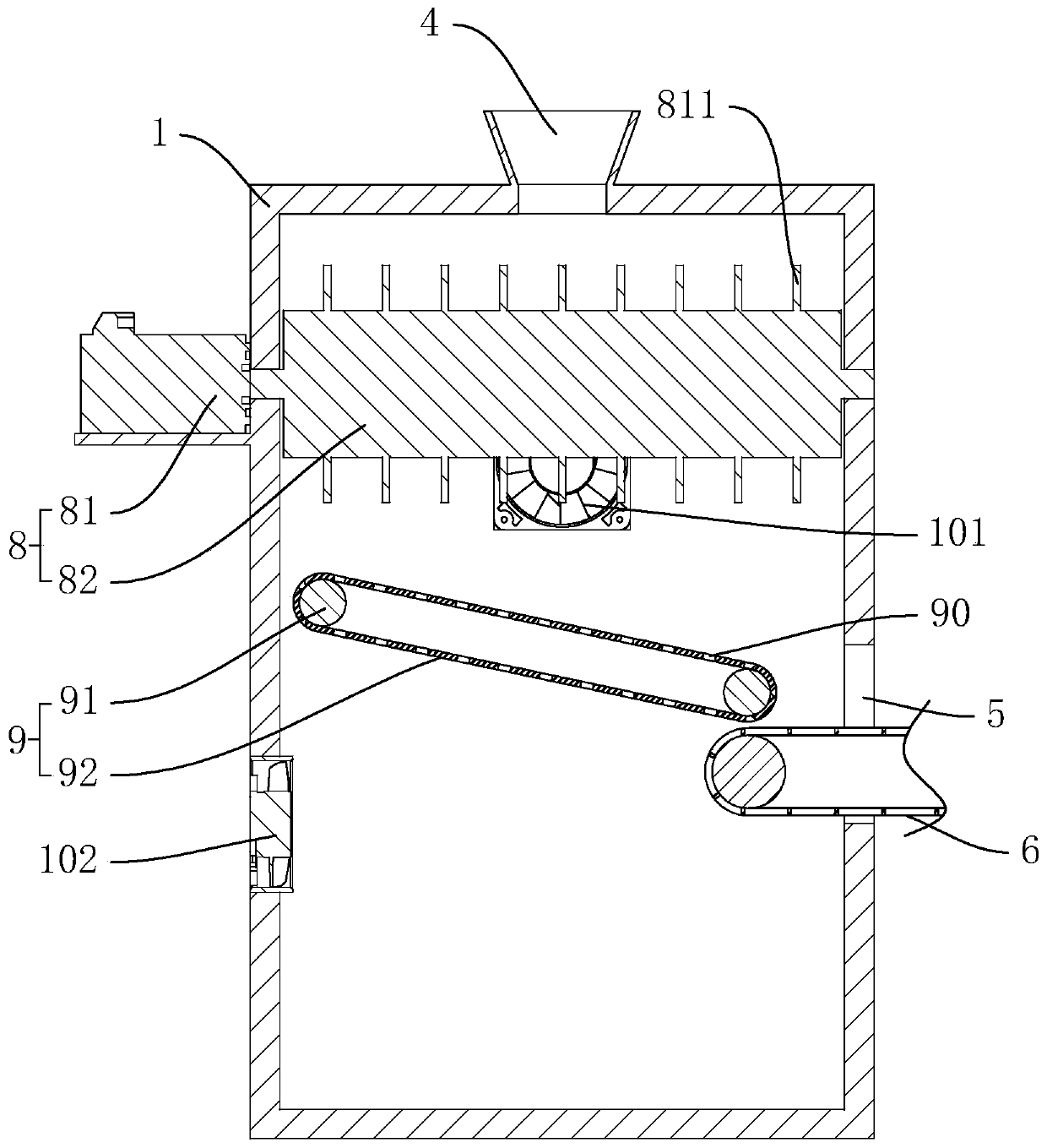

Pre-impurity-removal system and impurity removal method used before raw cotton processing

ActiveCN111519283AIncrease delivery speedImprove work efficiencyFibre cleaning/opening by air draught arrangementsFibre cleaning/opening machinesDust controlProcess engineering

The invention relates to a pre-impurity-removal system and impurity removal method used before raw cotton processing. The pre-impurity-removal system comprises a cotton opening dust removal box for preliminary dust removal, a first treatment module for preliminary treatment and a second treatment module for final treatment, wherein the first treatment module specifically comprises a photoelectricdetection unit and first high-pressure spray guns; after the preliminary treatment is carried out by the first treatment module, the second treatment module is used for further treatment; the second treatment module comprises a plurality of groups of high-definition CCD cameras which are sequentially arranged in parallel along the conveying direction of a cotton conveying belt, and second high-pressure spray guns; and the high-definition CCD cameras detect in regions, a detection region of each group of high-definition CCD cameras is relatively independent, and the detection regions are attached to one another along the length direction of the cotton conveying belt. The pre-impurity-removal system and the impurity removal method have the effects of complete and thorough impurity removal and high impurity removal efficiency.

