Patents

Literature

196results about "Fibre breaking machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

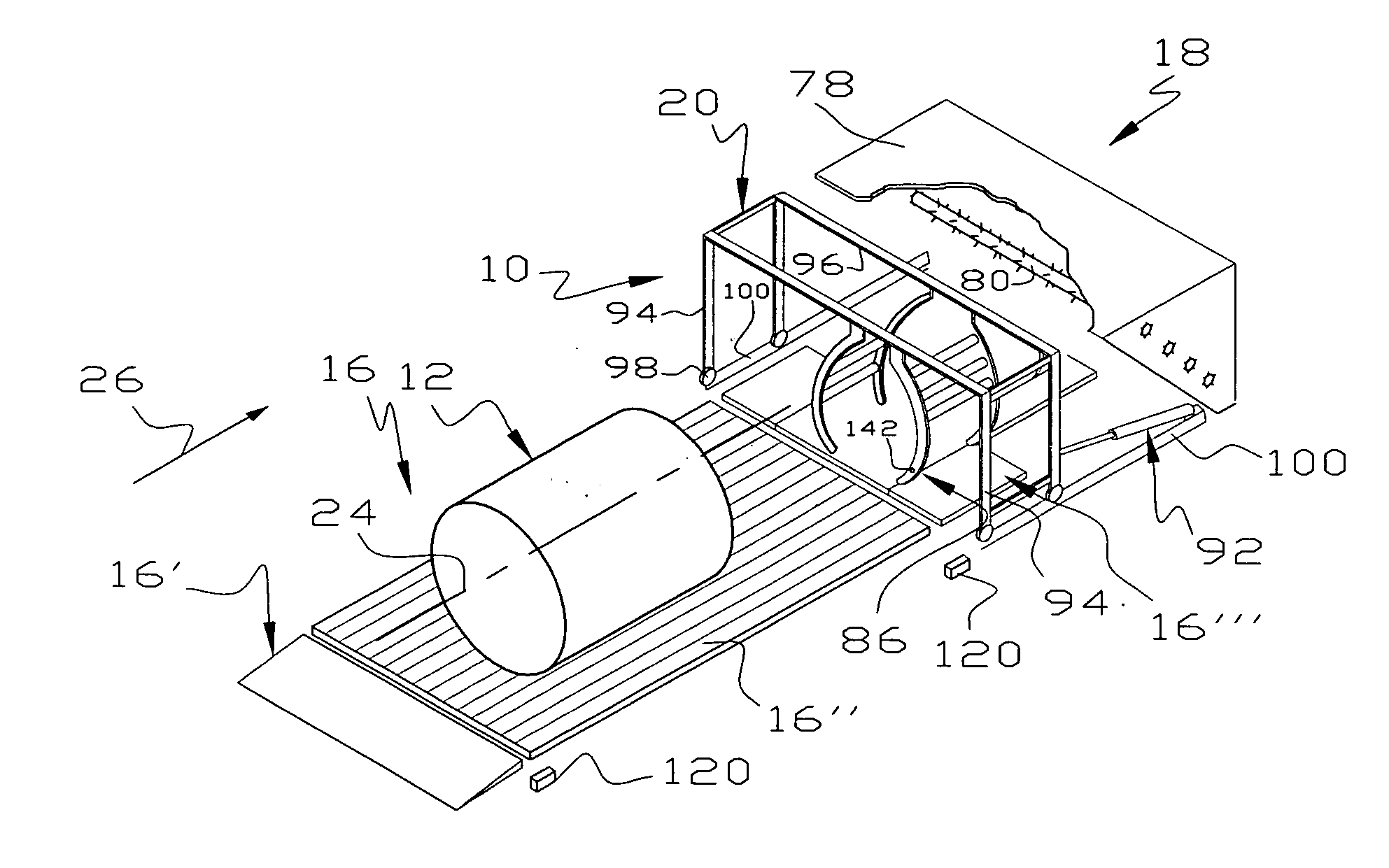

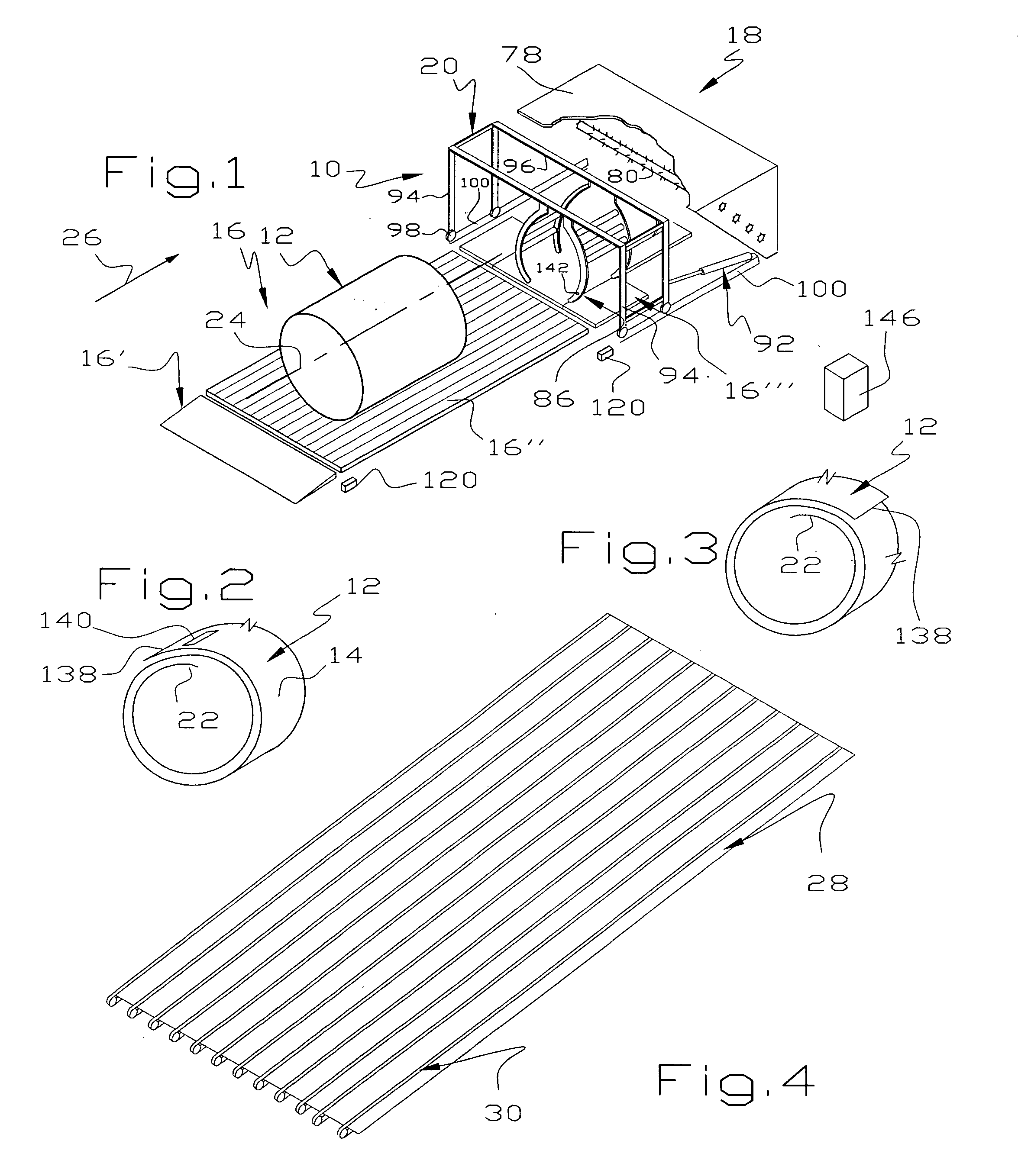

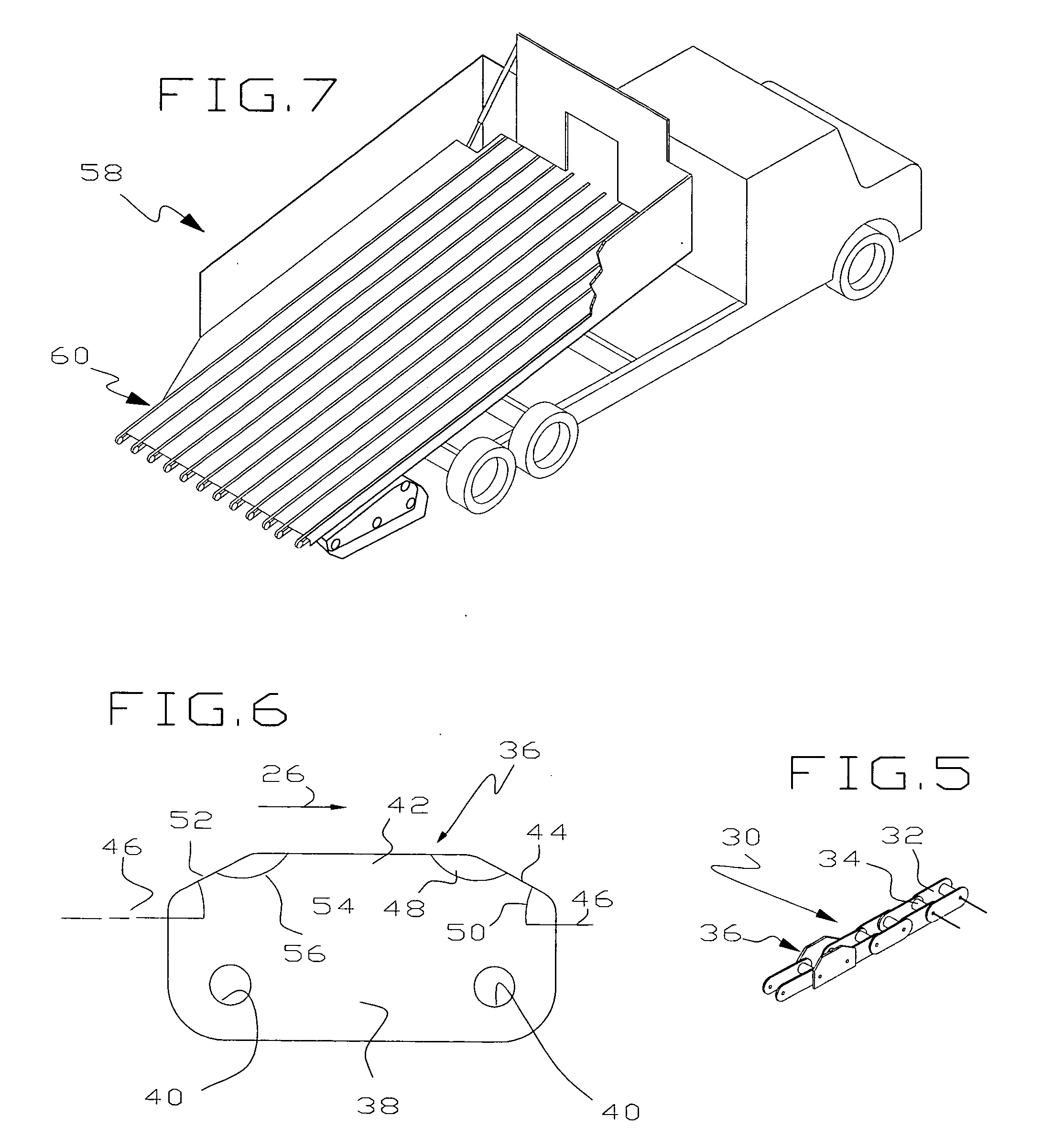

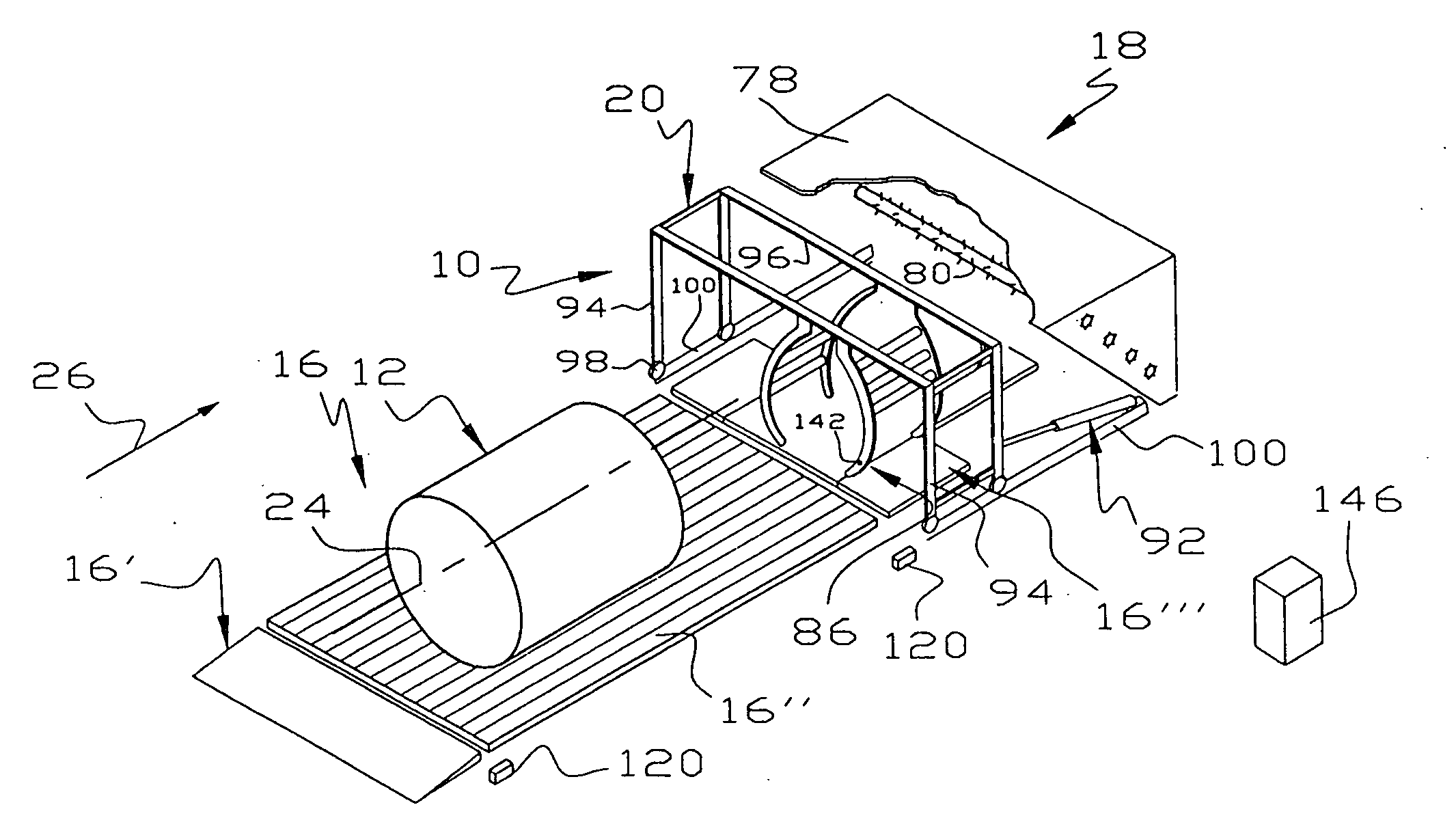

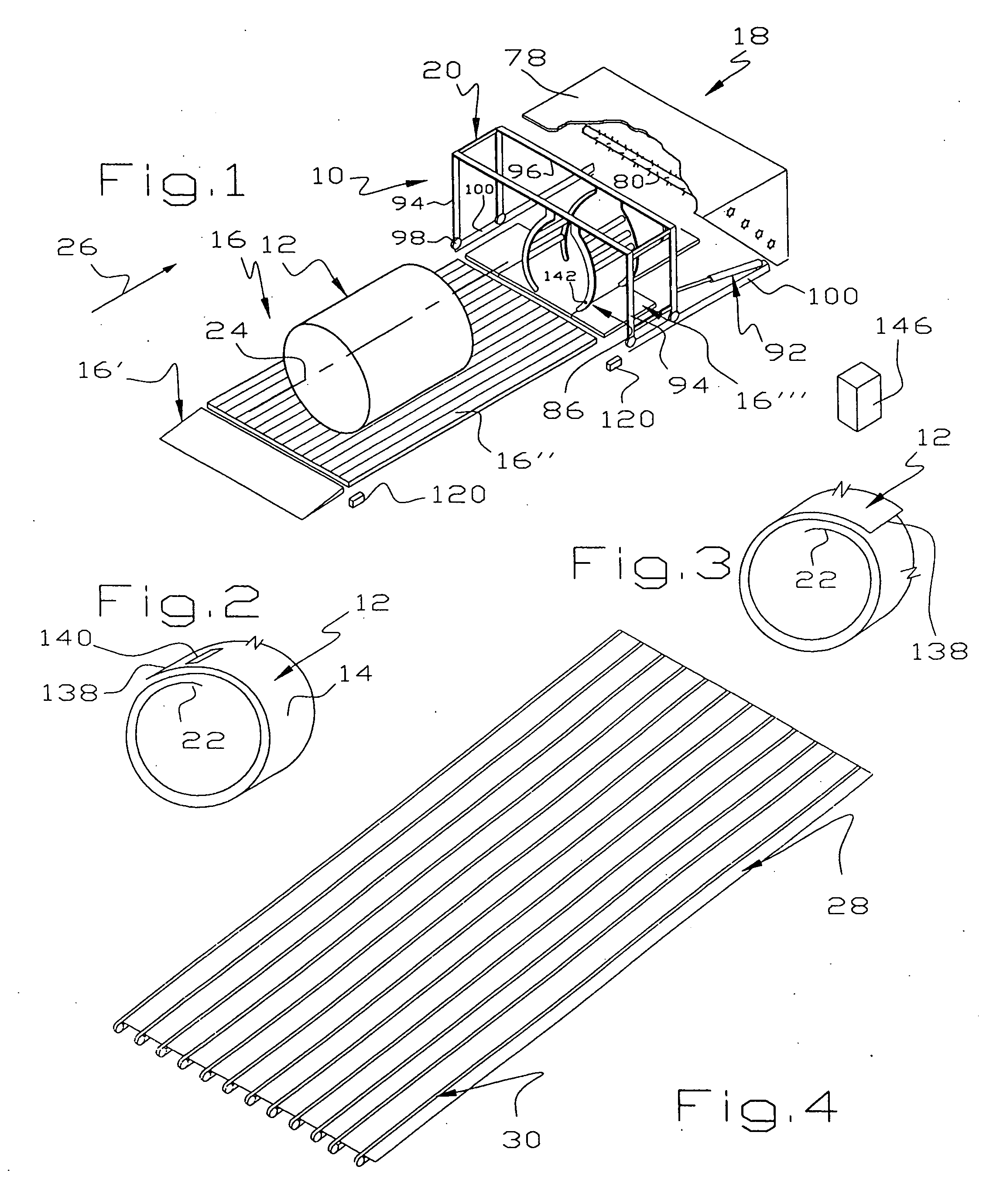

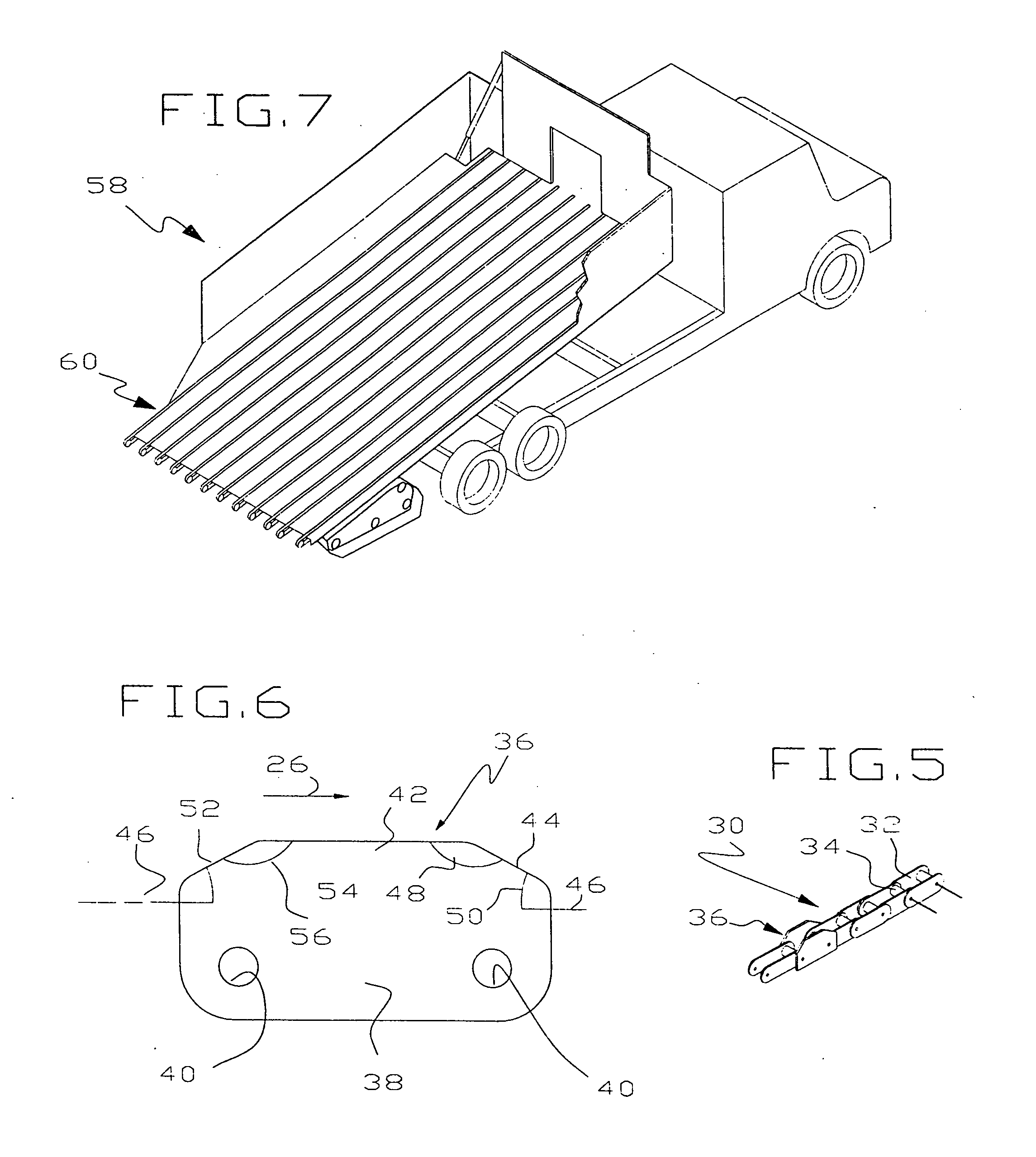

Technique for removing a cover from cylindrical modules

In one embodiment, a system for removing a plastic wrap from a cylindrical module includes a conveyor transporting the cylindrical module toward a disperser with the cylindrical axis of the module parallel to the direction of conveyor movement. In another embodiment, the disperser is a travelling head disperser thereby providing relative movement between the modules and the disperser. The direction of the wrap around the module is determined and the cover is removed during rotation of the module, either by unwrapping the plastic or by slitting the plastic and then rotating the module. The equipment used to handle a cylindrical module is moved out of the path of movement of a conventional rectangular module so an installation can handle both rectangular and wrapped cylindrical modules.

