Airflow scutching impurity removal device

A technology of airflow and cotton cleaning, which is applied in the direction of opening and cleaning with a suction device, can solve the problems of difficulty in reducing the lint rate of cotton batts, and the quality of cotton supply cannot meet the needs of the process, and achieves the effect of reducing the lint rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

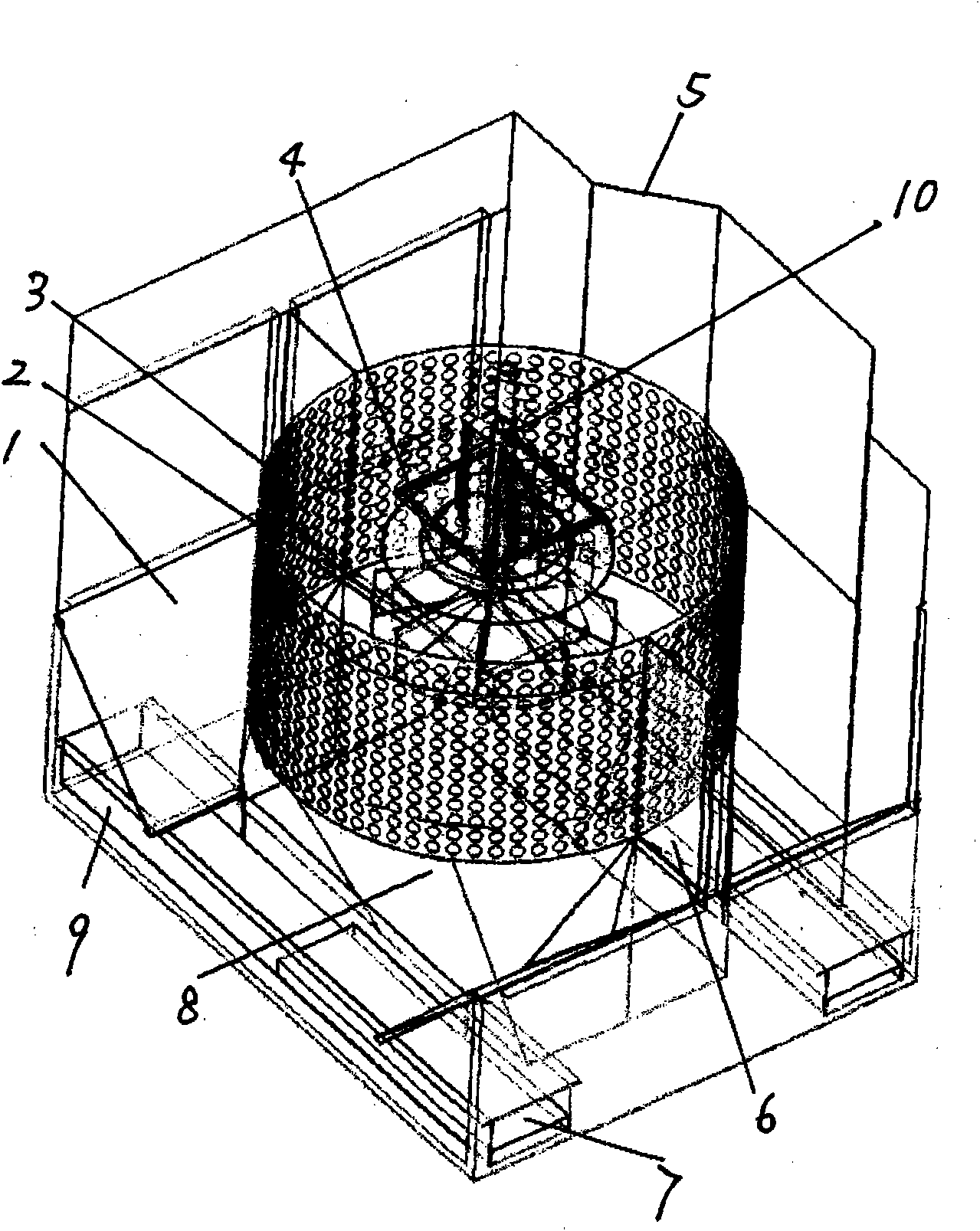

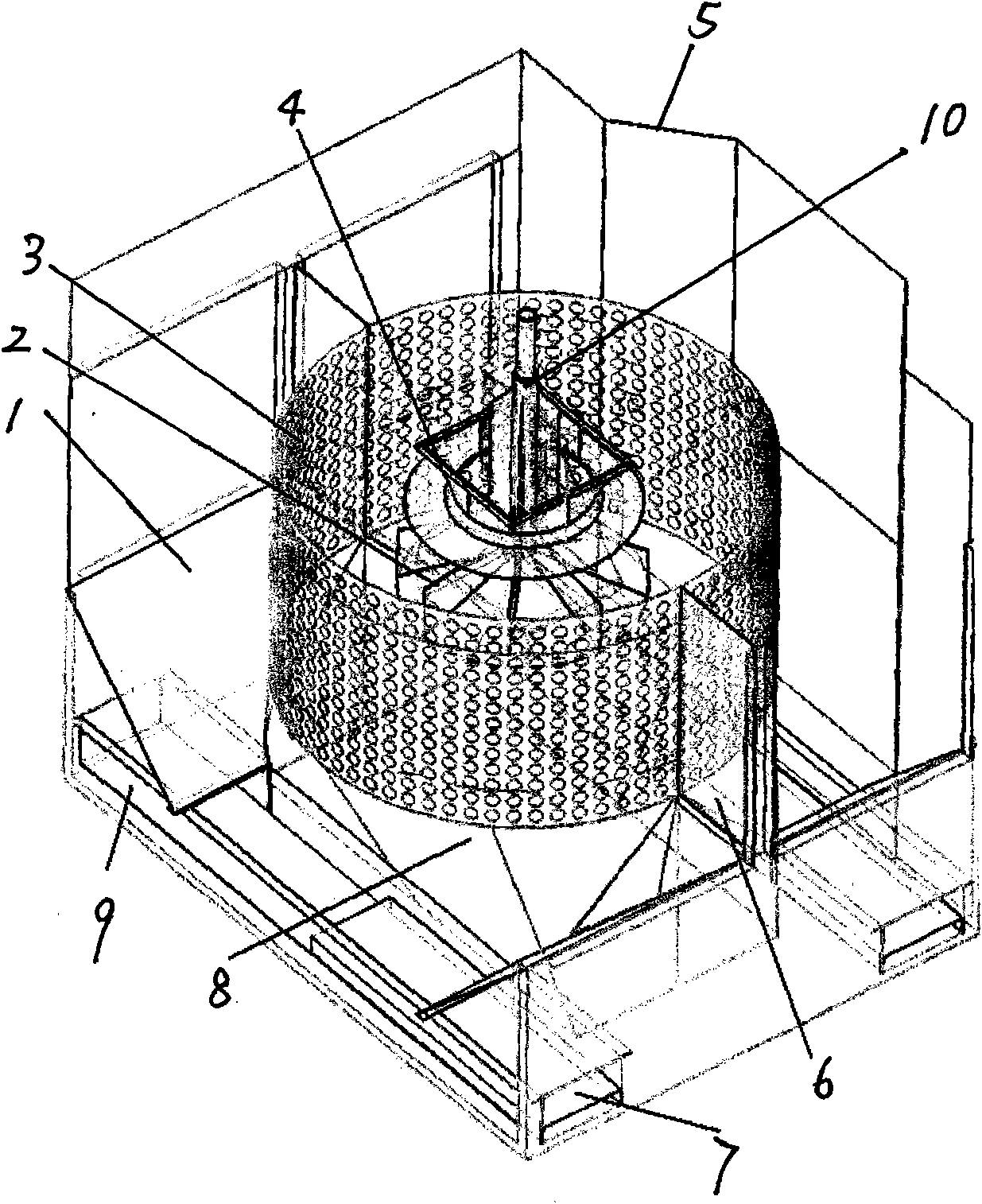

[0009] In the accompanying drawings of the description, there is a dust filter cage (3) in the casing (5), and in the dust filter cage (3), the motor transmission shaft (10) is connected with a cotton transport air flow channel (4) and an air flow nozzle (2), The outside of the dust filter cage (3) is connected with the dust collection funnel (8), the airflow pulse baffle (6) is fixed on the outside of the dust filter cage (3), the dust collection guide plate (1) is connected with the dust collection pipe (9), and the dust collection pipe ( 9) Link to each other with the dust collection outlet shutter (7). The air flow nozzle is composed of eight evenly distributed openings, and it is connected with the cotton air flow channel and can rotate 360 degrees on the motor drive shaft to adjust the speed to convey cotton; two air pulse baffles are symmetrically fixed on the outside of the dust filter cage.

[0010] The descriptions and implementations in this specification are all ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com