Owner:苏州基列德智能制造有限公司

Anti-blocking efficient cotton spinning dust removal and impurity removal device

InactiveCN107313132AAvoid cloggingSpeed up entryFibre cleaning/opening by air draught arrangementsCarding machinesMotor driveEngineering

The invention discloses a high-efficiency anti-blocking dust removal and impurity removal device for cotton spinning, which comprises a dust cage, a cotton stripping roller and a dust collection box. The cotton stripping roller is arranged on the left side of the dust cage; a rotating bearing and a bracket are arranged on the periphery of the dust cage; The lower end of the dust cage is equipped with internal gears, motors, driving gears, dust collection boxes, connecting air pipes, baffles and air pumps; the inside of the dust cage is equipped with dust collection covers, dust suction pipes, rotating shafts, support frame plates, fixed rods, swing rods and brush. In the present invention, the driving gear on the motor cooperates with the internal gear at the lower end of the dust cage to drive the dust cage to rotate, and at the same time, the motor drives the rotating shaft to rotate, and the brush can continuously clean the inner wall of the dust cage through the speed difference with the dust cage to avoid blockage; through the action of the air pump , the air enters the dust collection box through the dust suction hood, dust suction pipe and connecting air pipe, so that the dust can be efficiently removed while the gas emission is clean.

Owner:洪飞飞

Cotton opener

InactiveCN106381579AAvoid influenceQuality improvementFibre cleaning/opening by air draught arrangementsFibre cleaning and opening machine combinationsFiberCoupling

The invention discloses a cotton opener comprising a machine body; the feed inlet of the machine body is provided with a conveyer and a pre-opening unit; the pre-opening unit comprises a licker-in and a roller; an opening roller is arranged in the machine body; the surface of the opening roller is provided with opening thorns; one end of the opening roller is connected with a motor arranged outside the machine body through a coupling; the bottom in the cavity of the machine body is provided with a vibrator connected with one end of a screen plate; the other end of the screen plate is hinged to the inner wall of the machine body; the machine body below the screen plate is provided with a slag removal port; one side of the machine body is connected with a negative pressure tube; the negative pressure tube is connected with one end of a drawing fan; the other end of the drawing fan is connected with a cotton storage room through a pipeline; the vibrator and the screen plate of the cotton opener can separate the impurities from the cotton, so the impurities can be discharged, thus improving cotton fiber quality; the cotton storage room can collect opened cottons, thus preventing mess conditions caused by random stacking of the cottons.

Owner:华巧波

Uniform feeding cotton condensing device

InactiveCN106087125AImprove adsorption capacityUniform adsorptionFibre cleaning/opening by air draught arrangementsFibre cleaning/opening machinesEngineeringRaw material

The invention discloses a uniform feeding cotton condensing device which comprises a machine frame, a cotton condensing dust cage, a cotton stripping beating hand and a fan. Arc-shaped wood rings are buckled at the two ends of the cotton condensing dust cage, the cotton condensing dust cage is fixed to the machine frame through the arc-shaped wood rings at the two ends, and the inner ring surfaces of the arc-shaped wood rings are provided with sealing felt pads. The sealing felt pads press the ends of the two sides of the outer surface of the cotton condensing dust cage, and the cotton stripping beating hand is installed on the machine frame positioned below the cotton condensing dust cage. The cotton stripping beating hand is composed of a cotton stripping roller and a cotton scraping plate evenly installed on the cotton stripping roller. The machine frame below the cotton stripping beating hand is provided with a discharging port, the right side of the cotton condensing dust cage is connected with the fan, the outer surface of the cotton condensing dust cage is provided with a plurality of suction holes, and the number of the suction holes is sequentially increased from right to left in the length direction of the cotton condensing dust cage. The upper portion of the machine frame is provided with a cotton inlet, and the cotton inlet is connected with an adjusting channel. The uniform feeding cotton condensing device is simple in structure and good in dedusting effect, raw materials are adsorbed evenly, the discharge quality is high, and fires caused by heat generated by friction are avoided.

Owner:GUANGDE TIANYUN NEW TECH

Seed cotton foreign fiber cleaning and decontaminating equipment

ActiveCN105586664ALow impurity rateImprove cleanlinessFibre cleaning/opening by air draught arrangementsFiberEngineering

The invention relates to seed cotton foreign fiber cleaning and decontaminating equipment. The equipment comprises a machine frame, a cleaning box arranged on the machine frame, a cleaning roller component arranged on the bottom of the cleaning box, a conveying device arranged under the cleaning box, and a decontamination fan component arranged over the conveying device, wherein the conveying device is used for conveying seed cotton cleaned by the cleaning roller component, and the cleaning roller component comprises a cleaning roller set arranged in the cleaning box, installation side plates used for supporting the cleaning roller set, an impurity conveying device arranged under the cleaning roller set, and a driving device used for providing power for the cleaning roller component. According to the equipment, uniform feeding and winding cleaning can be conducted on seed cotton flow fed into the cleaning box by means of the cleaning roller set, fiber impurities in certain lengths can be removed, primary separation of light or heavy impurities in the cotton seed flow is achieved, and then a primary seed cotton product with low impurity rate is obtained and a standard uniform-thickness cotton layer is provided for foreign fiber selection based on the image recognition technique.

Owner:SHENXIAN FUHAO PHOTOELECTRIC TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com