Owner:STOVER EQUIP

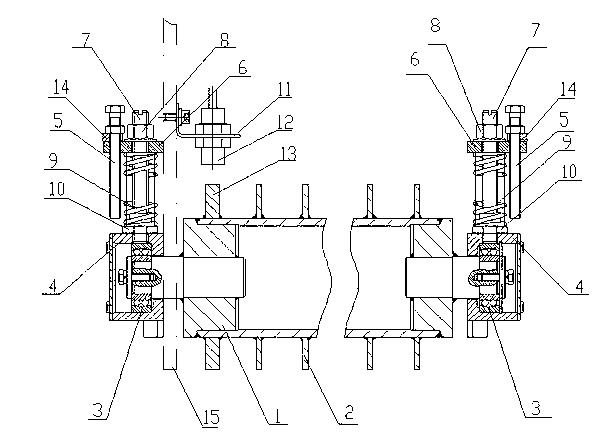

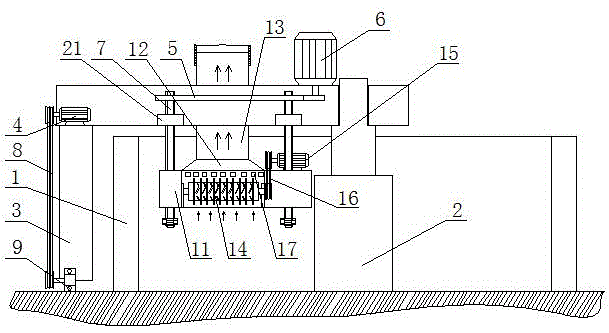

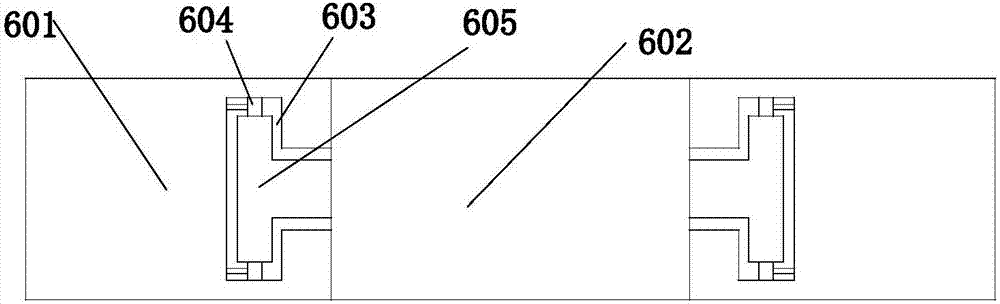

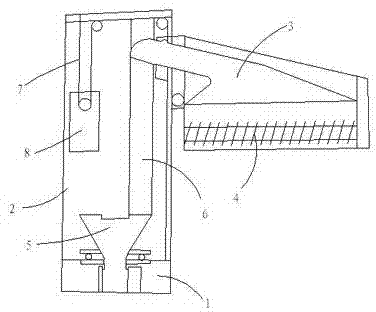

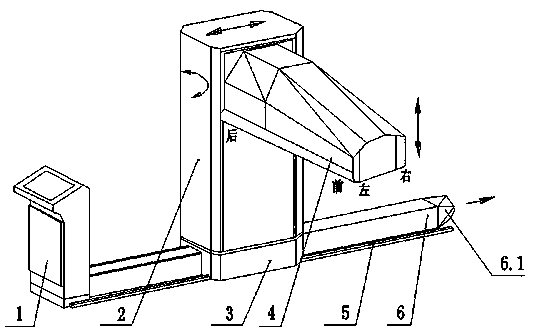

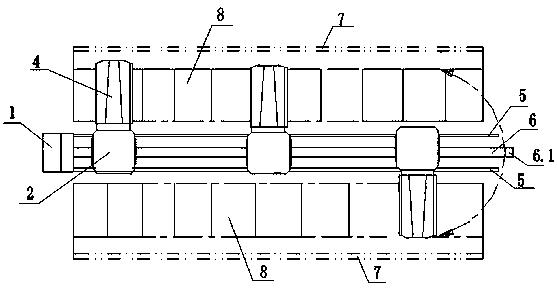

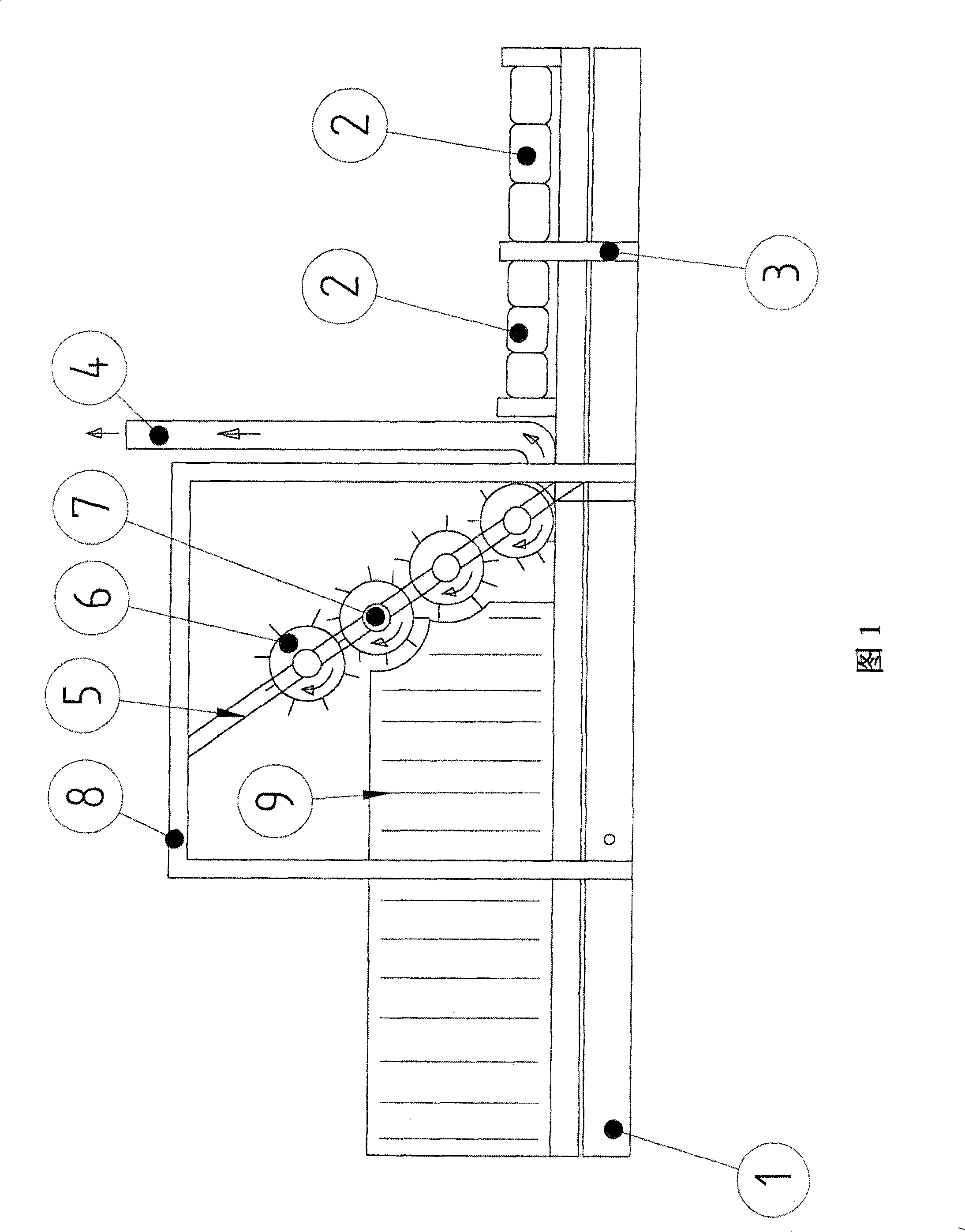

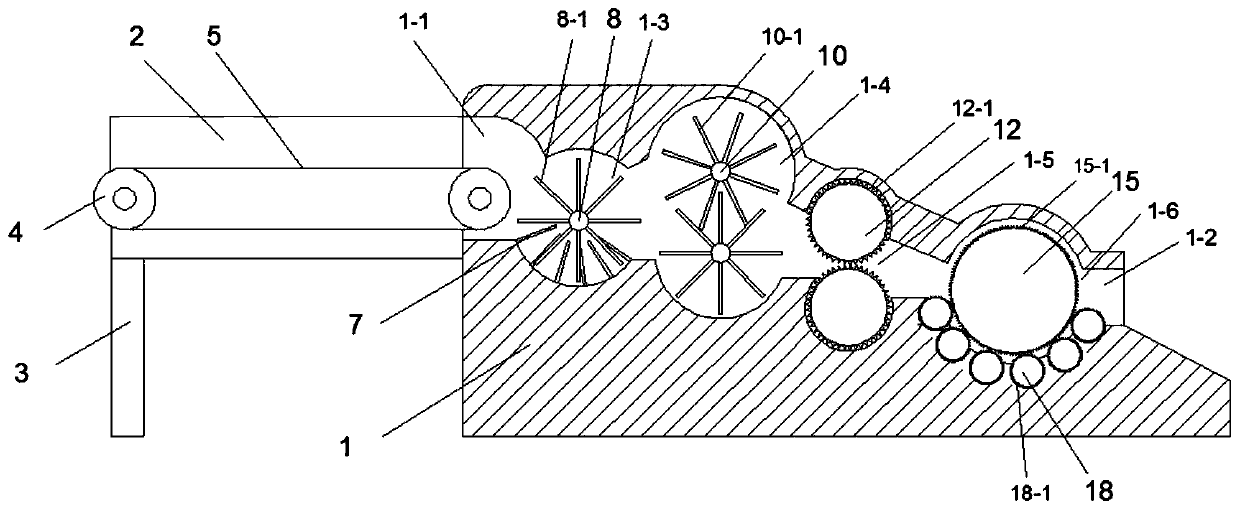

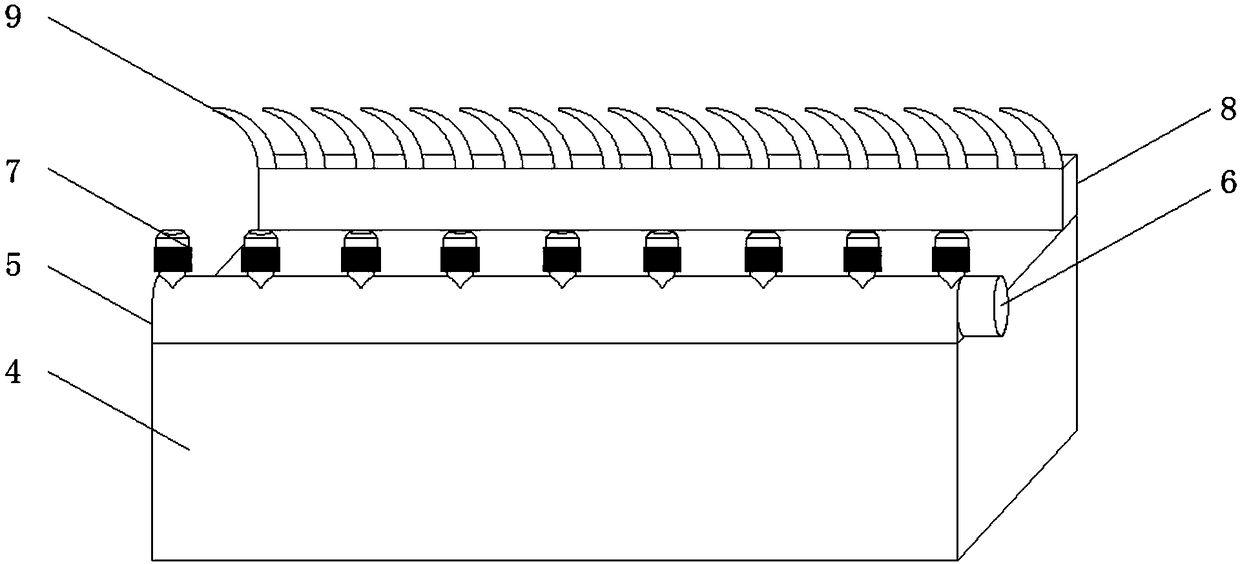

Transmission device of reciprocating bale plucker pressing roller

ActiveCN102995164AMove up and down freelyImprove performanceFibre breaking machinesFiberFree rotation

The invention provides a transmission device of a reciprocating bale plucker pressing roller. The transmission device comprises a grabbing arm, a tower body, a pressing roller barrel, a star-shaped toothed sheet, bearings and bearing blocks which are arranged on the two ends of the pressing roller and wallboards on the two sides of the pressing roller. The transmission device is characterized in that the bearings on the two ends of the pressing roller are rolling bearings, a baffle is arranged on the outer side surface of the wallboard on each side of the pressing roller, plain round holes are respectively formed on the baffles, the two baffles are respectively positioned right above the bearing blocks which correspond to one ends of the pressing roller, each bearing block is respectively connected with a threaded rod which is vertically arranged, a spring support and a compression spring are sleeved on each threaded rod, and the upper end of each threaded rod penetrates through the plain round hole of the corresponding baffle which is arranged above and is fixed through a nut. The transmission device is simple in structure, is convenient to regulate and use, and is low in manufacturing cost; when a reciprocating bale plucker operates, the motor-free rotation of the pressing roller is realized through the friction force between the star-shaped toothed sheet of the pressing roller and fibers so as to realize the purpose of pressing raw materials, and foundation is laid for the bale plucker to grab the raw materials.

Owner:QINGDAO HONGDA TEXTILE MACHINERY

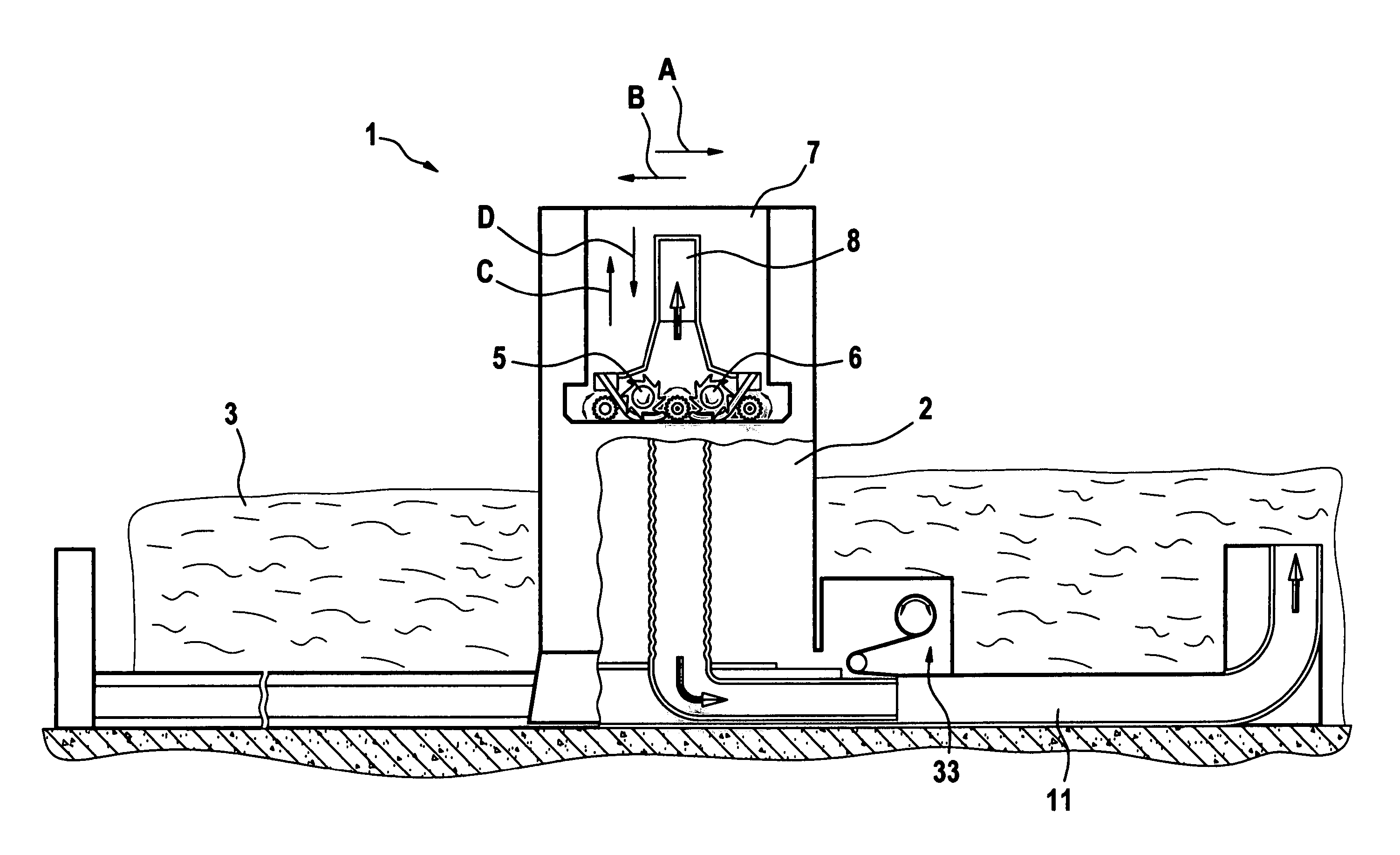

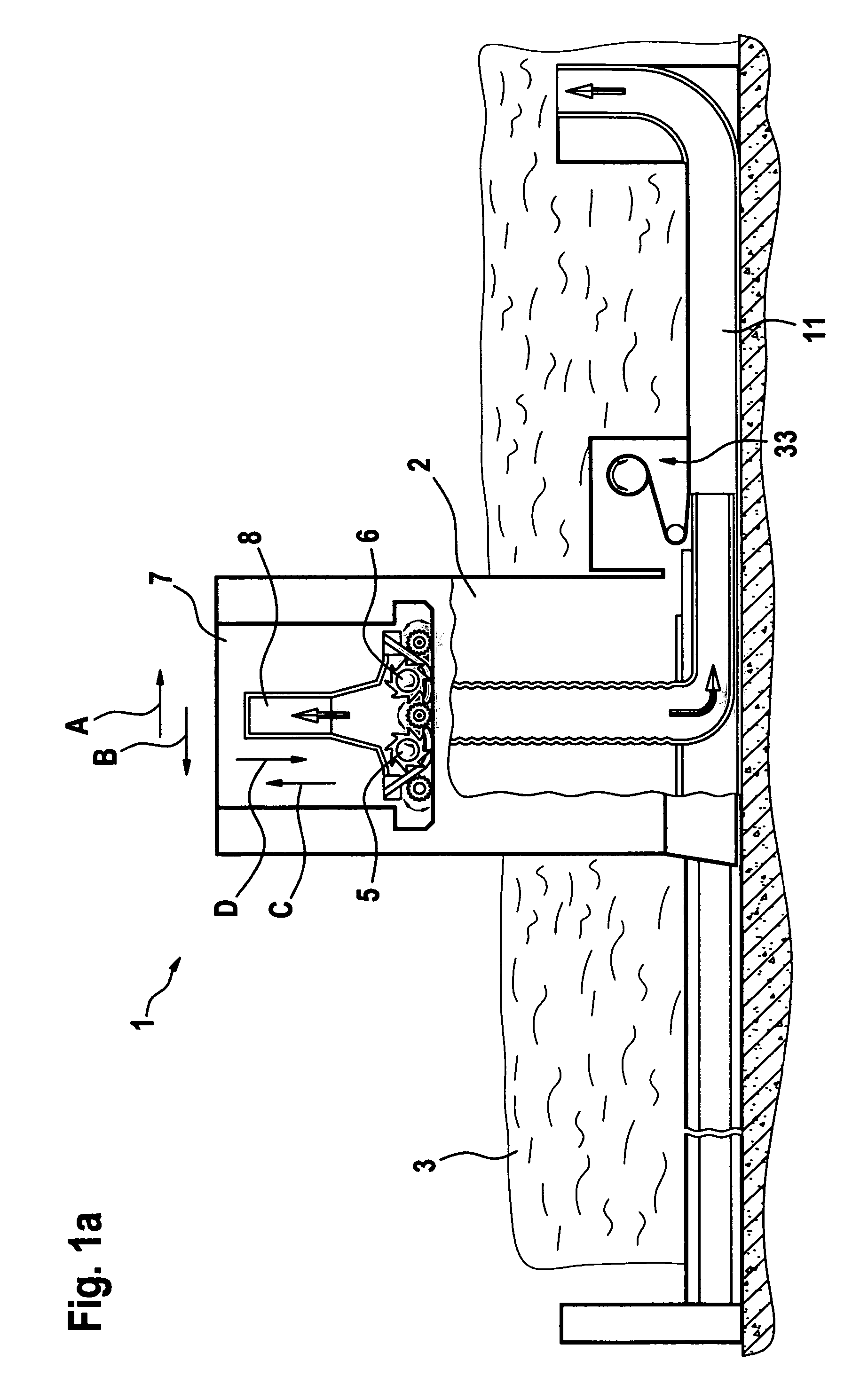

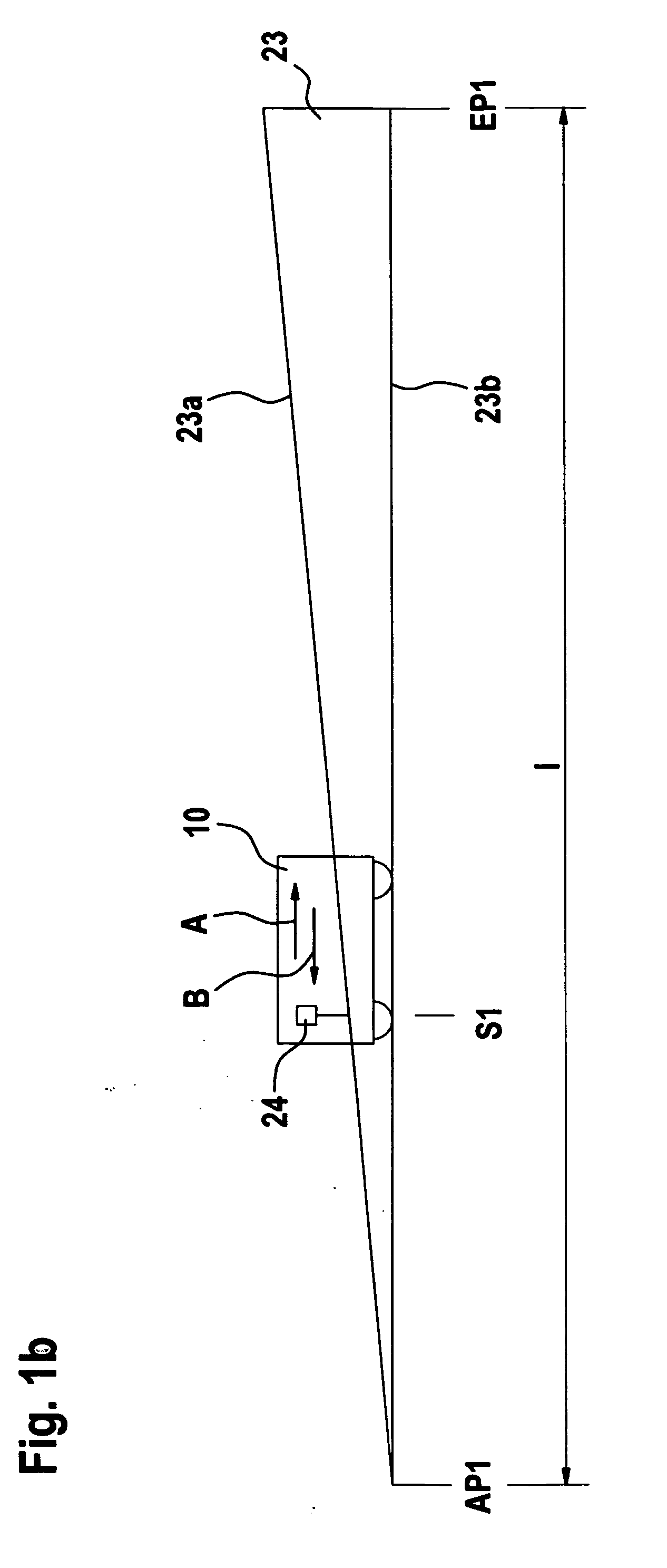

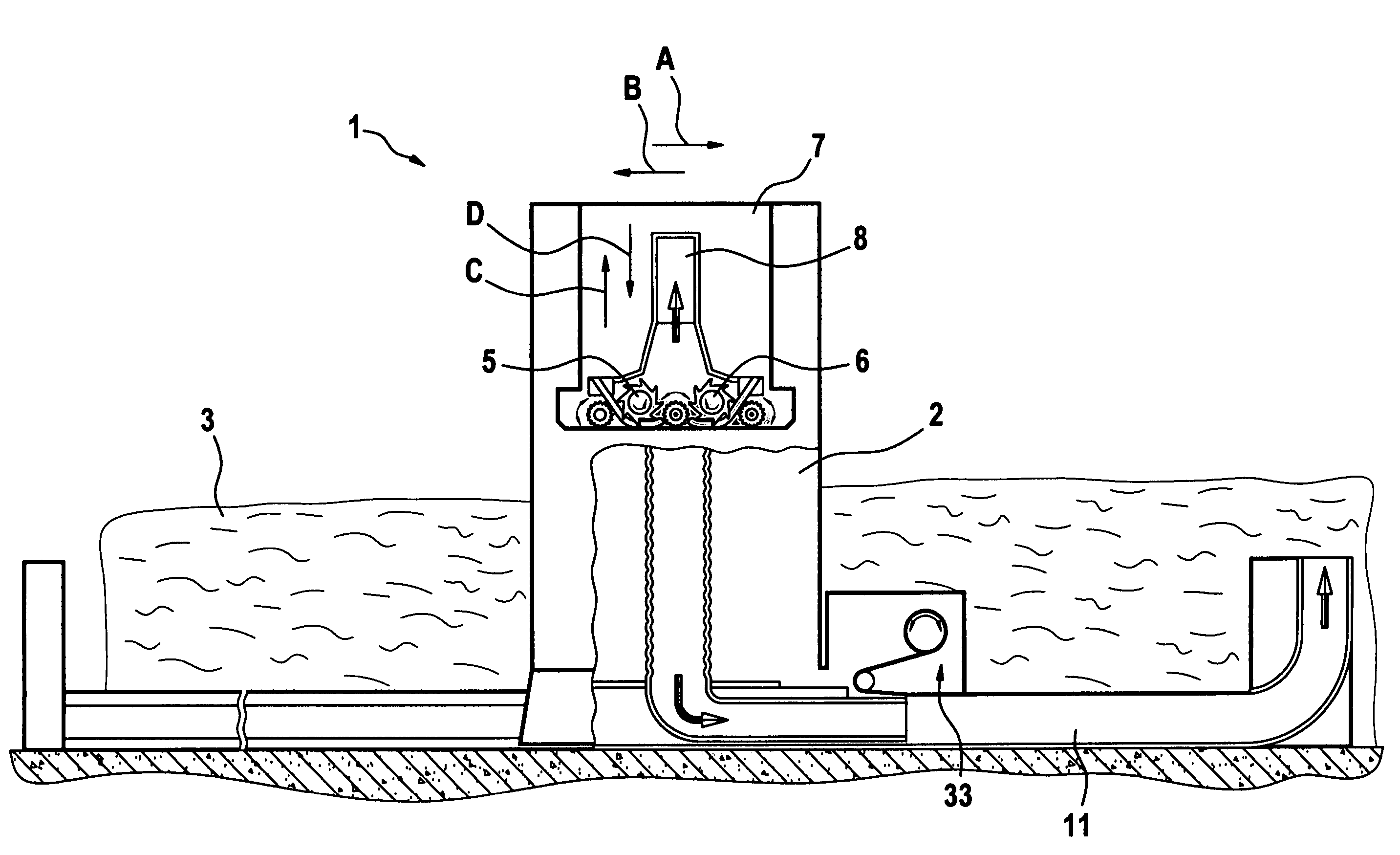

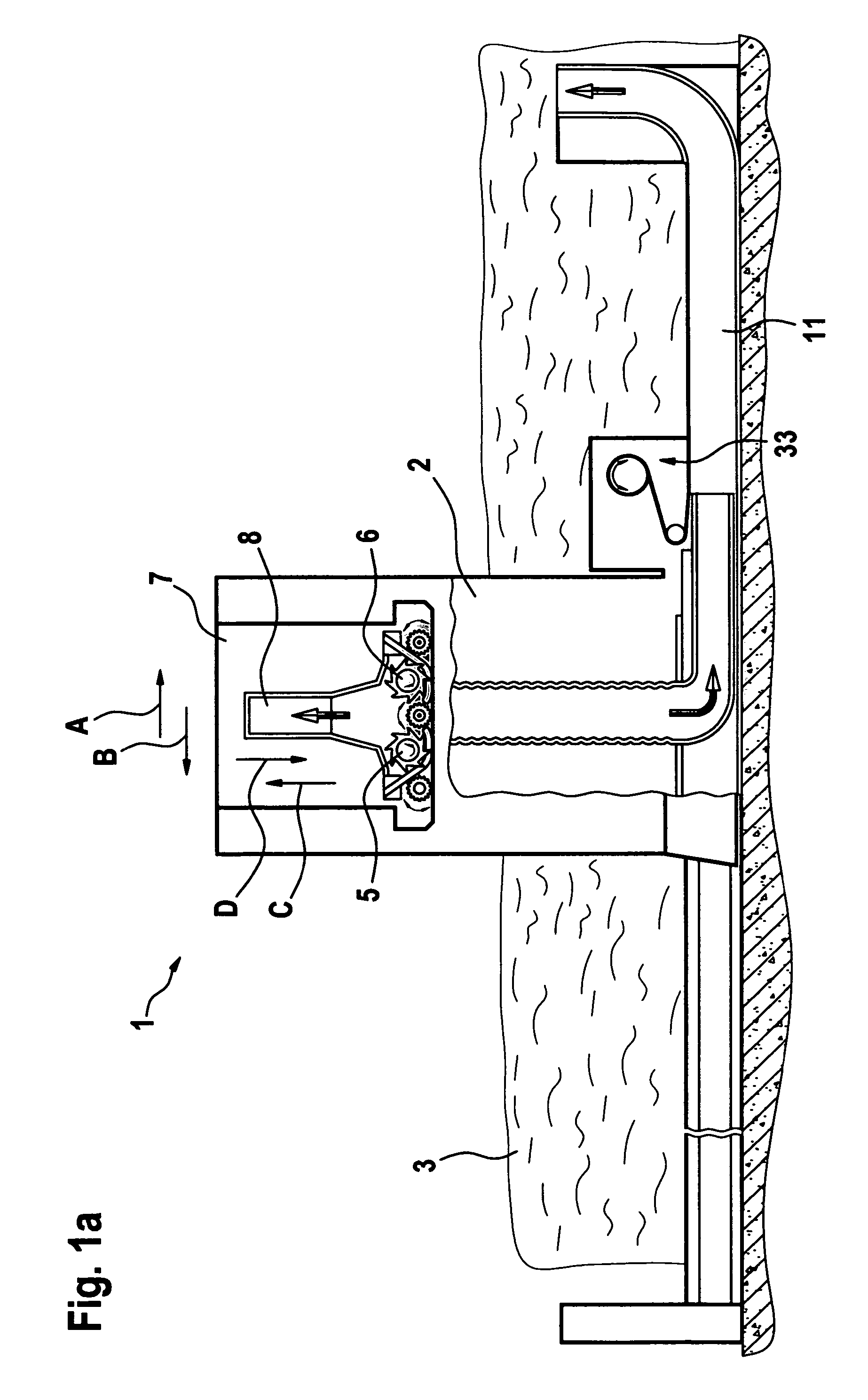

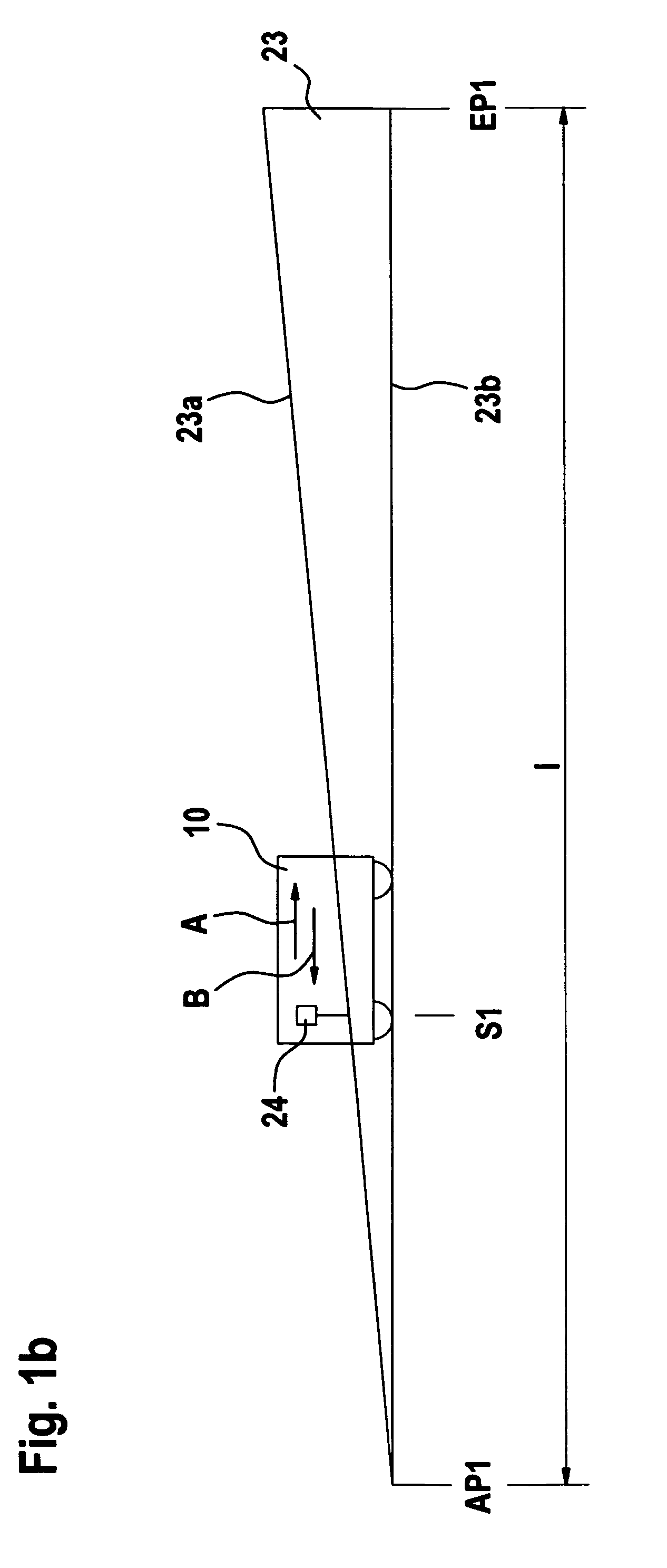

Apparatus for stripping fibre material from textile fibre bales of spinning material, for example cotton, synthetic fibres and the like

InactiveUS20060207064A1Reduce light lossNo wearFibre cleaning/openingCarding machinesTextile fiberEngineering

An apparatus for stripping fiber material from textile fiber bales has a tower, which can be moved to and fro in relation to the fiber material by means of a carriage having a travel motor or the like, and has at least one boom, which is provided with the stripping apparatus. The boom together with the stripping apparatus can be moved in the height direction of the tower by means of a lifting motor or the like. A movable distance sensor is provided for determination of the location in the length direction. In order to make possible, by simple means, an exact determination of location in the length and / or height direction, a movable distance sensor scans, for location determination in the length and / or height direction, the distances to a counterpart element and calculates from those distances the location.

Owner:TRUETZSCHLER GMBH & CO KG

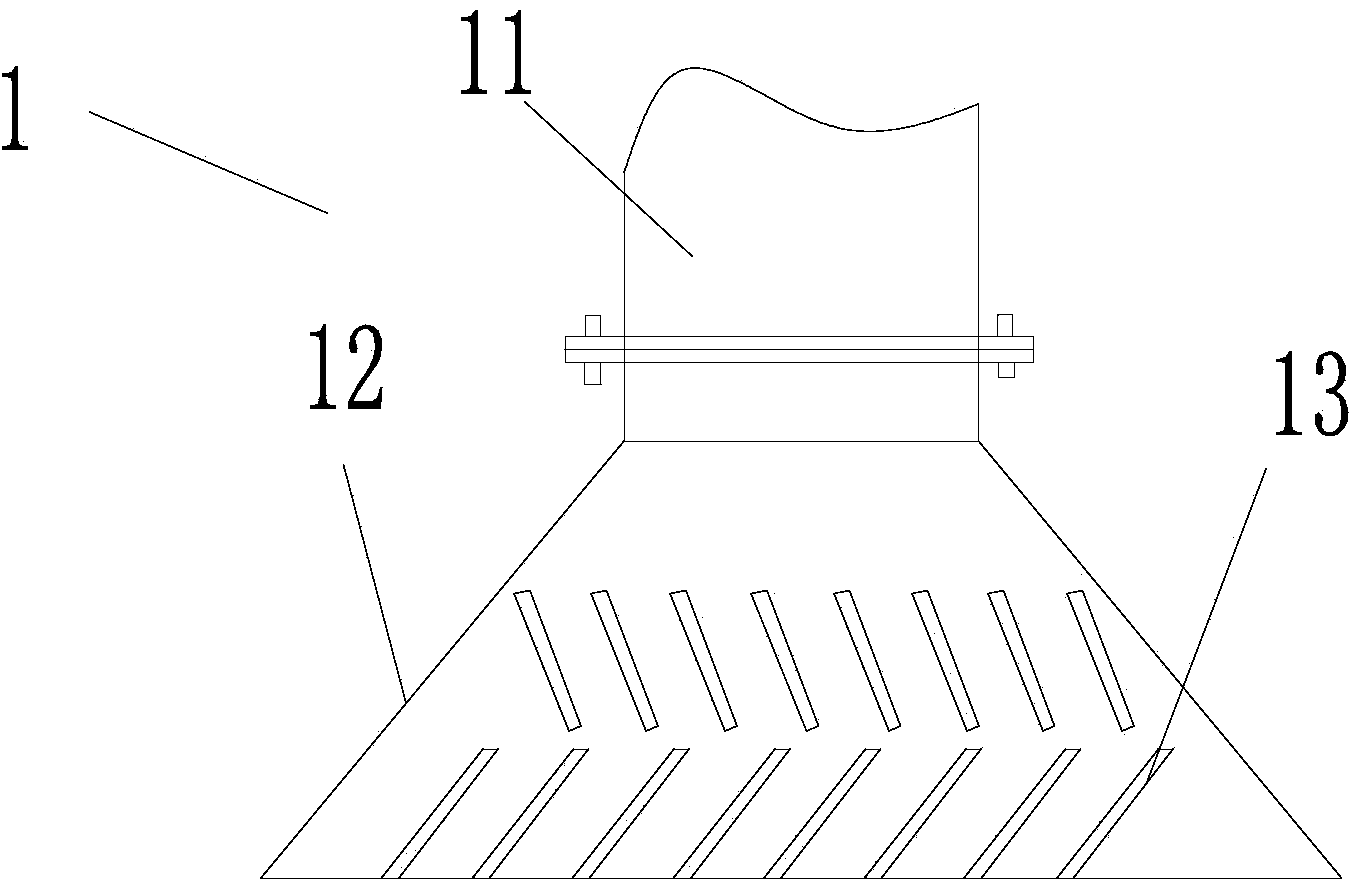

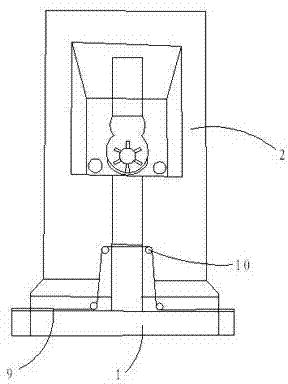

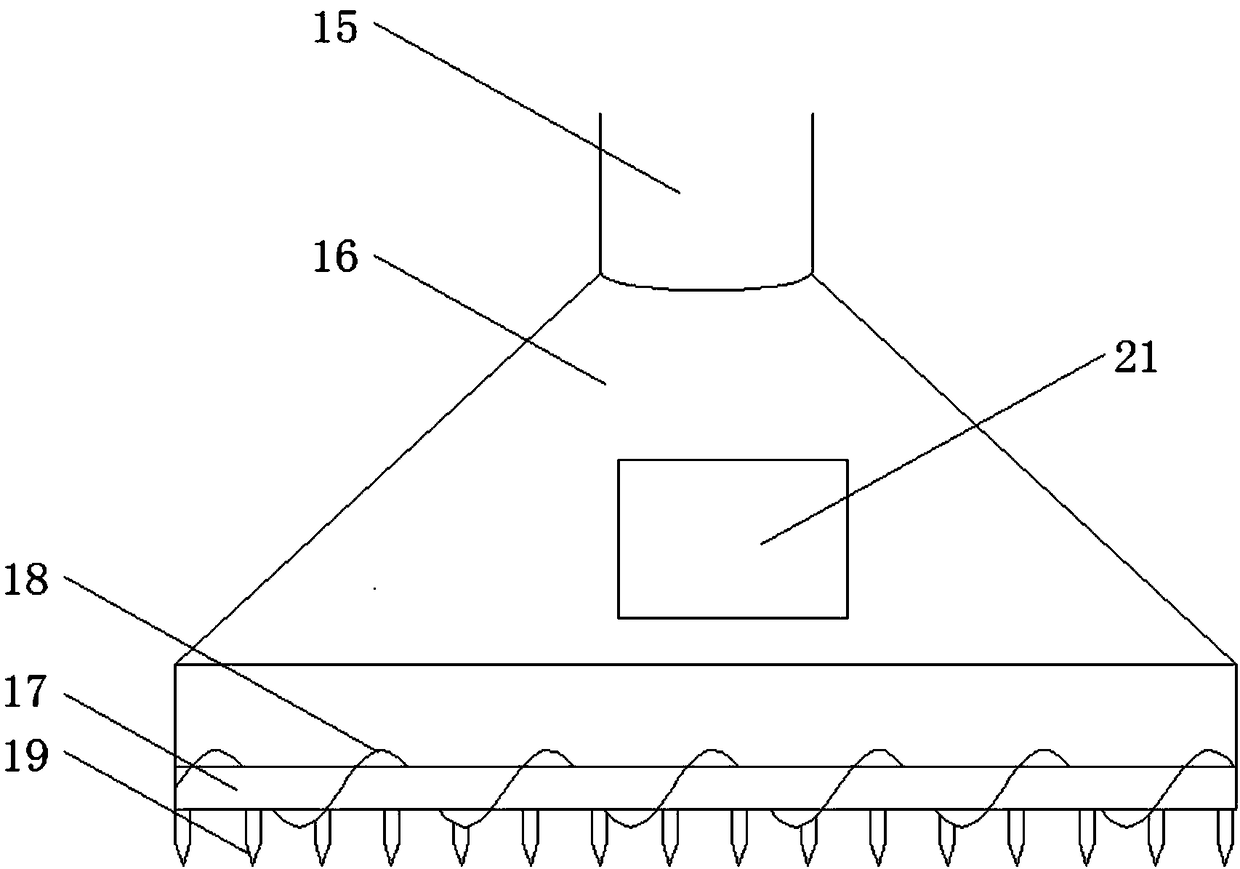

Bale plucker

InactiveCN103668563AComb evenlySimple structureFibre breaking machinesFibre breaking by beater armsEconomic benefitsPlucker

The invention discloses an automatic bale plucker with barrier plates. The bale plucker comprises a suspended hood and a transmission device. The suspended hood comprises an air draft pipeline and a suspended hood body, the suspended hood body is fixedly arranged at the end of the air draft pipeline, N sets of oblique barrier plates are arranged on the inner wall of the suspended hood body, and the inclination directions of every two adjacent barrier plates are opposite. The bale plucker is simple in structure, easy and convenient to operate and high in cotton plucking efficiency, manufacturing cost is reduced, a blocking phenomenon is not prone to occurring, cotton raw materials are scutched more uniformly, working efficiency is improved, and economic benefits are increased.

Owner:张家港市天江精密模具制造有限公司

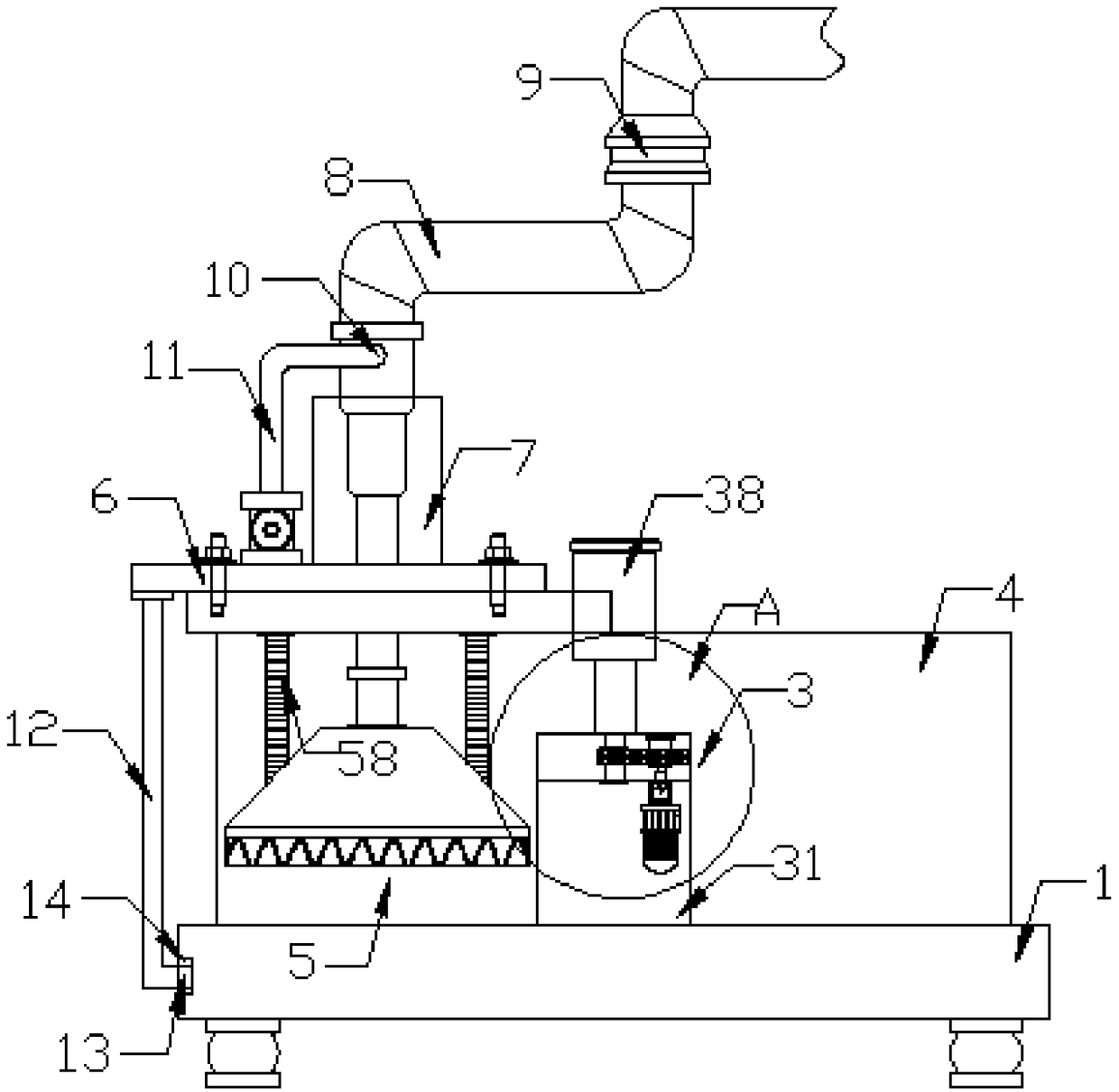

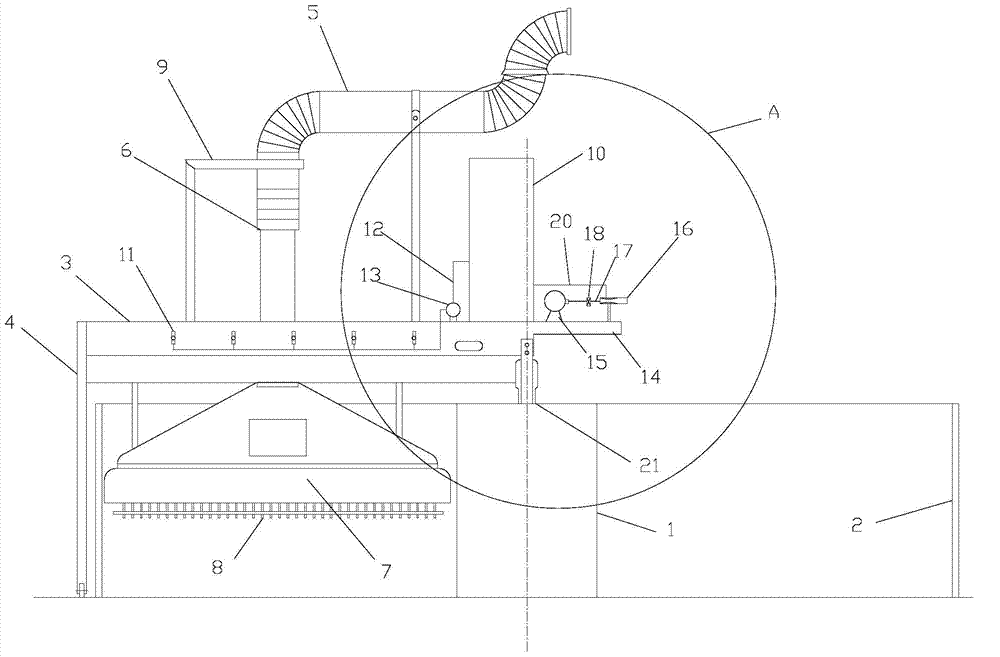

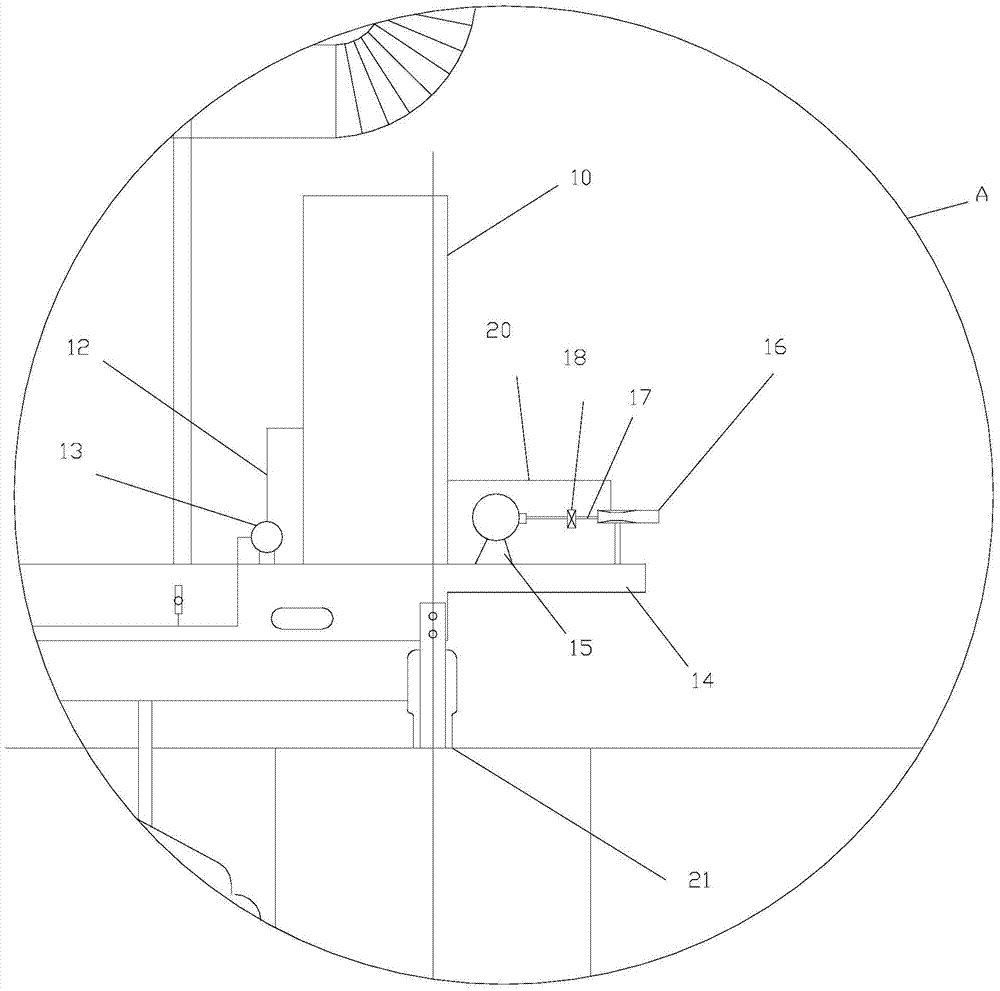

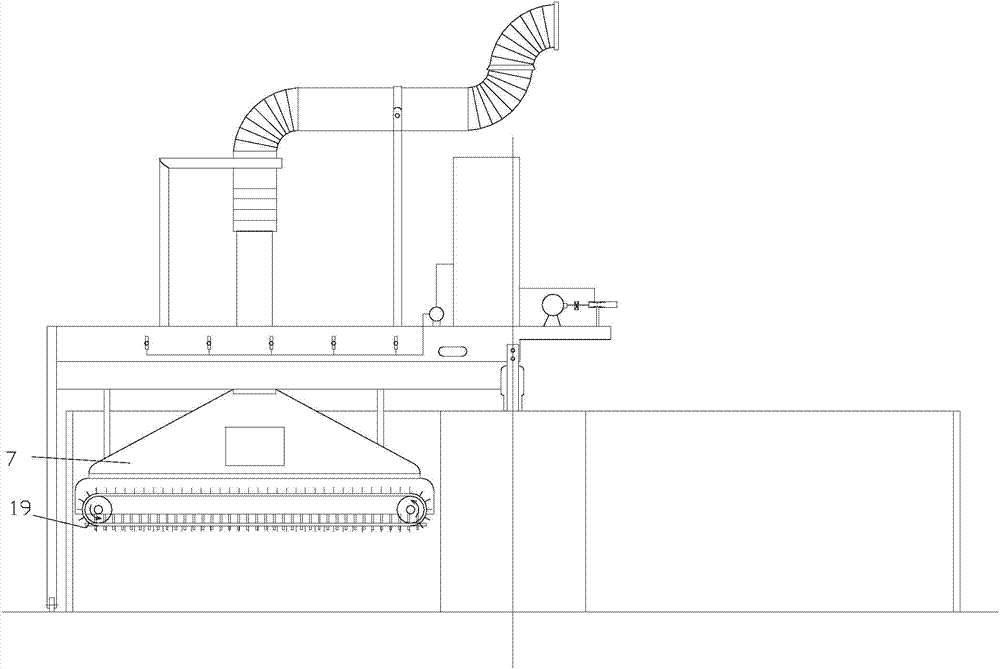

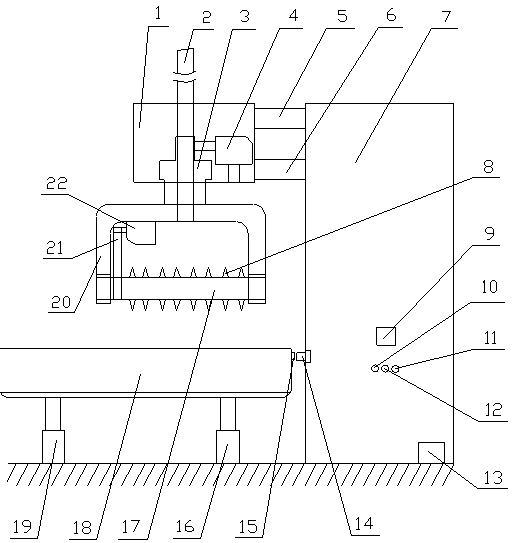

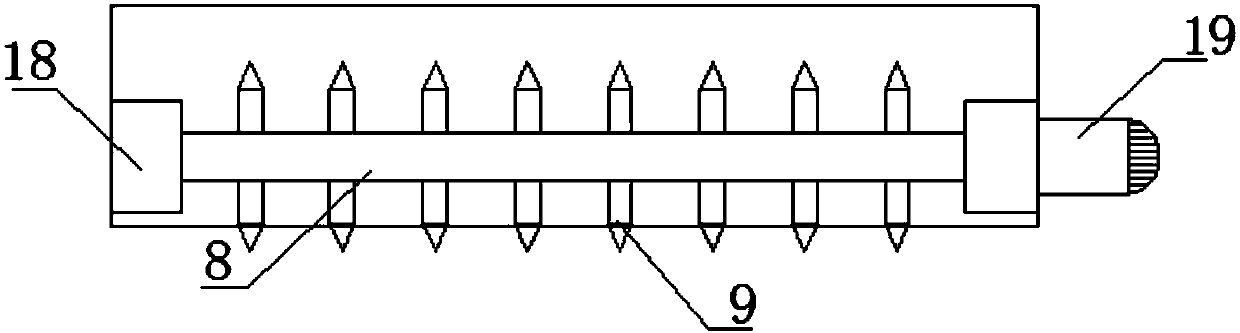

Bale plucker with self-cleaning device

PendingCN108004622AEasy to removeGuarantee normal productionFibre breaking machinesFibre breaking by beater armsSprayerEngineering

A bale plucker with a self-cleaning device comprises a bale plucker main body, wherein a cleaning strip is arranged above a bale plucking handle; a water delivering tube is arranged above the cleaningstrip; a sprayer is arranged at the lower end of the water delivering tube; one end of the water delivering tube extends out of a cotton suction cover and is connected with a flange; a sliding trackis arranged above the water delivering tube; a rodless cylinder is arranged on the sliding track; a sweeping plate is arranged at the lower end of the rodless cylinder; shearing blades are arranged ontwo sides of the sliding plate; a motor is arranged at the upper end of a central shaft of the bale plucker main body; a driving chain wheel is arranged on a rotating shaft of the motor; a lead screwand a guide column are separately arranged on two sides of a telescopic tube; a driven chain wheel is arranged on the lead screw; the driven chain wheel is connected with the driving chain wheel through a chain; a bearing block is arranged at the upper end of the lead screw; and a cleaning brush is arranged on the inner wall of the cleaning ring. In a working process of the bale plucker, the baleplucking handle and the telescopic tube can be cleaned, and normal operation of the bale plucker is prevented from being affected by flock and the like.

Owner:TAOJIANG HUANYU TEXTILE NEW MATERIAL SCI & TECH

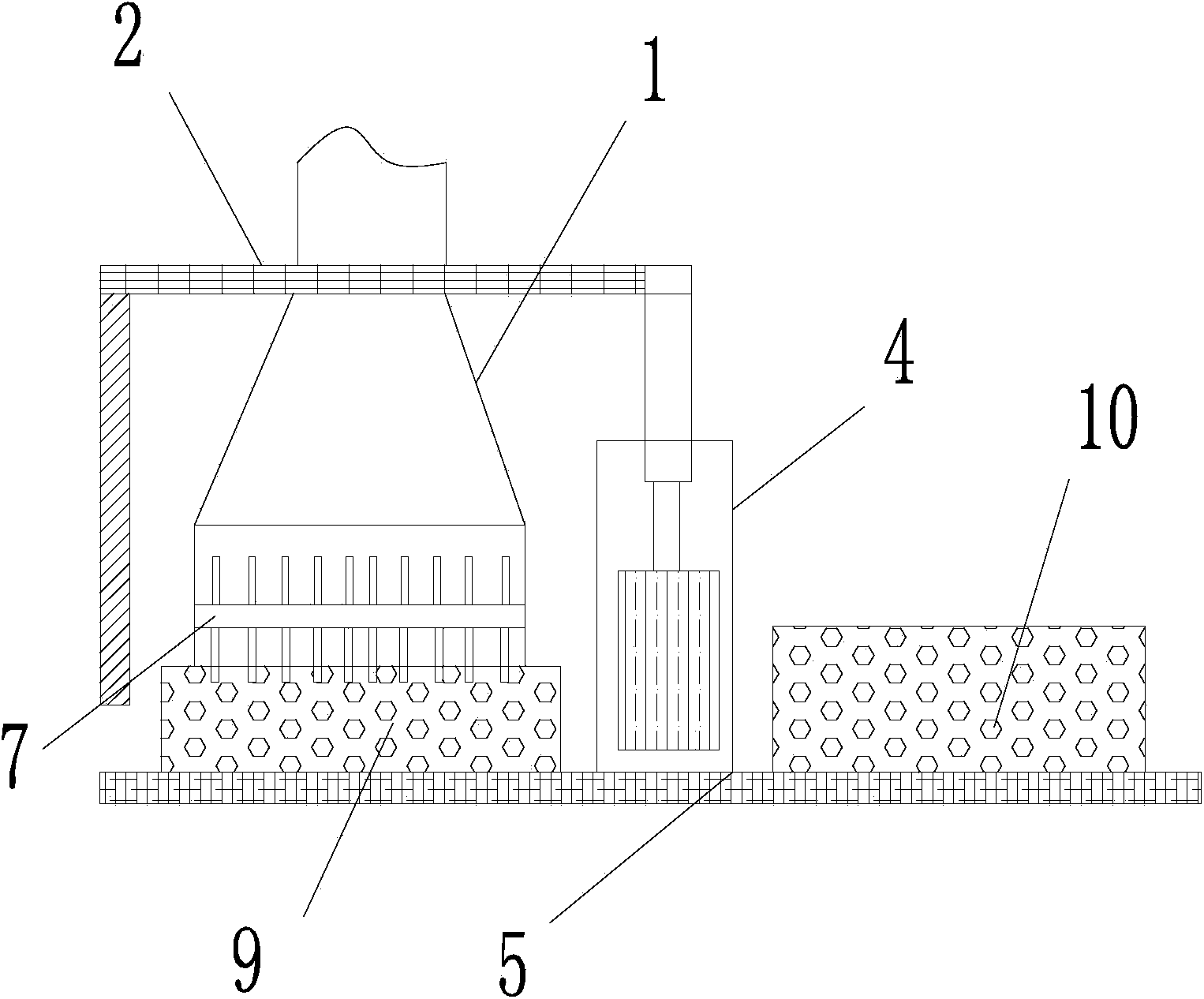

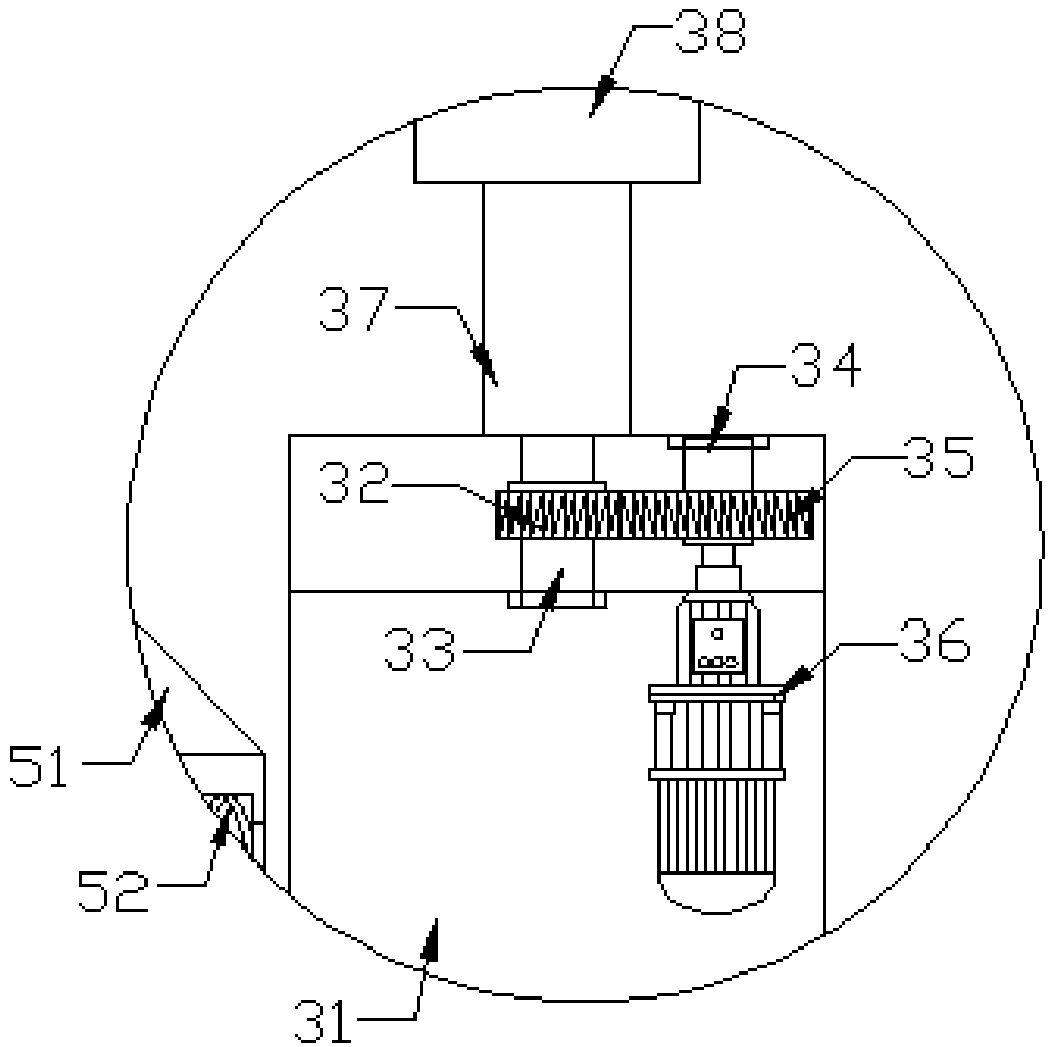

Disc plucker

ActiveCN105483867ASimple structureEasy to operateFibre breaking machinesFibre breaking by beater armsCircular discDrive wheel

The invention relates to a disc plucker and belongs to the technical field of textile machinery. The disc plucker comprises a stock bin, a center stand column, a drive floorstand, a drive motor, a drive wheel, a transmission motor, a transmission lead screw and a cotton collecting device; the center of the stock bin is provided with the center stand column; the center stand column is movably provided with the drive floorstand; one end of the drive floorstand extends to the outside of the stock bin; the position, extending to the outside of the stock bin, of the bottom of the drive floorstand is provided with the drive wheel through the drive motor and a transmission belt A, the transmission motor is arranged at the position, on one side of the center stand column, of the drive floorstand, the drive floorstand below the transmission motor is provided with the cotton collecting device through the transmission lead screw, and the transmission motor is connected with the transmission lead screw through a transmission belt B. The disc plucker is simple in structure and convenient to operate, the problems that a cotton collecting hopper of an existing plucker is easy to block, the structure is unwieldy, and efficiency is low are solved, and the disc plucker is particularly suitable for production and use of enterprises.

Owner:HUBEI JINAN TEXTILE GRP CO LTD

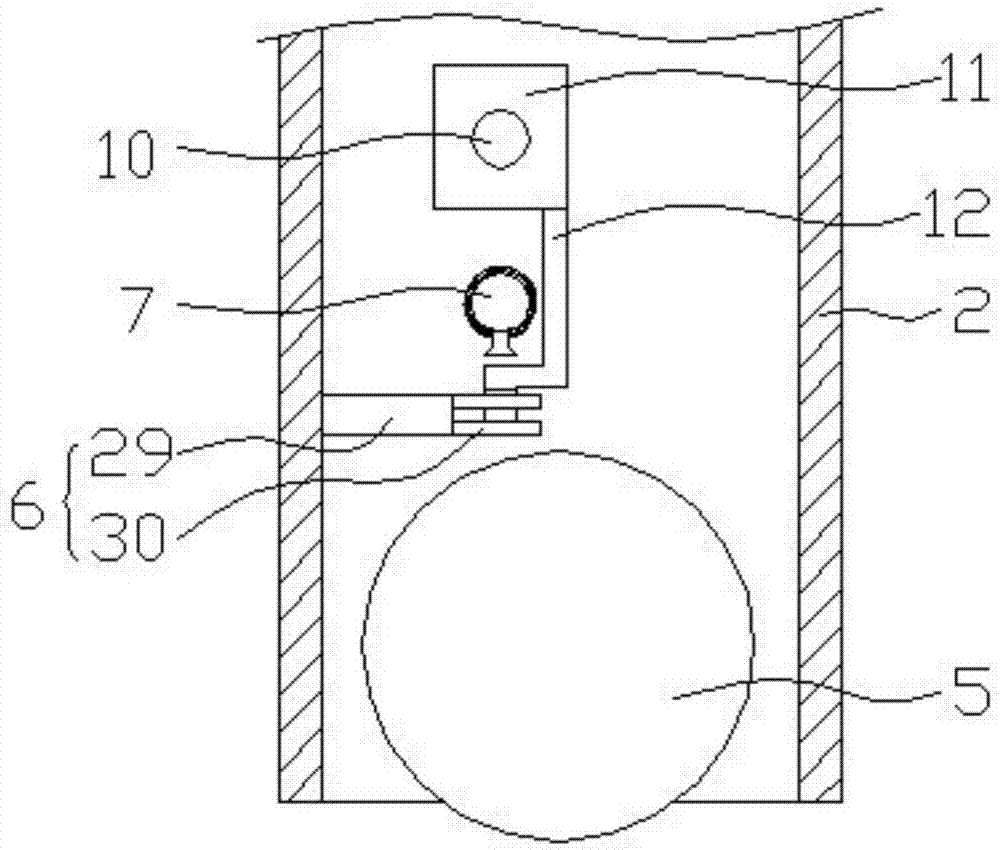

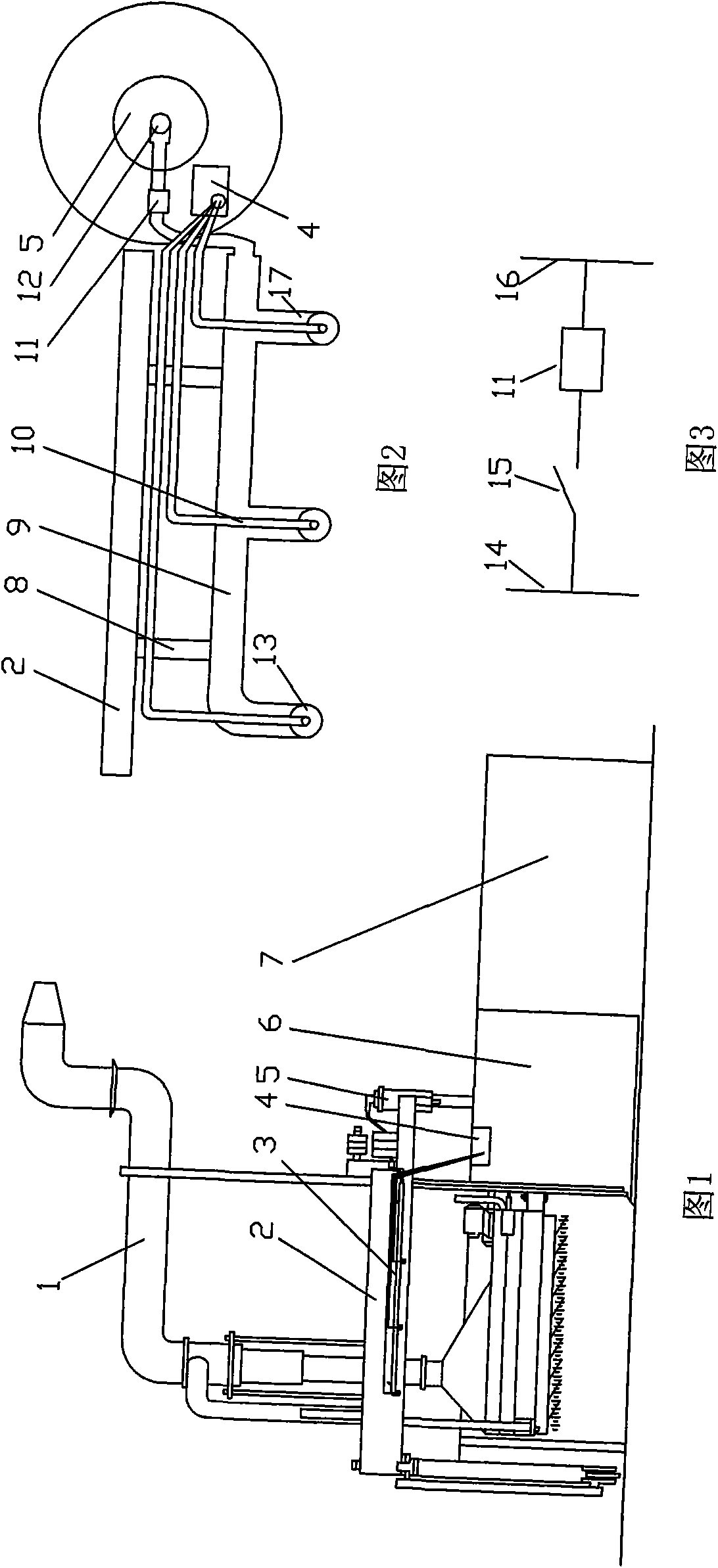

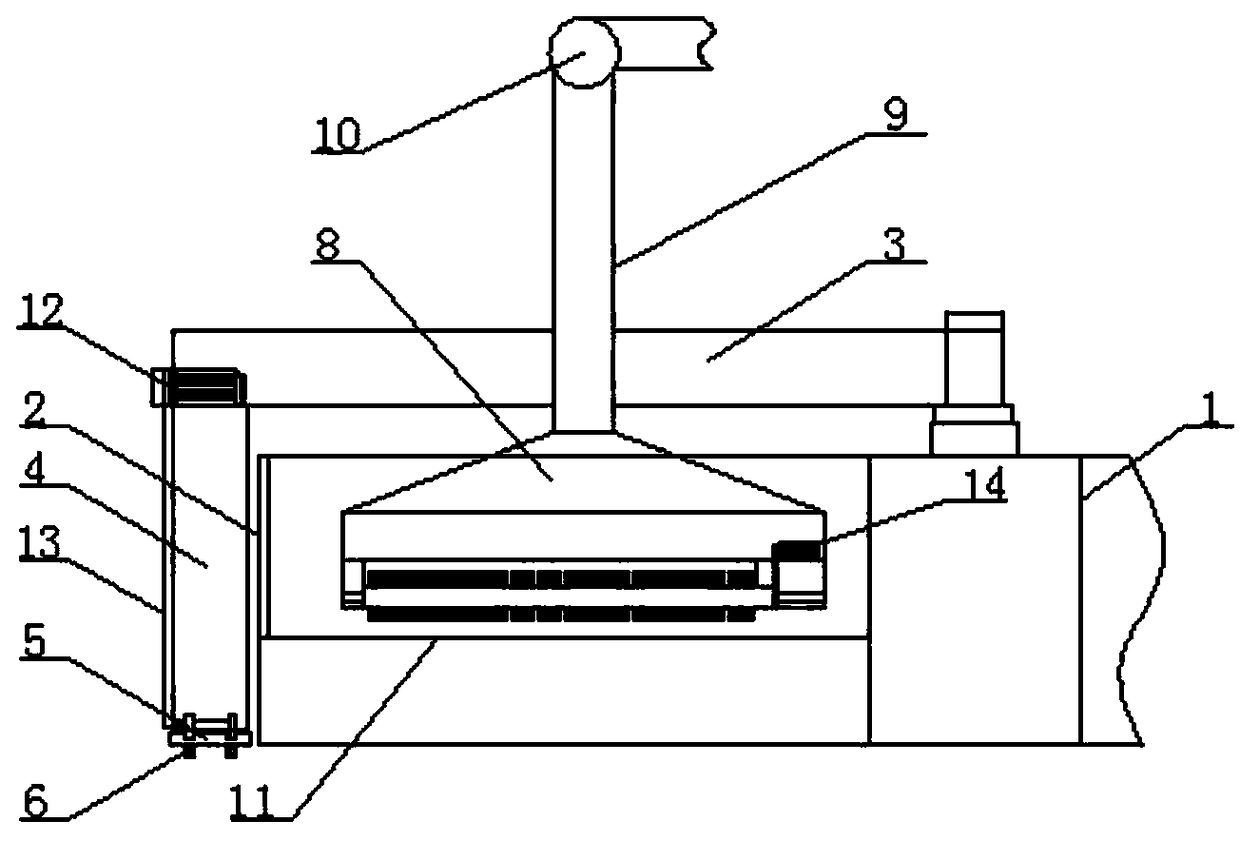

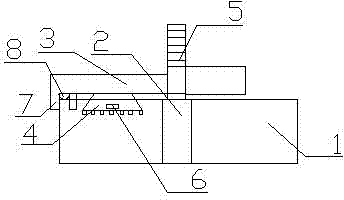

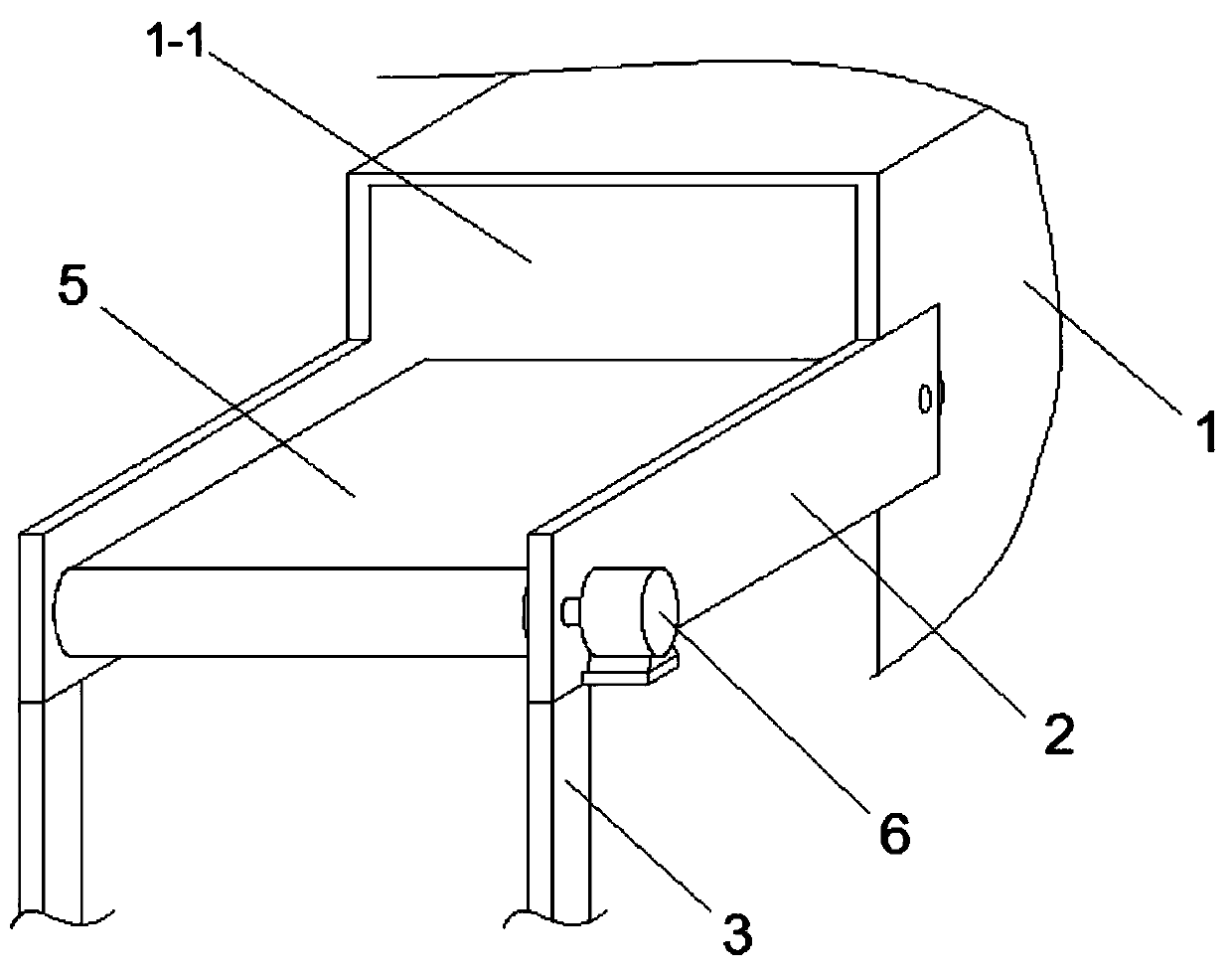

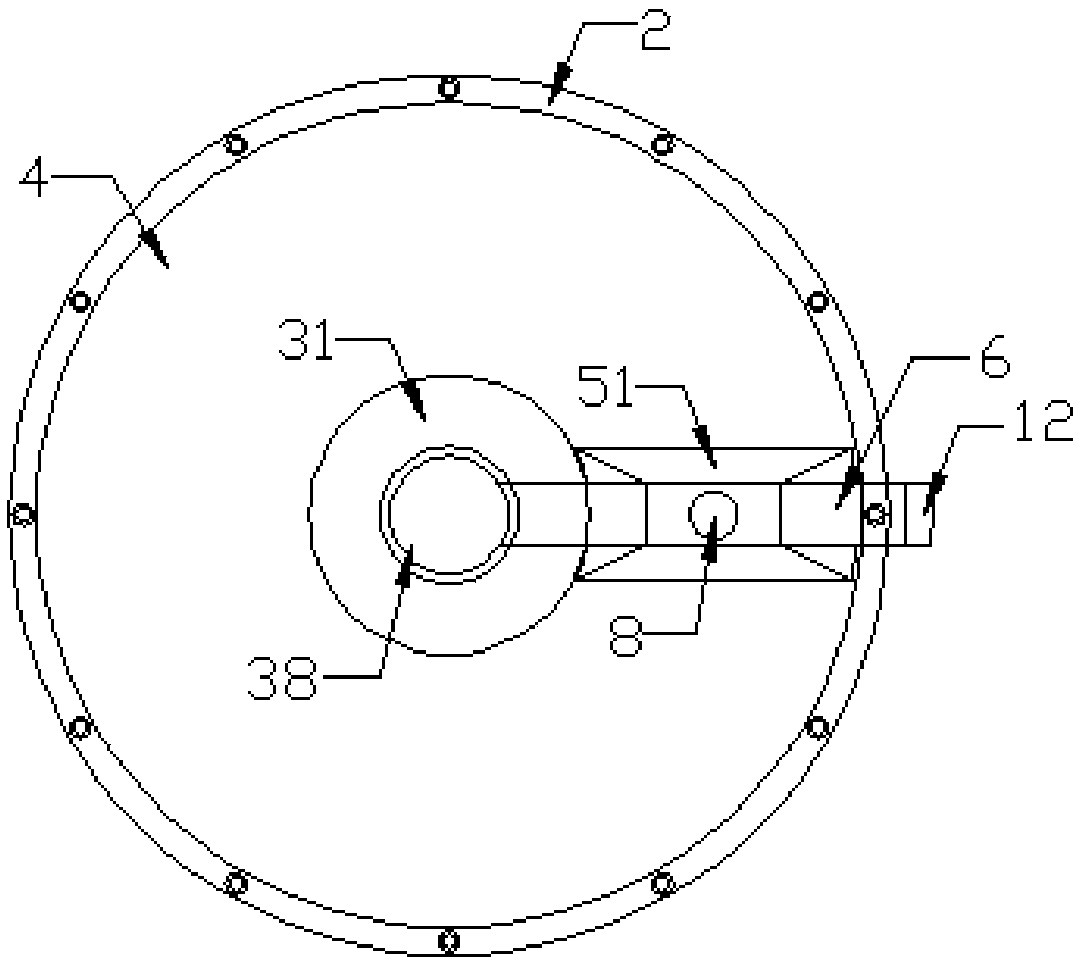

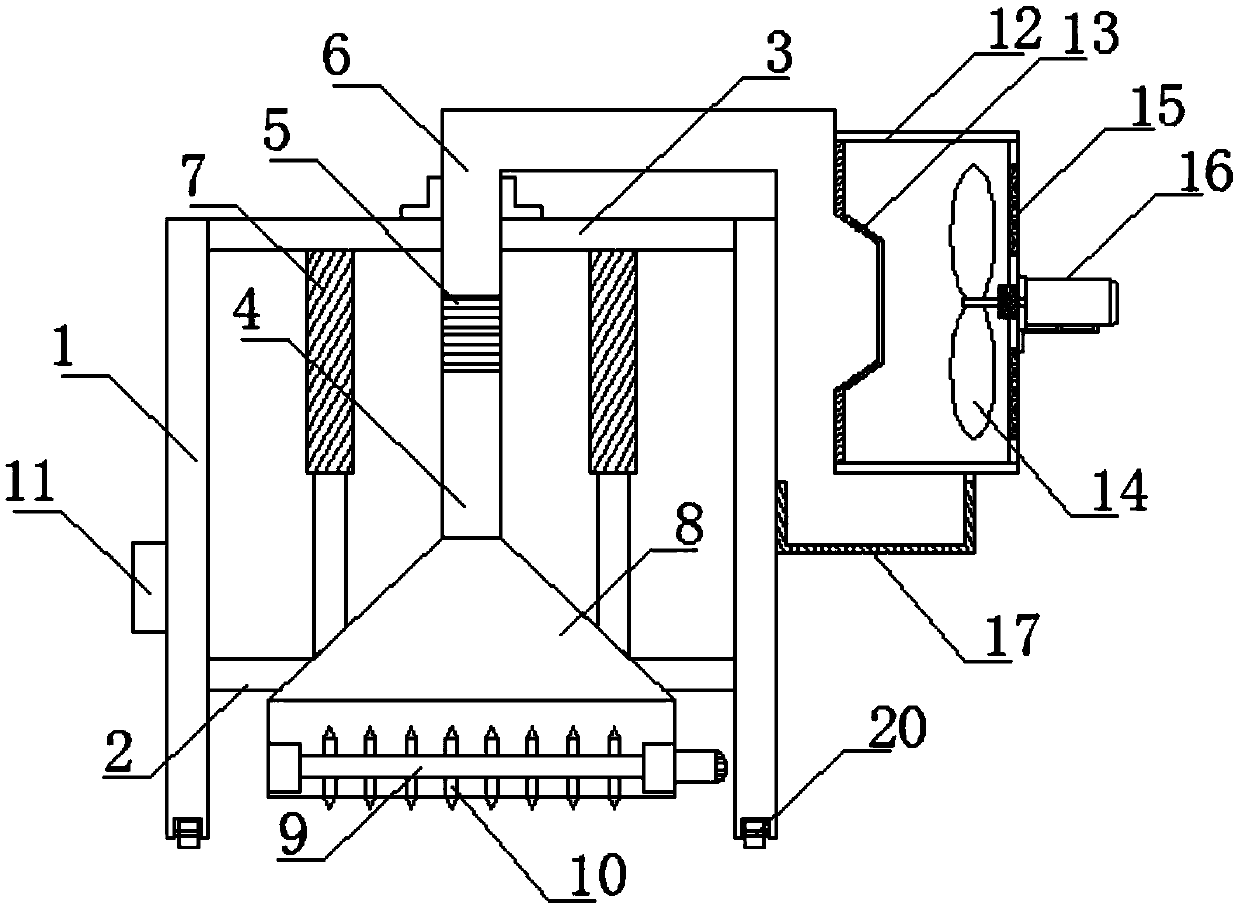

Spray humidifier for bale plucker disk

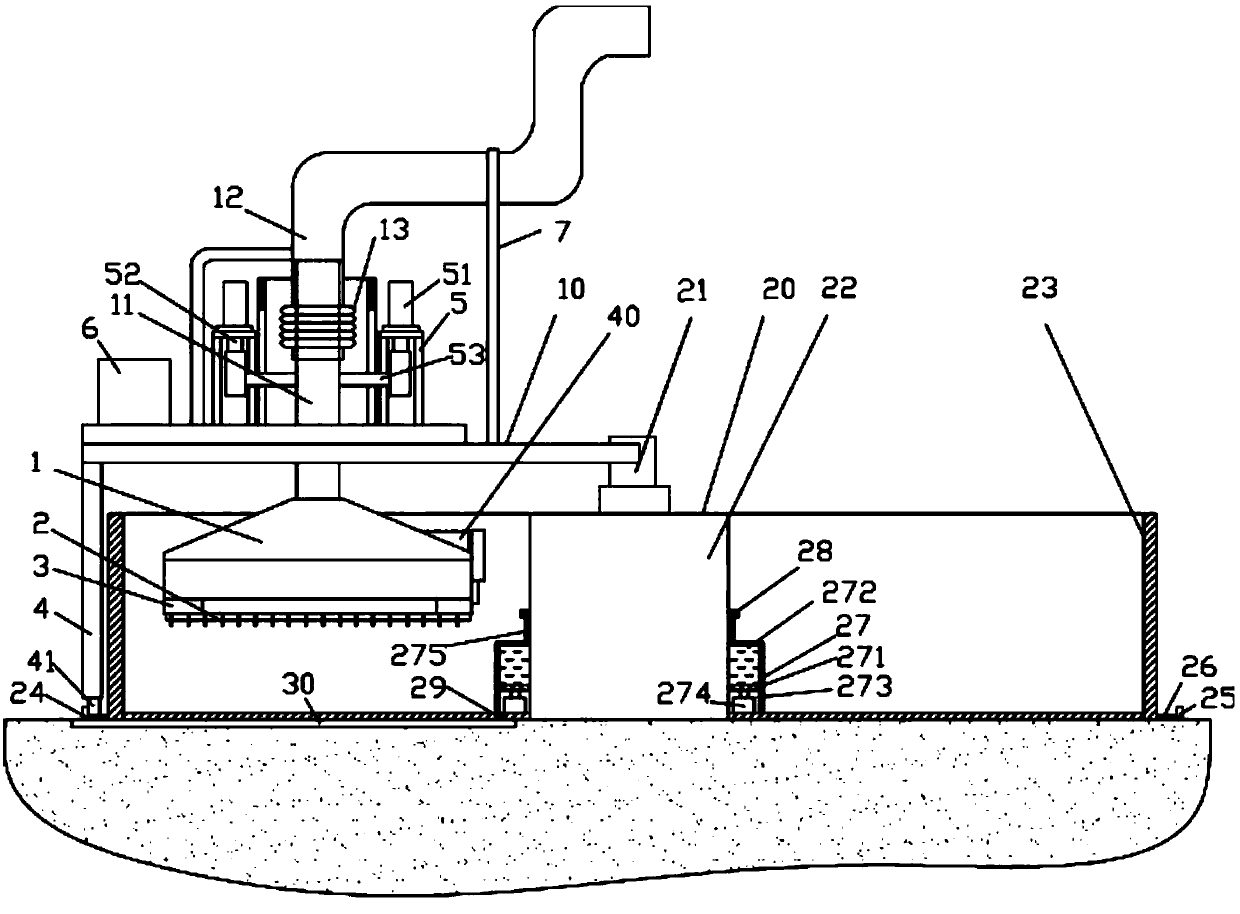

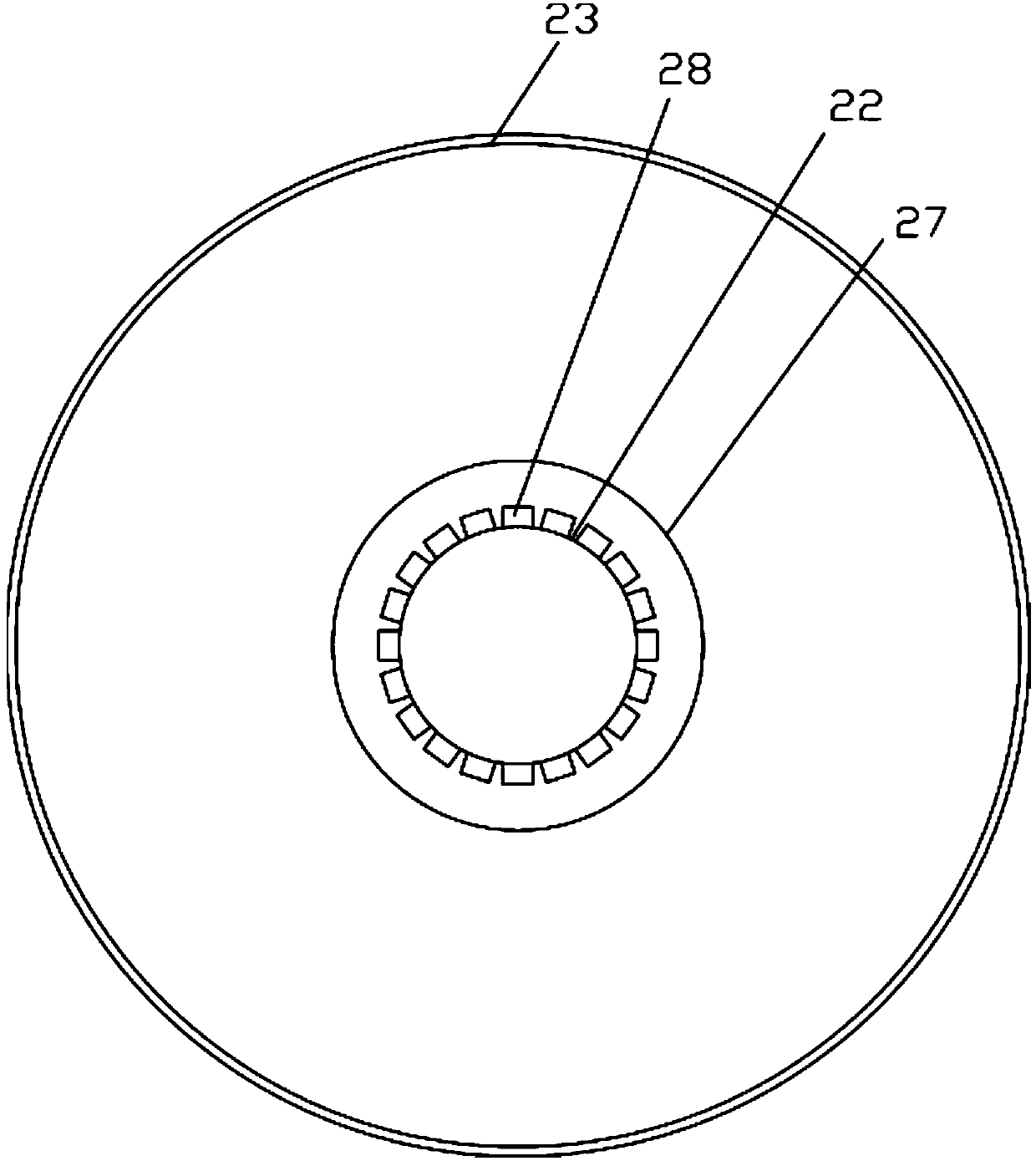

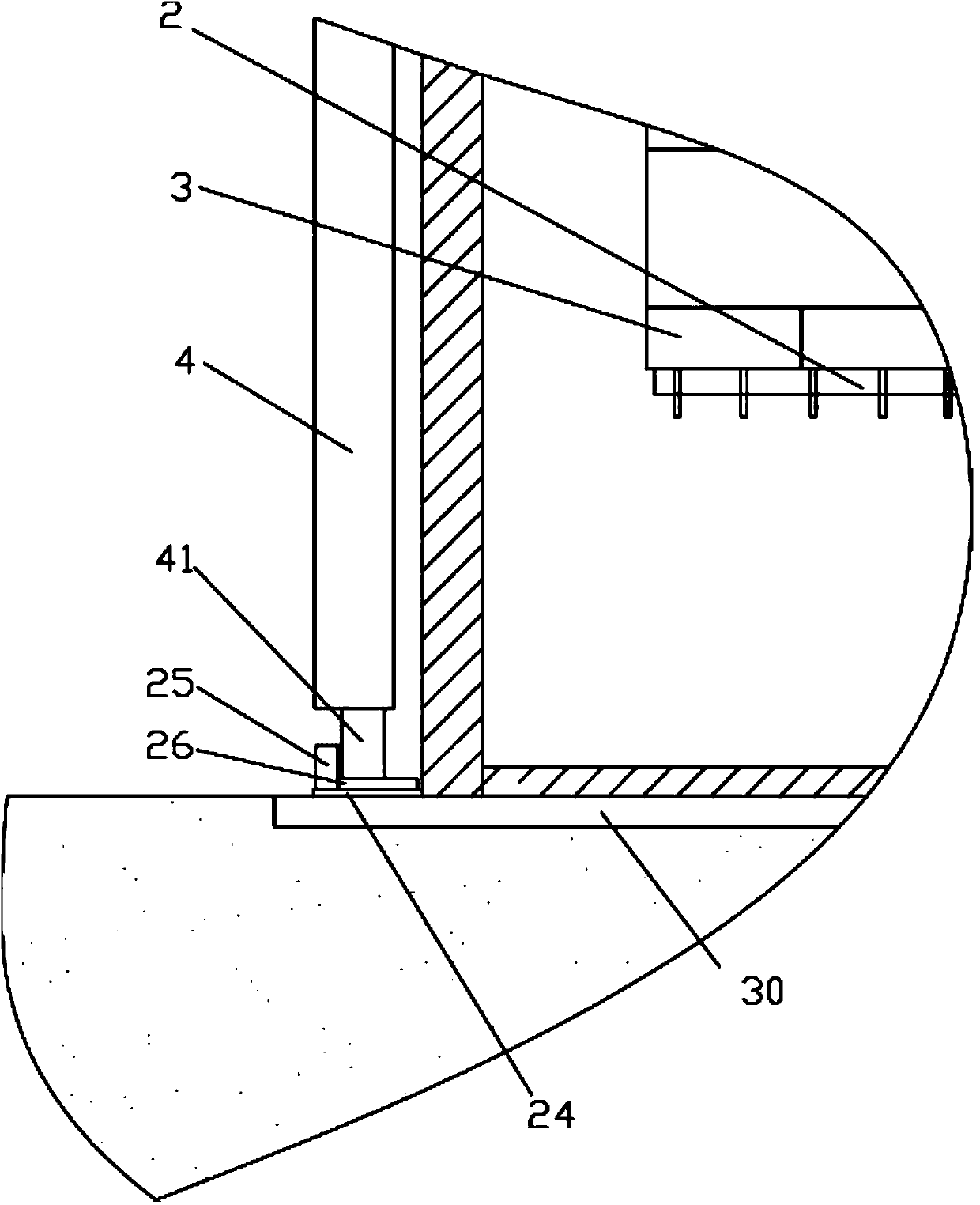

InactiveCN101629749AUniform humidificationSimple structureLighting and heating apparatusFibre cleaning/opening machinesArchitectural engineeringAir pump

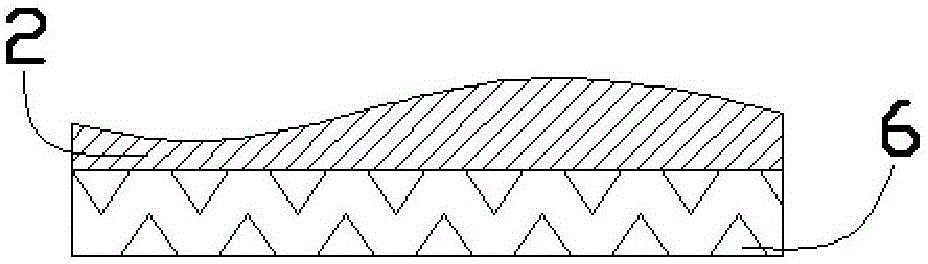

The invention discloses a spray humidifier for an A002 type bale plucker disk, which is characterized in that the left side of an A002 type bale plucker wall panel (2) is provided with two screw holes, an air pipe (9) is fixed on the screw holes of the wall panel through a bracket (8), one end of the air pipe (9) is connected with a nozzle (13), and the other end of the air pipe is connected with an electromagnetic valve (11); the electromagnetic valve (11) is connected to a universal rotary head (12) through another section of air pipe, and the universal rotary head (12) is fixed on a slip ring (5) and connected to an air compressor air pump through the air pipe; one end of a water pipe (10) is connected to the nozzle (13) respectively, and the other end of the water pipe (10) is arranged at the bottom of a water tank (4) respectively; and the water tank (4) is welded on an inner wall panel (6). The humidifier has the advantages of reasonable structure design, low production cost, convenient and even humidification, not only reduces the intensity of labor, but also increases the production efficiency of enterprises.

Owner:JIHUA 3542 TEXTILE CO LTD

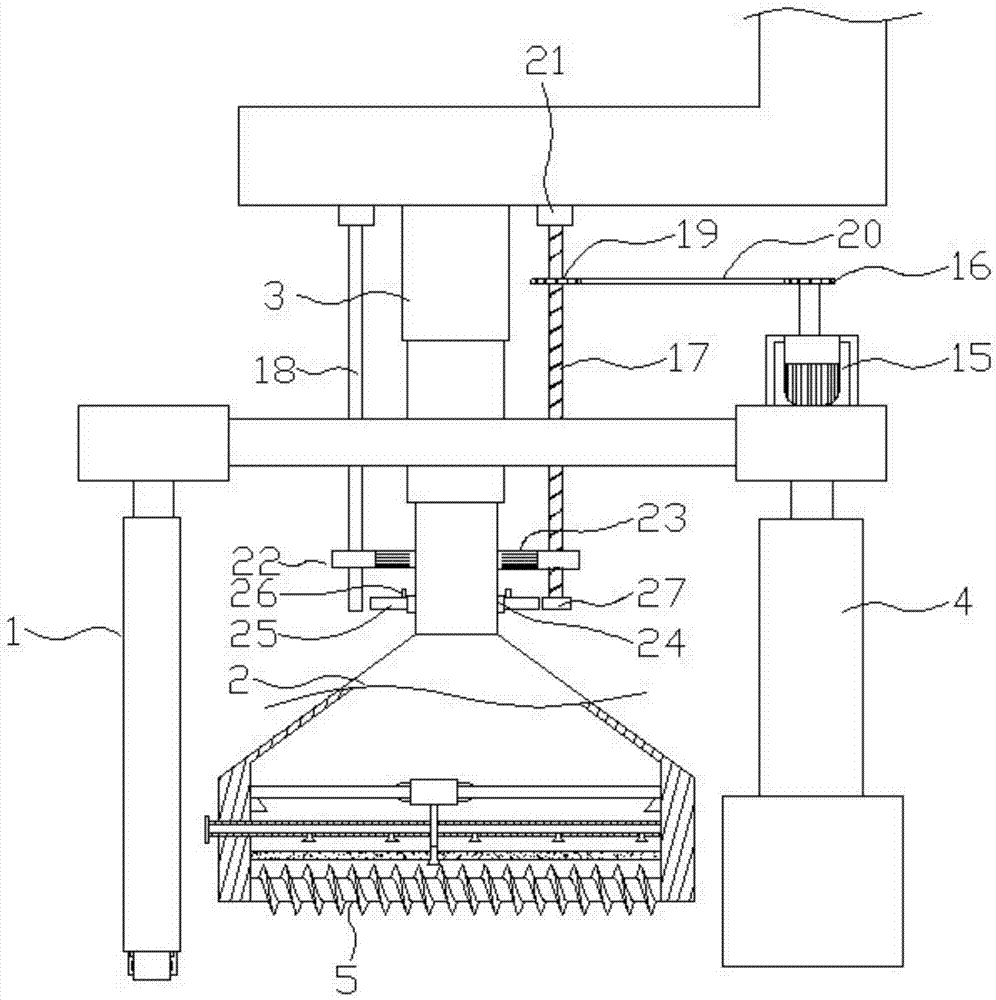

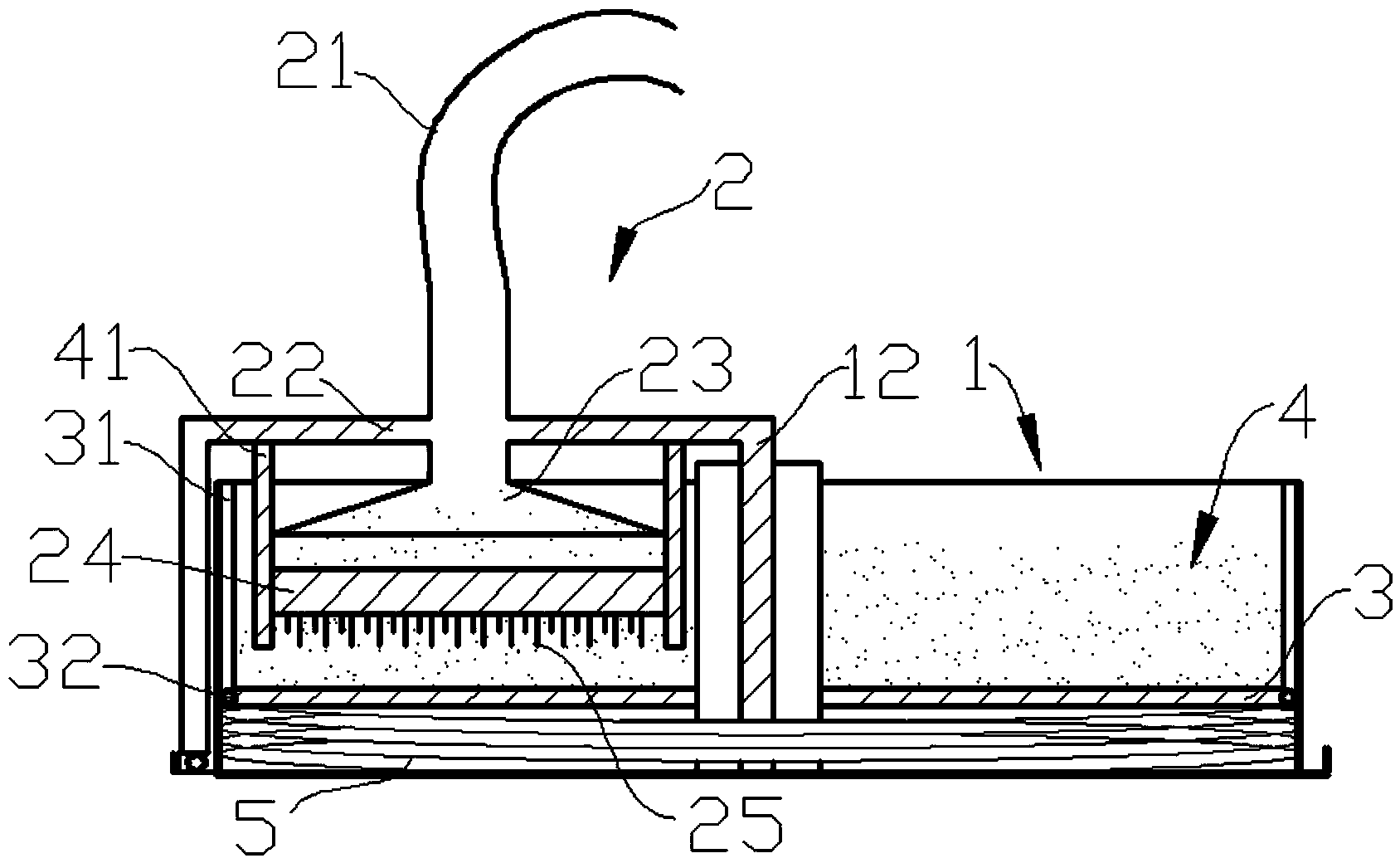

Disc type bale plucker

InactiveCN103726134ASimple structureFibre breaking machinesFibre breaking by beater armsFiberEngineering

The invention relates to a disc type bale plucker which comprises a disc base and a bale plucking trolley. A rotating shaft is arranged in the axis position of the disc base, the bale plucking trolley is connected with the rotating shaft, the disc base is divided into an upper layer and a lower layer through a sliding baffle, fibers required to be sorted out are arranged on the upper layer of the disc base, a plurality of compression springs are distributed on the lower layer of the disc base, the bale plucking trolley comprises a cotton conveying pipe, a transverse rod support, a cotton suction cover, a bale plucking beater and ribs, the bale plucking beater is mounted on a beater support perpendicularly connected with the transverse rod support and mounted below the cotton suction cover, the disc type bale plucker changes the deformation quantity of the compression springs through changes of the compression springs on the lower layer of the disc base by the fibers on the upper layer, the fibers required to be sorted out can be automatically lifted, and suitable for the height of the bale plucking beater, the structure is simple and convenient, and the working procedure of manually adjusting lifting of the bale plucking beater is reduced.

Owner:WUJIANG CITY ZHENZHONG TEXTILE

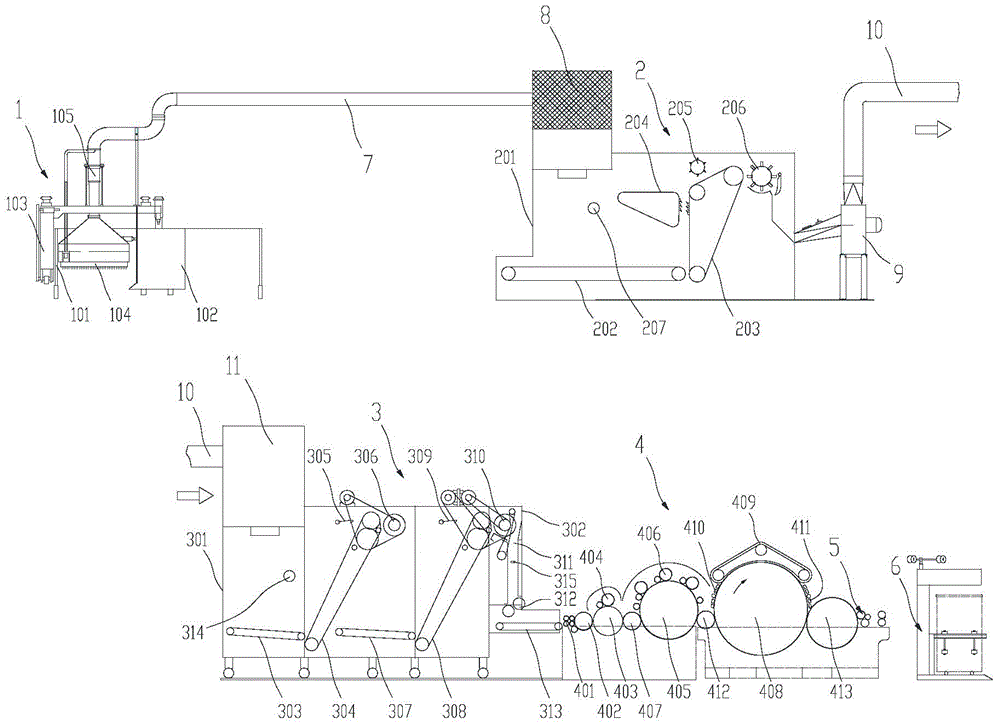

Automatic-feeding wool slivering machine complete equipment

ActiveCN105088428ASmooth feedingRealize continuous productionFibre mixingContinuous processingEngineeringMechanical engineering

The invention discloses automatic-feeding wool slivering machine complete equipment which comprises a wool balling mechanism, a wool mixing mechanism, a feeding mechanism, a carding mechanism, a stripping mechanism and a coiling mechanism. A first condenser is arranged on an inlet of the wool mixing mechanism. A first wool conveying pipeline is arranged between the wool balling mechanism and the first condenser. A wool mixing mechanism comprises a wool mixing box. A wool conveying curtain, a brad nail curtain, a wool pressing curtain, a wool homogenizing roller and a stripper beater are arranged inside the wool mixing box. The first condenser is located above the front portion of the wool conveying curtain. The brad nail curtain is located behind the wool conveying curtain. The wool pressing curtain is located in front of the brad nail curtain and above the rear portion of the wool conveying curtain. The wool homogenizing roller is located in front of the upper portion of the brad nail curtain. The stripper beater is located behind the upper portion of the brad nail curtain. A fan is connected to the rear portion of the wool mixing box. A second wool conveying pipeline is connected to the fan. A second condenser is arranged in an inlet of the feeding mechanism. The other end of the second wool conveying pipeline is connected with the condenser. The automatic-feeding wool slivering machine complete equipment is beneficial to achieving the continuous production process for wool slivering.

Owner:青岛东佳纺机(集团)有限公司

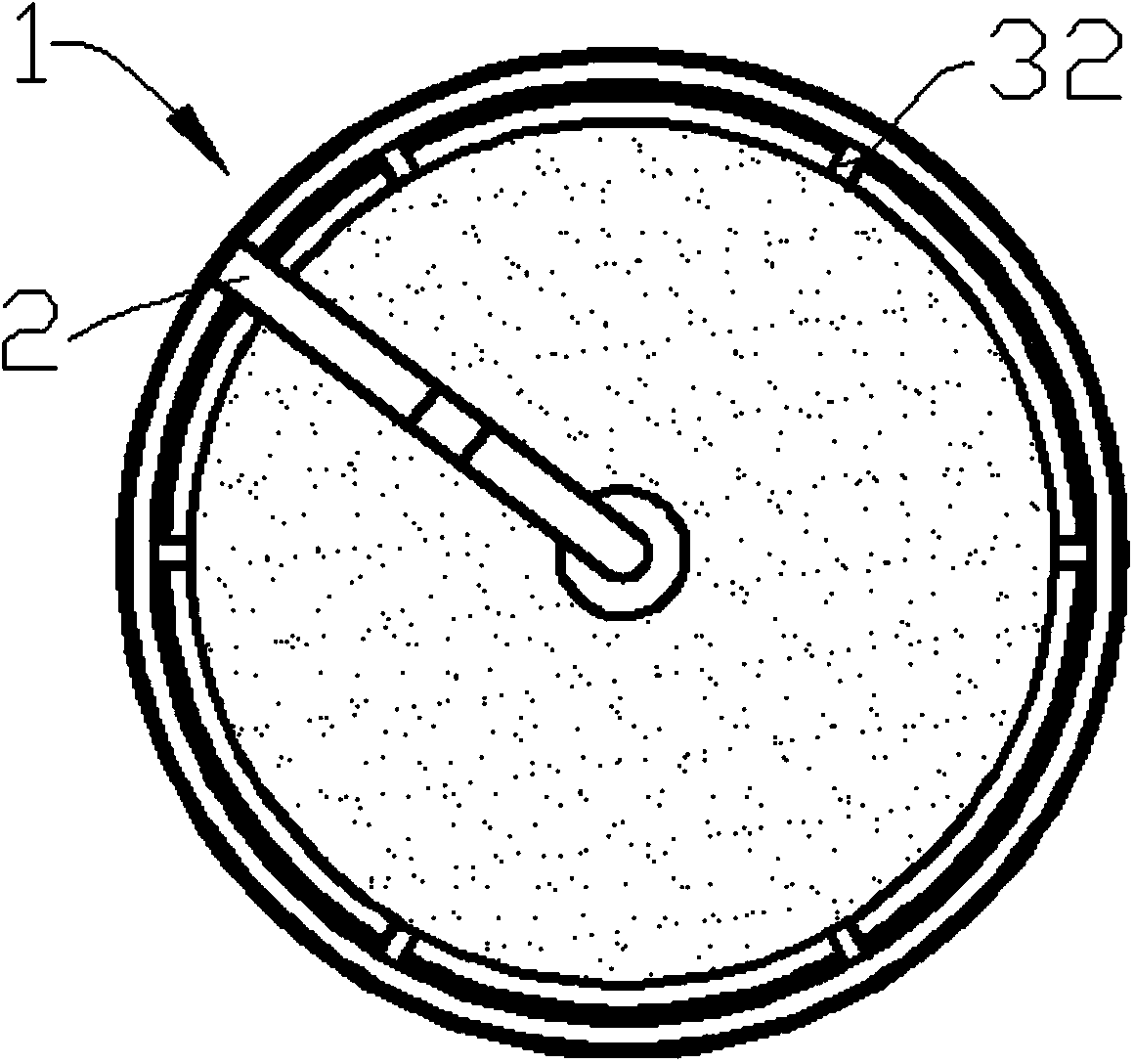

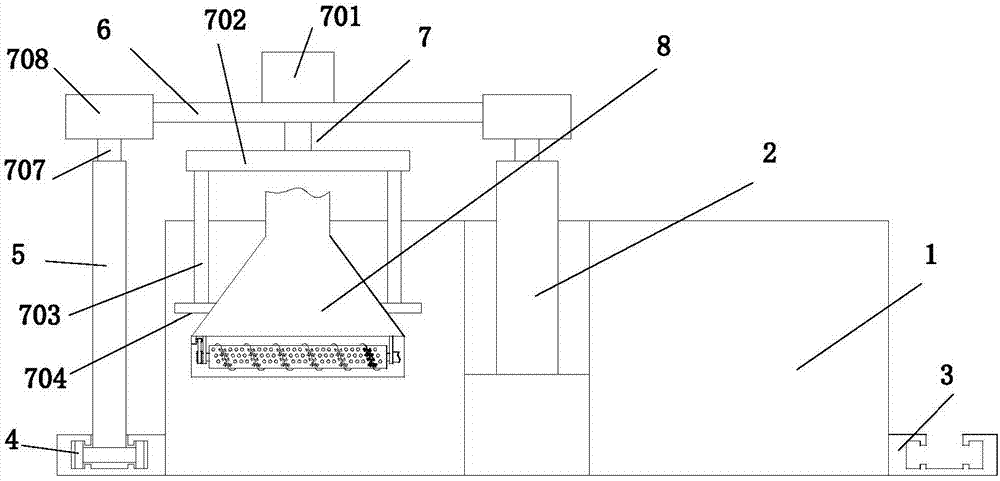

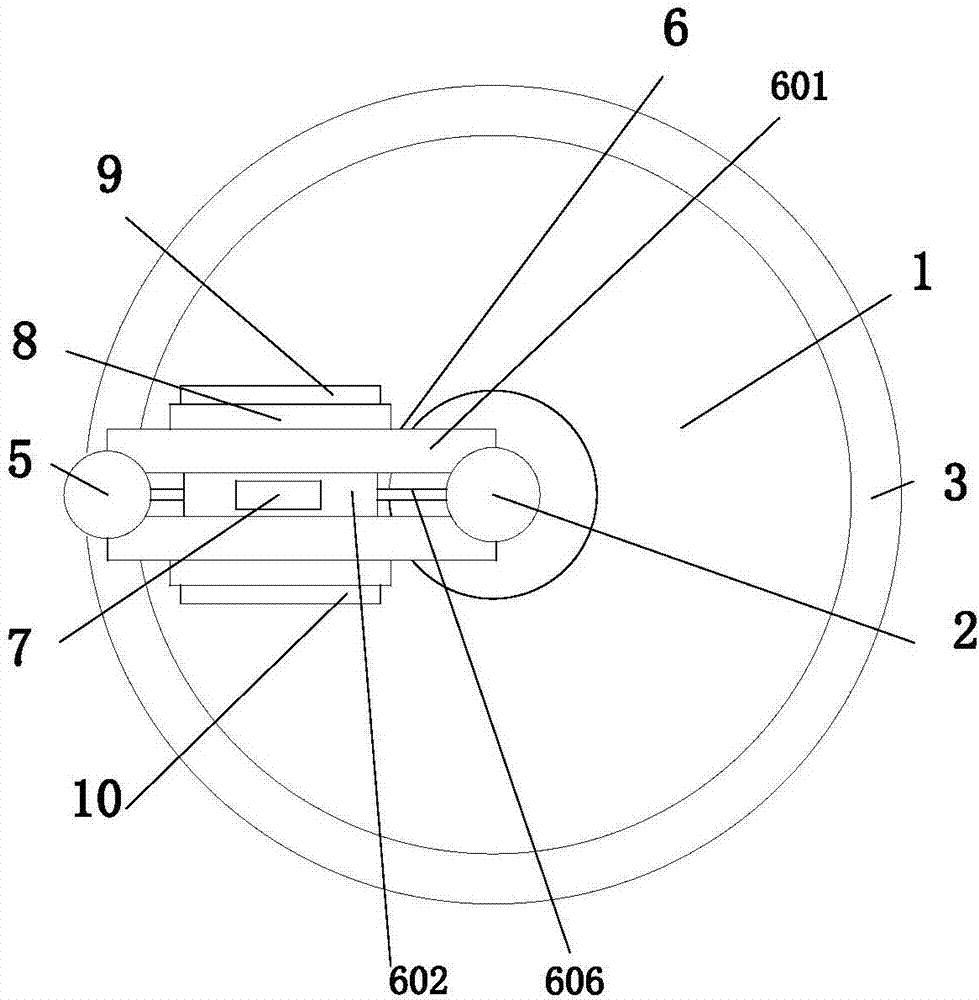

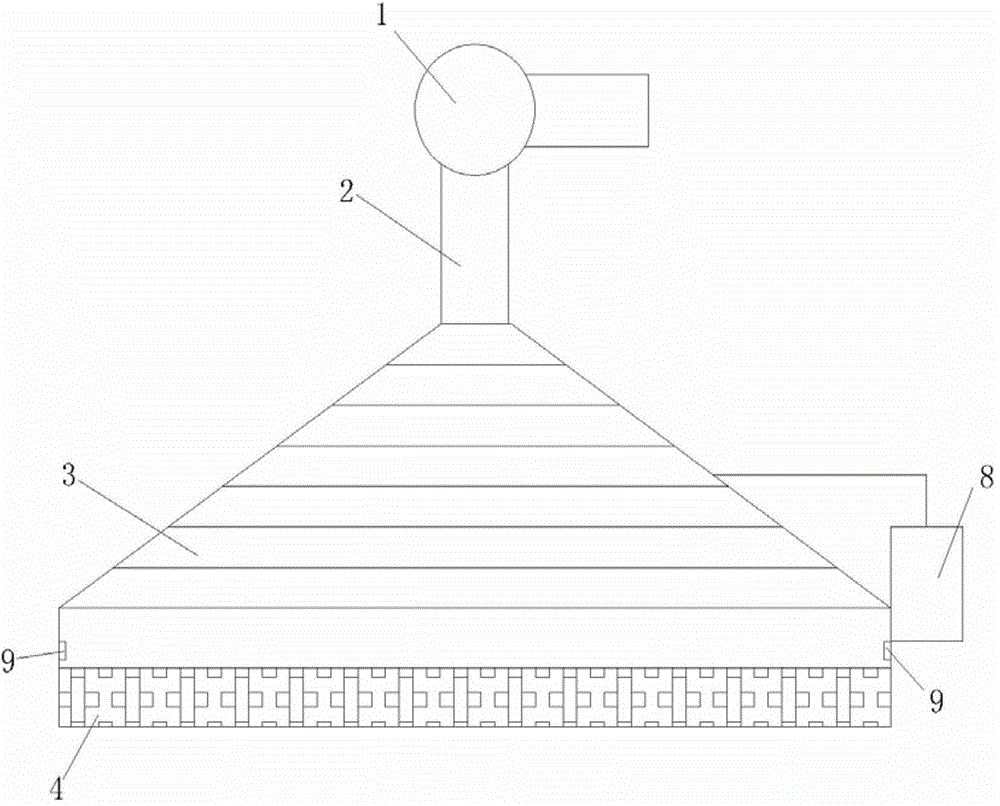

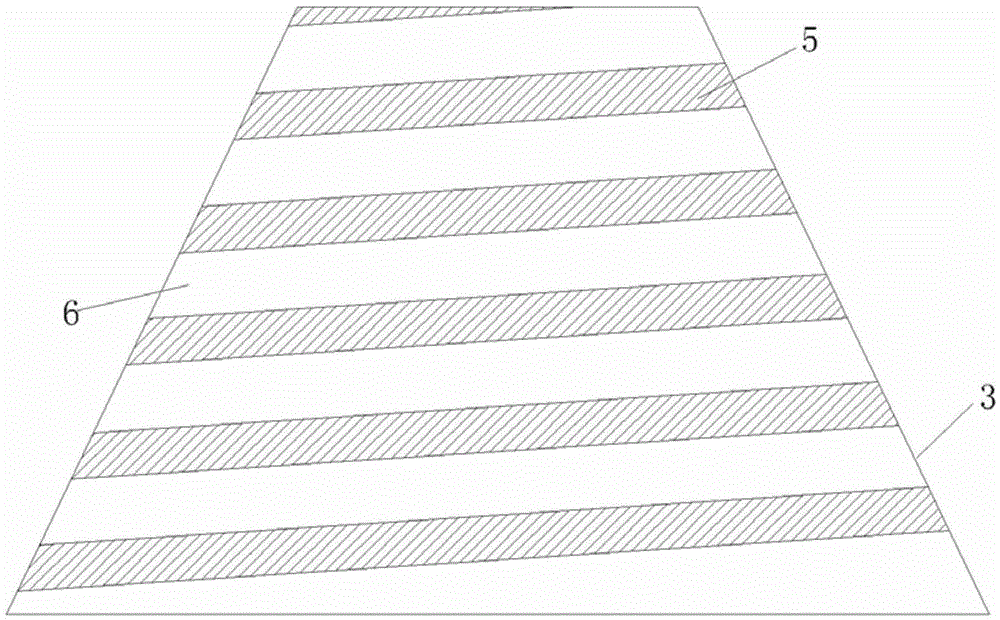

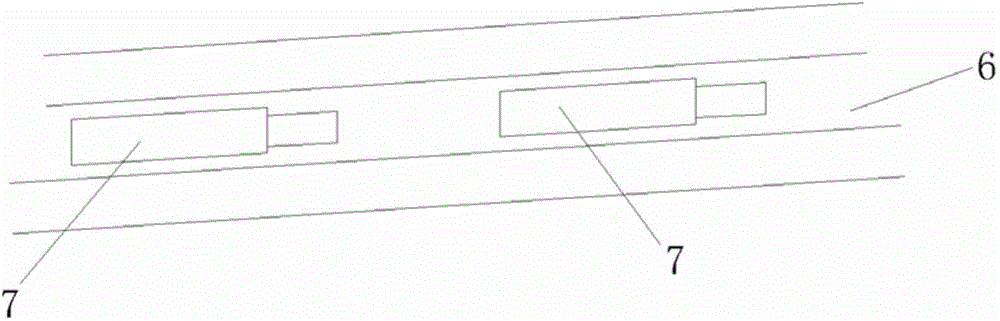

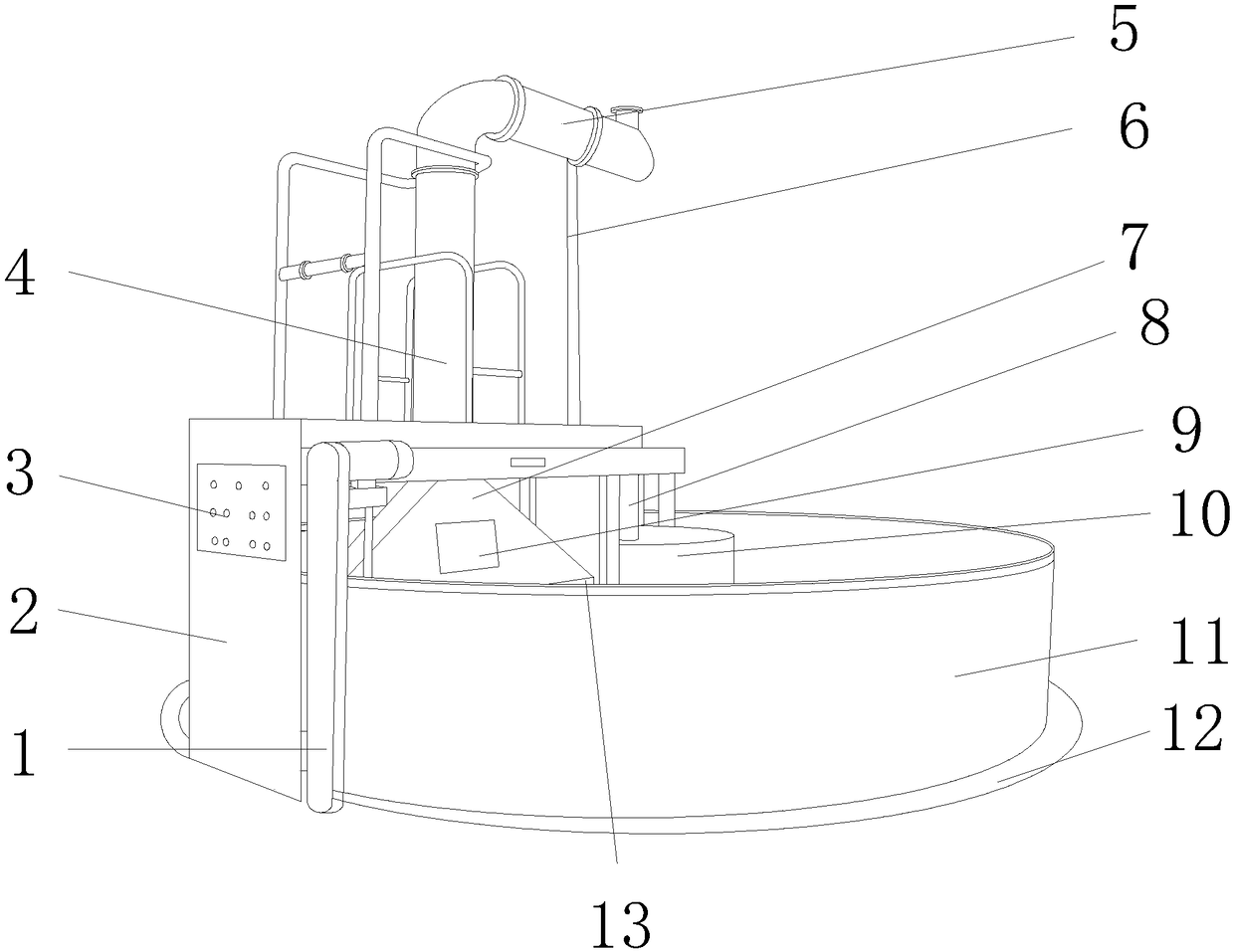

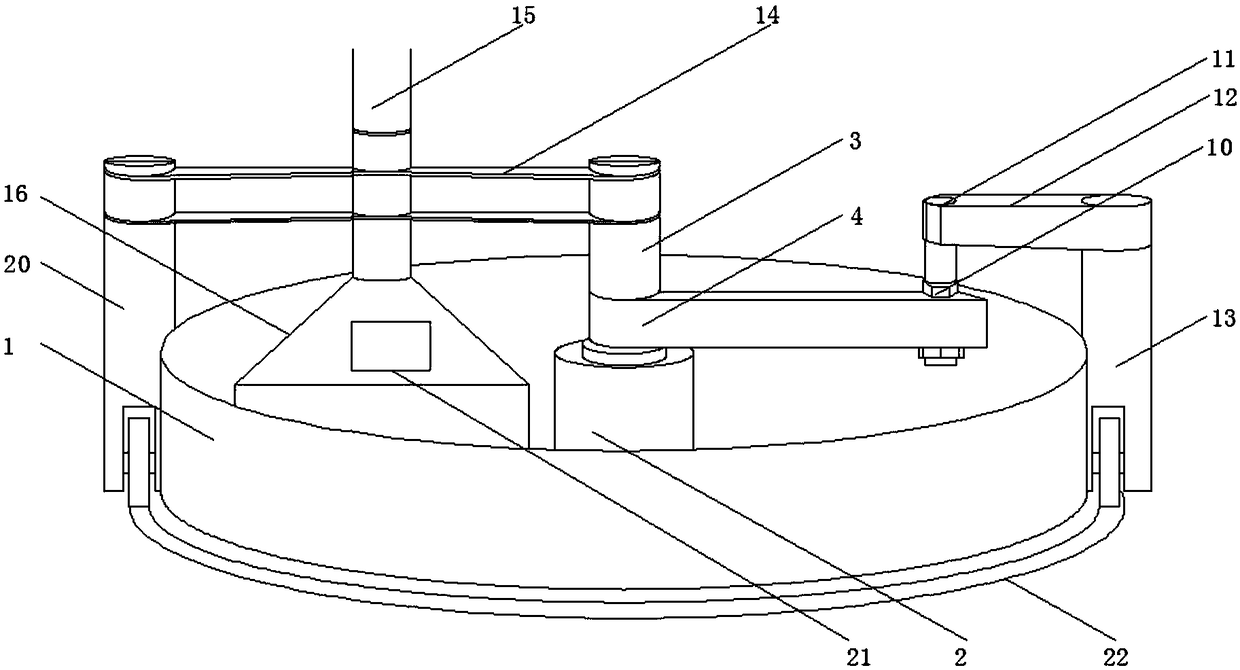

Disk plucker

InactiveCN107217336AIncrease contact areaIncrease contact frictionSafety devices for fibre treatmentFibre breaking machinesCircular discPlucker

The invention discloses a disc plucking machine, which comprises a silo (1), a rotating column (2) is arranged at the central position of the silo (1), an annular guide rail (3) is arranged on the outer wall of the silo (1), and the annular guide rail (3) is provided with a driving trolley (4), a driving column (5) is provided above the driving trolley (4), and a supporting sliding device (6) is provided between the driving column (5) and the rotating column (2) to support sliding The device (6) is provided with a lifting device (7), and the bottom of the lifting device (7) is provided with a cotton collection device (8), and the bottom of the cotton collection device (8) is respectively provided with an impurity removal device (9) and a humidification device (10) . The invention has the characteristics of improving cotton grasping efficiency, improving the impurity removal effect and reducing the clogging frequency of the cotton receiving hopper.

Owner:湖州南浔凯普纺织有限公司

Suction cowl device of plucker

The invention relates to the technical field of textile machines, in particular to a suction cowl device of a plucker. The suction cowl device of the plucker comprises a fan, a cotton delivery pipe, a suction cowl and a plucking beater; a plurality of air guide strips spirally arranged are formed on the inner wall of the suction cowl; a groove is formed between every two air guide strips; each groove is provided with electromagnets; the electromagnets are connected with a controller; the inner wall of the opening of the suction cowl is provided with a photoelectric sensor; the photoelectric sensor is electrically connected with the controller. The invention provides the suction cowl device of the plucker, which is high in cotton suction efficiency, and is capable of removing sheet iron in cotton so as to prevent the cotton delivery pipe from being blocked and damaged.

Owner:桐乡市建春塑业股份有限公司

Apparatus for stripping fibre material from textile fibre bales of spinning material, for example cotton, synthetic fibres and the like

InactiveUS7506410B2Reduce light lossMounting of the optical distance sensors is simpleCarding machinesMechanical fibre separationTextile fiberTower

Owner:TRUETZSCHLER GMBH & CO KG

Automatic plucker

ActiveCN104294411AHigh degree of automationFibre breaking machinesFibre breaking by beater armsMotor driveElectrical connection

The invention discloses an automatic plucker which comprises a base and a rack arranged on the base in a rotating mode through a rotating disc. The rotating disc is driven to rotate through a stepping motor, a cotton collecting pipe is vertically arranged on one side of the rack in a sliding mode, a cotton collecting beater is arranged at the lower end of the cotton collecting pipe, the cotton collecting pipe is communicated with a cotton collecting fan, a linkage pipe is arranged in the rack, the linkage pipe is communicated with the upper end of the cotton collecting pipe through a cotton inlet pipe, the base is connected with a conveying belt, a sensor used for detecting the thickness of a cotton layer is arranged below the cotton collecting pipe, and the sensor is in electrical connection with the stepping motor. When the sensor detects the thickness of the cotton layer to be smaller than a set value, the stepping motor drives the rotating disc to rotate, in other words, the rack rotates, the direction is changed so that a cotton layer on the other side can be grabbed, and the automation degree is high.

Owner:JIANGSU JINHUI AUTOMATION TECH

Disc type plucker

InactiveCN108823685APrevent crushingReduce vibrationFibre breaking machinesFibre breaking by beater armsEngineeringPlucker

The invention discloses a disc type plucker, and relates to the field of textile equipment. The plucker structurally comprises an inner wall board, an outer wall board, a platform, a rotary trolley, arail, anti-seismic anchors, a beater, a cotton suction cover, a cotton suction pipe and a cotton suction machine. The outer wall board is arranged outside the inner wall board, and annular cotton placement space is enclosed by the outer wall board and the inner wall board. The anti-seismic anchors are arranged under the rail. A connecting block is arranged at the bottom of the rail, and a grooveis formed in the bottom of the connecting block; the anti-seismic anchors comprise bases, supporting blocks and springs, the supporting blocks are arranged on the bases, the cross section area of eachsupporting block is matched with the area of the groove, the springs sleeve the supporting blocks and connected with the connecting block and the bases, and the bases sleeve the outer sides of the springs. The plucker can avoid that the trolley rotates and crushes the rail, the rail vibration is reduced, the rail deformation is avoided, the using durability of the plucker is strengthened, and a good impurity removing effect is achieved.

Owner:徐应盈

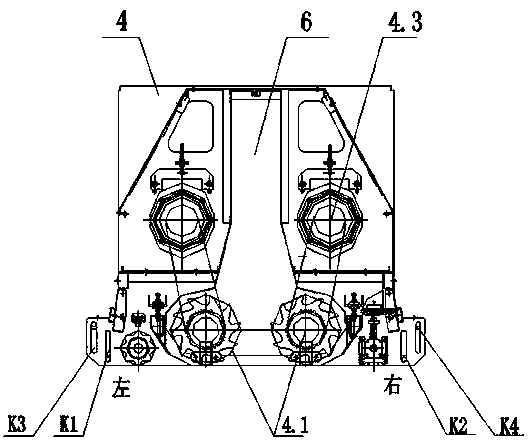

Reciprocating bale plucker automatic bag detecting and flatting system and control method

ActiveCN110241486AImprove sliver qualityTo achieve the purpose of automatic flat packagingFibre breaking machinesTotal factory controlTowerRetaining wall

The invention provides a reciprocating bale plucker automatic bag detecting and flatting system and a control method. The system comprises an electric console, a tower body, a tower seat, a grab arm provided with plucker rollers and a plucker roller blade set, a rail, a cotton suction groove and retaining walls, and is characterized in that two pairs of automatic detecting light controllers are arranged in the front and rear length directions of the two sides of the grab arm, wherein two pairs of the automatic detecting light controllers are arranged on a same low level plane, the other two pairs of the light controllers are arranged on a same high level plane, and output signals of the four pairs of light controllers are connected to the electric console. When the grab arm rises and falls along the tower body, the four pairs of light controllers are blocked by cotton bales at different height positions, a controller judges the fluctuation of the cotton bales according to the change of the output signals of the light controllers and the height of the grab arm, by calculating the initial plucker falling height and reciprocating plucker falling depth of the grab arm, the balance of the grabbing quantity is controlled, the equipment loss and potential safety hazards which are caused by non-uniform cotton supply are eliminated, and the card sliver quality of a post-carding machine is improved.

Owner:QINGDAO HONGDA TEXTILE MACHINERY

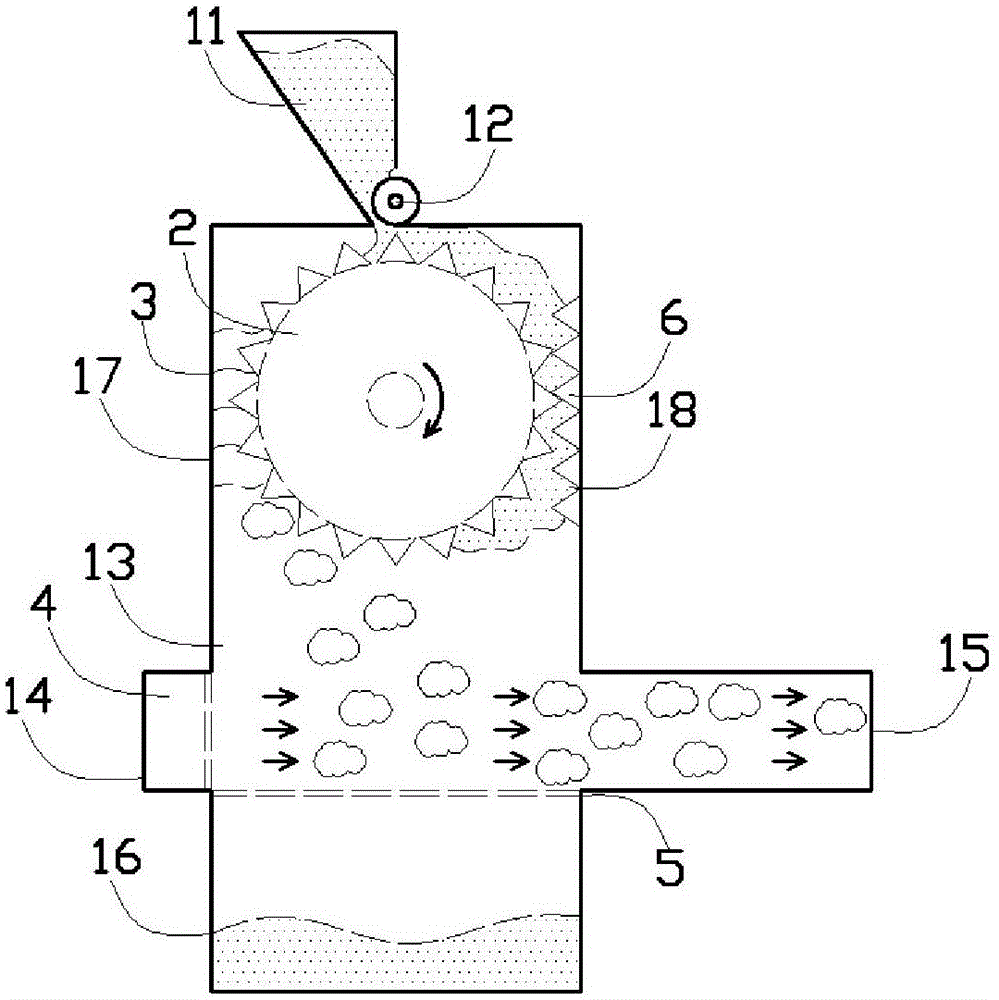

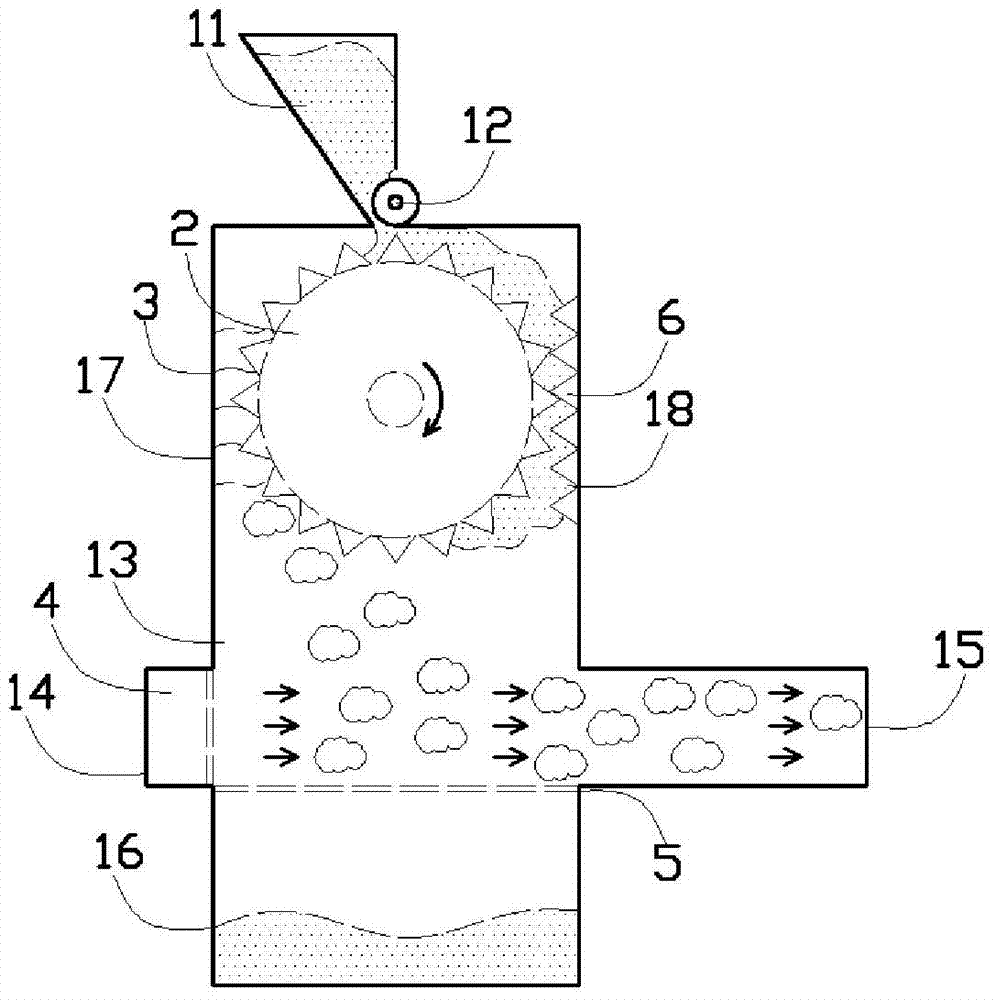

Rolling type cotton opener

ActiveCN105040167AAvoid congestionAvoid fireFibre breaking machinesFibre breaking by beater armsEngineeringTextile

The invention relates to a rolling type cotton opener, and relates to the field of textile machinery. According to the invention, a raw cotton jam problem is solved, and cotton blocks are prevented from twining around blades. The rolling type cotton opener comprises a cotton opener cabinet, a cotton opening beater, cotton block brushes, a cotton blowing fan and a filter screen. The cotton opener cabinet comprises a feeding port, a reeling roller, a cotton opening box, a blowing fan box, a discharging port and an impurity collecting box. The feeding port is fixed to the upper end of the cotton opening box; the reeling roller is mounted at the lower end of the feeding port in a rotatable manner; the blowing fan box is fixed to the lower end of the exterior of the cotton opening box; the discharging port is fixed to the lower end of the exterior of the cotton opening box; the impurity collecting box is mounted at the lower end of the cotton opening box; the cotton opening beater is mounted inside the cotton opening box in a rotatable manner; and the cotton block brushes are fixed inside the cotton opening box. The feeding amount of the raw cotton is controlled through the reeling roller, and the raw cotton twining around the blades of the cotton opening beater is brushed off through the cotton block brushes.

Owner:利津慈母坊纺织科技有限公司

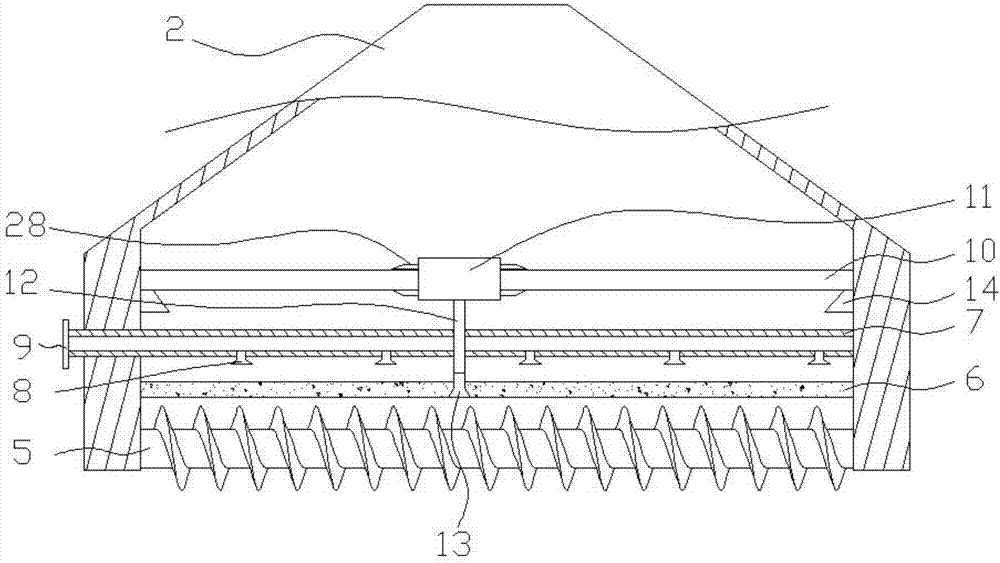

Novel automatic cotton suction machine

InactiveCN103806132ASpray evenlyGuarantee the effect of absorbing cottonTextile treatment by spraying/projectingFibre breaking machinesHydraulic cylinderAntistatic agent

The invention discloses a novel automatic cotton suction machine comprising a cotton grasping trolley and an annular cotton bin used for containing cotton, wherein the cotton grasping trolley comprises an inverted-funnel-type suction cup; a cotton grasping beater is transversely arranged below the suction cup; magnets used for removing scrape iron are arranged on the two sides of the cotton grasping beater; one end of the cotton grasping trolley is fixed to a center rotary shaft of a center rotary shaft mechanism of the annular cotton bin; a sliding block is fixed at the bottom end of a supporting arm at the other end of the cotton grasping trolley; the annular cotton bin comprises an inner wallboard and an outer wallboard; an annular guide rail is arranged on the outer side of the outer wallboard; the sliding block abuts against the annular guide rail in a pressed mode; a connection pipe is connected with the upper portion of the suction cup; the connection pipe is inserted into a cotton conveying pipeline in a sleeved mode; a hydraulic cylinder supporting base is fixed to the upper portion of the cotton grasping trolley and is fixedly provided with a hydraulic cylinder; a push rod of the hydraulic cylinder is downwards and fixedly provided with a connection rod; the connection rod is fixed to the side wall of the connection pipe. The novel automatic cotton suction machine can automatically lift the suction cup, ensure the cotton suction effect, evenly spray antistatic agents and ensure the quality.

Owner:YANCHENG KINGDA TEXTILE MACHINERY MFG

Bale breaker

InactiveCN101289773ALow costIncrease power valueCarding machinesFibre breaking machinesFiberEngineering

Owner:胡贝特·赫格特

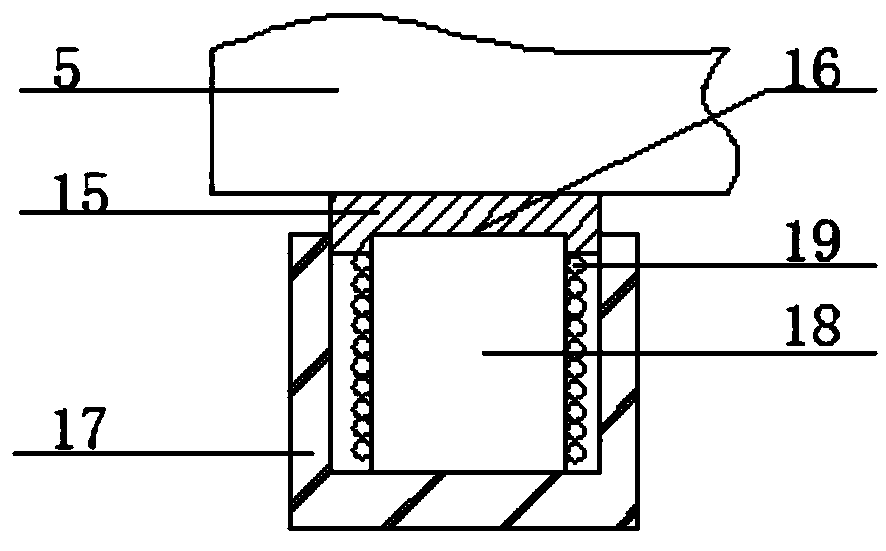

Induction type automatic bale plucker

InactiveCN104514043AHigh lifting precisionLow costFibre breaking machinesFibre breaking by beater armsBall bearingArchitectural engineering

The invention relates to a bale plucker, and specifically relates to an induction type bale plucker. The bale plucker comprises a base, a spindle, a rotating arm, and a tong; the spindle is installed in the middle of the base; the top end of the spindle is fixedly connected with the rotating arm; the bottom end of the rotating arm is fixed with the tong; the rotating arm is fixedly connected with the spindle via a self-locking lead screw lifter; a lateral end of the tong is fixed with a photoelectric inductor; the bottom end of the rotating arm is fixed with a concave groove; a ball bearing is installed inside the concave groove; a lateral edge of the base is encircled inside the concave groove and sticks to the ball bearing; the bale plucker is able to adjust the height of the tong by inducing the plucked amount; the lifting precision is higher; the cost is saved; and the effect is increased.

Owner:JIANGSU KANGYUAN TEXTILE

Spinning machine

InactiveCN108532031APlay a role in removing impuritiesImprove the quality of workFibre breaking machinesFibre breaking by beater armsEngineeringMagnet

The invention discloses a spinning machine. The spinning machine structurally comprises a phototube, a support, a control panel, a telescopic tube, a cotton delivery tube, a screw, a cart, a central shaft, an iron attracting device, inner-circle wall boards, outer-circle wall boards, a ground rail and a cotton grabbing beater, wherein the outer-circle wall boards are connected with the ground rail, the ground rail is movably connected with the support, the support is provided with the control panel, the control panel is connected with the phototube, the support is connected with the telescopictube, the bottom of the telescopic tube is connected with the cart, the iron attracting device is arranged in the cart, the bottom of the cart is movably connected with the cotton grabbing beater, the top of the telescopic tube is connected with the cotton delivery tube, the support is movably connected with the central shaft, the central shaft is movably connected with the inner-circle wall boards, the iron attracting device consists of a motor, a rotary shaft, an iron scraping plate, an iron collecting box and a powerful magnet, the motor is movably connected with the rotary shaft, the rotary shaft is connected with the powerful magnet, and the powerful magnet is movably connected with the iron scraping plate. The spinning machine can attract irony impurities in cotton, play an impurityremoving effect and improve the working quality.

Owner:王振兴

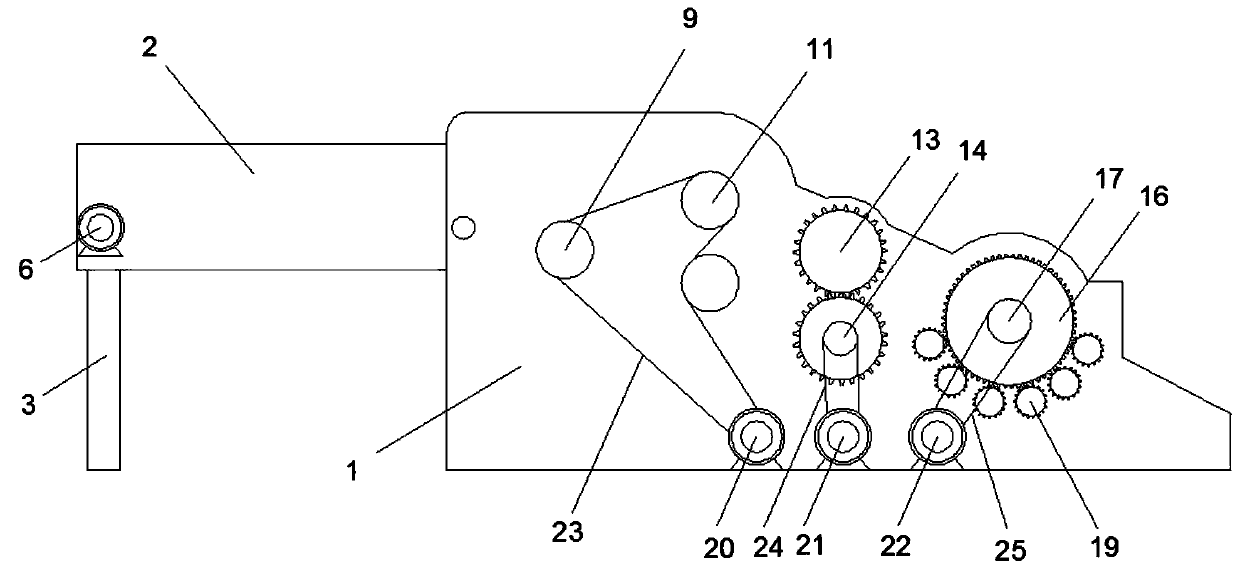

Novel opener for opening cotton slivers

A novel opener for opening cotton slivers comprises a shell, a feeding baffle plate, supporting legs, a conveying roller, a conveying belt, a conveying motor, a fixing rod, a primary loosening roller,a primary loosening roller belt pulley, a secondary loosening roller, a secondary loosening roller belt pulley, a primary garnetting roller, a primary garnetting roller gear, a primary garnetting roller belt pulley, a secondary garnetting roller, a secondary garnetting roller gear, a secondary garnetting roller belt pulley, a stripping roller, a stripping roller gear, a slackening motor, a primary garnetting motor, a secondary garnetting motor, a garnetting motor belt, a primary garnetting motor belt and a secondary garnetting motor belt. A first slackening cavity, a second slackening cavity,a first garnetting cavity and a second garnetting cavity are sequentially formed in the shell from one end to the other end. Raw materials can be sequentially slackened and garnetted, coarse treatment, fine treatment and stage treatment processes are performed in the opening process of the raw materials, and a system is strong in running continuity, stable in running and good in opening effect.

Owner:江西卫棉纺织集团有限公司

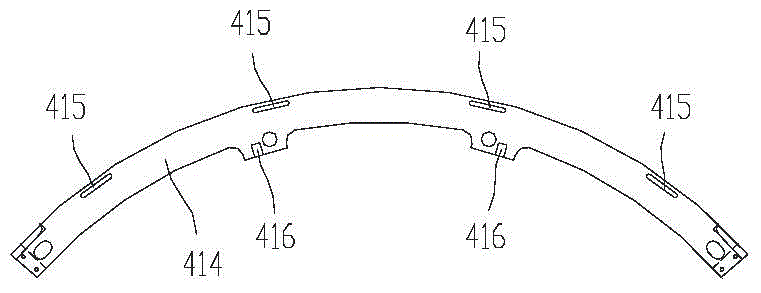

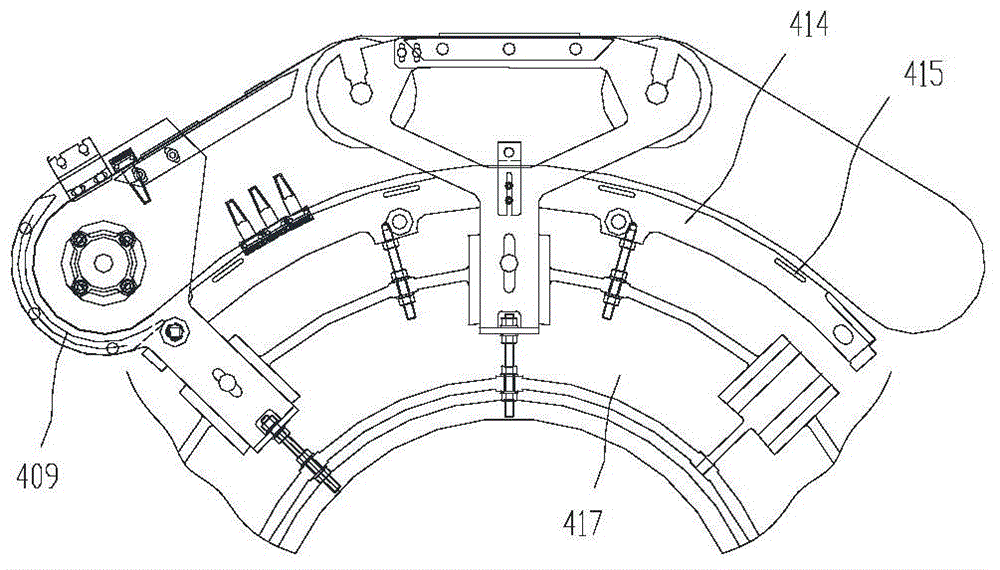

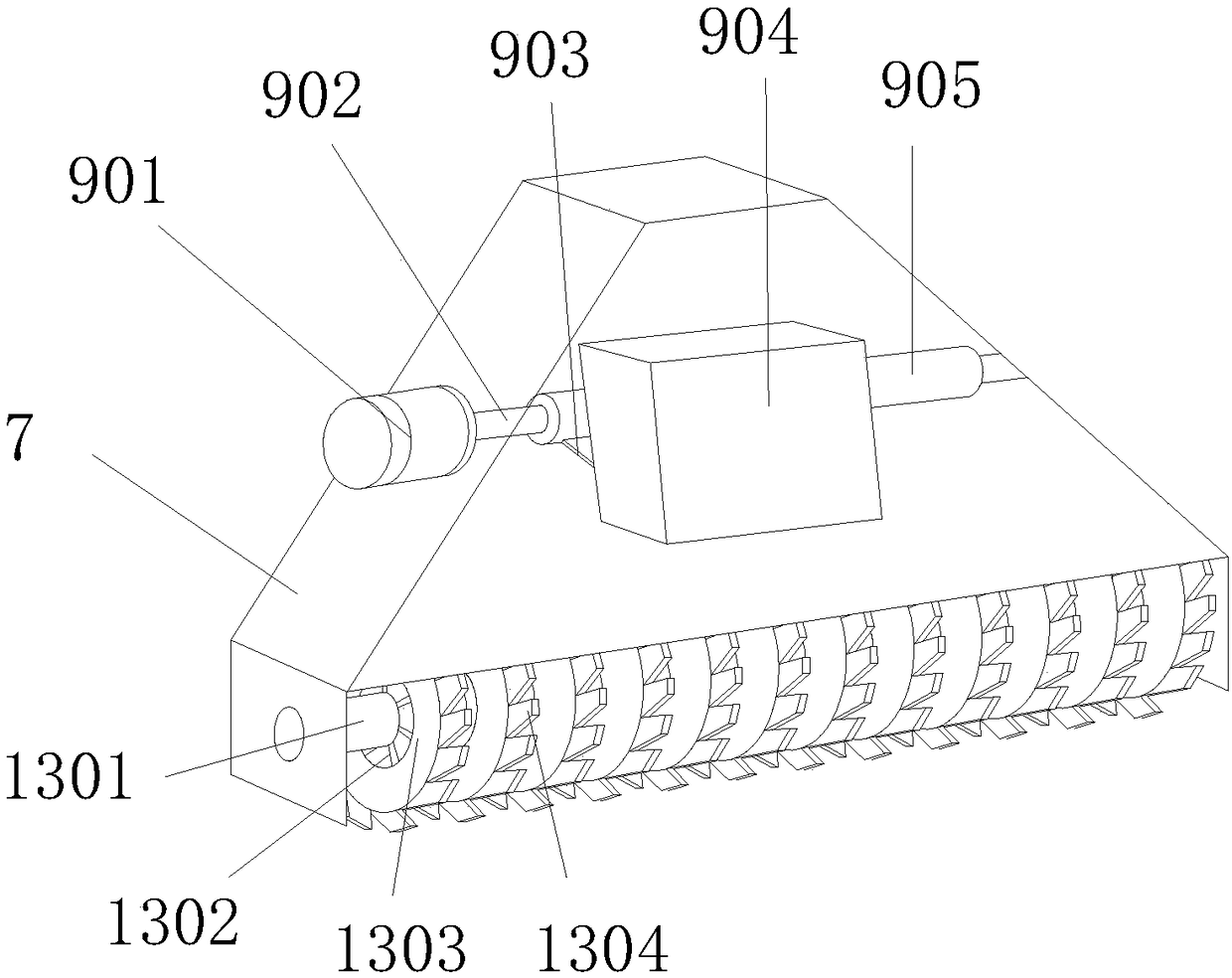

Reciprocating disc picking device for textile production

ActiveCN108914258AGuaranteed uptimePrevent proliferationFibre breaking machinesFibre breaking by beater armsEngineeringTextile production

The invention discloses a reciprocating disc picking device for textile production. The device comprises a bearing base, an annular side baffle, a cotton-picking travelling drive mechanism, an annularcotton-picking track, a travelling cotton-picking mechanism, a rotating frame, a cotton guide pipe, an out air pipe, a connecting frame and a circular slide rail; the top of the bearing base is provided with an annular side baffle; the cotton-picking travelling drive mechanism is fixedly mounted on the bearing base at the center inside the annular side baffle; the annular cotton-picking track isformed between the cotton-picking travelling drive mechanism and the annular side baffle; the travelling cotton-picking mechanism is installed inside the annular cotton-picking track; the rotating frame is installed on the top part of the travelling cotton-picking mechanism. The invention has the advantages of reasonable and simple structure and convenient use. The device operates stably, the double cotton-picking roller shaft is arranged, the cotton-picking time is shortened, the anti-winding blade and the external air source cooperate to clean the cotton-picking roller shaft, so as to ensurethe cotton-picking effect of the cotton-picking roller shaft and the cotton-picking beater, and has stronger practicability.

Owner:杭州萧山汇隆经编有限公司

Novel multifunctional automatic plucker

InactiveCN108468106AAvoid lossEasy to shapeTextile treatment machine partsTextile treatment by spraying/projectingMechanical equipmentEngineering

The invention discloses a novel multifunctional automatic plucker which comprises a cotton storage bin. An axle base is fixedly connected to the middle inside the cotton storage bin, a center shaft isrotationally connected to the middle of the top of the axle base, a humidification leveling device is fixedly connected to the outer side of the bottom end of the center shaft, a connecting steel plate is fixedly connected to the side, away from the humidification leveling device, of the center shaft, a cotton conveying pipeline is fixedly connected to the side, away from the center shaft, of theconnecting steel plate, a cotton conveying bin is fixedly connected to the bottom end of the cotton conveying pipeline, a rotating shaft is rotationally connected to the interior of the cotton conveying bin, and a beater is fixedly connected to the surface of the rotating shaft. The invention relates to the technical field of spinning mechanical equipment. According to the novel multifunctional automatic plucker, the purpose of humidifying and conveying raw material cotton is achieved, shaping and conveying of the raw material cotton are facilitated, the raw material cotton can be effectivelyhumidified and leveled through the humidification leveling device, grabbing and conveying of cotton materials are facilitated, and pelletizing and splashing of cotton materials are reduced.

Owner:安吉利宏纺织有限公司

Annular bale plucker

InactiveCN103938299AMoisturize delicately and evenlyImprove dust removal effectFibre breaking machinesFiberPhysical health

The invention discloses an annular bale plucker which comprises an inner ring wall board, an outer ring wall board, a platform, a trolley, a cotton conveying tube, a telescopic tube, a cotton sucking cover, a beater and a support. A reversed extended section is arranged on one side, opposite to the trolley of the platform, an air pump and an atomizing nozzle which can spray mist outwards are arranged on the reversed extended section, a water tank is further connected with a water inlet of the atomizing nozzle through a second water pipe, the air pump is connected with an air inlet of the atomizing nozzle through an air pipe, and an air valve is arranged on the air pipe. According to the bale plucker, the nozzle can spray mist outwards to achieve the main functions of humidification and dust removal. The atomizing nozzle can spray mist outwards 180 degrees away from the nozzle to cover the area between the inner ring wall board and the outer ring wall board, and finally the mist can fall on cotton layers between the inner ring wall board and the outer ring wall board. Mist humidification is fine and even and can be complementary with an existing nozzle to enable the cotton layers to be humidified evenly. On the other hand, the annular bale plucker can prevent cotton fibers from flying to guarantee physical health of operators.

Owner:罗静

Handling cylindrical and rectangular modules

In one embodiment, a system for removing a plastic wrap from a cylindrical module includes a conveyor transporting the cylindrical module toward a disperser with the cylindrical axis of the module parallel to the direction of conveyor movement. In another embodiment, the disperser is a travelling head disperser thereby providing relative movement between the modules and the disperser. The direction of the wrap around the module is determined and the cover is removed during rotation of the module, either by unwrapping the plastic or by slitting the plastic and then rotating the module. The equipment used to handle a cylindrical module is moved out of the path of movement of a conventional rectangular module so an installation can handle both rectangular and wrapped cylindrical modules.

Owner:STOVER JIMMY R

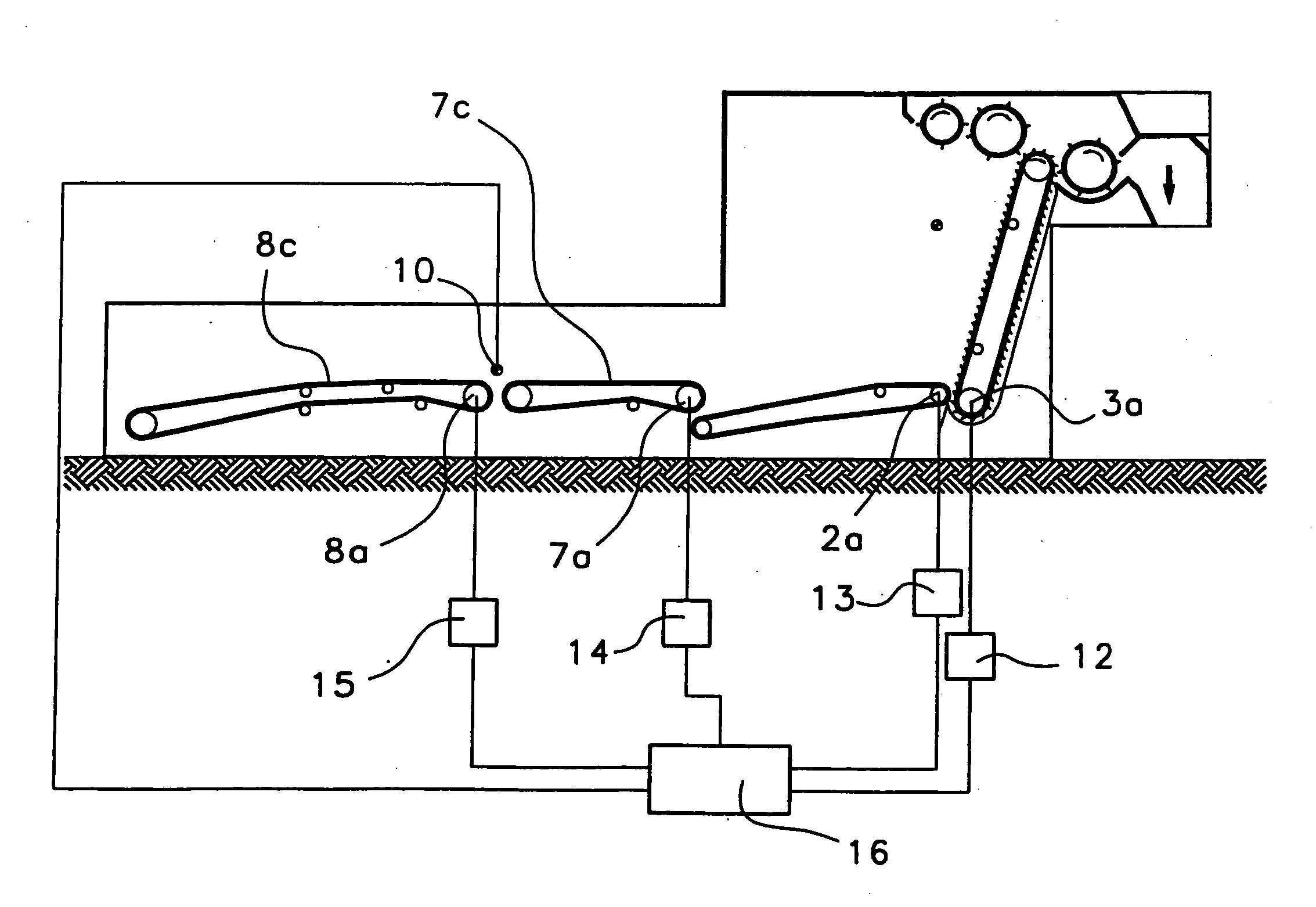

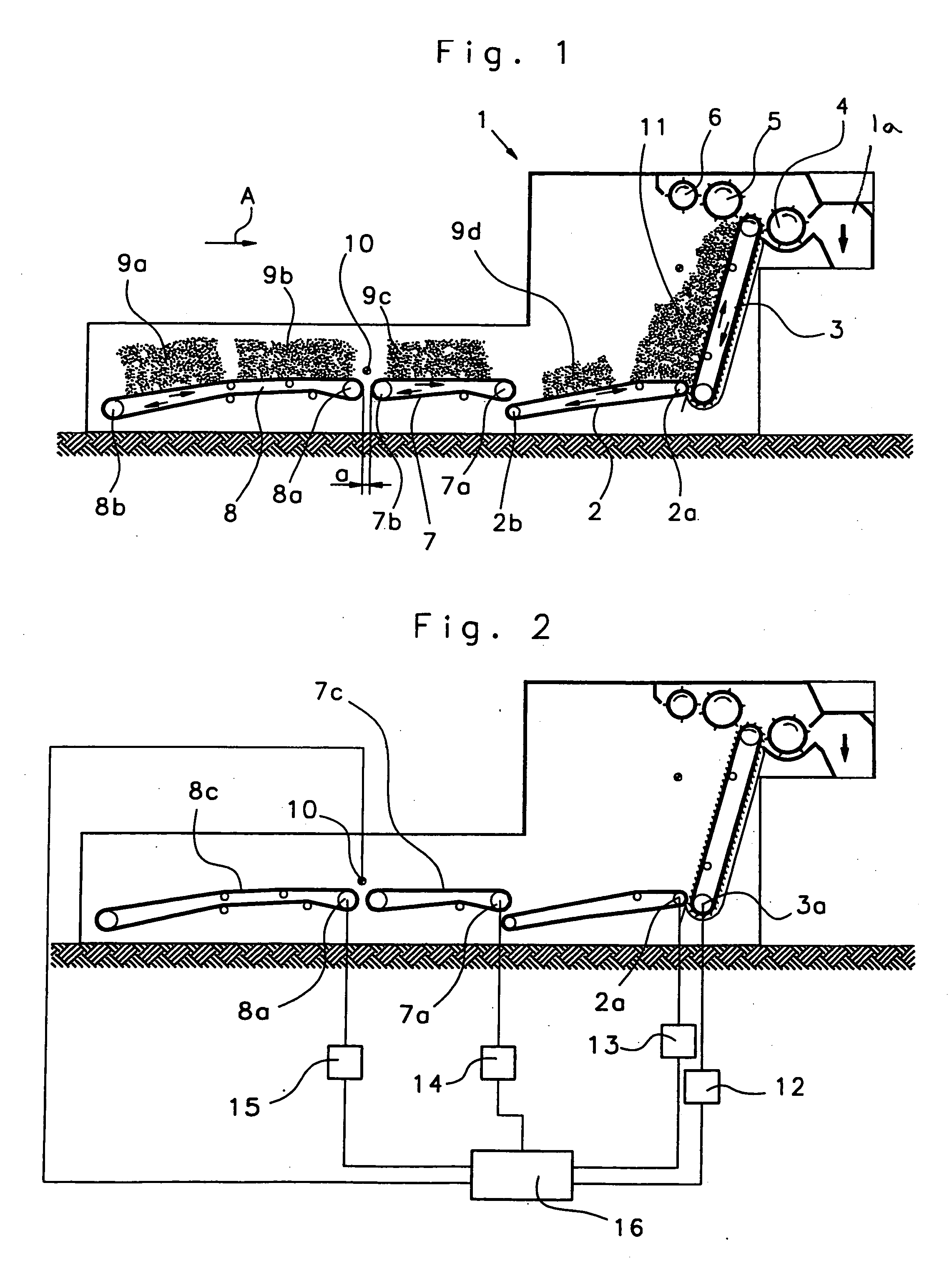

Apparatus for operating a feed device for fiber material, for example, a hopper feeder

In an apparatus for operating a feed device for fibre material, for example, a hopper feeder, there is provided a drivable, endless conveyor belt guided around two rotatable rolls. The conveyor belt is associated at one end, looking in the conveying direction, with an endless, upwardly inclined spiked lattice. Upstream of the other end of conveyor belt, looking in the opposition direction to the conveying direction, there is arranged an endless feed belt (reserve belt) for receiving fibre bales or the like. To convey fibre material to the hopper feeder in a simple manner, without interruption to production, there is arranged between the conveyor belt and the reserve belt 8a continuously circulating transition belt, and the absence of fibre material on the reserve belt is detectable.

Owner:TRUETZSCHLER GMBH & CO KG

Plucker for cotton thread processing

InactiveCN110616475AReduce processing costsAchieve processing benefitsFibre breaking machinesFibre breaking by toothed membersHydraulic cylinderTransmission belt

A plucker for cotton thread processing comprises a plucker head, a conveying pipe, a rotating shaft, a rotating motor, a first supporting rod, a second supporting rod, a plucker body, a plucking blade, a plucking switch, a rotating switch, a lifting switch, a first hydraulic cylinder, a plucking wheel, a cotton batt tank, a second hydraulic cylinder, a plucking wheel platform, a transmission coverand a plucking motor. The plucker head is mounted on the side face of the plucker body through the first supporting rod and the second supporting rod, the cotton batt tank is mounted on the first hydraulic cylinder and the second hydraulic cylinder and positioned on the lateral side of the plucker body, the plucking wheel is mounted on the lower portion in the plucking wheel platform, the plucking blade is arranged on the plucking wheel, the plucking motor is mounted on the upper portion in the plucking wheel platform, a transmission belt is arranged in the transmission cover, one end of thetransmission belt in the transmission cover is connected with the plucking motor while the other end of the same is connected with the plucking wheel, and the rotating shaft is arranged on the upper portion of the plucking wheel platform. The plucker is simple in structure and convenient for plucking operation, cotton thread processing cost is lowered, and cotton thread processing benefit is realized.

Owner:余庆县鸿祥棉纺有限责任公司

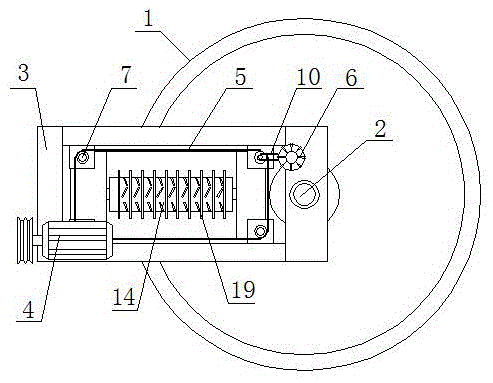

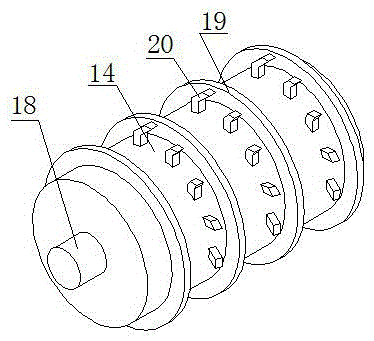

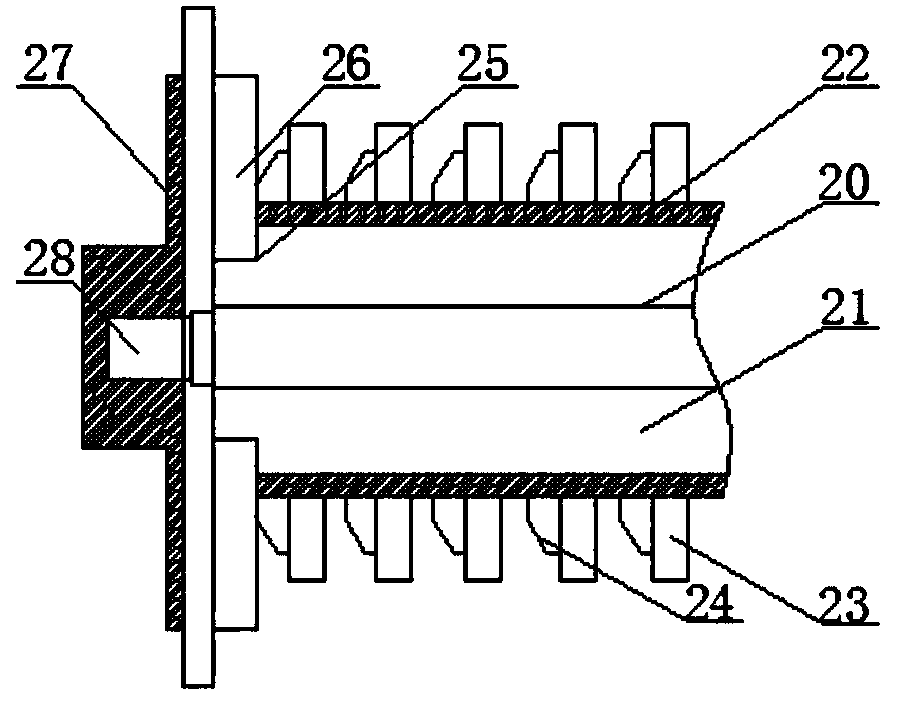

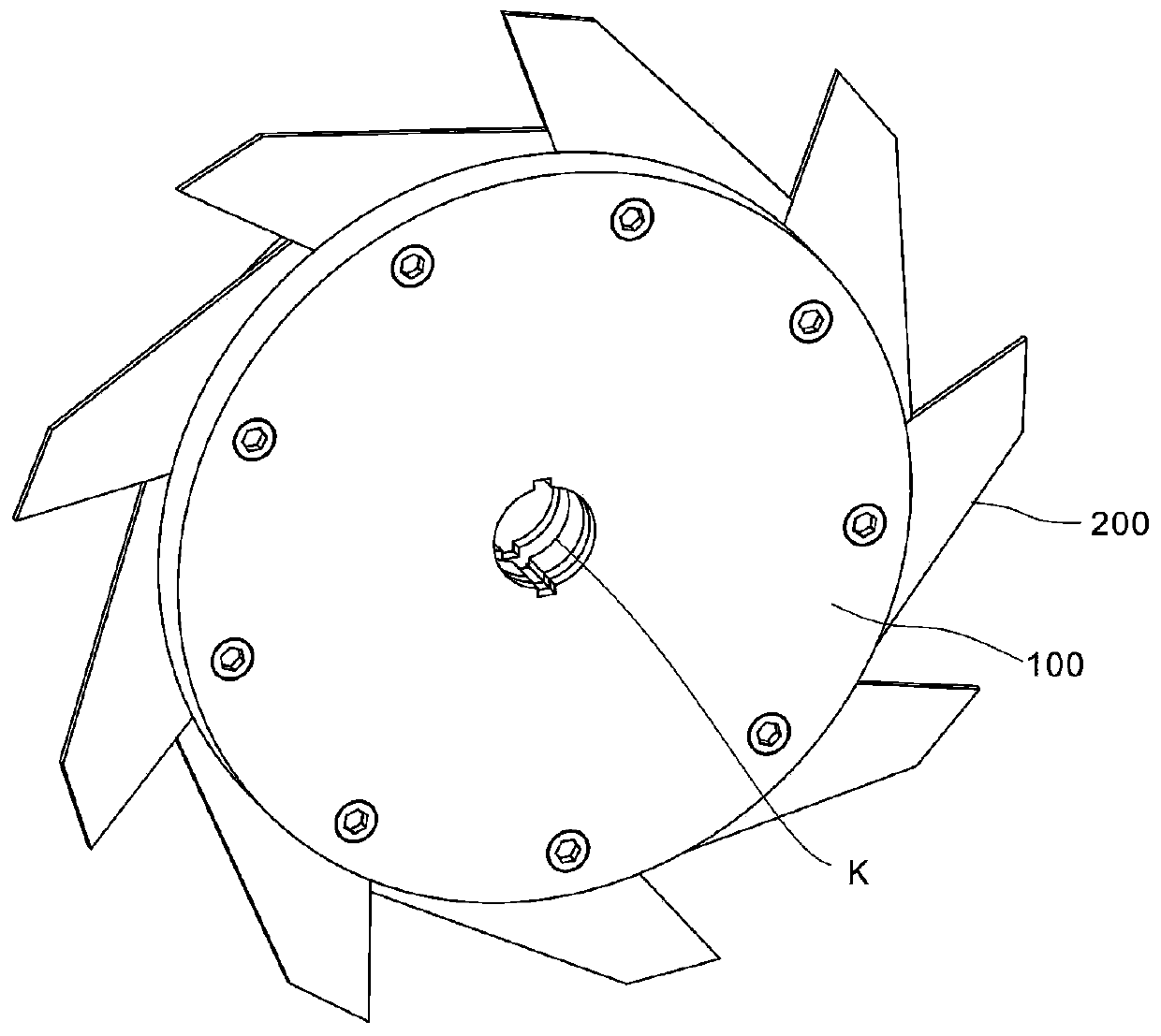

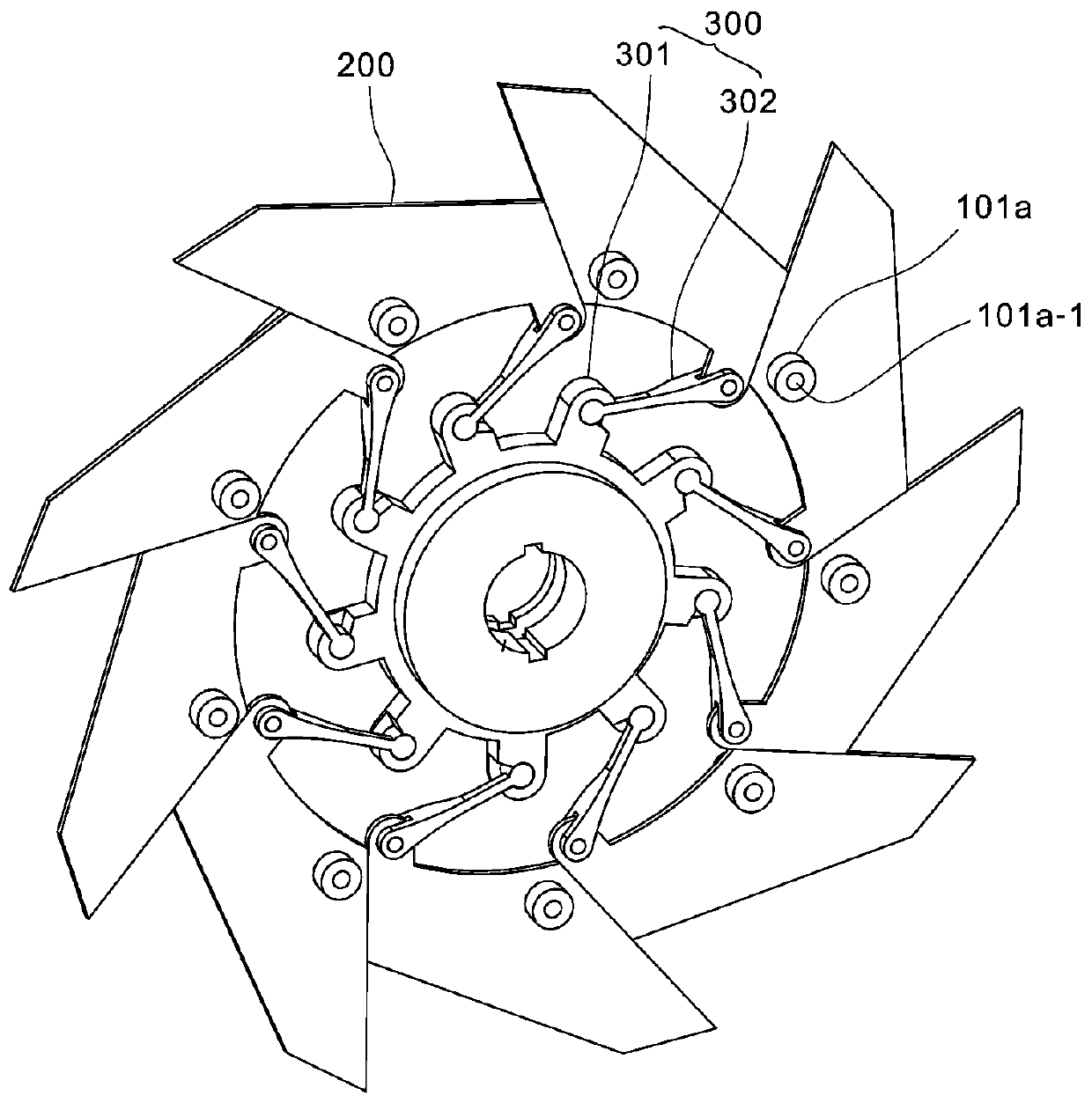

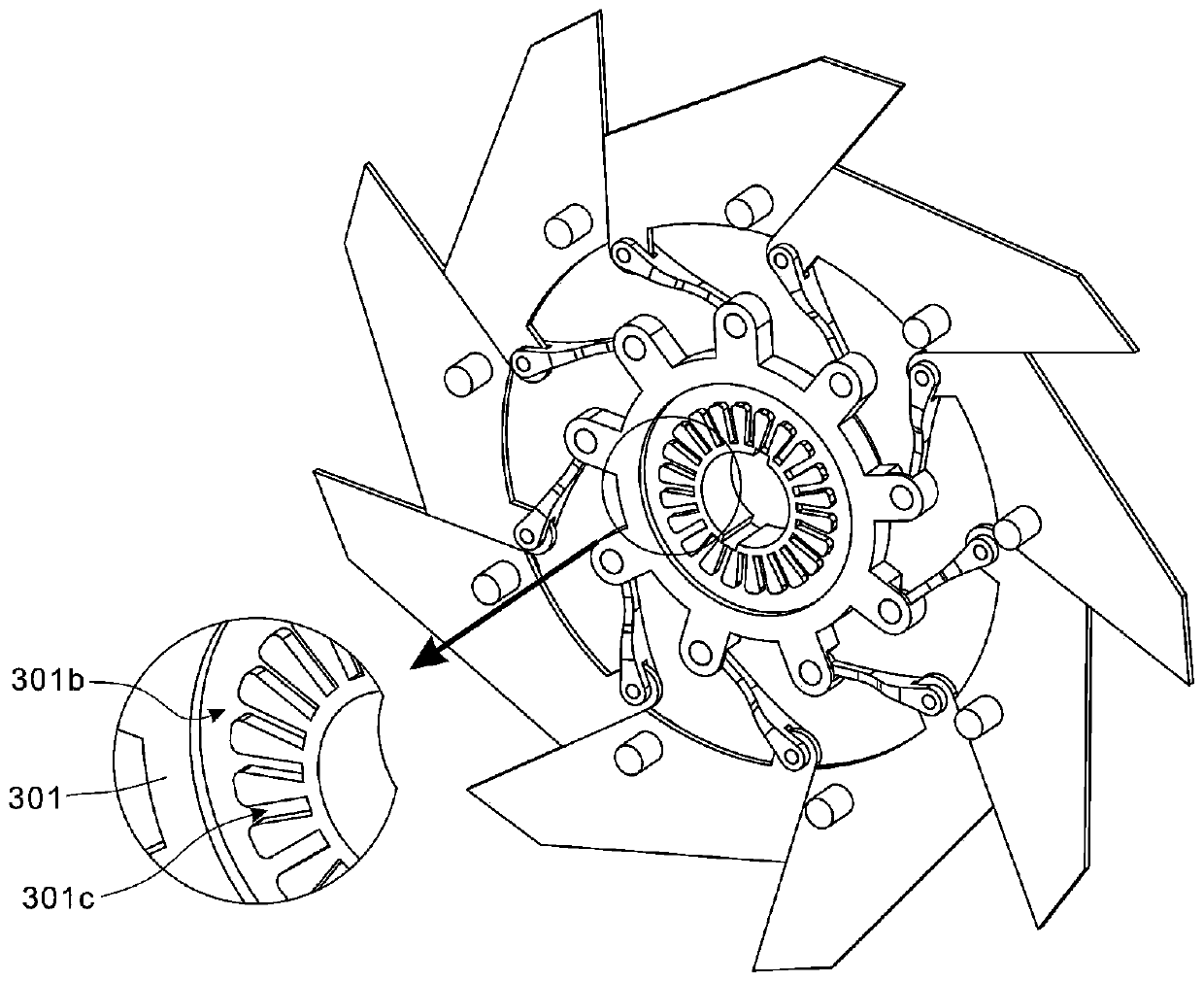

Cotton plucking bearer disk

ActiveCN110055629AAchieve regulationIncrease flexibilityFibre breaking machinesFibre breaking by beater armsEngineeringPlucker

The invention discloses a cotton plucking bearer disk which comprises a shell and blades. The shell comprises a first end cover and a second end cover which are parallel each other, hinge shafts are peripherally and equidistantly distributed in the first end cover, the number of the blades is the same as that of the hinge shafts, the blades are hinged onto the corresponding hinge shafts and clamped in the middle by the first end cover and the second end cover, and the first end cover is detachably connected with the second end cover. According to the cotton plucking bearer disk, overturning angles and exposed heights of the blades can be controlled as required, states of the blades can be adjusted, the cotton plucking bearer disk is independently modular, a plurality of cotton plucking bearer disks can be parallelly mounted on a rotating shaft of a cotton plucker as required, overall specifications of a cotton plucking bearer are adjusted, and the cotton plucking bearer disk has high flexibility and variability.

Owner:安徽新蕾家纺有限公司

Automatic cotton plucker

InactiveCN107557916AEasy to absorbEasy to grabFibre breaking machinesFibre breaking by toothed membersElectric machineryPlucker

The invention discloses an automatic cotton plucker which comprises a supporting plate, a suction bin bucket and an air suction box. A supporting column is fixed at each of two ends of the supportingplate, the bottom end of a top plate is fixedly connected with two electric extensible rods, the bottom ends of the electric extensible rods are fixedly connected with the suction bin bucket, a rotating shaft at one end of a cotton plucking roller is fixedly connected with an output shaft of a speed reducing motor, a plurality of plucking teeth are arranged on the cotton plucking roller, the middle of the top end of the suction bin bucket is communicated with a cotton conveying pipe, and an extensible hose is arranged on one section of the cotton conveying pipe. Cotton is stripped and pluckedthrough the plucking teeth, so that convenience is brought to the cotton conveying pipe to absorb the cotton; by arranging the electric extensible rods, height of the suction bin bucket can be adjusted, and convenience is brought to plucking and sucking in the cotton no matter the cotton is more or less; by arranging a shaft sleeve on the rotating shaft of the cotton plucking roller, the shaft sleeve is fixed on the inner wall of the suction bin bucket to prevent the cotton from being close to the rotating shaft, and the circumstance that the rotating shaft of the cotton plucking roller is entangled is prevented.

Owner:湖州世韩进出口有限公司

A roll-in cotton opener

ActiveCN105040167BAvoid congestionAvoid fireFibre breaking machinesFibre breaking by beater armsEngineeringTextile

Owner:利津慈母坊纺织科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com